Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Milking robot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

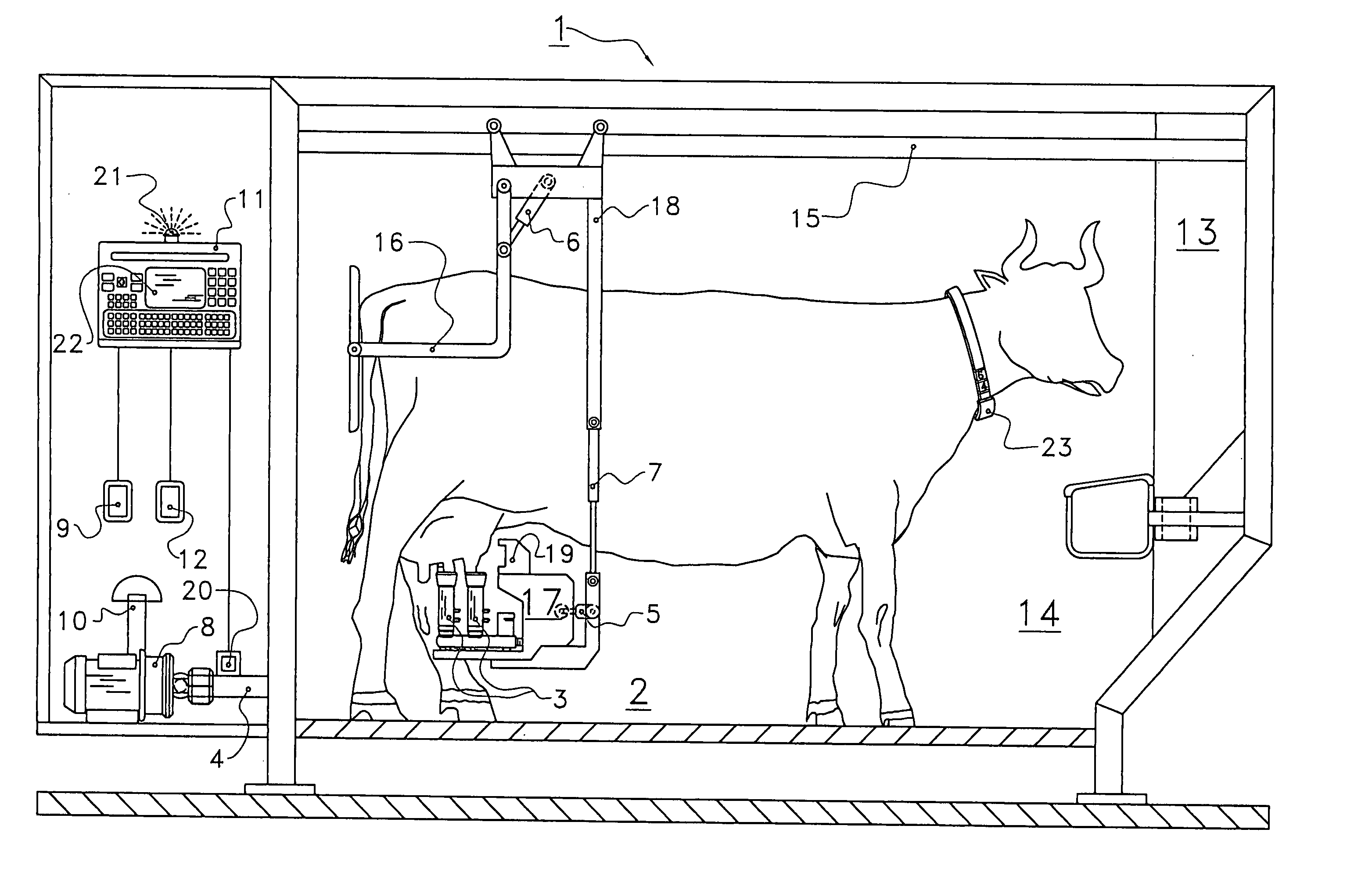

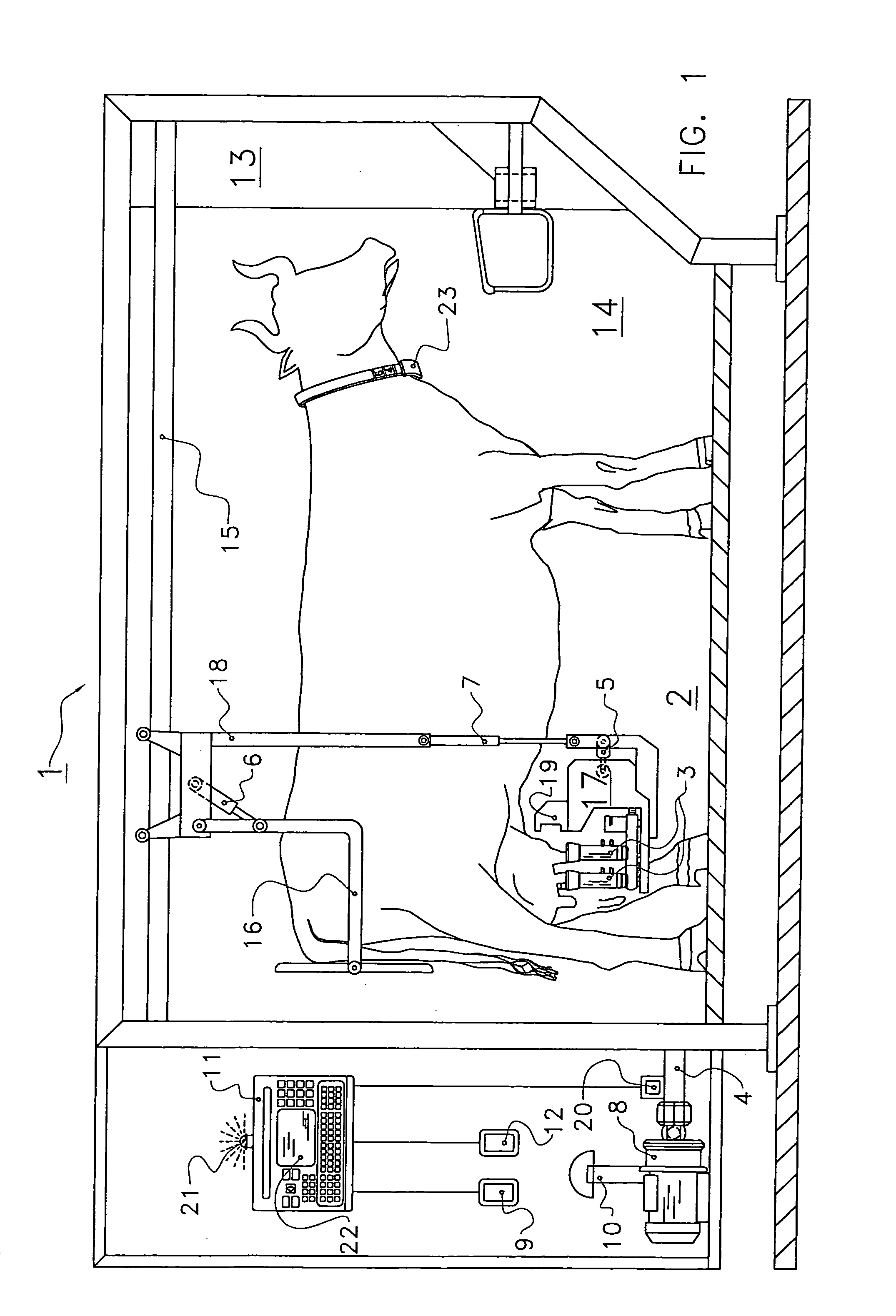

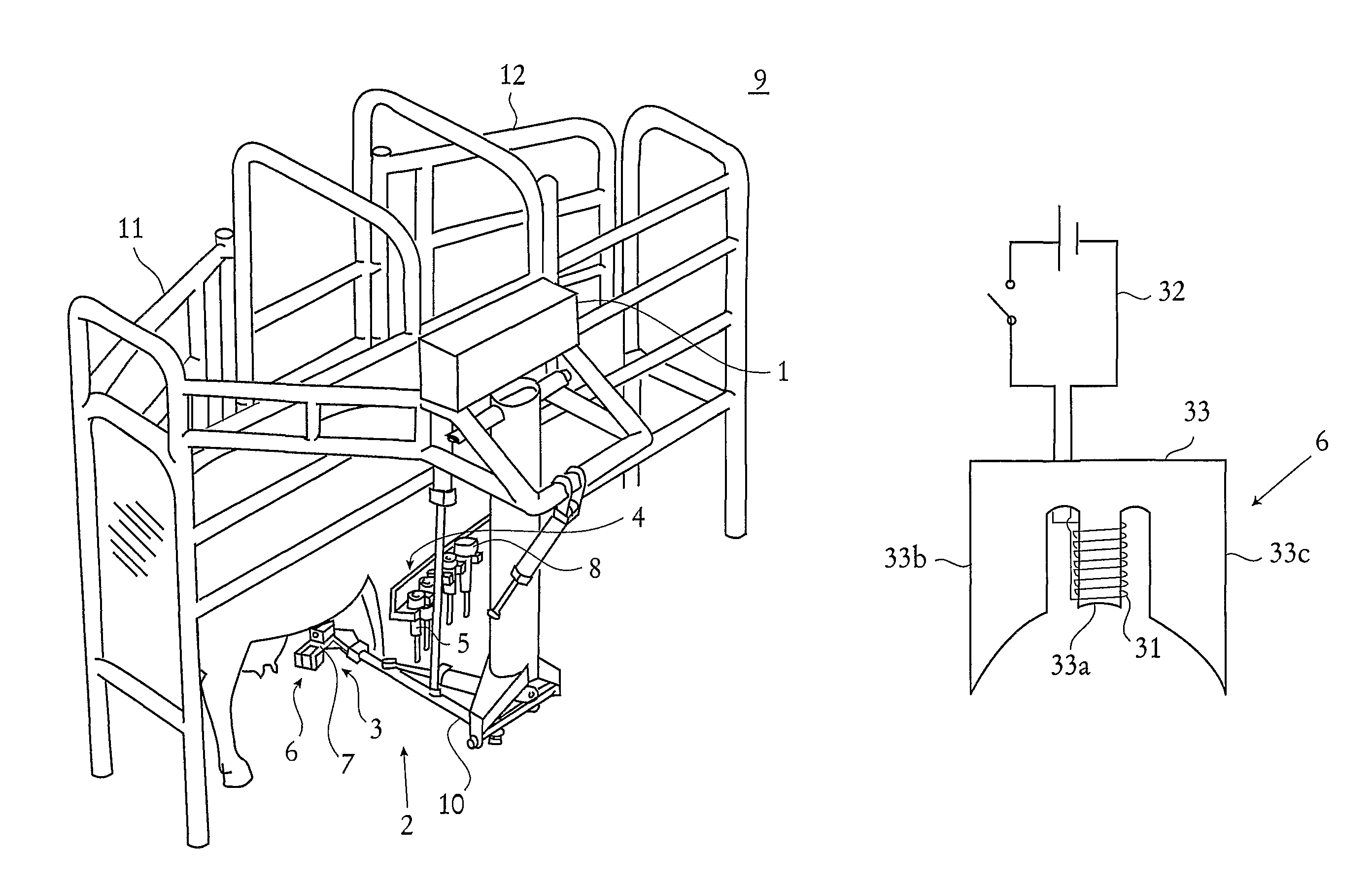

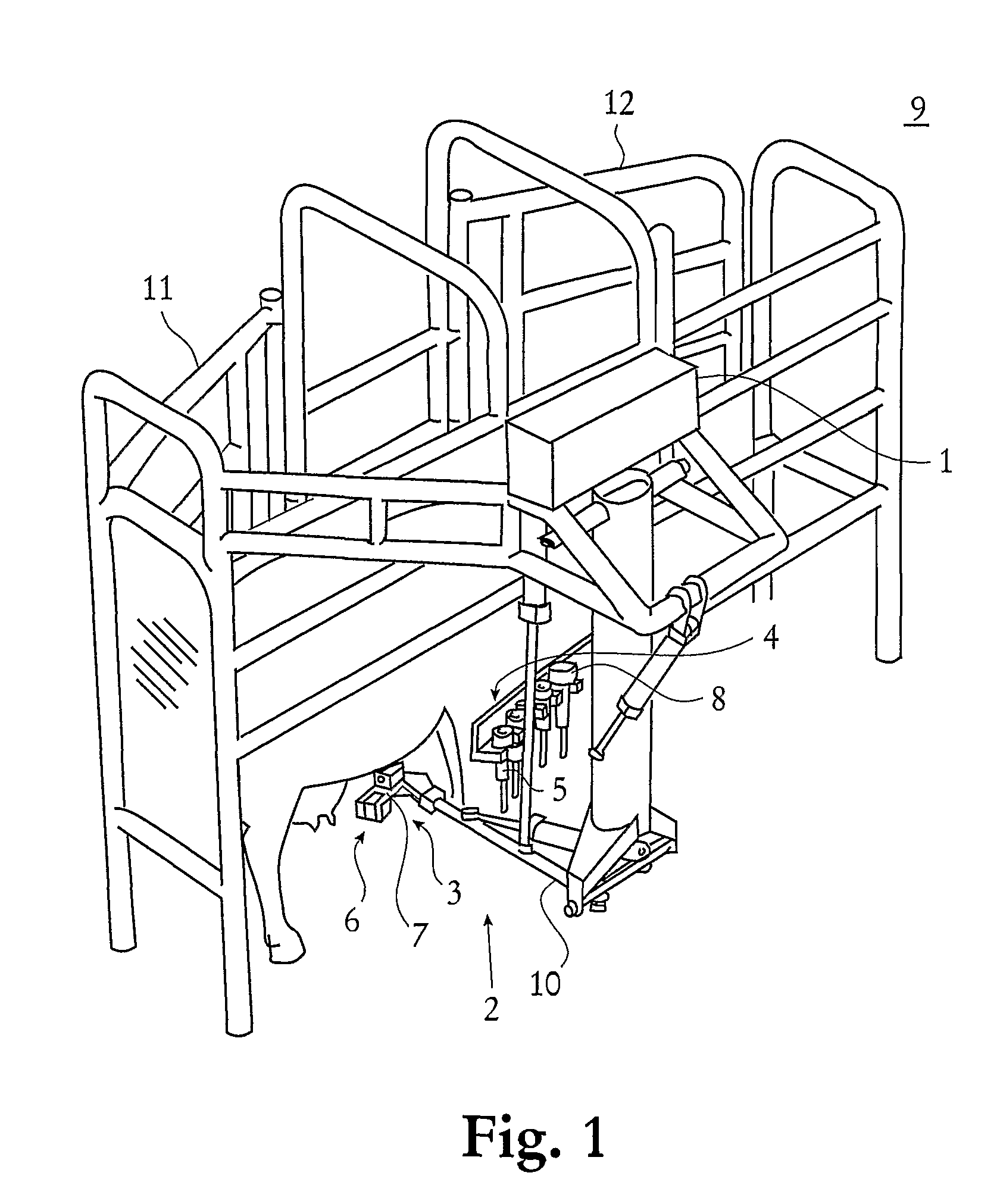

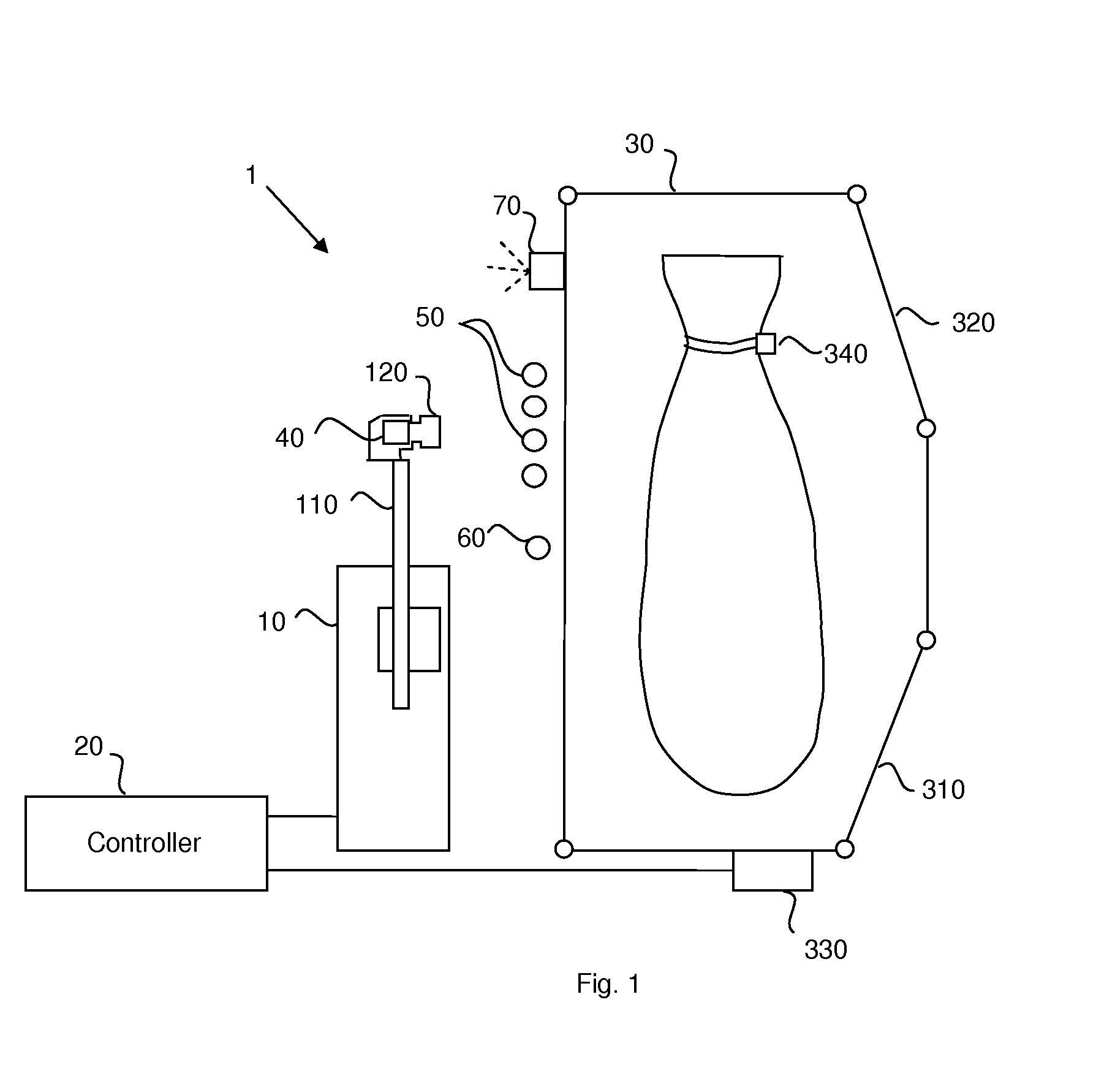

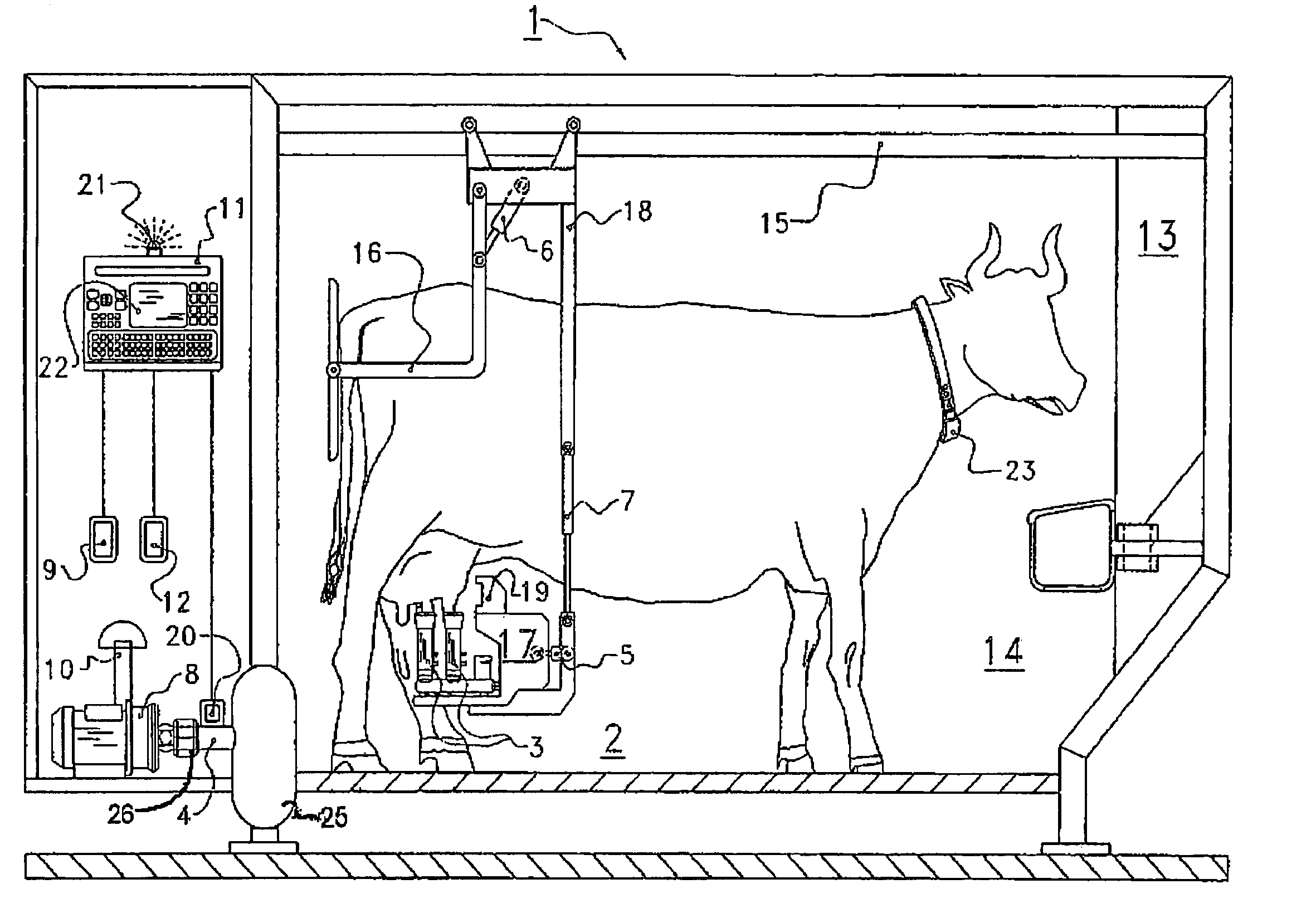

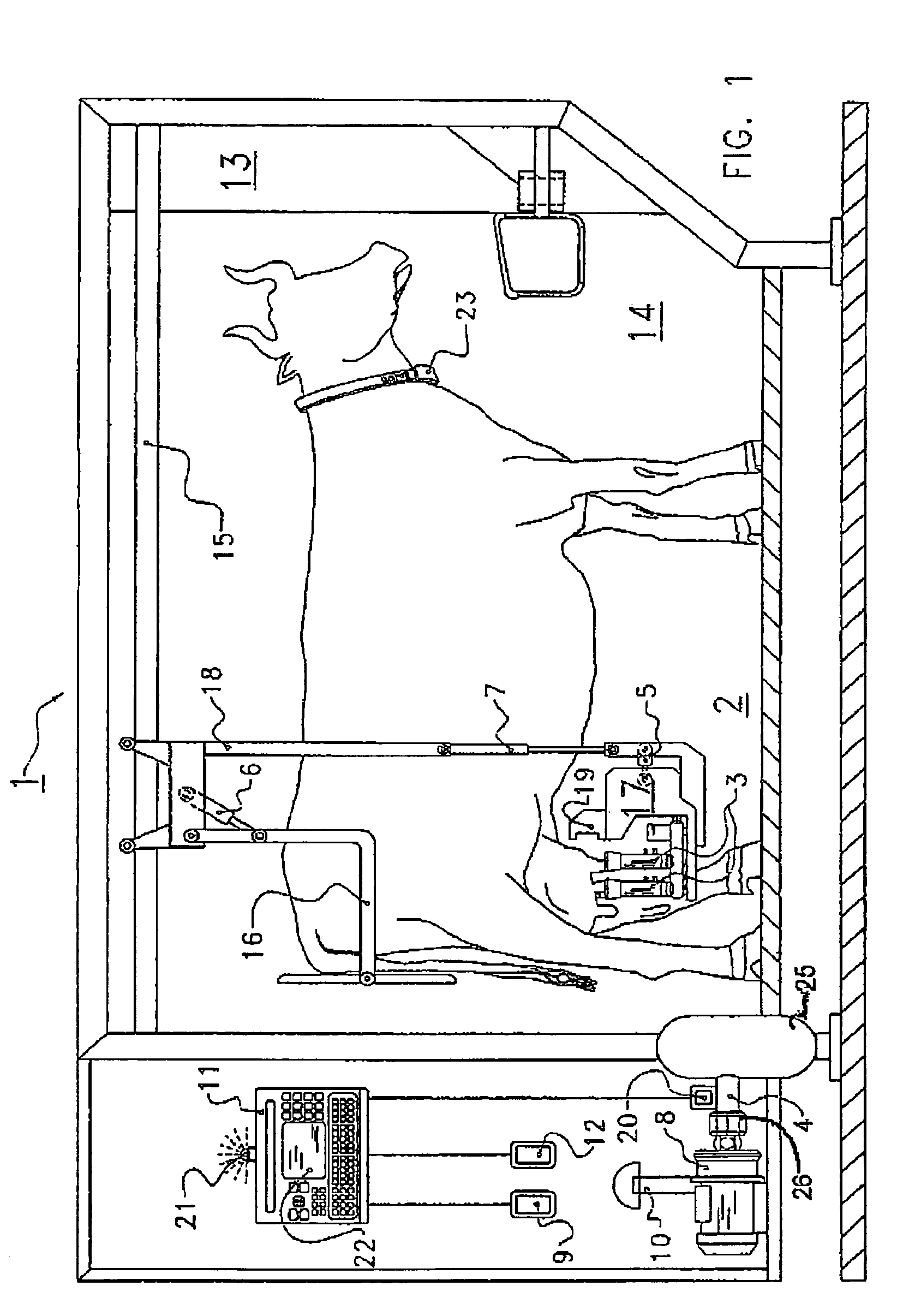

Method and apparatus for cleaning of a teat cleaning device

InactiveUS6626130B1Risk minimizationMinimum delayOther apparatusMilking devicesEngineeringMilking robot

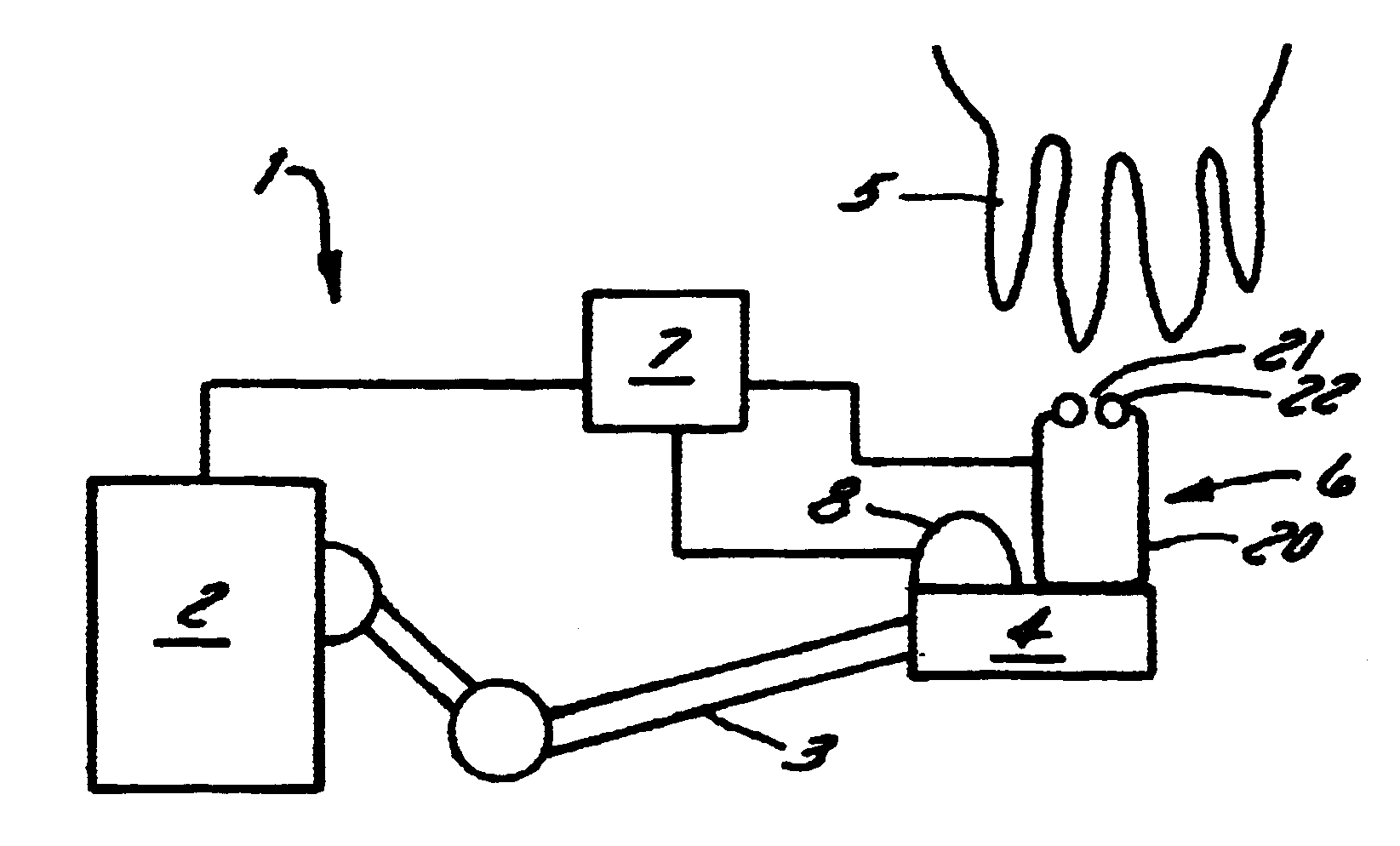

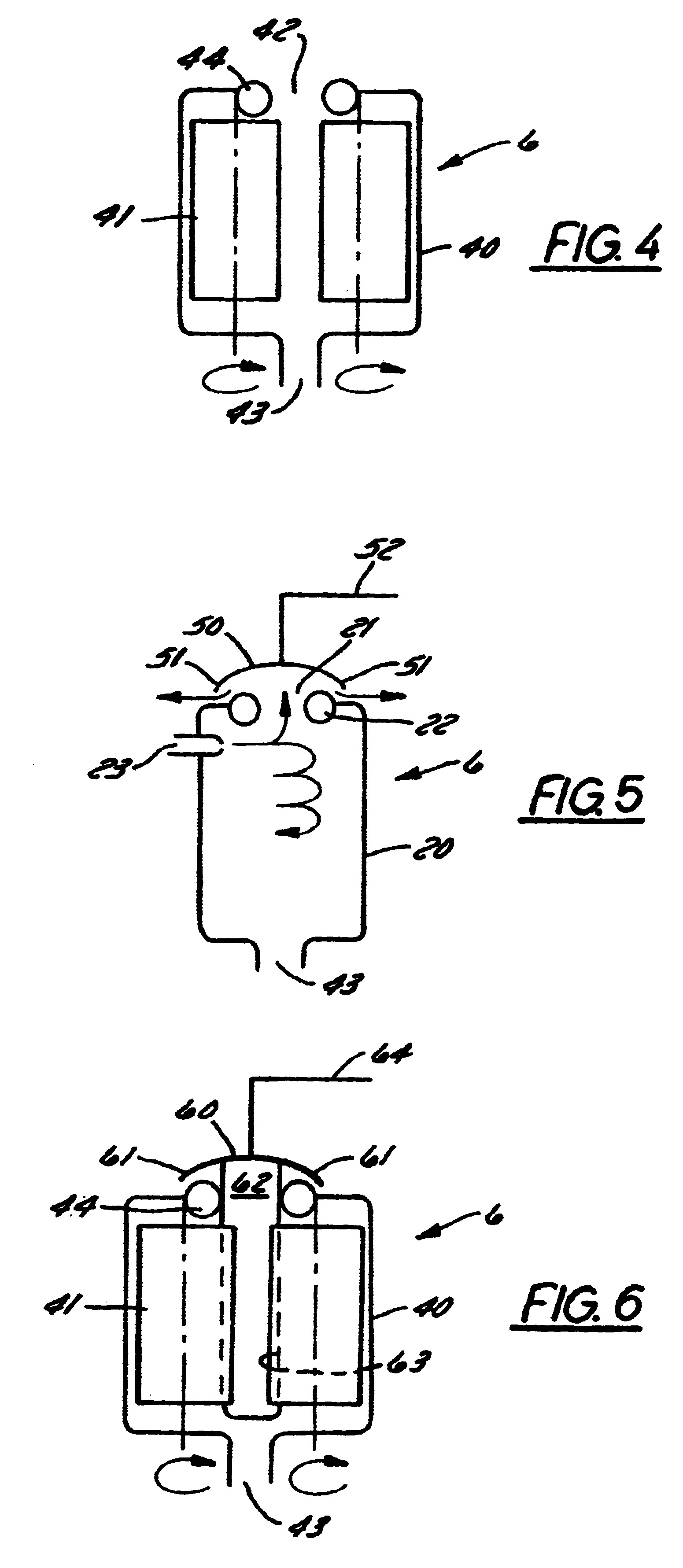

A teat cleaning arrangement (1) for milking equipment, comprising a teat cleaning device (6) with teat cleaning means (23, 41). A milking robot (2) with a robot front end (4) is devised to move the teat cleaning device (6) into engagement with a teat (5), and control means (7) are connectable to the robot (2) for controlling motion thereof. The control means are also connectable to the teat cleaning device (6) for controlling the teat cleaning means (23, 41), and engagement and disengagement with a teat (5). The control means (7) are devised to activate said teat cleaning means (23, 41) to clean said teat cleaning device (6) after each teat disengagement.

Owner:DELAVAL HLDG AB

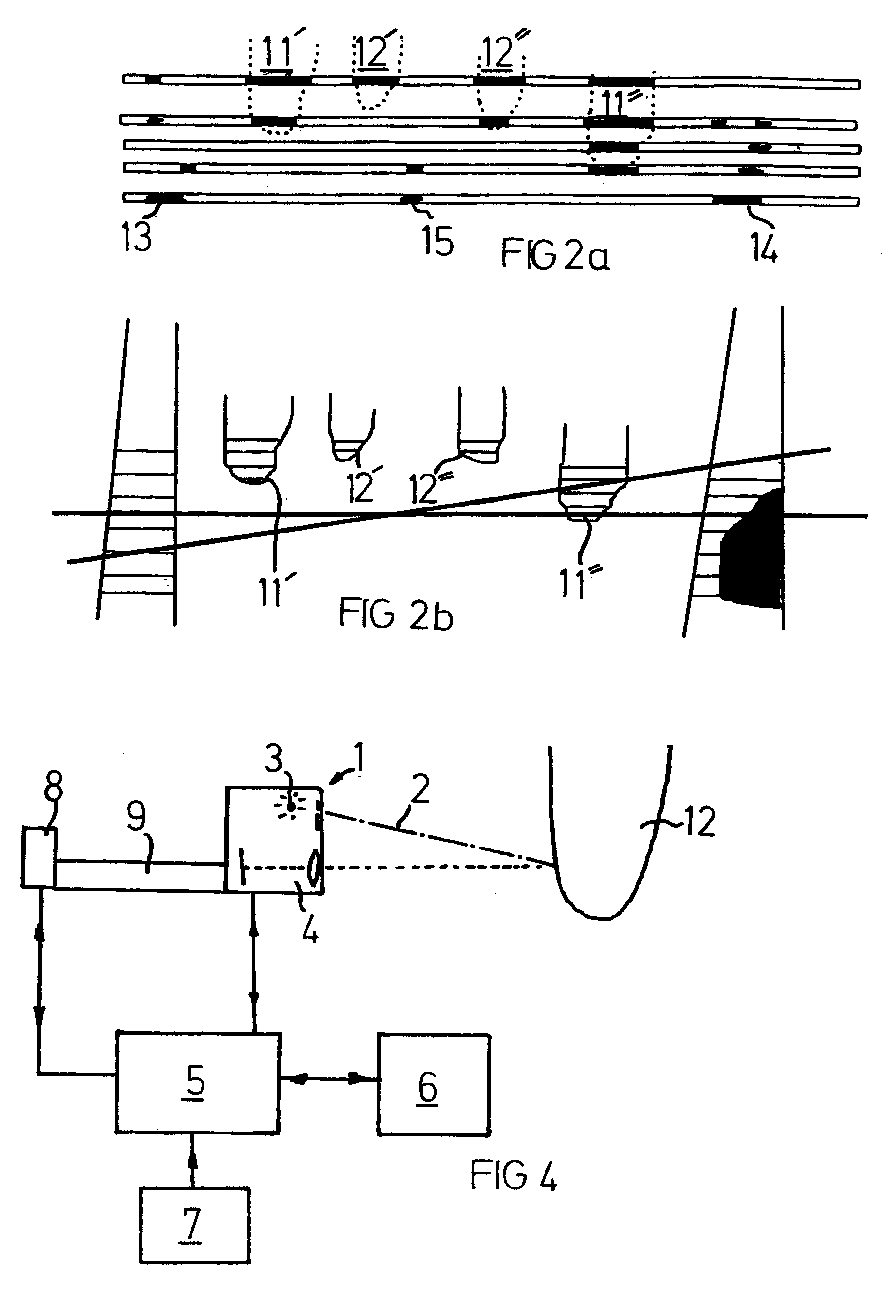

Method and apparatus for recognizing and determining a position and robot including such an apparatus

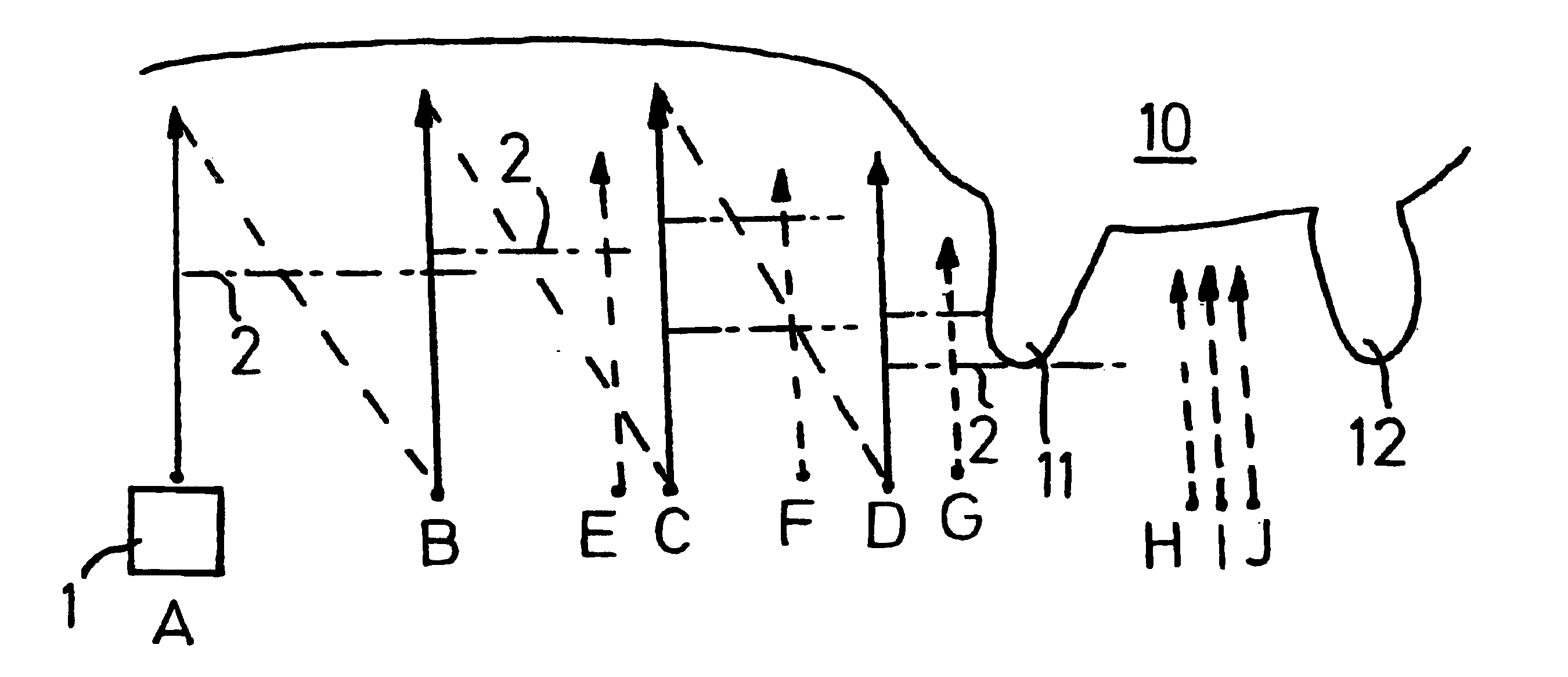

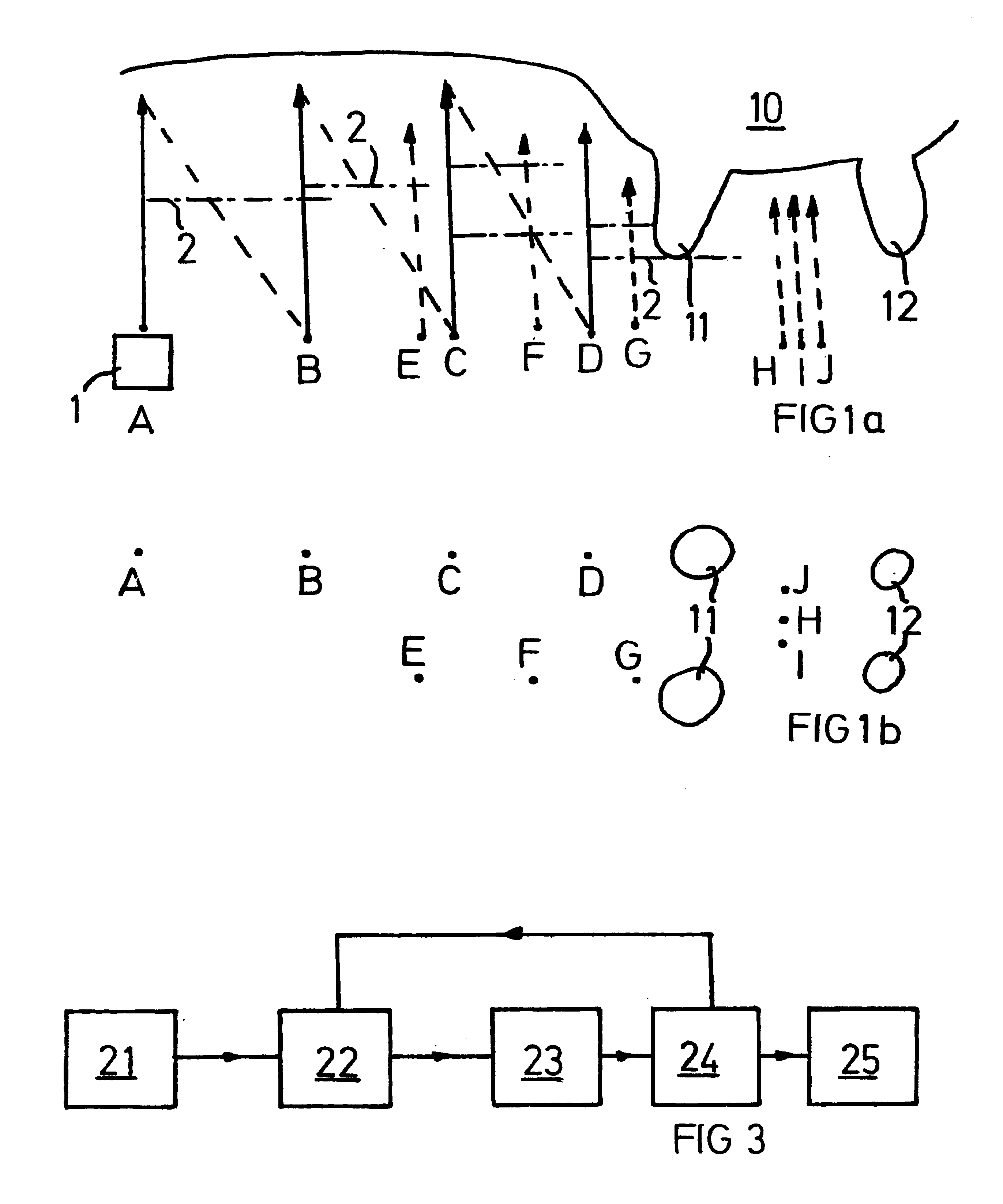

A method for recognizing and determining the position of at least one teat of a milking animal, including the steps: moving a scanning head including a light source to a region containing the teat or teats, capturing at least one image formed by said light, evaluating the image or images so as to determine if each image describes said teat or teats. The scanning head (1) is moved to a fixed initial position (A) in the room which is under the animal and clearly in front of an udder and thereby the teats of all known relevant animals, thereafter the scanning head is moved in determined steps (A-J) under the animal: upwards towards the animal, downwards, backwards towards the udder, upwards, downwards etc., while carrying out the scanning procedure. The invention also concerns an apparatus carrying out the process and a milking robot including such an apparatus.

