Wavelength conversion device, manufacture method thereof, correlative light-emitting device, and projection system

A technology of a wavelength conversion device and a light-emitting layer is applied in the fields of wavelength conversion devices and their preparation, related light-emitting devices, and projection devices. The effect of interface thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

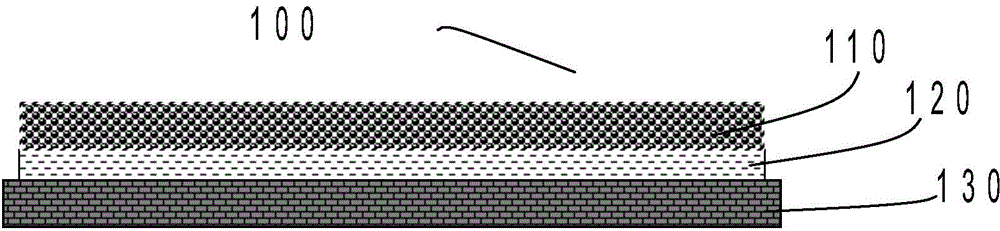

[0039] See figure 1 , figure 1 It is a schematic structural diagram of Embodiment 1 of the wavelength conversion device of the present invention. As shown in the figure, the wavelength conversion device 100 includes a light emitting layer 110 , a diffuse reflection layer 120 and a ceramic substrate 130 . Wherein the light emitting layer 110 is a sintered body comprising phosphor powder and the first glass powder, and the diffuse reflection layer 120 is a sintered body comprising white scattering particles and the first glass powder.

[0040] After the excitation light emitted by the excitation light source is incident on the light-emitting layer 110, the phosphor powder is excited to emit the subject light. After the excited light and the unexcited excitation light pass through the light-emitting layer 110, they are incident on the diffuse reflection layer 120, and then are reflected back to the light-emitting layer 110, wherein the excited light and part of the unexcited ex...

Embodiment 2

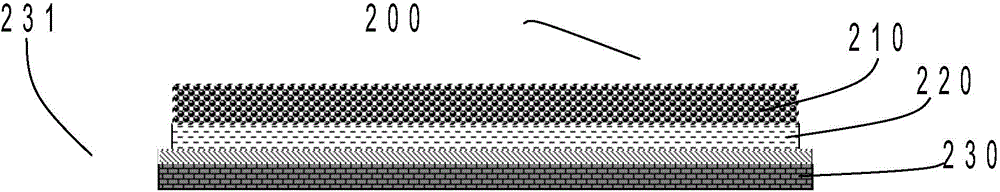

[0075] See figure 2 , figure 2 It is a schematic structural diagram of Embodiment 2 of the wavelength conversion device of the present invention. As shown in the figure, the wavelength conversion device 200 includes a light-emitting layer 210 , a diffuse reflection layer 220 and a ceramic substrate 230 . Different from Embodiment 1, in this embodiment, the wavelength conversion device 200 also includes an interface bonding layer 231 .

[0076] In this embodiment, the ceramic substrate 230 is an aluminum nitride substrate, the interface bonding layer 231 is an alumina layer, and the alumina layer 231 is formed on the surface of the aluminum nitride substrate 230 and is a part of the ceramic substrate 230 .

[0077] The preparation method of the wavelength conversion device 200 in this embodiment is as follows:

[0078] Step 1: providing an aluminum nitride substrate 230, and performing surface densification treatment on the aluminum nitride substrate 230, specifically inclu...

Embodiment 3

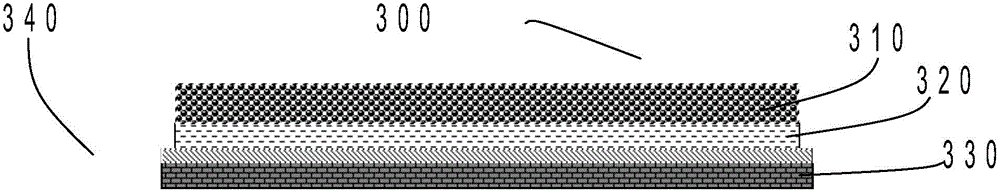

[0086] See image 3 , image 3 It is a structural schematic diagram of Embodiment 3 of the wavelength conversion device of the present invention. As shown in the figure, the wavelength conversion device 300 includes a light emitting layer 310 , a diffuse reflection layer 320 , a ceramic substrate 330 and an interface bonding layer 340 . Different from the second embodiment, in this embodiment, the interface bonding layer 340 is a layer structure independent of the ceramic substrate 330 .

[0087] In this embodiment, the interface bonding layer 340 is a glass bonding layer, and the glass bonding layer includes the same first glass frit as that in the diffuse reflection layer 320 .

[0088] Due to the problem of the preparation process, when the diffuse reflection layer 320 is fired on the ceramic substrate 330 , there may be white scattering particles in direct contact with the ceramic substrate 330 . Since the white scattering particles do not undergo a softening and reshap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com