Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

157results about How to "Deterioration can be suppressed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

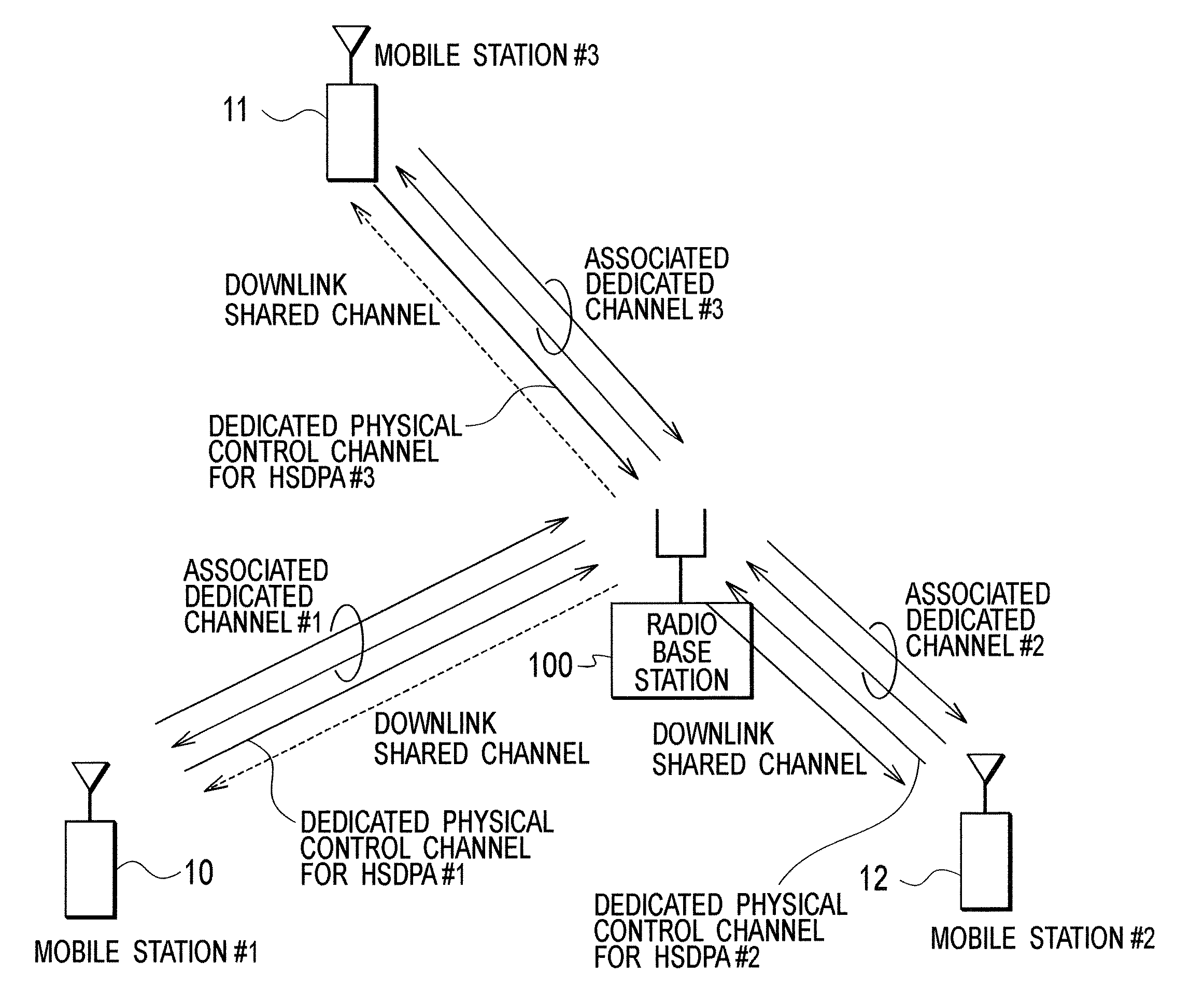

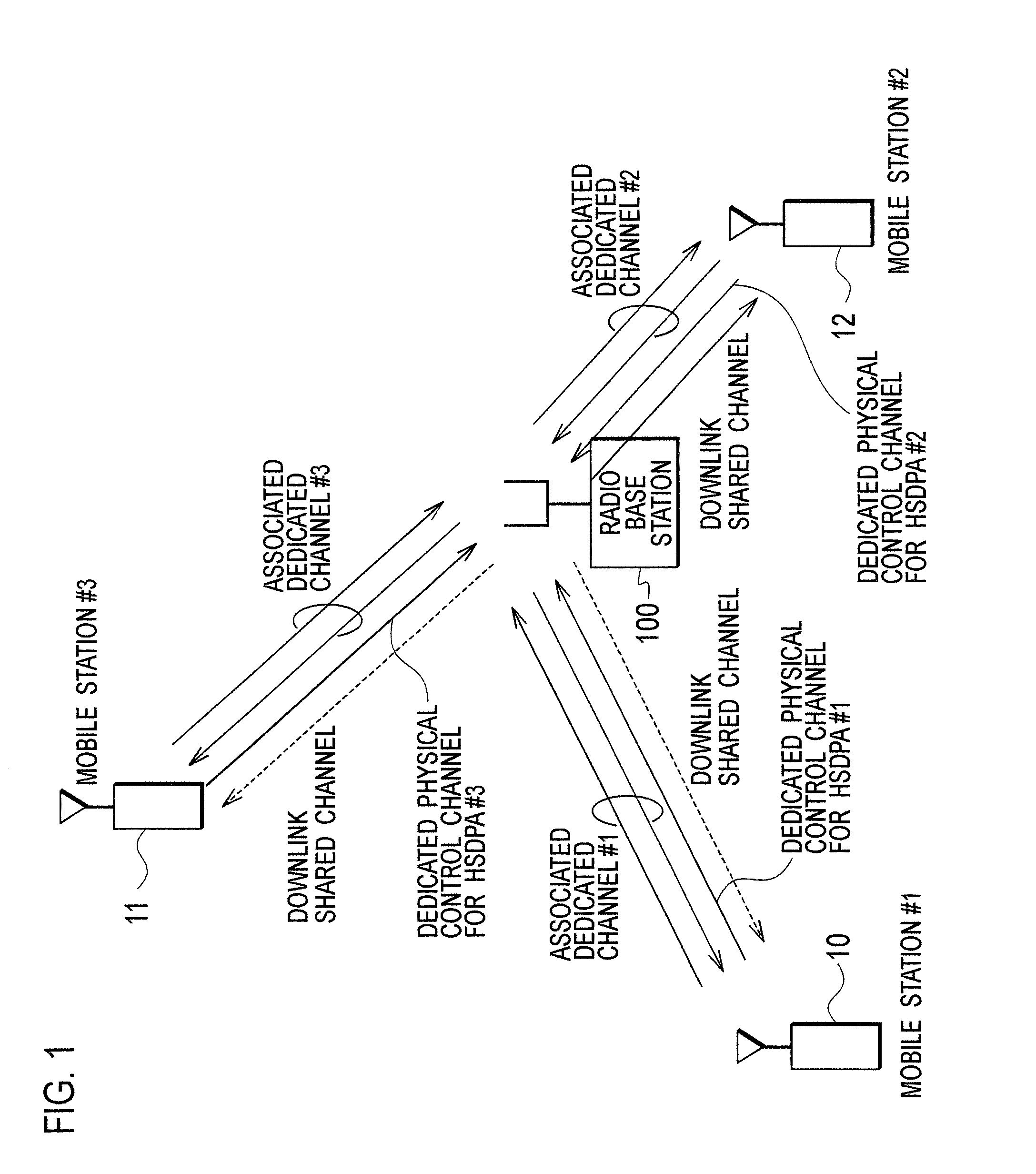

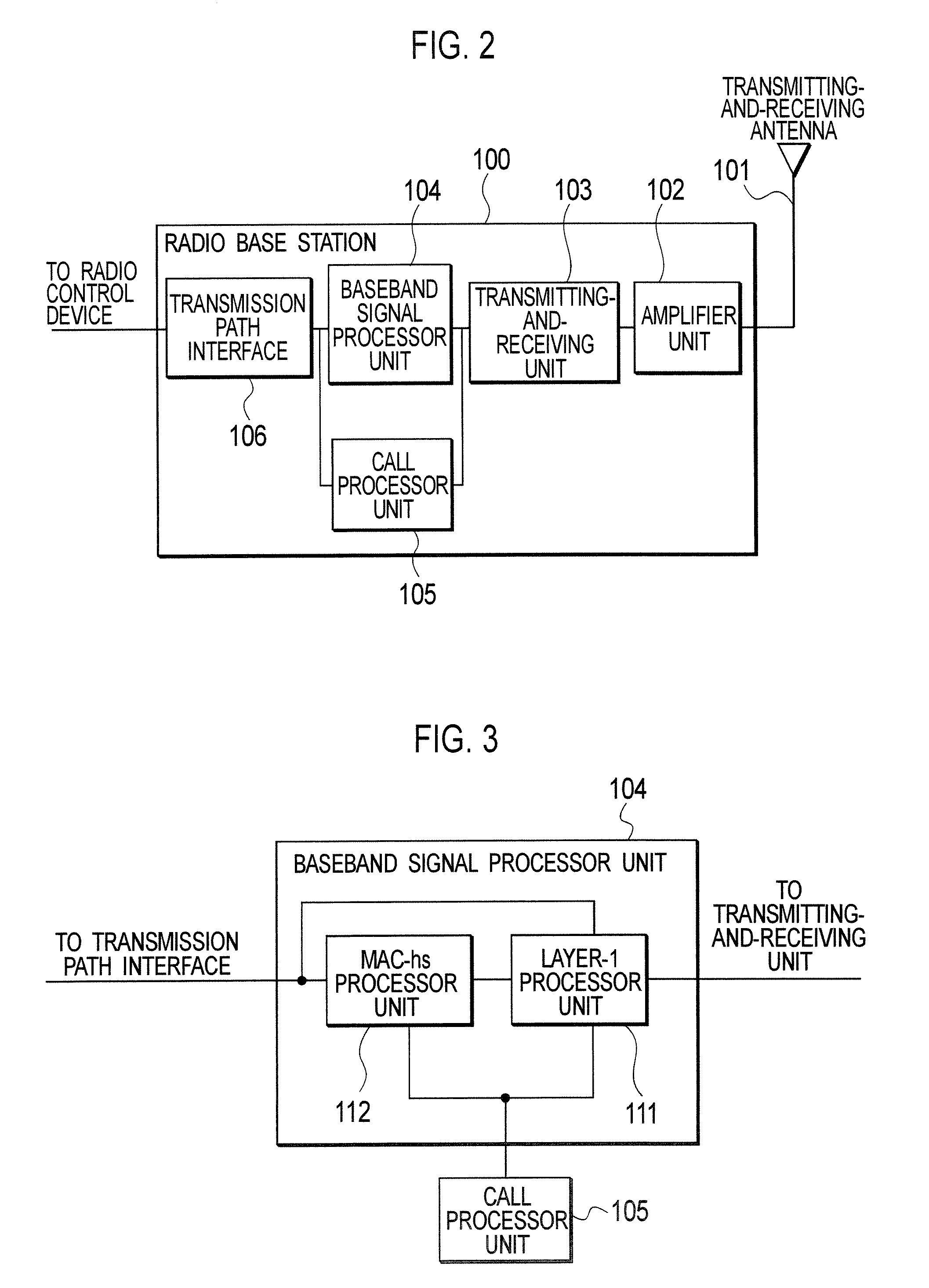

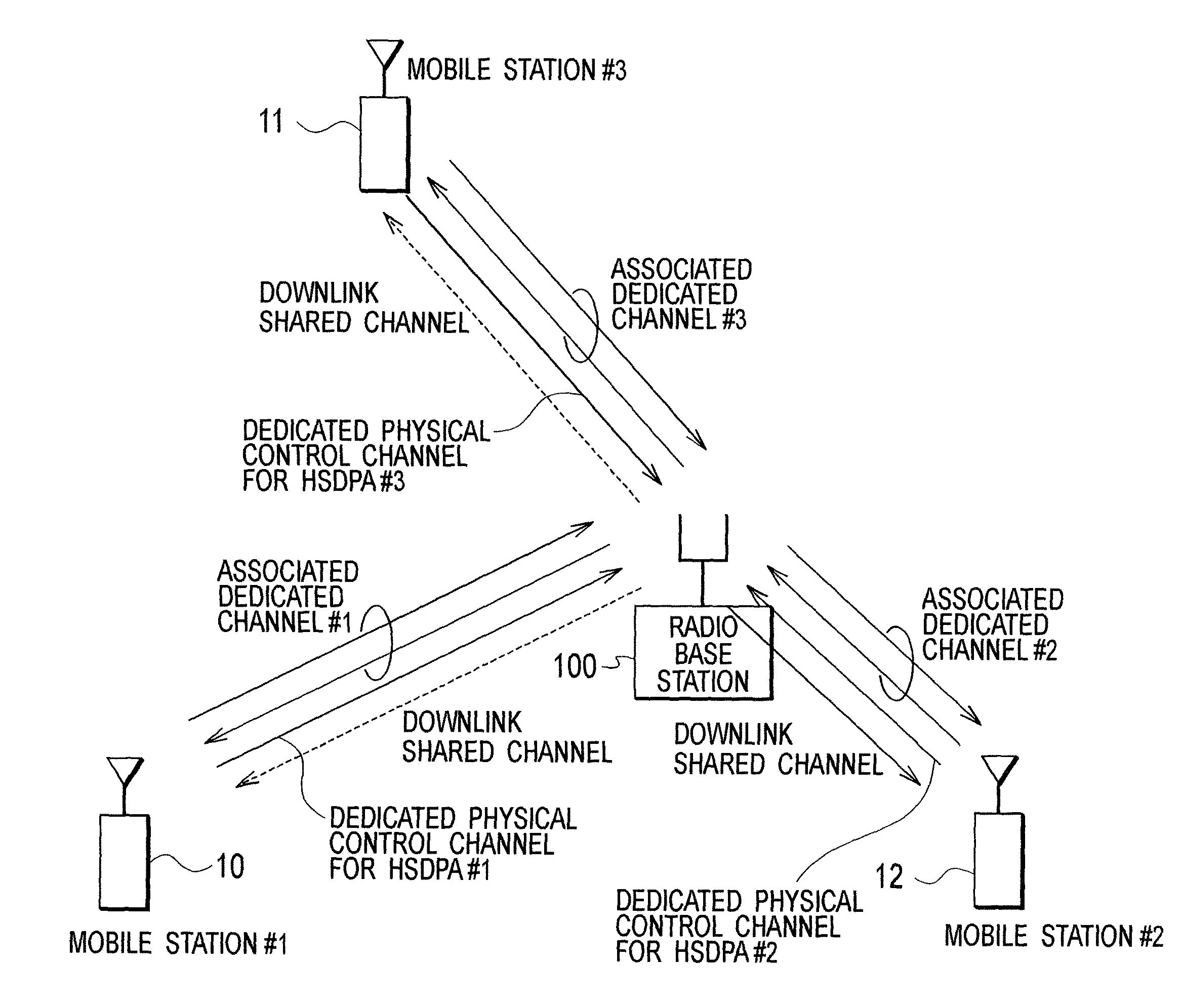

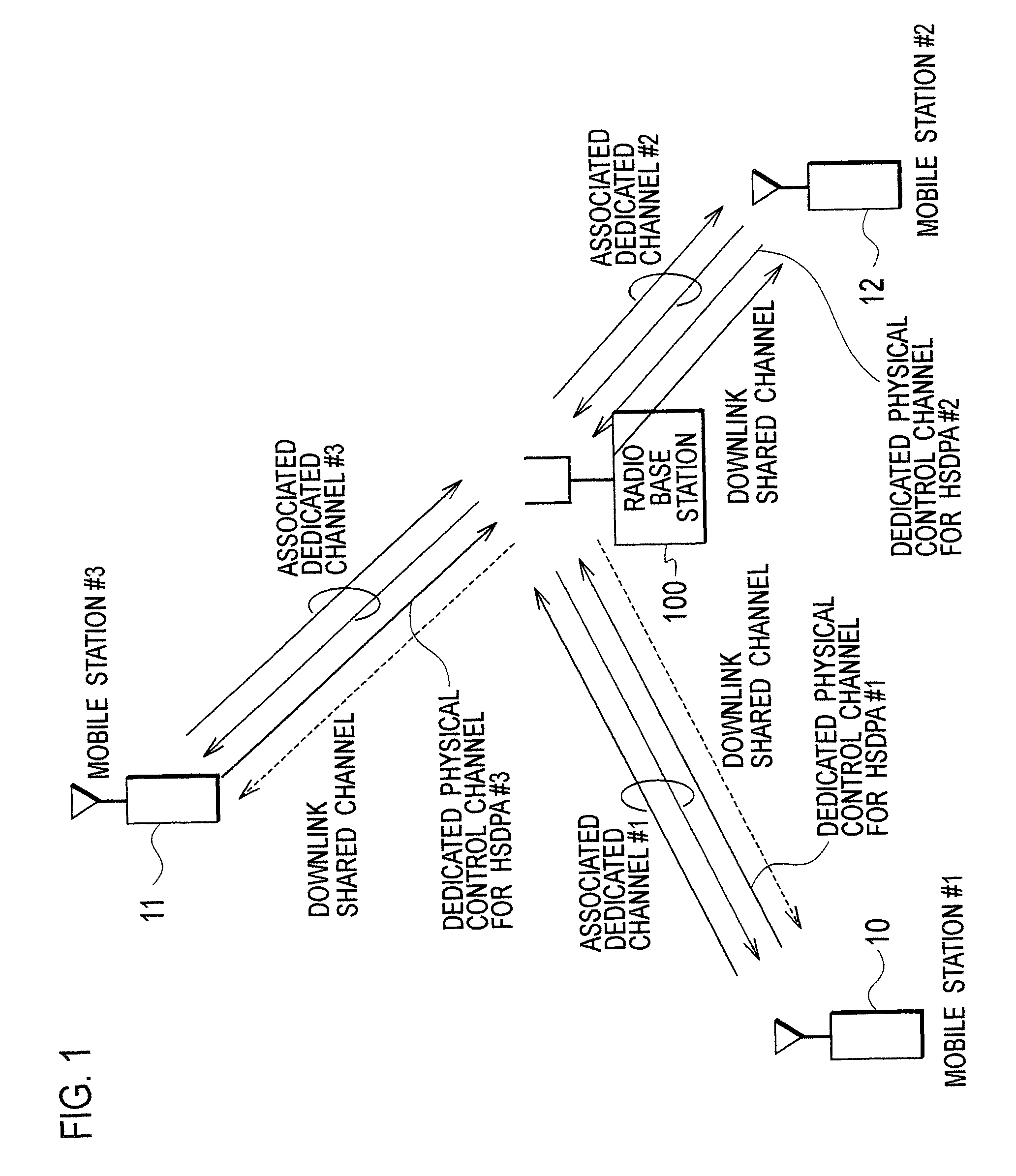

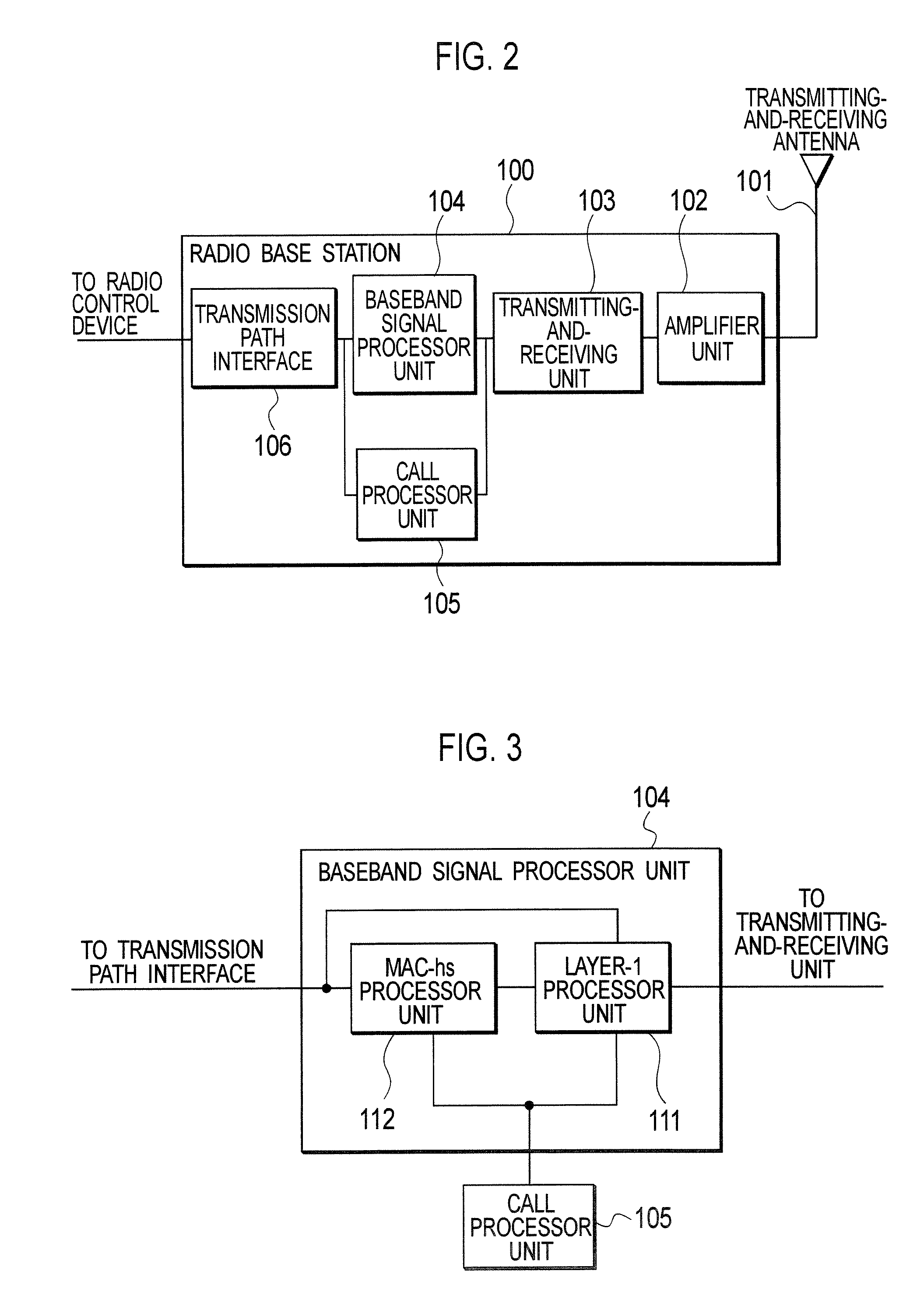

Packet Transmission Control Device and Packet Transmission Control Method

ActiveUS20080043657A1Easy to useDeterioration can be suppressedPower managementNetwork traffic/resource managementMobile stationPacket transmission

A packet transmission control device relating to the present invention includes: a storage unit configured to store a transmission resource available for use in the packet transmission, radio quality information on the downlink, and a transmission method to be used in the packet transmission while associating them with one another; a determination unit configured to determine a transmission method to be used in the packet transmission on the basis of the radio quality information, on the downlink reported from the mobile stations and the transmission resource available for use in the packet transmission, by referring to the storage unit; and a packet transmission unit configured to transmit the packet by using the determined transmission method.

