Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2202 results about "First glasses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick Answer. According to About, the first pair of eyeglasses was invented in Italy around 1284 by Salvino D'Armate. While Salvino D'Armate is credited with having invented the first wearable spectacles, a handheld vision aid was invented around 1000.

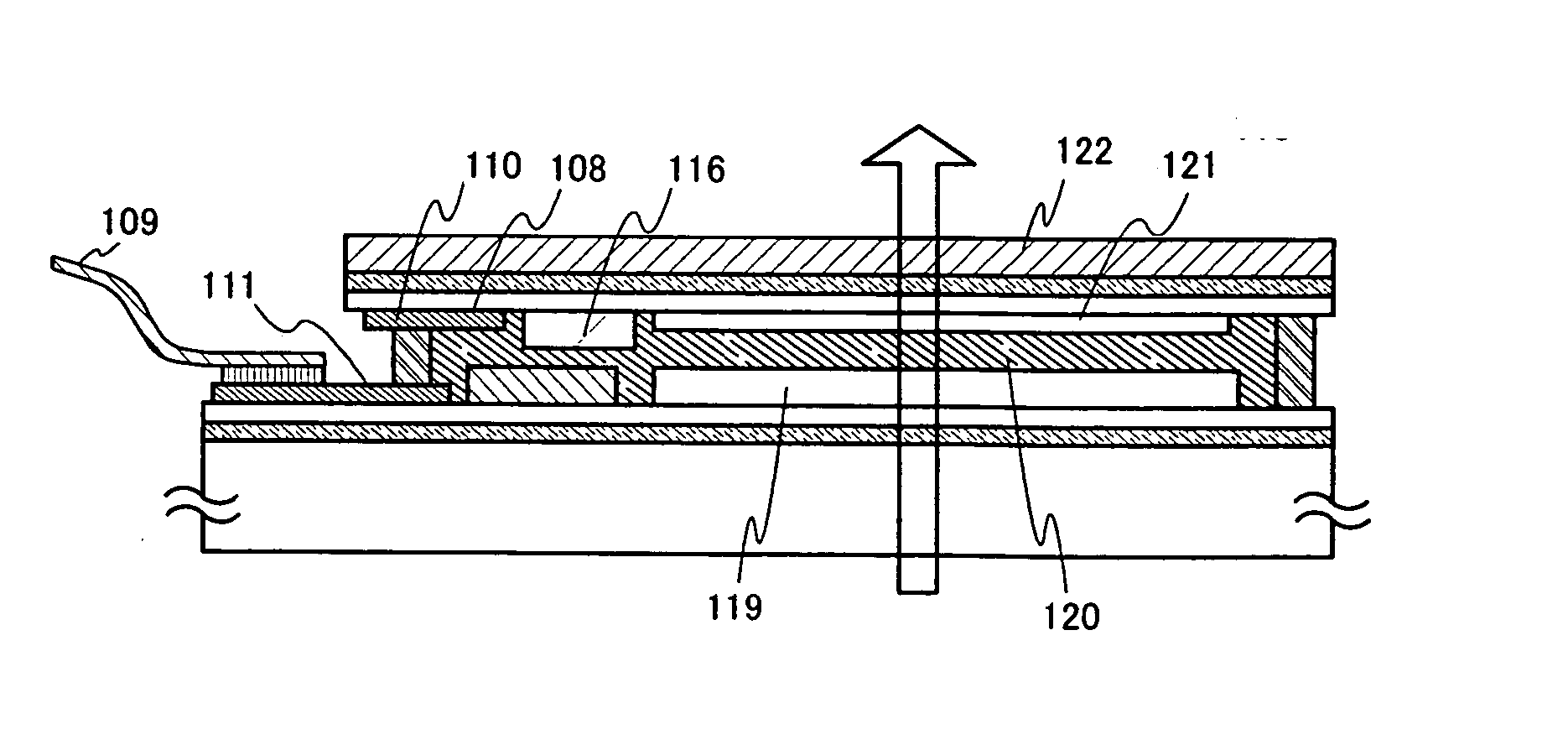

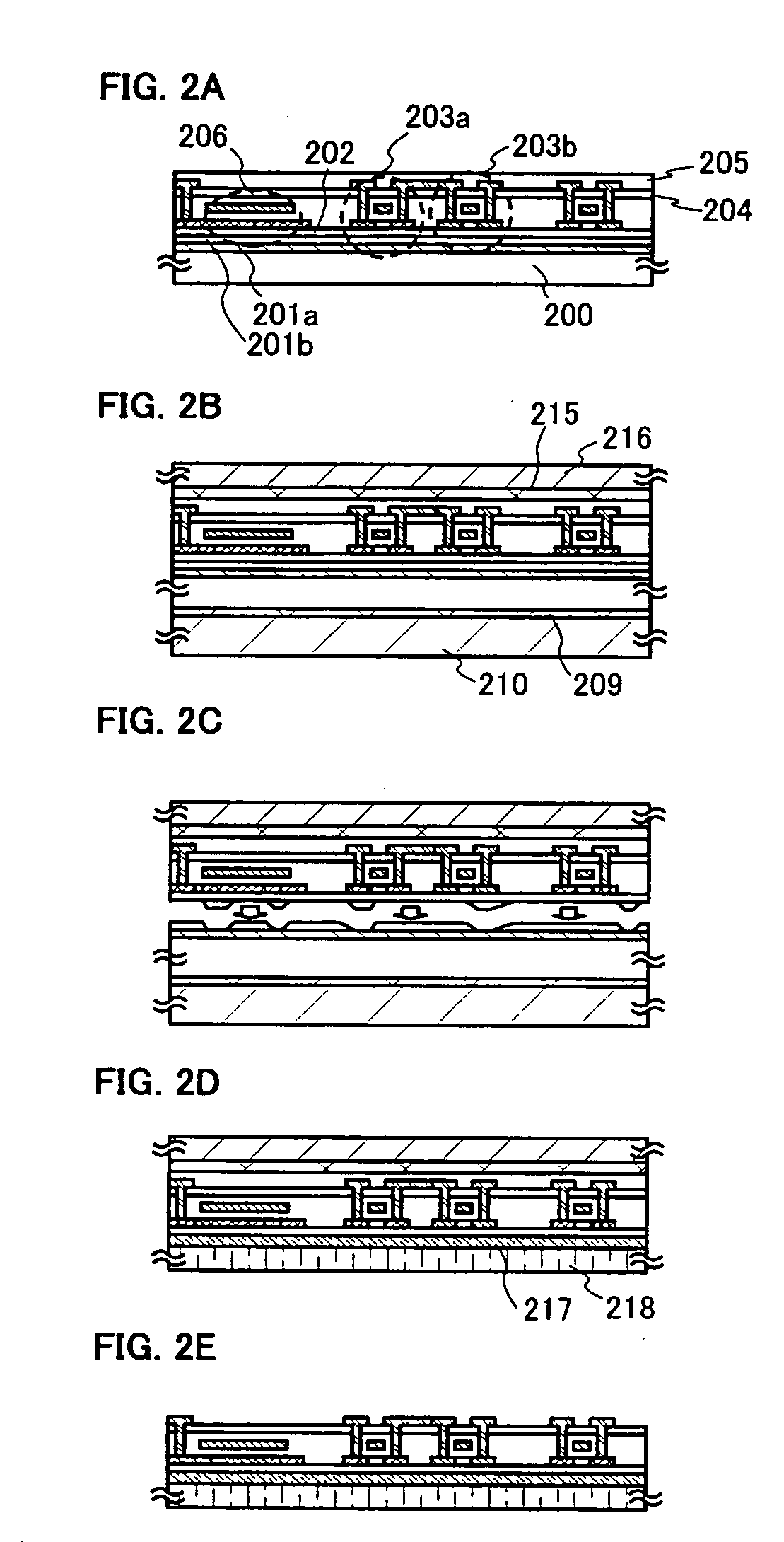

Semiconductor device and method for manufacturing the same

To realize a high-performance liquid crystal display device or light-emitting element using a plastic film. A CPU is formed over a first glass substrate and then, separated from the first substrate. A pixel portion having a light-emitting element is formed over a second glass substrate, and then, separated from the second substrate. The both are bonded to each other. Therefore, high integration can be achieved. Further, in this case, the separated layer including the CPU serves also as a sealing layer of the light-emitting element.

Owner:SEMICON ENERGY LAB CO LTD

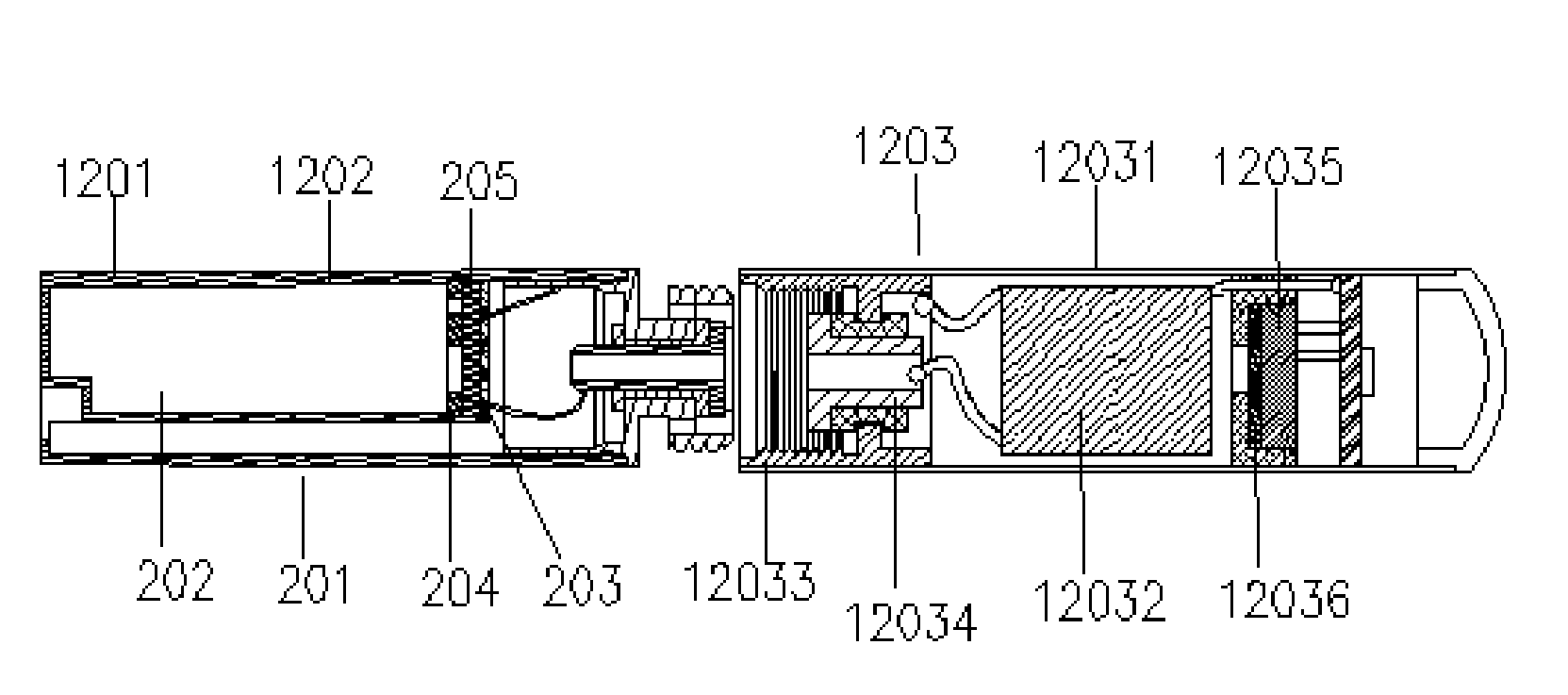

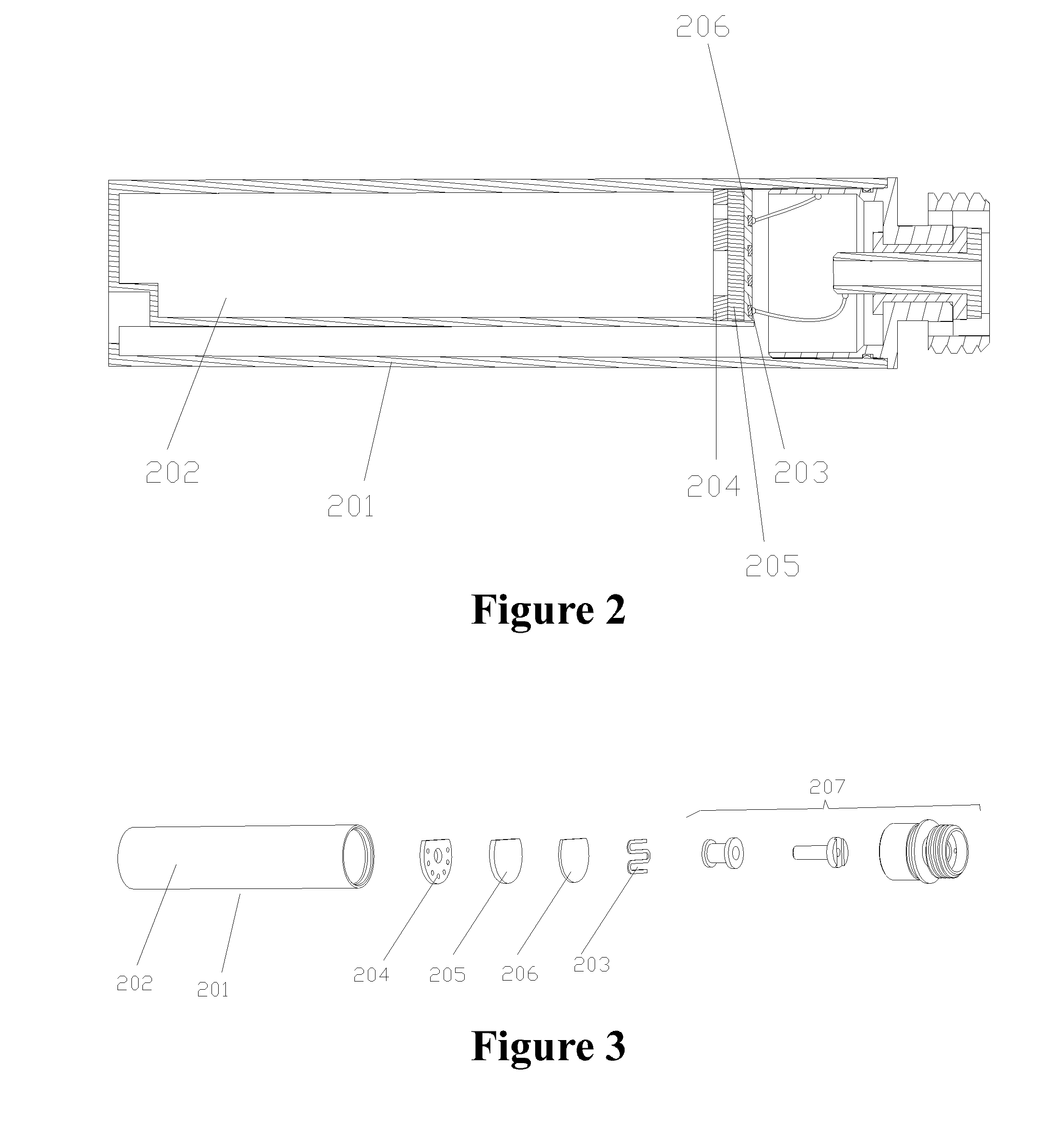

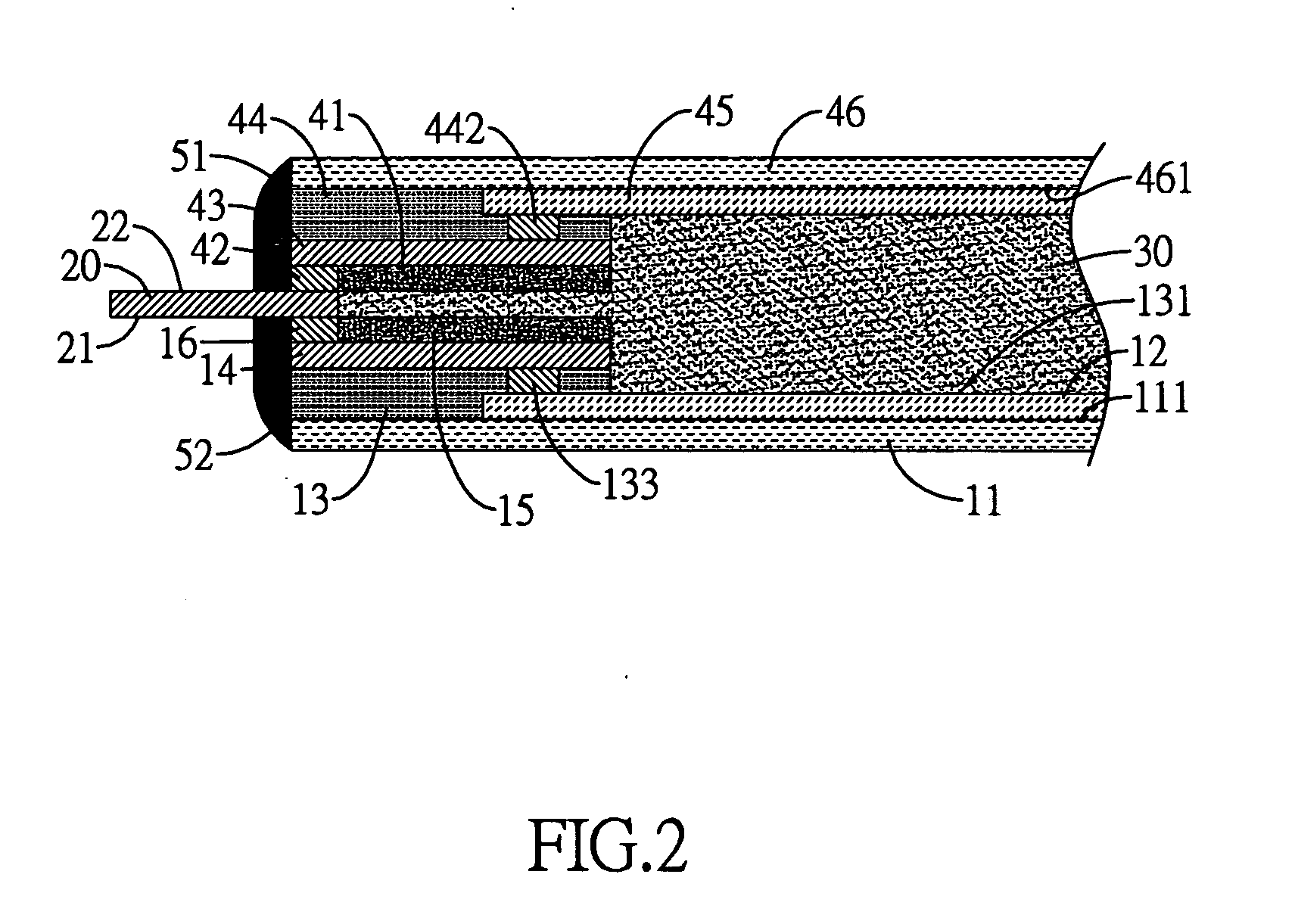

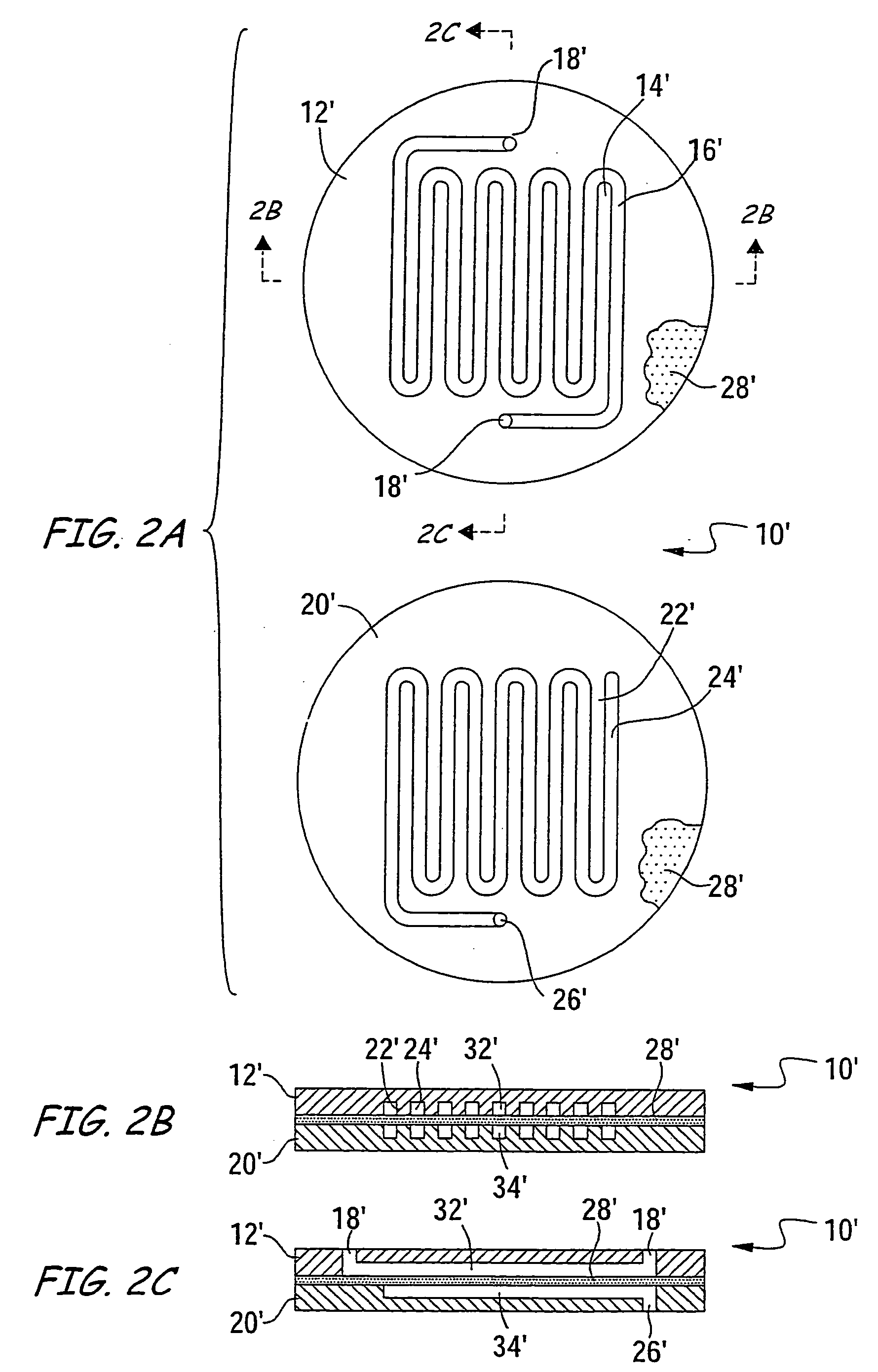

Atomizer and electric cigarette

InactiveUS20170006916A1Increase electrical lengthAvoids non-uniform aerosol volumeOhmic-resistance electrodesOhmic-resistance waterproof/air-tight sealsFiberGlass fiber

An atomizer and an electronic cigarette are provided. The atomizer includes: an atomizer cartridge, a liquid storage chamber, a liquid separation plate, an electric heating element, a cigarette liquid locking member, a first glass fiber cloth, and an atomizing electrode assembly. The electric heating element twists along the transverse direction of the atomizer, and is laid on the first glass fiber cloth, and the electric heating element laid on the first glass fiber cloth has a snakelike sheet structure. The cigarette liquid can be uniformly transferred to the electric heating element, and the volume of the aerosol is uniform. Furthermore, the quantity of the cigarette liquid transferred to the electric heating element is ensured to be uniform. In addition, the length of the electric heating element and the contact area of the electric heating element in contact with the first glass fiber cloth are effectively increased.

