Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3782 results about "Gas passing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

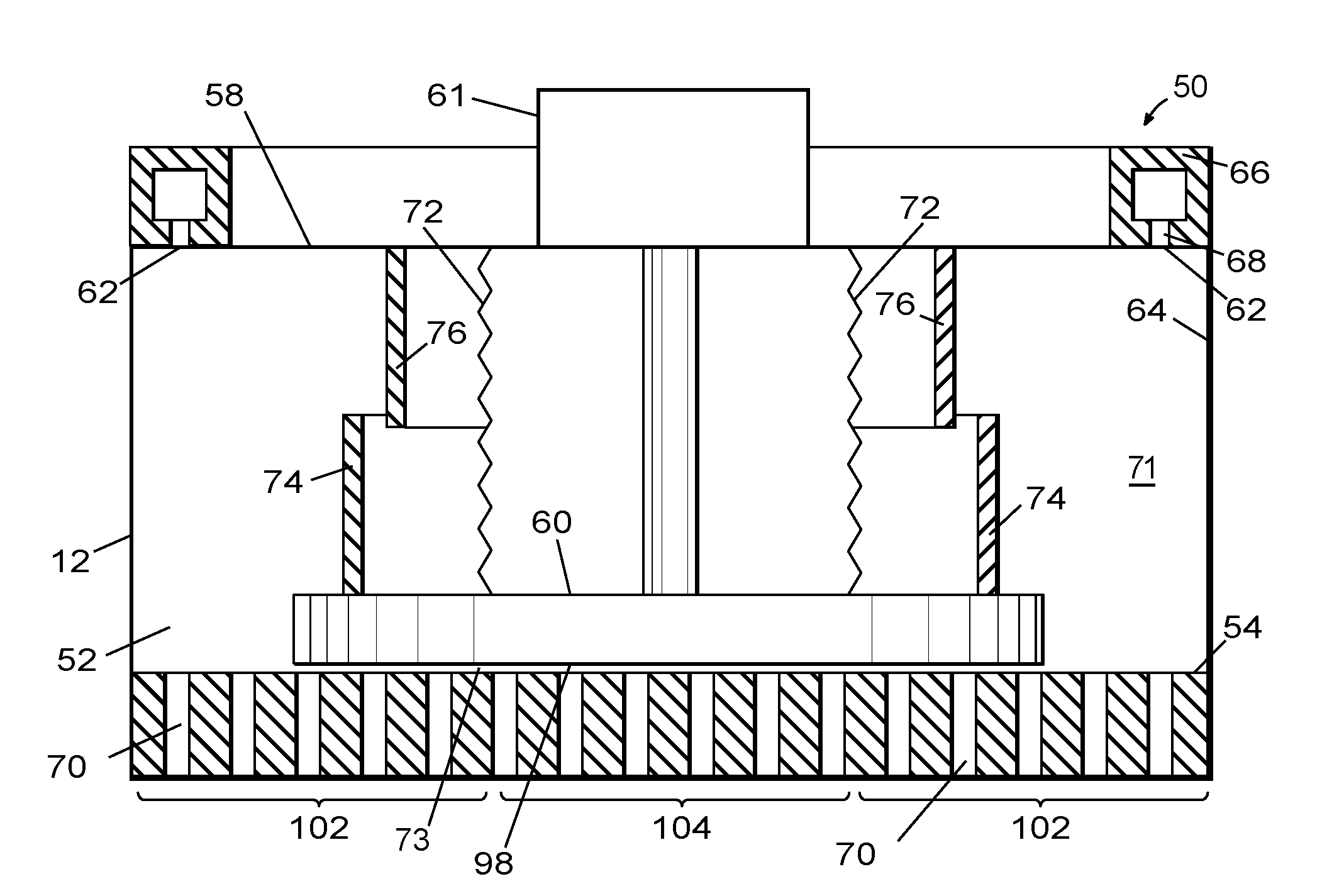

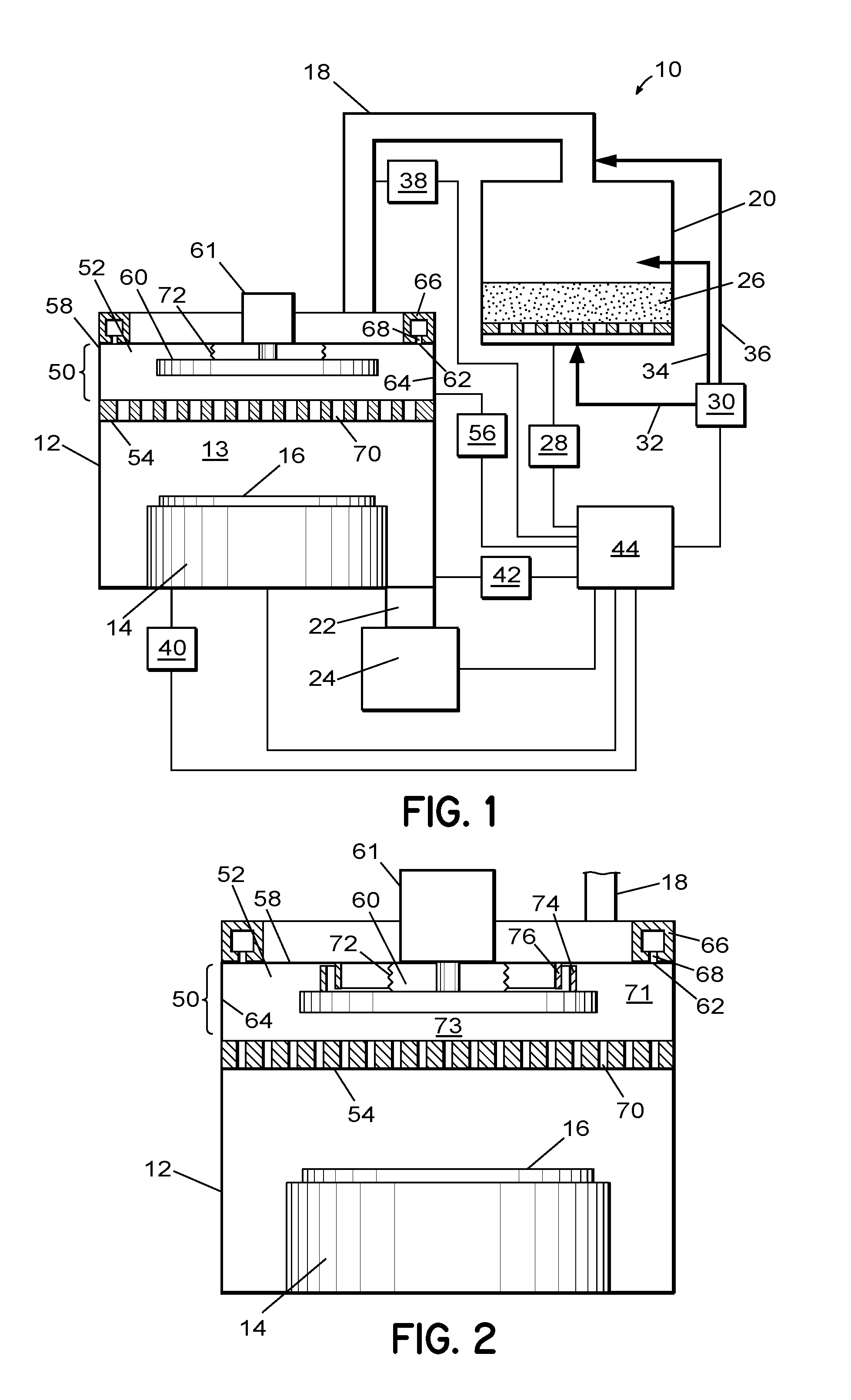

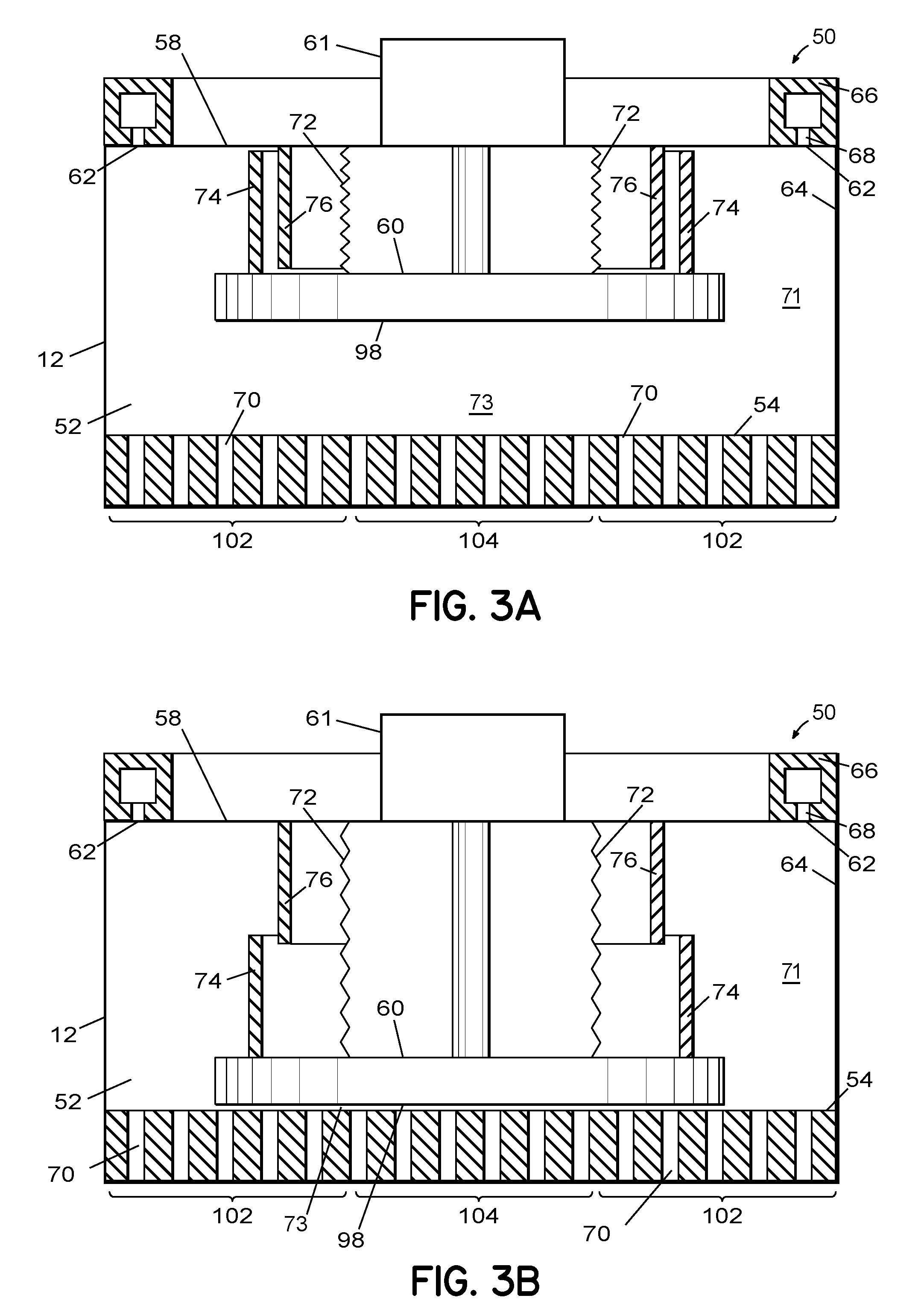

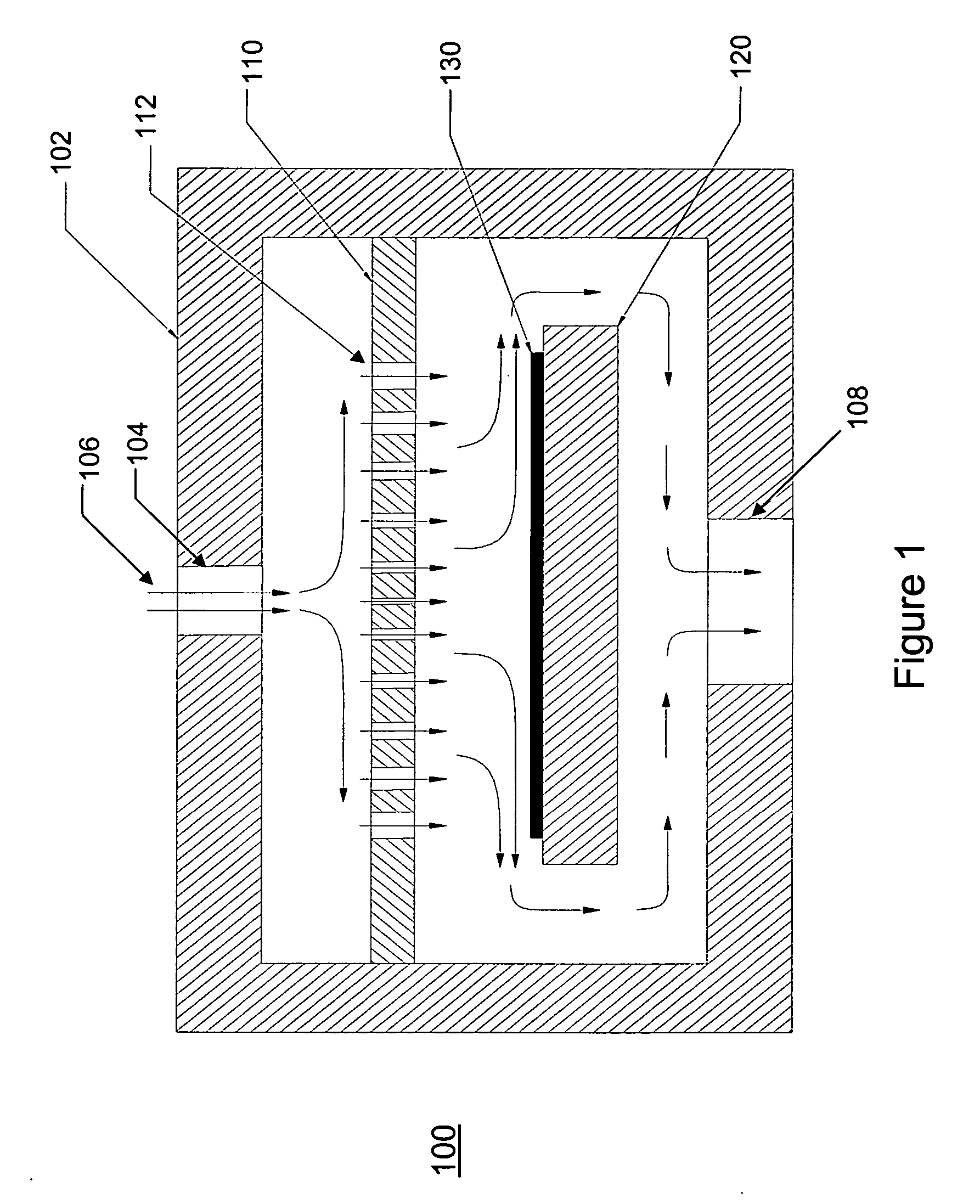

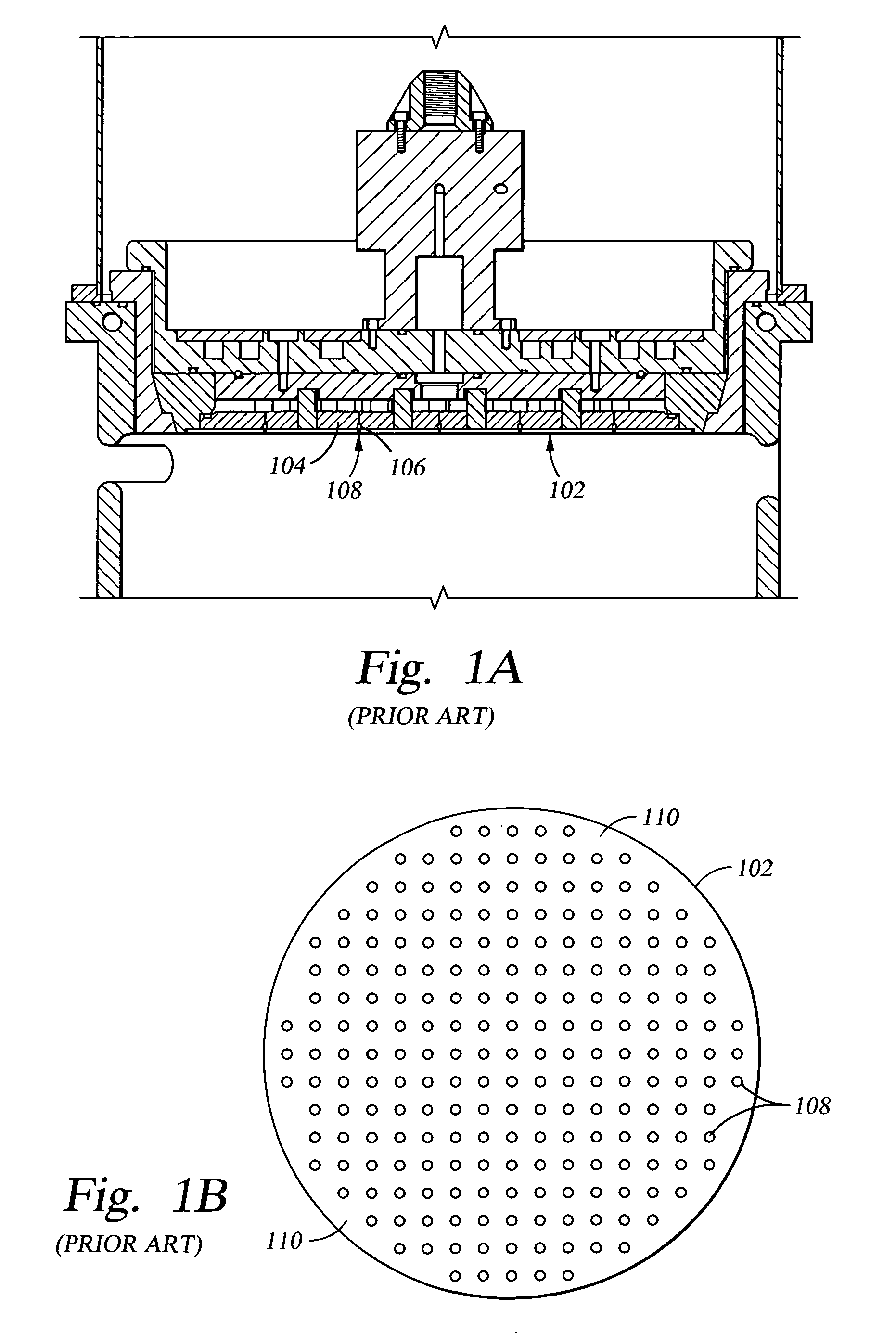

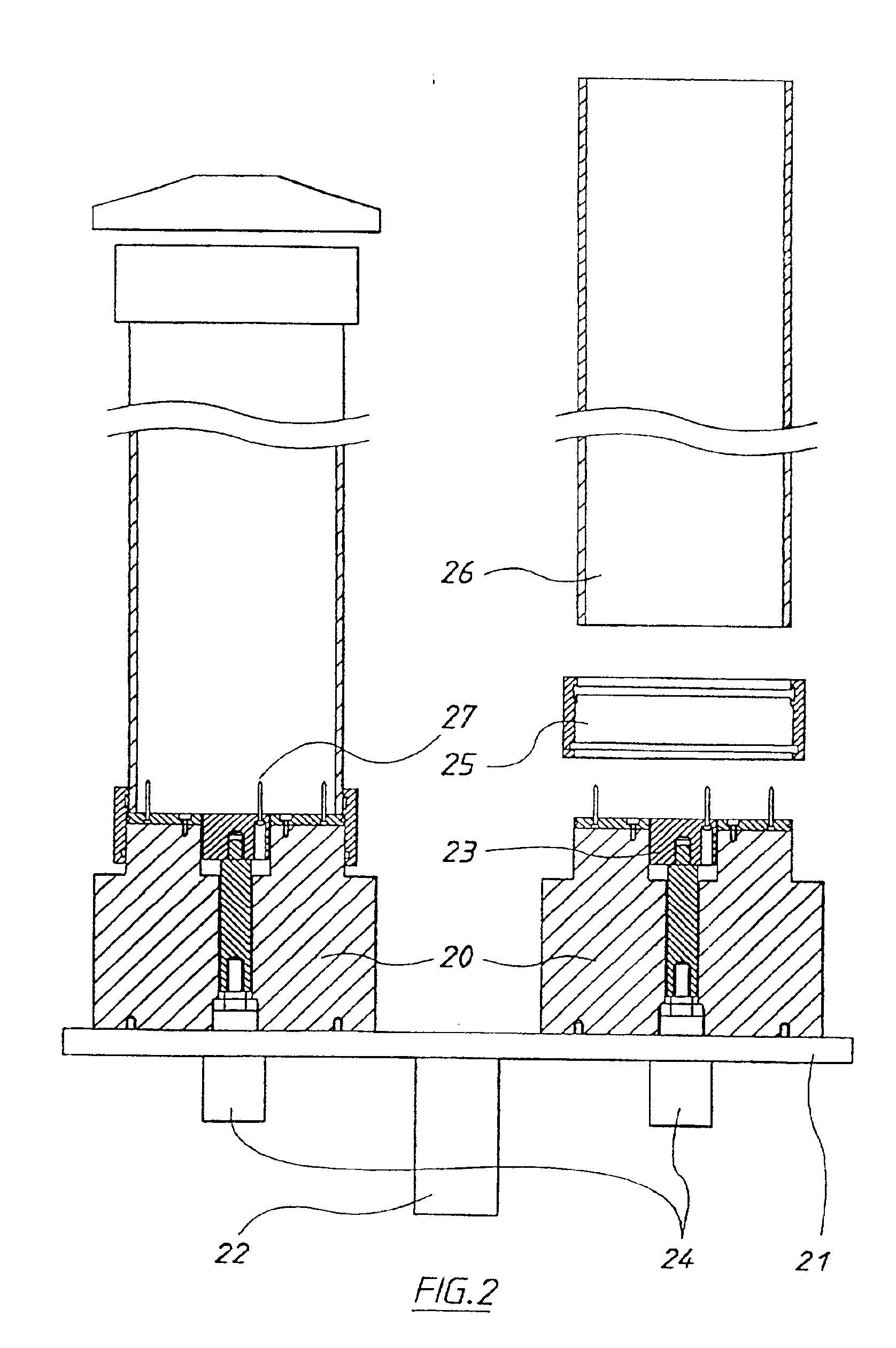

Gas distribution system and method for distributing process gas in a processing system

ActiveUS8252114B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseDistribution system

An apparatus and related method for distributing process gas in a vapor deposition system is described. The gas distribution system includes a vertically movable piston within its plenum, and the movement of the piston controls the flow rate of process gas through the vapor distribution plate of the gas distribution system. The piston can be used to accommodate changes in processing parameters that affect flow characteristics and to create edge-enhanced, uniform, and center-enhanced profiles of deposited material on a substrate without the need to replace the vapor distribution plate.

Owner:TOKYO ELECTRON LTD

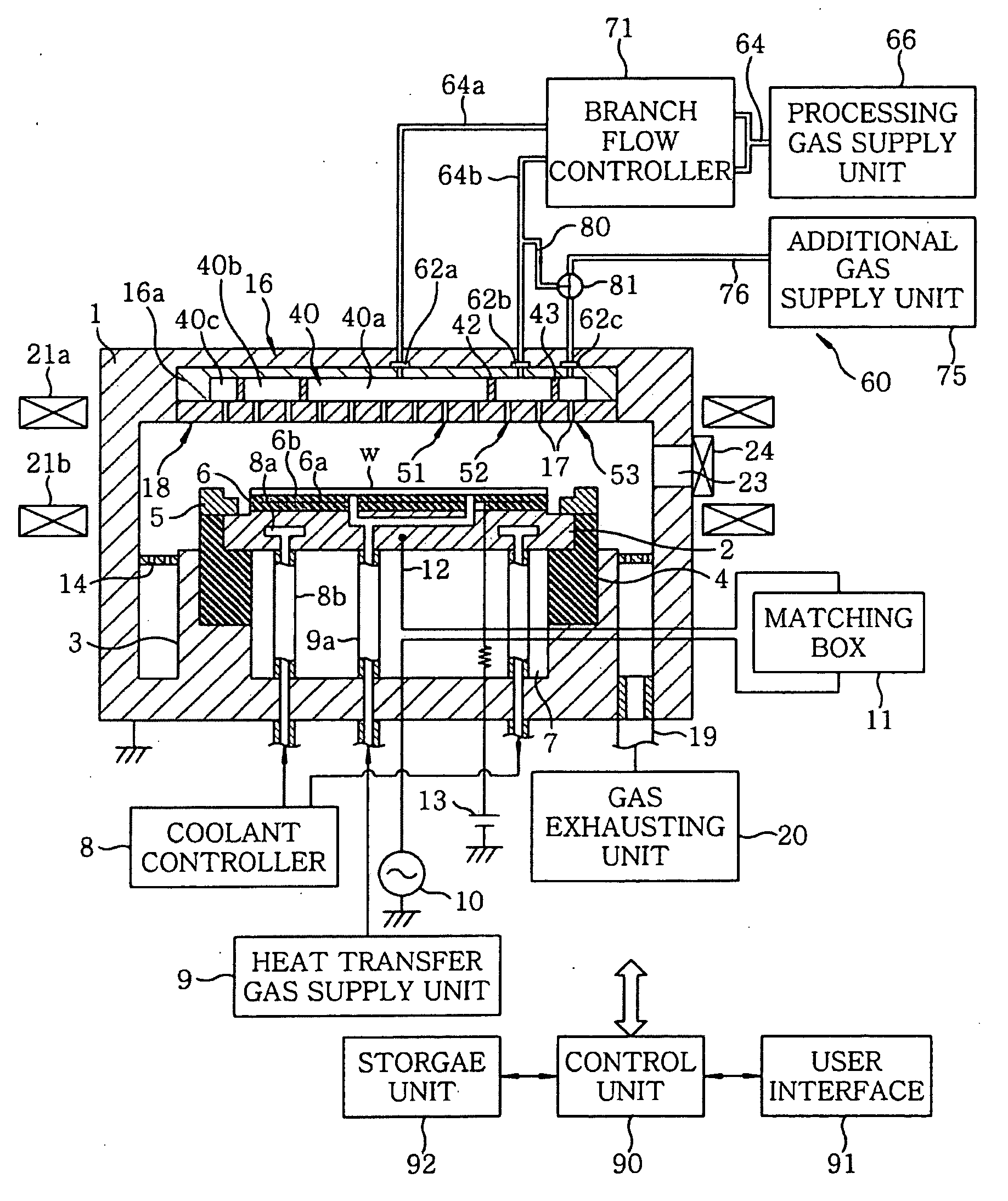

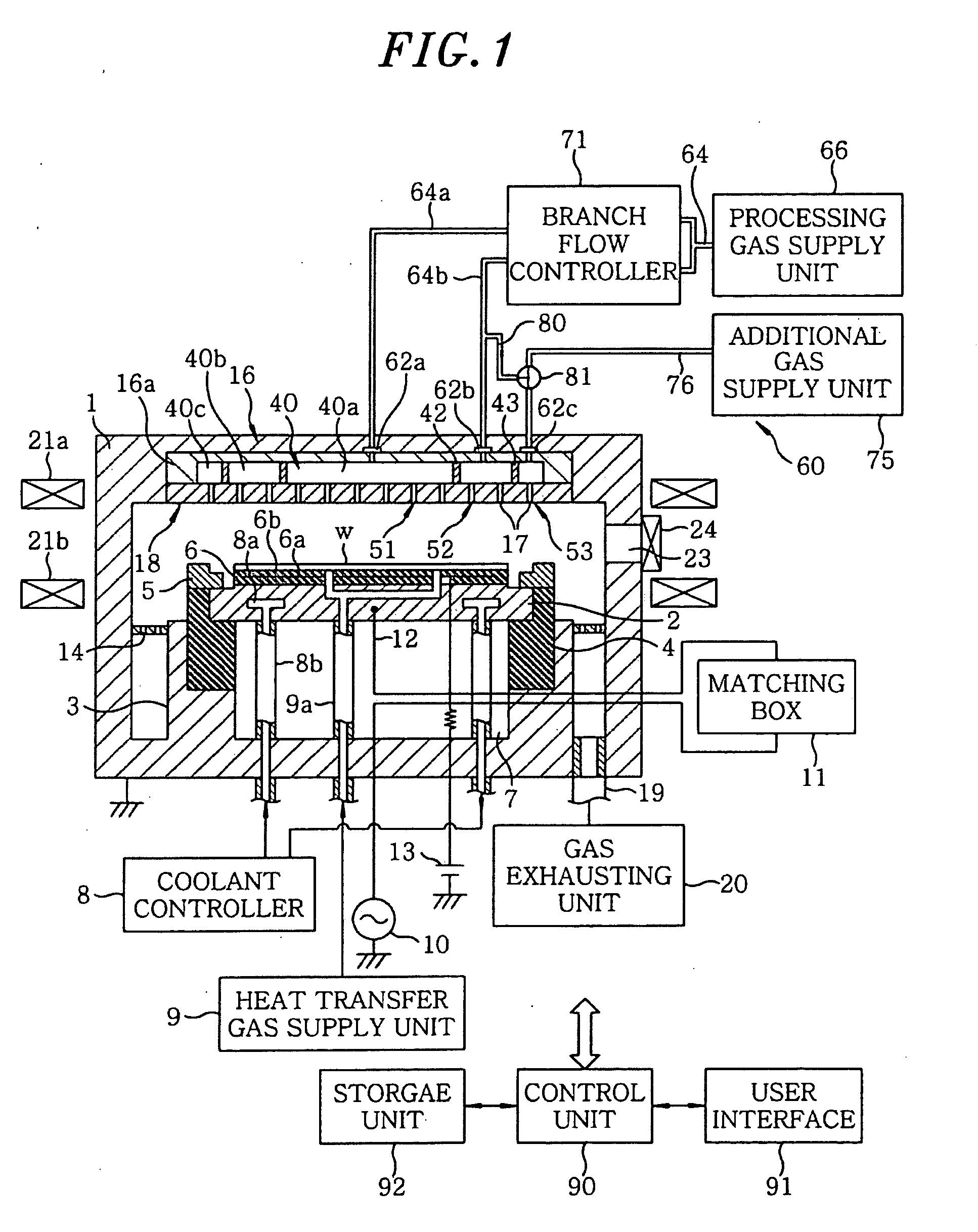

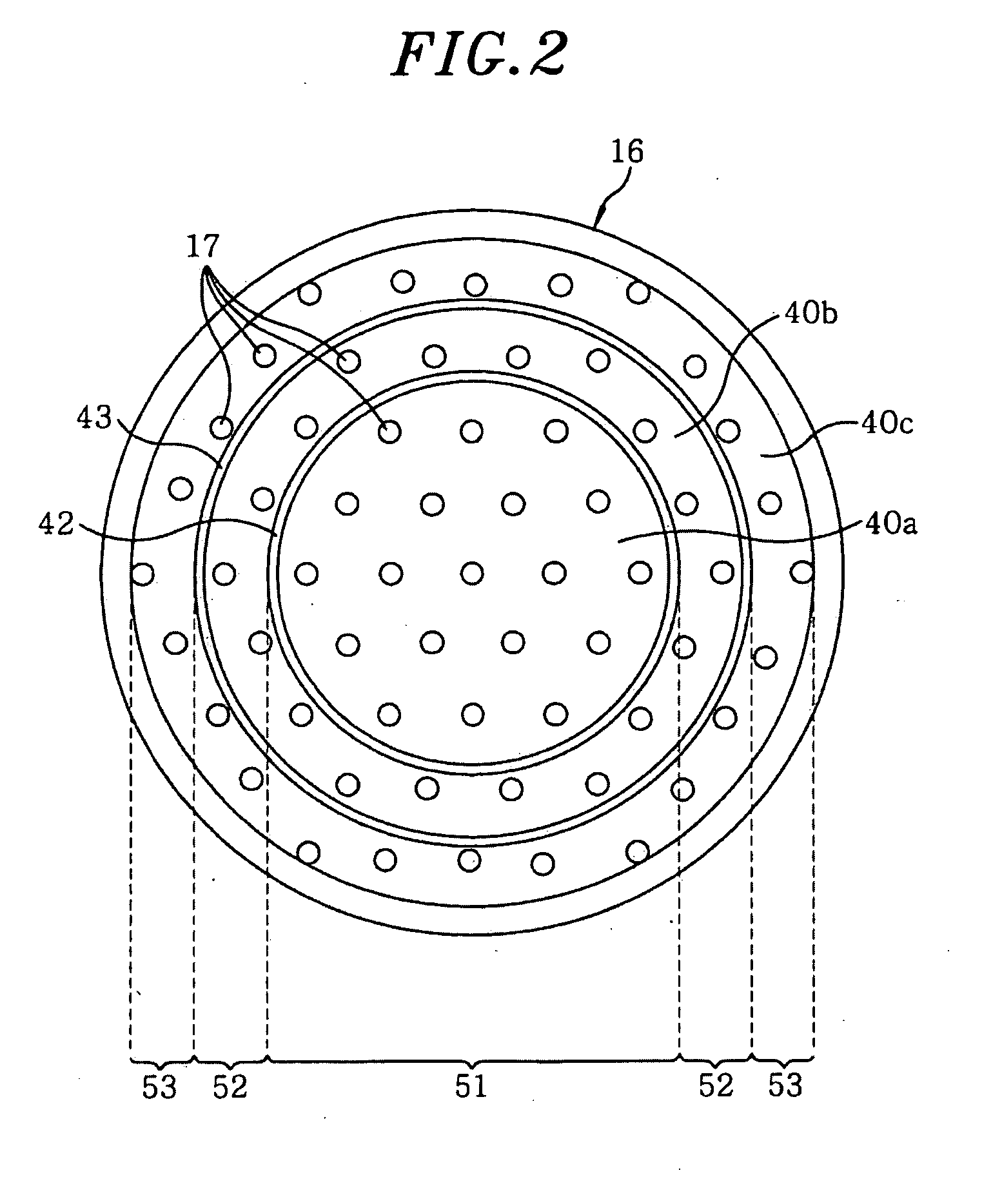

Gas supply device, substrate processing apparatus and substrate processing method

ActiveUS20090117746A1Effective correctionEfficiency optimizationLiquid surface applicatorsSemiconductor/solid-state device manufacturingGas passingProcess engineering

A gas supply mechanism includes a gas introduction member having gas inlet portions through which a gas is introduced into a processing chamber, a processing gas supply unit, a processing gas supply path, branch paths, an additional gas supply unit and an additional gas supply path. The gas inlet portions includes inner gas inlet portions for supplying the gas toward a region where a target substrate is positioned in the chamber and an outer gas inlet portion for introducing the gas toward a region outside an outermost periphery of the target substrate. The branch paths are connected to the inner gas inlet portions, and the additional gas supply path is connected to the outer gas inlet portion.

