Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112 results about "Automatic milking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic milking is the milking of dairy animals, especially of dairy cattle, without human labour. Automatic milking systems (AMS), also called voluntary milking systems (VMS), were developed in the late 20th century. They have been commercially available since the early 1990s. The core of such systems that allows complete automation of the milking process is a type of agricultural robot. Automated milking is therefore also called robotic milking. Common systems rely on the use of computers and special herd management software.Also it used to monitor the health status of cows.

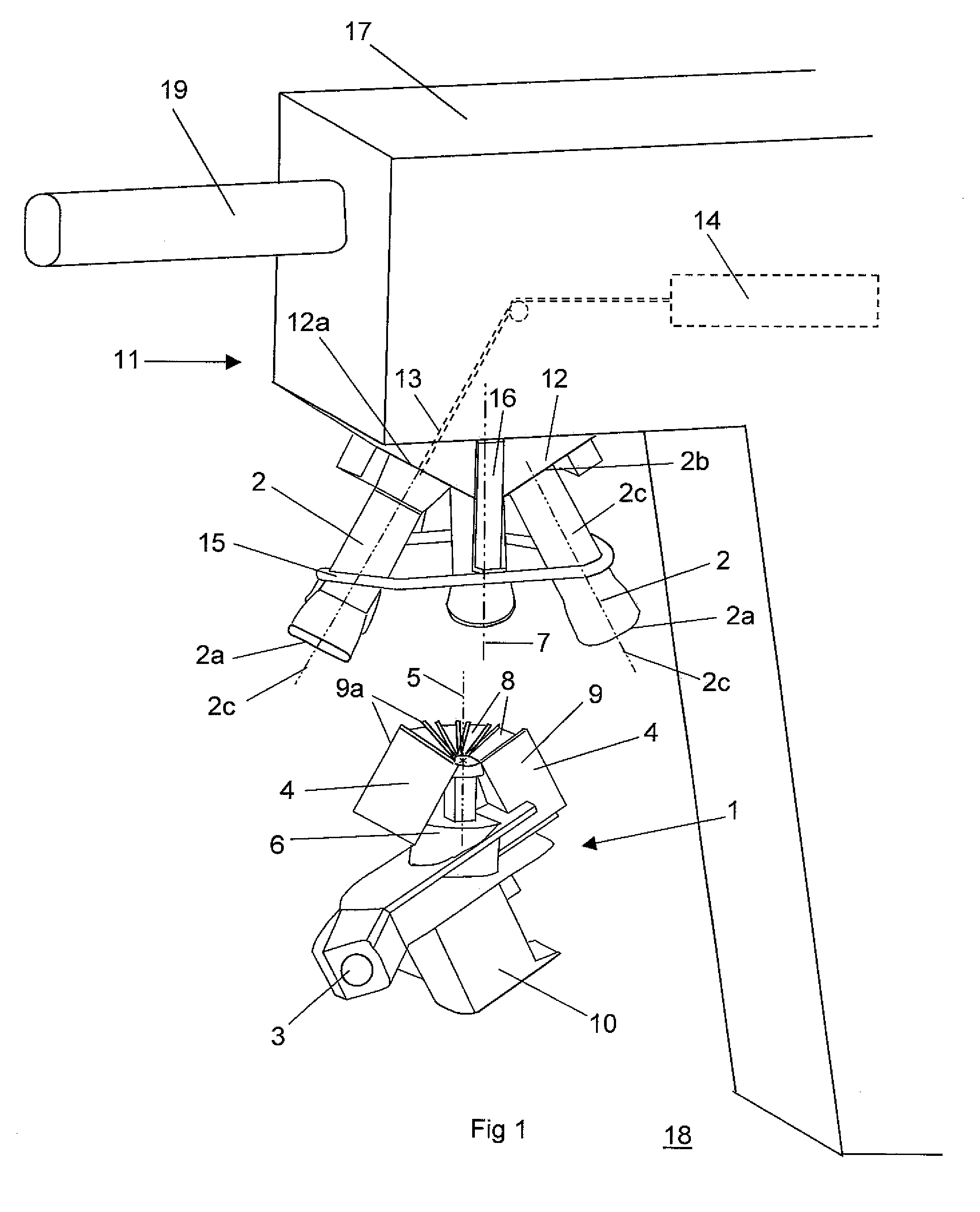

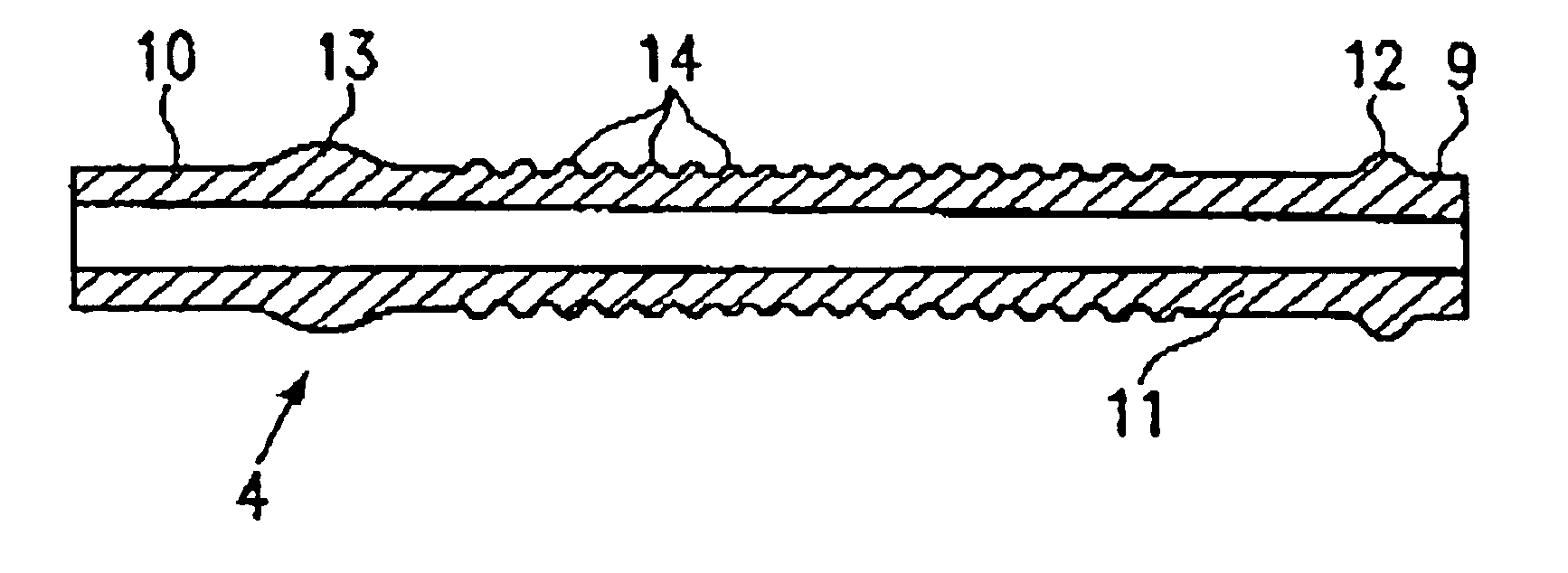

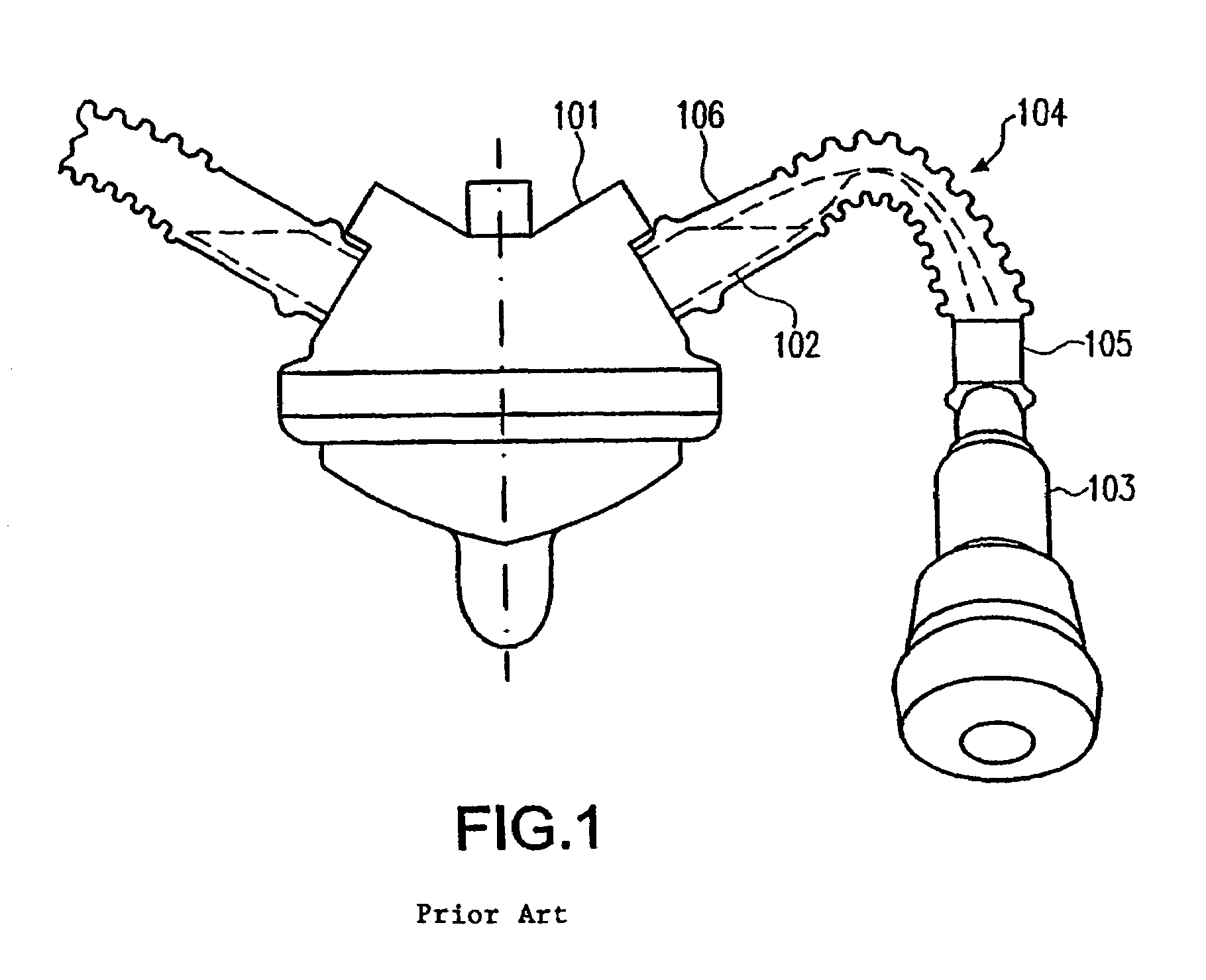

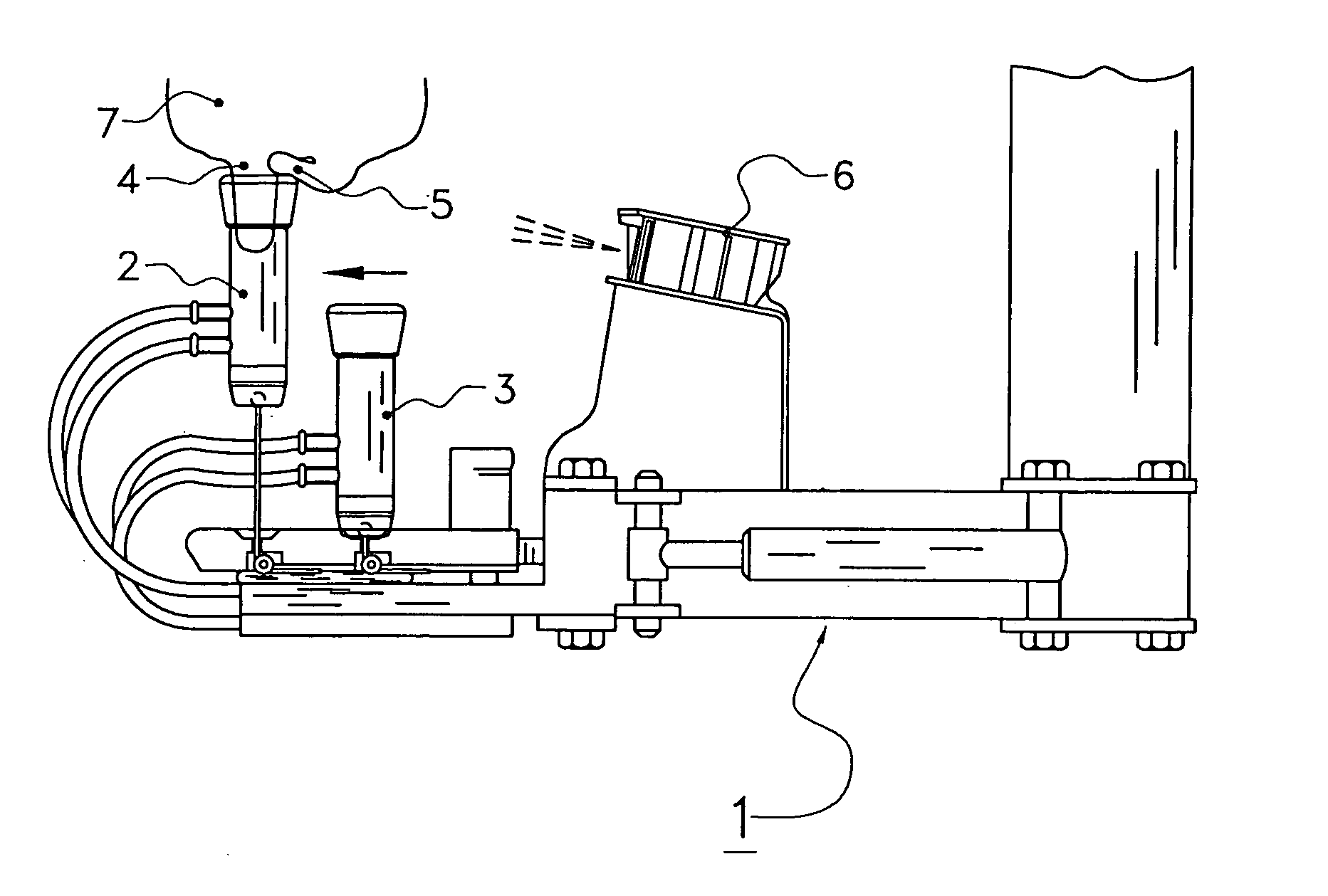

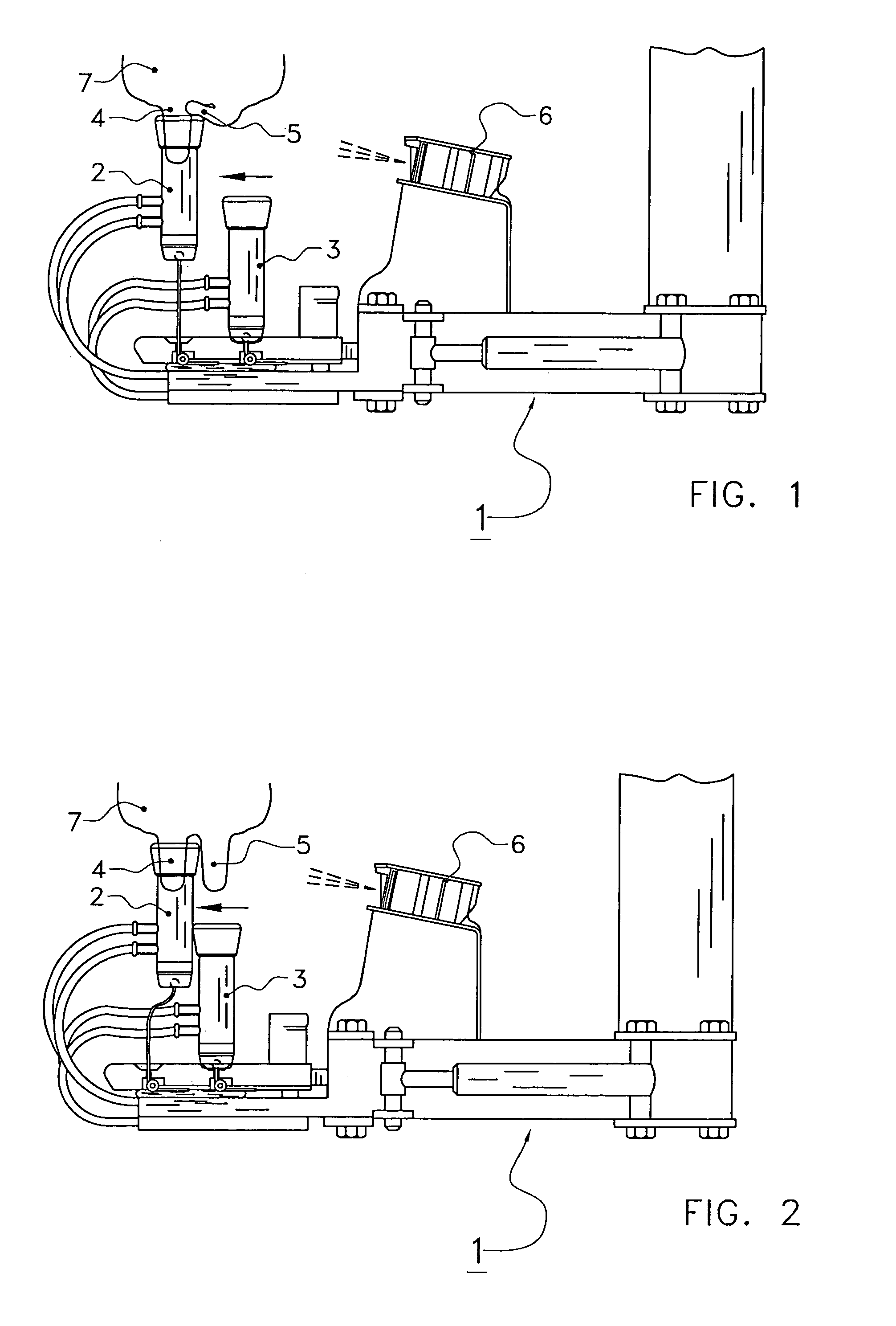

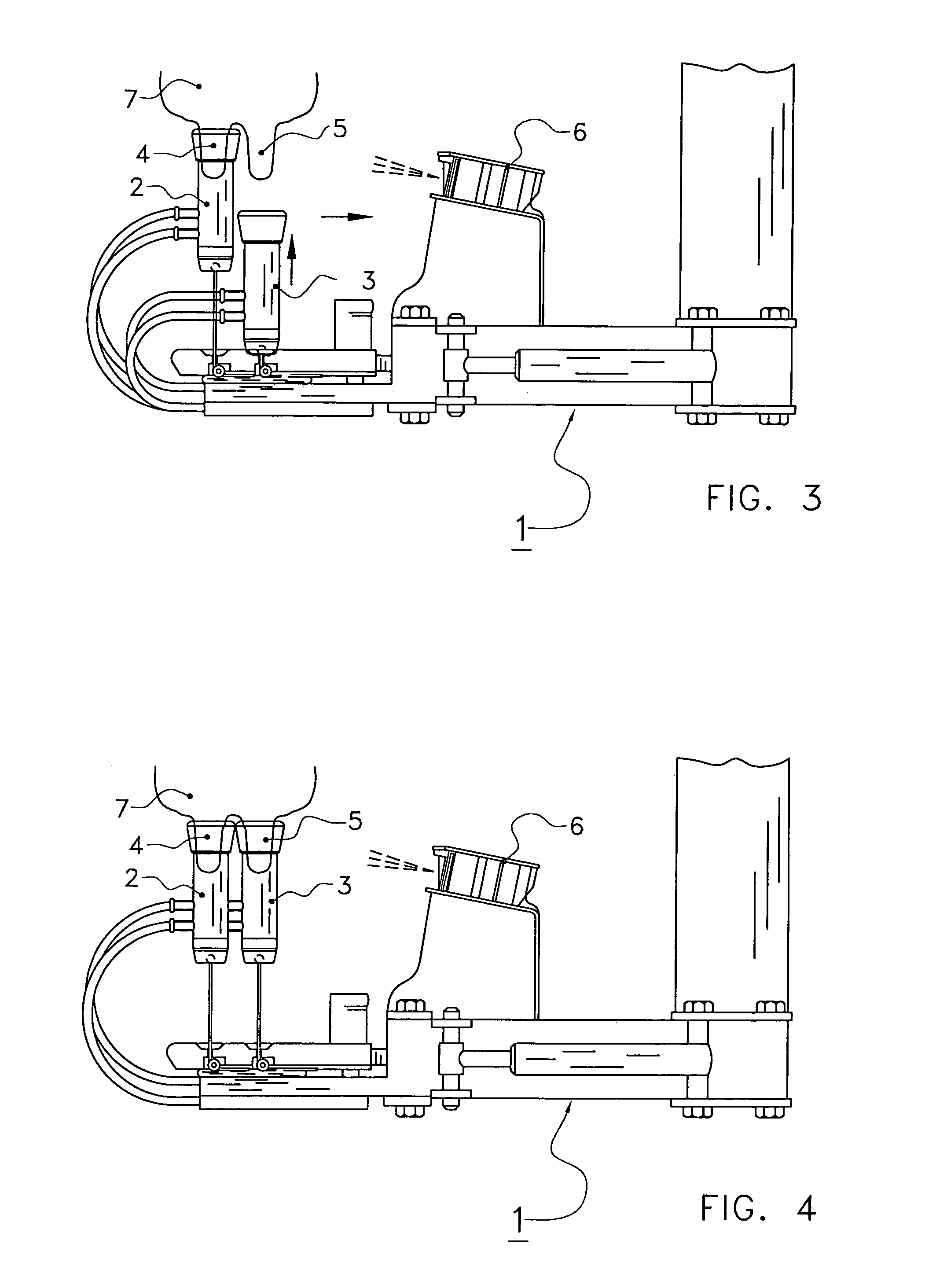

Method and apparatus for treating the teats of an animal

InactiveUS7377232B2Good choiceImprove versatilityLiquid surface applicatorsCathetersAnimal scienceMedicine

