Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1281 results about "Lateral displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lateral displacement is the mechanism in which light changes its path when it travells from one medium to the another. if the second medium is thicker/denser from the first one then the light moves towards the normal and if the second medium is lighter/rarer than the first medium then the light ray move away from normal.

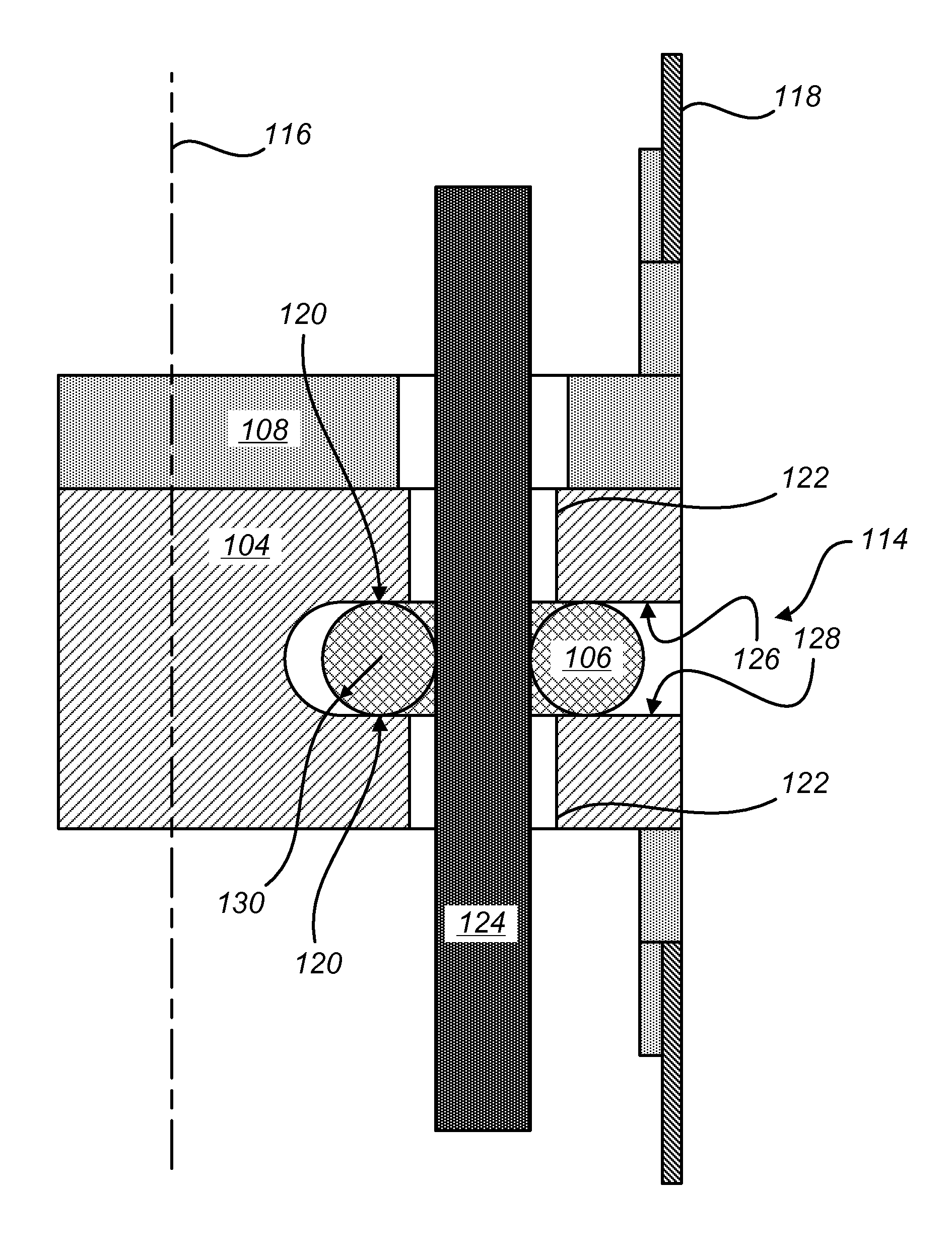

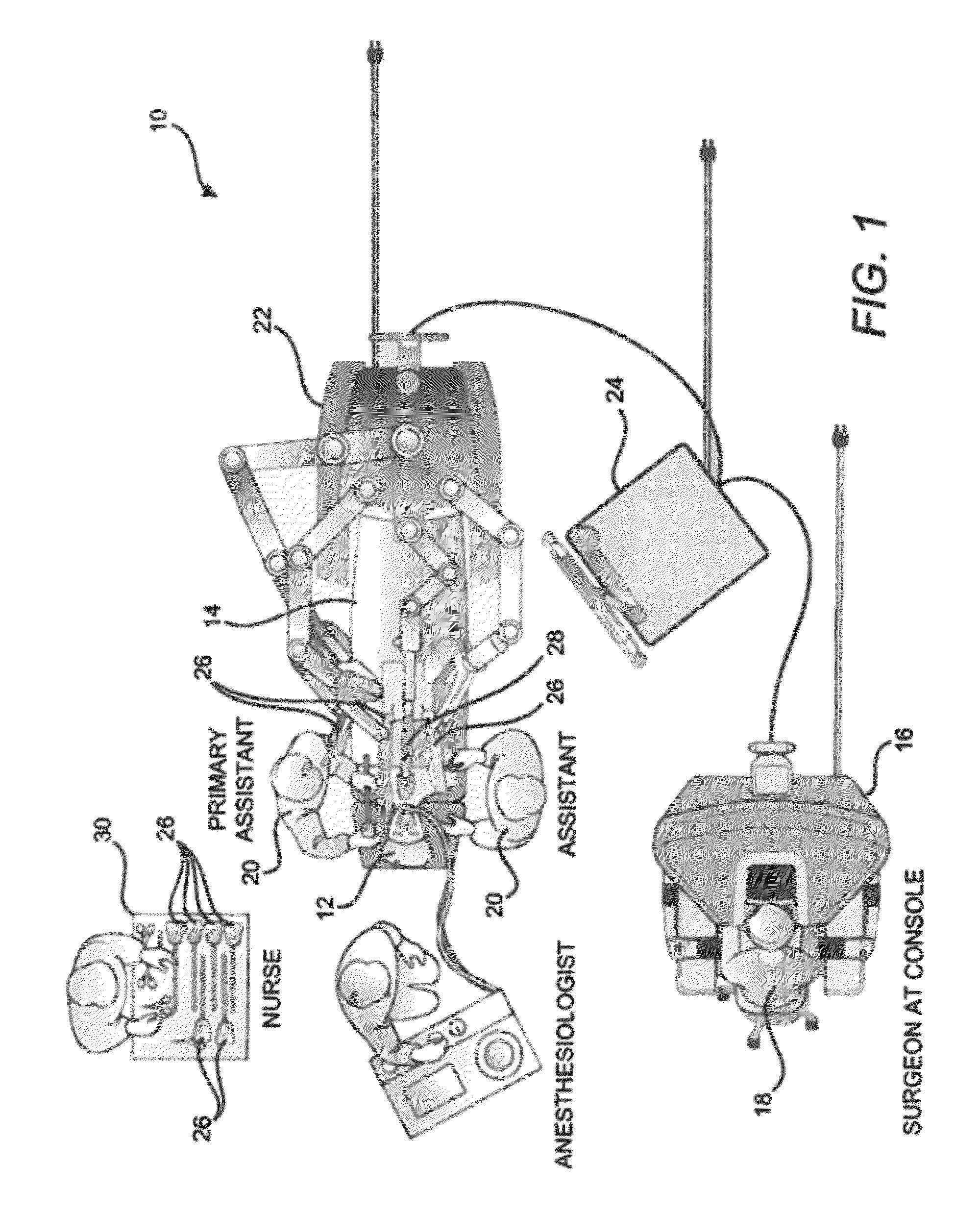

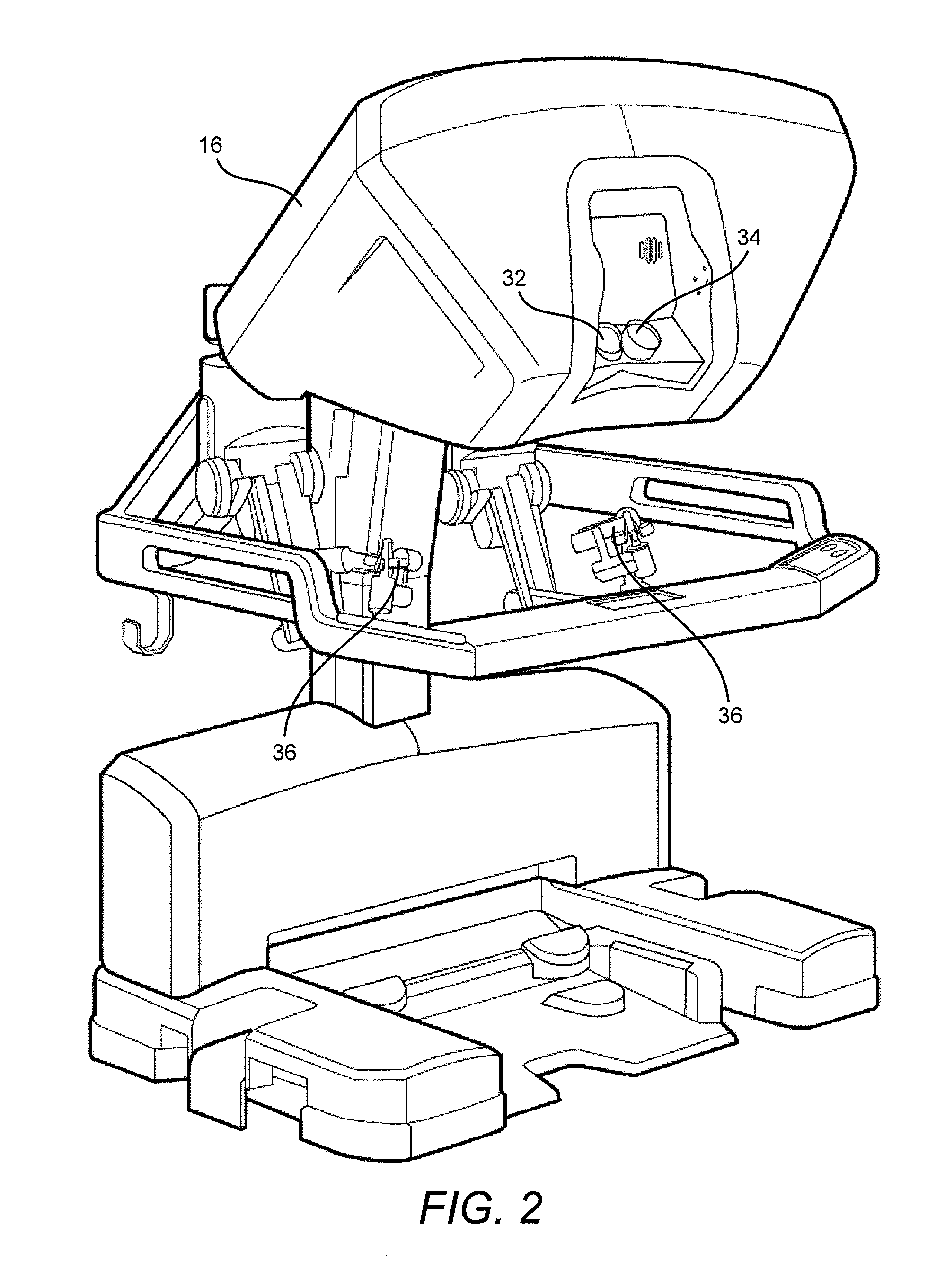

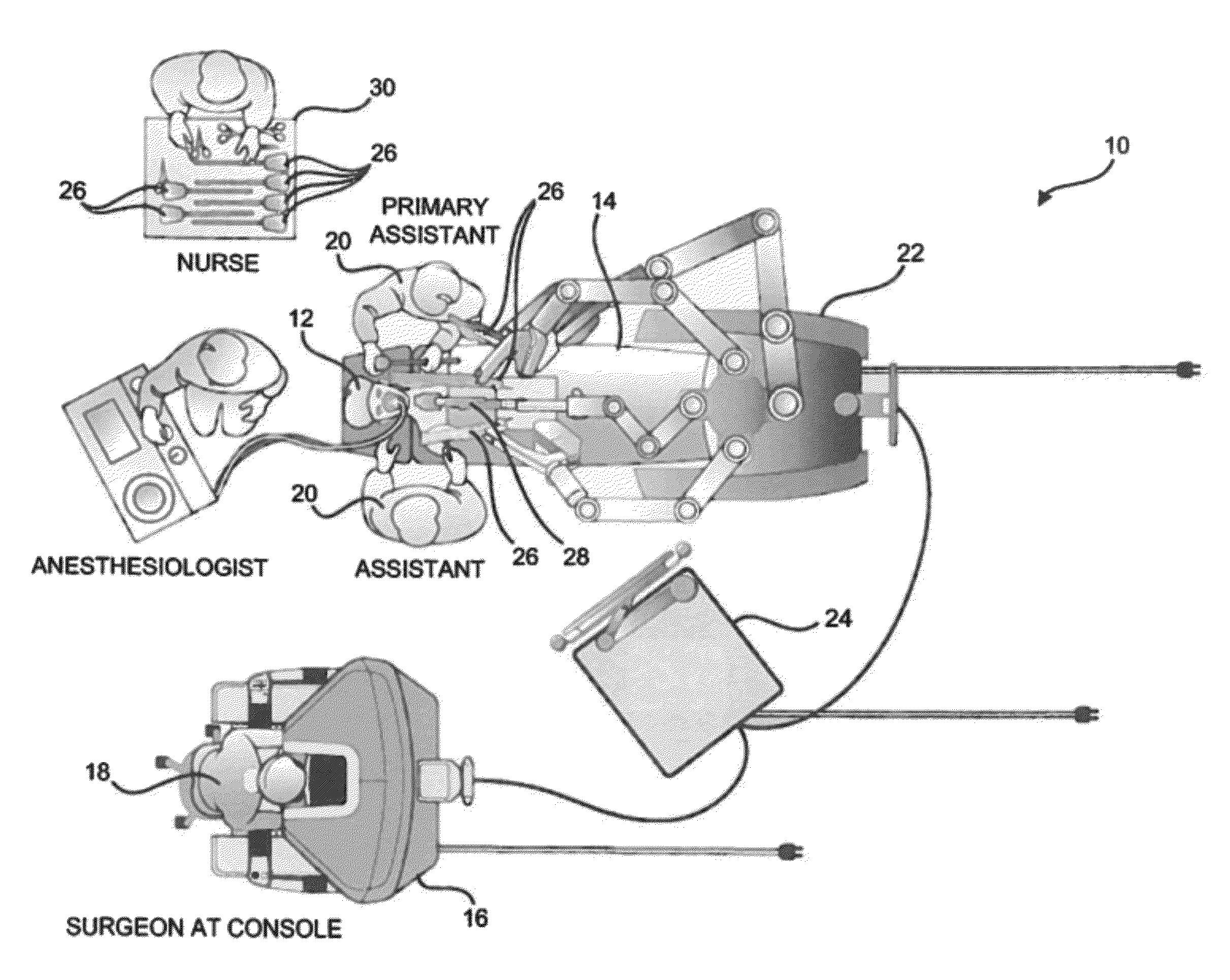

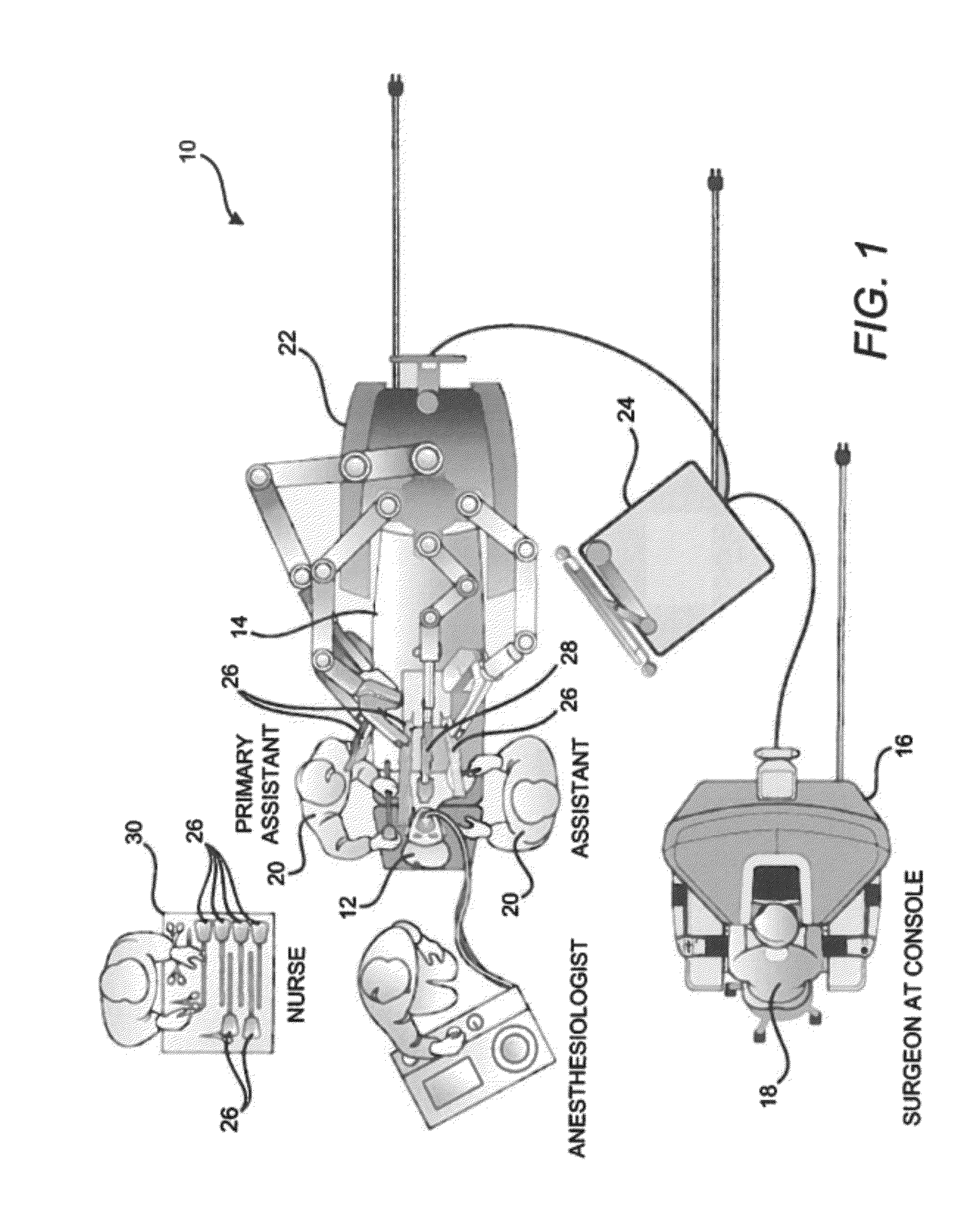

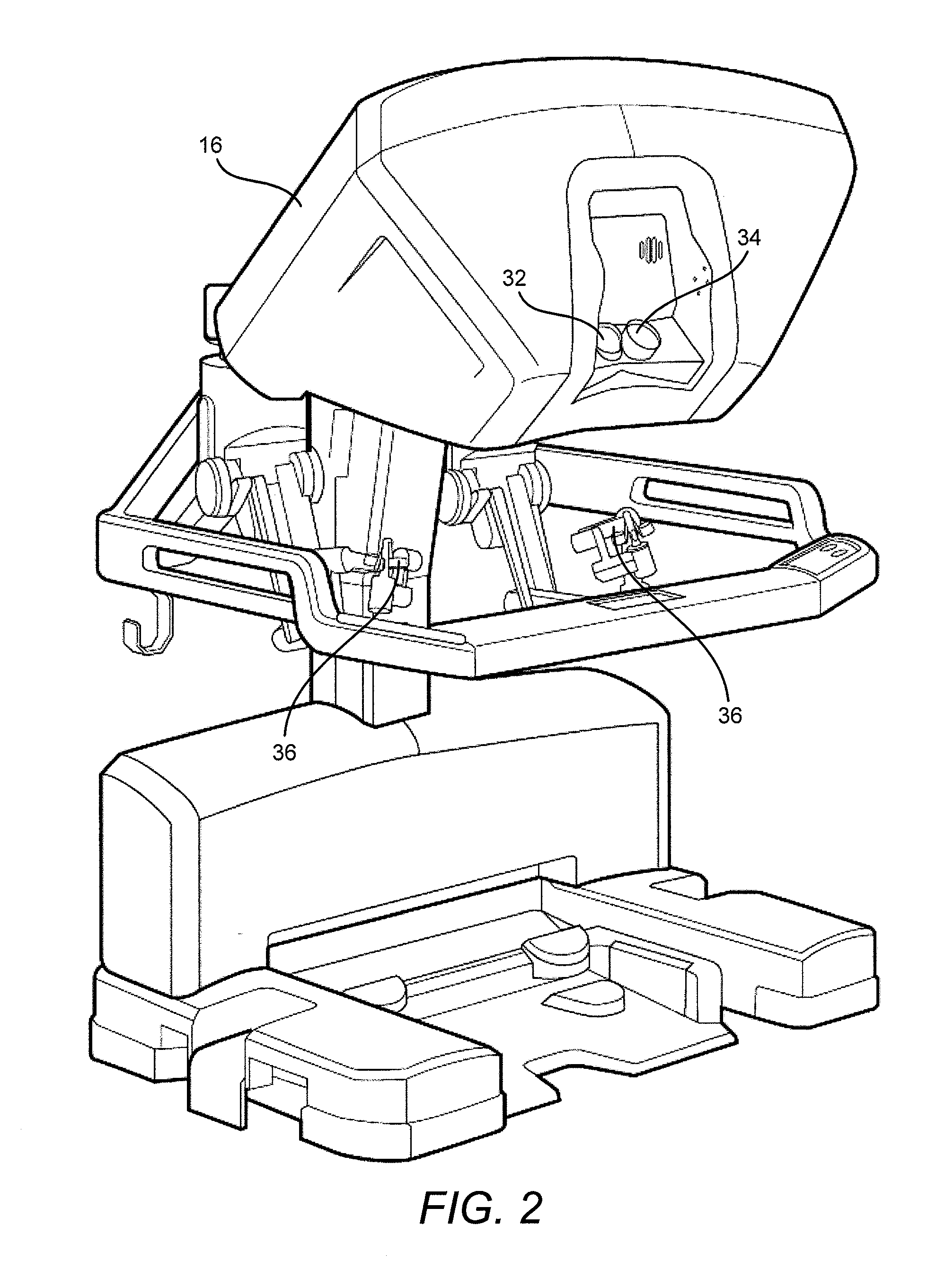

Seals and sealing methods for a surgical instrument having an articulated end effector actuated by a drive shaft

Owner:INTUITIVE SURGICAL OPERATIONS INC

Seals and sealing methods for a surgical instrument having an articulated end effector actuated by a drive shaft

Sealing assemblies and methods are disclosed for sealing a surgical instrument having an internal drive shaft subject to lateral displacement. A sealing assembly includes a rigid portion shaped to interface with an instrument shaft of the surgical instrument. A laterally oriented slot is open at a radially perimeter location and configured to receive an o-ring seal via the perimeter location. Apertures are disposed on opposing sides of the slot and open to the slot. The apertures are configured to receive the drive shaft there through and are larger than the drive shaft to accommodate lateral displacement of the drive shaft. The slot includes opposing internal sides spaced to interface with opposed axial surfaces of the o-ring seal. The seal inhibits axial transmission of an insufflated gas and / or bodily fluids while accommodating lateral displacement of the drive shaft.