Owner:TOKYO ELECTRON LTD

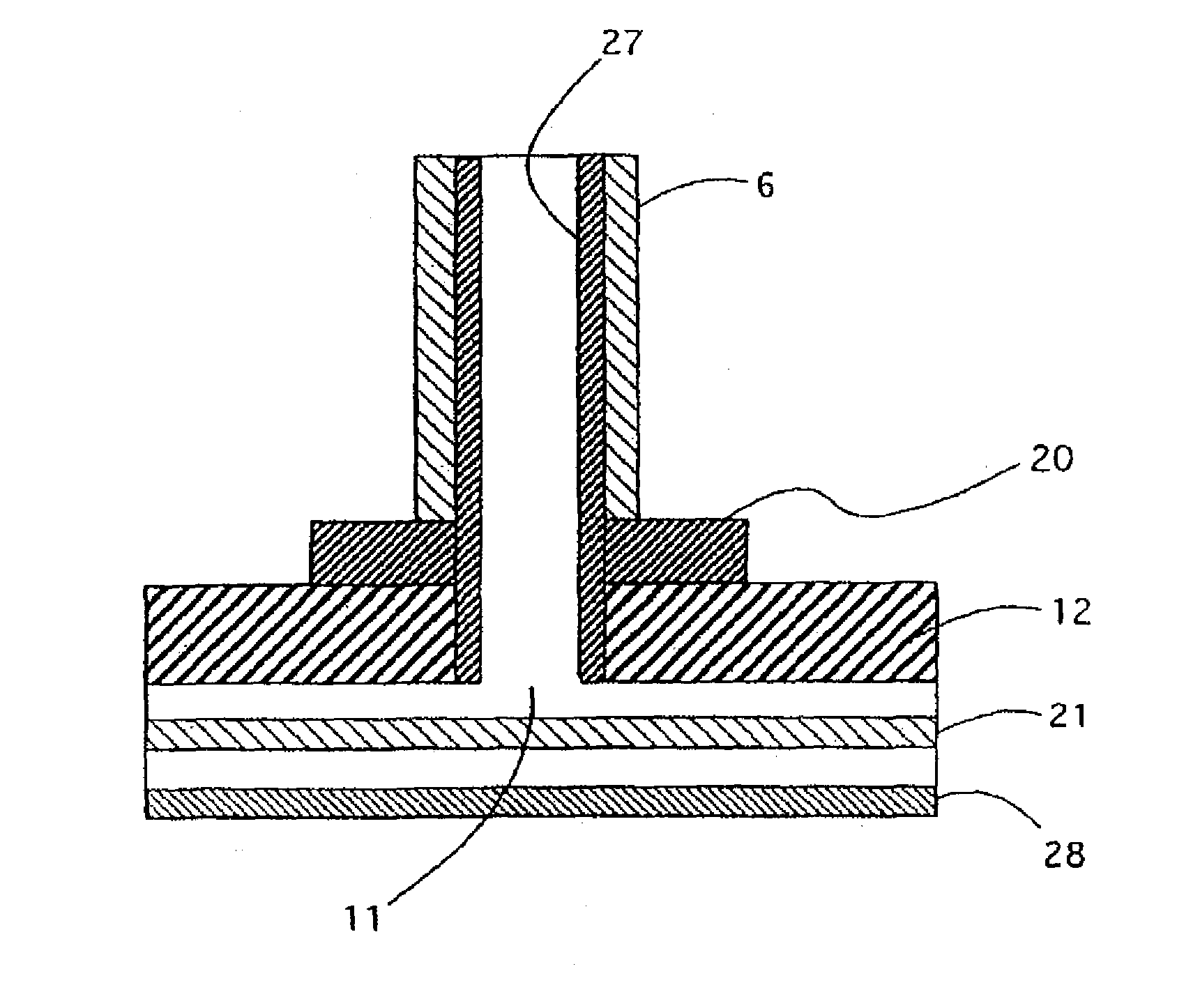

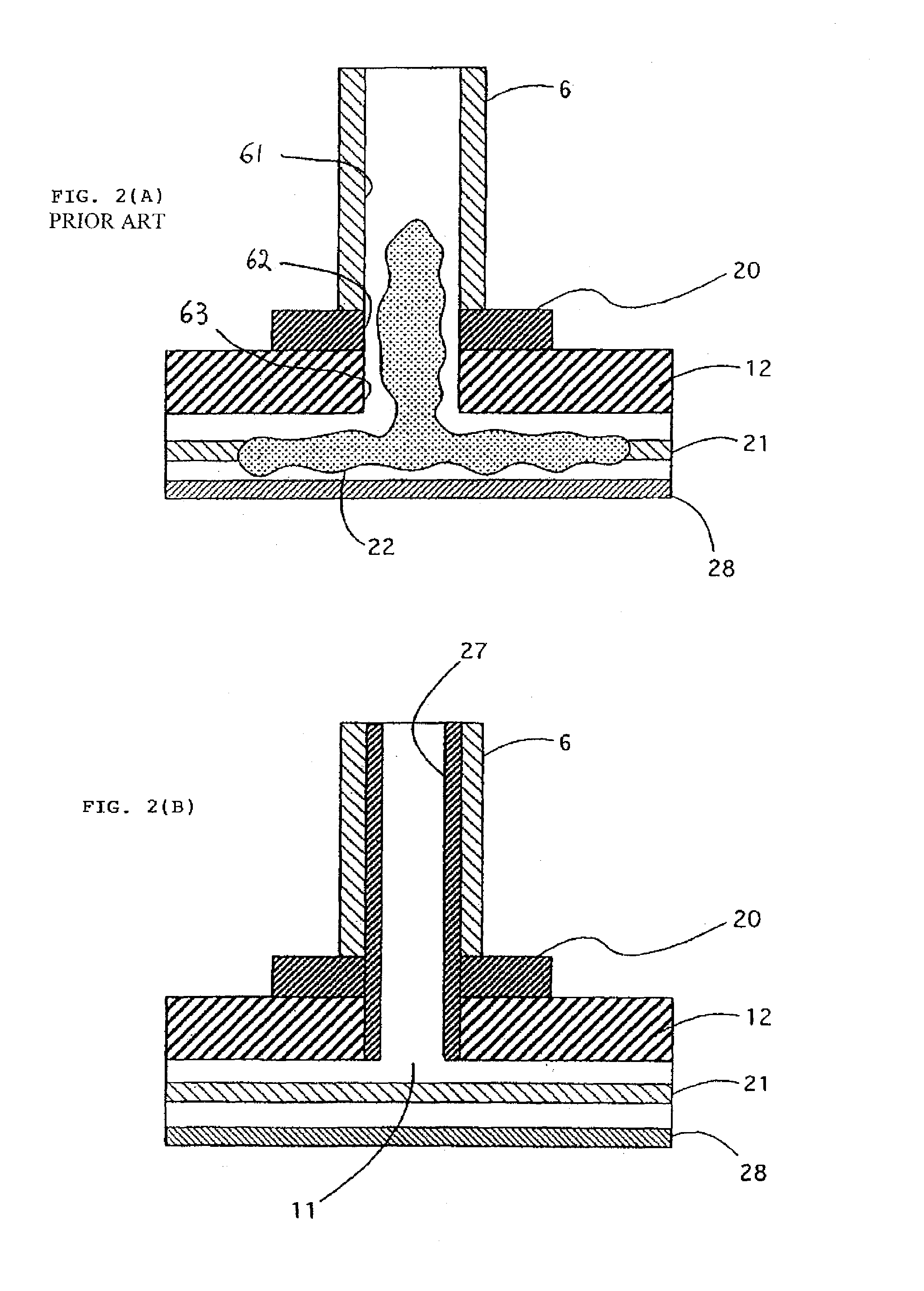

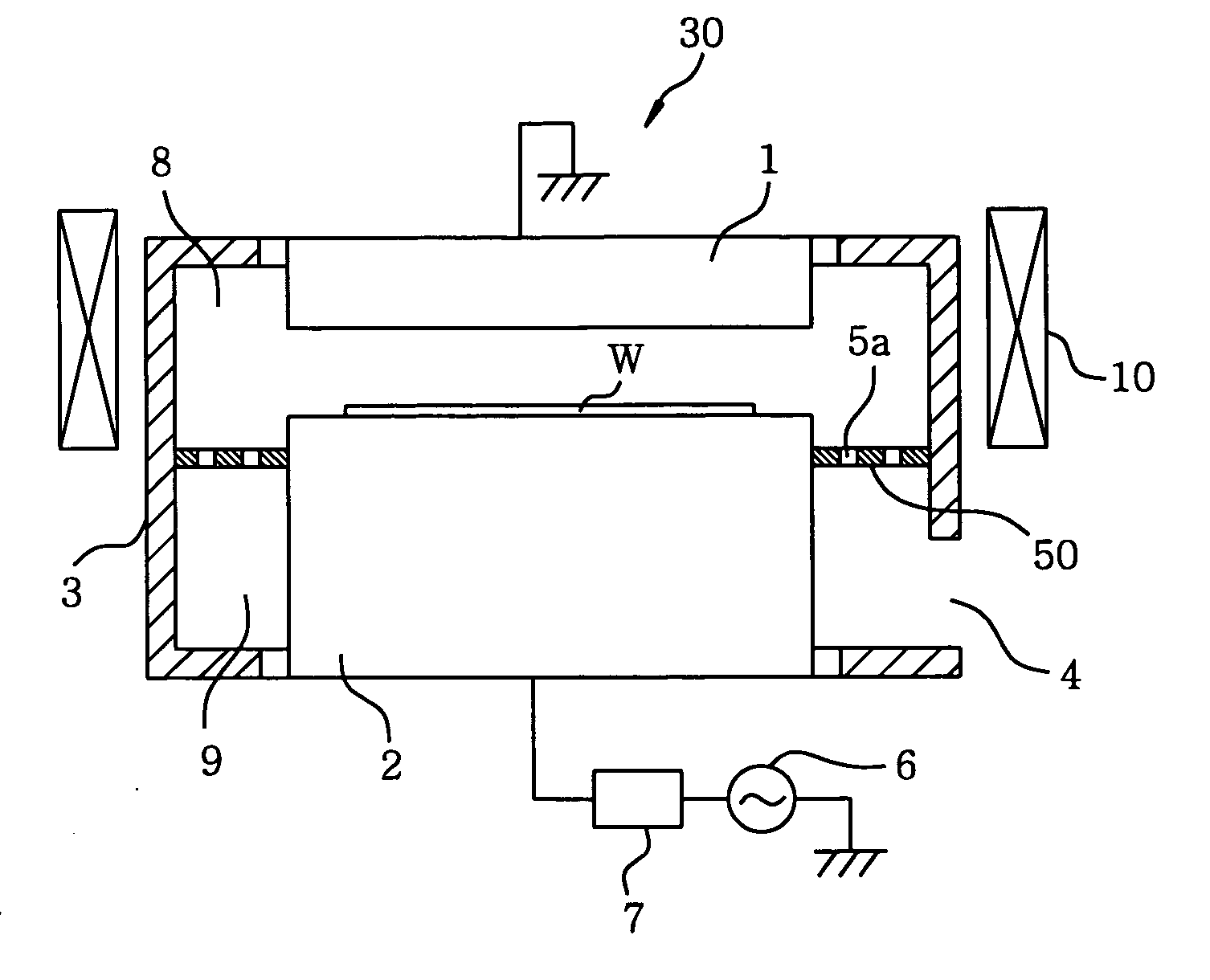

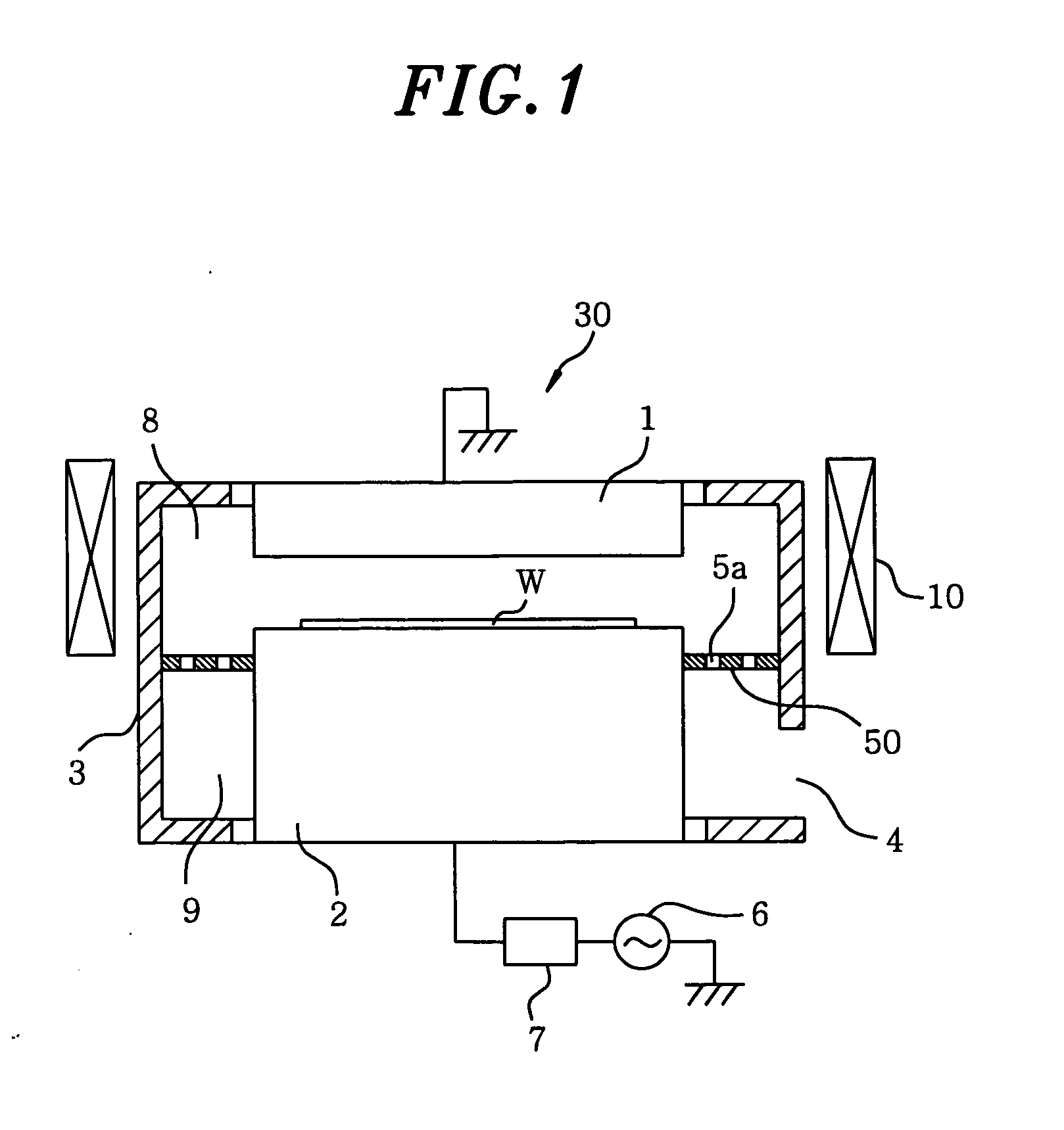

Plasma processing apparatus with insulated gas inlet pore

ActiveUS7712435B2Low reliabilityReduce throughputElectric discharge tubesSemiconductor/solid-state device manufacturingGas passingProduct gas

A plasma processing apparatus includes: a reaction chamber; two electrodes provided inside the reaction chamber for generating a plasma therebetween, wherein at least one of the electrodes has at least one gas inlet pore through which a gas is introduced into the reaction chamber; and a gas inlet pipe coupled to the gas inlet pore for introducing the gas into the reaction chamber. The gas inlet pipe is grounded and insulated from the gas inlet pore, wherein an insulation member is placed inside the gas inlet pipe and the gas inlet pore.

Owner:ASM JAPAN

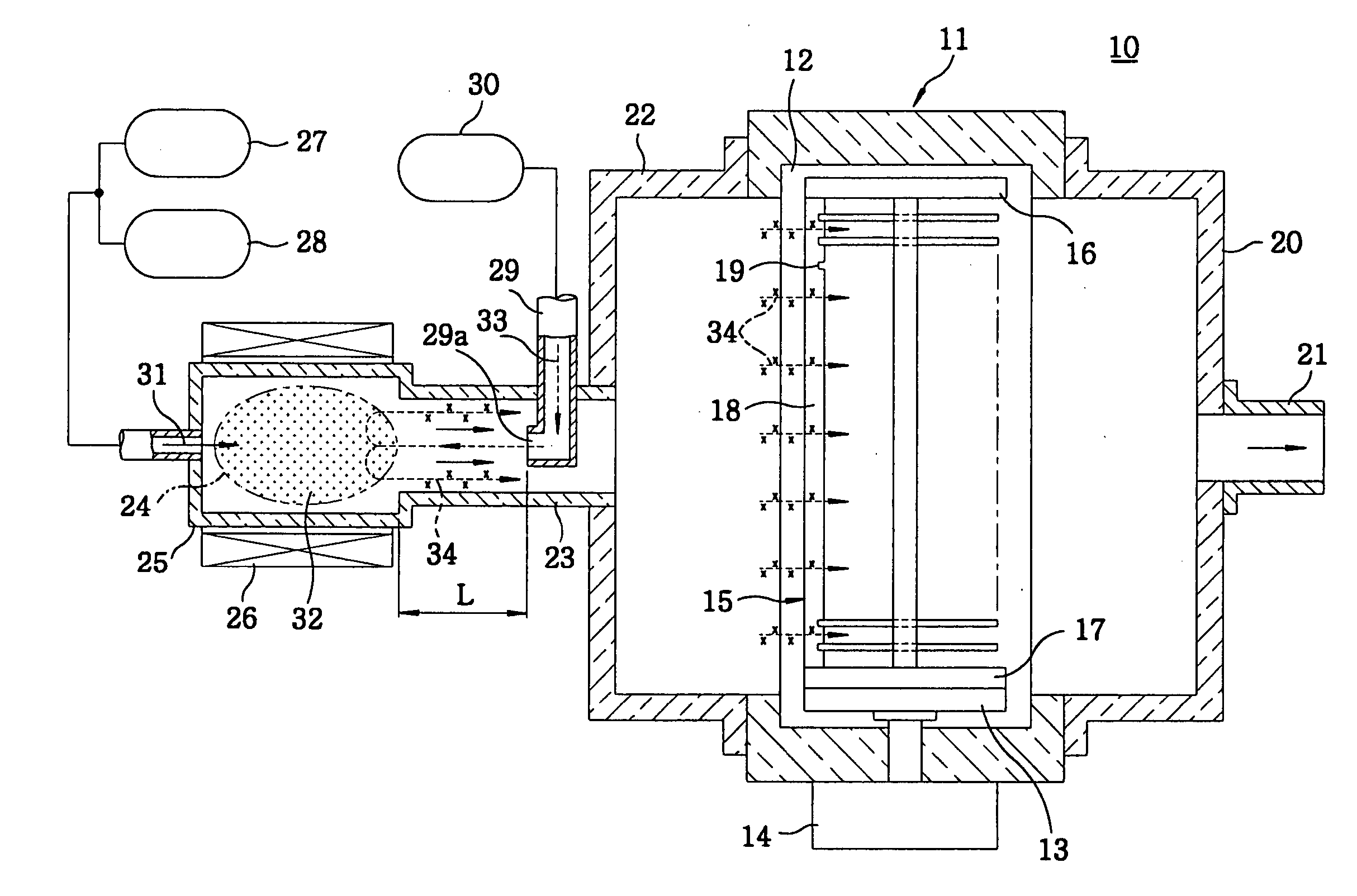

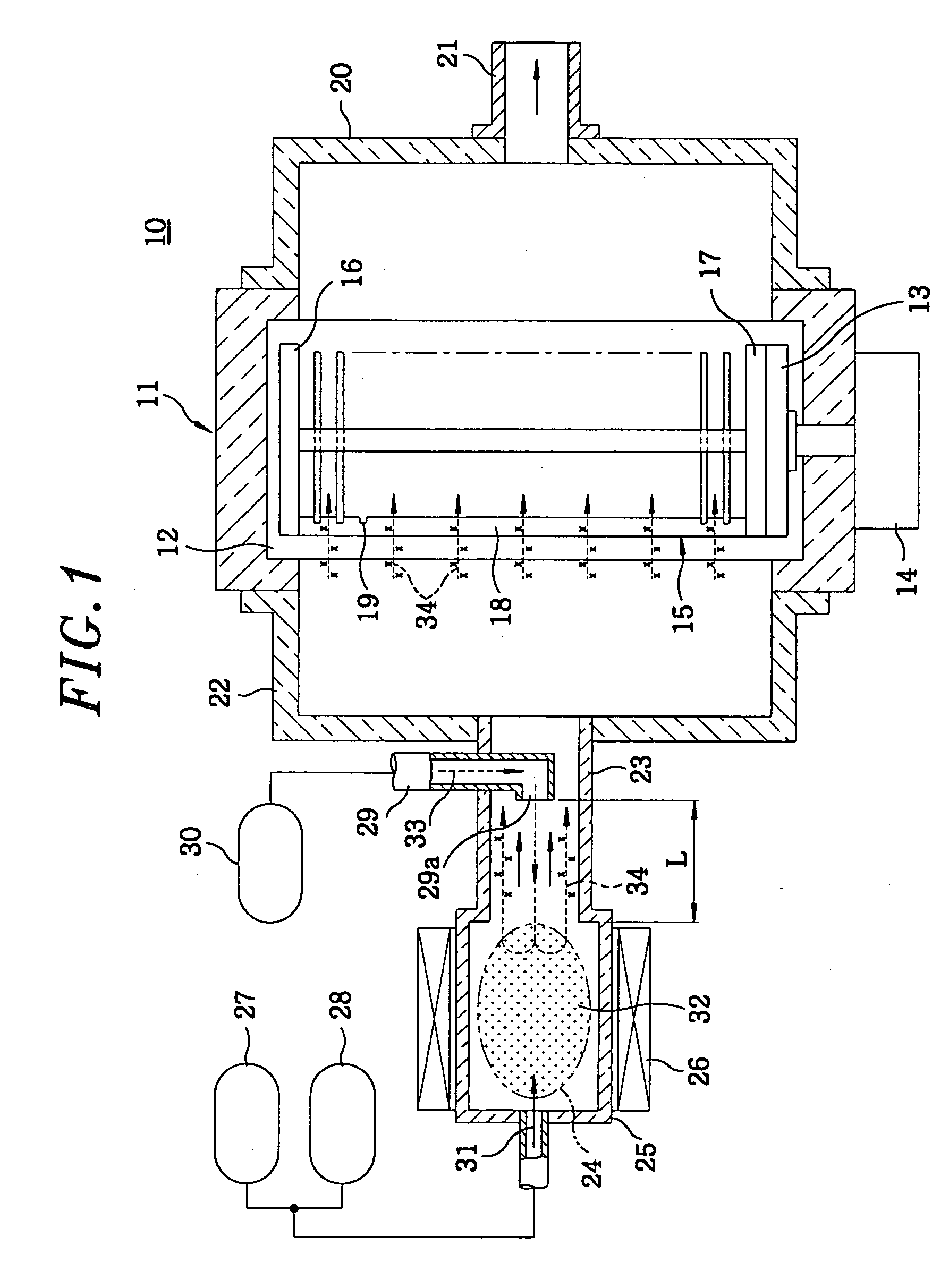

Method and apparatus for processing substrates

InactiveUS20070062646A1Improve throughputUniform removalElectric discharge tubesSemiconductor/solid-state device manufacturingGas passingProcess engineering

A substrate processing apparatus includes a processing chamber and a gas supply line, wherein a natural oxide film removing gas including a first gas activated by a second gas activated by a plasma discharge is supplied to the processing chamber through the gas supply line to remove a natural oxide film on a wafer, and wherein the first gas and the second gas are supplied to the gas supply line along a first direction and a second direction and an angle between the first and the second direction ranges from about 90° to 180°.