Owner:NTT DOCOMO INC

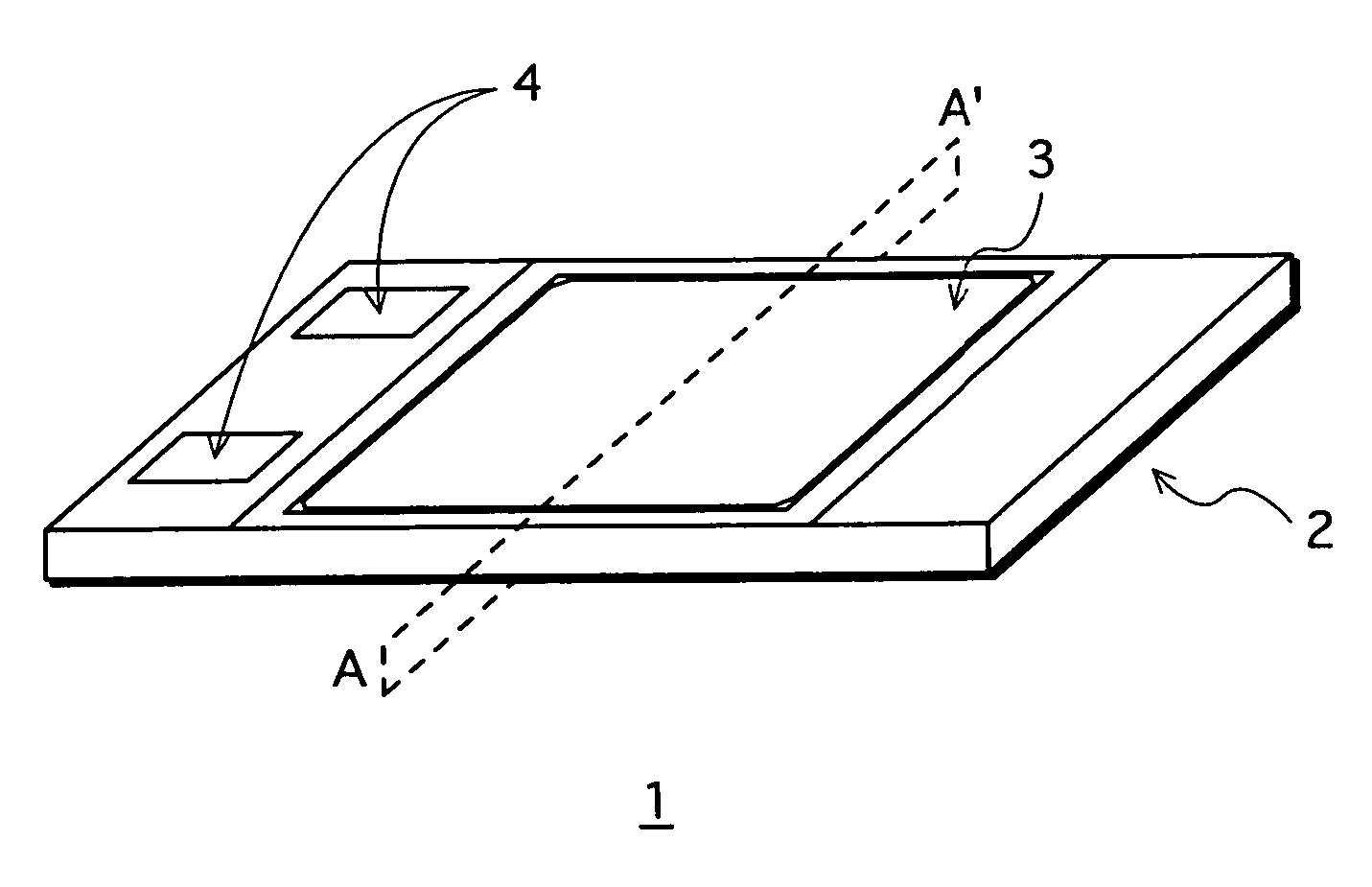

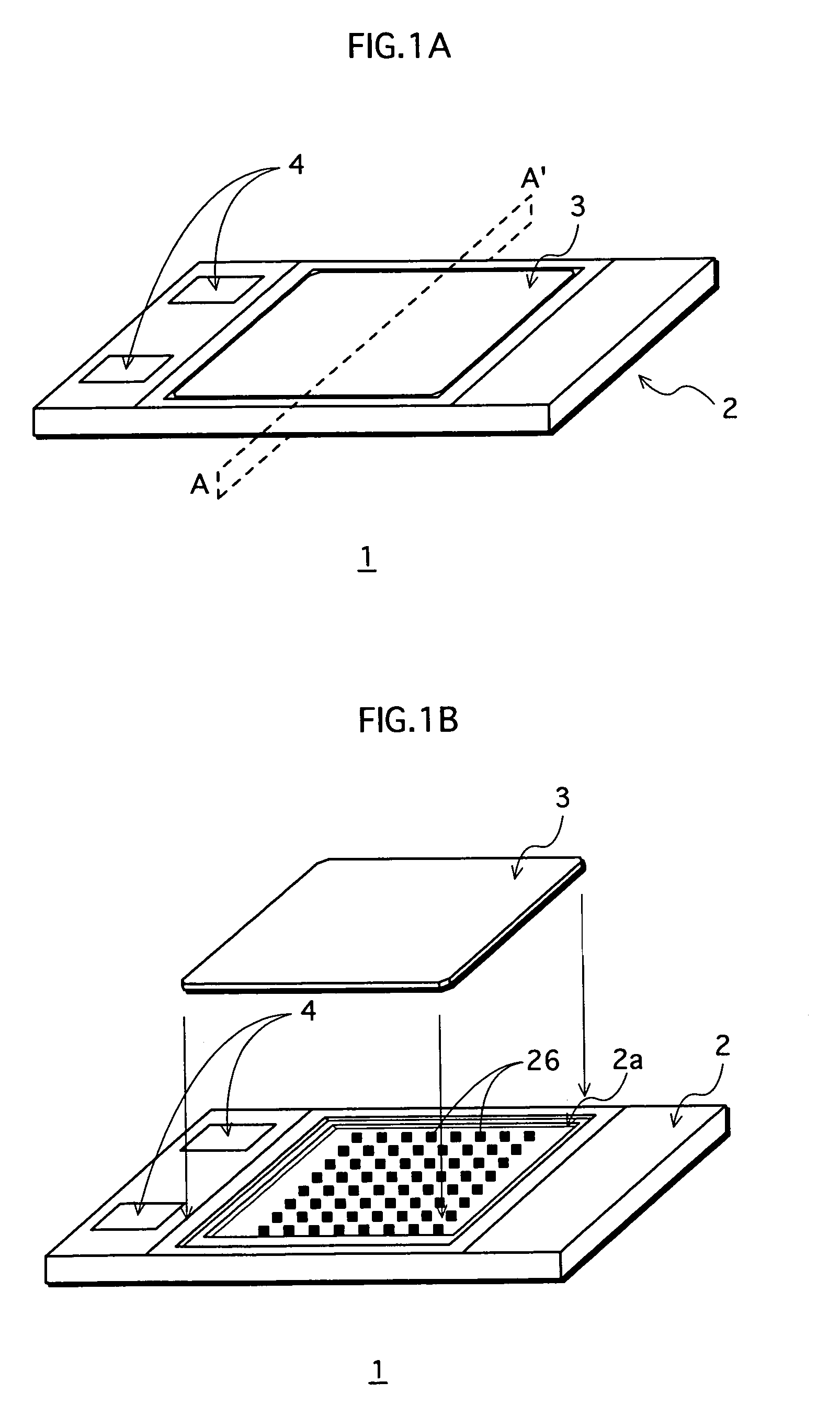

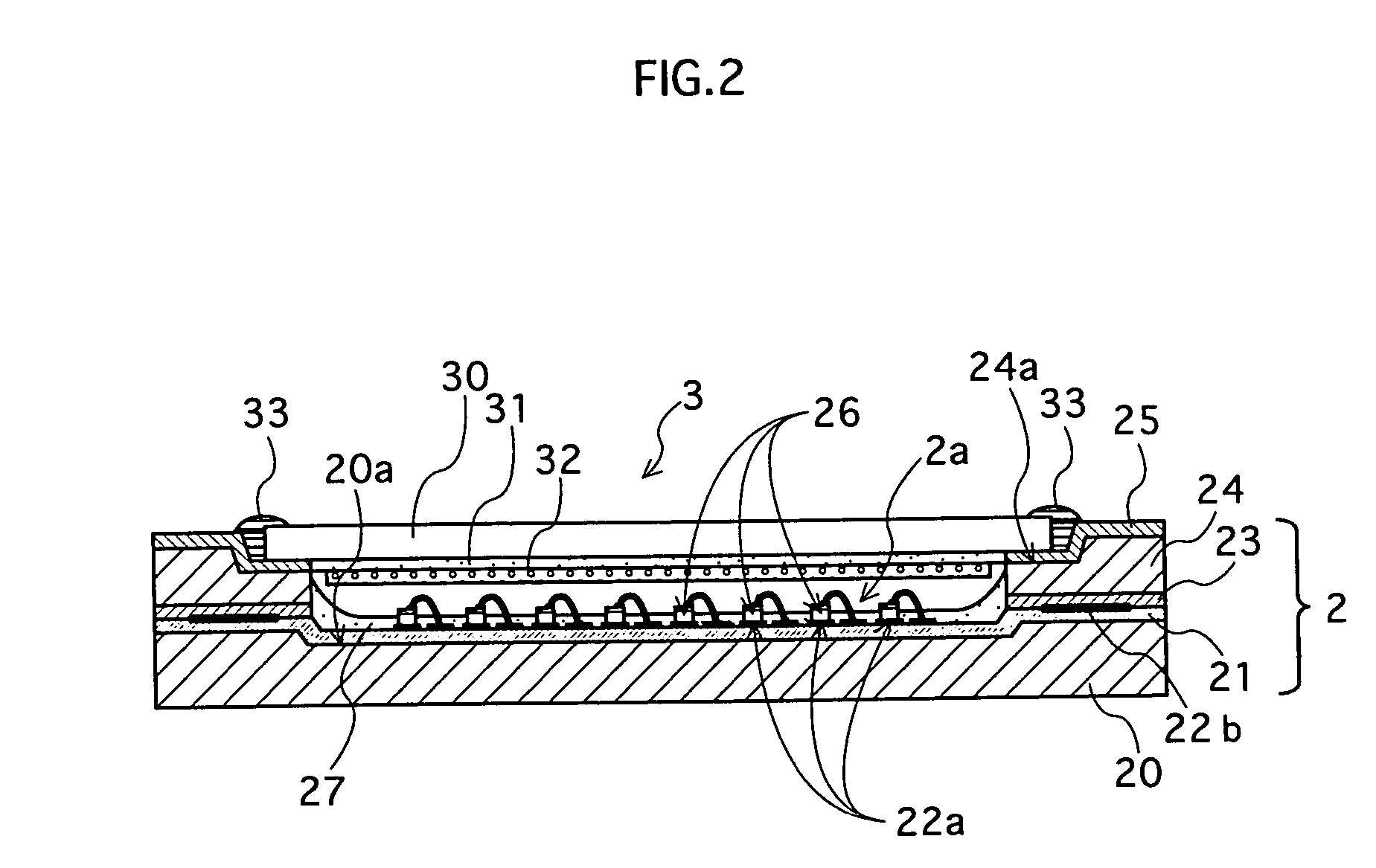

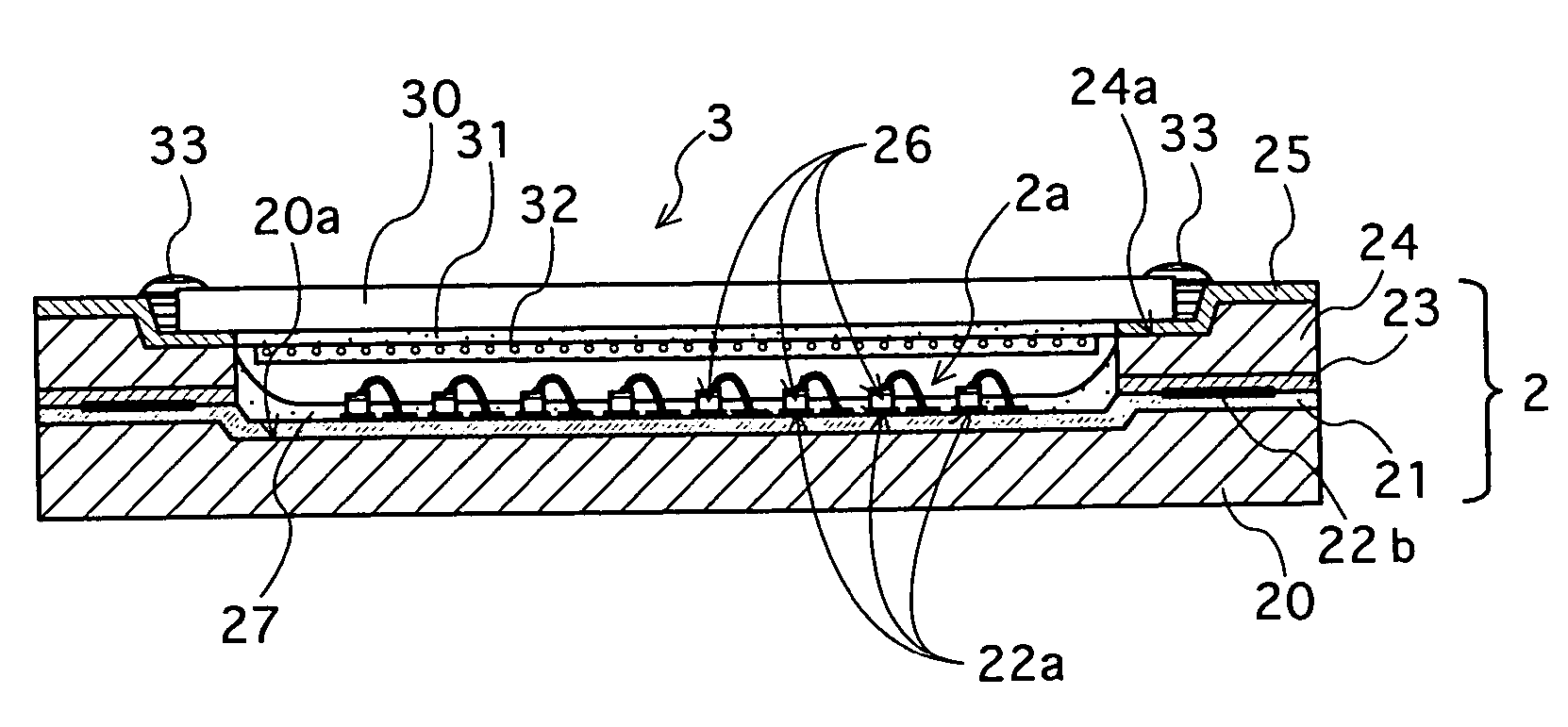

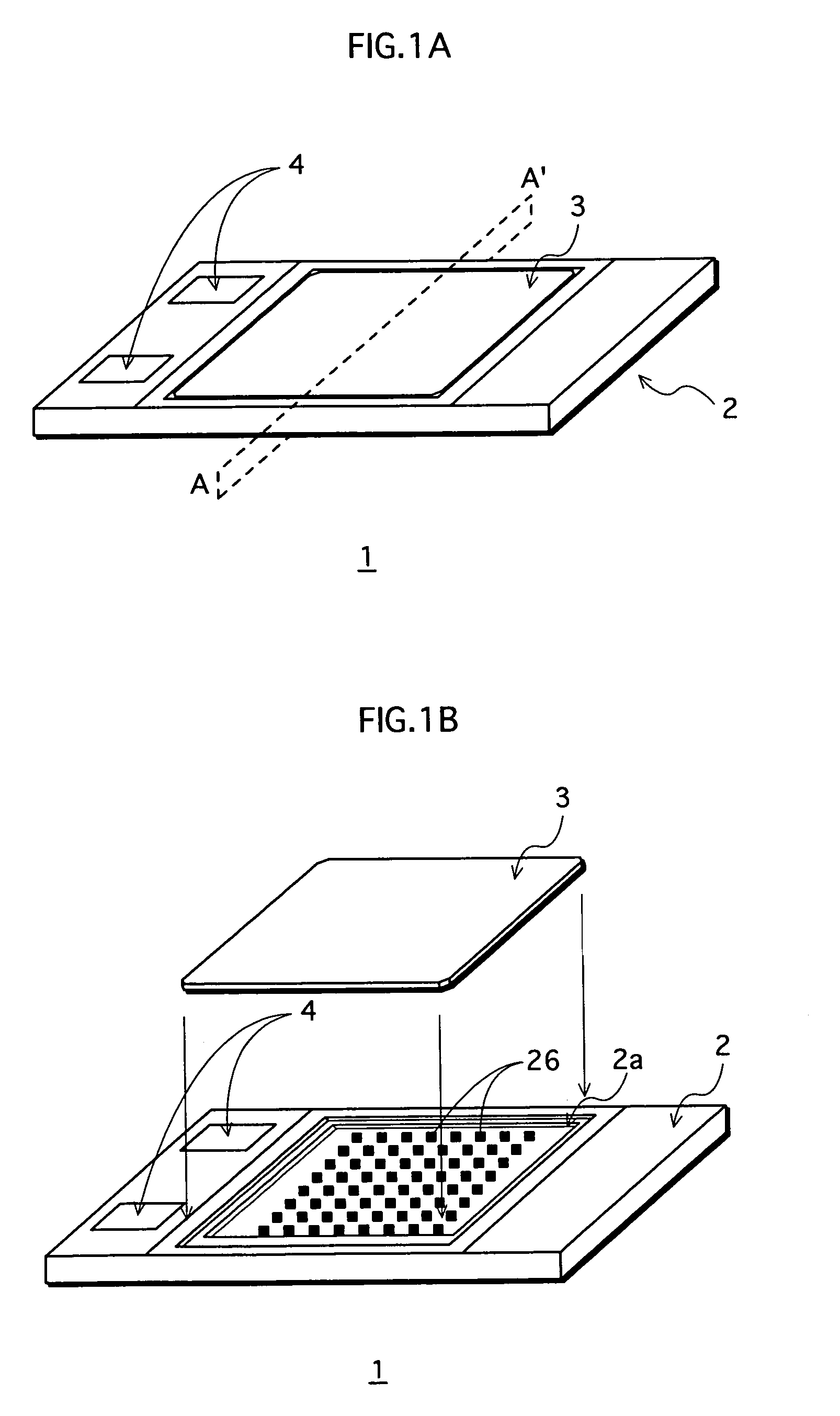

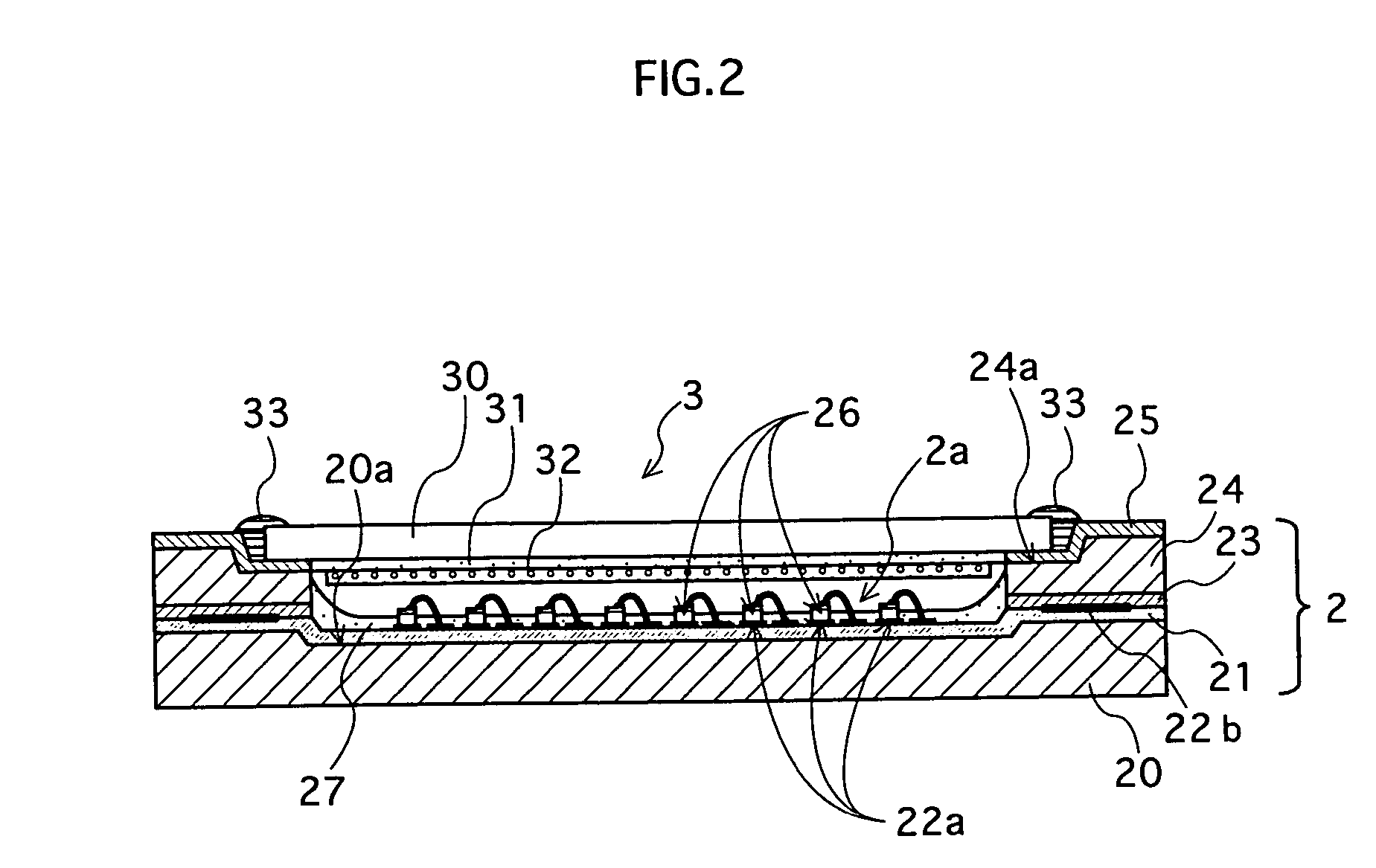

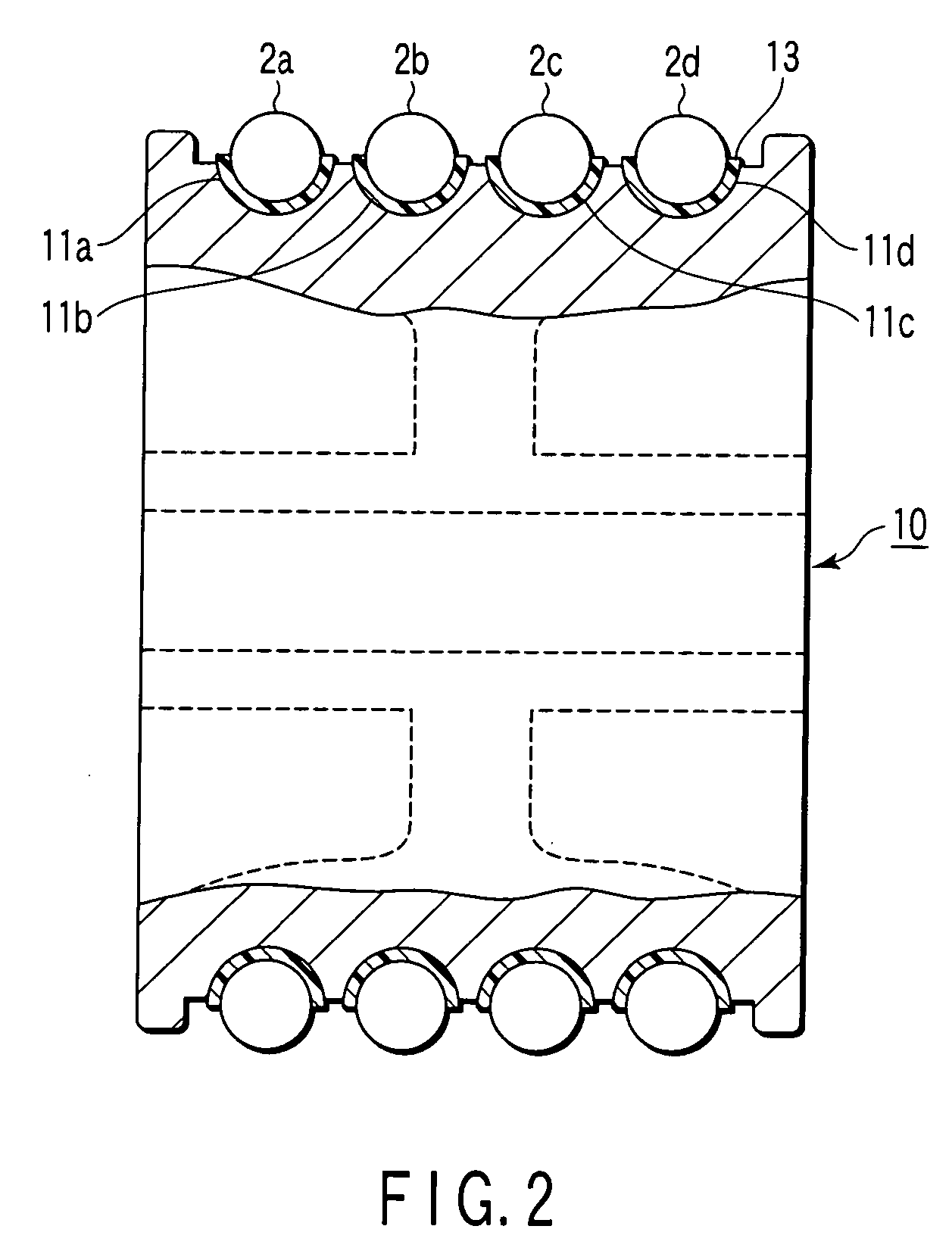

Light emission apparatus

ActiveUS20040129946A1Reduce the amount requiredDeterioration can be suppressedPlanar light sourcesLaser detailsFluorescencePhosphor

A light emission apparatus that can restrict deterioration of resin used for the light emission apparatus, and that has a reasonable structure fit for actual use is provided, in which a light reflective layer is provided to cover the side surfaces of the chips 26 provided in the concave 2a. According to this, excitation light reflected by the phosphor layer 32, such as ultraviolet light, is reflected again by the light reflective layer 27. Therefore, the excitation light will not reach the resin layer 21, thereby restraining the deterioration of the resin. Moreover, the light reflective layer 27 covers the side surfaces of the chips 26, thereby efficiently conducting the heat emitted from the chips 26 to the metal substrate 20 via the resin layer 21. This improves the heat-dissipation efficiency of the chips 26.

Owner:SIGNIFY HLDG BV

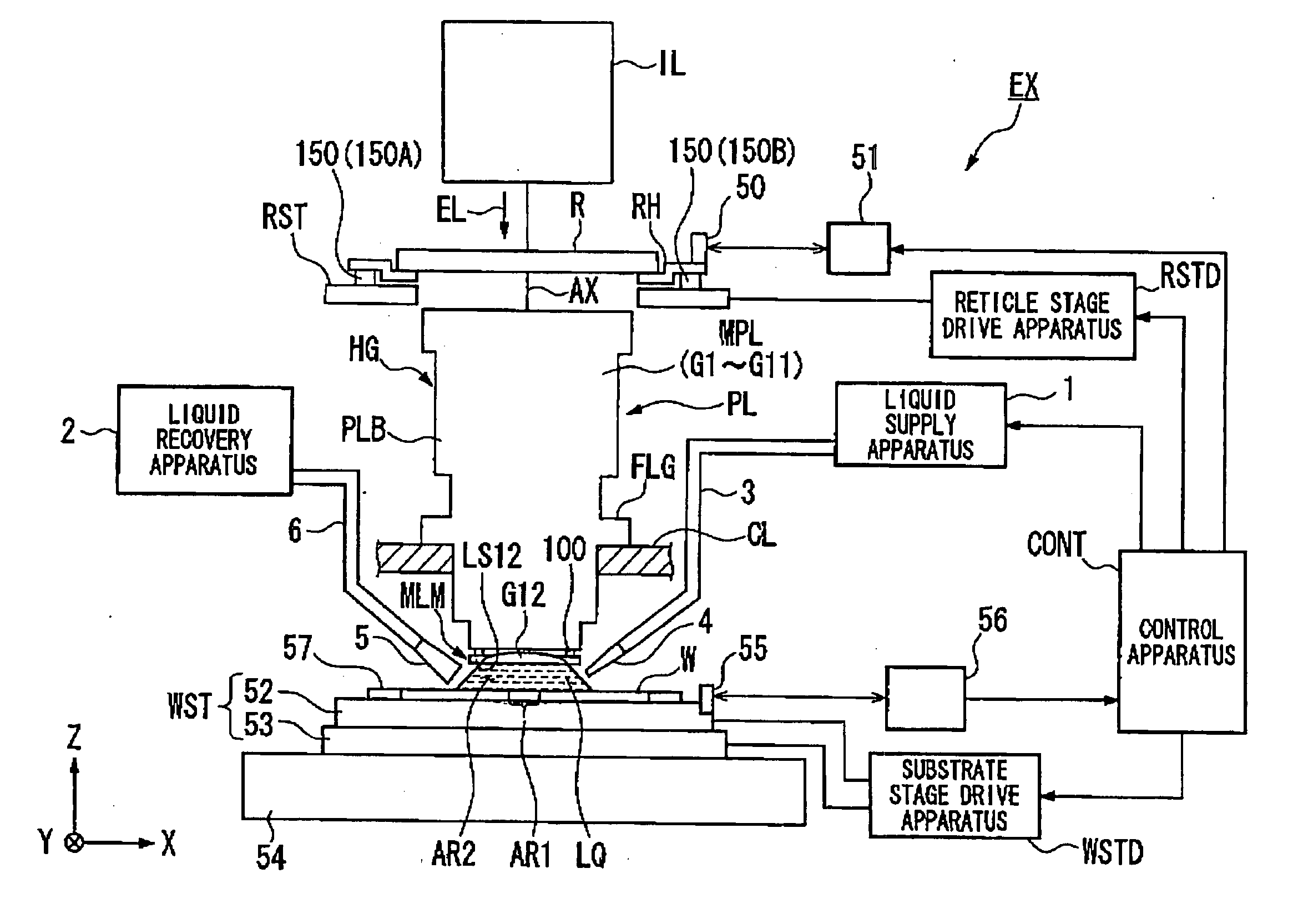

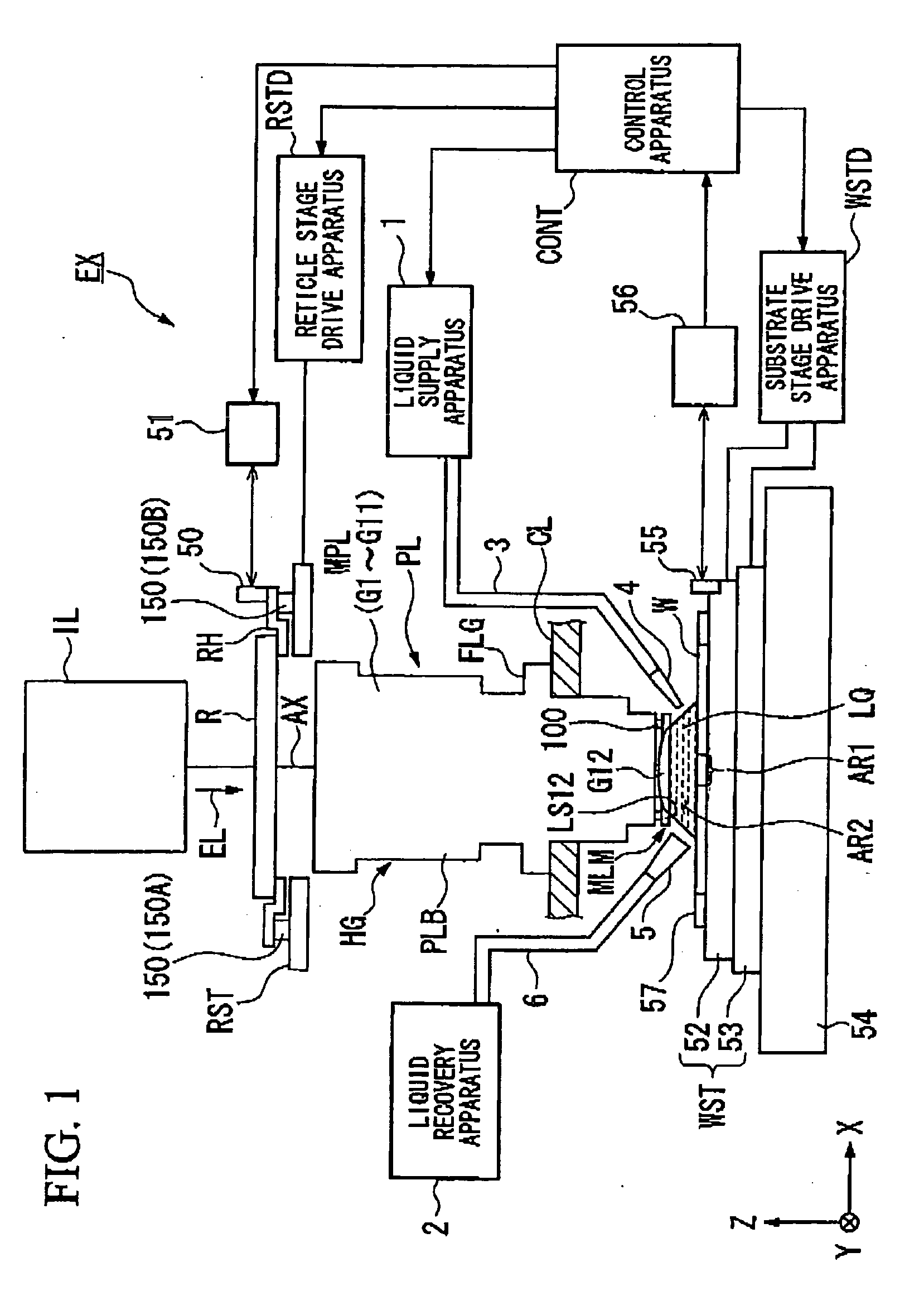

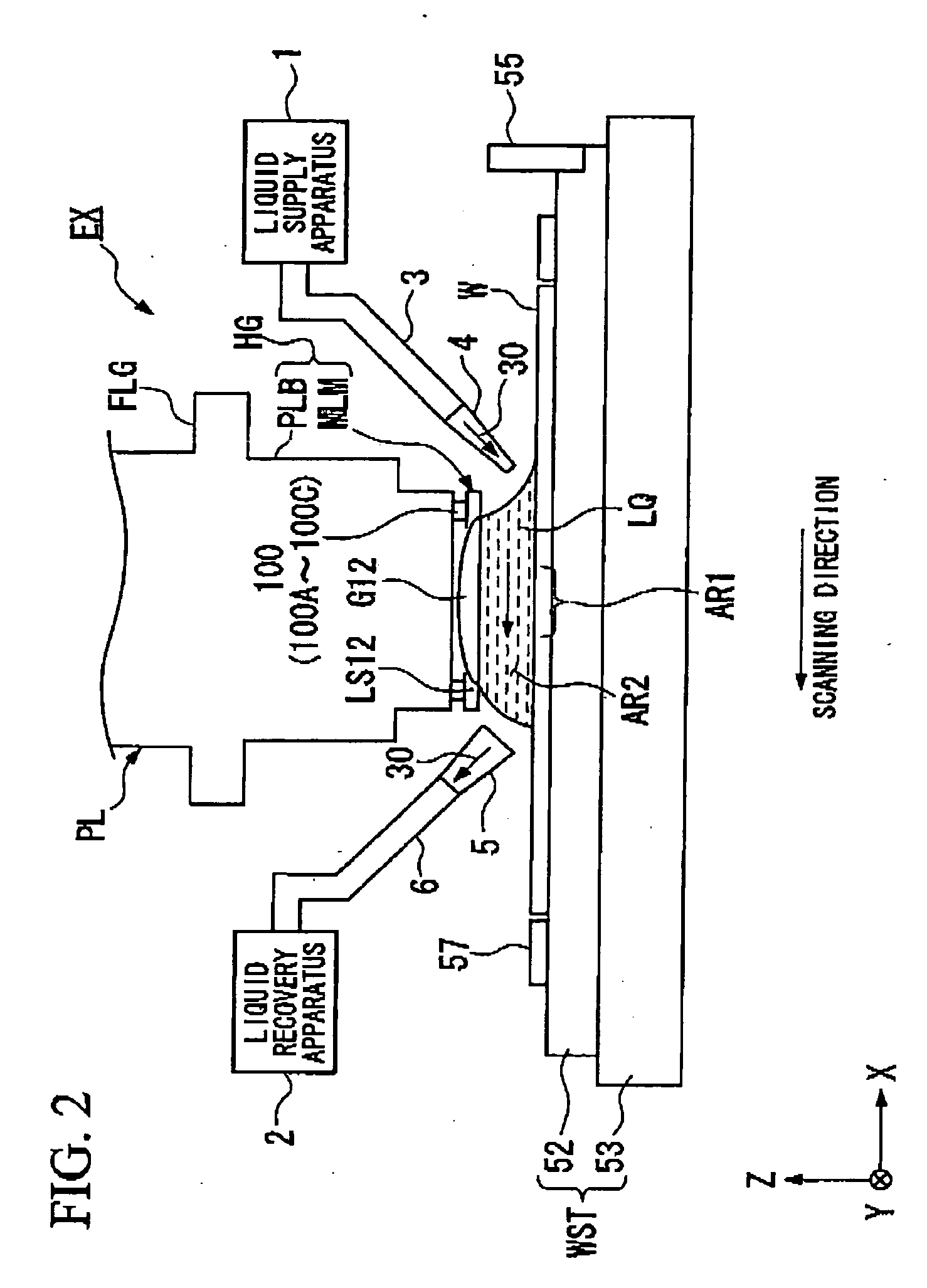

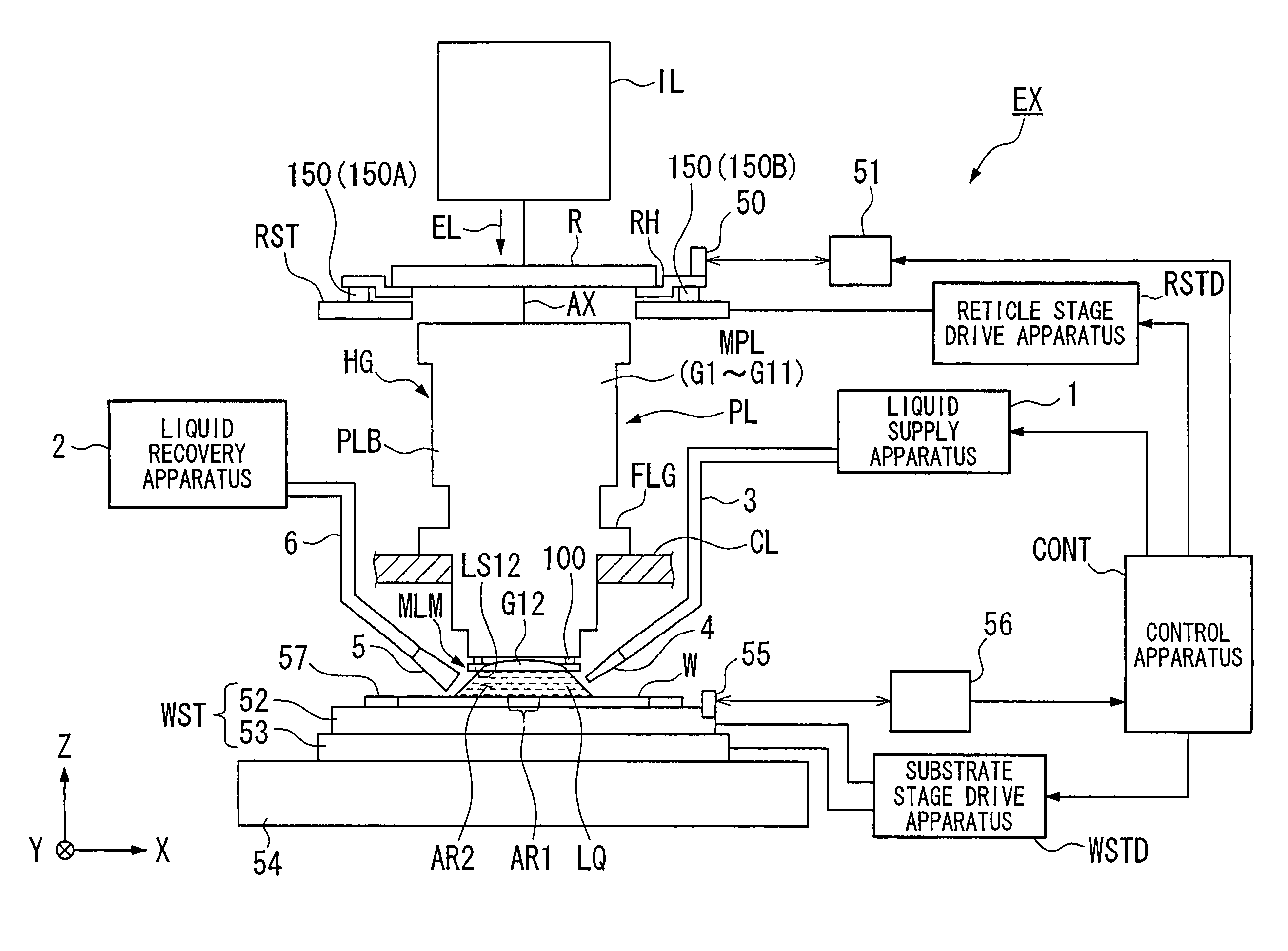

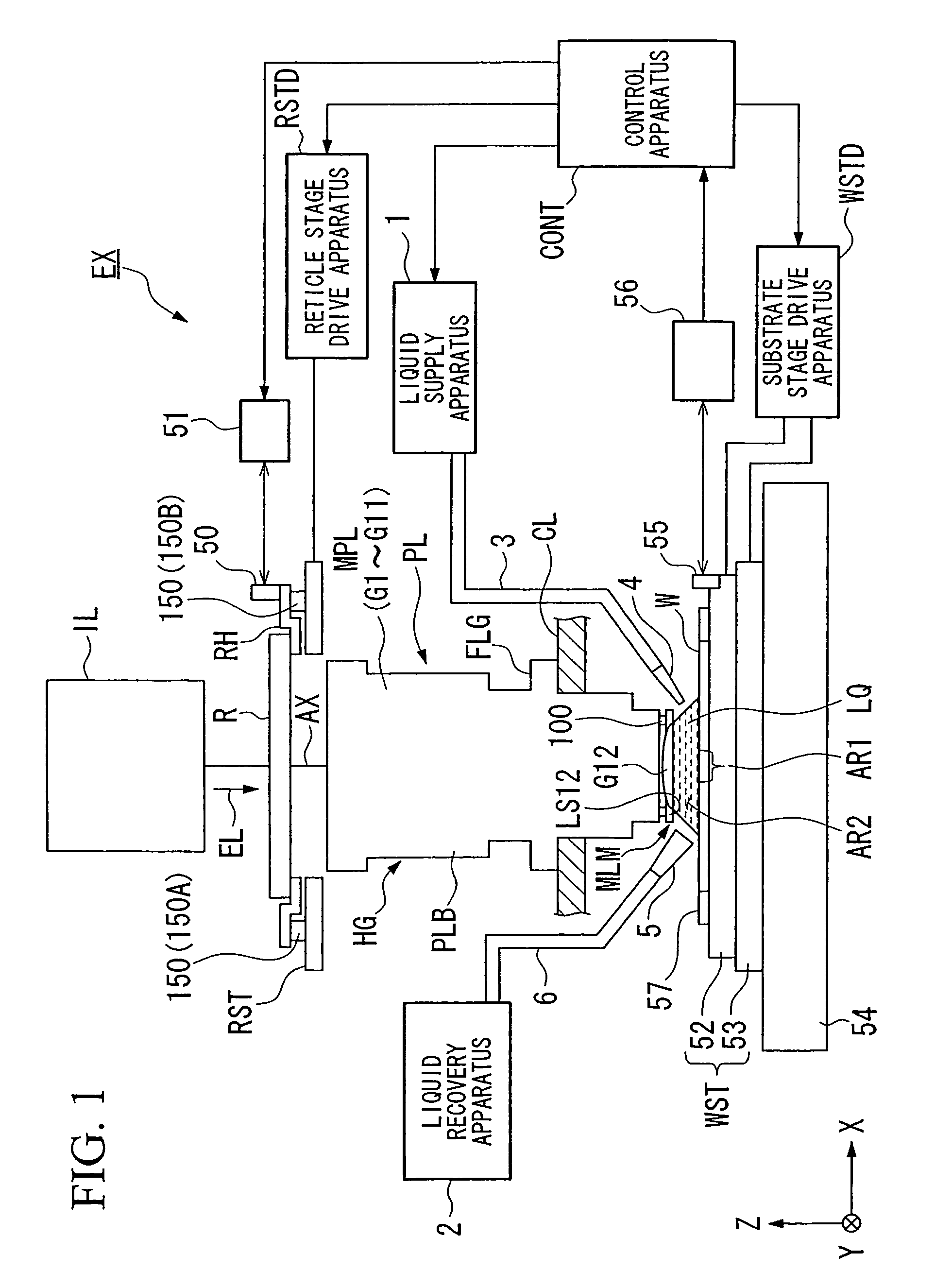

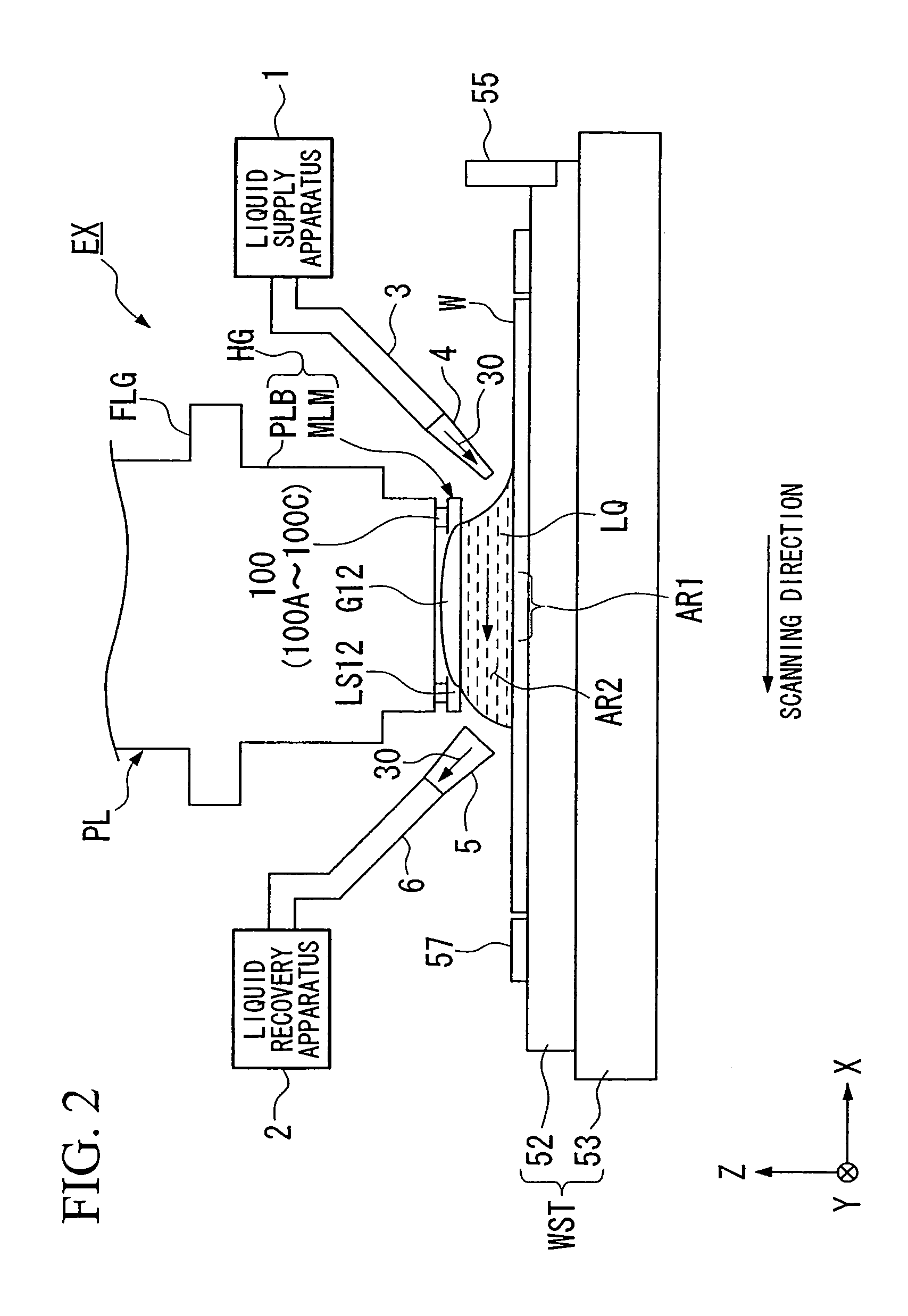

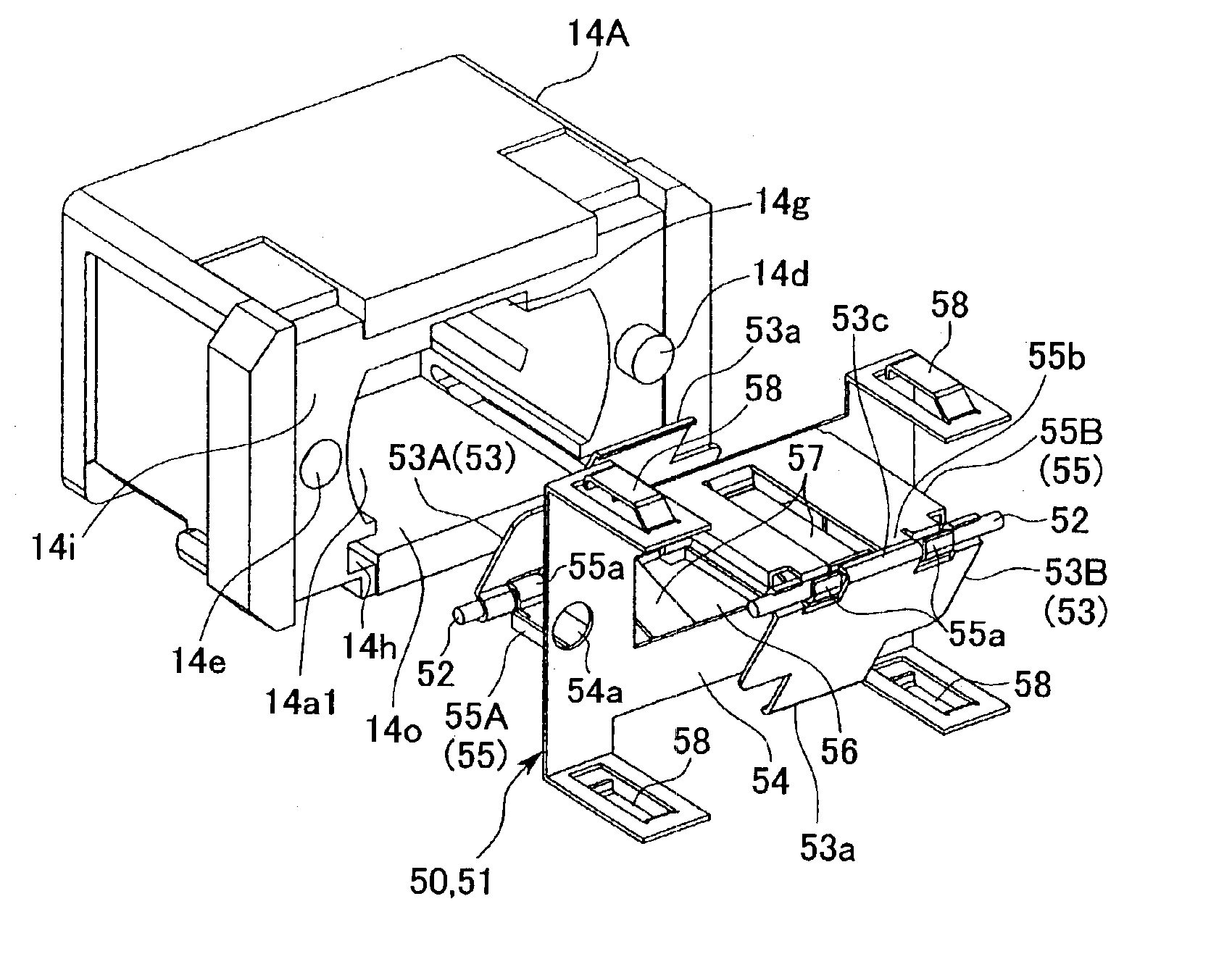

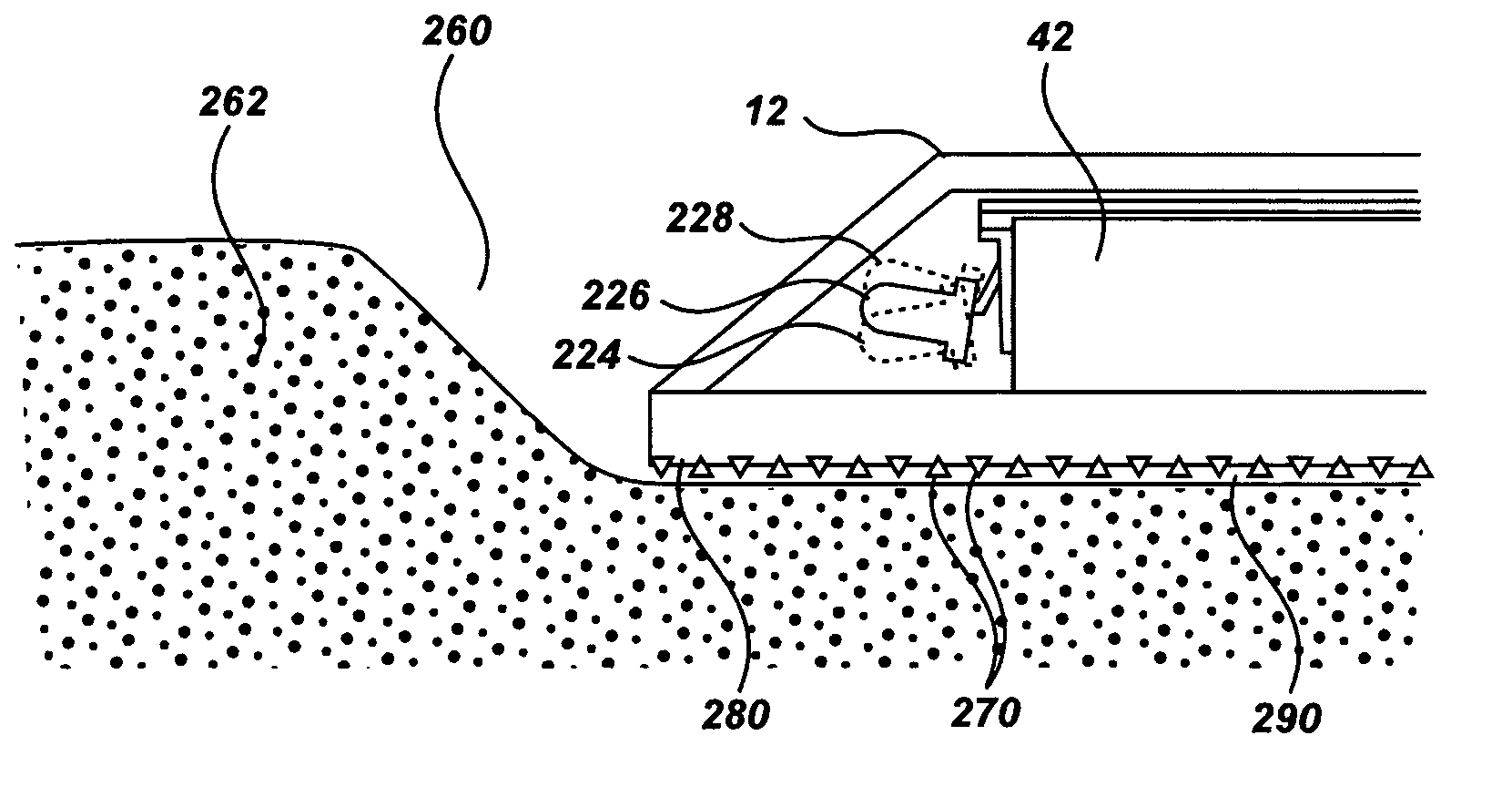

Exposure apparatus and device manufacturing method

InactiveUS20060209278A1Avoid flowPrevent penetrationPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringReticle

An exposure apparatus projects a pattern image onto a substrate via a projection optical system and a liquid, and the projection optical system has an optical member that comes into contact with the liquid and an optical group arranged between the optical member and a reticle. A holding mechanism that holds the optical member and the optical group holds the optical member so that it is movable relative to the optical group.