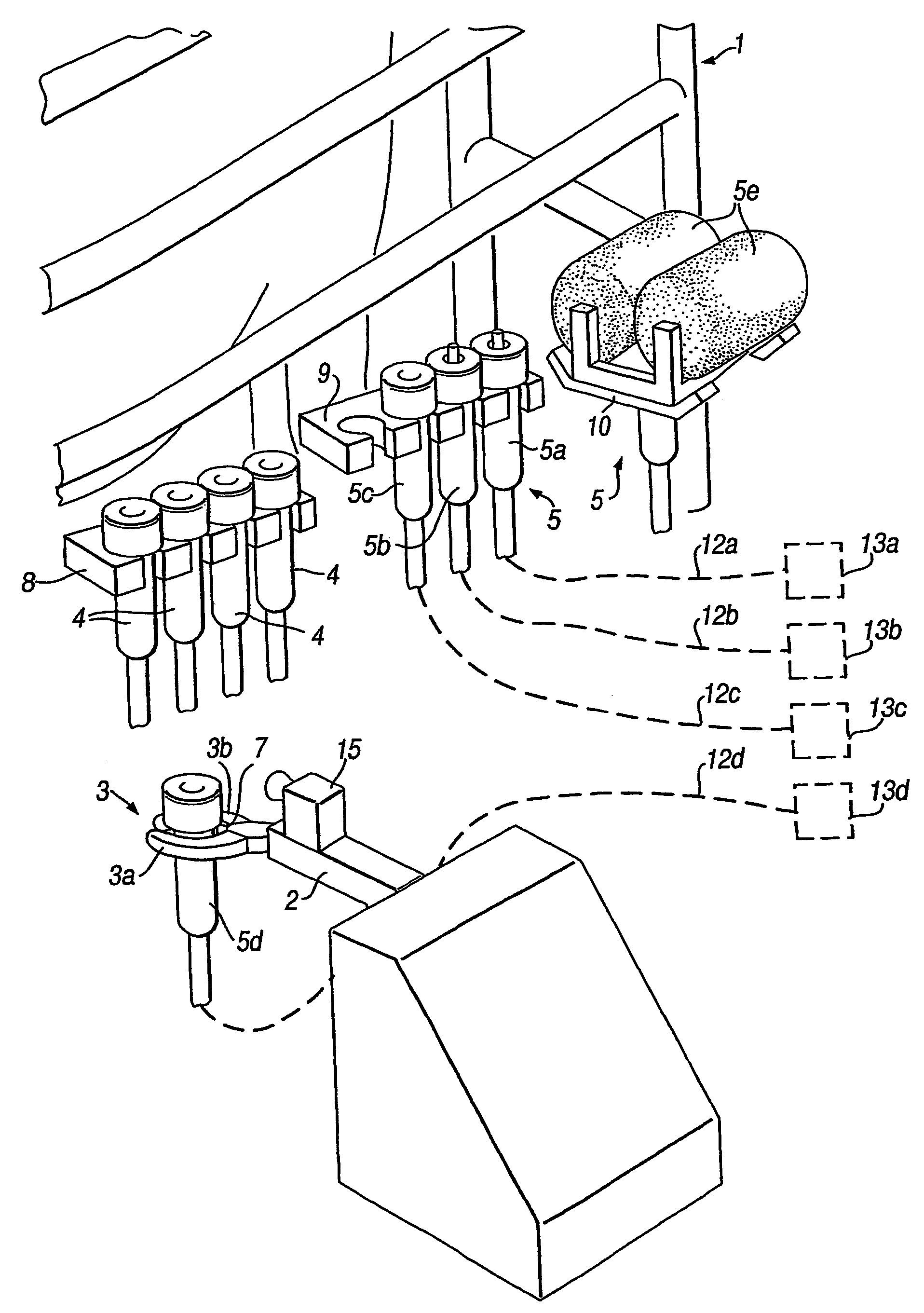

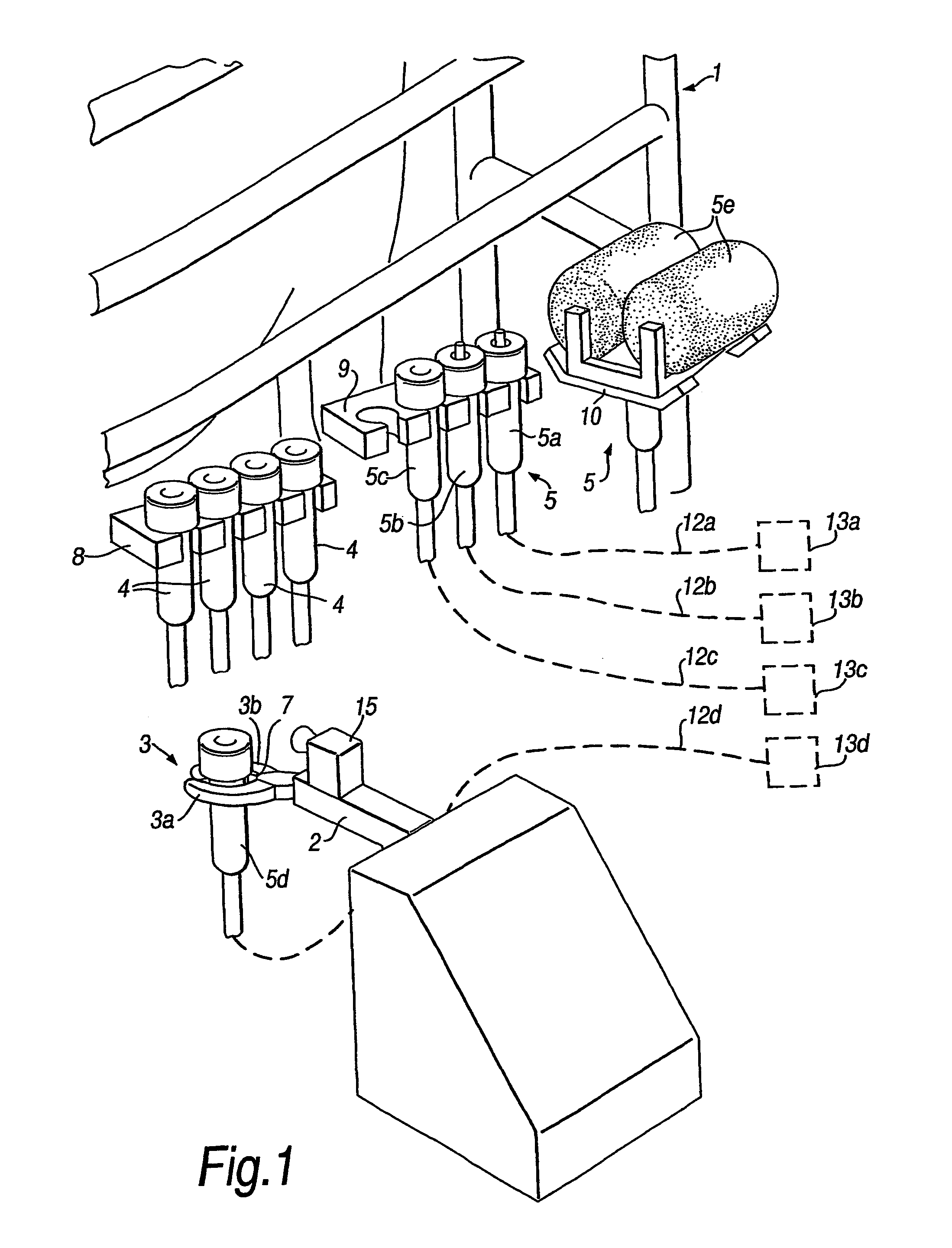

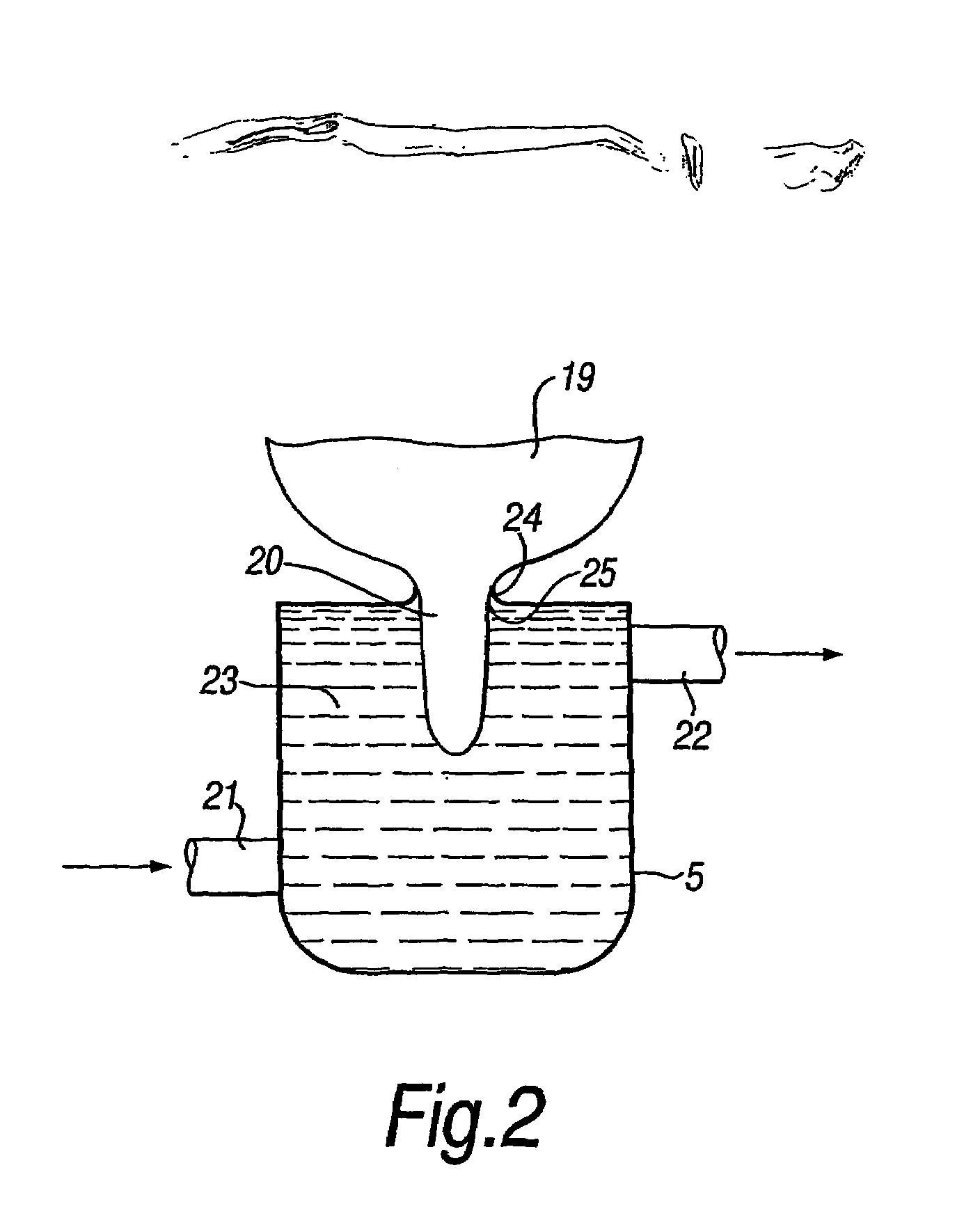

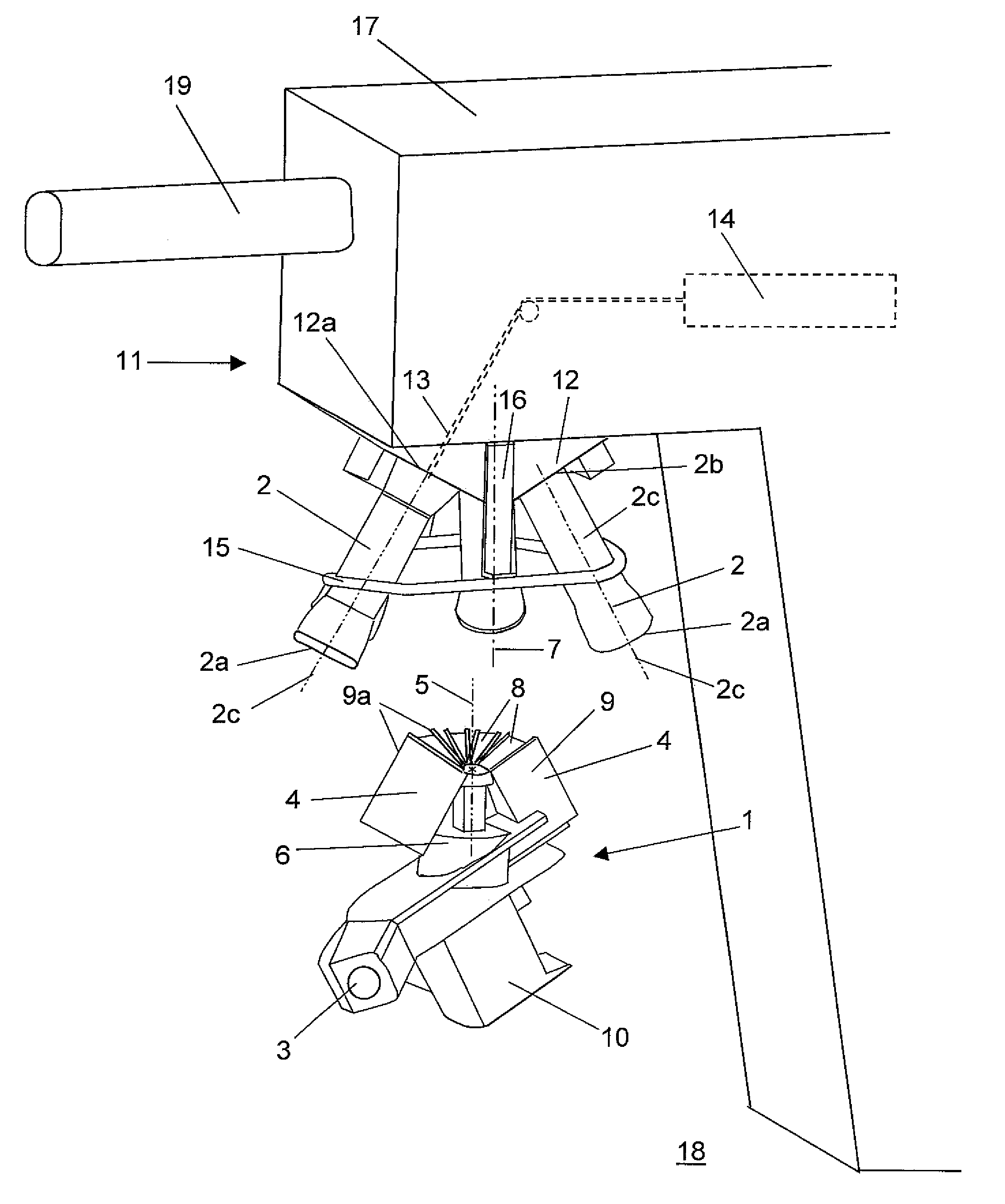

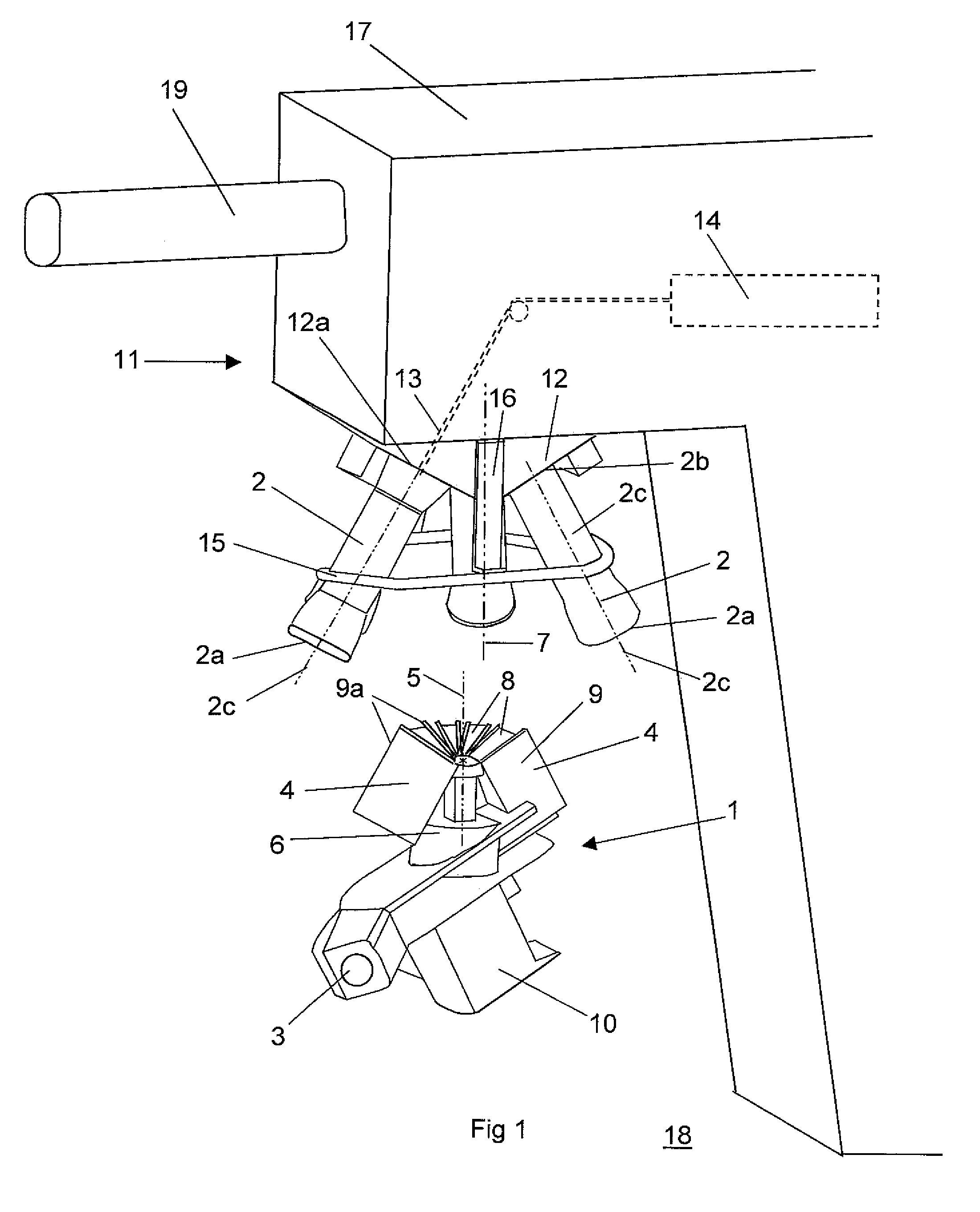

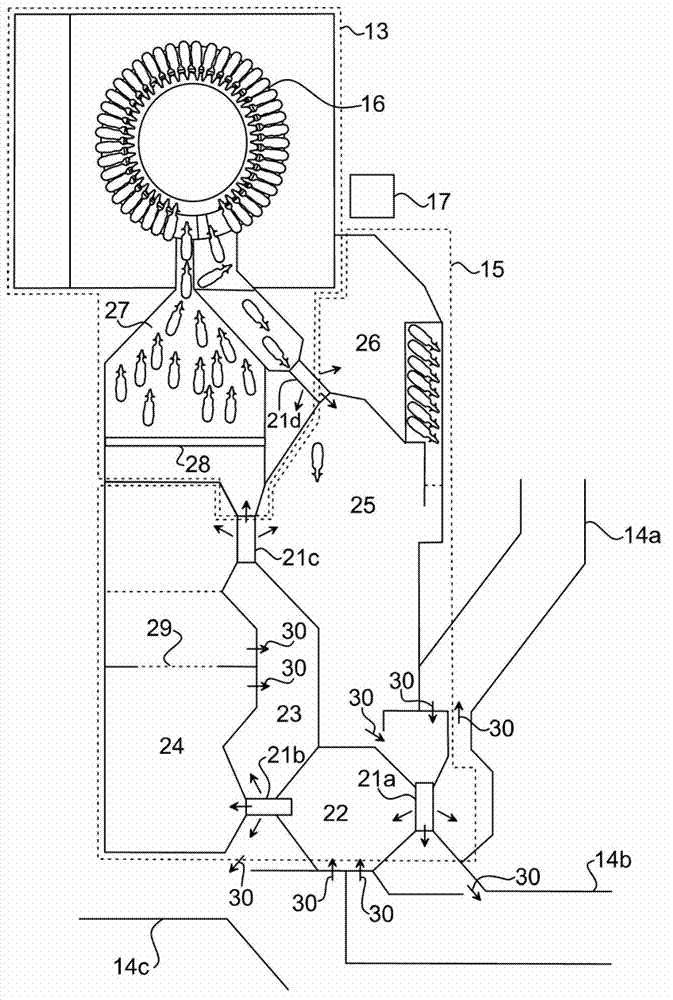

In an automatic milking installation including a robot arm (2) with a gripper (3) for attaching teat cups (4) to the teats of an animal, e.g. a cow, to be milked, for applying a teat dip to the teats after milking different members, such as spray nozzles (5a, 5b), dipping cups (5c, 5d) and sponge or cloth rollers (5e), are provided for applying different teat dip compositions. Under the control of a computer, the robot arm collects the member (5) appropriate for supplying the selected composition and takes it to a position appropriate for application of that composition. The selection can e effected in dependence upon the teat skin condition, e.g. detected by a camera (15) and / or environmental conditions.

Owner:DELAVAL HLDG AB

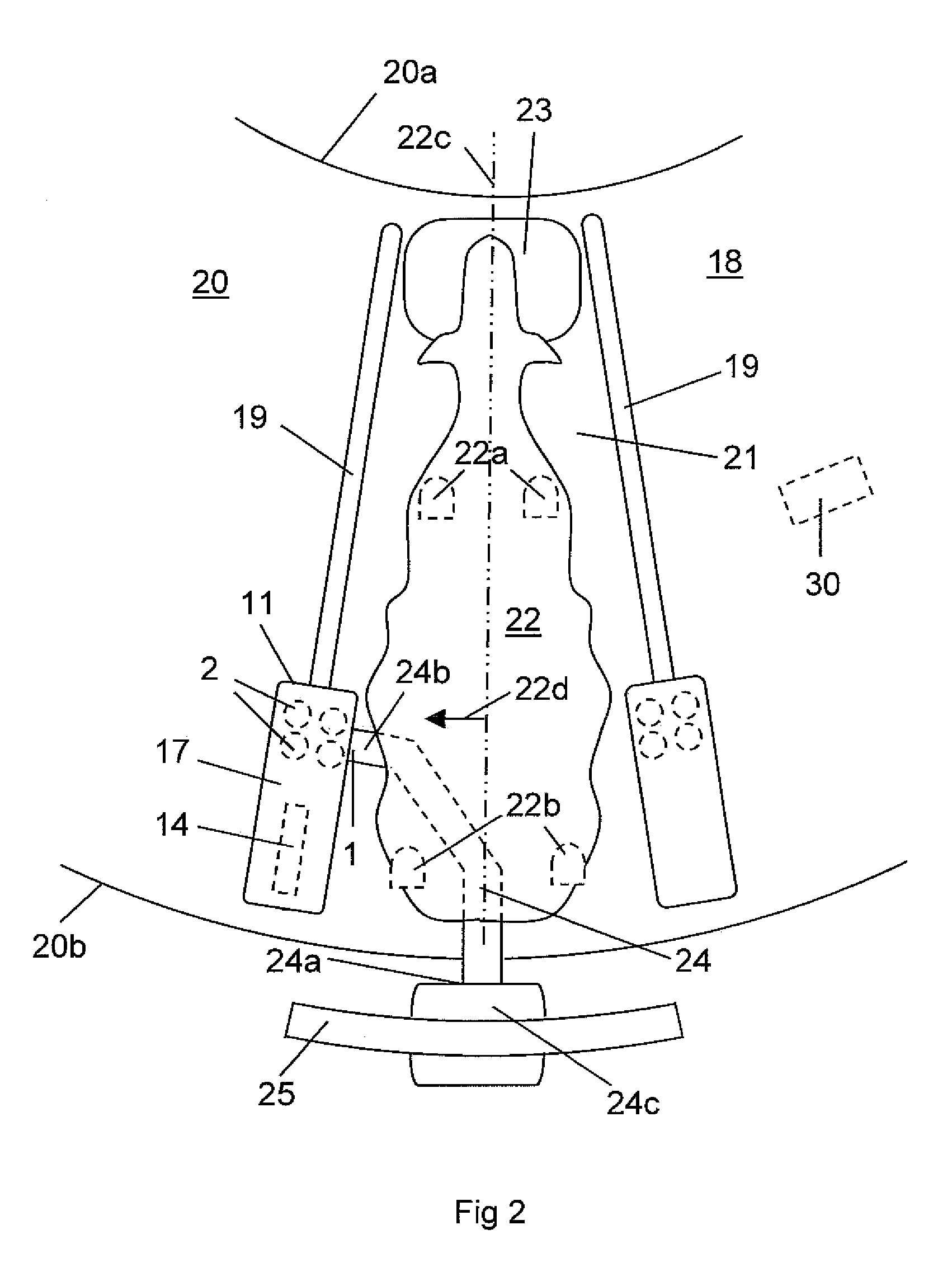

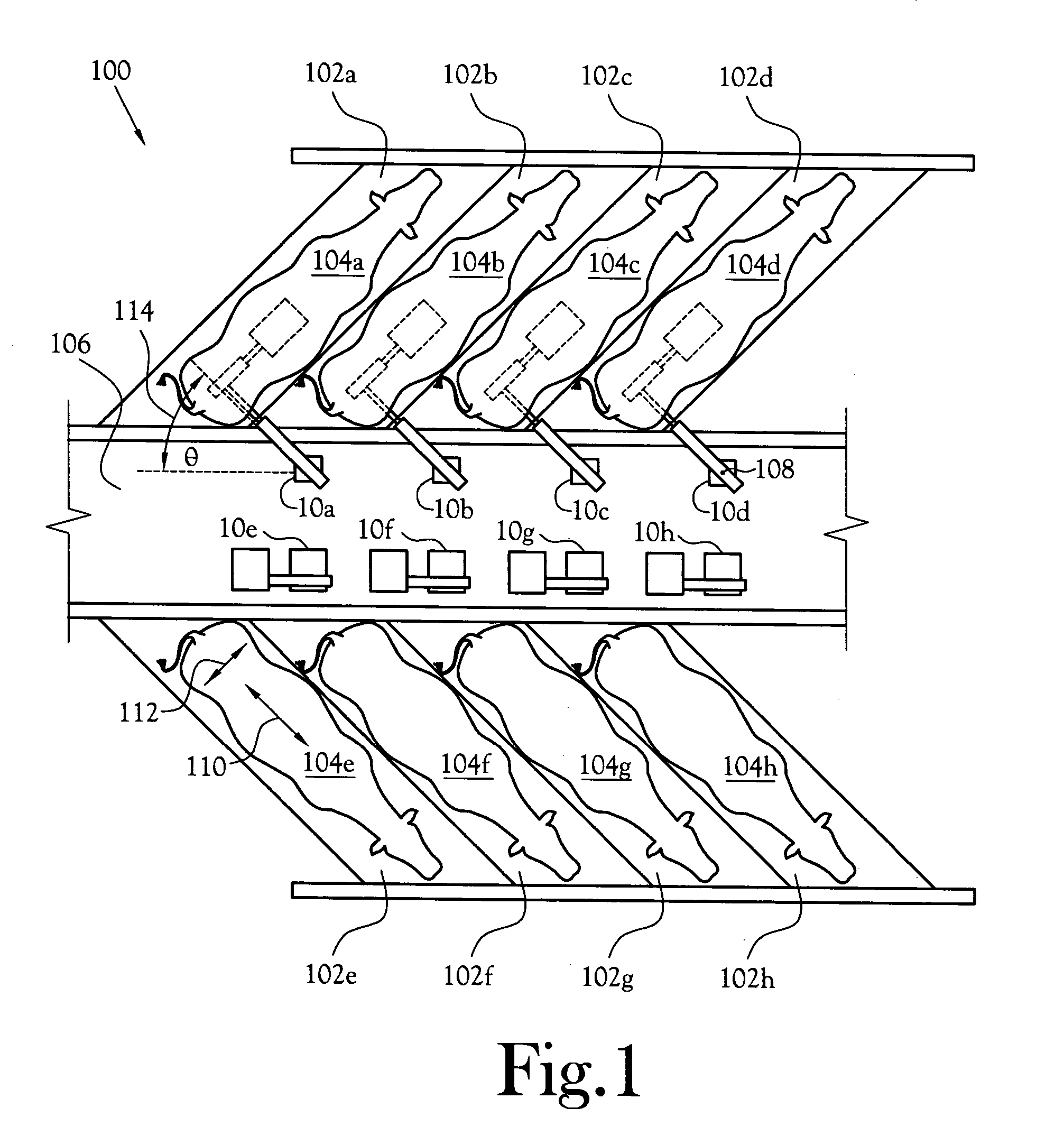

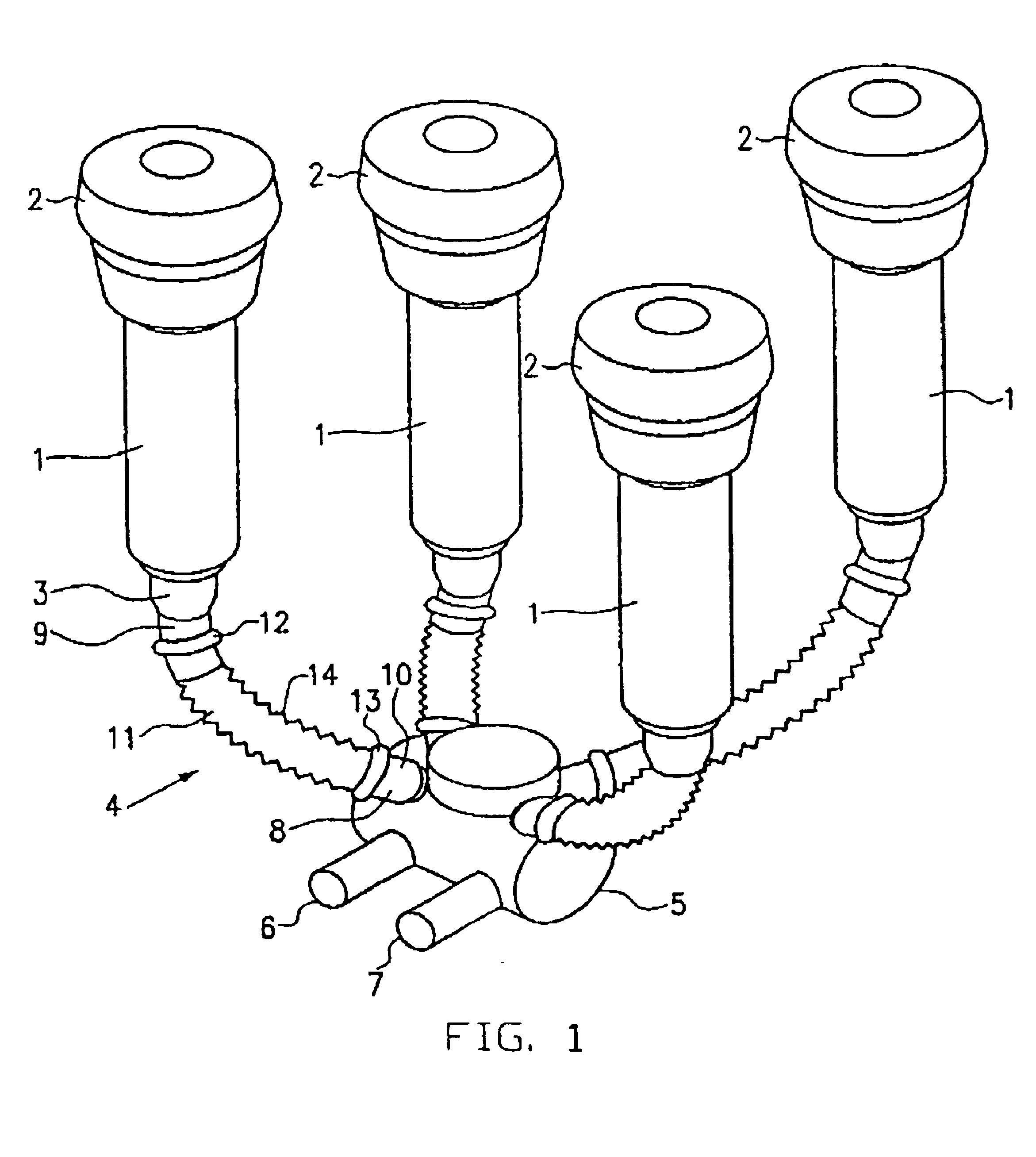

Rotary parlour for automatic milking of animals and a method for attaching teat cups to milking animals on a rotary platform

ActiveUS20100031889A1Fast attachmentEliminate needCathetersAnimal housingEngineeringAutomatic milking

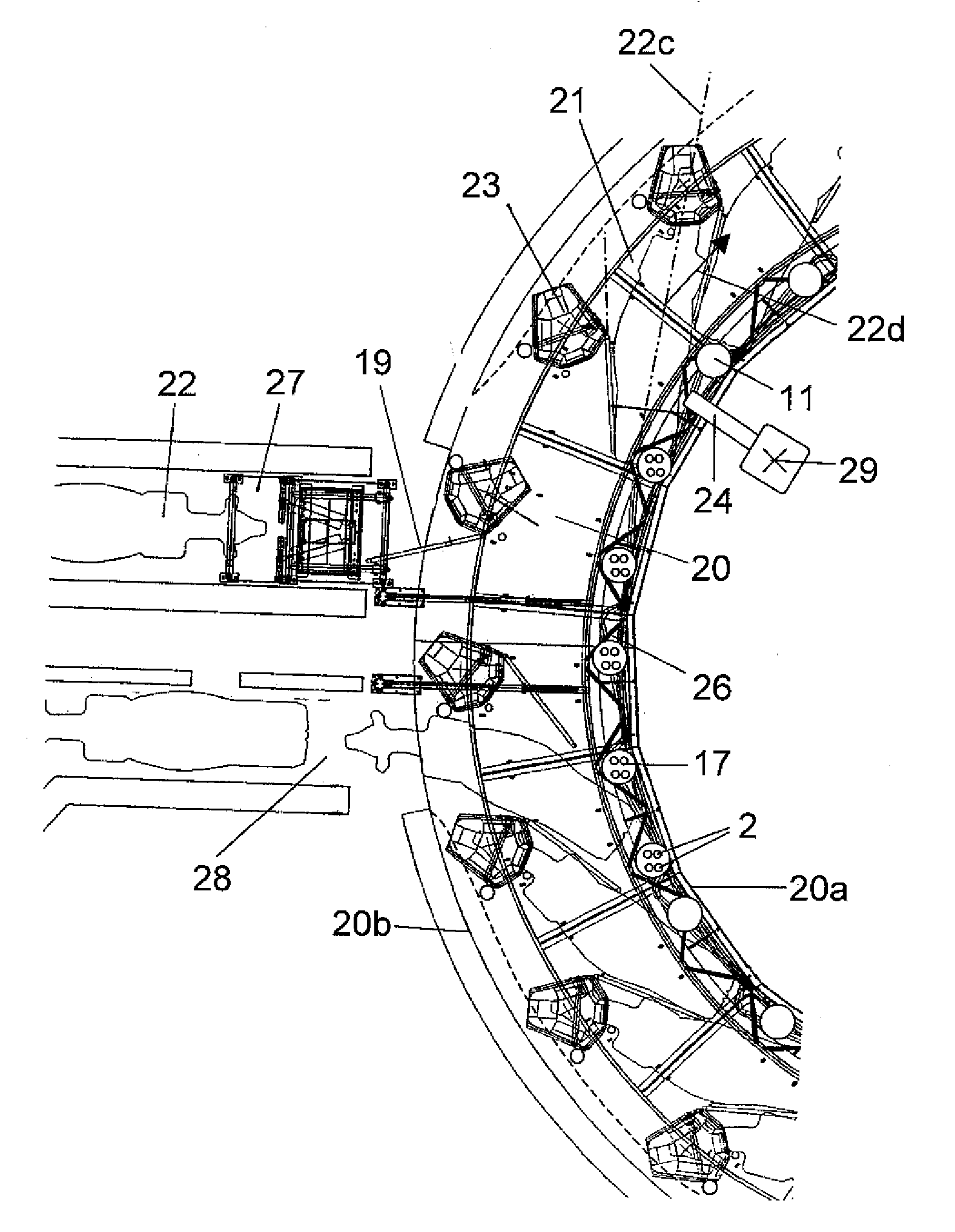

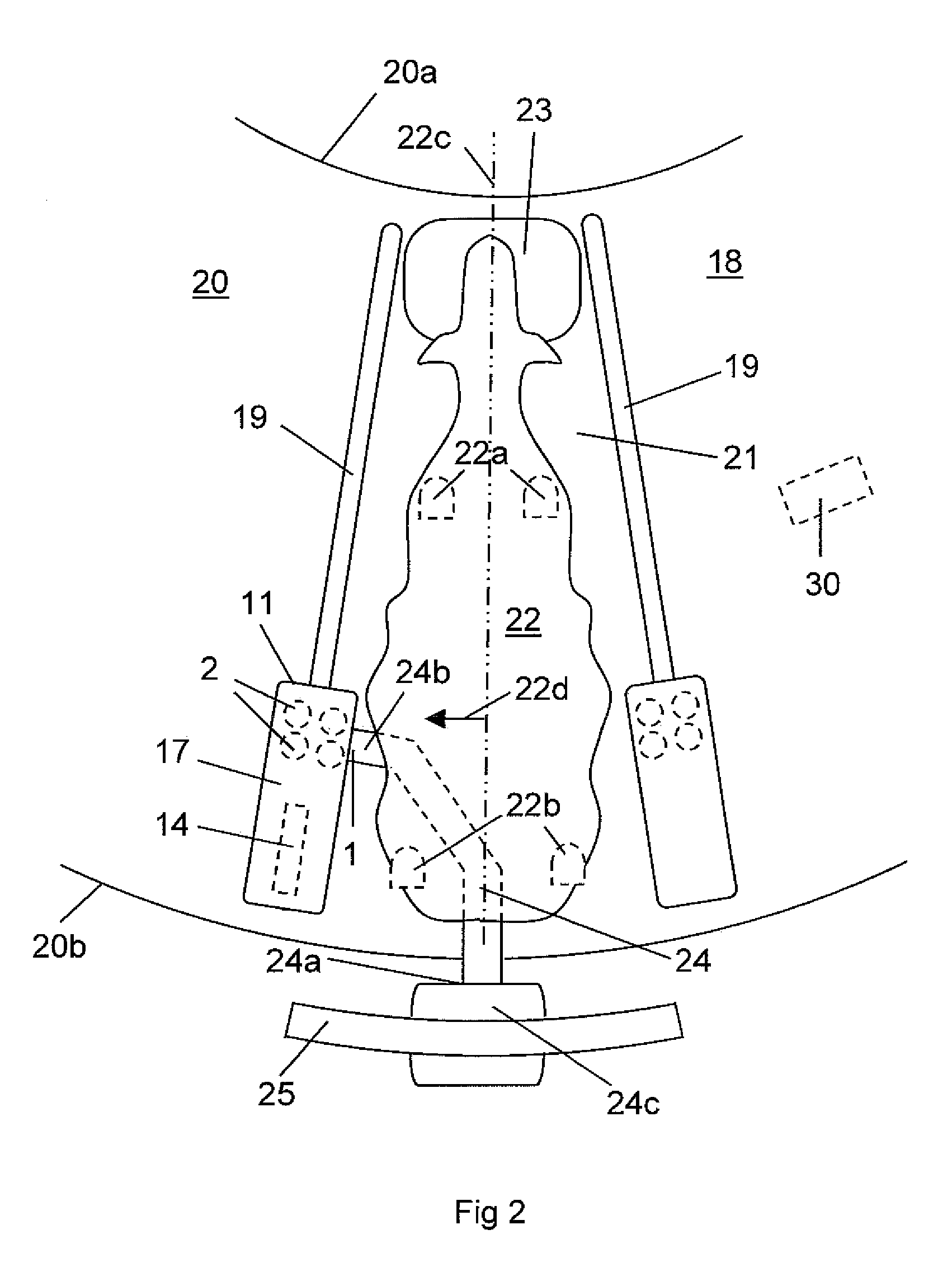

A rotary parlour for milking of animals includes an annular rotary platform (20) adapted to form a support surface (18) for the animals (22), positioning elements (19, 23) for arranging the animals (1) in milking positions on the platform (20), a drive mechanism (30) adapted to supply a rotational motion to the platform (20), and teat cup storing devices (11) for holding parked teat cups (2, 2′) in predetermined storing positions. The teat cup storing devices (11) are mounted in positions such that the teat cups (2, 2′) are located vertically above the platform (20) in their storing positions.

Owner:DELAVAL HLDG AB

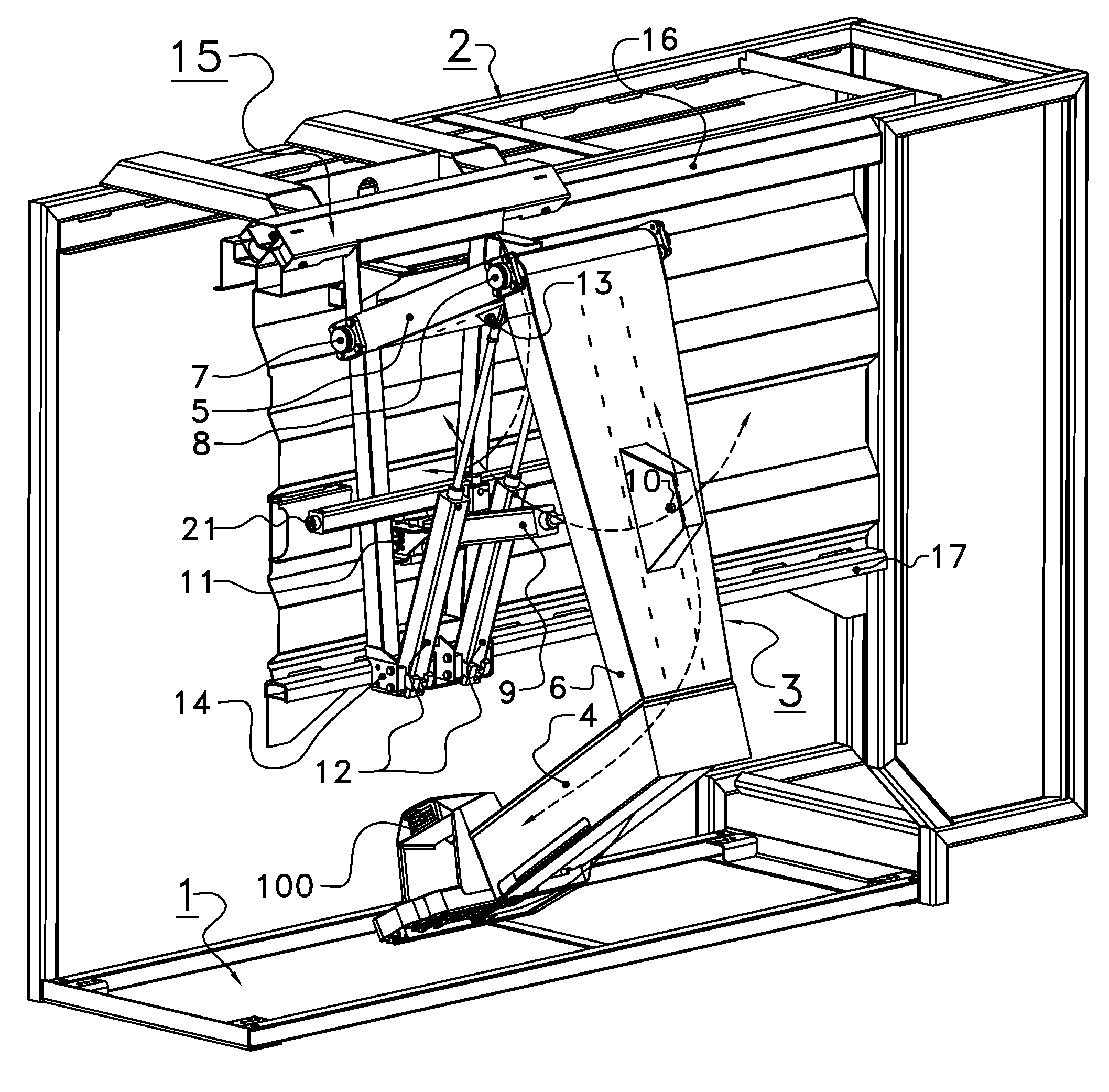

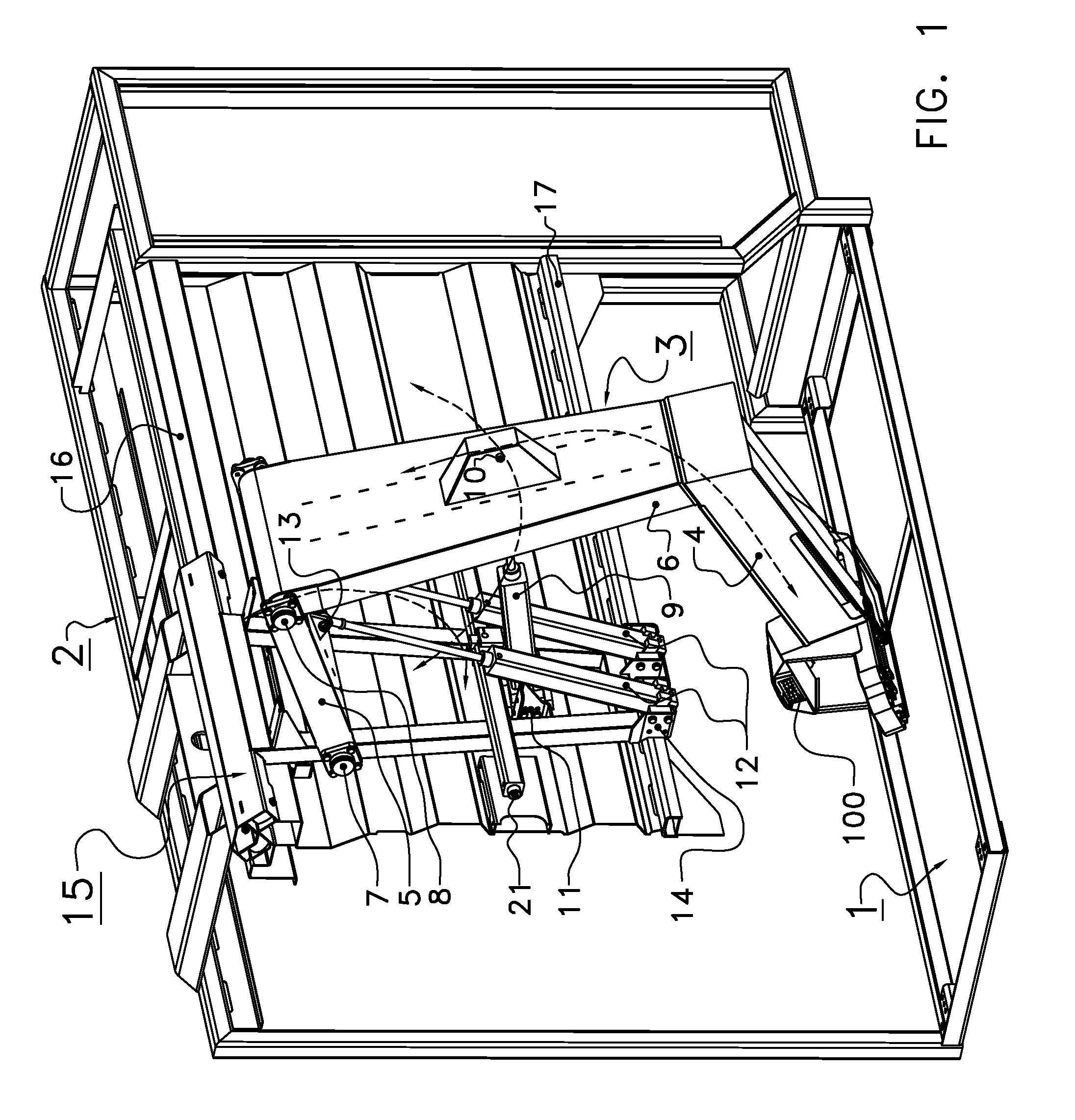

Implement for automatically milking a dairy animal

ActiveUS20100186675A1High resolutionMaximum of constructive simplicityCathetersRobotPhase differenceMilk cow's

An implement for automatically milking a dairy animal, such as a cow, comprises a milking parlour, a sensor for observing a teat, and a milking robot for automatically attaching a teat cup to the teat. The milking robot comprises a robot control that is connected to the sensor. The sensor comprises a radiation source for emitting light, a receiver for receiving electromagnetic radiation reflected from the dairy animal, a lens, and sensor control unit. The sensor comprises a matrix with a plurality of rows and a plurality of columns of receivers. The sensor control unit is designed to determine for each of the receivers a phase difference between the emitted and the reflected electromagnetic radiation in order to calculate the distance from the sensor to a plurality of points on the part to be observed of the dairy animal.

