Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1631results about "Controlled members" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

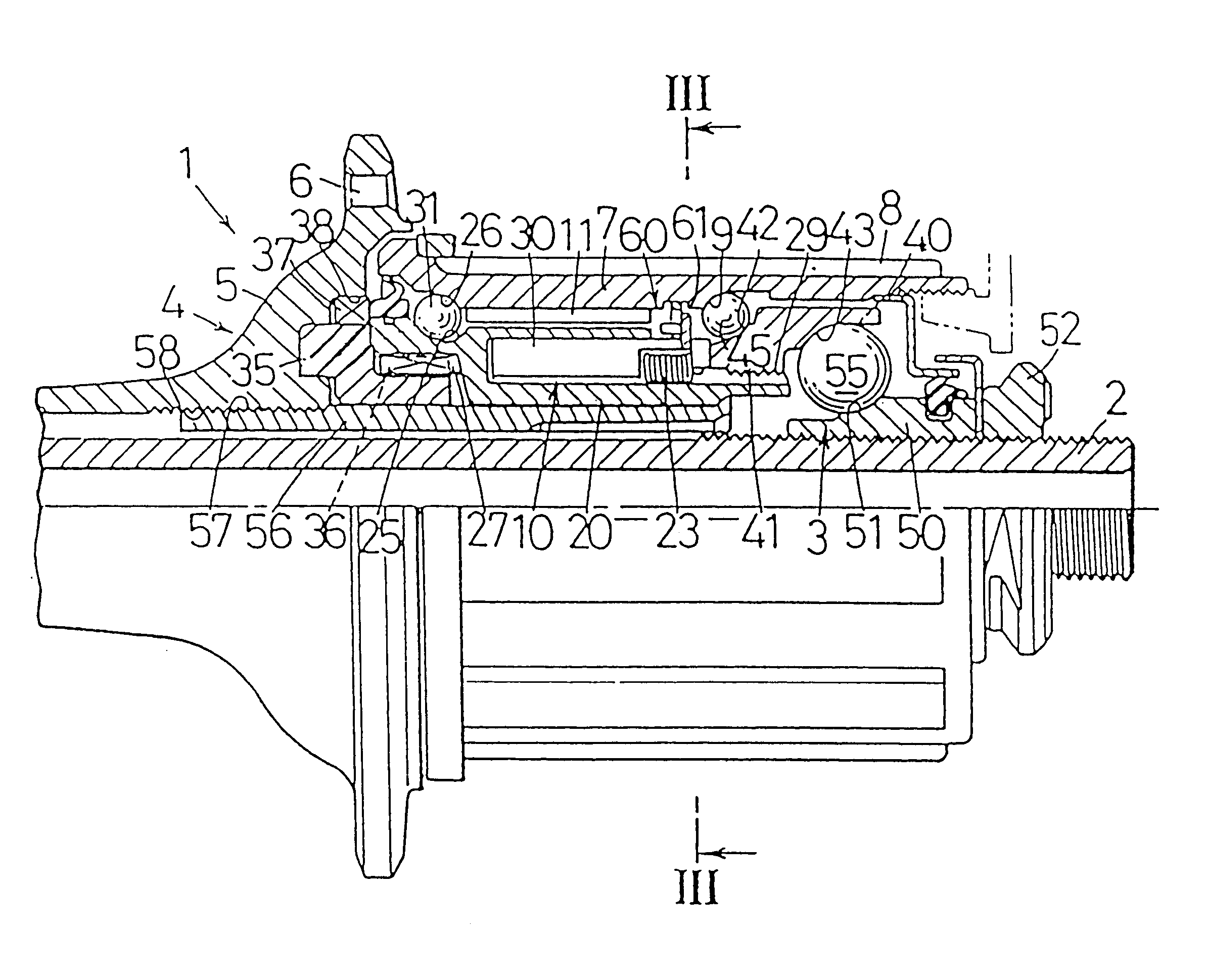

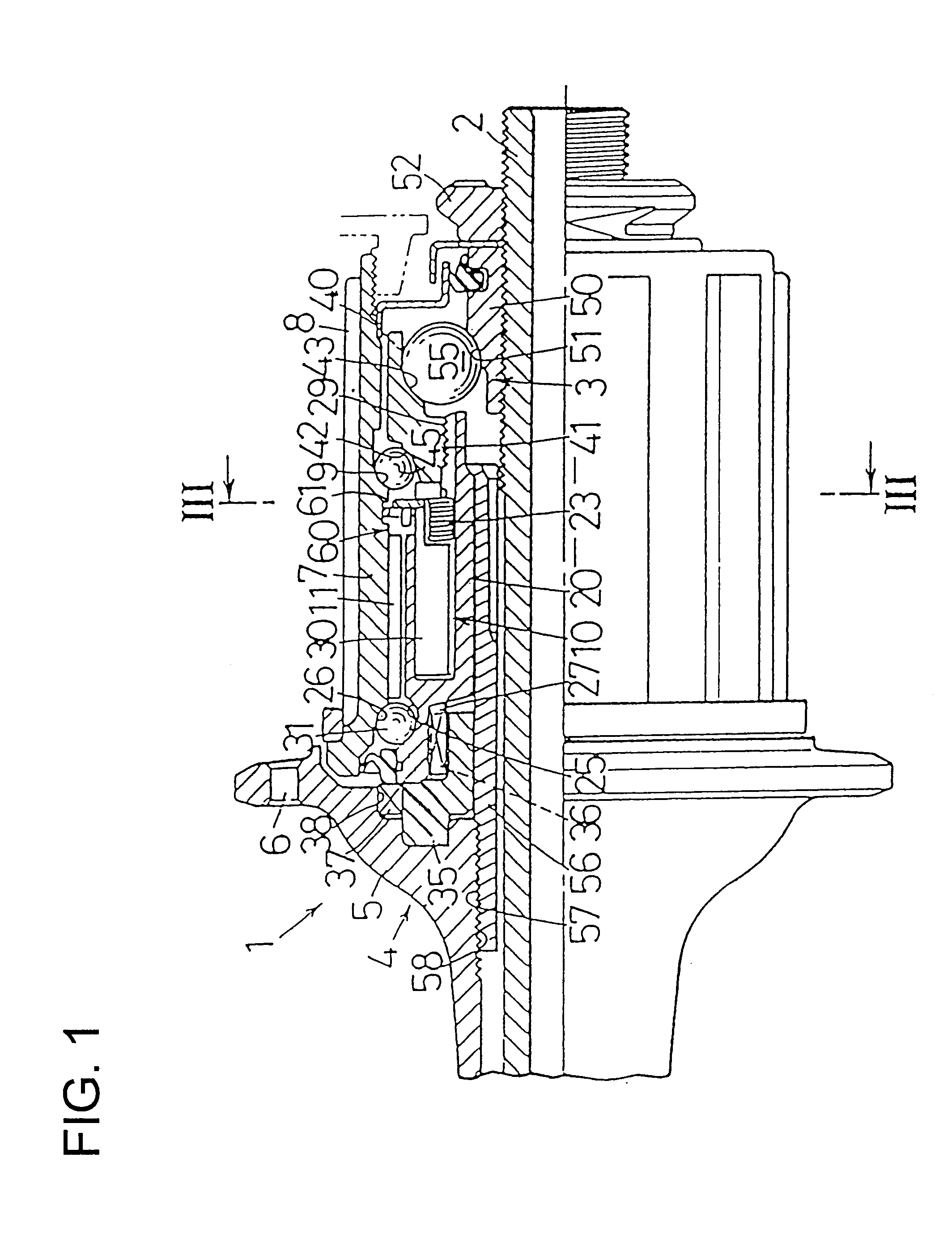

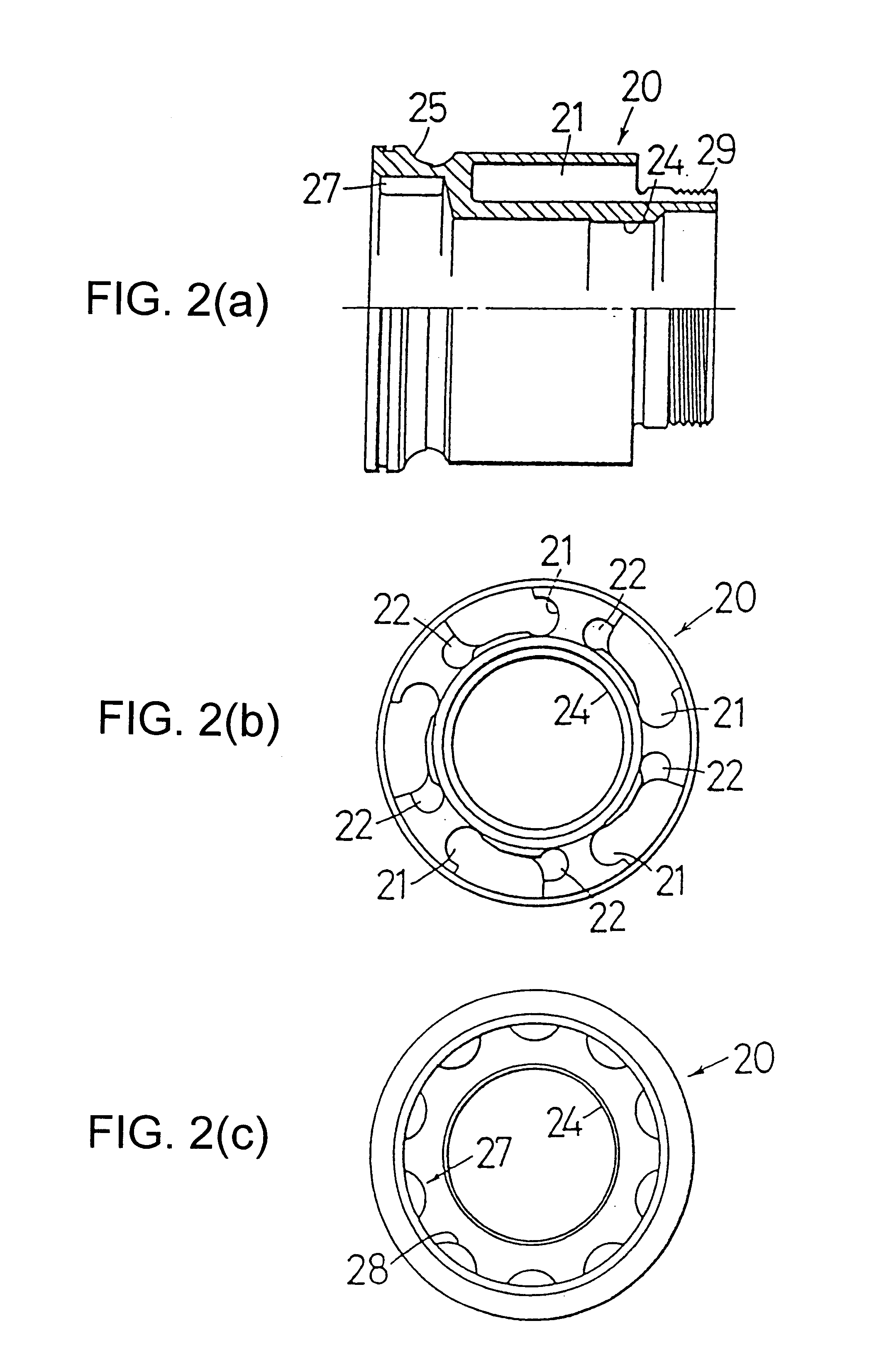

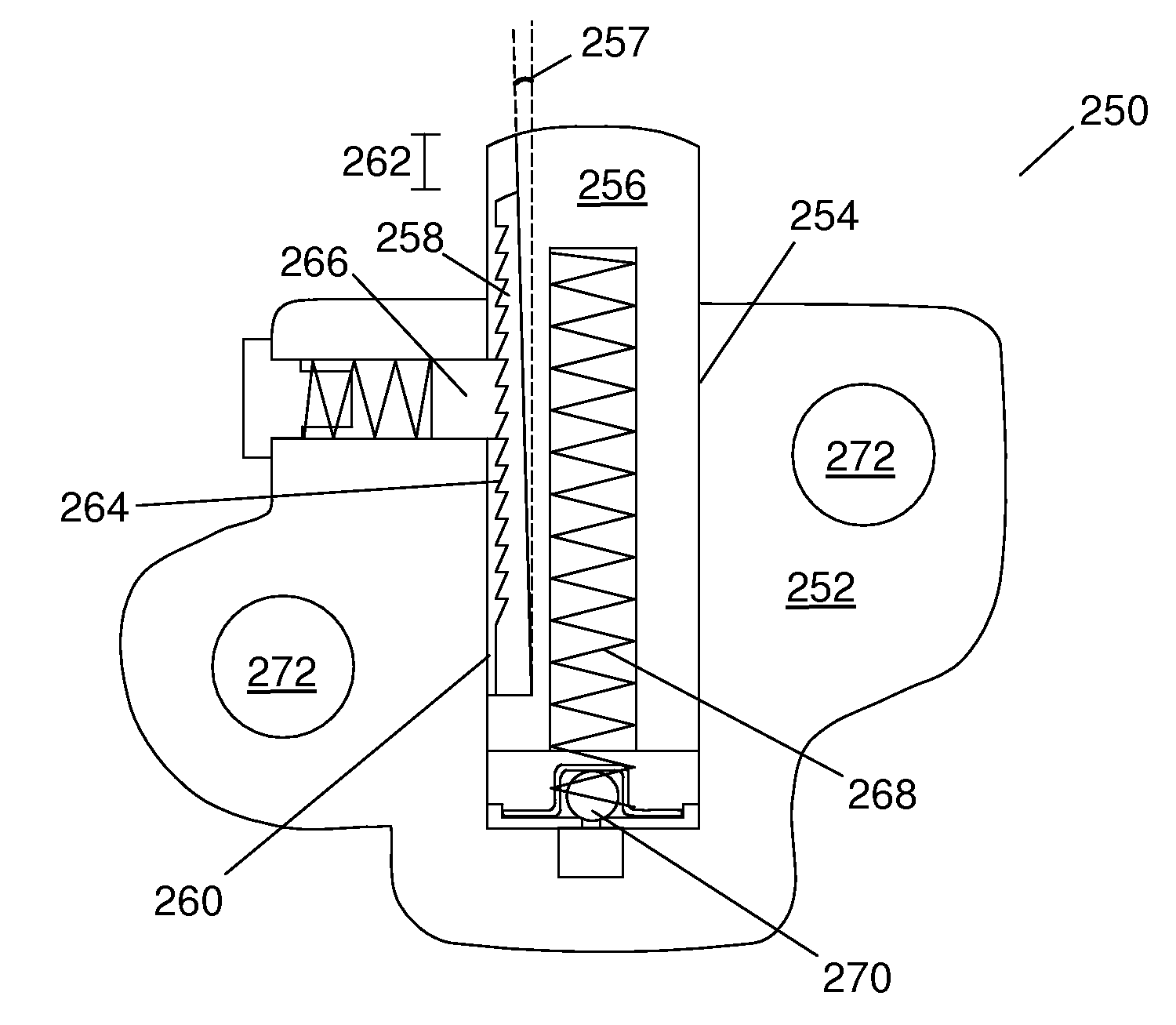

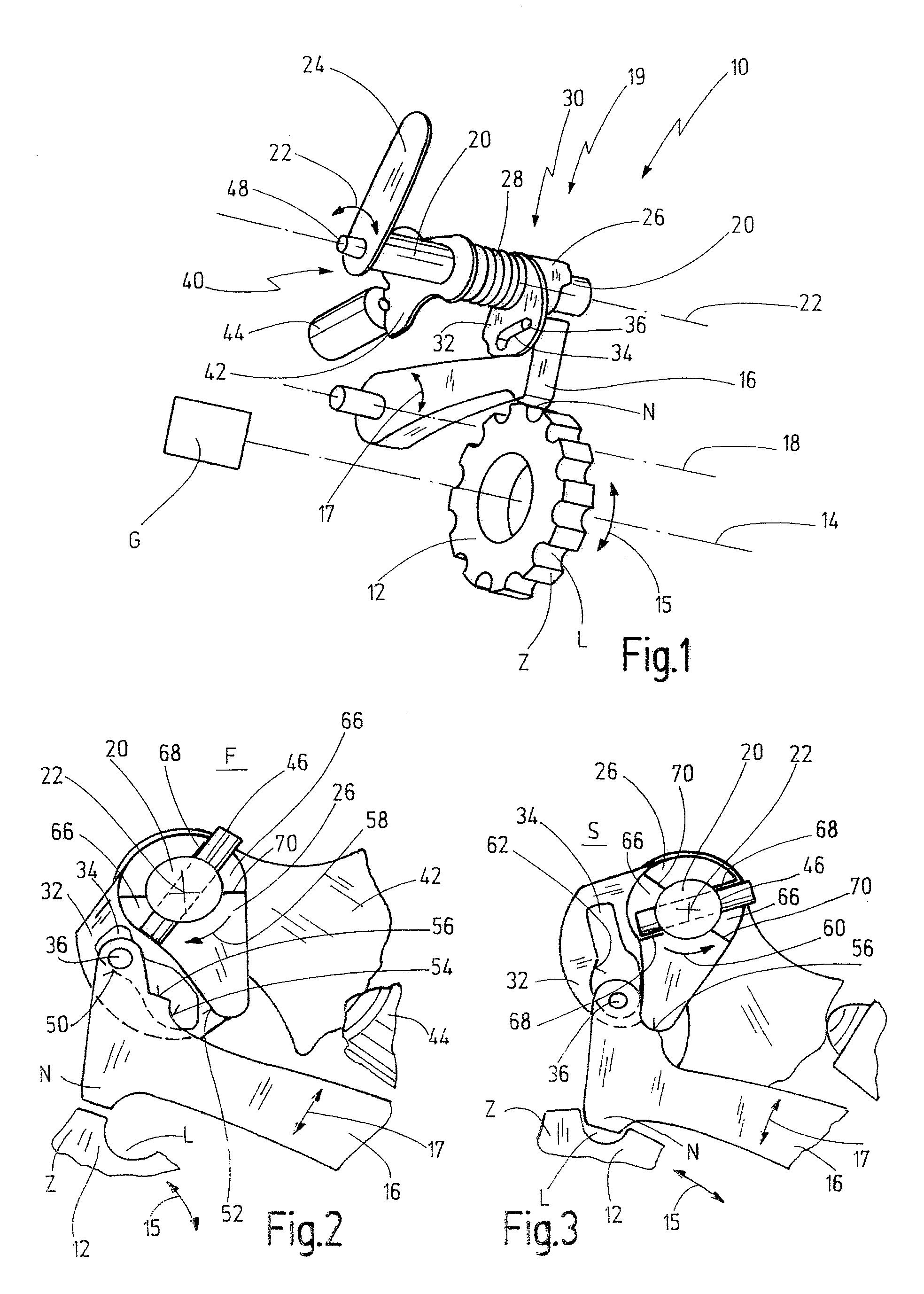

Pawl noise dampening mechanism for a bicycle freewheel

InactiveUS6202813B1Reduce wearAvoid contactControlling membersControlled membersFreewheelEngineering

A ratchet mechanism for a bicycle hub includes a first hub member and a second hub member, wherein the first hub member and the second hub member are rotatable relative to each other. A pawl is supported by the first hub member, a ratchet tooth is supported by the second hub member, and a biasing mechanism is provided for biasing the pawl toward the ratchet tooth. A pawl control mechanism is responsive to relative rotation of the first hub member and the second hub member for allowing the pawl to contact the ratchet tooth when the first hub member and the second hub member rotate relative to each other in one direction and for preventing the pawl from contacting the ratchet tooth when the first hub member and the second hub member rotate relative to each other in an opposite direction.