Owner:KIMREE HI TECH

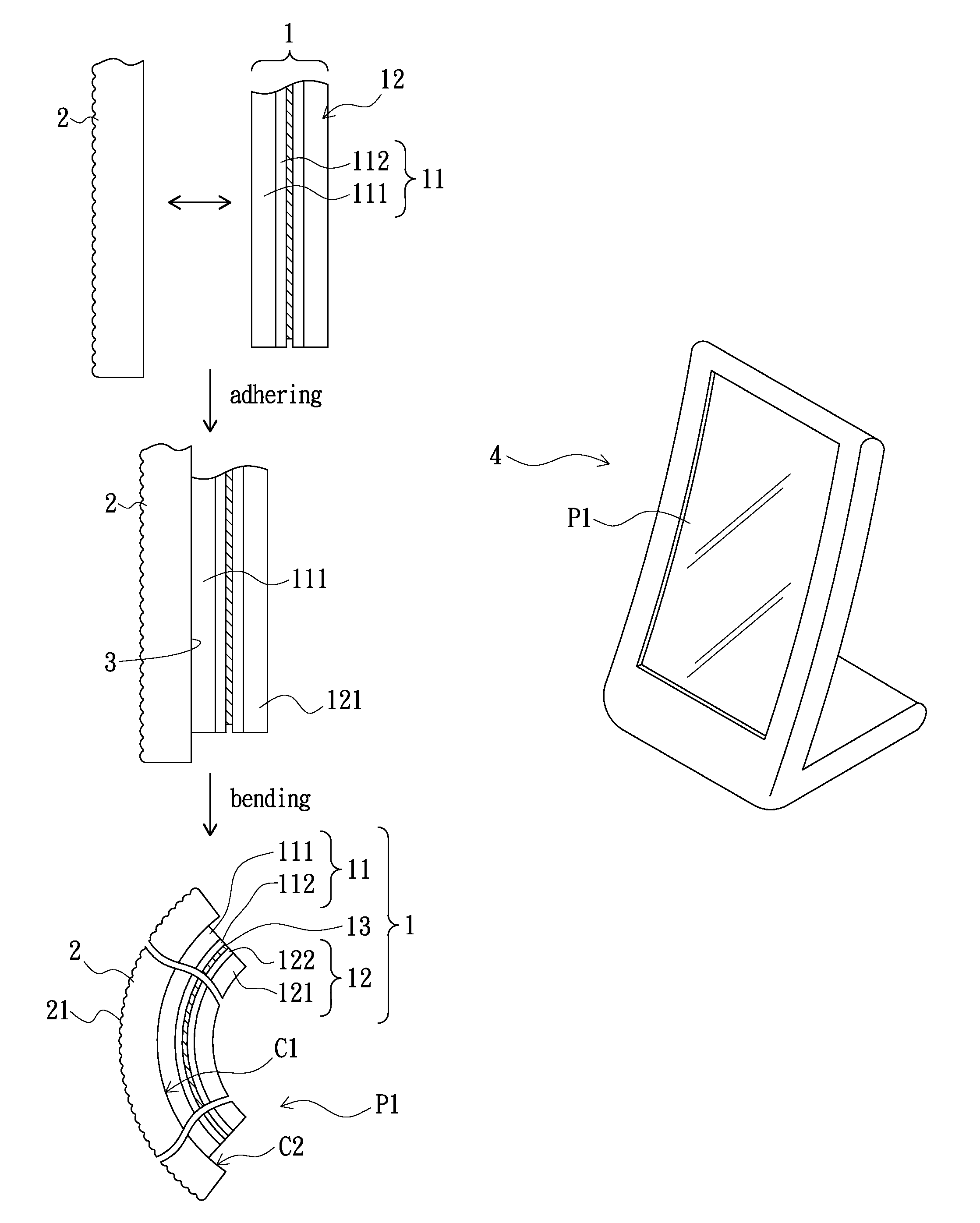

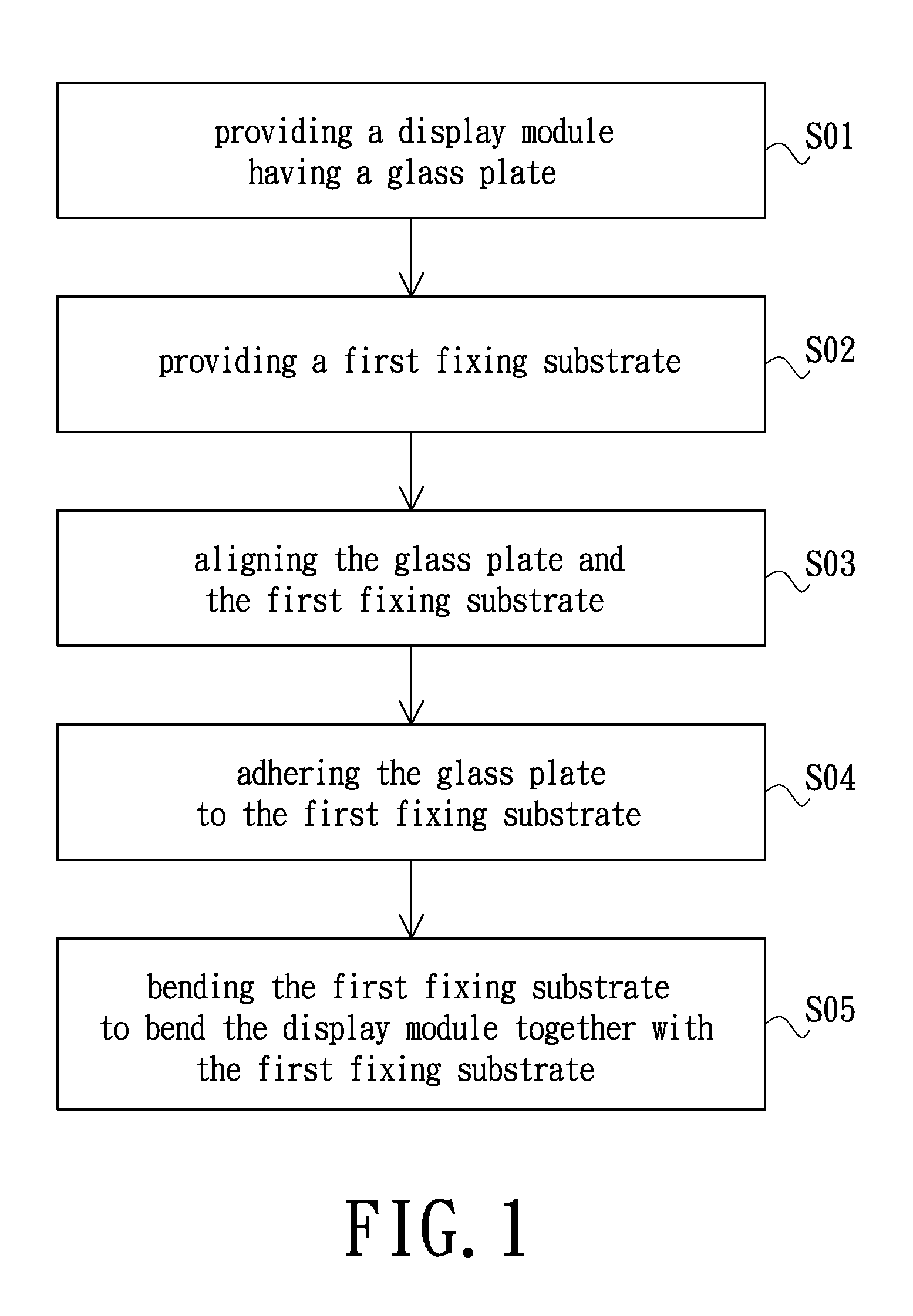

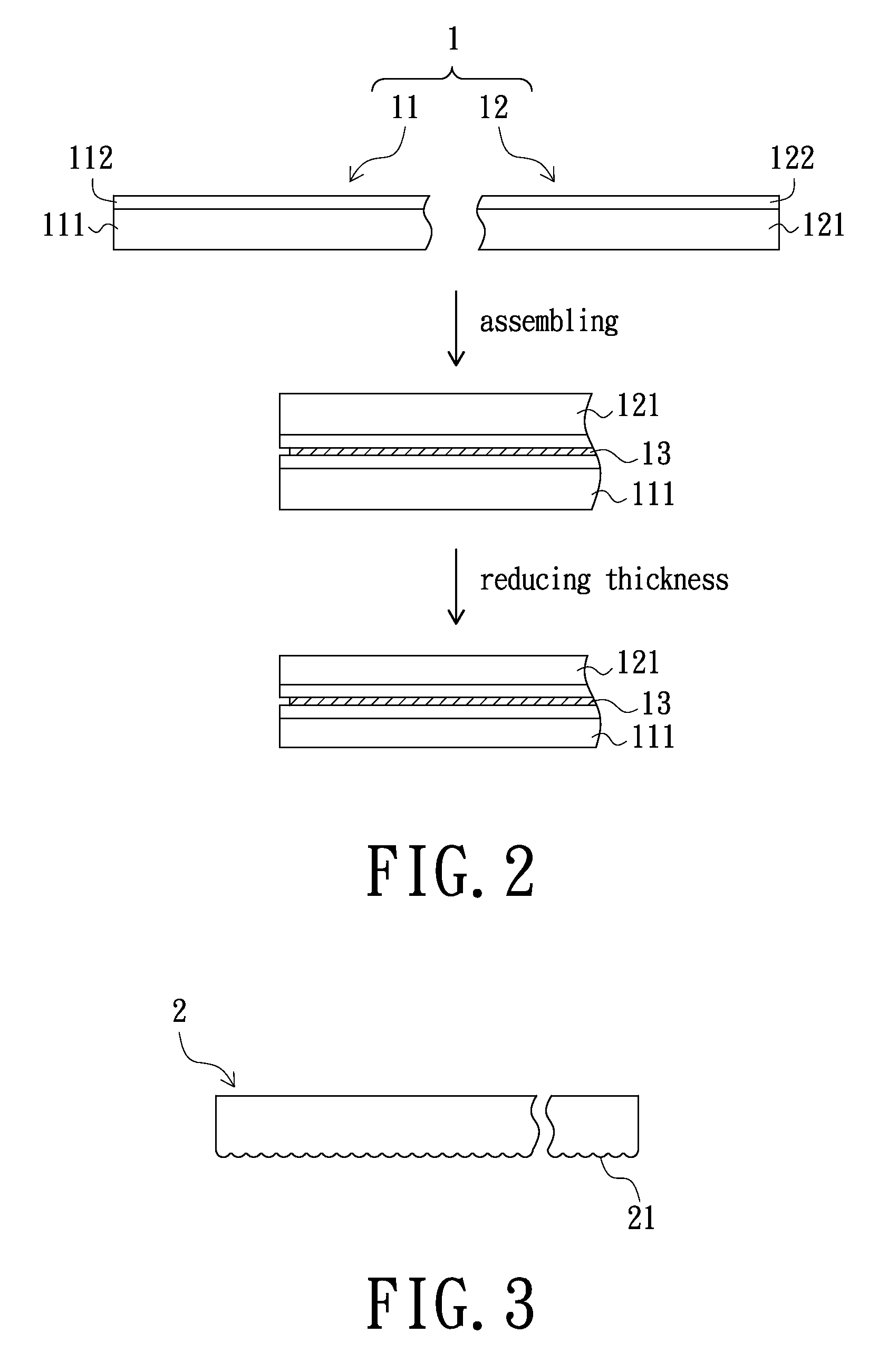

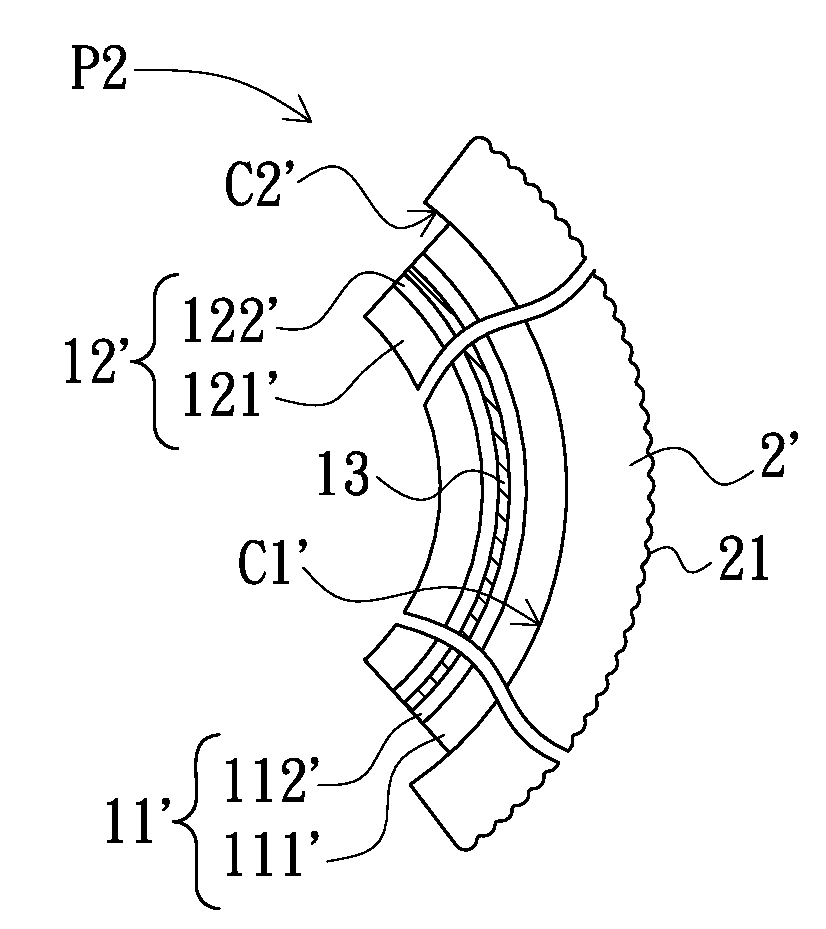

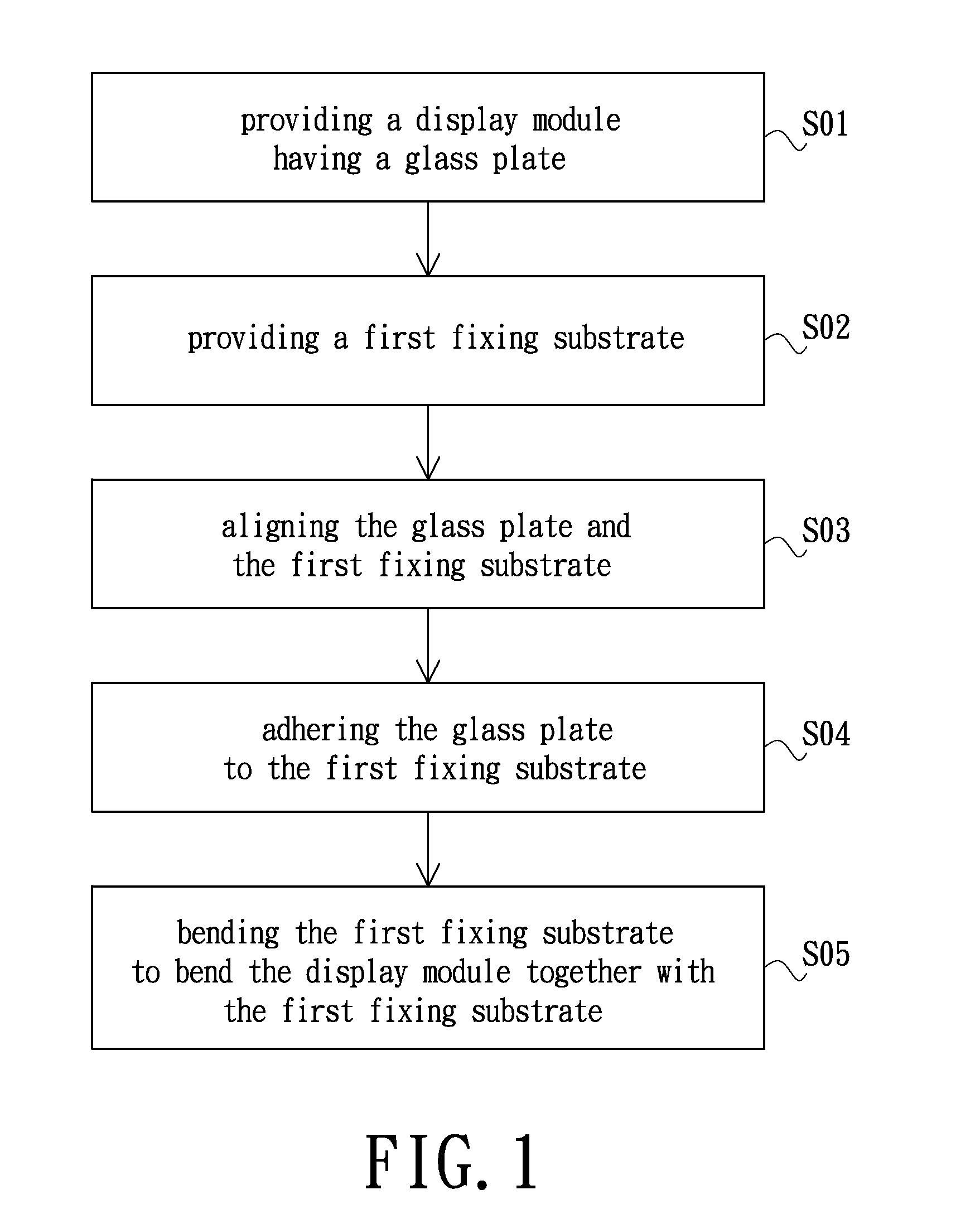

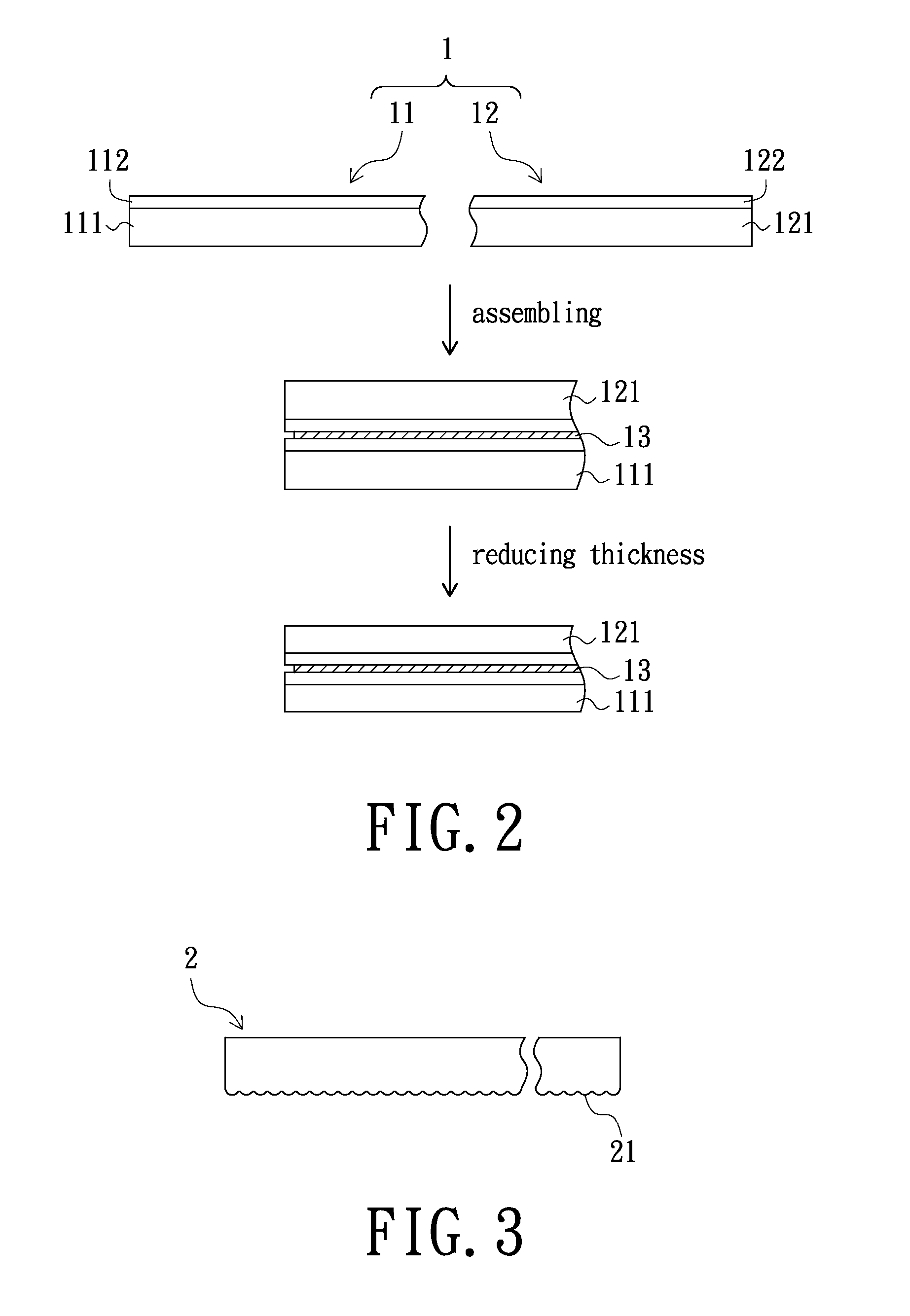

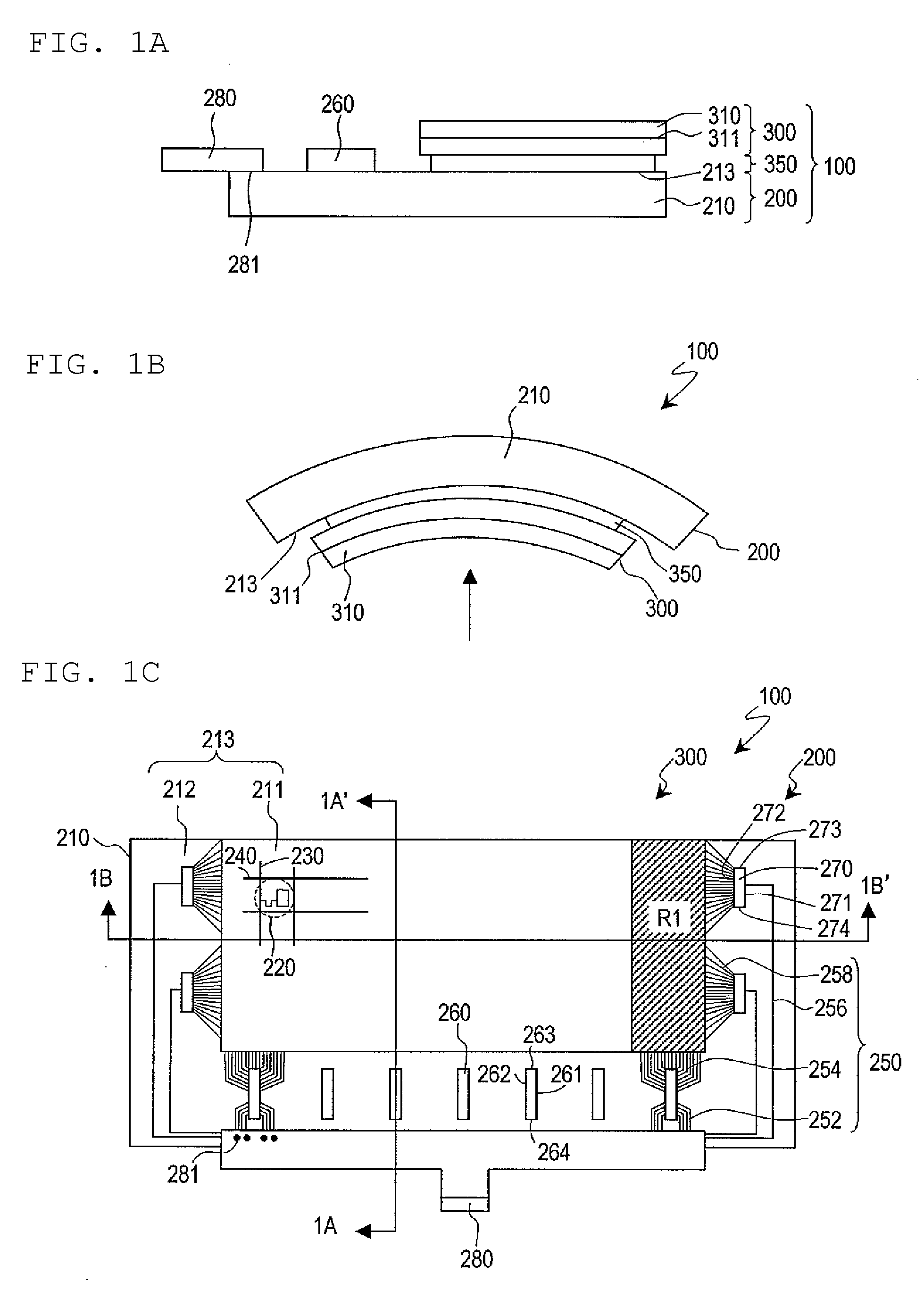

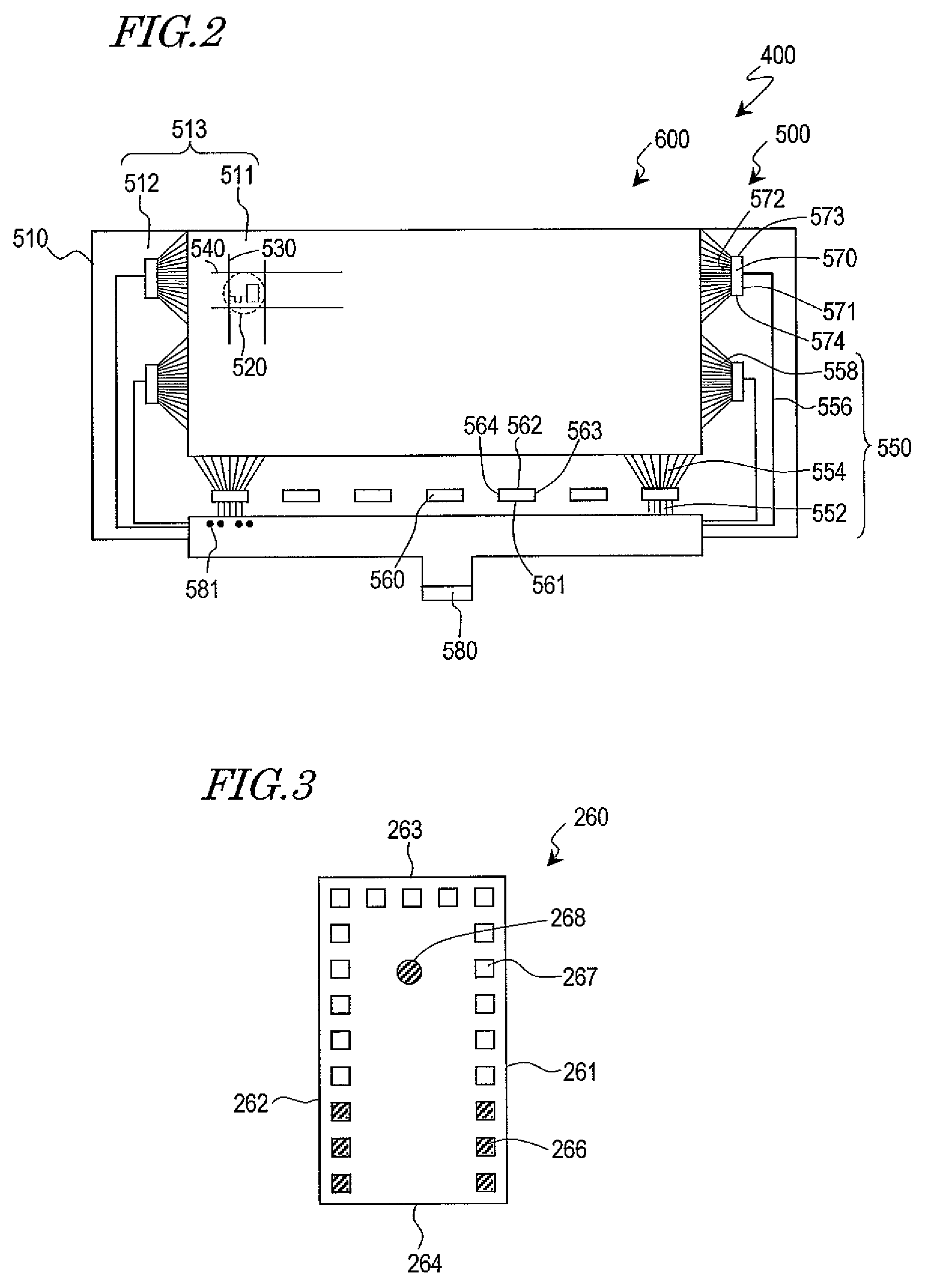

Curved display panel and method for manufacturing the same

ActiveUS8305743B2Improve production yieldIncrease stickinessDisposition/mounting of recording headsDigital data processing detailsEngineeringGlass sheet

Owner:OPTRONIC SCI LLC

Method and system for forming shaped glass articles

ActiveUS20140234581A1Forming accuratelyLayered productsDigital data processing detailsPoiseGlass sheet

A method of forming a shaped glass article includes placing a glass sheet on a mold such that a first glass area of the glass sheet corresponds to a first mold surface area of the mold and a second glass area of the glass sheet corresponds to a second mold surface area of the mold. The first glass area and the second glass area are heated such that the viscosity of the second glass area is 8 poise or more lower than the viscosity of the first glass area. A force is applied to the glass sheet to conform the glass sheet to the mold surface. During the heating of the second glass area, the first mold surface area is locally cooled to induce a thermal gradient on the mold.

