Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1439results about How to "Simple action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Work holding mechanism

ActiveUS7748760B2Improve shipping speedVacuum operationGripping headsSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:DAIHEN CORP

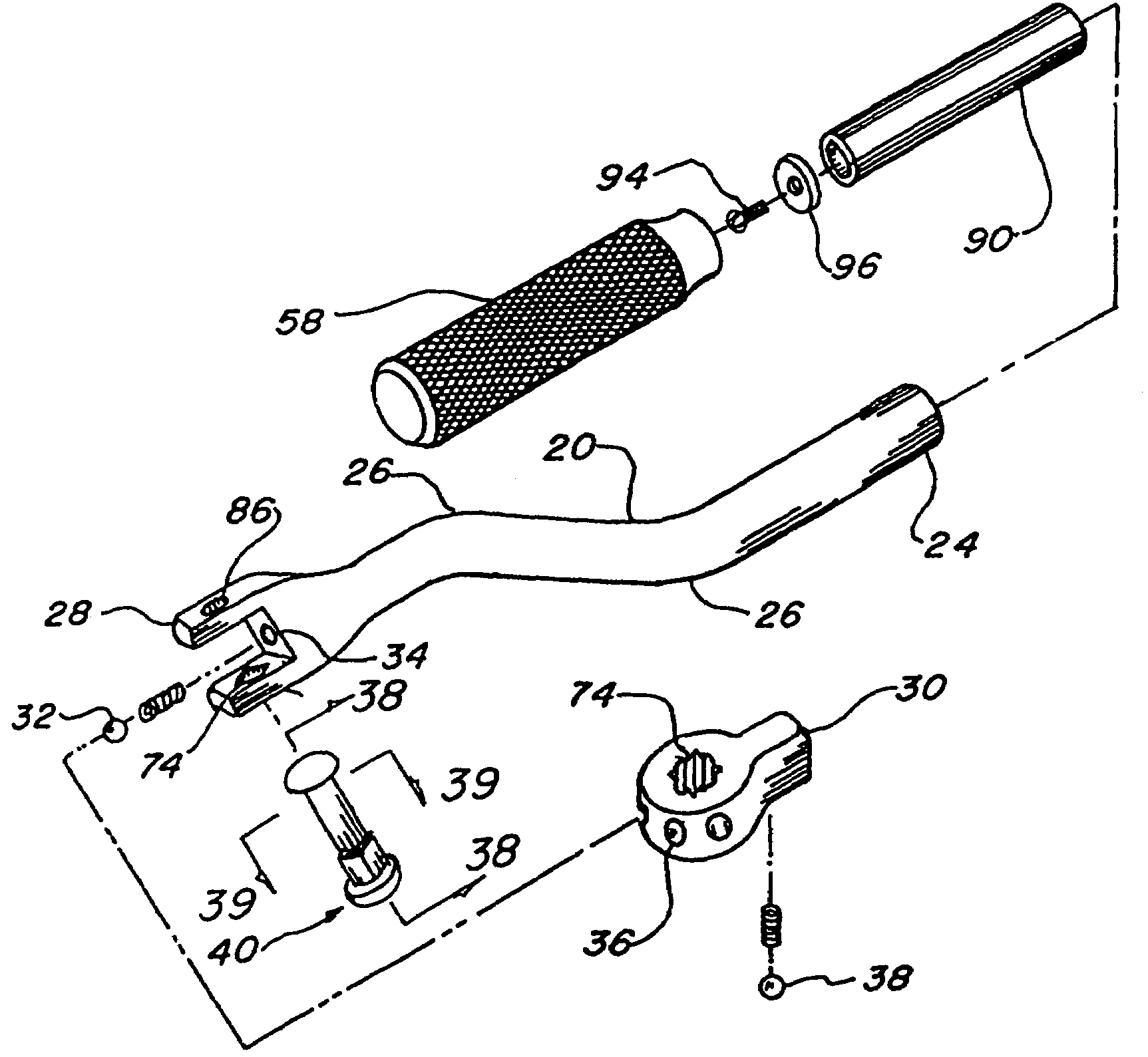

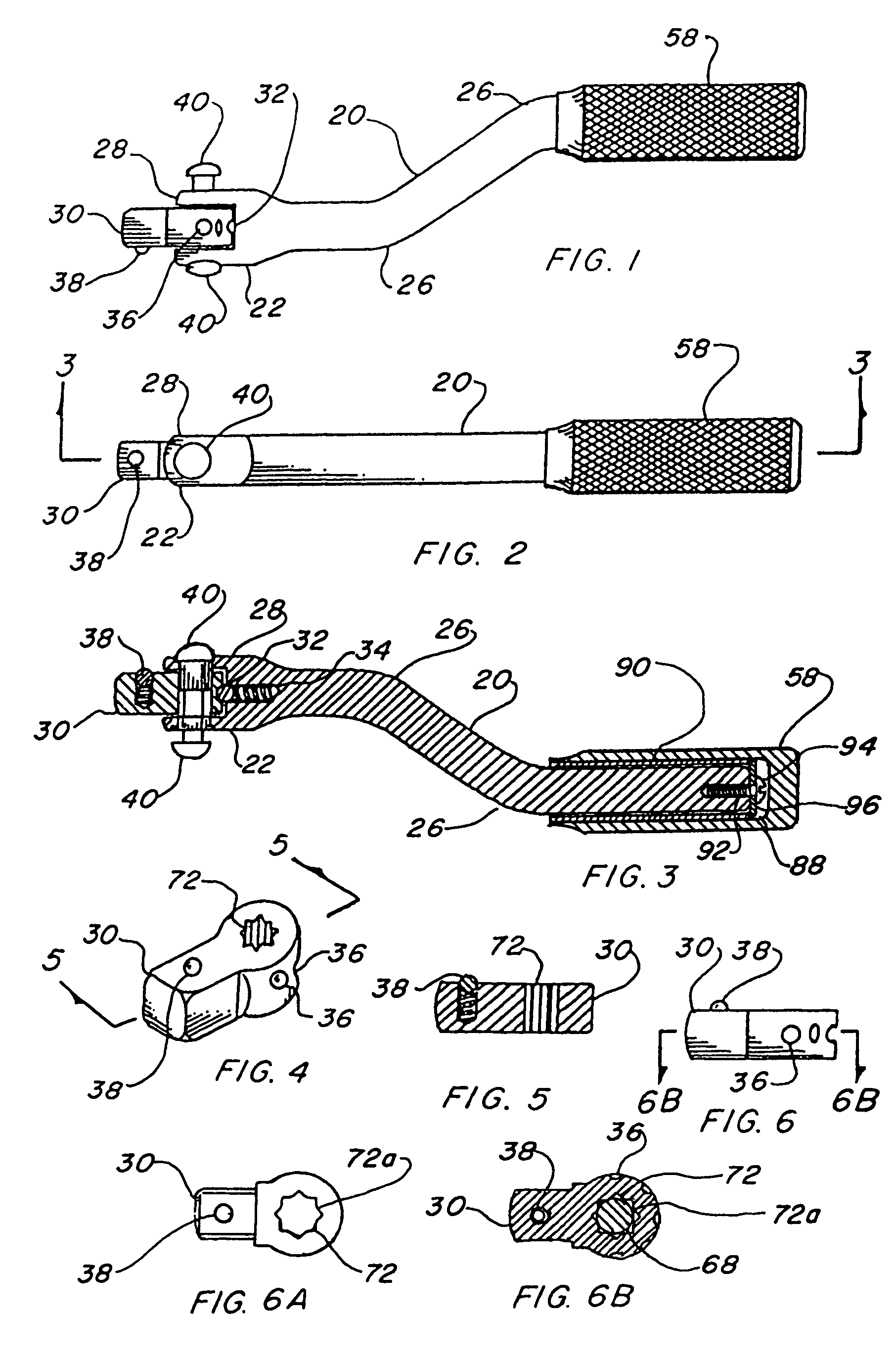

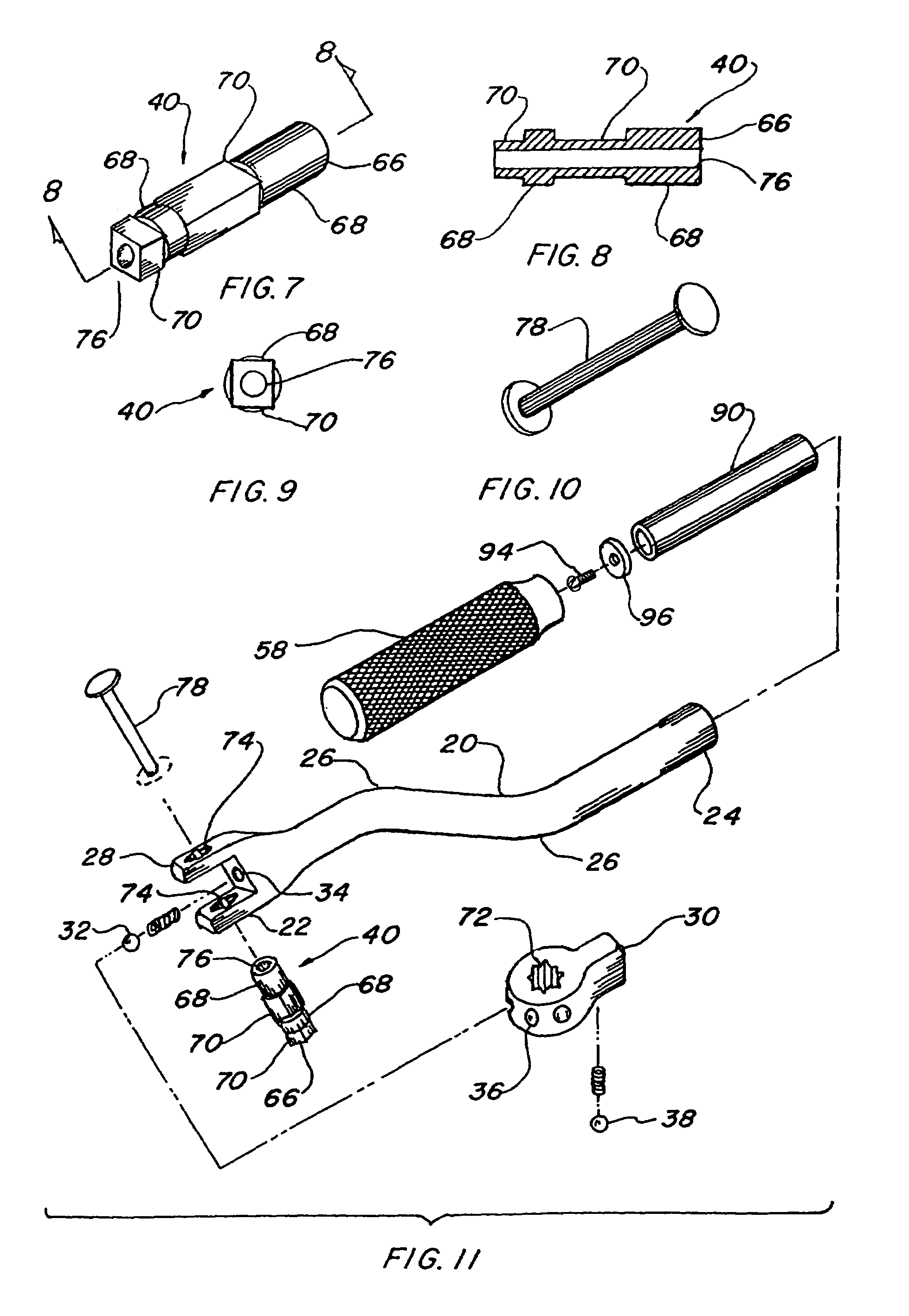

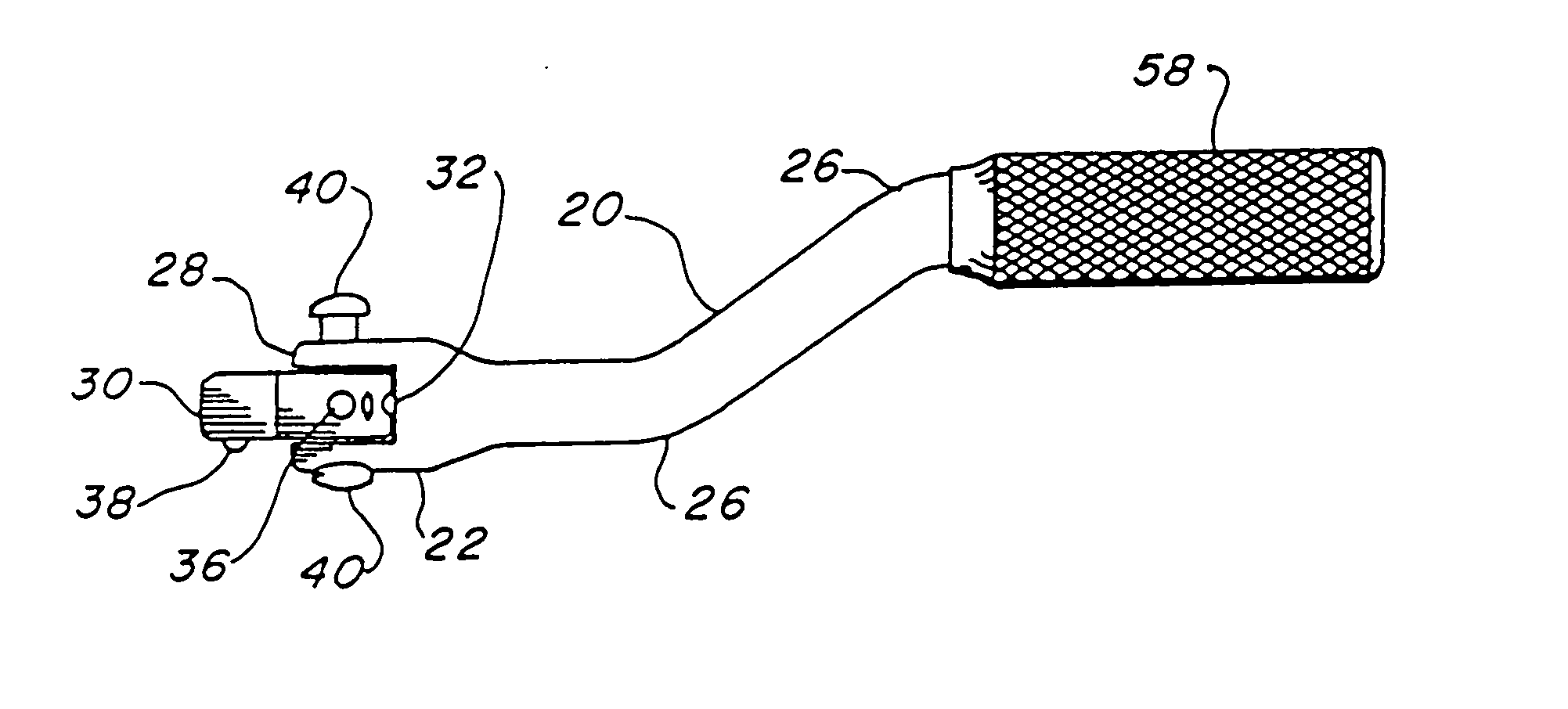

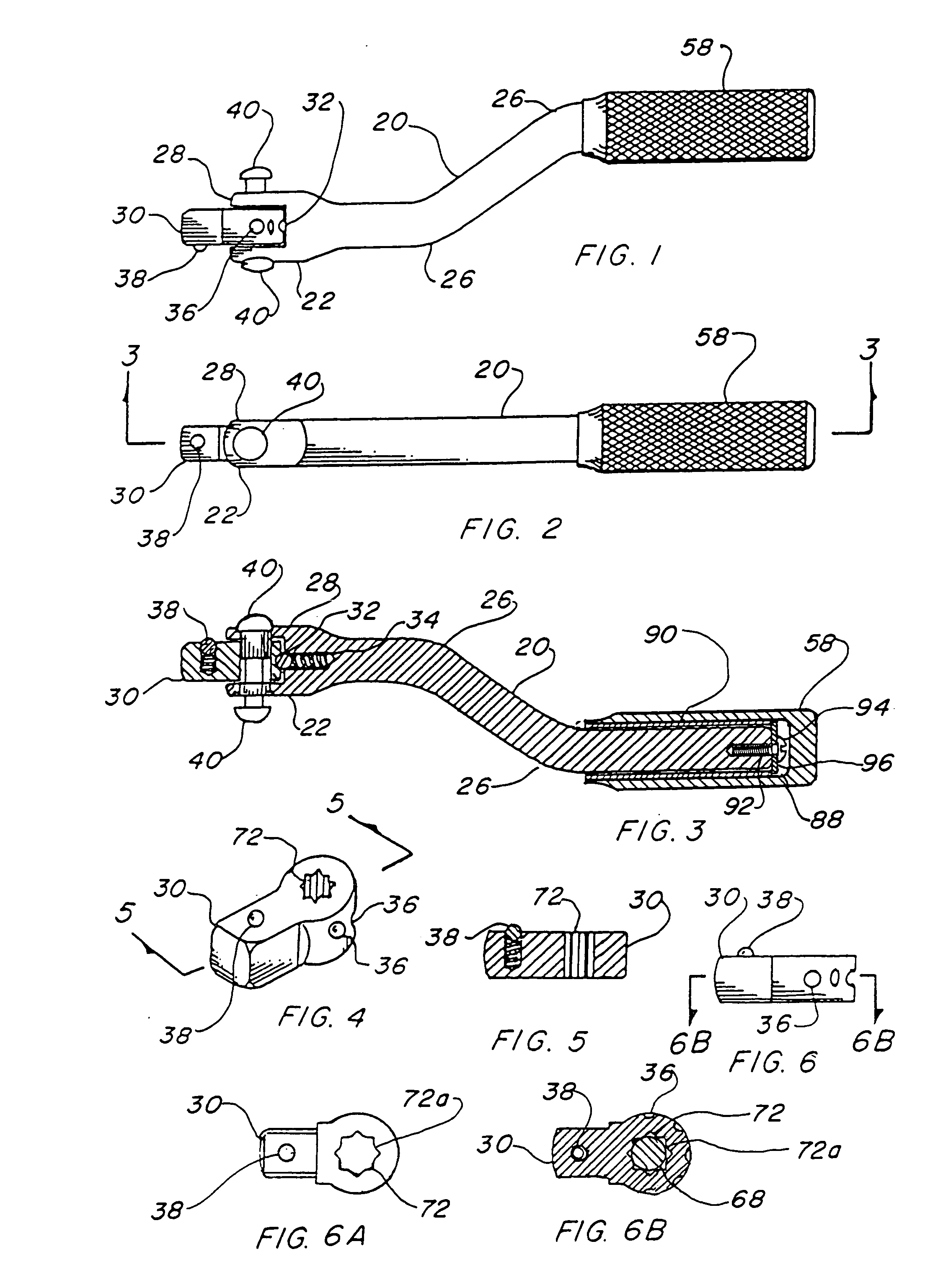

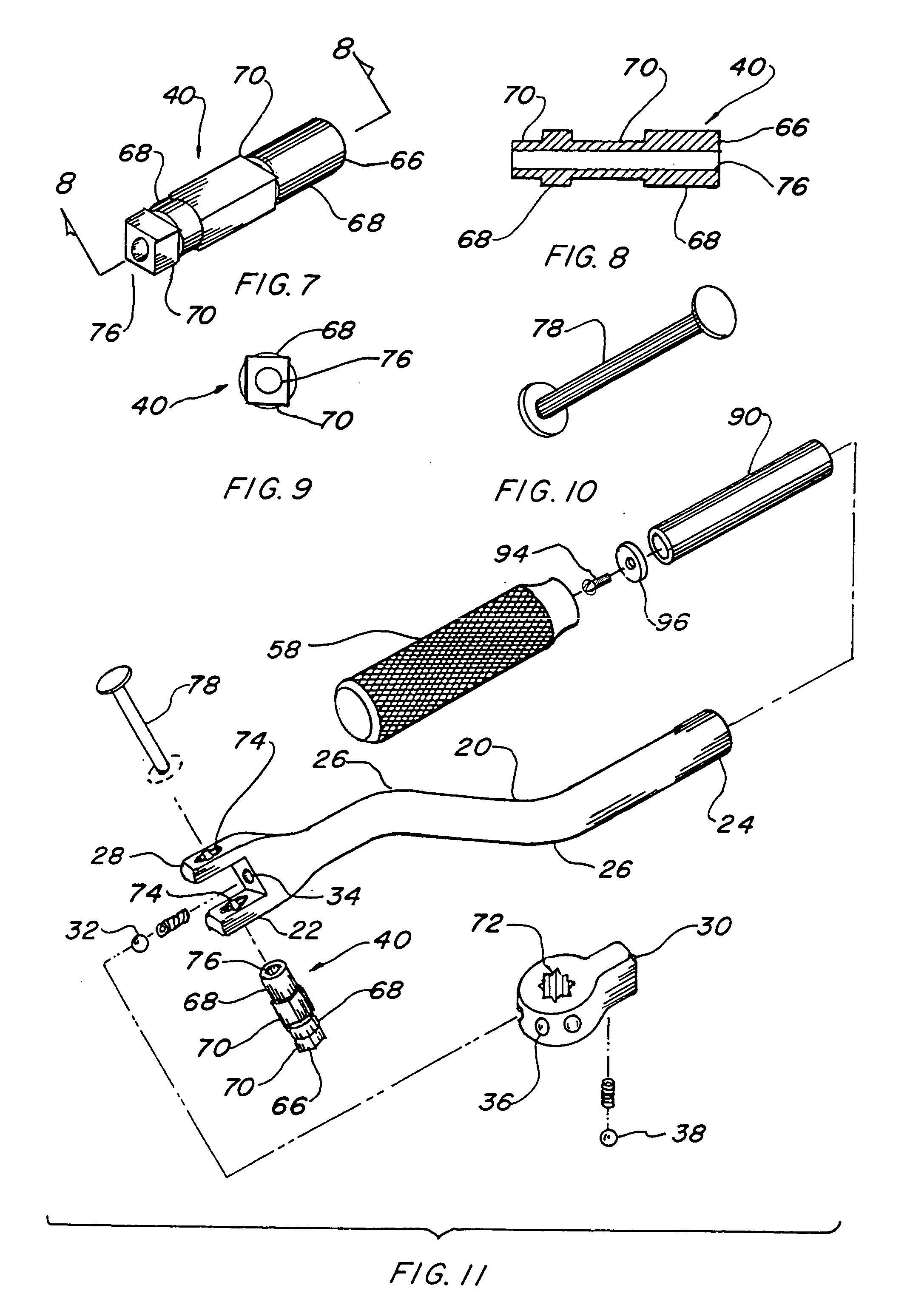

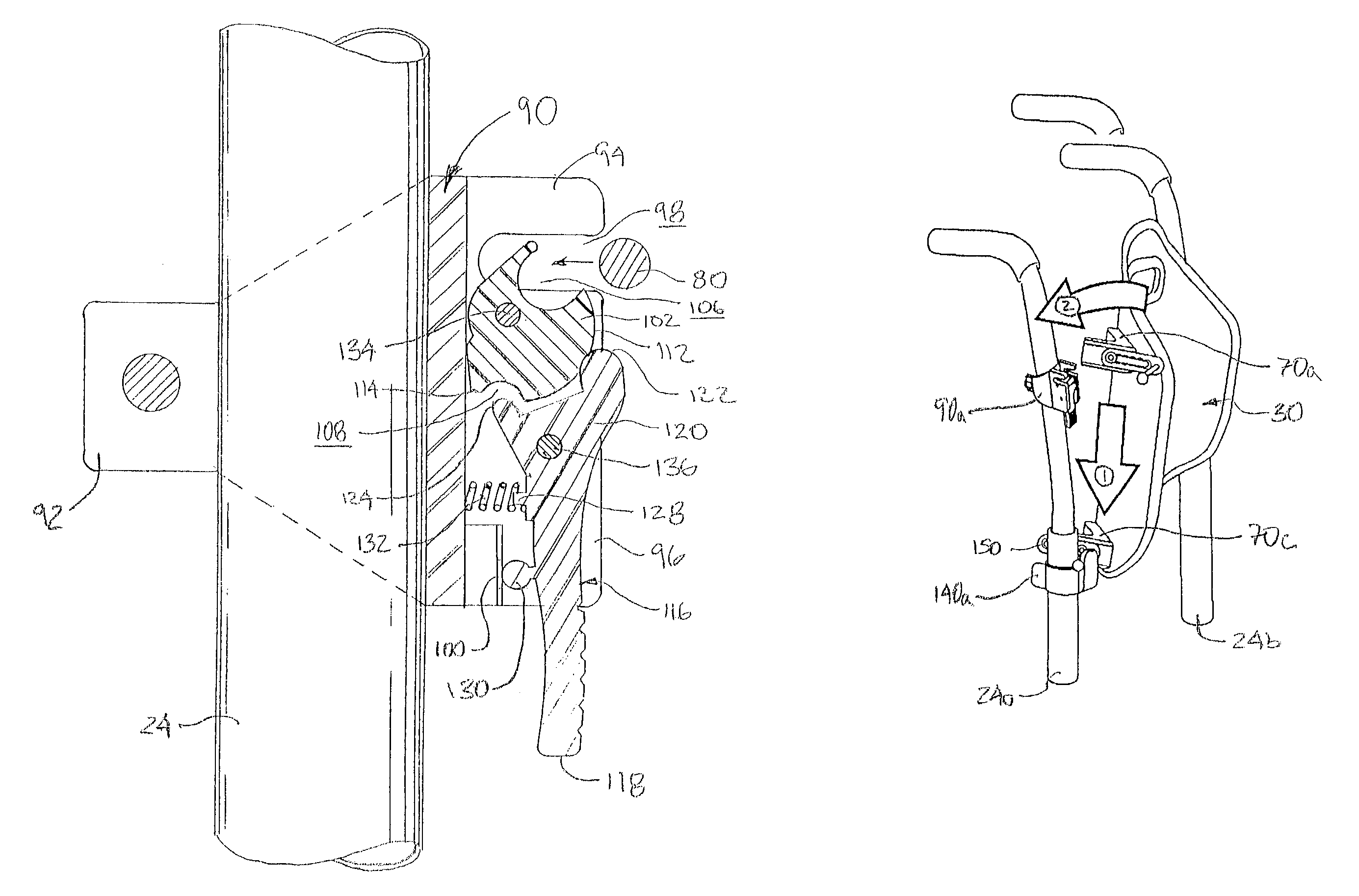

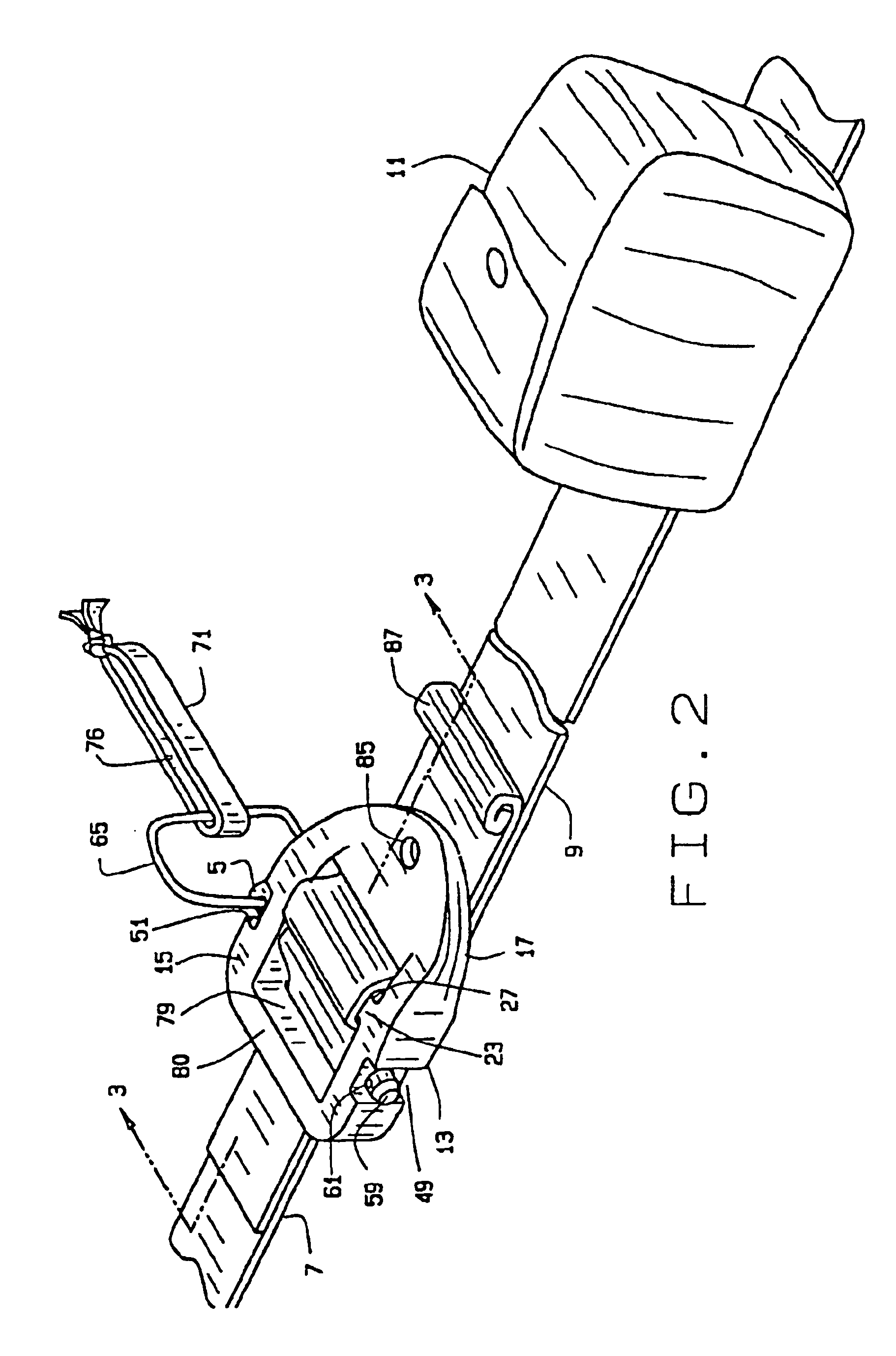

Hinged socket wrench speed handle

InactiveUS7197965B1Shorten the timeFast spinSpannersWrenchesAngular displacementStructural integrity

A hinged socket wrench speed handle having an offset shank (20) with a first end (22) and a second end (24). Attached to the first end (22) is a clevis (28) which receives a 180-degree drive head that is held by a hinge pin (40). The drive head consists of either a square drive head (30) or a ratchet drive head (31). To the second end (24) is attached a handle (58), which rotates the wrench. A second embodiment of the hinged socket wrench includes a second clevis (28) that is added to the second end (24) of the offset shank. The second clevis (28) adds further combinations of angular displacement of the handle (58). Thus increasing the value of the wrench as a tool and also its utility in difficult work areas. The wrench consists of five hinge pin (40) variations which provide additional surface interface with both the hinge pin and the handle yoke, thereby improving the structural integrity and prolonging the tool's life.

Owner:ANDERSON STEVEN P

Hinged socket wrench speed handle

InactiveUS20050120836A1Improve tool lifeShorten the timeSpannersWrenchesEngineeringAngular displacement

A hinged socket wrench having an offset shank (20) with a first end (22) and a second end (24). Attached to the first end (22) is a clevis (28) which receives a 180-degree drive head held by a hinge pin (40). The drive head consists of either a square drive head (30) or a ratchet drive head (31). To the second end is attached a rotatable handle (58), which rotates the wrench upon reciprocation of the handle (58). A second embodiment of the hinged socket wrench includes a second clevis (28) that is added to the second end (24) of the offset shank. The second clevis (28) adds further combinations of angular displacement of the handle (58). Thus, increasing the value of the wrench as a tool and also its productivenss in difficult work areas. Five configurations of the hinge pin (40) provide additional surface interface with both the hinge pin and the handle yoke improving the structural integrity and prolonging tool life.

Owner:ANDERSON STEVEN P

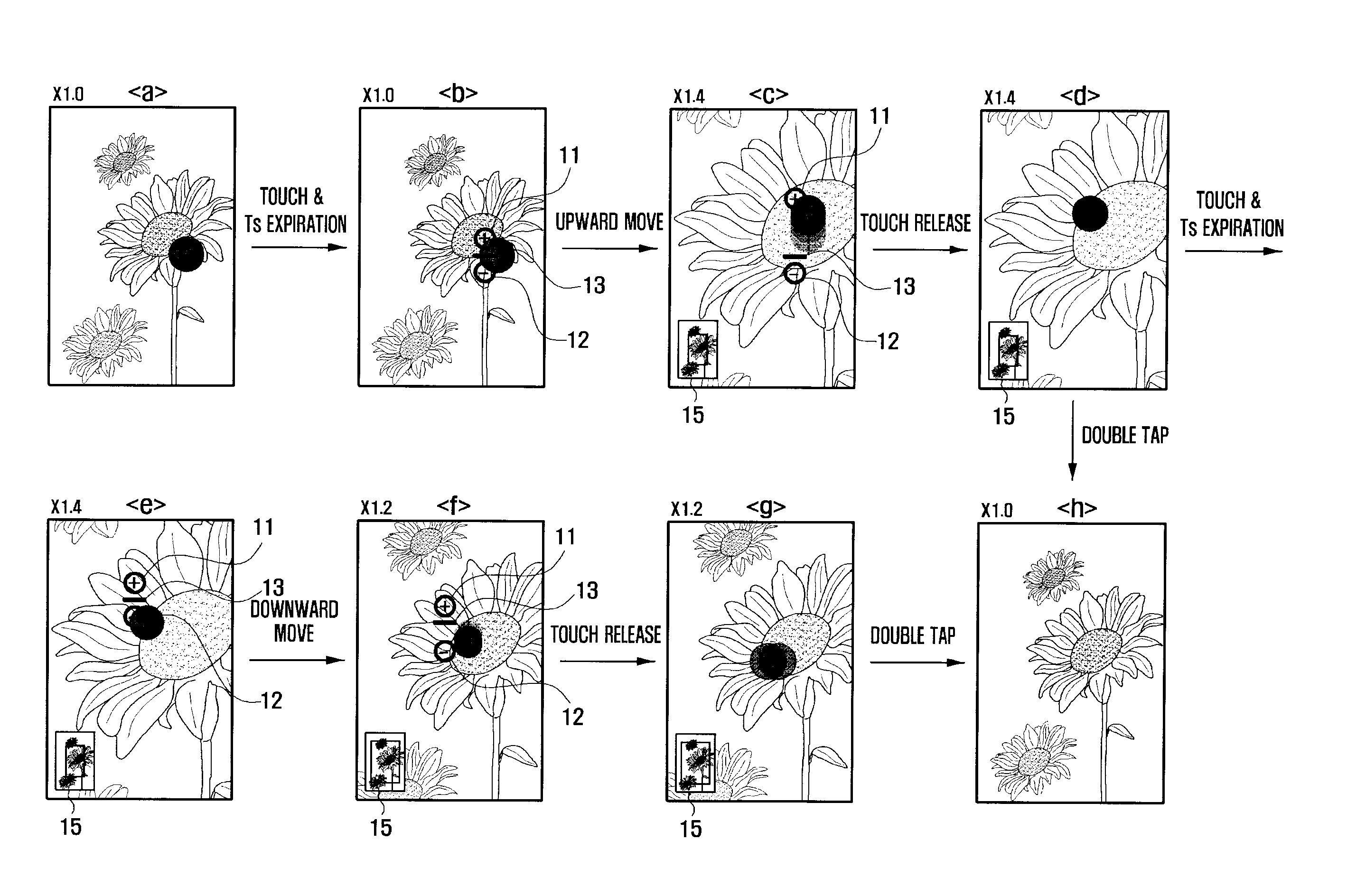

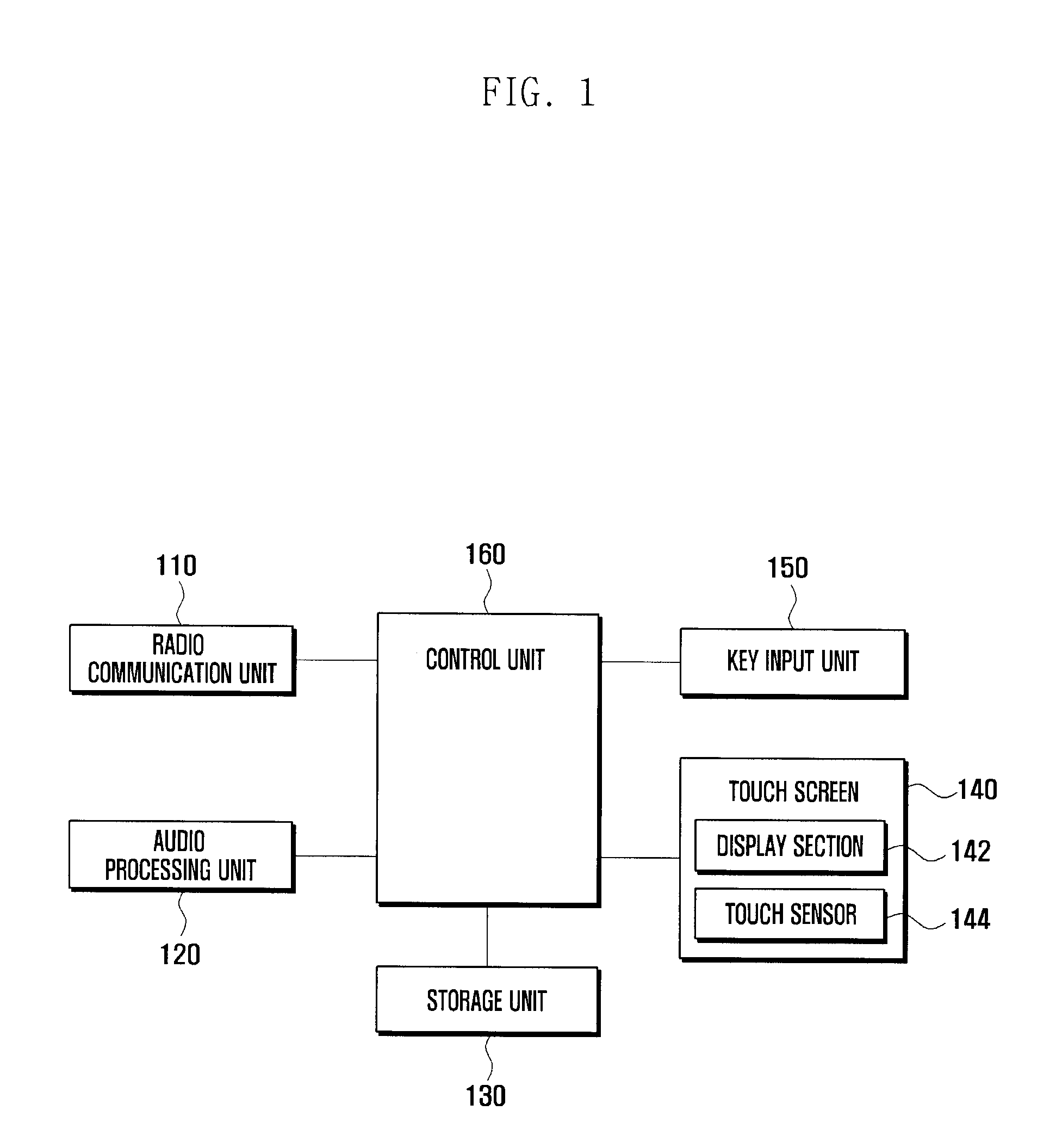

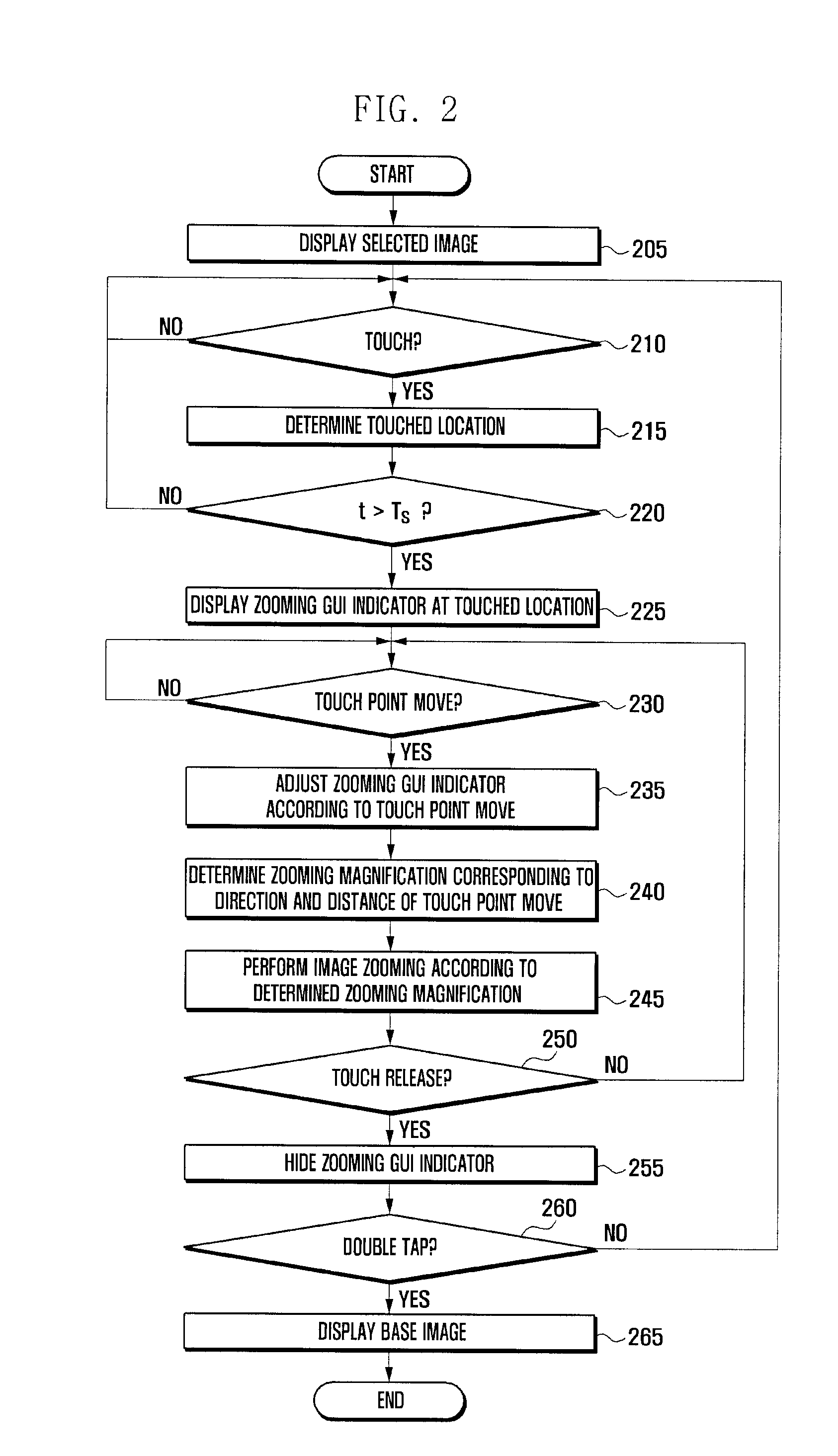

Image processing method for mobile terminal

ActiveUS20100289825A1Easy and fast image zooming methodSimple actionCathode-ray tube indicatorsDigital output to display deviceImaging processingTouchscreen

An image processing method based on zooming for a mobile terminal permits touch zooming on touch screens of a plurality of devices. The image processing method preferably includes: displaying, in response to entering a touch on a touch screen displaying an image, a zooming GUI indicator for image zooming operation; performing image zooming on the touch screen in response to entering a touch point move while retaining the touch; and hiding the zooming GUI indicator from the touch screen in response to entering a touch release.