Owner:DELAVAL HLDG AB

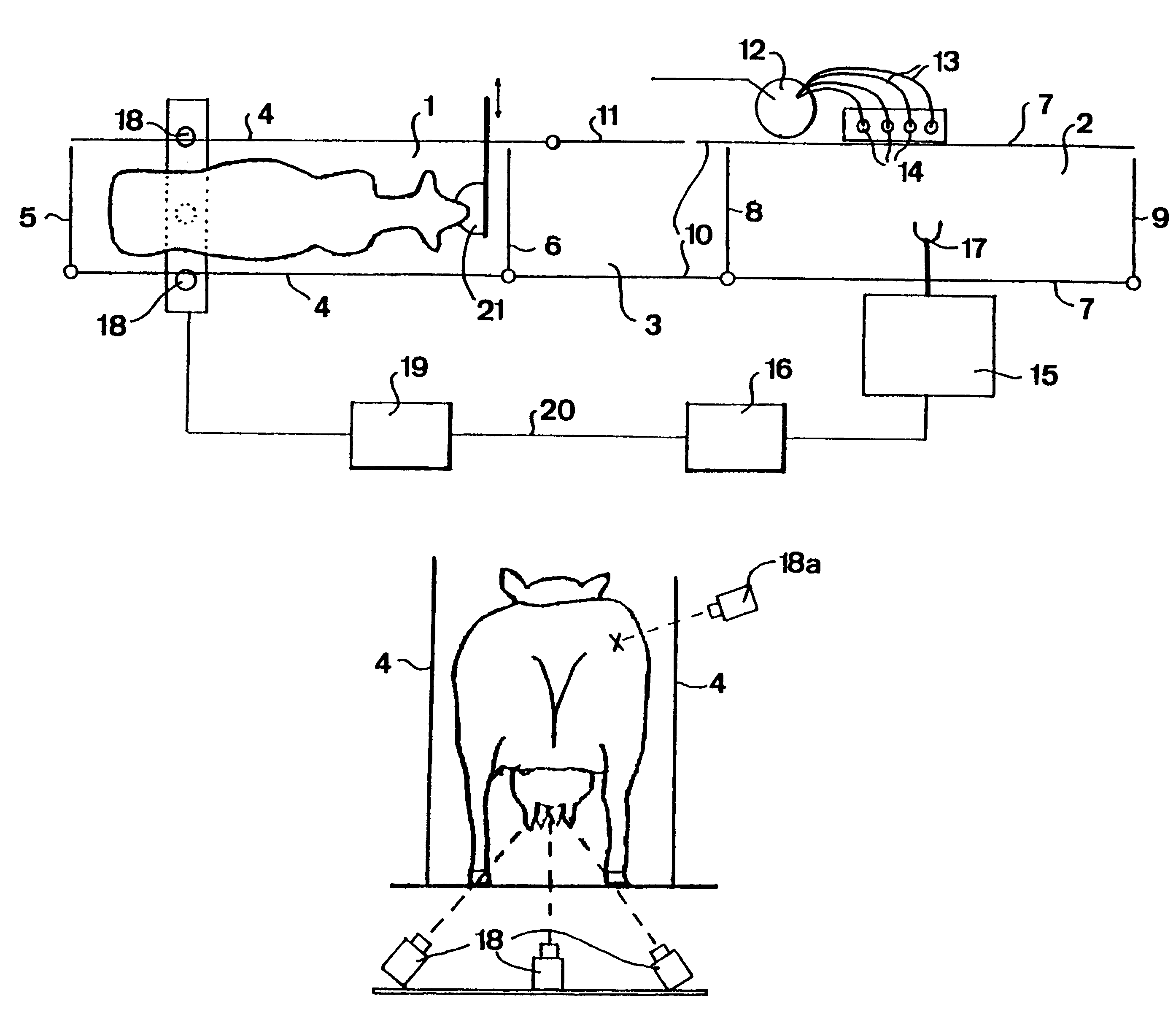

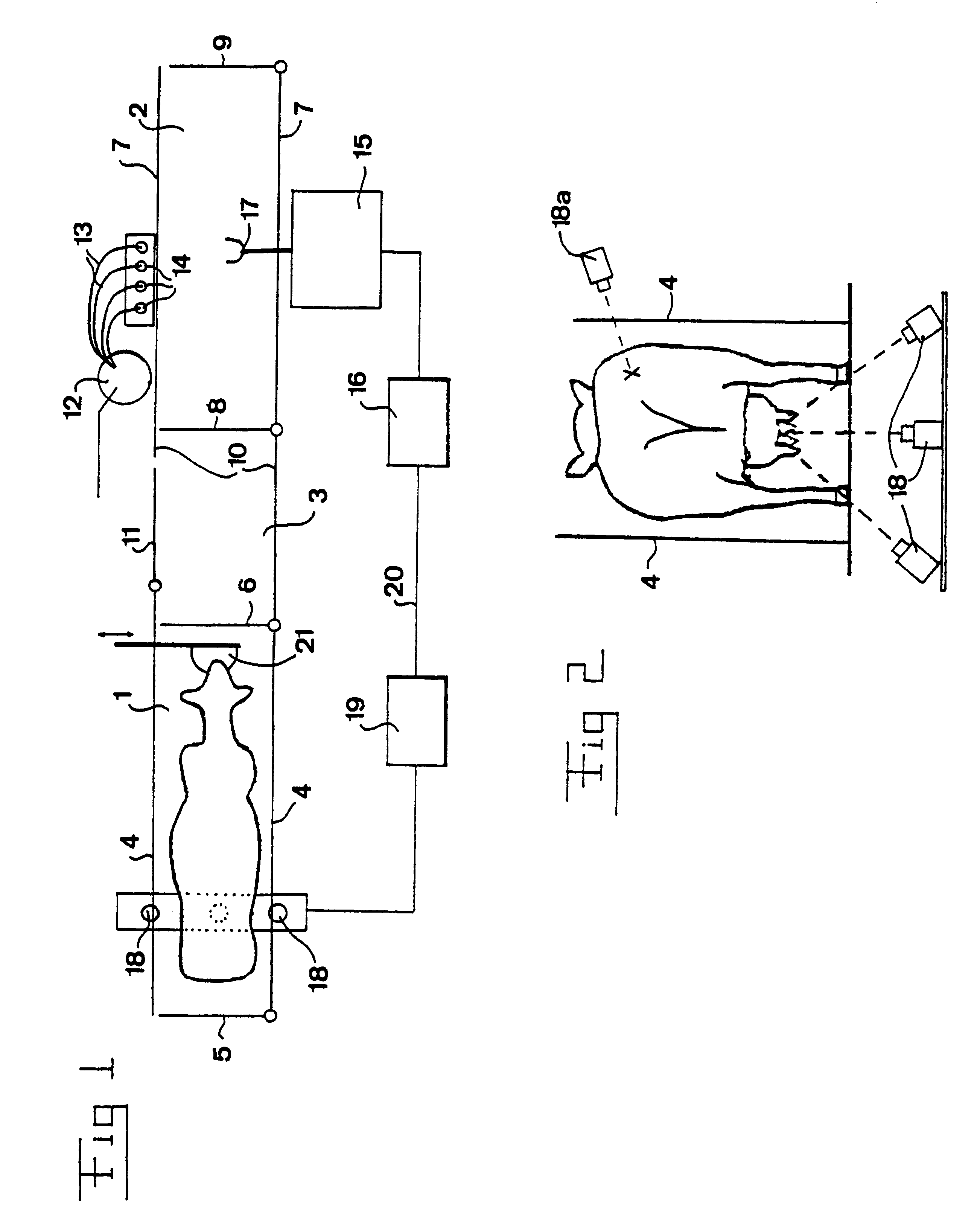

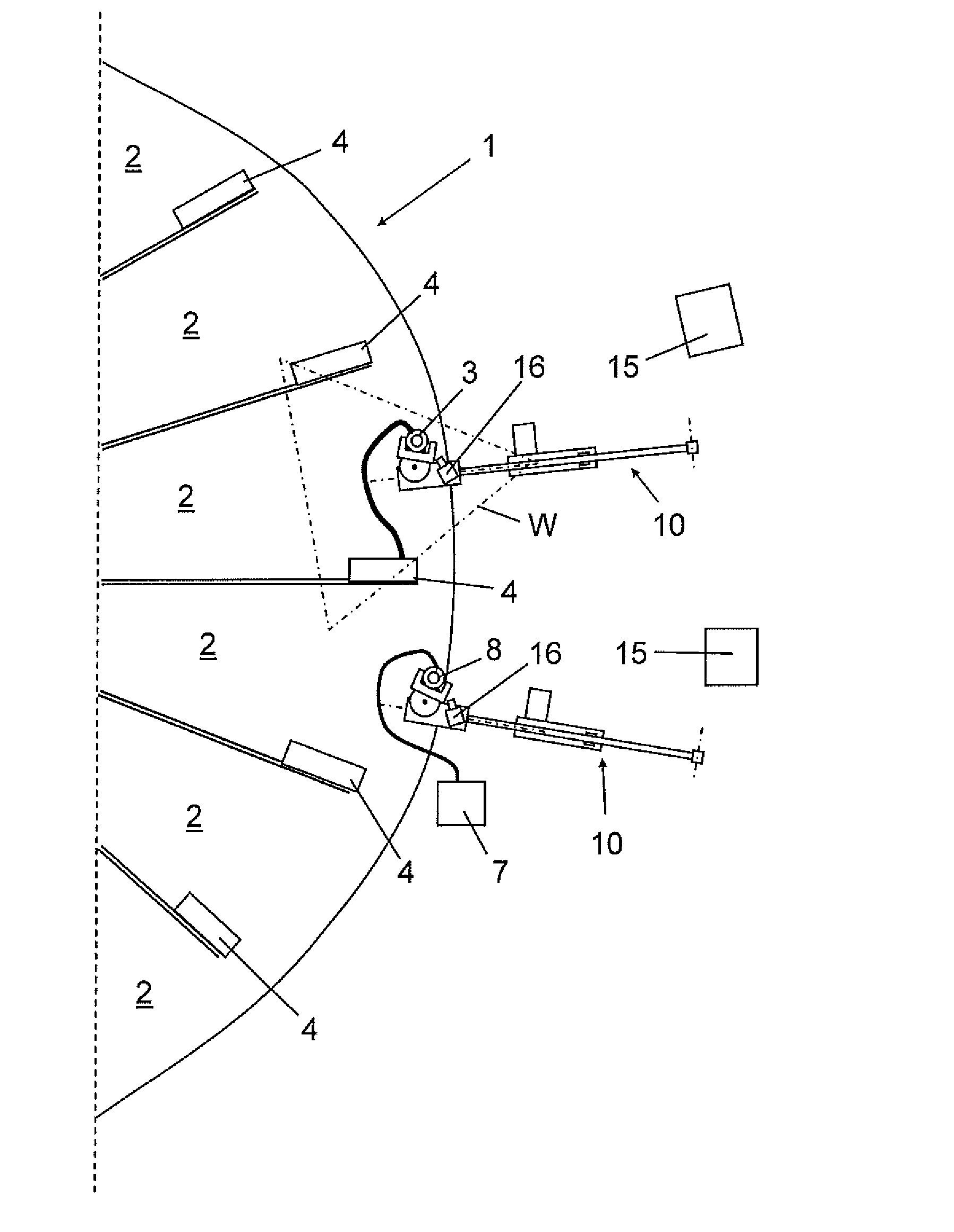

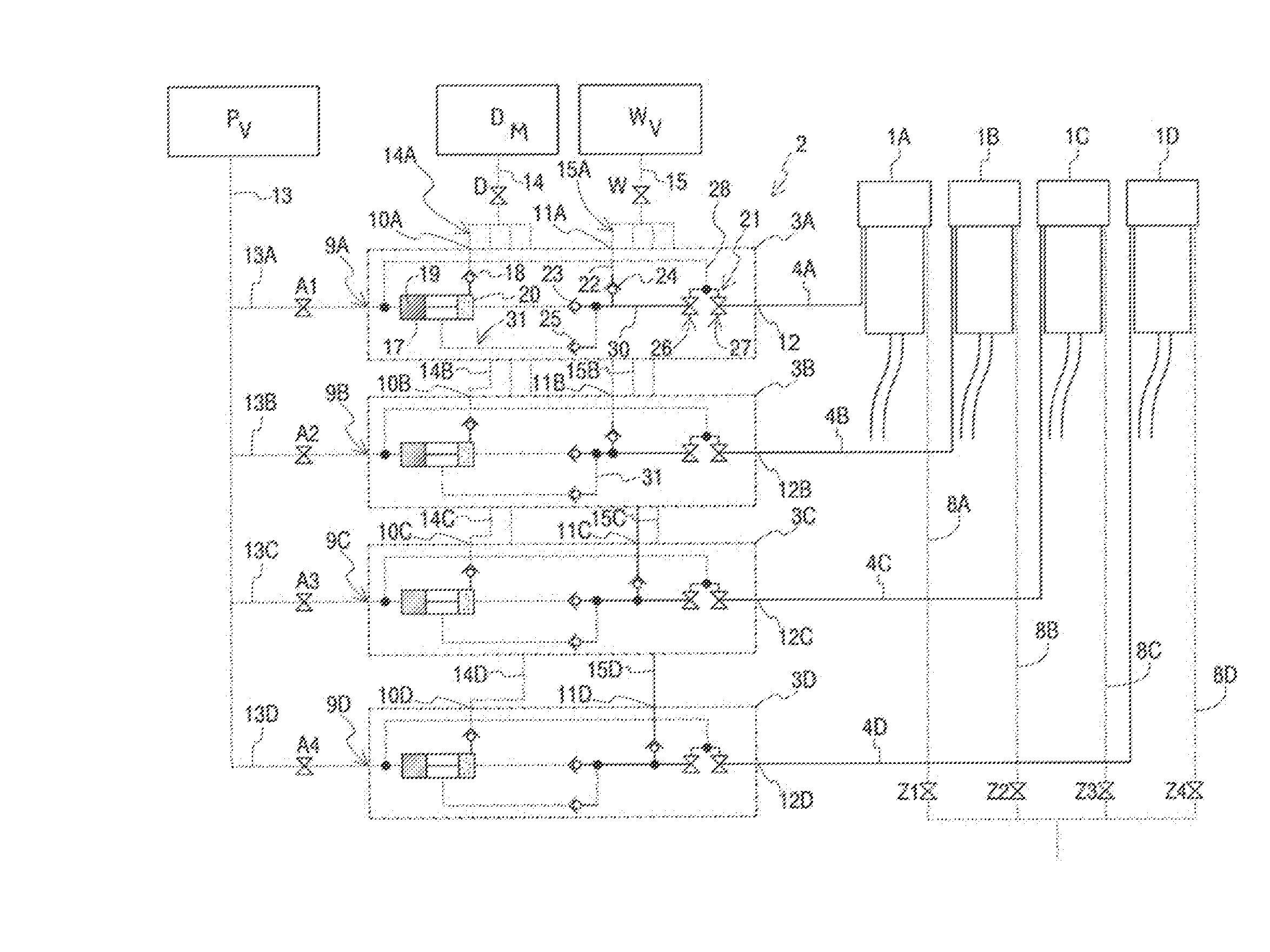

Arrangement and a method of performing an animal-related action

InactiveUS6167839B1Improve performanceEfficient use ofCathetersAnimal housingEngineeringLocation determination

An arrangement for performing an animal-related action on an animal includes a position determining component having a detector and a processing unit for determining the position of an animal part to be subjected to the animal-related action, and a performance component such as an animal handling unit or milking robot for performing the animal-related action. The position determining component is located at a first location including a station for housing an animal and the performance component is located at a second location including a station for housing an animal at a distance from the first location. A signal line is provided for transferring the coordinates of the position determined at the first location to the performance component at the second location in order to enable the performance of the action with regard to the animal part.

Owner:DELAVAL INT

Implement for automatically milking a dairy animal

ActiveUS20100186675A1High resolutionMaximum of constructive simplicityCathetersRobotPhase differenceMilk cow's

An implement for automatically milking a dairy animal, such as a cow, comprises a milking parlour, a sensor for observing a teat, and a milking robot for automatically attaching a teat cup to the teat. The milking robot comprises a robot control that is connected to the sensor. The sensor comprises a radiation source for emitting light, a receiver for receiving electromagnetic radiation reflected from the dairy animal, a lens, and sensor control unit. The sensor comprises a matrix with a plurality of rows and a plurality of columns of receivers. The sensor control unit is designed to determine for each of the receivers a phase difference between the emitted and the reflected electromagnetic radiation in order to calculate the distance from the sensor to a plurality of points on the part to be observed of the dairy animal.