Owner:CORNING INC

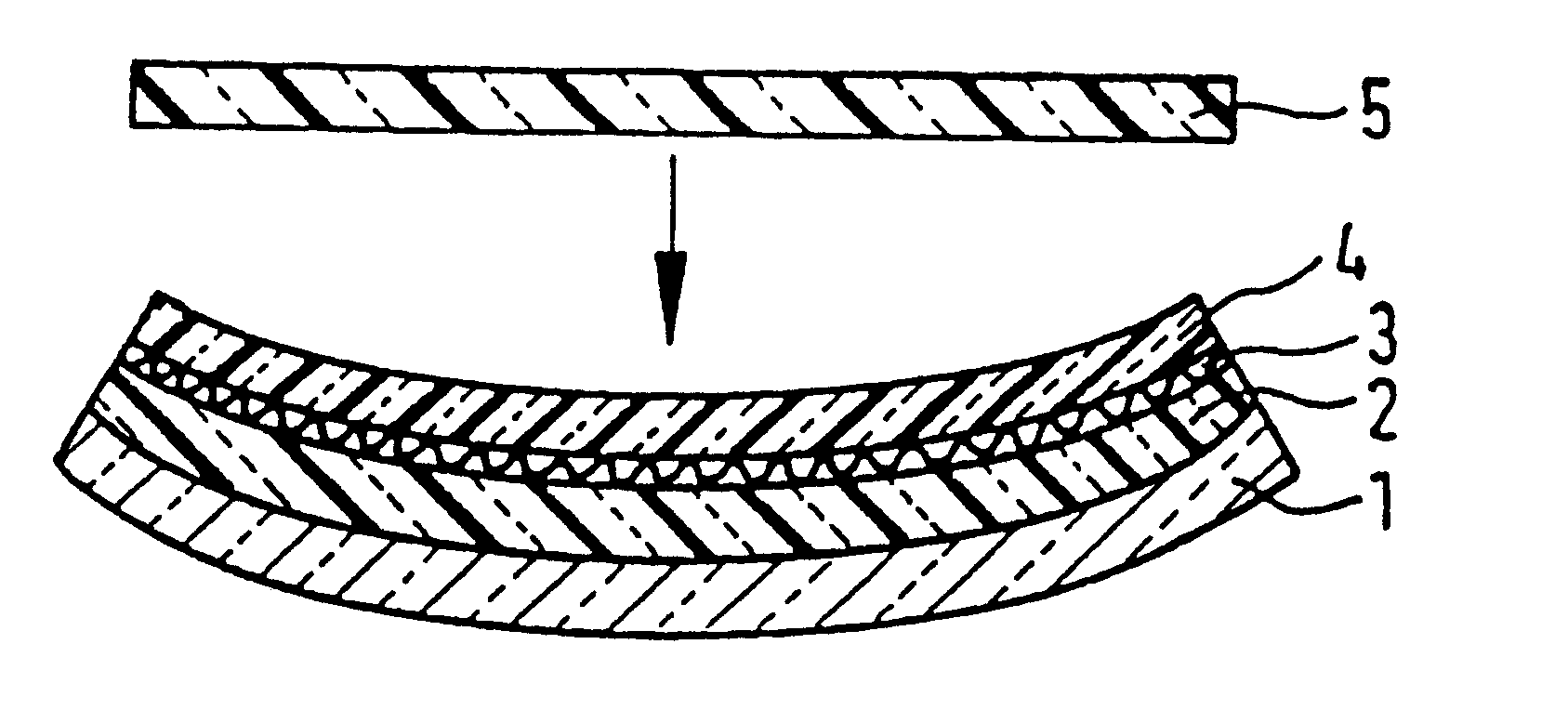

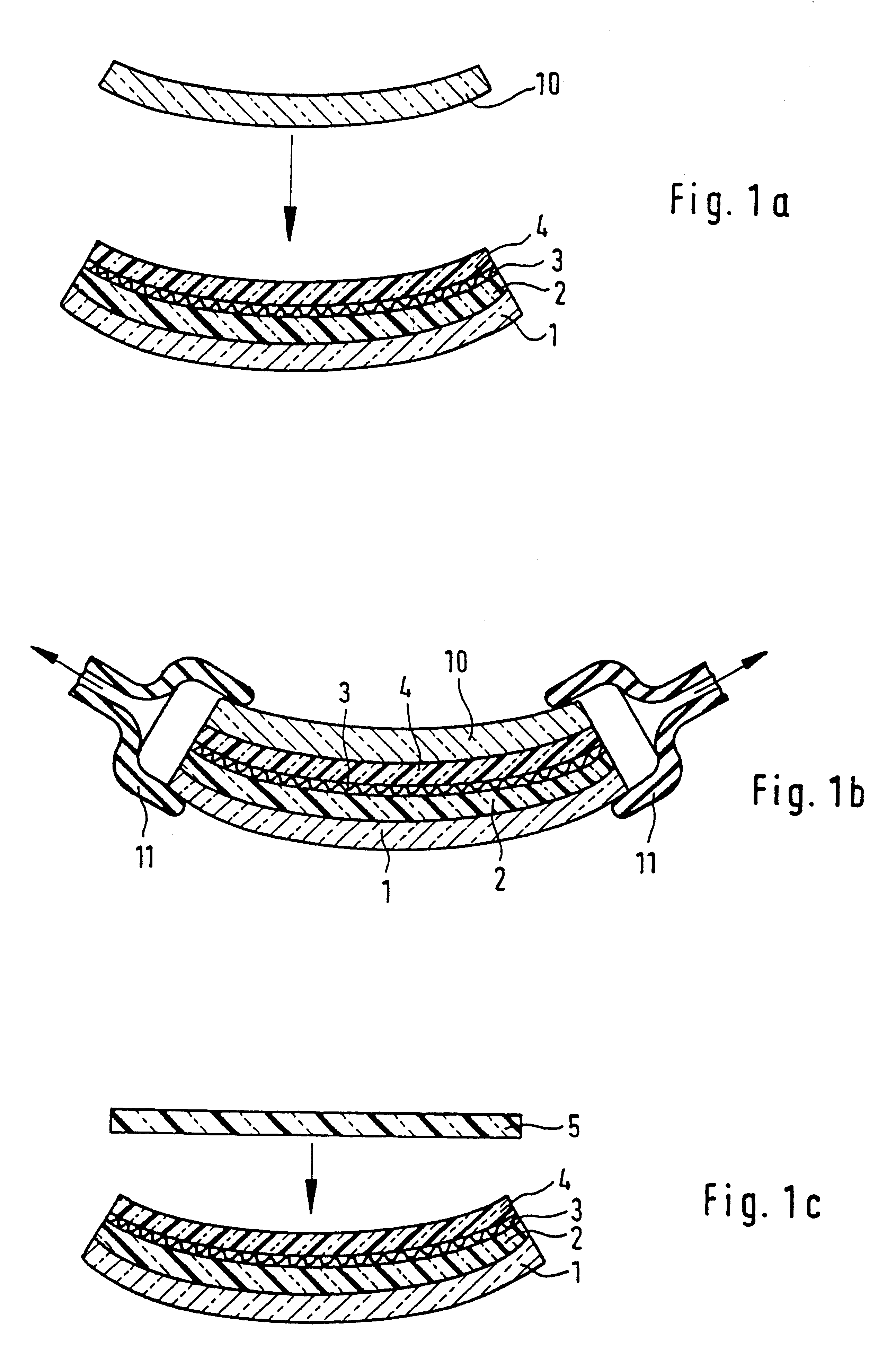

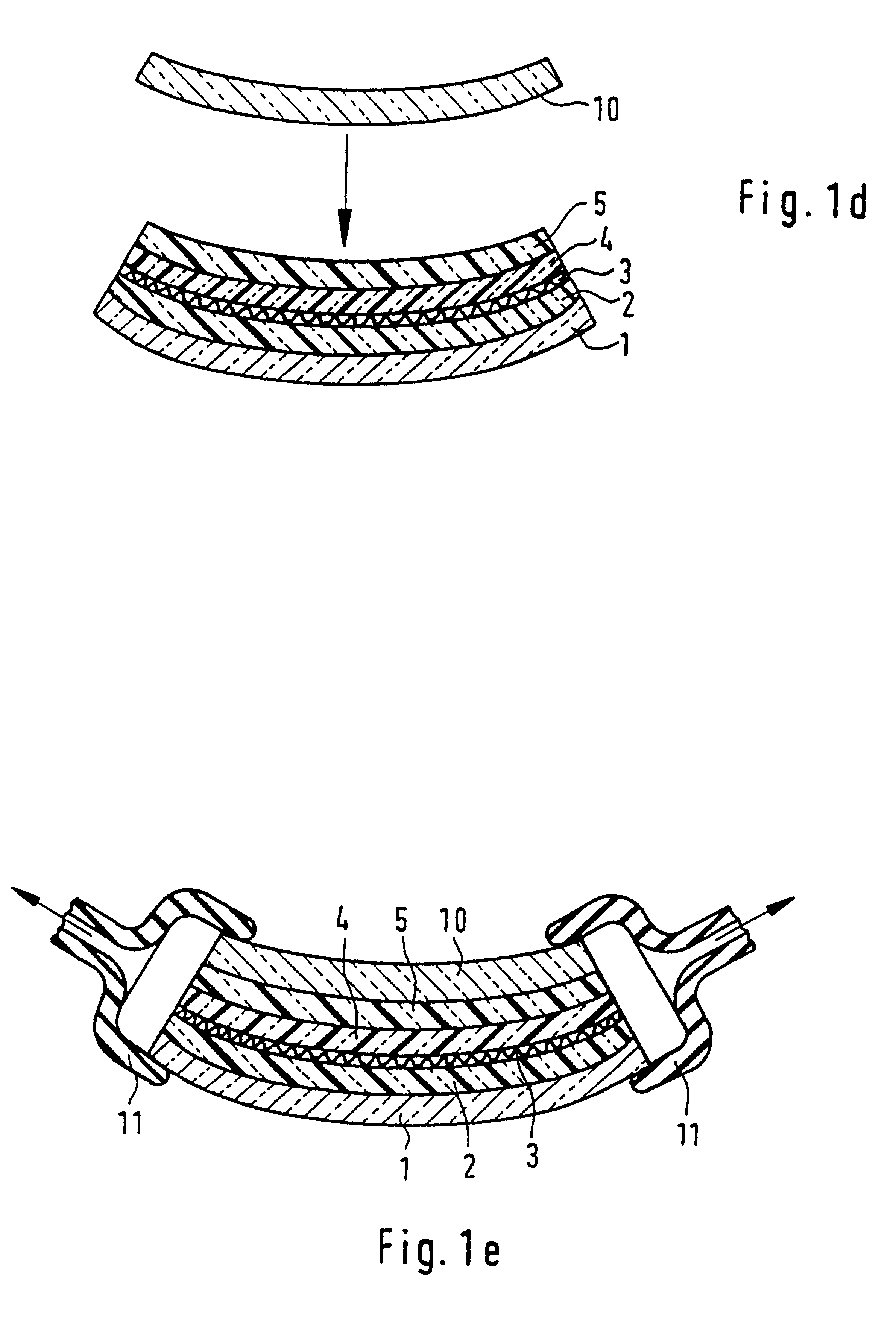

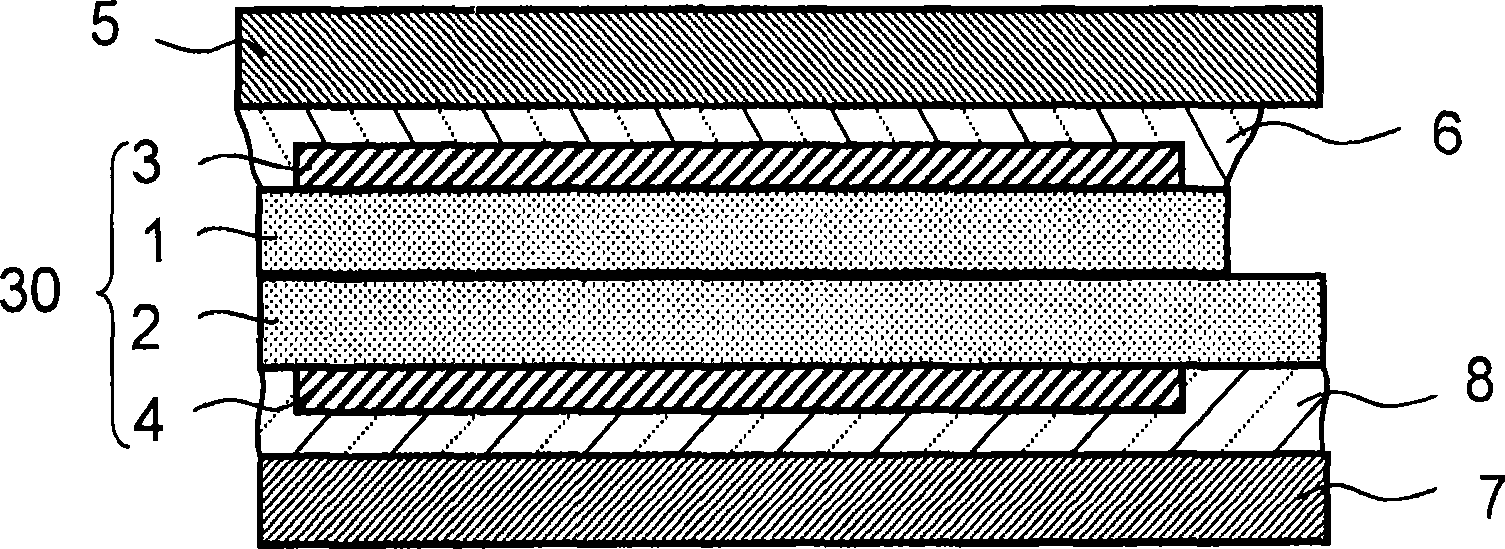

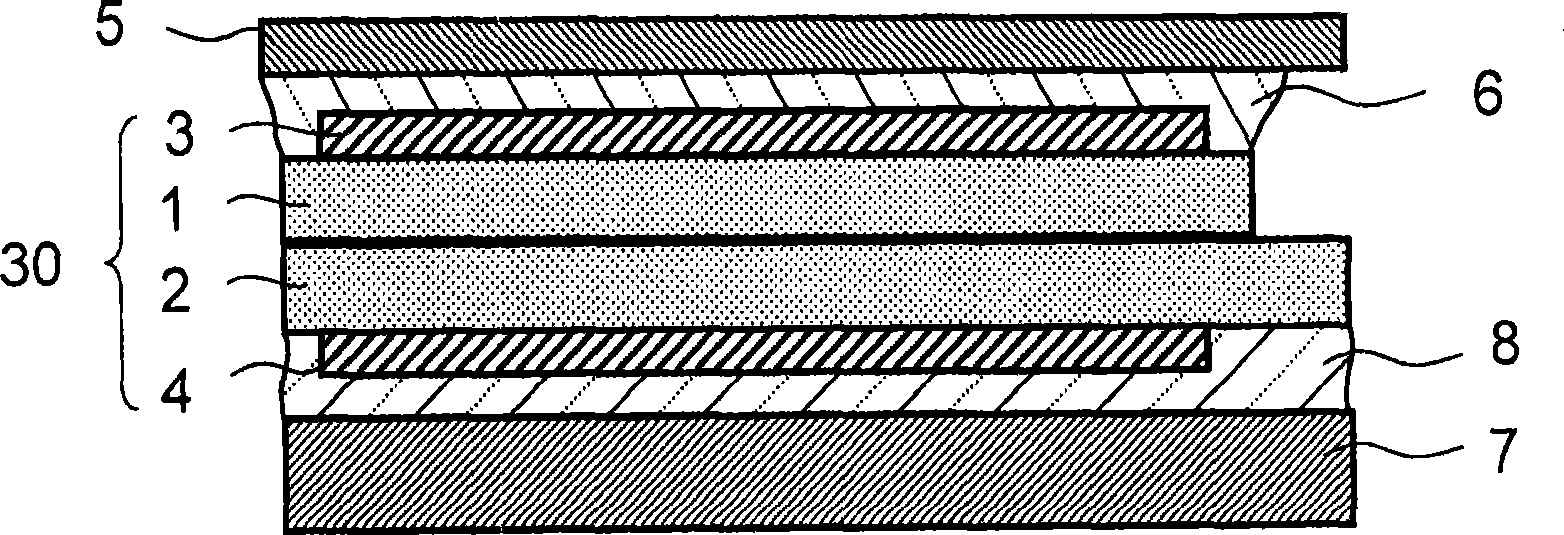

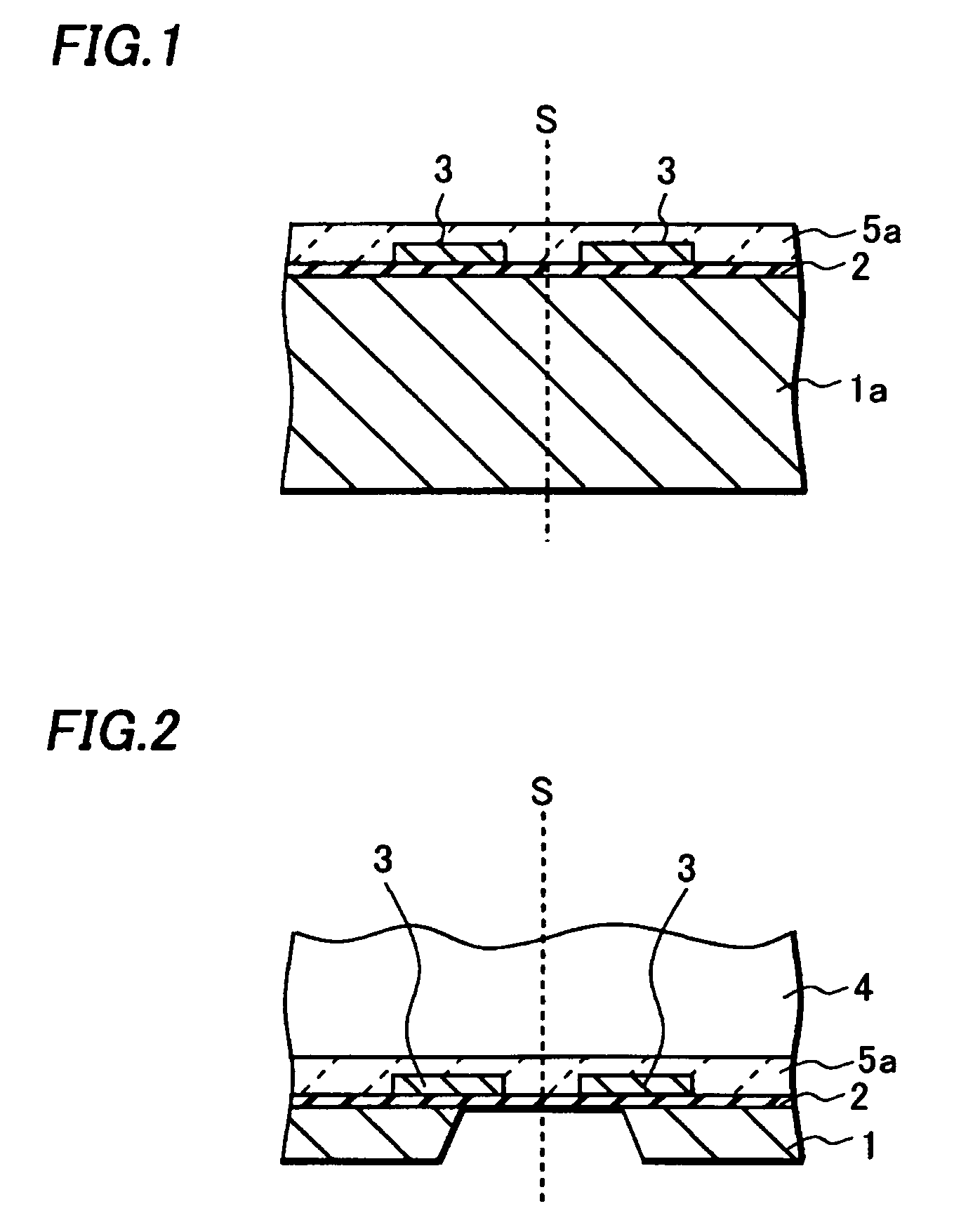

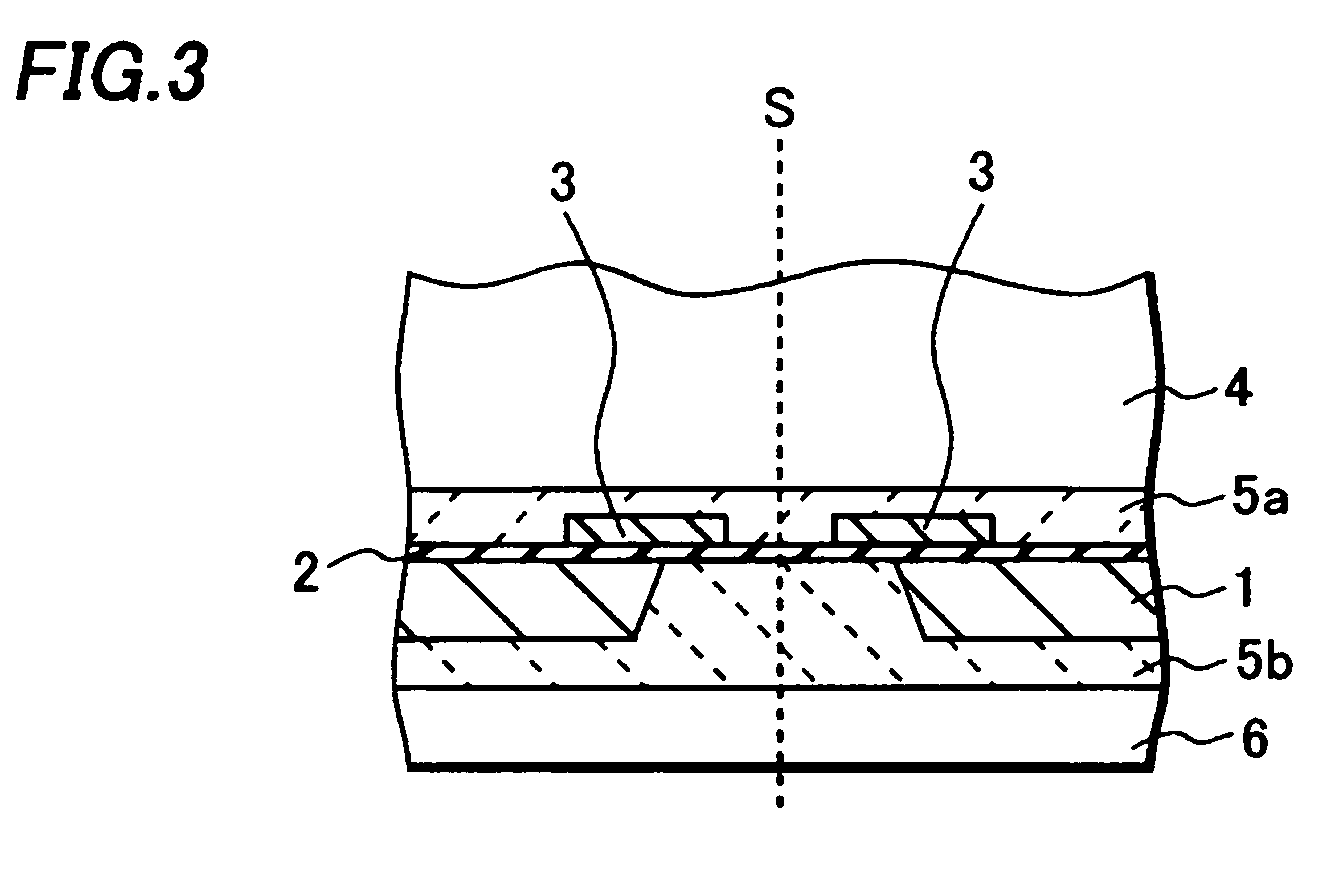

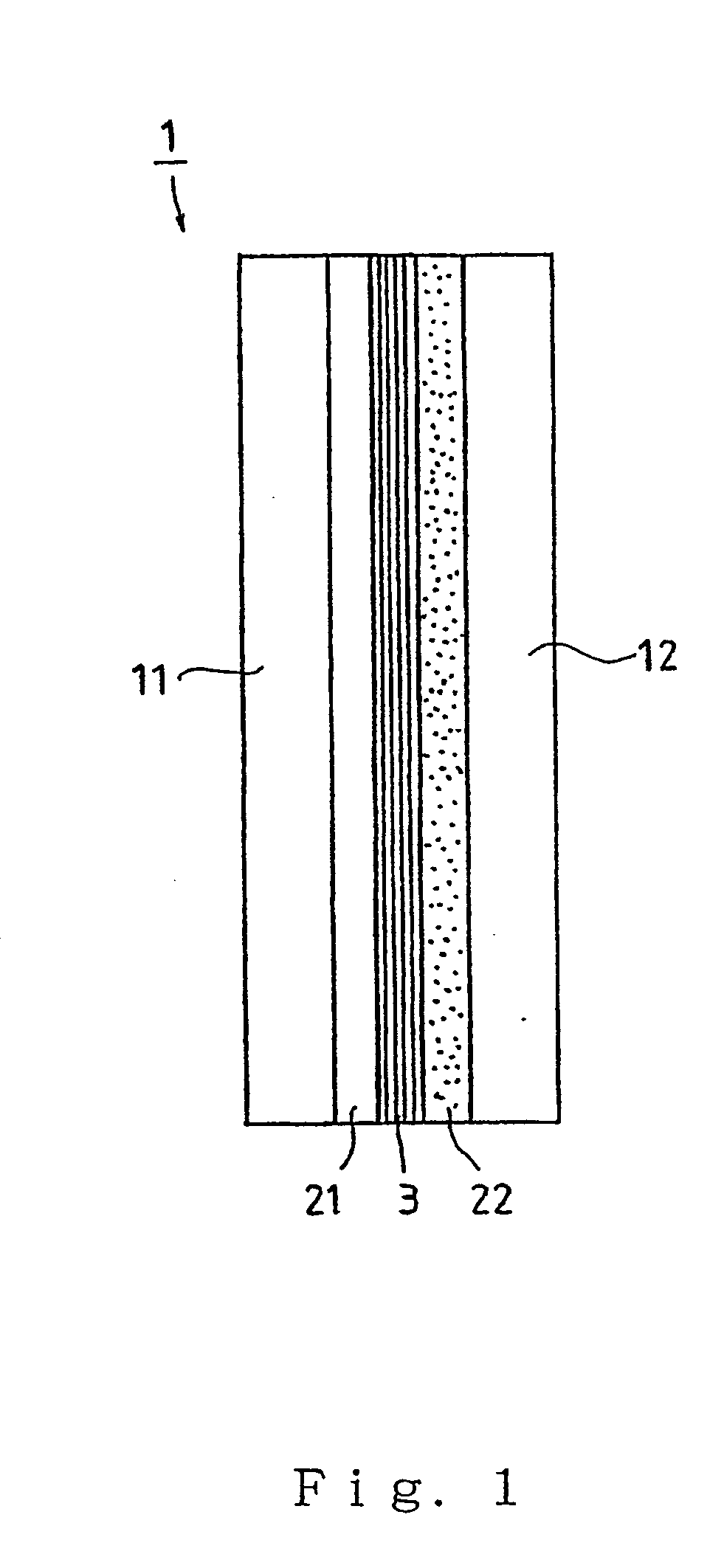

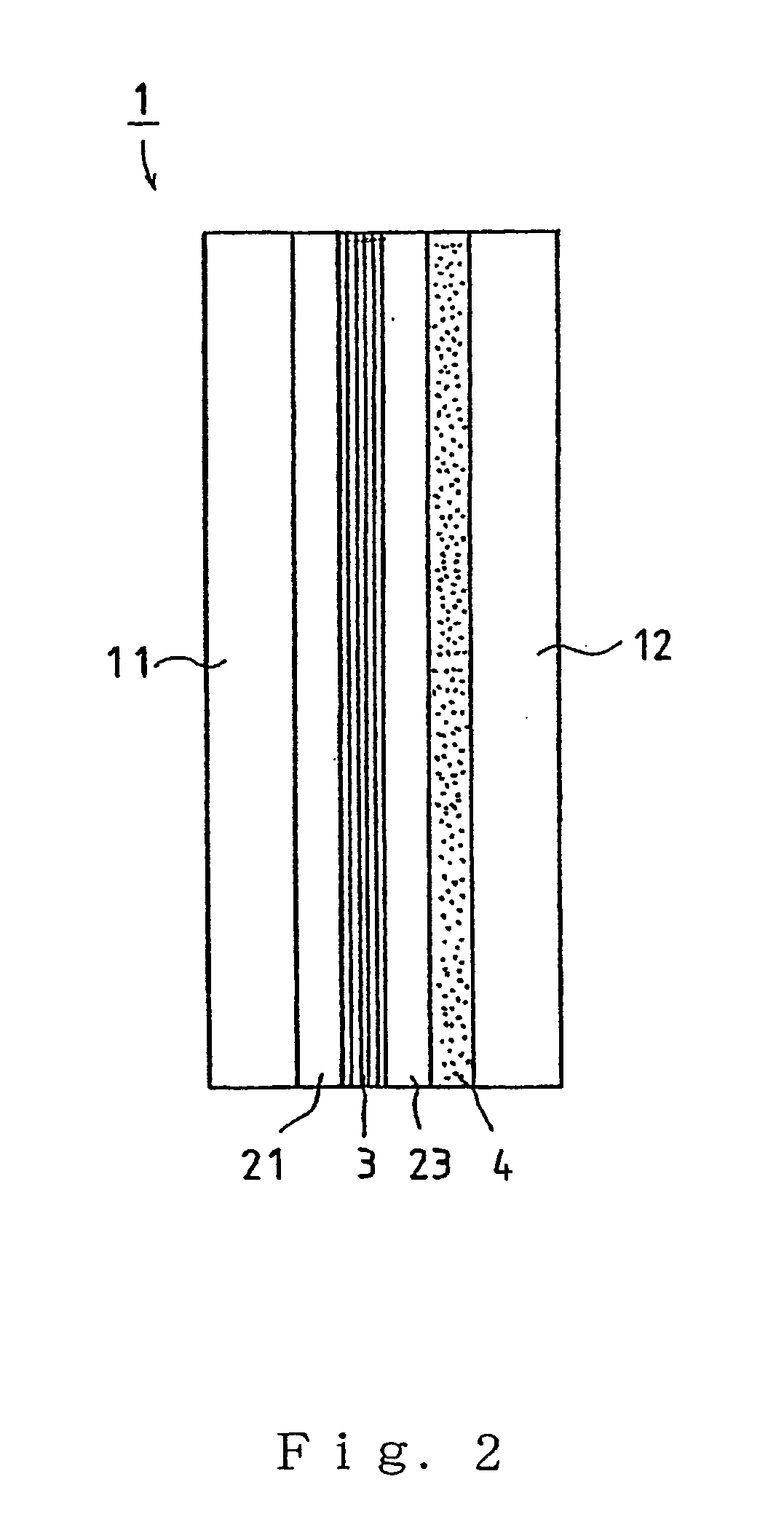

Process for producing a curved laminated safety glass sheet

InactiveUS6261398B1Avoid wrinklesSimple preparation processLaminationLamination apparatusThin layerEngineering

This invention concerns a process for producing a curved, laminated safety glass sheet from a first curved glass sheet (1), a first laminated layer (2), a thermoplastic substrate sheet (4) with a biaxially drawn thin-layer system (3), a second laminated layer (5), and a second curved glass sheet (10) conforming to the first one. To avoid formation of folds in the substrate layer, the process has the following steps: (a) a prelaminated sheet consisting of the first laminated layer (2) and the substrate sheet (4) is superimposed with its laminated layer facing the first glass sheet, (b) a bend-resistant cover sheet (10) conforming to the first glass sheet (1) is superimposed on the prelaminated sheet, (c) the glass layer packet formed out of the first glass sheet (1) and the prelaminated sheet with the cover sheet (10) superimposed upon it is preliminarily bonded by removing the air and subjecting it to pressure and heat, (d) the cover sheet (10) is removed, (e) the second laminated layer (5) and the second glass sheet (10) are superimposed on the preliminarily bonded glass-film pocket, (f) the laminate so formed is preliminarily bonded by removing the air and subjecting it to pressure and heat, (g) the preliminarily bonded laminate is finally bonded into a laminated safety glass sheet by subjecting it to pressure and heat.

Owner:PILKINGTON AUTOMOTIVE DEUT GMBH

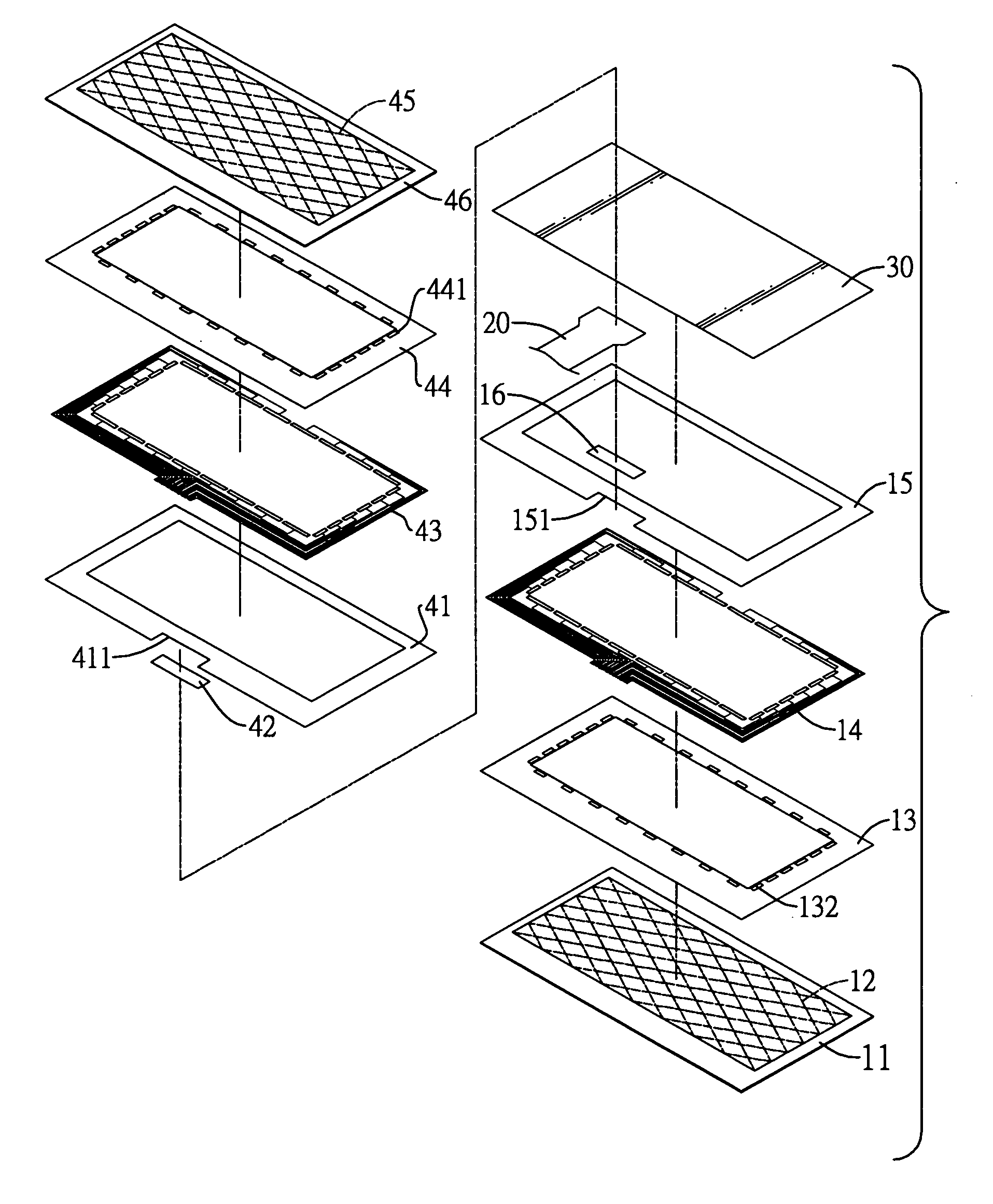

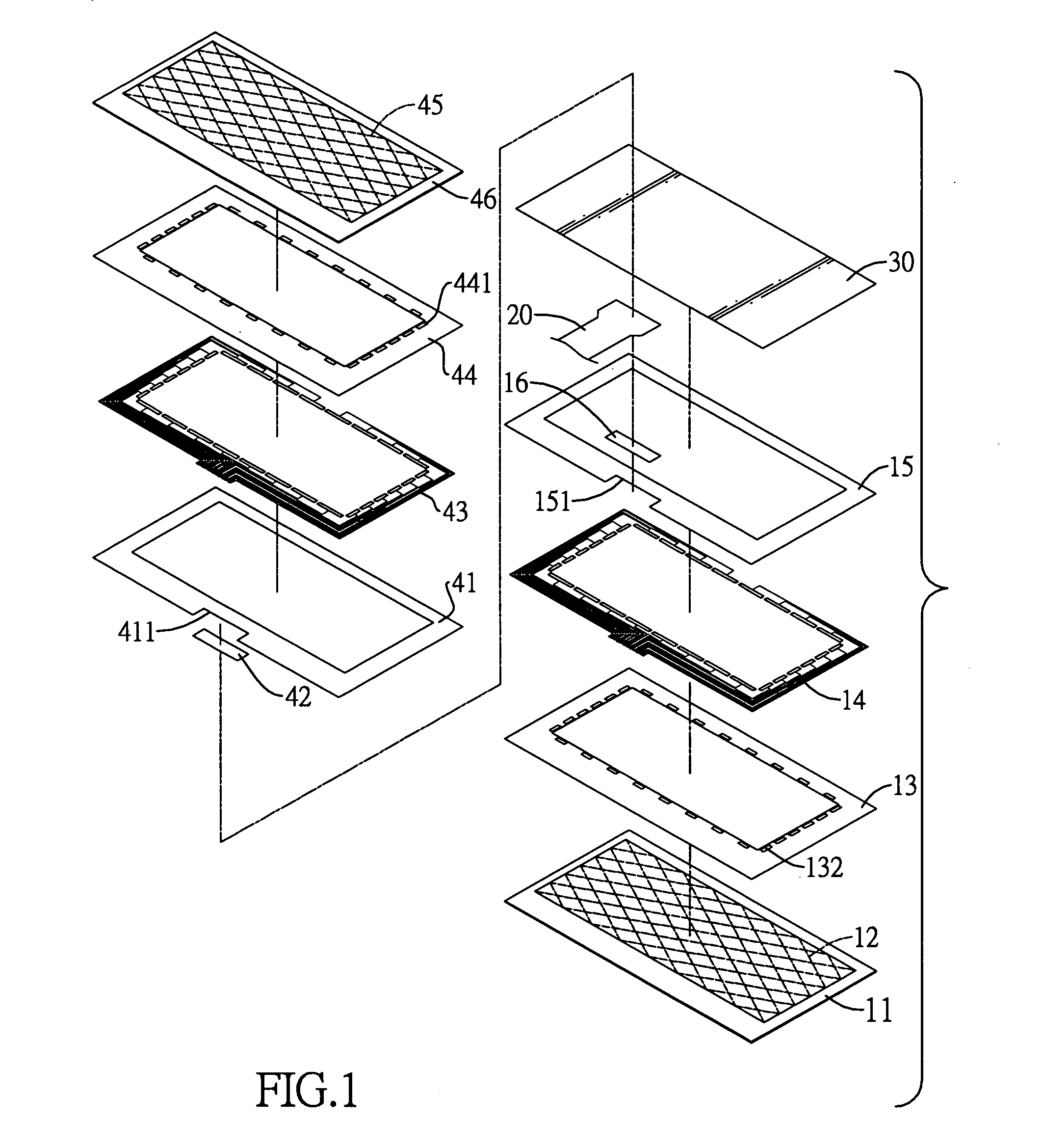

Capacitive touch panel

ActiveUS20120007824A1High yieldSuitable for manufactureElectronic switchingInput/output processes for data processingProduction rateFlexible circuits

A capacitive touch panel sequentially has a first glass substrate, a lower touch sensitive layer, a lower insulation ink layer, a lower conductor layer, a lower insulation layer, a lower conductive adhesive layer, a flexible circuit board, a transparent insulation adhesive layer, an upper insulation layer, an upper conductive adhesive layer, an upper conductor layer, an upper insulation ink layer, an upper touch sensitive layer and a second glass substrate. The aforementioned structure allows fabrication of the capacitive touch panel to be separated into a lower panel fabrication process and an upper panel fabrication process. The two independent fabrication processes prevent the capacitive touch panel from being damaged in one of the processes when the process is completed so as to increase the yield in production and further facilitate producing large-size touch panel.

Owner:TPK HLDG

Curved Display Panel and Method for Manufacturing the same

ActiveUS20090284904A1Increase stickinessPromote generationTube/lamp screens manufactureTelevision system detailsEngineeringGlass sheet

Owner:AU OPTRONICS CORP

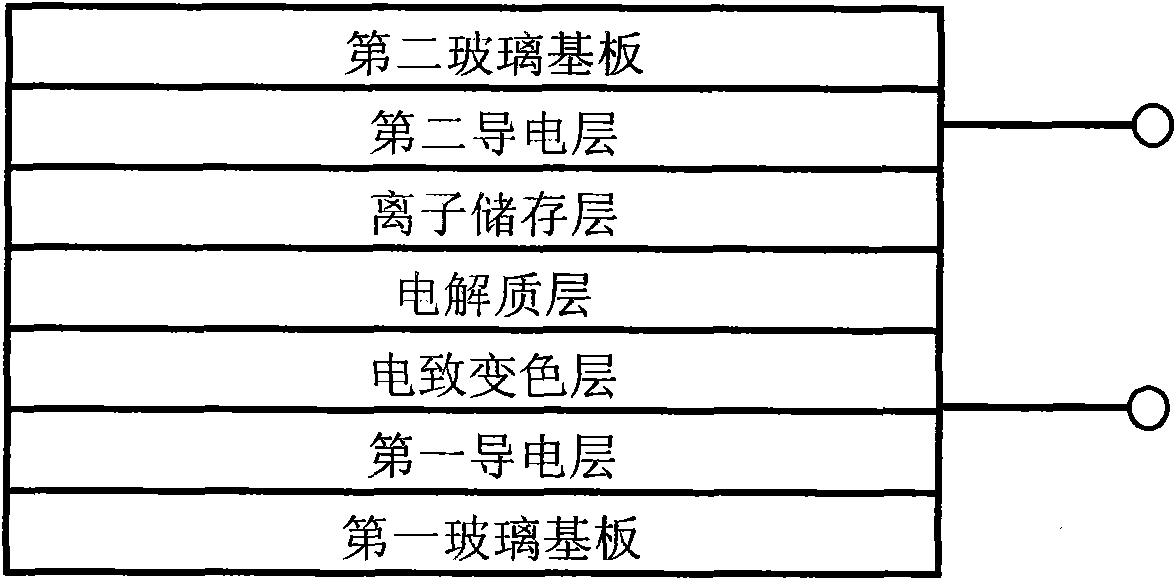

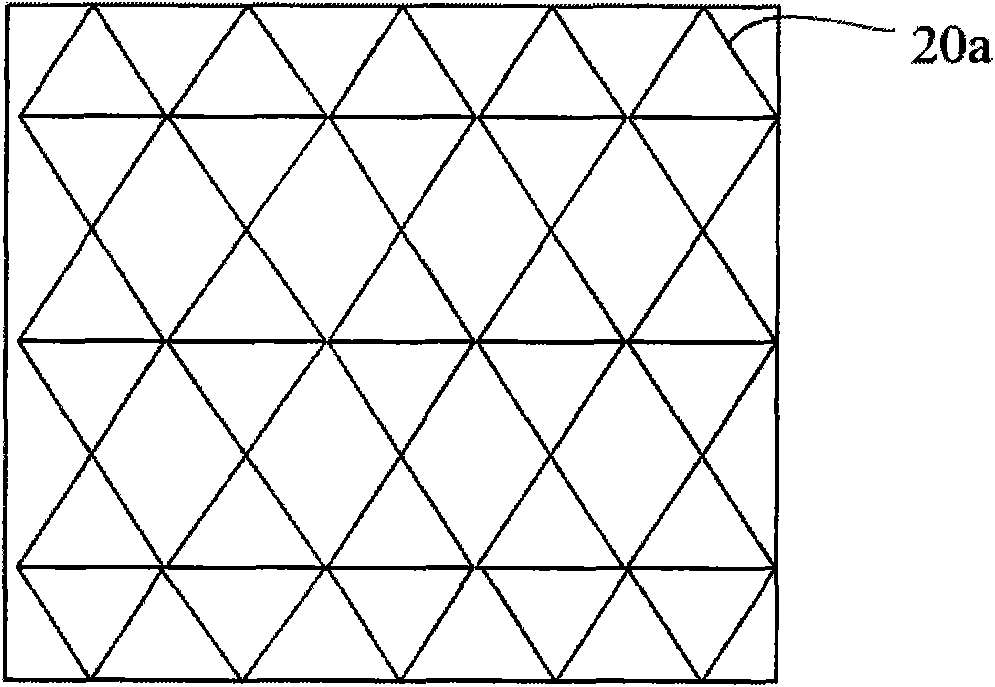

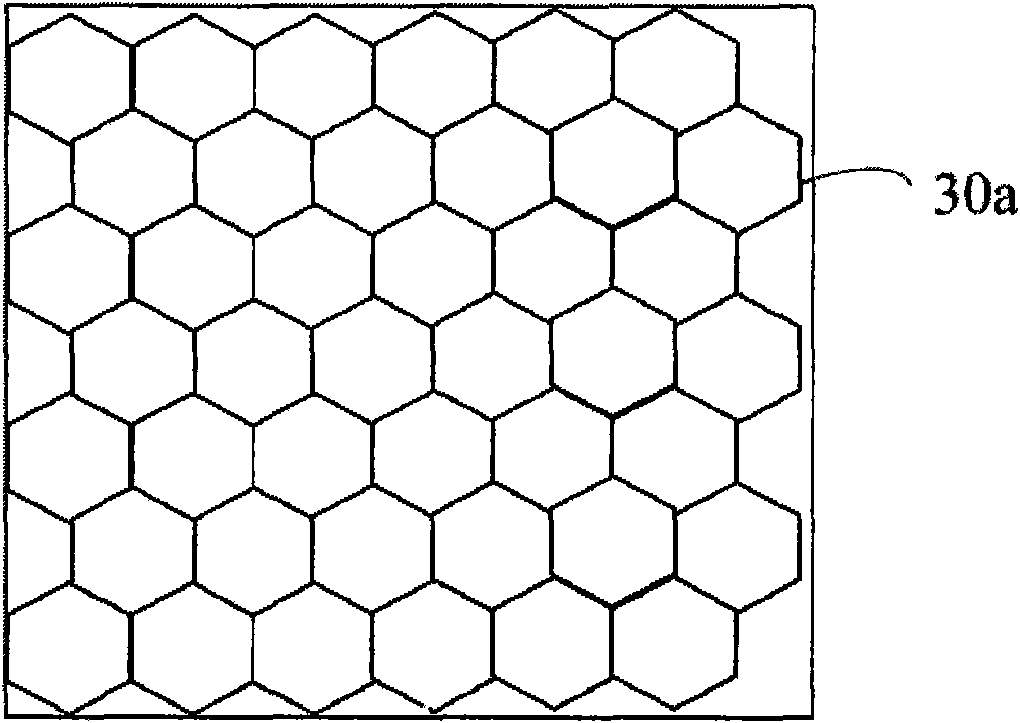

Intelligent dimming glass

InactiveCN101833211AHigh electrochromic efficiencyLow external voltageNon-linear opticsOptical elementsFiberOptoelectronics

The invention discloses intelligent dimming glass comprises a first glass base plate and a second glass base plate which are stacked at the top and the bottom, a first conductive layer, an electrochromic layer, an electrolyte layer, an iron storage layer and a second conductive layer are sequentially arranged between the first glass base plate and the second glass base plate; one ends of the first conductive layer and the second conductive layer are respectively connected with an anode and a cathode; and the first conductive layer and the second conductive layer are conductive films having infrared reflection performance, and the surfaces of the conductive films are coated with active carbon fibers. Compared with the prior art, the intelligent dimming glass has the characteristics of infrared reflection effect, high electrochromic efficiency, lower required external voltage and the like, can not only reduce indoor heat losses and realize the purpose of saving energy sources, but also prolong the service life of the intelligent dimming glass, thereby meeting the requirements of daily life and architectural decoration of people.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

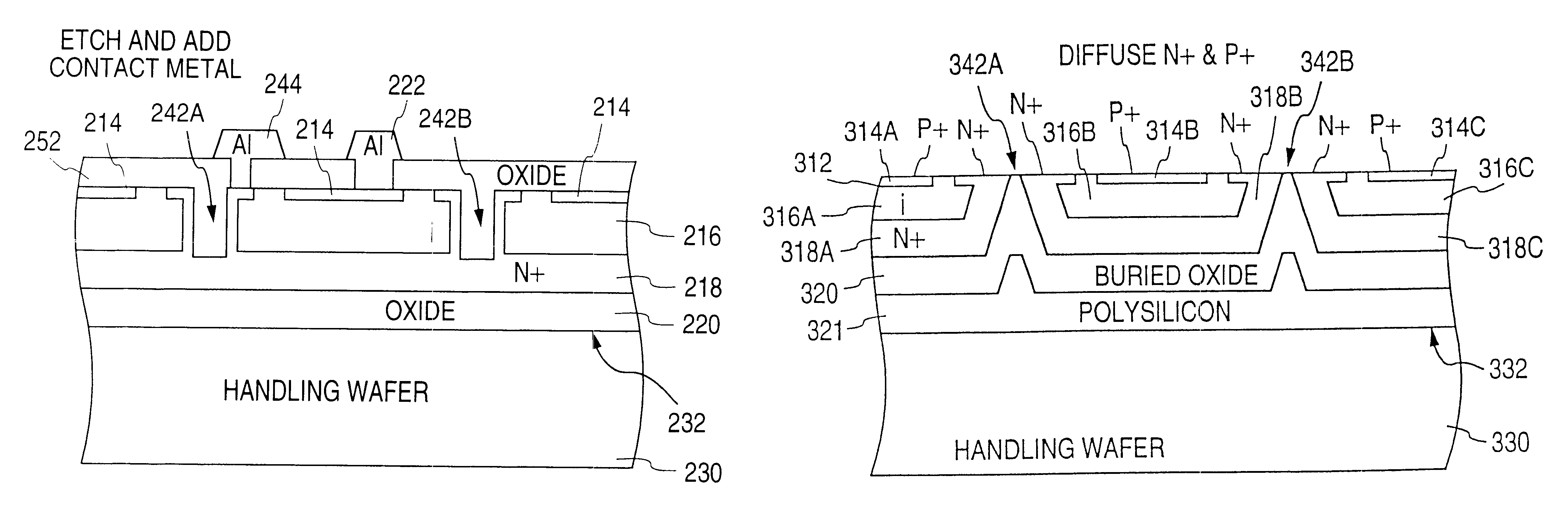

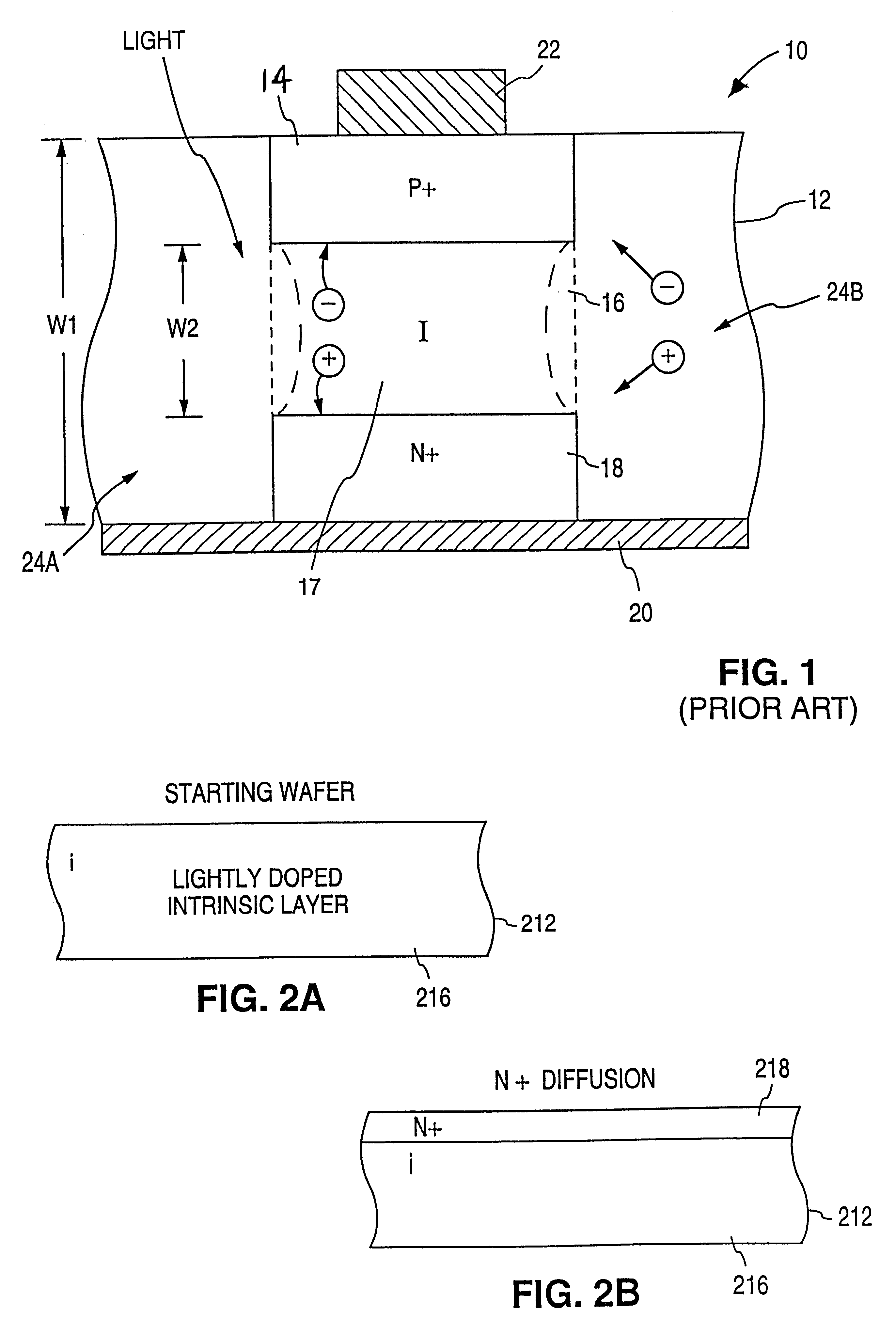

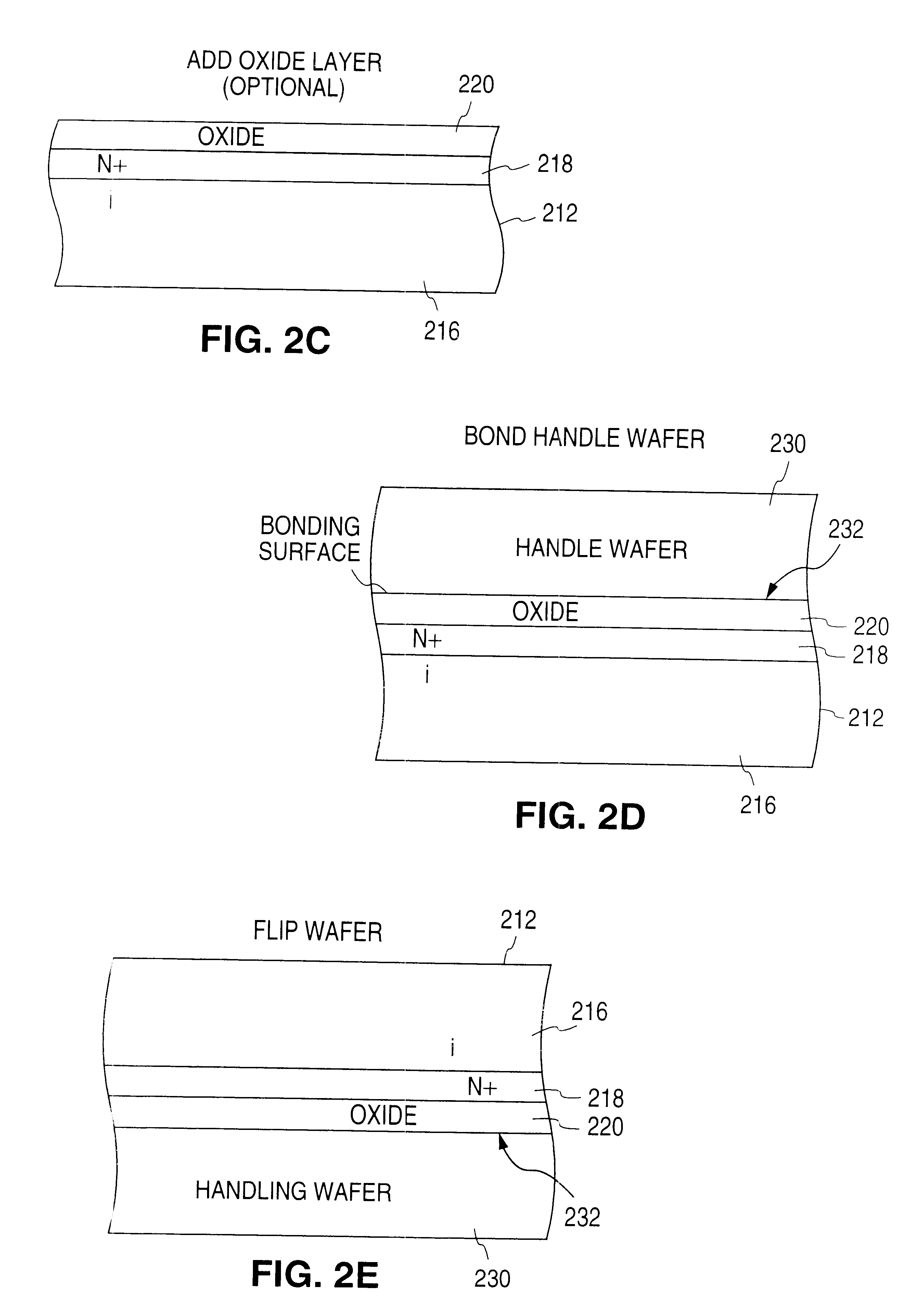

Process for producing an isolated planar high speed pin photodiode with improved capacitance

InactiveUS6458619B1Avoid it happening againImprove isolationSemiconductor/solid-state device manufacturingPhotovoltaic energy generationParasitic capacitancePhotodiode

A method is shown for producing a PIN photodiode having low parasitic capacitance and wherein an intrinsic layer of the photodiode can be made arbitrarily thin. A fabrication substrate is lightly doped to have a first conductivity type in order to form the intrinsic layer of the photodiode. A first active region of the photodiode having the first conductivity type is formed on a first surface of the fabrication substrate. An oxide layer is also formed upon the first surface of the fabrication substrate. A first glass layer is formed on a first surface of a handling substrate. The first surface of the handling substrate is bonded to the first surface of the fabrication substrate. A second surface of the fabrication substrate is then lapped to a obtain a preselected thickness of the intrinsic layer. A second active region of the photodiode having a second conductivity type is formed on the second surface of the fabrication substrate. A groove is etched from the second surface of the fabrication substrate through the intrinsic region to the first surface in order to isolate the photodiode. A second glass layer may be formed on a second surface of the handling substrate to further reduce parasitic capacitance.

