Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2772 results about "Manufactured apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing semiconductor device

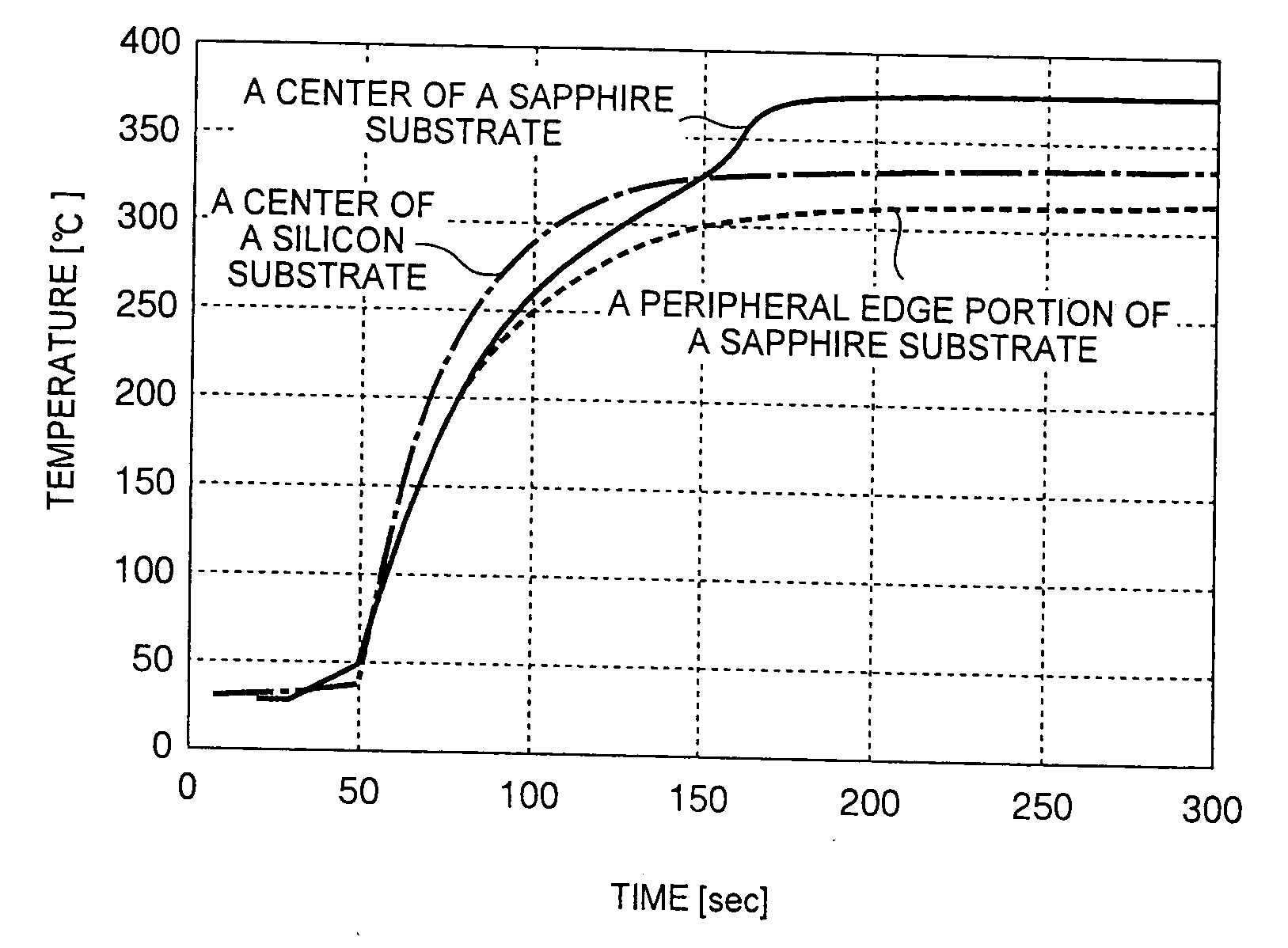

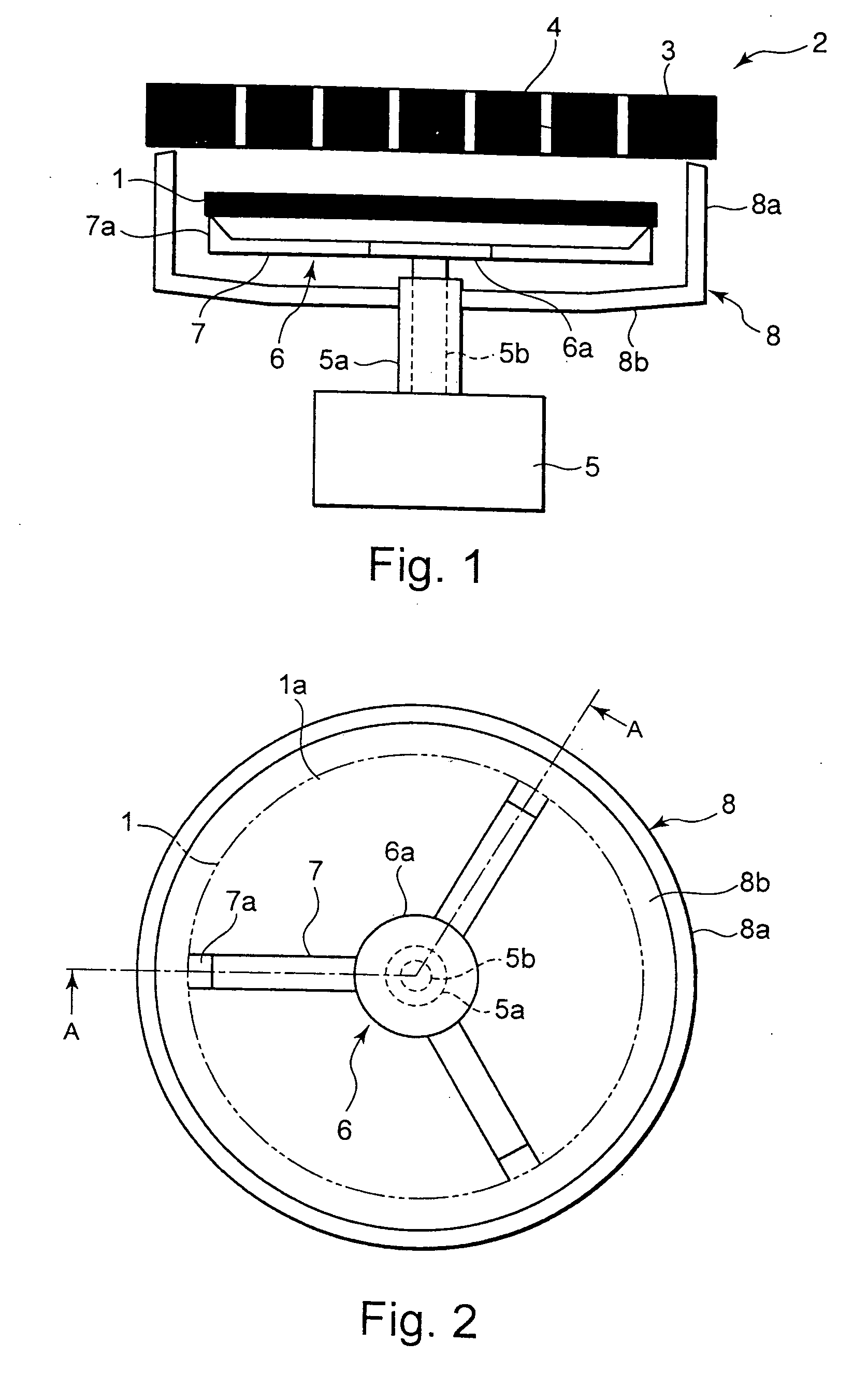

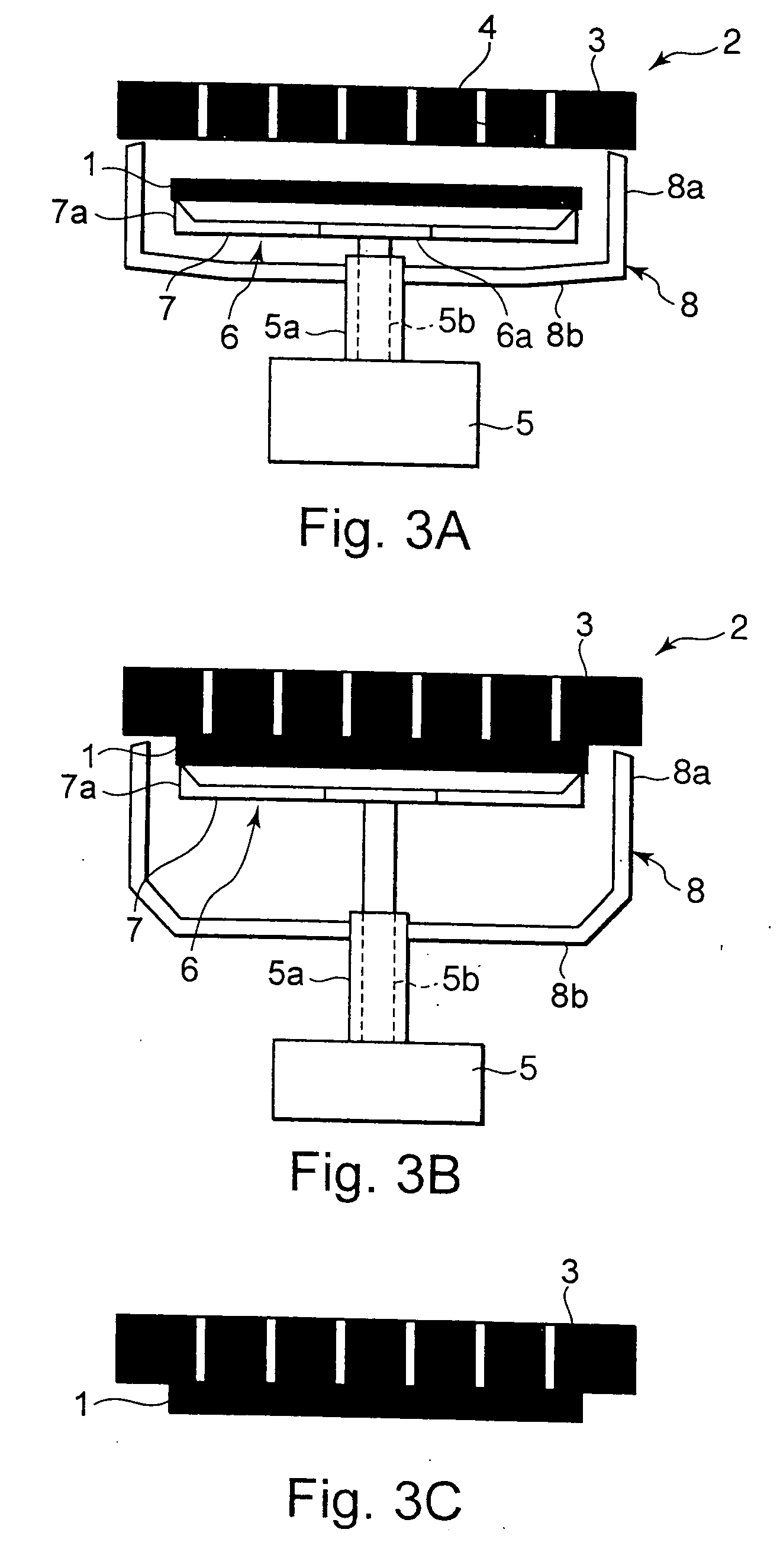

InactiveUS20060240574A1Warpage suppressionPolycrystalline material growthSemiconductor/solid-state device manufacturingDevice materialManufactured apparatus

A semiconductor manufacturing apparatus A semiconductor manufacturing apparatus comprises a hot plate which heats a sapphire substrate; a support table having a support plate disposed with being spaced away from the hot plate by a predetermined interval, and support portions which respectively support the sapphire substrate with being spaced by a predetermined interval between the hot plate and the support plate and support the sapphire substrate in such a manner that back surfaces of the hot plate and the sapphire substrate are opposite to each other; an elevating device which moves the support table up and down; and a shielding cover which externally blocks off spacing defined between the hot plate and the sapphire substrate and spacing defined between the sapphire substrate and the support plate.

Owner:LAPIS SEMICON CO LTD

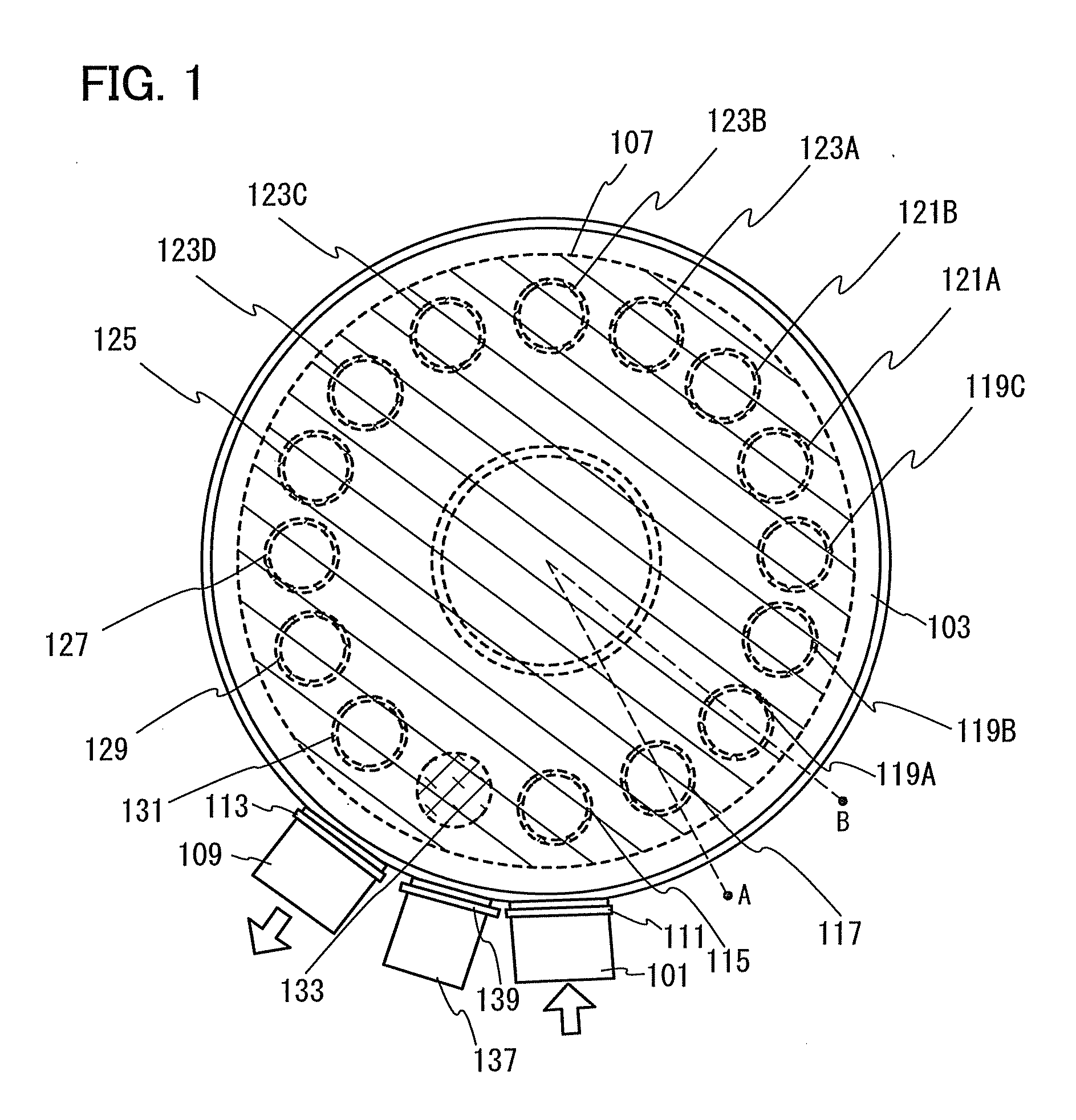

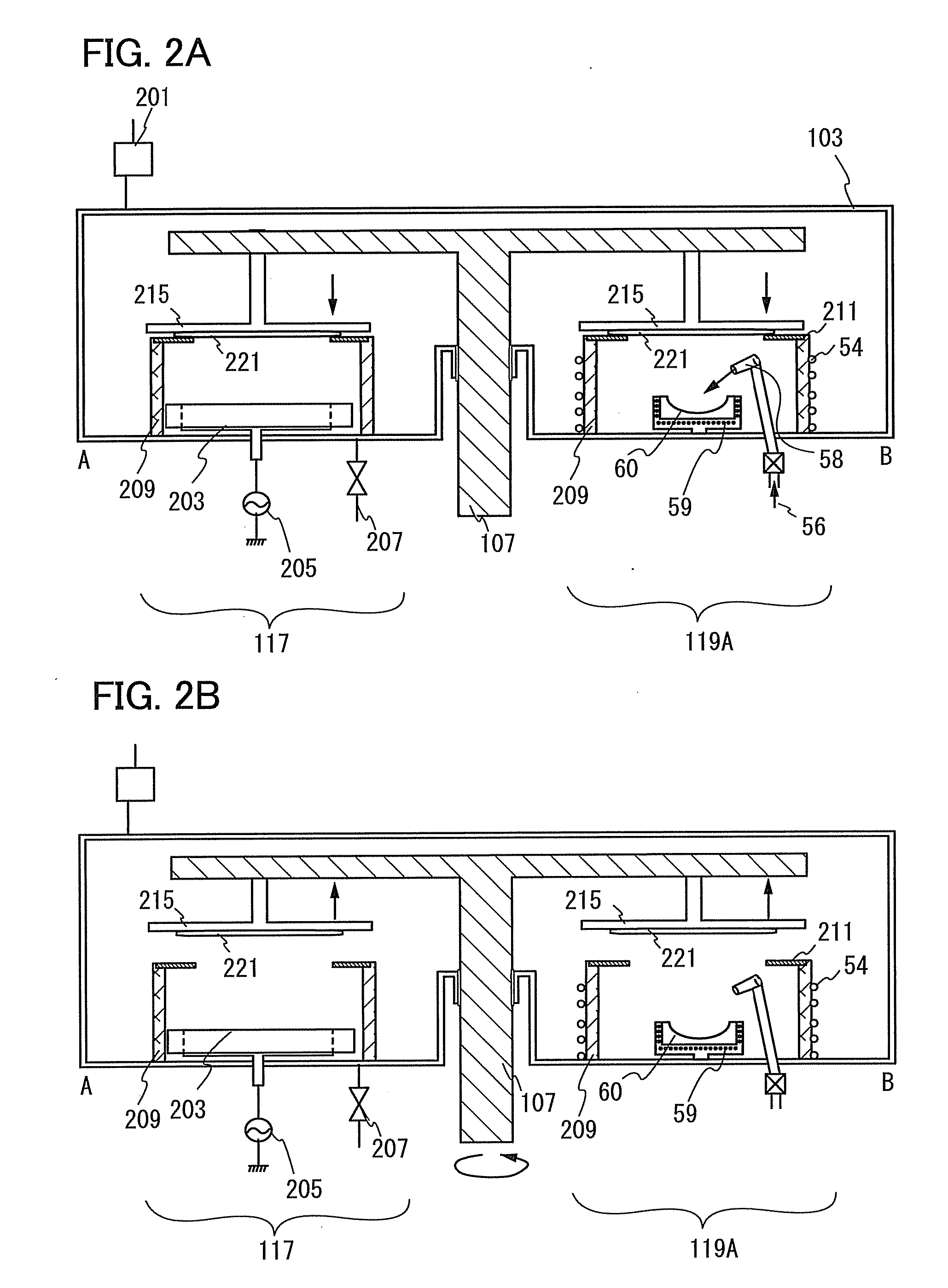

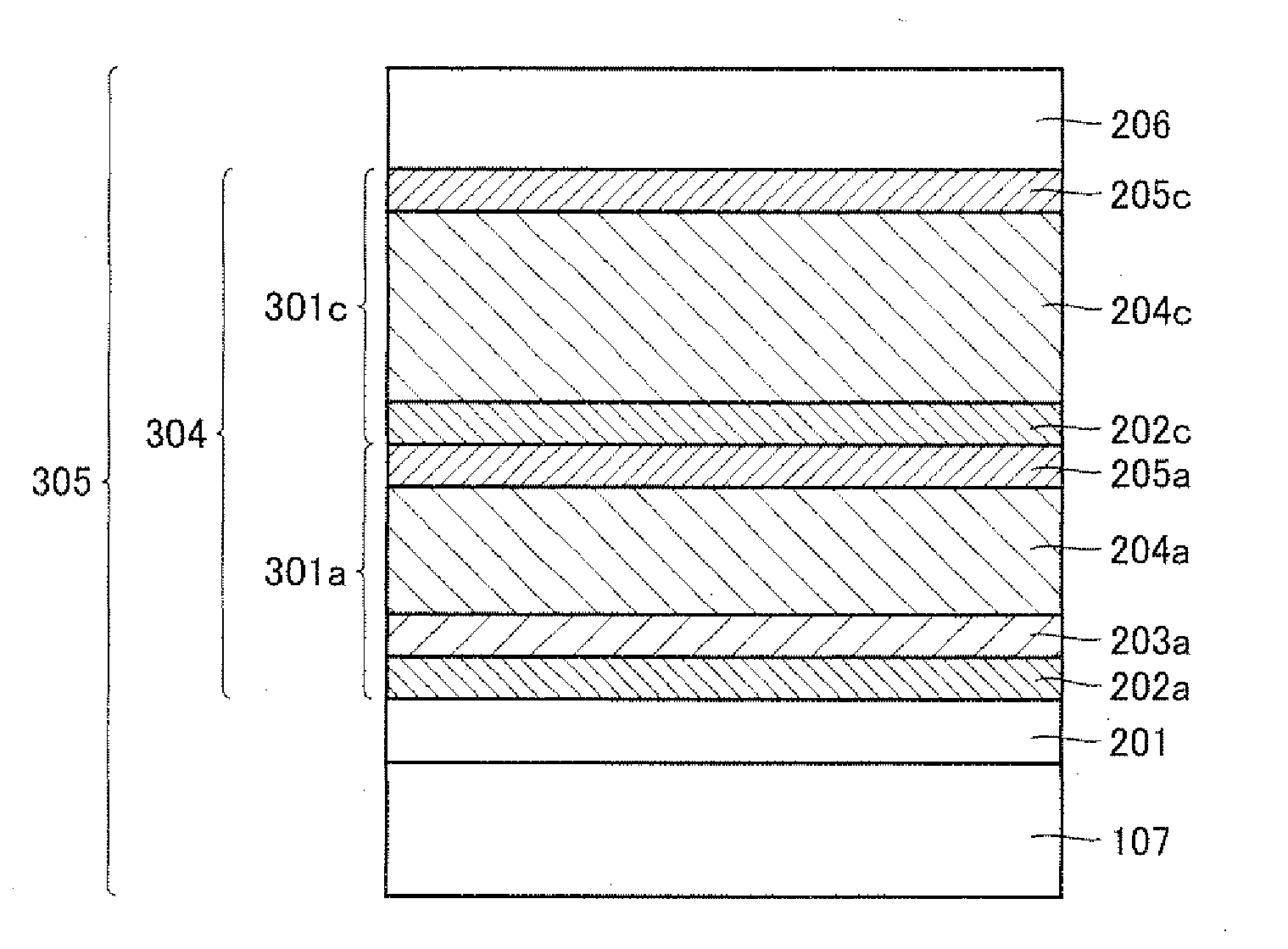

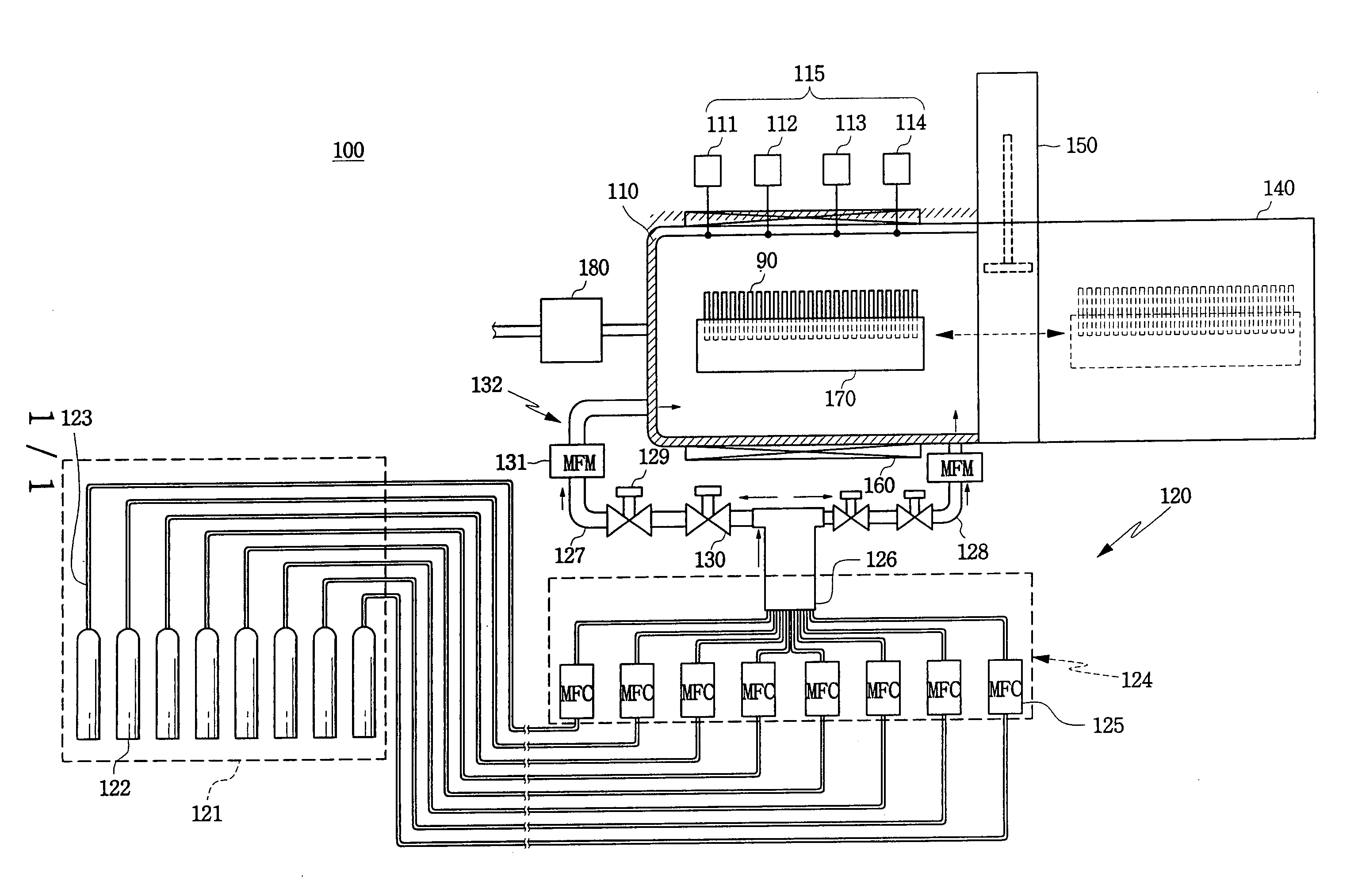

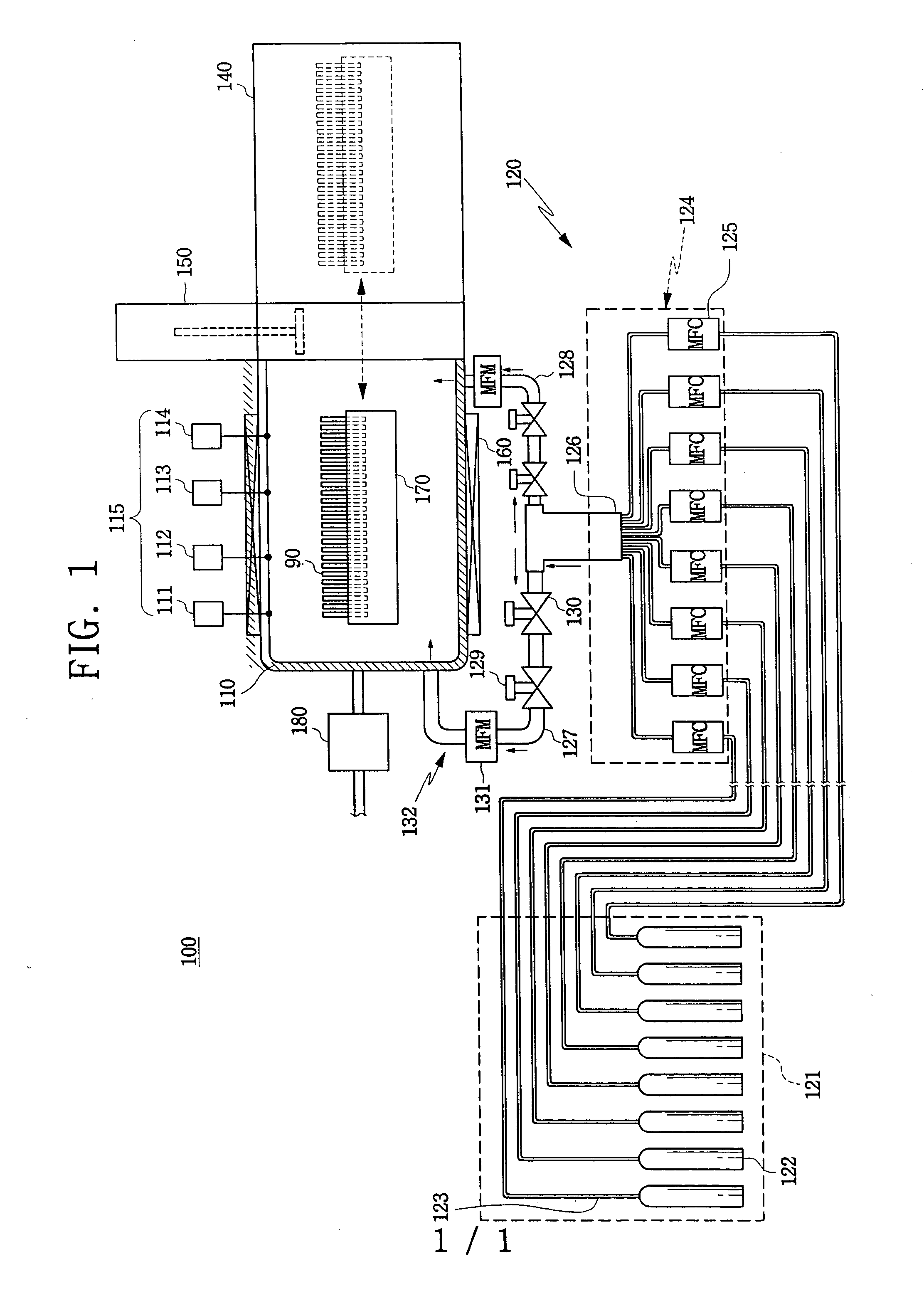

Manufacturing Apparatus and Manufacturing Method of Lighting Device

InactiveUS20100236691A1Improve efficiencyReduce manufacturing costVacuum evaporation coatingSolid-state devicesInter layerManufactured apparatus

A manufacturing apparatus of a lighting device, including a vacuum chamber, an exhaust system by which the vacuum chamber is set to a reduced-pressure state, and a transfer chamber from which a substrate is transferred to the vacuum chamber is provided. The vacuum chamber of the manufacturing apparatus includes a plurality of deposition chambers in which a first electrode, a first light-emitting unit including at least a light-emitting layer, an intermediate layer, a second light-emitting unit including at least a light-emitting layer, a second electrode, a sealing film are formed, and a substrate transfer means by which the substrate is sequentially transferred to the deposition chambers.