Owner:SHIMANO INC

Compact counter balance for robotic surgical systems

In one embodiment of the invention, an apparatus is provided including a linkage and a balancing mechanism coupled to the linkage around a pivotal joint. The linkage couples to a support structure at a first end and support a weight applied to a second end. The balancing mechanism counter balances the weight applied to the second end of the linkage. As the linkage is deformed to vertically adjust the height of the weight with a different moment arm length, the balancing mechanism varies a cable path length to modify the compression of a spring and a tension in a cable to adjust the amount of counter balance force applied to the linkage.

Owner:INTUITIVE SURGICAL OPERATIONS INC

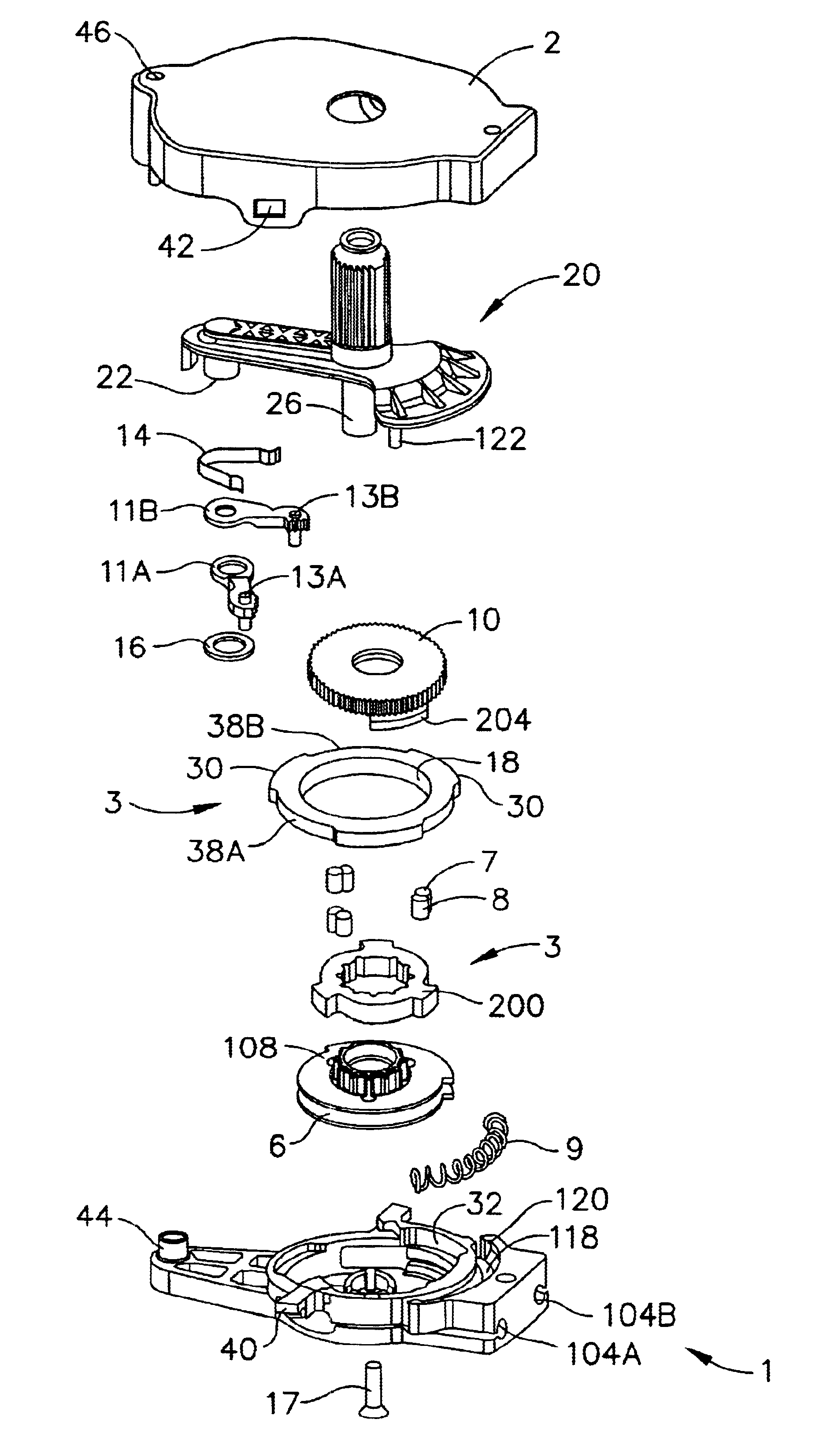

Cable retraction mechanism for trigger shifters

ActiveUS7000496B2Simple processReduce in quantityControlling membersControlled membersVariatorEngineering

A bicycle shifter having a housing mountable to a handlebar, a takeup mechanism for pulling a shift cable and a release mechanism for releasing the shift cable. The takeup mechanism includes a takeup tooth segment, a takeup pawl and an actuation element. The release mechanism includes retaining and locking tooth segments, retaining and locking pawls and a release element. The takeup, retaining and locking tooth segments are arranged on one disk element.