Owner:SAMSUNG ELECTRONICS CO LTD

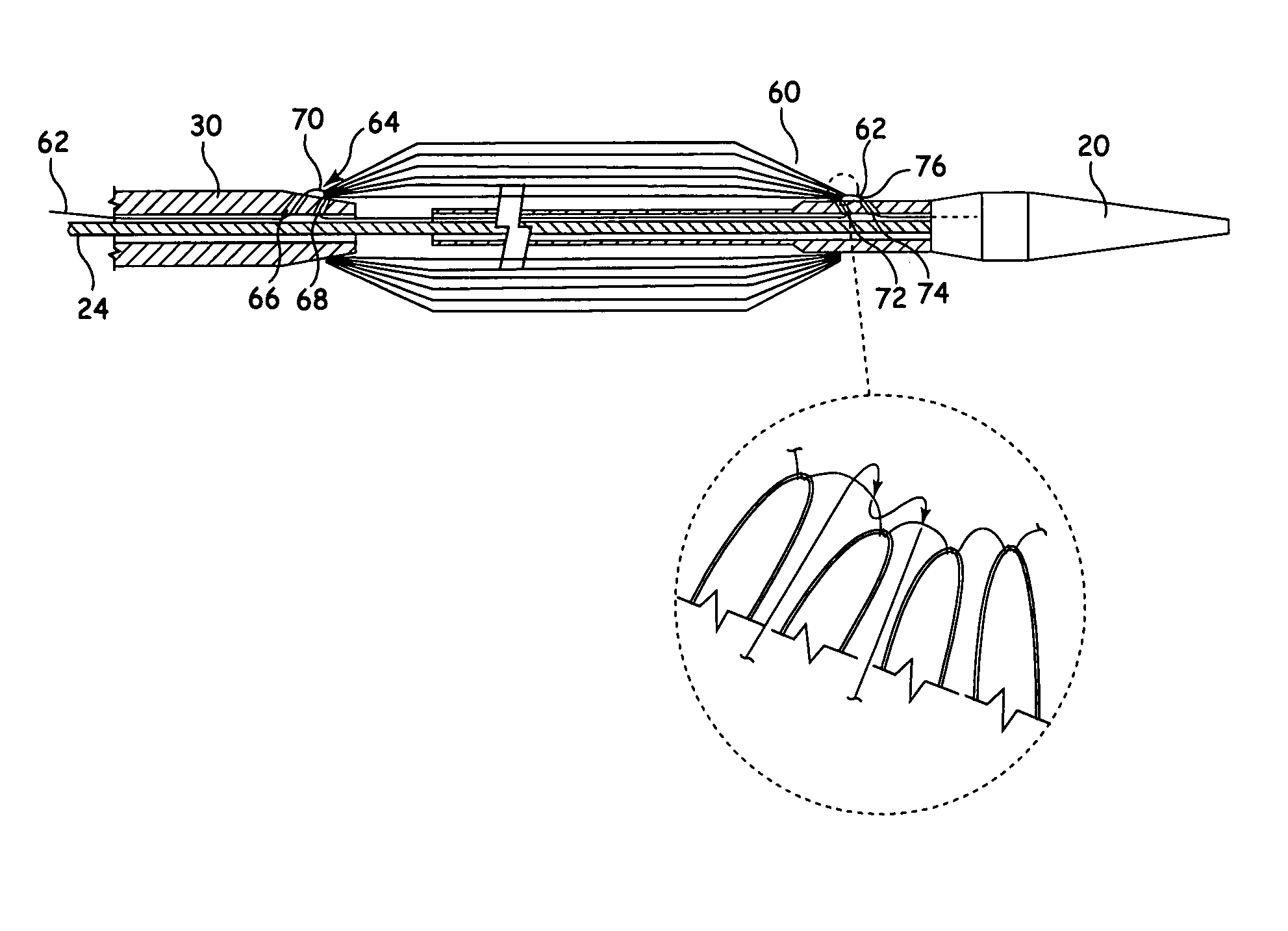

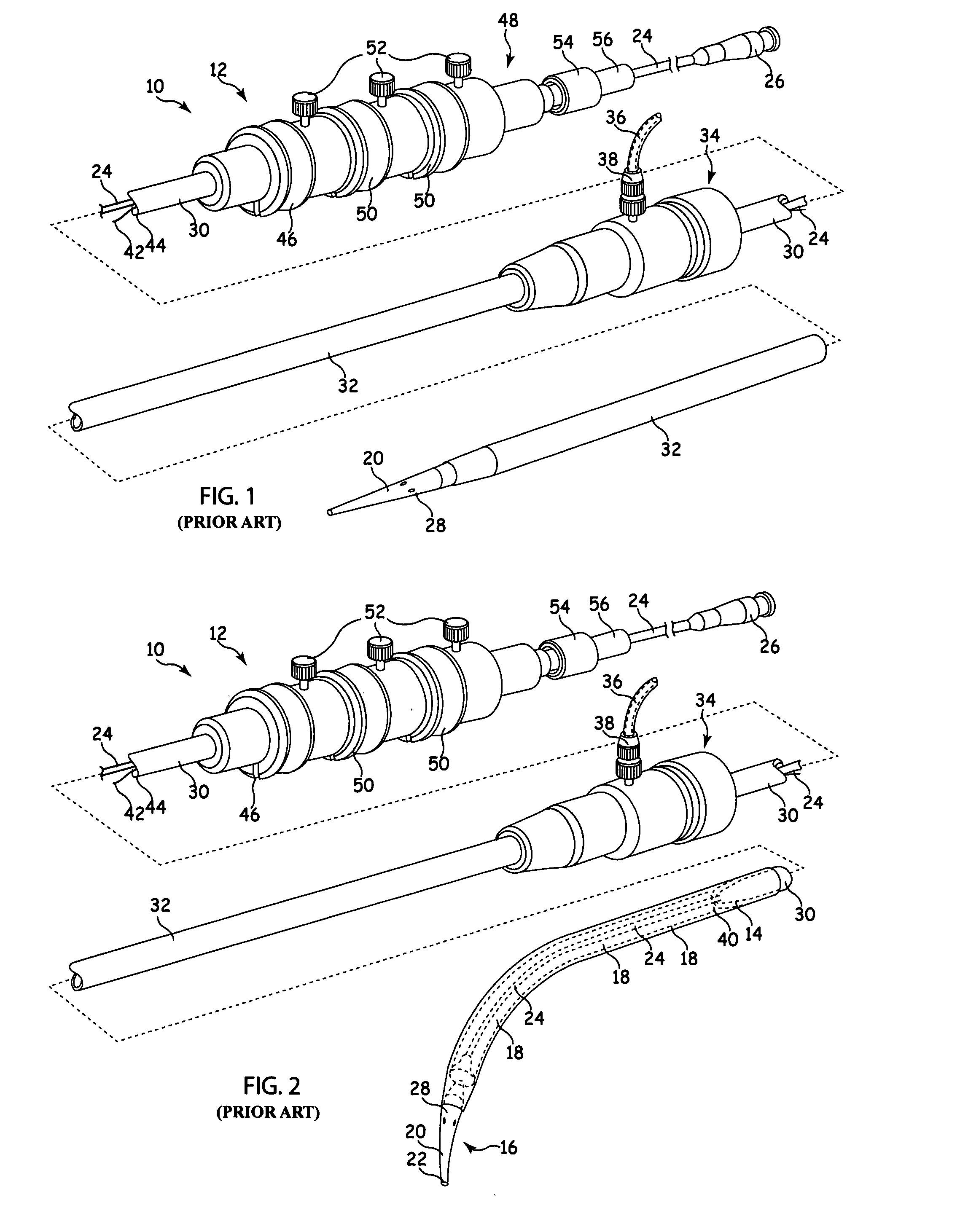

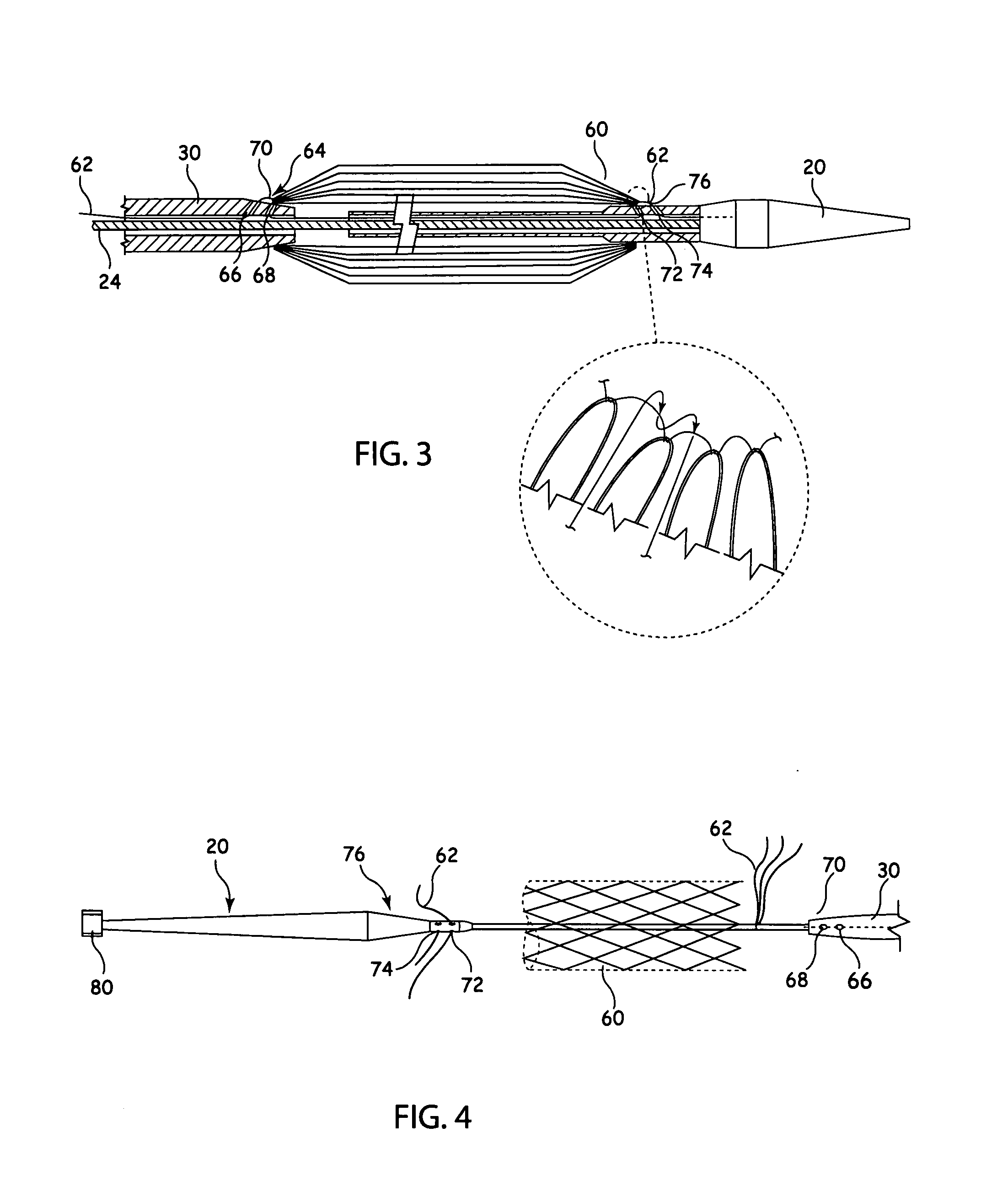

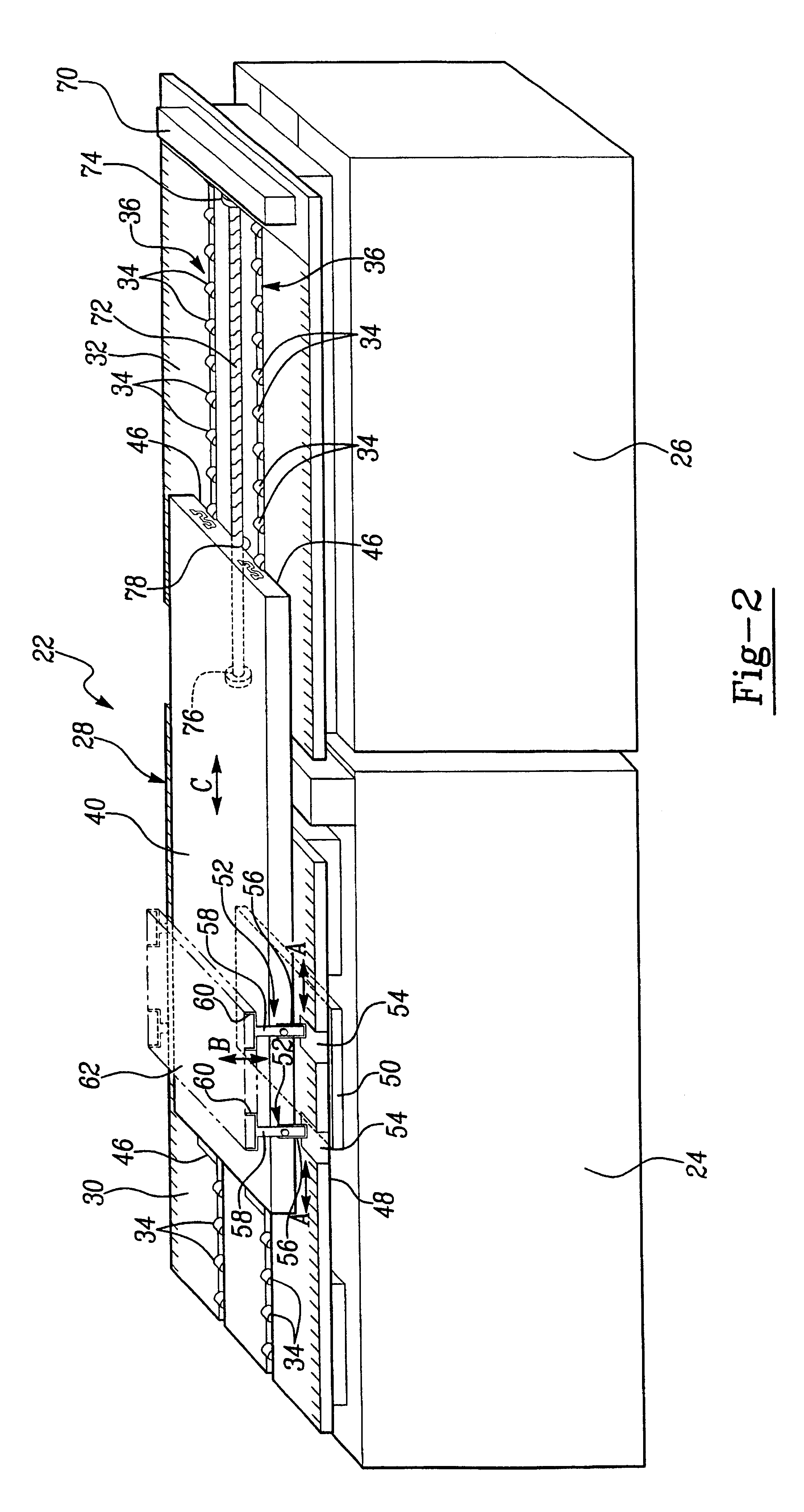

Implant release mechanism

An implant release mechanism for releasing, for example, a stent ( 60 ) is provided with three restraining wires ( 62 ) which pass in the space between a wire guide catheter ( 24 ) and a pusher sheath or dilator ( 30 ) and are arranged substantially equi-angularly threrearound. Each restraining wire ( 62 ) holds both the proximal and distal ends of the stent ( 60 ), in this case each holding a proportion of the ends of the stent ( 60 ). When the restraining wires ( 62 ) are pulled they will first unwrap from the proximal end of the stent ( 60 ) and will then release the distal end of the stent ( 60 ) so as to allow the stent to become fully deployed within the lumen of the patient. The use of common release wires improves deployment of implants and reduces the number and volume of components in the device, thereby allowing it to occupy a smaller volume.

Owner:COOK MEDICAL TECH LLC

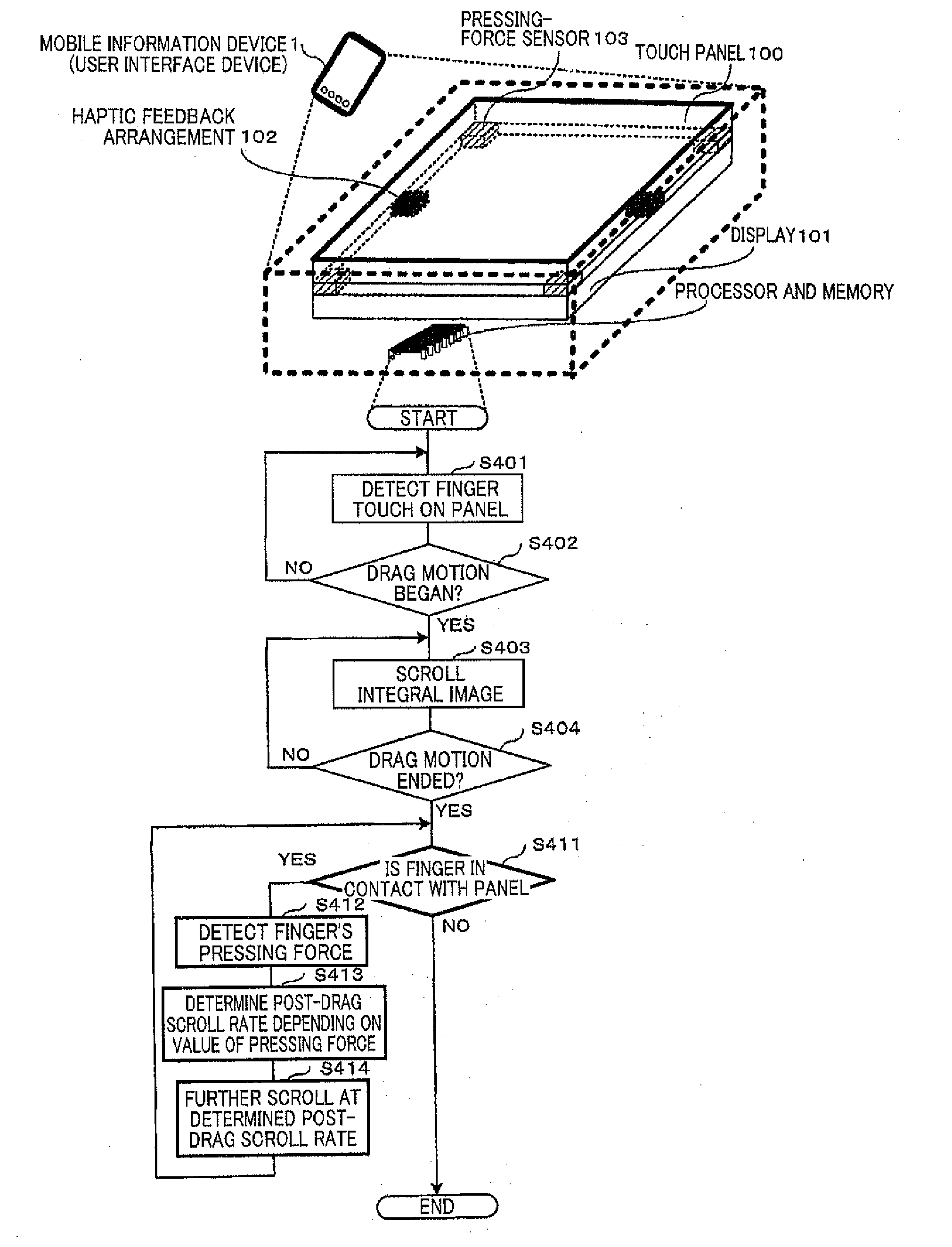

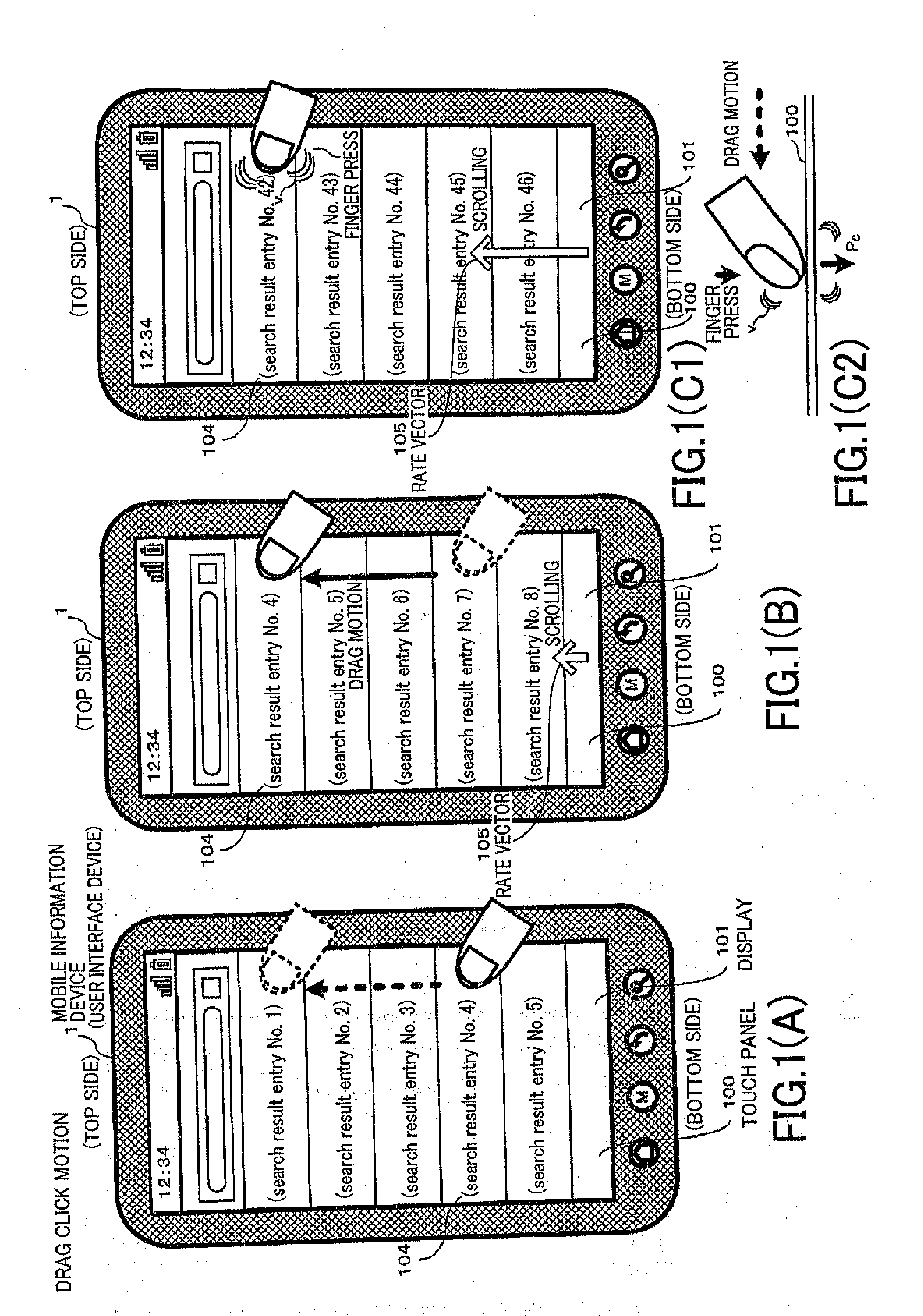

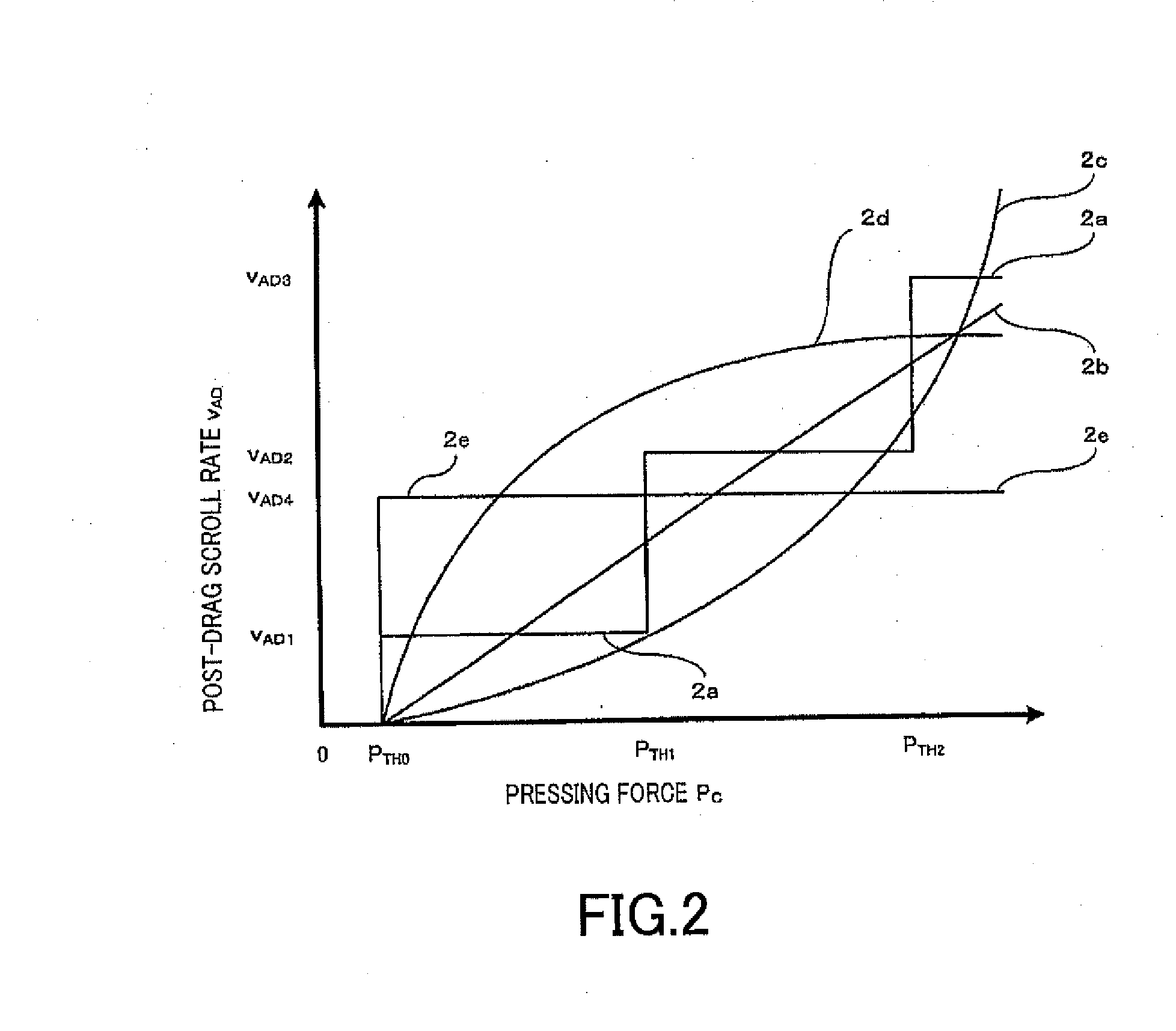

User interface device capable of image scrolling not accompanying finger movement, image scrolling method, and program

ActiveUS20140139471A1Simple actionInput/output for user-computer interactionGraph readingTouchscreenScrolling

A process is disclosed of scrolling an image on a user interface device configured to display the image on a display screen and enable a user to input with the user's finger touch on a touch screen in association with the displayed image, the process including: scrolling the image in response to the finger's drag motion on the touch screen; and, in response to an event occurring in which, after the drag motion ended, the finger is held in touch with the touch screen at substantially the same location as where the finger was located when the drag motion ended, without releasing from the touch screen, further scrolling the image to perform follow-up scrolling, after experiencing an idle period or not.