Owner:SEMICON ENERGY LAB CO LTD

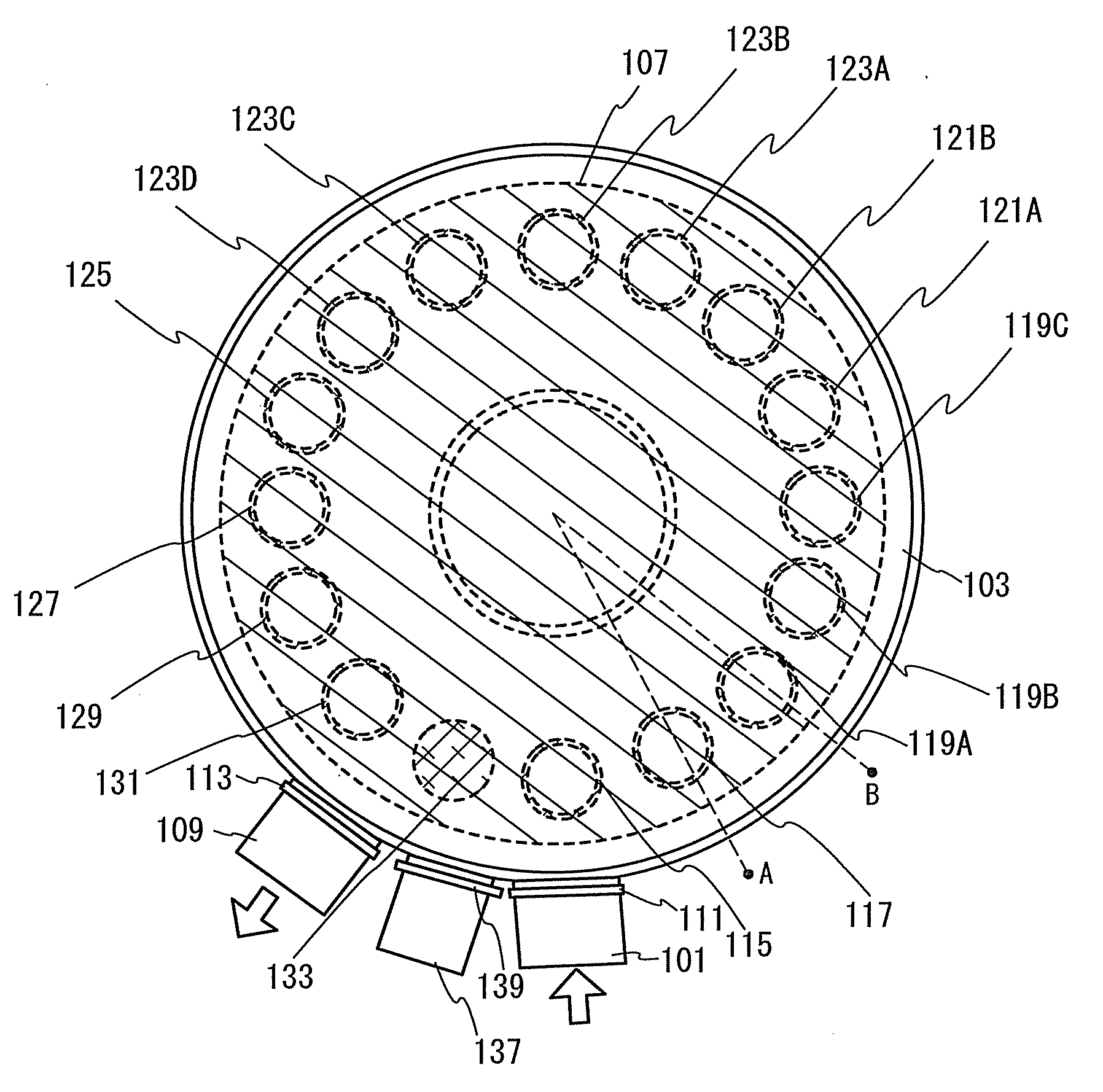

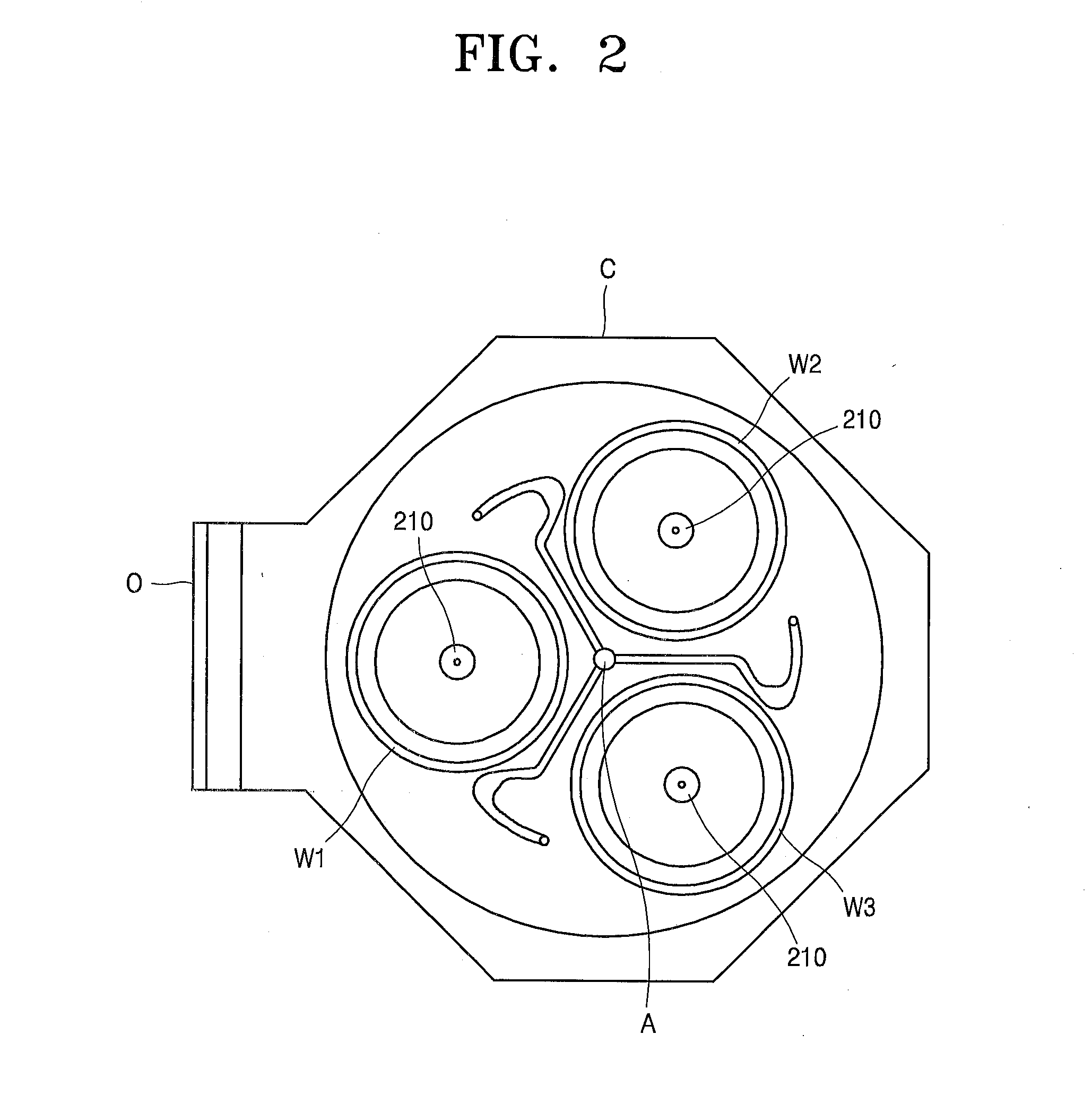

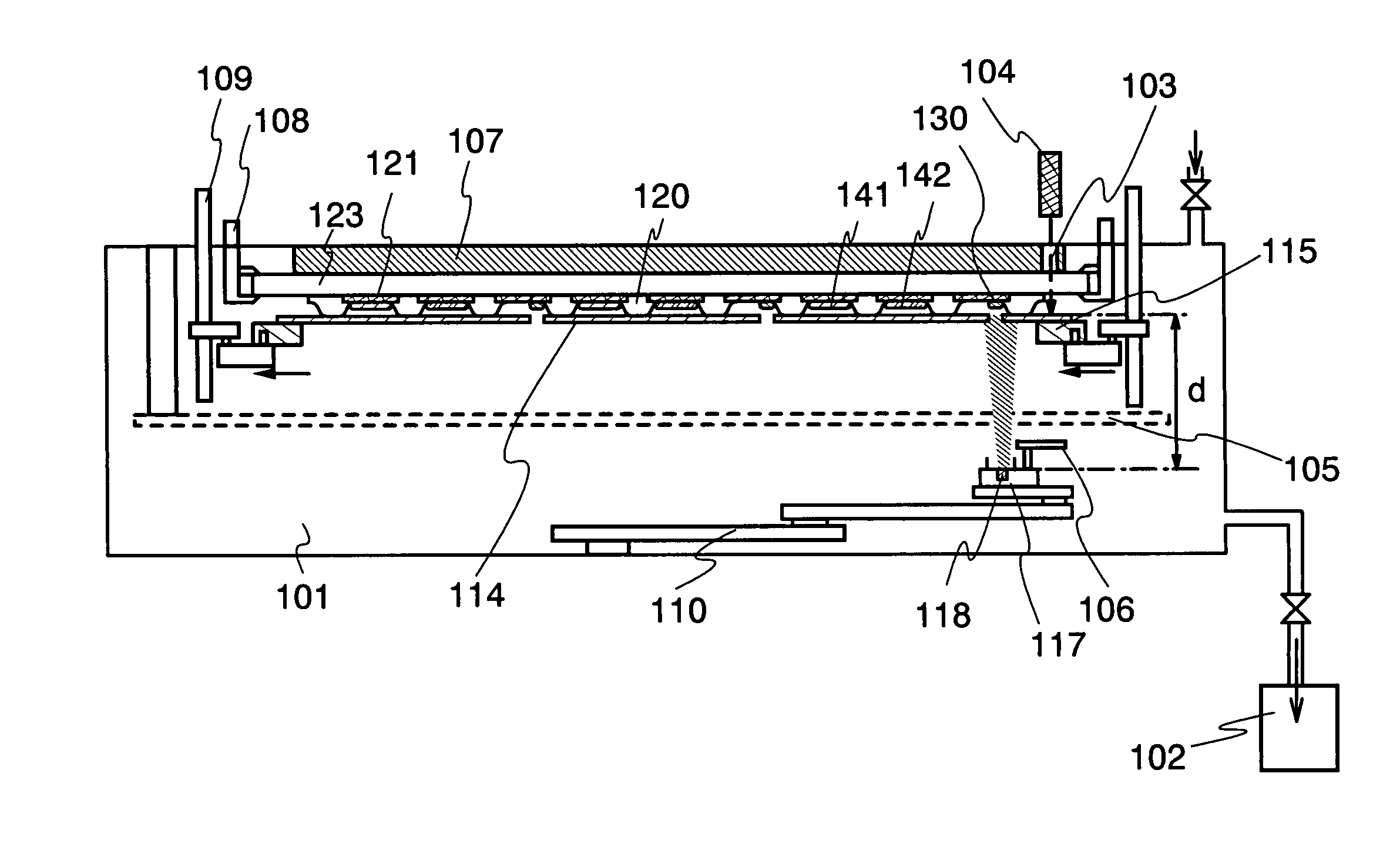

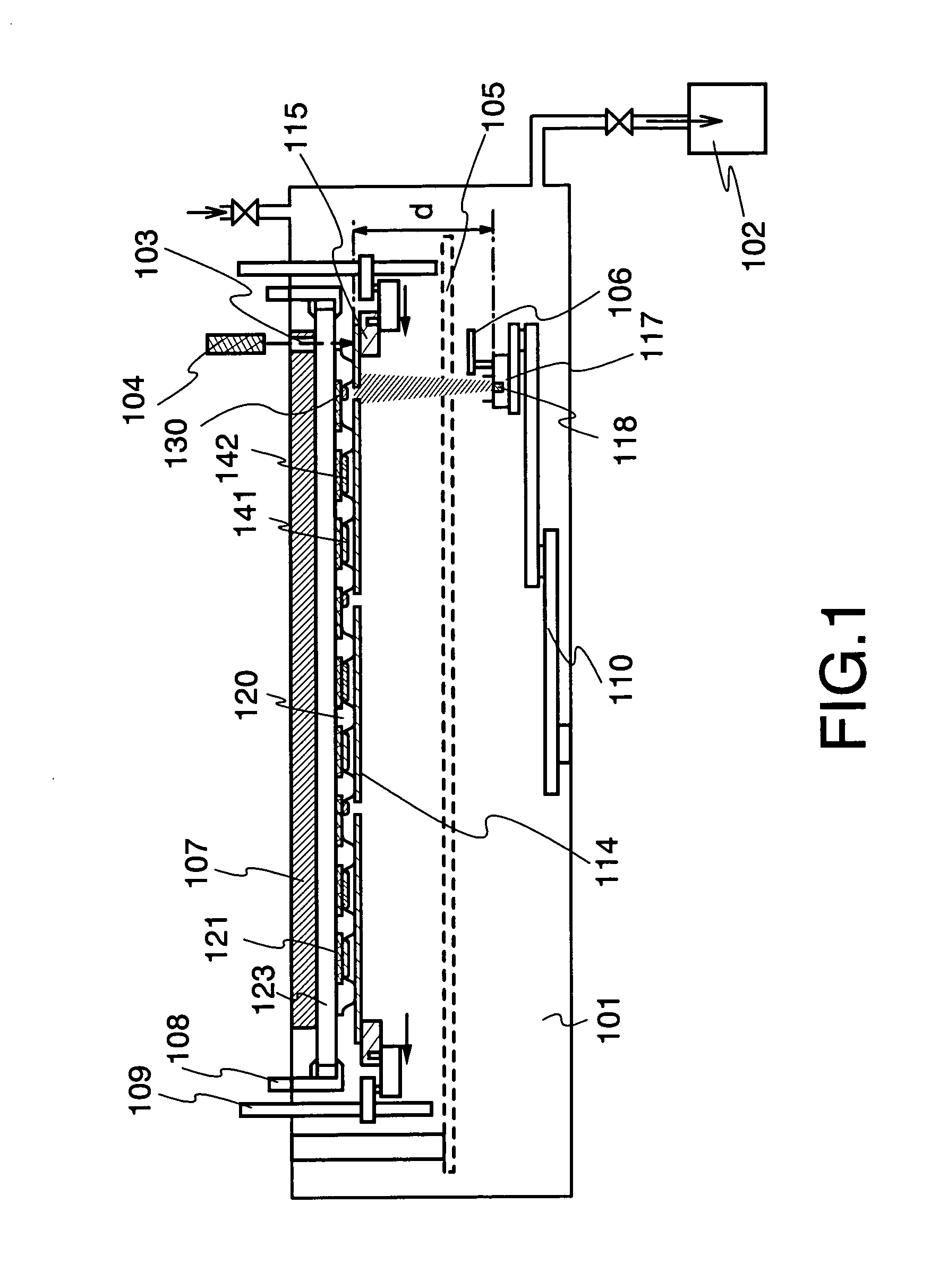

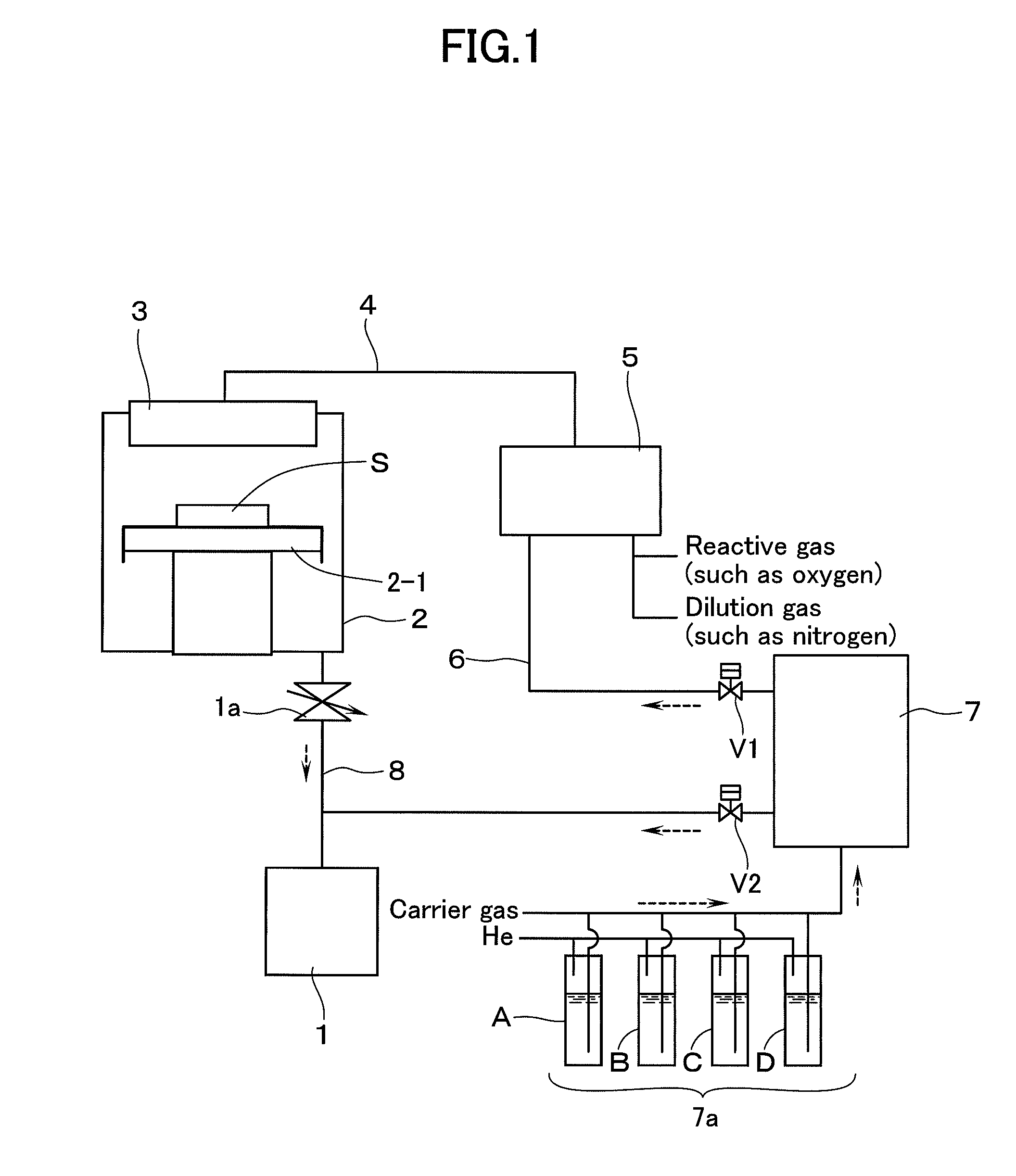

Semiconductor layer manufacturing method, semiconductor layer manufacturing apparatus, and semiconductor device manufactured using such method and apparatus

InactiveUS20100024872A1Quality improvementImprove batch productivityLiquid surface applicatorsFinal product manufactureHermetic sealManufactured apparatus

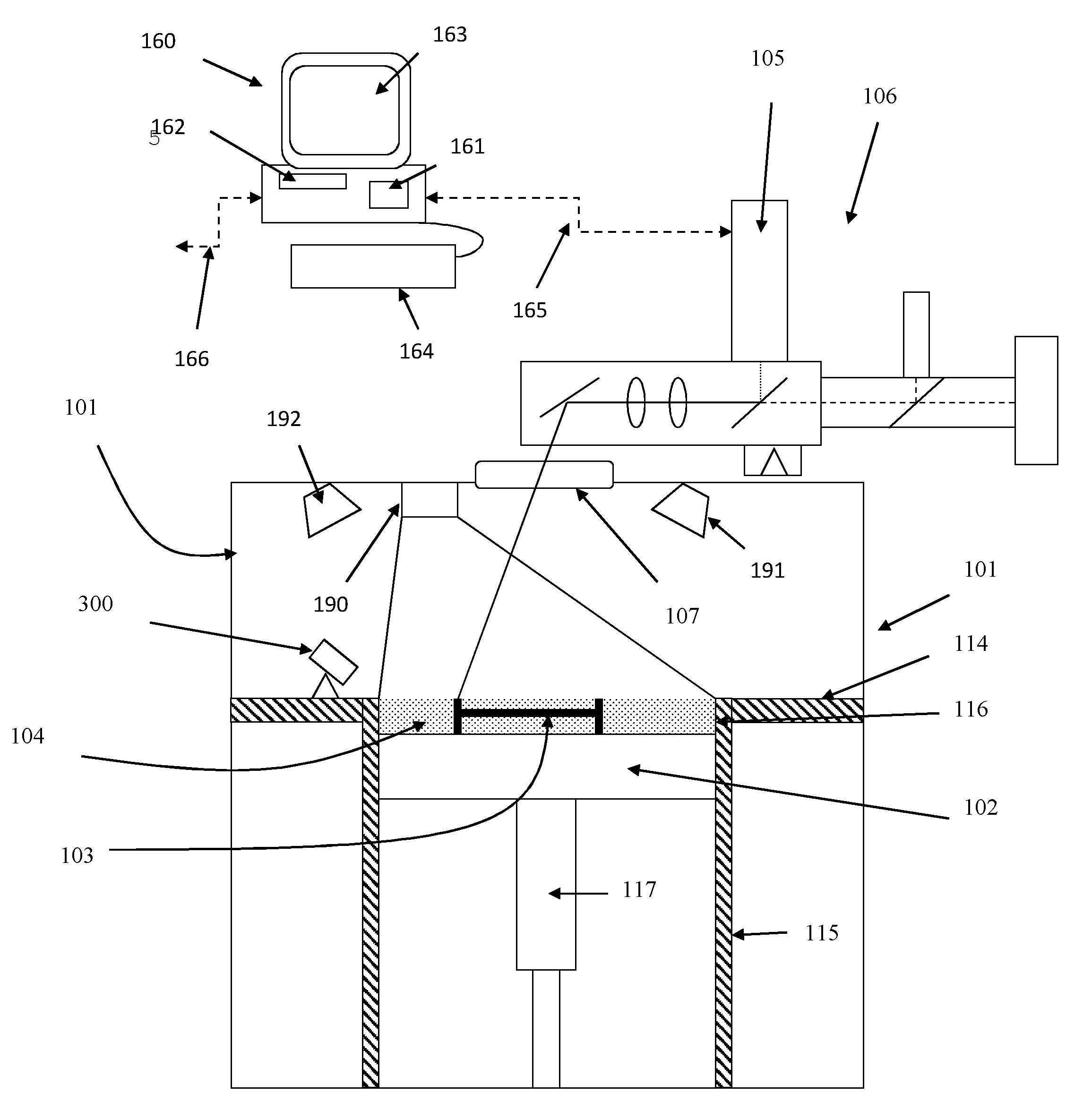

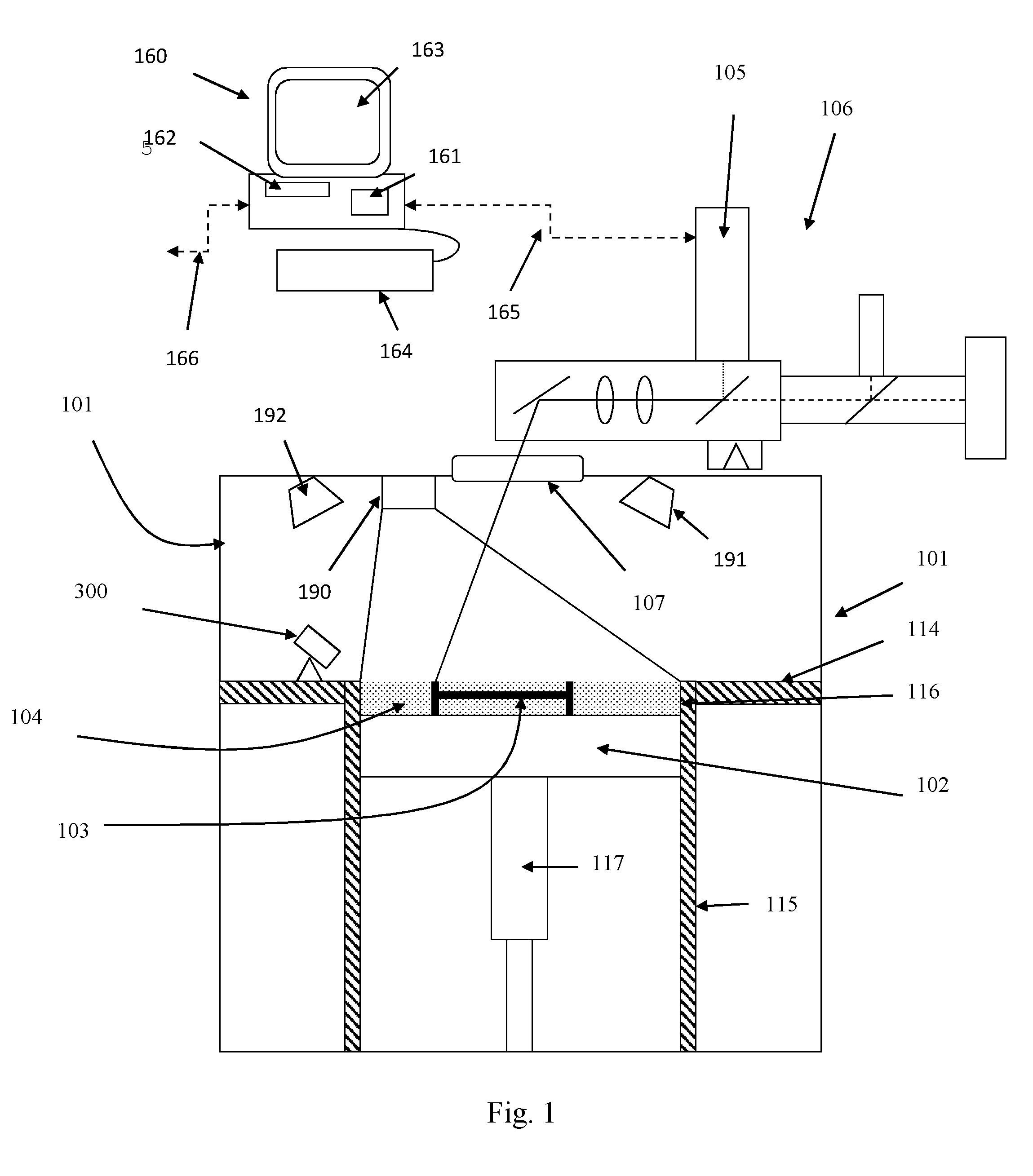

Provided are a semiconductor layer manufacturing method and a semiconductor manufacturing apparatus capable of forming a high quality semiconductor layer even by a single chamber system, with a shortened process time required for reducing a concentration of impurities that exist in a reaction chamber before forming the semiconductor layer. A semiconductor device manufactured using such a method and apparatus is also provided. The present invention relates to a semiconductor layer manufacturing method of forming a semiconductor layer inside a reaction chamber (101) capable of being hermetically sealed, including an impurities removing step of removing impurities inside the reaction chamber (101) using a replacement gas, and a semiconductor layer forming step of forming the semiconductor layer, the impurities removing step being a step in which a cycle composed of a replacement gas introducing step of introducing the replacement gas into the reaction chamber (101) and an exhausting step of exhausting the replacement gas is repeated a plurality of times, the impurities removing step being performed at least before the semiconductor layer forming step.

Owner:SHARP KK

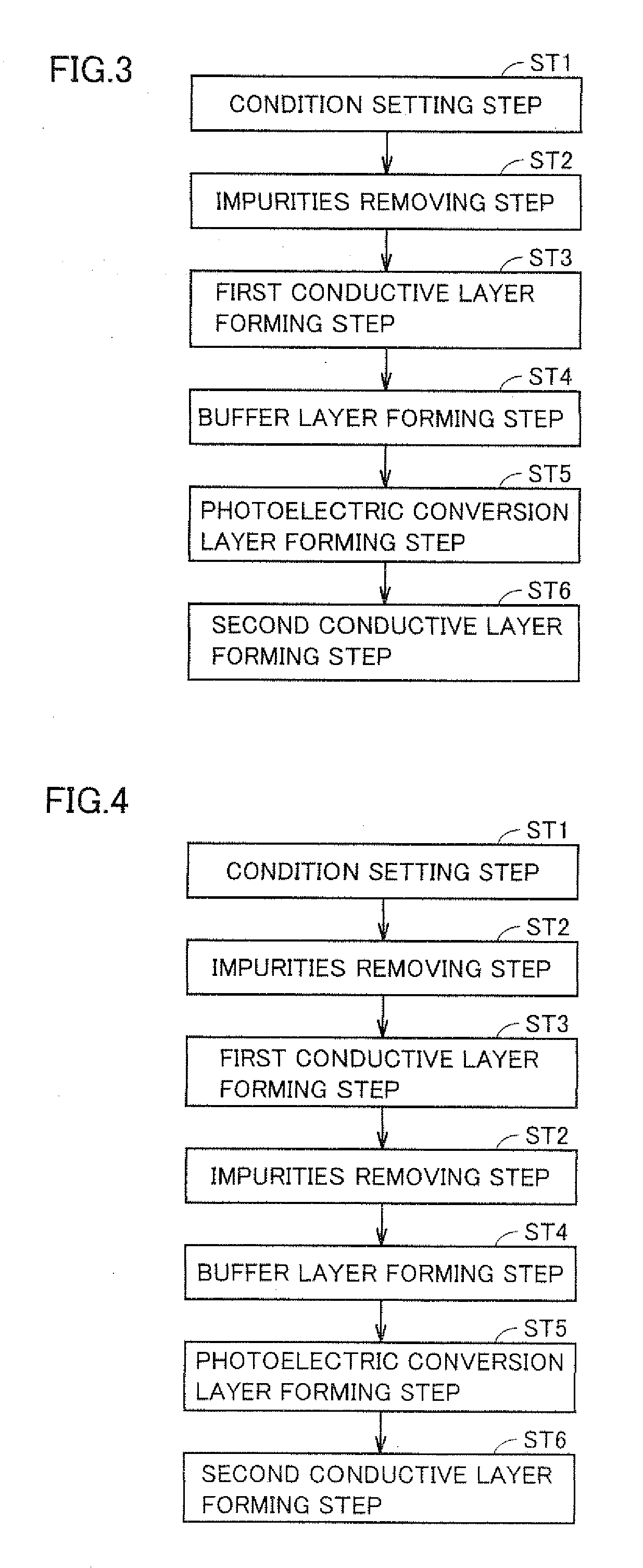

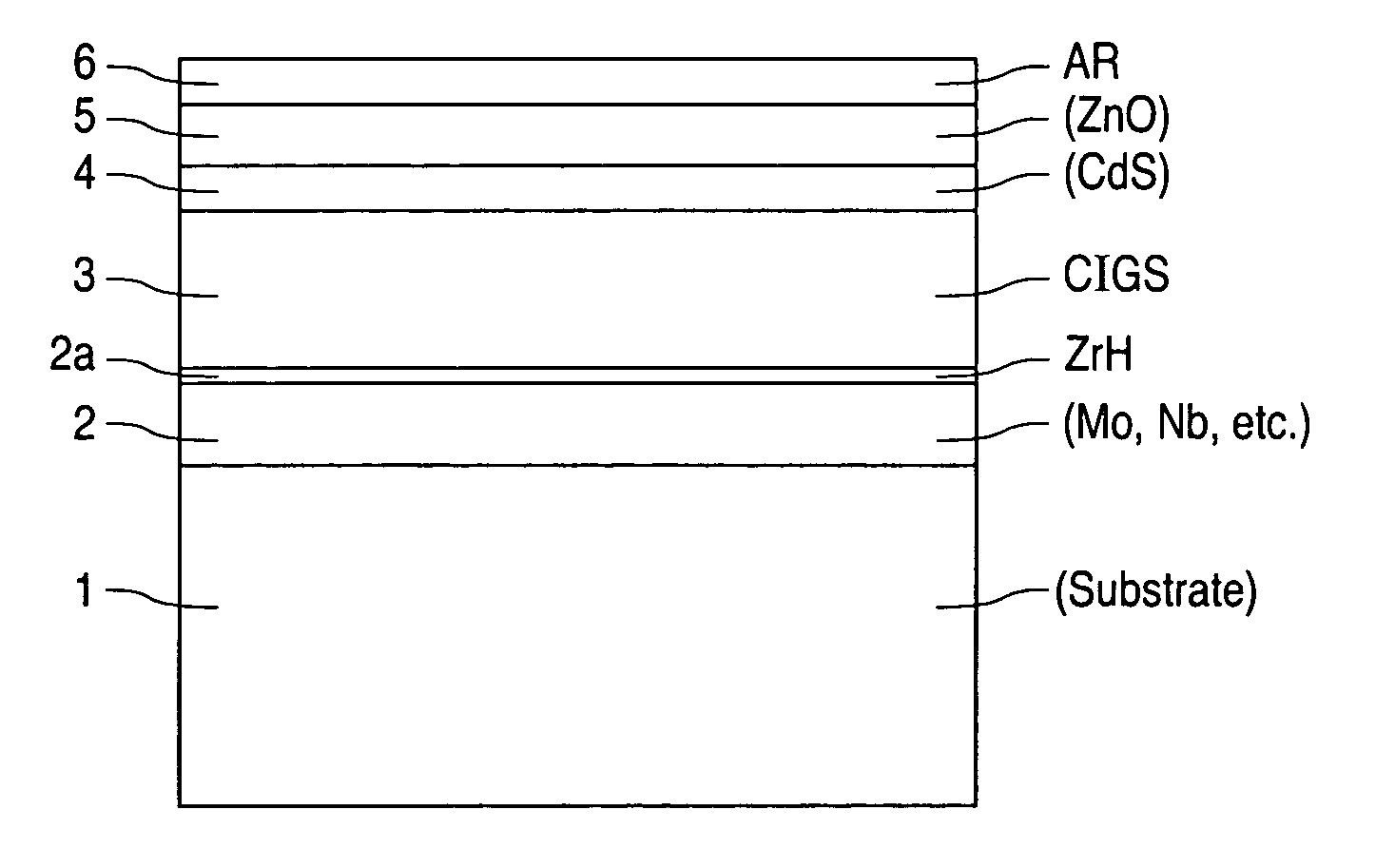

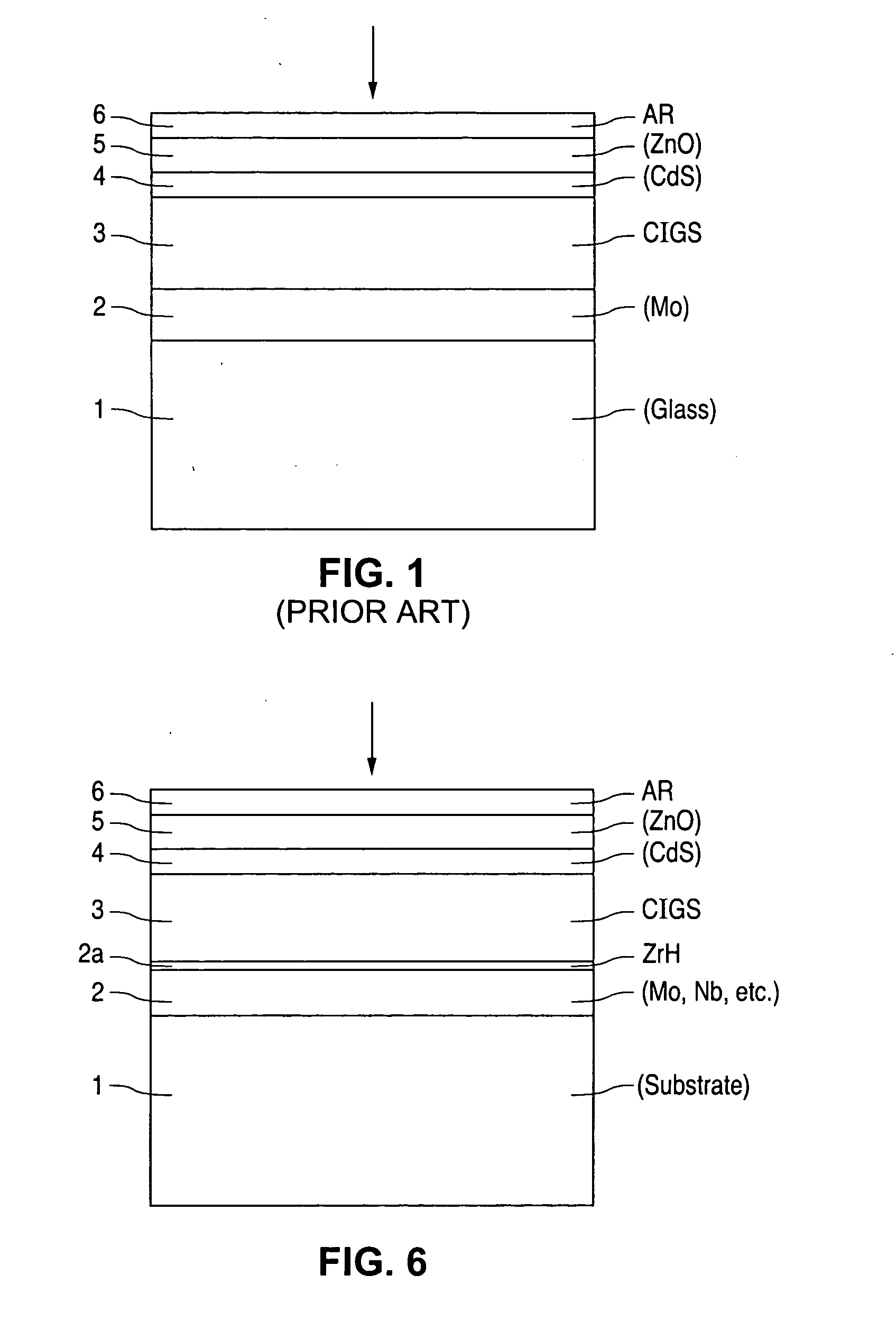

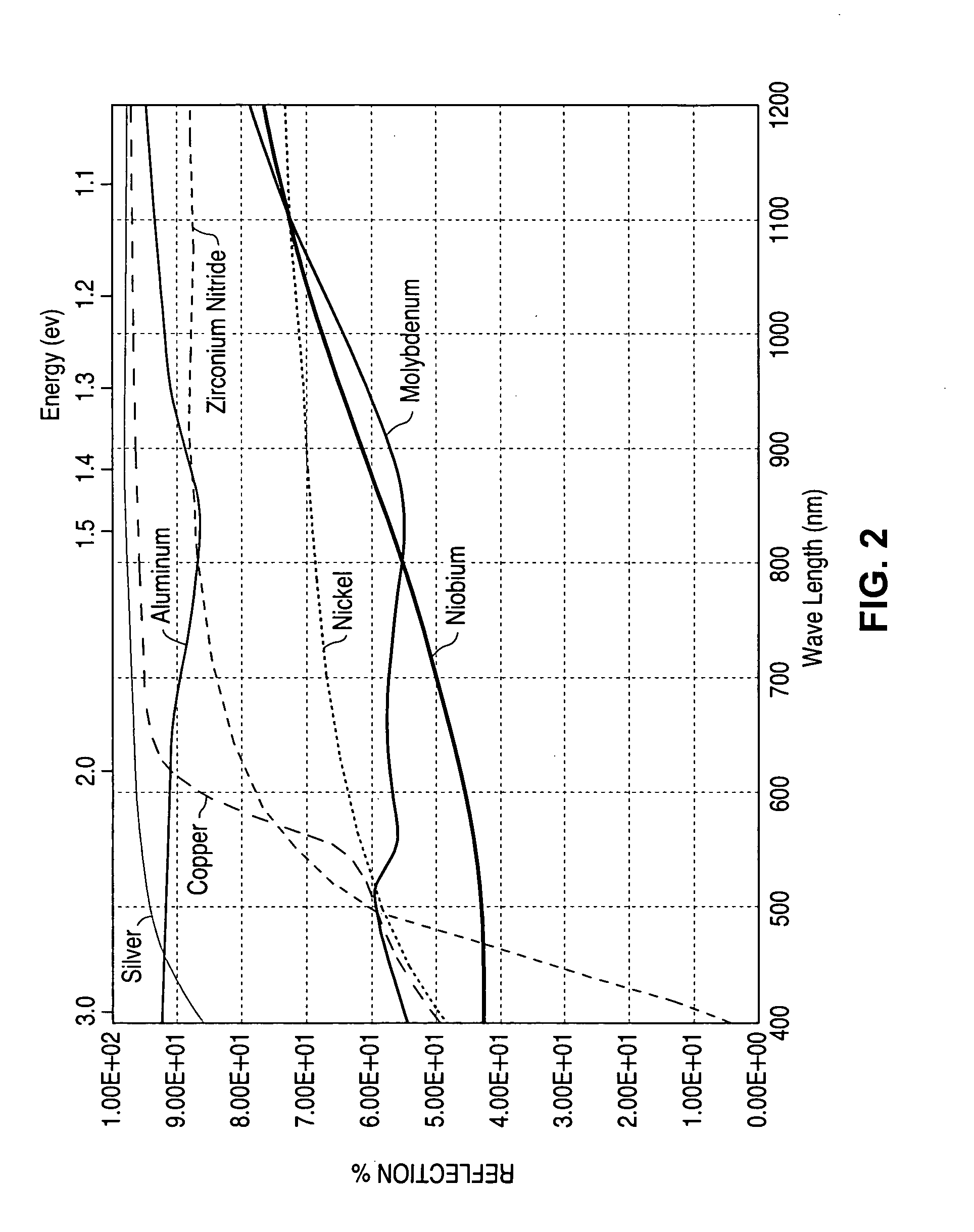

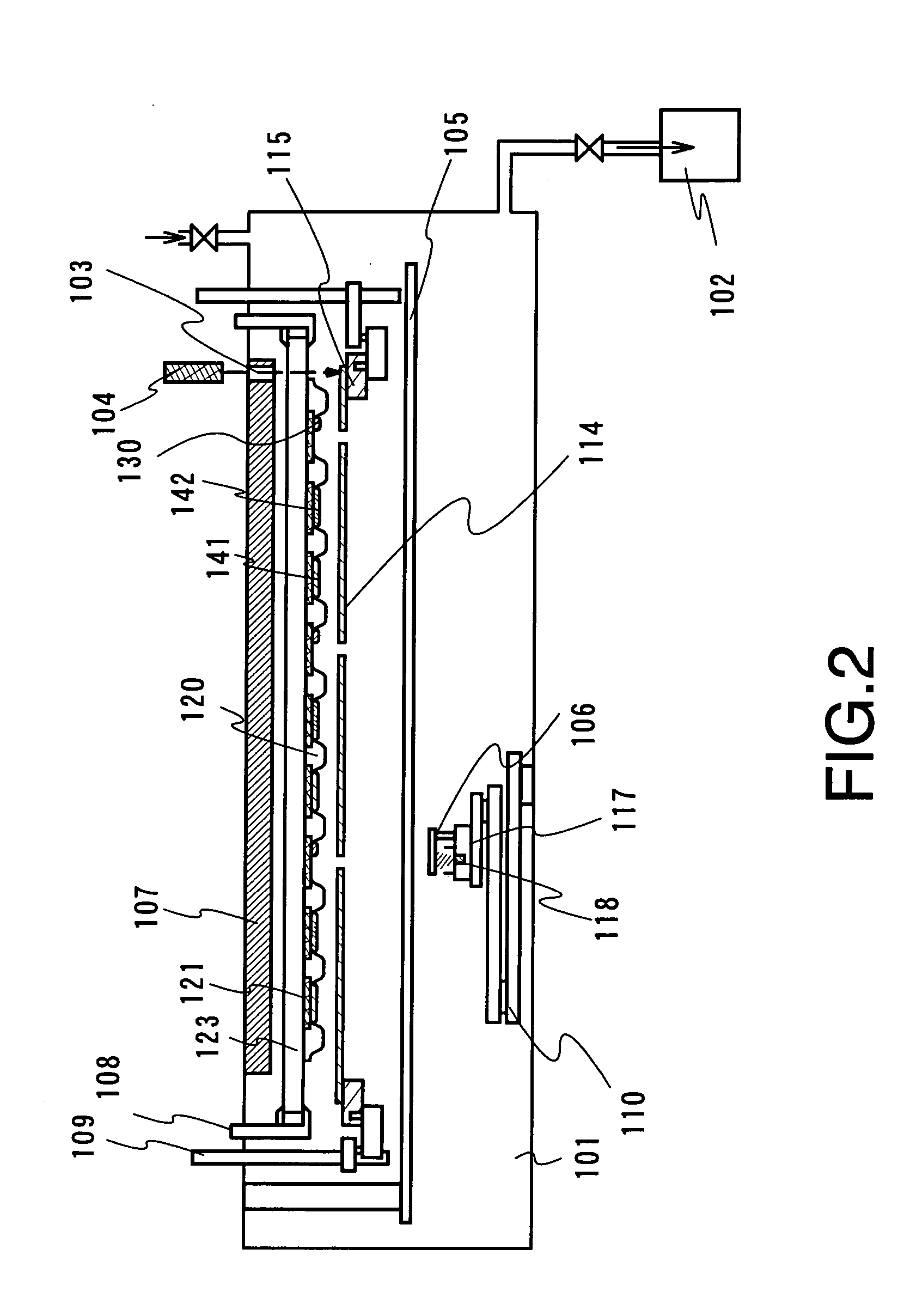

Manufacturing apparatus and method for large-scale production of thin-film solar cells

ActiveUS20050109392A1Cheap productionLow costPV power plantsFinal product manufactureIndiumElectrical battery

A method of manufacturing improved thin-film solar cells entirely by sputtering includes a high efficiency back contact / reflecting multi-layer containing at least one barrier layer consisting of a transition metal nitride. A copper indium gallium diselenide (Cu(InXGa1-x)Se2) absorber layer (X ranging from 1 to approximately 0.7) is co-sputtered from specially prepared electrically conductive targets using dual cylindrical rotary magnetron technology. The band gap of the absorber layer can be graded by varying the gallium content, and by replacing the gallium partially or totally with aluminum. Alternately the absorber layer is reactively sputtered from metal alloy targets in the presence of hydrogen selenide gas. RF sputtering is used to deposit a non-cadmium containing window layer of ZnS. The top transparent electrode is reactively sputtered aluminum doped ZnO. A unique modular vacuum roll-to-roll sputtering machine is described. The machine is adapted to incorporate dual cylindrical rotary magnetron technology to manufacture the improved solar cell material in a single pass.

Owner:BEIJING APOLLO DING RONG SOLAR TECH

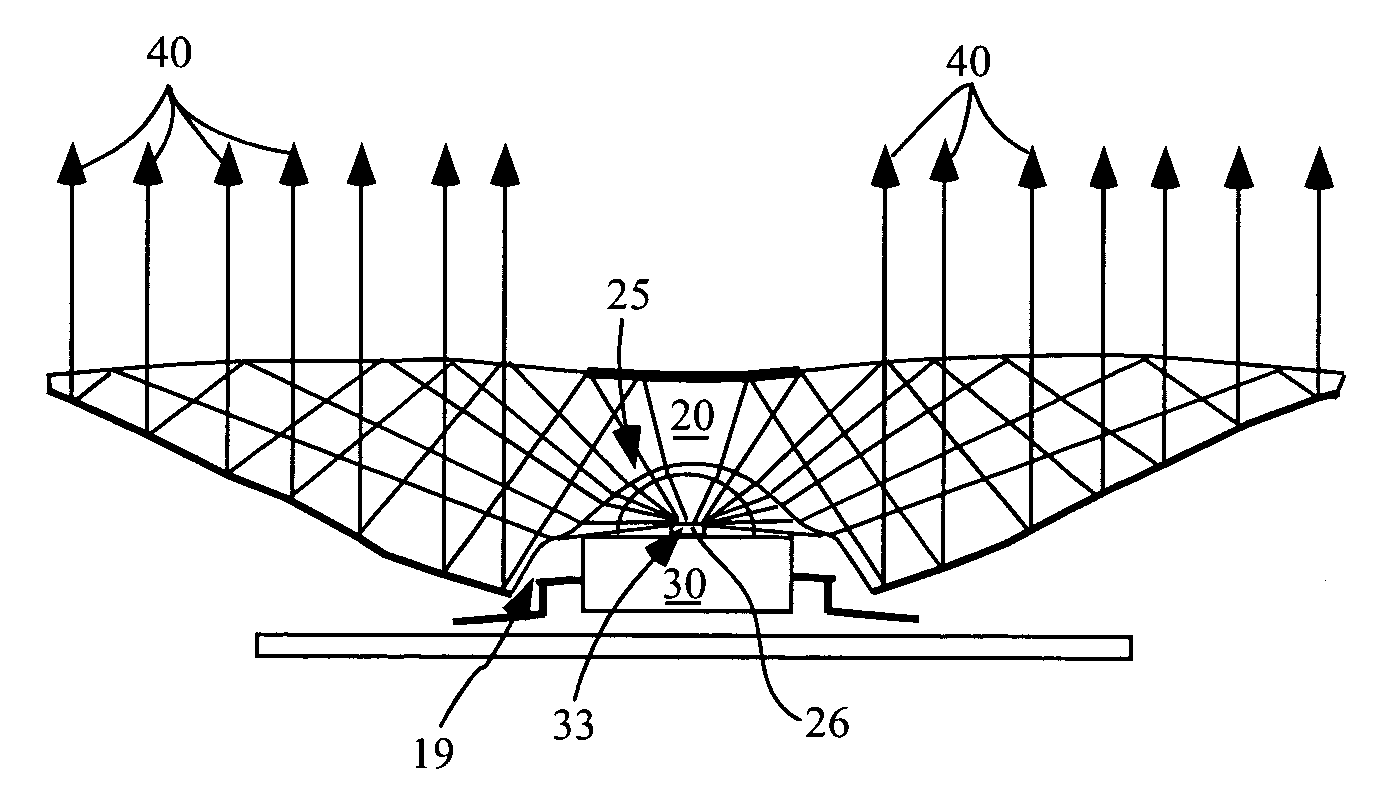

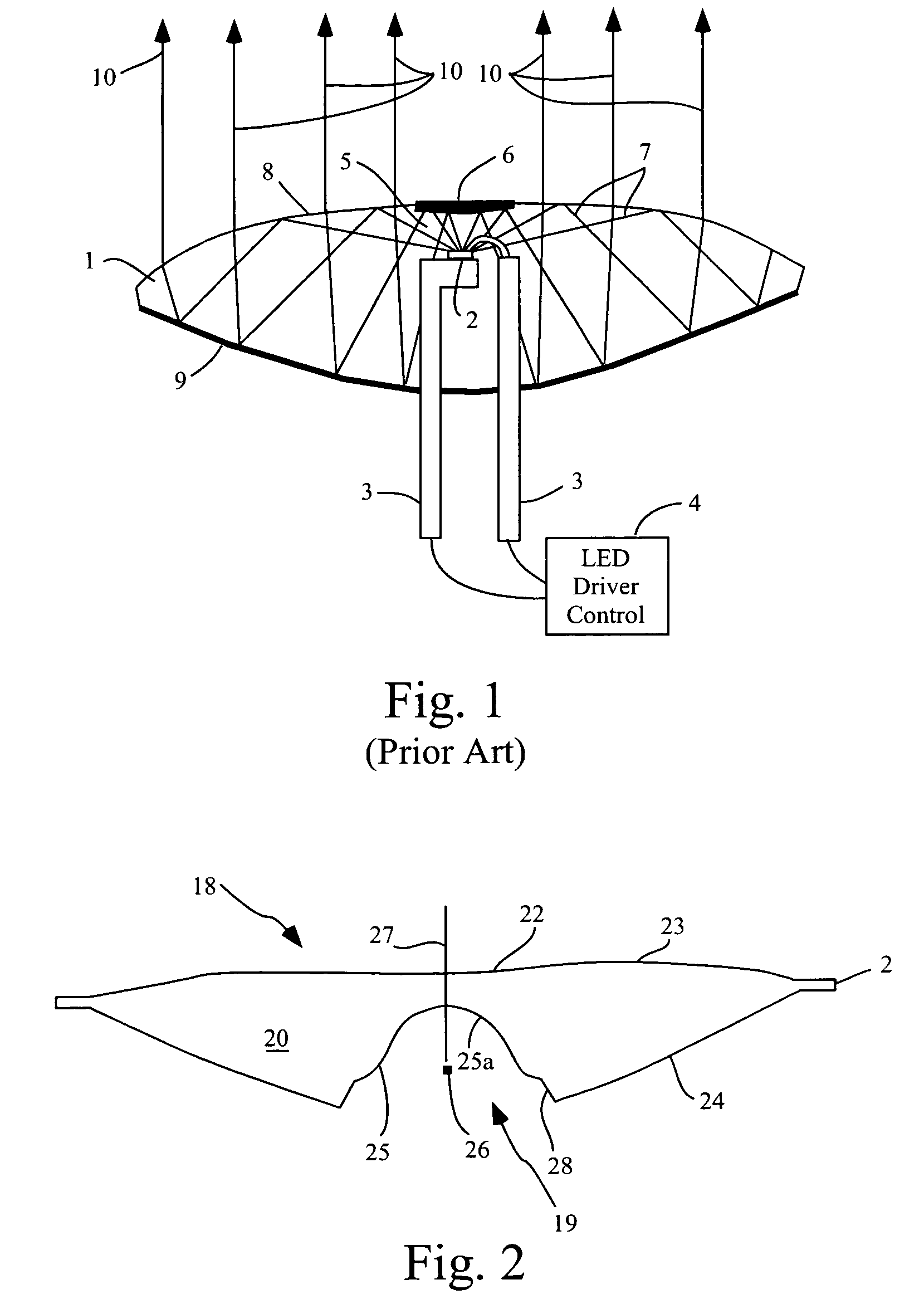

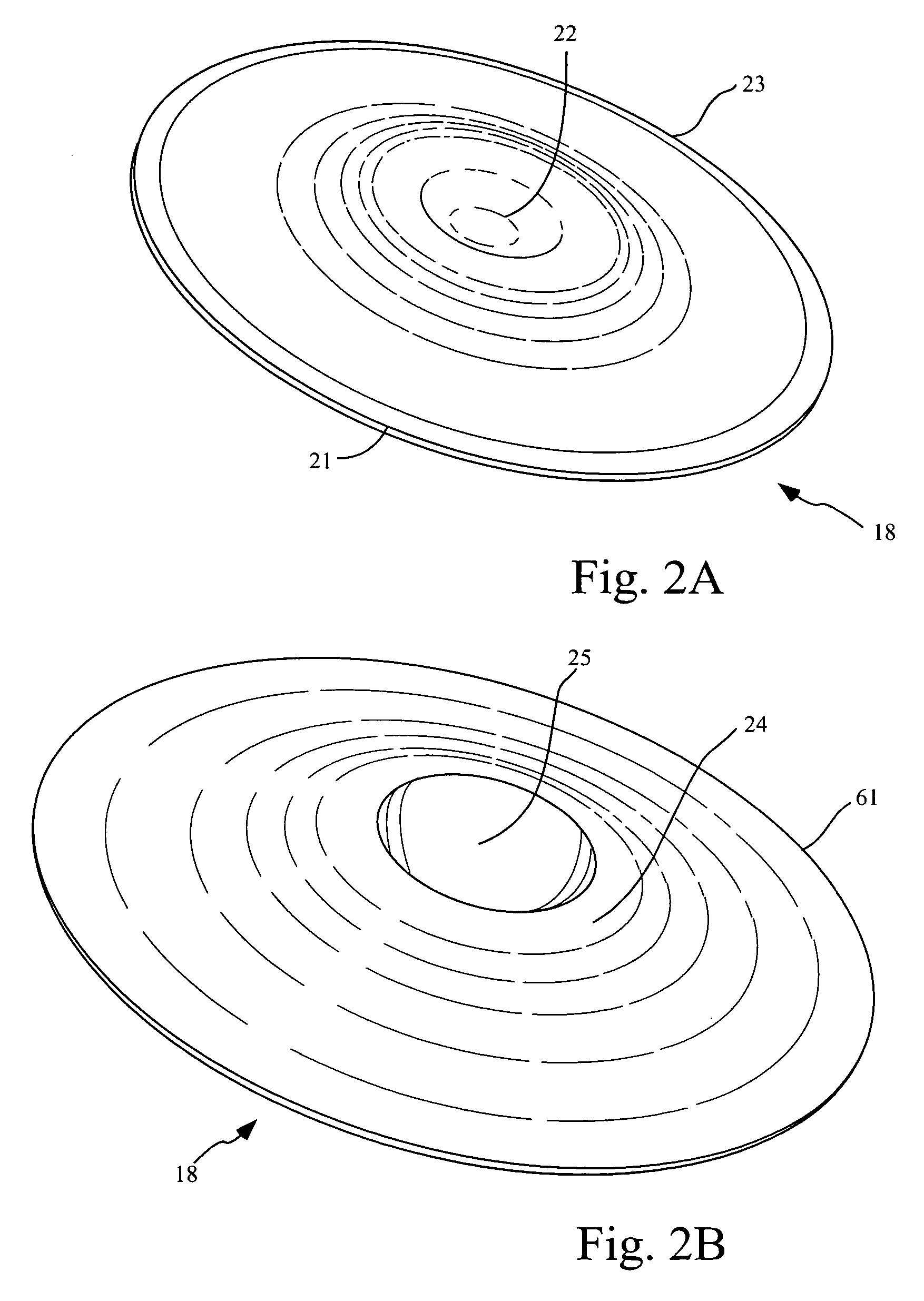

Compact folded-optics illumination lens

The present embodiments provide for apparatuses, and methods for manufacturing apparatuses to convert a first distribution of an input radiation to a second distribution of output radiation. The apparatus can be defined in some embodiments by generating a two-dimensional representation of three active optical surfaces including calculating a segment of first, entry and second surfaces based on first second, and third generalized Cartesian ovals, respectively, and successively repeating the calculating of the segments of the first and second surfaces, and rotationally sweeping the two-dimensional representation about a central axis providing a three-dimensional representation. In some embodiments, portion of the first and / or second surfaces can be totally internally reflective.