Owner:MAASLAND

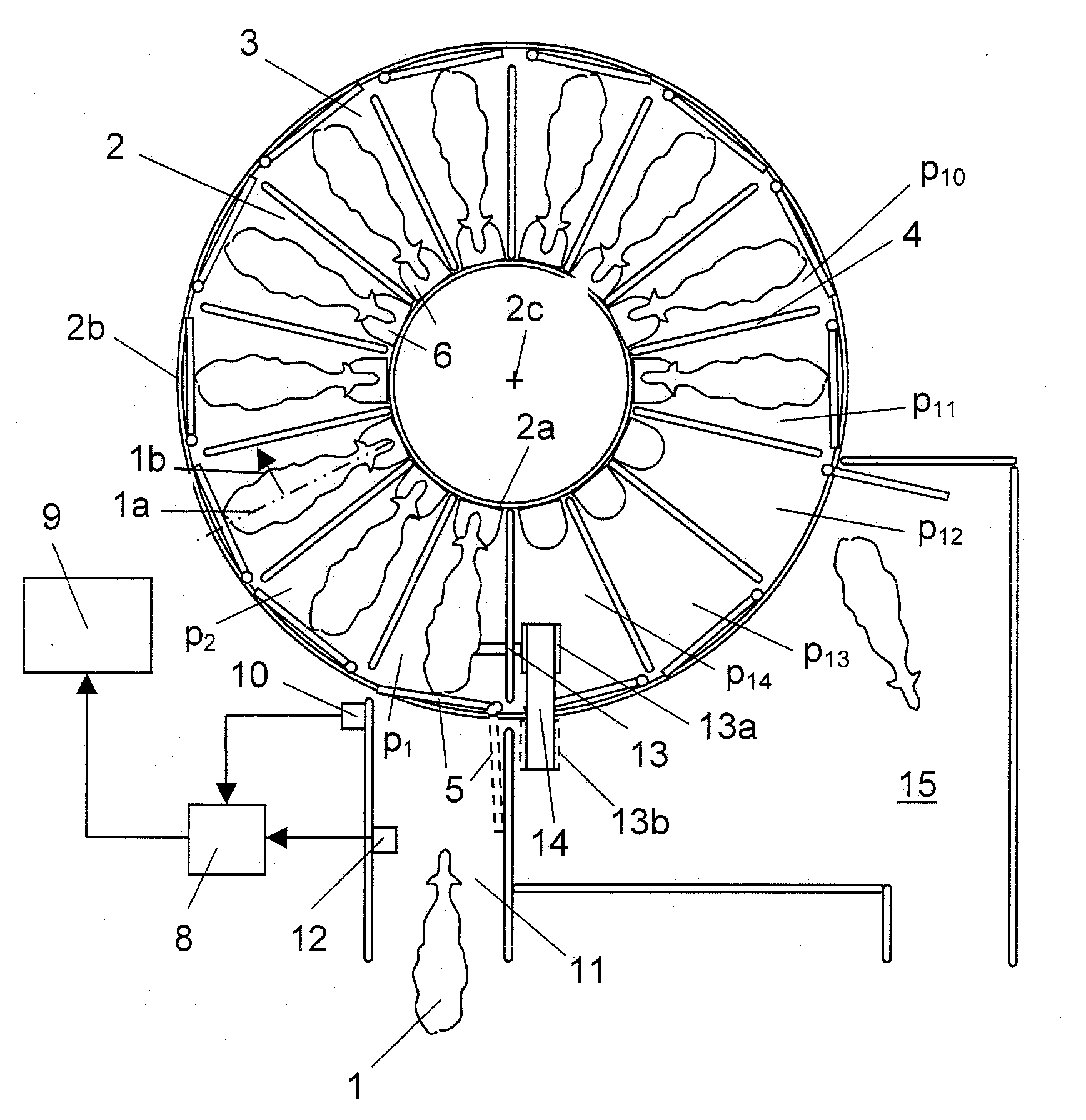

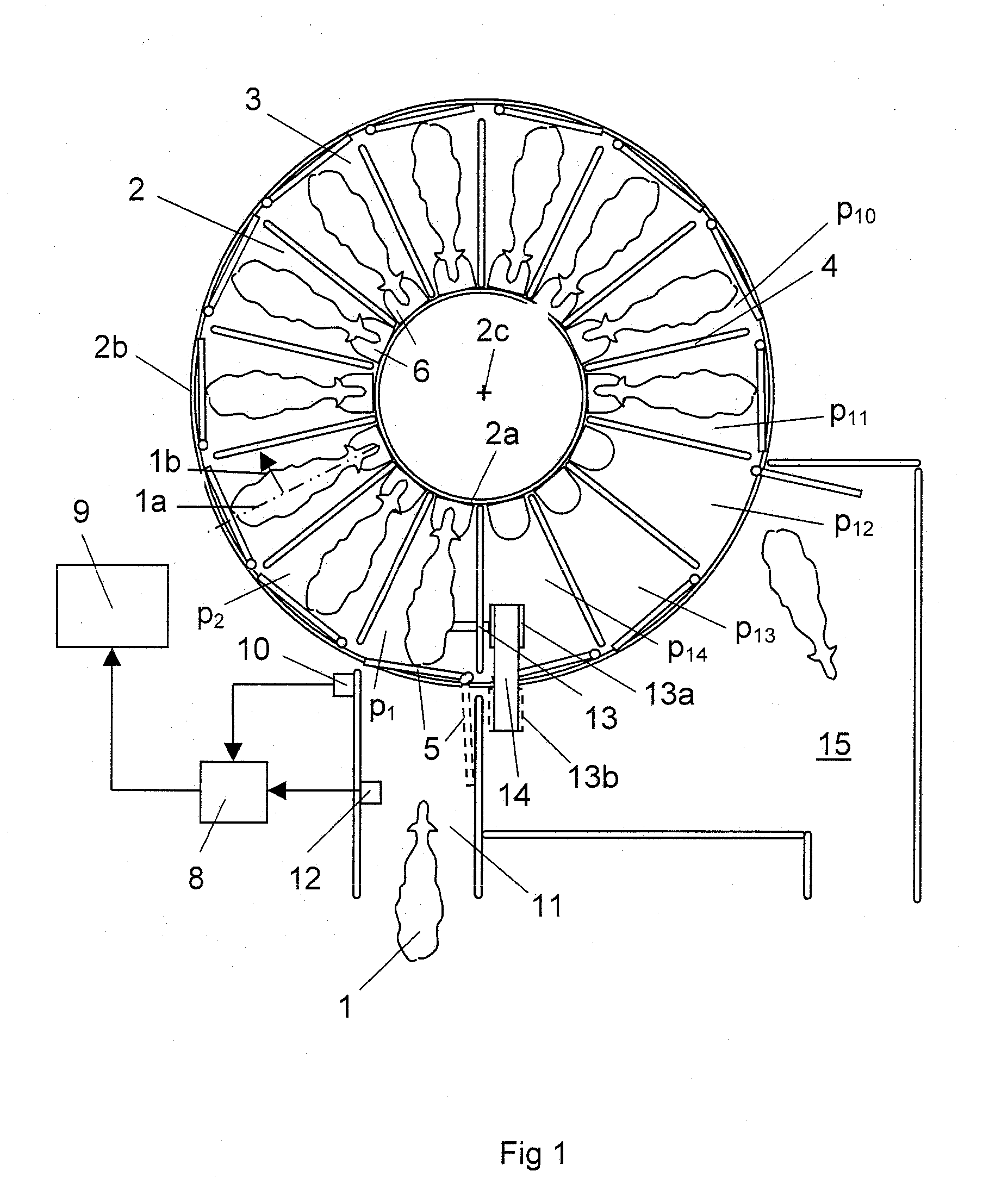

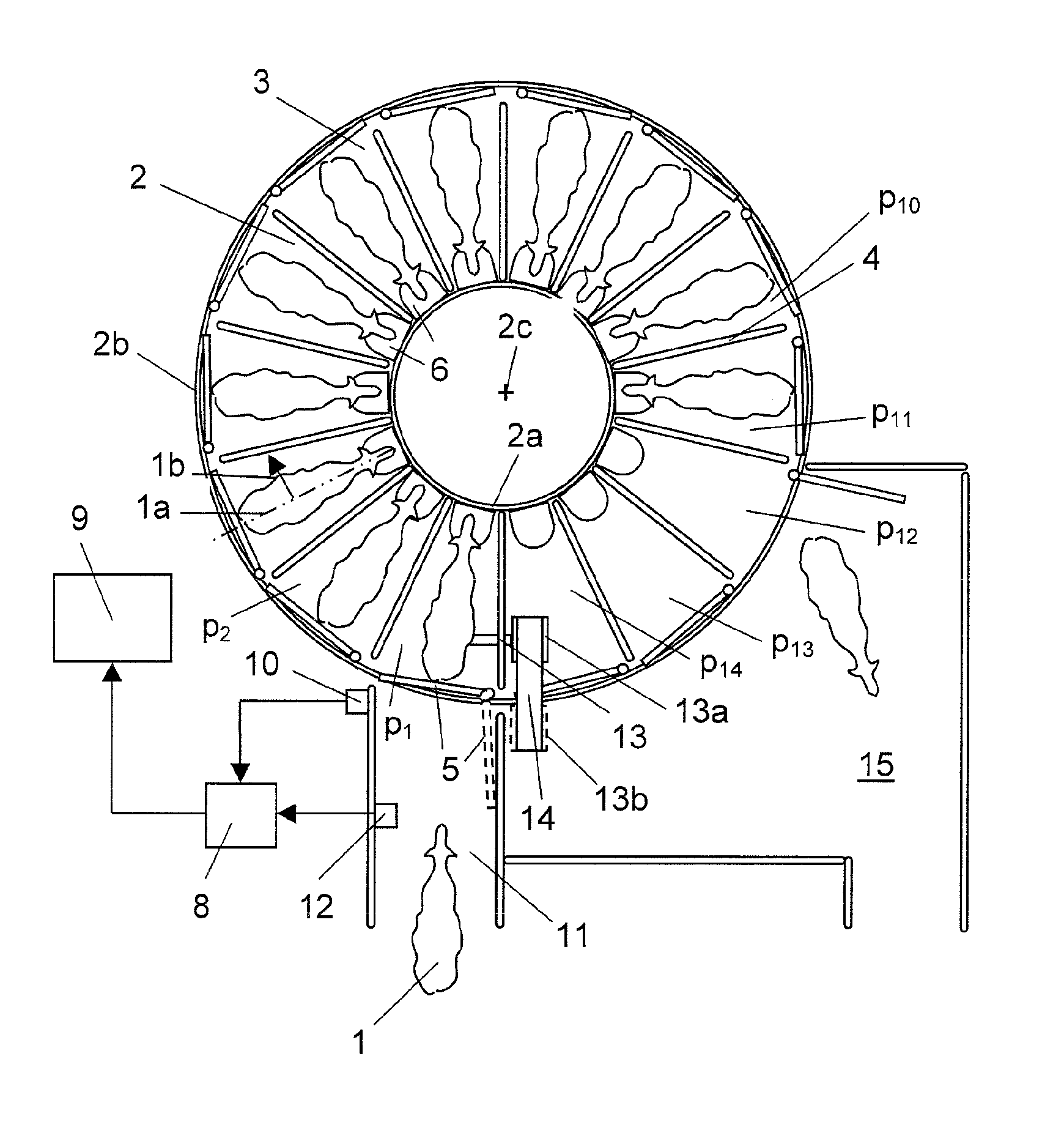

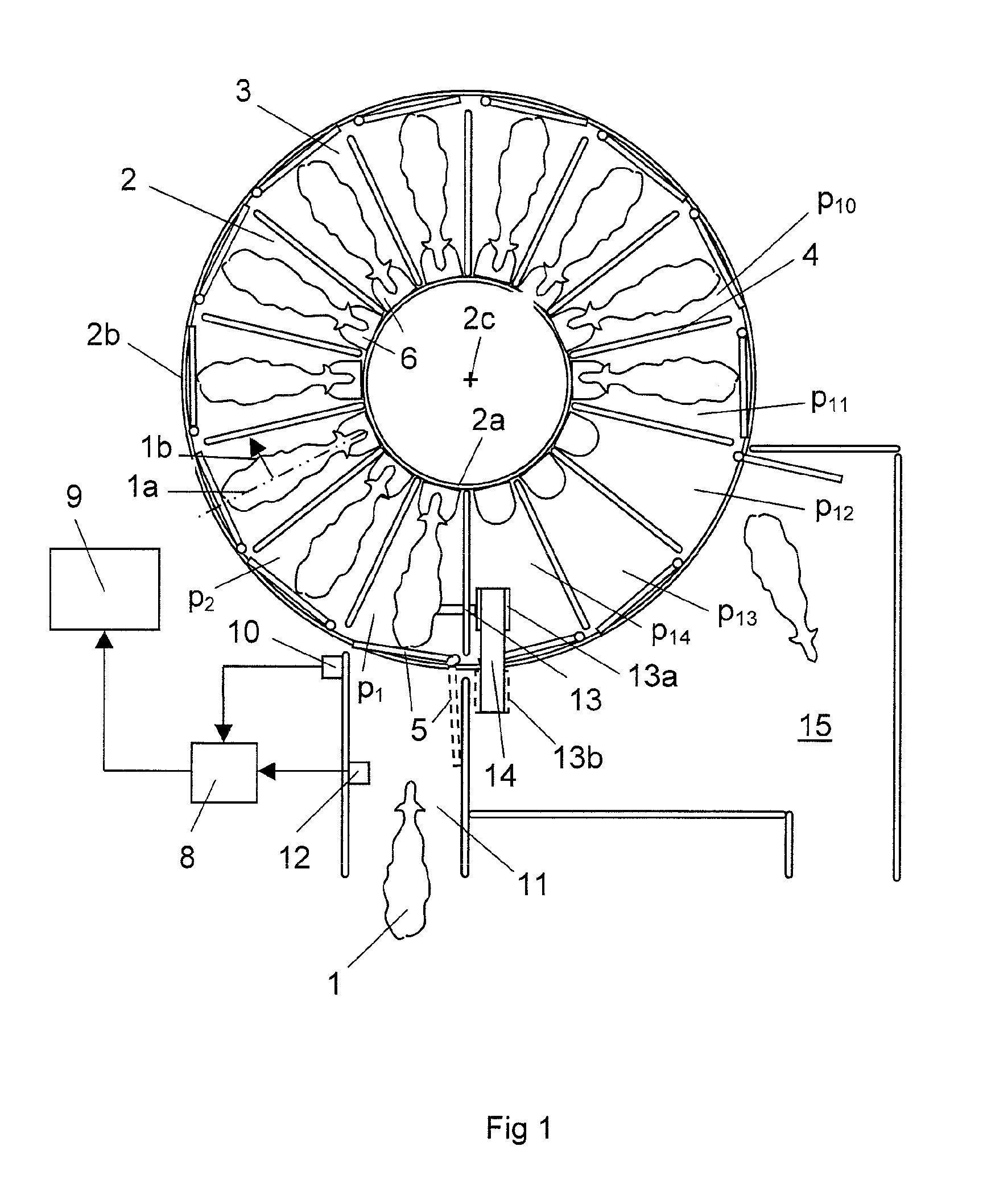

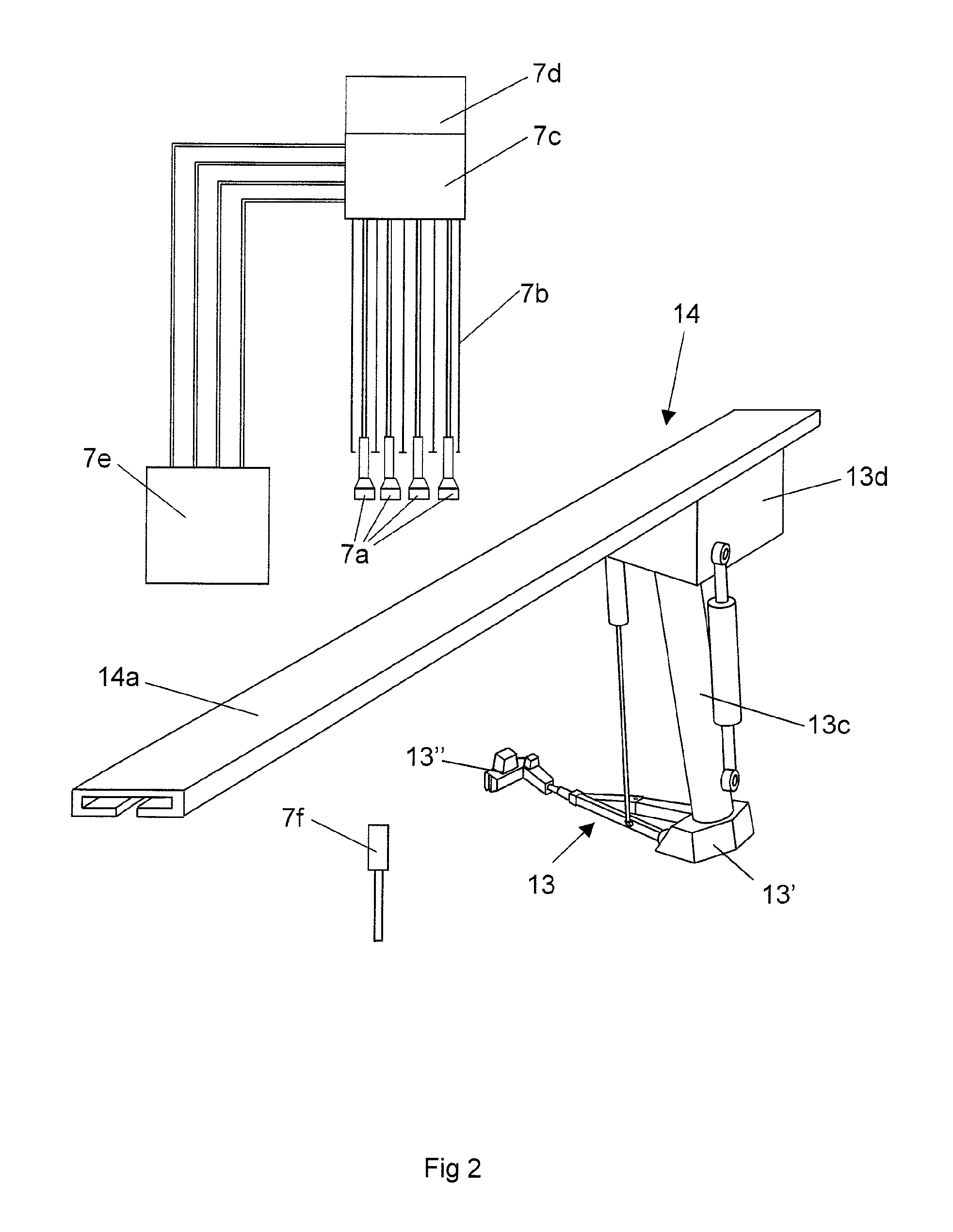

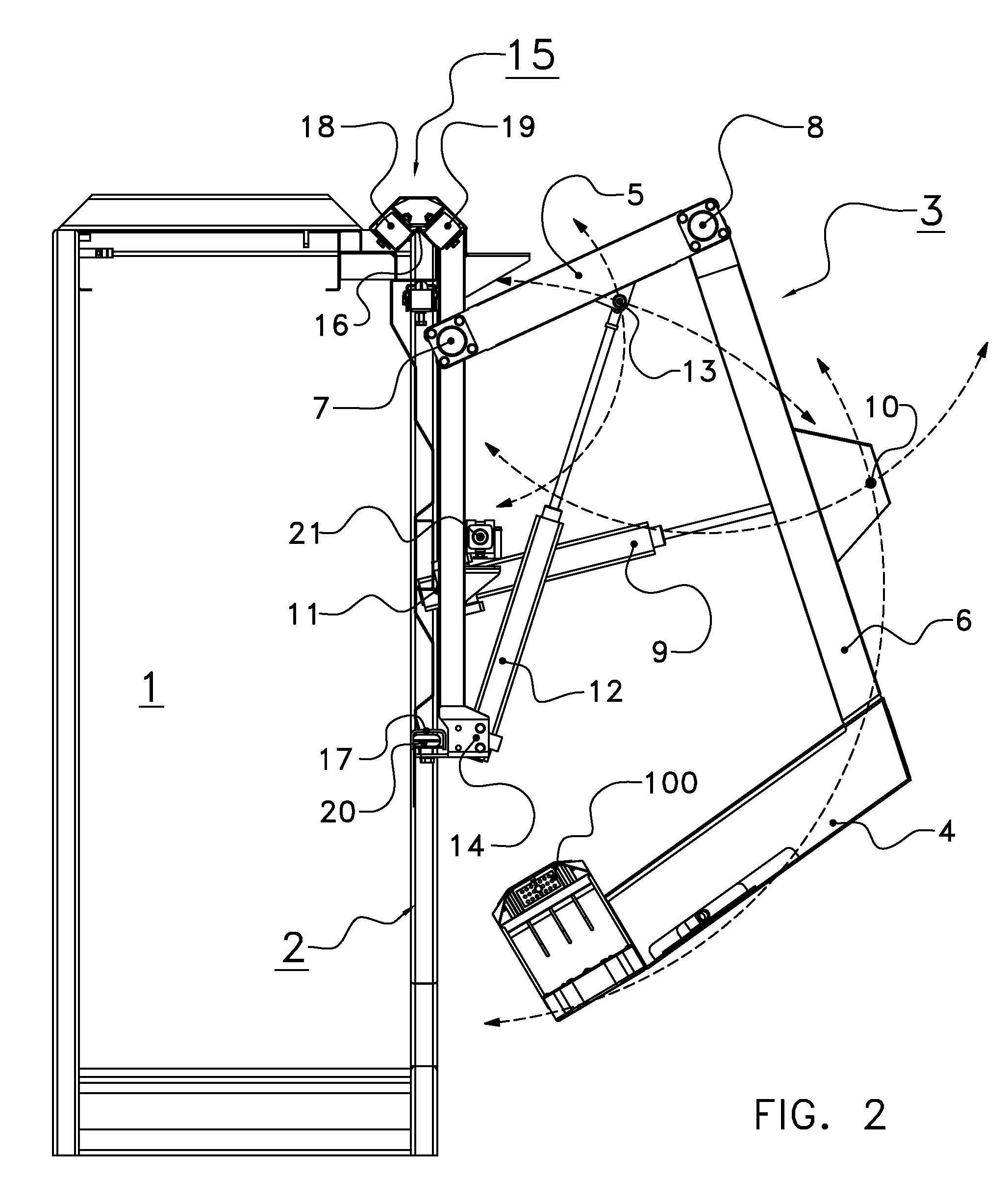

Rotary parlour for automatic milking of animals

A rotary parlour for automatic milking of animals includes an annular rotary platform (2) adapted to form a support surface for the animals (1), driving element (9) for supplying a rotary motion to the platform (2), positioning element for arranging the animals in predetermined milking positions (3) on the platform, in which an longitudinal axis (1a) of the animals forms an angle to the direction of motion (1b) of the animals standing on the rotary platform (2), and a robot arm (13) adapted to attach teat cups (7a) to the teats of an animal (1) which has entered a milking position (3) on the platform (2). The entire robot arm (13) is located in a working position vertically above or on the platform (2) when it attaches the teat cups to the teats of the animals (1).

Owner:DELAVAL HLDG AB

Rotary parlour for automatic milking of animals

Owner:DELAVAL HLDG AB

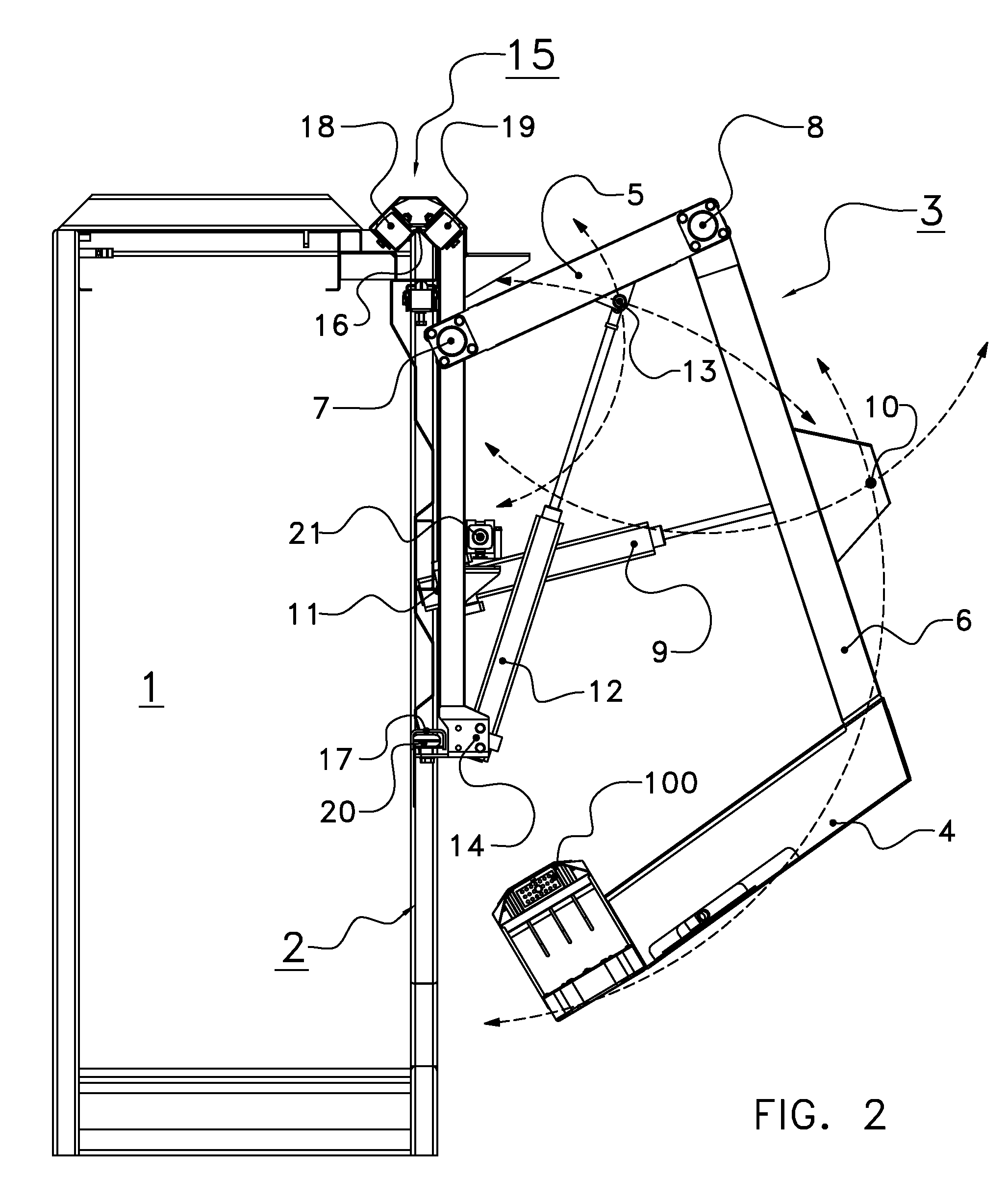

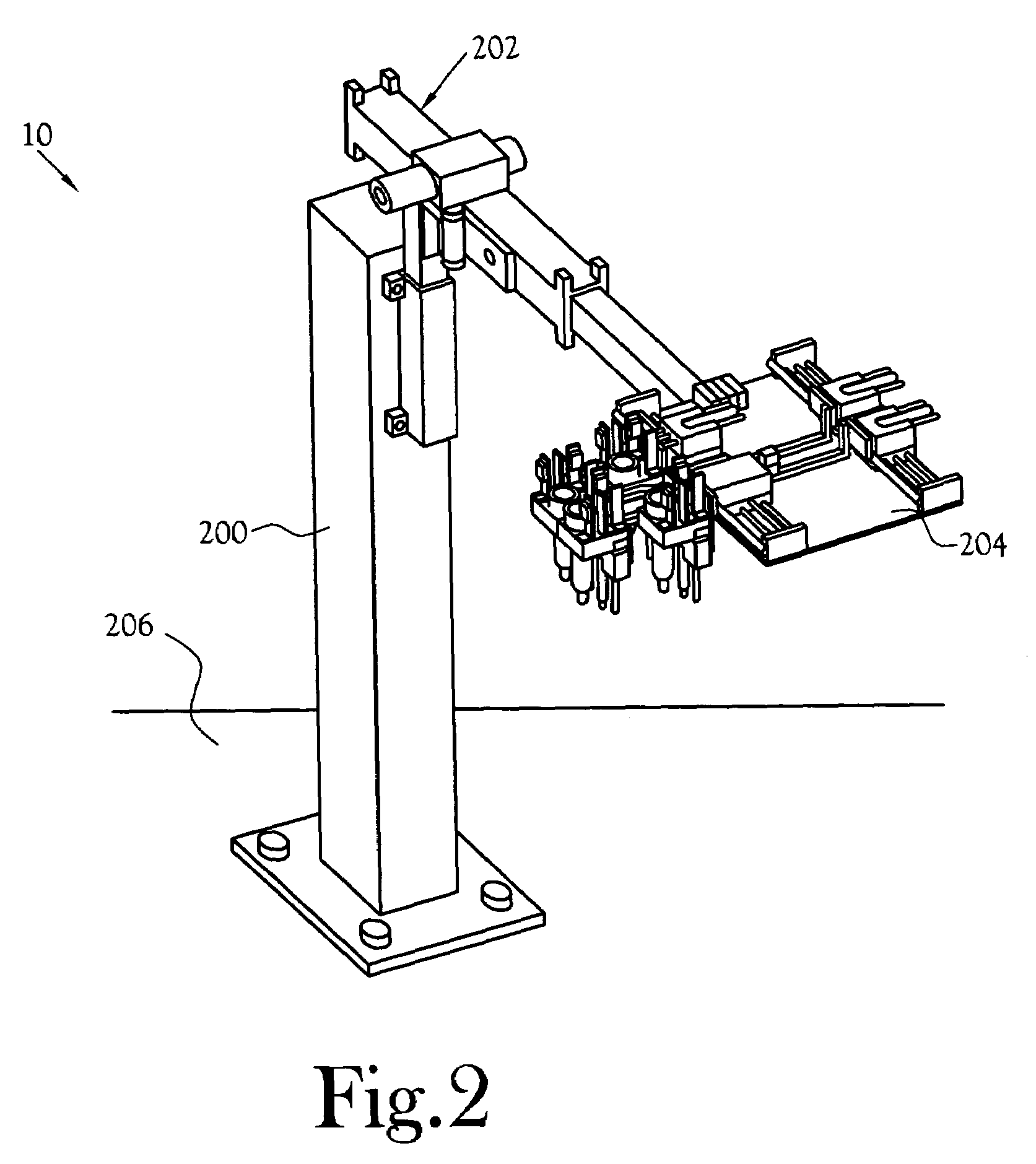

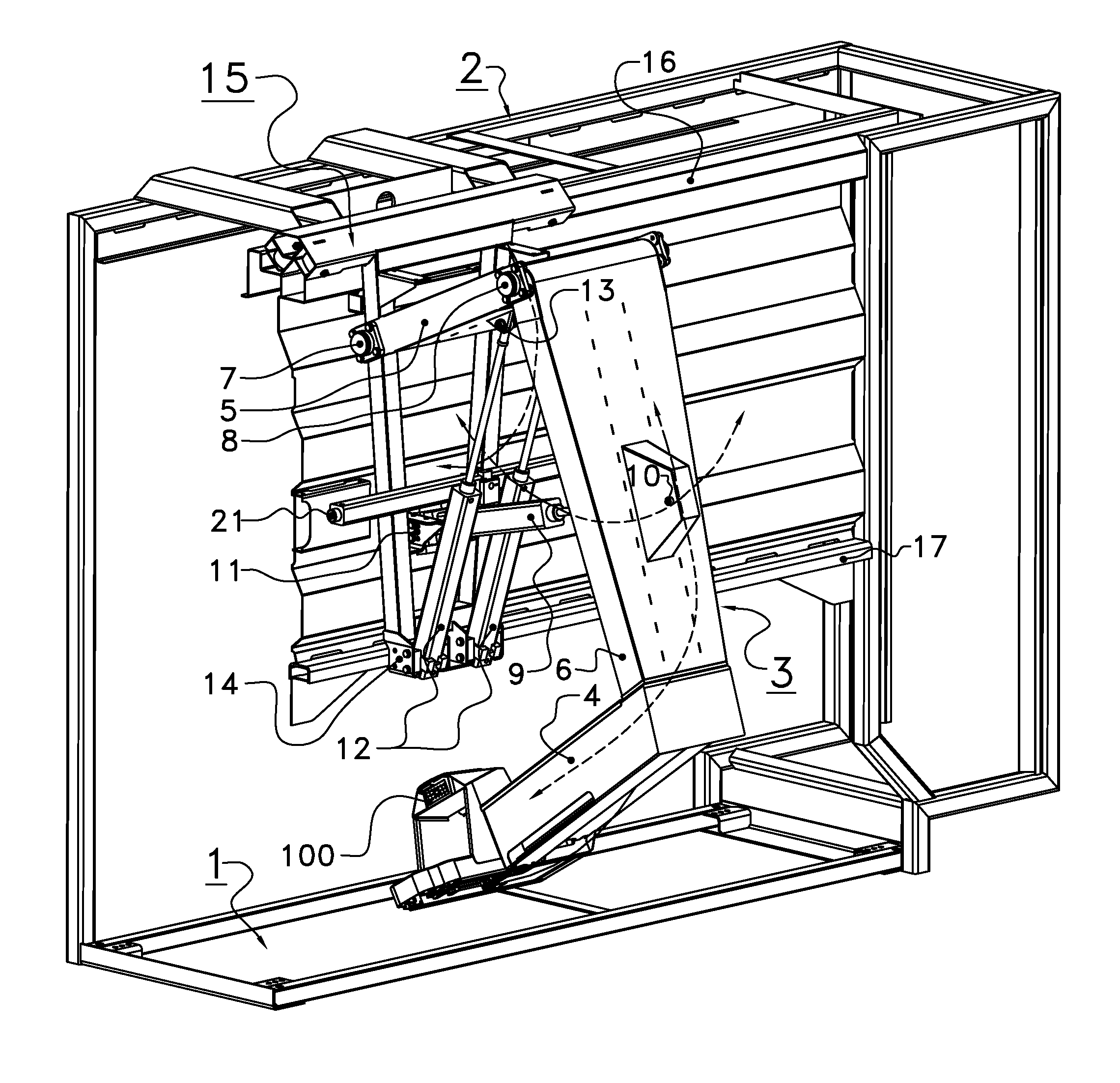

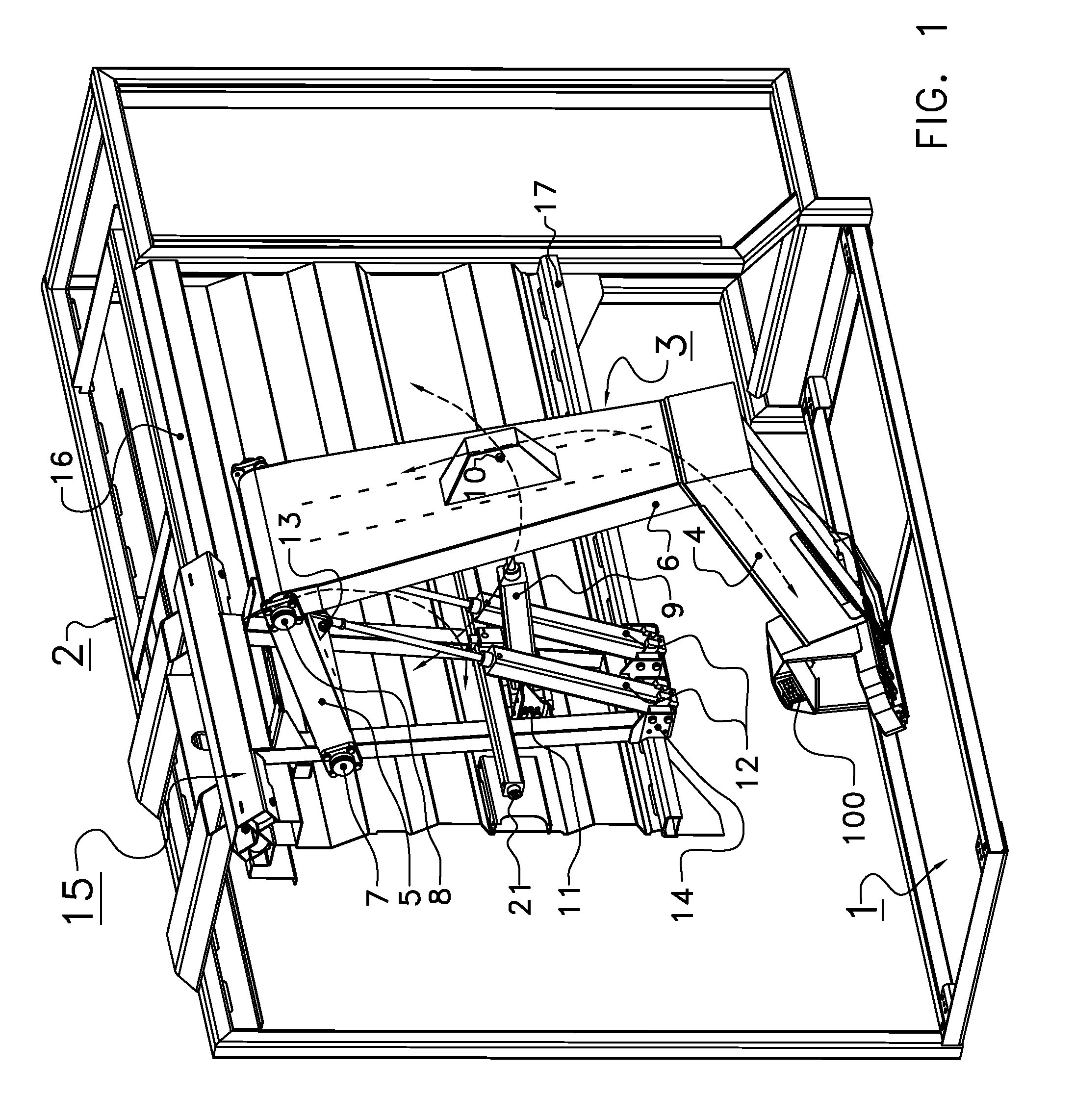

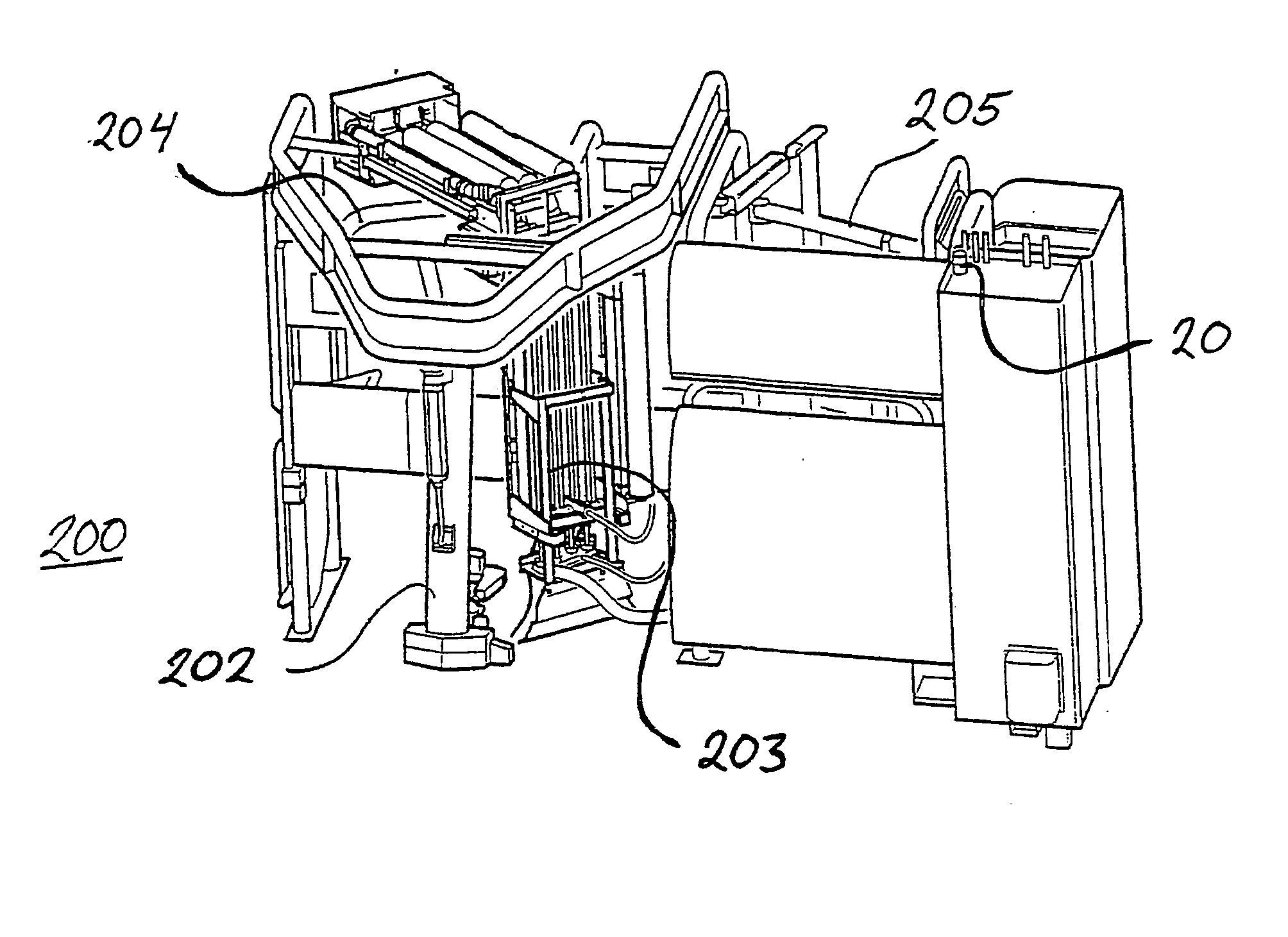

Live capture automated milking apparatus and method

A method and apparatus for the automated milking of dairy cattle employing live capture of the teats of a dairy cow without requiring identification of a particular dairy cow or the prior knowledge of the location of the individual teats. The live capture milking apparatus locates the individual teats of a dairy cow and attaches a teatcup to the teat without the need for human intervention. After the milking operation is completed, the live capture milking apparatus returns to a home position where cleaning and sanitization the milking equipment occurs.

