Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

618results about How to "Increase contact pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

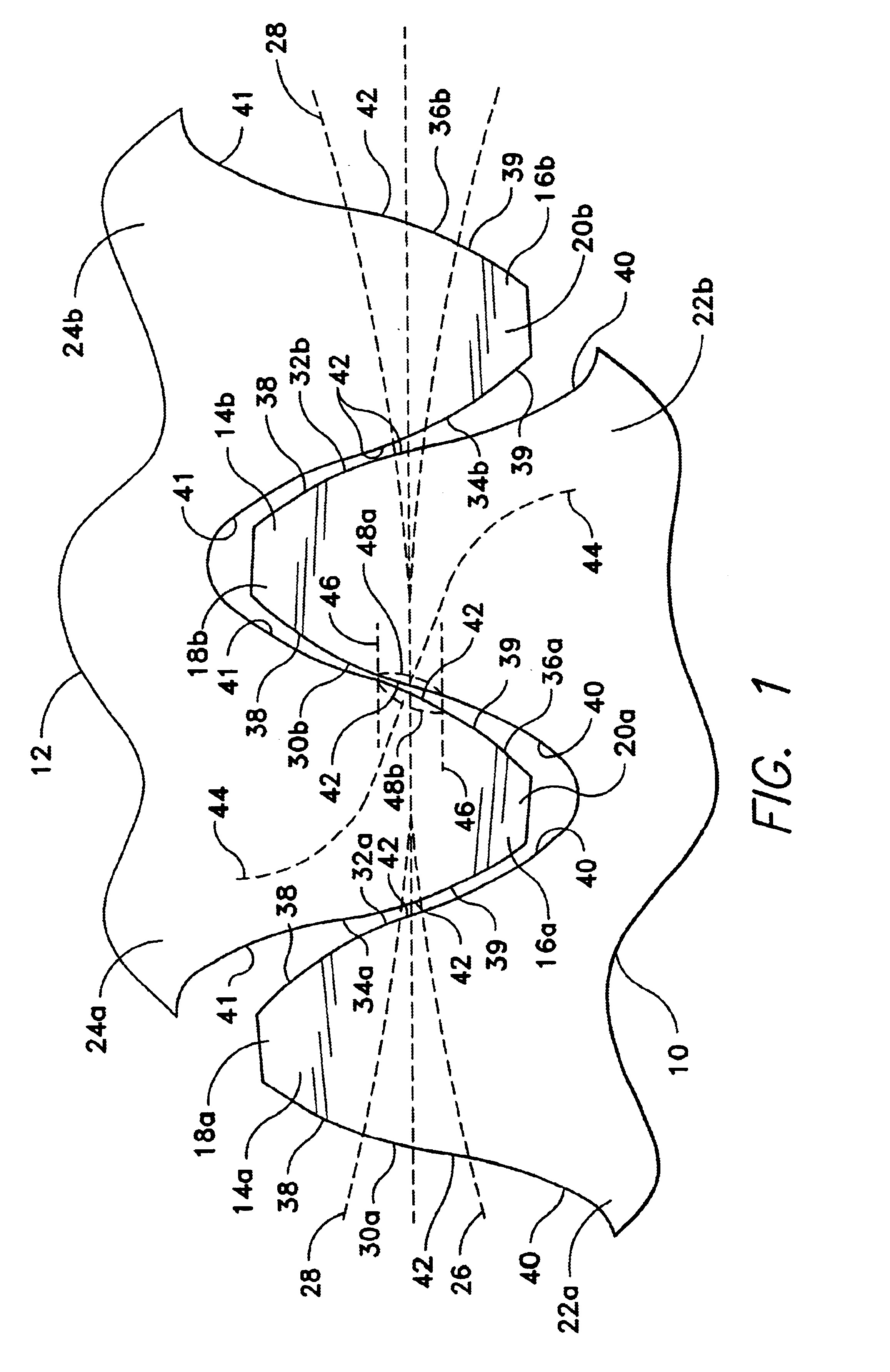

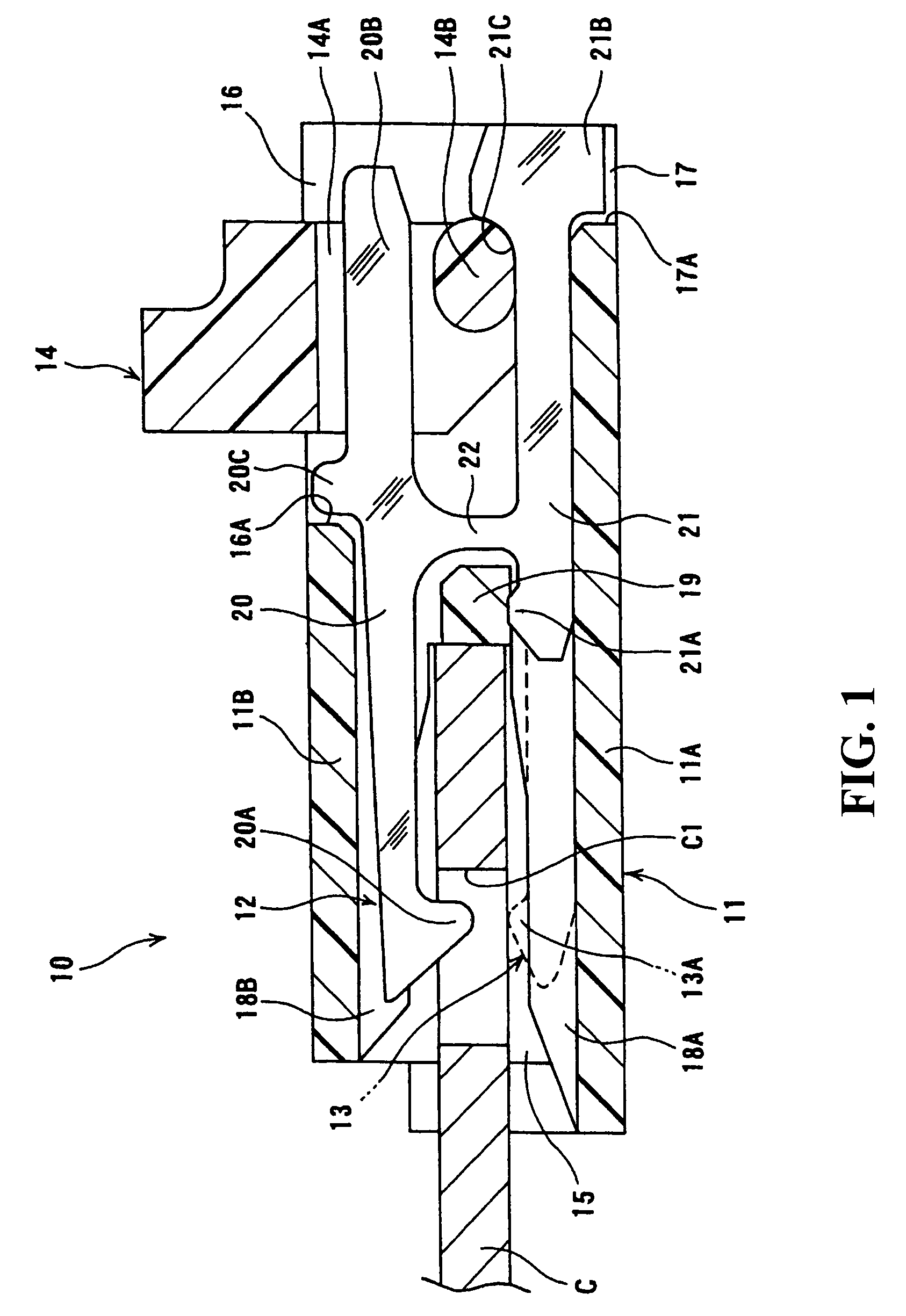

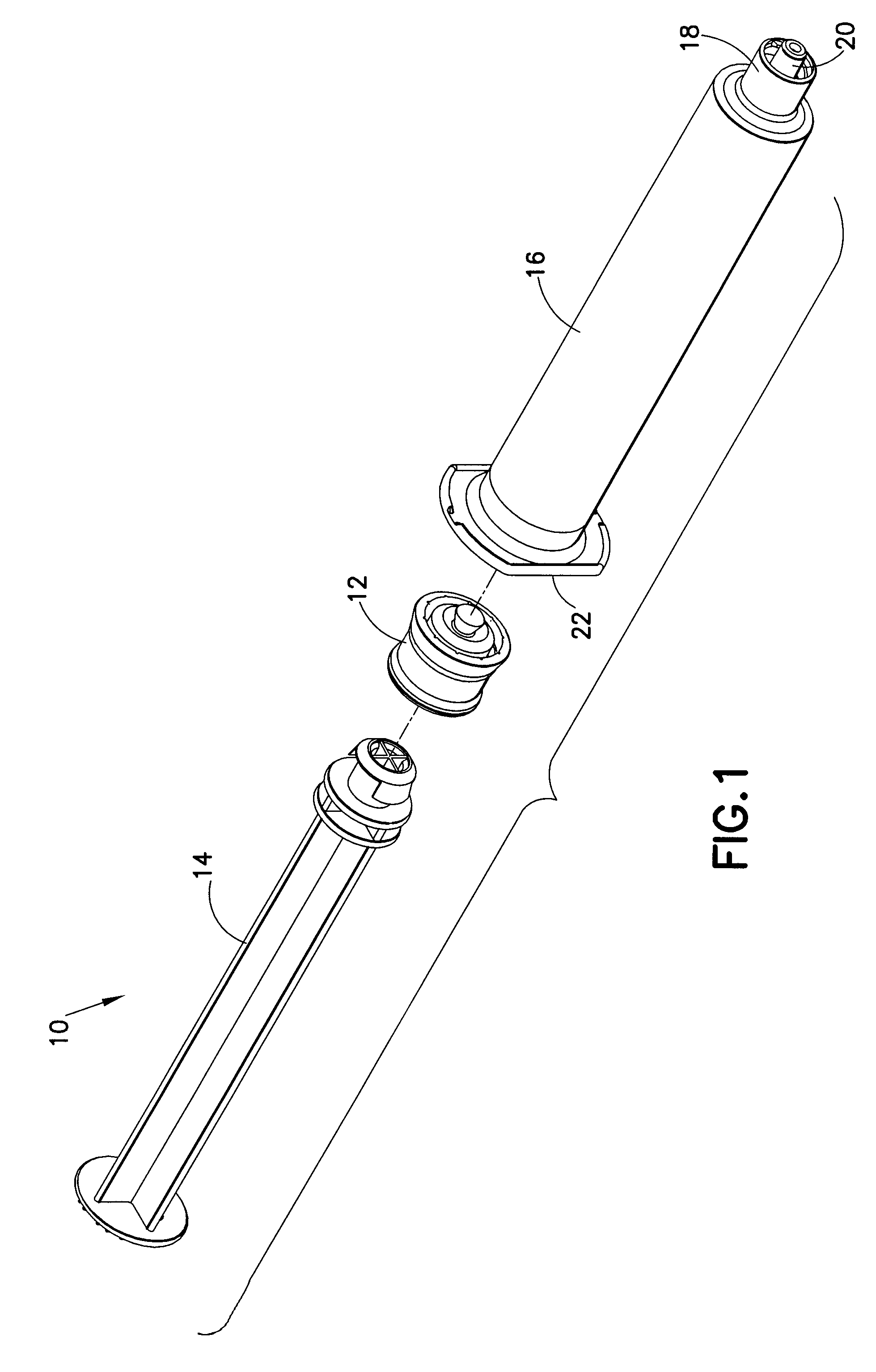

Systems and methods for electrode contact assessment

ActiveUS20070100332A1Increase contact pressureReduce contact pressureCatheterDiagnostic recording/measuringElectricityDistal portion

Systems and methods are disclosed for assessing electrode-tissue contact for tissue ablation. An exemplary electrode contact sensing system comprises an electrode housed within a distal portion of a catheter shaft. At least one electro-mechanical sensor is operatively associated with the electrode within the catheter shaft. The at least one electro-mechanical sensor is responsive to movement of the electrode by generating electrical signals corresponding to the amount of movement. The system may also include an output device electrically connected to the at least one electro-mechanical sensor. The output device receives the electrical signals for assessing a level of contact between the electrode and a tissue.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

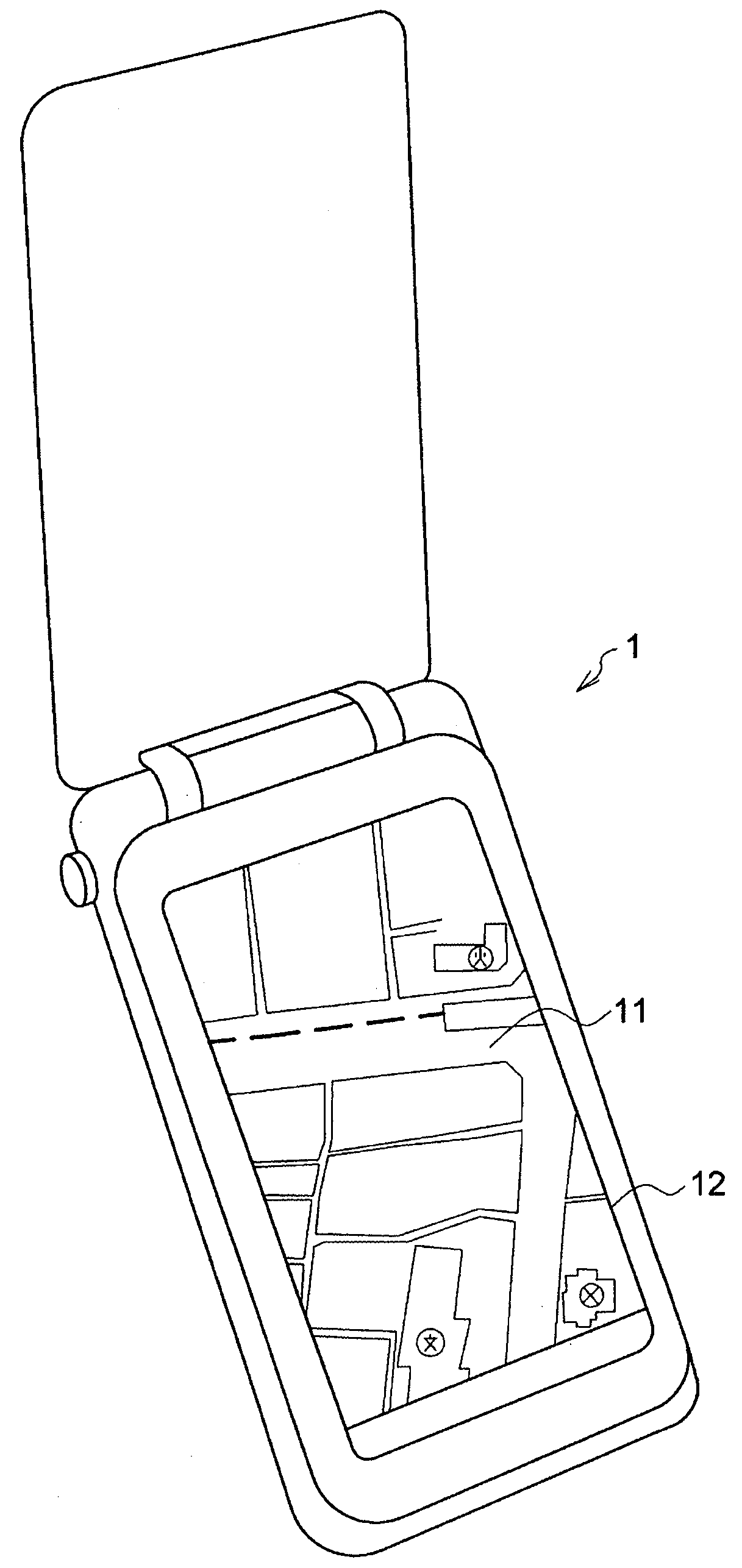

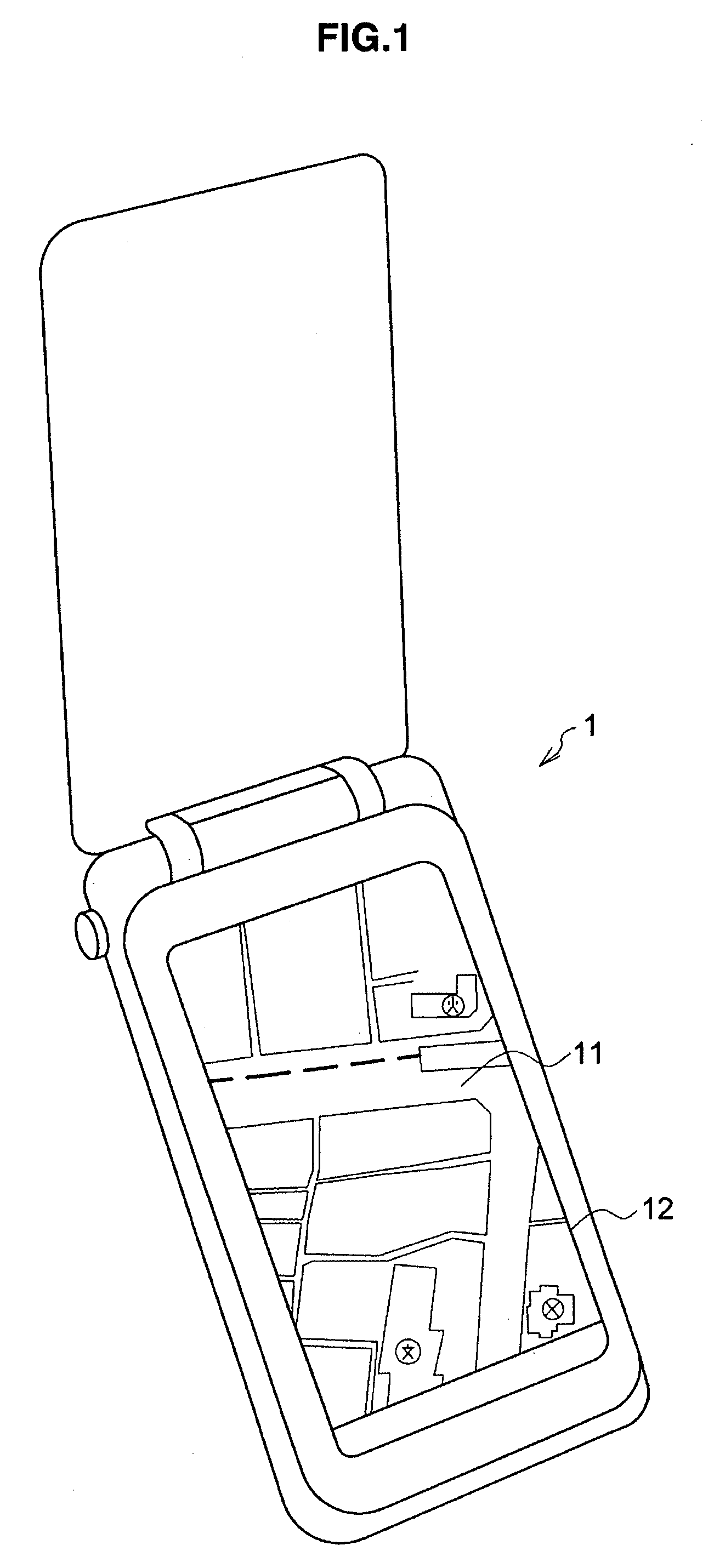

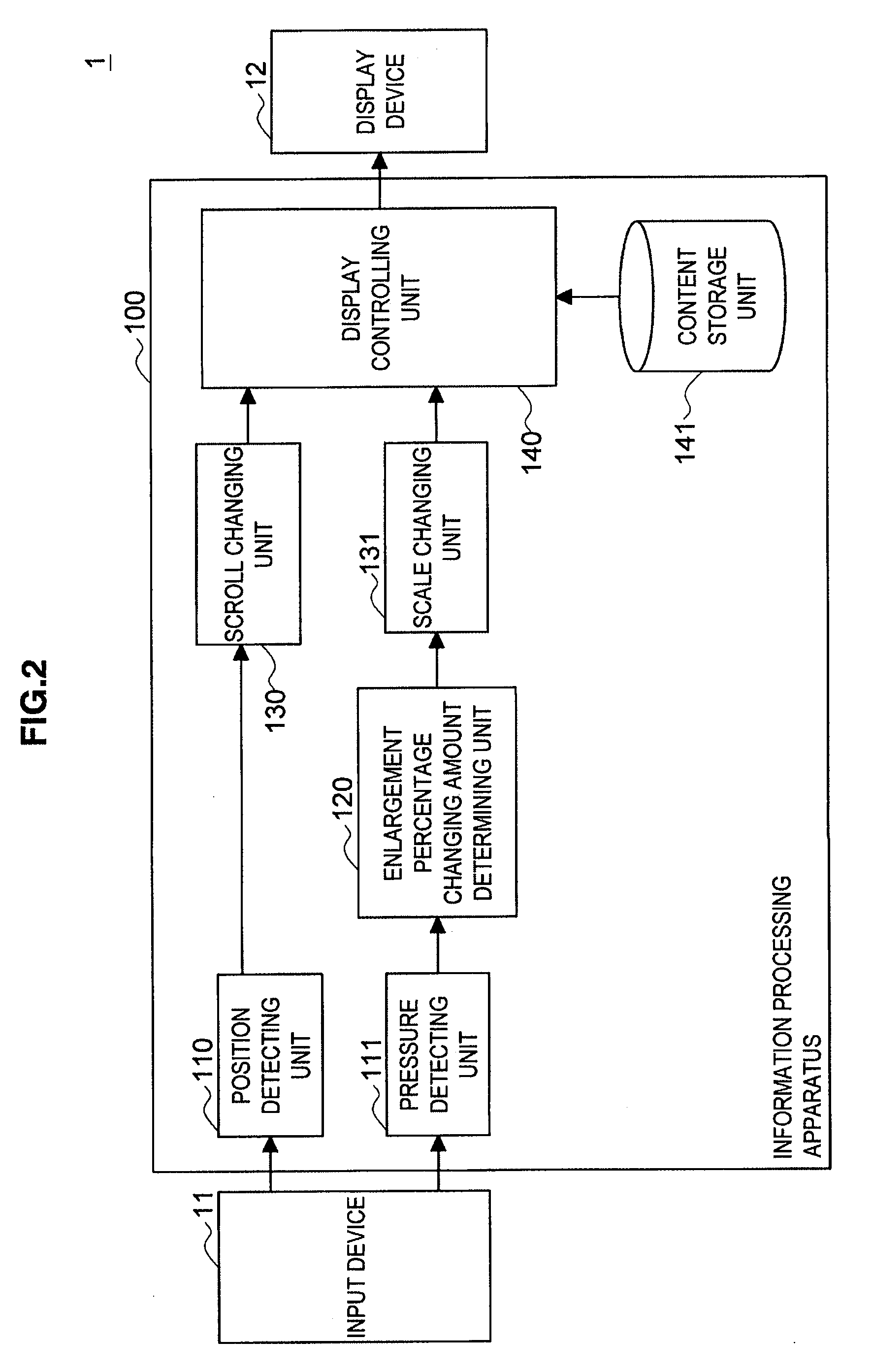

Information processing apparatus, information processing method, and program

InactiveUS20090160793A1Enhance operabilityConstant gainInput/output processes for data processingInput deviceDisplay device

An information processing apparatus includes a pressure detecting unit for detecting a magnitude of a contacting pressure of a contacted object with respect to an input device operated when physically contacted by the contacted object; and a changing unit for changing a display region displayed on a display device of predetermined information to be displayed on the display device according to an output signal output from the input device at a speed corresponding to the magnitude of the contacting pressure detected by the pressure detecting unit.