Owner:SILICON LAB INC

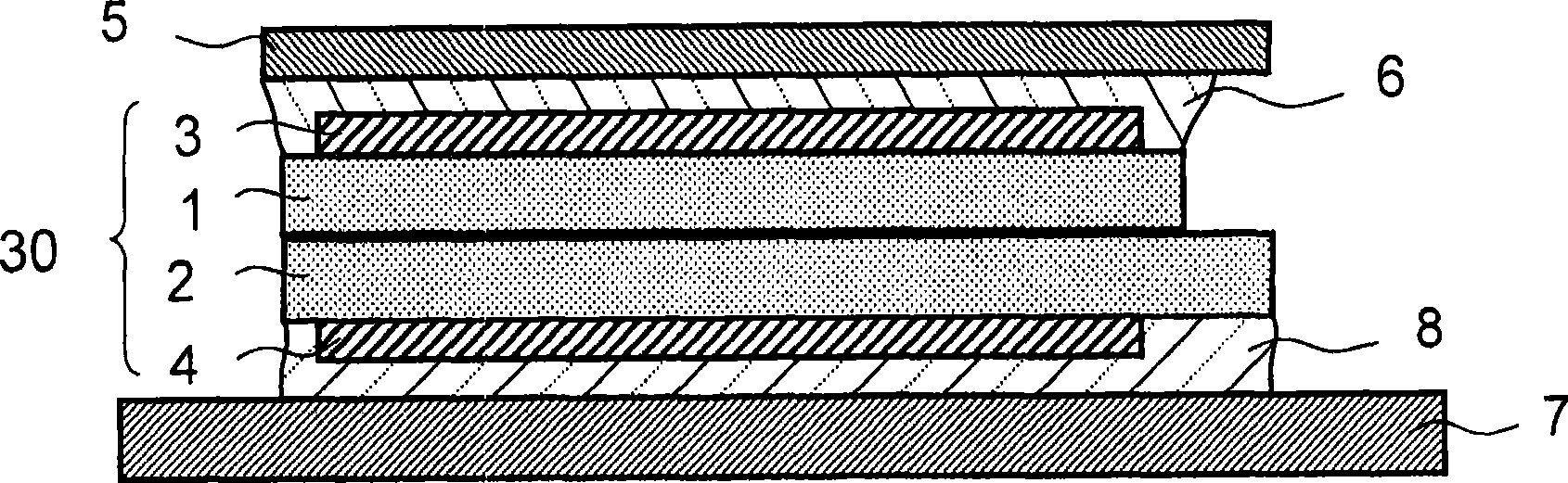

Display device

InactiveCN101523275APrevent prominenceNon-linear opticsIdentification meansOptical bondingLiquid-crystal display

An enforcing glass plate is attached to the entire display region of the display side and the opposite side of a liquid crystal panel (30) so as to improve the applied weight resistance against an external shock or pressure, which enables reduction of the thickness of the liquid crystal panel (30). That is, a display device includes: a liquid crystal panel (30) which sandwich liquid crystal inside two transparent substrates and having an optical film arranged on at least one of the external surfaces of the transparent substrates; a first glass plate bonded to the display surface side of the liquid crystal panel (30) via a first adhesive formed by an optical adhesive or a transparent adhesive sheet; and a second glass bonded to the rear surface side of the liquid crystal panel (30) via a second adhesive formed by an optical adhesive or a transparent adhesive sheet.

Owner:SEIKO INSTR INC

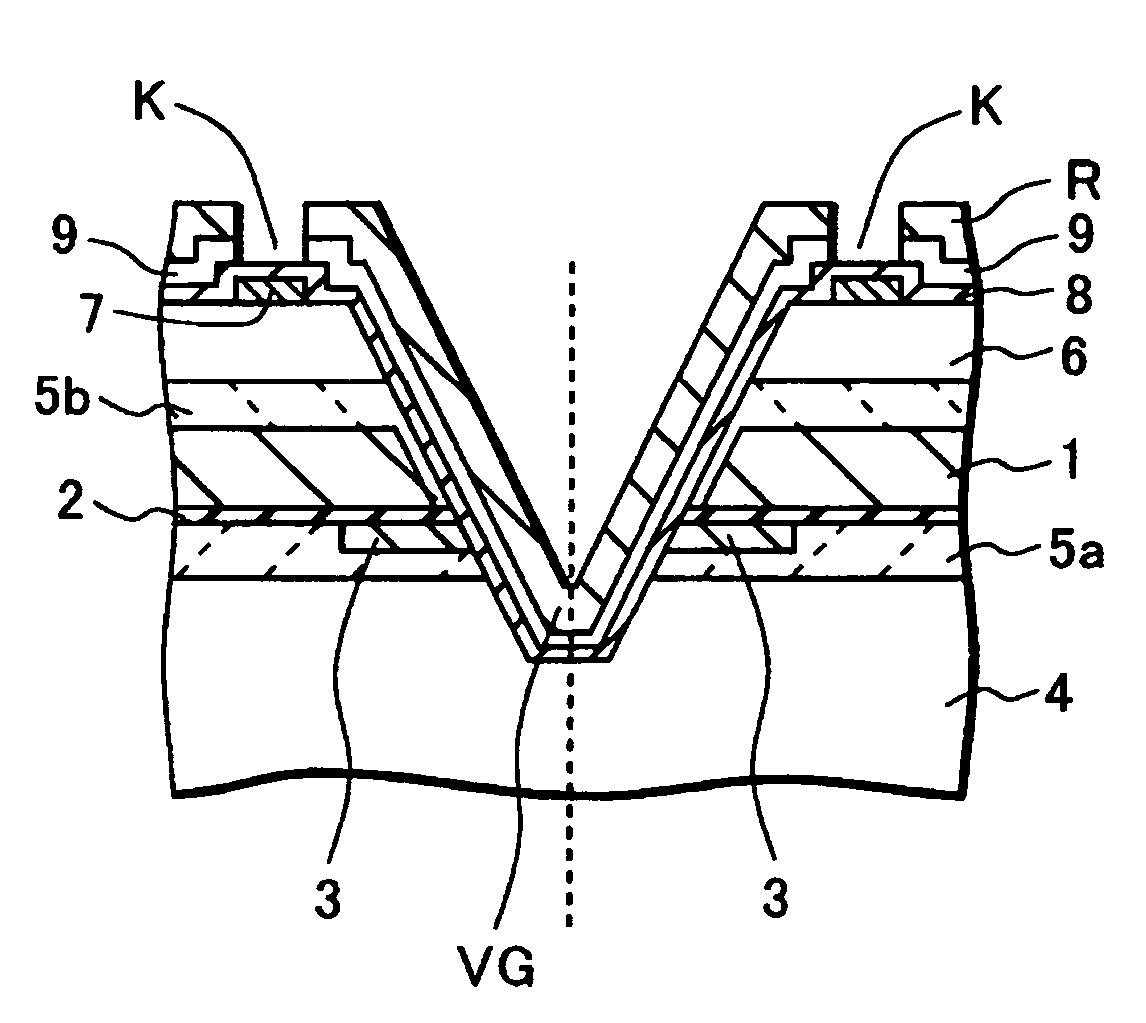

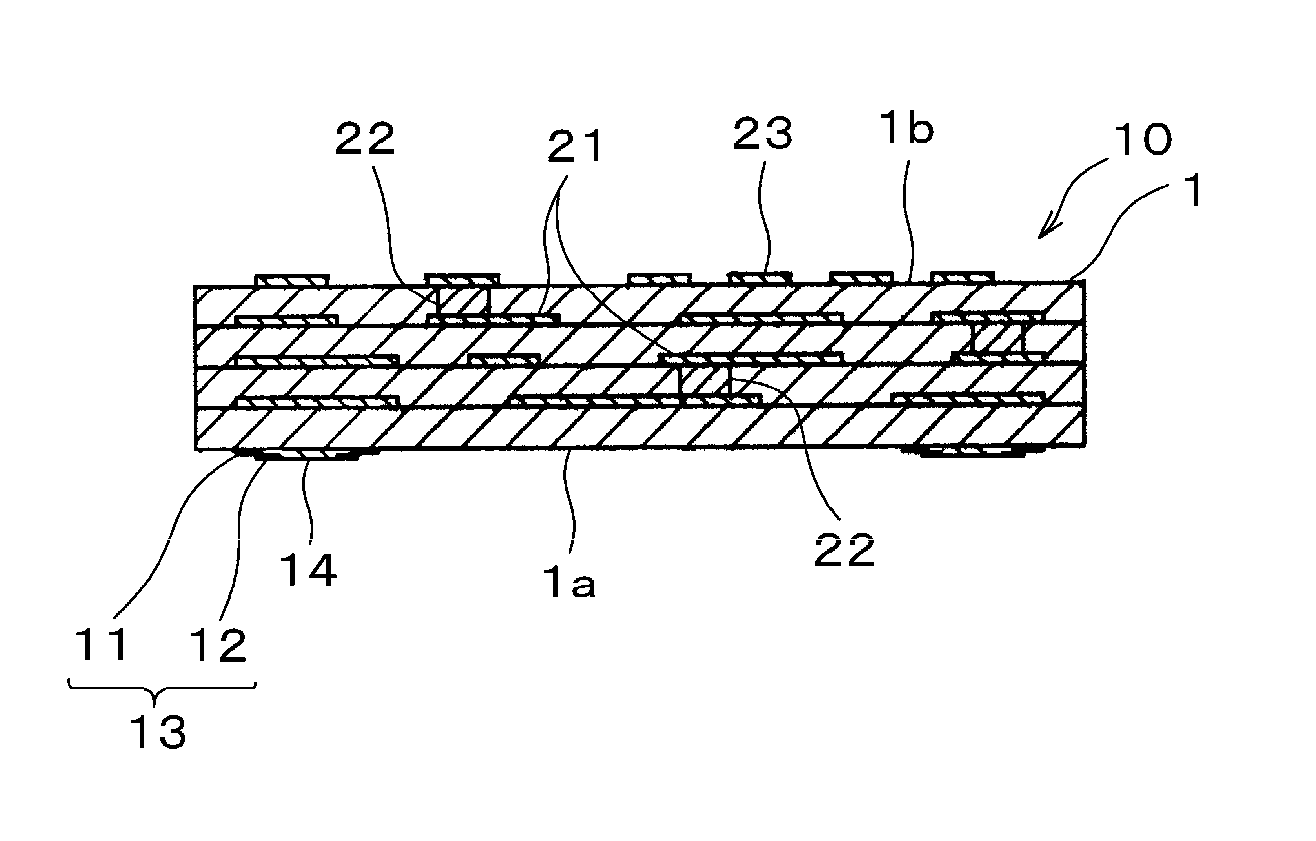

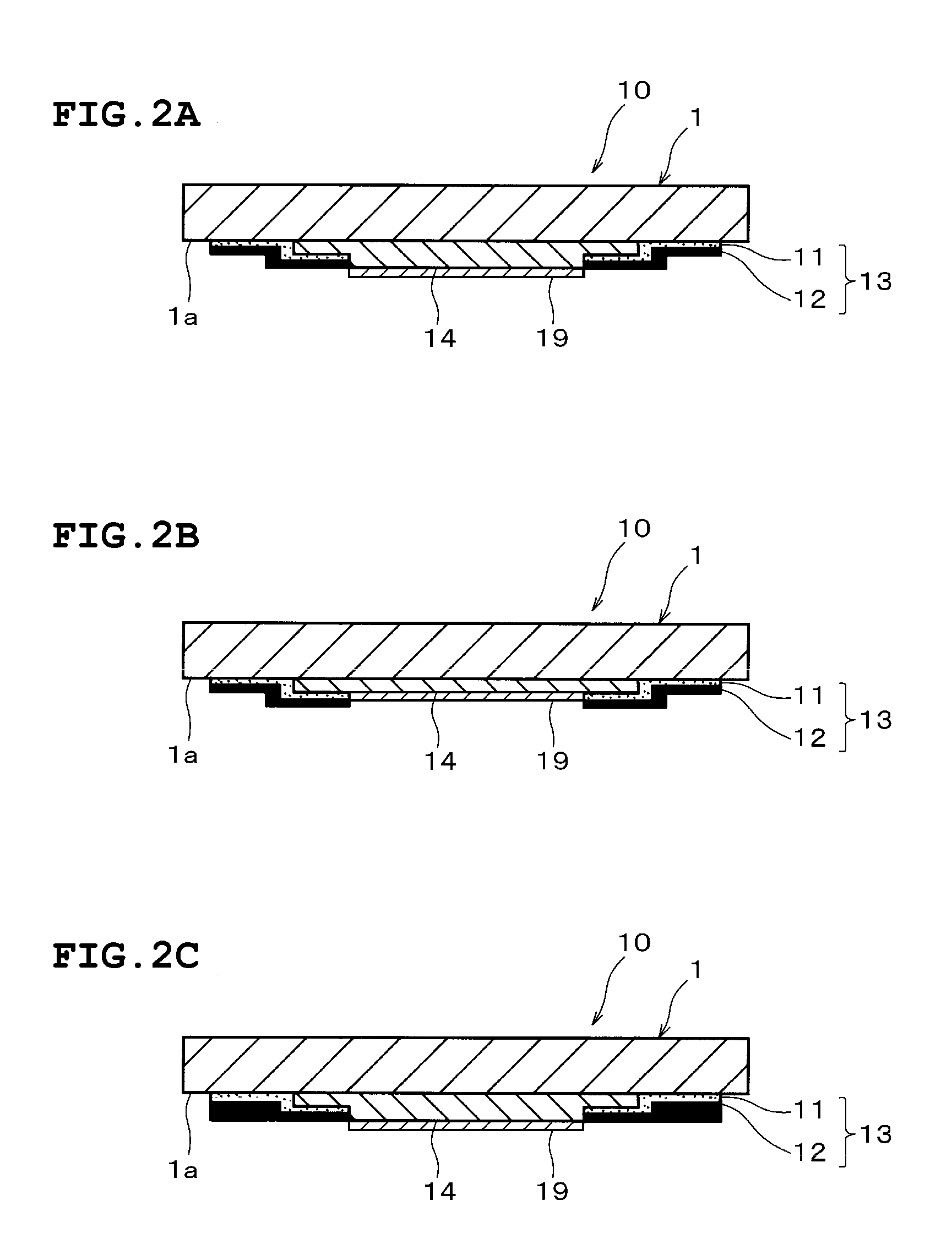

Manufacturing method of semiconductor device

ActiveUS7101735B2High yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesCushioningScreen printing

A first glass substrate is bonded through a resin to a top surface of a semiconductor wafer on which a first wiring is formed. A second glass substrate is bonded to a back surface of the semiconductor wafer through a resin. A V-shaped groove is formed by notching from a surface of the second glass substrate through a part of the first glass substrate. A second wiring connected with the first wiring and extending to the surface of the second glass substrate is formed. A protection film composed of an organic resin and a photoresist layer to provide the protection film with an opening are formed on the second wiring by spray coating. A conductive terminal is formed by screen printing using the protection film as a solder mask. A cushioning material may be formed on the second glass substrate by spray coating.

Owner:SEMICON COMPONENTS IND LLC

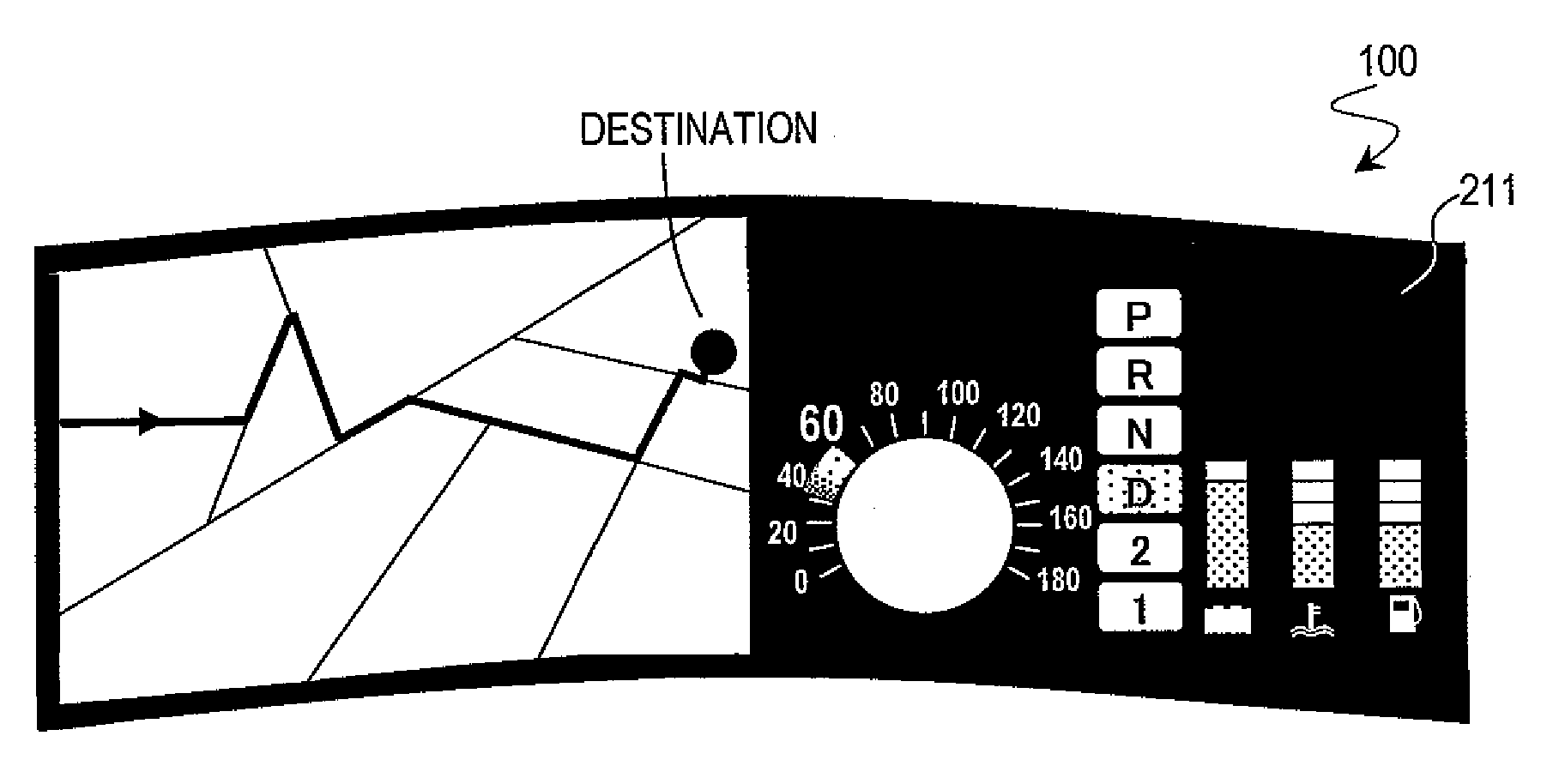

Display device

InactiveUS20090179840A1Prevent disengagementStatic indicating devicesNon-linear opticsDisplay deviceDriven element

In a display device, a first glass substrate is curved. When signal line driving elements and scanning line driving elements are viewed from a normal direction of a principal surface of the first glass substrate, the signal line driving elements and the scanning line driving elements each have a rectangular or substantially rectangular shape with two longer sides and two shorter sides. The signal line driving elements and the scanning line driving elements are mounted so that the longer sides thereof are parallel or substantially parallel to one another.

Owner:SHARP KK

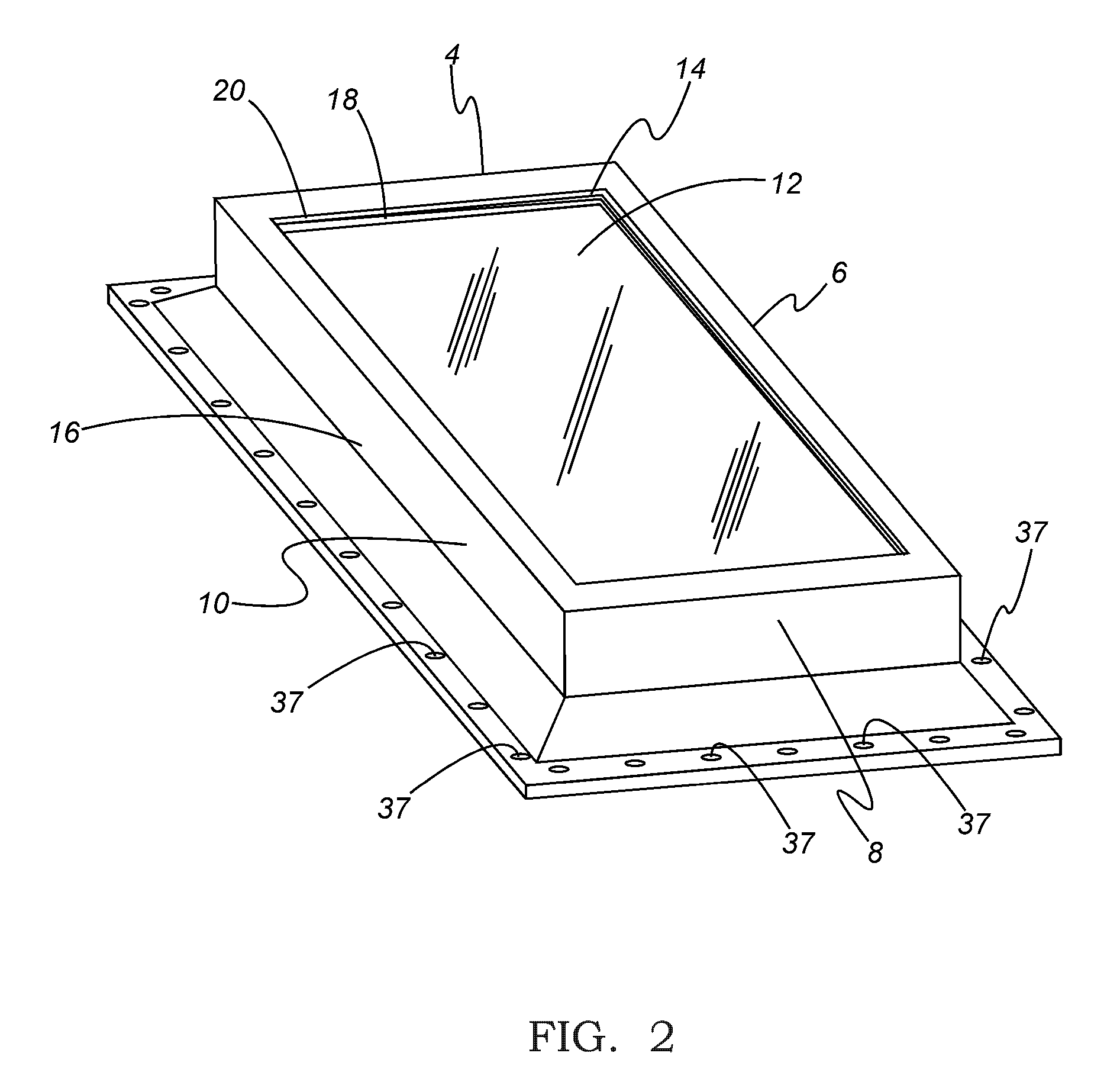

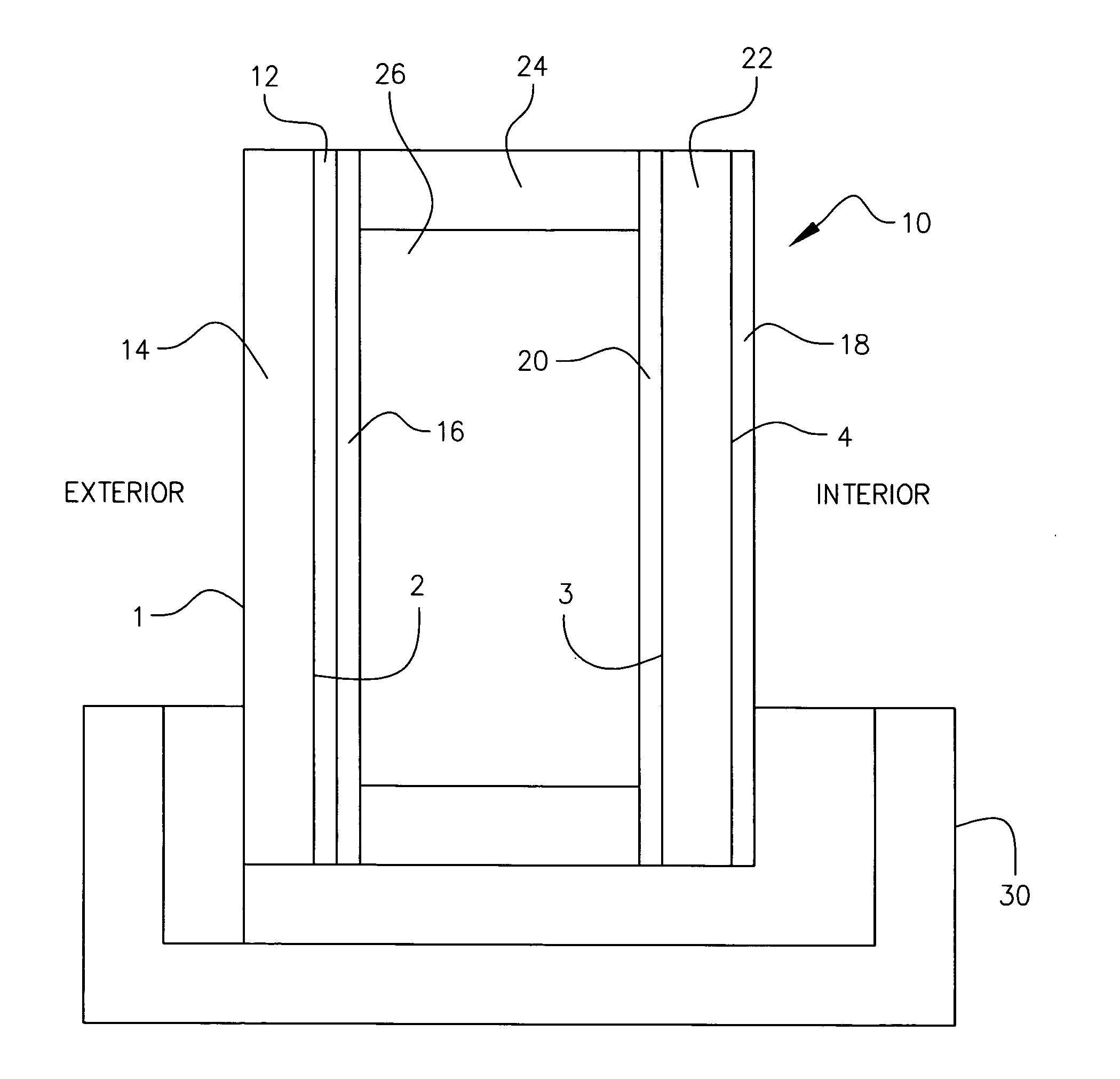

Skylight having a molded plastic frame

The present invention provides a skylight frame design that is adapted to receive at least two panels of glass. The skylight frame comprises a stepped frame section that includes a lower step surface and an upper step surface. The lower step surface is adapted to receive a first glass panel so that a section of the first glass panel lies flush against the lower step surface. Similarly, the upper step surface is adapted to receive a second glass panel so that the second glass panel lies flush against the upper step surface. The skylight frame design of the invention is either incorporated into a skylight frame that may be attached to a curb unit on a roof or it may be an integral part of a skylight frame-curb assembly that also contains a curb section. In another embodiment of the invention, a skylight frame design which directly incorporates one or more panels of glass during molding is provided.