Owner:SRAM

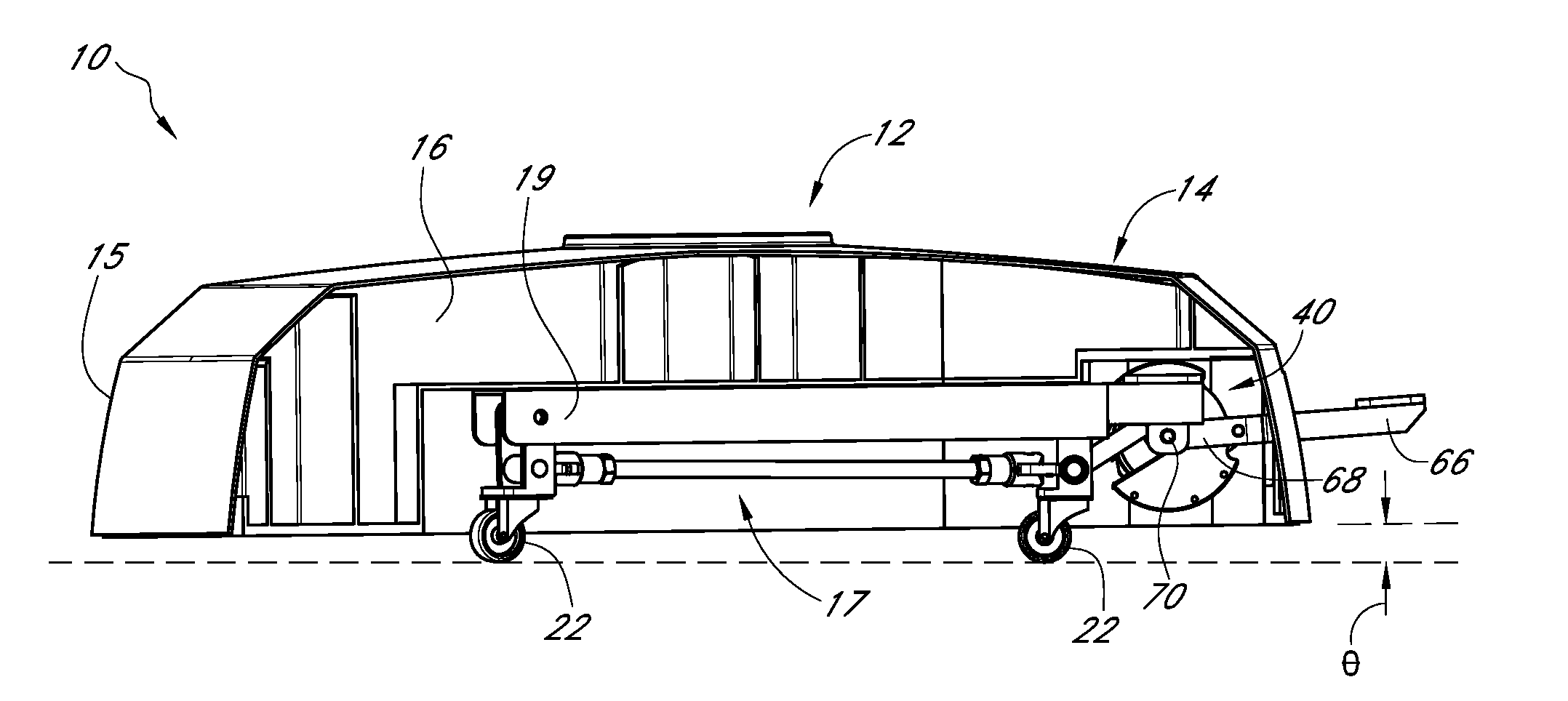

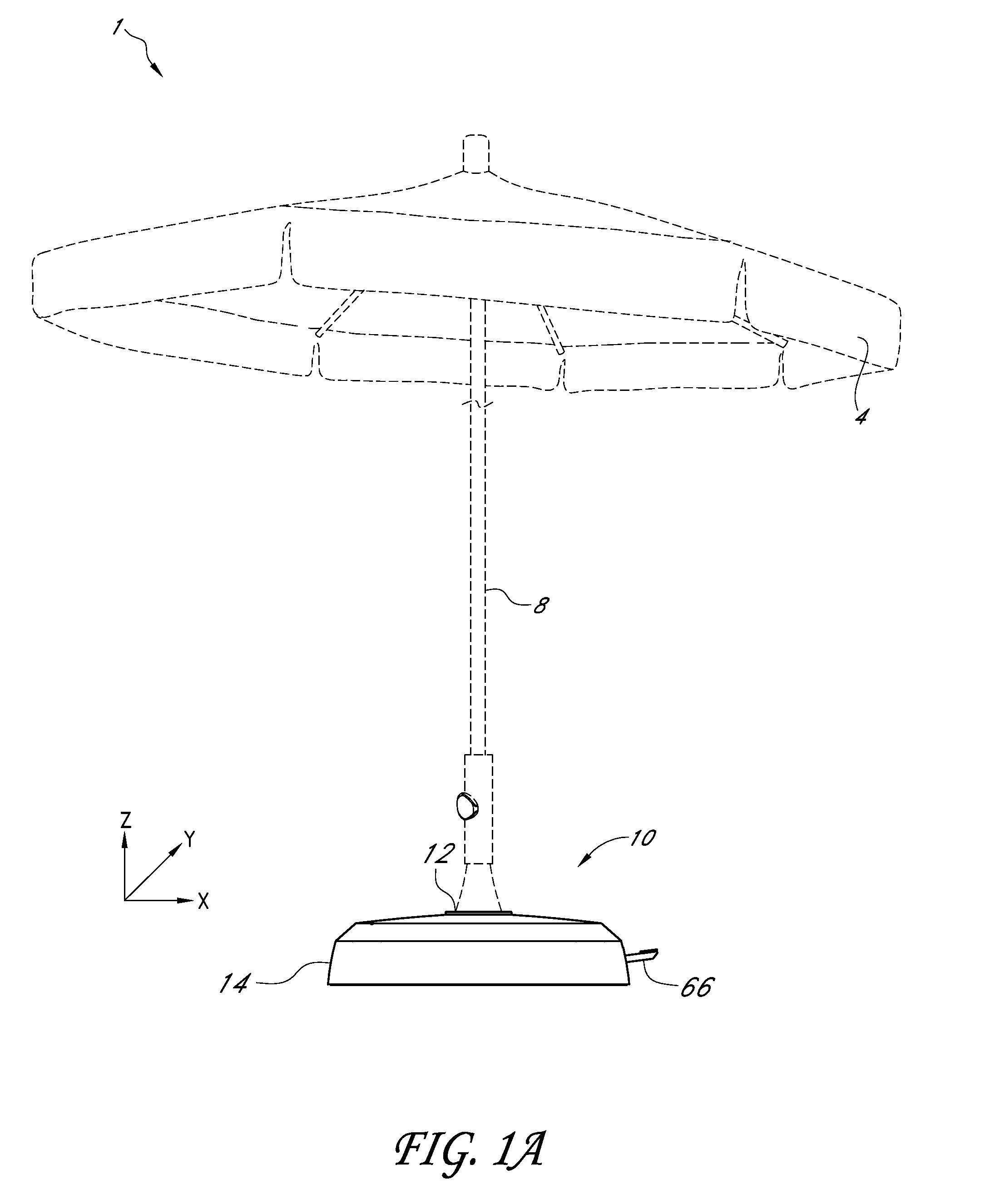

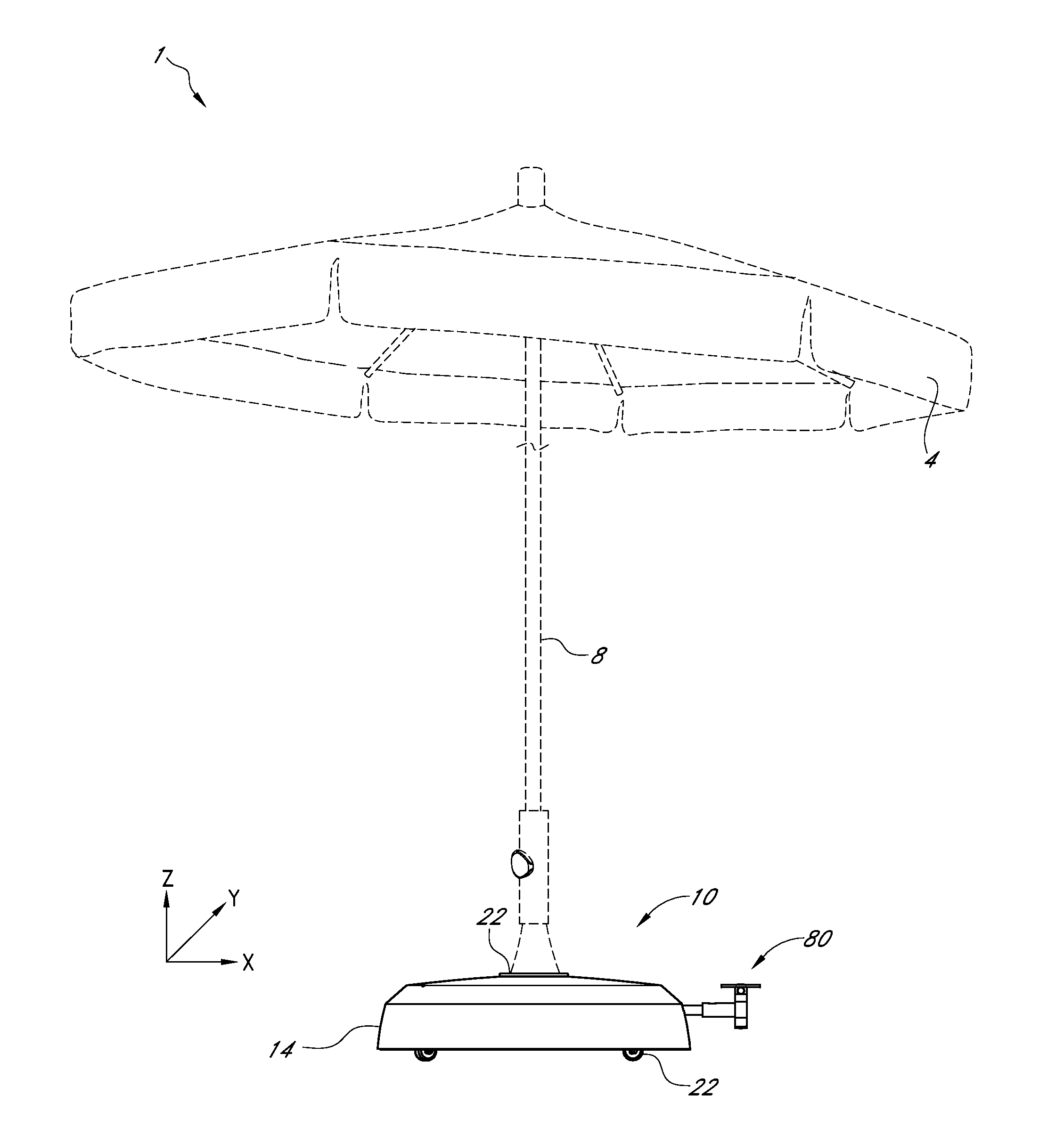

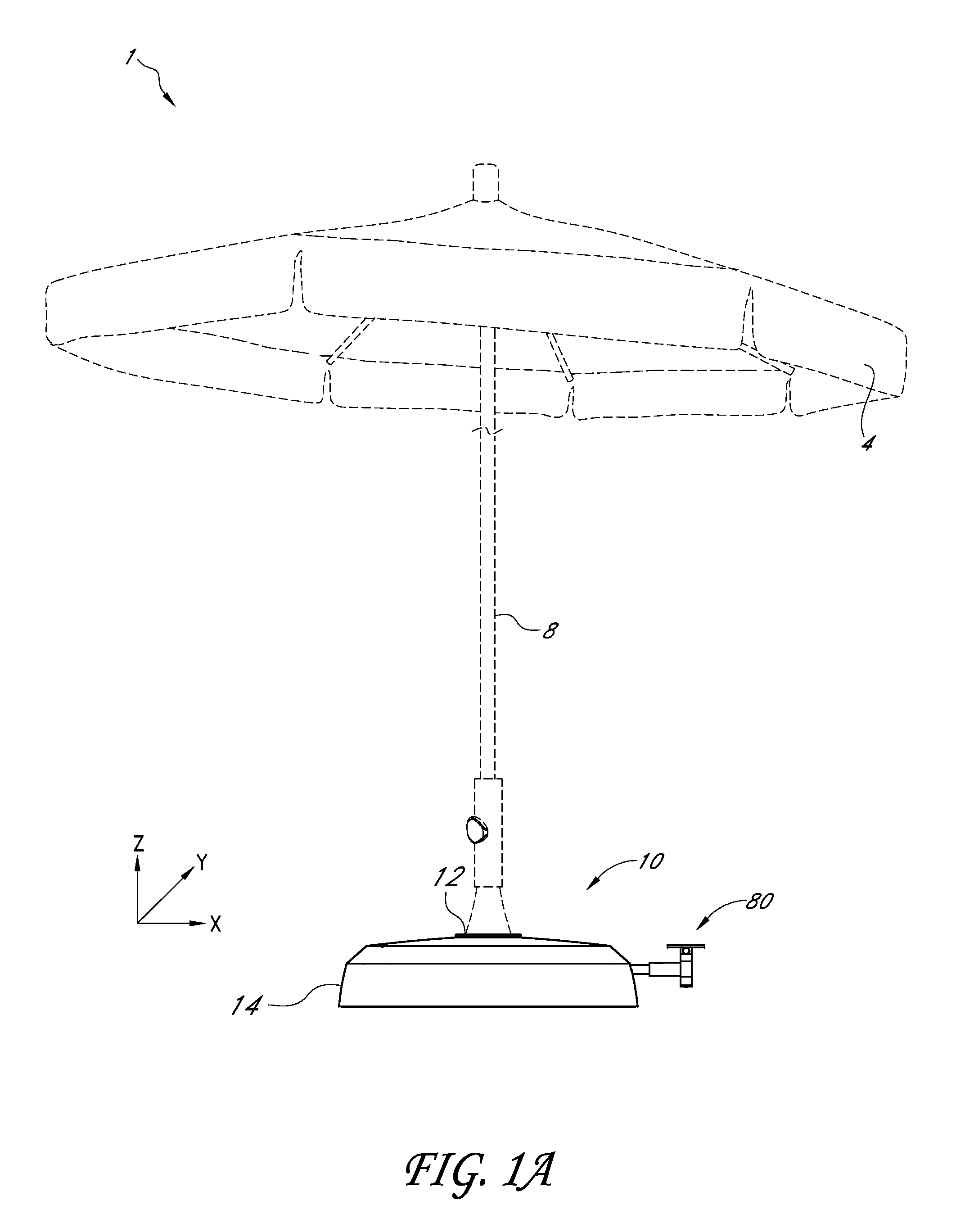

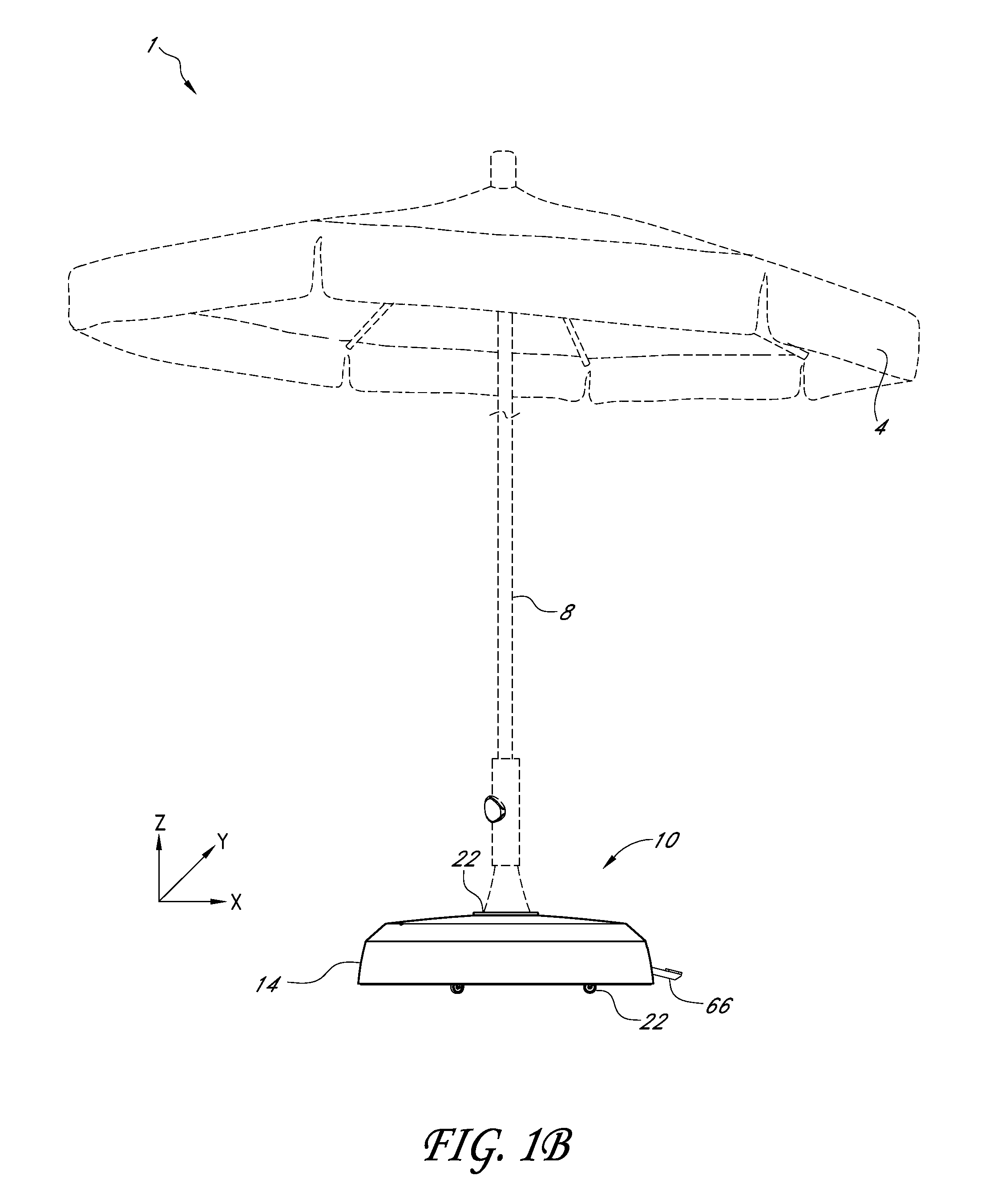

Movable base with wheels deployable by cyclic driving assembly

A ratcheting assembly can include a housing, a ratcheting gear, a first ratchet pawl, a motion translation member, and a ratcheting actuation member. The ratcheting gear can rotatably mount within the housing and include a plurality of ratchet teeth and an eccentric opening. The eccentric opening can include a rotational center of the ratcheting gear. The first ratchet pawl can mount to the housing adjacent to the ratcheting gear to allow rotation in a first direction and to hinder rotation in a second direction opposite the first direction. The motion translation member can mount within the opening such that rotation of the ratcheting gear can cause a movement of the motion translation member via rotation of the eccentric opening. The ratcheting actuation member can mount to the housing and include a second ratchet pawl. The second ratchet pawl can mount to the ratcheting actuation member adjacent to the ratcheting gear such that actuation of the ratcheting actuation member in the first direction can cause a rotation of the ratcheting gear and actuation of the ratcheting actuation member in the second direction opposite the first direction does not cause a rotation of the ratcheting gear.

Owner:OLIVER JOEN AN MA

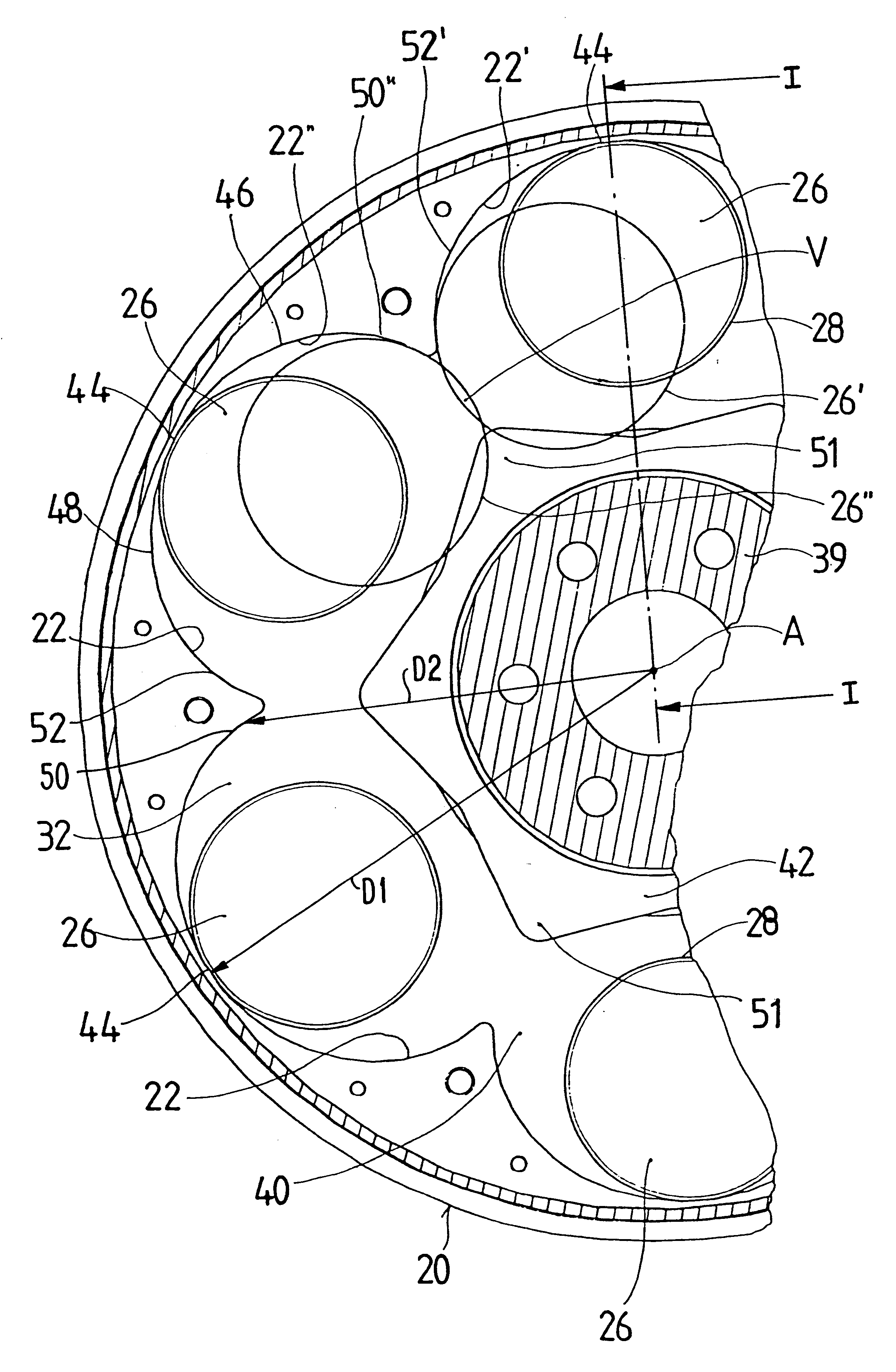

Vibration damping device

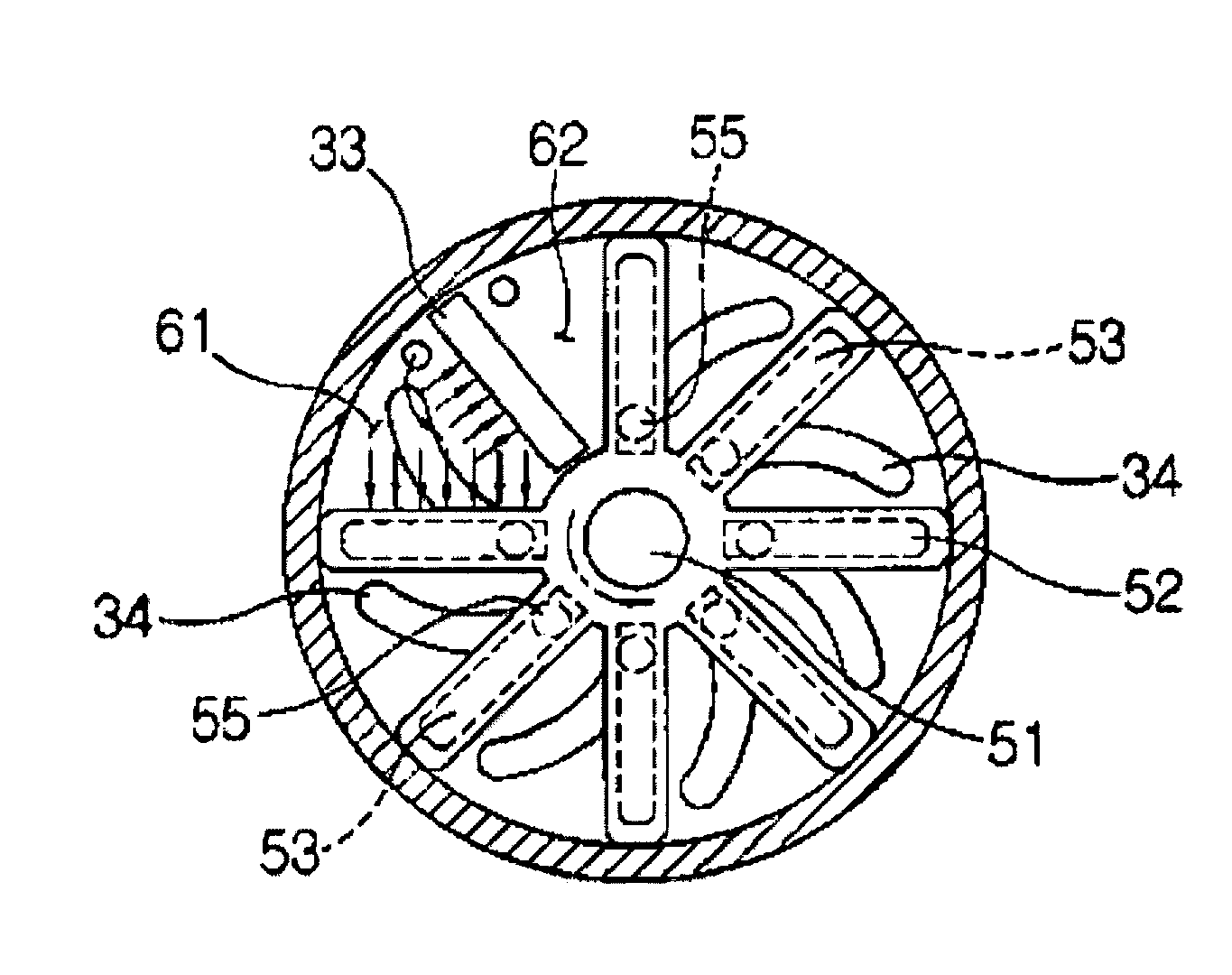

InactiveUS6382050B1Avoid knockingEasy constructionRotating vibration suppressionControlling membersMobile vehicleRotational axis

A vibration damping device for a drive system of a motor vehicle includes a base body arranged for rotating about an axis of rotation and a deflection mass arrangement arranged in said base body and having at least one deflection mass and a deflection path associated with the at least one deflection mass and along which the deflection mass is movable during rotation of the base body about the axis of rotation. The deflection path has a vertex area at a position furthest from the axis of rotation and deflection areas on both sides of the vertex area extending from the vertex area to ends areas. The deflection areas have a decreasing distance from the axis of rotation (A) proceeding from the vertex area toward their end areas. A braking arrangement acts in the end areas of the deflection areas for gradually slowing the approach of the at least one deflection mass to a respective end area of the deflection path.

Owner:ZF FRIEDRICHSHAFEN AG

Method for controlling repeated gear engagement in DCT (dual clutch transmission) synchronizer gear engaging process

InactiveCN104154225AImprove shift qualityExtend your lifeControlled membersGearing controlControl engineeringProcess engineering

The invention provides a method for controlling repeated gear engagement in a DCT (dual clutch transmission) synchronizer gear engaging process. By the method, the problems that in a DCT gear shifting process, gear shifting cannot be realized or impact of gear shifting is caused under conditions that teeth face to each other, gear shifting fails and a synchronizer is worn are solved. In the method, a whole gear shifting process is divided into three stages comprising (1) a stage of approaching a synchronizing ring, (2) a synchronizing stage, and (3) a gear engaging stage after a gear sleeve is connected with connecting teeth. After the three stages are analyzed, the conditions that the teeth face to each other comprise the following two types of conditions: (1) teeth of the gear sleeve face teeth of the synchronizing ring; and (2) the teeth of the gear sleeve face the connecting teeth. The two types of conditions are analyzed, flexible gear engaging is realized and the synchronous ring is protected from being impacted by repeatedly engaging a gear, so that the service life of the synchronizing ring is prolonged, and the gear engaging success rate is increased.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