Owner:INTUITIVE SURGICAL OPERATIONS INC

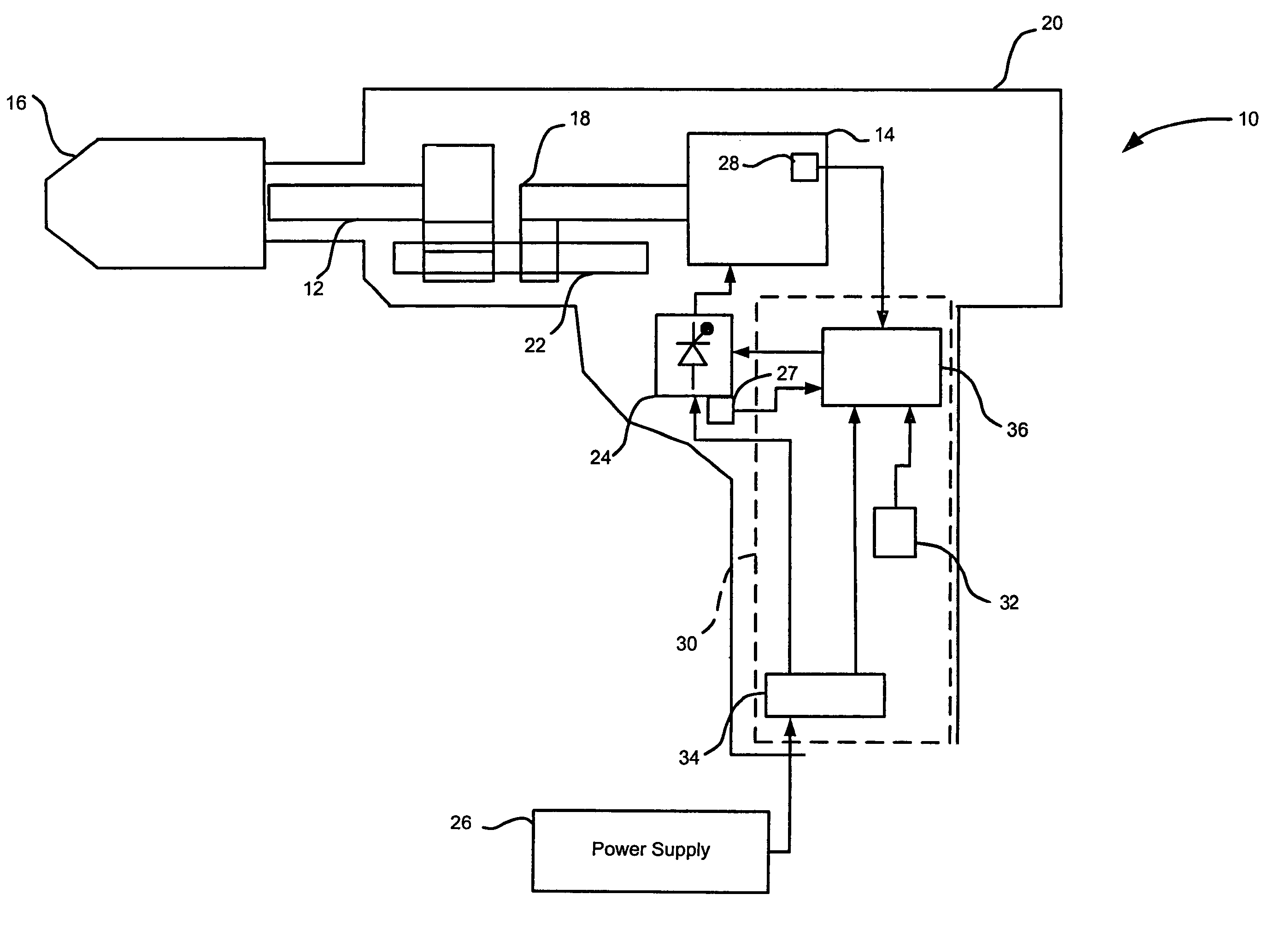

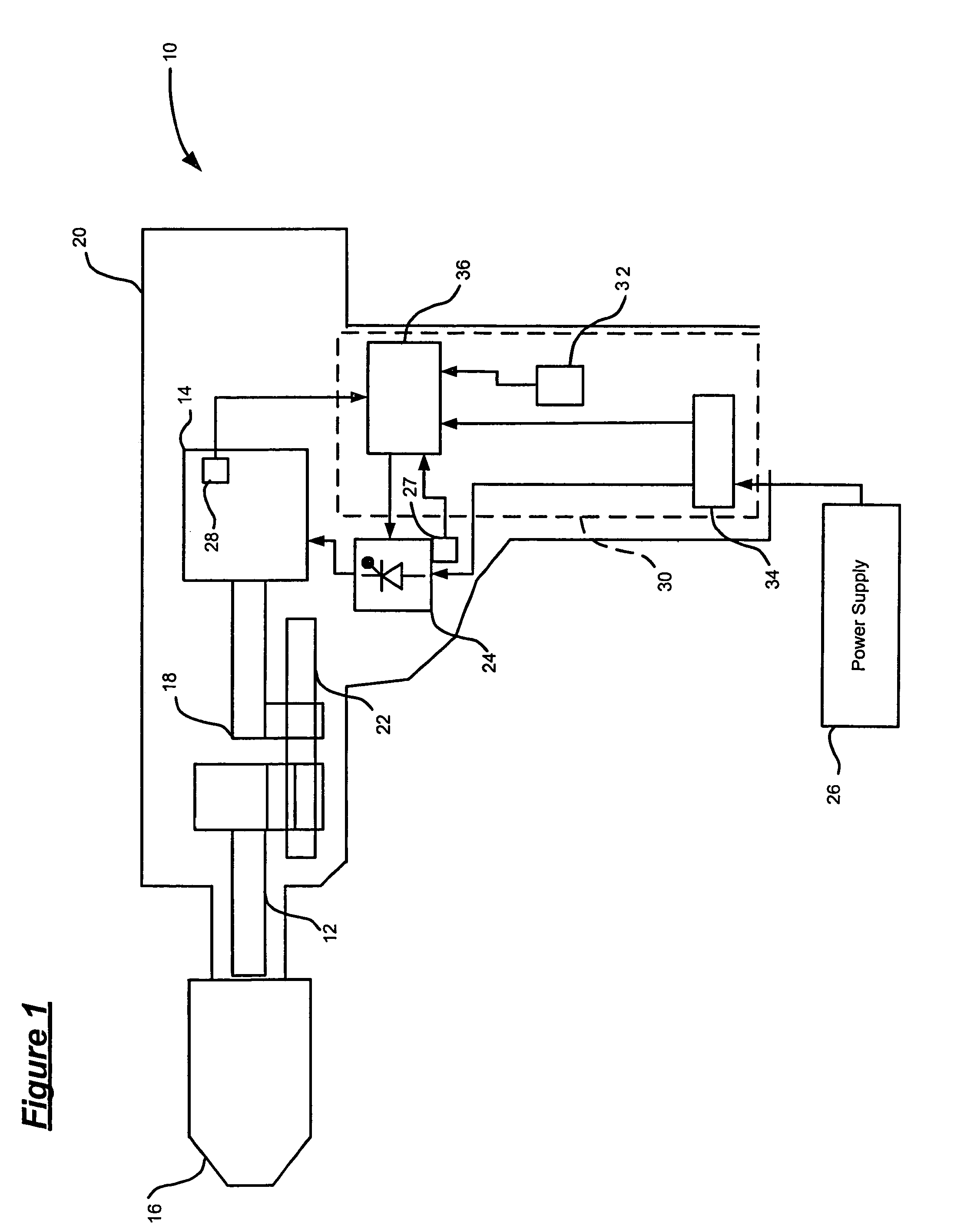

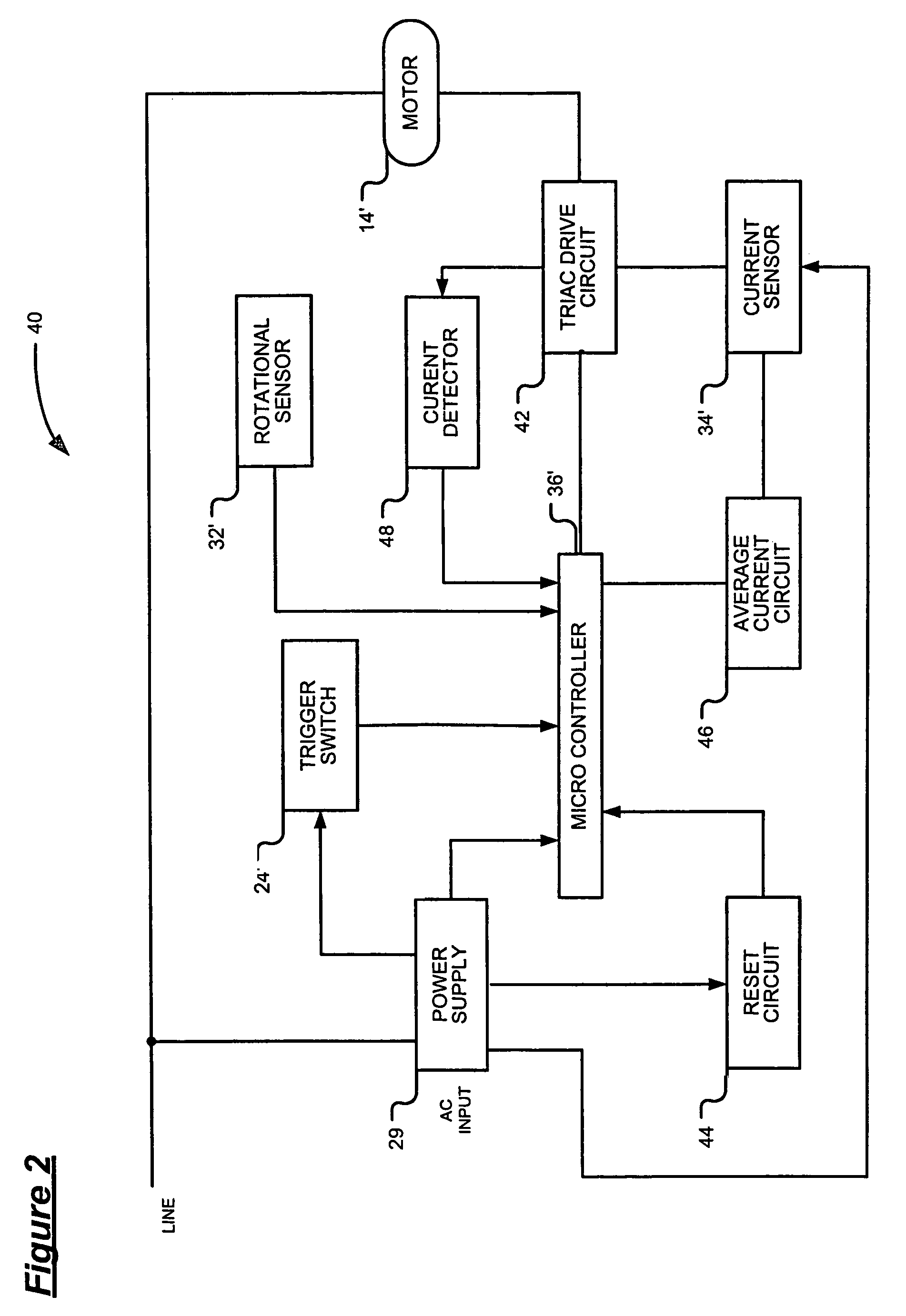

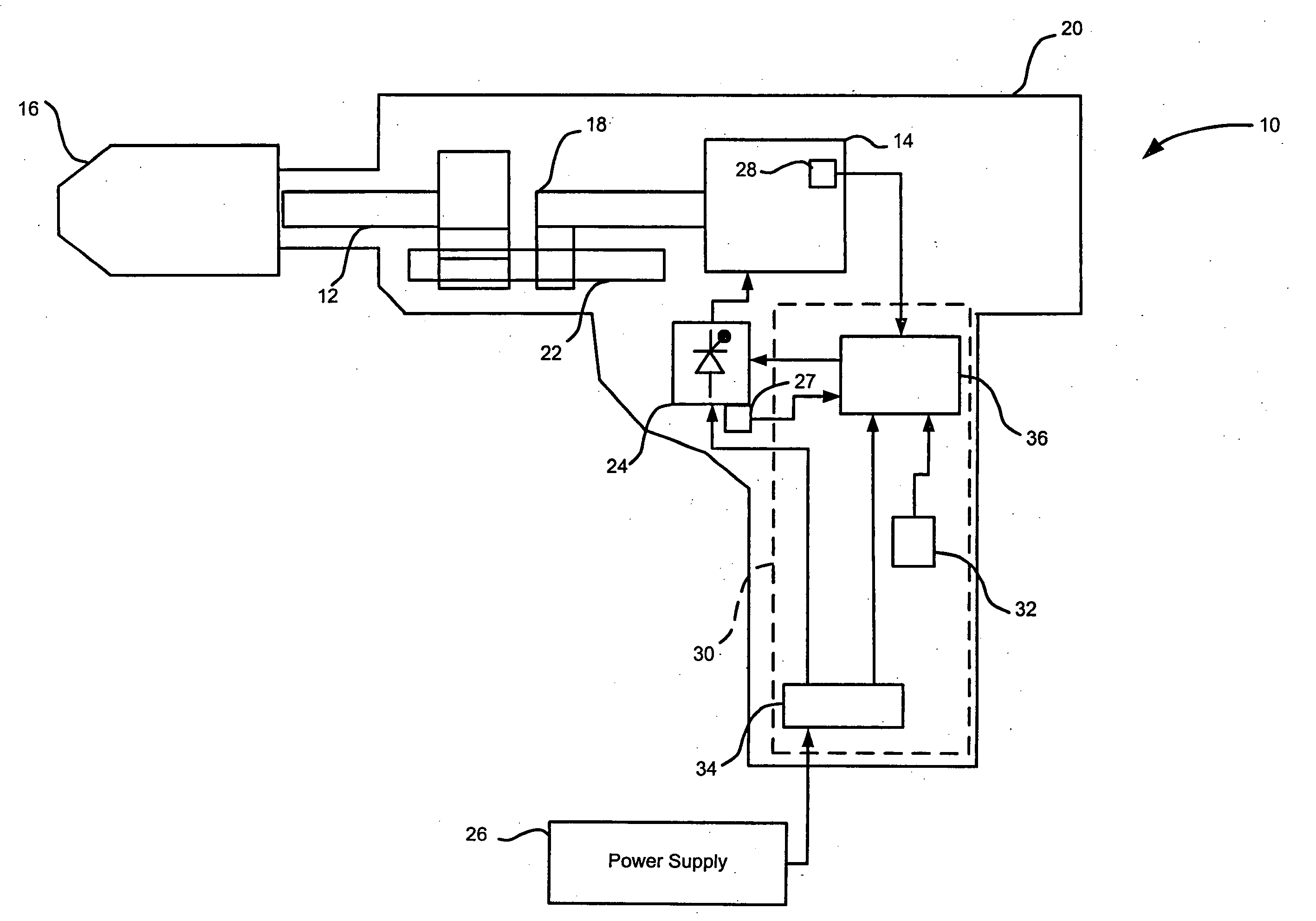

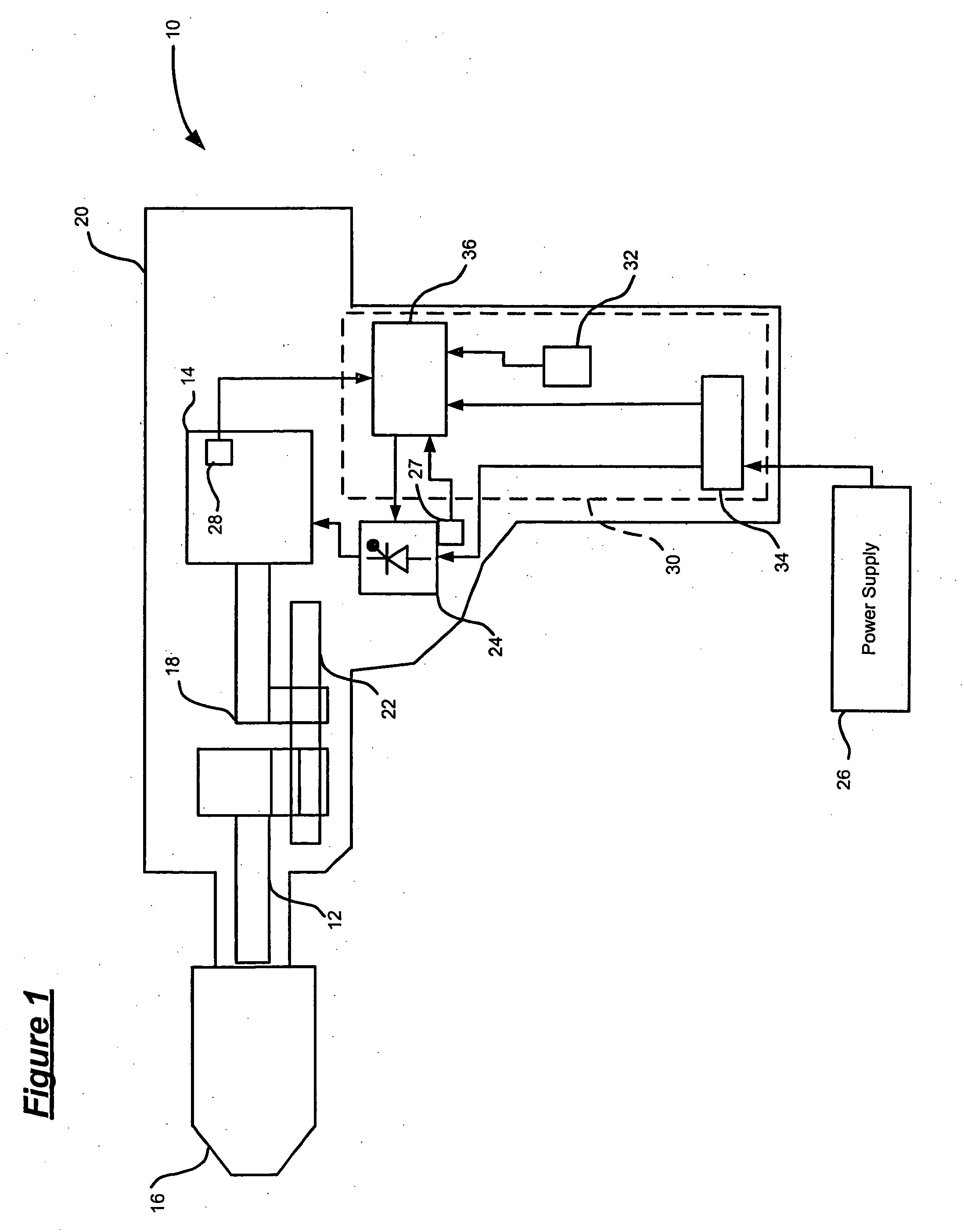

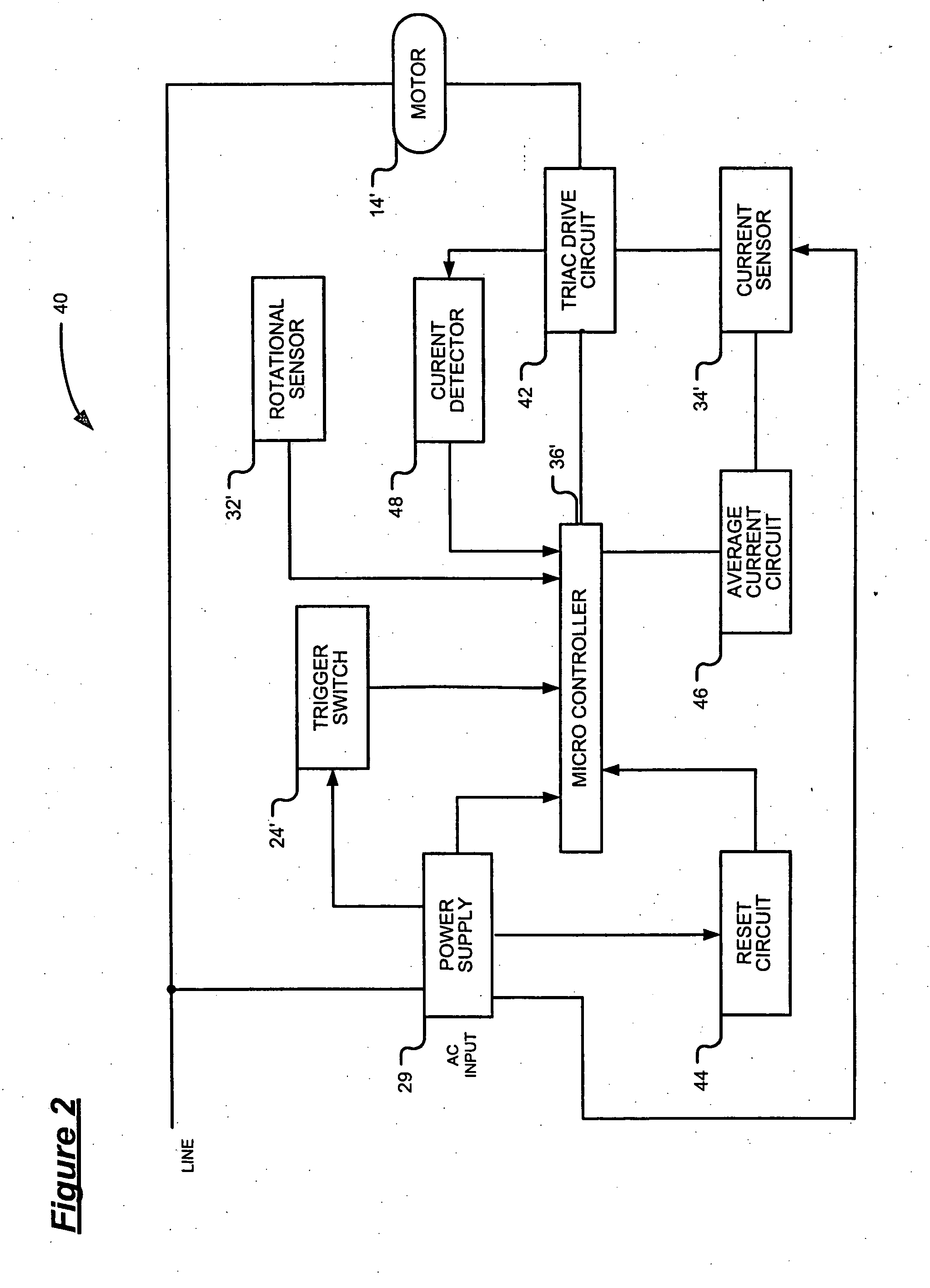

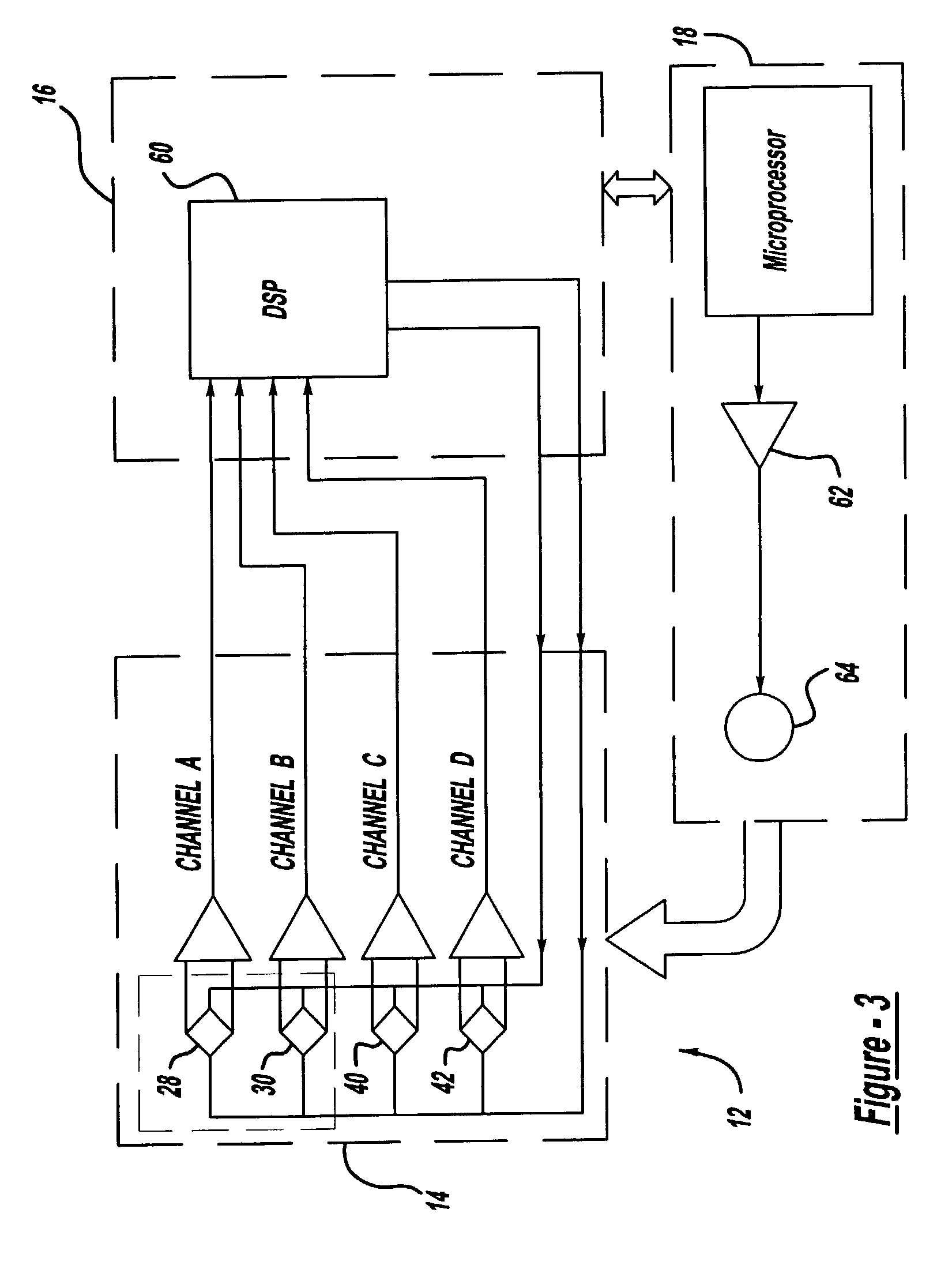

Power tool anti-kickback system with rotational rate sensor

A control system is provided for use in a power tool. The control system includes: a rotational rate sensor having a resonating mass and a controller electrically connected to the rotational rate sensor. The rotational rate sensor detects lateral displacement of the resonating mass and generates a signal indicative of the detected lateral displacement, such that the lateral displacement is directly proportional to a rotational speed at which the power tool rotates about an axis of the rotary shaft. Based on the generated signal, the controller initiates a protective operation to avoid further undesirable rotation of the power tool. The control scheme employed by the power tool may initiate different protective operations for different tool conditions.

Owner:BLACK & DECKER INC

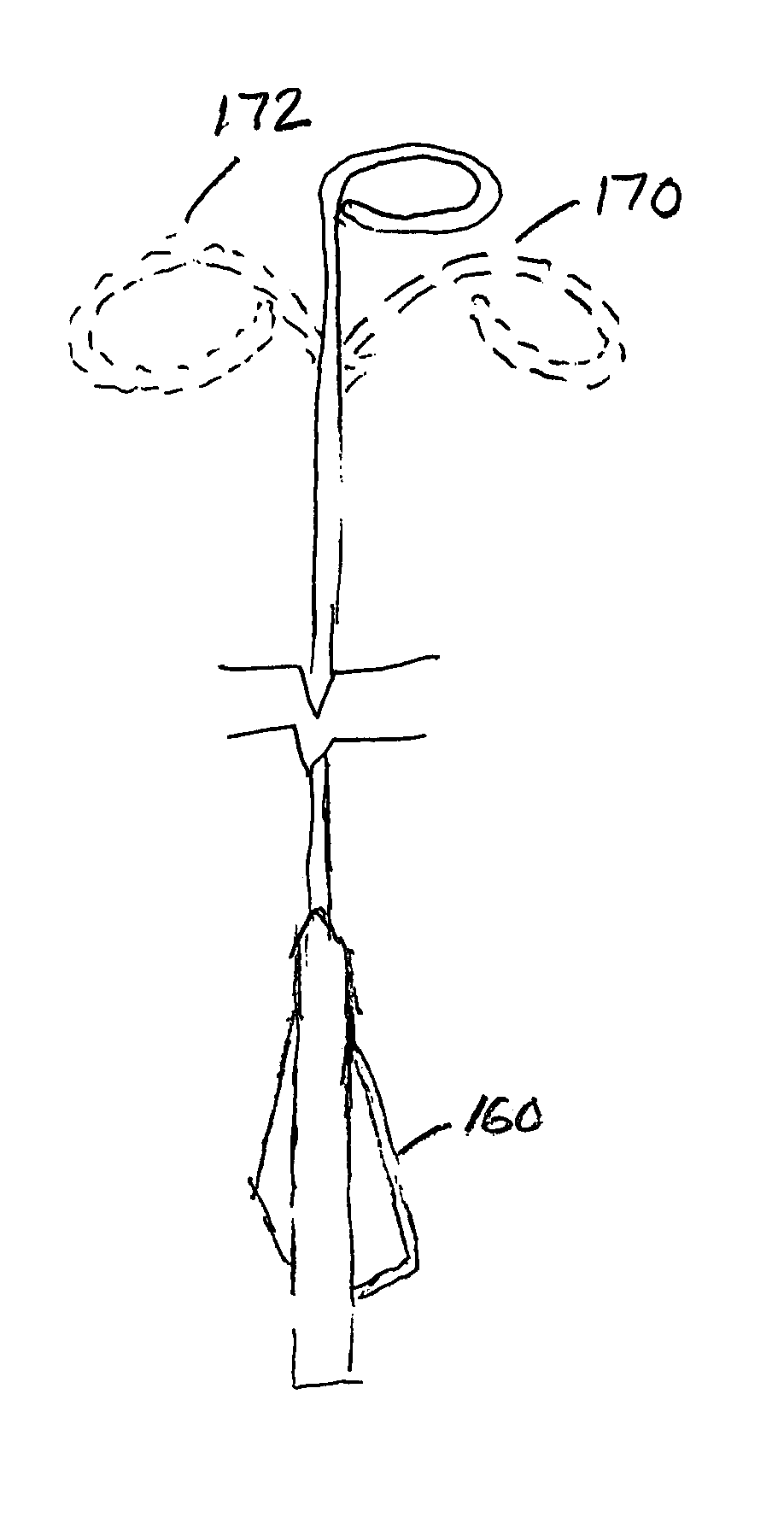

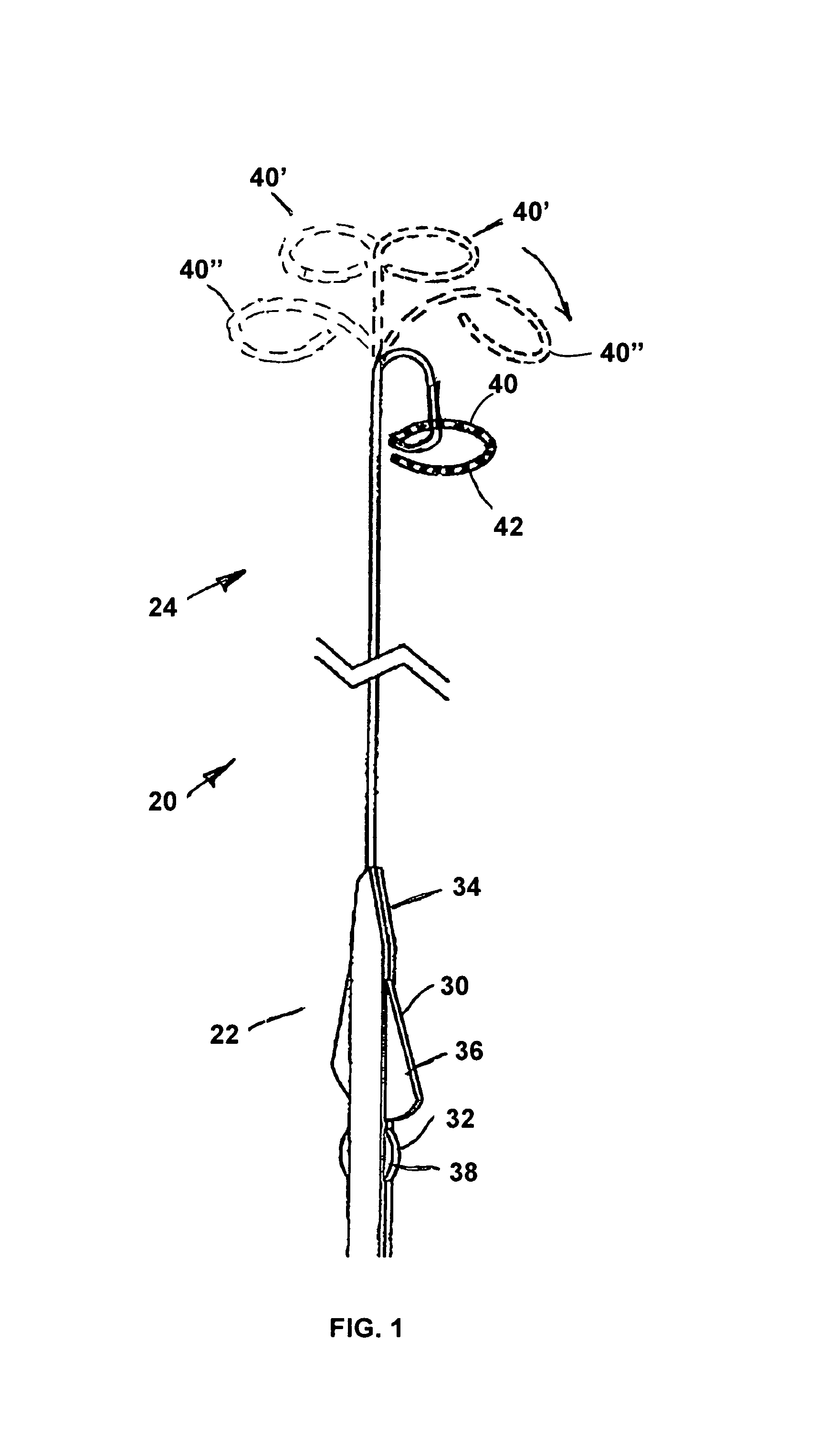

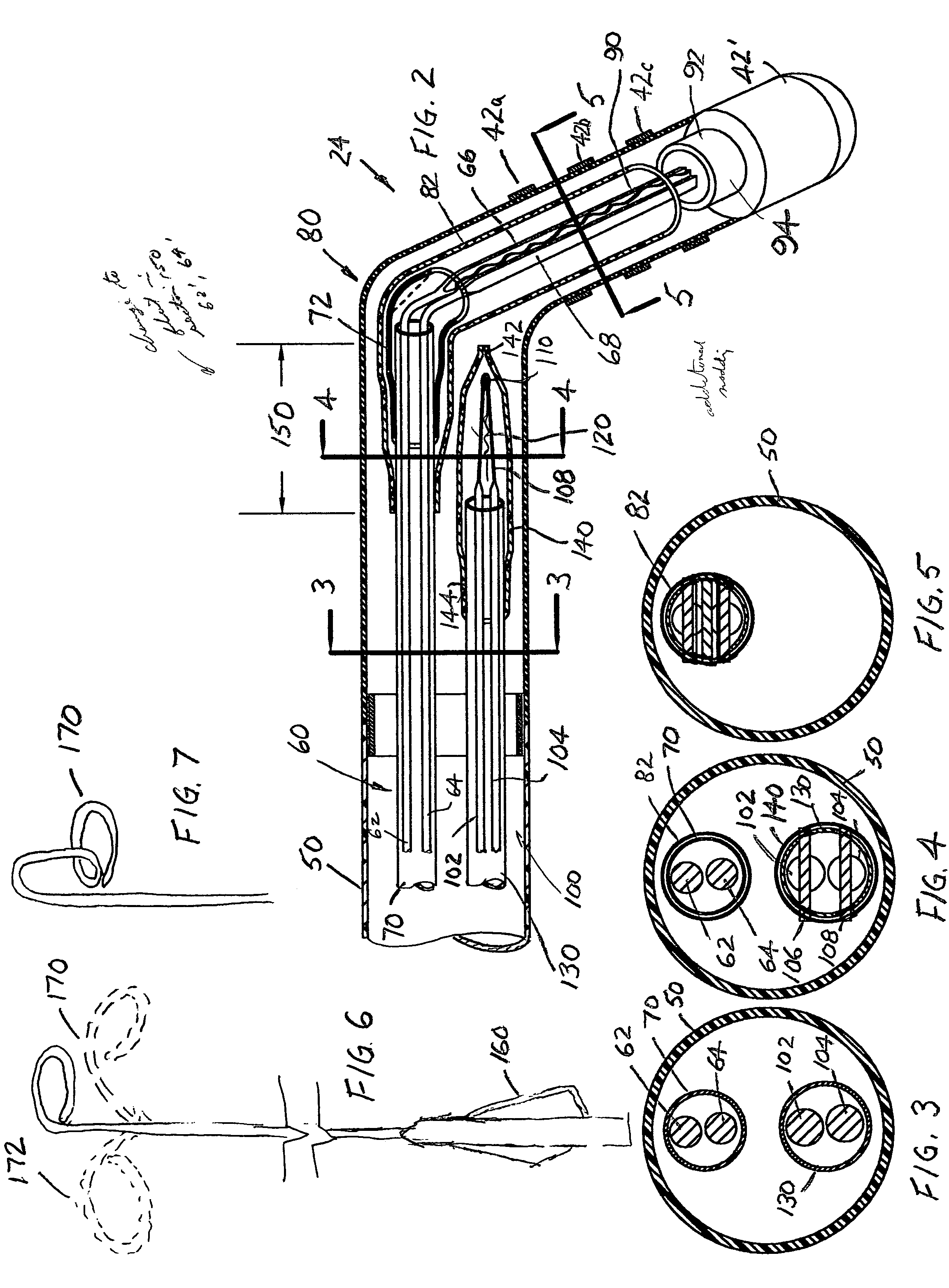

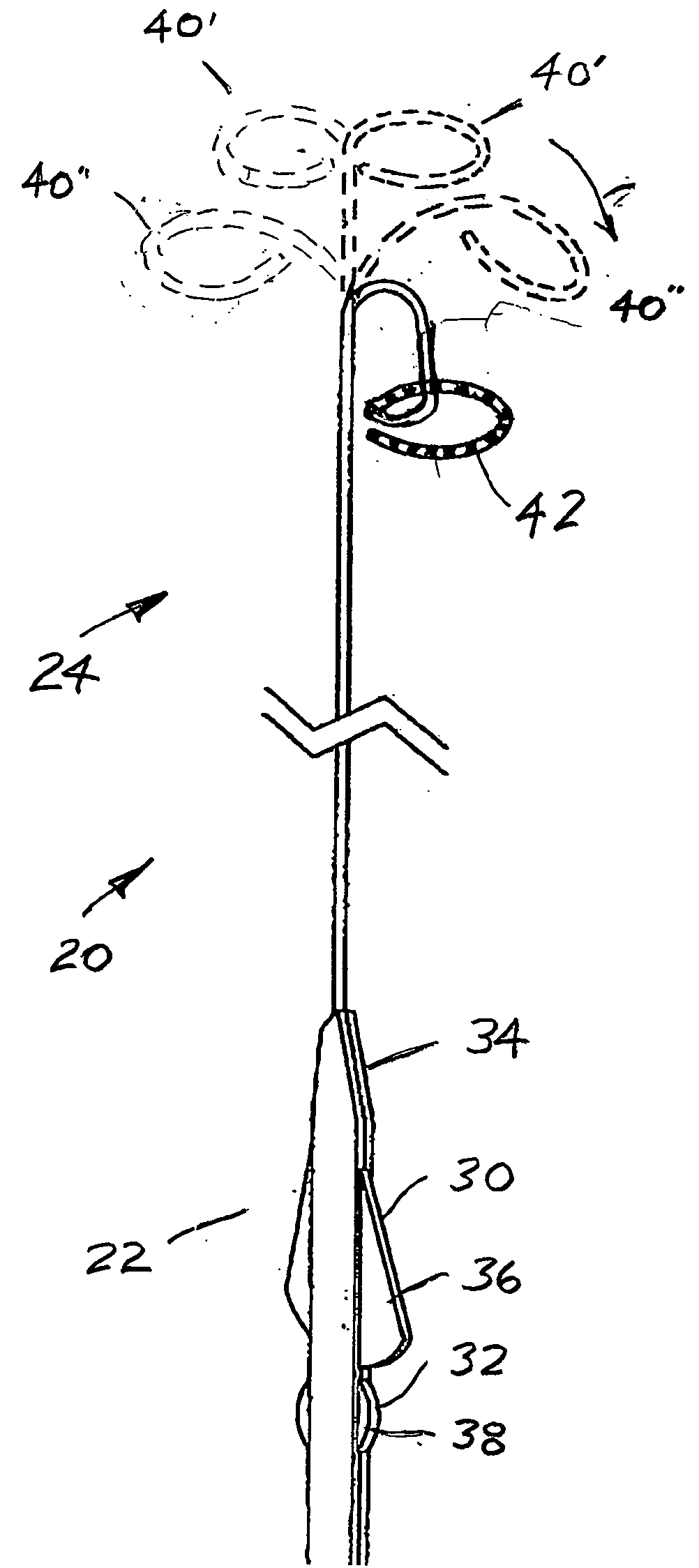

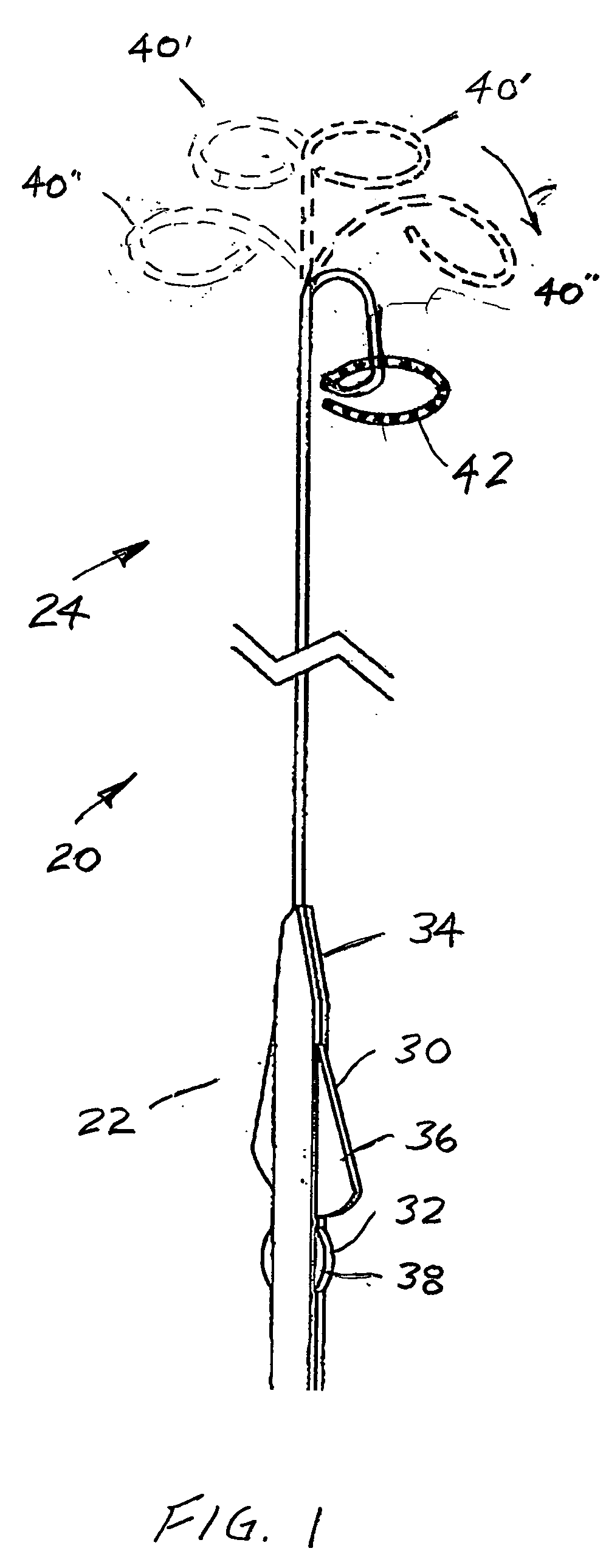

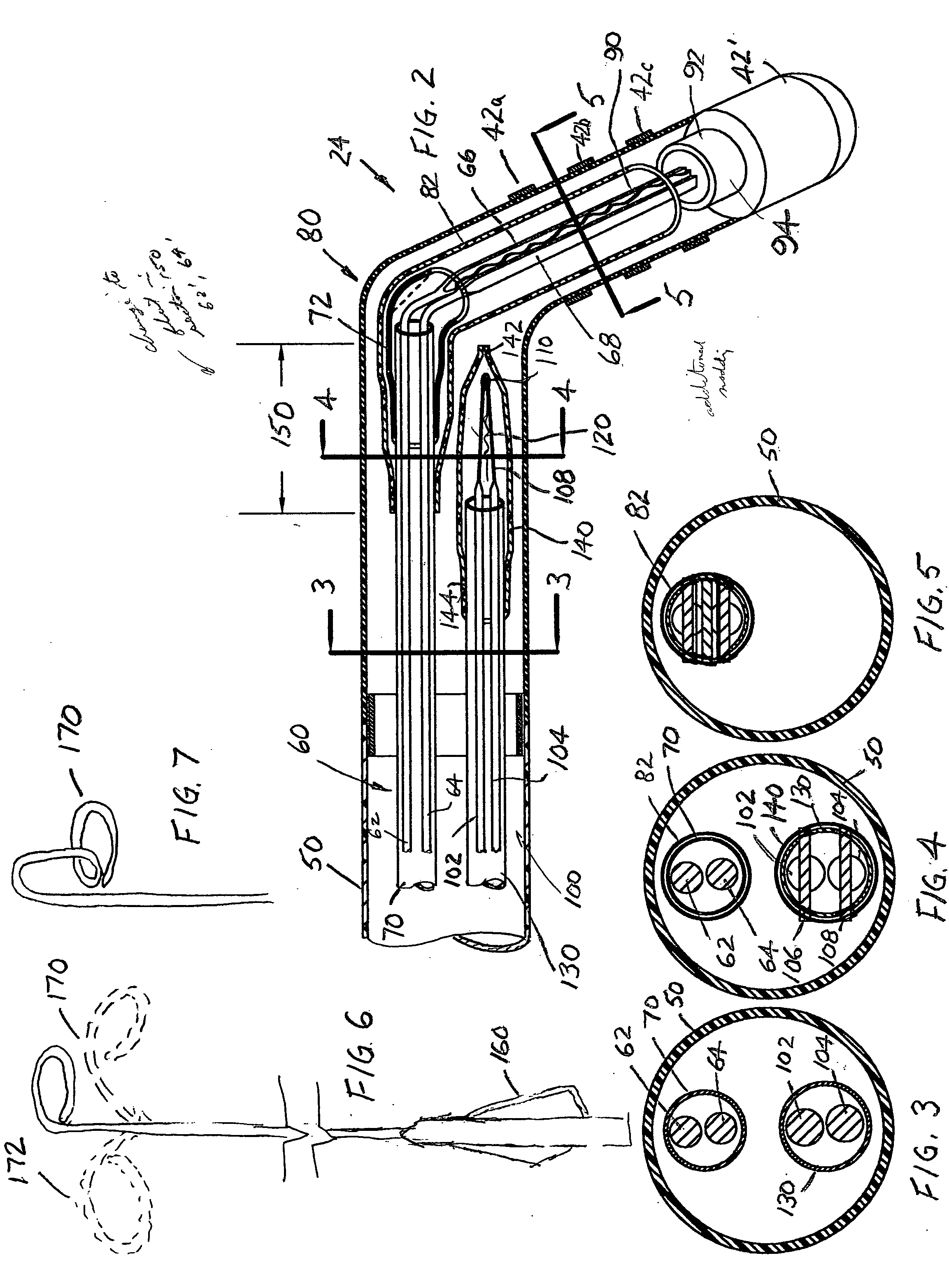

Electrophysiology/ablation catheter having deflection assembly

An electrophysiology / ablation catheter assembly includes an elongated flexible casing that received a first catheter deflection assembly. Electrical leads are connected to each electrode on a distal portion of the catheter assembly and extend through the casing for external connection at a proximal end of the catheter assembly. A first actuator is operatively connected to the first catheter deflection assembly and operable upon movement to selectively effect displacement of the distal end. A second catheter deflection assembly is also disposed in the casing. A second actuator is connected adjacent the proximal end of the catheter deflection assembly and operable upon movement to selectively effect lateral displacement of the catheter at a location spaced from the first curved configuration of the distal end.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Power tool anti-kickback system with rotational rate sensor

A control system is provided for use in a power tool. The control system includes: a rotational rate sensor having a resonating mass and a controller electrically connected to the rotational rate sensor. The rotational rate sensor detects lateral displacement of the resonating mass and generates a signal indicative of the detected lateral displacement, such that the lateral displacement is directly proportional to a rotational speed at which the power tool rotates about an axis of the rotary shaft. Based on the generated signal, the controller initiates a protective operation to avoid further undesirable rotation of the power tool. The control scheme employed by the power tool may initiate different protective operations for different tool conditions.