Owner:LIGHT ENGINE

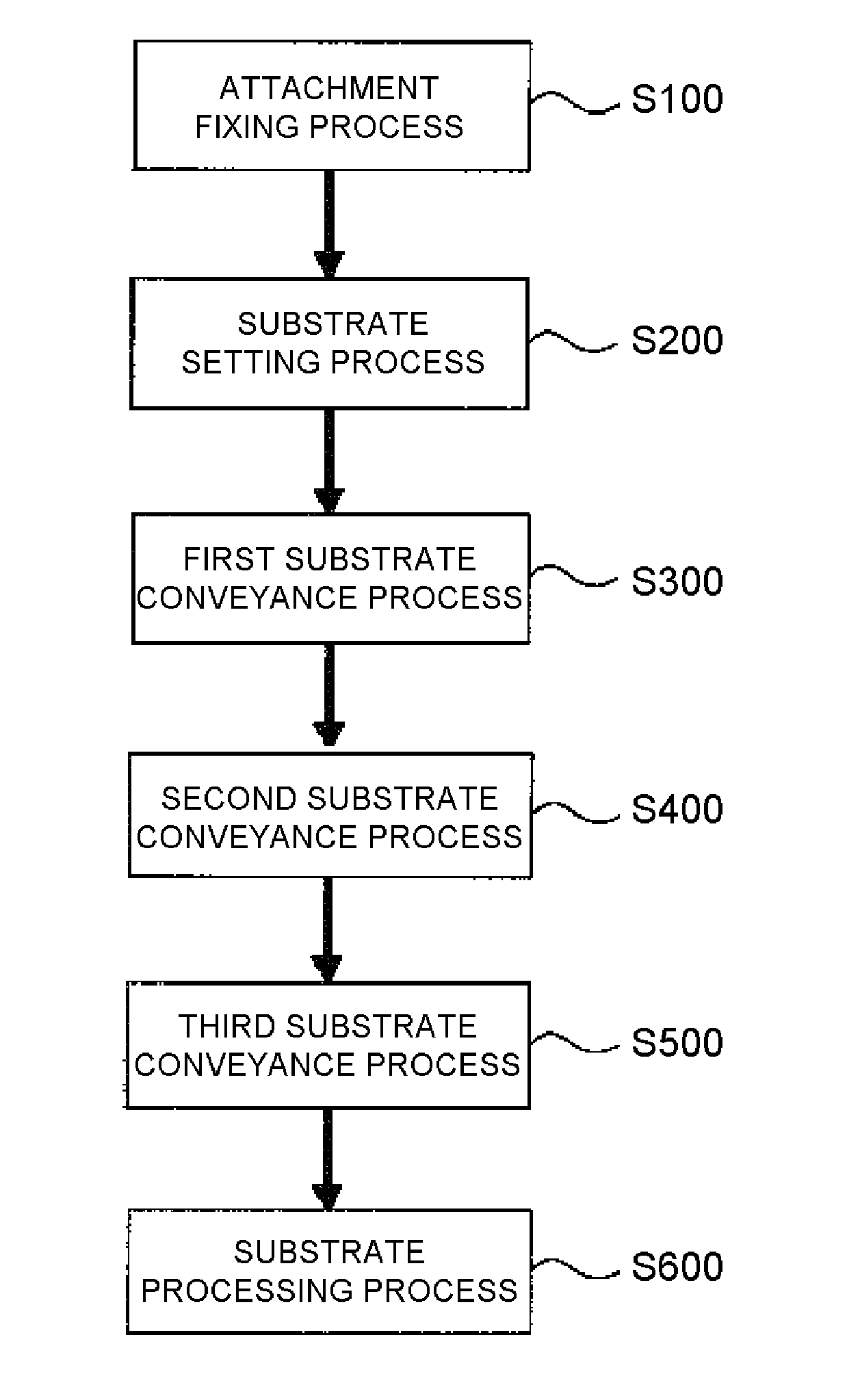

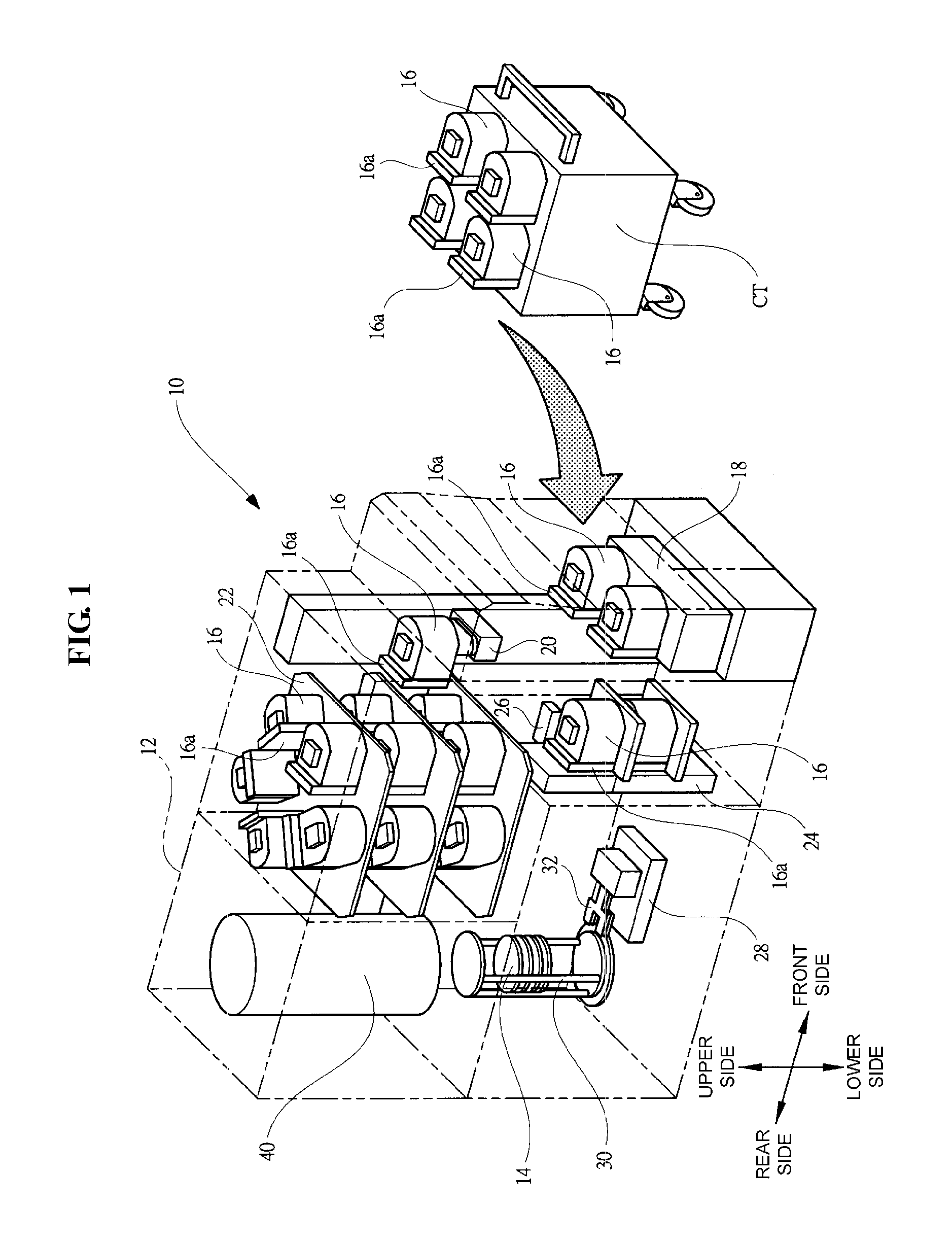

Attachment for substrates having different diameters, substrate processing apparatus, and method of manufacturing substrate or semiconductor device

InactiveUS20120216743A1Low costImprove film-forming precisionPolycrystalline material growthSemiconductor/solid-state device manufacturingReactive gasDevice material

A downsized substrate may be housed in a substrate accommodation vessel (FOUP) constituting a transfer system corresponding to a large diameter substrate. An attachment includes an upper plate and a lower plate supported by a first support groove that can support an 8-inch wafer, and holding columns installed at the upper plate and the lower plate and including a second support groove that can support a 2-inch wafer (if necessary, via a wafer holder and a holder member). Accordingly, the 2-inch wafer can be housed in a pod corresponding to the 8-inch wafer, and the pod, which is a transfer system, can be standardized to reduce cost of a semiconductor manufacturing apparatus. In addition, a distance from each gas supply nozzle to the wafer can be increased to sufficiently mix reactive gases before arrival at the wafer and improve film-forming precision to the wafer.

Owner:KOKUSA ELECTRIC CO LTD

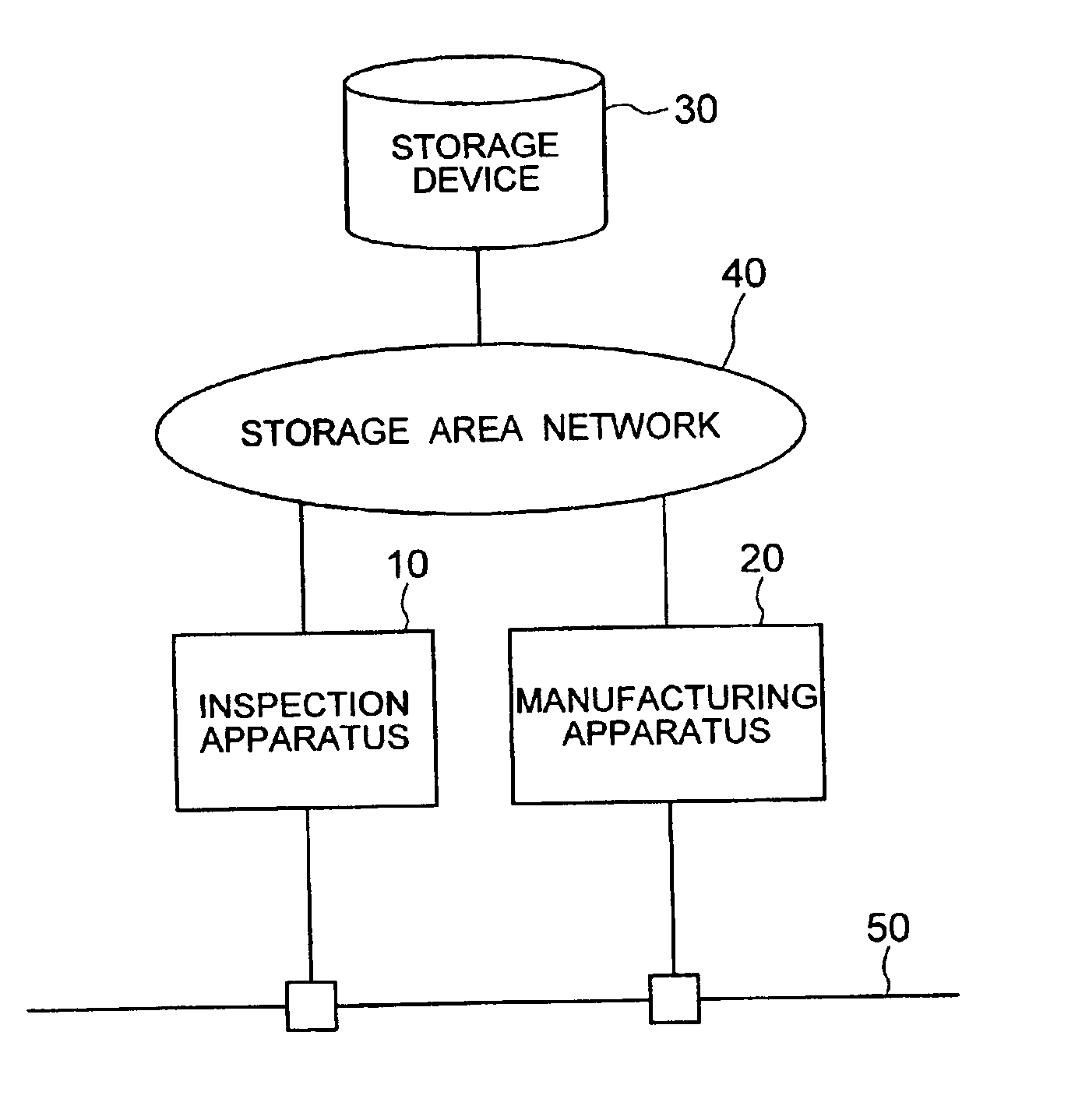

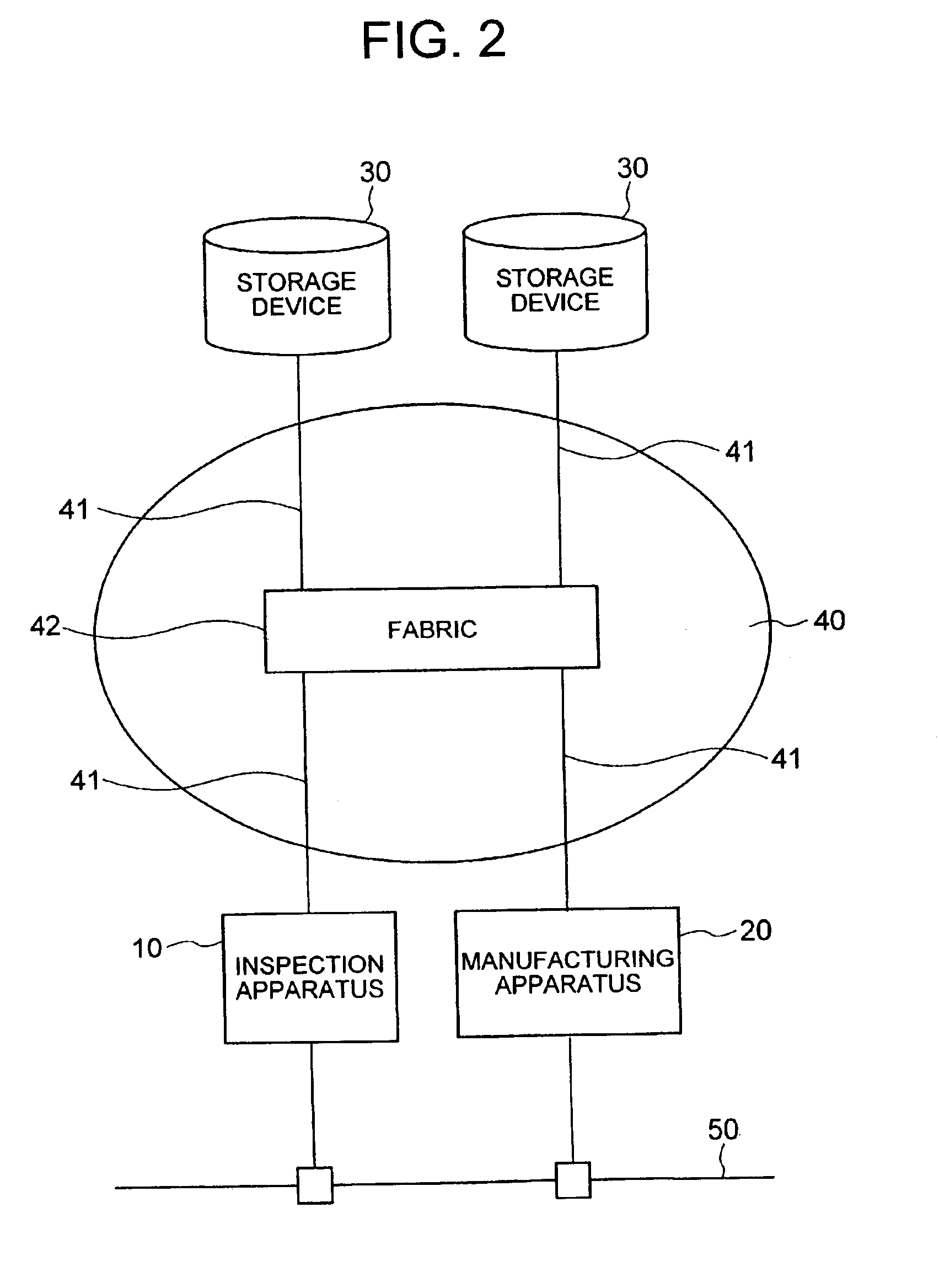

Semiconductor production system

InactiveUS6850854B2Improve system throughputIncrease in sizeSemiconductor/solid-state device testing/measurementElectronic circuit testingStorage area networkObservation unit

A semiconductor production system has a semiconductor manufacturing apparatus having an exposure unit, a control unit for controlling the exposure unit and a storage device; a semiconductor inspection apparatus having an observation unit, a control unit for controlling the observation unit and a storage device; and a storage device commonly used by the semiconductor manufacturing apparatus and the semiconductor inspection apparatus. The manufacturing apparatus, the inspection apparatus and the commonly used storage device are interconnected via a storage area network. With the semiconductor manufacturing apparatus and the storage device linked together via the storage area network, a large volume of image data or design data can be communicated at high speed, thus improving the system throughput.

Owner:HITACHI LTD

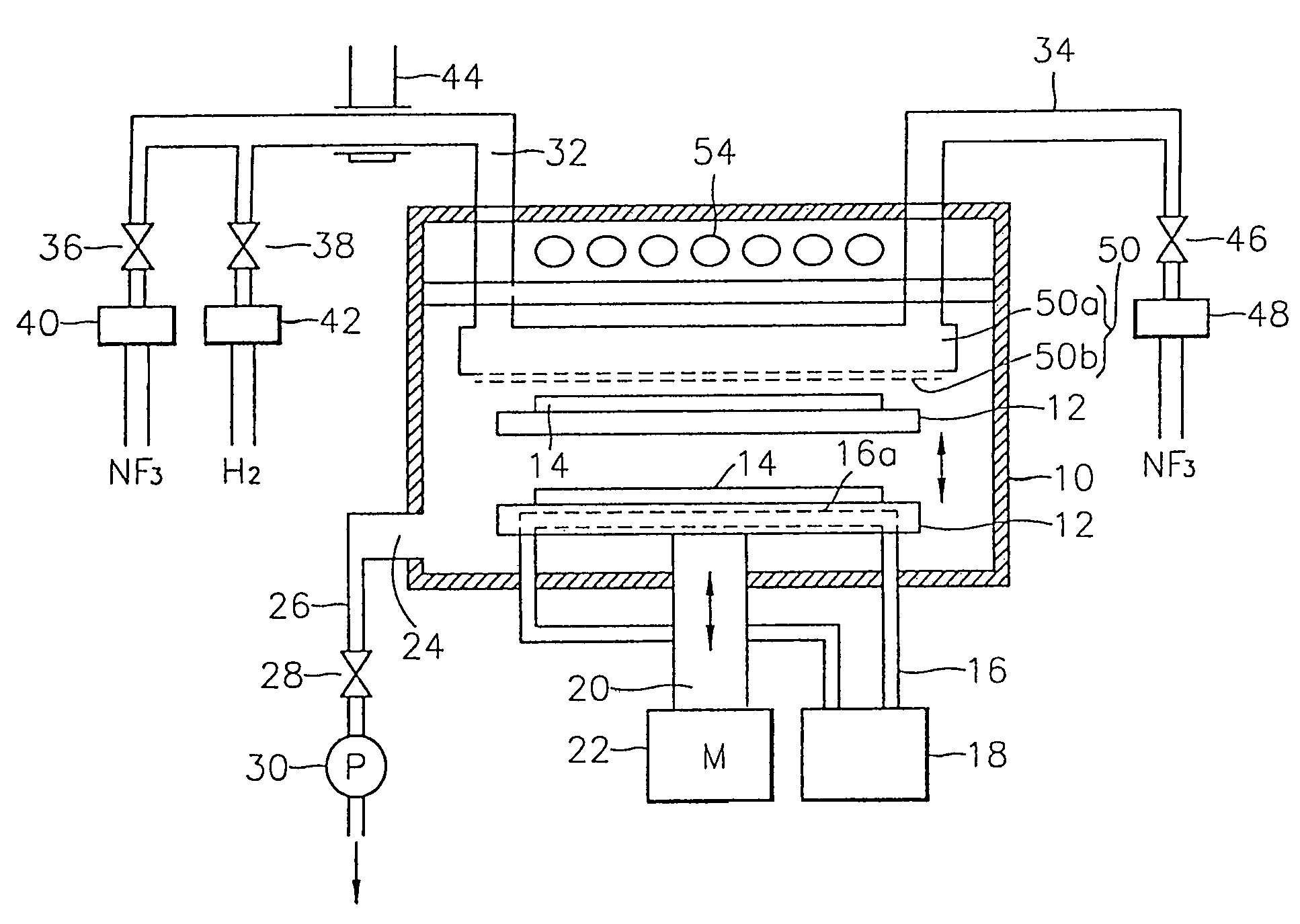

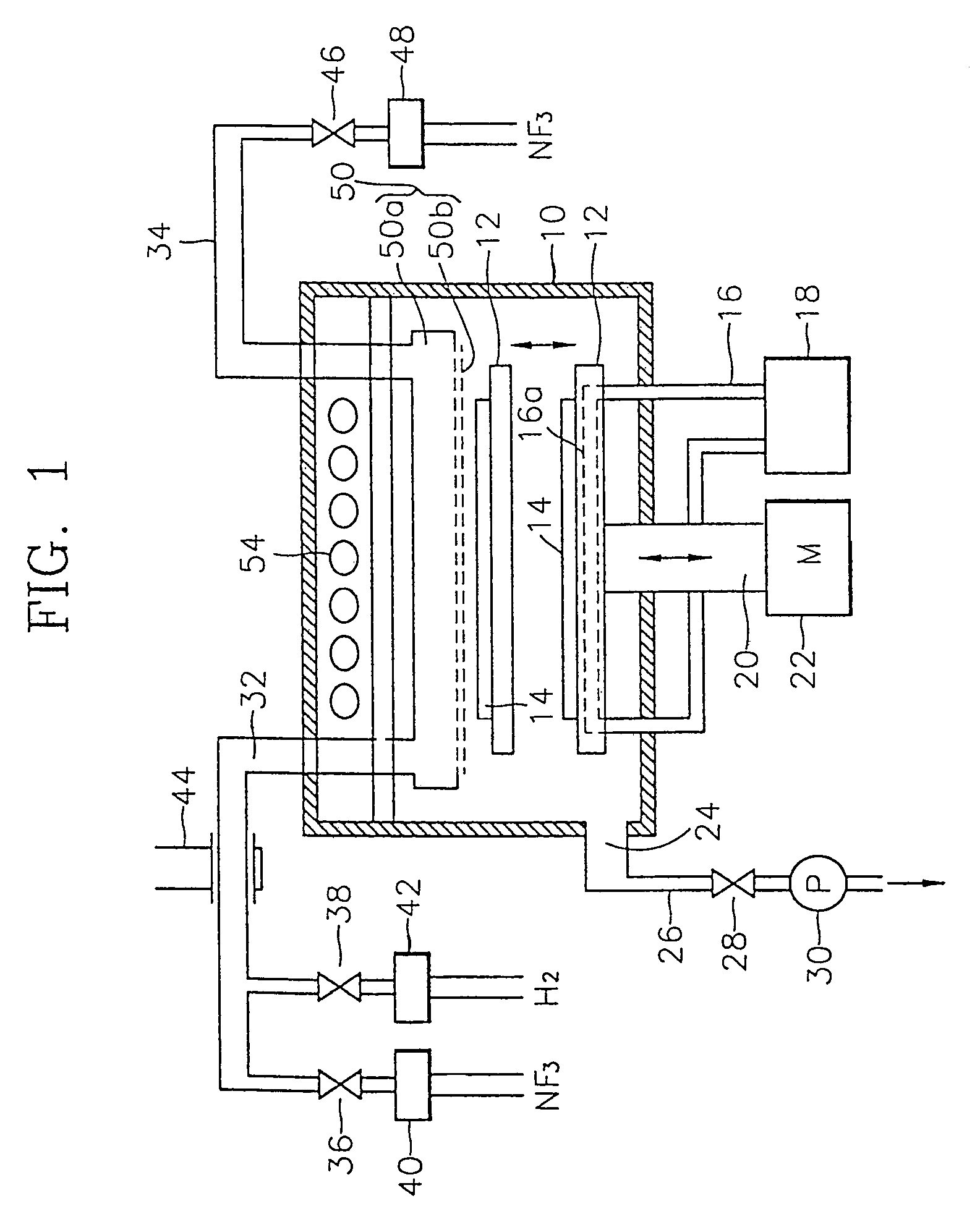

Method of removing oxide layer and semiconductor manufacturing apparatus for removing oxide layer

InactiveUS7488688B2High selectivityEven contactDecorative surface effectsSemiconductor/solid-state device manufacturingReaction layerSusceptor

A method for removing an oxide layer such as a natural oxide layer and a semiconductor manufacturing apparatus which uses the method to remove the oxide layer. A vertically movable susceptor is installed at the lower portion in a processing chamber and a silicon wafer is loaded onto the susceptor when it is at the lower portion of the processing chamber. The air is exhausted from the processing chamber to form a vacuum condition therein. A hydrogen gas in a plasma state and a fluorine-containing gas are supplied into the processing chamber to induce a chemical reaction with the oxide layer on the silicon wafer, resulting in a reaction layer. Then, the susceptor is moved up to the upper portion of the processing chamber, to anneal the silicon wafer on the susceptor with a heater installed at the upper portion of the processing chamber, thus vaporizing the reaction layer. The vaporized reaction layer is exhausted out of the chamber. The oxide layer can be removed with a high selectivity while avoiding damage or contamination of the underlying layer.

Owner:SAMSUNG ELECTRONICS CO LTD

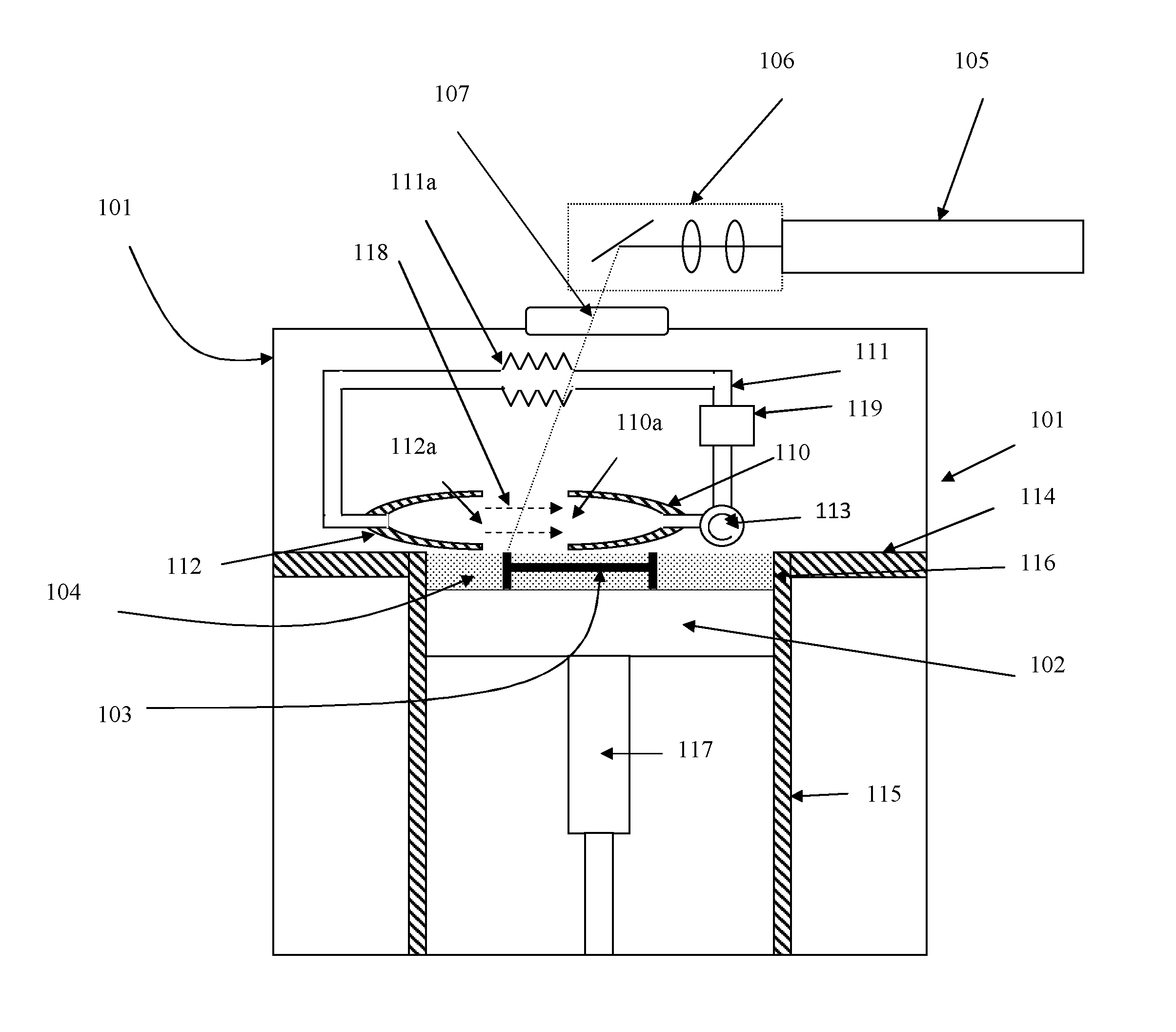

Additive manufacturing apparatus and method

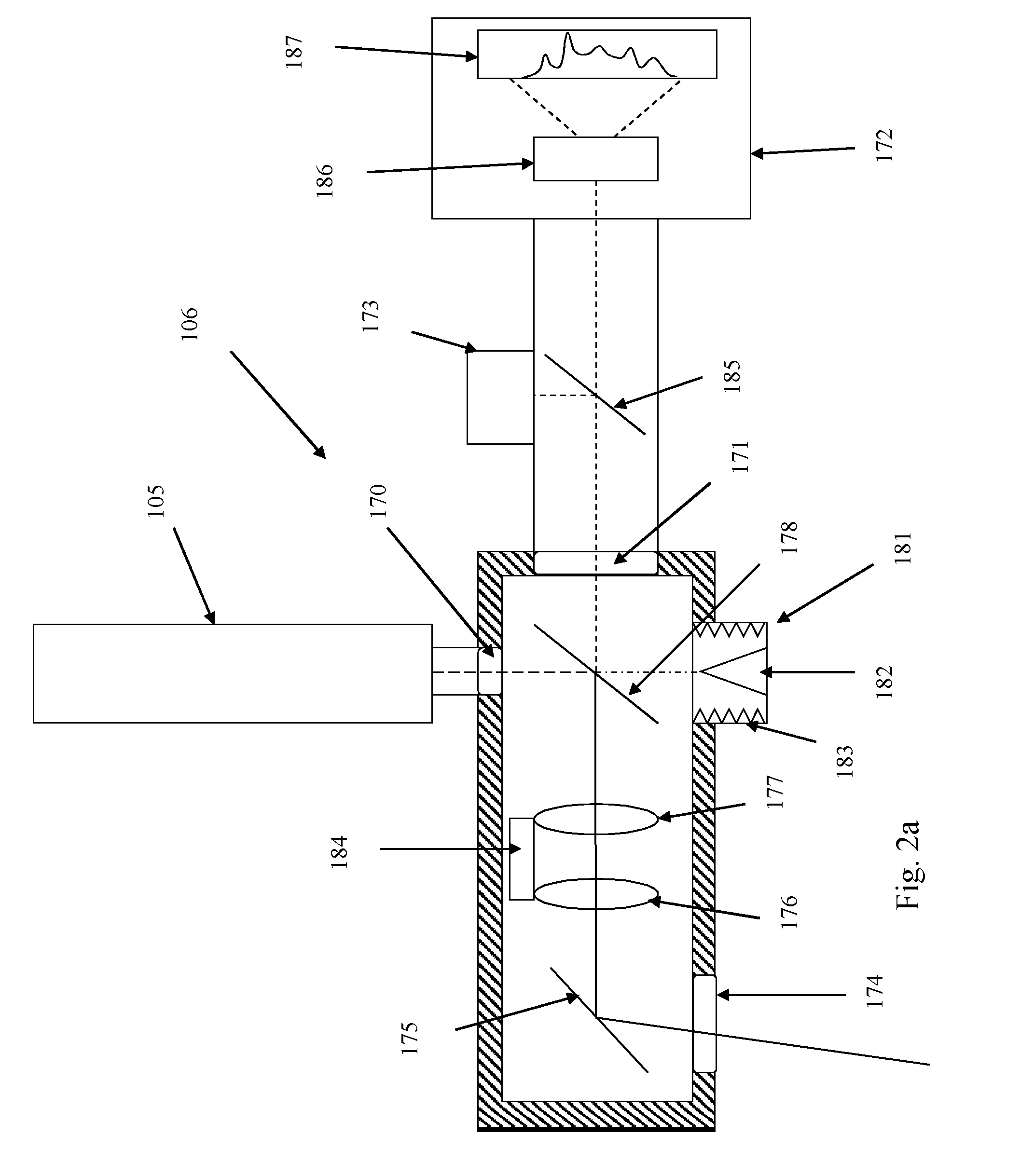

ActiveUS20160236279A1Sufficient reflectivityAdditive manufacturing apparatusSpectrum investigationManufactured apparatusFeedback control

This invention concerns a laser solidification apparatus for building objects by layerwise solidification of powder material. The apparatus including a build chamber containing a build platform, a device for depositing layers of powder material on to the build platform, an optical unit for directing a laser beam to selectively solidify areas of each powder layer and a spectrometer for detecting characteristic radiation emitted by plasma formed during solidification of the powder by the laser beam. The invention also relates to a spectrometer for detecting characteristic radiation generated by interaction of the metal with the or a further laser beam. The spectra recorded using the spectrometer may be used for feedback control during the solidification process.

Owner:RENISHAW PLC

Thin film deposition apparatus

ActiveUS20170044666A1Reduce and prevent problemFrom chemically reactive gasesChemical vapor deposition coatingManufactured apparatusGas supply

Disclosed are a substrate holder and a semiconductor manufacturing apparatus including the substrate holder. The substrate holder provides a reaction region by making face-sealing contact with a reactor wall. The substrate holder has an elastic behavior when pressure is applied thereto while the substrate holder makes face-sealing contact with the reactor wall. The semiconductor manufacturing apparatus includes the substrate holder and a gas supply unit configured to supply gas to the reaction region provided by the reactor wall and the substrate holder.