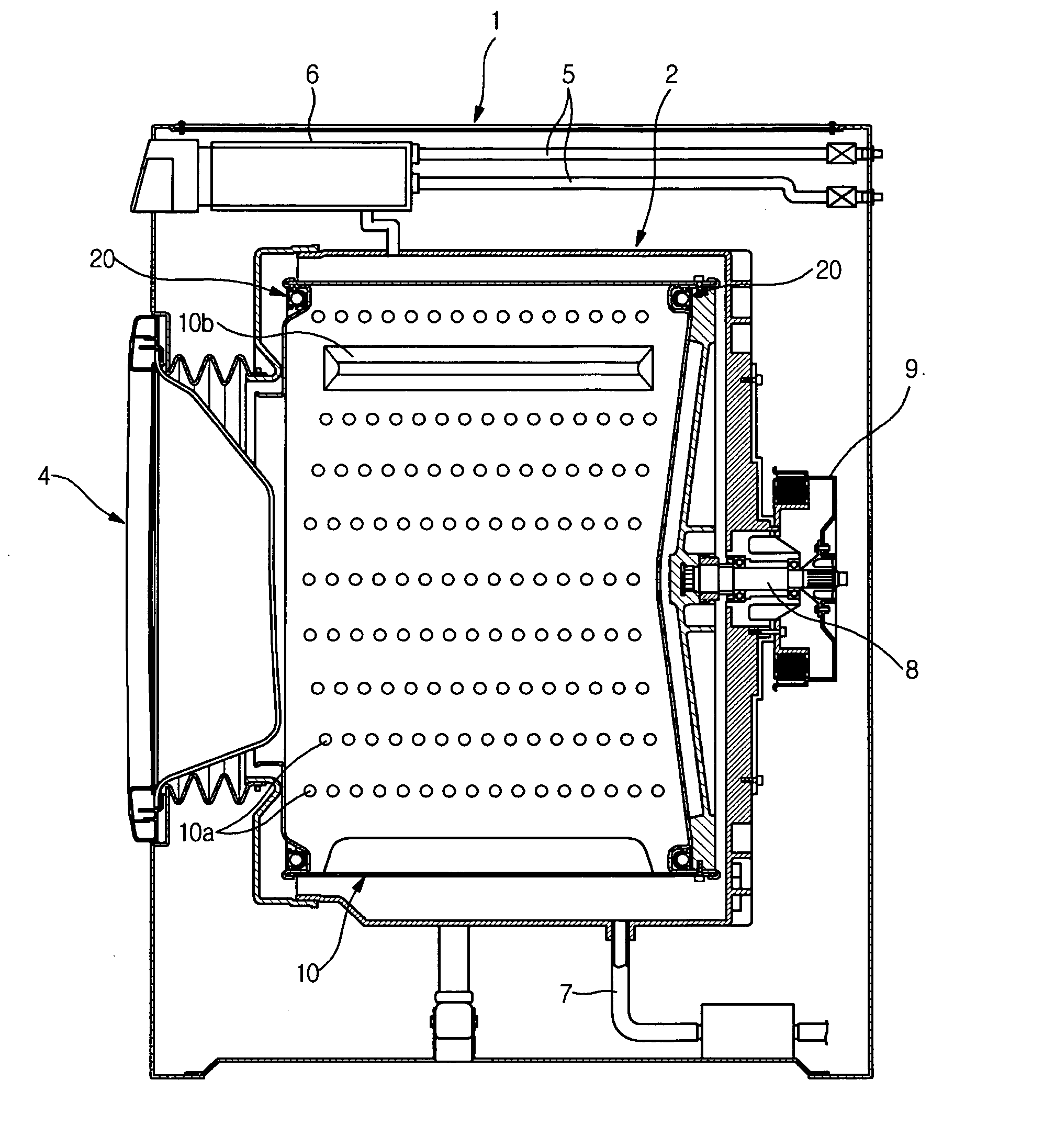

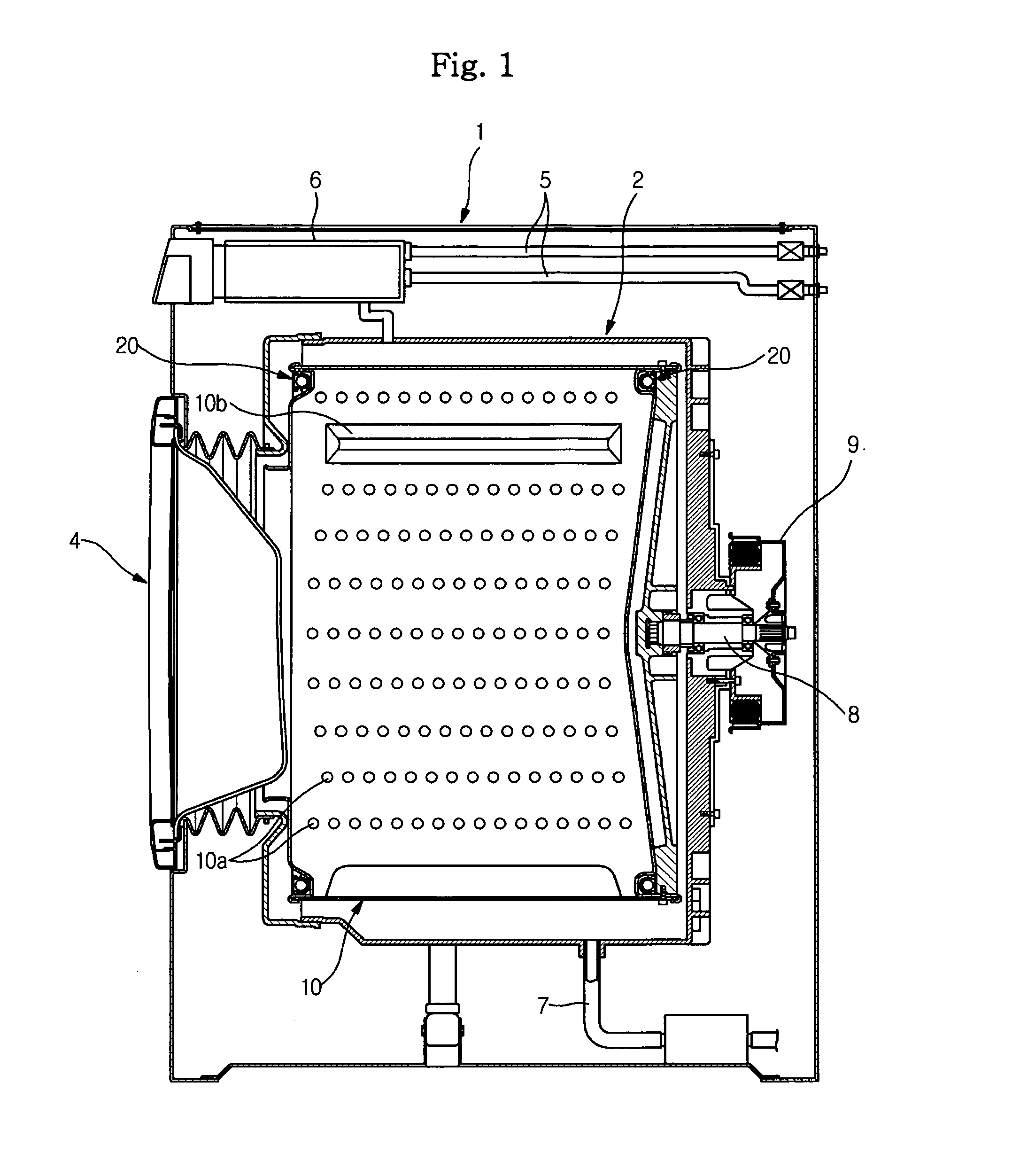

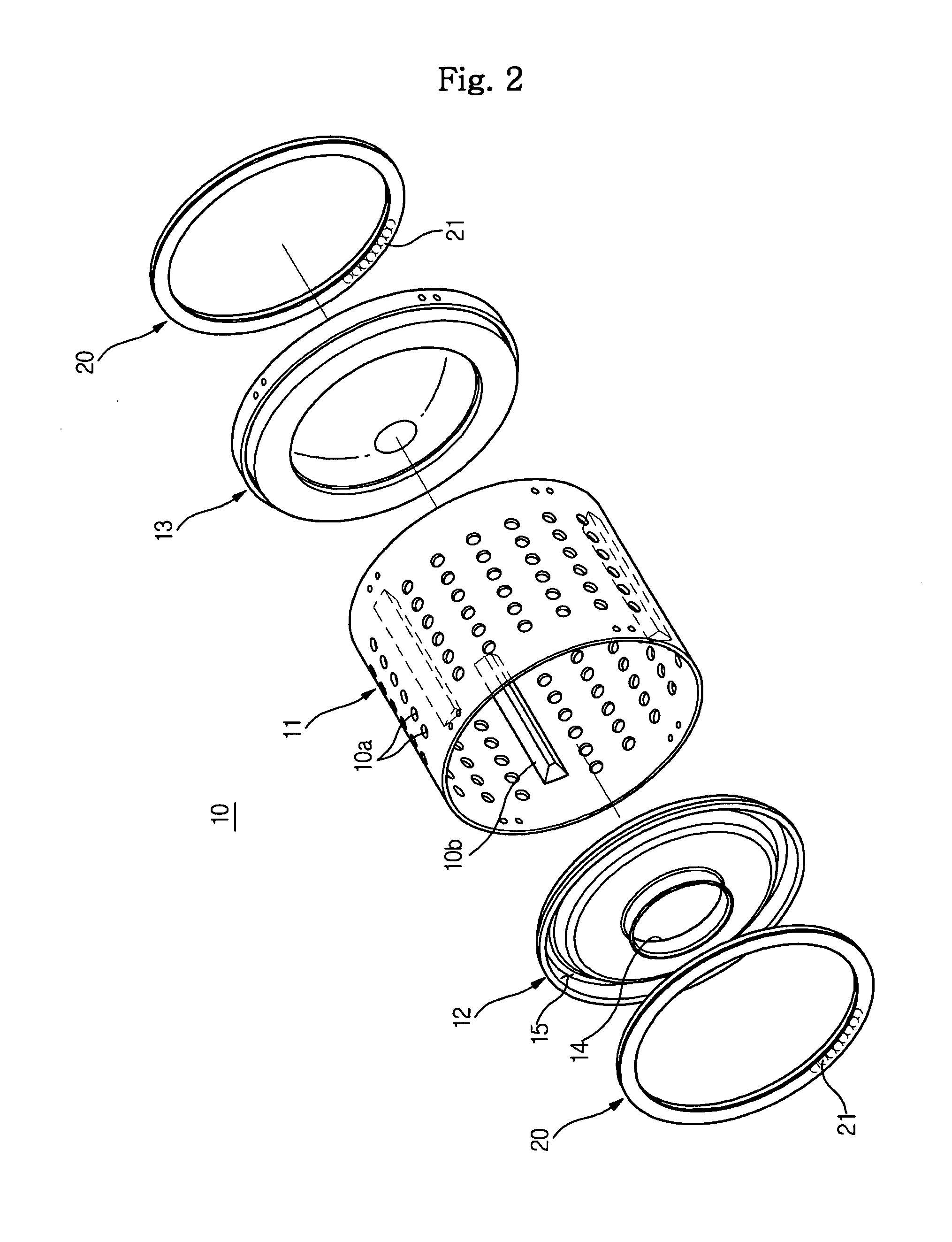

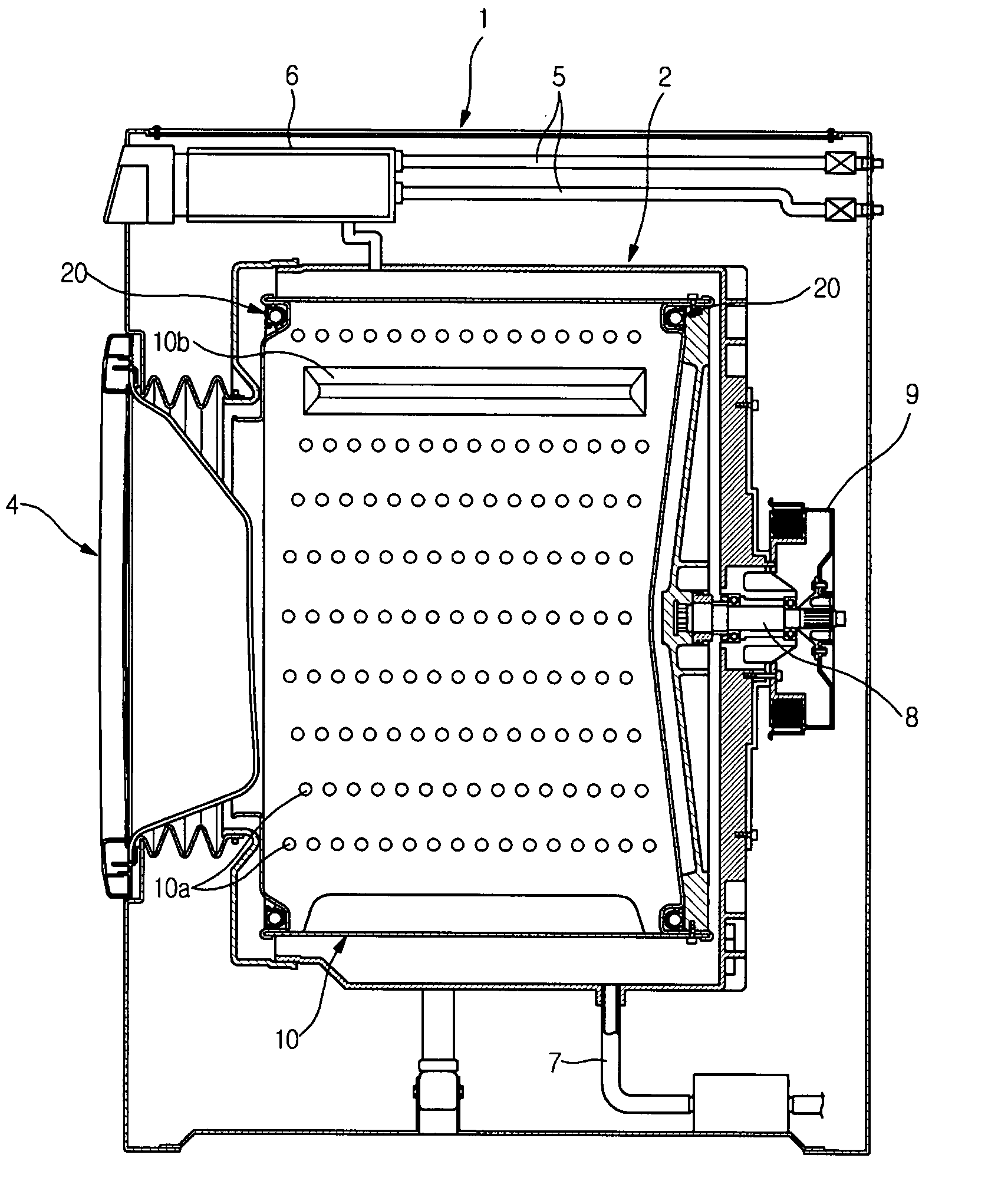

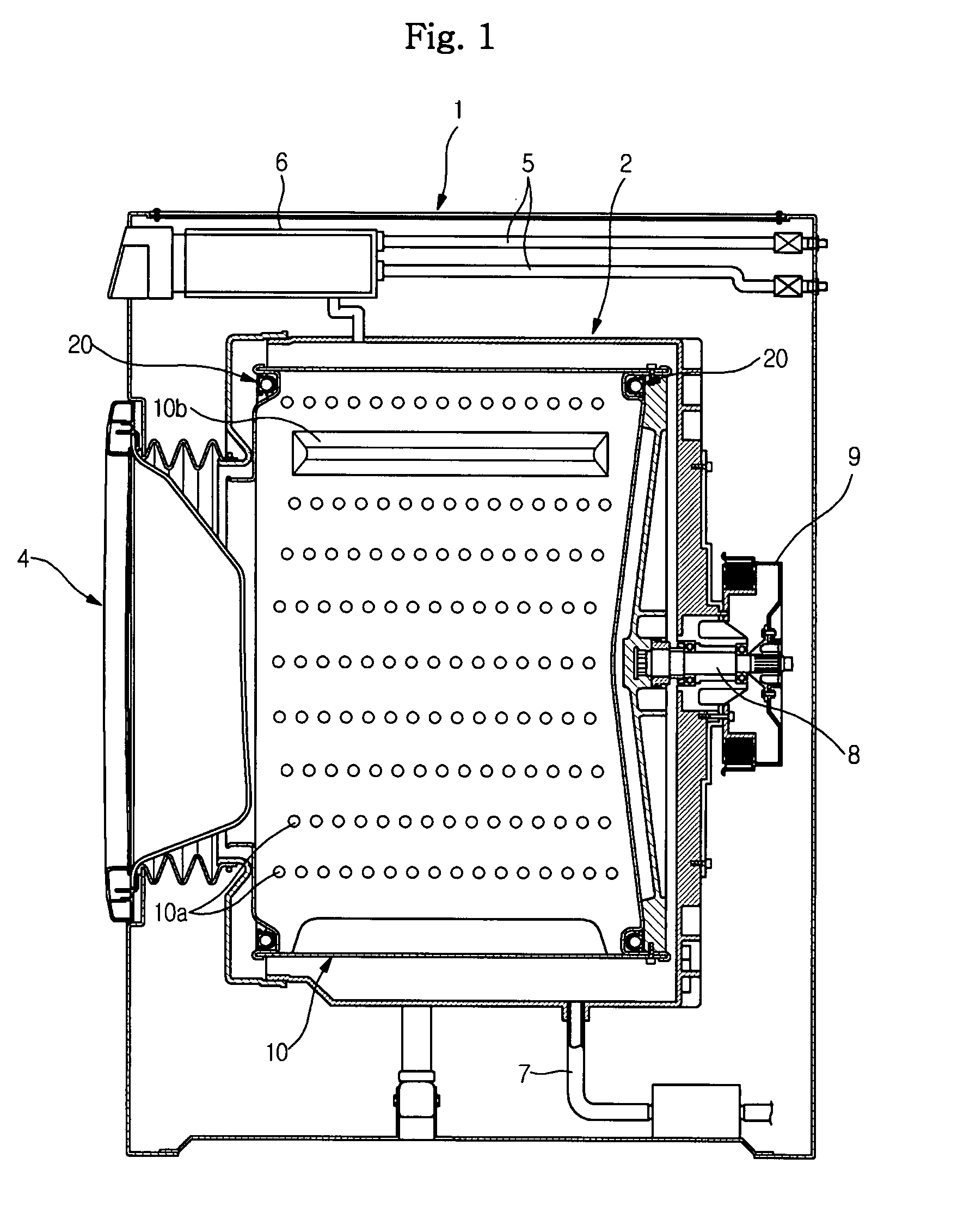

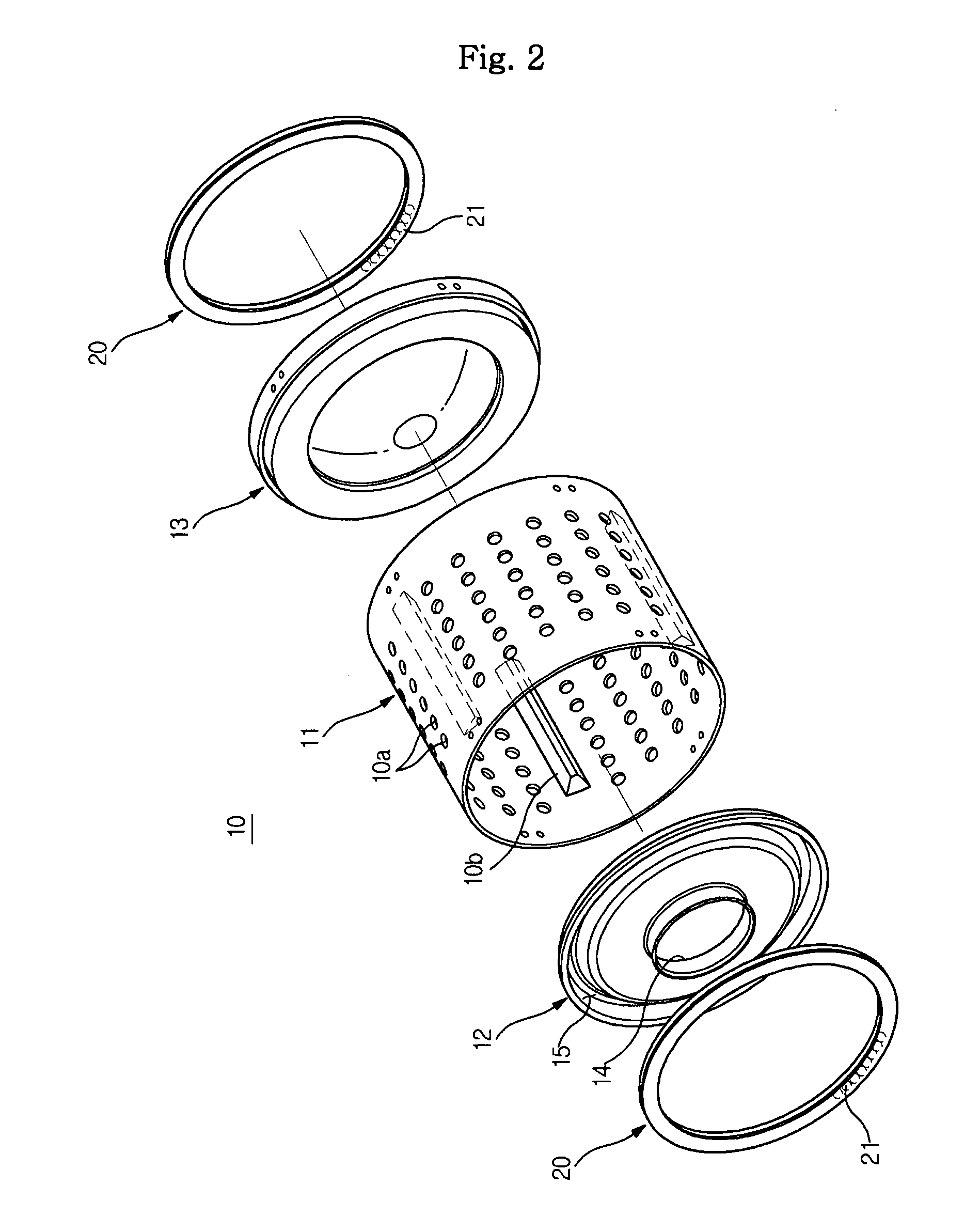

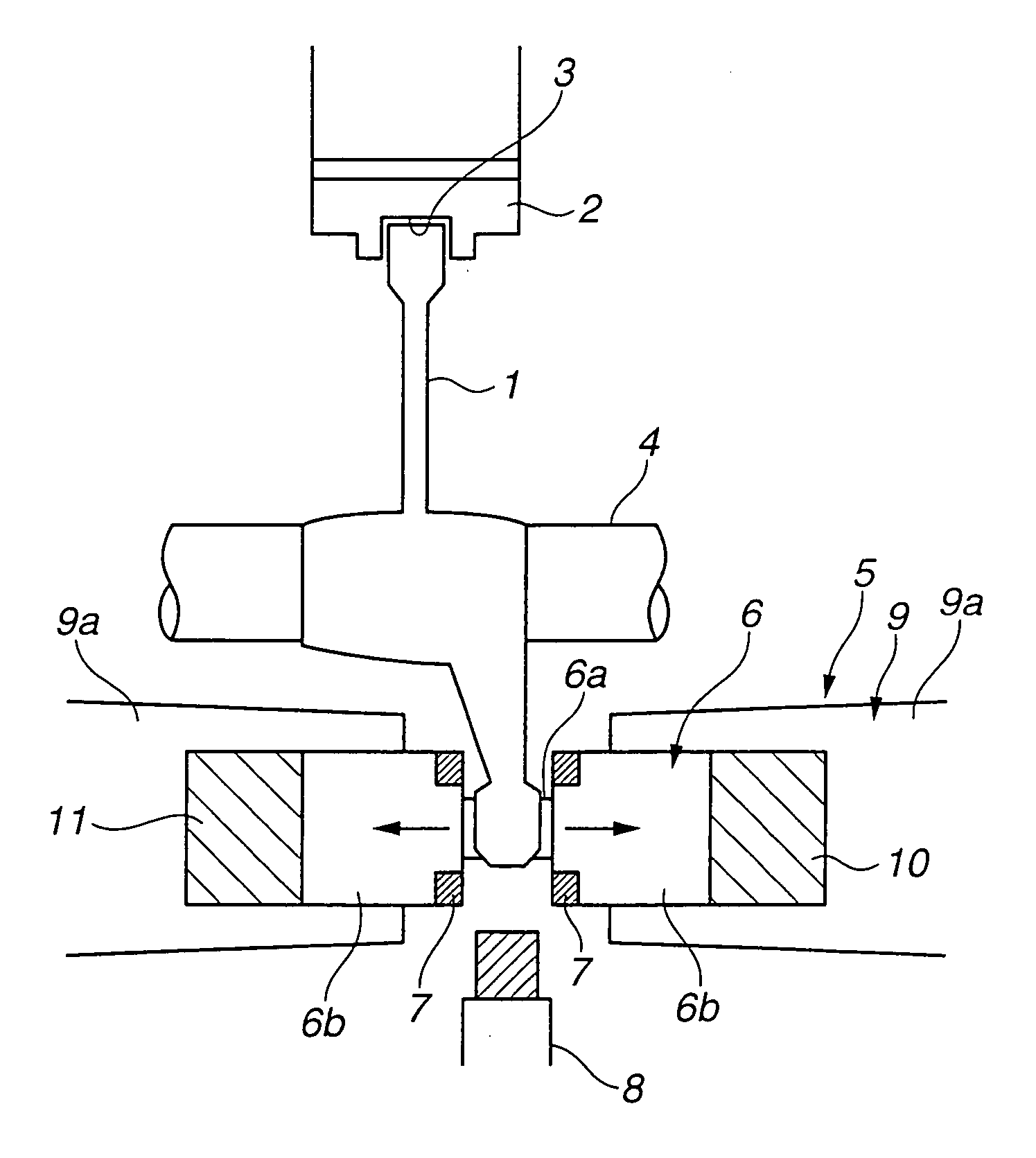

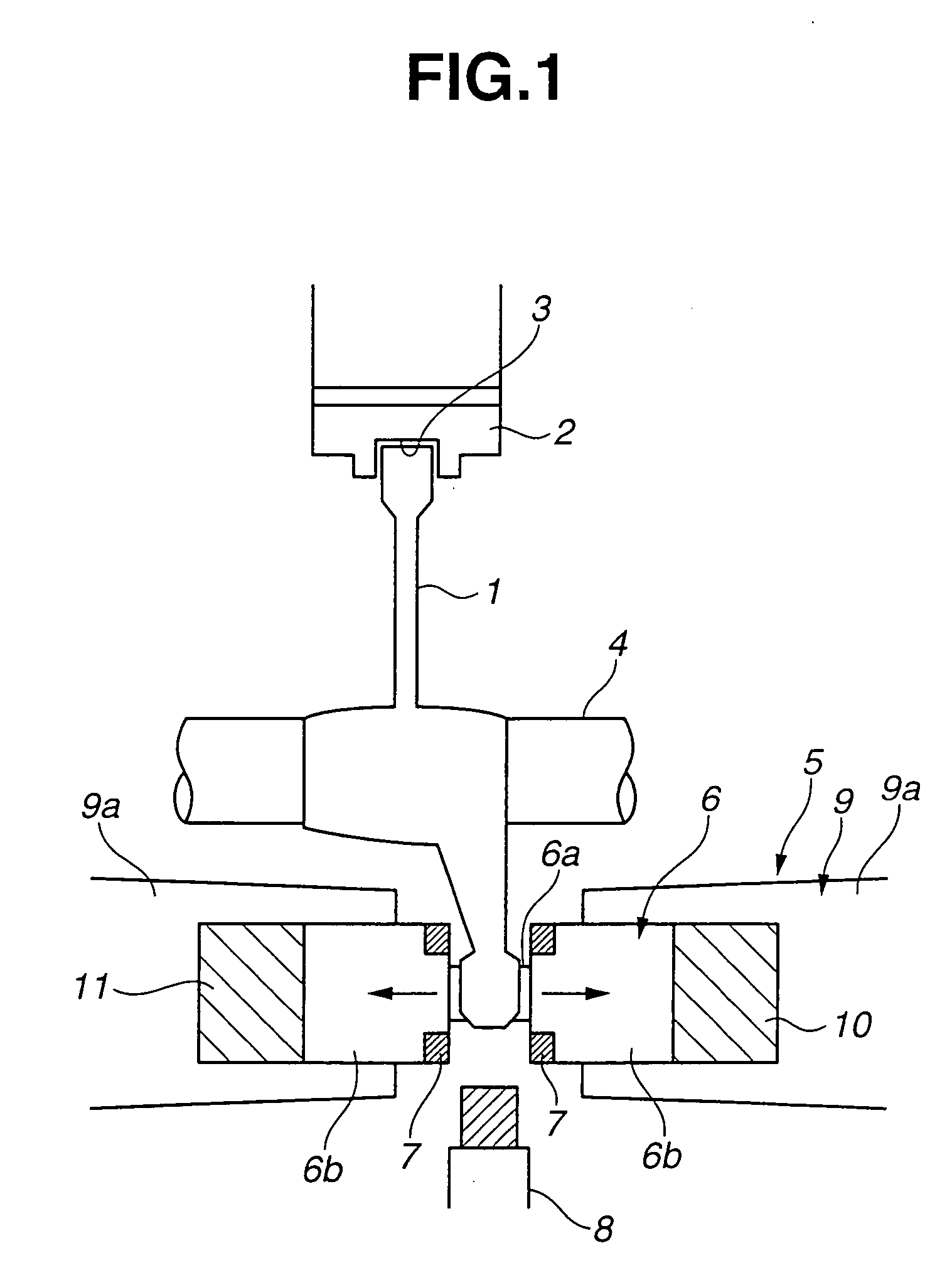

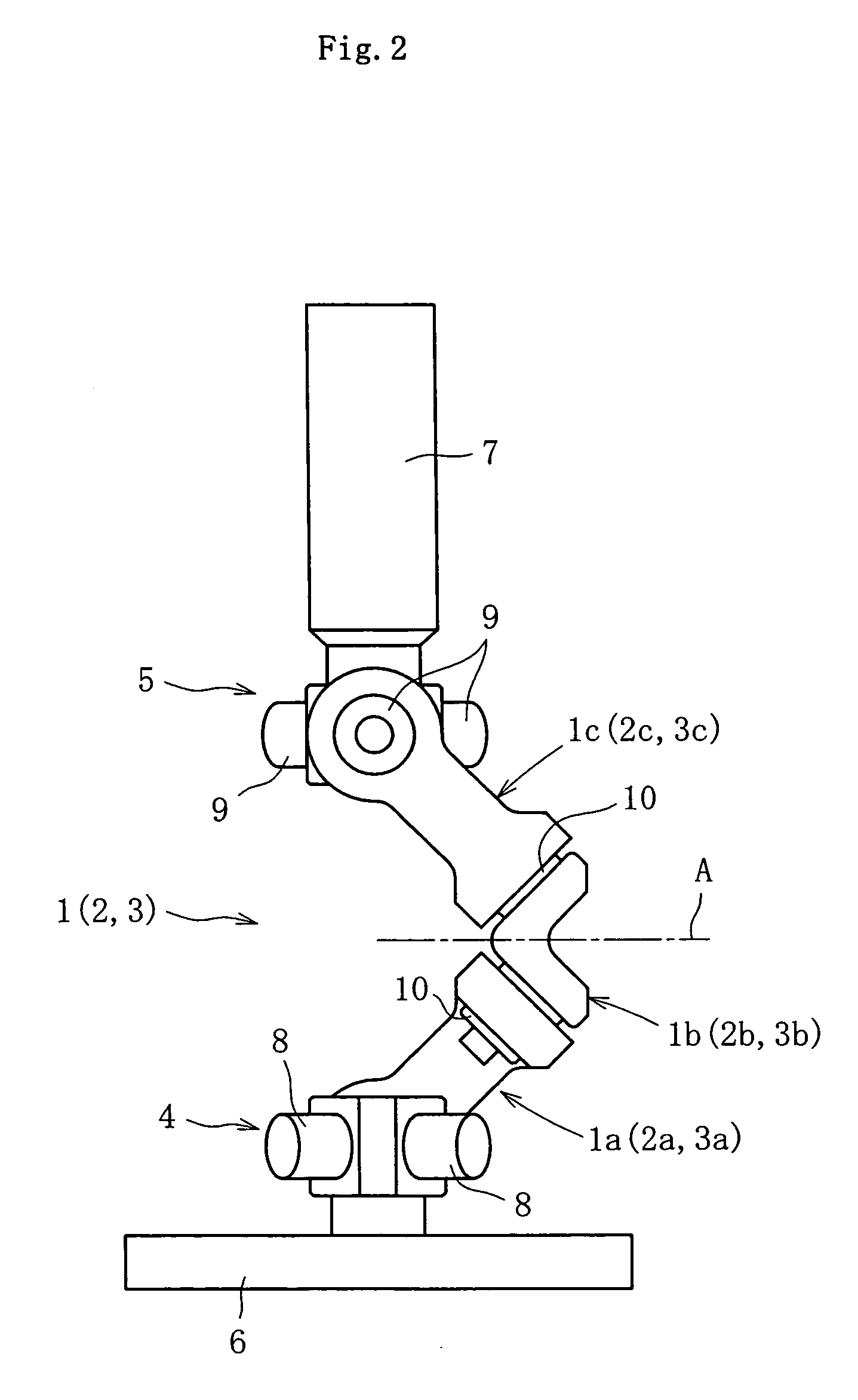

Washing machine having ball balancers

ActiveUS20110203325A1Reducing of vibration and noiseMaintain dynamic balanceRotating vibration suppressionControlling membersMechanical engineeringViscous oil

A washing machine having a ball balancer coupled to the drum to compensate for a dynamic imbalance during rotation of the drum, the ball balancer including a ring-shaped racer having a closed internal space in which a plurality of balls and viscous oil are accommodated, the ring-shaped racer including a first injection molded member and a second injection molded member joined to each other to form the closed internal space, the first injection molded member including a first side wall, a second side wall and a connecting wall between the first side wall and the second side wall, the first injection molded member having an open side opposite to the connecting wall, and the second injection molded member is adapted to cover the open side of the first injection molded member.

Owner:SAMSUNG ELECTRONICS CO LTD

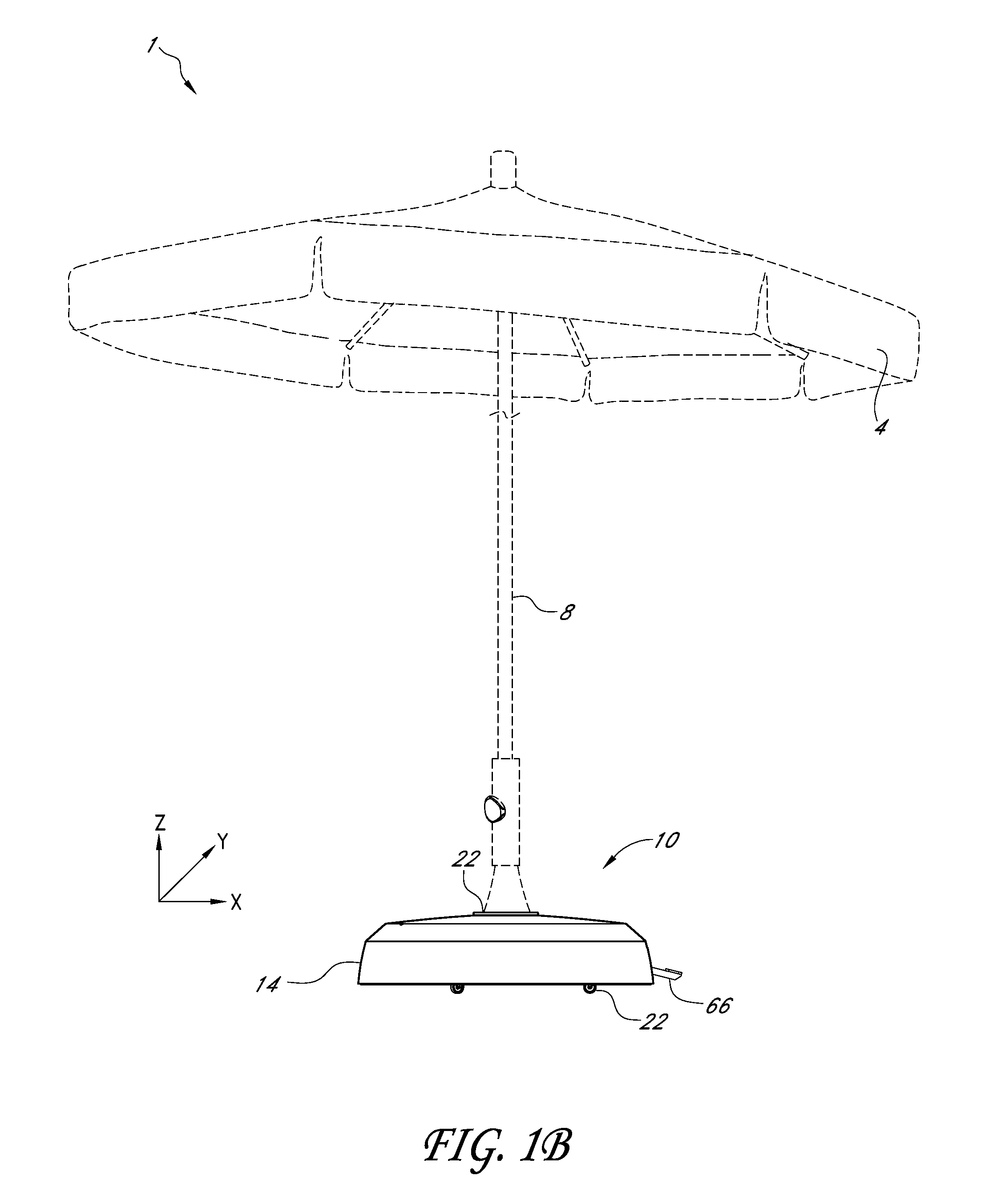

Movable base with wheels deployable by reversible driving assembly

A ratchet assembly includes an elongated shaft, a gear housing, a ratcheting member, and an arm. The elongated shaft can have a gear and be supported by the gear housing to allow rotation about a primary axis of the shaft. The ratcheting member can mount in the housing and be biased toward the gear to engage with the gear hindering relative rotation about the shaft axis in a first direction and allowing rotation about the shaft axis in a second direction opposite the first direction. The ratcheting member can rotatably mount within the housing about a second axis. The arm can couple to the gear housing in a first configuration to provide torque to rotate the housing about the shaft axis in the first direction when the arm is pressed downward. The arm can also be coupled to the gear housing in a second configuration to rotate the housing about the shaft axis in a second direction opposite the first direction when the arm is pressed downward.