Owner:V TECH PATENTS

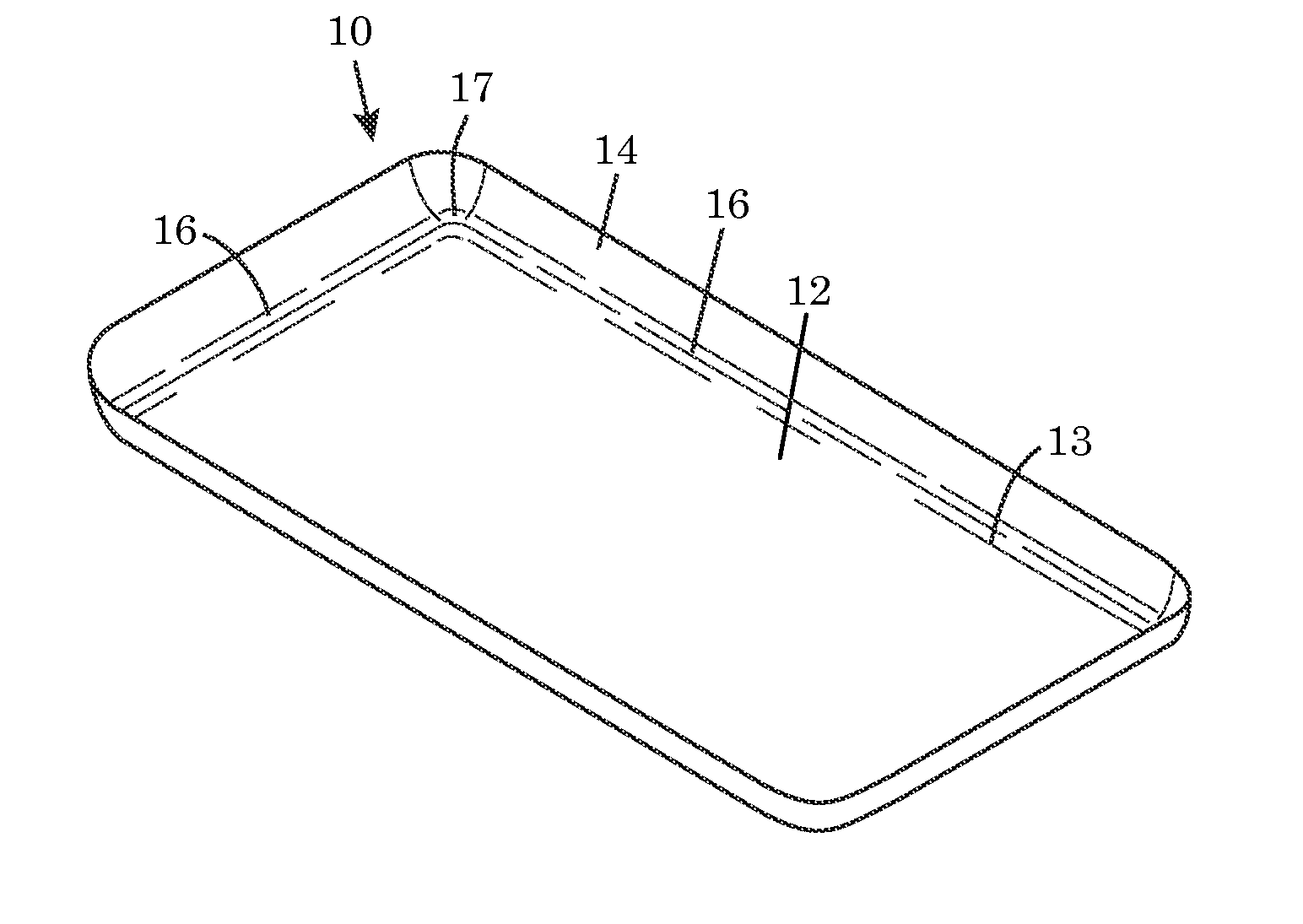

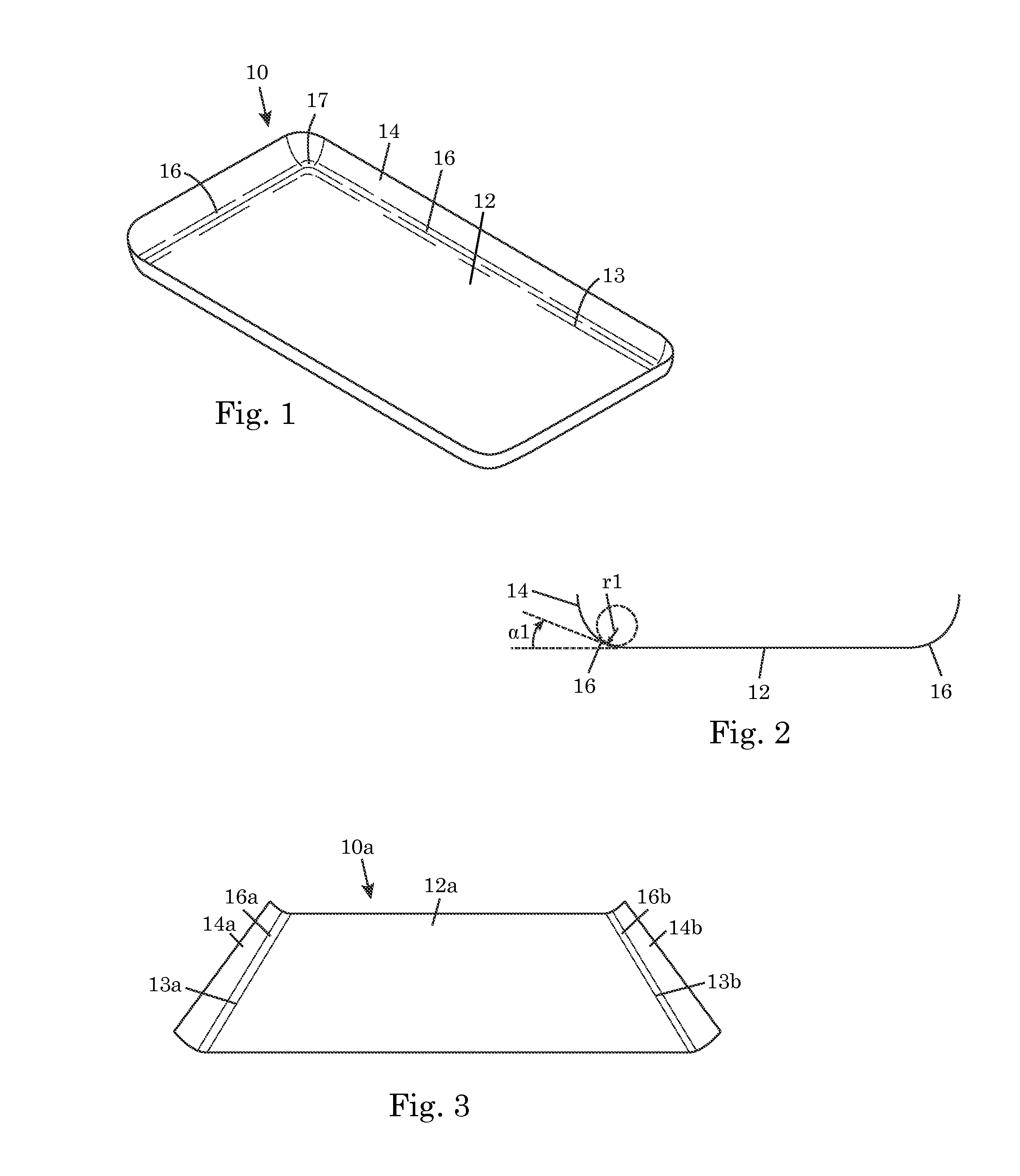

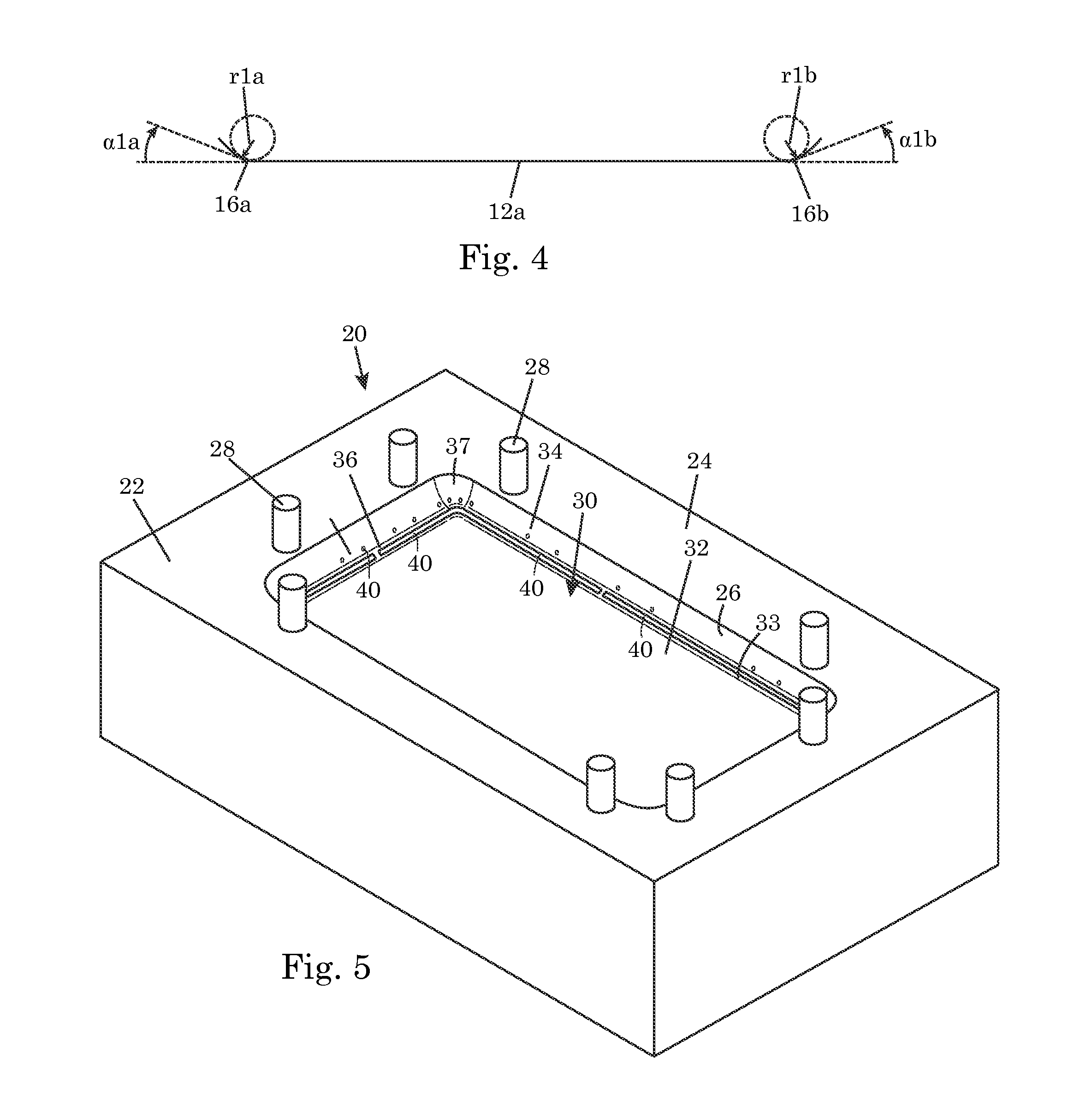

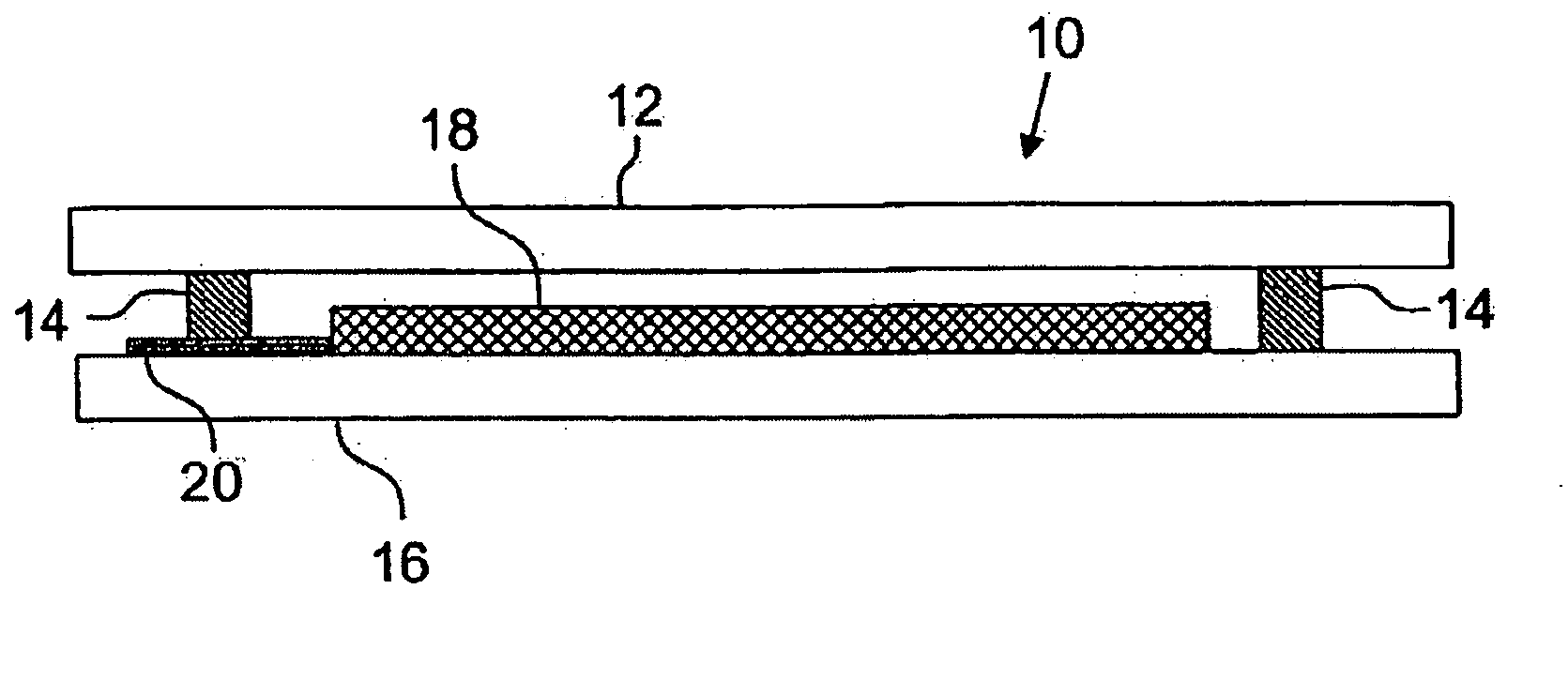

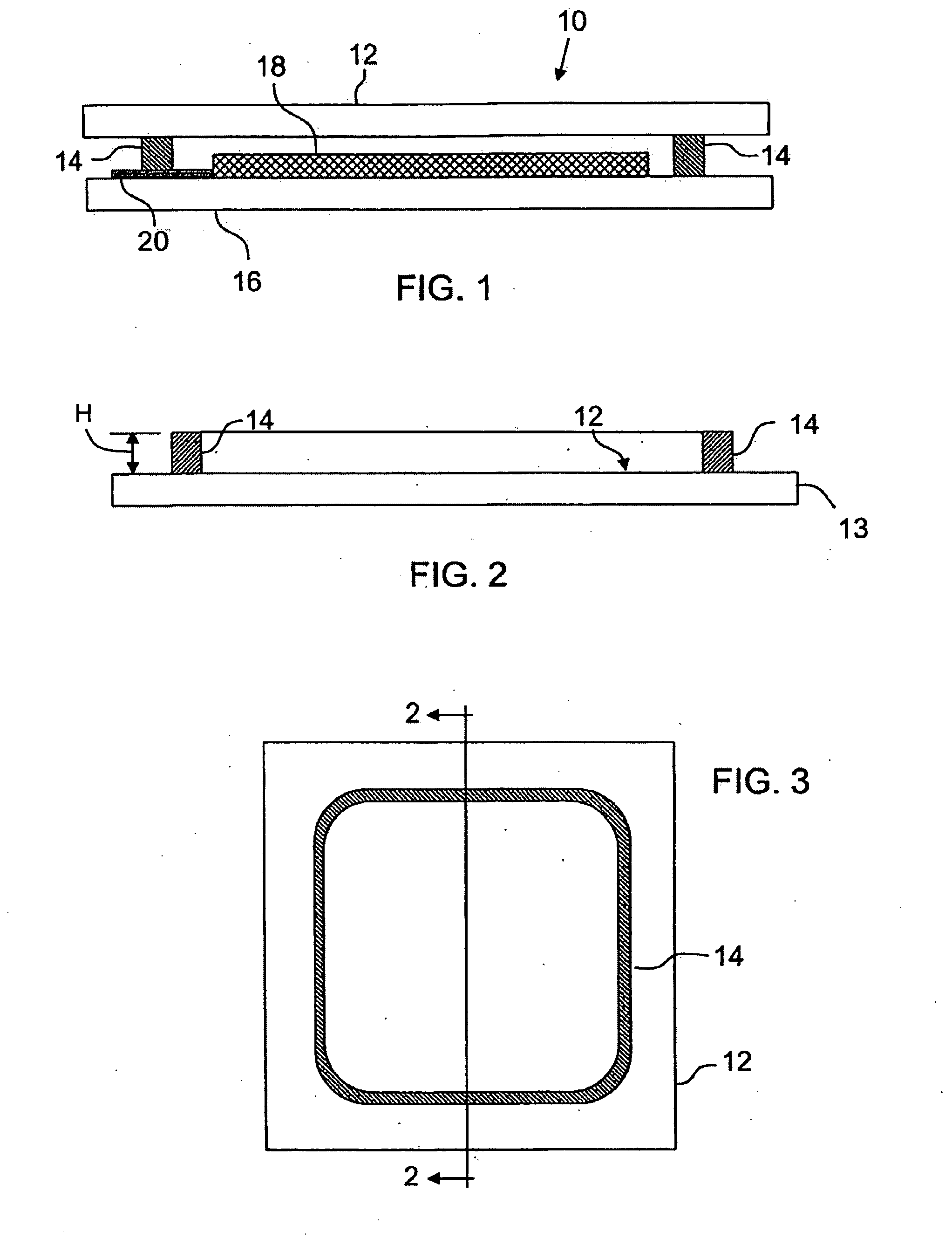

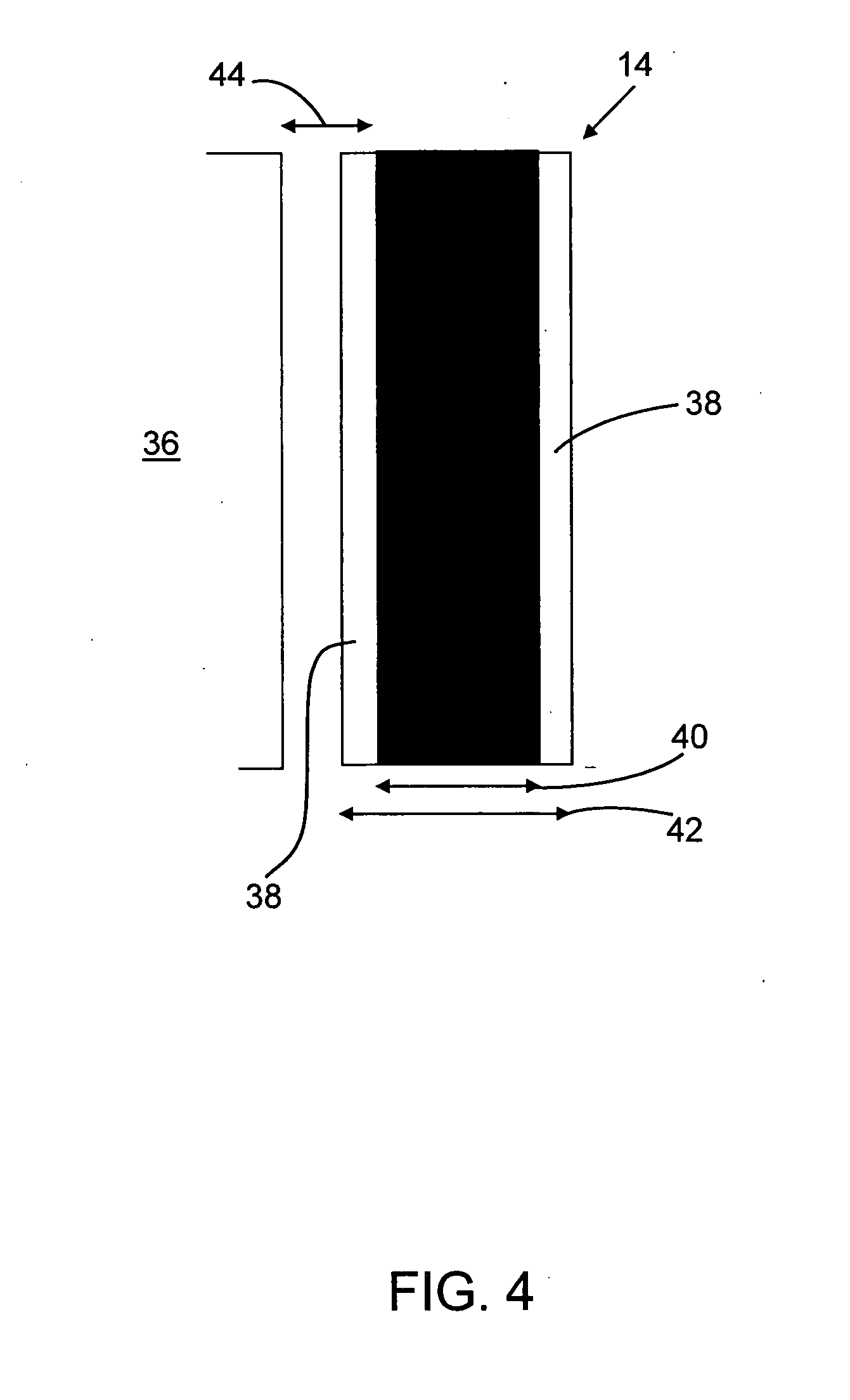

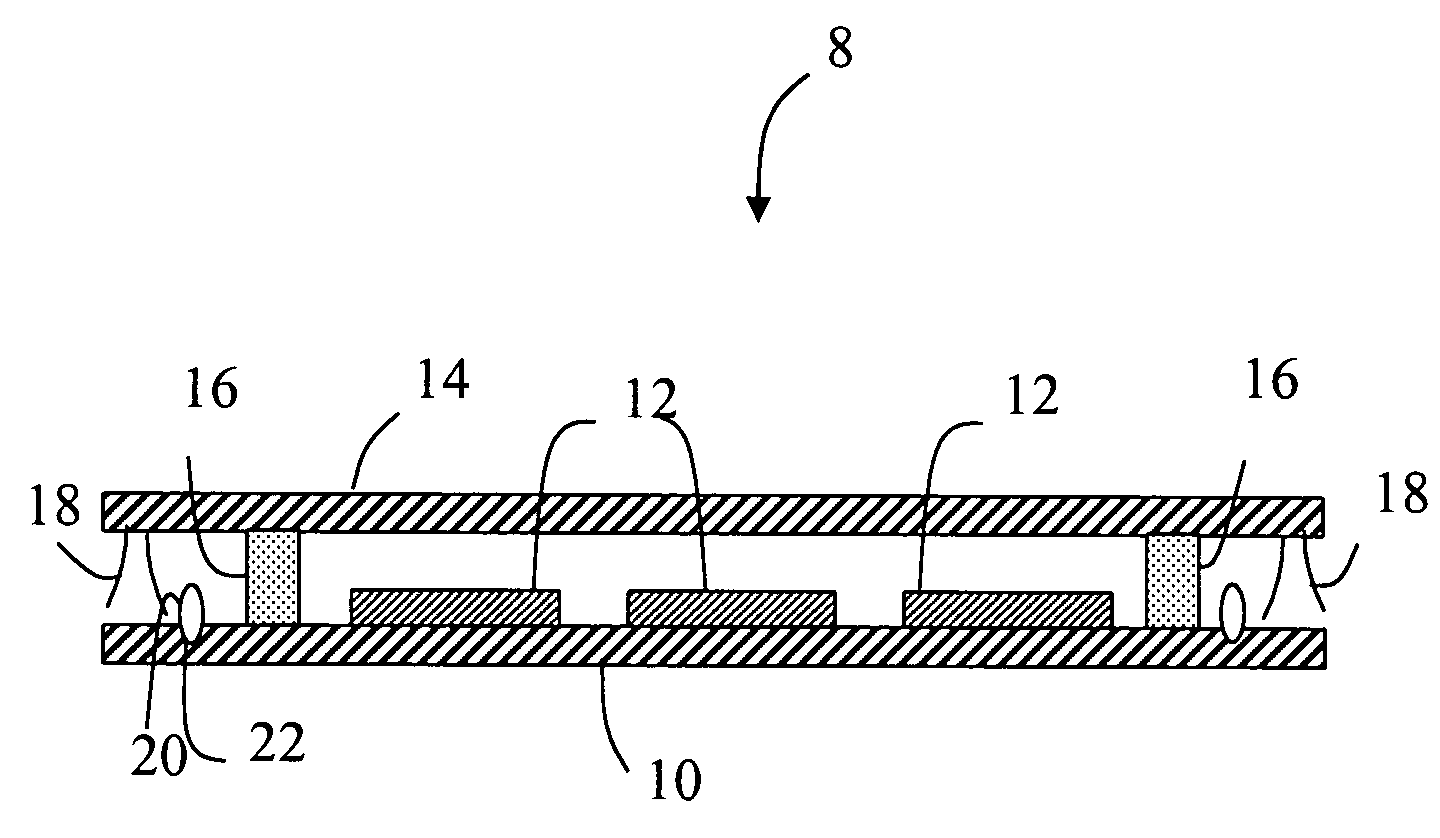

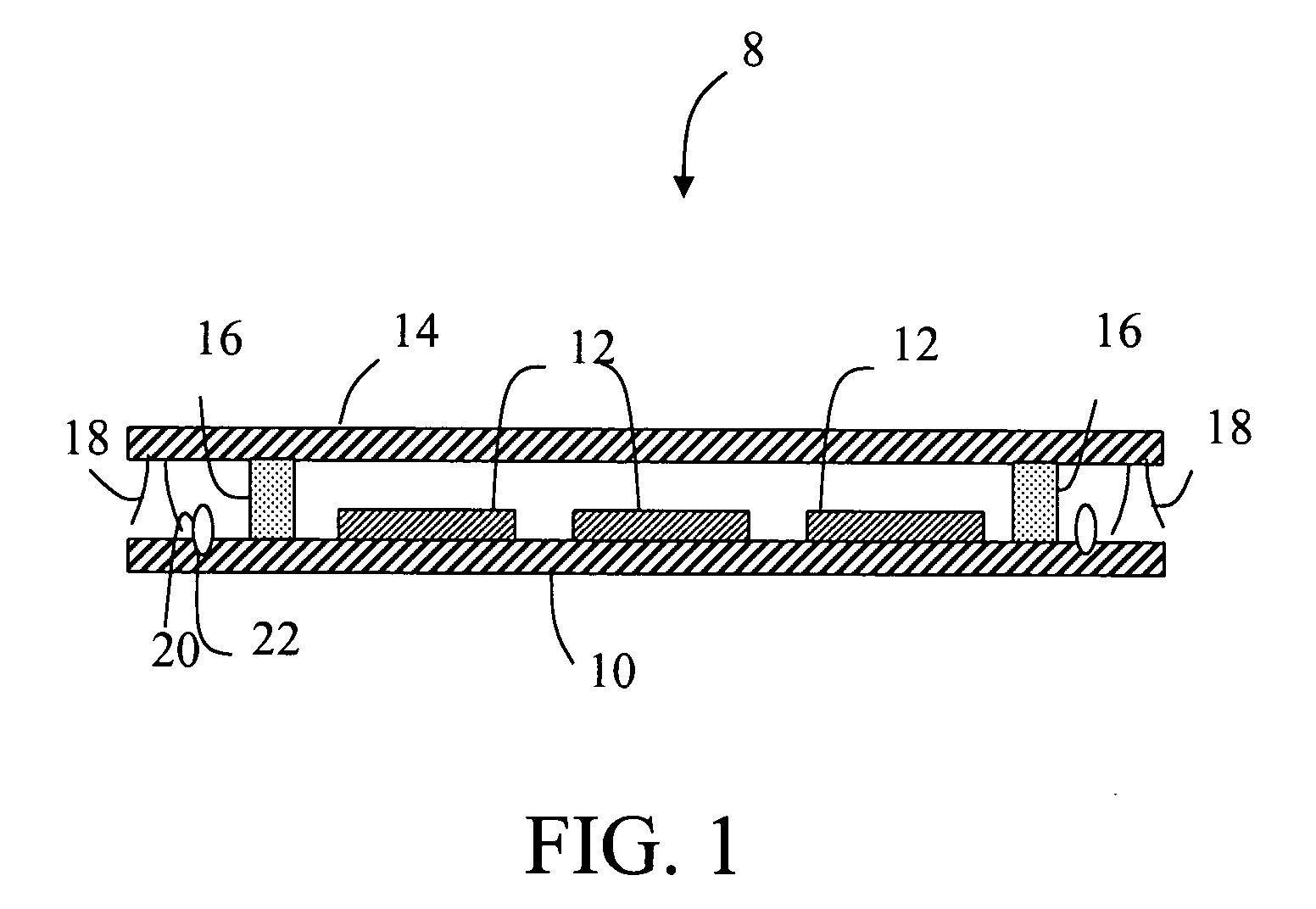

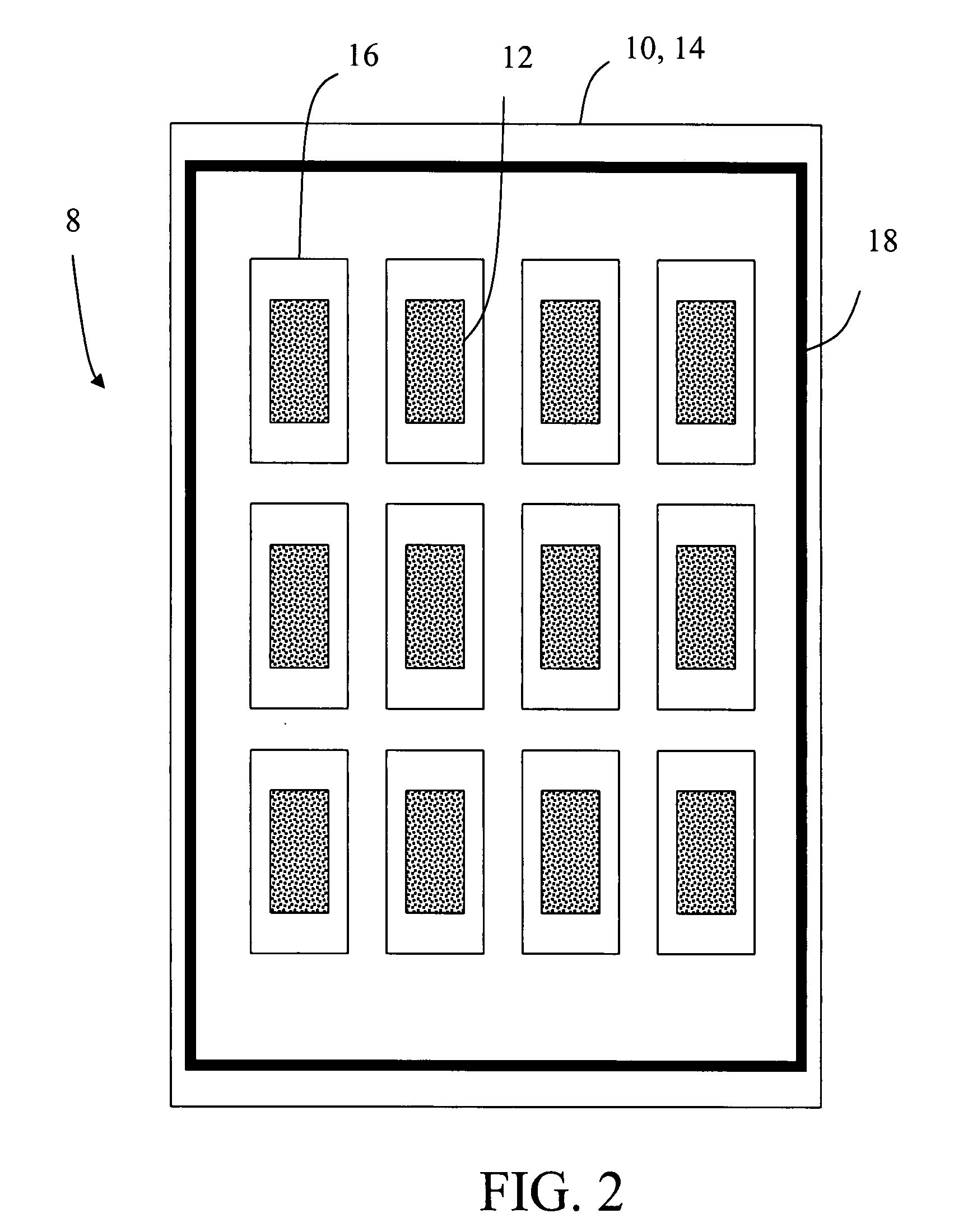

Methods and apparatus for packaging electronic components

InactiveUS20090142984A1Easy to passDischarge tube luminescnet screensElectroluminescent light sourcesFritElectronic component

Packages for elements, e.g., OLEDs, that are temperature sensitive are provided. The packages have a first glass substrate (12), a second glass substrate (16), and a wall (14) that separates the first and second substrates (12,16) and hermetically seals at least one temperature sensitive element (18,28,36) between the substrates (12,16). The wall (14) comprises a sintered frit and at least a portion of the wall is laser sealed to the second substrate (16) by melting a glass component of the sintered frit. The minimum width (40) of the laser-sealed portion of the wall (14) at any location along the wall (14) is greater than or equal to 2 millimeters so as to provide greater hermeticity and strength to the package. The laser sealing is performed without substantially degrading the temperature sensitive element(s) (18,28,36) housed in the package.

Owner:CORNING INC

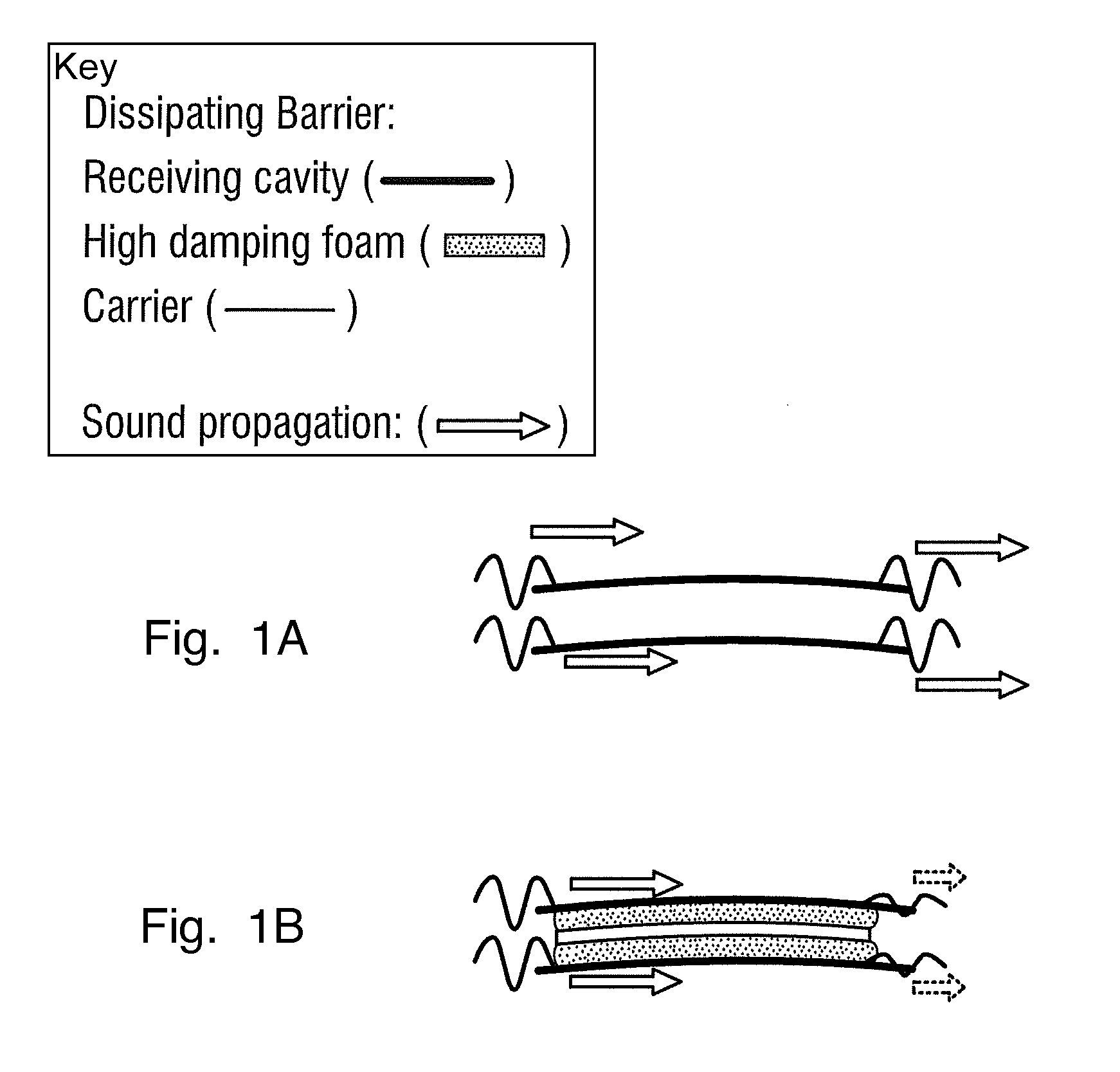

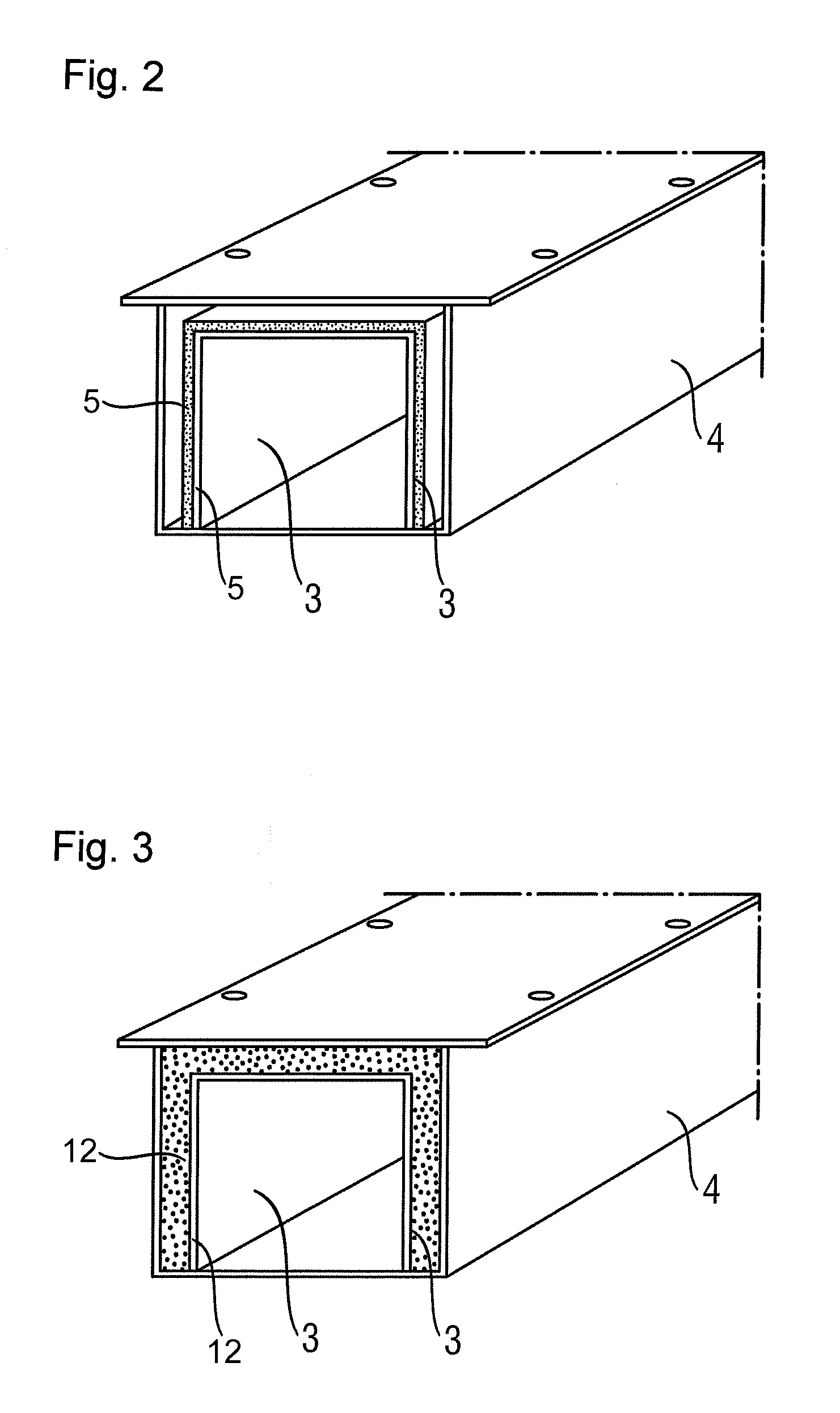

Highly damping expandable material and devices

InactiveUS20100314813A1Film/foil adhesivesSound producing devicesVitrificationThermoplastic elastomer

A thermally expandable material comprising a first thermoplastic elastomer having a first glass transition temperature, a second thermoplastic elastomer having a second glass transition temperature, wherein the first and the second glass transition temperature differ by at least 10° C.; at least one thermoplastic polymer selected from the group consisting of polymers and copolymers with at least one polymerizable C═C double bond, optionally at least one tackifying resin, at least one latent chemical blowing agent in an amount effective to cause the expandable material to expand at least 50% in volume when heated.