Owner:BLACK & DECKER INC

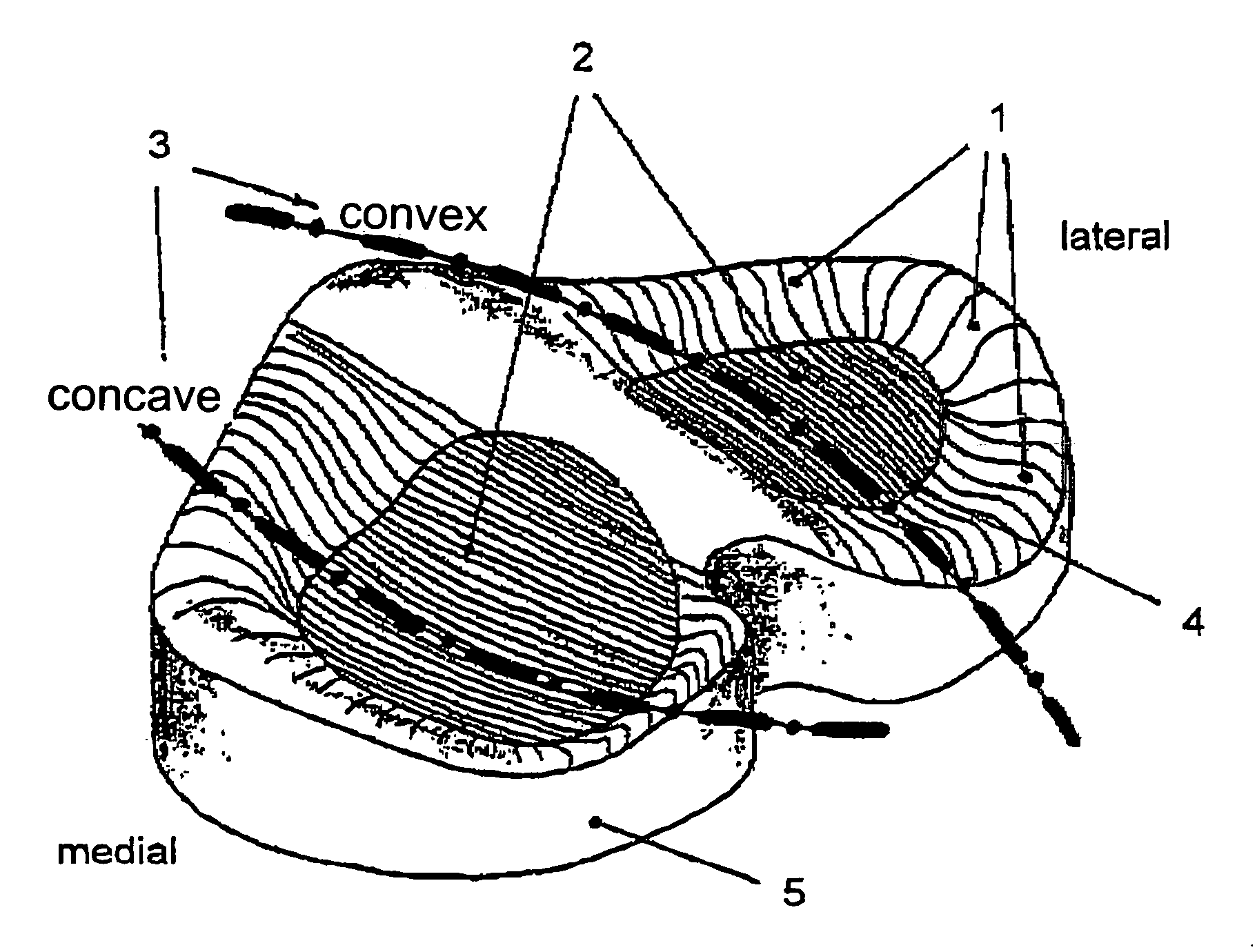

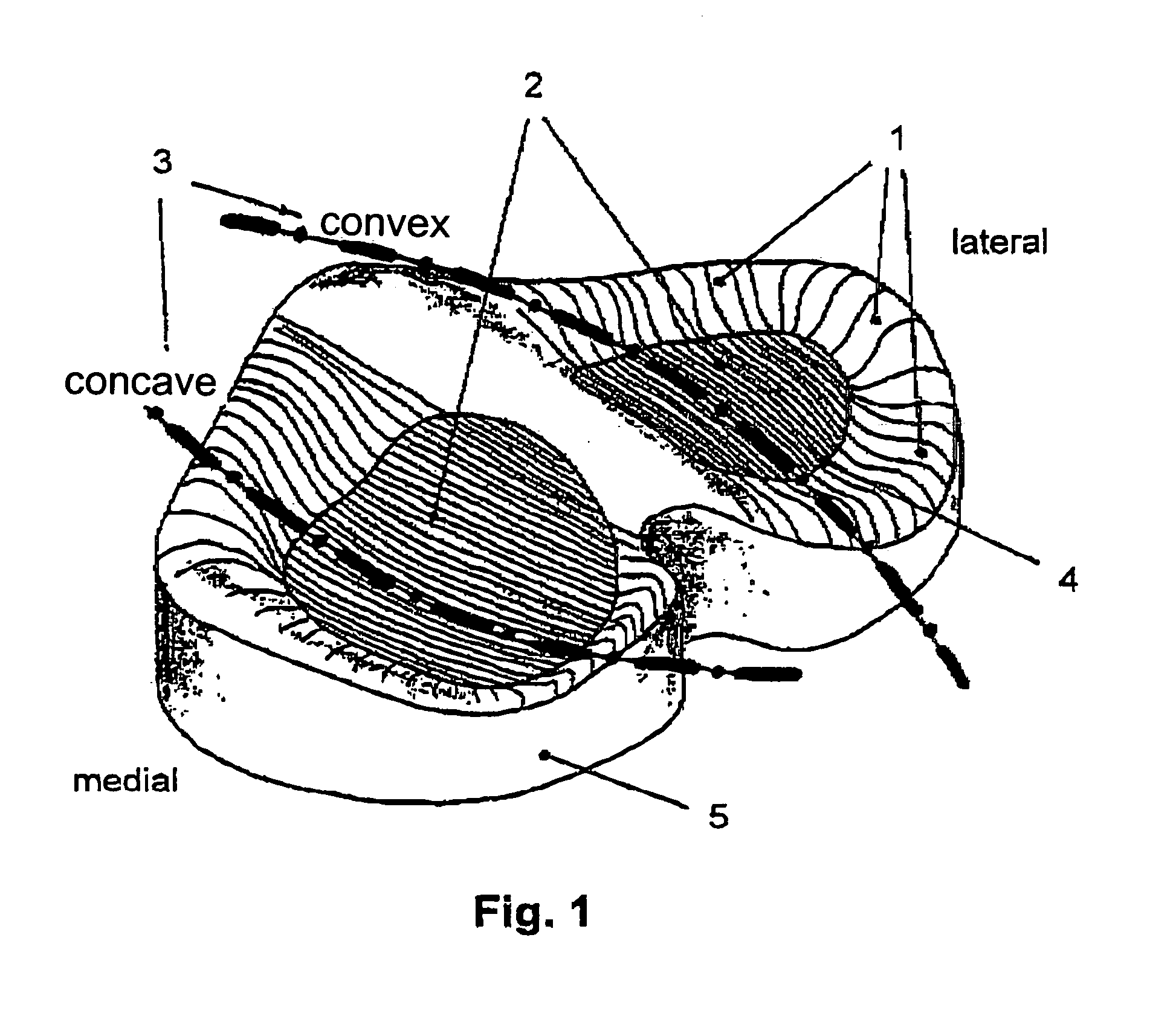

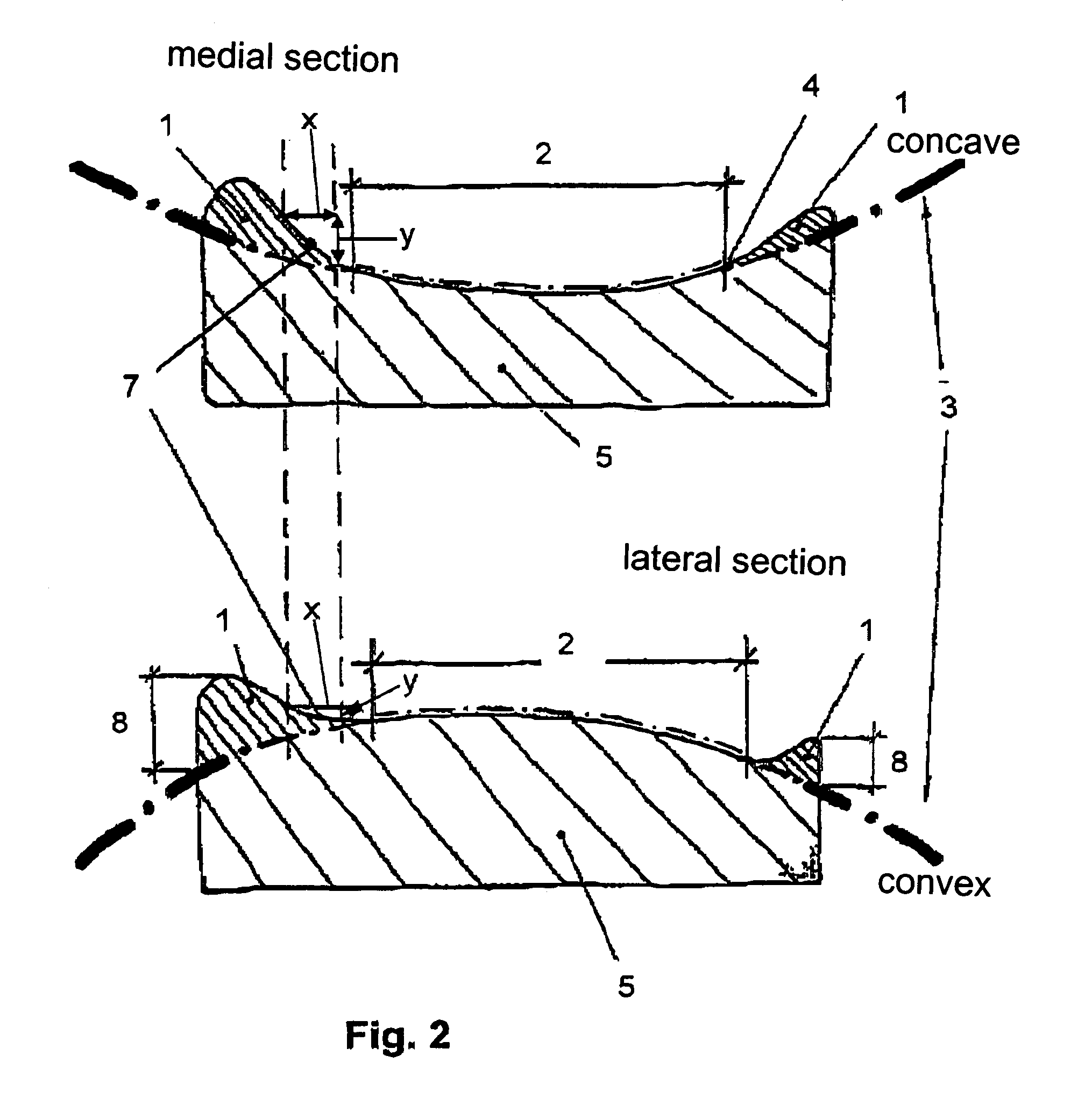

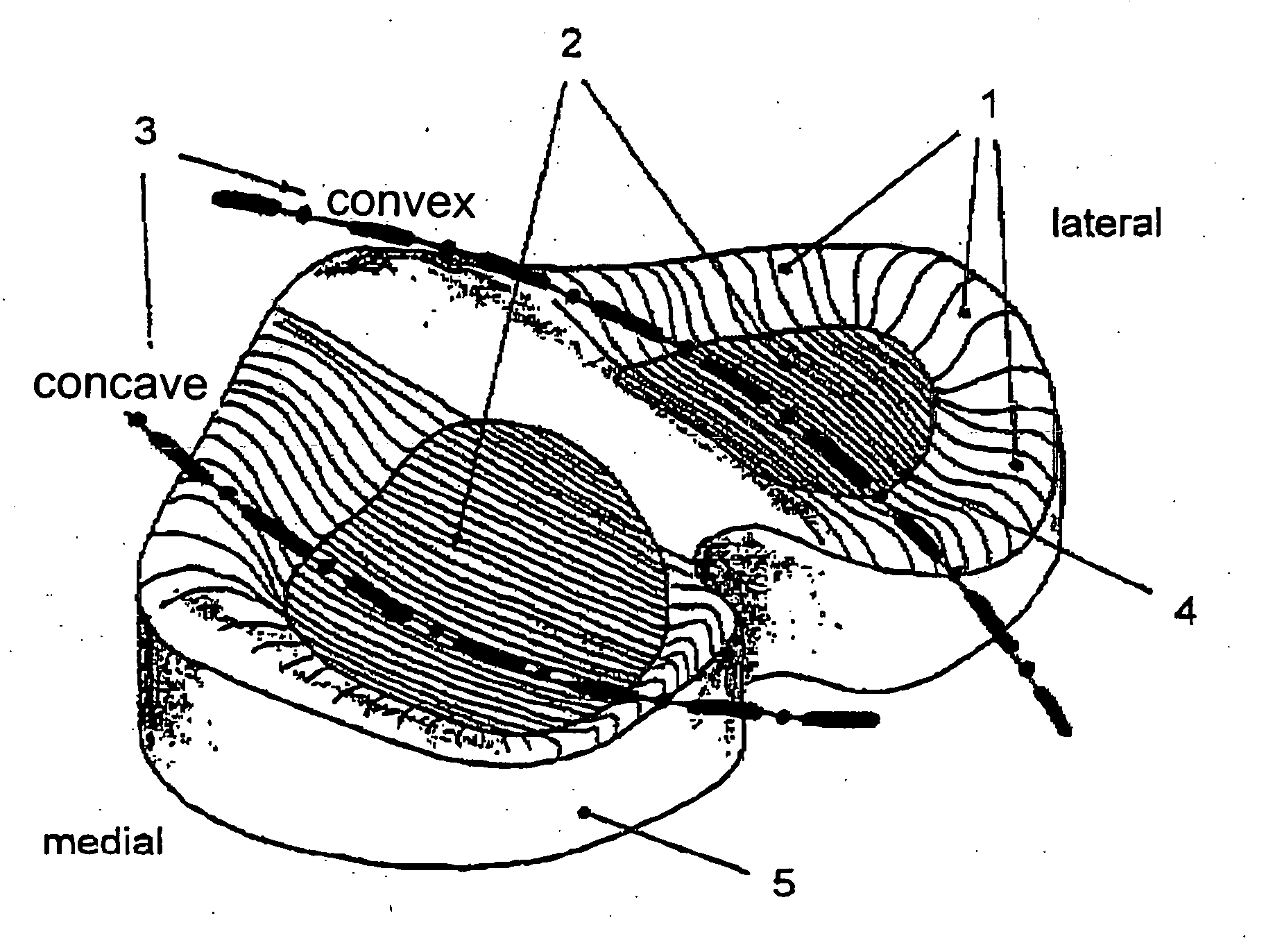

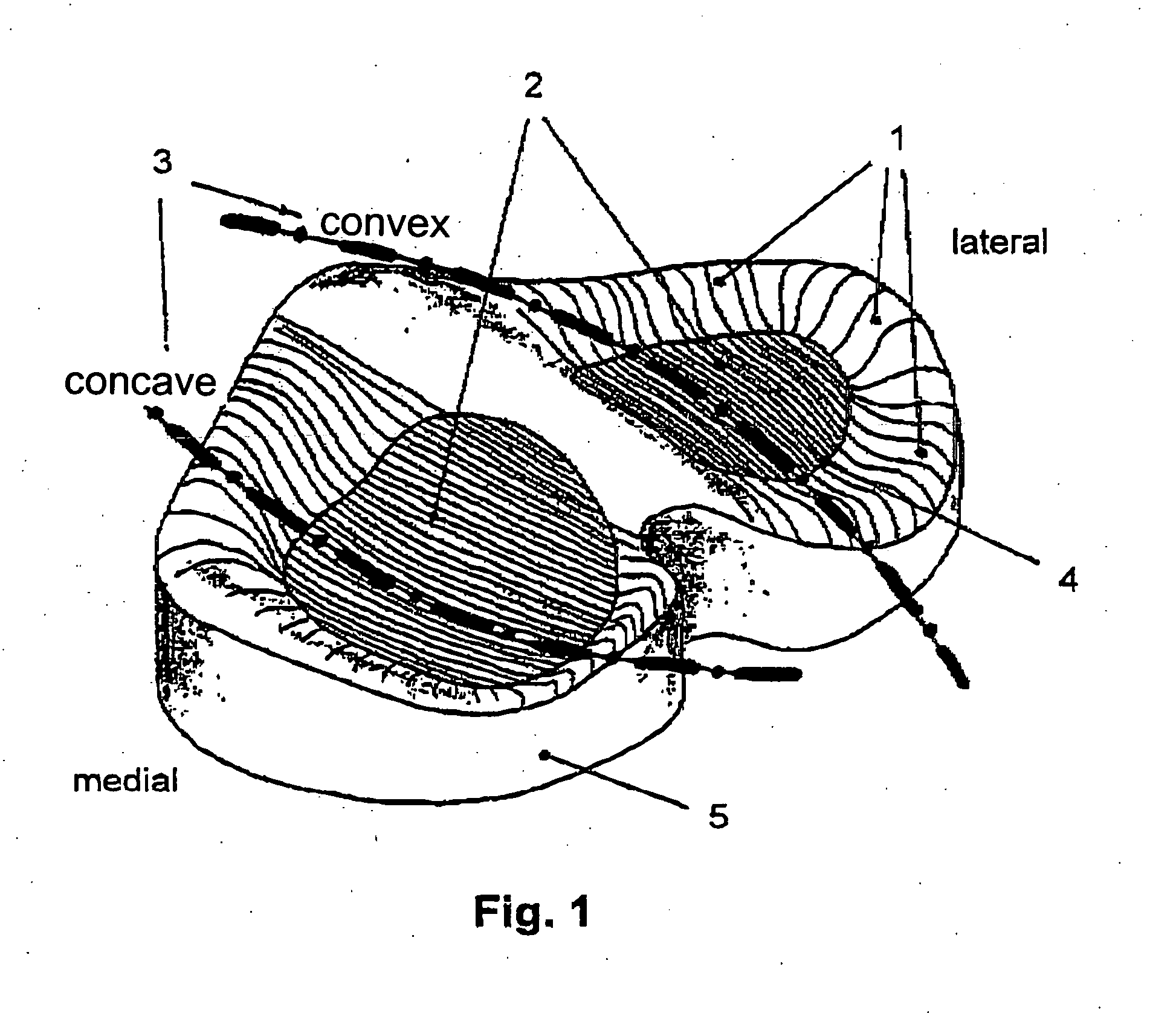

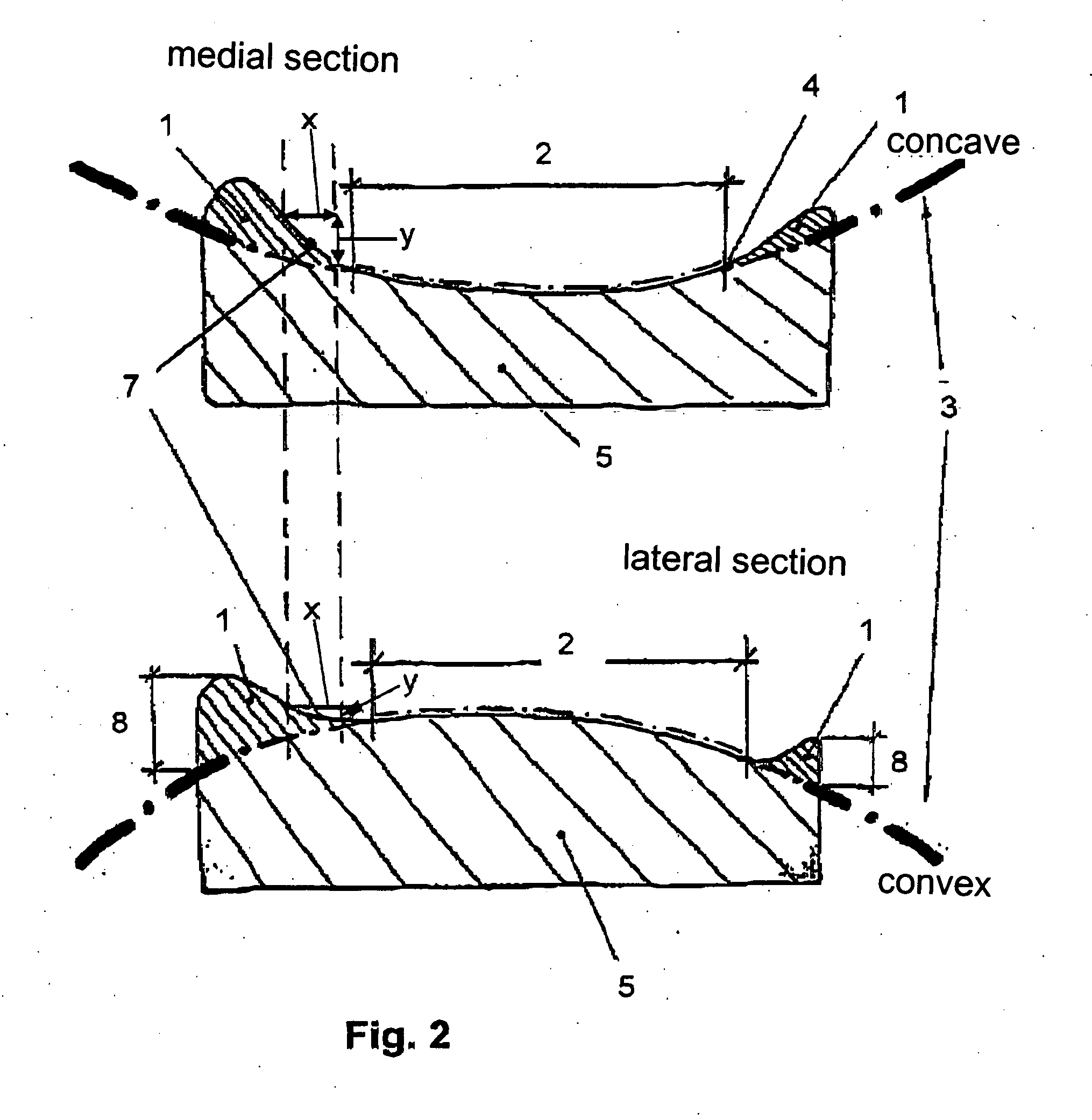

Tibia plateau for a replacement joint

ActiveUS7066963B2Restrict movementAvoid lateral displacementJoint implantsKnee jointsTibiaArticular surfaces

Owner:LIMA CORPORATE SPA

Tibia plateau for a replacement joint

ActiveUS20050197710A1Restrict movementAvoid lateral displacementJoint implantsKnee jointsTibiaArtificial joints

A tibia plateau for a replacement joint, particularly an endoprosthesis for a human knee joint, in which the head and socket artificial joint parts have convex and concave articulation surfaces, respectively, and the articulation surfaces are arranged in pairs, so that the functional surfaces which are formed can roll against one another along a curved contact line, especially a circularly arcuate contact line, formed on each articulation surface. A gently sloping bulge (1) is formed in the area (4) adjacent the functional surfaces (2) which bulge prevents excessive rolling movement and lateral displacement of the joint parts relative to each other.

Owner:LIMA CORPORATE SPA

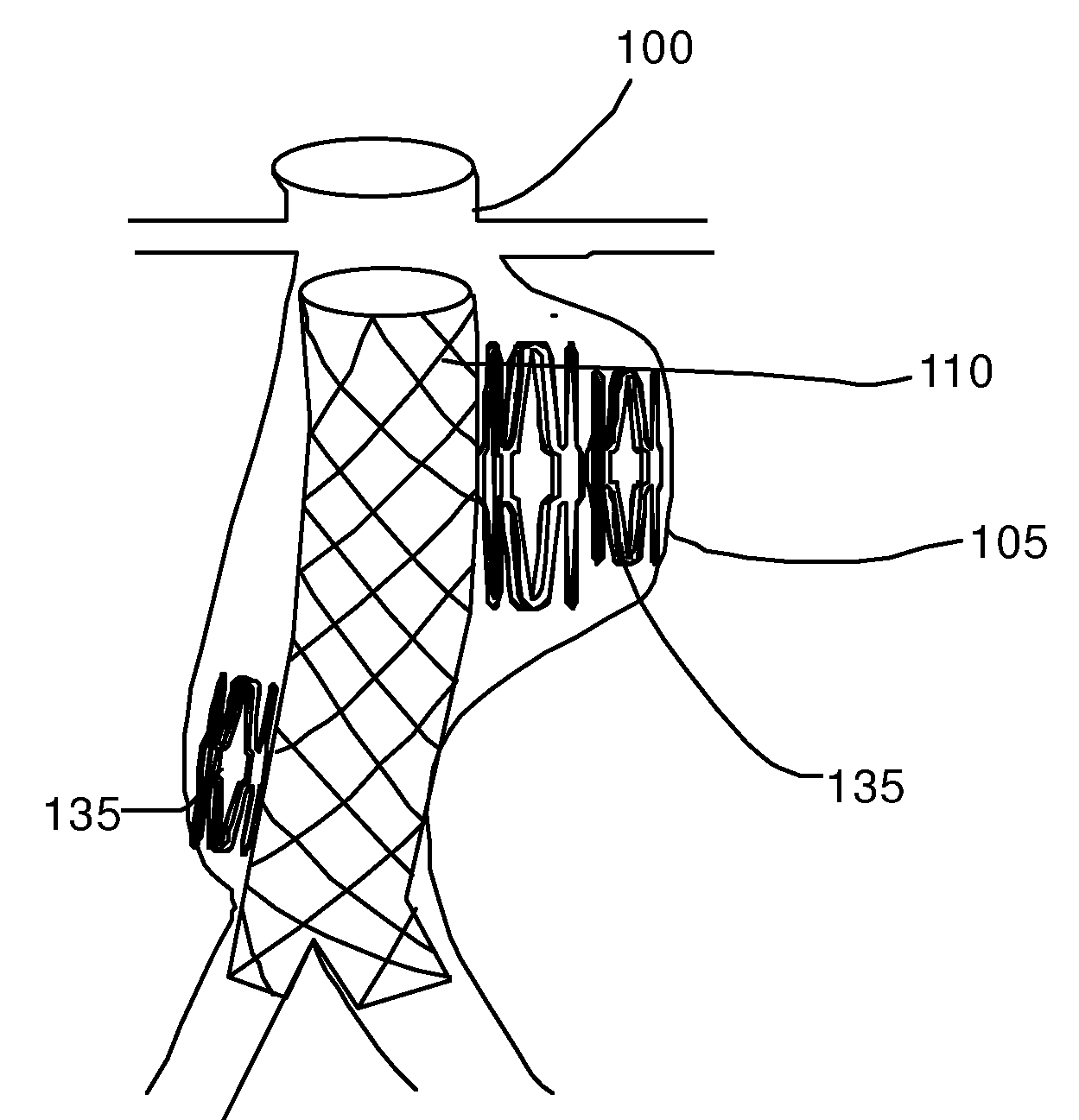

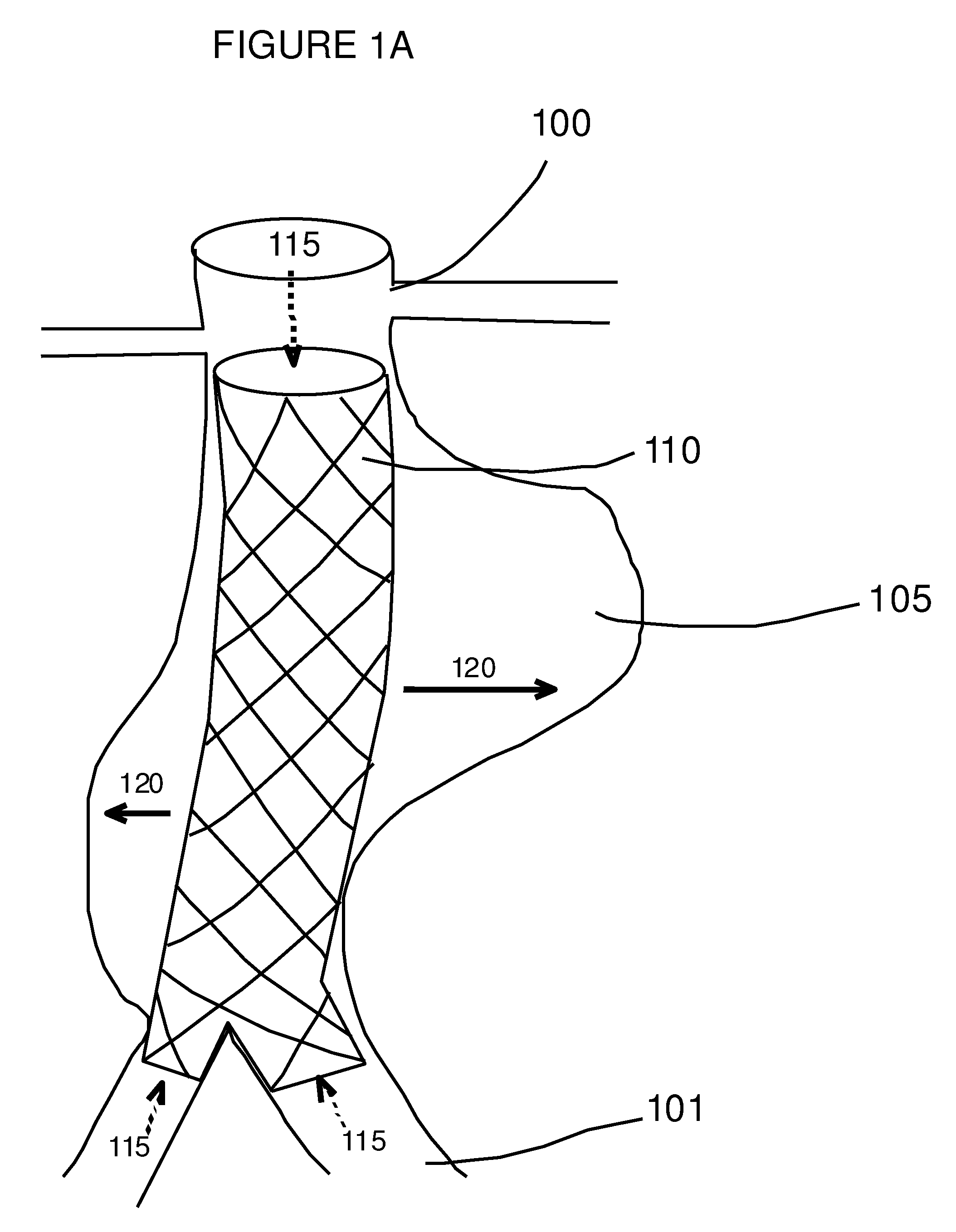

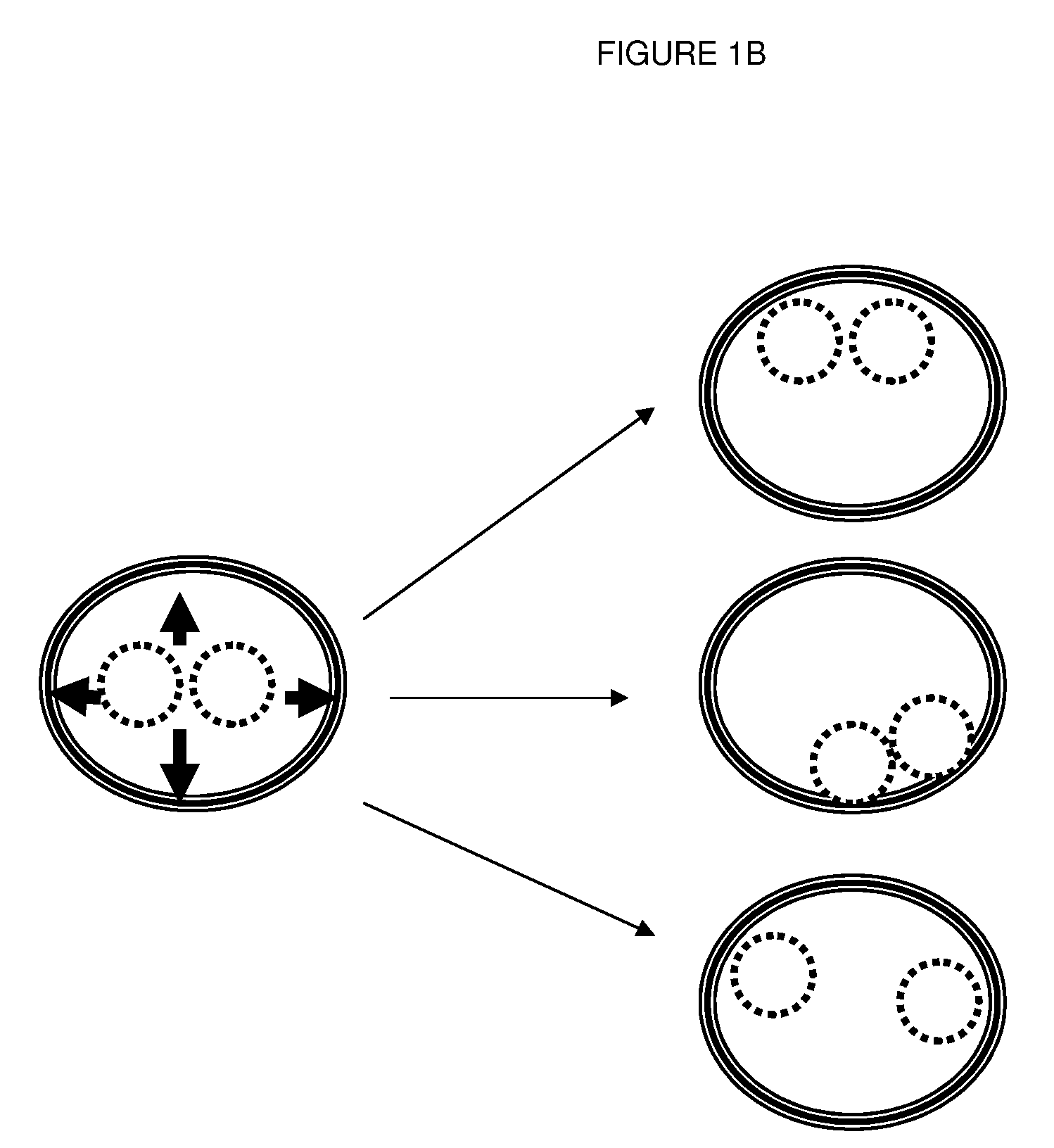

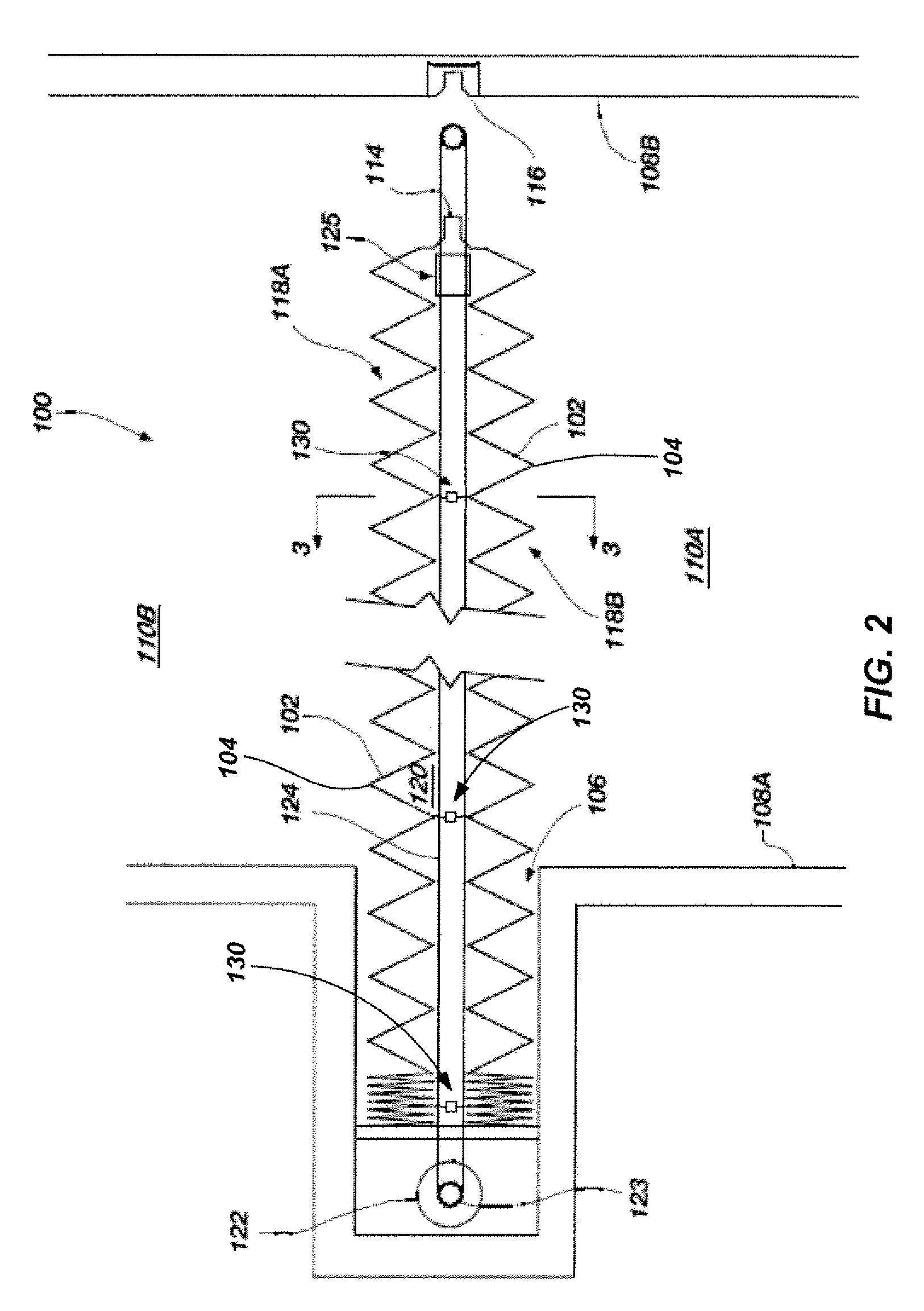

Prevention of displacement of prosthetic devices within aneurysms

InactiveUS20080275536A1Augmenting resistance to migrationAvoid lateral displacementStentsBlood vesselsStent graftingImplanted device

Devices and methods are provided for reducing the lateral displacement of an endovascular device, e.g. a stent graft, within an aneurysm sac. A stabilization system comprising one or more stabilizing elements is inserted within the aneurysm space between an implanted device and the vessel wall. Filling this space prevents changes in curvature of the implanted endovascular device, and prevents longitudinal displacement, thereby providing for improved long-term stability and durability of endovascular repair.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Driverless vehicle guidance system and method

InactiveUS6971464B2Prevent false detectionAutomatic initiationsNon-mechanical steering controlMagnetic markerEngineering

A vehicle guidance system for guiding a vehicle along a magnetic marker including a first magnetic sensor having a sensing axis, the first sensor measuring a first magnetic field. A second magnetic sensor has a sensing axis, the second sensor measuring a second magnetic field. The sensing axis of the second magnetic sensor crosses the sensing axis of the first magnetic sensor at a vehicle guide point. A processor is configured to receive data representative of the magnetic field measured by the first and second sensors and to calculate a lateral offset between the guide point and the magnetic marker based upon the measured magnetic fields. A method for guiding a vehicle in response to a marker having magnetic field is also disclosed. The steps of the method include measuring magnetic field strength proximate the marker, measuring ambient magnetic field strength remote from the marker, nulling the ambient magnetic field by removing the remote magnetic field strength from the proximate magnetic field strength, calculating a lateral displacement between the vehicle and the marker using the nulled magnetic field strength, and guiding the vehicle in response to the lateral displacement between the vehicle and the marker.

Owner:JERVIS B WEBB INT CO

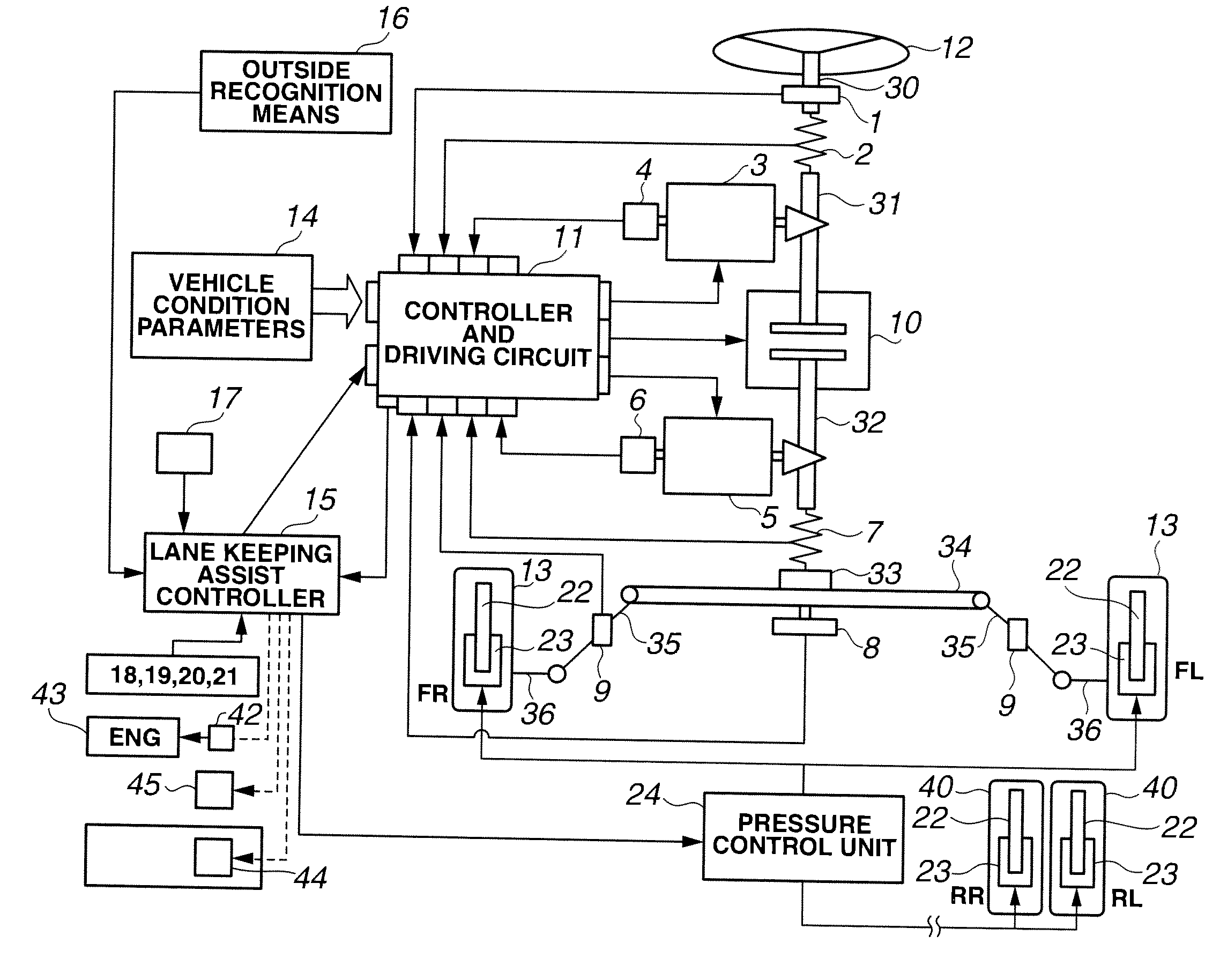

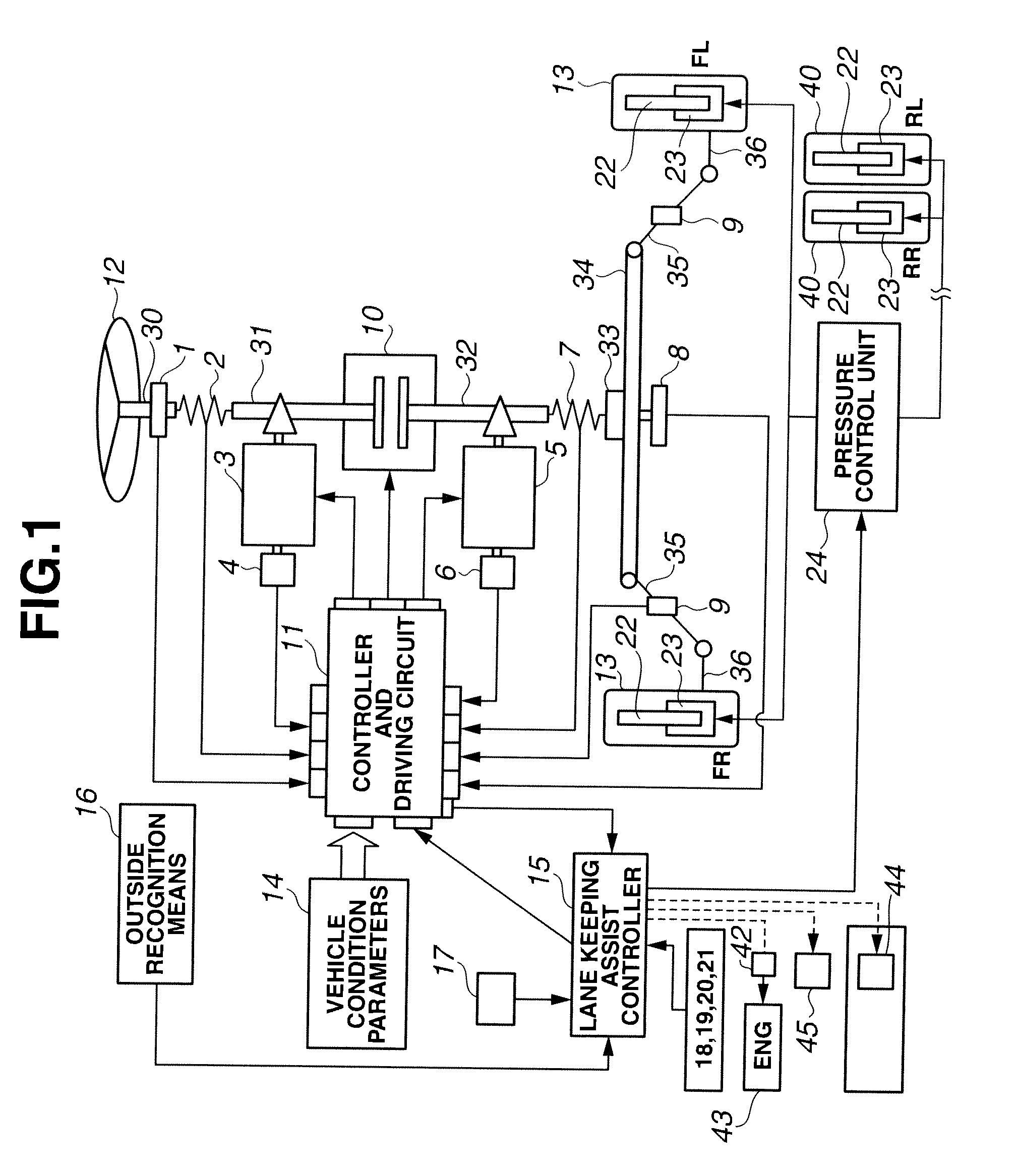

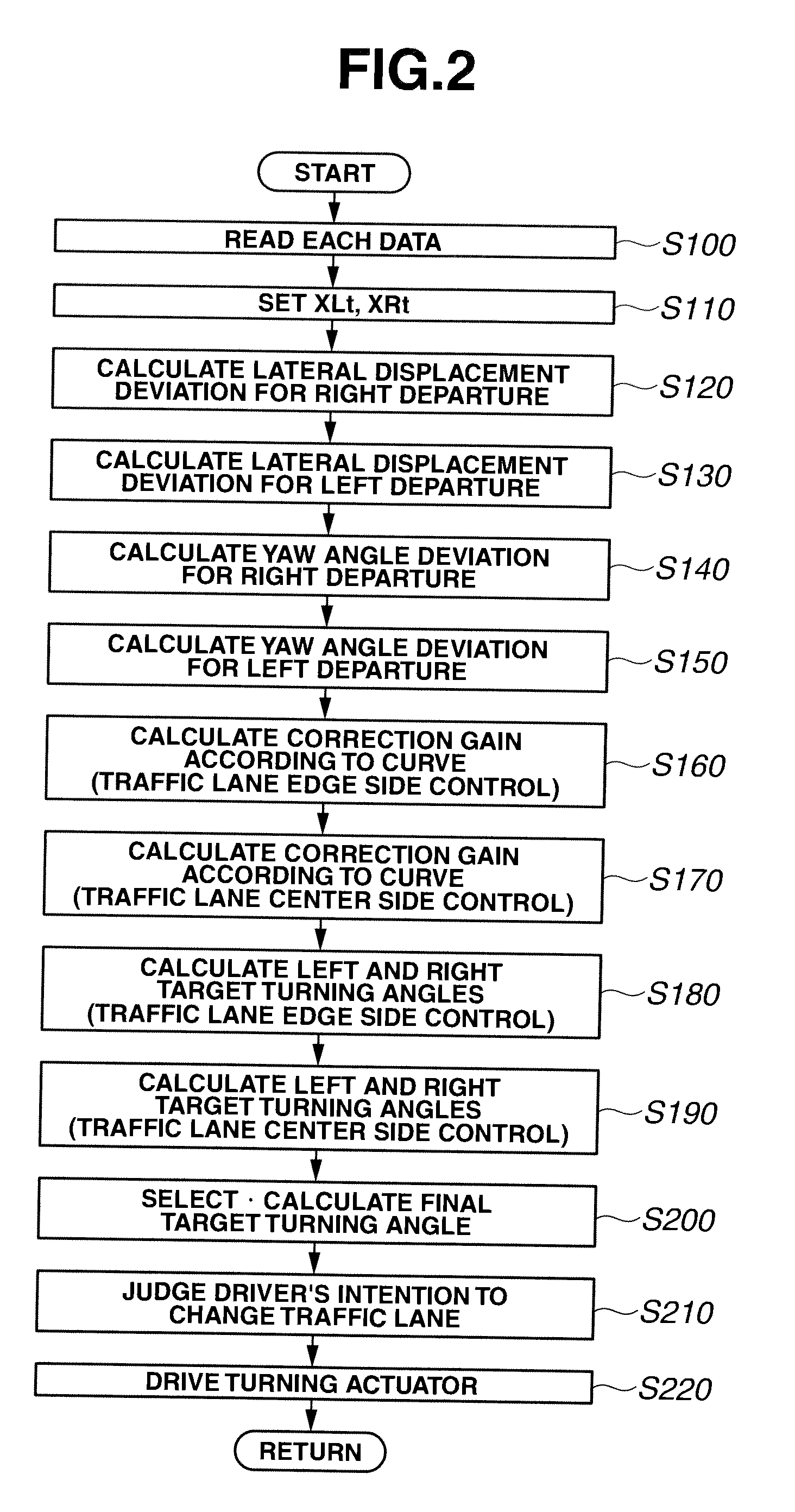

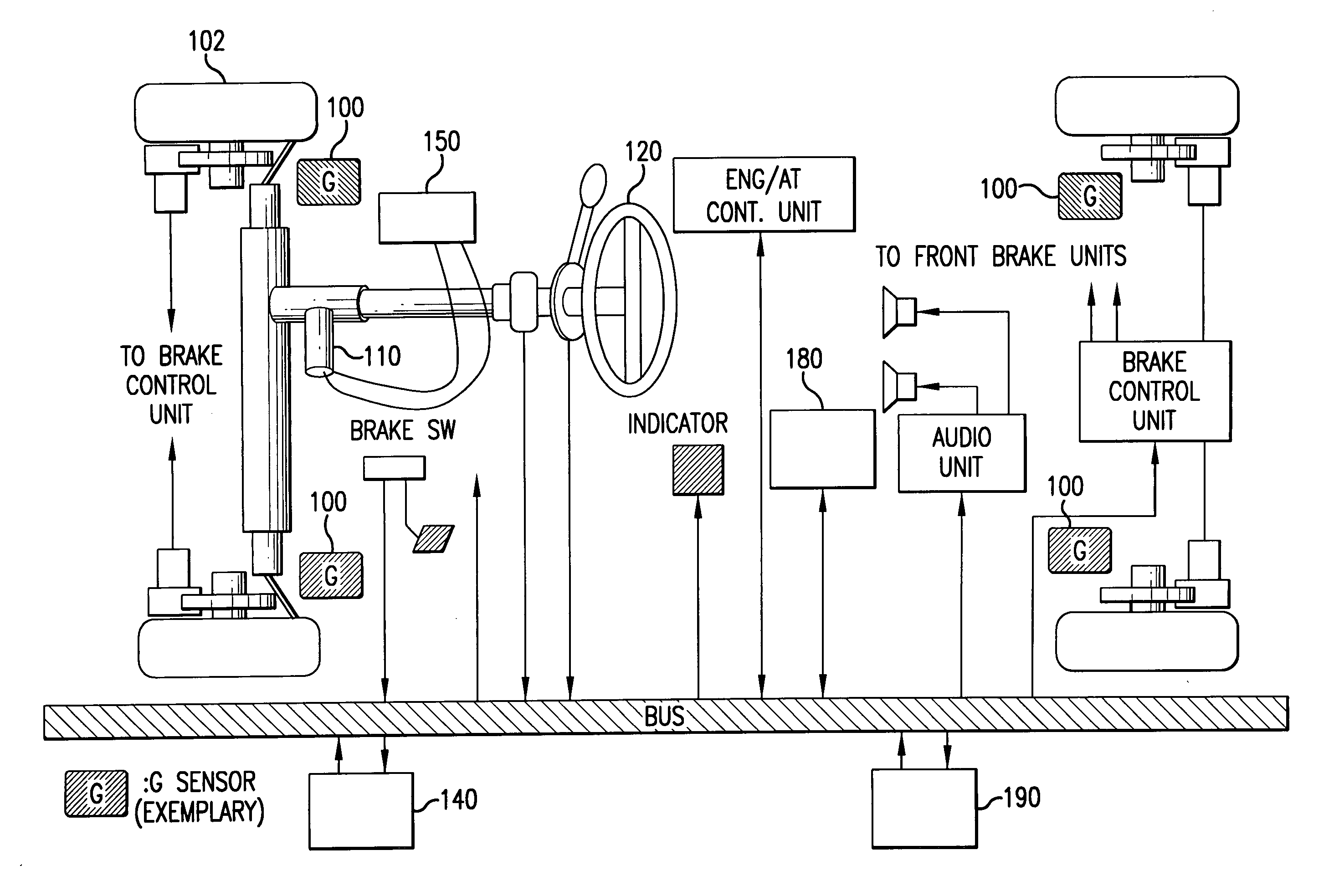

Lane keeping assist device and lane keeping assist method

ActiveUS20110015850A1Lessen awkward feelingAvoid performance degradationDigital data processing detailsAutomatic steering controlFeedback controlLateral displacement

