Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1507results about How to "Prevent sagging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

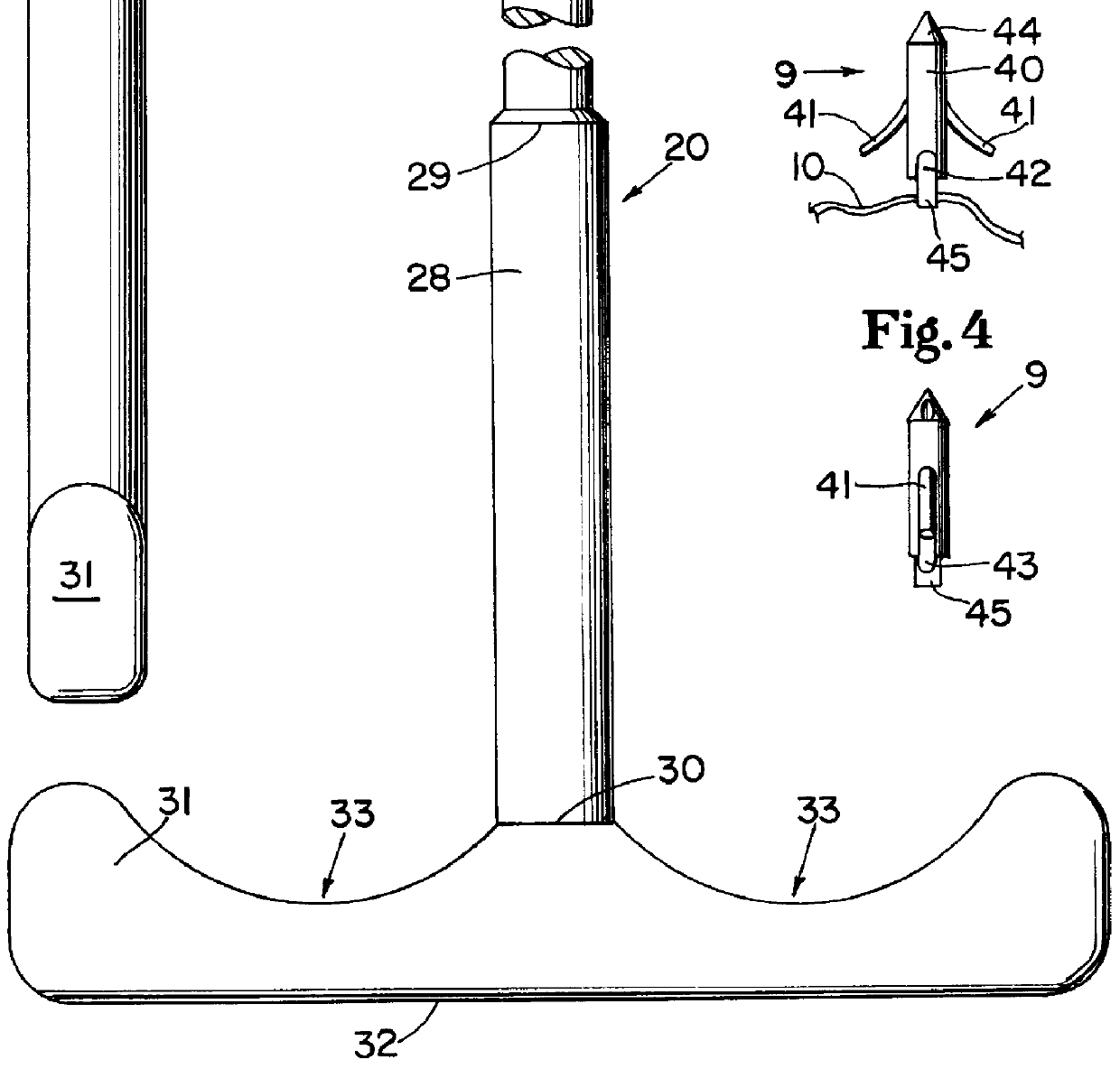

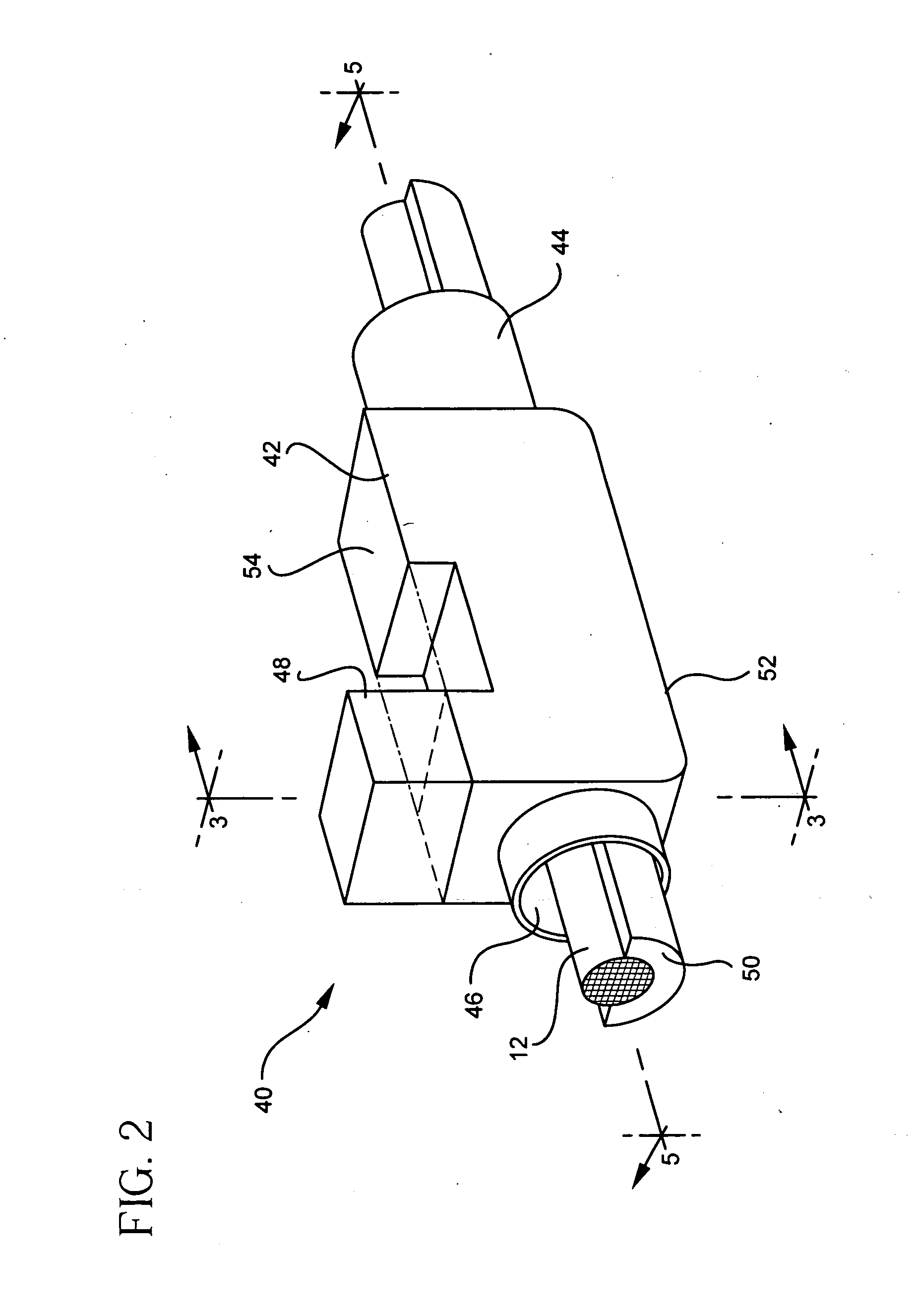

Bone anchor-insertion tool and surgical method employing same

InactiveUS6042583APrevent saggingSufficient pressureSuture equipmentsDiagnosticsEngineeringSurgical template

An anchor-insertion tool for securing an anchor having a suture extending therefrom to a structure within a patient's body is provided. The anchor-insertion tool comprises an elongate shaft having distal and proximal ends, an anchor-receiving tip at the distal end, at least one groove extending from the tip at least partially along the length of the shaft, and at least one depression extending about the circumference of the shaft and intersecting the groove. A loaded anchor-insertion tool is provided, along with a surgical method for employing the anchor-insertion tool. A surgical template and suture retriever are also provided.

Owner:R J & J A FAMILY LLP +1

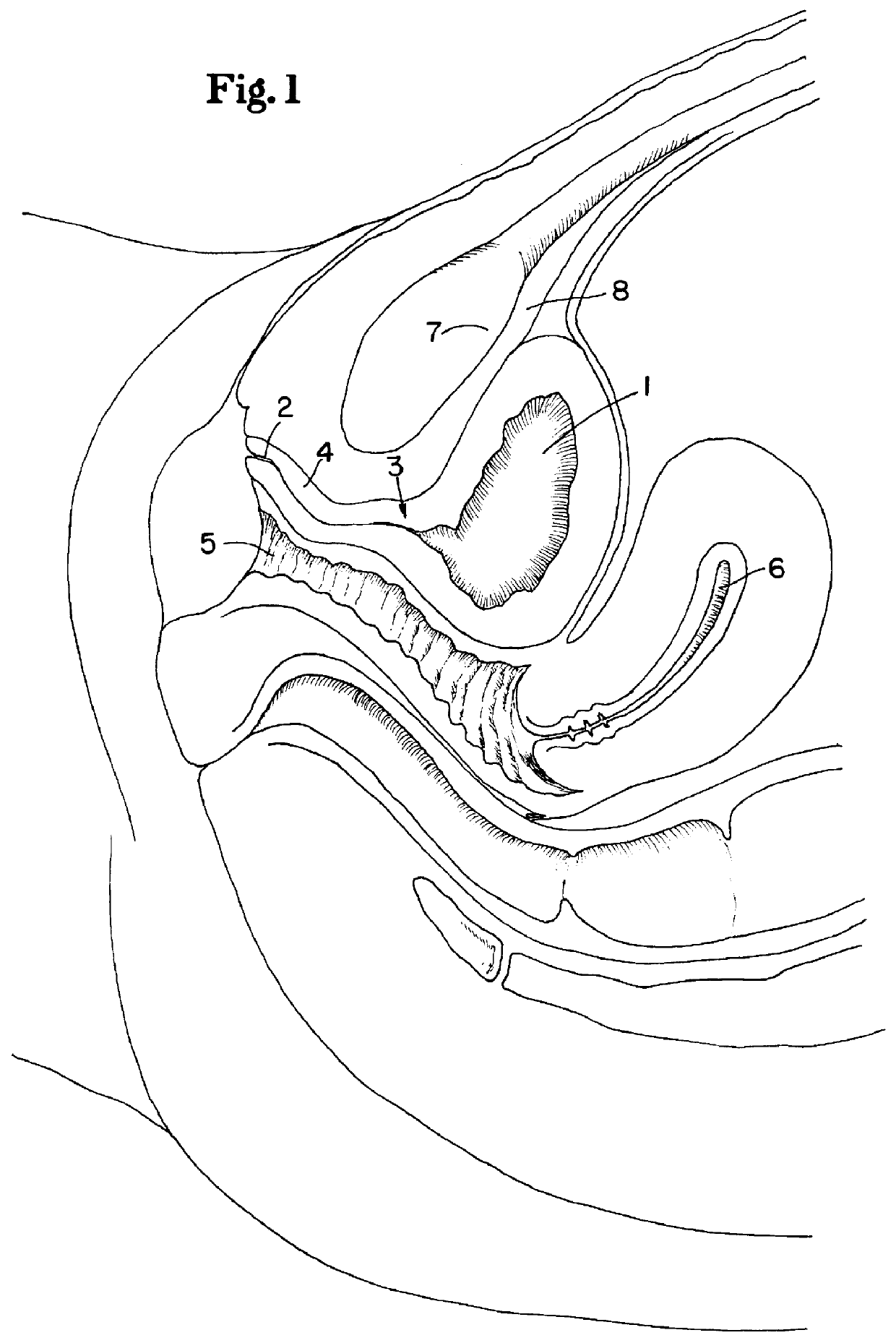

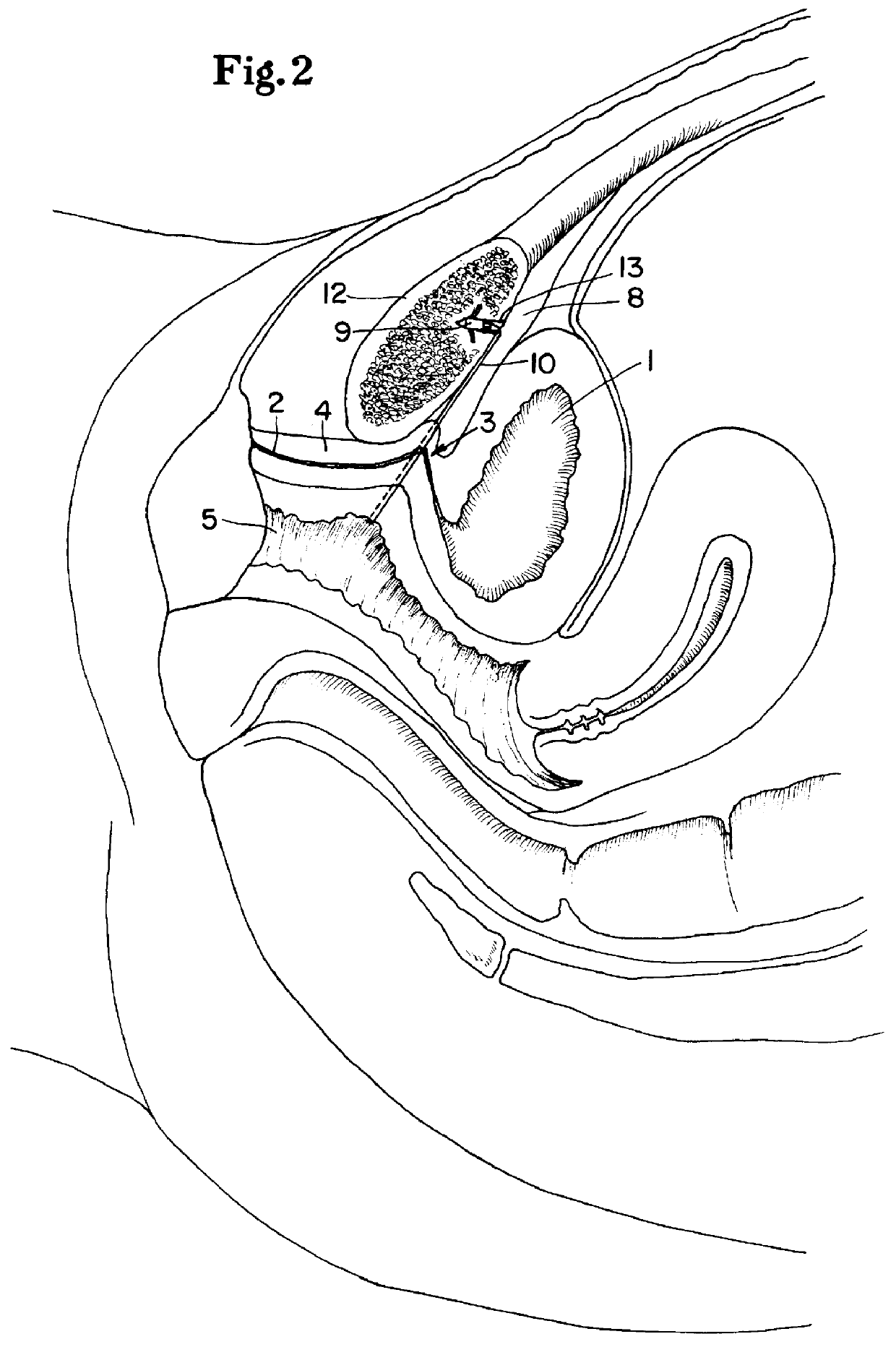

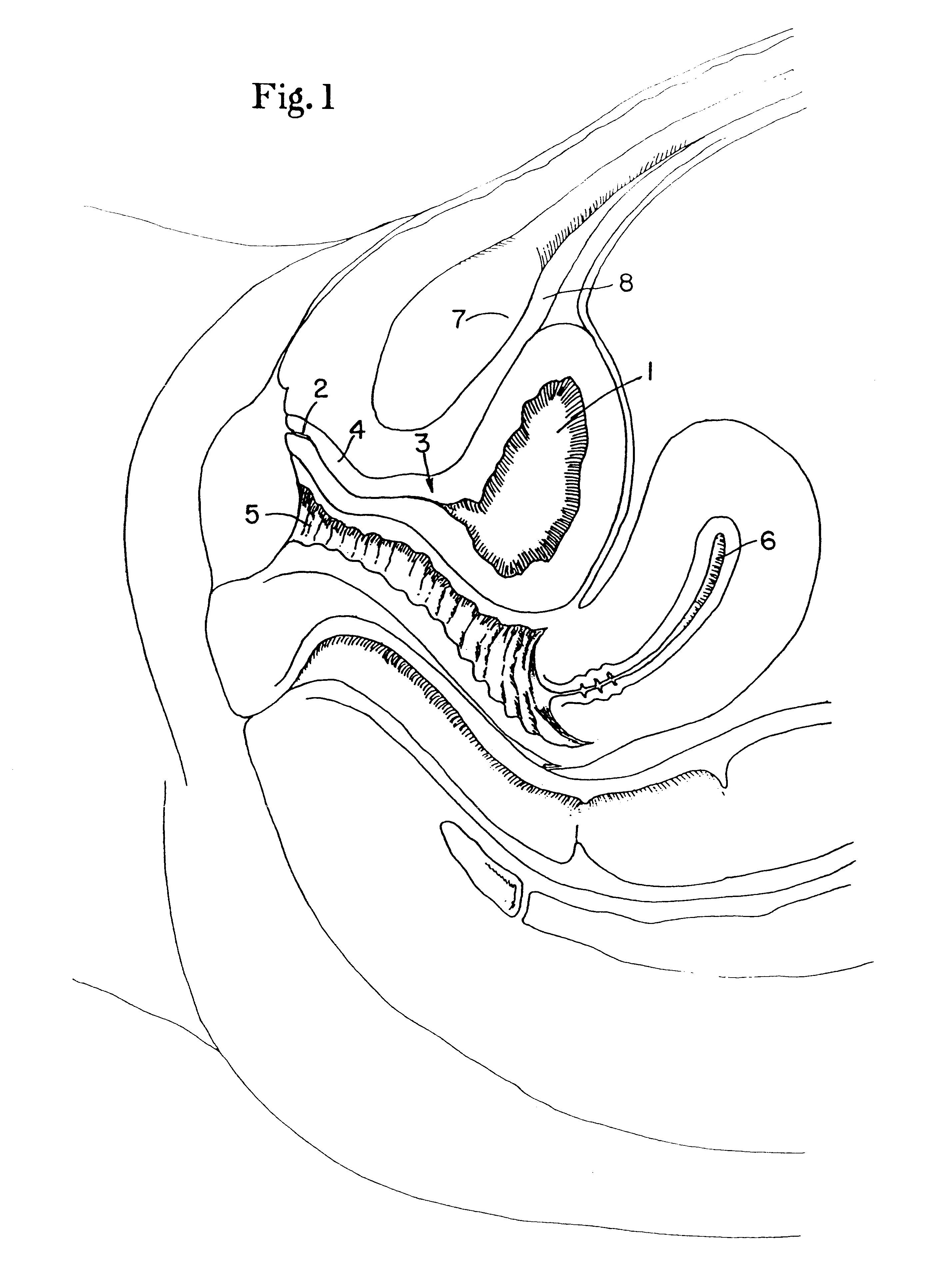

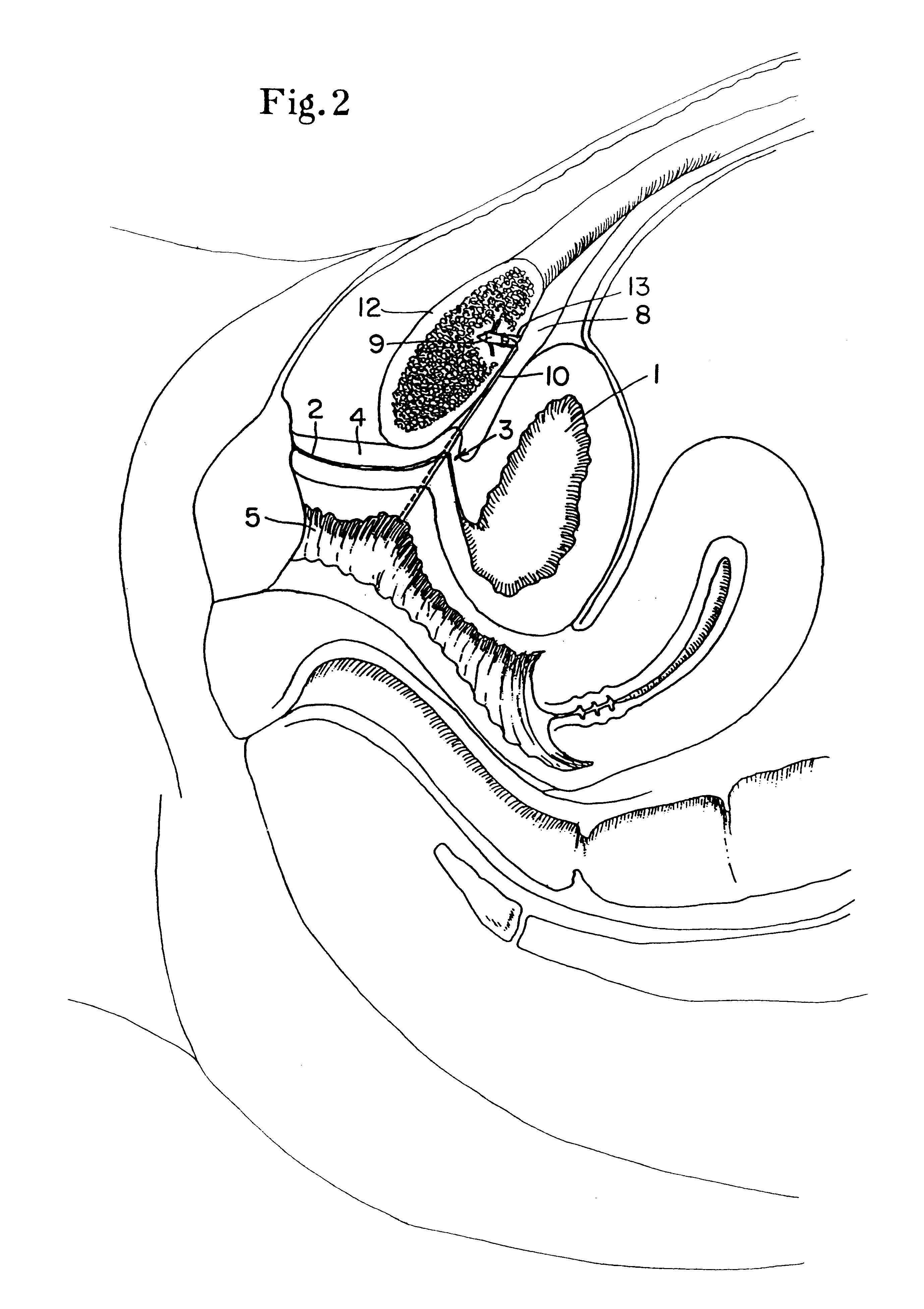

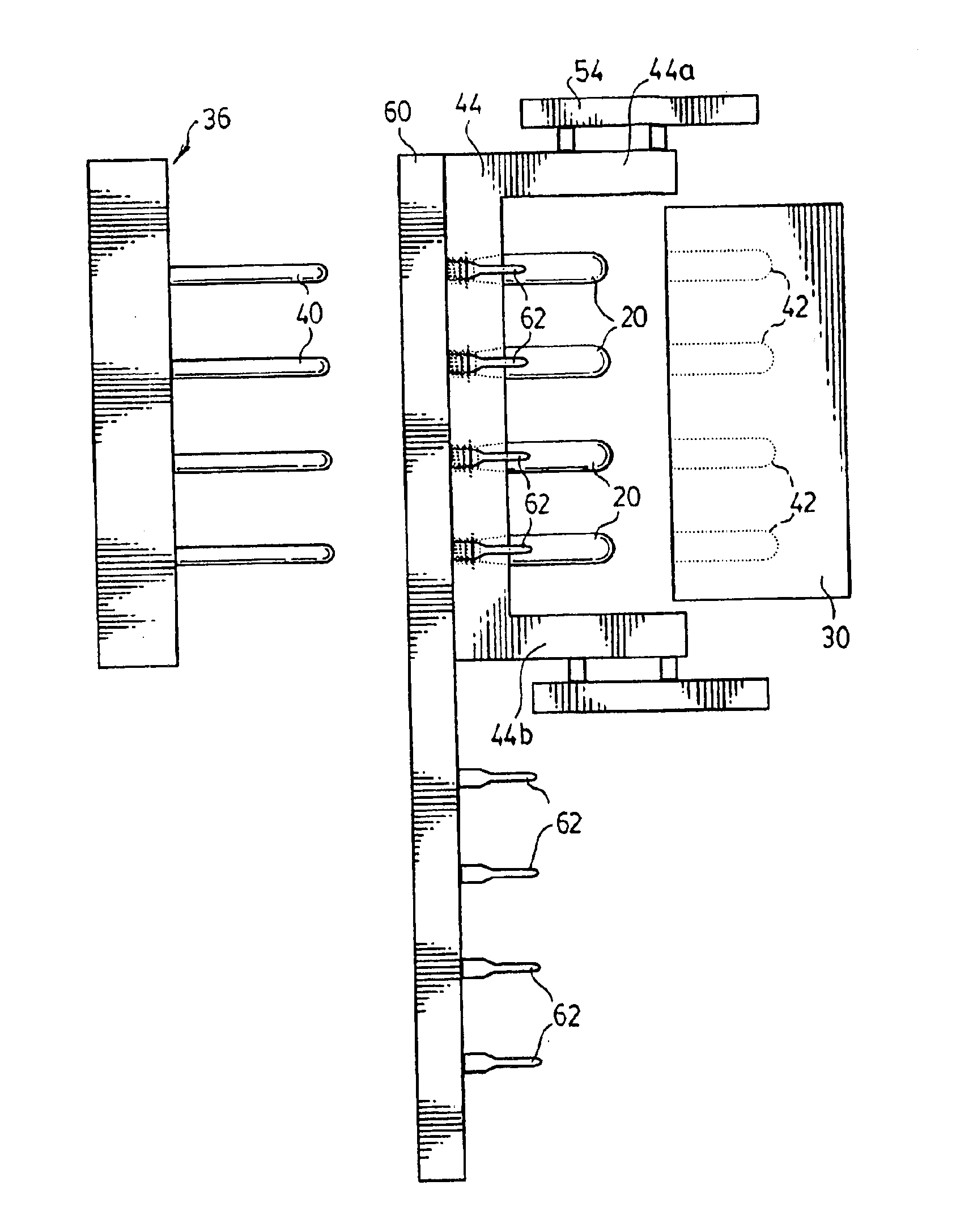

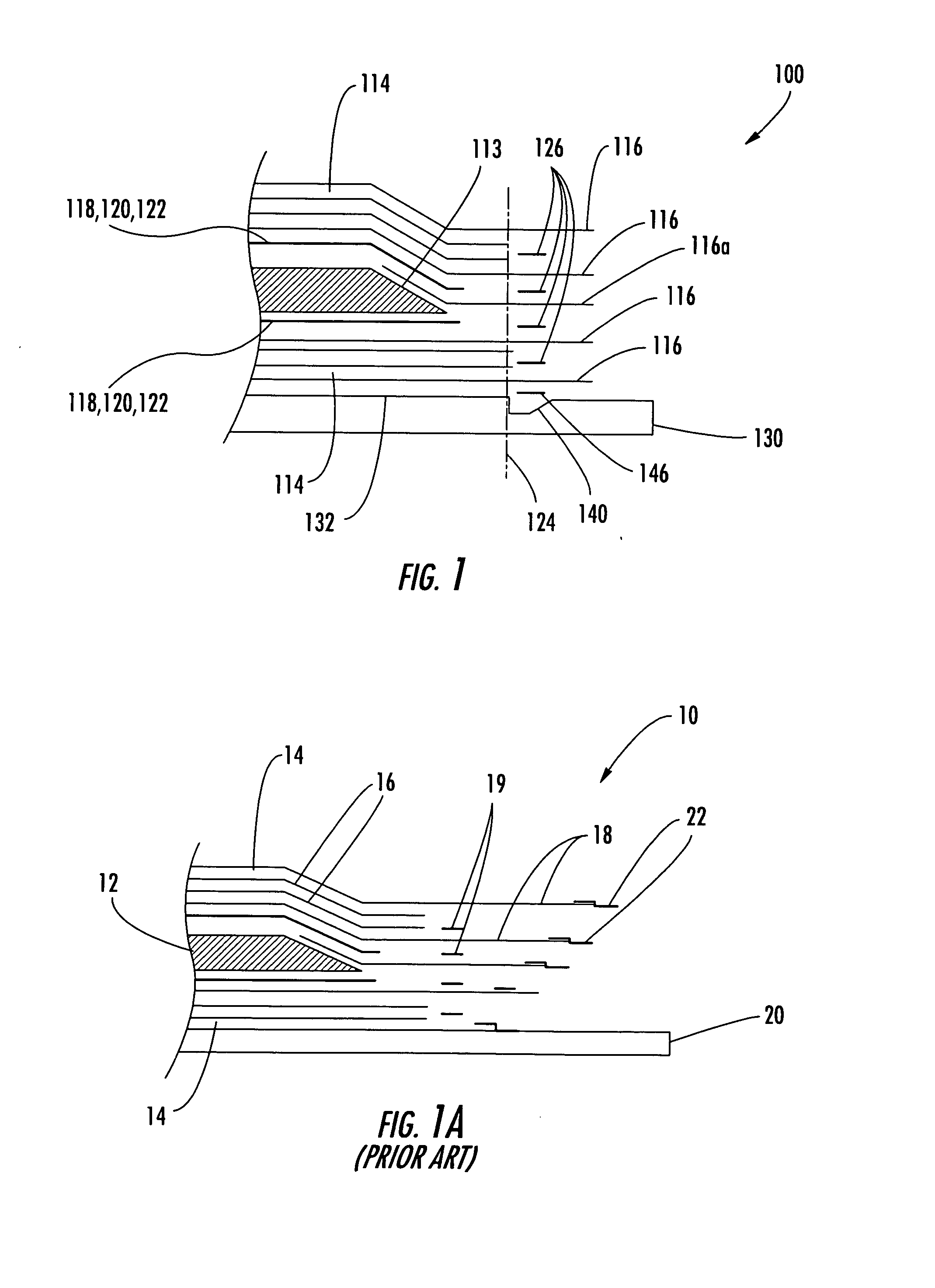

Surgical method for treating urinary incontinence, and apparatus for use in same

A surgical method for treating urinary incontinence by securing a suture within a patient's body, retrieving a portion of the suture into the patient's vagina, and supporting the patient's urethra using the suture. A surgical method for elevating a patient's urethra in order to treat urinary incontinence, a surgical method for securing an anchor in a patient, a helical anchor and an anchor-insertion tool are also provided.