Owner:SONY CORP

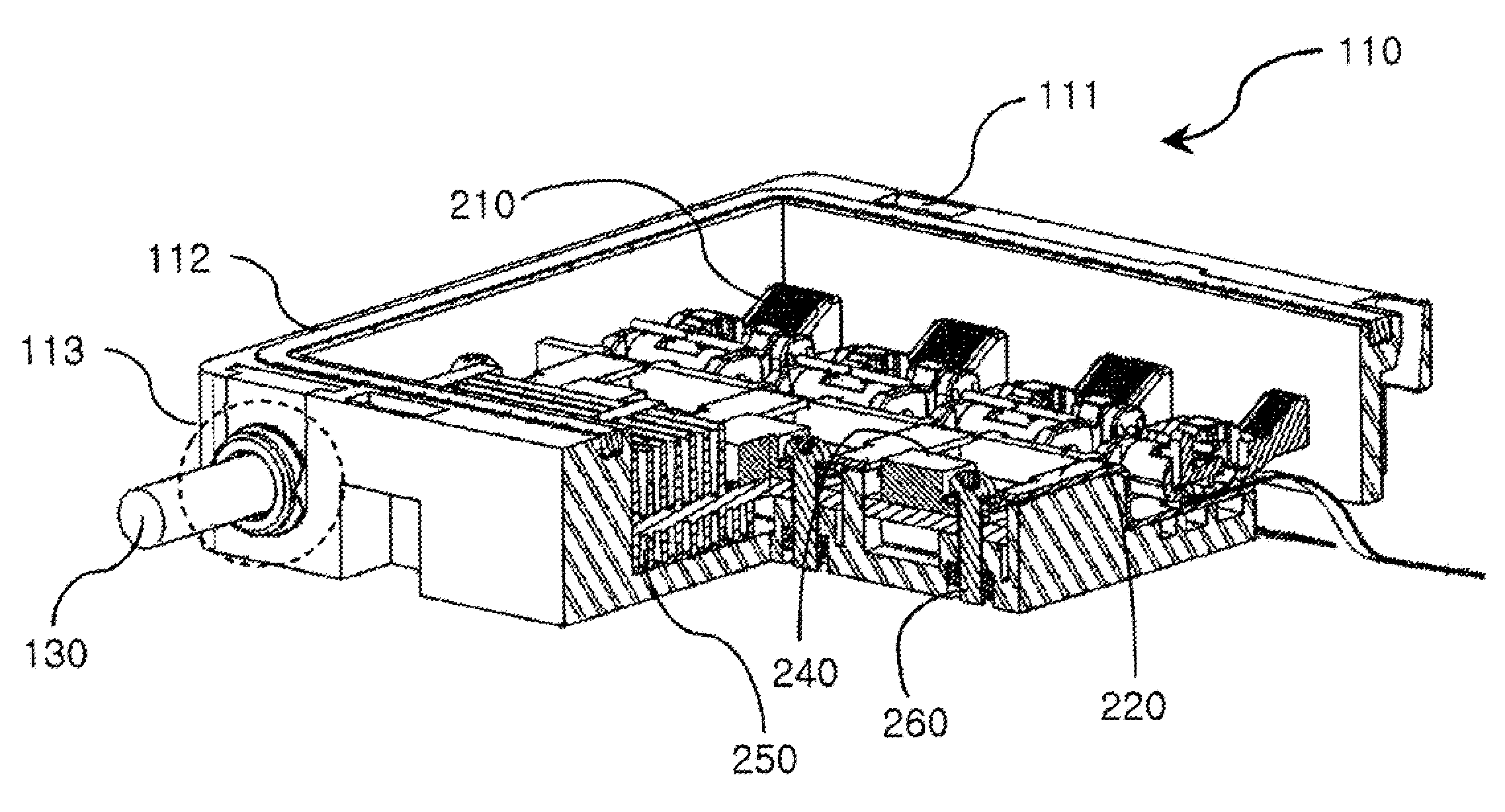

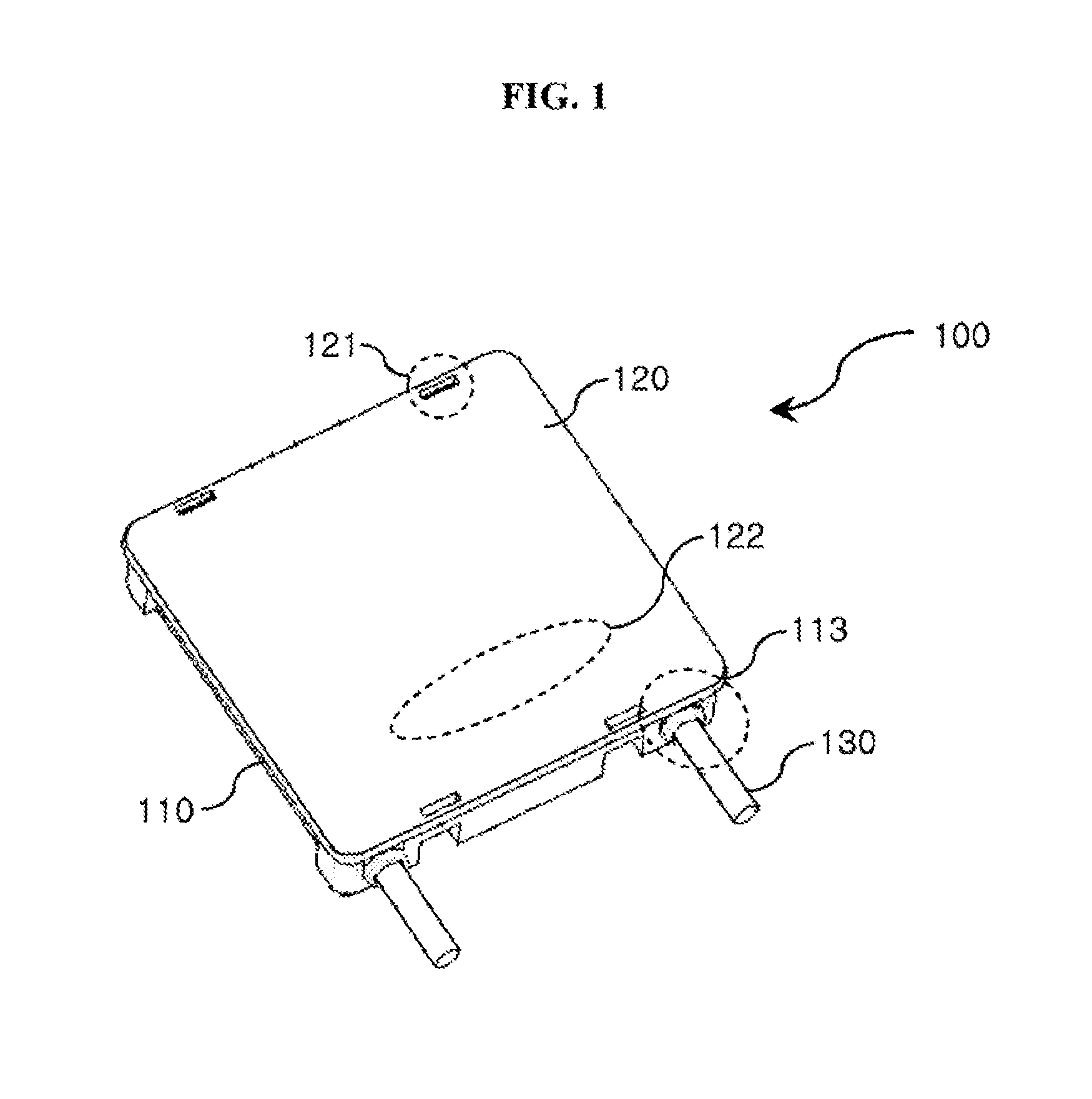

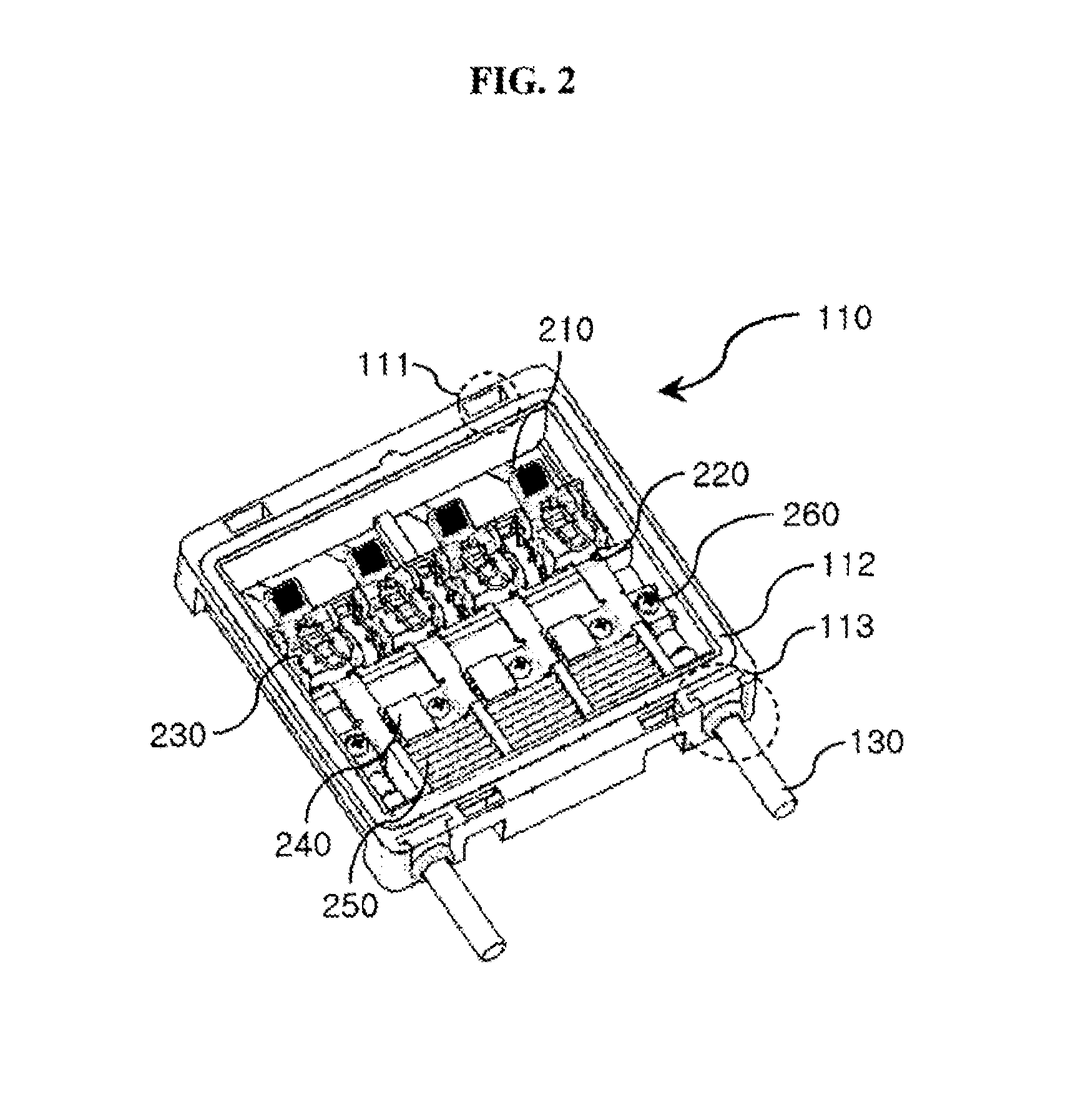

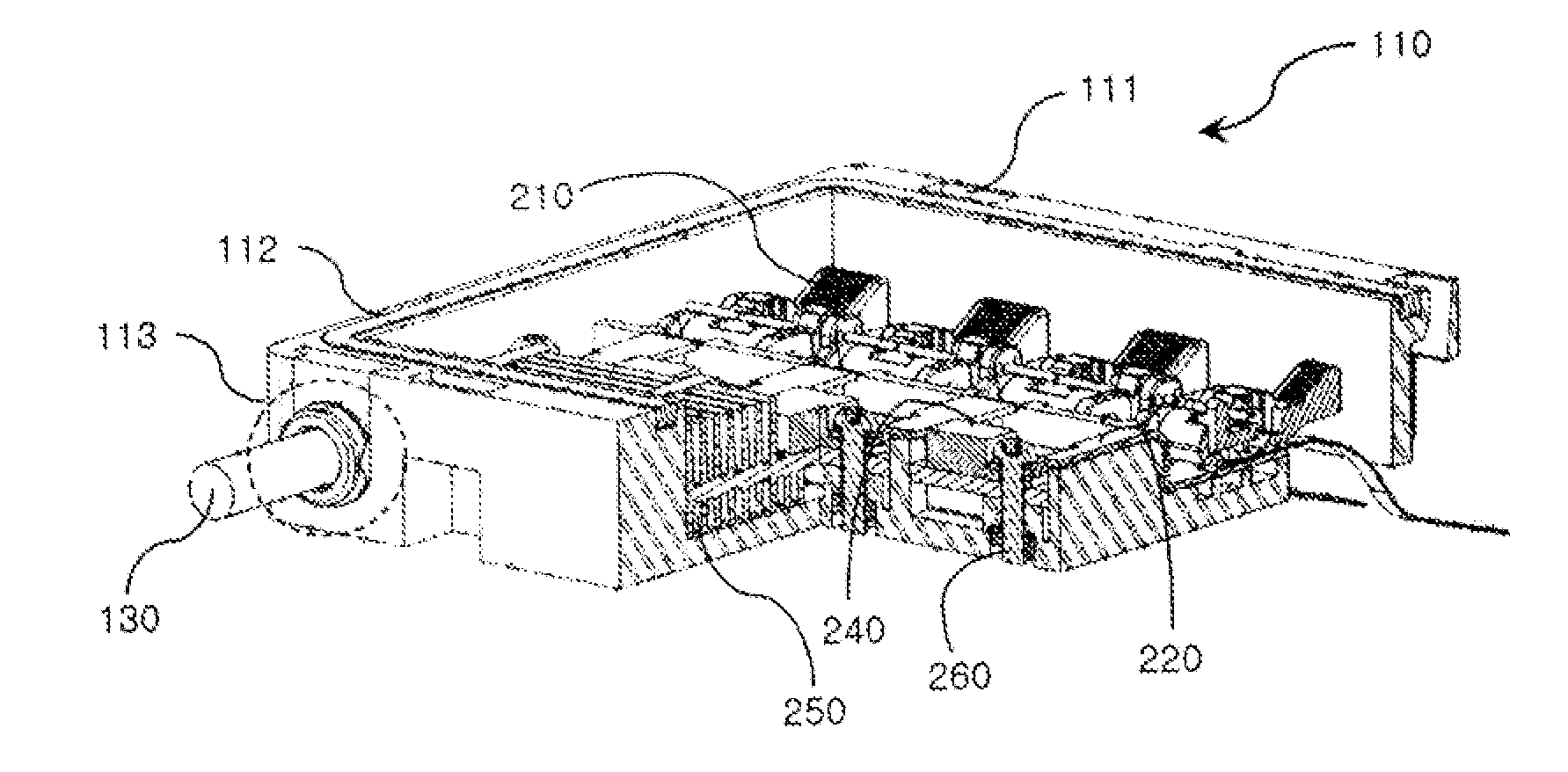

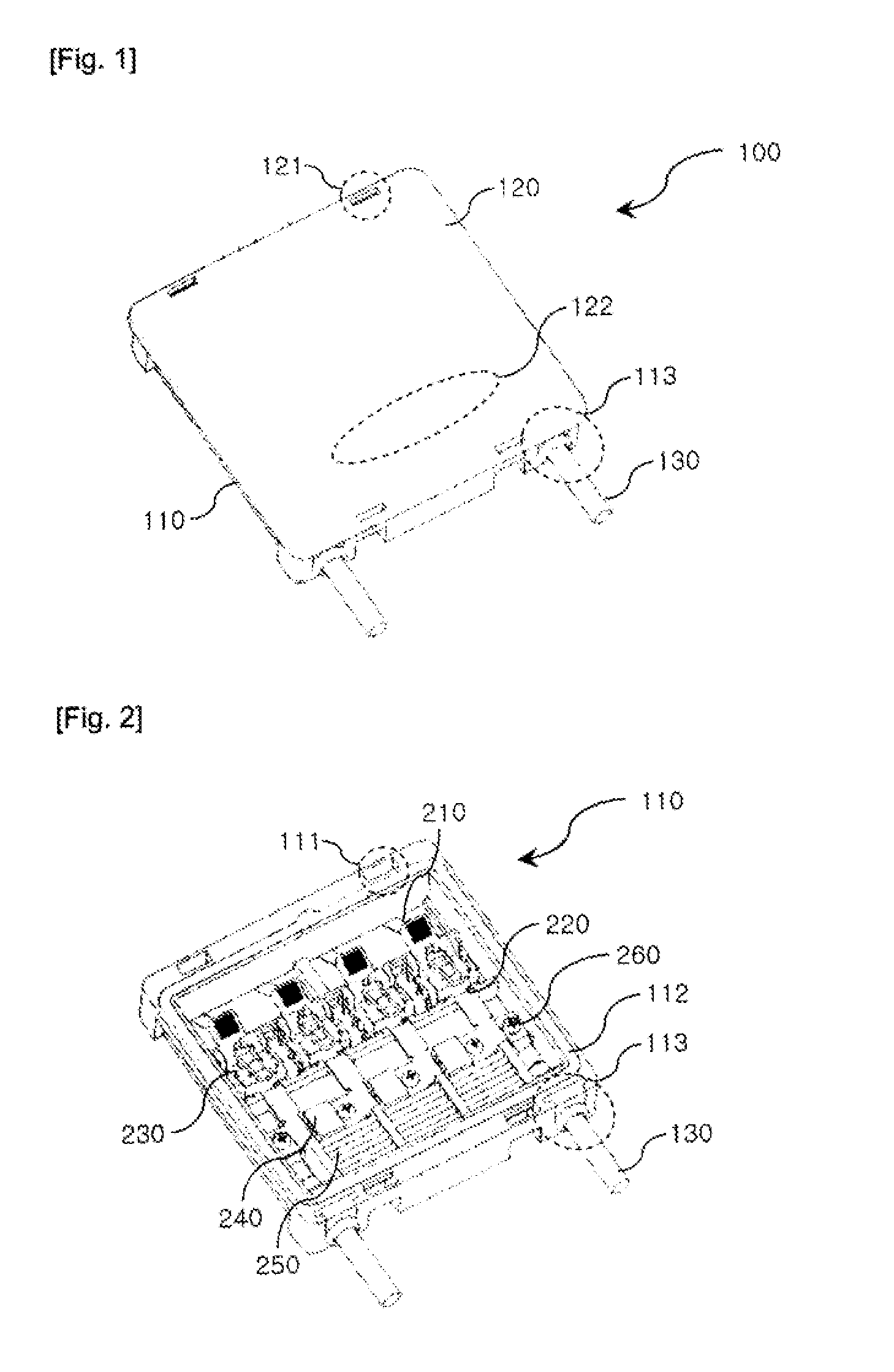

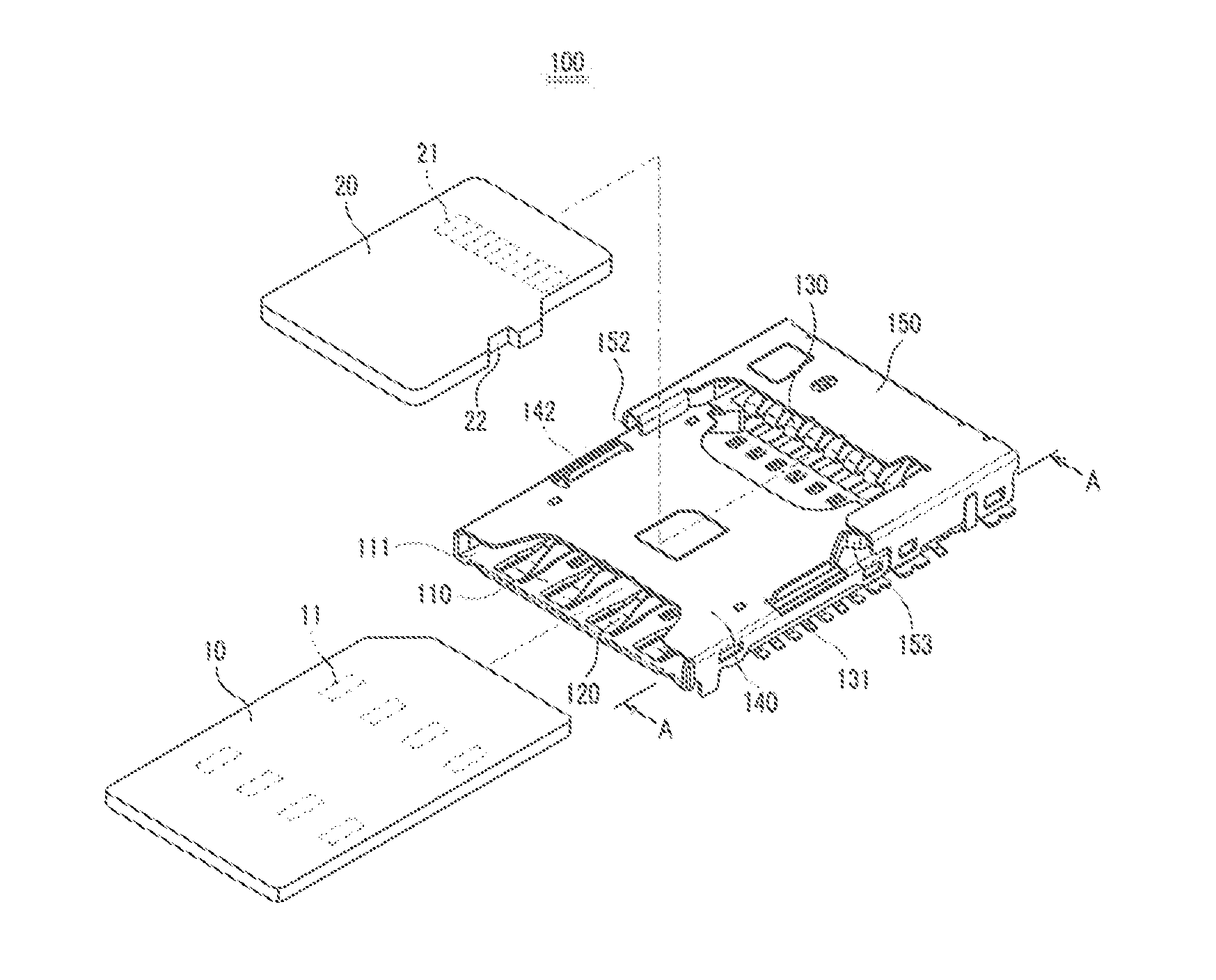

Smart junction box for solar cell module

InactiveUS8248804B2Increase contact pressureEfficient emissionsSubstation/switching arrangement detailsPhotovoltaic monitoringElectricityBand shape

The present invention relates to a smart junction box for a solar cell module, and provides a smart junction box for a solar cell module which enables an operator to easily connect and separate ribbon cables using the operation of the levers of pressing units, thereby being able to improve the contact stability of ribbon cables, and which has a heat sink structure, thereby effectively emitting the heat generated by the ribbon cables and the diodes to the outside. For this purpose, the smart junction box for a solar cell module of the present invention includes bus bars for transmitting electricity flowing from ribbon cables; and pressing units for selectively fastening and separating the ribbon cables located on contact portions of the bus bars depending on whether both ends of the lever projected by the manipulation of an operator are inserted into recesses formed in a body.

Owner:CONNEX ELECTRONICS +2

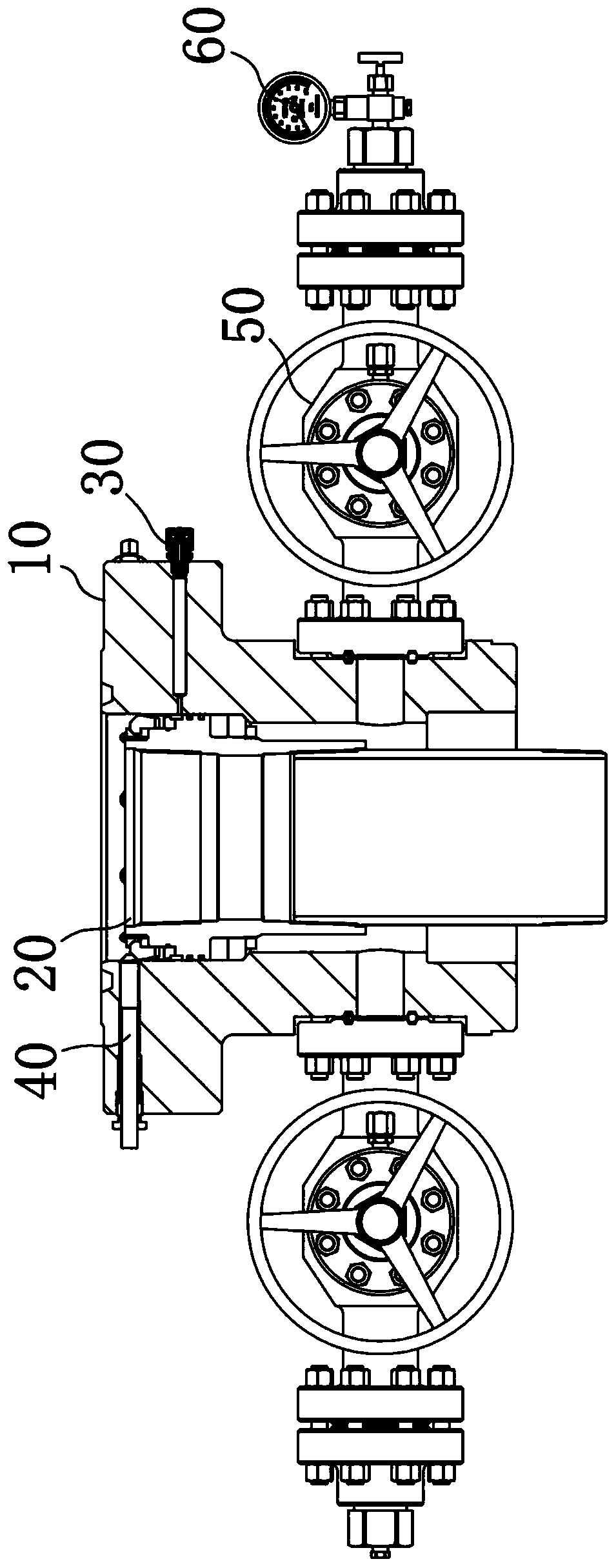

Composite drive mandrel anchoring casing head

The invention discloses a composite drive mandrel anchoring casing head and relates to the technical field of wellhead devices, the composite drive mandrel anchoring casing head comprises a casing head shell and an anchoring mandrel unit, a pressurizing hole is further formed in the side wall of the casing head shell, the first end of the pressurizing hole is connected with an anchoring hole part,and the second end of the pressurizing hole extends to the outer side of the casing head shell. The anchoring mandrel unit comprises an anchoring mandrel body, a slip exciting piece, an anchoring slip and an annular piston body, wherein the slip exciting piece, the anchoring slip and the annular piston body are sequentially arranged on the outer side of the anchoring mandrel body from top to bottom in a sleeving mode. The casing head can meet the hanging requirement of a mandrel hanger, after the anchoring mandrel body and the casing head shell are anchored, pipe column shifting can be avoided, and the stability and the reliability of the casing head are improved.

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

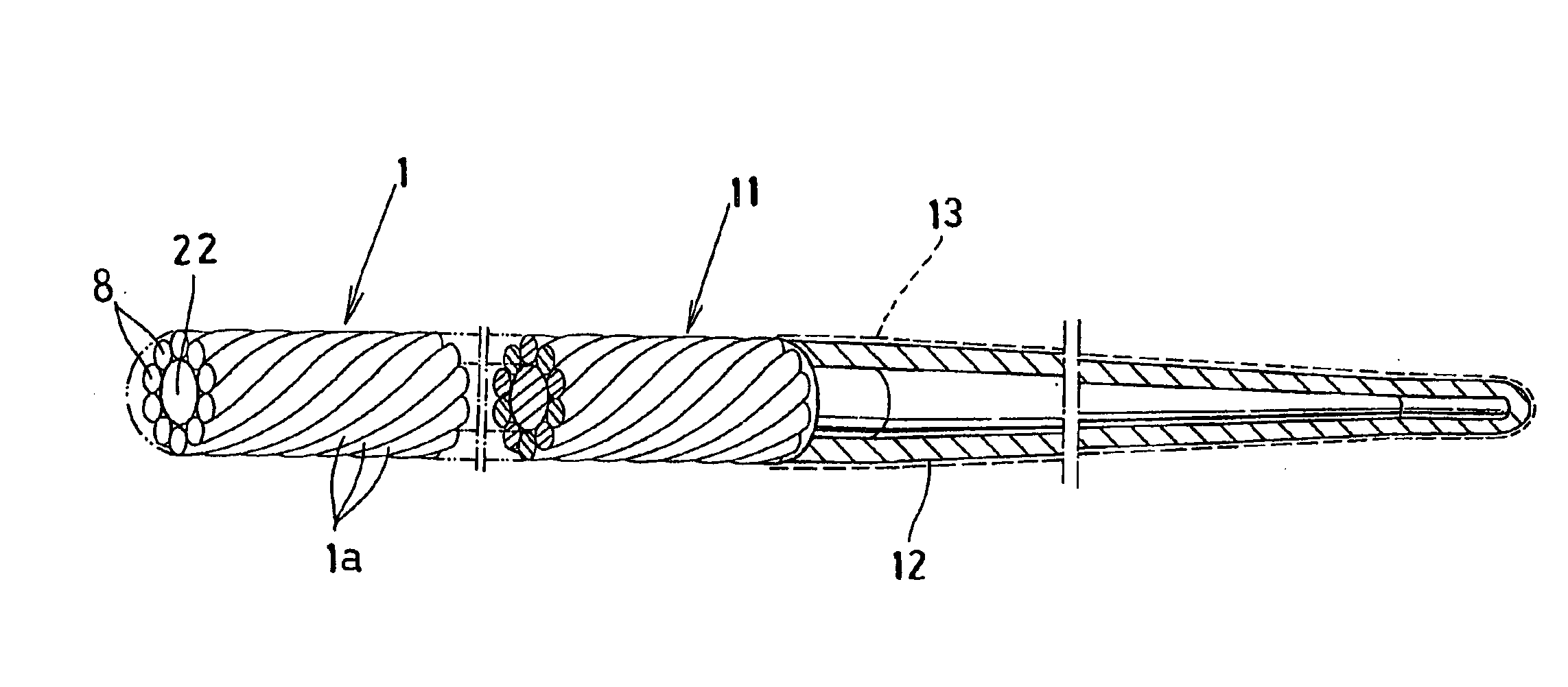

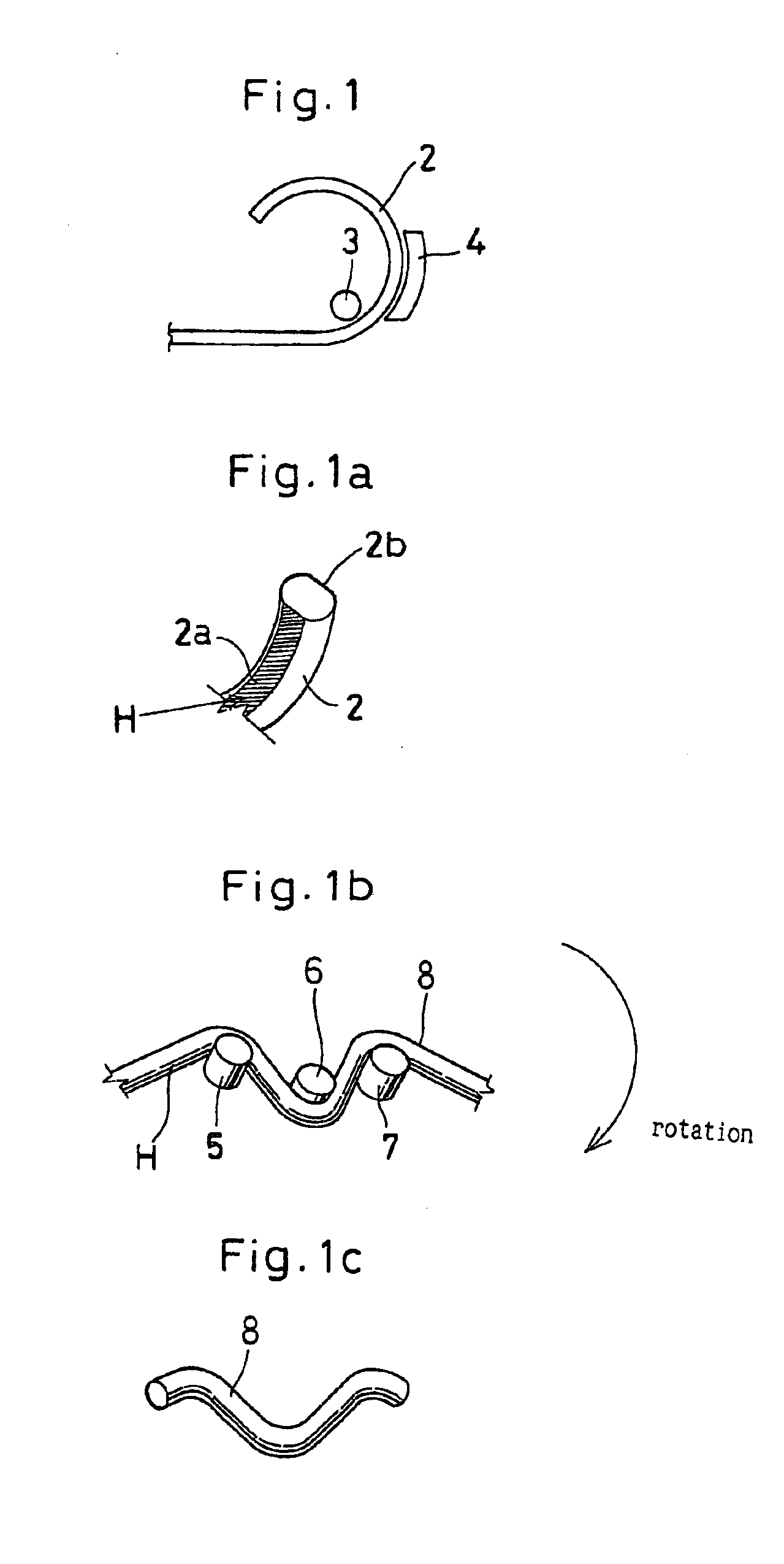

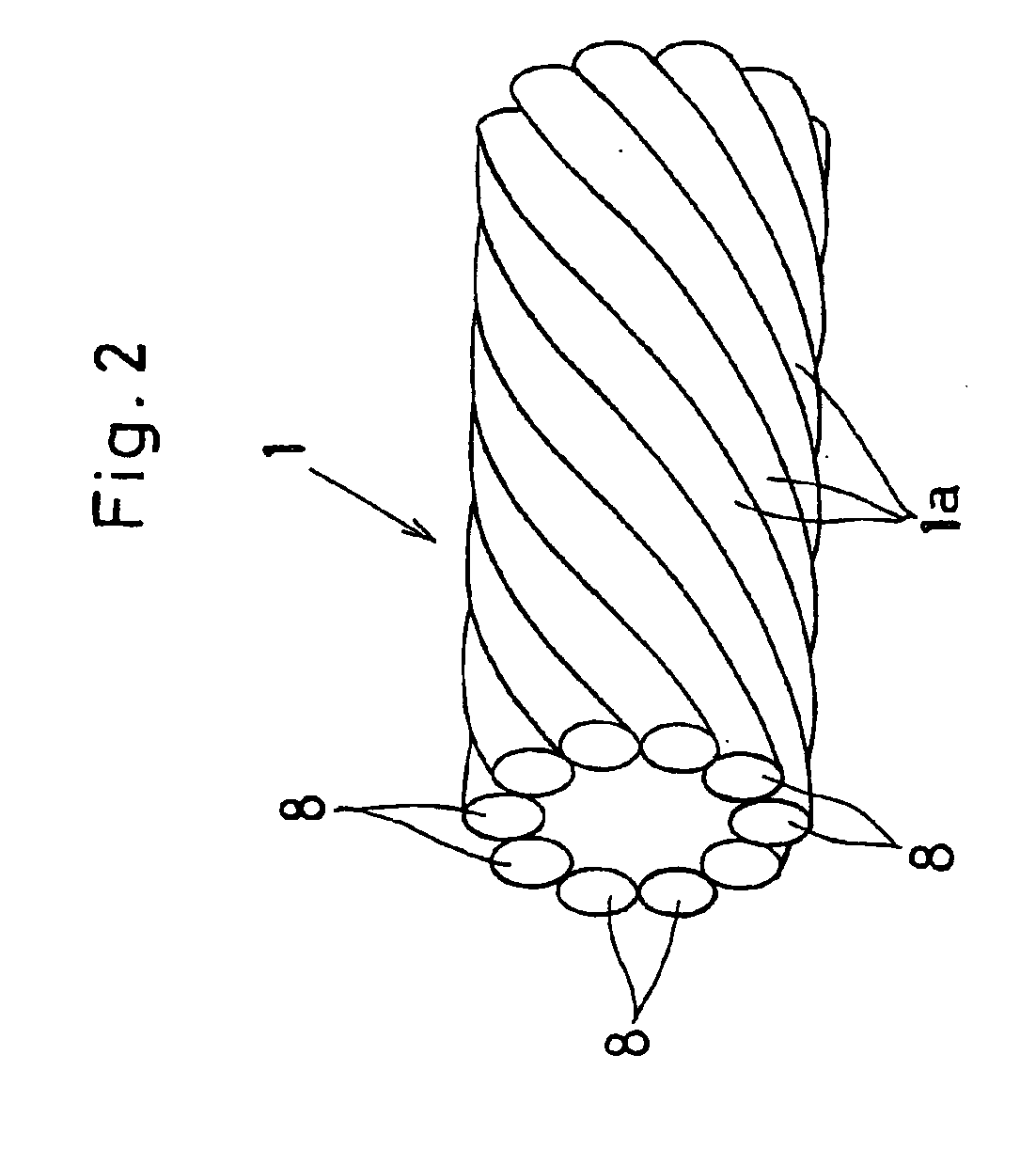

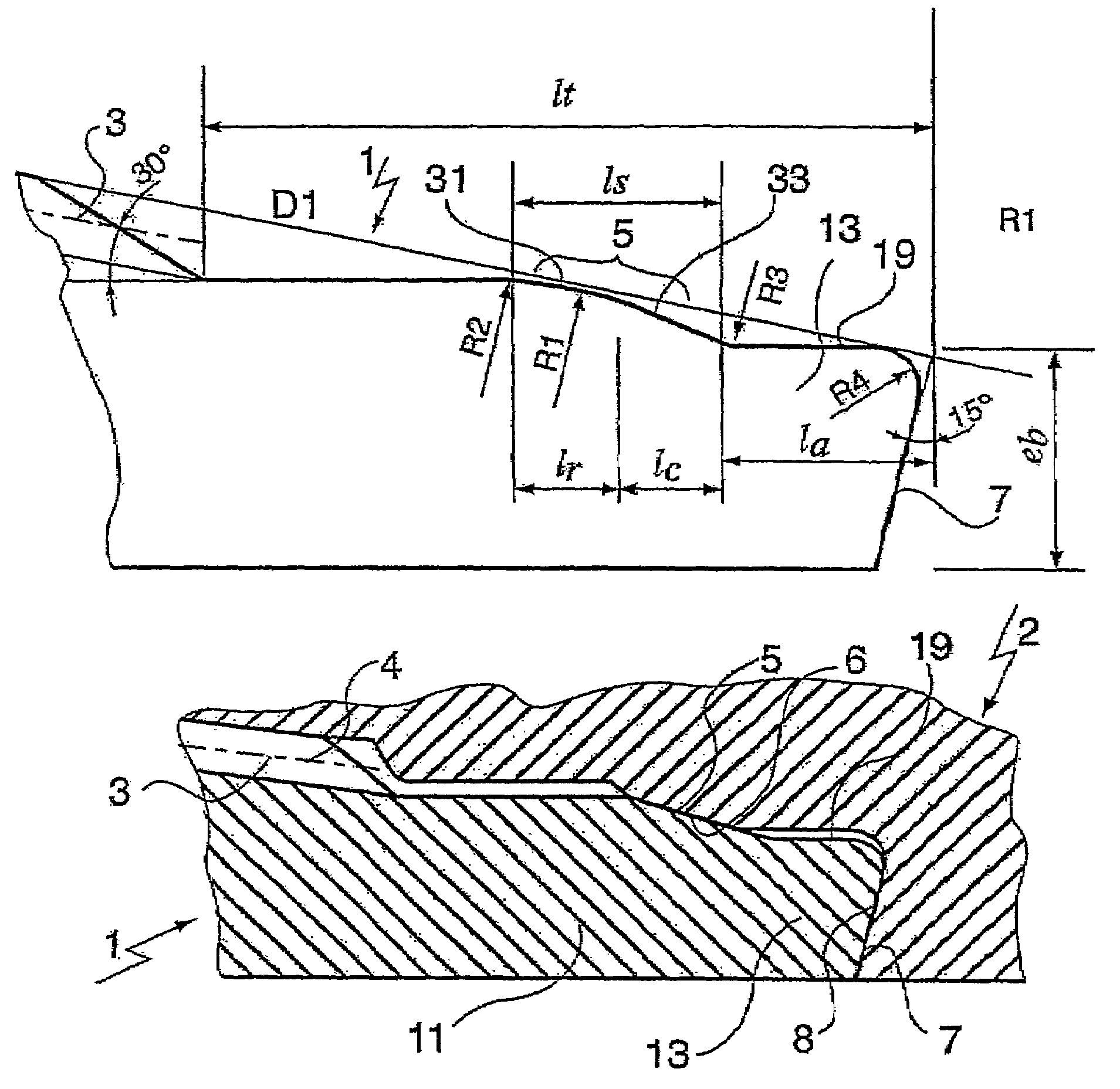

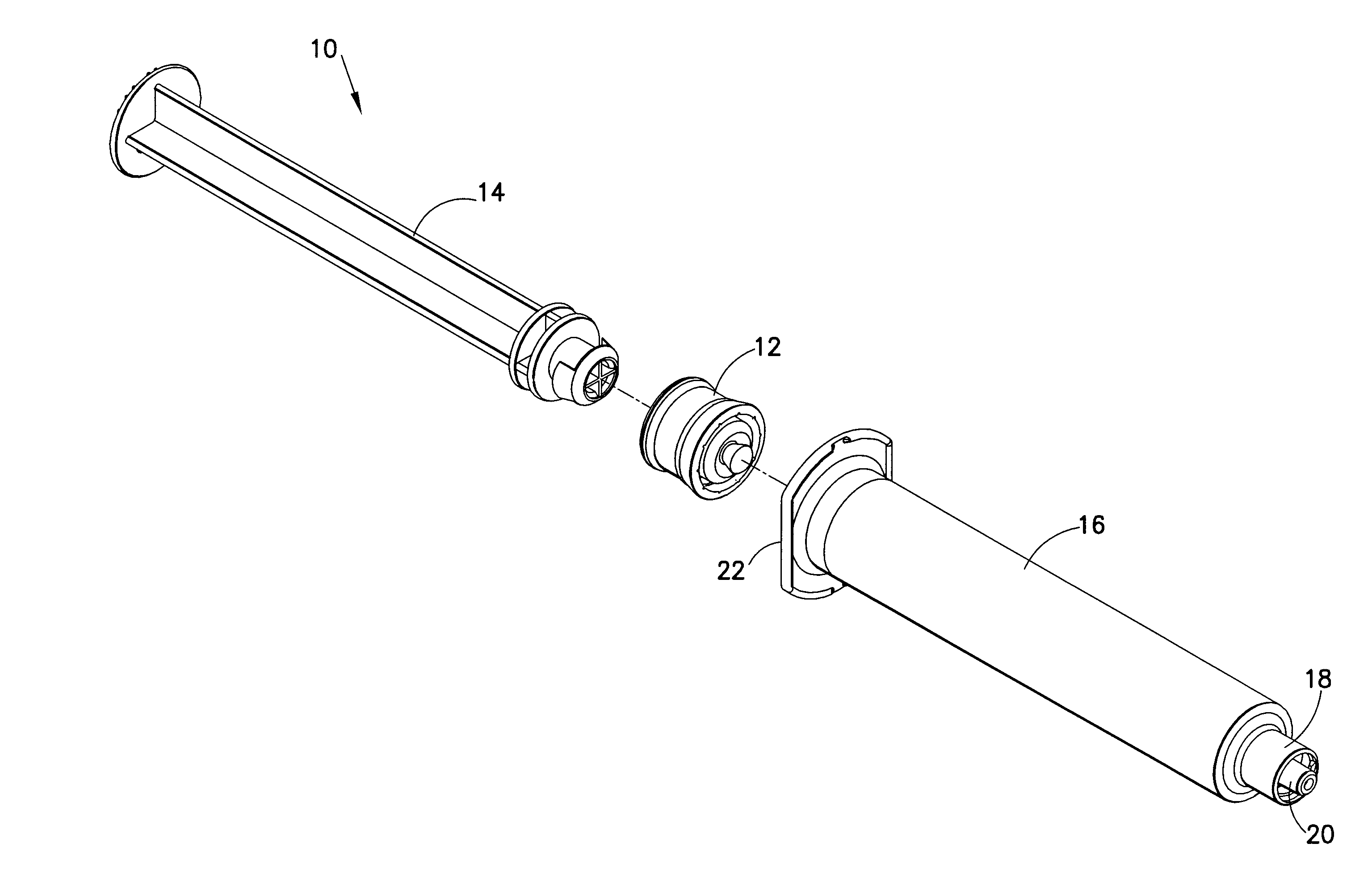

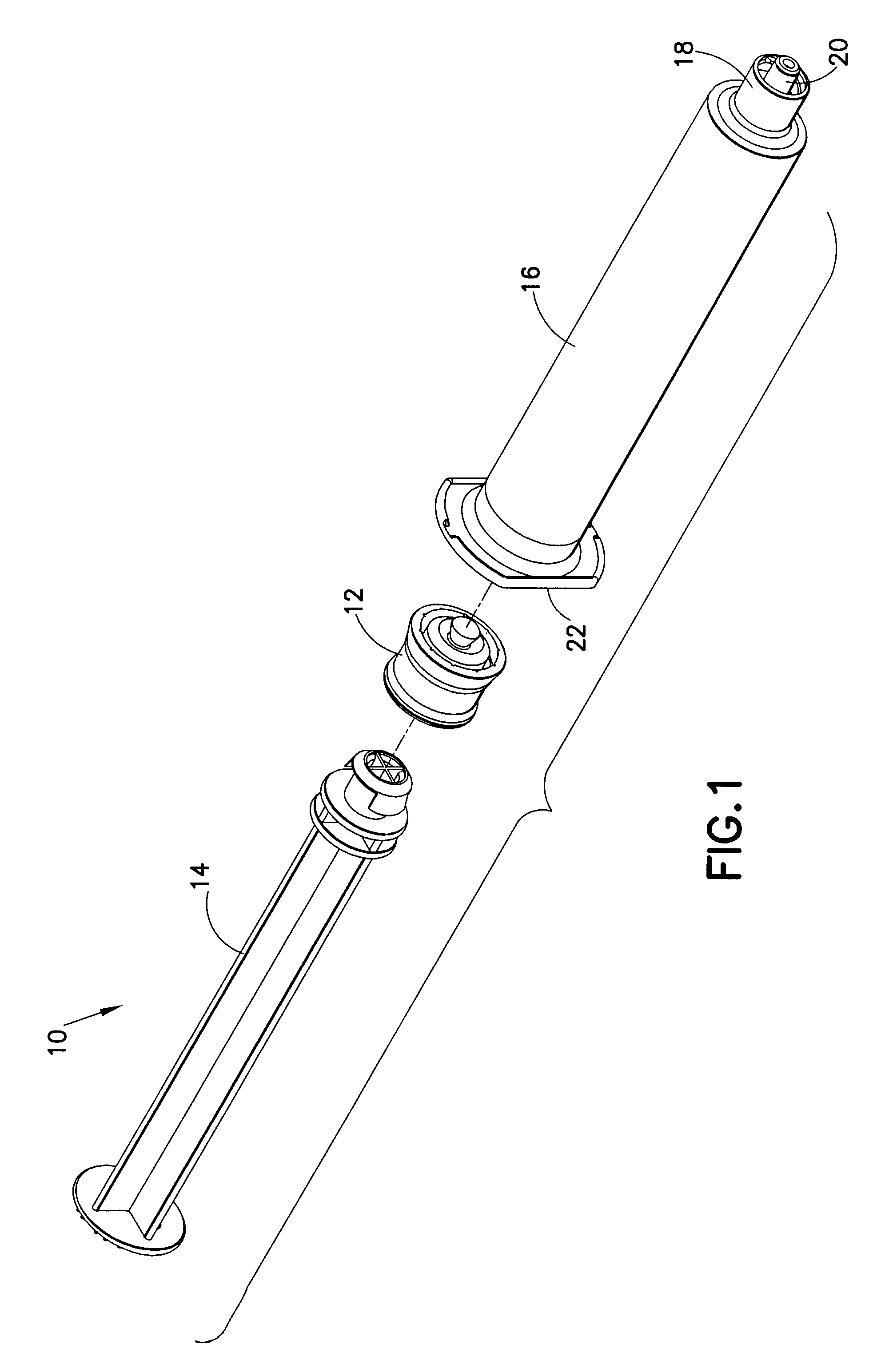

Wire-stranded medical hollow tube, and a medical guide wire

InactiveUS6881194B2Good flexibilitySmoothly introducedGuide wiresMedical devicesContact pressureEngineering

In a wire-stranded hollow tube (1), a plurality of metallic wires (8) preformed with a predetermined forming rate are twisted along a circular line into a careless hollow configuration. When twisting the metallic wires (8), the neighboring metallic elements (1a, 1a) are subjected to compression with no gap between the neighboring metallic elements (1a, 1a). This increases a contact pressure between the neighboring metallic elements (1a, 1a) to attain a good tightness with a good circularity and diametrical uniformity secured therebetween, thus preventing the wire-stranded hollow tube (1) from inadvertently collapsing. A tightness is strengthened between the neighboring metallic elements (1a, 1a) when the metallic elements (1a, 1a) of different helical pitch are used. By applying the wire-stranded hollow tube (1) to a medical guide wire, a quick torque response and a good torque transmissibility are ensured which lead to a good manipulatability with a favorable follow-on capability.

Owner:ASAHI INTECC CO LTD

Positive displacement stopper for a pre-filled syringe

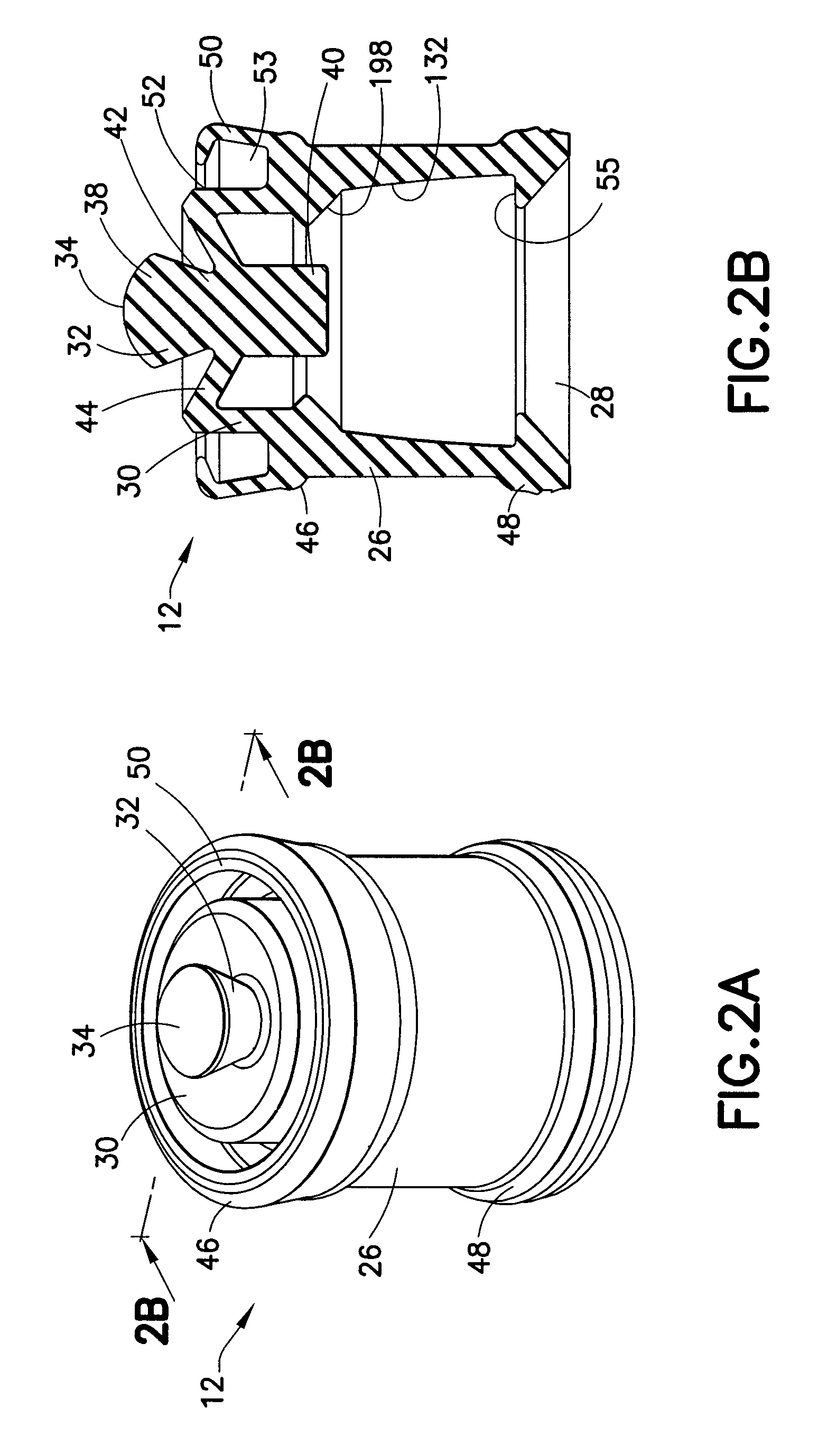

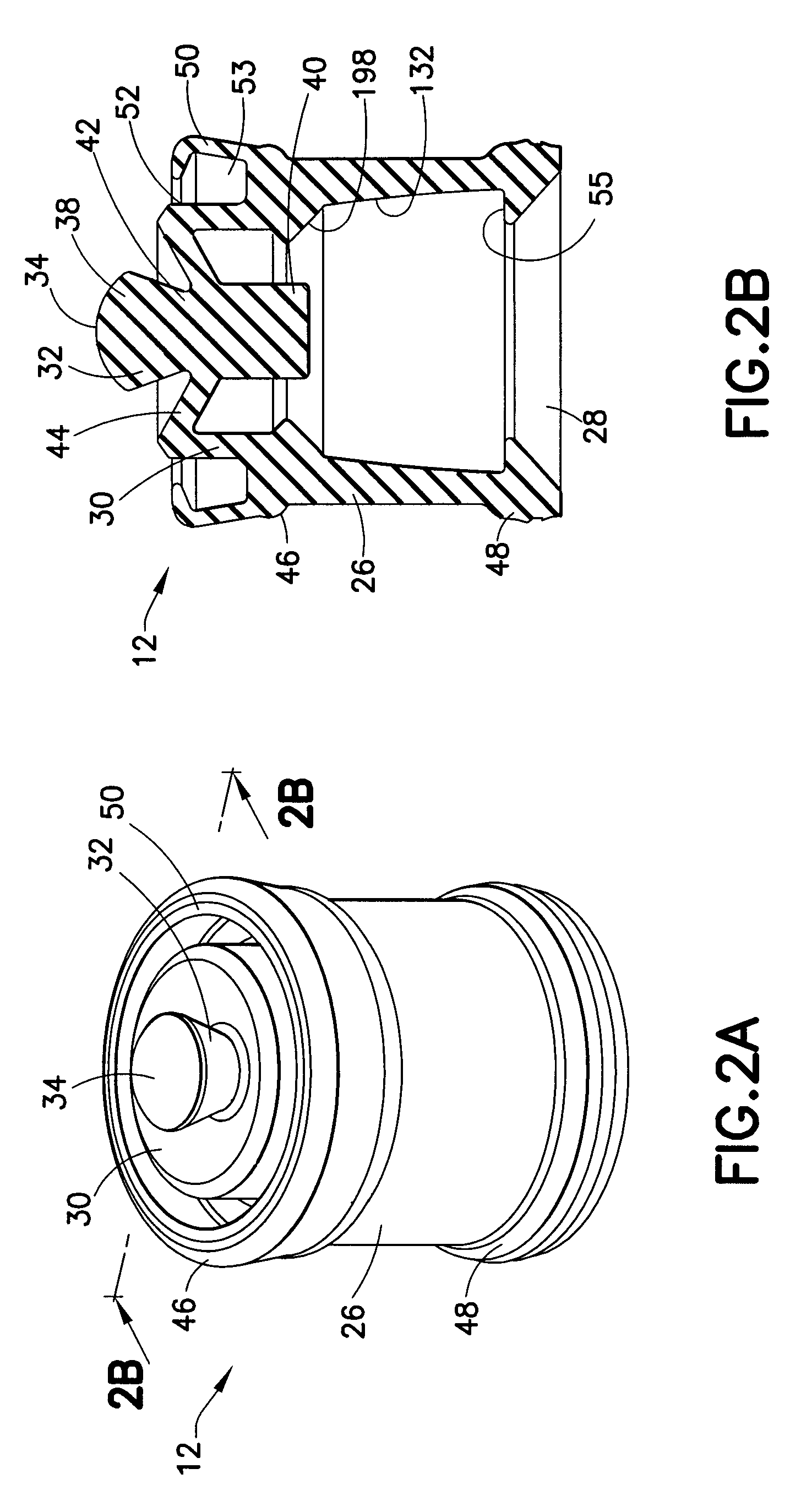

ActiveUS20080300550A1Prevent leakageEffectively and consistently reducing and eliminating refluxInfusion syringesIntravenous devicesPrefilled SyringeNose

A stopper adapted for attachment with a plunger rod for use within a syringe barrel is disclosed. The stopper includes a main body defining an open rearward end and a closed front end. The open rearward end is adapted to receive a front forward end attachment portion of the plunger rod. The stopper also includes a core member integrally formed with said main body adjacent the closed front end. The core member includes a nose portion having a profile adapted to create a positive seal with an outlet opening of such syringe barrel.