Owner:ASM IP HLDG BV

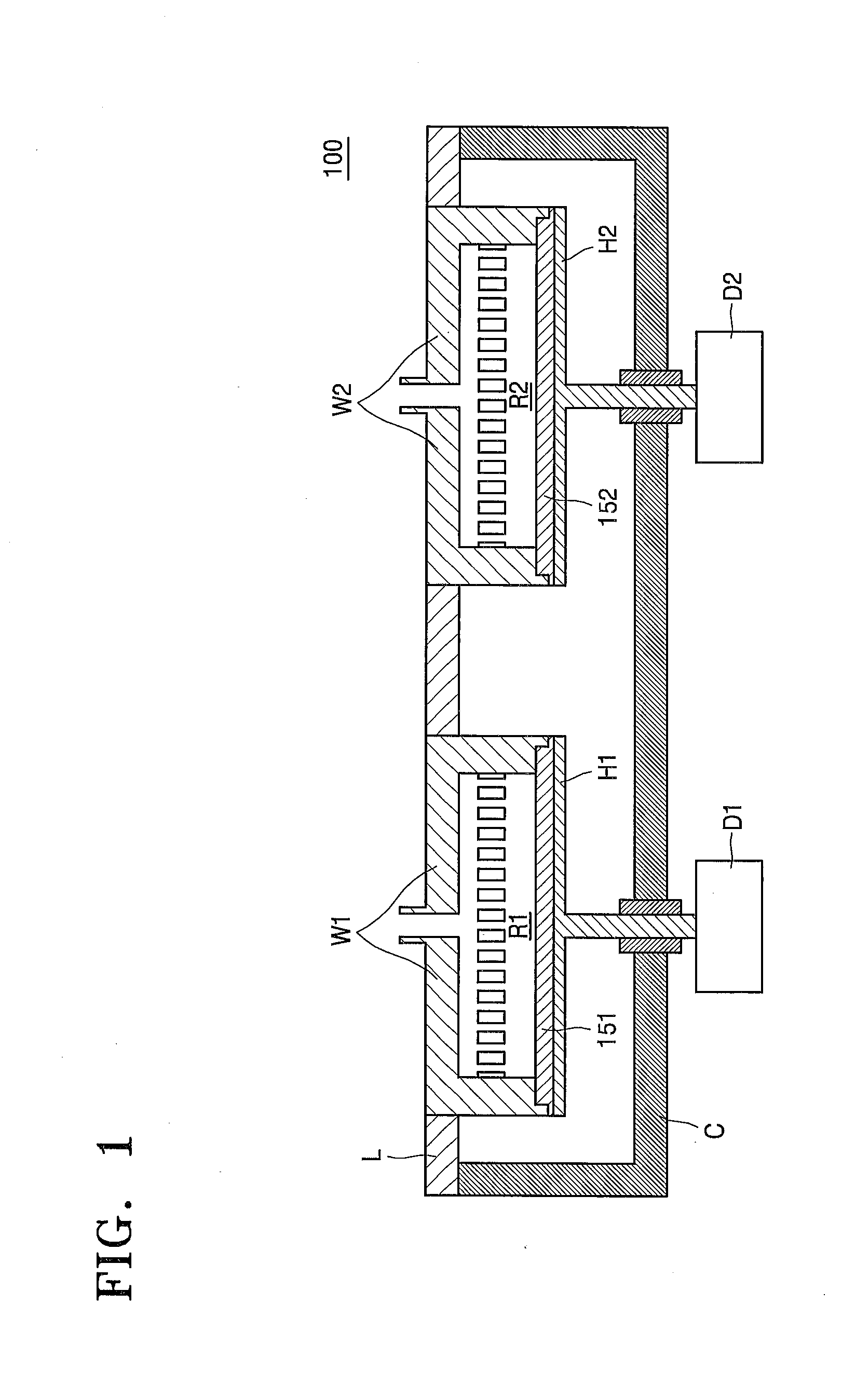

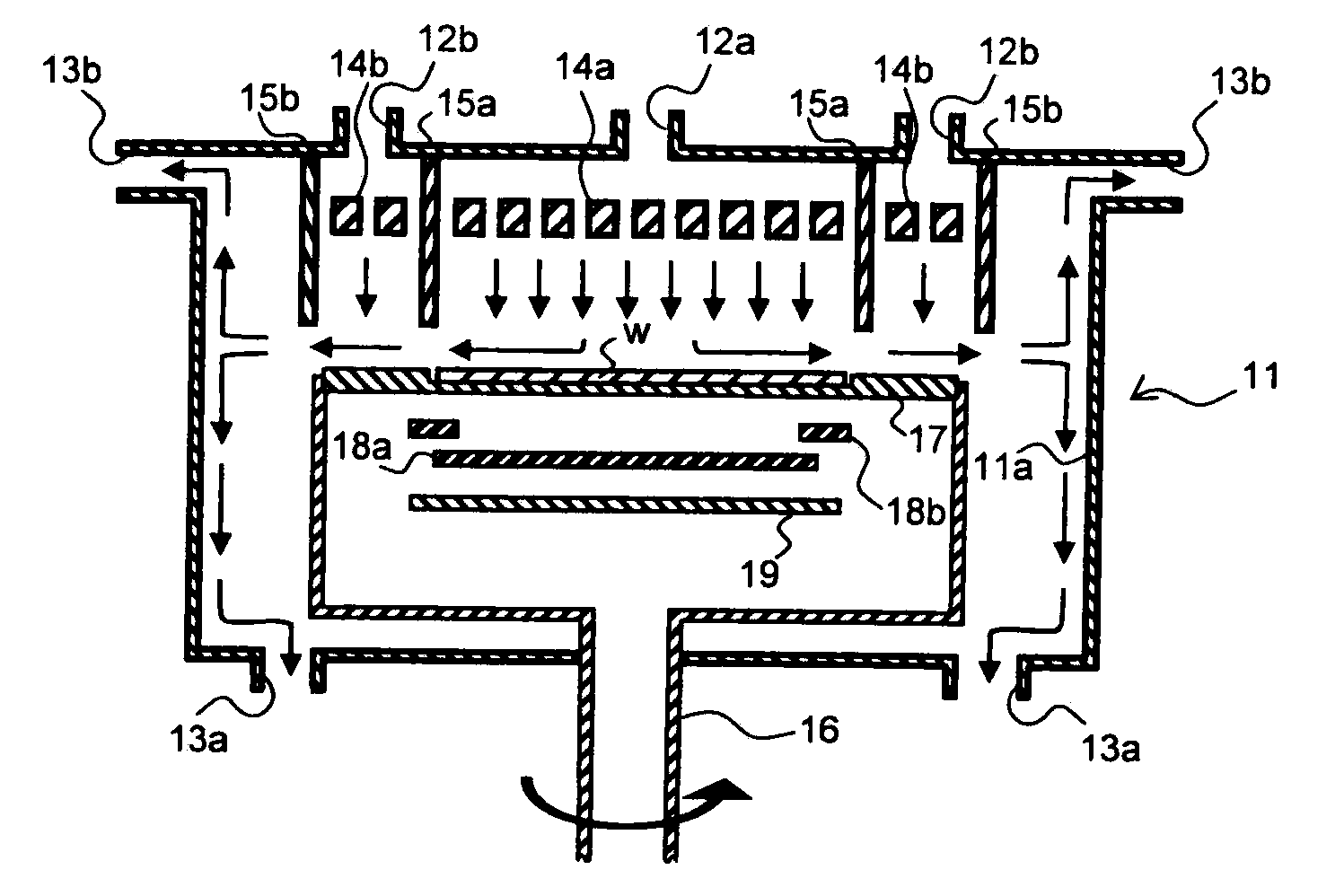

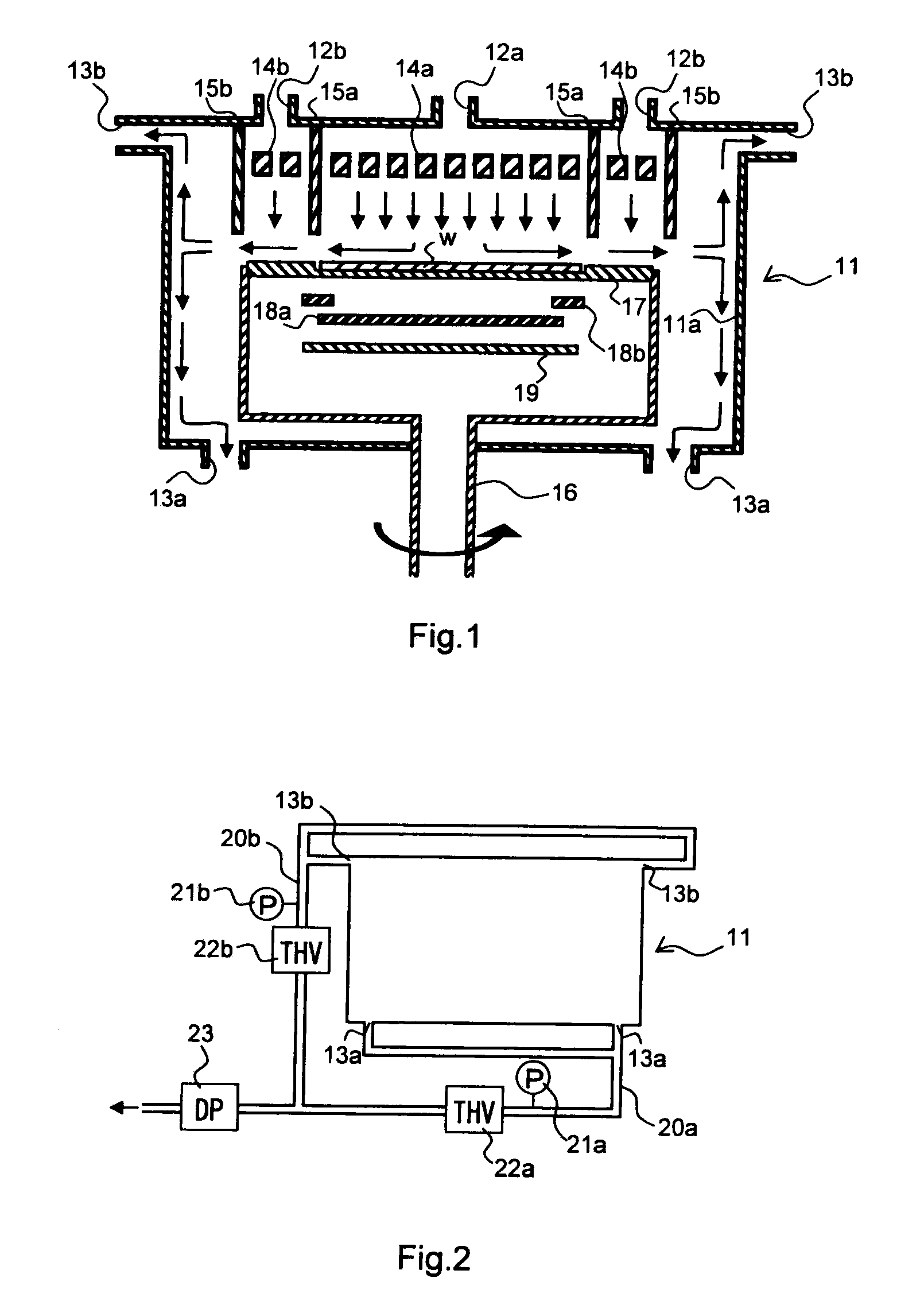

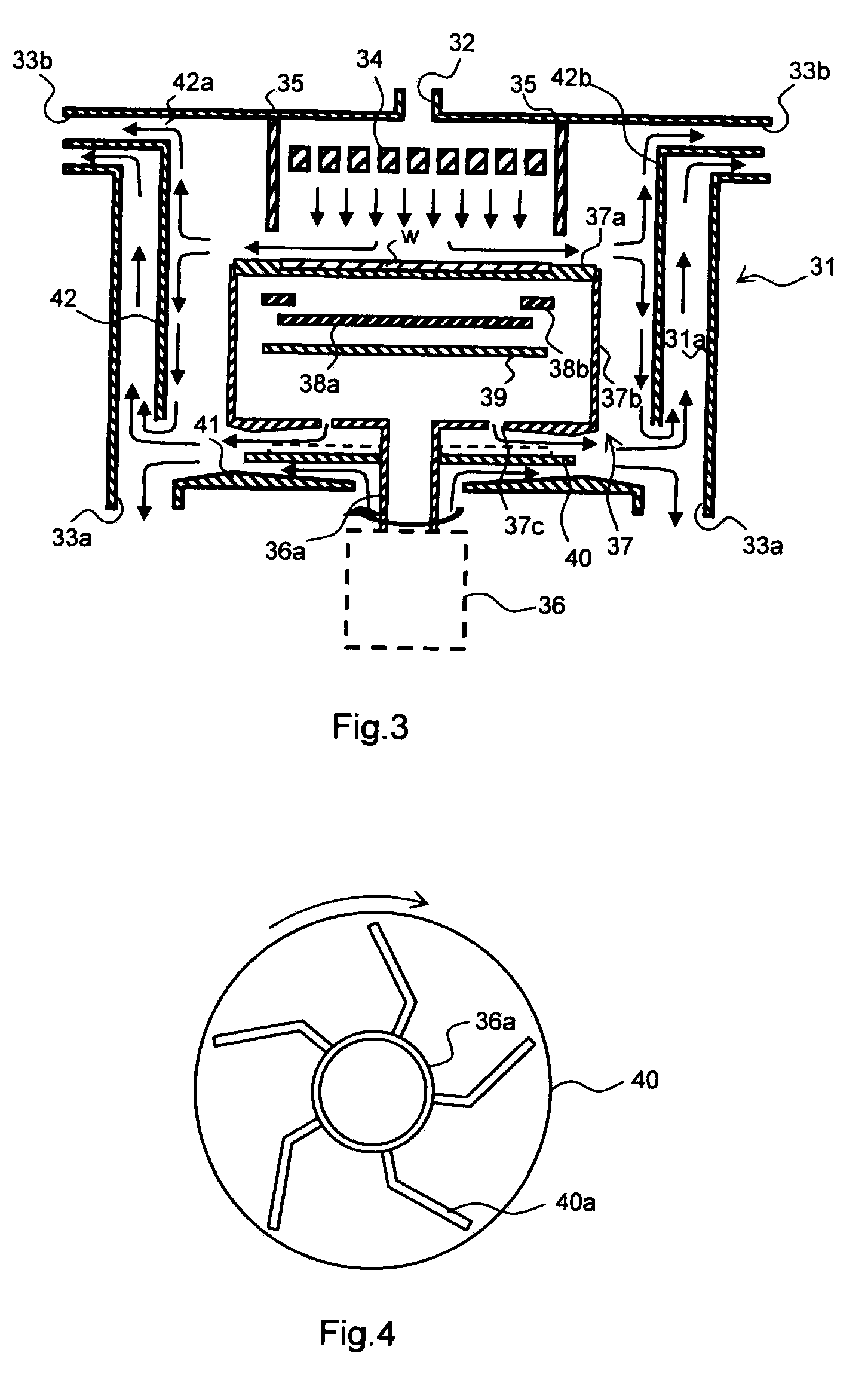

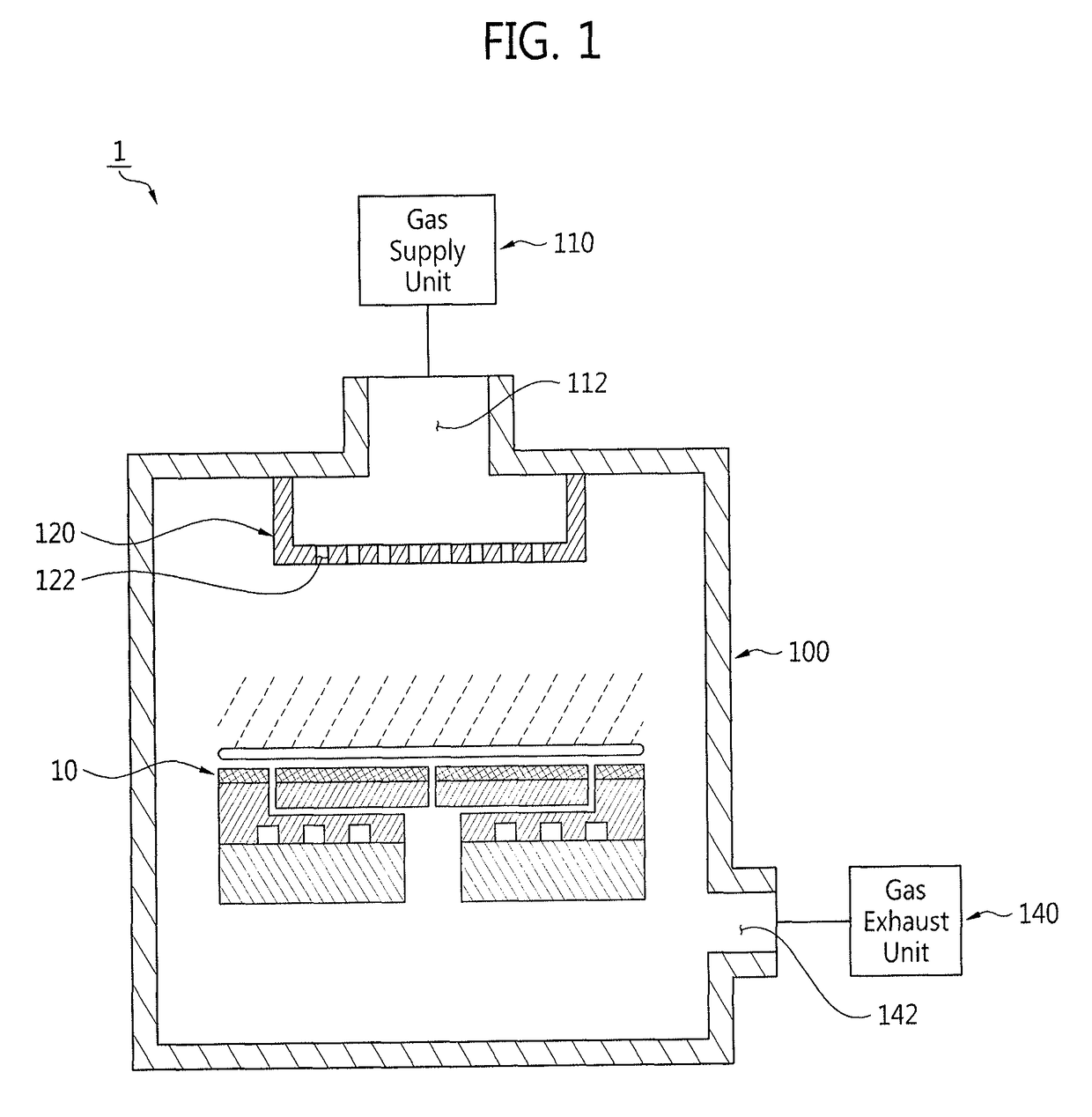

Manufacturing apparatus for semiconductor device and manufacturing method for semiconductor device

ActiveUS20090142933A1Improve productivityUniform film formationMovable spraying apparatusSemiconductor/solid-state device manufacturingSusceptorManufactured apparatus

A manufacturing apparatus for a semiconductor device, includes: a reaction chamber to which a wafer w is loaded; a gas supply port for supplying first process gas including source gas from an upper portion of the reaction chamber; a first rectifying plate for supplying the first process gas onto the wafer in a rectifying state; a first gas exhaust port for exhausting gas from a lower portion of the reaction chamber; a second gas exhaust port for exhausting gas from the upper portion of the reaction chamber; a heater for heating the wafer w; a susceptor for retaining the wafer w; and a rotation drive unit for rotating the wafer w.

Owner:NUFLARE TECH INC

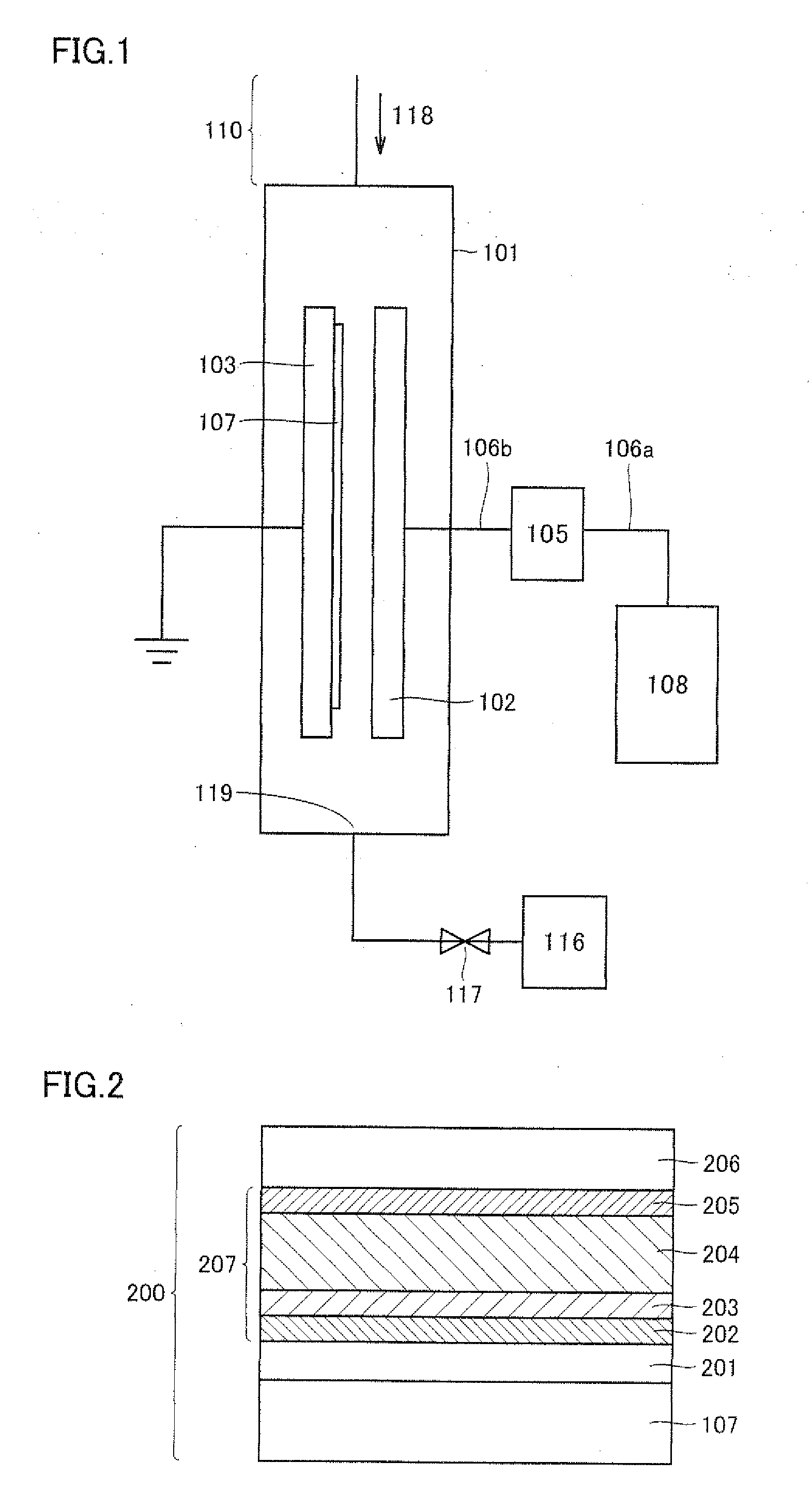

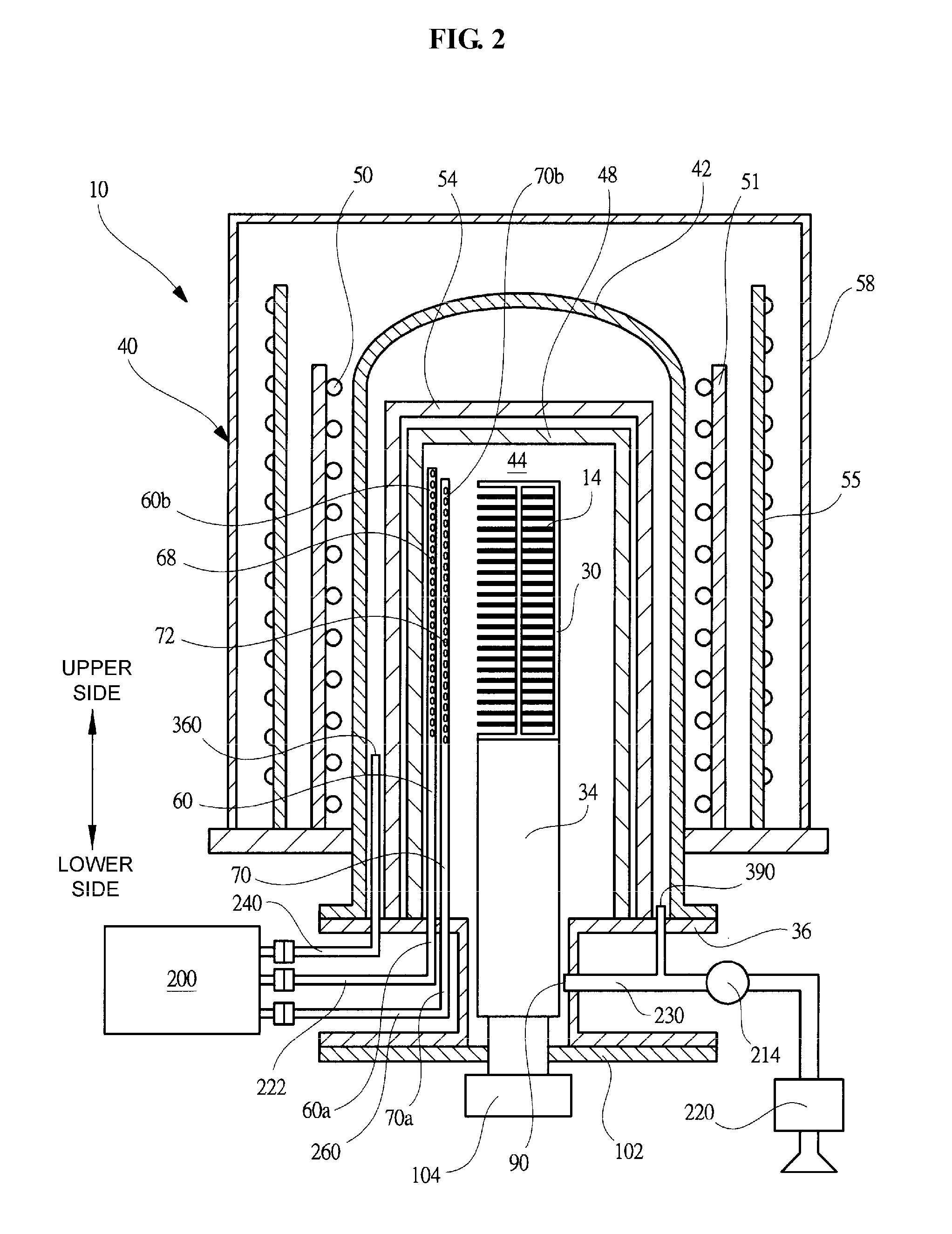

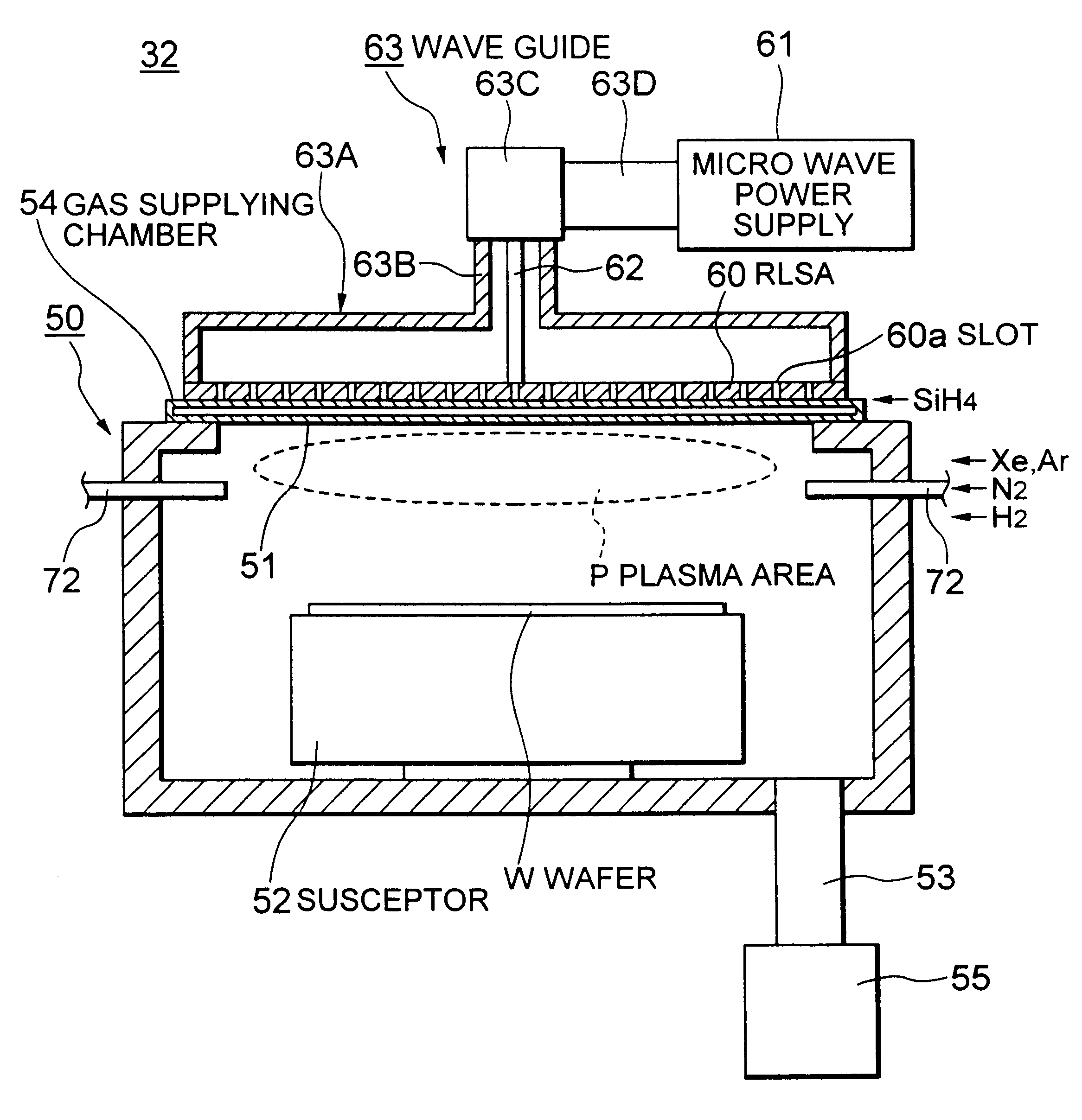

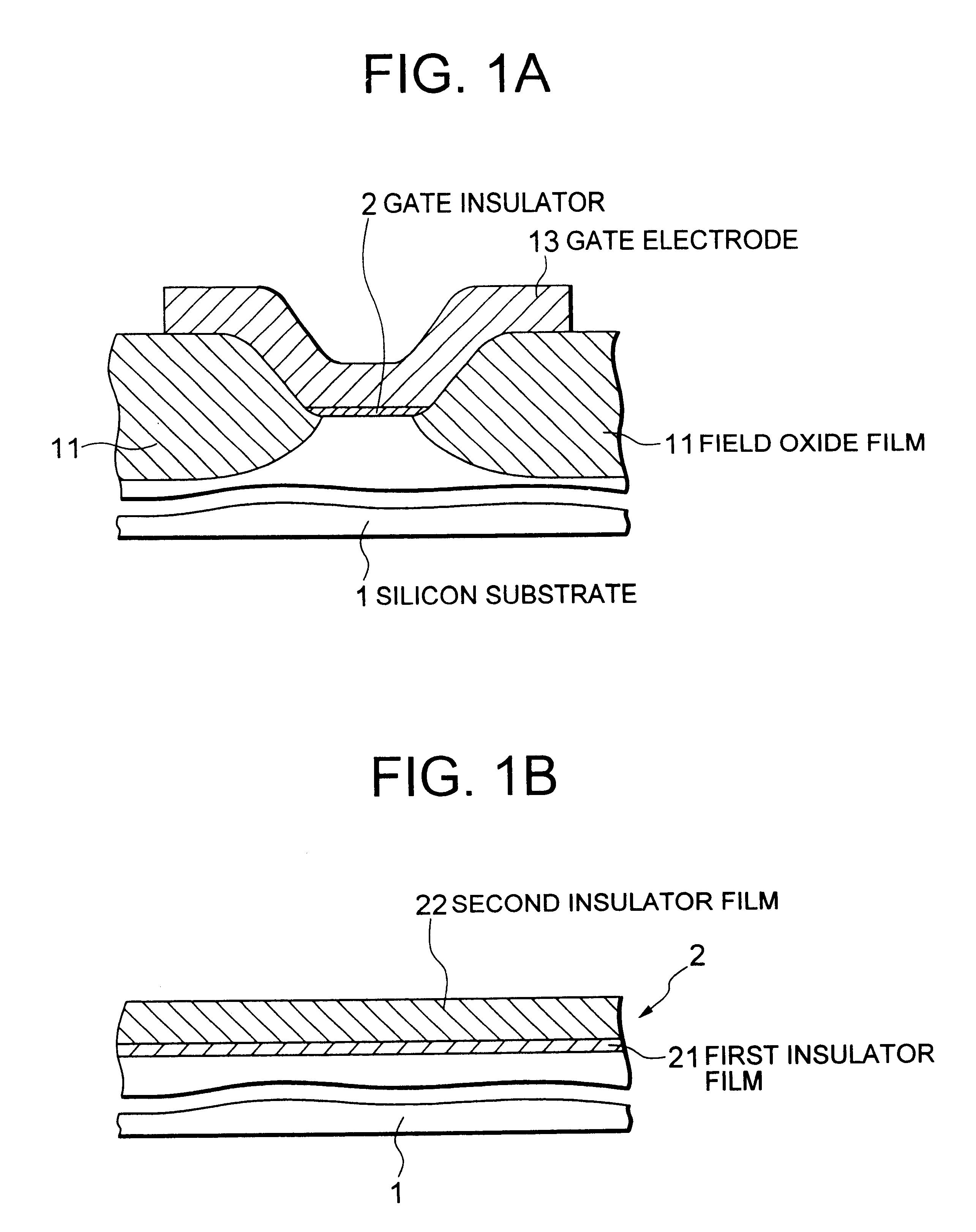

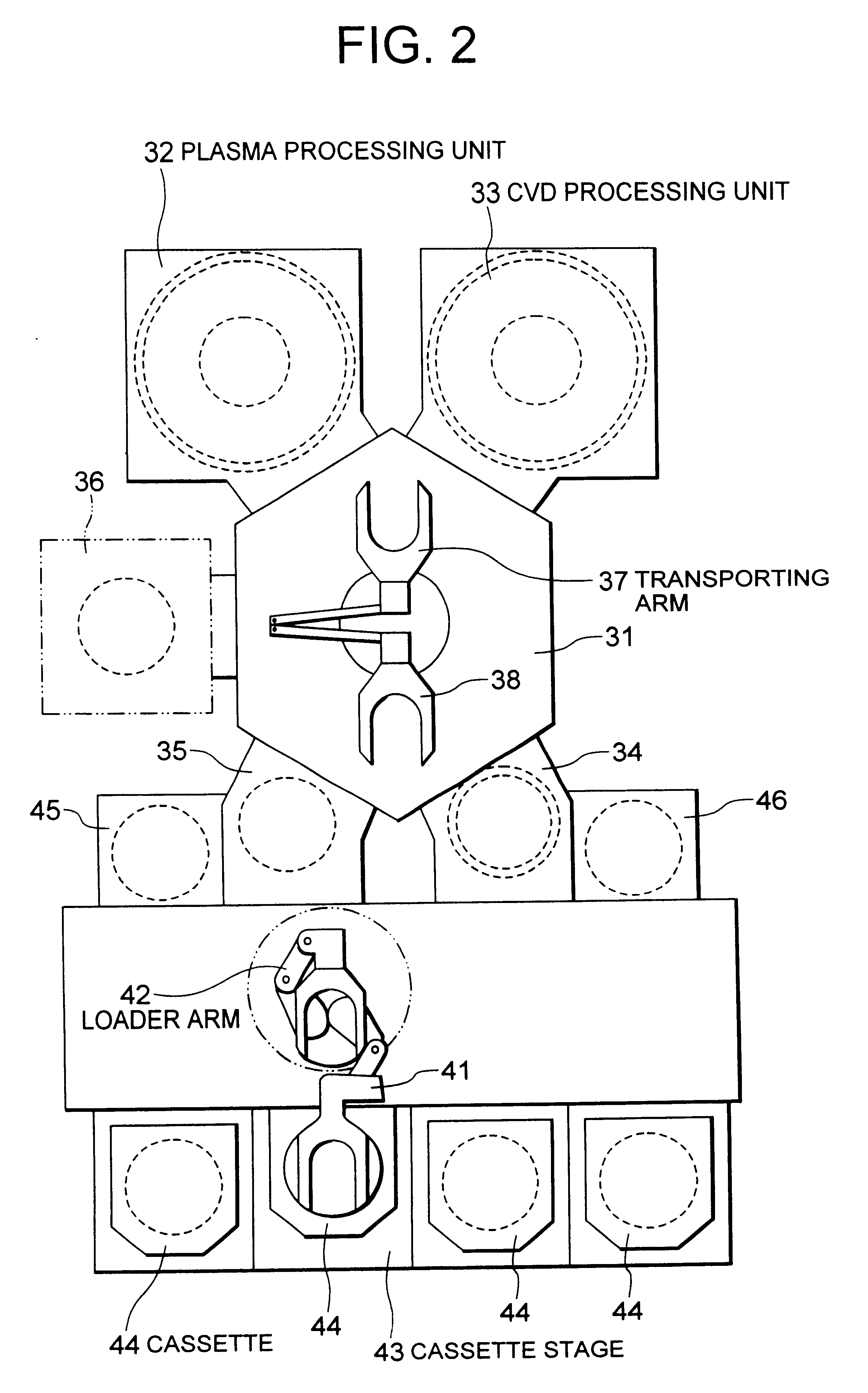

Semiconductor manufacturing method and semiconductor manufacturing apparatus

InactiveUS6399520B1Quality improvementShort timeElectric discharge tubesSemiconductor/solid-state device manufacturingMicrowaveWafering

In an atmosphere of processing gas, on a wafer W consisting mainly of silicon, through a planar-array antenna RLSA 60 having a plurality of slits, microwaves are irradiated to generate plasma containing oxygen, or nitrogen, or oxygen and nitrogen and to implement therewith on the surface of the wafer W direct oxidizing, nitriding, or oxy-nitriding to deposit an insulator film 2 of a thickness of 1 nm or less in terms of oxide film. A manufacturing method and apparatus of semiconductors that can successfully regulate film quality of the interface between a silicon substrate and a SiN film and can form SiN film of high quality in a short time can be obtained.

Owner:TOKYO ELECTRON LTD

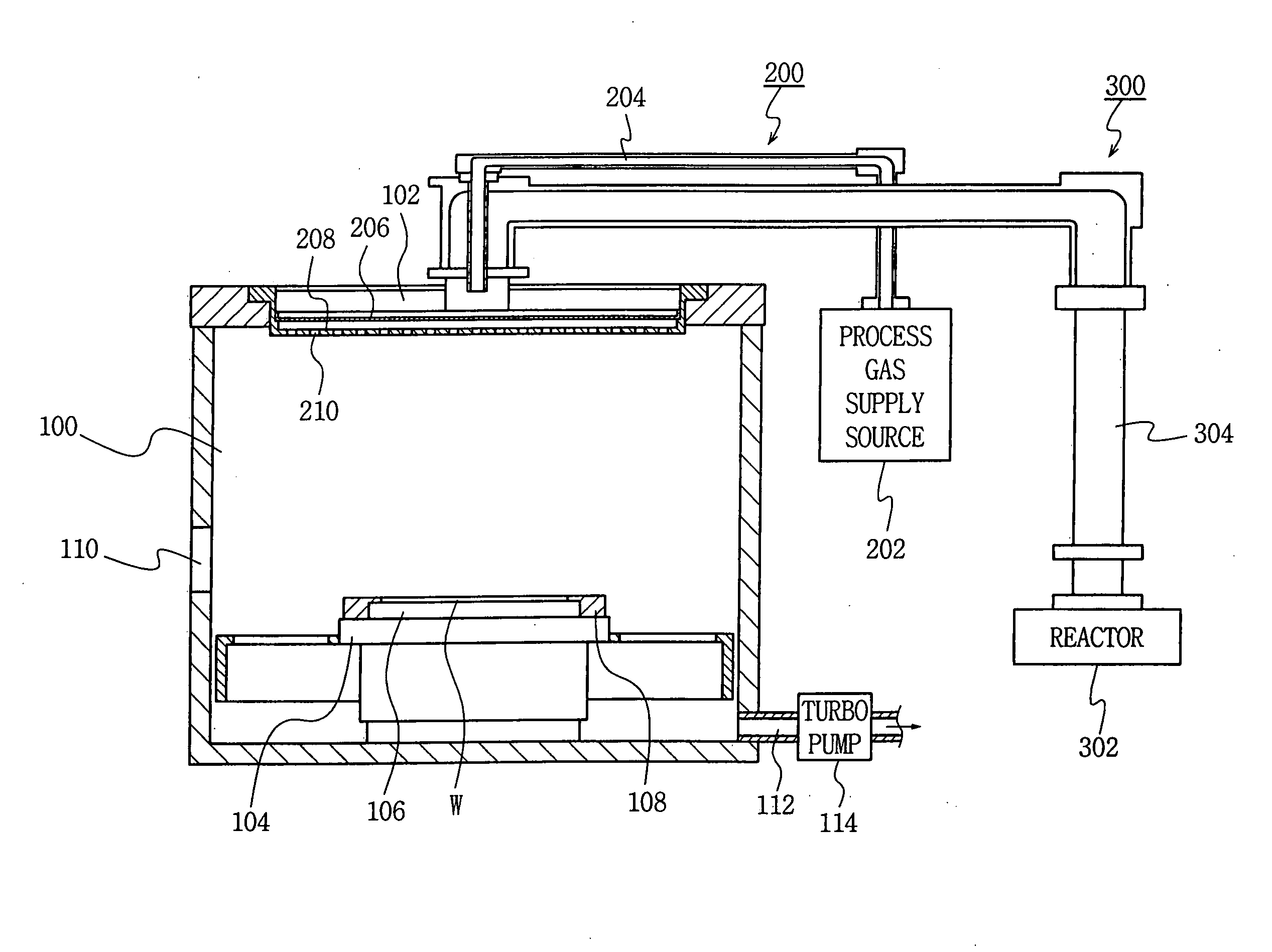

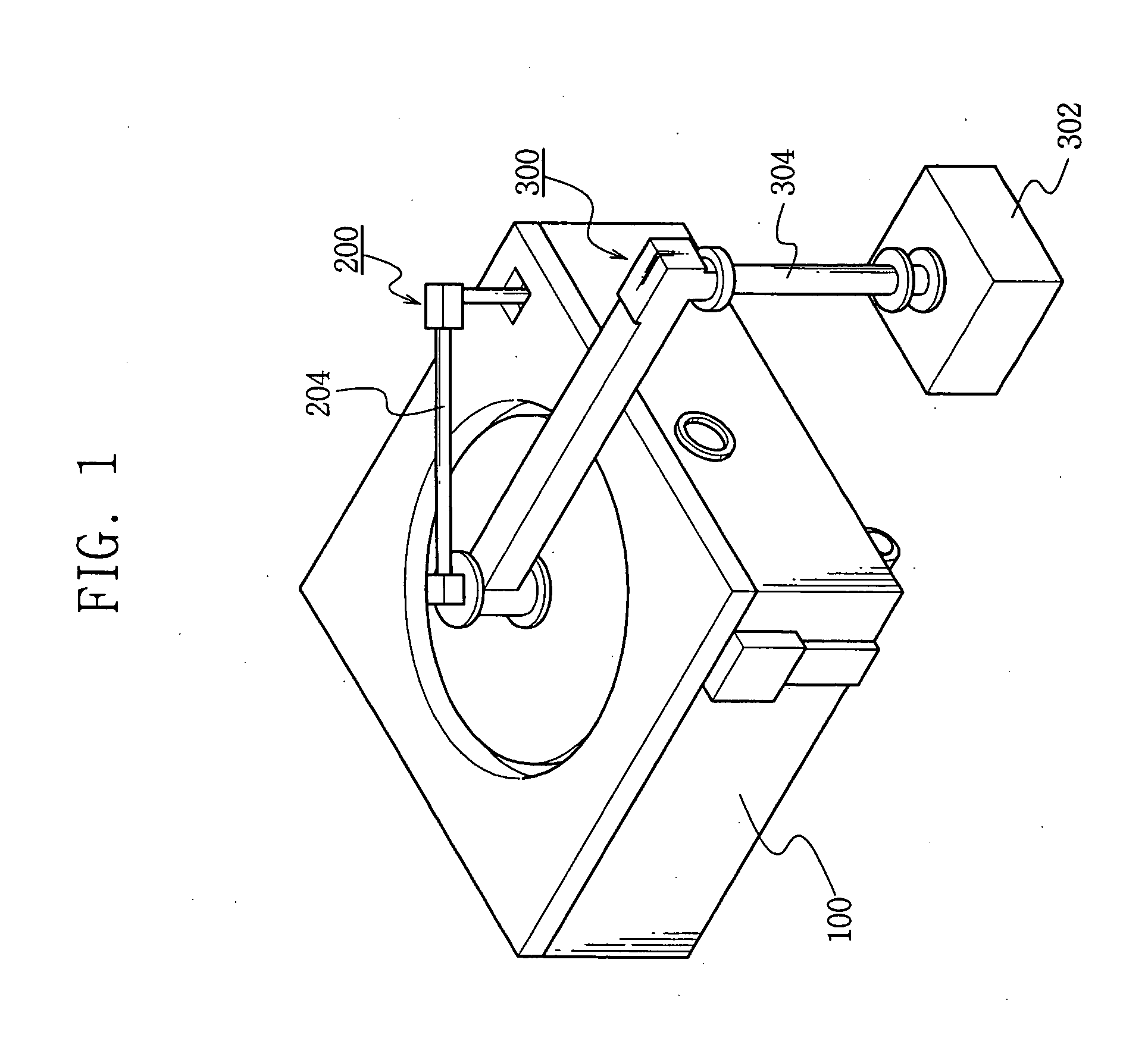

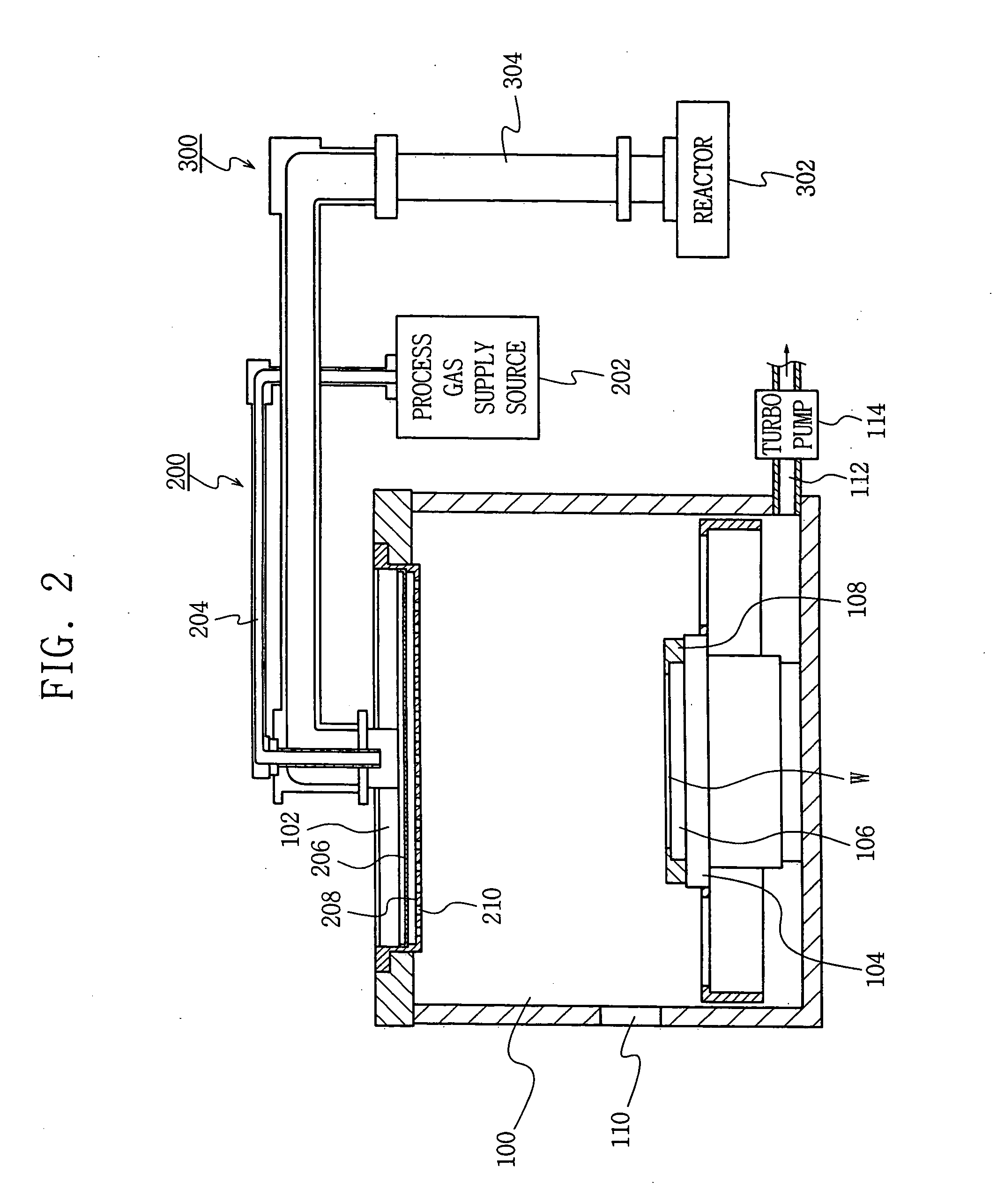

Semiconductor device manufacturing apparatus and method of using the same

InactiveUS20070266946A1Short amount of timeElectric discharge tubesChemical vapor deposition coatingPlasmonic waveguideRemote plasma

A semiconductor device manufacturing apparatus and a method for use in the manufacturing of such devices minimize the amount of particles which accumulate in the process chamber of the apparatus and clean the interior of the process chamber with a high degree of effectiveness. The semiconductor device manufacturing apparatus has a showerhead located at an upper portion of the process chamber, a plate-like gas diffuser disposed in the showerhead, and both a fluid supply line and a plasma waveguide connected to the showerhead. After a substrate is processed in the process chamber using process gas delivered to the showerhead through the fluid supply line, plasma is supplied into the upper portion of the process chamber from a remote plasma reactor via the plasma waveguide.