Owner:KOKUSA ELECTRIC CO LTD

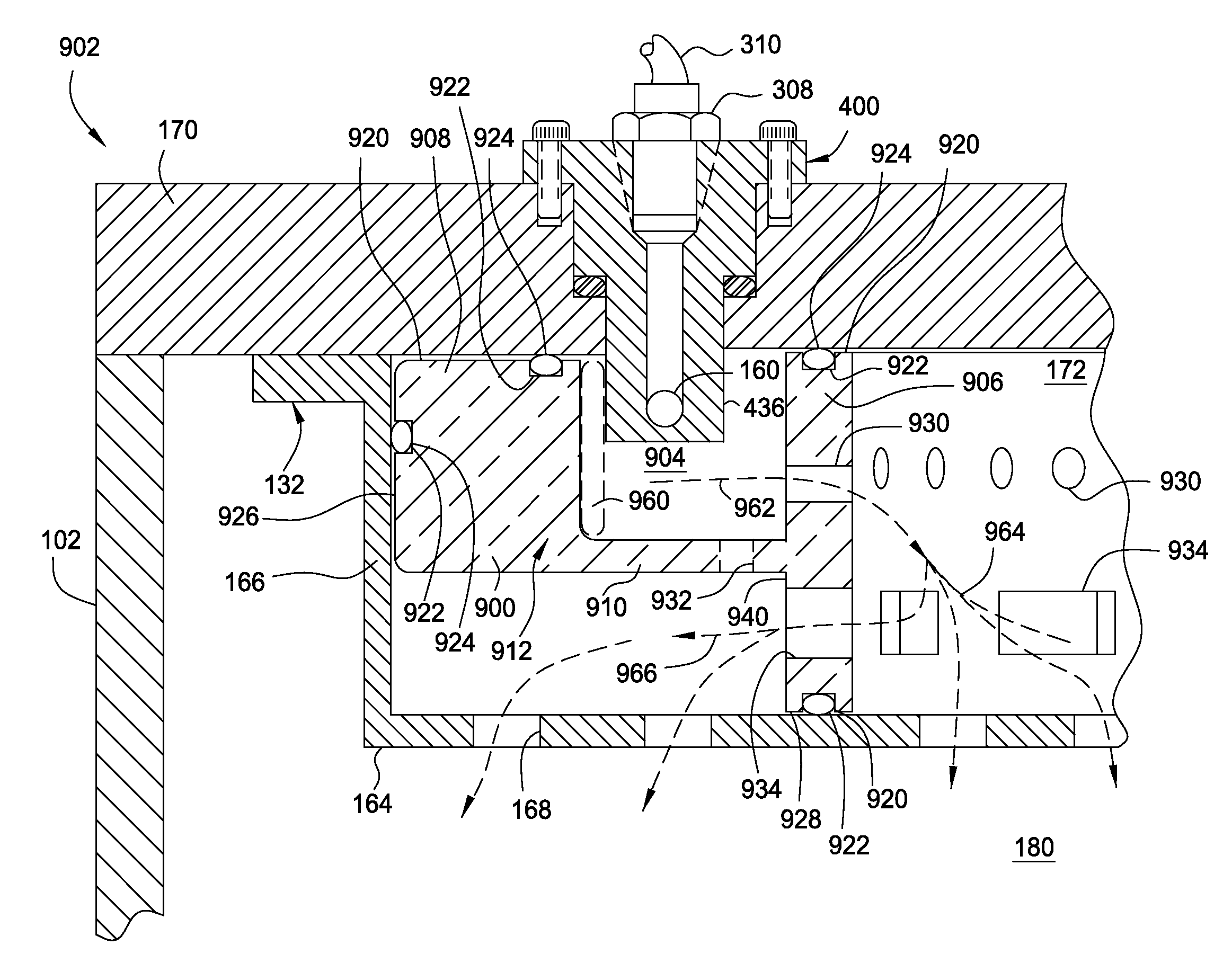

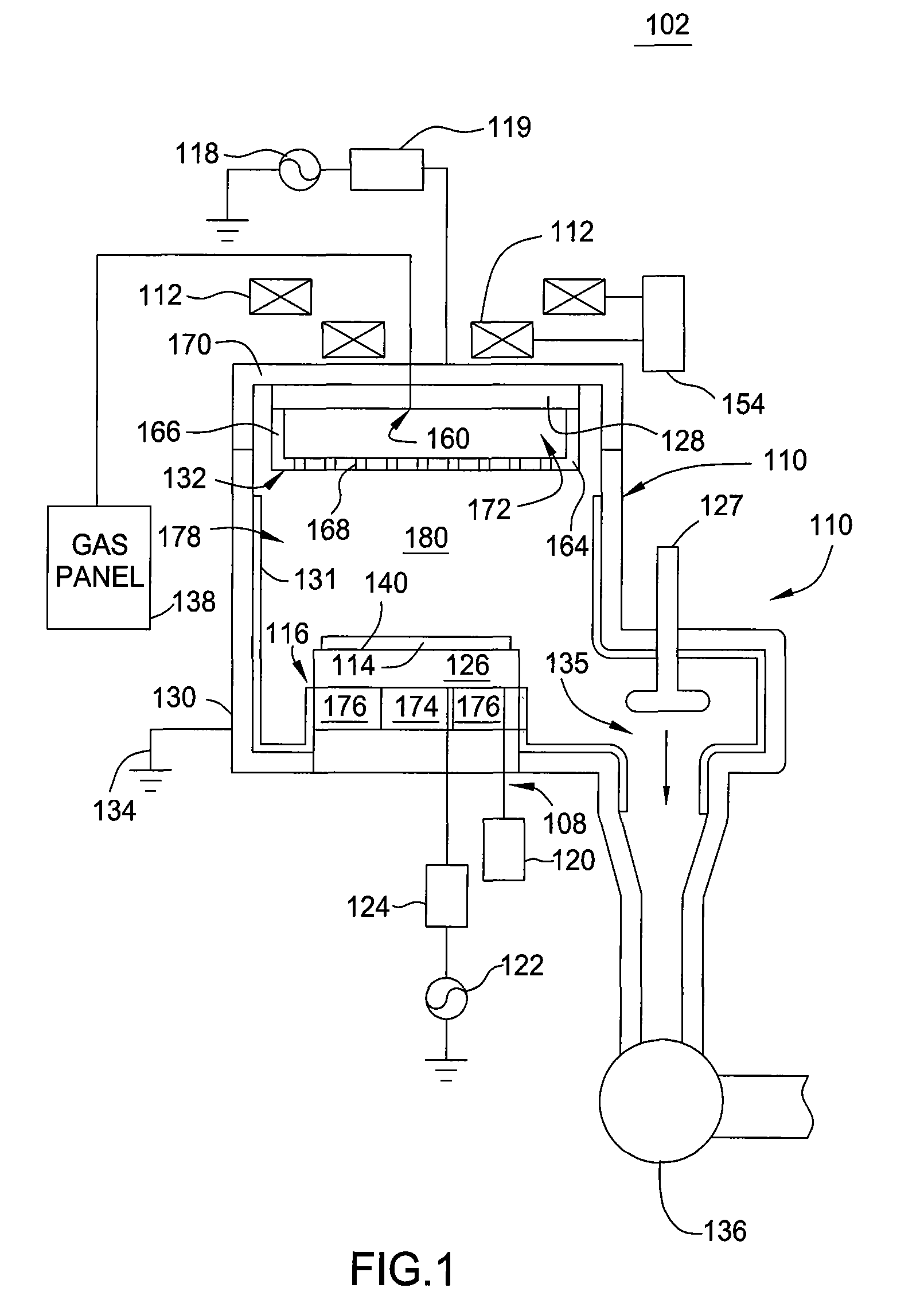

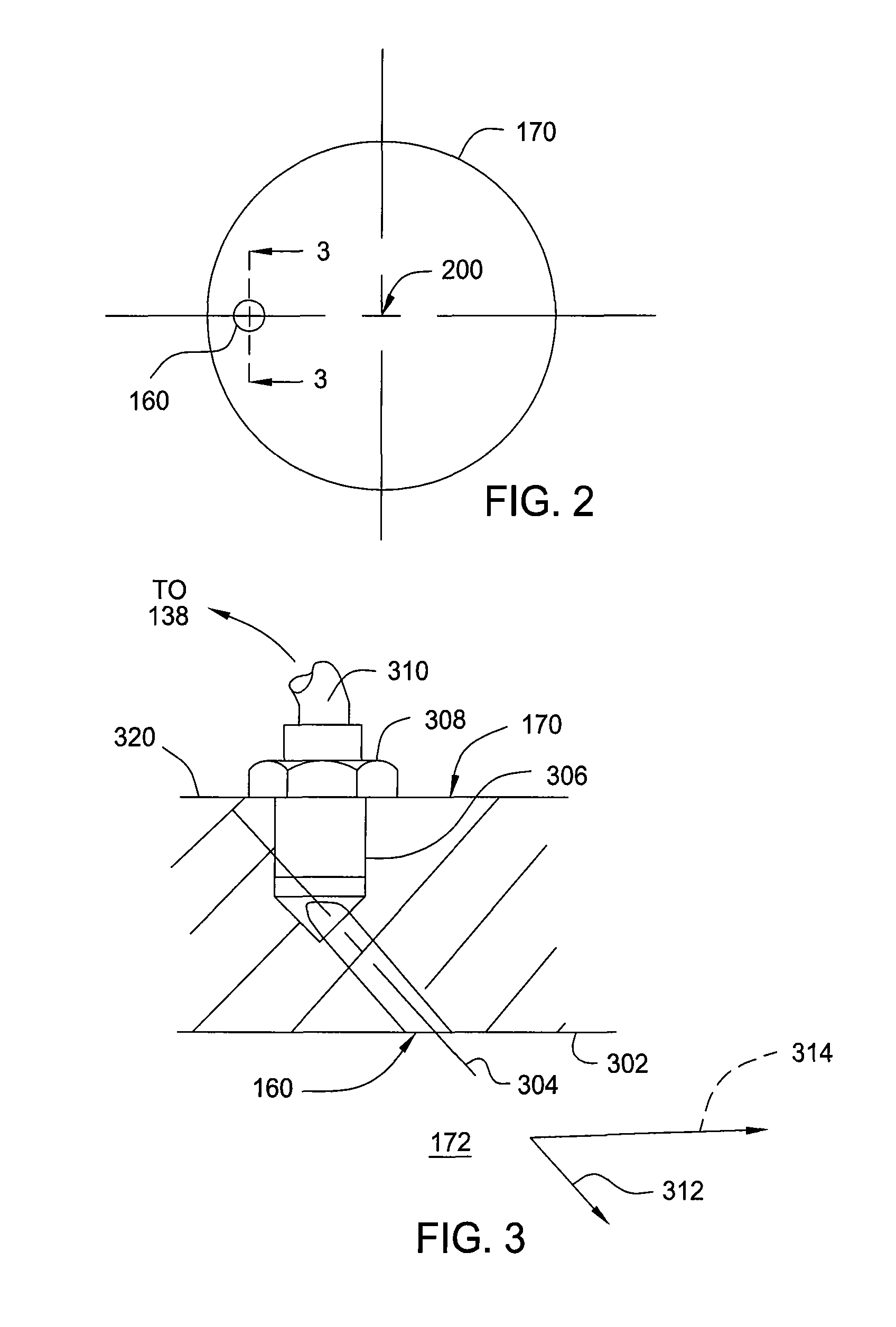

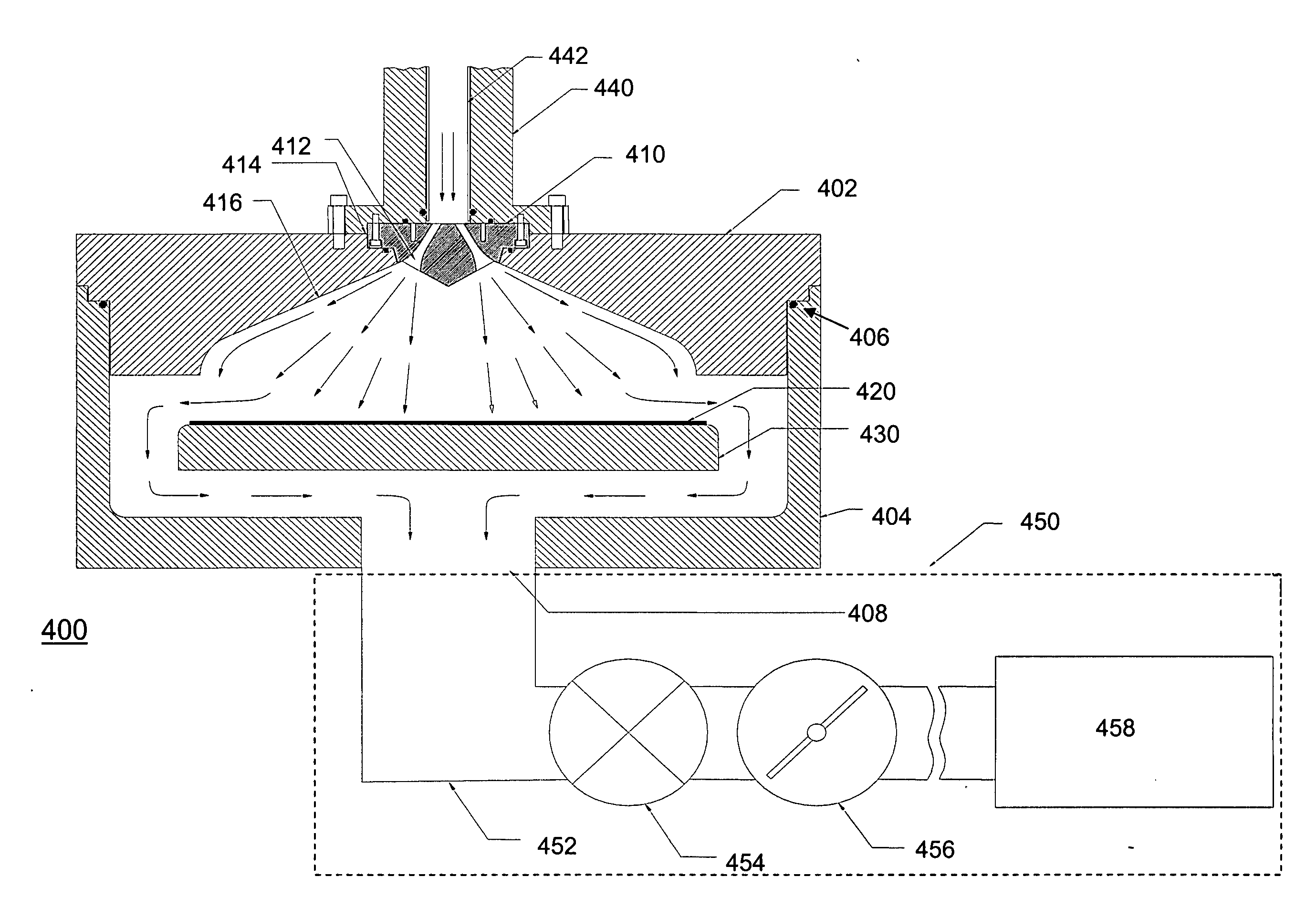

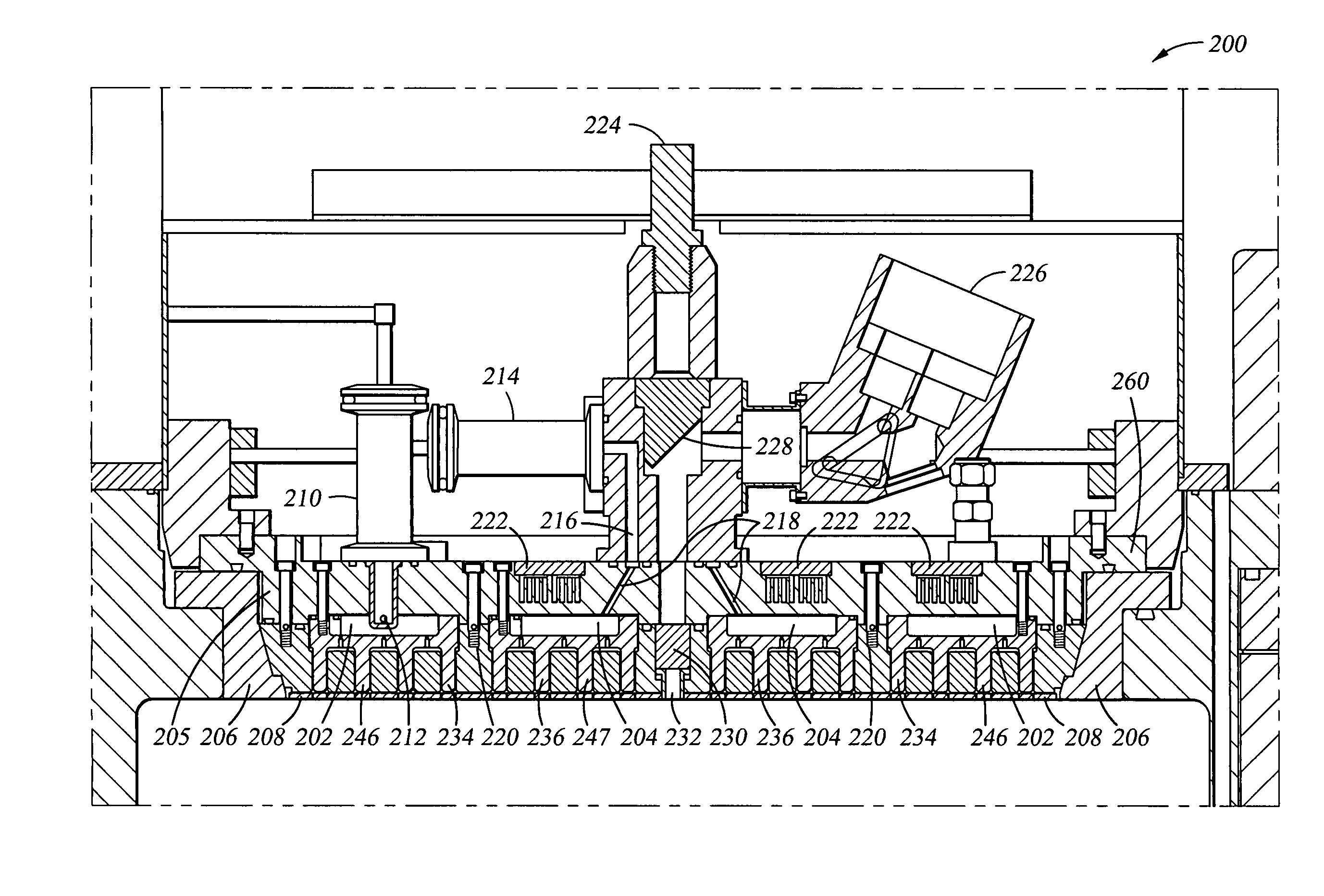

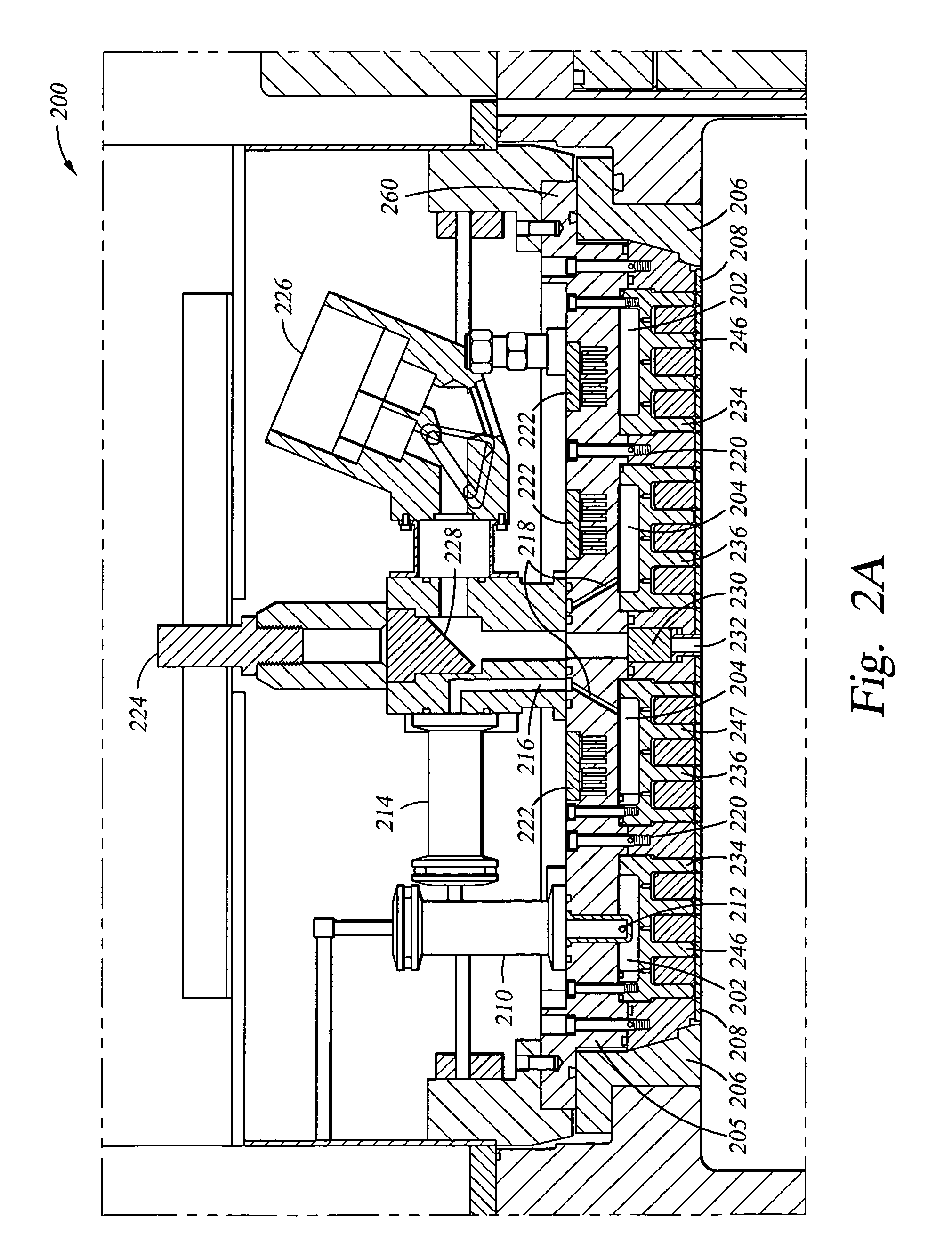

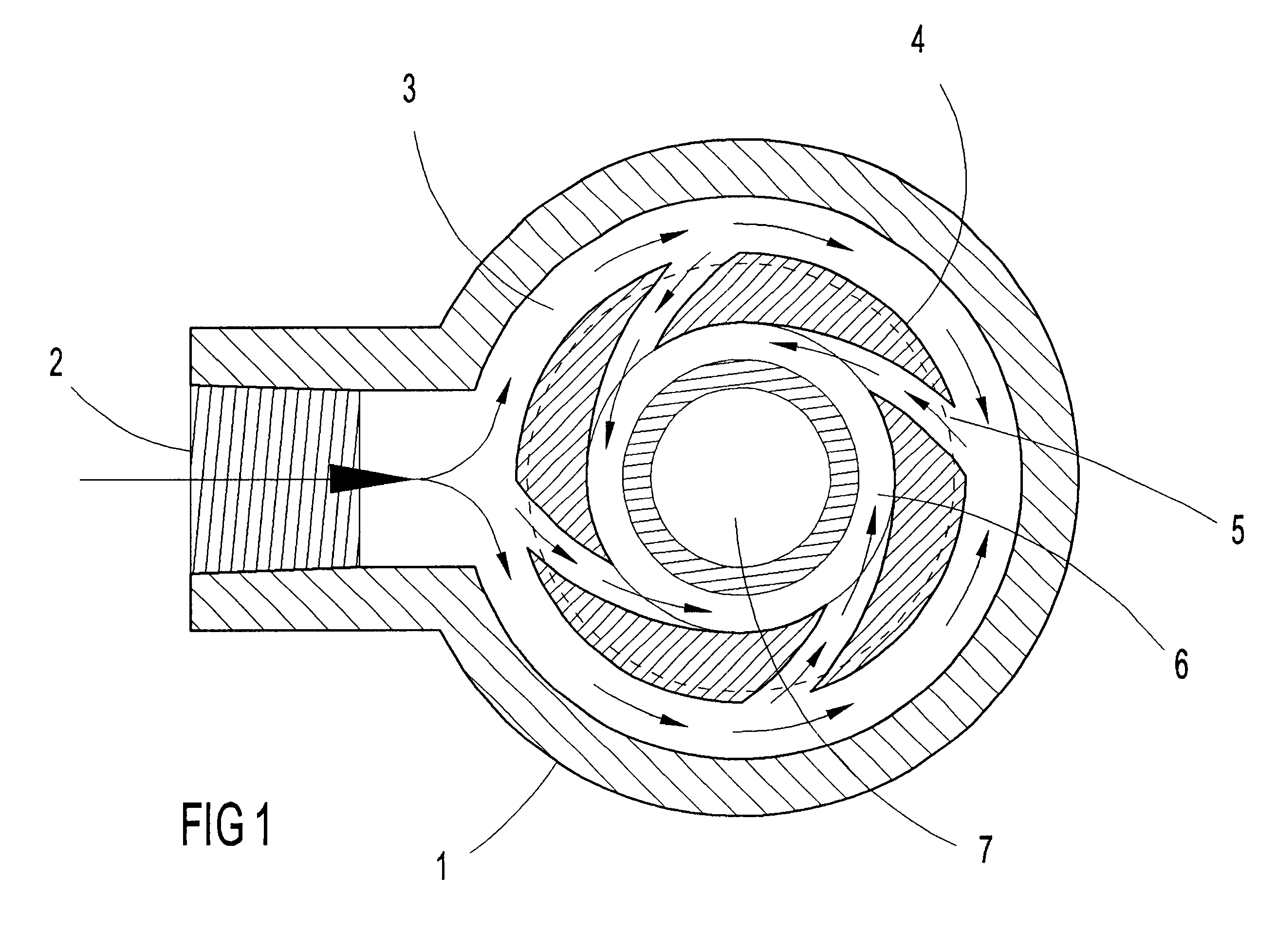

Plasma processing chamber with enhanced gas delivery

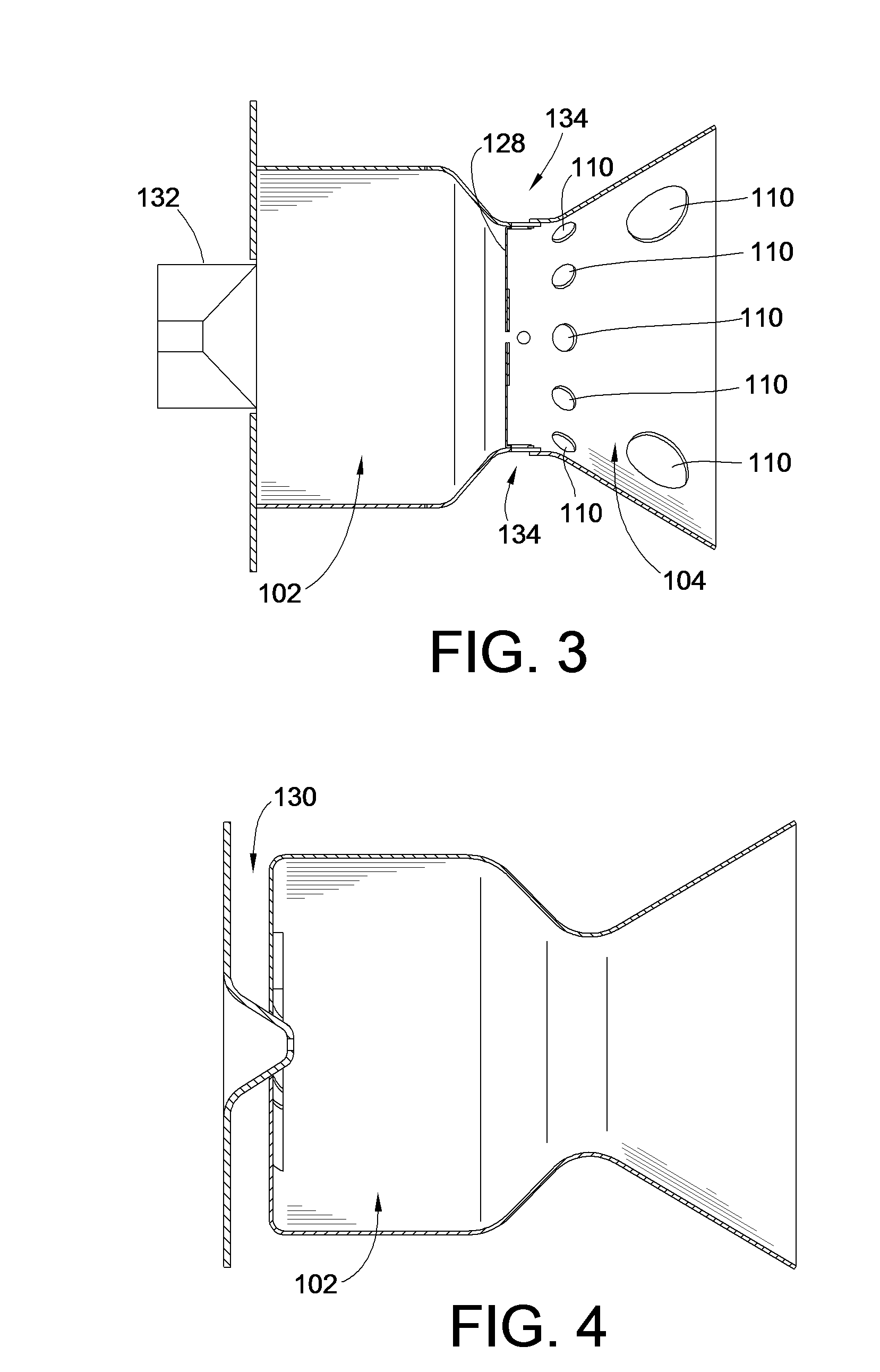

A method and apparatus for providing flow into a processing chamber are provided. In one embodiment, a vacuum processing chamber is provided that includes a substrate support pedestal disposed in an interior volume of a chamber body, a lid enclosing the interior volume, a gas distribution plate positioned below the lid and above the substrate support pedestal, and a vortex inducing gas inlet oriented to induce a vortex of gas circulating in a plenum around a center line of the chamber body prior to the gas passing through the gas distribution plate.

Owner:APPLIED MATERIALS INC

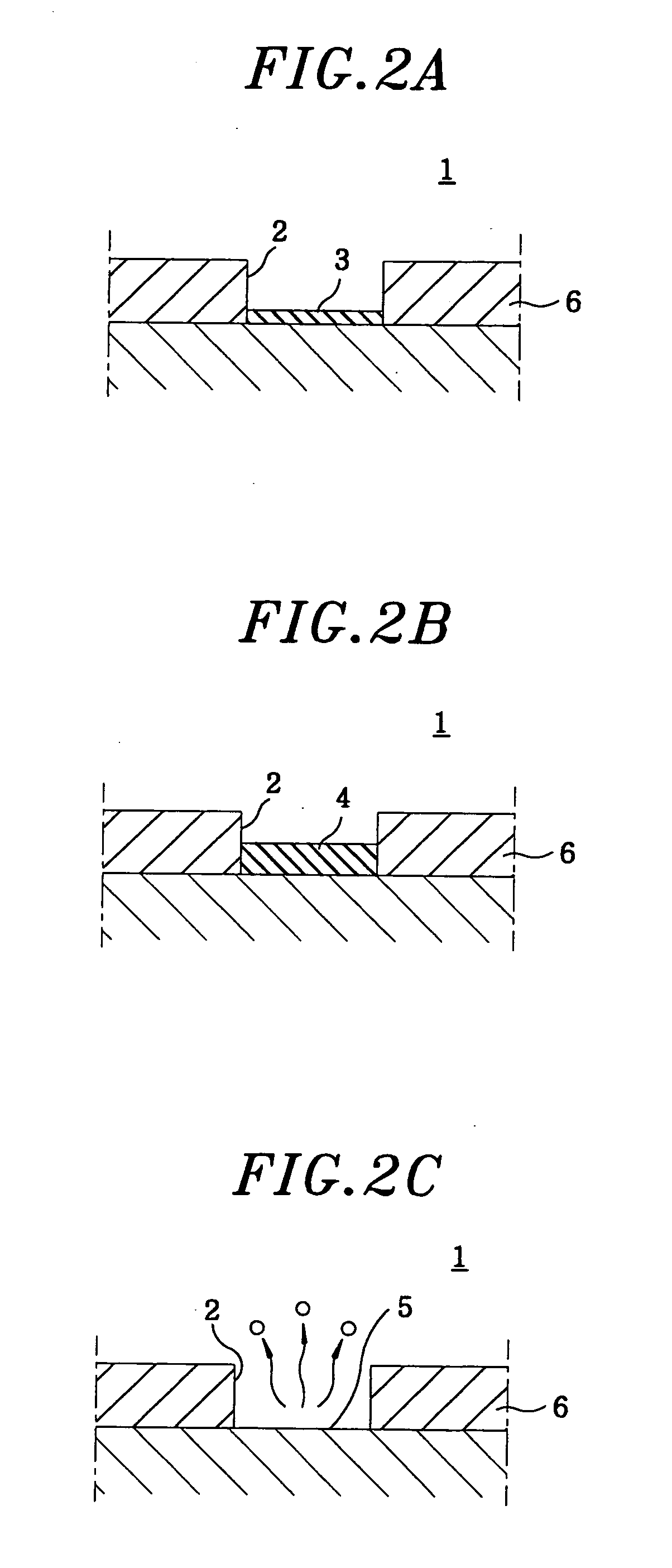

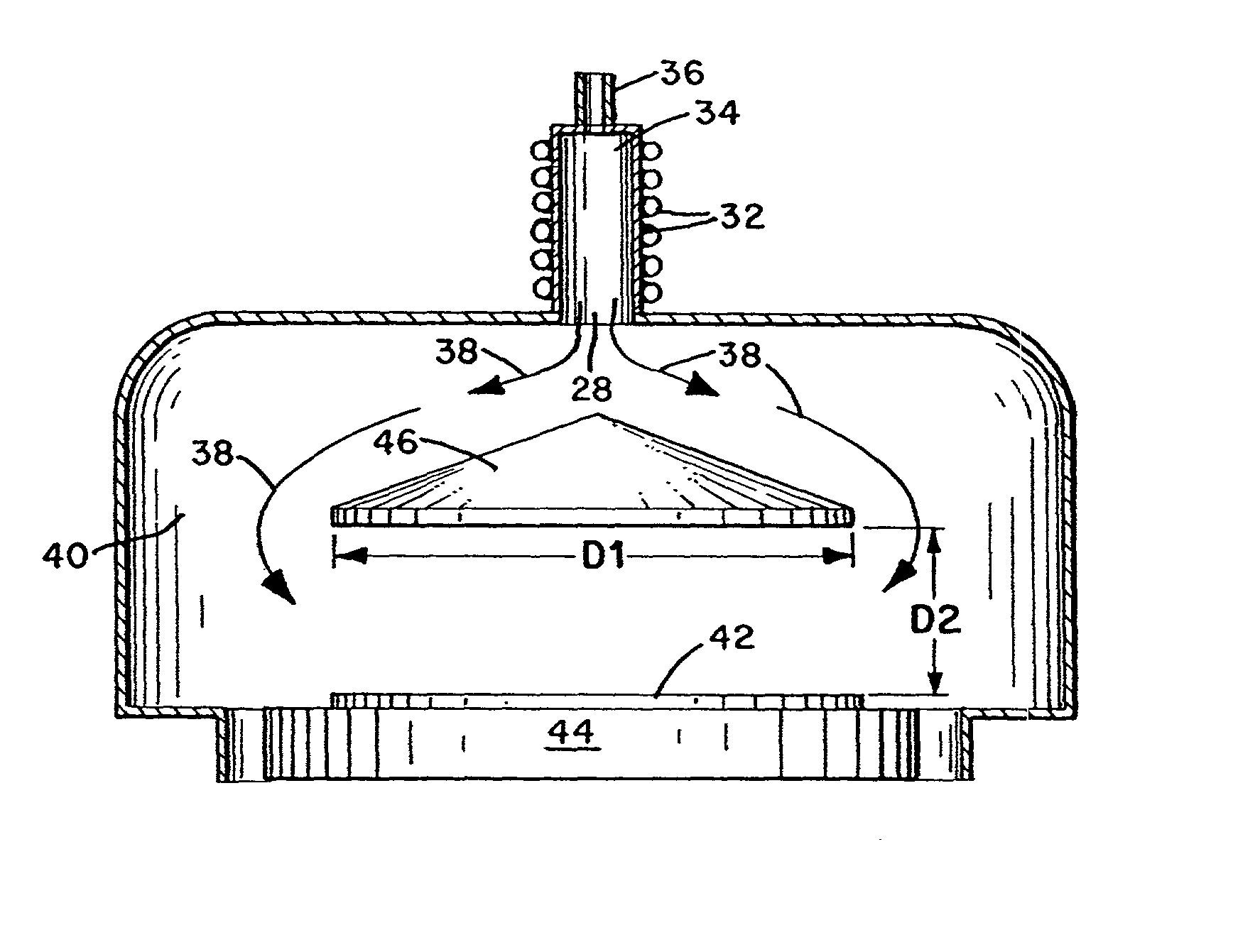

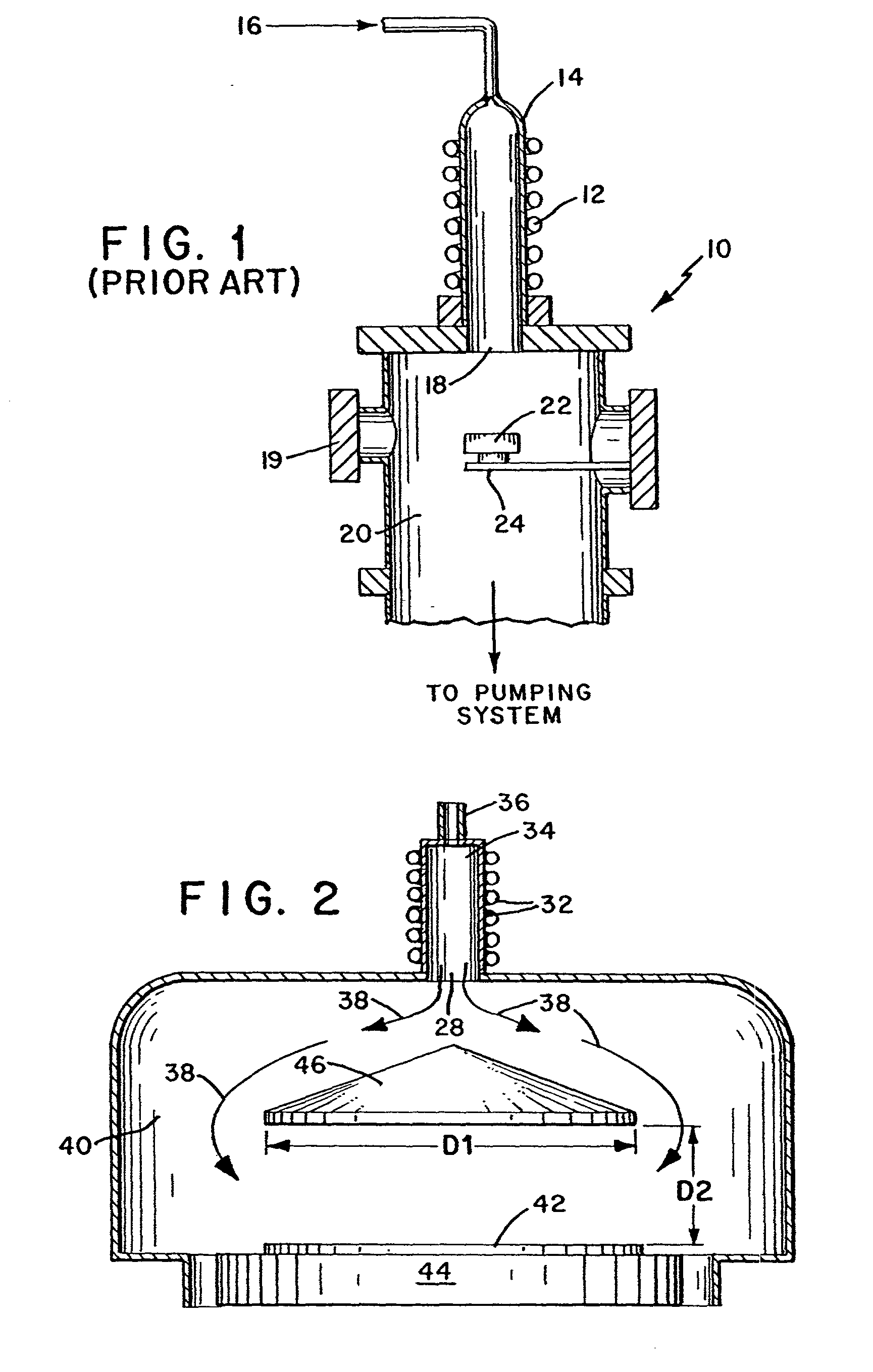

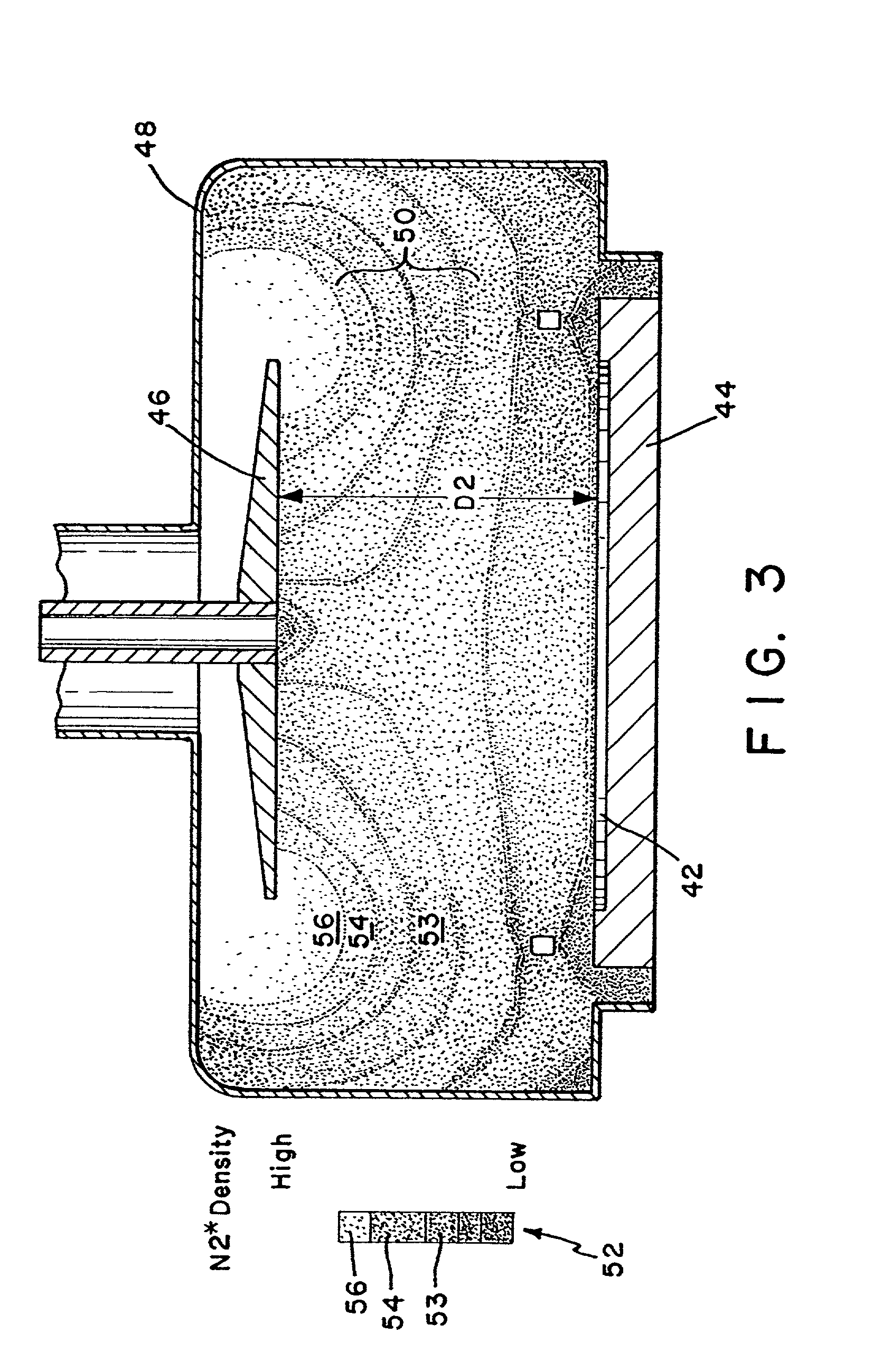

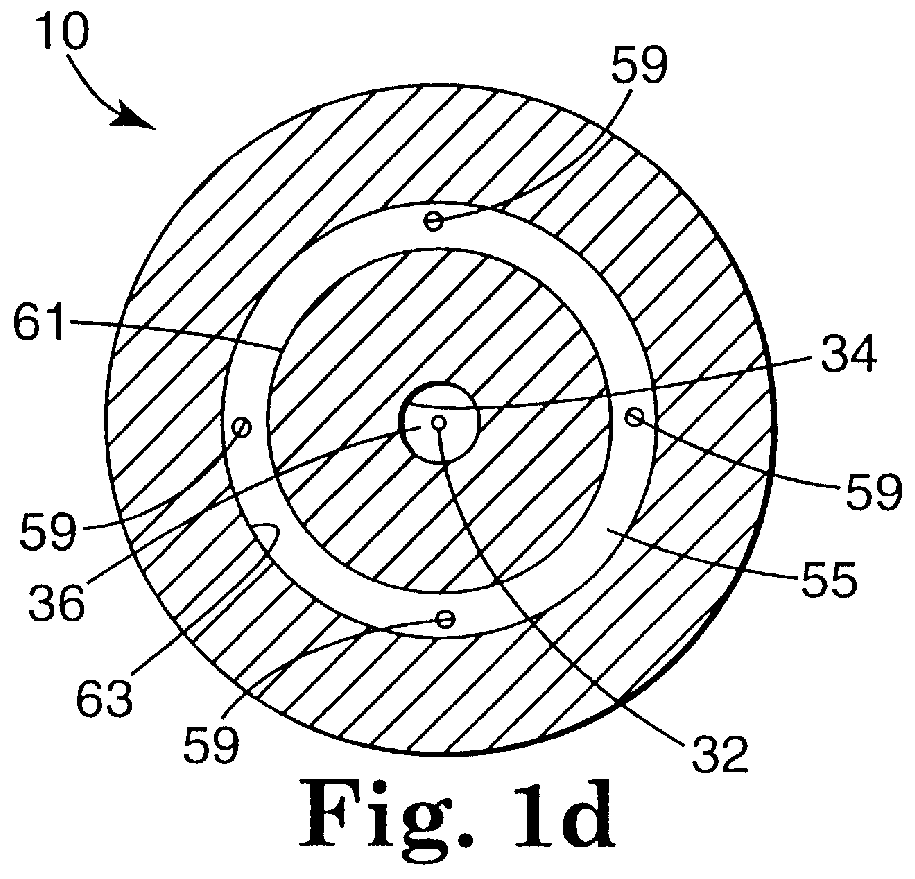

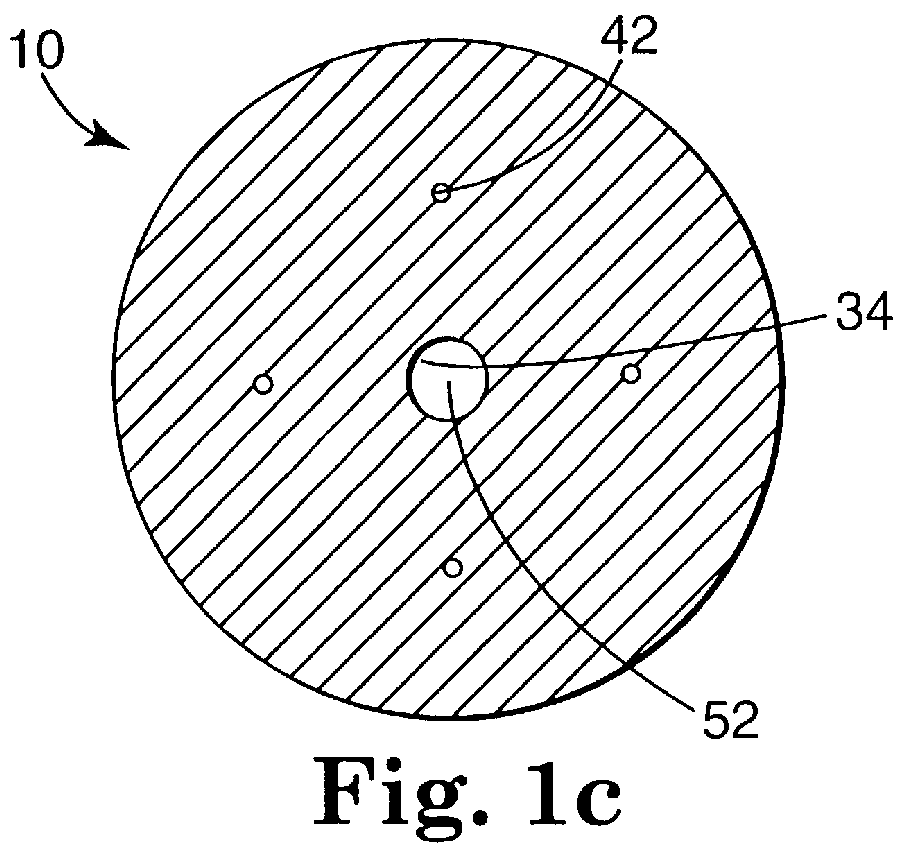

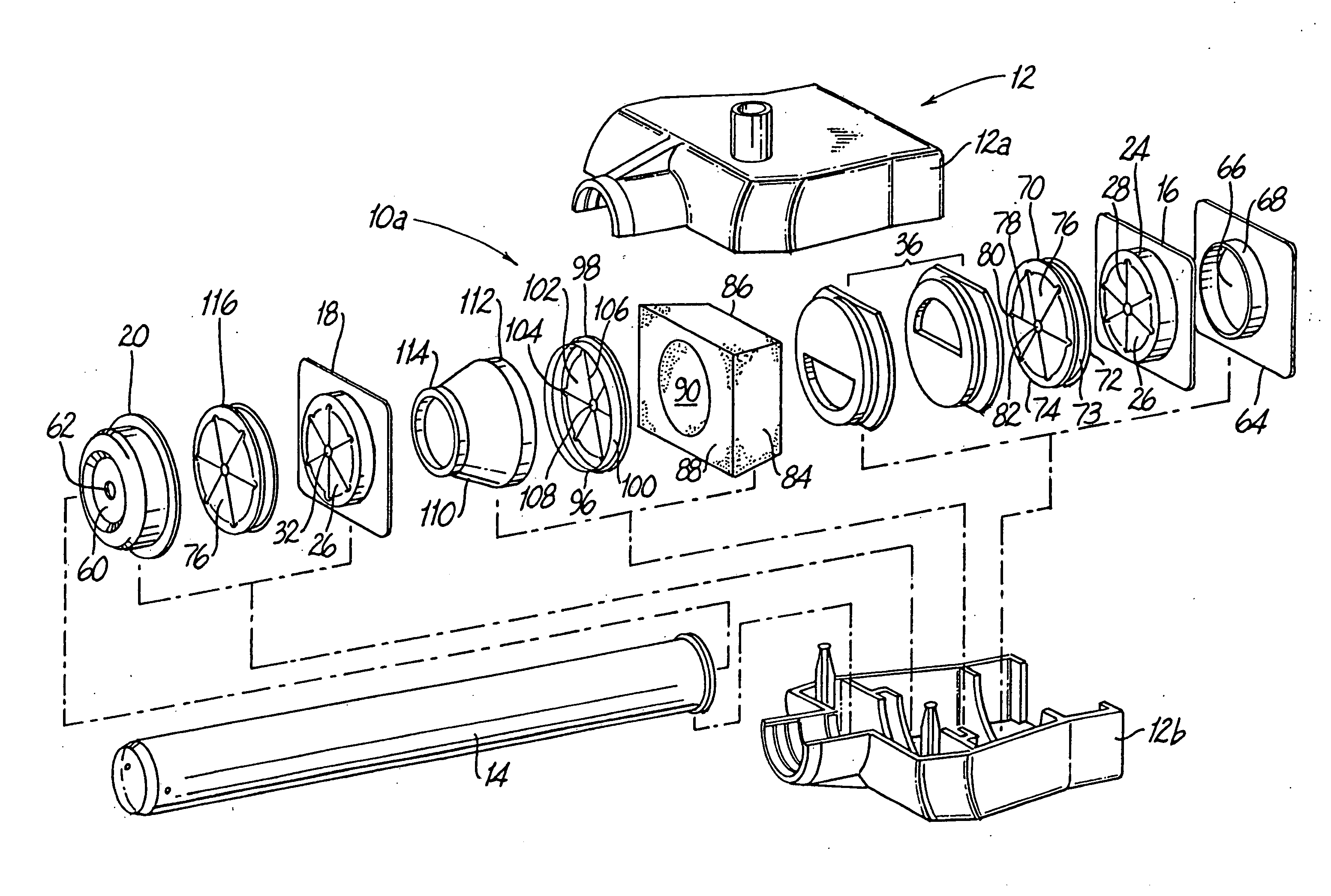

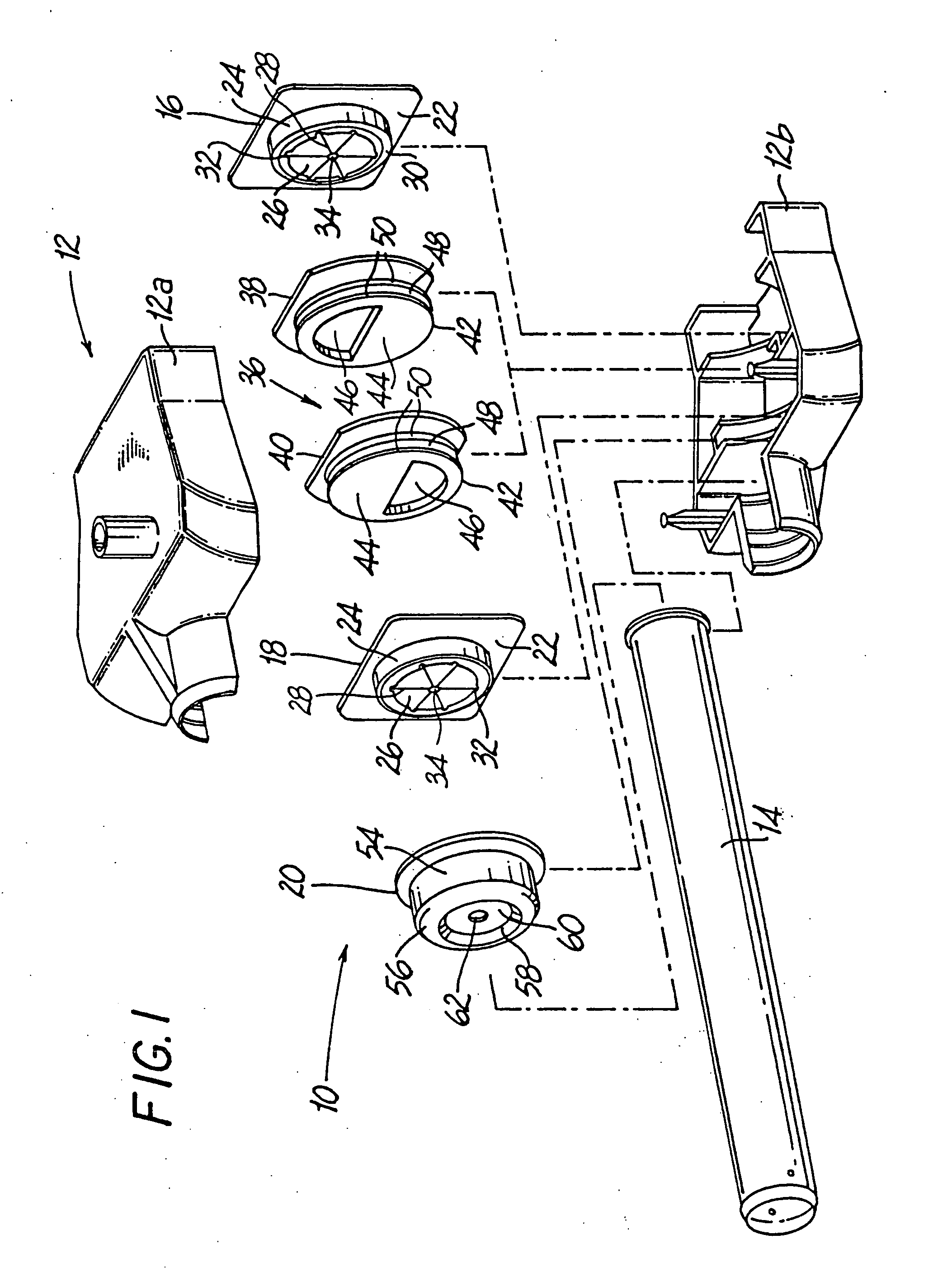

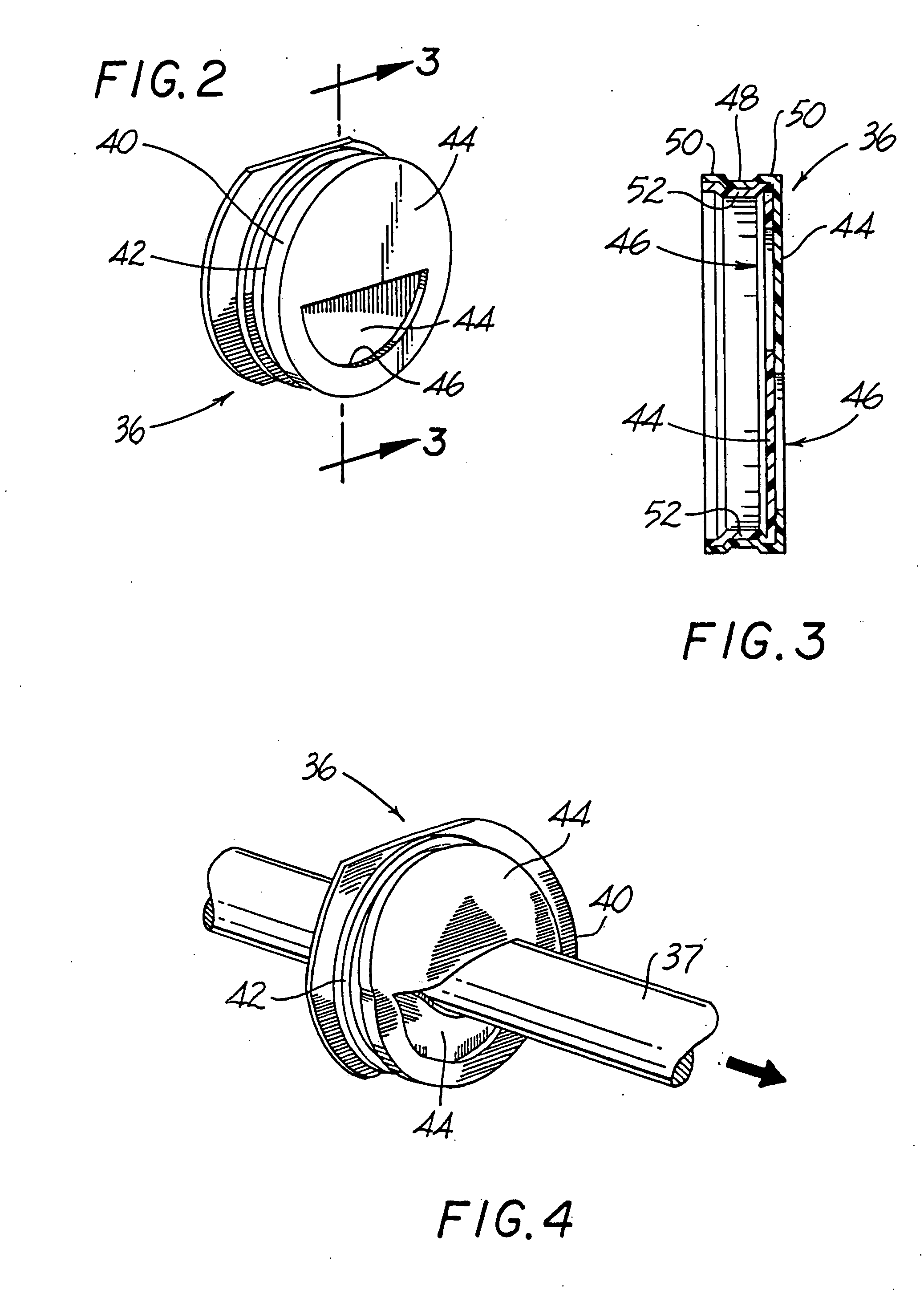

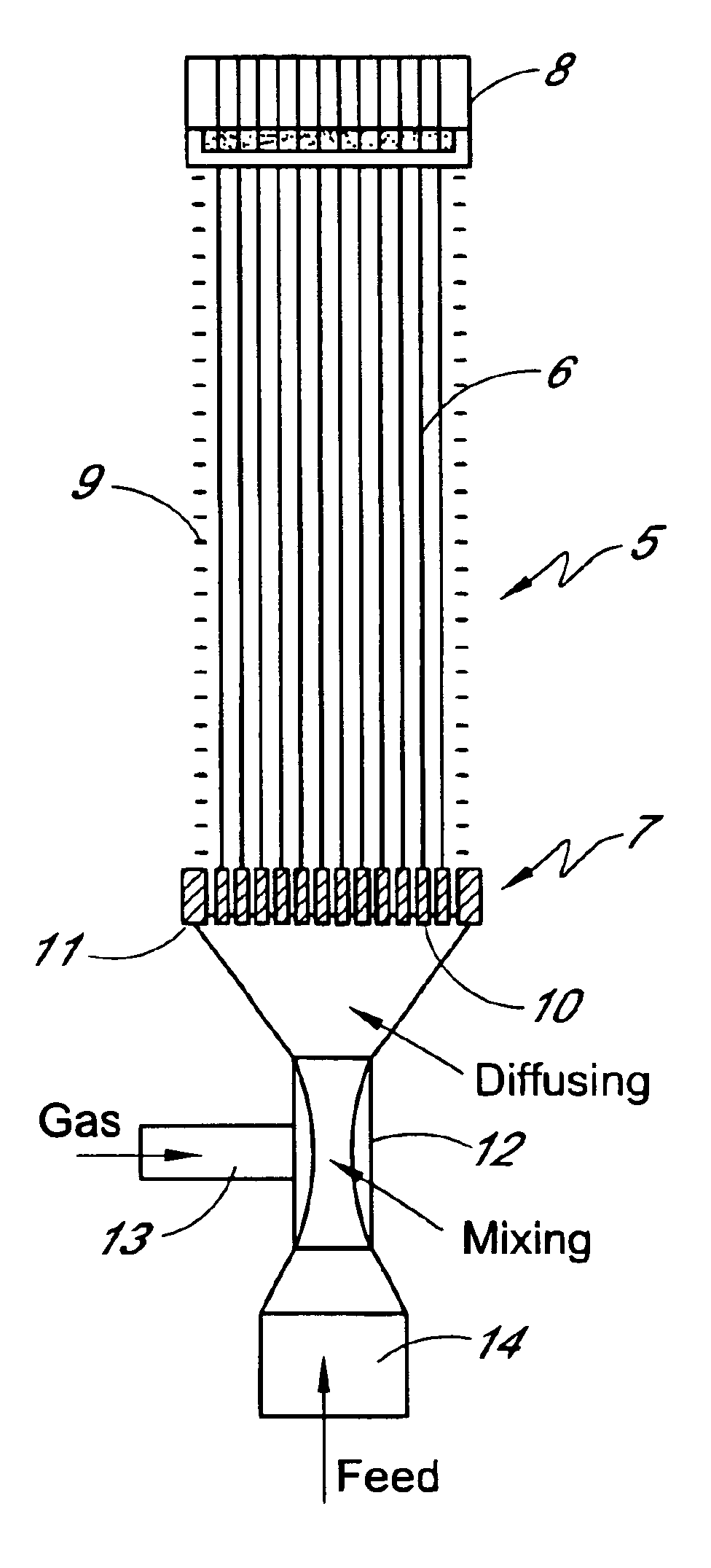

Apparatus and method for injecting and modifying gas concentration of a meta-stable or atomic species in a downstream plasma reactor

InactiveUS20020029747A1Reduce lossesElectric discharge tubesChemical vapor deposition coatingGas passingActive matter

This invention provides an apparatus and method for injecting gas within a plasma reactor and tailoring the distribution of an active species generated by the remote plasma source over the substrate or wafer. The distribution may be made more or less uniform, wafer-edge concentrated, or wafer-center concentrated. A contoured plate or profiler is provided for modifying the distribution. The profiler is an axially symmetric plate, having a narrow top end and a wider bottom end, shaped to redistribute the gas flow incident upon it. The profiler is situated below an input port within the plasma reactor chamber and above the wafer. The method for tailoring the distribution of the active species over the substrate includes predetermining the profiler diameter and adjusting the profiler height over the substrate. A coaxial injector tube, for the concurrent injection of activated and non-activated gas species, allows gases (or gas mixtures) to be delivered in an axially symmetric manner whereby one gas can be excited in a high density RF plasma, while the other gas can be prevented from excitation and / or dissociation caused by exposure to the plasma or heated surfaces in the source apparatus. The gas admixture that is not to be excited or dissociated prior to contact with the wafer surface is shielded from direct exposure to the RF field surrounding the plasma confinement tube. The tube walls are also shielded from the infrared energy emitted from the plasma. The profiler is used in conjunction with the coaxial injector tube for redistributing the excited gases emerging from the injector tube, while allowing the non-excited gases to pass through its center.