Owner:HENKEL KGAA

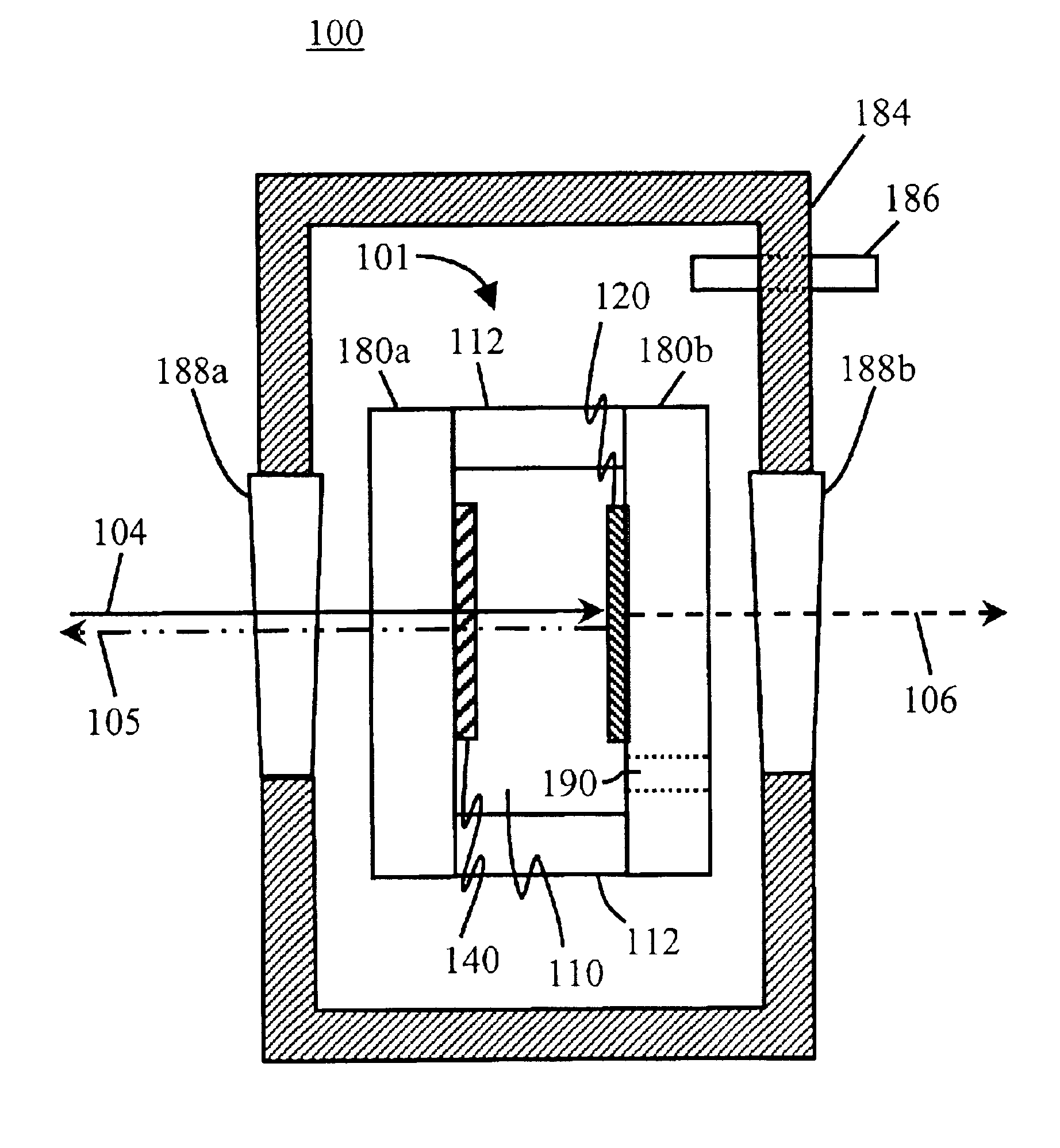

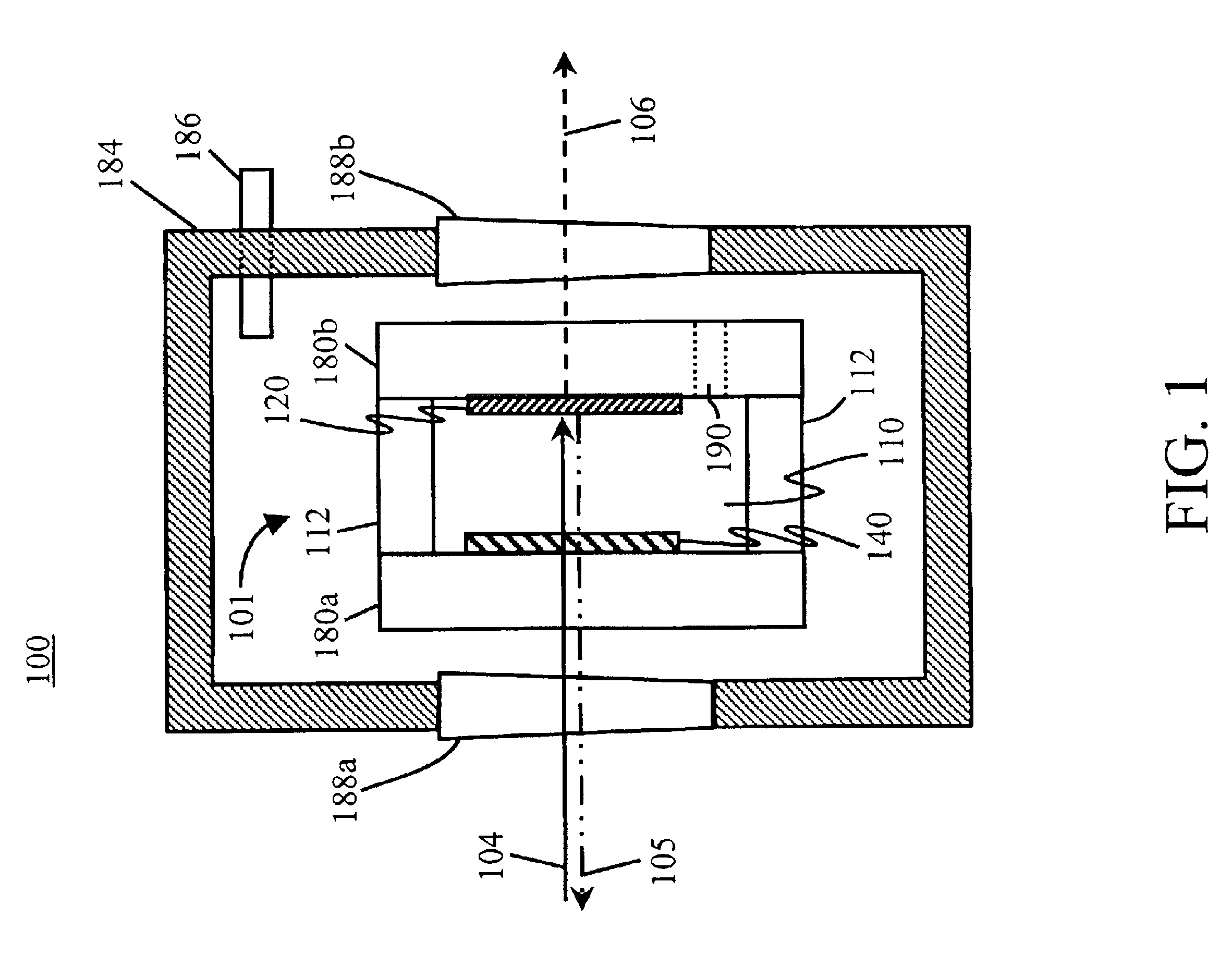

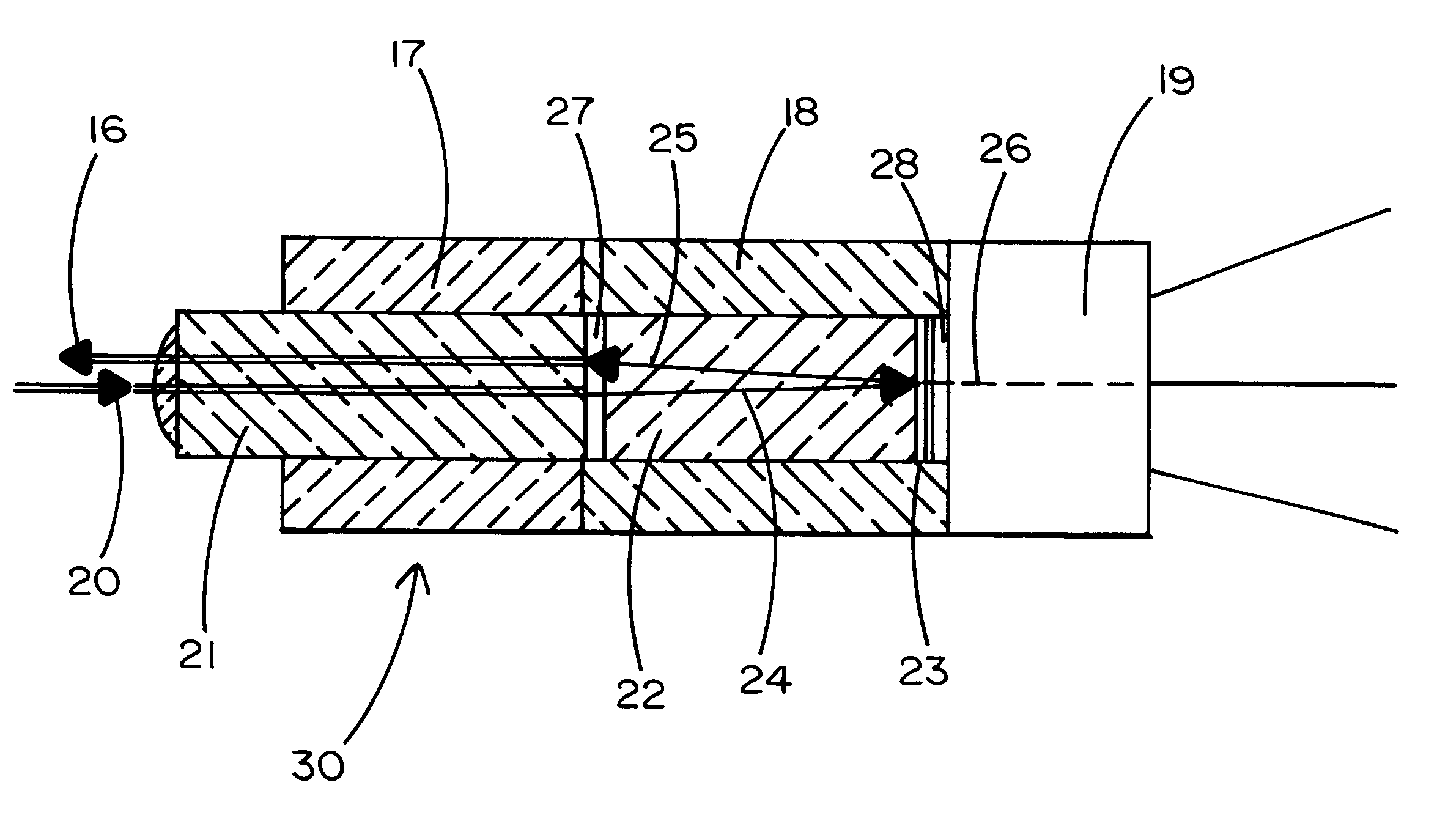

Method and apparatus for tunable interferometer utilizing variable air density

InactiveUS6867868B1Little changeUsing optical meansOptical light guidesSpacer couplingOptical coupling

An air-density-tuned interferometer includes: a hermetically sealed enclosure; a front window coupled to the hermetically sealed enclosure; an interferometer residing within the hermetically sealed enclosure; and a pressure changing device coupled to the hermetically sealed enclosure. The interferometer within the enclosure includes: a first glass plate optically coupled to the front window; a first reflective coating coupled to the first glass plate; a second reflective coating optically coupled to the first reflective coating; a second glass plate coupled to the second reflective coating; and a plurality of spacers coupled to the first and second glass plates, forming an optical interometric cavity therein. The pressure changing device manipulates the gas pressure within the cavity. The air-density-tuned interferometer does not incorporate additional elements into the optical path within the interferometer and that does not disturb or move any of the optical components disposed within or associated with this optical path.

Owner:II VI DELAWARE INC

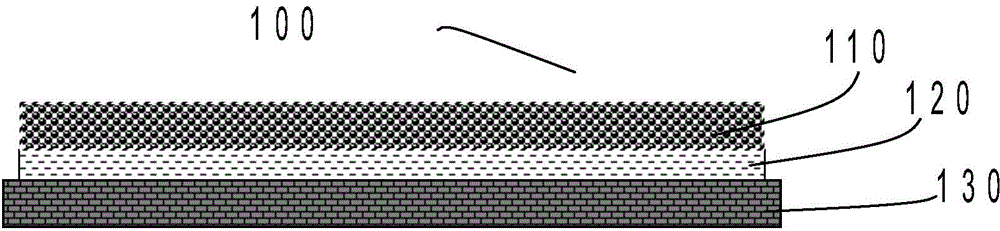

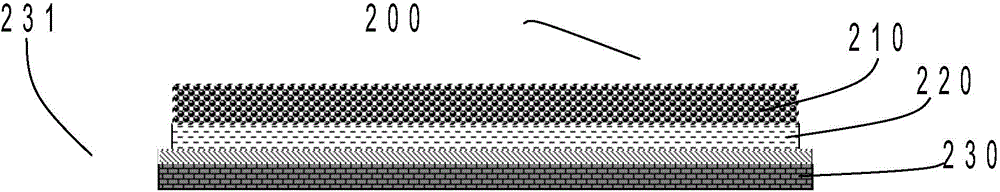

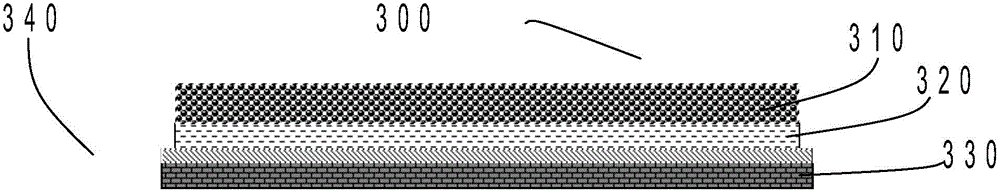

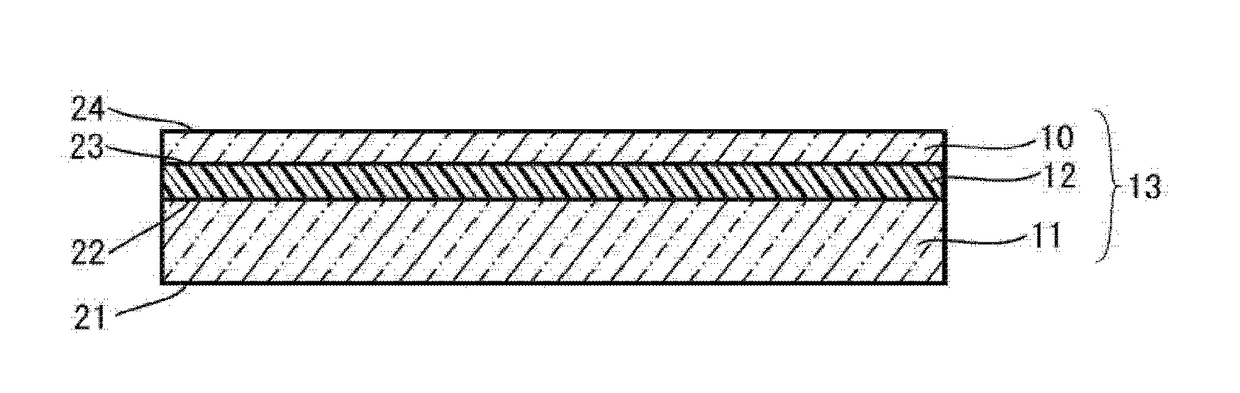

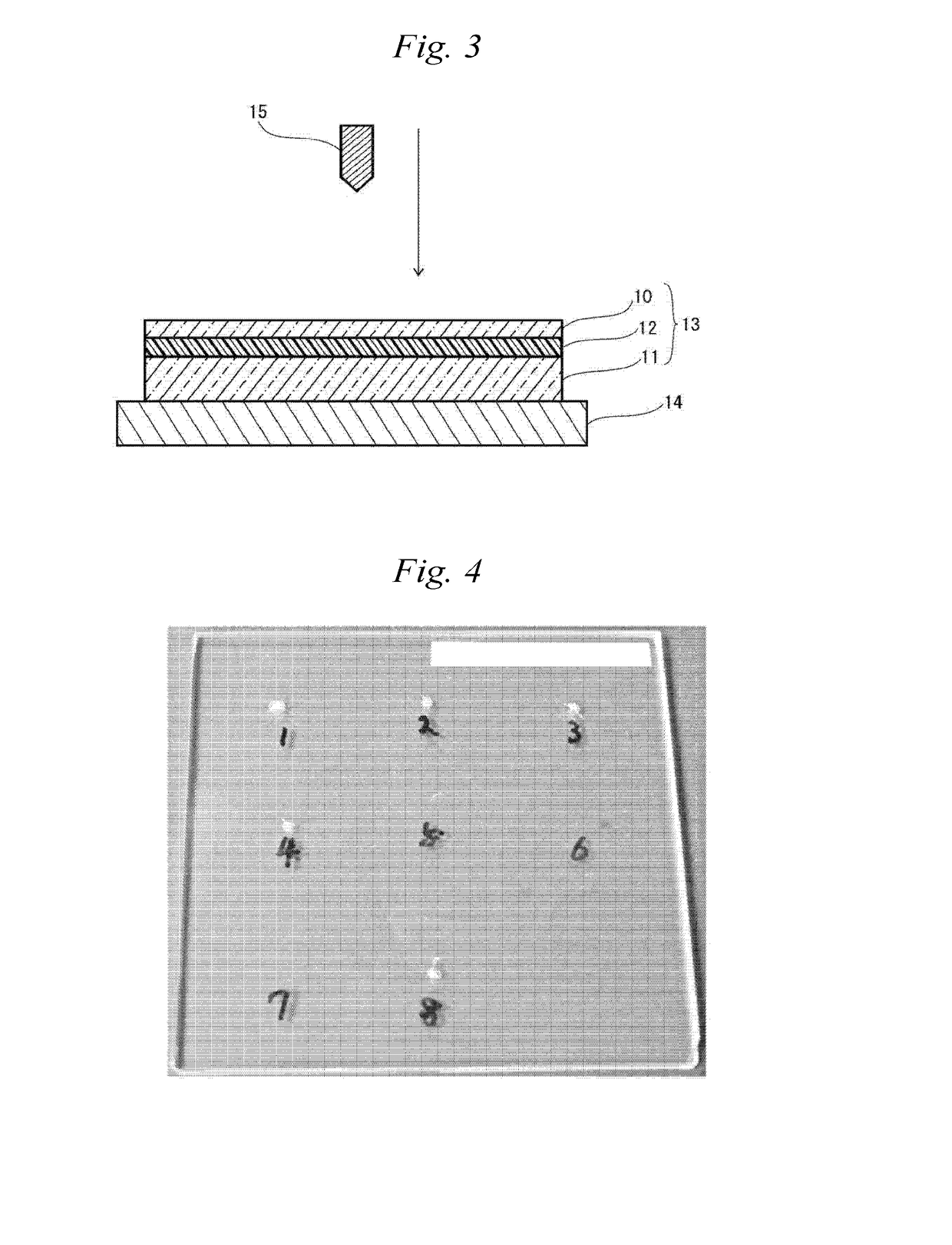

Wavelength conversion device, manufacture method thereof, correlative light-emitting device, and projection system

ActiveCN105278225AImprove luminous efficiencyImprove reflectivityDiffusing elementsProjectorsDiffuse reflectionProjection system

The invention discloses a wavelength conversion device, a manufacture method thereof, a correlative light-emitting device, and a projection system. The wavelength conversion device comprises a light-emitting layer, a diffuse reflection layer, and a ceramic substrate which are successively stacked. The light-emitting layer comprises fluorescent powder and first glass powder. The volume fraction of the fluorescent powder to the light-emitting layer is from 14.1 to 38.7 percent. The diffuse reflection layer comprises white scattering particles and the first glass powder. The volume fraction of the white scattering particles to the diffuse reflection layer is from 22.0 to 62.9 percent. The coefficient of linear expansion of the ceramic substrate is greater than that of the first glass powder but less than those of the ceramic substrate and the white scattering particles. By adjustment of the volume fraction of the fluorescent powder in the light-emitting layer and the volume fraction of the white scattering particles in the diffuse reflection layer, the light-emitting layer and the diffuse reflection layer have high enough light-emitting efficiency and reflectivity and low internal thermal resistance and interface thermal resistance so as to achieve a beneficial effect of obtaining emergent light with high light-emitting efficiency.

Owner:APPOTRONICS CORP LTD

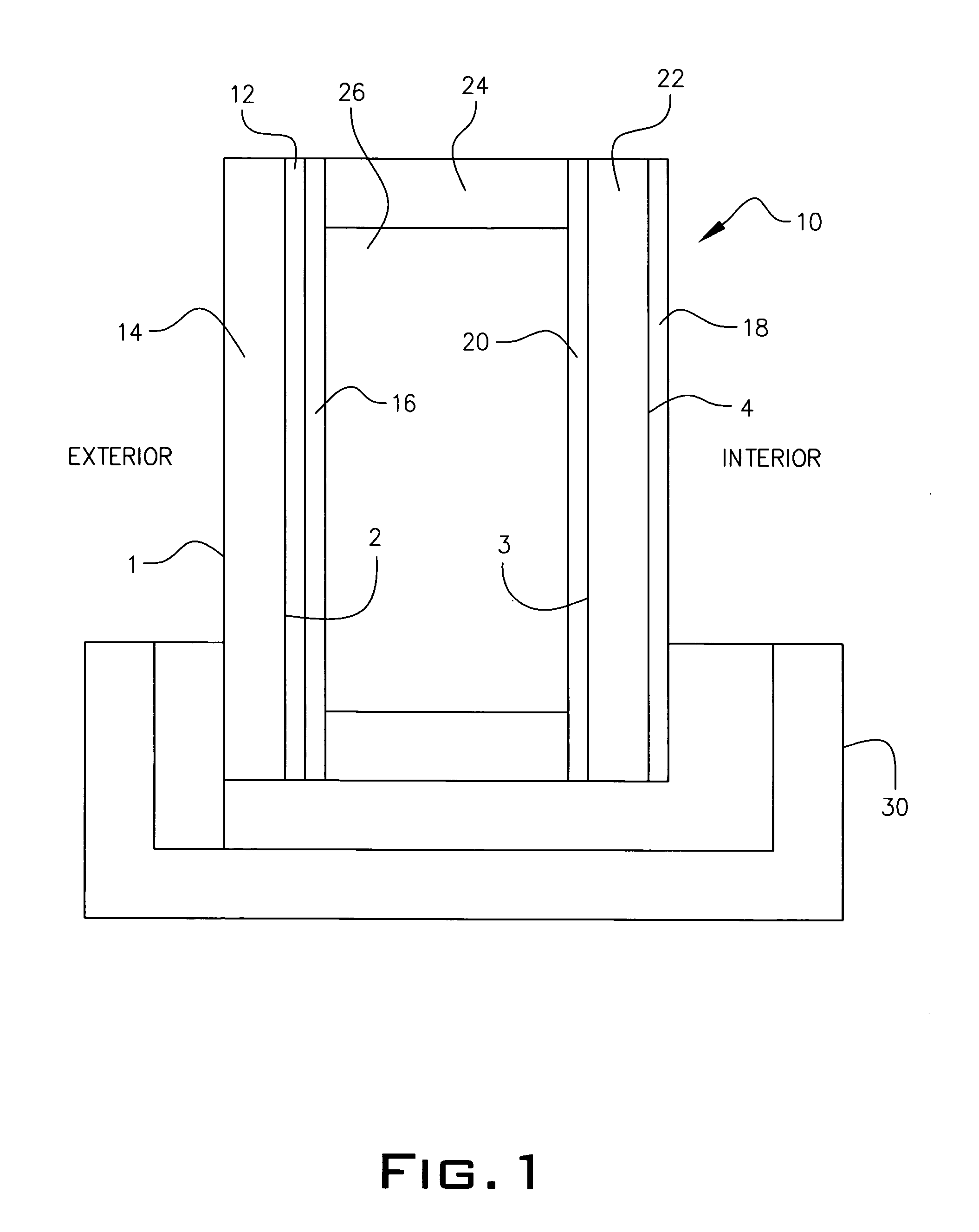

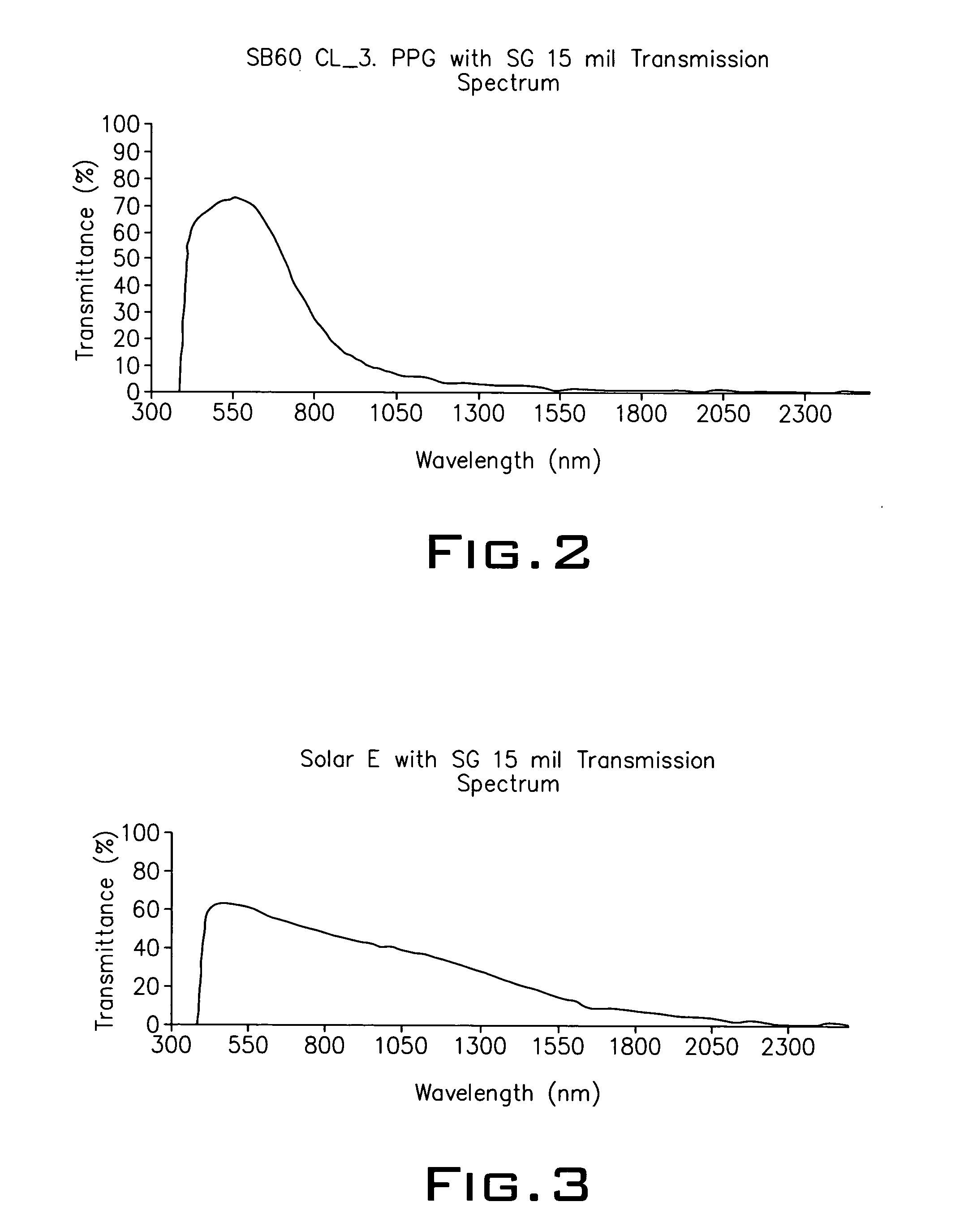

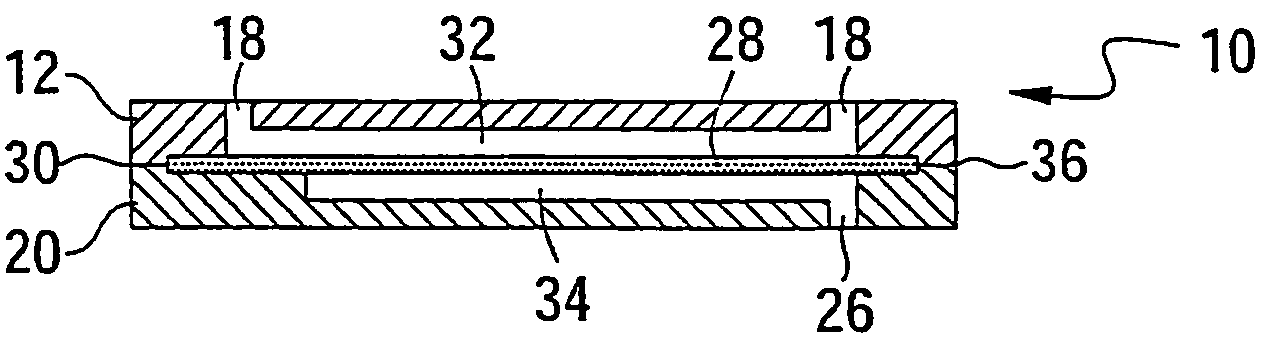

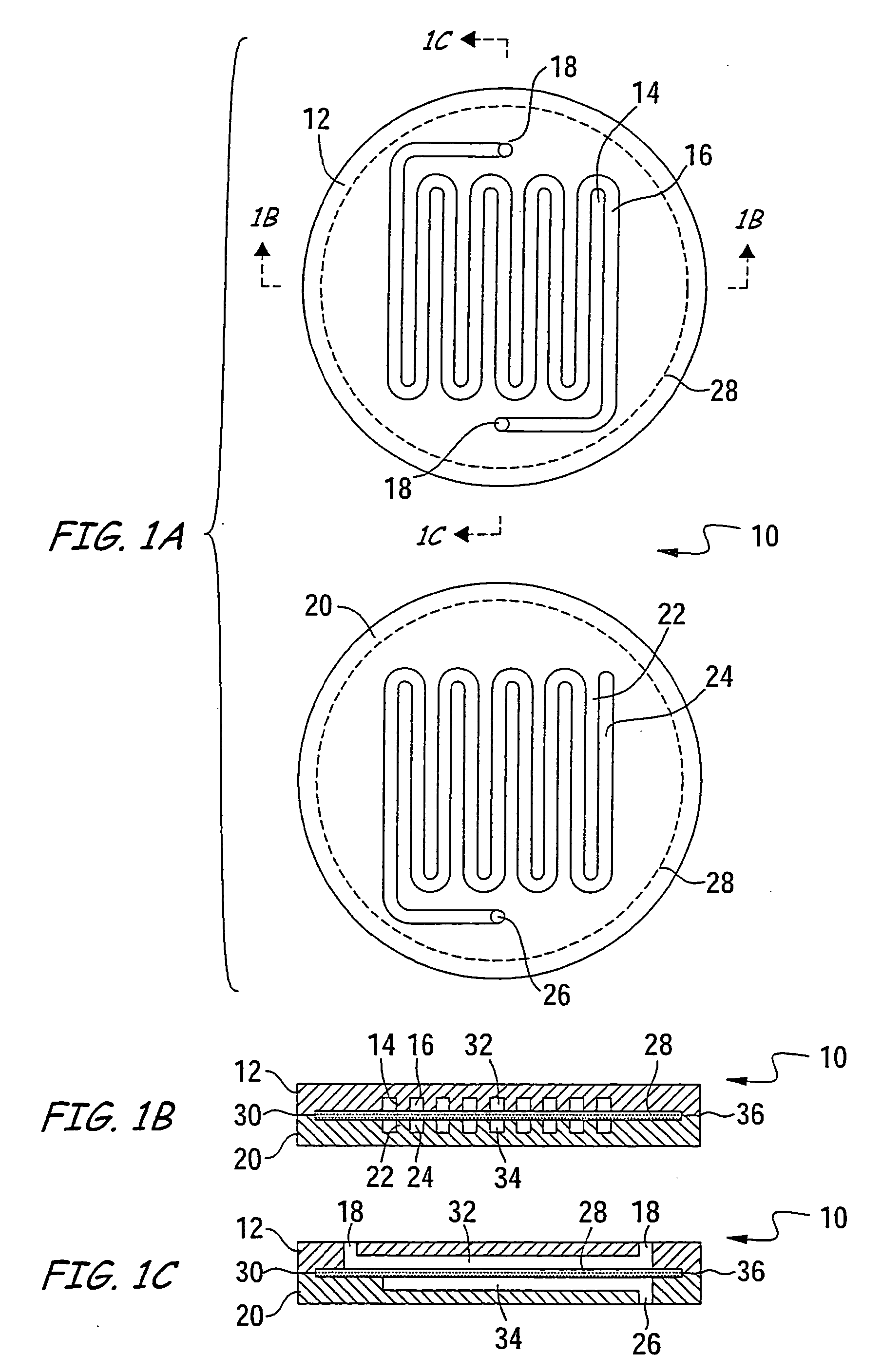

Method of manufacturing an impact resistant and insulated glass unit composite with solar control and low-E coatings

A solar control coating is applied to a first glass pane interior surface and a low-E coating is applied to a second glass pane exterior surface. A safety film is applied over the coating on the interior surface of the first glass pane. The second glass pane has a low-E coating facing the interior of a room. A safety film is applied to the reverse side of the glass. The two glass panes are separated by a spacer and structural silicone is backfilled from each outboard end of the spacer to the coated inside surfaces of the first and second glass panes to form a two-glass pane composite.