Owner:NIKON CORP

Exposure apparatus and device manufacturing method

InactiveUS7433019B2Deterioration can be suppressedAvoid spreadingPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringReticle

An exposure apparatus projects a pattern image onto a substrate via a projection optical system and a liquid, and the projection optical system has an optical member that comes into contact with the liquid and an optical group arranged between the optical member and a reticle. A holding mechanism that holds the optical member and the optical group holds the optical member so that it is movable relative to the optical group.

Owner:NIKON CORP

Light emission apparatus

ActiveUS7101061B2Reasonable structureSuitable structurePlanar light sourcesLaser detailsFluorescencePhosphor

A light emission apparatus that can restrict deterioration of resin used for the light emission apparatus, and that has a reasonable structure fit for actual use is provided, in which a light reflective layer is provided to cover the side surfaces of the chips 26 provided in the concave 2a. According to this, excitation light reflected by the phosphor layer 32, such as ultraviolet light, is reflected again by the light reflective layer 27. Therefore, the excitation light will not reach the resin layer 21, thereby restraining the deterioration of the resin. Moreover, the light reflective layer 27 covers the side surfaces of the chips 26, thereby efficiently conducting the heat emitted from the chips 26 to the metal substrate 20 via the resin layer 21. This improves the heat-dissipation efficiency of the chips 26.

Owner:SIGNIFY HLDG BV

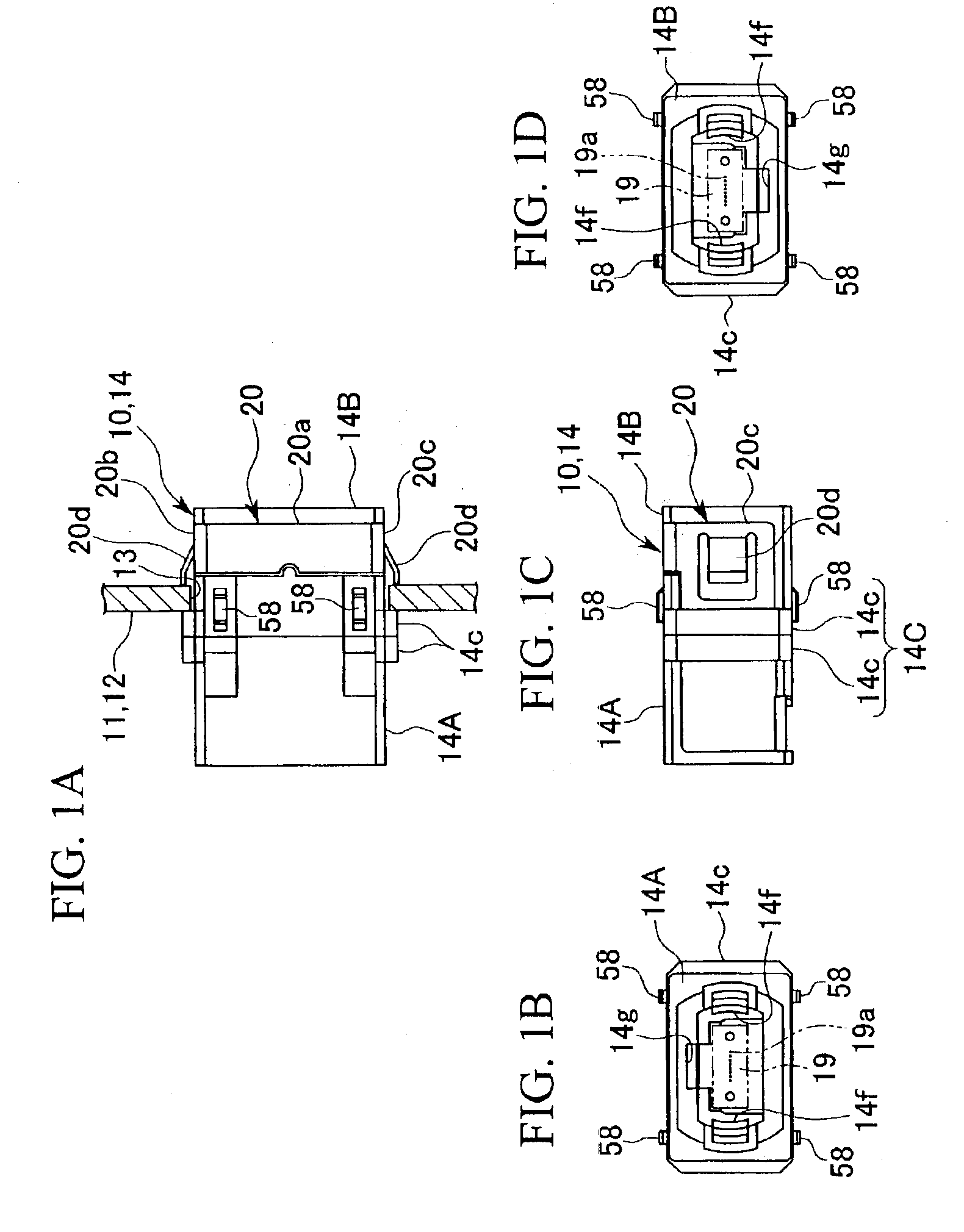

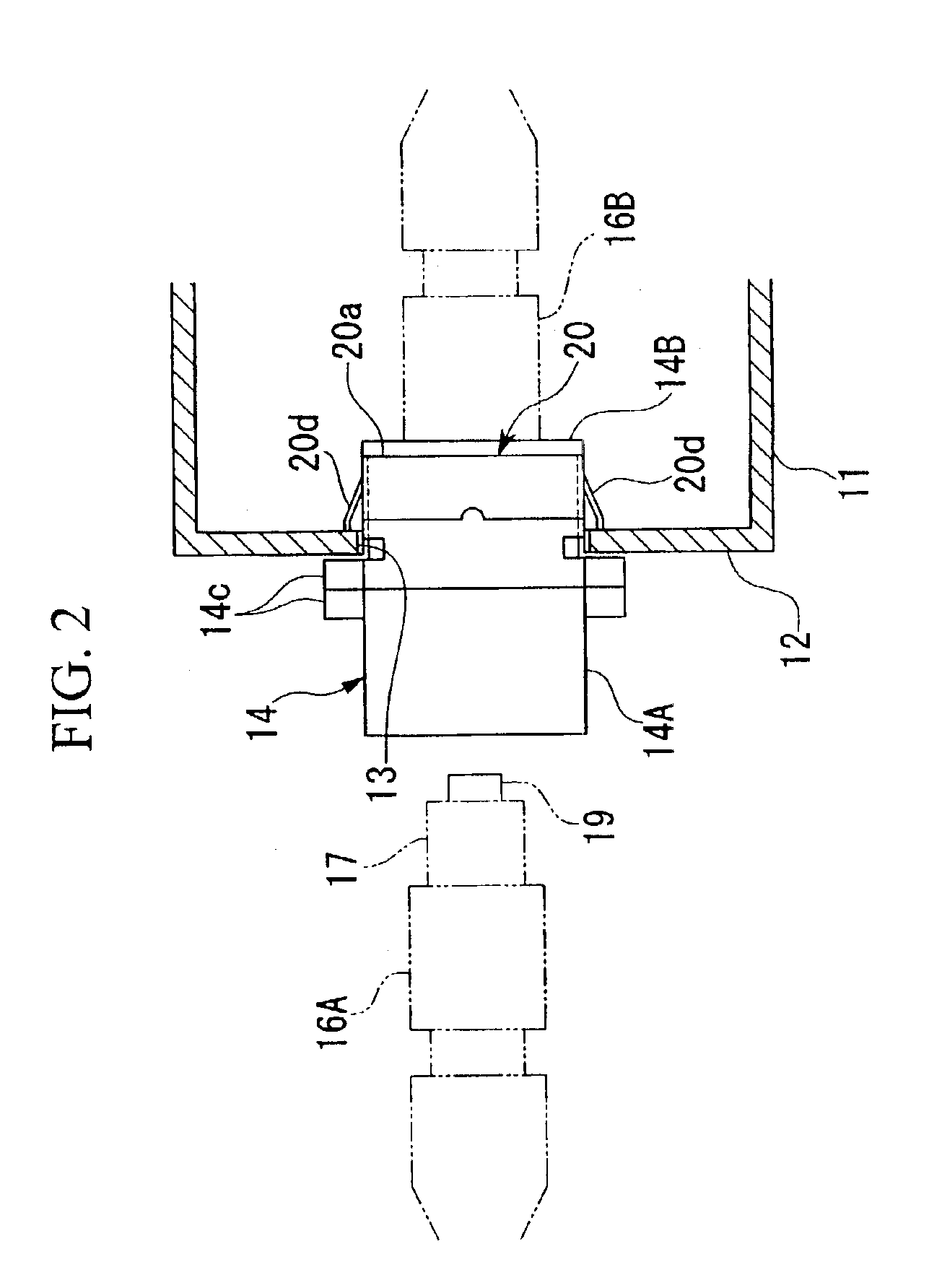

Optical connector with shutter

InactiveUS6866424B2Reduce the amount requiredDeterioration can be suppressedCoupling light guidesEngineeringElectromagnetic shielding

This optical connector with a shutter is for blocking emitted light from the connected optical connector, such as an optical connector adaptor, provided in a connector hole of a connector housing by using a shutter. In this optical connector with a shutter, the shutter unit is assembled in the center part of the connector housing, and the emitted light in the connector hole from the connected optical connector is blocked by shutter pieces of the shutter unit. Furthermore, an electromagnetic shielding capacity can be obtained without enlarging the optical connector by making the shutter unit from electrically conducting members.

Owner:FUJIKURA LTD

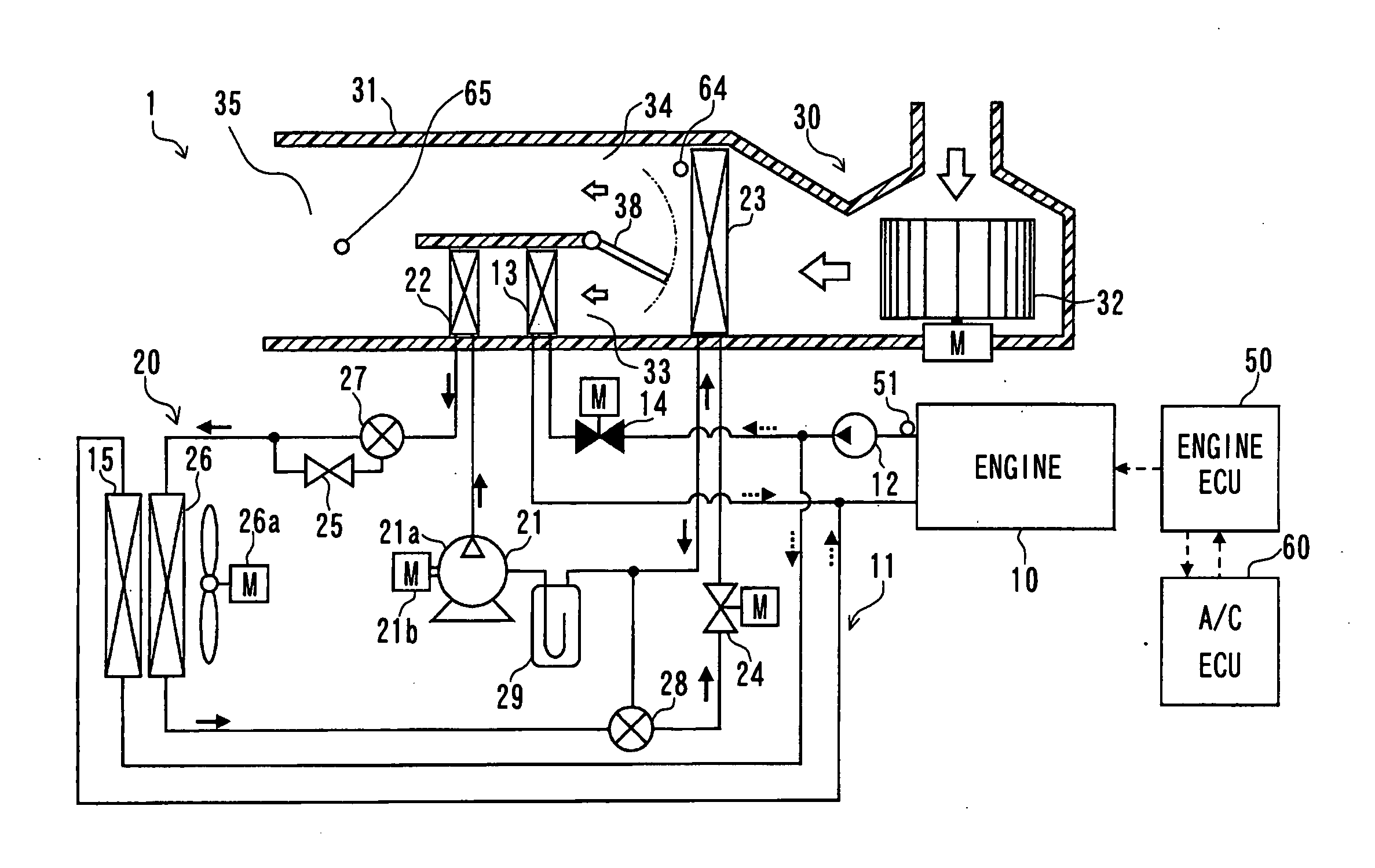

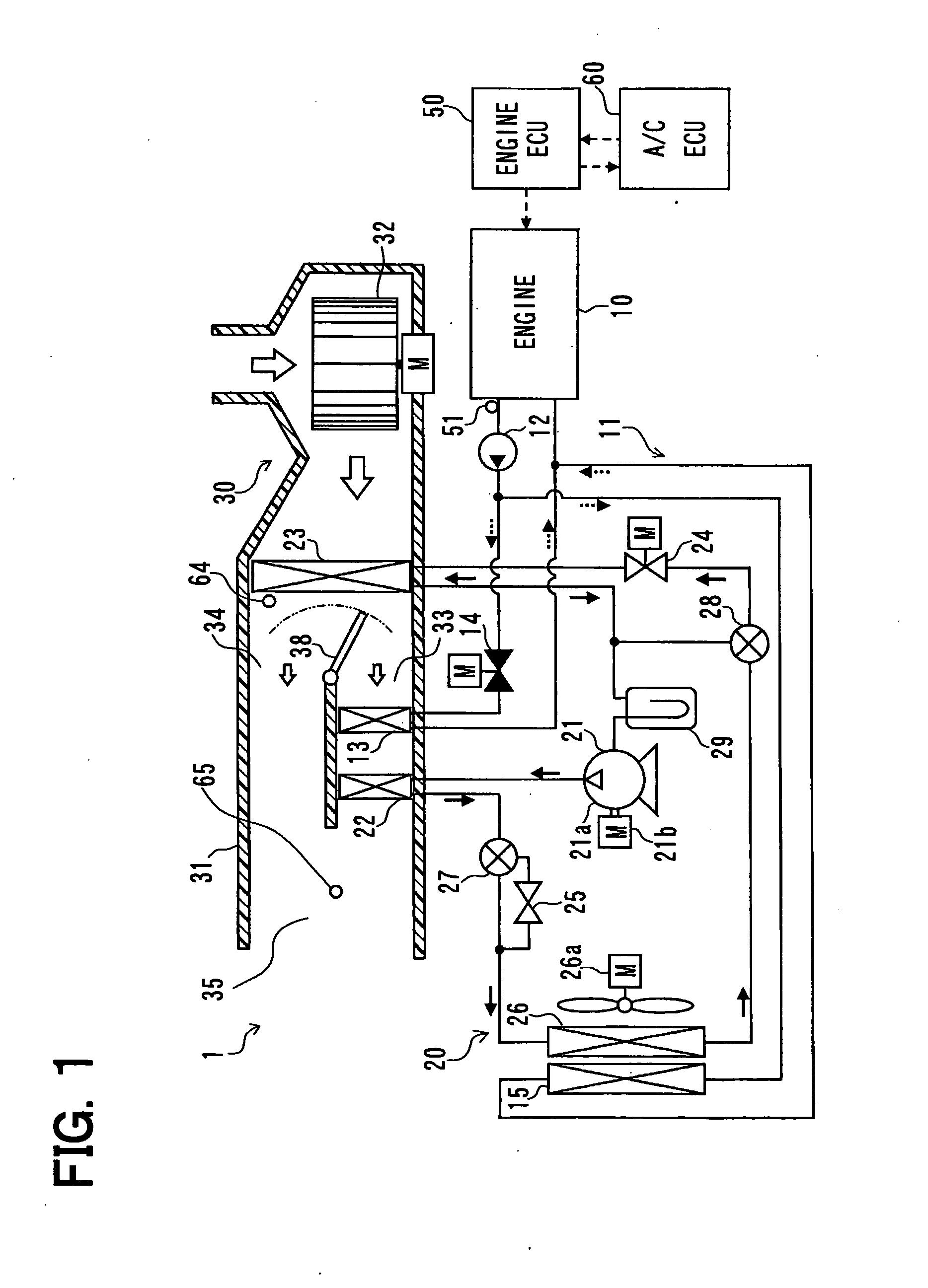

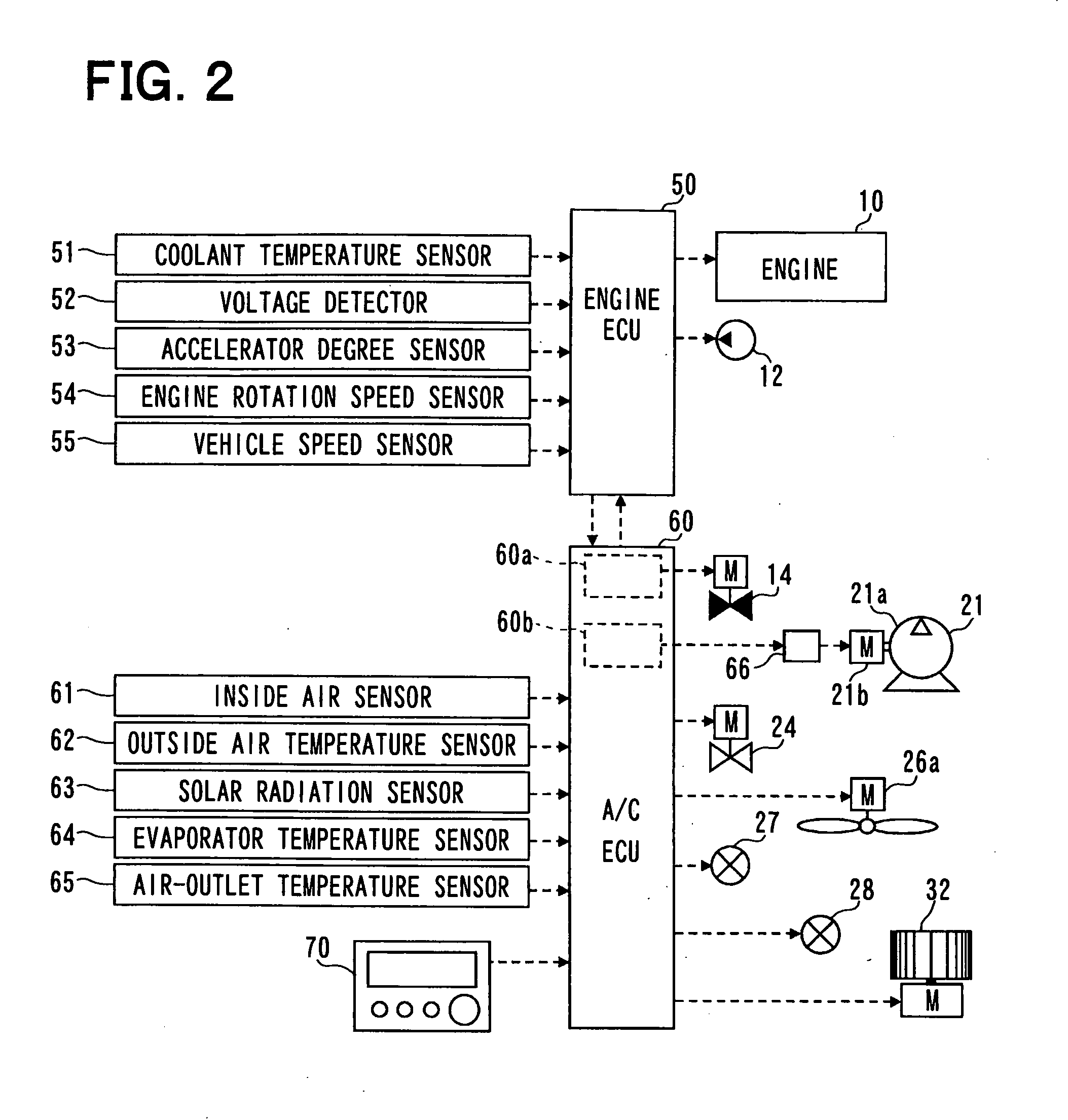

Air conditioner for vehicle

InactiveUS20110048671A1Deterioration can be suppressedIncrease temperatureAir-treating devicesRailway heating/coolingEngineeringThermal fluids

In an air conditioner for a vehicle with an equipment controlled in accordance with a traveling state of the vehicle, a first heater is disposed to heat air to be blown into a vehicle compartment by using a coolant of the equipment as a heat source, and a second heater is adapted as an auxiliary heater to further heat the air heated by the first heater. A heating capacity of the first heater is controlled such that a temperature of the equipment is approached to a predetermined temperature when the thermal fluid after passing through the first heater returns the equipment, and a heating capacity of the second heater is controlled such that a temperature of air to be blown into the vehicle compartment becomes a desired temperature.

Owner:DENSO CORP

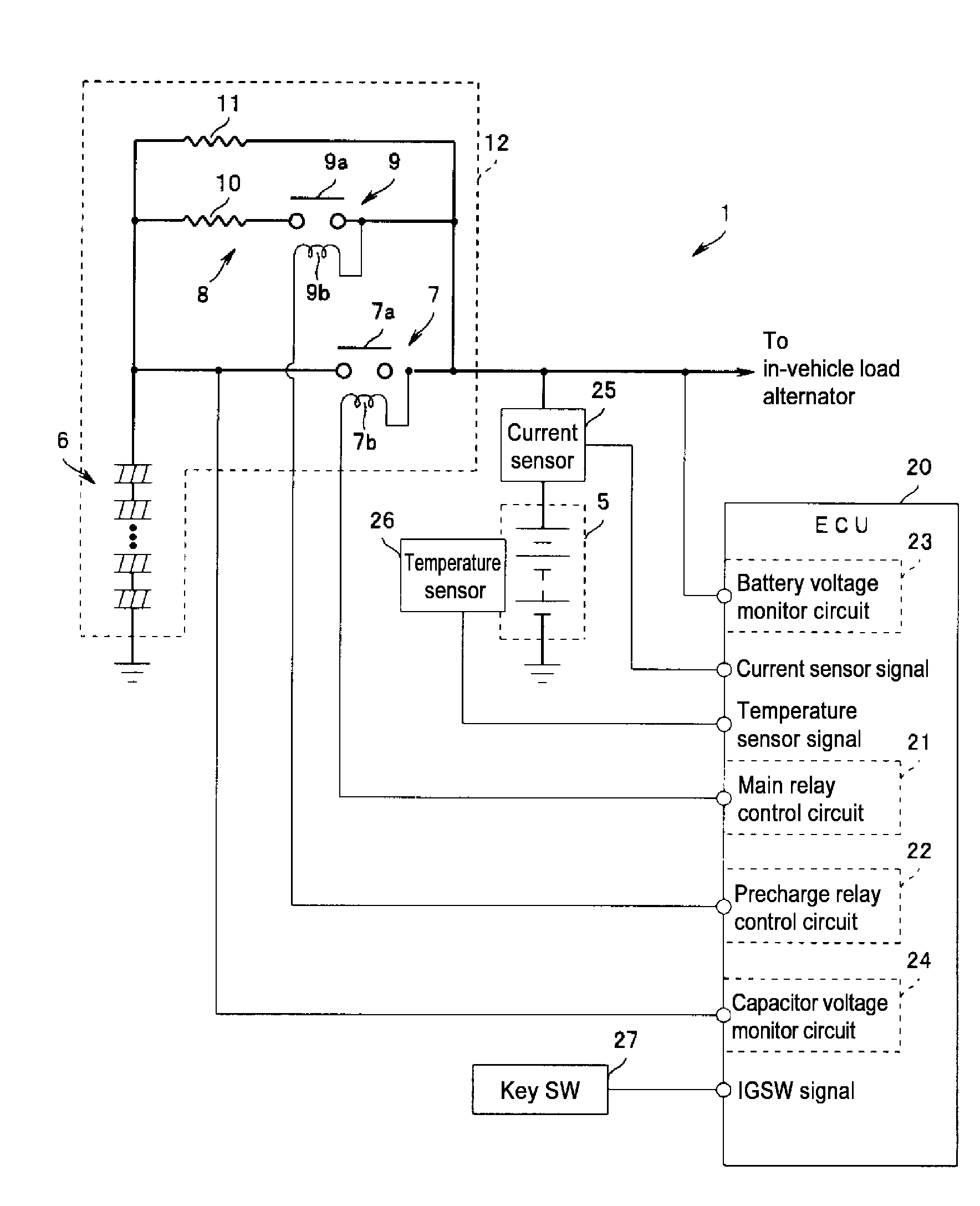

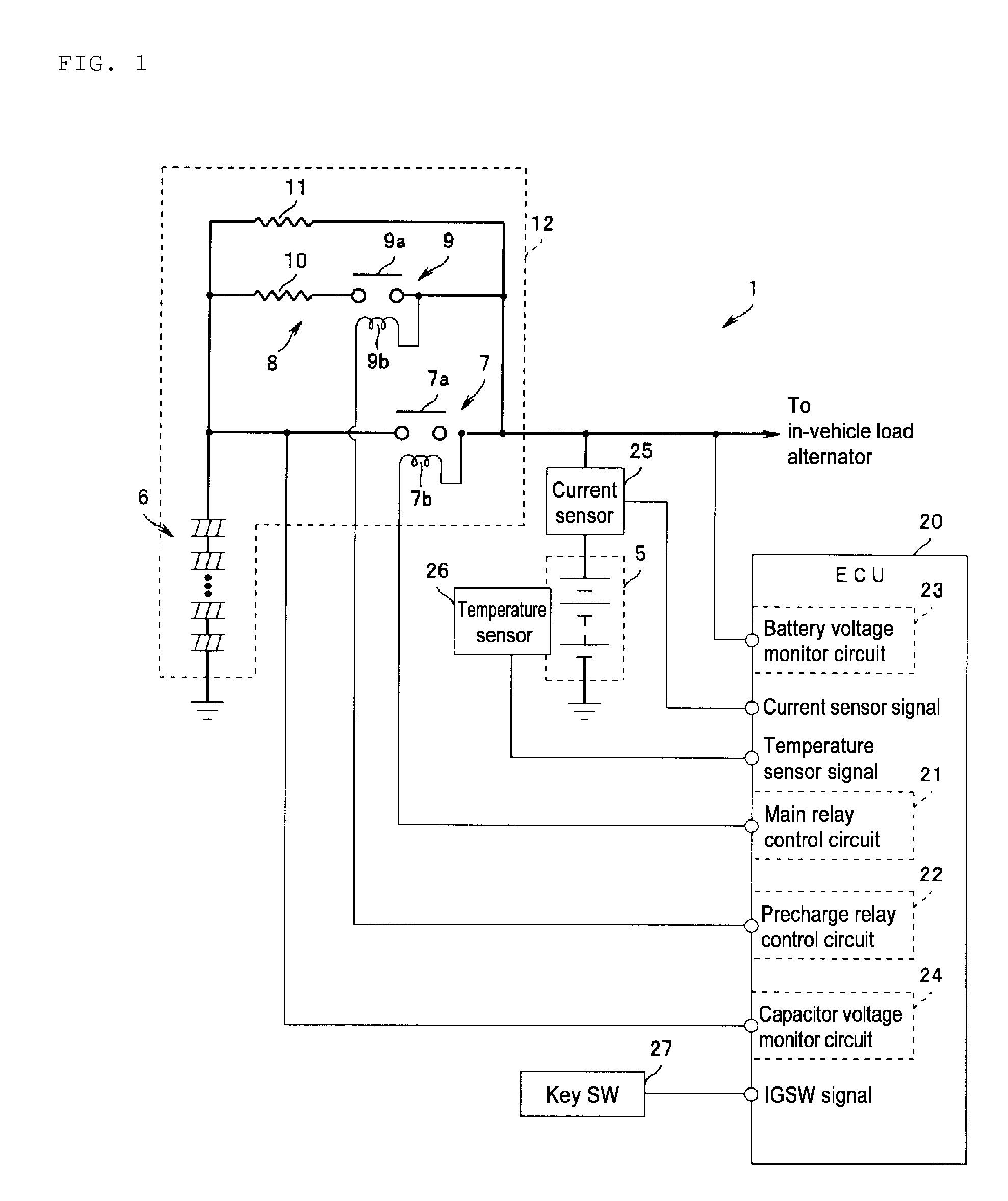

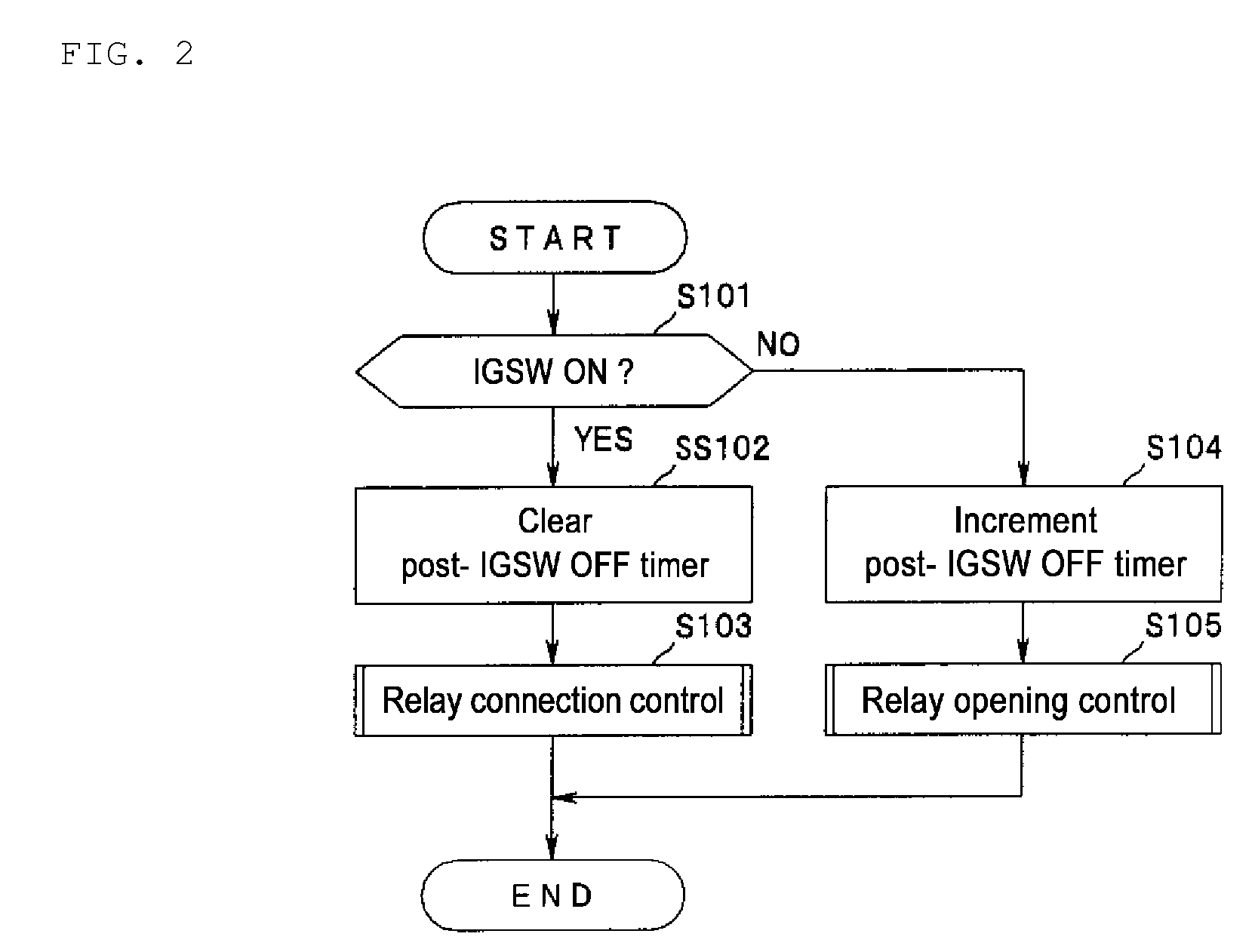

Vehicle power supply device

ActiveUS20090230766A1Deterioration can be suppressedReduce pre-charge timeBatteries circuit arrangementsElectric devicesEngineeringPower loss

Owner:SUBARU CORP

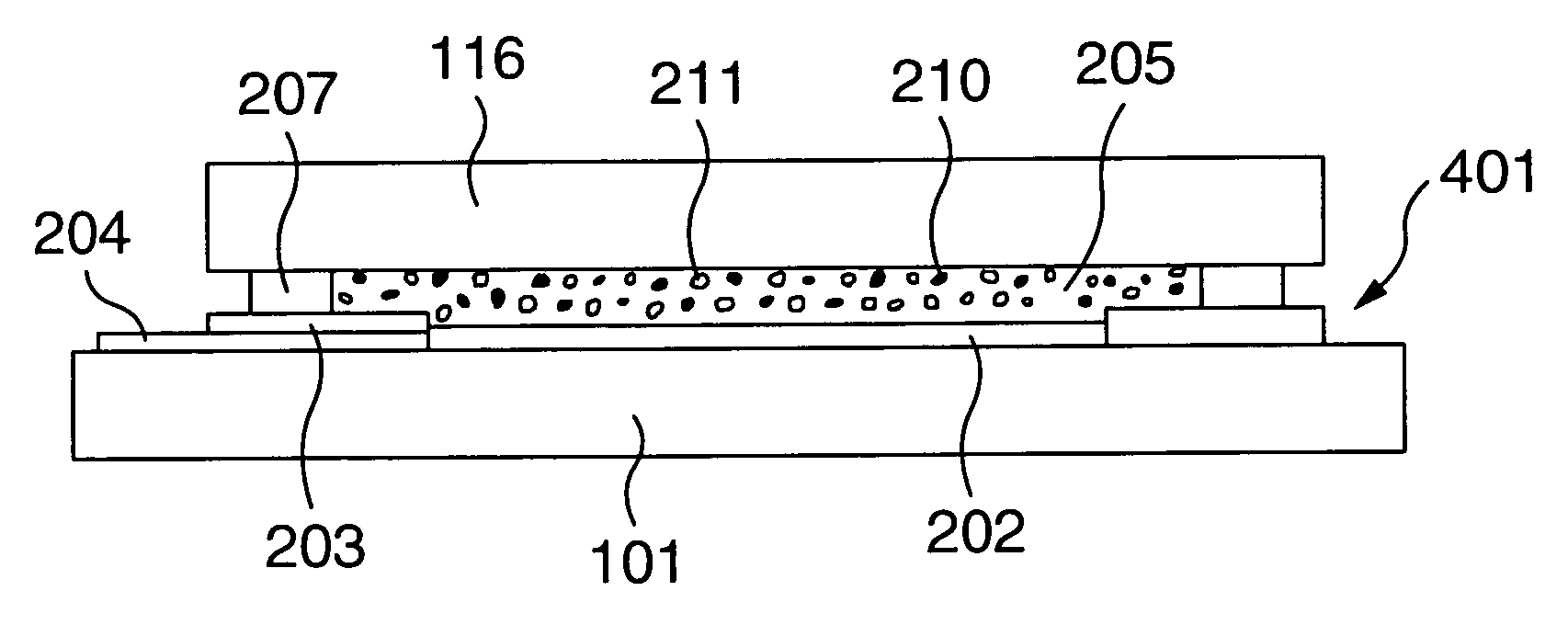

Organic electroluminescence display device

ActiveUS7063902B2Increase thermoconductivity and electroconductivityMechanical strength be secureDischarge tube luminescnet screensElectroluminescent light sourcesOrganic electroluminescenceFlat panel display

An OLED display device having a laminate encapsulating structure containing: an OLED substrate having a leading wire and a pixel area which carries a number of OLEDs on a glass substrate; and an encapsulating plate; and a filler filling a space between the OLED substrate and the encapsulating plate, wherein the filler is dispersed with a desiccant and fine metallic partides for improving electroconductivity and thermoconductivity. This structure not only can prevent an inflow of moisture into the OLEDs and secure a mechanical strength of the OLED display device as a flat panel display device, but also accelerate a heat radiation and improves electroconductivity of a conductive layer.