Owner:NOVELLUS SYSTEMS

High strip rate downstream chamber

ActiveUS20060219361A1Avoid radiationAbsorb thermal expansionElectric discharge tubesDecorative surface effectsSpray nozzleGas passing

A gas chamber contains upper and lower chamber bodies forming a cavity, a heating chuck for a wafer, a remote gas source, and an exhaust unit. Gas is injected into the cavity through channels in an injector. Each channel has sections that are bent with respect to each other at a sufficient angle to substantially eliminate entering light rays entering the channel from exiting the channel without reflection. The channels have funnel-shaped nozzles at end points proximate to the chuck. The injector also has thermal expansion relief slots and small gaps between the injector and mating surfaces of the chamber and gas source. The temperature of the injector is controlled by a cooling liquid in cooling channels and electrical heaters in receptacles of the injector. The upper chamber body is funnel-shaped and curves downward at an end of the upper chamber body proximate to the chuck.

Owner:LAM RES CORP

Gas injection apparatus for semiconductor processing system

InactiveUS7252716B2Improve uniformityEvenly distributedVacuum evaporation coatingSemiconductor/solid-state device manufacturingReactive gasGas passing

A gas injection apparatus for injecting a reactive gas into a reaction chamber of a semiconductor processing system includes an injector in contact with an inner surface of a wall of the reaction chamber. The injector has a plurality of nozzles through which the reactive gas is injected into the reaction chamber. A gas inlet penetrates the wall of the reaction chamber. A manifold is disposed between the wall of the reaction chamber and the injector, and supplies the reactive gas flowing through the gas inlet to the nozzles. Gas channels in the manifold are arranged on a plurality of levels to equalize the lengths of gas paths connecting the gas inlet to each of the plurality of nozzles. This configuration makes the flow rate of reactive gas supplied through each of the plurality of nozzles to the reaction chamber uniform.

Owner:SAMSUNG ELECTRONICS CO LTD

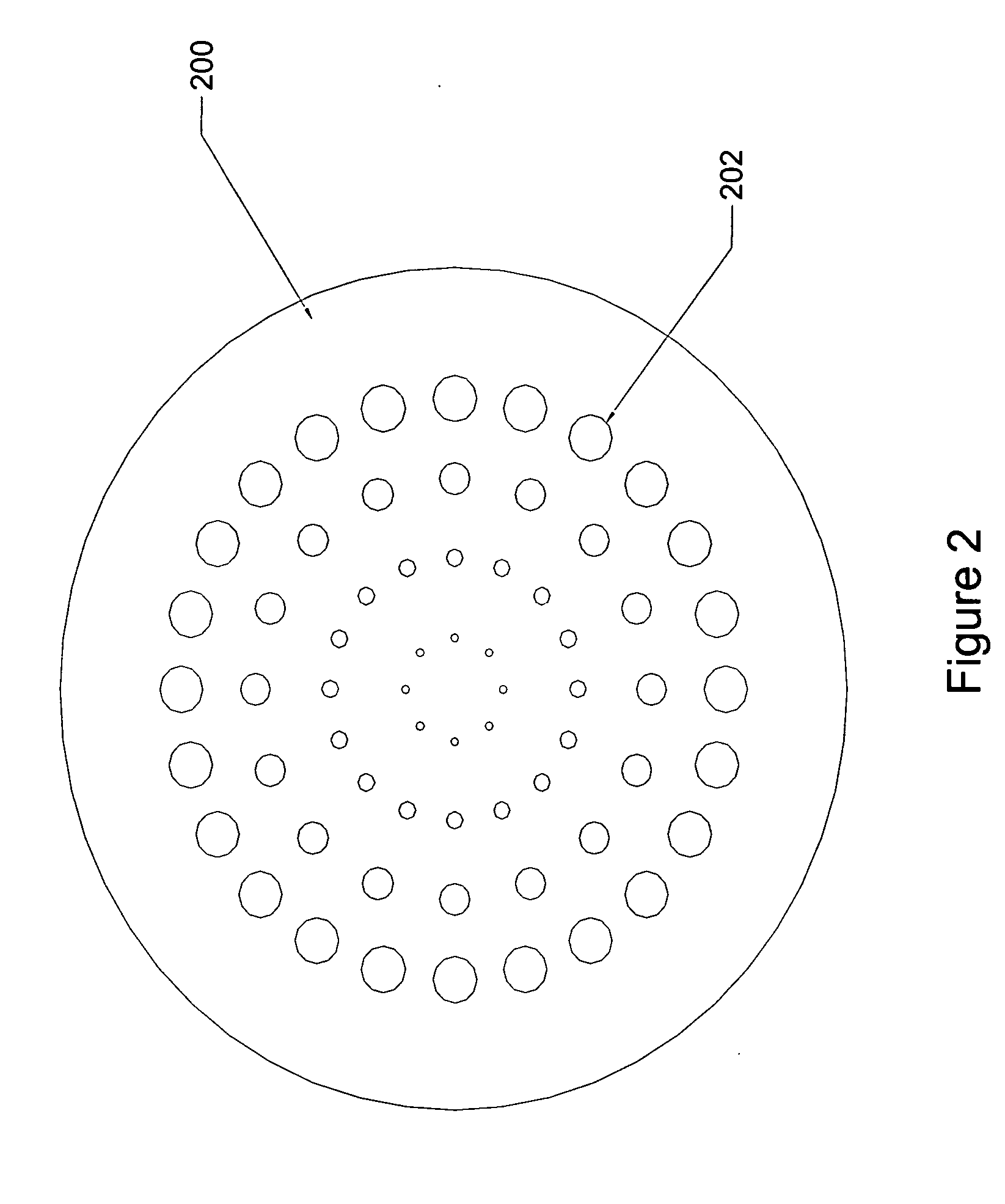

Gas distribution showerhead for semiconductor processing

ActiveUS6983892B2Easy to disassembleAvoid ignitionSelf-acting watering devicesSpray nozzlesGas passingEngineering

Owner:APPLIED MATERIALS INC

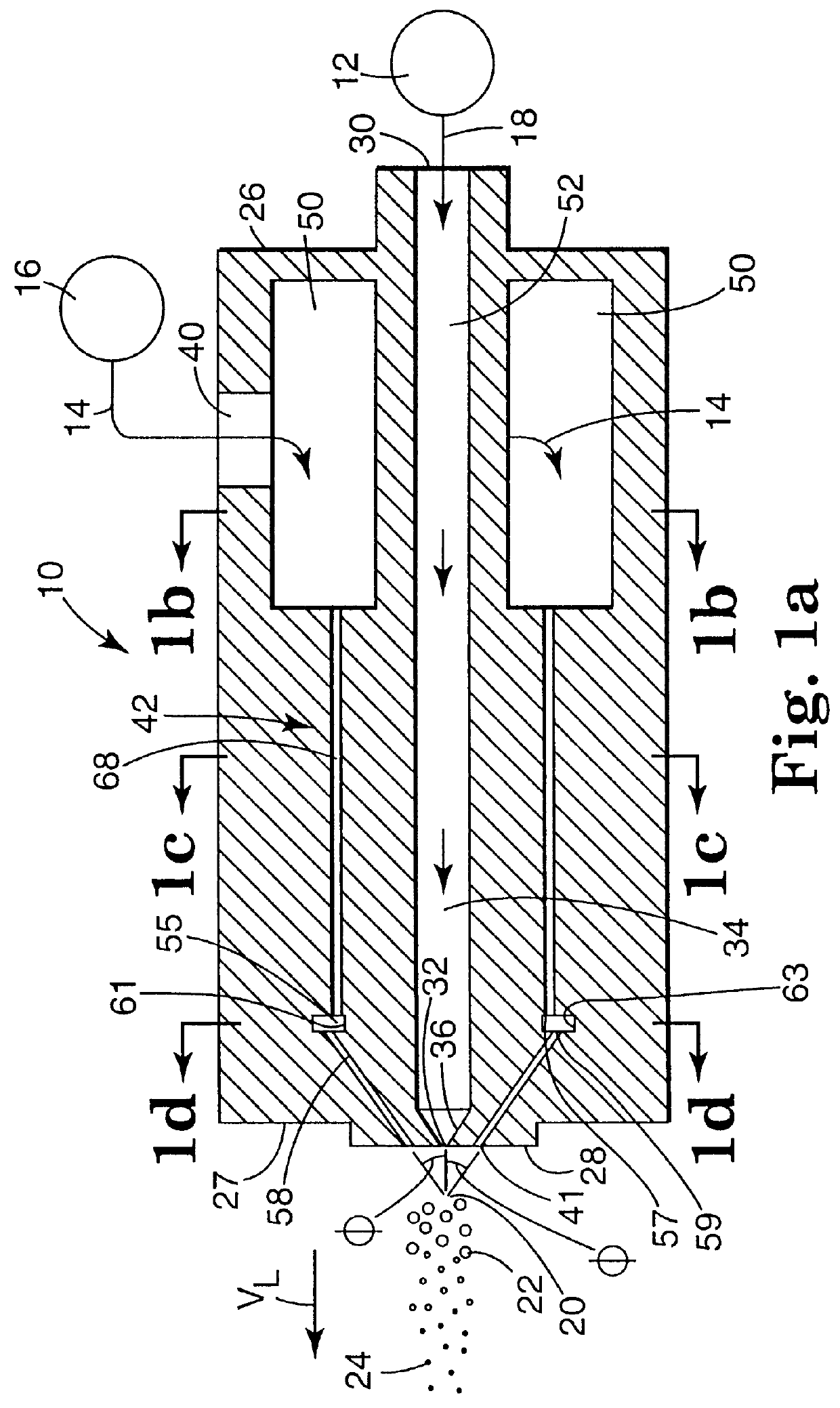

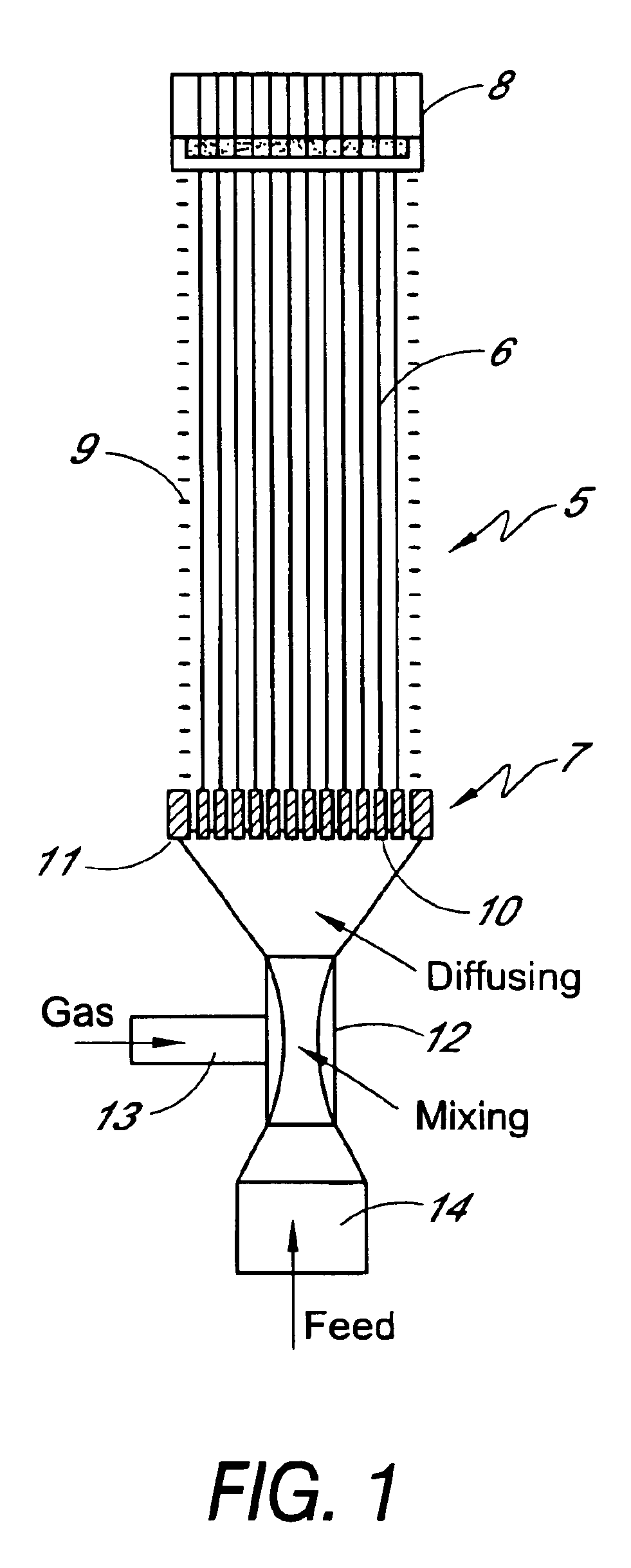

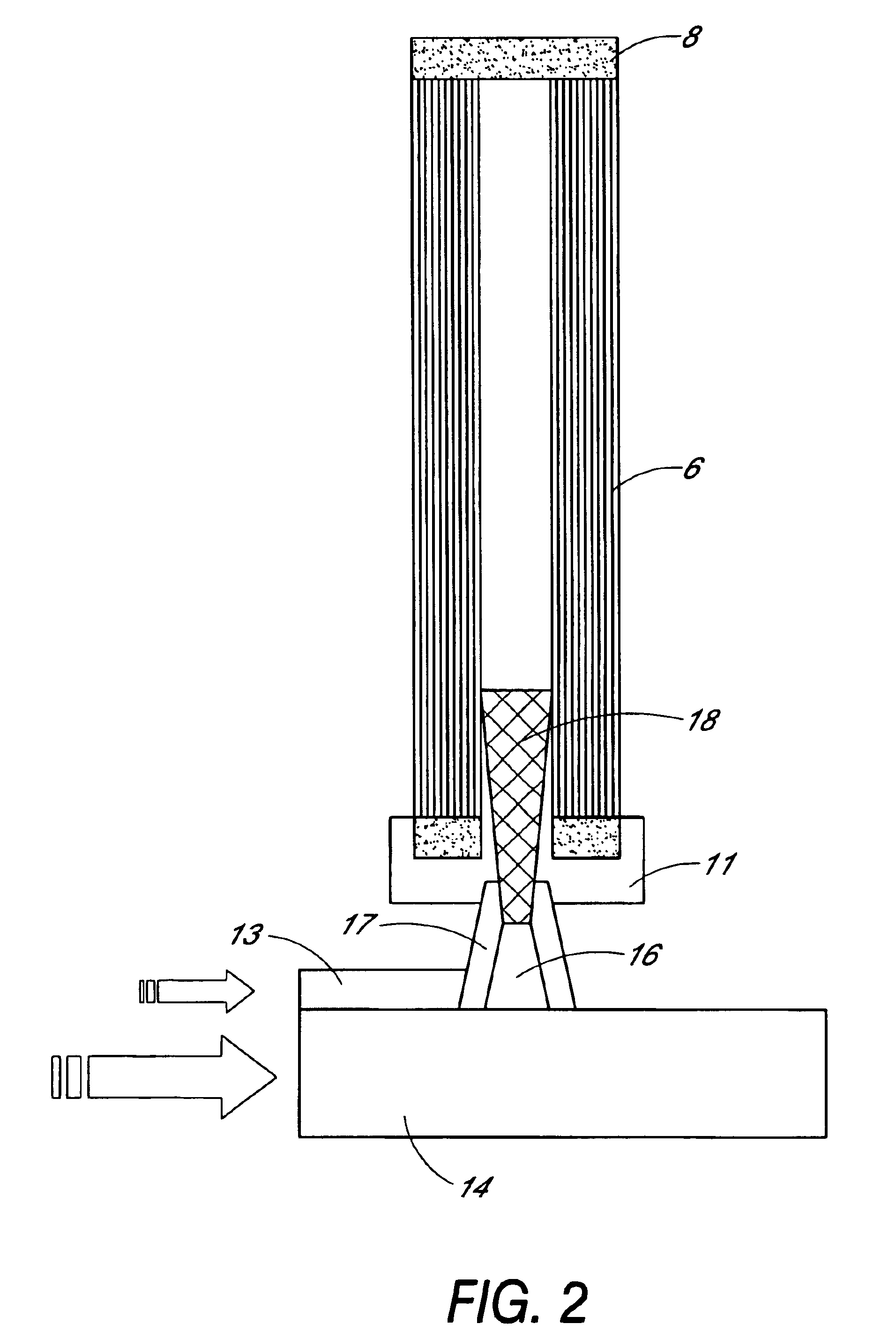

Apparatus and method of atomizing and vaporizing

InactiveUS6012647AMinimal slippageVaporization fastBurnersSpray nozzlesGas passingProcess engineering

Apparatus suitable for atomizing and vaporizing at least a first liquid by colliding at least one gas with the first liquid. The apparatus includes a gas inlet through which the gas enters the apparatus and a first liquid inlet through which the first liquid enters the apparatus. A discharge end of the apparatus includes at least one first liquid discharge outlet through which at least one stream of the first liquid is discharged from the apparatus. The discharge end also includes at least one gas discharge outlet through which at least one stream of gas is discharged from the apparatus to collide with and thereby atomize the discharged stream of the first liquid. A first liquid passageway interconnects the first liquid inlet with the first liquid discharge outlet. A gas passageway interconnects the gas inlet with the at least one gas discharge outlet. In one embodiment, the gas passageway comprises at least one gas chamber in thermal contact with an initial portion of the first liquid passageway such that a heated quantity of the gas in the chamber preheats the first liquid in the initial portion of the first liquid passageway. In alternative embodiments, the gas passageway includes a pressure dampening chamber allowing gas to be continuously discharged without pulsating.

Owner:3M INNOVATIVE PROPERTIES CO

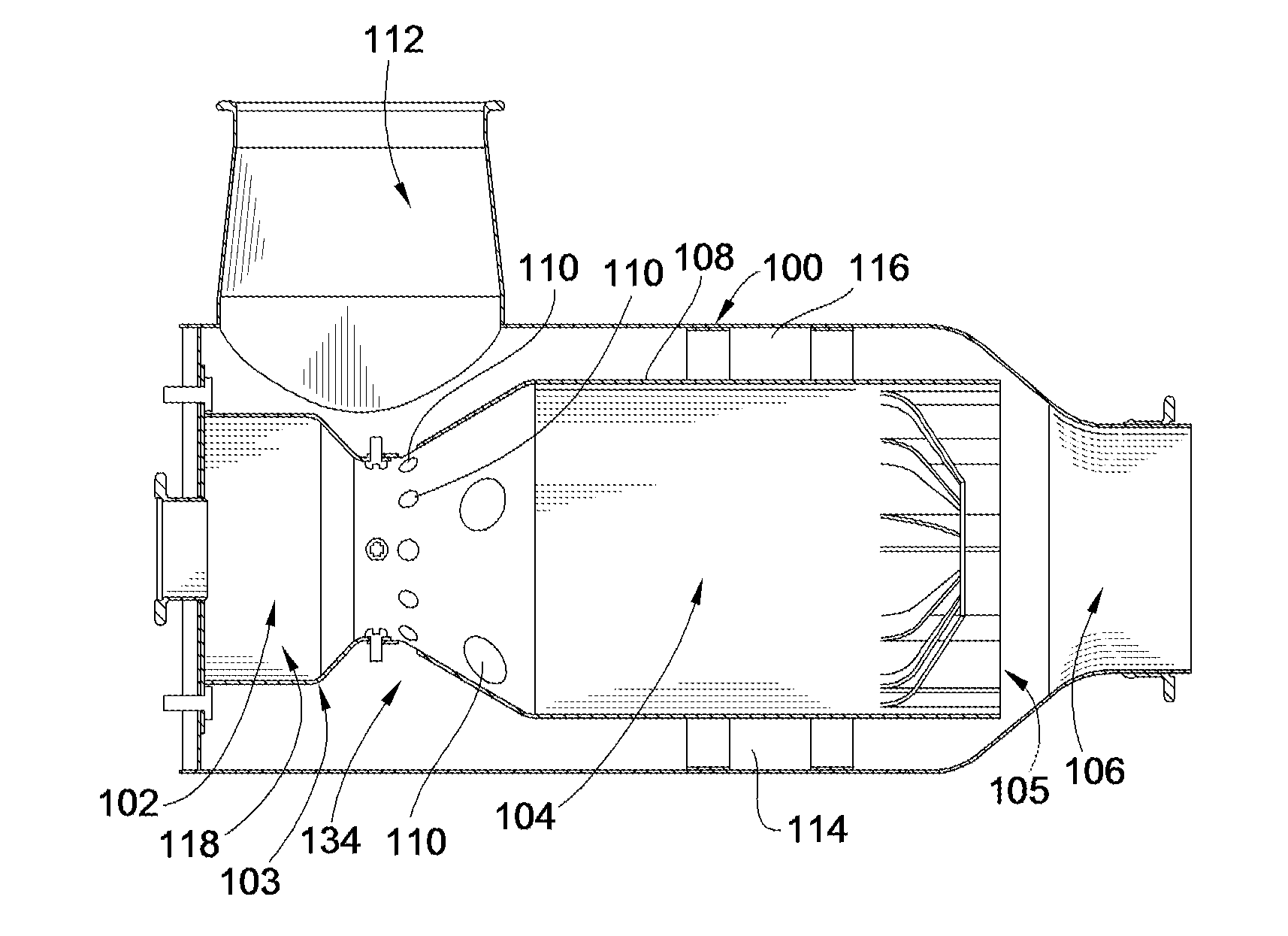

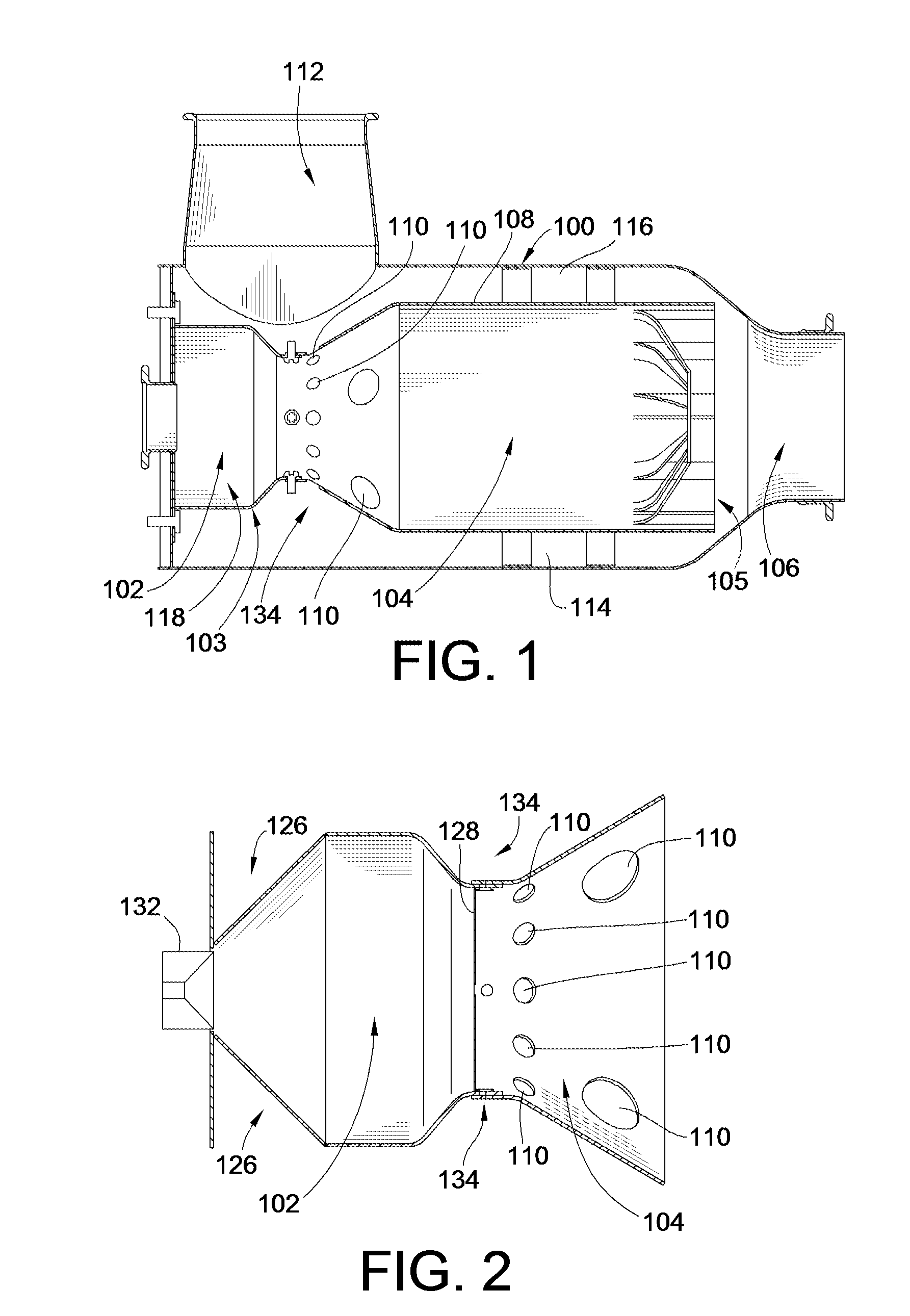

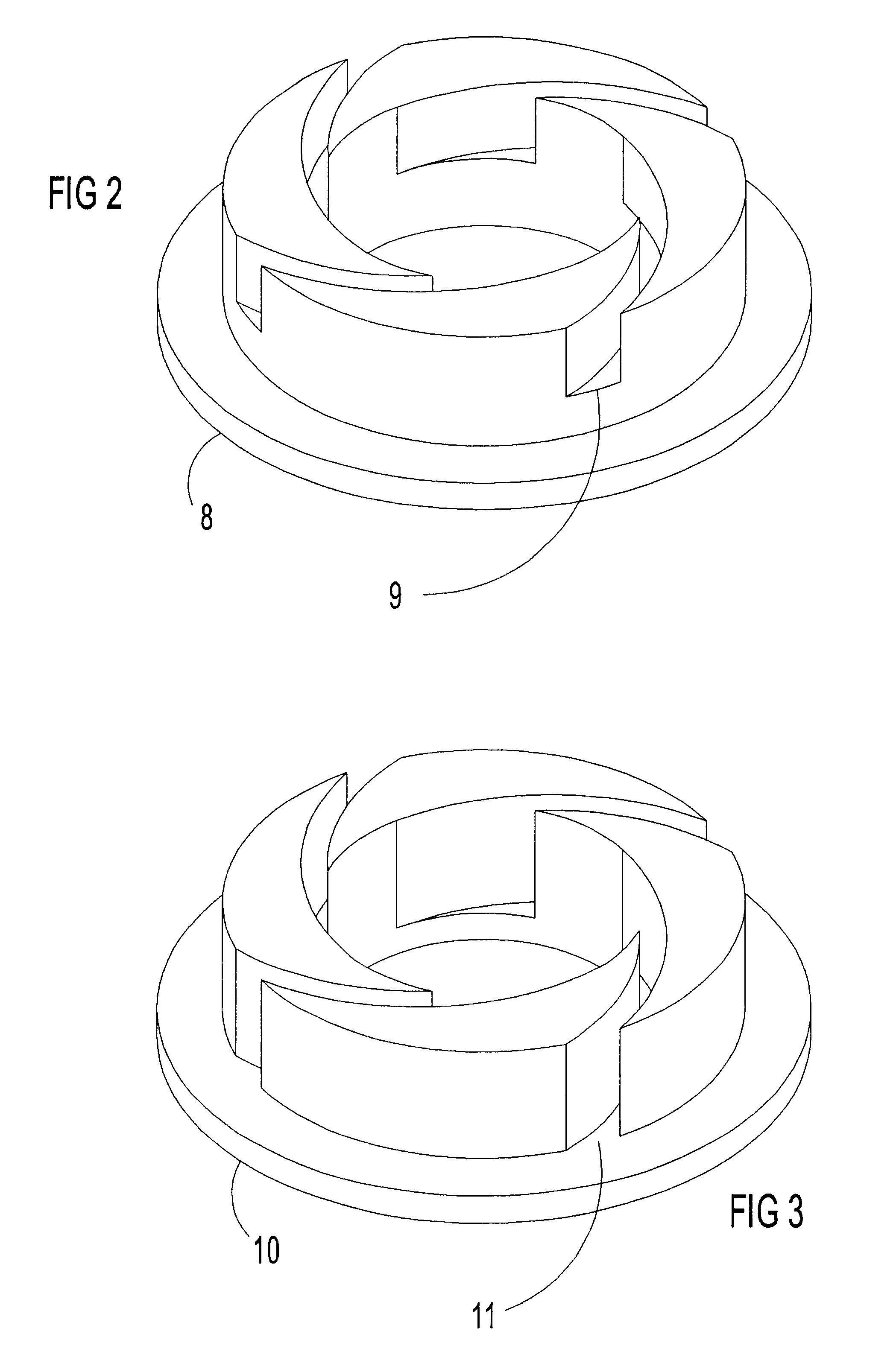

Low Pressure Drop Mixer for Radial Mixing of Internal Combustion Engine Exhaust Flows, Combustor Incorporating Same, and Methods of Mixing

ActiveUS20090255242A1Increase surface areaEnhanced interactionInternal combustion piston enginesFlow mixersCombustion chamberCombustor

An exhaust aftertreatment system is provided. The exhaust aftertreatment system includes a mixing arrangement for mixing flows of exhaust along a flow path. The mixing arrangement radially and angularly rearranges segments of two different portions of flow to mix the different portions of flow. The mixing arrangement initially converts a generally radially stratified temperature profile into an angularly stratified temperature profile to increase surface area between cool segments of exhaust gas and hot segments of exhaust gas. The aftertreatment system may also include a combustion chamber, a combustor housing and a combustor liner. The mixing arrangement is downstream from the combustion chamber to direct radially outward hot gas passing through the combustor liner and to direct radially outer cool gas passing between the liner and the combustor housing radially inward in an interleaving fashion.

Owner:WOODWARD GOVERNOR CO

Valve assembly for introducing instruments into body cavities

A valve assembly is provided for permitting the introduction of a surgical instrument into a patient's body while providing a substantial seal about the instrument. The valve assembly includes a sealing gasket assembly providing a fluid tight seal before instrument insertion, and is configured and dimensioned for accommodating an instrument and providing a substantial fluid tight seal after insertion of an instrument. The valve assembly may further include a deformable sealing member having a substantially central aperture for accommodating the instrument. The sealing member provides a substantial seal about the instrument when the instrument is passed therethrough impeding the egress of fluids and gasses through the valve assembly.