Lateral displacement reference positions LXL, LXR are set on left and right from a center in a width direction of a traffic lane L where a vehicle travels. Then, at least in a case where the vehicle is positioned on an inner side of the left and right lateral displacement reference position LXL, LXR, the vehicle is feedback-controlled so as to decrease a yaw angle deviation. Further, in a case where the vehicle is positioned at an outer side of the left and right lateral displacement reference position LXL, LXR with respect to the traffic lane center, the feedback control is performed so as to decrease the angle deviation and a lateral displacement deviation.

Owner:NISSAN MOTOR CO LTD

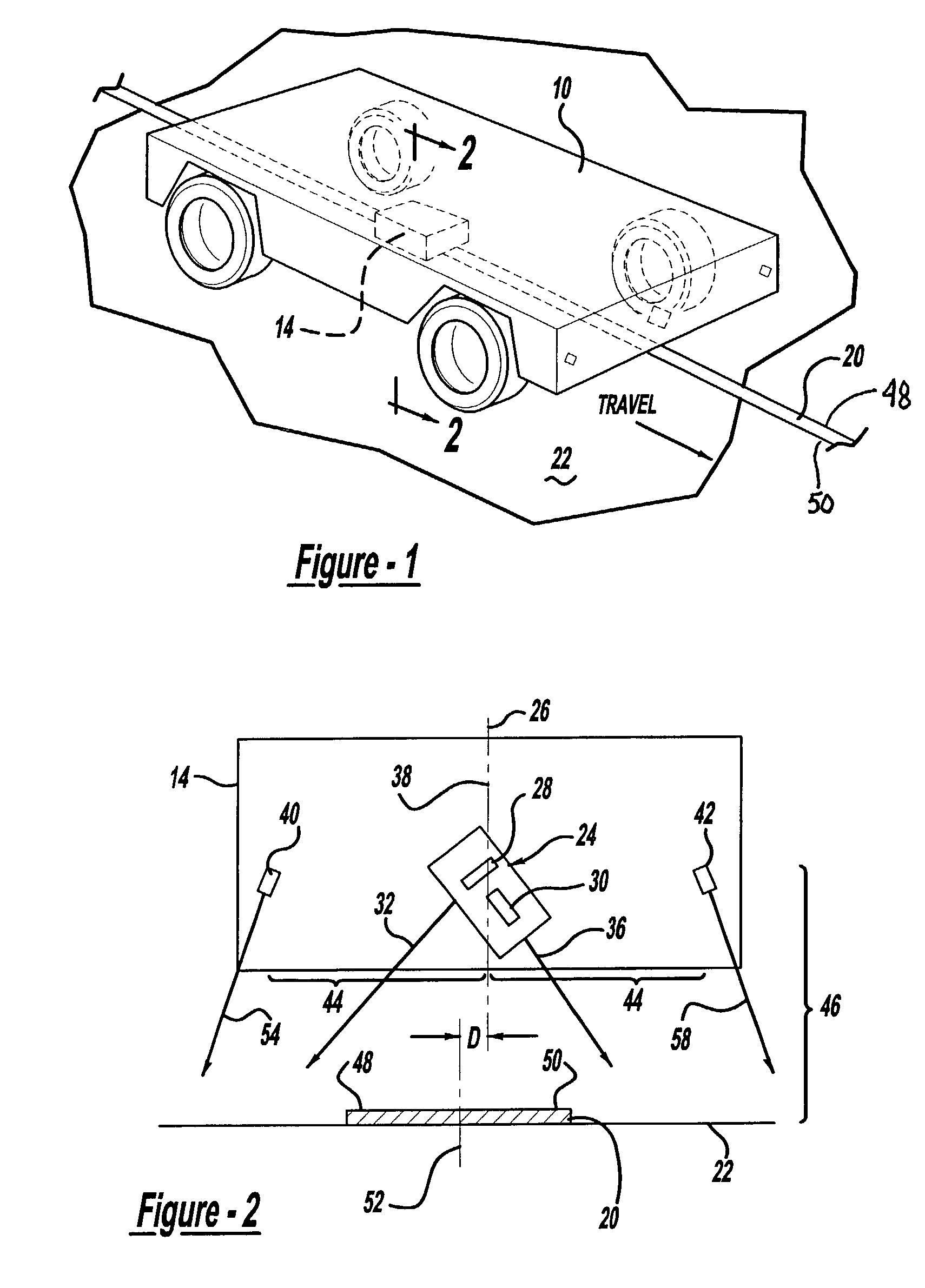

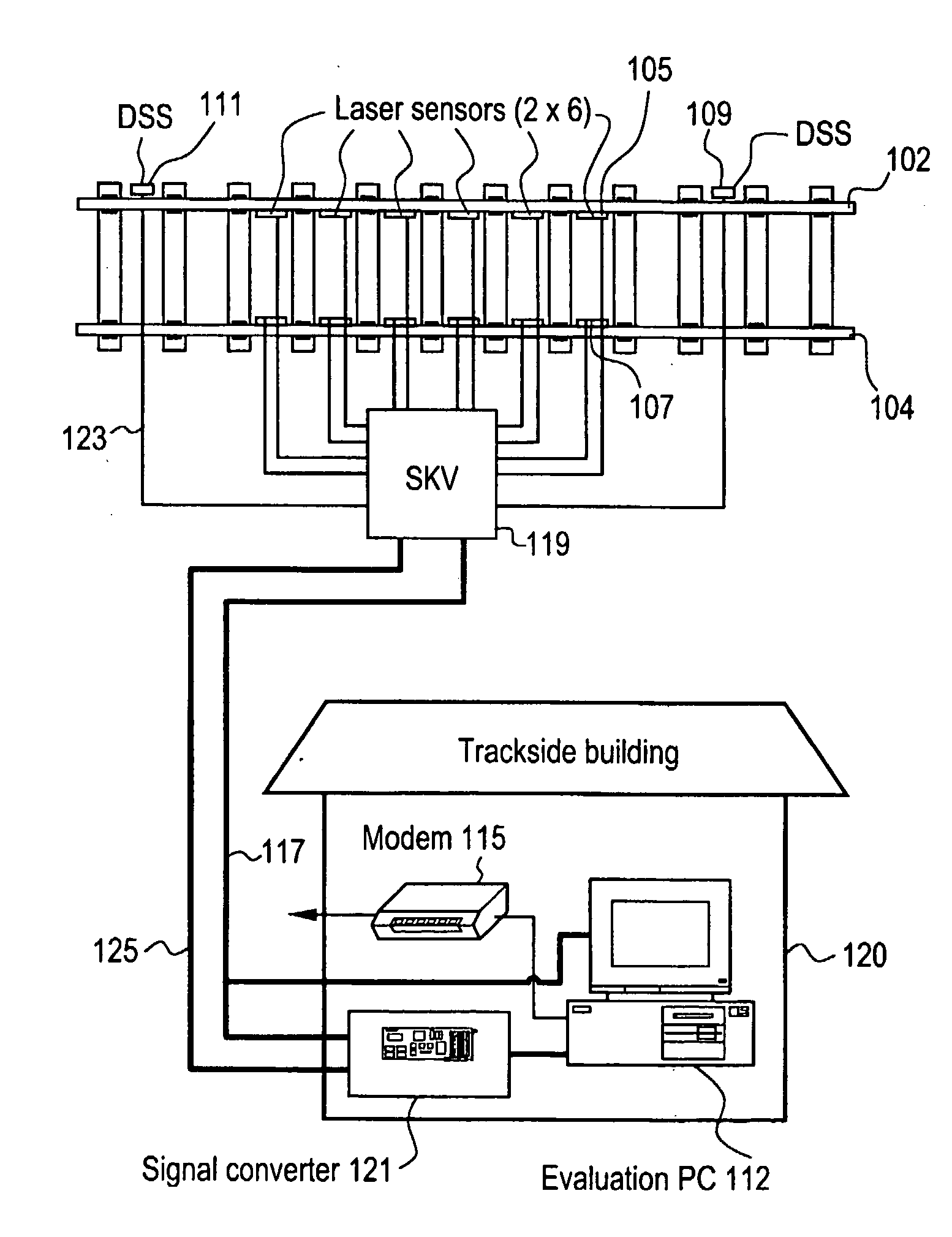

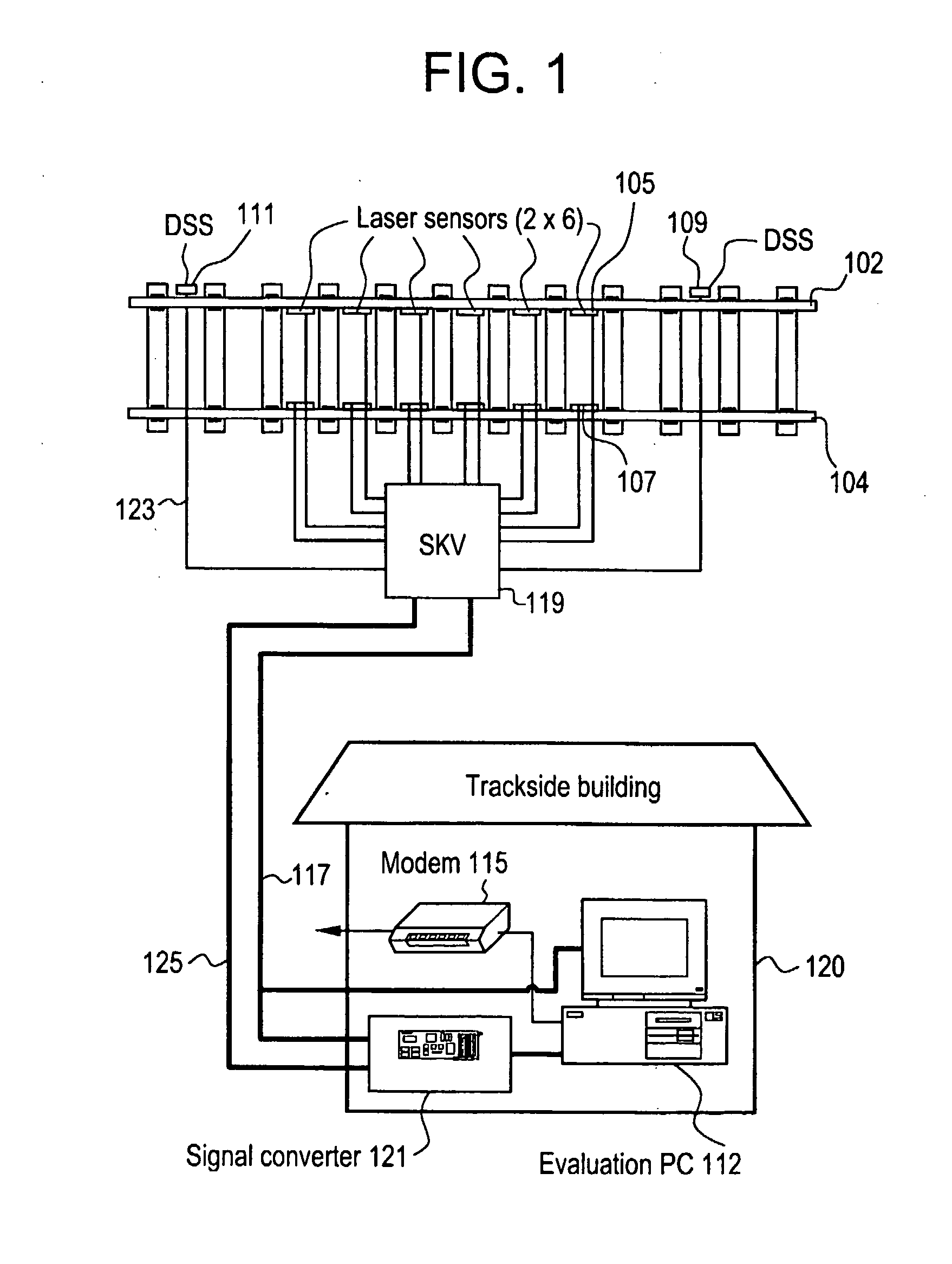

Rail Sensing Apparatus Method

ActiveUS20080304065A1Measure directlyMaterial analysis by optical meansUsing optical meansBogieLaser sensor

A rail sensing and analysis system utilizes a laser sensor 105, 107 to detect displacement of a rail 102, 104 resulting from loads imposed by a passing rail vehicle. Vertical and / or lateral displacements / loads may be sensed. Signatures in the resulting signals are indicative of useful information about the rail vehicle; such as wheel condition, bearing condition, truck condition, degree of bogie hunting, total load, load distribution, etc. The ratio of Lateral over Vertical force (L / V) may be used as an evaluation criterion.

Owner:PROGRESS RAIL SERVICES

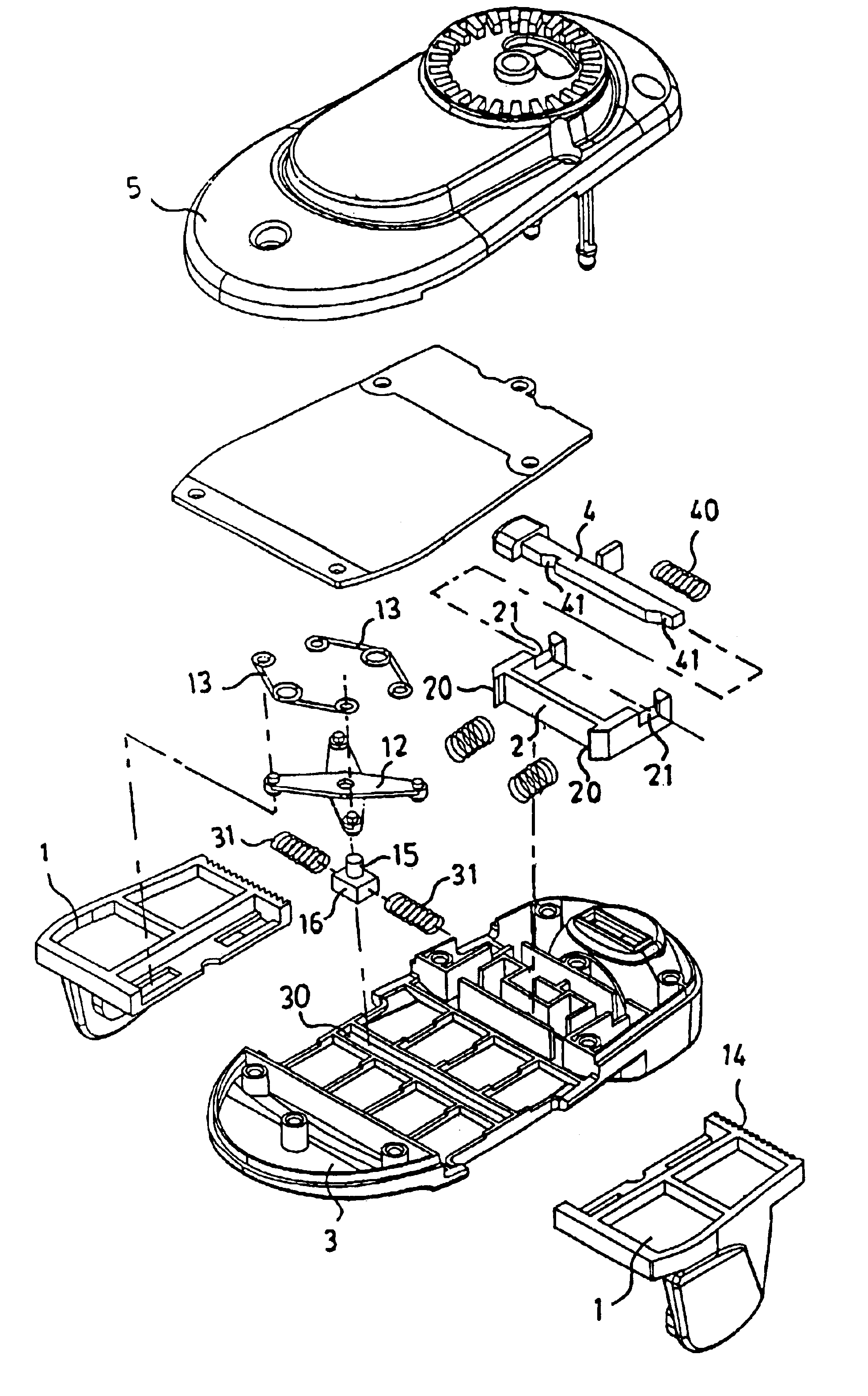

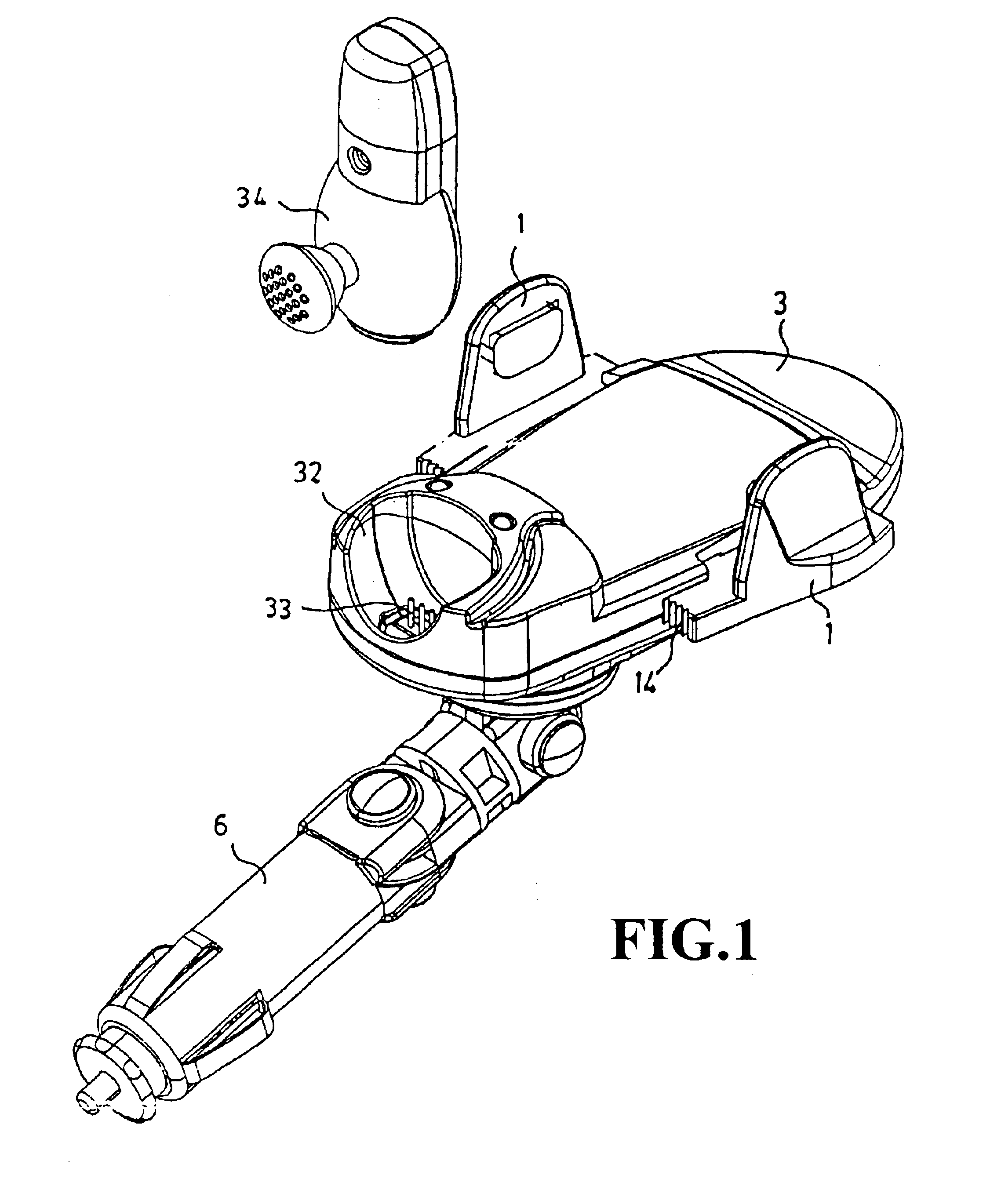

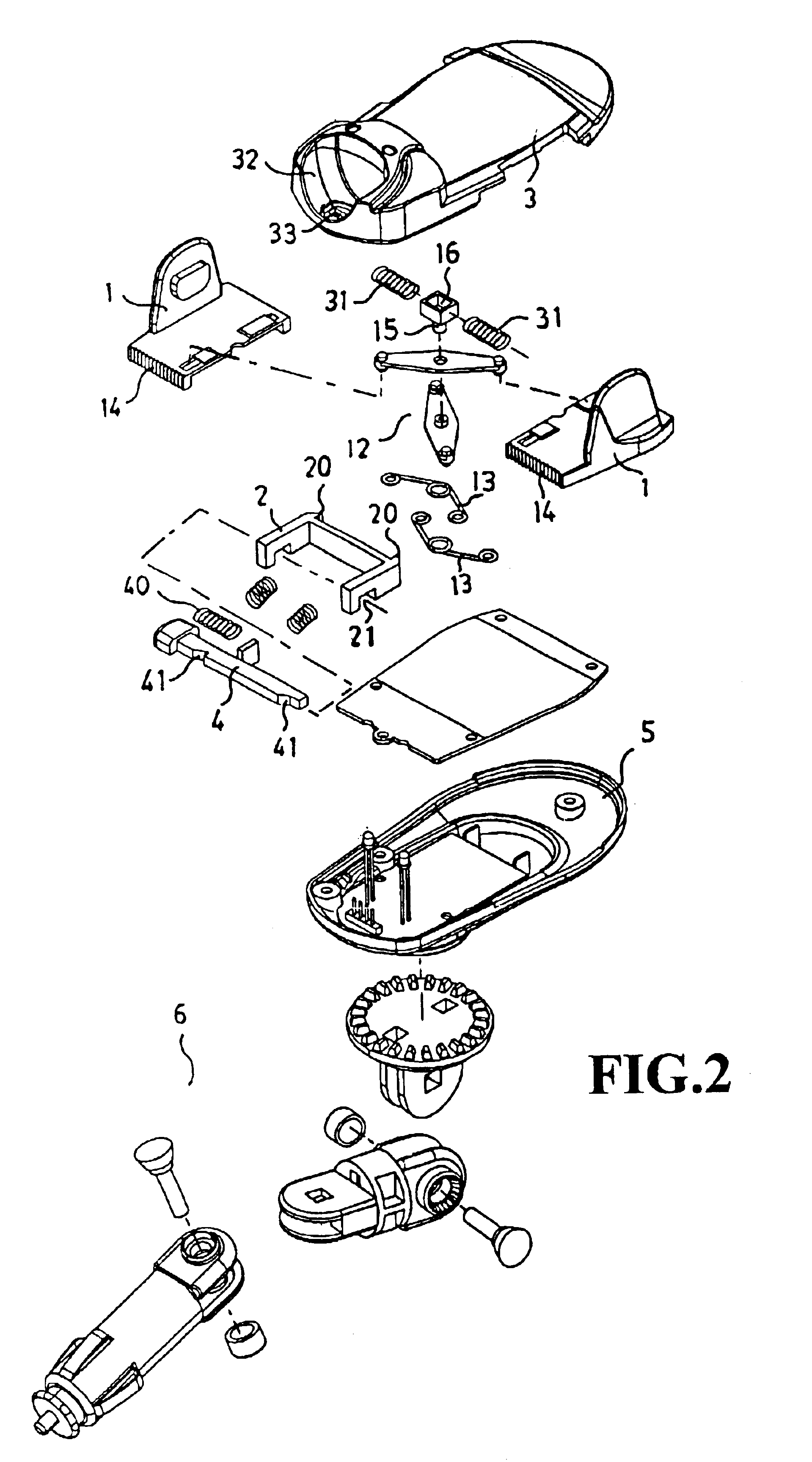

Mobile phone hand-free holder

InactiveUS6944294B2Simple structureSubstation speech amplifiersVehicle componentsCross-linkHands free

An improved structure of a mobile phone hand-free holder, includes a holder, an upper casing, a lower casing, a resilient locking seat and a press lever; a cross link pivoted to the center; an insertion protruding from end of the pivot to slide in a lateral slide way in the upper casing, both ends of the cross link being connected respectively to both sides of the holder; one side of the holder is serrated at the edge; the locking seat being provided by the serration to have two stoppers protruding into the serration to force the holder to only press inwardly to be held in position; an earphone socket also functioning as a switch to control transmission of an incoming call to be received by a cordless earphone or an external speaker or a car radio; the lateral displacement of the cross link in the slide way to deflect the center to hold a mobile phone with its plug socket not provided at the center.

Owner:TSAY WEN FENG

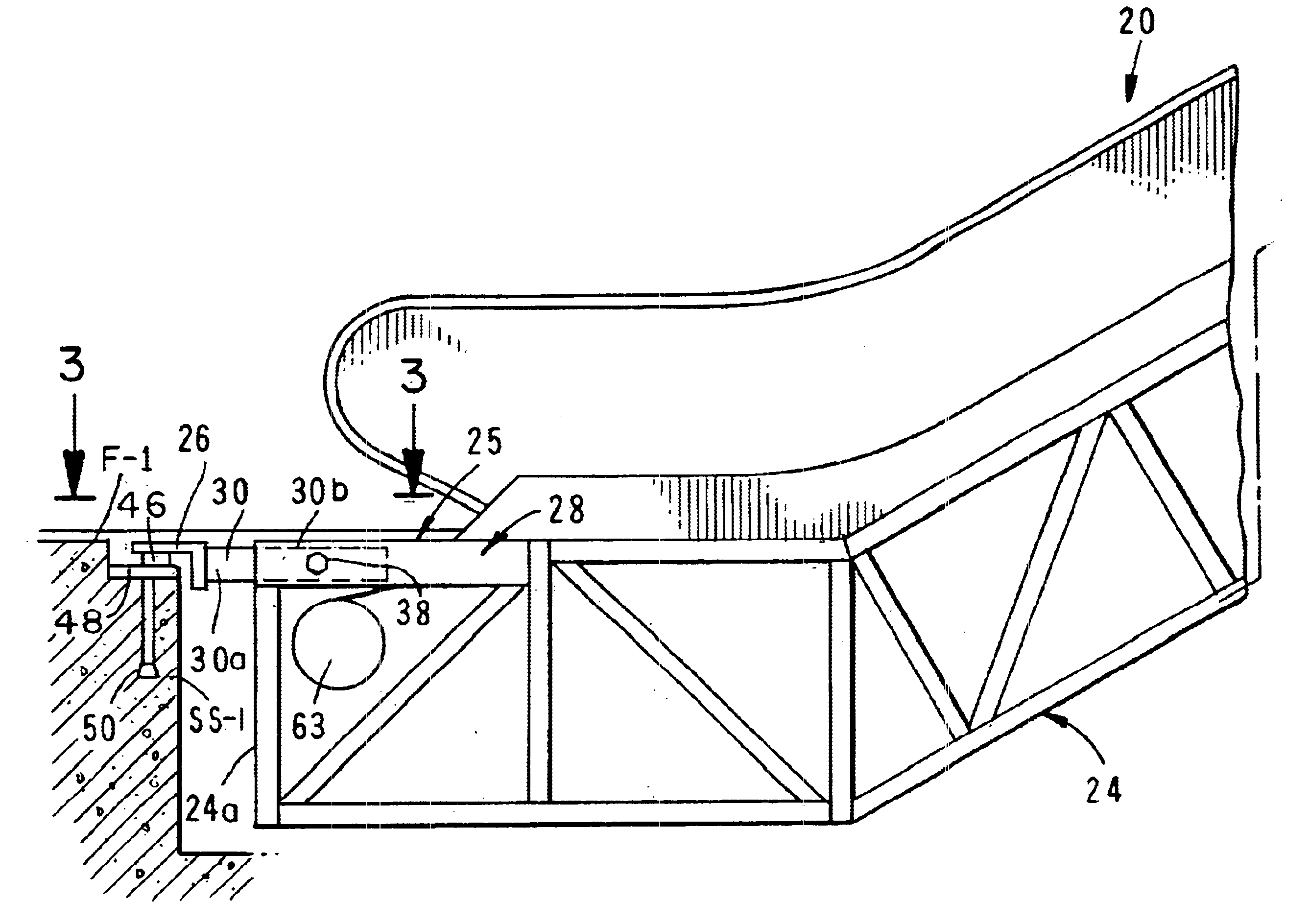

Telescoping escalator seismic restraint

An escalator or moving stairway that is constructed to accommodate oscillation and lateral displacement of a first story relative to a second story of a building between which the escalator or moving stairway extends such as which may occur during an earthquake. The escalator includes novel telescoping connector mechanisms that are connected at one end to a structural support of the building and are connected at the other end to supporting trusses of the escalator in a manner to permit relative movement between the supporting trusses and the floors of the first and second stories of the building.

Owner:SNEED TERRYLE L

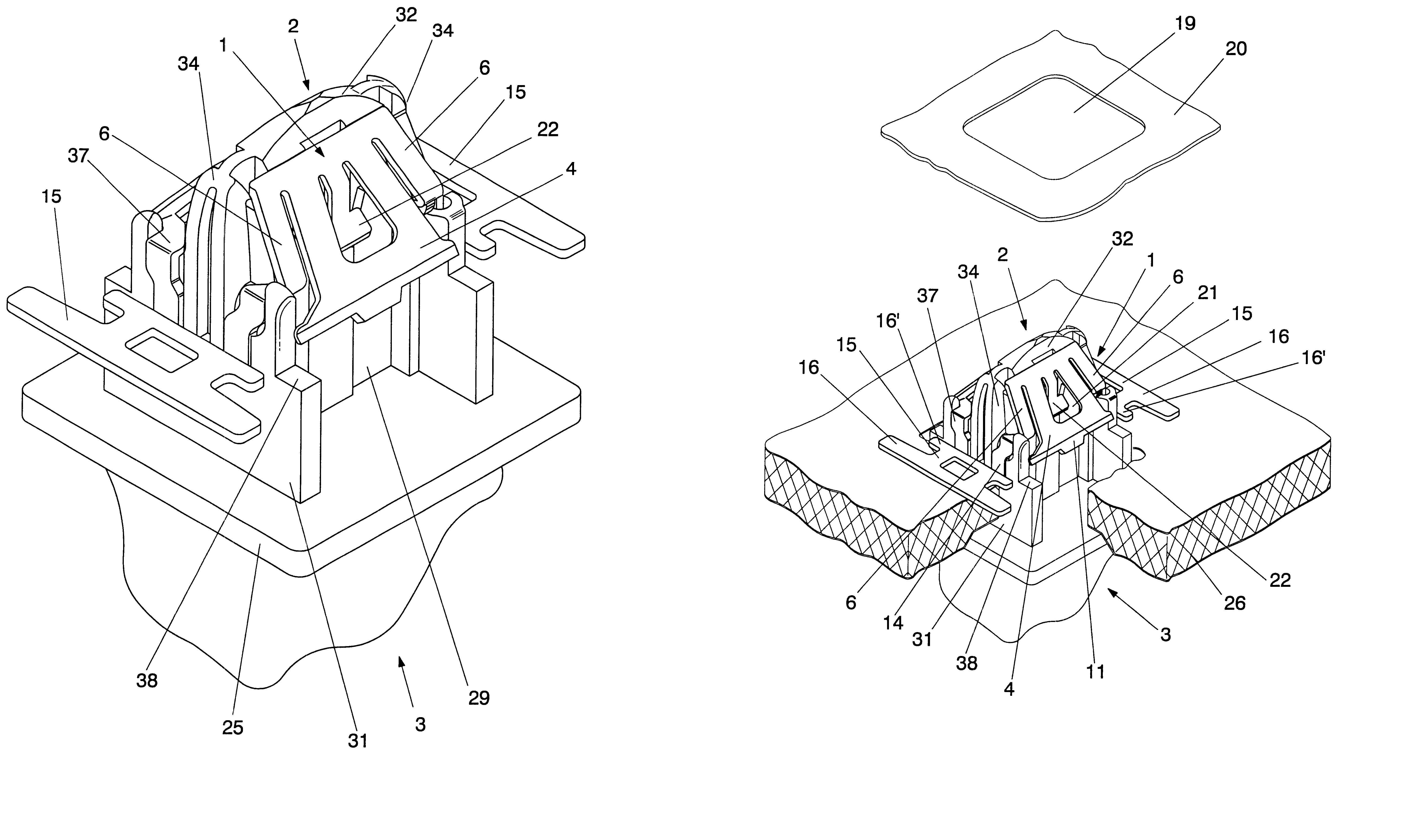

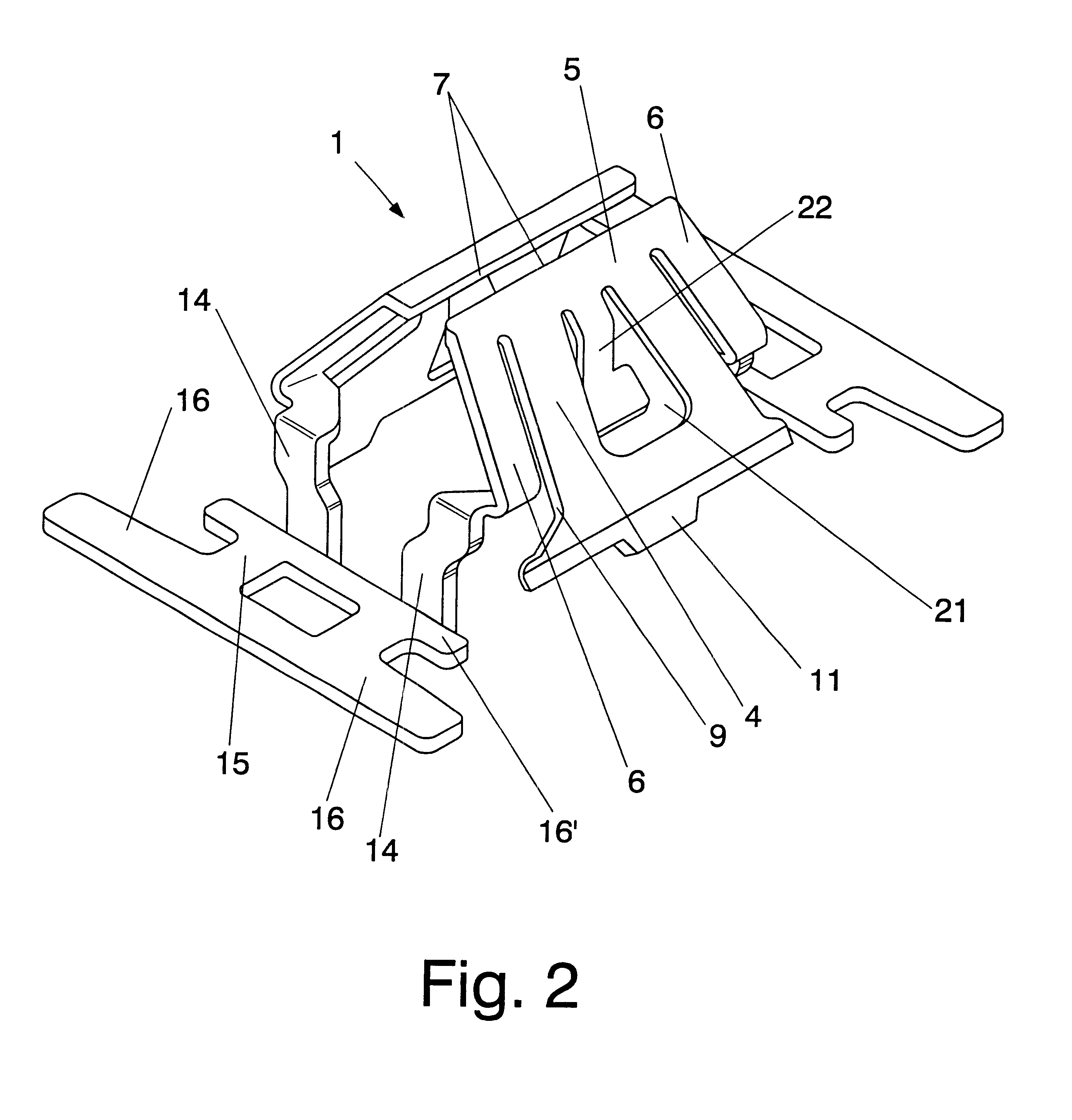

Metallo-plastic clip for attaching vehicle roofs and accessories to the body of a vehicle

InactiveUS6438804B1Improve stabilitySturdy and reliable attachmentSnap fastenersSnap-action fastenersEngineeringLateral displacement

The metallo-plastic clip comprises a clip and a plastic shank of which is part the corresponding accessory to be placed in an opening provided on the vehicle body, with an interposed vechicle roof. The clip provided with flexible flaps with a bend after which there is a horizontal segment of maximum size with a notch for attaching the clip to the opening of the vechicle body, while in a central area the flexible flaps are provided with a cut without loss of material forming center segments projected towards the center and with rounded corners which allow passage between them, with their corresponding lateral displacement and thereby also of the flaps, of any tool in order to free the clip from the shank. The maximum size of the horizontal segments and therefore of the notch for attaching the clip is obtained by a bend of lateral sectors which form part of the clip itself, above the bend of the corresponding flexible flap, with these lateral sectors projecting inwards and ending in end extensions for support of the clip on the vehicle roof.