Owner:INNOVATIVE AUTOMATION

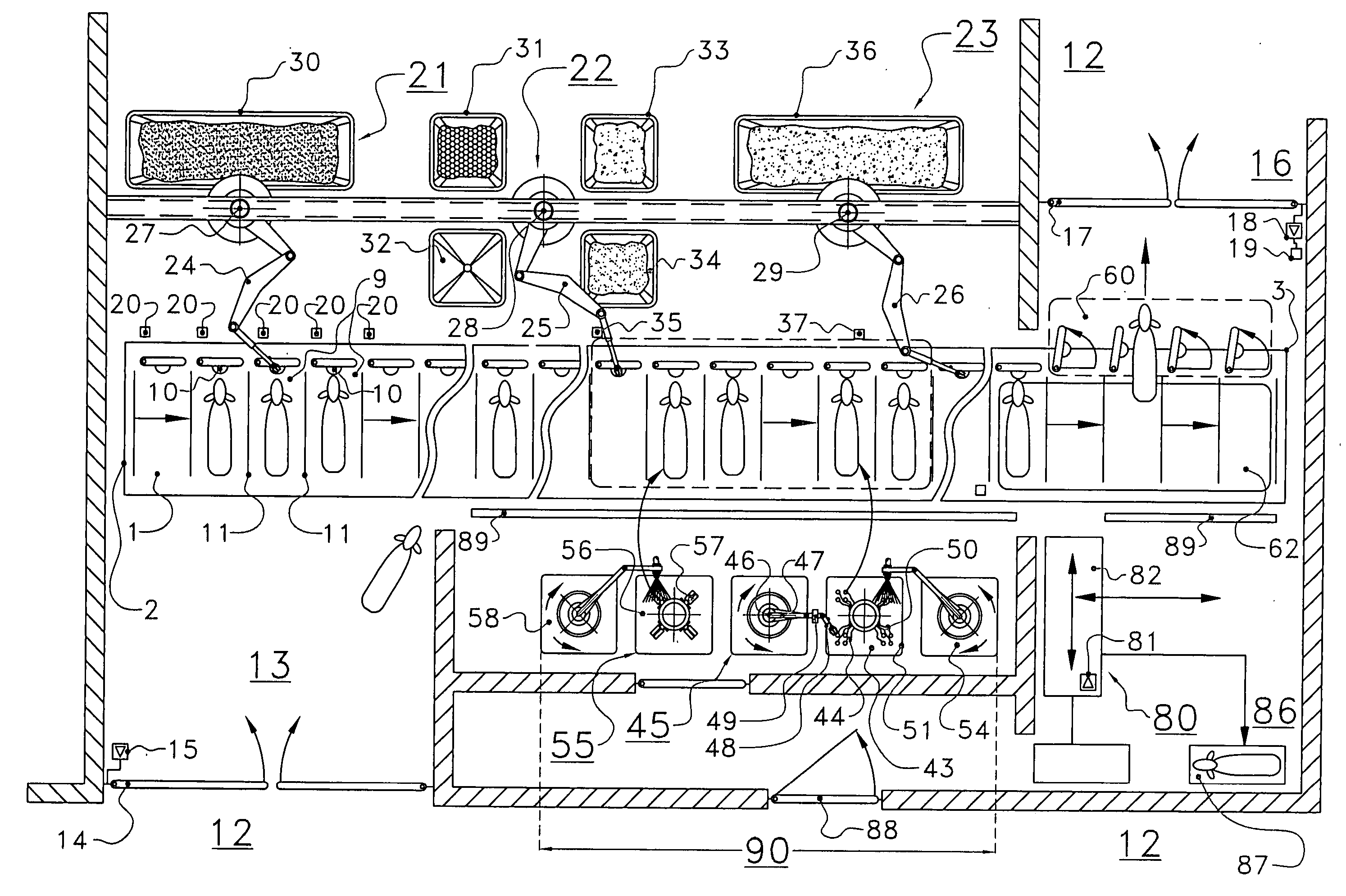

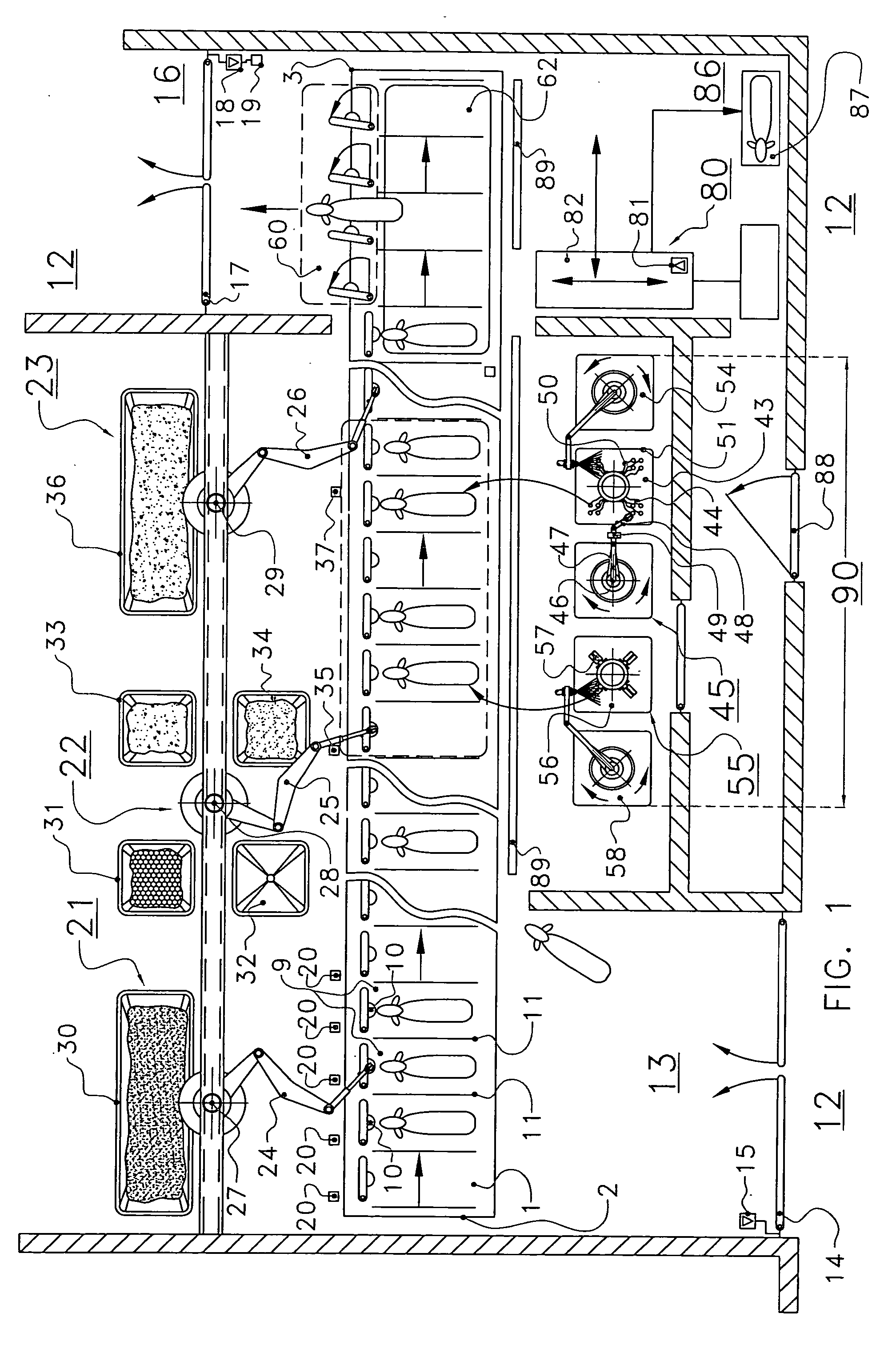

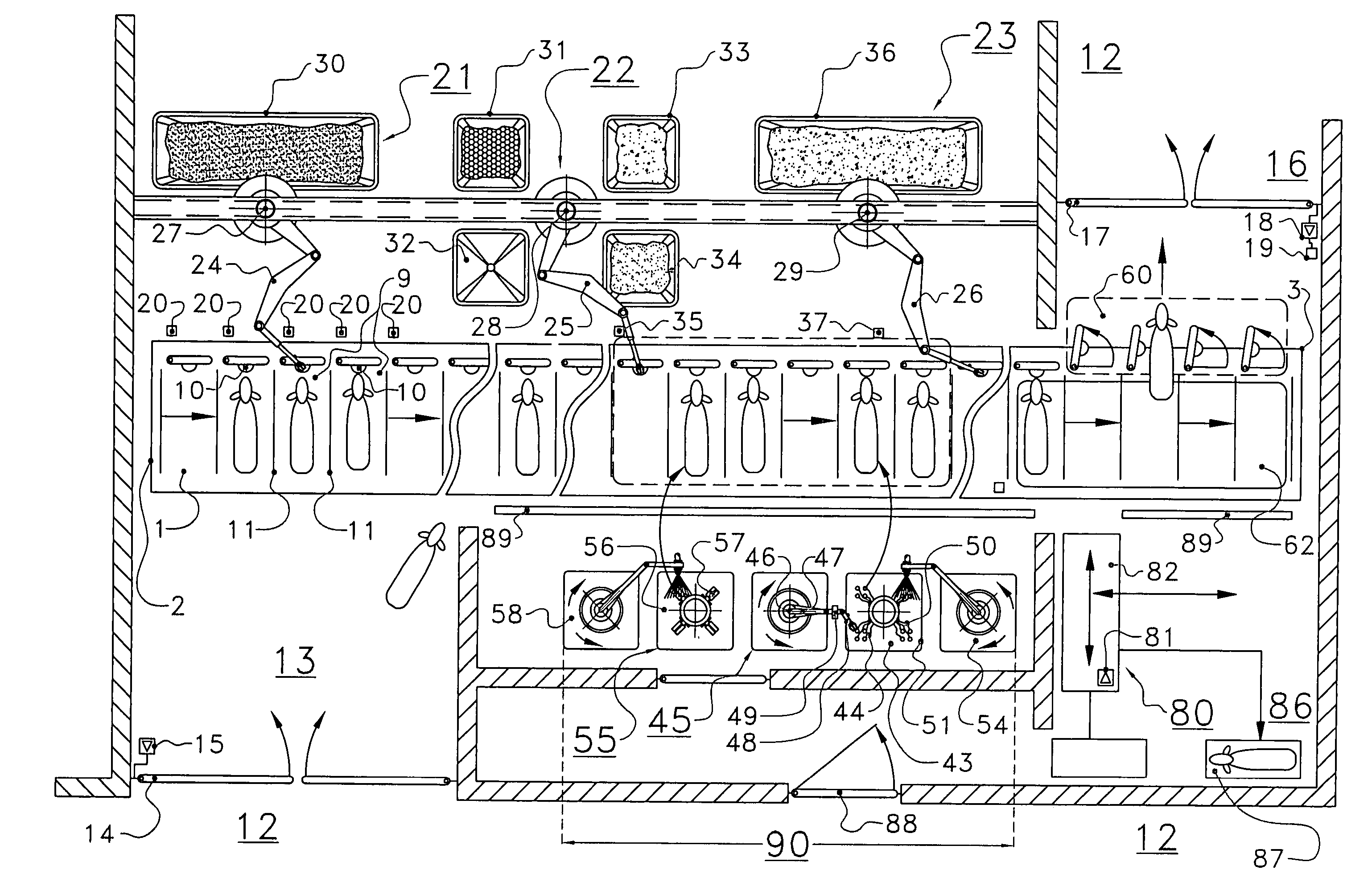

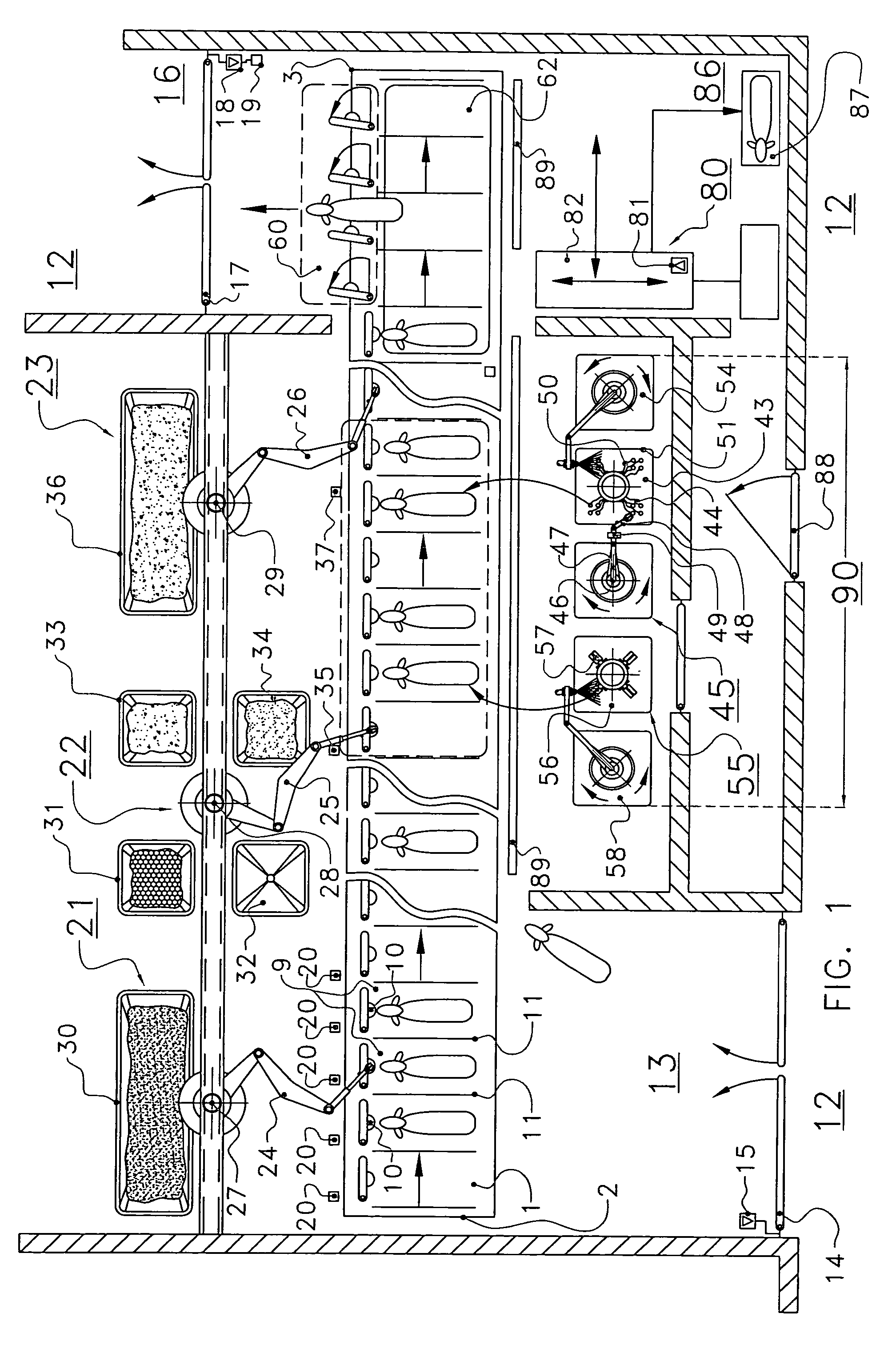

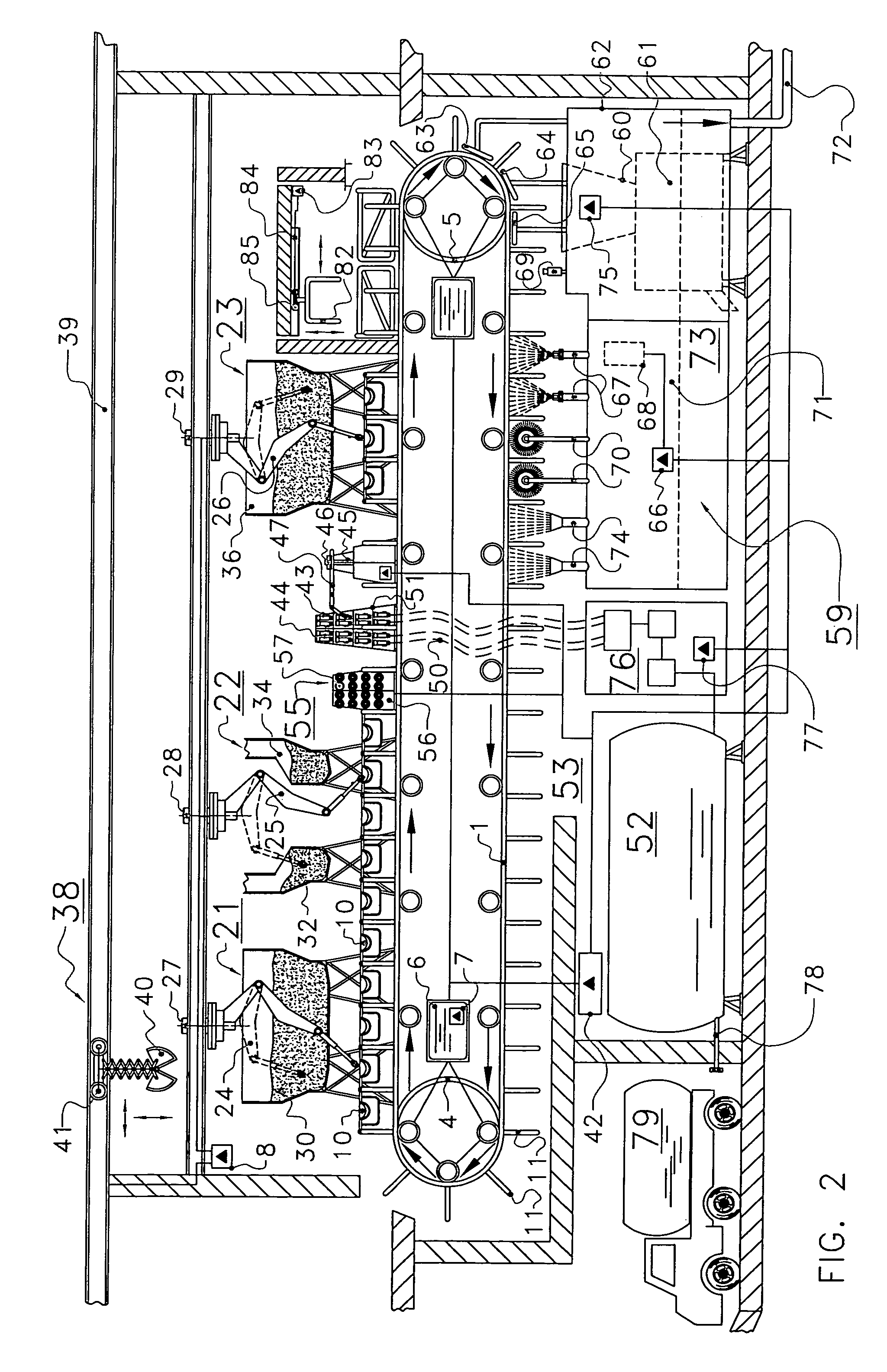

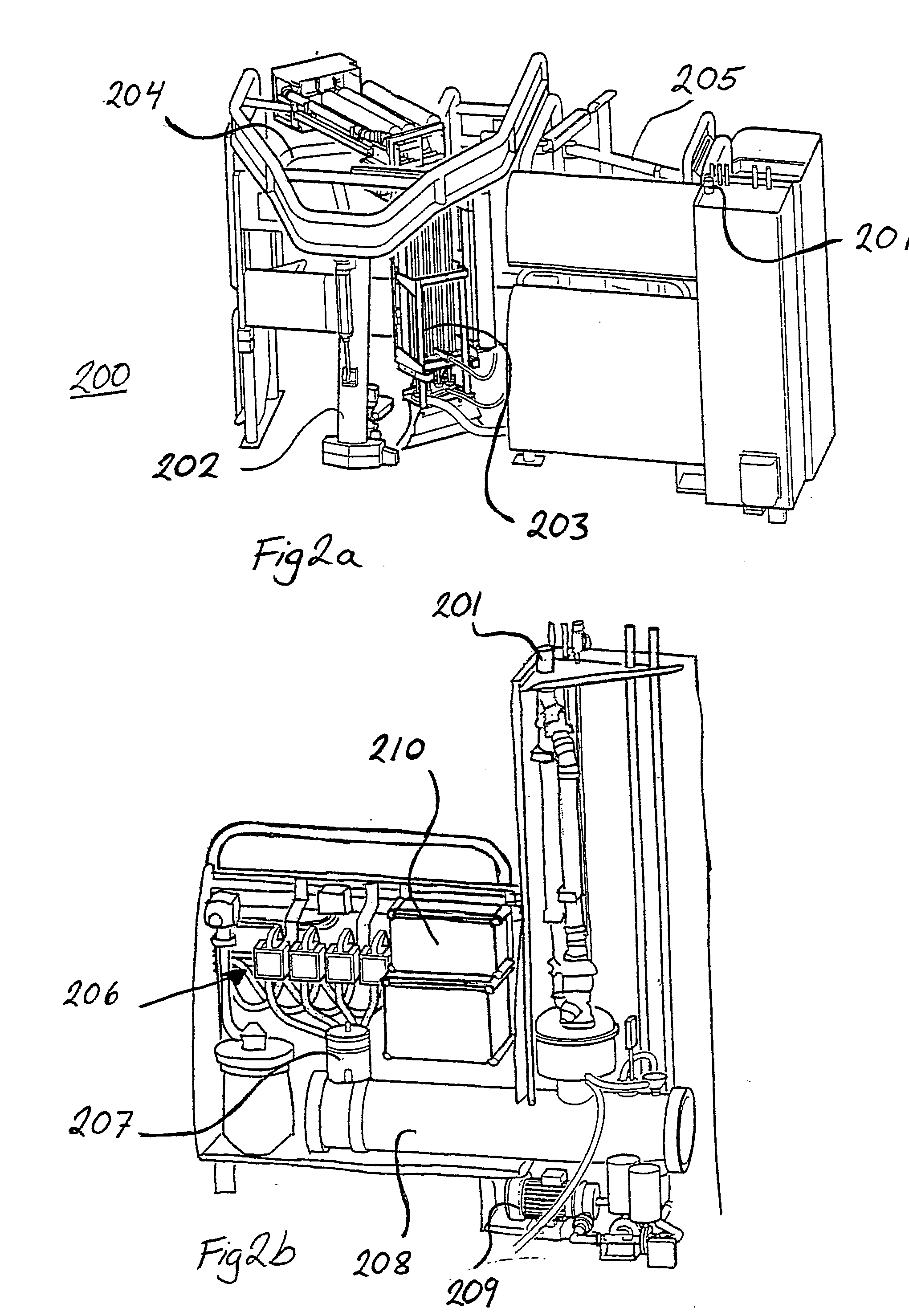

Assembly for and a method of feeding and milking animals, a feed platform, a milking pre-treatment device, a milking post-treatment device, a cleaning device, a separation device and a milking system all suitable for use in such an assembly

InactiveUS20050076840A1Control freedomIncrease heightCathetersAnimal housingEngineeringAutomatic milking

An assembly for feeding and milking animals is disclosed. The assembly comprises a feeding system with a movable feed platform and a drive unit for driving the feed platform. The feed platform is provided with a number of feeding places. The assembly further comprises a milking system for automatically milking animals on the feed platform, which milking system comprises sets of teat cups. At least a large number of the sets of teat cups is disposed separately from the feed platform.

Owner:LELY ENTERPRISES

Optimization of milking

Owner:DELAVAL HLDG AB

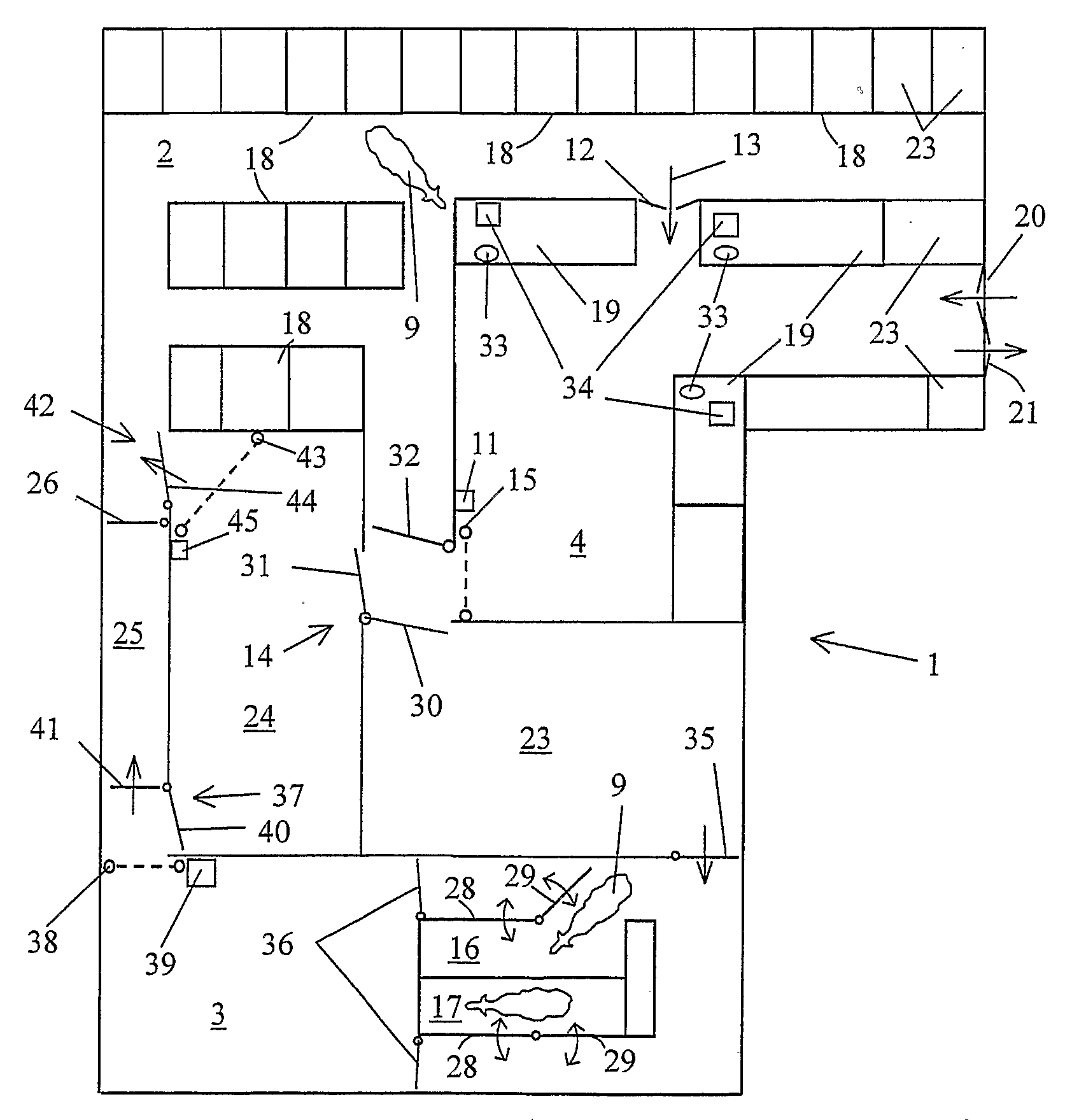

Device and Method for Automatic Milking of Animals

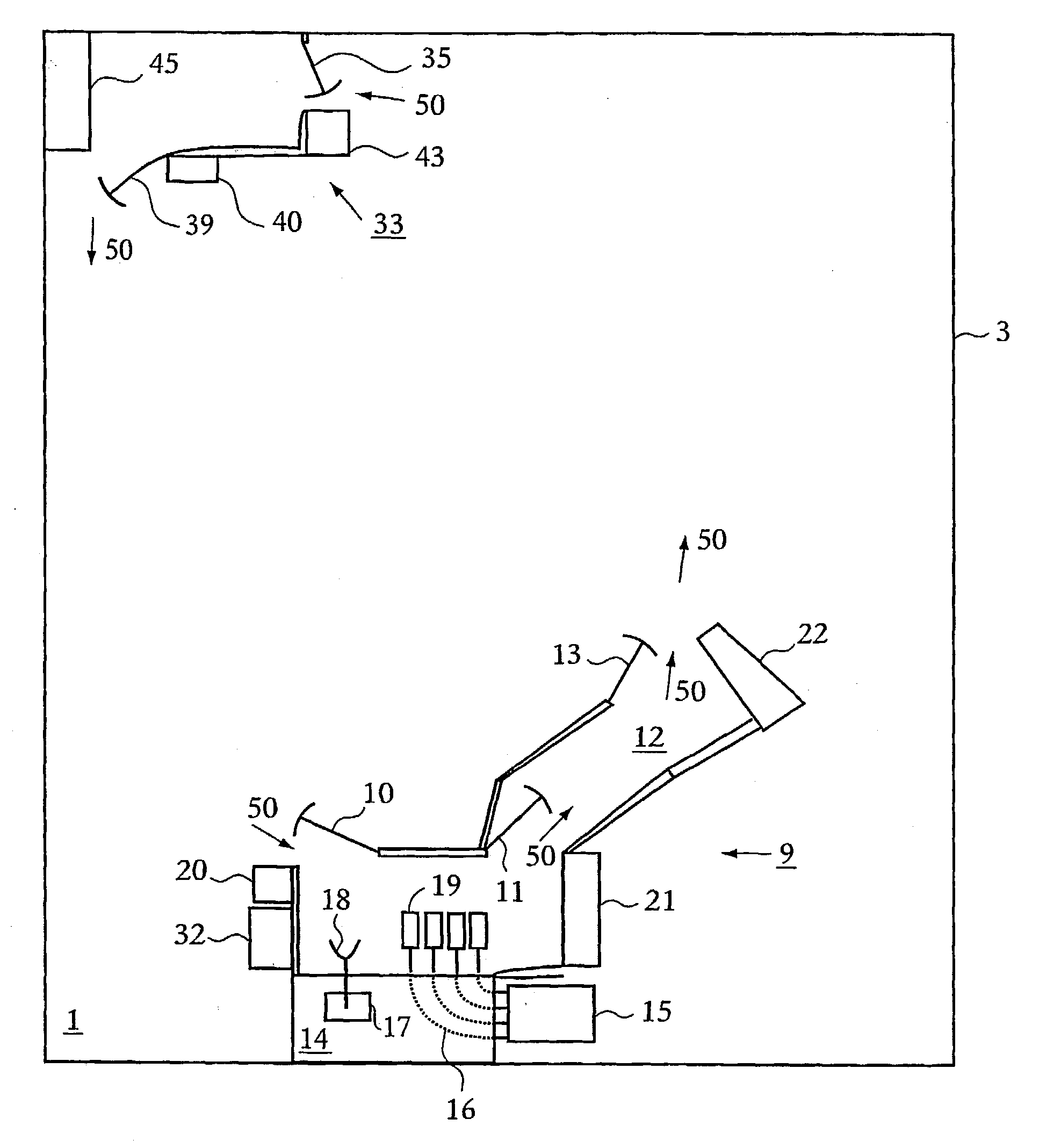

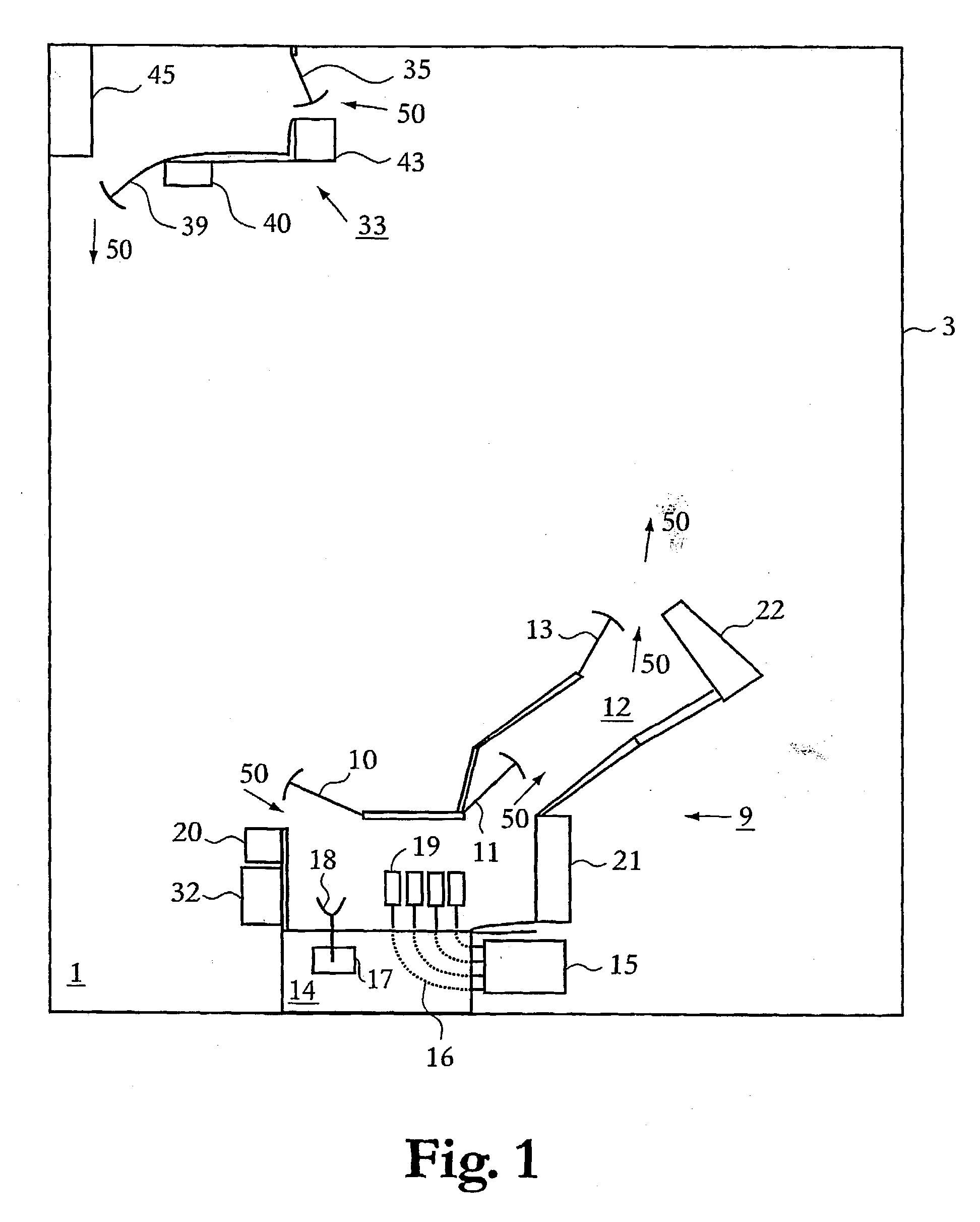

A milking arrangement (1) for automatic milking of animals (9) is described. The milking arrangement includes a feeding area (4) arranged for supplying food to the animals (9), a resting area (2) arranged for allowing the animals (9) to rest, and a milking area (3) with at least one milking station (16, 17) for milking the animals. The milking arrangement also includes a oneway gate (12) arranged between the resting area (2) and the feeding area (4) allowing access from the resting area (2) to the feeding area (4) and at least a first access device (14) arranged between the feeding area (4) and the milking area (3) allowing access between the feeding area (4) and the milking area (3) only in the direction from the feeding area (4) to the milking area (3). A method for managing animals within a milking arrangement is also described.

