Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

358results about How to "Uniform removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

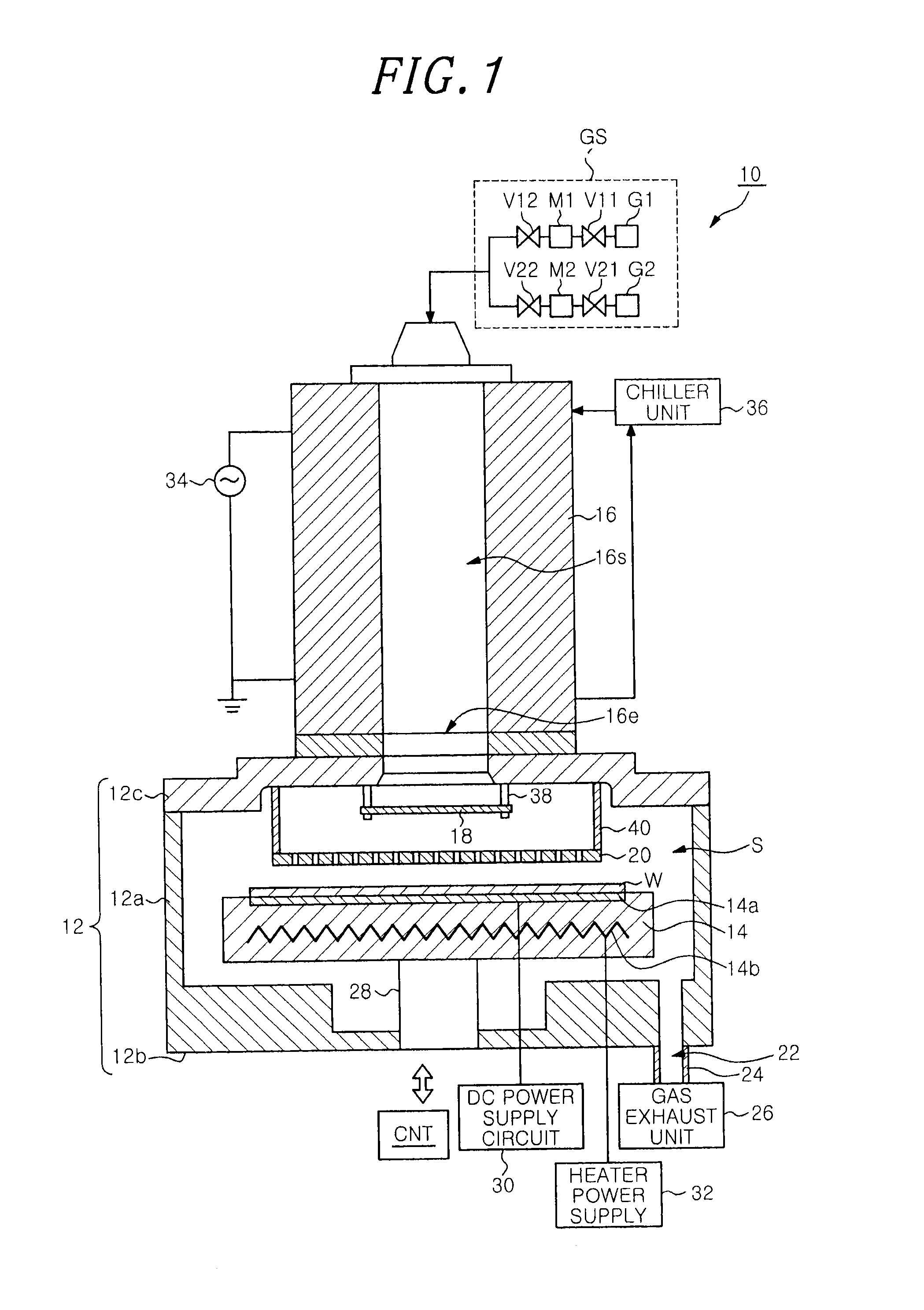

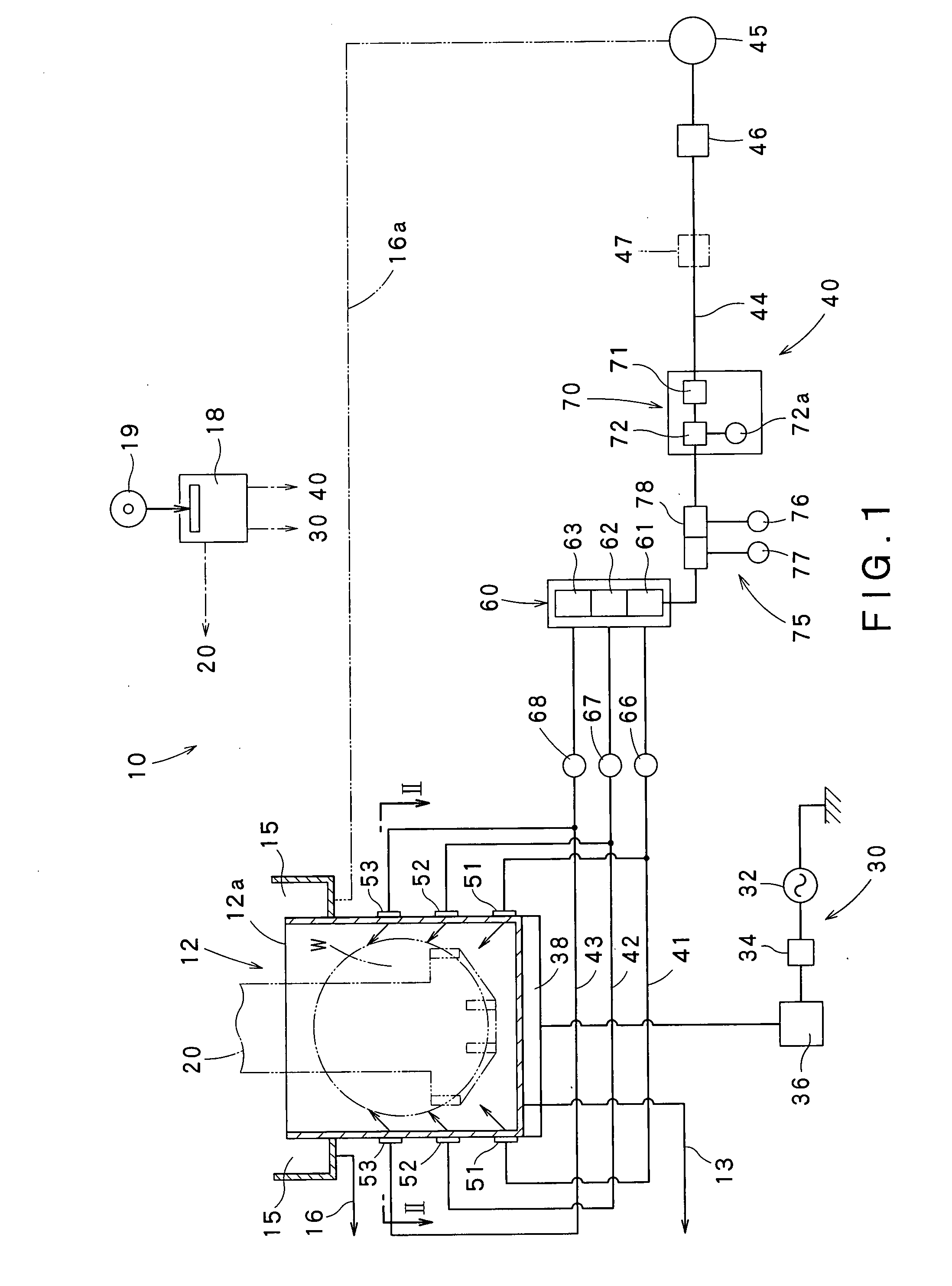

Method and apparatus for processing substrates

InactiveUS20070062646A1Improve throughputUniform removalElectric discharge tubesSemiconductor/solid-state device manufacturingGas passingProcess engineering

A substrate processing apparatus includes a processing chamber and a gas supply line, wherein a natural oxide film removing gas including a first gas activated by a second gas activated by a plasma discharge is supplied to the processing chamber through the gas supply line to remove a natural oxide film on a wafer, and wherein the first gas and the second gas are supplied to the gas supply line along a first direction and a second direction and an angle between the first and the second direction ranges from about 90° to 180°.