Owner:MA

Washing machine having ball balancers

ActiveUS20080110212A1Reduce vibrationReduce noiseControlling membersRotating vibration suppressionProcess engineeringViscous oil

Disclosed is a washing machine having ball balancers, which adjust a relation between a gap, between the inner wall of a racer of each of the ball balancers and balls, and viscous oil, so as to reduce the vibration and noise of the washing machine. Each of the ball balancers of the washing machine includes balls and viscous oil accommodated in a racer, and the viscosity of the viscous oil is varied in proportion to a gap between the racer and the balls. When the viscosity of the viscous oil is 1˜100 cSt, the gap is set to 0.5˜1.0 mm, when the viscosity of the viscous oil is 100˜380 cSt, the gap is set to 1.0˜2.0 mm, and when the viscosity of the viscous oil is 380˜1,000 cSt, the gap is set to 2.0˜3.0 mm. Thereby, the relation between the gap and the viscous oil is optimized, and the ball balancers effectively exhibit a balancing function and thus minimize the vibration and noise of the washing machine.

Owner:SAMSUNG ELECTRONICS CO LTD

Movable base with wheels deployable by cyclic driving assembly

A ratcheting assembly can include a housing, a ratcheting gear, a first ratchet pawl, a motion translation member, and a ratcheting actuation member. The ratcheting gear can rotatably mount within the housing and include a plurality of ratchet teeth and an eccentric opening. The eccentric opening can include a rotational center of the ratcheting gear. The first ratchet pawl can mount to the housing adjacent to the ratcheting gear to allow rotation in a first direction and to hinder rotation in a second direction opposite the first direction. The motion translation member can mount within the opening such that rotation of the ratcheting gear can cause a movement of the motion translation member via rotation of the eccentric opening. The ratcheting actuation member can mount to the housing and include a second ratchet pawl. The second ratchet pawl can mount to the ratcheting actuation member adjacent to the ratcheting gear such that actuation of the ratcheting actuation member in the first direction can cause a rotation of the ratcheting gear and actuation of the ratcheting actuation member in the second direction opposite the first direction does not cause a rotation of the ratcheting gear.