Owner:DEXTERITY SURGICAL

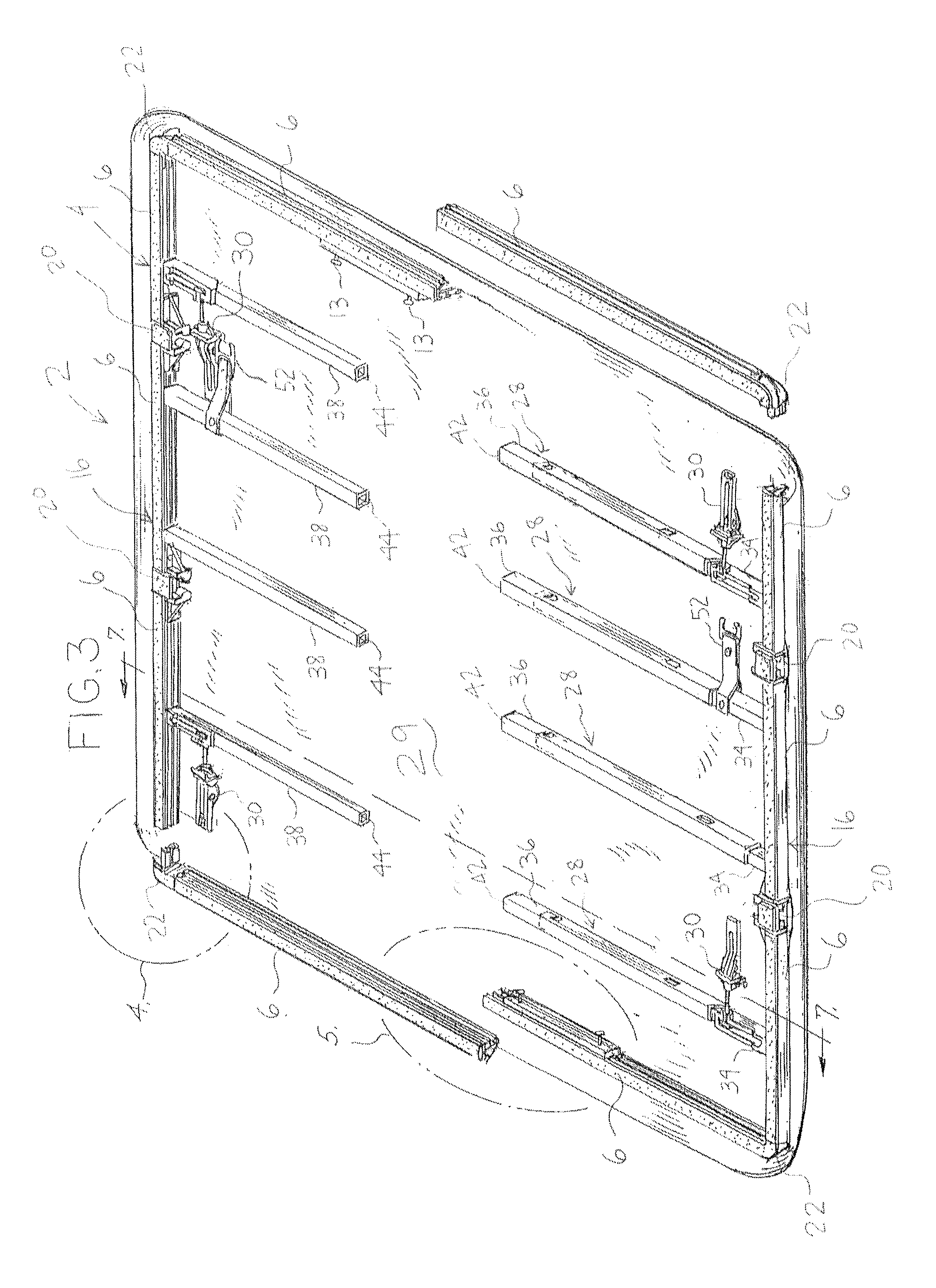

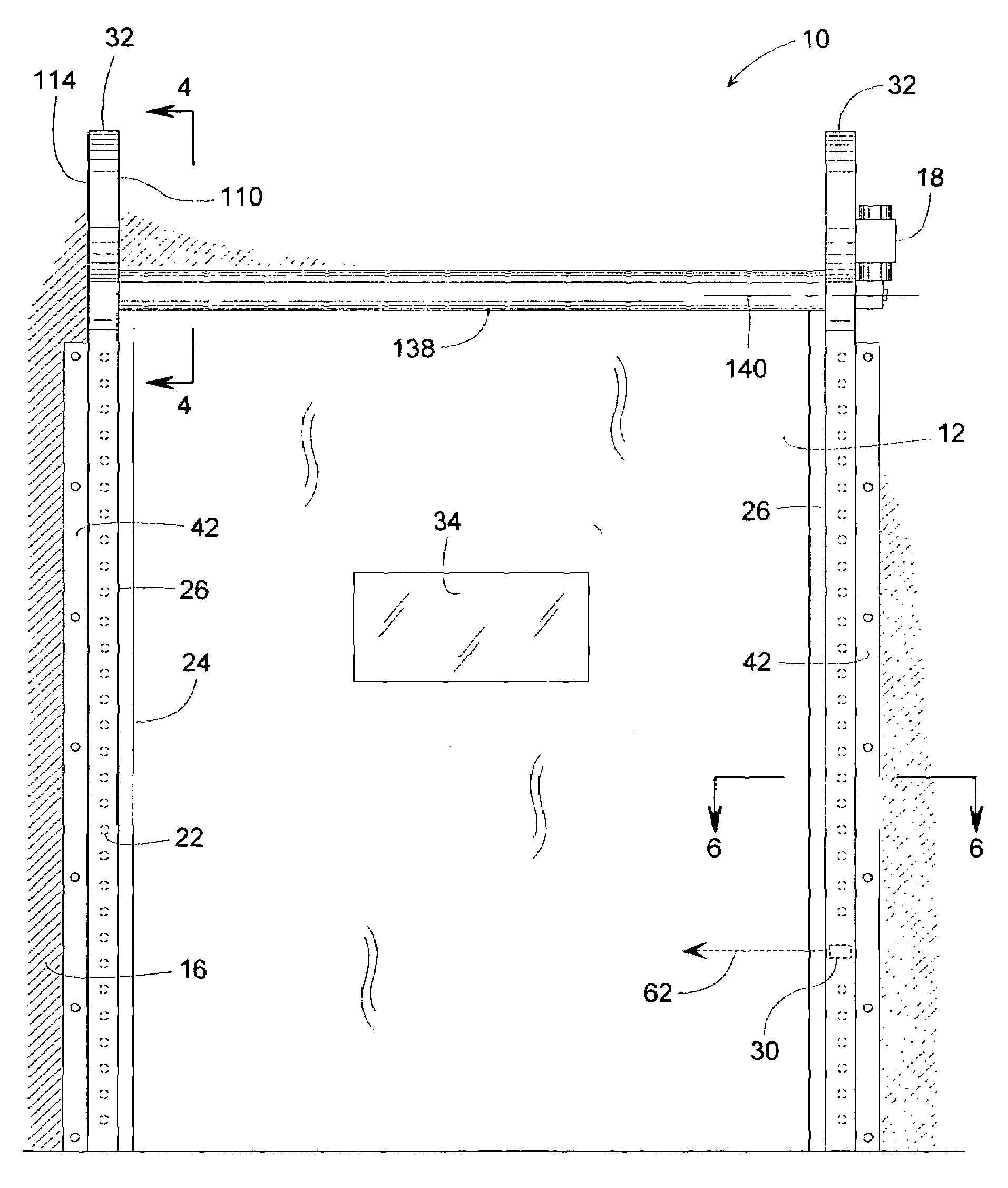

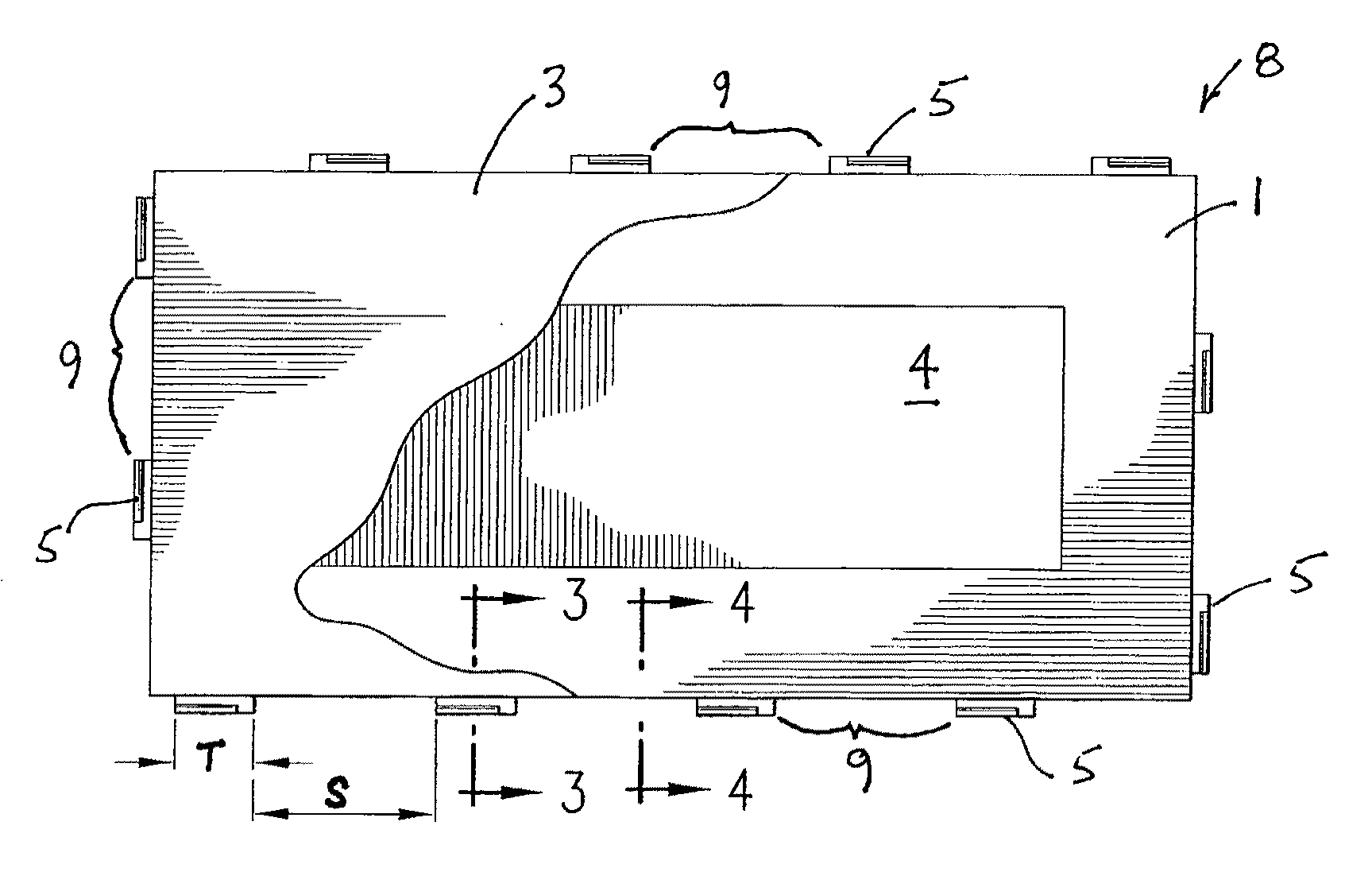

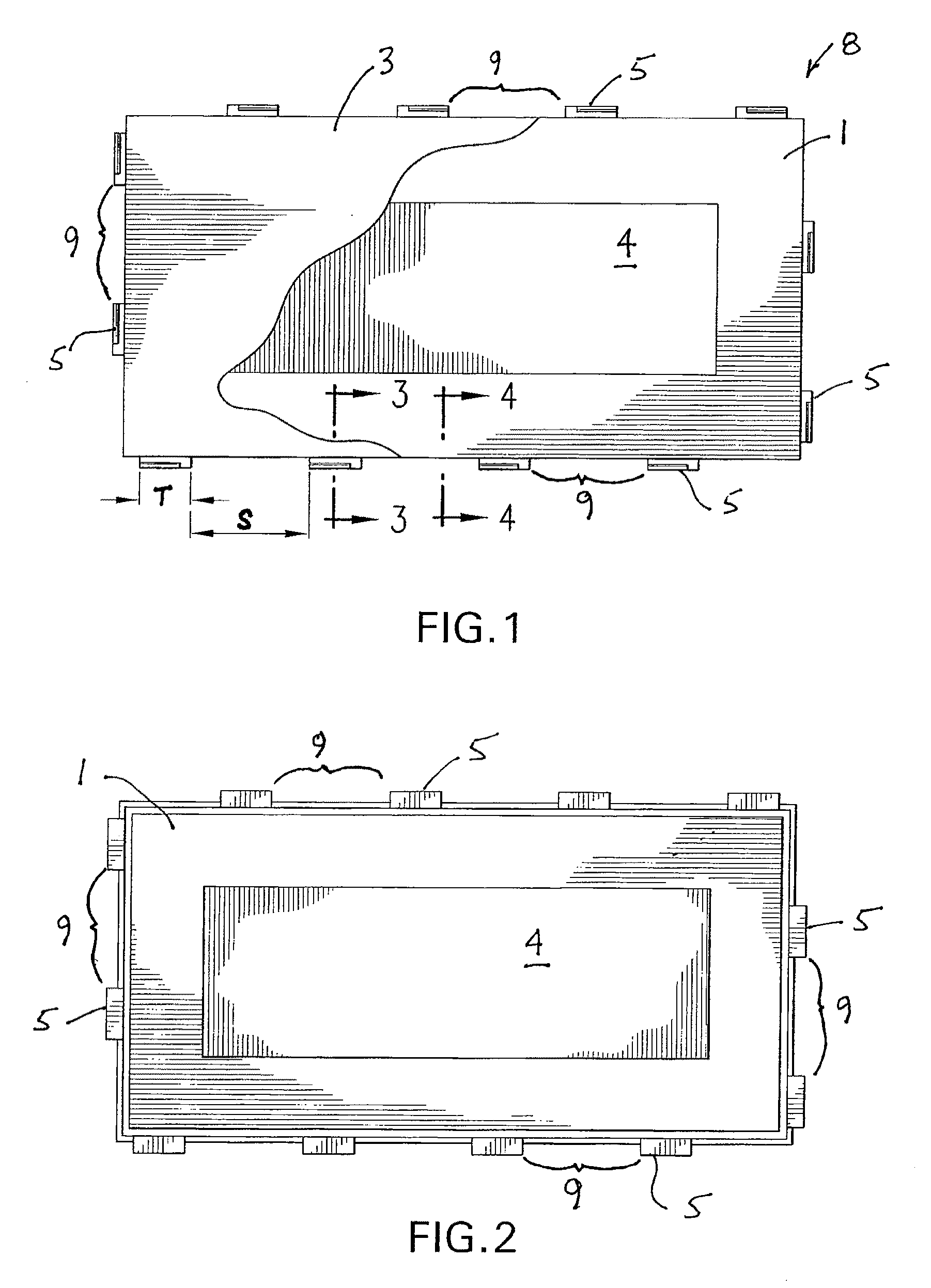

Display system having a continuous flexible display with display supports

InactiveUS20130342094A1Relieve stressKeep displayStatic indicating devicesAdvertisingDisplay deviceSpring force

A display system comprises a continuous flexible display and two main display supports being hingeably connected with respect to each other between a closed storage position and a planar open position for fixing the flexible display in an open position. Each of the supports is structurally configured to support respectively a first and a second portion of the flexible display, a segment of the flexible display is located between the said respective portions of the flexible display in the open position. The display system comprises a spring force biased mechanism operative in either the open or closed position or both the open and closed positions of the flexible display, biasing said segment of the flexible display in the respective position.

Owner:SAMSUNG ELECTRONICS CO LTD

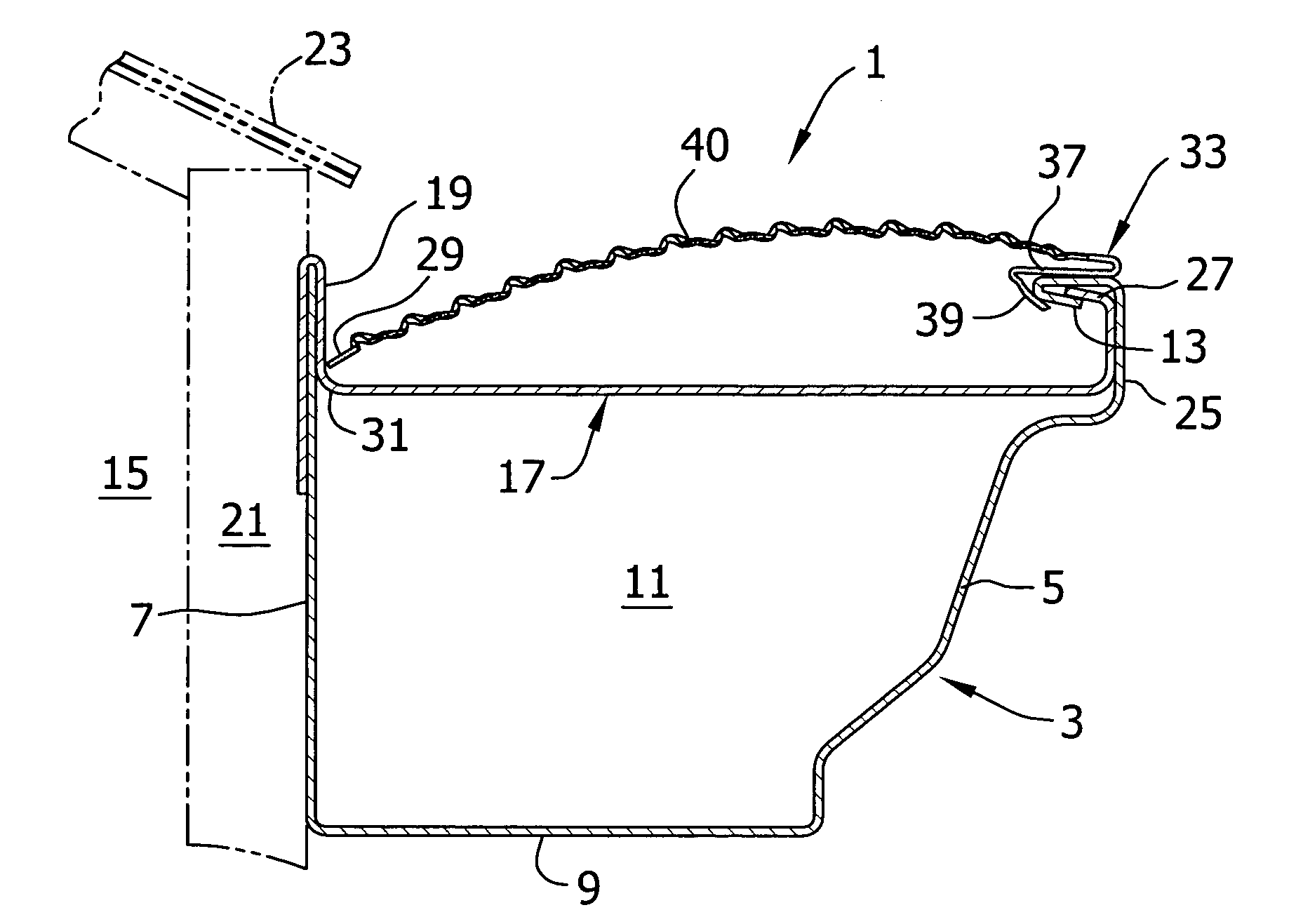

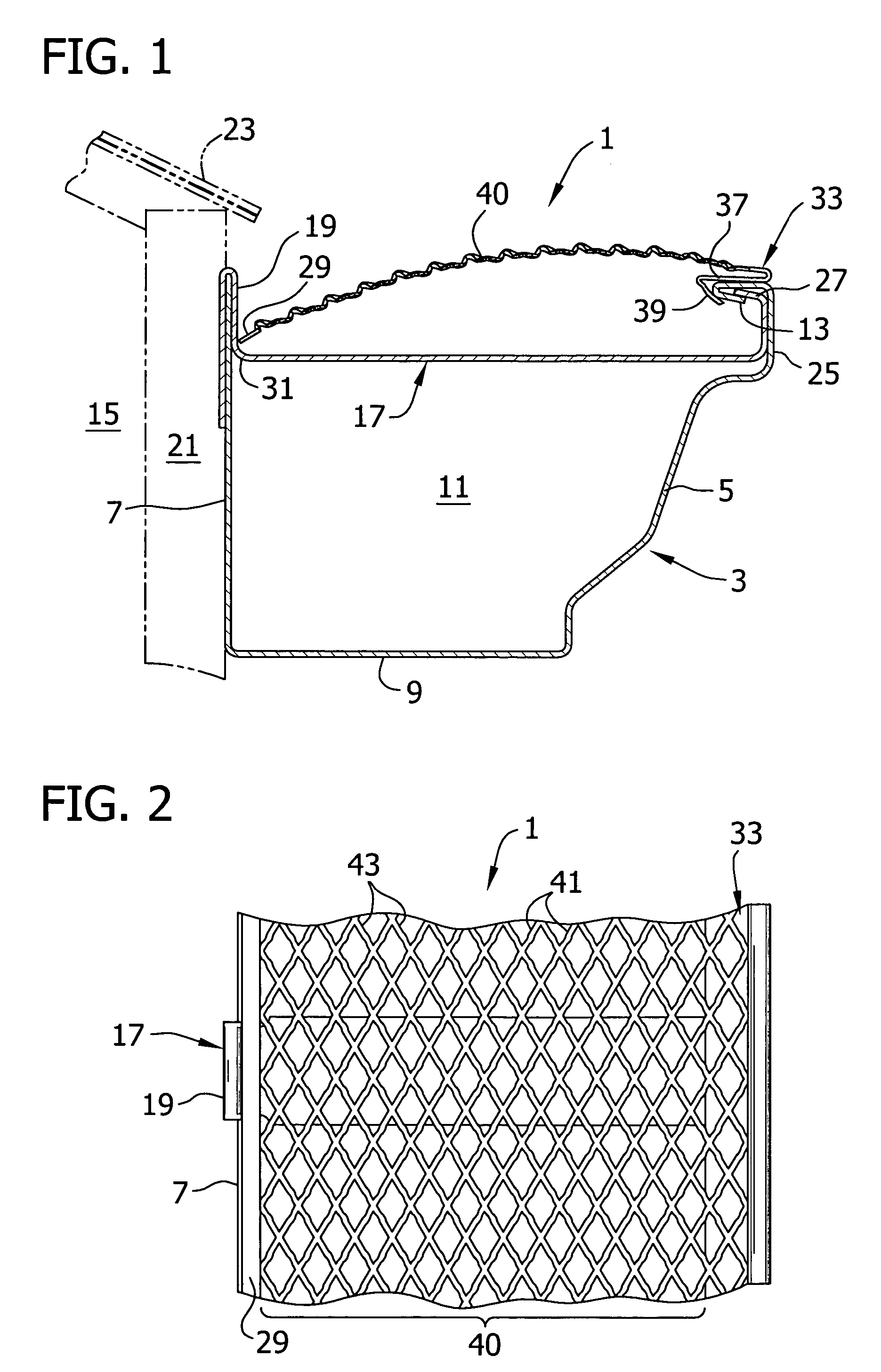

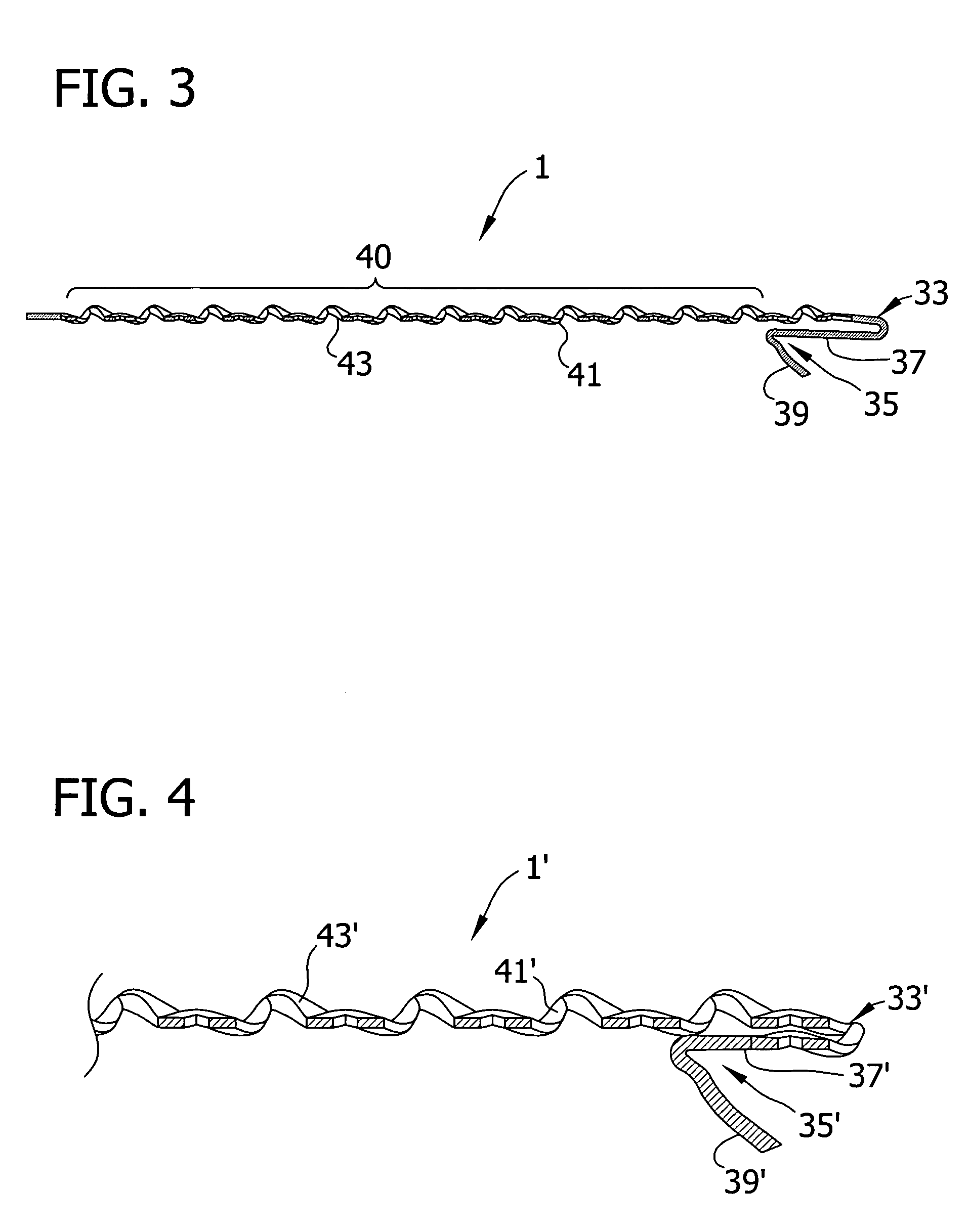

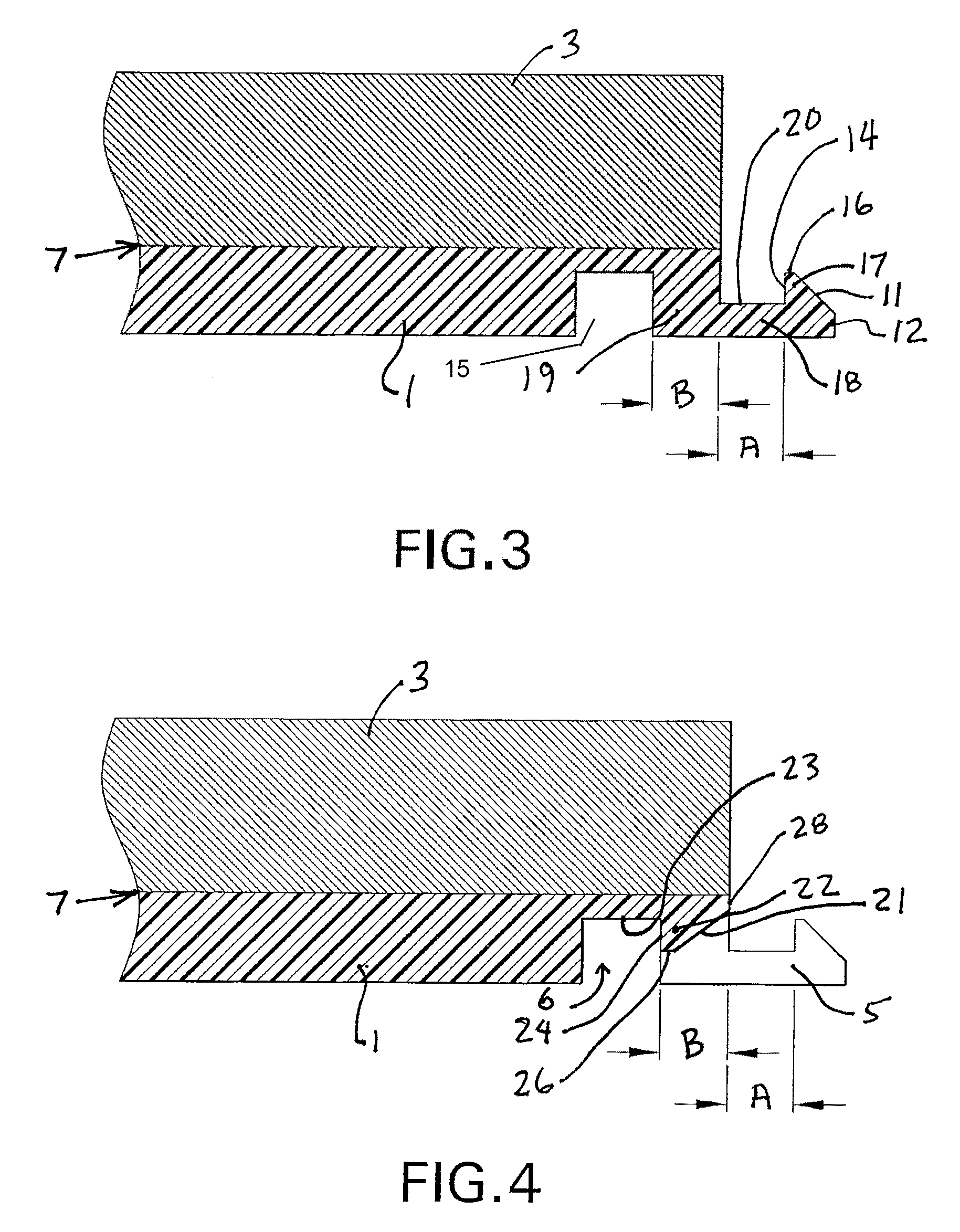

Solid edge gutter screen

A one-piece, integral metal gutter screen includes an expanded metal screen section for covering a gutter. A front edge margin is sized and shaped to engage the gutter, the front edge margin having no sharp edges. A rear edge margin is sized and shaped to engage at least one of a gutter hanger and a roof, the rear edge margin having no sharp edges. The gutter screen is formed of a single piece of elongate, flexible, resilient metal. The gutter screen includes strands and non-circular holes between the strands in at least the screen section. The strands and non-circular holes are sized and shaped to prevent leaves and debris from falling into the gutter. At least the front edge margin of the screen is solid, unperforated metal for facilitating safe handling of the screen and for ease of installation.

Owner:EALER JAMES E SR

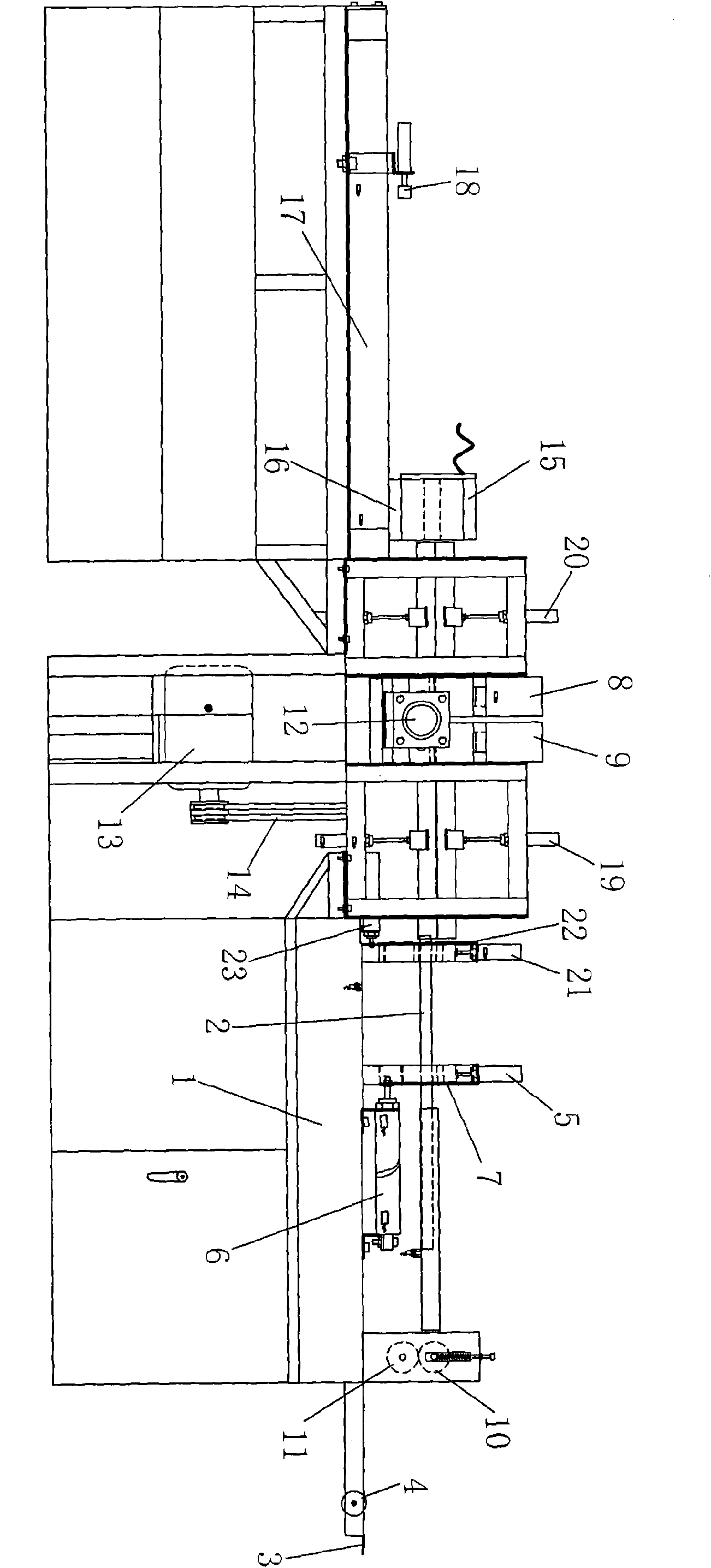

Full-automatic fixed-length cutting device of metallic hose

InactiveCN101623780ARealize fixed-length automatic cuttingIncrease productivityMetal-working feeding devicesTube shearing machinesFixed lengthMetal hose

The invention relates to a full-automatic fixed-length cutting device of a metallic hose, comprising a base, a strip conveyer and a conveying chute. The strip conveyer is used for conveying the metallic hose and is erected on the base; the conveying chute vertically penetrates through the strip conveyer which is provided with a positioning mechanism, a conveying mechanism and a clamp, wherein the conveying mechanism sends the metallic hose into the clamp and pulls the metallic hose away for a certain distance, and then, the metallic hose is cut by a cutting mechanism which is arranged on the base. The invention realizes the automatic fixed-length cutting of the metallic hose, greatly improves the production efficiency, and achieves higher consistency degree of a cut product.