Owner:DELAVAL HLDG AB

Arrangement and method for milking a plurality of milking animals

ActiveUS7874263B2Good overall control and monitoring and treatmentImprove efficiencyCathetersAnimal housingAutomatic milkingEngineering

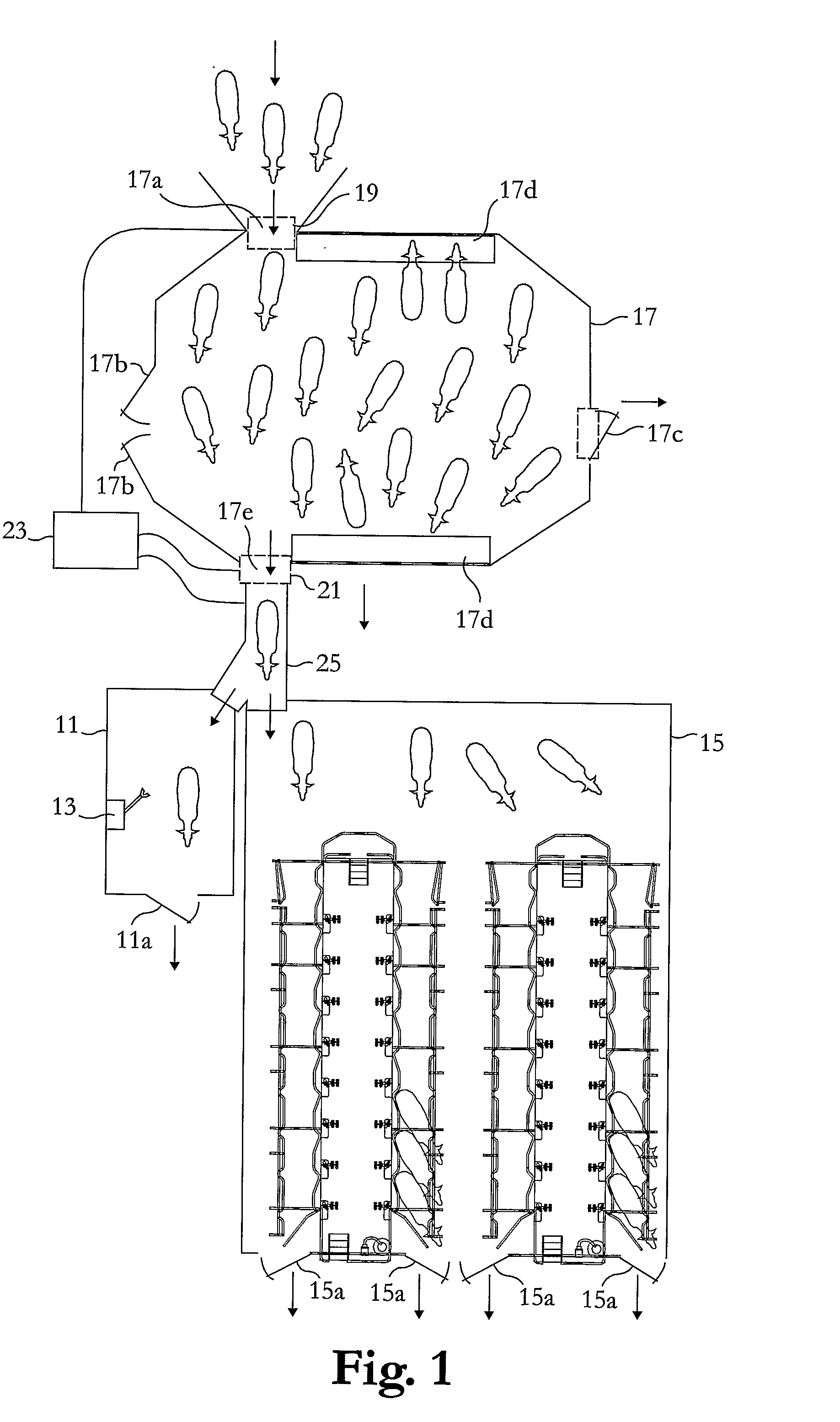

An arrangement for milking a plurality of milking animals comprises an automated milking system (11) provided with a milking robot (13) for automatically milking a milking animal; a milking system (15) provided for batchwise milking of multiple milking animals; an identification arrangement (19, 21) provided for identifying each of the plurality of milking animals prior to being milked; decision means (23) connected to the identification arrangement for deciding, for each of the plurality of milking animals, whether that milking animal should be milked by the automated milking system or by the milking system for batchwise milking; and means connected (25) to the decision means for guiding each of the plurality of milking animals to the automated milking system or to the milking system for batchwise milking depending on the decision made for that milking animal.

Owner:DELAVAL HLDG AB

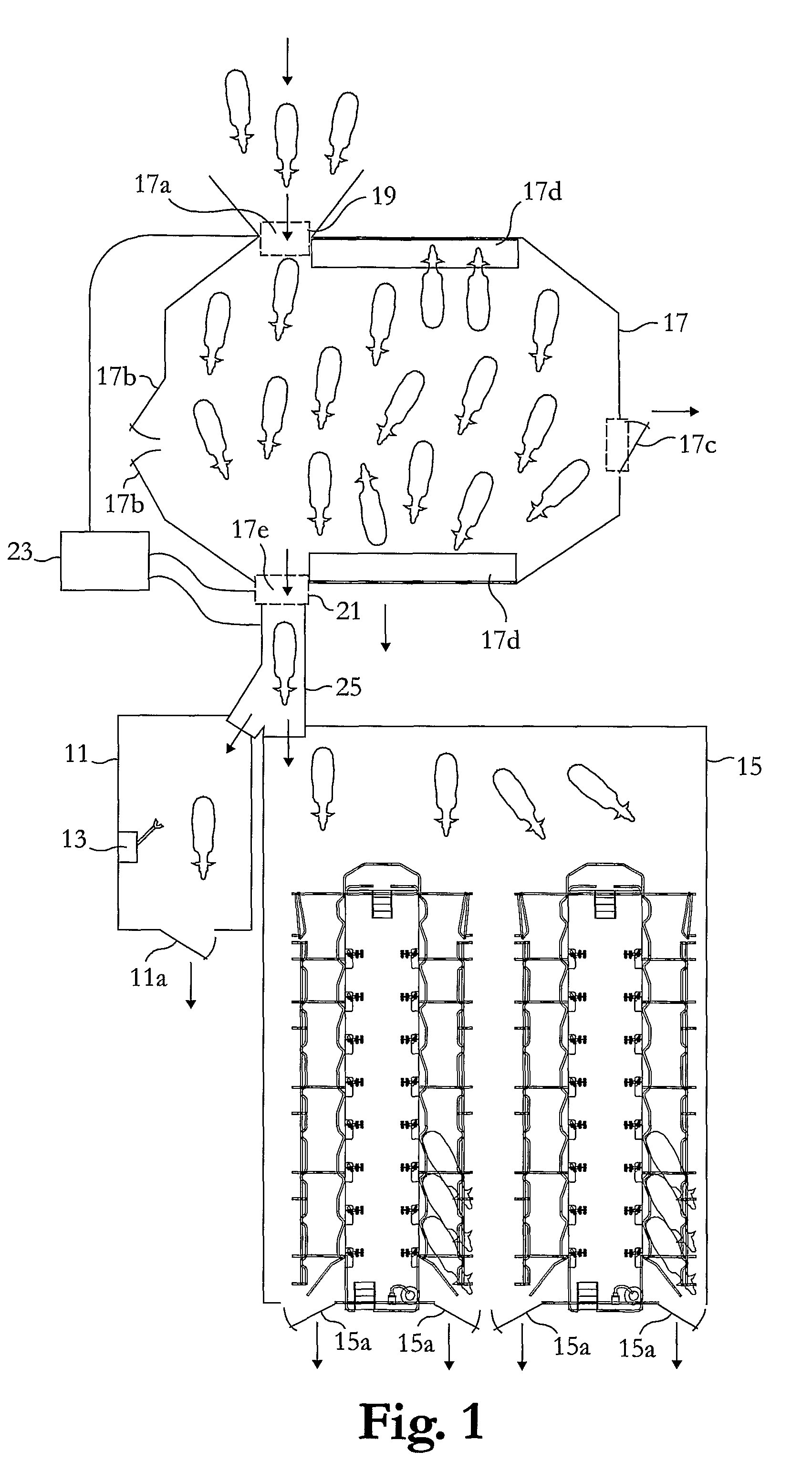

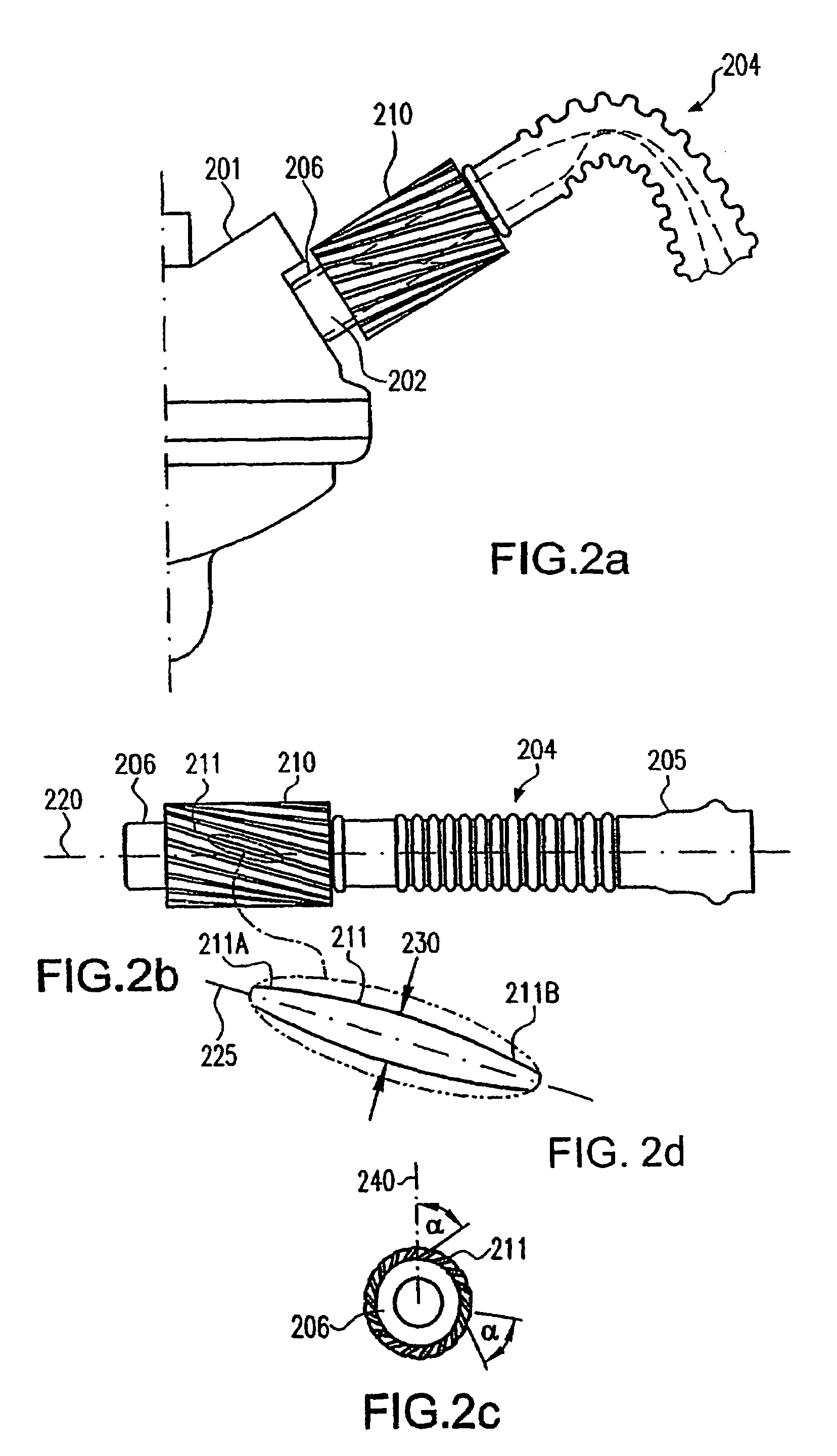

Flexible milk hose for an automatic milking plant

InactiveUS6895890B1Guaranteed mechanical stabilityUniform materialFlexible pipesMilking devicesMechanical stabilityAutomatic milking

An automatic milking plant is provided with a short milk hose, which, due to spaced-apart elevations in its center piece, has sufficient mechanical stability vis-a-vis pressure differences as well as a high flexibility. The use of the short milk hose according to the present invention leads to a reduction of the mechanical strain on the udder and thus also reduces irritations of the animal to be milked.

Owner:MAIER JR JAKOB

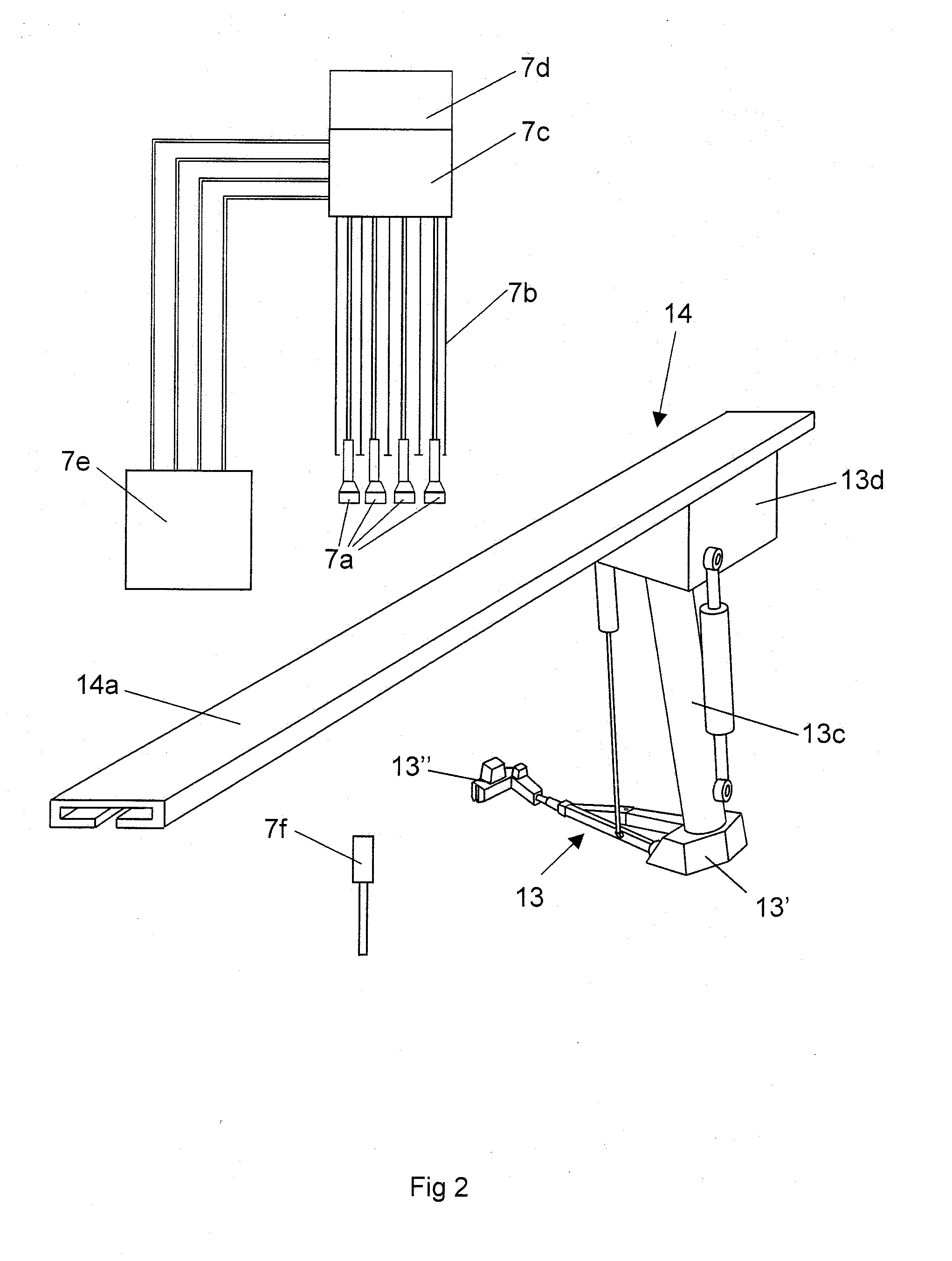

Milk sampling apparatus and method

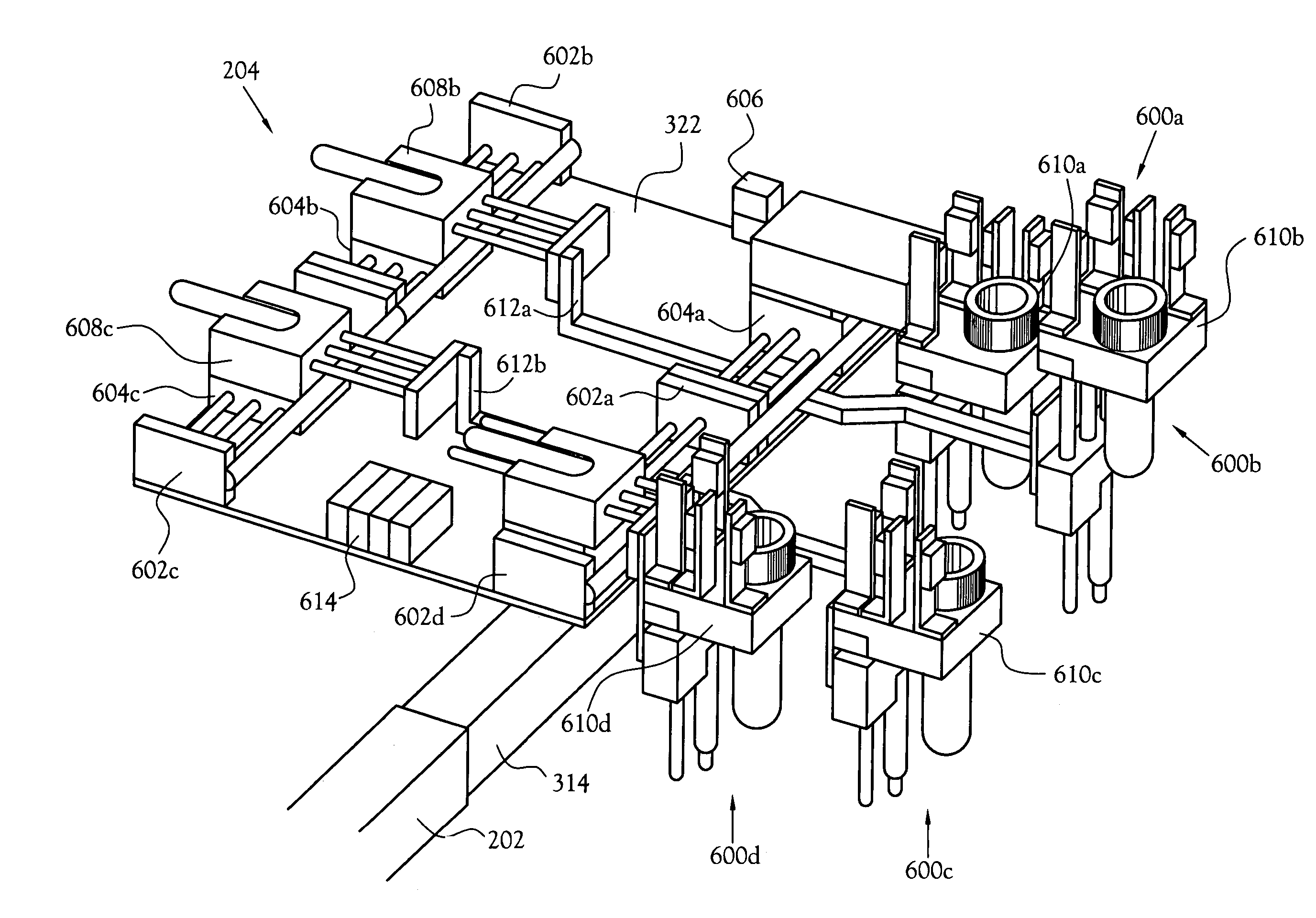

The present invention refers to a milk sampling apparatus and method for use with an automated milking system. The apparatus comprises a cassette (7) wherein milk sample collecting elements (9) are placed, and at least one filling member (27) capable of being placed above a selected one of said milk sample collecting elements (9) by means of a positioning system, and capable of bringing a milk sample, representatively taken from milk yielded during the milking of an animal by means of said automated milking system, into said selected one of said milk sample collecting elements (9). The positioning system comprises an arm (34) extending in a first dimension (Y) in a plane (XY) above said milk sample collecting elements (9) and being movable in a second direction (X) in said plane (XY), said first (Y) and second (X) directions being orthogonal; a runner (32) holding said filling member (27) and being movable along said arm (34); and first (29) and a second (31) drive means, wherein said first drive means (29) is effective to move said arm (34) and said second drive means (31) is effective to move said runner (32) such that said filling member (27) is positioned above said selected one of said milk sample collecting elements (9).

Owner:DELAVAL HLDG AB

Automatic milking device and method of controlling an automatic milking device

InactiveUS20100050947A1Reliable functionRemove outliersCathetersAnimal housingAutomatic milkingGravity center

An automatic milking device for milking a dairy animal, comprising a control device and a weighing floor with weight sensors for supplying weight signals, and with a filter for filtering the weight signals into a filtered signal indicative of the position of the centre of gravity of the dairy animal, wherein the control device is configured for controlling the milking by the automatic milking device on the basis of the weight signal filtered by the filter. The control device is arranged for controlling the automatic milking device on the basis of the unfiltered weight signal after the milking has been finished. As a result thereof, it is possible to respond more quickly to movements of the dairy animal, without the filter having a delaying effect.

Owner:LELY PATENT

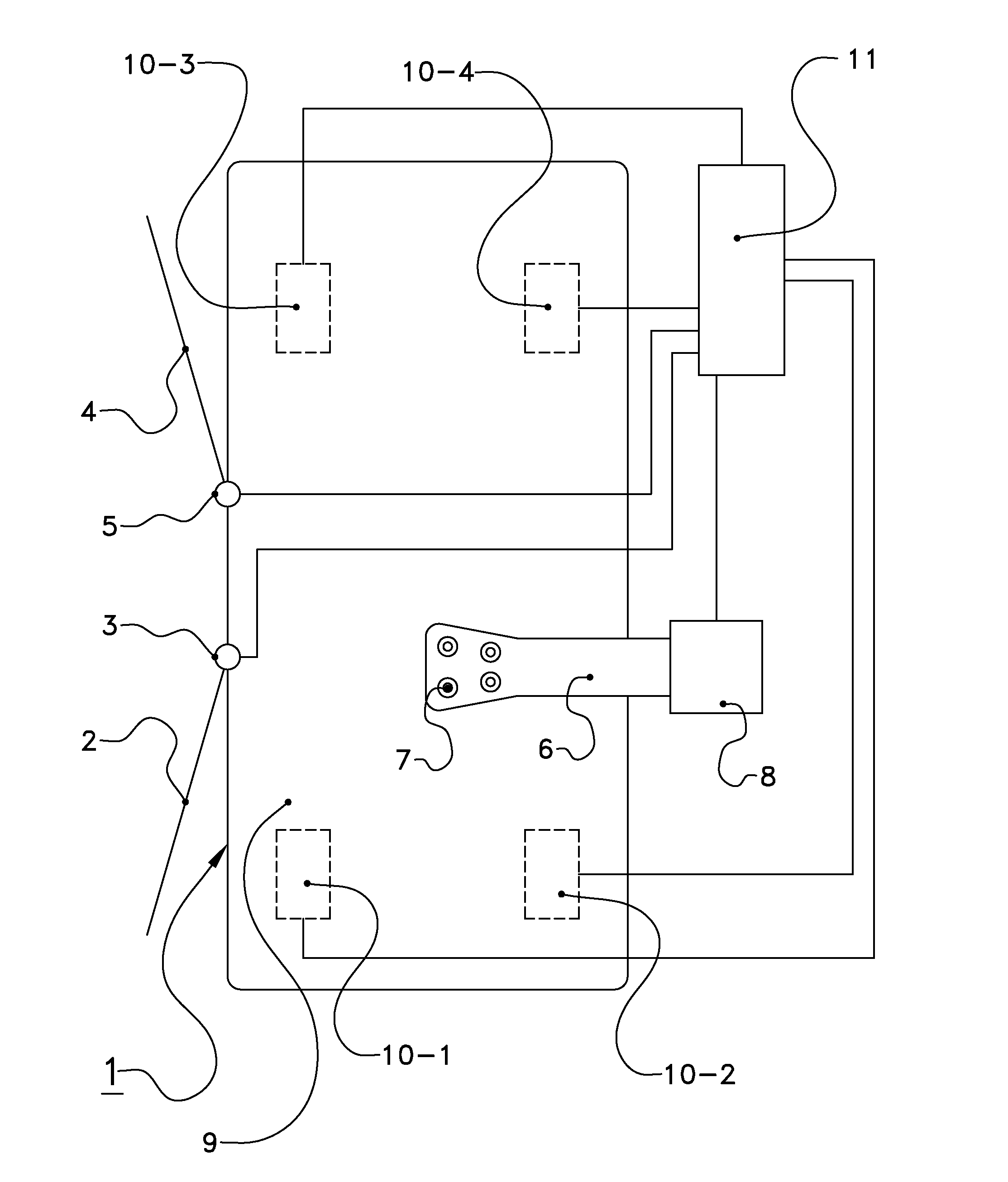

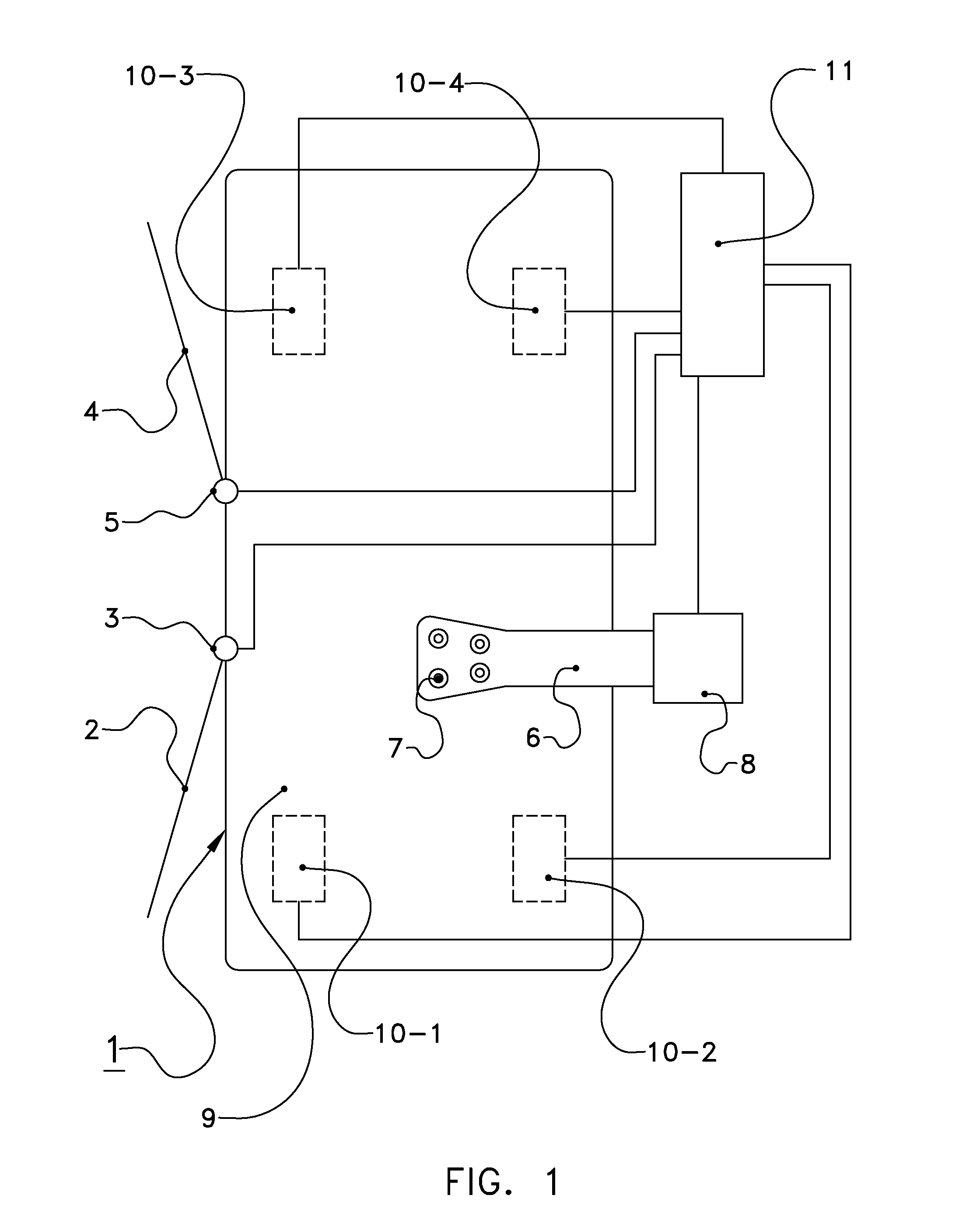

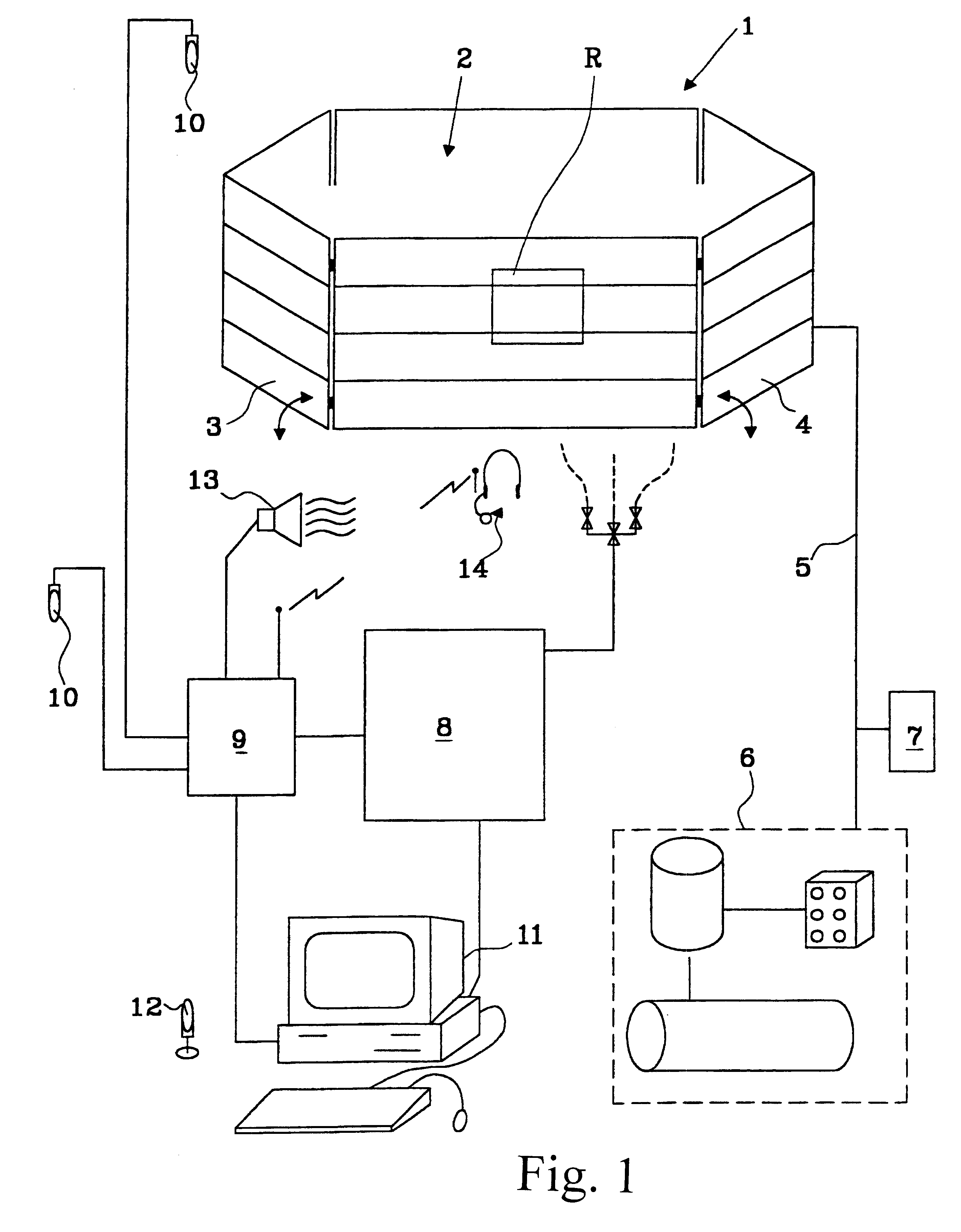

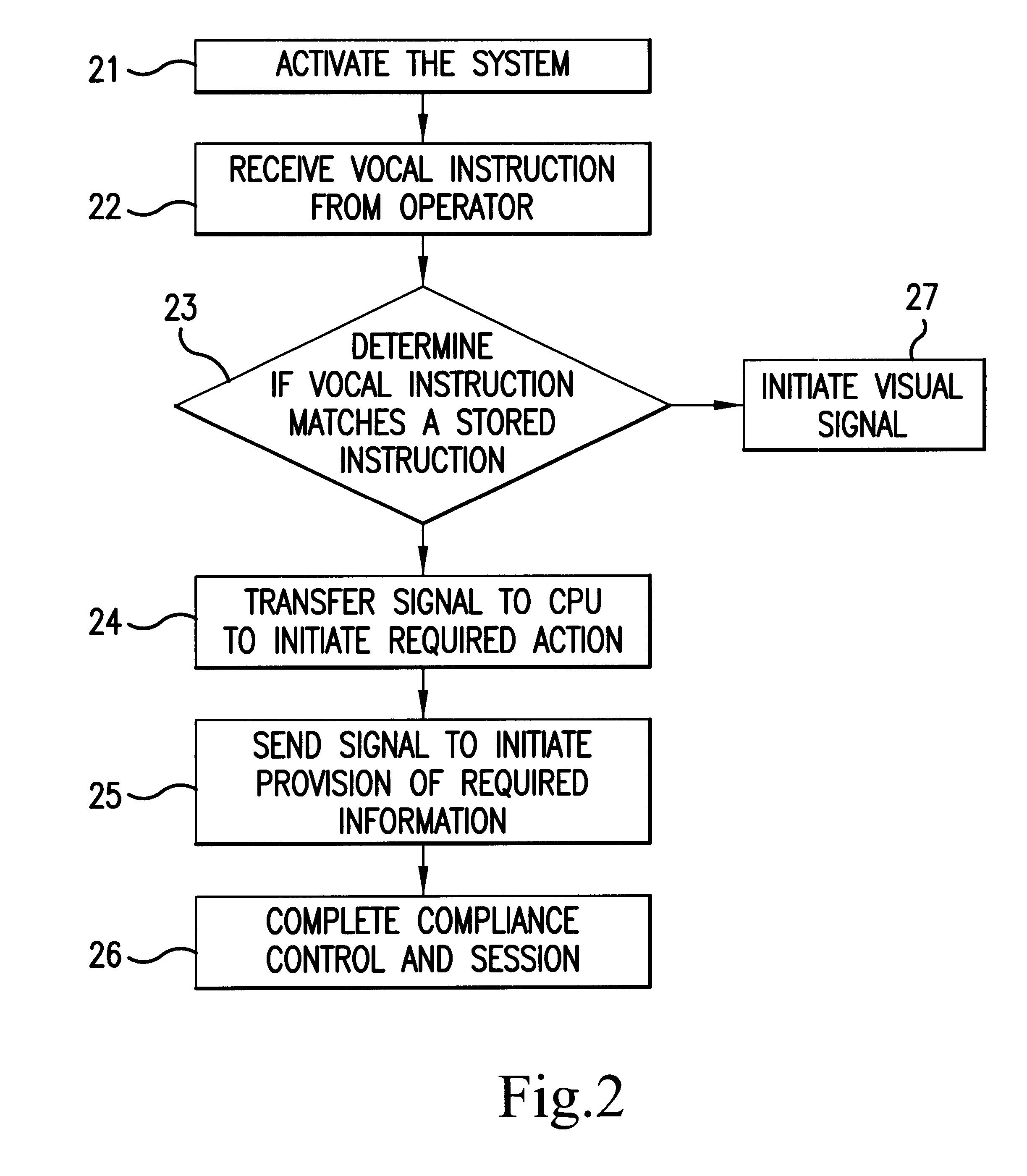

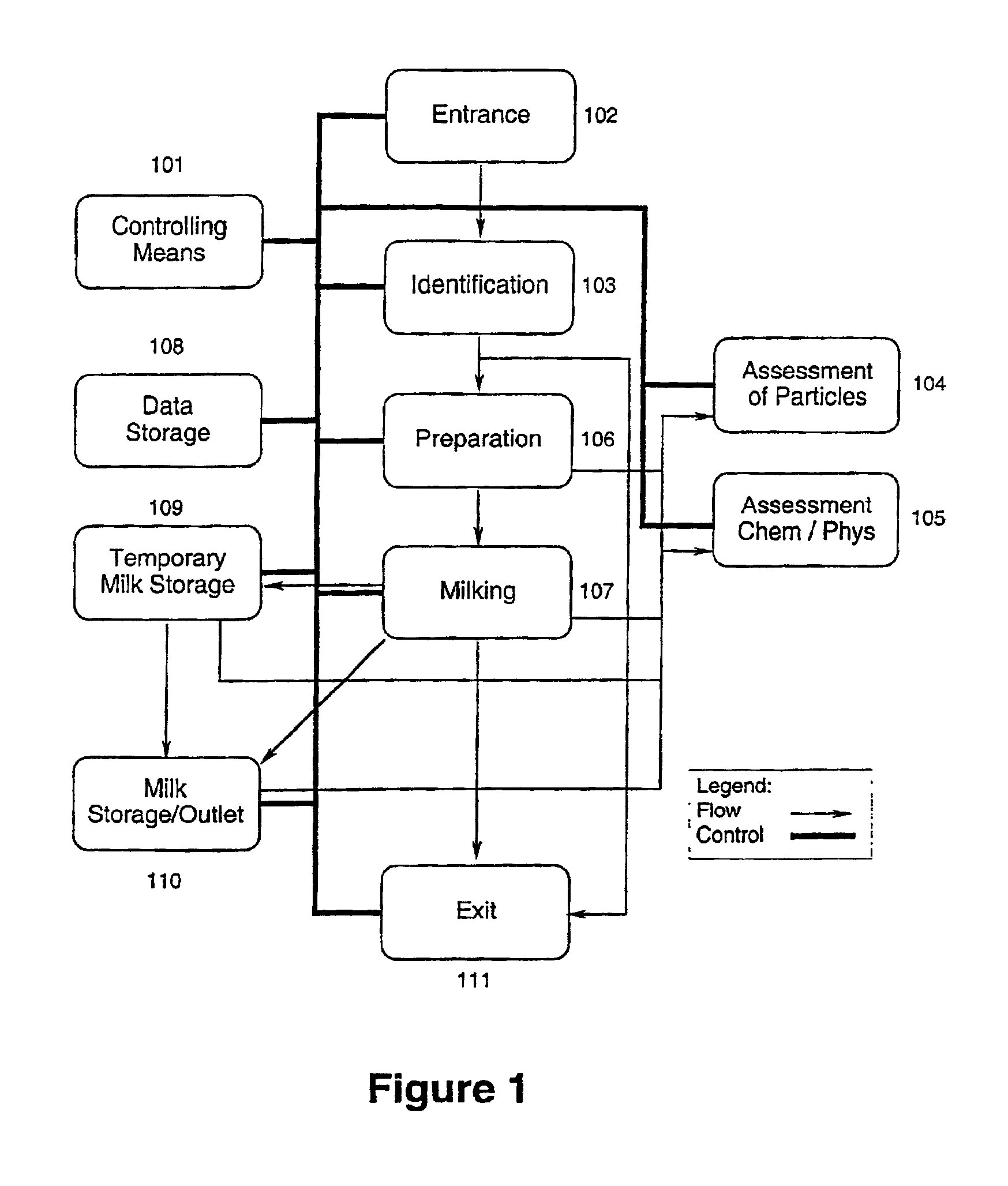

System and method for controlling and monitoring the operation of an automatic milking system

A system and method for controlling and monitoring the operation of an automatic milking system (1), wherein a central processing unit (8) is arranged to receive signals from peripheral hardware units (3, 4, 5, 6, 7, R) and to process the signals for obtaining hardware status related information or milking animal status related information. An interface (9, 10, 11, 12, 13) is arranged for communication between the central processing unit and an operator. The interface includes a device for understanding and interpreting vocal instructions from an operator and translating them into machine understandable instructions. The central processing unit includes a device for controlling or regulating at least one of the peripheral hardware units, or to provide status related information in vocal form as a response to said vocal instructions.