Owner:SAMSUNG ELECTRONICS CO LTD

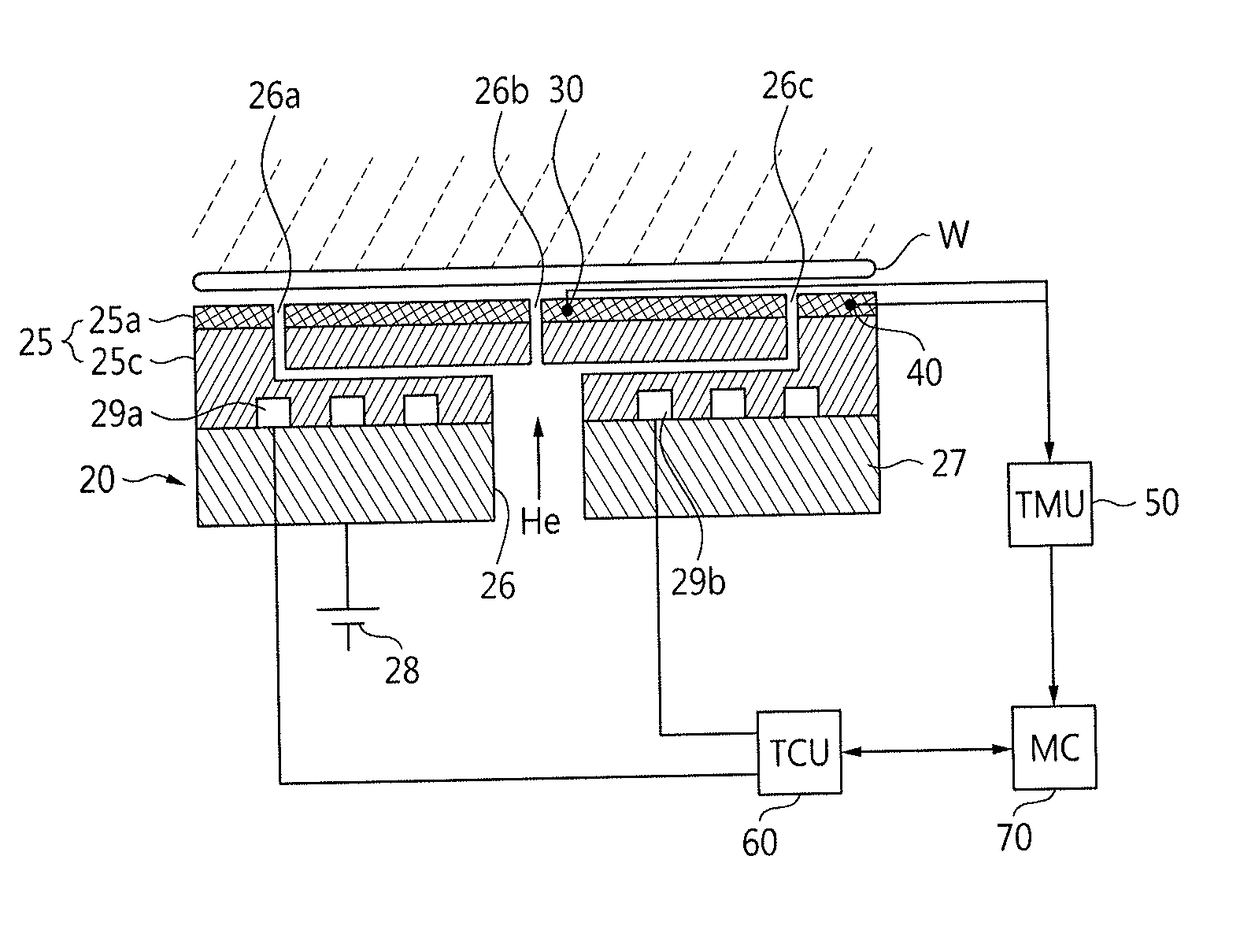

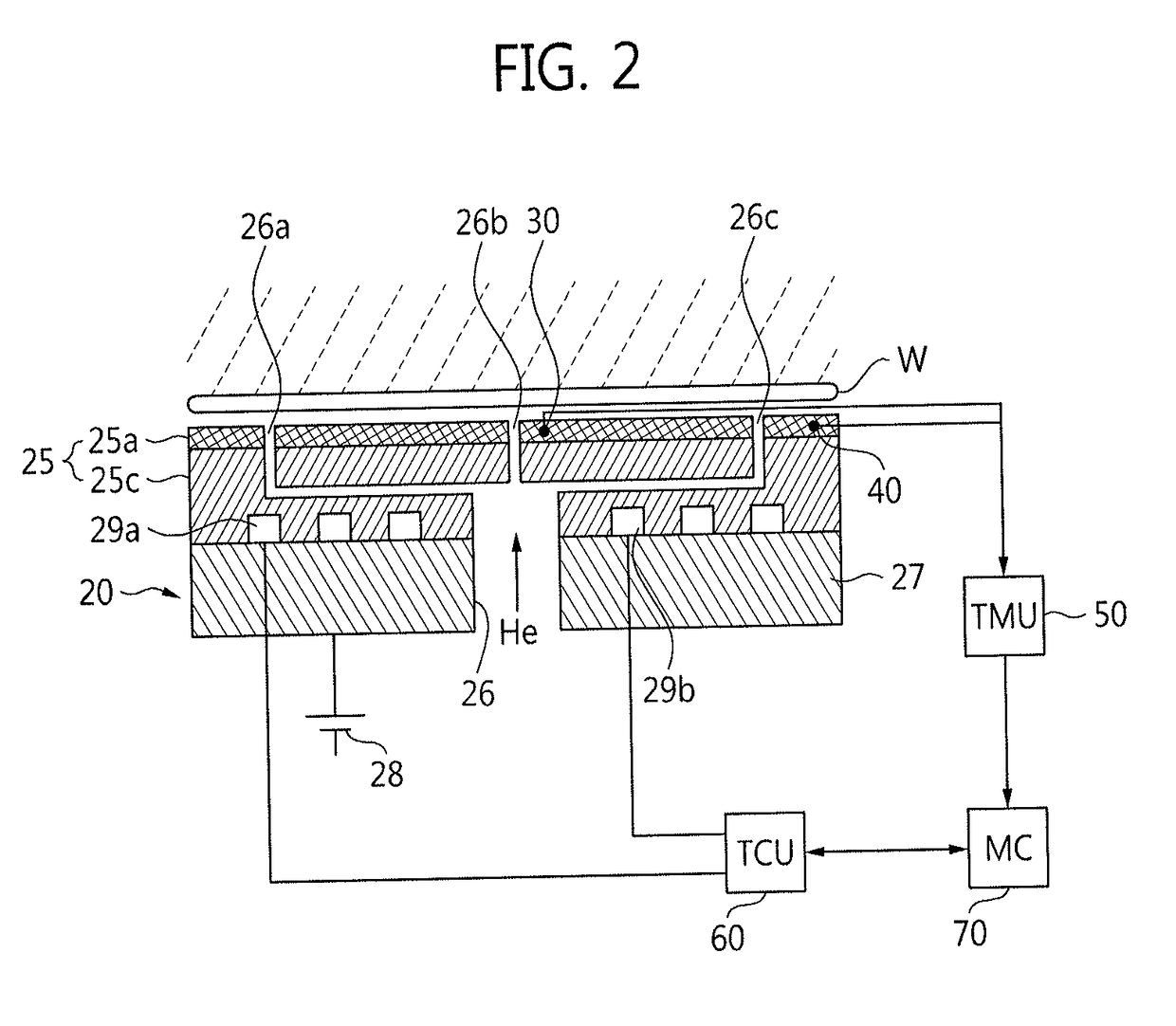

Electrostatic chuck assembly, semiconductor manufacturing apparatus having the same, and method of measuring temperature of electrostatic chuck

ActiveUS9812372B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingManufactured apparatusSemiconductor

An electrostatic chuck assembly includes a reference temperature sensor, a measurement zone temperature sensor, and a measurement zone temperature calculator. The reference temperature sensor measures a reference temperature of the electrostatic chuck. The measurement zone temperature sensor is spaced from the reference temperature sensor on the electrostatic chuck and senses temperature signals of a plurality measurement zones of the electrostatic chuck. The measurement zone temperature calculator calculates a temperature of each of the measurement zones by setting a measurement range within a temperature range, previously determined based on the reference temperature measured by the reference temperature sensor, and measures the temperature signal of each of the measurement zones sensed by the measurement zone temperature sensor within the measurement range.

Owner:SAMSUNG ELECTRONICS CO LTD

Quartz Jig and Semiconductor Manufacturing Apparatus

InactiveUS20080092821A1Easy to storeAvoid exposureSemiconductor/solid-state device manufacturingFrom chemically reactive gasesSusceptorManufactured apparatus

A quartz jig of this invention is such as being provided inside a semiconductor manufacturing apparatus allowing therein growth of an epitaxial layer on a main surface of a semiconductor wafer, capable of supporting a soaking jig which keeps, during epitaxial growth, uniform temperature of a susceptor allowing thereon placement of the semiconductor wafer, and has the top surface thereof aligned almost at the same level of height with the top surface of the susceptor, and is characterized as being composed of transparent quartz at least in a portion thereof brought into contact with the soaking jig. This configuration successfully provides a quartz jig supporting the soaking jig in the semiconductor manufacturing apparatus while suppressing generation of particles, and a semiconductor manufacturing apparatus provided with this sort of quartz jig.

Owner:SHIN-ETSU HANDOTAI CO LTD

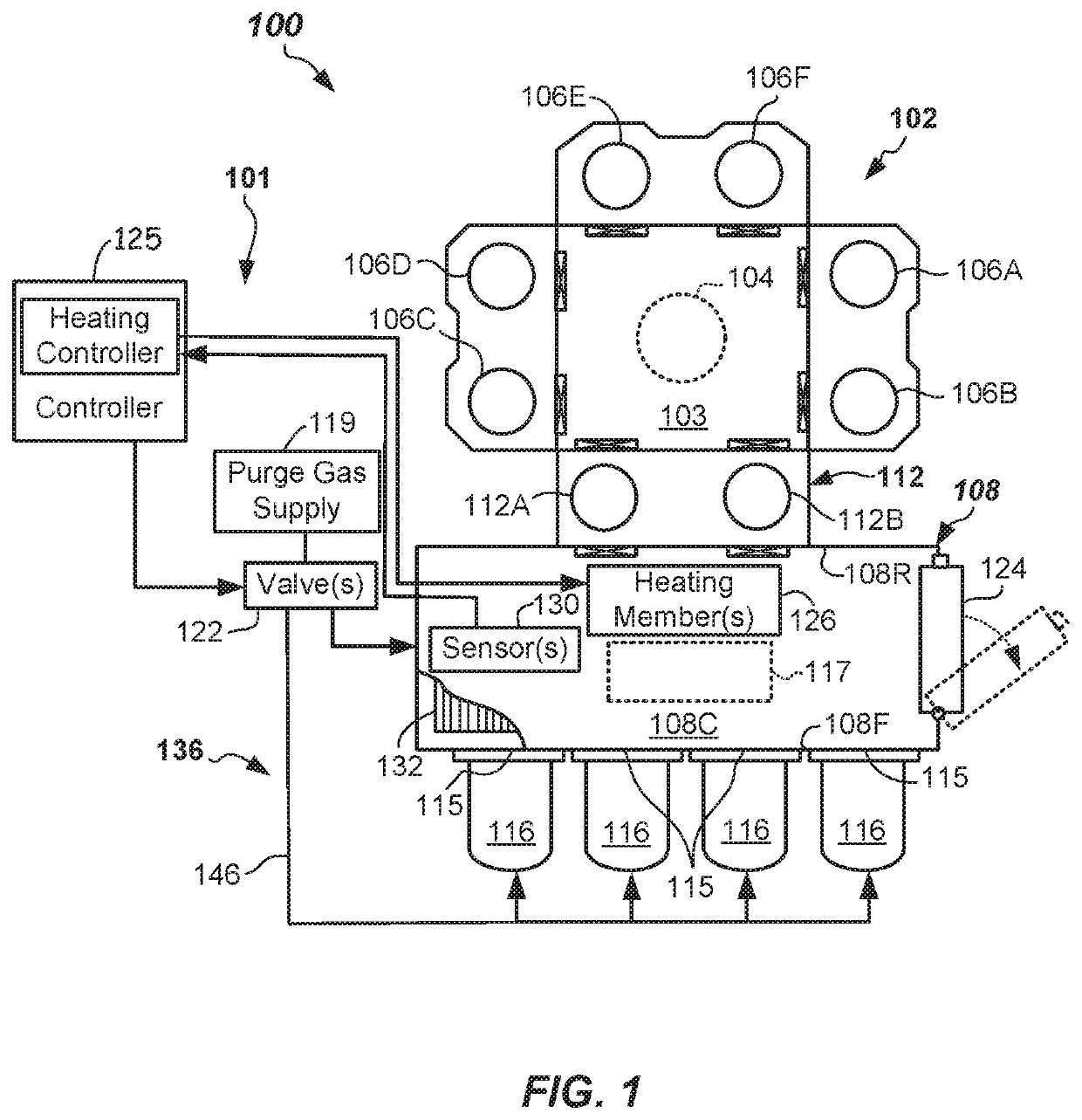

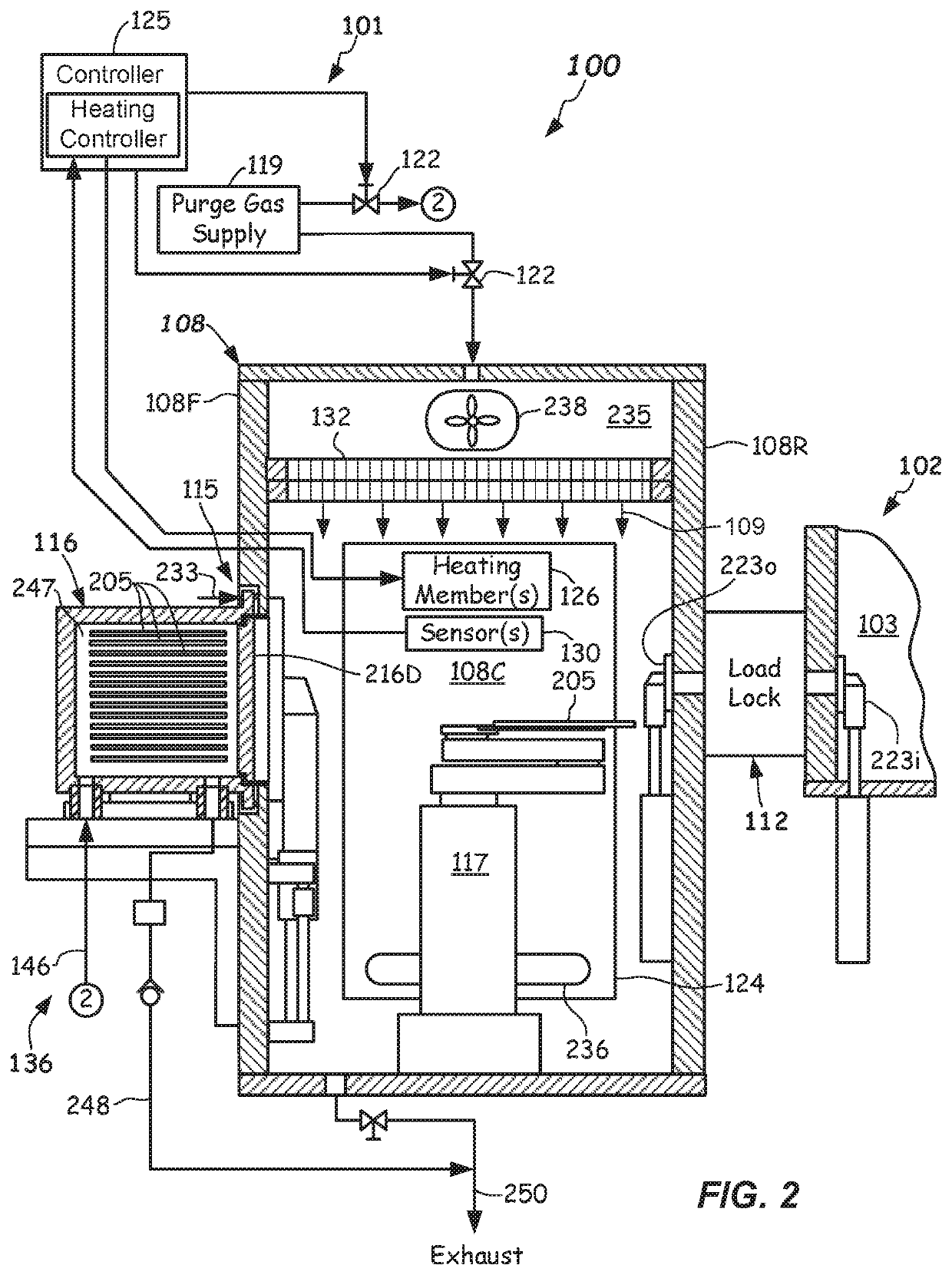

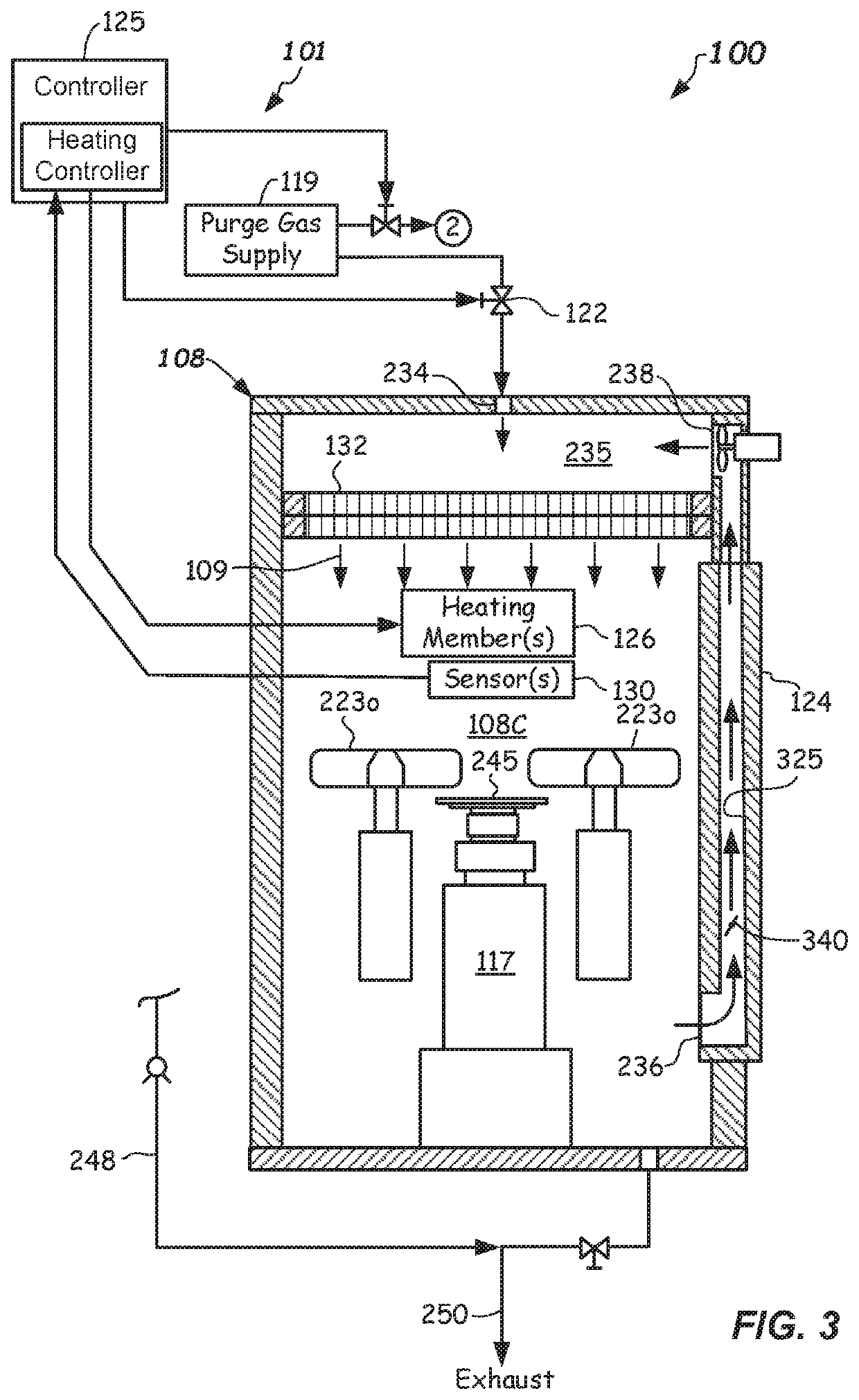

Substrate manufacturing apparatus and methods with factory interface chamber heating

PendingUS20190362989A1Reduce heatGas treatmentDispersed particle filtrationChemical compoundManufactured apparatus

Electronic device processing apparatus including a factory interface chamber purge apparatus with purge gas heating. The factory interface chamber purge apparatus includes one or more heating elements configured to heat the purge gas. In some embodiments, the provision of heated purge gas to the chamber filter assembly can rapidly reduce moisture contamination after the access door is opened for factory interface servicing. In further embodiments, the provision of heated purge gas to the factory interface chamber can aid in desorbing certain chemical compounds from the substrates following processing when a low-humidity environment is provided. Purge control methods and apparatus are described, as are numerous other aspects.

Owner:APPLIED MATERIALS INC

Gas supply unit and semiconductor device manufacturing apparatus using the same

InactiveUS20050016452A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialManufactured apparatus

A semiconductor device manufacturing apparatus is provided. The semiconductor device manufacturing apparatus comprises a furnace having a closed predetermined space for seating a wafer, a loading device located at one side of the furnace to load the wafer on which a prior process may have been performed, a gate valve interposed between the furnace and the loading device to selectively open / close a pathway between the furnace and the loading device, a heater for heating an interior of the furnace, a vacuum pump for maintaining the interior of the furnace with a suitable pressure necessary to the process, a gas reservoir for storing individually various kinds of reaction gases supplied from an exterior of the space, a gas mixing device connected to the gas reservoir to mix the various kinds of reaction gases supplied from the gas reservoir with an even mixing ratio, at least two mixed gases supply pipes connected to the gas mixing device to supply the reaction gases mixed in the gas mixing device to each direction of the furnace, and a mixed gases flow control unit installed at the mixed gases supply pipe to control the flow of the reaction gases supplied through the mixed gases supply pipe.

Owner:SAMSUNG ELECTRONICS CO LTD

Manufacturing apparatus

InactiveUS20060011136A1High definitionIncrease opening ratioVacuum evaporation coatingSputtering coatingManufacturing cost reductionGas phase

It is an object of the present invention to provide a manufacturing apparatus that reduces a manufacturing cost by enhancing efficiency in the use of an EL material and that is provided with a vapor deposition apparatus which is one of manufacturing apparatuses superior in uniformity in forming an EL layer and in throughput in the case of manufacturing a full-color flat panel display using emission colors of red, green, and blue. According to one feature of the invention, a mask having a small opening with respect to a desired vapor deposition region is used, and the mask is moved accurately. Accordingly, a desired vapor deposition region is vapor deposited entirely. In addition, a vapor deposition method is not limited to movement of a mask, and it is preferable that a mask and a substrate move relatively, for example, the substrate may be moved at a μm level with the mask fixed.

Owner:SEMICON ENERGY LAB CO LTD

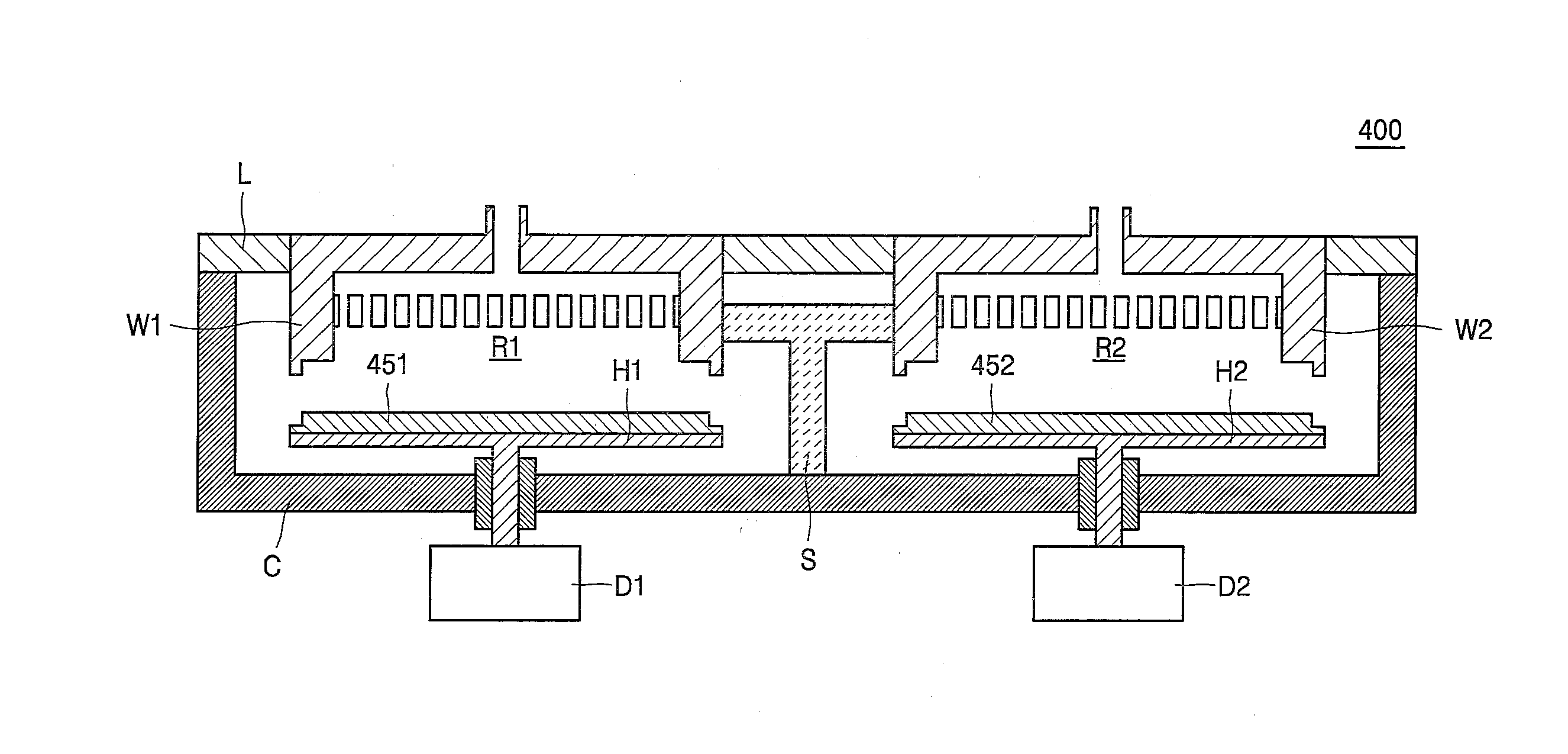

Flat panel display manufacturing apparatus

InactiveUS20050103267A1Simple structureEasy to manufactureElectric discharge tubesSemiconductor/solid-state device manufacturingInterior spaceDisplay device

Disclosed herein is a flat panel display manufacturing apparatus in a predetermined process is performed using plasma generated therein. In such a flat panel display manufacturing apparatus, a process gas is supplied into a chamber in an evenly diffused state to generate even plasma inside a symmetrical interior space of the chamber. Consequently, the flat panel display manufacturing apparatus can appropriately control flow rate of the plasma, thereby being capable of performing even processing on a large-scale substrate. In the flat panel display manufacturing apparatus, a substrate pedestal thereof is provided with a combination of vertical and horizontal shielding members, thereby being entirely protected from attack of the plasma, resulting in an increased life-span.

Owner:ADVANCED DISPLAY PROCESS ENG

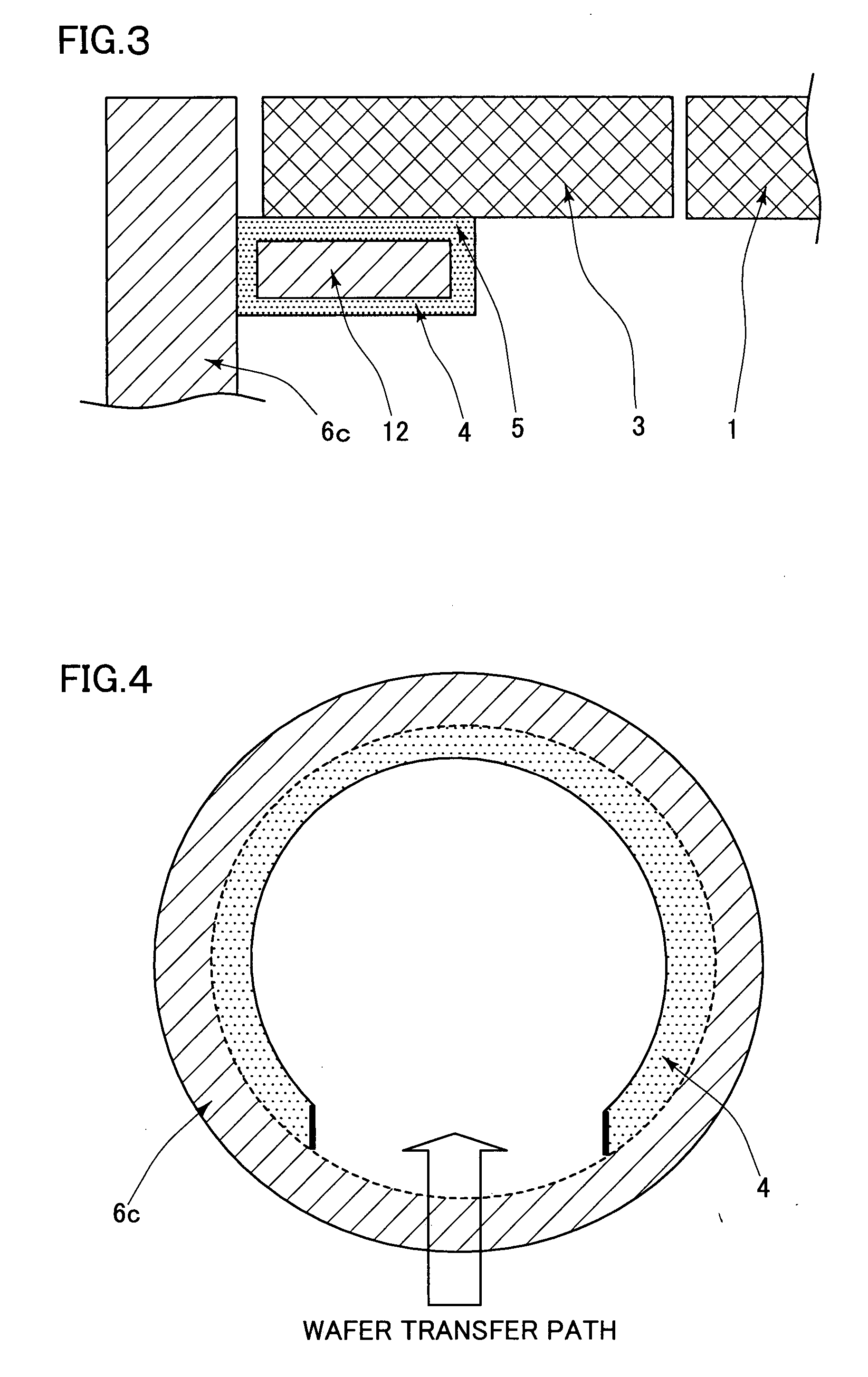

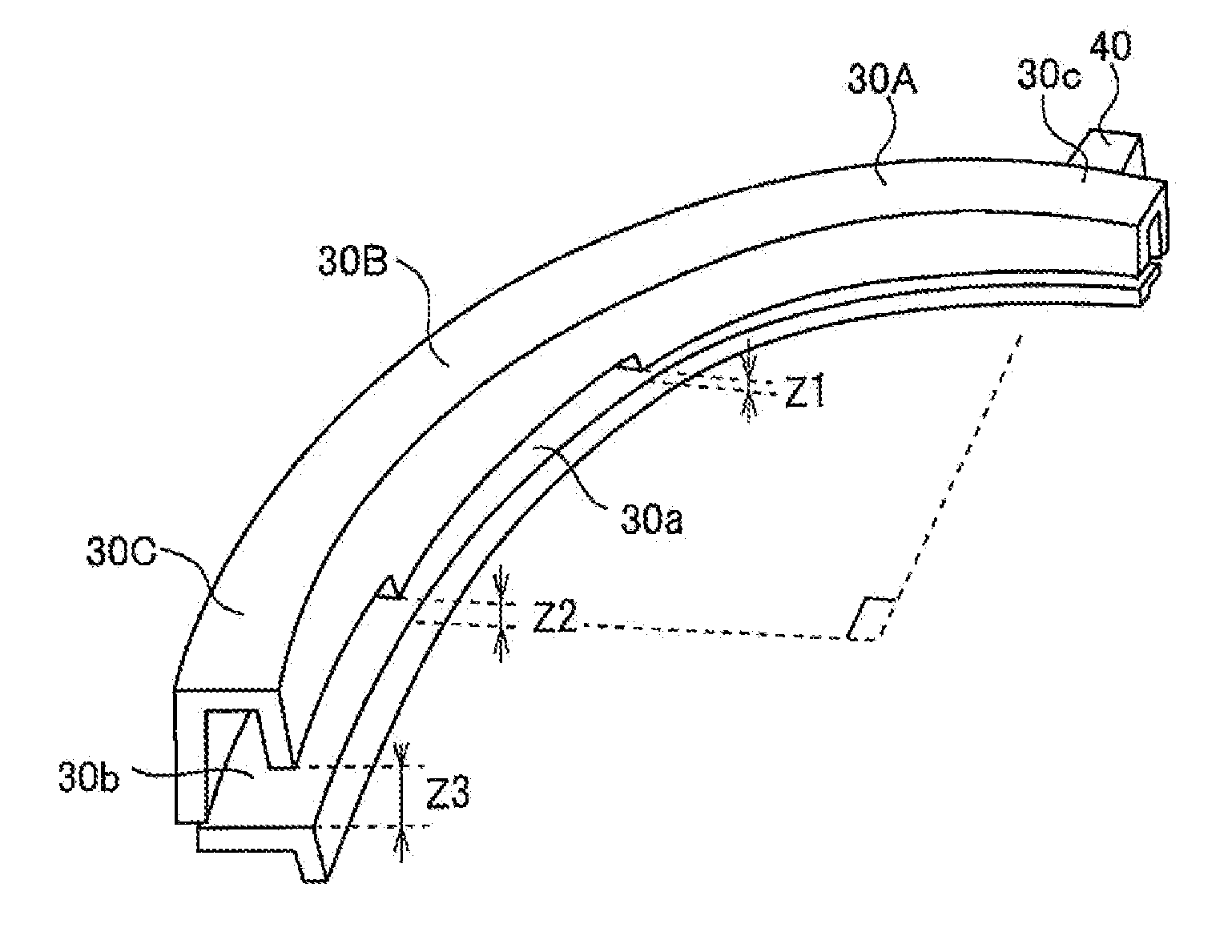

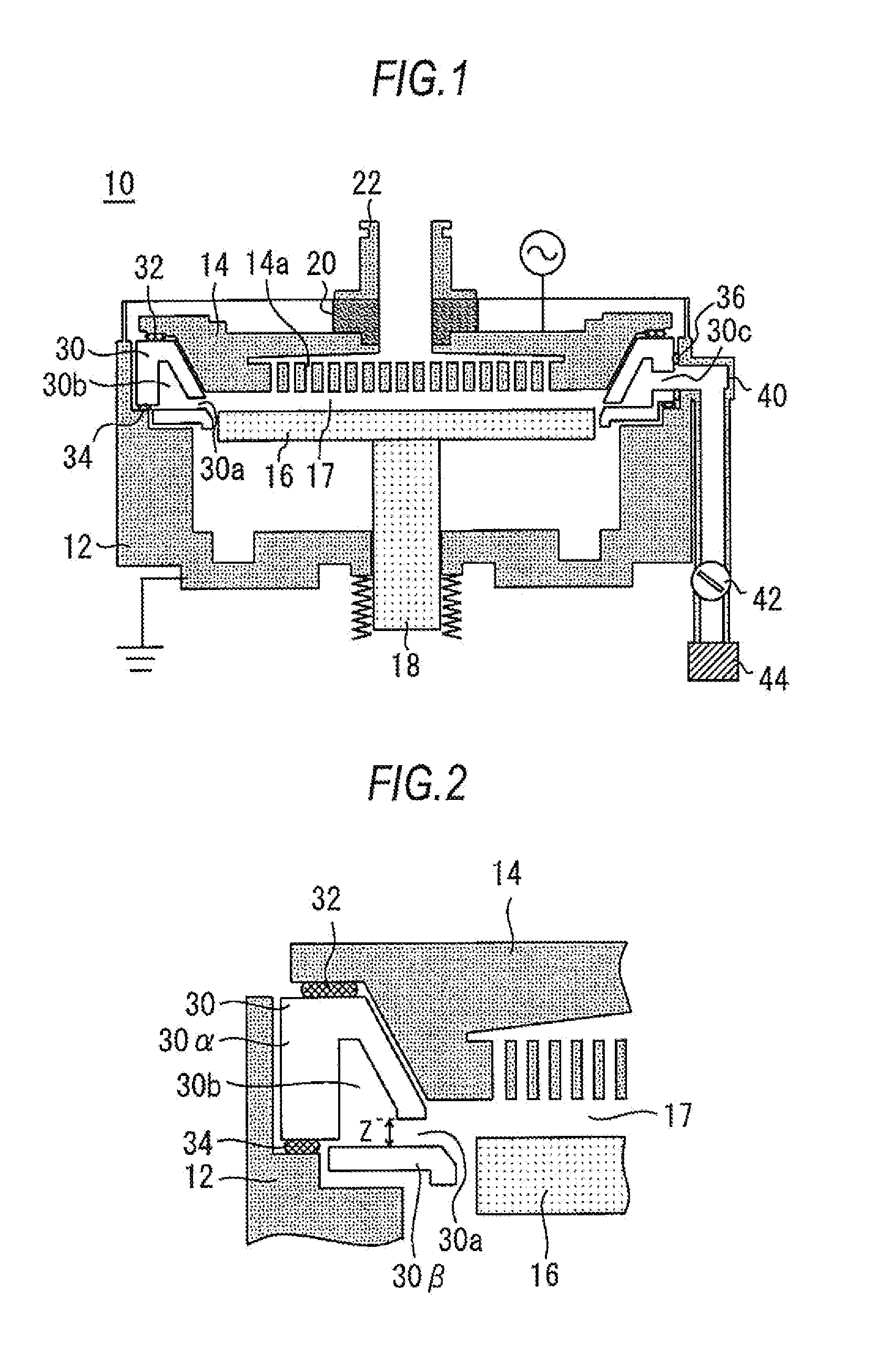

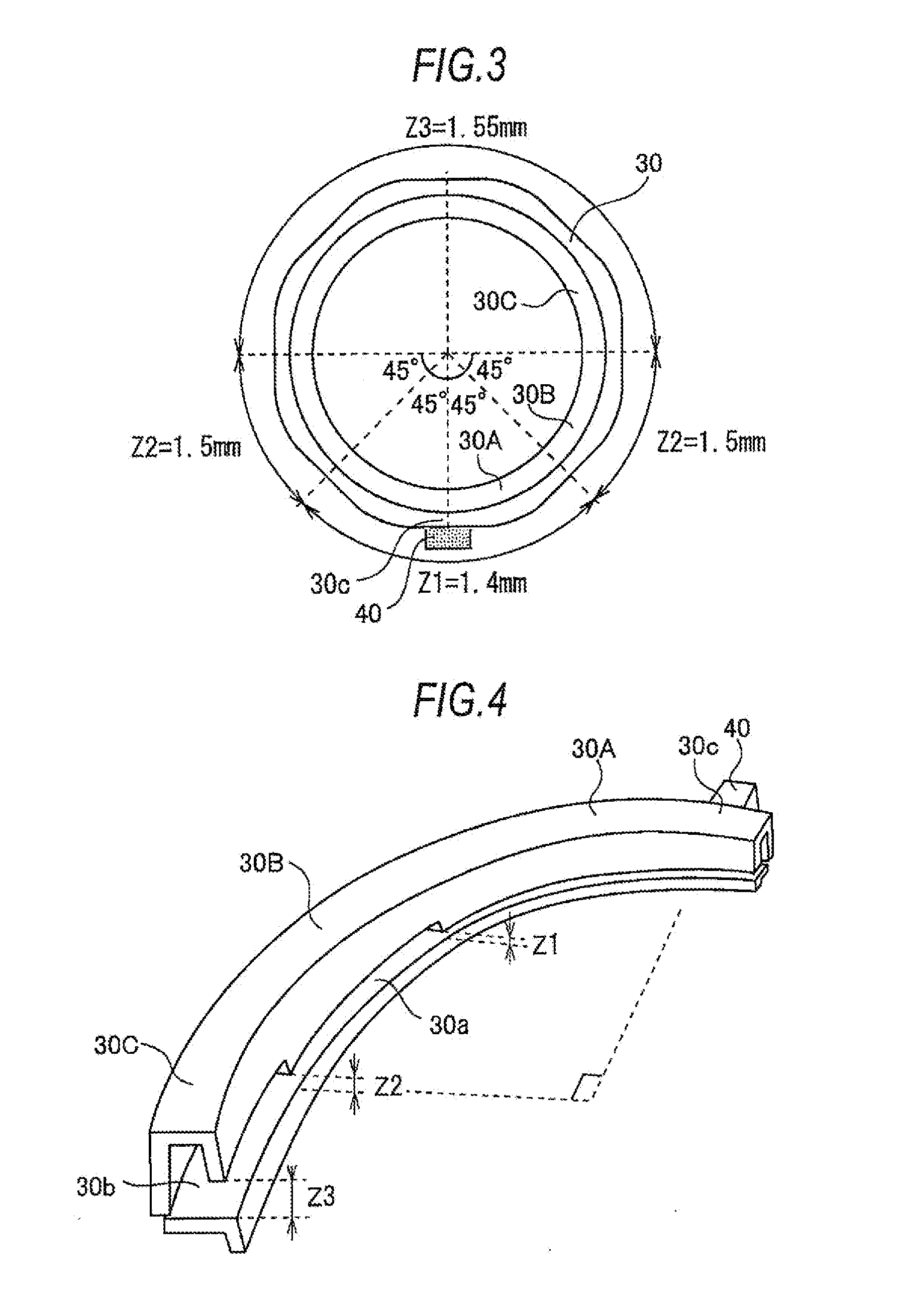

Semiconductor manufacturing apparatus

ActiveUS20160237559A1Improve uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingManufactured apparatusGas passing

A semiconductor manufacturing apparatus includes a stage, and an exhaust duct having an annular passage surrounding a processing space over the stage, an annular slit through which a gas supplied to the processing space is led into the annular passage, and an exhaust port through which the gas in the annular passage is discharged to the outside, wherein the opening-area percentage of the slit is increased with increase in distance from the exhaust port.