Owner:SAMSUNG DISPLAY CO LTD +1

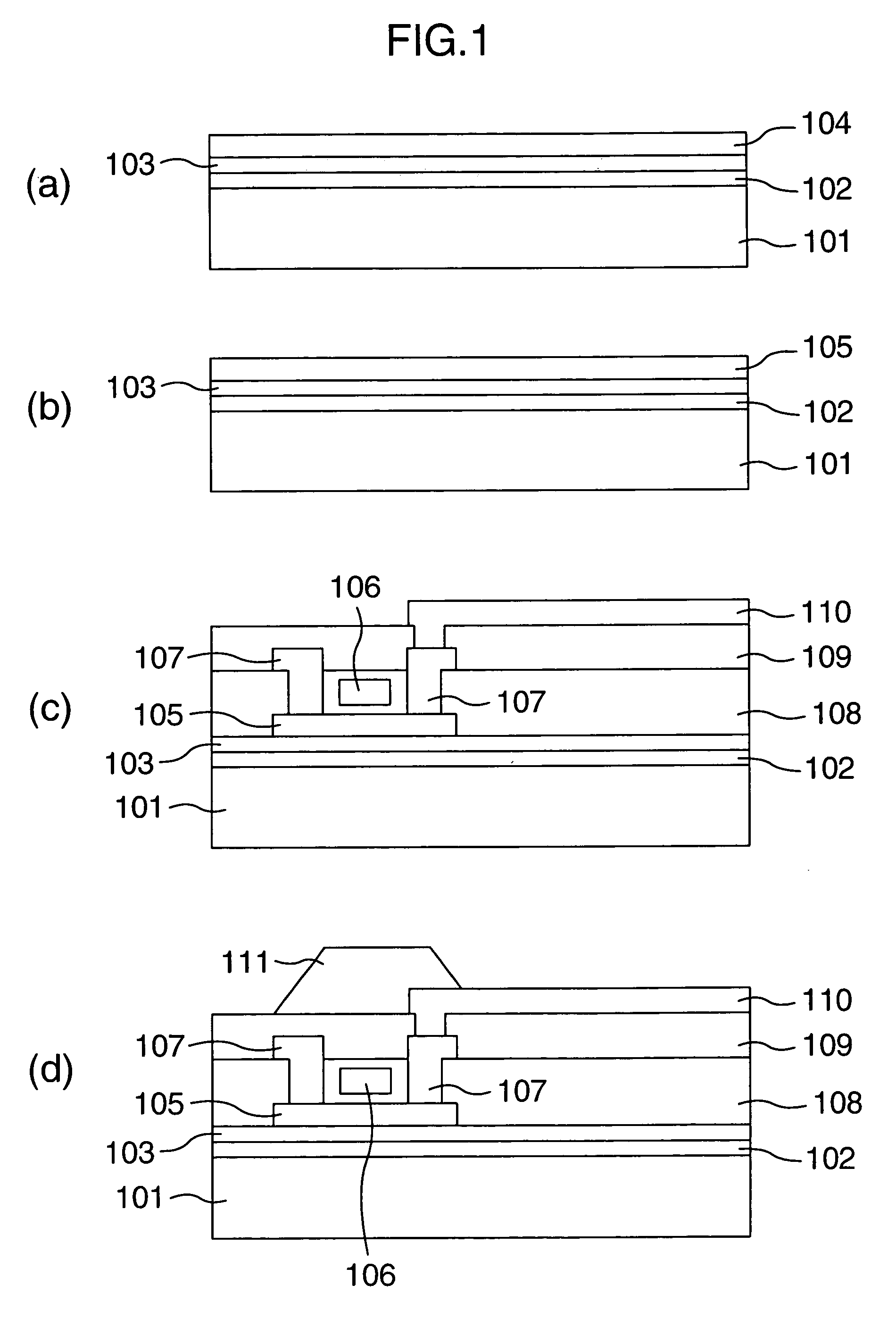

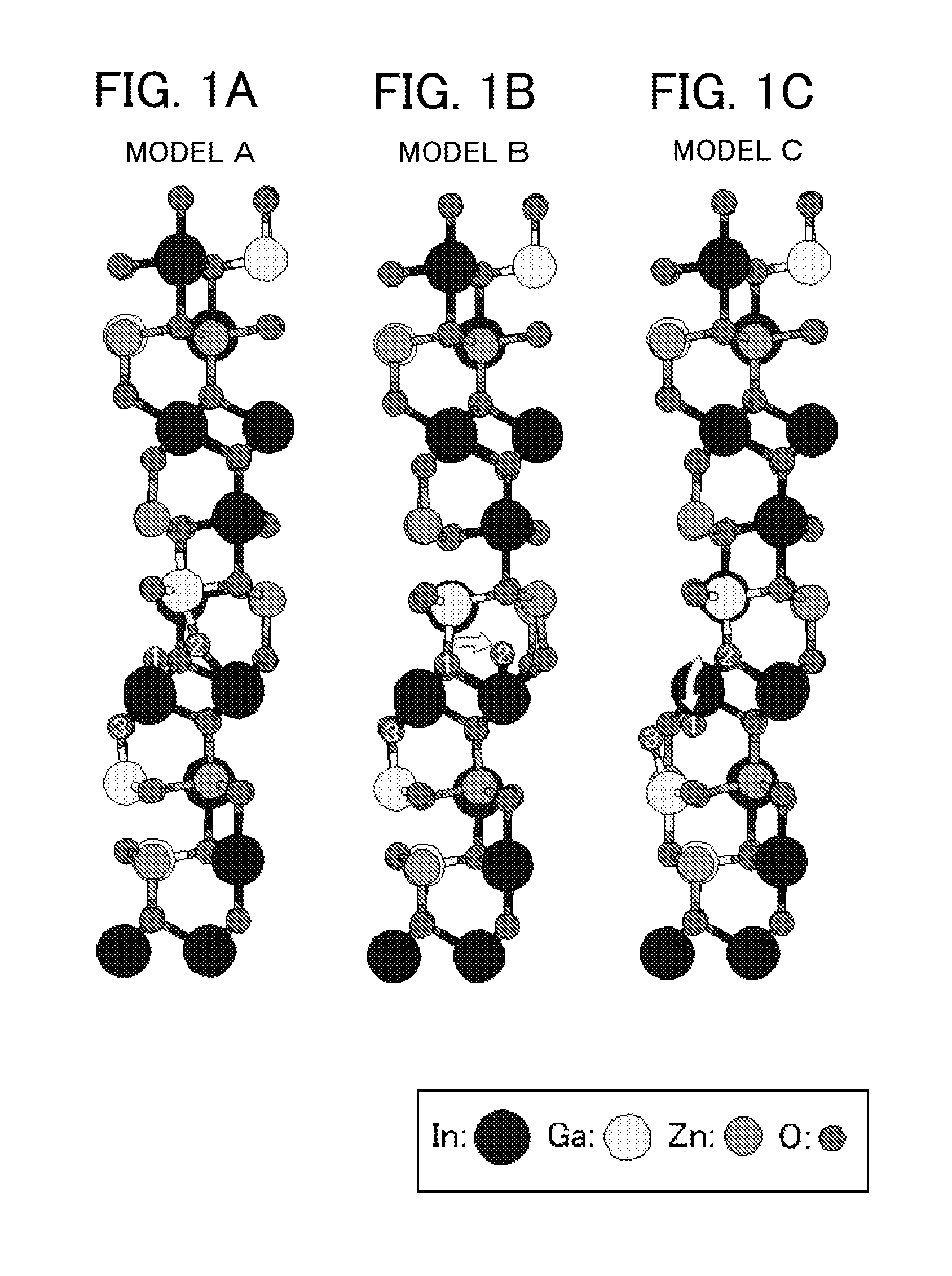

Semiconductor device and method for manufacturing the same

InactiveUS20130161611A1Improve reliabilityChange in electric characteristics of the transistorTransistorSemiconductor/solid-state device manufacturingDevice materialEngineering

Release of oxygen at a side surface of an island-shaped oxide semiconductor film is controlled and decrease in resistance is prevented. A semiconductor device includes an island-shaped oxide semiconductor film at least partly including a crystal, a first gate insulating film provided to cover at least a side surface of the island-shaped oxide semiconductor film, and a second gate insulating film provided to cover at least the island-shaped oxide semiconductor film and the first gate insulating film. The first gate insulating film is an insulating film that supplies oxygen to the island-shaped oxide semiconductor film, and the second gate insulating film is an insulating film which has a low oxygen-transmitting property

Owner:SEMICON ENERGY LAB CO LTD

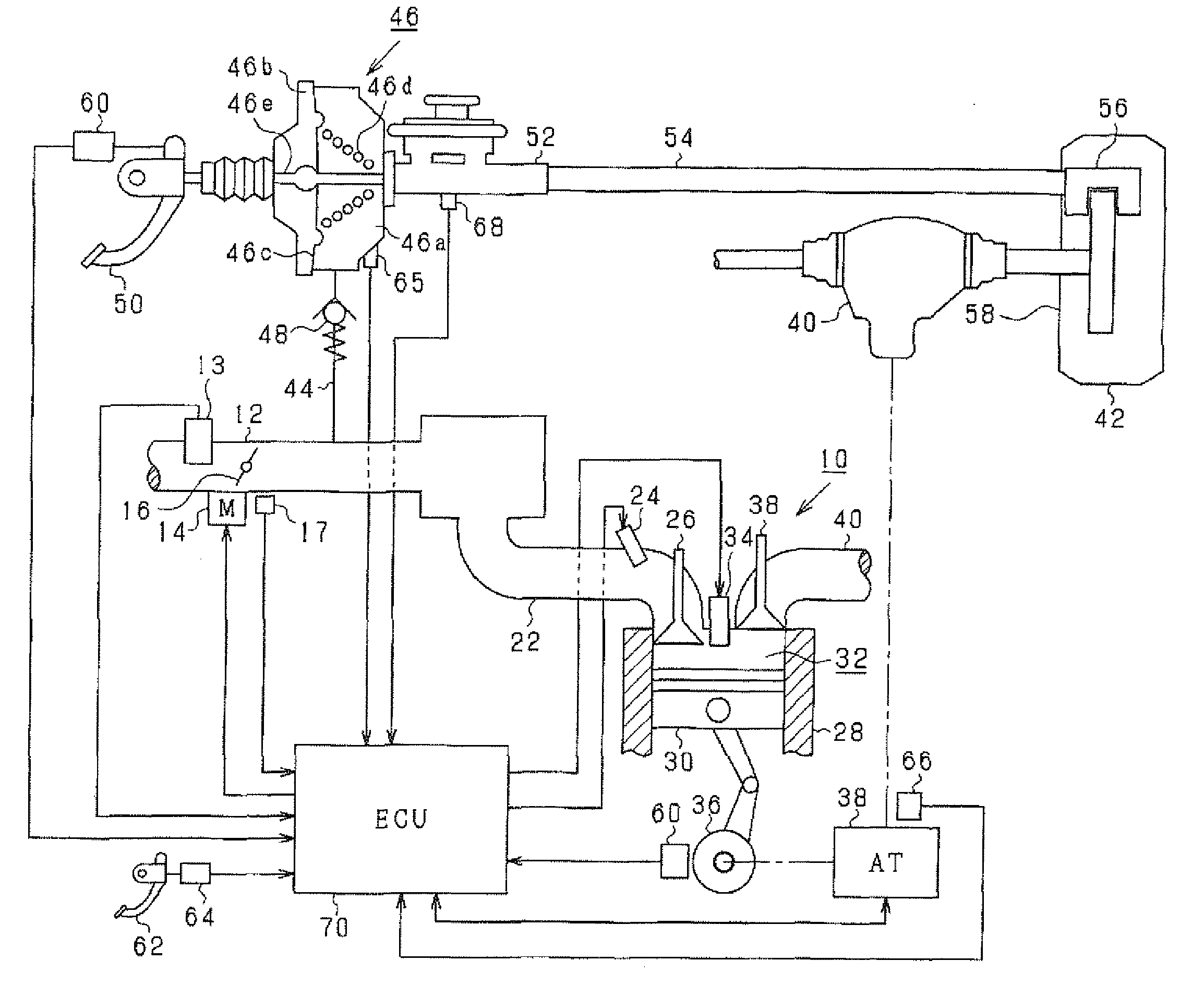

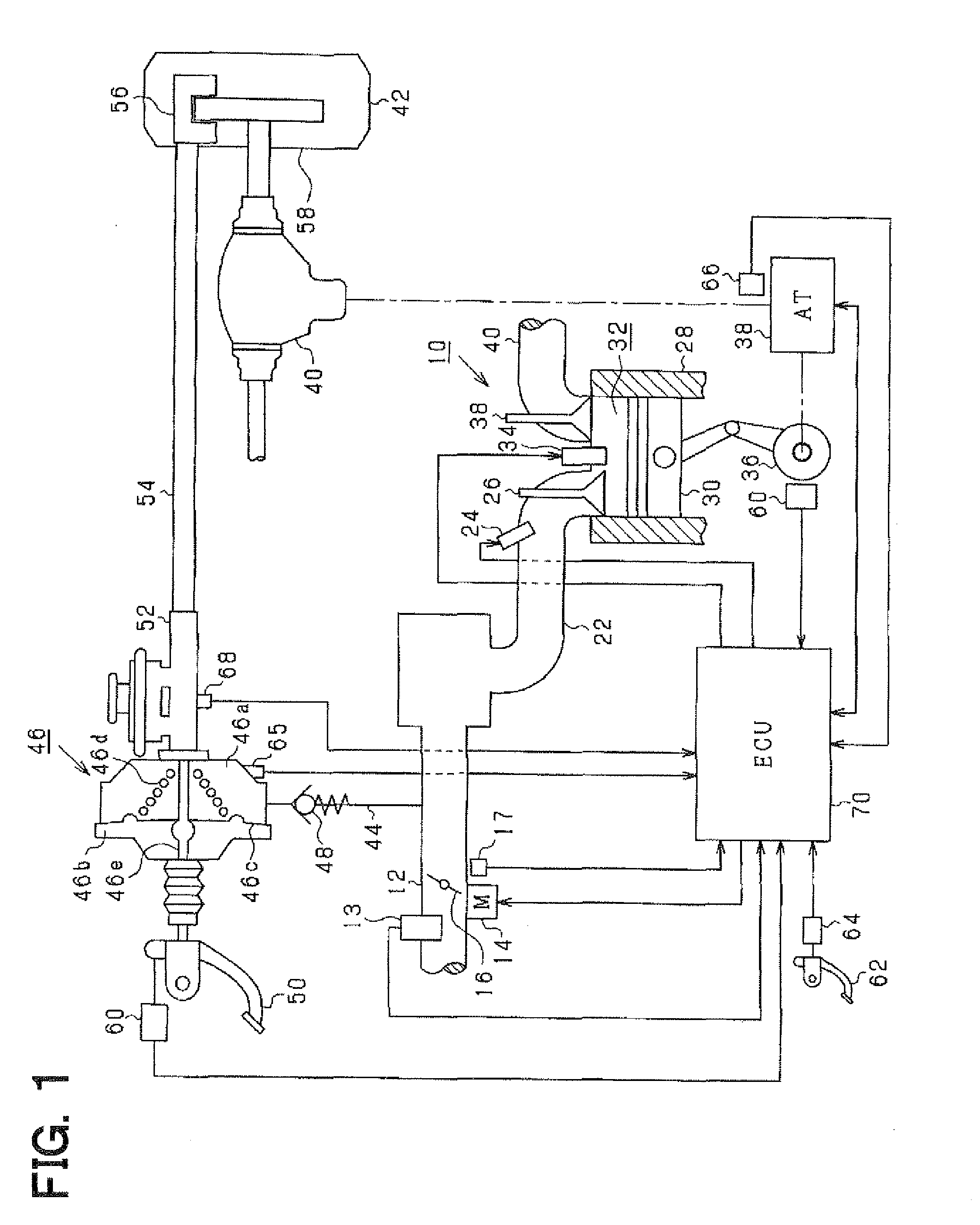

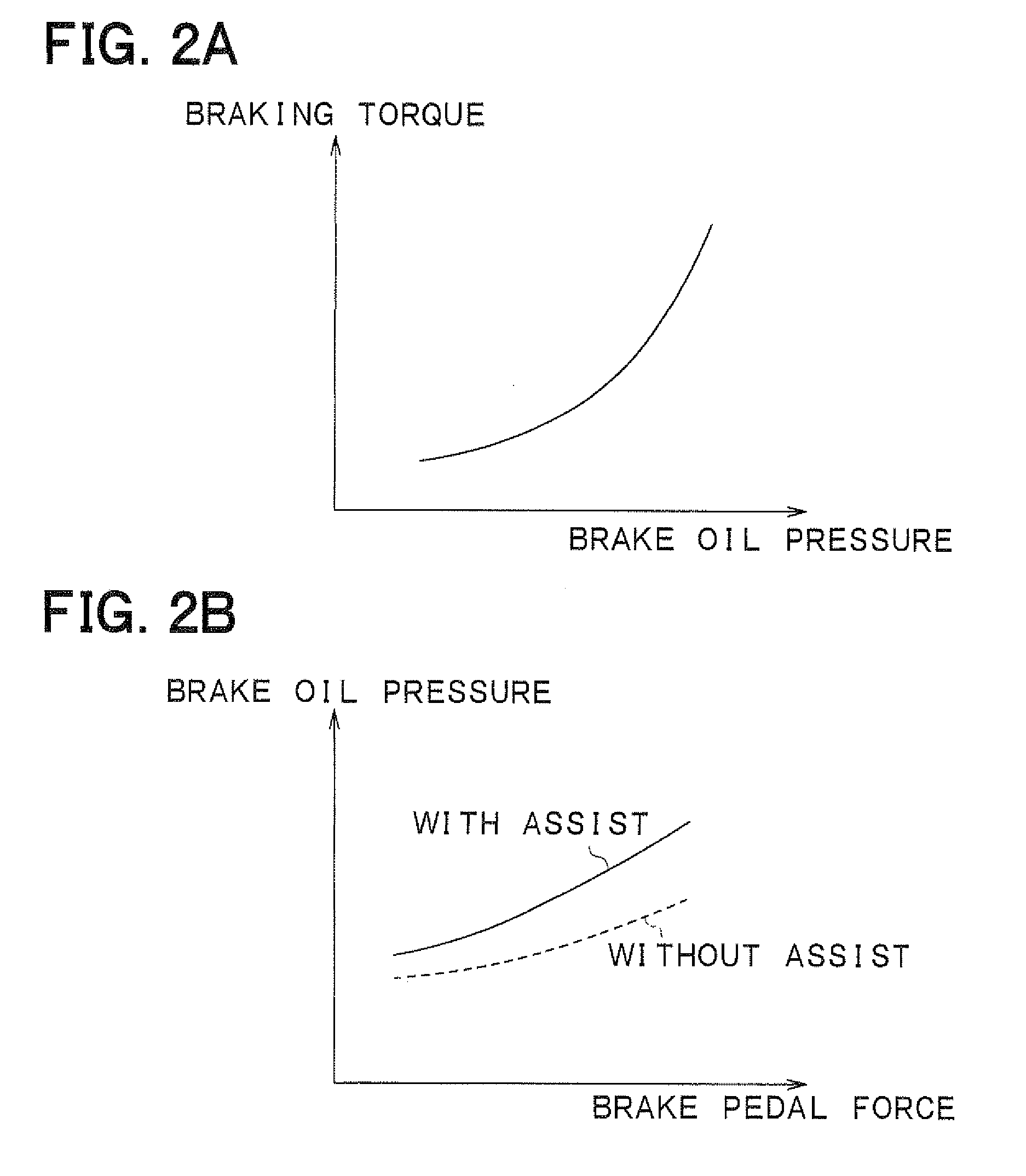

Torque controller for on-vehicle power generator

InactiveUS20100036566A1Reduce torqueReduce the required powerElectrical controlDigital data processing detailsOil pressureElectric generator

When it is determined that accelerator operation and brake operation are performed at the same time based on the output values of an accelerator sensor and a stop lamp switch, a torque of an engine is reduced based on a brake pedal force which is computed based on a pressure in a negative pressure chamber of a master bag and a brake oil pressure.

Owner:DENSO CORP

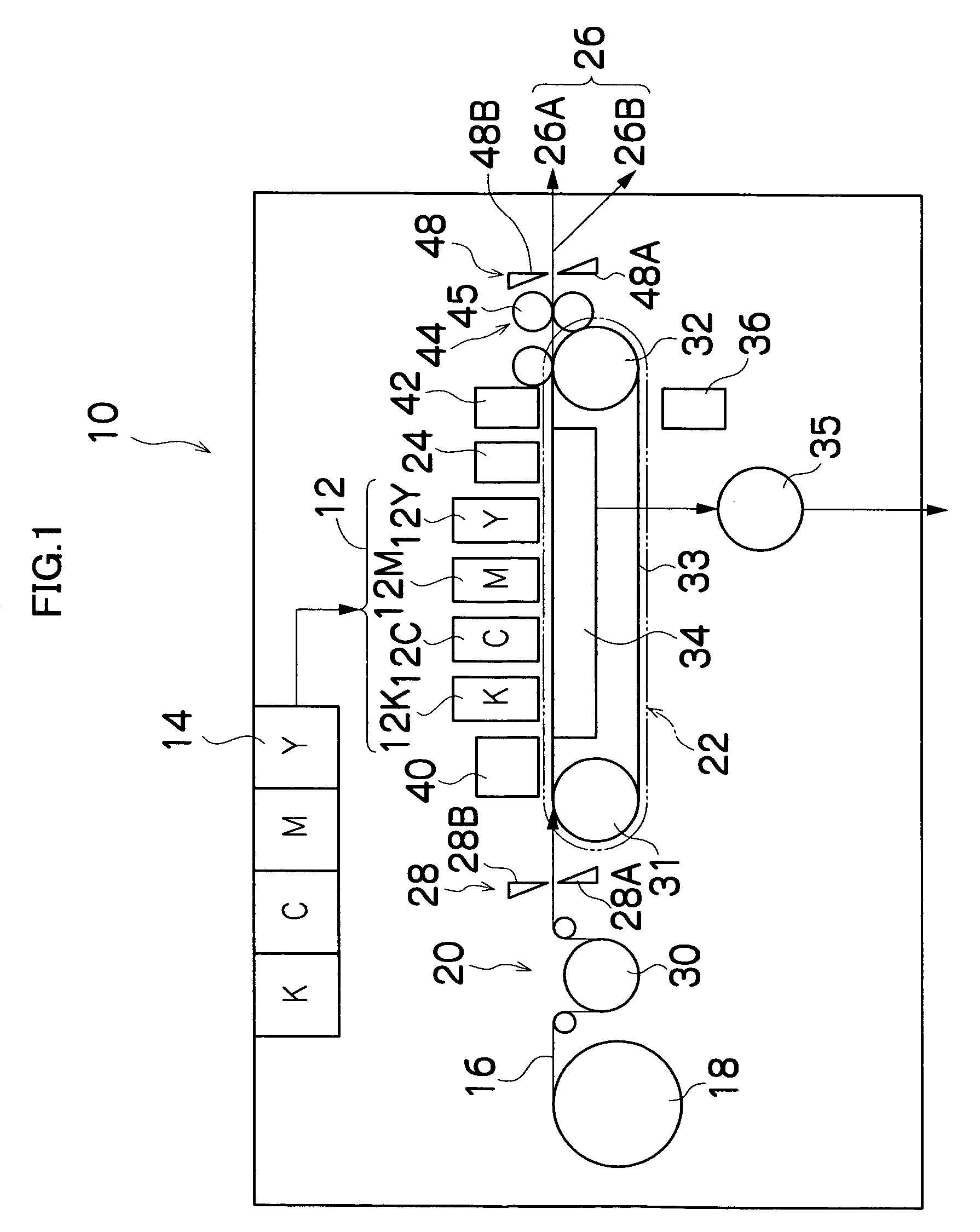

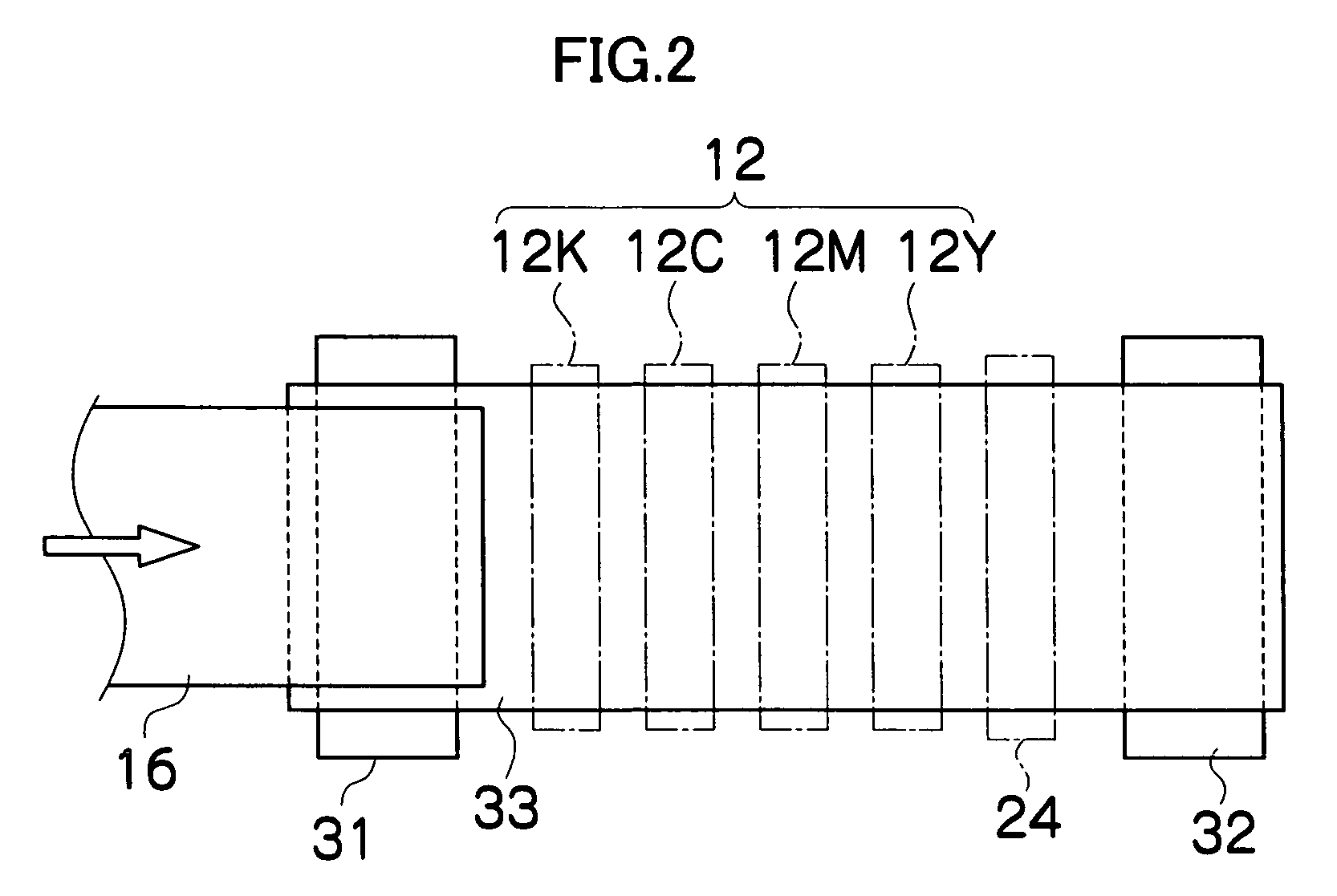

Image forming apparatus and method

InactiveUS7448706B2Deterioration can be suppressedOther printing apparatusImage formationRelative motion

The image forming apparatus comprises: a recording head which includes a plurality of nozzles through which droplets of liquid are ejected to and deposited on a recording medium to form dots on the recording medium, the nozzles being arranged in a nozzle row; a conveyance device which causes the recording head and the recording medium to move relatively to each other by conveying at least one of the recording head and the recording medium in a relative movement direction; a storage device which, of information indicating an amount of deposition position displacement from an ideal deposition position of the dots formed by the droplets ejected from the nozzles, stores information about the amount of deposition position displacement in at least a direction perpendicular to the relative movement direction of the conveyance device; a line figure recognition processing device which carries out processing for recognizing line figures from image data for printing; an ideal line identification device which determines an ideal line obtained by linking centers of the respective dots formed when printing a line figure, assuming that there is absolutely no deposition position displacement produced by any of the nozzles, in respect of the line figure recognized by the line figure recognition processing device; and an ejection timing control device which, when printing a line figure, controls ejection timing of a defective nozzle which produces deposition position displacement in a direction perpendicular to the relative movement direction, according to the information about the amount of deposition position displacement stored in the storage device and the ideal line determined by the ideal line identification device, in such a manner that a deposition center position of a dot formed by a droplet ejected from the defective nozzle moves closer to the ideal line, along the relative movement direction.

Owner:FUJIFILM CORP

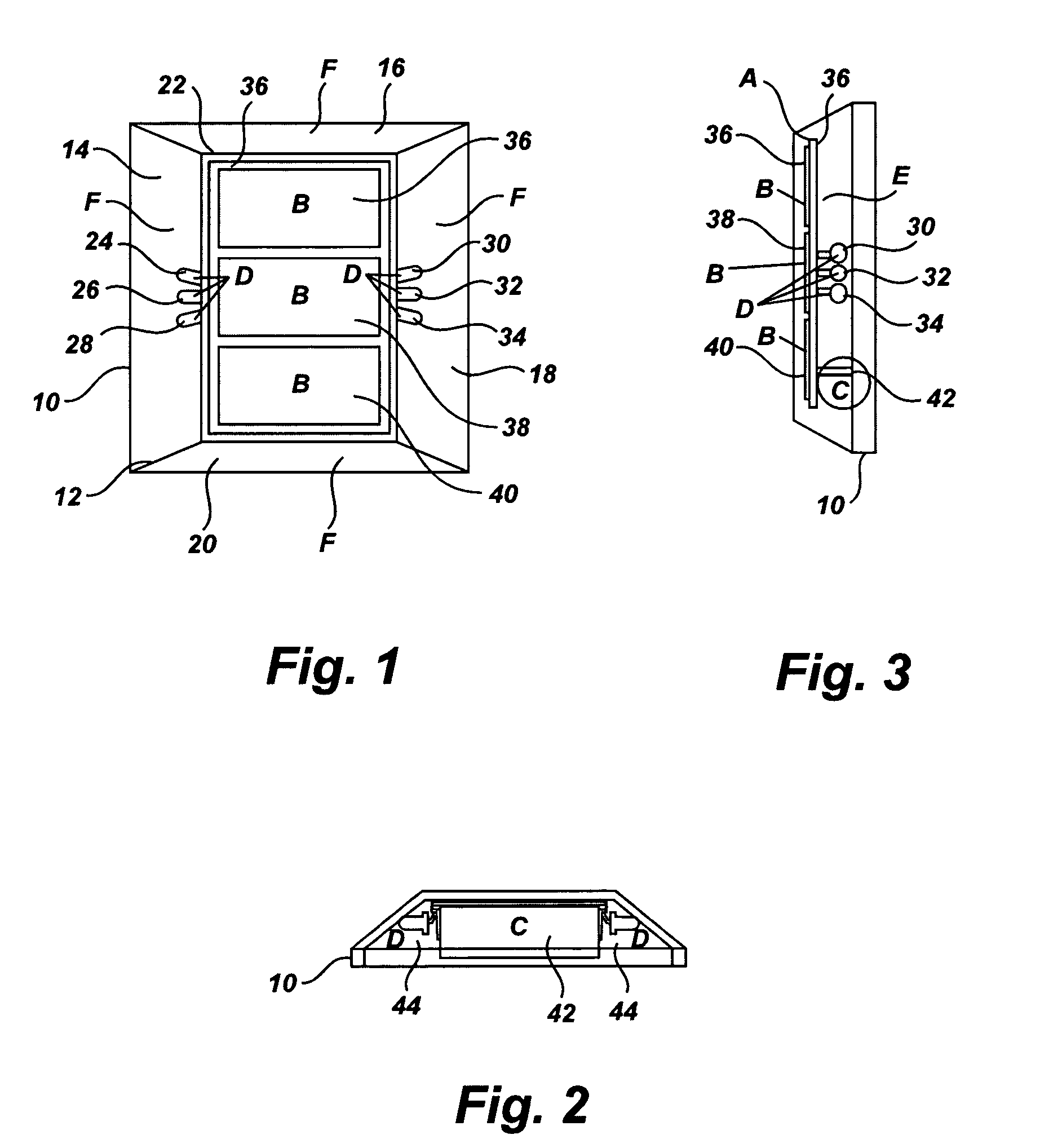

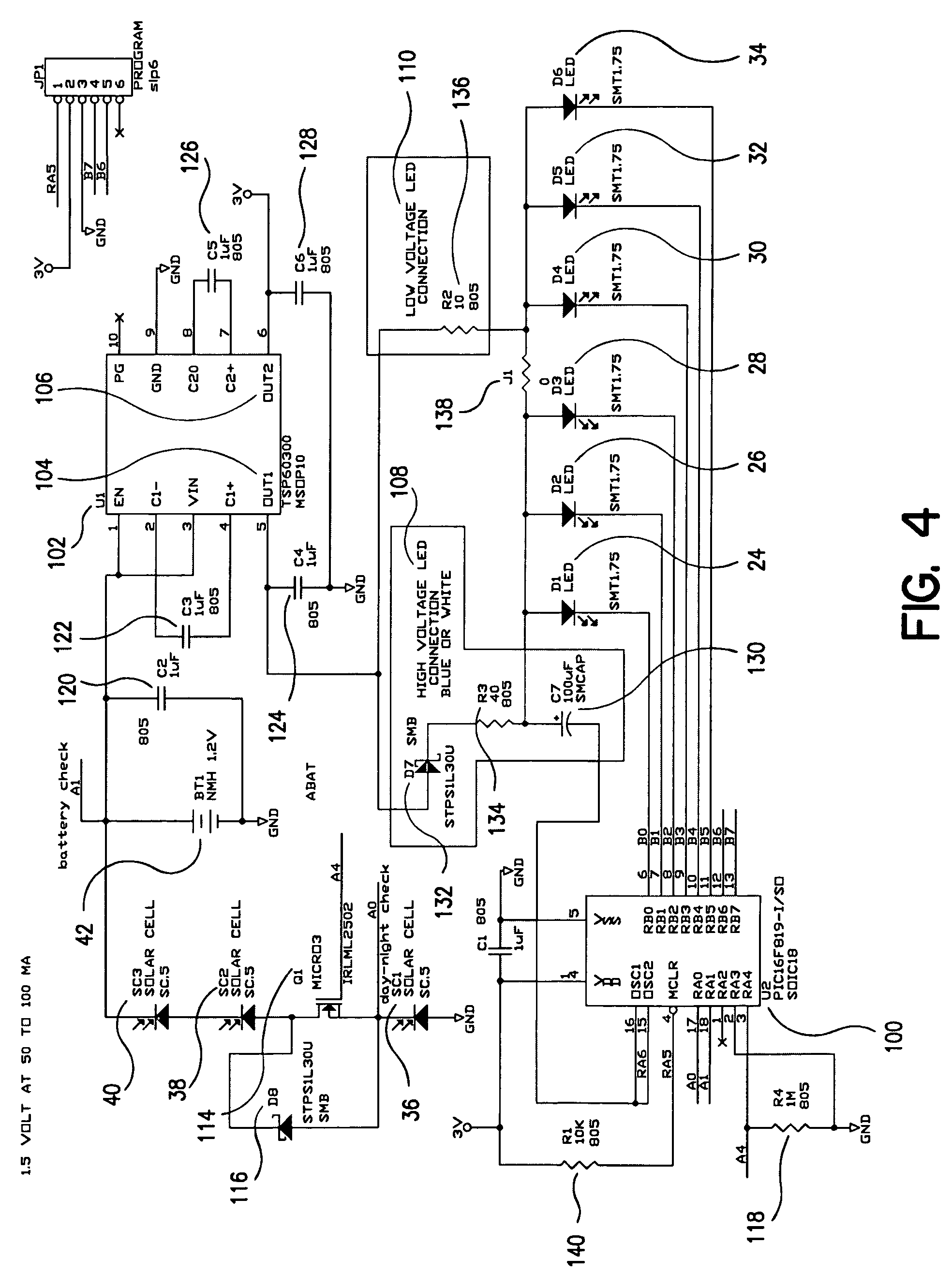

Long life intelligent illuminated road marker

InactiveUS7018131B2Solution to short lifeDeterioration can be suppressedTraffic signalsEmbedding padsElectrical batteryEngineering

Self-contained solar-powered long-life intelligent illuminated road markers are provided comprising a one-piece housing formed of optionally colored plastic capable of transmitting light. Light is reflected by reflective coating or generated internally by LED which is powered by a long life battery, the charging of which is controlled by electrical circuitry which comprises a peripheral interface controller. The electrical circuitry provides intelligent control for a variety of modes corresponding to diverse driving conditions, and can enter a low-power sleep mode to conserve battery life.