Owner:DELAVAL HLDG AB

Implement for automatically milking a dairy animal

ActiveUS8807080B2High resolutionMaximum of constructive simplicityCathetersRobotMilk cow'sPhase difference

An implement for automatically milking a dairy animal, such as a cow, comprises a milking parlor, a sensor for observing a teat, and a milking robot for automatically attaching a teat cup to the teat. The milking robot comprises a robot control that is connected to the sensor. The sensor comprises a radiation source for emitting light, a receiver for receiving electromagnetic radiation reflected from the dairy animal, a lens, and sensor control unit. The sensor comprises a matrix with a plurality of rows and a plurality of columns of receivers. The sensor control unit is designed to determine for each of the receivers a phase difference between the emitted and the reflected electromagnetic radiation in order to calculate the distance from the sensor to a plurality of points on the part to be observed of the dairy animal.

Owner:MAASLAND

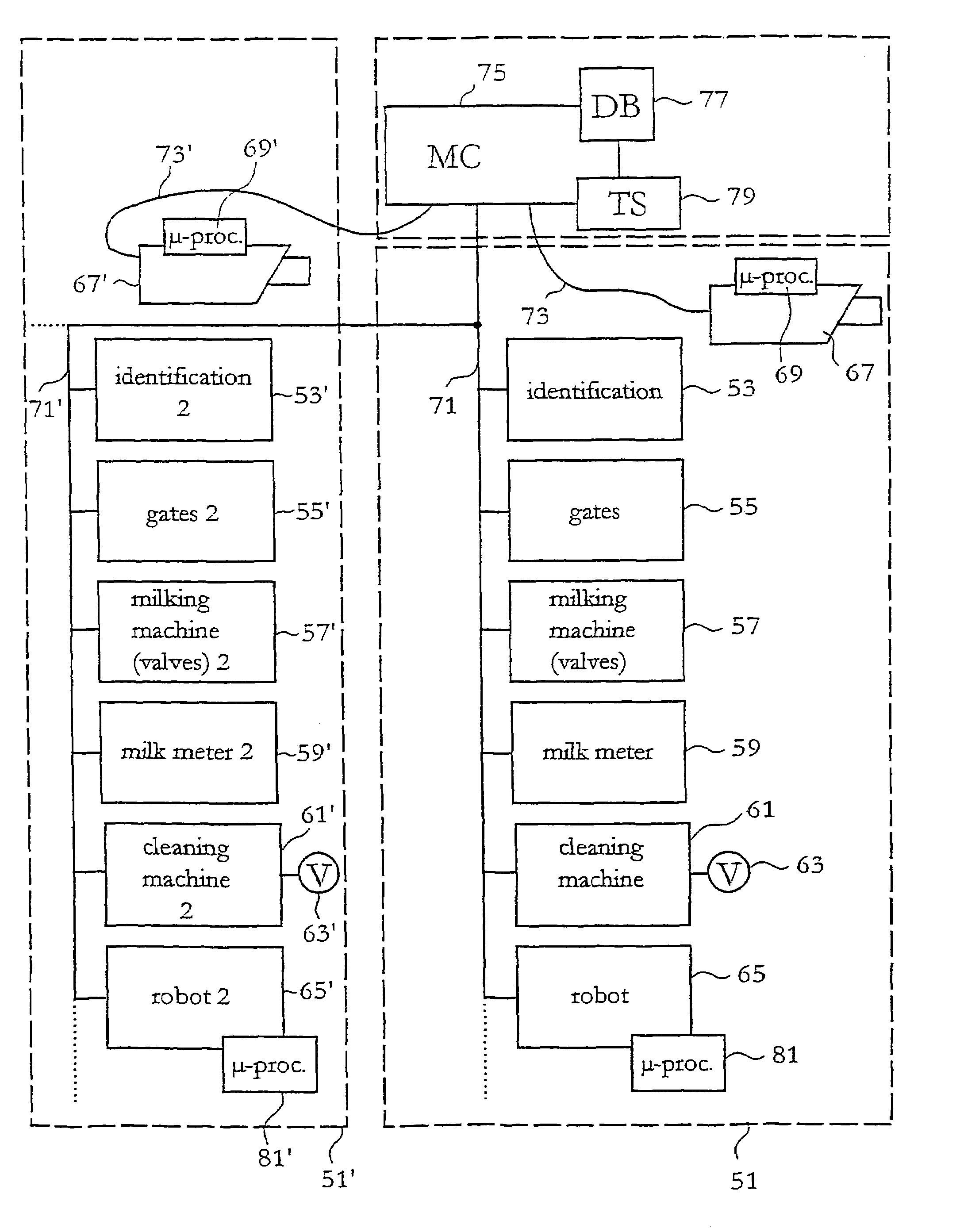

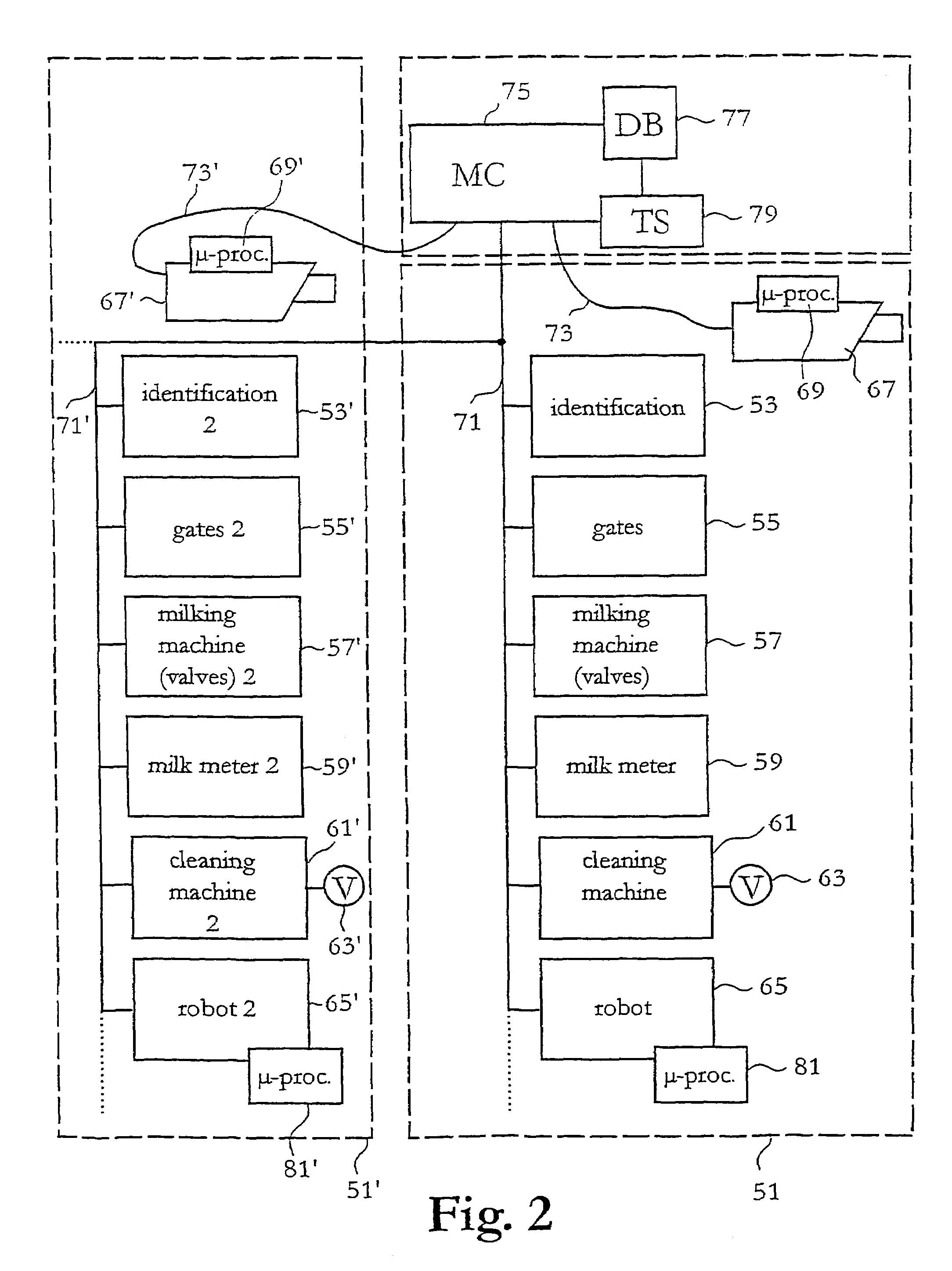

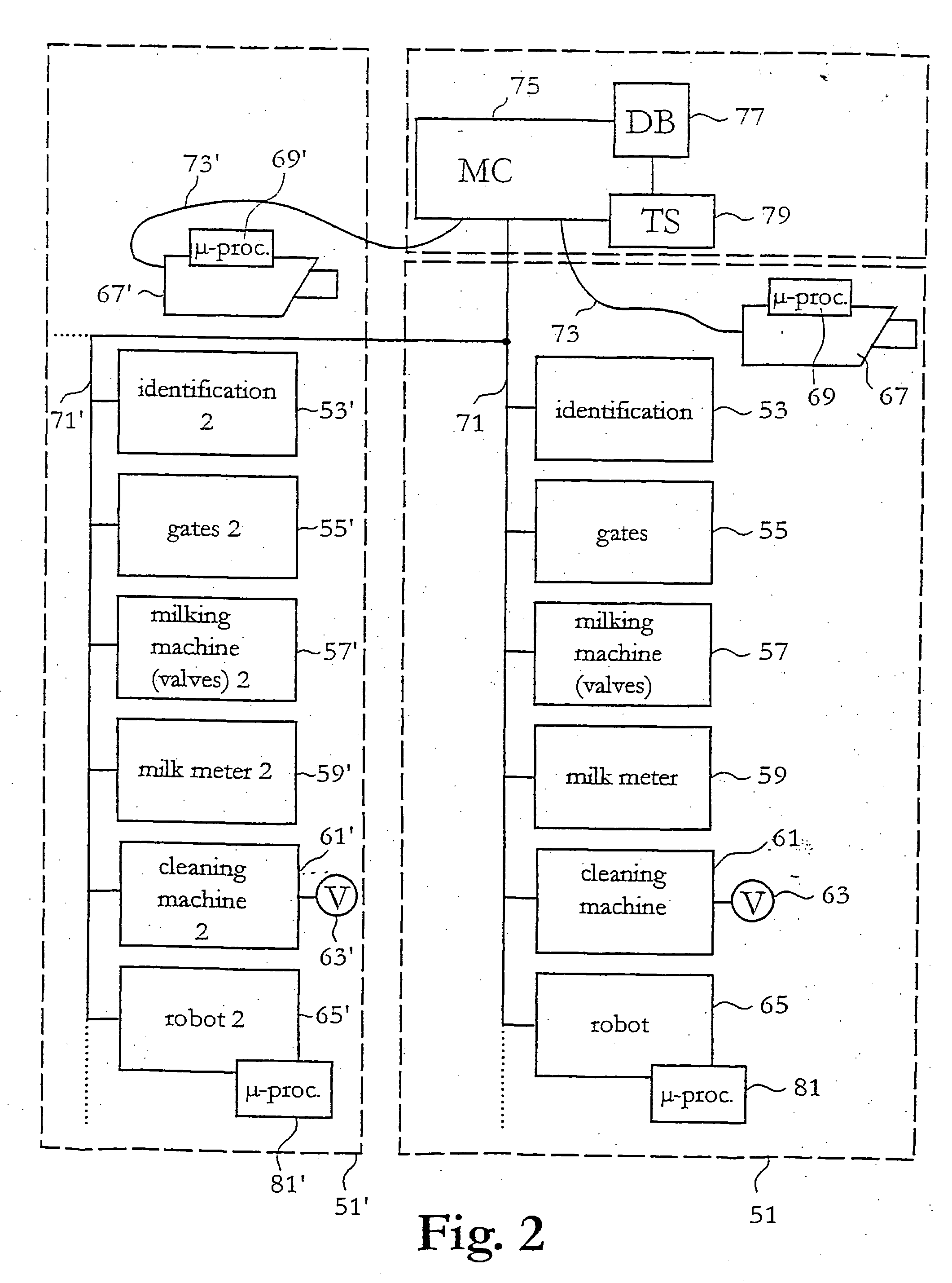

System and method for milking animals

A milking system may include a milking stall (1, 51), which an animal may visit to be milked automatically. The milking stall including an animal identifier (9, 53); a gate controller (7, 55) for opening an entry and exit gates (3, 5); a milking machine (11, 57), wherein the teat cups, during milking of a milking animal in the milking stall, are applied to the teats of the milking animal and are connected to vacuum (19, 63) such that milk can be drawn from the milking animal and be collected in the vessel; and a robot (13, 65) provided with a robot arm (21) and a gripper (23) for automatic application of the teat cups to the teats of the animal. The milking system may also include a master computer (75) adapted to hold a database (77) of milking animals capable of visiting the milking stall, to receive an identification of a milking animal from the animal identifier, and adapted to control the gate controller, the milking machine, and the robot depending on the received identification. The robot may include a slave processor (81), connected to receive information from the master computer, according to which movement of the robot arm of the robot is to be performed, and adapted to control the robot to move the robot arm of the robot according to the received information.

Owner:DELAVAL HLDG AB

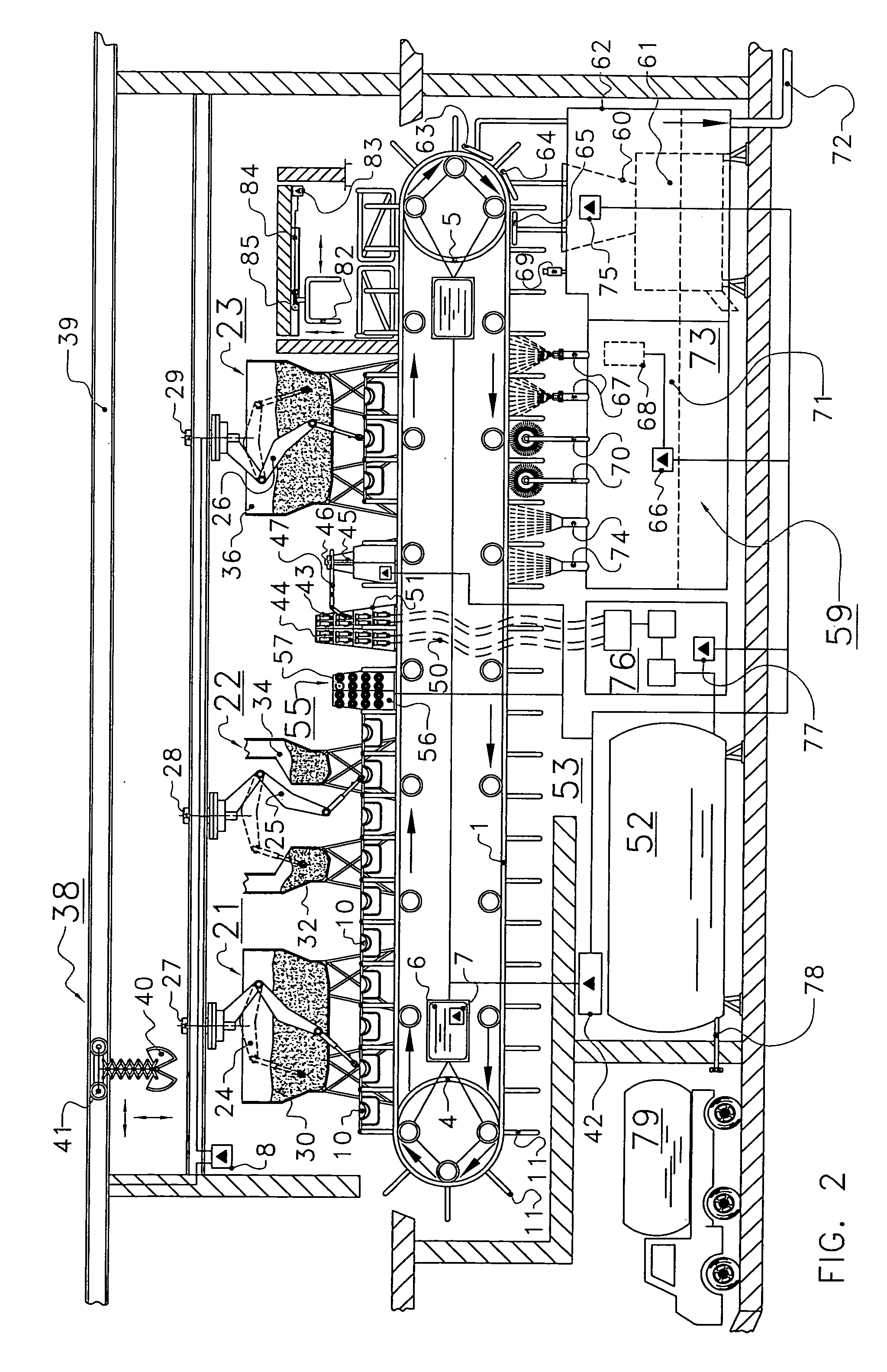

Assembly for and a method of feeding and milking animals, a feed platform, a milking pre-treatment device, a milking post-treatment device, a cleaning device, a separation device and a milking system all suitable for use in such an assembly

InactiveUS7270078B2Control freedomIncrease heightCathetersAnimal housingEngineeringAutomatic milking

An assembly for feeding and milking animals comprises a feeding system with a movable feed platform and a drive unit for driving the feed platform. The feed platform is provided with a number of feeding places. The assembly further comprises a milking system for automatically milking animals on the feed platform, which milking system comprises sets of teat cups. At least a large number of the sets of teat cups is disposed separately from the feed platform.

Owner:LELY ENTERPRISES

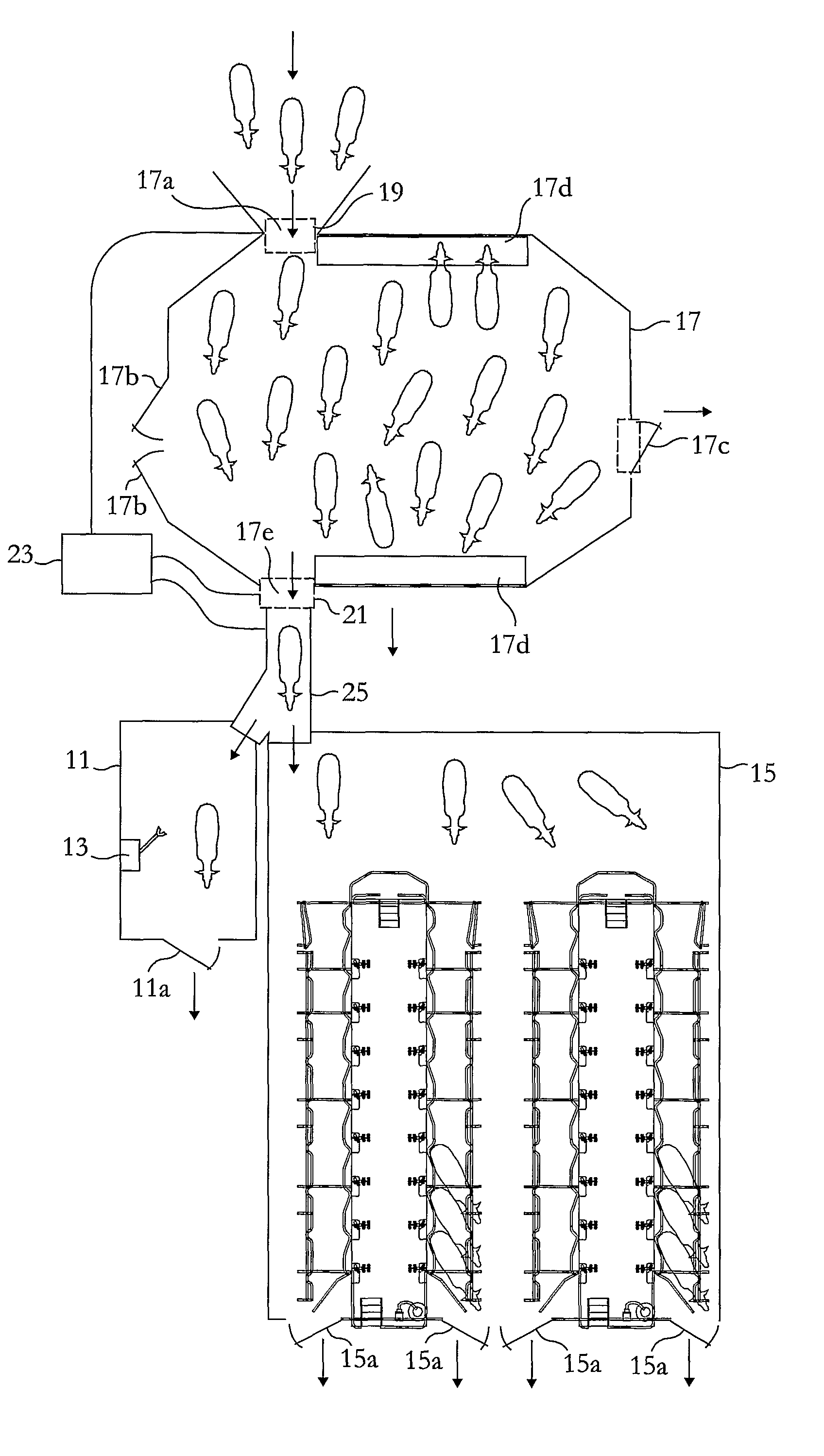

Arrangement and Method for Milking a Plurality of Milking Animals

ActiveUS20080282985A1Milk production can be maximizedGood animal healthCathetersAnimal housingEngineeringAutomatic milking

An arrangement for milking a plurality of milking animals comprises an automated milking system (11) provided with a milking robot (13) for automatically milking a milking animal; a milking system (15) provided for batchwise milking of multiple milking animals; an identification arrangement (19, 21) provided for identifying each of the plurality of milking animals prior to being milked; decision means (23) connected to the identification arrangement for deciding, for each of the plurality of milking animals, whether that milking animal should be milked by the automated milking system or by the milking system for batchwise milking; and means connected (25) to the decision means for guiding each of the plurality of milking animals to the automated milking system or to the milking system for batchwise milking depending on the decision made for that milking animal.

Owner:DELAVAL HLDG AB

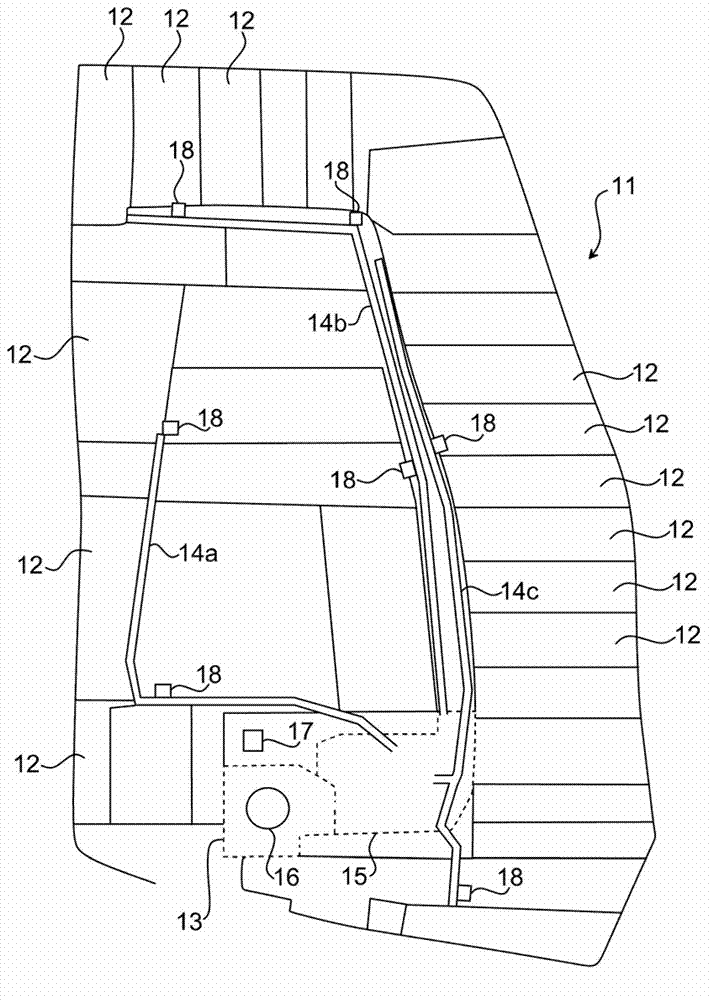

Rotary parlour for automatic milking of animals and a method for attaching teat cups to milking animals on a rotary platform

ActiveUS8205573B2Reliable retracting motionSimple actionCathetersAnimal housingAnimal scienceMedicine

A rotary parlour for milking of animals includes an annular rotary platform (20) adapted to form a support surface (18) for the animals (22), positioning elements (19, 23) for arranging the animals (1) in milking positions on the platform (20), a drive mechanism (30) adapted to supply a rotational motion to the platform (20), and teat cup storing devices (11) for holding parked teat cups (2, 2′) in predetermined storing positions. The teat cup storing devices (11) are mounted in positions such that the teat cups (2, 2′) are located vertically above the platform (20) in their storing positions.