Owner:严光辉

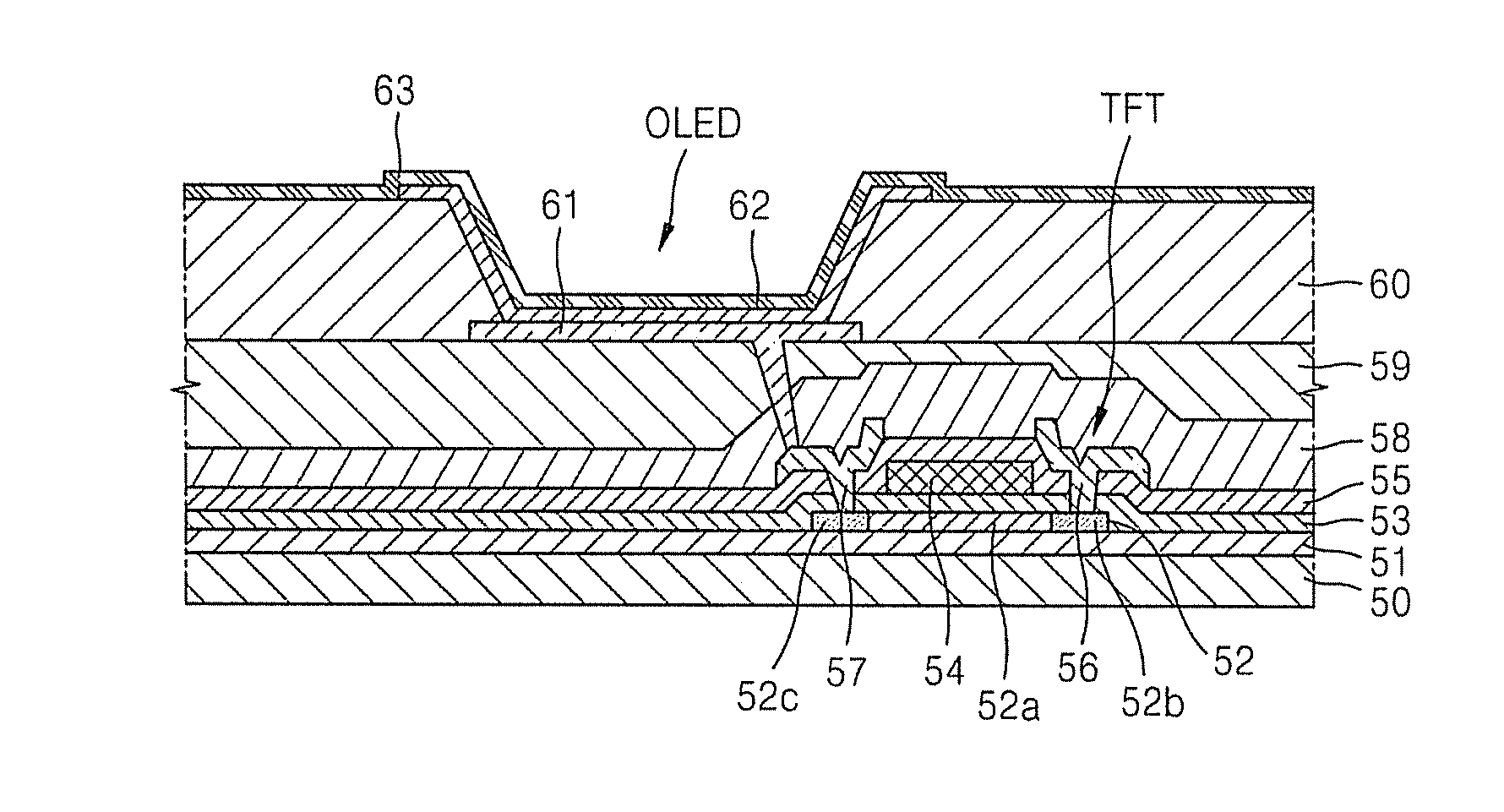

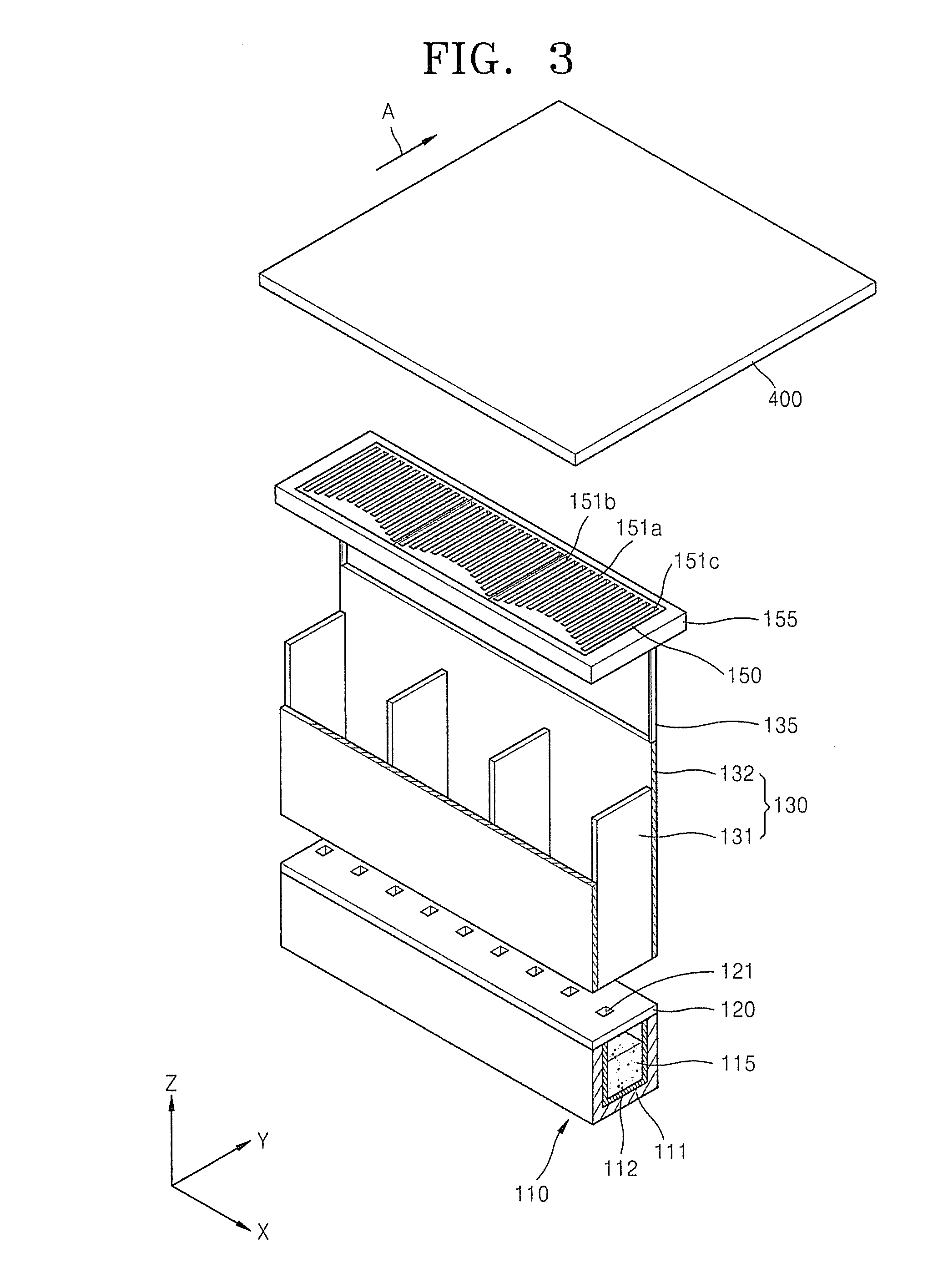

Thin film deposition apparatus and method of manufacturing organic light-emitting display device by using the same

InactiveUS20110053300A1Easy to manufactureIncrease depositionLiquid surface applicatorsVacuum evaporation coatingDisplay deviceEngineering

A thin film deposition apparatus that can be applied to manufacture large-sized display devices on a mass scale and that improves manufacturing yield, and a method of manufacturing an organic light-emitting display device by using the thin film deposition apparatus.

Owner:SAMSUNG DISPLAY CO LTD

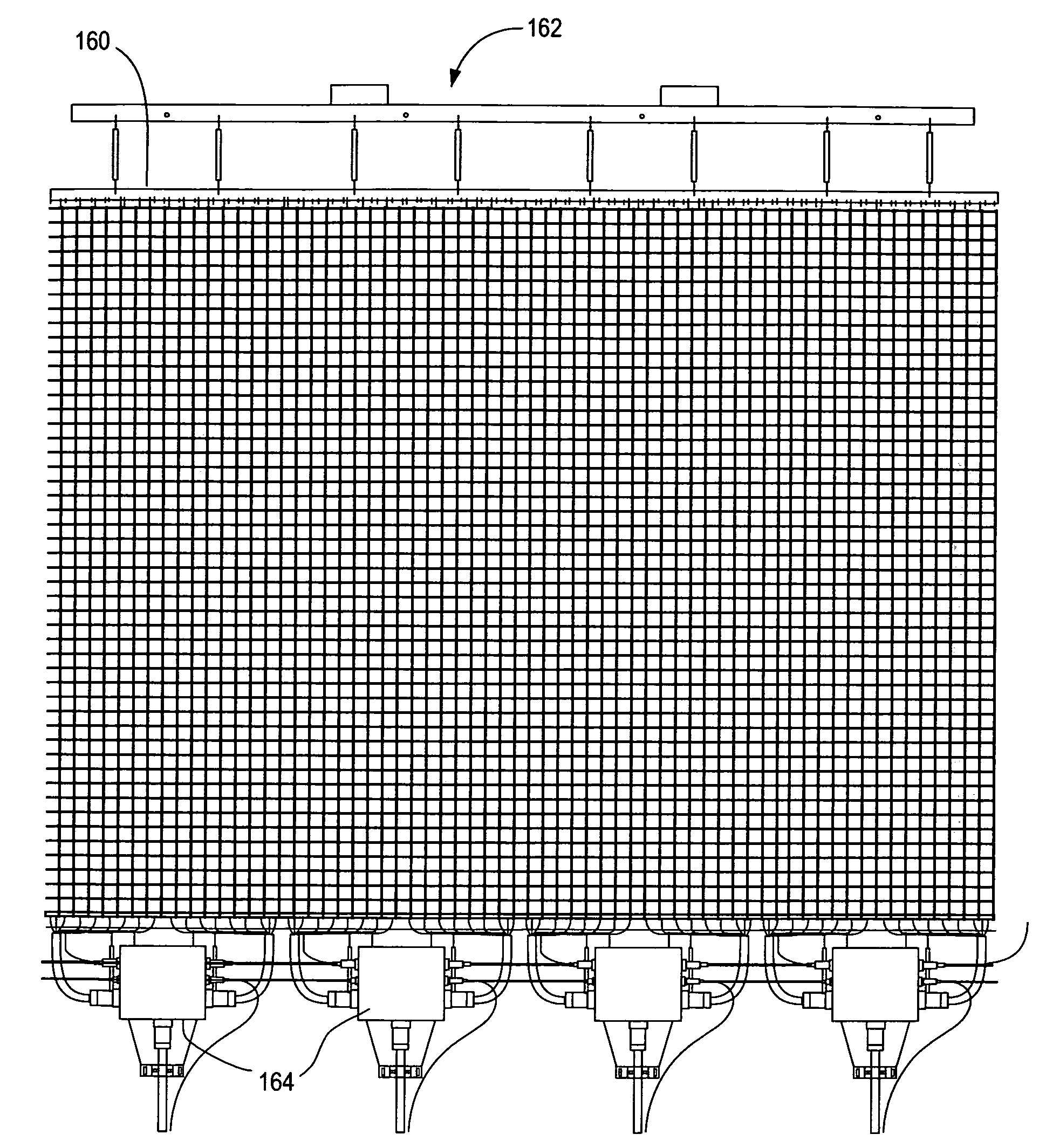

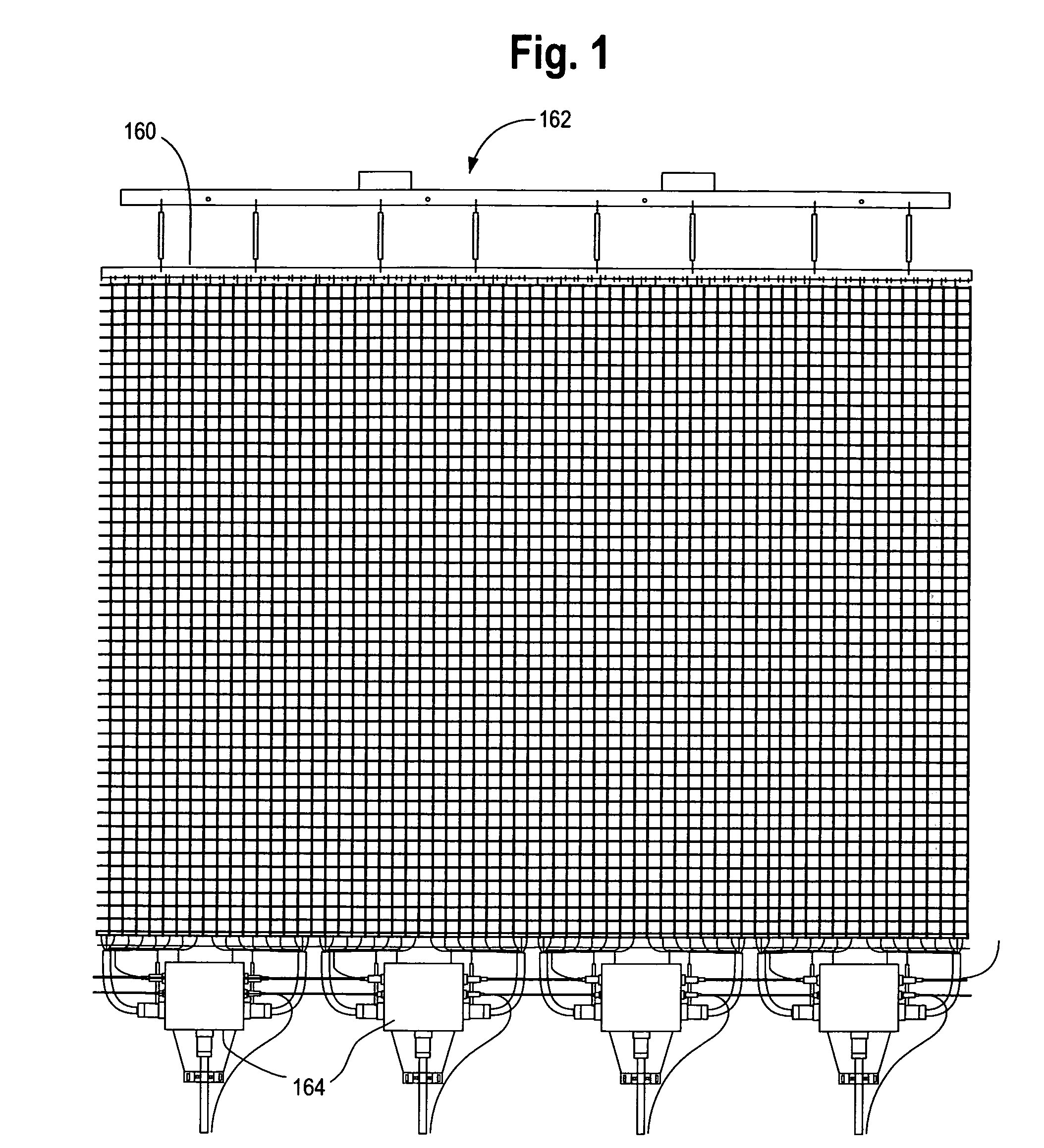

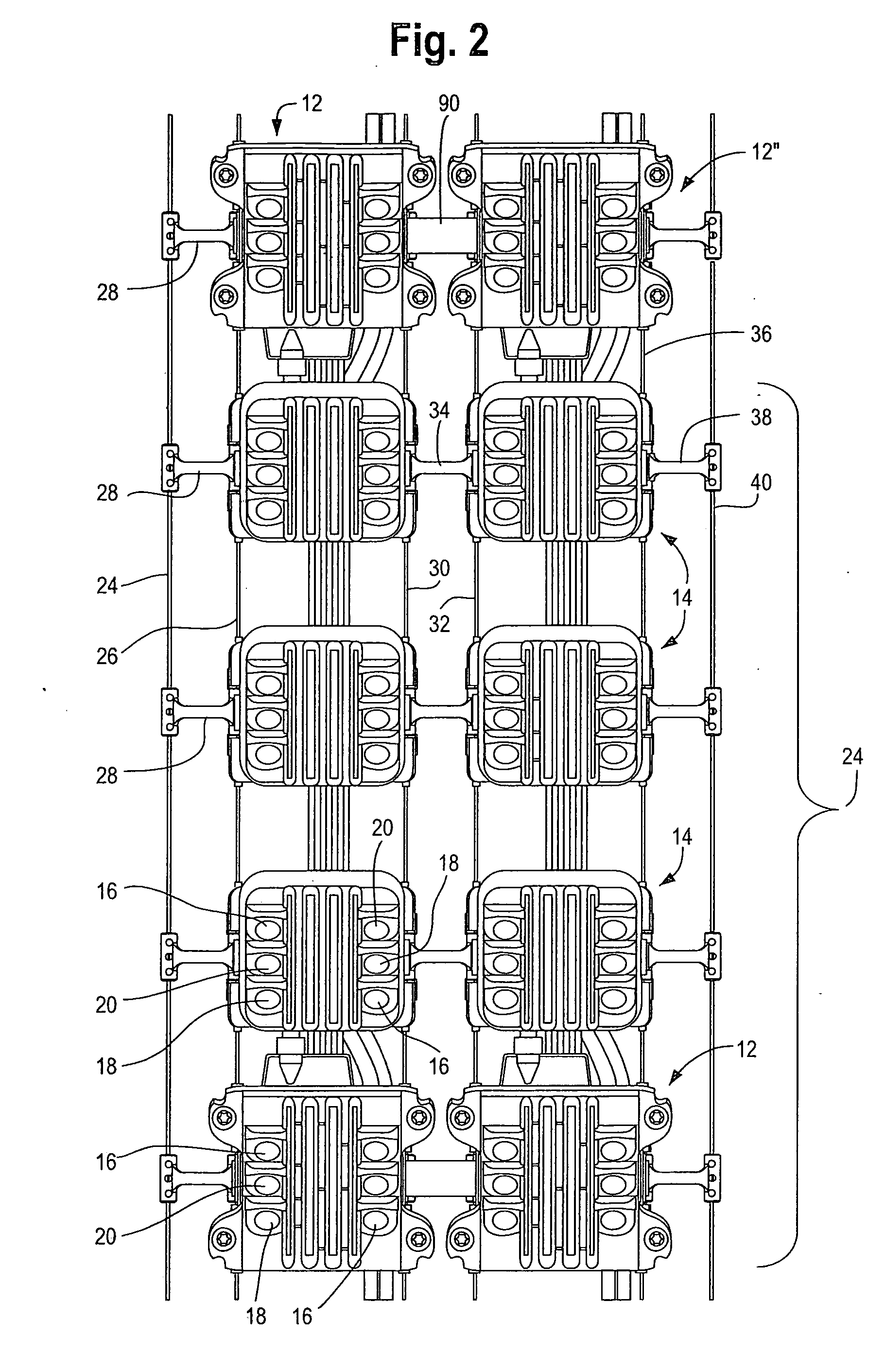

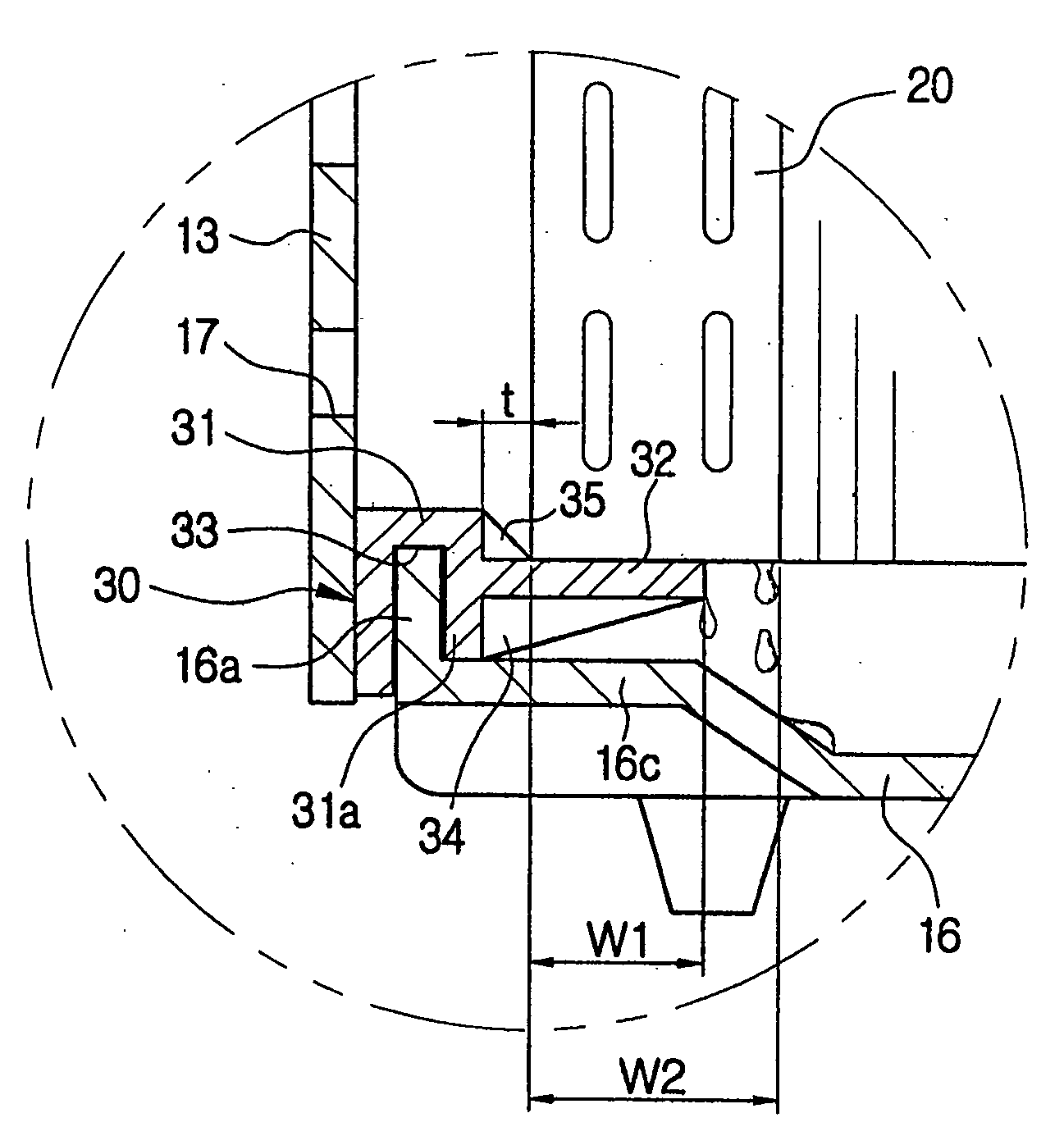

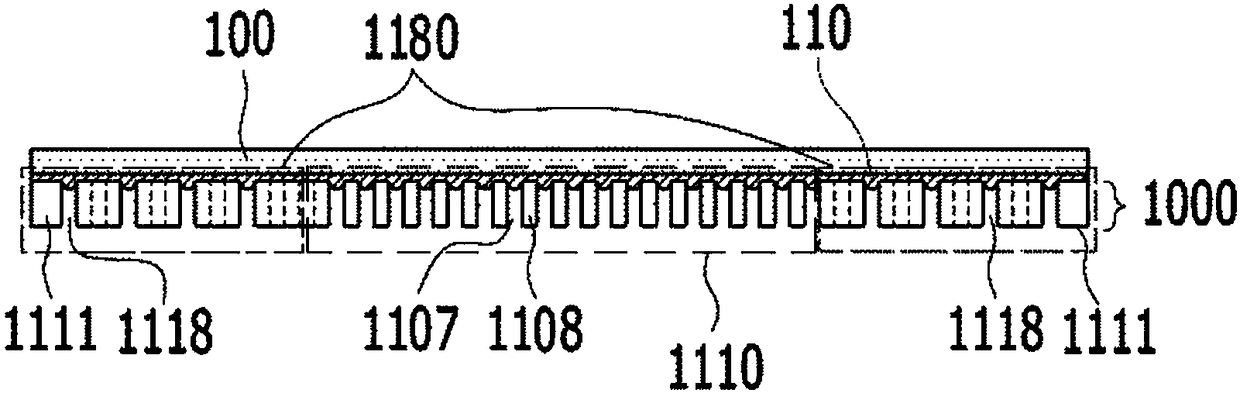

Large scale LED display

InactiveUS20090146918A1Prevent twistingPrevent saggingAdvertisingCathode-ray tube indicatorsLED displayDisplay device

A large scale LED display has a cable and rigid link support structure for a number of LED modules. The cable and rigid link support structure is flexible but has sufficient structural integrity to prevent misalignment of the pixel modules. The LED modules are removable from the support structure individually and as a group so as to facilitate repair of the display. The LED modules are rugged so as to withstand harsh outdoor conditions and they provide sufficient luminescence for use in sunlight.

Owner:ADTI MEDIA

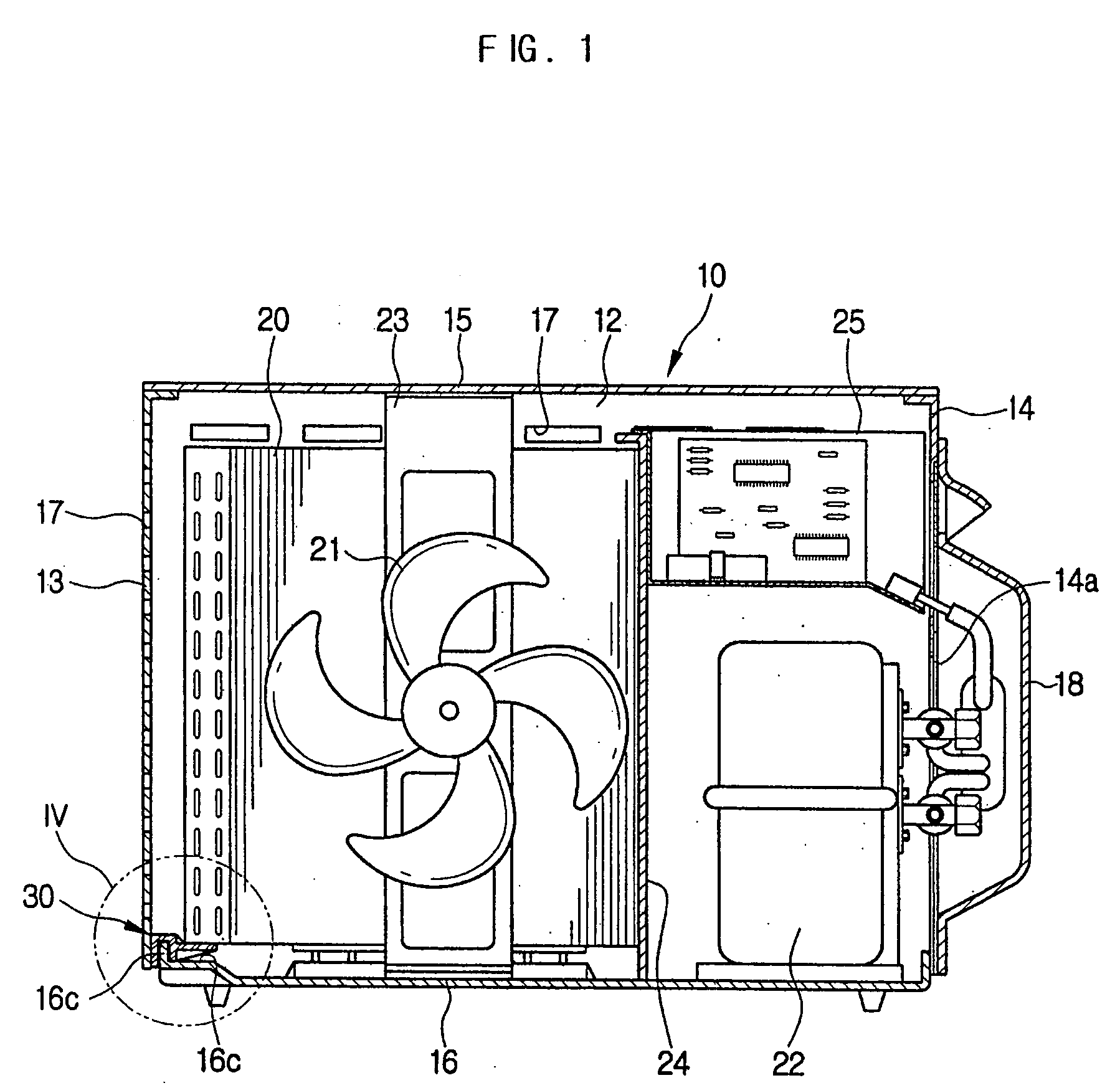

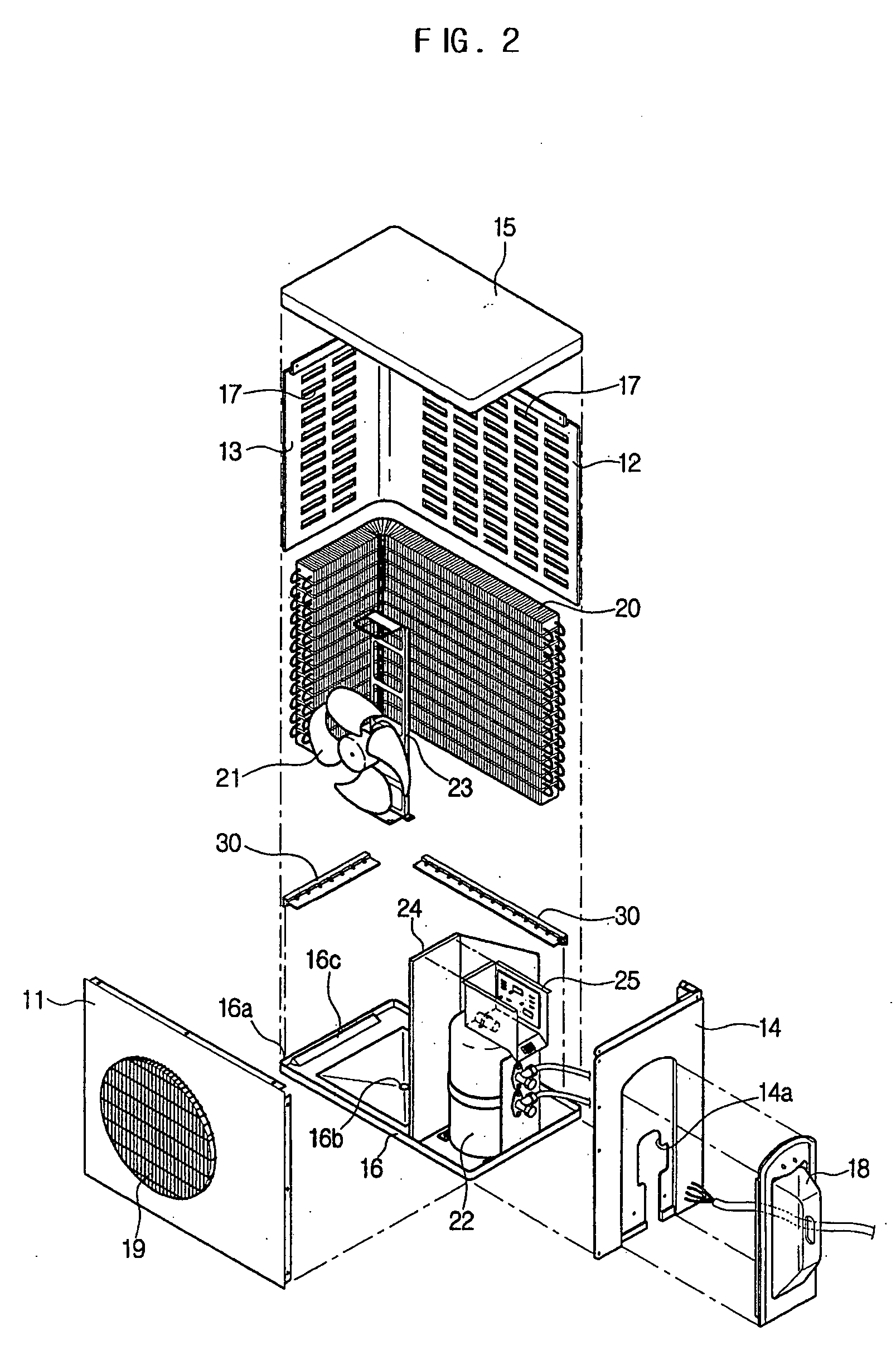

Outdoor unit for air conditioner

InactiveUS20050034471A1Easy dischargePreventing the condensed water from freezingThermal insulationCondensate preventionMechanical engineeringWaste management

An outdoor unit for an air conditioner allows condensed water generated from an outdoor heat exchanger to be easily discharged, and prevents coldness from the outdoor heat exchanger from being transmitted to a bottom of the outdoor unit, thus preventing freezing of the condensed water on the bottom. The outdoor unit includes a cabinet having a bottom panel, an outdoor heat exchanger installed in the cabinet, and a support member made of heat insulating material supporting the outdoor heat exchanger with a spacing between a lower end of the outdoor heat exchanger and the bottom panel of the cabinet, to prevent condensed water generated from the outdoor heat exchanger from freezing.