Owner:BECTON DICKINSON & CO

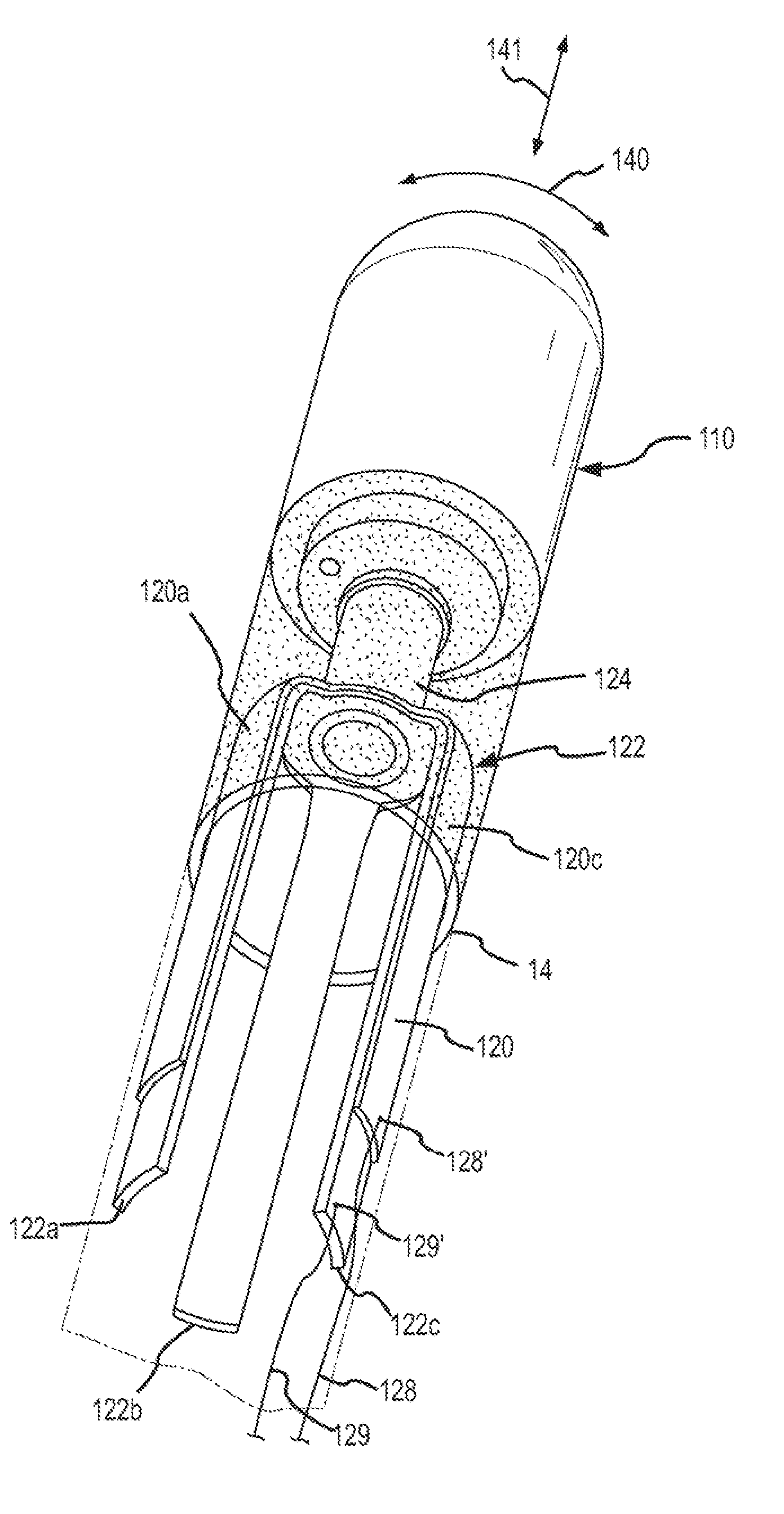

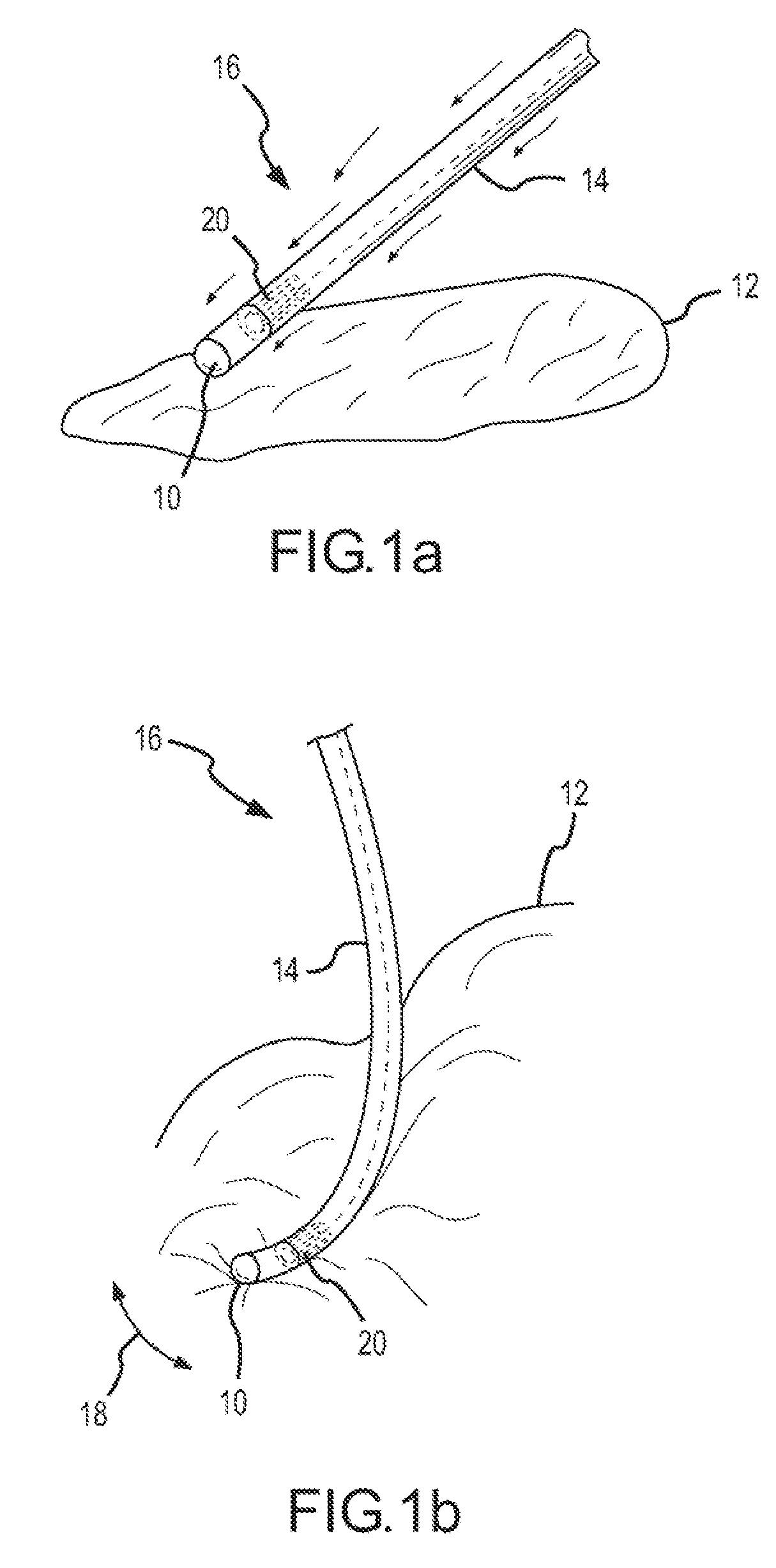

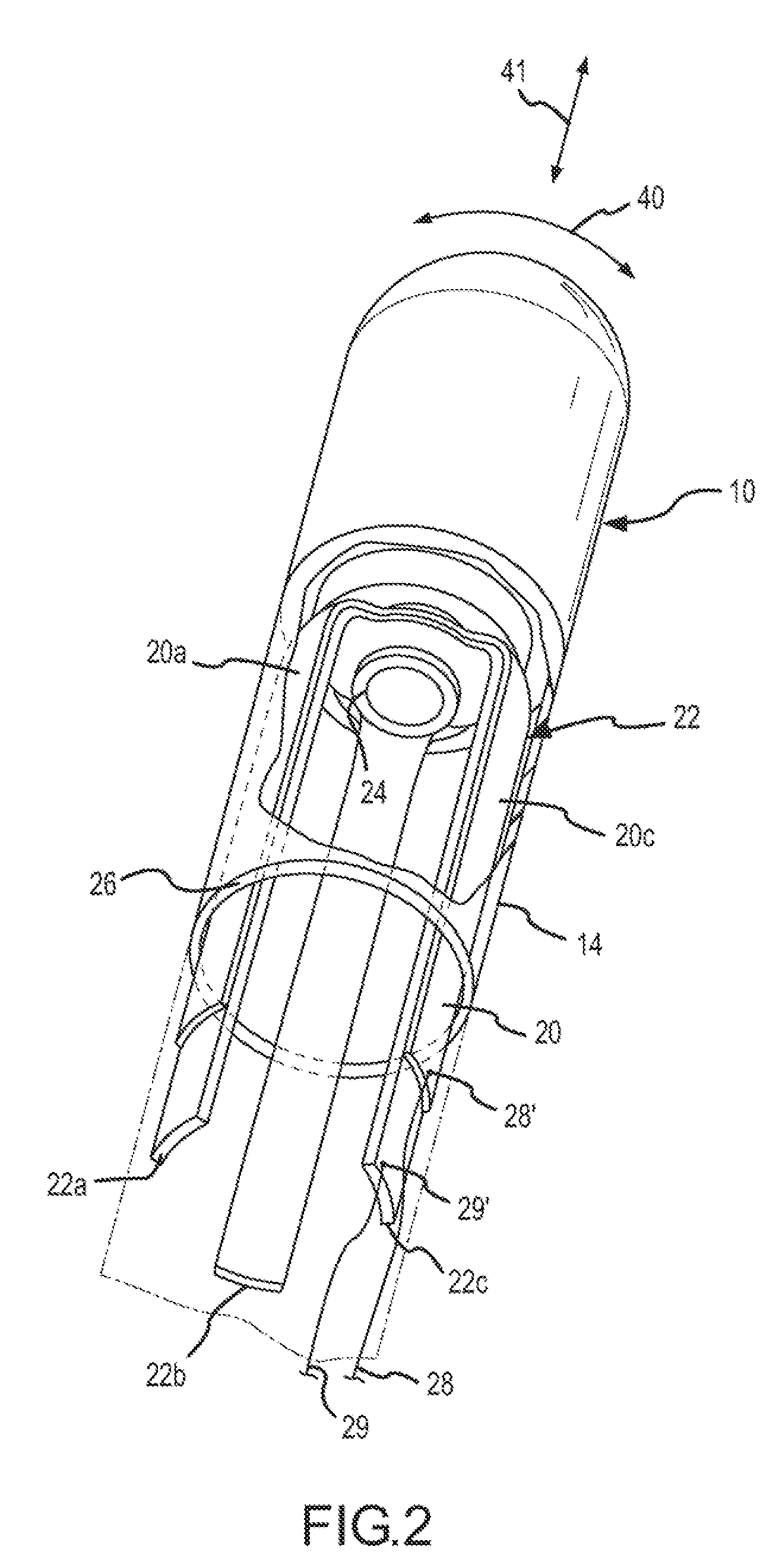

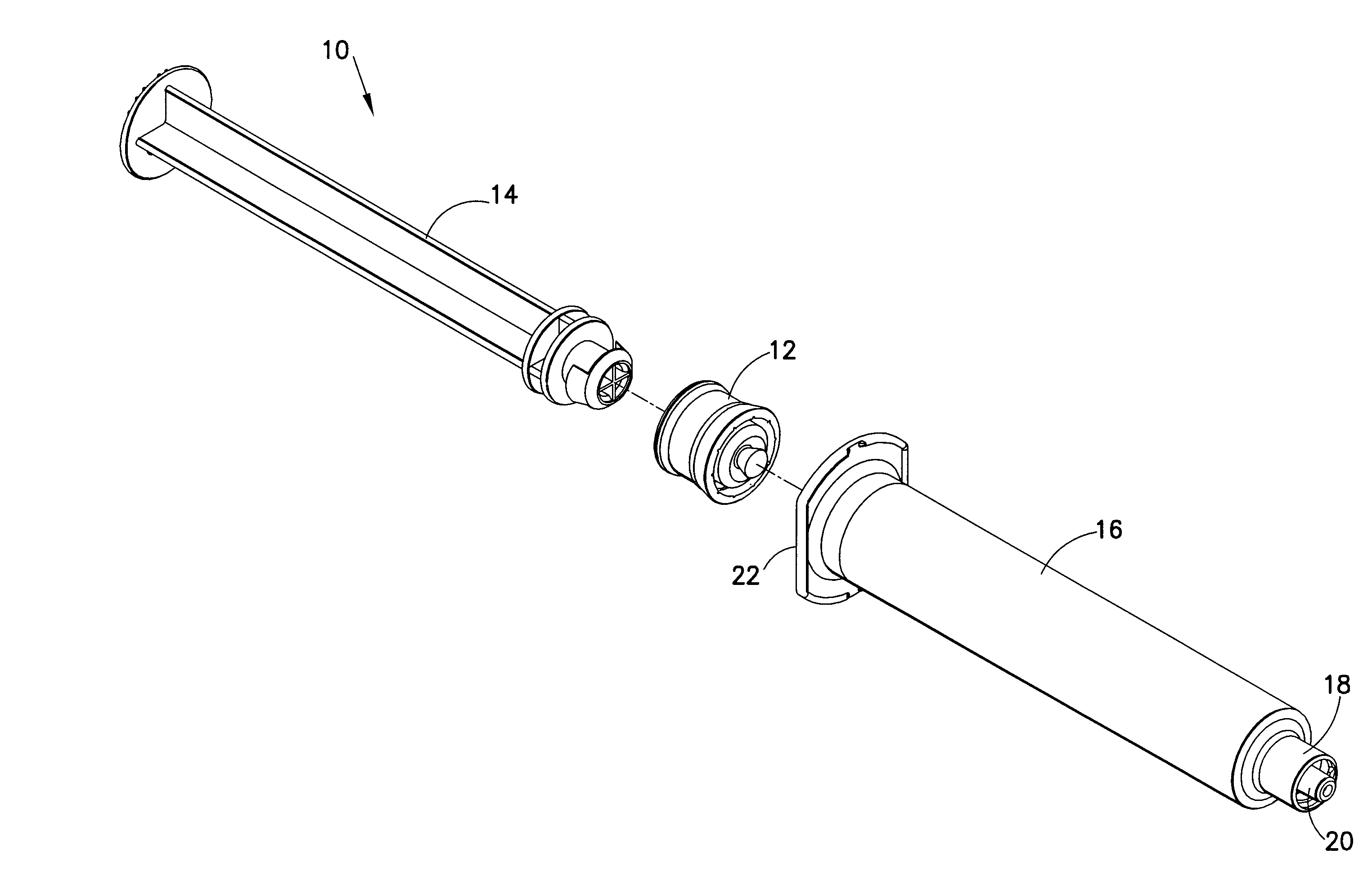

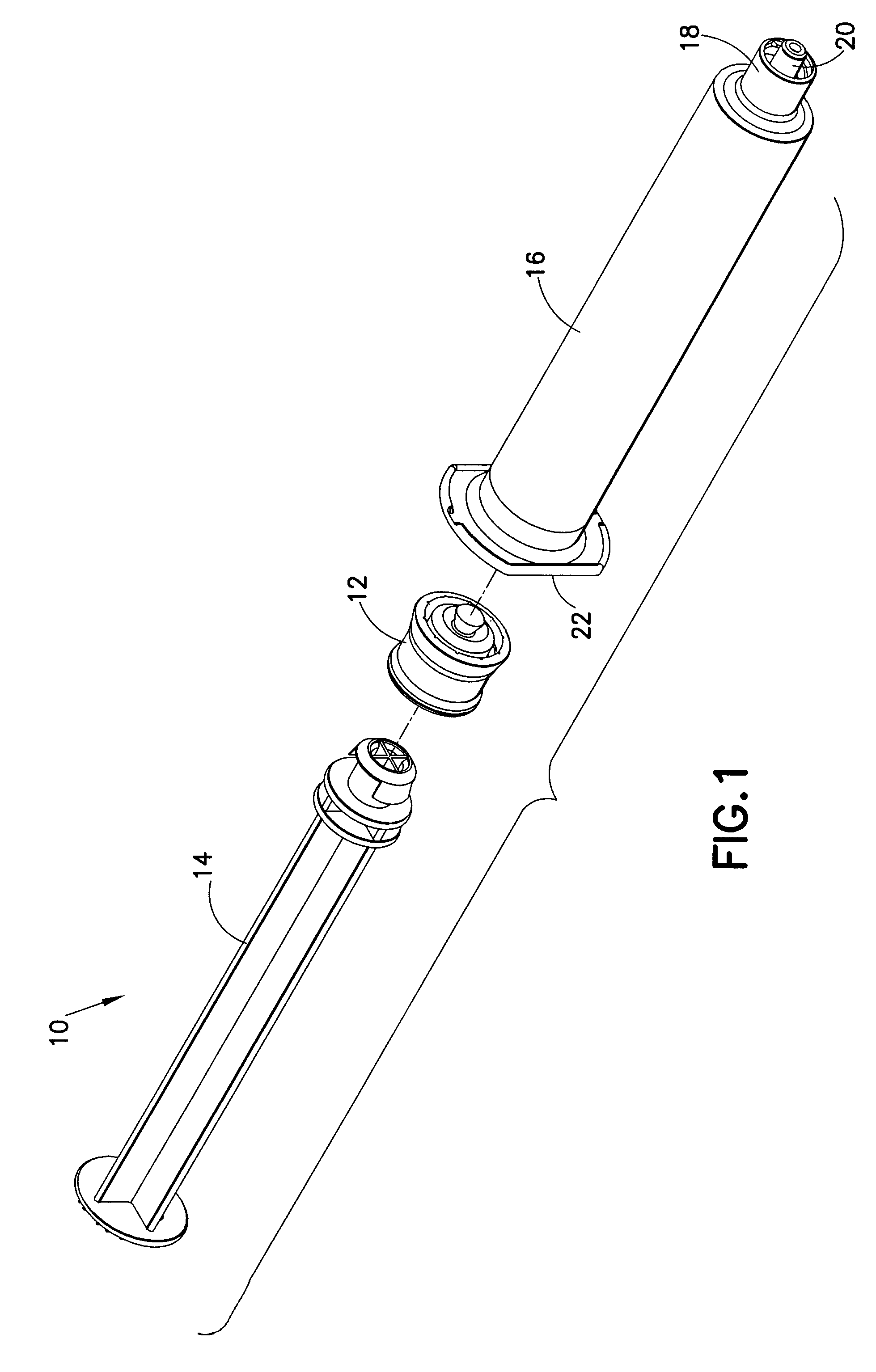

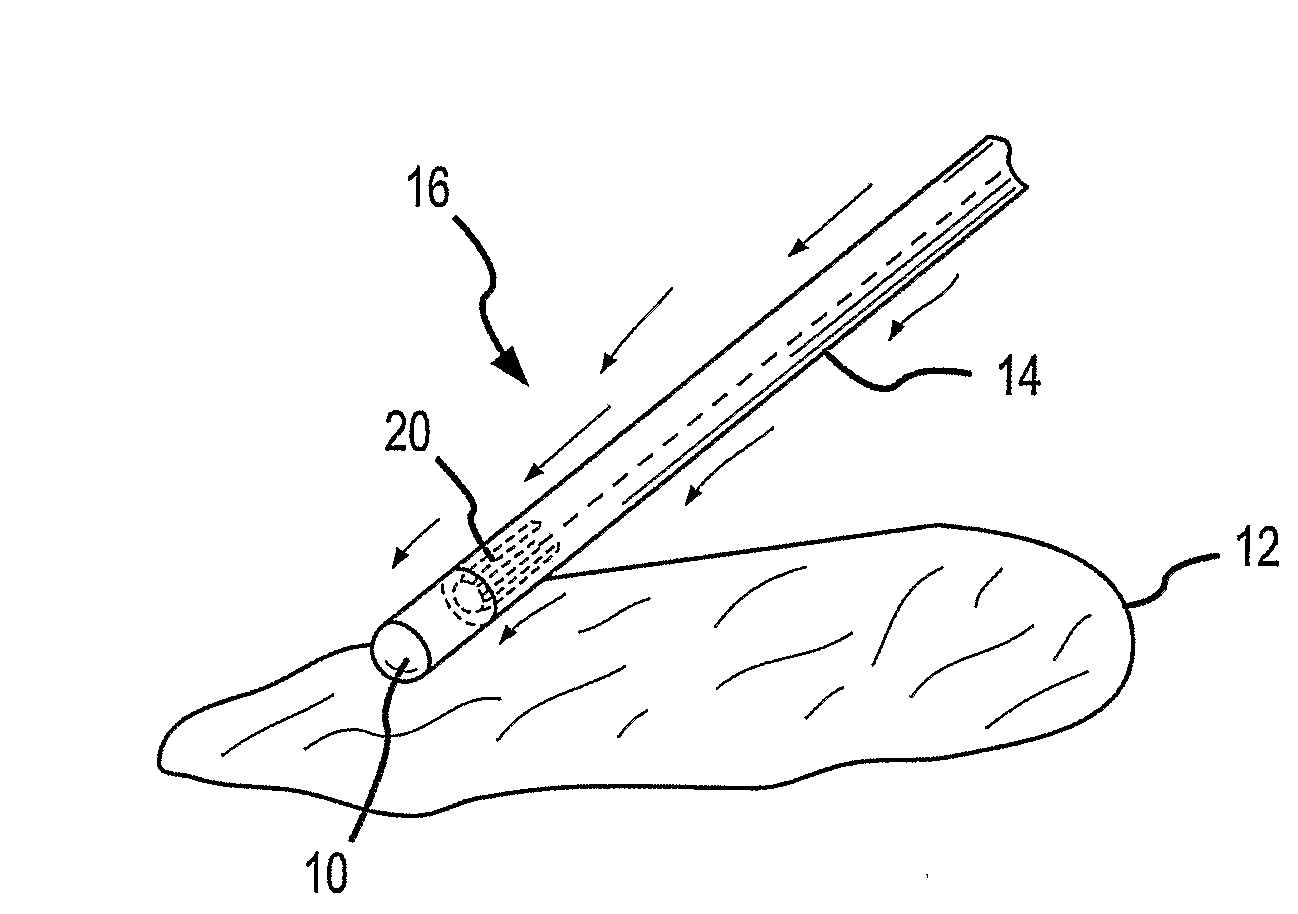

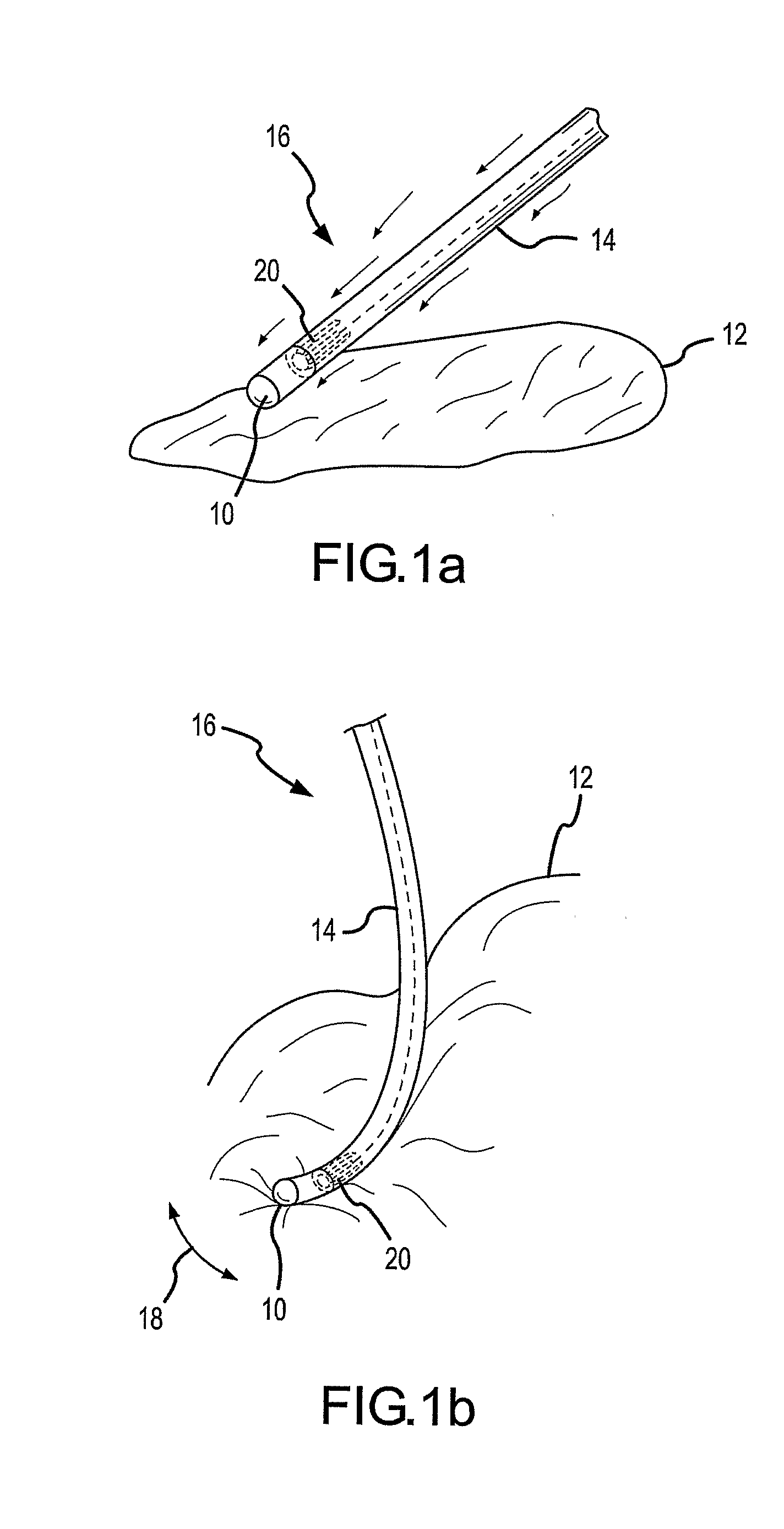

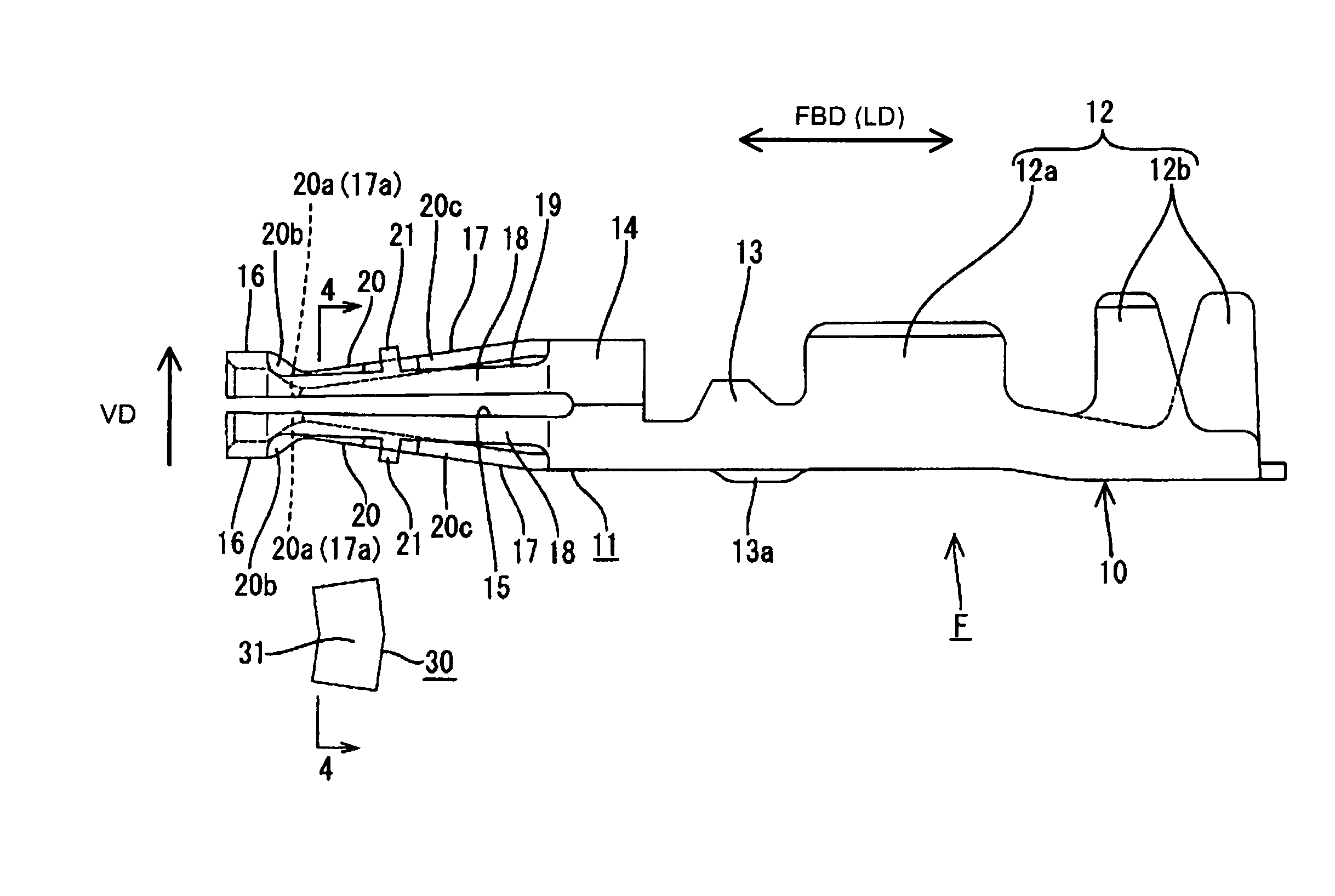

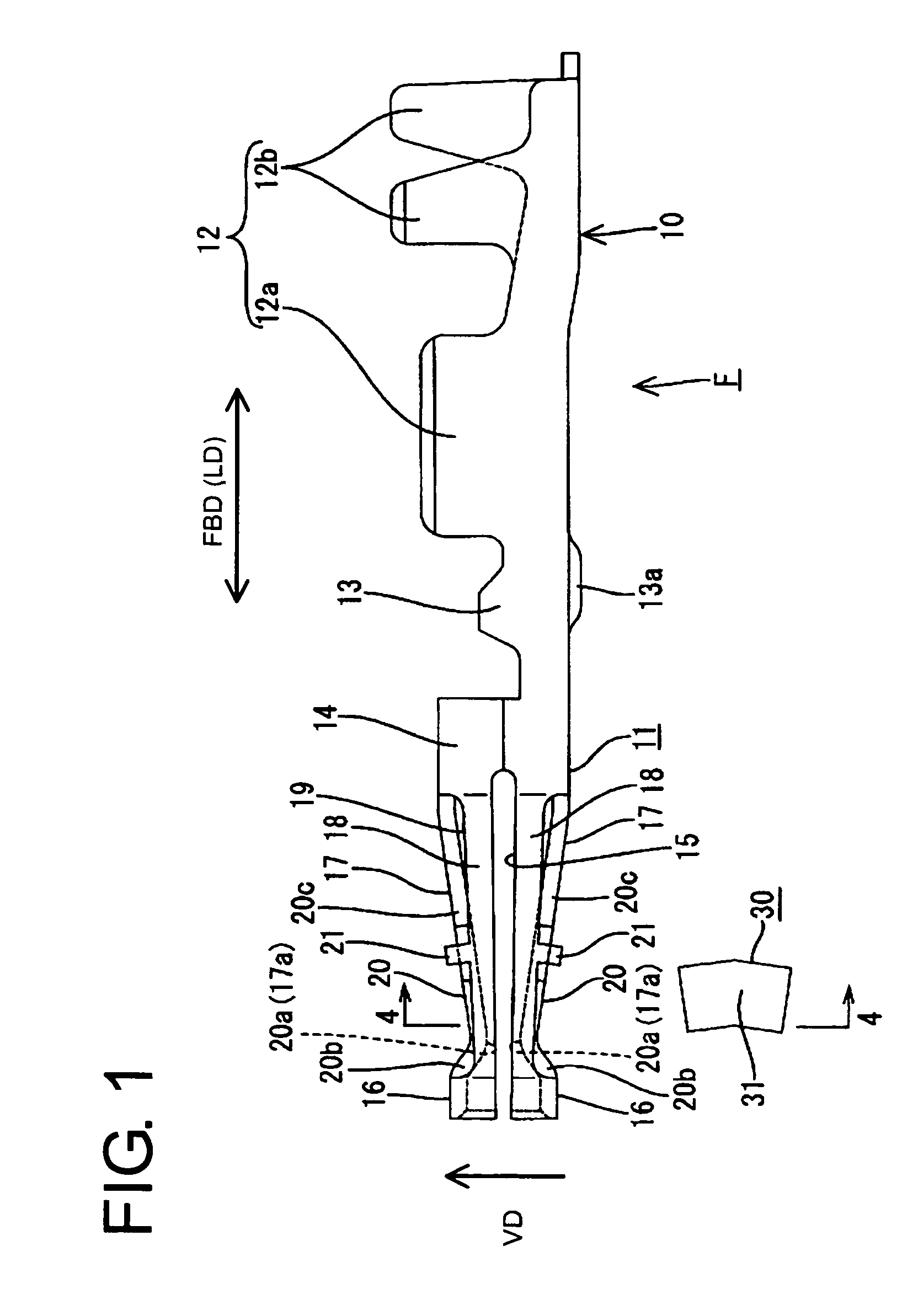

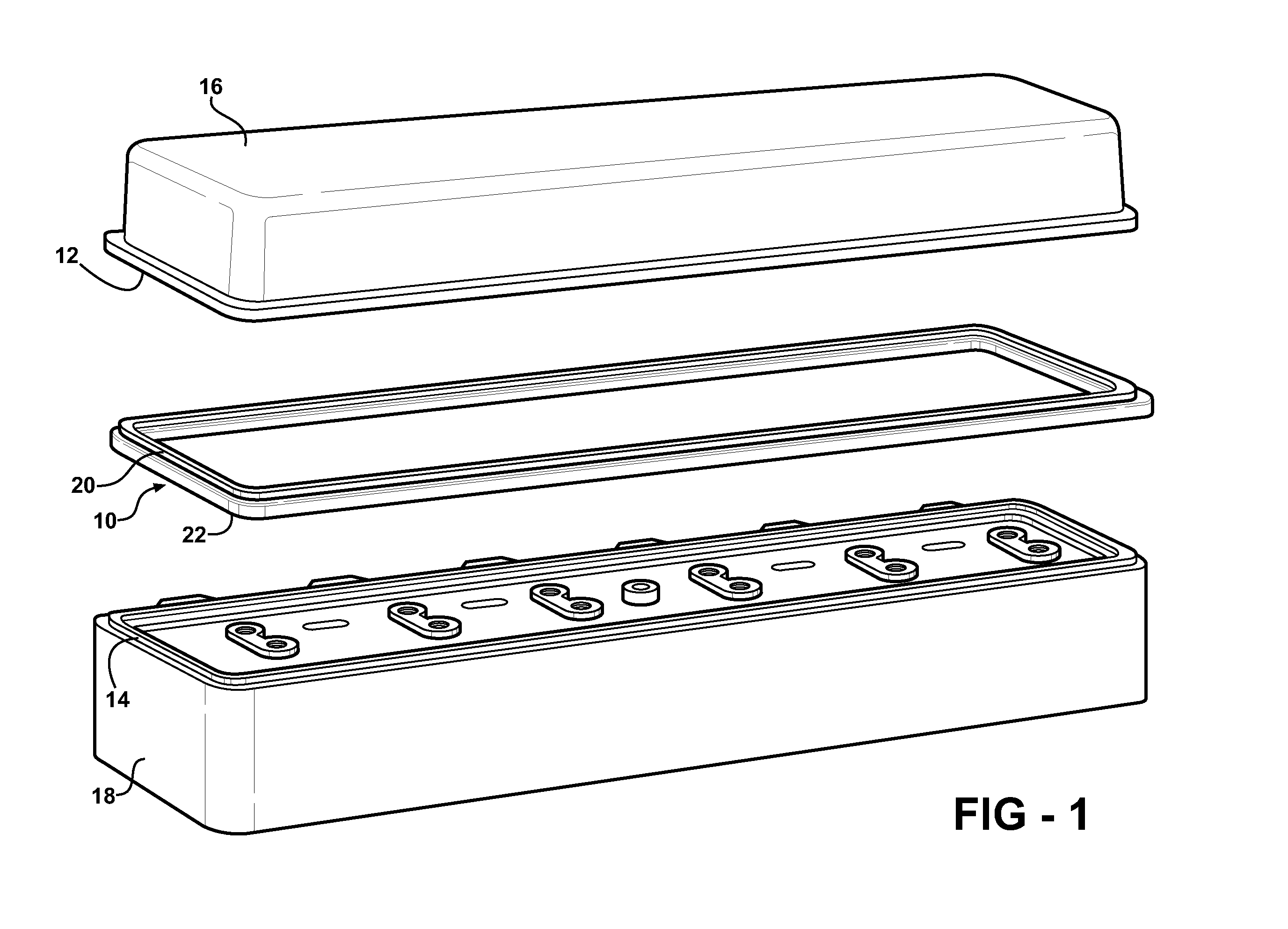

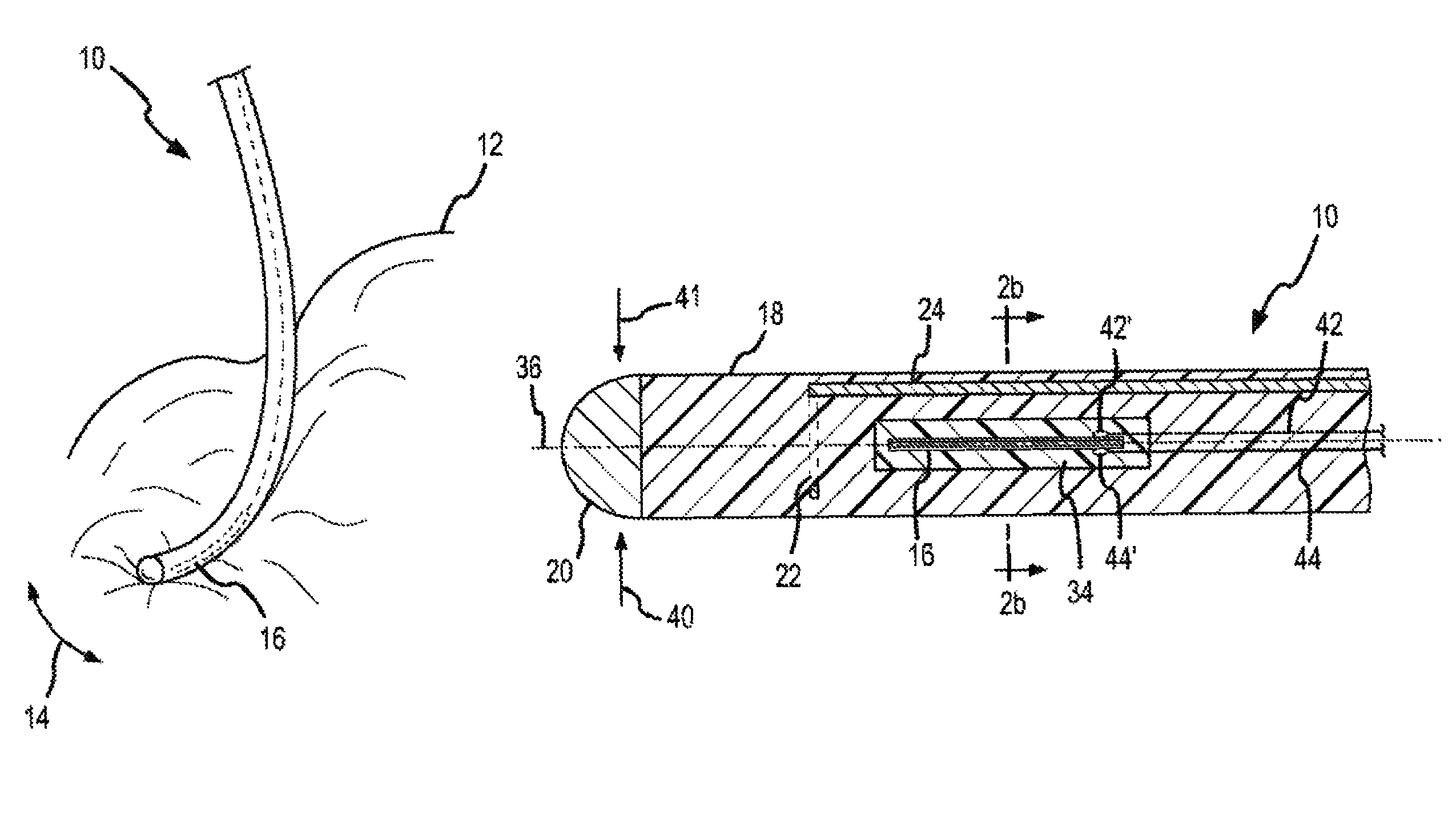

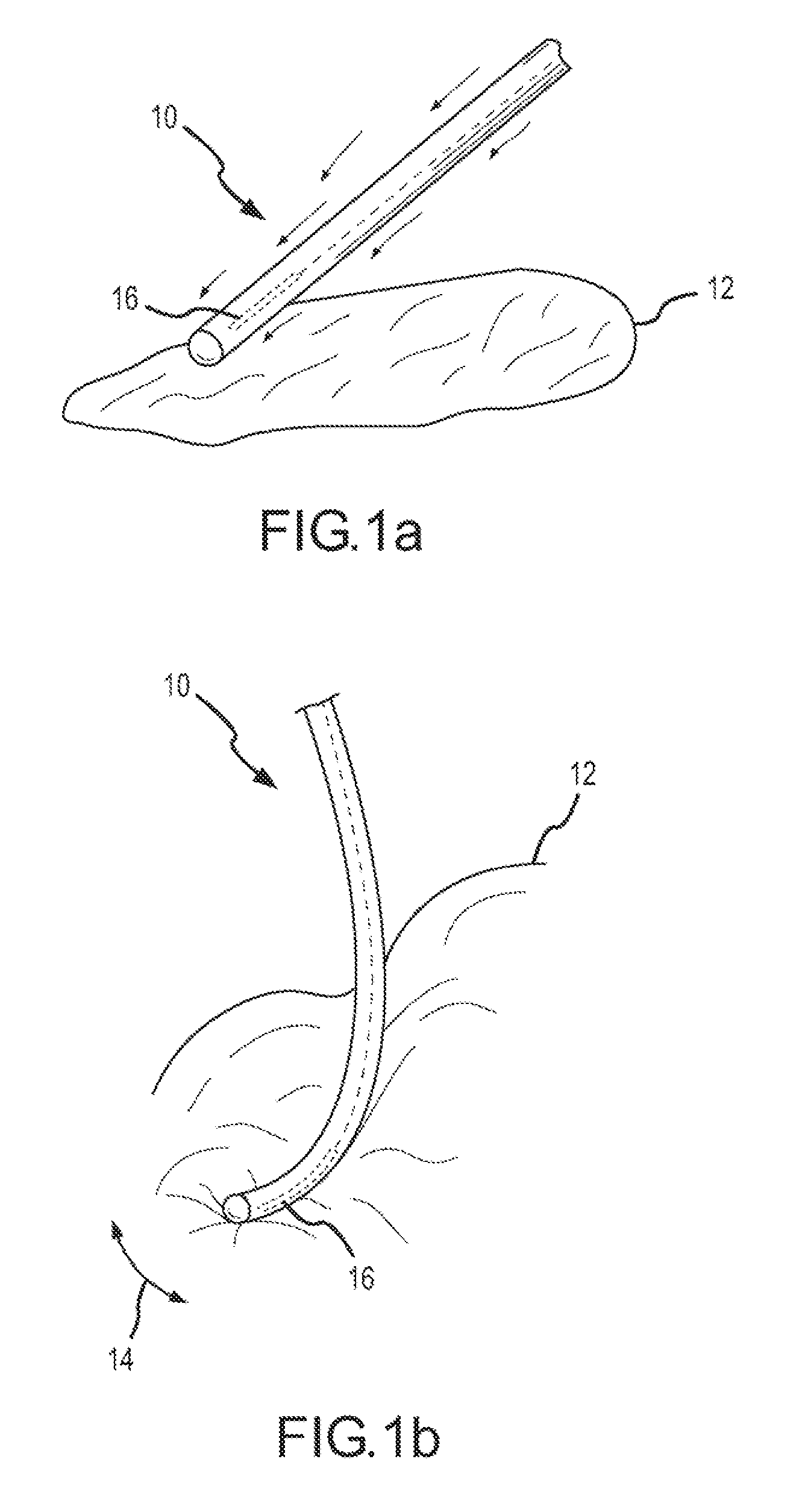

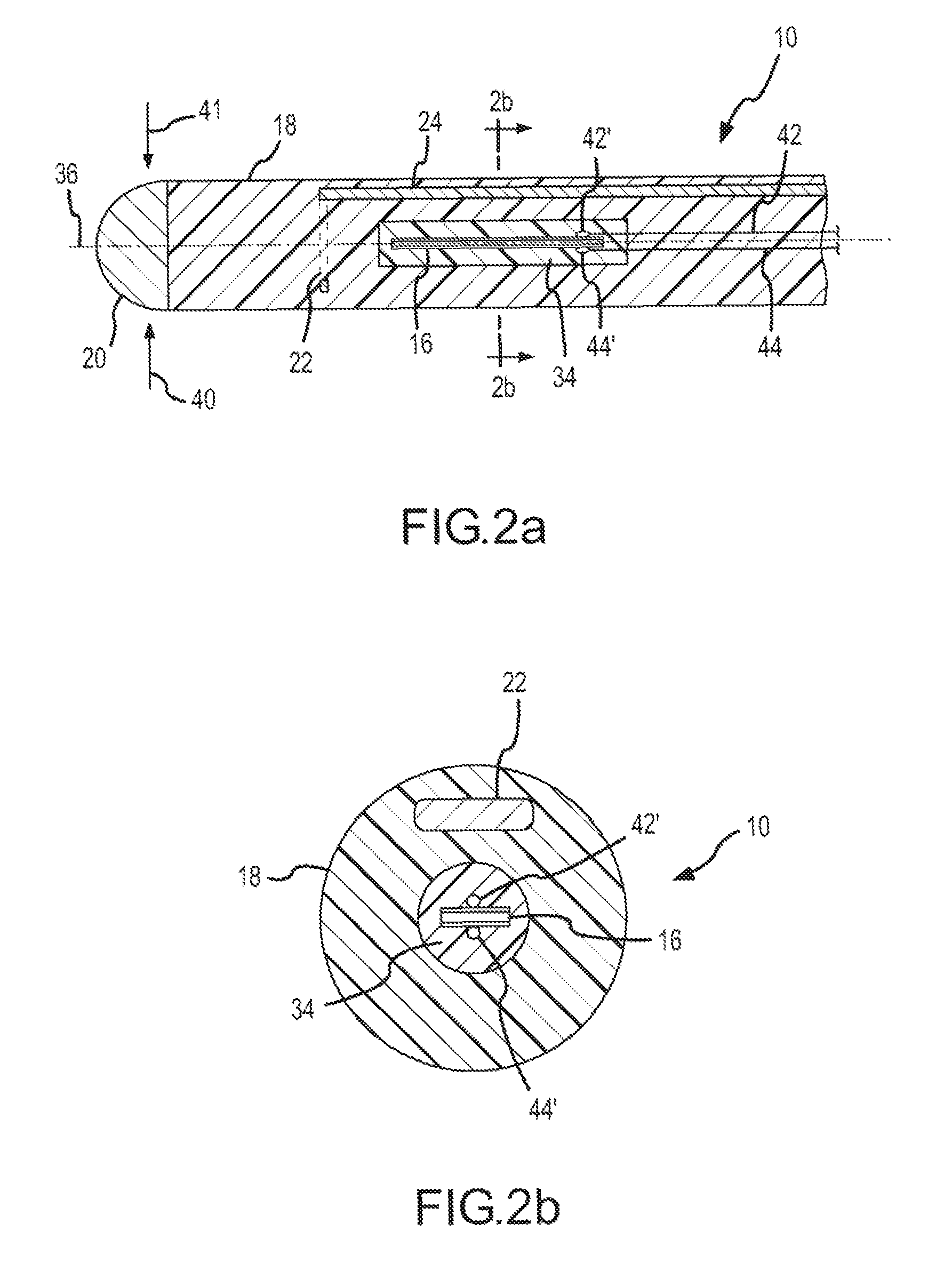

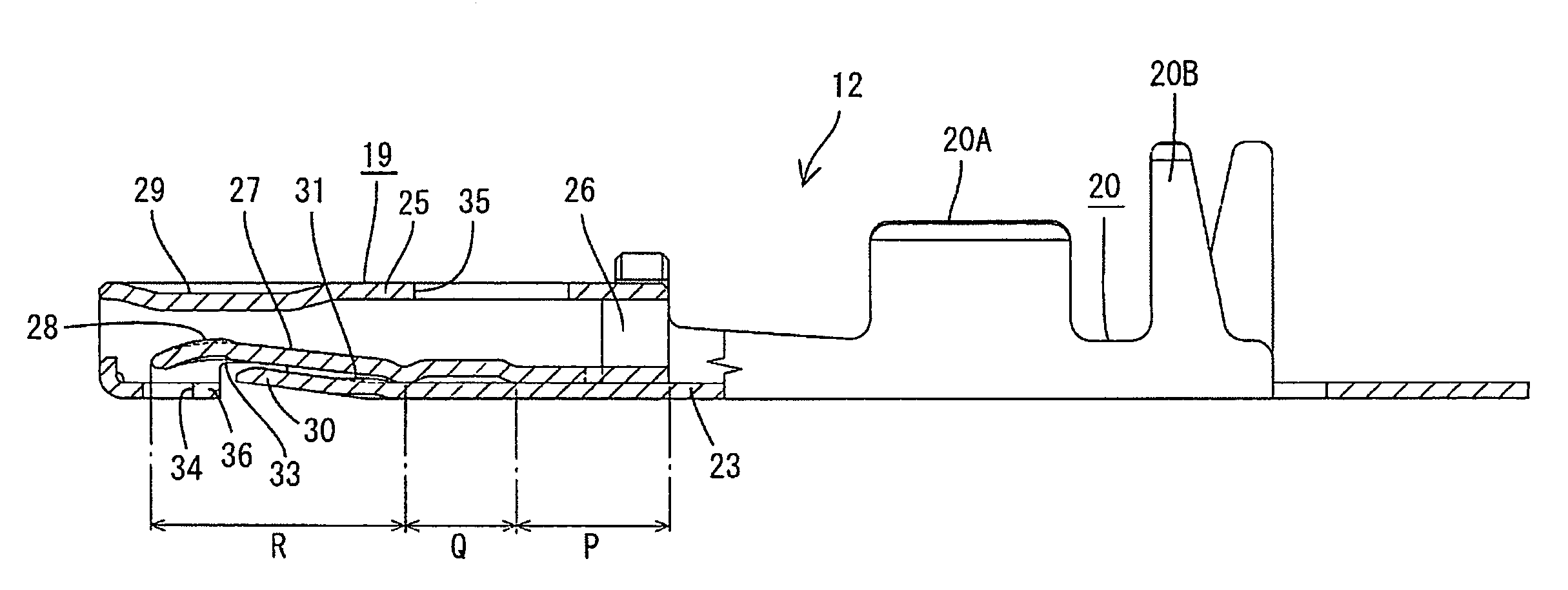

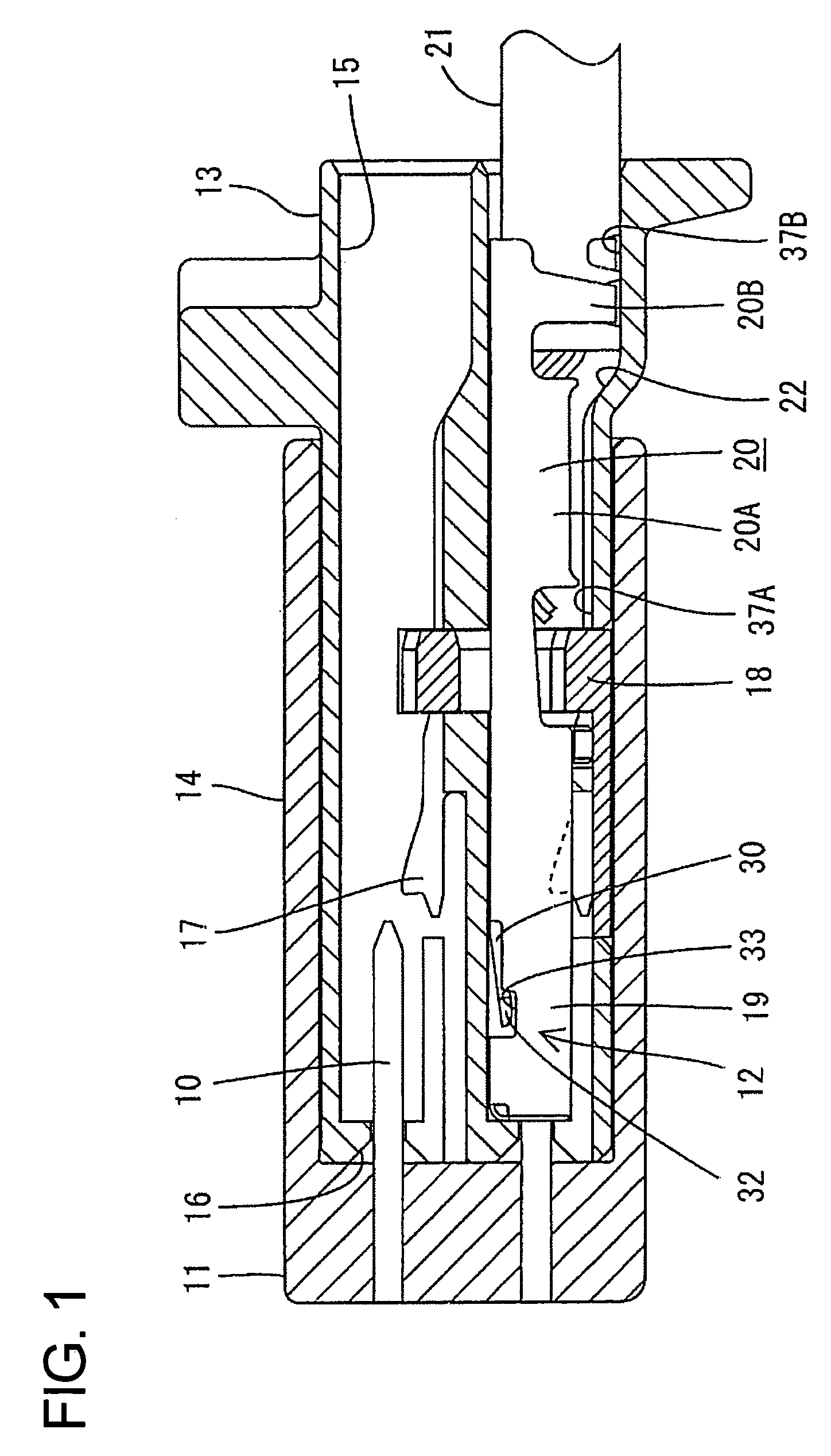

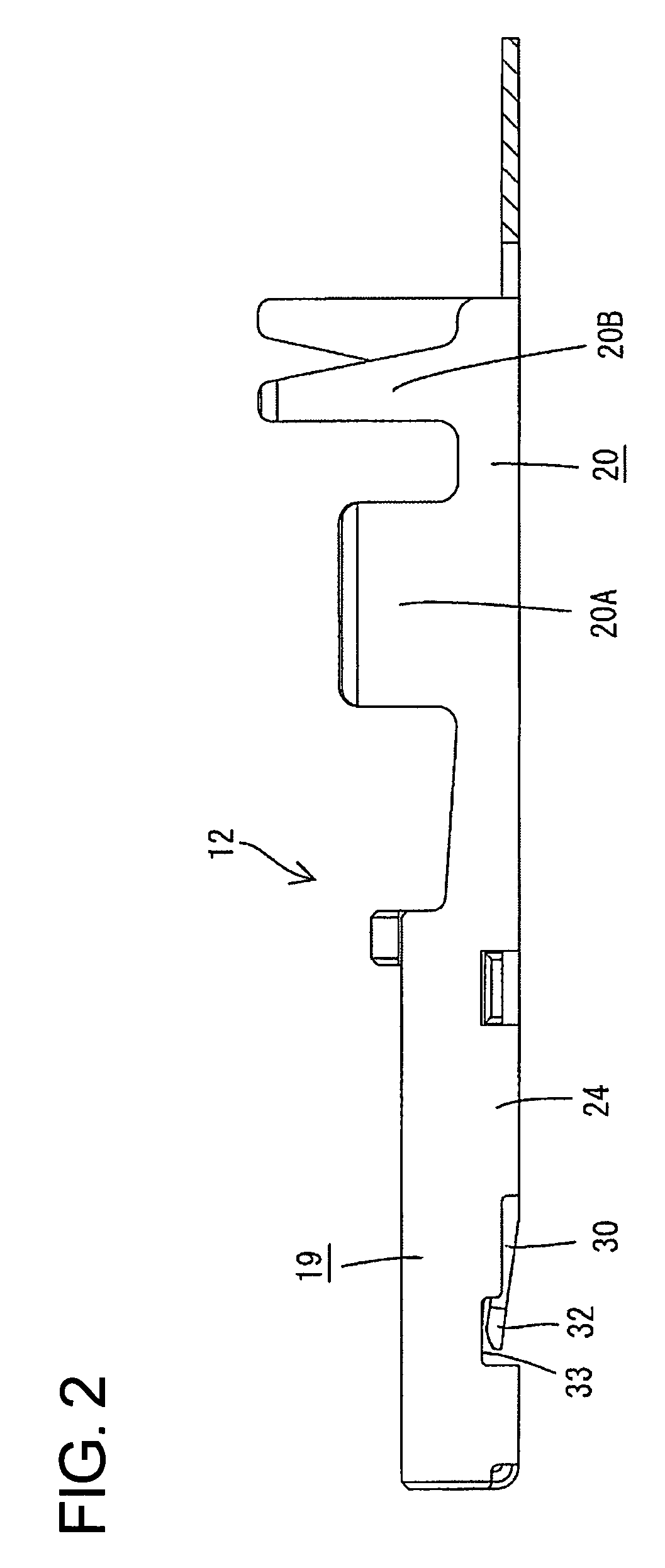

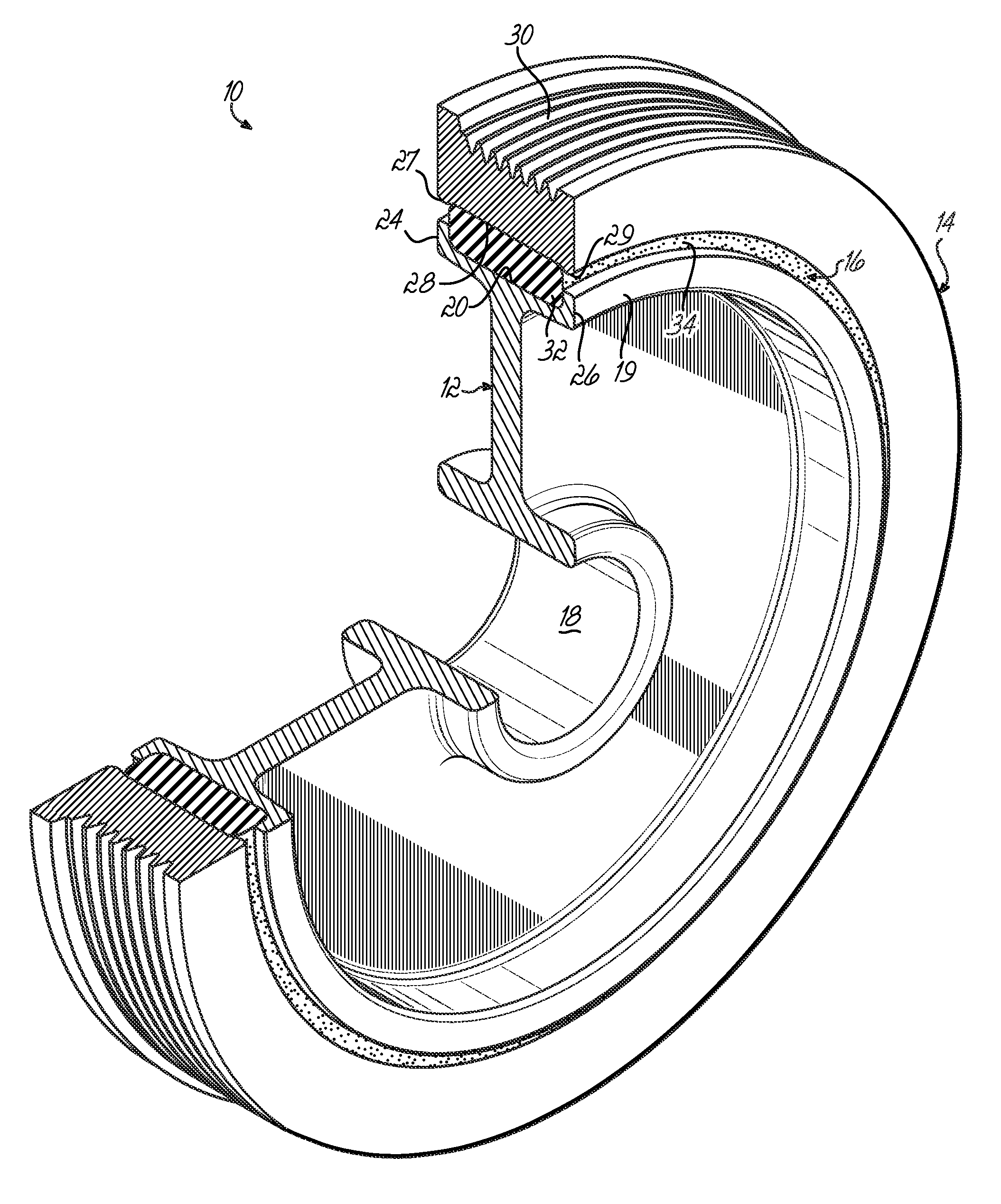

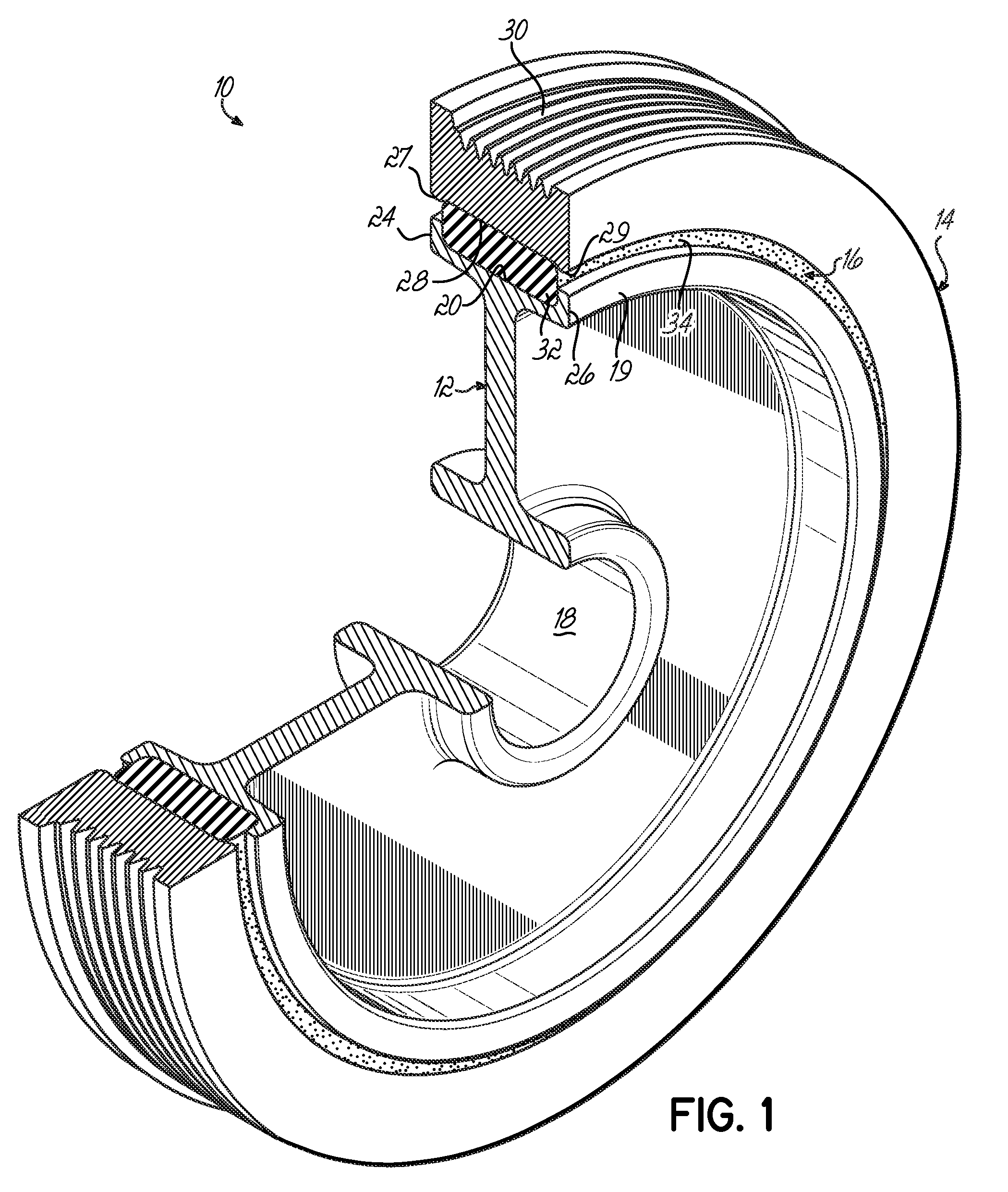

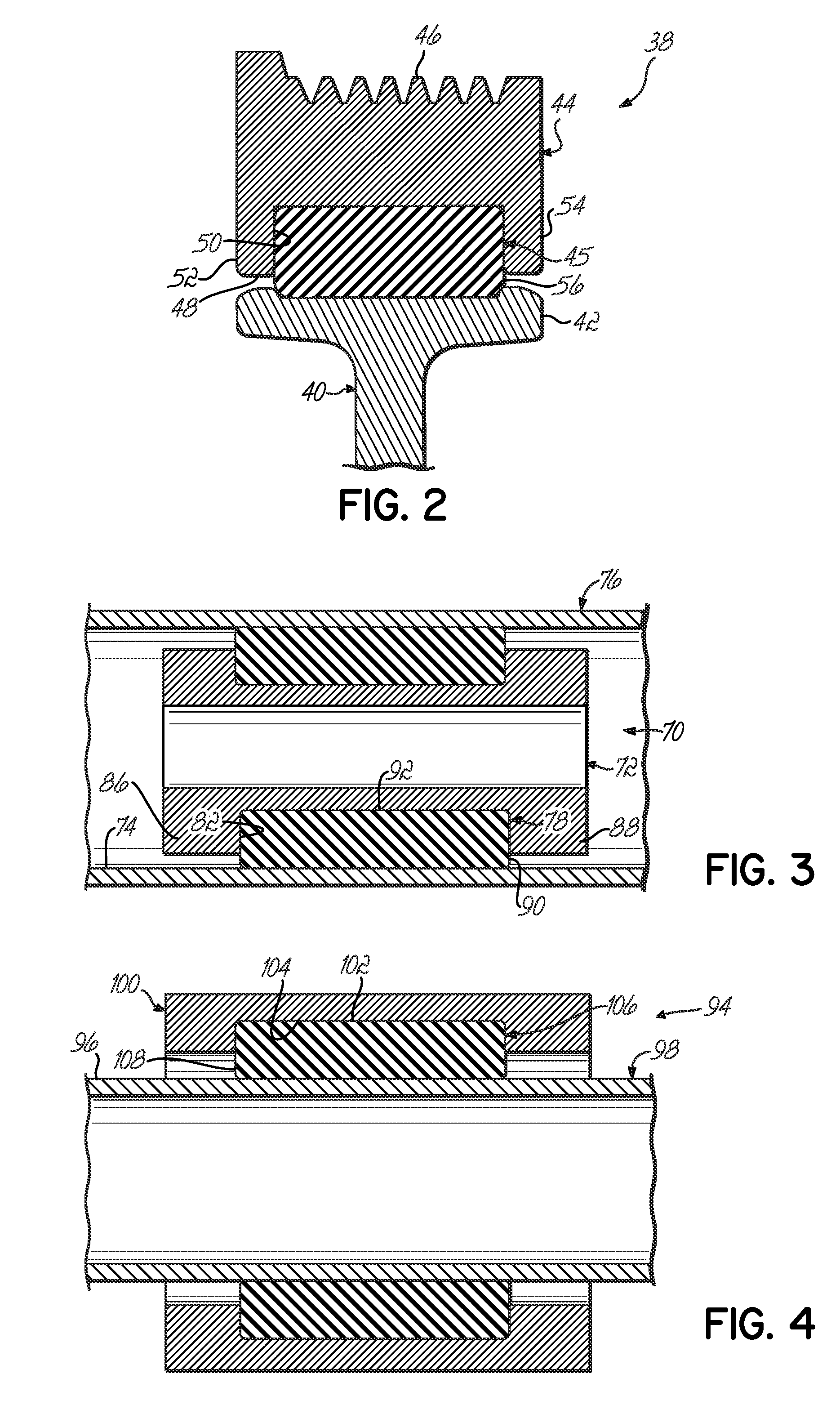

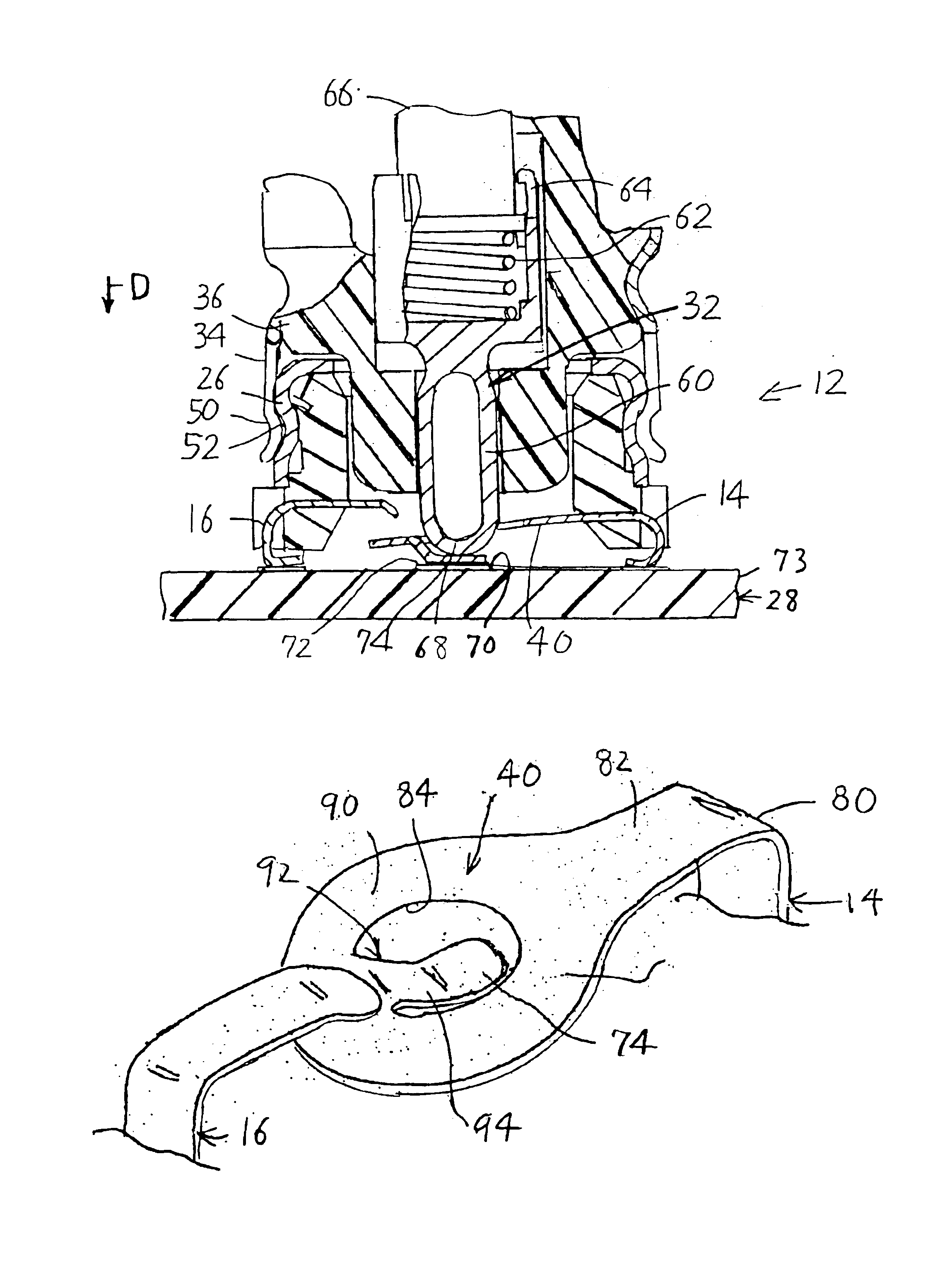

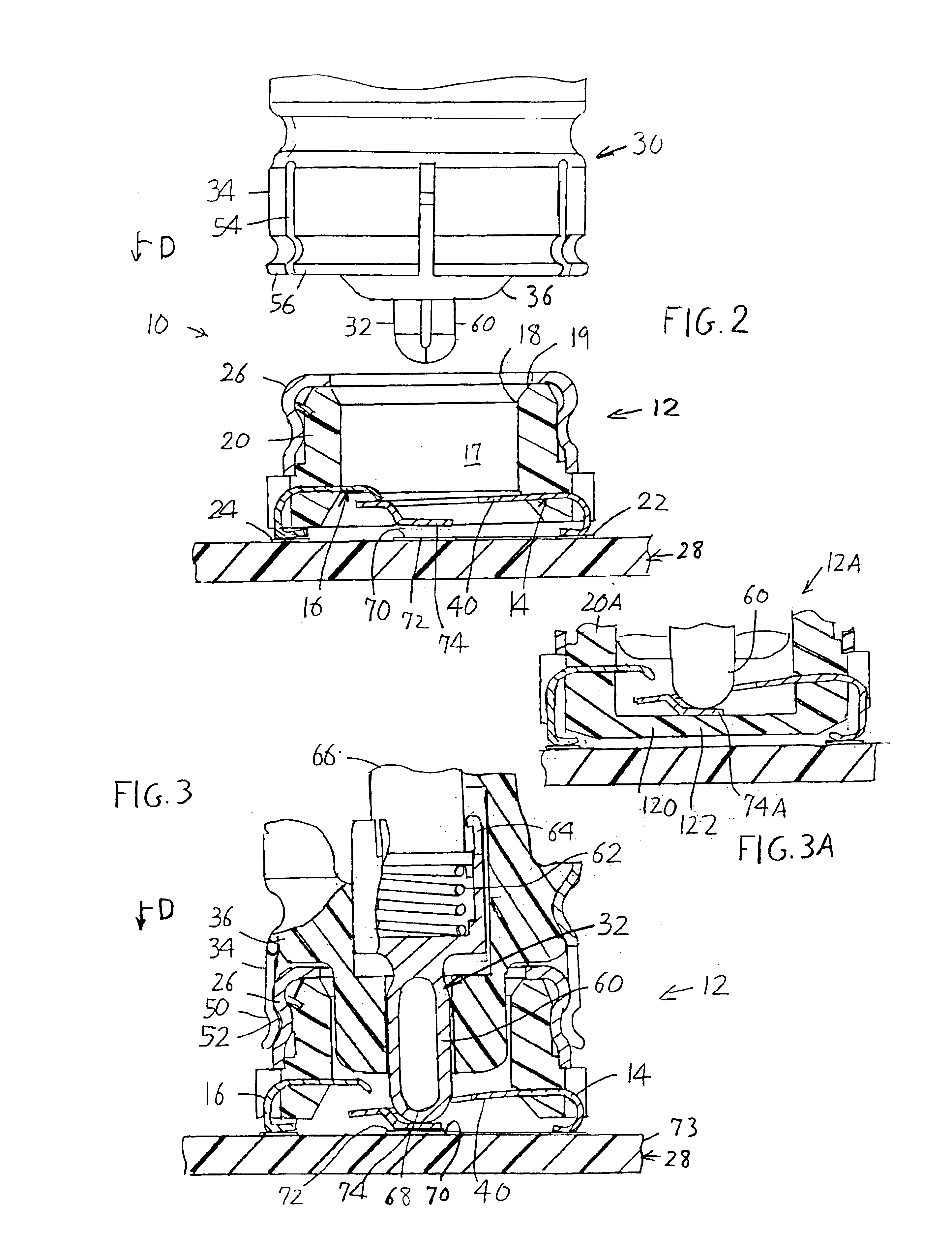

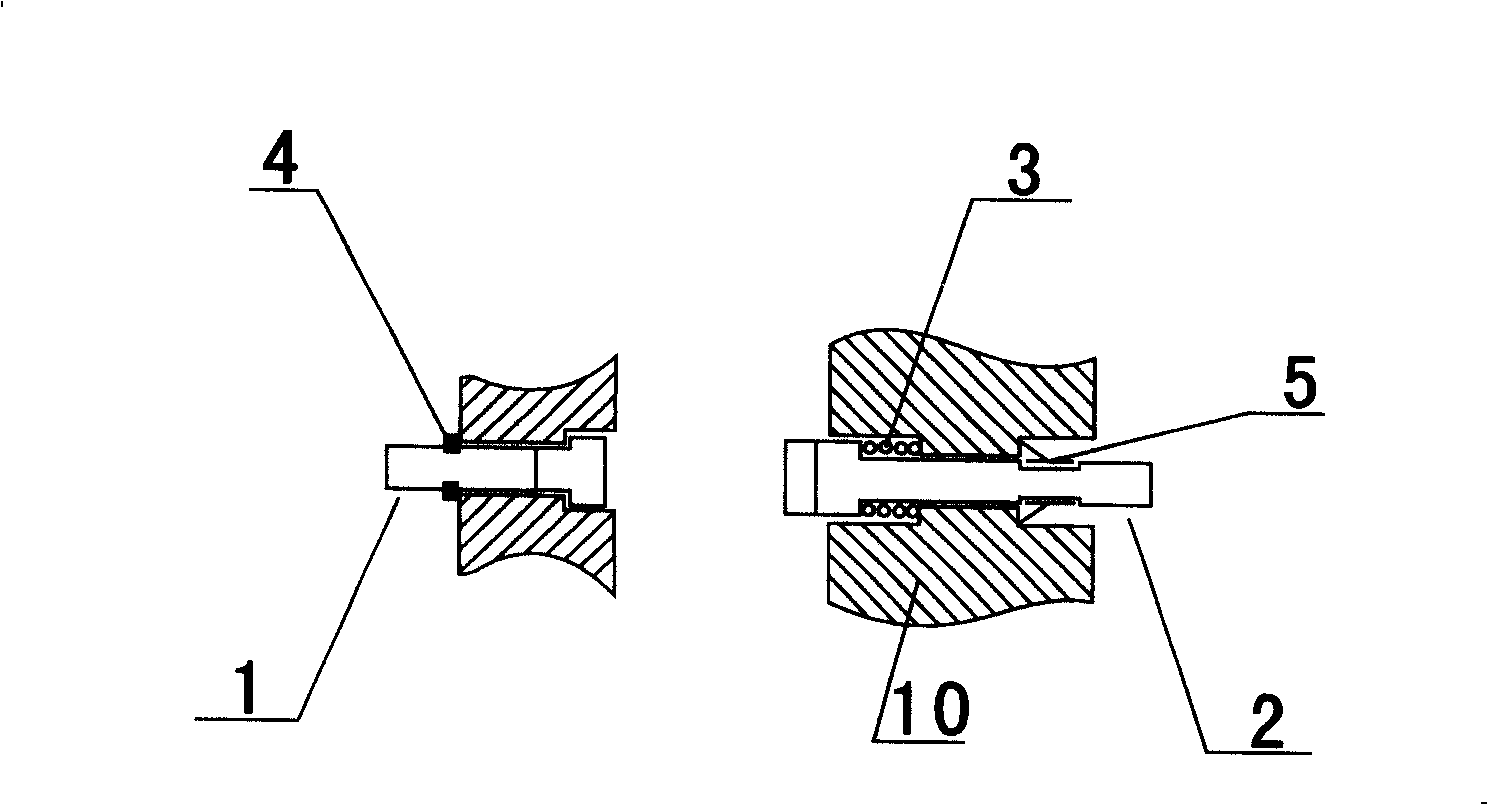

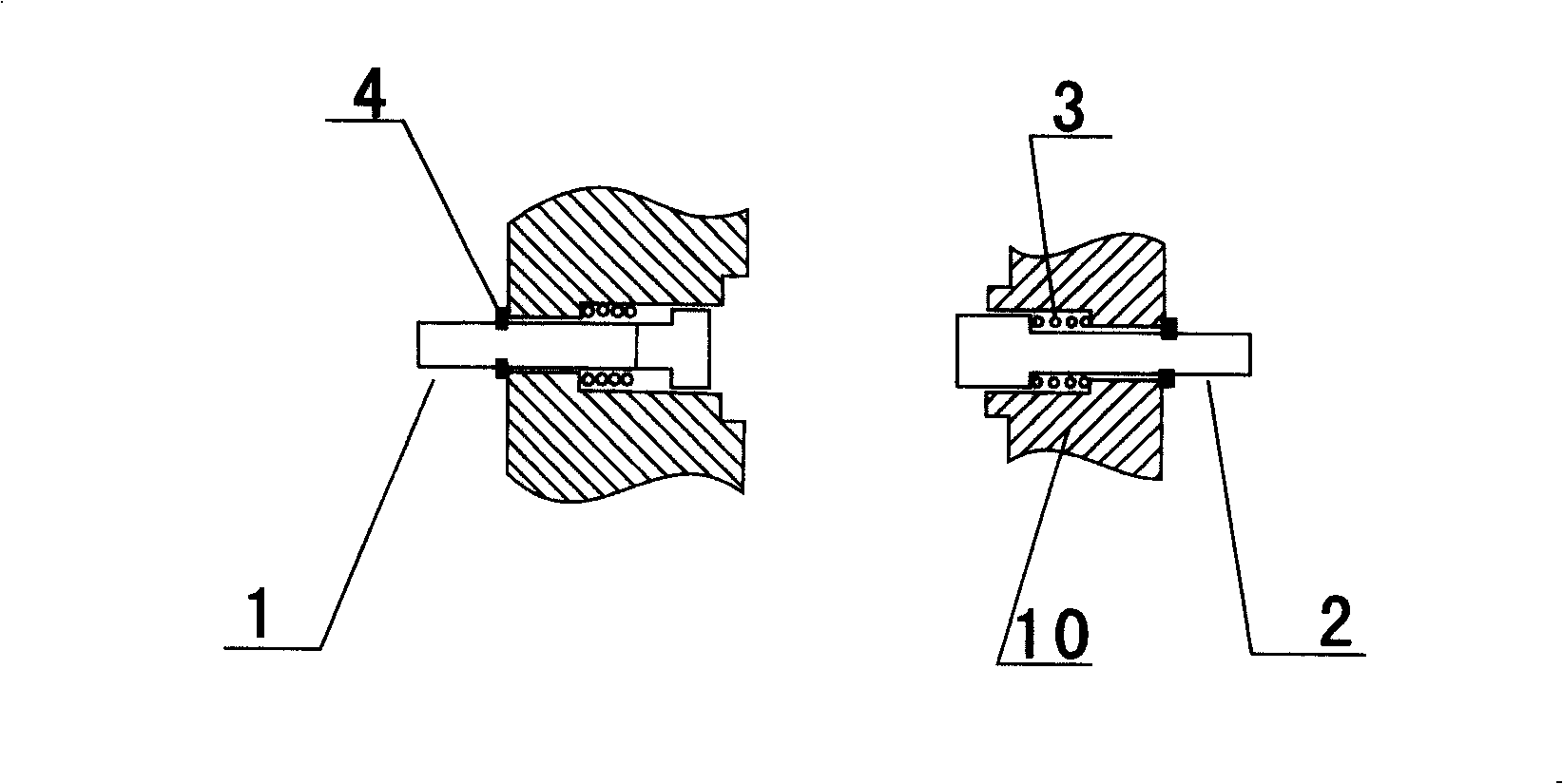

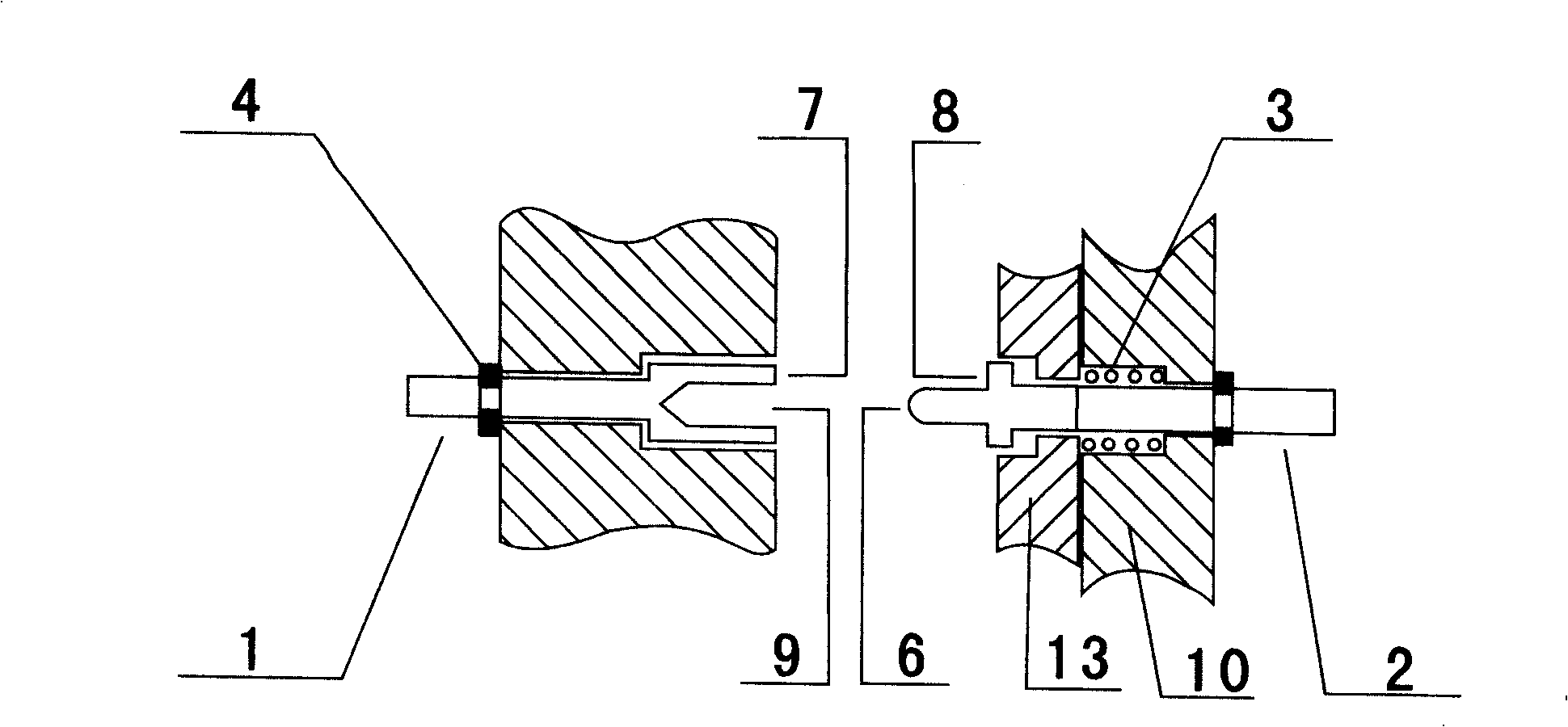

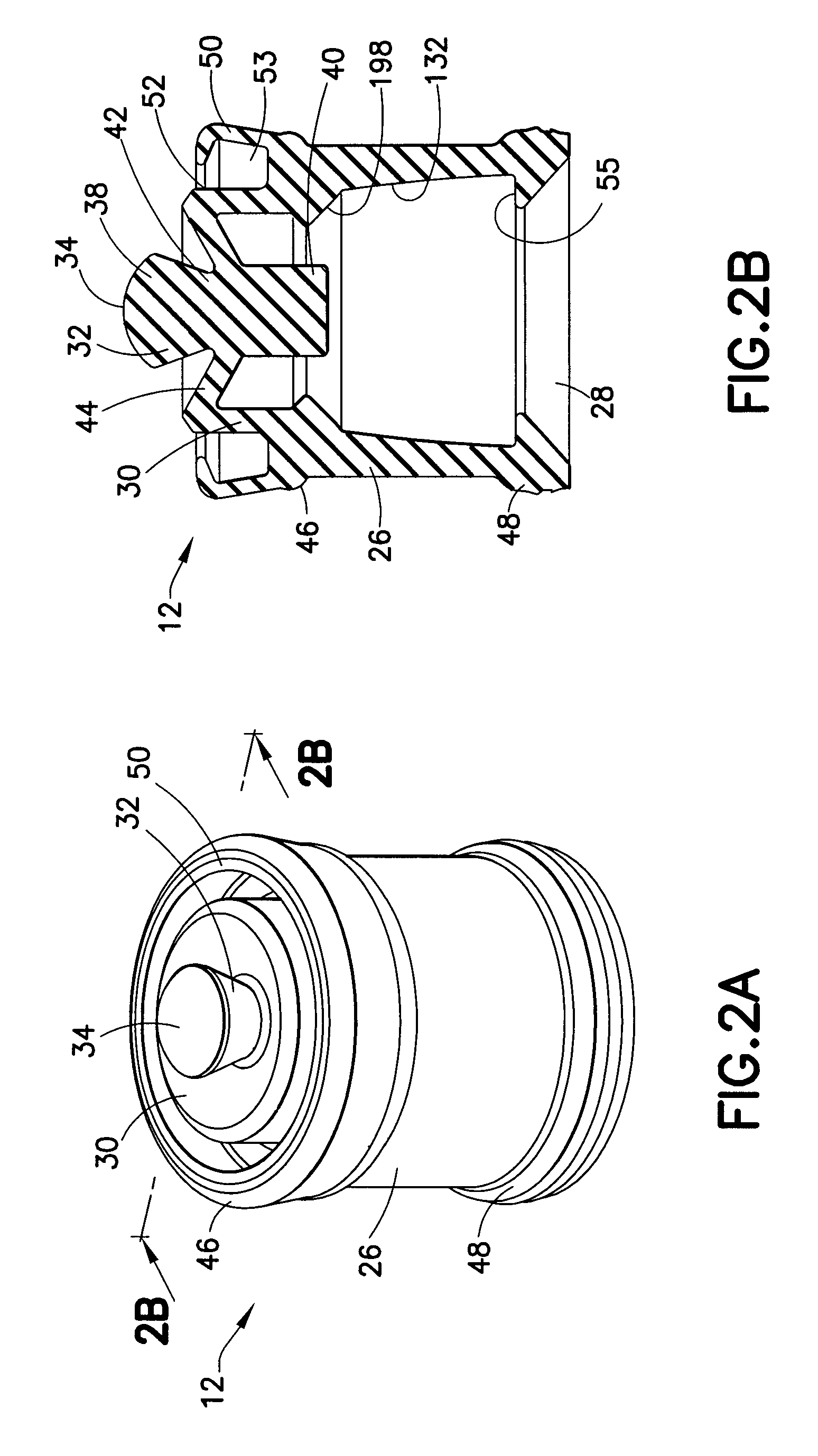

Systems and Methods for Electrode Contact Assessment

ActiveUS20080275442A1Increase contact pressureReduce contact pressureCatheterDiagnostic recording/measuringElectricityDistal portion

Systems and methods are disclosed for assessing electrode-tissue contact for tissue ablation. An exemplary electrode contact sensing system comprises an electrode 10 housed within a distal portion of a catheter shaft 14. At least one electromechanical sensor 20 is operatively associated with the electrode 10 within the catheter shaft 14. The at least one electromechanical sensor 20 is responsive to movement of the electrode 10 by generating electrical signals corresponding to the amount of movement. The system may also include an output device electrically connected to the at least one electromechanical sensor 20. The output device receives the electrical signals for assessing a level of contact between the electrode 10 and a tissue 12.