Owner:KDDI CORP

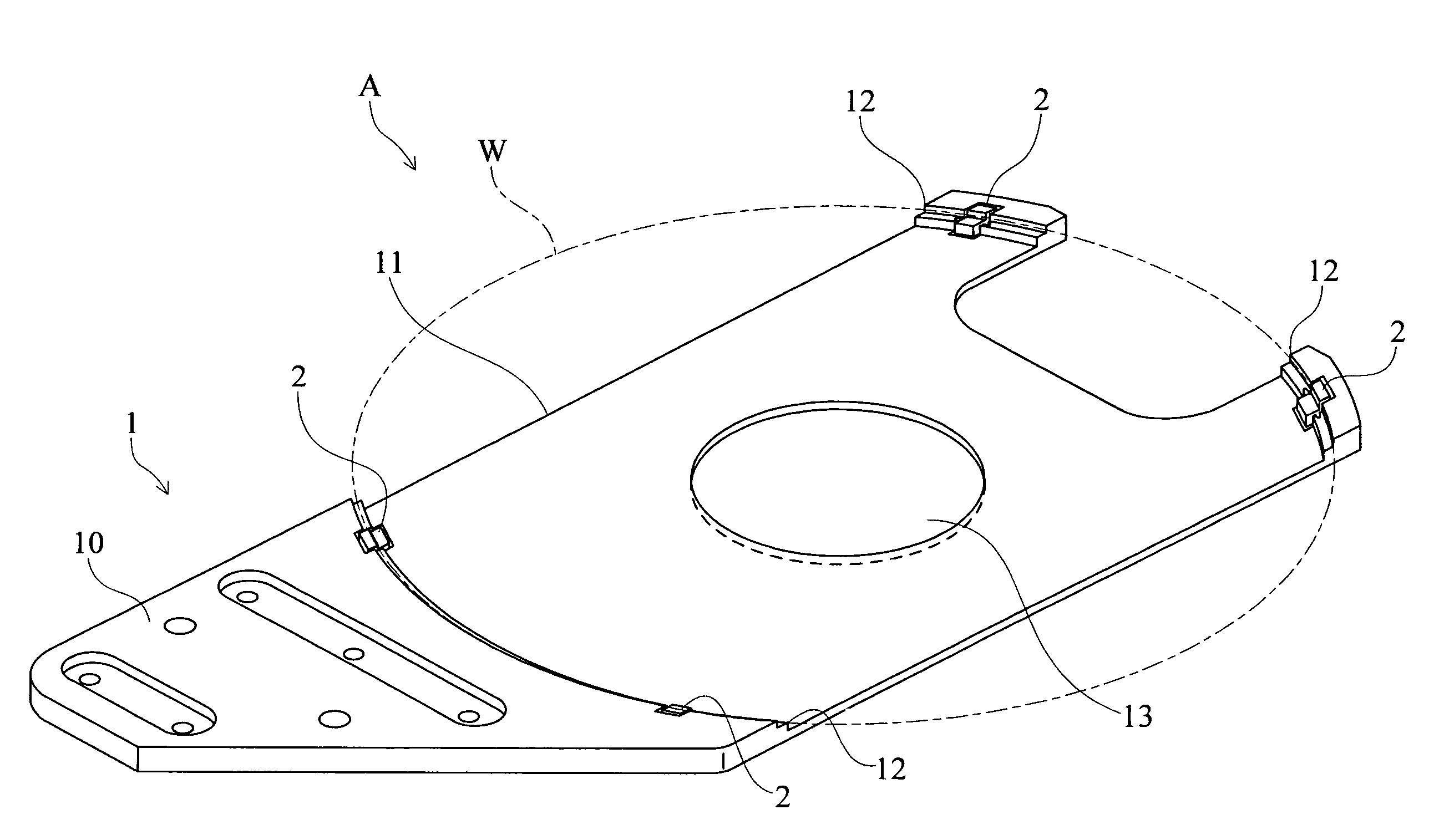

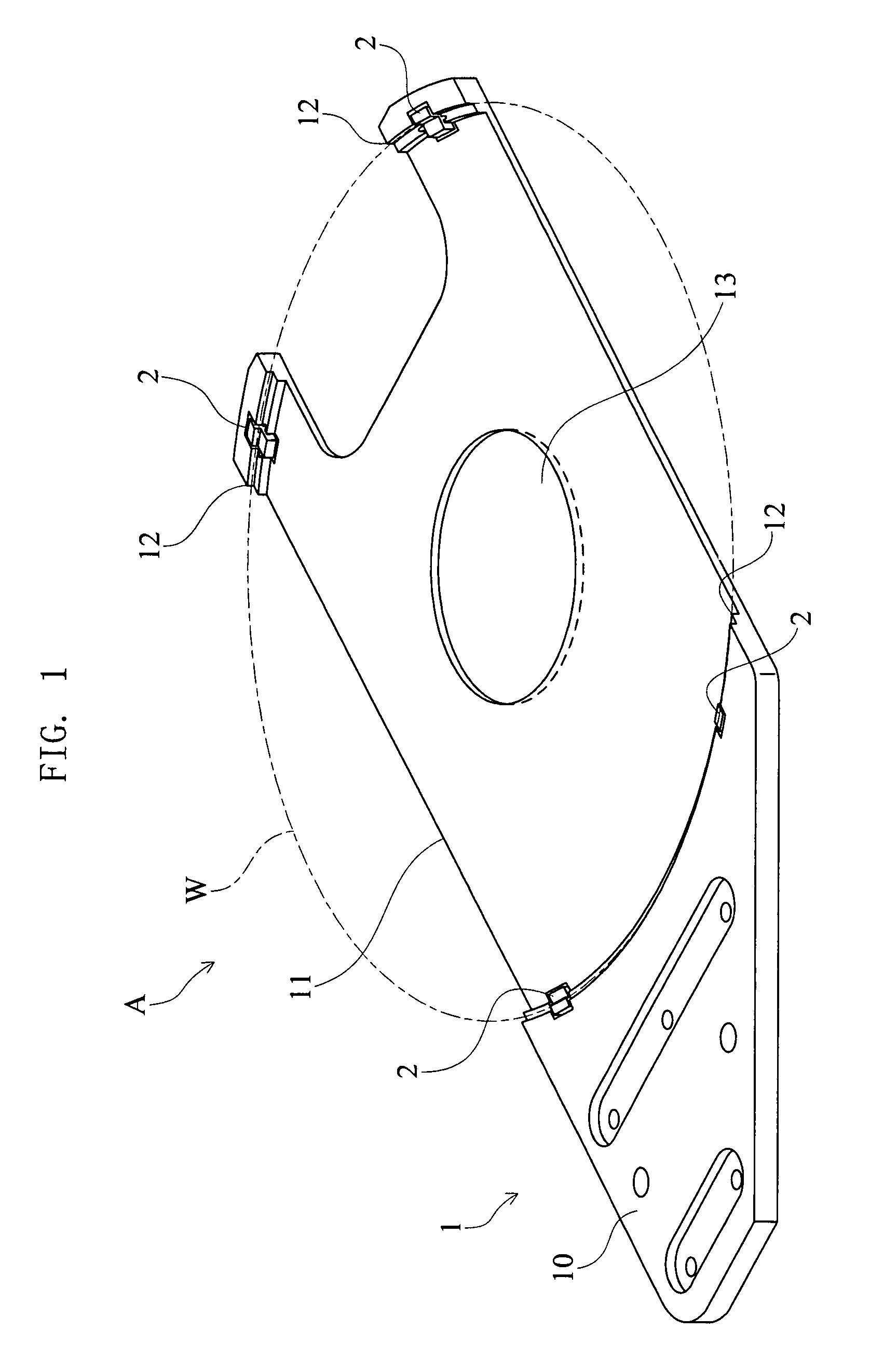

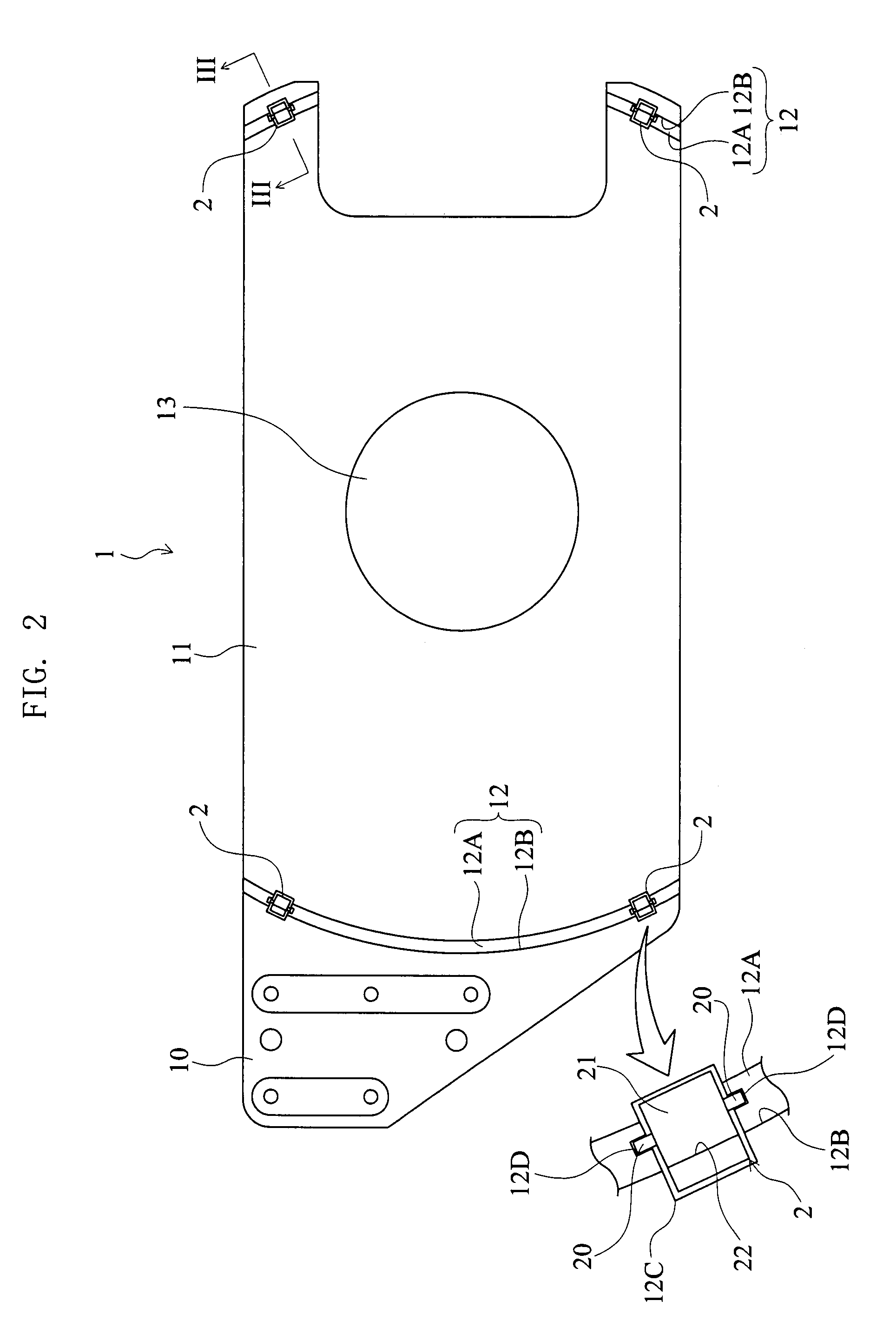

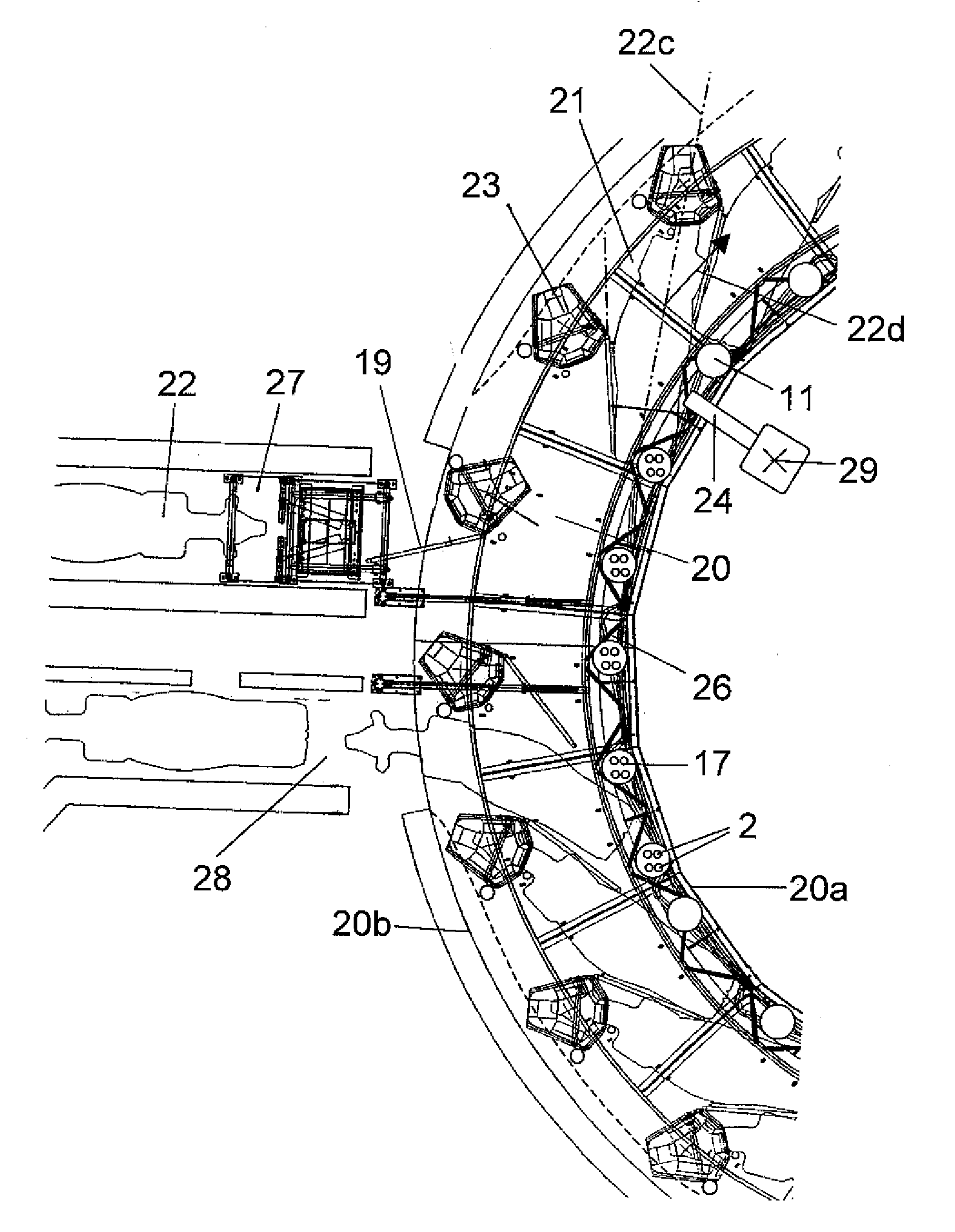

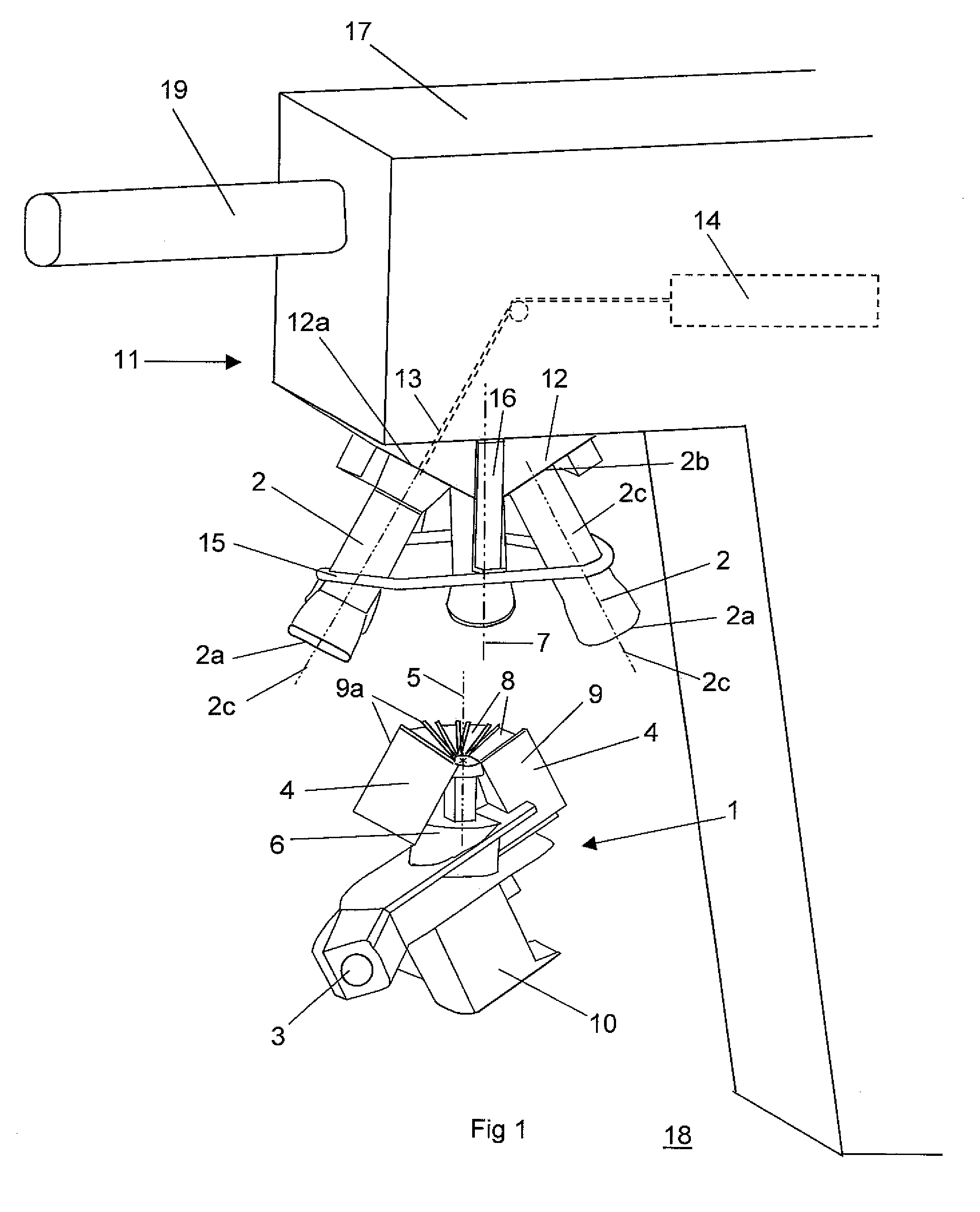

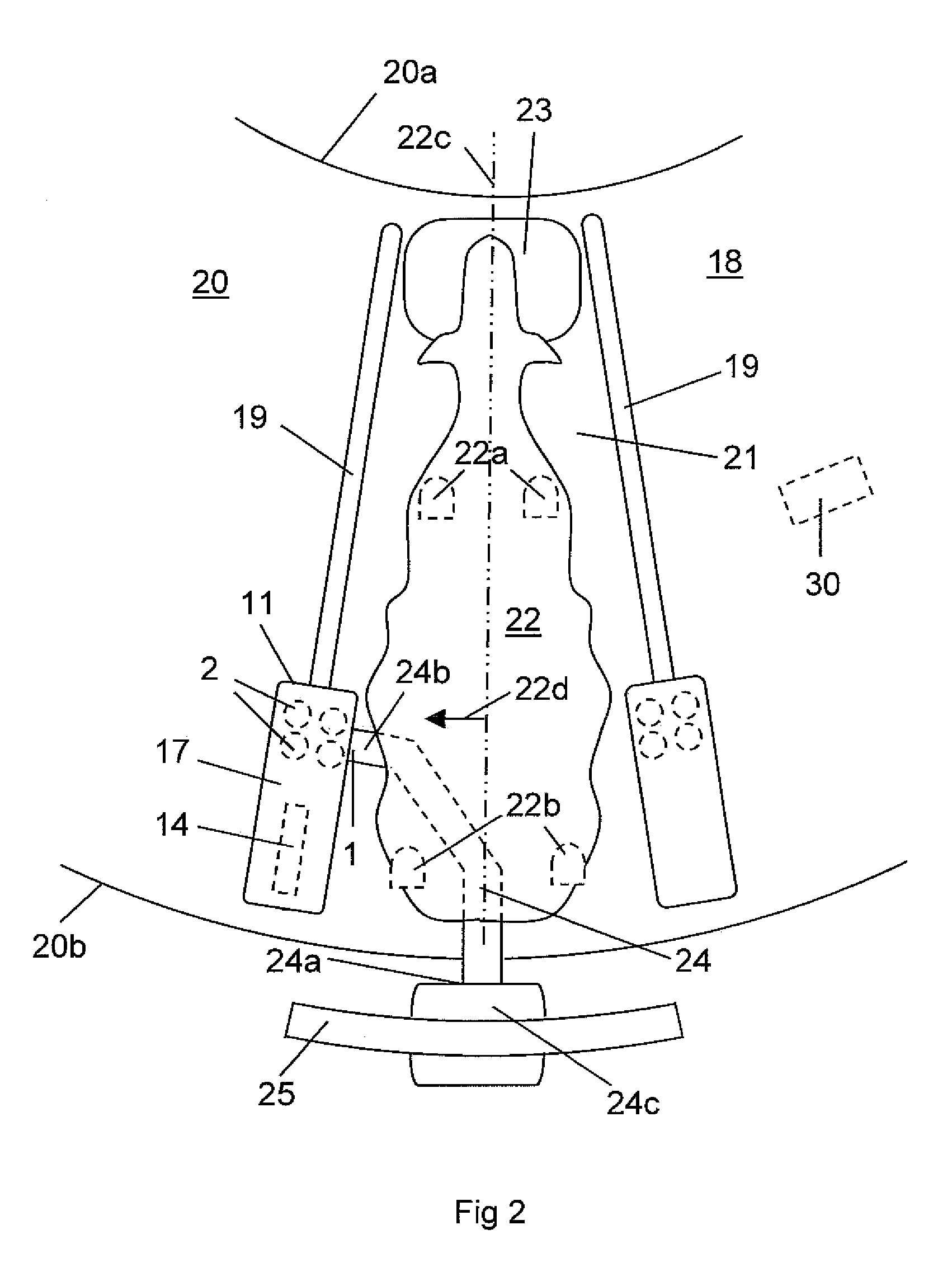

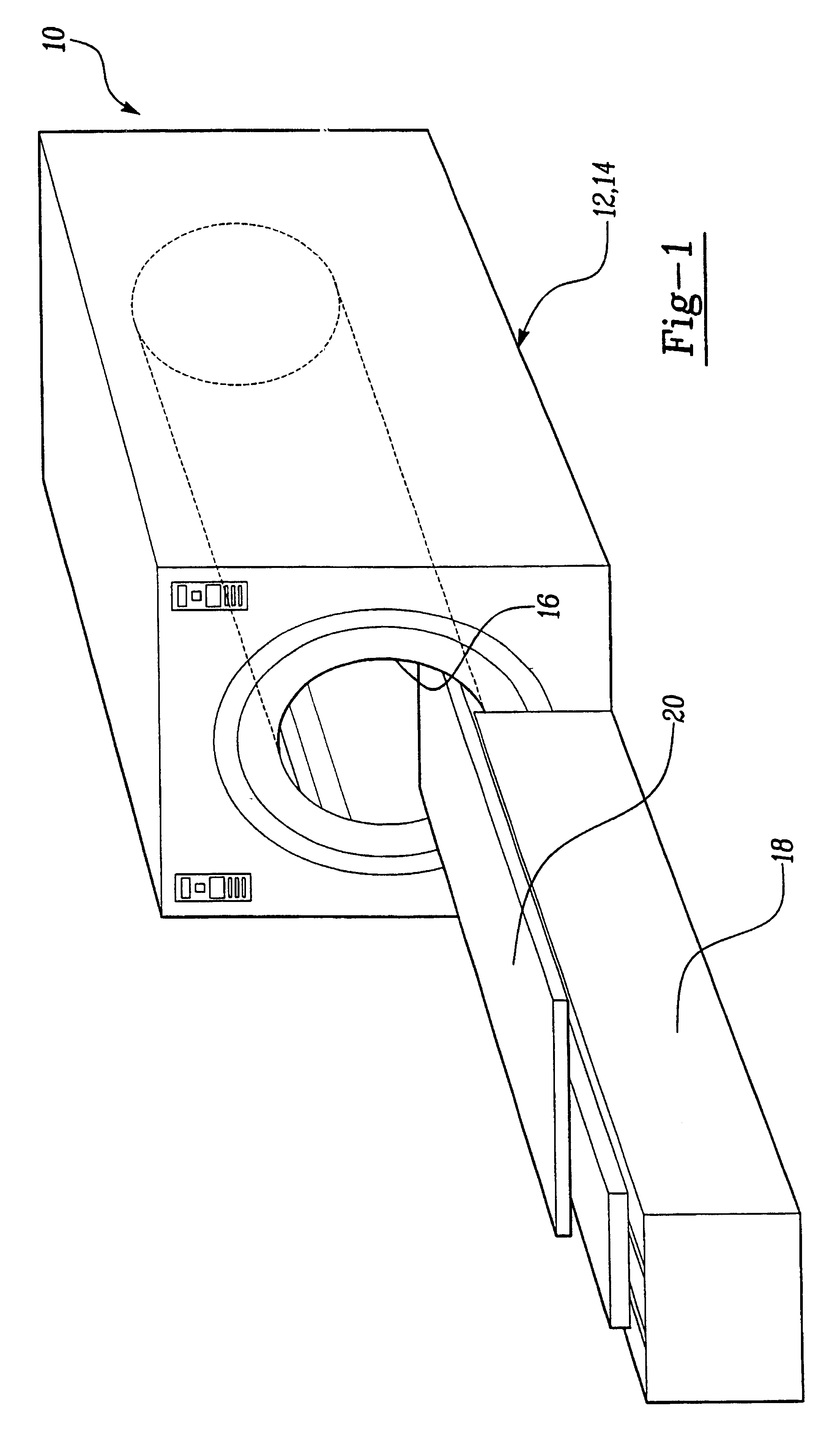

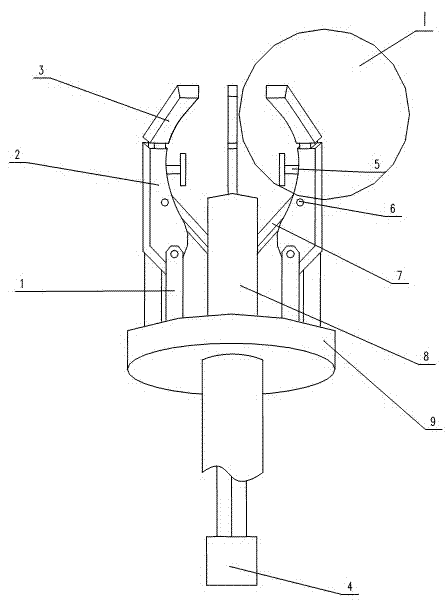

Rotary parlour for automatic milking of animals and a method for attaching teat cups to milking animals on a rotary platform

ActiveUS20100031889A1Fast attachmentEliminate needCathetersAnimal housingEngineeringAutomatic milking

A rotary parlour for milking of animals includes an annular rotary platform (20) adapted to form a support surface (18) for the animals (22), positioning elements (19, 23) for arranging the animals (1) in milking positions on the platform (20), a drive mechanism (30) adapted to supply a rotational motion to the platform (20), and teat cup storing devices (11) for holding parked teat cups (2, 2′) in predetermined storing positions. The teat cup storing devices (11) are mounted in positions such that the teat cups (2, 2′) are located vertically above the platform (20) in their storing positions.

Owner:DELAVAL HLDG AB

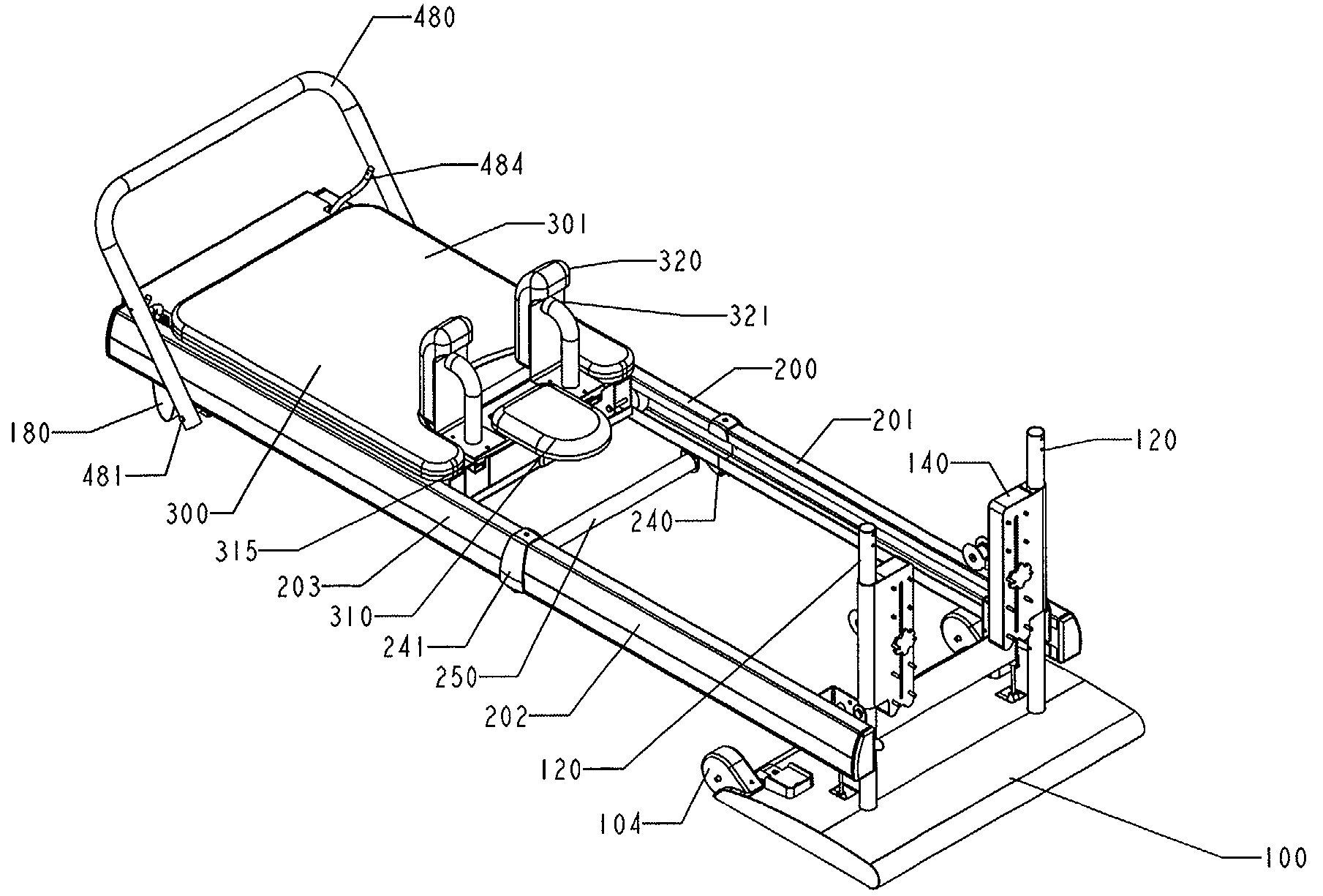

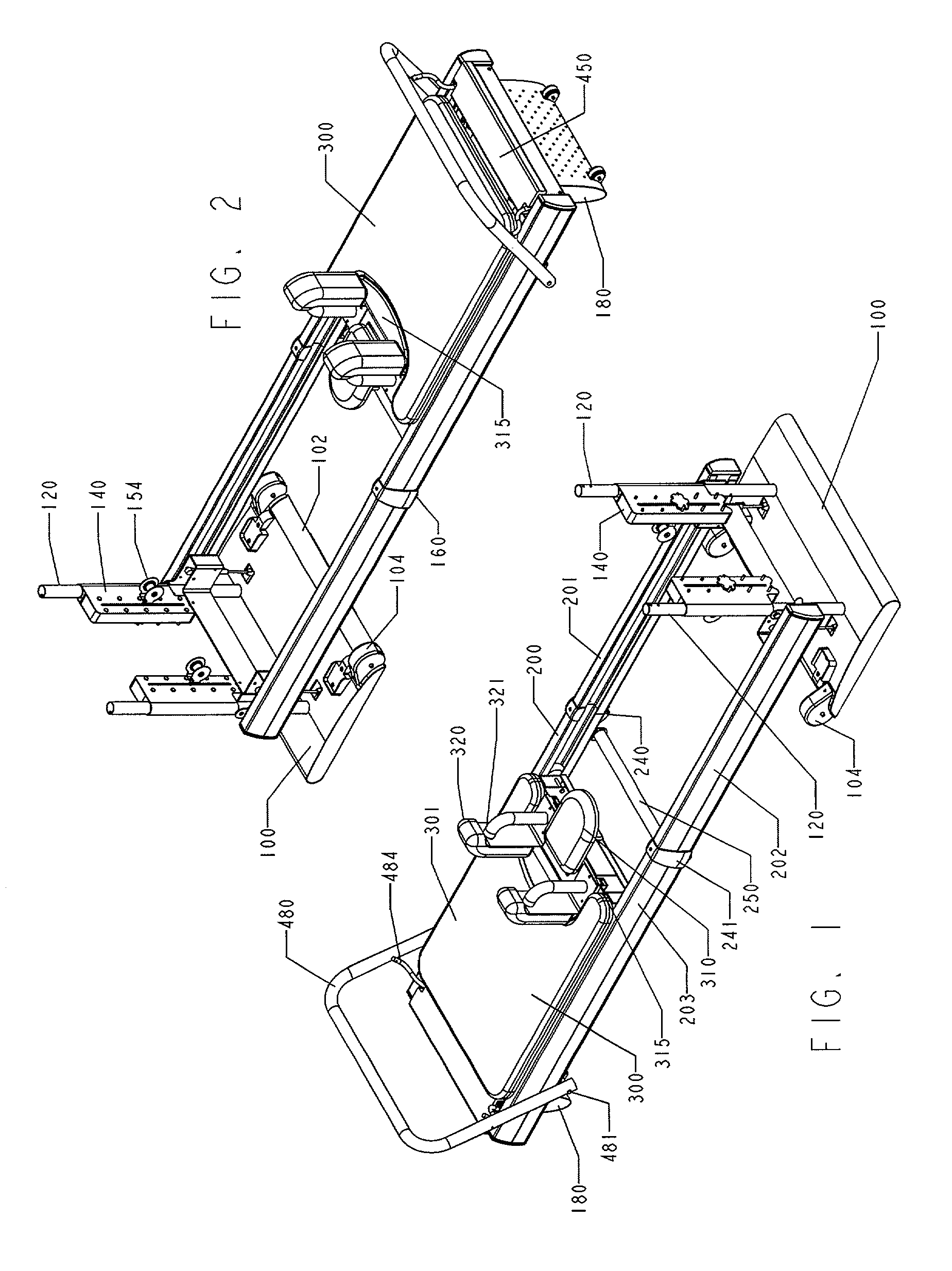

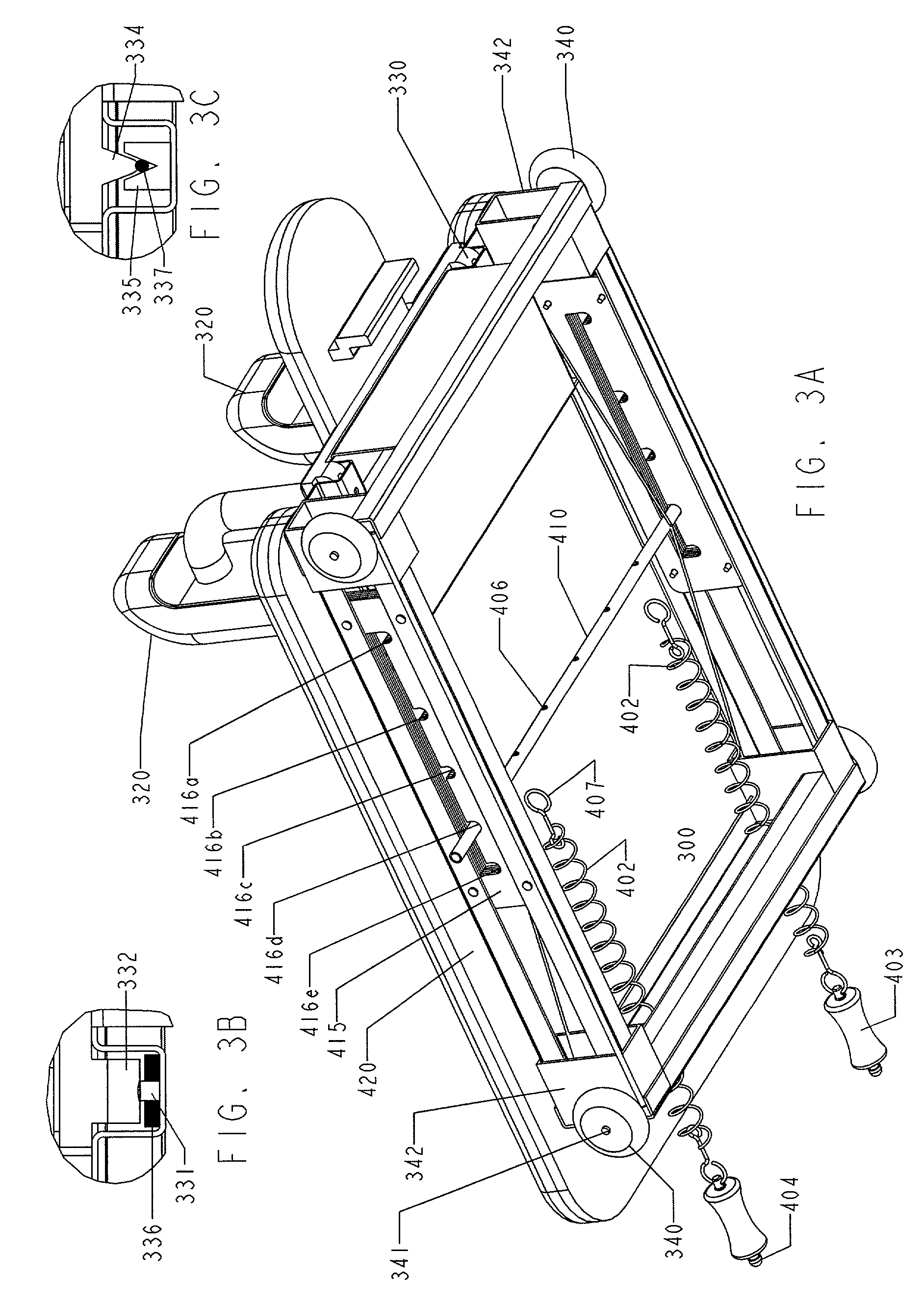

Foldable transportable multiple function pilates exercise method and apparatus

InactiveUS7104937B2Improved Pilates machineEasy to changeResilient force resistorsStiltsCarriageElectric cables

A multi-function Pilates exercise apparatus featuring a foldable frame, a wheeled base, a rotatable pulley riser with a flexible pulley mount, gear changing apparatus and adjustable footbar. The frame is designed to fold into an upright position and to be rolled to a desired location. The pulley mount includes a section of flexible cable which permits the pulley to freely move relative to its mounting pole, thereby reducing binding during operation. The gear changing apparatus permits the user to adjust the carriage position with a single operation. The exercise system includes a reformer, pole apparatus, and a long / short box that also serves as a chair.