Owner:SAMSUNG ELECTRONICS CO LTD

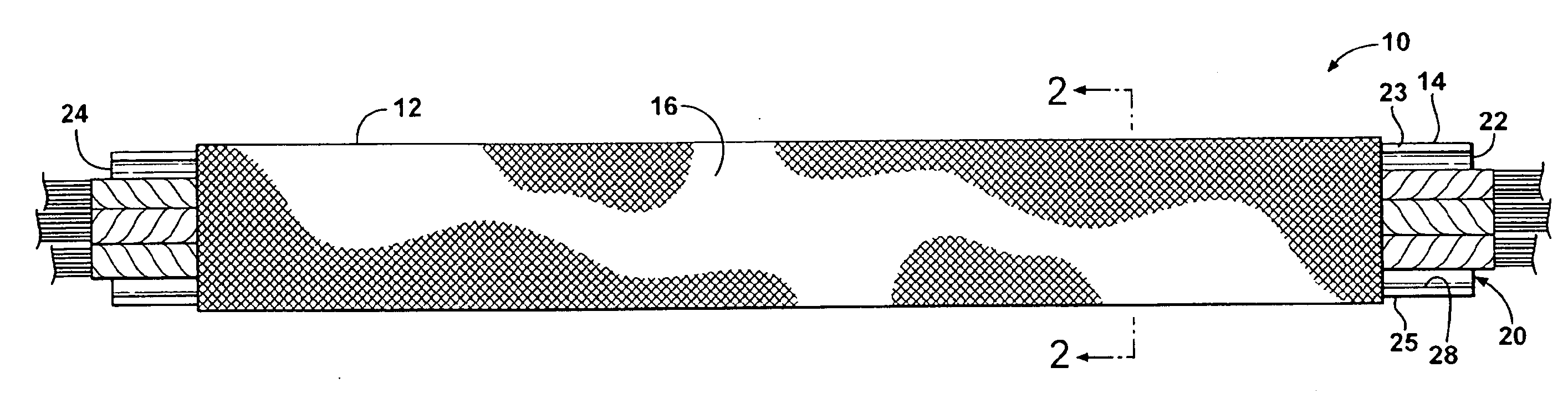

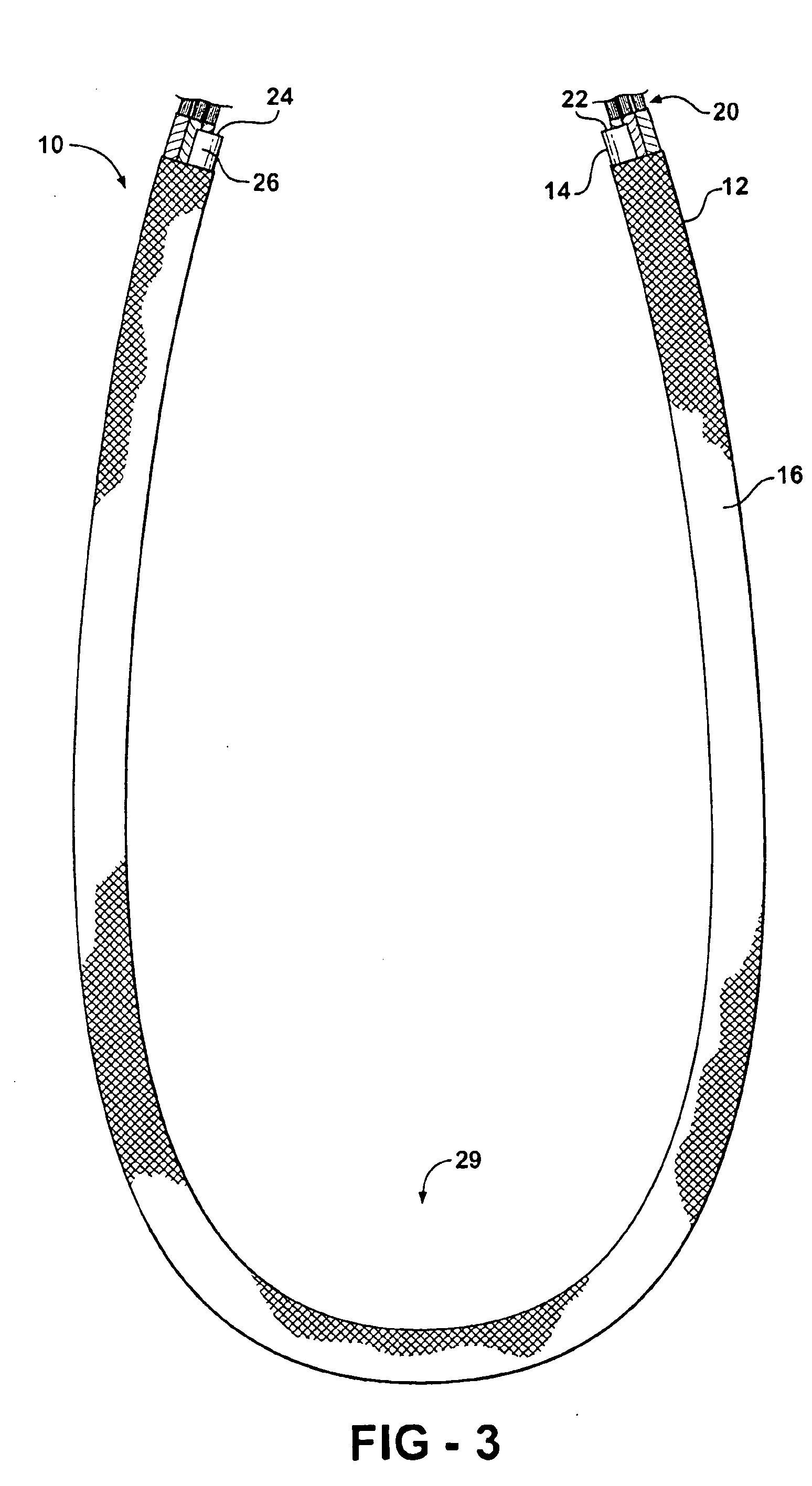

Protective sleeve assembly having a support member and method of construction

InactiveUS20080135119A1Avoid damageEasy maintenanceOrnamental textile articlesElectrical apparatusEngineeringArcuate shape

An elongate sleeve for protecting elongate members and method of construction thereof has a textile sleeve with a wall having an inner surface providing a cavity extending along a longitudinal axis of the sleeve for receiving the elongate members. A resilient support member is arranged in communication with the wall. The support member has an arcuate shape in lateral cross-section with an outer convex surface facing outwardly from the axis for flush engagement with the inner surface of the wall and an inner concave surface facing inwardly toward the axis. The support member extends less than completely about a circumference of the inner surface.

Owner:FEDERAL MOGUL POWERTAIN LLC

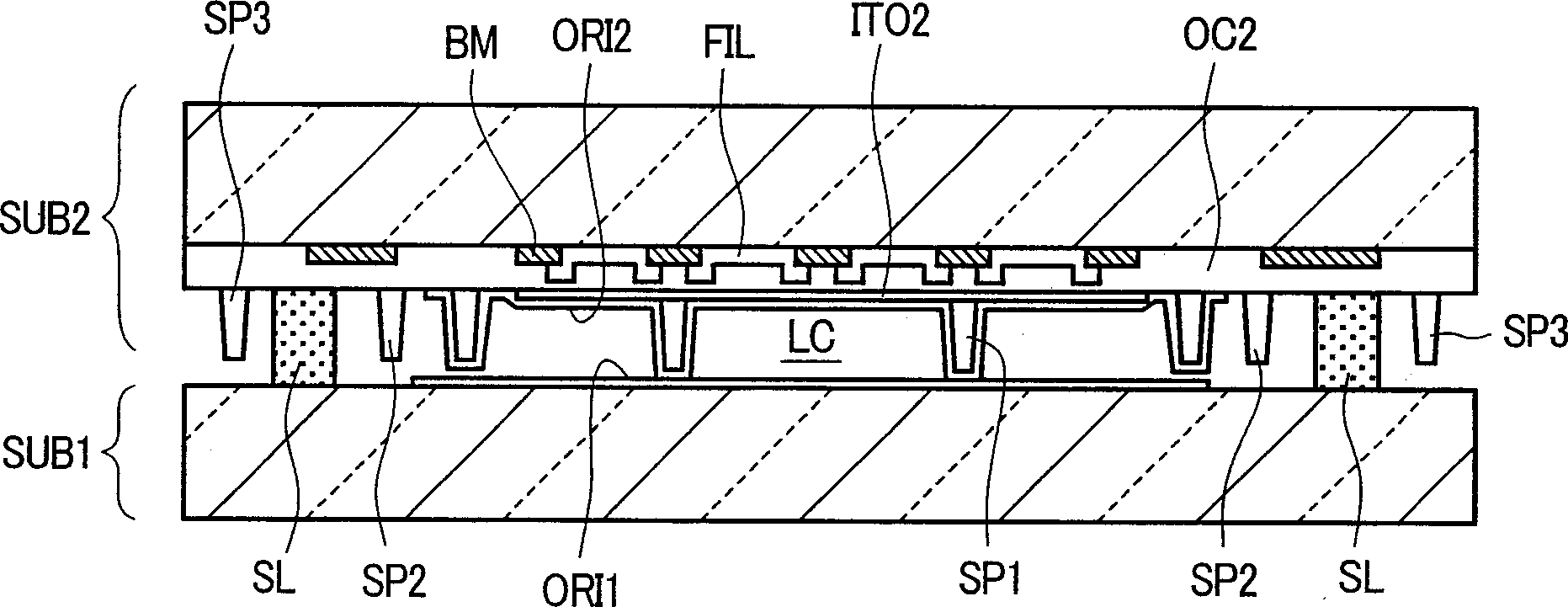

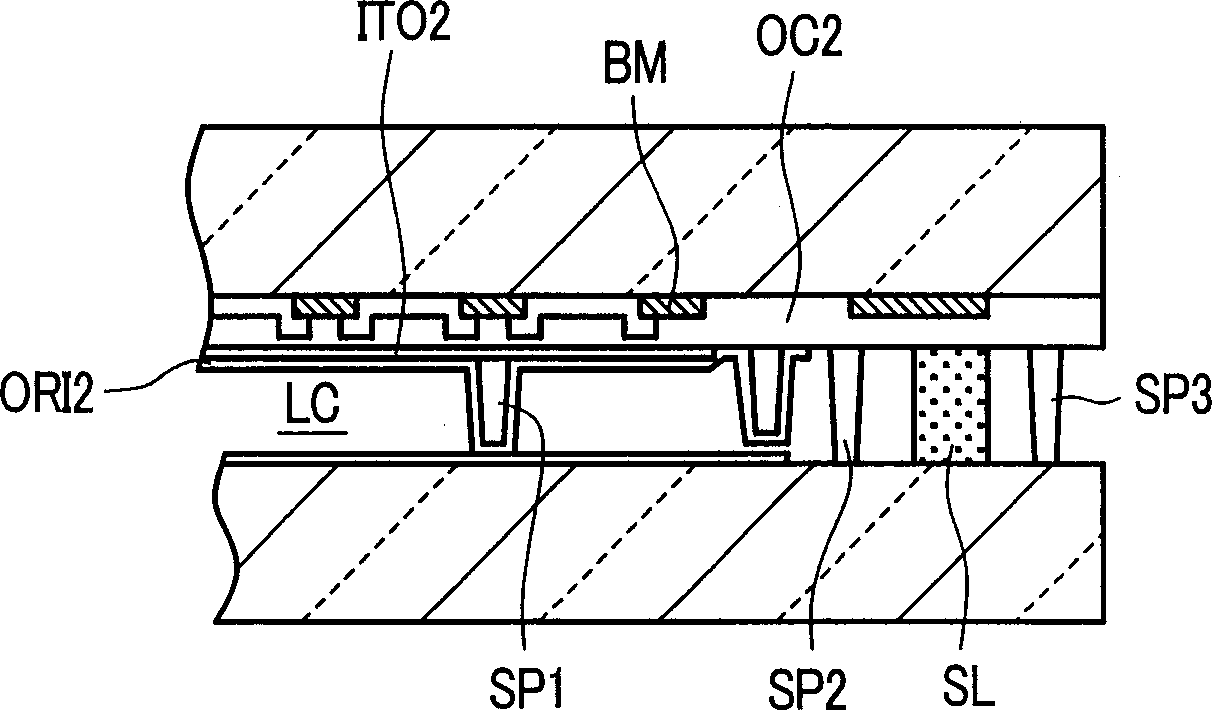

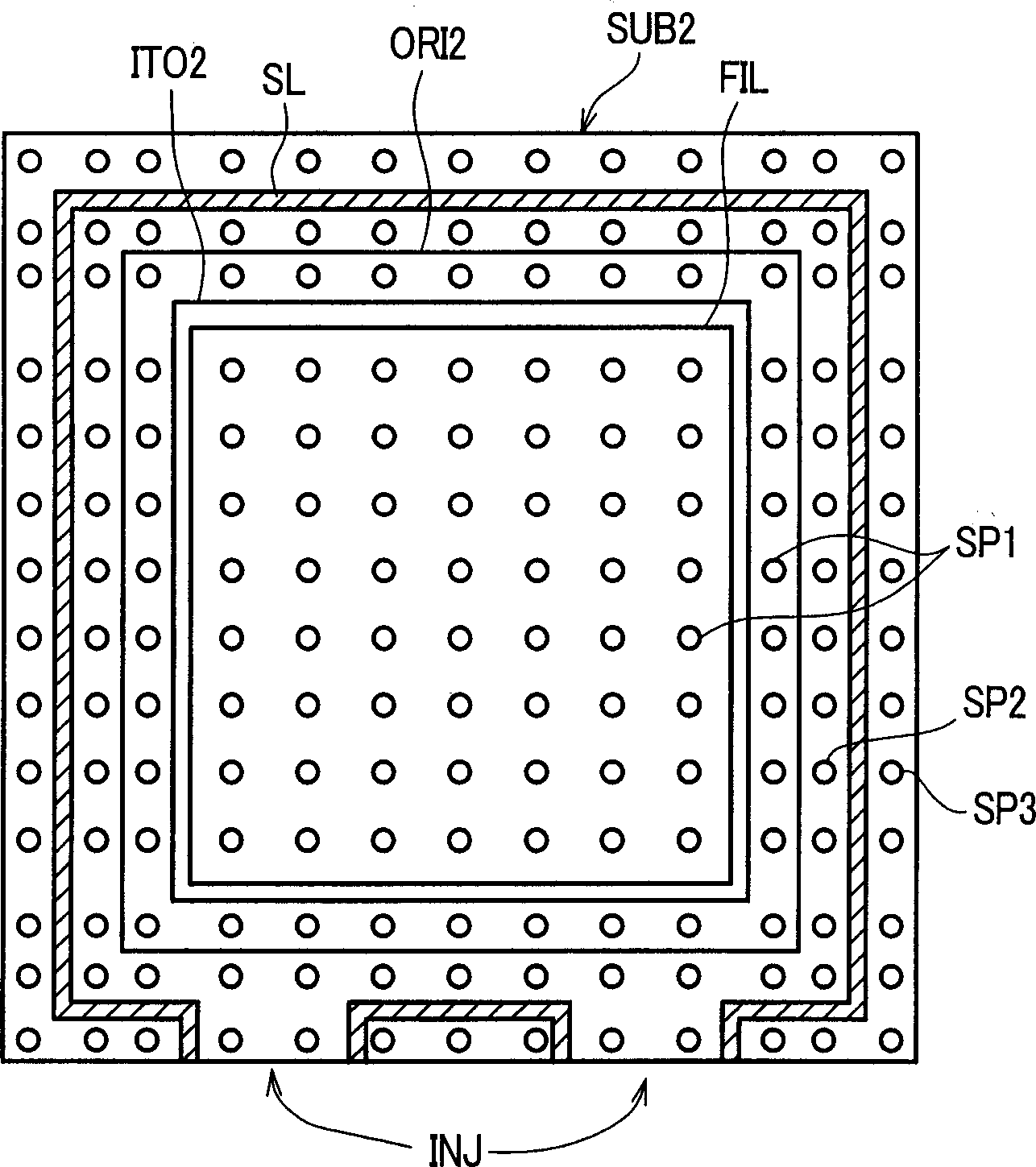

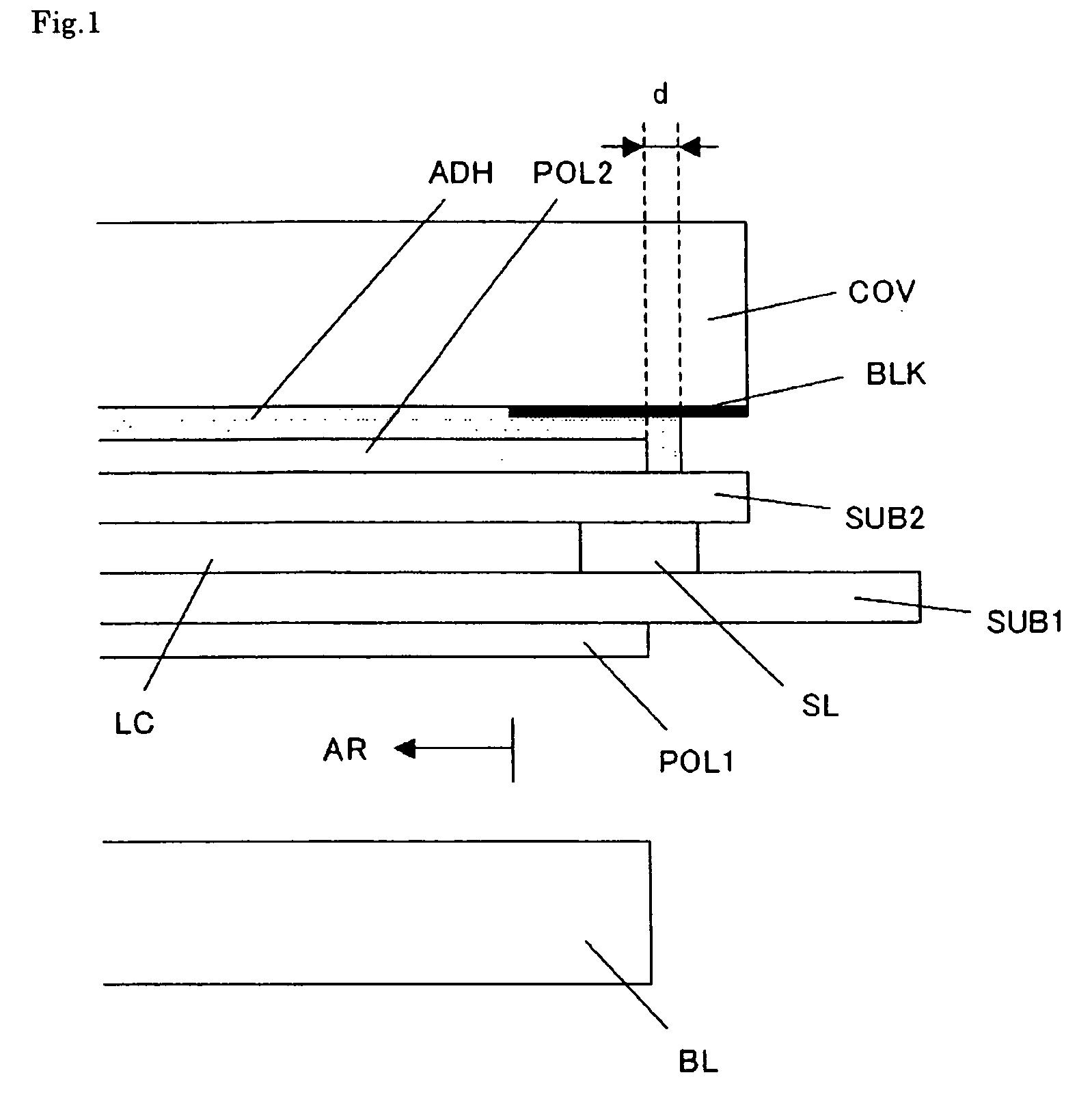

Liquid crystal display device

InactiveCN1400500AShort circuit between electrodes and wiringNo short circuit between electrodes and wiringNon-linear opticsColor gelEngineering

The present invention provides a liquid crystal display unit to prevent a shortcircuit between a common electrode on the side of a color filter substrate and a wiring and an electrode on the side of a thin film transistor and to set a precise cell gap in the entire area including the sealing area of two substrates. In which, columnar spacers SP1 are fixed in prescribed positions by forming the columnar spacers on the common electrode ITO2 and on a transparent protective film OC2 where the common electrode does not exist at the color filter substrate SUB2 and coating the columnar spacers on the common electrode with an alignment layer. Columnar spacers SP2 and SP3 are provided in the vicinity of the inner and the outer parts of a sealing area SL to secure the prescribed cell gap in the entire area of the two substrates and the sagging and to secure the height of the applied sealing material.

Owner:JAPAN DISPLAY INC

Microwave stiffening system for ceramic extrudates

InactiveUS20050093209A1Prevent saggingPreventing handling deformationDielectric heatingDrying solid materials with heatMicrowaveMetallurgy

An apparatus and method for stiffening an wet extruded ceramic body for improved handling prior to drying and firing. The ceramic body is formed from a plastically deformable material including inorganic raw materials, and organics, such as a binder having a thermal gel point. As the ceramic body log exits the extruder die it is passed through a microwave energy field to be heated to above the gelling point of the organic binder. The ceramic body then stiffens and can be easily handled without deformation.