Owner:GRP ANTOLIN ING SA

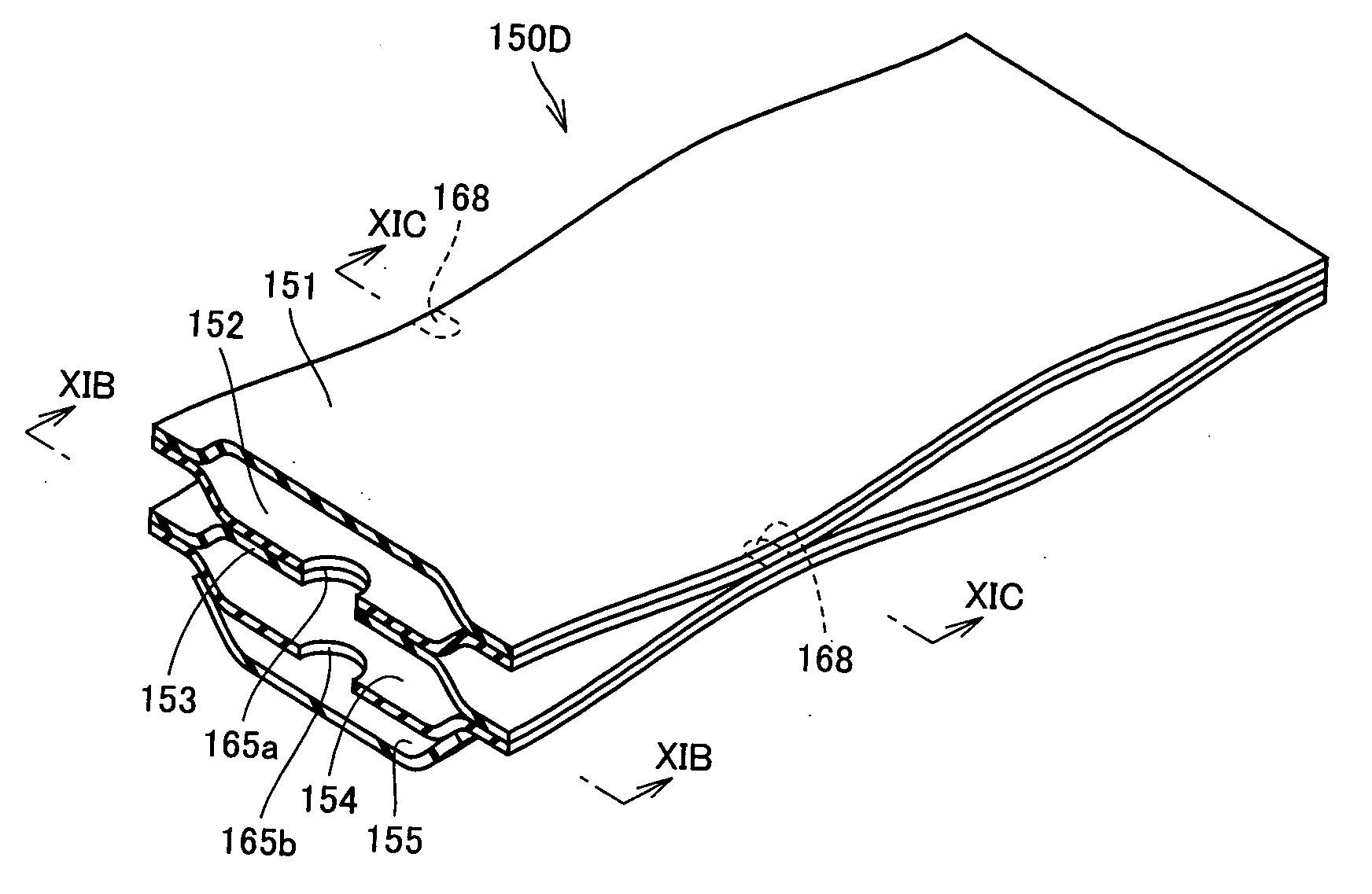

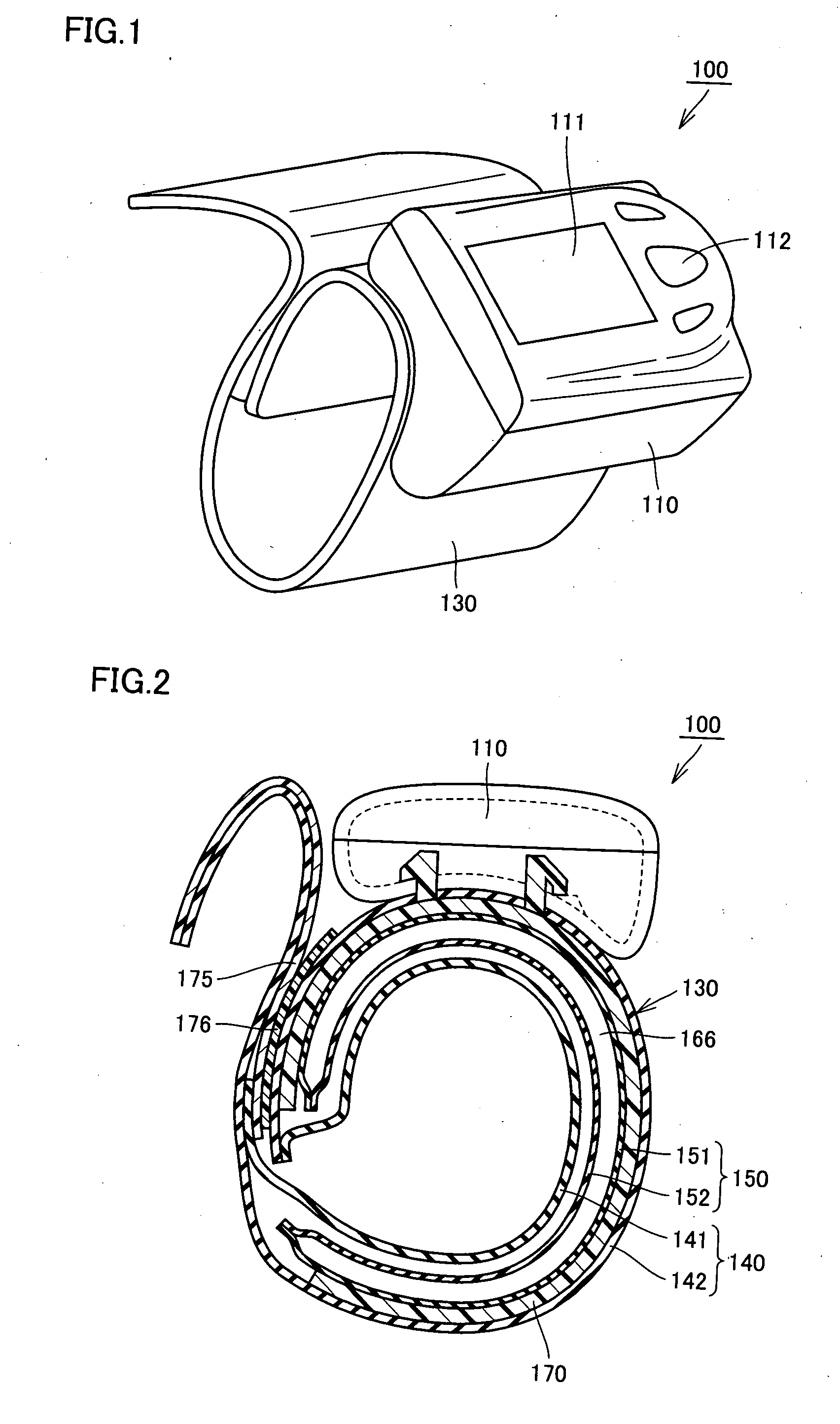

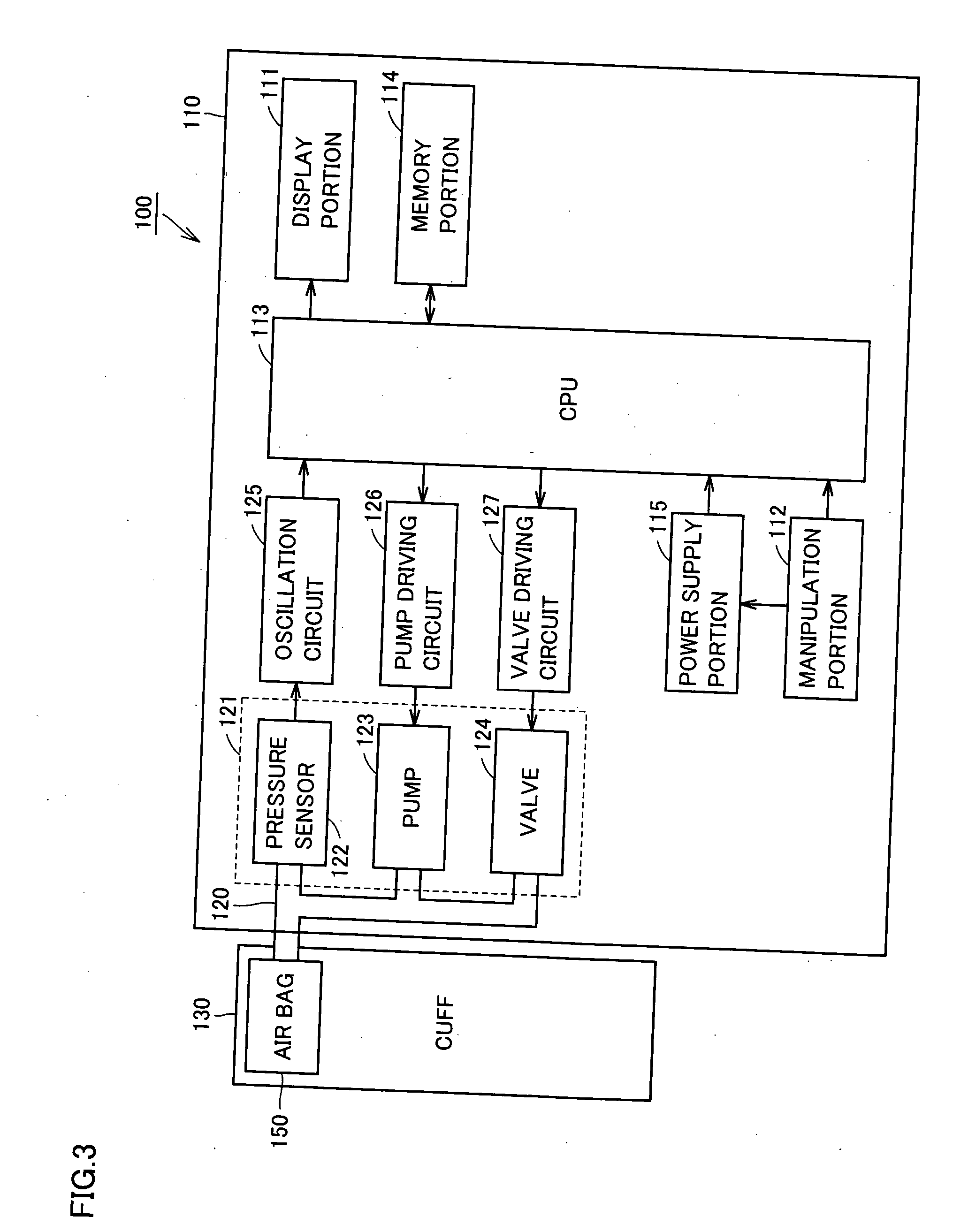

Cuff for blood pressure monitor, and blood pressure monitor having the same

InactiveUS20060135873A1Reliable blood pressureAvoid lateral displacementEvaluation of blood vesselsCatheterBiological bodyBlood pressure monitors

A cuff for a blood pressure monitor has an air bag inflated / deflated as the air comes in / out. The air bag has an inner wall portion located on the inner side in the fitted state of the cuff and an outer wall portion located outer than the inner wall portion, and a side wall portion connecting side end portions of the inner and outer wall portions and folded inwards in the deflated state of the air bag to form a gusset at each side end portion of the air bag. A bonded portion is provided at a region of the air bag in its winding direction around the living body, for reducing expansion of the gusset formed by the side wall portion. Thus, occurrence of lateral displacement of the cuff is prevented, and a highly reliable blood pressure monitor of high performance can be obtained.

Owner:OMRON HEALTHCARE CO LTD

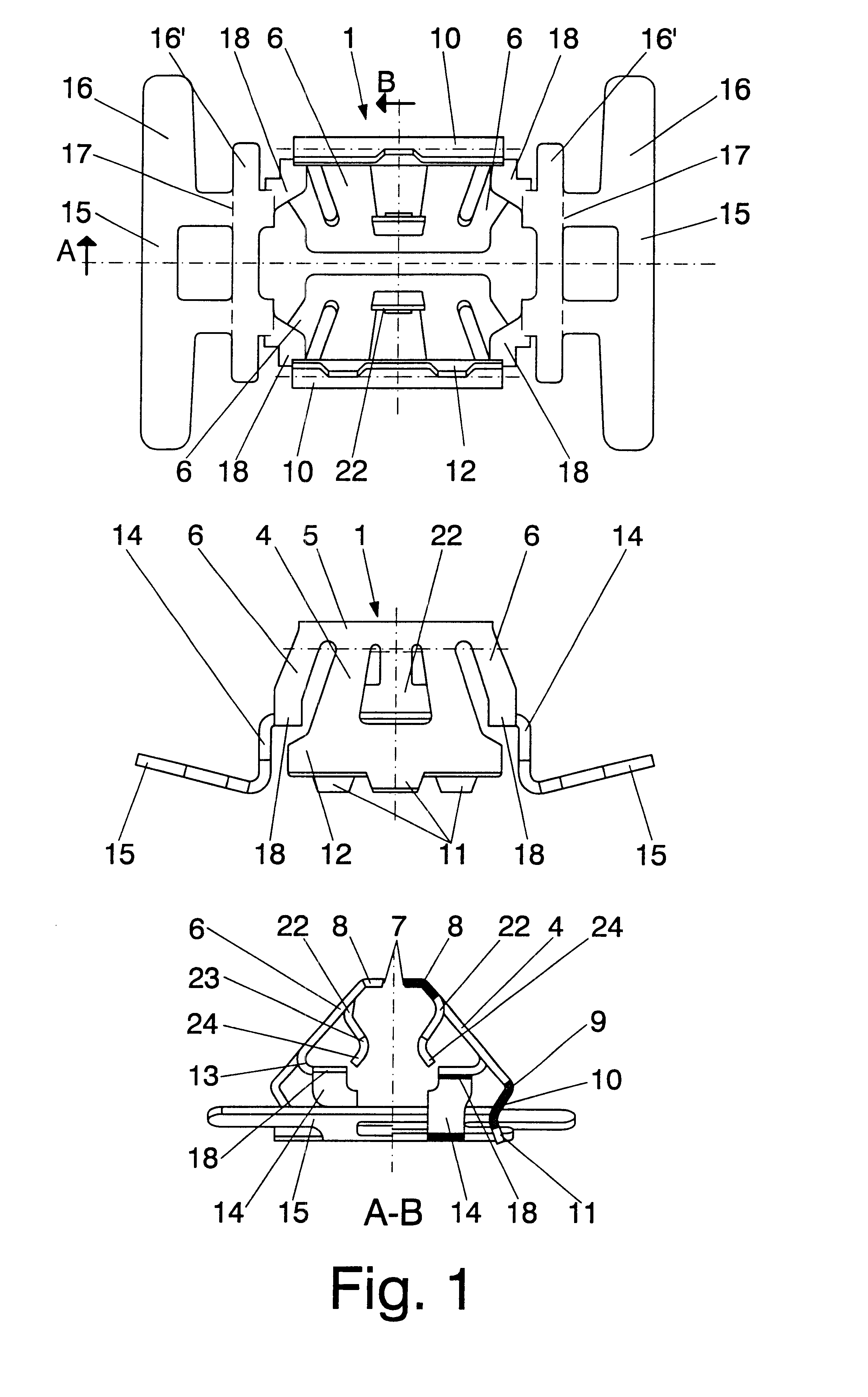

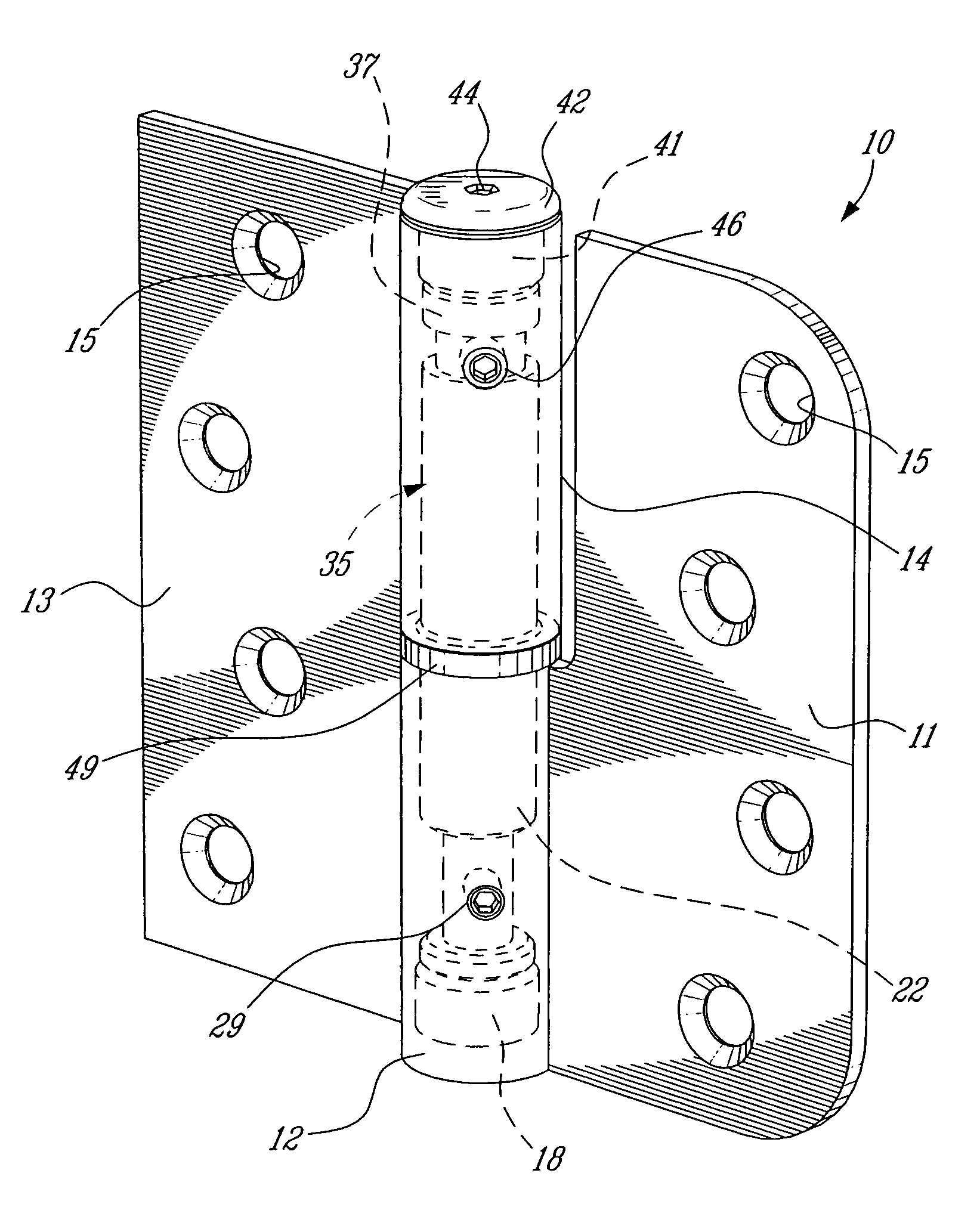

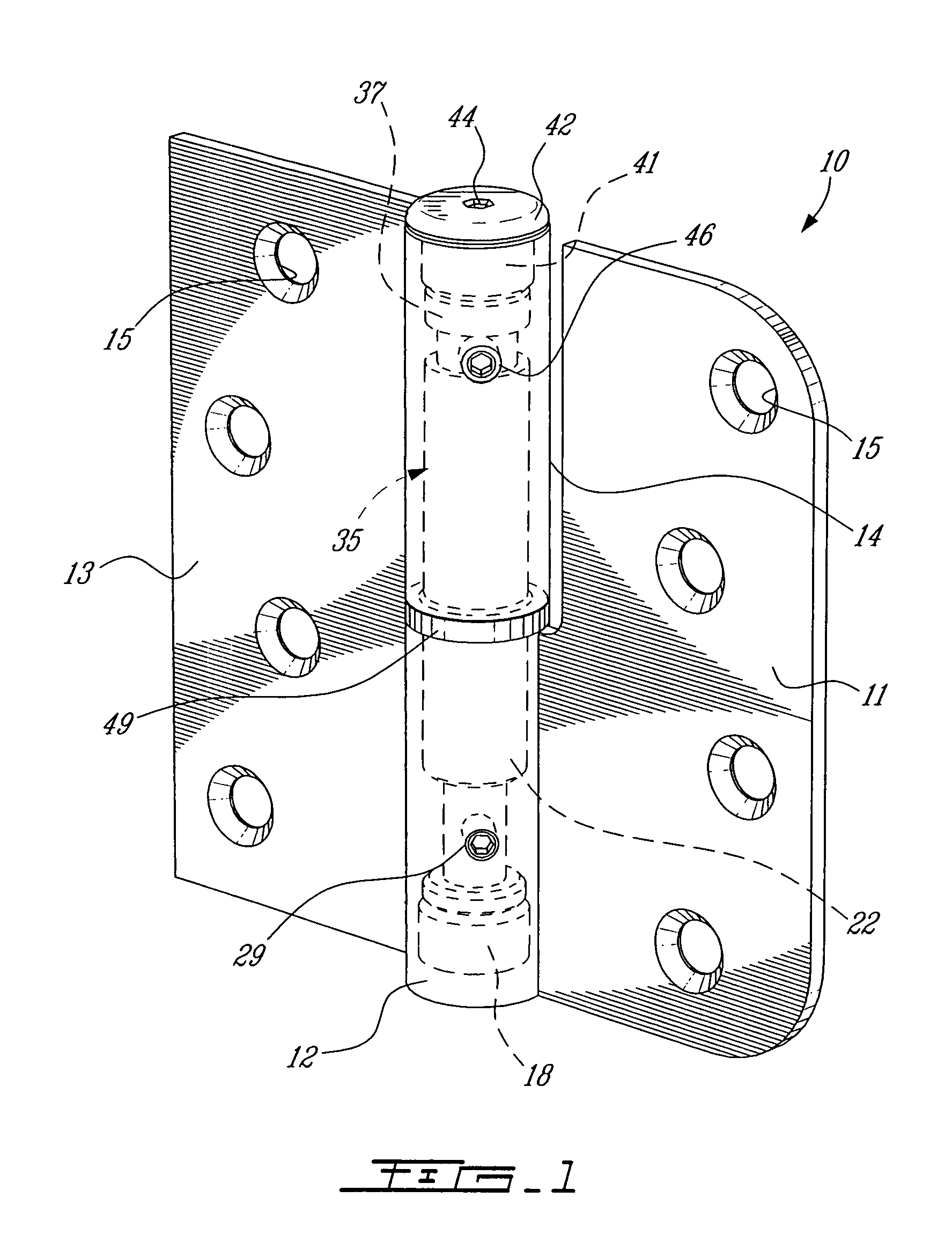

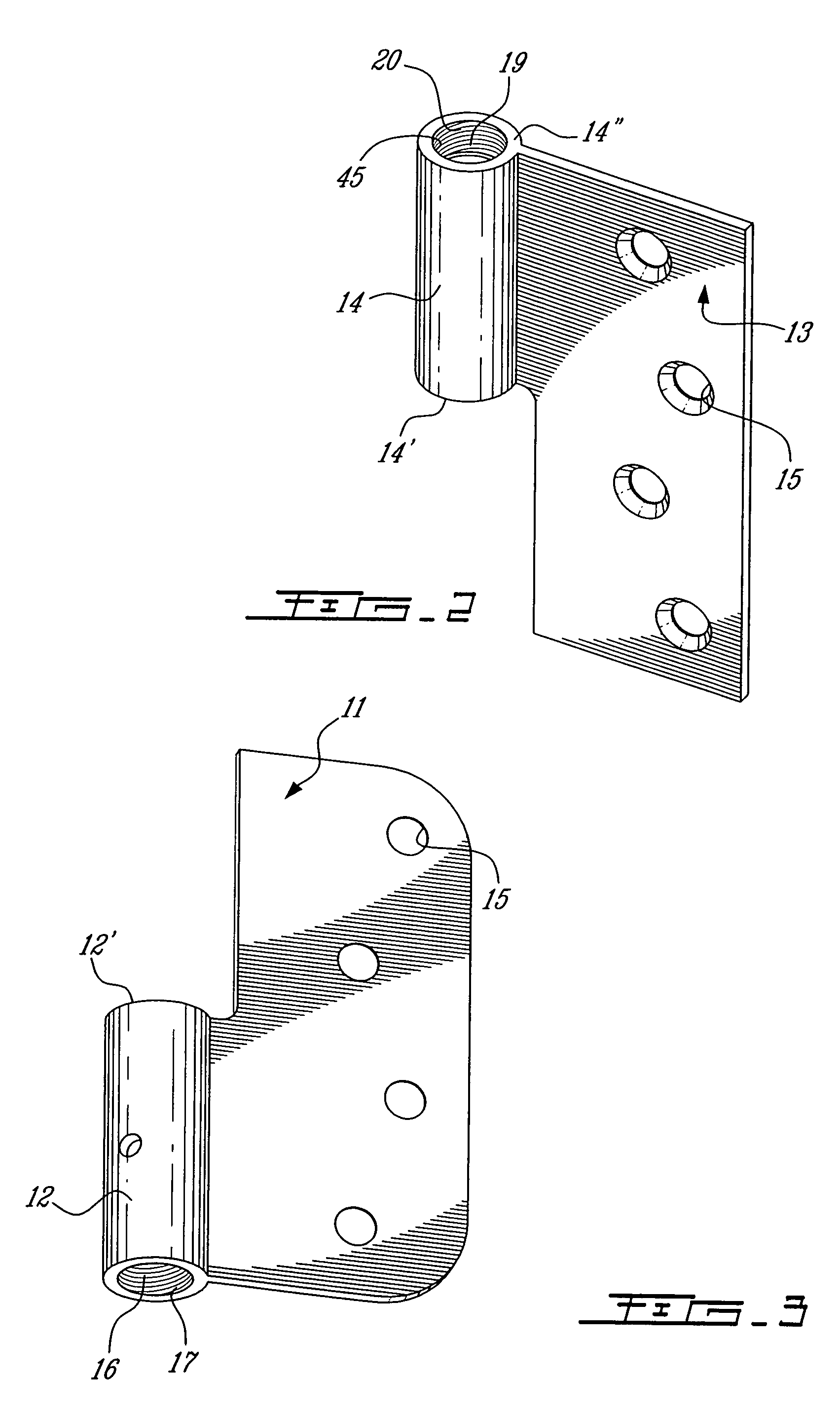

Multi-position adjustable door hinge

A multi-position adjustable door hinge is comprised of a frame leaf having a lower barrel section and a door leaf having an upper barrel section. An eccentric pivot pin is disposed in axial rotational fit in a through bore of the lower barrel section and is in contact at a lower end with an adjustment screw. The eccentric pivot pin has an upper cylindrical portion eccentrically displaced from the lower cylindrical portion and extends into a cylindrical bore of an eccentric compensator cylinder adjustably retained in the through bore of the upper barrel section. The eccentric pivot pin and the eccentric compensator cylinder are both axially displaceable from one another whereby to impart relative lateral displacement thereof and of the barrels to a desired position. The adjustment screw at the bottom of the lower barrel section provides vertical adjustment between the frame leaf and the door leaf. Set screws are provided to lock the eccentric pivot pin and the eccentric compensator cylinder at the desired position.

Owner:FERCO ARCHITECTURAL HARDWARE

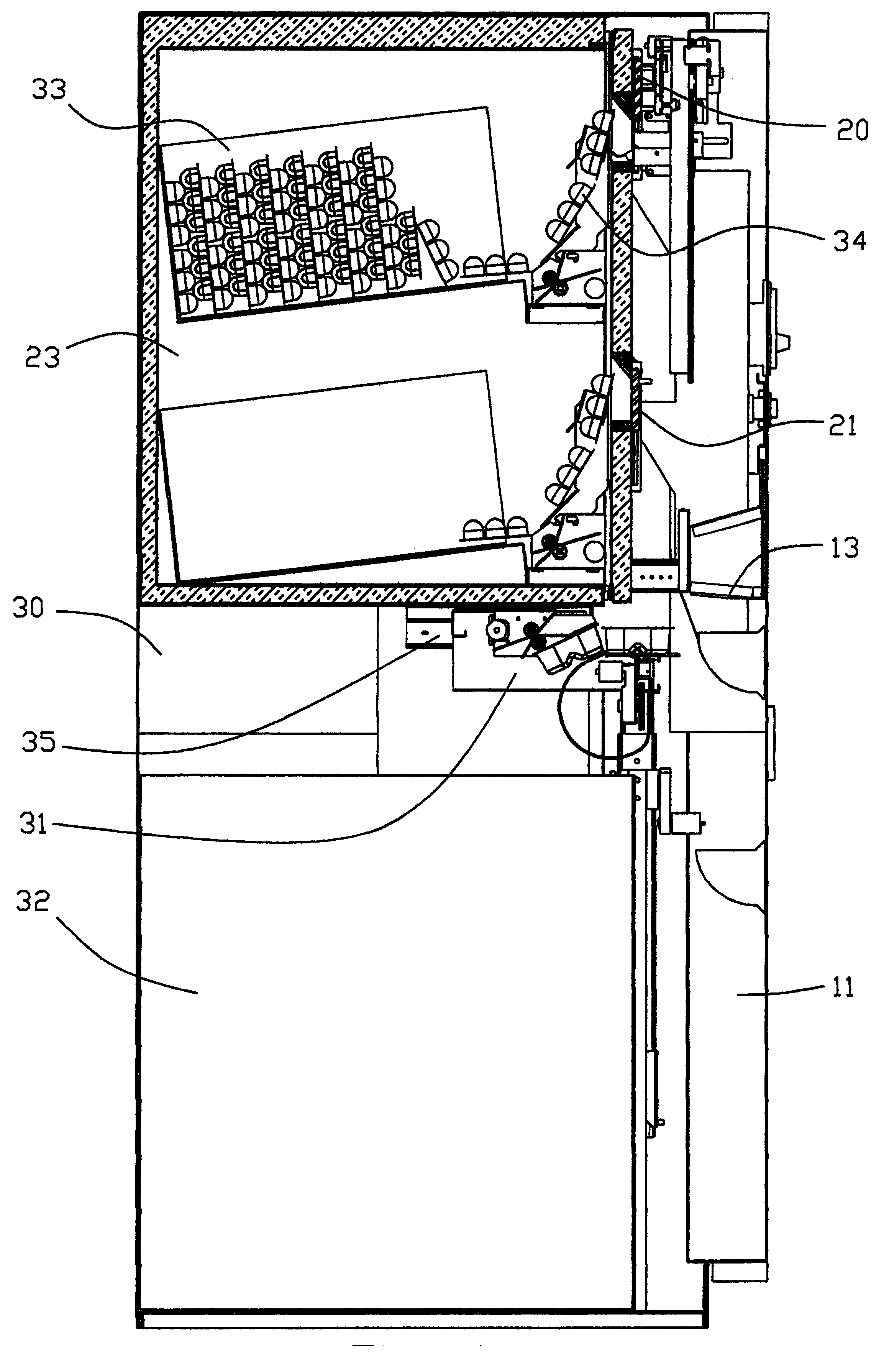

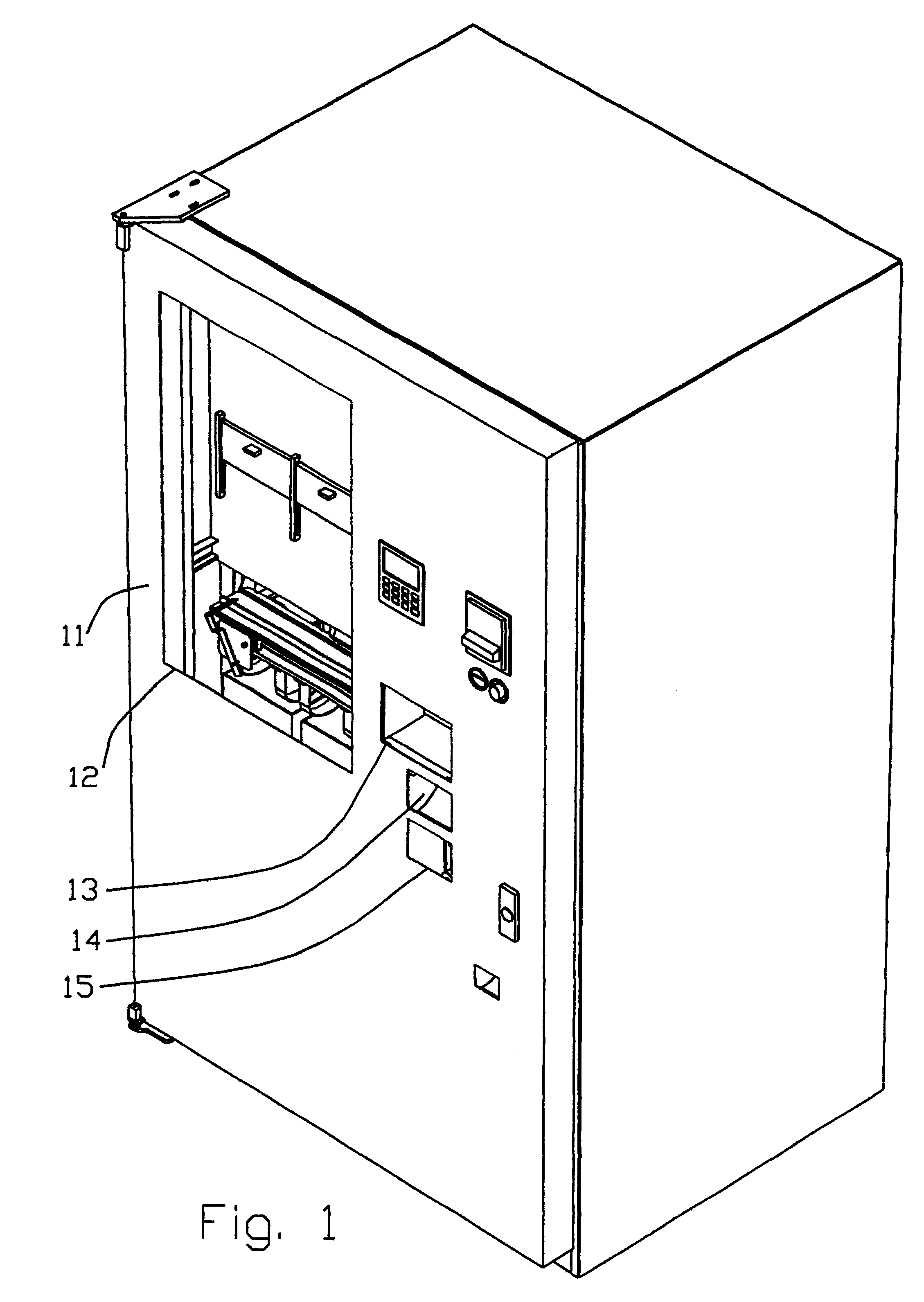

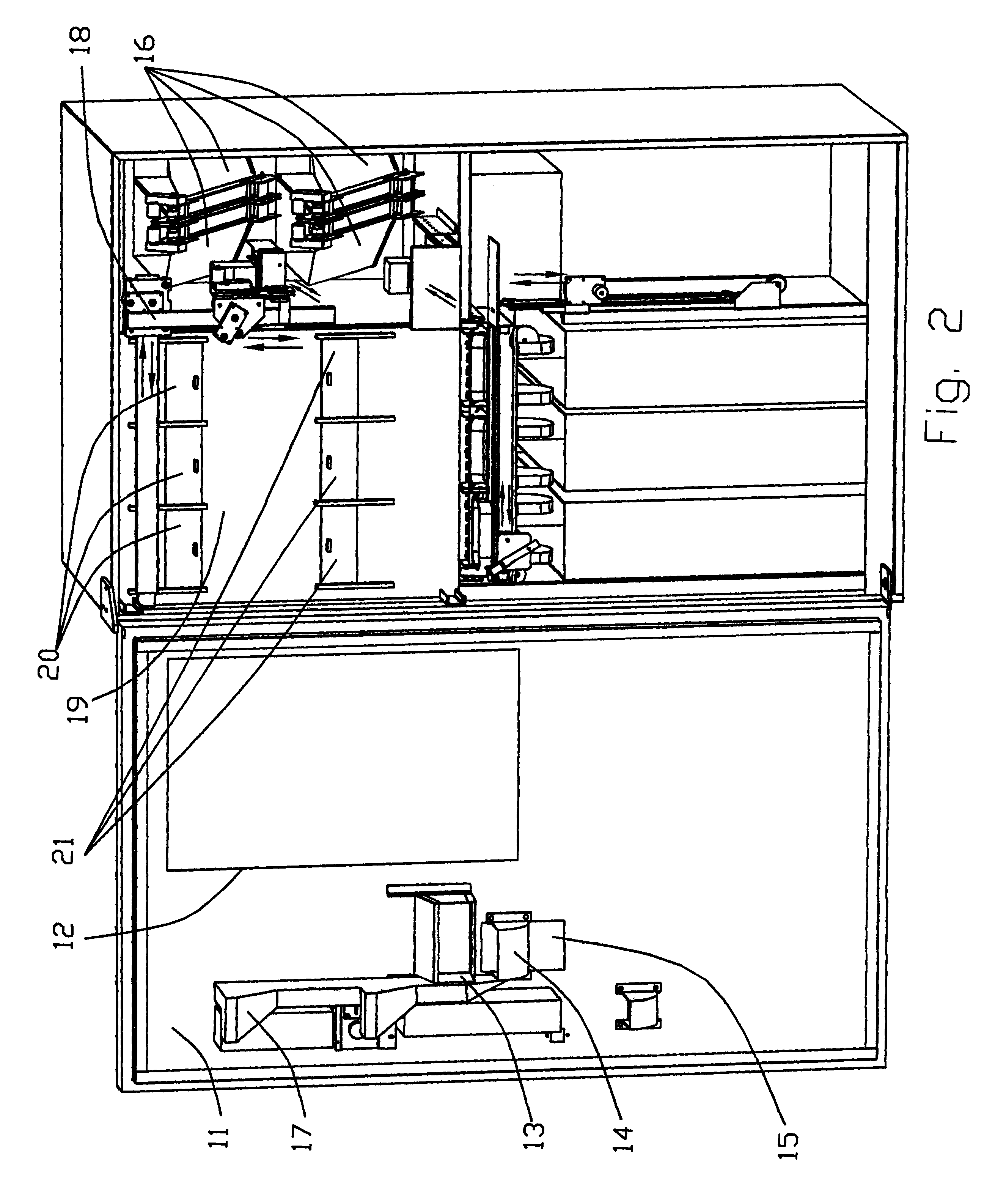

Method and apparatus for preparing and dispensing a combination of food products in a vending machine

Method and apparatus for preparing and dispensing a combination of food products in a vending machine from a selection of components prepackaged in a plurality of trays sealed with a single peel off tape. The method comprises dispensing a top component onto a positioning releasable support and moving it into an oven, independently dispensing a tray with bottom component, sliding it to and raising into a moveable oven, independently heating components, removing components from ovens, moving said moveable oven out of the tray path, moving components to close proximity of each other and releasing top component into the tray. The apparatus has means for dispensing each of the individual components toward front of said vending machine; means for three-dimensional positioning of the releasable support for top components; means for bottom component tray lateral displacement; stationary oven, moveable oven, and an elevator laterally aligned with said product delivery opening.