Owner:MAD DOGG ATHLETICS

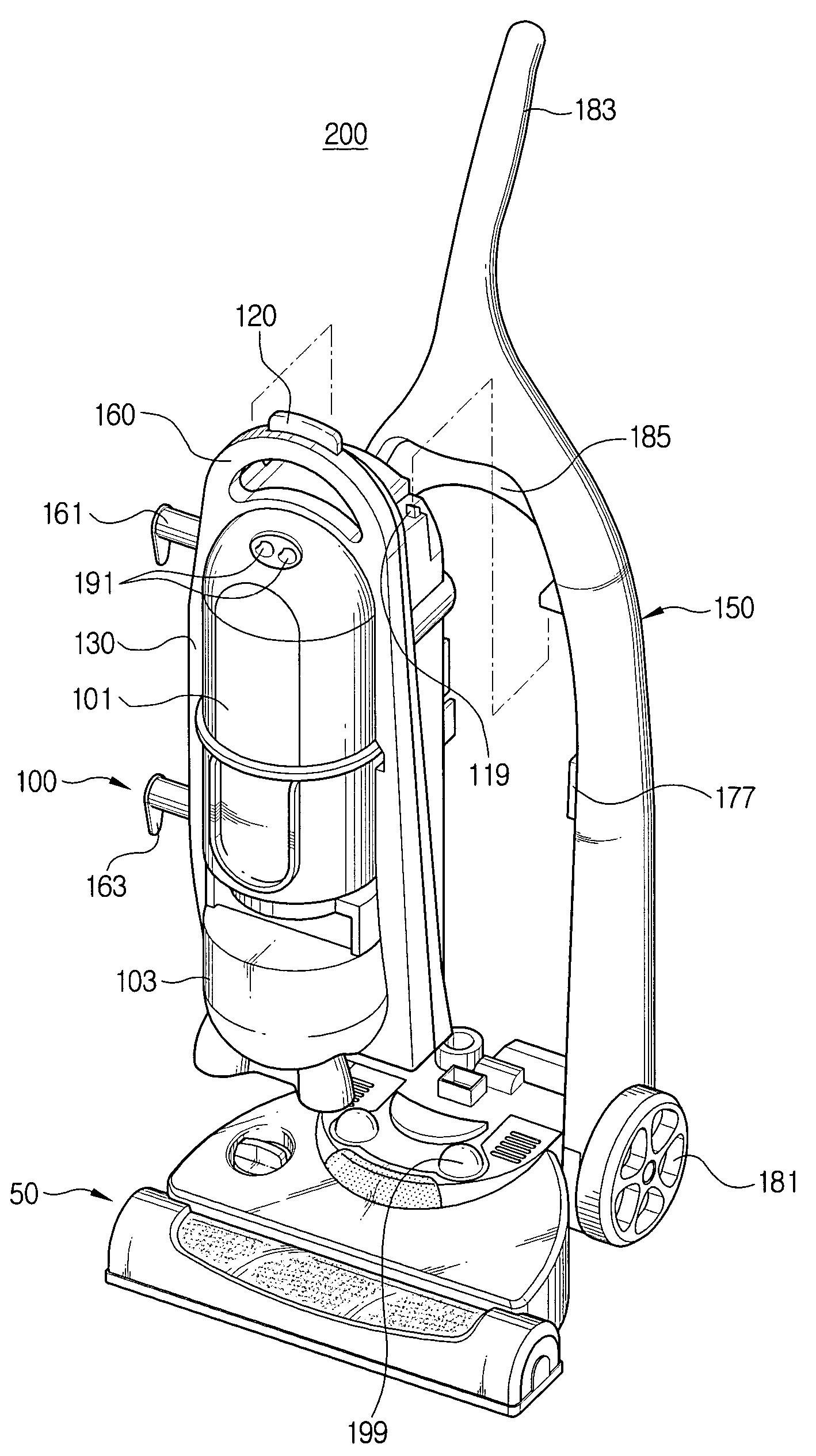

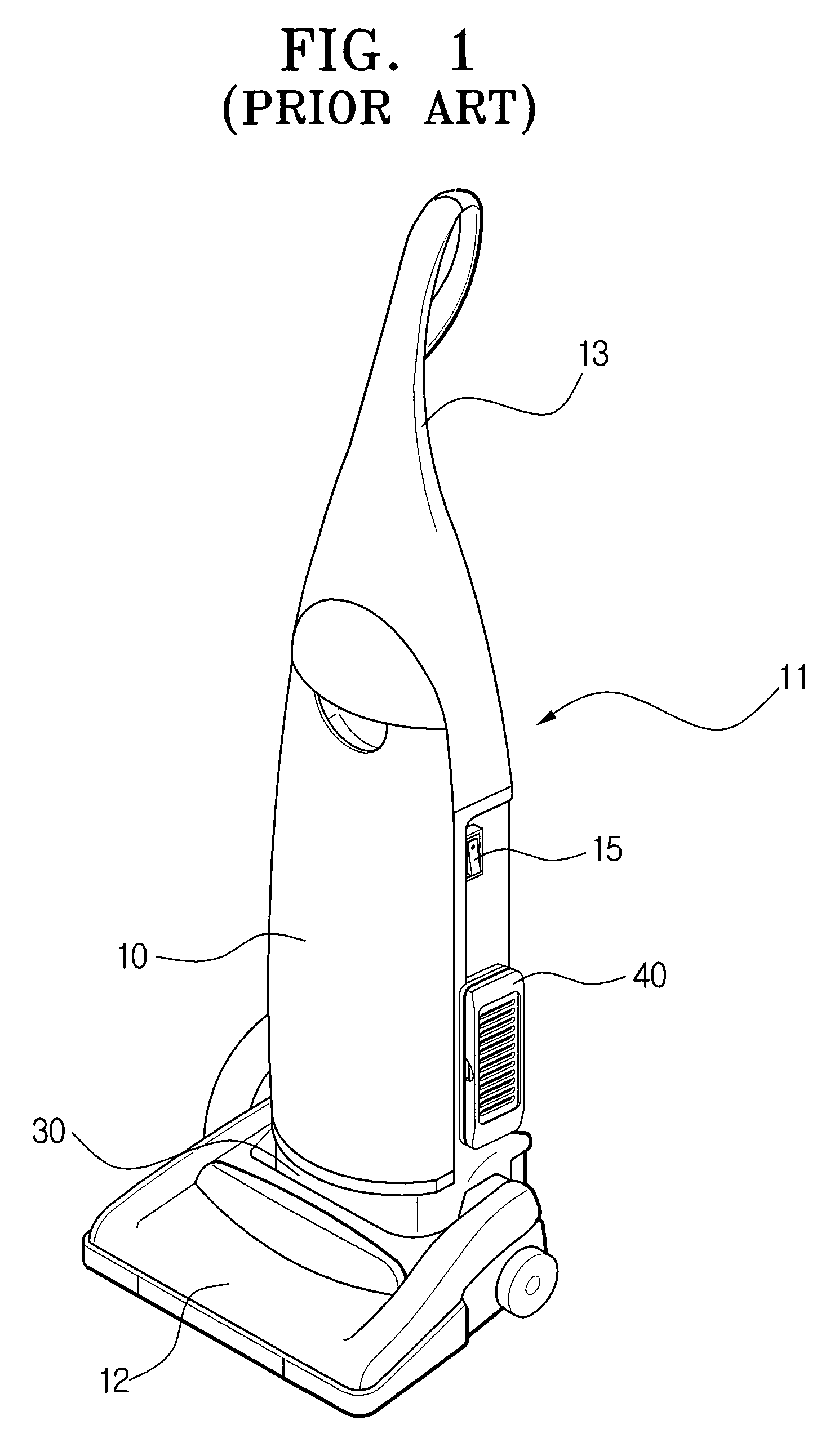

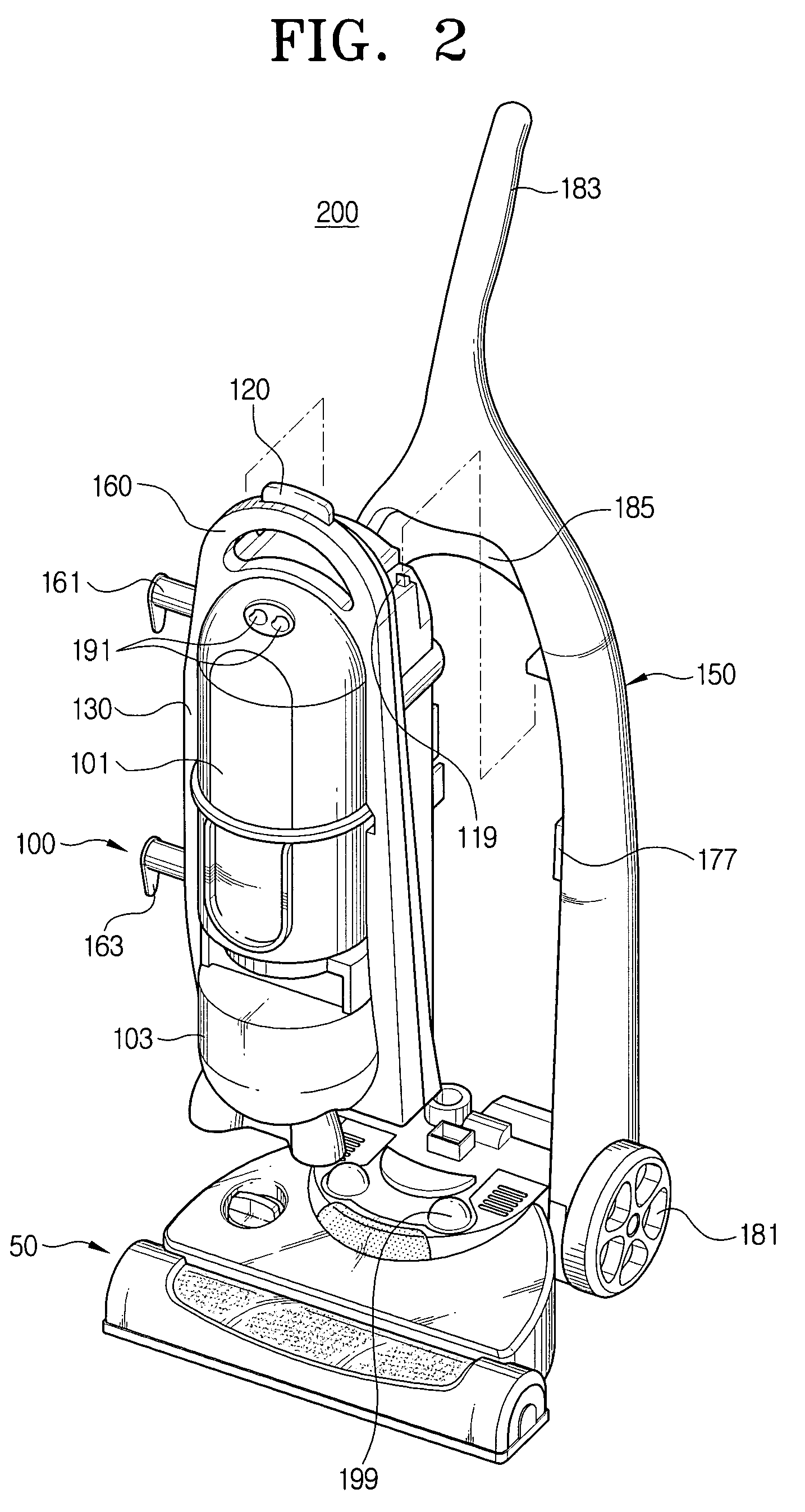

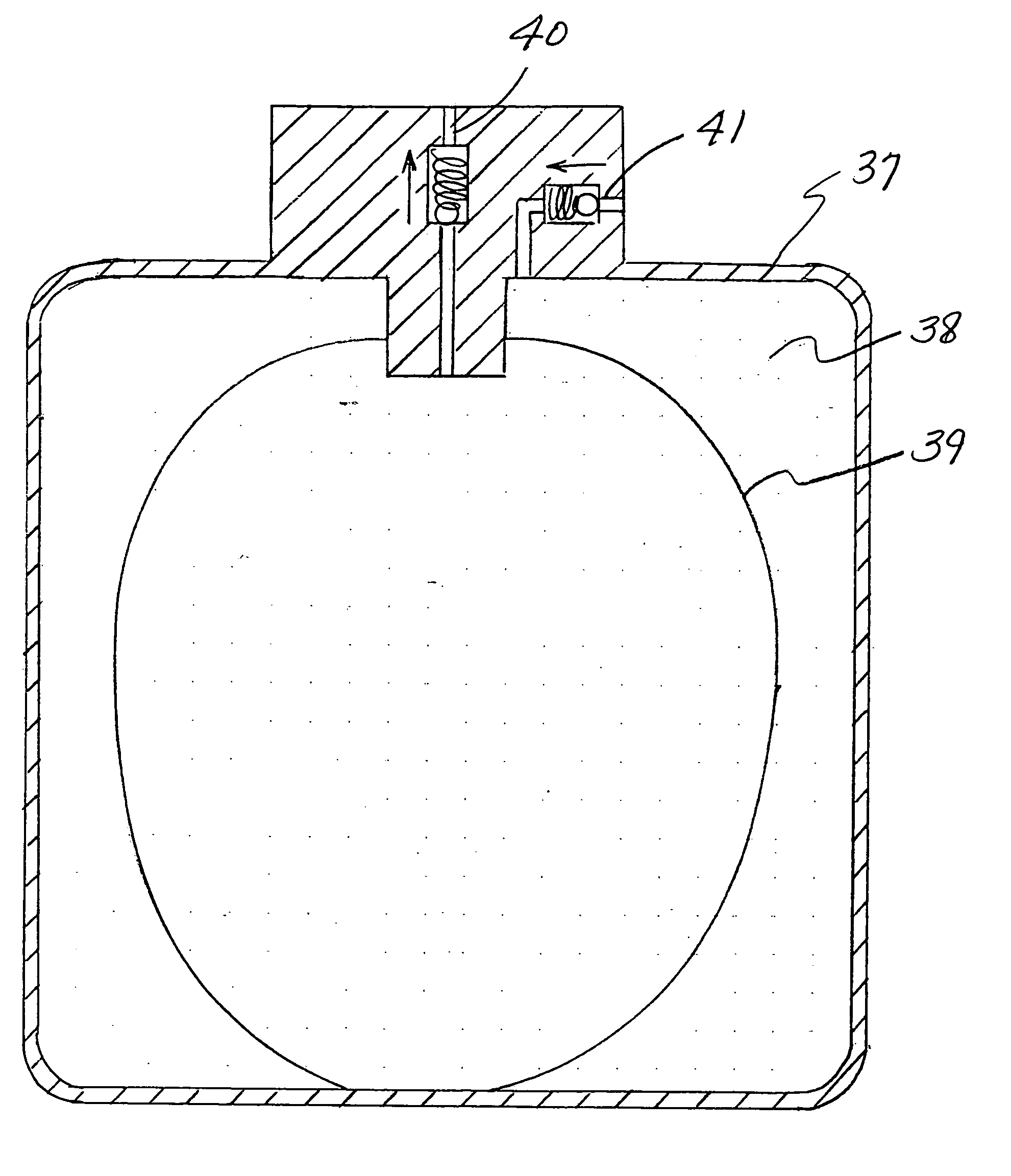

Multifunction vacuum cleaner

InactiveUS7377008B2Good adhesionEasy to separateCleaning filter meansSuction filtersEngineeringVacuum cleaner

A multifunction vacuum cleaner, in which a main body is removably connected to a frame portion, comprises a nozzle assembly for suctioning in an air including dusts or dirt on a cleaning area, a main body having a cyclone dust collector for centrifugally separating the dusts or dirt from the sucked air, a dust receptacle for collecting the separated dusts or dirt, a main body frame having an upper casing and a lower casing, a button operation portion formed on an upper part of the main body frame, and a connecting projection integrally formed with the button operation portion and moving elastically, and a frame portion which is pivotably connected with the nozzle assembly, and having a connecting groove to correspond to the connecting projection. The main body of the vacuum cleaner is removably mounted in the frame portion. As a result, the main body can be conveniently connected with or separate from the frame portion.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

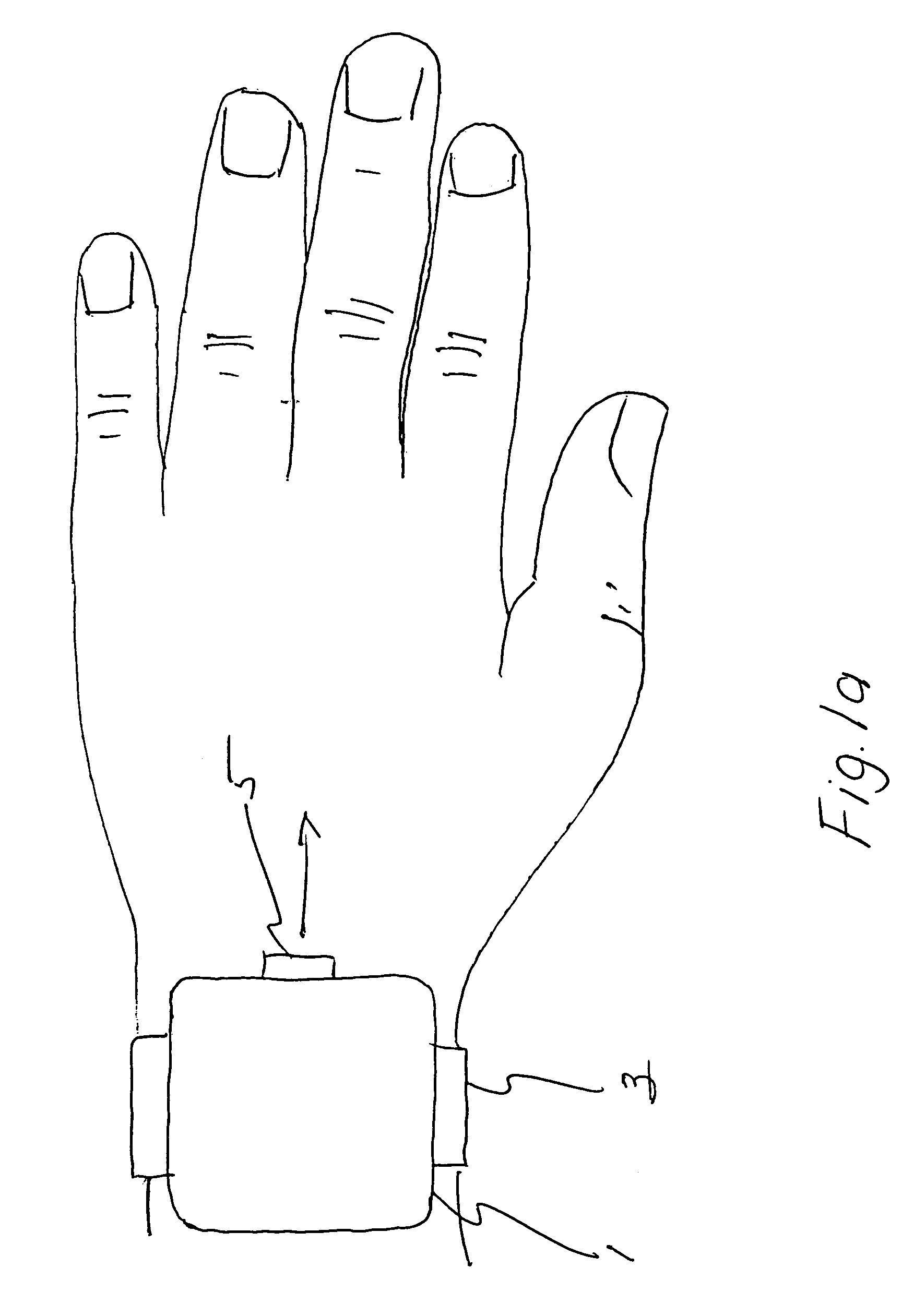

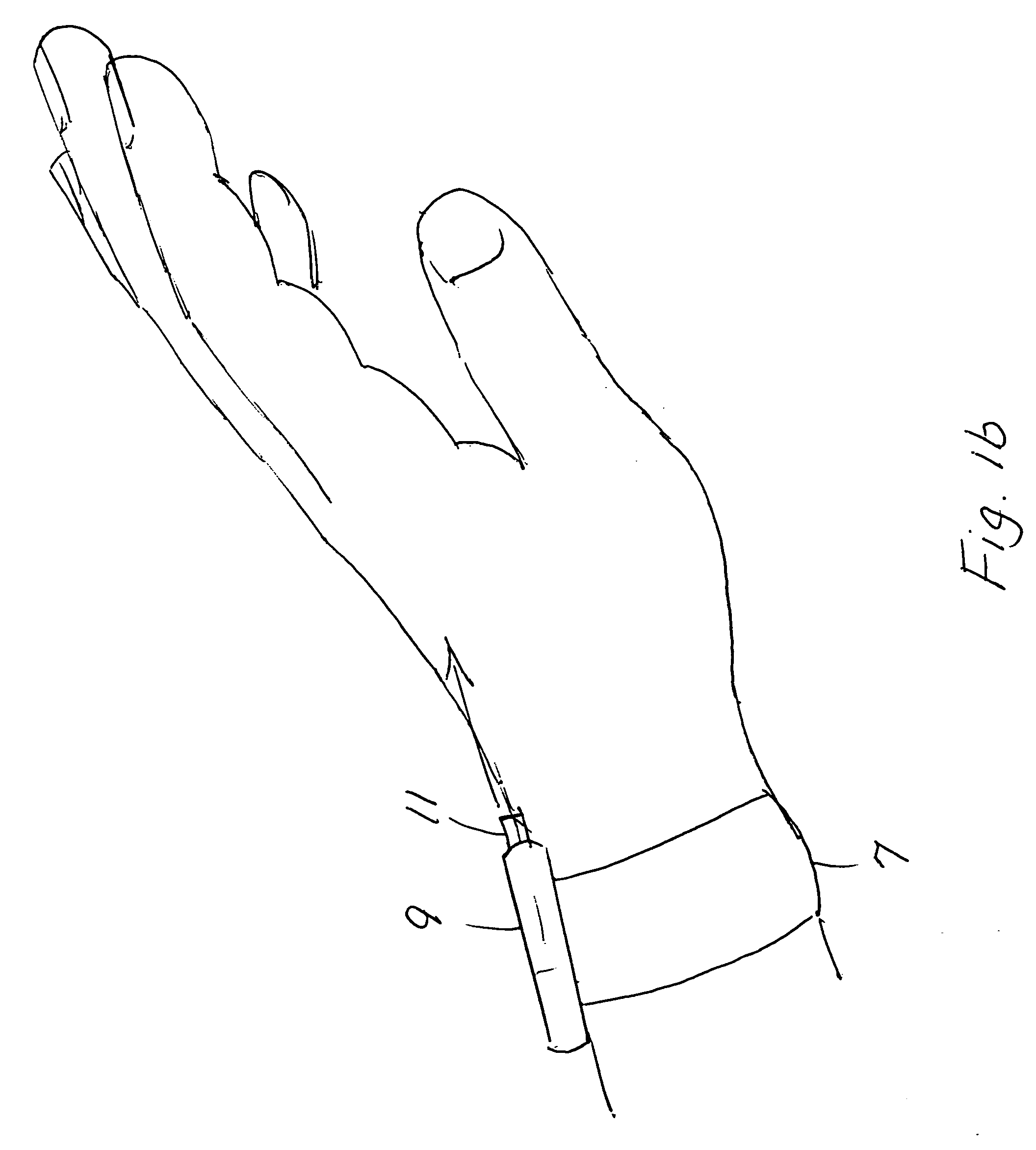

Portable device for dispensing skin treatments

InactiveUS7135011B2Simple actionEasy to startTravelling sacksTravelling carriersSkin treatmentsBiomedical engineering

A portable, extremity-attachable device for dispensing skin treatment comprises a deformable housing having a skin treatment reservoir that is caused to dispense such treatment upon squeeze actuation. A set of valves permit proper operation of the device with different modes of use. Embodiments include a simple deformable, wrist-mounted device and a pumped based device with a rigid housing.

Owner:PURGO CREATIONS

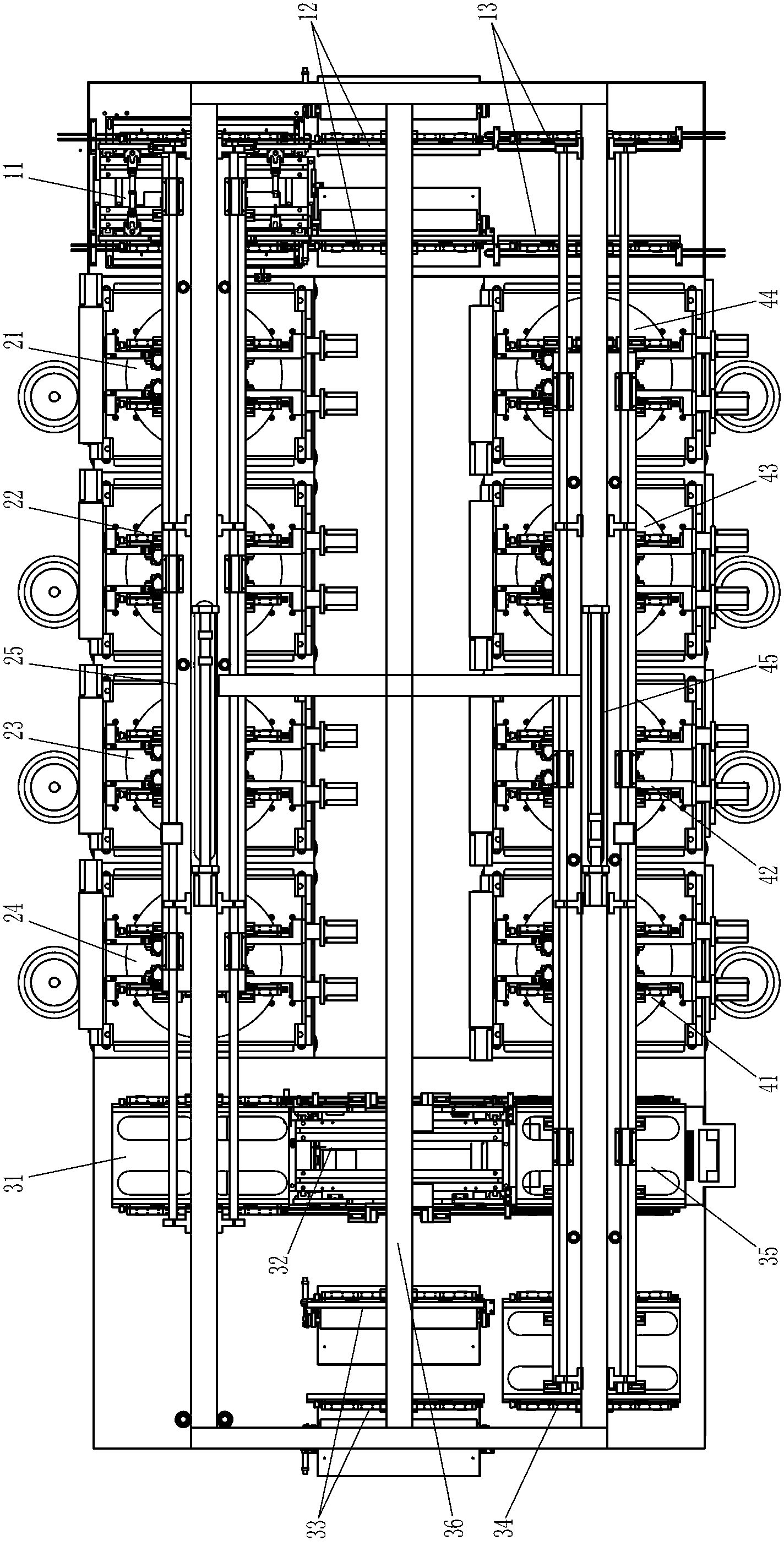

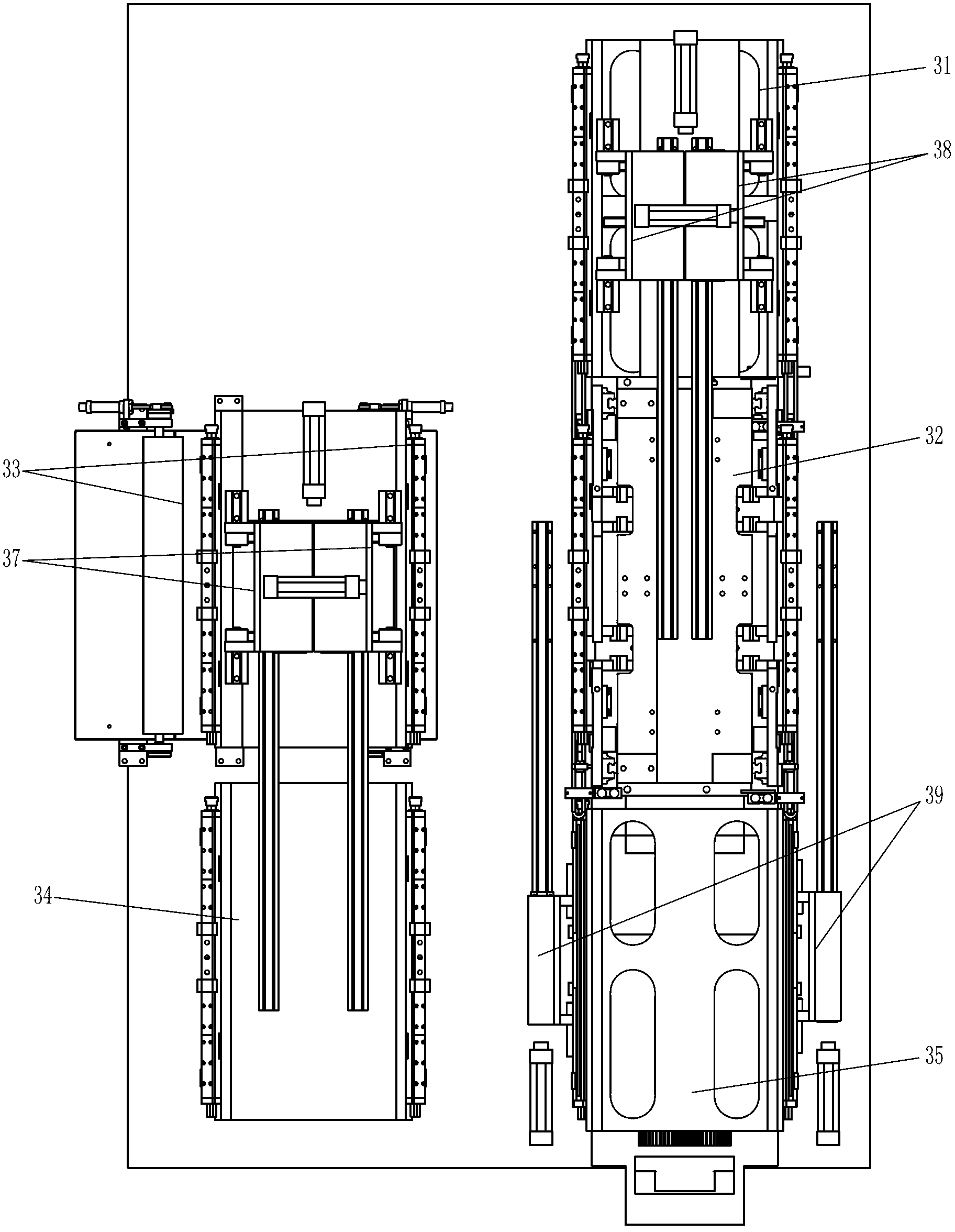

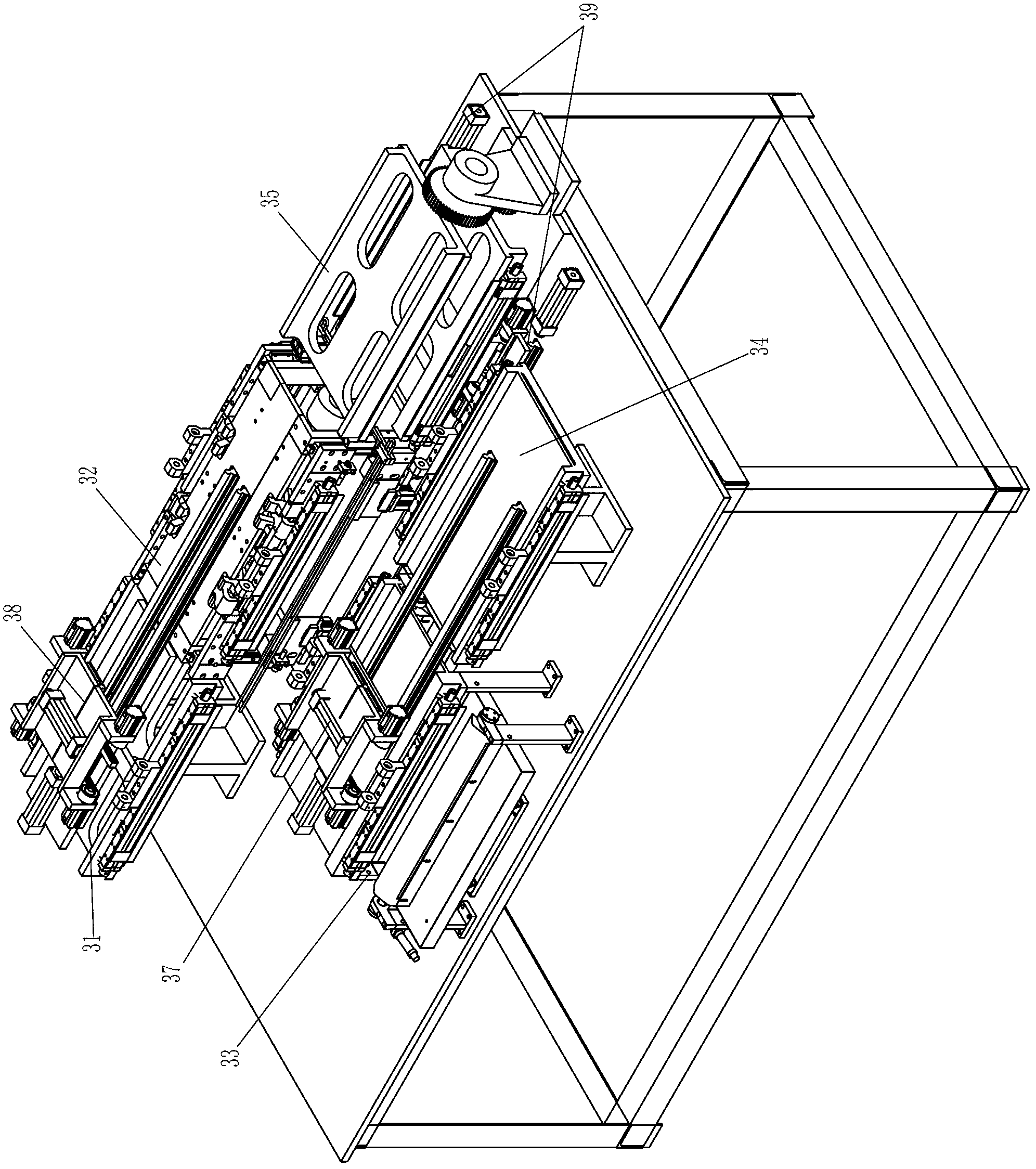

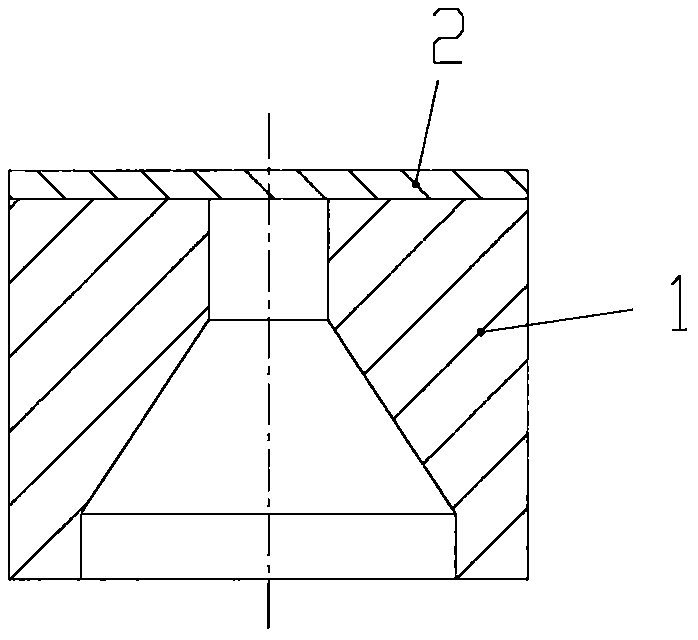

Automatic crystal blank polishing and burnishing system and docking mechanism thereof

ActiveCN103072059AExcellentExcellent efficiencySpherical surface grinding machinesGrinding work supportsEngineeringTransfer mechanism

The invention discloses a docking mechanism, comprising a docking machine frame, wherein a docking position, a switching position, a powder soaking position and a transition position are arranged on the docking machine frame; the docking bracket is fixedly mounted in the docking position, a docking component is arranged on the docking bracket, and the docking component comprises an upper sliding fixture seat and a lower fixed fixture seat; a switching bracket is arranged in the switching position, the switching bracket is driven by a switching bracket driving device to rotate around a horizontal shaft, and an upper fixture fixing part and a lower fixture fixing part are arranged on the switching bracket; a powder soaking component is arranged in the powder soaking position; a first fixture placement rack is arranged in the transition position; and the docking mechanism also comprises a first front-and-back transfer mechanism and a second front-and-back transfer mechanism. The invention also discloses an automatic crystal blank polishing and burnishing system adopting the docking mechanism. According to the technical scheme, the docking precision and the bonding firmness of crystal blanks are guaranteed, the docking working position is reasonable in structure, and the docking efficiency and the processing efficiency of the whole automatic polishing and burnishing system are improved.

Owner:虞雅仙

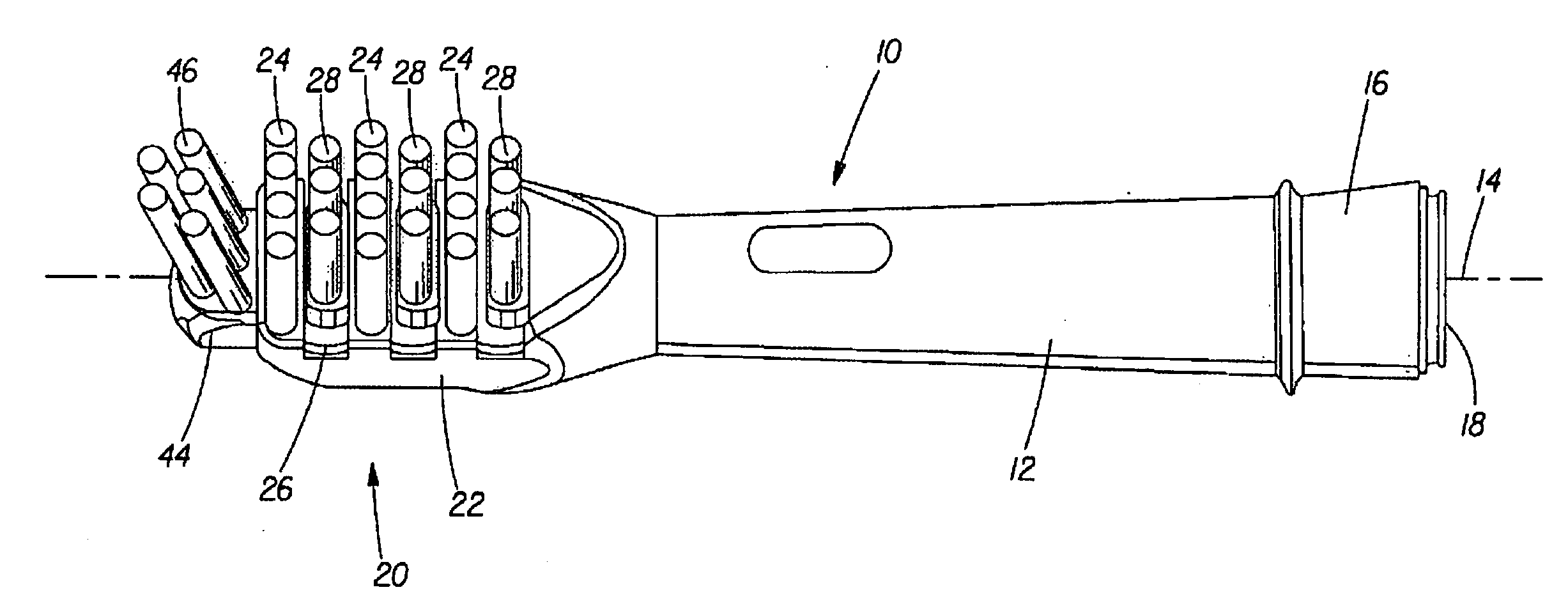

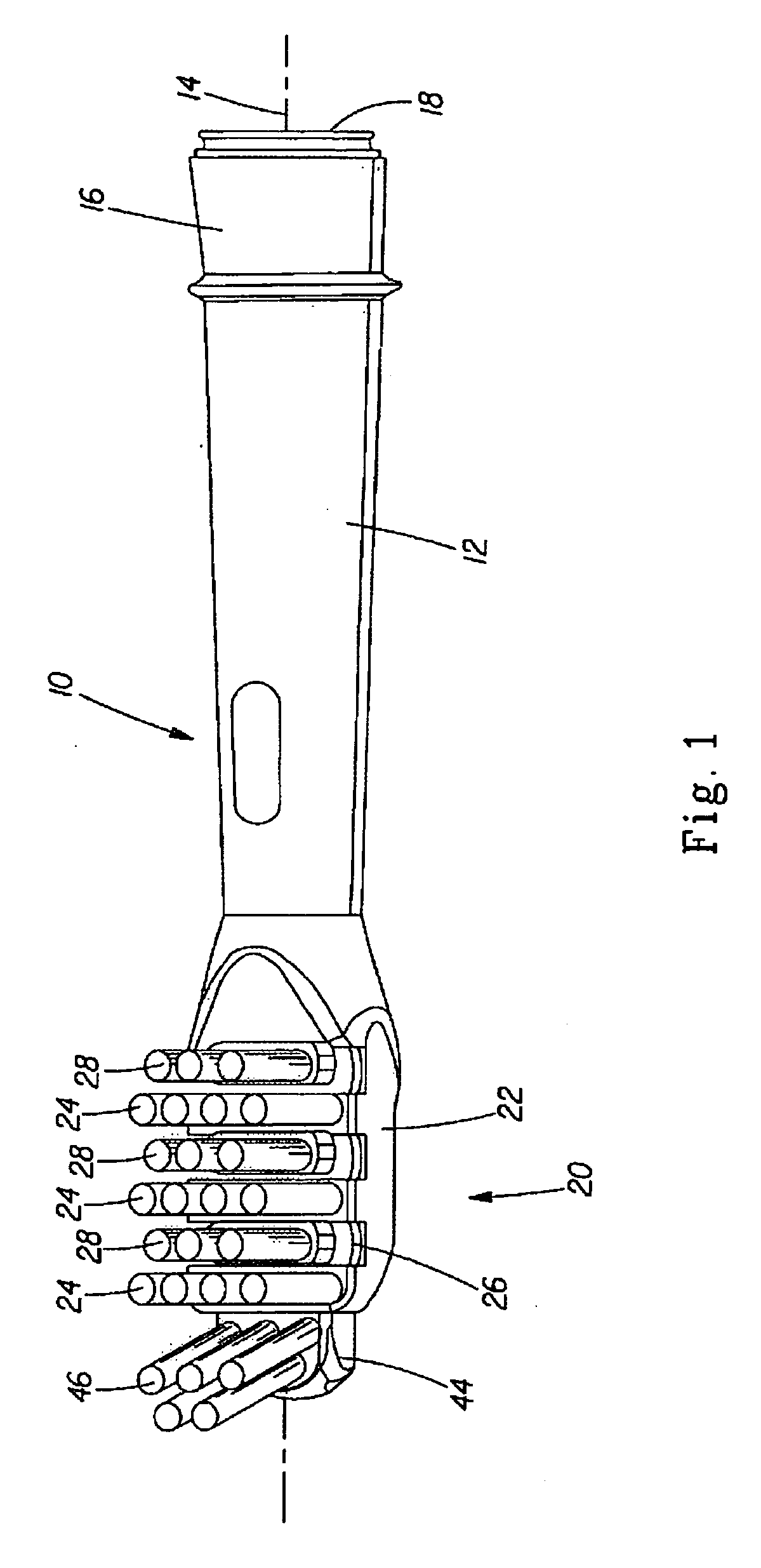

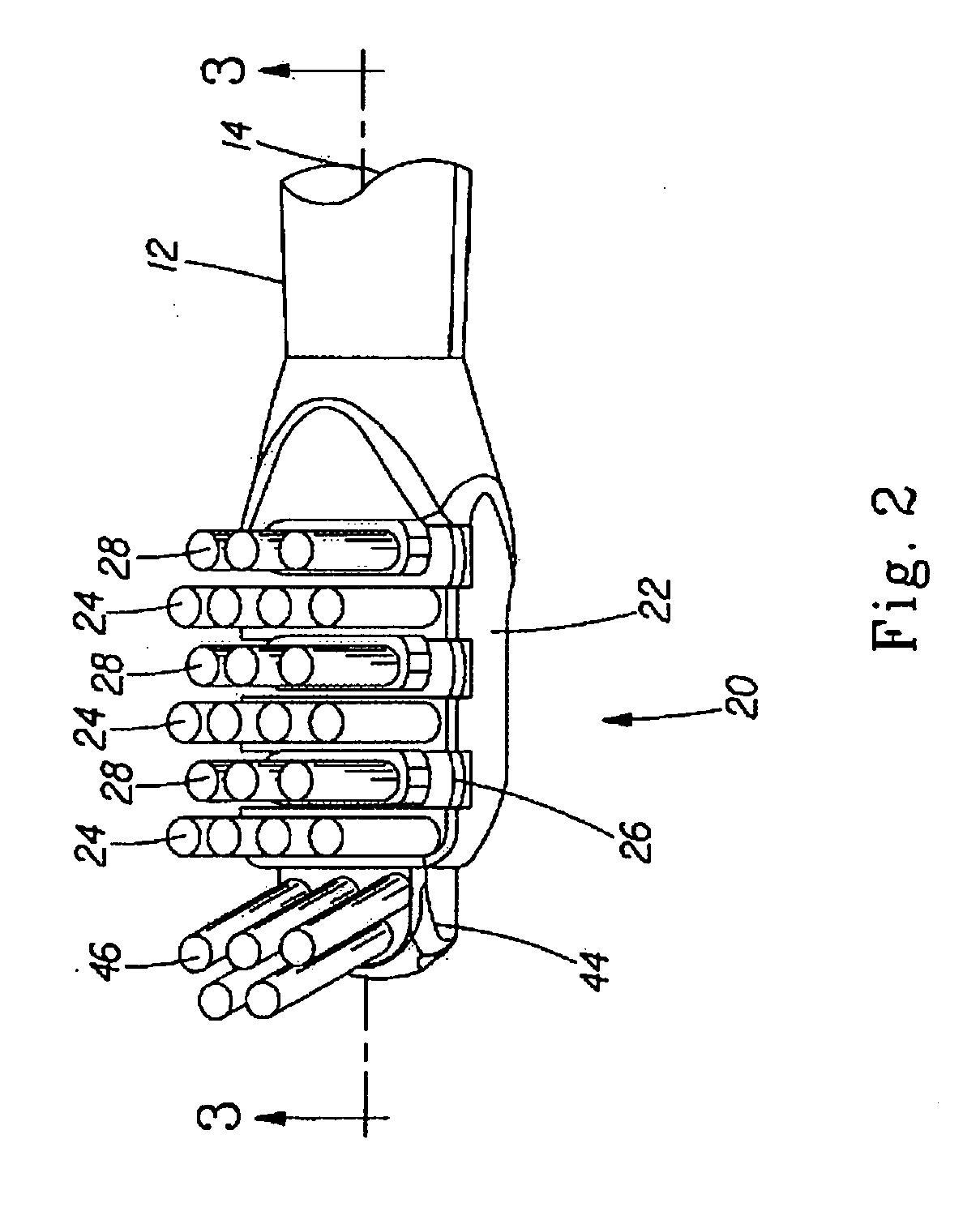

Brush section for an electric toothbrush

ActiveUS20080307591A1Easy alignmentPrevent rotationCarpet cleanersBrush bodiesDrive shaftEngineering

A brush section for use with an electric toothbrush includes a relatively large brush head portion having a generally rectangular shape, although oblong, elliptical and other such shapes having a length to width aspect ration greater than 1 may be employed. The brush head portion is secured to a shaft portion of the brush section that may be configured to couple to a handle section. The handle section may include an electric drive including drive shaft, and the drive shaft may couple to the brush head via a coupling member positioned within the shaft portion. The electric drive may impart a rotary, oscillating rotary-oscillating or other suitable drive motion to the drive shaft that is, in turn, imparted upon the brush head by virtue of the coupling member.