Owner:MADICO INC

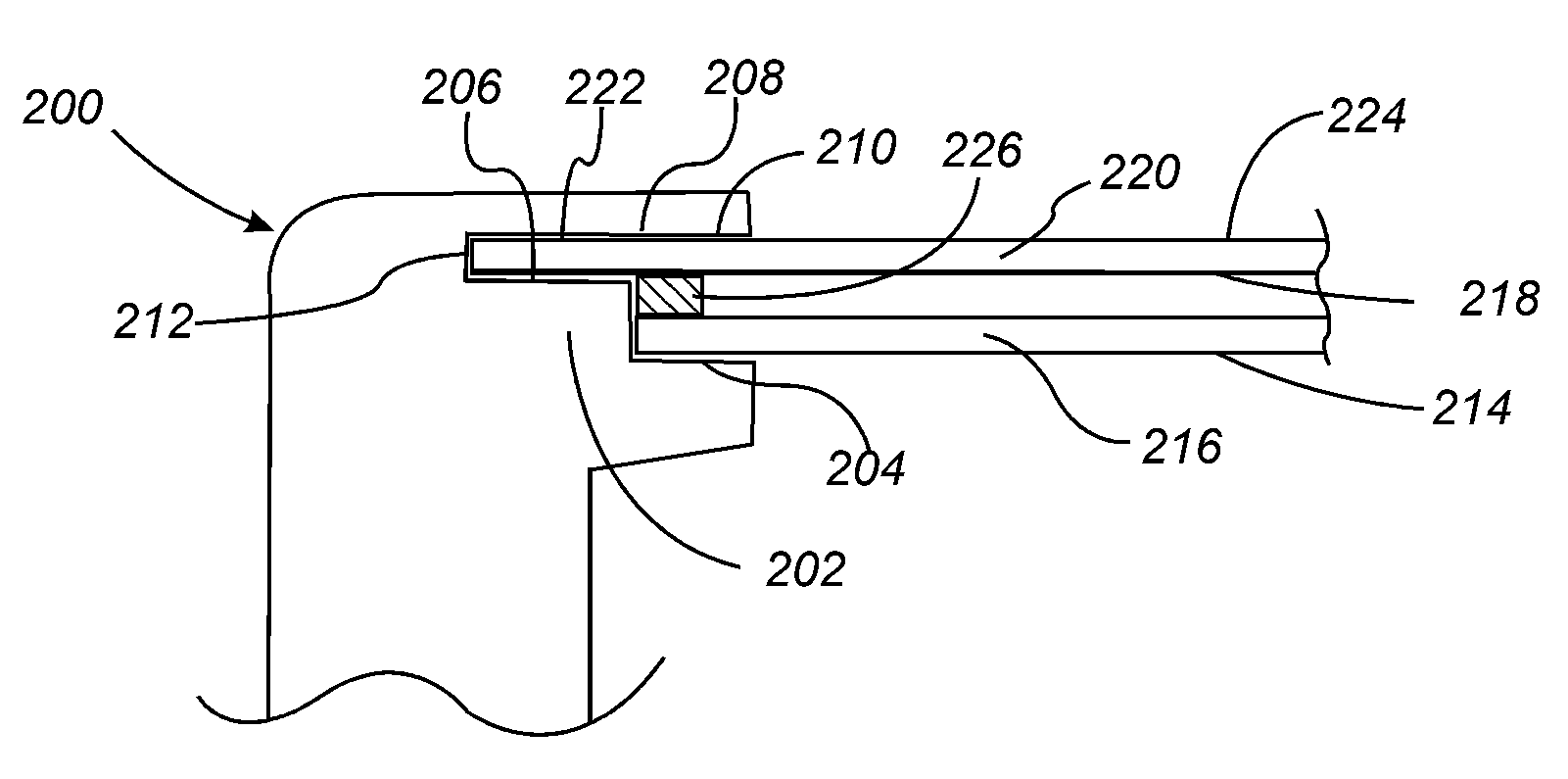

Porous membrane microstructure devices and methods of manufacture

InactiveUS20050167354A1Maximizes fluid interactionLarge specific surface areaMembranesUltrafiltrationPorous membraneGlass-ceramic

A membrane microstructure device is disclosed. The membrane microstructure device includes a first glass, ceramic or glass-ceramic plate defining a first recess, a second glass, ceramic or glass-ceramic plate defining a second recess, and a non-metallic porous membrane sandwiched between the first and second plates. The first plate, second plate and porous membrane are joined together and the porous membrane is arranged to cover the first and second recesses to define a first microchannel between the first plate and the porous membrane and a second microchannel in fluid communication with the first microchannel between the second plate and the porous membrane. A method of manufacturing a membrane microstructure device is also disclosed.

Owner:CORNING INC

Laminated glass

To achieve an excellent solar radiation shielding properties and a visible light reflectance of at least 70%, the interlayer portion of the laminated glass of the present invention includes a heat reflecting film and a film having a heat shielding function that is provided between the heat reflecting film and the second glass sheet. The heat reflecting film may be an optical interference multilayer film obtained by laminating layers of two types of polymer thin films having different refractive indices. The film having the heat shielding function can contain fine particles of at least one selected from hexaboride and ITO. The laminated glass can be bent to have a convex surface and a concave surface. In this laminated glass, the convex surface is formed by the first glass sheet and the concave surface is formed by the second glass sheet.

Owner:NIPPON SHEET GLASS CO LTD

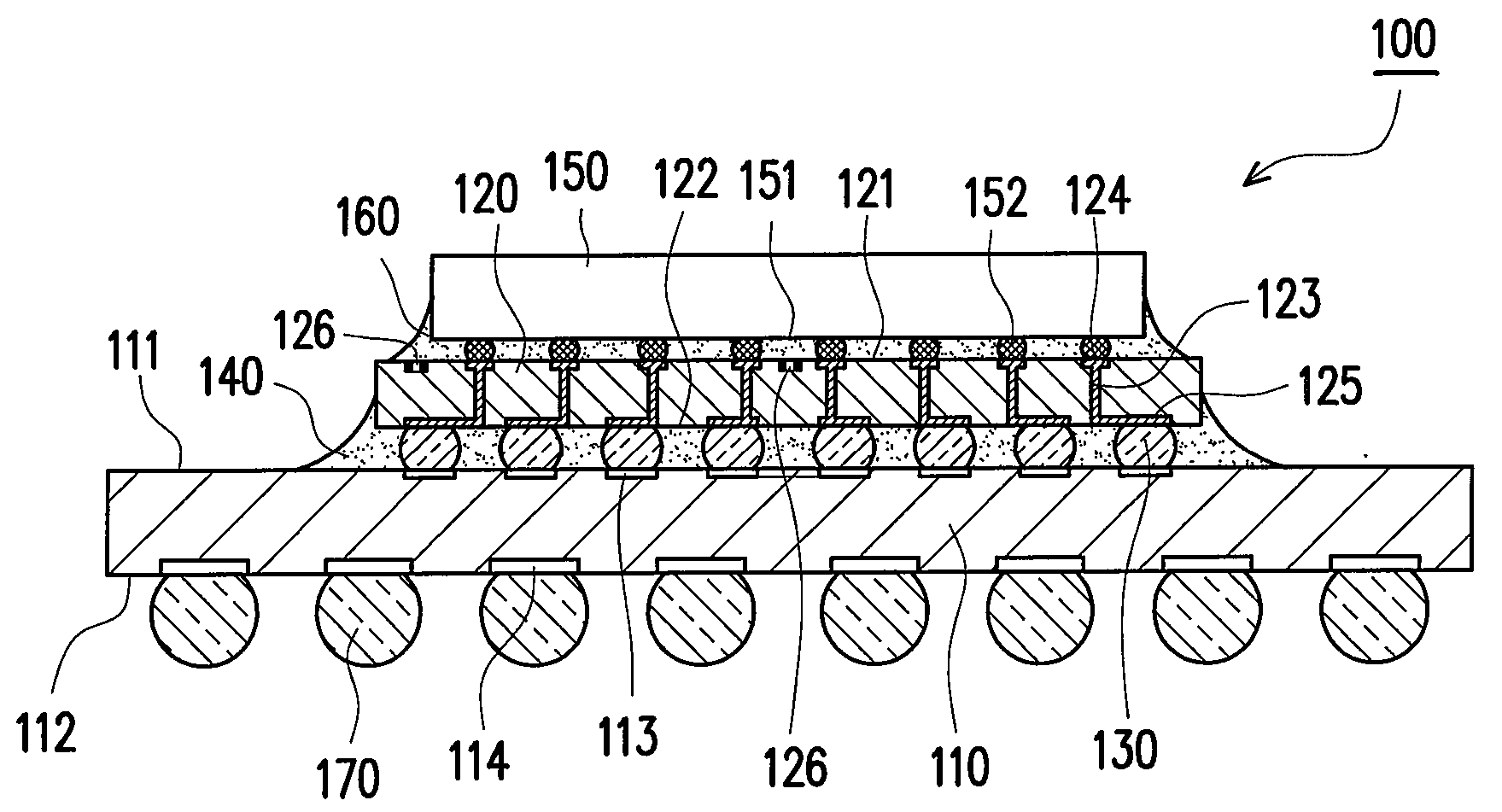

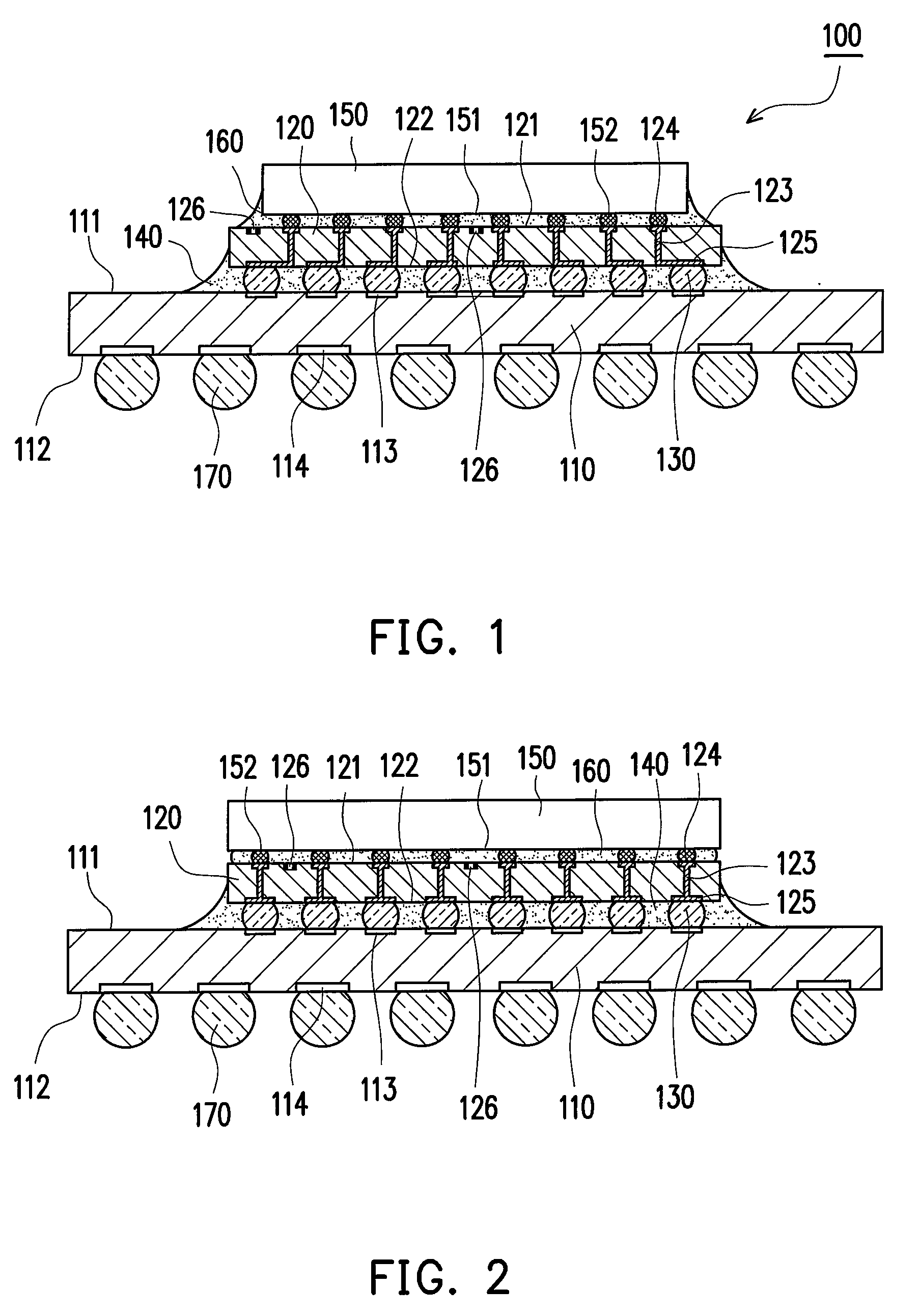

Chip package structure

InactiveUS20080272486A1Reduce inner stressHigh yieldSemiconductor/solid-state device detailsPrinted circuit aspectsVitrificationInterposer

A chip package structure includes a carrier, an interposer, a plurality of electrically conductive elements, a first sealant, a chip, and a second sealant. The interposer is disposed on the carrier. The electrically conductive elements electrically connect the interposer and the carrier. The first sealant seals the electrically conductive elements. A plurality of bumps of the chip is connected to the interposer. The second sealant seals the bumps. A first glass transition temperature of the first sealant is higher than a second glass transition temperature of the second sealant. Since glass transition temperatures of the first sealant and the second sealant are different, and the first glass transition temperature of the first sealant is higher than the second glass transition temperature of the second sealant, the inner stress will be lowered and the yield is promoted.

Owner:ADVANCED SEMICON ENG INC

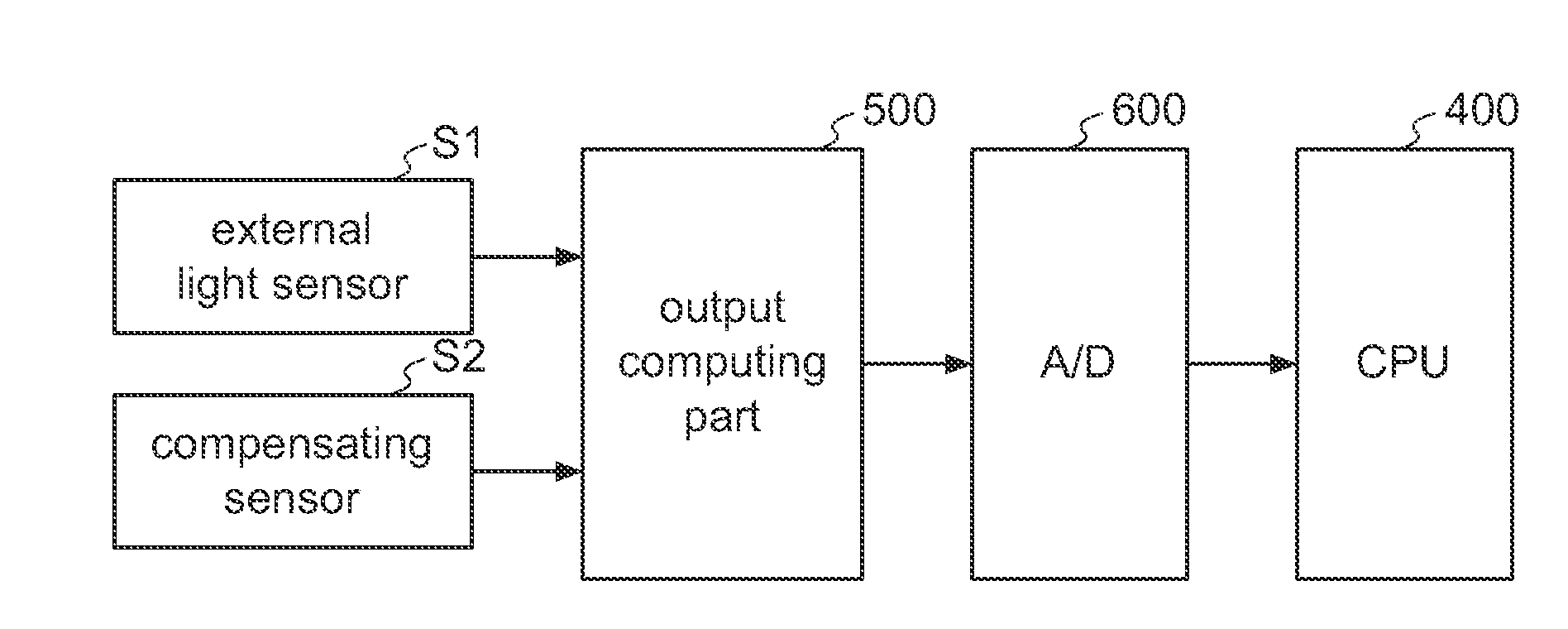

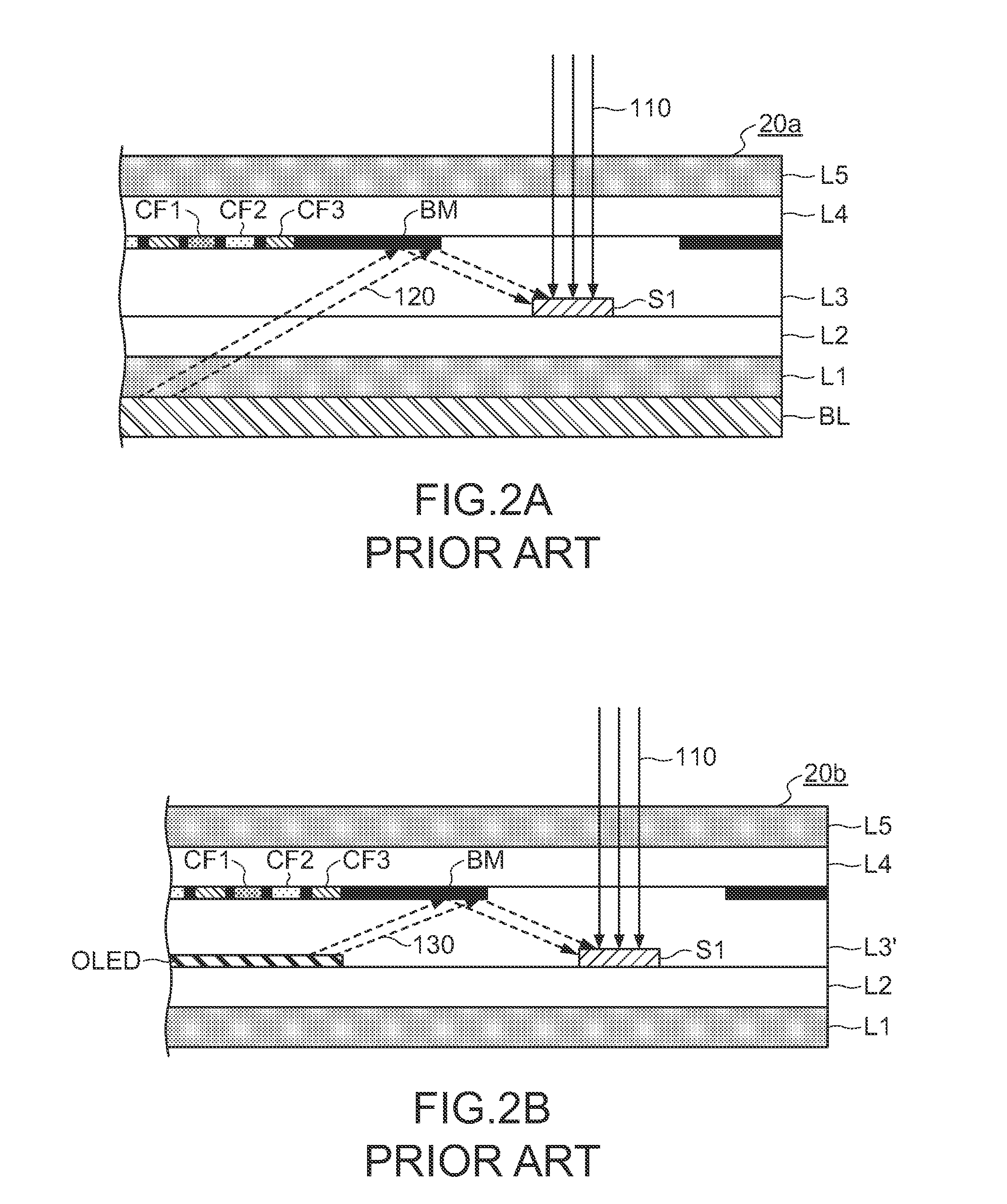

Display device and electronic apparatus equipped with the same

InactiveUS20100253660A1Accurate detectionReduce impactSolid-state devicesCathode-ray tube indicatorsTransmittanceDisplay device

A display device includes a display layer, a first glass substrate, a second glass substrate, an external light sensor, a black matrix and a color filter layer. The display layer has polarizing or light-emitting display components, which are arranged in a matrix. The first glass substrate and the second glass substrate are respectively disposed over and under the display layer. The external light sensor is disposed on an interface between the first glass substrate and the display layer for detecting an external light passing through the second glass substrate incident to the external light sensor. The black matrix is disposed on an interface between the second glass substrate and the display layer. The external light passing through the second glass substrate is sheltered by the black matrix. The color filter layer is deposited on the black matrix and has a specified transmittance spectrum property.

Owner:INNOLUX CORP

Method for forming a temporary hermetic seal for an OLED display device

InactiveUS20070267972A1Easy to understandDischarge tube luminescnet screensElectroluminescent light sourcesHermetic sealFrit

A method of forming a temporary hermetic seal for an OLED device. The method includes the steps of providing a first glass substrate having at least one OLED device disposed thereon, providing a second glass substrate having one or more frit walls disposed thereon, disposing sealant grease about a periphery of the first or second substrate and joining the first substrate to the second substrate to form an hermetically sealed glass envelop containing at least one OLED device.

Owner:CORNING INC

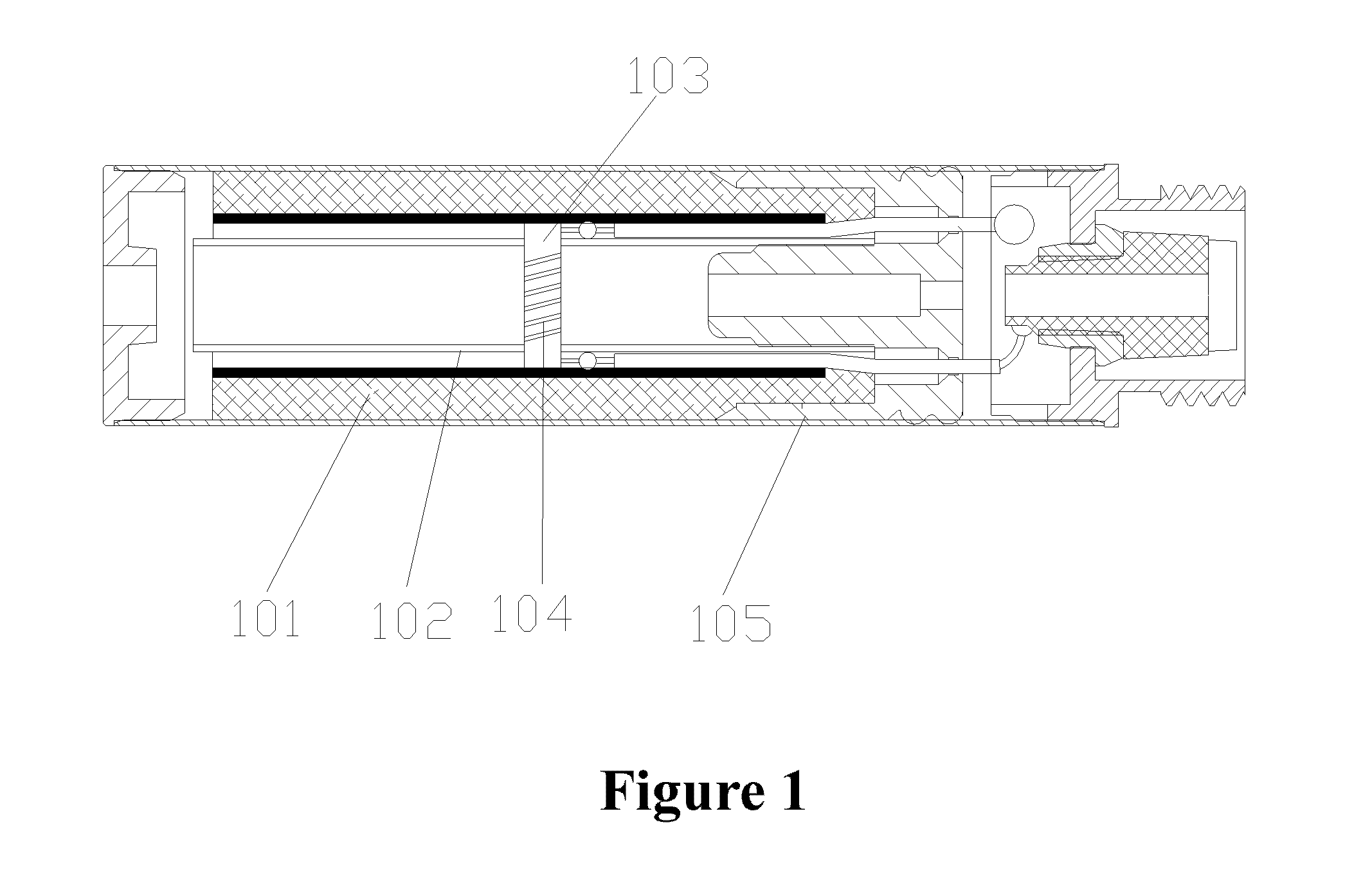

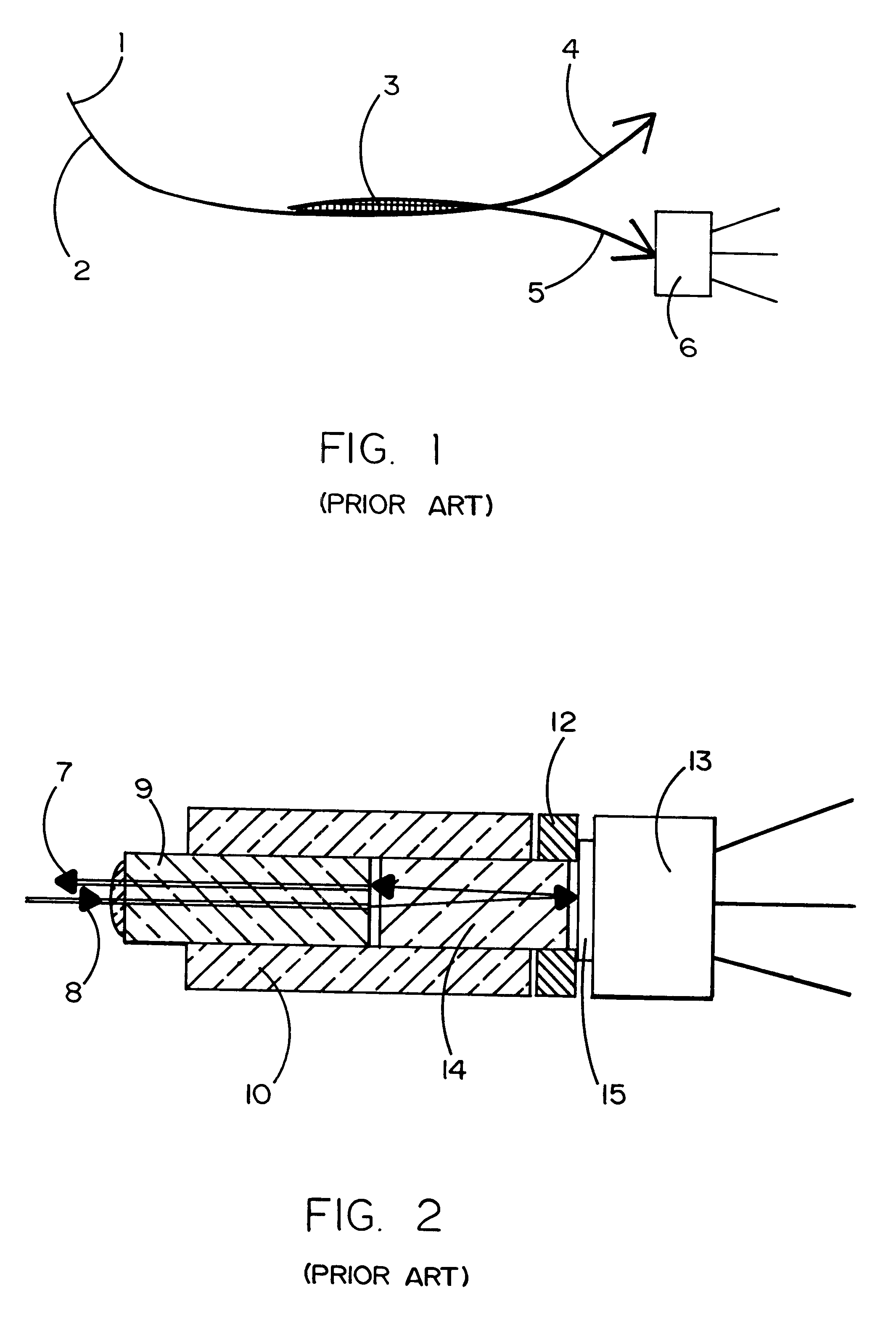

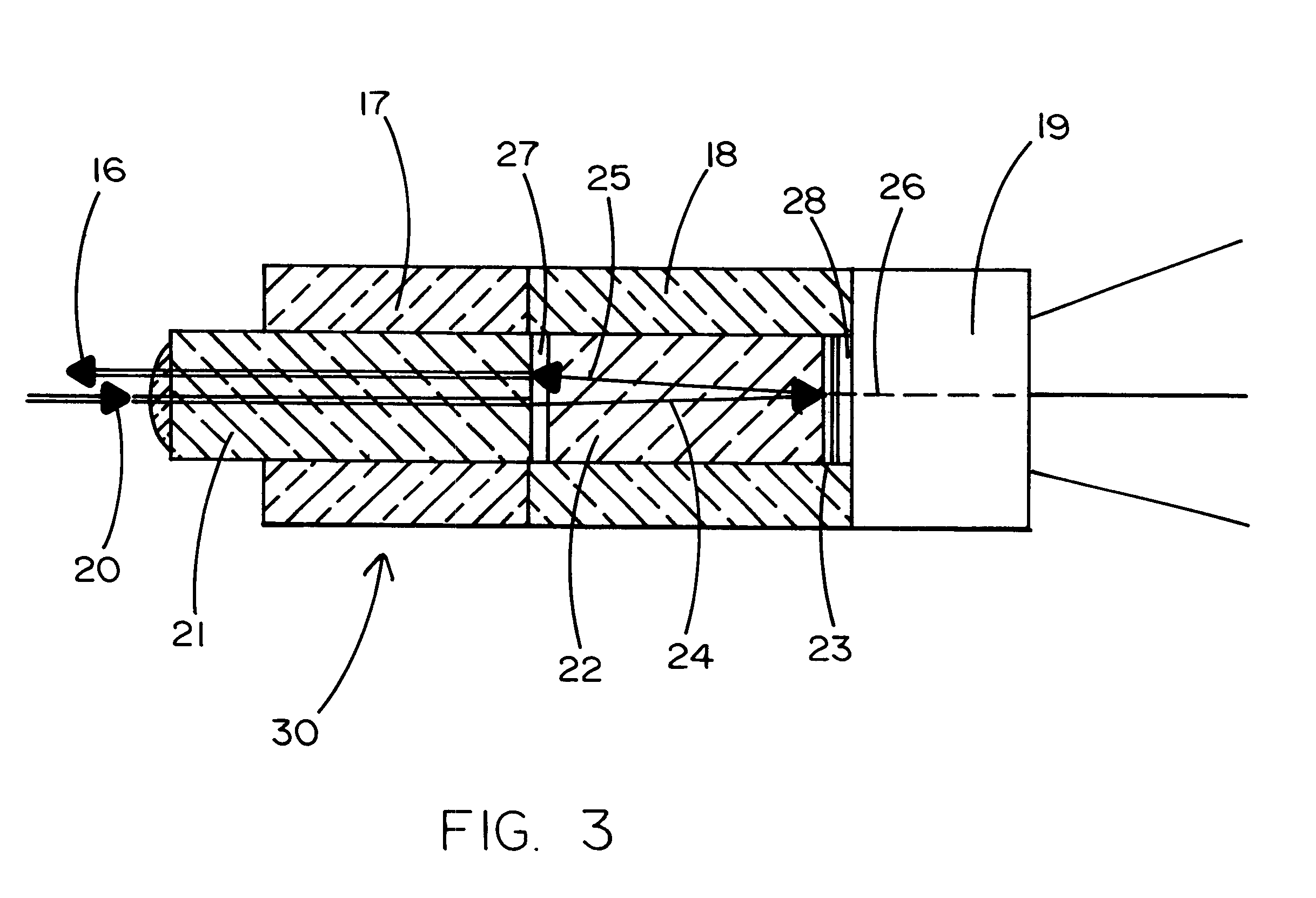

Multi-port optical power monitoring package and method of manufacturing

An optical power monitor comprises a fiber and ferrule assembly telescopically embedded in a first glass tube enclosure and a collimating lens telescopically embedded in a second glass tube enclosure. The two glass tube enclosures are bonded together at their respective facing axial ends. The collimating lens is at a first end substantially adjacent the fiber and ferrule assembly. A second end of the lens is coated with a partially transmissive mirror surface for passing a portion of incident light to a photon detector which is bonded to the second glass tube enclosure.

Owner:HARBIN NEXFON OPTRONICS

Cosmetic Composition Containing a Polymer Blend

InactiveUS20090035335A1Improve compatibilityAvoid potential macro-phase separationCosmetic preparationsMake-upFiberCross-link

The present invention relates to a cosmetic composition containing a unique polymer blend, which includes: (a) a first polymeric film-former having a first glass transition temperature ranging from about −20° C. to about 0° C.; (b) a second polymeric film-former having a second glass transition temperature that is at least 50° C. higher than the first glass transition temperature; and (c) a third cross-linked polymeric film-former. The cosmetic composition of the present invention can be applied to human skin or keratinous fibers for forming a film thereon with exceptionally long wearability, reduced flaking and smudge properties, and good removability by warm water.

