Water-proof coiled material layer

A technology of waterproof roll material and laying machine, which is applied to tools used in roofing engineering, roofing, construction, etc. It can solve the problems of harmful gas pollution, damage to human health, and high construction costs, and achieve pollution reduction, labor intensity reduction, and construction quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

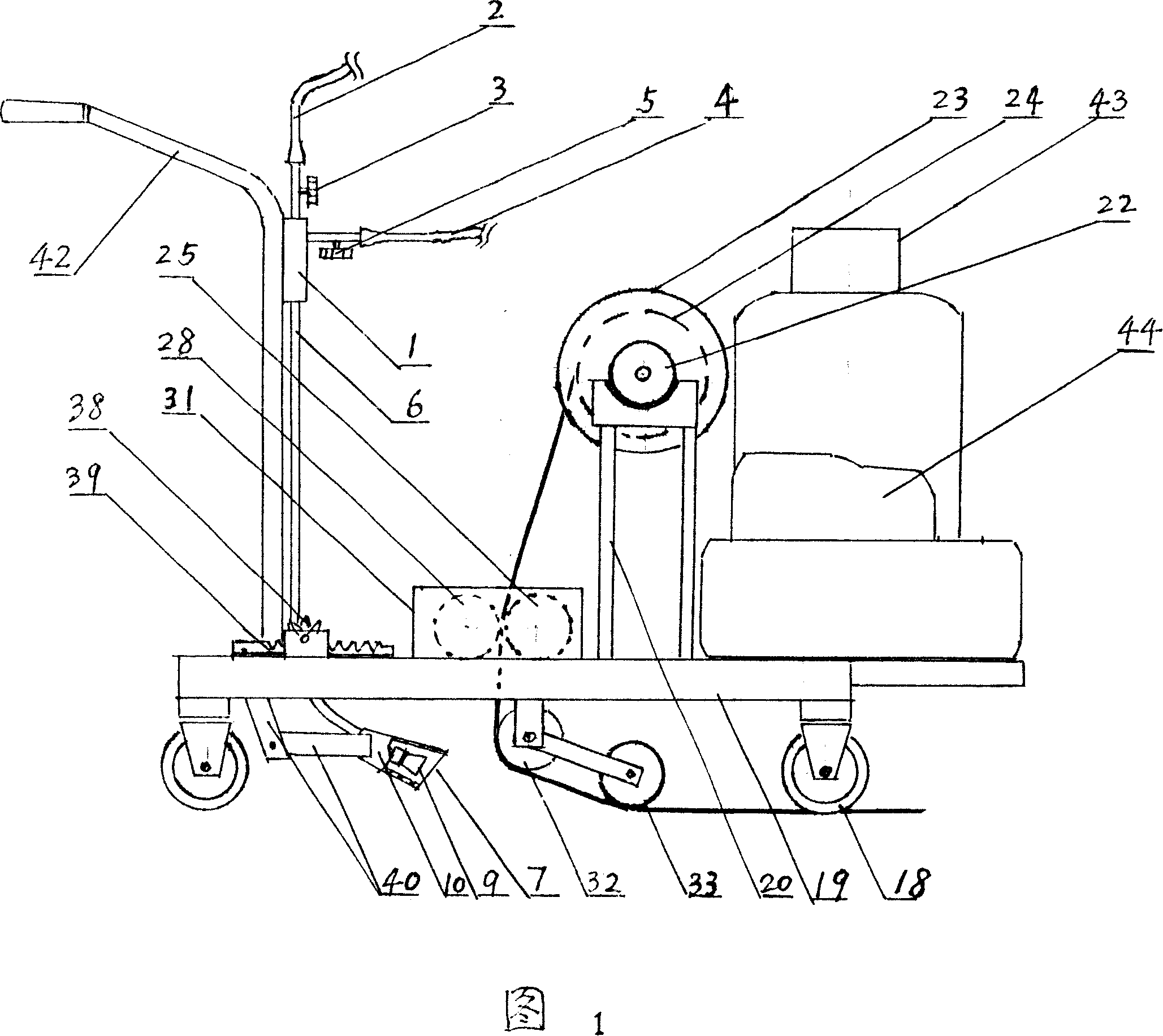

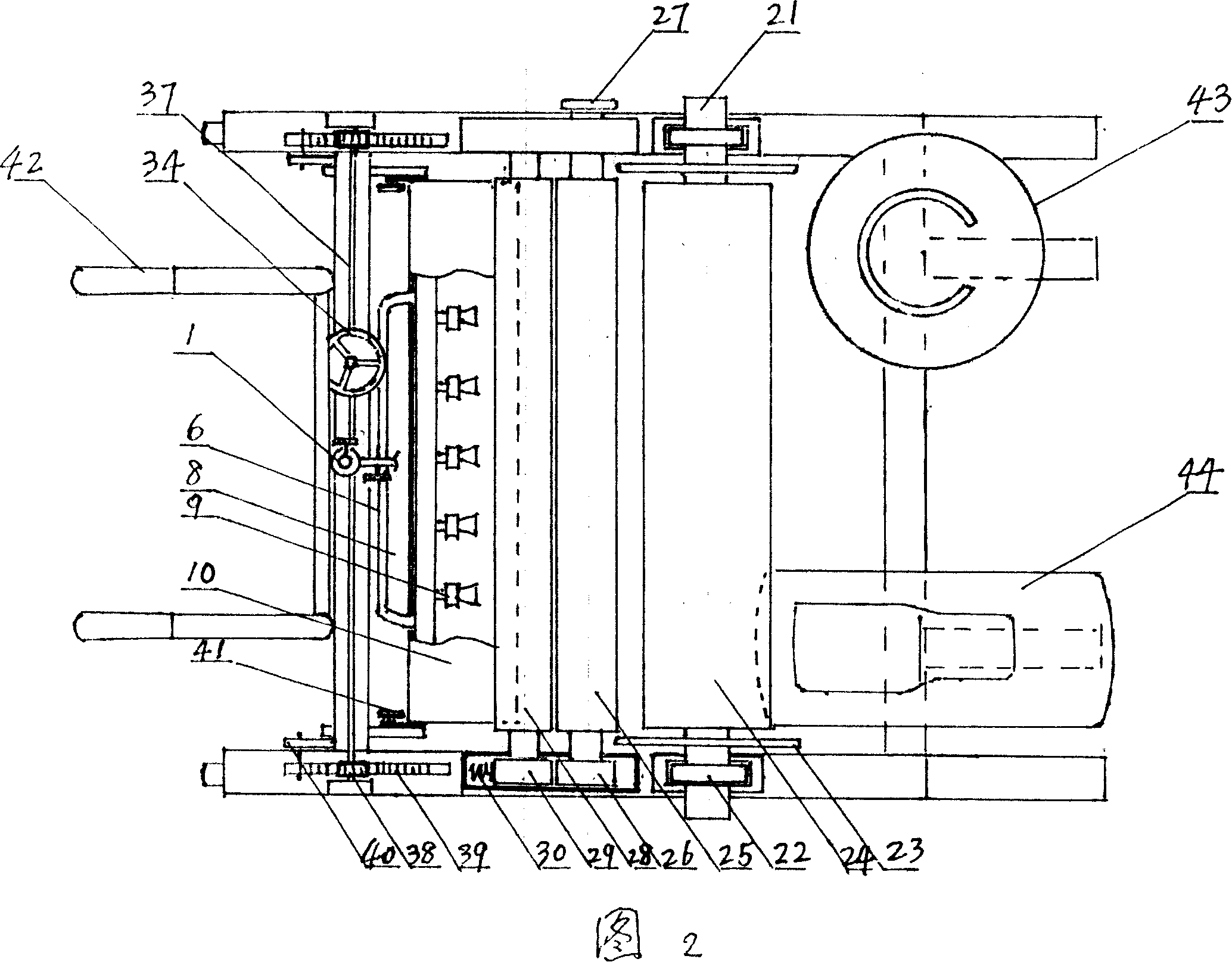

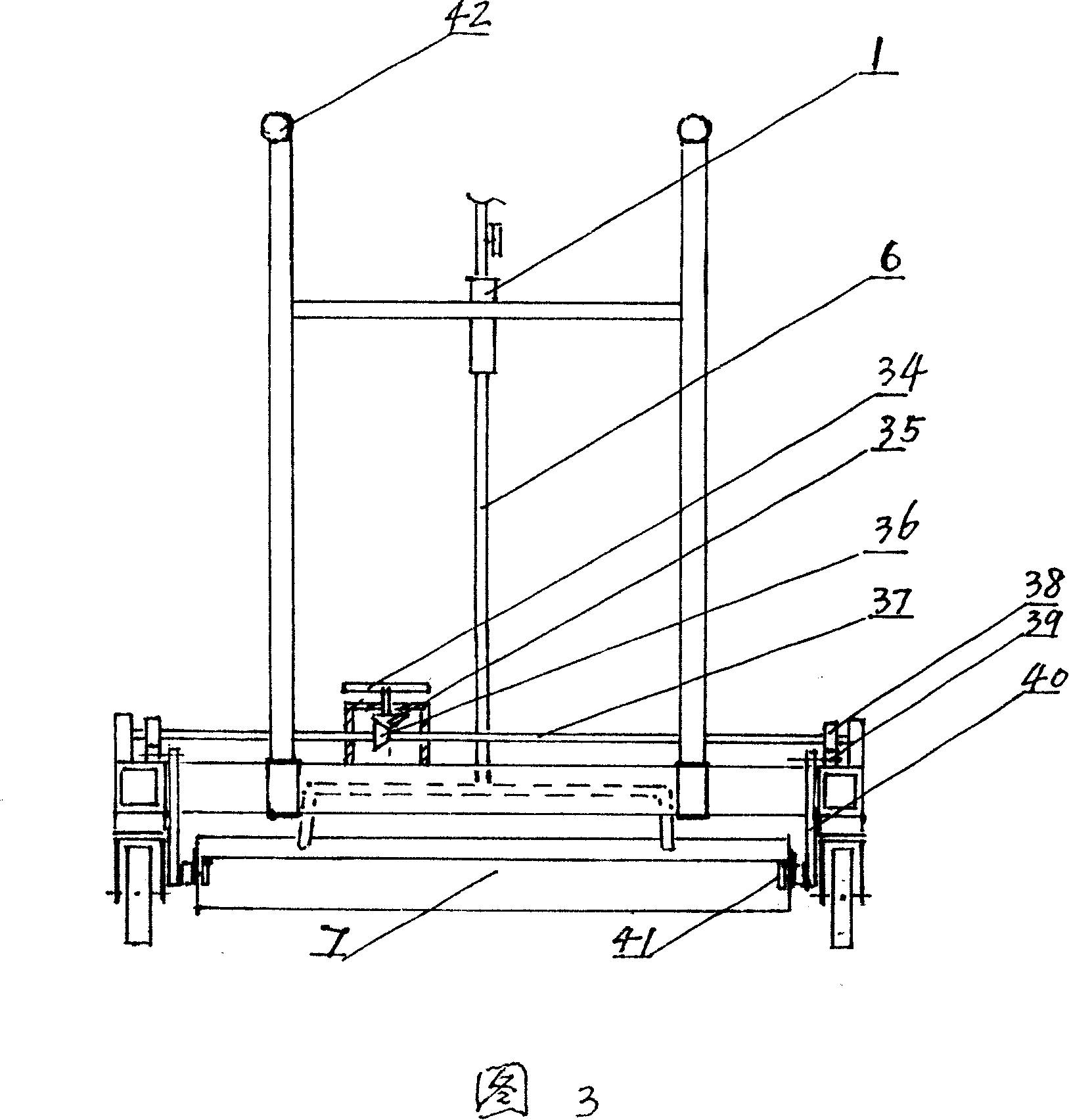

[0014] The basic structure of the present invention can be expressed by accompanying drawing 1 front view of the present invention, accompanying drawing 2 top view of the present invention and accompanying drawing 3 left view of the present invention. There are walking wheels 18 under the frame 19, and the front beam is equipped with handles 42, which can be laid in reverse when laying (the rear handles can also be installed on the rear beam according to the situation, and the front and rear two people can control the construction). Liquefied gas cylinder 43 and air compressor 44 are placed. The laying device is that the coiled material shaft 21 of the set coiled material is placed on the vertical frame 20 in the middle of the frame, the two end bearings of the coiled material shaft are seated in the bearing seats on the vertical frame, and the two ends of the coiled material shaft are respectively equipped with partitions 23, Suit waterproof coiled material 24 between two div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com