Owner:THE PROCTER & GAMBLE COMPANY +1

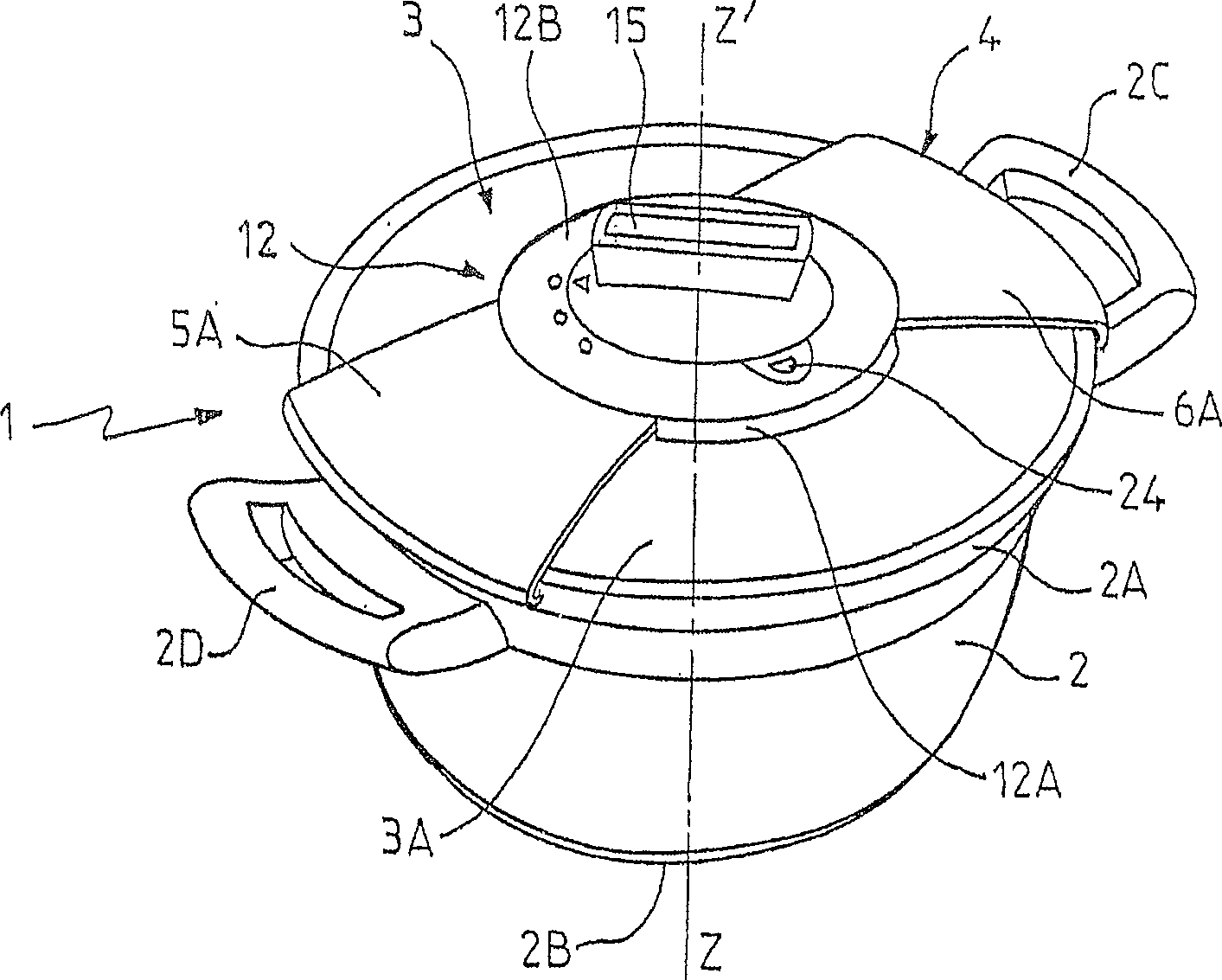

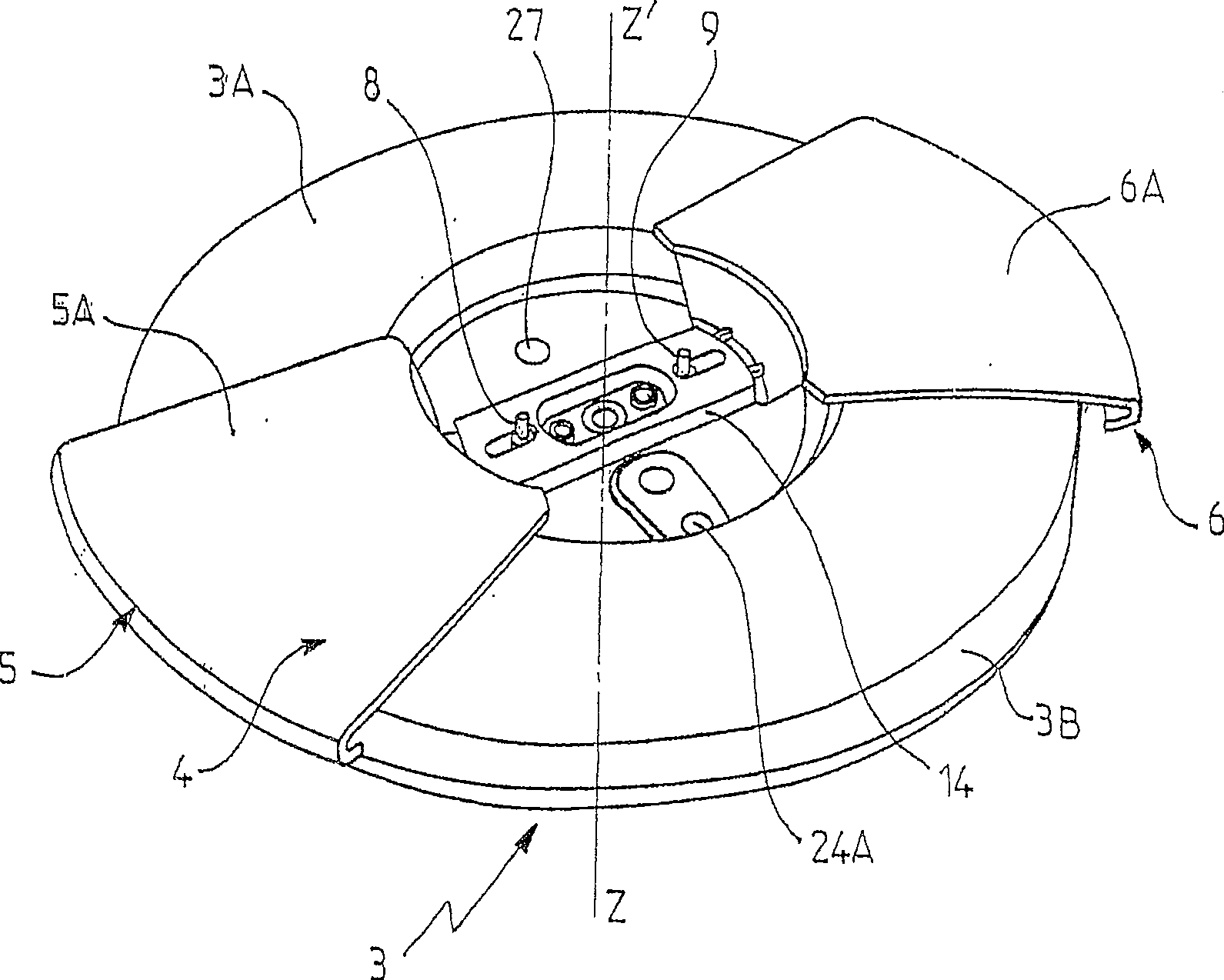

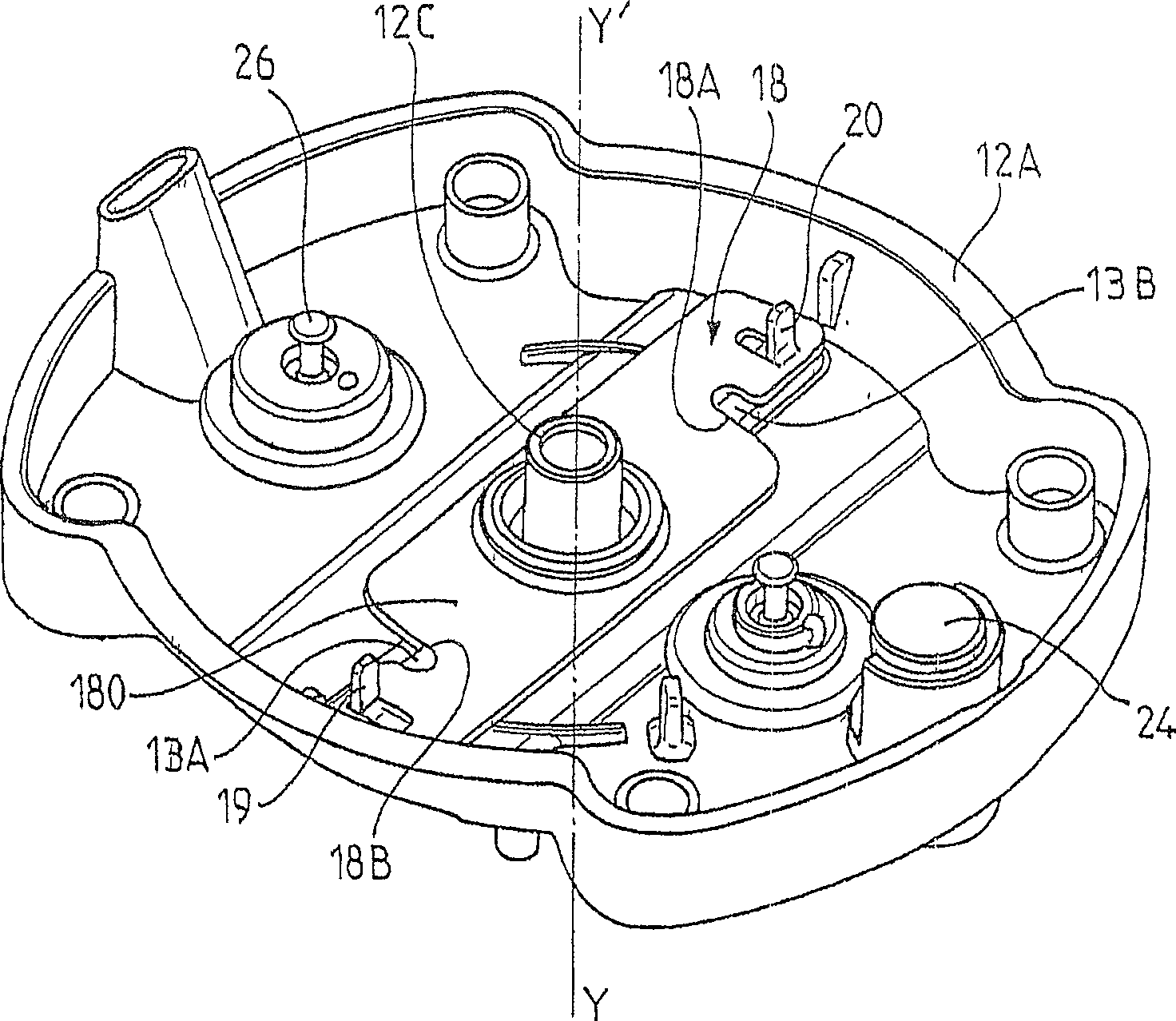

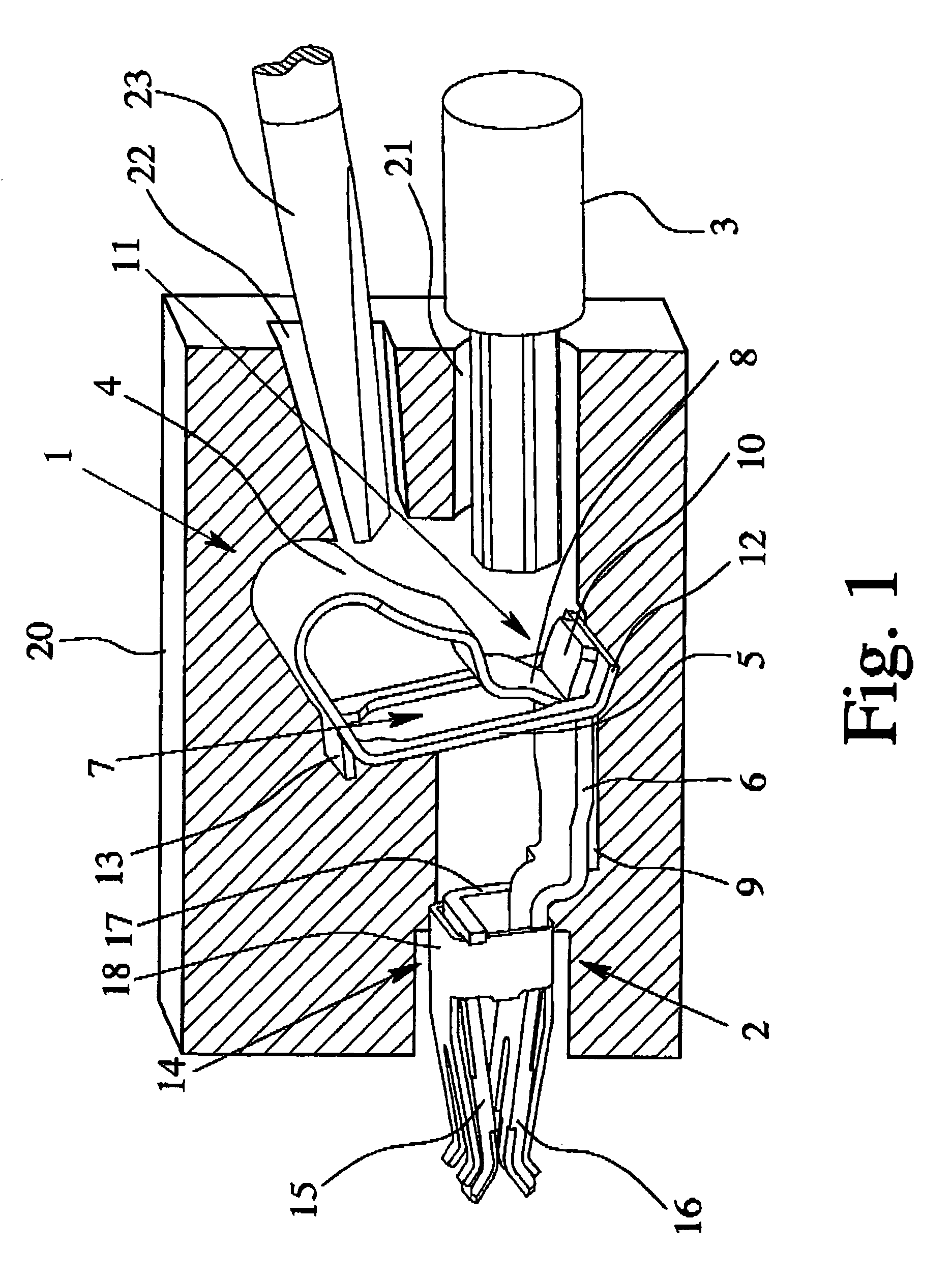

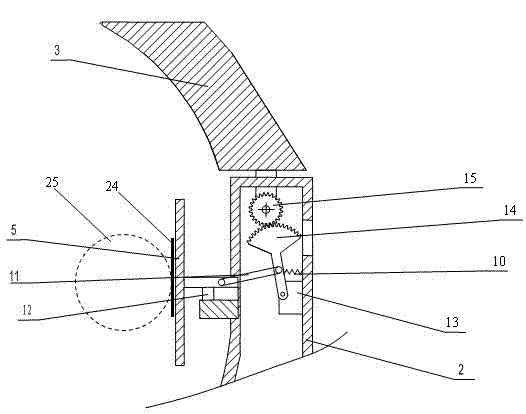

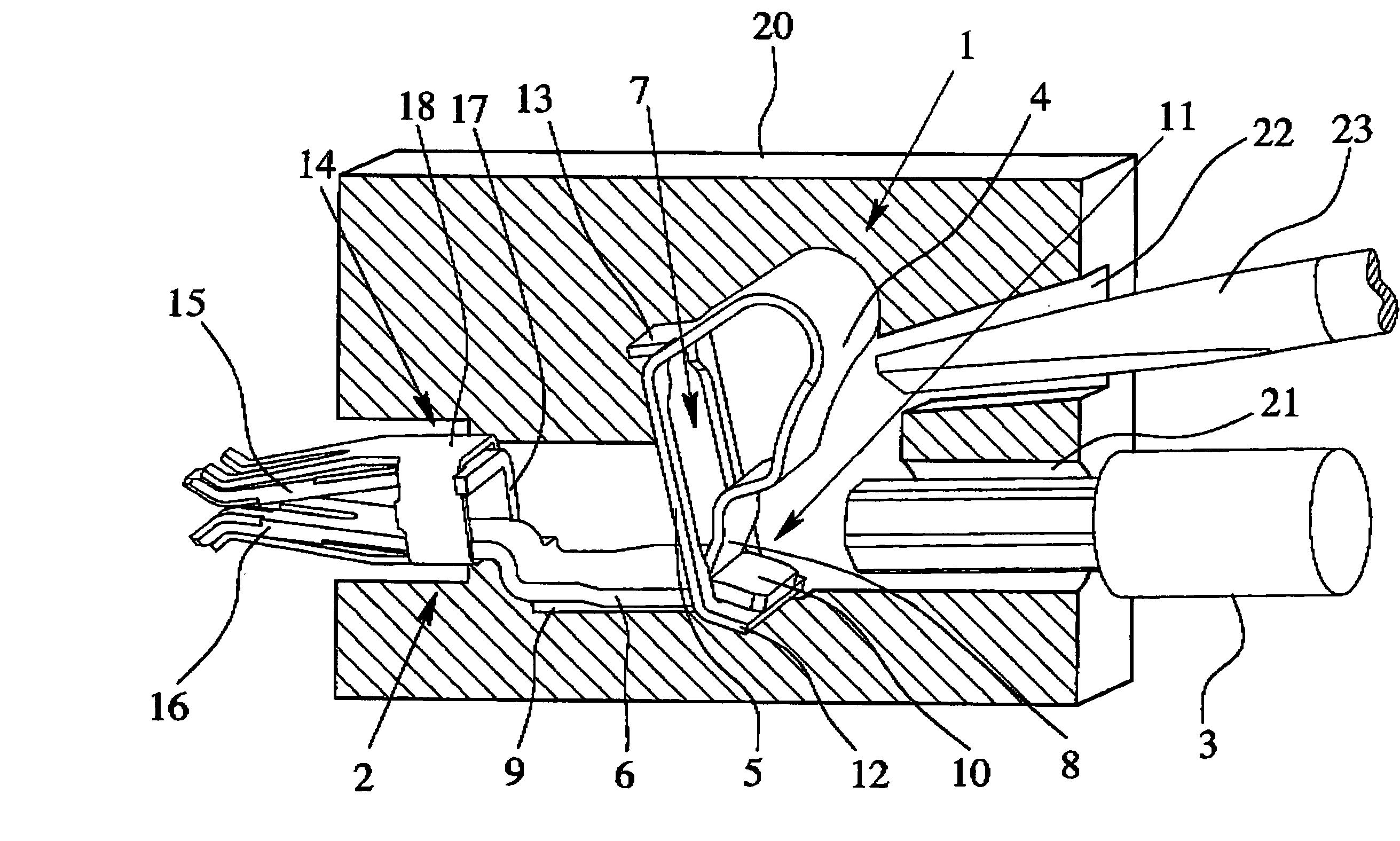

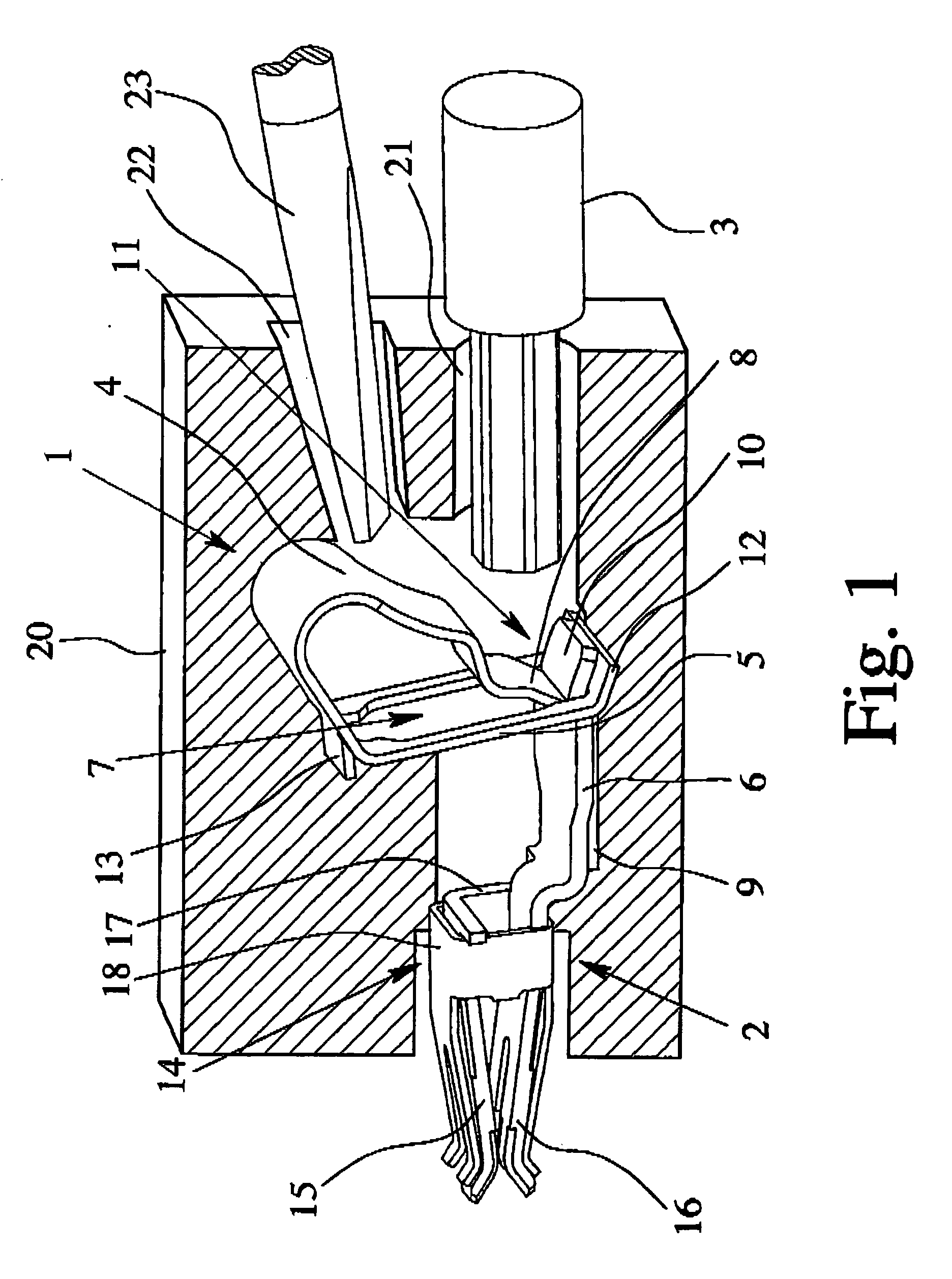

Pressure cooking appliance with improved safety system

The present invention provides a pressure cooking appliance with an improved safety system. The pressure cooking appliance (1) of the present invention includes: a bowl (2) and a lid (3); a device (4) for locking the lid (3) relative to the bowl (2) and is installed to movement between a locked position and an unlocked position; and a device (7) for controlling the movement of the locking / unlocking device (4) and mounted for movement between an open position and a closed position. The invention is characterized in that the appliance includes a blocking device (18) mounted movable between a position blocking the locking / unlocking device (4) and a position releasing the locking / unlocking device (4) . In addition, the blocking device (18) cooperates with the above-mentioned control device (7), so that when the control device (7) moves from the closed position to the open position, the blocking device (18) moves from the blocking position to the release position. .

Owner:SEB SA

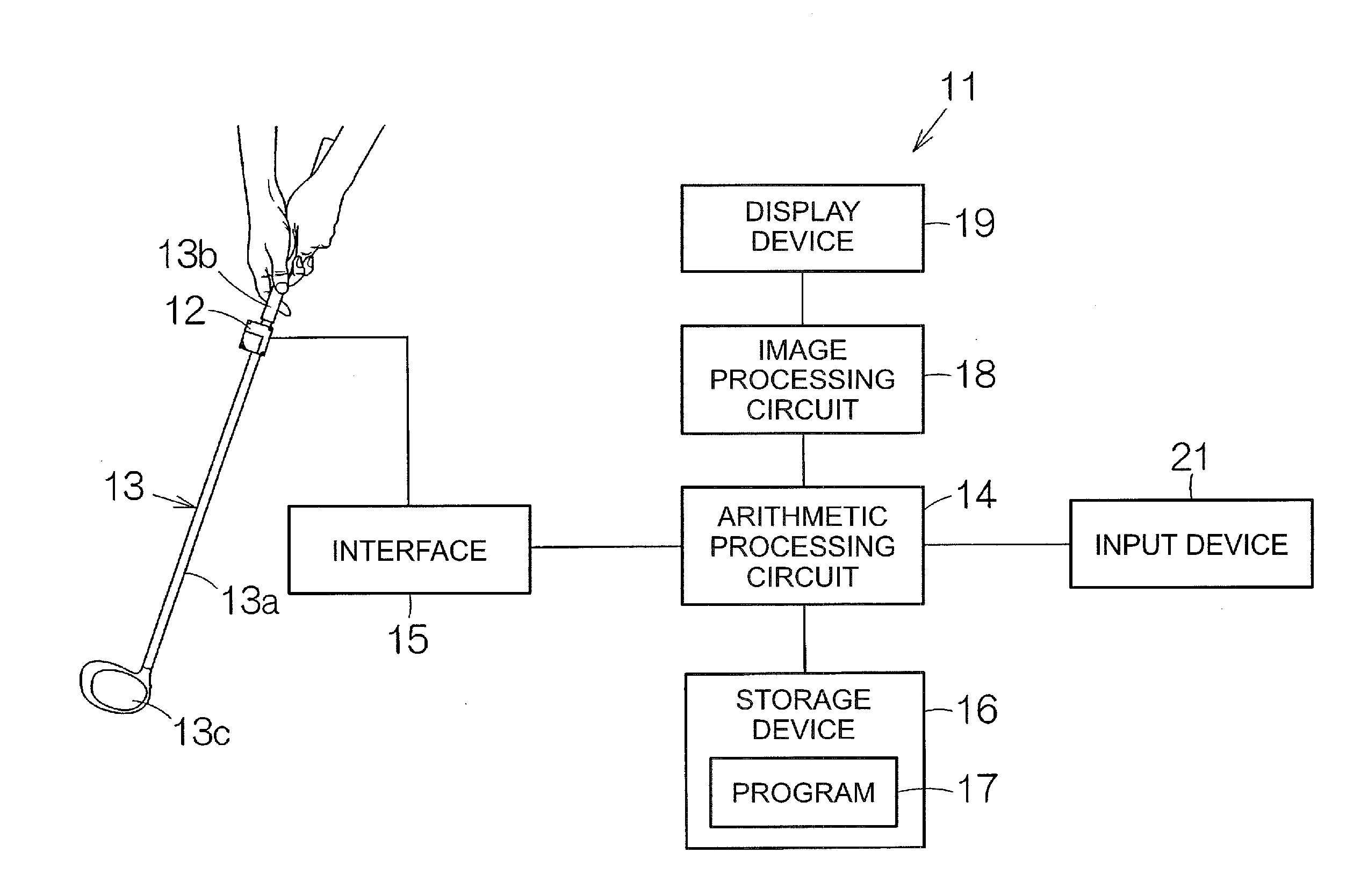

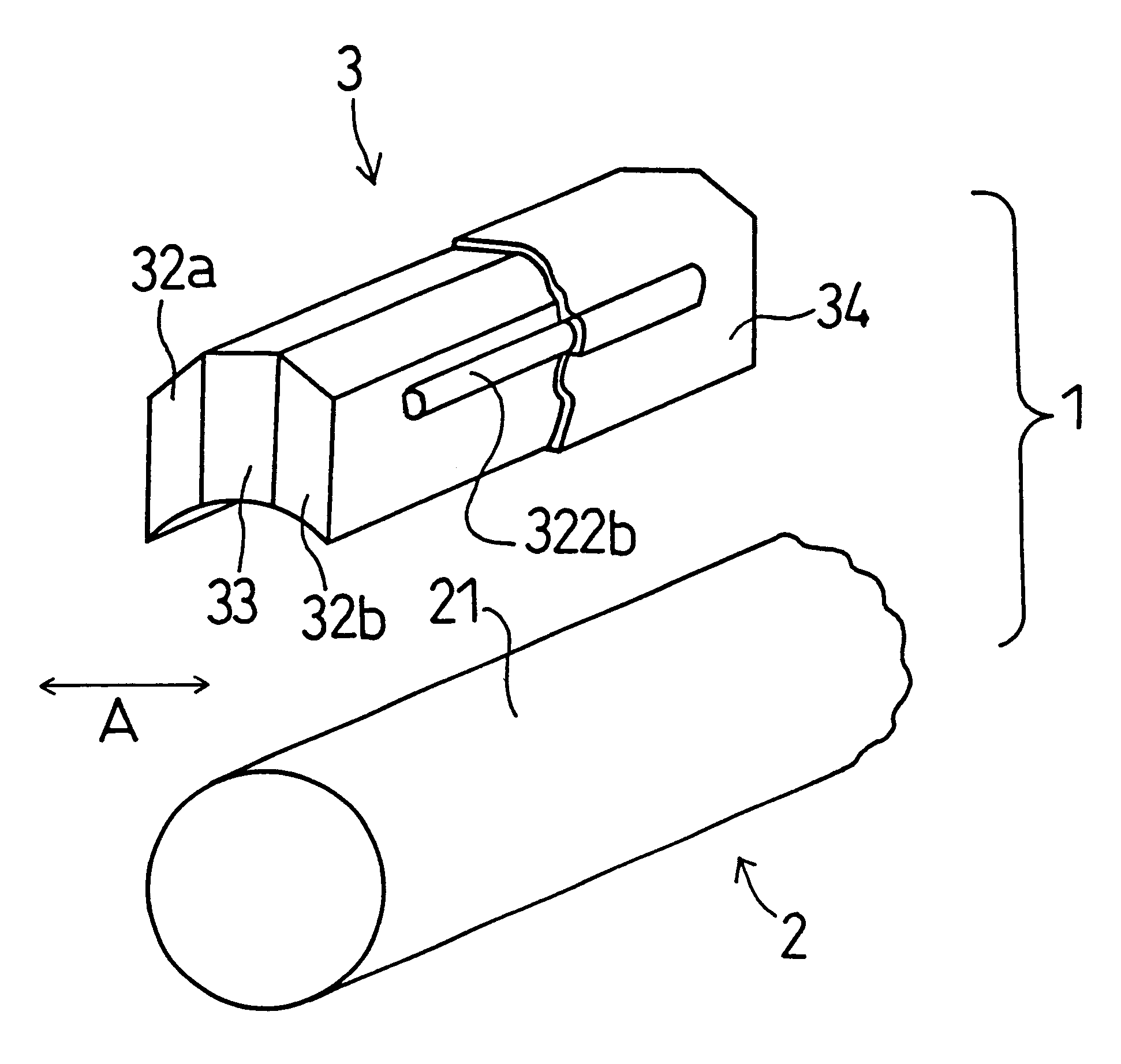

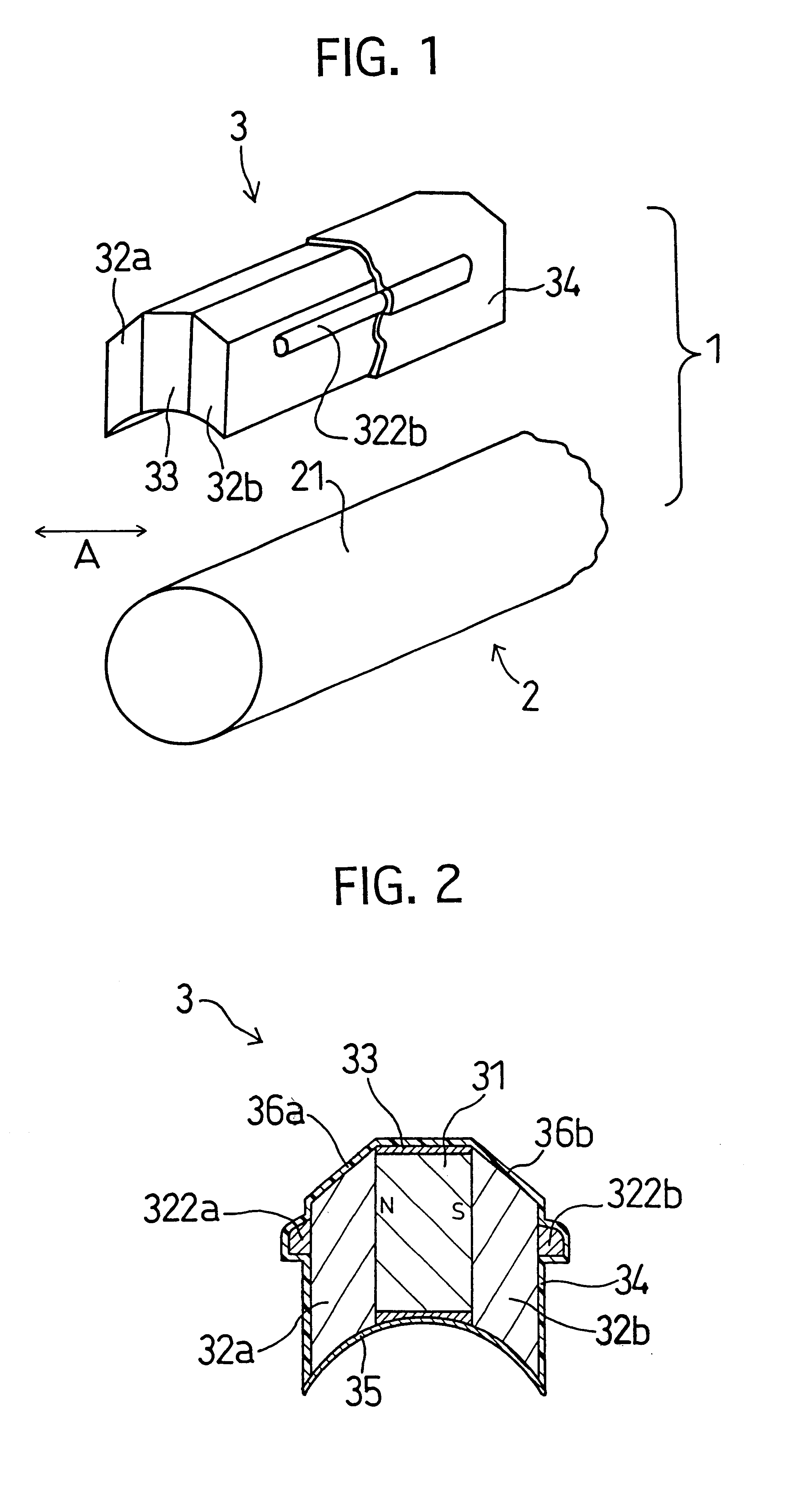

Motion analysis device

InactiveUS20140379295A1Easy to presentSimple actionClubsAcceleration measurement using interia forcesState variationSports equipment

In a motion analysis device, a first detection section detects a first state of a shaft portion of sporting equipment using an output of an inertial sensor. The first state corresponds to, for example, a resting state. A second detection section detects a second state of the shaft portion of the sporting equipment using the output of the inertial sensor. The second state corresponds to, for example, an impact. The second detection section detects a relative rotational angle of the shaft portion having varied around an axis of the shaft portion from the first state.