Owner:CORNING INC

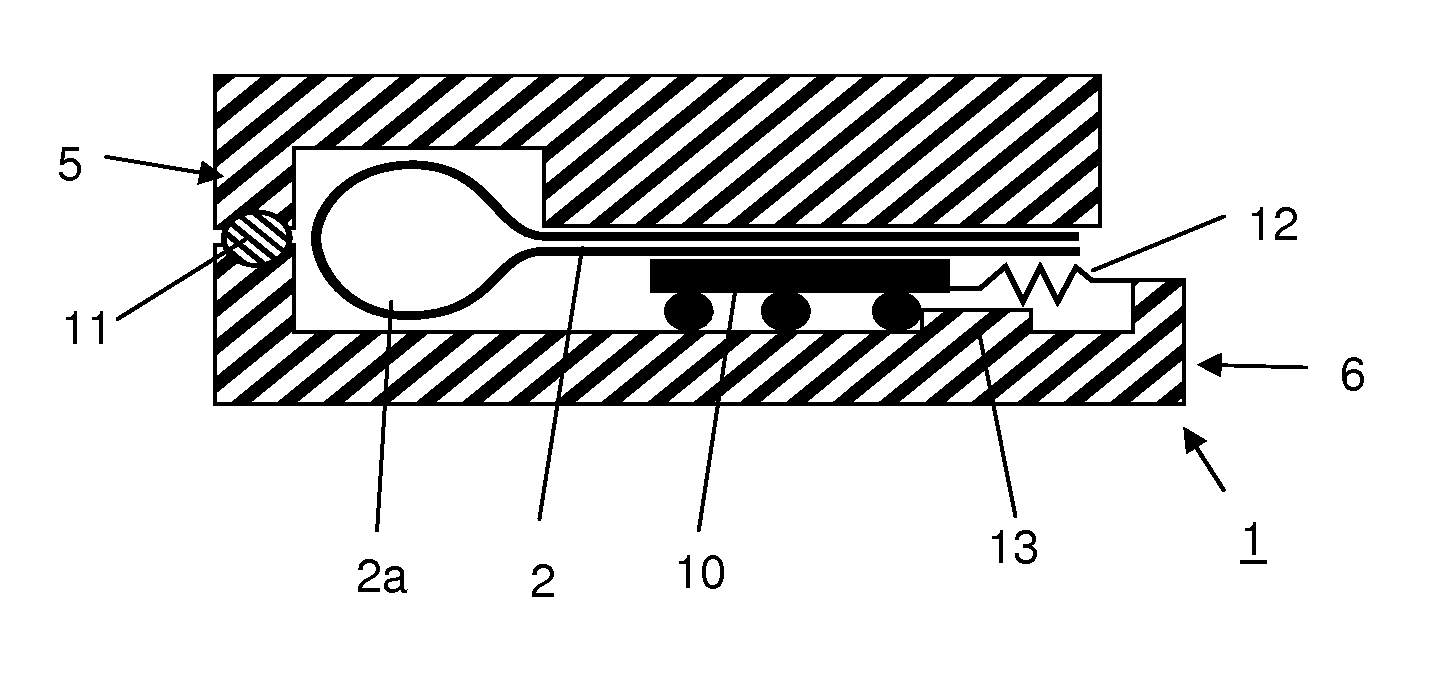

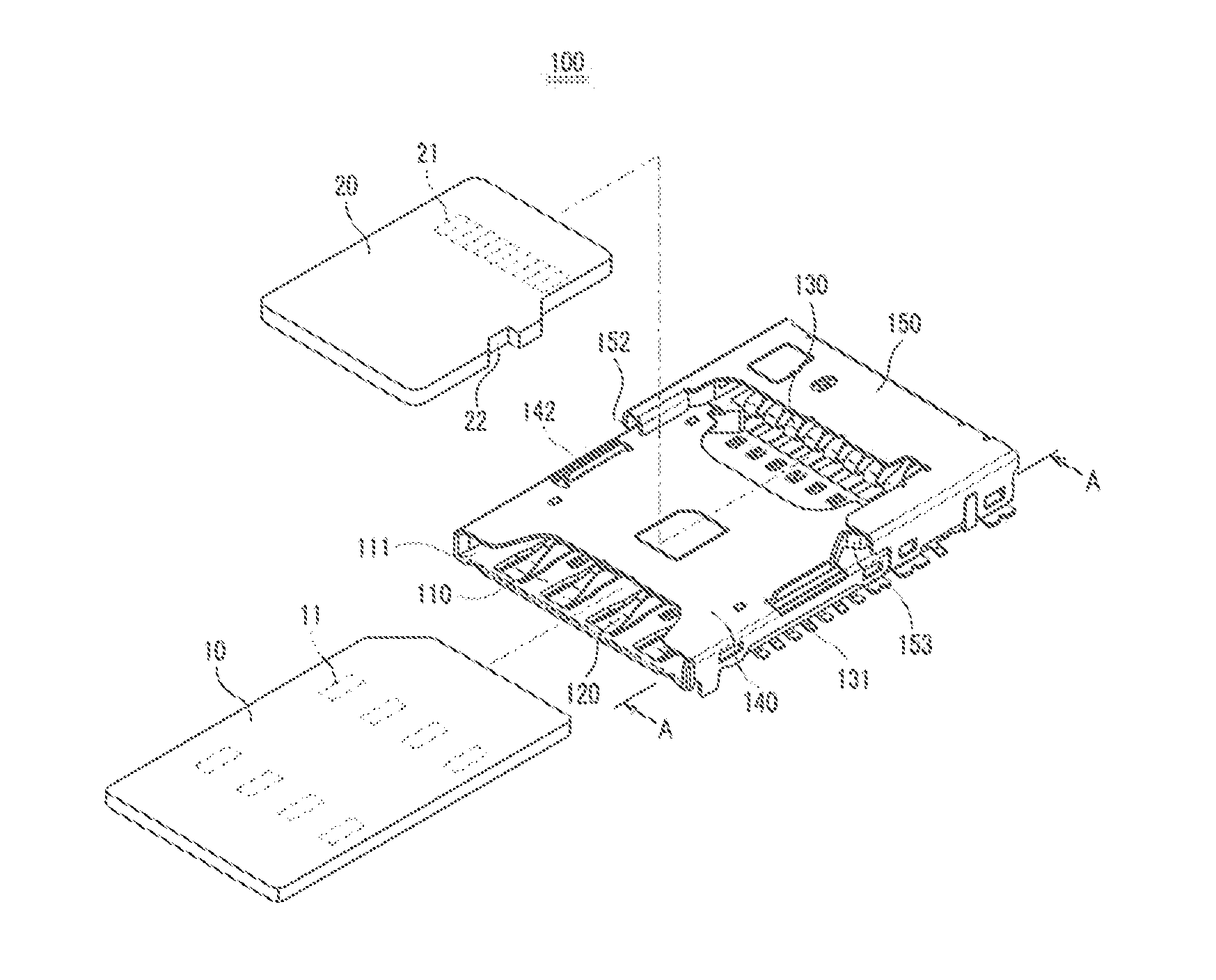

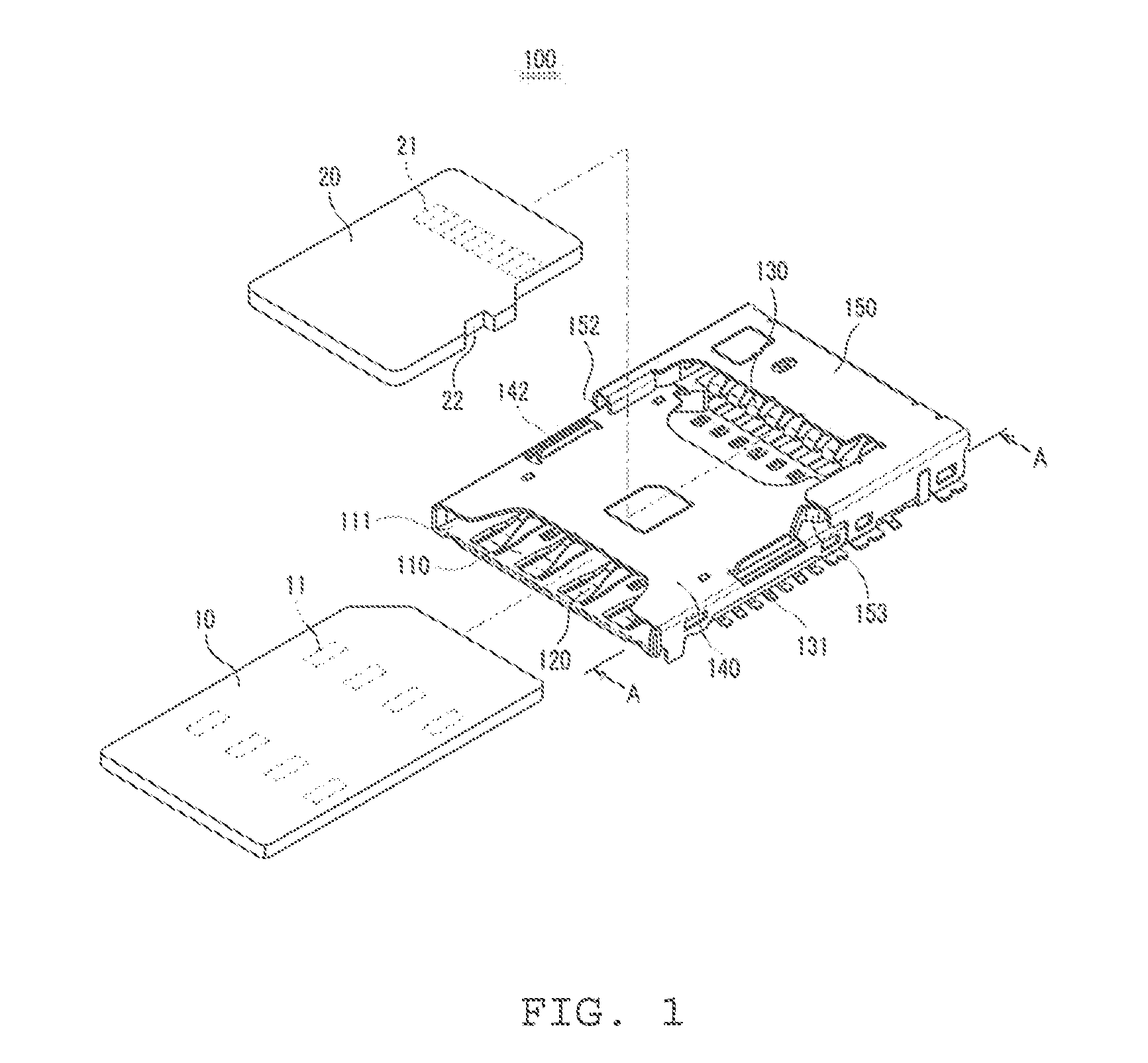

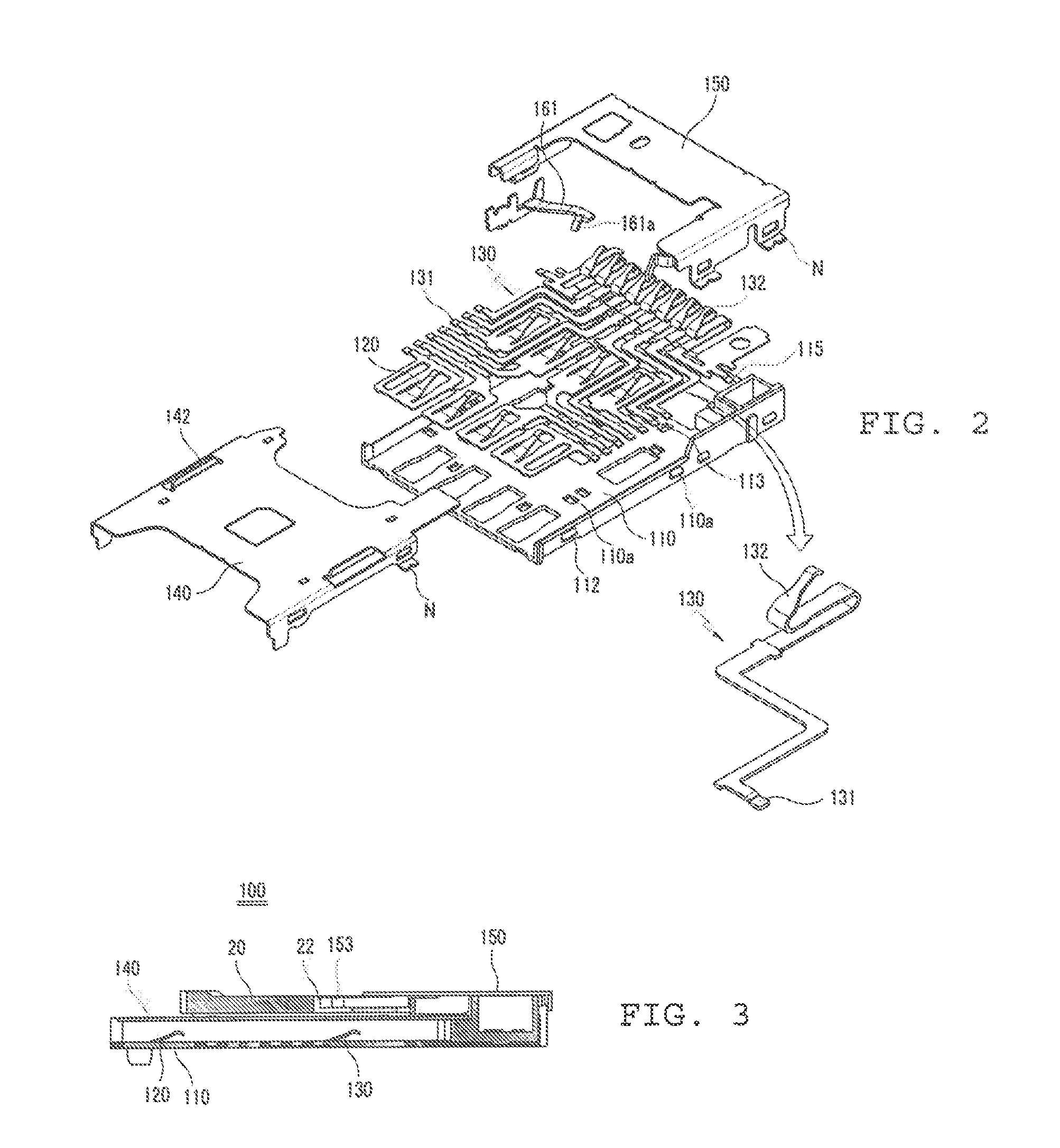

Dual memory card socket

ActiveUS20130288535A1Prevent saggingReduce manufacturing costCoupling device detailsTwo-part coupling devicesEngineeringMemory cards

The Present Disclosure relates to mold a micro SIM card connecting terminal and a micro SD card connecting terminal by means of an integrated terminal mold, so as to significantly reduce the whole length of the dual memory card socket and manufacturing method thereof. The Present Disclosure is formed by a structure manufactured by molding the micro SIM card connecting terminal and the micro SD card connecting terminal by means of an integrated terminal mold, and then separating them by a cutting process.

Owner:MOLEX INC

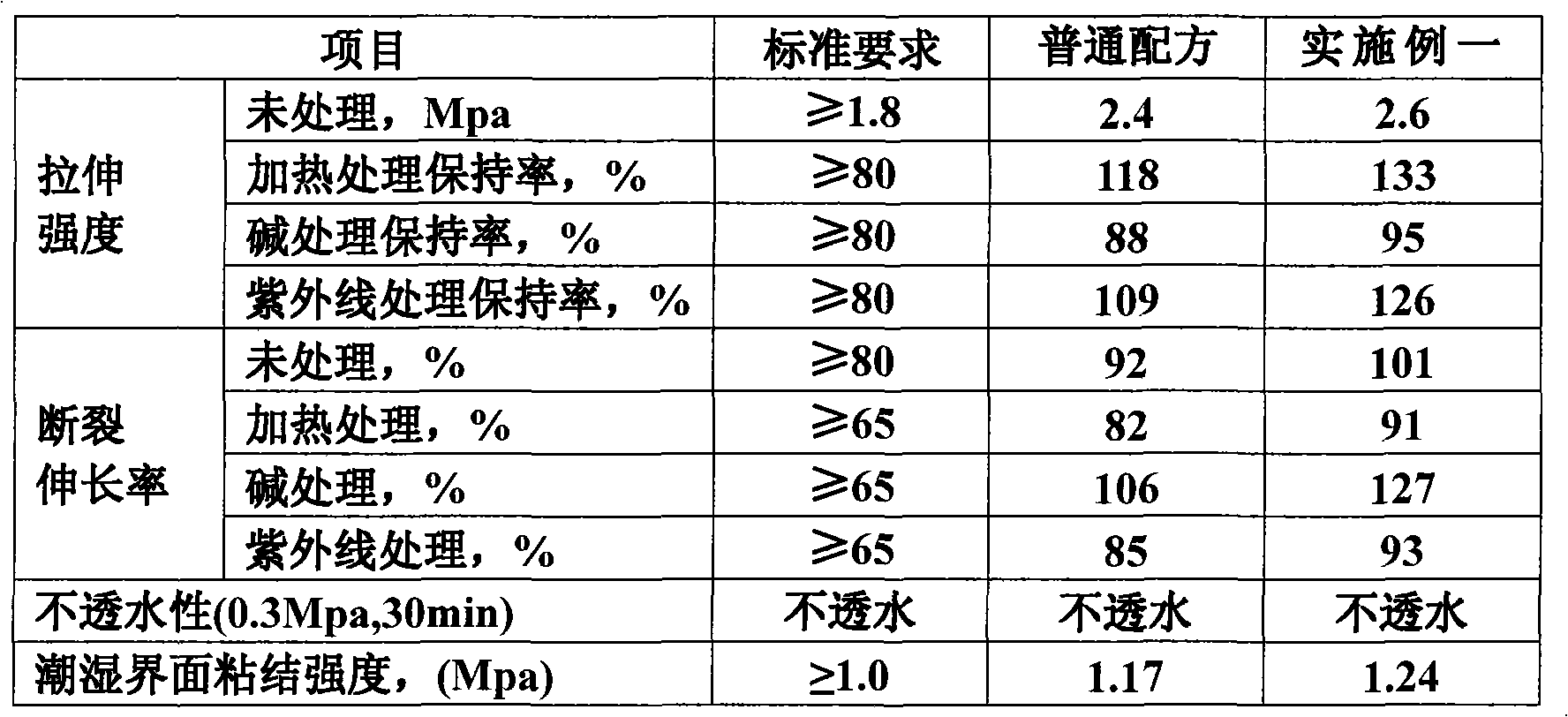

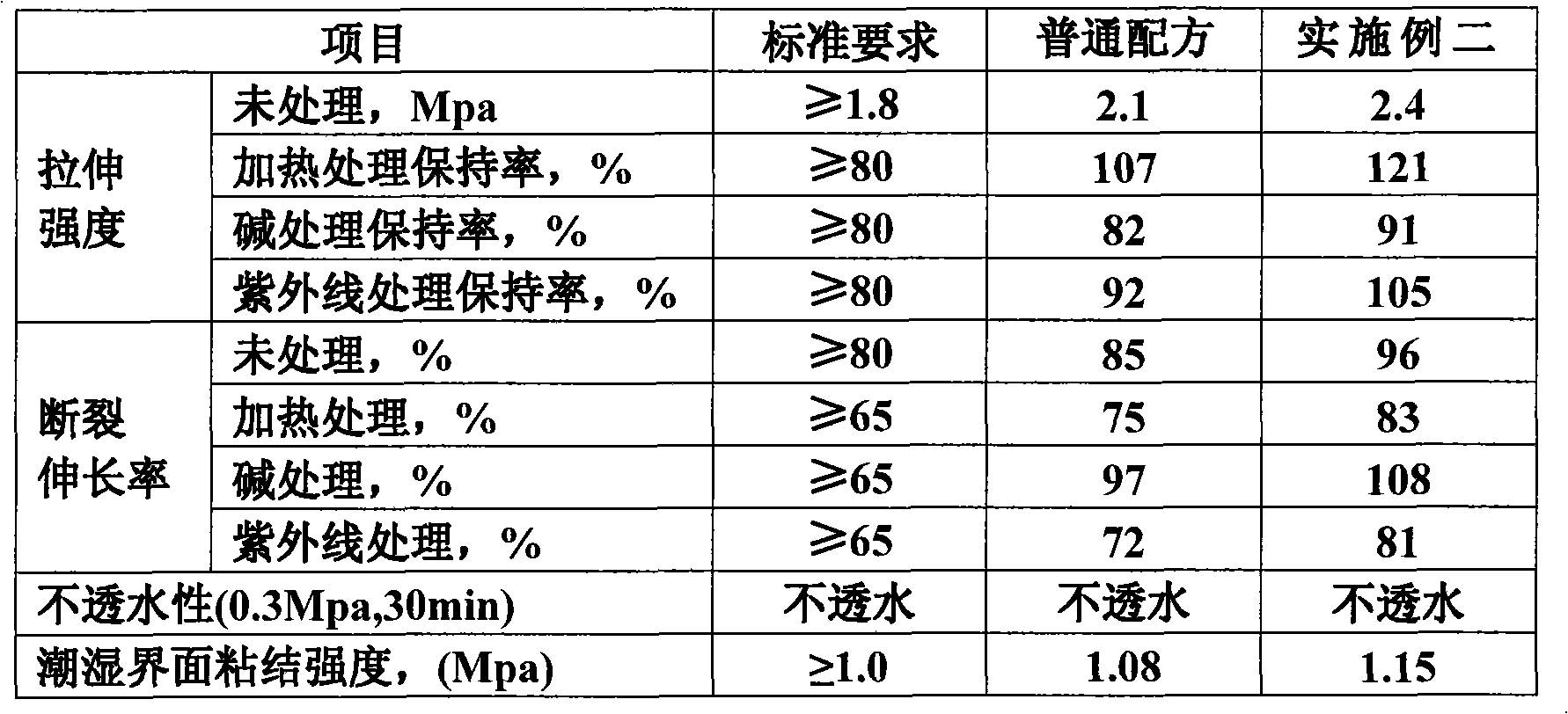

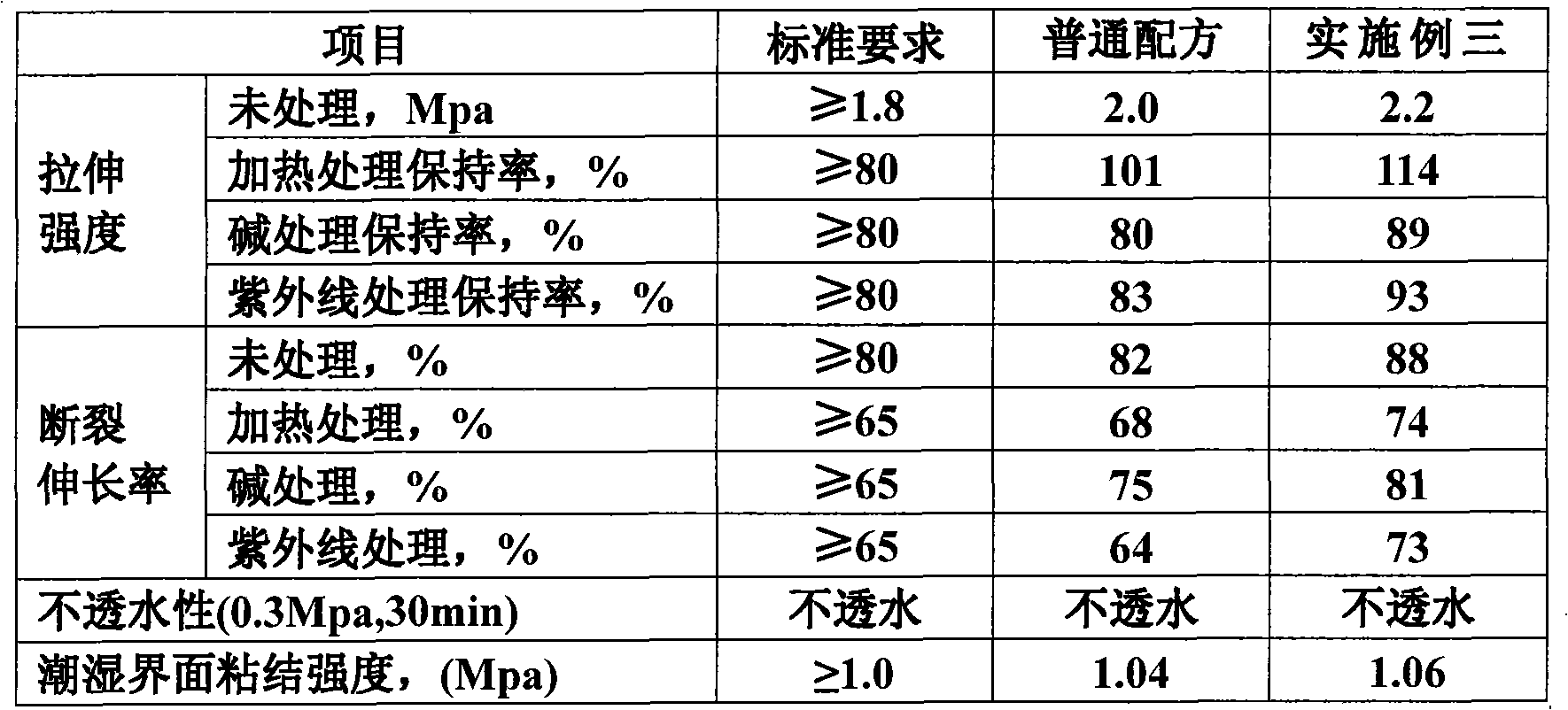

II-type polymer cement waterproofing coating modified by nano materials and preparation method thereof

ActiveCN101550309AImprove thixotropyPrevent saggingAntifouling/underwater paintsPaints with biocidesPlasticizerPolymer

The invention discloses a II-type polymer cement waterproofing coating modified by nano materials, which consists of a liquid material component and a powder material component, wherein the liquid material component comprises the following ingredients by weight: 85-95 percent of acrylic ester latex, 0.5-2 percent of plasticizer, 0.2-0.4 percent of dispersant, 0.2-0.5 percent of silicone antifoam agent, 0.1-0.3 percent of preservative, 0.3-0.6 percent of active ingredient content of pre-dispersed nano silicon dioxide solution, 0.02-0.06 percent of active ingredient content of pre-dispersed nano alumina solution, and the balance of water. The mixture ratio of the liquid material component to the powder material component is 10:14-20 according to proportions by weight. The invention greatly improves the thixotropy of the coating, prevents coating elevation construction from sagging, reduces loss in coating construction, simultaneously enhances all properties of the coating such as water resistance, alkaline resistance and the like, and obtains obvious effects.

Owner:苏州市姑苏新型建材有限公司

Foldable tonneau cover

ActiveUS7384090B1Prevent saggingSmooth appearanceRemovable external protective coveringsLoad coveringEngineeringTruck

A flexible tonneau cover for trucks that is easily folded for storage or shipping. The tonneau cover has a collapsible peripheral frame, with supporting bows spanning the width of the frame. The bows include separable parts for storage or shipping and can be assembled and expanded to spread the frame.

Owner:ADVANTAGE TRUCK ACCESSORIES

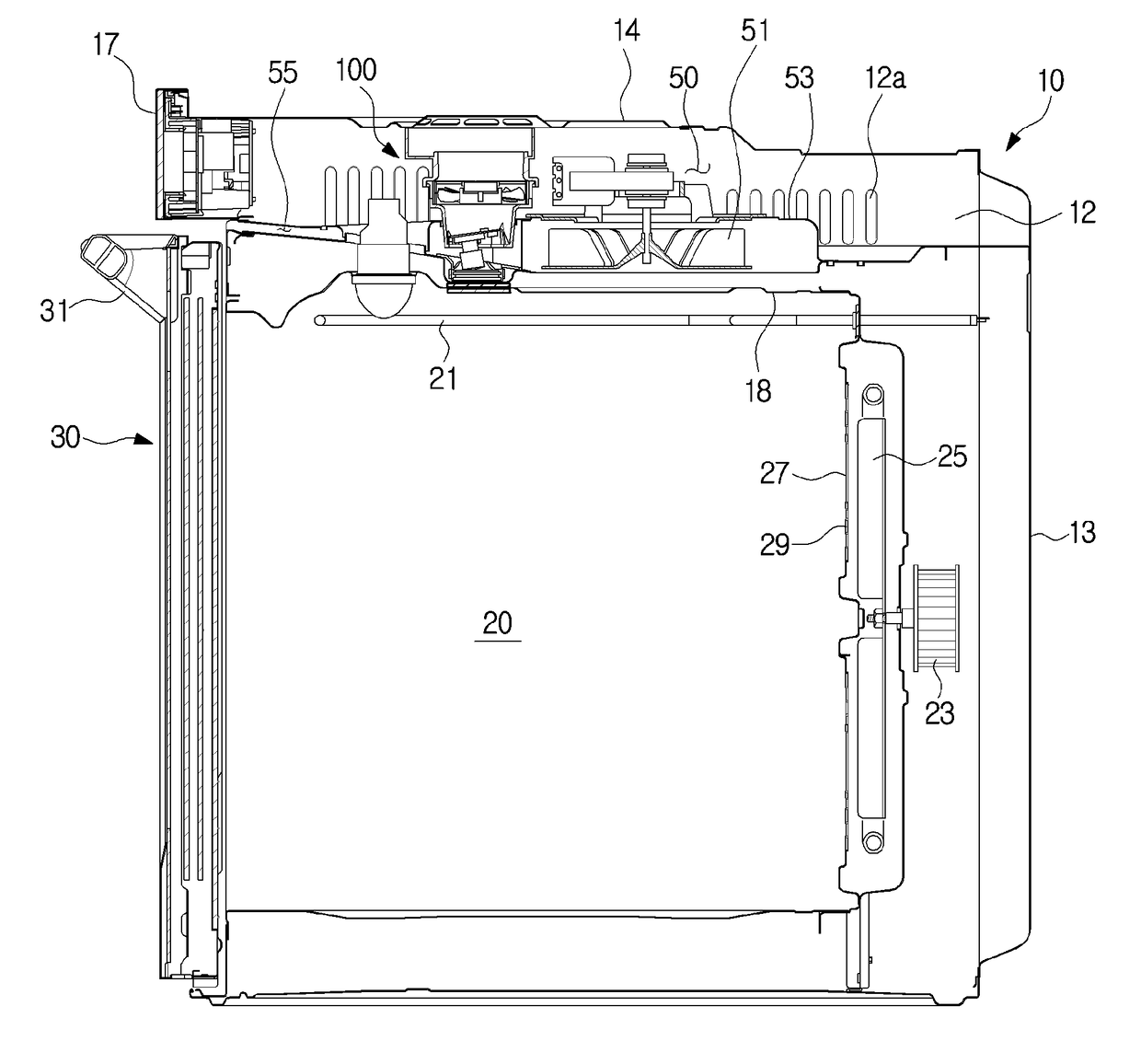

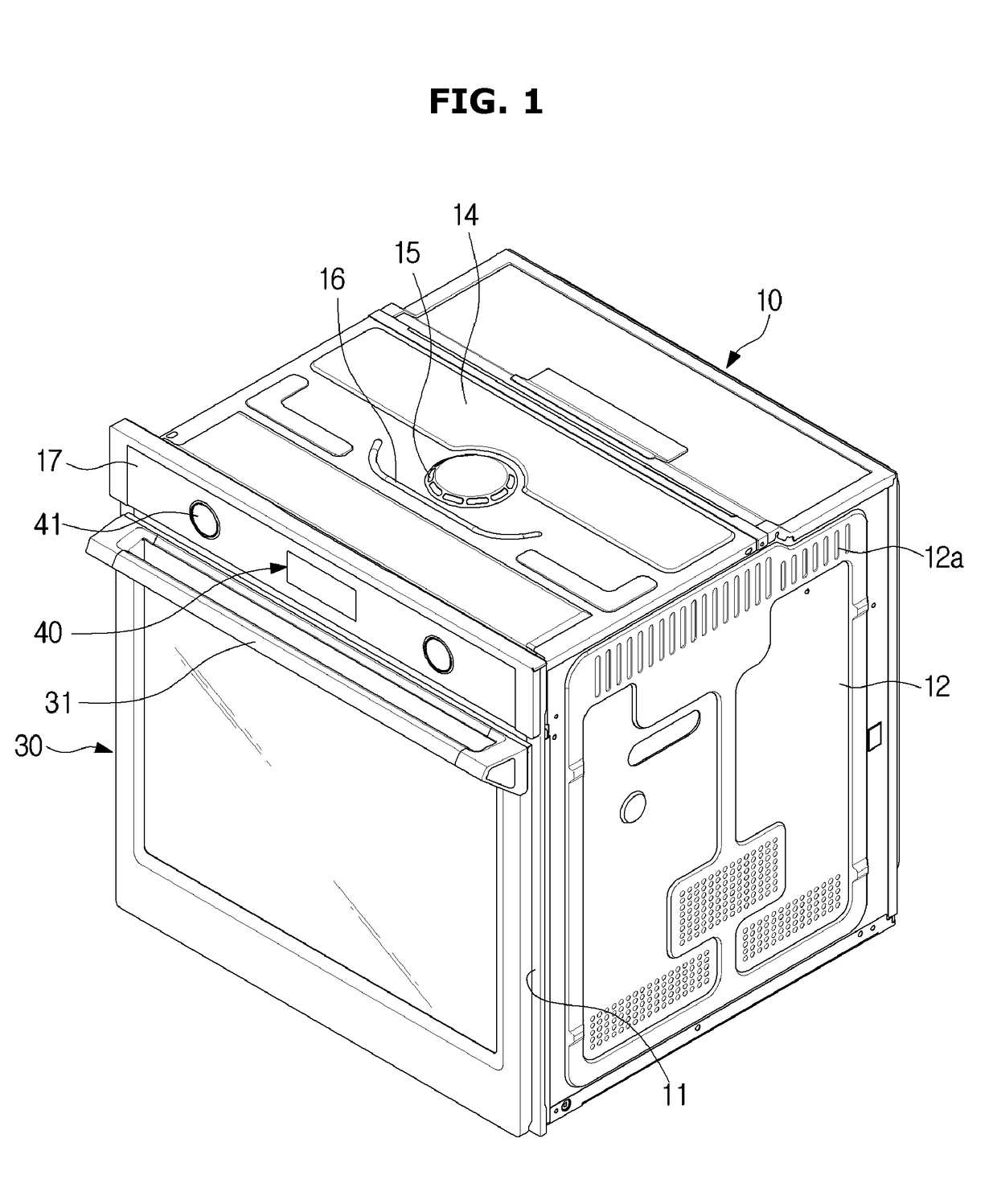

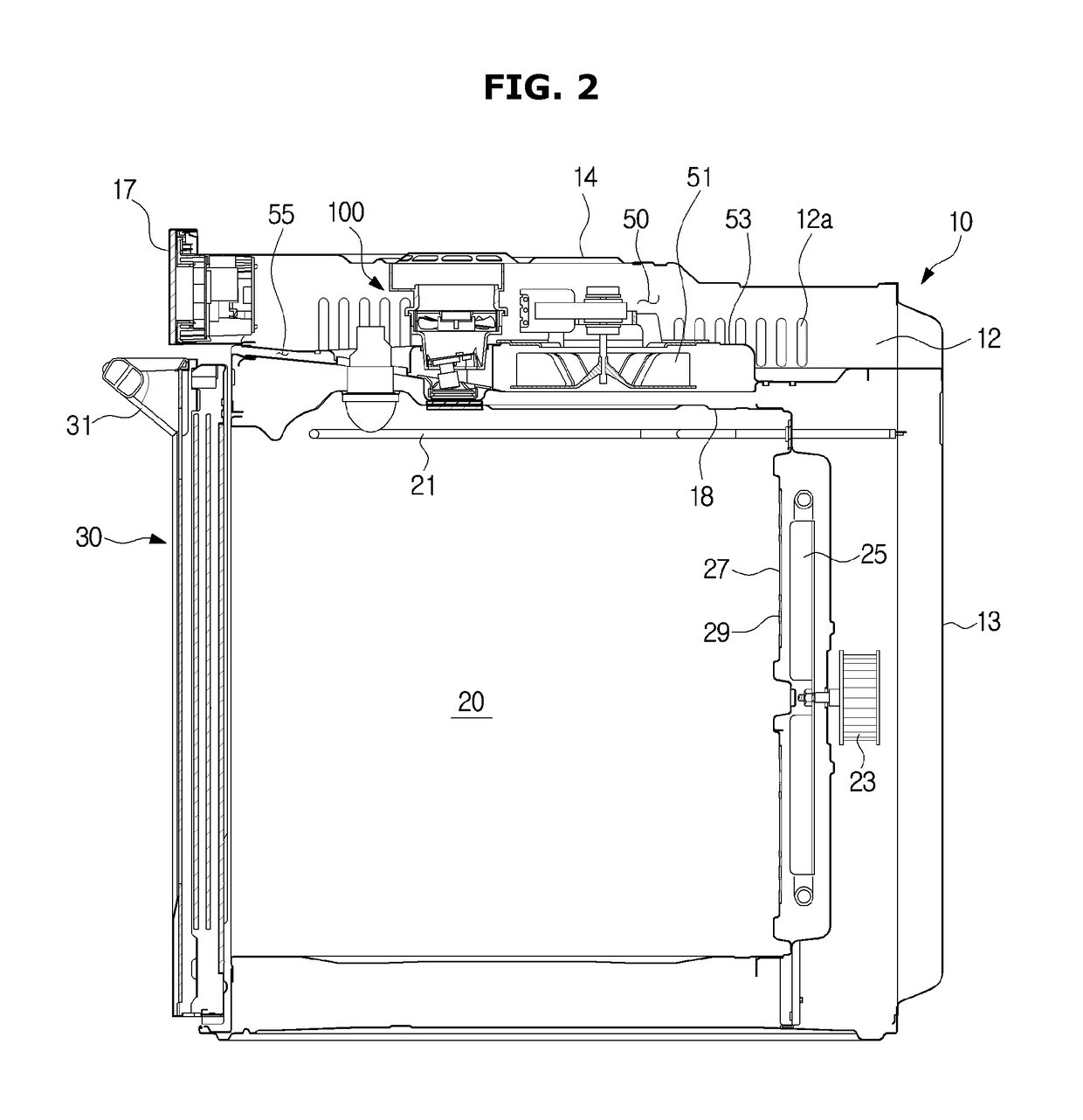

Oven

ActiveUS20180058702A1Avoid temperatureAvoid passingDomestic stoves or rangesFurnace componentsEngineeringFirst glasses

Owner:SAMSUNG ELECTRONICS CO LTD

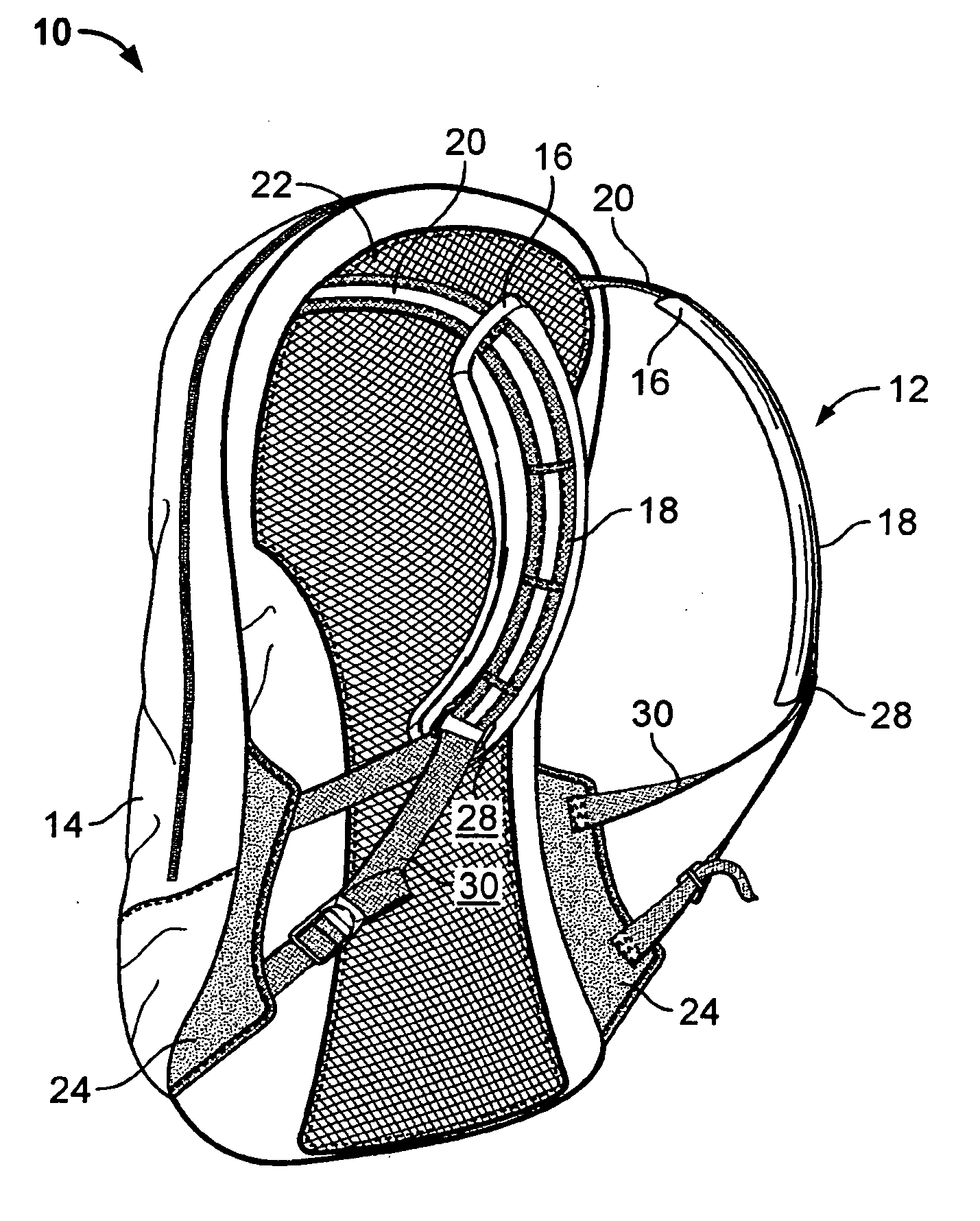

Backpack having distributed-load shoulder strap system

A backpack is provided, having a pack body and a shoulder strap system configured to hold the pack body securely against the user even during periods of high activity. The strap system includes two shoulder straps each having a lower portion attached to a coupler having an extended interface with the pack body, to inhibit sagging and secure the pack body to the user.