Owner:MAASLAND

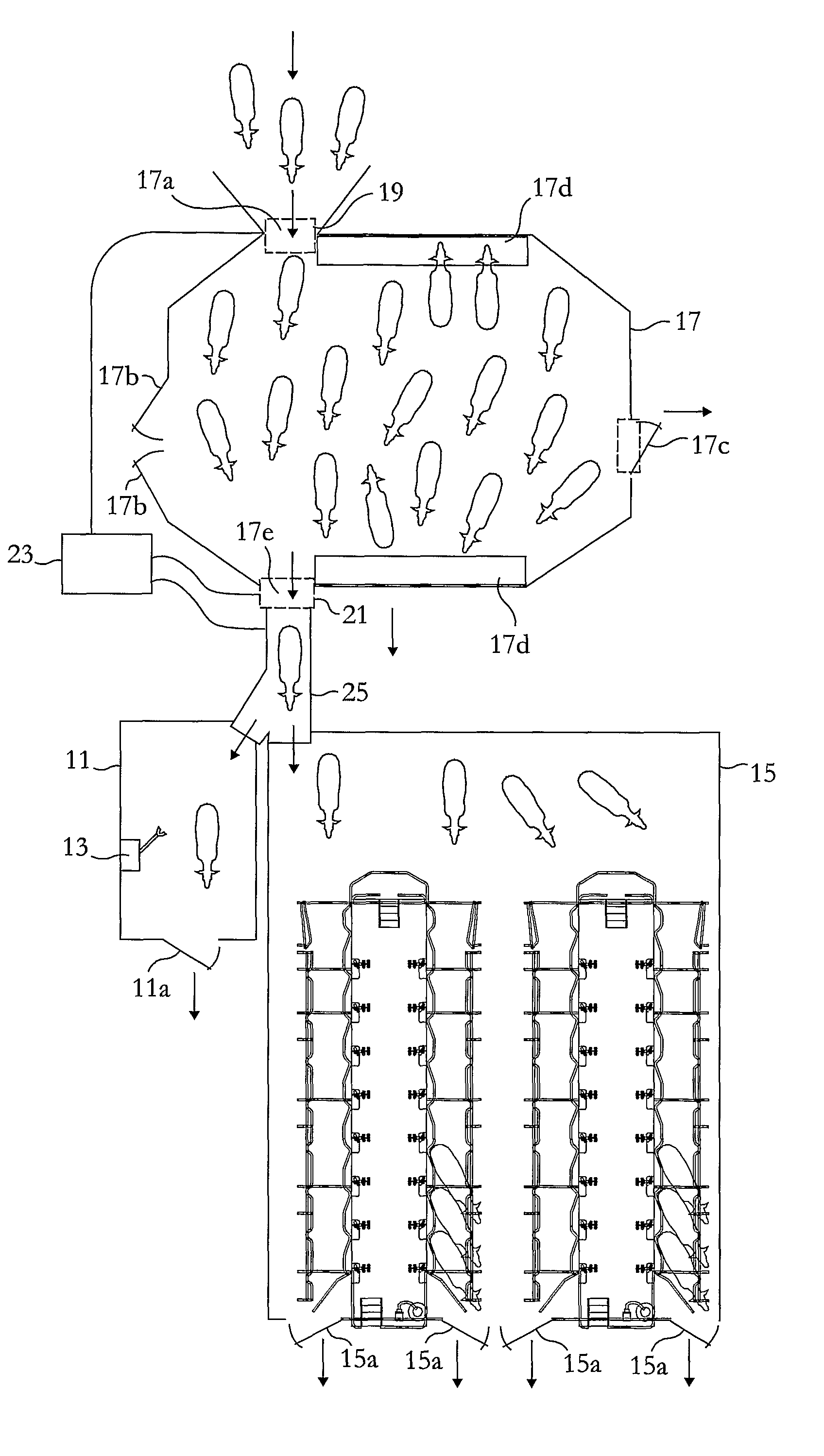

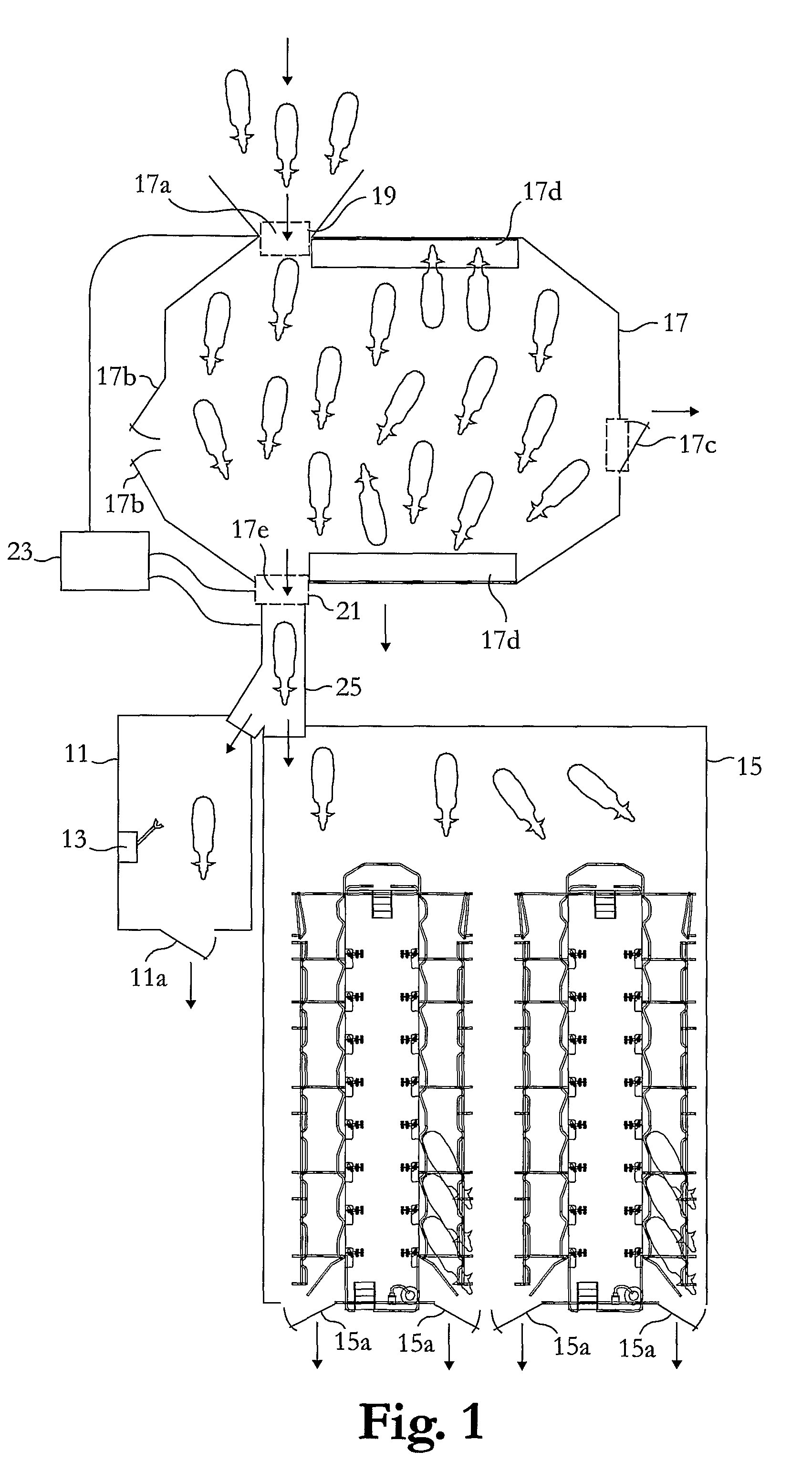

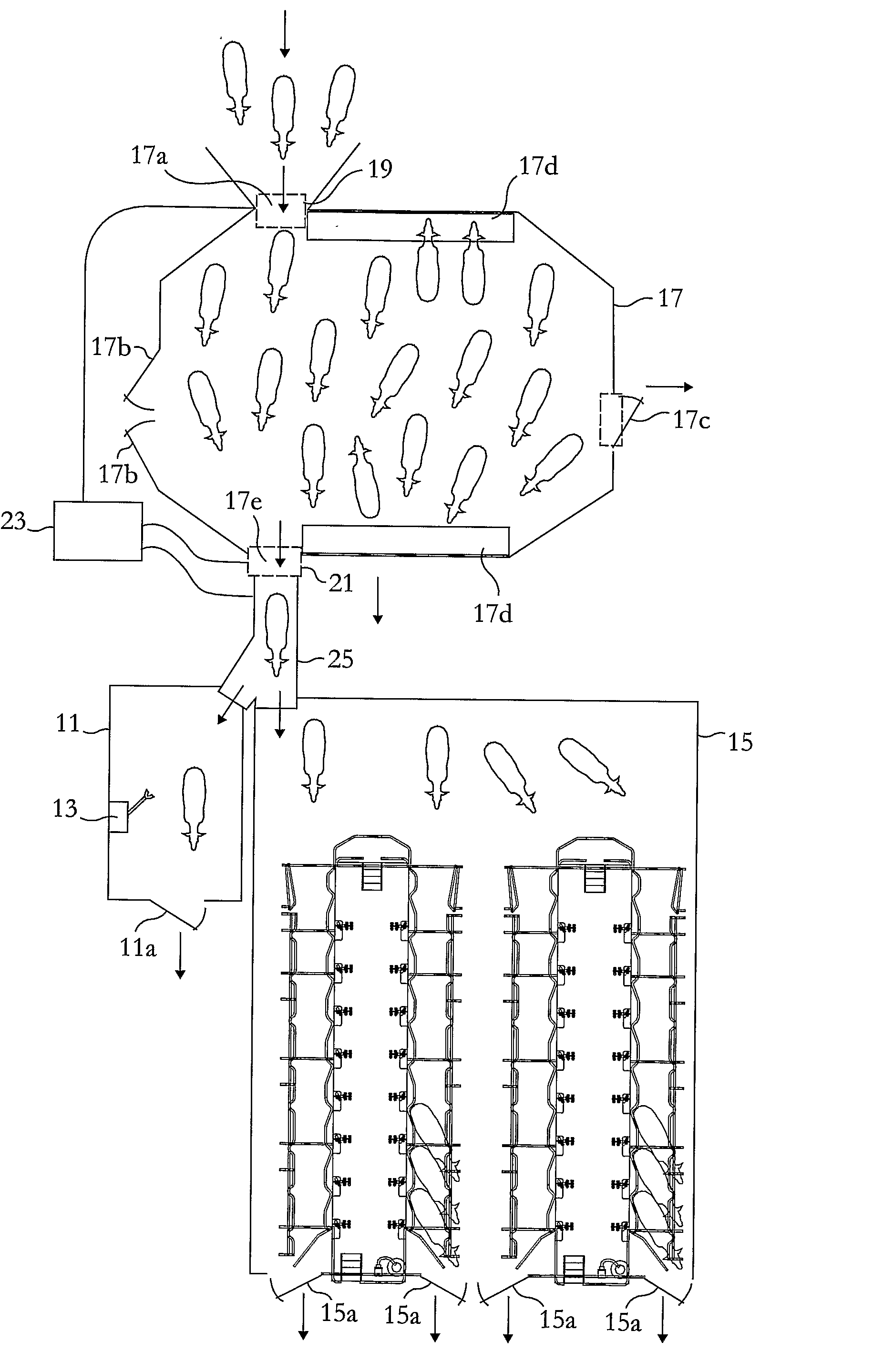

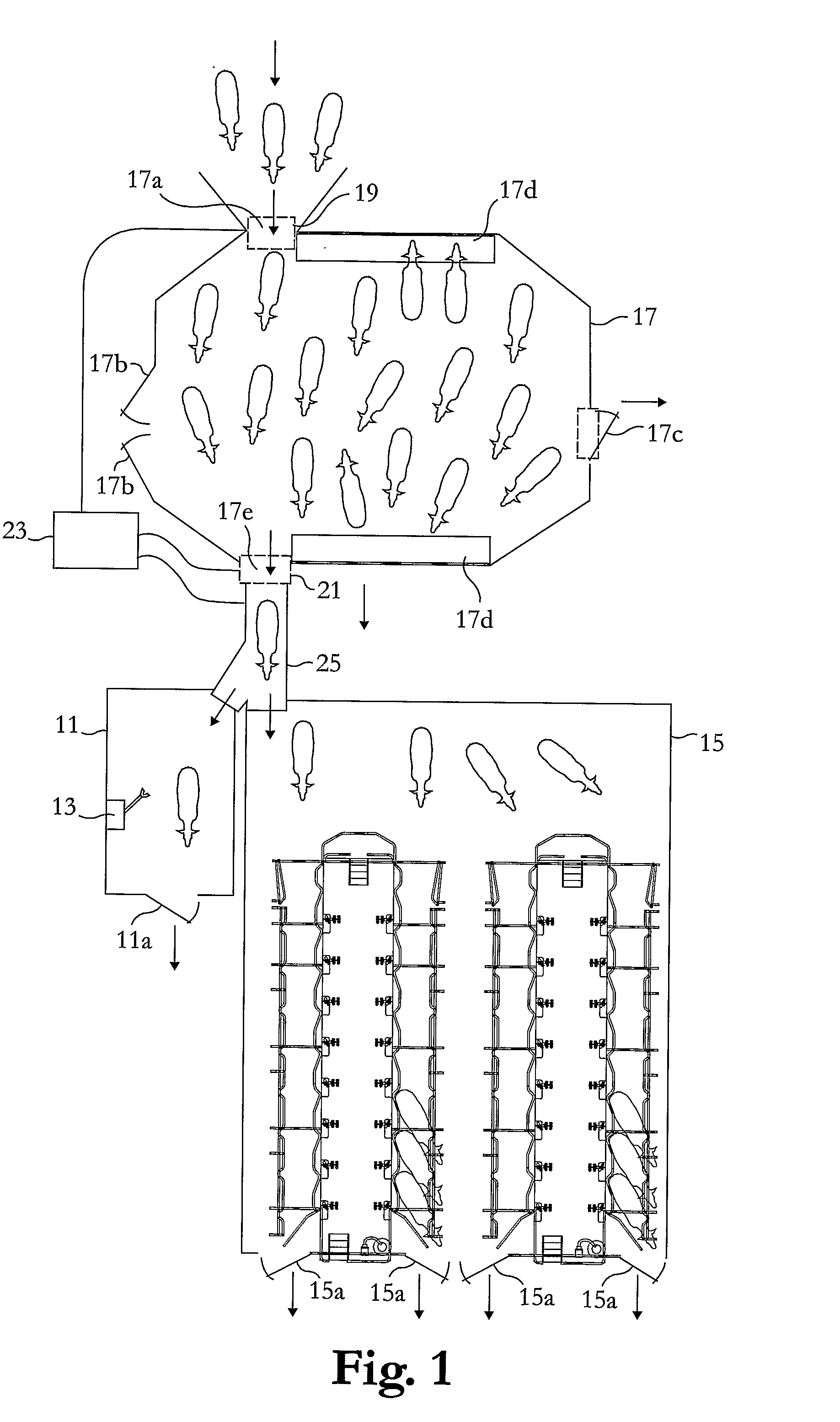

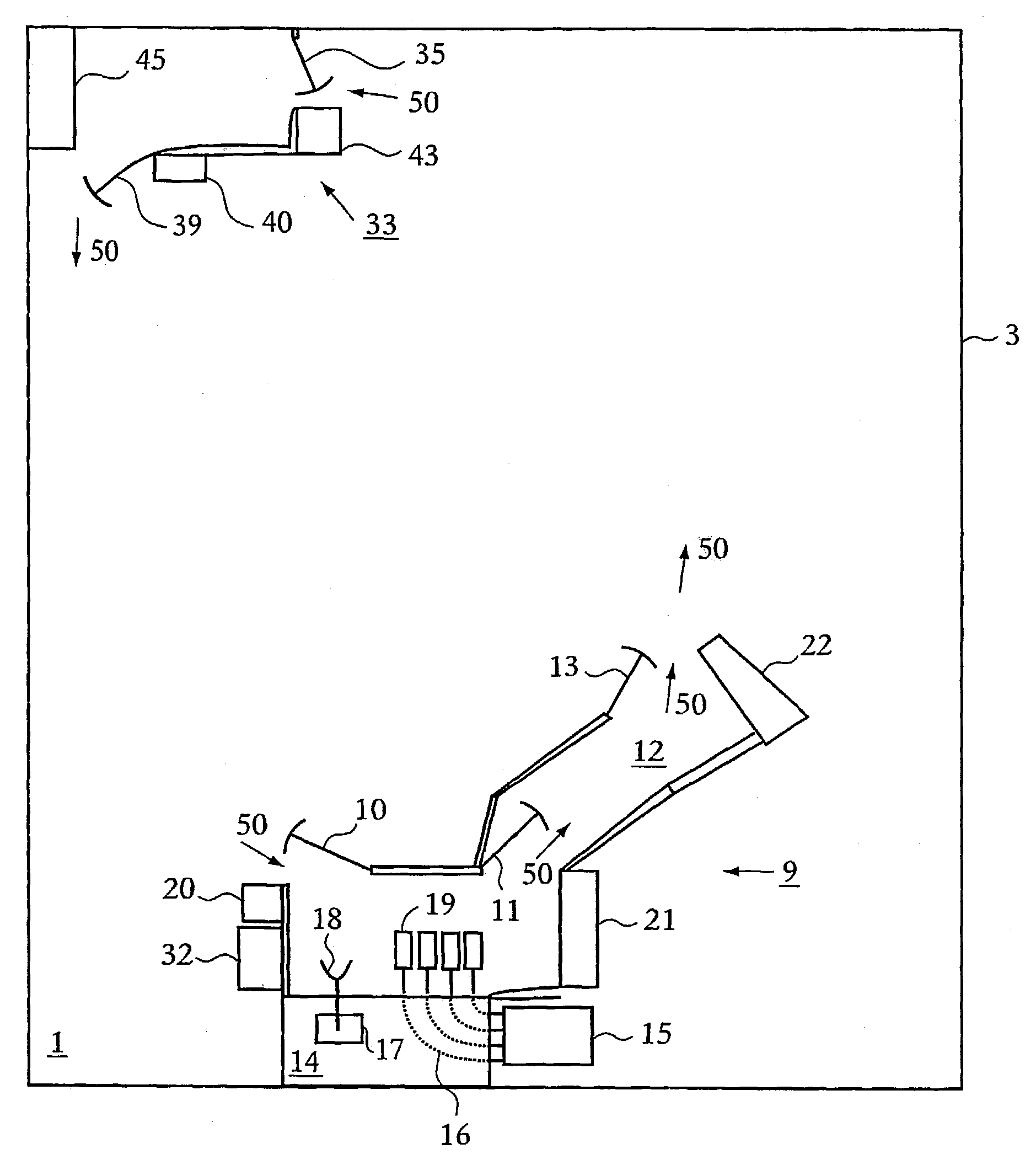

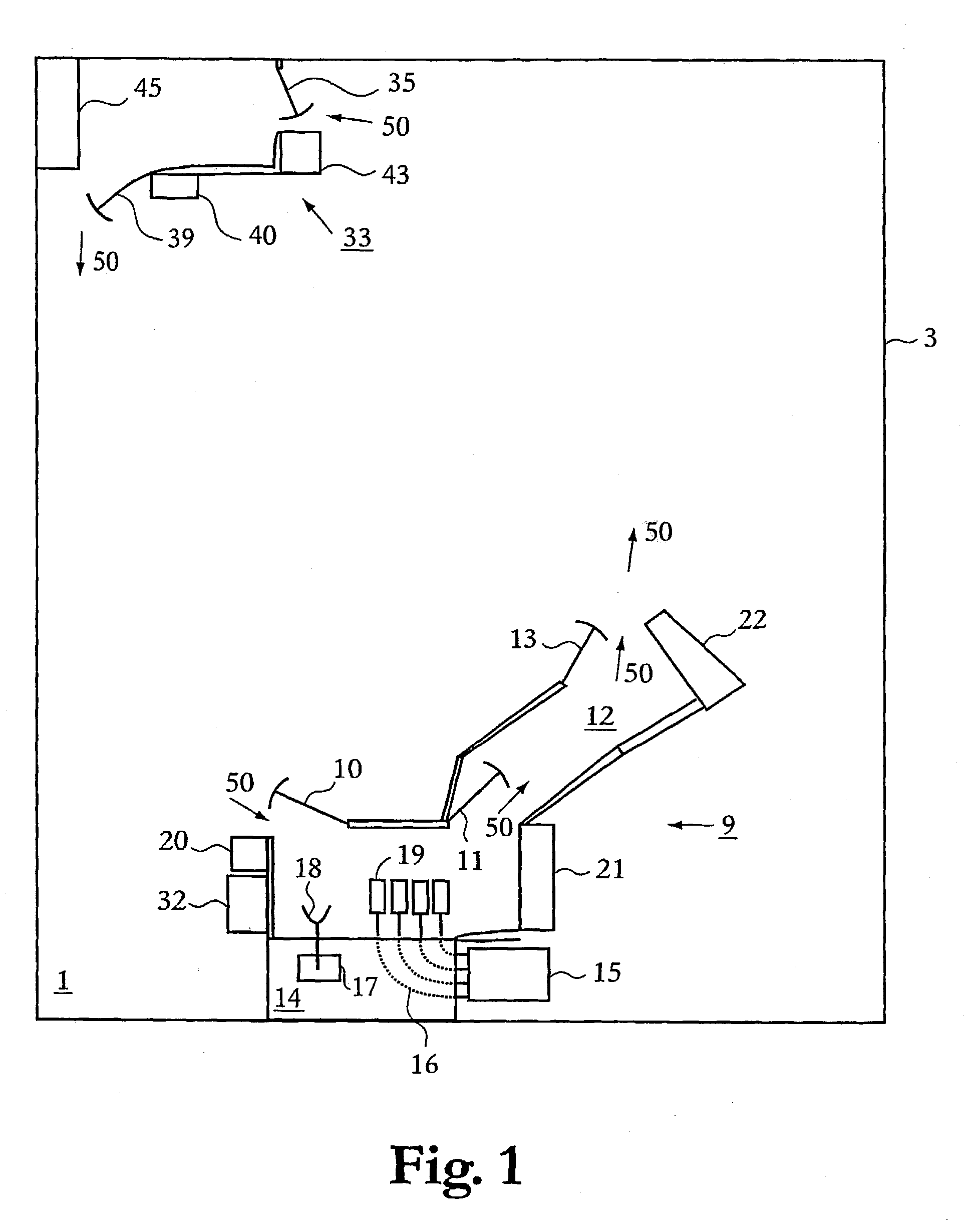

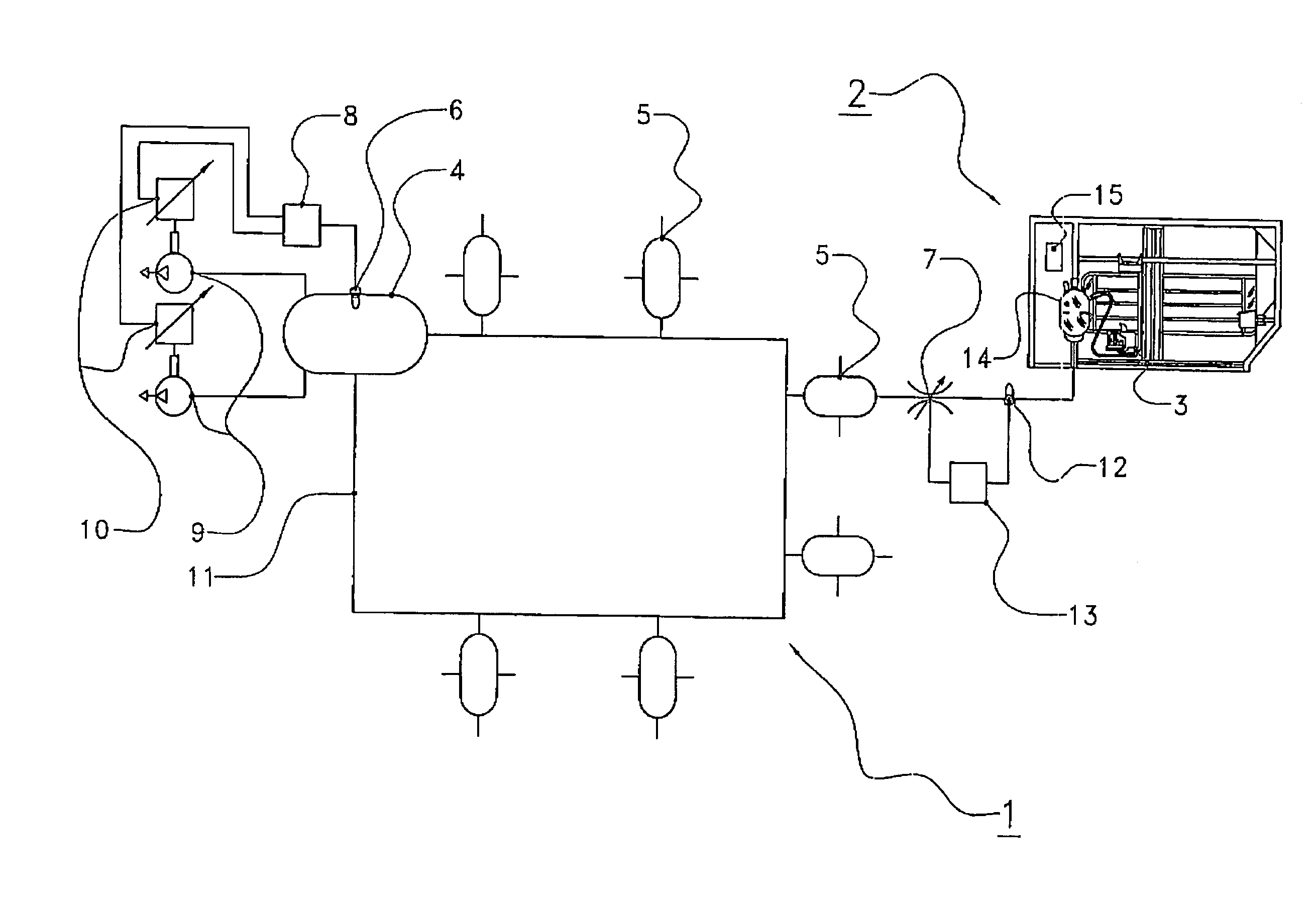

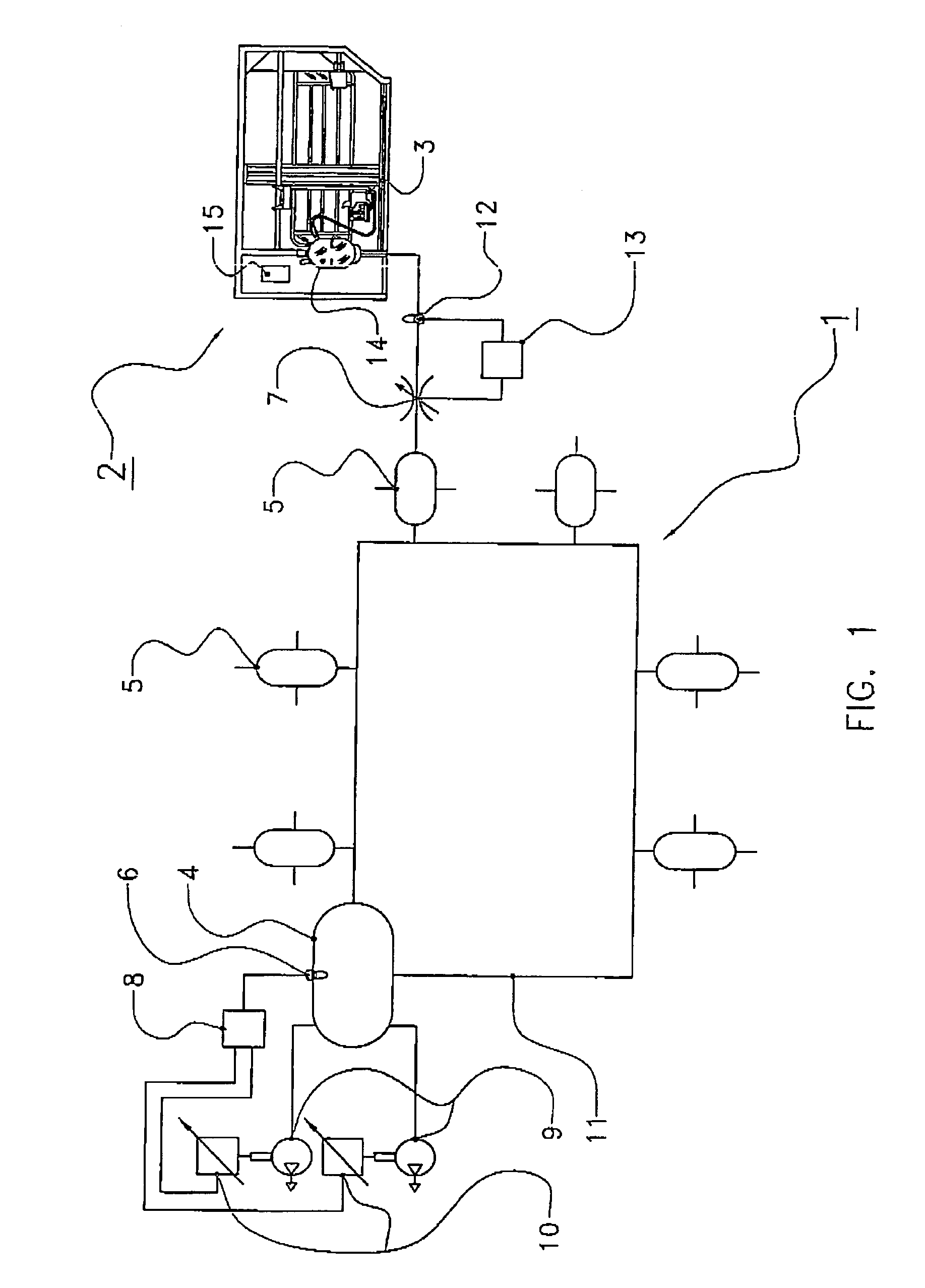

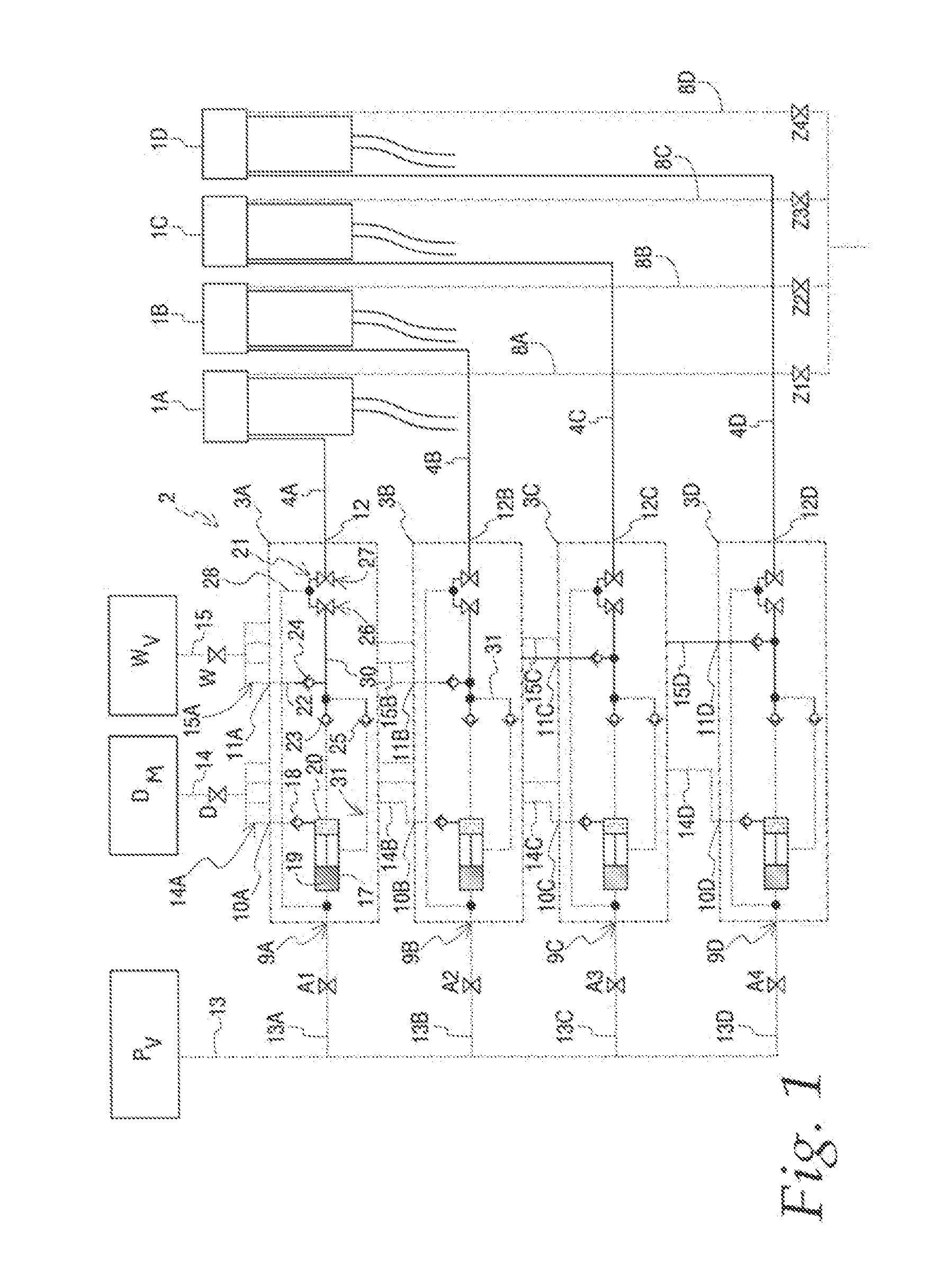

Arrangement and method for milking a plurality of milking animals

ActiveUS7874263B2Good overall control and monitoring and treatmentImprove efficiencyCathetersAnimal housingAutomatic milkingEngineering

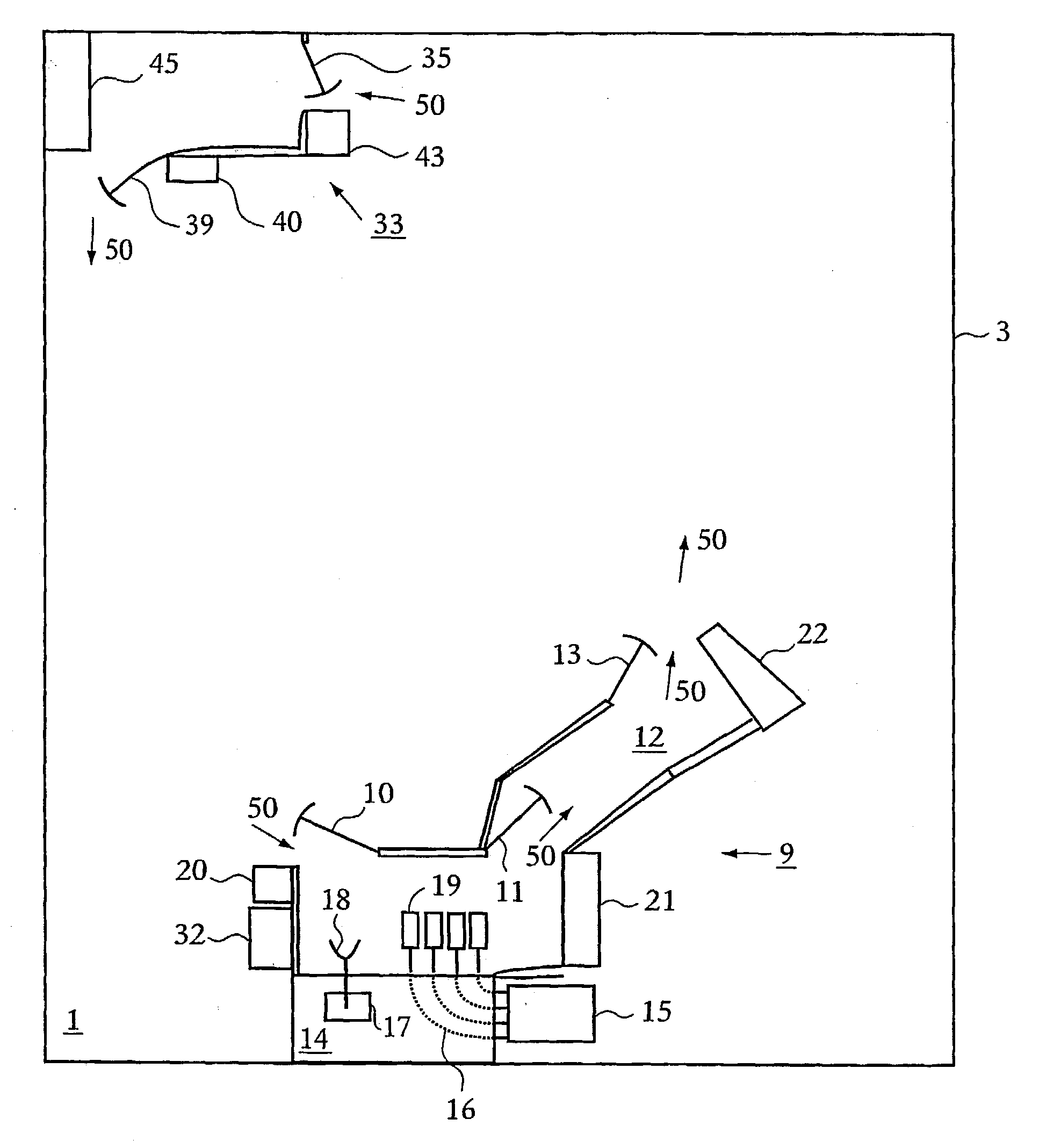

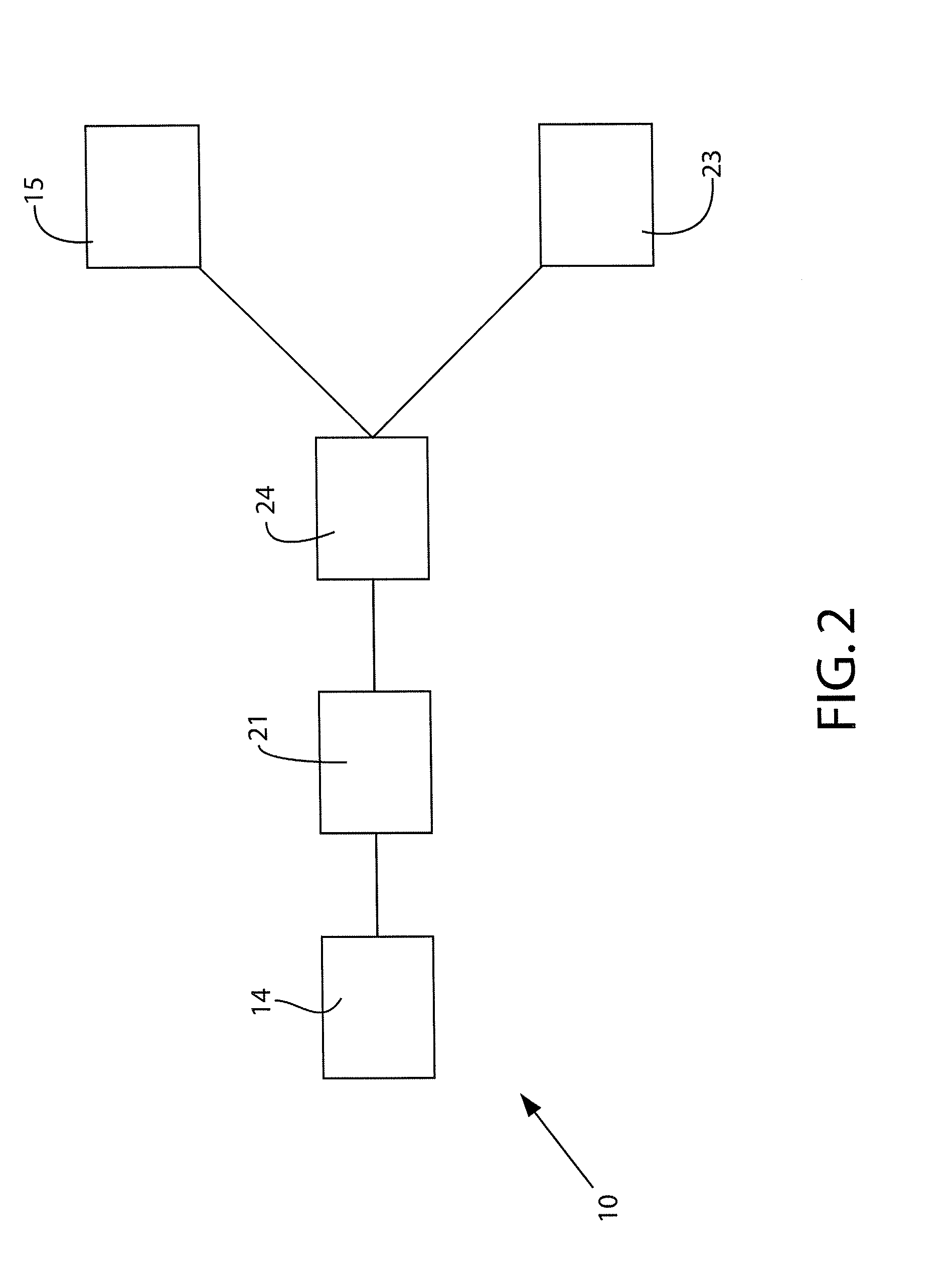

An arrangement for milking a plurality of milking animals comprises an automated milking system (11) provided with a milking robot (13) for automatically milking a milking animal; a milking system (15) provided for batchwise milking of multiple milking animals; an identification arrangement (19, 21) provided for identifying each of the plurality of milking animals prior to being milked; decision means (23) connected to the identification arrangement for deciding, for each of the plurality of milking animals, whether that milking animal should be milked by the automated milking system or by the milking system for batchwise milking; and means connected (25) to the decision means for guiding each of the plurality of milking animals to the automated milking system or to the milking system for batchwise milking depending on the decision made for that milking animal.

Owner:DELAVAL HLDG AB

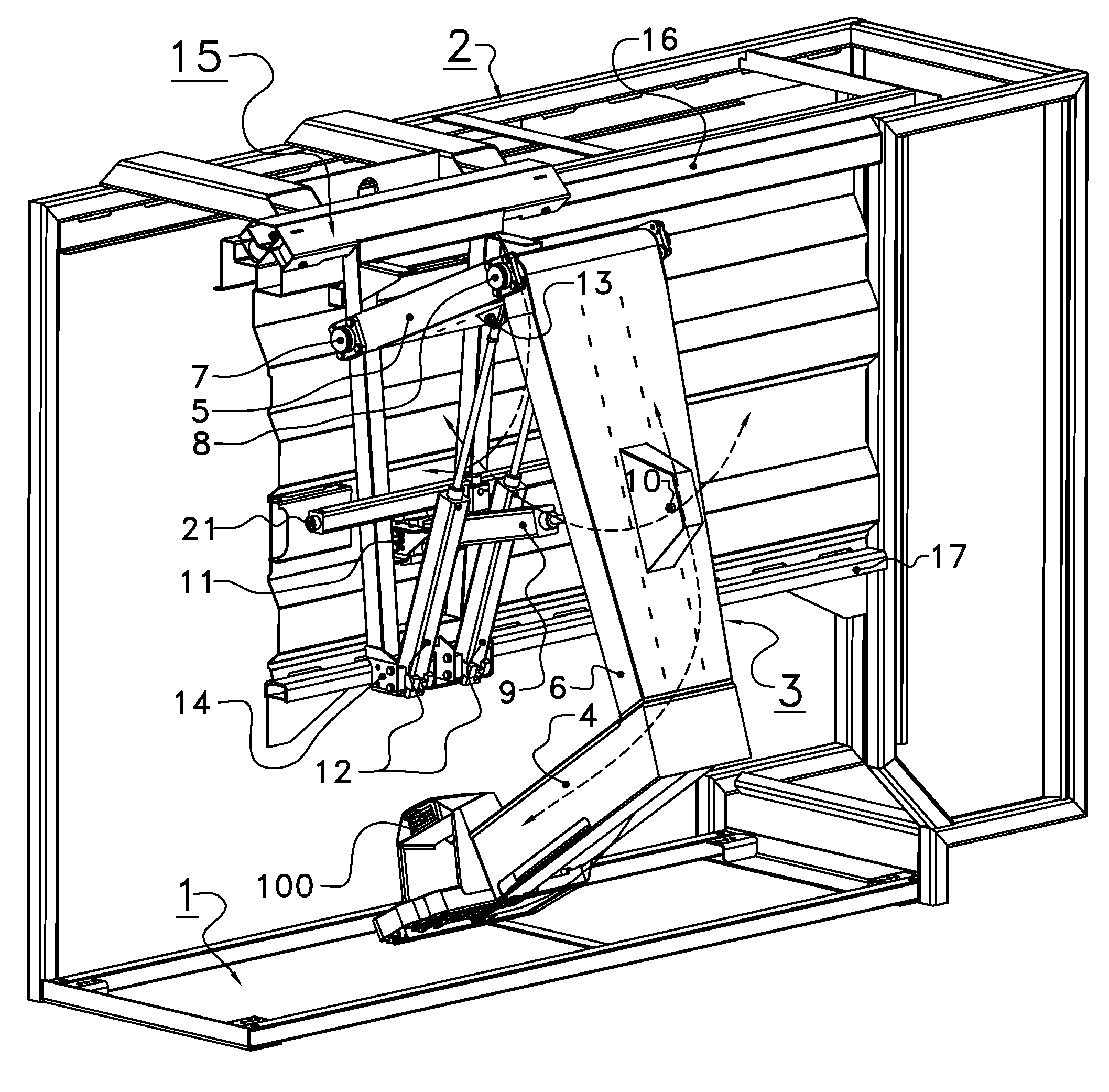

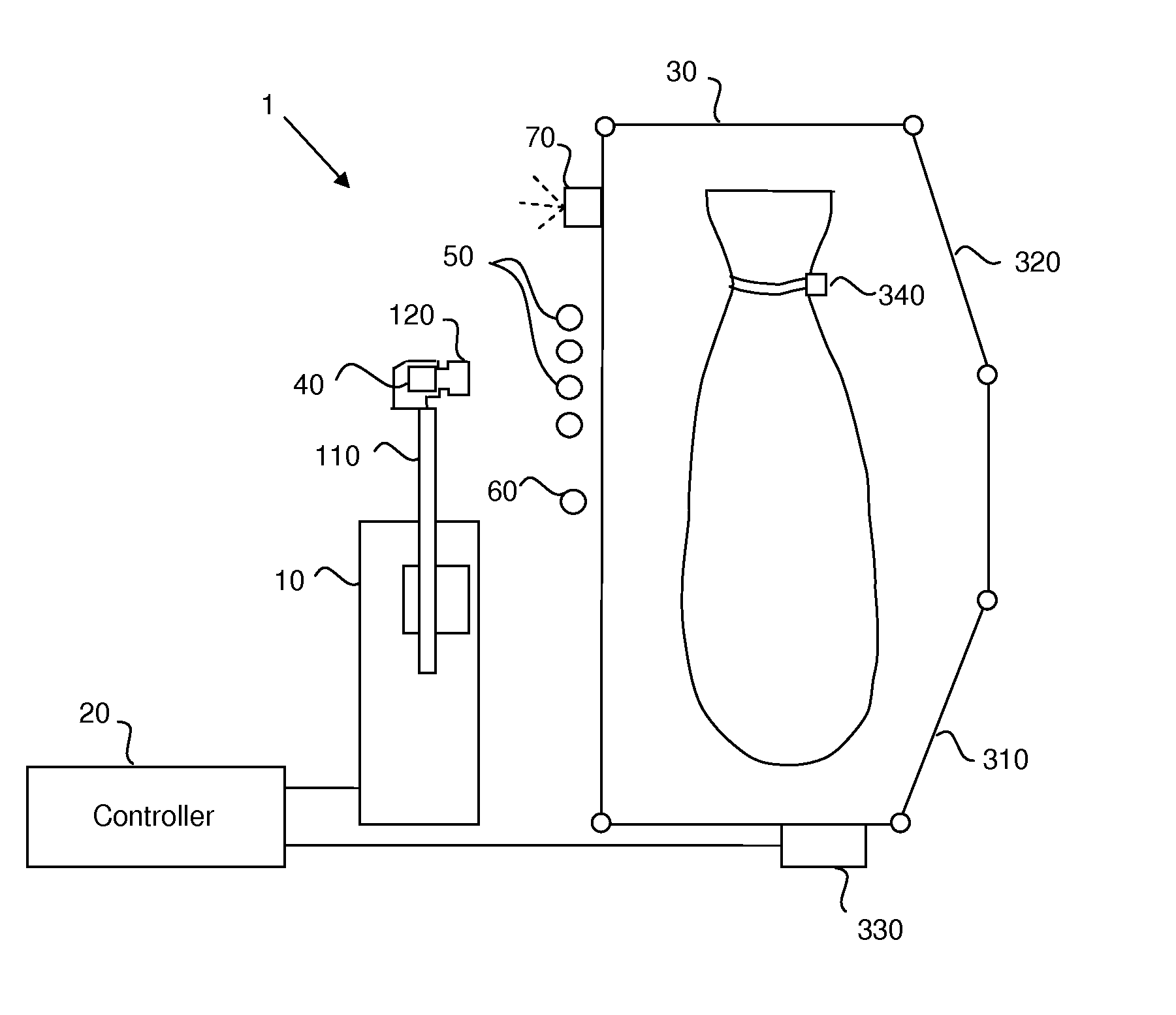

Milking apparatus and holder for receiving teat cups

An apparatus for milking livestock, which apparatus has a milking box; a milking robot disposed close to or in the milking box; and a holder for receiving therein teat cups which during use are arranged on an animal for milking by the milking robot, and a holder for such an apparatus. The holder has a guard, a carriage with an engaging mechanism for engaging the teat cups and with a displacer for displacing the carriage between a first position, in which at least the teat cups are protected by the guard in the situation engaged by the carriage, and a second position, in which the teat cups are released for removal by the milking robot.