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Smart junction box for solar cell module

InactiveUS20110058337A1Efficient emissionsGuaranteed uptimeSubstation/switching arrangement detailsPhotovoltaic monitoringElectricityBand shape

The present invention relates to a smart junction box for a solar cell module, and provides a smart junction box for a solar cell module which enables an operator to easily connect and separate ribbon cables using the operation of the levers of pressing units, thereby being able to improve the contact stability of ribbon cables, and which has a heat sink structure, thereby effectively emitting the heat generated by the ribbon cables and the diodes to the outside. For this purpose, the smart junction box for a solar cell module of the present invention includes bus bars for transmitting electricity flowing from ribbon cables; and pressing units for selectively fastening and separating the ribbon cables located on contact portions of the bus bars depending on whether both ends of the lever projected by the manipulation of an operator are inserted into recesses formed in a body.

Owner:CONNEX ELECTRONICS +2

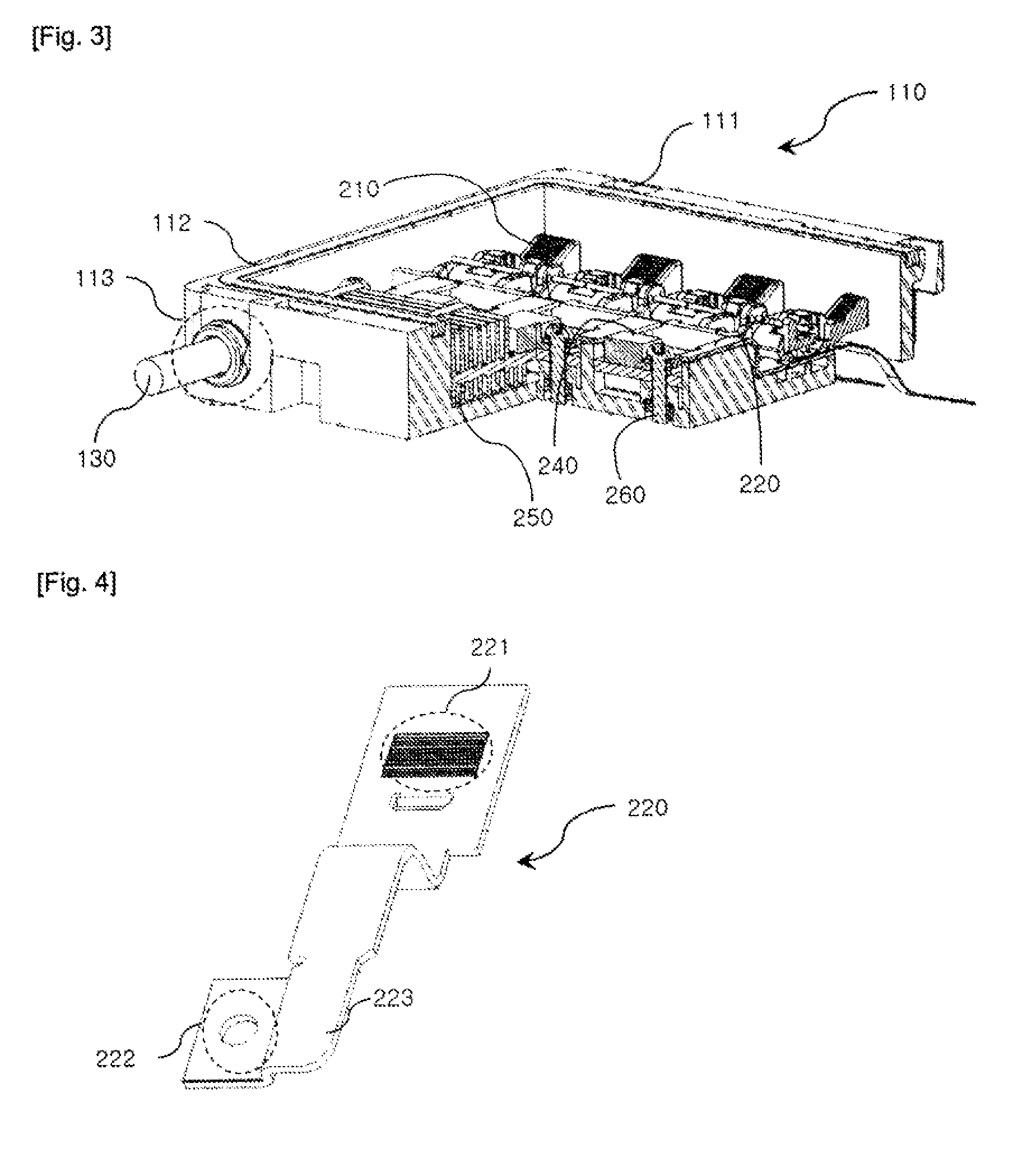

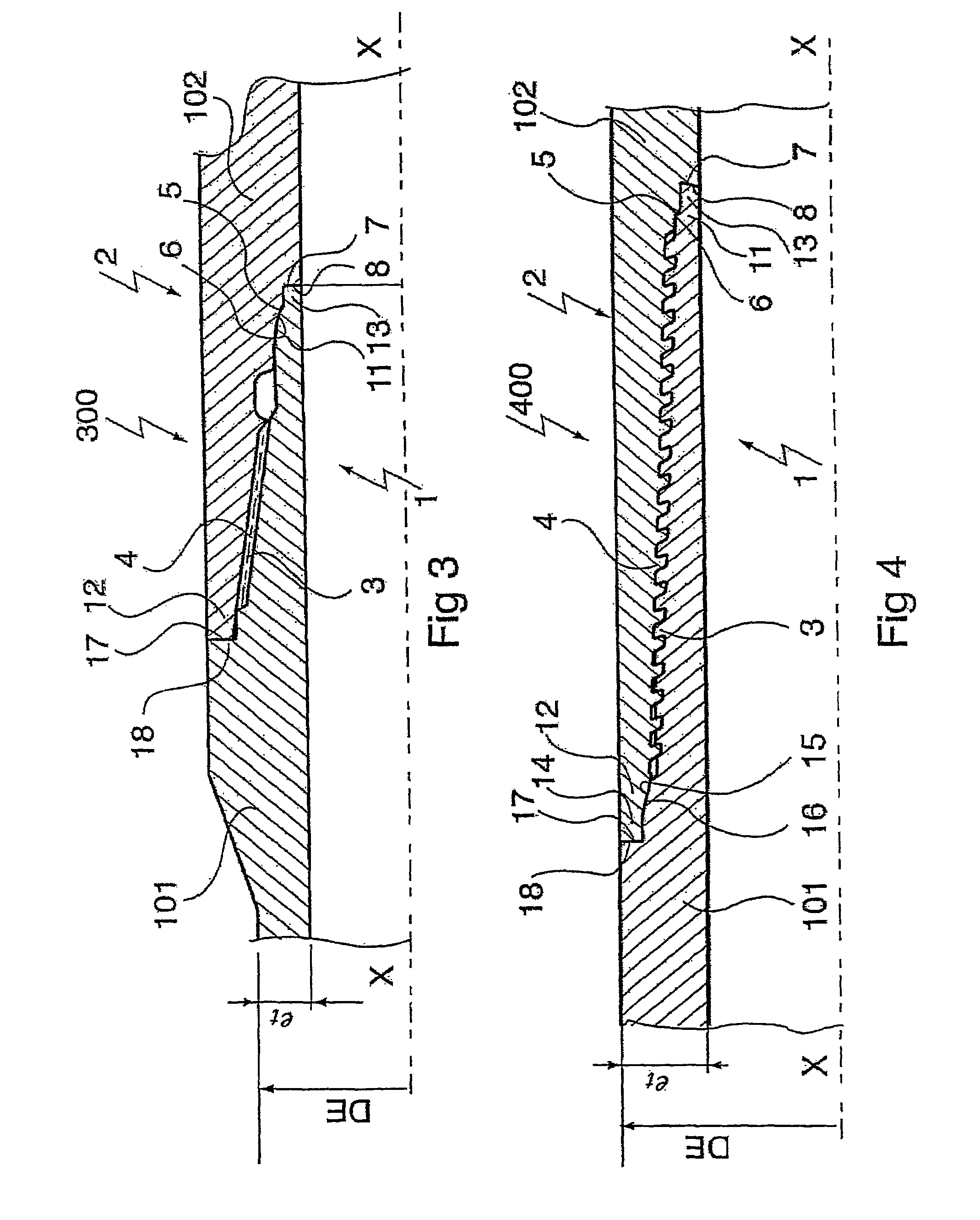

Premium threaded tubular joint comprising at least a threaded element with end lip

InactiveUS7334821B2Reduce axial stiffnessImprove elastic deformation abilityDrilling rodsFluid pressure sealed jointsThreaded pipeAxial compression