Owner:OLIVER JOEN AN MA

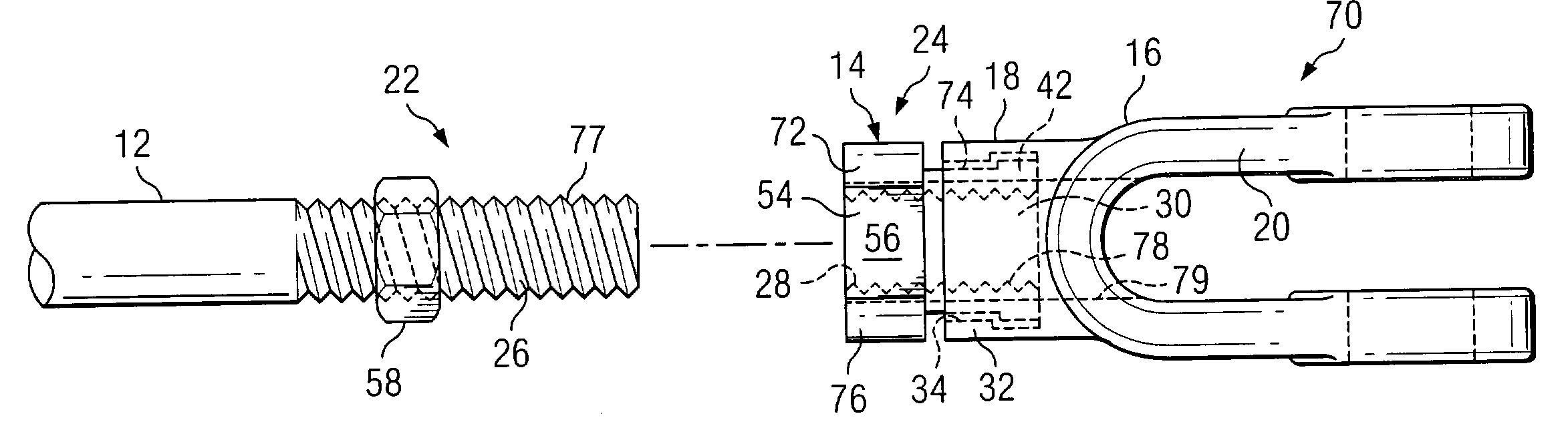

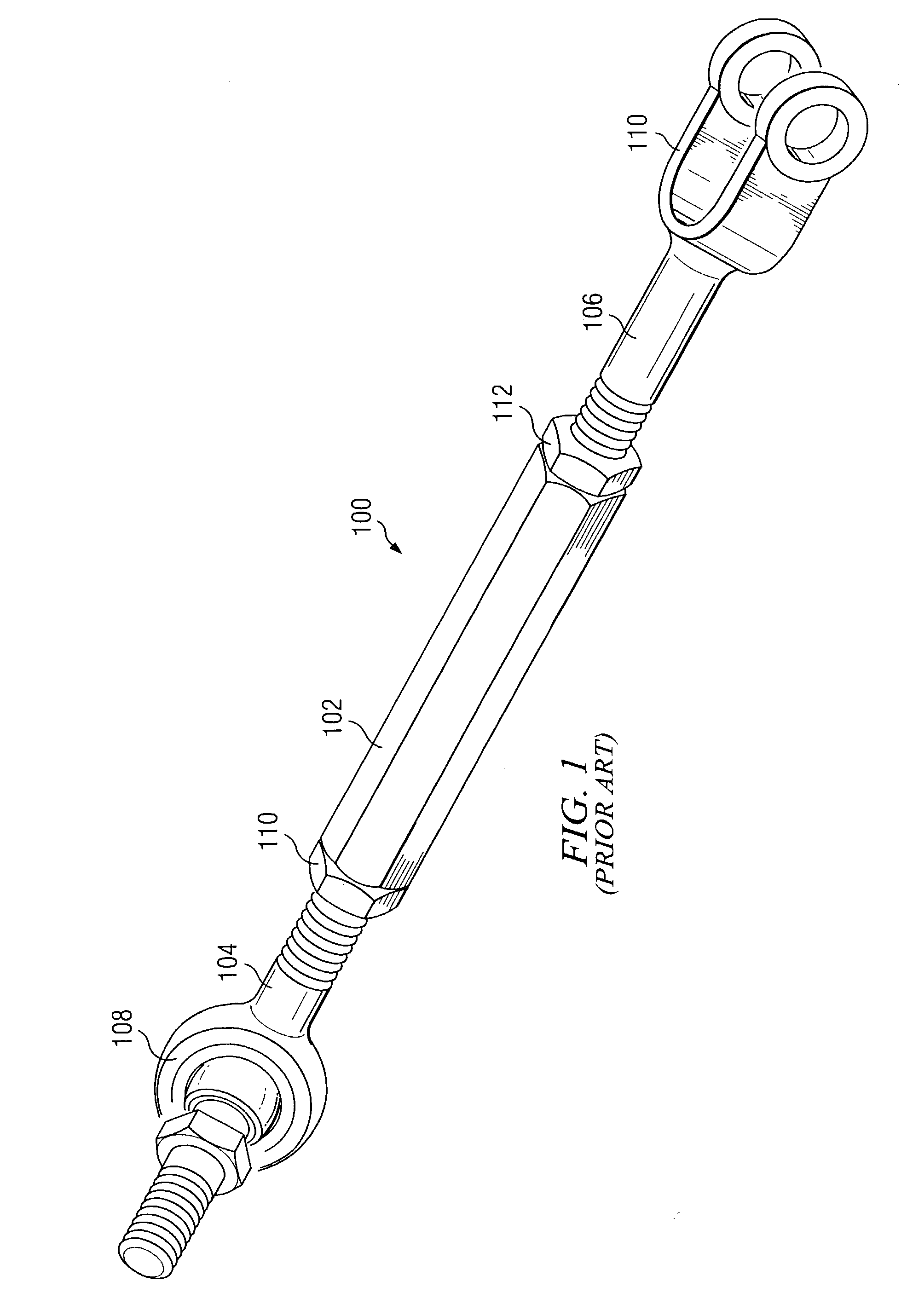

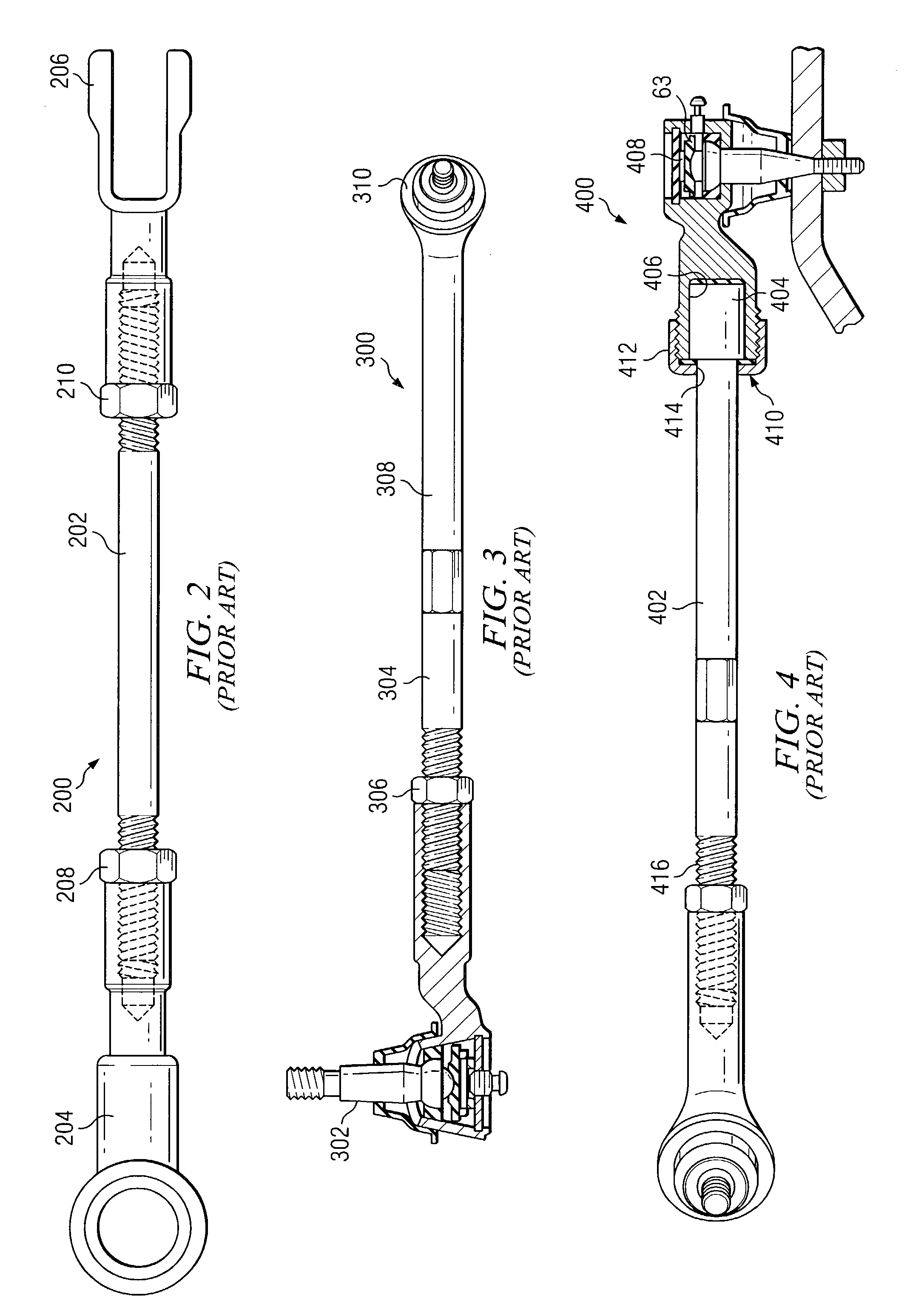

Turnbuckle linkage assembly

InactiveUS6902341B1Significant translationControlling membersConnecting rodsInterference fitEngineering

A turnbuckle linkage assembly is provided for transmitting a force between first and second locations in a machine. The assembly includes a first link for connecting to the first location such as a rod, tube or cable, a second link for connecting to the second location, and a turnbuckle. A first, threaded connection connects the turnbuckle to the first link, and a second connection connects the turnbuckle to the second link. The second connection and the second link are arranged along an axis, and an interference fit at the second connection is formed by the turnbuckle and the second link permitting the turnbuckle to rotate relative to the second link but axially affixing the turnbuckle to the second link.

Owner:MIDWEST CONTROL PROD

Sliding rack ratchet tensioner

InactiveUS20100022339A1Reduce manufacturing costEasy to assembleControlling membersControlled membersEngineeringMechanical engineering

The high-performance sliding rack ratchet tensioner is inexpensively manufactured. A rack having rack teeth is slidingly received in a rack slot on the side of the piston. The rack slot is preferably open-ended on the end facing the tensioner arm. The rack and piston are both received in a piston bore in the tensioner body. The rack length is preferably shorter than the rack slot length to provide backlash. A pawl mounted in a pawl bore perpendicular to the rack bore engages the rack. The open-ended rack slot allows the rack to be inserted after the piston during assembly. The rack and pawl preferably have shark fin-shaped teeth. The pawl preferably has dummy teeth to ensure that the load is shared by the center teeth.

Owner:BORGWARNER INC

Drive force transmitting apparatus for vehicle

InactiveUS20070272511A1Reduce the number of partsLow costBraking element arrangementsControlled membersDrive shaftActuator

A drive force transmitting apparatus for a vehicle including a drive source, a drive force transmitting path adapted to be connected to a drive shaft to transmit a drive force from the drive source to the drive shaft, and a clutch mechanism capable of connecting and disconnecting the drive force transmitting path. The drive force transmitting apparatus further includes a parking mechanism provided in the drive force transmitting path and capable of stopping the rotation of the drive shaft and an actuator mechanism capable of selectively operating the clutch mechanism and the parking mechanism.

Owner:HONDA MOTOR CO LTD

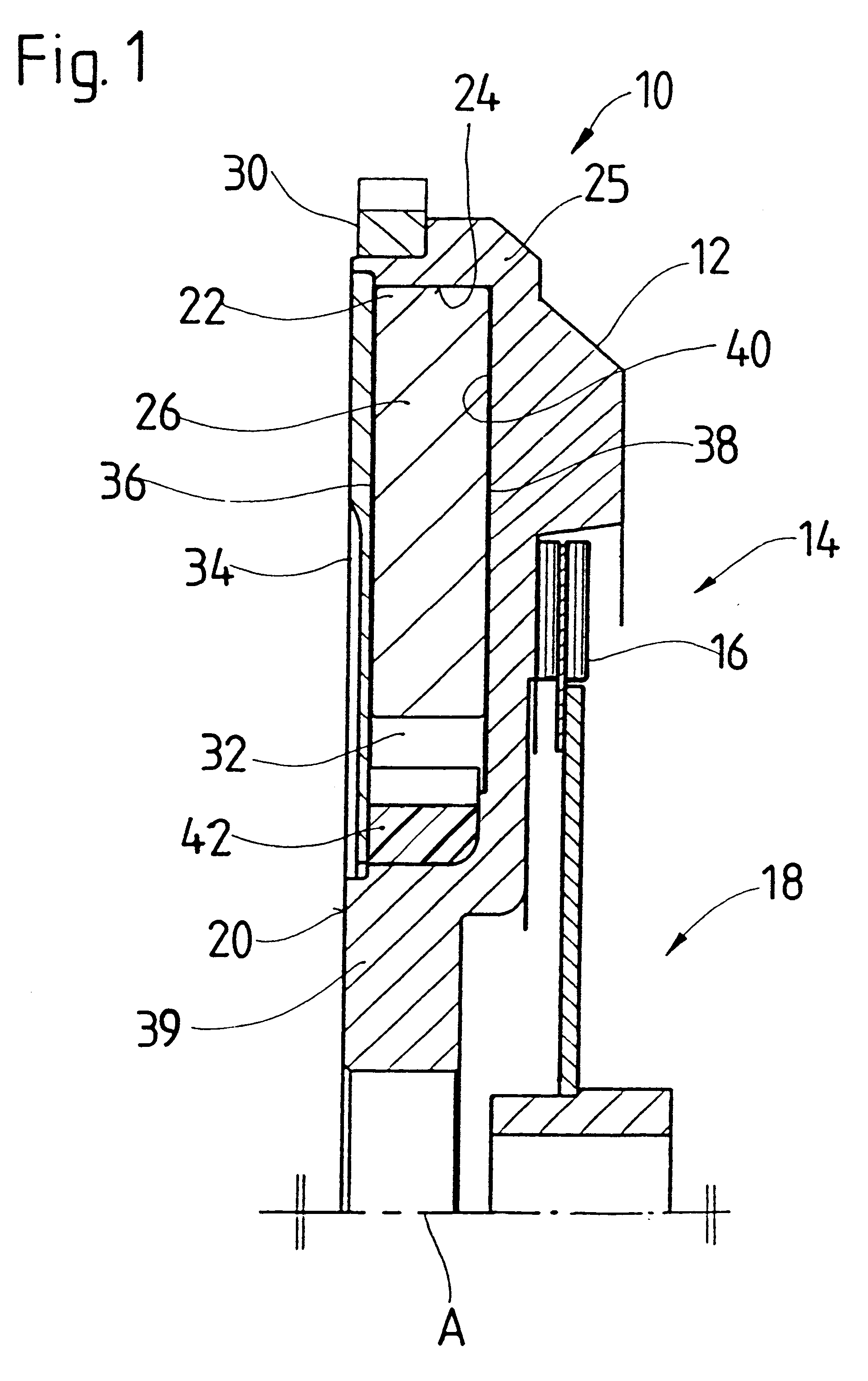

Parking lock arrangement

ActiveUS20090193931A1Simple actionSimple mechanismControlling membersBraking element arrangementsEngineeringMotorized vehicle

A parking lock arrangement for a motor vehicle gearbox. A parking lock cog can be fixed to a shaft of the motor vehicle gearbox rotatable about a first axis. A parking lock pawl is supported so that it can pivot about a second axis. An actuating mechanism can pivot the parking lock pawl into a locking position, in which the parking lock pawl meshes with the parking lock cog. A release mechanism can pivot the parking lock pawl out of the locking position into a release position, in which the parking lock pawl is decoupled from the parking lock cog. The actuating mechanism has a cam, which is supported so that it can pivot about a third axis and which in a first cam position holds the parking lock pawl in the locking position.

Owner:GETRAG GETRIEBE & ZAHNRADFABRIK HERMANN HAGENMEYER GMBH & CO KG

Counter balance system and method with one or more mechanical arms

InactiveUS7428855B2Minimizes rotational inertiaControlling membersControlled membersEngineeringSupport point

A system for counterbalancing the gravitation moment on a link when the link is supported at a point. A first spring mechanism balances the link about all axes that pass through the support point. The link can be balanced throughout a large range of motion.

Owner:DUVAL EUGENE F

Gearing and power transmission apparatus

InactiveUS7240578B2Simple operation structureReduce component countControlled membersToothed gearingsNeutral positionPower transmission

Owner:AISIN AI CO LTD

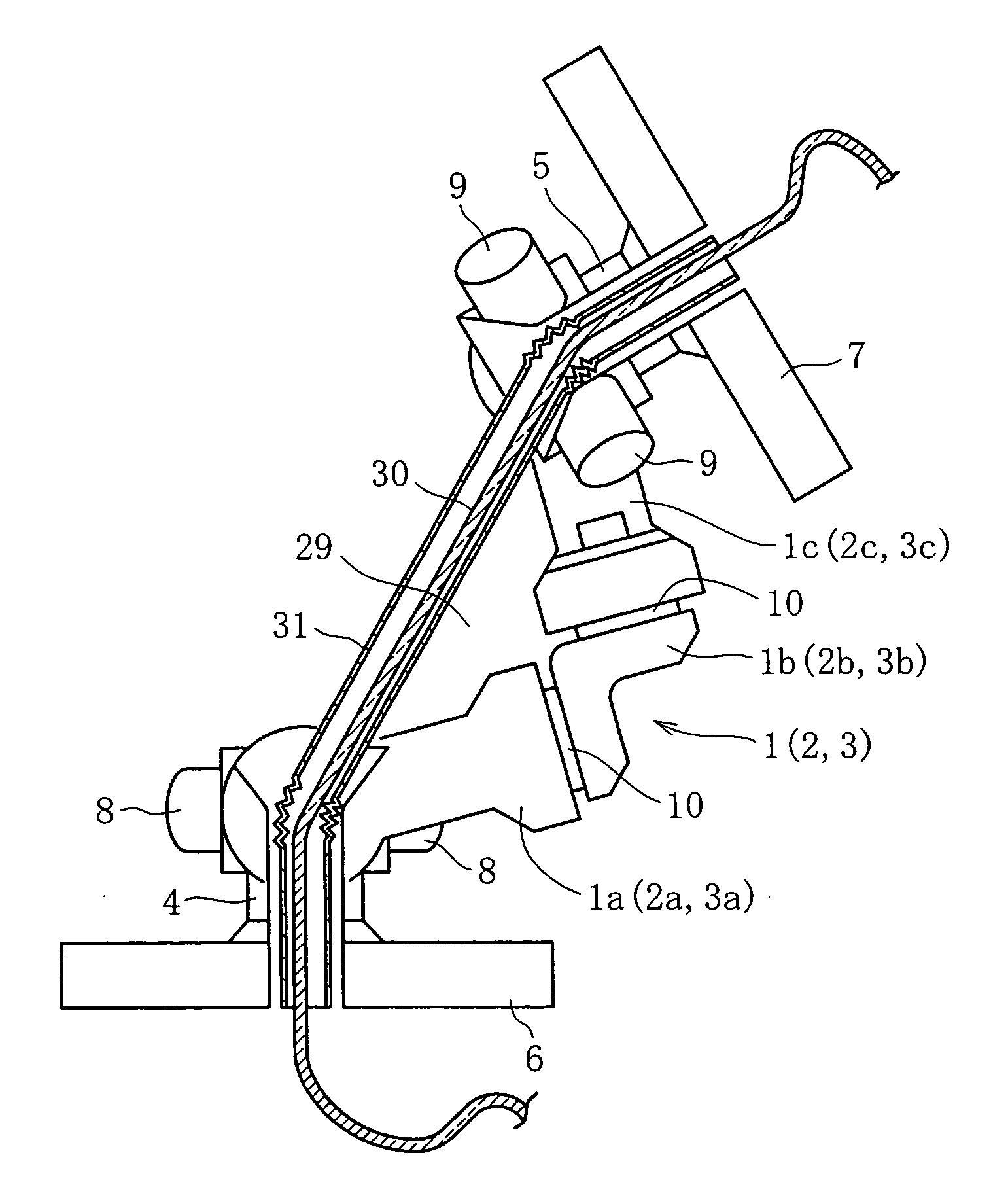

Shift fork position detecting device for manual transmission

InactiveUS20060011008A1Easy to assembleAdd supportControlled membersGearing controlCouplingEngineering

A shift fork position detecting device for a manual transmission is provided. The manual transmission includes a coupling sleeve constituting a synchronizer, a shift fork movable with the coupling sleeve and an actuator for moving the shift fork. The actuator has a stationary main body and a reciprocal output member operatively connected to the shift fork. The shift fork position detecting device includes a magnet mounted on the output member of the actuator, and a magnetic sensor mounted on the main body of the actuator to cooperate with the magnet for detecting the position of the shift fork.