Owner:ASM IP HLDG BV

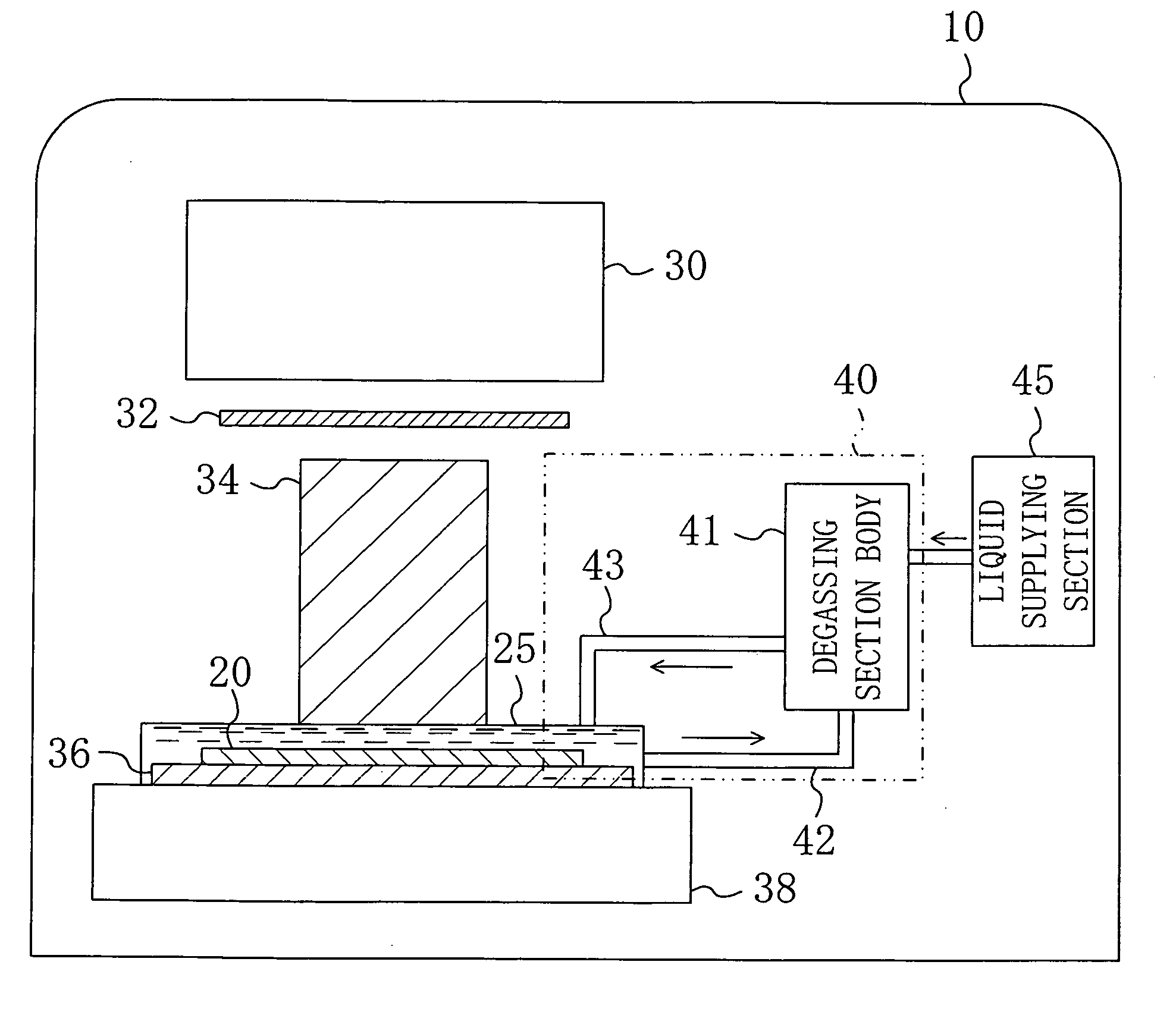

Semiconductor manufacturing apparatus and pattern formation method

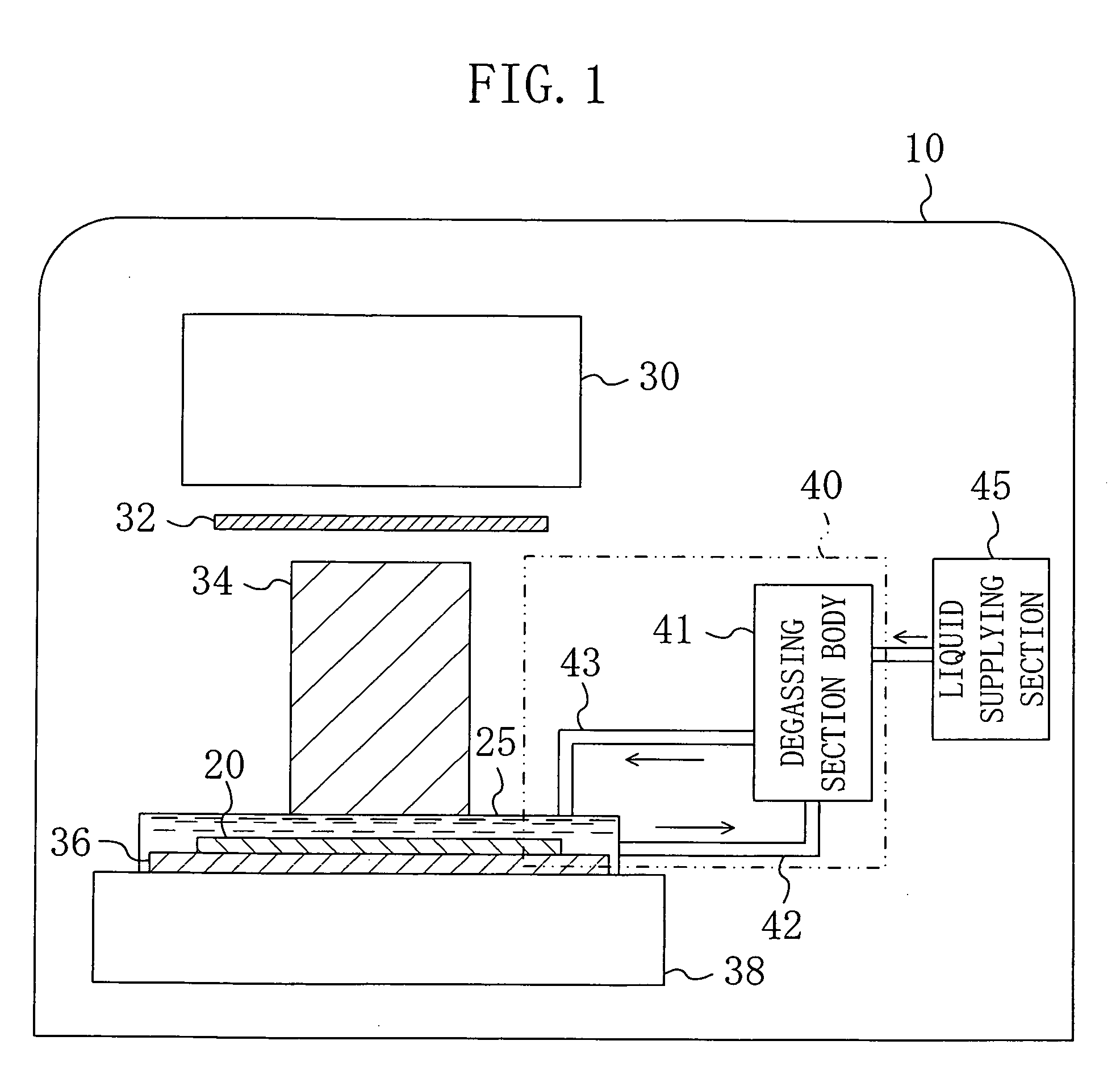

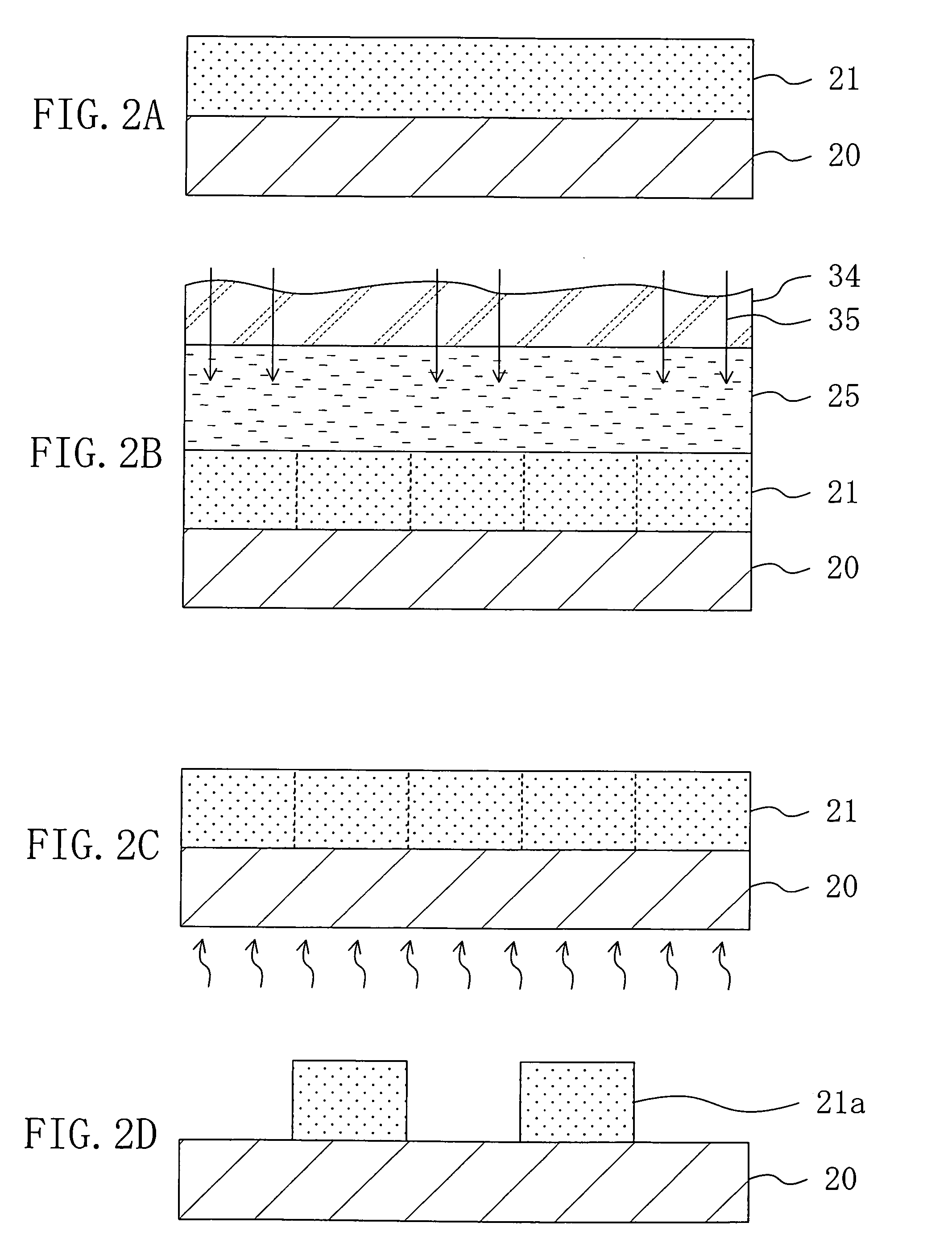

InactiveUS20050106512A1Good body shapeAvoid focusPhotosensitive materialsSemiconductor/solid-state device manufacturingResistManufactured apparatus

A semiconductor manufacturing apparatus includes a liquid supplying section for supplying a liquid onto a stage for holding a wafer on which a resist film is formed; an exposing section for irradiating the resist film with exposing light through a mask with the liquid provided on the resist film; and a removing part for removing, from the liquid, a gas included in the liquid. Thus, the liquid from which the gas has been removed is provided on the resist film, and therefore, foams included in the liquid or formed during the exposure can be removed. Accordingly, exposure abnormality such as diffraction abnormality can be prevented, resulting in forming a resist pattern in a good shape.

Owner:RPX CORP

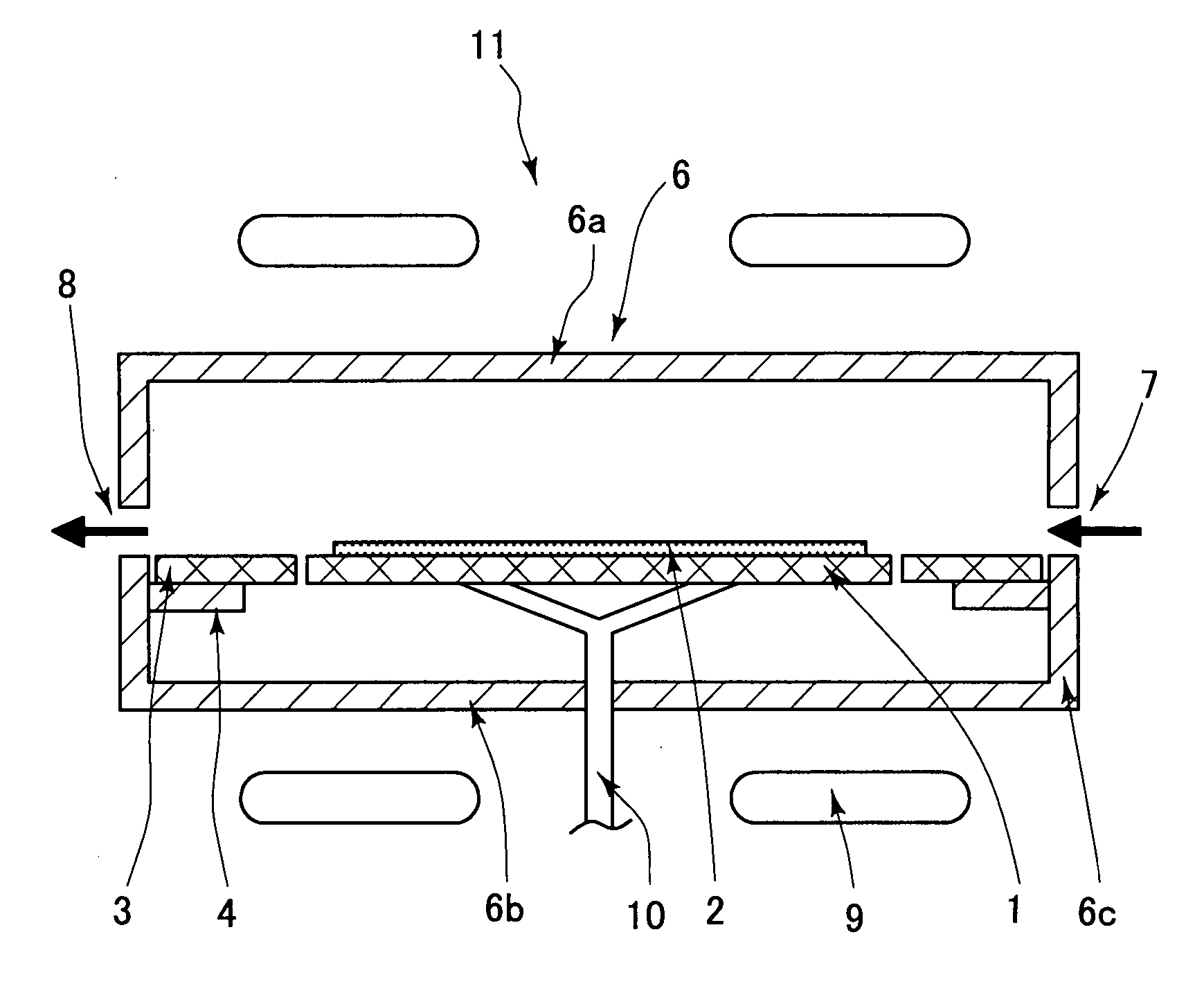

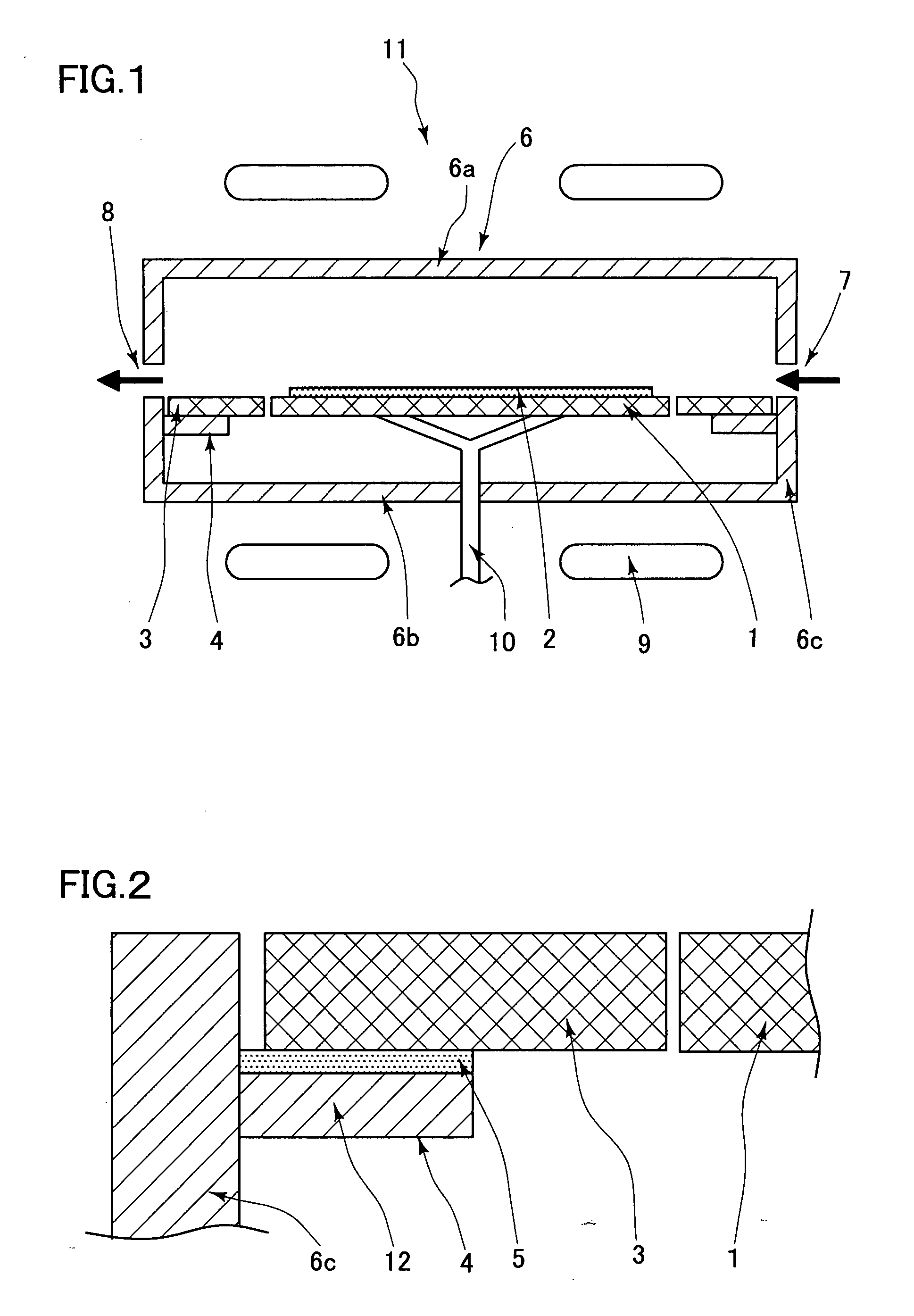

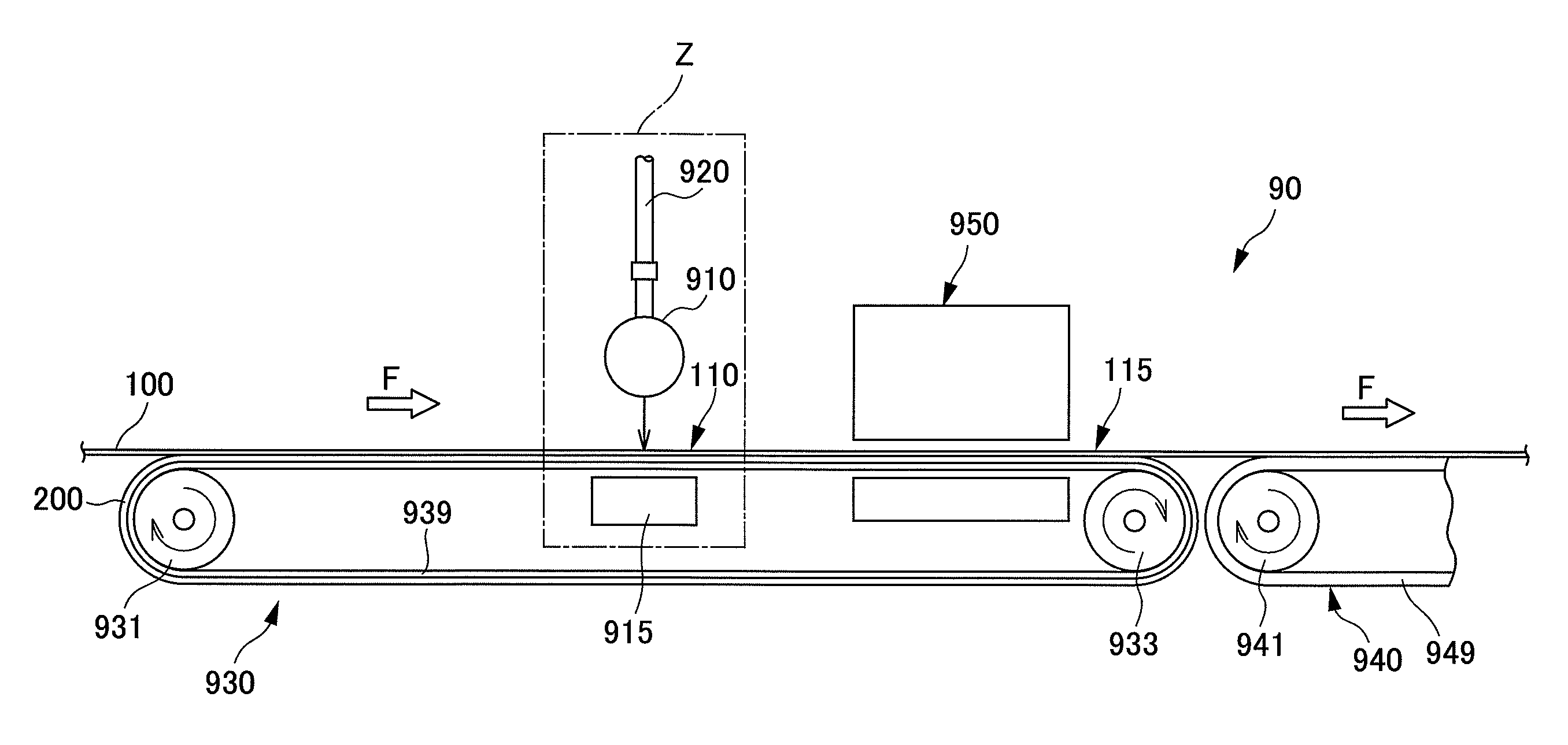

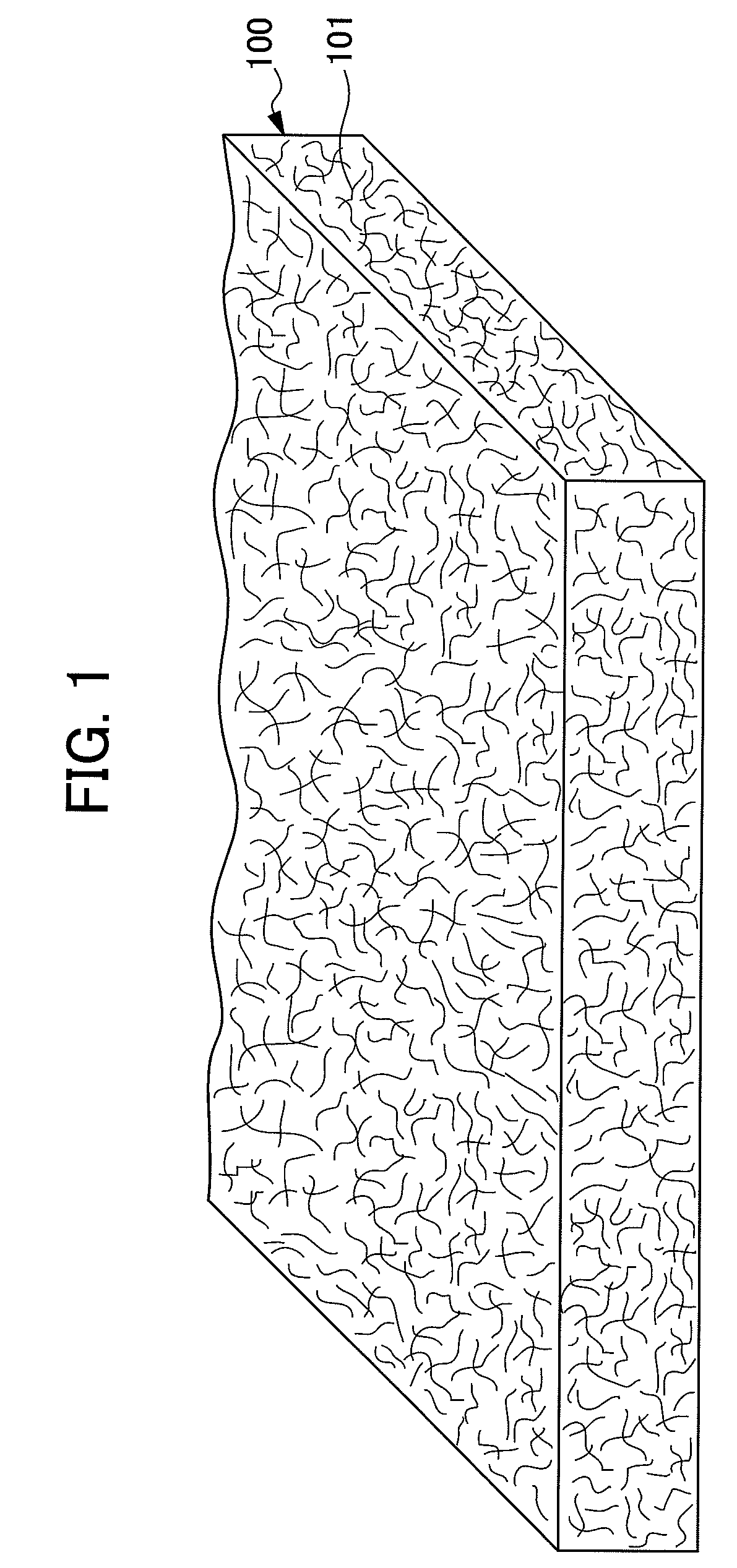

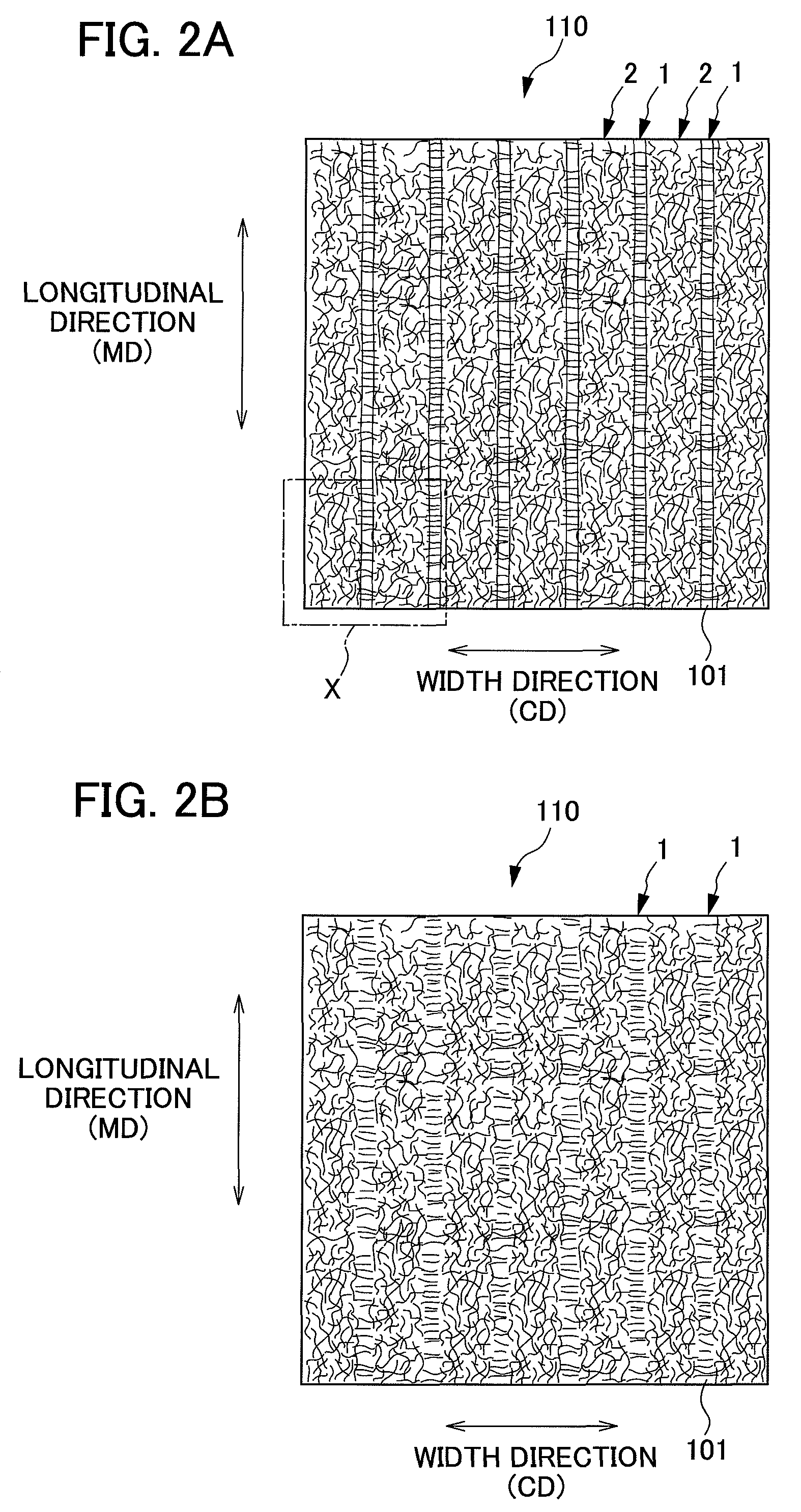

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

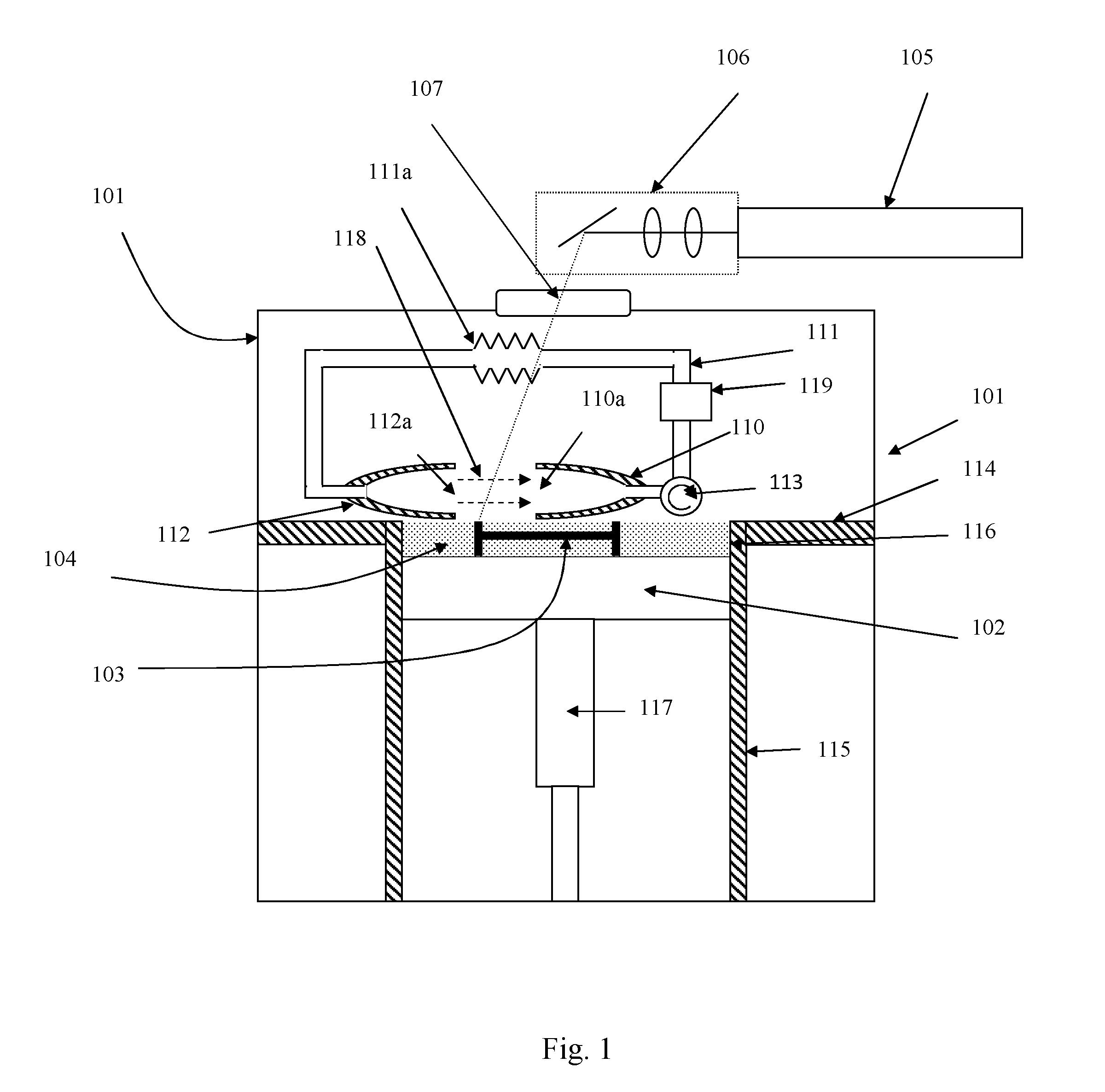

Additive manufacturing apparatus and method

ActiveUS20160136731A1Additive manufacturing apparatusDirt cleaningManufactured apparatusProcess engineering

An additive manufacturing apparatus for building objects by layerwise consolidation of material. The apparatus includes a build chamber containing a working area, a high energy beam for consolidating material deposited in the working area in layers and a flow device for generating a gas flow across at least a part of the working area from a gas inlet to a gas outlet. The gas inlet and gas outlet are arranged to be movable within the build chamber.

Owner:RENISHAW PLC

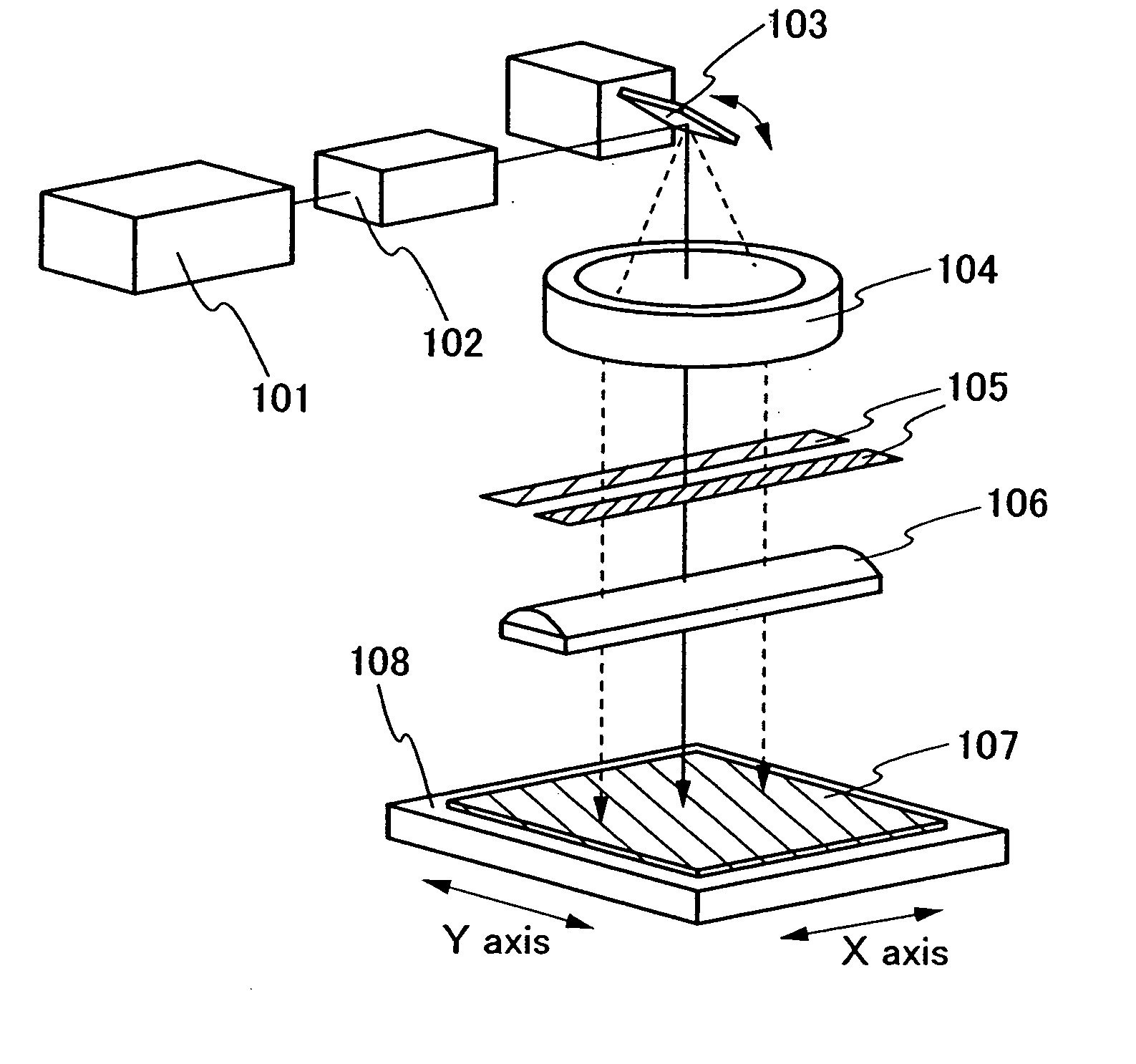

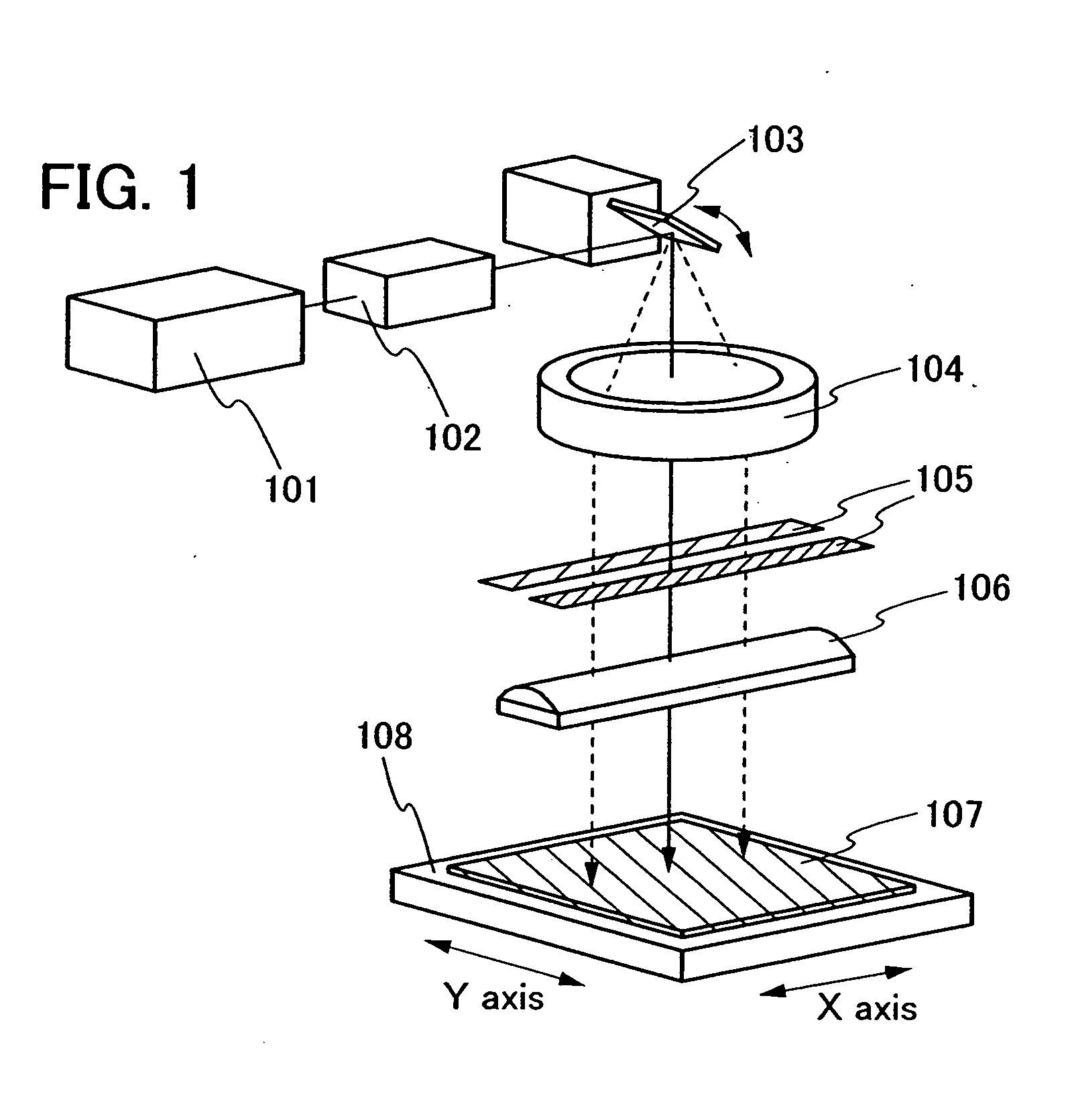

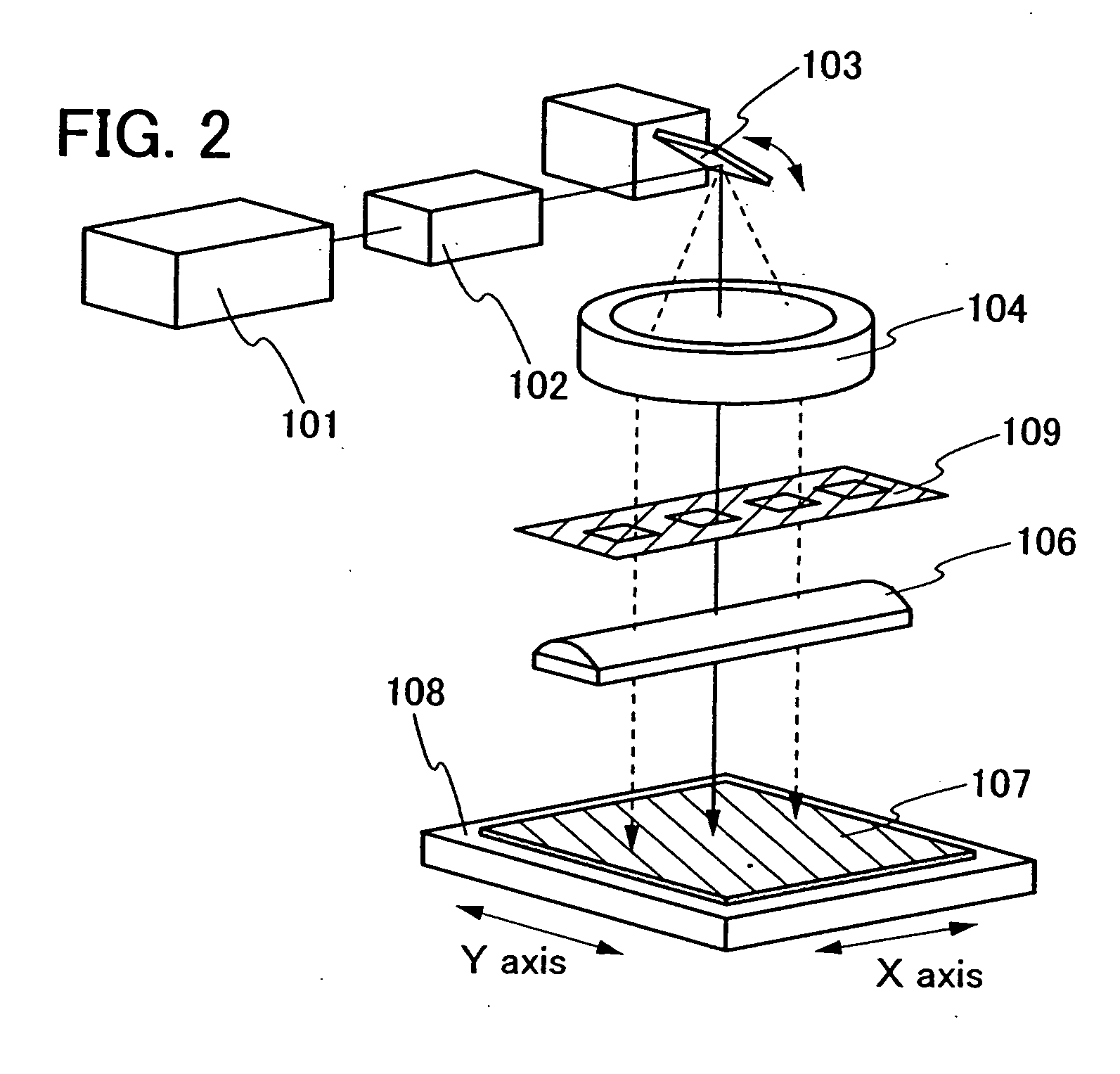

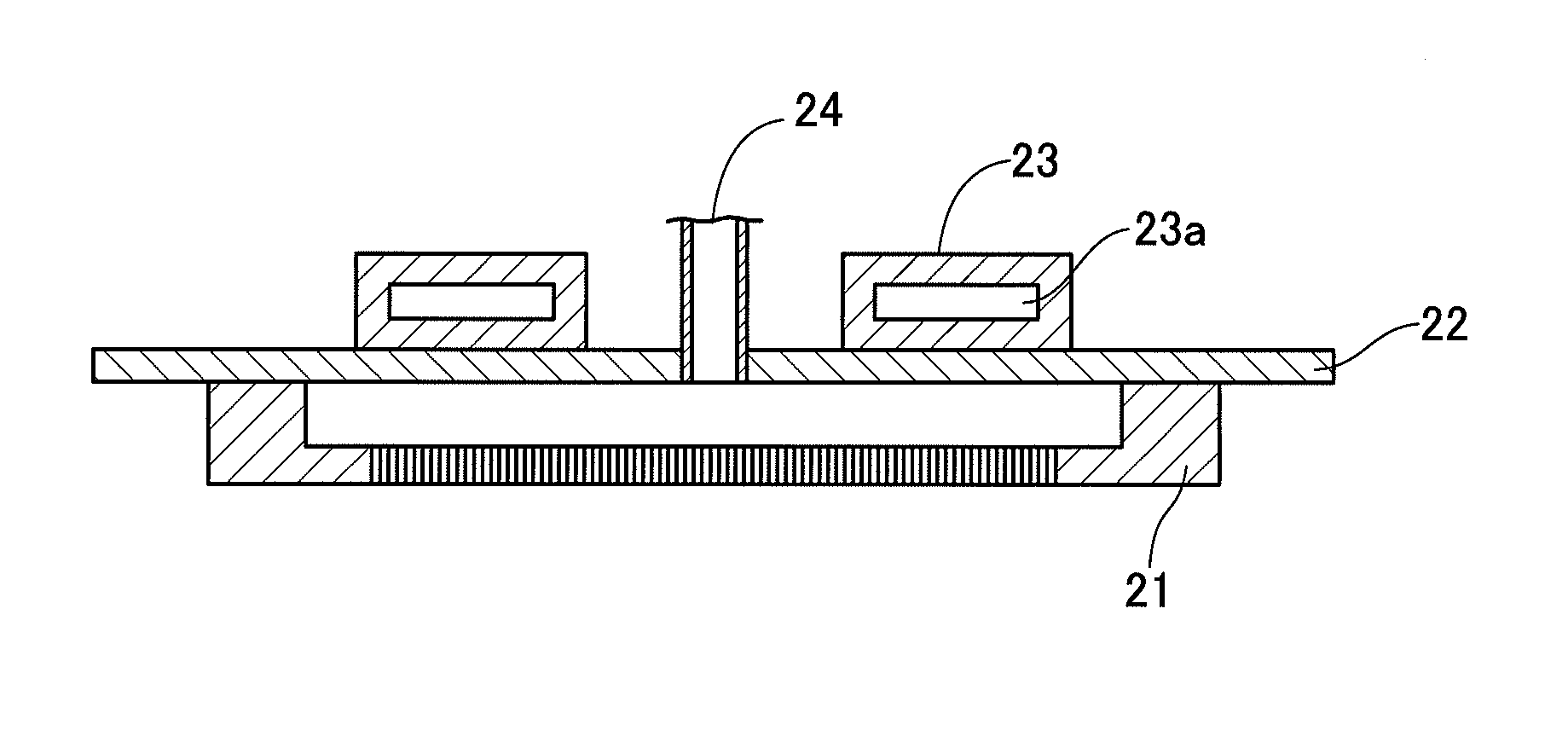

Laser irradiation apparatus, laser irradiation method, and manufacturing method of semiconductor device

ActiveUS20070138151A1Facilitate conductionEasily projectedSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser processingDevice material

To provide a laser irradiation apparatus and a laser irradiation method in which a region formed with microcrystals in a region irradiated with laser beams is decreased by disposing a slit in an optical system using a deflector, and laser processing can be favorably conducted to a semiconductor film. Further to provide a semiconductor manufacturing apparatus using the above-described laser irradiation apparatus and the laser irradiation method. In the optical system, an f-θ lens having an image space telecentric characteristic or a slit the shape of which is changed in accordance with the incidence angle of a laser beam, is used. The slit is disposed between the f-θ lens and an irradiation surface, and an image at a slit opening portion is projected onto the irradiation surface by a projection lens. By the above-described structure, laser irradiation can be uniformly conducted to a whole region scanned with laser beams.