A premium threaded tubular connection including, on at least one threaded element, a distal abutment surface at the free end of a threaded element, and a lip sealing surface at a given distance from the threading. The lip includes an appendix that extends the lip towards its free end beyond the lip sealing surface so that the lip has both high radial stiffness and low axial stiffness. This results in enhanced performance as regards the seal of the threaded connection under pressure and / or under tension, and other advantages of precision of real makeup torque, mechanical strength in axial compression, a shock barrier effect, and tolerance in engaging the threaded elements.

Owner:NIPPON STEEL CORP

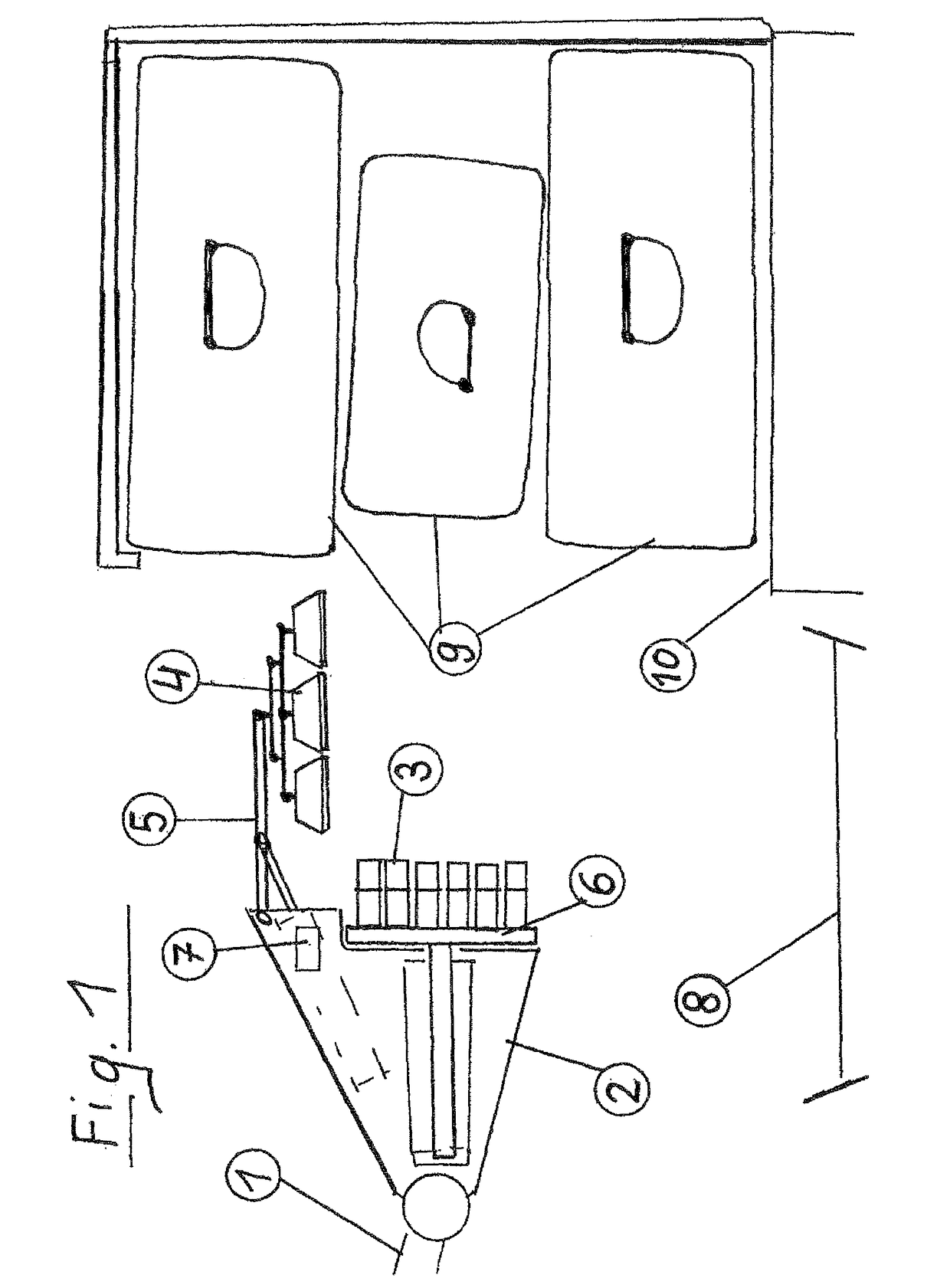

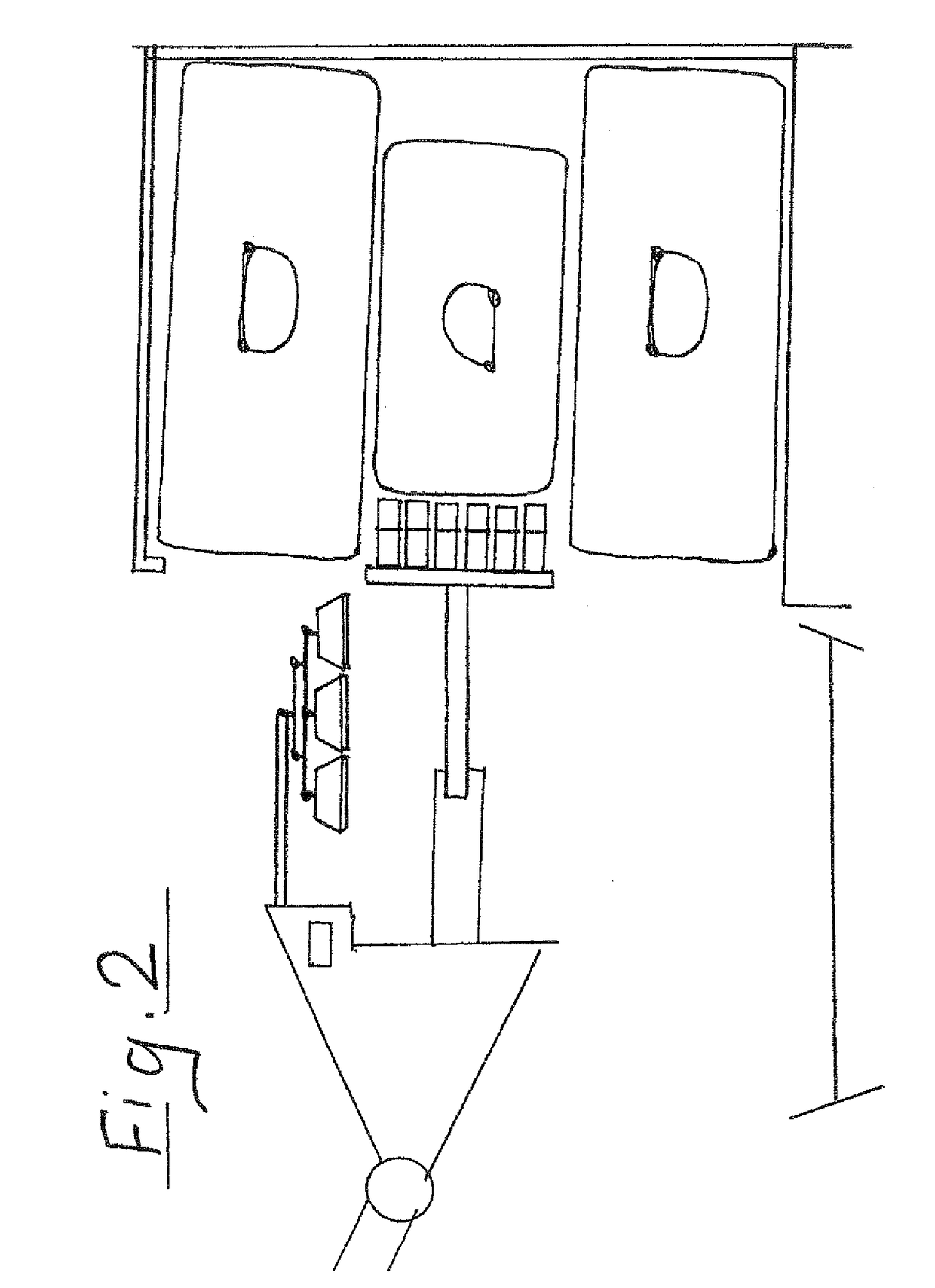

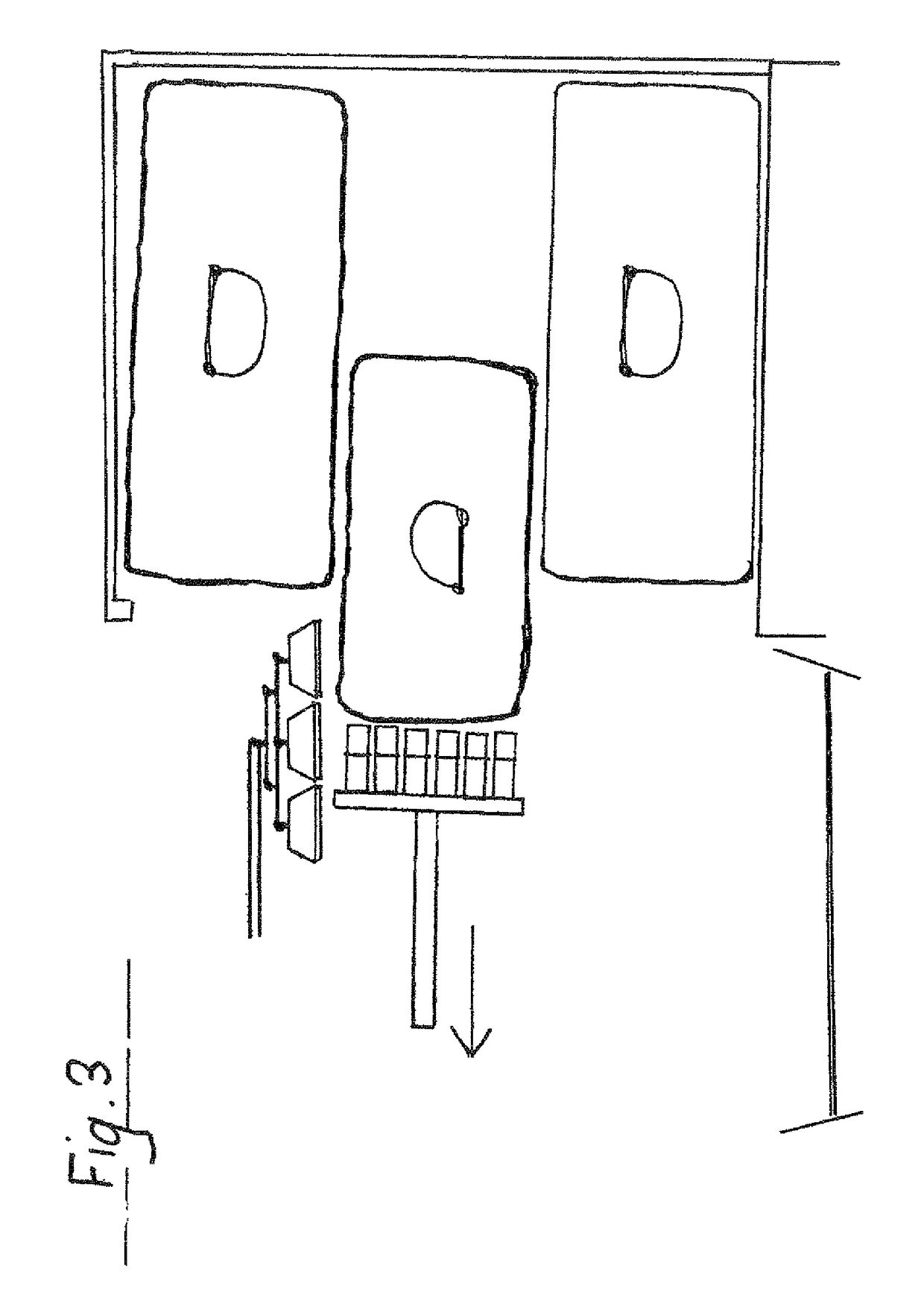

Method and apparatus for gripping and transferring pieces of luggage

ActiveUS8473094B2Increase suction pressureIncrease contact pressureDigital data processing detailsGripping headsEngineeringGrippers

A method and an apparatus for automatically removing pieces of luggage that have different surface properties and dimensions and getting the pieces of luggage ready for further transport by means of a gripper that is hingedly connected to a robot arm is described. The method includes: a) moving the gripper and the container that is to be emptied close together; b) determining the first piece of luggage to be removed; (c) gripping the piece of luggage using a horizontal suction elements (3) and withdrawing the luggage horizontally; d) if the vertical suction elements (4) are not yet able to sufficiently grip the luggage, the vertical suction elements (4) are repositioned and turned off, the vertical suction elements (5) are repositioned, and then turned on to re-grip the piece of luggage.