Owner:SAMSONITE IP HLDG SARL

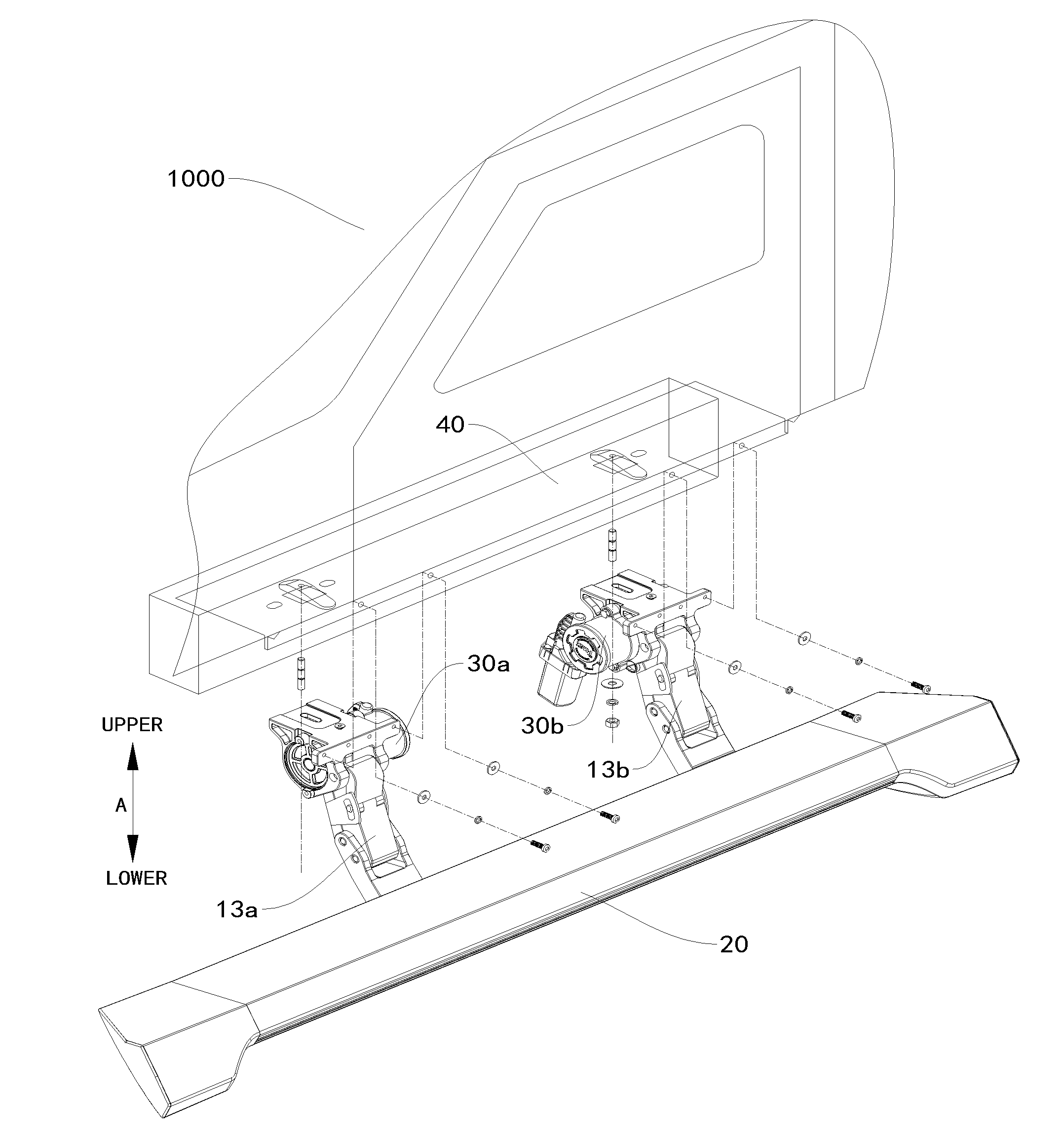

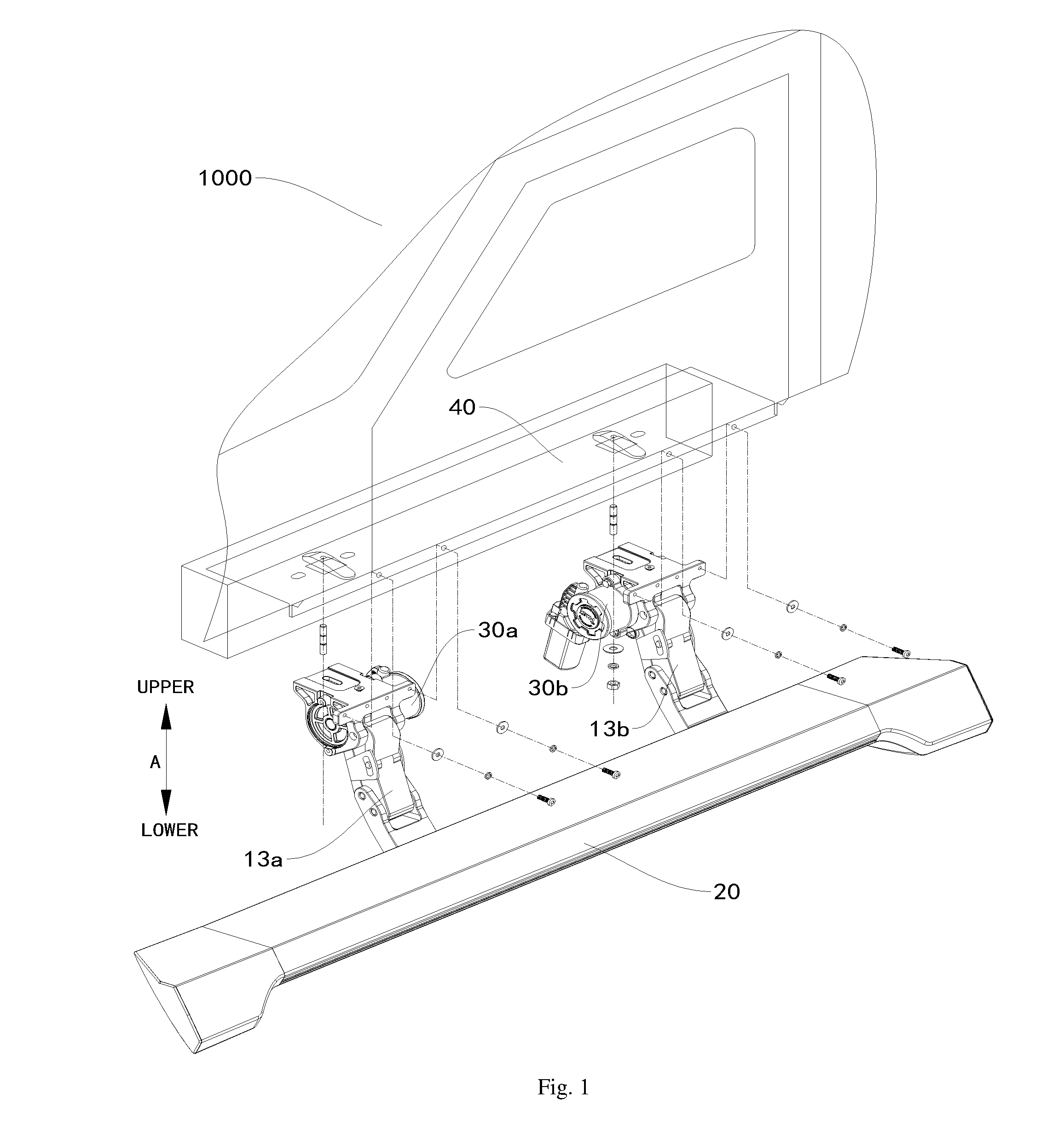

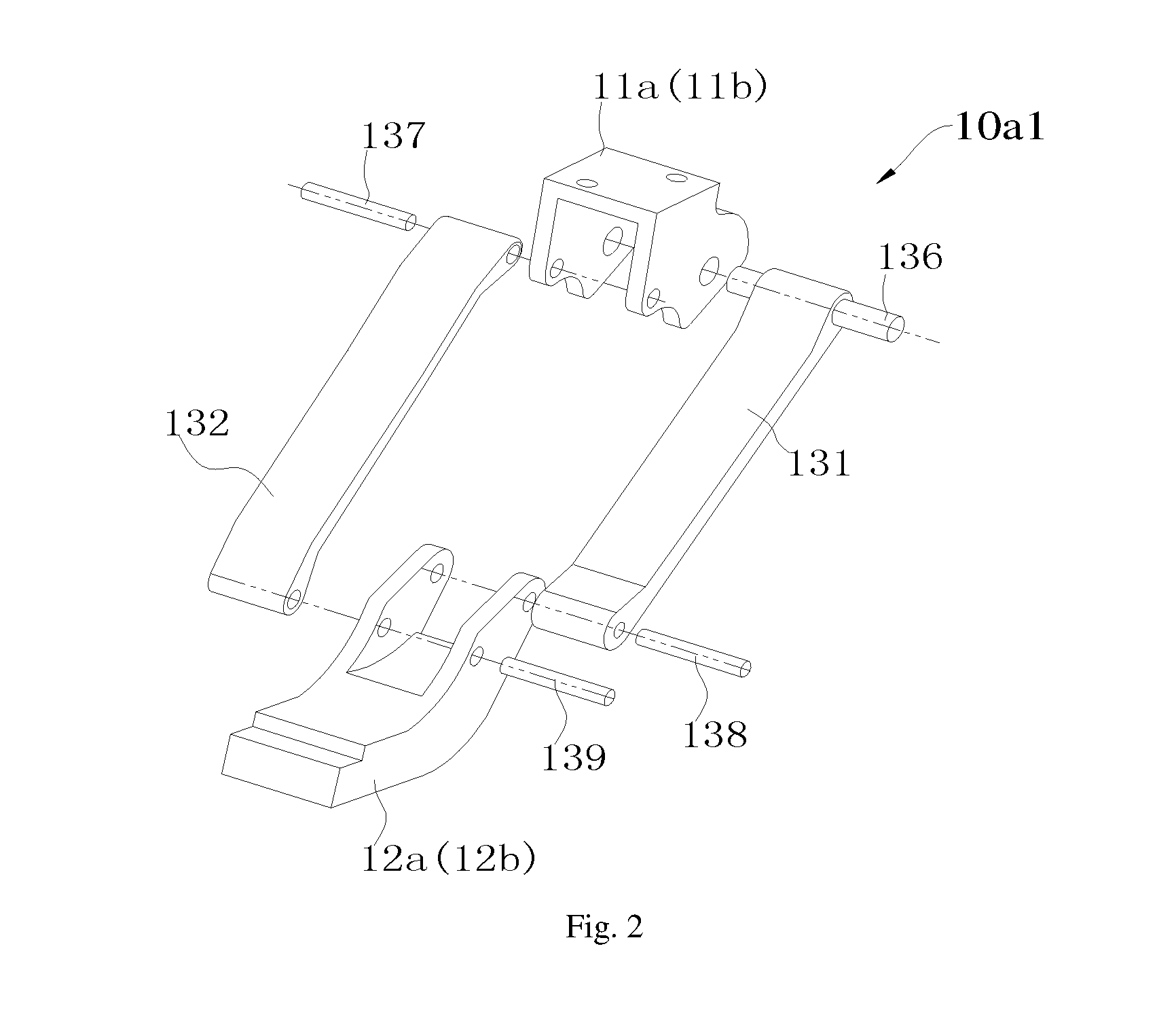

Vehicle and vehicle step apparatus

ActiveUS20170036607A1Low manufacturing costLong working lifeSteps arrangementEngineeringPermanent magnet dc motor

A vehicle step apparatus including a first extending and retracting device having a first mounting bracket, a first step bracket, and a first arm assembly configured to drive the first step bracket to move between a first extending position and a first retracting position; a second extending and retracting device comprising a second mounting bracket, a second step bracket, and a second arm assembly configured to drive the second step bracket to move between a second extending position and a second retracting position; a step mounted on the first and second step bracket; a first permanent magnet direct current motor mounted on the first mounting bracket and coupled with the first arm assembly to drive the first arm assembly; and a second permanent magnet direct current motor mounted on the second mounting bracket and coupled with the second arm assembly to drive the second arm assembly.

Owner:HANGZHOU TIANMING TECH CO LTD

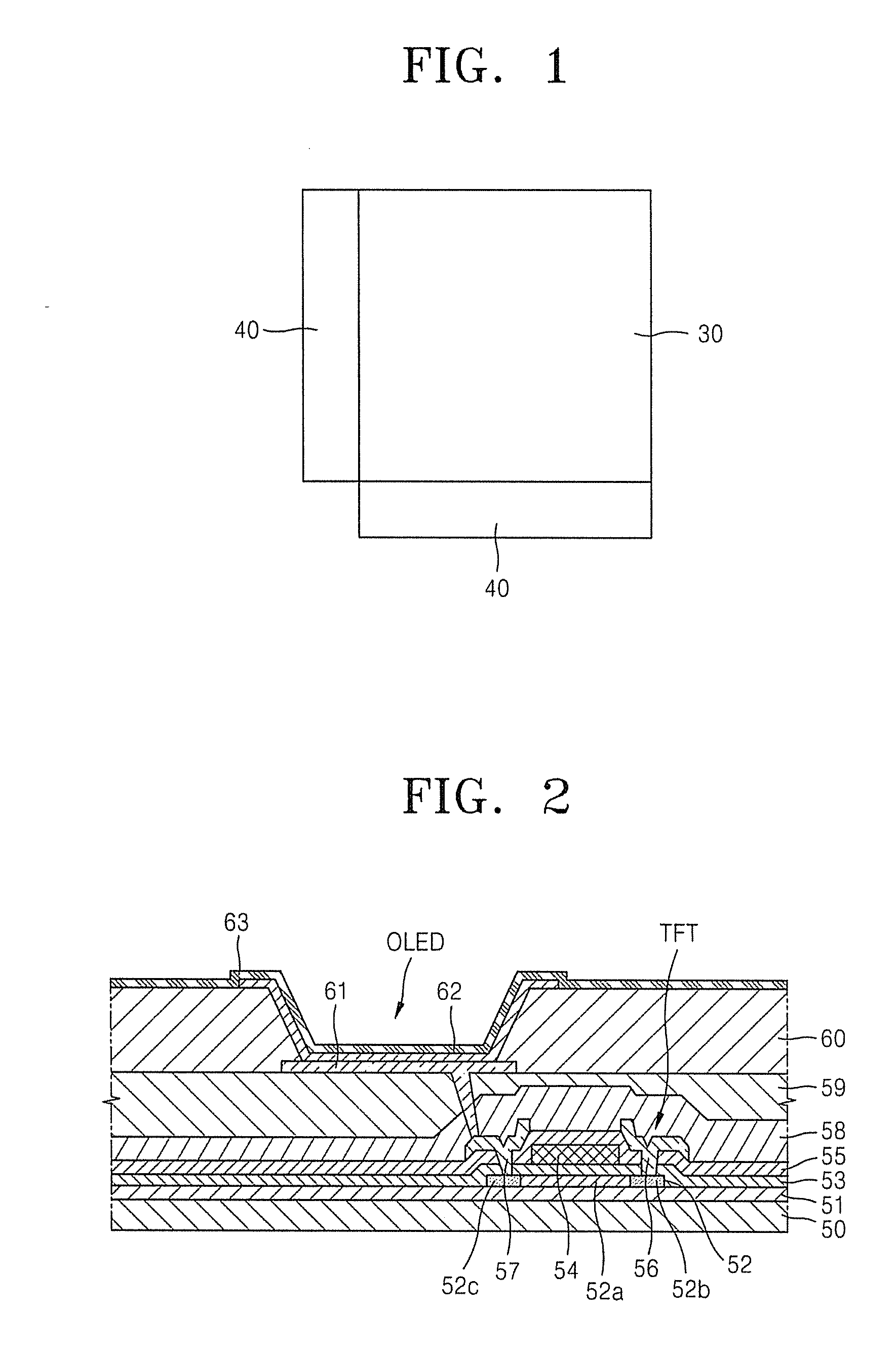

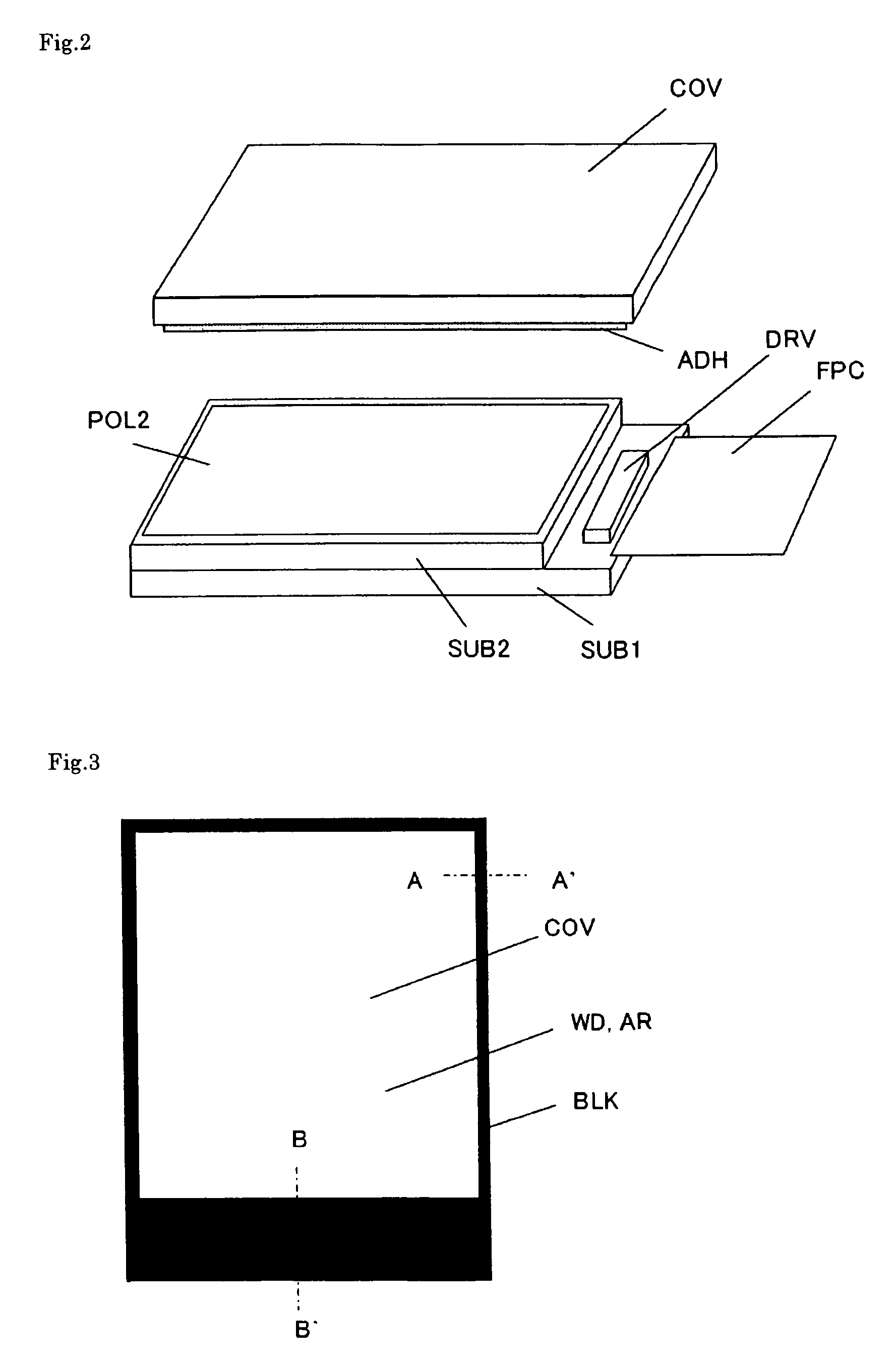

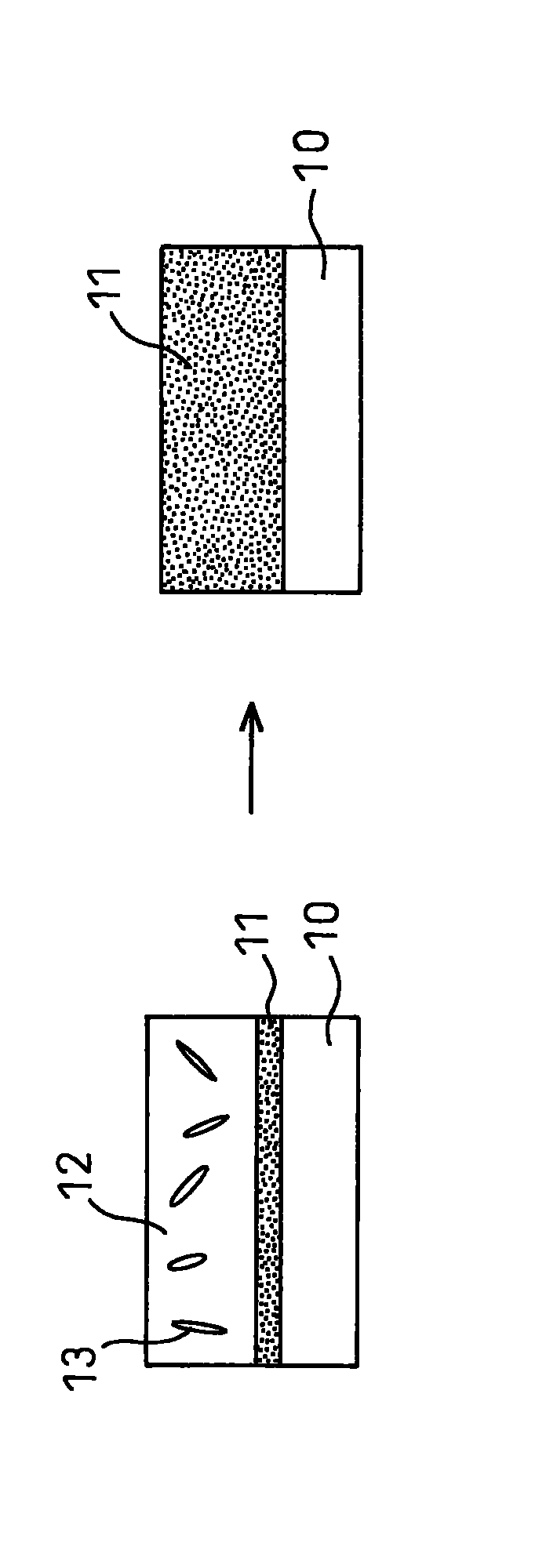

Display device

ActiveUS20090066862A1Prevent saggingMoisture can be preventedNon-linear opticsLiquid-crystal displayAdhesive

The present invention is directed to providing a technology for display devices where a transparent cover is pasted on a display panel according to which inconsistencies resulting from expansion of the polarizing plate in the vicinity of an end portion caused by moisture can be prevented, and the adhesive can be prevented from sagging when the display panel and the transparent cover are pasted together. A display device according to the invention is provided with: a liquid crystal display panel having a first substrate, a second substrate provided on the viewer side of the above described first substrate and a liquid crystal layer sandwiched between the above described first substrate and the above described second substrate; and a transparent cover pasted on the surface of the above described liquid crystal display panel on the above described viewer side using an adhesive. The above described liquid crystal display panel has a polarizing plate between the above described second substrate and the above described transparent cover. The above described adhesive covers the entirety of a side of the above described polarizing plate, and the form of the outer periphery of the above described adhesive in a plane is uneven.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Track and guide system for a door

ActiveUS20070277942A1Smoothen engagementPrevent saggingScreensShutters/ movable grillesDistortionSurface plate

A vertically operating door and its drive system can be configured to push a door panel along a track to various overhead storage configurations including vertical, horizontal. inclined and coiled. Semi-flexible drive strips extend continuously along lateral edges of the curtain. The system includes a drive gear that engages a series of projections on at least one drive strip so that the gear can push the door between its open and closed positions. To protect the door from being damaged by collisions, the track can include a breakaway feature that allows at least a portion of the panel with its drive strip to separate from the track without permanent distortion. The drive strip and panel remain together as they break away from the track. The threshold of the breakaway force can be changed by selecting a retention strip from a plurality of interchangeable strips having different degrees of flexibility.

Owner:RITE HITE HLDG CORP

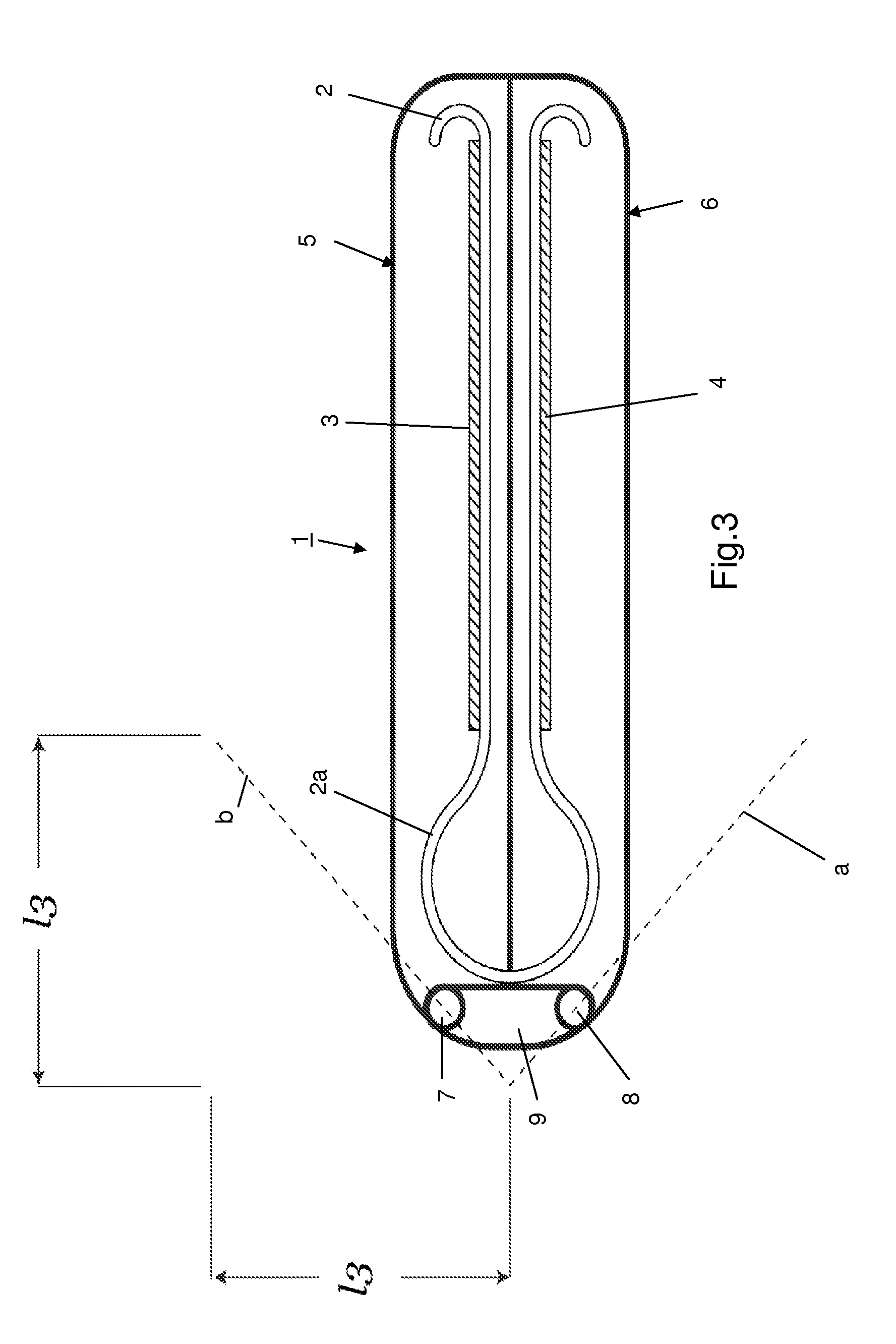

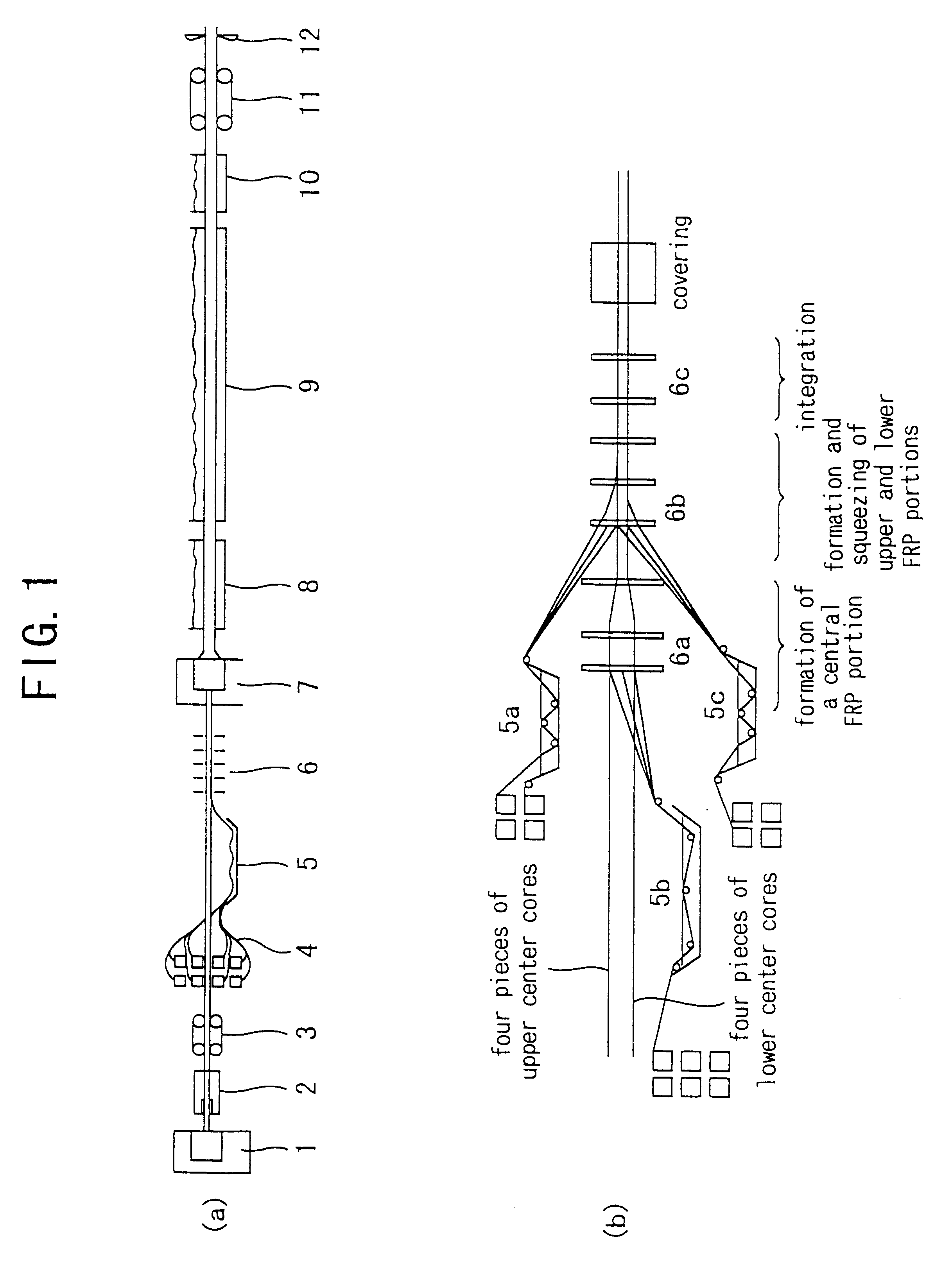

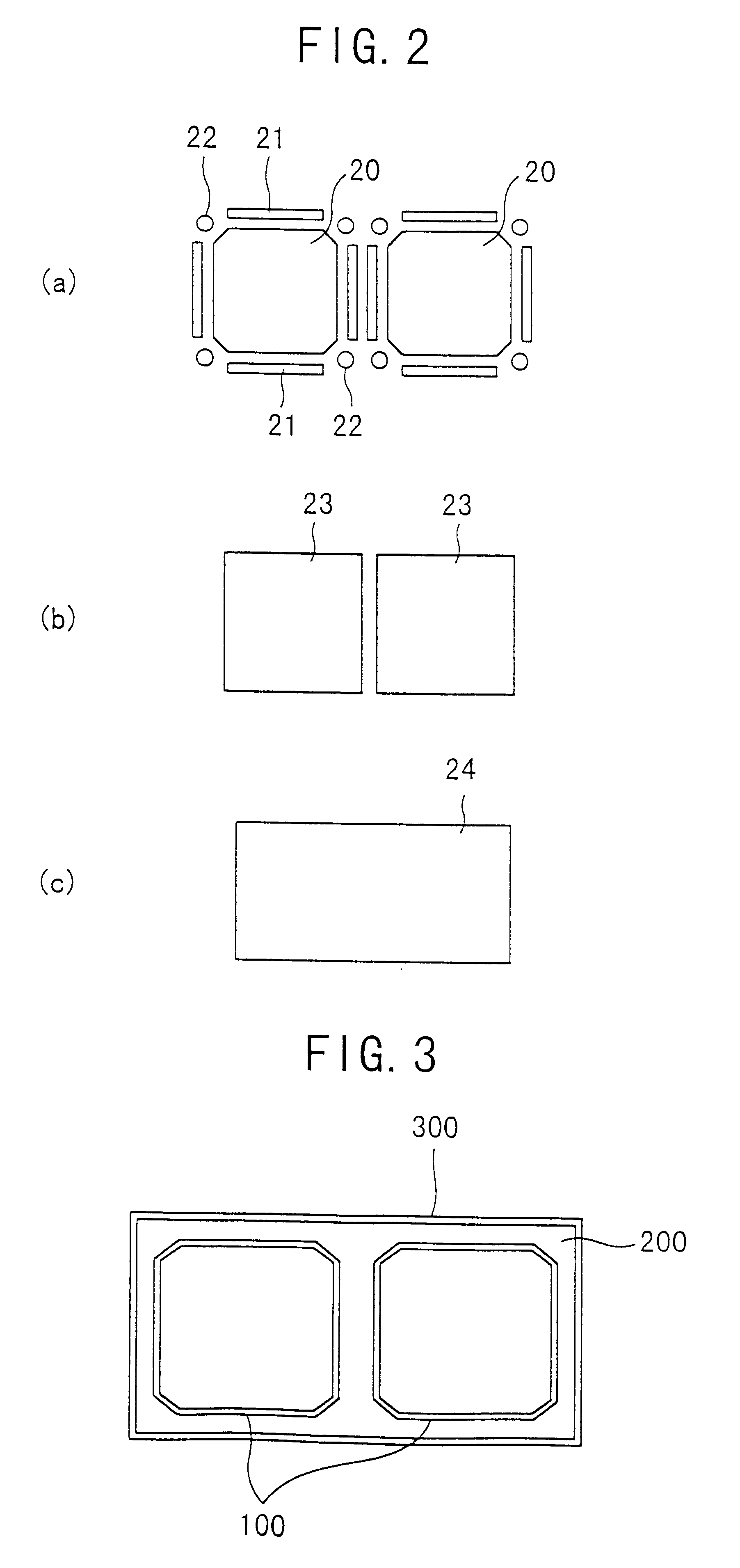

Fiber-reinforced composite hollow structure, method for production thereof, and apparatus therefor