Owner:SEMICON ENERGY LAB CO LTD

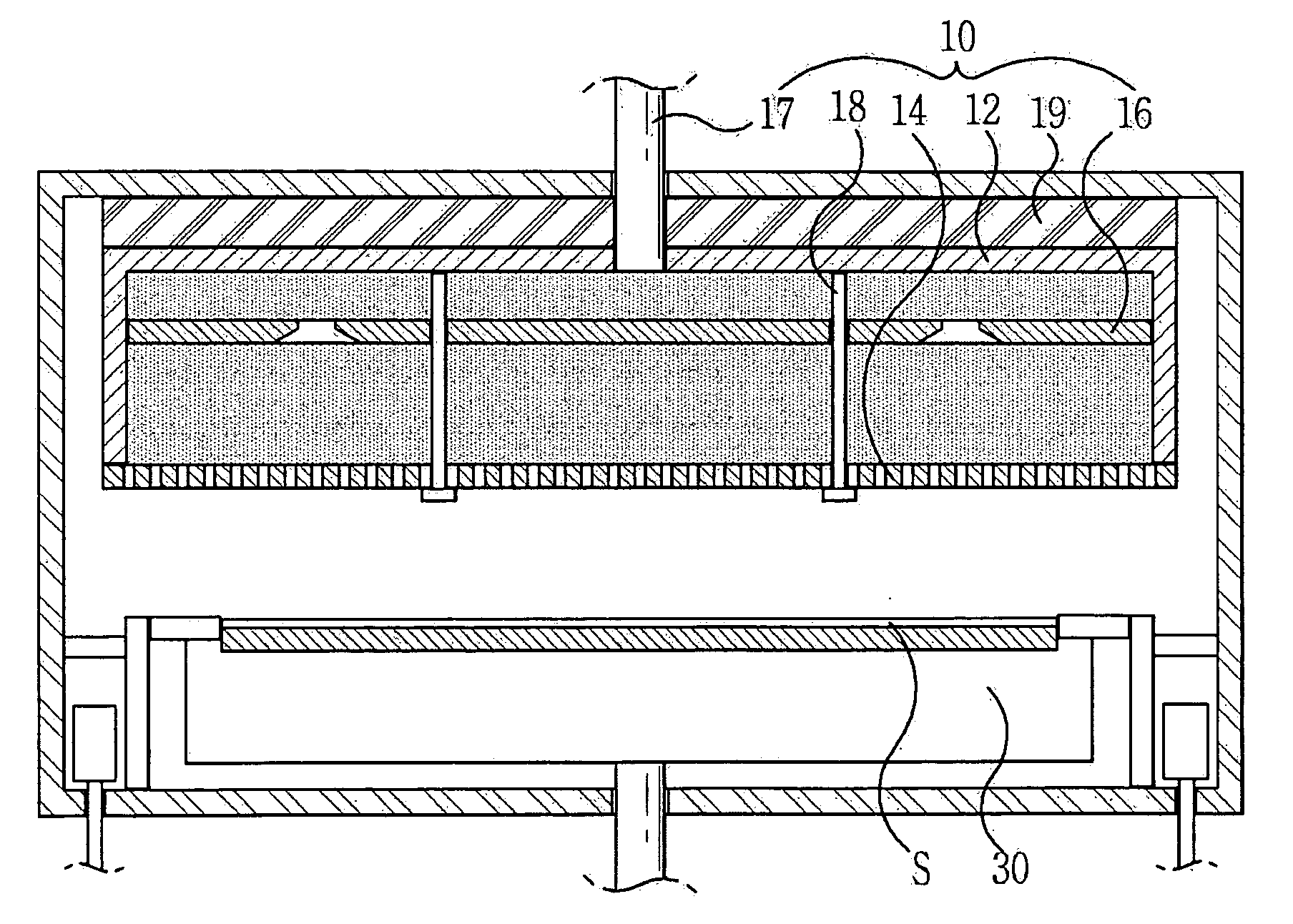

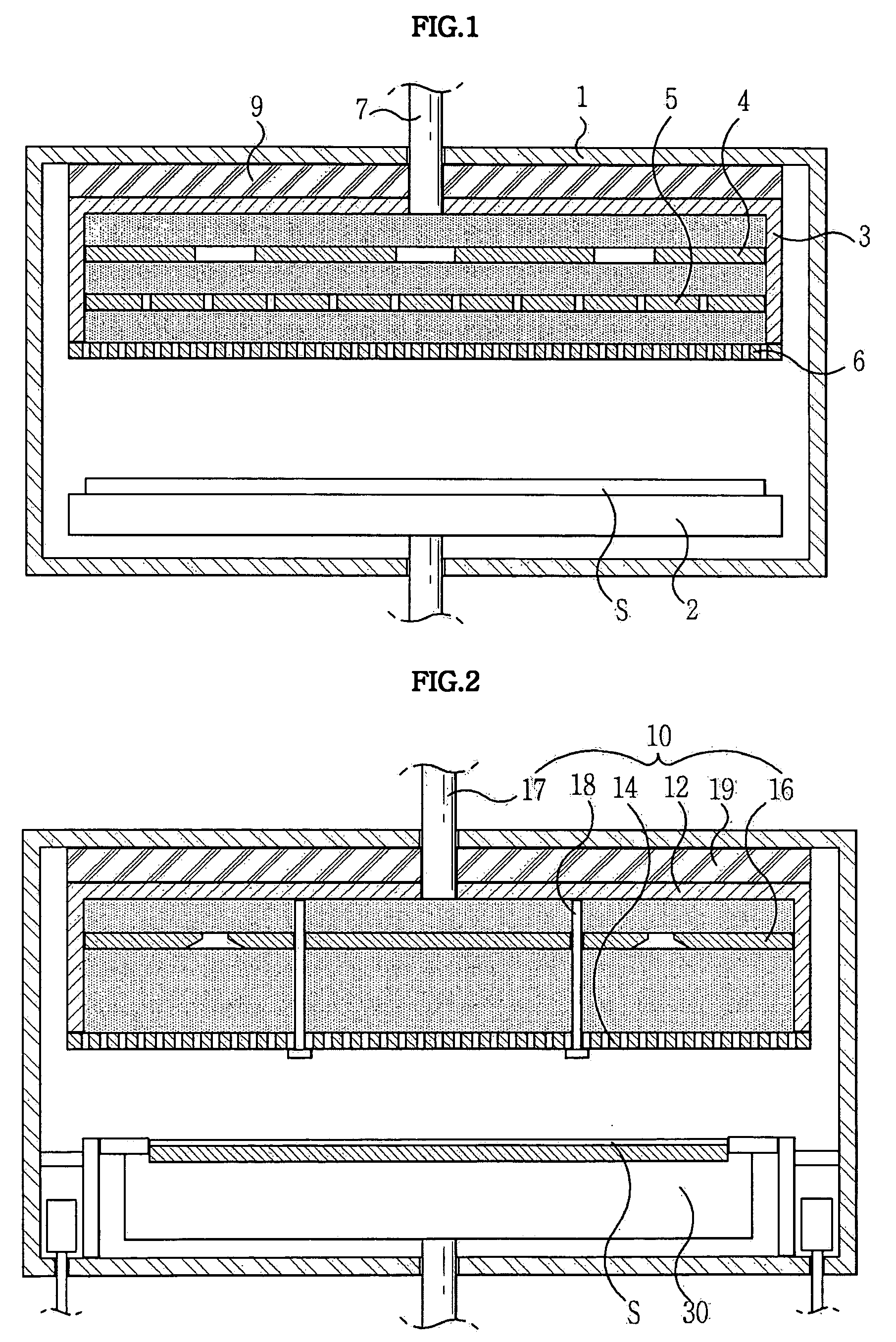

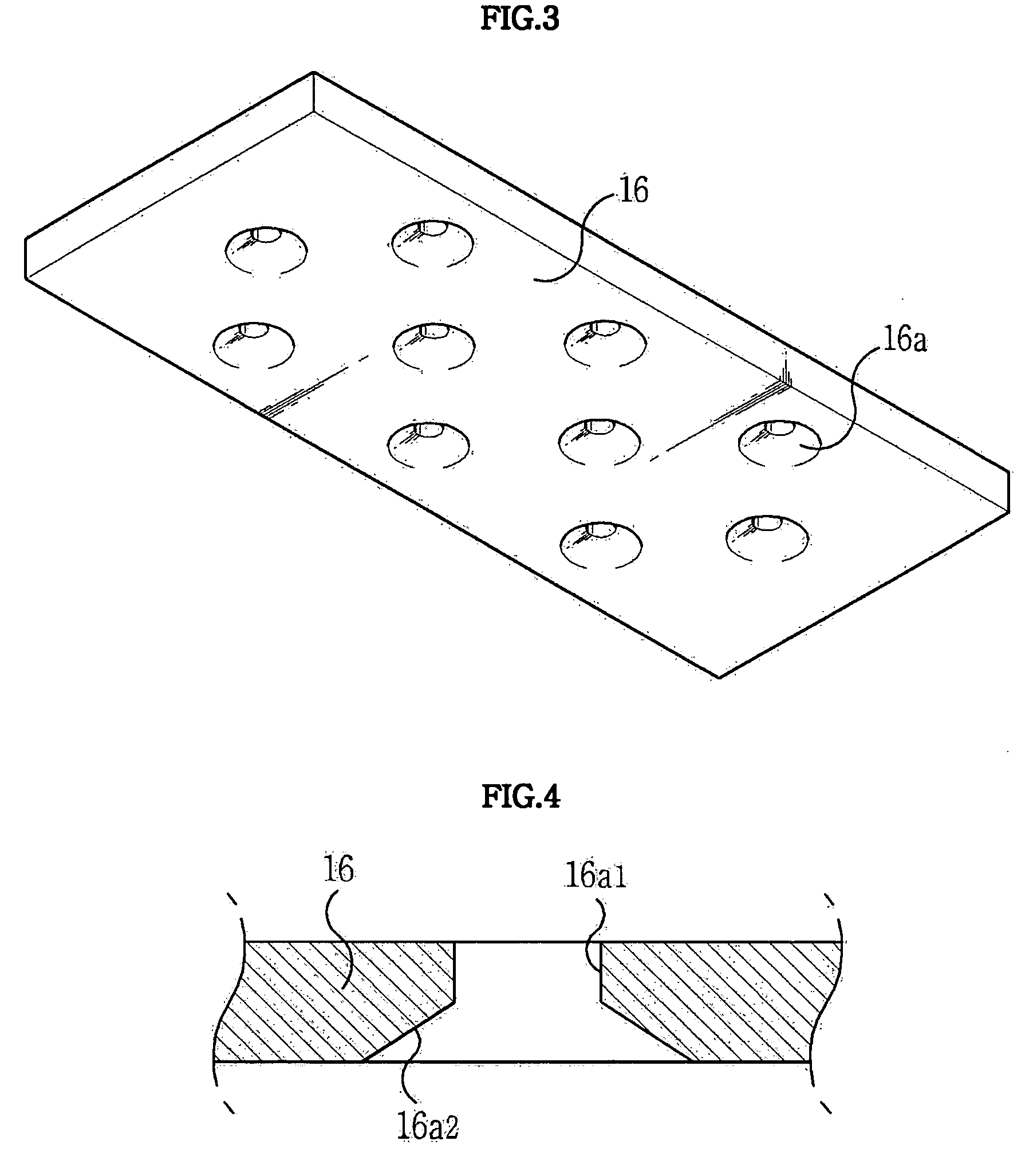

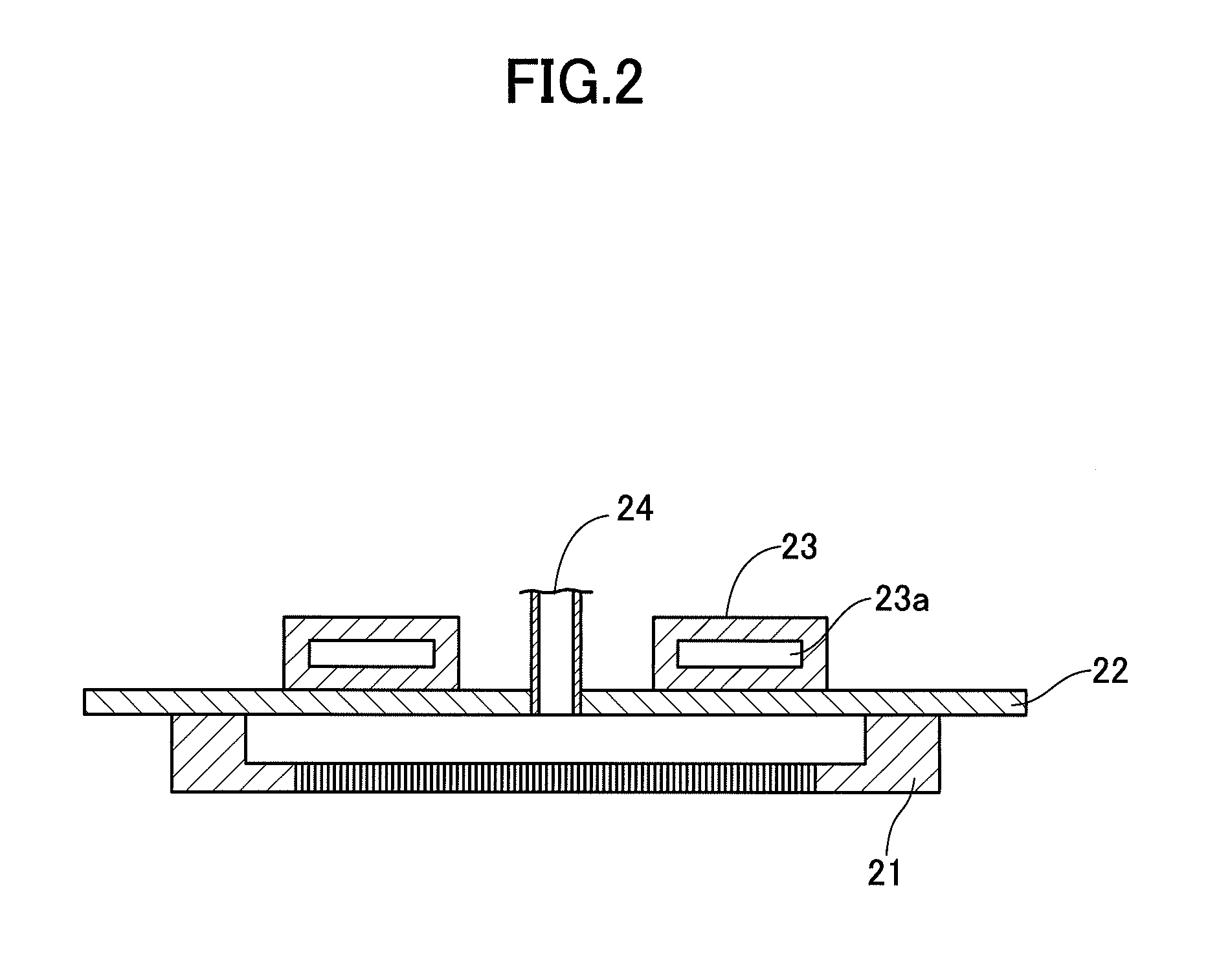

Thin film manufacturing apparatus, thin film manufacturing method and method for manufacturing semiconductor device

InactiveUS20130023062A1Easy temperature controlGood effectLiquid surface applicatorsSemiconductor/solid-state device manufacturingManufactured apparatusThermal radiation

In an apparatus for manufacturing a ceramic thin film by employing a thermal CVD method, an internal jig, which is provided with a heat radiation material film on the surface, is provided at a position that faces a substrate (S) on which the film is to be formed. The thin film and a semiconductor device are manufactured using such apparatus.

Owner:ULVAC INC

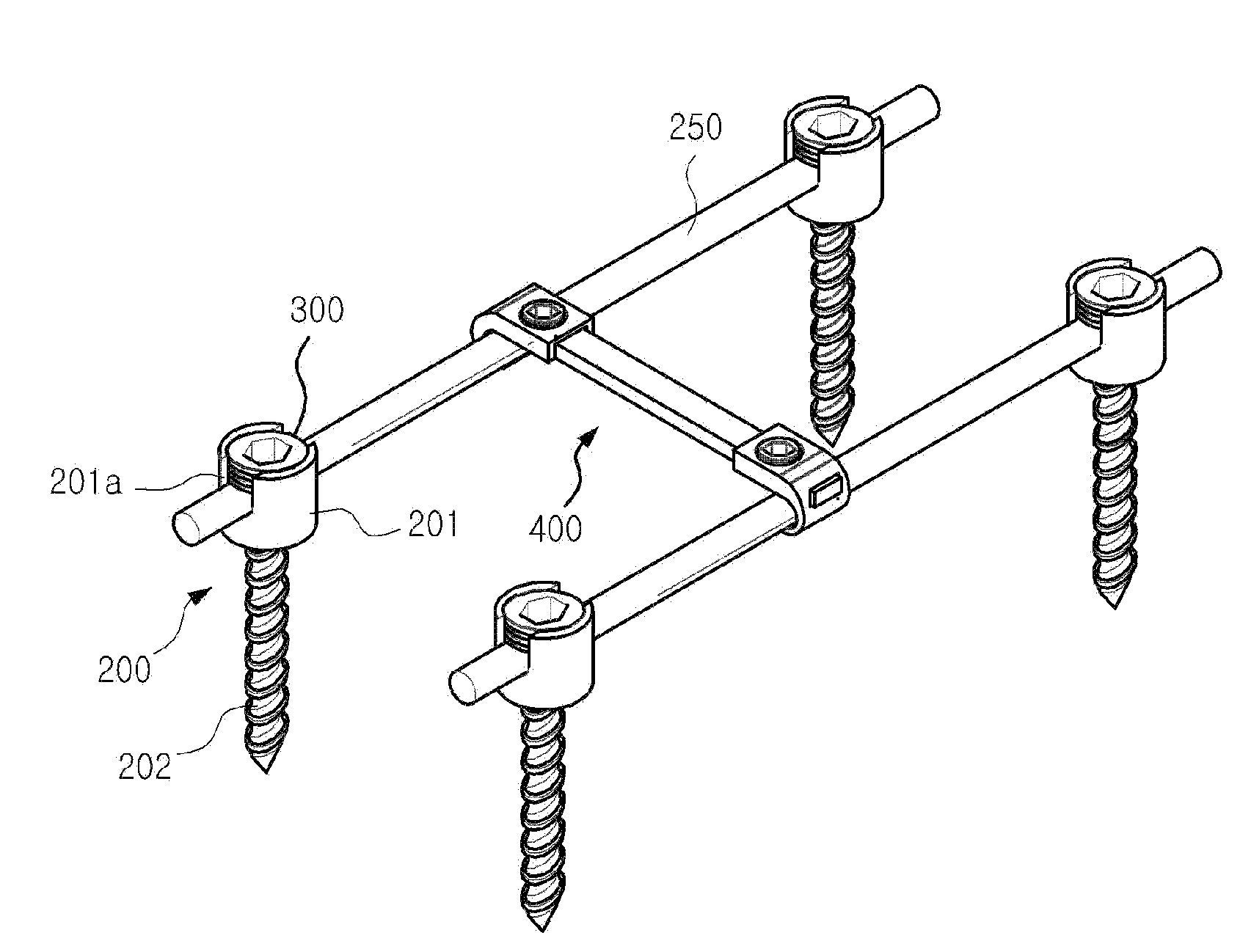

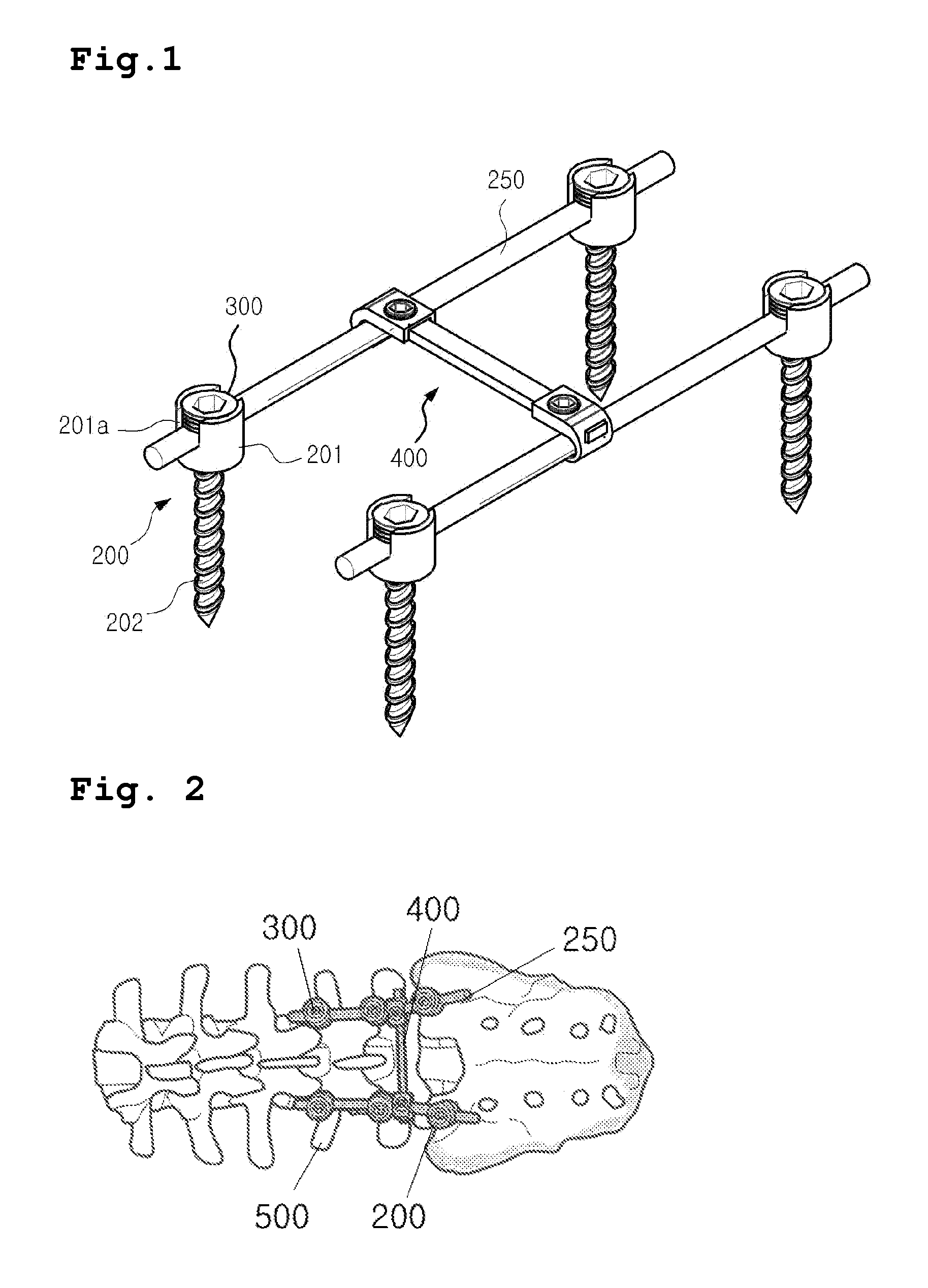

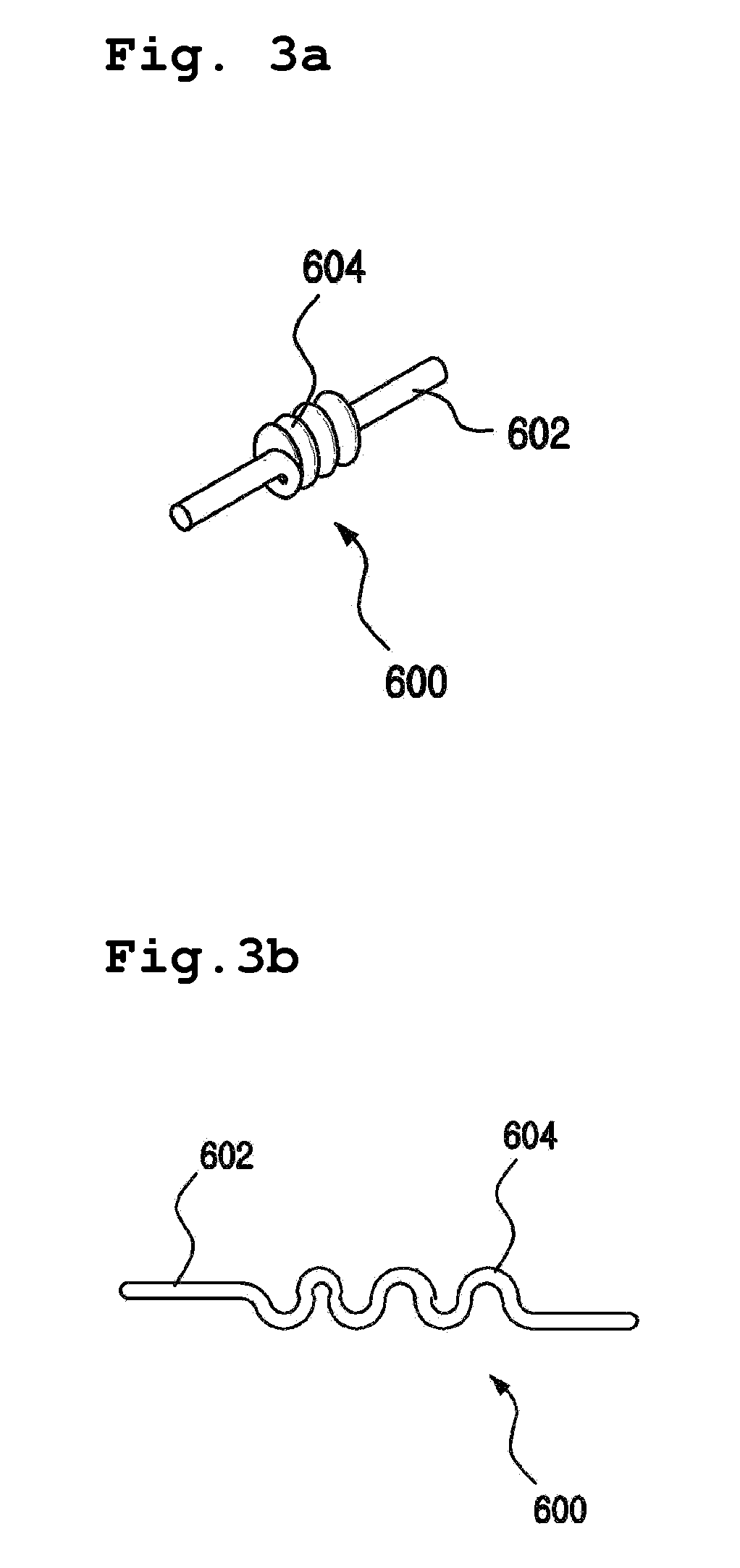

Flexible rod manufacturing apparatus and method for a spinal fixation and the flexible rod manufactured through the same

ActiveUS20080065071A1Easy to fixInternal osteosythesisJoint implantsManufactured apparatusEngineering

The present invention relates to a rod capable of securely connecting pedicle screws in a pedicle screw system for correcting a damaged or transformed spine and a method and an apparatus for fabricating the same and, more particularly, to a flexible pedicle rod with superelasticity in order to provide a flexibility to a fixation between spine segments and a method and an apparatus capable of fabrication the same in mass production. The apparatus according to the present invention comprises a body; an X- and Y-axis moving element mounted on a top surface of the body, the X- and Y-axis moving element simultaneously moving in X-axis and Y-axis directions to wind a material at an angle of 90 degrees; a magazine mounted on the X- and Y-axis moving element to load a material; a material withdrawing element for withdrawing materials one by one from the magazine; and a material molding element mounted on the X- and Y-axis moving element, the material molding element gripping both ends of the material withdrawn from the material withdrawing element and rotating to mold a portion of the material in a spring shape.