Owner:DELAVAL HLDG AB

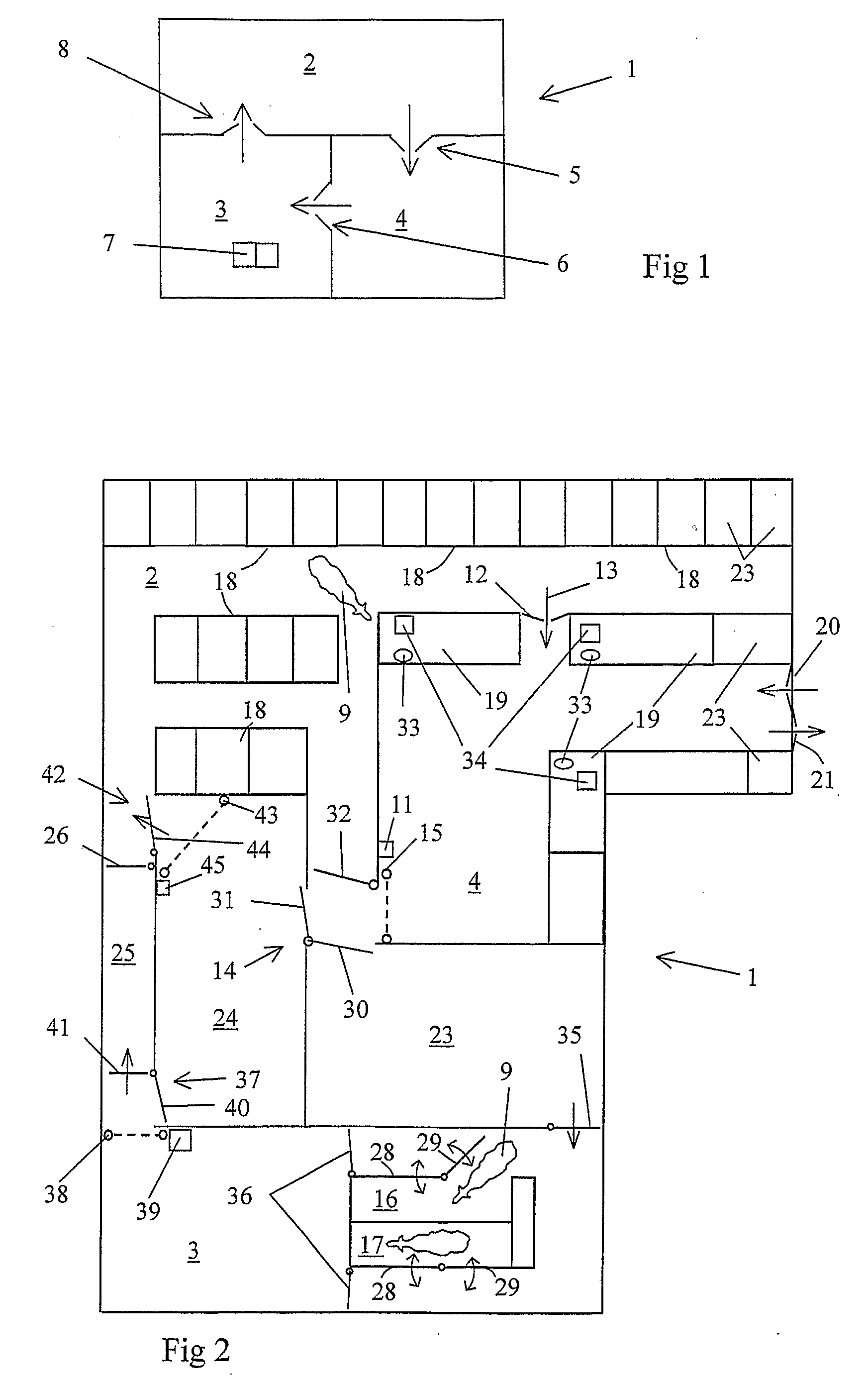

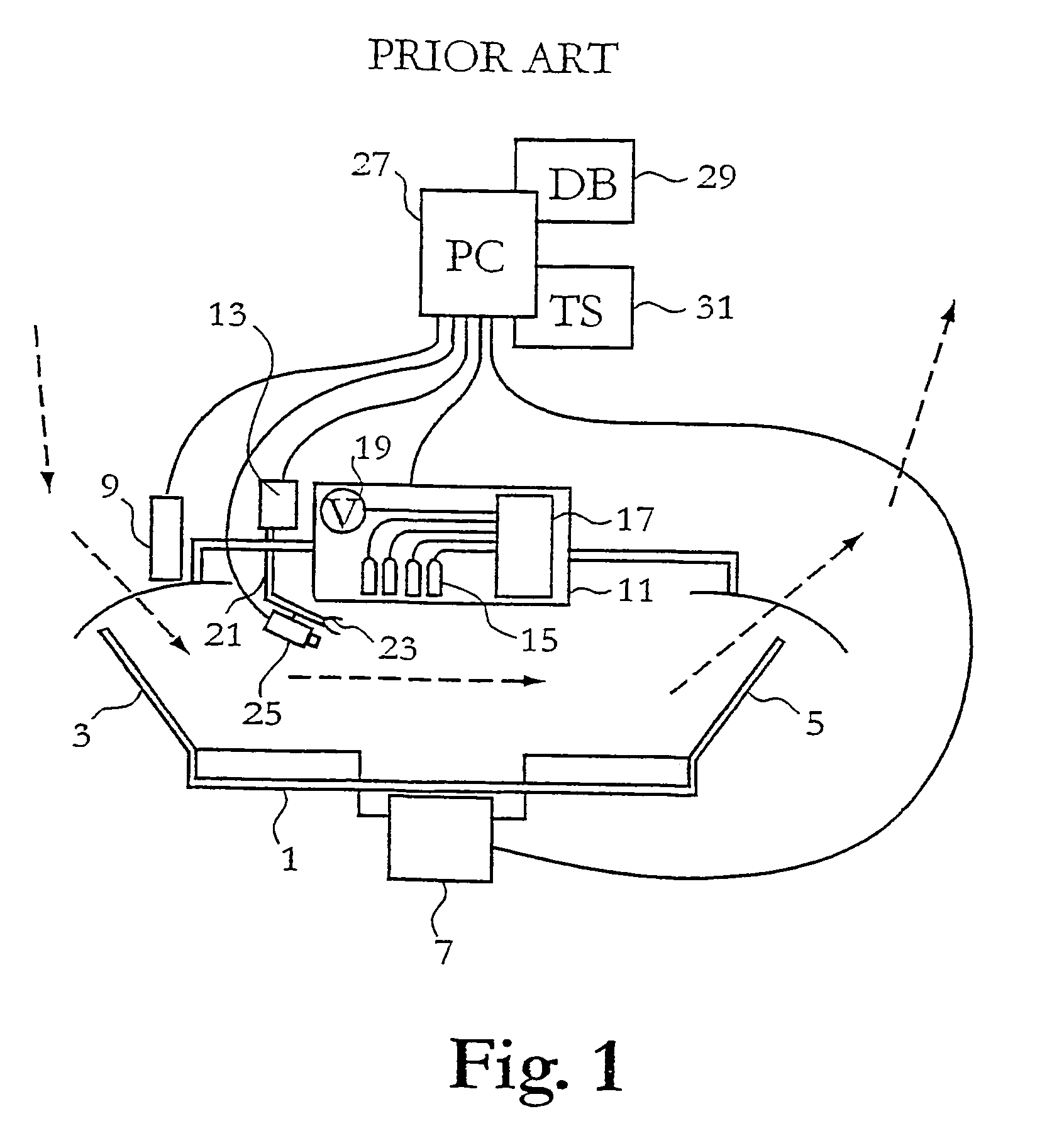

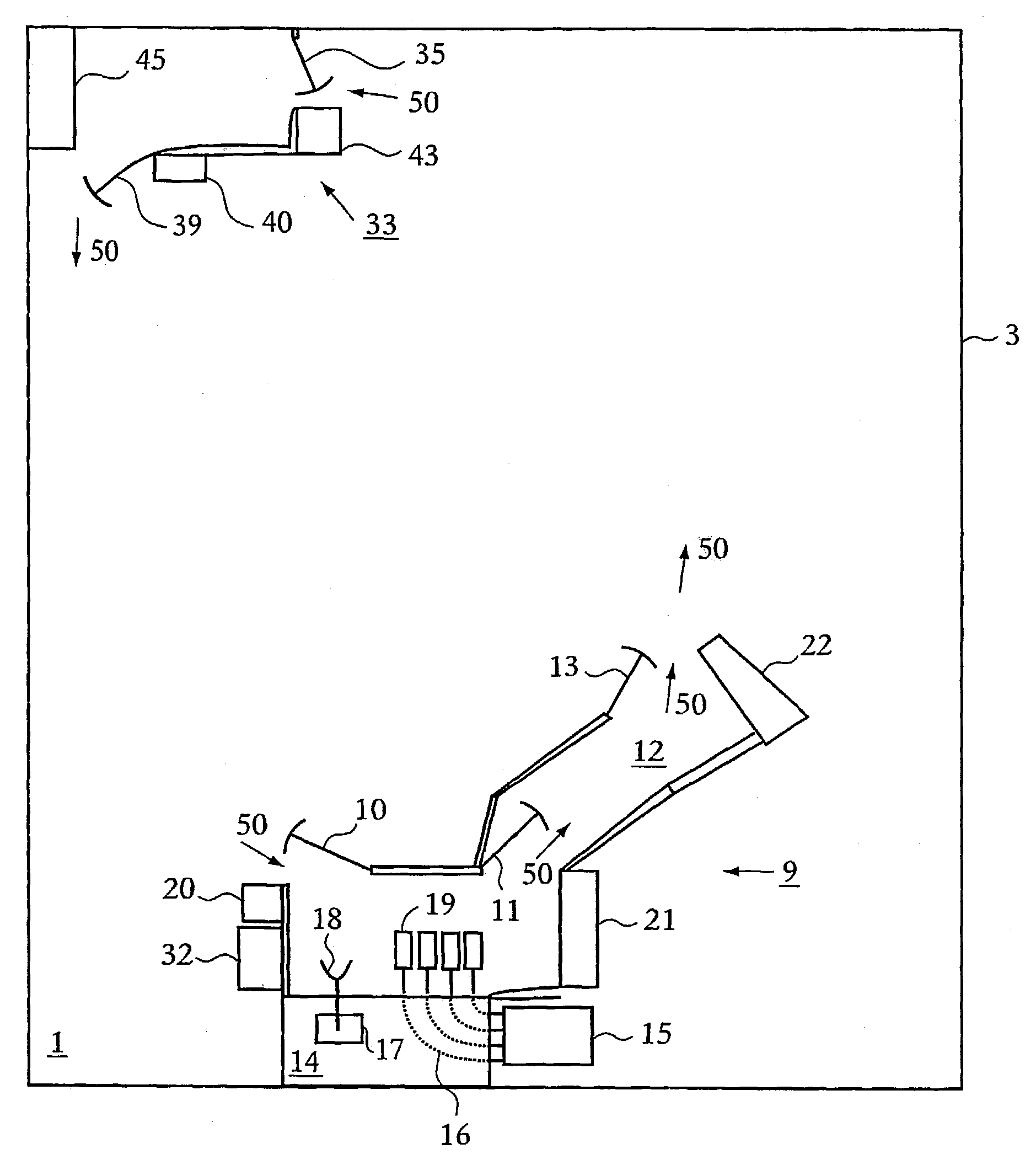

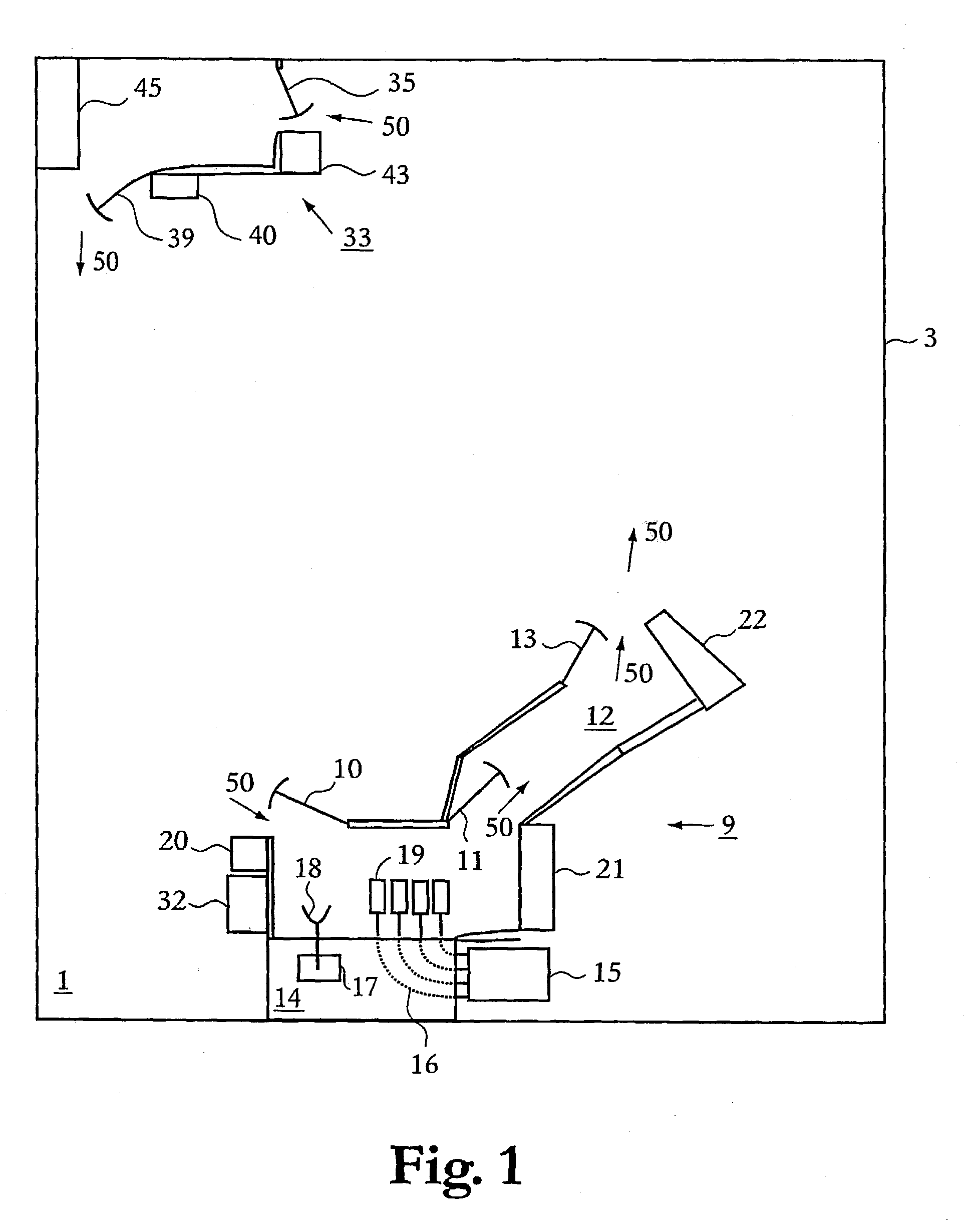

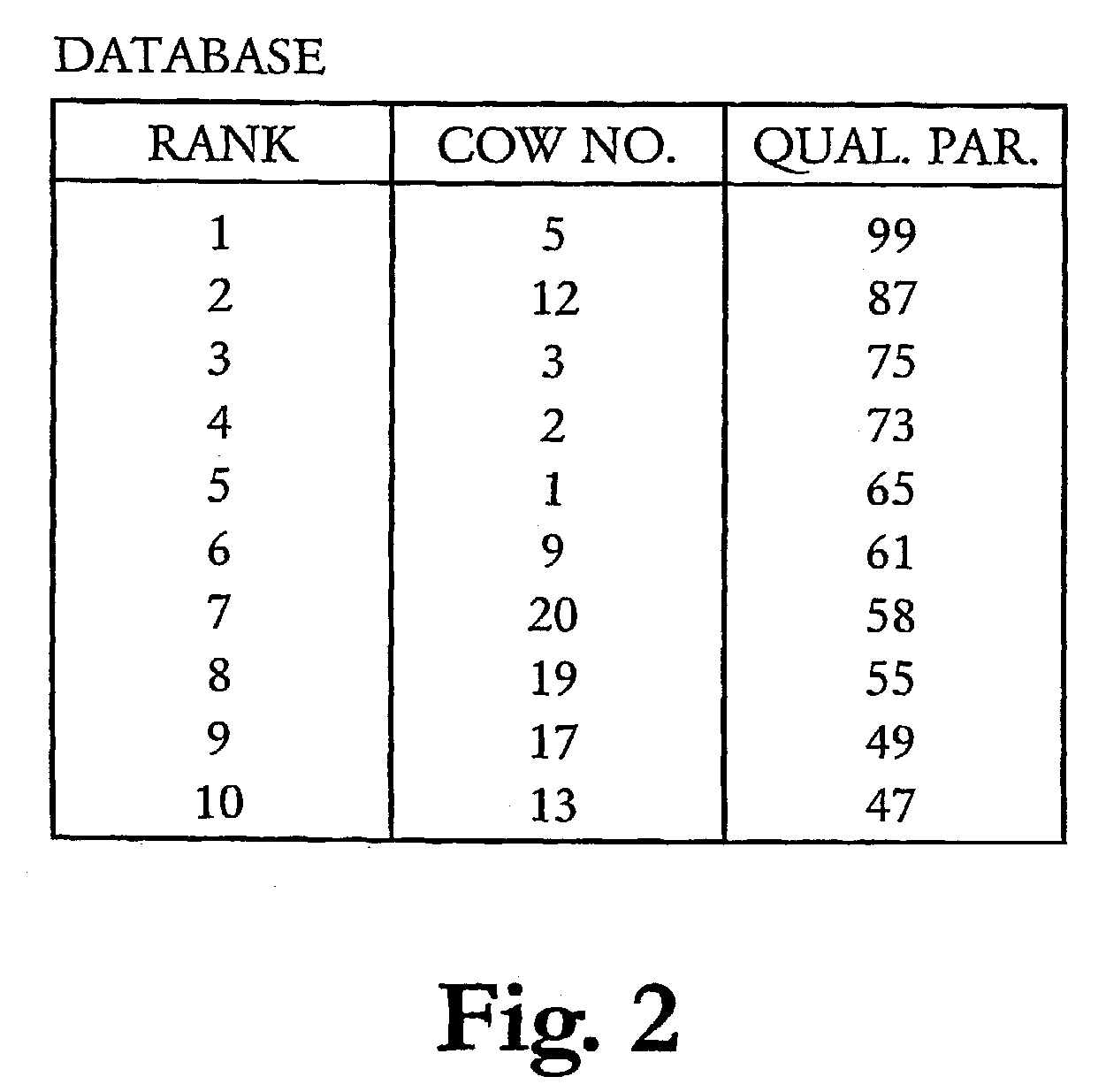

System and method for milking animals

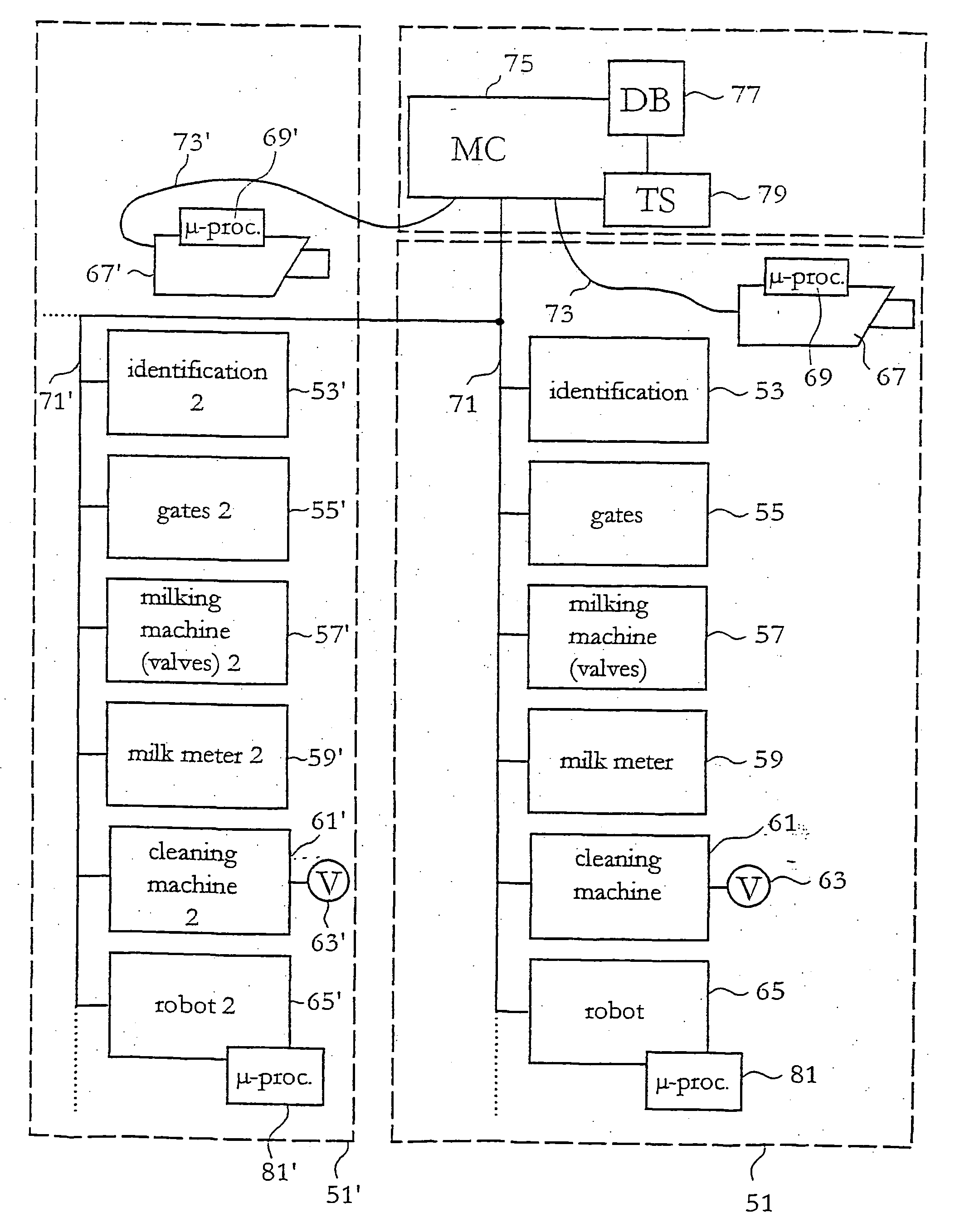

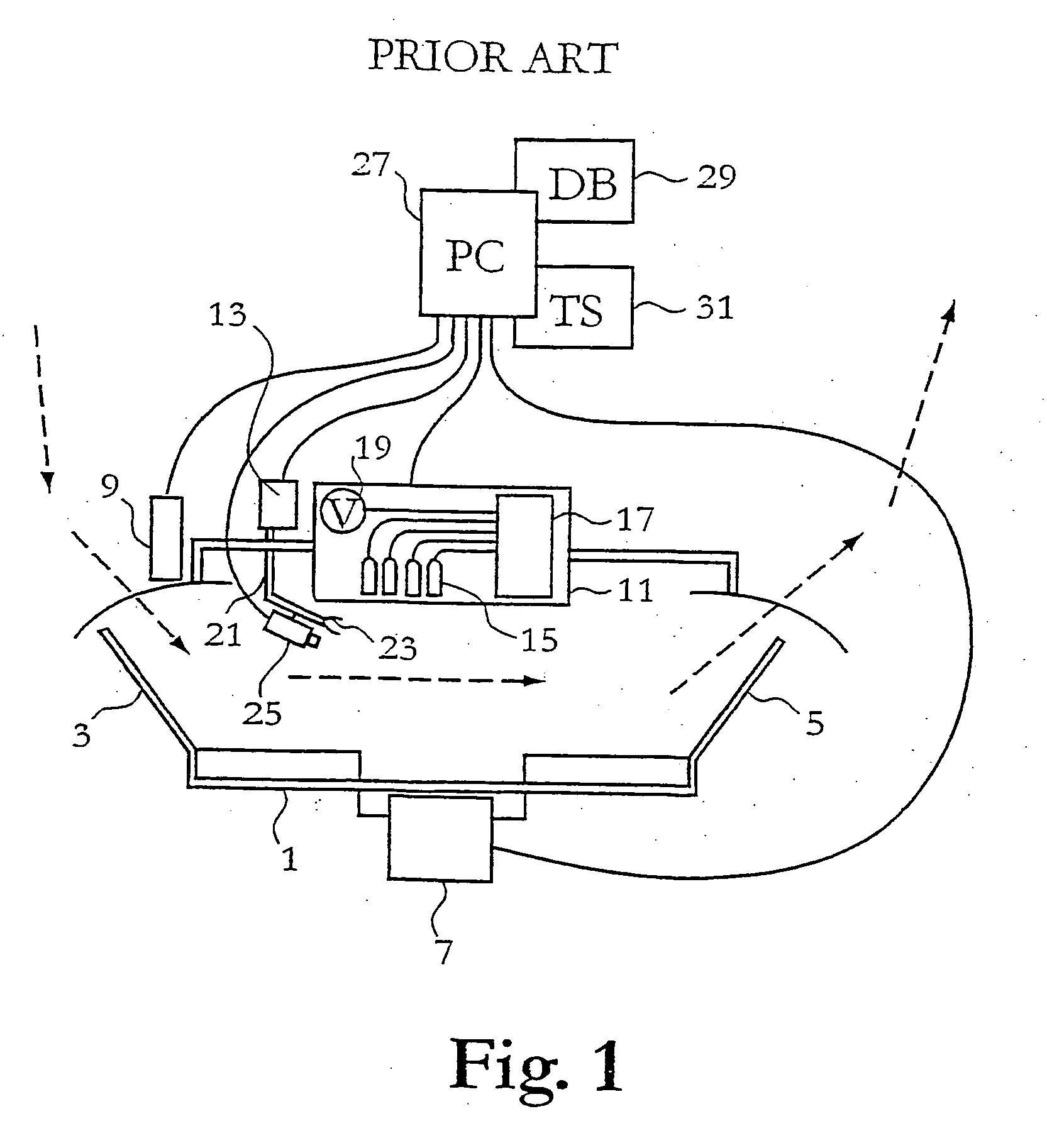

InactiveUS20040182325A1Facilitates milkingFacilitates milking of at least two animals simultaneouslyCathetersAnimal housingAutomatic milkingEngineering

A milking system comprising a milking stall (1, 51), which an animal may visit to be milked automatically, said milking stall including an animal identifier (9, 53); a gate controller (7, 55) for opening an entry and exit gates (3, 5); a milking machine (11, 57), wherein the teat cups, during milking of a milking animal in said milking stall, are applied to the teats of the milking animal and are connected to vacuum (19, 63) such that milk can be drawn from the milking animal and be collected in the vessel; and a robot (13, 65) provided with a robot arm (21) and a gripper (23) for automatic application of the teat cups to the teats of the animal. The milking system features a master computer (75) adapted to hold a database (77) of milking animals capable of visiting the milking stall, to receive an identification of a milking animal from said animal identifier, and adapted to control the gate controller, the milking machine, and the robot depending on the received identification; wherein the robot includes a slave processor (81), connected to receive information from the master computer, according to which movement of the robot arm of the robot is to be performed, and adapted to control the robot to move the robot arm of the robot according to said received information.

Owner:DELAVAL HLDG AB

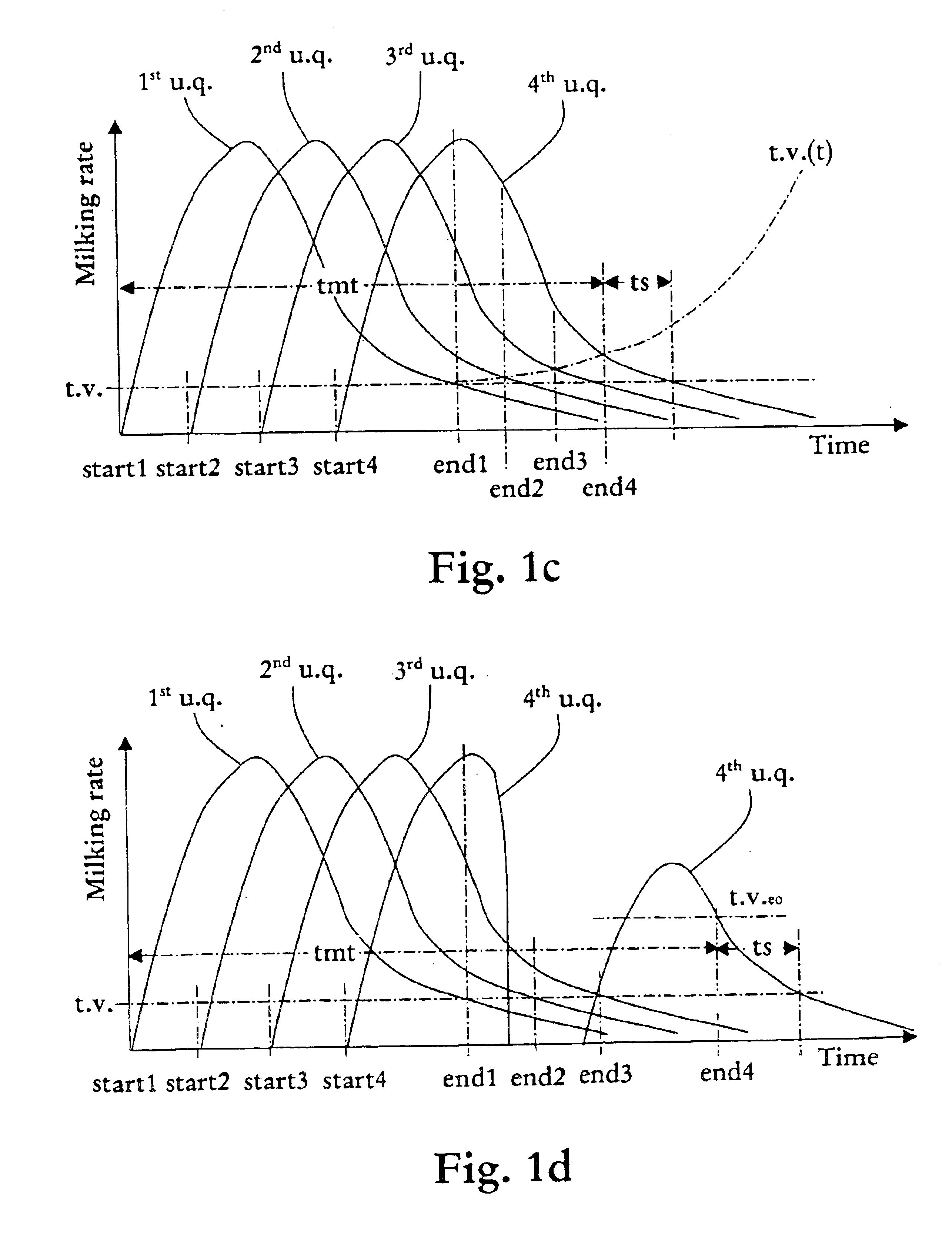

Method and arrangement for control of the milking

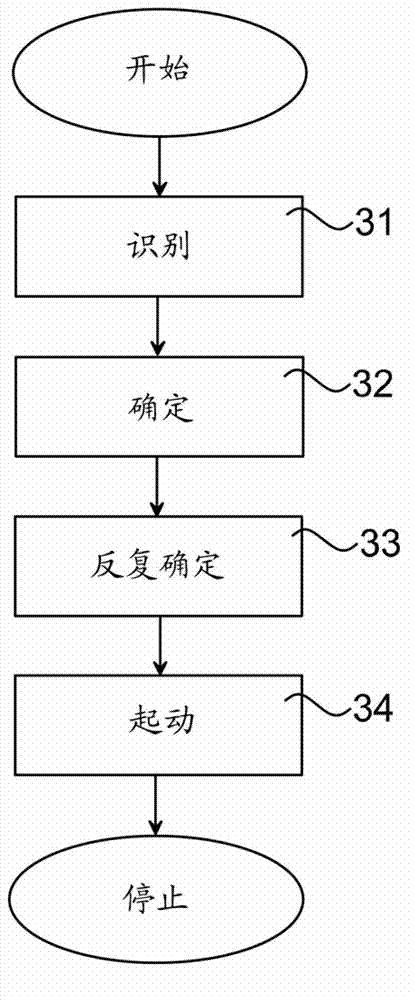

InactiveCN102958351AImprove milking productivityIncrease incomeAnimal housingMilking devicesEngineeringAutomatic milking

Owner:DELAVAL HLDG AB

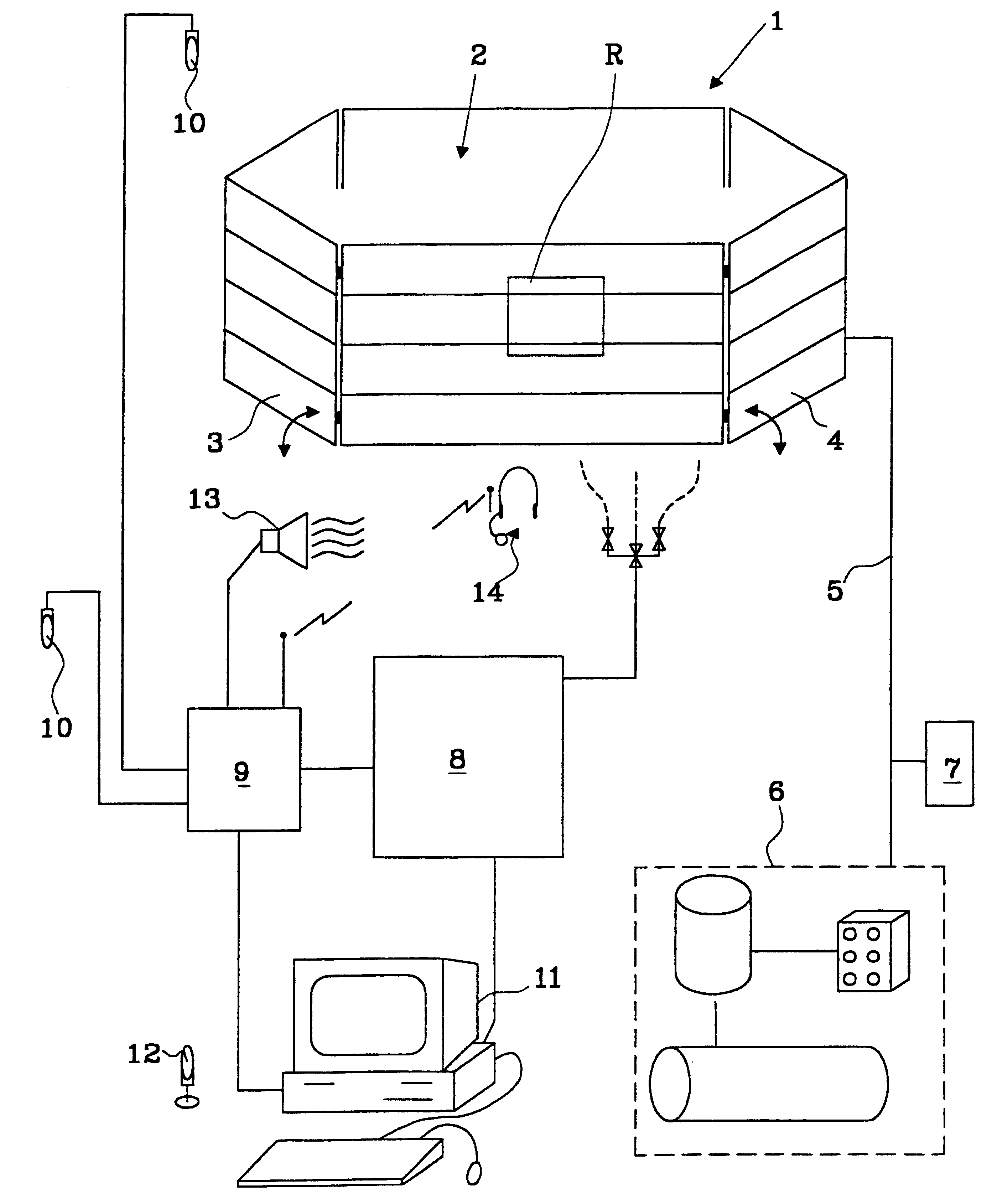

Method of miling and milking parlor

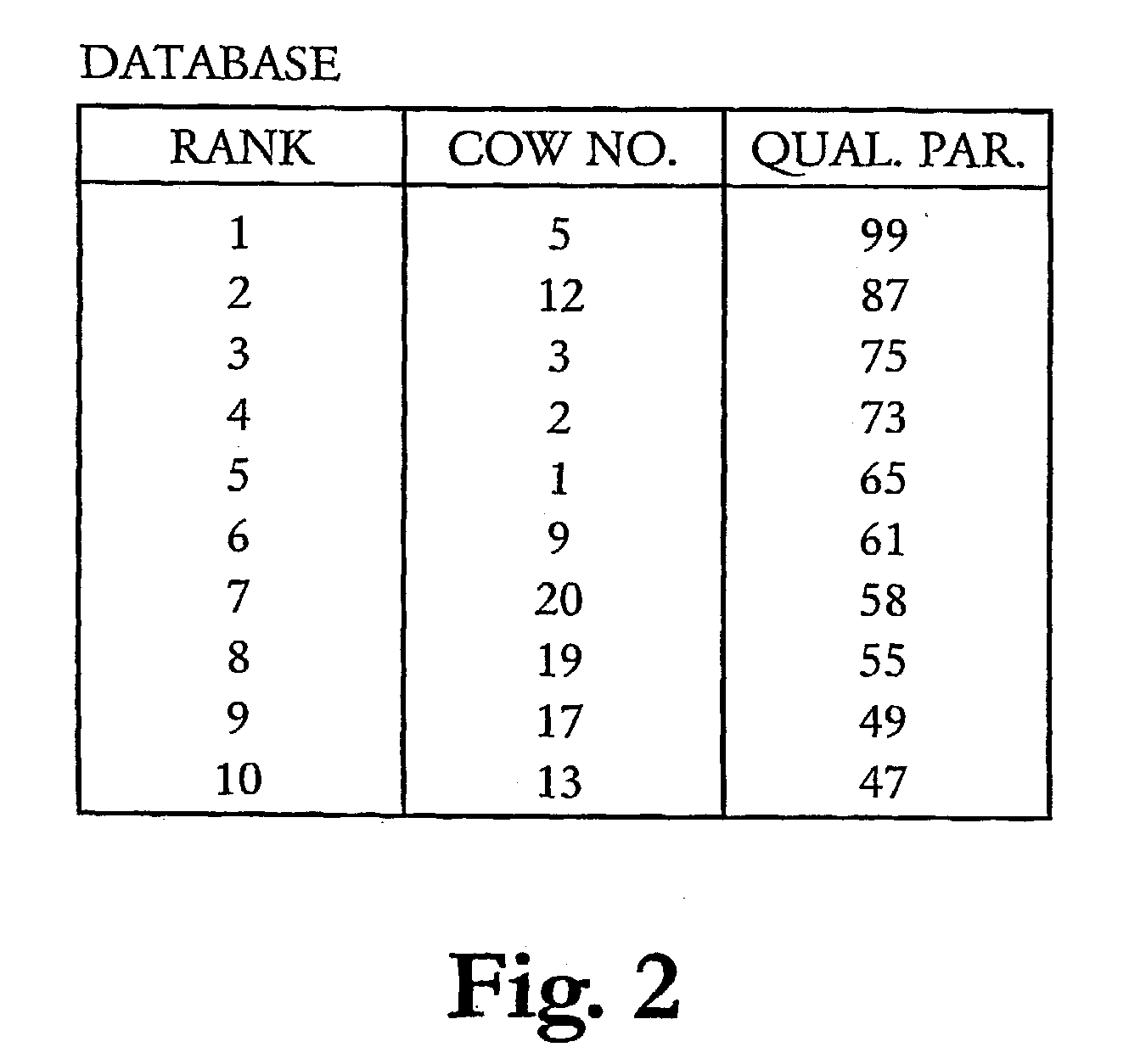

A method of automatically milking animals, such as cows, which are allowed to move freely in an area (1) intended therefore and to visit individually a milking parlor (9) comprising a fully automatic milking machine or milking robot (14) and an animal identification system (20), comprises the steps of dynamically assigning a milking qualification parameter to each of the animals that are allowed to move freely in said area, the respective milking qualification parameter indicating the degree of suitability that the respective animal, to which the milking qualification parameter is assigned, shall be milked; dynamically ranking the animals in accordance with their respective milking qualification parameters; and milking an animal during a visit to the milking parlor only if said animal is identified as belonging to the X highest ranked animals, i.e. the X animals that are best suited to be milked from a milk production optimization viewpoint, X being a positive integer.