Owner:IDENTO ELECTRONICS

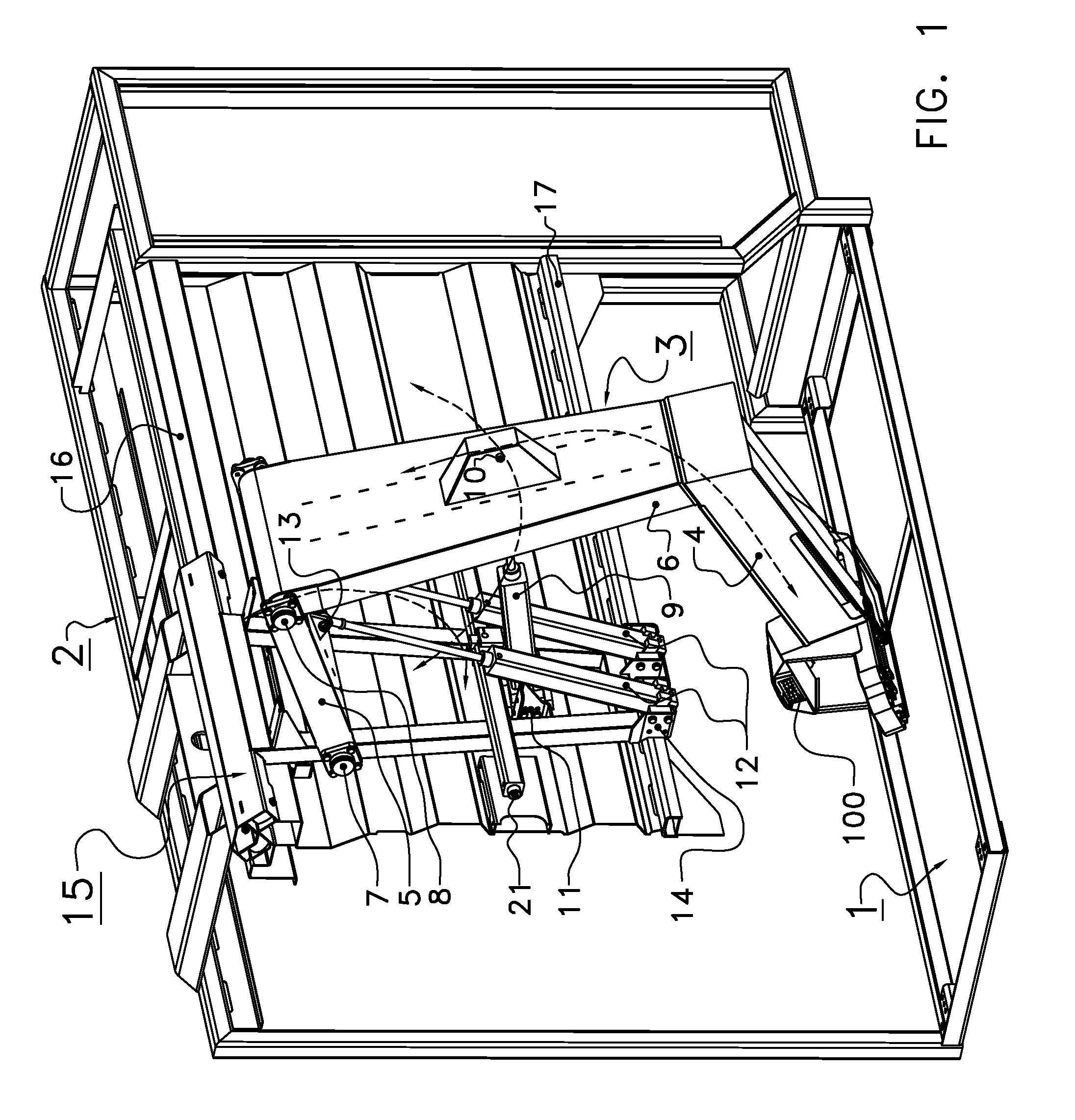

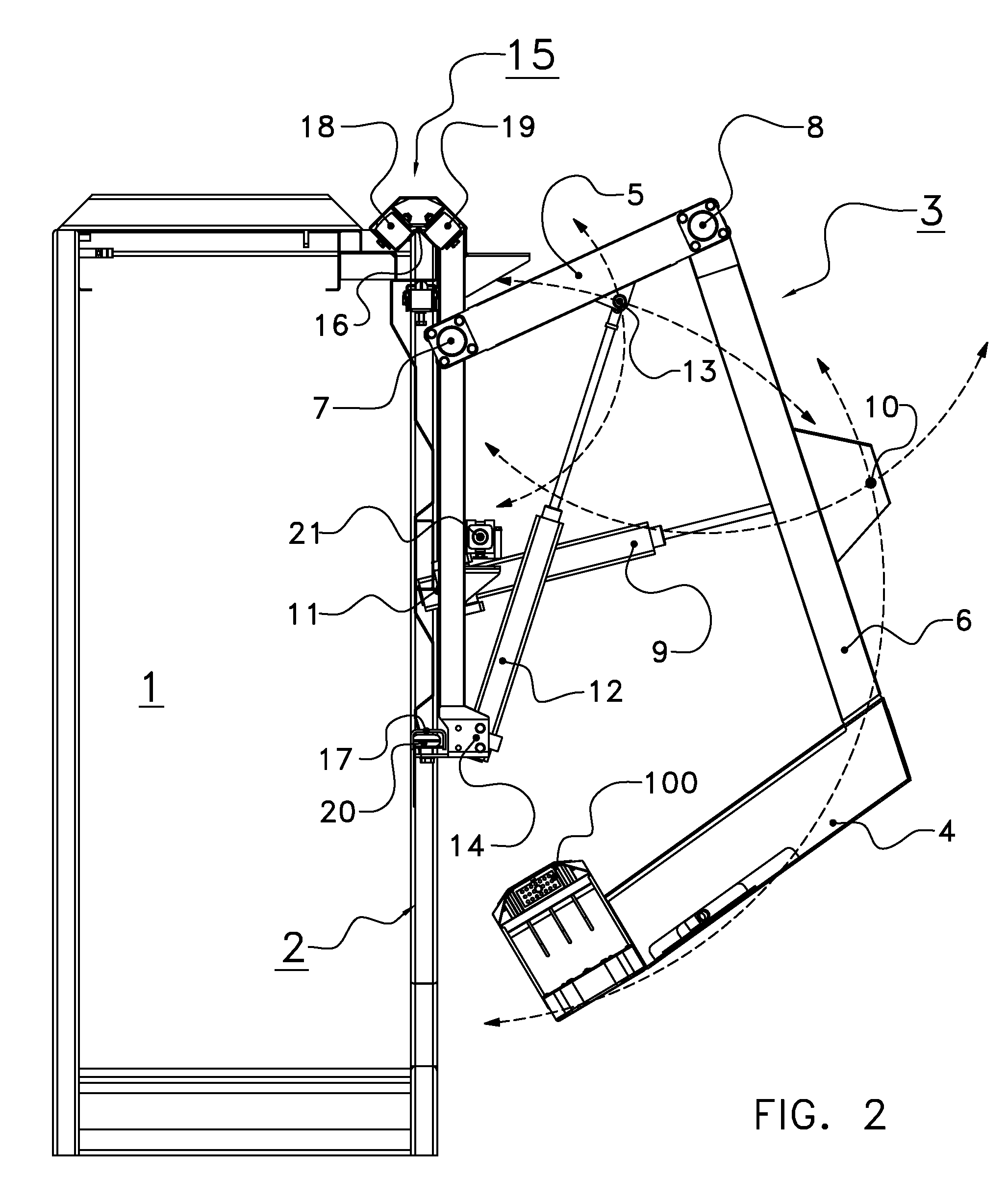

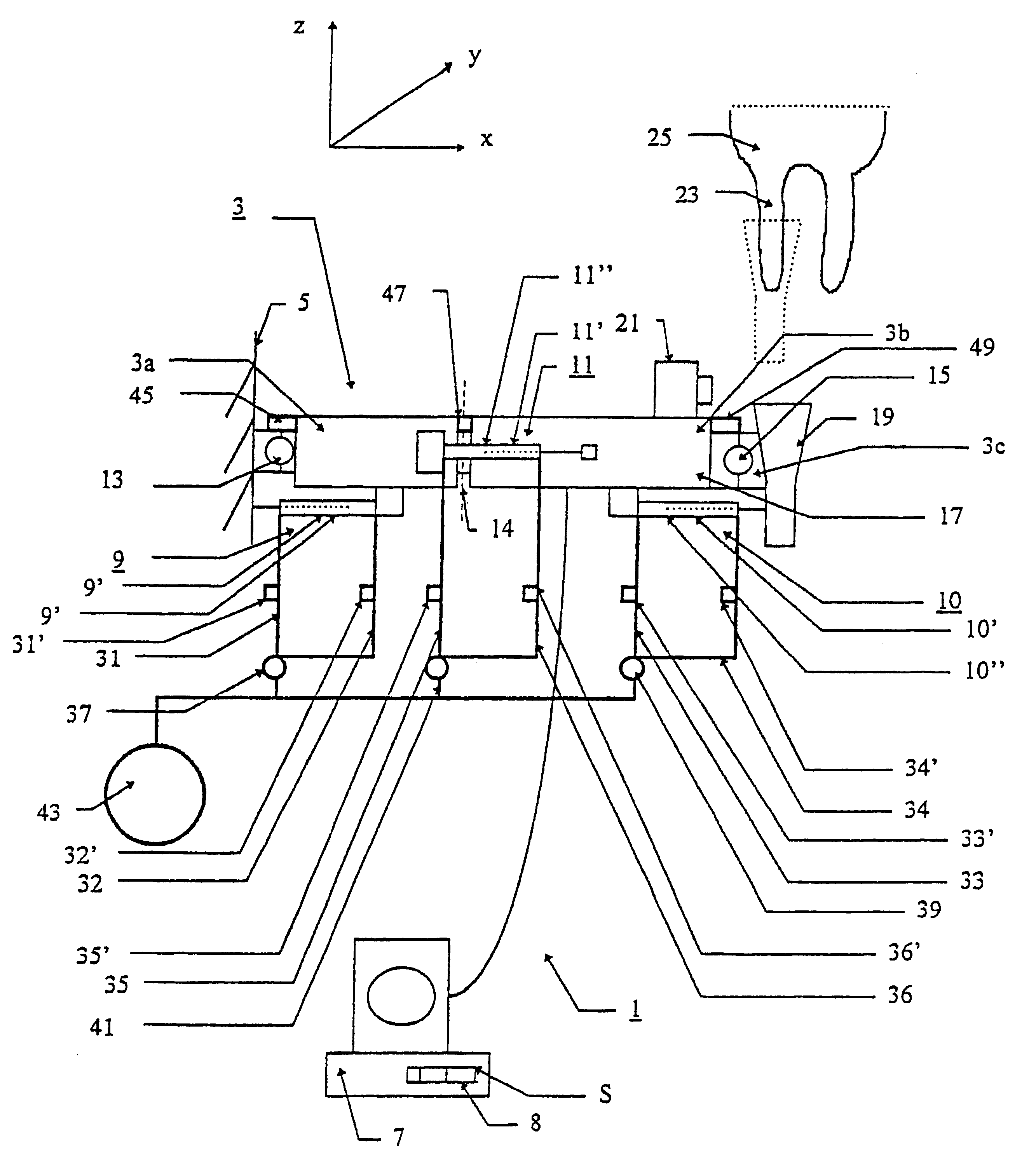

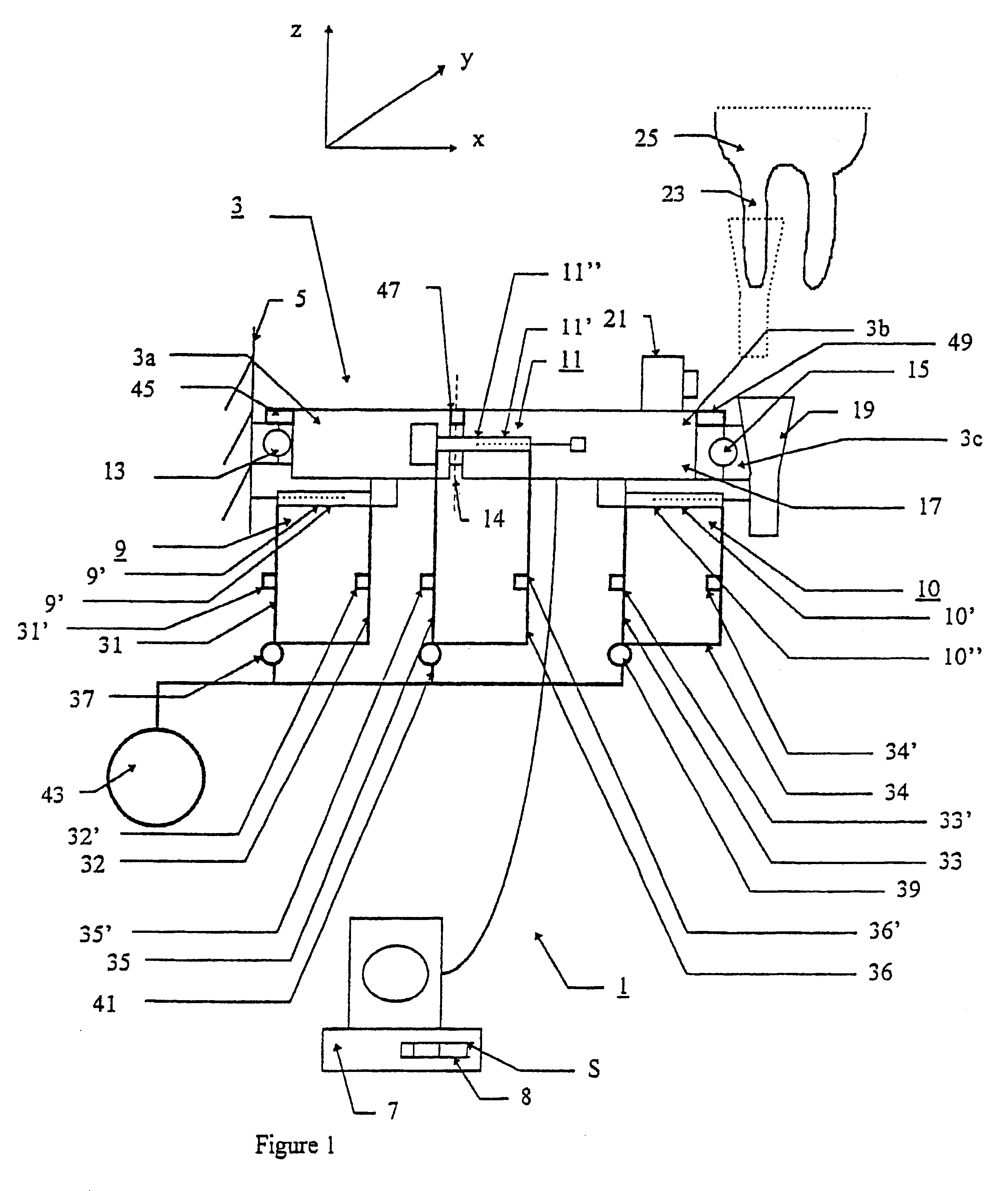

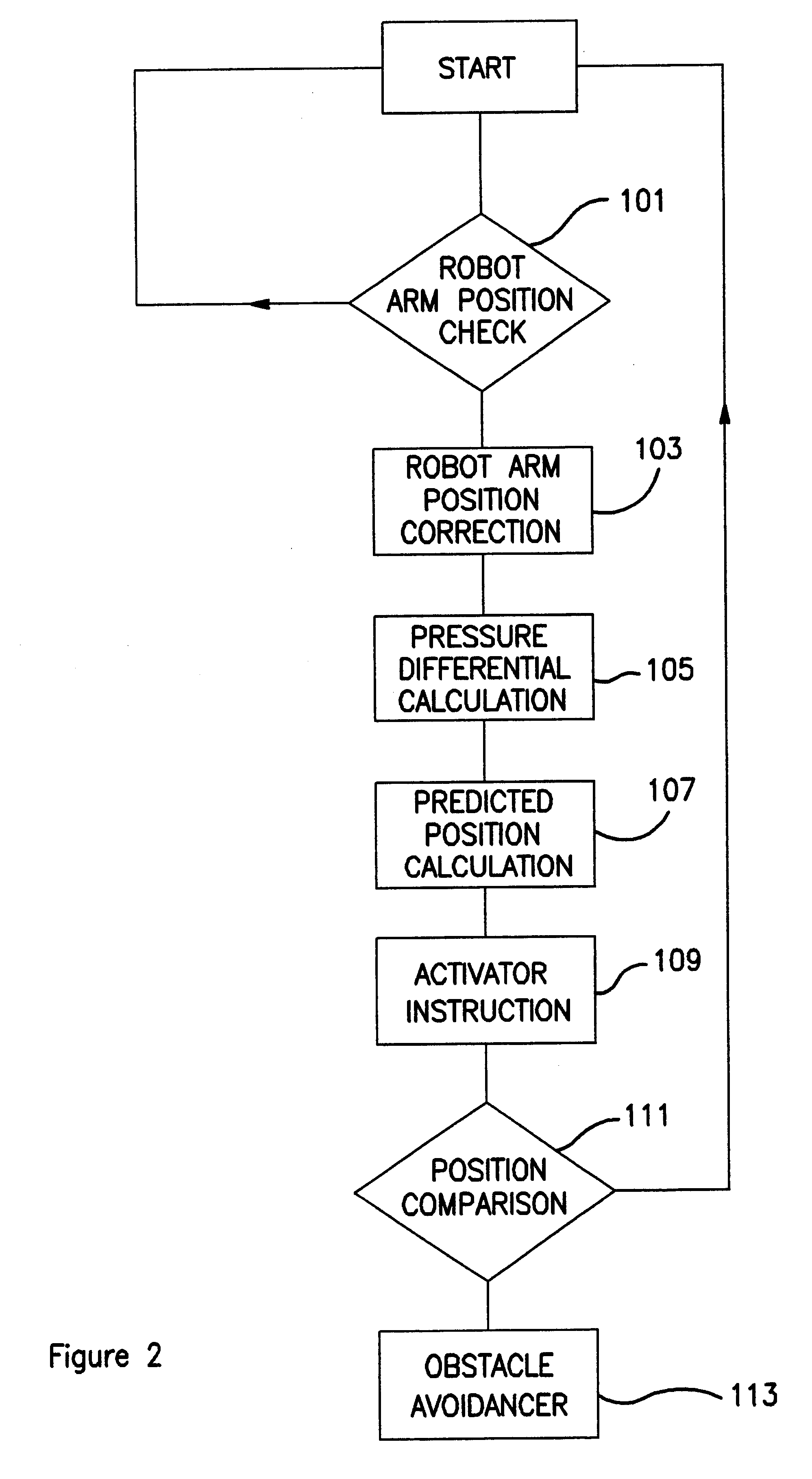

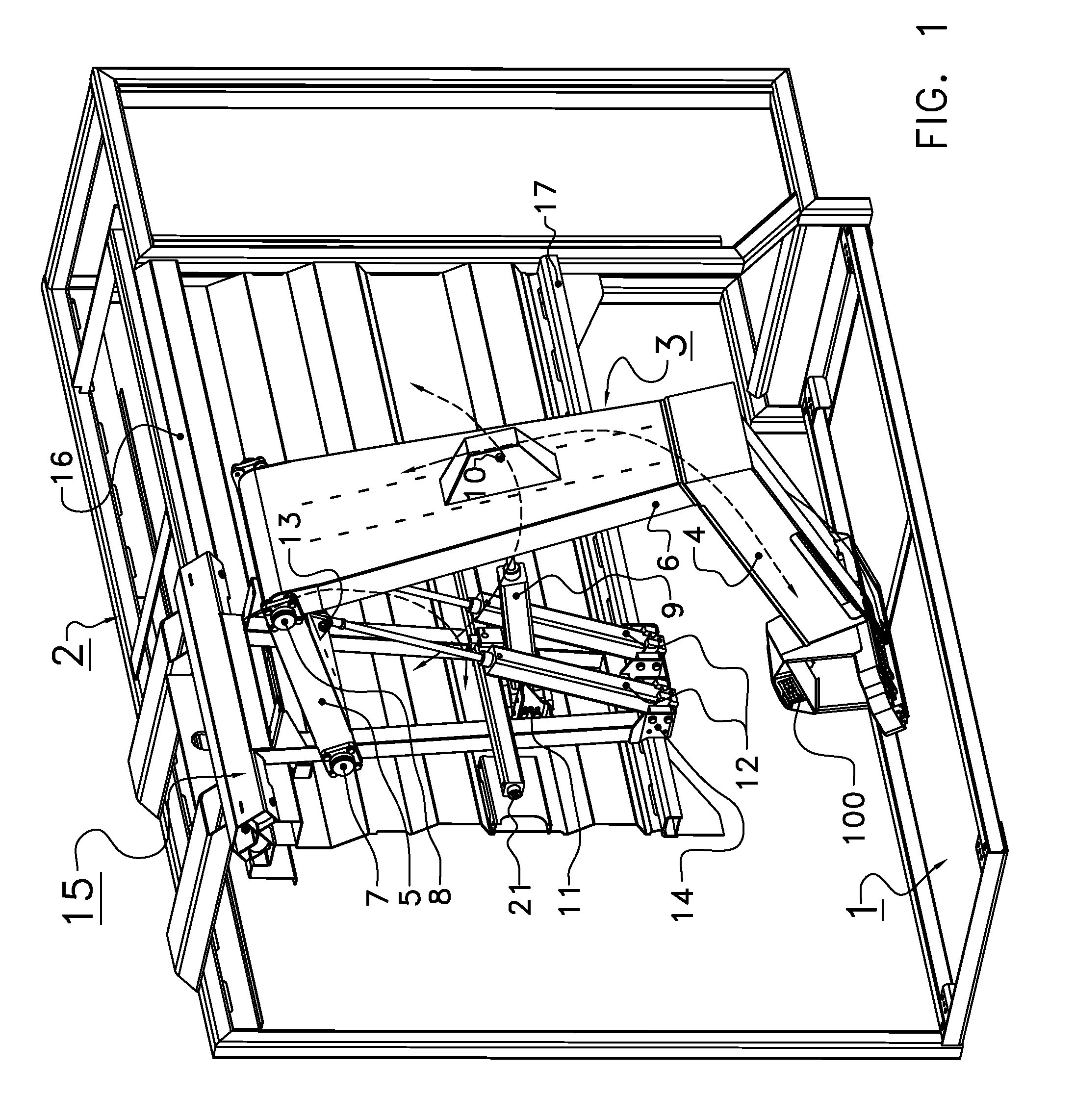

Method and device for controlling the movement of a movable part

InactiveUS6476574B1Avoid injuryProgramme-controlled manipulatorComputer controlControl theoryMoving parts

A method and device (1) for controlling the movement of a movable part such as a robot arm (3) in a milking robot (1). A control (7) controls the movement of the arm (3) from an actual position (Pxa, Pya, Pza) to a desired position (Pxd, Pyd, Pzd) A detector (45, 47, 49) detects the actual position of the robot arm (3) and transmits signals corresponding to the actual position to the control (7). The predicted position (Pxp, Pyp, PyP), that the robot arm (3) will pass through as it moves from the actual position to the desired position our model (S). The control (7) makes a comparison (S) of the actual positions of the arm (3) against to the predicted positions, and the movement of the robot arm (3) is modified if its actual position at any time differs by more than a predetermined amount from the predicted position at the same time.

Owner:DELAVAL HLDG AB

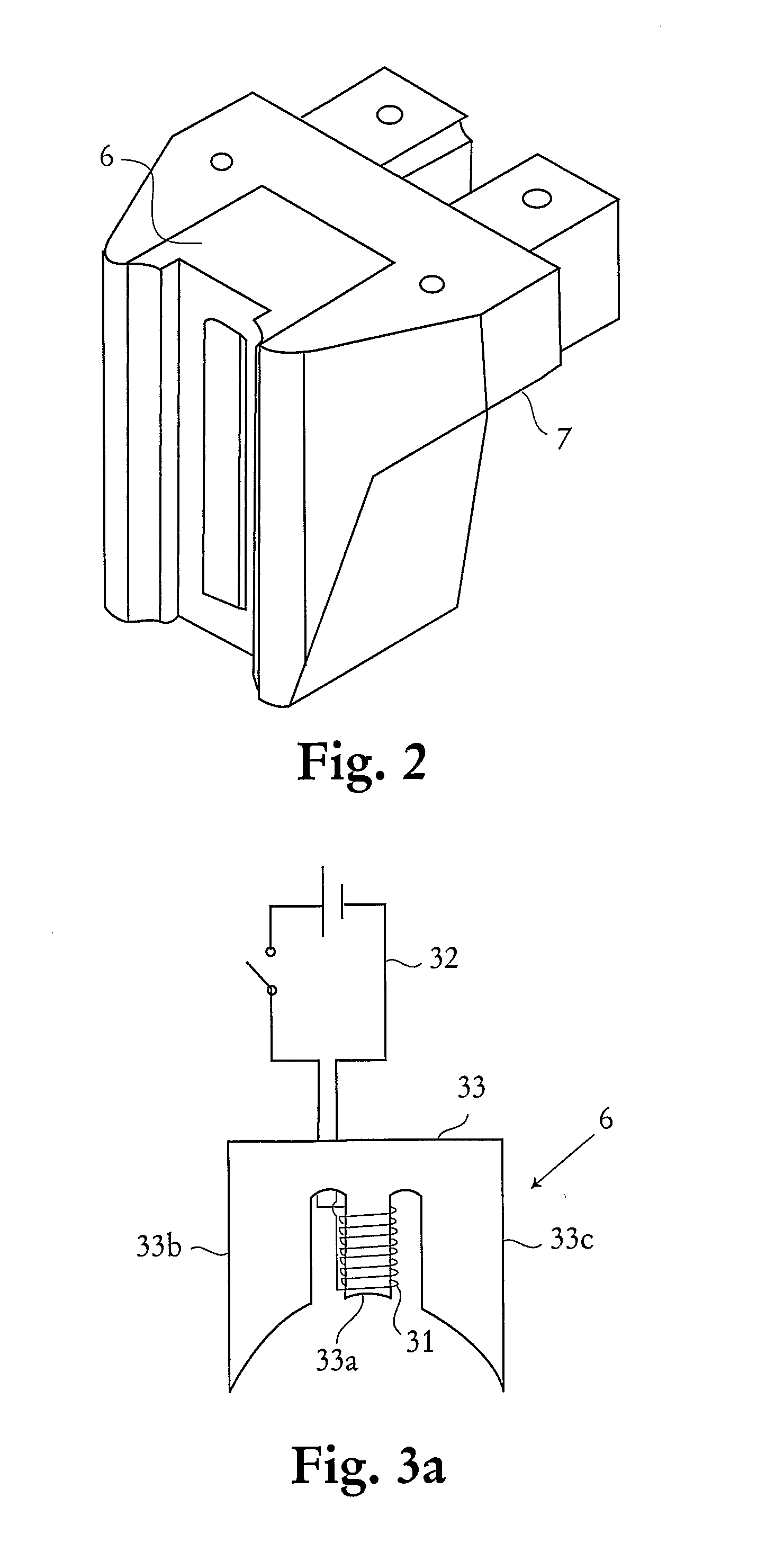

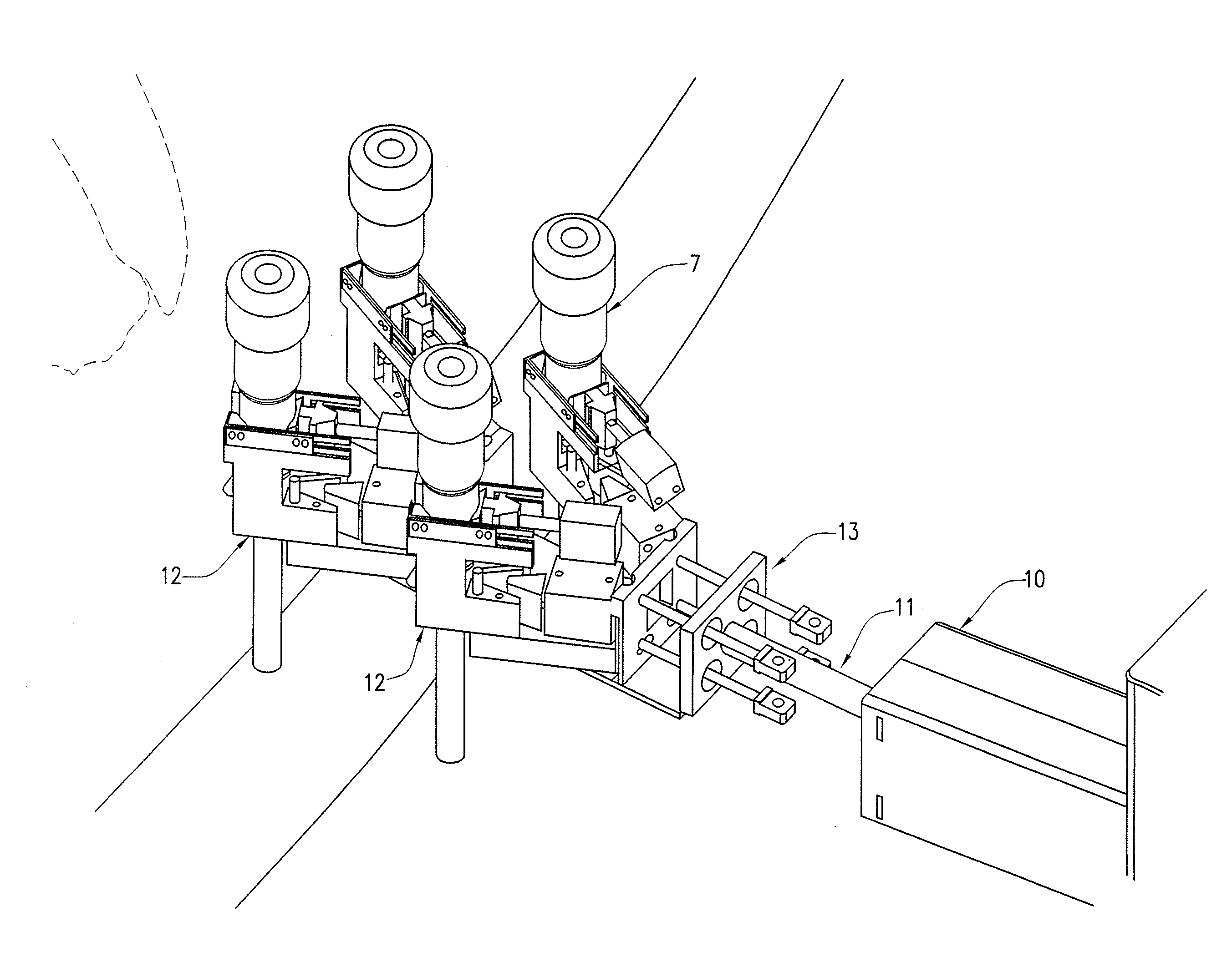

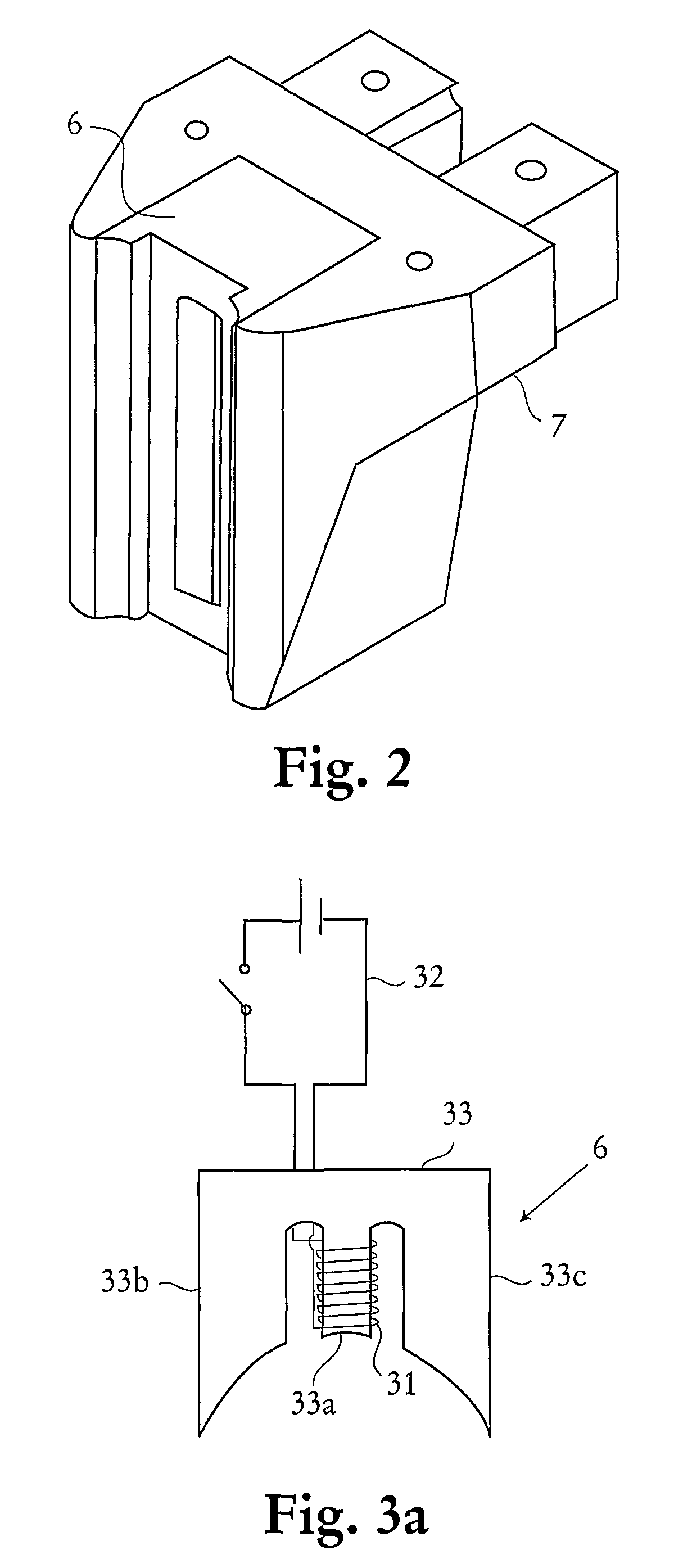

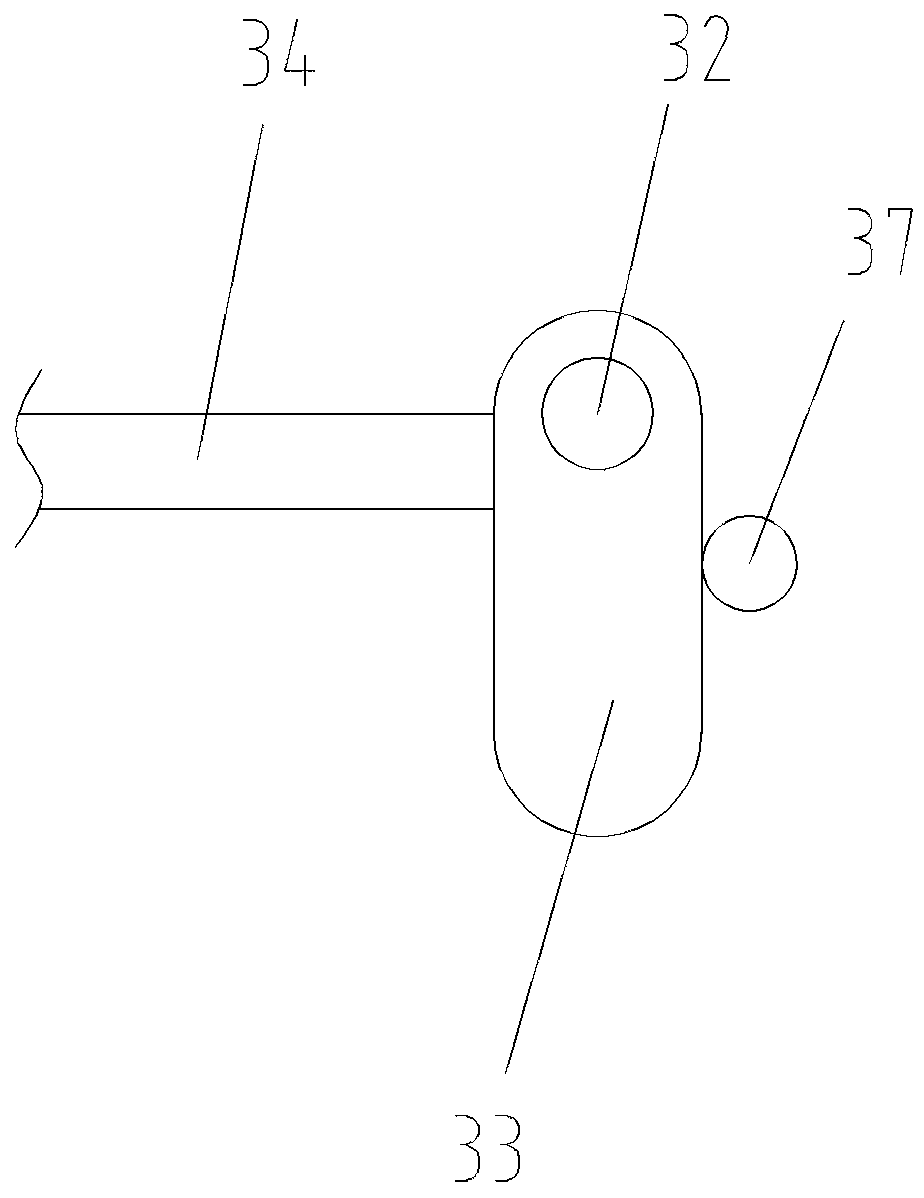

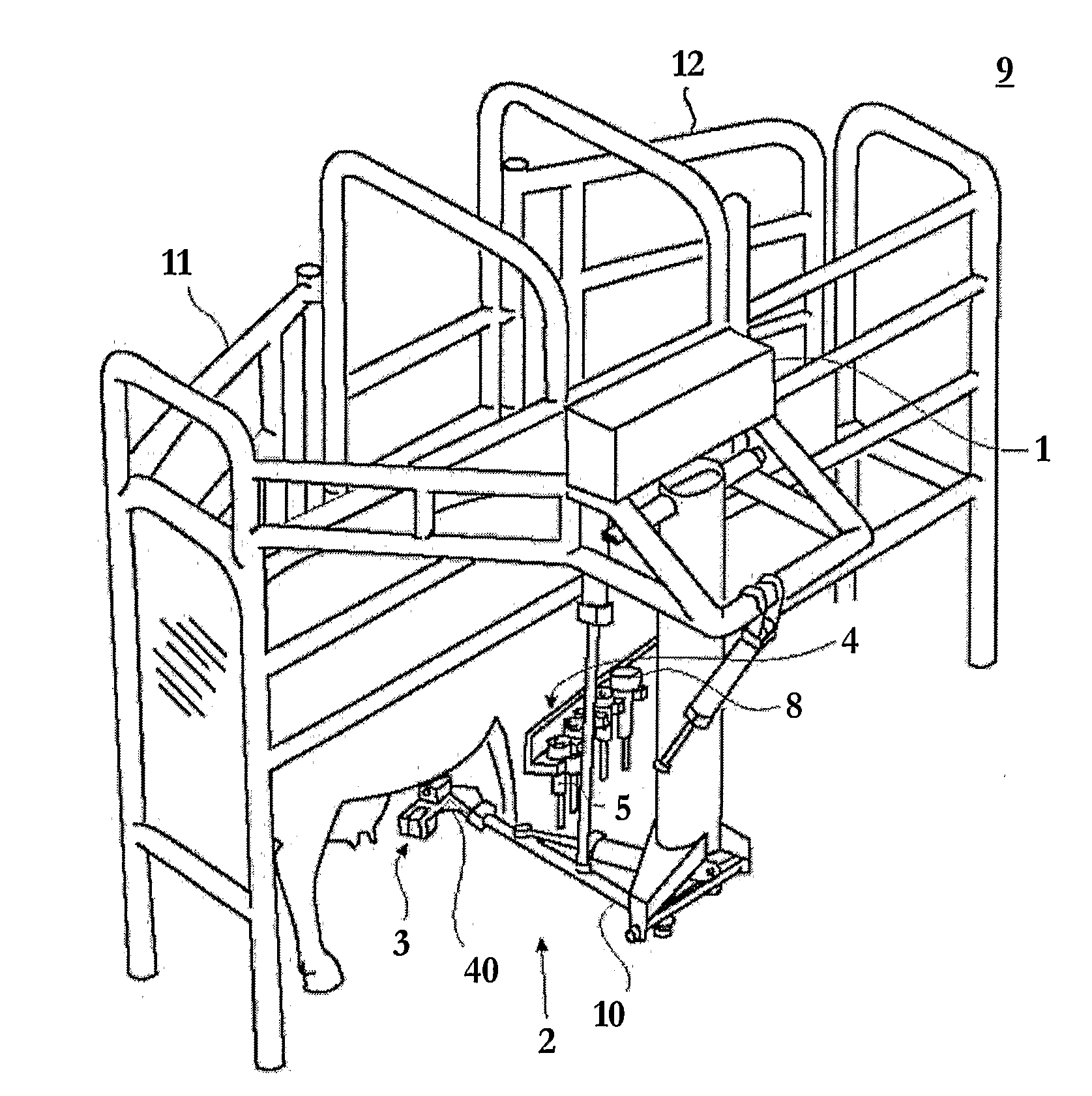

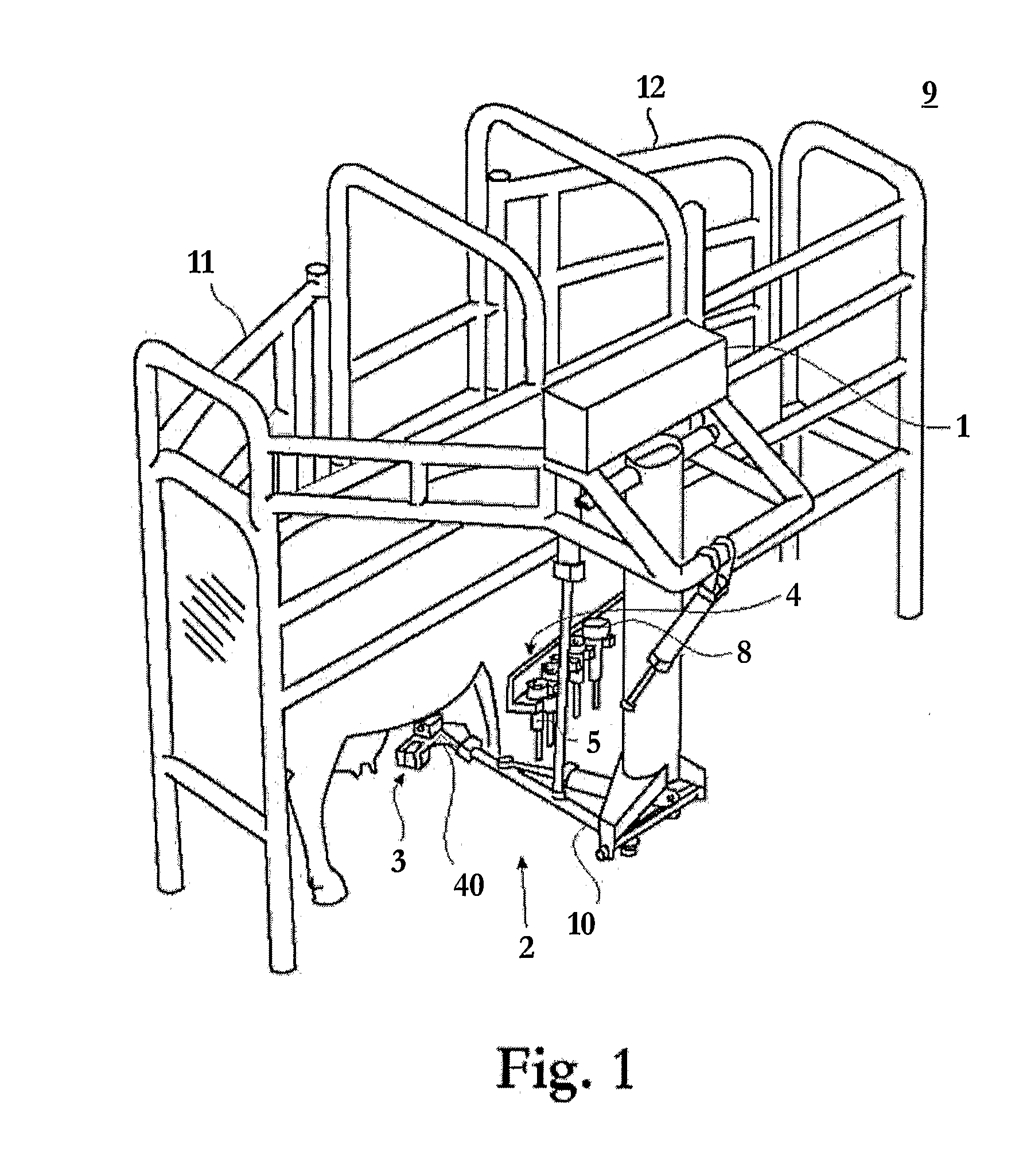

Gripper Device, Robot Arm, and Milking Robot

ActiveUS20080022933A1Few moving partsUncomplicated and reliable and inexpensive to manufacture and assemble and useCathetersGripping headsEngineeringMechanical engineering

A gripper device mountable on a robot arm (10) of a milking robot (2) provided for automatically attach teat cups (5) to the teats of a milking animal, the gripper device comprises an electromagnet (6) for gripping teat cups made of a magnetic material, the electromagnet including a coil (31) feedable with a current and a core (33) of a magnetic material arranged at least partly within the coil; and a support structure (7) for holding the electromagnet. The core comprises two end portions (33a-b) in a single face of the electromagnet, wherein the two end portions constitute different poles of the electromagnet, and are shaped to be engagable with each of the teat cups in a close fit.