Owner:SEIKO EPSON CORP

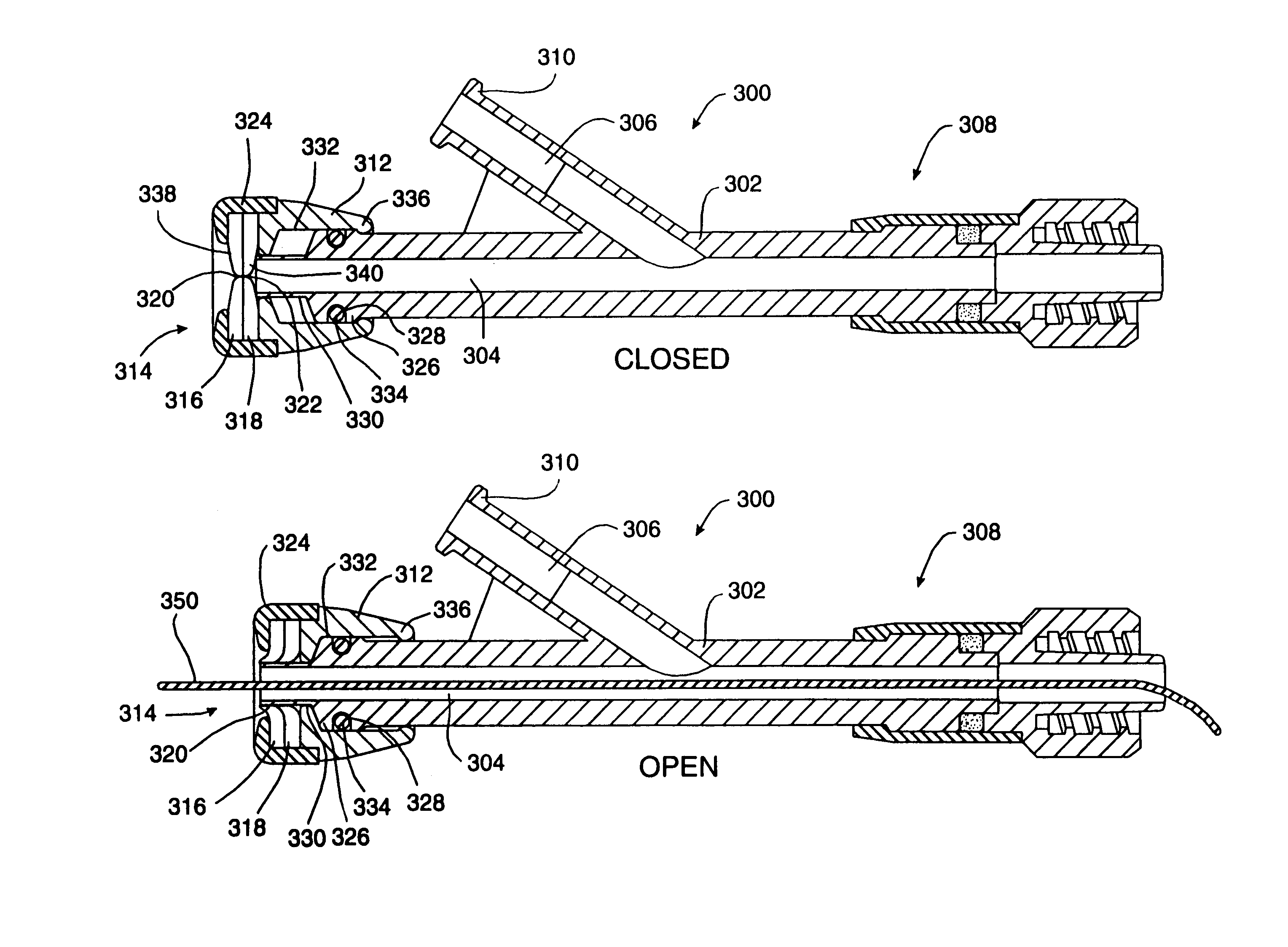

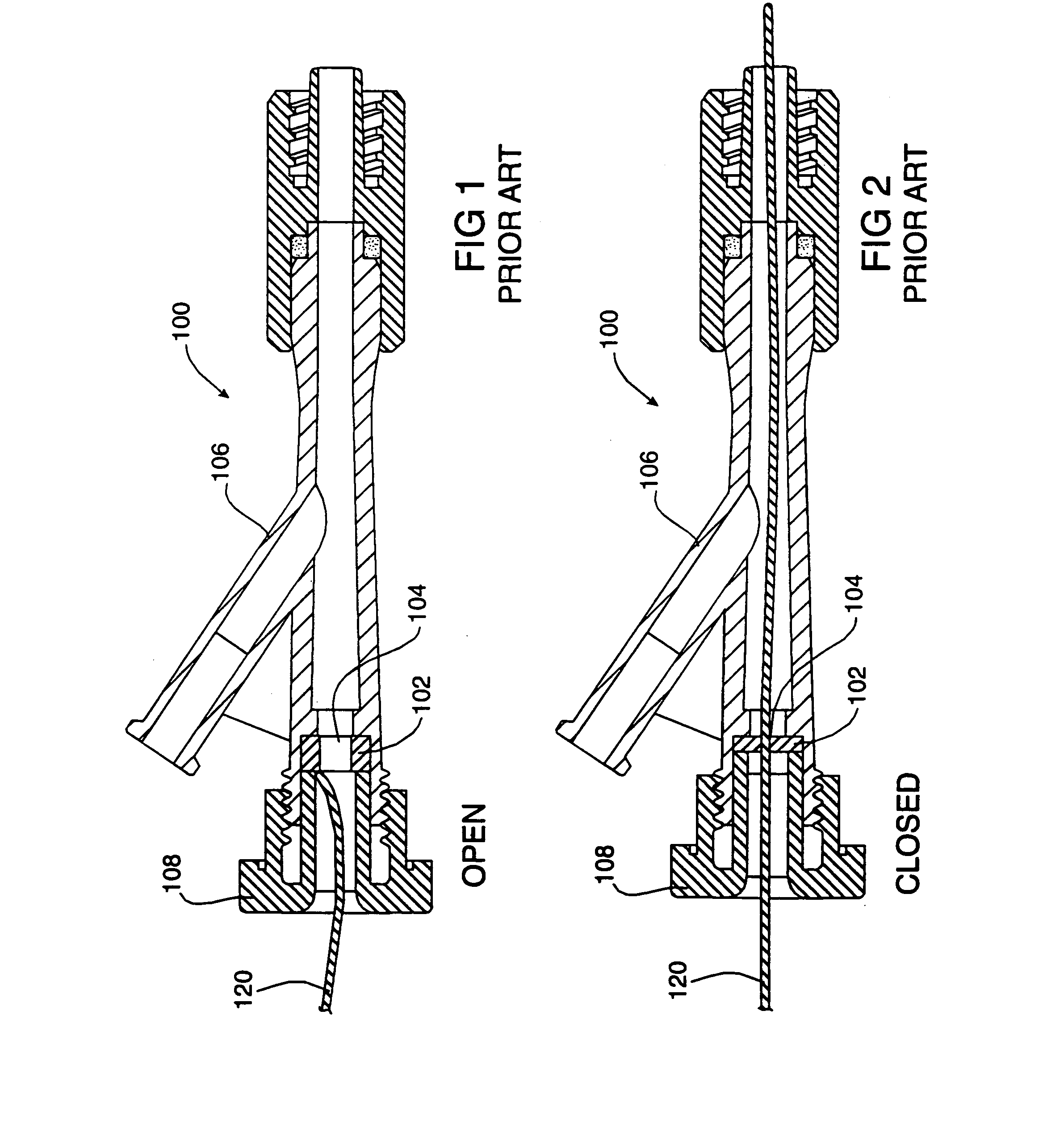

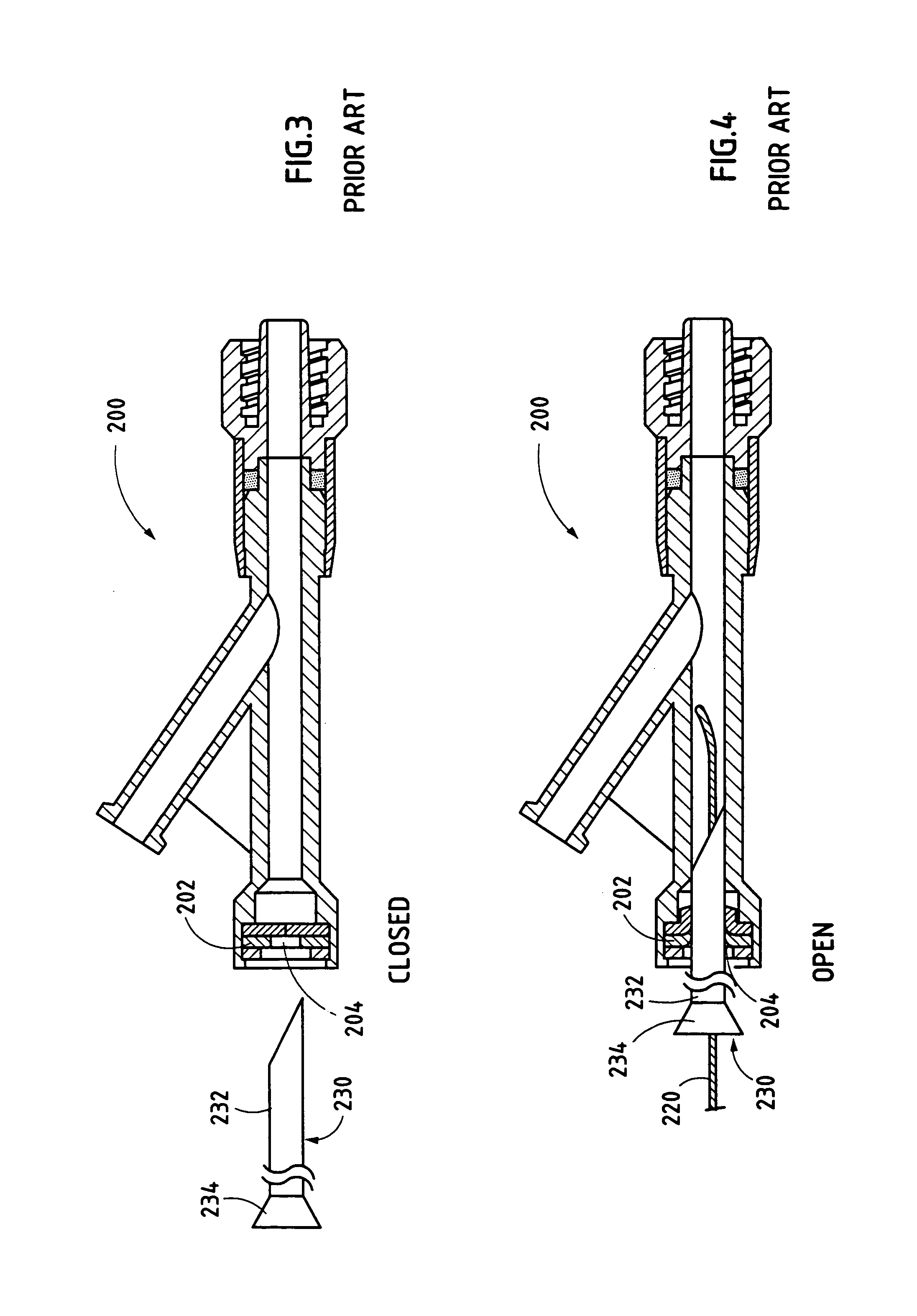

Valved connector with closure operated by axial movement of the valve

InactiveUS7335182B1Safely introducedSimple actionCheck valvesHaemostasis valvesMain channelEngineering

A valved connector apparatus is described having an integral opening and closing system operated by axial movement of the valve. The body of the valved connector apparatus is in a Y-shaped configuration with a main channel and a lateral channel branching off of the main channel. A normally dosed, passive hemostasis valve is housed in a valve body that is slidably connected to the proximal end of the main channel. The hemostasis valve is opened by sliding the valve body distally with respect to the Y-shaped connector body so that a cylindrical extension extending from the proximal end of the Y-shaped connector body penetrates a central opening in the hemostasis valve, creating an open passage for insertion of guidewires, catheters or other instruments. The valved connector apparatus allows safe introduction of extremely flexible or fragile guidewires, catheters or other instruments.

Owner:ARTHESYS

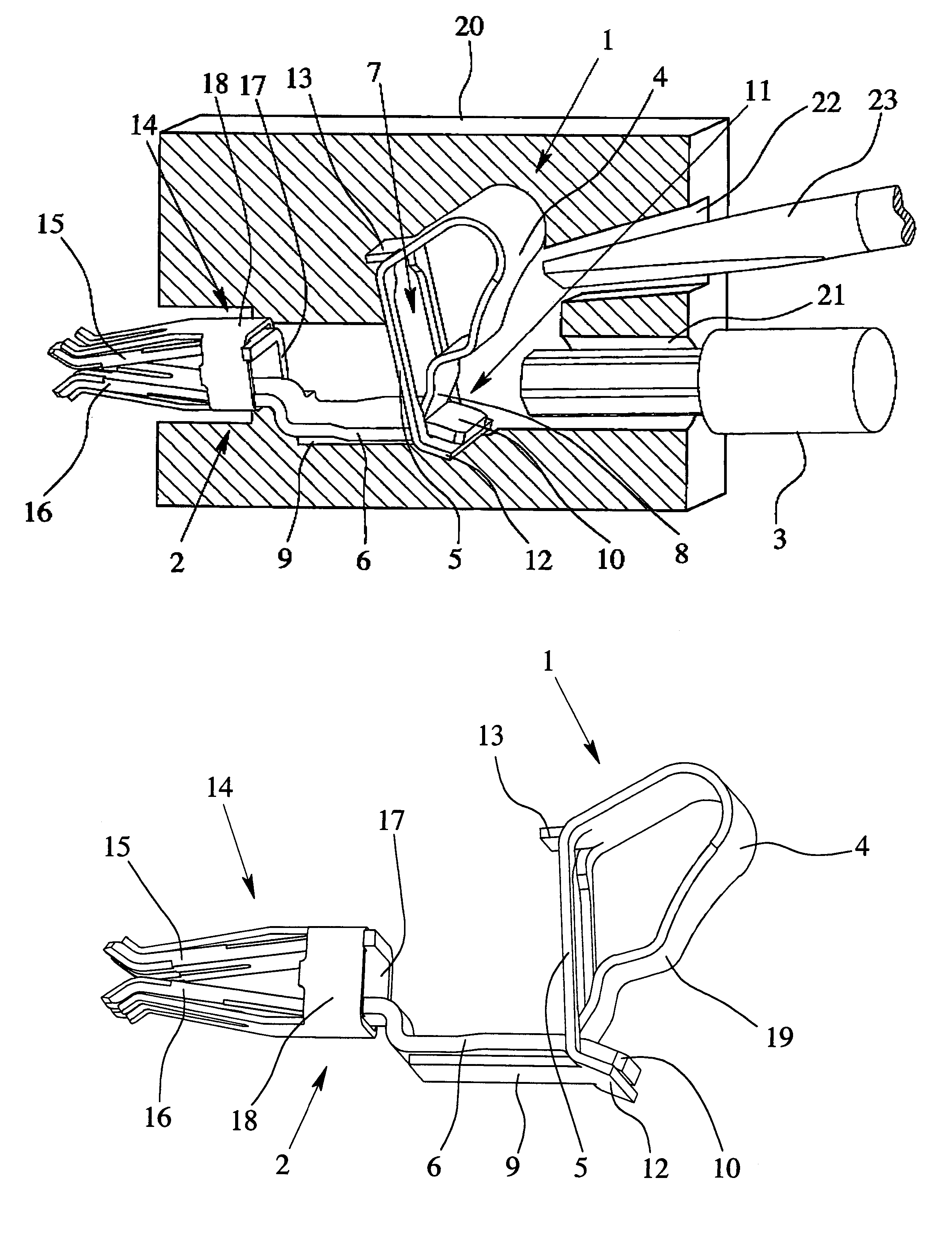

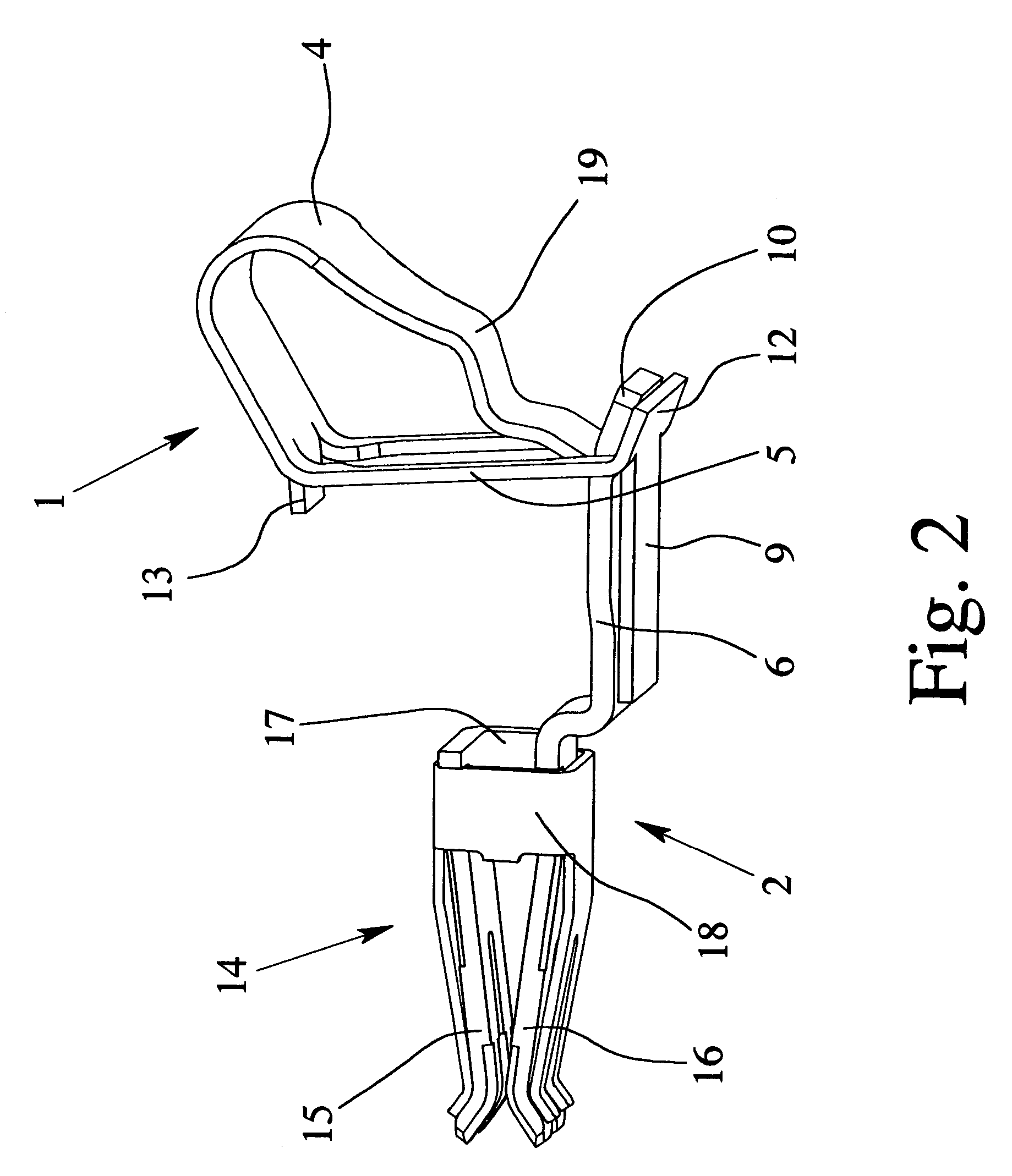

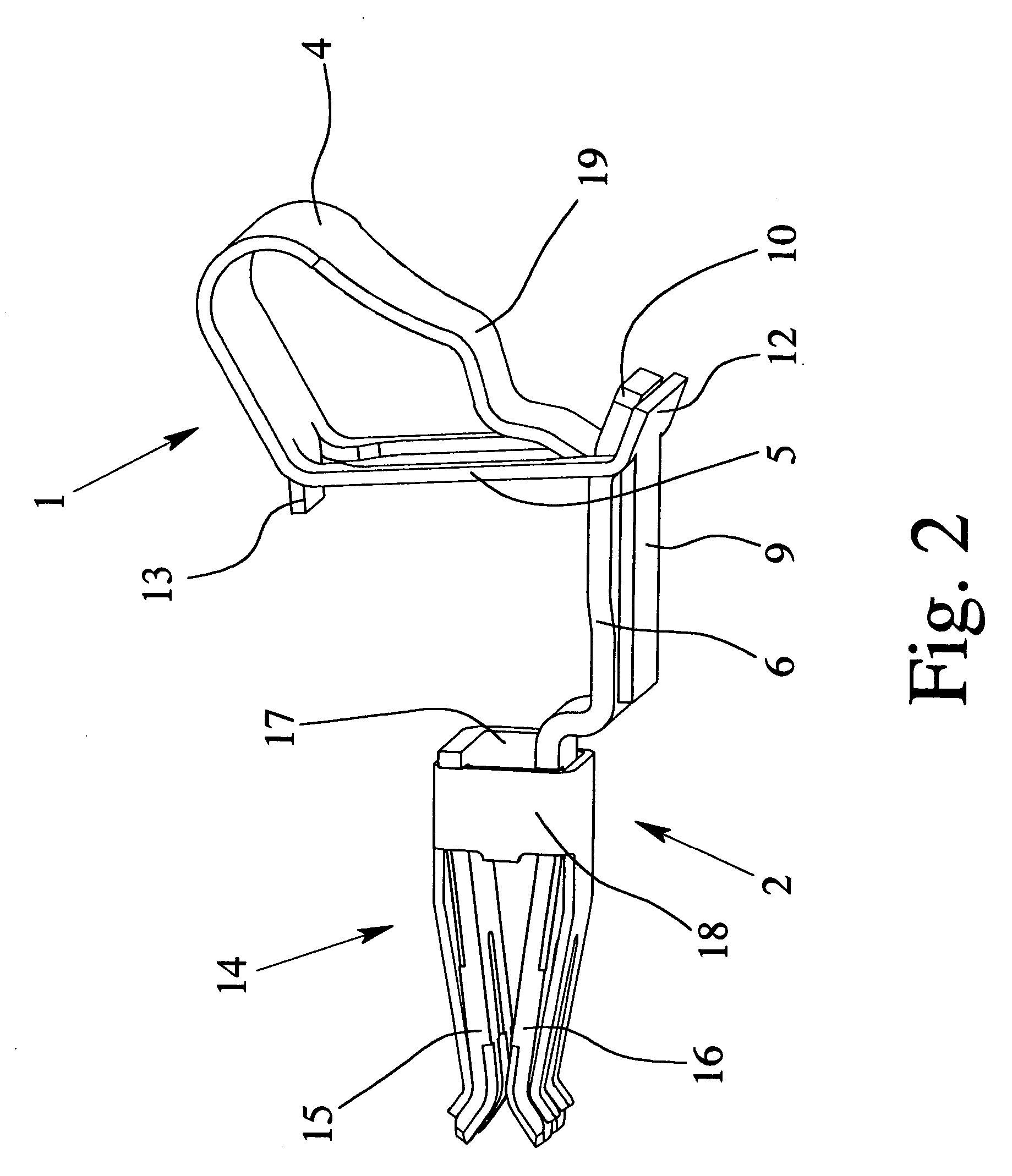

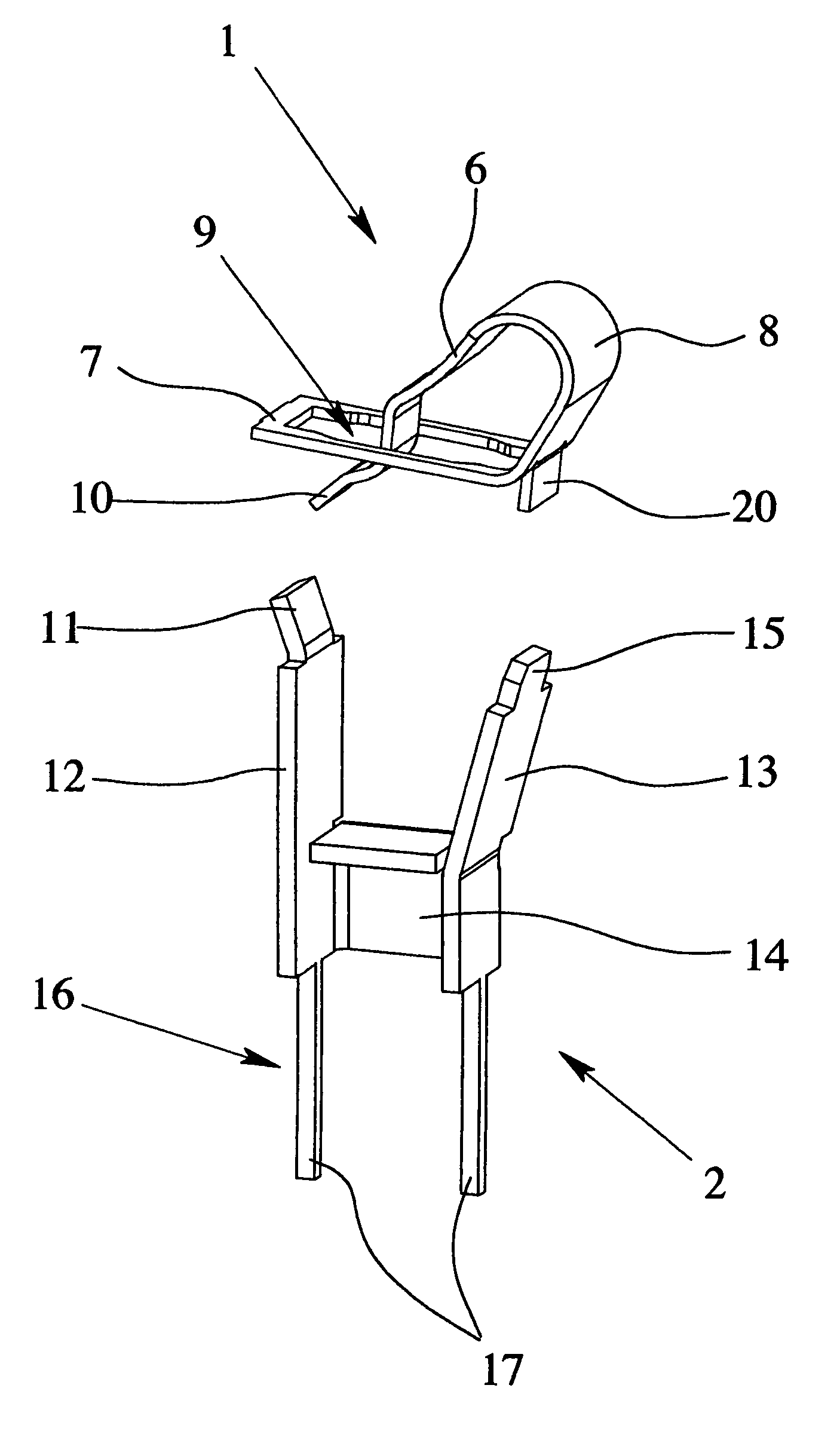

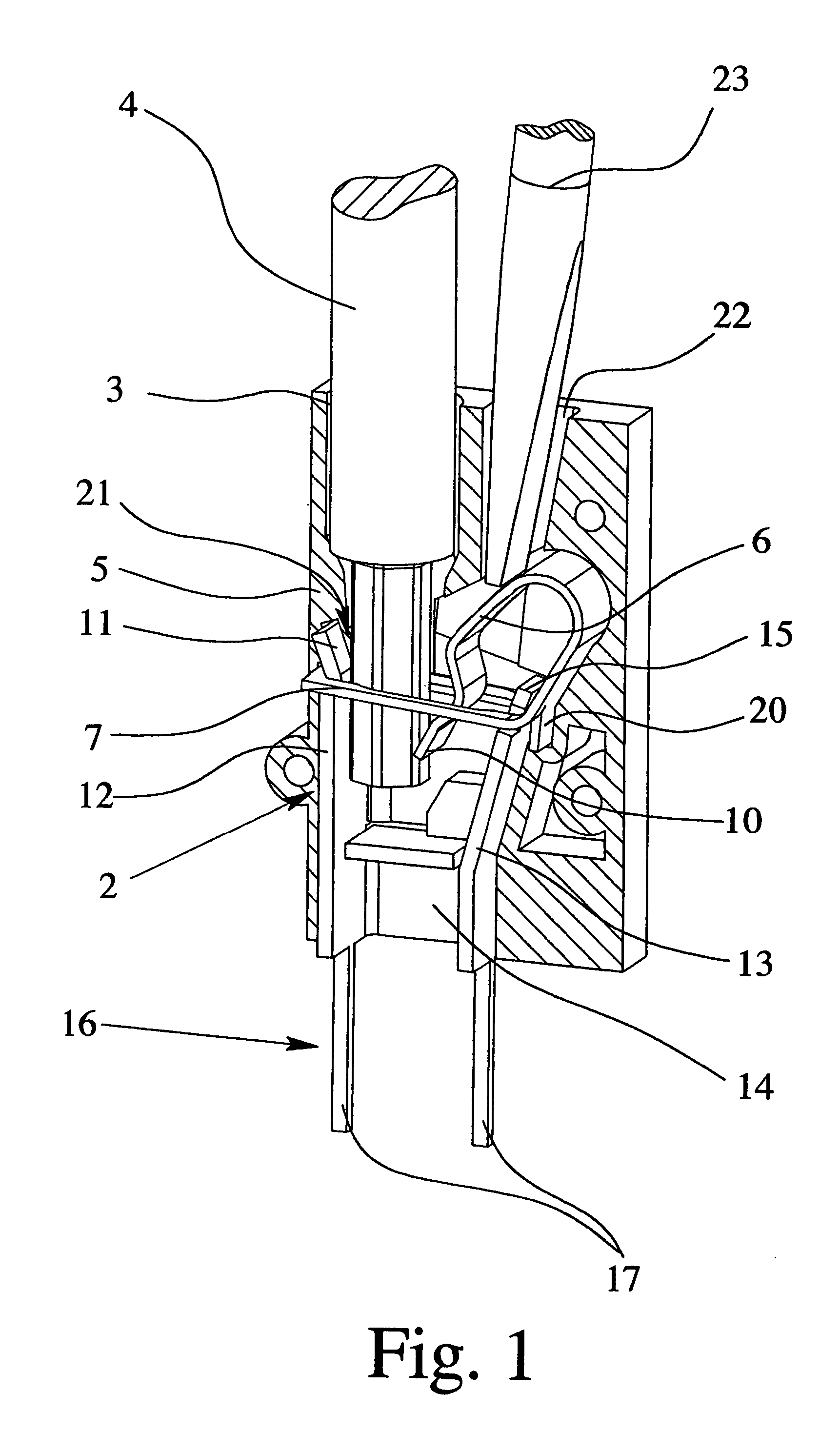

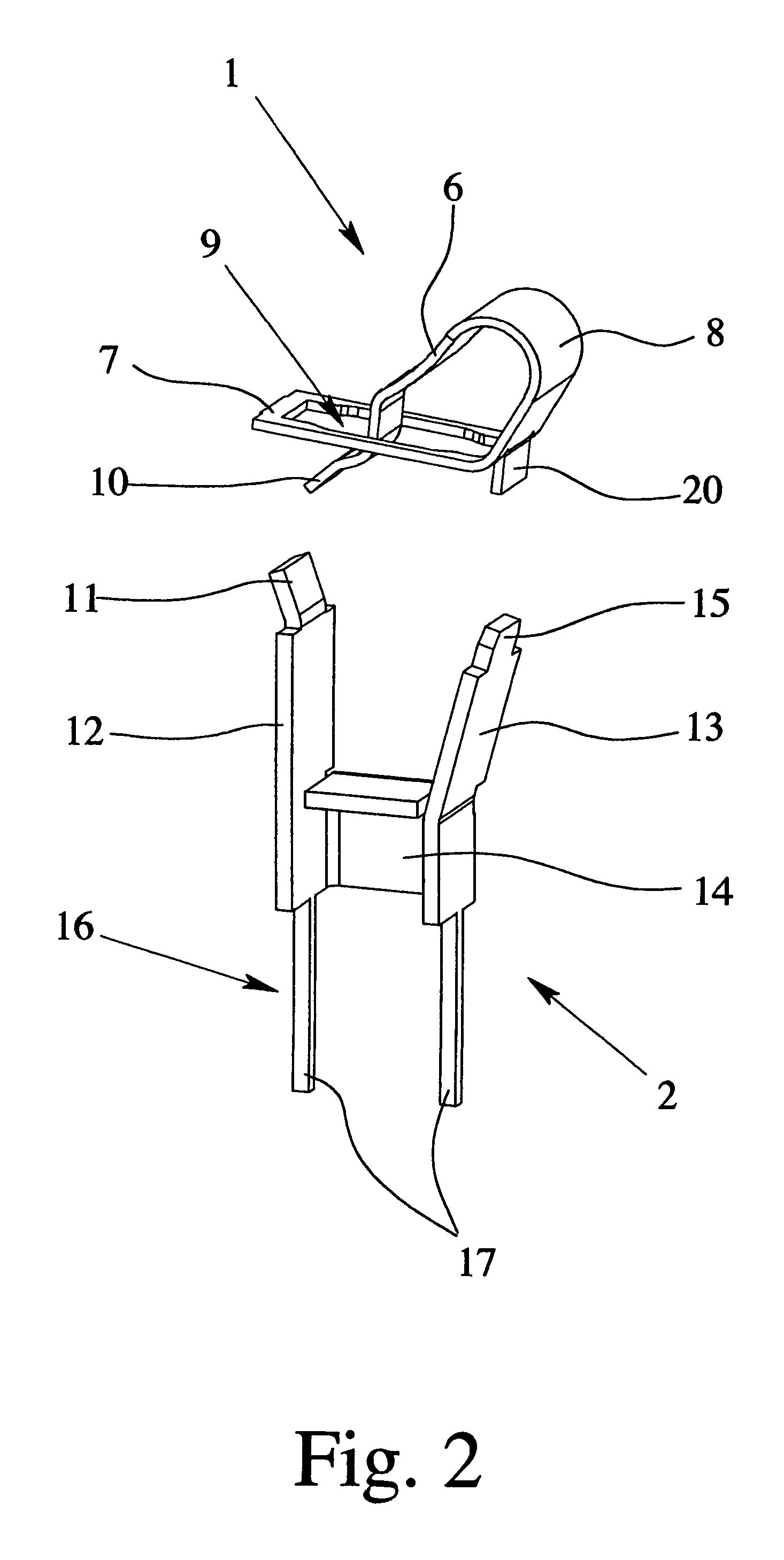

Electrical supply or connecting terminal

InactiveUS7083463B2Easy and fast wiringEasy to produceCoupling device detailsContact members penetrating/cutting insulation/cable strandsElectrical conductorSpring force

An electrical supply or connecting terminal with a clamping spring and a metal part, the clamping spring having a clamping leg and a contact leg, and the metal part having a conductor bar piece. The clamping leg and the conductor bar piece form a spring force clamp connection for the electrical conductor. The contact leg of the clamping spring has a recess for insertion of the electrical conductor, and an end of the clamping leg extends through the recess. The clamping spring has a retaining section which runs essentially parallel to the insertion direction of the electrical conductor and parallel to the conductor bar piece and the conductor bar piece has been inserted though the recess in a direction opposite the insertion direction of the electrical conductor, the conductor bar piece being clamped securely between the end of the clamping leg and the retaining section.

Owner:PHOENIX CONTACT GMBH & CO KG

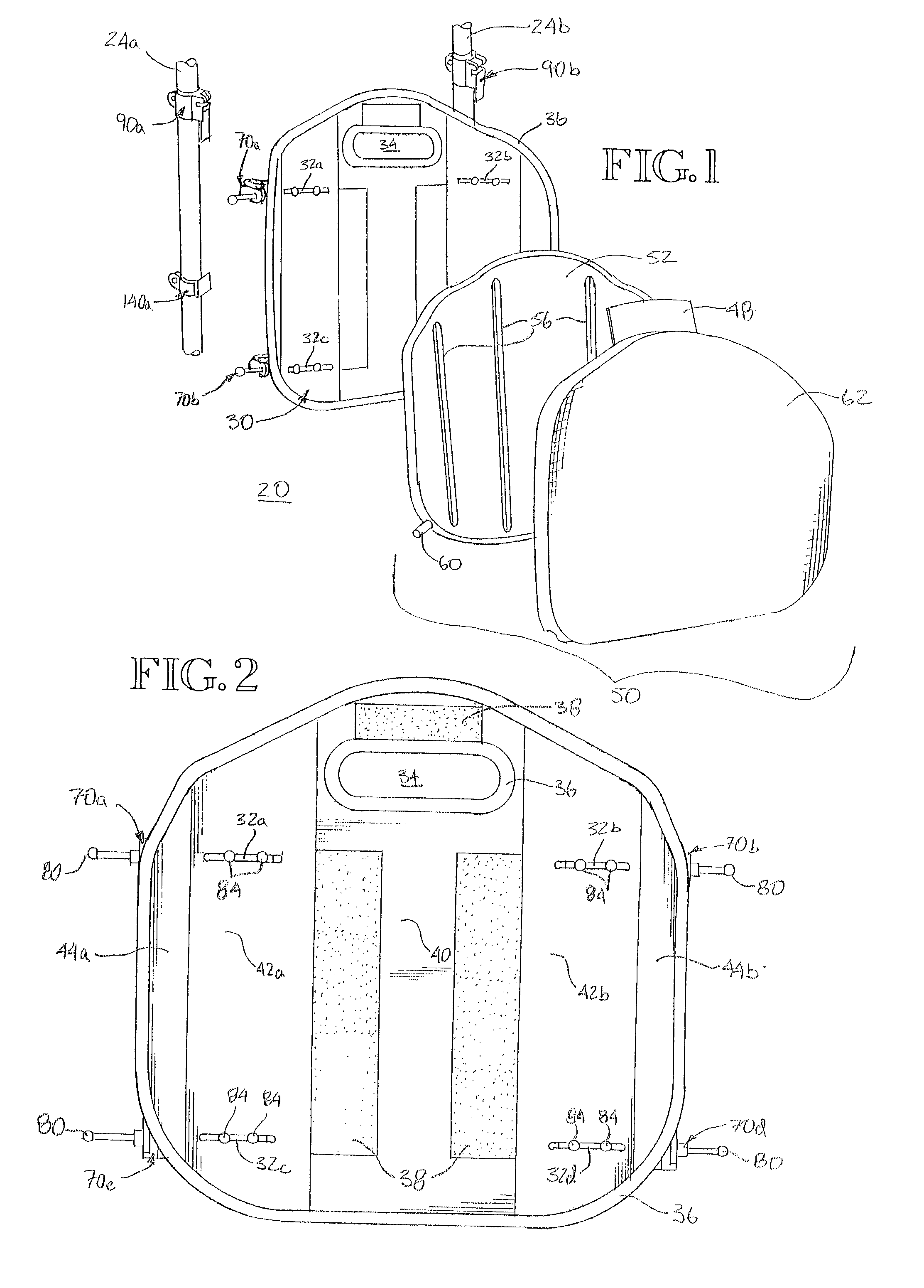

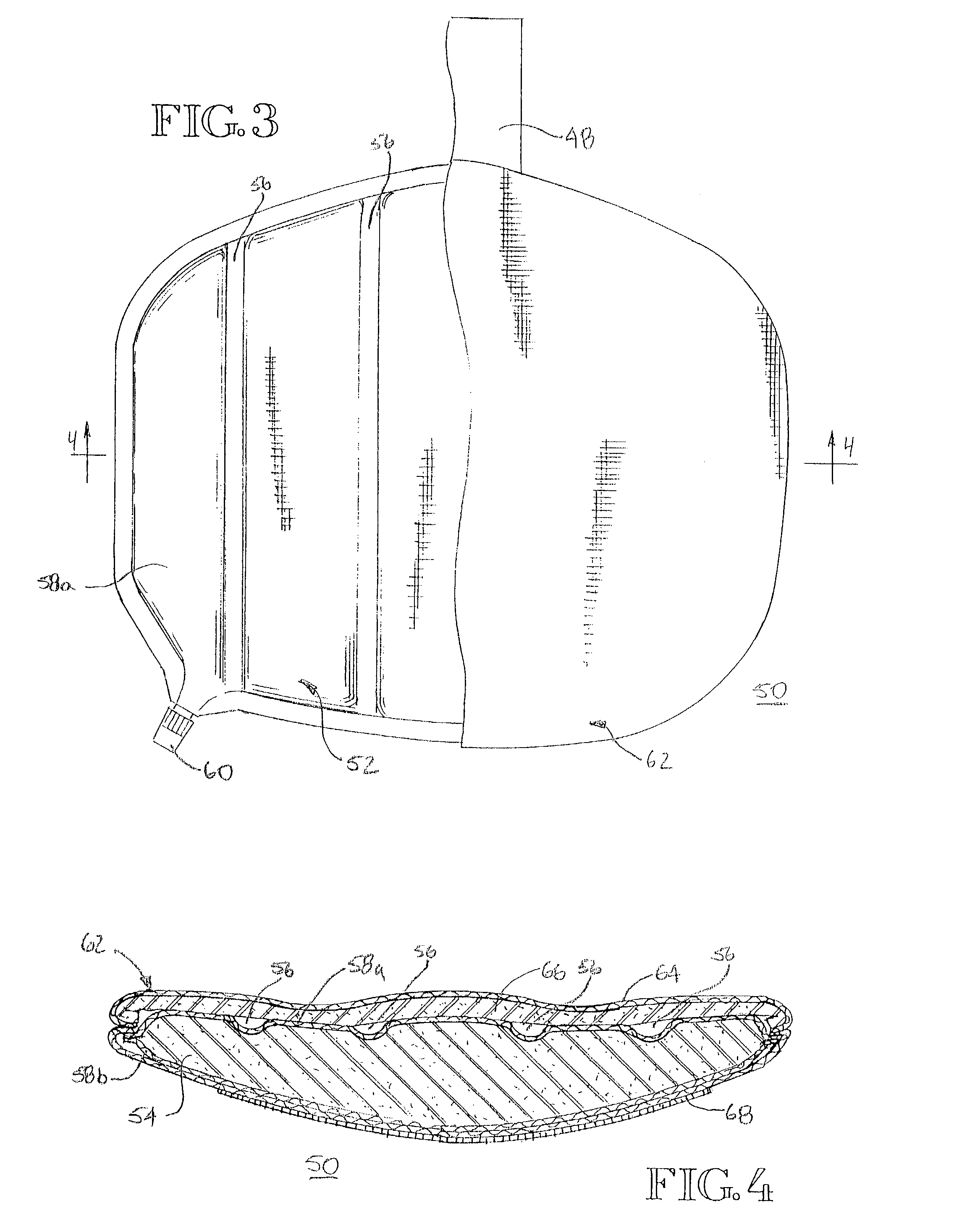

Adjustable quick release seatback system particularly for use with wheelchairs

InactiveUS7066549B2Improve adjustabilityEasy to modifyWheelchairs/patient conveyanceStoolsWheelchairEngineering

A wheelchair seatback assembly suitable for detachable mounting to the back-supporting posts of a wheelchair. The back assembly includes a relatively rigid shell member carrying post-engaging pins and a plurality of mounting clips attachable to wheelchair posts. At least selected ones of the mounting clips are further formed to releasably engage the post-engaging pins. The mounting units are also formed for single-handed automatic unlocking and release of the pair of hooks from the mounting units and posts upon rotation of the shell member forwardly over the wheelchair seat by an amount in excess of any displacement occurring during normal use of the wheelchair.