Owner:JORDAN WESLEY B

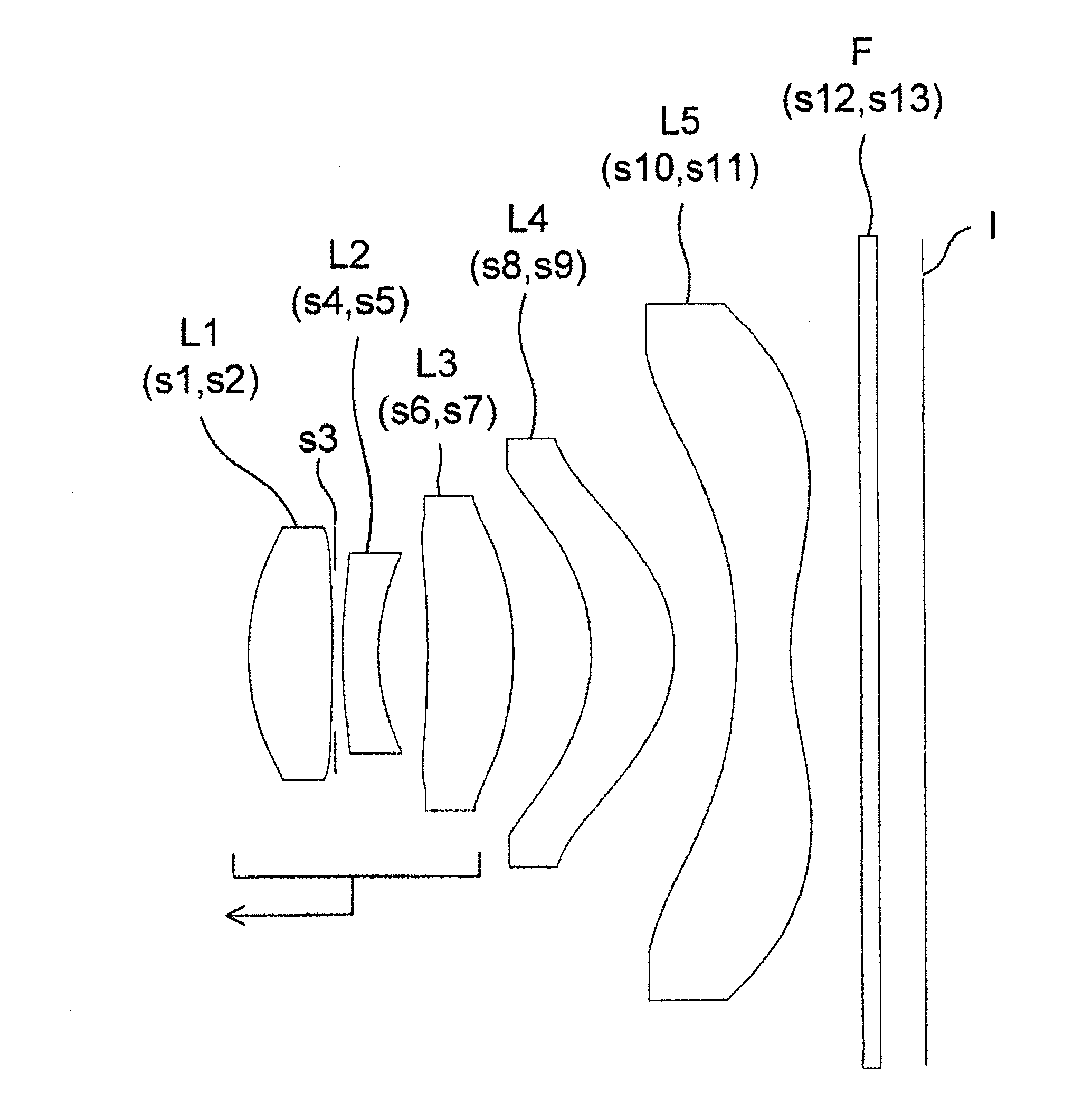

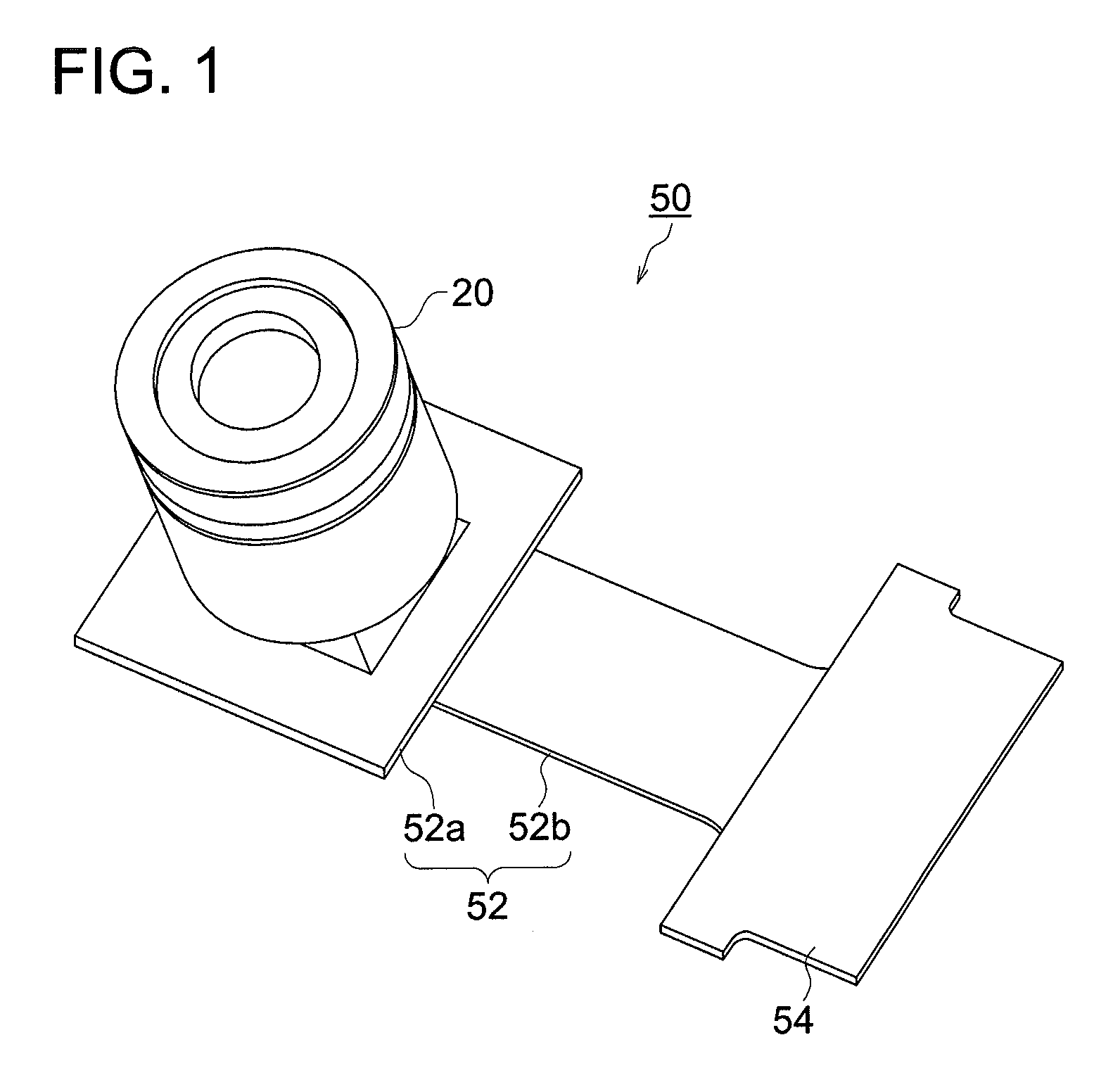

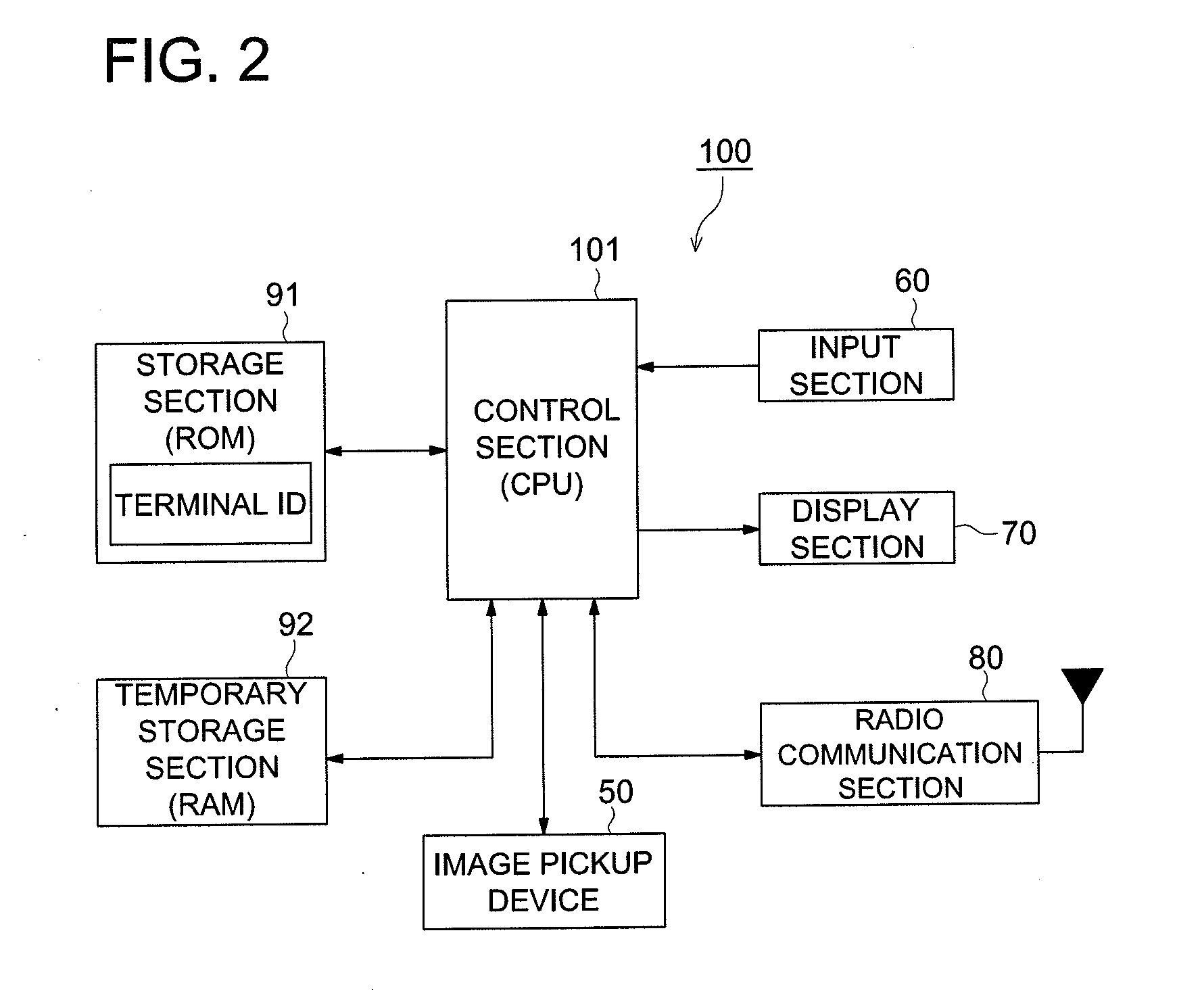

Image Pickup Lens, Image Pickup Device Provided with Image Pickup Lens, and Mobile Terminal Provided with Image Pickup Device

Provided is an image pickup lens that forms an image on an image pickup element with light from a subject. In the image pickup lens, a lens that is disposed on an image pickup element side is fixed in position, and a focusing lens group having a plurality of lenses including a lens closest to the subject is moved in an optical axis direction, thereby performing focusing.

Owner:KONICA MINOLTA OPTO

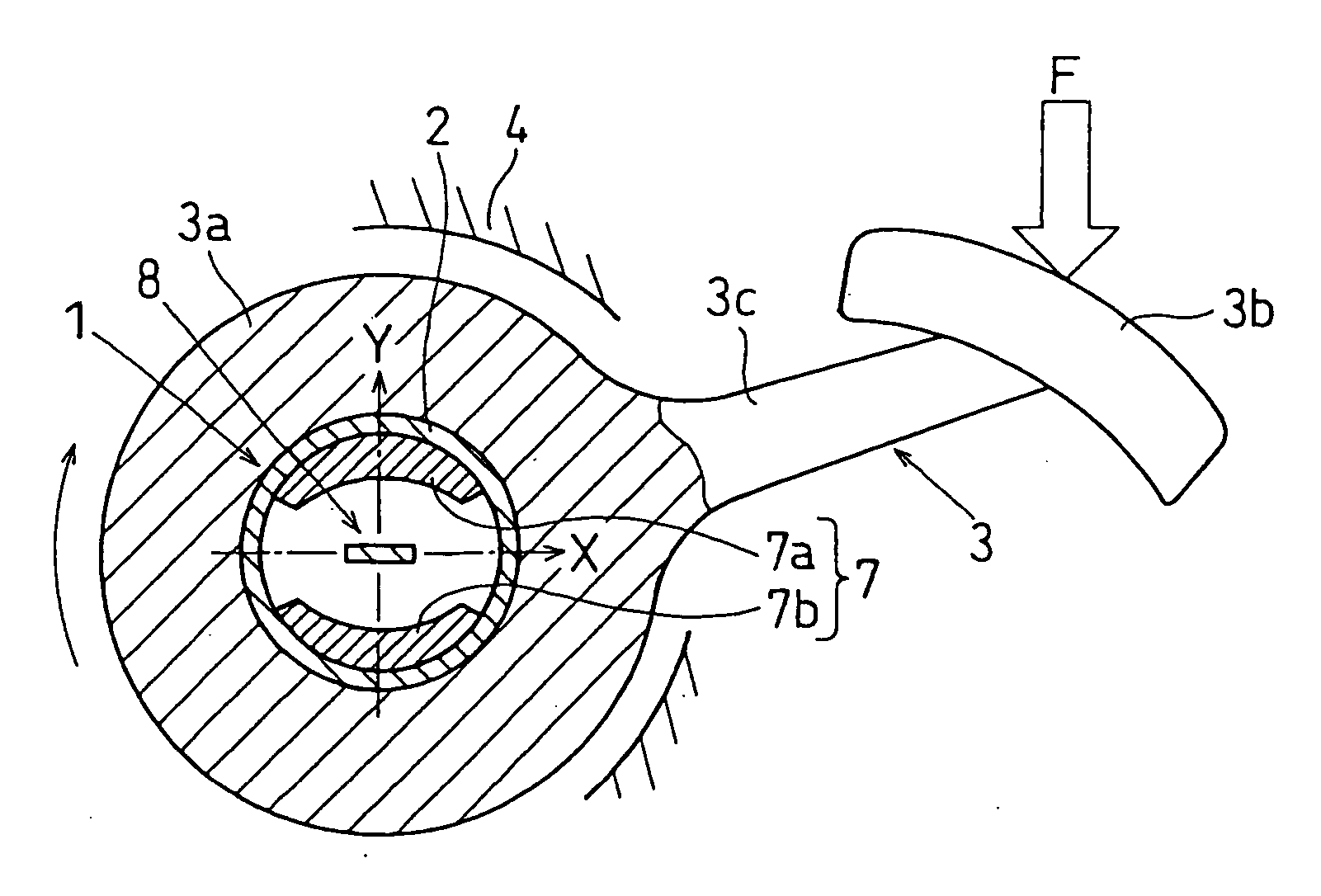

Golf clubhead

InactiveUS20040127300A1Increasing backspin effectEasy to controlGolf clubsGolfing accessoriesSurface roughnessEngineering

Golf clubhead (1) made from metal, having a strike face (2) which has a loft angle alpha of greater than 45°°, said strike (2) face having has a plurality of parallel grooves (10), characterized in that the strike face (2) has a surface roughness Ra of less than 0.25 micrometre, and in that the Vickers hardness of the strike face (2) is greater than 5 GigaPascal.

Owner:ROGER CLEVELAND GOLF

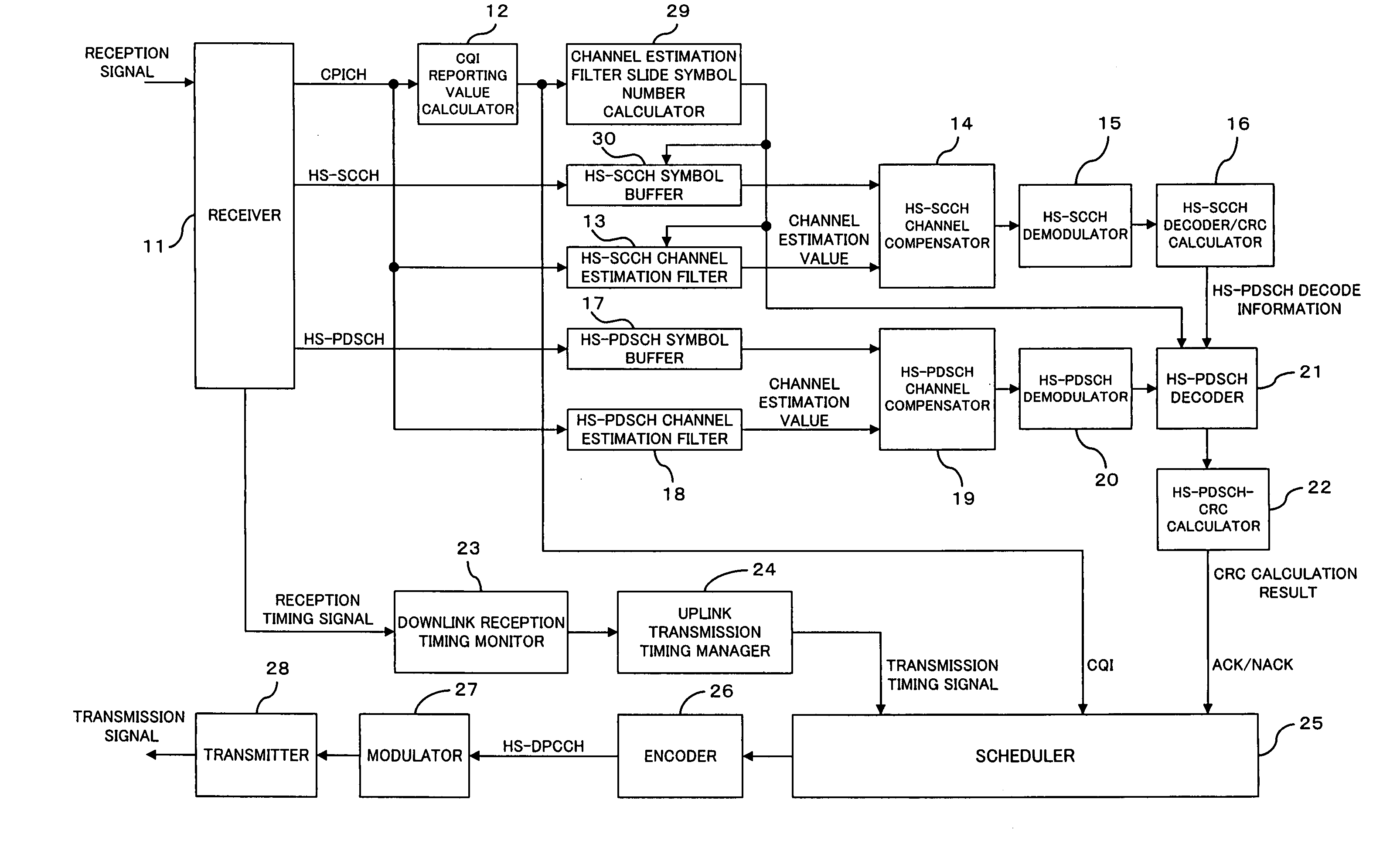

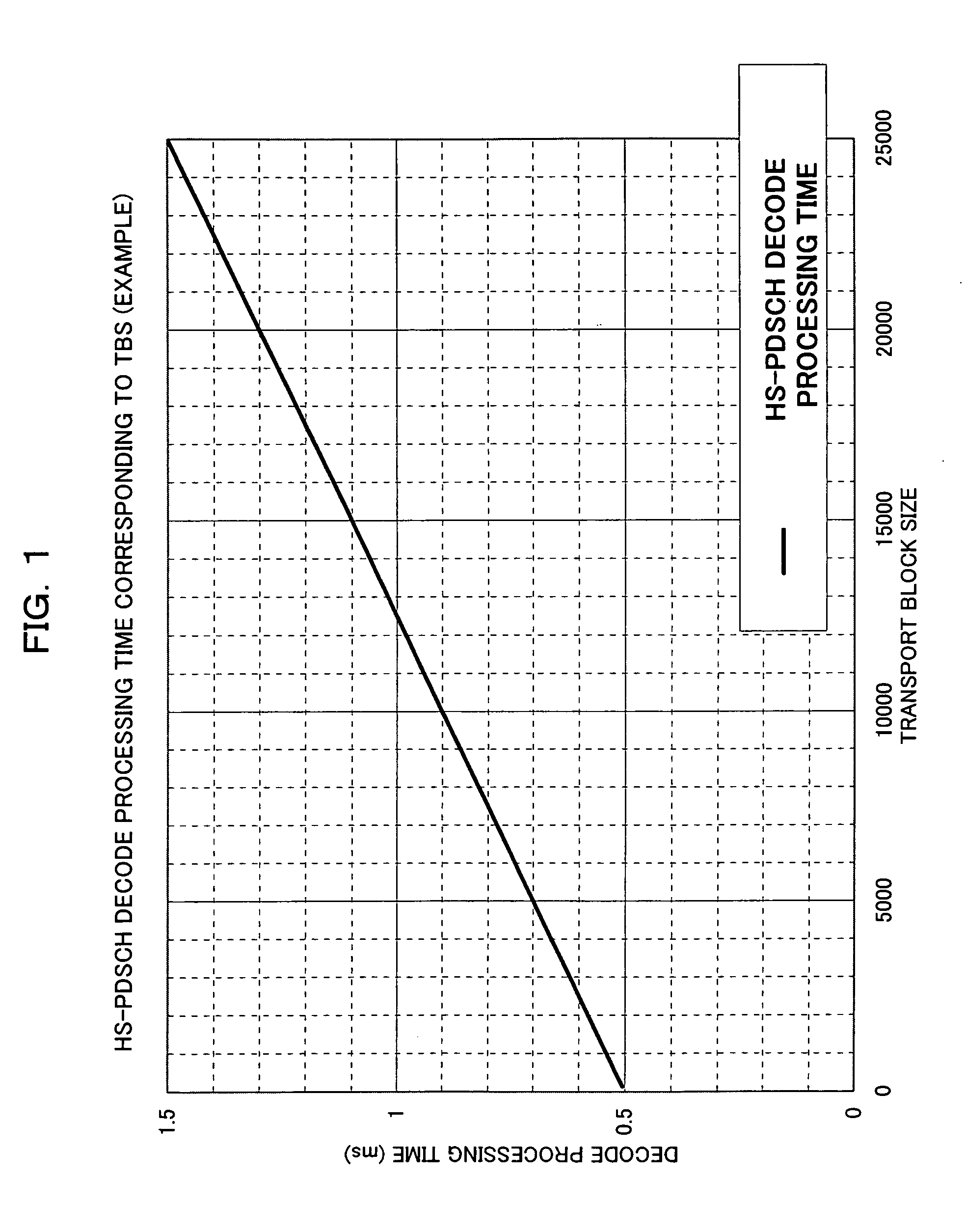

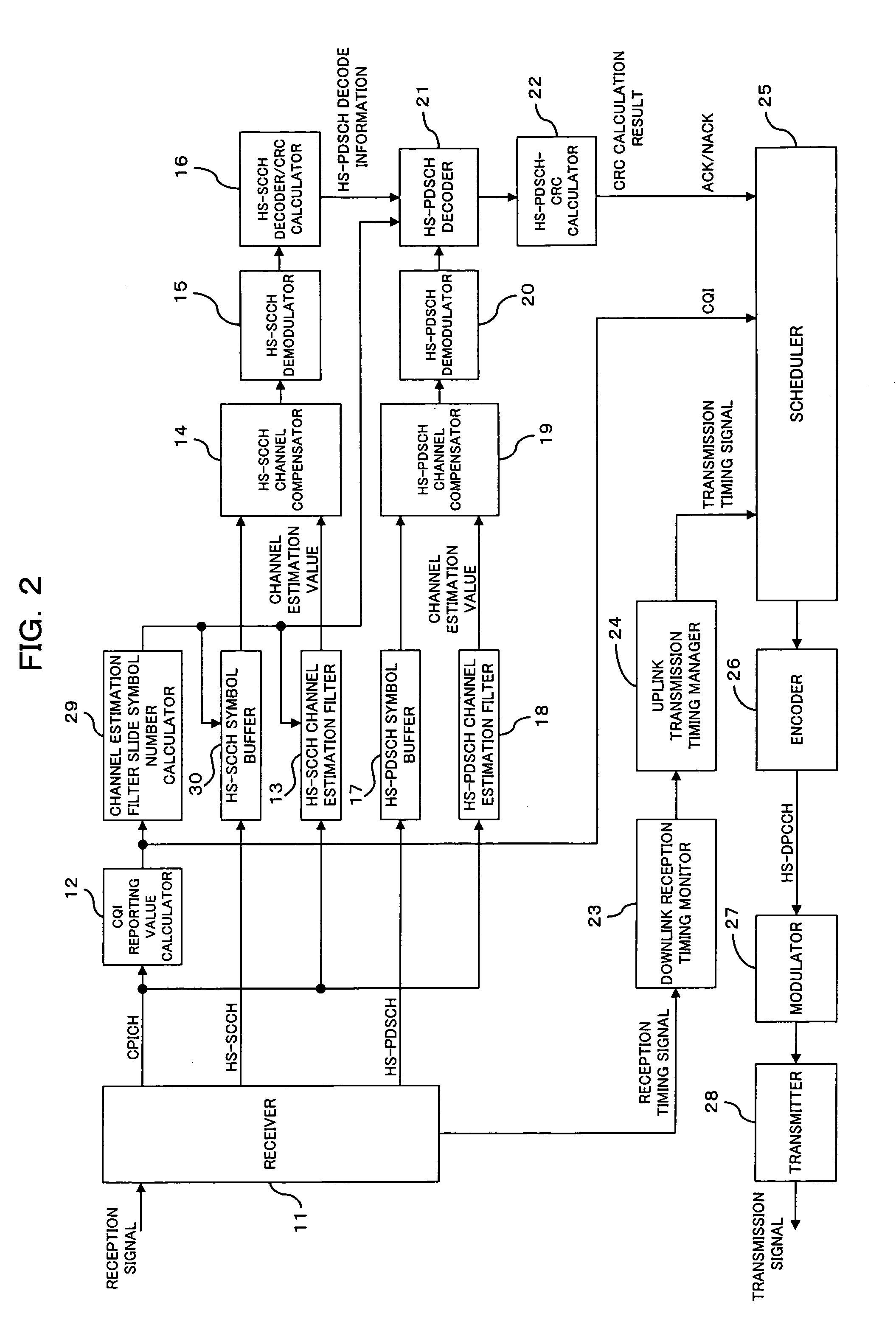

Mobile terminal apparatus and channel compensation method of the same

InactiveUS20070147289A1Improve throughputControl deteriorationNetwork traffic/resource managementData switching by path configurationTerminal equipmentControl channel

A mobile terminal includes a channel estimation processor to obtain the channel estimation value of a first channel reception signal in use of a plurality of known signals received from a base station within a channel estimation period; a channel compensation processor to perform a compensation process of the first channel reception signal in use of the channel estimation value; and a controller to control the channel estimation period so as to use a known signal which is received after the reception of the first channel reception signal for channel compensation. With this, throughput in downlink communication can be improved by controlling the deterioration of HS-SCCH reception quality itself without any particular transmission power control with the base station even under an environment such as high speed fading.

Owner:FUJITSU LTD

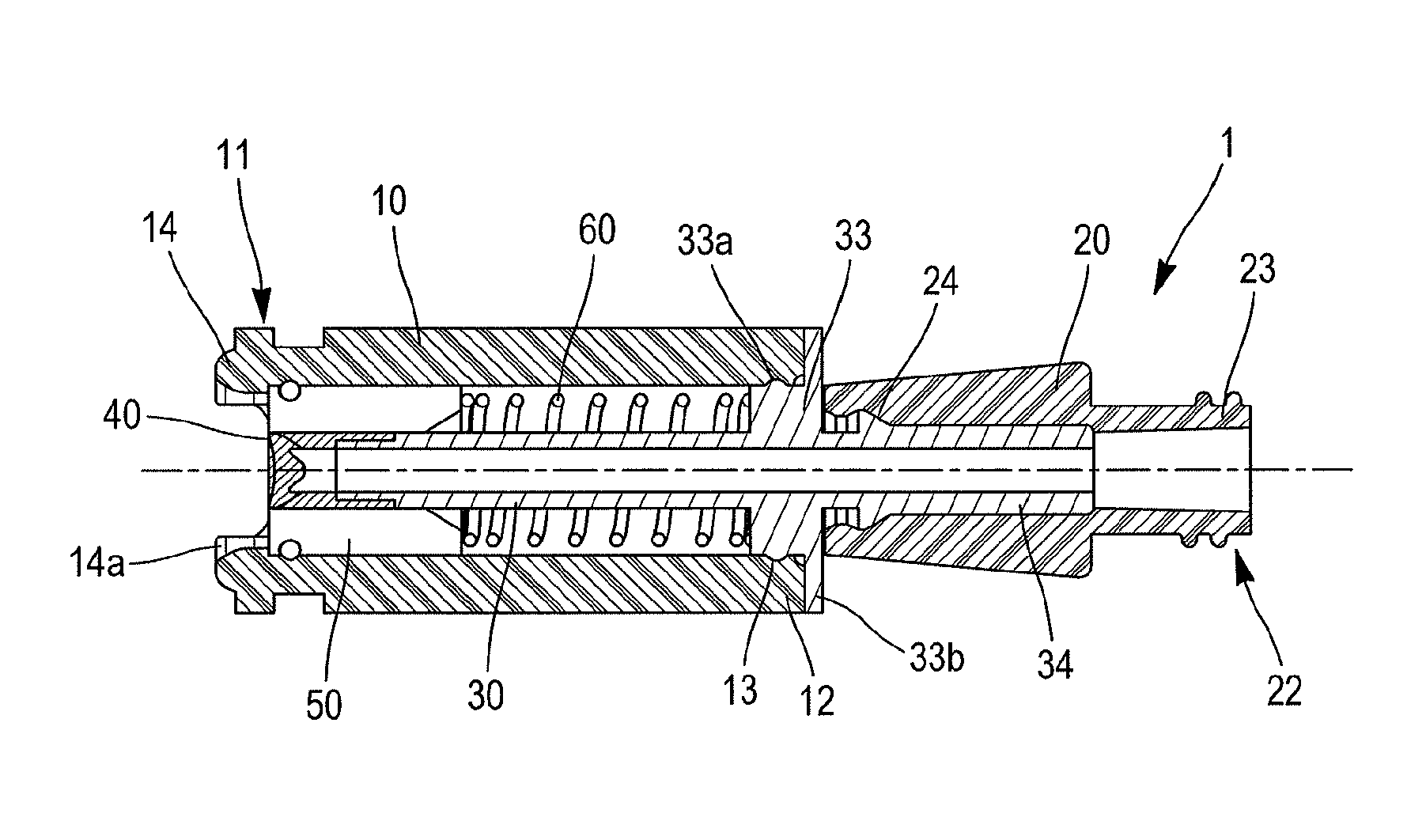

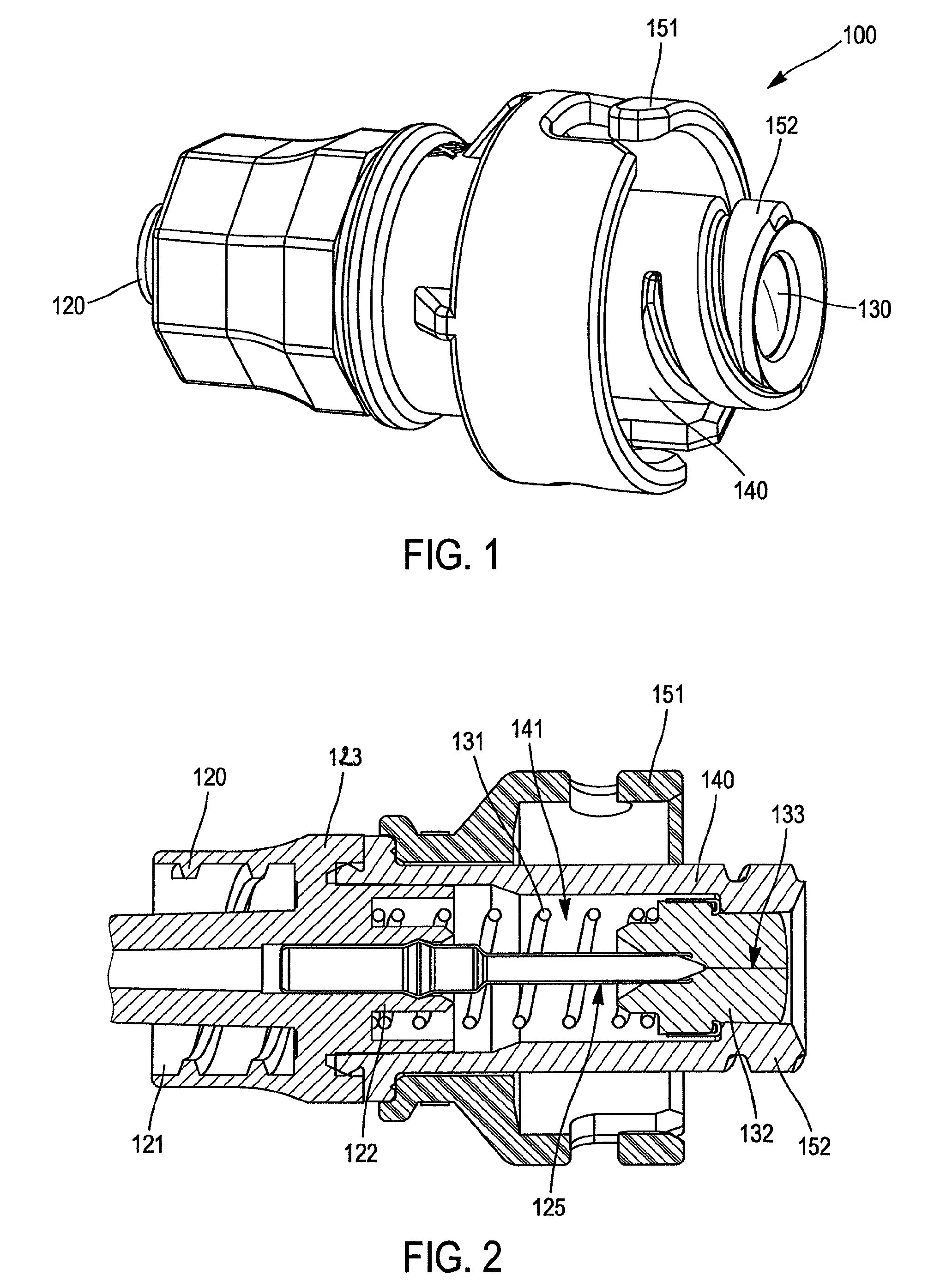

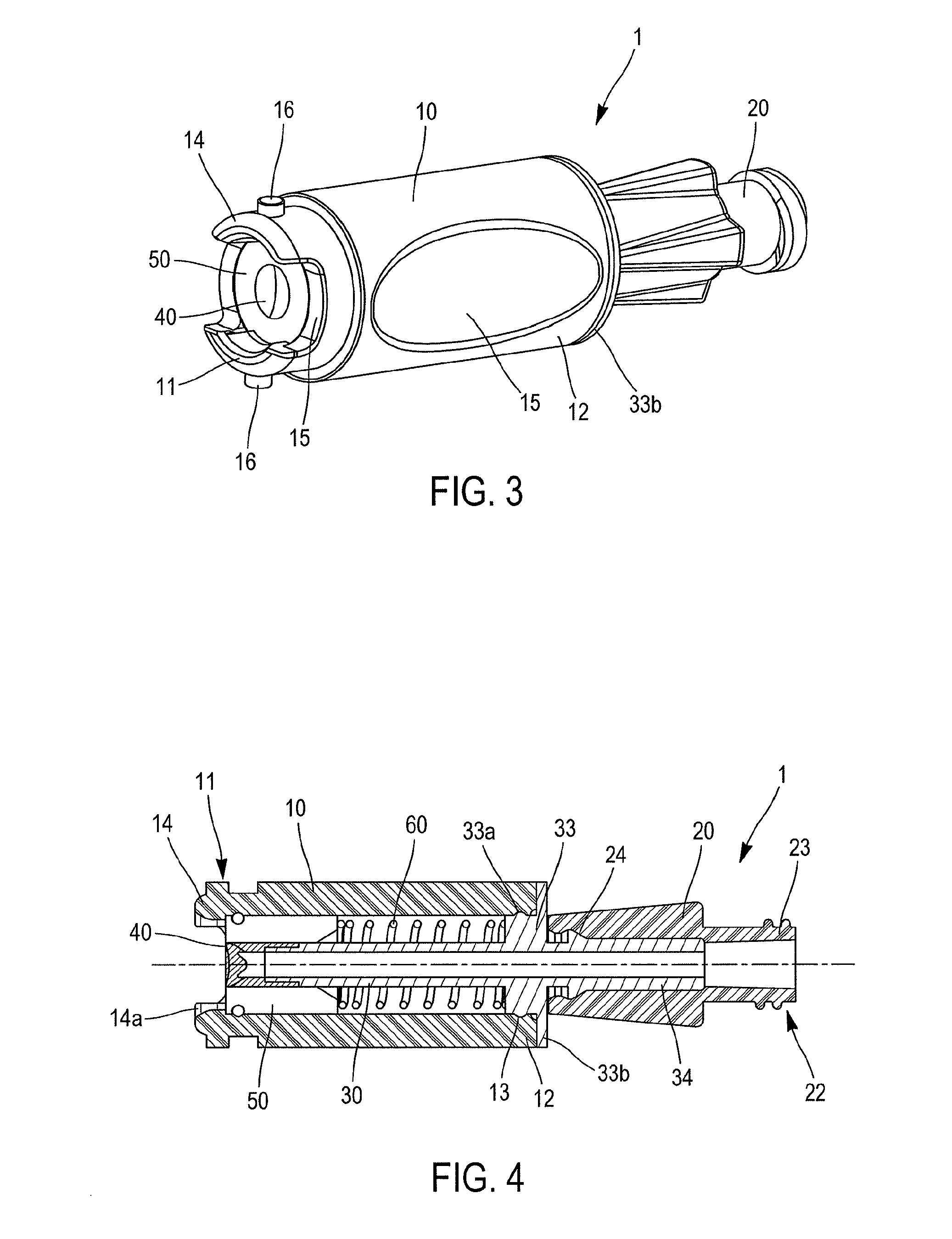

Non-drip, direct-flow connectors with secure locking

ActiveUS9234616B2Limiting orSeparation is worsenedJoints with fluid cut-off meansCouplingsEngineeringEXPOSE