Owner:DELAVAL HLDG AB

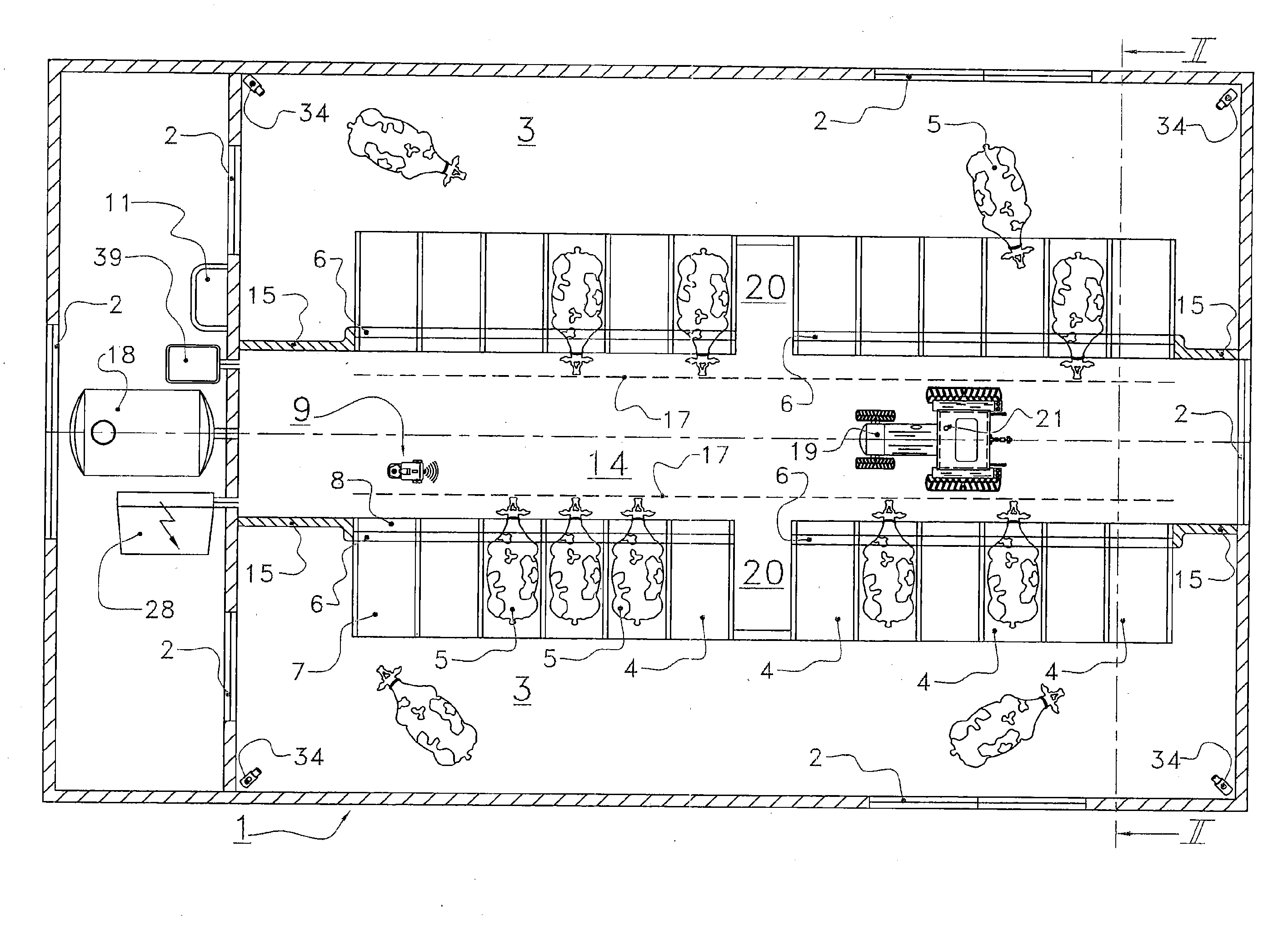

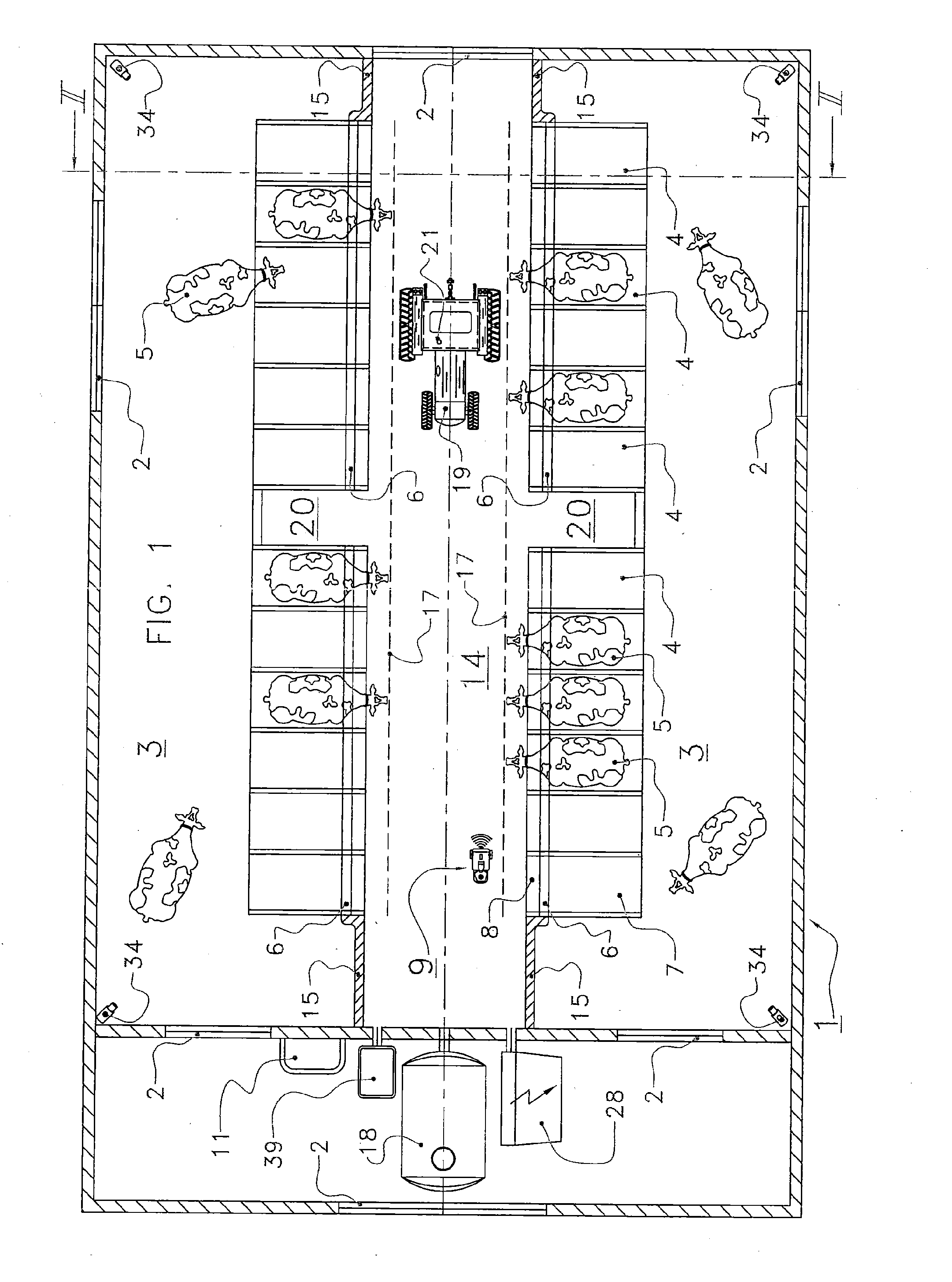

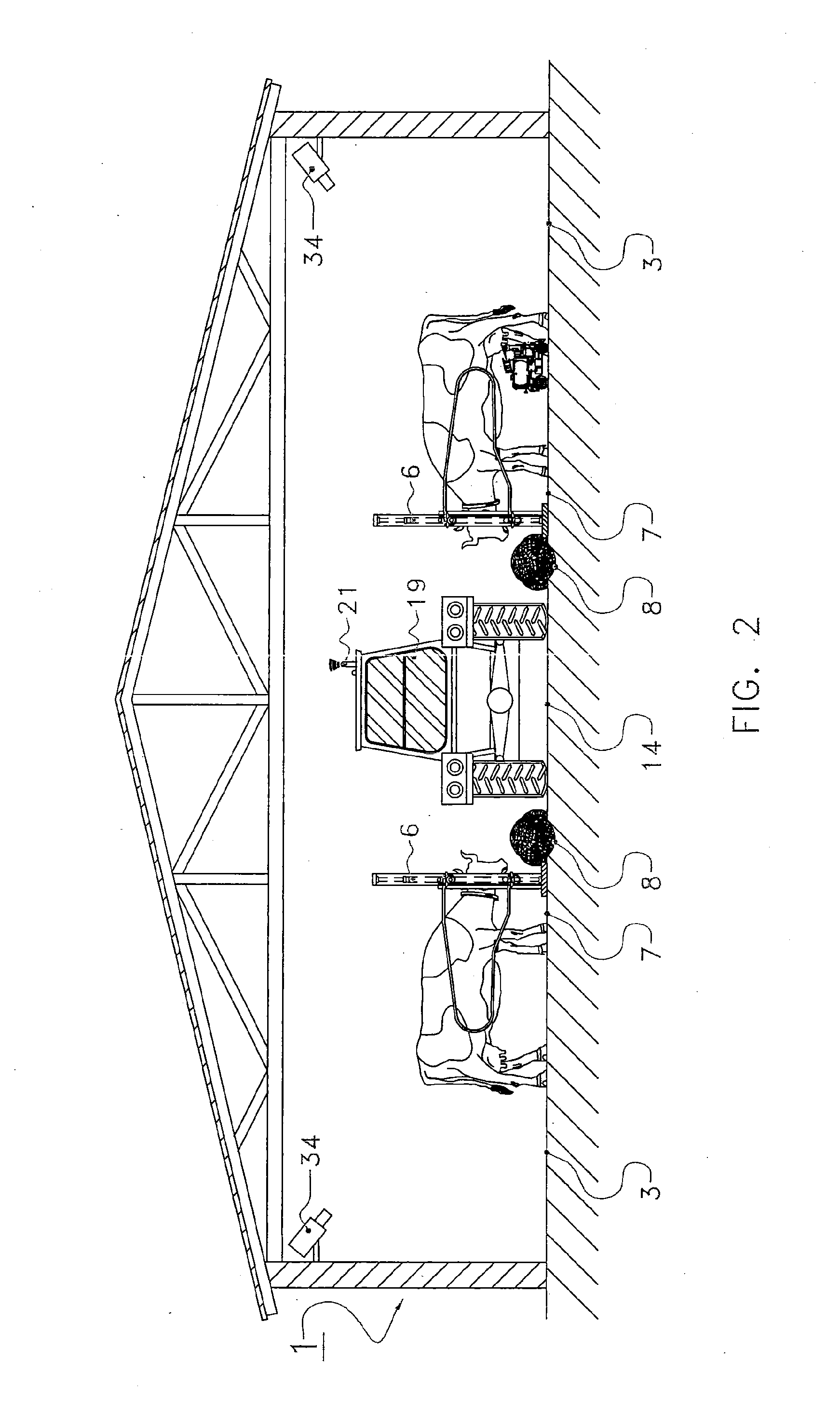

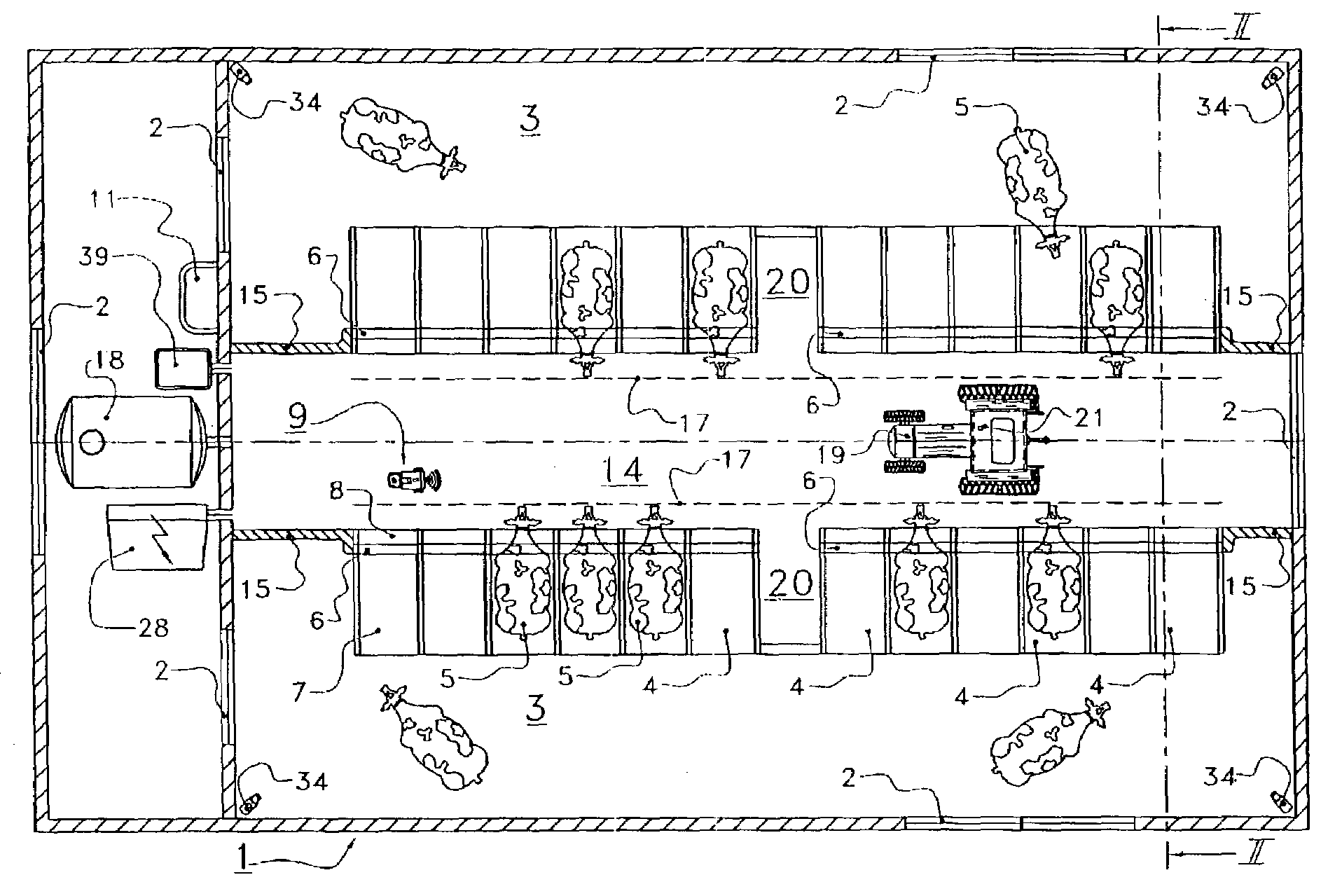

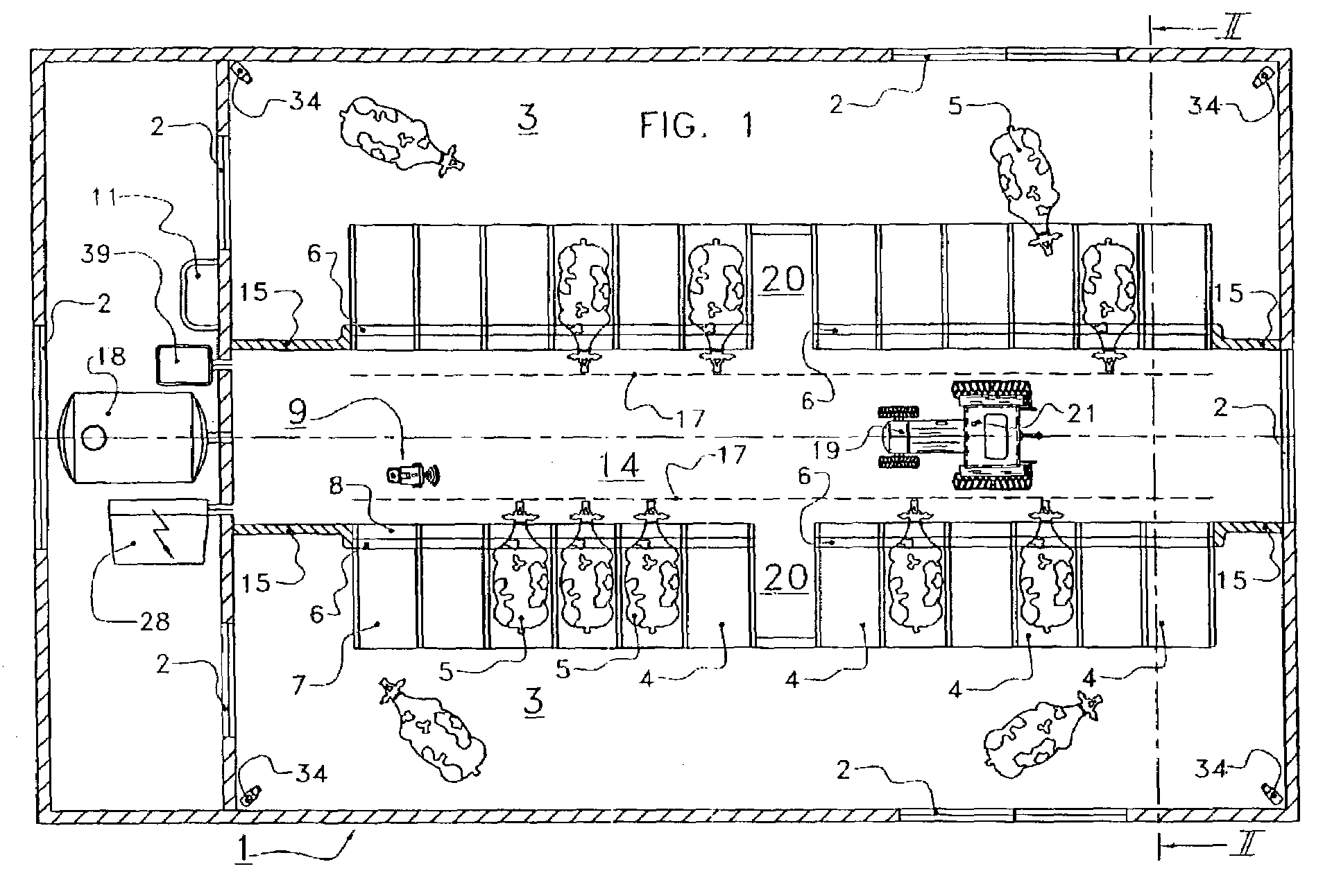

Assembly for feeding and milking animals, and a method of feeding and milking animals

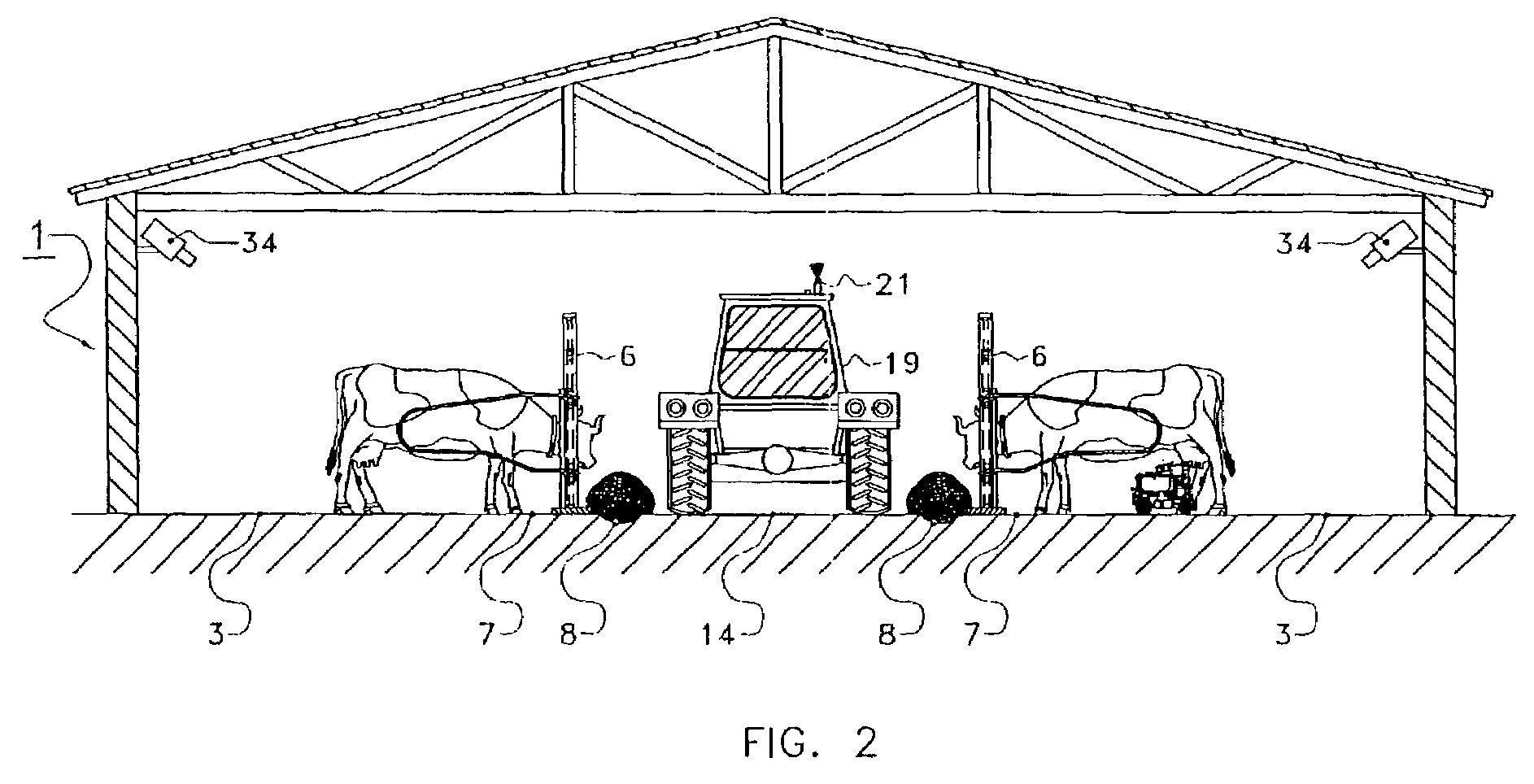

InactiveUS20100064974A1Inexpensive mannerNo longer frighteningProgramme-controlled manipulatorCathetersComputerized systemEngineering

An assembly and method for feeding and milking animals is disclosed. The assembly is provided with an area where the animals are allowed to move freely, with a number of juxtaposed feeding stations for the animals, and with a retaining device for retaining an animal at a feeding station. The retaining device can be activated for retaining an animal and can be deactivated for releasing an animal. A mobile milking robot connects at least one teat cup to a teat of an animal, a computer system controlling the operation and movement of the milking robot. The mobile milking robot is a self-propelled mobile milking robot, and the retaining device is fixedly disposed at the feeding station.

Owner:LELY ENTERPRISES

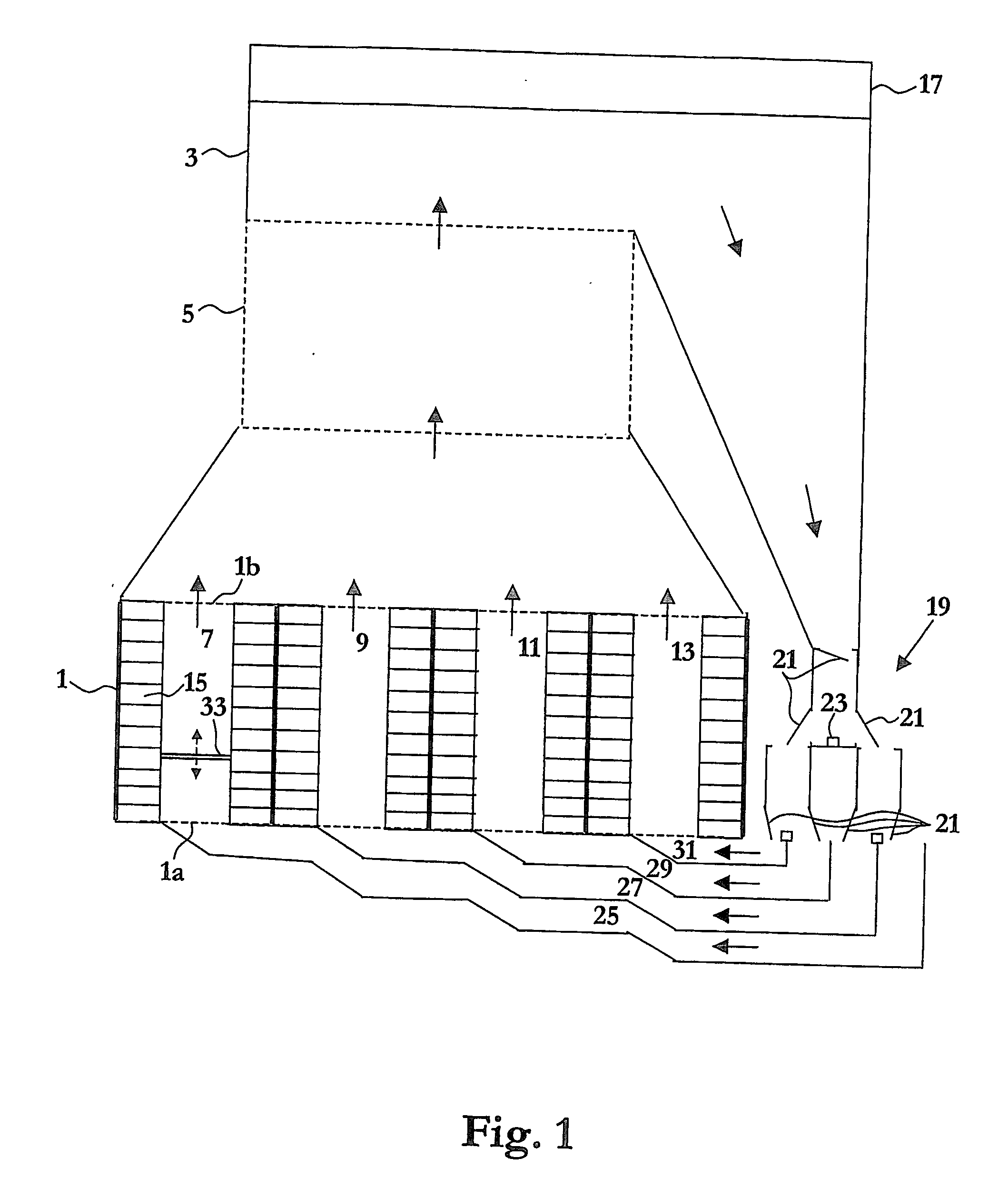

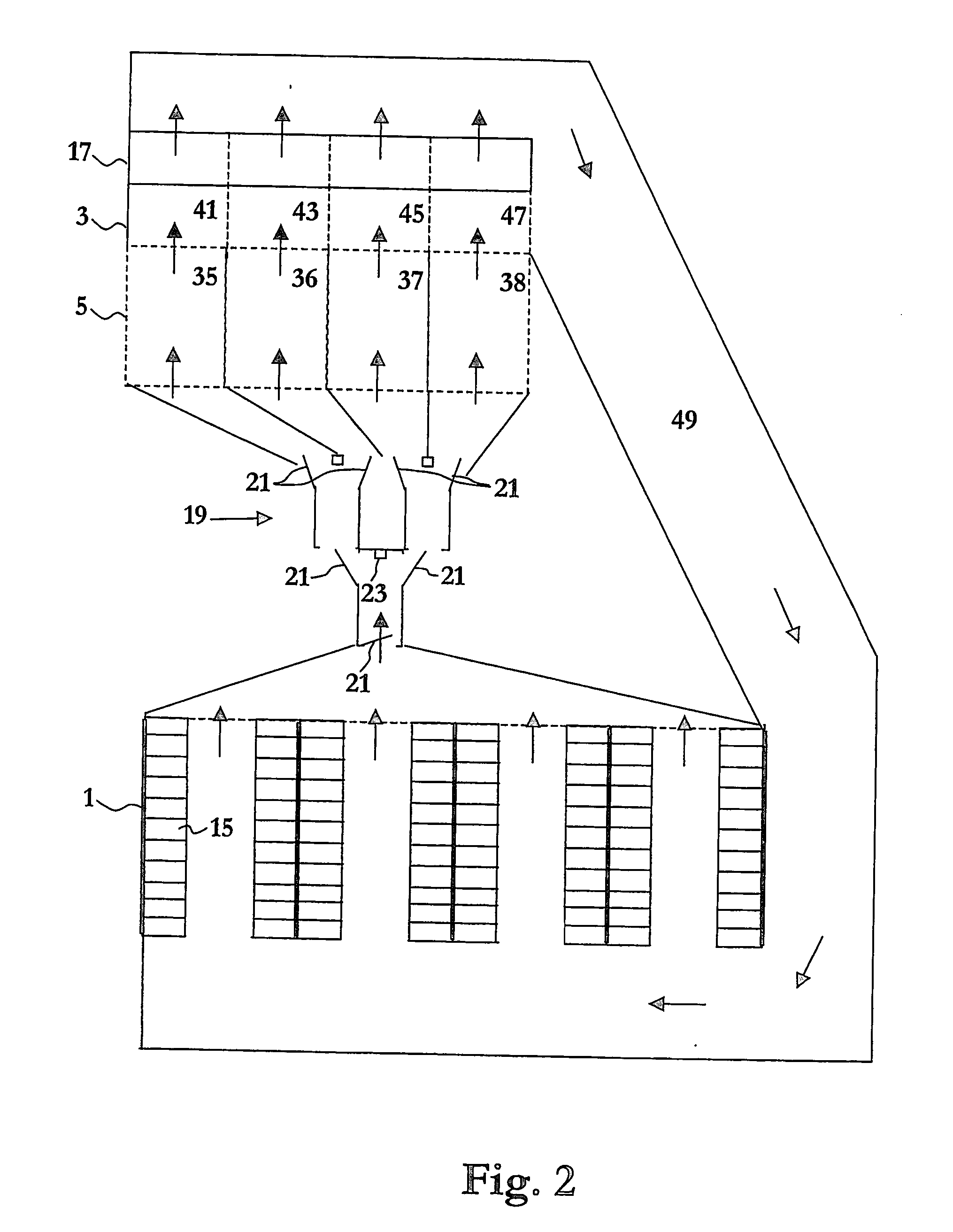

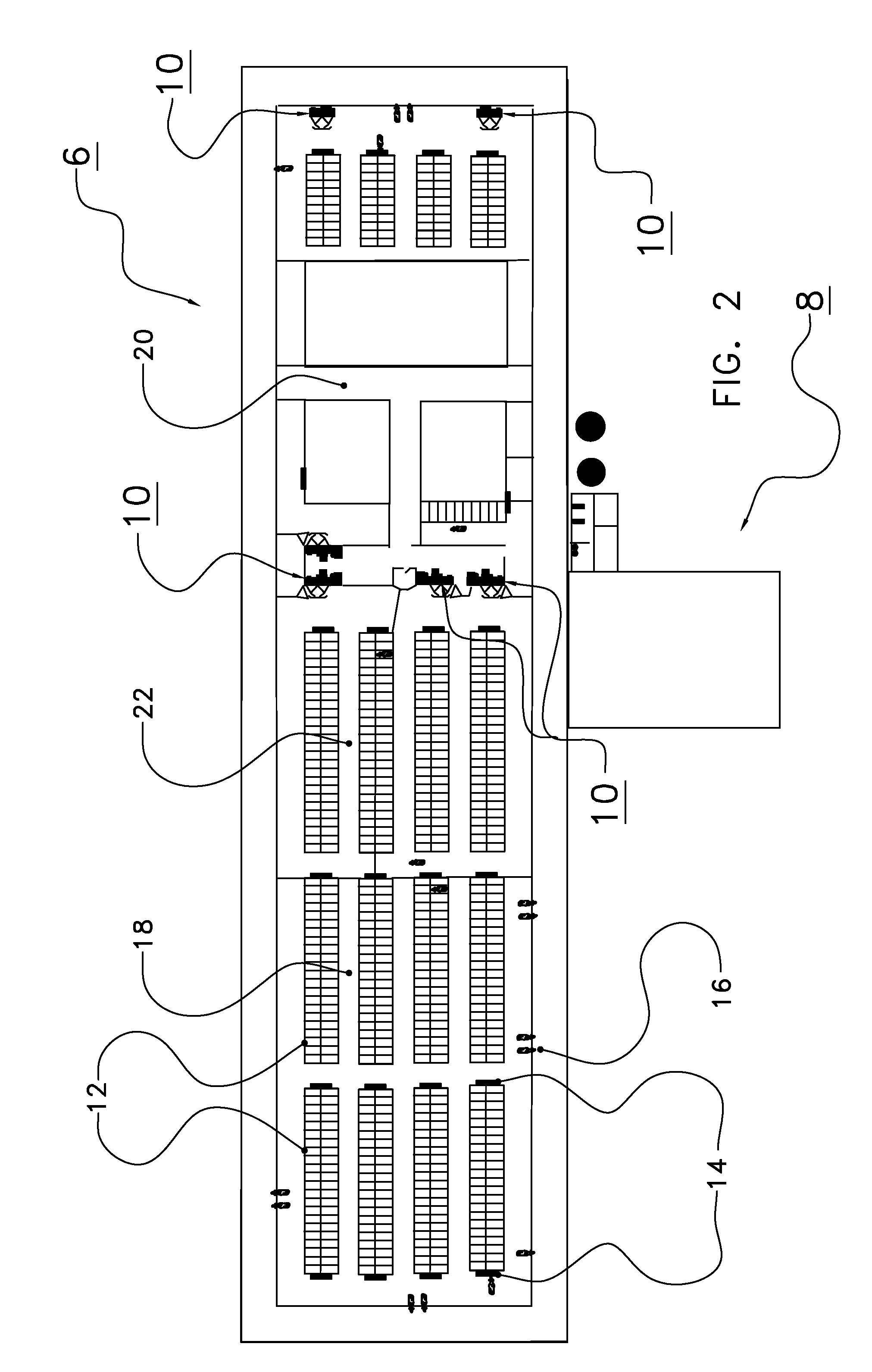

Arrangement for housing milking animals

InactiveUS20060249083A1Easy to controlImprove overall utilizationCathetersAnimal housingEngineeringMilking robot

An arrangement for housing a large number of milking animals, each of which belongs to one of a plurality of groups, comprises a resting area (1) wherein the milking animals are allowed to rest; a feeding area (3) wherein the milking animals are fed; and a milking area (5) housing at least one milking robot for milking the milking animals, wherein the resting area (1) or the feeding area (3) is partitioned in sections (7, 9, 11, 13; 41, 43, 45, 47), the number of which corresponds to the number of the groups; and a device (19; 53) is provided for directing each of the milking animals moving towards the resting area (1) or the feeding area (3), which is partitioned in sections, into one of the sections depending on the group, to which the respective milking animal belongs, so that that each of said sections will house milking animals belonging to one of said groups.

Owner:DELAVAL HLDG AB

Implement for automatically milking a dairy animal

ActiveUS8807080B2High resolutionMaximum of constructive simplicityCathetersRobotMilk cow'sPhase difference

An implement for automatically milking a dairy animal, such as a cow, comprises a milking parlor, a sensor for observing a teat, and a milking robot for automatically attaching a teat cup to the teat. The milking robot comprises a robot control that is connected to the sensor. The sensor comprises a radiation source for emitting light, a receiver for receiving electromagnetic radiation reflected from the dairy animal, a lens, and sensor control unit. The sensor comprises a matrix with a plurality of rows and a plurality of columns of receivers. The sensor control unit is designed to determine for each of the receivers a phase difference between the emitted and the reflected electromagnetic radiation in order to calculate the distance from the sensor to a plurality of points on the part to be observed of the dairy animal.

Owner:MAASLAND

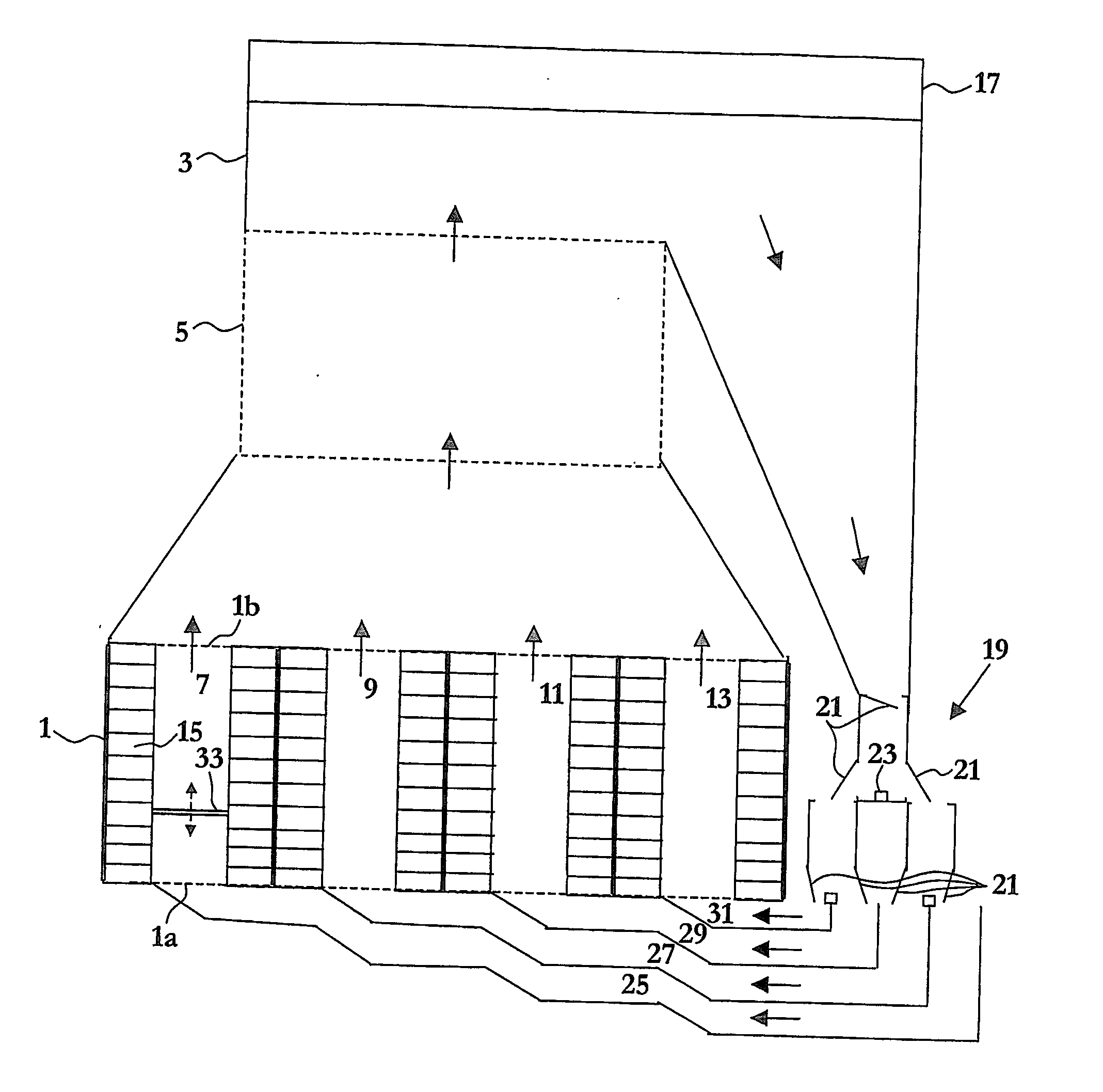

Arrangement and Method for Milking a Plurality of Milking Animals

ActiveUS20080282985A1Milk production can be maximizedGood animal healthCathetersAnimal housingEngineeringAutomatic milking

An arrangement for milking a plurality of milking animals comprises an automated milking system (11) provided with a milking robot (13) for automatically milking a milking animal; a milking system (15) provided for batchwise milking of multiple milking animals; an identification arrangement (19, 21) provided for identifying each of the plurality of milking animals prior to being milked; decision means (23) connected to the identification arrangement for deciding, for each of the plurality of milking animals, whether that milking animal should be milked by the automated milking system or by the milking system for batchwise milking; and means connected (25) to the decision means for guiding each of the plurality of milking animals to the automated milking system or to the milking system for batchwise milking depending on the decision made for that milking animal.