Owner:TYCO HEALTHCARE GRP LP

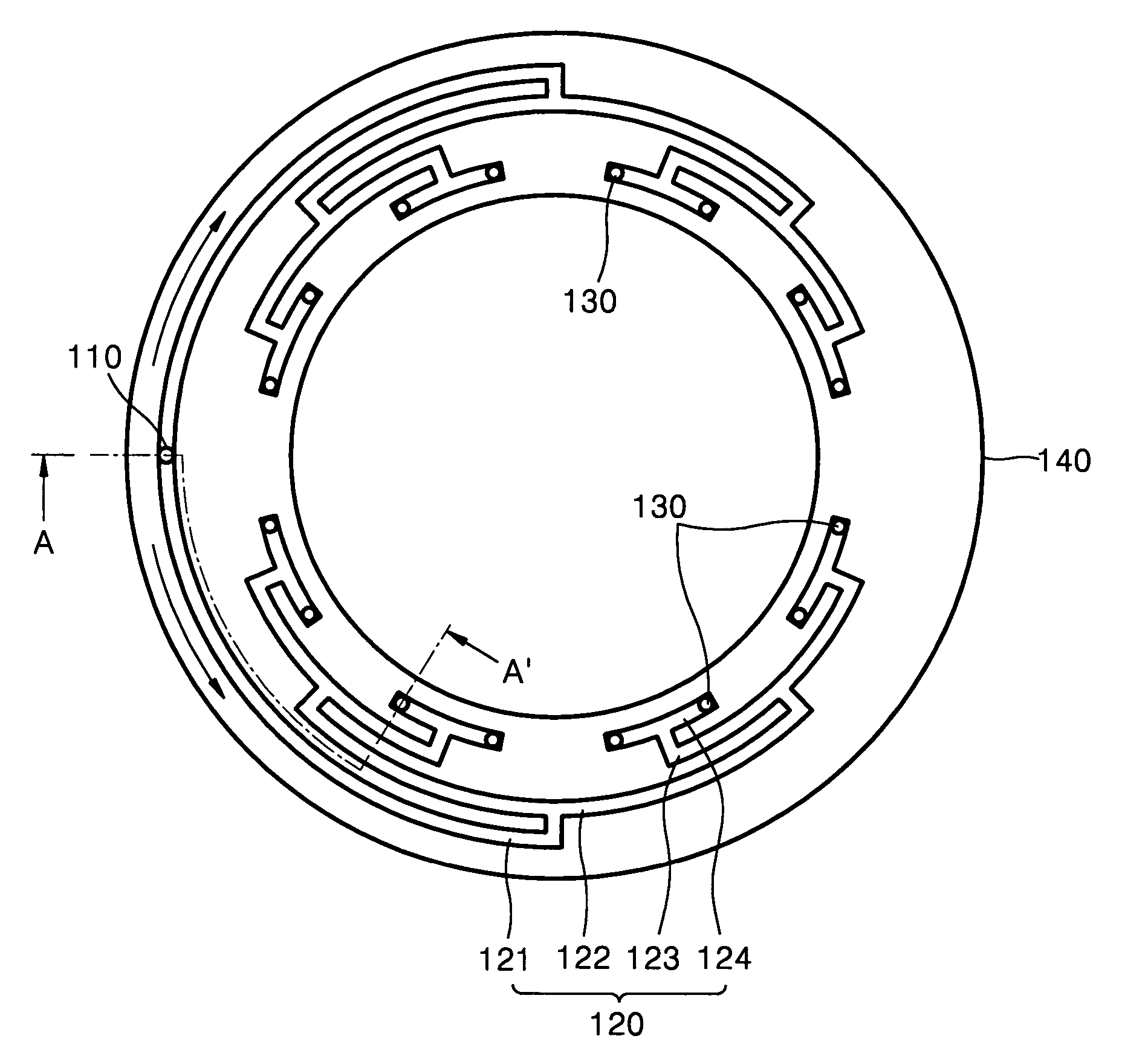

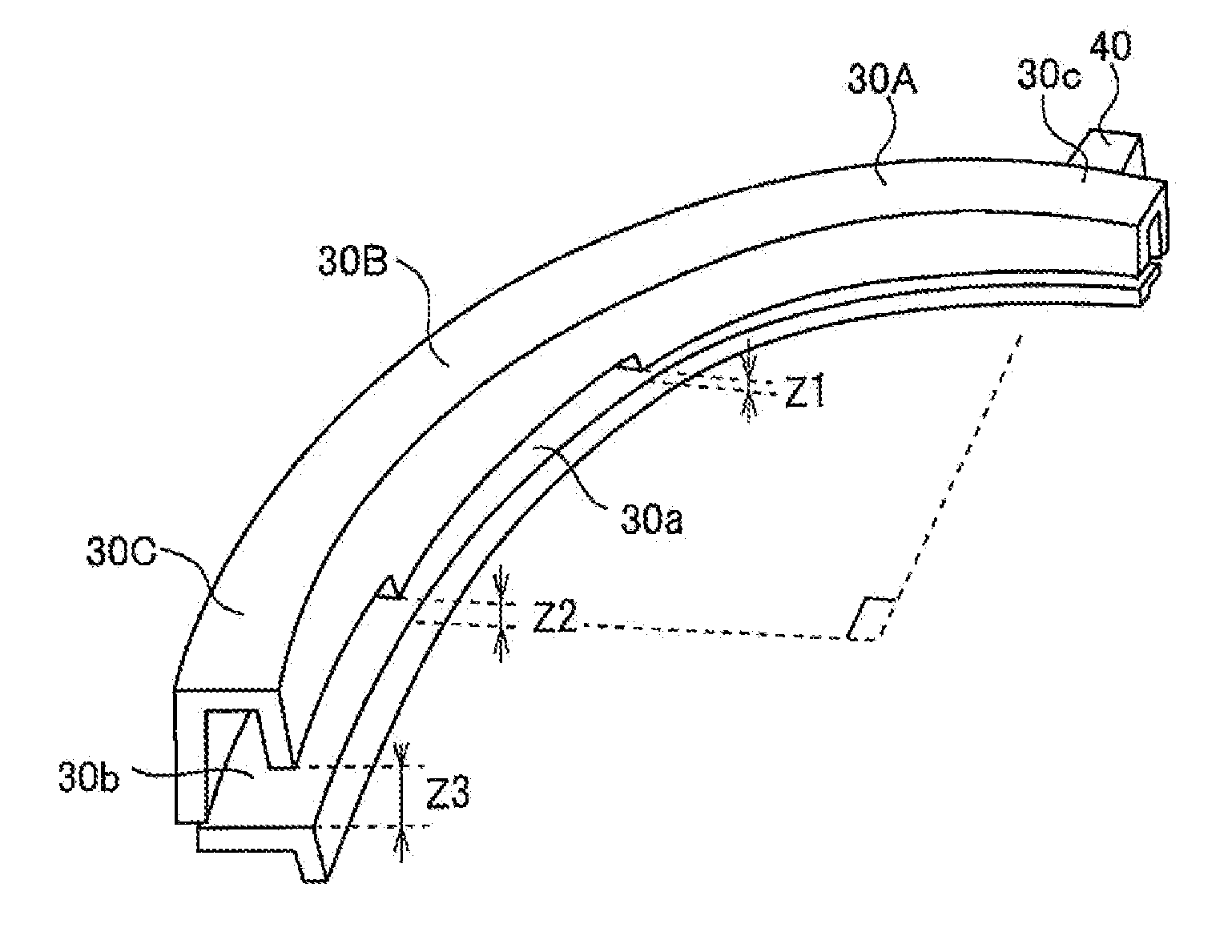

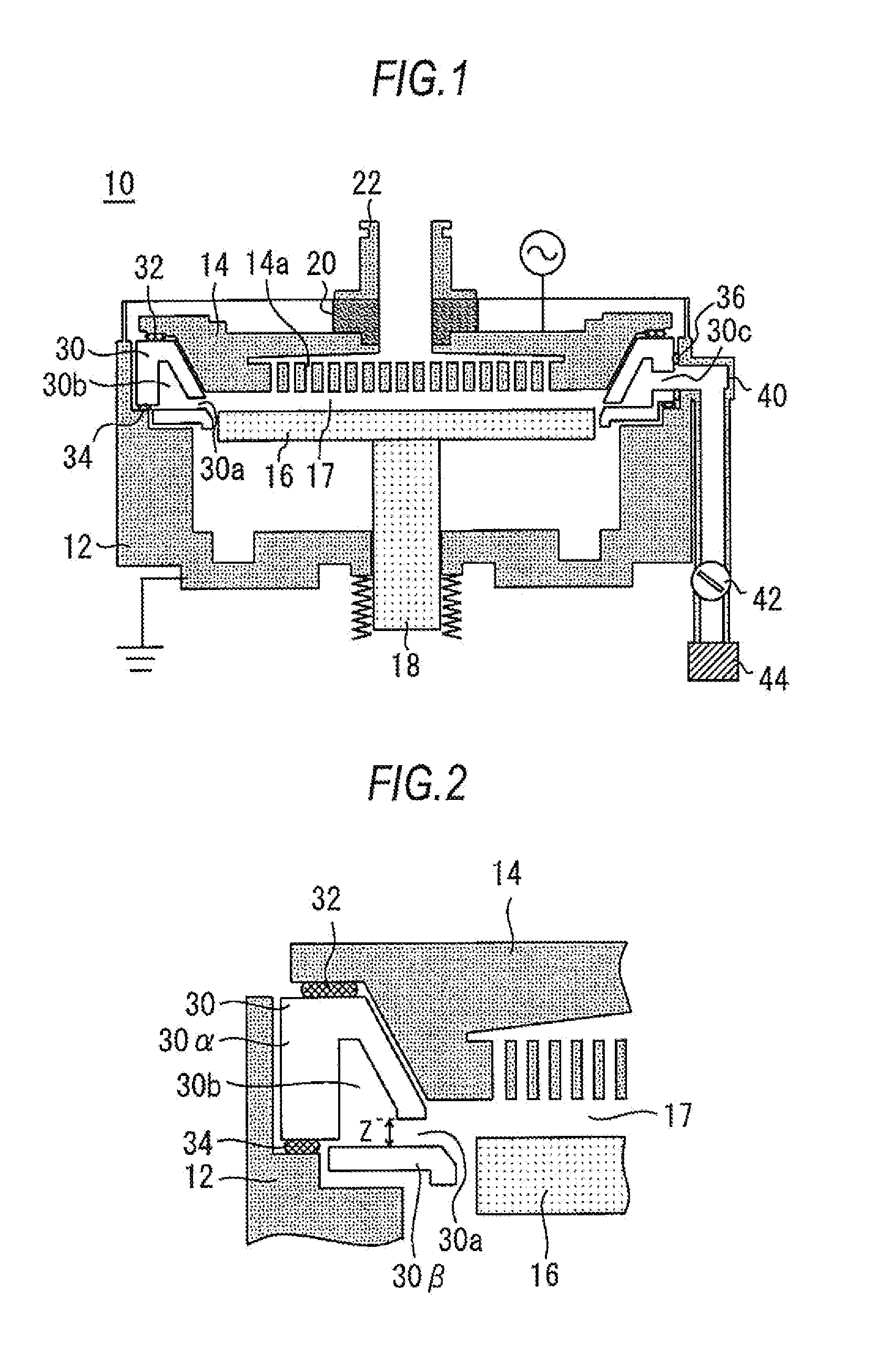

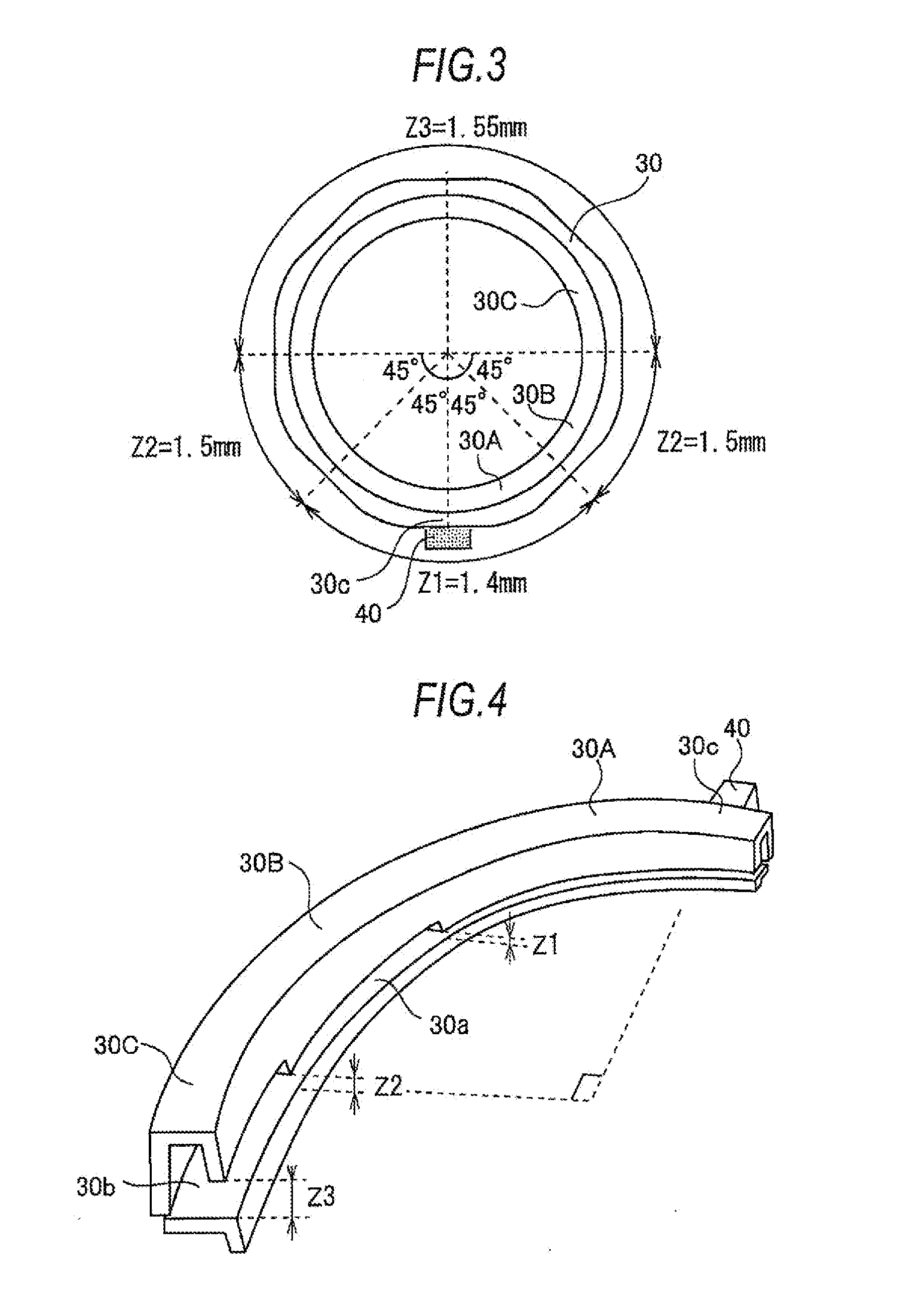

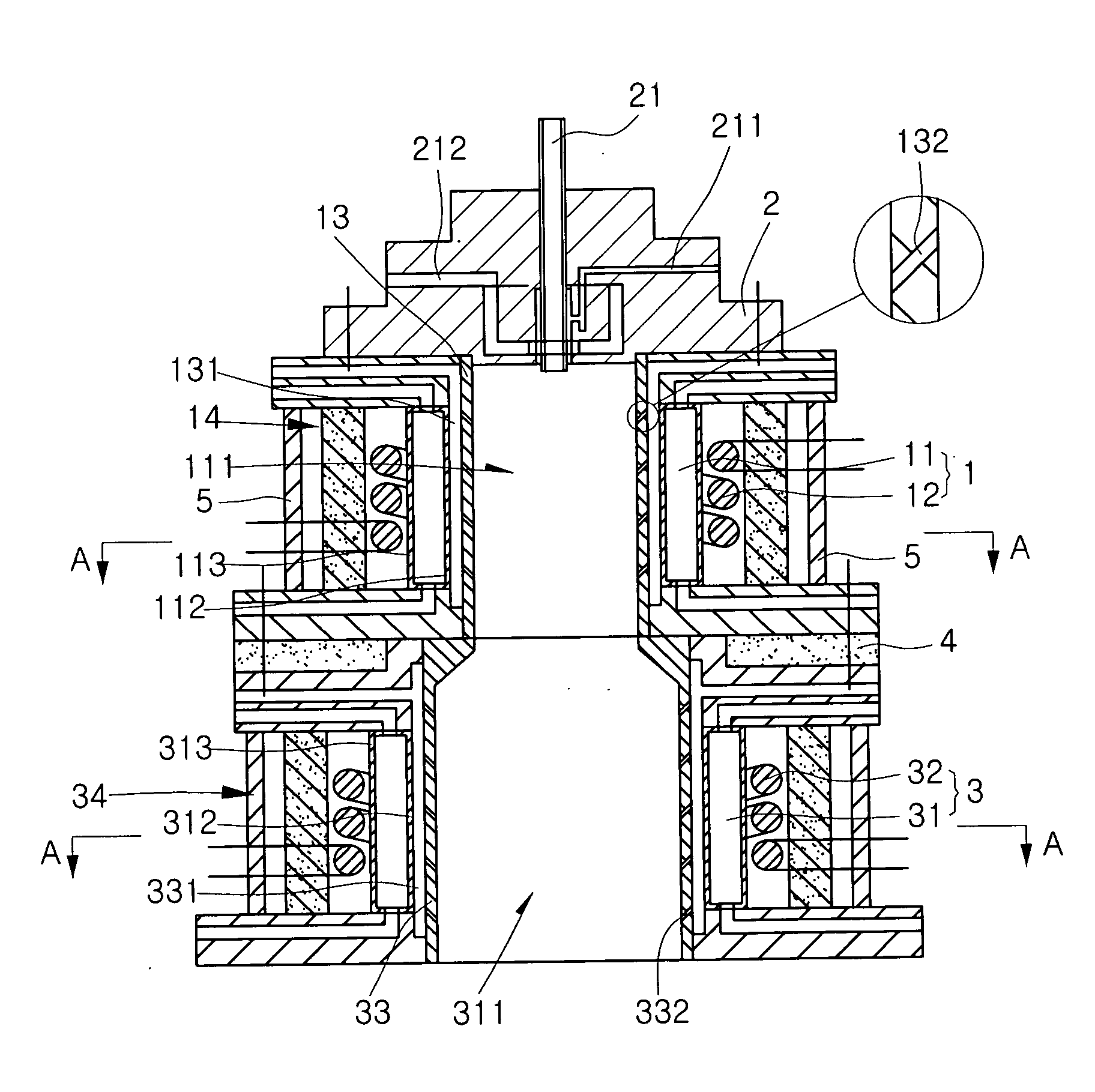

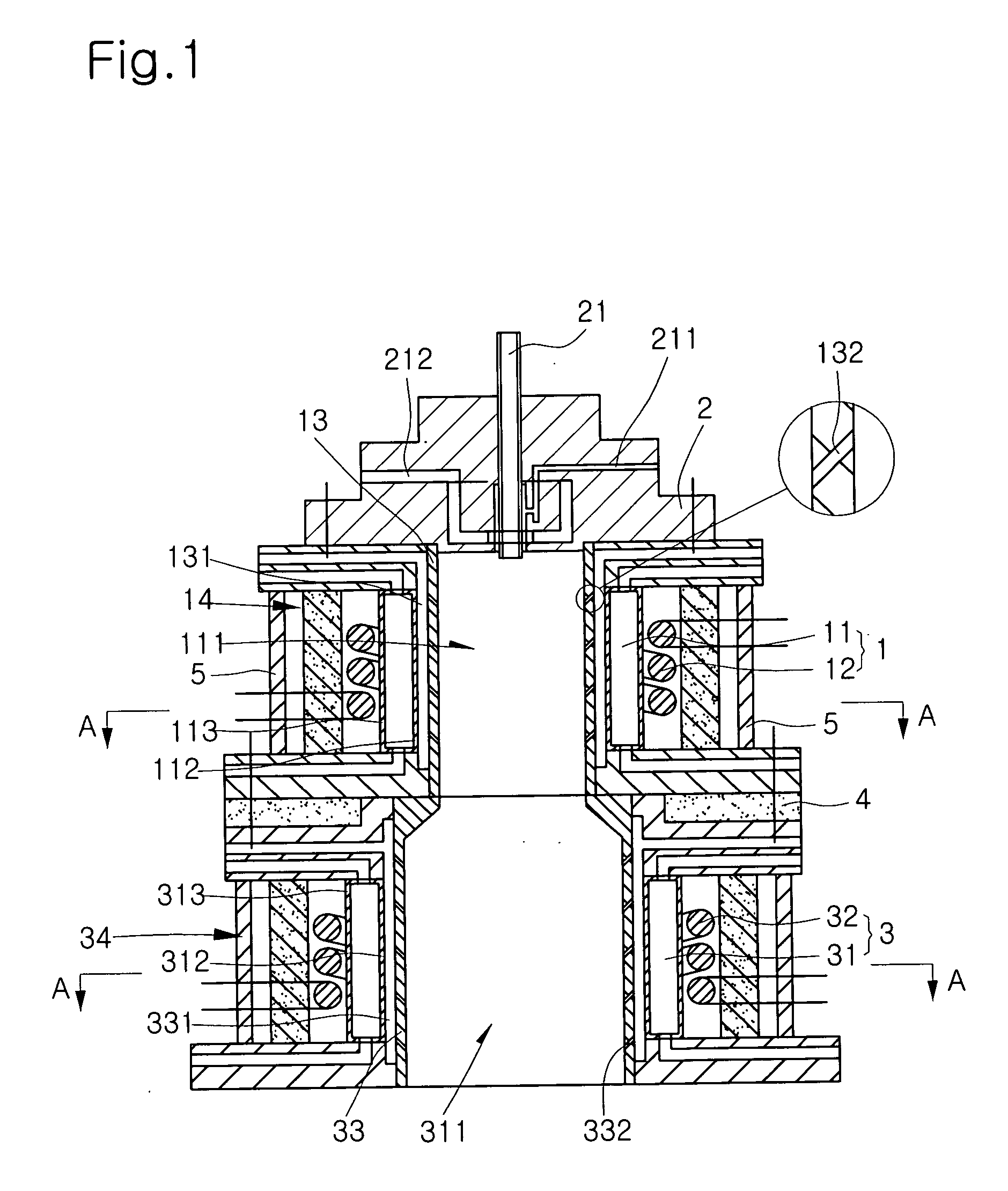

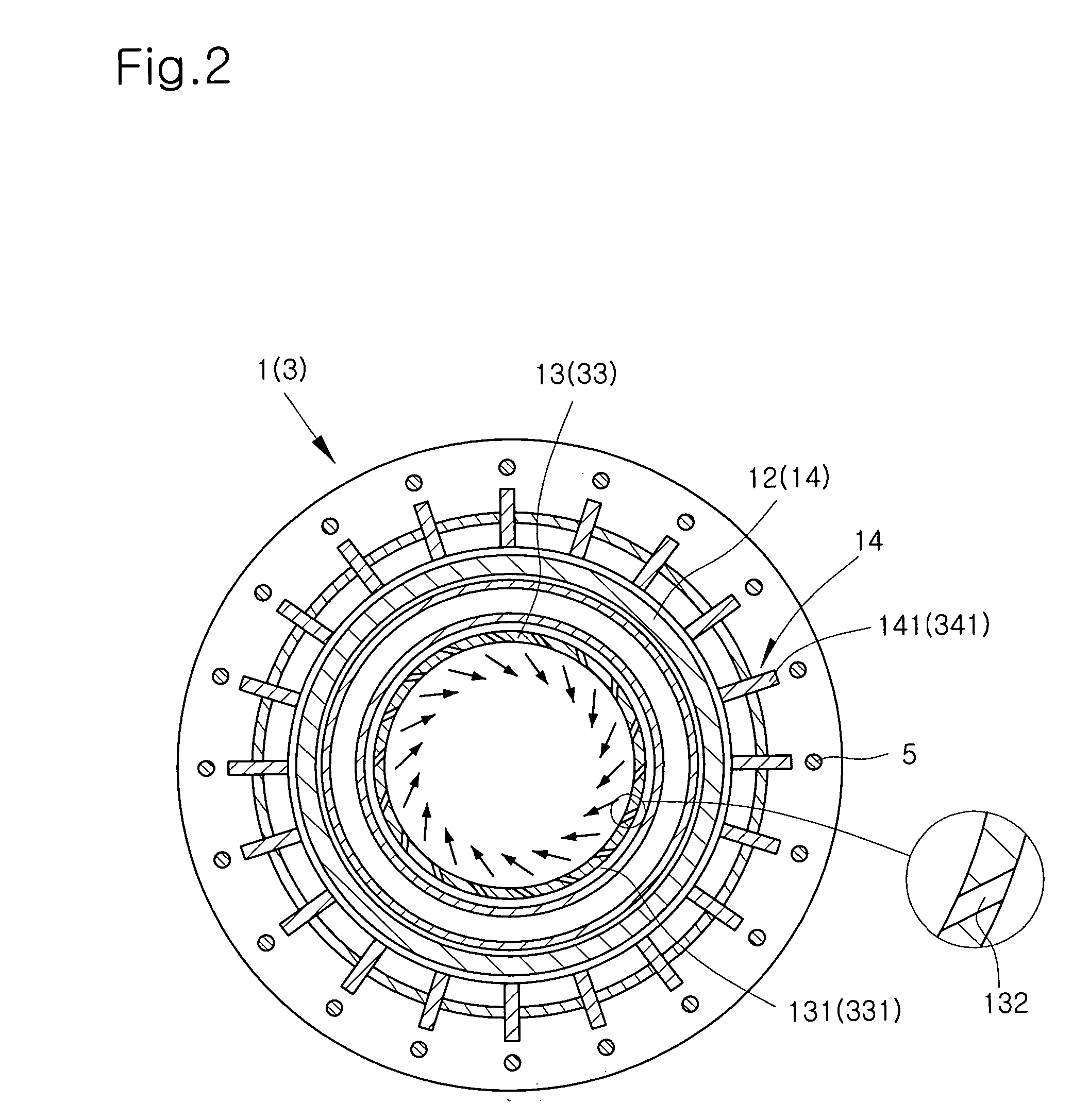

Semiconductor manufacturing apparatus

ActiveUS20160237559A1Improve uniformityElectric discharge tubesSemiconductor/solid-state device manufacturingManufactured apparatusGas passing

A semiconductor manufacturing apparatus includes a stage, and an exhaust duct having an annular passage surrounding a processing space over the stage, an annular slit through which a gas supplied to the processing space is led into the annular passage, and an exhaust port through which the gas in the annular passage is discharged to the outside, wherein the opening-area percentage of the slit is increased with increase in distance from the exhaust port.

Owner:ASM IP HLDG BV

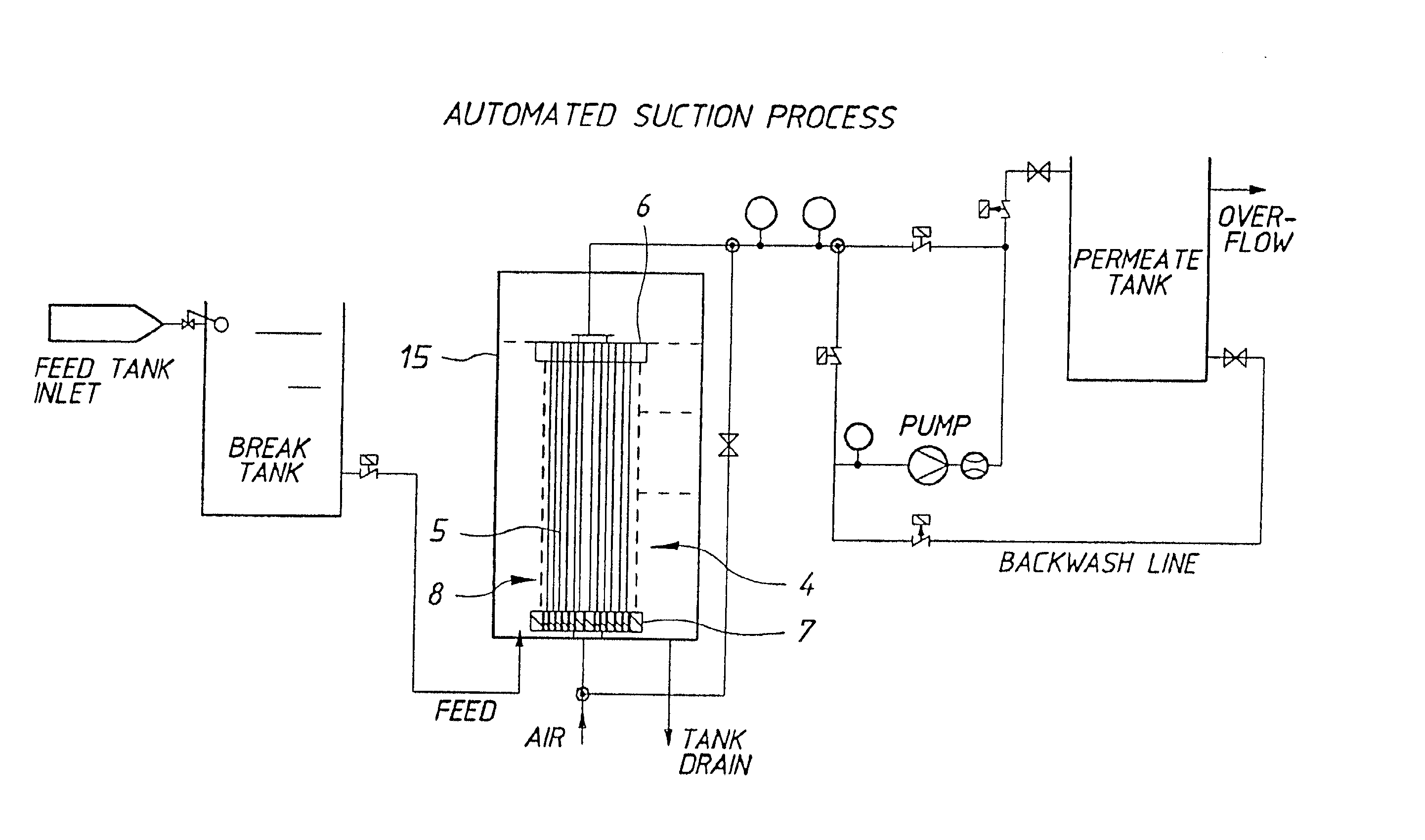

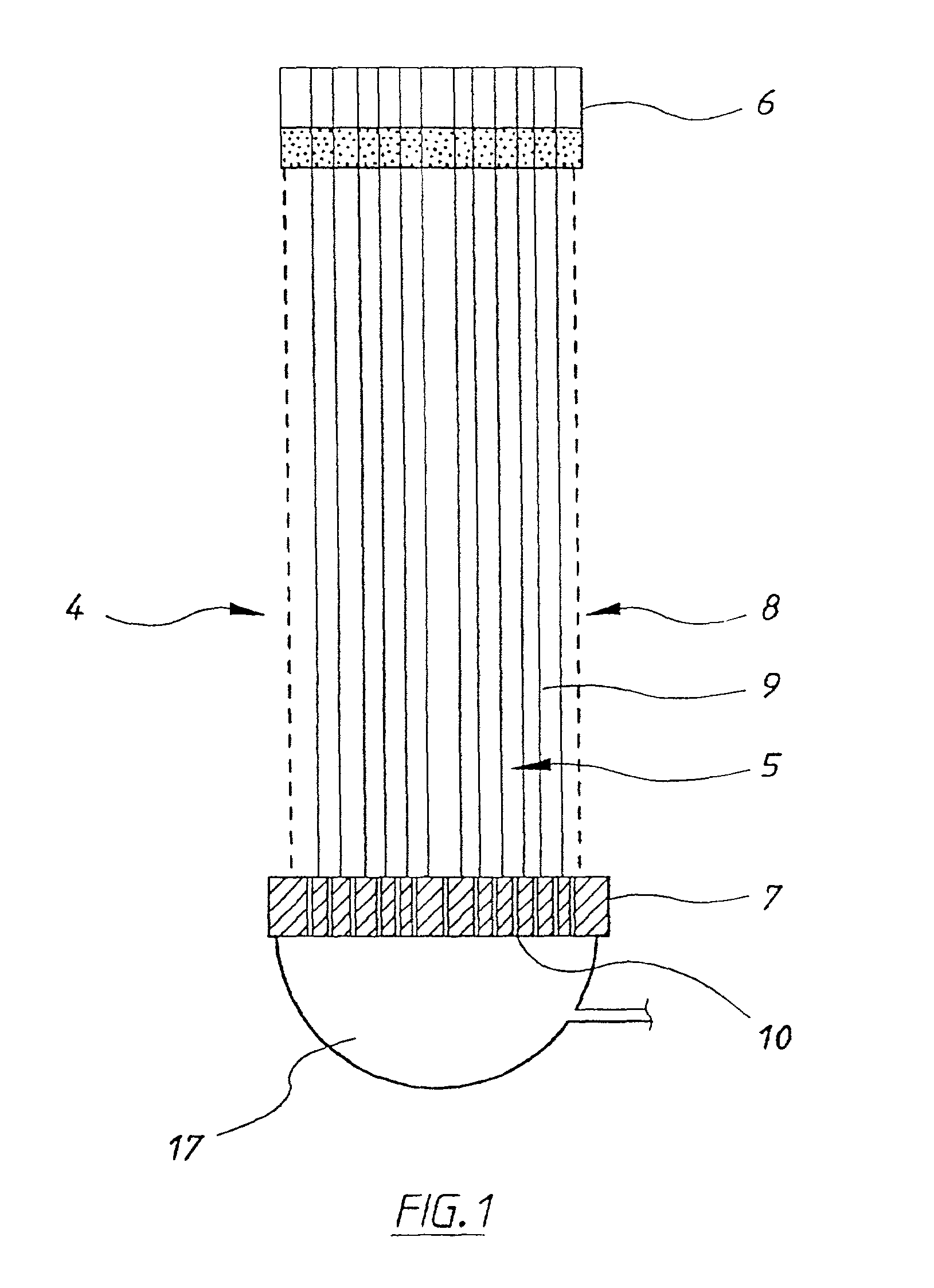

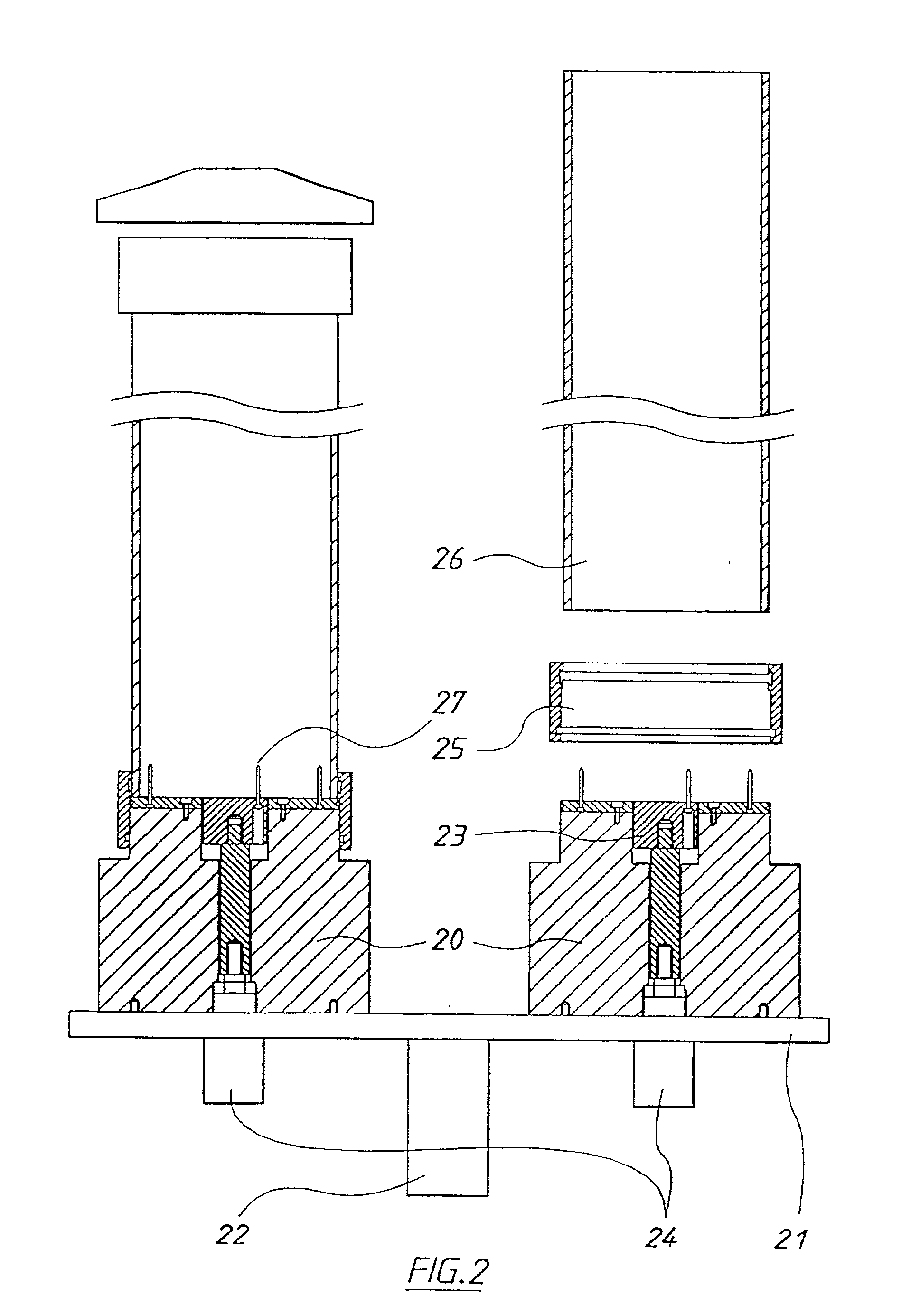

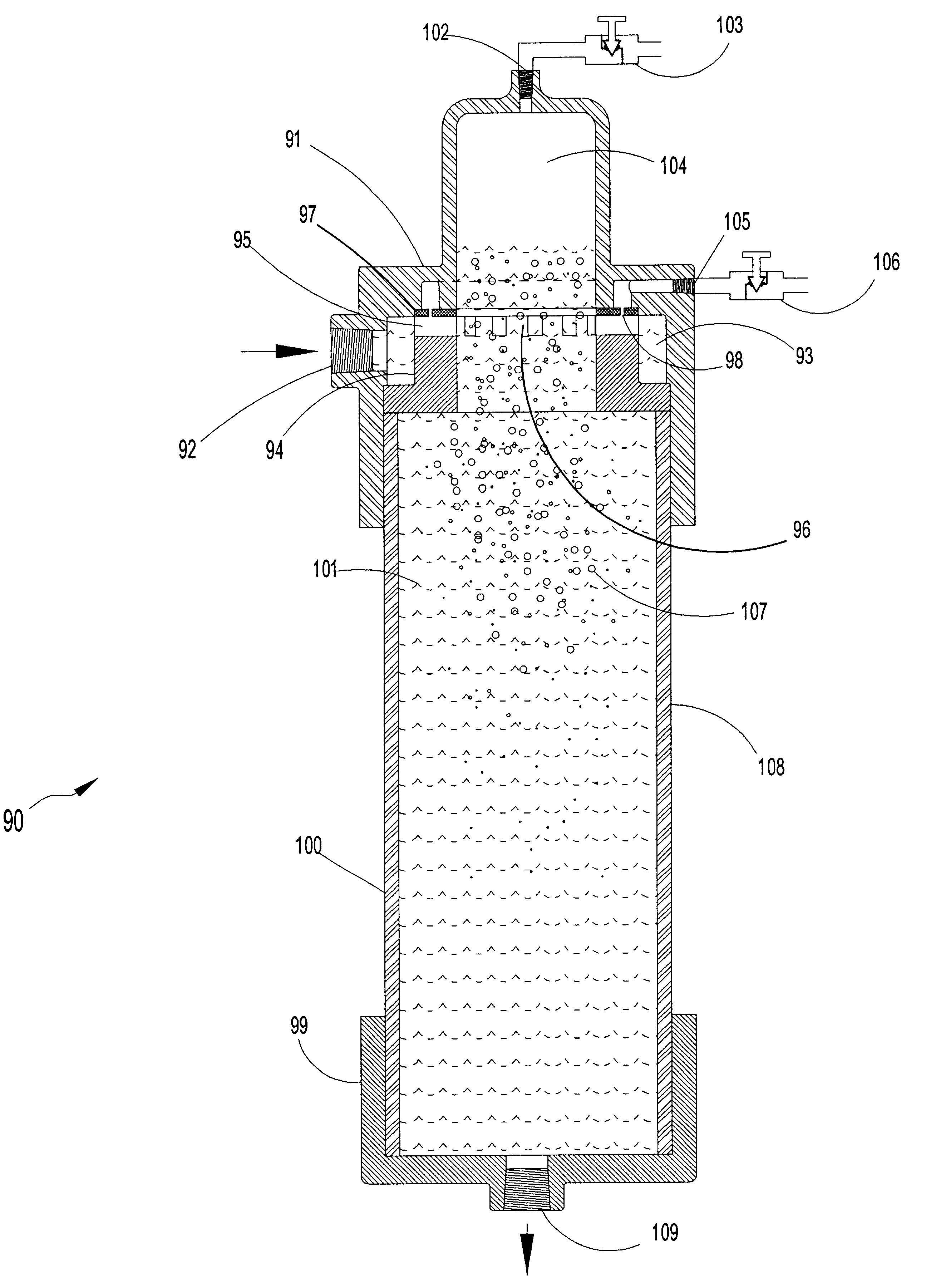

Apparatus and method for cleaning membrane filtration modules

InactiveUS6841070B2Easy to cleanReduce concentrationSemi-permeable membranesMembranesFiltrationPorous membrane

A method and apparatus for cleaning a membrane module, the membrane module having a plurality of porous membranes, the membranes being arranged in close proximity to one another and mounted to prevent excessive movement therebetween and means for providing, from within the module, by means other than gas passing through the pores of the membranes, gas bubbles entrained in a liquid flow such that, in use, the liquid and bubbles entrained therein move past the surfaces of the membranes to dislodge fouling materials therefrom, the gas bubbles being entrained in the liquid by flowing the liquid past a source of gas to draw the gas into the liquid flow. The gas bubbles are preferably entrained into the liquid using a venturi type device. The membranes are preferably partitioned into discrete groups to assist cleaning while maintaining high packing density.