Owner:DELAVAL HLDG AB

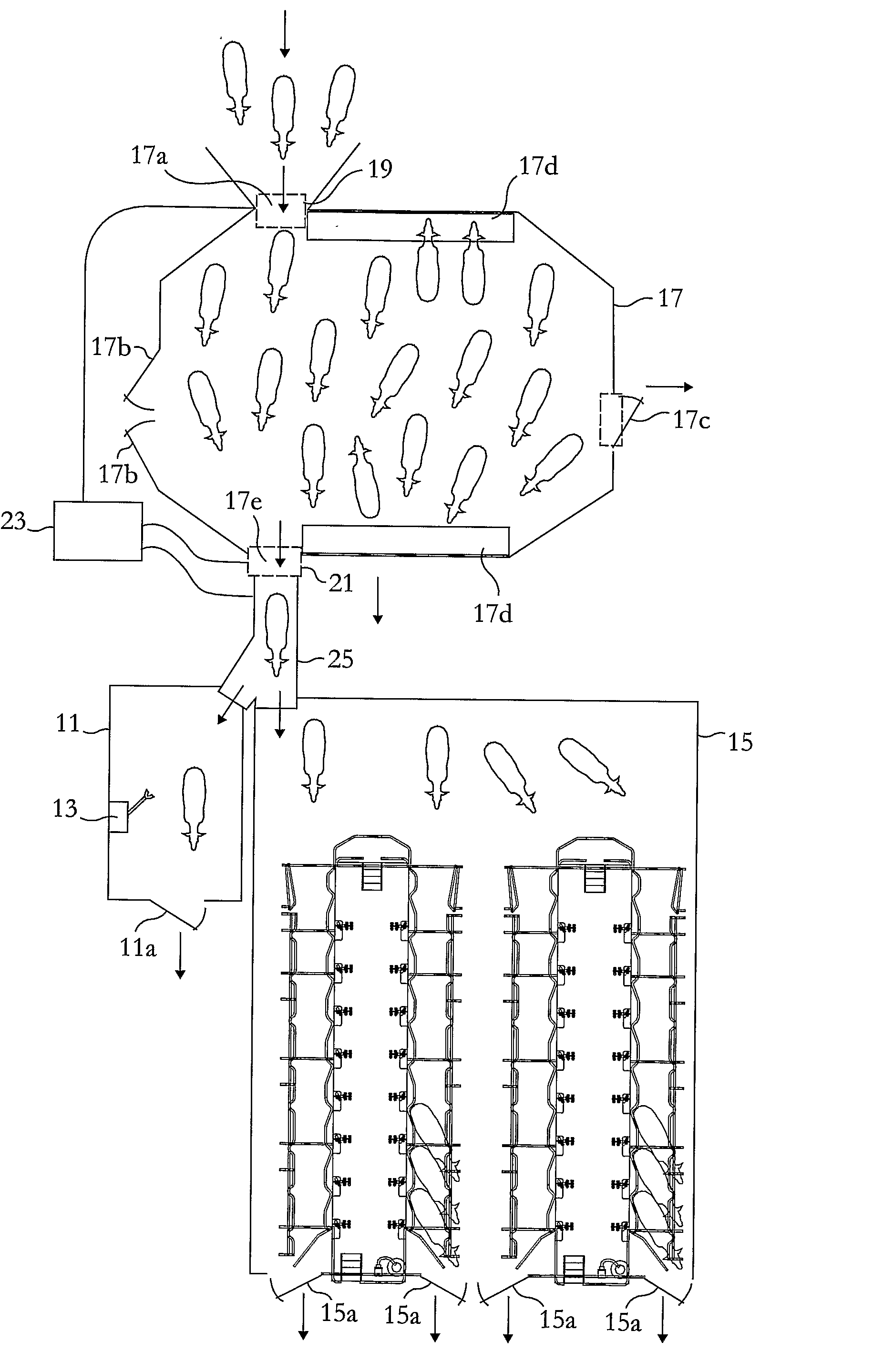

Milking facility and method for milking therein

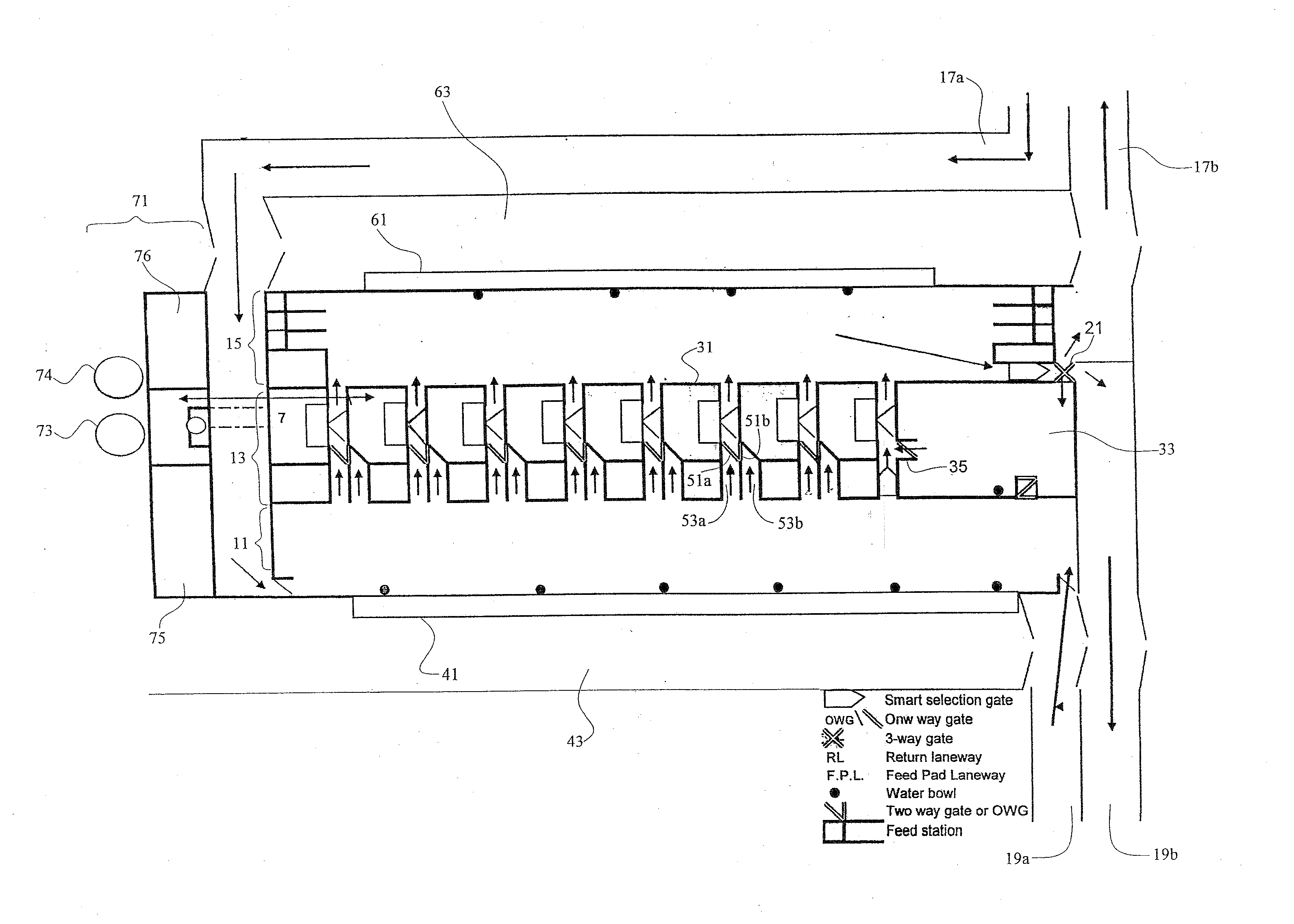

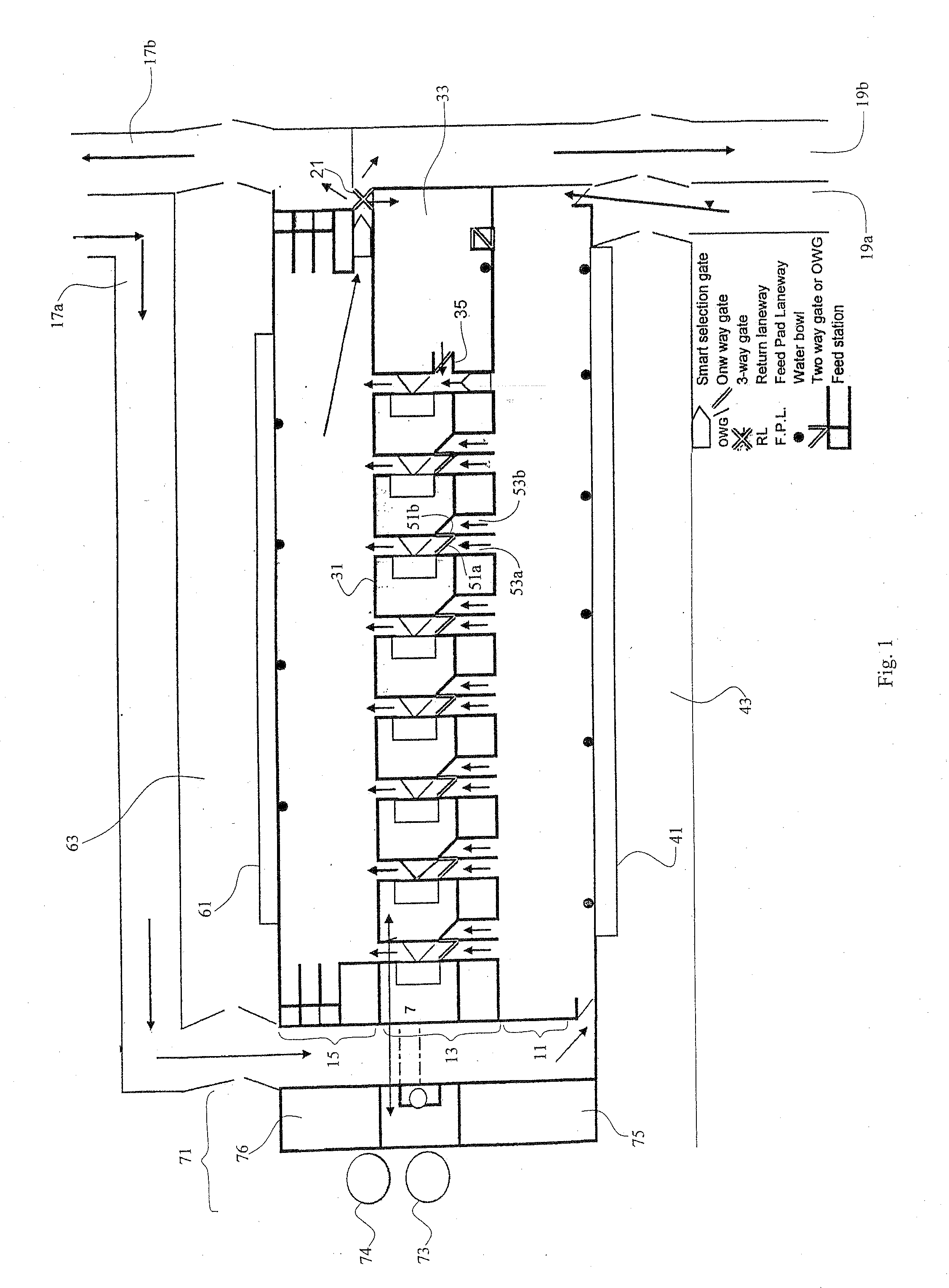

ActiveUS20100192860A1Cost-efficient productionImprove overall utilizationCathetersAnimal housingHerdAutomatic milking

A space-saving milking facility includes an entrance passage way (17a) provided for receiving milking animals on a voluntary basis, a waiting area (11), a milking area (13) housing automatic milking stations (31), a post-milking area (15), and an exit passage way (17b), through which milking animals may leave the milking facility. The automatic milking stations (31) are arranged side by side along a row, the waiting area (11) and the post-milking area (15) are elongated and parallel with the row of automatic milking stations (31), the entrance passage way (17a) is joined to the waiting area (11) at a short side thereof, and the exit passage way (17b) is joined to the post-milking area (15) at a short side thereof. The milking facility is particularly aimed for herds of milking animals at grazing.

Owner:DELAVAL HLDG AB

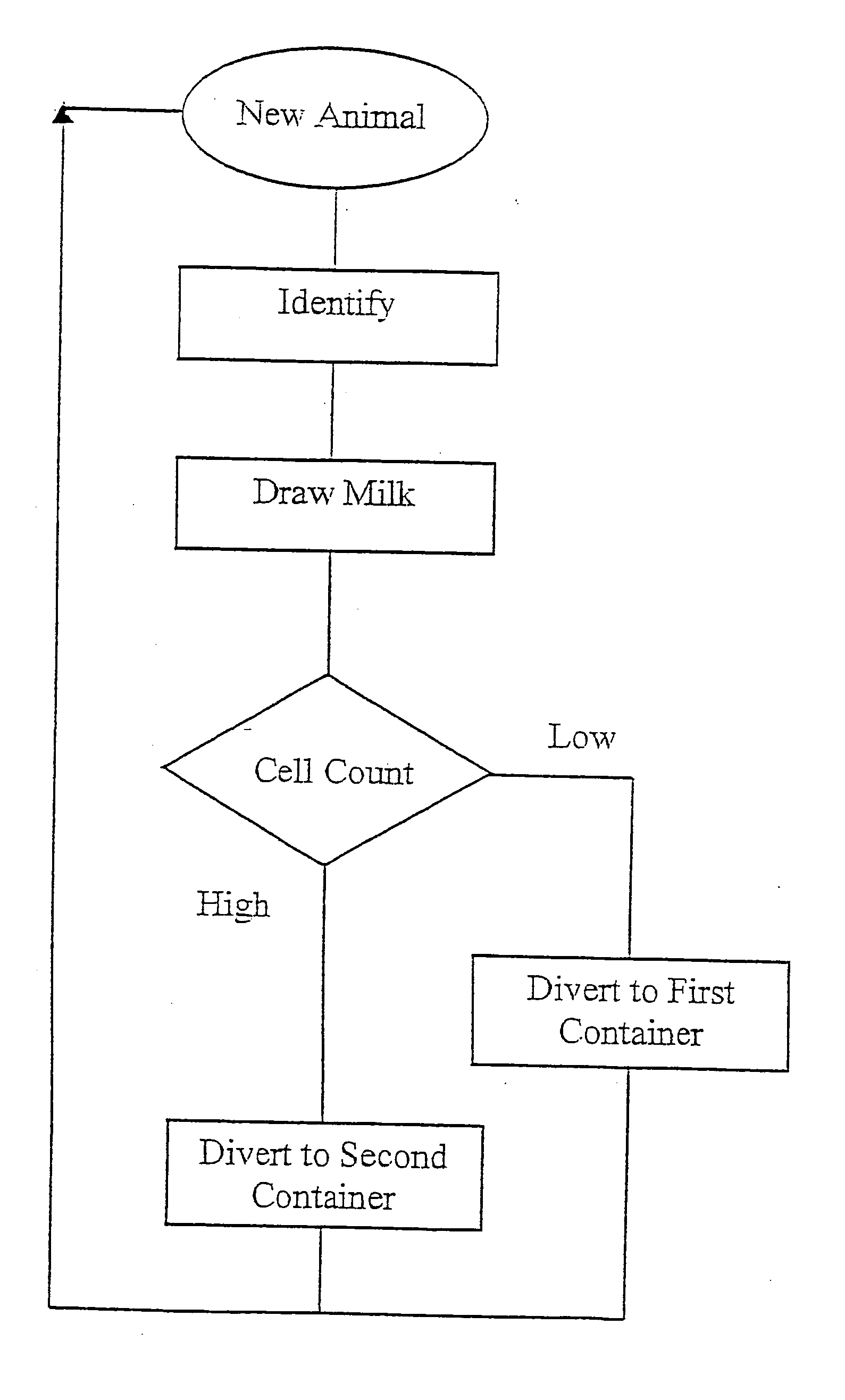

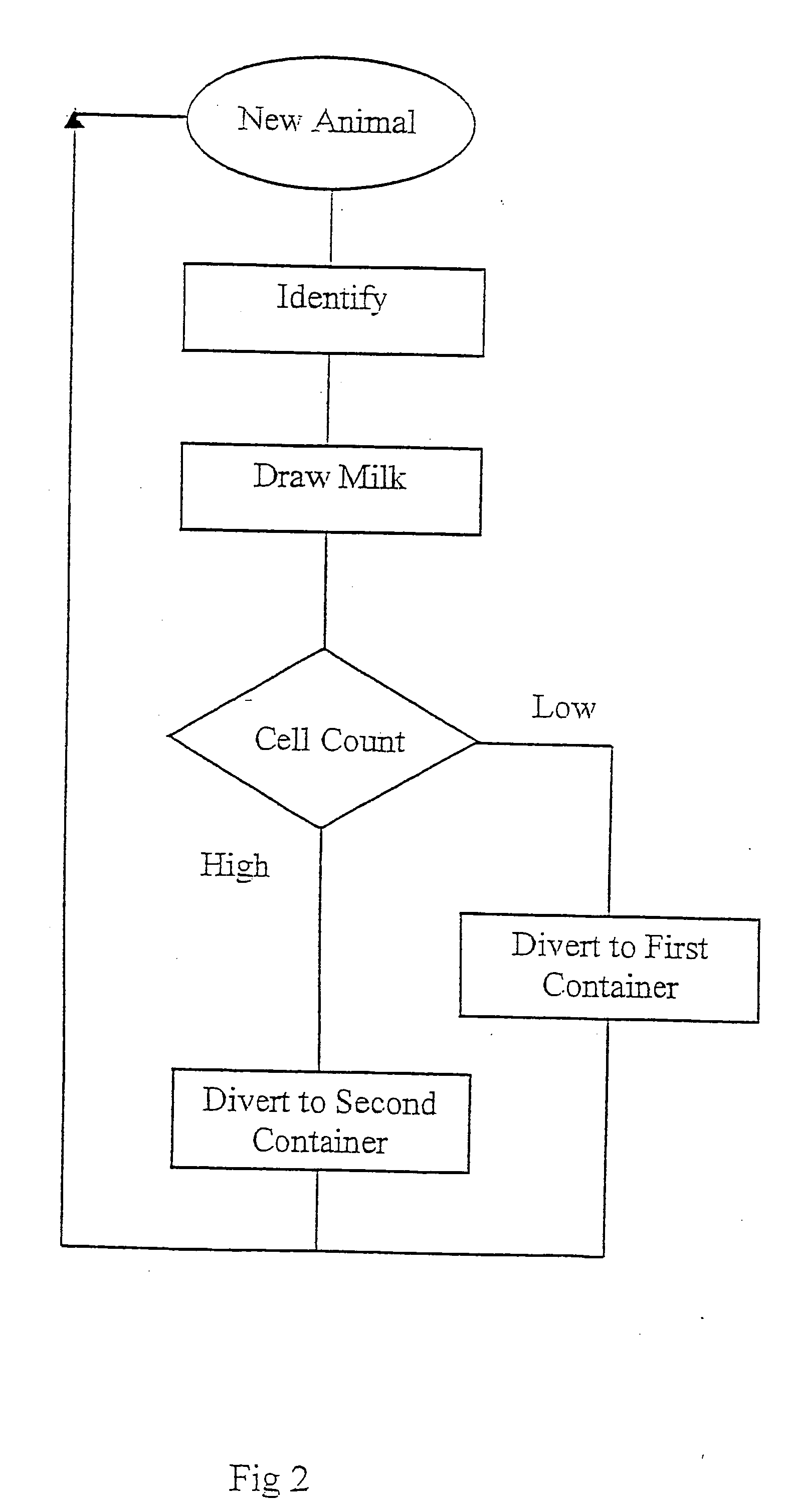

Automatic milk separation

The present invention, relates to separating a first quantity of milk drawn from a milking animal in an automatic milking machine from a second quantity of milk drawn from a milking animal in said milking machine. Comprising the steps of milking an animal using said automatic milking machine, collecting a small representative amount of said milk during said milking, analysing at least a part of said small representative amount of milk using an on-line cell counter for counting the number of cells in said milk, and operating a valve depending on the counted number of cells so that if the counted number of cells are below a threshold said milk is collected in a first container and if said counted number of cells are equal to or above said threshold said milk are directed to either a drain or a second container.

Owner:DELAVAL HLDG AB

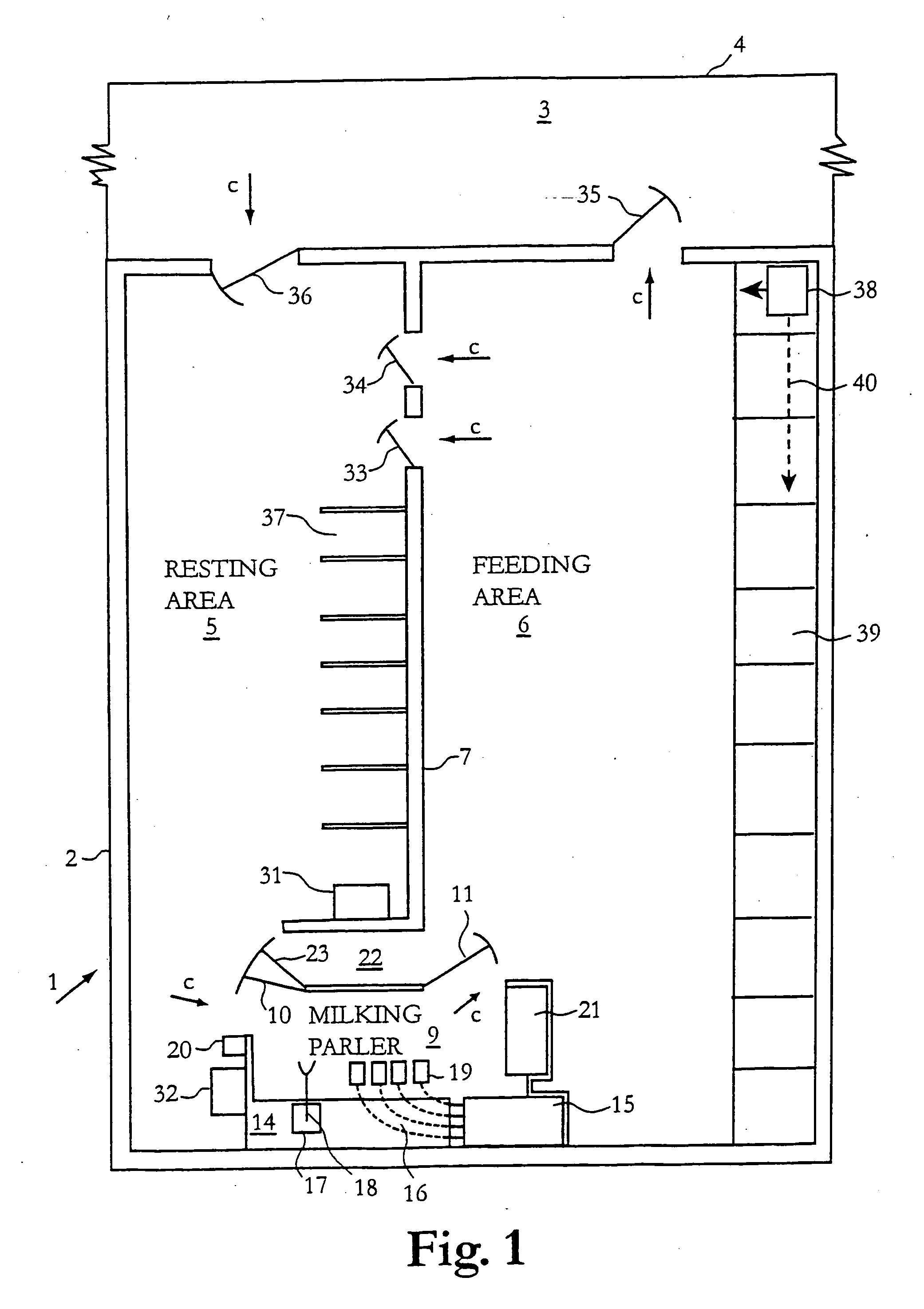

Methods of managing animals and milking station

A method of automatically milking animals, which are allowed to move in an area (3, 5, 6) intended therefore, the area including a resting area (5) and a feeding area (6) and housing a milking station (9), which the animals are allowed to visit individually and which a selected group of said animals have to visit in order to move from the resting area to the feeding area, comprises the steps of establishing a condition for low utilization of the milking station; and feeding the animals by means of a feeding device (38) when the condition for low utilization of said automatic milking machine is met to thereby entice animals in the resting area to move to the feeding area and to therewith present themselves at the milking station.

Owner:DELAVAL HLDG AB

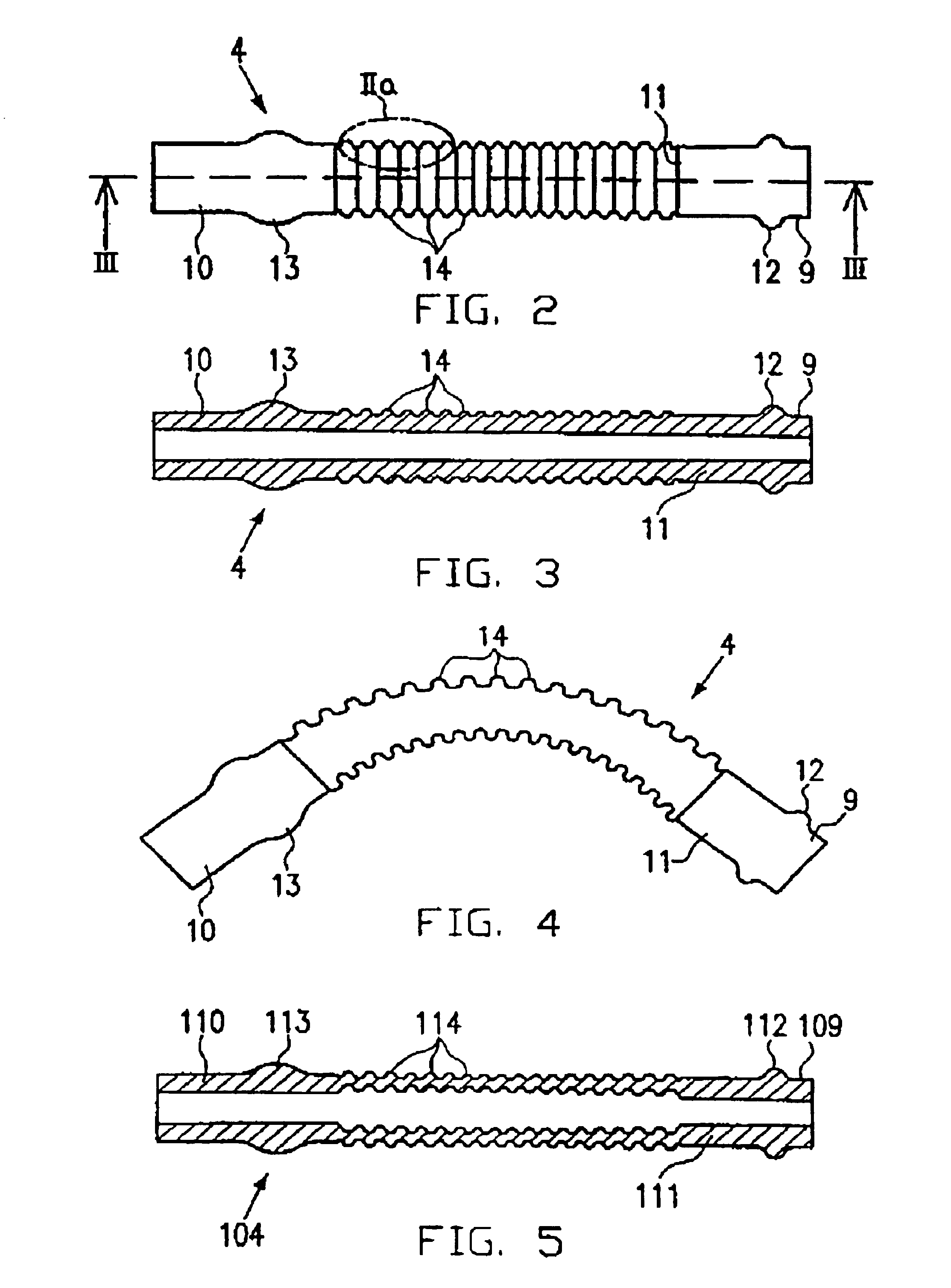

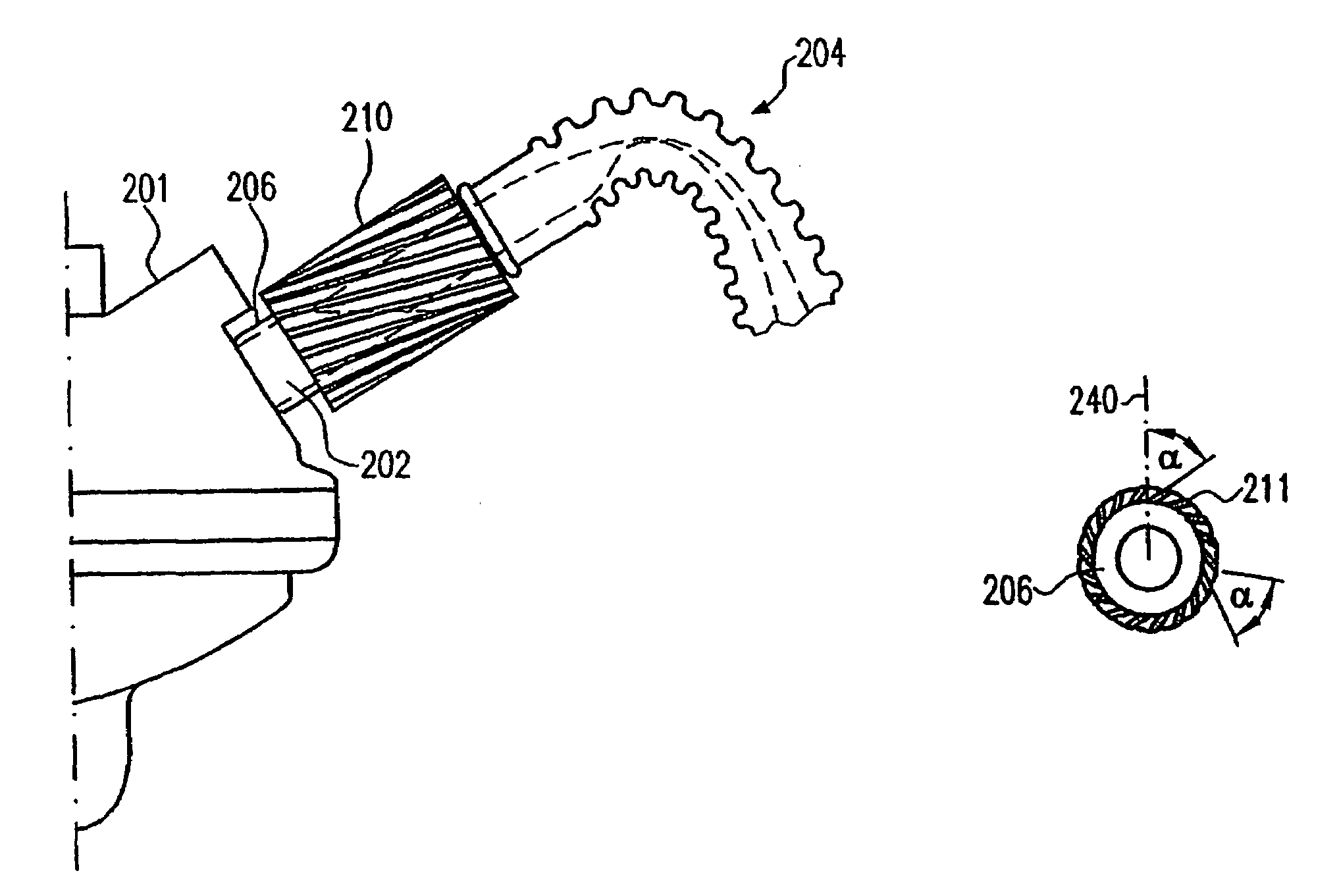

Milk hose with impact-absorbing area

InactiveUS7637228B2Effective bufferReduce material fatiguePipe elementsMilking devicesEngineeringAutomatic milking

A milk hose for connecting a milk collecting piece to a teat cup in an automatic milking plant comprises a first end area which is adapted to be fixed to the connection element of the teat cup and a second end area which is adapted to be fixed to the connection element of the milk collecting piece. Furthermore, said second end area has provided thereon an impact-absorbing area comprising elongate impact-absorbing elements, which, when subjected to a radial impact load, are deformed and / or bent at least sectionwise in a predefined preferred direction, and / or nipple-shaped impact-absorbing elements which are deformed and / or bent when subjected to said radial impact load. In addition, an impact-absorbing device for mounting on a milk hose is described.

Owner:HATZACK WILFRIED +1

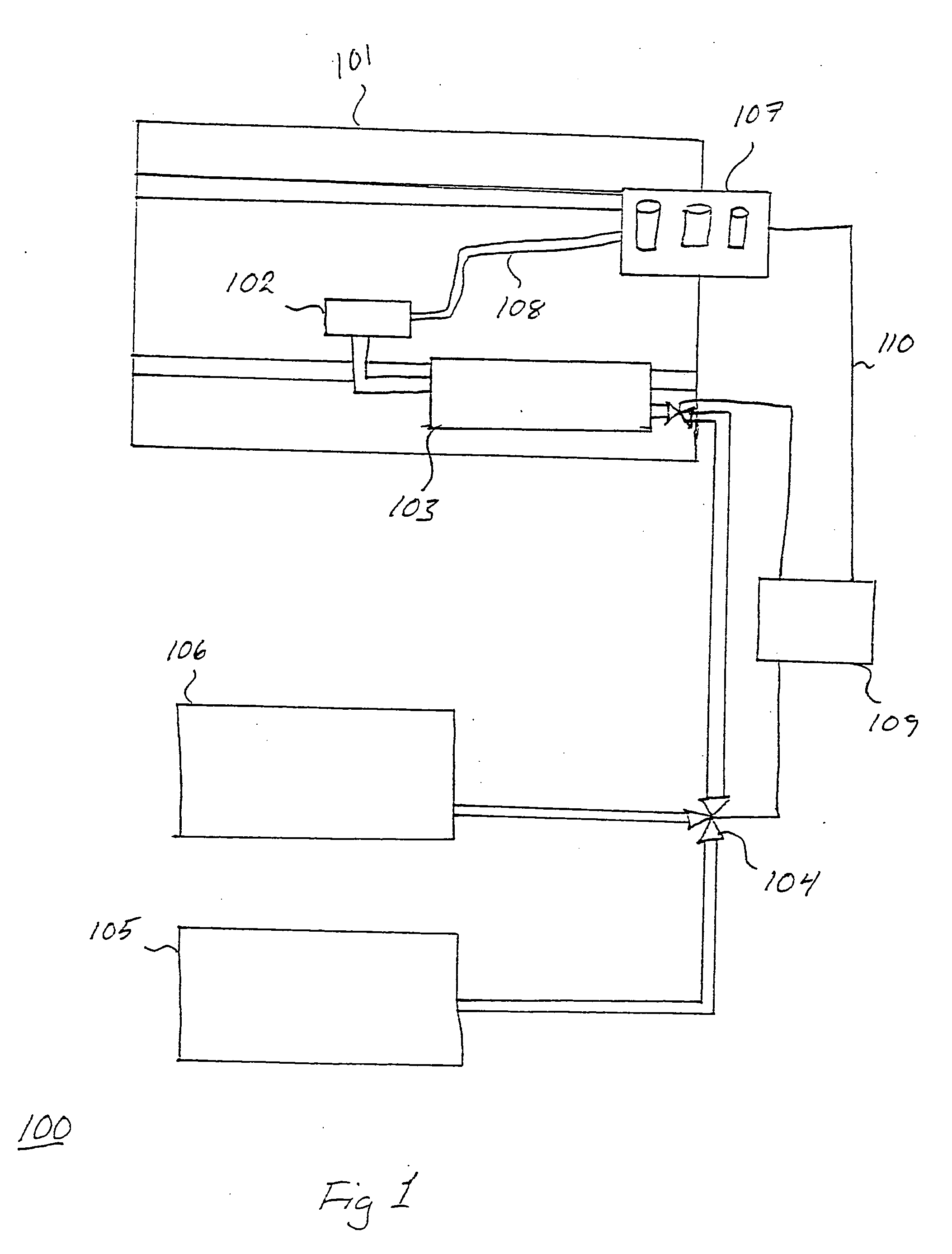

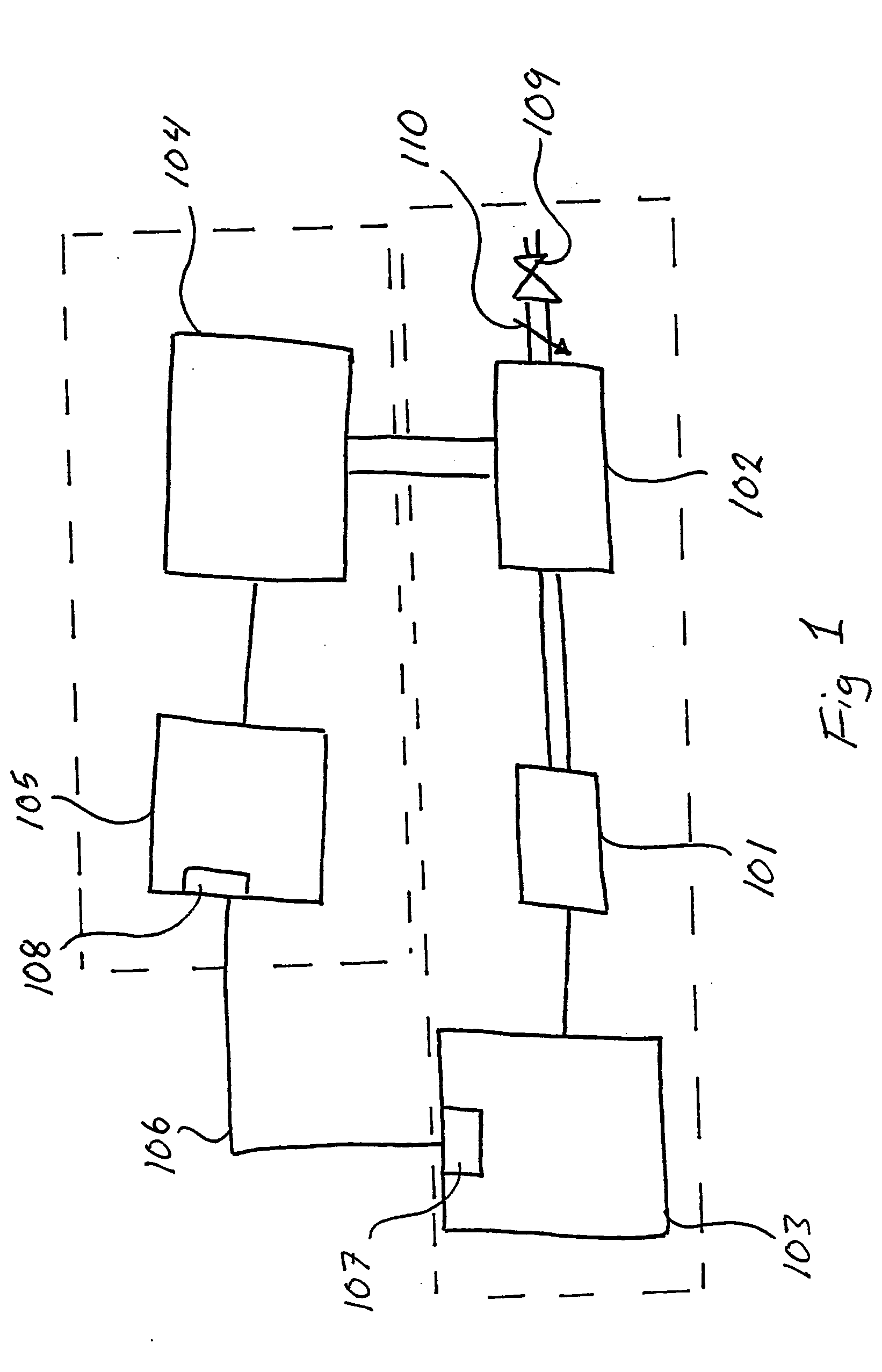

Vacuum system communication

The present invention relates to controlling vacuum parameters relating to a vacuum pump arrangement in a automatic milking system, said automatic milking system comprising a vacuum pump arrangement (101), said automatic milking system comprises a milking system controller (105) arranged to control milking system parameters and said vacuum pump arrangement comprises a vacuum system controller (103) for controlling vacuum system parameters. Communication means (106) is coupled to said vacuum system controller and to said milking system controller for establishing communication between said vacuum system controllers and said milking system controller. Said milking system controller comprises signal transmitting means (108) for transmitting a message to said vacuum system controller. Said vacuum system controller comprises signal receiving means (107) for receiving said message from said milking system controller, and said vacuum system controller is arranged to change a least one of said vacuum system parameters depending on said received message.

Owner:DELAVAL HLDG AB

System for regulating the handling of milk during the milking process and a method for regulating said milking process

InactiveUS7155345B1Substantial simplification improvement to automationSimple and reliable processDough treatmentDigital data processing detailsAutomatic milkingMastitis

Owner:DELAVAL HLDG AB

Method of automatically milking a dairy animal

A method of automatically milking a dairy animal by means of an automatic milking device includes successively the steps of:a) automatic connection of a first teat cup to a first teat of the dairy animalb) pushing away the first teat cup connected to the first teat, andc) automatic connection of a second teat cup to a second teat of the dairy animal alter the first teat cap has been connected to the first teat.

Owner:LELY ENTERPRISES

Method of milking and milking parlor

A method of automatically milking animals, such as cows, which are allowed to move freely in an area (1) intended therefore and to visit individually a milking parlor (9) comprising a fully automatic milking machine or milking robot (14) and an animal identification system (20), comprises the steps of dynamically assigning a milking qualification parameter to each of the animals that are allowed to move freely in said area, the respective milking qualification parameter indicating the degree of suitability that the respective animal, to which the milking qualification parameter is assigned, shall be milked; dynamically ranking the animals in accordance with their respective milking qualification parameters; and milking an animal during a visit to the milking parlor only if said animal is identified as belonging to the X highest ranked animals, i.e. the X animals that are best suited to be milked from a milk production optimization viewpoint, X being a positive integer.

Owner:DELAVAL HLDG AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com