Owner:CASCADE DESIGNS INC

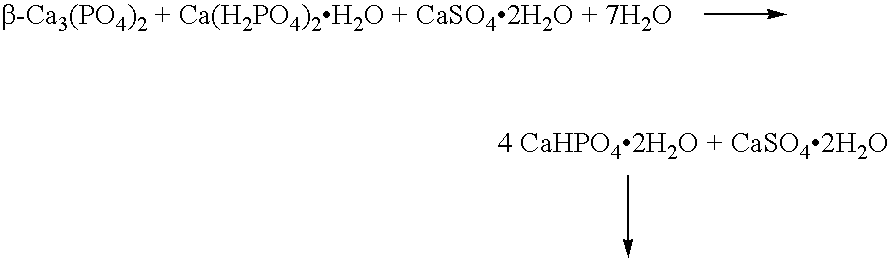

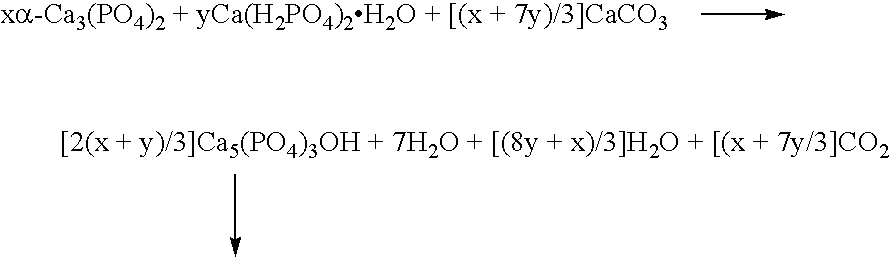

Pasty or liquid multiple constituent compositions for injectable calcium phosphate cements

InactiveUS20040244651A1Simple actionImpairment of mechanical propertyImpression capsSurgical adhesivesCalcium biphosphateInjectable bone

The invention concerns injectable bone filling cements, in particular hydraulic calcium phosphate cements, the latter being prepared from at least two initial liquid or pasty constituents comprising each a species reactive in solution or in suspension, the solidification process being initiated when said constituents are being mixed.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

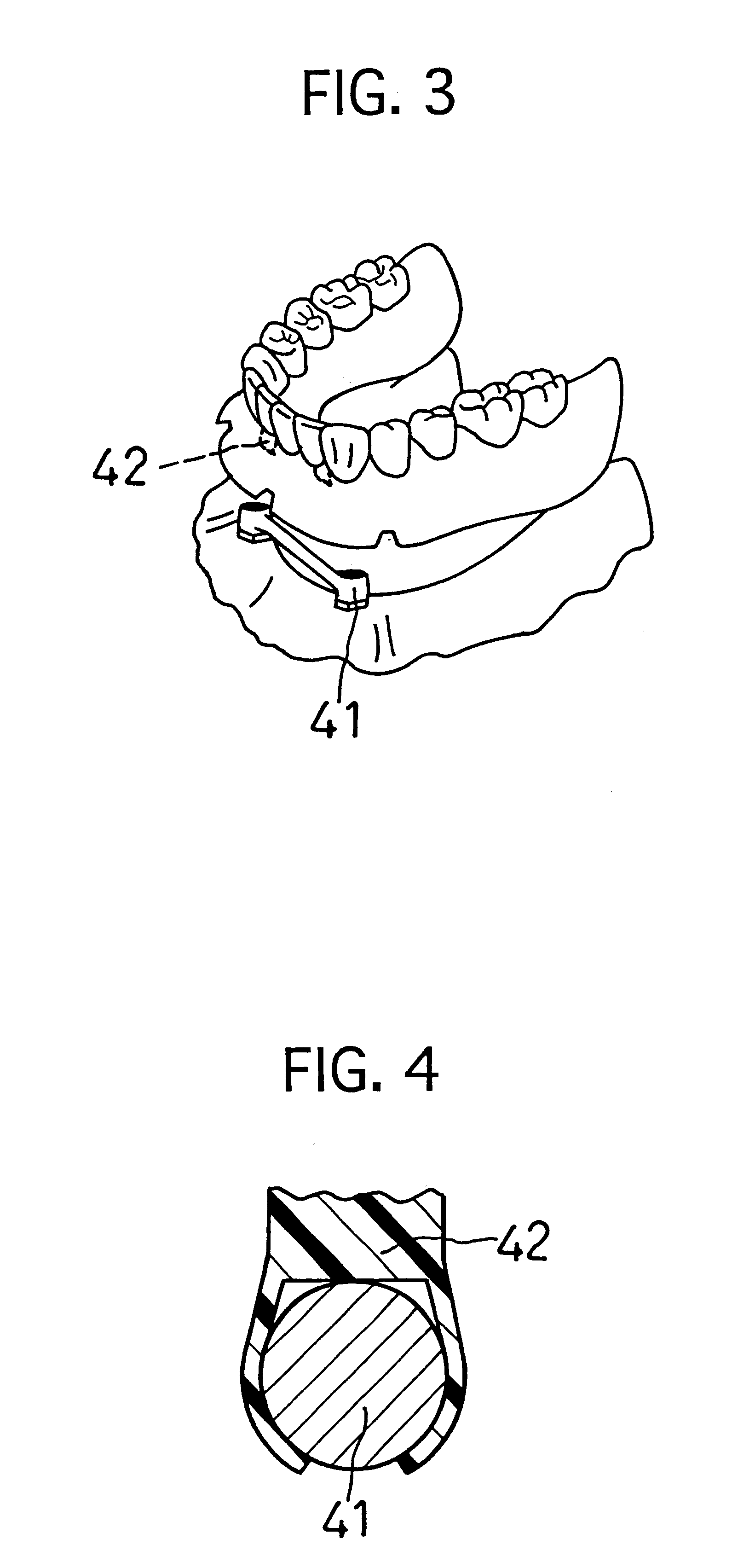

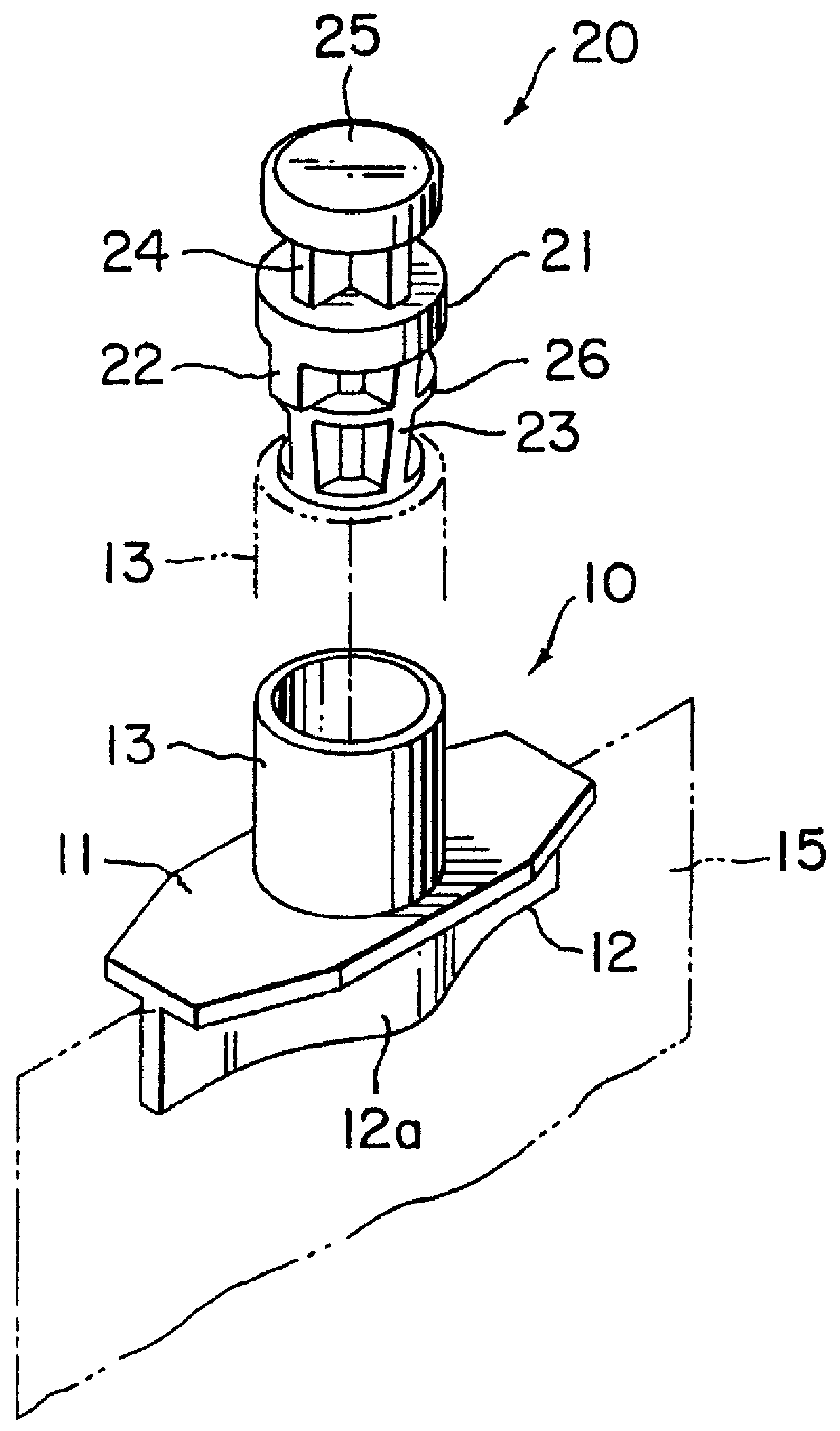

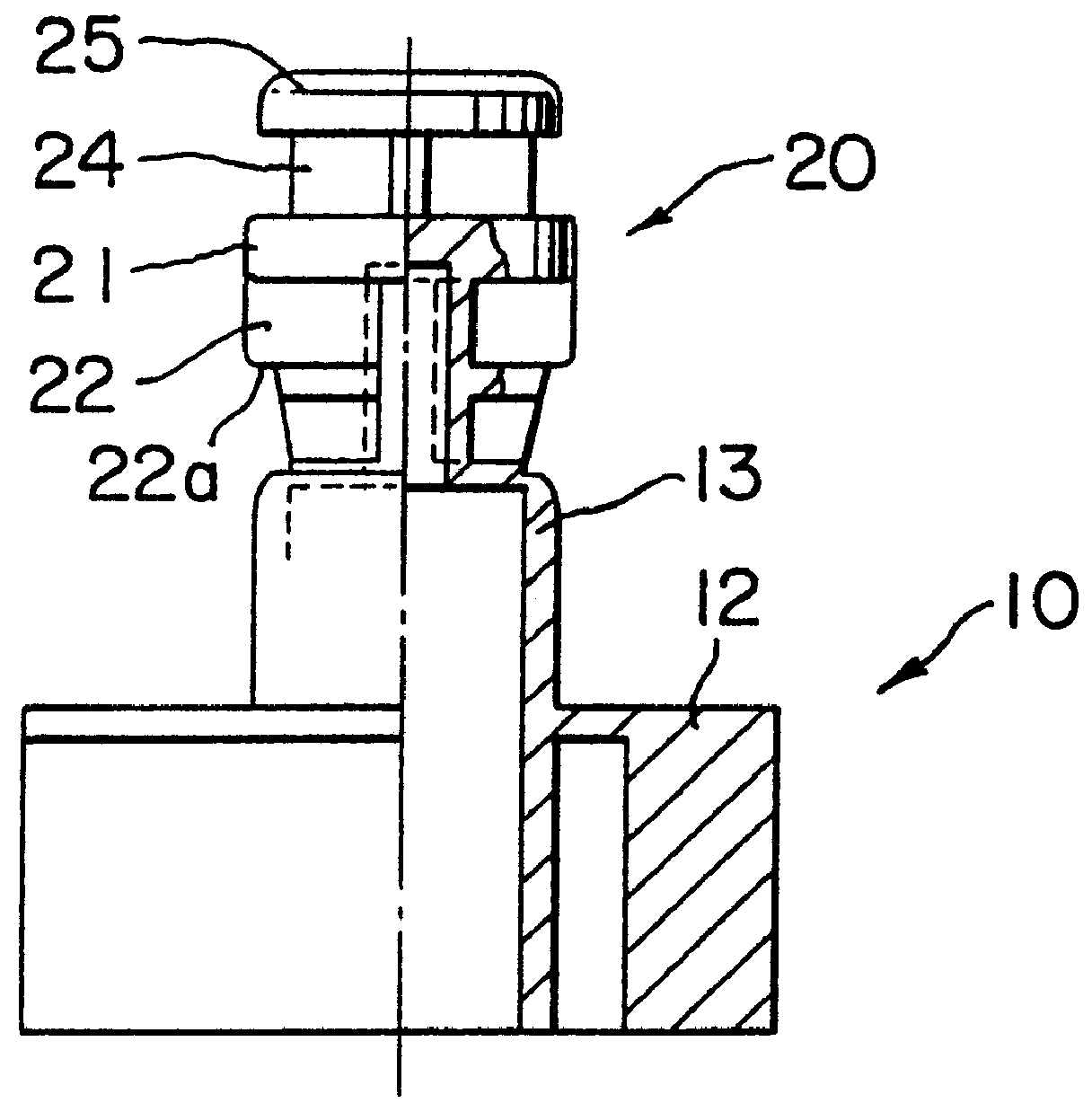

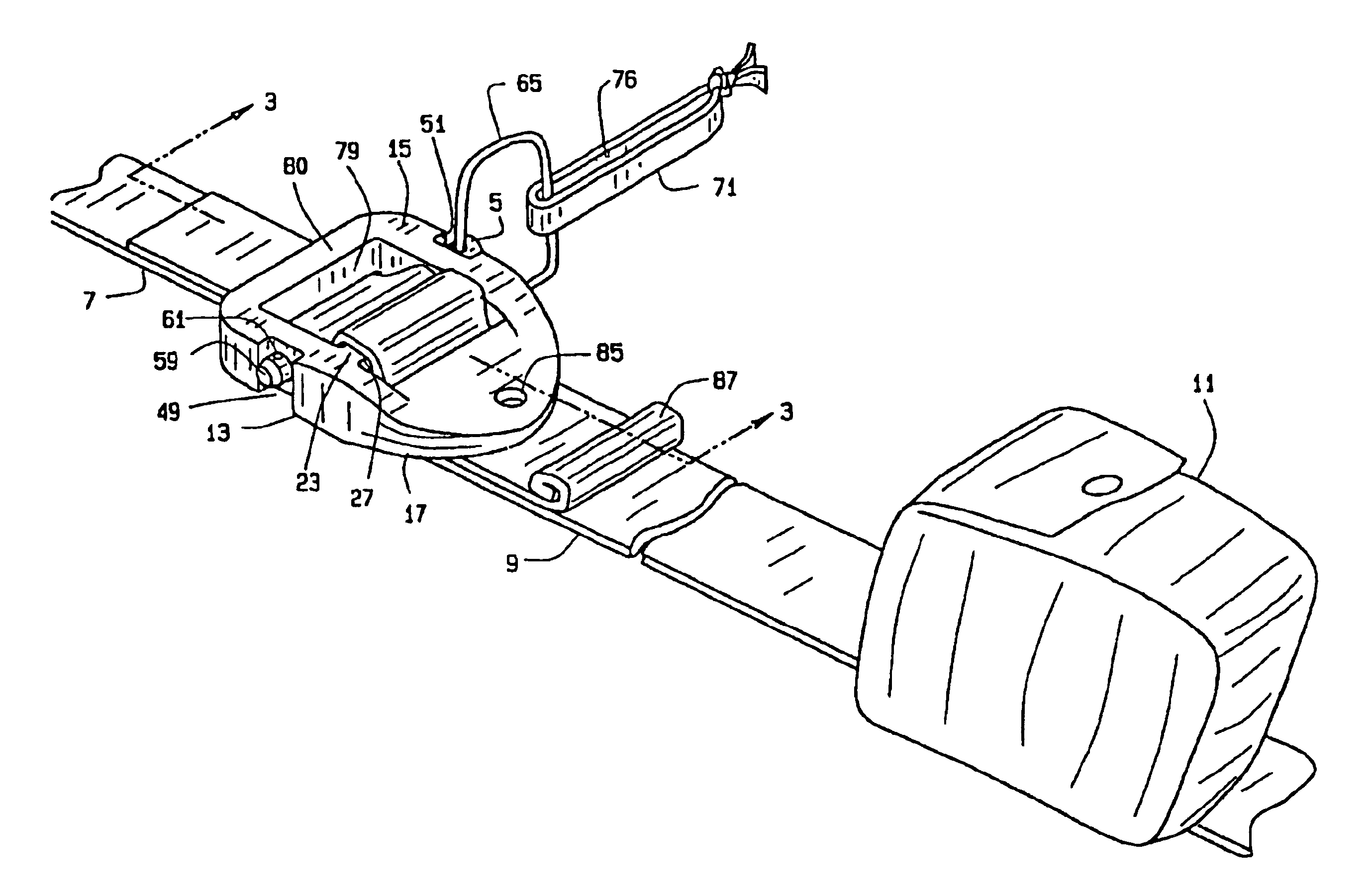

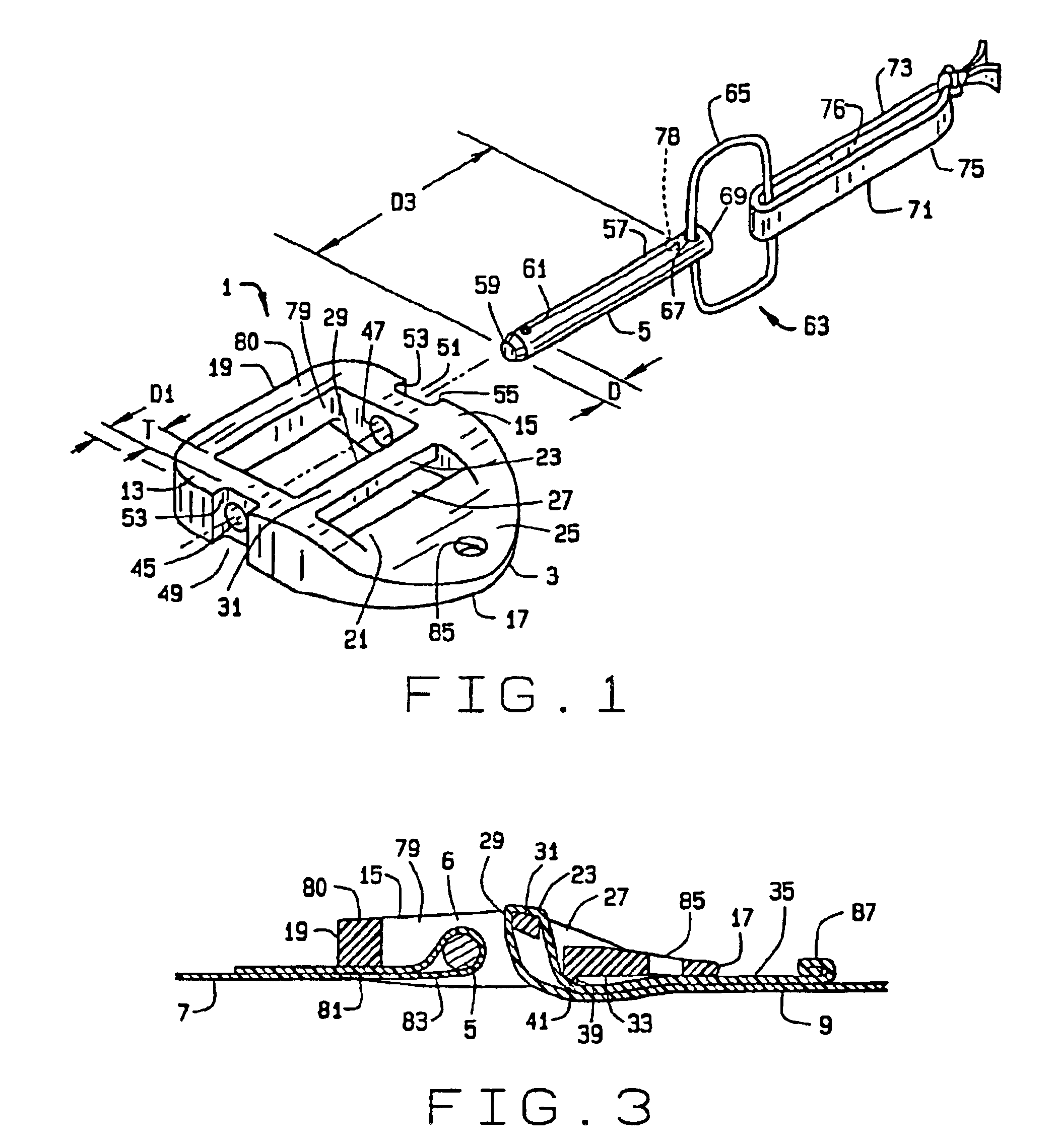

Dental bar attachment for implants

InactiveUS6652278B2Easy to installEasy to insertDental implantsFastening prosthesisDenturesEngineering

Owner:AICHI STEEL

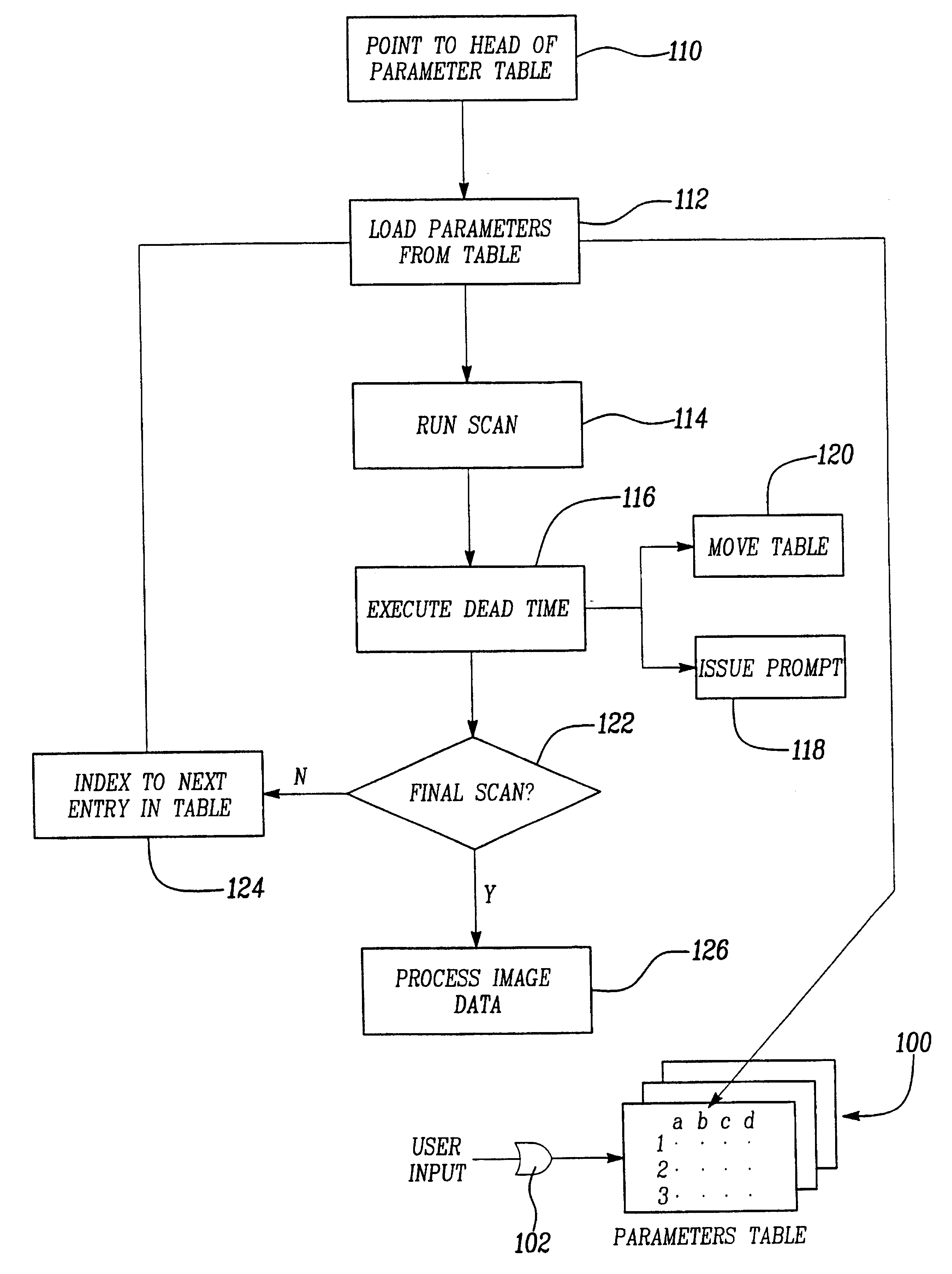

Rapid magnetic resonance imaging and magnetic resonance angiography of multiple anatomical territories

InactiveUS6493571B1Reduce osmotic pressureHigh resolutionBedsDiagnostic recording/measuringIodinated Contrast AgentSingle injection

A procedure and apparatus are provided which allow rapid positional change in the patient centering in order to facilitate the imaging of blood vessels in a series of different views. This procedure and apparatus can also facilitate the imaging of other tissues of the body at different spatial locations as well. The procedure and apparatus reduce the time required for obtaining the necessary images for a medical imaging examination using a single injection of an MRI or iodinated contrast agent.

Owner:WILLIAM BEAUMONT HOSPITAL

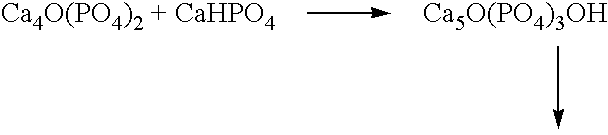

Spout assembly, spout assembly manufacturing apparatus and package with spout assembly

A spout assembly comprises a spout (10) and a cap (20). The spout has a cylindrical outer tube (13) to be placed outside a package (15) and a base (12) to be bonded to the inner surface of the package (15). The cap (20) is separably connected to an extremity of the cylindrical outer tube (13) coaxially with the cylindrical outer tube (13) in a position in which the cap (20) is pushed into the cylindrical outer tube (13).

Owner:DAI NIPPON PRINTING CO LTD

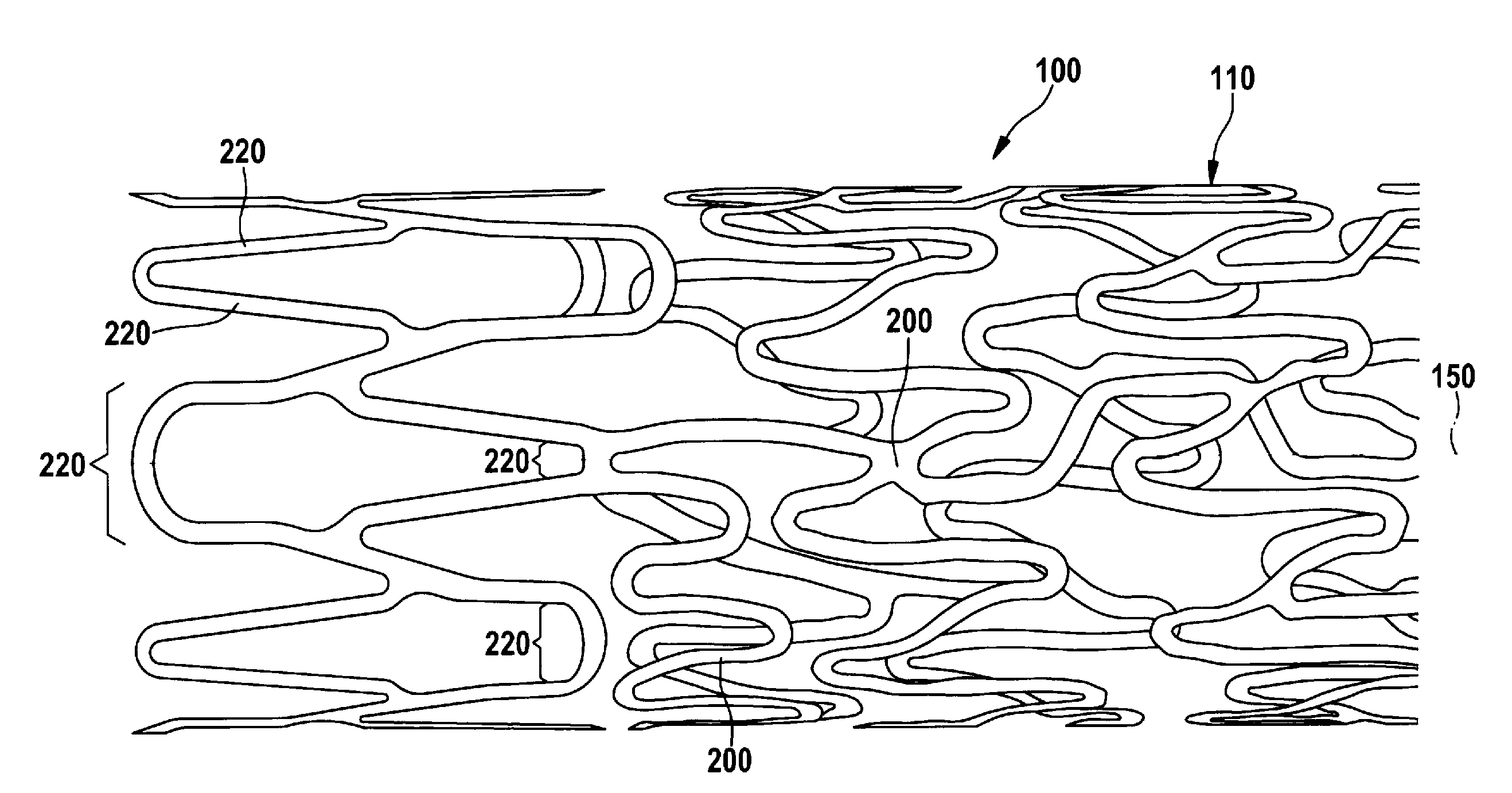

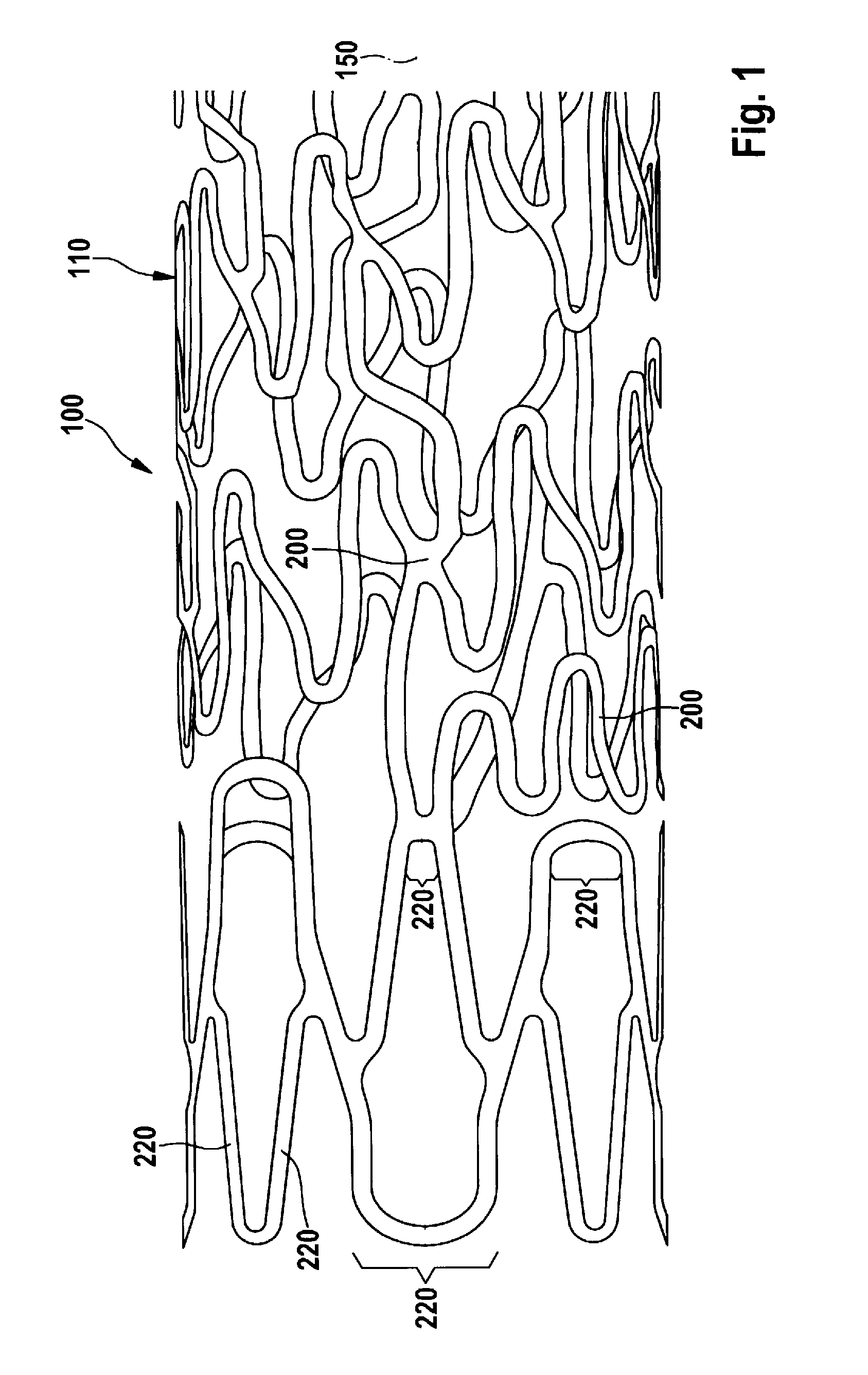

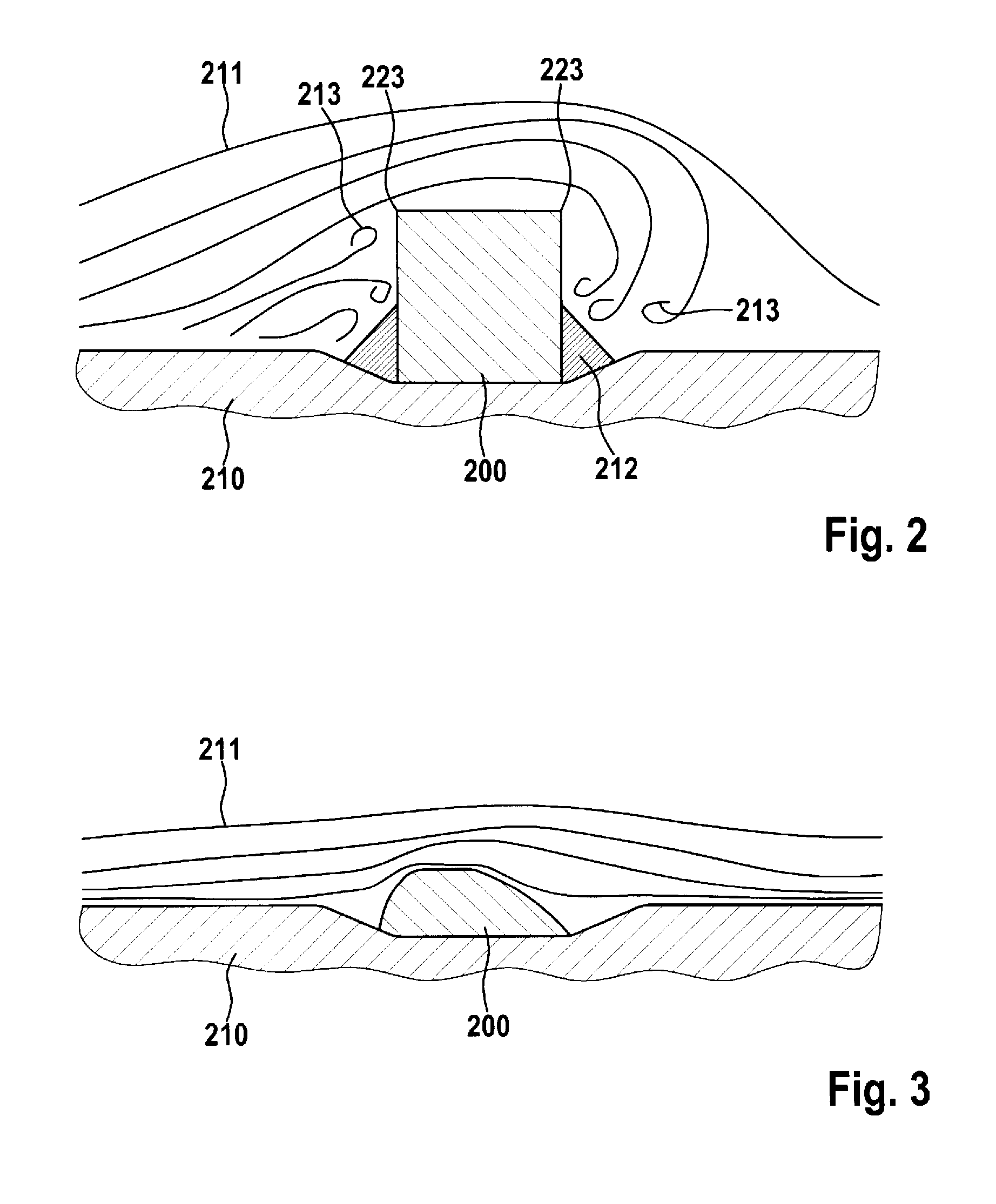

Stent and Method and Device for Fabricating the Stent

ActiveUS20100049300A1Stress minimizationAvoid injuryStentsElectrolysis componentsInsertion stentBiomedical engineering

Stent, as well as a method and device for fabricating the stent, wherein the stent has a tubular lattice structure comprising individual struts and at least one strut of which at least one longitudinal section runs with at least one directional component in the radial circumferential direction of the stent, wherein the surface of the longitudinal section facing the outside of the stent is curved only about the longitudinal axis of the stent. According to the invention, the surface of longitudinal section of the strut, which surface faces the inside of the stent, has such a curvature that the strut cross section is fluidically optimized.