Owner:KHODOR LEONID +1

Electrophysiology/ablation catheter having deflection assembly

ActiveUS20050187455A1Increase usageIncrease capacityElectrocardiographyCatheterDistal portionActuator

An electrophysiology / ablation catheter assembly includes an elongated flexible casing that received a first catheter deflection assembly. Electrical leads are connected to each electrode on a distal portion of the catheter assembly and extend through the casing for external connection at a proximal end of the catheter assembly. A first actuator is operatively connected to the first catheter deflection assembly and operable upon movement to selectively effect displacement of the distal end. A second catheter deflection assembly is also disposed in the casing. A second actuator is connected adjacent the proximal end of the catheter deflection assembly and operable upon movement to selectively effect lateral displacement of the catheter at a location spaced from the first curved configuration of the distal end.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

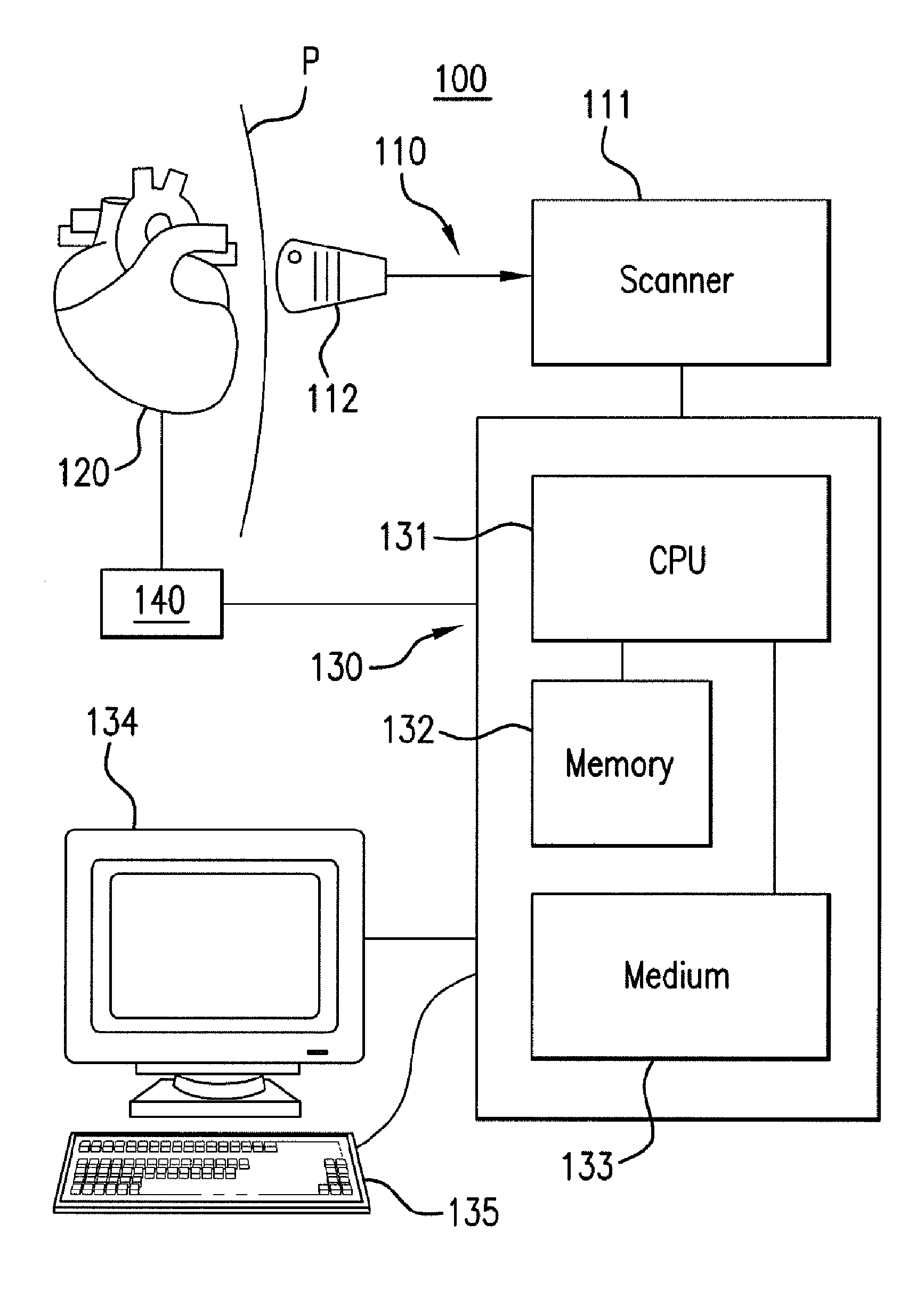

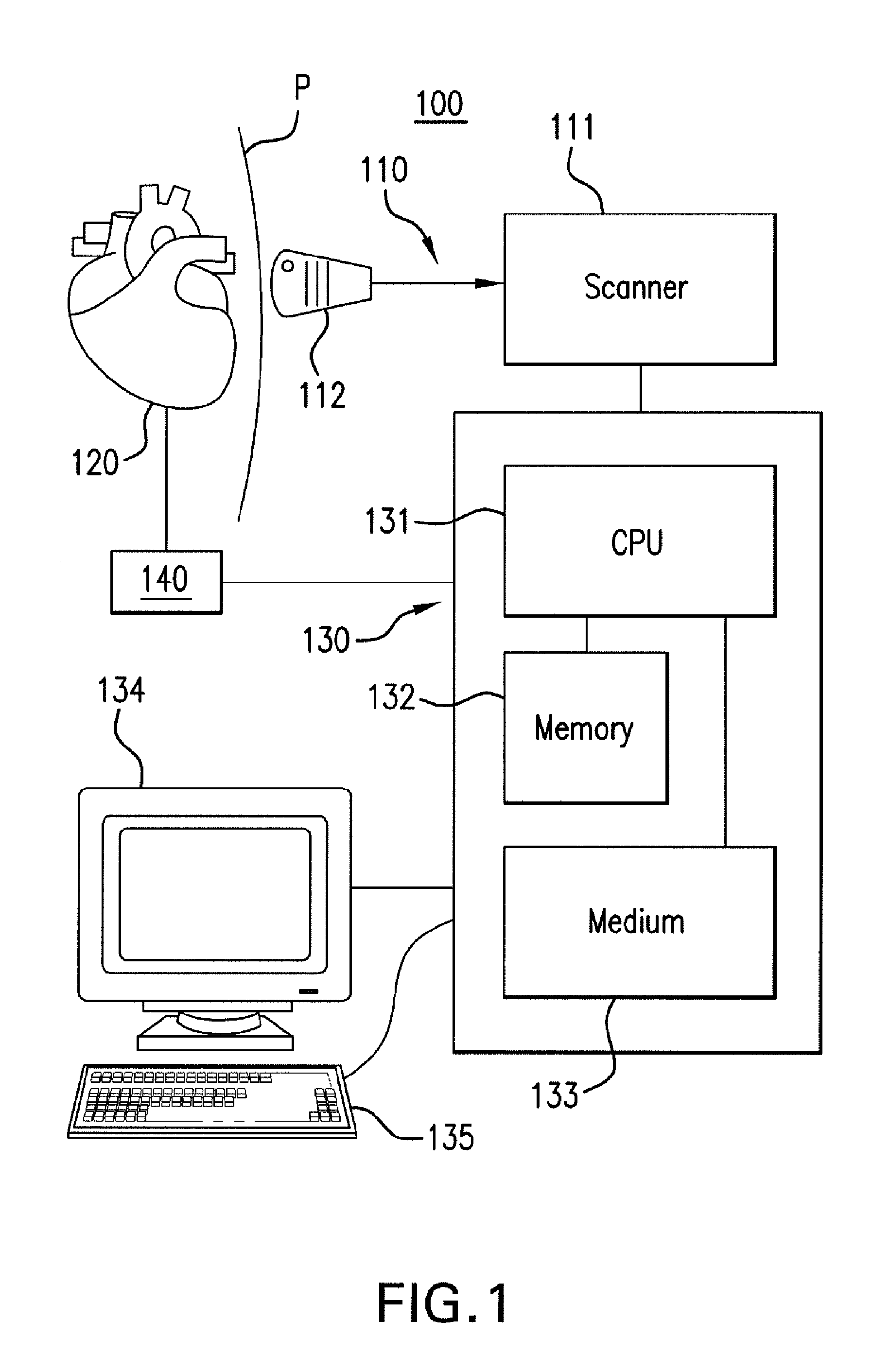

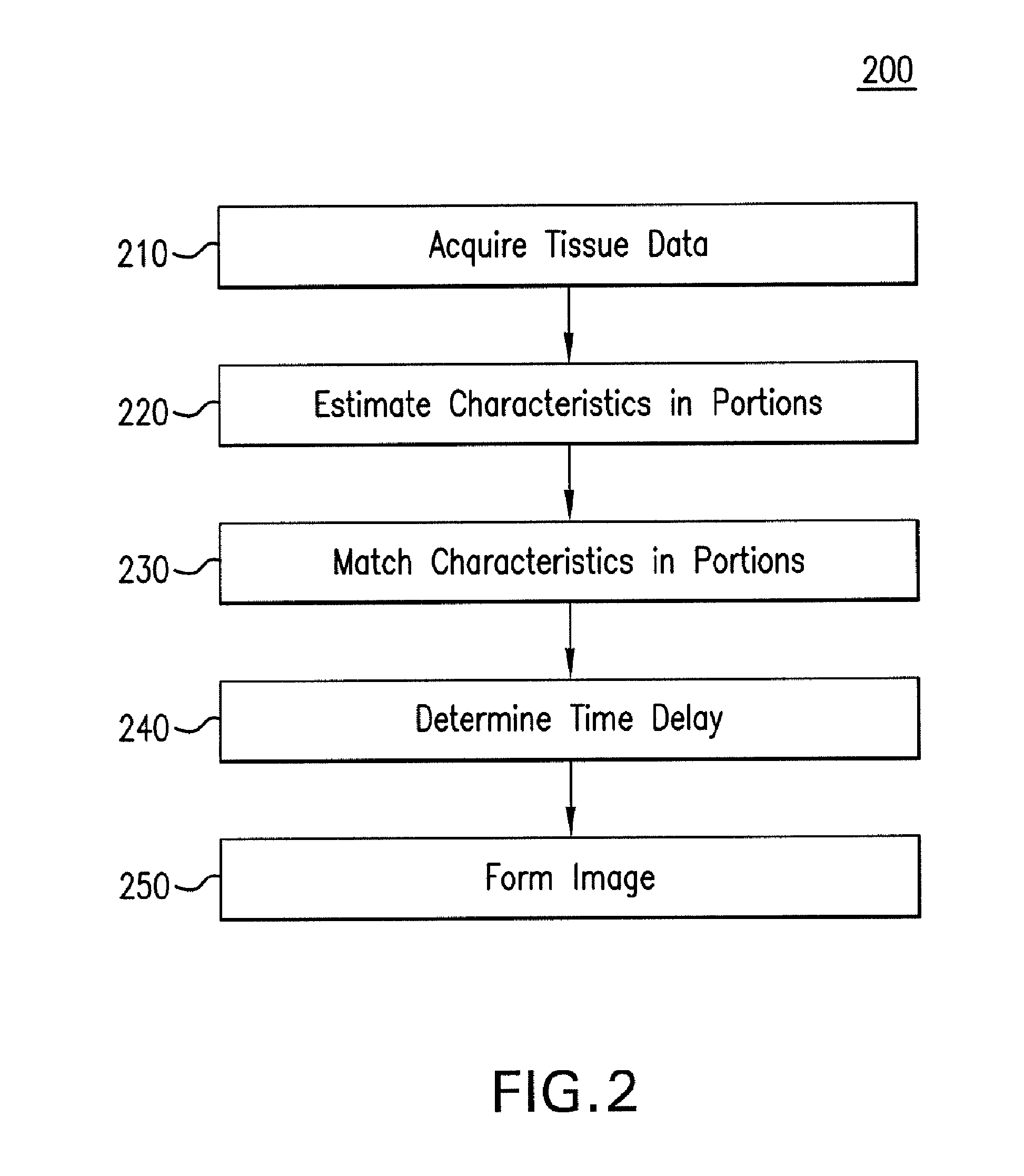

Systems And Methods For Matching And Imaging Tissue Characteristics

Systems and methods for matching a characteristic of multiple sectors of a moving tissue to verify an overlap thereof are disclosed herein. In an exemplary method, tissue data for at least a first sector and a second sector of a moving tissue is acquired. A characteristic of at least a portion of the first and second sectors is estimated from the acquired tissue data, and the estimated characteristics are matched to verify whether a portion of the first sector overlaps with a portion of the second sector. Estimating can include estimating a displacement such as an axial displacement and / or lateral displacements. Estimating can further include estimating a strain, a velocity, a strain rate and / or a stiffness or equivalent.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

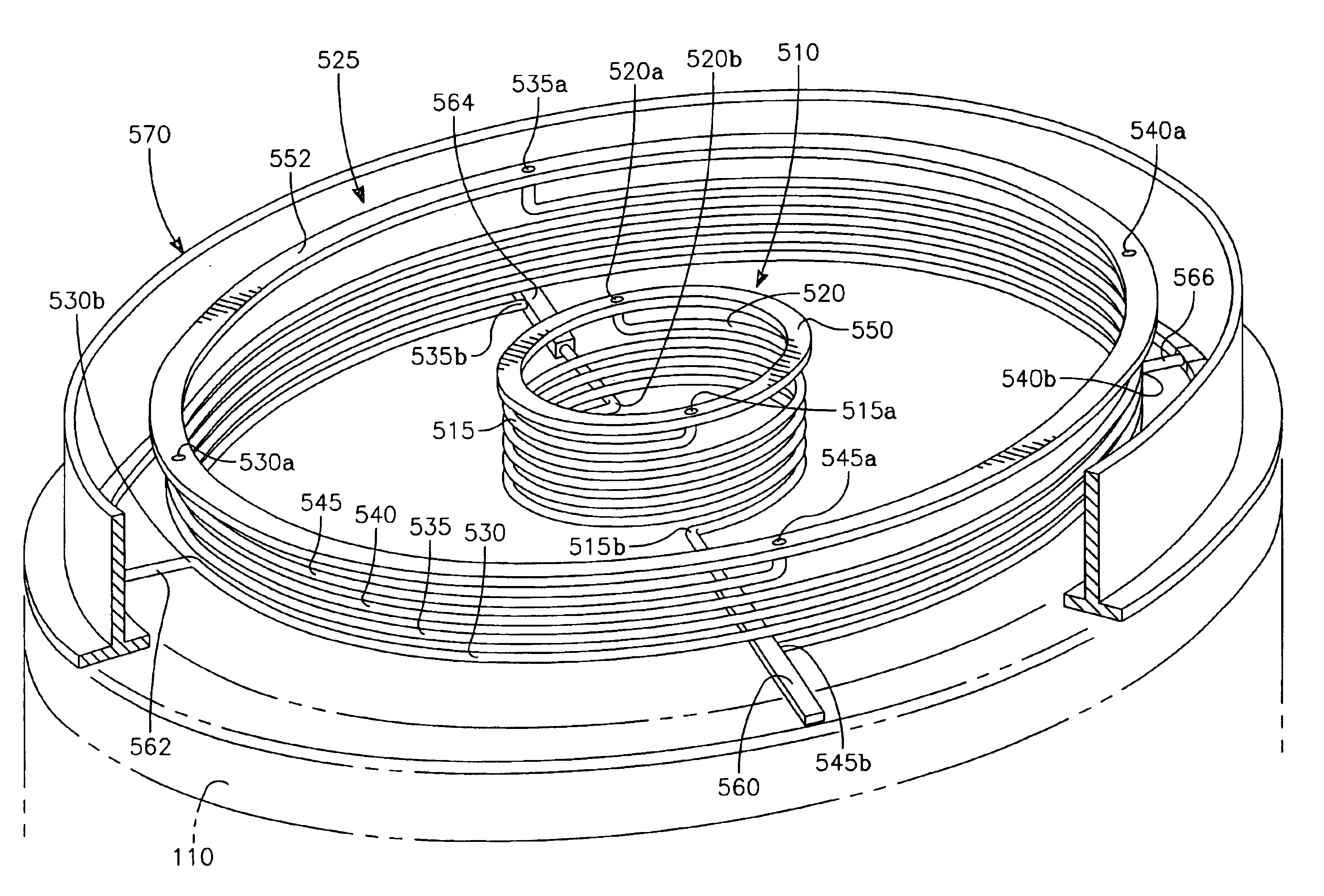

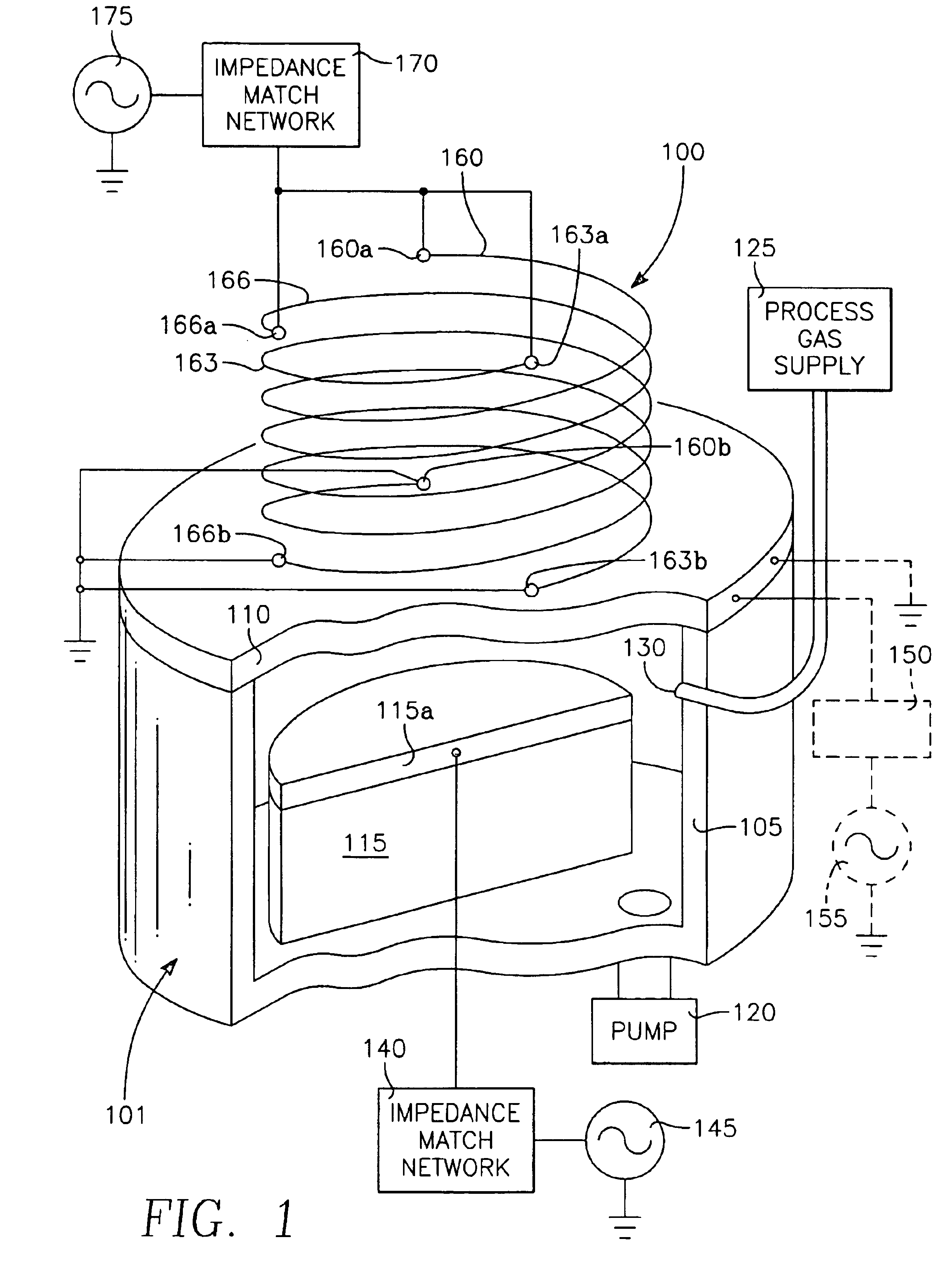

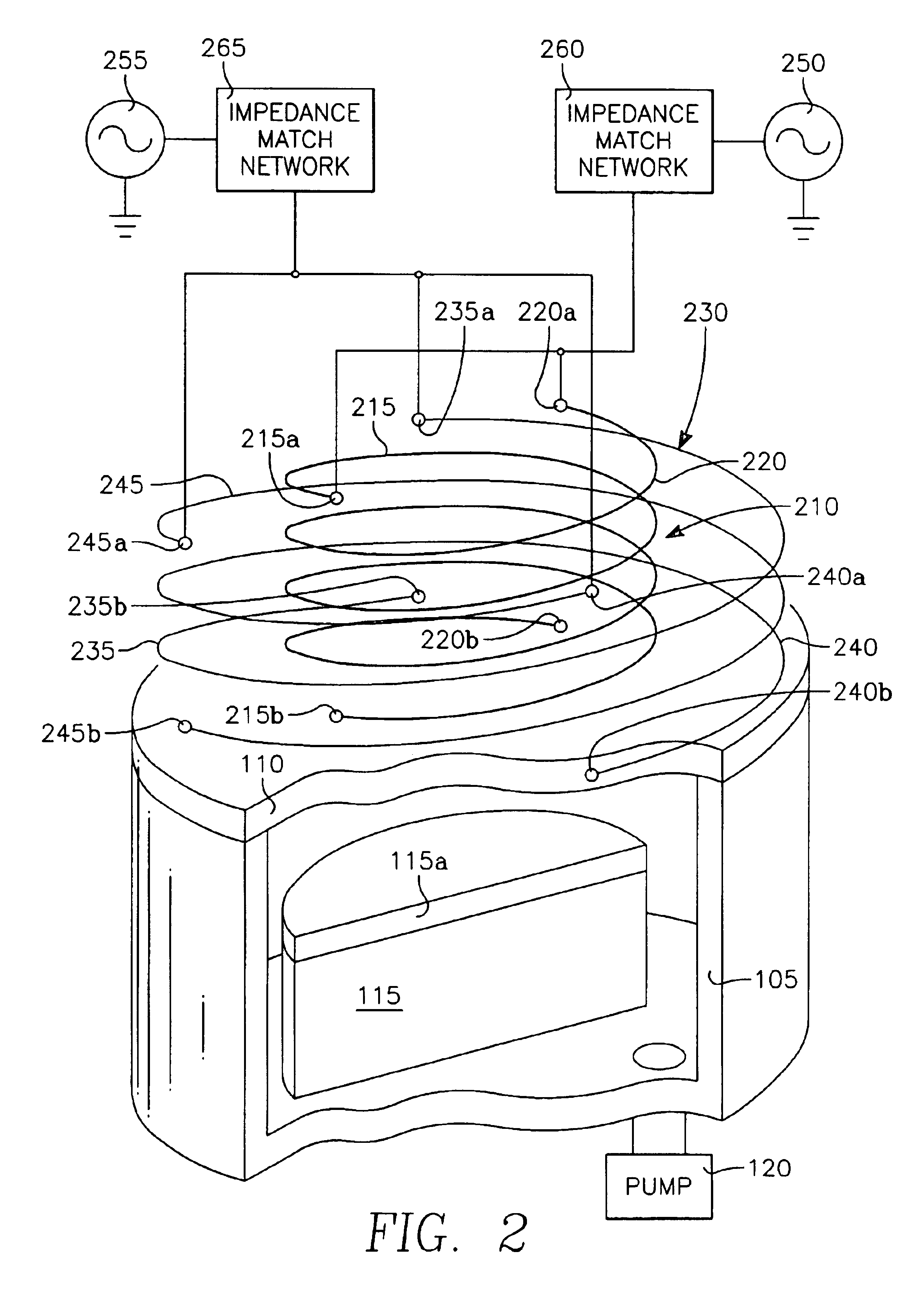

Plasma reactor having a symmetric parallel conductor coil antenna

InactiveUS6893533B2Maximize differential effectMaximize the effectVacuum tubesLiquid surface applicatorsAxis of symmetryElectrical conductor

The invention in one embodiment is realized in a plasma reactor for processing a semiconductor workpiece. The reactor includes a vacuum chamber having a side wall and a ceiling, a workpiece support pedestal within the chamber and generally facing the ceiling, a gas inlet capable of supplying a process gas into the chamber and a solenoidal interleaved parallel conductor coil antenna overlying the ceiling and including a first plurality conductors wound about an axis of symmetry generally perpendicular to the ceiling in respective concentric helical solenoids of at least nearly uniform lateral displacements from the axis of symmetry, each helical solenoid being offset from the other helical solenoids in a direction parallel to the axis of symmetry. An RF plasma source power supply is connected across each of the plural conductors.

Owner:APPLIED MATERIALS INC

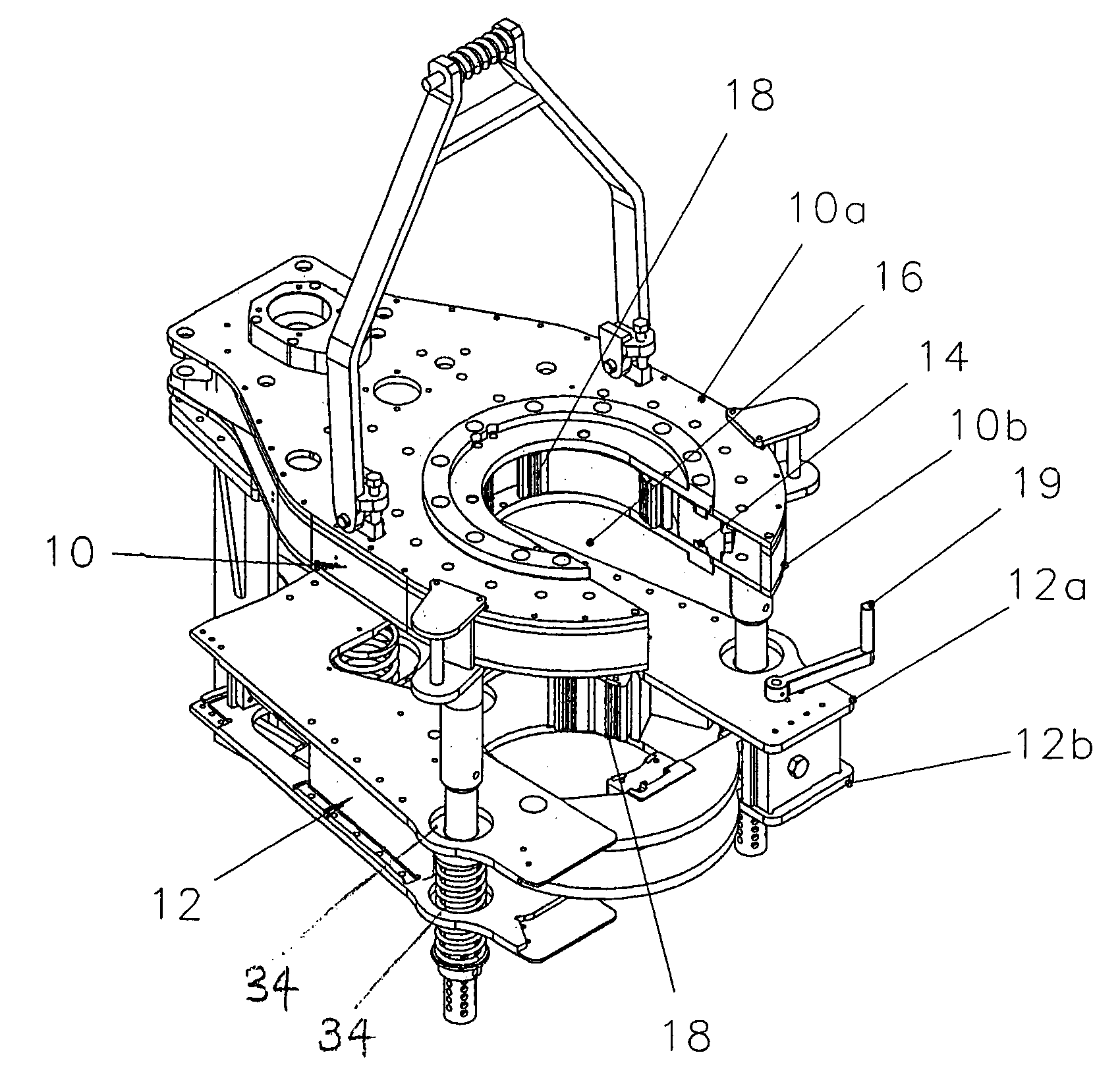

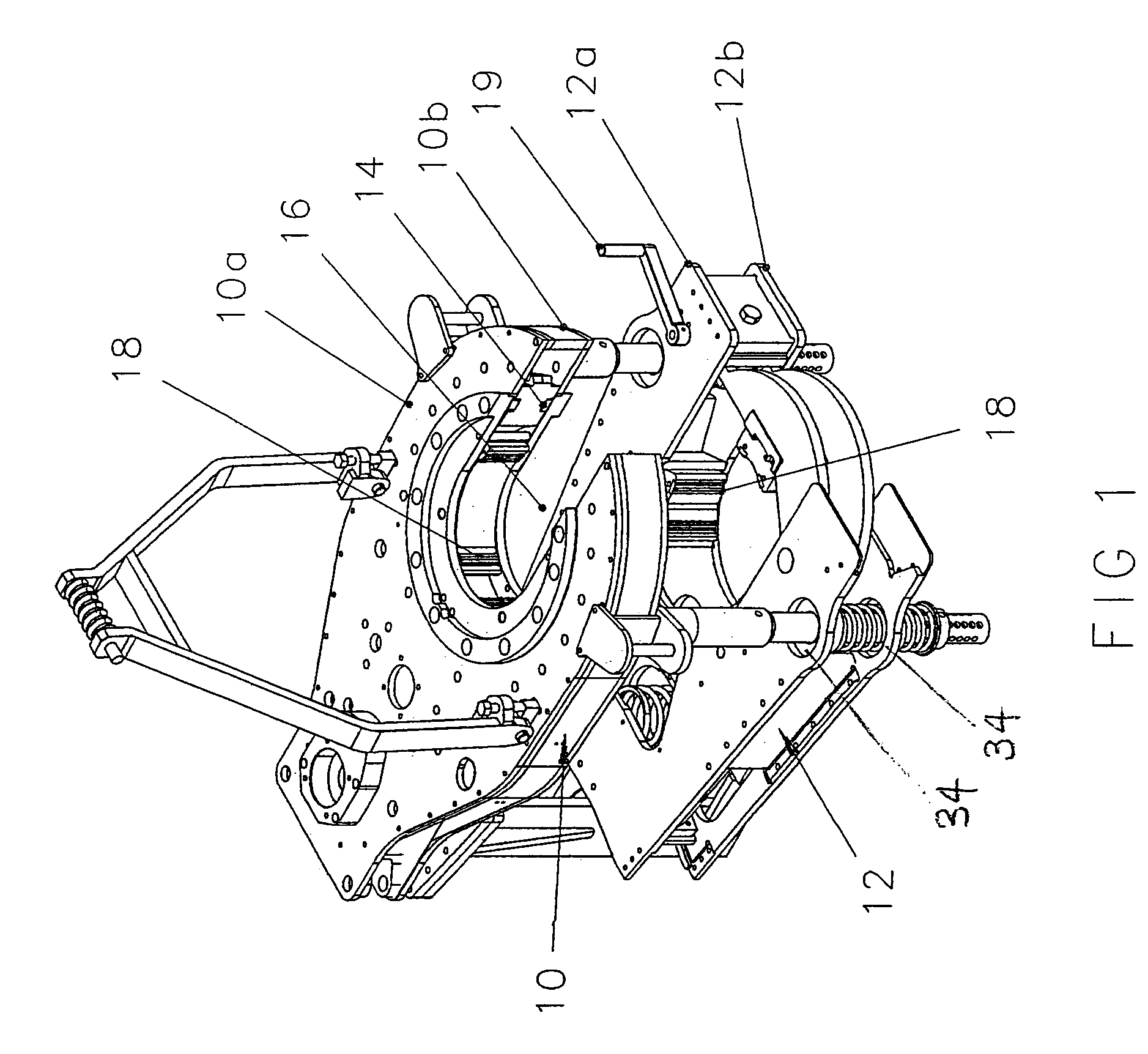

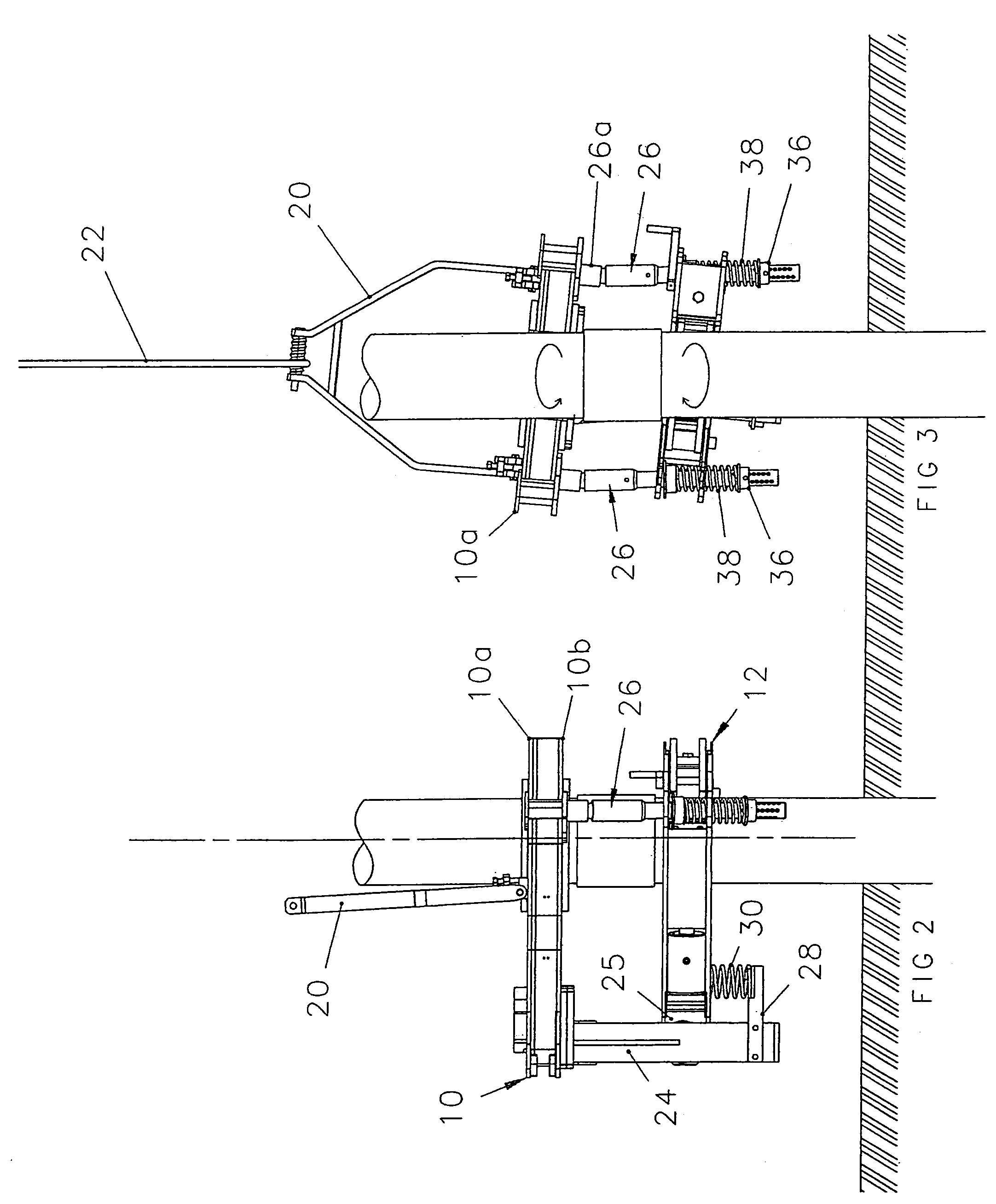

Support system for power tong assembly

InactiveUS7000503B2Effectively rigidMinimizing any tendencyDrilling rodsConstructionsSupporting systemEngineering

A tong assembly having a powered tong mounted over a backup tong is supported at its rear by a post with torque measuring means. The powered tong is supported at its front, near its throat, by one or more struts that extend downwardly to the backup tong. Such strut (s) provide support for the powered tong when the assembly is placed on a support surface for storage. The struts each have a joint with a retracted condition in which the joint is rigid when the tong is placed on a support surface, and an extended condition in which the joint allows a degree of lateral displacement when the tong assembly is applying torque to a pipe string. This maximizes the amount of torque passing through the rearward post, and therefore ensures a more accurate sensing of applied torque by the torque-measuring device.

