Pit supporting structure and construction method thereof

A foundation pit support and construction method technology, which is applied in the field of building foundations, can solve the problems of inconvenience in basement construction, prolong the construction period of foundation pits, and increase project costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

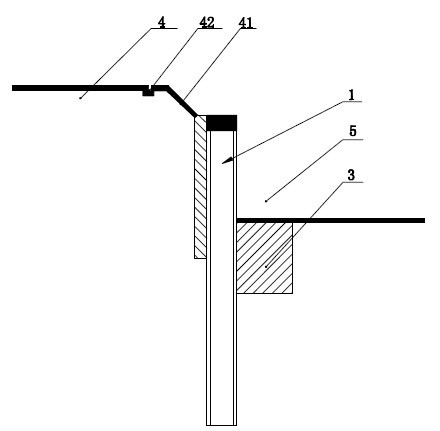

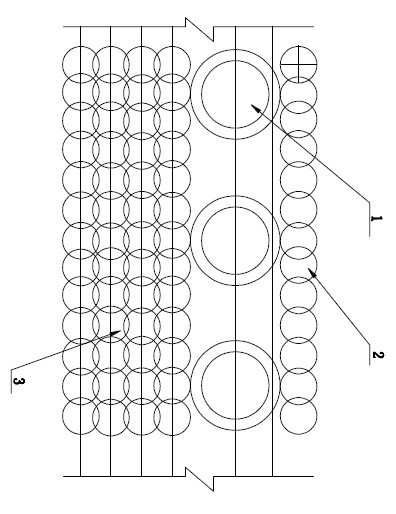

[0022] See attached figure 1 to attach Figure 5 , a foundation pit support structure disclosed by the present invention comprises a foundation pit support row pile 1, a water stop and soil stop curtain 2, and an anti-side row pile 3, and the foundation pit support row pile 1 is set to be long The cast-in-place concrete thin-walled pipe piles separated by piles 11 and short piles 12 are preferred in this embodiment. The long piles 11 of the cast-in-place concrete thin-walled pipe piles are evenly distributed, and there are two equidistantly distributed between every two long piles 11. 12 short piles. The water-stop and soil-stop curtain 2 and the anti-side row piles 3 are all set as cement mixing piles, and the water-stop and soil-stop curtain 2 are set as a row of interlocking cement mixing piles (that is, each cement mixing pile is connected to the adjacent part of the cement mixing pile overlaps), the anti-side row pile 3 is set as several rows of two-way interlocking cem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com