Owner:PARK KYUNG WOO

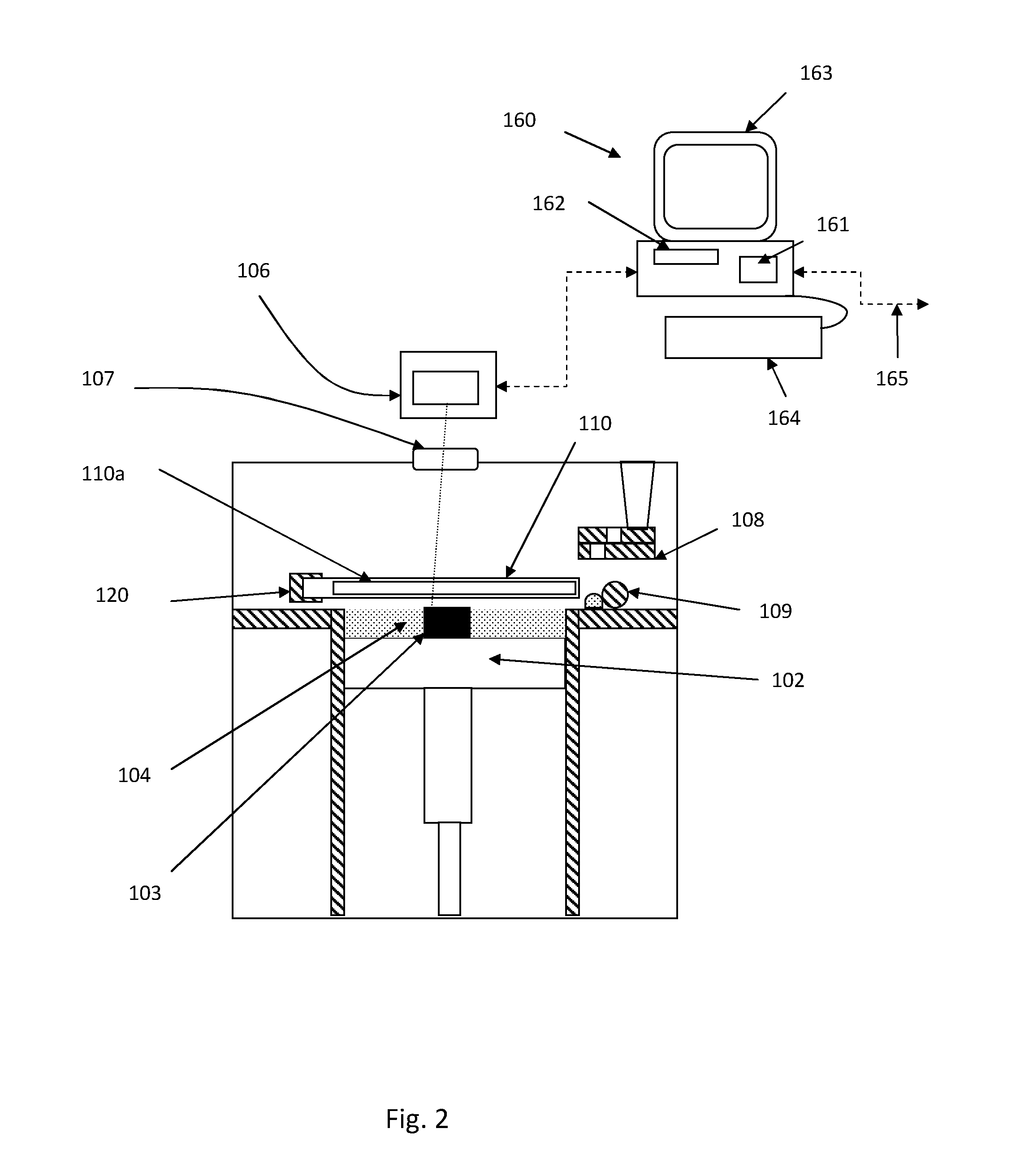

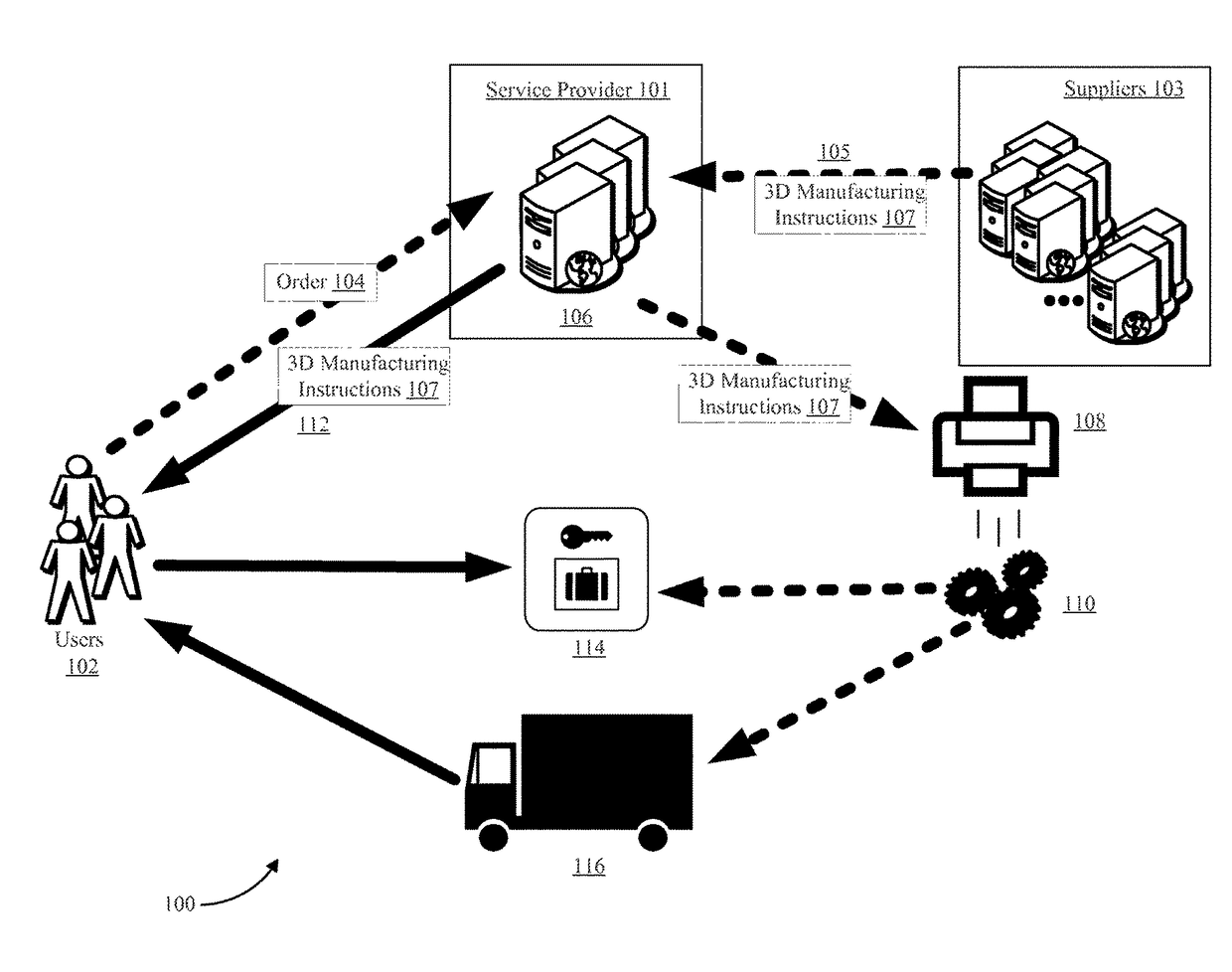

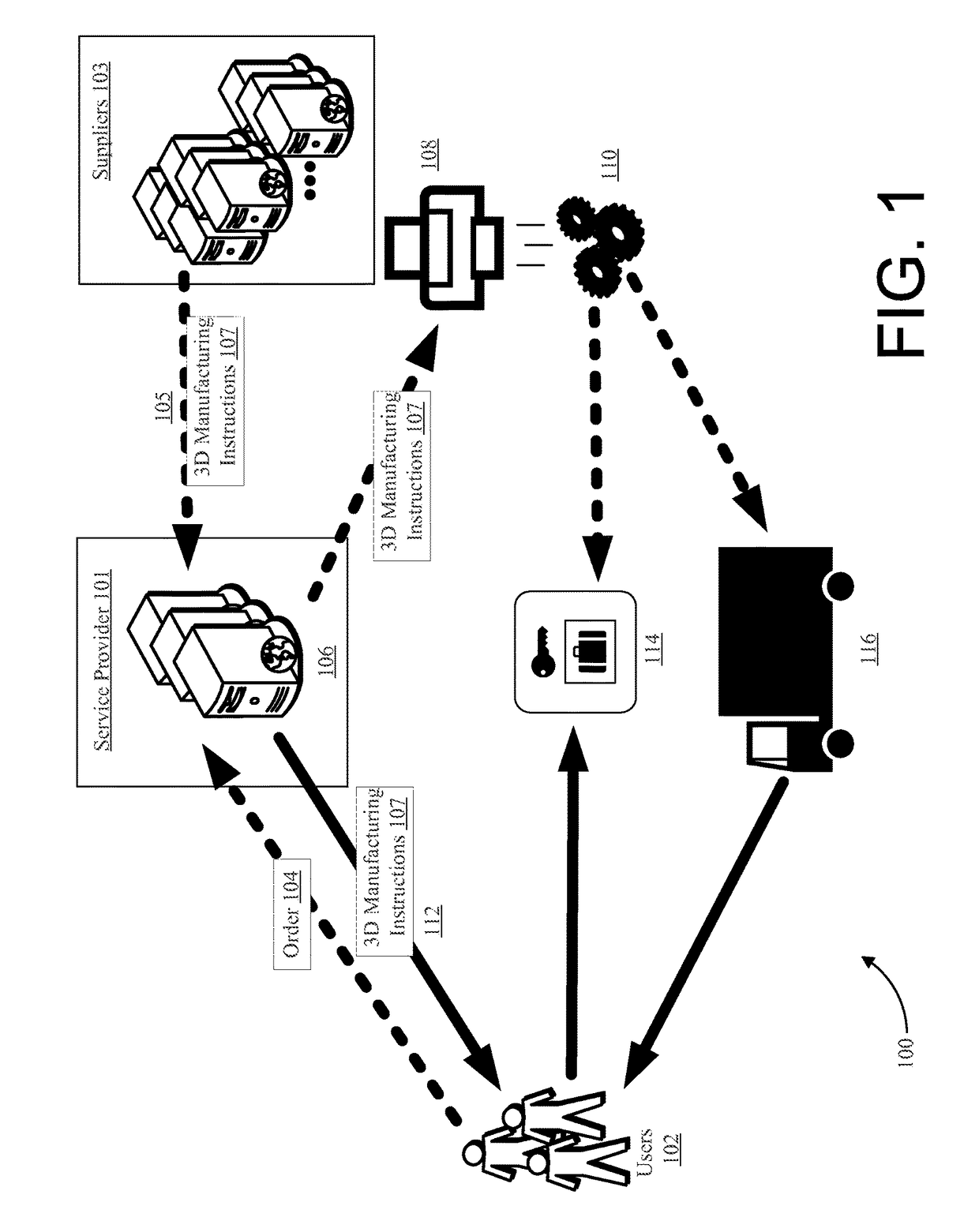

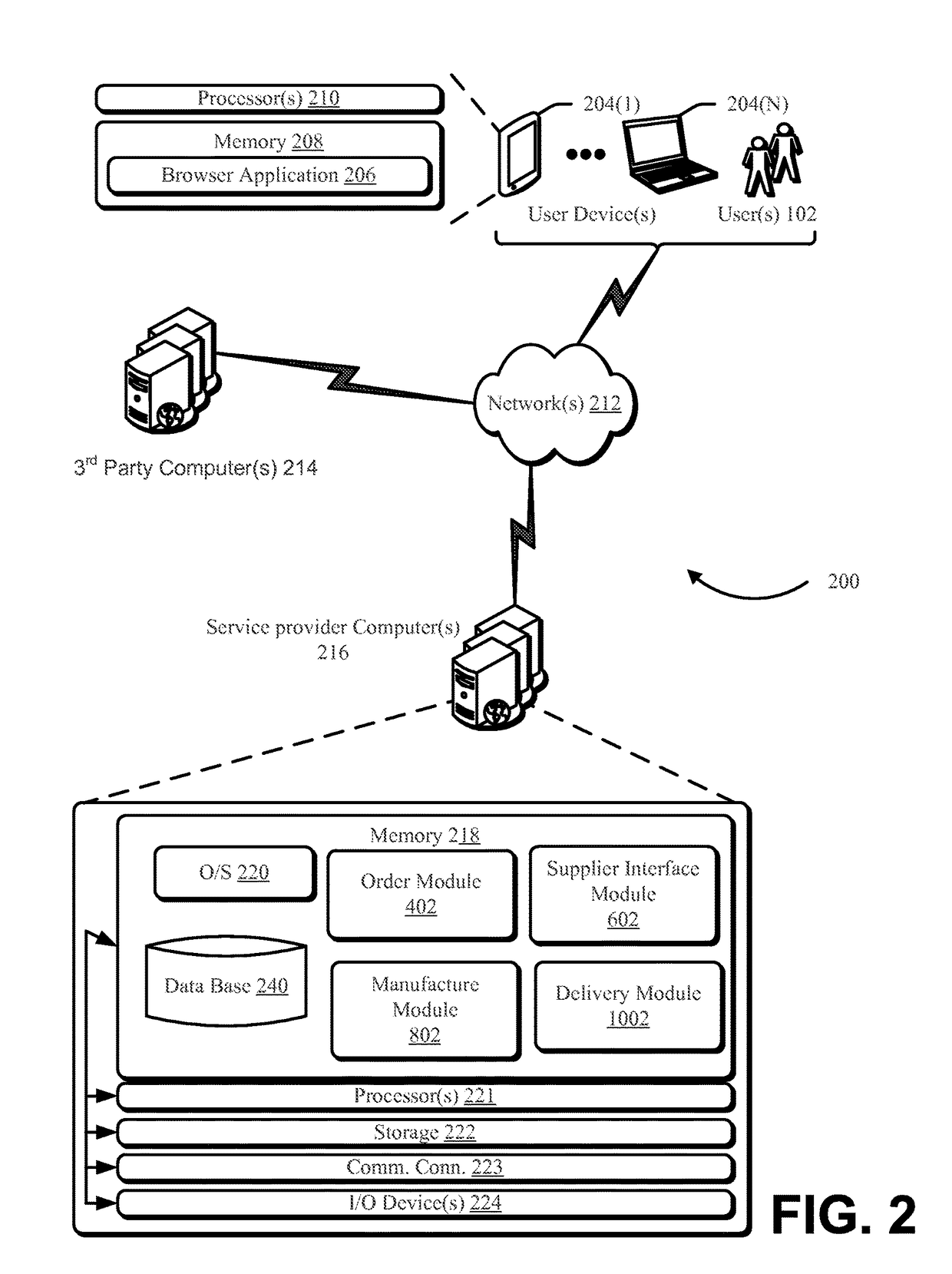

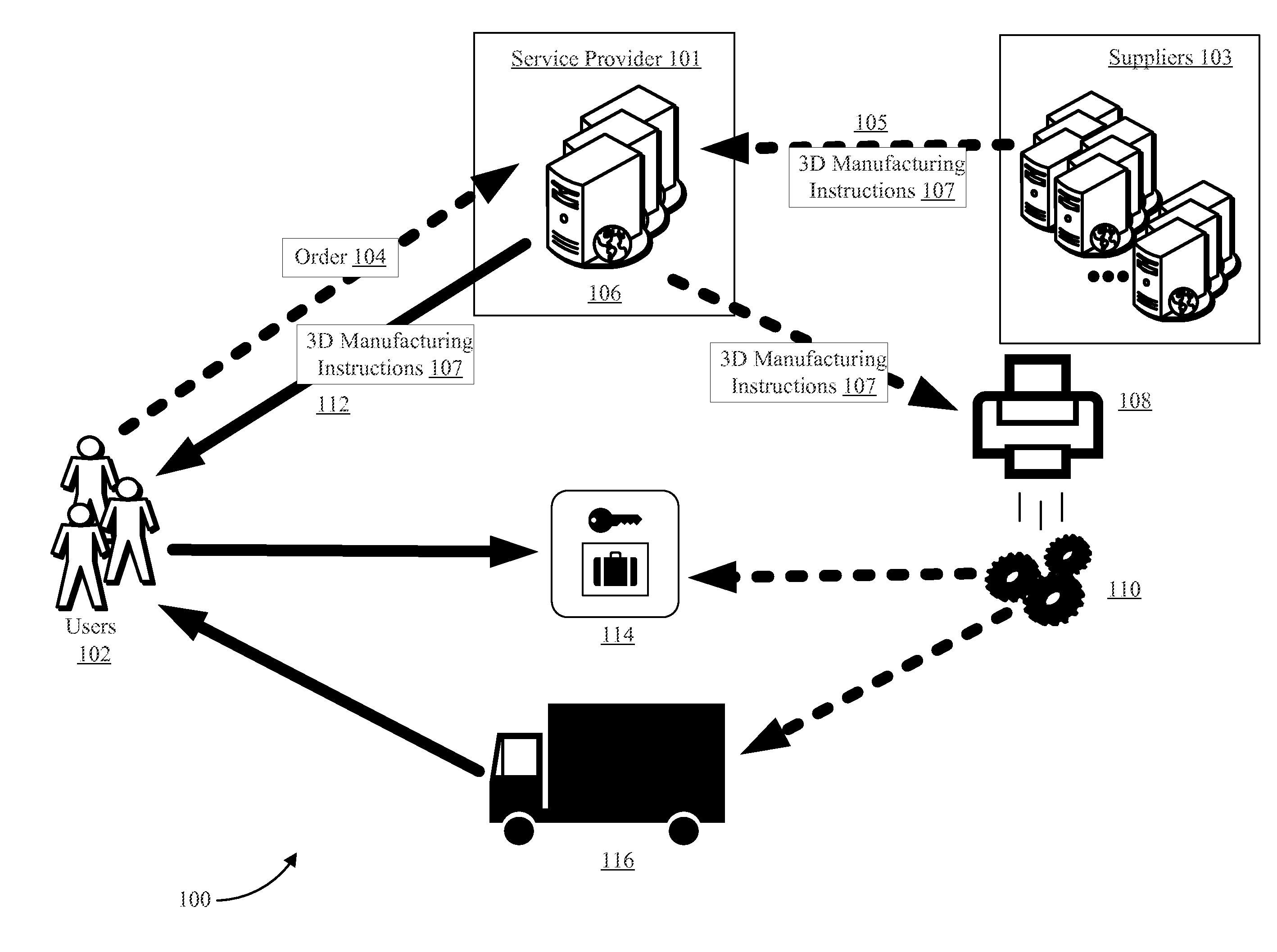

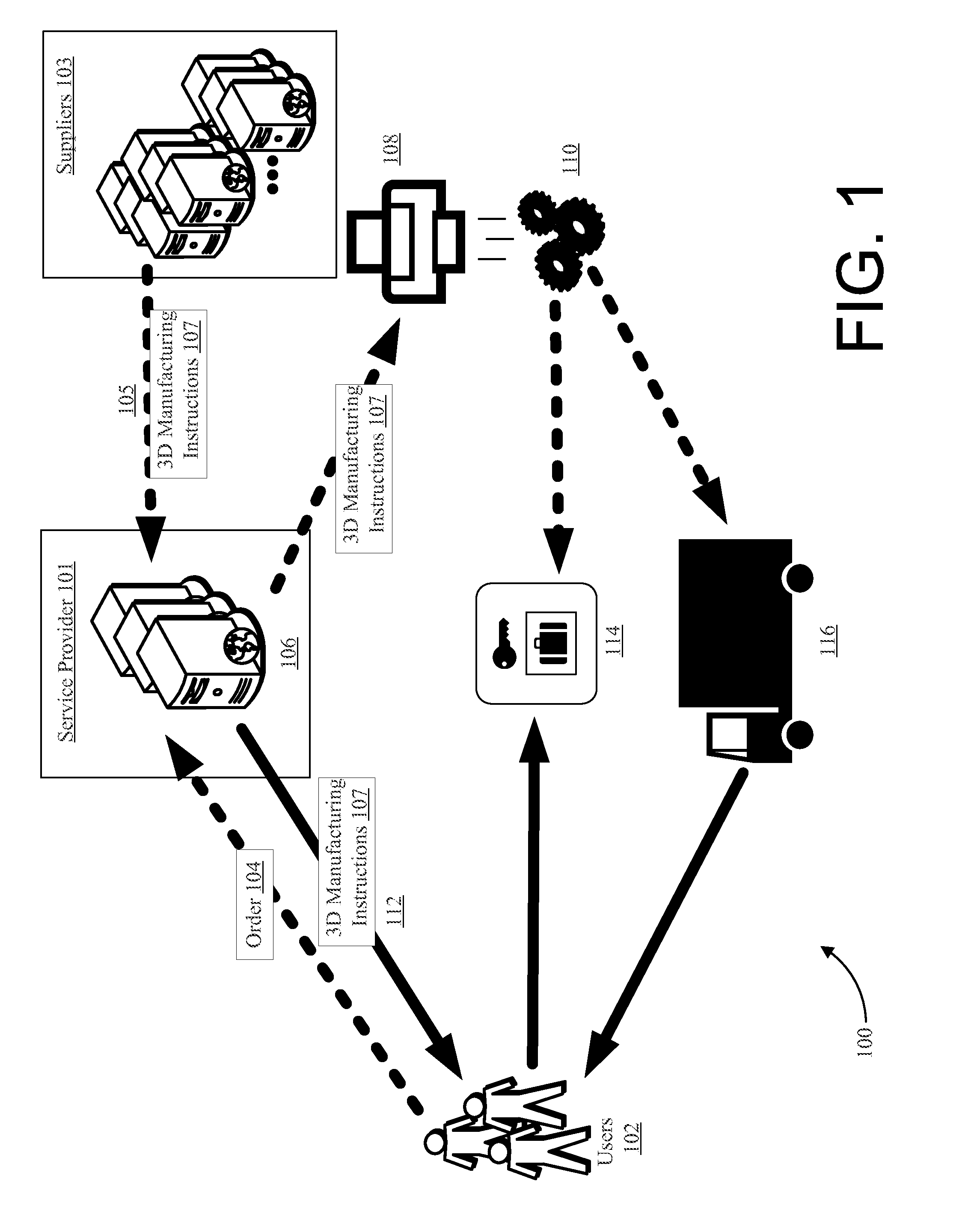

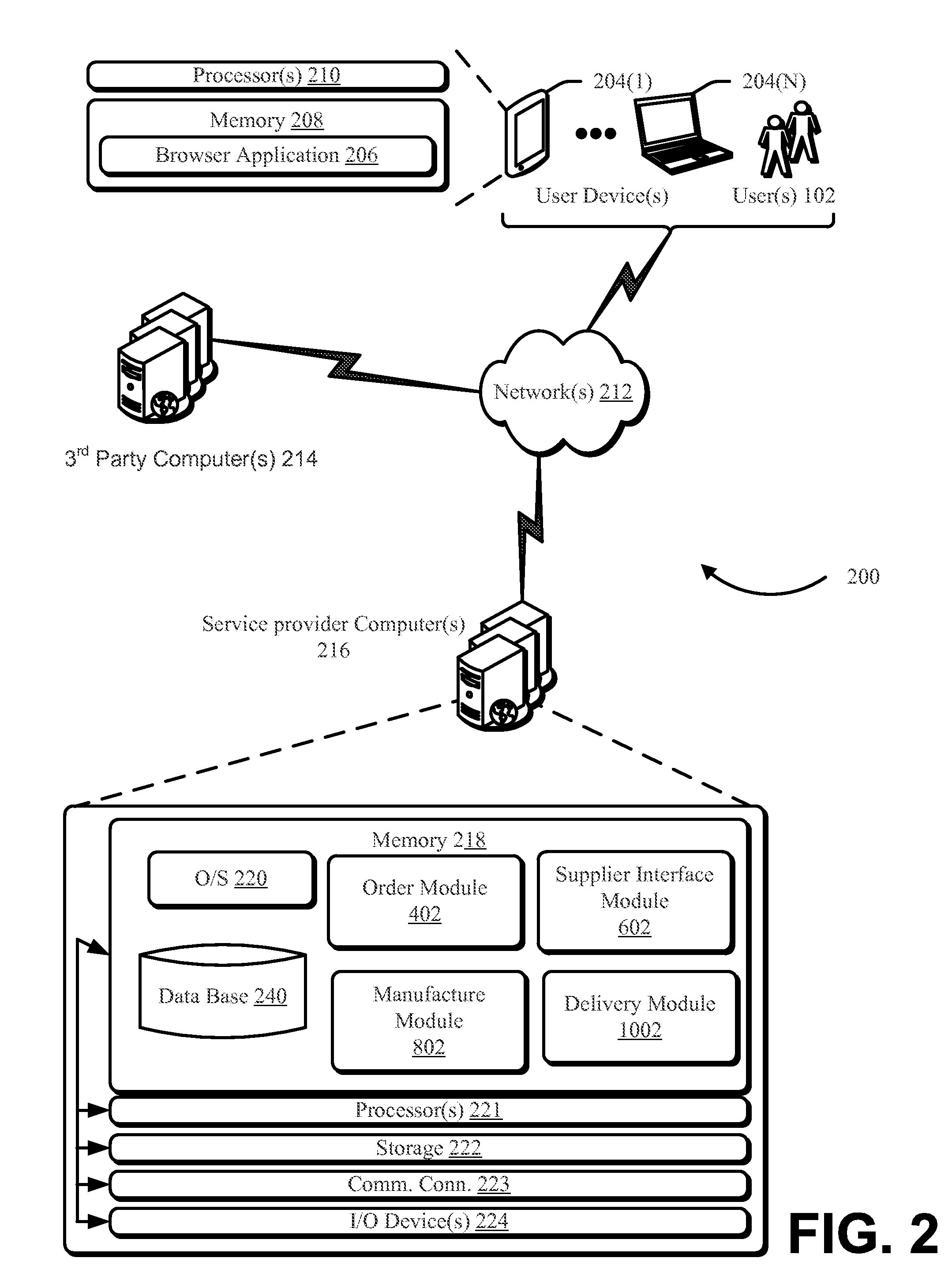

Vendor interface for item delivery via 3D manufacturing on demand

ActiveUS9858604B2Geometric CADAdditive manufacturing apparatusManufactured apparatusComputer science

Methods and systems can be provided for providing items manufactured on demand to users. A user request for an item can be received. The item can have 3D manufacturing instructions associated therewith. A delivery method for the item can be determined. A manufacturing apparatus can be selected to manufacture the item based on the 3D manufacturing instructions. Instructions can be sent to the manufacturing apparatus to manufacture the item based on the 3D manufacturing instructions. Delivery instructions can be provided for delivering the item according to the delivery method.

Owner:AMAZON TECH INC

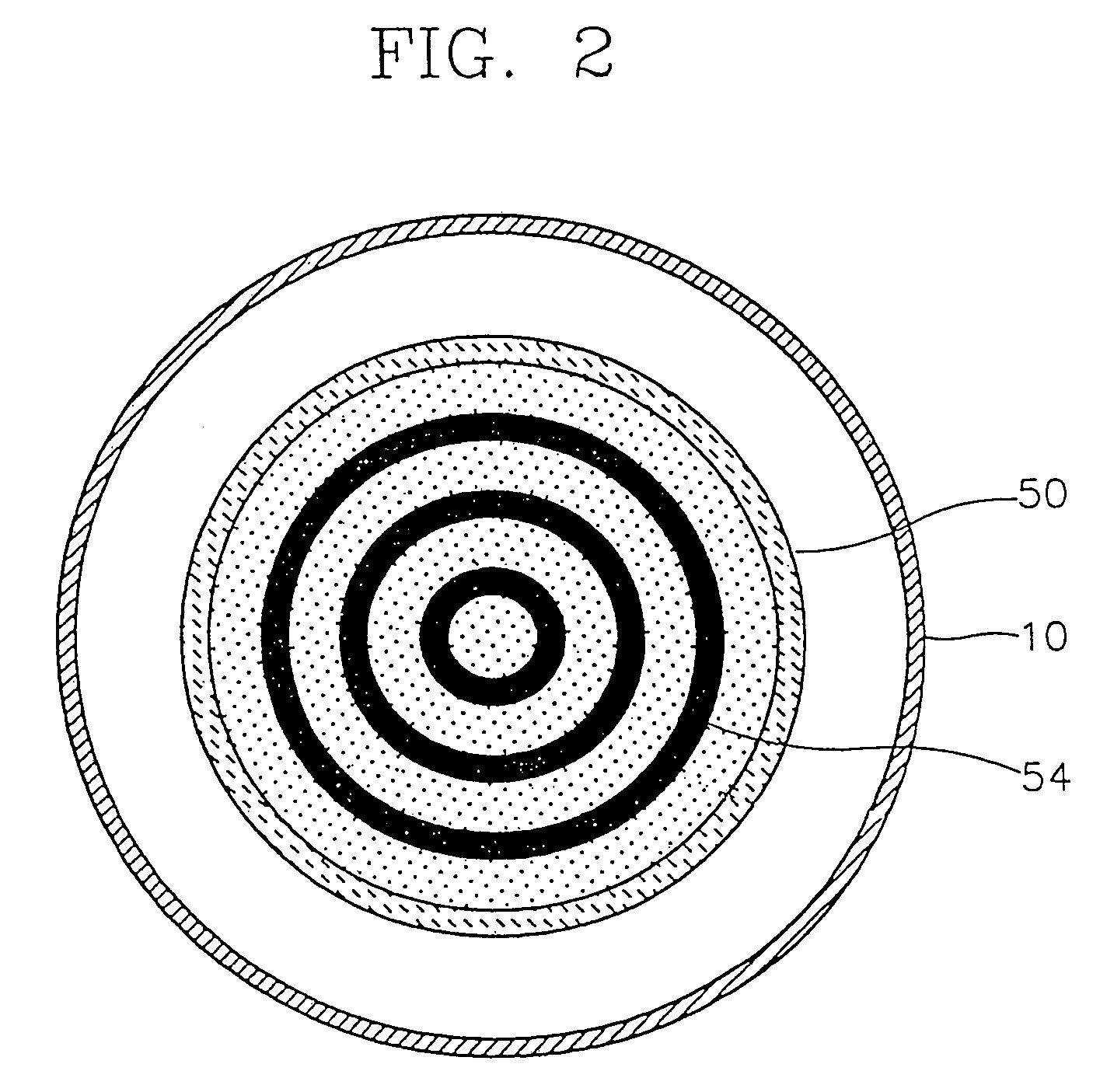

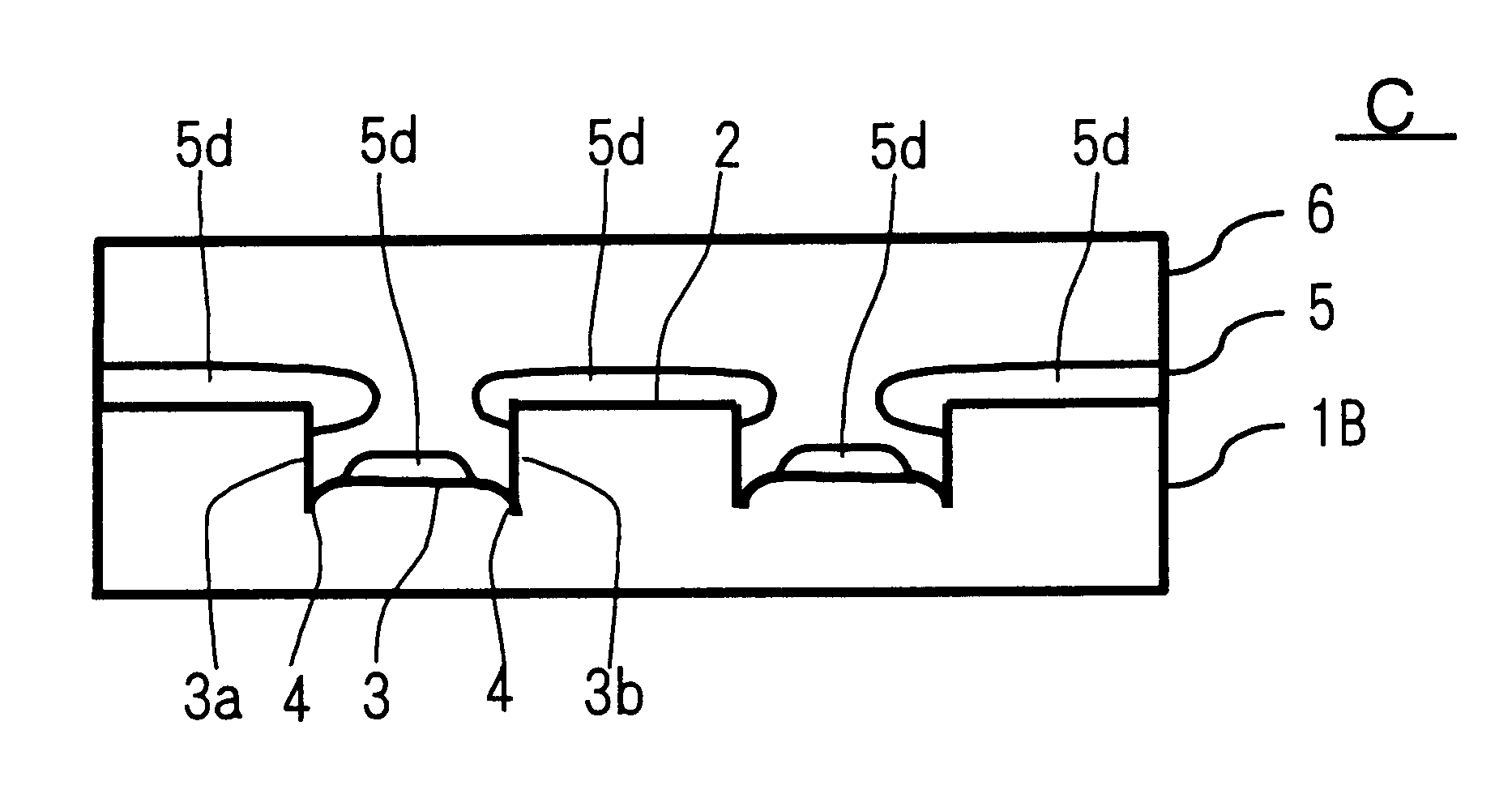

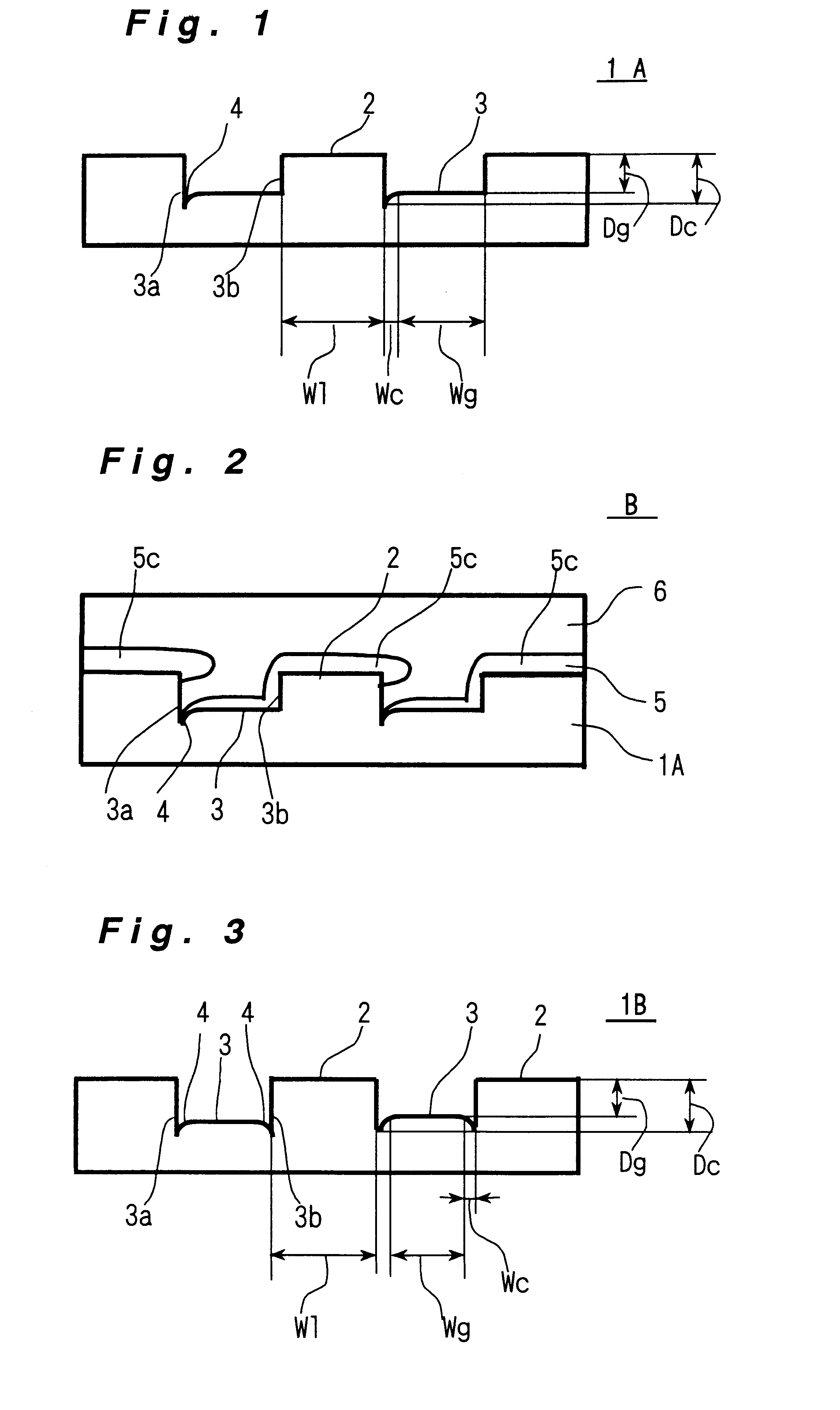

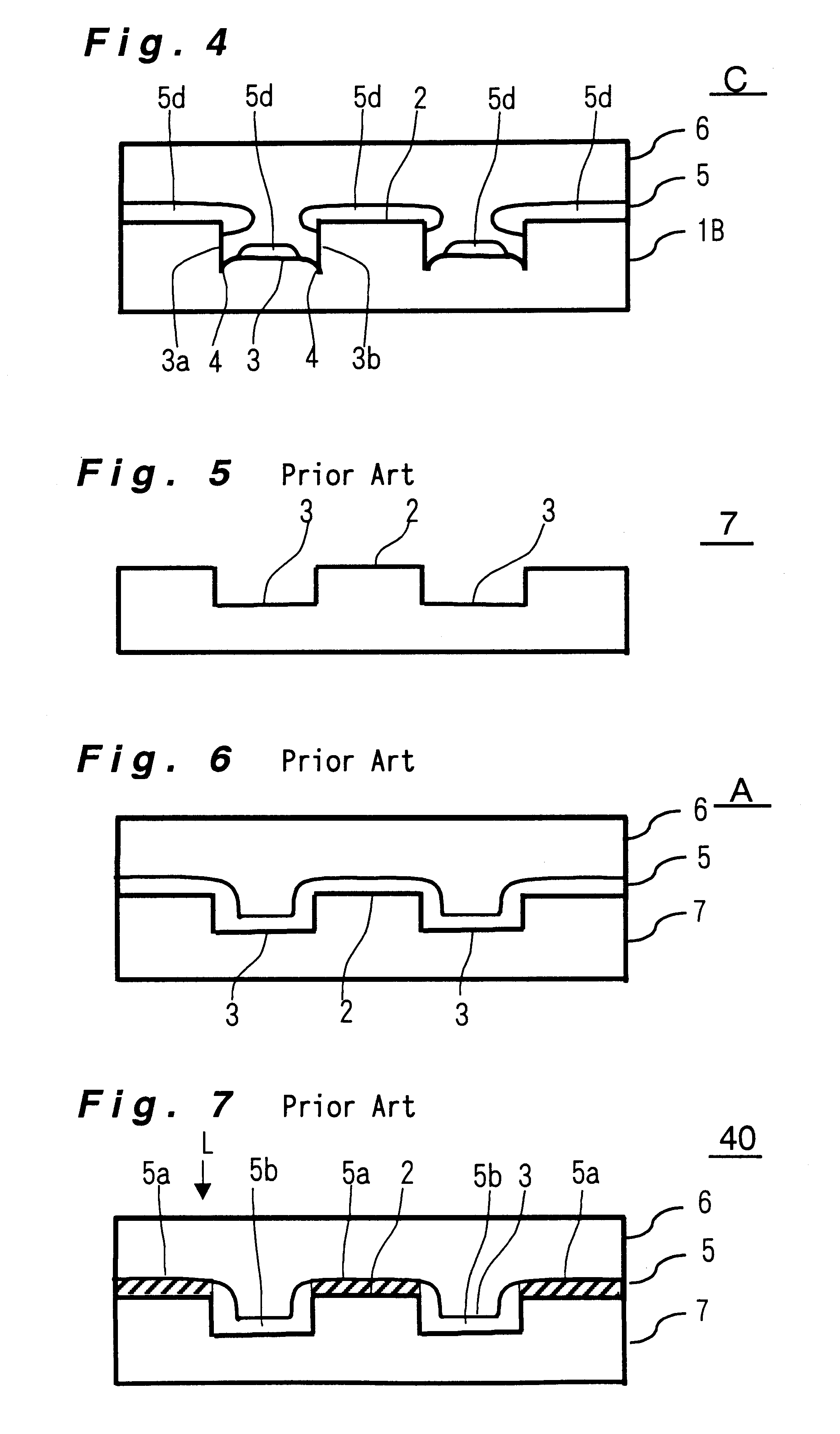

Information recording mediums, supporter used in the mediums, manufacture methods of the supporter, manufacturing apparatus of the supporter and stampers for producing the mediums

InactiveUS6254966B1Magnetic materials for record carriersLayered productsHigh densityManufactured apparatus

An information recording medium and a supporter used for the information recording medium capable of recording a land / groove recording by using a high density recording technique such as a super-resolution, resulting in a high density recording. An information recording medium B has a supporter 1A, on which a recording layer 5 is formed. On the supporter 1A, lands 2 and groove 3 are alternately formed as a minute track pattern. A crevice 4 having a depth Dc larger than a depth Dg of the respective grooves 3 is formed in the respective grooves 3 at one end of the respective grooves 3 in a width direction of the respective grooves.

Owner:RAKUTEN INC

Fulfillment of orders for items using 3D manufacturing on demand

ActiveUS20150052025A1Design optimisation/simulation3D object support structuresOrder formManufactured apparatus

Methods and systems can be provided for providing items manufactured on demand to users. A user request for an item can be received. The item can have 3D manufacturing instructions associated therewith. A delivery method for the item can be determined. A manufacturing apparatus can be selected to manufacture the item based on the 3D manufacturing instructions. Instructions can be sent to the manufacturing apparatus to manufacture the item based on the 3D manufacturing instructions. Delivery instructions can be provided for delivering the item according to the delivery method.

Owner:AMAZON TECH INC

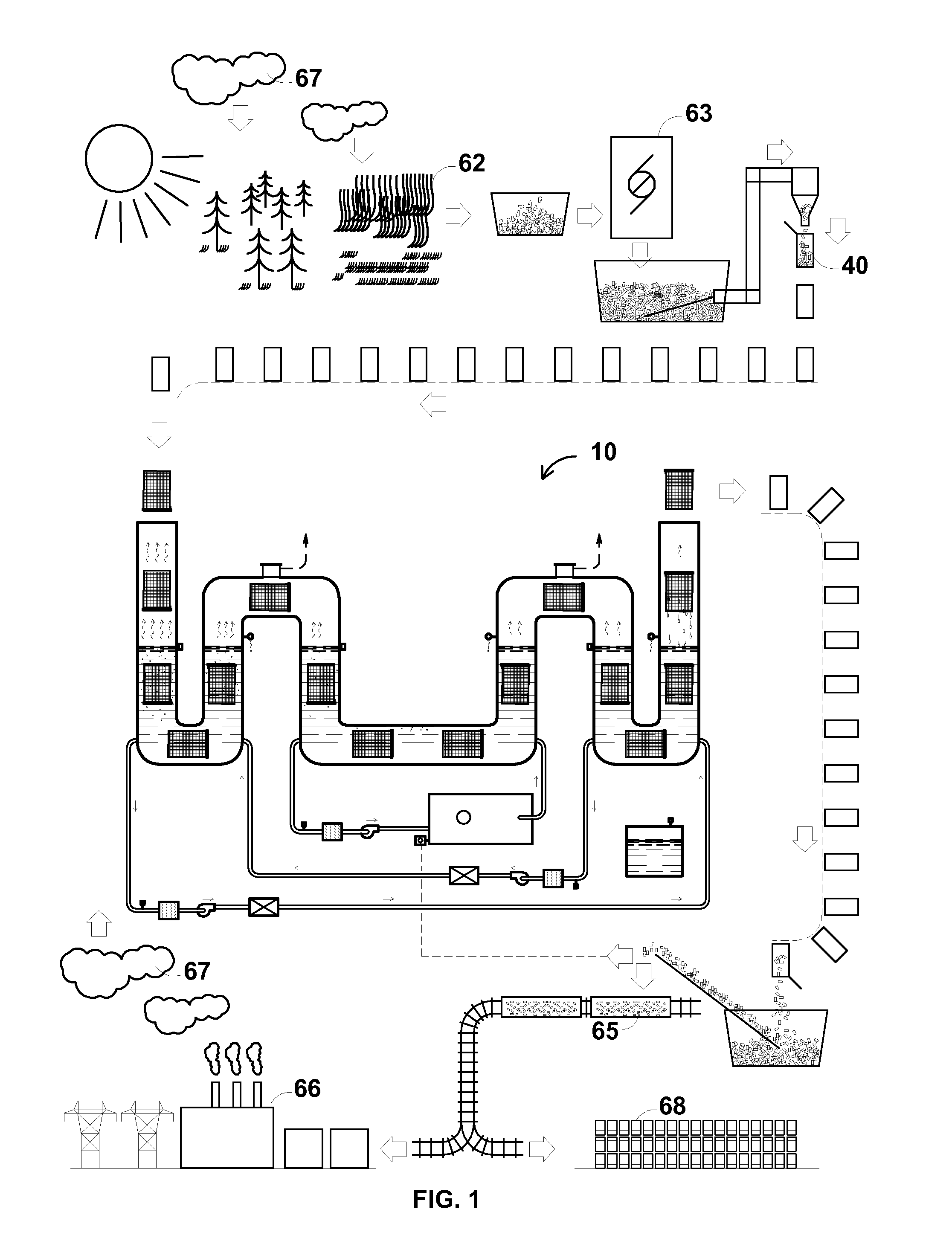

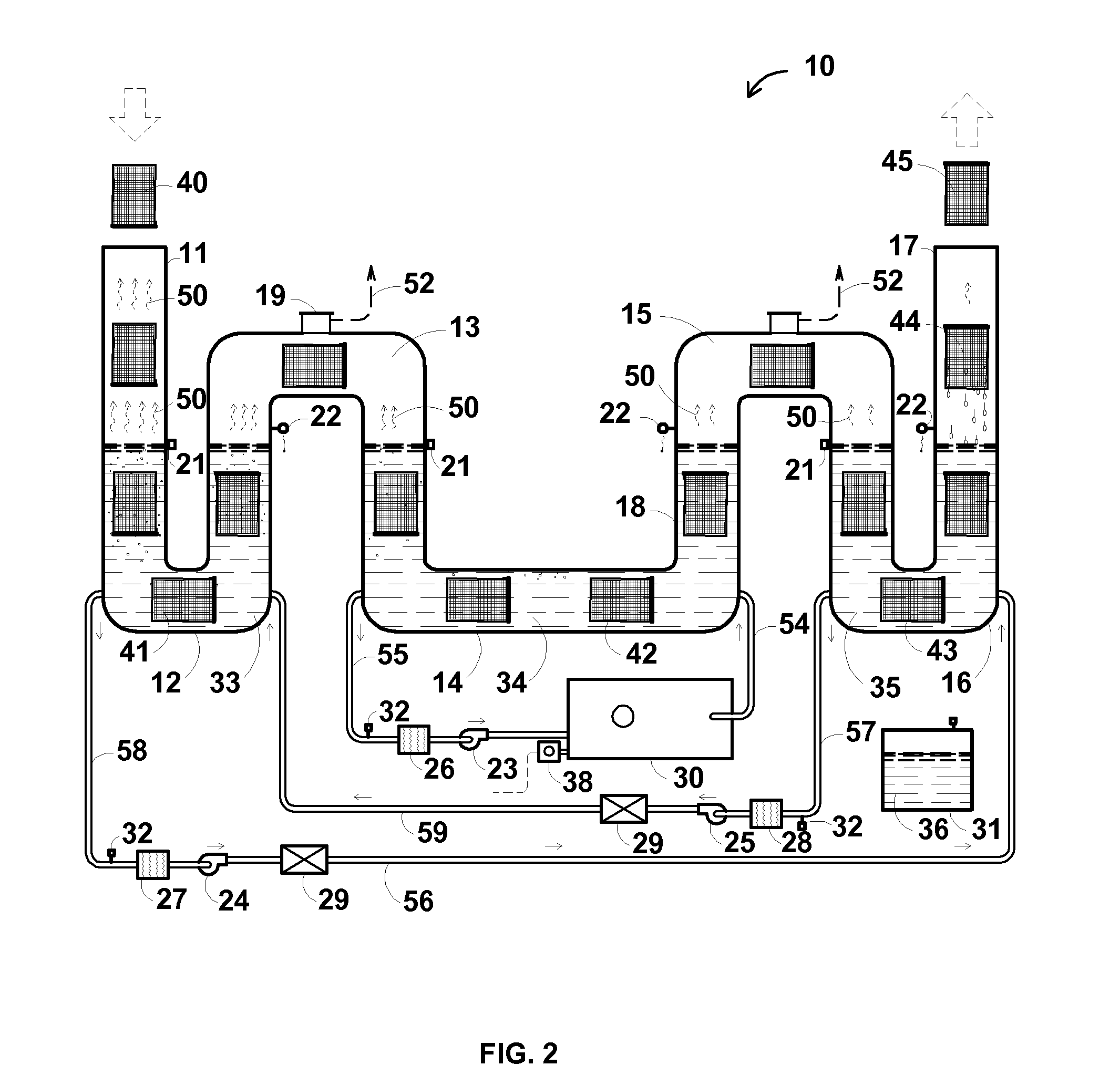

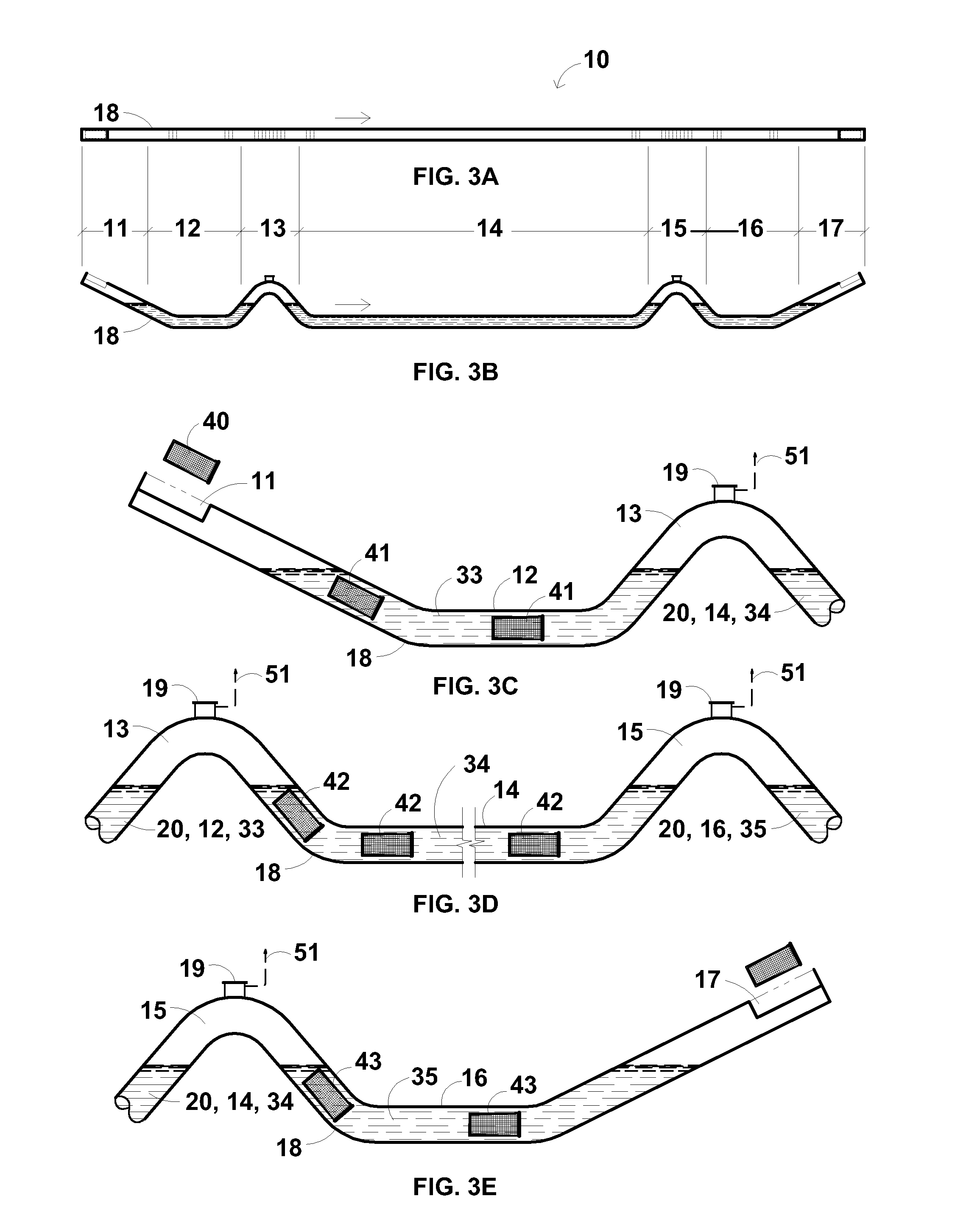

Method and apparatus for biomass torrefaction, manufacturing a storable fuel from biomass and producing offsets for the combustion products of fossil fuels and a combustible article of manufacture

ActiveUS20070266623A1Reduce air pollutionEasy to storeSolid fuel pretreatmentBiofuelsHigh elevationManufactured apparatus

Apparatus for biomass torrefaction which includes a serpentine elongated housing, the housing having three generally U-shaped axial portions having first and second axial extremities and an intermediate section, the first and second axial extremities are disposed in normal use at a higher elevation than the first and second axial extremities, the intermediate section being configured for holding a liquid. Other forms of the invention include the method for biomass torrefaction which includes providing a quantity of biomass, providing a liquid heat transfer fluid, providing at least a first housing for holding the heat transfer liquid, elevating the temperature of the liquid heat transfer liquid, heat treating the biomass by passing it through the heat transfer liquid in the first housing at a temperature and duration sufficient to accomplish torrefaction of the wood. In some forms of the method, the process further includes the step of pelletizing the biomass prior to performing the treating step.

Owner:PAOLUCCIO JOHN A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com