Owner:BIOTRONIK AG

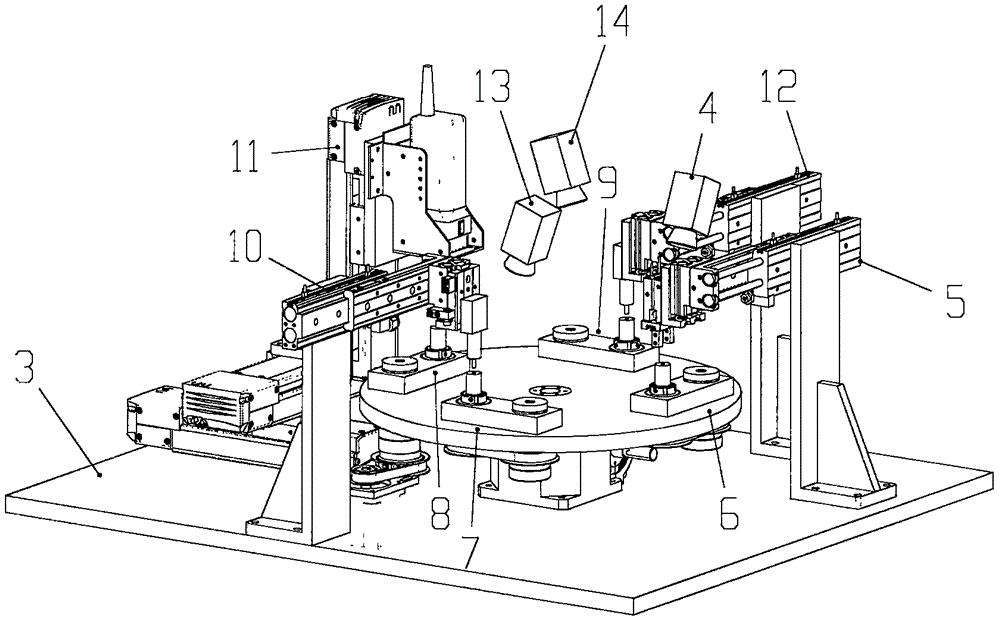

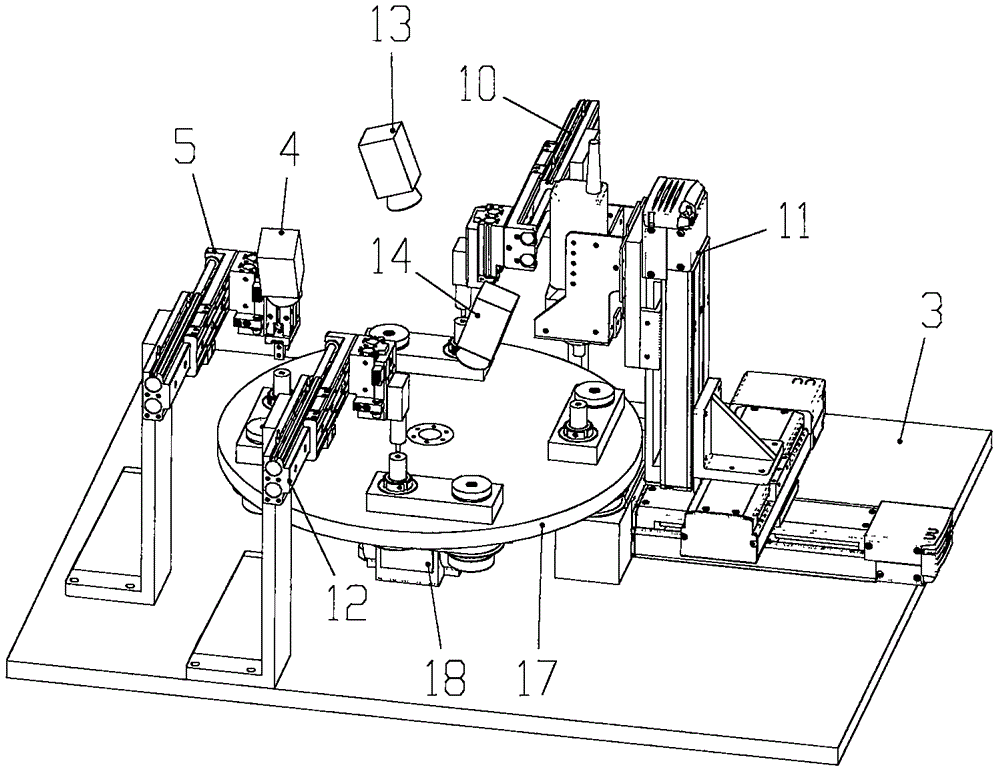

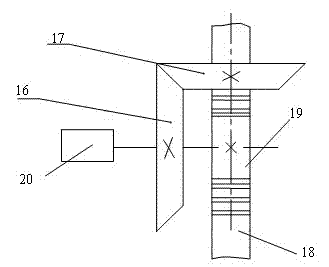

Automatic multi-station laser welding complete equipment

ActiveCN105772943AAction in placeNo human intervention requiredLaser beam welding apparatusEngineeringFully automatic

The invention relates to automatic welding equipment, in particular to automatic processing equipment for laser welding. Automatic multi-station laser welding complete equipment comprises a workbench, a valve seat feeding manipulator, an iron sheet feeding manipulator, a laser welding mechanism, a discharging manipulator, a mandrel, a turnplate and a cutter, wherein the cutter is fixedly connected to the workbench, and the turnplate is fixedly connected to a flange disc of the cutter; and the valve seat feeding manipulator, the iron sheet feeding manipulator, the laser welding mechanism and the discharging manipulator are arranged at the periphery of the turnplate. The automatic multi-station laser welding complete equipment is used for realizing fully-automatic laser welding operation on iron sheets and valve seats, utilizes industrial cameras to carry out visual detection on all work stations and ensures that production is sequentially carried out.

Owner:山西得中电气有限公司

Quick release detachable buckle

InactiveUS6851160B2Quick and positive separationSimple actionSnap fastenersClothes buttonsBiomedical engineering

Owner:EAGLE INDS UNLTD

End effector device of under-actuated picking manipulator

The invention discloses an end effector device of an under-actuated picking manipulator. The end effector device comprises three fingers with the same structure, a transmission mechanism, three contacting plates, three connecting rods, a driving rod and a rotary disk, wherein each finger has three joints, and one end of the first joint of each finger is uniformly arranged on the rotary disk; and each finger is provided with one contacting plate. The working mechanism of the end effector is that the driving rod is driven by a motor to move and drives the three fingers to oppositely move to close by the connecting rods; when the contacting plates of the fingers contact fruits and vegetables, the fruits and vegetables can push the contacting plates to slide so as to drive the incomplete gear movement in the second joints of the fingers, and the meshed gears drive the third joints of the fingers to move; when force sensors on the surfaces of the contacting plates detect preset grasping force, signals are fed back to the motor, the driving rod is controlled to stop moving, and the motor drives the rotary disk to rotate, so that the picking of the fruits and vegetables is realized. The end effector device can be used for picking fruits and vegetables, and if the end effector device is used together with other device such as a robot, the high-efficiency and high-reliability picking operation is achieved.

Owner:ZHEJIANG SCI-TECH UNIV

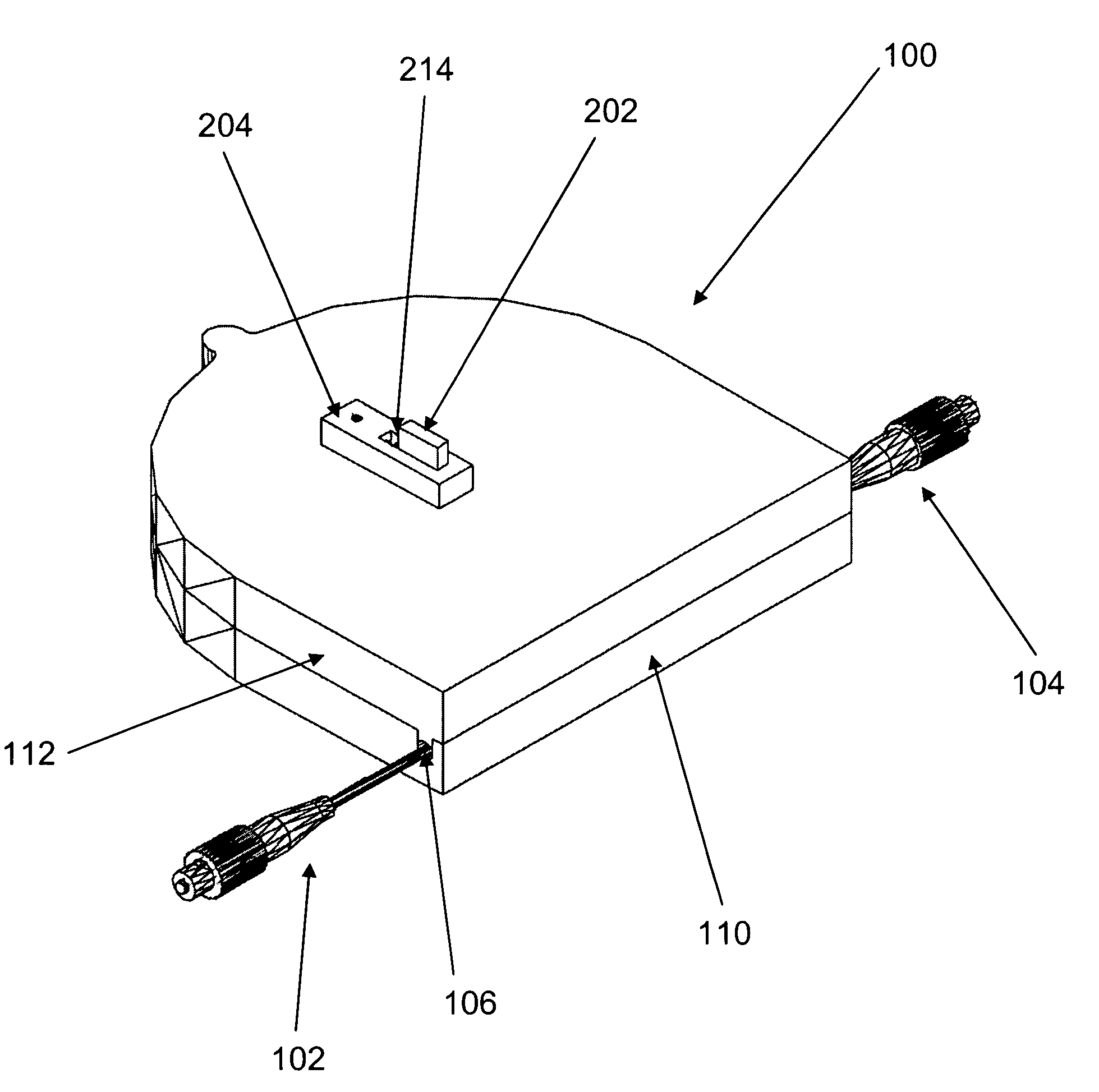

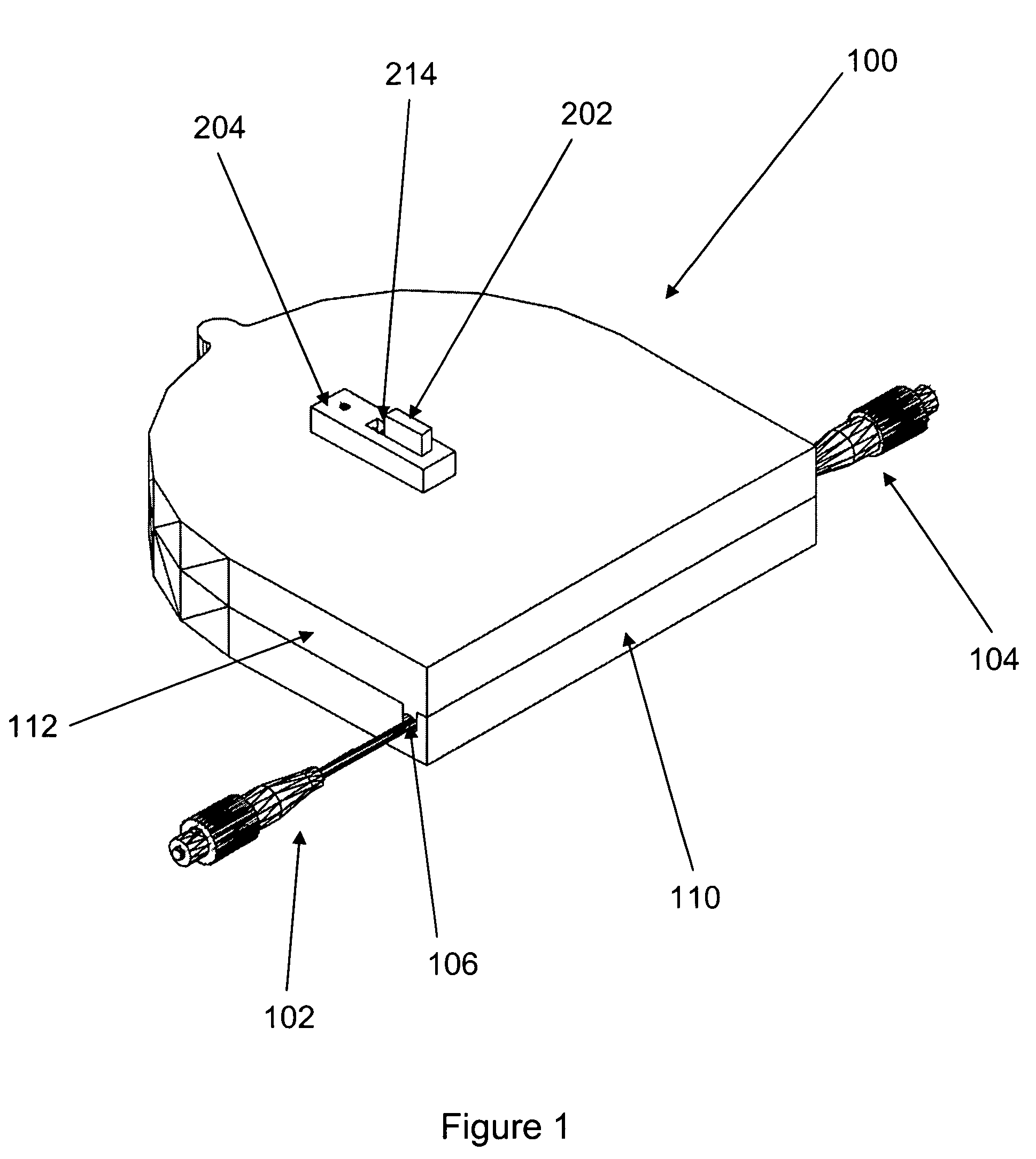

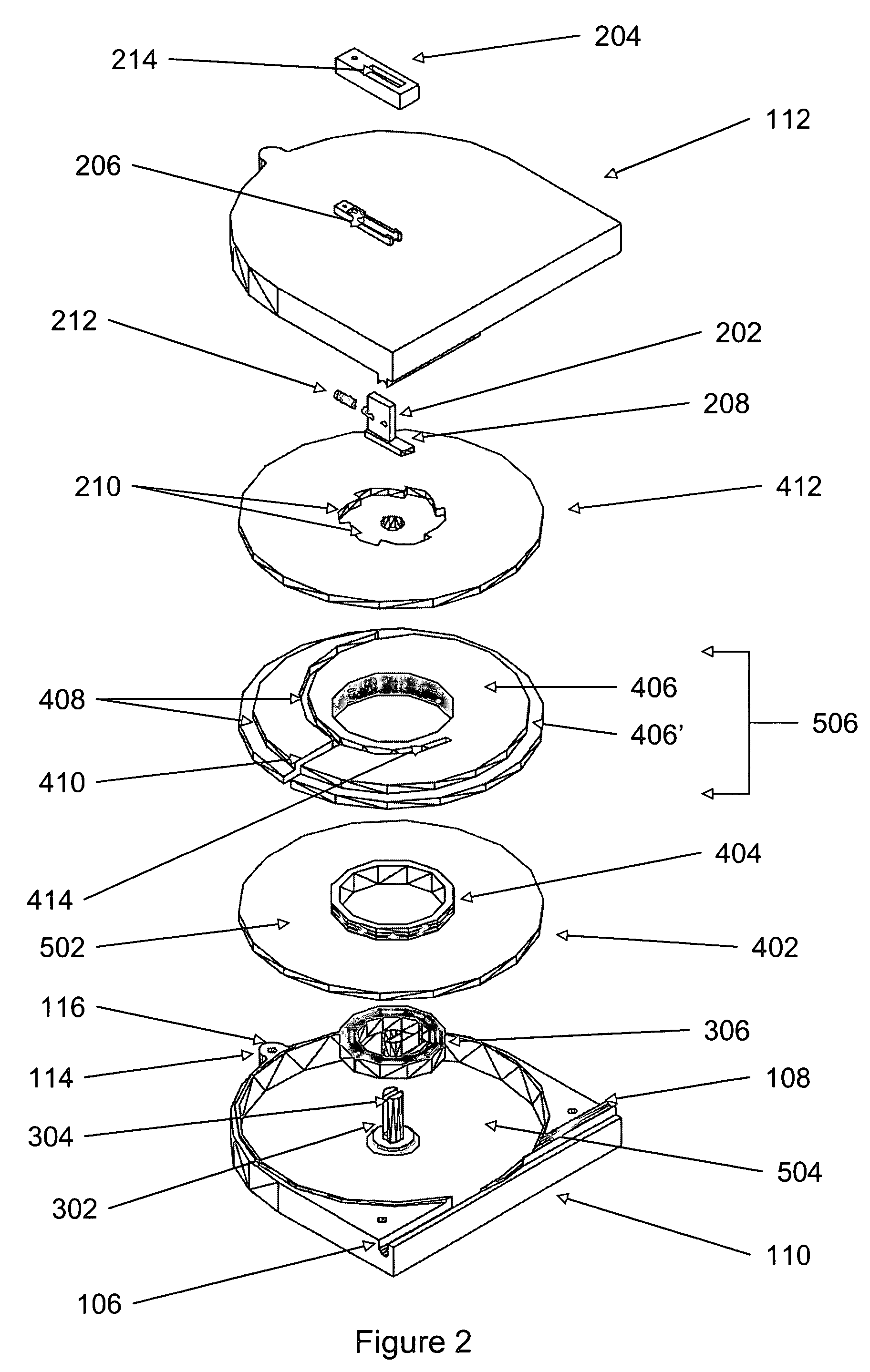

Retractable cable winder

InactiveUS7017846B2Simple actionEliminate damageFasteningsFibre mechanical structuresEngineeringBend radius

A cable winder is disclosed. The winder takes into consideration the minimum-bending radius of the optical fiber cables and minimizes cable attenuation when optical fiber cables are being stored. The winder allows only one end of the cable to be extended and rewind, while the other end of the cable, which operatively connects to the retractable cable, remains stored inside the cable winder without being damaged by the axial twist resulted from the winding action of the retractable cable. The winder enables a user to pre-determine the dimension of cable length and cable efficiency in order to maximize operation effectiveness.

Owner:COMSTAR COMM

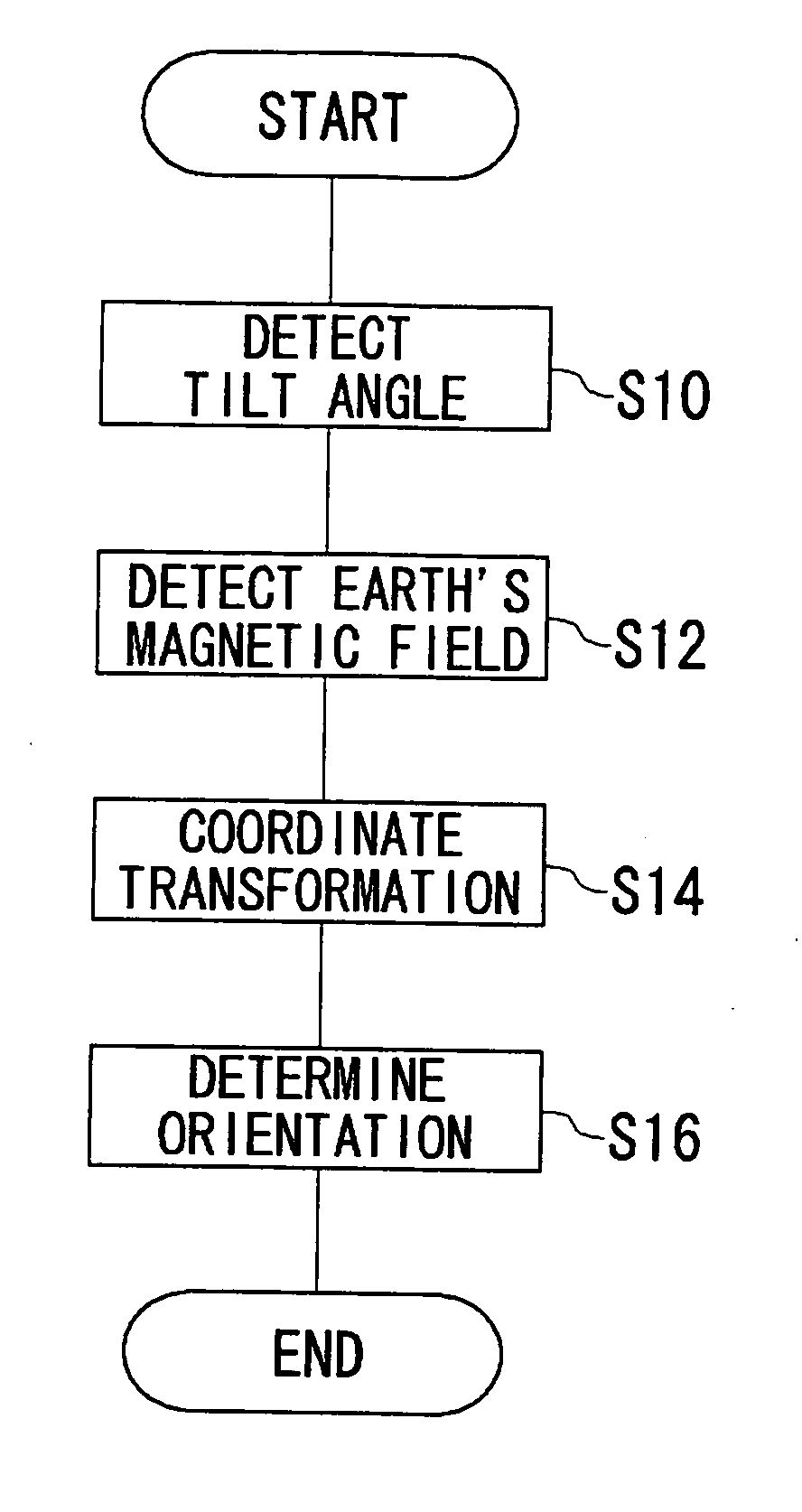

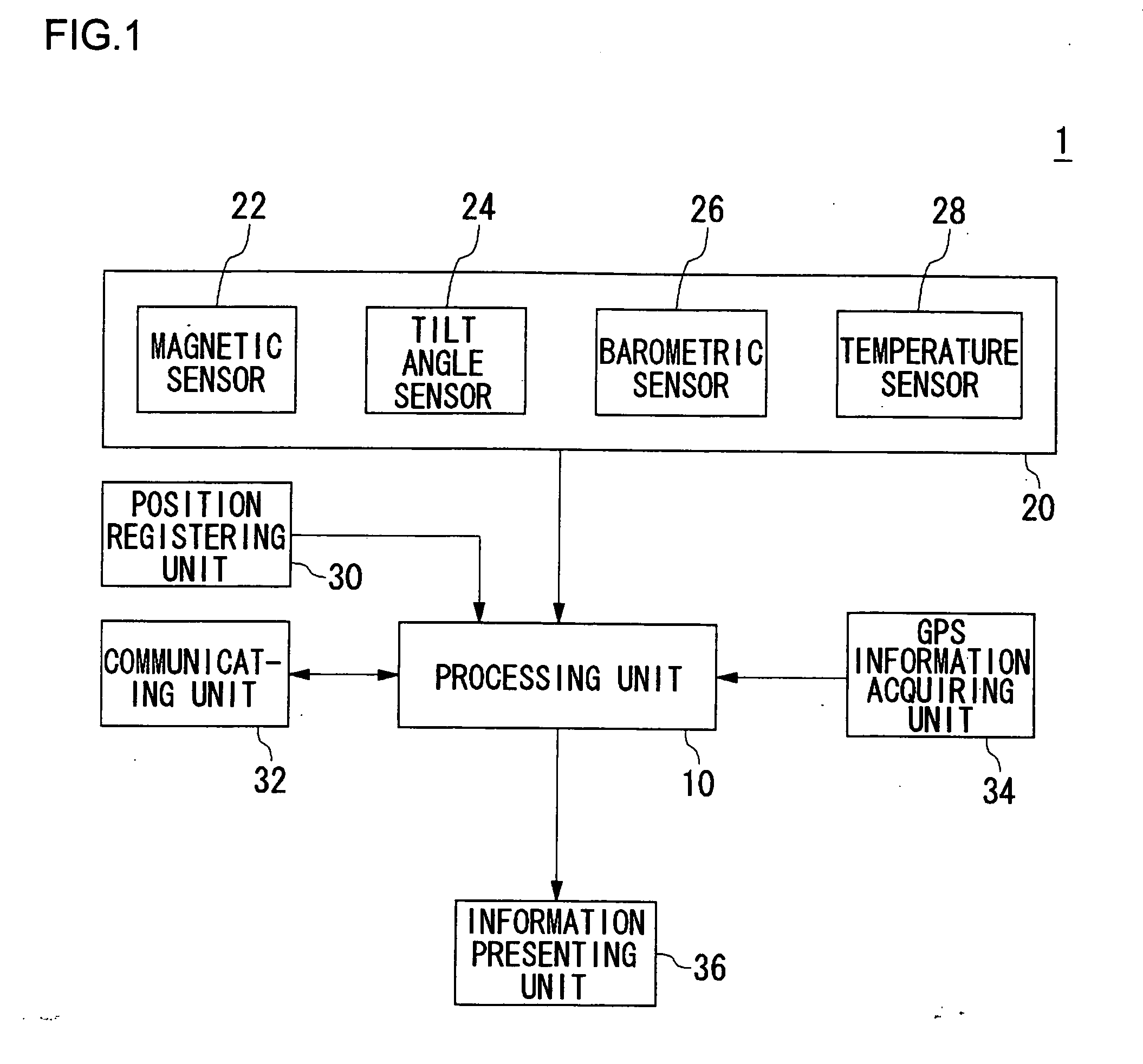

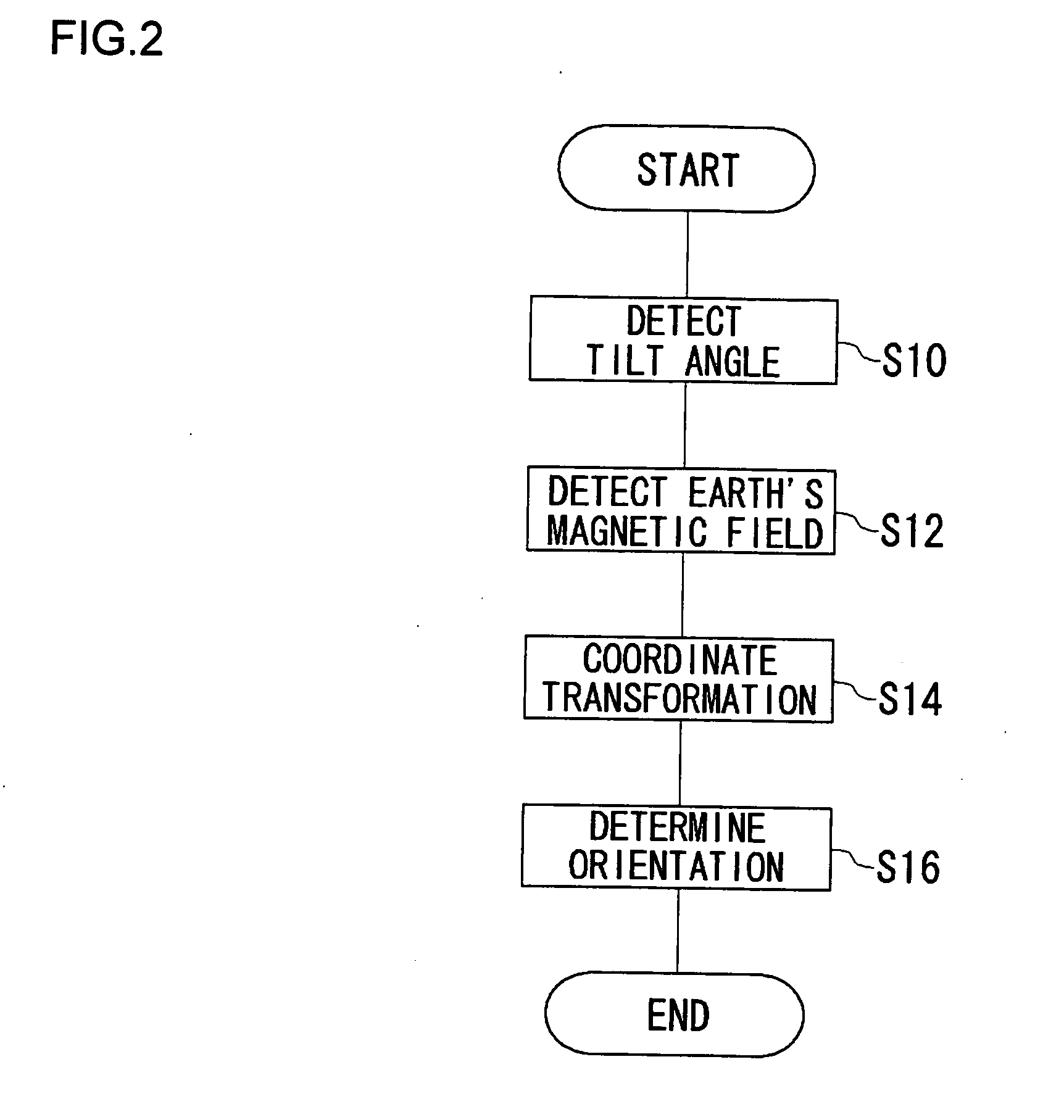

Mobile terminal apparatus

InactiveUS20050222802A1EffectiveSolve low usageNavigational calculation instrumentsDigital computer detailsTerminal equipmentEngineering

A mobile terminal apparatus 1 uses an acceleration sensor as a tilt angle sensor 24 and delivers a variety of applications based on a result of detection. A processing unit 10 counts the number of steps that a person takes, based on low-frequency acceleration components detected by the tilt angle sensor 24. Further, the processing unit 10 is capable of turning on or off a power supply or adjusting a screen scroll speed in accordance with the detected acceleration. By taking advantage of the result of detection by the tilt angle sensor 24, it is possible to configure the mobile terminal apparatus 1 as a highly useful apparatus.

Owner:VITEC

Electrical supply or connecting terminal

InactiveUS20060063419A1Easy and fast wiringEasy to produceCoupling device detailsContact members penetrating/cutting insulation/cable strandsElectrical conductorSpring force

An electrical supply or connecting terminal with a clamping spring and a metal part, the clamping spring having a clamping leg and a contact leg, and the metal part having a conductor bar piece. The clamping leg and the conductor bar piece form a spring force clamp connection for the electrical conductor. The contact leg of the clamping spring has a recess for insertion of the electrical conductor, and an end of the clamping leg extends through the recess. The clamping spring has a retaining section which runs essentially parallel to the insertion direction of the electrical conductor and parallel to the conductor bar piece and the conductor bar piece has been inserted though the recess in a direction opposite the insertion direction of the electrical conductor, the conductor bar piece being clamped securely between the end of the clamping leg and the retaining section.

Owner:PHOENIX CONTACT GMBH & CO KG

Spring clamp electrical terminal

ActiveUS7238043B2Possible to fixEasy to fixContact members penetrating/cutting insulation/cable strandsFixed connectionsElectrical conductorSpring force

An electrical supply or connecting terminal with a clamping spring and a metal part located in an insulating housing having a conductor inlet opening for an electrical conductor. The clamping spring has a clamping leg and a contact leg, and the clamping leg and the metal part form a spring force clamp connection for the electrical conductor. The contact leg of the clamping spring is arranged essentially perpendicular to the insertion direction of the electrical conductor and a recess is formed in the contact leg for insertion of the electrical conductor. The clamping leg and the contact leg of the clamping spring are bent toward one another with the end of the clamping leg extending through the recess. The metal part has at least one mounting section inserted through the recess of the clamping spring in a direction opposite the insertion direction of the electrical conductor.

Owner:PHOENIX CONTACT GMBH & CO KG

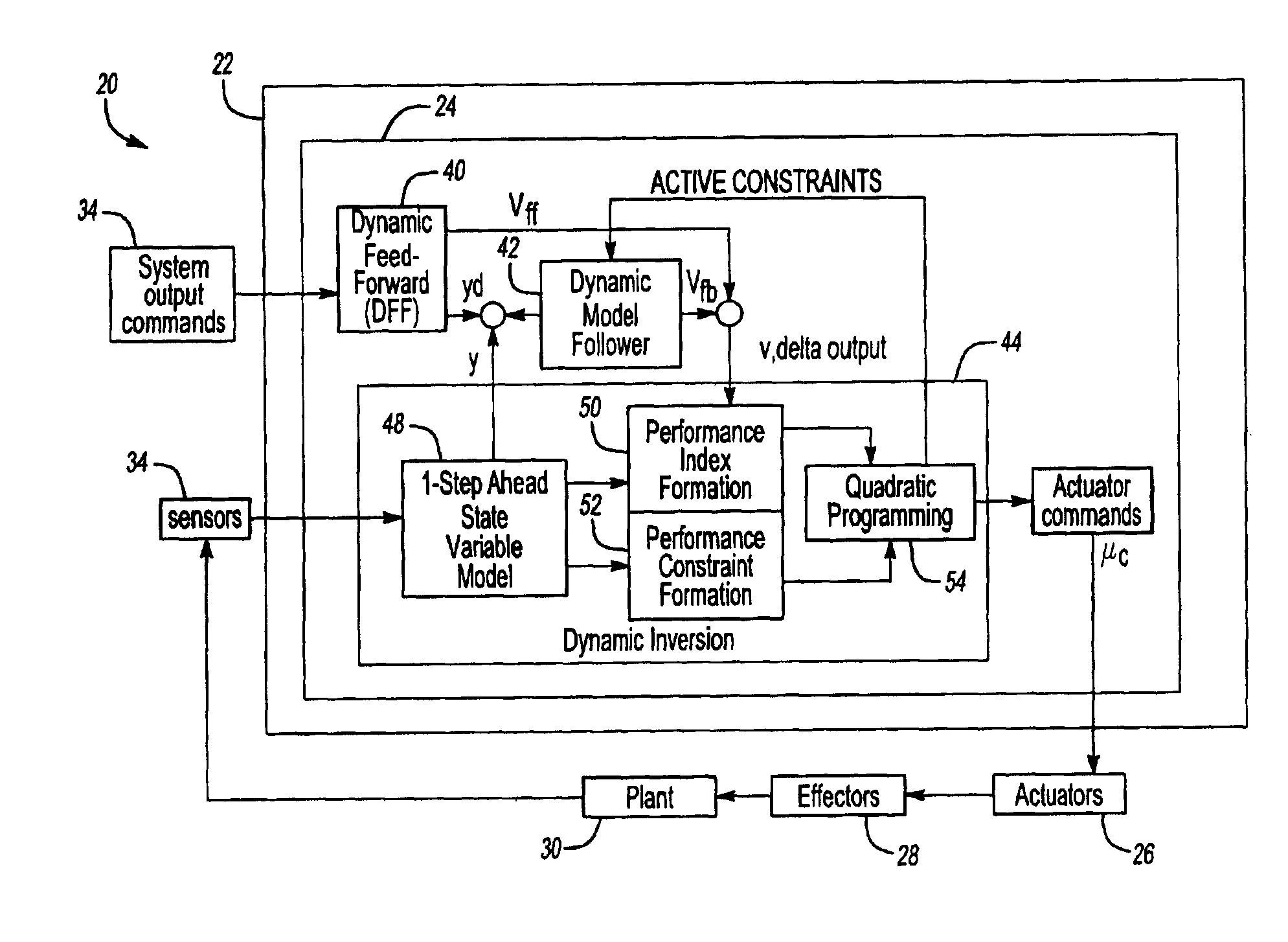

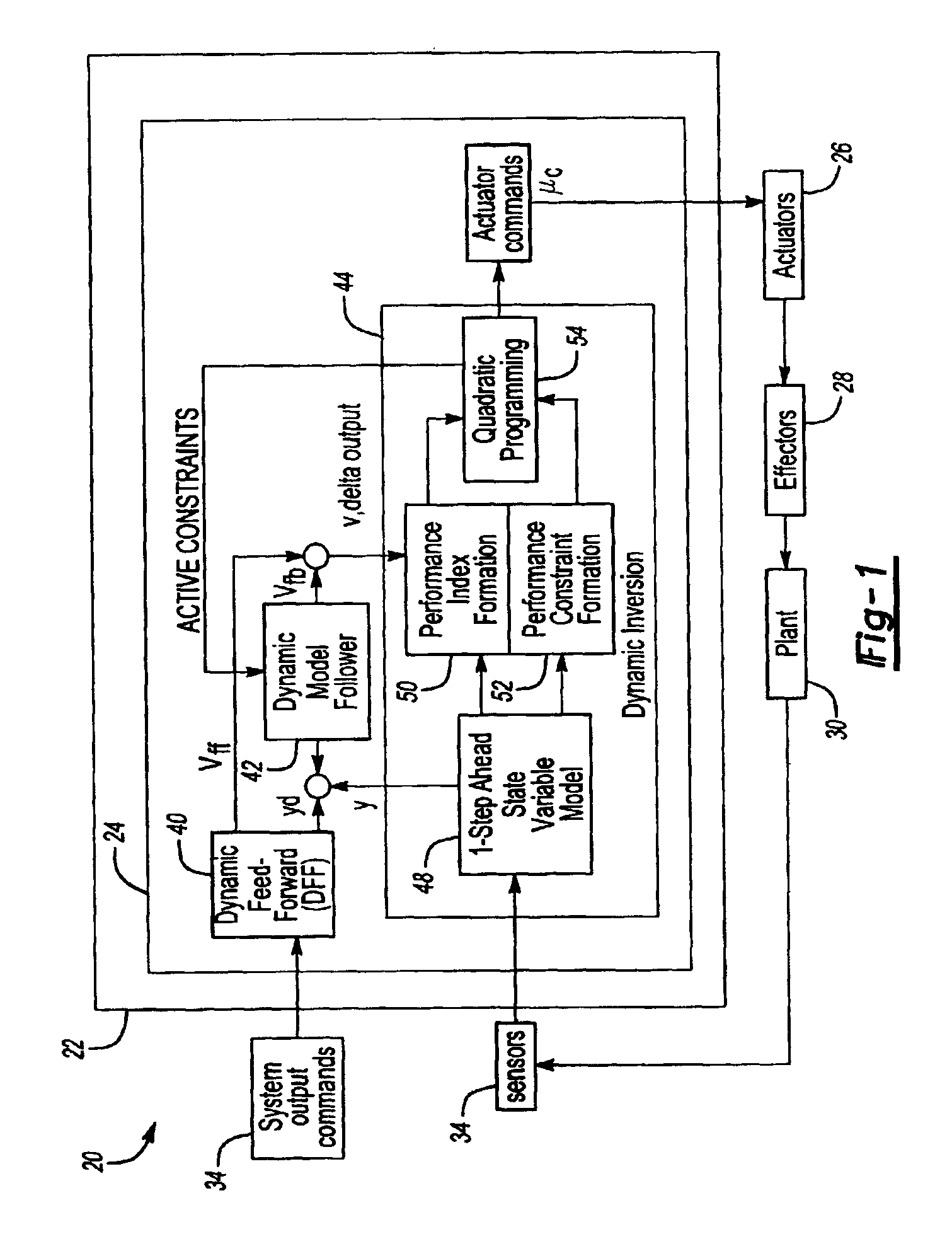

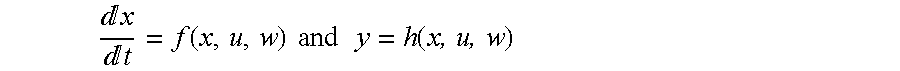

Constrained dynamic inversion control algorithm

ActiveUS6882889B2Eliminate the effects ofReduce impactSampled-variable control systemsDigital computer detailsControl systemPointing systems

A method of controlling a multivariable system includes the step of receiving a plurality of sensor signals indicating current conditions of the system and receiving a plurality of commands. The desired dynamic response of the system is then determined based upon the commands and the sensor signals. The problem of controlling the system to achieve the desired dynamic response without violating numerous actuator and physical constraints is then formulated as a quadratic programming problem. By solving the quadratic programming problem, the effector commands are determined and the physical constraints are enforced.

Owner:RAYTHEON TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com