Owner:GRENZEBACH MASCHINENBAU GMBH

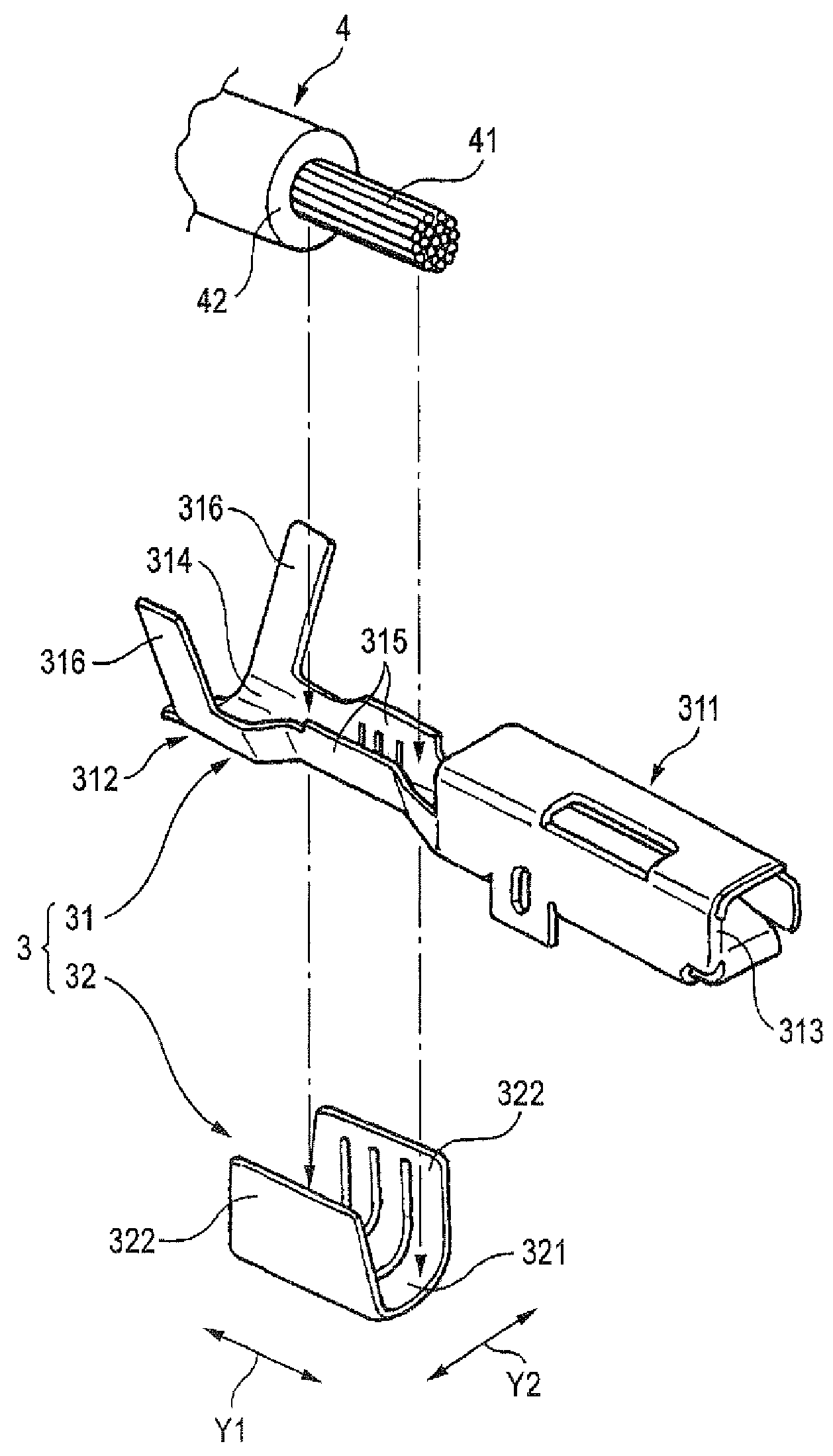

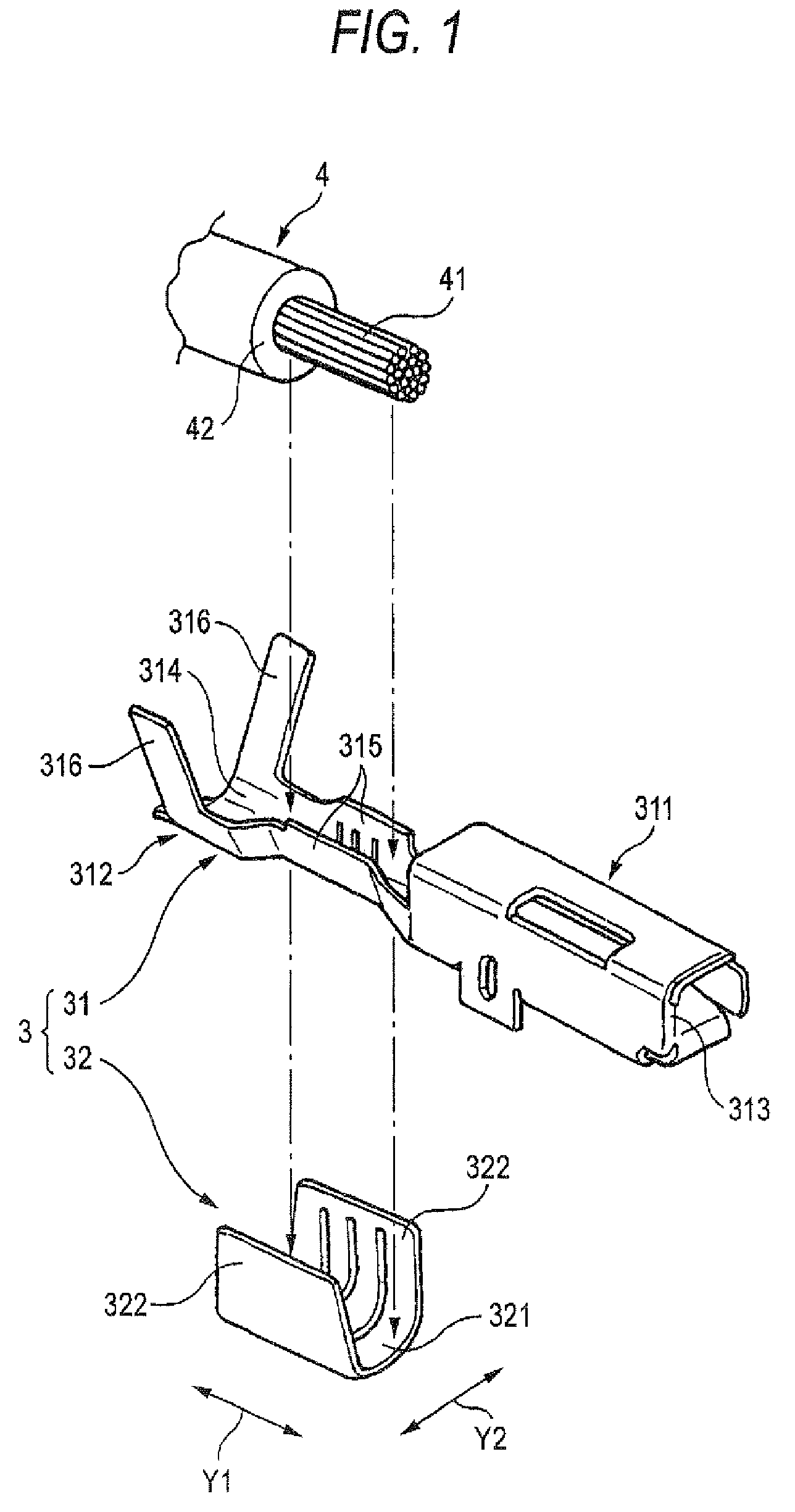

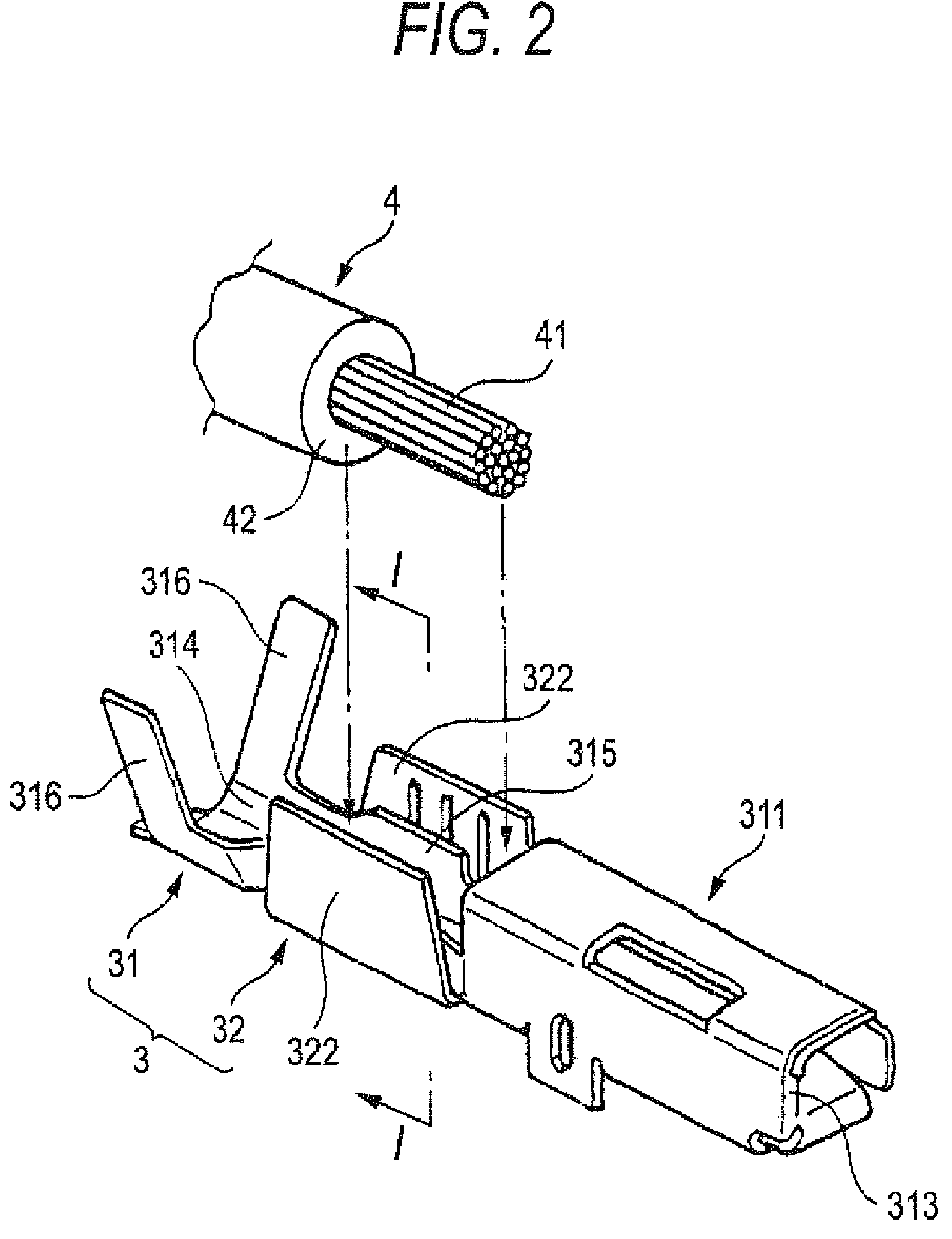

Female terminal fitting and method of assembling such terminal fitting

InactiveUS7094114B2Sufficient widthIncrease contact pressureCoupling contact membersClamped/spring connectionsElectrical and Electronics engineering

Owner:SUMITOMO WIRING SYST LTD

Stopper and plunger rod for a pre-filled syringe

ActiveUS20080300551A1High contact pressurePrevent leakageInfusion syringesIntravenous devicesPrefilled SyringeBiomedical engineering

A plunger rod adapted for attachment with a stopper for use with a syringe barrel is disclosed. The plunger rod includes an elongated member having a front end and a back end, the plunger rod extending along a longitudinal axis. The plunger rod includes at least one deflecting arm associated with the front end of the elongated member. The deflecting arm is capable of deflecting radially inward during insertion of the plunger rod into a stopper, and deflecting outward into contact with an inner surface of the stopper after insertion to lock the plunger rod within the stopper.

Owner:BECTON DICKINSON & CO

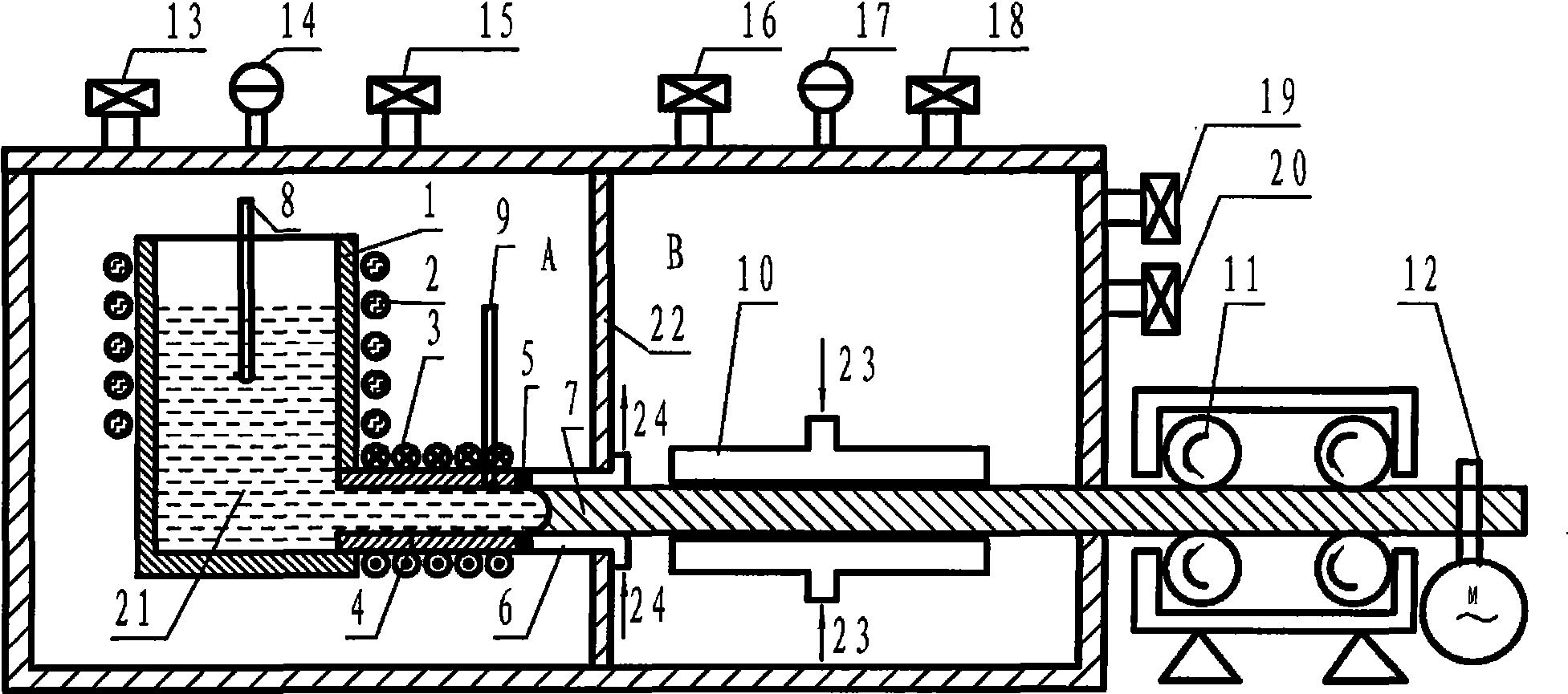

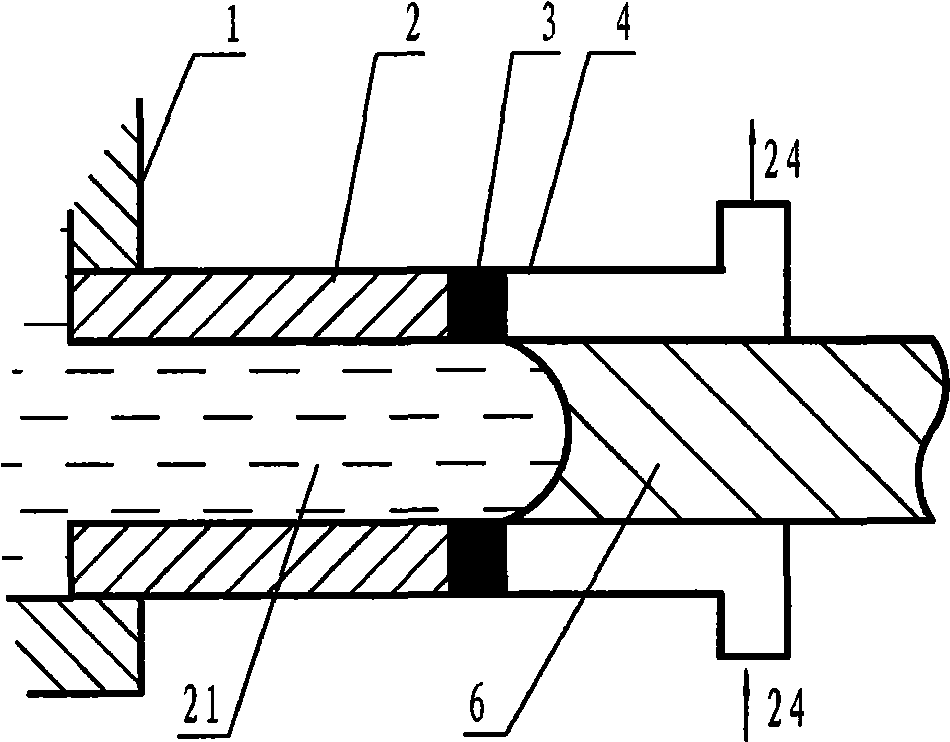

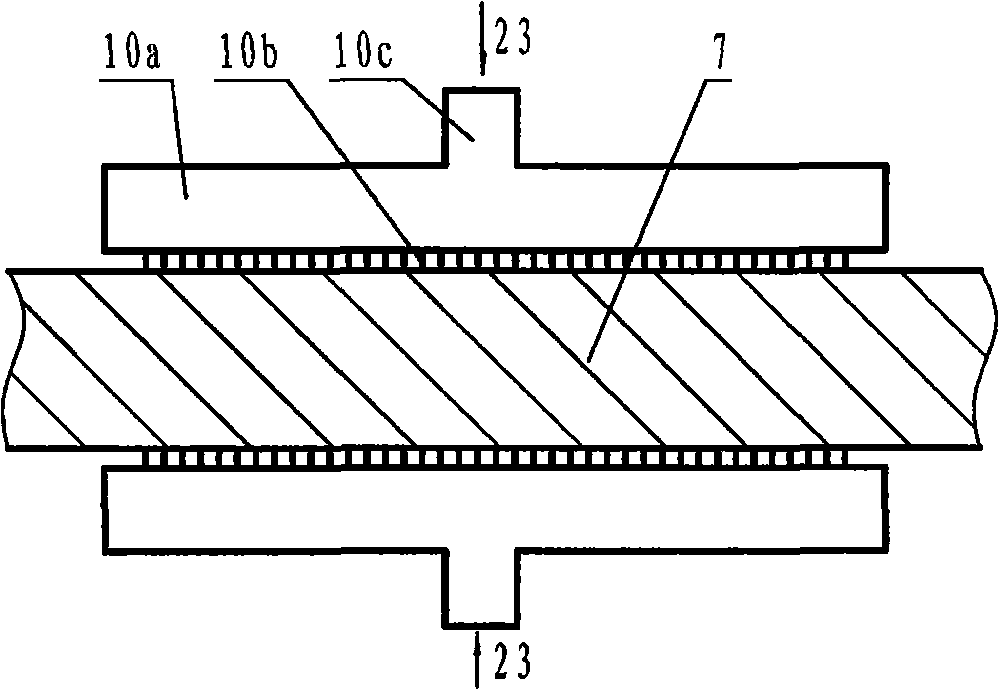

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

Terminal fitting having bi-metallic caulking pieces

ActiveUS7494388B2Suppression of contact resistanceEasy to installCoupling contact membersConnections effected by permanent deformationEngineeringMetal

Owner:YAZAKI CORP

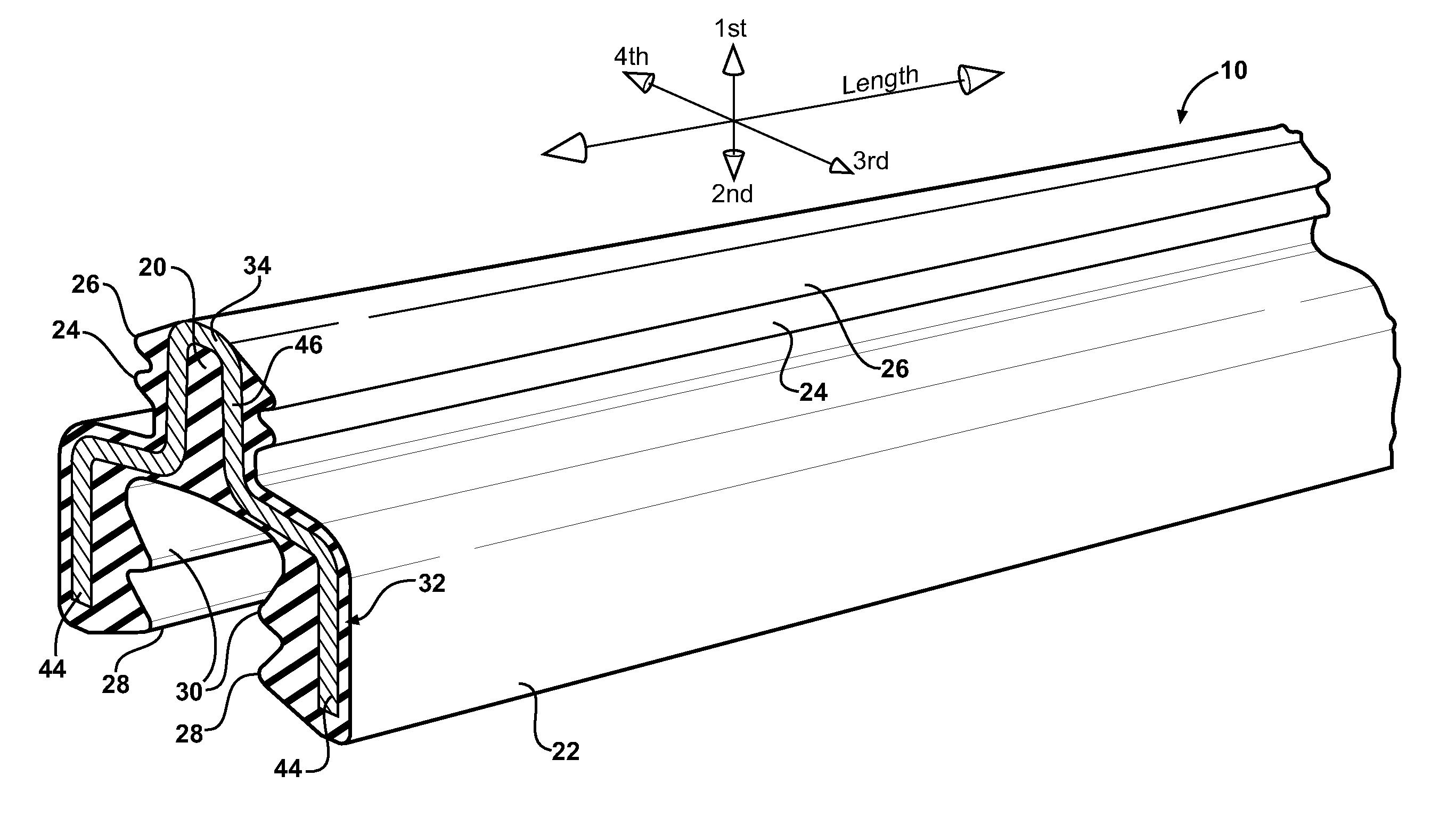

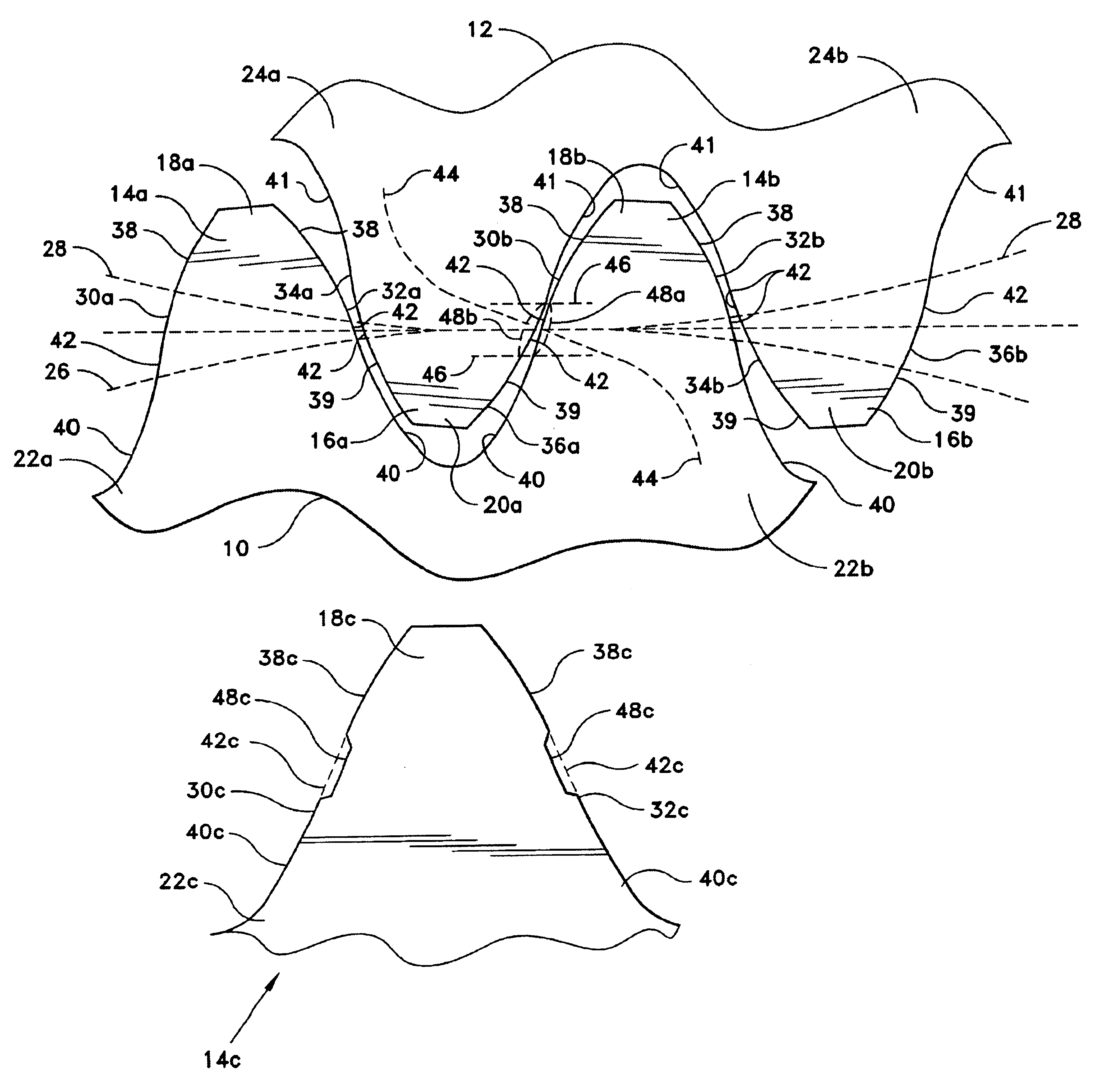

Lateral sealing gasket and method

An elongated elastomeric gasket (10) seals a pair of opposing flanges (12, 14) against the passage of liquid without compressing the flanges (12, 14) together. A reinforcing spring (32) is embedded within the elastomeric gasket (10) and is shaped so as to react when deflected by the operation of installing the gasket (10) into an operative position between the flanges (12, 14). A strategically located U-shaped bend (34) formed in the reinforcing spring (32) causes, in a preferred embodiment, contact pressure to be increased between opposed sealing beads at the other end of the gasket. More specifically, lateral contact pressure between a first pair of sealing beads (24) and their associated contact faces (38) is increased as a direct result of the reinforcing spring (32) being displaced during the assembly process. Likewise, lateral contact pressure between a second pair of beads (28) and their respective contact faces (42) is increased in direct response to the lateral displacement of the reinforcing spring (32) in the region of the first beads (24) during assembly.

Owner:FEDERAL MOGUL WORLD WIDE

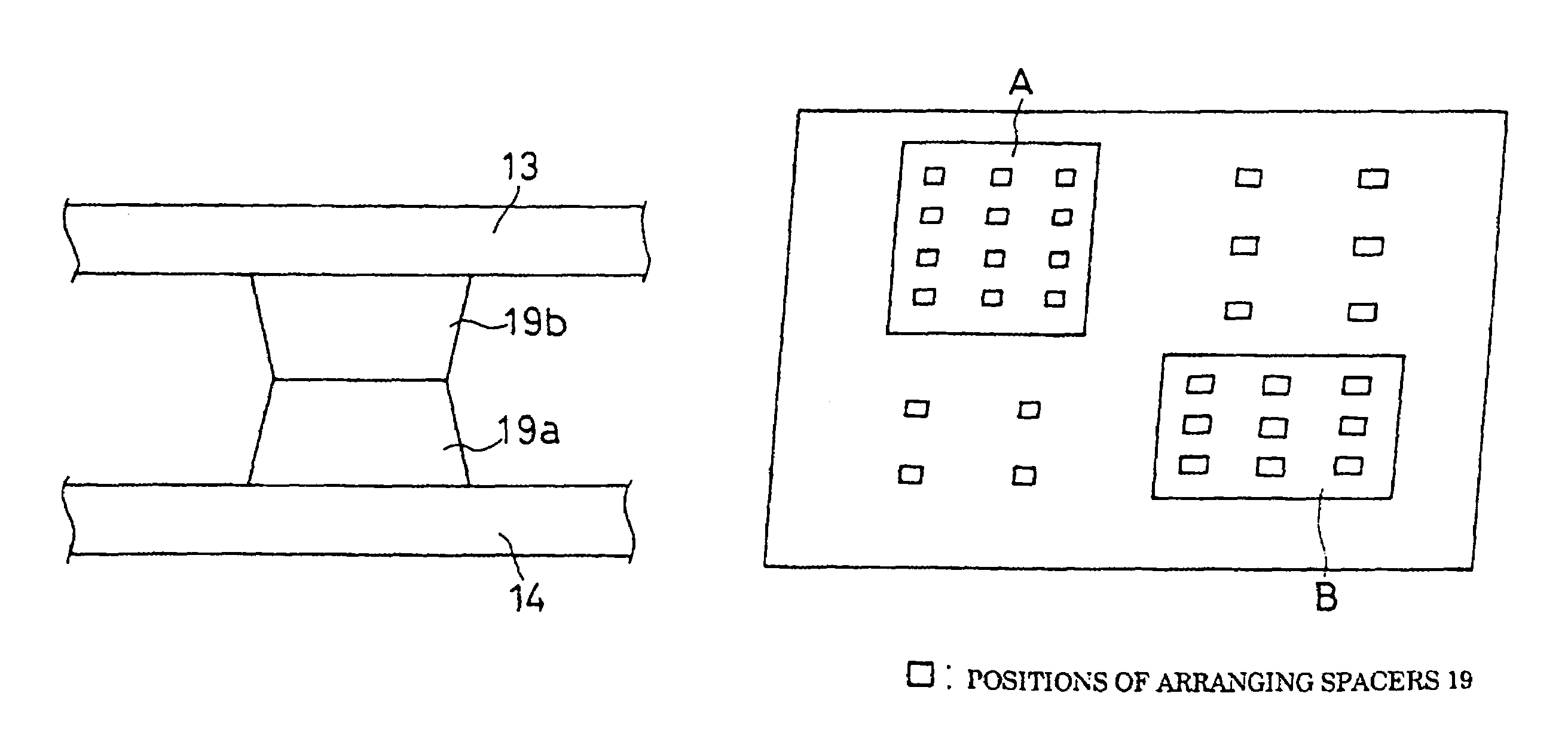

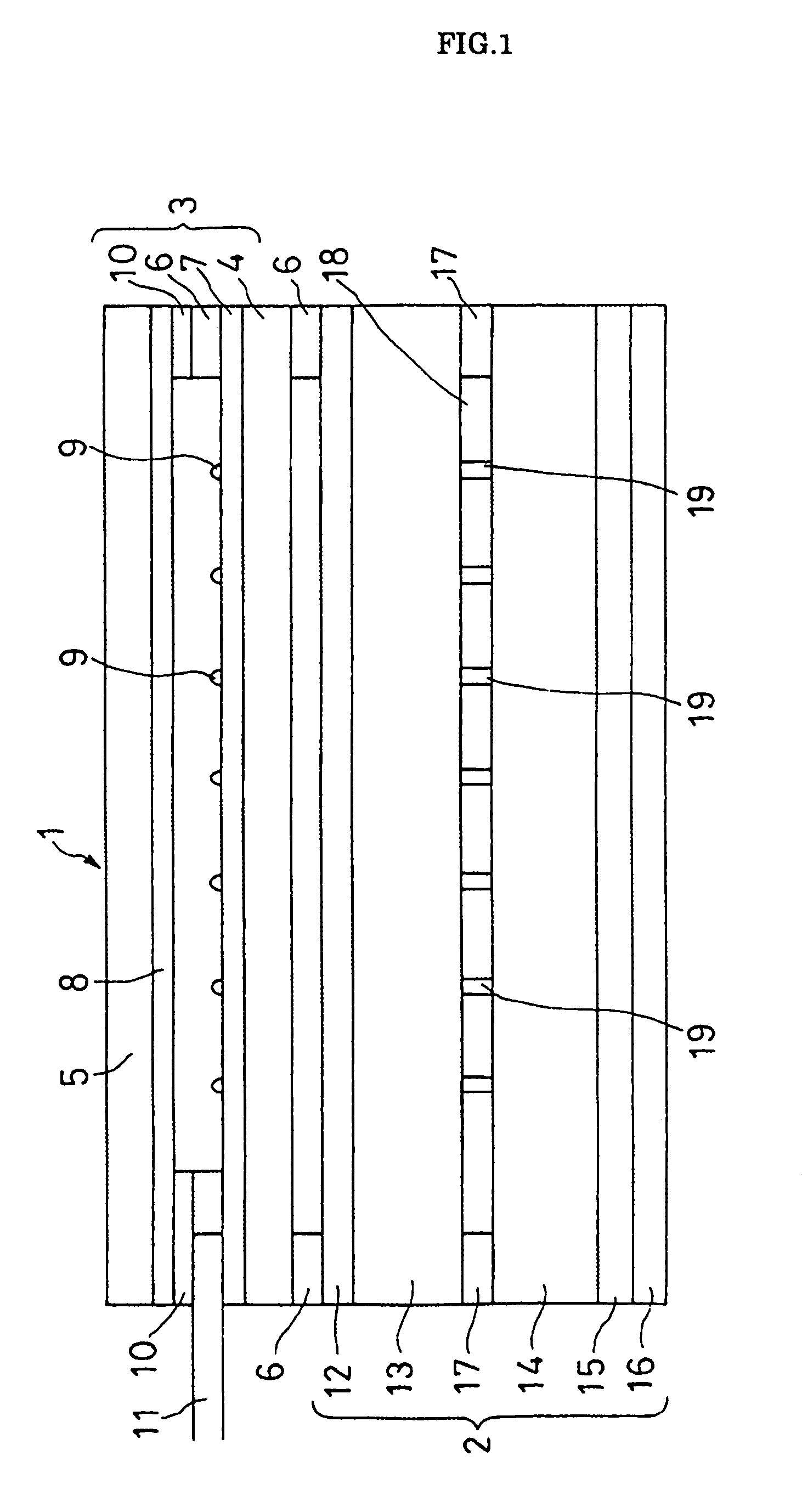

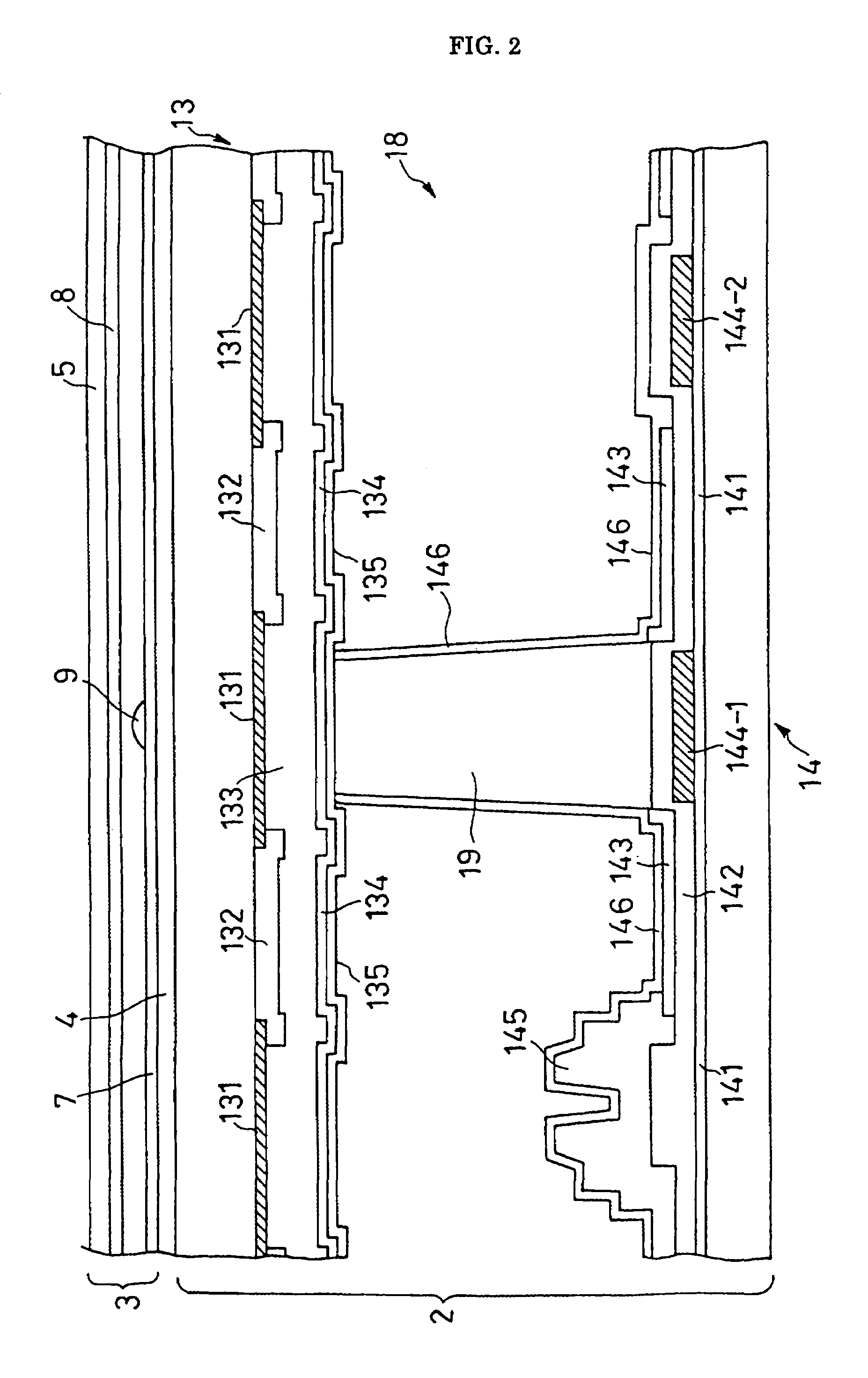

Touch sensor type liquid crystal display having a plurality of spacers, each comprising two members adapted to slide relative to each other in response to a contact force

InactiveUS7274424B1Convenient ArrangementSatisfy functionInput/output for user-computer interactionNon-linear opticsLiquid-crystal displayEngineering

A touch sensor type liquid crystal display is disclosed to provide a touch sensor type liquid crystal display which can endure long-time use while achieving a weight reduction. The touch sensor type liquid crystal display includes: a liquid crystal display panel 2 having an array substrate 14 and a color filter substrate 13, which are arranged oppositely to each other by interpolating a liquid crystal layer 18; and a touch sensor panel 3 having a movable electrode plate 4 and a fixed electrode plate 5, which are arranged oppositely to each other by a specified gap. These panels 2 and 3 are laminated together. A gap controlling spacer 19 is fixed in the array substrate 14 to restrict a spacer movement in a planar direction.