Owner:EVOQUA WATER TECH LLC

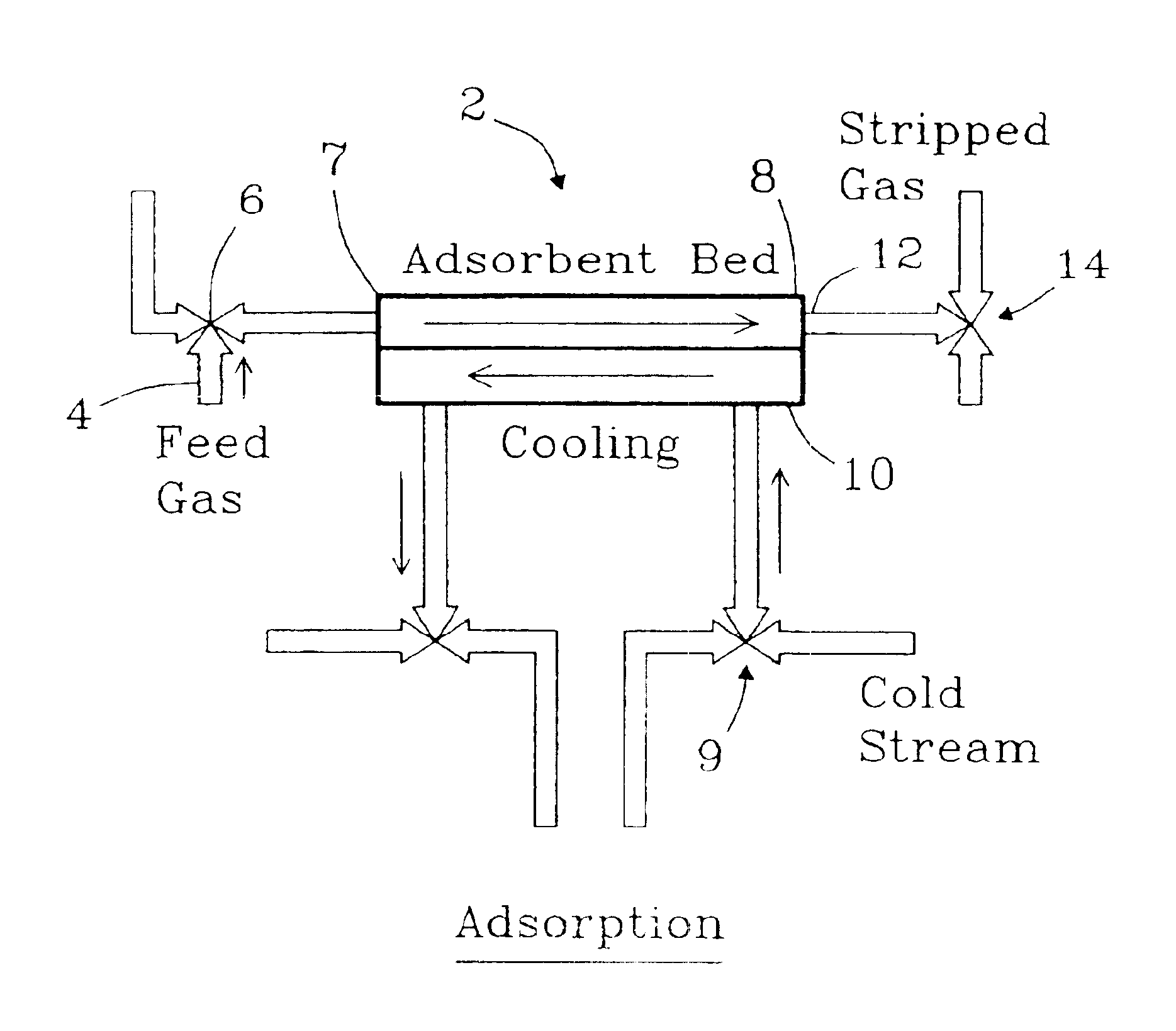

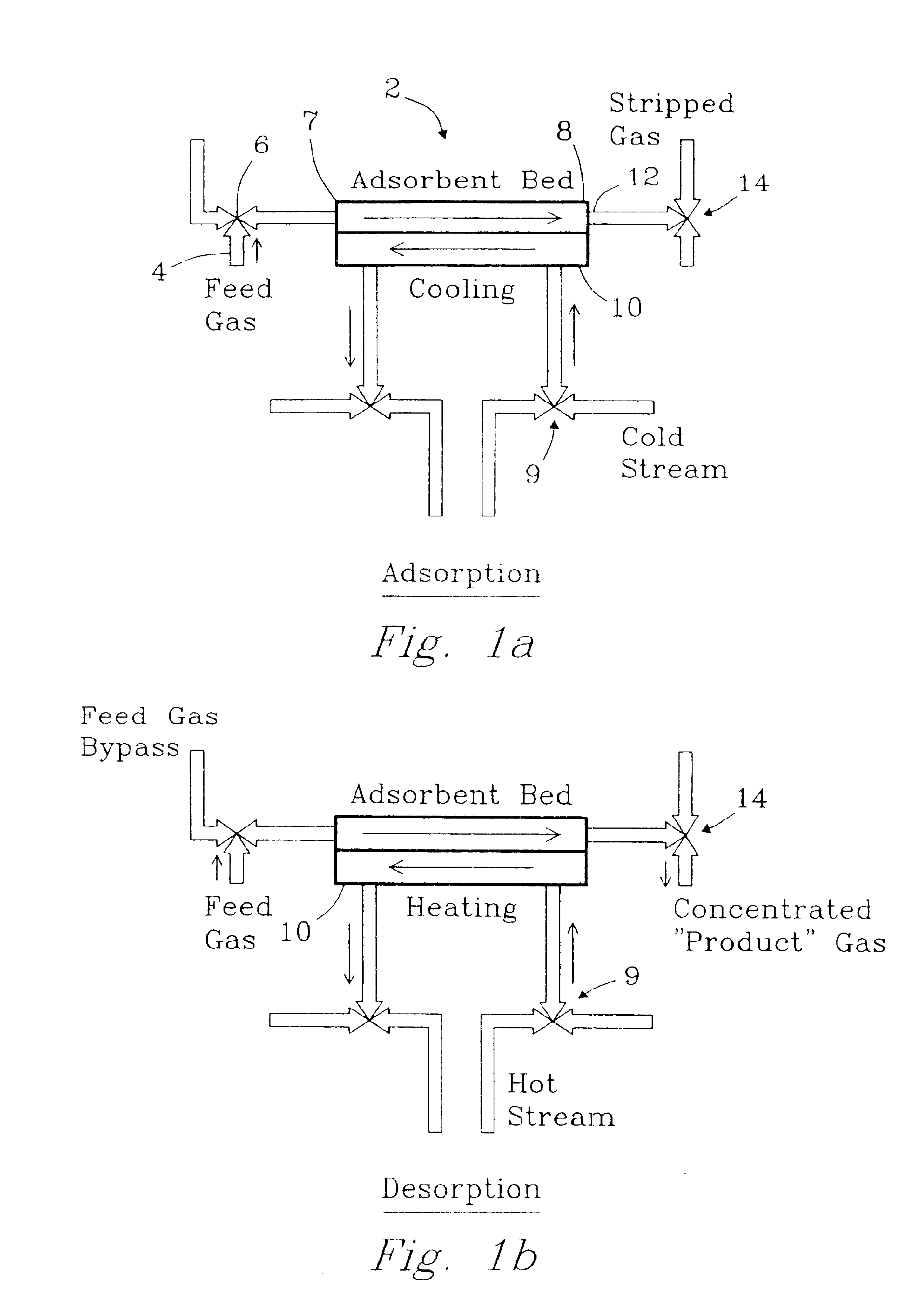

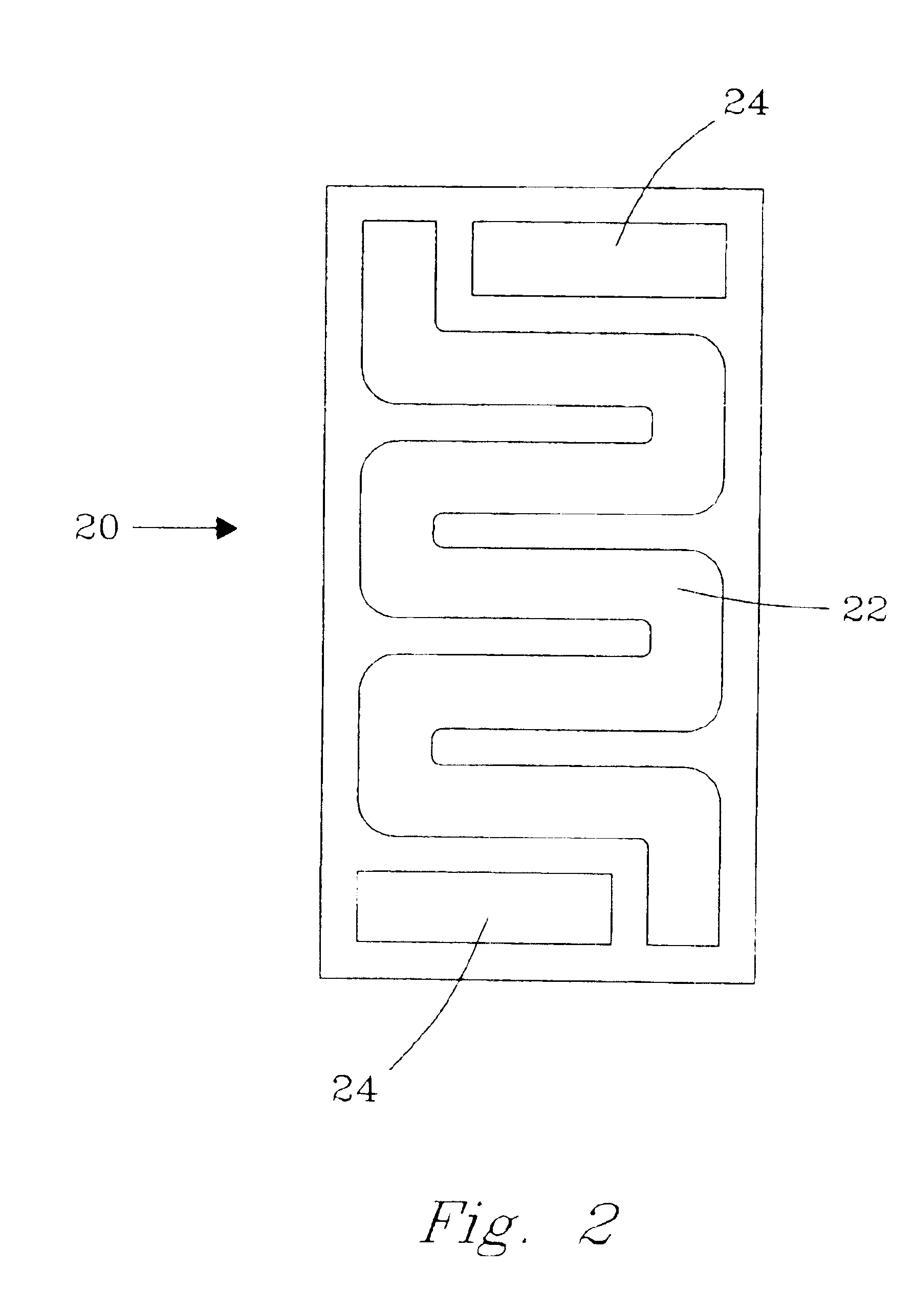

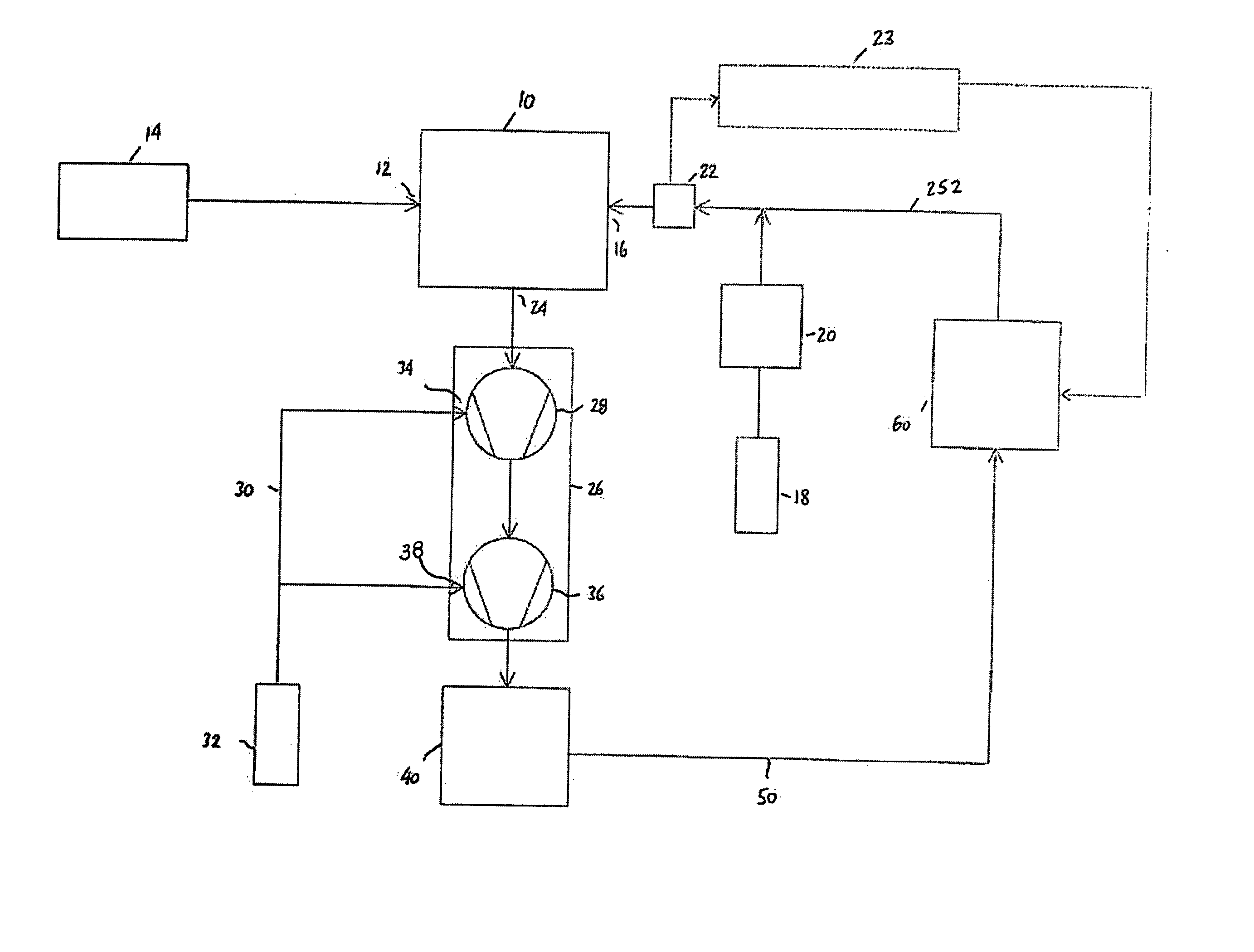

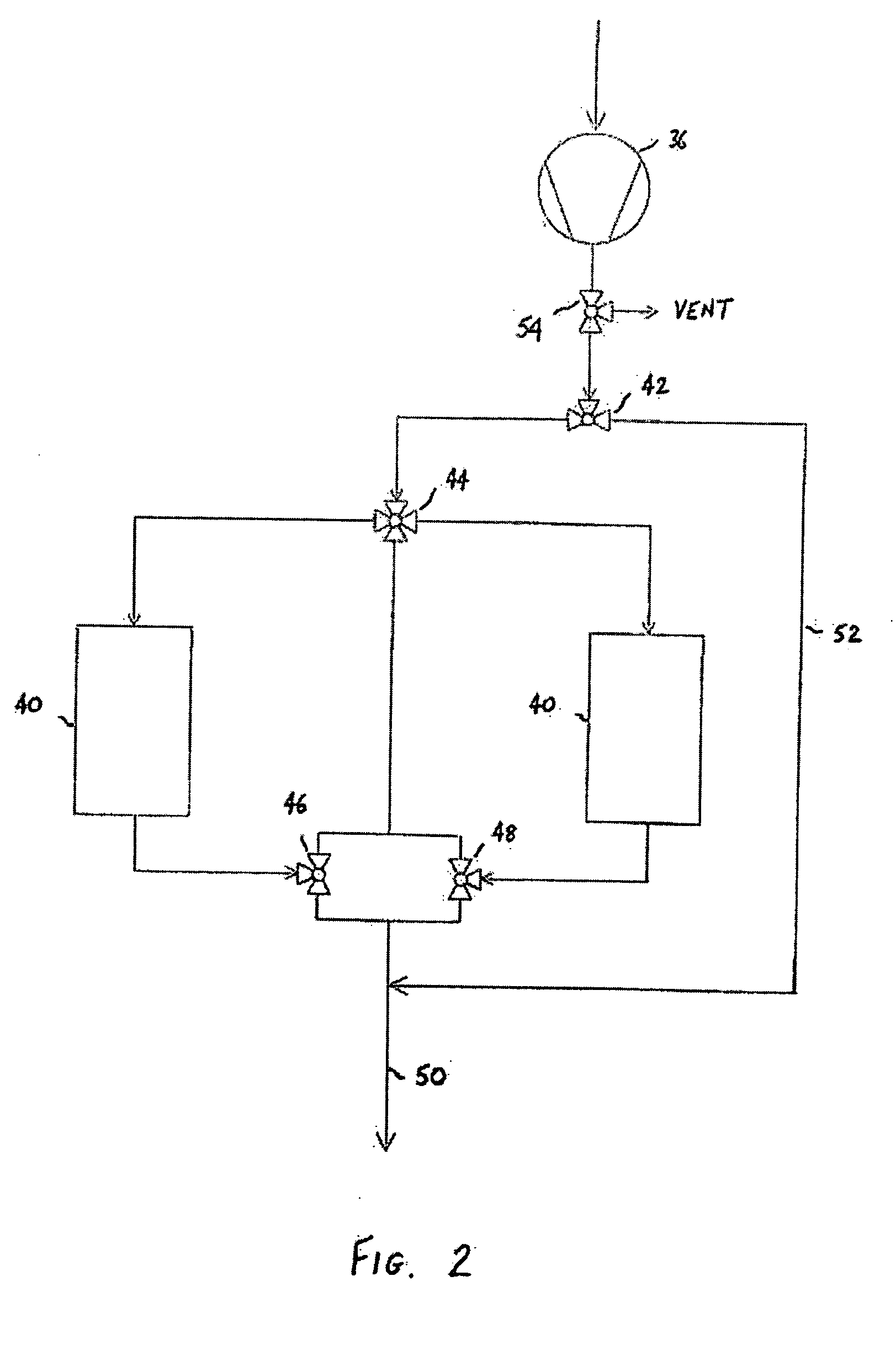

Apparatus for thermal swing adsorption and thermally-enhanced pressure swing adsorption

The present invention provides compact adsorption systems that are capable of rapid temperature swings and rapid cycling. Novel methods of thermal swing adsorption and thermally-enhanced pressure swing adsorption are also described. In some aspects of the invention, a gas is passed through the adsorbent thus allowing heat exchangers to be very close to all portions of the adsorbent and utilize less space. In another aspect, the adsorption media is selectively heated, thus reducing energy costs. Methods and systems for gas adsorption / desorption having improved energy efficiency with capability of short cycle times are also described. Advantages of the invention include the ability to use (typically) 30-100 times less adsorbent compared to conventional systems.

Owner:BATTELLE MEMORIAL INST

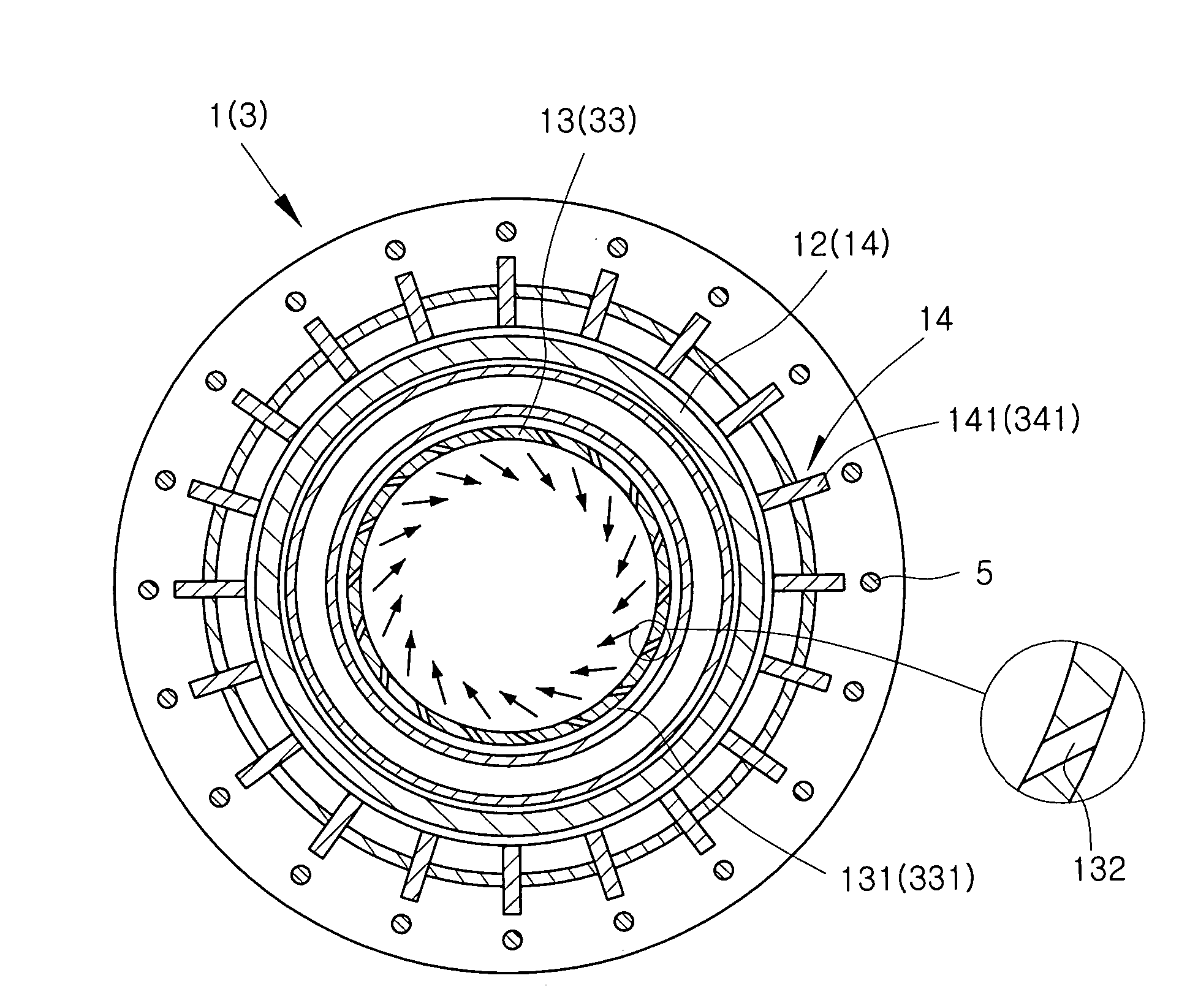

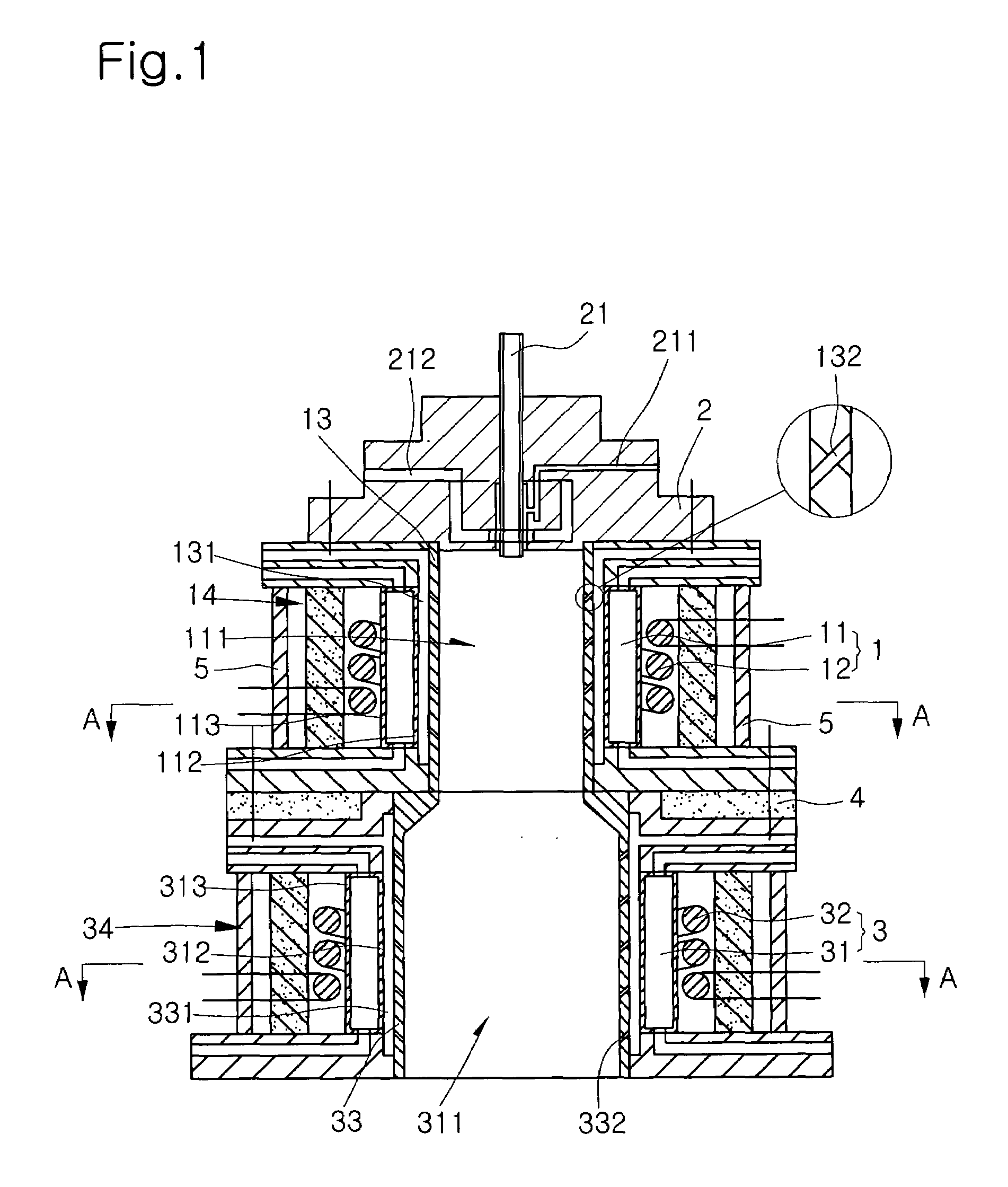

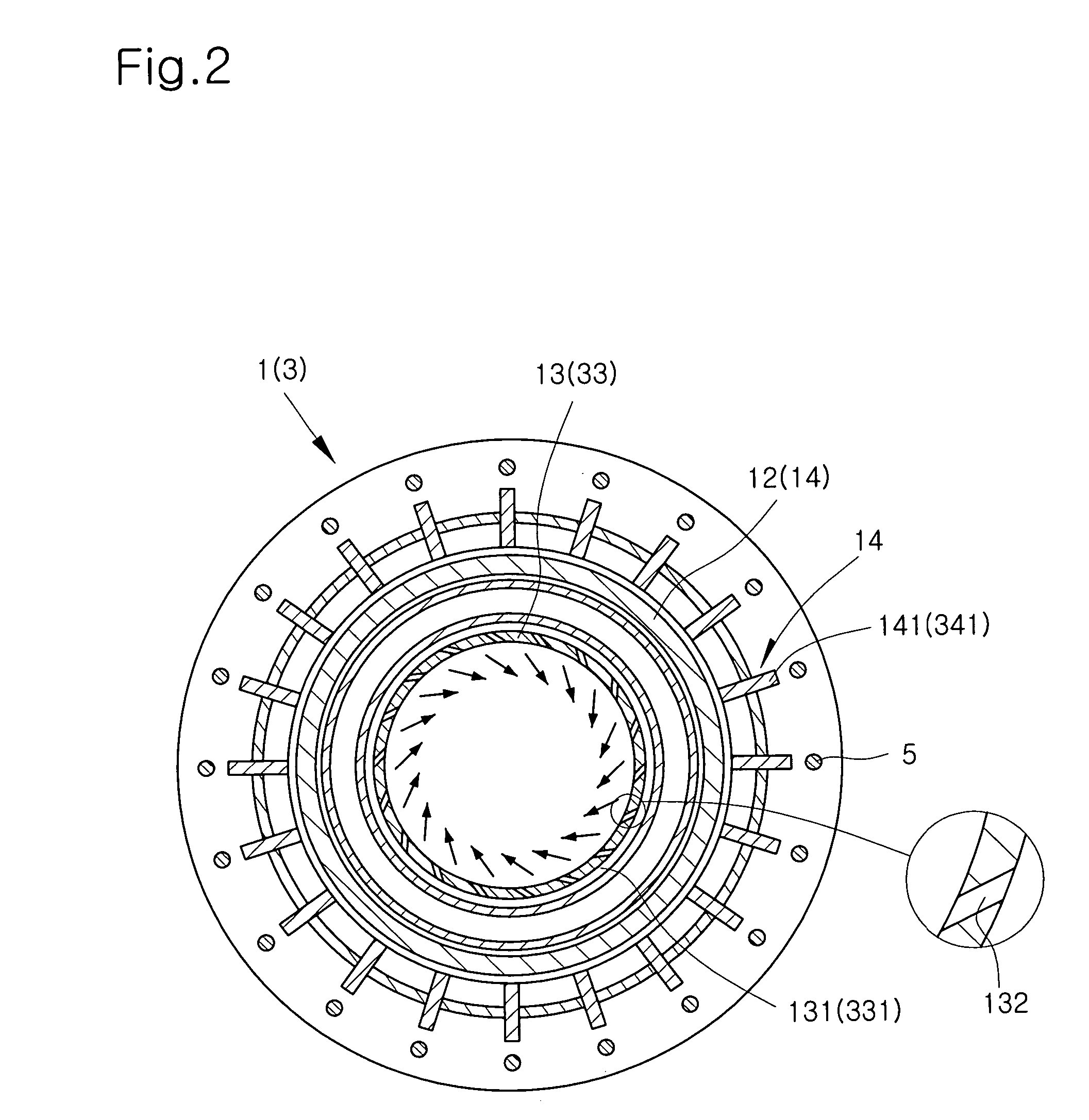

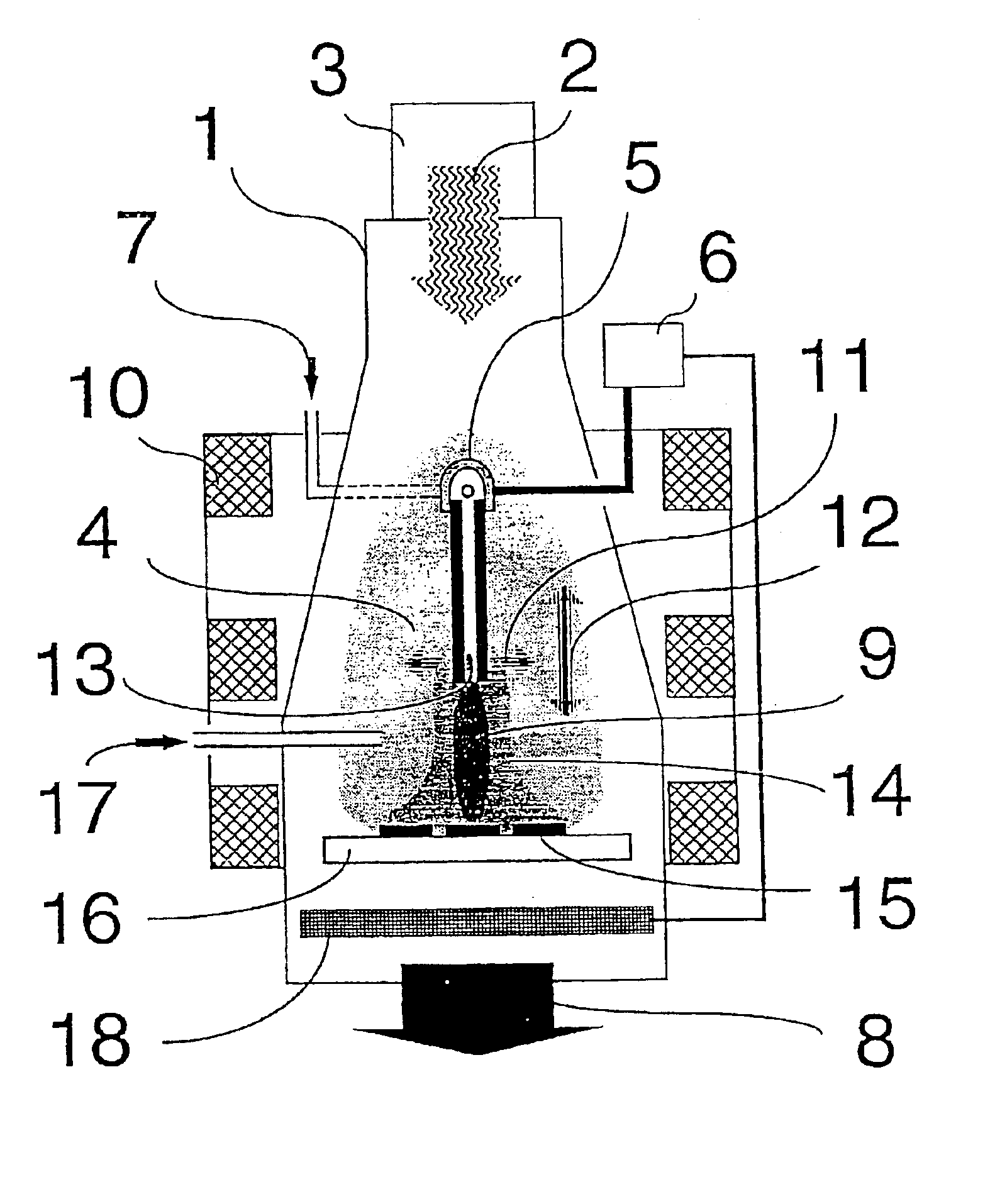

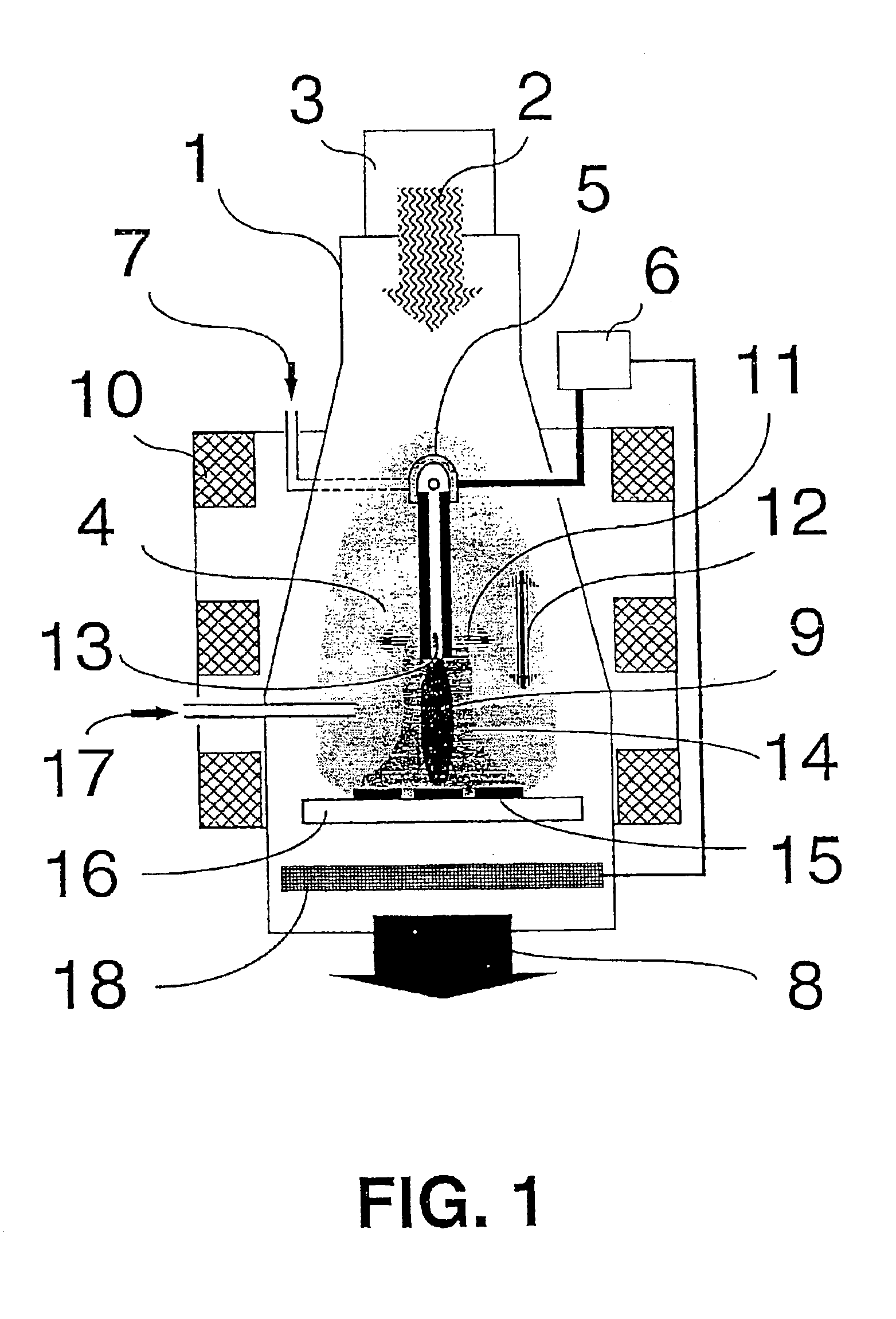

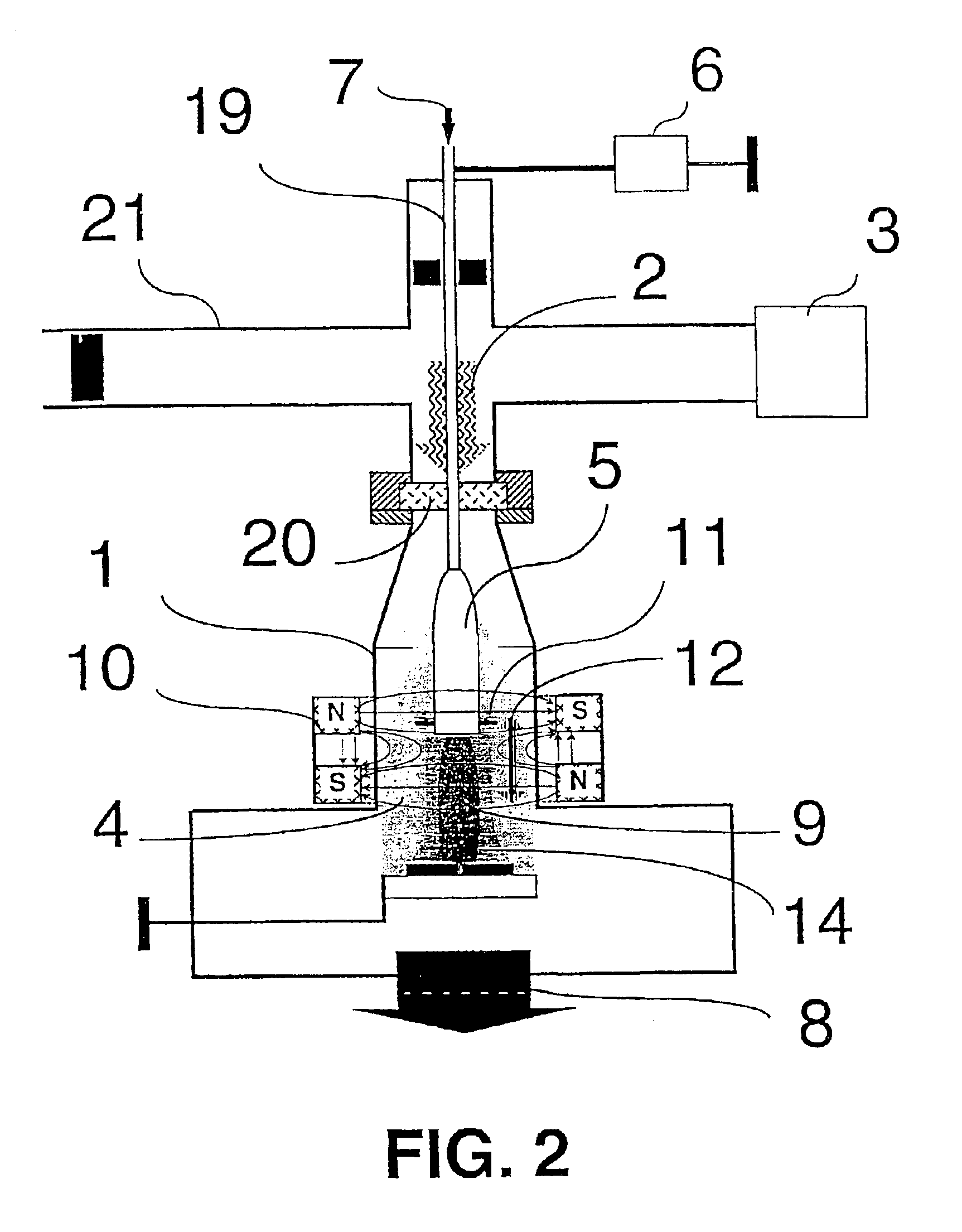

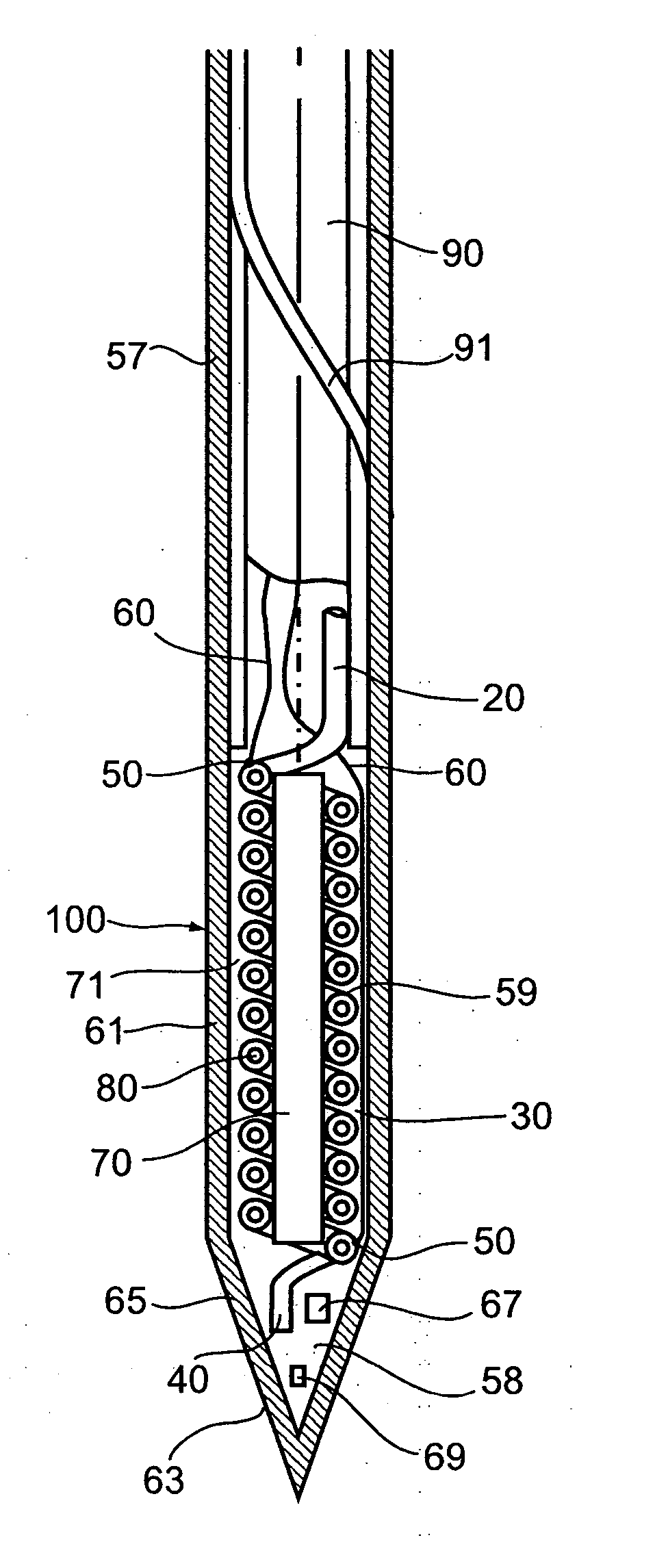

Inductively coupled plasma reactor for producing nano-powder

InactiveUS7323655B2Growth inhibitionGuaranteed to move normallyNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