InactiveUS6607798B1Prevent saggingUniform coverageEnvelopes/bags making machineryWrappers shrinkageEngineeringFiber-reinforced composite

Center cores are formed by extrusion-molding ABS resin. Seven pieces of the center cores, which are juxtaposed to each other in the horizontal direction, are supplied by a pultruder, and reinforcing long-fibers impregnated with an unsaturated polyester resin are allowed to pass through dispersion guides and squeezing nozzles, to thus squeezing-mold a fiber-reinforced composite hollow structure having FRP made legs. A final squeezing nozzle is disposed in a cross head die through a cooling jacket, and the hollow structure thus molded is allowed to pass therethrough to be covered with the ABS resin in a state in which the outer periphery of the hollow structure is heated. The hollow structure thus covered is subjected to cooled-sizing through a plurality of horizontal and vertical pairs of rollers, and then cured in a hot curing tank. The surface covered with the ABS resin is subjected to a surface-treatment of imparting irregularities for giving an antislipping function to the surface. A thermoplastic resin-made protective cap is fitted to an end of the center core. The apparatus for manufacturing a composite hollow structure has a plurality of pairs of rotatable and heat-resisting sizing rollers. The plurality of pairs of the sizing rollers are disposed in the pultruding direction while being gradually cooled in the order from those positioned on the upstream side to those positioned on the downstream side for sizing the softened outer layer covering the outer periphery of the intermediate layer.

Owner:UBE NITTO KASEI CO LTD

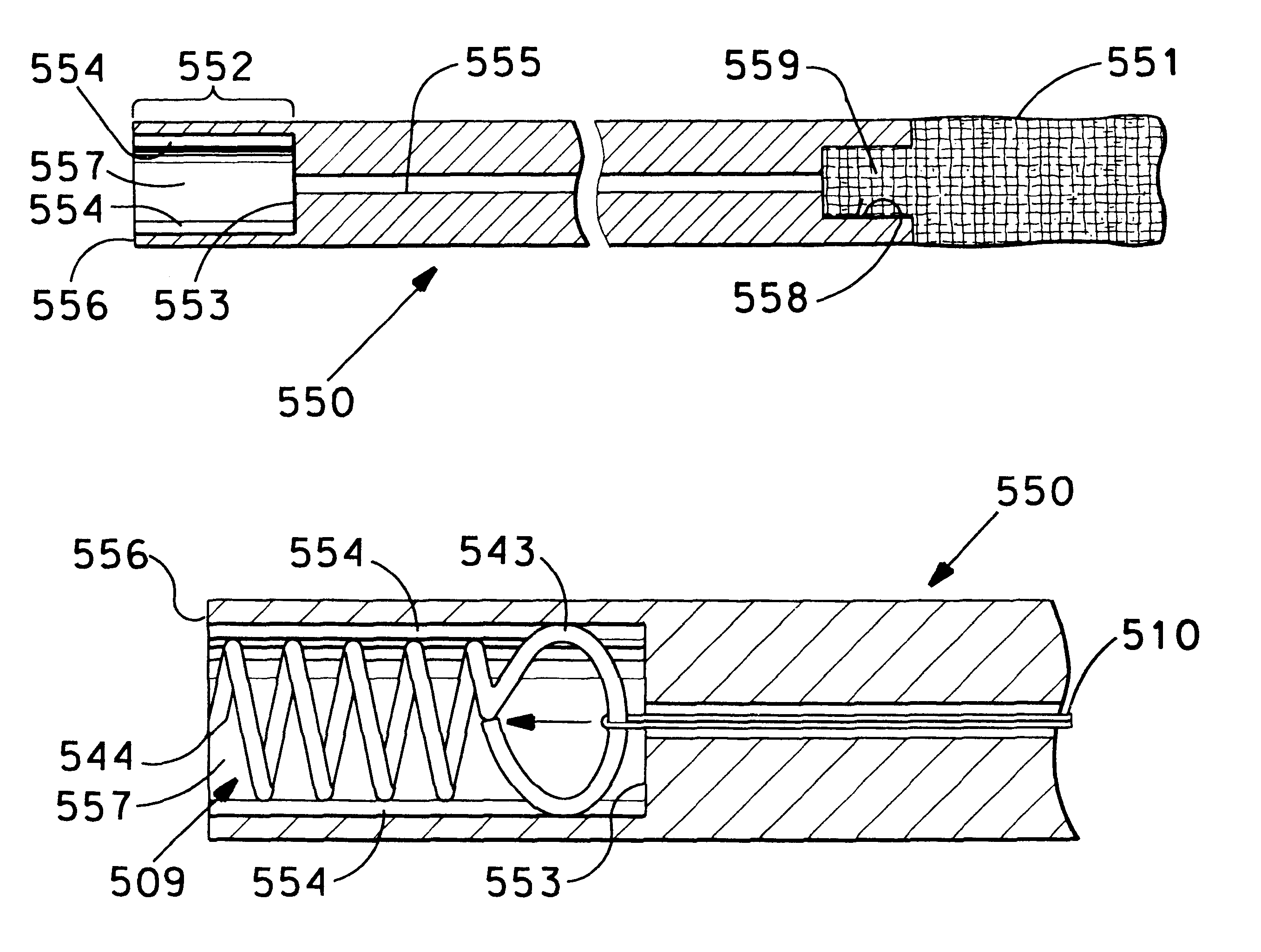

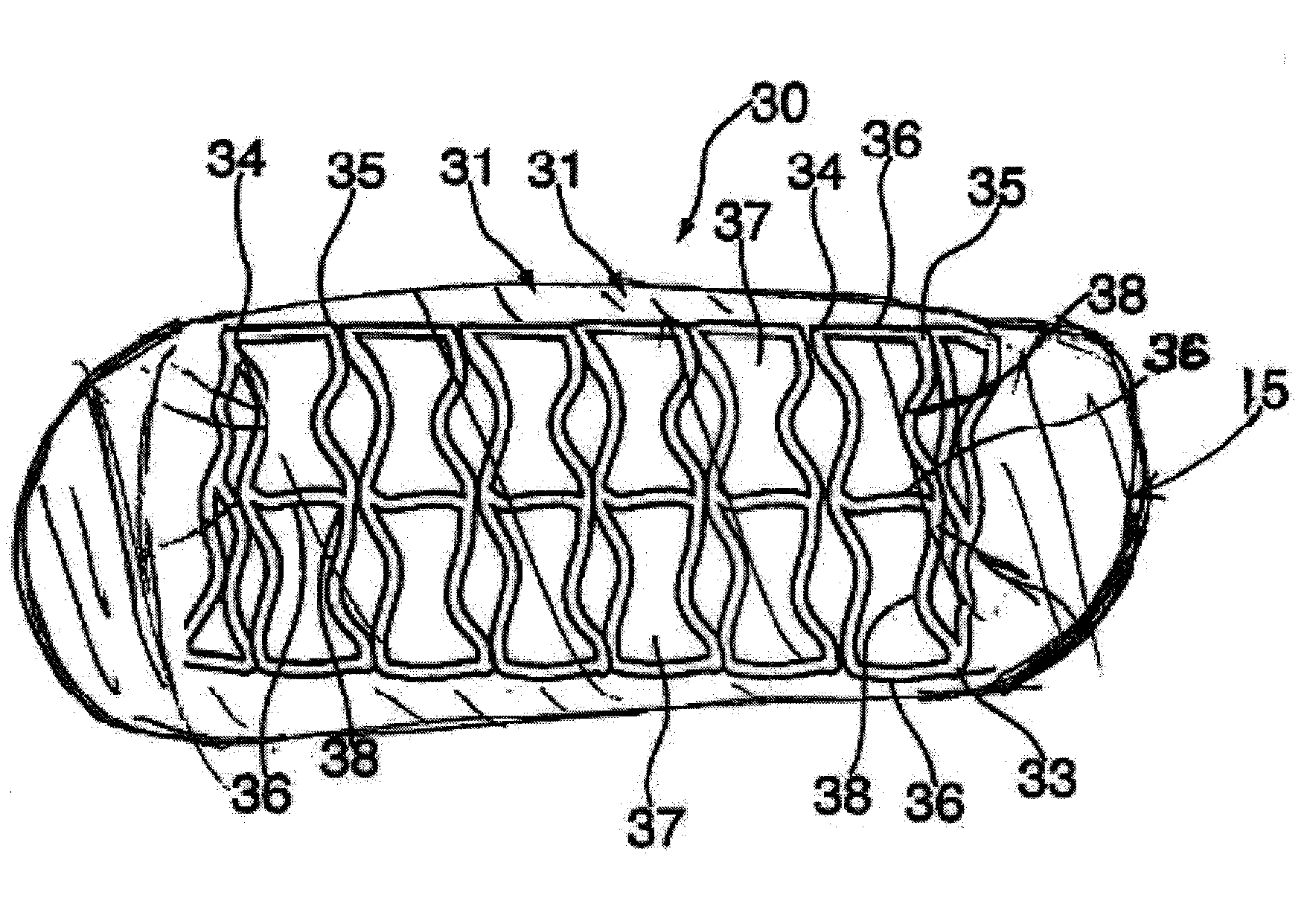

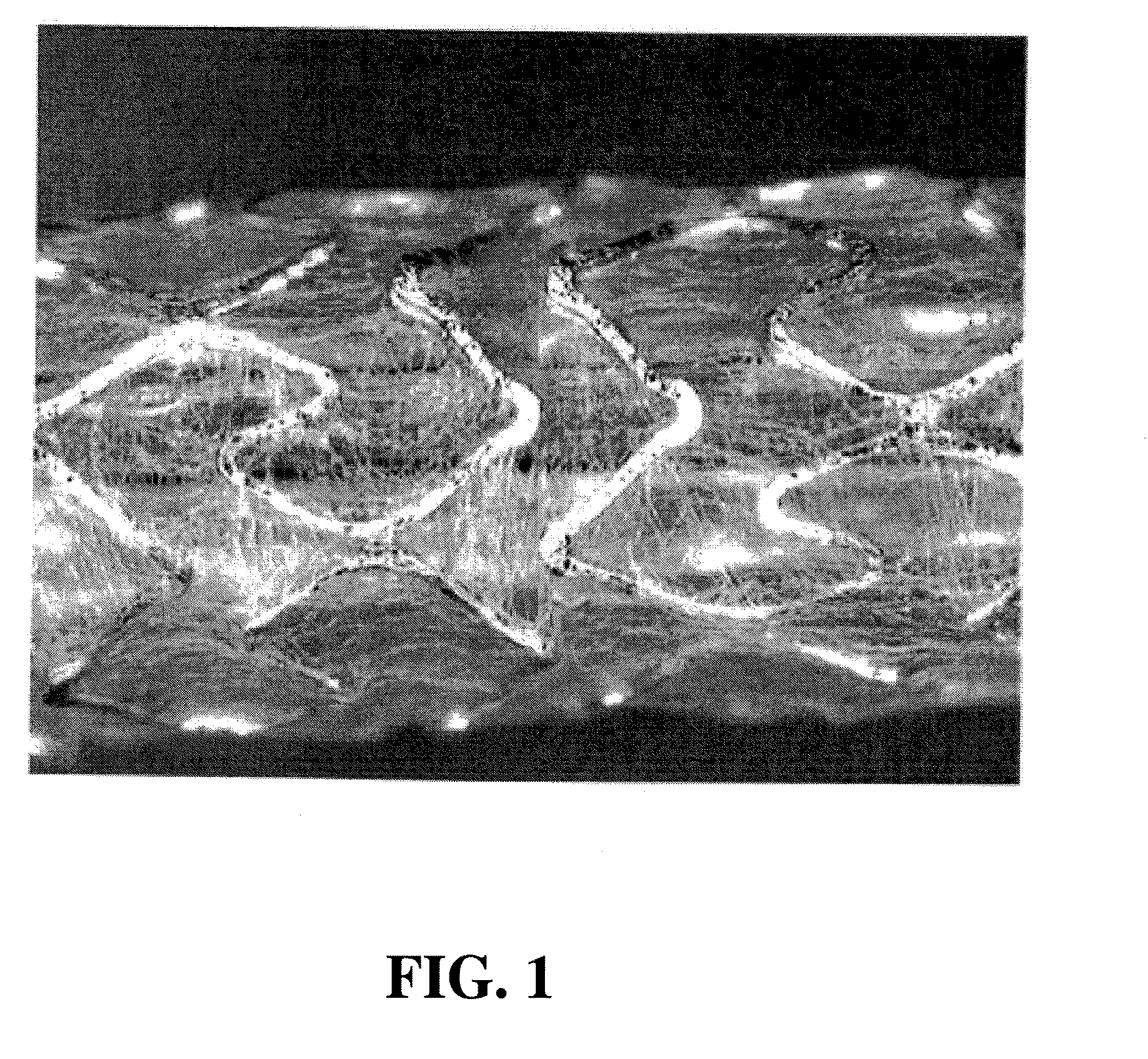

Helical hybrid stent

ActiveUS20090234433A1Easy to trackAvoid tilts and bendsStentsOrganic active ingredientsMedicineHelical coil

An expandable helical stent is provided, wherein the stent may be formed of an amorphous metal alloy or other non-amorphous metal with a securement. The stent is formed from flat or tubular metal in a helical coiled structure which has an undulating pattern. The main stent component may be formed of a single helically coiled component. Alternatively, a plurality of helically coiled ribbons may be used to form a stent heterogeneous in design, material, or other characteristic particular to that stent. The helical tubular structure may be secured with a securement, such as a weld, interlock or a polymer, to maintain the helical coils in a tubular configuration. The helical coils of the main stent component may be spaced apart or nestled to each other. The nestling of the undulation of adjacent helical coils contributes to maintaining the tubular shape of the helically coiled stent. In addition, the nestling of helical coils may prevent the polymer layer from sagging at any point between cycles of the helical coils.

Owner:MEDINOL LTD

Board assembly

ActiveUS20120317911A1Stable qualityEasily assembleConstruction materialRoof covering using tiles/slatesEngineeringHigh pressure

A floor board assembly convenient to lay is characterized in that, in one embodiment, it comprises a frame, a filler board and an upper material with the frame and filler board affixed to the underside of the upper material. The frame includes latch tongues that extend outwardly from the lower side edges of the frame, and the tongues have locking projections that fit into recesses arranged just inside the periphery of the underside of the frame. The tongues and intervening spaces (with locking bars behind them) are space along the periphery of the board, such that any side of one board may be joined to any side of a similarly configured board. The upper material may be selected from a variety of materials, including LVT (luxury vinyl tile), carpet, high pressure laminate or other decorative material. The filler board may be selected to accomplish reduced cost, and / or improved acoustics. In other embodiments, a frame and / or upper material may be absent. The floor board assembly requires a lower manufacture cost and lower equipment investment, has stable quality, versatility and ease of installation.

Owner:HONG KONG MEI LI SHENG FLOORING +1

Post mold cooling of preforms

InactiveUS6887418B2Improve cooling effectPrevent saggingDischarging arrangementMouldsInjection mouldingMaterials science

Owner:MOLD MASTERS 2007

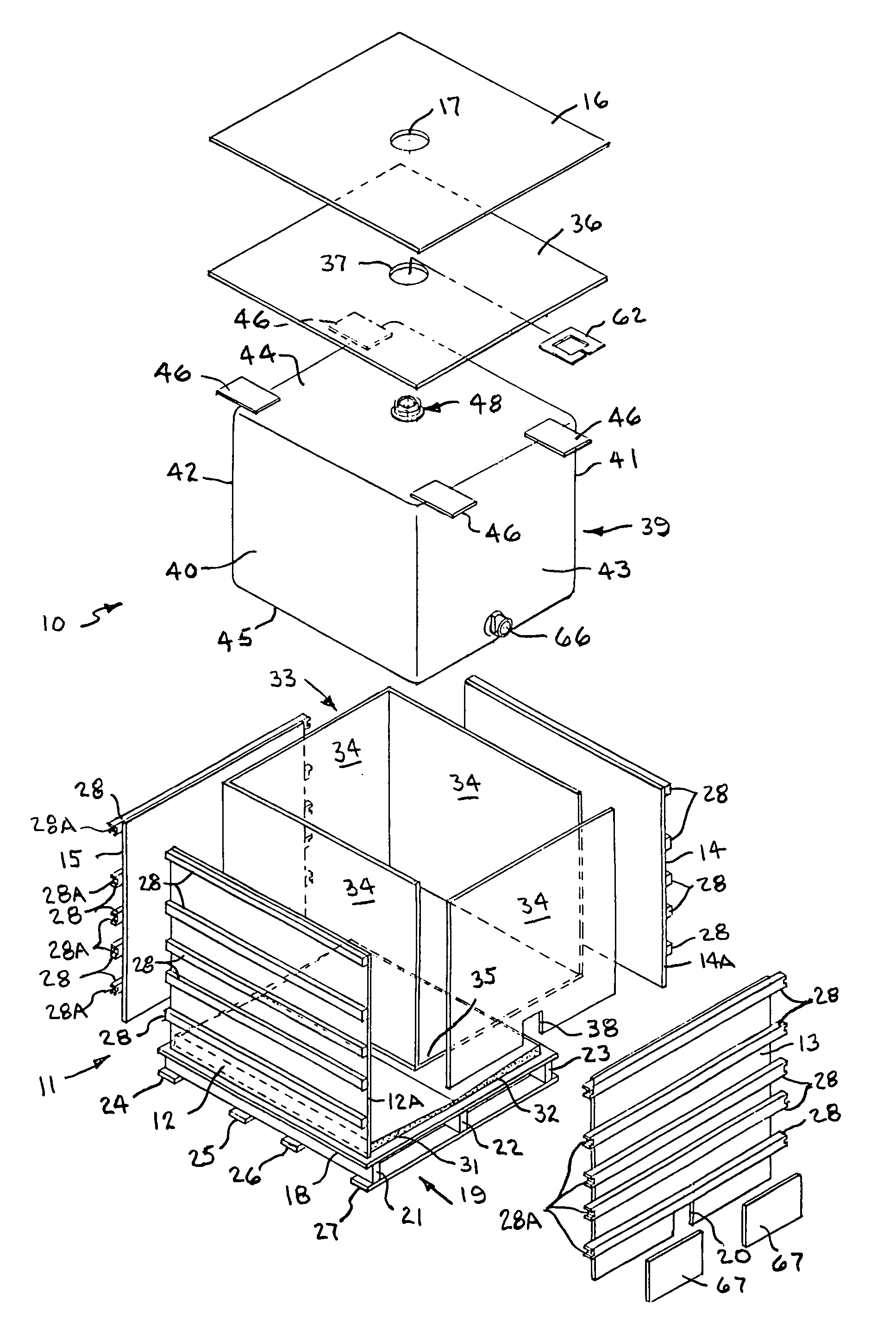

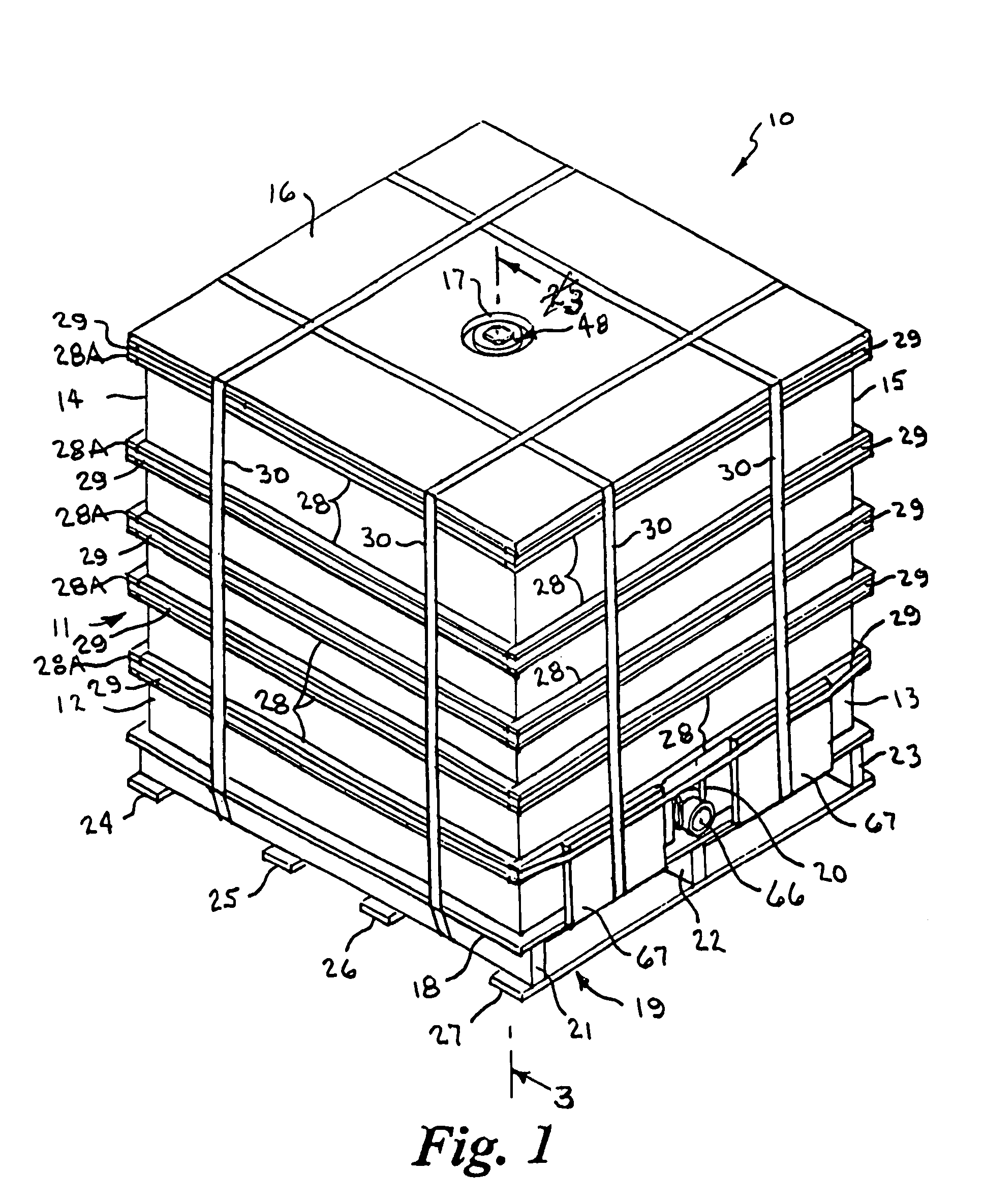

Container for bulk handling of fluids

InactiveUS7337908B2Prevent the top of the bag from saggingReduce the amount requiredLarge containersOther accessoriesCushioningEngineering

Owner:MILLAN BOX

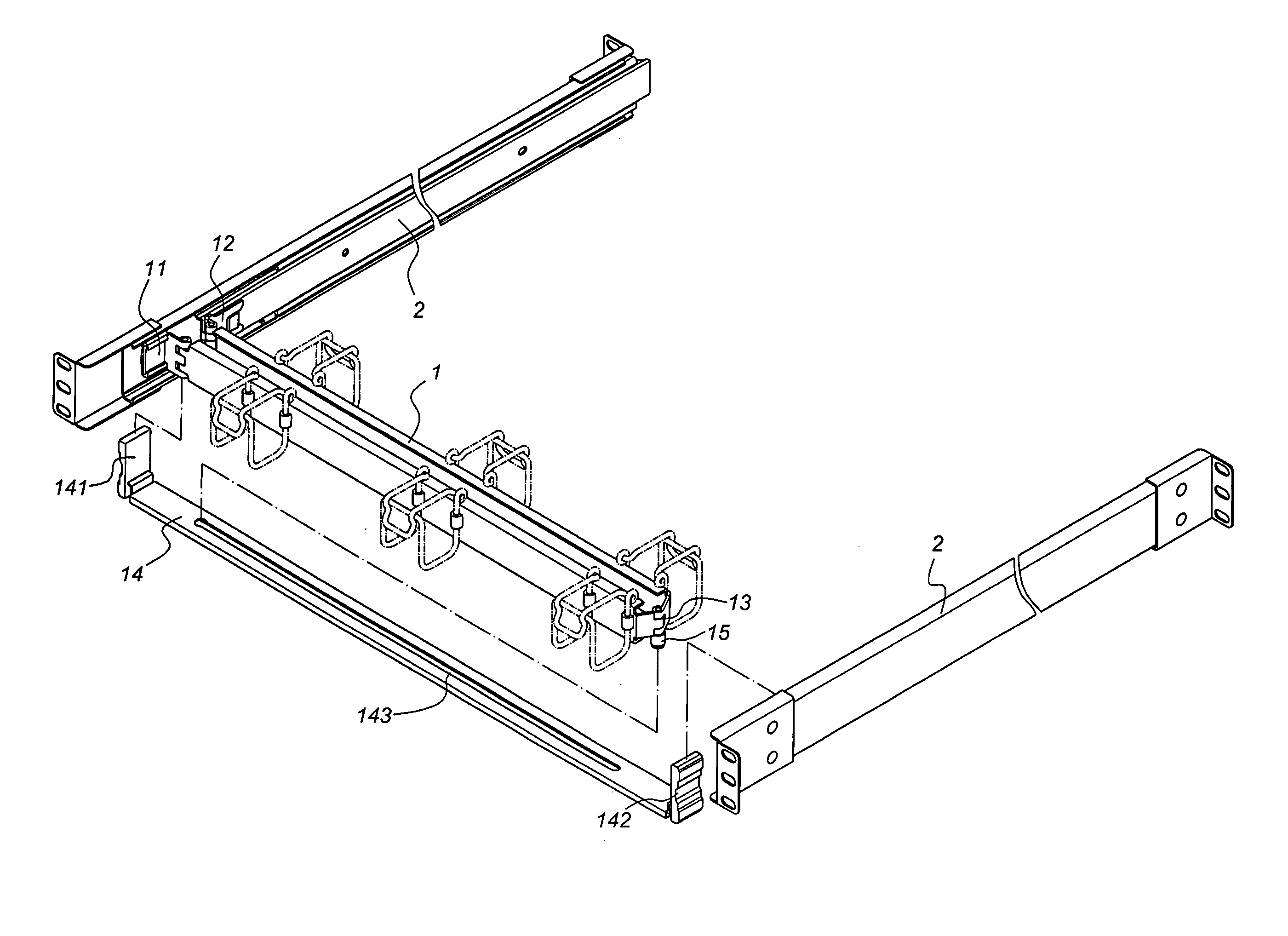

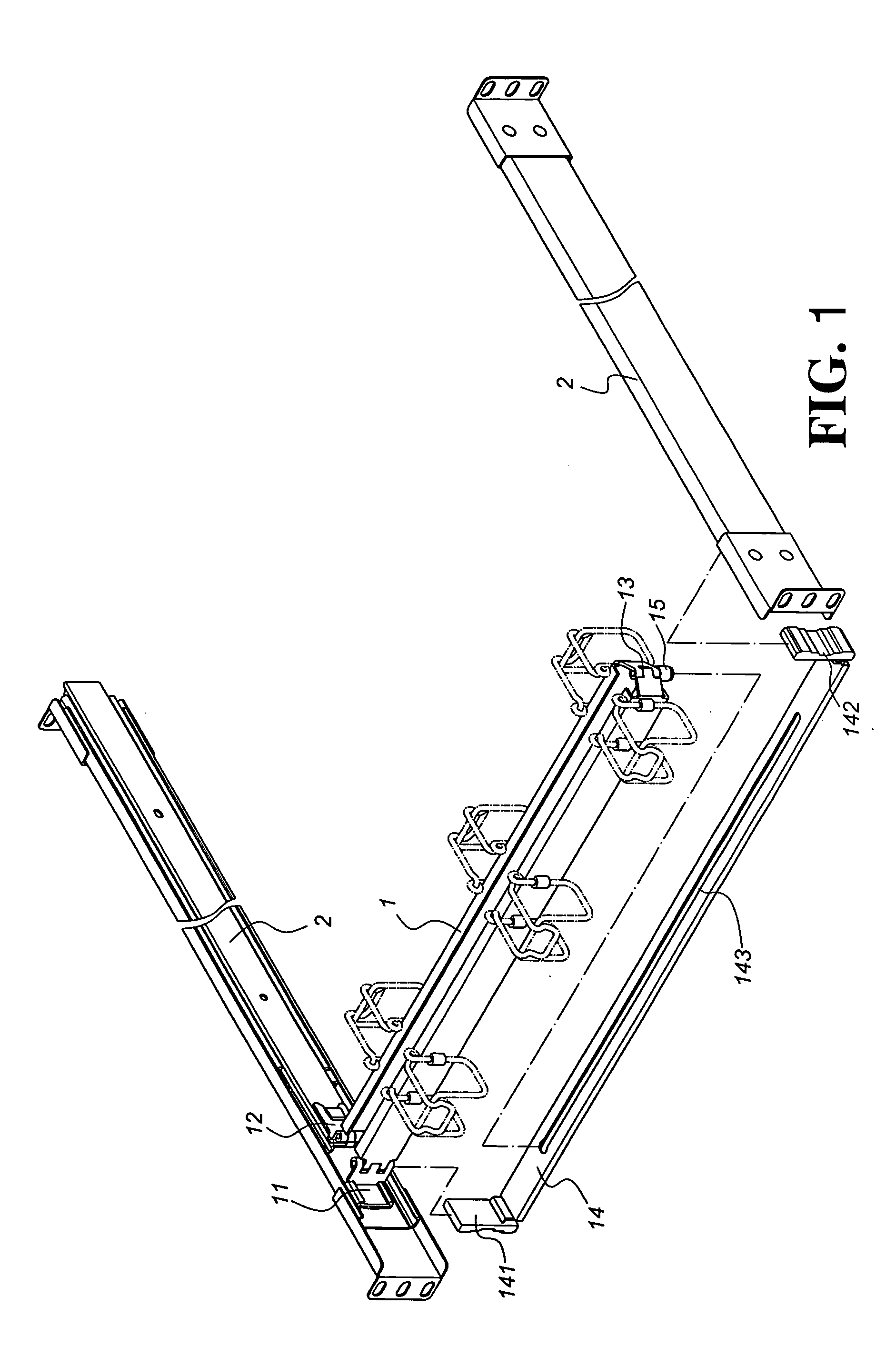

Cable management arm

InactiveUS20060081735A1Extended service lifeEasy to operatePipe supportsServersCable managementEngineering

A cable management arm adapted with a pair of slides has one end and another end. A retractable member is provided between the two ends of the cable management arm. The cable management arm further comprises a support slide with two ends respectively traveling along the slides. A sliding member is provided between the two ends of the cable management arm. The sliding member travels in relation to the support slide and is supported by the support slide.