Owner:IBM CORP

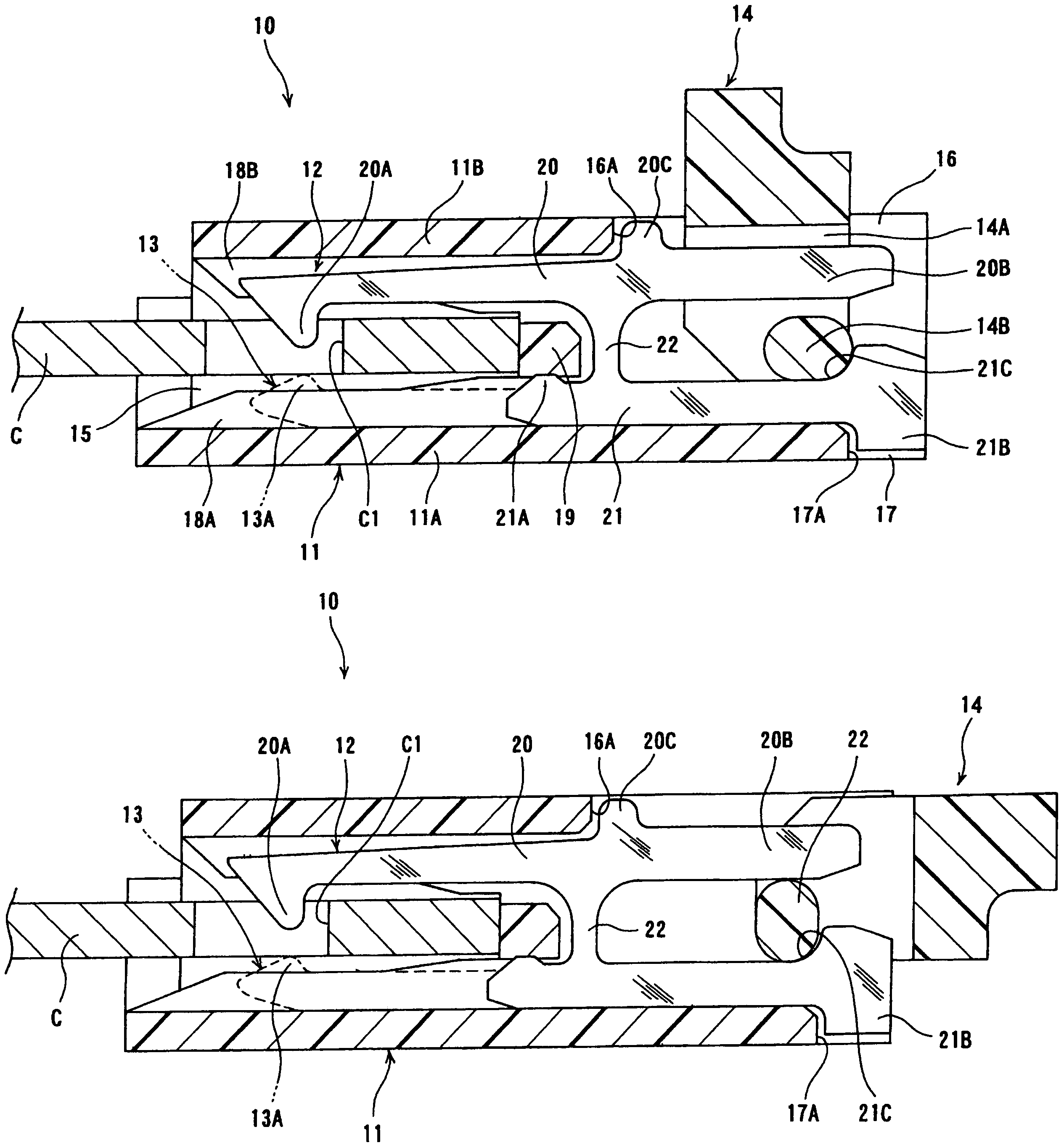

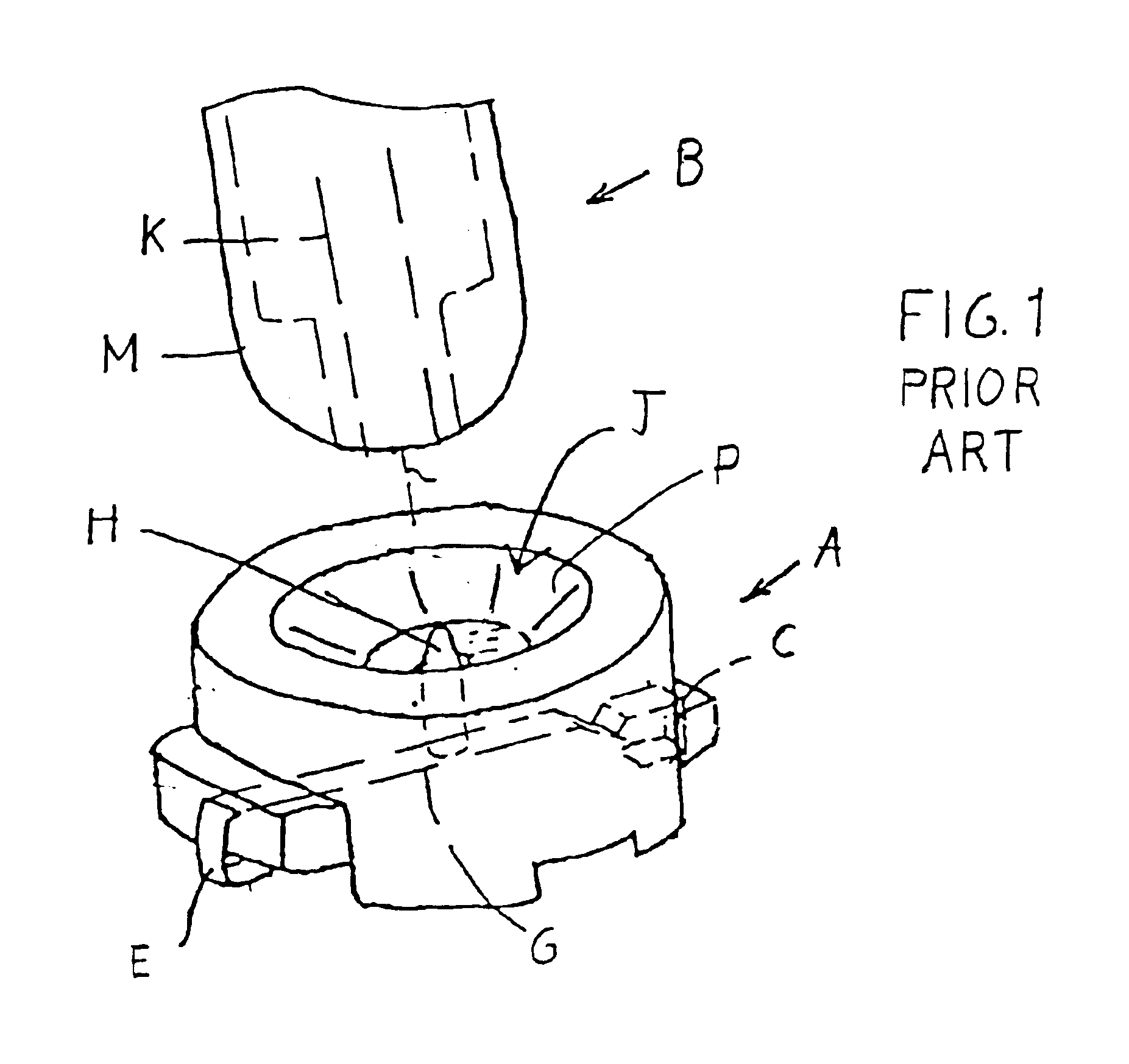

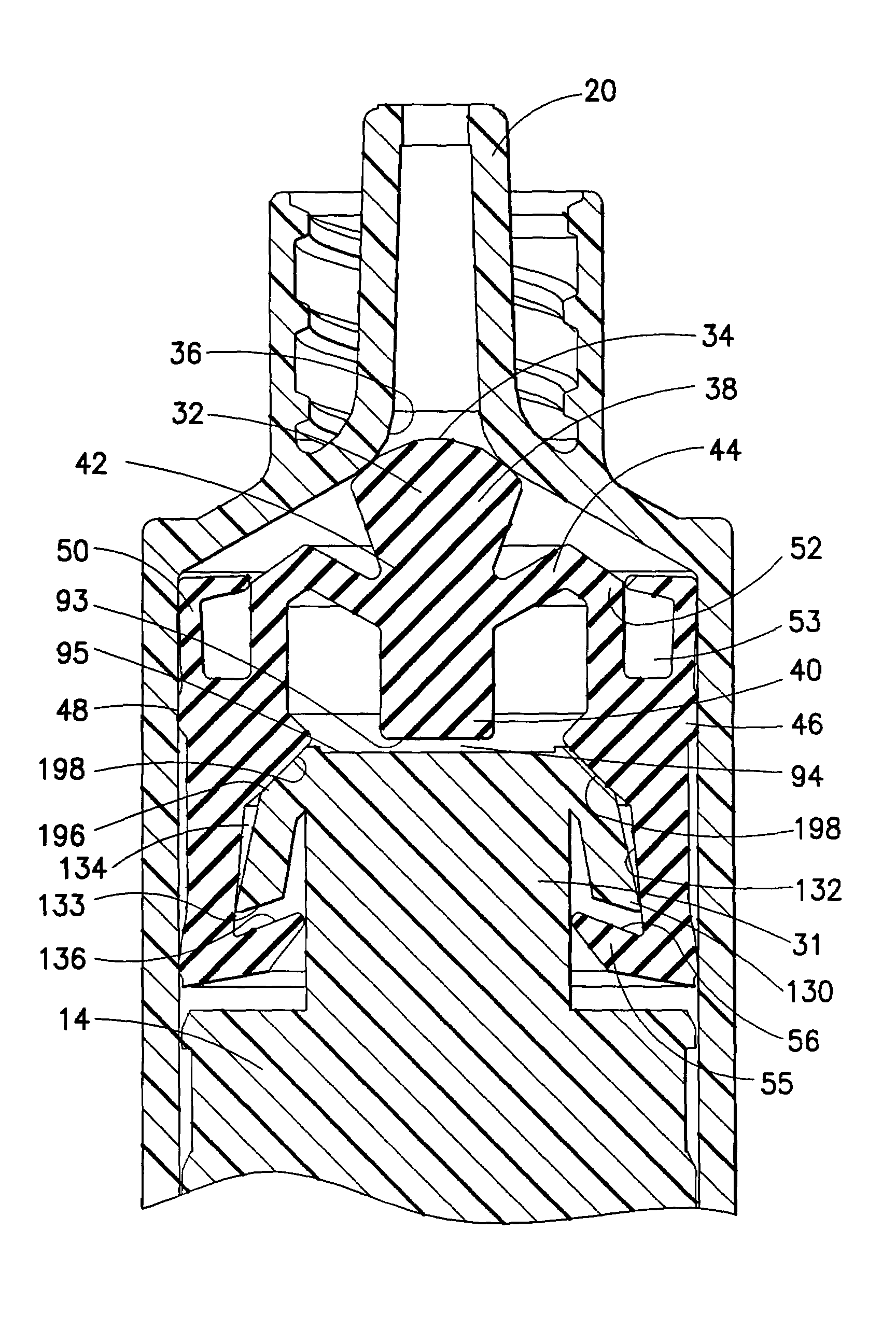

Dynamic contact assessment for electrode catheters

ActiveUS8679109B2Increase contact pressureReduce contact pressureSurgical instrument detailsDiagnostic recording/measuringElectricityOutput device

An electrode catheter and a method for assessing catheter-tissue contact for tissue ablation are disclosed. An exemplary electrode catheter comprises a flexible catheter shaft. At least one piezoelectric sensor is oriented coaxial to the flexible catheter shaft. The at least one piezoelectric sensor is responsive to movement of the flexible catheter shaft by generating electrical signals corresponding to the amount of movement. The system may also include an output device electrically connected to the at least one piezoelectric sensor. The output device receives the electrical signals for dynamically assessing a level of contact between the flexible catheter shaft and a moving tissue. In another exemplary embodiment, the system may be implemented in a hydrodynamic environment.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

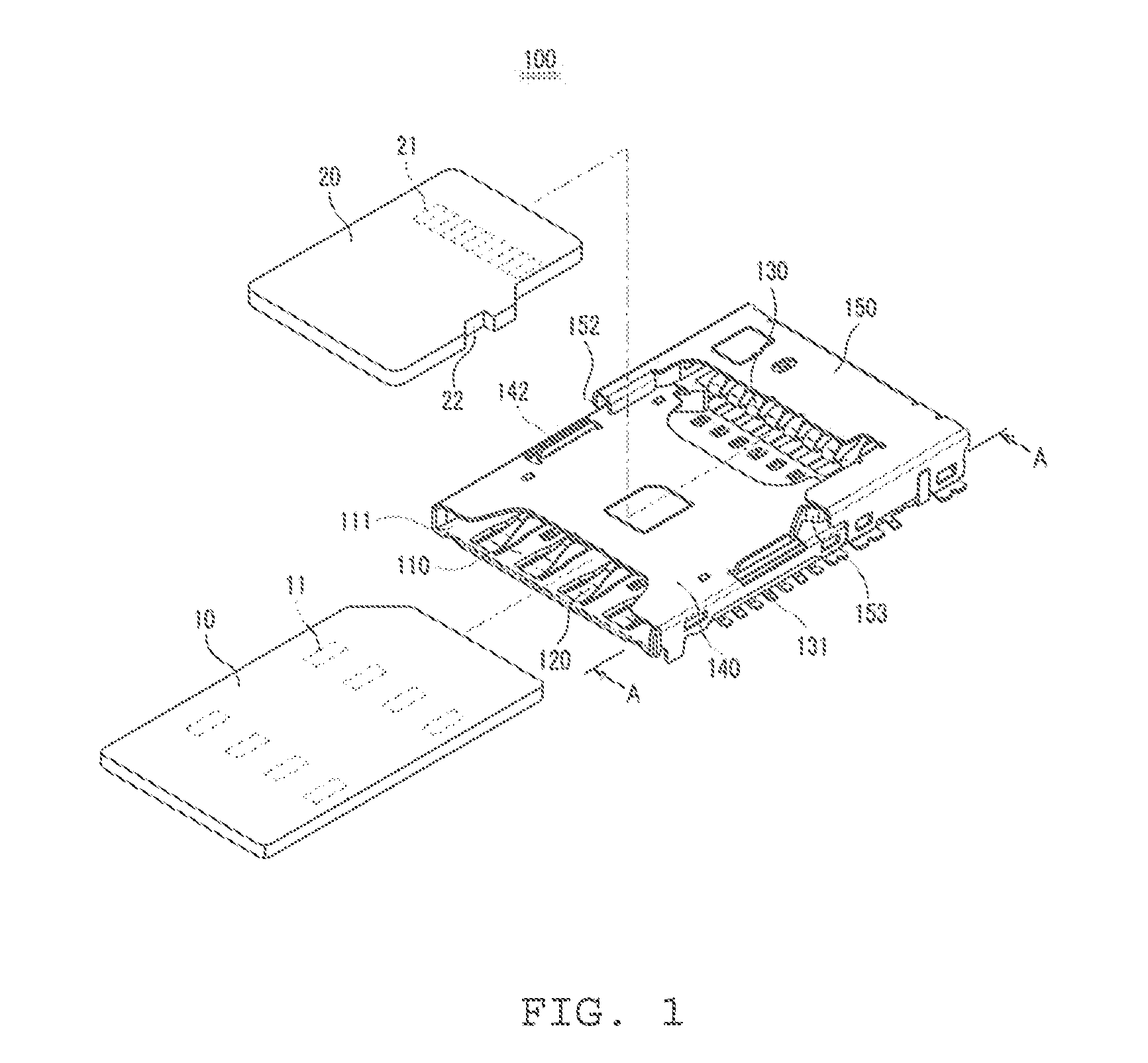

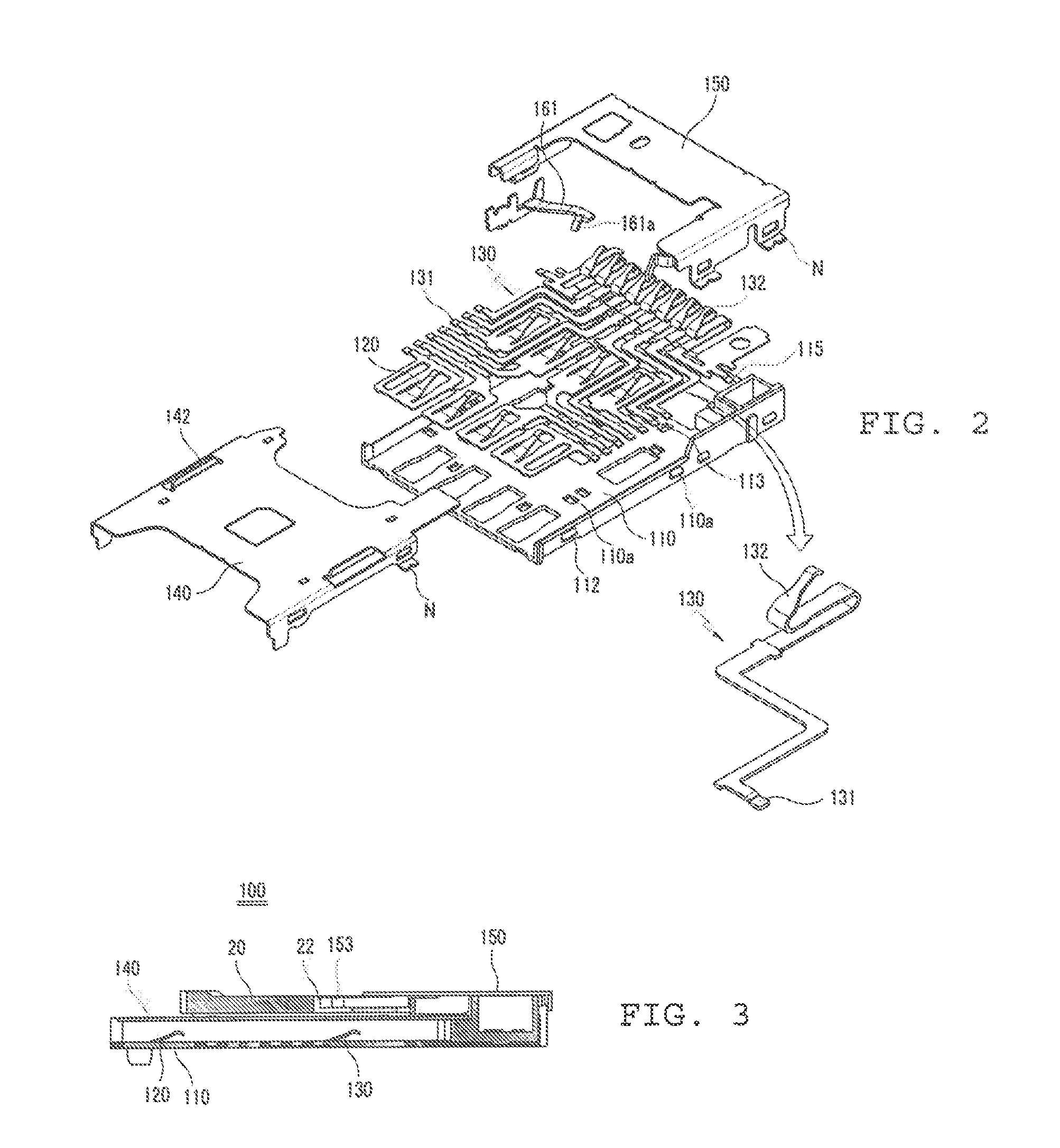

Dual memory card socket

ActiveUS20130288535A1Prevent saggingReduce manufacturing costCoupling device detailsTwo-part coupling devicesEngineeringMemory cards

The Present Disclosure relates to mold a micro SIM card connecting terminal and a micro SD card connecting terminal by means of an integrated terminal mold, so as to significantly reduce the whole length of the dual memory card socket and manufacturing method thereof. The Present Disclosure is formed by a structure manufactured by molding the micro SIM card connecting terminal and the micro SD card connecting terminal by means of an integrated terminal mold, and then separating them by a cutting process.

Owner:MOLEX INC

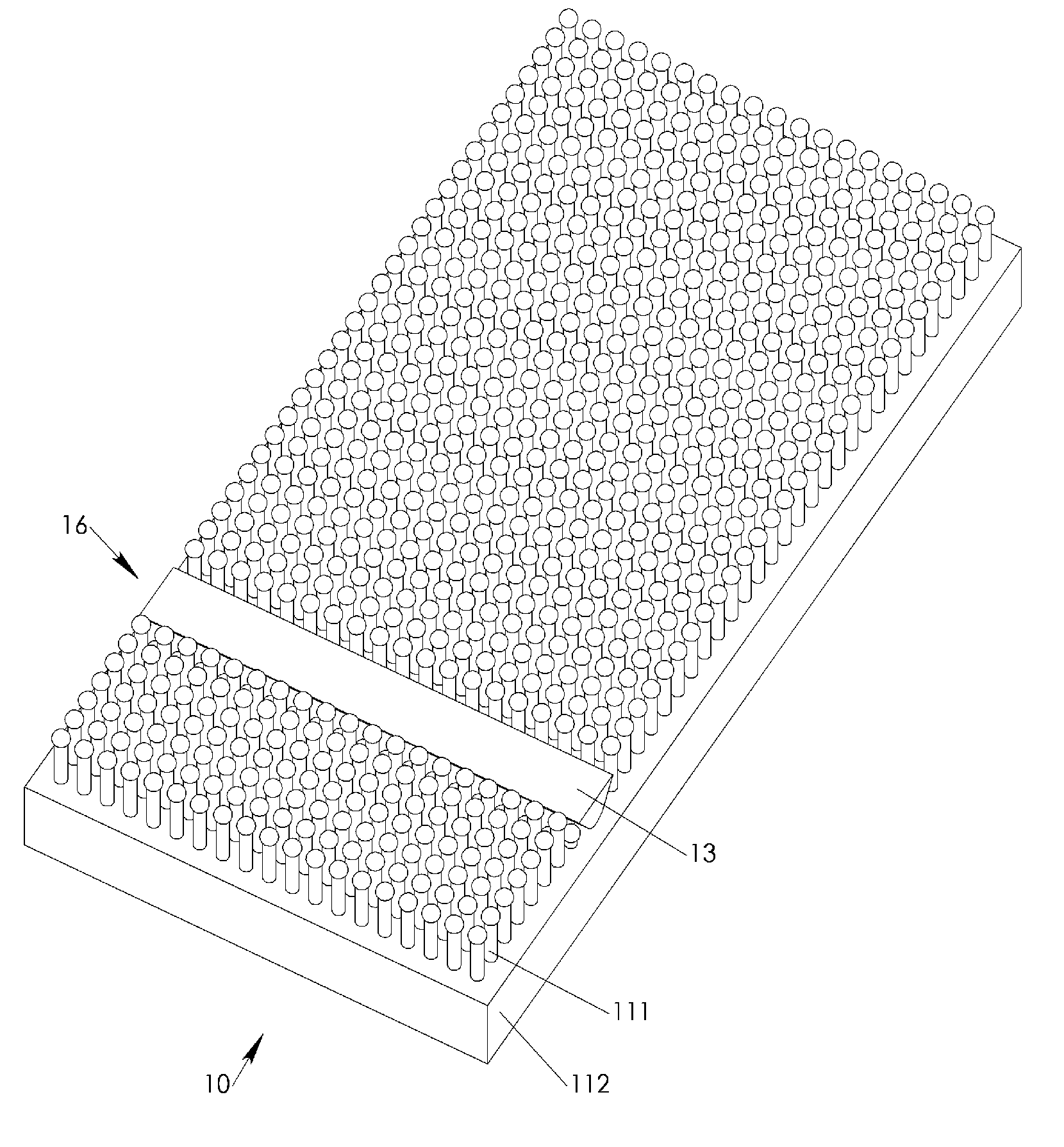

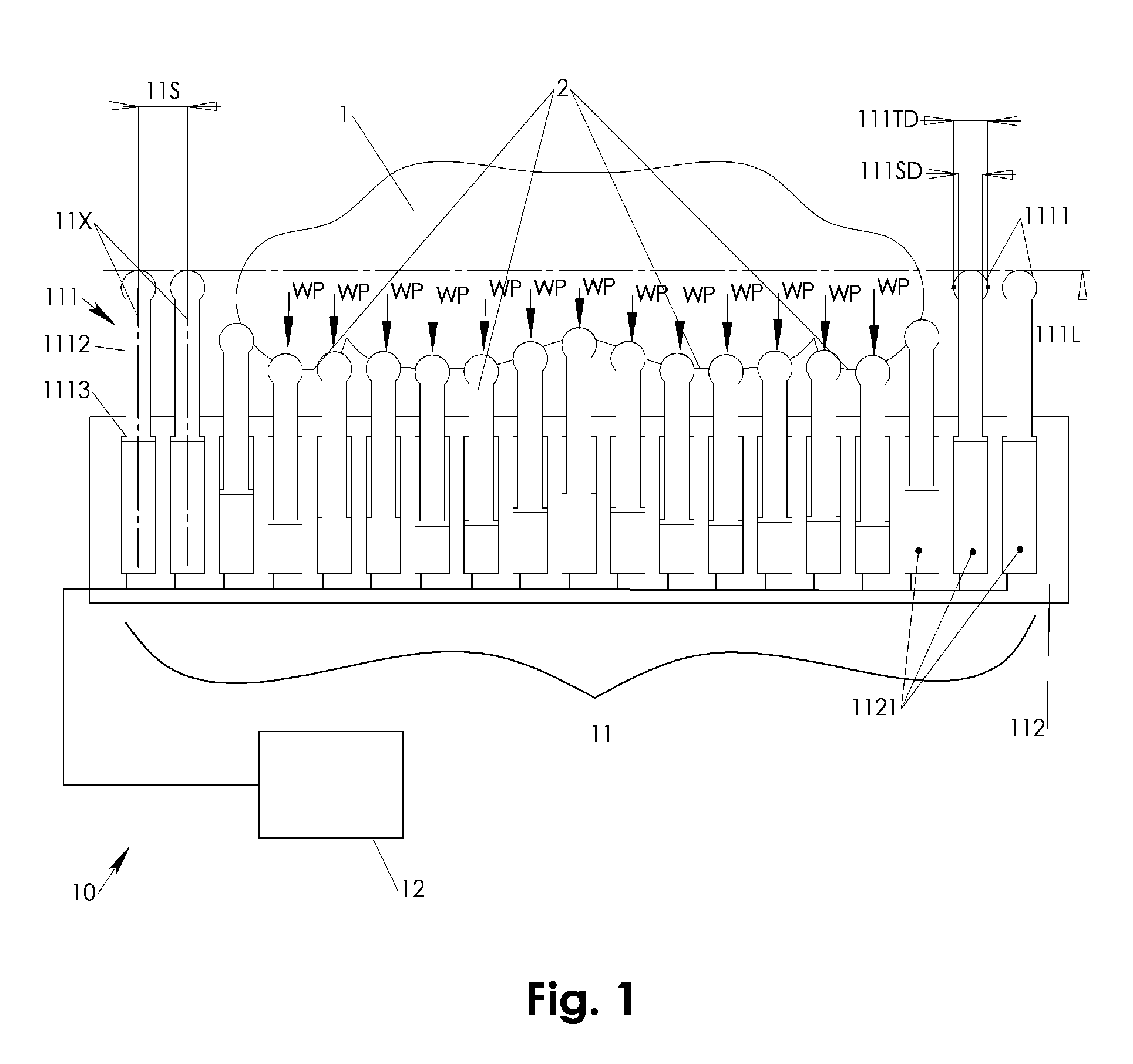

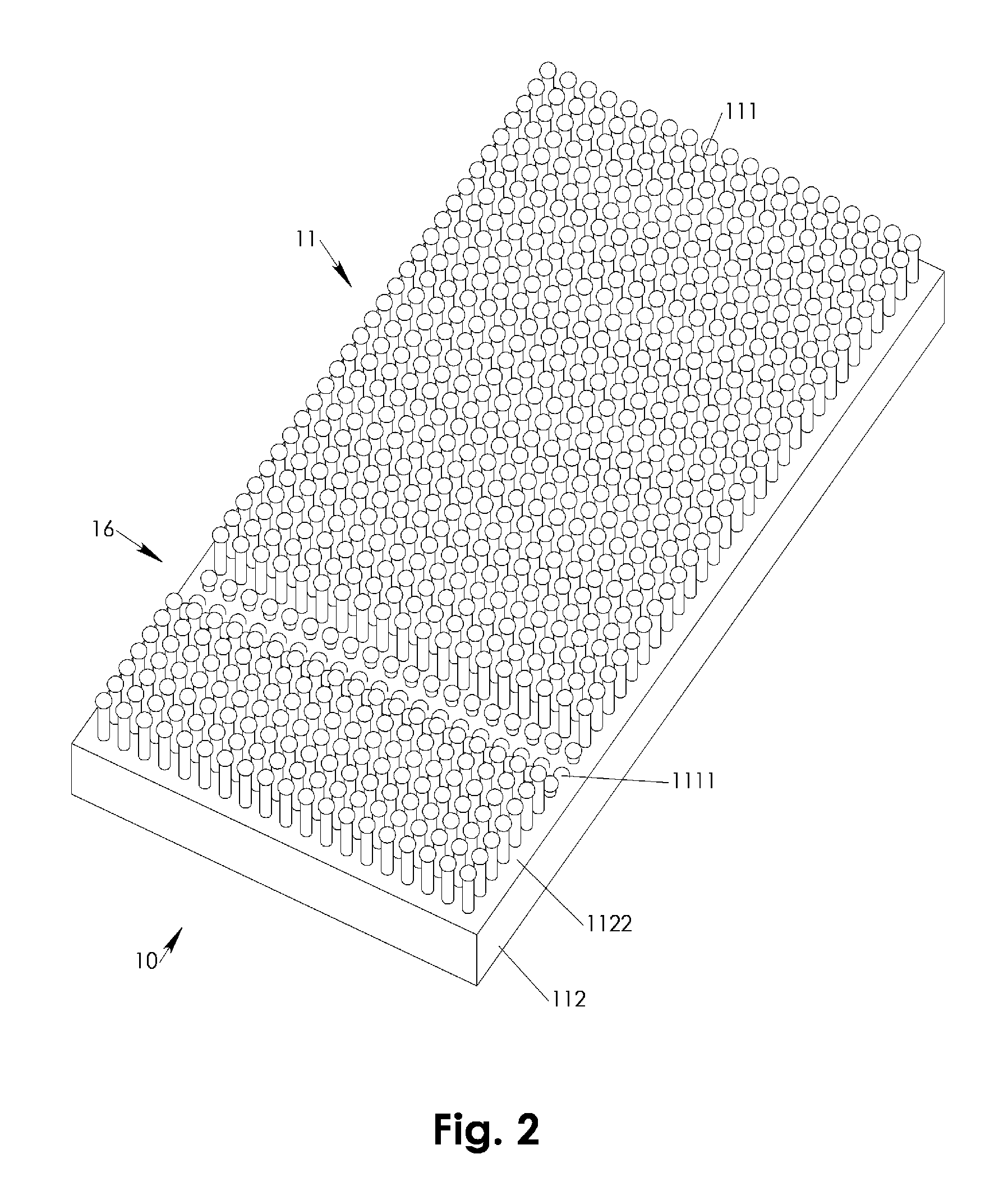

Patient bedding system with dense matrix or individually suspended directly body supporting pins

InactiveUS7520011B1Eliminated pressure peakReduce weighing pressureSpring mattressesSofasContact pressureControl system

A support pin matrix features a number of support pins densely two dimensionally arrayed and individually springily suspended such that a patient's body or body portions may be bedded directly on the support pins. The pins are preferably pressurized by a fluid pressure system for highly balanced contact pressure irrespective the individual pins' load deflection. A control system may provide a pin retraction wave of the support pins. A body resting surface accessing device may be moved across the support pin matrix and beneath a bedded patient in conjunction with the pin retraction wave. The resting surface accessing device may be configured for cleaning, drying, inspecting, irradiating, and / or massaging the body resting surface and / or for maintaining the body support pin matrix. A body carrying net may be retracted and raised in between the body support pins to lift the patient off the support pin matrix.

Owner:LIBERKOWSKI JANUSZ

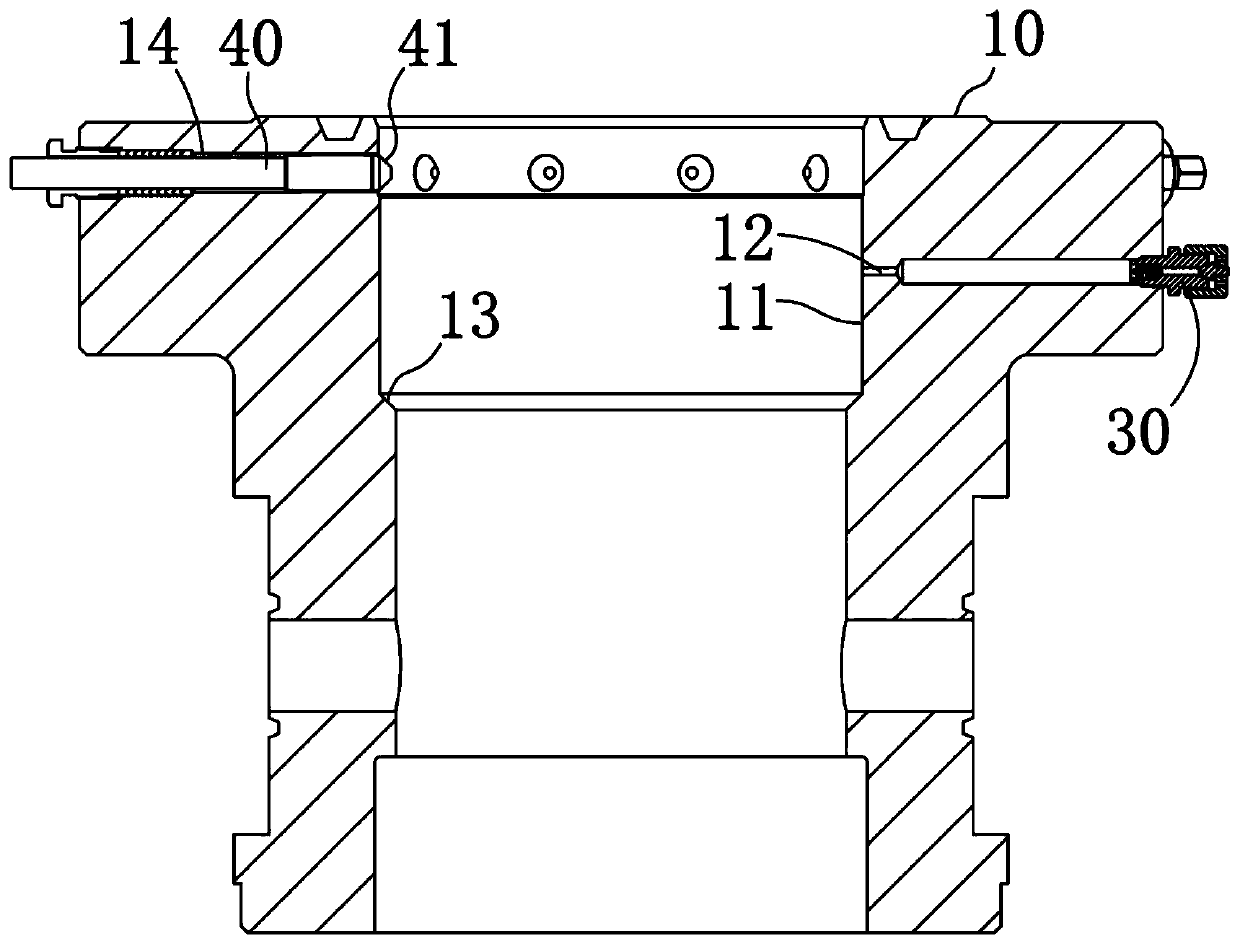

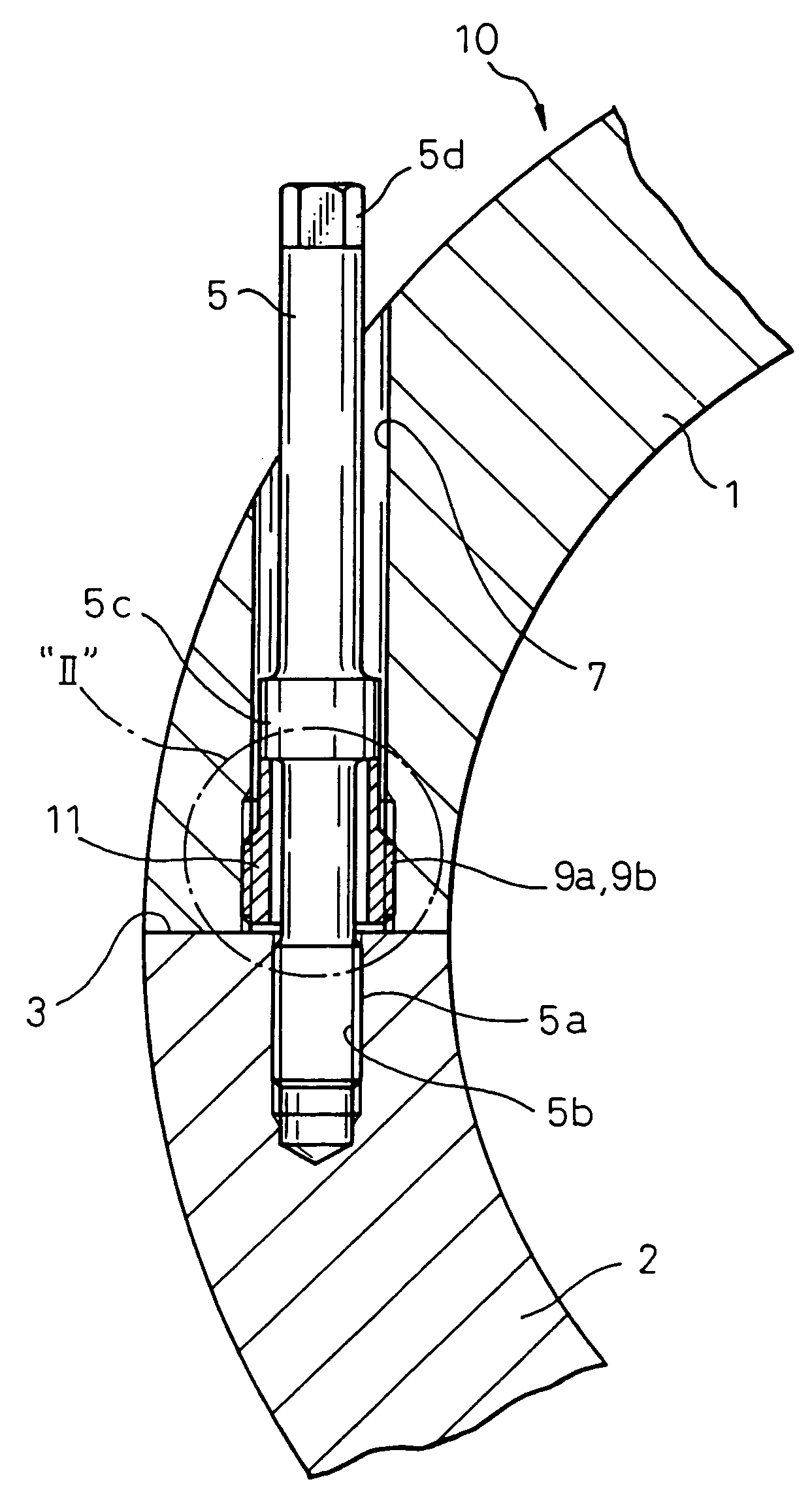

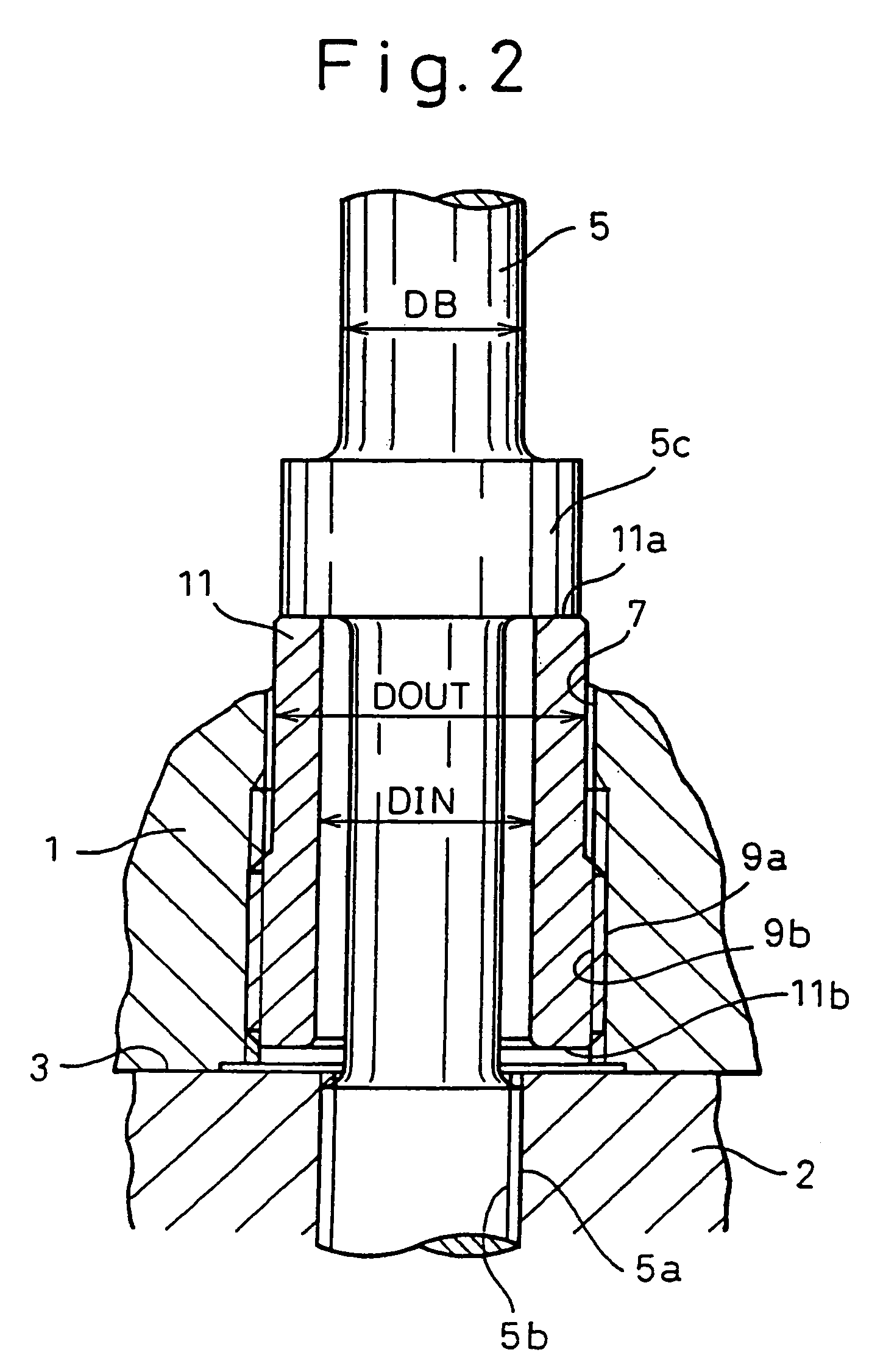

Fastening arrangement for a split casing

InactiveUS7198465B1Increase contact pressureIncrease effective wall thicknessWashersPump componentsGas turbinesEngineering

A casing of a hydraulic machine such as a gas turbine is formed as a horizontally split type flangeless casing. The flangeless casing consists of an upper casing and a lower casing joined together at joint faces and fastened by fastening bolts. The fastening bolt has a screw thread which engages the threaded hole on the joint face of the lower casing. A bolt hole having an internal screw thread and through which the fastening bolt passes is provided in the upper casing. A sleeve having an external screw thread is fitted into the bolt hole of the upper casing by engaging the external screw of the sleeve with the internal sleeve of the bolt hole. An enlarged diameter portion is formed on a shaft of the fastening bolt at the portion where the enlarged diameter portion abuts an upper end face of the sleeve when the fastening bolt is screwed into the threaded hole in the lower casing. When the fastening bolt is tightened, the shaft tensile force of the bolt is received by the abutment of the enlarged diameter portion and the upper end face of the sleeve and, then, transferred from the sleeve to the upper casing through the engagement of the external screw thread of the sleeve and the internal screw thread of the bolt hole of the upper casing and generates the fastening force which presses the upper casing to the lower casing.