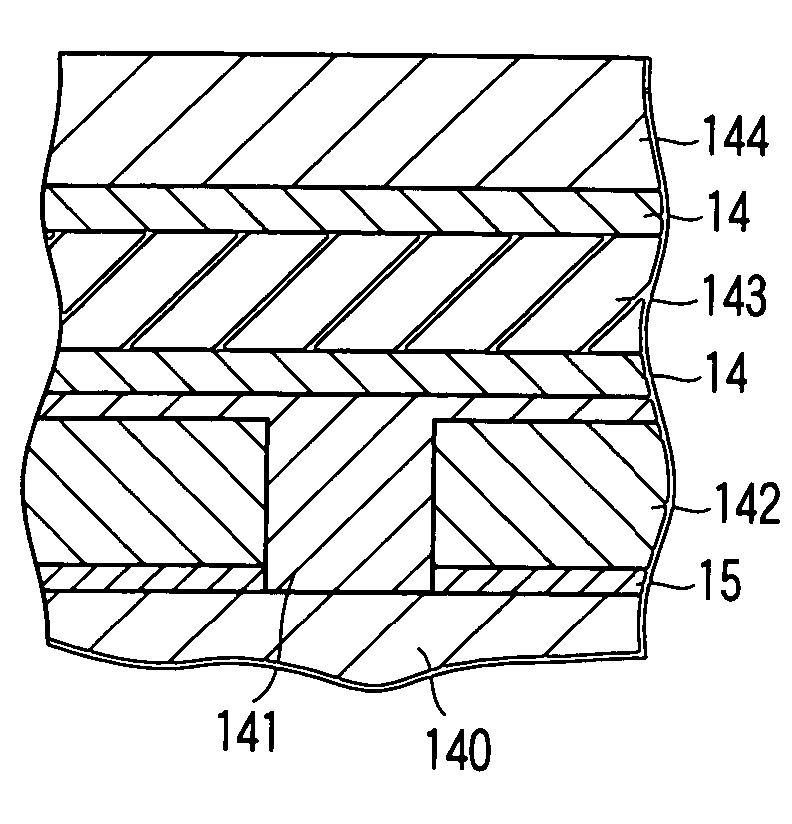

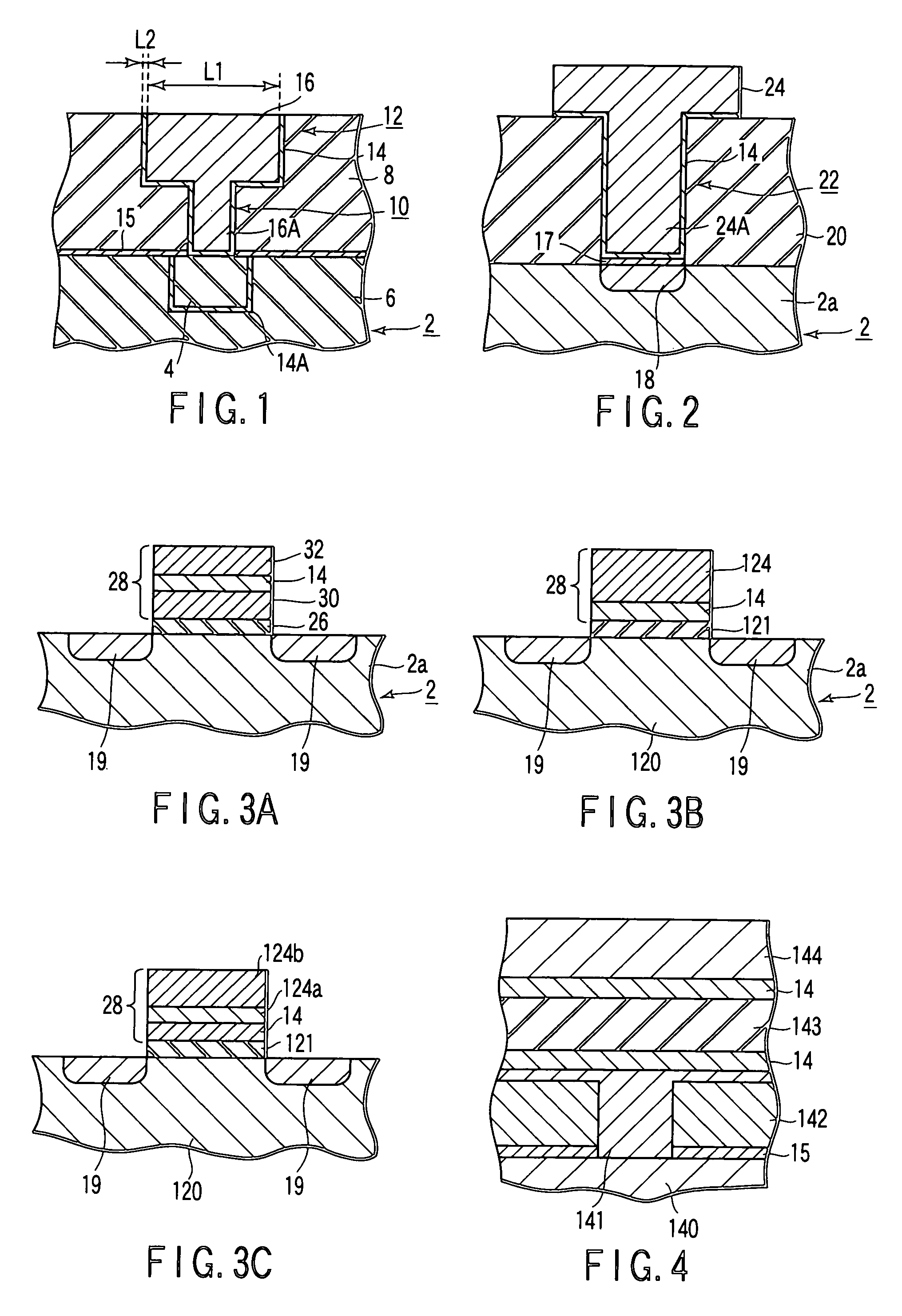

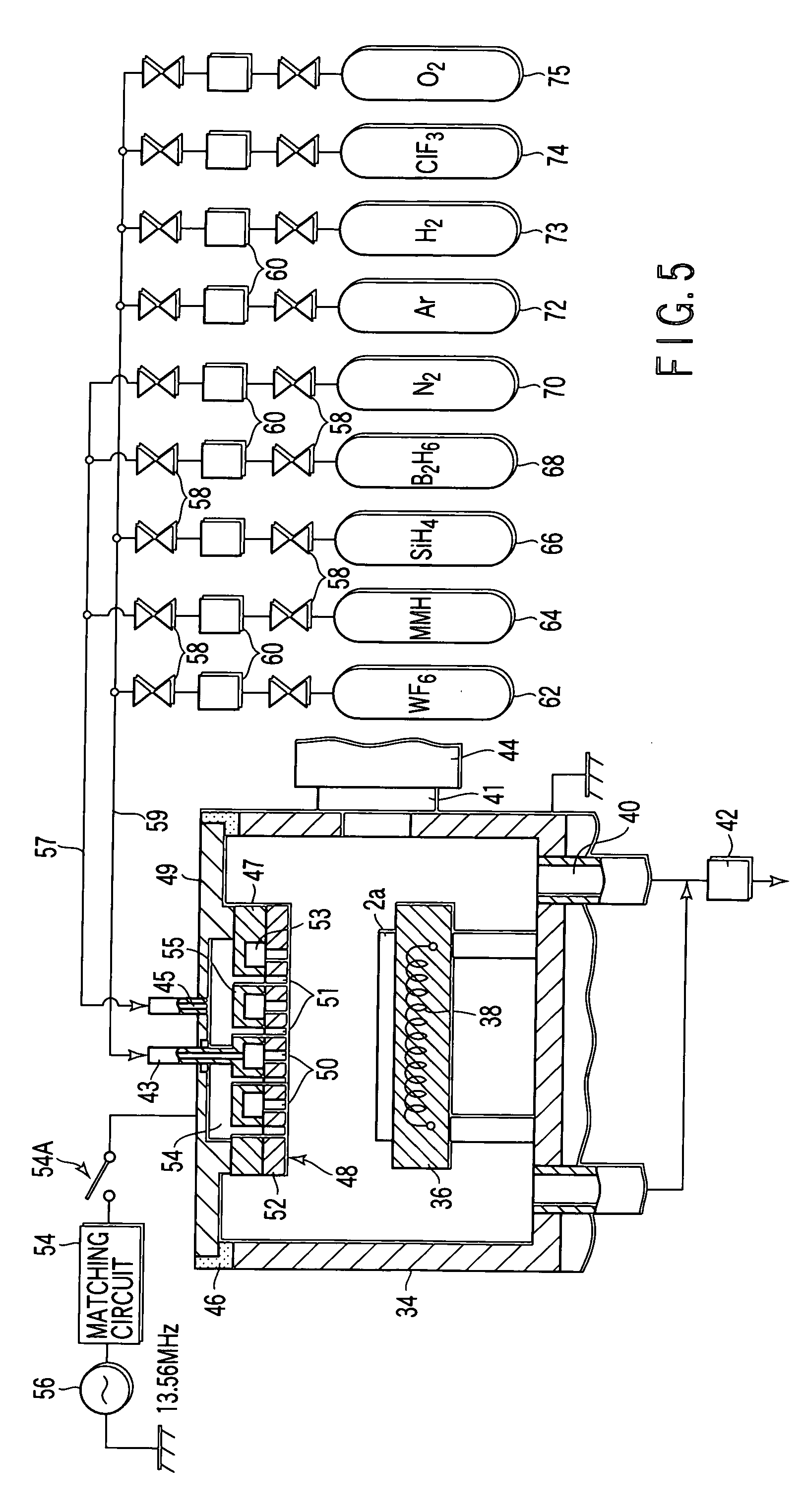

Method of forming a metal film for electrode

InactiveUS20050191803A1Semiconductor/solid-state device detailsSolid-state devicesGroup elementProcess engineering

A method of forming a refractory metal film doped with III or V group elements. The first process gas is supplied from a first gas source through a first gas introducing member to and through a gas supply mechanism toward a substrate within a processing vessel. The second process gas is supplied from a second gas source through a second gas introducing member to and through the gas supply mechanism toward the substrate within the processing vessel. The processing vessel is purged by evacuating the processing vessel by an evacuating mechanism, while supplying the inert gas from a third source through a third gas introducing member to and through the gas supply mechanism into the processing vessel. The supplying the first process gas and the supplying the second process gas are repeated with the supplying the purging gas being carried out between supplying the first and second gases performed so that residual gas present in the processing vessel after performing the supplying of the first and second process gases is reduced to a level of 1 to 30% based on the entire capacity of the processing vessel.

Owner:TOKYO ELECTRON LTD

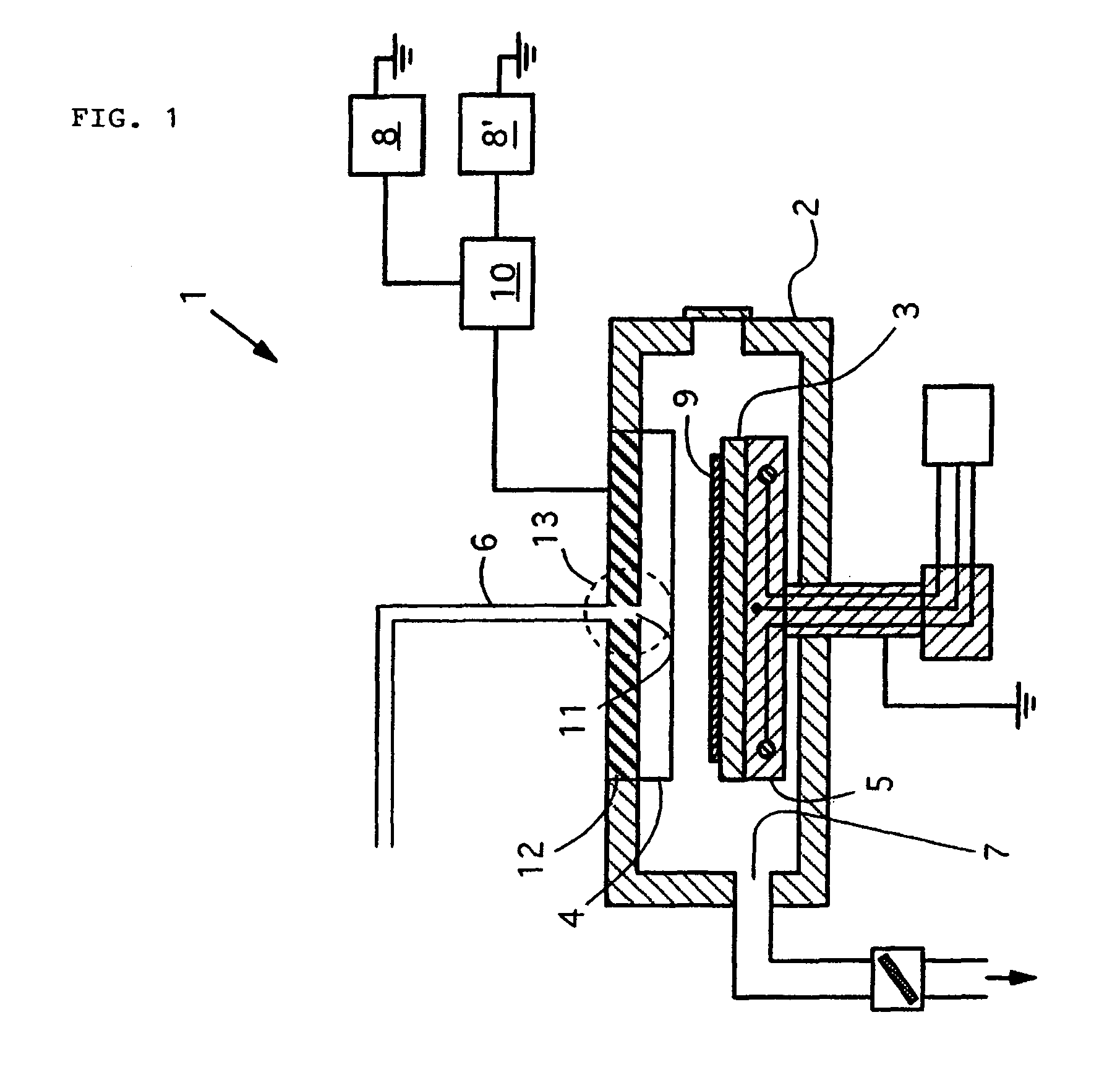

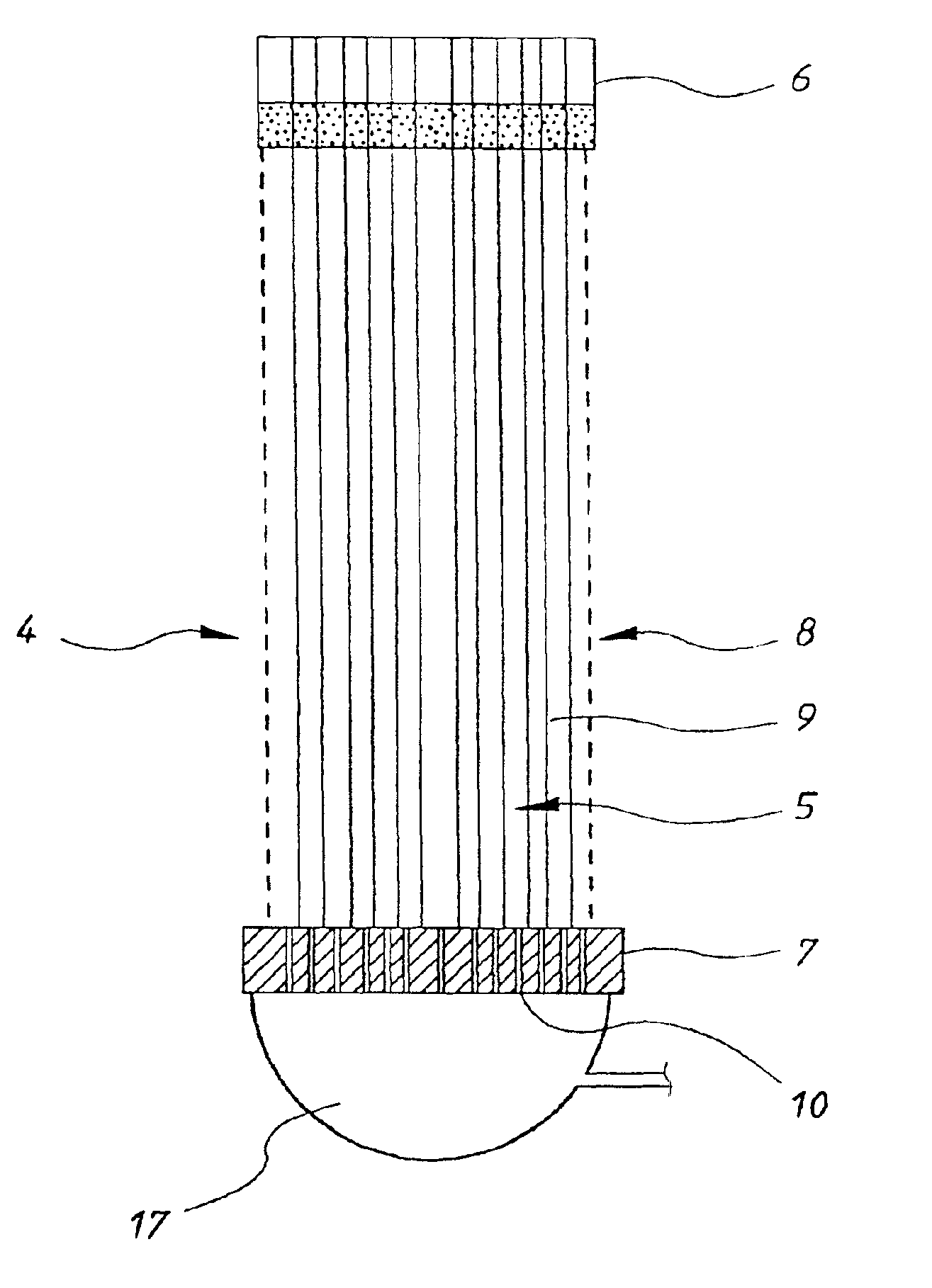

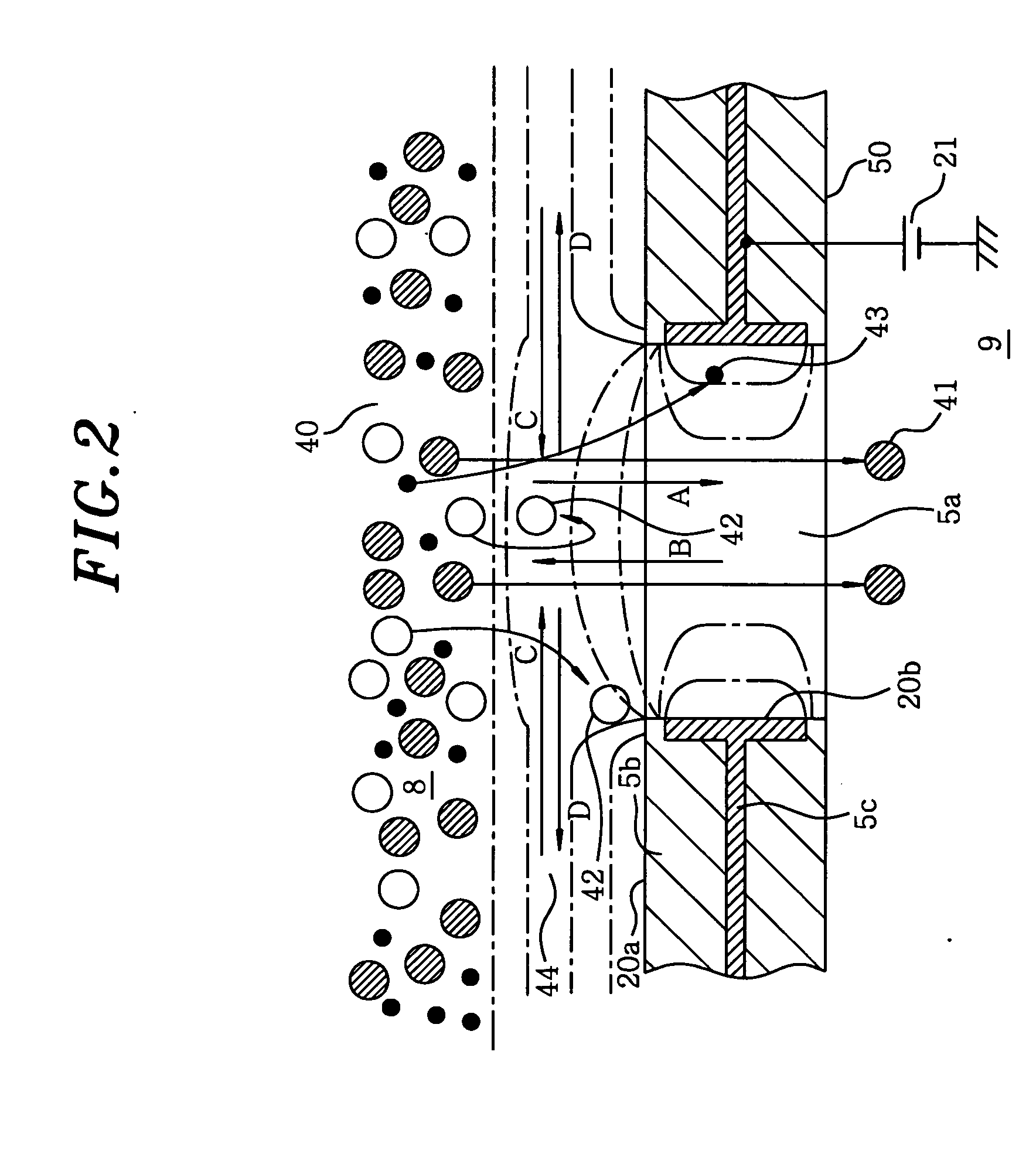

Device for hybrid plasma processing

InactiveUS6899054B1Add deviceElectric discharge tubesSemiconductor/solid-state device manufacturingGas passingPerpendicular magnetic field

A device for hybrid plasma processing, particularly for deposition of thin films and for plasma treatment of samples, in a plasma reactor with pumping system characterized in that at least one feeder of microwave power (2) is installed in the plasma reactor (1) and connected to a microwave generator (3) for generation of a microwave plasma (4) in contact with at least one hollow cathode (5) in the plasma reactor, where the hollow cathode is powered from a cathode power generator (6). At least one inlet for a processing gas (7) is installed behind the hollow cathode and the gas is admitted into the plasma reactor through the hollow cathode where a hollow cathode plasma (9) is generated. A magnetic element (10) is used for generation of a perpendicular magnetic field (11) and / or a longitudinal magnetic field (12) at an outlet (13) from the hollow cathode.

Owner:BARDOS LADISLAV +1

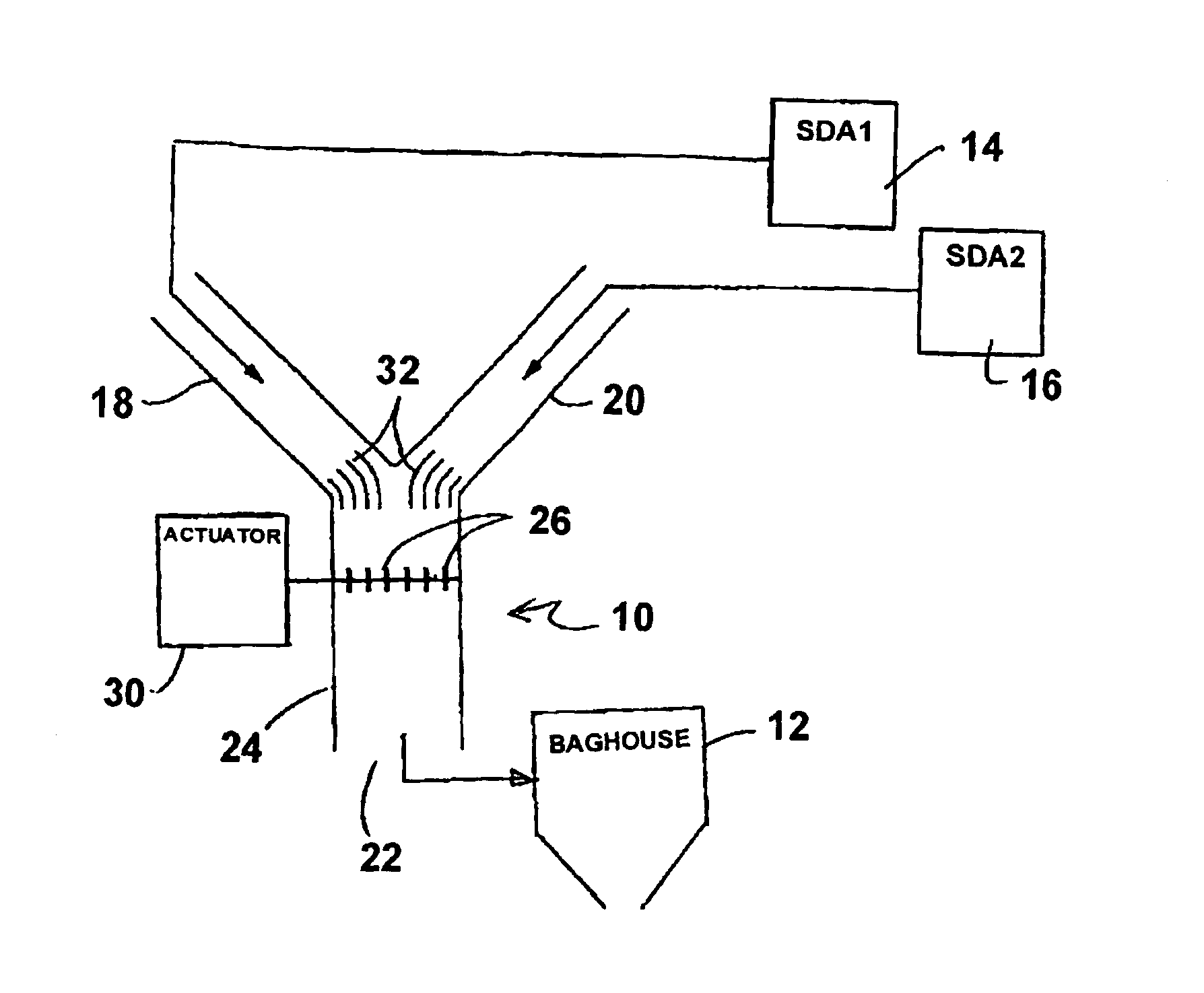

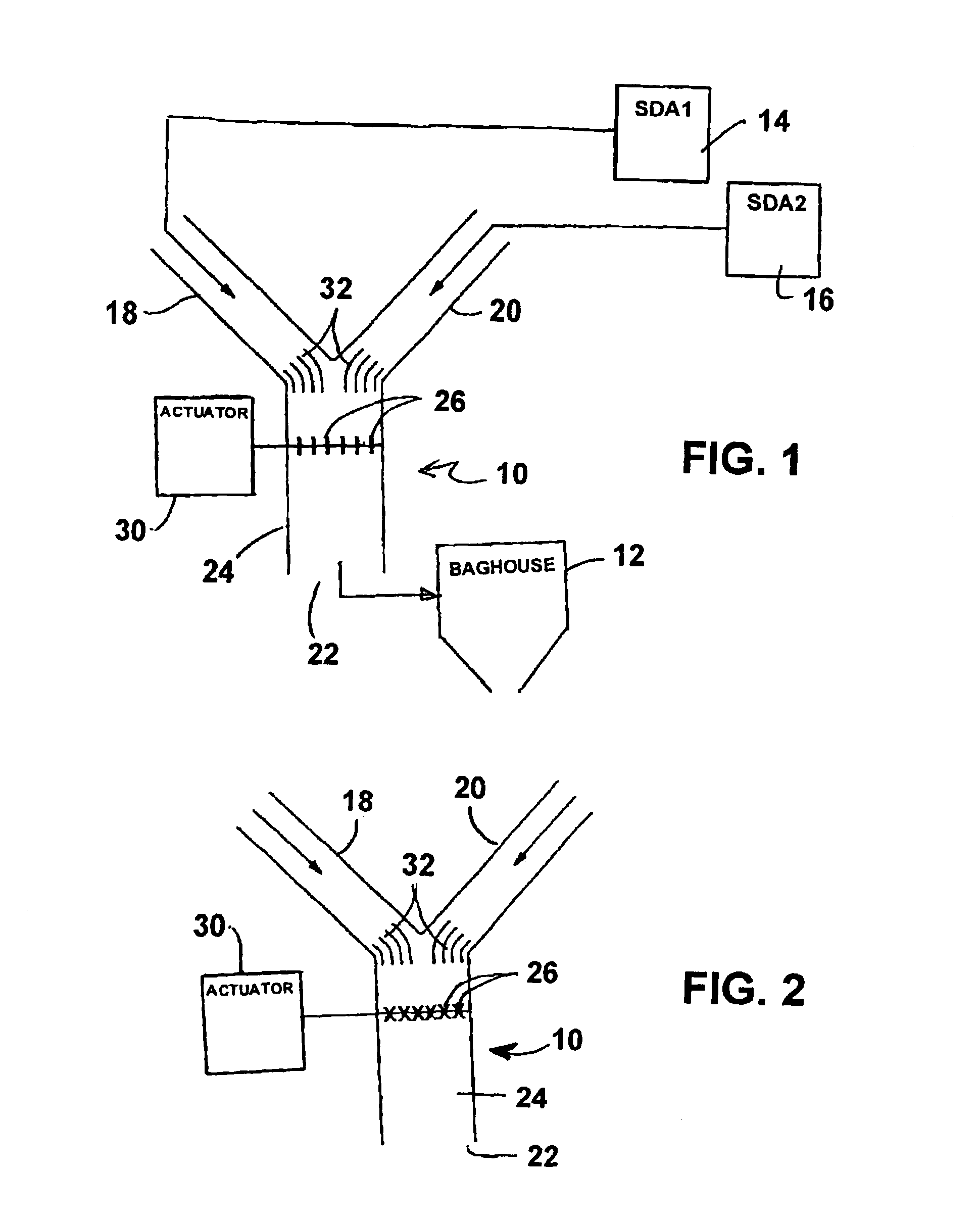

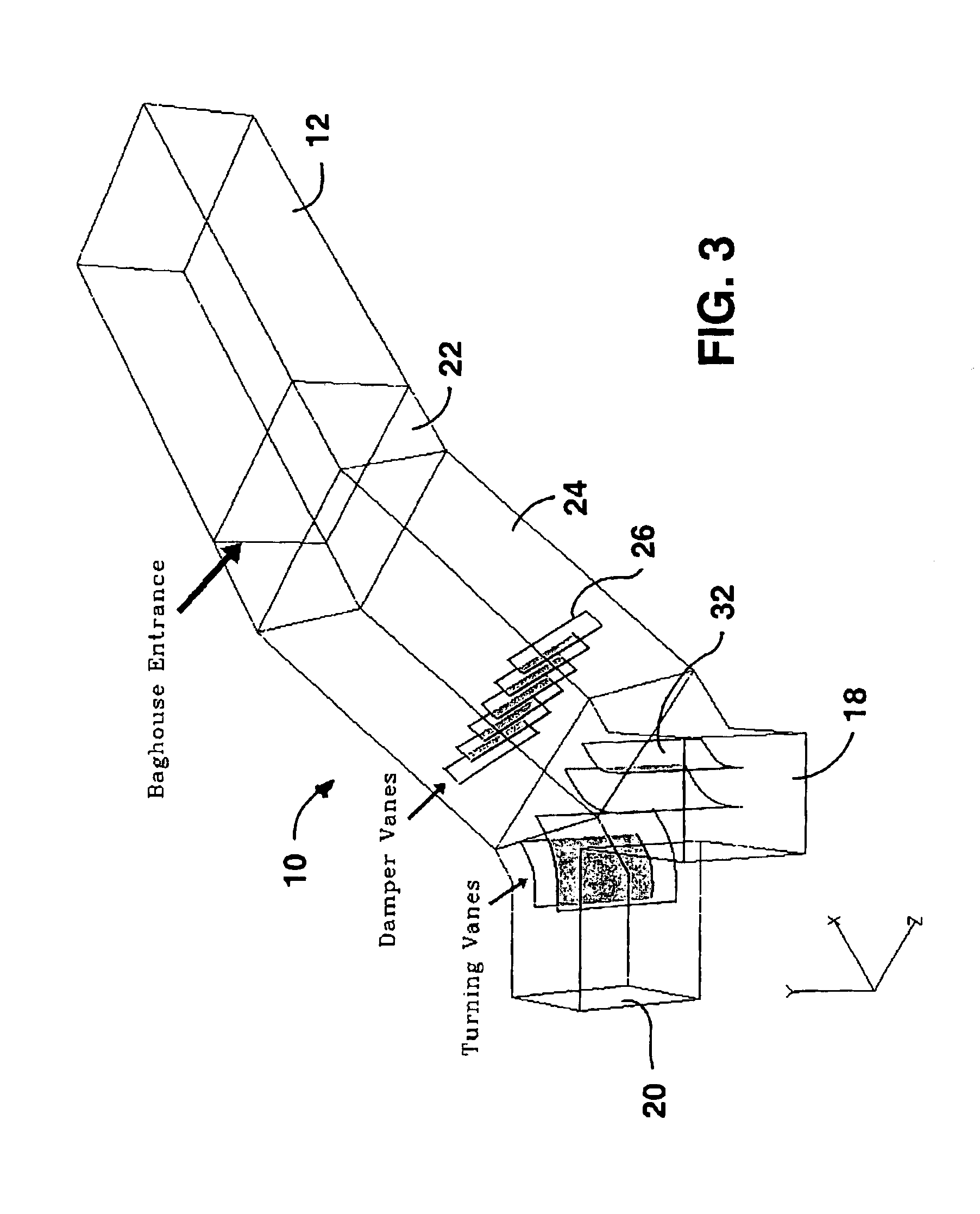

Intermittent mixer with low pressure drop

InactiveUS6946011B2Reduce the temperatureAuxillary pretreatmentOther chemical processesChemical compositionFlue gas

A thermal mixer reduces the temperature of flue gas supplied to a fabric filter. Two spray dry absorbers are operable to cool flue gas. A housing of the mixer has first and second inlet passages for gas from the absorbers, an outlet passage for gas to the fabric filter, and a mixing passage. A set of damper vanes extends in the mixing passage and has a mixing position for mixing the flue gases from the inlet passages to supply mixed gas to the outlet passage at relatively high pressure drop but lower temperature if one of the absorbers in not operating. They have a non-mixing position for passage of gases without mixing and at low pressure drop when both absorbers are operating. The invention can also be used to improve mixing of combined gas streams initially having different chemical compositions or amounts of particle loading.

Owner:THE BABCOCK & WILCOX CO

Inductively coupled plasma reactor for producing nano-powder

InactiveUS20050258766A1Inhibit growthAvoid adsorptionNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

Scouring method

InactiveUS20020195390A1Avoid excessive movementAvoid enteringMembranesUltrafiltrationGas passingPorous membrane

A method and apparatus for removing fouling materials from the surface of a plurality of porous membranes (9) arranged in a membrane module (4) by providing, from within the module, by means (10) other than gas passing through the pores of said membranes, gas bubbles in a uniform distribution relative to the porous membrane array such that the bubbles move past the surfaces of the membranes (9) to dislodge fouling materials therefrom. The membranes (9) are arranged in close proximity to one another and mounted to prevent excessive movement therebetween. The bubbles also produce vibration and rubbing together of the membranes to further assist removal of fouling materials.

Owner:EVOQUA WATER TECH LLC

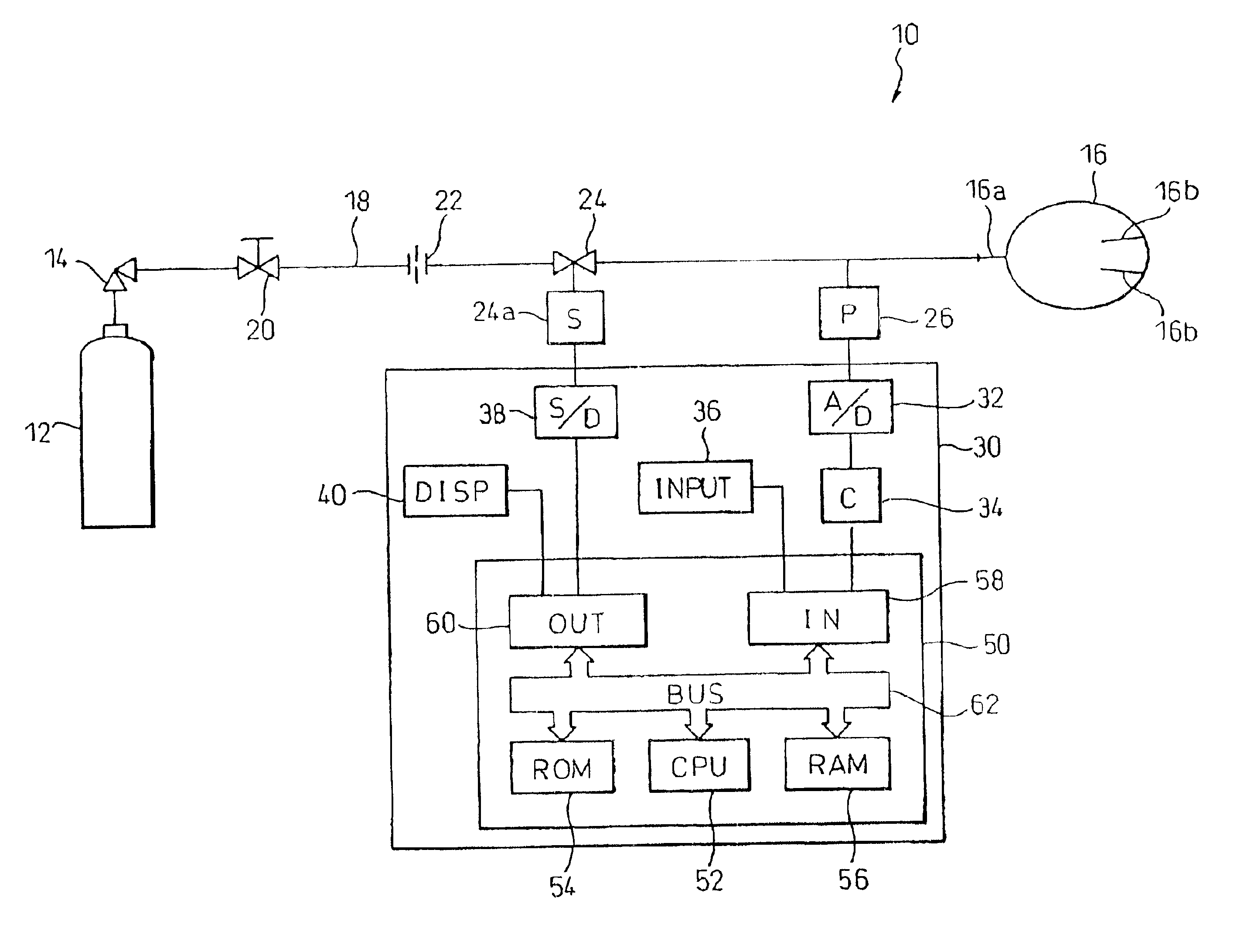

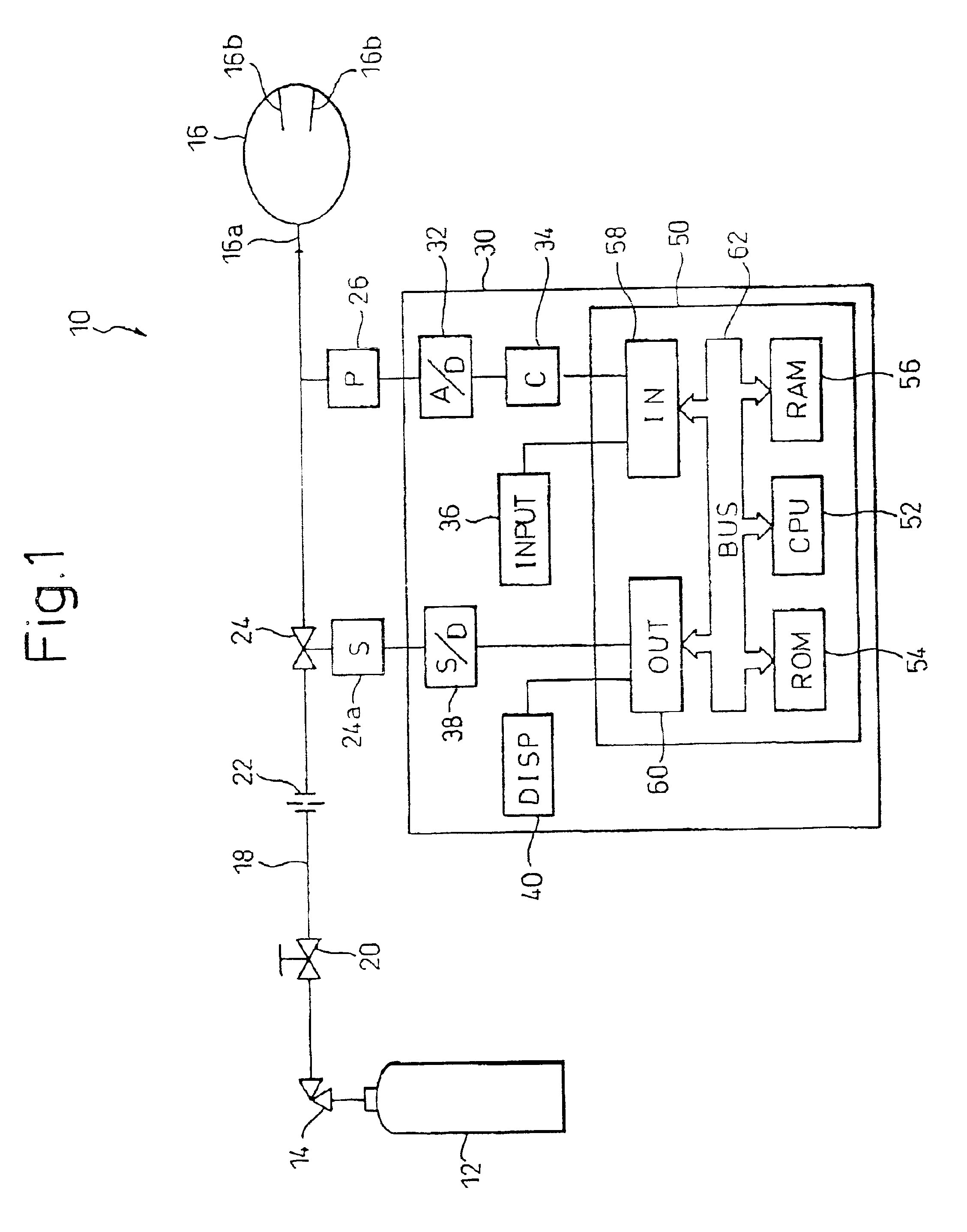

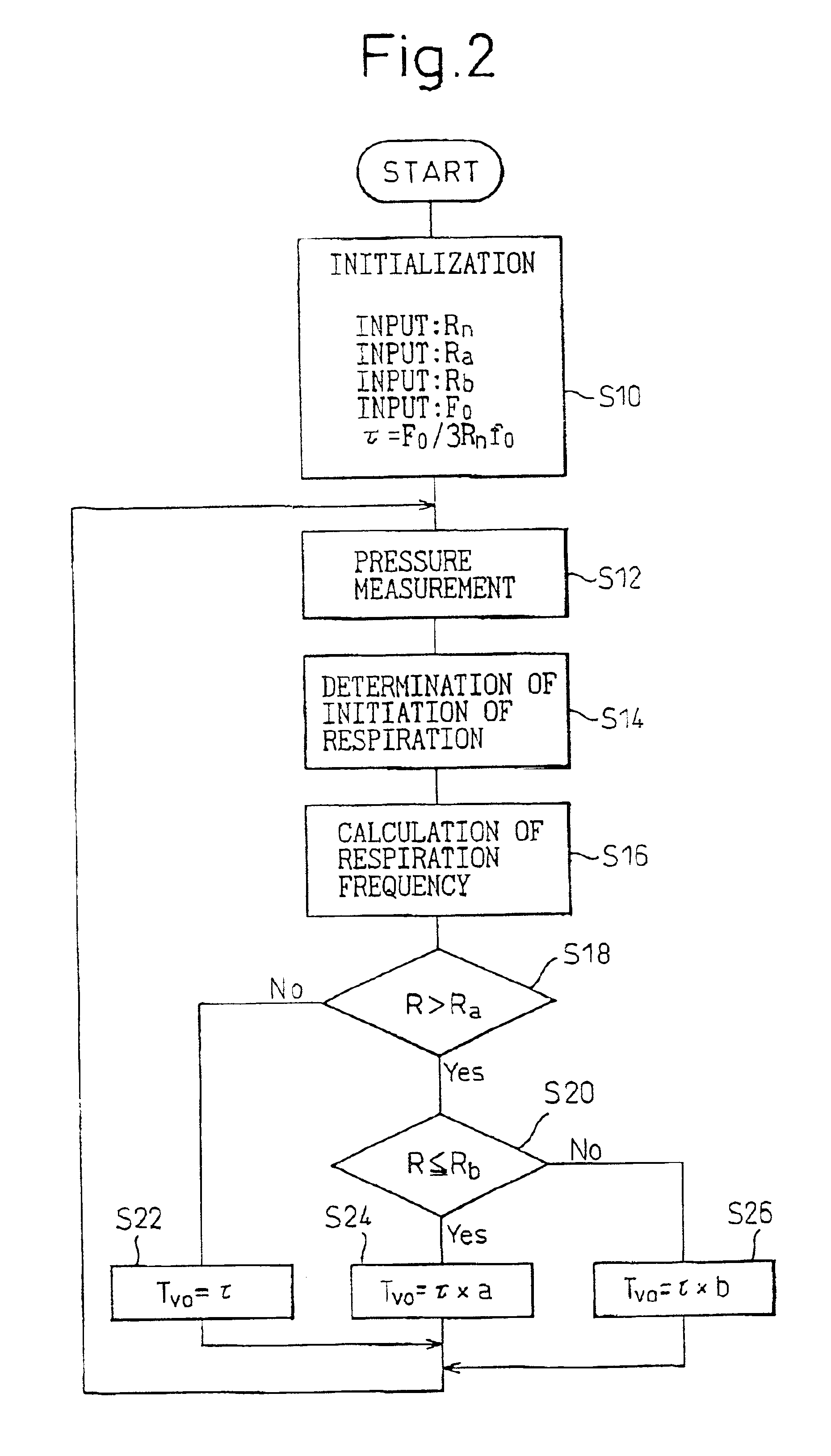

Apparatus for supplying a therapeutic oxygen gas

InactiveUS6880556B2Increase volumeOperating means/releasing devices for valvesRespiratory masksNasal passageIncreased respiratory rate

The apparatus includes a cylinder for containing a pressurized therapeutic oxygen gas, a nasal cannula, adapted to be introduced into a nasal passage of a patient, and a conduit extending between the cylinder and the nasal cannula for directing the therapeutic oxygen gas to the nasal cannula from the cylinder. A pressure sensor is provided on the conduit for detecting the pressure in the conduit. A valve is provided, in the conduit, which allows and blocks the fluid communication between the cylinder and the nasal cannula. A controller controls the operation of the valve in synchronization with the respiration of a patient, based on the changes in the pressure detected by the pressure sensor. The volume of the oxygen therapeutic gas passing through the valve for each respiration is increased, compared with a normal respiration condition, when the respiratory frequency increases.