Owner:KING SLIDE WORKS CO LTD

Mandrel and method for manufacturing composite structures

ActiveUS20050051262A1Low costLess thermal massLaminationLamination apparatusAdhesiveHoneycomb structure

An apparatus and method for retaining composite structures, such as composite honeycomb structures, during manufacture are provided. The composite structure is cured on a mandrel that defines a layup surface with a grip feature. The grip feature is configured to engage the composite structure during manufacture and retain the structure in a predetermined configuration. A film adhesive can be provided between the grip feature and a tiedown ply that extends from the composite structure.

Owner:THE BOEING CO

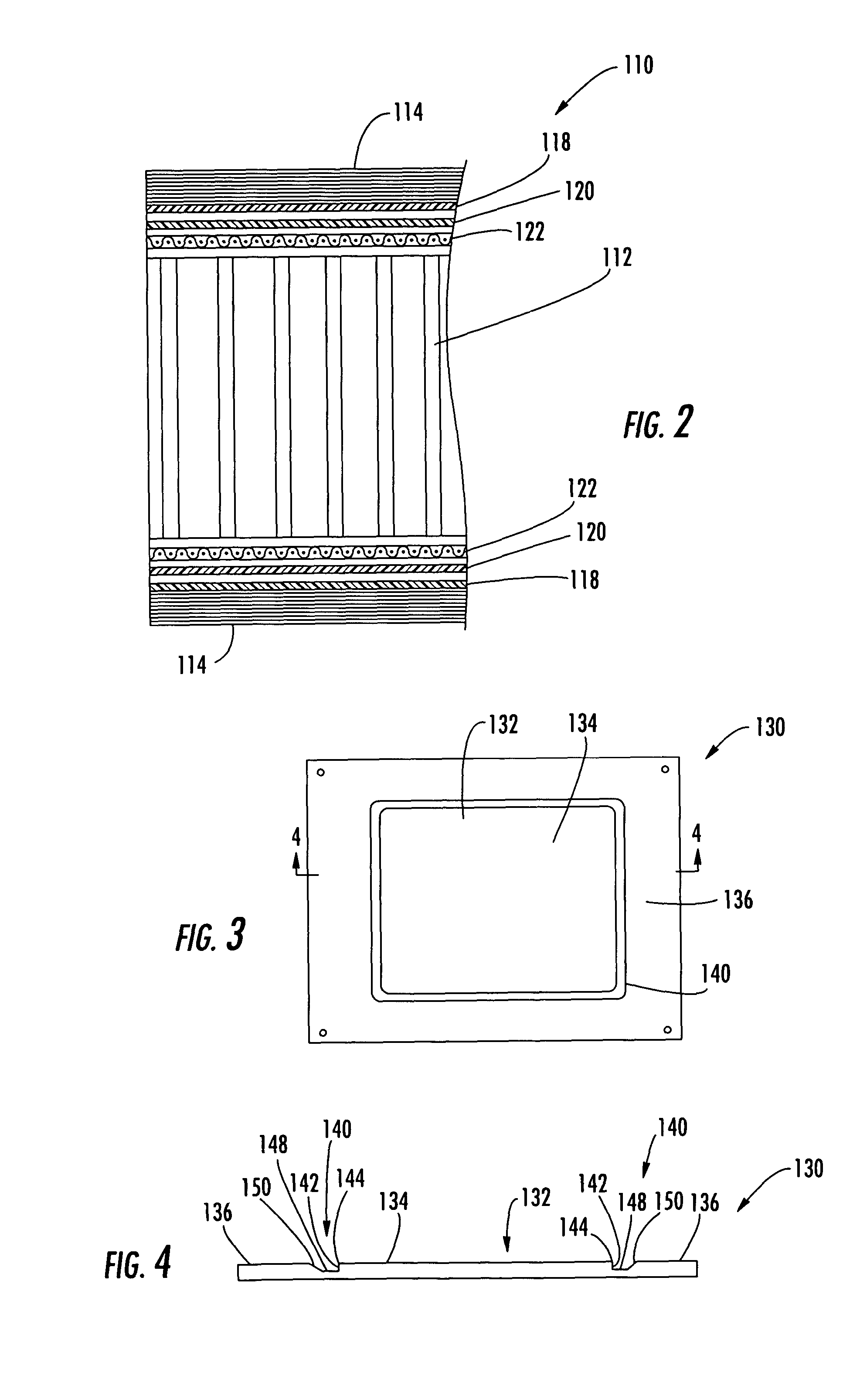

Frame assembly and frame component for tensioning fabric about a panel of a partition system

InactiveUS20030136073A1Efficient receptionStable supportScreensCeilingsIndustrial engineeringSupport surface

A frame for a partition system and a component of the frame are disclosed. The component automatically and evenly tensions a fabric about a partition panel. The component of the frame includes a support element and a lockable element. The support element defines a cavity that receives and supports the panel. The lockable element extends from the support element and supports the fabric that is to be tensioned about the panel. Also, the lockable element is moveable relative to the support element. The component further includes an integral hinge between the support element and the lockable element. The integral hinge enables the movement of the lockable element relative to the support element. As a result, the fabric supported on the lockable element is automatically and evenly tensioned about the panel upon the movement of the lockable element. The component also includes a backing strip to protect the fabric from the integral hinge.

Owner:QUANEX HOMESHIELD LLC

Aluminum-plated steel sheet for hot pressing with rapid heating, process for producing same, and method of hot-pressing same with rapid heating

ActiveCN102089451AIncrease production capacityPrevent saggingHot-dipping/immersion processesBell type furnacesHydrogenSheet steel

An aluminum-plated steel sheet for hot pressing is provided which is free from the conventional problem that an aluminum-plated steel sheet, when applied to hot pressing, suffers aluminum melting during preheating for the hot pressing. The steel sheet is further free from the problem concerning delayed fracture caused by residual hydrogen. Also provided are: a process for producing the aluminum-plated steel sheet; and a method of hot pressing with rapid heating in which the aluminum-plated steel sheet is used. The aluminum-plated steel sheet for hot pressing is produced by annealing an aluminum-plated steel sheet in a coiled state in an annealing box furnace under holding-time and temperature conditions which are within the range shown in Fig 5, whereby the aluminum deposit is alloyed with the steel sheet. The method of hot pressing with rapid heating is characterized in that a blank cut out of the aluminum-plated steel sheet for hot pressing is preheated at a heating rate of 40 DEG C / sec or higher on the average so that the time period over which the blank is exposed to an environment of 700 DEG C or higher is 20 seconds or shorter, and the preheated blank is hot-pressed.

Owner:NIPPON STEEL CORP

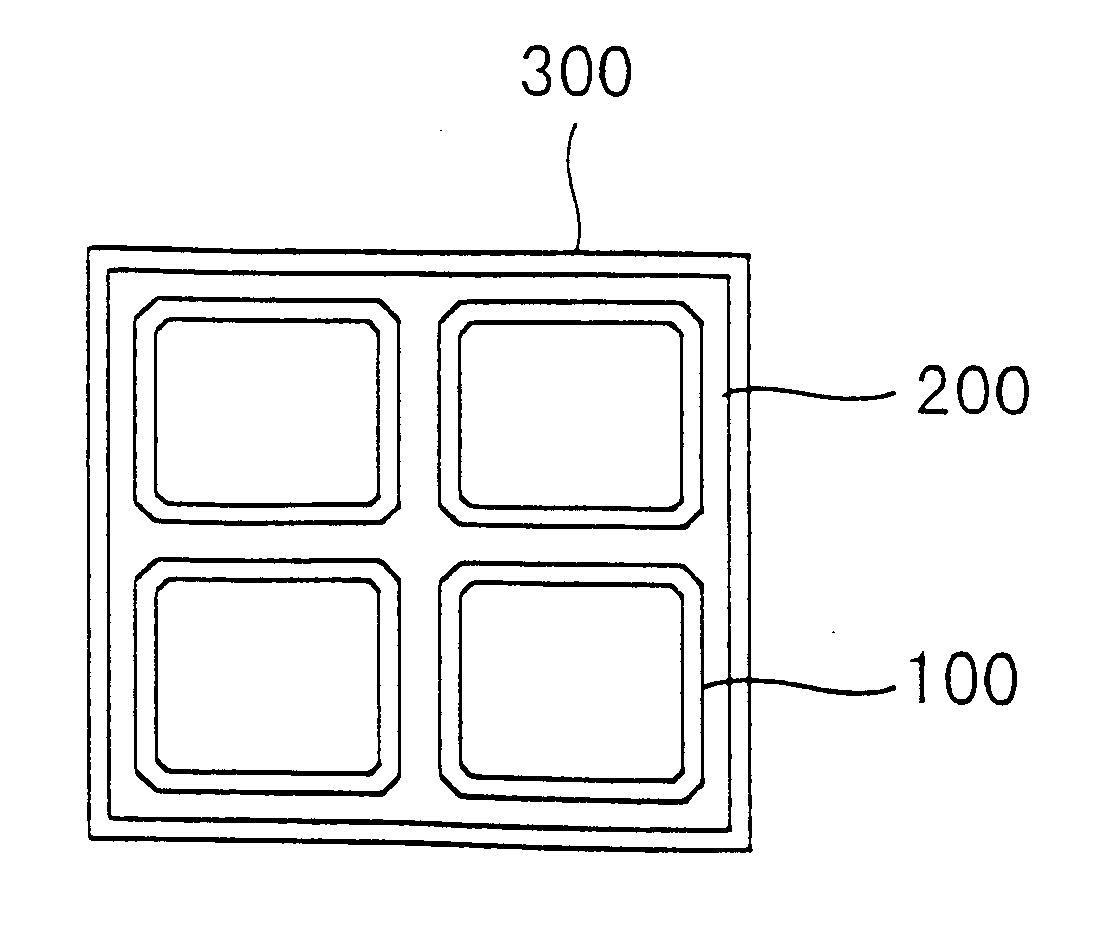

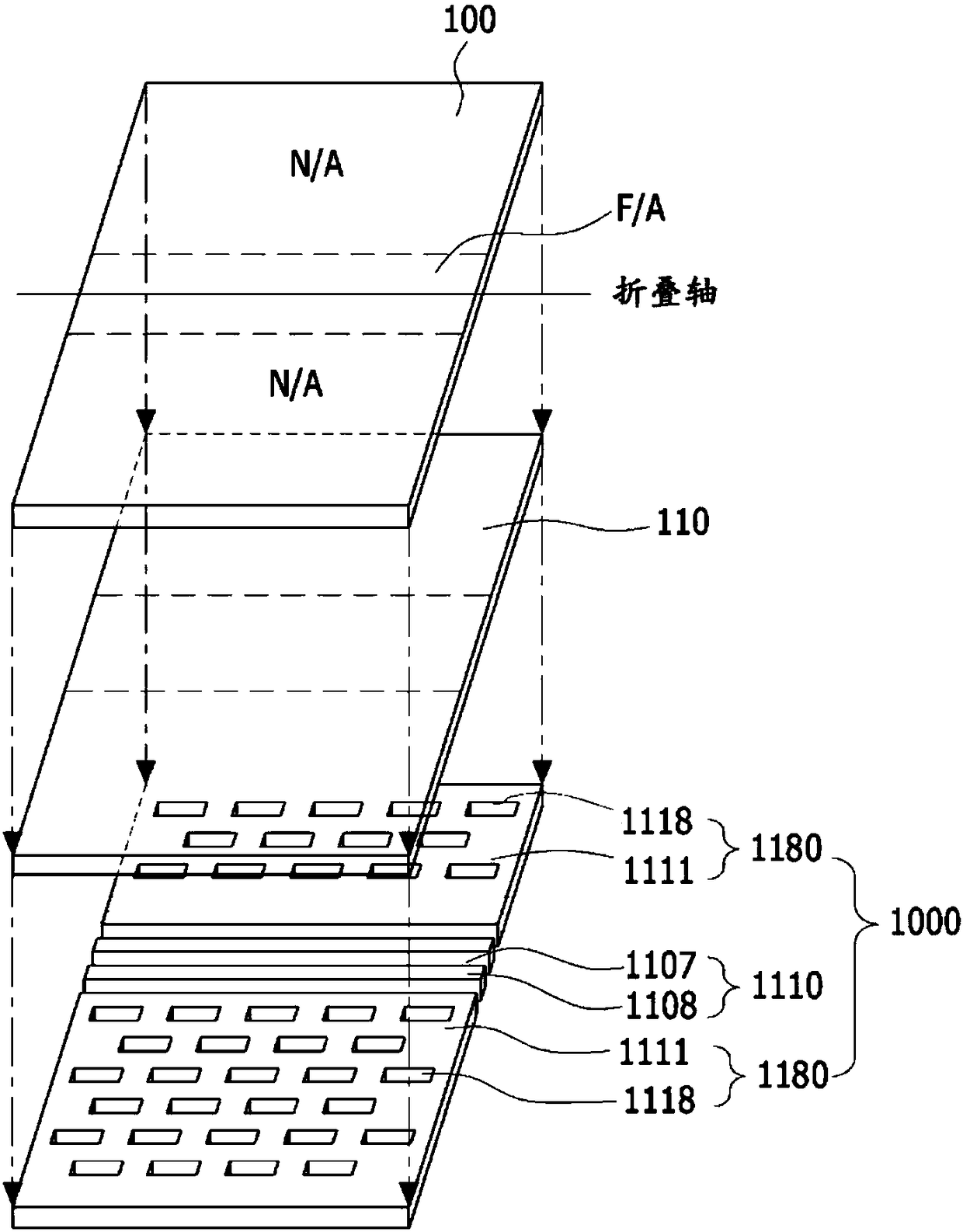

Foldable display device

ActiveCN108268170APrevent saggingReduce transferDigital data processing detailsElectrical equipmentDisplay deviceStructural engineering

Disclosed is a foldable display device capable of preventing distortion of a folding part of a display screen due to deformation of the folding part. The foldable display device includes a display panel including a folding part and non-folding parts, and a back cover attached to the rear surface of the display panel via an adhesive layer, wherein the back cover includes folding patterns and open patterns, both of which are disposed at the folding part, and unevenness compensation patterns disposed on areas of a surface of the back cover contacting the adhesive layer, the areas of the surface of the back cover corresponding to the non-folding parts. The unevenness compensation patterns may be a plurality of open patterns, which are fully formed through the back cover, or may be a pluralityof grooves, which are not fully formed through the back cover.

Owner:LG DISPLAY CO LTD

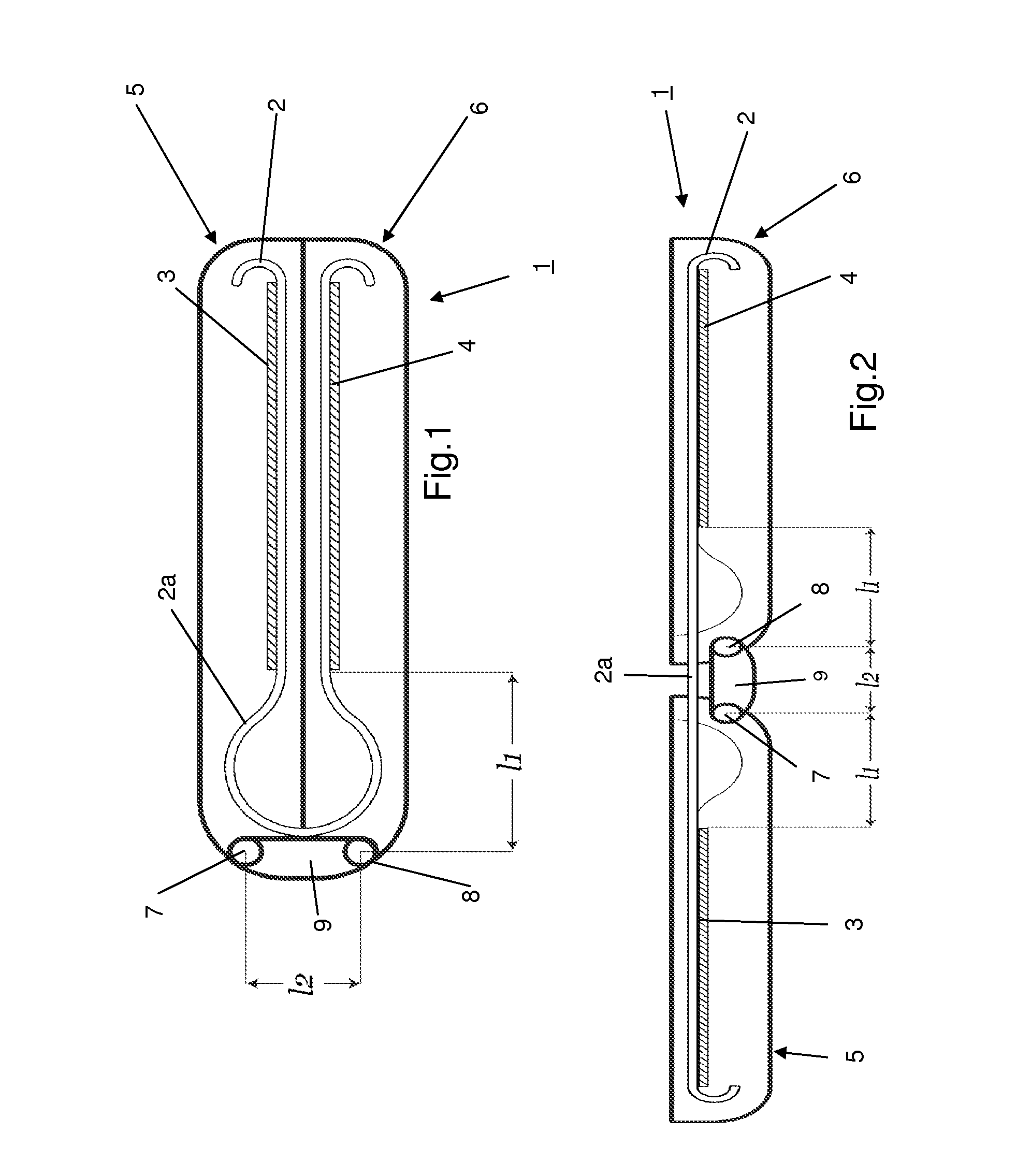

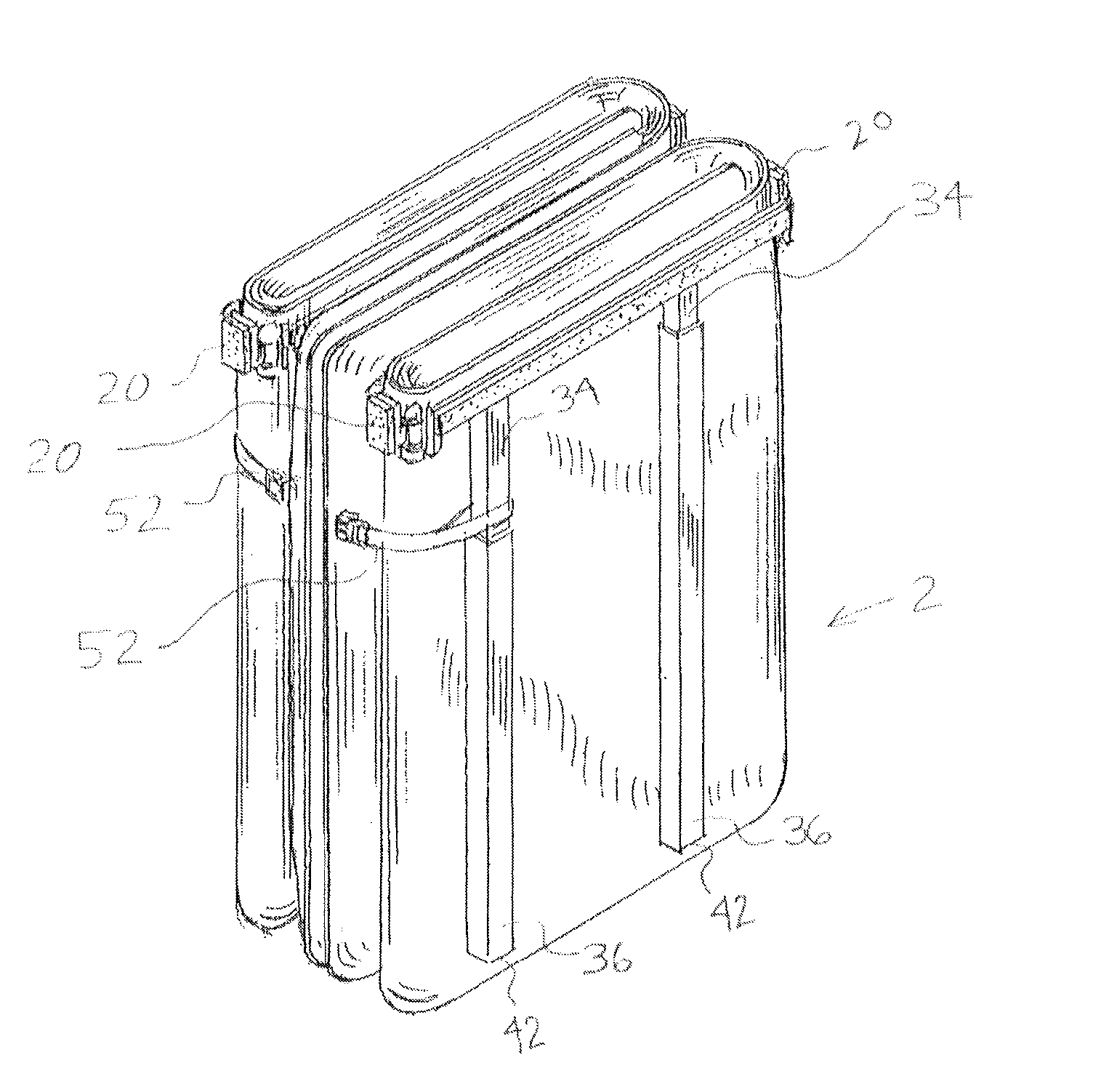

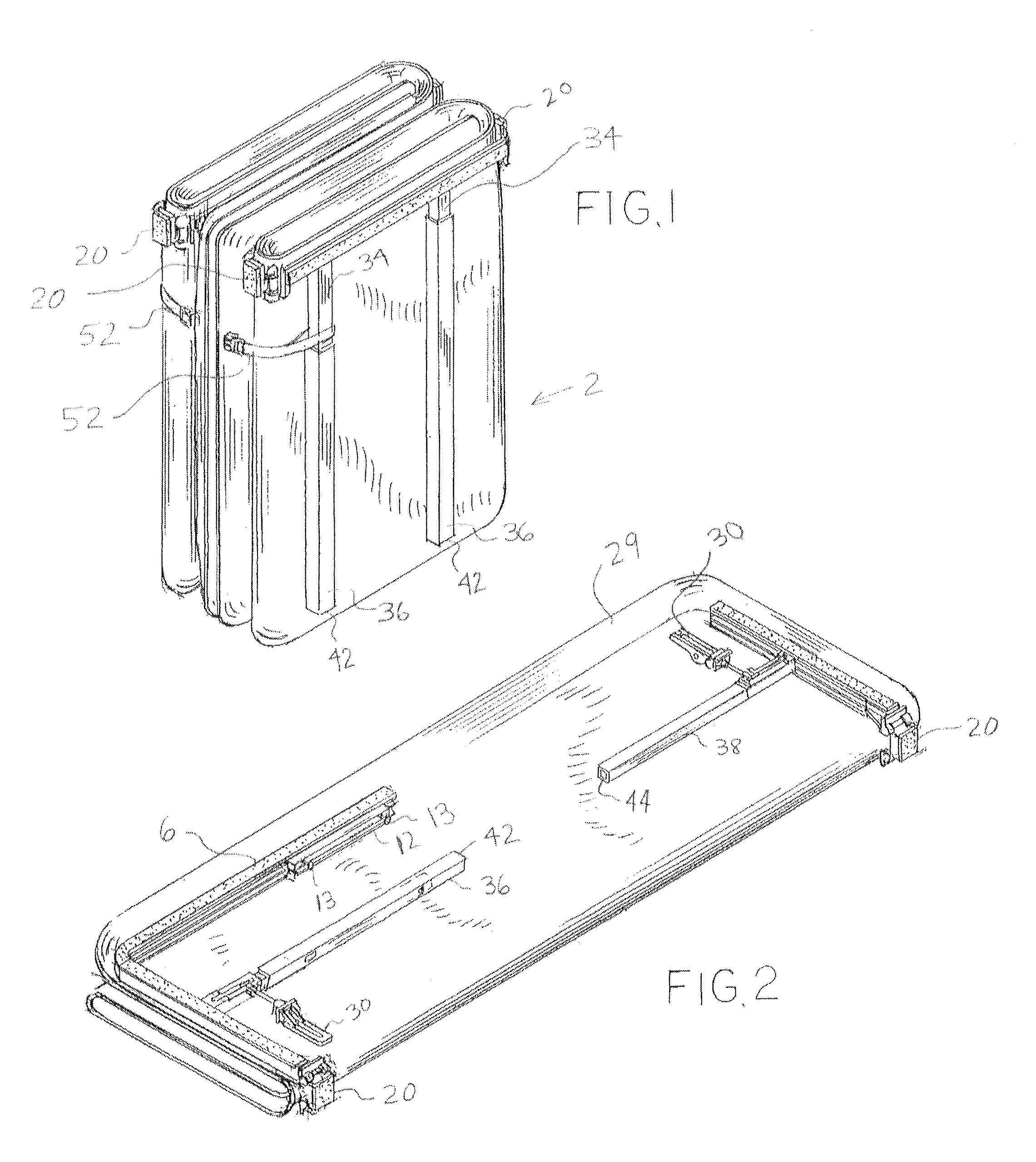

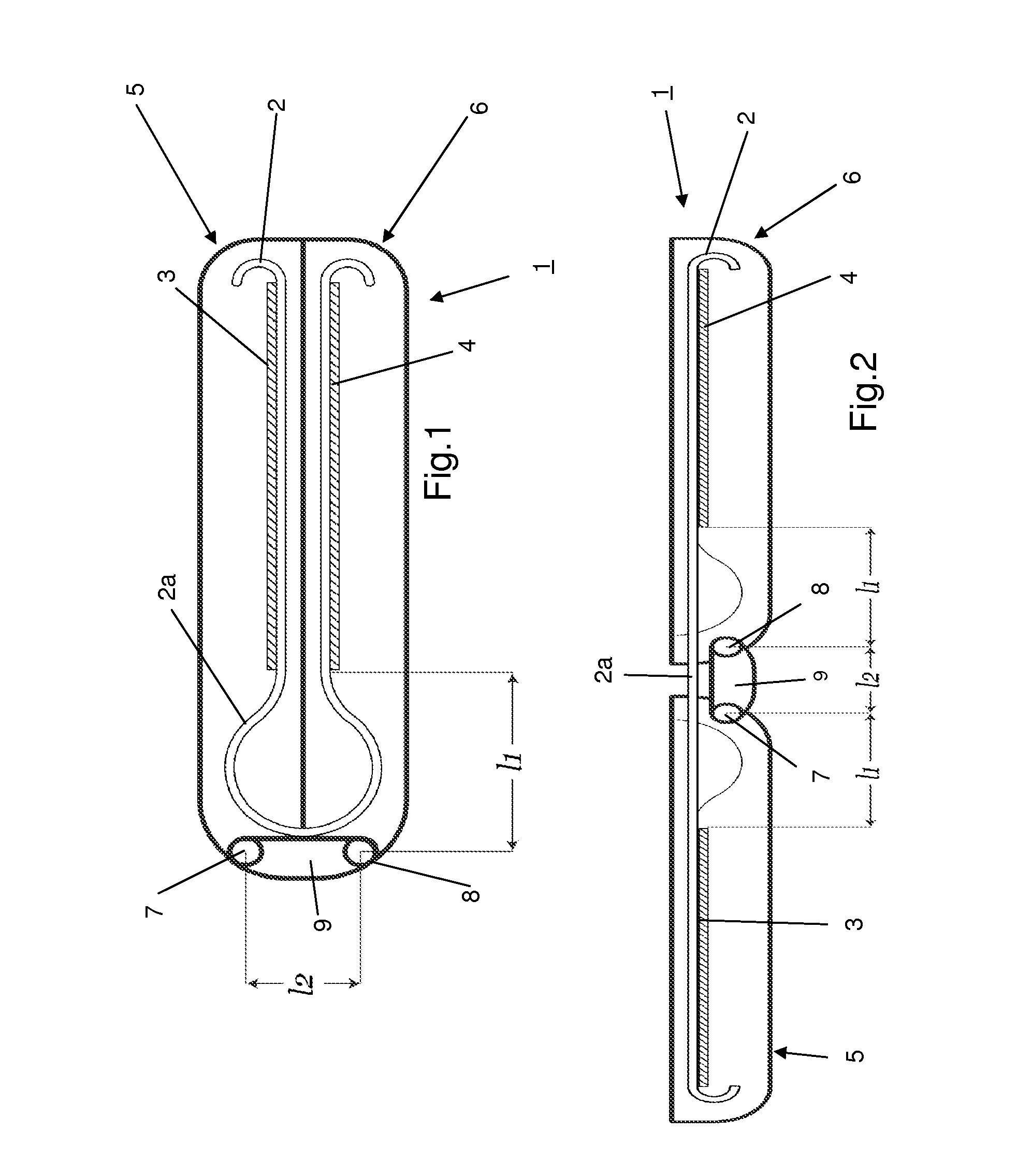

Display system having a continuous flexible display with display supports

InactiveUS8908365B2More roomPrevent saggingStatic indicating devicesAdvertisingDisplay deviceSpring force

A display system comprises a continuous flexible display and two main display supports being hingeably connected with respect to each other between a closed storage position and a planar open position for fixing the flexible display in an open position. Each of the supports is structurally configured to support respectively a first and a second portion of the flexible display, a segment of the flexible display is located between the said respective portions of the flexible display in the open position. The display system comprises a spring force biased mechanism operative in either the open or closed position or both the open and closed positions of the flexible display, biasing said segment of the flexible display in the respective position.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com