Owner:DELAVAL HLDG AB

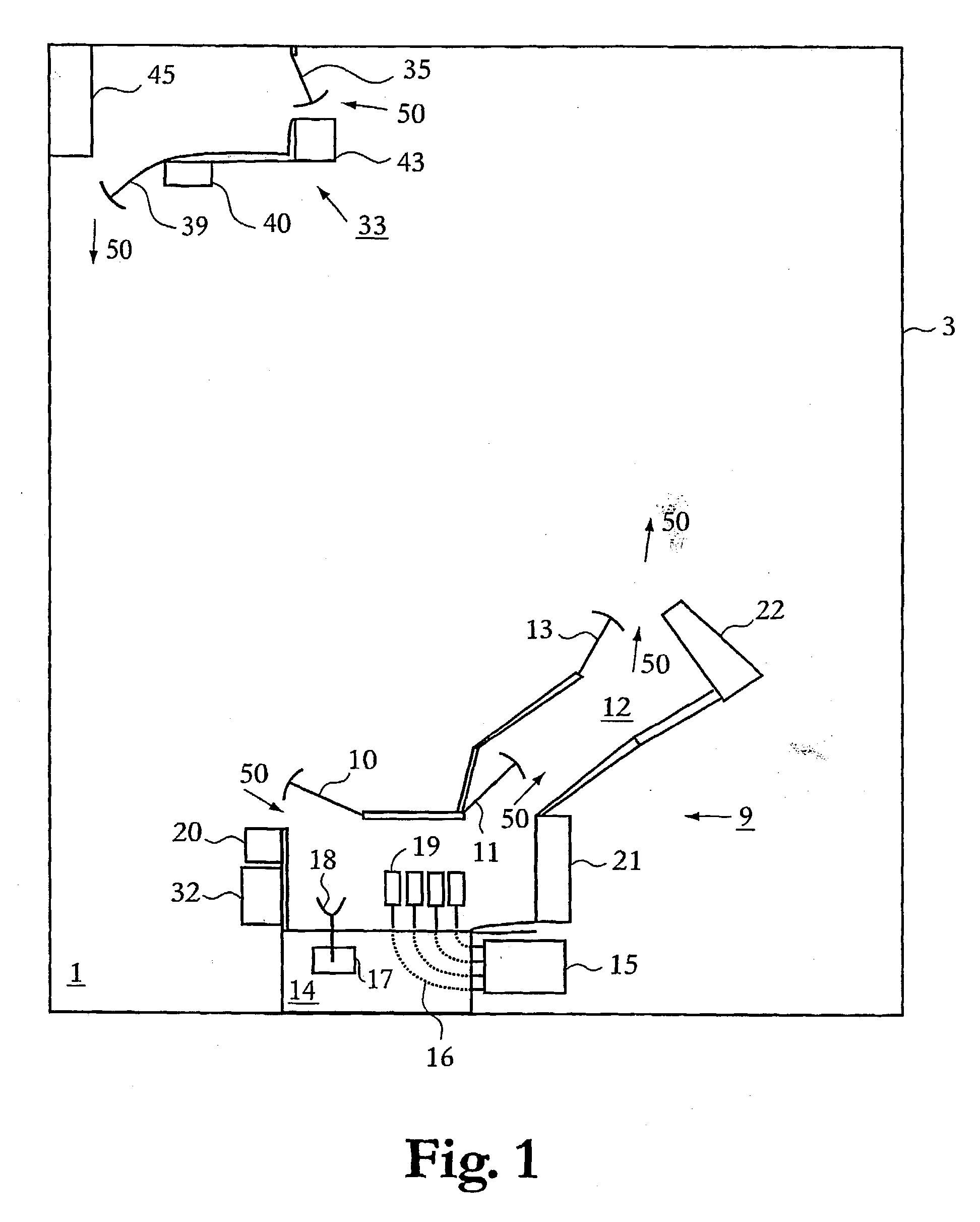

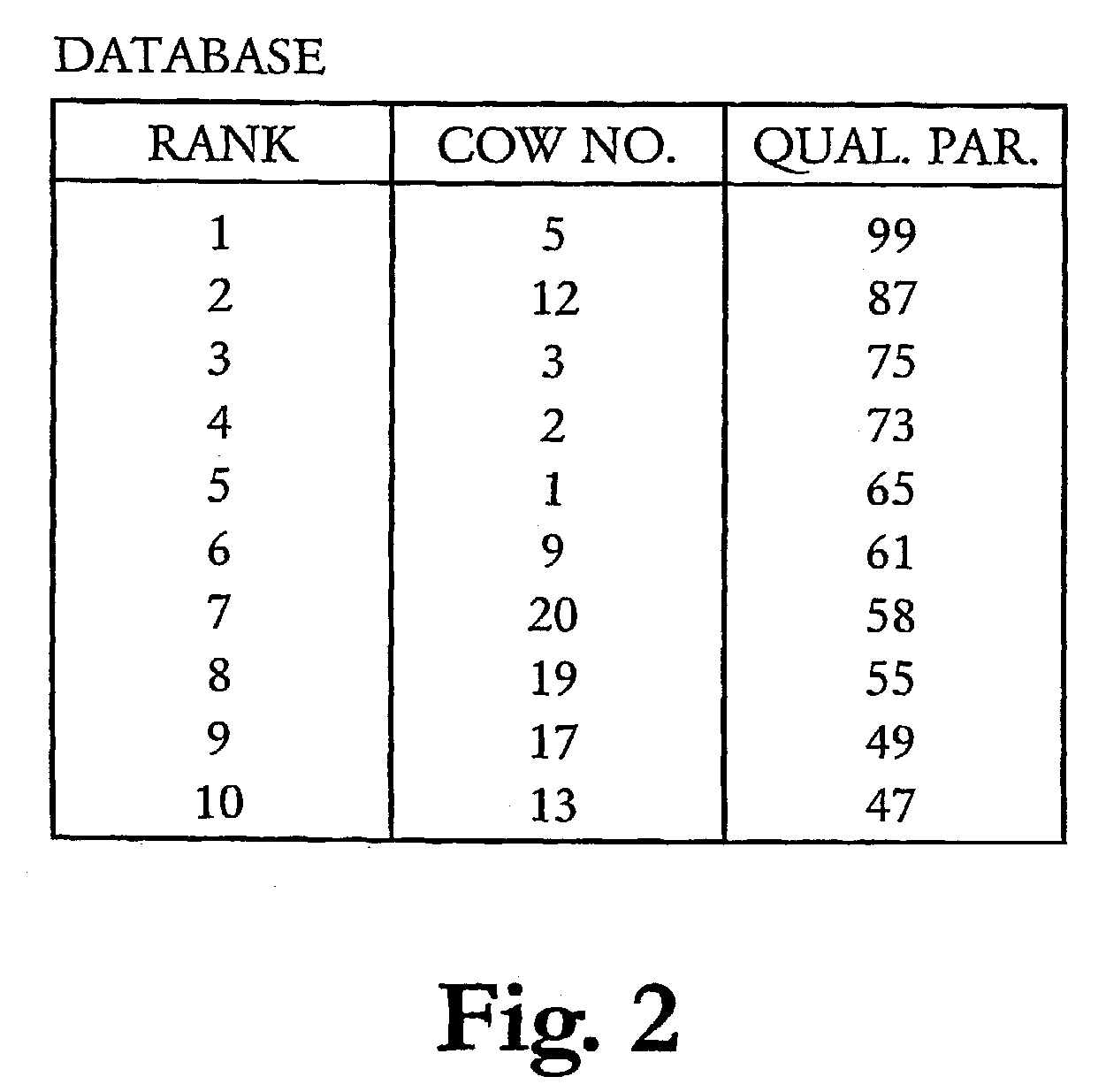

Method of miling and milking parlor

A method of automatically milking animals, such as cows, which are allowed to move freely in an area (1) intended therefore and to visit individually a milking parlor (9) comprising a fully automatic milking machine or milking robot (14) and an animal identification system (20), comprises the steps of dynamically assigning a milking qualification parameter to each of the animals that are allowed to move freely in said area, the respective milking qualification parameter indicating the degree of suitability that the respective animal, to which the milking qualification parameter is assigned, shall be milked; dynamically ranking the animals in accordance with their respective milking qualification parameters; and milking an animal during a visit to the milking parlor only if said animal is identified as belonging to the X highest ranked animals, i.e. the X animals that are best suited to be milked from a milk production optimization viewpoint, X being a positive integer.