Owner:TEIJIN LTD

Scouring method

InactiveUS6969465B2The process is simple and effectiveAvoid excessive movementMembranesUltrafiltrationPorous membraneGas passing

A method and apparatus for removing fouling materials from the surface of a plurality of porous membranes (9) arranged in a membrane module (4) by providing, from within the module, by means (10) other than gas passing through the pores of said membranes, gas bubbles in a uniform distribution relative to the porous membrane array such that the bubbles move past the surfaces of the membranes (9) to dislodge fouling materials therefrom. The membranes (9) are arranged in close proximity to one another and mounted to prevent excessive movement therebetween. The bubbles also produce vibration and rubbing together of the membranes to further assist removal of fouling materials.

Owner:EVOQUA WATER TECH LLC

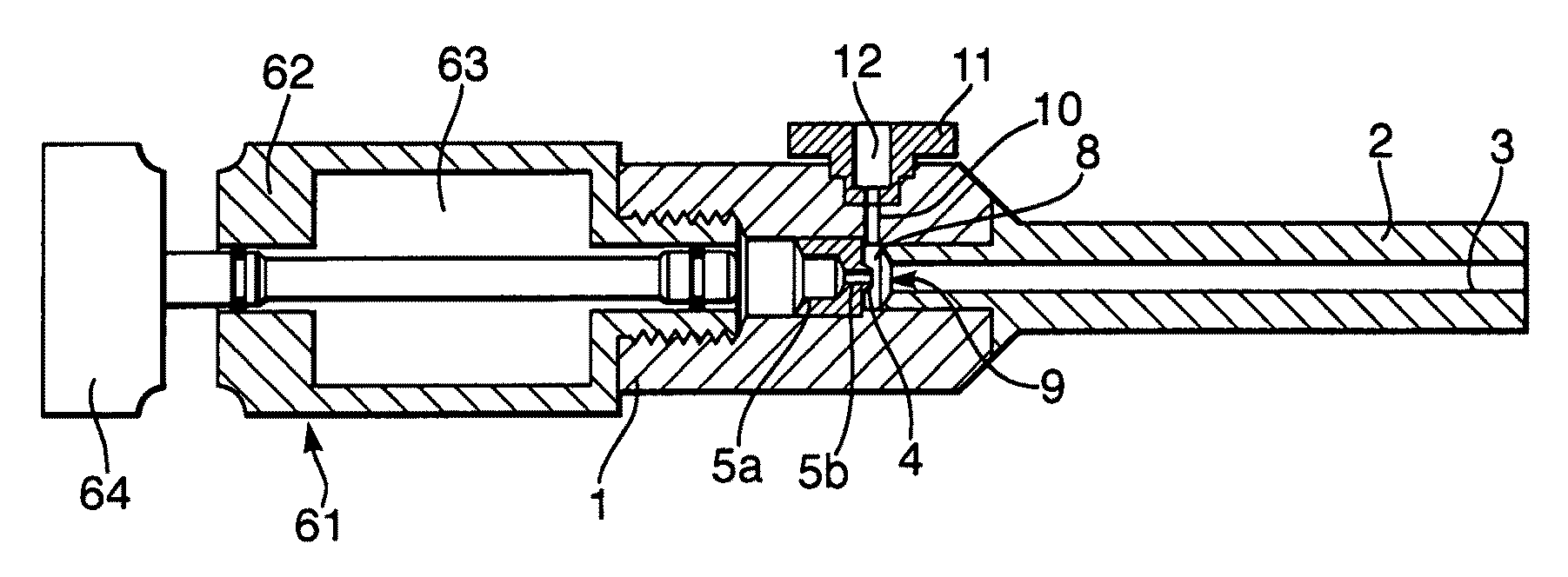

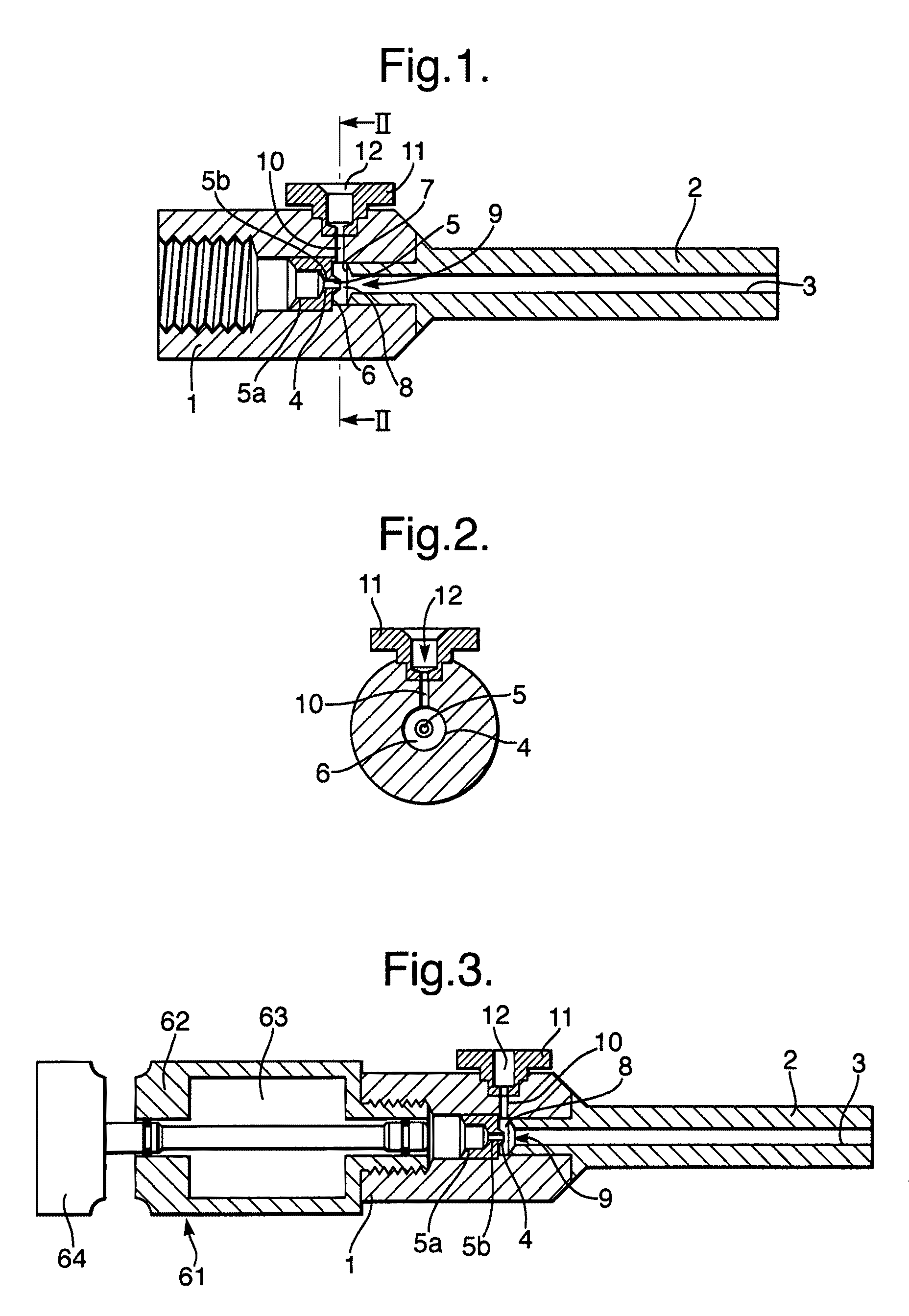

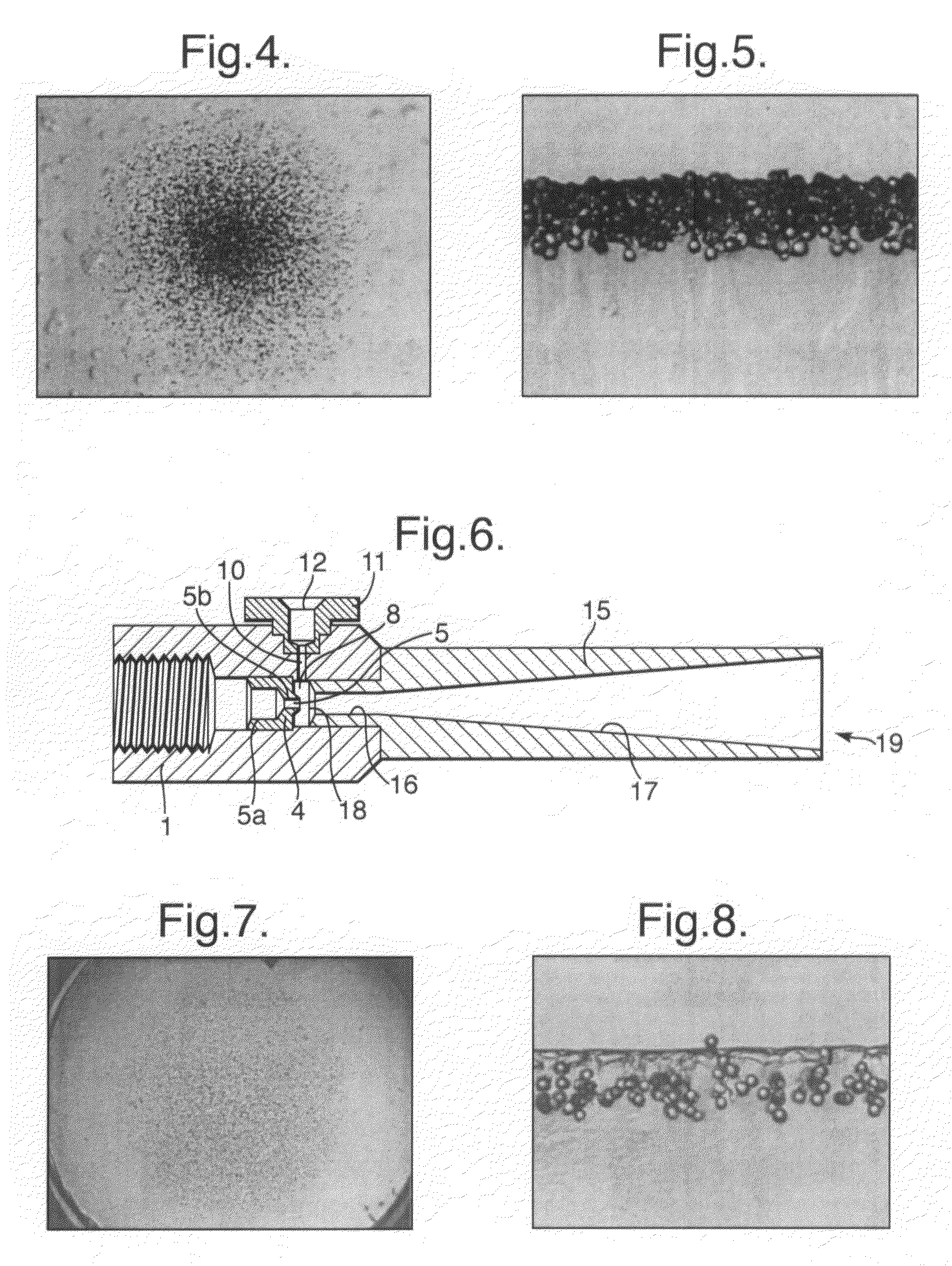

Needleless syringe

ActiveUS7547292B2Reduce pressureWork moreJet injection syringesAutomatic syringesNeedle Free InjectionGas passing

A method of distributing particles in a flow of gas and a needleless syringe for use in the needleless injection of particles into the skin or mucosa of a vertebrate subject are disclosed. The syringe includes a convergence which reduces pressure of the gas flowing in the gas flow path due to the Venturi effect such that particles initially located outside of the gas flow path are drawn into the gas flow path under the action of the reduced pressure and become entrained in the gas. An exit nozzle accelerates the particles so entrained. In another aspect of the invention, there is provided a method of creating a gas flow in a needleless syringe which comprises flowing gas through a first convergence into a chamber to form a transsonic gas jet in the chamber and passing the gas jet from the chamber into a second convergence and along the nozzle.

Owner:POWDER PHARM INC

Plasma processing device and baffle plate thereof

InactiveUS20050167052A1Maintenance of such surfaceElectric discharge tubesSemiconductor/solid-state device manufacturingParallel plateGas passing

A plasma processing device able to positively enhance a process-gas exhaust efficiency in a processing region and restrict plasma leaking. A processing container of a magnetron type parallel plate plasma processing device has a separator for separating the inside of the processing container into a processing region and an exhaust region. The separator has a plurality of gas passage holes to establish communication between the processing region and the exhaust region, and includes a non-conductive member. A conductive member is disposed on a gas passage-side surface facing the gas passage holes. A voltage V is applied by a power supply to the conductive member so that the gas passage-side surface is at a potential higher than that of a processing-region surface.

Owner:TOKYO ELECTRON LTD

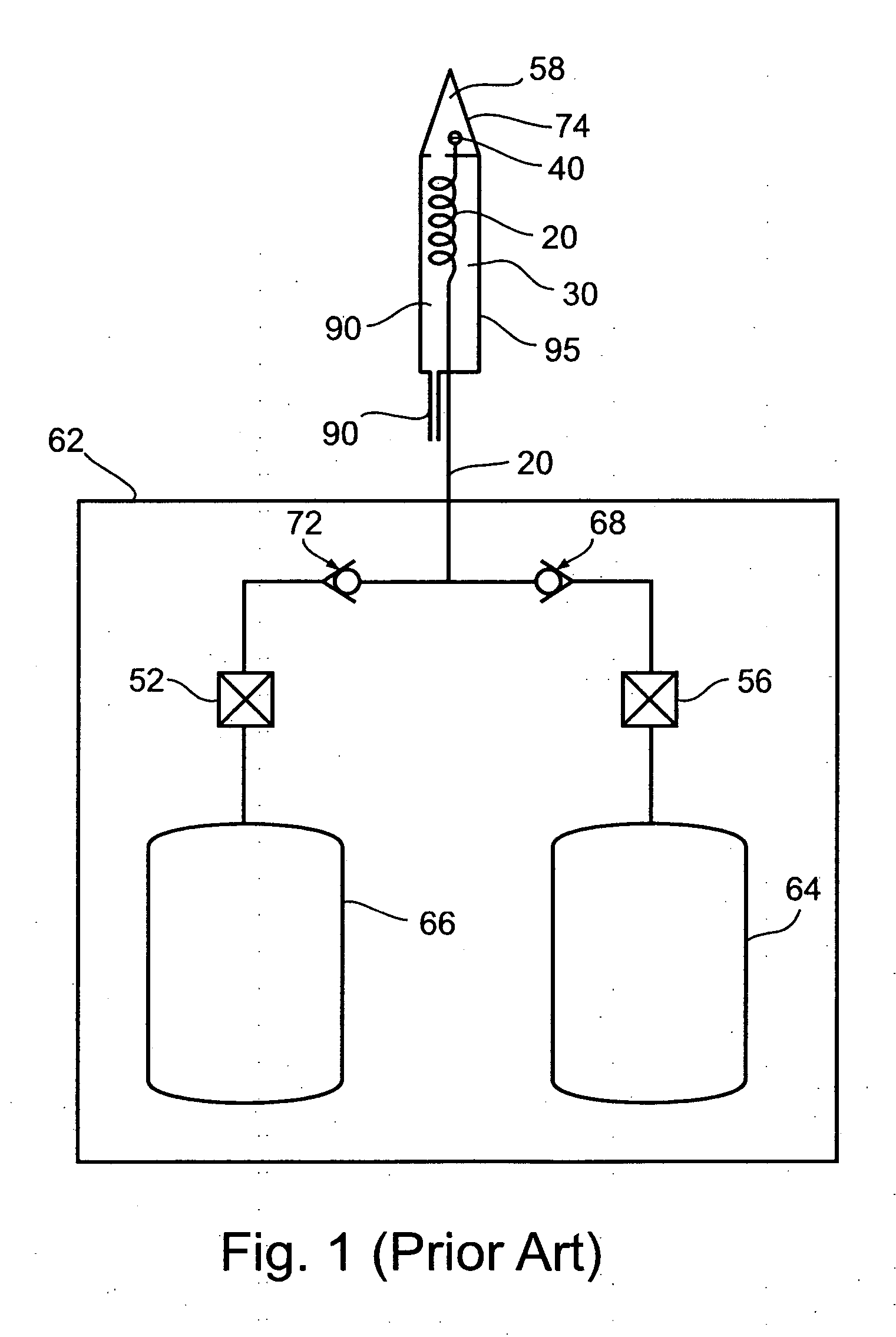

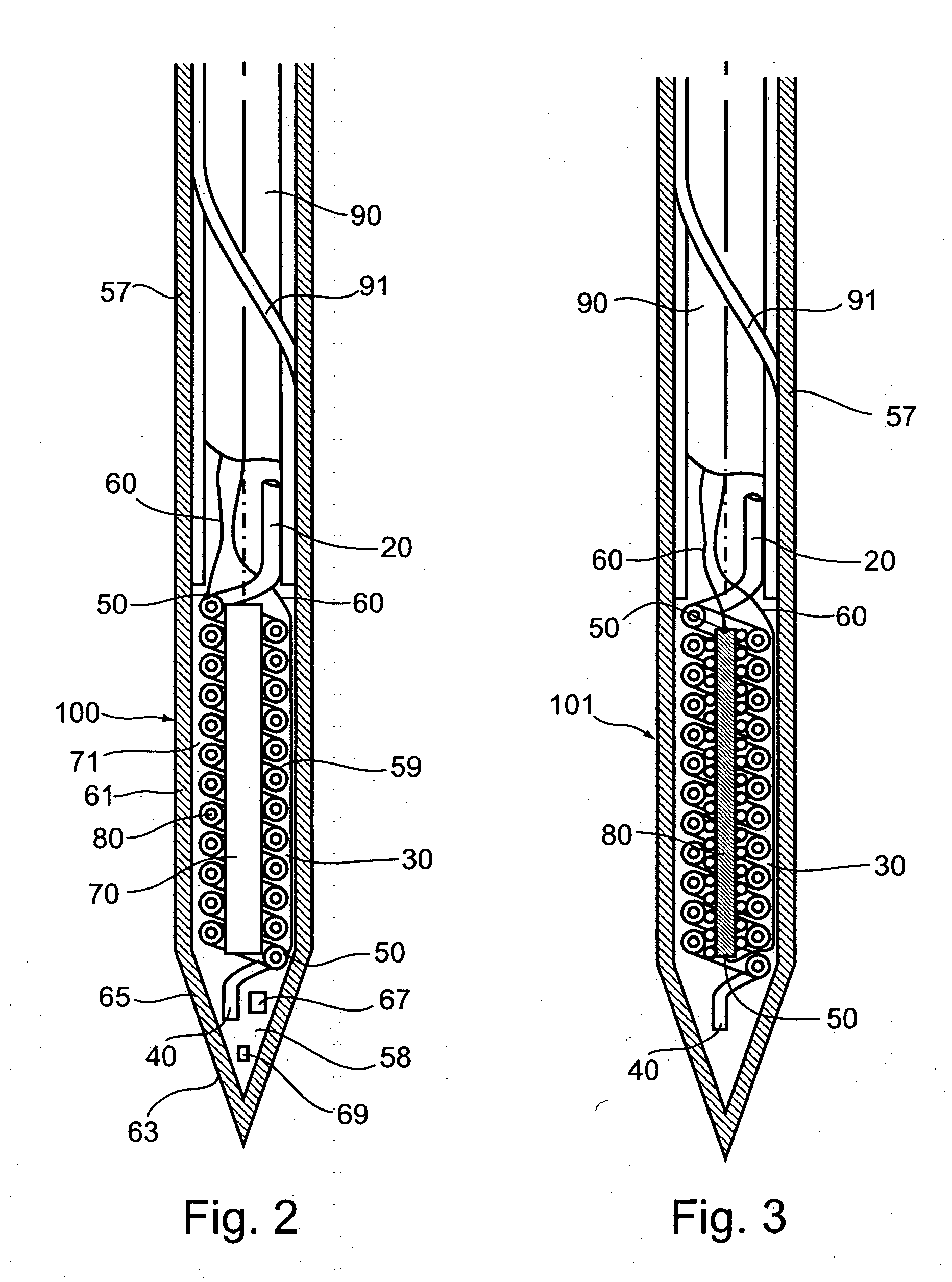

Gas-heated gas-cooled cryoprobe utilizing electrical heating and a single gas source

ActiveUS20060122590A1Quick switchHeating fastSurgical instruments for coolingElectrical resistance and conductanceElectricity

The present invention is of device, system, and method for cooling and heating an operating tip of a cryoprobe using a single source of compressed gas. Cooling of the operating tip is effected by Joule-Thomson expansion of a high-pressure cooling gas through a Joule-Thomson orifice into an expansion chamber. Heating of the operating tip is effected by electrical resistance heating. In preferred embodiments, heating of the operating tip is effected by electrical resistance heating of low-pressure gas flowing towards the operating tip. Preferably, gas from a single gas source is supplied to the probe during both cooling and heating phases, a cooling gas being supplied at high pressure when used for cooling and at low pressure when used for heating. Low-pressure gas supplied during the heating phase is heated as it flows towards the operating tip, preferably by electrical resistance heating within the body of the probe. A single gas input lumen is used during both cooling and heating phases to transport gas into the probe, and a single gas exhaust lumen is used during both cooling and heating phases to conduct gas out of the probe.

Owner:GALIL MEDICAL

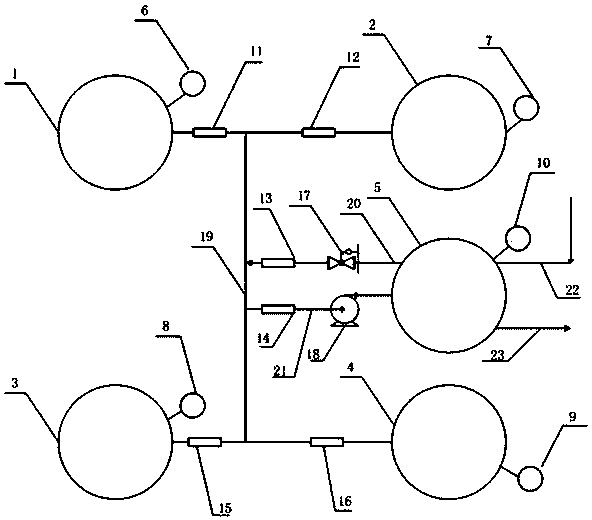

Safe and environment-friendly method for protecting storage tanks

InactiveCN104370000AShort processReduce dosageLarge containersEnvironmental resistancePositive pressure

The invention relates to a safe and environment-friendly method for protecting storage tanks to mainly solve the problems that in the prior art, the gas consumption of nitrogen protection is excessively large, cost is high, and sulfur-containing gas and other peculiar smell gas are hard to treat. According to the safe and environment-friendly method for protecting the storage tanks, the gas produced by liquid in the storage tanks enters a compressor (18) through a main gas pipe (19) and an inflation pipe (21), the gas is pressurized by the compressor (18) and stored in a buffering tank (5) to serve as one part of positive-pressure protection gas, when the gas stored in the buffering tank (5) cannot meet the positive-pressure protection of all storage tanks, the nitrogen from a nitrogen inlet pipeline (22) is used for performing supplementation, and when the pressure stored in the buffering tank (5) exceeds the designed pressure, the residual gas is sent to a torch or combustion furnace through a torch or combustion furnace leading pipeline (22), the problems are well solved through the technical scheme, and the method can be used in storage tank protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment of effluent gases

A method is described for recovering a noble gas, such as xenon or krypton, from a first gas mixture comprising a plurality of components, one of which is the noble gas and the others are typically helium and / or nitrogen, argon, and relatively light fluorocarbons. The gas mixture is first conveyed to a gas chromatography column for separating the noble gas from the other components of the gas mixture. As the noble gas travels relatively slowly through the column, the other components are exhaust from the column before the relatively slow noble gas. Following the exhaust of these other components, a purge gas is supplied to the column to flush the noble gas therefrom. A second gas mixture comprising the noble gas and the purge gas is conveyed from the column to a membrane separator to separate the second gas mixture into a noble gas-rich gas stream and a purge gas-rich gas stream, which may be recirculated back to the column for re-use.

Owner:THE BOC GRP PLC

Apparatus for mixing fluids

InactiveUS6669843B2Eliminate needLiquid separation auxillary apparatusSpace heating and ventilationGas passingSolid particle

Owner:HYDROTREAT

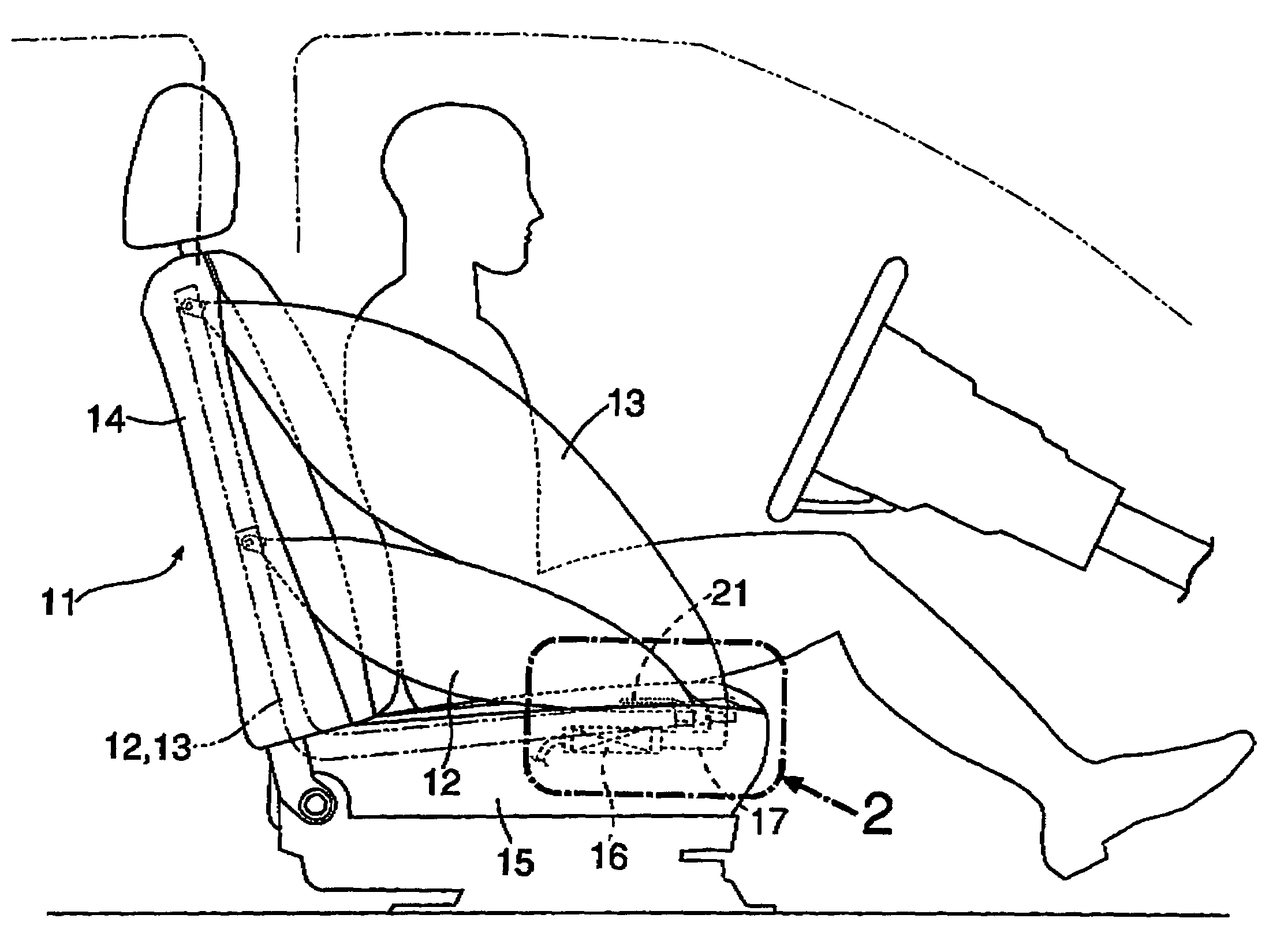

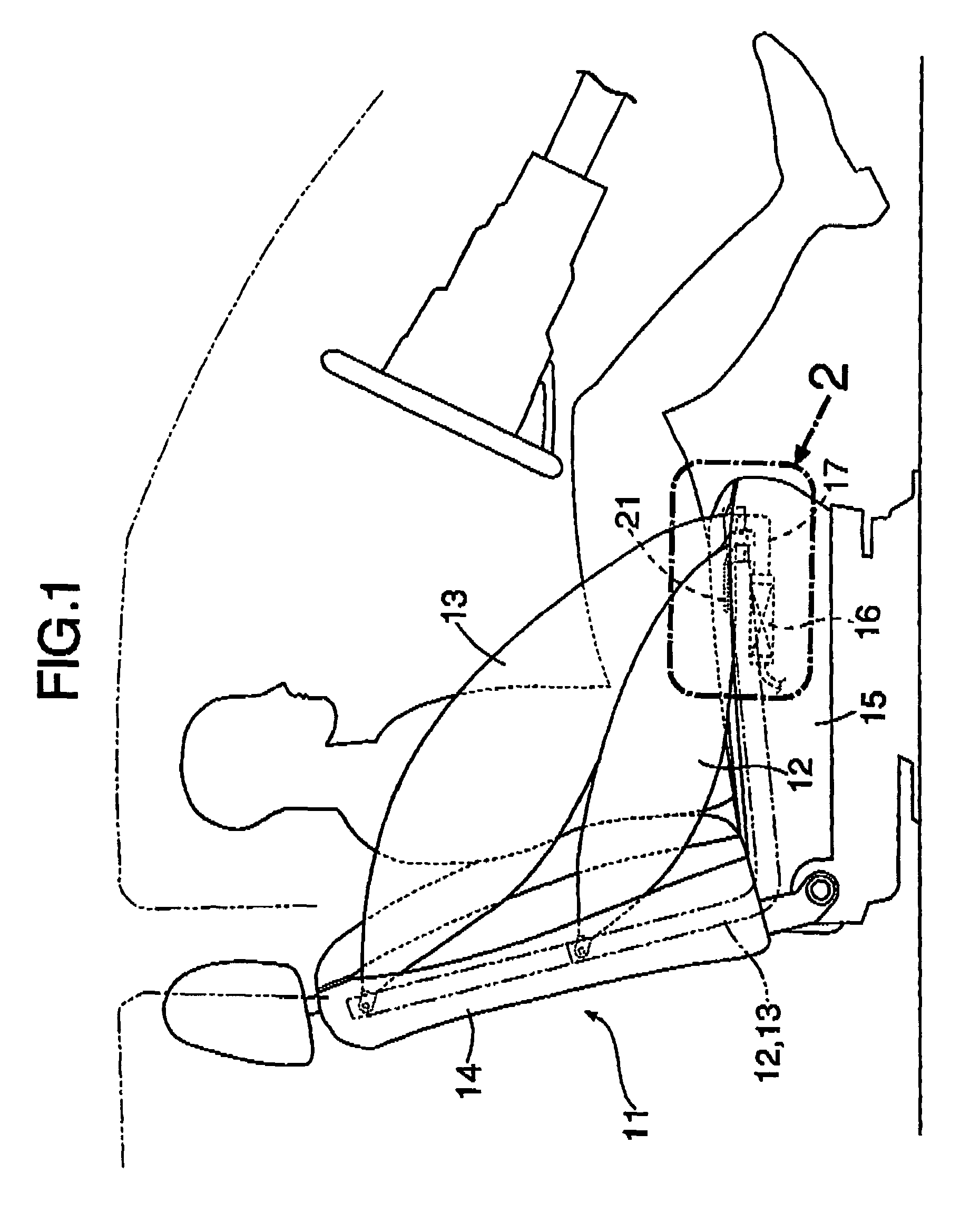

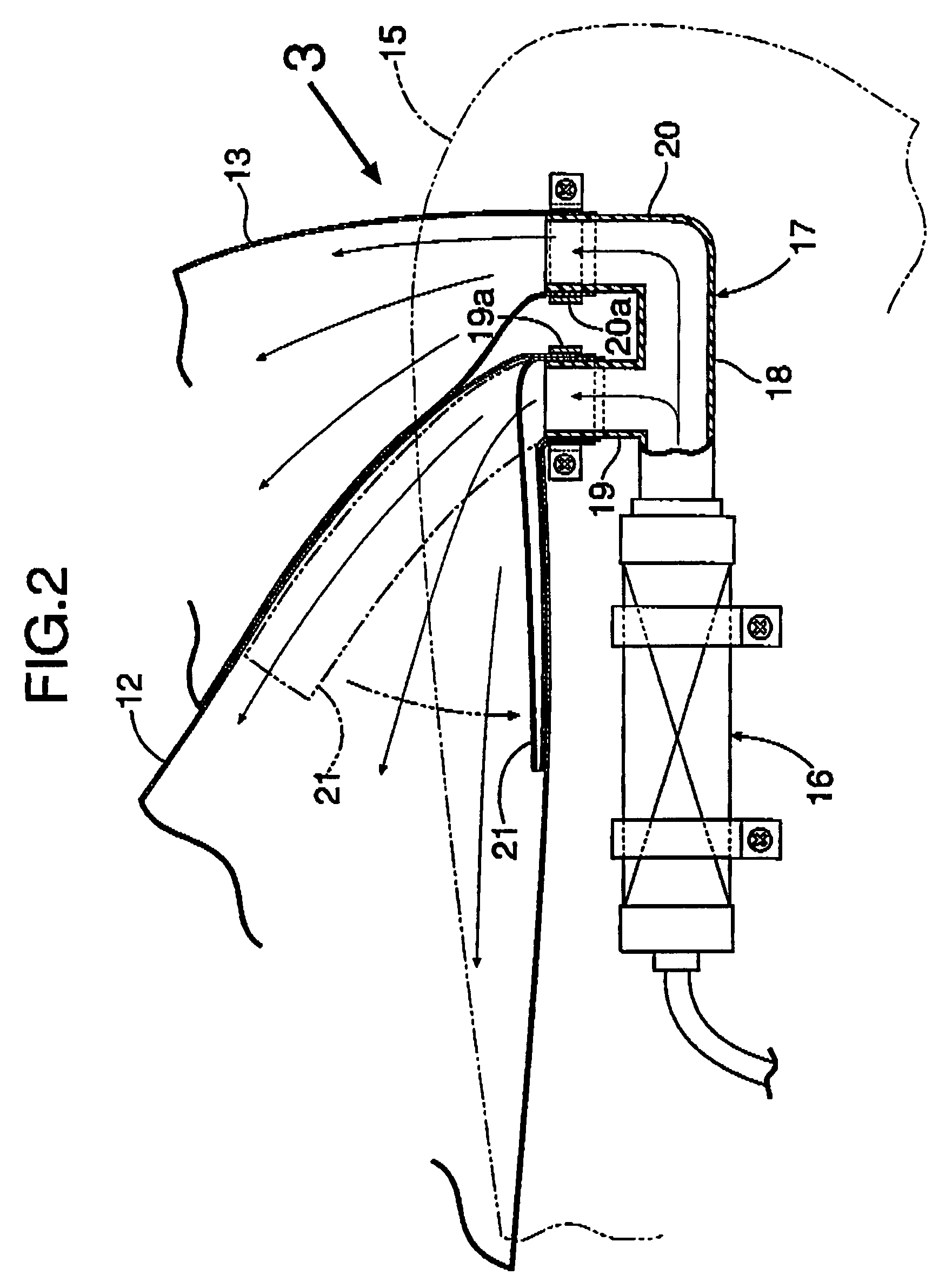

Side air bag device

InactiveUS7086663B2Minimize the numberInhibit gas flowPedestrian/occupant safety arrangementInternal pressureGas passing

A gas generated by an inflator is supplied through a branching pipe to first and second air bags, which are deployed from a side of a seat to a space between an inner surface of a side of a vehicle compartment and an occupant. A one-way valve mounted in the branching pipe permits the gas to move from the second air bag to the first air bag and inhibits a back flow of the gas, whereby the internal pressure in the first air bag can be maintained higher than that in the second air bag, to thereby restrain the occupant's waist more strongly than the occupant's breast. Moreover, the gas generated by the single inflator is diverted by the branching pipe and supplied to the two air bags. Therefore, the two air bags can be deployed while minimizing the number of the inflator.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com