Owner:ELC MANAGEMENT LLC

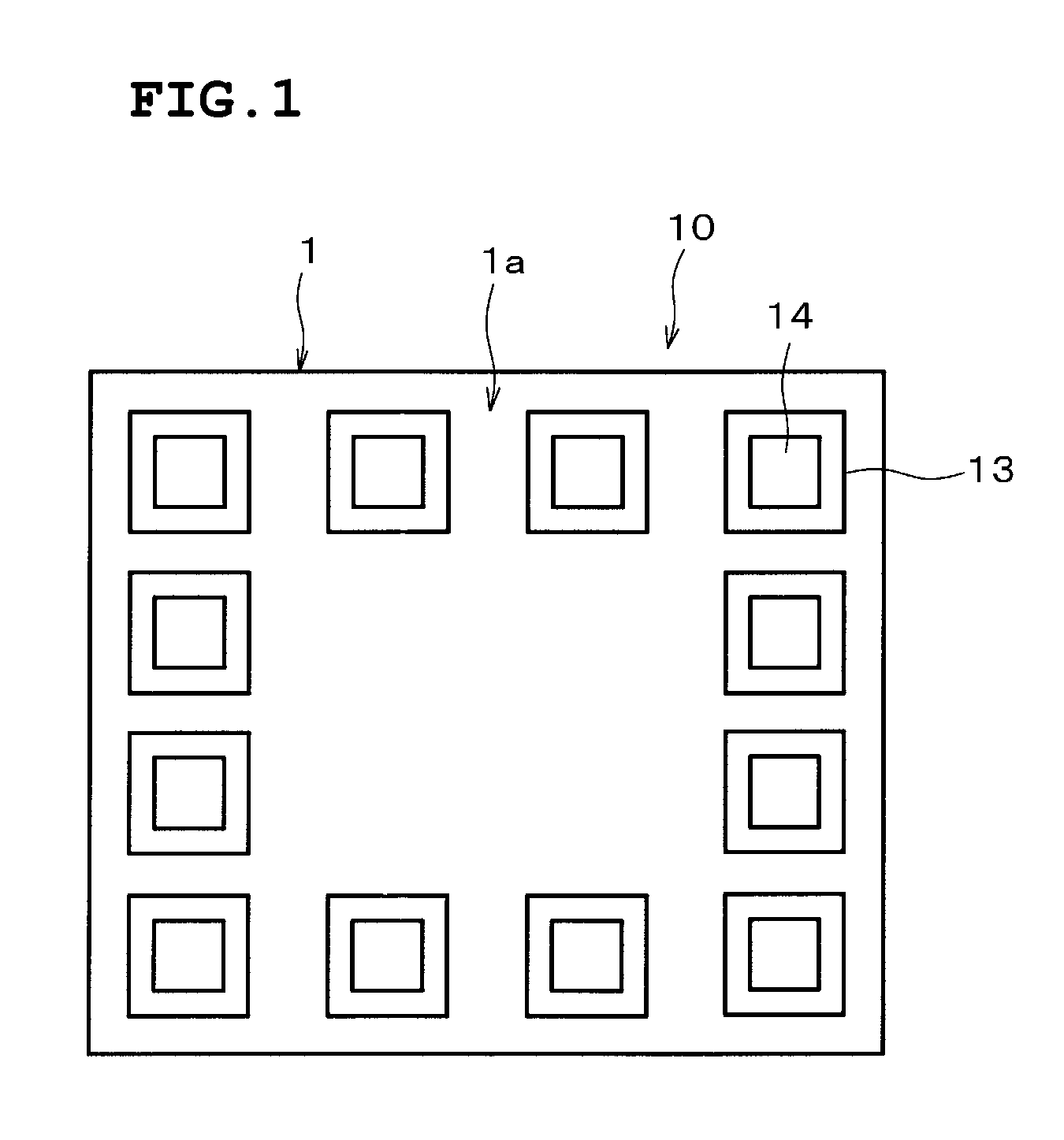

Ceramic substrate, electronic apparatus, and method for producing ceramic substrate

ActiveUS20070224400A1Improve adhesionImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorMetallurgy

A ceramic substrate includes a glass layer partially overlaying a conductor, and the glass layer has satisfactory adhesion to the main body of the ceramic substrate and having satisfactory plating resistance. The glass layer is arranged to extend from a portion of the conductor formed on a first main surface of the main body of the ceramic substrate to the first main surface of the main body of the ceramic substrate and which has a double-layered structure including a first glass sublayer composed of a first glass material, and a second glass sublayer formed on the first glass sublayer and composed of a second glass material that is different from the second glass material defining the first glass sublayer, the first glass material having more satisfactory adhesion to the main body of the ceramic substrate than the second glass material, and the first glass material having more satisfactory plating resistance than the first glass material.

Owner:MURATA MFG CO LTD

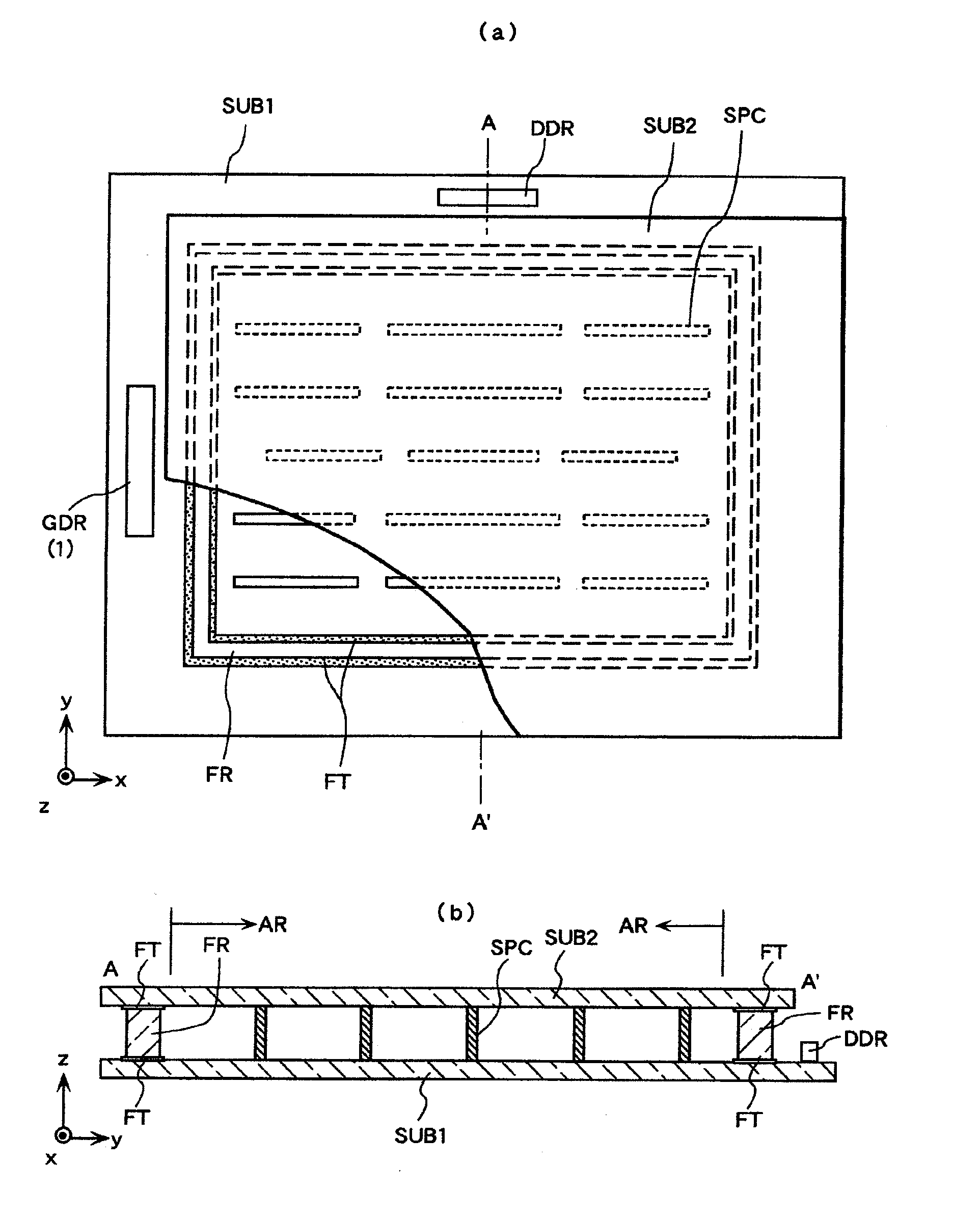

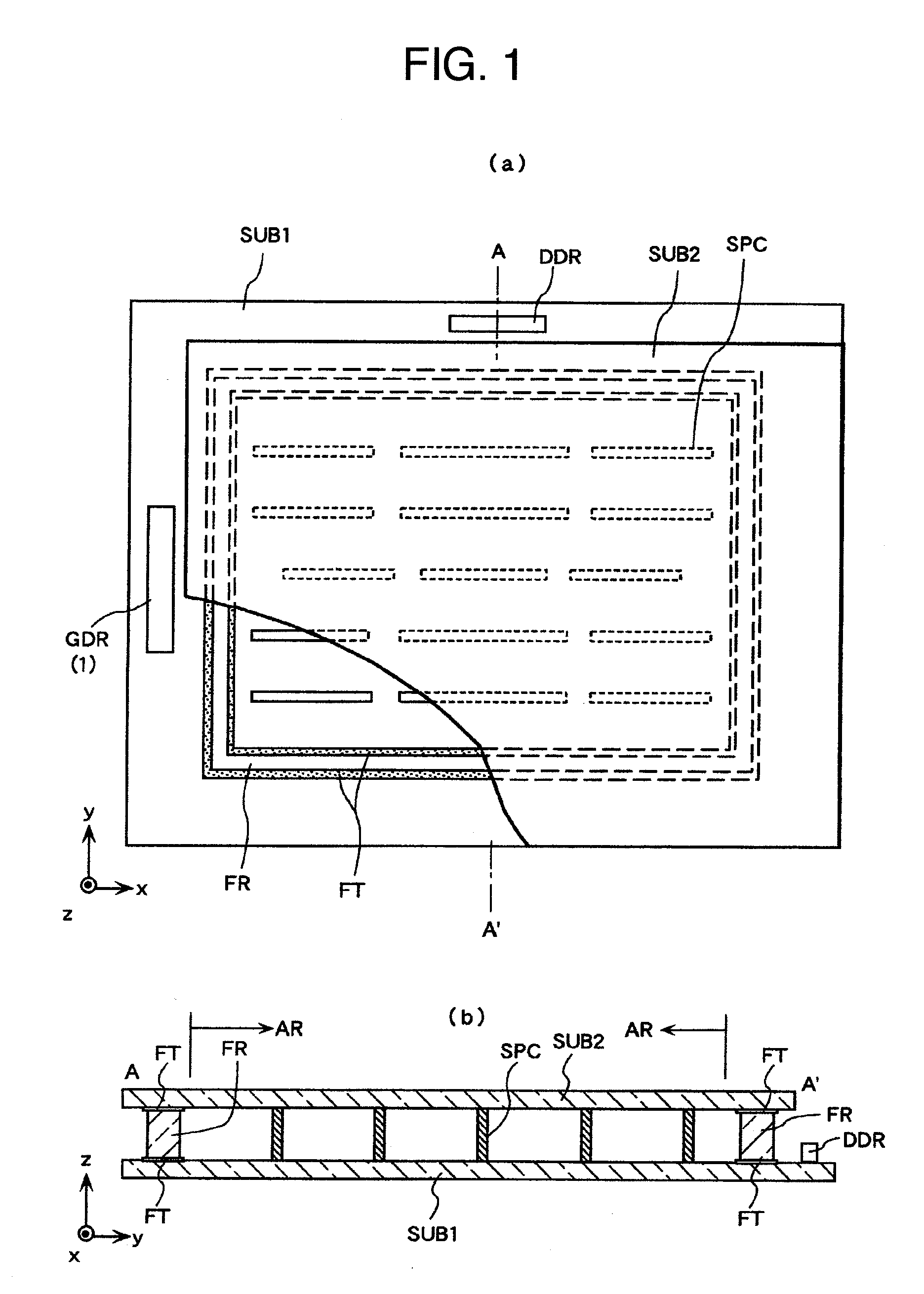

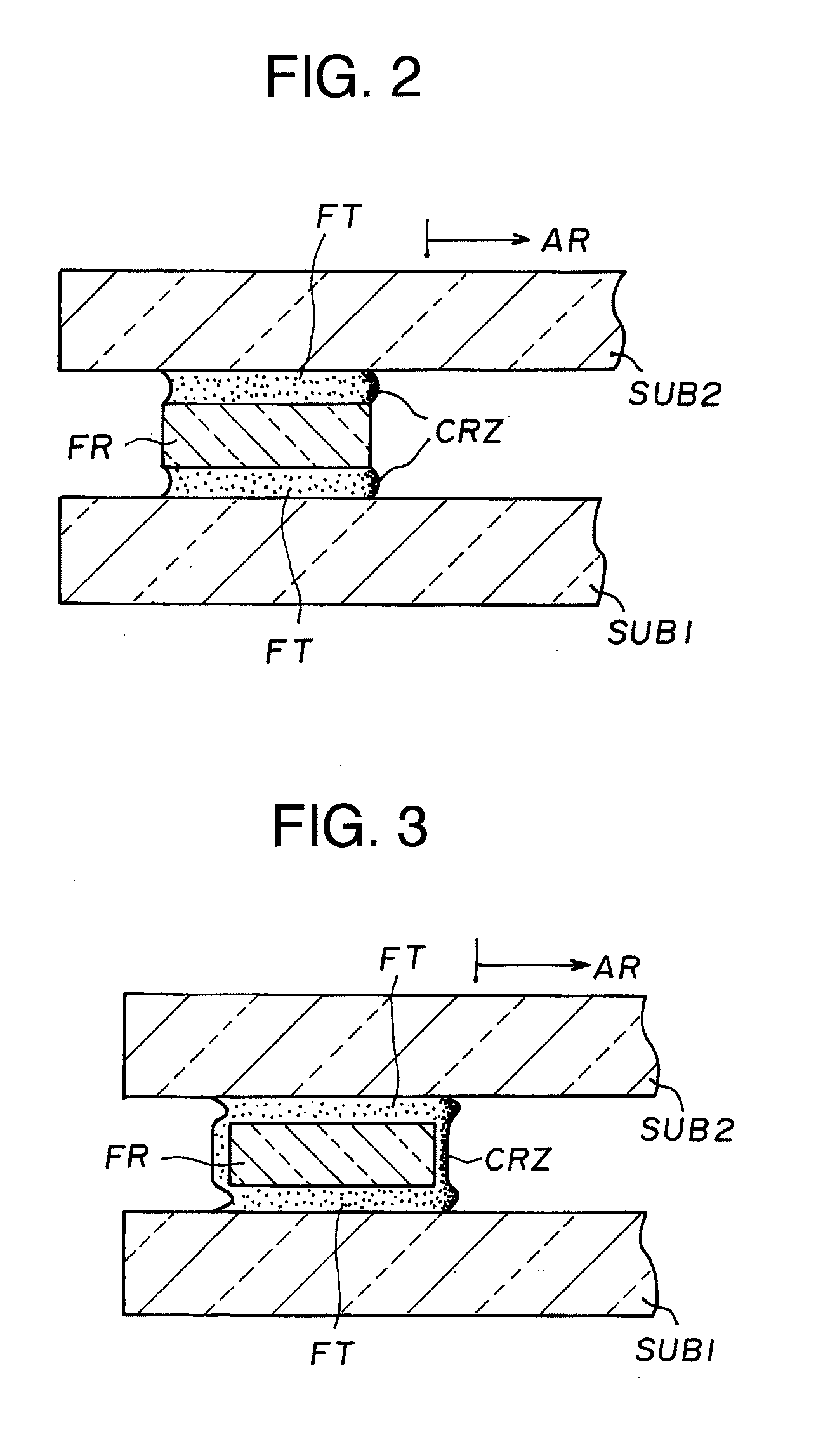

Display Device and Production Method Thereof

InactiveUS20070158021A1Easily crystallizesEasy to useLiquid crystal compositionsCathode ray tubes/electron beam tubesVacuum pumpingDisplay device

An object of the present invention is to provide a highly reliable display device by preventing an adhesive layer from being drawn to the inside at the time of vacuum pumping and by securing a sufficient adhesive strength. A crystalline layer CRZ is formed in the surface of an adhesive layer FT between the respective contact surfaces of a first glass substrate SUB1 and a sealing frame FR, as well as of a second glass substrate SUB2 and the sealing frame FR.

Owner:HITACHI DISPLAYS

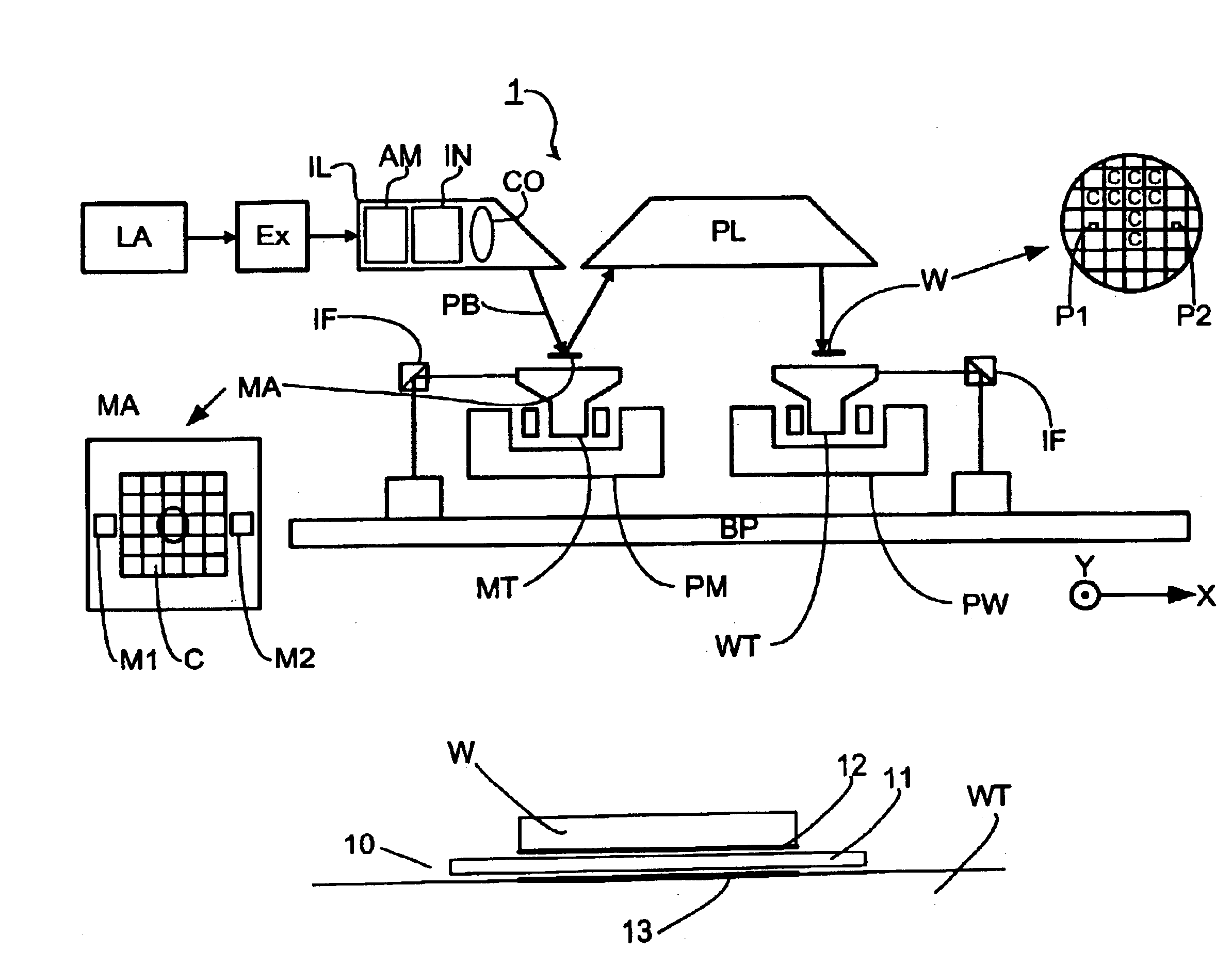

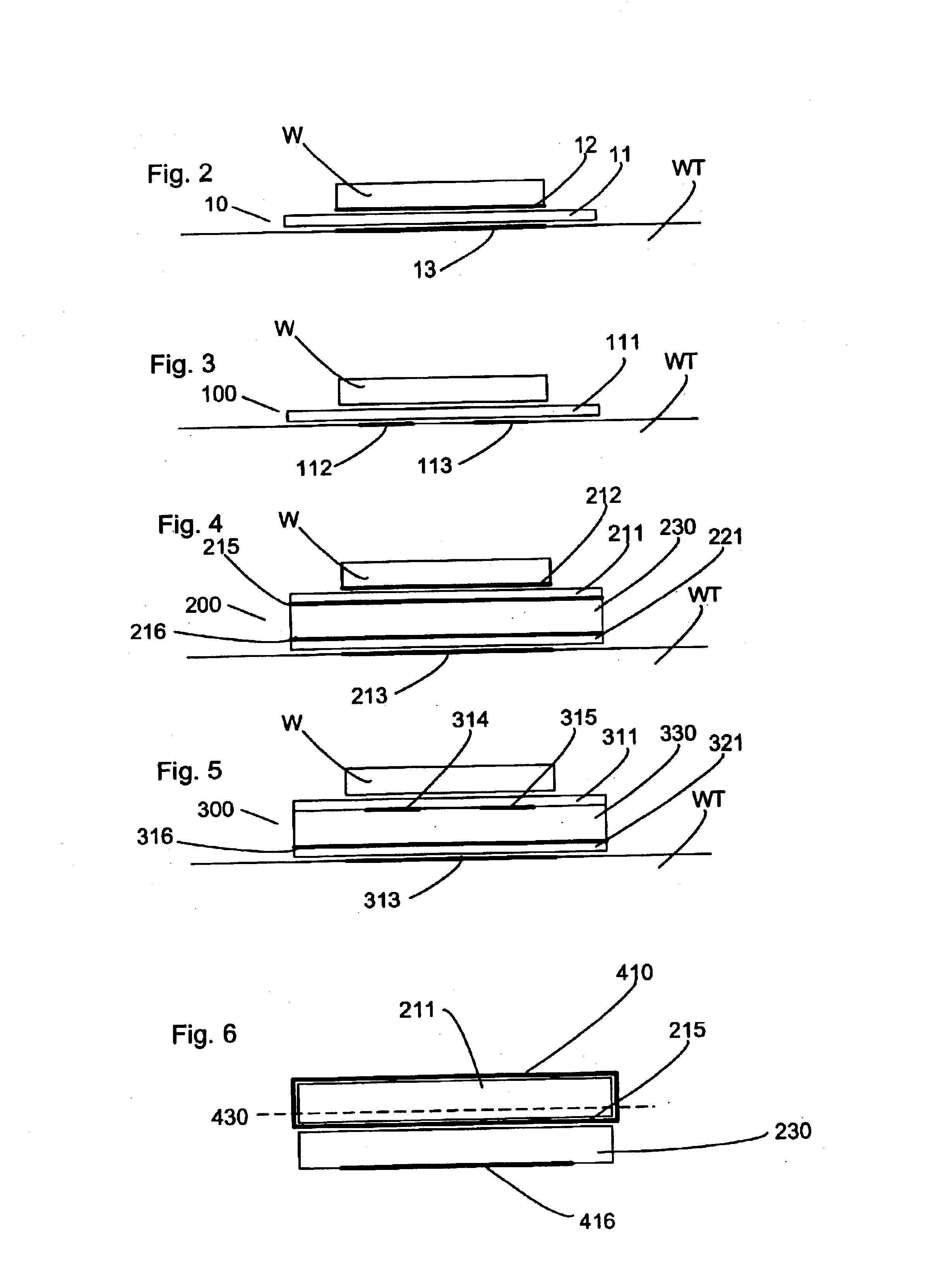

Chuck, lithographic projection apparatus, method of manufacturing a chuck and device manufacturing method

InactiveUS6864957B2Easy to disassembleReduction factorSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusDielectricPotential difference

A lithographic projection apparatus with a chuck in which a dielectric element of the electrostatic chuck has a specific resistivity of at least 1016 Ωcm so that once the potential difference between electrodes of the chuck is removed the force on the article to be clamped reduces below a predetermined minimum level quickly. The dielectric element also has a coefficient of thermal expansion of less than 0.02×10−6K−1. A method of manufacturing a chuck includes joining a first glass ceramic element with a second glass element with an electrode therebetween in which a current is passed through the second glass element.

Owner:ASML NETHERLANDS BV

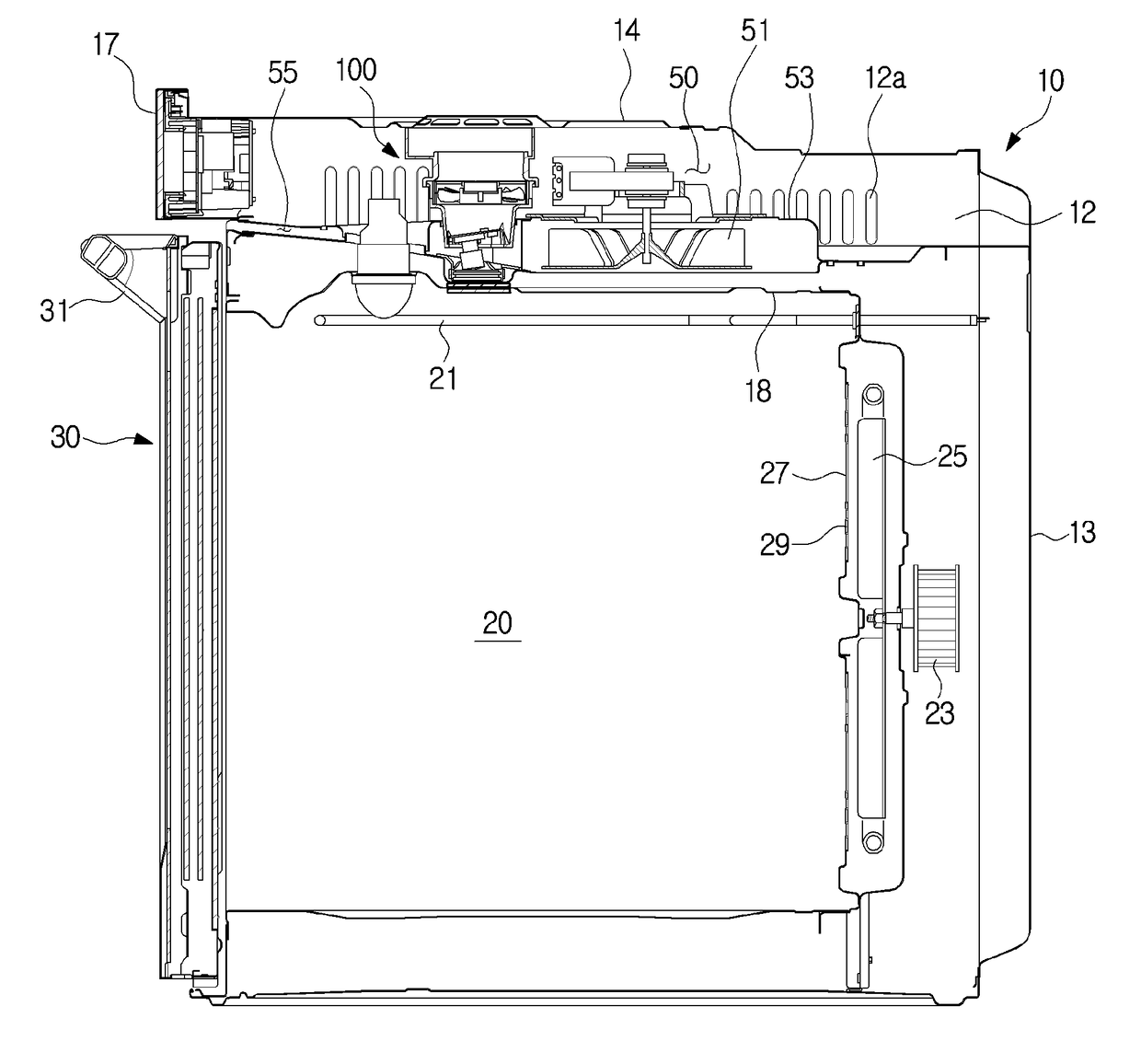

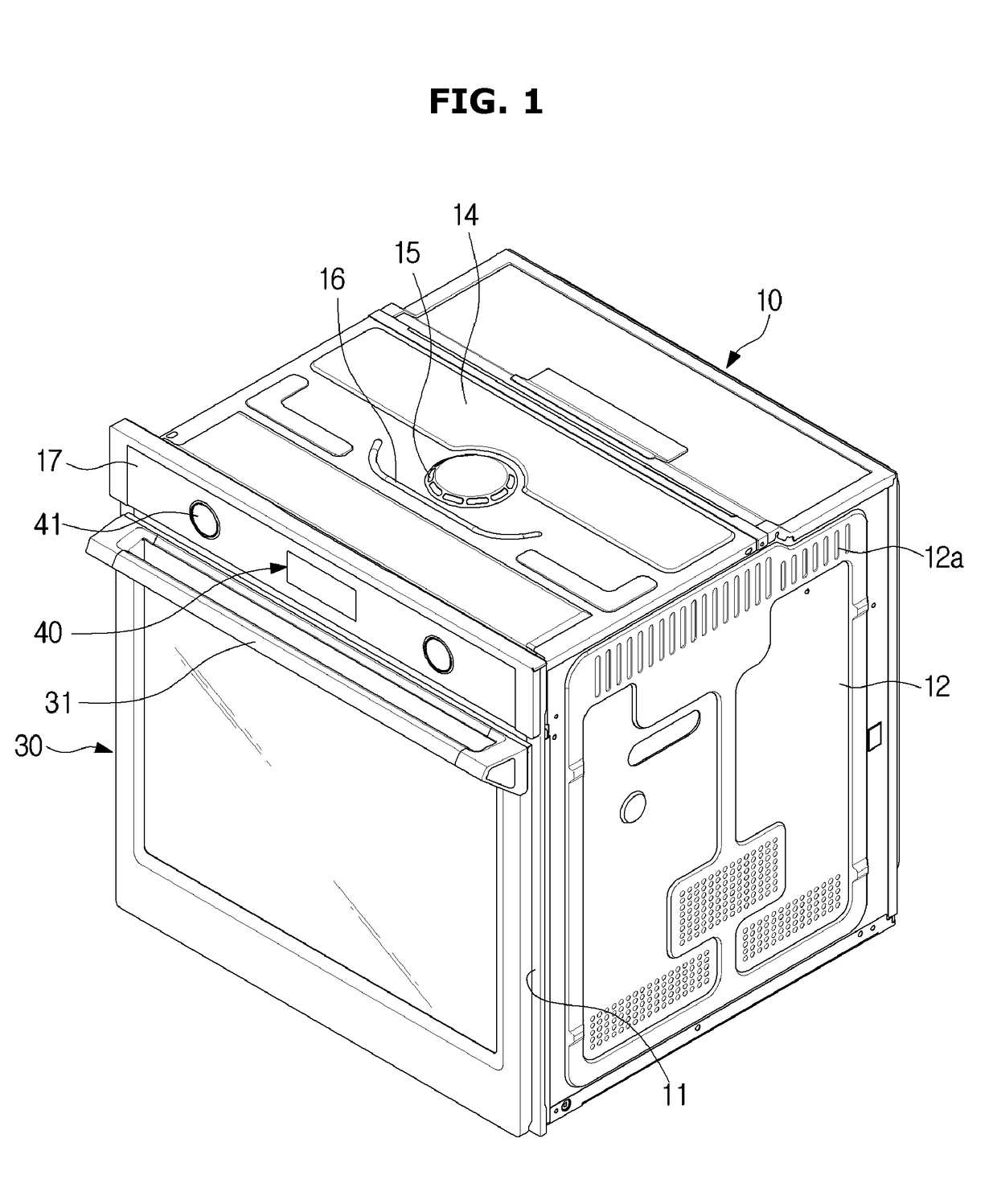

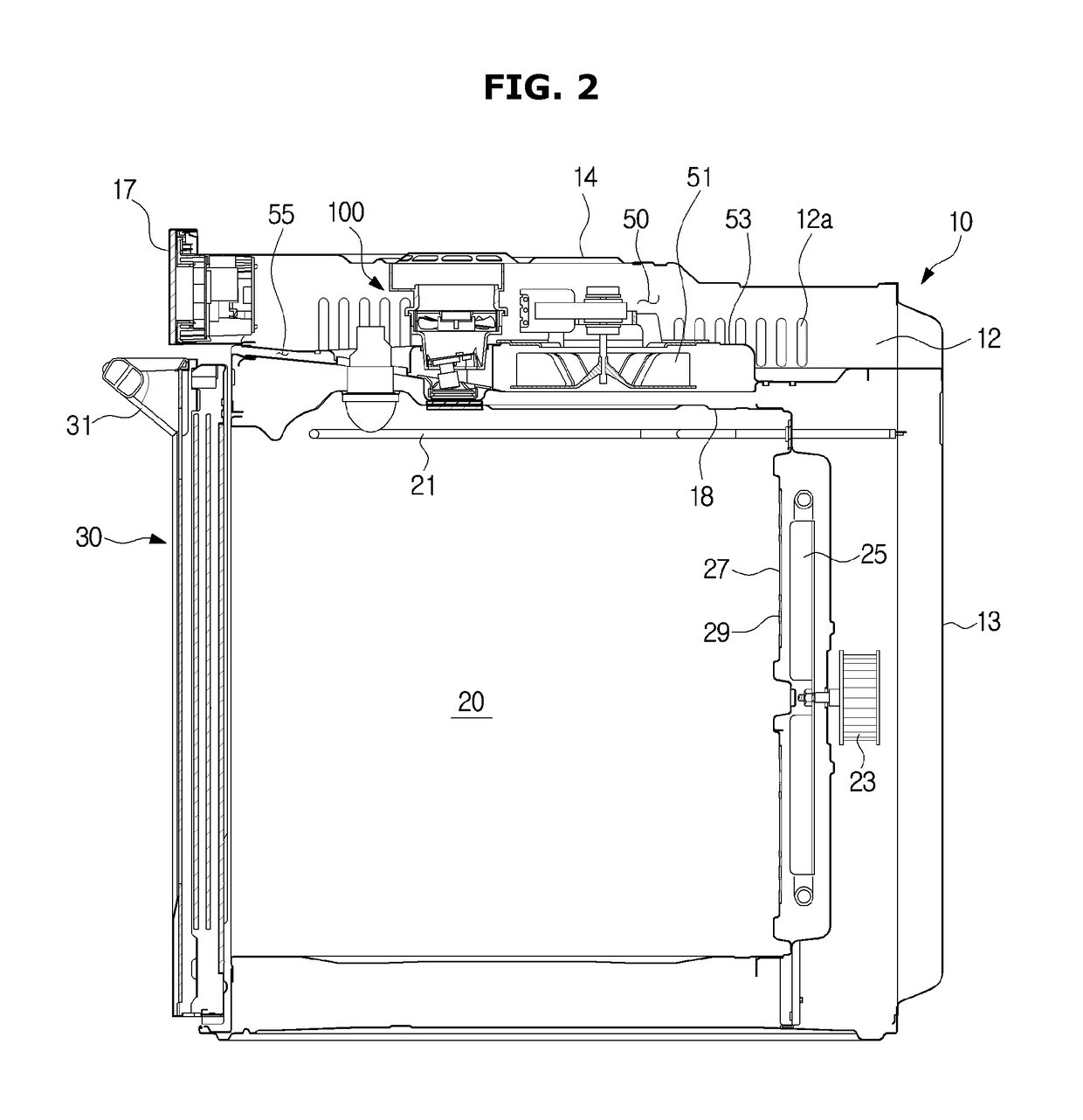

Oven

ActiveUS20180058702A1Avoid temperatureAvoid passingDomestic stoves or rangesFurnace componentsEngineeringFirst glasses

Owner:SAMSUNG ELECTRONICS CO LTD

Laminated glass

InactiveUS20170066223A1Easy to visually identifyVehicle componentsGlass/slag layered productsEngineeringGlass sheet

The present invention relates to a laminated glass including a first glass plate, a second glass plate and an intermediate layer provided between the first glass plate and the second glass plate, in which the first glass plate has a first face and a second face opposing the first face, the second glass plate has a third face and a fourth face opposing the third face, the intermediate layer is provided between the second face and the third face, the second glass plate is a chemically-strengthened glass, and in the second glass plate, when a compressive stress on the third face is denoted as CS(3), a tensile stress generated in an interior of the second glass plate is denoted as CT, a thickness of the second glass plate is denoted as t, a depth of the compressive stress on a side of the third face is denoted as DOL(3) and a depth of a compressive stress on a side of the fourth face is denoted as DOL(4), CS(3) / [CT2×{t−(DOL(3)+DOL(4))}] is greater than 1.1 MPa−1×mm−1.

Owner:ASAHI GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com