Owner:NISSAN MOTOR CO LTD

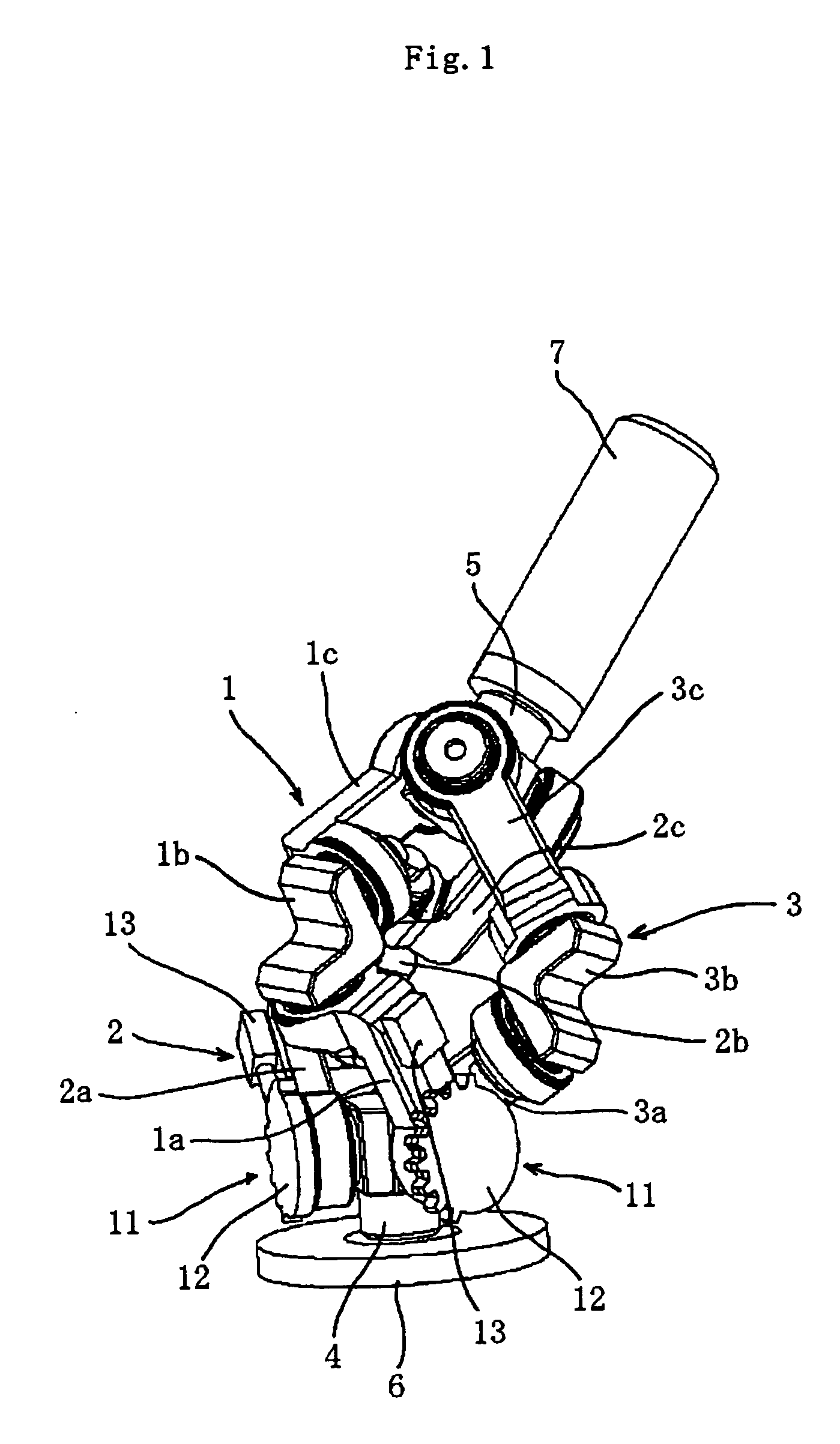

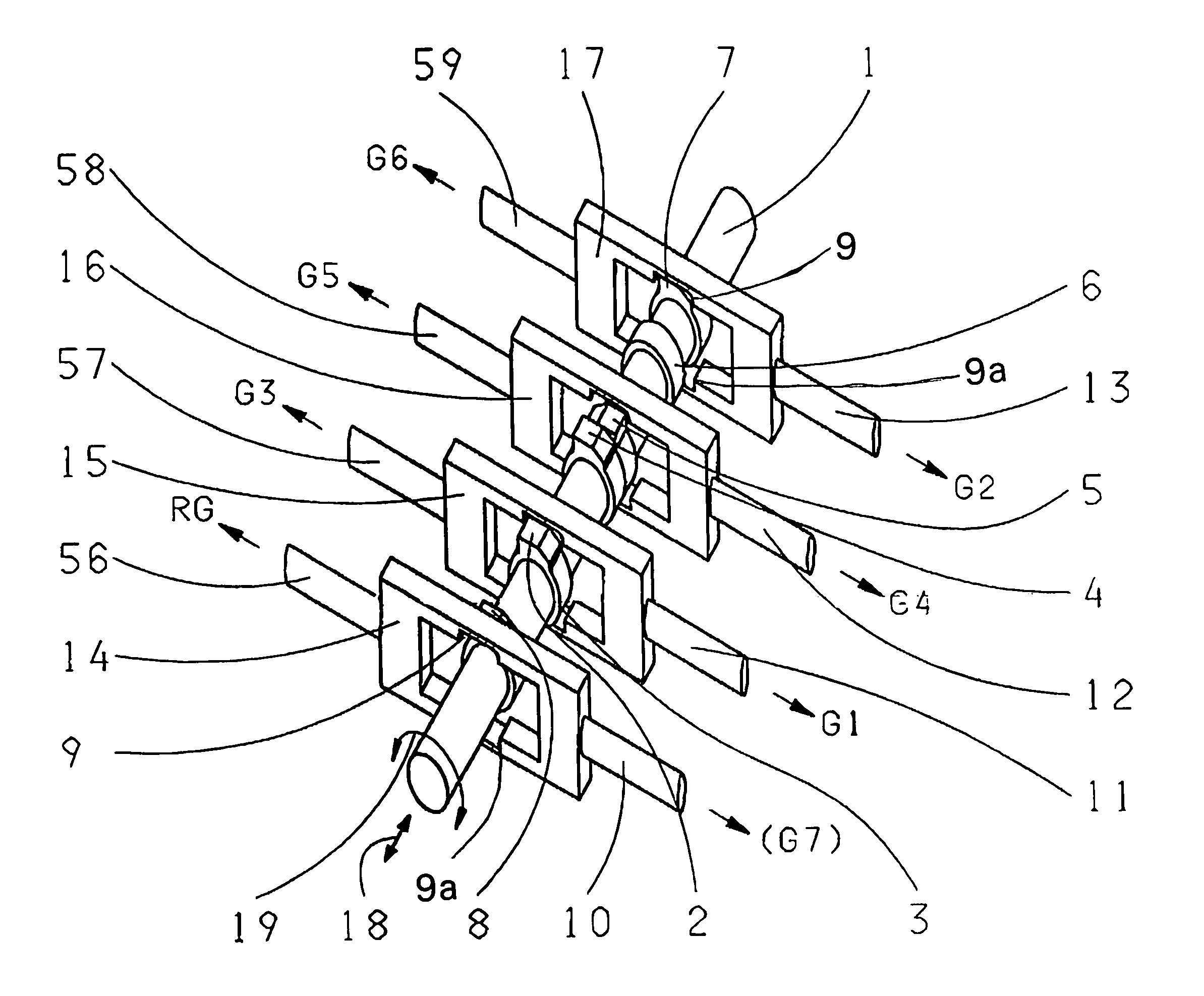

Linkage System

InactiveUS20080028881A1Large loading capacityImprove rigidityManual control with multiple controlled membersProgramme-controlled manipulatorEngineeringLoad capacity

A linkage system is provided which is equipped with a compact and high-rigidity link mechanism with a large load capacity. The linkage system includes three or more link mechanisms. Each link mechanism consists of a center link member and end link members rotatably coupled to the center link member and to link hubs that are provided to an input member and an output member, respectively. An input side and an output side of a center cross-sectional plane of each link mechanism are geometrically identical. One or more of revolute joints of two or more of the link mechanisms that are coupled to the input member are provided with a stopping mechanism for stopping the output member at a given position.

Owner:NTN CORP

Gear shift mechanism of six-speed automobile speed changer

ActiveCN101555942AReasonable designSimple structureControlled membersGearing controlSelf lockingEngineering

Owner:山东蒙沃变速器有限公司

Oil separating structure of automatic transmission

There is provided an oil separating structure of an automatic transmission, which makes it difficult for an oil strainer of an oil pump to draw oil containing air bubbles. A baffle plate base separates a space around the oil strainer and a space around a driven sprocket as well as a final gear, and therefore, oil containing air bubbles formed as a result of agitation by the driven sprocket, chain, and final gear does not flow directly into the oil strainer. As a result, the oil strainer is unlikely to draw oil containing air bubbles.

Owner:JATCO LTD

Barrel cam shift mechanism

A shift mechanism for a dual clutch transmission employs a rotating barrel cam having at least three tracks which are engaged by and translate at least three associated cam followers. The cam followers extend from shift fork bodies which slide on rails and include shift forks which bi-directionally translate at least three synchronizer clutches which engage at least five forward gears or speeds and reverse. A single electric motor and gear train drive the barrel cam.