Owner:DELAVAL HLDG AB

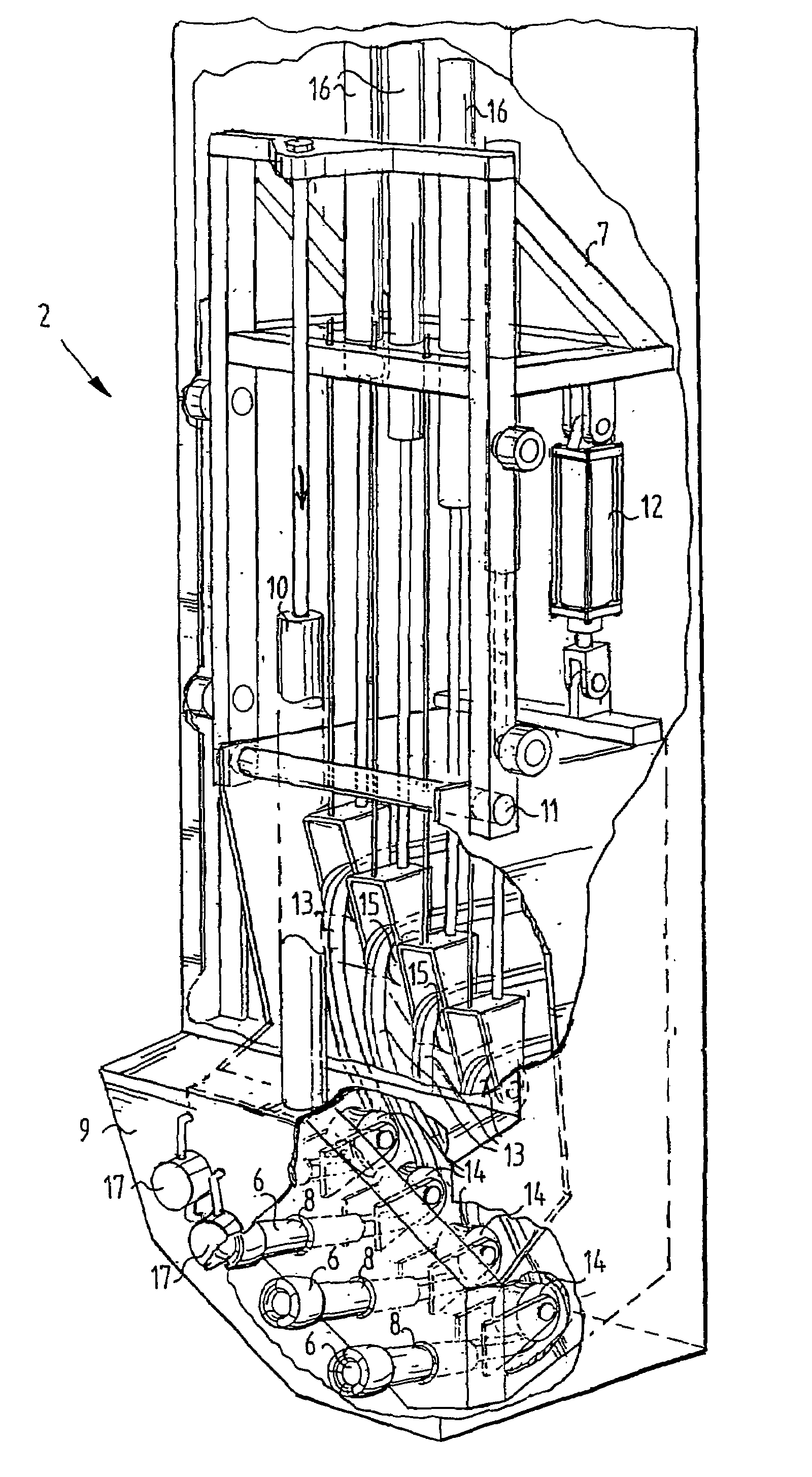

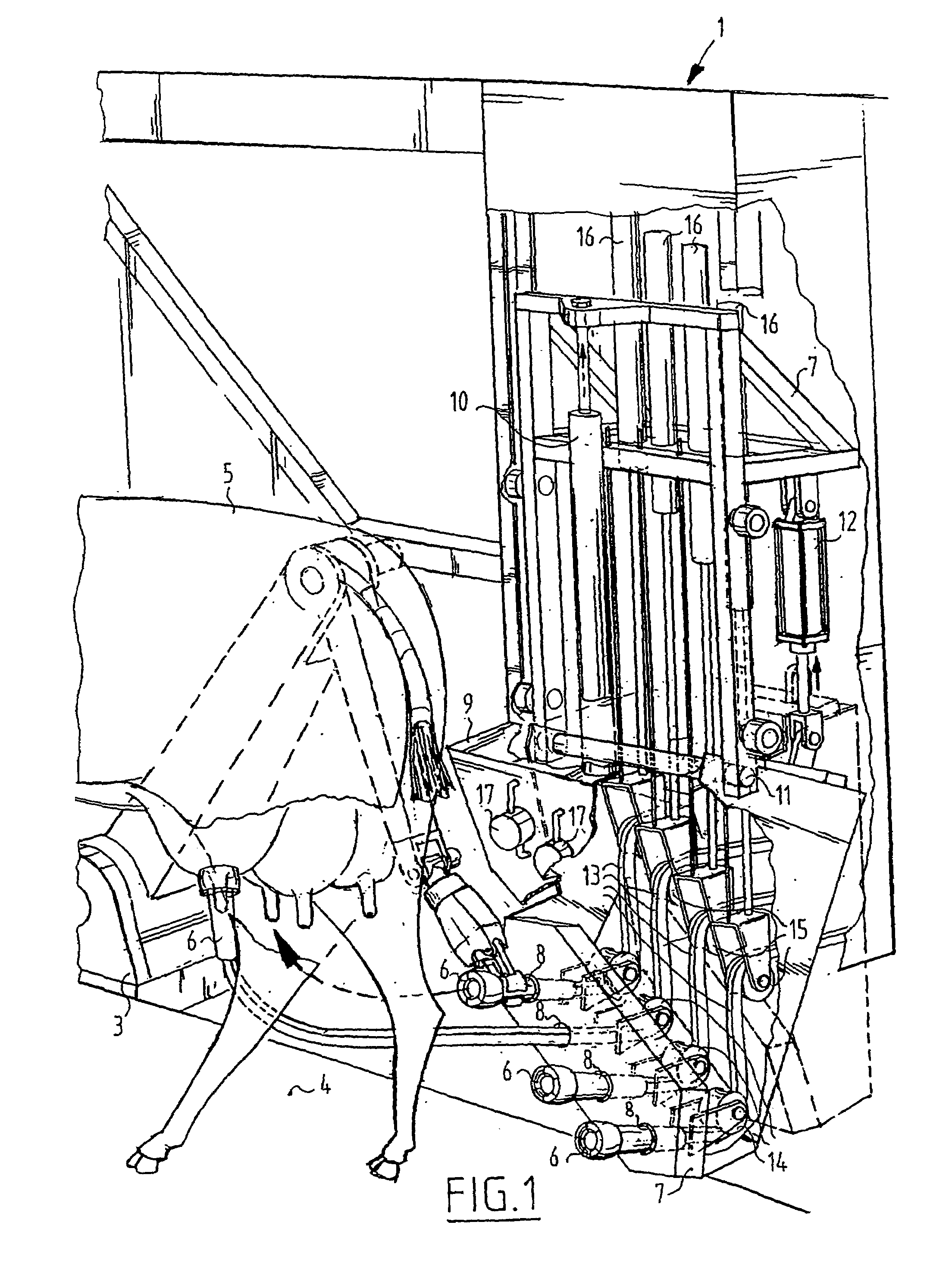

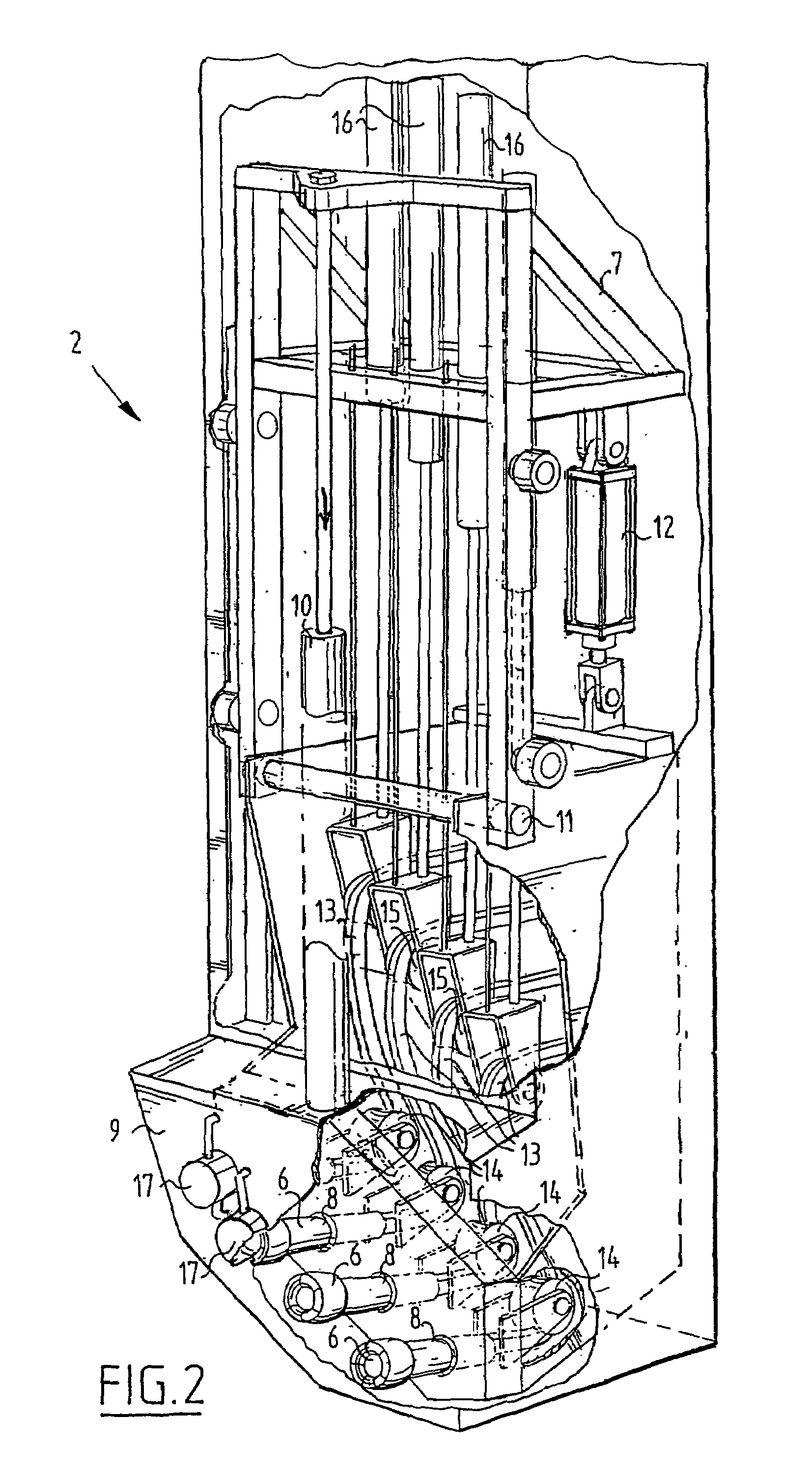

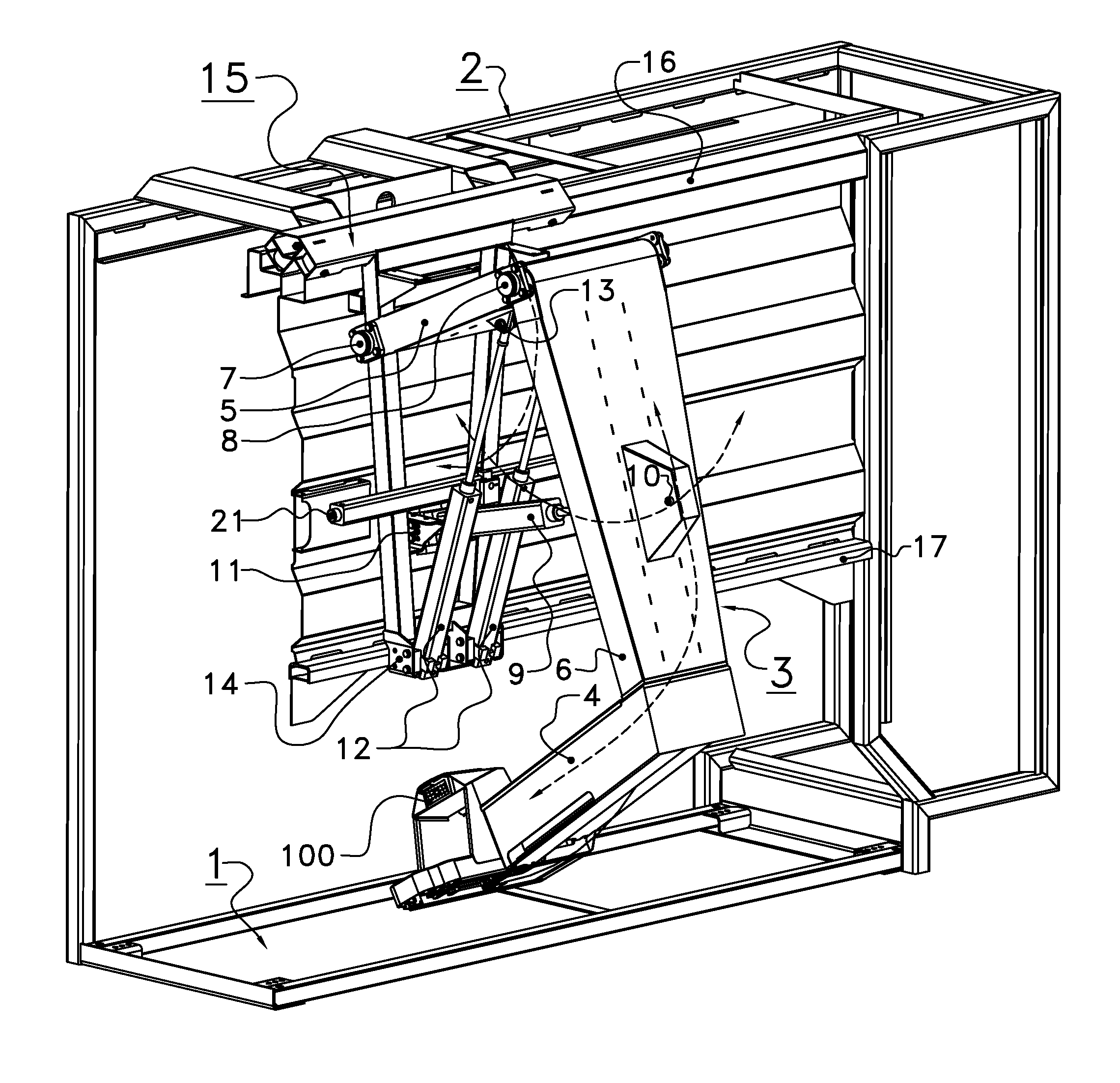

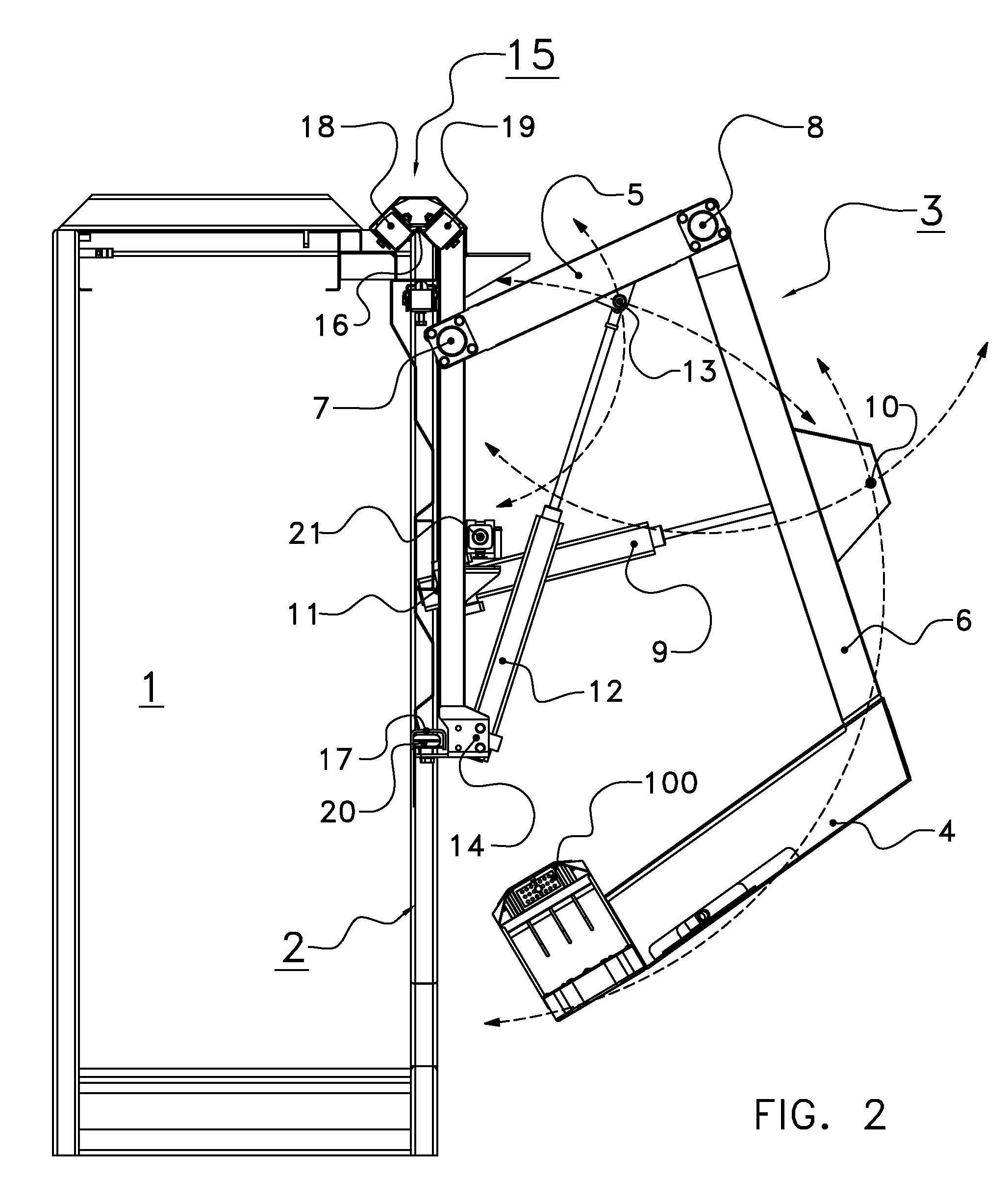

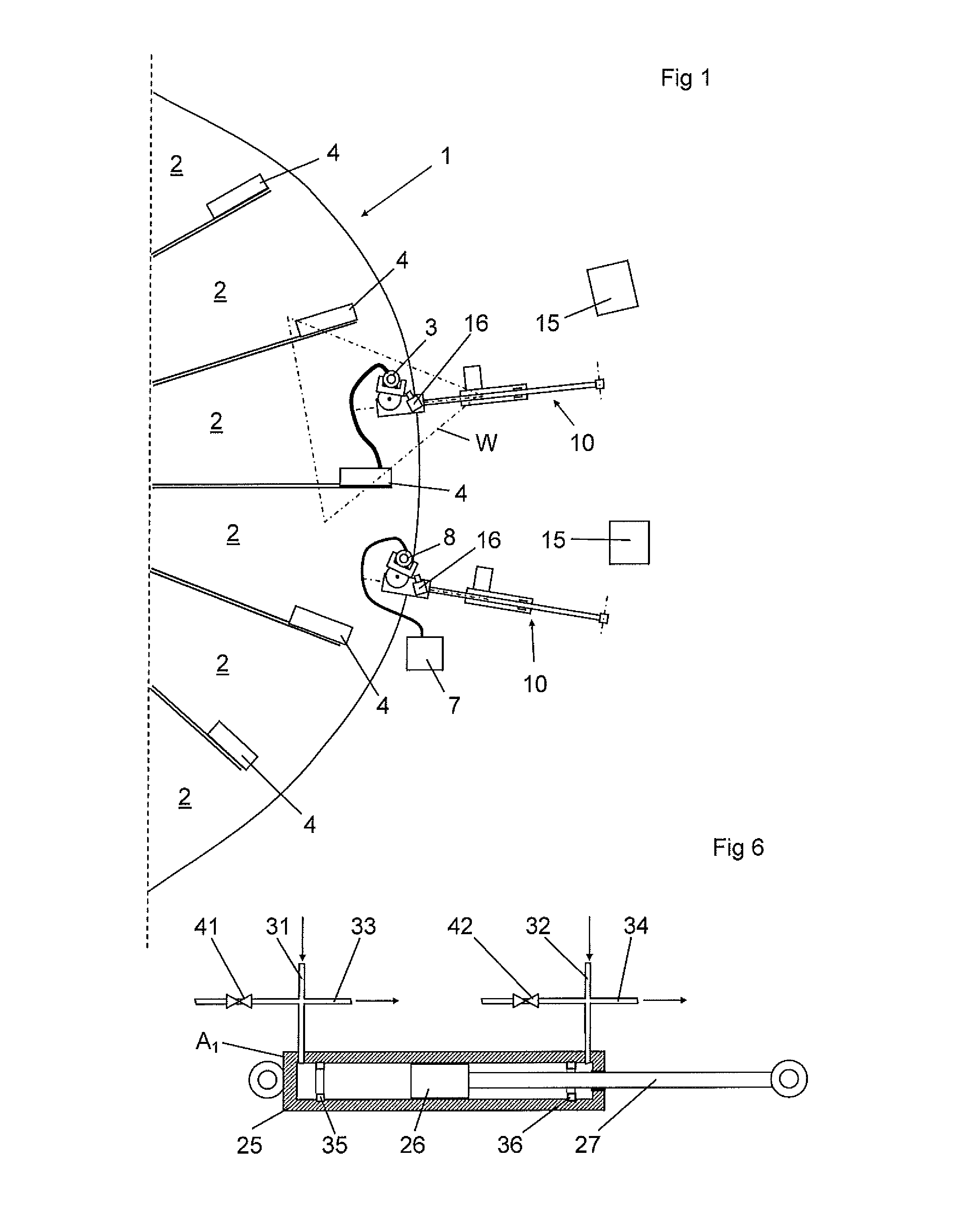

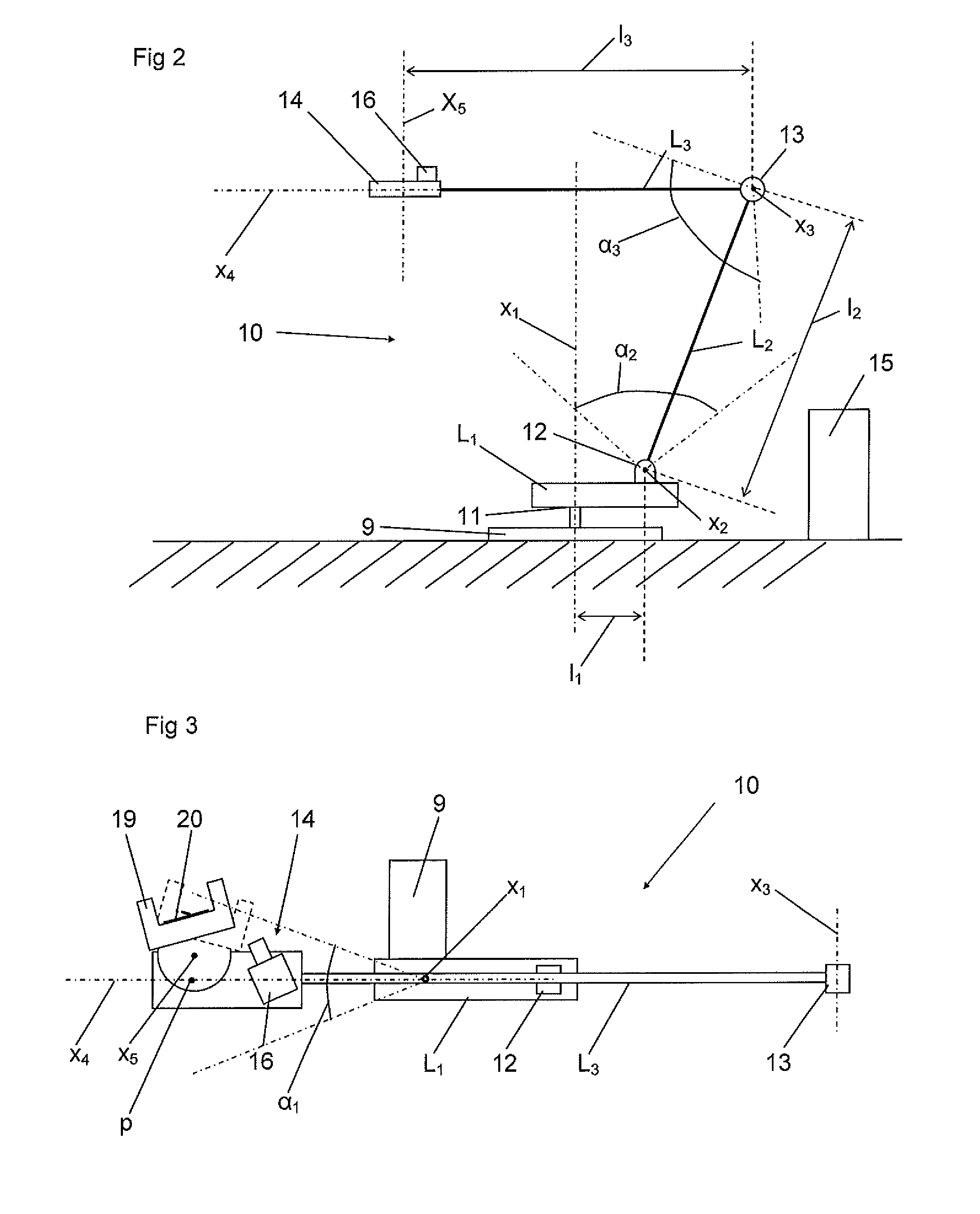

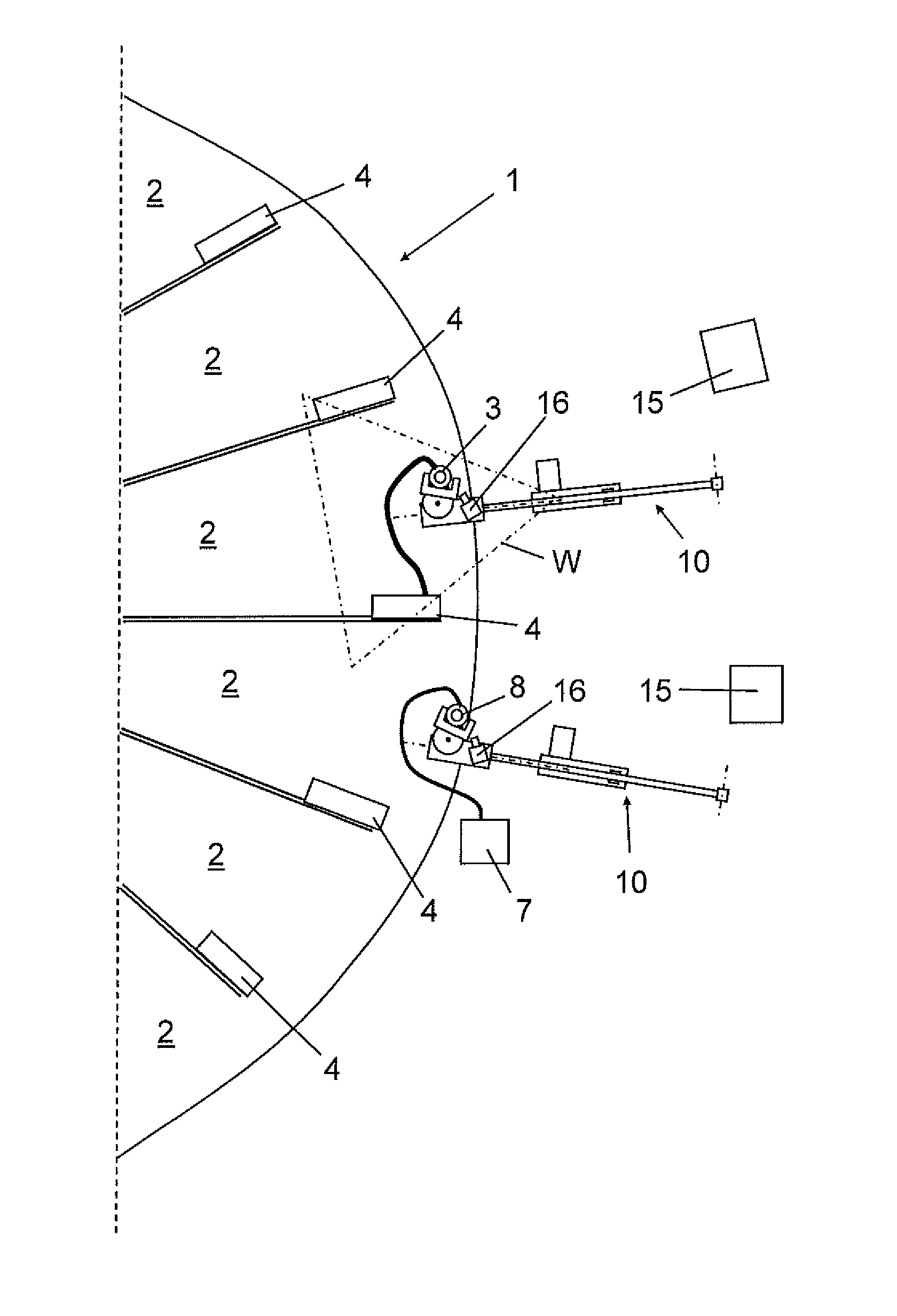

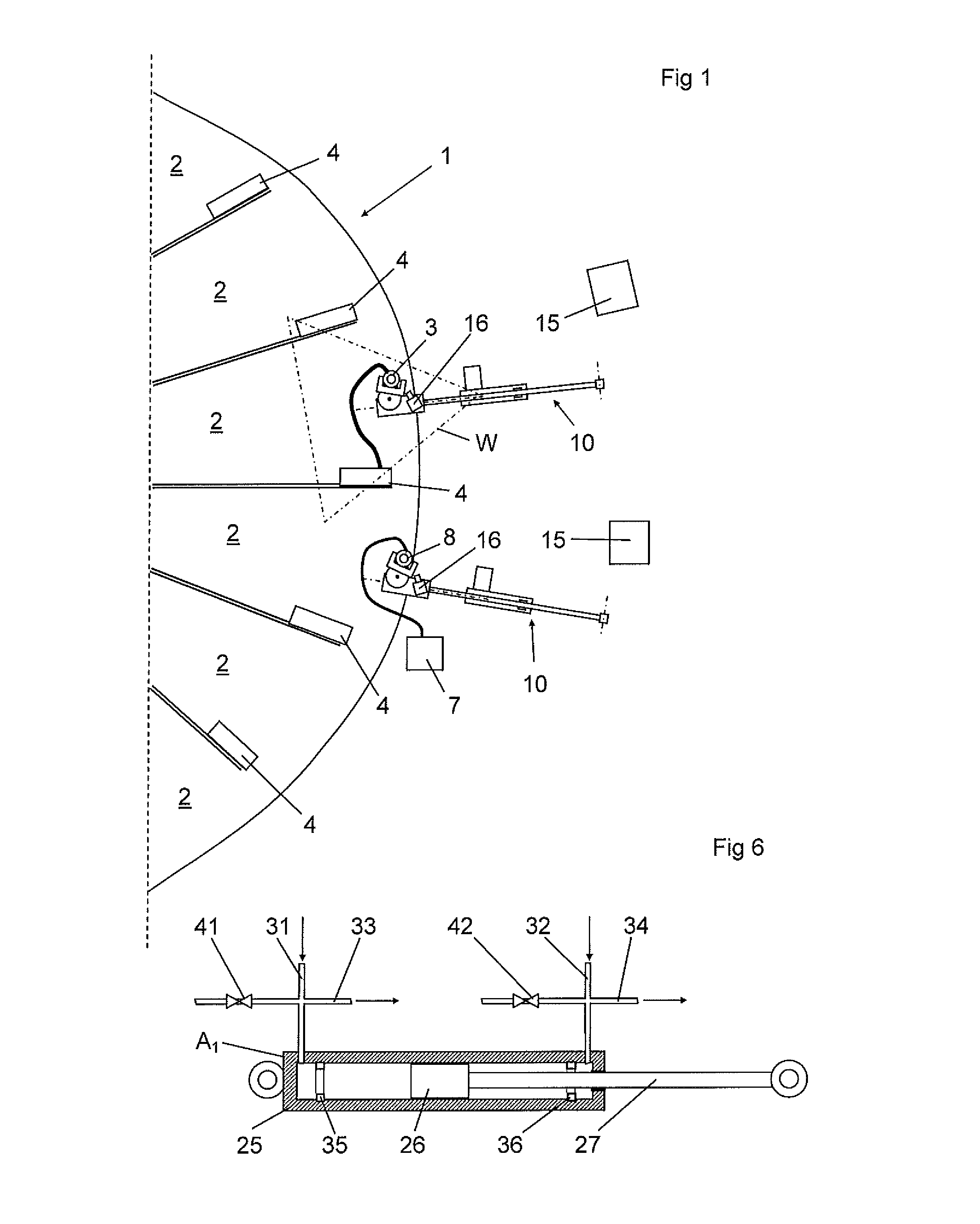

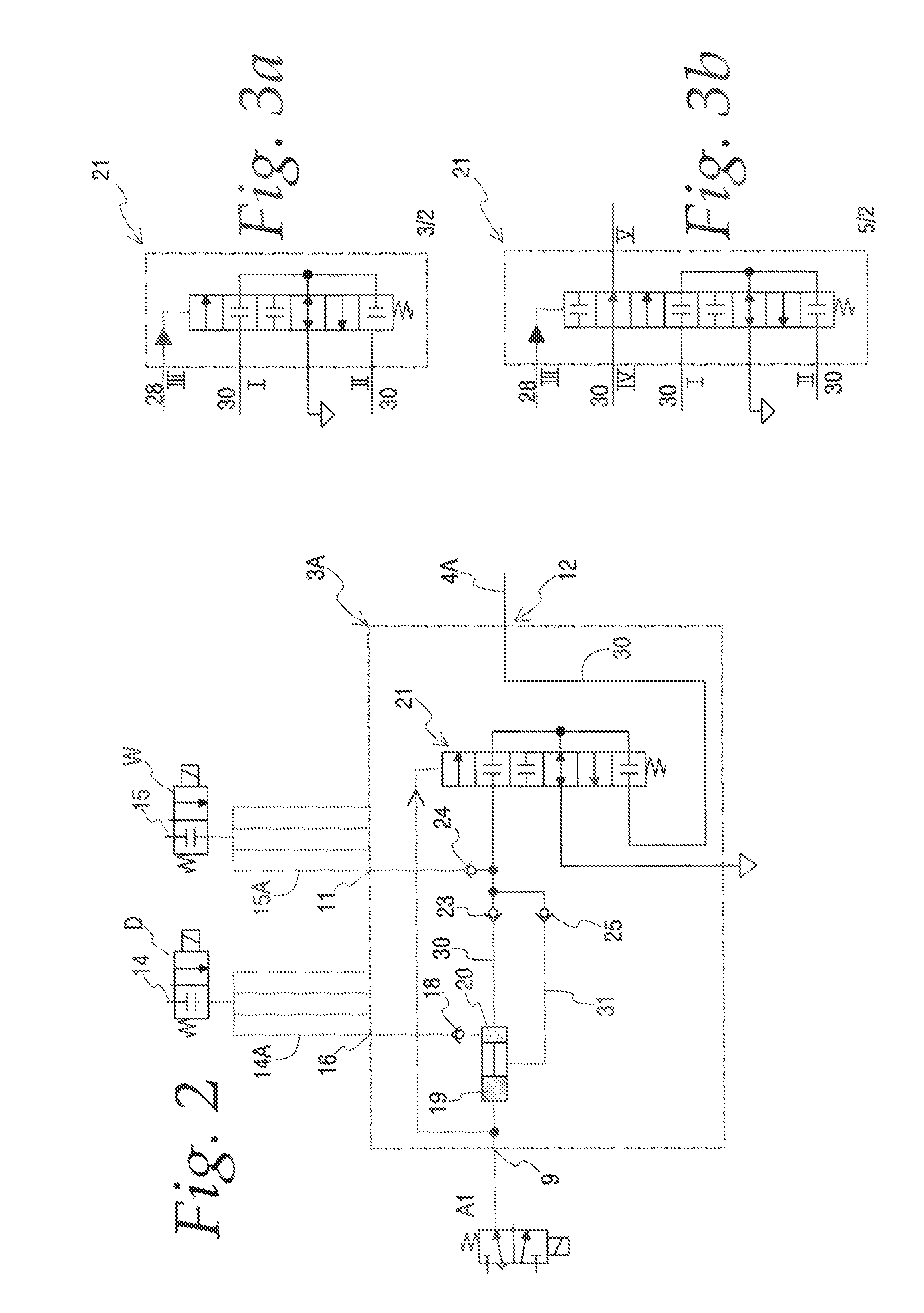

Milking robot, and a milking arrangement

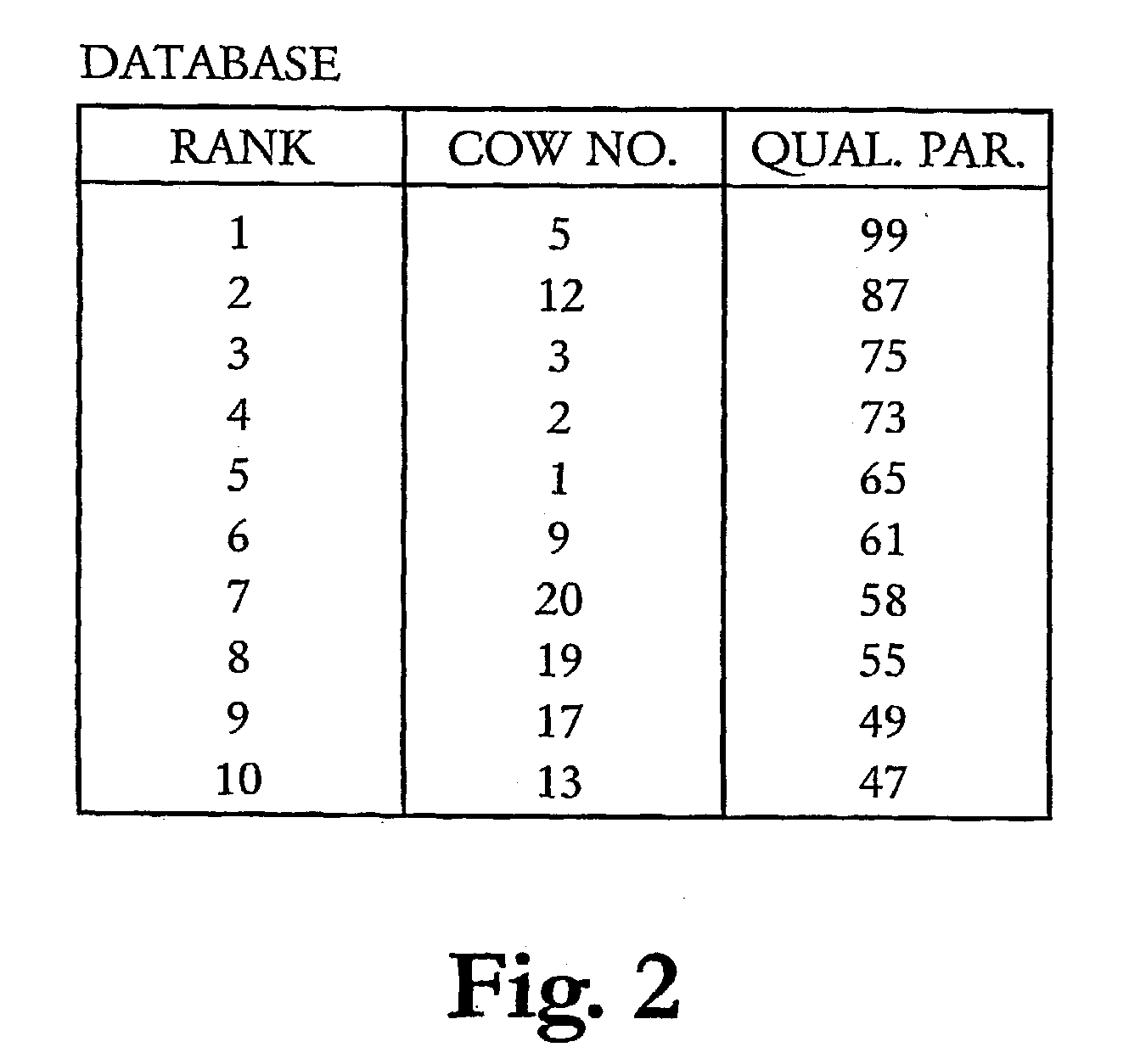

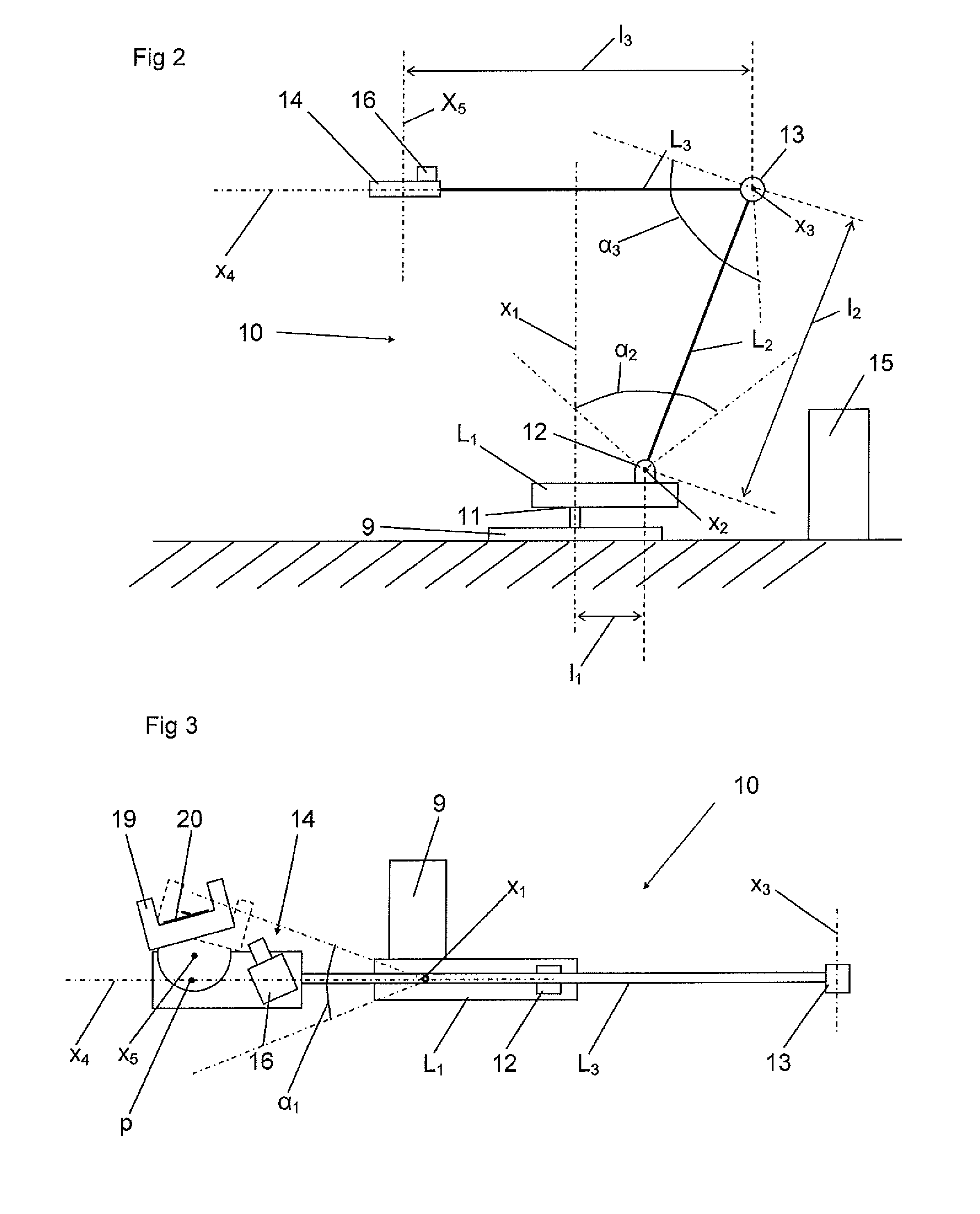

ActiveUS20130074775A1Simple and inexpensive and light designCalibration accuracyProgramme-controlled manipulatorCathetersWorkspaceEngineering

A milking arrangement includes a milking robot (10) having a first link (L1), a second link (L2), a third link (L3), an end effector (E), sensor (16) and a control unit (15). The first link is rotatable to a first angle within a first angle range (α1) via a first joint (11). The second link is rotatable to a second angle within a second angle range (α2) via a second joint (12). The third link (L3) is rotatable to a third angle within a third angle range (α3) via third joint (13). The links (L1, L2, L3) are rotatable so that the end effector is movable within a three-dimensional workspace (W). Each position of the end effector within the workspace corresponds to a single combination of the first, second and third angles.

Owner:DELAVAL HLDG AB

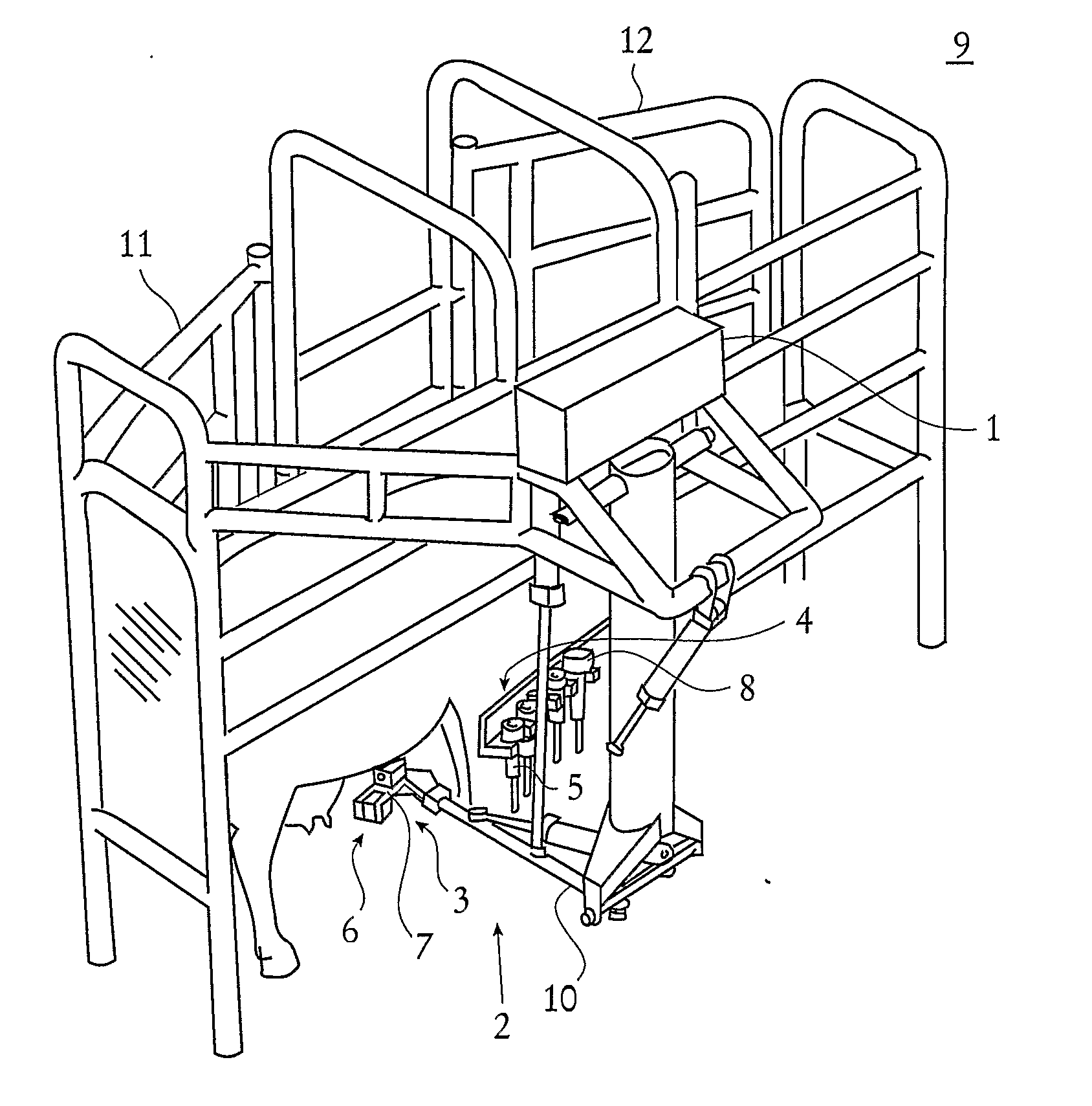

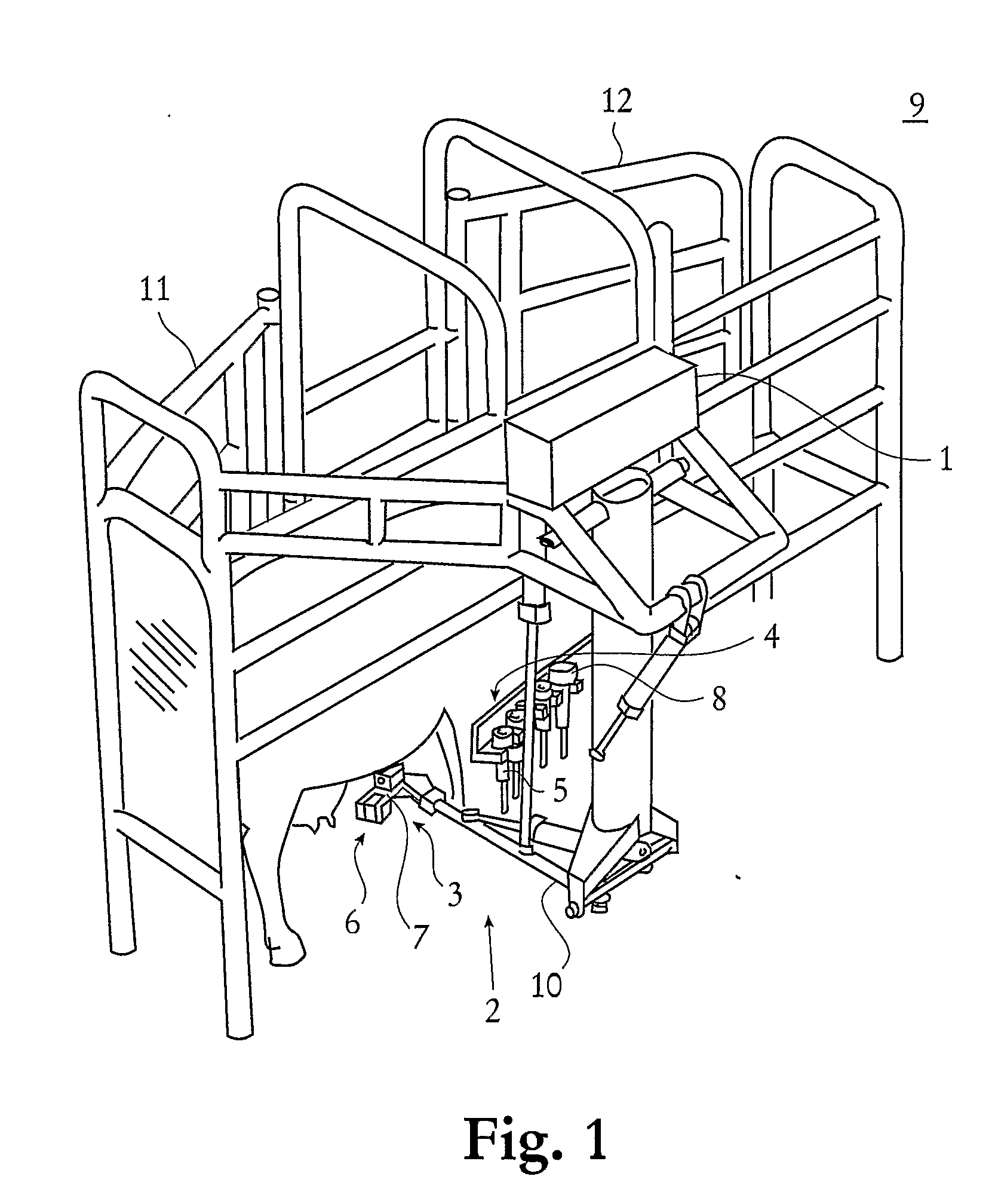

Assembly for feeding and milking animals, and a method of feeding and milking animals

InactiveUS7640889B2Inexpensive mannerNo longer frighteningCathetersAnimal feeding devicesComputerized systemEngineering

An assembly and method for feeding and milking animals is disclosed. The assembly is provided with an area where the animals are allowed to move freely, with a number of juxtaposed feeding stations for the animals, and with a retaining device for retaining an animal at a feeding station. The retaining device can be activated for retaining an animal and can be deactivated for releasing an animal. A mobile milking robot connects at least one teat cup to a teat of an animal, a computer system controlling the operation and movement of the milking robot. The mobile milking robot is a self-propelled mobile milking robot, and the retaining device is fixedly disposed at the feeding station.

Owner:LELY ENTERPRISES

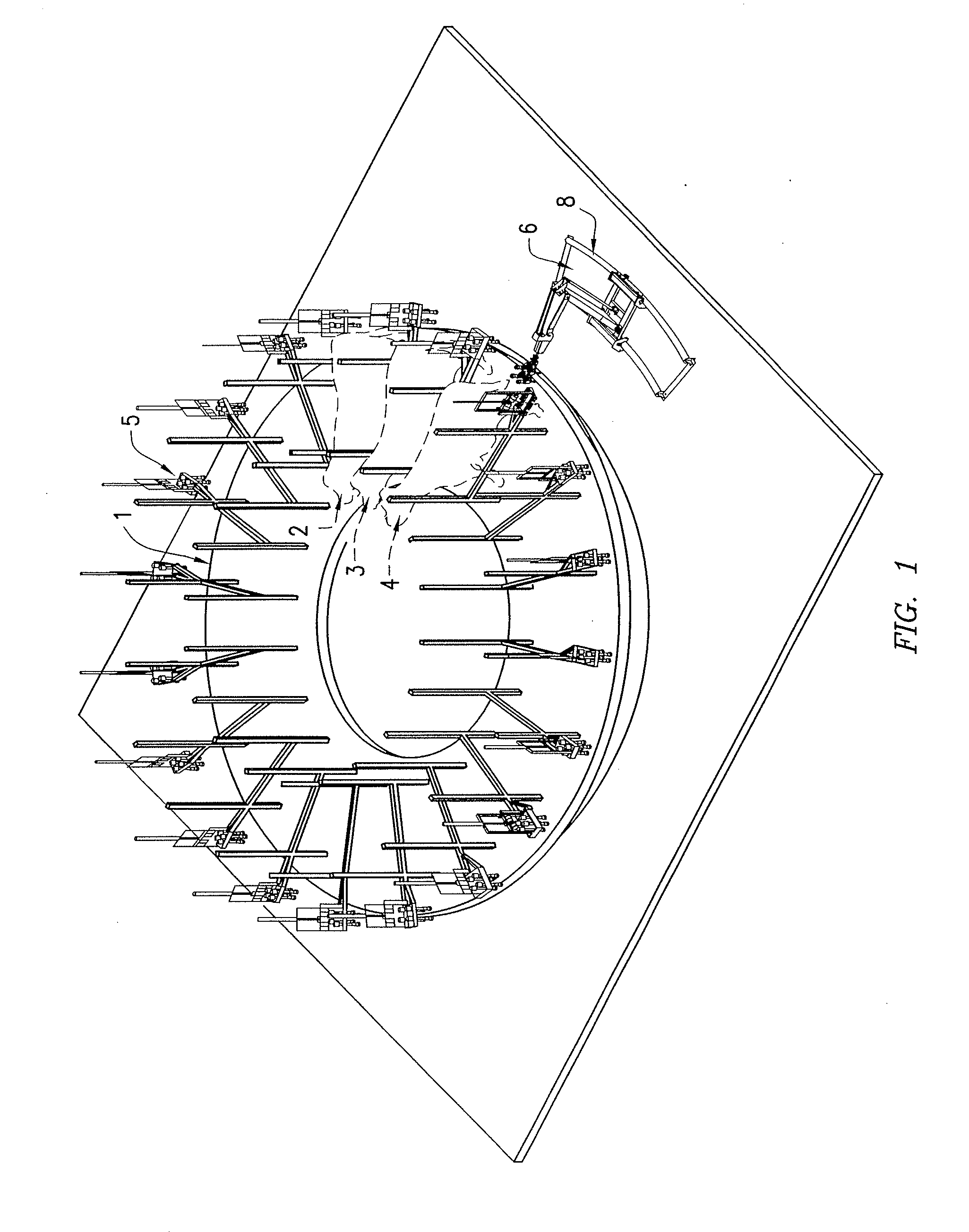

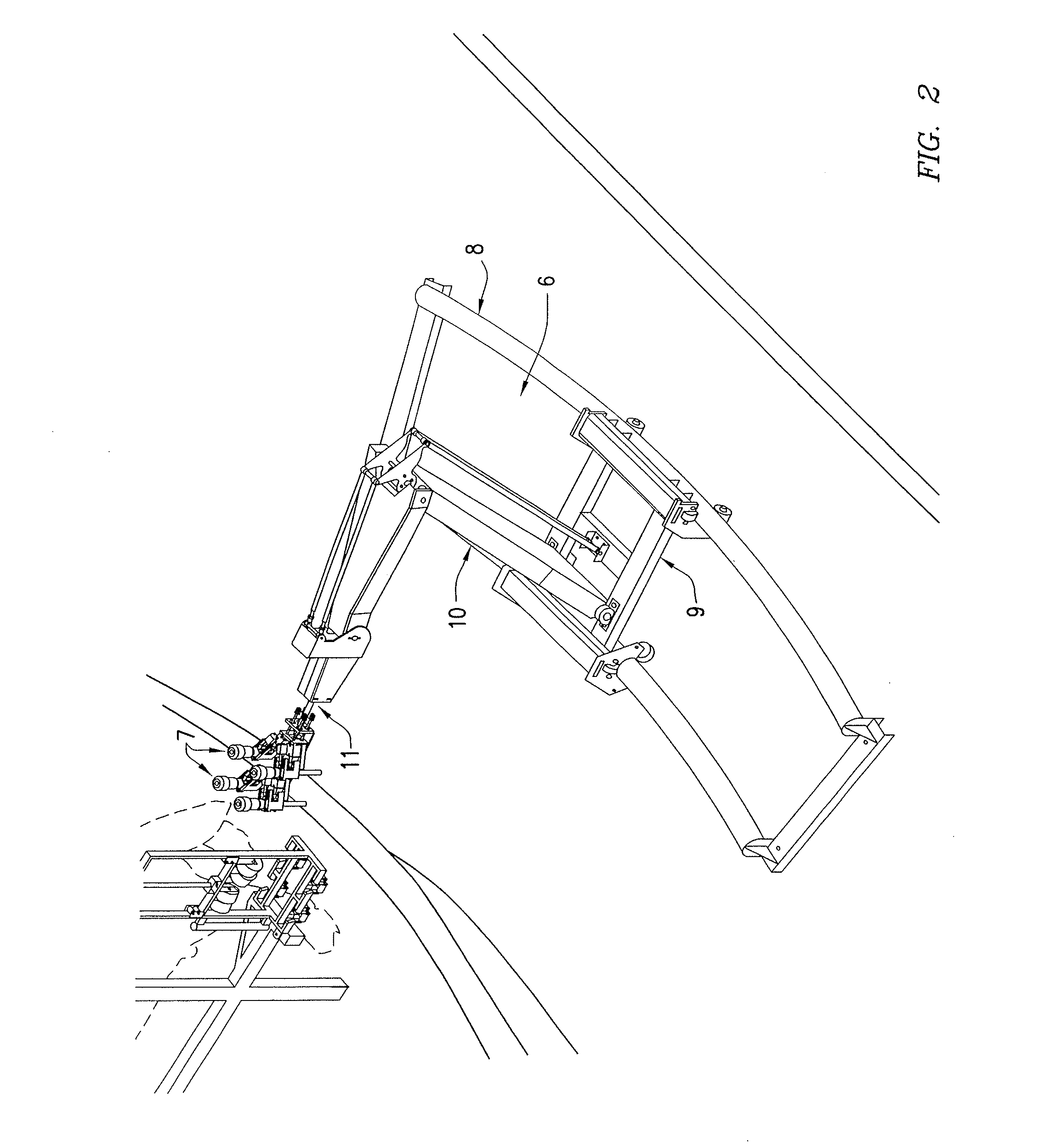

Robot and method for milking a cow by this robot

A milking robot comprises a frame that is movable along a guide track that is positioned adjacent to a rotary platform such that the frame can move in conjunction with the movement of the rotary platform. The milking robot further comprises a moveable arm having a first end that couples to the frame and a second end that extends in a longitudinal direction, and at least one gripper coupled to the movable arm at the second end. The gripper is extendable in the longitudinal direction of the movable arm.

Owner:TECH HLDG

Milking installation

ActiveUS20050000455A1Excessive condensationProduce quicklyFluid parameterDomestic cooling apparatusLine tubingEngineering

A milking installation comprises a compressed air system with a compressed air line, a pneumatically controllable cylinder and a compressed air pump for supplying compressed air for the cylinder. The compressed air system comprises a dew point sensor for measuring the dew point of the compressed air and for emitting a dew point signal that is representative of the dew point. The milking installation may comprise or form part of a milking robot for automatically connecting teat cups to the teats of a dairy animal.

Owner:LELY ENTERPRISES

Method of milking and milking parlor

A method of automatically milking animals, such as cows, which are allowed to move freely in an area (1) intended therefore and to visit individually a milking parlor (9) comprising a fully automatic milking machine or milking robot (14) and an animal identification system (20), comprises the steps of dynamically assigning a milking qualification parameter to each of the animals that are allowed to move freely in said area, the respective milking qualification parameter indicating the degree of suitability that the respective animal, to which the milking qualification parameter is assigned, shall be milked; dynamically ranking the animals in accordance with their respective milking qualification parameters; and milking an animal during a visit to the milking parlor only if said animal is identified as belonging to the X highest ranked animals, i.e. the X animals that are best suited to be milked from a milk production optimization viewpoint, X being a positive integer.

Owner:DELAVAL HLDG AB

System for managing a group of dairy animals

ActiveUS20100012038A1Avoid delayAvoid reportingCathetersAnimal housingDiary foodsProgram instruction

A system for managing a group of dairy animals to be milked fully automatically, where the dairy animals go through a lactation cycle comprising phases of calving, inmilking, producing milk, and being dry. The system includes a computer executing program instructions for recording information and processing data indicating a division of the group of dairy animals into subgroups of a plurality of dairy animals, an insemination period determined per subgroup within which the dairy animals of the subgroup concerned are to be inseminated, which insemination period is so short that substantially all dairy animals in the subgroup concerned go simultaneously through the lactation cycle, and a separation of pregnant dairy animals of at least one of the subgroups in a separate area, around the beginning of the being dry phase of the subgroup concerned. The system also includes at least one milking robot for automatically milking the dairy animals, operatively connected to the computer for receiving first instructions from the computer for milking the dairy animals in the non-separated subgroups, and second instructions from the computer for milking the dairy animals in the separated subgroup in the separate area.

Owner:MAASLAND

Device for milking animals

A device for milking animals is provided with at least two milking robots, each for automatically connecting at least one teat cup to a teat of an animal. Each milking robot is provided with a milking vacuum unit for generating a milking vacuum for milking an animal. The device is provided wit a common ring line and wit a controllable, central vacuum system for generating a vacuum with a first pressure on the common ring line. Each milking vacuum unit is connected to the ring line via a passage, a control device being provided for controlling the size of the passage.

Owner:LELY ENTERPRISES

Gripper device, robot arm, and milking robot

ActiveUS7908998B2Uncomplicated and reliable and inexpensive to manufacture and assemble and useFew moving partsGripping headsCathetersEngineeringMechanical engineering

A gripper device mountable on a robot arm (10) of a milking robot (2) provided for automatically attach teat cups (5) to the teats of a milking animal, the gripper device comprises an electromagnet (6) from gripping teat cups made of a magnetic material, the electromagnet including a coil (31) feedable with a current a core (33) of a magnetic material arranged at least partly within the coil; and a support structure (7) for holding the electromagnet. The core comprises two end and portions (33a-b) in a single face of the electromagnet, wherein the two end portions constitute different poles of the electromagnet, and are shaped to be engagable with each of the teat cups in a close fit.

Owner:DELAVAL HLDG AB

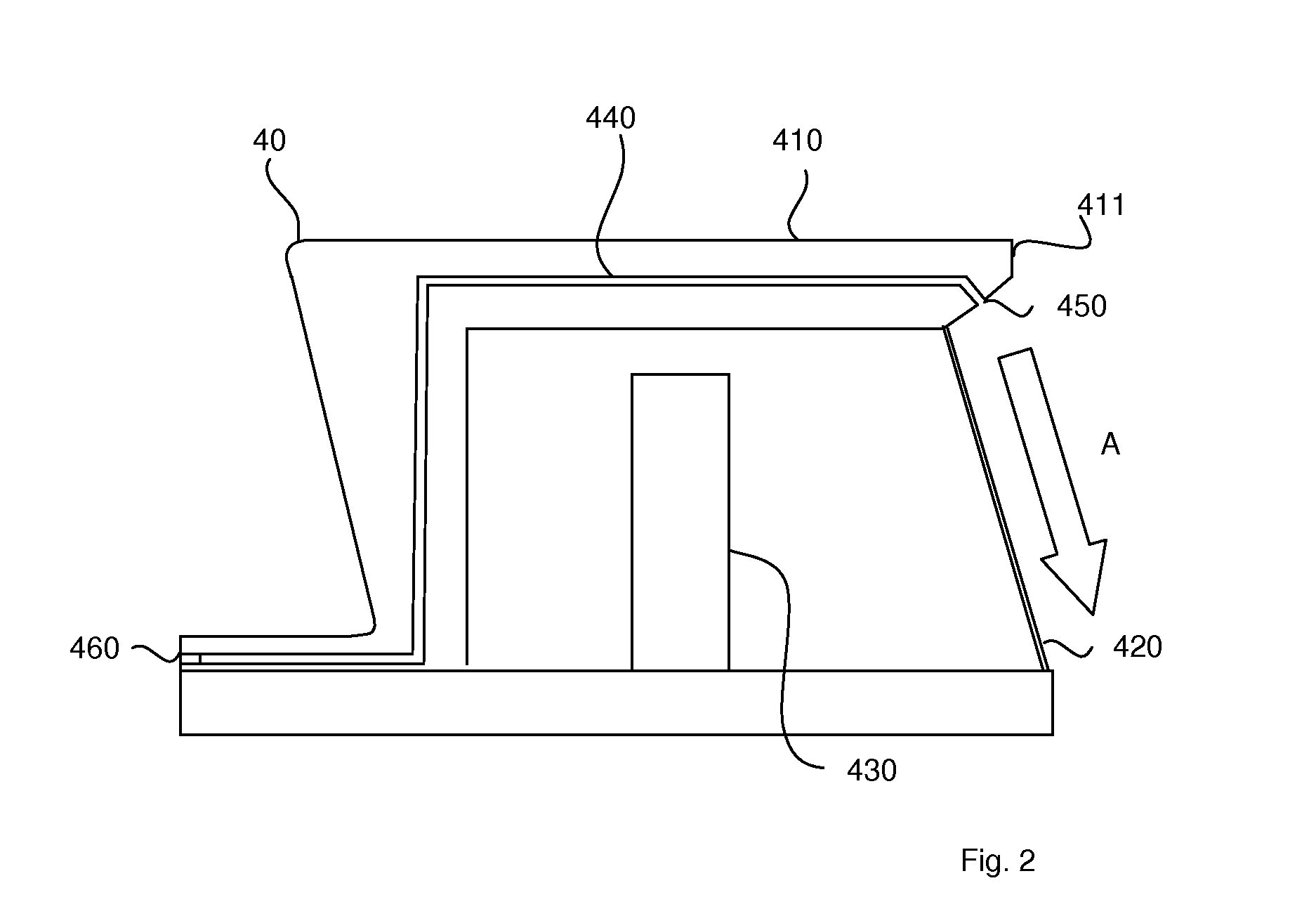

Method and apparatus for protecting an optical detection device from contamination

ActiveUS20130247827A1Clean effectReduce operating costsCathetersMechanical engineeringOptical detector

A milking system includes a milking robot with a robot arm for applying teat cups to the teats of an animal, an optical detector (40) for detecting radiation emitted and / or reflected from the animal and a controller. The detector has a housing (410) with a window (420) and a detecting element (430) enclosed in the housing that is sensitive to the emitted or reflected radiation passing through the window. In order to prevent contamination from impacting on the detector window, an airflow arrangement is provided that can be connected to a source of pressurized air and has at least one aperture (411) disposed adjacent the detector window (420) for generating a curtain of air that flows parallel with the surface of the window. The controller controls the generation of the air curtain to coincide with the start of at least one further operation controlled by the controller.

Owner:DELAVAL HLDG AB

Milking robot, and a milking arrangement

ActiveUS8505484B2Simple and inexpensive and light designCalibration accuracyProgramme-controlled manipulatorCathetersEngineeringControl unit

A milking arrangement includes a milking robot (10) having a first link (L1), a second link (L2), a third link (L3), an end effector (E), sensor (16) and a control unit (15). The first link is rotatable to a first angle within a first angle range (α1) via a first joint (11). The second link is rotatable to a second angle within a second angle range (α2) via a second joint (12). The third link (L3) is rotatable to a third angle within a third angle range (α3) via third joint (13). The links (L1, L2, L3) are rotatable so that the end effector is movable within a three-dimensional workspace (W). Each position of the end effector within the workspace corresponds to a single combination of the first, second and third angles.

