Method for constructing water-proof telescopic seam between new and old concrete building joints and structure thereof

A new and old concrete and concrete structure technology, applied in building components, building insulation materials, etc., can solve the problems of unsafe, unable to form waterproof structural nodes, affecting the quality of buildings, etc., and achieve the effect of improving quality and good waterproof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

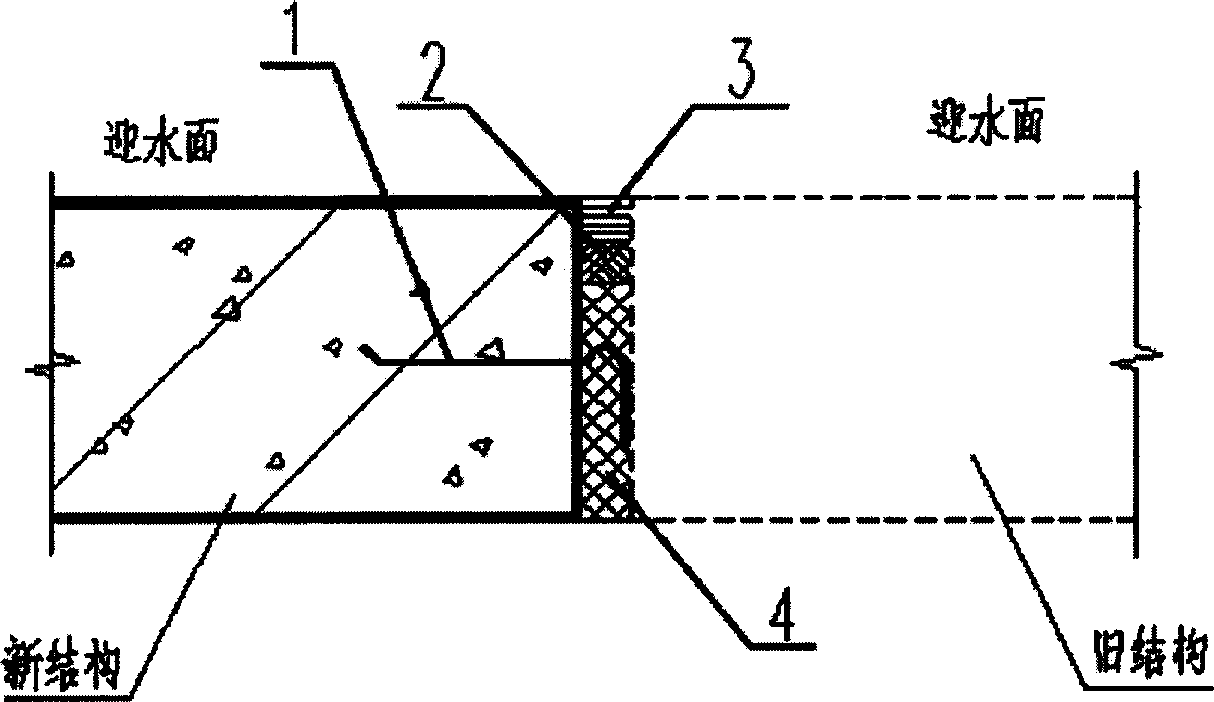

[0010] Embodiments of the present invention: according to the specific conditions of old and new building foundations, according to the attached figure 2 Make a waterstop (1) according to the requirements. Clean the old concrete structural surface first, and chisel it slightly, and then paste one end of the waterstop (1) on the old concrete structural surface with waterproof structural adhesive. The other end of (1) is put in place, and the new structure is poured. After the expansion joint is removed from the formwork, lay the caulking material (4) on the top and bottom of the waterstop (1), put the expansion strip (2) on the water-facing surface of the caulking material (4), and finally place the expansion strip (2) Fill the caulking material (3) to form a complete expansion joint waterproof structure. Waterstop (1) is made of 3mm stainless steel plate, and expansion strip (2) is made of rubber, and this rubber has the performance of water swelling.

[0011] As a specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com