Owner:MCCOY GLOBAL

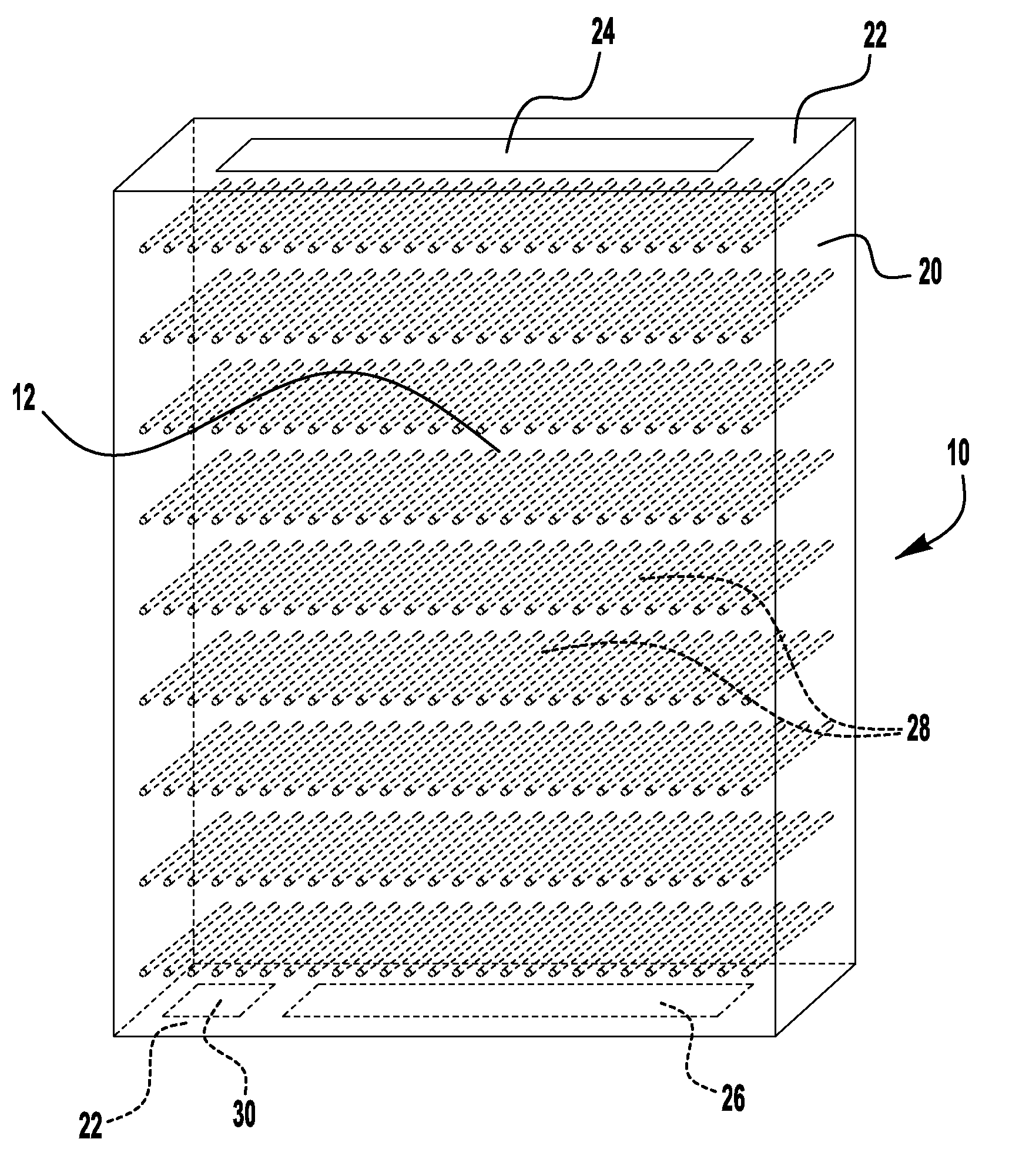

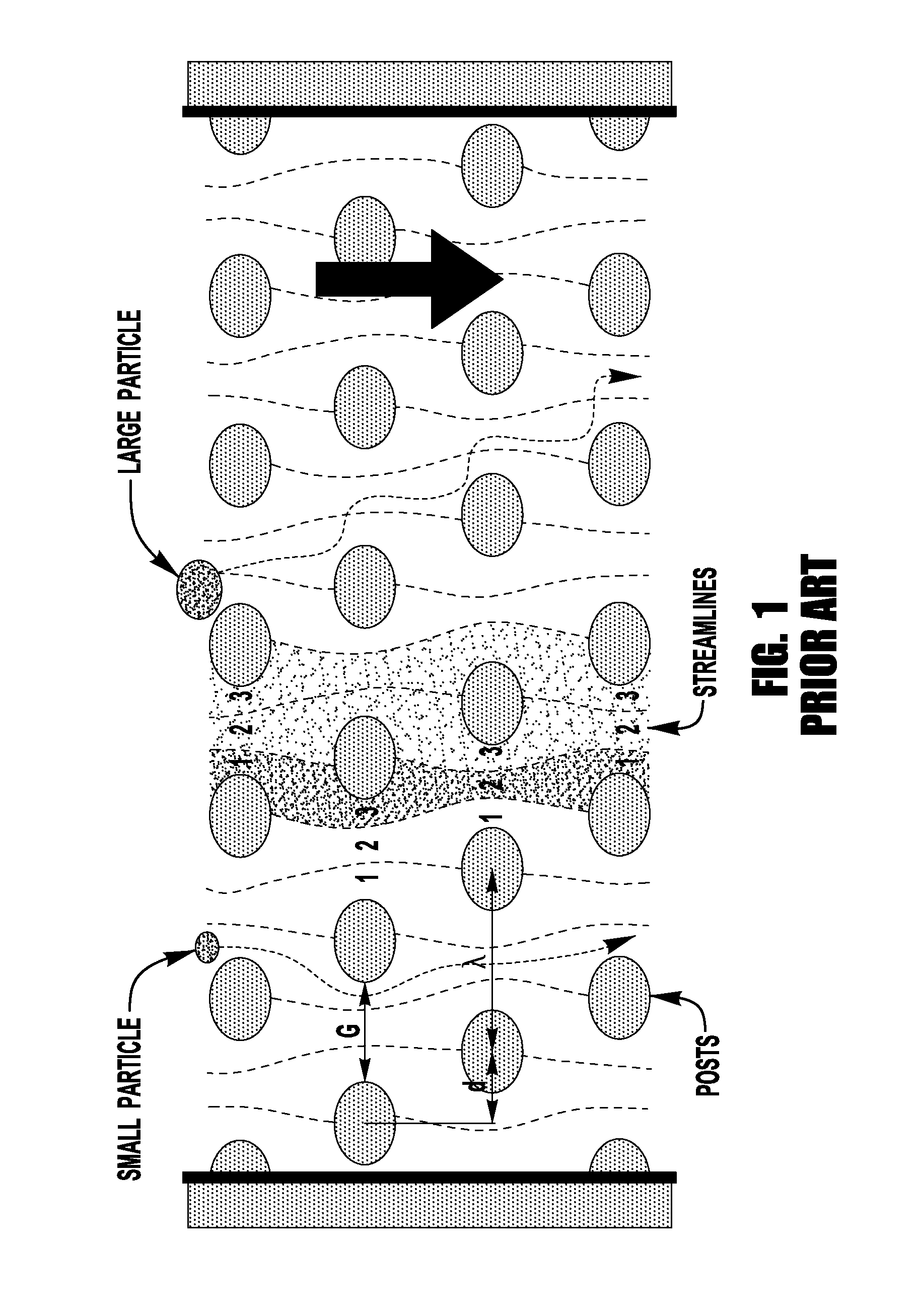

Lateral displacement array for microfiltration

InactiveUS20120037544A1Easy to manufactureEasy to assembleGas current separationLaboratory glasswaresVolumetric Mass DensityEngineering

A lateral displacement array that includes a conduit in which there is an array that includes a number of vertically asymmetrical posts that are positioned in an ordered fashion that is asymmetric with respect to the direction of liquid flow within the array such that particles of at least a critical size will be laterally displaced as they flow through the array is described. Methods for separating particles having at least a critical diameter from 16 a liquid using a lateral displacement array and a microfiltration system including a number of lateral displacement arrays are also described. Array subunits suitable for the assembly of the lateral displacement array are also described that include posts on either side of a floor that are arranged on each side with half the usual density so that when the subunits are combined a lateral displacement array with the desired array of posts is formed.

Owner:LOGOS ENERGY INC

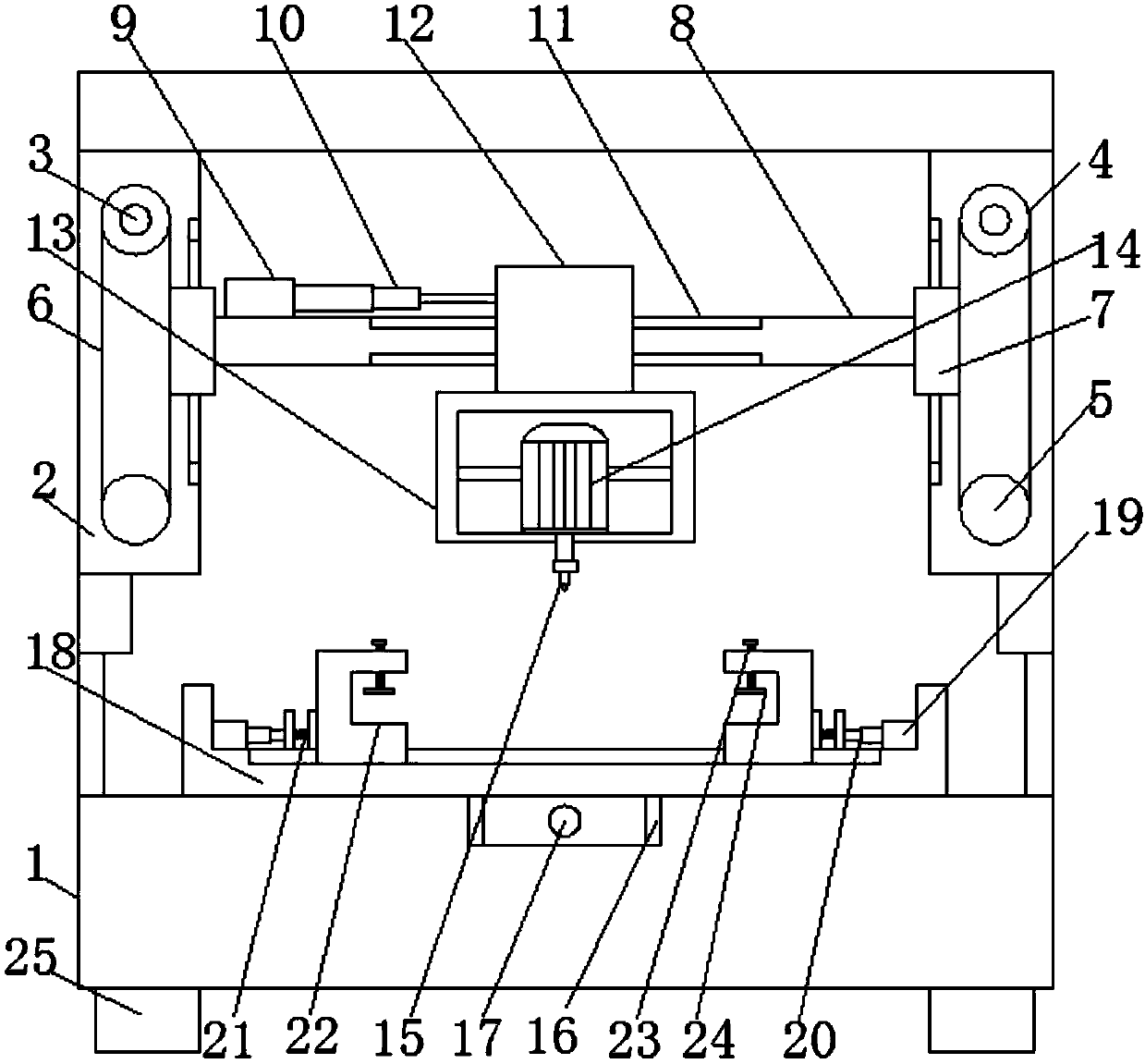

Steel structure drilling device

InactiveCN107824828AAvoid distortionAvoid stickingFeeding apparatusPositioning apparatusDrive wheelArchitectural engineering

The invention discloses a drilling device for a steel structure, which comprises a machine body. Both sides above the inner wall of the machine body are provided with organic casings. One motor, the output shafts of the two first motors are fixedly sleeved with driving wheels, the inner chambers of the two casings are provided with driven wheels, and belts are movably connected between the two driving wheels and the driven wheels, and the two belts Both of them are fixedly connected with fixed blocks, and the two fixed blocks are slidably connected to the inner wall of the through groove, and a support frame is fixedly connected between the two fixed blocks, and the left side of the top of the support frame is provided with a first cylinder. The invention solves the problem that the drill cannot be displaced laterally by adding a device for lateral movement to the drill, and achieves the purpose of the clamp device being able to move forward and backward by setting the turntable and the screw rod, and solves the problem that the existing steel structure drilling cannot be clamped at one time Problem with drilling multiple times.

Owner:余骆杨

Rumble strip responsive systems

ActiveUS20050236210A1Increase volumeBelt retractorsDigital data processing detailsDriver/operatorVehicle driving

An embodiment of the present invention includes a device to alter transfer characteristics of a road departure warning installation installed on a road to a driver of a vehicle, including a rumble strip sensor to sense input from a rumble strip and an adjustable vehicle component in communication with the rumble strip sensor, the adjustable vehicle component configured to automatically adjust to increase an amount of input from the rumble strip sensed by the driver. Another embodiment of the present invention includes a device to estimate lateral displacement of a vehicle based on the location of a rumble strip installed on a road with respect to the vehicle, the device including a processor configured to receive four signals indicative of contact of a rumble strip with respective associated four tires of the vehicle and to estimate a lateral distance that the vehicle has traveled beyond the detected rumble strip.

Owner:NISSAN MOTOR CO LTD

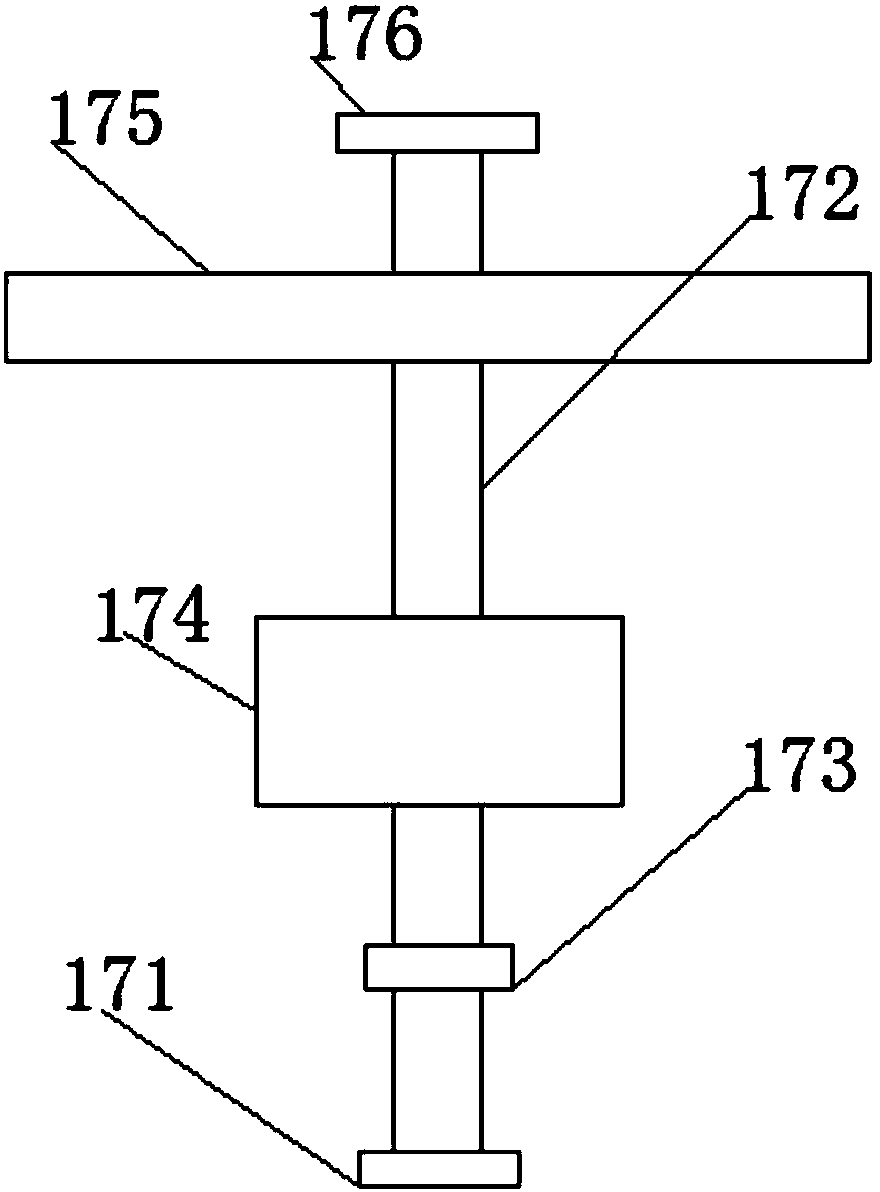

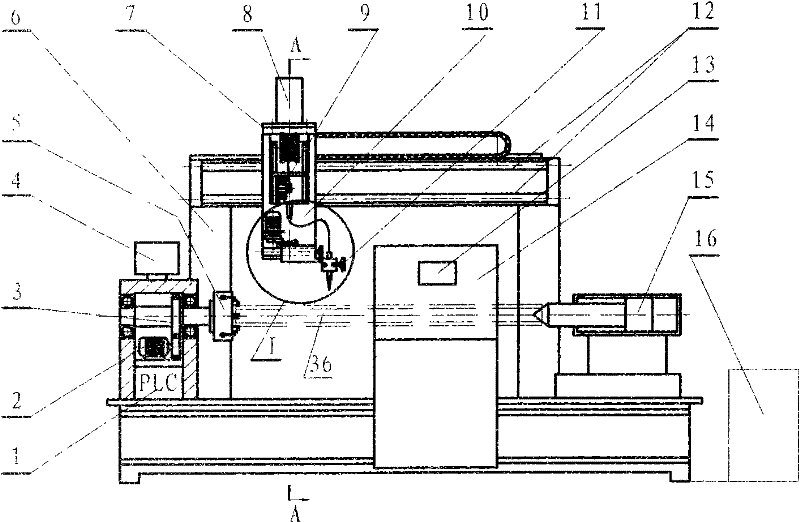

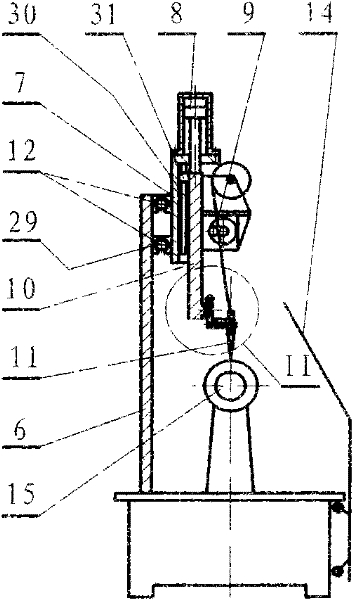

Program-controlled side-moving oil cylinder peripheral seam welding machine

InactiveCN102275032AHigh degree of automationImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlPower flow

The invention relates to a program-controlled side-moving oil cylinder circumferential seam welding machine, which consists of seven parts: an automatic control system, a power clamping mechanism, a lateral shifting device, a vertical lifting device, a welding torch swinging device, a position fine-tuning device and a welding mechanism. The invention adopts a PLC programmable controller as a main control unit, and adopts a Chinese display and video touch screen as a parameter adjustment dialogue interface. The touch screen can set the welding voltage, current welding speed and swing speed of each layer, and it is equipped with automatic and manual buttons for welding torch up and down. The invention adopts the mode of rotating the workpiece and fixing the welding torch; the welding torch is equipped with a fine-tuning mechanism and a two-axis angle adjustment device, which can adjust different welding angles; the welding torch is controlled by air pressure, and the micro DC motor drives the welding torch to swing; the tailstock is tightened by air pressure, and the machine head The three-jaw clamping method is adopted to realize automatic, manual and semi-automatic operation. The invention has the advantages of high degree of automation, good welding quality, safety and reliability.

Owner:YANCHENG EAST MACHINERY MFG CO LTD

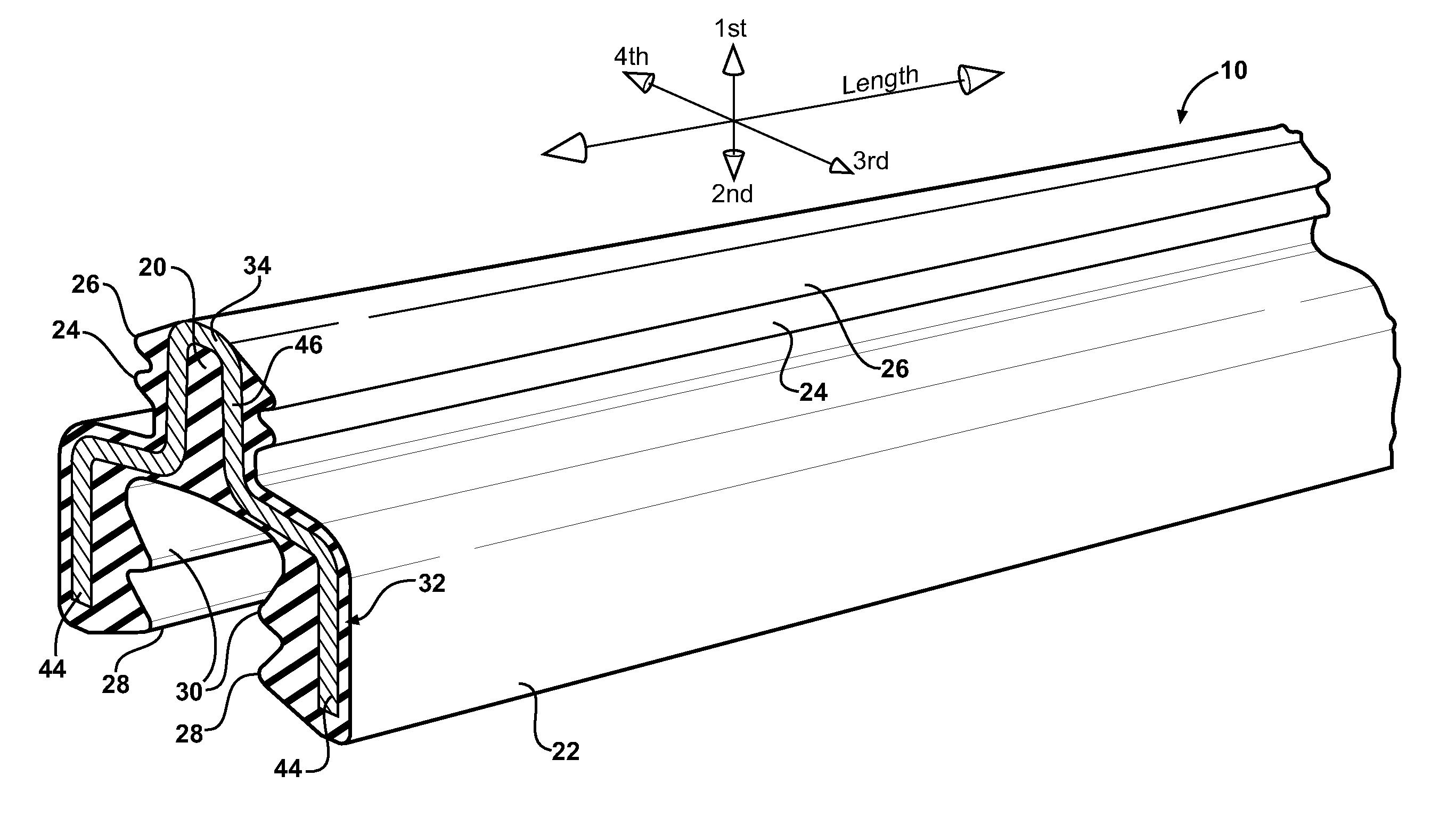

Lateral sealing gasket and method

An elongated elastomeric gasket (10) seals a pair of opposing flanges (12, 14) against the passage of liquid without compressing the flanges (12, 14) together. A reinforcing spring (32) is embedded within the elastomeric gasket (10) and is shaped so as to react when deflected by the operation of installing the gasket (10) into an operative position between the flanges (12, 14). A strategically located U-shaped bend (34) formed in the reinforcing spring (32) causes, in a preferred embodiment, contact pressure to be increased between opposed sealing beads at the other end of the gasket. More specifically, lateral contact pressure between a first pair of sealing beads (24) and their associated contact faces (38) is increased as a direct result of the reinforcing spring (32) being displaced during the assembly process. Likewise, lateral contact pressure between a second pair of beads (28) and their respective contact faces (42) is increased in direct response to the lateral displacement of the reinforcing spring (32) in the region of the first beads (24) during assembly.

Owner:FEDERAL MOGUL WORLD WIDE

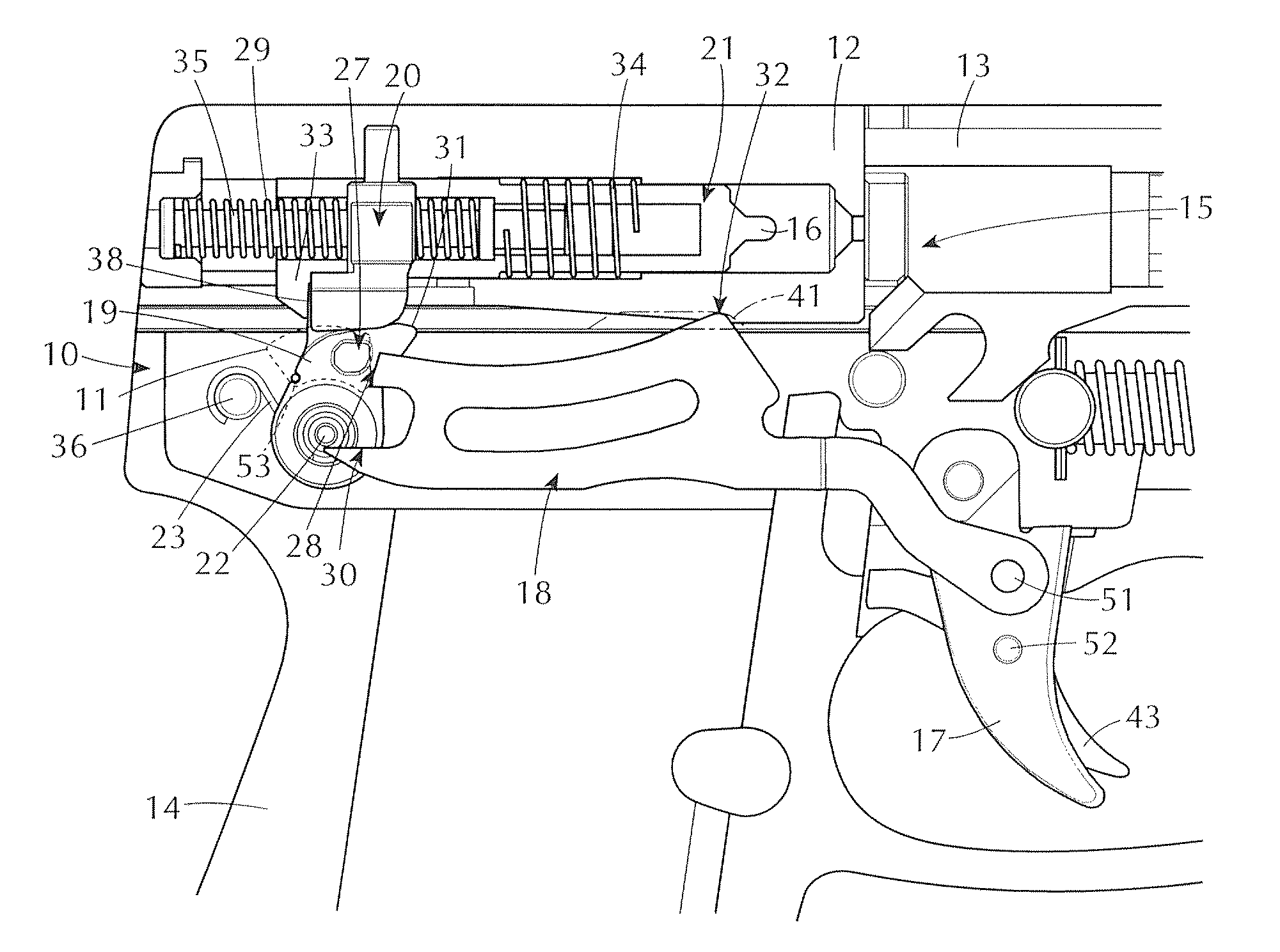

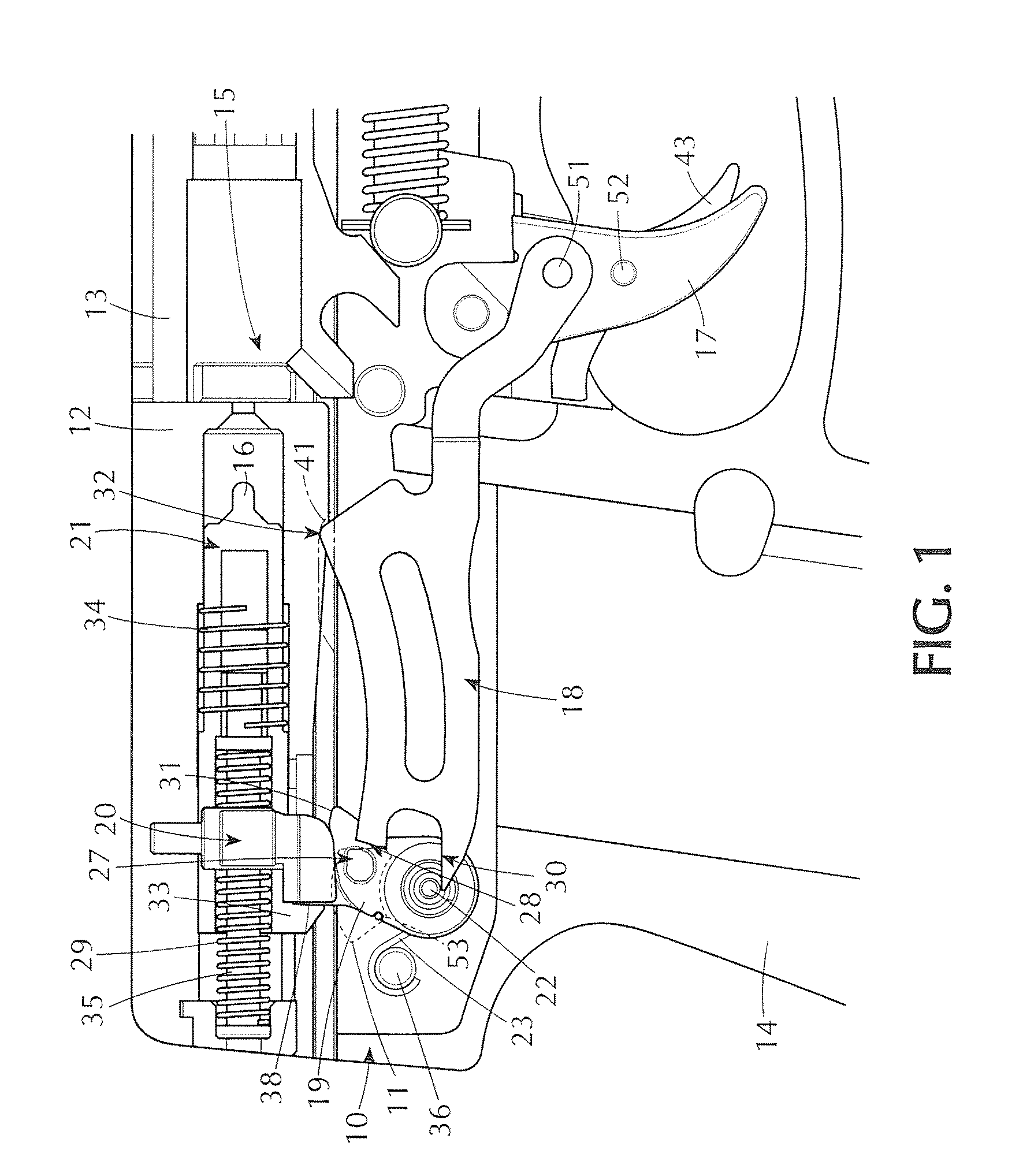

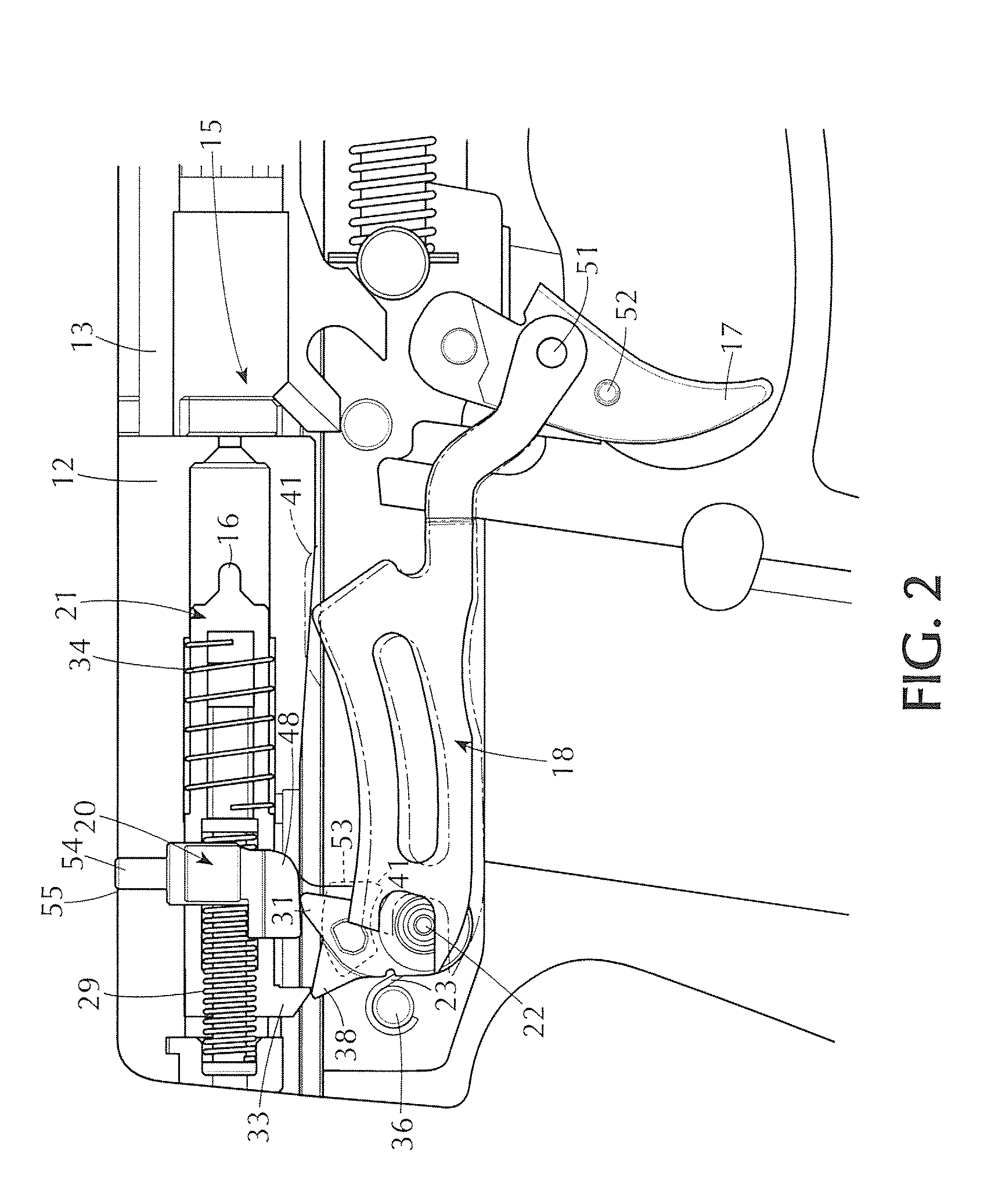

De-cocking mechanism for striker-fired semi-automatic pistols

ActiveUS20110289811A1Reduce manufacturing costVulnerableSafety arrangementFiring/trigger mechanismsSemi automaticEngineering

A cocking / de-cocking mechanism for semi-automatic striker-fired pistols having a multi-function cocking lever for controlling, by rotational movement, the cocking or arming of the tiring pin, while effecting de-cocking by the lateral displacement of the cocking lever on its support pin.