Owner:VYGON SA

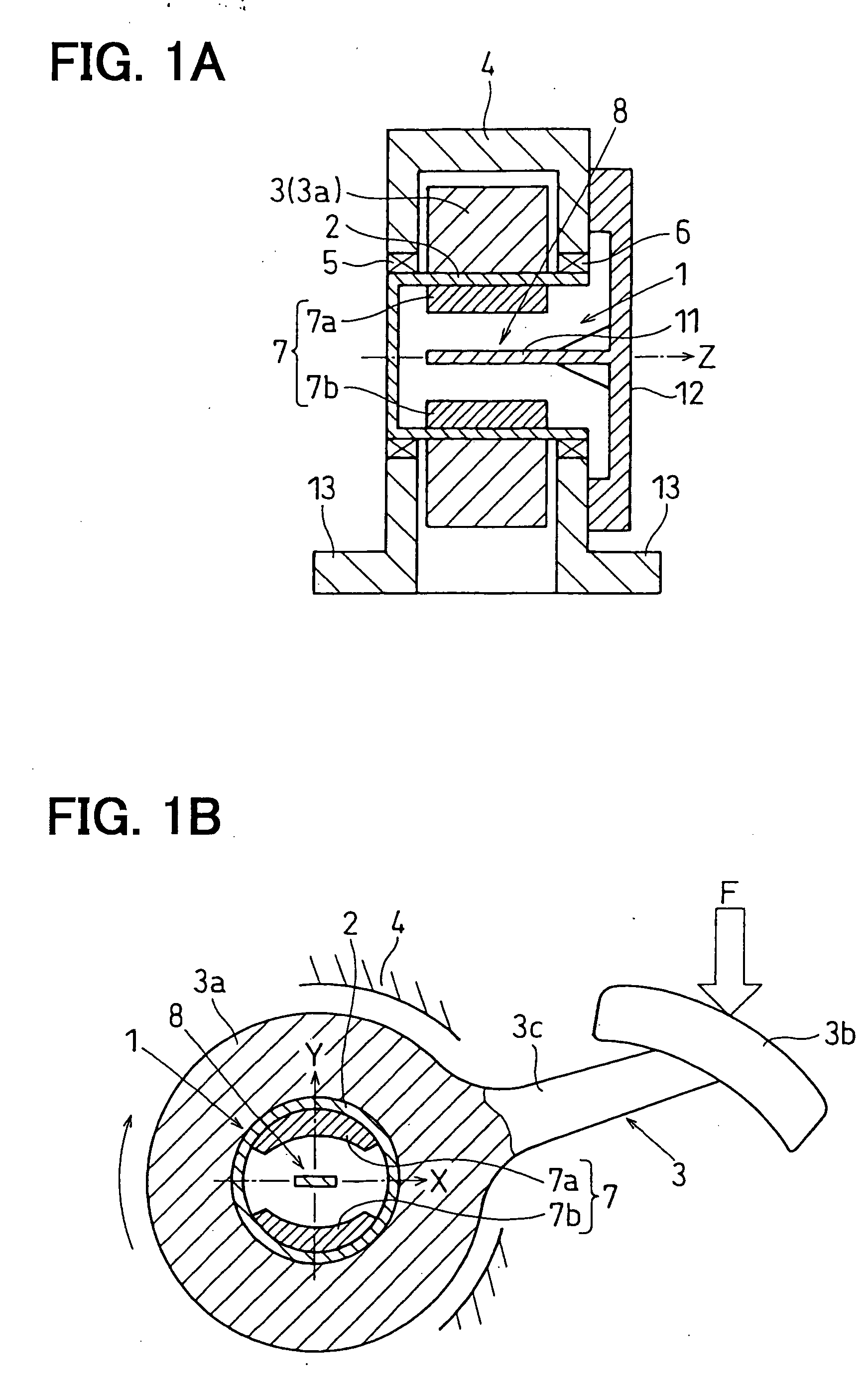

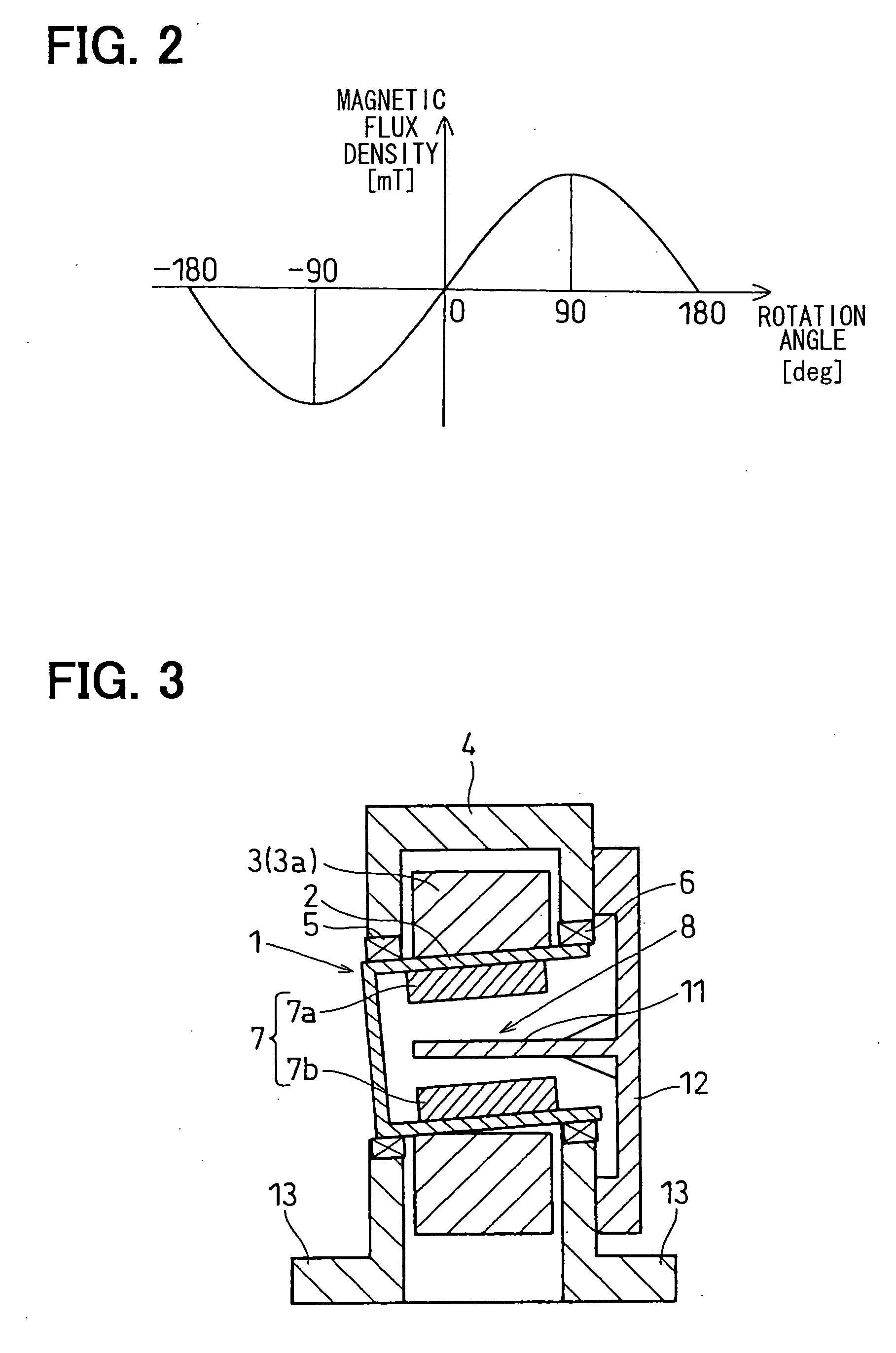

Rotation angle detection device

InactiveUS20070103149A1Deterioration can be suppressedLow costControlling membersSolid-state devicesMagnetic tension forceEngineering

A rotation angle detection device for detecting a rotation angle of an object has a substantially cylinder-shaped yoke, a magnetism generation unit which is fixed to an inner surface of the yoke, a magnetism detection member which is arranged substantially in a center axis of the yoke, at least one bearing which rotatably supports the yoke, and a support member which holds the bearing. The yoke is made of a magnetic metal, and fixedly mounted at the object to be rotatable integrally with the object. The magnetism generation unit generates a magnetic field substantially perpendicular to the center axis of the yoke. The magnetism detection member generates an output corresponding to a variation of the magnetic field to detect the rotation angle of the object relative to the magnetism detection member.

Owner:DENSO CORP

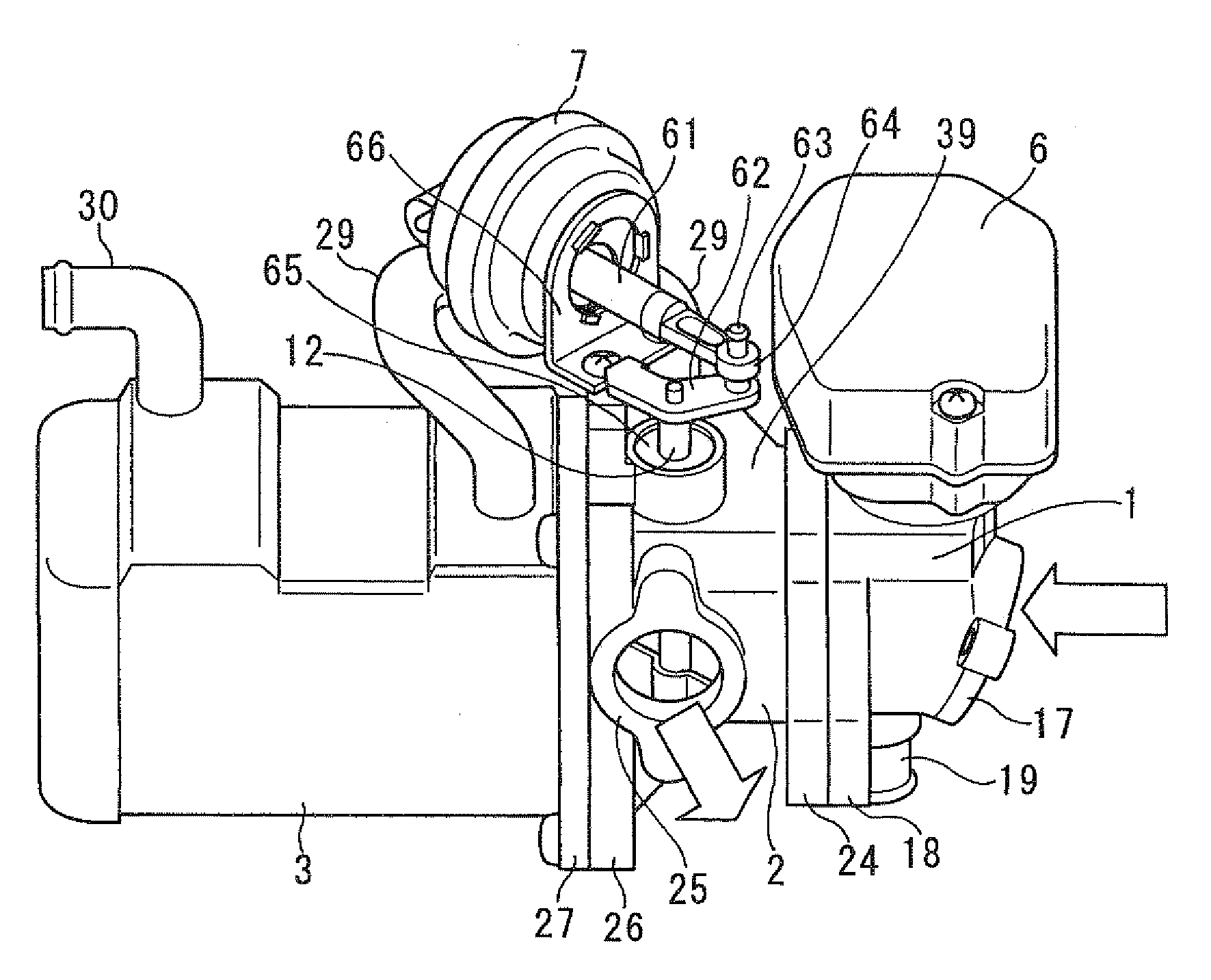

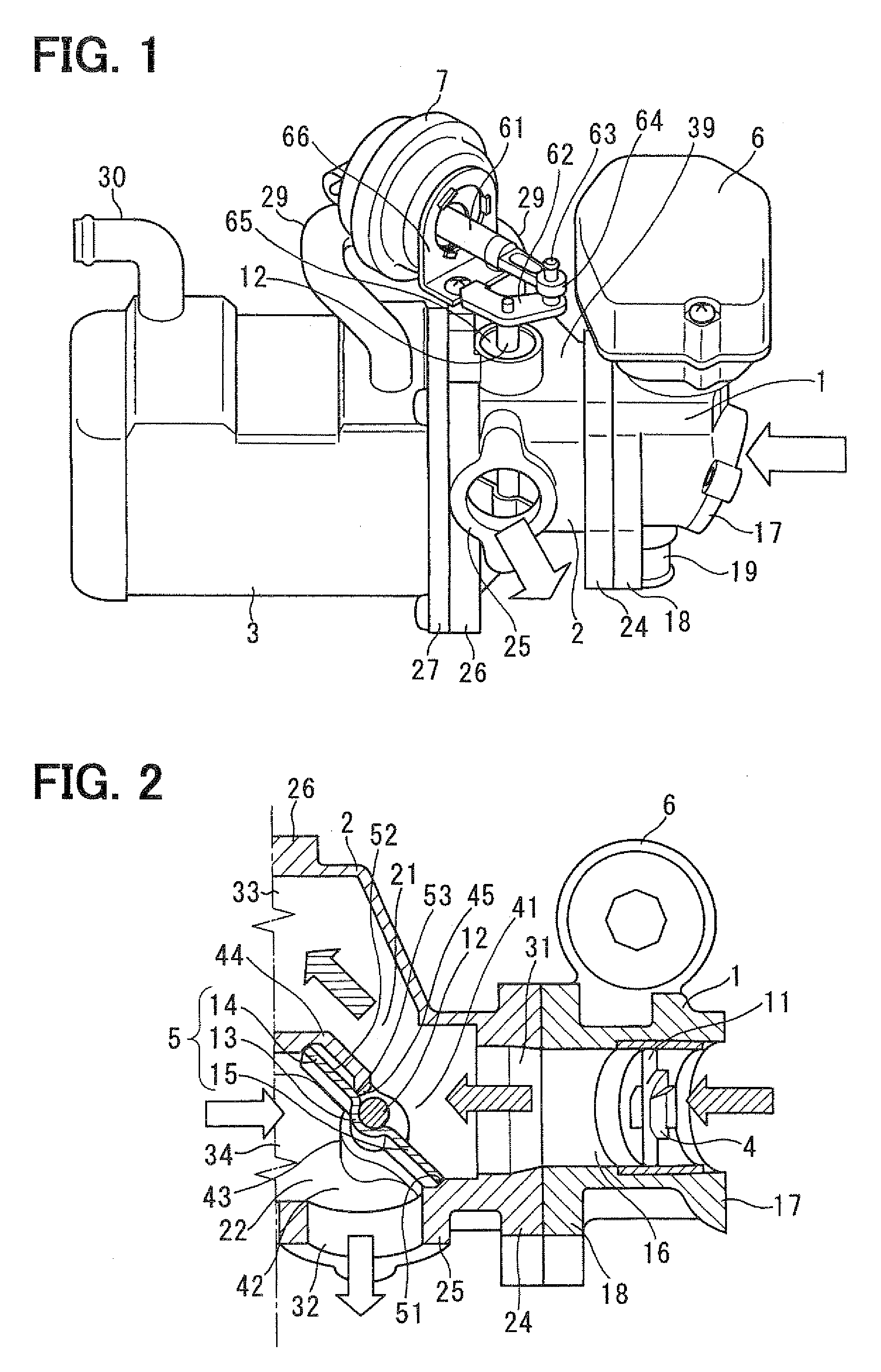

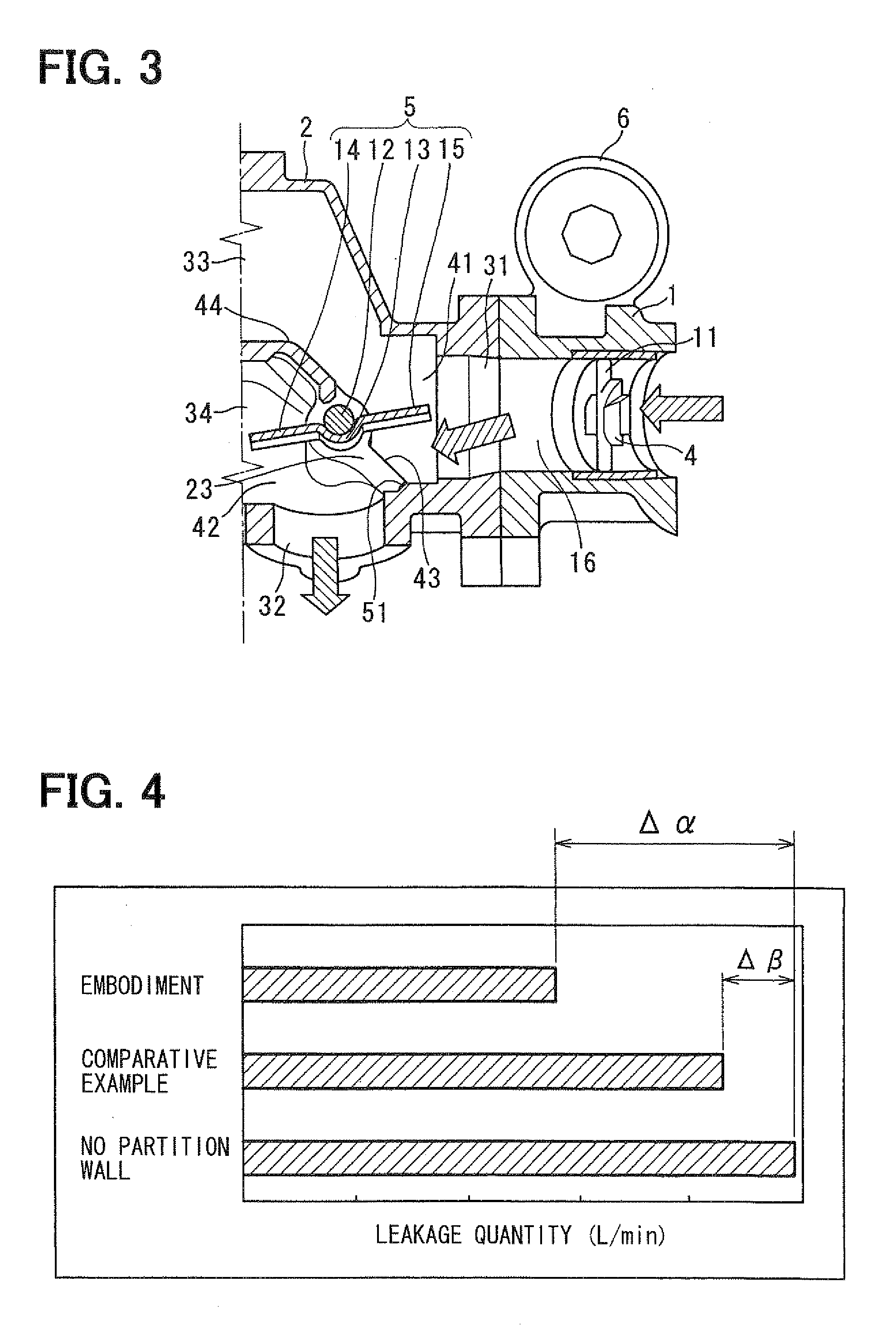

Exhaust gas switching valve

InactiveUS20090235654A1Lower performance requirementsDeterioration can be suppressedNon-fuel substance addition to fuelInternal combustion piston enginesEngineeringButterfly valve

A partition wall partitioning a cooler inlet port and a cooler outlet port extends from a cooler connecting surface of a connecting portion to a vicinity of a shaft supporting a four-way butterfly valve. An EGR gas leakage around a first valve plate can be restricted. Thus, an increase in temperature of EGR gas flowing through an EGR gas outlet port can be restricted at a cooled mode. A deterioration of emission reducing performance can be avoided.

Owner:DENSO CORP

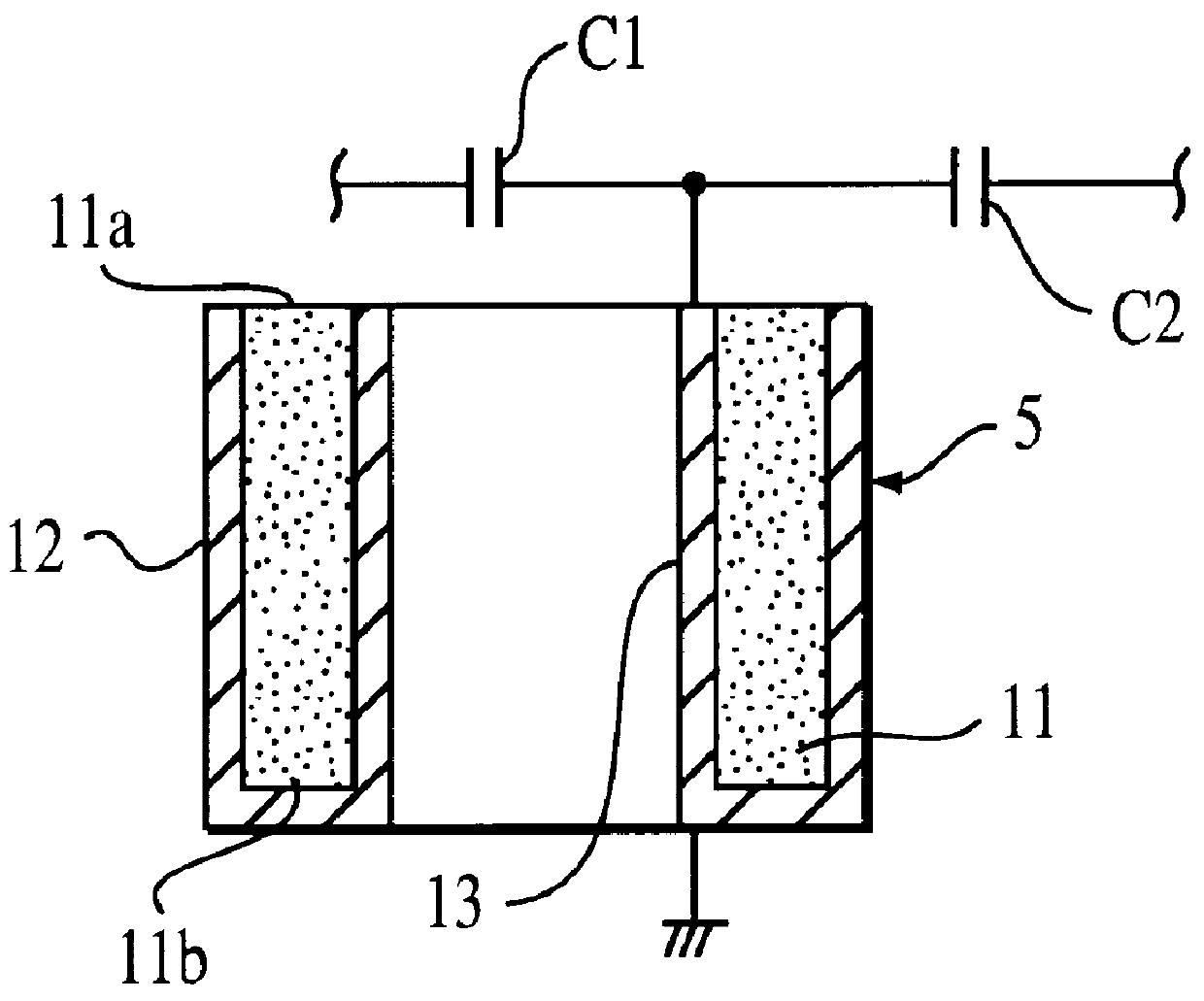

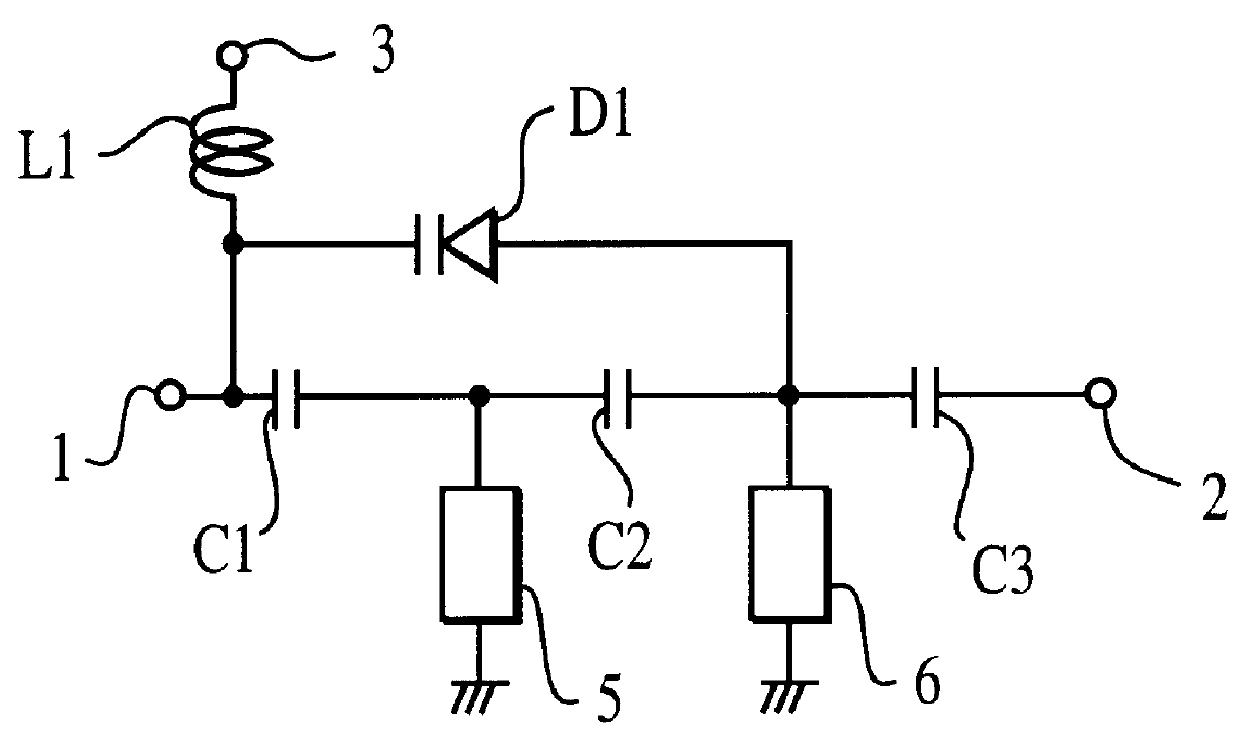

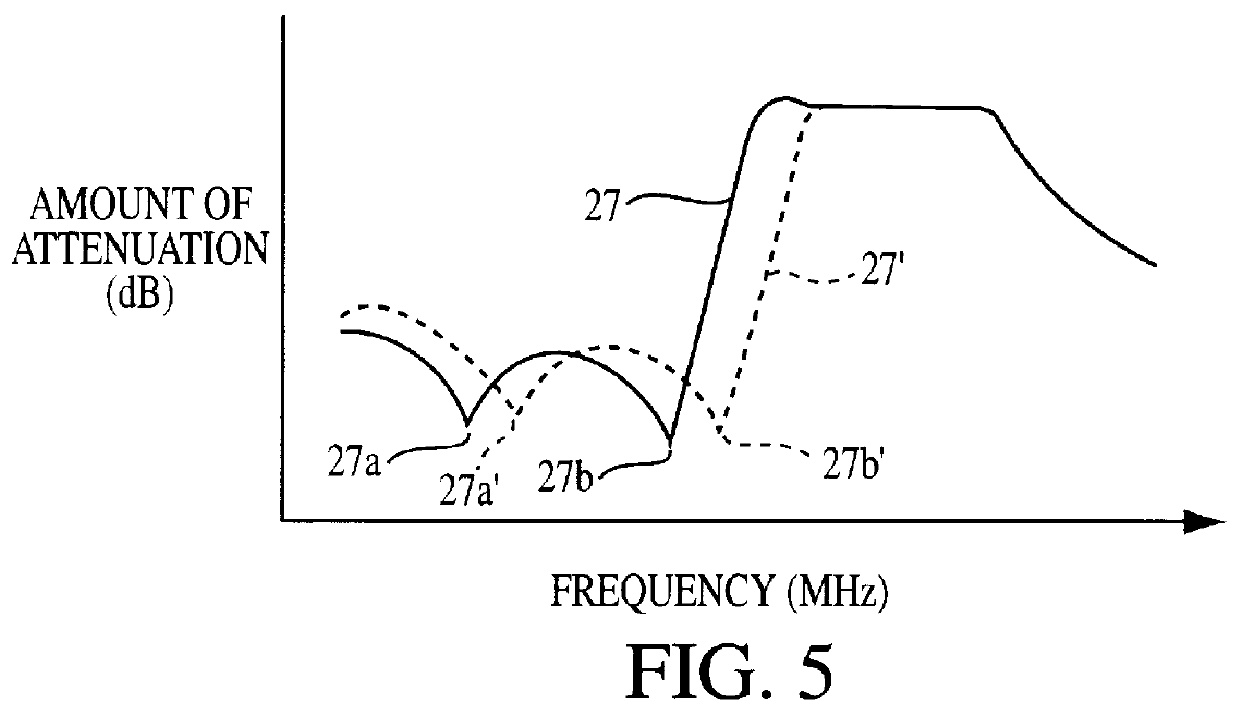

Dielectric variable-frequency filter having a variable capacitance connected to a resonator

InactiveUS6111482AReduced insertion lossReduce the amount of solutionResonatorsTransmissionCapacitanceFrequency filtering

A dielectric resonator 5 is electrically connected to an input terminal 1 through a coupling capacitor C1. A dielectric resonator 6 is electrically connected to an output terminal 2 through a coupling capacitor C3. The dielectric resonators 5 and 6 are electrically connected to each other through a coupling capacitor C2. A voltage control terminal 3 is electrically connected to the cathode of a variable-capacitance diode D1 and to one end of the coupling capacitor C1 through a choke coil L1. The anode of the variable-capacitance diode D1 is electrically connected to the dielectric resonator 6. That is, the variable-capacitance diode D1 comprises a path interconnecting at least two of said dielectric resonators in a filter 15.