Owner:MITSUBISHI HEAVY IND LTD

Non-involute gears with conformal contact

InactiveUS6837123B2Eliminate high contact pressure peakEasy to adaptPortable liftingGearing elementsInvolute gearTorque transmission

Several embodiments of various non-involute gear tooth profiles incorporate relief areas formed across the area of the tooth face generally symmetrically to each side of the pitch circle of the gear. The relief area serves to preclude contact across the areas of meshing or mating gear teeth where convex-to-convex contact would otherwise occur, thus precluding high pressure contact between the two gear teeth at the area of the relief. The remainder of the contact of such non-involute gear tooth profiles provides conformal contact, i. e., convex-to-concave mating faces with correspondingly low pressures developed between the tooth portions. The present invention enables a given gear set to absorb considerably greater torque and force than would otherwise be they case, or alternatively allows gear sets to be made considerably smaller and lighter for a given torque transmission, than would otherwise be the case.

Owner:HAWKINS RICHARD M

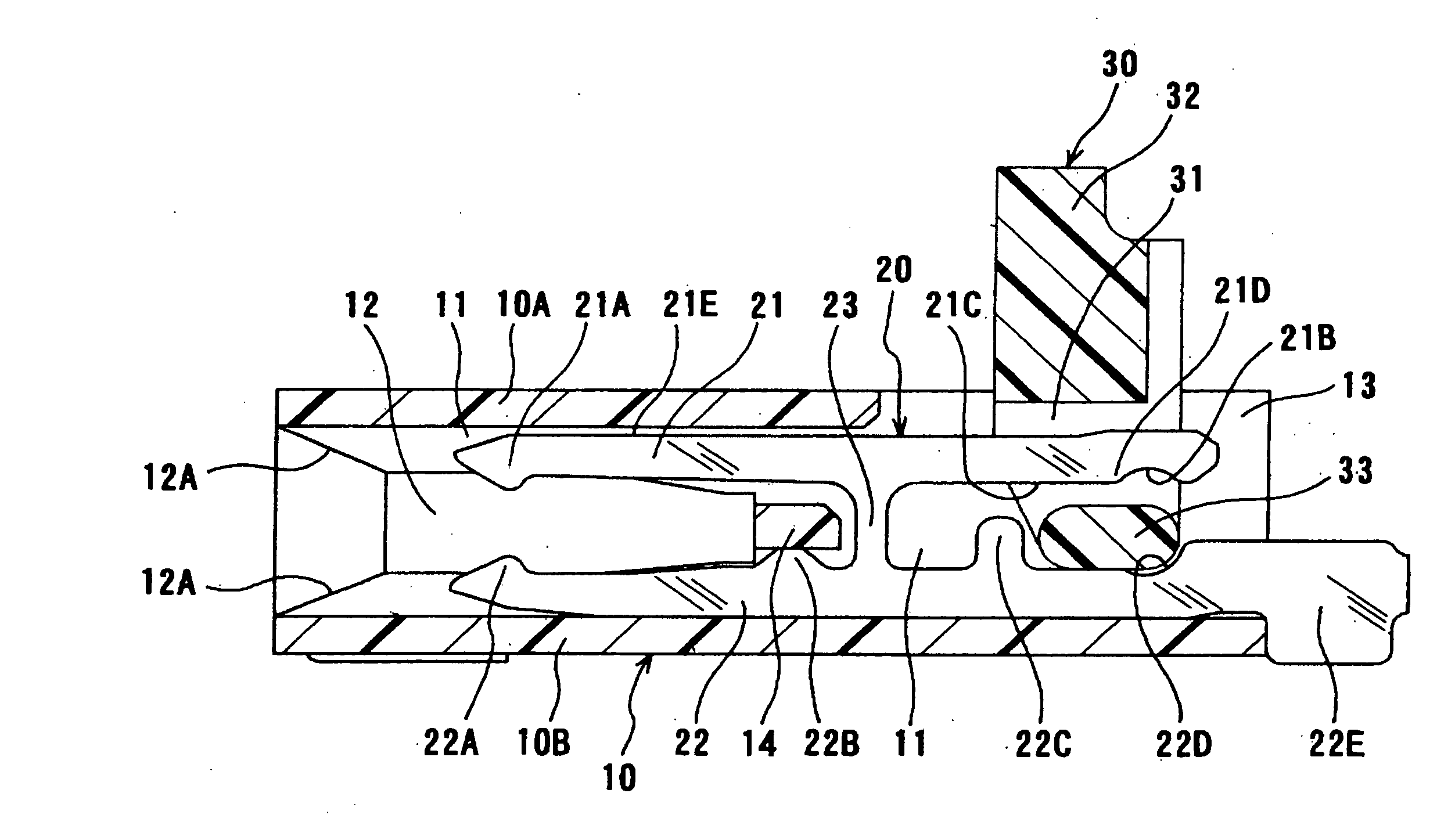

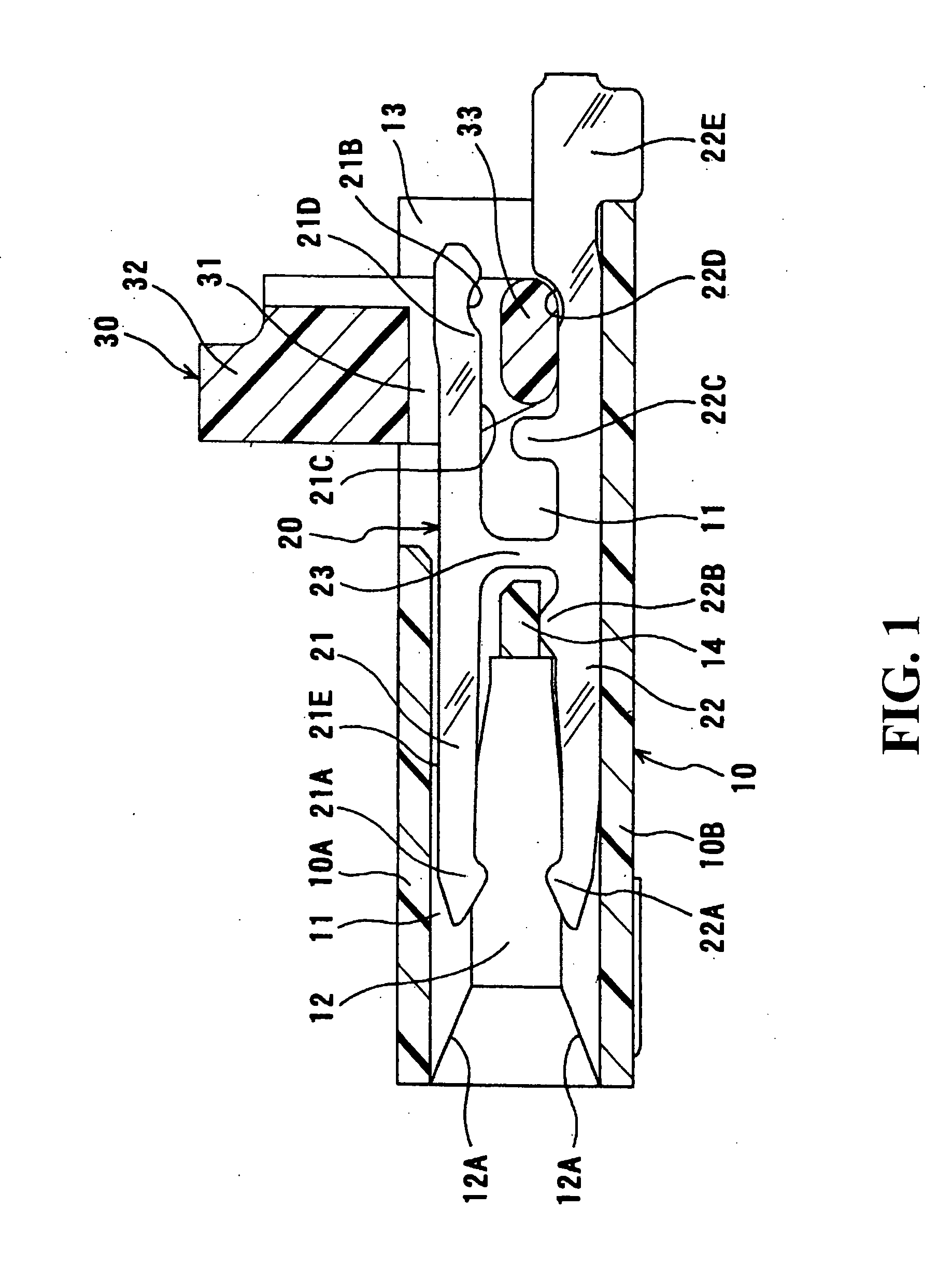

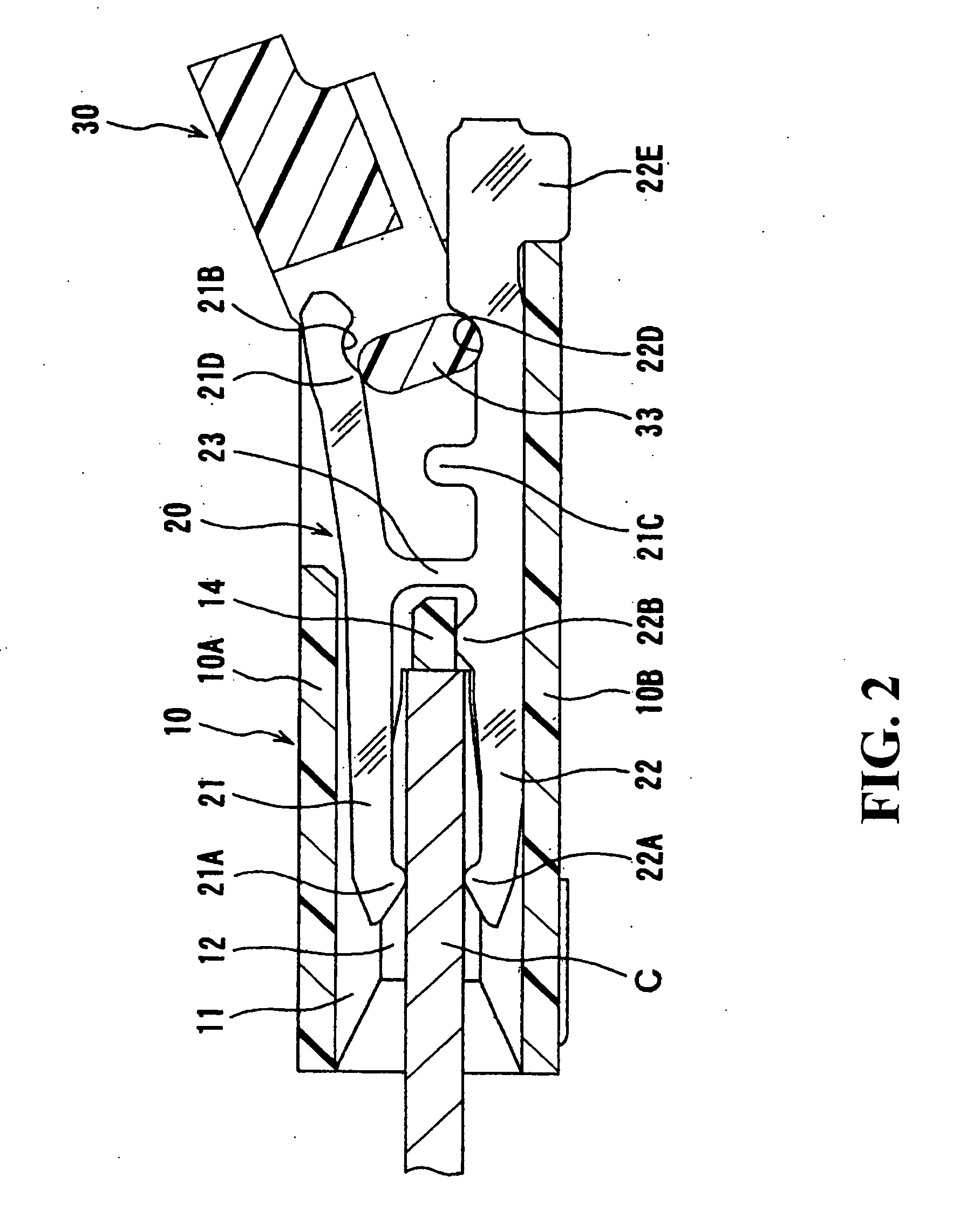

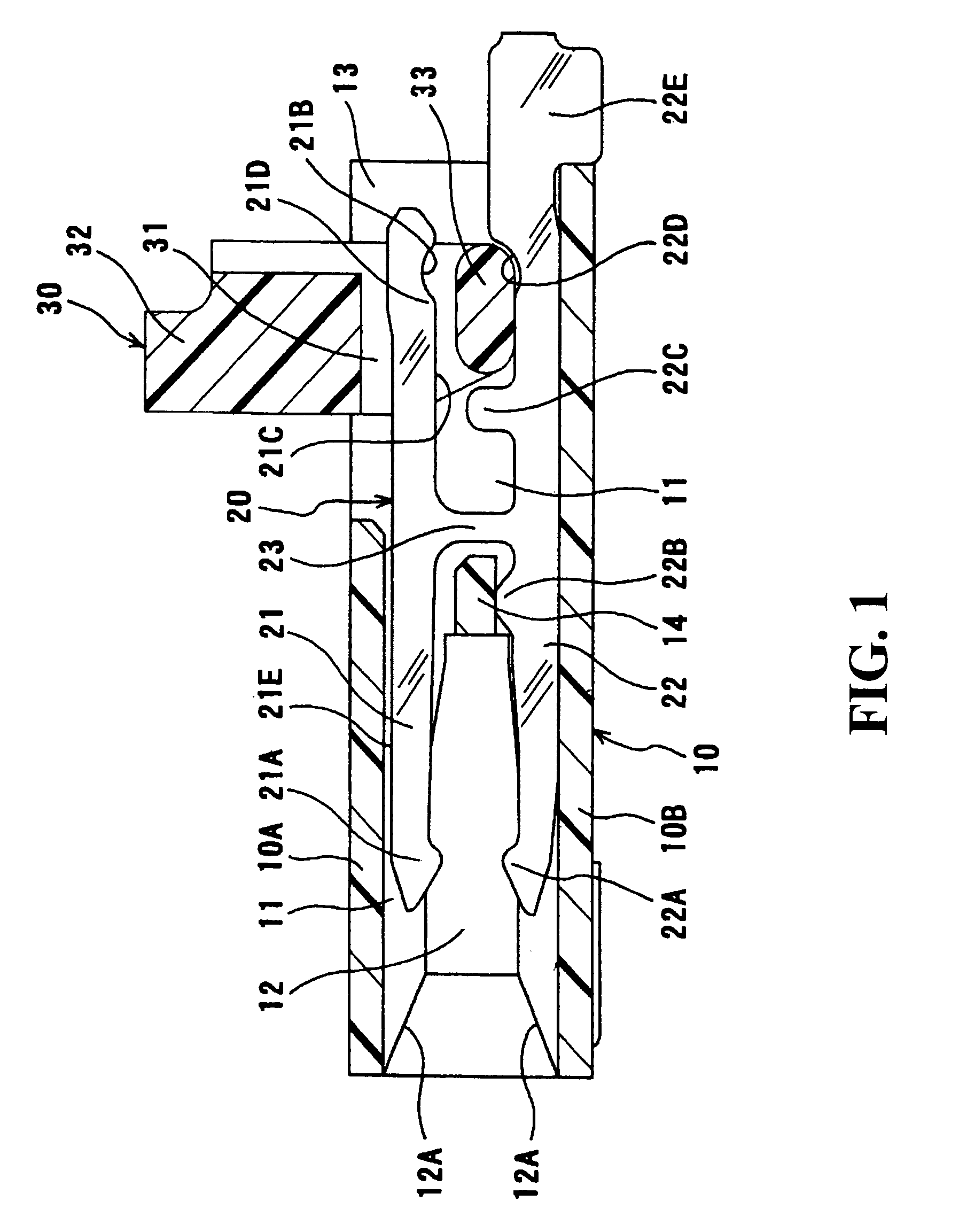

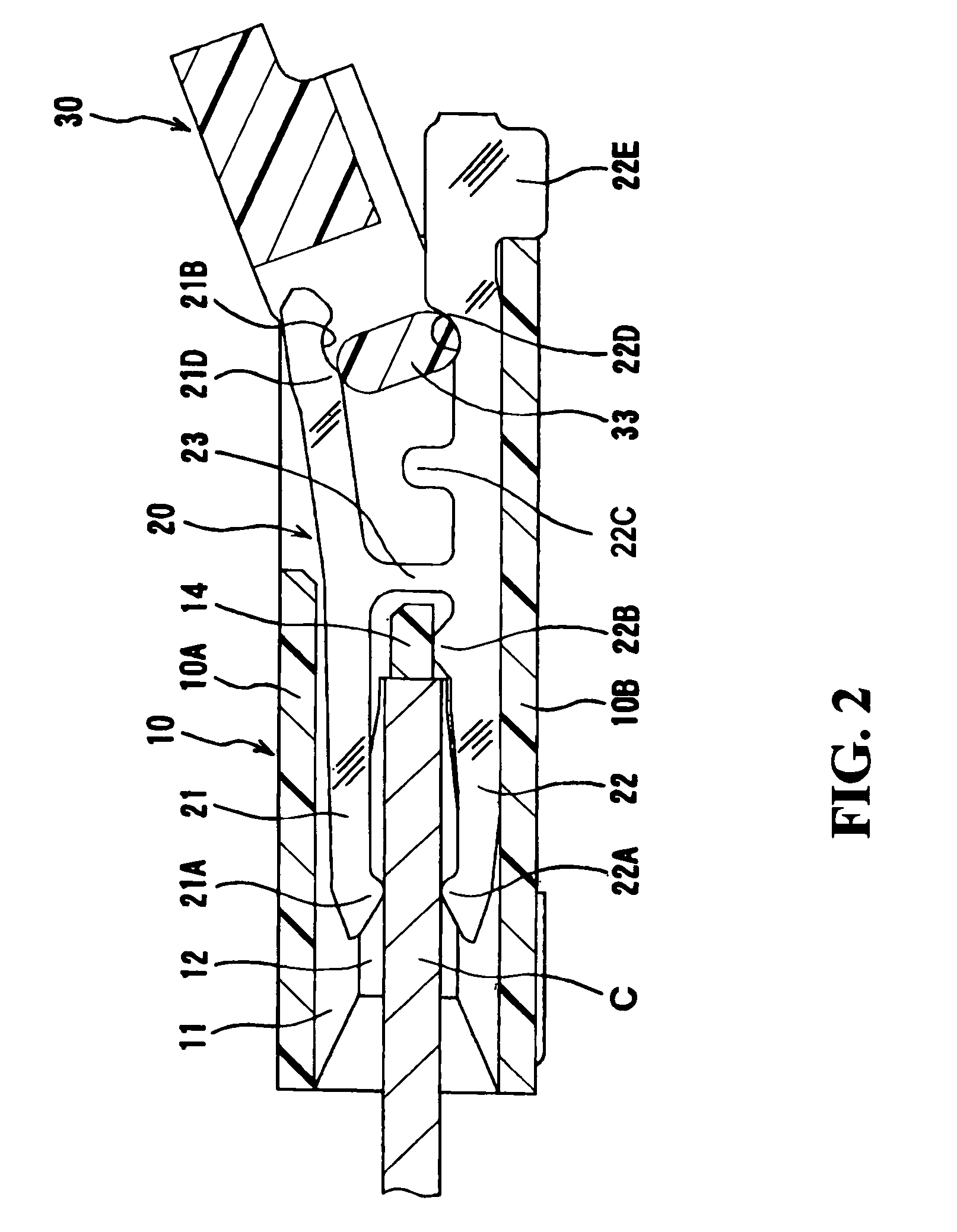

Flat cable electrical connector

ActiveUS20070032115A1Satisfactory click sensationHigh contact pressureEngagement/disengagement of coupling partsCoupling contact membersCamEngineering

When the movable member (30) is at the open position, the cam portion (33) of the movable member (30) is out of contact with the pressure receiving portion of a lever arm (21), making it possible to insert a flat cable into the connector on the contact side. When the movable member (30) is at the closed position, the cam portion (33) comes into contact with the pressure receiving portion that consists of a shoulder (21D) and a concave indentation (21B). While the movable member (30) is moving to the closed position, the cam portion (33) pushes the shoulder (21D) to provide the pressure receiving portion with the highest pressure. When the movable member (30) reaches the closed position, the cam portion (33) rests in the concave indentation (21B) while maintaining a pressure less than the highest pressure.

Owner:HIROSE ELECTRIC GROUP

Terminal fitting and a connector using such a terminal fitting

InactiveUS7156704B2Avoid displacementPrevent excessive deformationCoupling contact membersElectric connection basesEngineeringElectrical and Electronics engineering

Owner:SUMITOMO WIRING SYST LTD

Electrical connector for a flat-type cable

InactiveUS7255584B2Increase contact pressureAvoid displacementEngagement/disengagement of coupling partsCoupling contact membersElectrical connectorMechanical engineering

The latching metallic piece (12) has a lever-like arm (20) that extends in the direction of receiving the flat-type cable C. The lever-like arm (20) has a latching claw (20A) at one end, a fulcrum section (22) at the middle point, and an extending section at the other end. A pressuring member (14) has a restricting section that does not contact with the extending section (20B) of the latching metallic piece (12) at the open position, and that prevents the displacement of the extending section at the closed position. When the pressuring member is at the open position, the lever-like arm (20) is in the state that it can be freely displaced so as to allow insertion / removal of the flat-type cable. When the pressuring member is at the closed position, the displacement of the lever-like arm relative to the latching section in the direction that increases the latching of the latching claw (20A) is prevented, and the displacement of the lever-like arm in the direction that reduces the latching is prevented.

Owner:HIROSE ELECTRIC GROUP

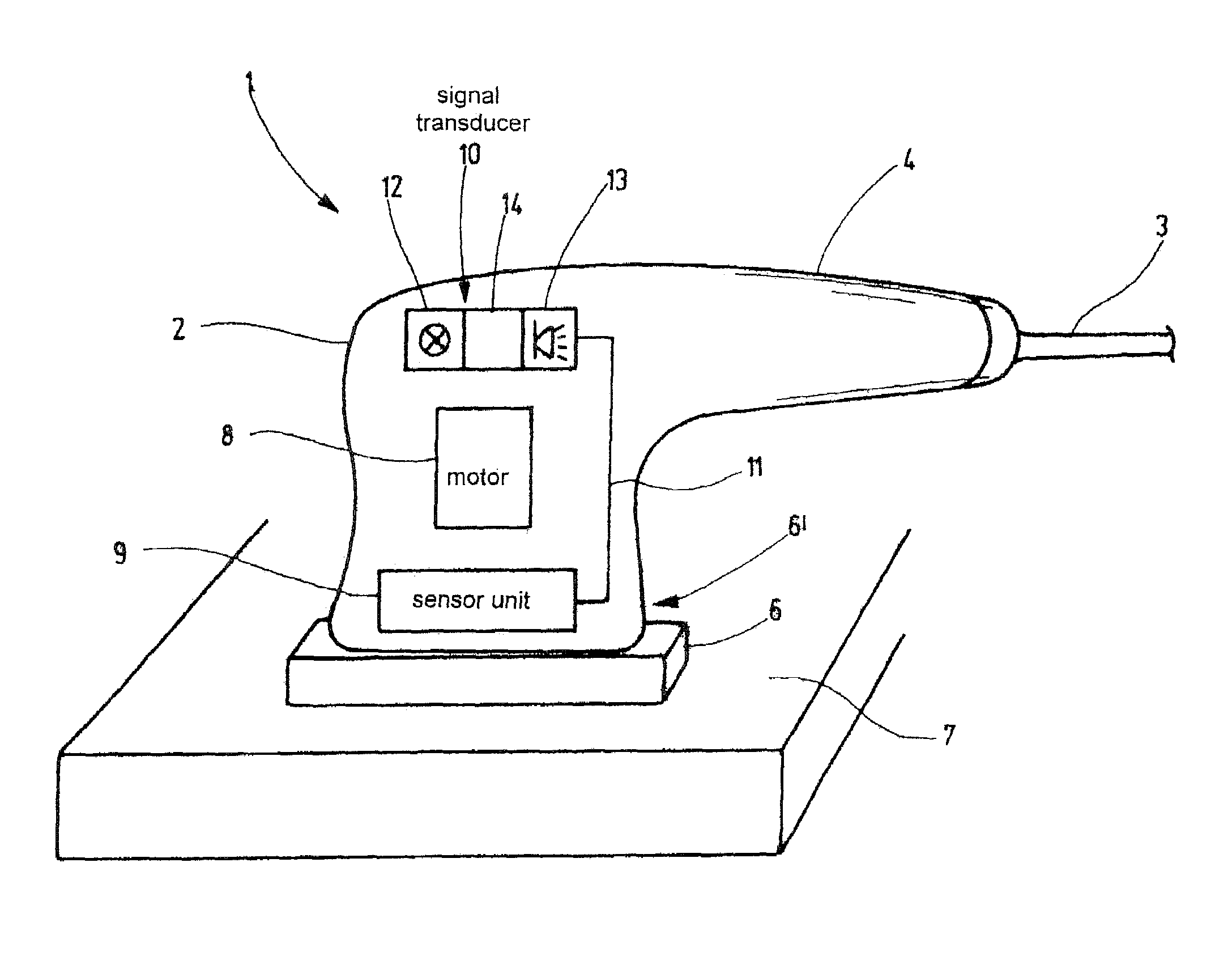

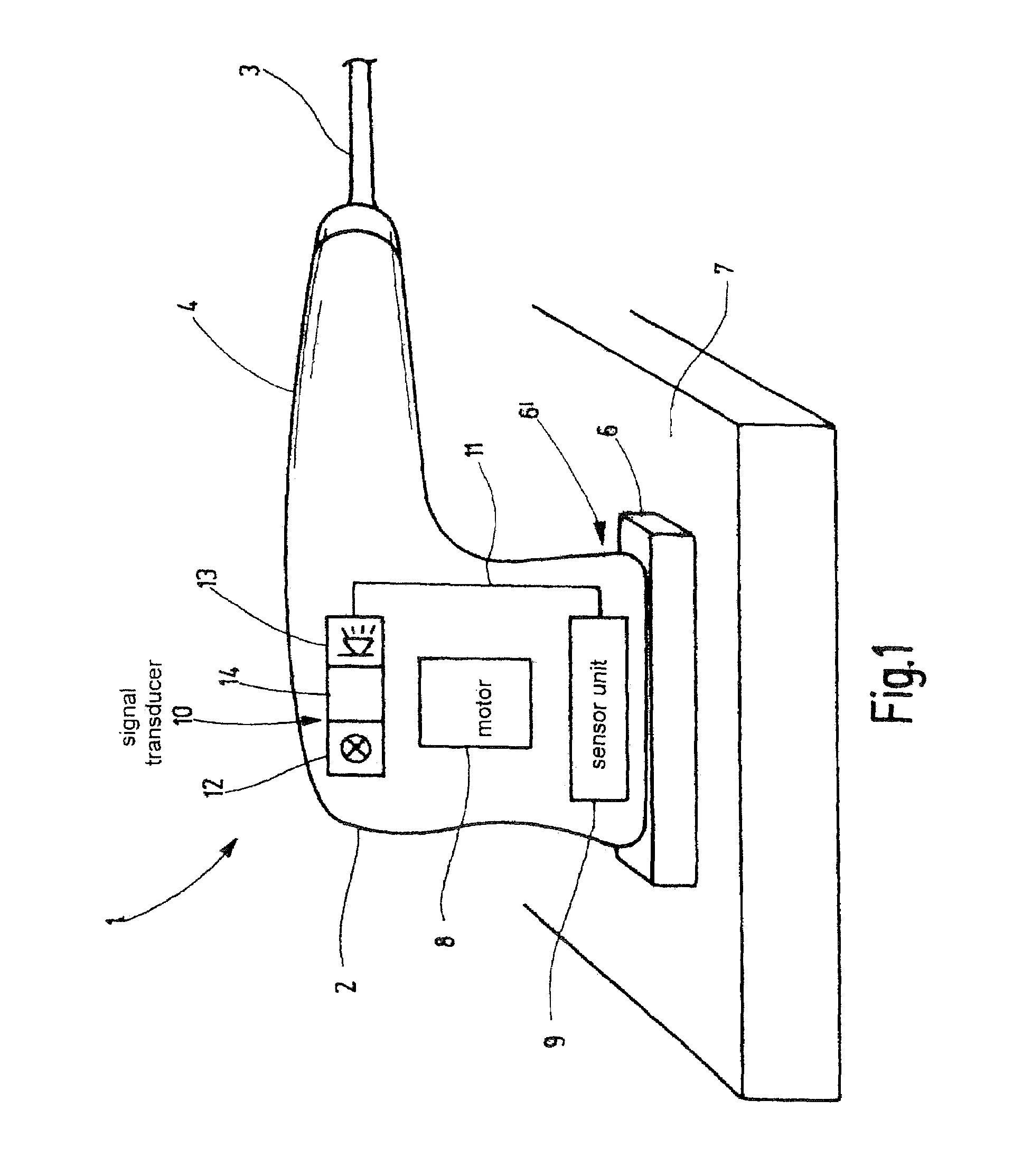

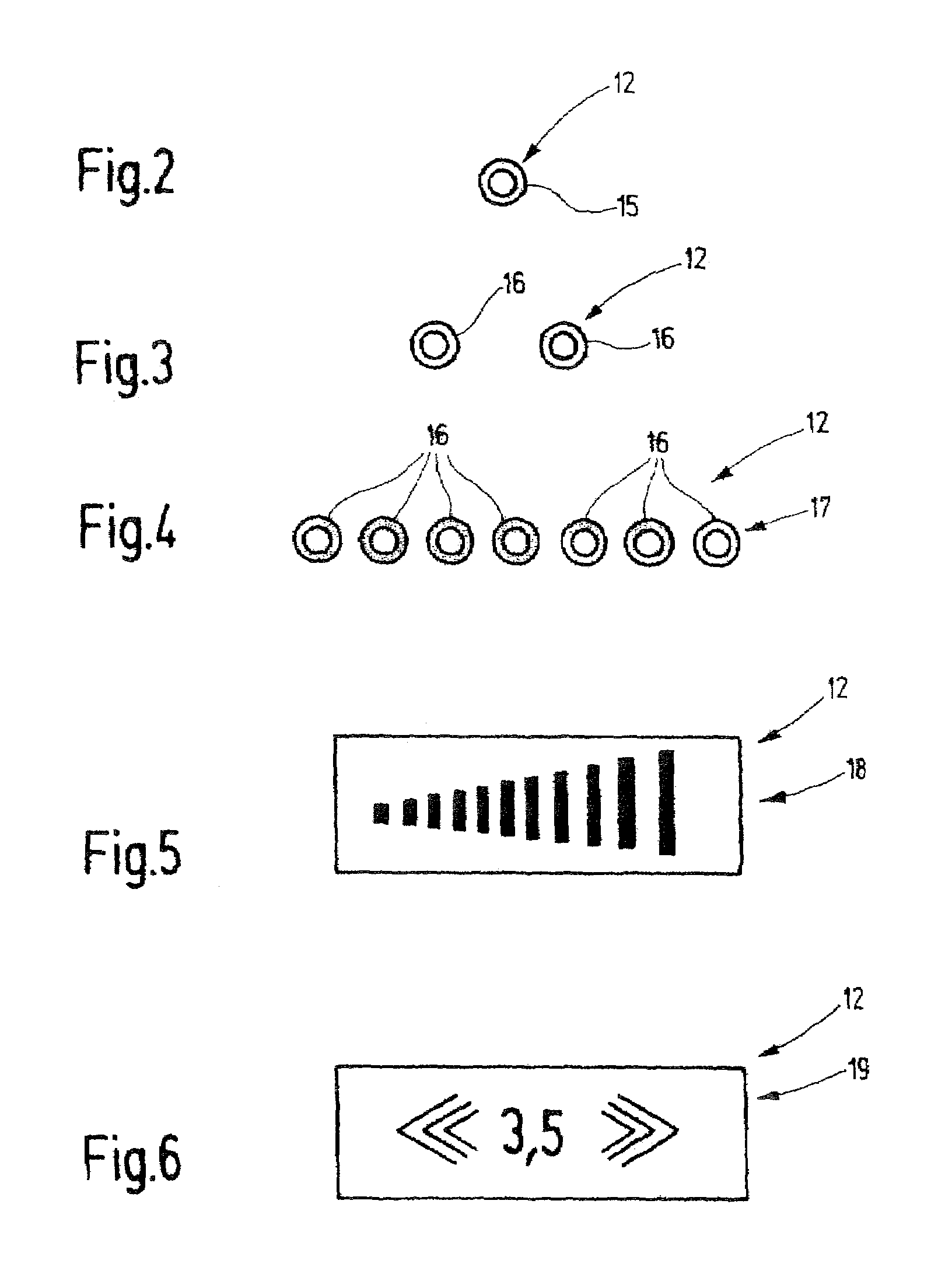

Electric power tool with optimized operating range

InactiveUS7504791B2Address bad outcomesReduce contact pressureDC motor speed/torque controlElectric motor controlContact pressureElectric power system

The invention relates to an electric power tool (1), having an electric motor (8) that serves to drive a tool (6). The electric power tool (1) is characterized in that a sensor unit (9) that detects the contact pressure of the tool (6) against a workpiece (7) cooperates with a signal transducer (10).

Owner:ROBERT BOSCH GMBH

Recessed belt damper

ActiveUS20090000422A1High slip torque and contact pressureSignificant contact pressureRotating vibration suppressionRotary machine partsRotational axisEngineering

A torsional vibration damper includes an inertia mass and a rotating shaft or hub with an elastomeric ring between the inertia mass and the rotating shaft or hub. A large portion of said elastomeric member is located in a channel located either in the inertia mass or in the hub. This allows one to achieve high contact pressure without creating a significant fatigue on the elastomeric member. This can be used with either a crankshaft damper or an internal or external drive shaft damper.

Owner:DAYCO IP HLDG

Connection-switch arrangement

InactiveUS6881082B2Minimize deflectionHigh pressure contactTwo pole connectionsCoupling device detailsShortest distanceShort distance

A connection arrangement includes a first connector (12) with an opening leading to first and second contacts (14, 16), where the first contact includes a beam (40) that is biased upwardly against the second contact but which can be depressed out of engagement with the second contact. The beam is depressed by a plug inner contact (32) of a mating second connector (30) that passes into the opening and depresses the beam, in an arrangement that assures firm engagement of the plug inner contact with the beam despite small beam movement. A stop (70) lying under the beam, limits its downward movement by the plug inner contact. The plug inner contact is spring biased downwardly with respect to the second connector frame (36) but can move up, so the second connector can continue to move down a short distance after the plug inner contact has pushed the beam against the stop, to enable-full engagement of largely coaxial outer contacts (26, 34) of the first and second connectors. The arrangement enables reduced downward movement of the beam while assuring considerable pressure contact between the plug inner contact and beam.

Owner:ITT MFG ENTERPRISES LLC

Flat cable electrical connector

ActiveUS7347720B2Satisfactory click sensationIncrease contact pressureEngagement/disengagement of coupling partsCoupling contact membersElectrical connectorHigh pressure

When the movable member (30) is at the open position, the cam portion (33) of the movable member (30) is out of contact with the pressure receiving portion of a lever arm (21), making it possible to insert a flat cable into the connector on the contact side. When the movable member (30) is at the closed position, the cam portion (33) comes into contact with the pressure receiving portion that consists of a shoulder (21D) and a concave indentation (21B). While the movable member (30) is moving to the closed position, the cam portion (33) pushes the shoulder (21D) to provide the pressure receiving portion with the highest pressure. When the movable member (30) reaches the closed position, the cam portion (33) rests in the concave indentation (21B) while maintaining a pressure less than the highest pressure.

Owner:HIROSE ELECTRIC GROUP

Axial elastic force-applying connection method for electric connector contact pair

InactiveCN101355208AEmission reductionSimple structureCoupling contact membersRelative displacementElectrical resistance and conductance

The invention provides a method for the axial elastic force application connection of electrical connector contact pairs. The method adopts an elastic element to apply axial external force to a contact pair consisting of a contact piece A (1) and a contact piece B (2), so as to combine the two tightly, thereby forming the electric connection with lower conductive resistance. One end of the elastic element is in contact with an insulating base so as to turn into a relative fixed end; and the other end of the elastic element directly acts on a preset fixed end face of an electric conductor contact piece, and is a relative displacement end during axial force application. The contact pair is independently formed by the end planes of the two contact pieces with simple structure. As axial elastic connection can not be affected by shock or other external factors, the connection reliability is higher. The contact pair can be formed by a positive contact piece and a negative contact piece as well, which ensures that the radial and axial directions of the contact pair are uniform in stress and contact.

Owner:徐志

Positive displacement stopper for a pre-filled syringe

ActiveUS8475415B2Prevent leakageEffectively and consistently reducing and eliminating refluxInfusion syringesIntravenous devicesNosePrefilled Syringe

A stopper adapted for attachment with a plunger rod for use within a syringe barrel is disclosed. The stopper includes a main body defining an open rearward end and a closed front end. The open rearward end is adapted to receive a front forward end attachment portion of the plunger rod. The stopper also includes a core member integrally formed with said main body adjacent the closed front end. The core member includes a nose portion having a profile adapted to create a positive seal with an outlet opening of such syringe barrel.

Owner:BECTON DICKINSON & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com