Owner:DELAVAL HLDG AB

Multiple cell voluntary milking method and system, comprising a mobile milking robot having a minimal footprint

Owner:AFIMILK AGRI COOP

Milking installation

ActiveUS7231887B2Avoid damageExcessive condensationFluid parameterCathetersEngineeringCompressed air

Owner:LELY ENTERPRISES

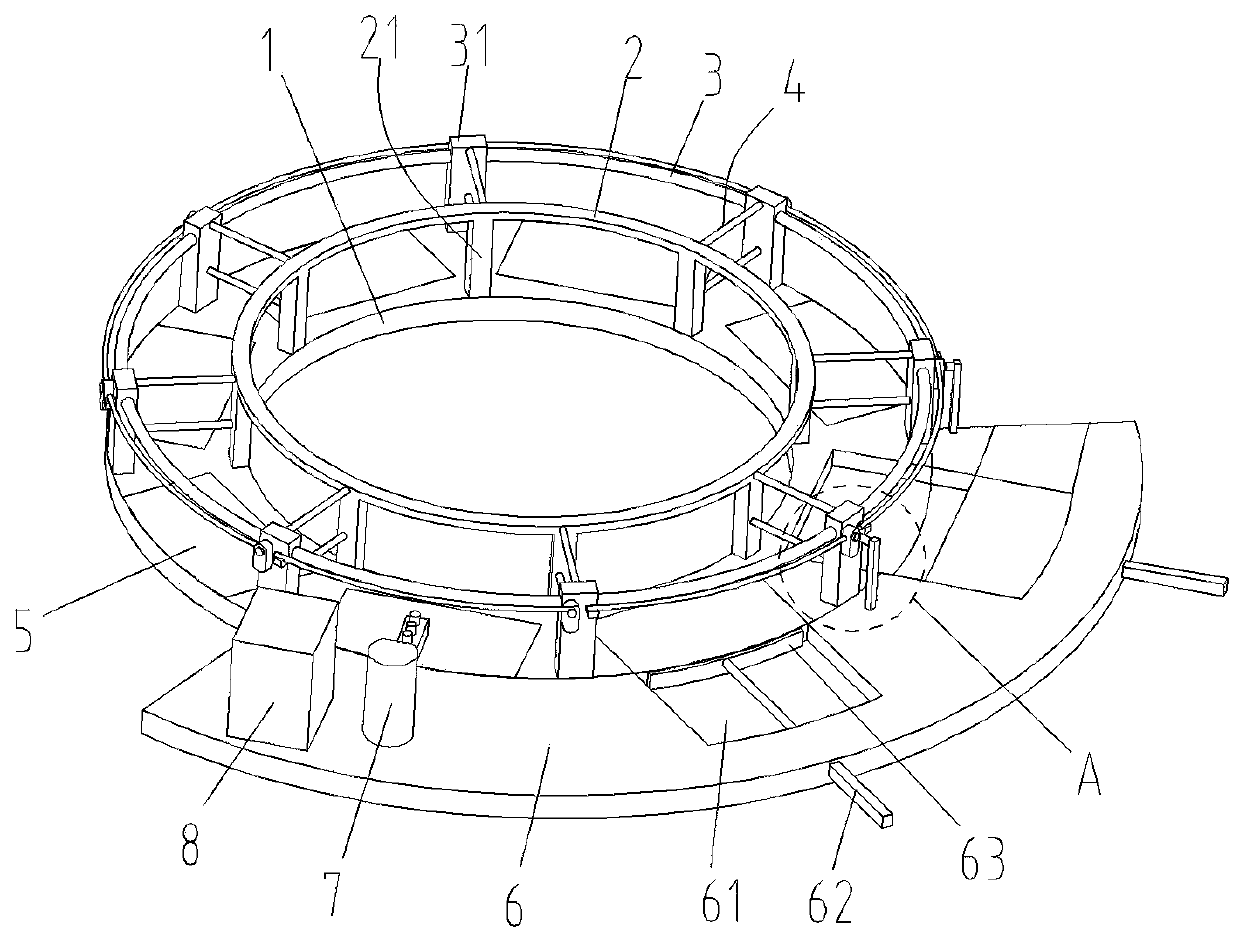

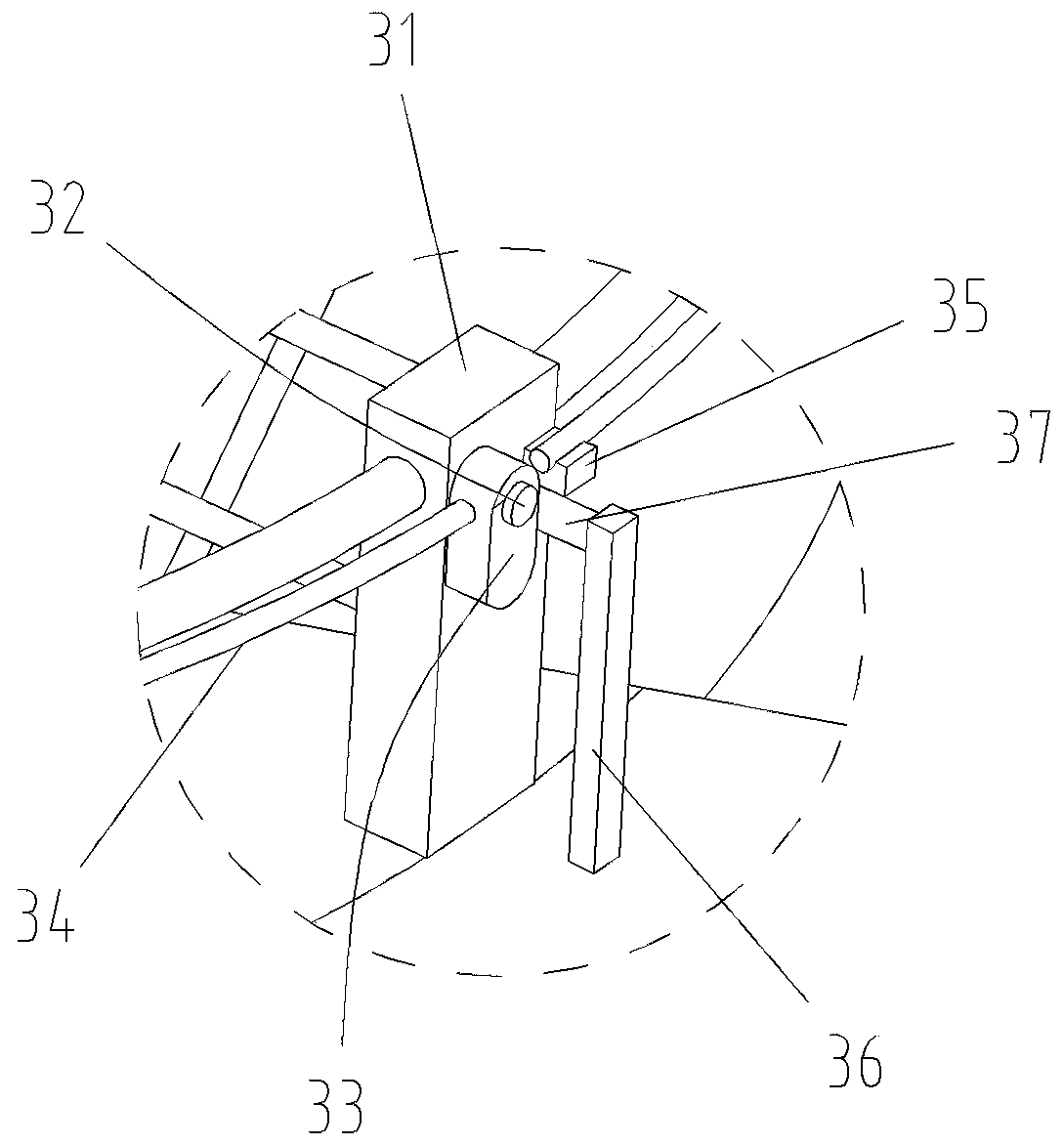

Rotating disk type milking robot

PendingCN111328716APrevent running outAutomate operationsMilk receptaclesCircular discDisks (device)

The invention discloses a rotating disk type milking robot. The rotating disk type milking robot comprises a rotating disk device, wherein a working plate is arranged on one side of the rotating diskdevice; and a milking device and a storing tank are arranged on the working plate. The rotating disk type milking robot disclosed by the invention has the advantages that each station of a disk of therotating disk type milking robot provided by the invention rotates, a position where each sliding plate can be moved from corresponding vacating grooves to the corresponding sliding groove by corresponding first electric telescopic rods is a first station; the disk sequentially rotates anticlockwise, and a second station, a third station, a fourth station, a fifth station, a sixth station, a seventh station and an eighth station are sequentially arrayed; at the first station, under the effect of round rods, rotating blocks are in a horizontal state, isolation rods are under a vertical state;then a cow is placed on one of the sliding plates, and the sliding plate is pushed into the corresponding sliding grooves in the disk at the first station; and the disk sequentially rotates, and eachcow is pushed into the upper part of the disk once.

Owner:ANHUI SCI & TECH UNIV +1

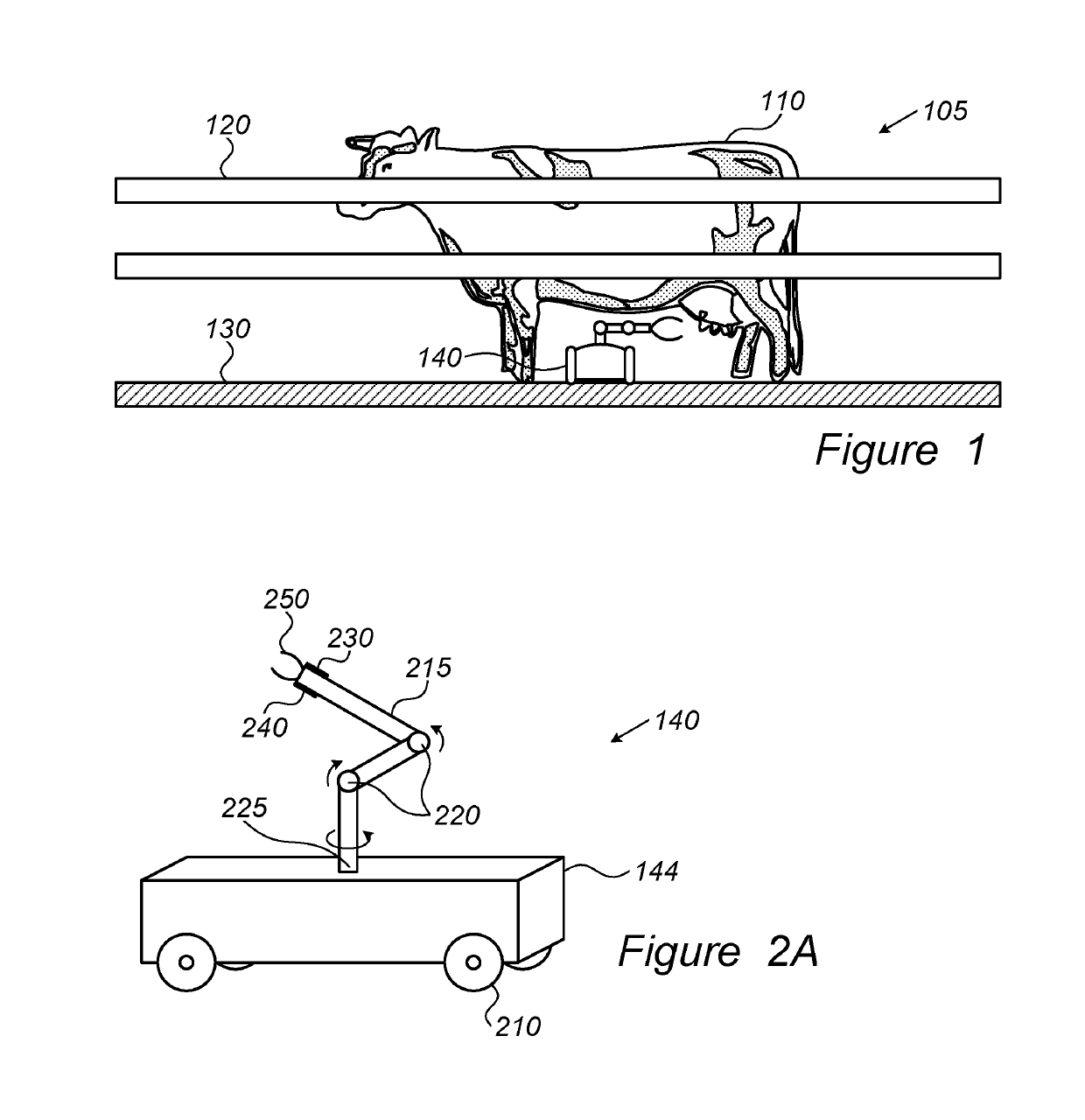

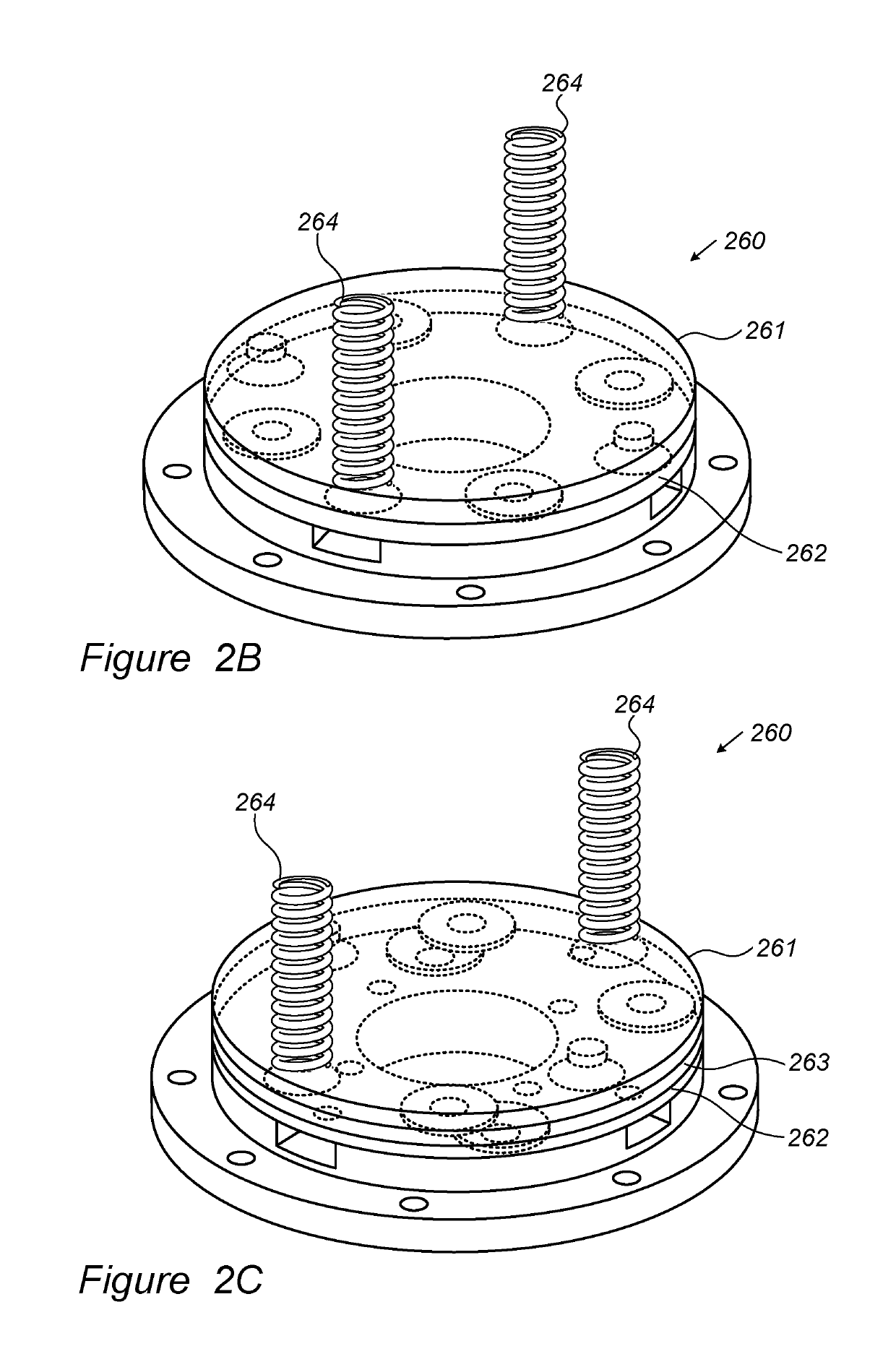

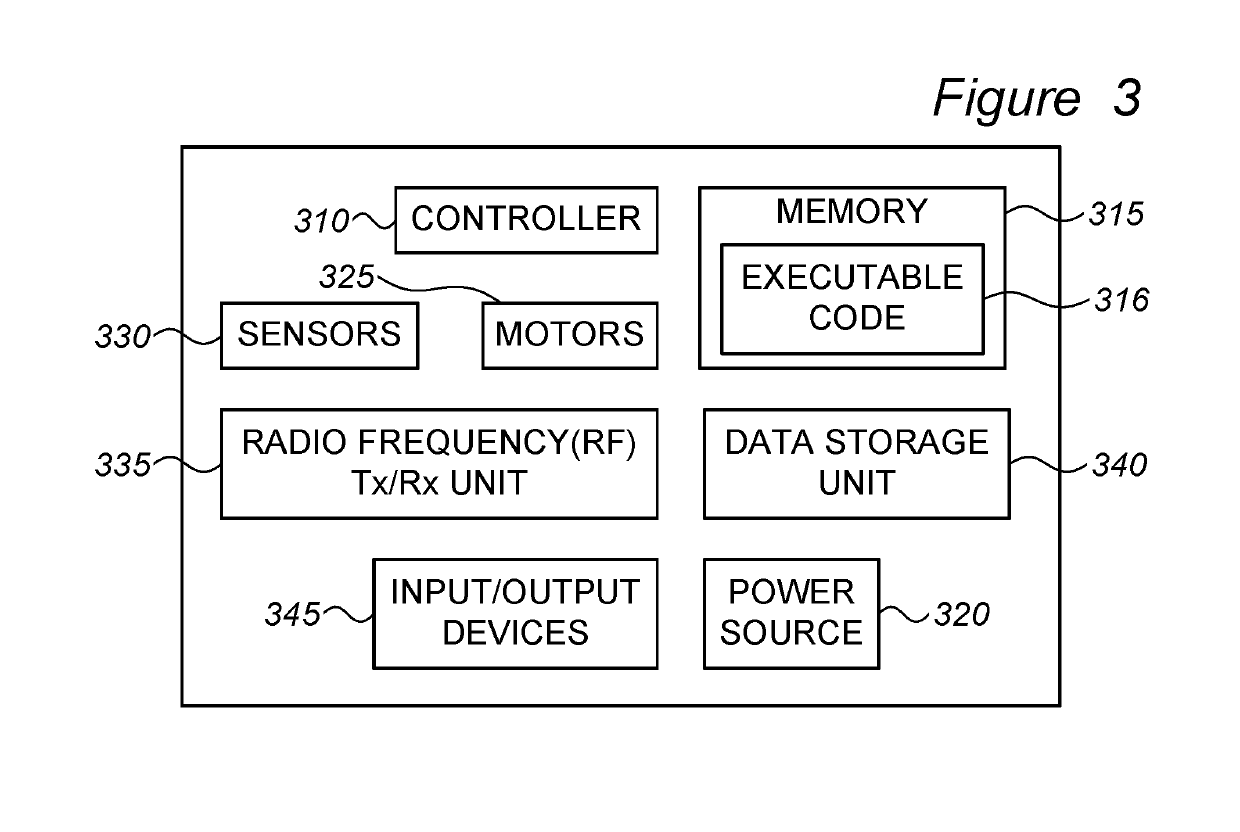

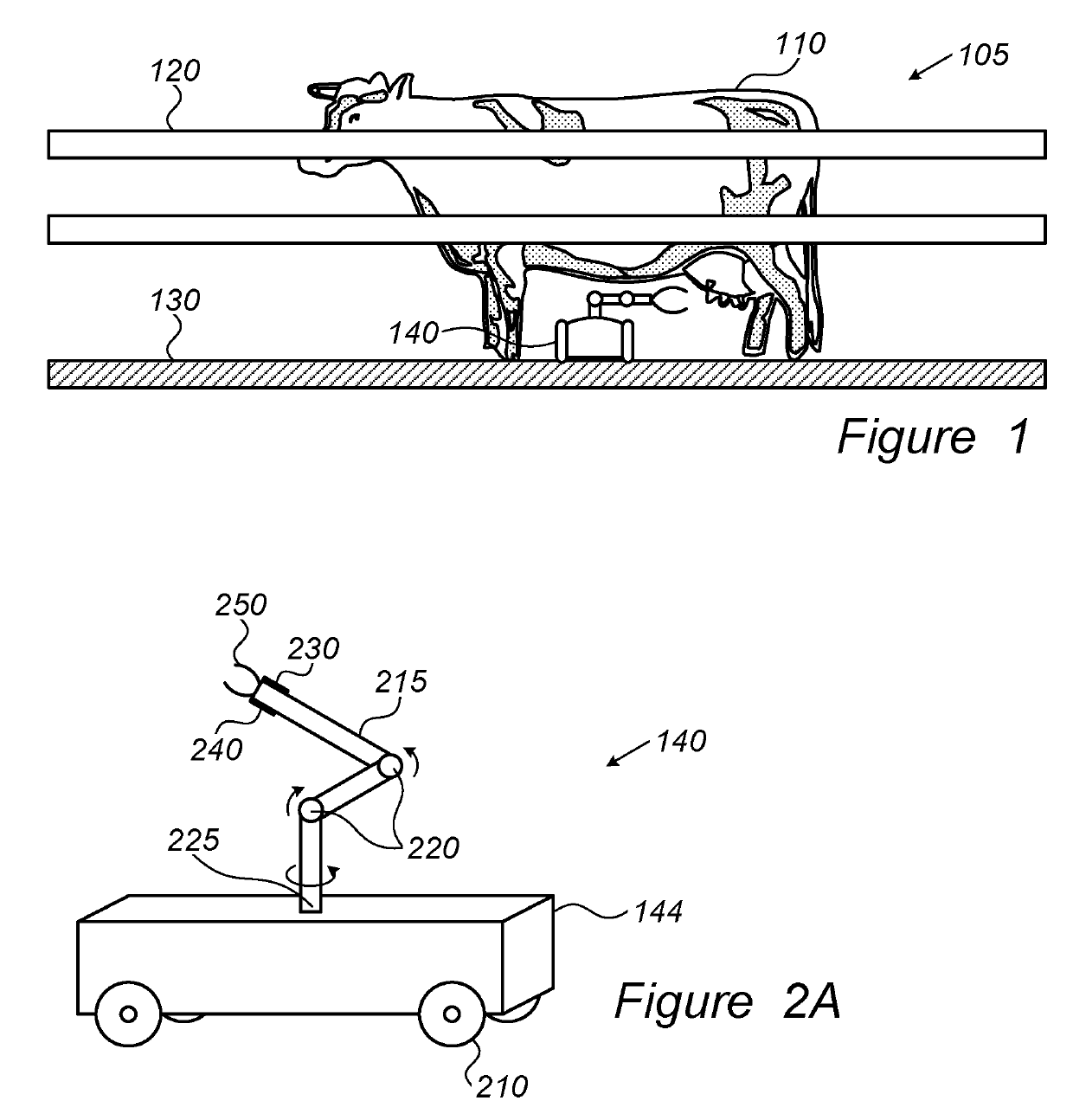

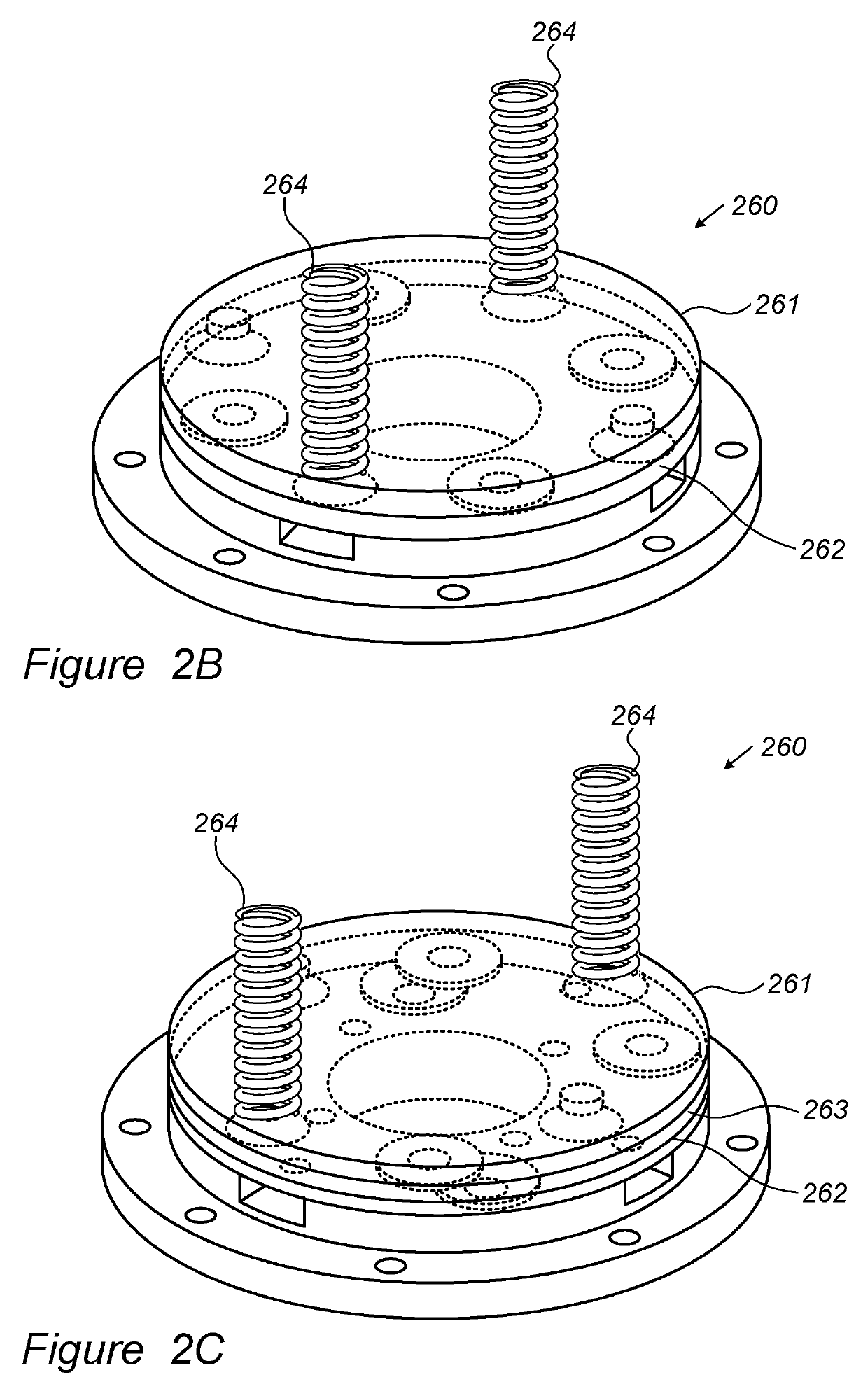

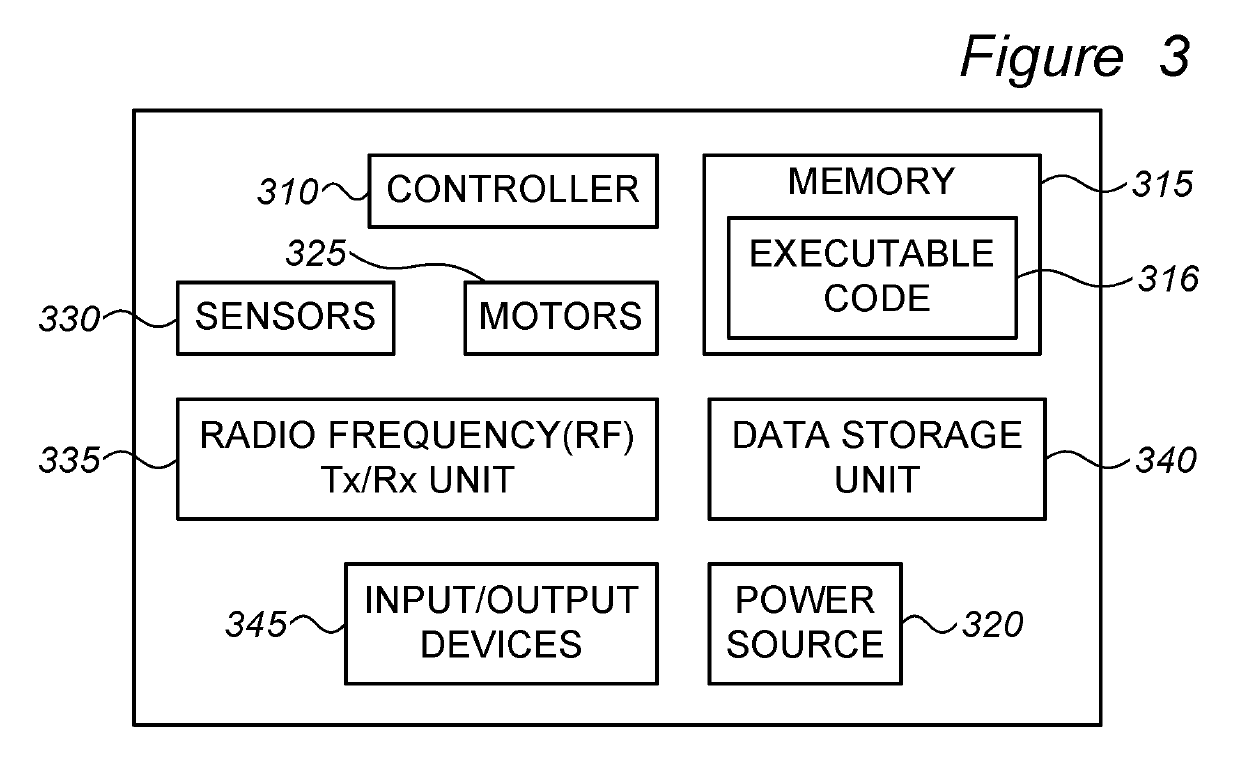

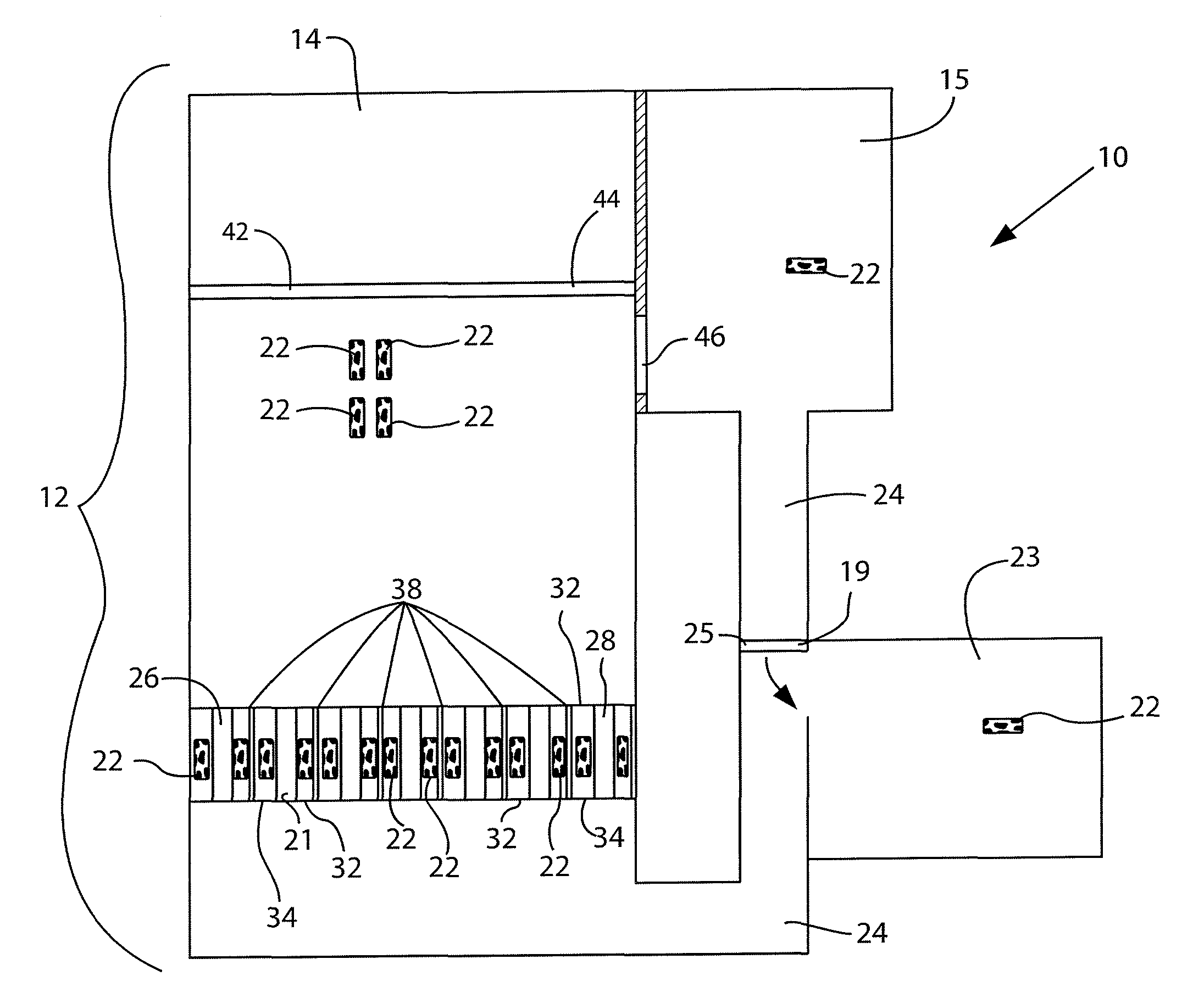

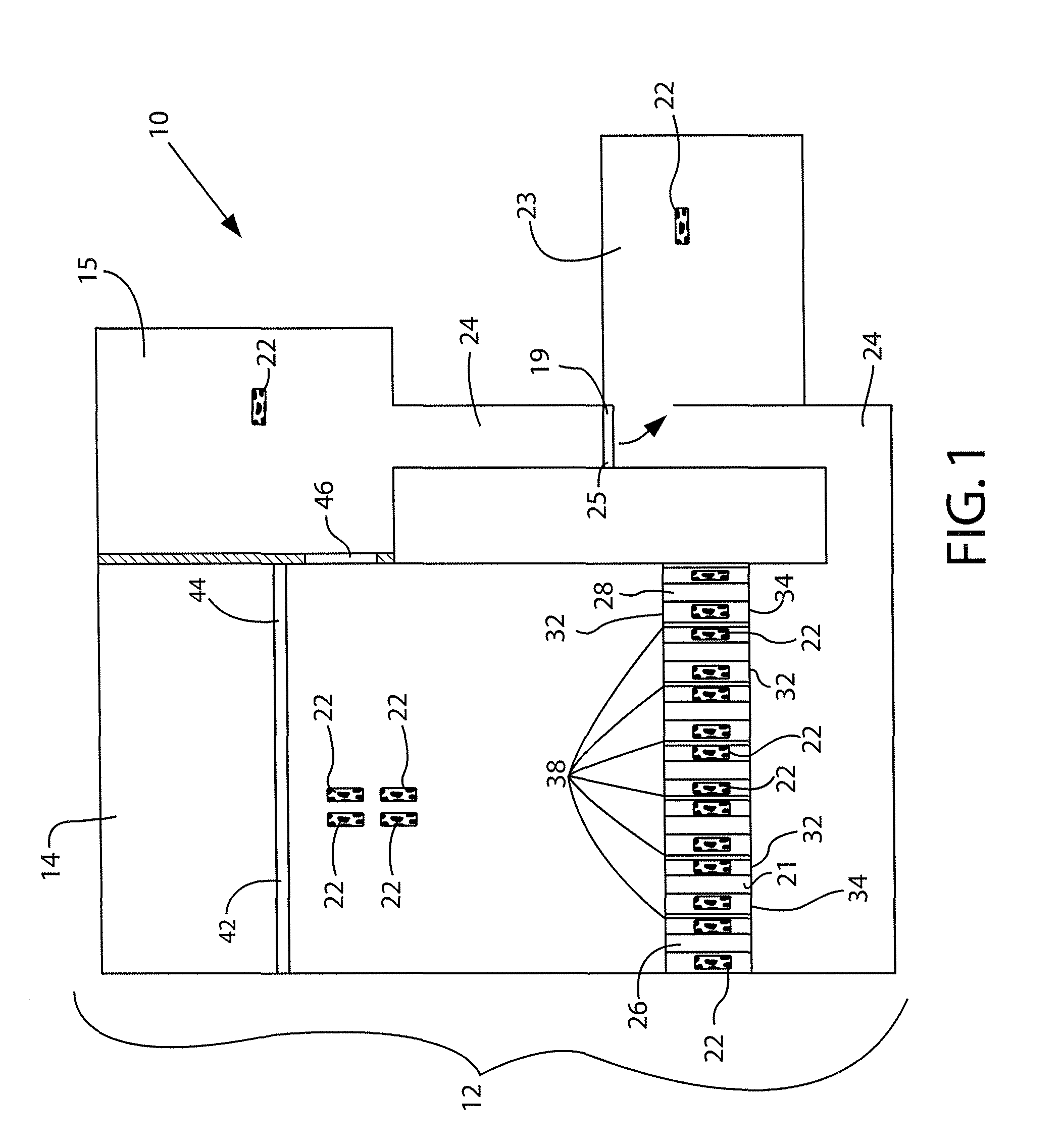

Mobile milking robot with minimal footprint

Disclosed is a system for treating dairy livestock having fore legs and hind legs, wherein the system comprises a milking parlor ramp, livestock stalls positioned along at least part of the milking parlor ramp, wherein each stall is configured to contain one dairy livestock, at least one vertical upright teat cup holder comprising teat cups and a mobile unit. The mobile unit comprises equipment for treating livestock and a processor, where the mobile unit is configured to travel between the fore legs and hind legs of the dairy livestock on the milking parlor ramp and use the equipment to perform at least one action related to a treatment of the dairy livestock. Also disclosed is that the equipment includes an arm configured to withdraw the teat cups from the vertical upright teat cup holder and connect them to the dairy livestock.

Owner:AFIMILK AGRI COOP

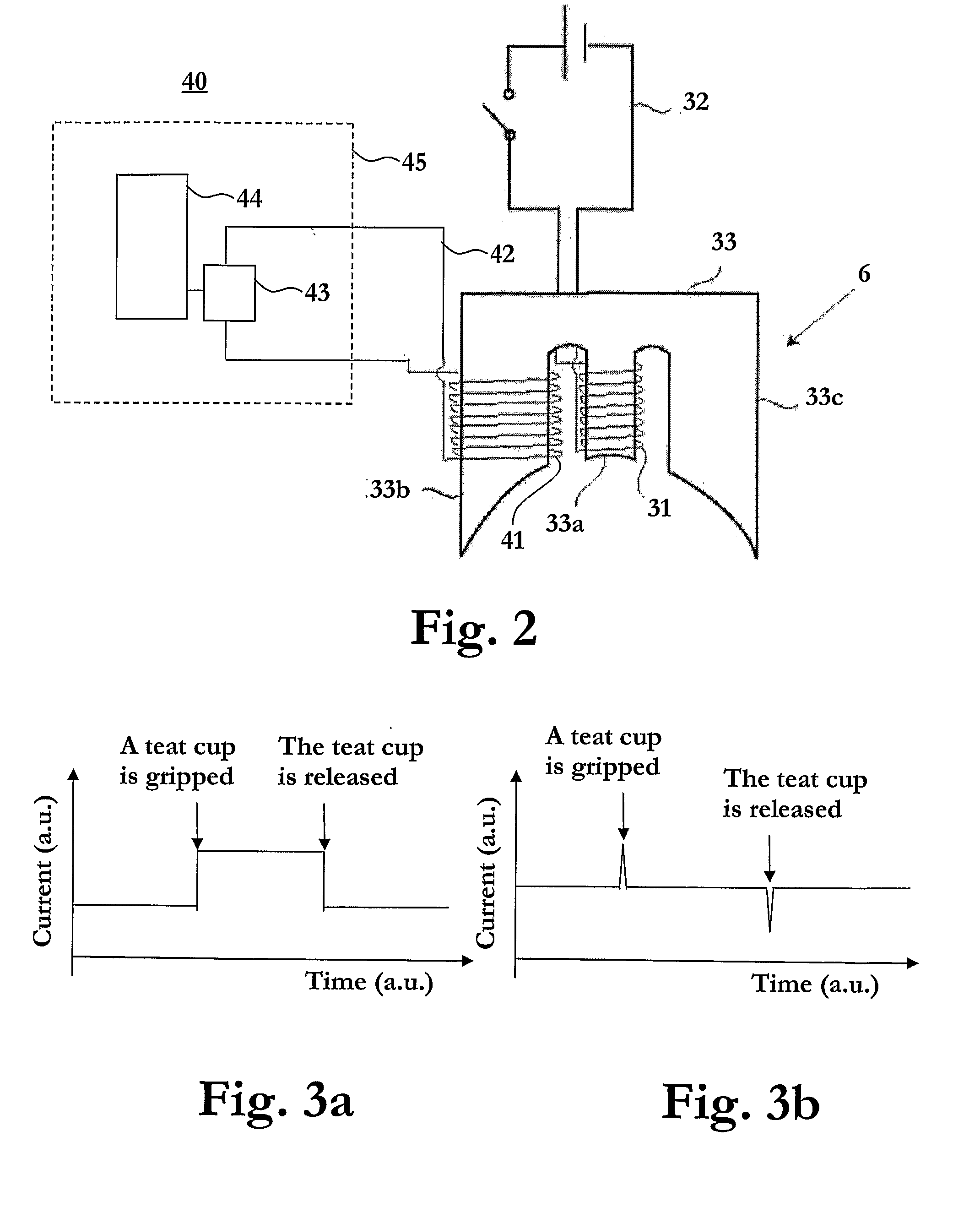

Detecting arrangement and method for a magnetic gripper device

A detecting arrangement for a magnetic gripper device (3) mountable on a robot arm (10) of a milking robot (2) provided for automatically attaching teat cups (5) to the teats of a milking animal, wherein the magnetic gripper device is adapted for gripping teat cups made of or comprising a magnetic material and comprises a primary coil (31) feedable with a current and a core (33) of a magnetic material arranged at least partly within the primary coil. The detecting arrangement comprises means (41, 43; 43; 53) for repetitively sensing a magnetic field, an inductance, or a change thereof, as caused by a teat cup (5) when being present at, or gripped by, the magnetic gripper device (3); and means (44; 54) for repetitively detecting whether the magnetic gripper device is holding a teat cup or not based on said repetitive sensing of the magnetic field, the inductance, or the change thereof.

Owner:DELAVAL HLDG AB

Method and device for automatically bringing a fluid into contact with the teats of an animal

A dipping device for a milking system, especially for an automatic milking system designed as a milking robot with teat cups to be placed onto the teats of an animal to be milked, which is designed for contacting the teats of the animal with at least one fluid or several fluids, and the device has several dipping valve arrangements so that the dipping agent introduction to each teat of the animal can be controlled separately.

Owner:GEA FARM TECH

System for milking cows and method

ActiveUS20100313812A1Great stability and consistencyCost efficientComputer controlSimulator controlBiomedical engineeringMilking robot

A system for milking cows includes a structure for retaining cows therein. Such structure includes at least one holding area within such structure, at least one exit alley connected to and extending from a predetermined portion of such at least one holding area to at least one of a predetermined housing area, at least one additional holding area, and a combination thereof. At least one of at least one milking robot, at least one automated milking machine, and a combination thereof is disposed within such at least one holding area for automatically milking at least one predetermined cow when such at least one predetermined cow is closely adjacent a predetermined side of such at least one of such at least one milking robot, such at least one automated milking machine, and such combination thereof. A method for milking cows is also provided.

Owner:WATERLANDER HARMEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com