Owner:MURATA MFG CO LTD

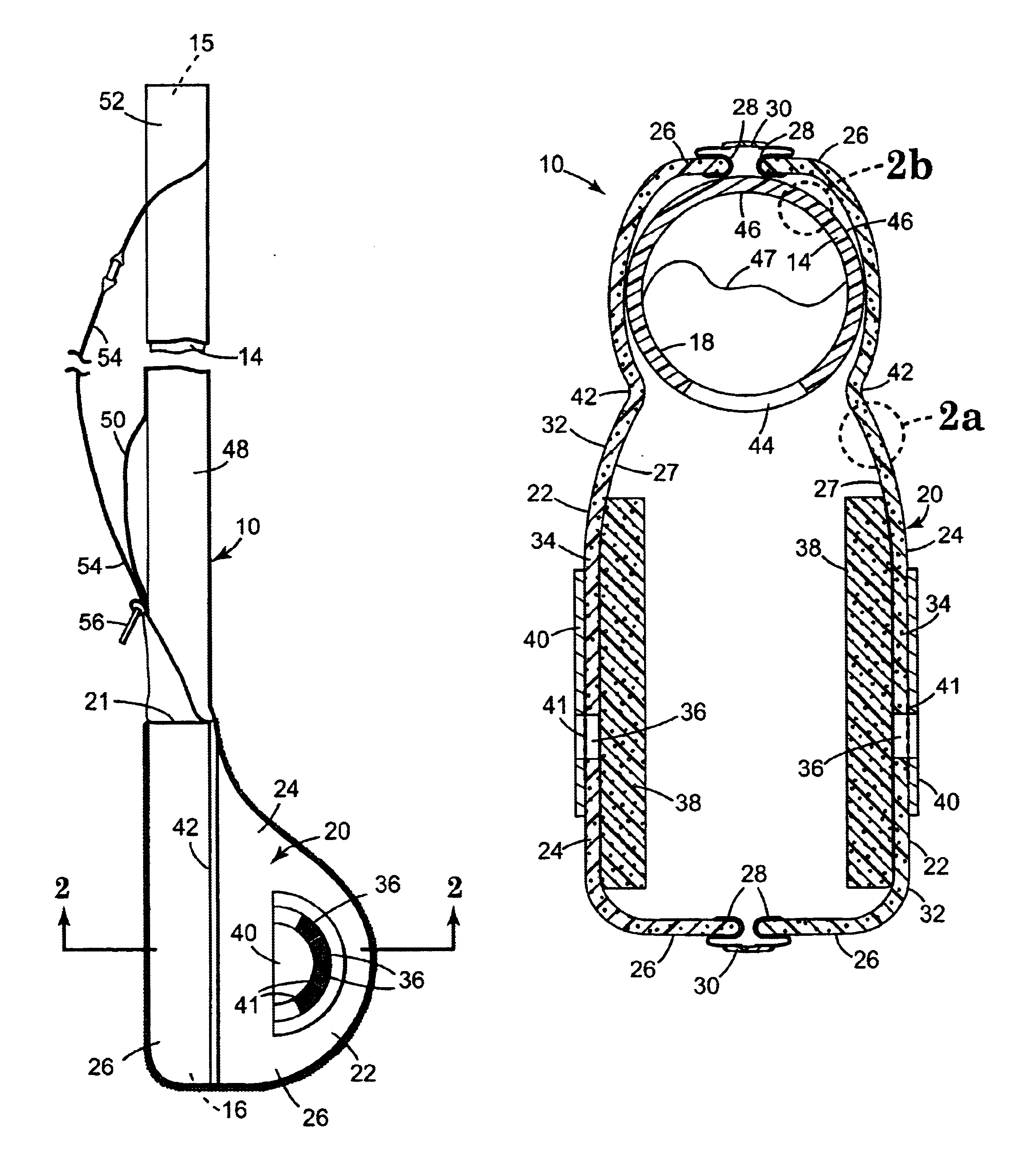

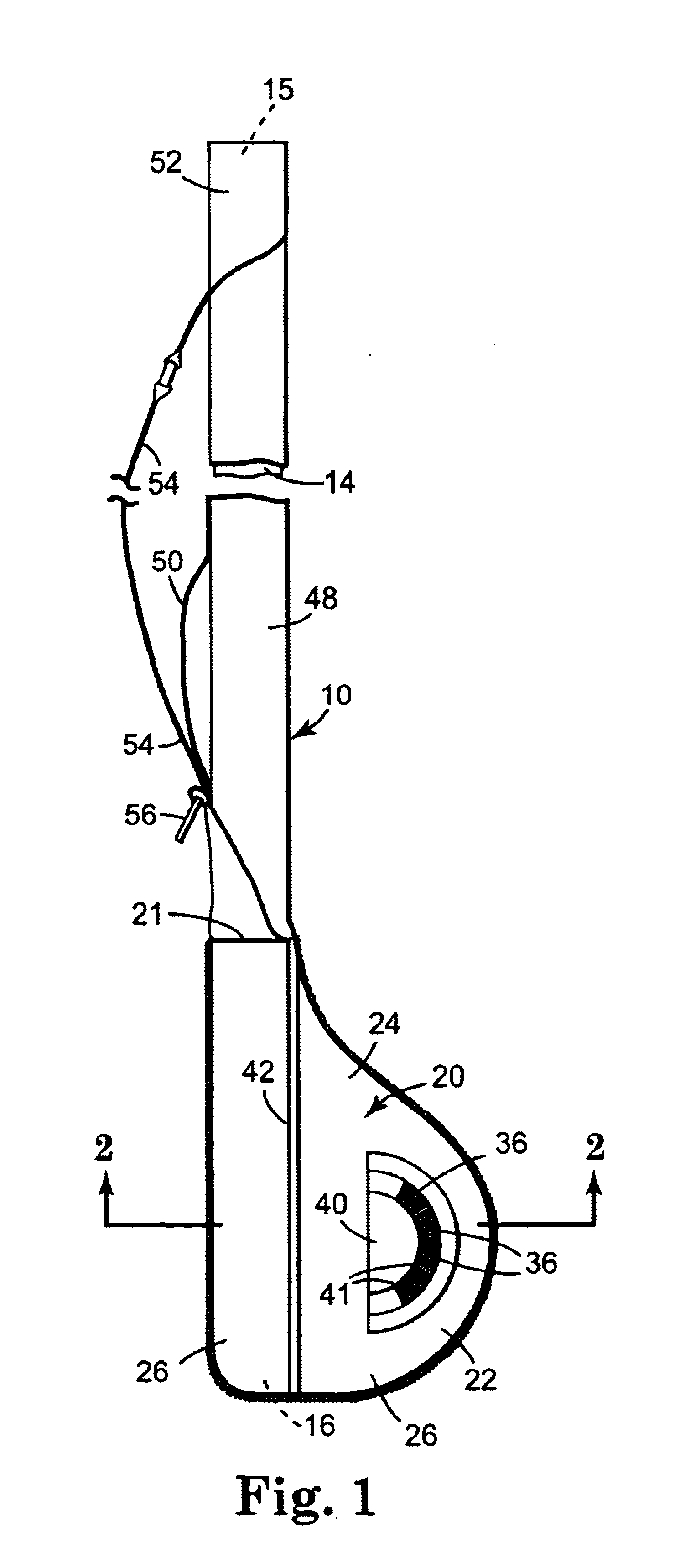

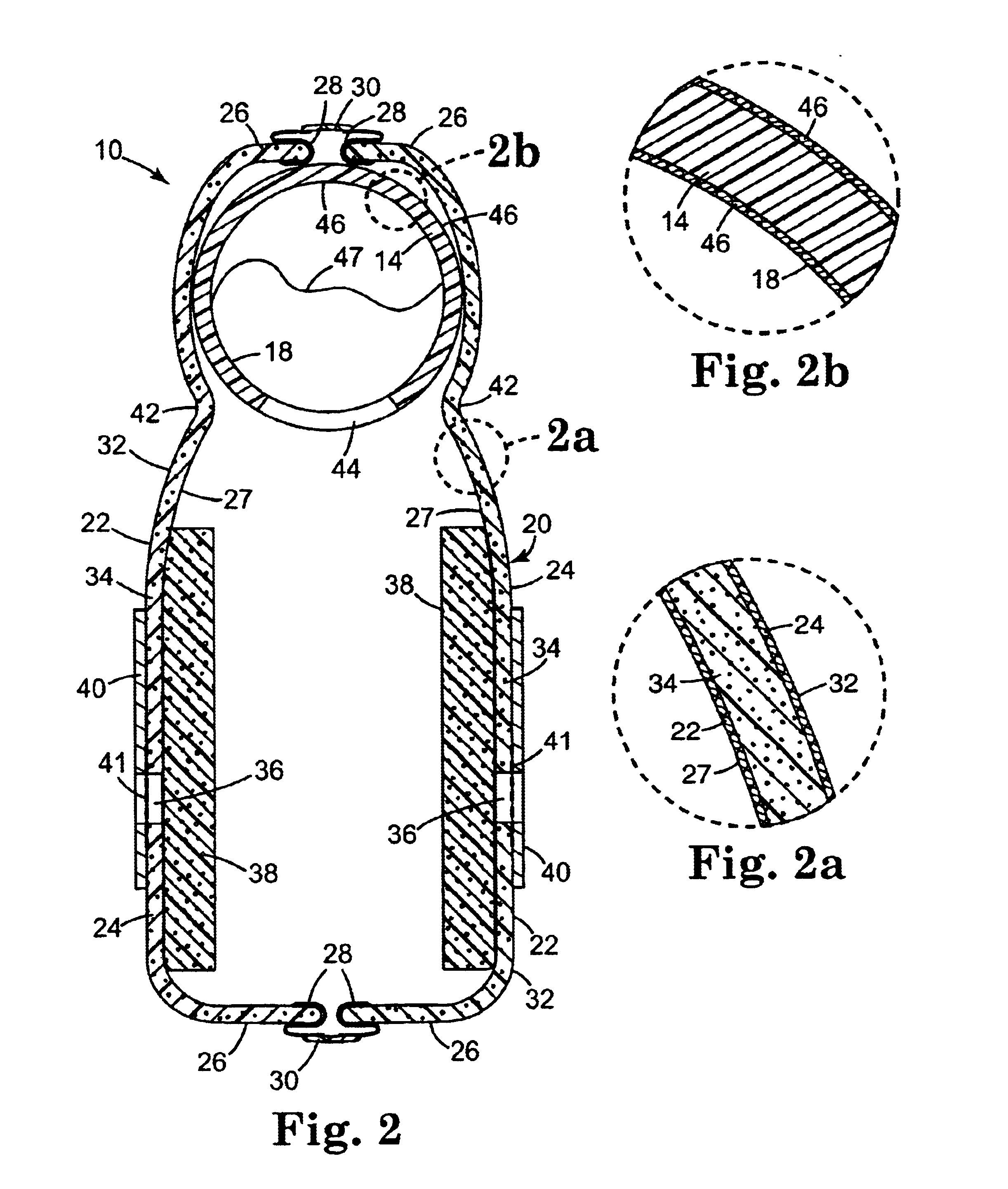

Fishing rod and reel container

InactiveUS6865841B2Improve protectionFacilitates evaporation of moistureTravelling carriersOther accessoriesEvaporationEngineering

A protective container for a fishing rod with a reel mounted on a handle portion of the rod. The container includes a rigid elongate tube having an inner surface defining a cavity adapted to receive the fishing rod; and a flexible housing attached to the tube adjacent one end that is adapted to enclose the reel and the handle portion of the rod on which the reel is mounted. That housing includes opposite wall portions having side wall parts each adapted to lie along and across a different side of the reel and handle portion of the rod, which wall portions include peripheral parts extending toward each other from the peripheries of the side wall parts that can be releasably attached together so that opposed inner surfaces of the wall portions define a cavity that can receive the reel and the handle portion of the rod on which it is mounted. The wall portions can be separated to allow the rod and reel to be placed in or removed from the container. The wall portions of the housing include layers of fabric defining their inner and outer surfaces, and layers of thermo formed foam between and bonded to those layers of fabric that provide stiff, shape retaining, flexible, side wall portions shaped and adapted to protect the reel. The side wall portions can have through vent openings that allow evaporation of moisture from the rod and reel when the container is closed.

Owner:3M INNOVATIVE PROPERTIES CO

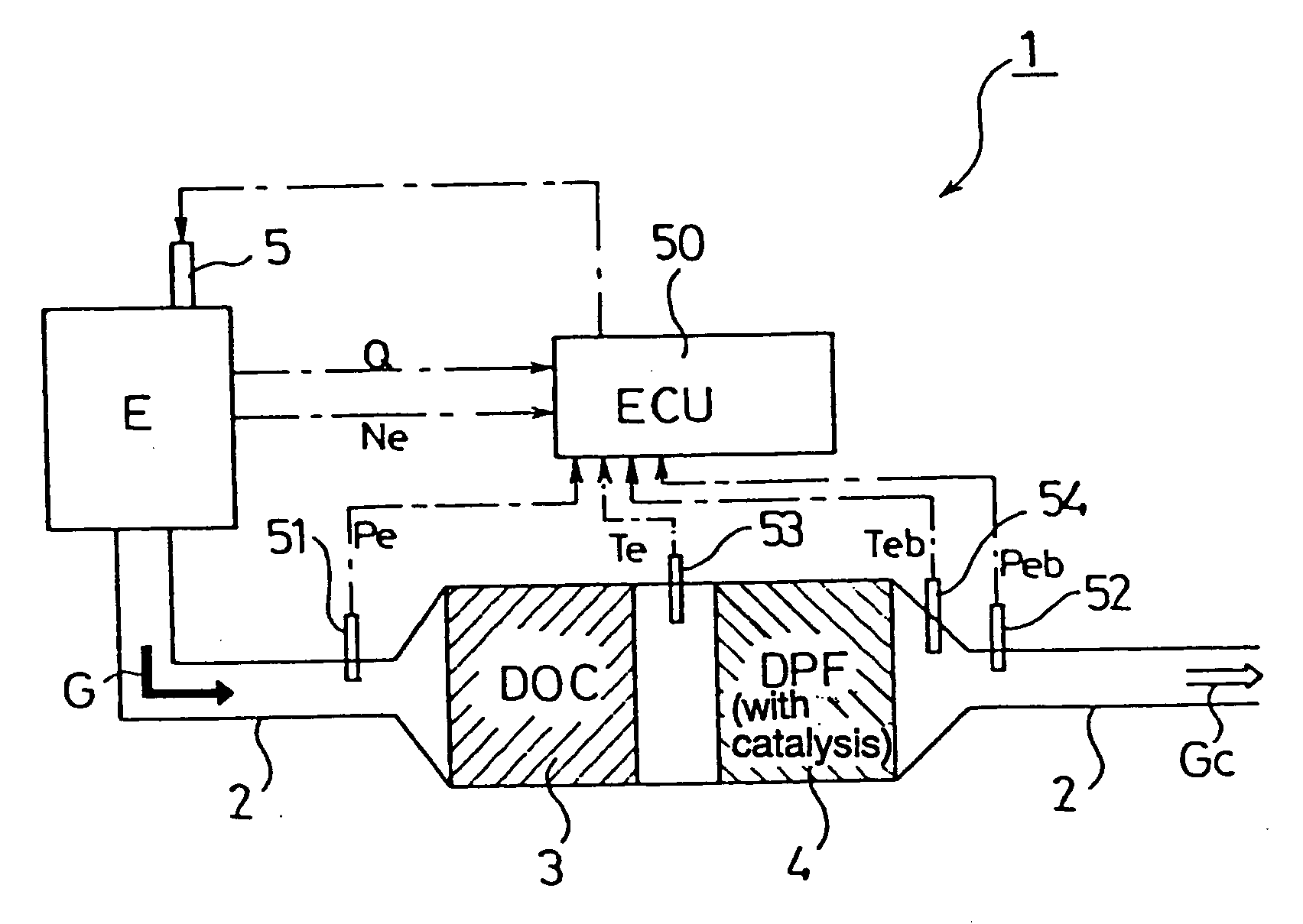

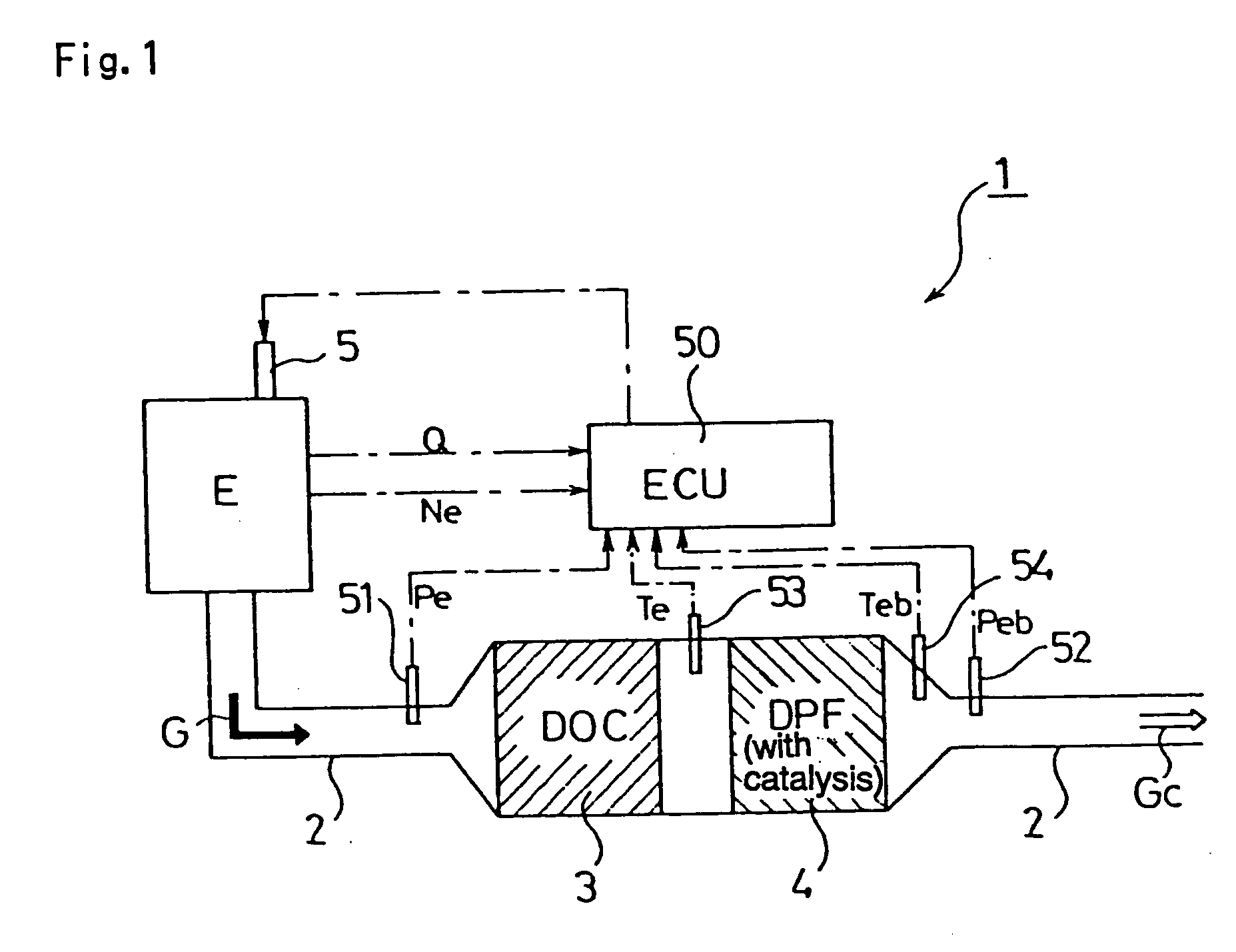

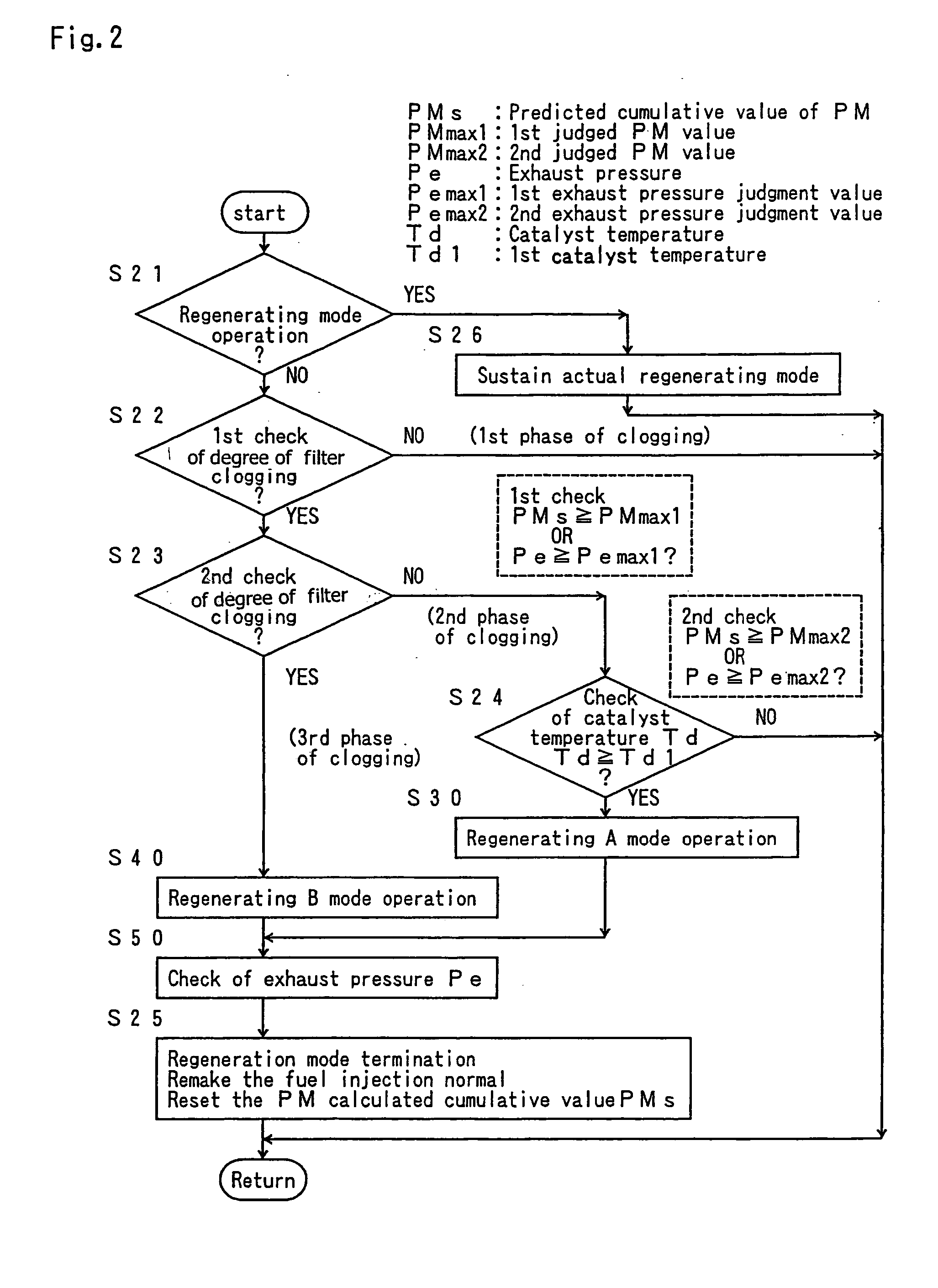

Regeneration control method for continuously regenerating diesel particulate filter device

InactiveUS20050284138A1Deterioration can be suppressedEfficient removalElectrical controlInternal combustion piston enginesDiesel particulate filterWaste management

A regeneration control method for regenerating a continuously regenerating diesel particulate filter device capable of regenerating a filter by efficiently removing PM while suppressing the deterioration of fuel consumption and preventing a drivability from being deteriorated, wherein the clogged-state of the filter is judged in three or more phases of the clogged-state and, when the clogged-state of the filter reaches a specified phase, a specified regenerating mode operation set in correspondence with the reached phase is performed.

Owner:ISUZU MOTORS LTD

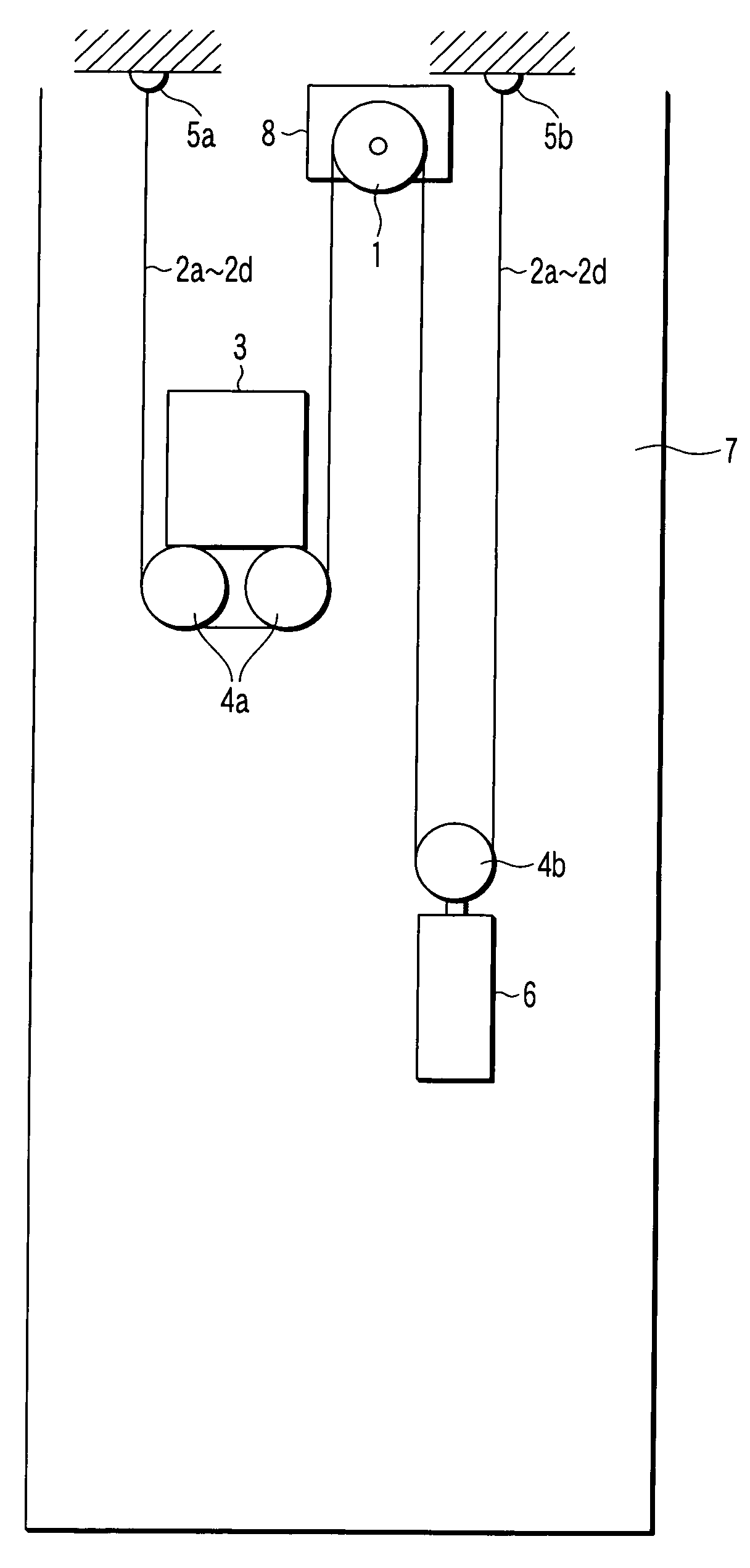

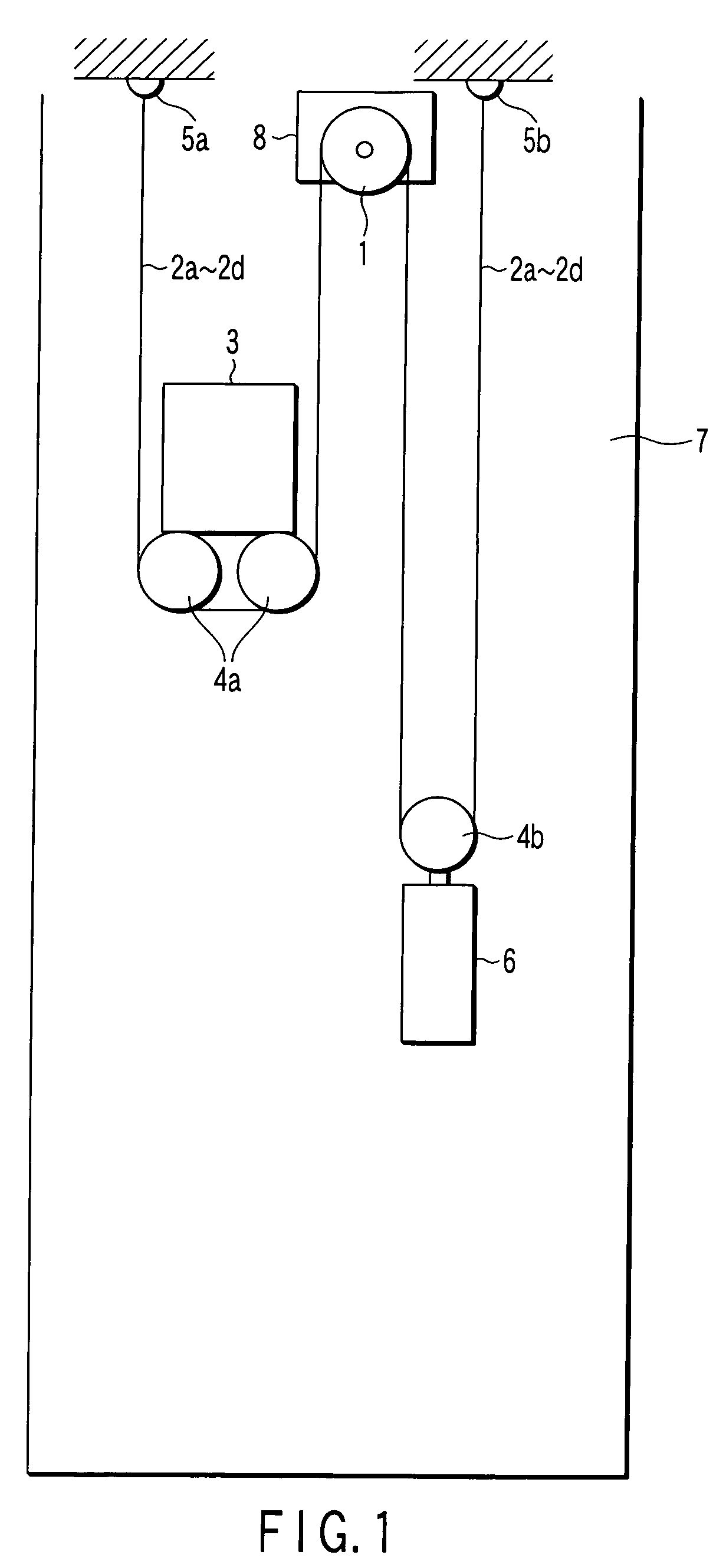

Sheave for elevator

InactiveUS20060070822A1Reduce fatigueDeterioration can be suppressedElevatorsBuilding liftsBiomedical engineeringLow friction

Coating layers of low-friction coating materials helping a rotating action generated on ropes are provided on surfaces of grooves formed on an outer peripheral surface of a base of a sheave. Thus, difference in tension between the ropes can be solved, generation of twist on the ropes can be prevented, and deterioration of portions of the ropes which are in contact with the sheave can be prevented to extend the lifetime of the ropes.

Owner:TOSHIBA ELEVATOR KK

Packet transmission control device and packet transmission control method

ActiveUS8031648B2Easy to useDeterioration can be suppressedPower managementNetwork traffic/resource managementMobile stationComputer science

A packet transmission control device relating to the present invention includes: a storage unit configured to store a transmission resource available for use in the packet transmission, radio quality information on the downlink, and a transmission method to be used in the packet transmission while associating them with one another; a determination unit configured to determine a transmission method to be used in the packet transmission on the basis of the radio quality information, on the downlink reported from the mobile stations and the transmission resource available for use in the packet transmission, by referring to the storage unit; and a packet transmission unit configured to transmit the packet by using the determined transmission method.

Owner:NTT DOCOMO INC

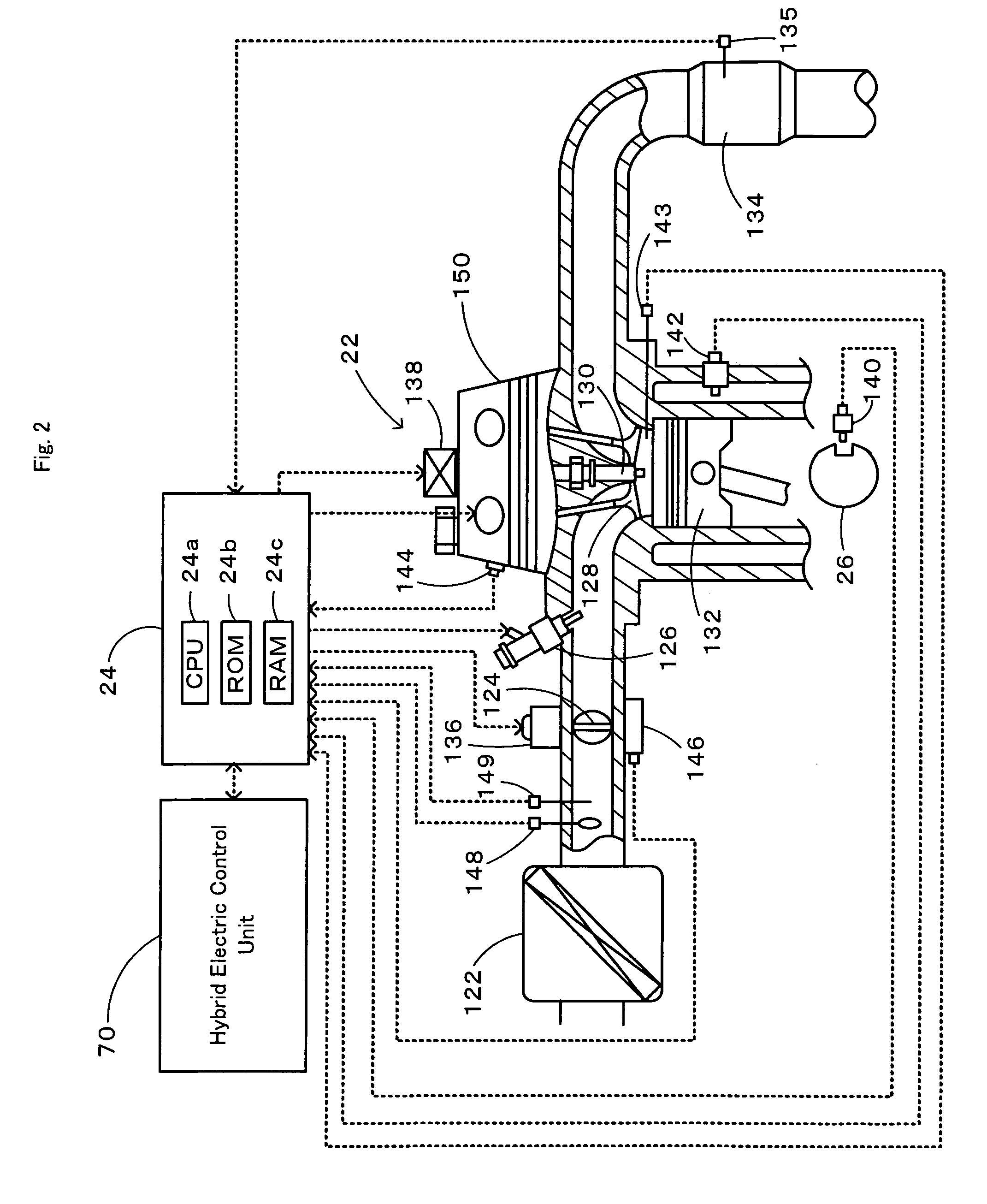

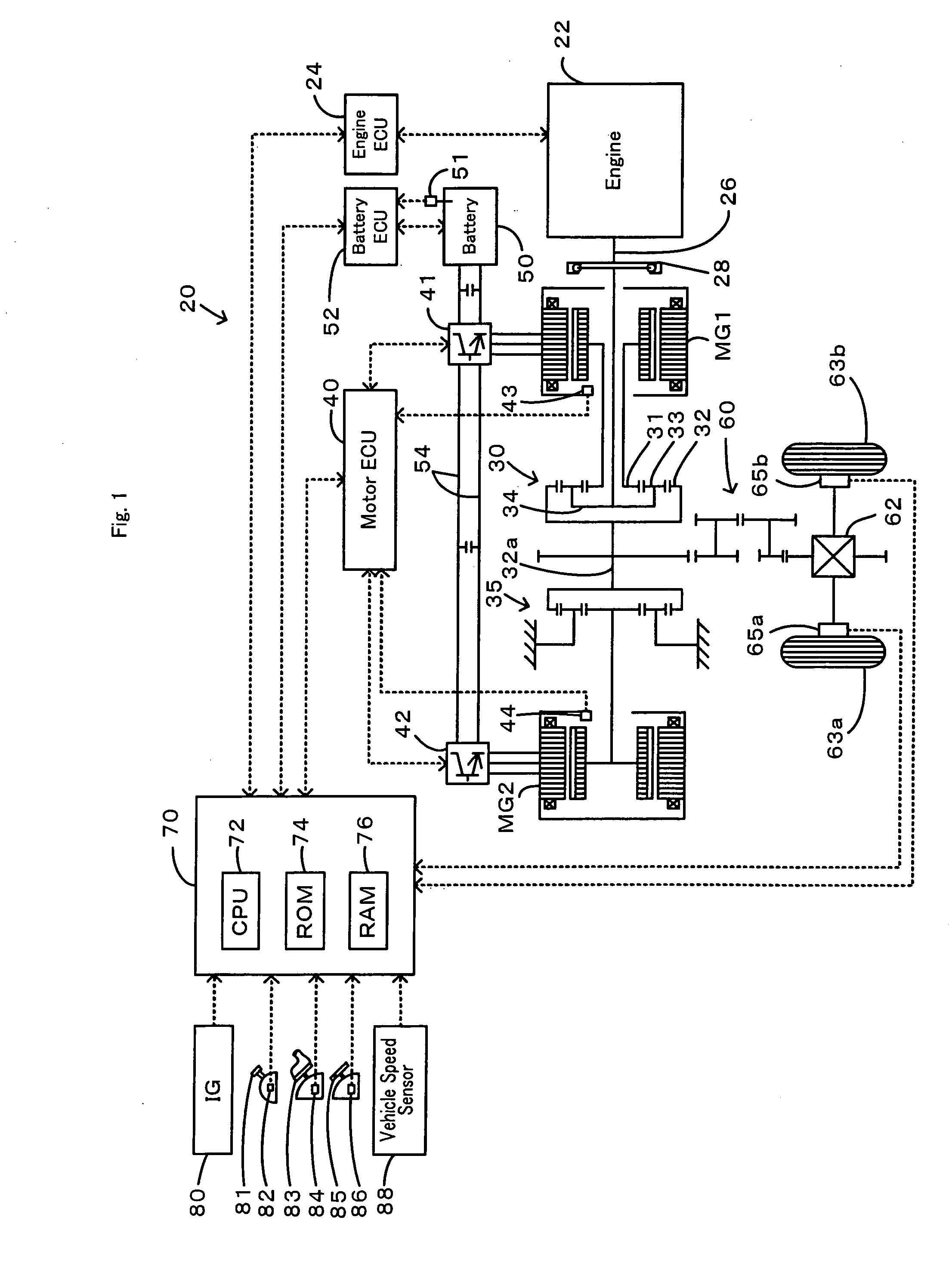

Hybrid vehicle and control method thereof

InactiveUS7958957B2Effectively controls deteriorationStrengthen restrictionsHybrid vehiclesAuxillary drivesEngineeringLimit value

A hybrid vehicle 20 sets a tentative limit value Win0 of determining a fuel increase relation with respect to a selected gearshift position SP for driving (S220, S230, S350), and performs increasing correction of a fuel injection amount according to either a first OT increase factor setting map or a second OT increase factor setting map that is enabled based on a relation of an input limit Win of the battery 50 to the tentative limit value Win0. Prohibition of fuel cutoff may be cancelled, based on a relation of the input limit Win to a driving force demand in an accelerator-off state set at the selected gearshift position SP. Even in this case, the increasing correction enables temperature regulation of an exhaust gas purification catalyst, with a view to controlling deterioration of the exhaust gas purification catalyst in an actual fuel cutoff condition after cancellation of the prohibition of the fuel cutoff. The deterioration of the exhaust gas purification catalyst is thus favorably controlled, irrespective of the selected gearshift position SP.