Owner:GM GLOBAL TECH OPERATIONS LLC

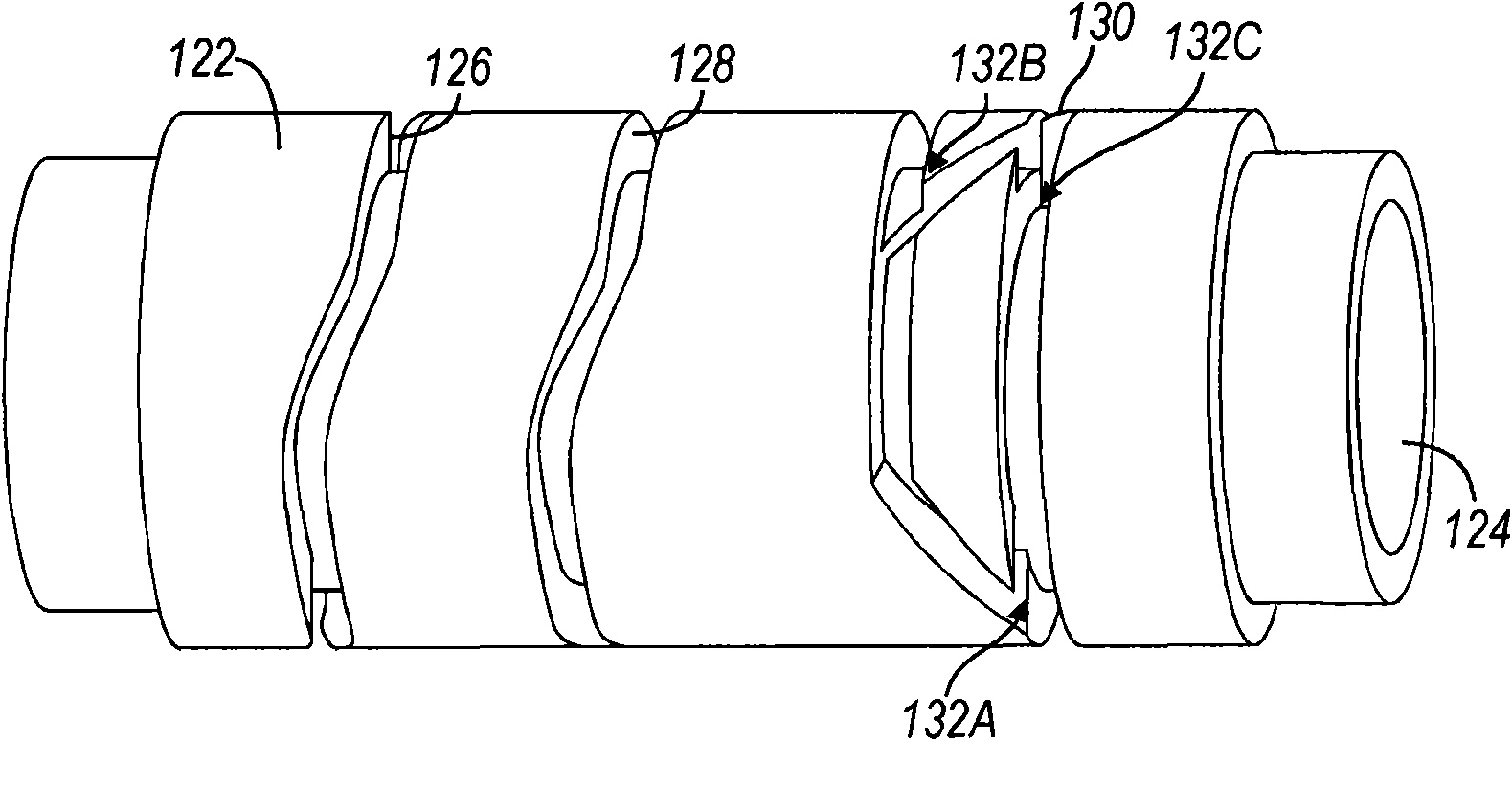

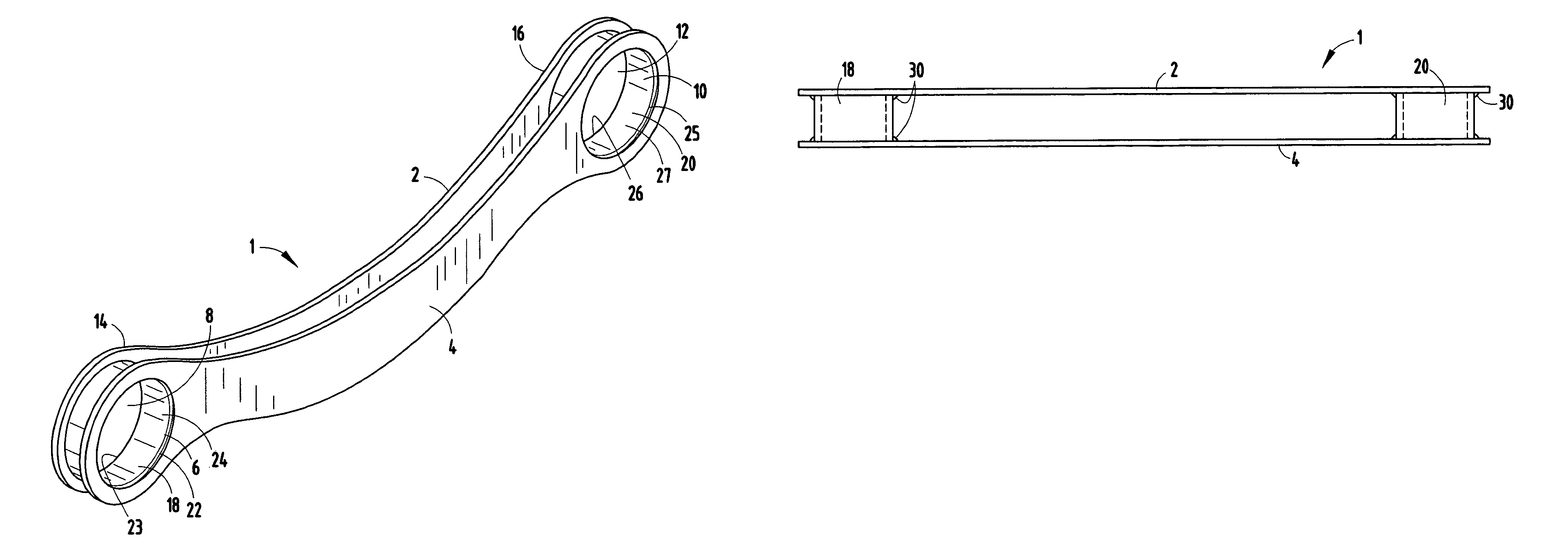

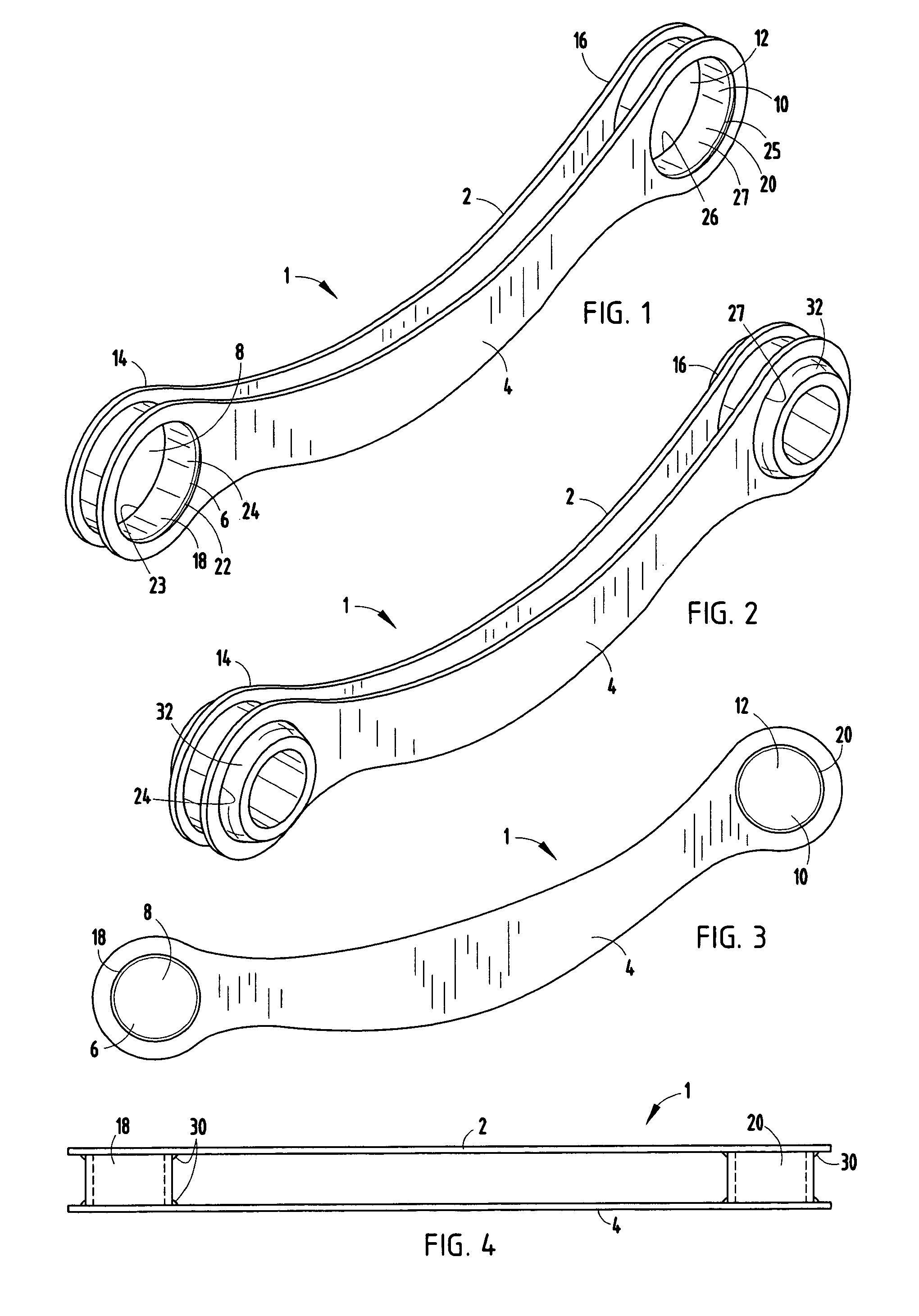

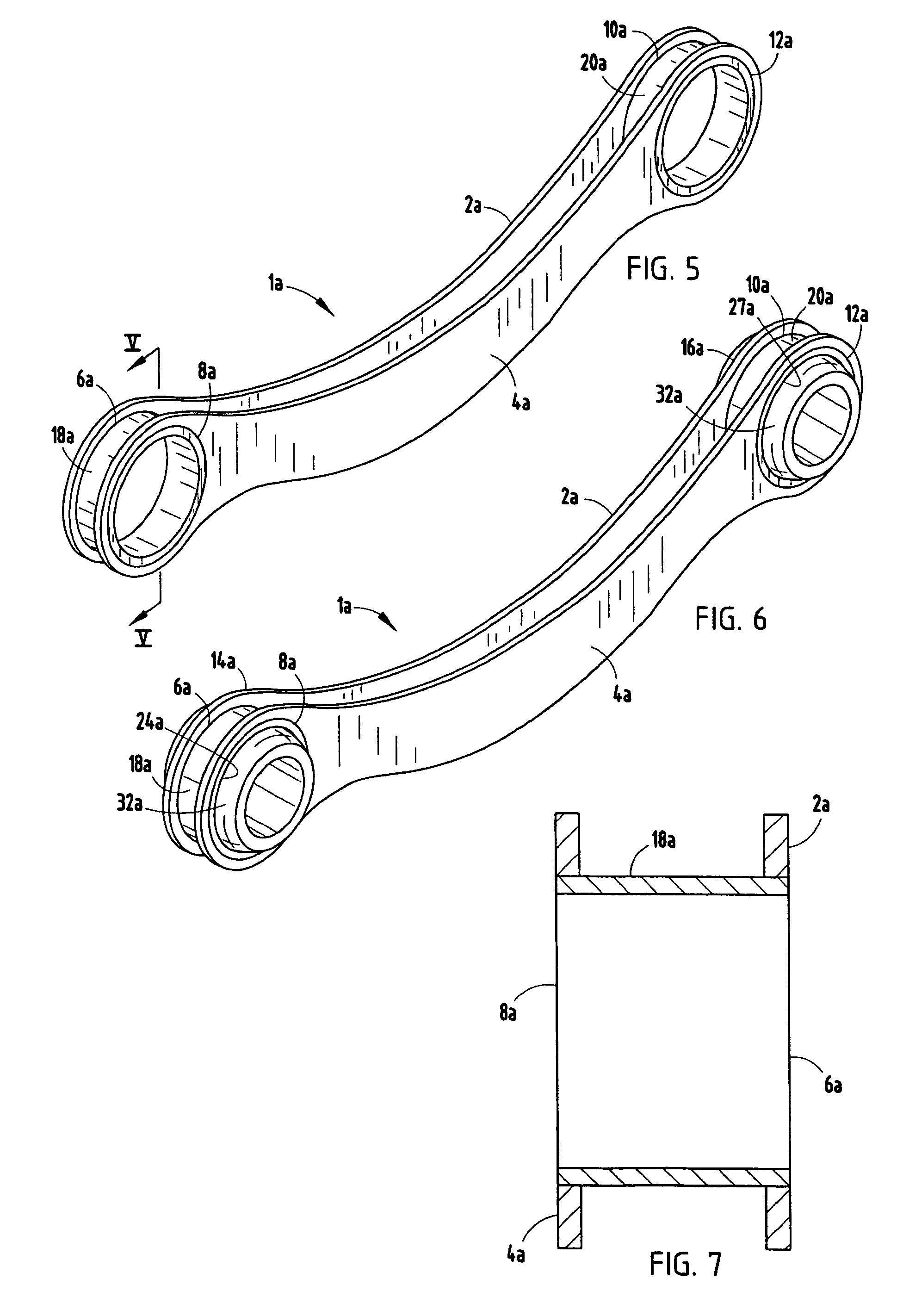

Vehicle suspension control arm and method

InactiveUS7506444B2High strengthLow costControlling membersConnecting rodsControl armMechanical engineering

A control arm for vehicle suspension systems has first and second rigid arm plates having first and second apertures extend laterally through opposing faces of the body adjacent opposite ends thereof. The arm plates are disposed in a mutually parallel, laterally spaced apart and aligned relationship. The first apertures are generally concentric and the second apertures are generally concentric. First and second spacers each have a rigid body with opposite ends and a central bushing aperture extending therebetween. The spacers are disposed between the arm plates adjacent opposite ends thereof. The central bushing aperture of the spacers is positioned generally concentrically with the apertures. Also included is a related method for making vehicle suspension links from ultra high strength steel.

Owner:BENTELER AUTOMOTIVE CORP

Movable base with wheels deployable by reversible driving assembly

ActiveUS20120024330A1Easy to movePrevent rotationWalking sticksControlling membersEngineeringMechanical engineering

A ratchet assembly includes an elongated shaft, a gear housing, a ratcheting member, and an arm. The elongated shaft can have a gear and be supported by the gear housing to allow rotation about a primary axis of the shaft. The ratcheting member can mount in the housing and be biased toward the gear to engage with the gear hindering relative rotation about the shaft axis in a first direction and allowing rotation about the shaft axis in a second direction opposite the first direction. The ratcheting member can rotatably mount within the housing about a second axis. The arm can couple to the gear housing in a first configuration to provide torque to rotate the housing about the shaft axis in the first direction when the arm is pressed downward. The arm can also be coupled to the gear housing in a second configuration to rotate the housing about the shaft axis in a second direction opposite the first direction when the arm is pressed downward.

Owner:MA

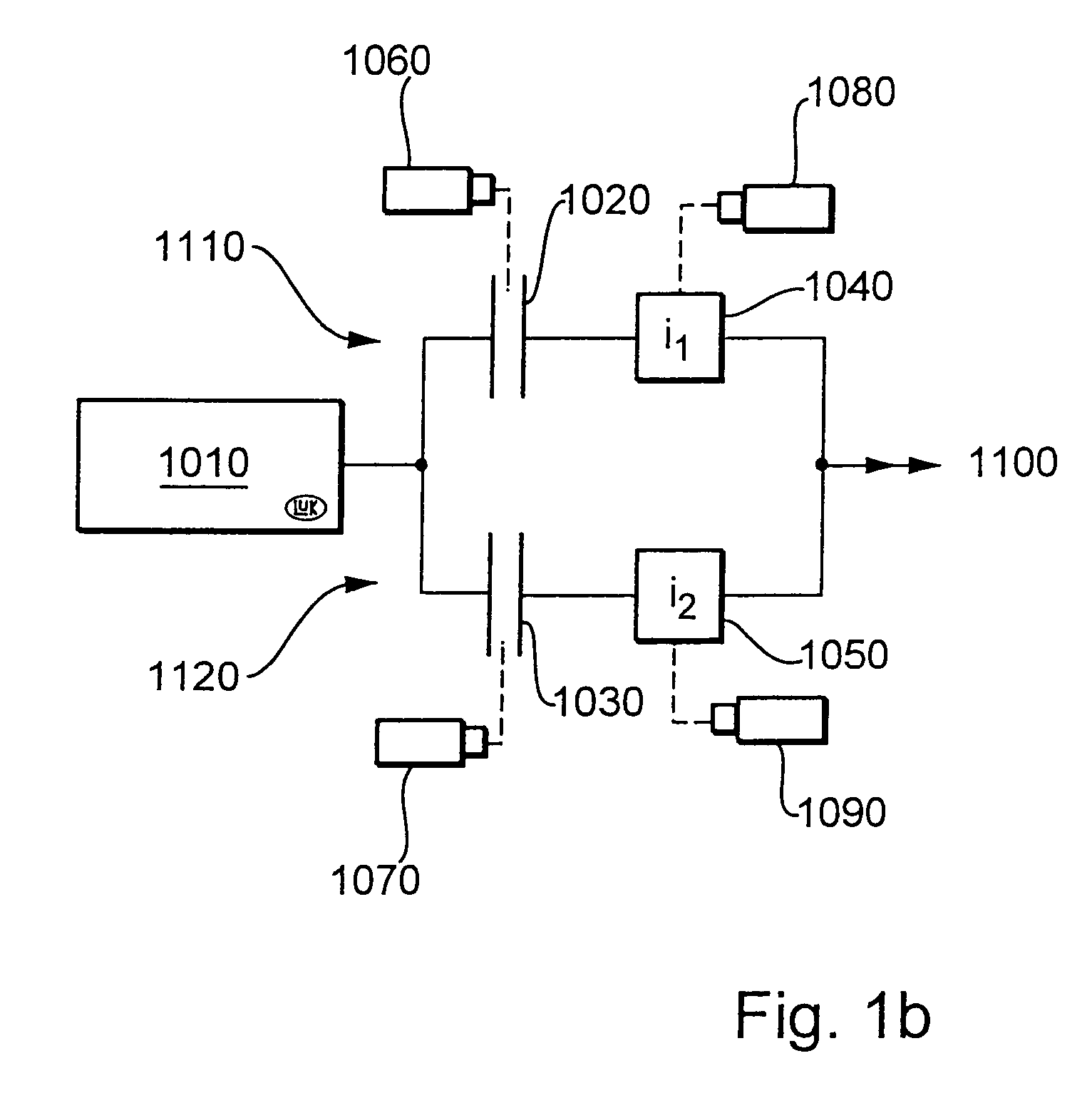

Transmission

InactiveUS7093511B2Ensure protectionMaximum performanceControlled membersElectric propulsion mountingElectric power transmissionMobile vehicle

A power transmission for a motor vehicle. The transmission includes a plurality of transmission ratio steps defined by pairs of gear carried on parallel shafts, and final output mechanisms for engaging desired transmission ratio steps. The final output mechanisms are operable for controlling the engagement of respective transmission ratio steps to minimize tractive force interruption by allowing rapid gear changes to be effected to reduce the times between shifts of gears. By sensing accelerator pedal position and vehicle speed a new transmission ratio step to be subsequently engaged can be pre-selected while an engaged gear remains engaged.

Owner:SCHAEFFLER TECH AG & CO KG

Shifting device for a transmission

InactiveUS7353726B2Simple designManual control with multiple controlled membersControlled membersGear wheelElectrical and Electronics engineering

A shifting device for a transmission, in which at least one gearshift package is allocated to two non-successive gears and each of these gearshift packages is coupled with a gearshift lever. An H- or a multiple H-shifting diagram is allocated to the gearshift lever, in which the gears that can be selected within a gearshift path are allocated to different gearshift packages. The gearshift lever and the gearshift packages are connected to a conversion device with which a gearshift lever movement to take out a previous gear in a gearshift path causes this gear to be taken out in a first gearshift package. A gearshift lever movement for putting in the new gear in the same gearshift path, a second gearshift package puts in this new gear. The conversion device functions in such a way that the gearshift lever is coupled with an axially displaceable and radially pivotable shift finger shaft.

Owner:ZF FRIEDRICHSHAFEN AG

Variable inertia flywheel apparatus

InactiveUS7044022B2Efficiency sometimes variesControlling membersRotating vibration suppressionFlywheelHydraulic pressure

In a flywheel having variable inertia, first and second guide grooves are respectively formed at a body and a rotatable member such that an overlapping position thereof is varied according to a relative rotation thereof. A movable mass is disposed at the overlapping position, and the rotatable member rotates relatively to the body by hydraulic pressure.

Owner:HYUNDAI MOTOR CO LTD

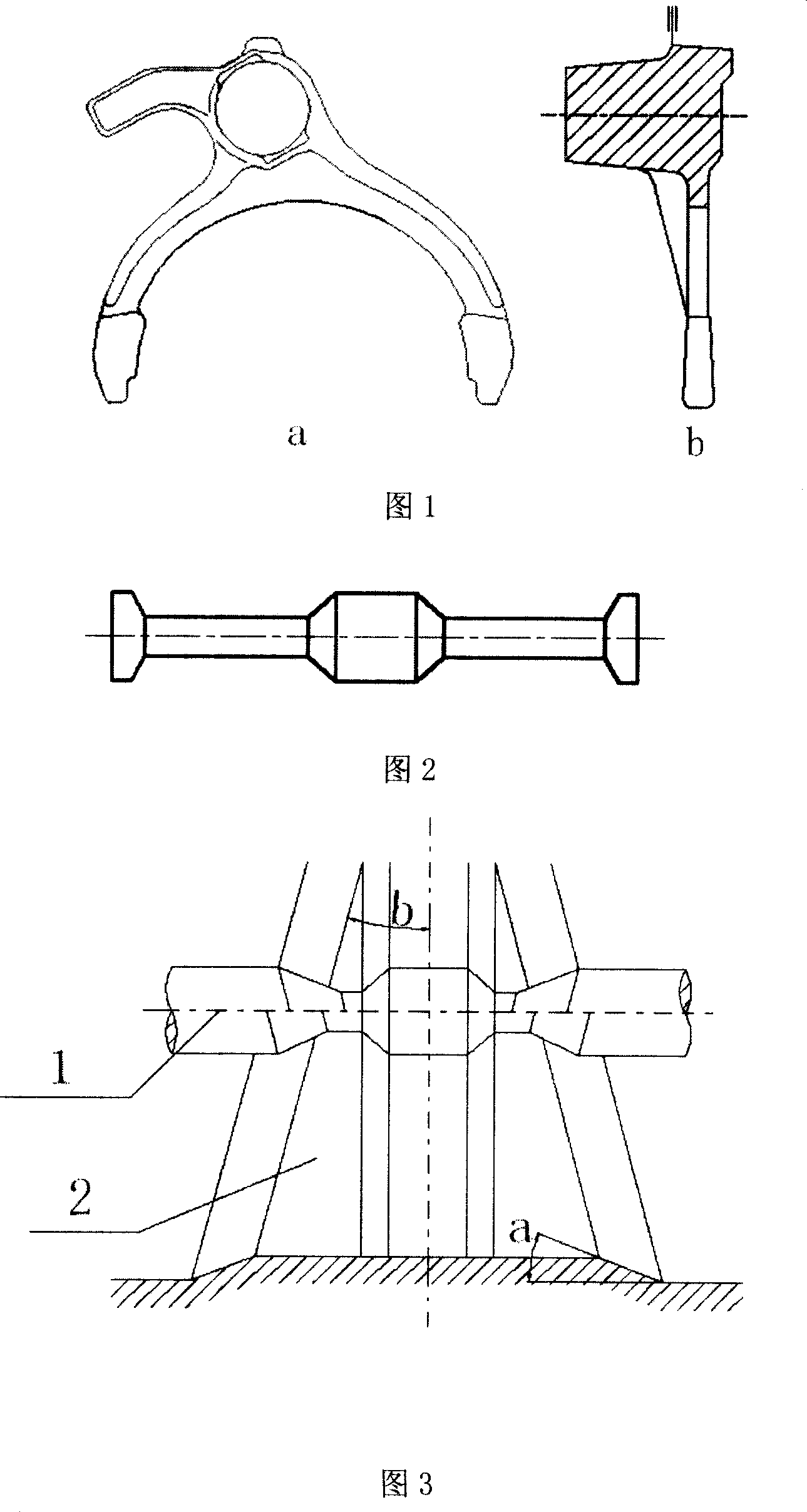

Shifting fork forging method of auto parts

InactiveCN101007378AReduce sizeIncrease profitControlled membersRoll mill control devicesEngineeringForging

A vehicle parts shifting fork forging method belongs to forging technology field. The invention adds two steps of producing blanks and bending after heating of prior technologies, then pre-forging, final forging, trimming and fine finishing. Said producing blank step produces blanks with the heated blank materials using plate wedge cross rolling, the shaping range of reduction of cross-sectional area is : 40%-65%; the shaping angle a range is: 18degree<=a<=32degree; the stretching angle b range is: 4degree<=b<=12degree; said bending step bends the blanks twice through the press machine, the shape after second bend is the contra-outcome from product shape size, but the bend inner arc of size is smaller than product inner arc; the bend outer arc of size is bigger than product outer arc; the first bend calculation is inversion result according the shape after second bend, the length after the second bend shape one side expansion just is the distance between one end and positioning point when first bending. The invention can save products materials and improve product mold life.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

One-way clutch apparatus

InactiveUSRE38498E1Restrict movementIncrease speedControlling membersControlled membersClutchEngineering

A one-way clutch apparatus comprising a driving member having a plurality of recesses, a corresponding plurality of biasing members disposed in the recess, a corresponding number of keys or struts disposed over the biasing members in the recesses, and a driven member having a plurality of key-engaging notches formed circumferentially about an inside surface. Each of the keys includes a pair of laterally protruding arm portions and each of the arm portions has a ramp formed thereon which acts as a relief to allow the inside surface of the driven member to be placed to close proximate relationship with the inside surface of a driving member and to overlay portions of the recess. The overlaying enables the driven member to damp or otherwise limit the movement of a back end portion of each key when the driving member is moved in either a free-wheeling direction or driving direction, while the ramp portions allow a front end portion of the key to be urged outwardly without any portion of the arm portion interfering with the inside surface of the driven member overlaying portions of each recess. The one-way clutch apparatus is not as dependent upon a copious and continuous supply of lubricant to damp unwanted movement of the key as prior art developed one-way clutch systems.

Owner:MEANS IND INC

Centrifugal-effect vibration generator having coaxial contrarotating rotors

ActiveUS20060266153A1Bulk of componentsWeight bulkInertia force compensationLiquid resistance brakesEngineeringElectromagnetic drive

A device for generating forces that are variable and controllable in amplitude, in direction, and in frequency, the device includes two unbalanced rotors (18, 20, 35 to 38) mounted coaxially in a casing (11). The device further includes electromagnetic drive elements for driving a first of the two rotors in rotation relative to the second of the two rotors, and brake elements (43 to 45) for braking the second rotor (20, 36, 38) relative to the casing.

Owner:EUROCOPTER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com