Owner:BERETTA USA CORP

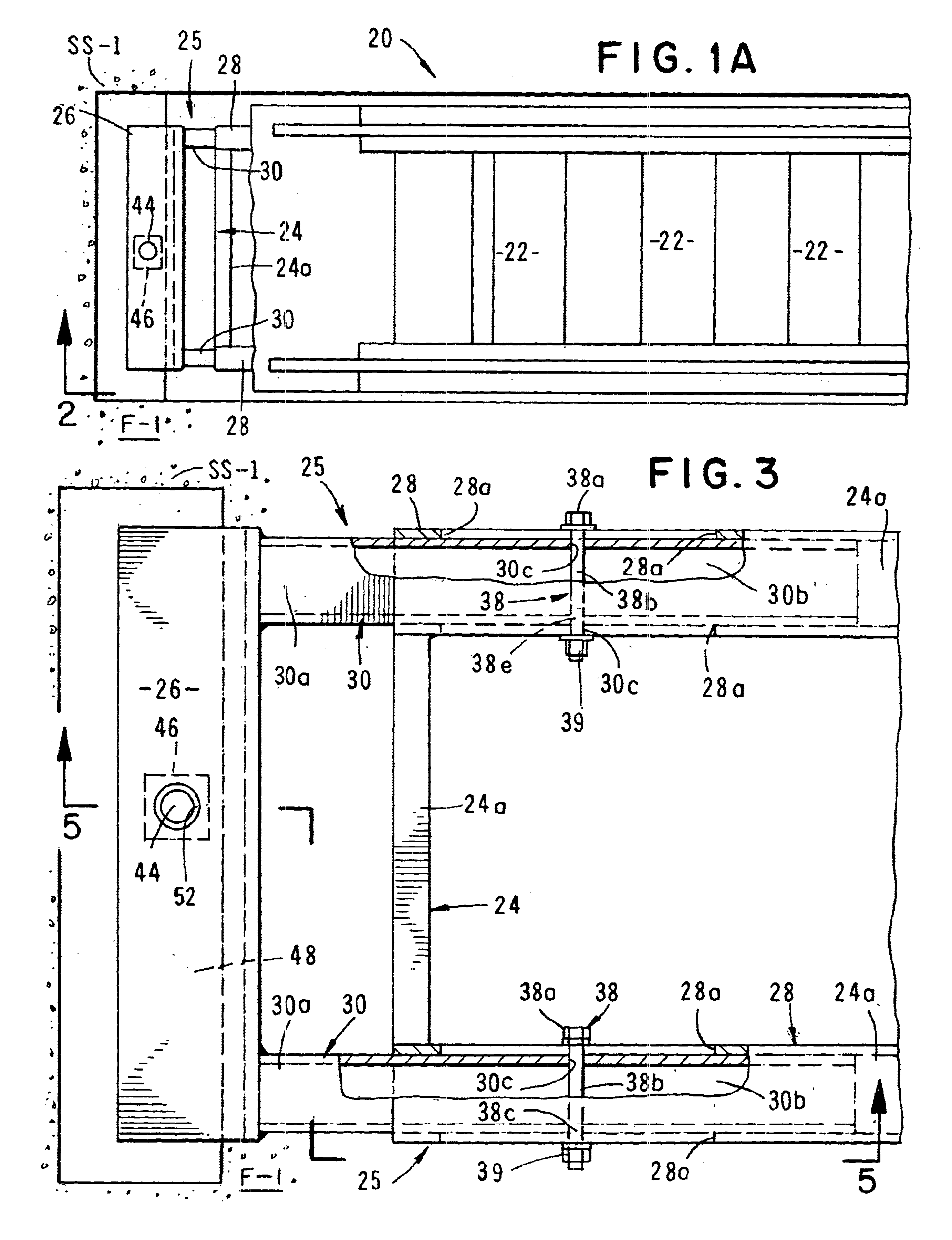

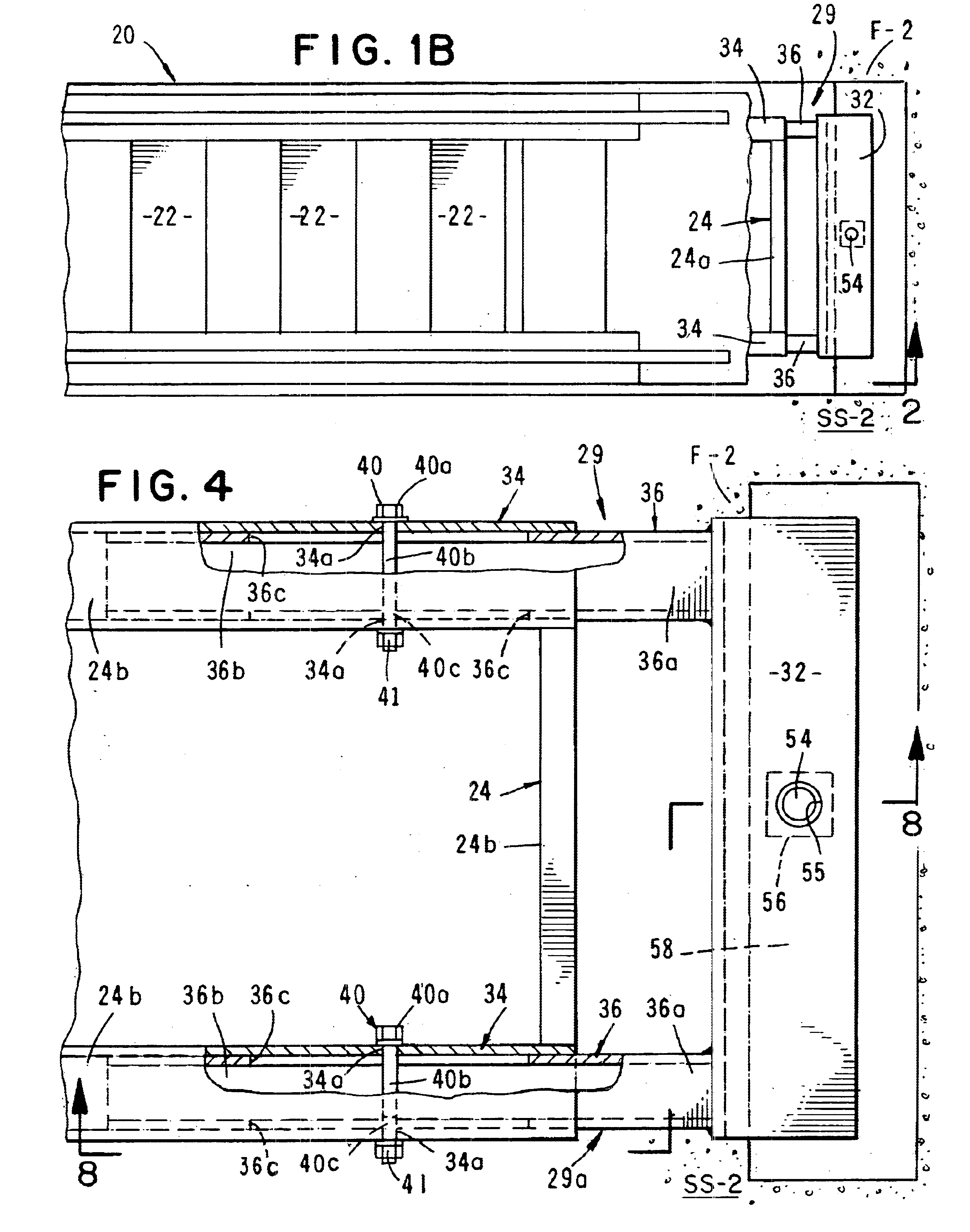

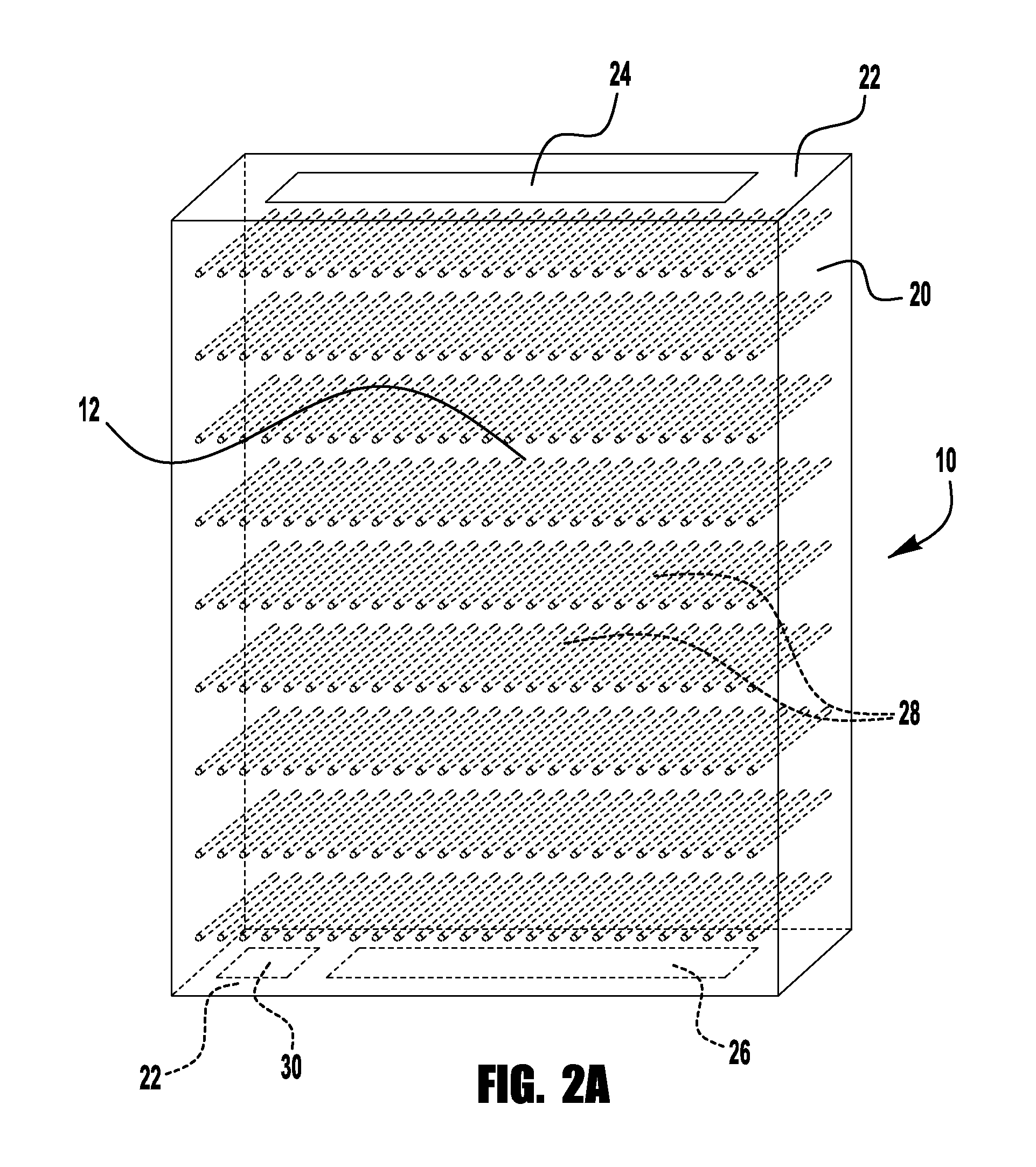

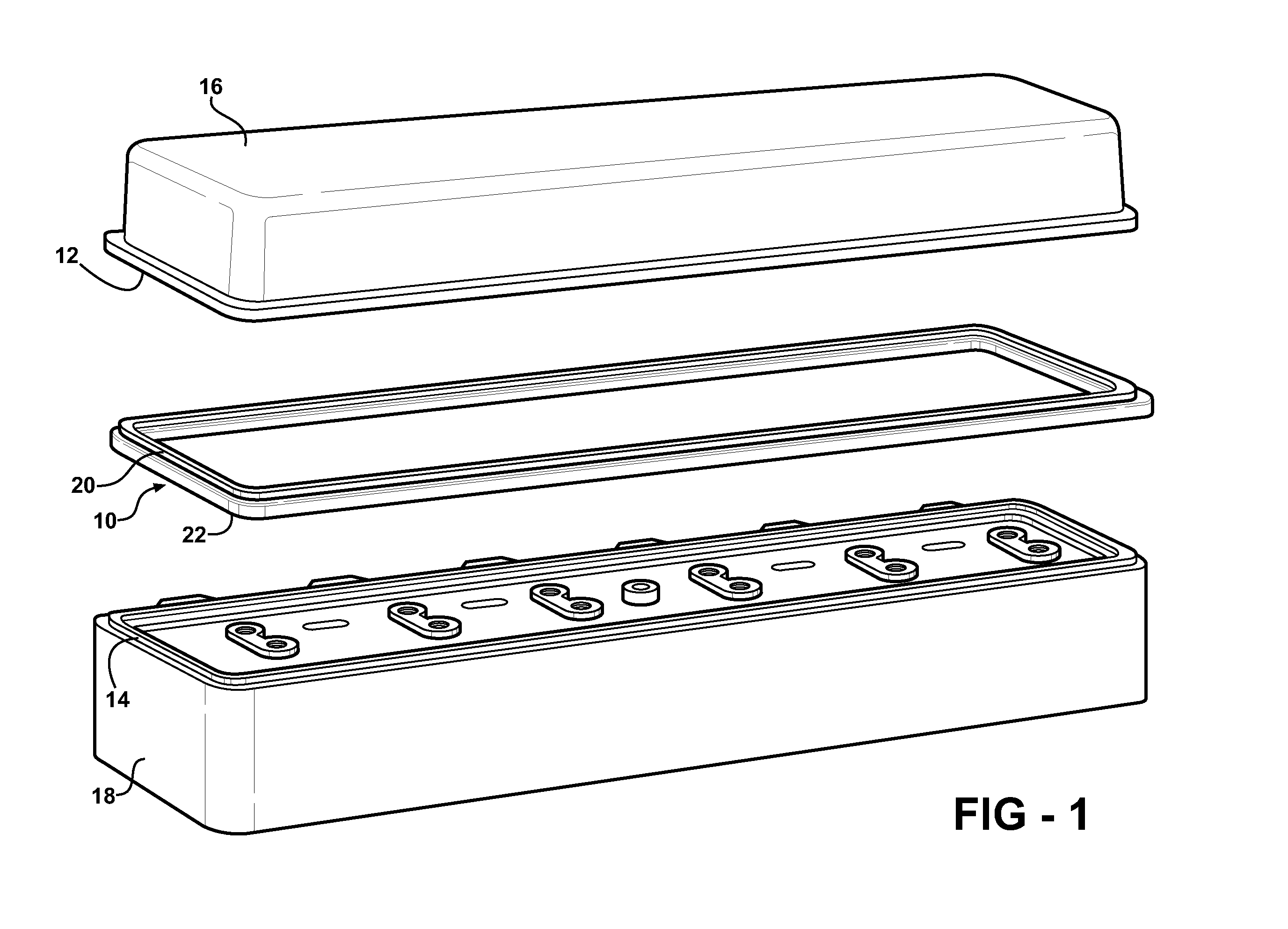

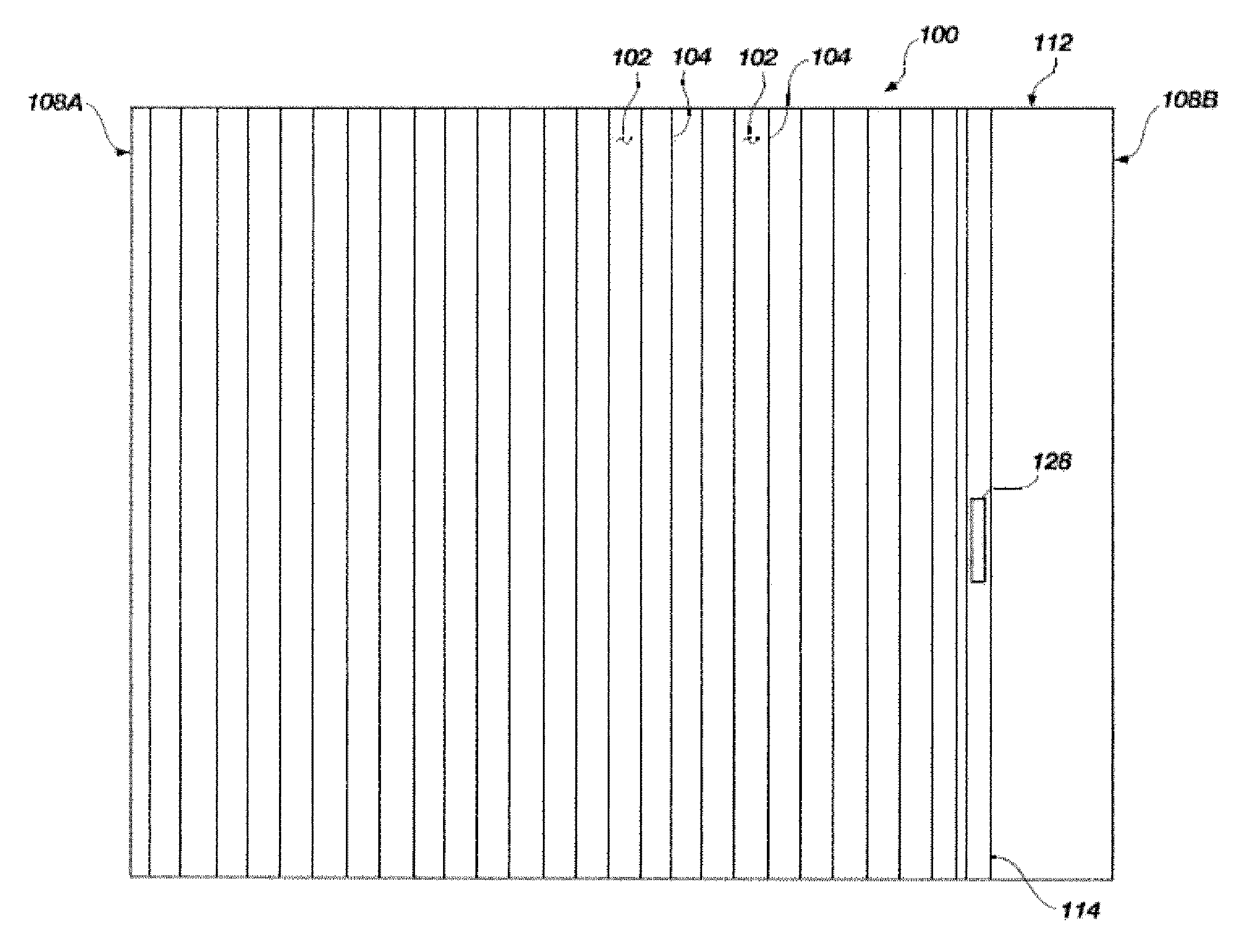

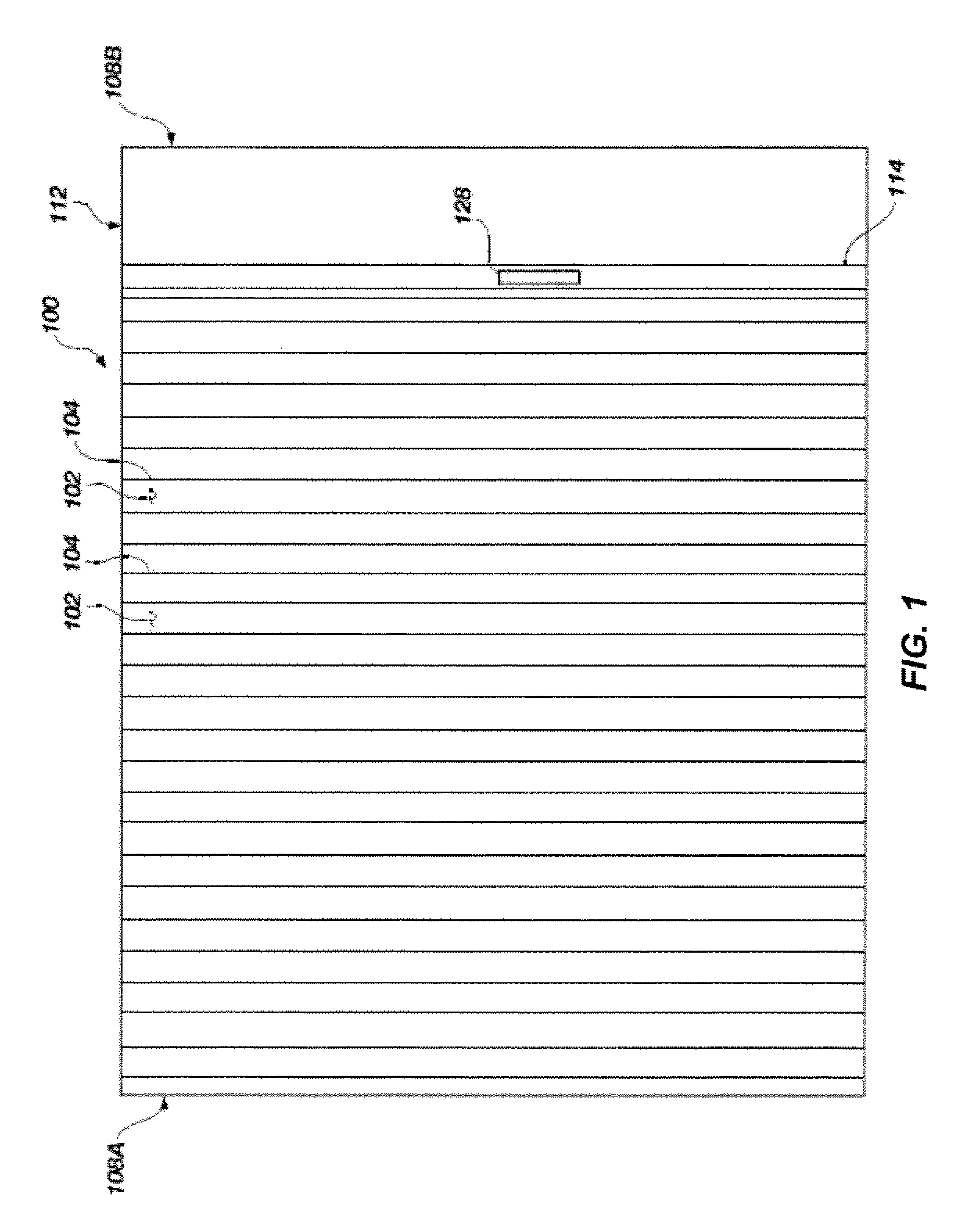

Movable partitions with lateral restraint devices and related methods

ActiveUS20080115896A1Prevent lateral movementDisplacement of moreExtensible doors/windowsCurtain accessoriesEngineeringFace sheet

Embodiments of the present invention include movable partitions and devices, methods and systems that help to limit or prevent lateral displacement of movable partitions. In accordance with one embodiment of the present invention, a movable partition includes two structures, each structure having a first plurality of panels, and each panel being hingedly coupled to an adjacent panel. The two panels are each supported from an overhead track at laterally spaced locations. One or more lateral restraint devices are supported from the overhead track at a location between the two laterally spaced structures. The lateral restraint device may include a trolley disposed in a channel of the overhead track and an elongated member coupled with the trolley and extending away from the trolley to a location proximate a lower edge of the first structure and a lower edge of the second structure.

Owner:WOW DOOR CORP

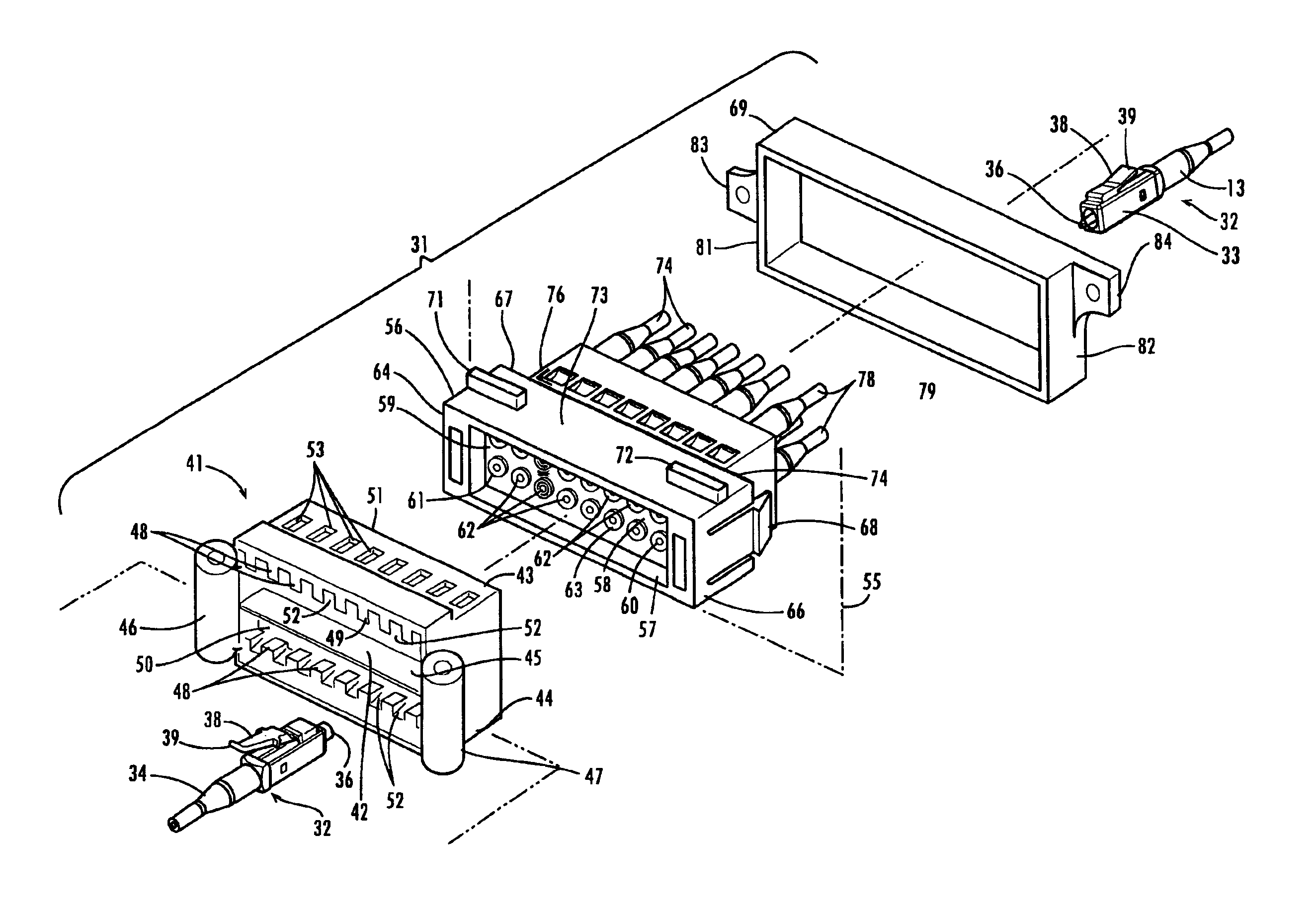

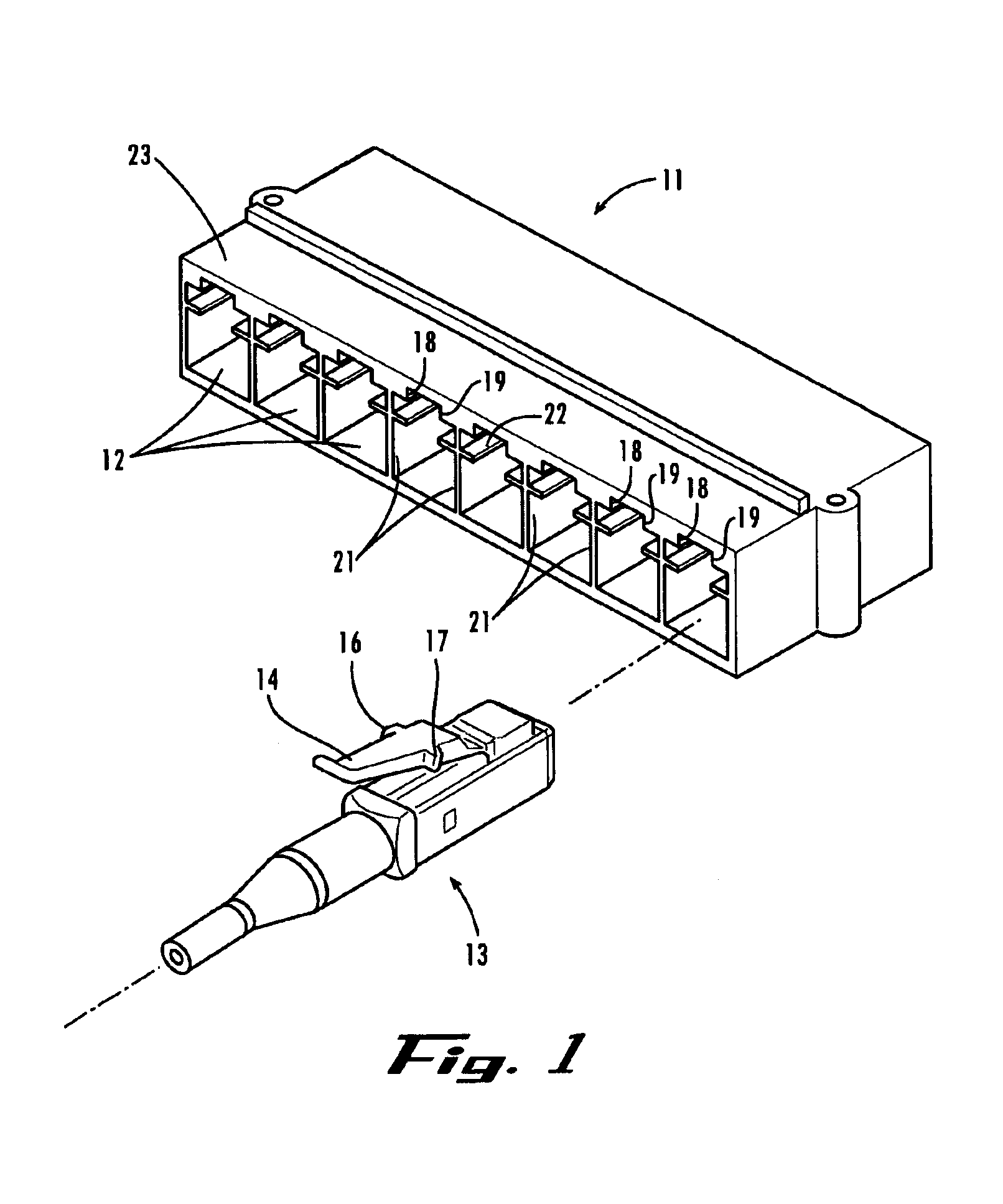

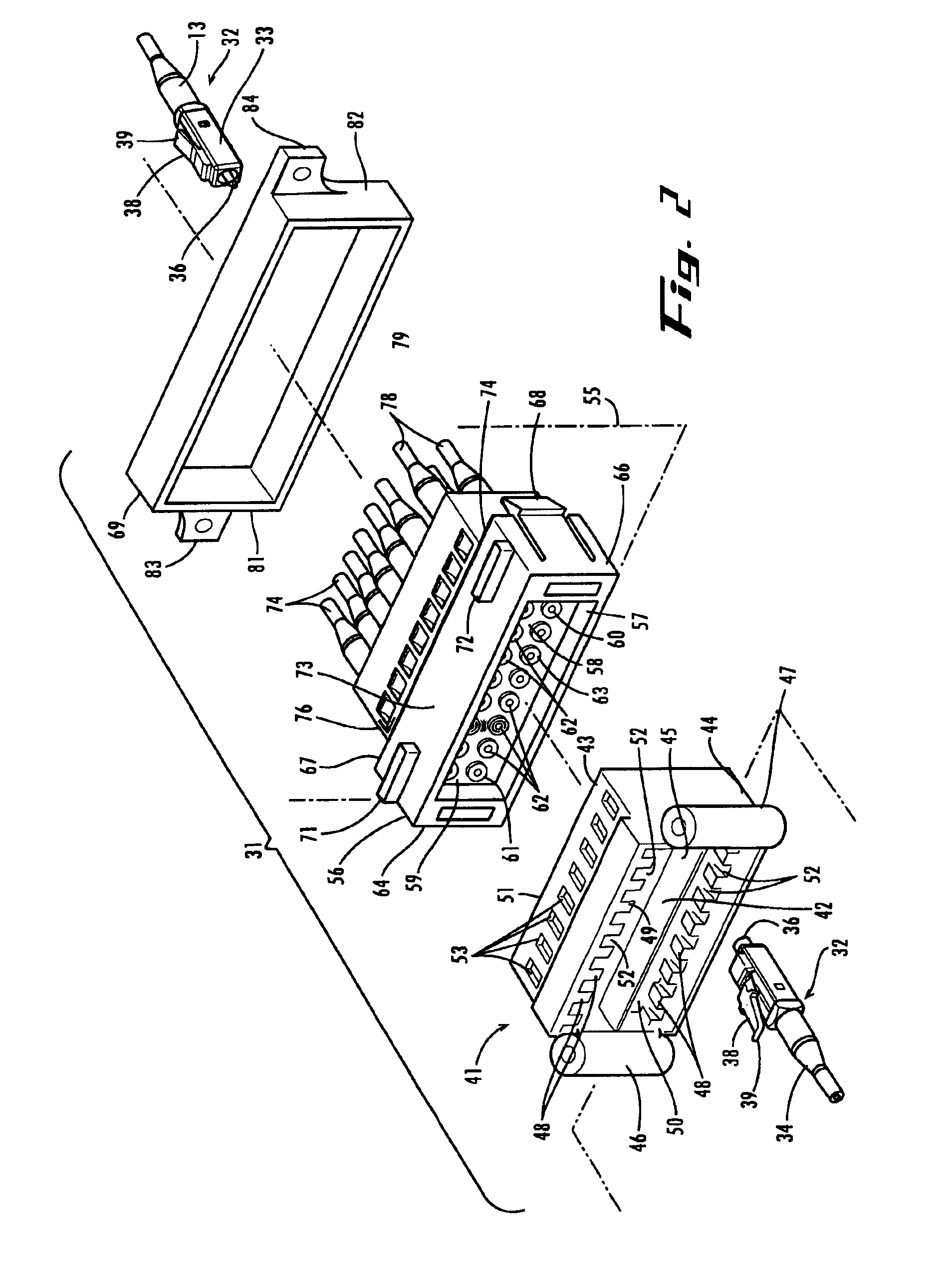

High density modular backplane connector for fiber optics

A high density panel mounting assembly has a first connector housing having first and second arrays of channels for receiving modified connectors, separated by a shelf. An adapter assembly for receiving the ferrules of the connectors has an interior wall having first and second arrays of bored projections forming sleeves for receiving the connector ferrules. The adapter assembly has a second connector housing substantially identical with the first connector housing mounted to or integral with the rear of the adapter housing for receiving individual connectors. Each of the connector housings has an array of apertures along the top and bottom surfaces for latching the connectors in place. Each of the connectors has a resilient latching arm having a distal end having a latching surface thereon which bears against the end of its corresponding aperture to latch the connector in place within the connector housing. The first and second connector housings each receives the connectors in an aperture, the width of which is substantially equal to the sum of the widths o the connectors so that the connectors, when in place, bear against each other to prevent lateral displacement thereof.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

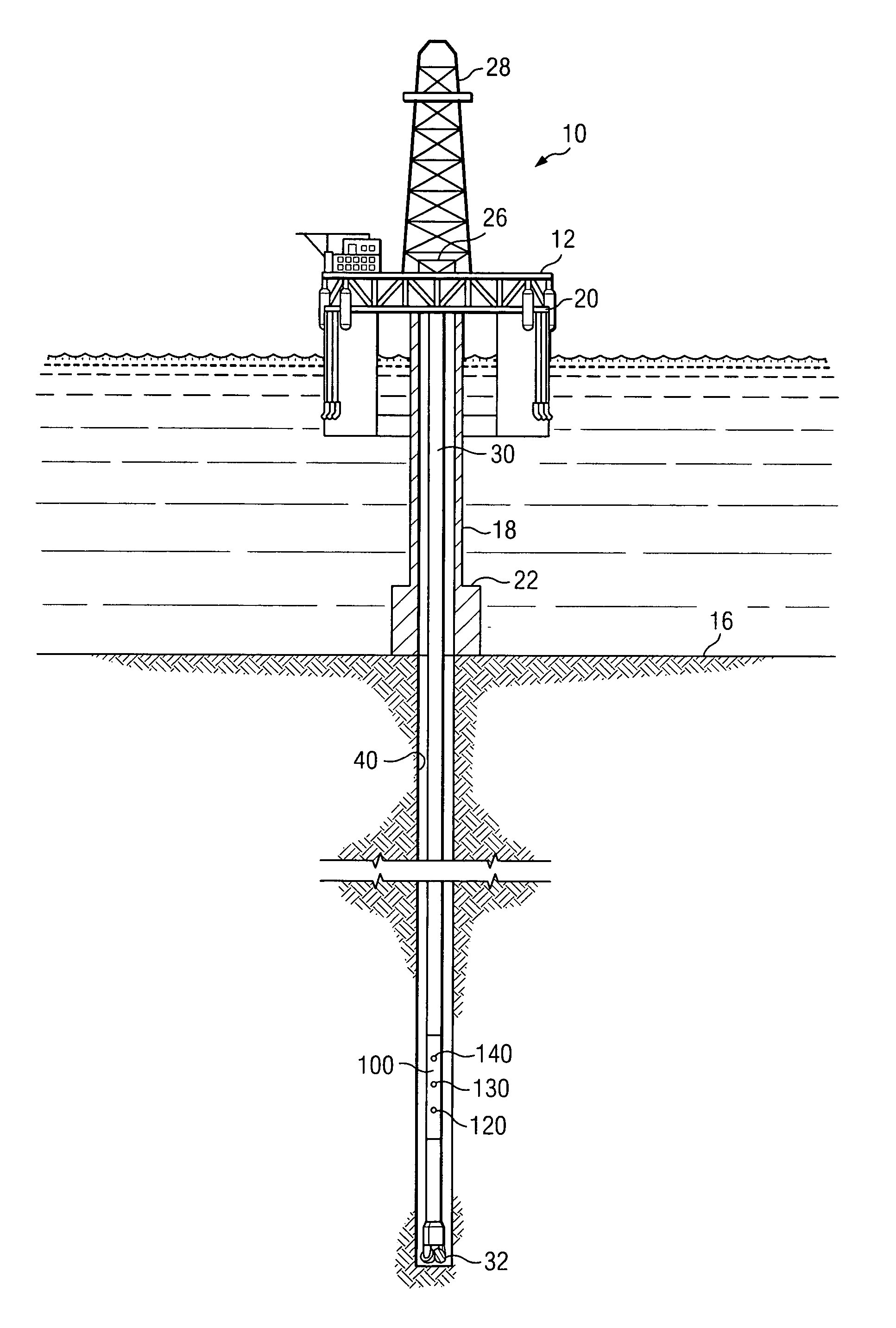

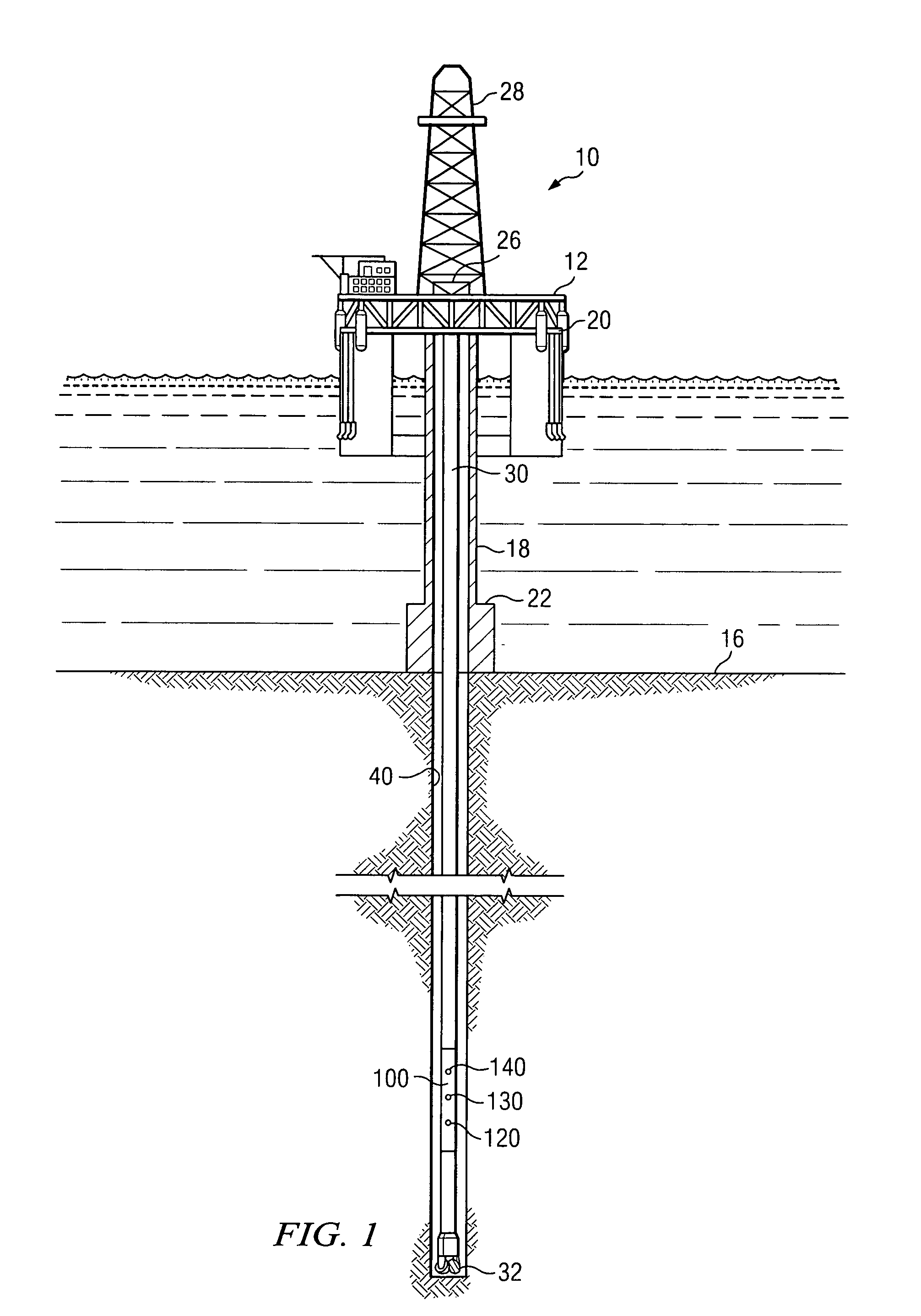

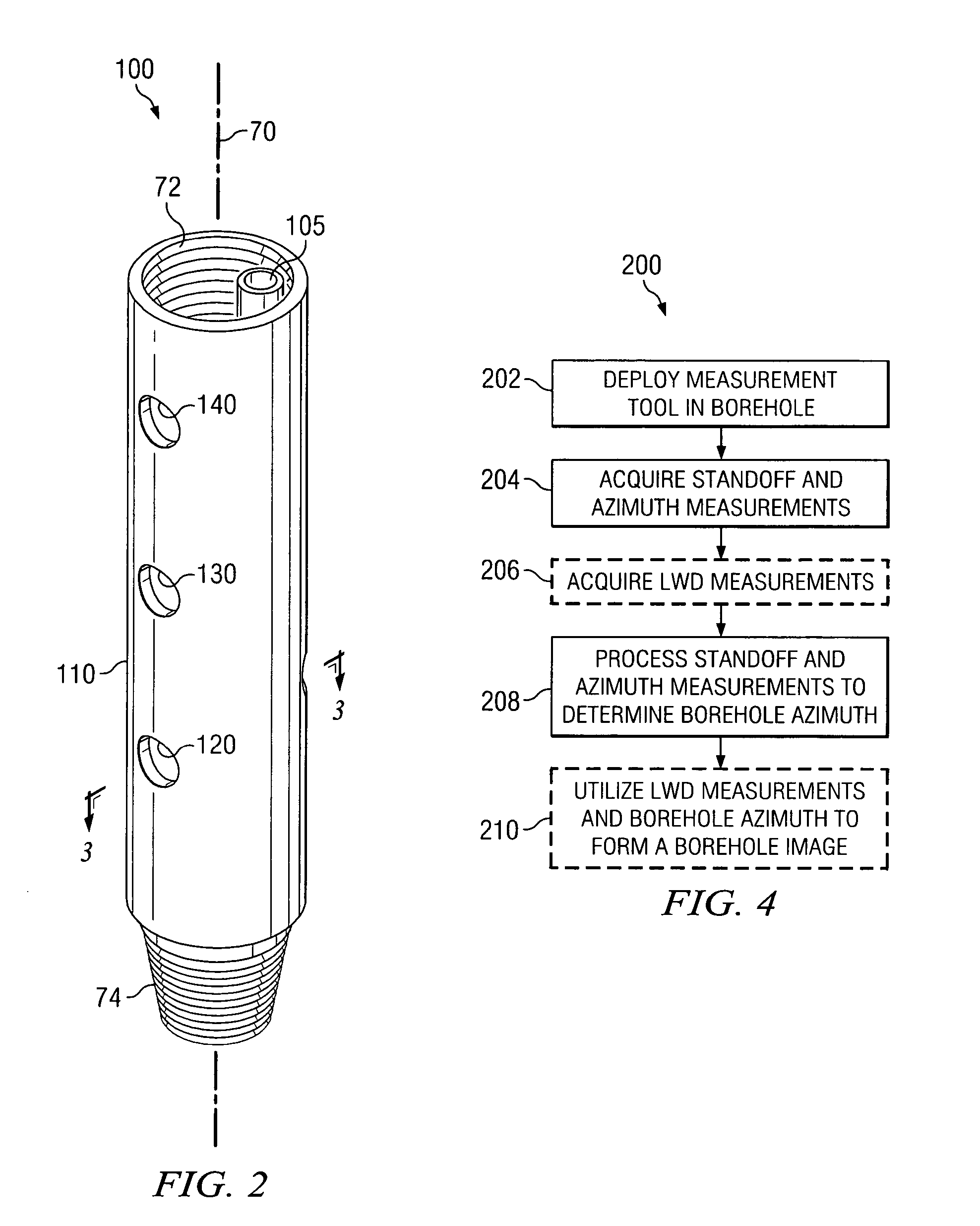

Determination of borehole azimuth and the azimuthal dependence of borehole parameters

ActiveUS20060096105A1Improve imaging resolutionSuperior noise rejectionElectric/magnetic detection for well-loggingSurveyImage resolutionImaging technique

A method for determining a borehole azimuth in a borehole is disclosed. In one exemplary embodiment, the method includes acquiring at least one standoff measurement and a tool azimuth measurement at substantially the same time. Such measurements are then processed, along with a lateral displacement vector of the downhole tool upon which the sensors are deployed in the borehole, to determine the borehole azimuth. The computed borehole azimuths may be advantageously correlated with logging sensor data to form a borehole image, for example, by convolving the correlated logging sensor data with a window function. As such, exemplary embodiments of this invention may provide for superior image resolution and noise rejection as compared to prior art LWD imaging techniques.

Owner:SCHLUMBERGER TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com