Owner:TOYOTA JIDOSHA KK

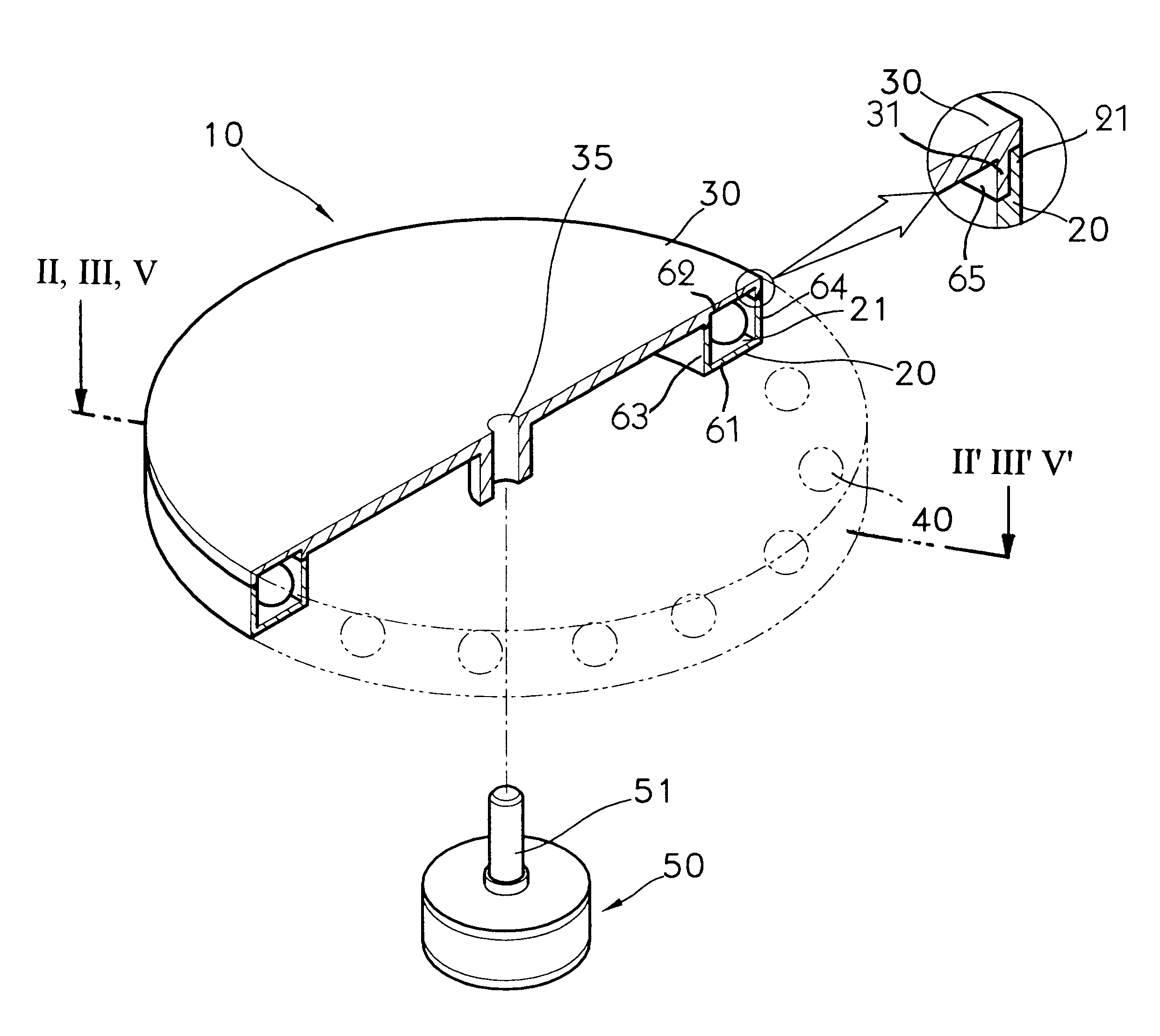

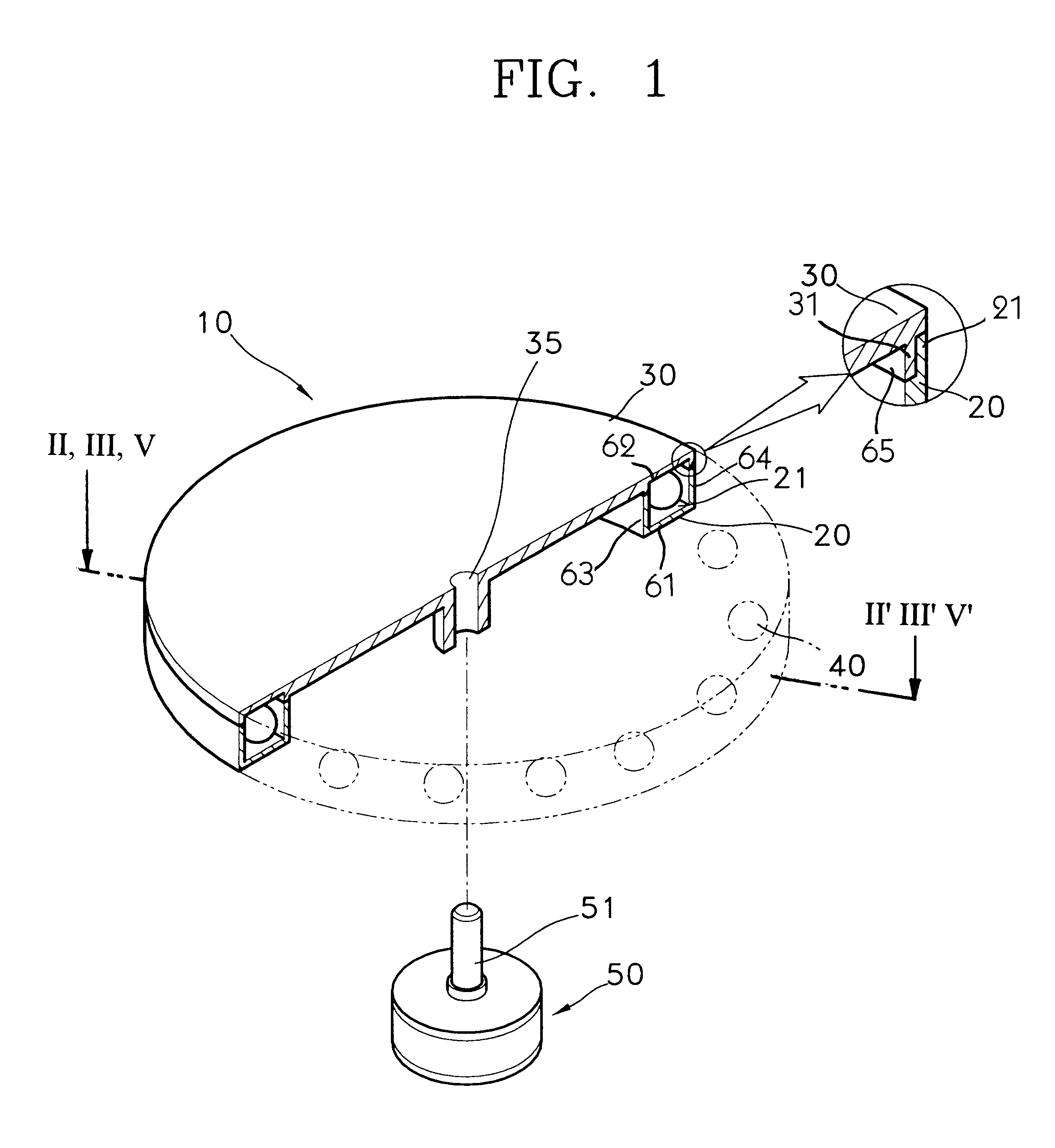

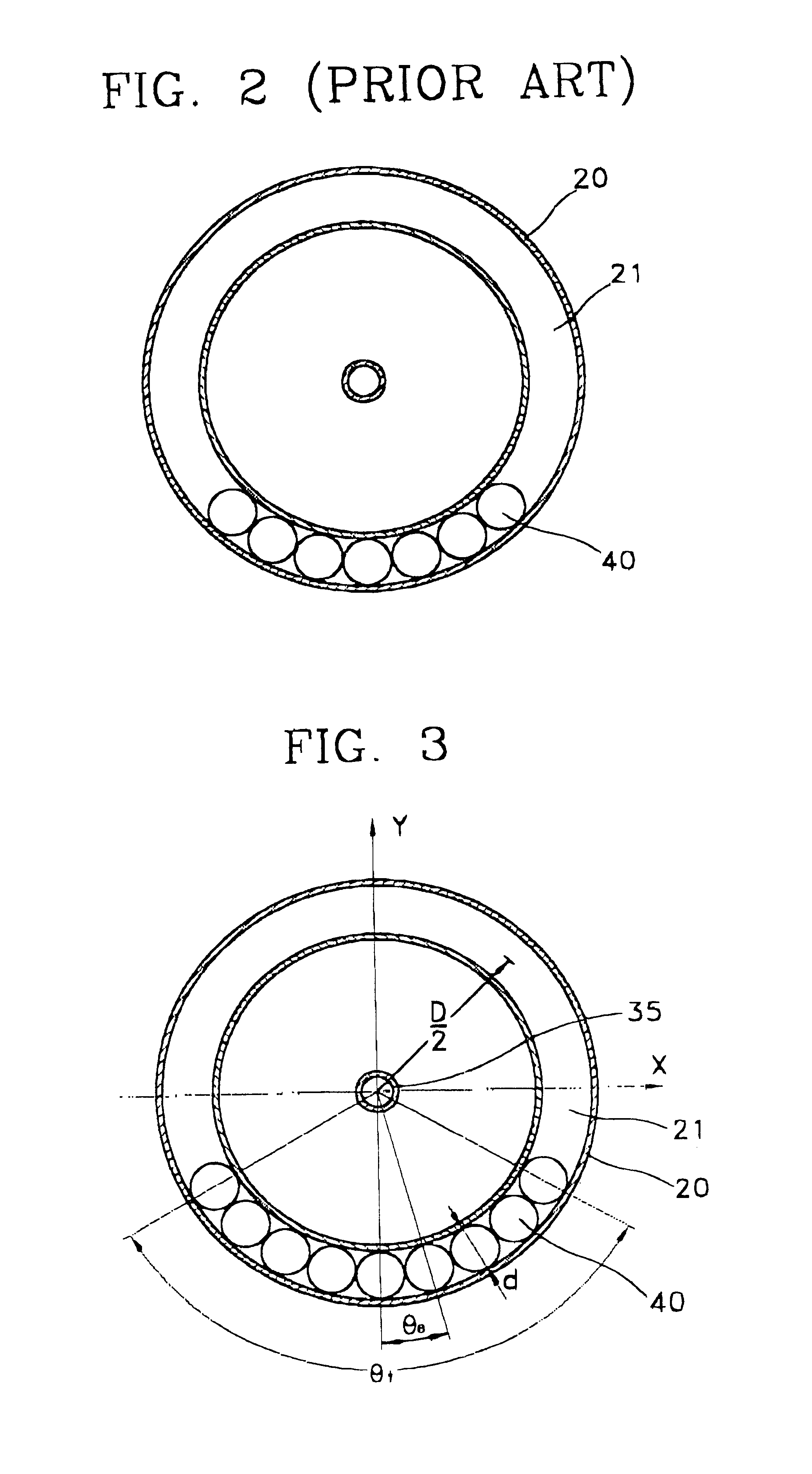

Self-compensating dynamic balancer

InactiveUS6212973B1Deterioration can be suppressedReduce frictionControlling membersControlled membersInterior spaceEngineering

In a self-compensating dynamic balancer, a main body is installed at a rotating body to restrict internal vibrations due to eccentric mass of the rotating body. The main body has a circular race formed therein around a rotation shaft of the rotating body. A plurality of rigid bodies are disposed in the race to be capable of moving freely and are as many as necessary to occupy at least half of the inner space of the race.

Owner:SAMSUNG ELECTRONICS CO LTD

Method of preventing flavor component from degradation

InactiveUS20050287259A1Appearance be impairedTaste be impairedFruit and vegetables preservationMilk preservationFlavorAlcohol

The present invention relates to a deterioration preventive for a flavor component, which is an oil-in-water and / or -polyhydric alcohol type emulsion, comprising an extracted tocopherol, wherein d-δ-tocopherol is contained in an amount of 45% by weight or more of a total tocopherol, ferulic acid and / or a derivative thereof, and a polyglycerol fatty acid ester; a deterioration preventive for a flavor component, which is an oil-in-water and / or -polyhydric alcohol type emulsion, comprising (A) the above-mentioned extracted tocopherol, (B) ferulic acid and / or a derivative thereof, and (C) an emulsifying agent having an HLB of 9 or more; a flavor for foodstuff, comprising the above-mentioned deterioration preventive; an emulsion flavor for foodstuff, comprising the above-mentioned extracted tocopherol, a catechin; and a polyglycerol fatty acid ester; and foodstuff comprising the above-mentioned deterioration preventive for a flavor component, the above-mentioned flavor for foodstuff, or the above-mentioned emulsion flavor for foodstuff.

Owner:TAIYO KAGAKU CO LTD

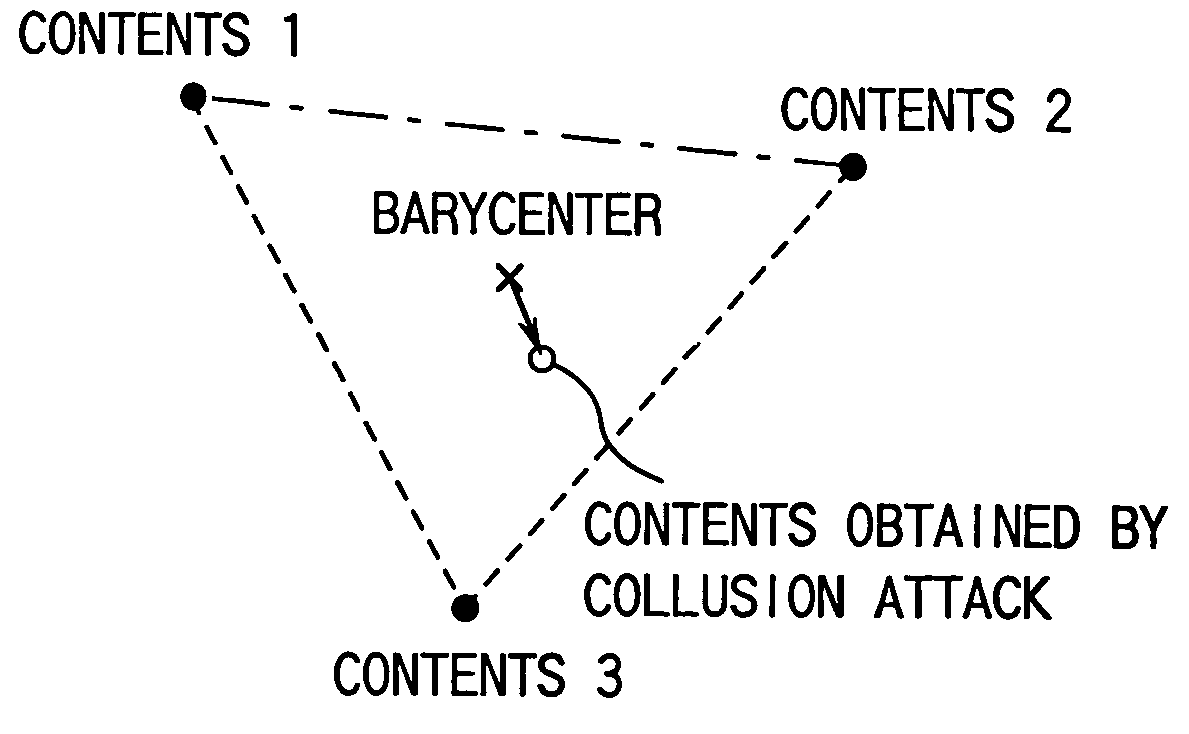

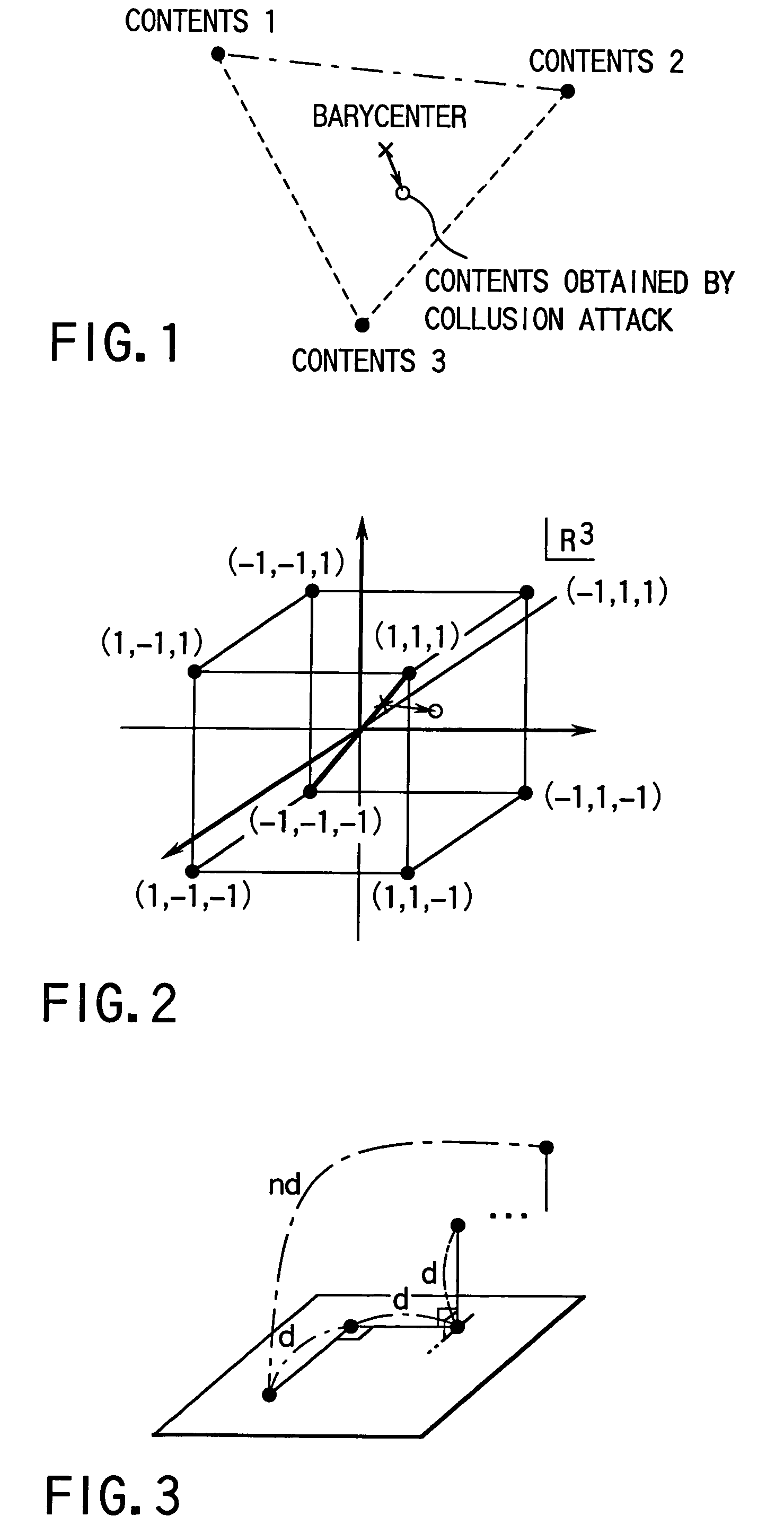

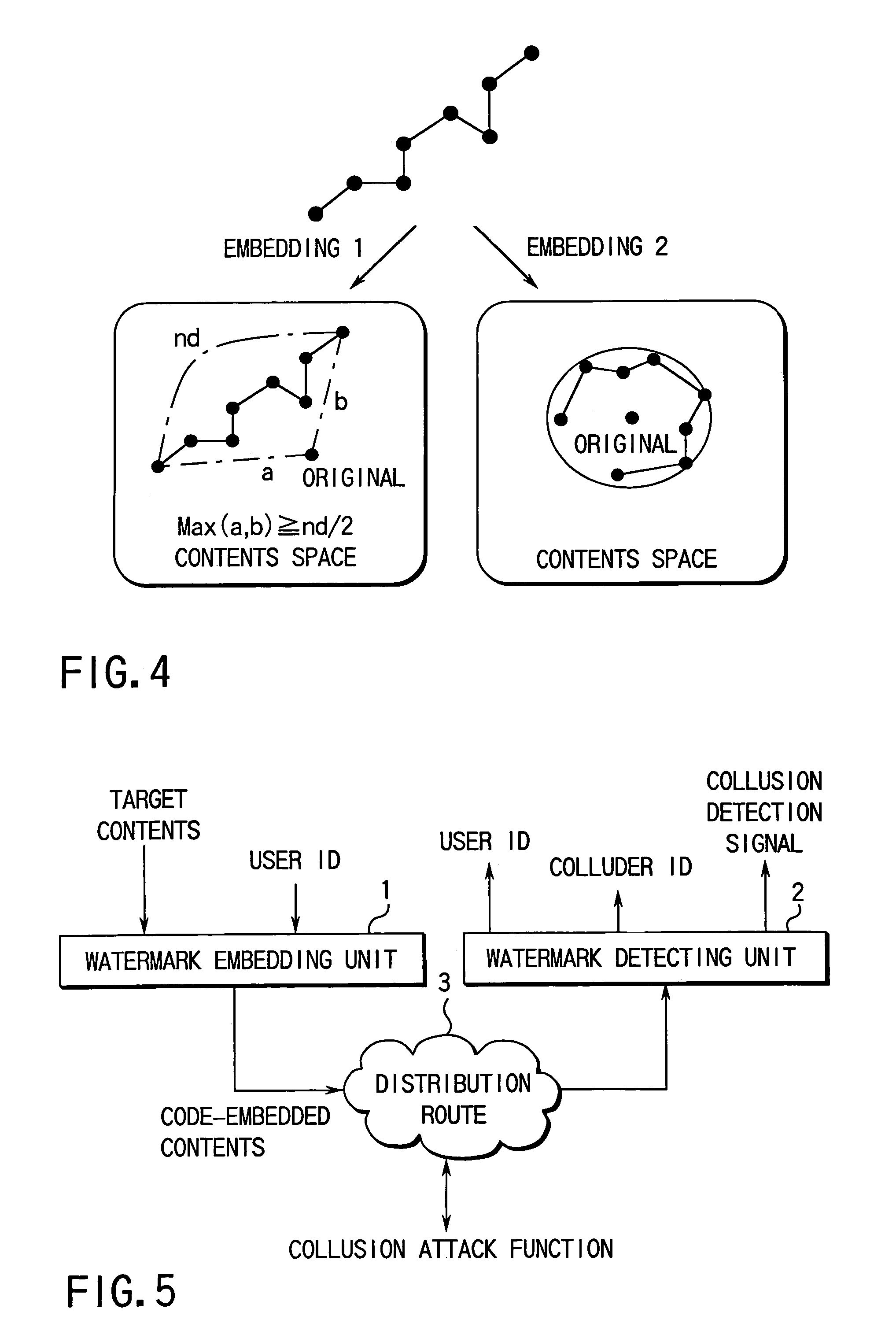

Code generating method and unit thereof, code detecting method and unit thereof, and watermark embedding unit and watermark detecting unit

InactiveUS7082537B2Deterioration can be suppressedResist attackPulse modulation television signal transmissionBroadcast systems characterised by watermarksComputer architectureWatermark embedding

Residue calculating sections respectively obtain residues which take a plurality of integers as modulus, with respect to a user ID. The plurality of integers are stored in modulus storage sections and are prime to each other. Based on these residues and parameters stored in a coding parameter storage section, component codes constructed by continuous sequences of 1 and 0 using a predetermined number of bits as a unit are respectively generated by component code generating sections. These component codes are concatenated by a concatenating section, thereby to obtain a code to be embedded, which constructs watermark information.

Owner:KK TOSHIBA

Power Output Apparatus, Control Method of Power Output Apparatus, and Vehicle Equipped With Power Output Apparatus

InactiveUS20090105924A1Wasteful fuel consumptionImprove energy efficiencyAnalogue computers for vehiclesElectrical controlCombustionDriver/operator

In response to the driver's depression of a brake pedal in requirement of catalyst deterioration control with a catalyst deterioration control flag Fc set equal to 1, the braking control of the invention controls the operation of a motor to make a rotation speed Ne of an engine approach to a target rotation speed Ne* in a state of continued combustion (firing) of the engine (steps S180 and S190). Such control ensures a quick decrease of the rotation speed Ne of the engine to the target rotation speed Ne*, thus effectively reducing the wasteful fuel consumption due to the continued operation of the engine at a high rotation speed and enhancing the overall energy efficiency of the vehicle.

Owner:TOYOTA JIDOSHA KK

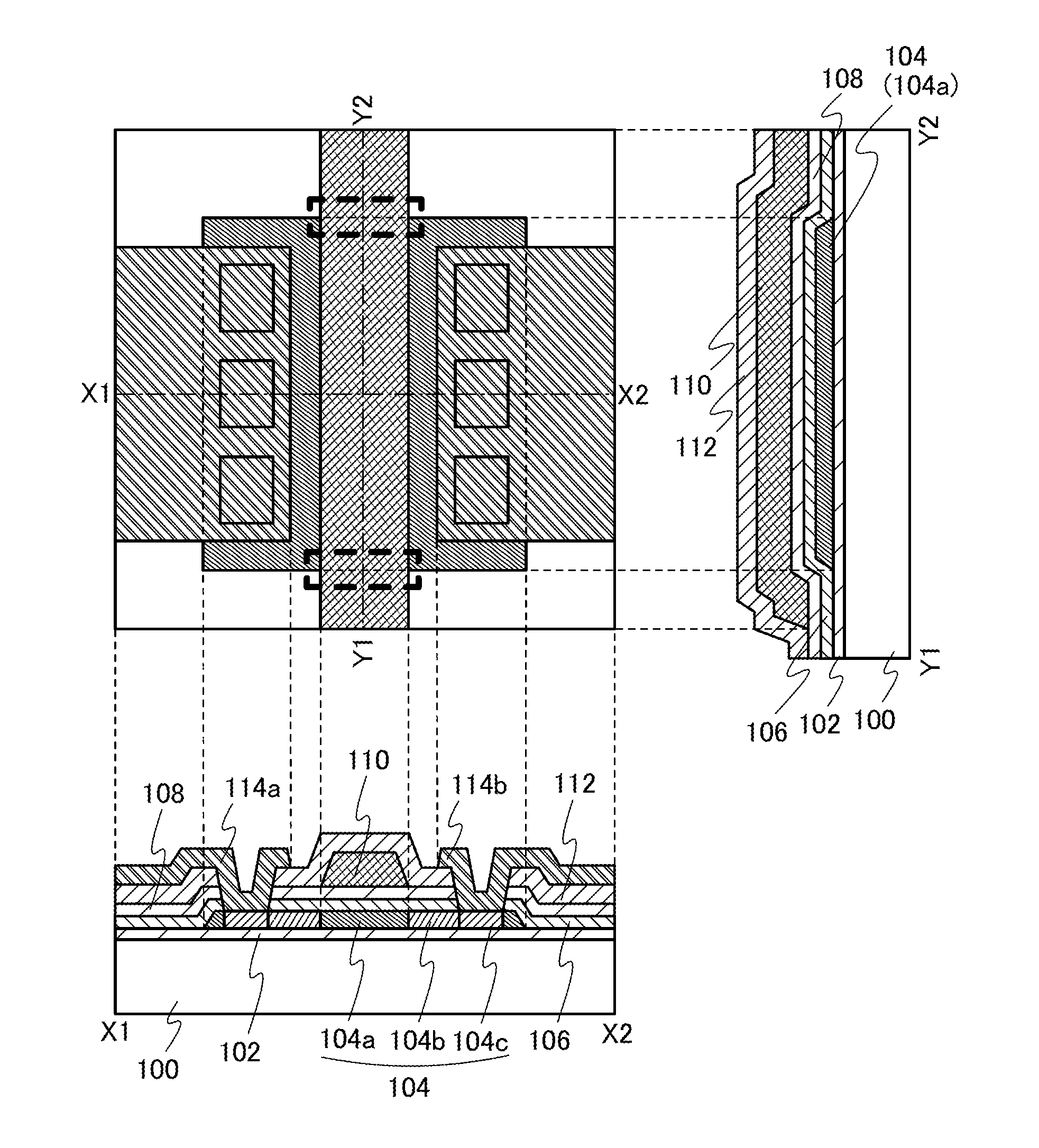

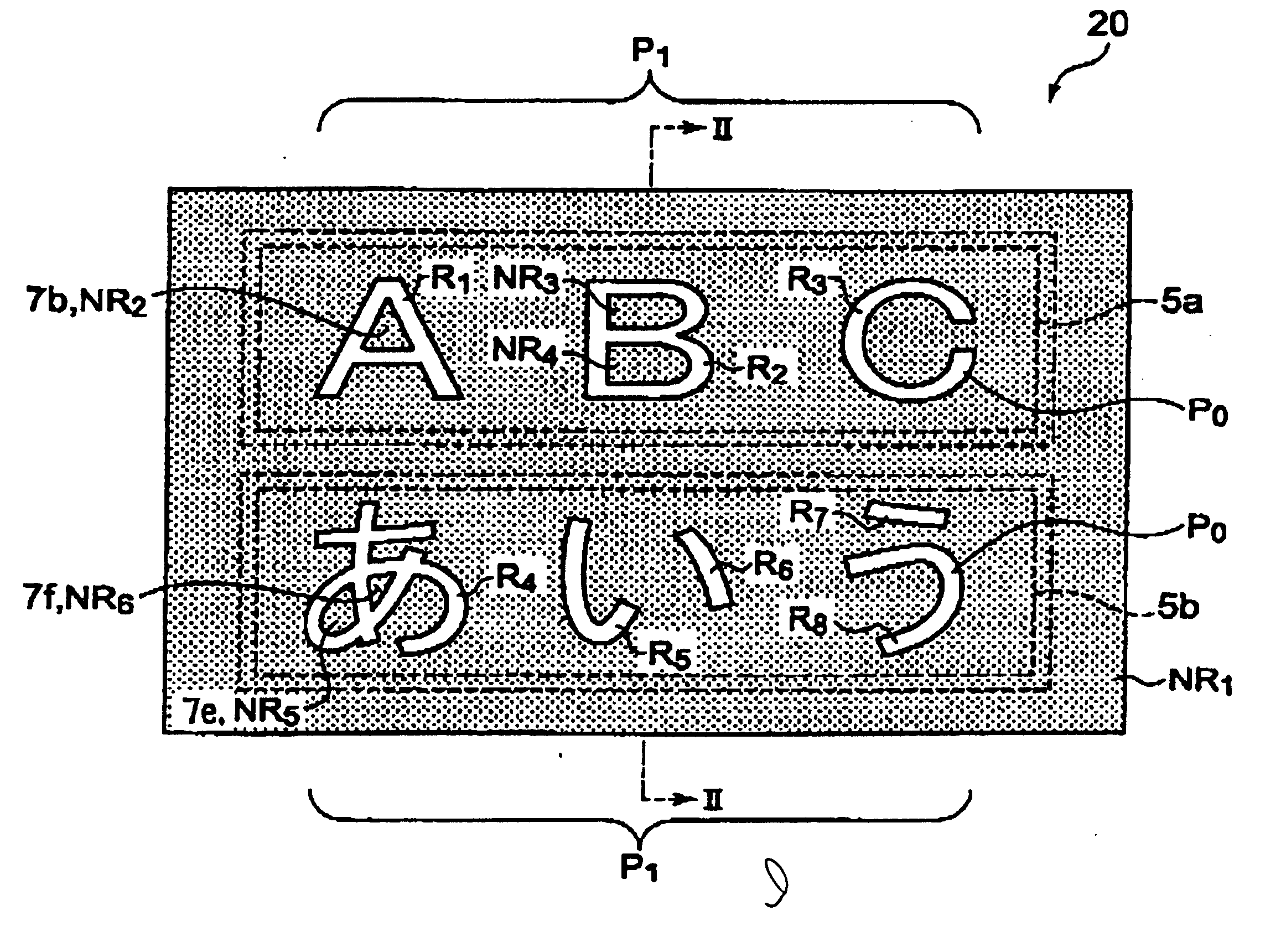

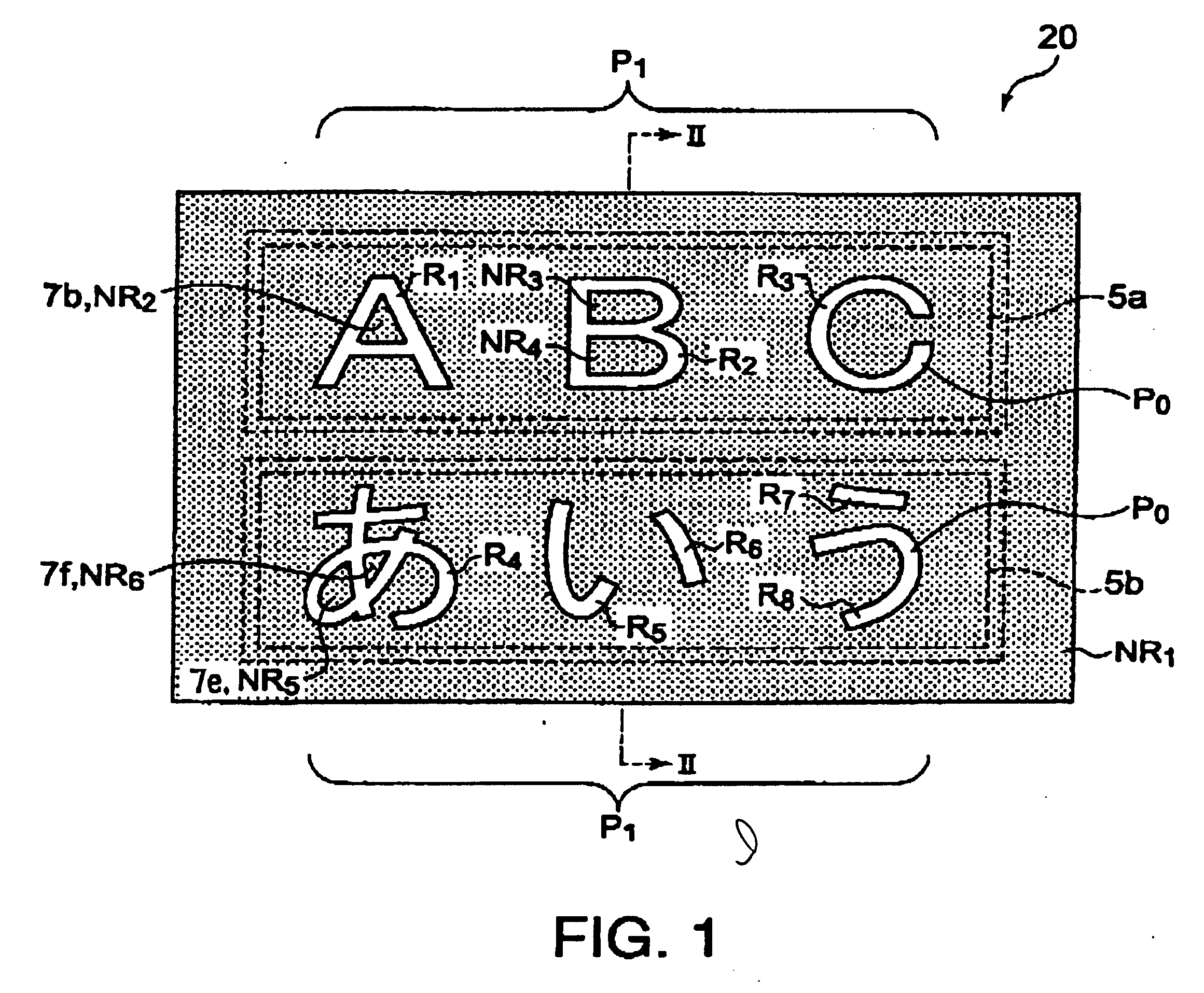

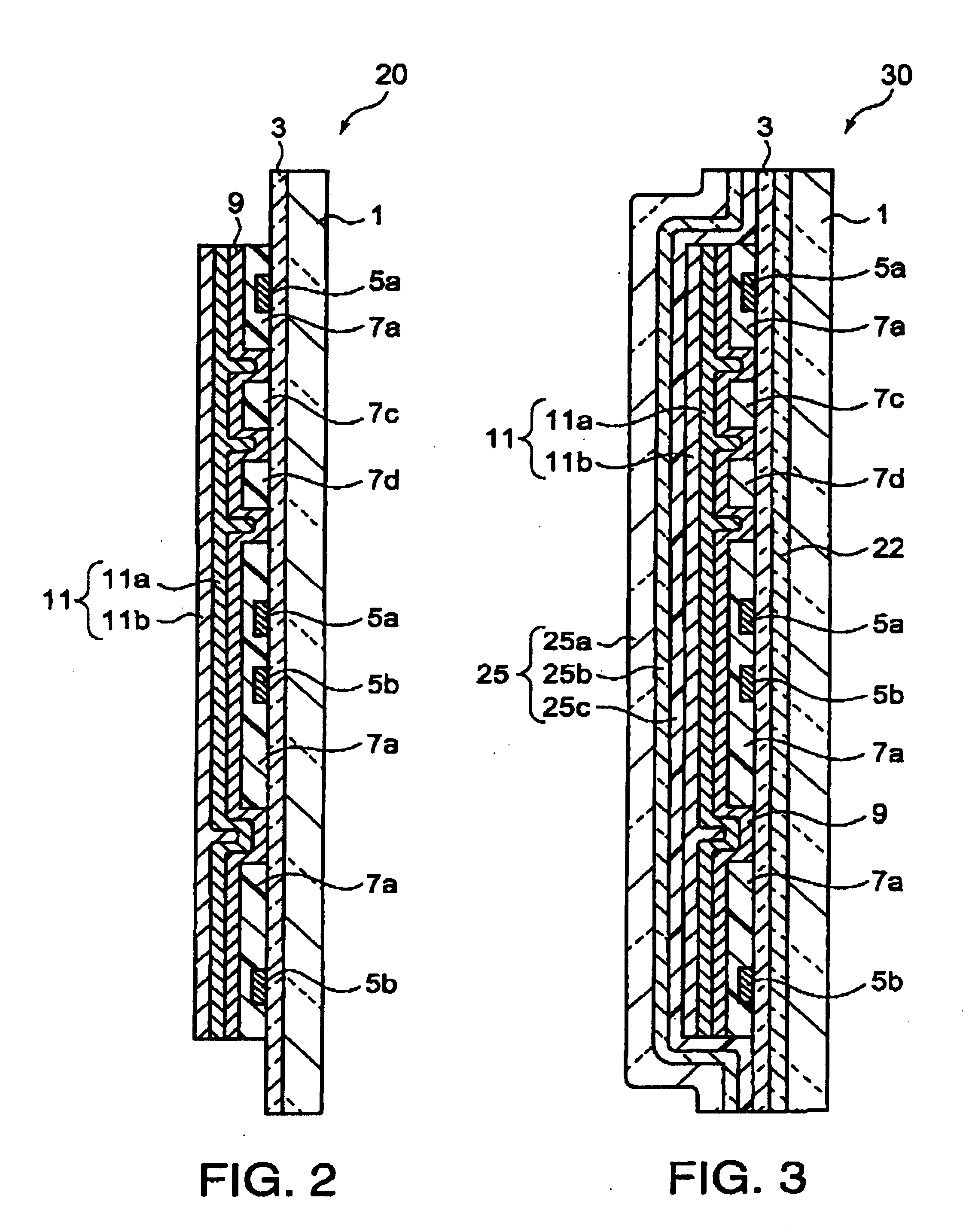

Luminescence display panel

InactiveUS20060091796A1Improve image qualityAttractive visual effectDischarge tube luminescnet screensStatic indicating devicesInsulation layerLuminescence

A luminescence display panel 20 includes: a flexible transparent substrate 1; a transparent electrode 3 formed on the transparent substrate 1, over a luminescence region and a non-luminescence region; and auxiliary electrodes 5a and 5b formed on the transparent electrode 3, over the non-luminescence region. Electric insulation layers 7a, 7c, and 7d are formed over the non-luminescence region of the transparent electrode 3, so as to cover the auxiliary electrodes 5a and 5b. An organic luminescence part 9 is formed on the transparent electrode, at least over the luminescence region. A rear electrode 11 is formed on the organic luminescence part 9.

Owner:DAI NIPPON PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com