Owner:KOKUSA ELECTRIC CO LTD

Plasma processing apparatus and cleaning method for removing metal oxide film

InactiveUS20140060572A1Good removal effectEasy passElectric discharge tubesElectrostatic cleaningRemote plasmaHydrogen

Owner:TOKYO ELECTRON LTD

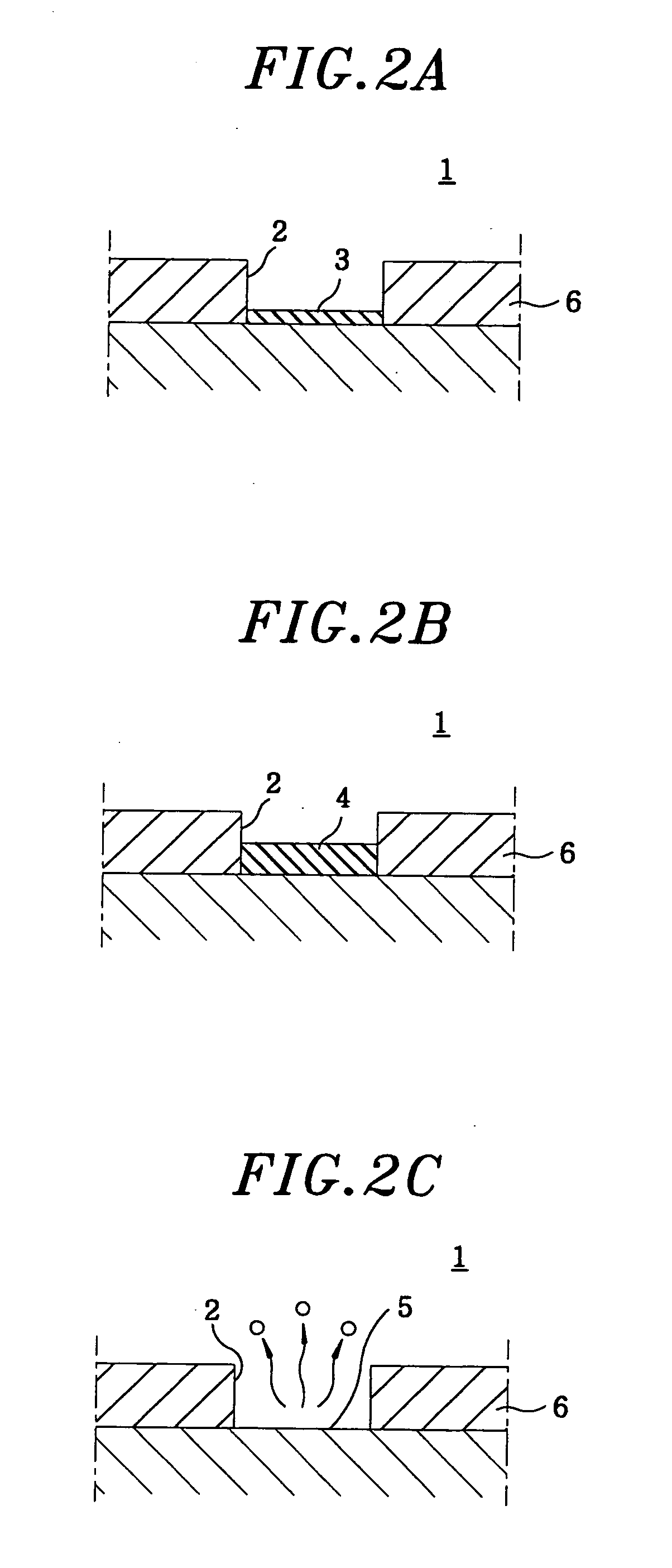

Dry etch process

InactiveUS8765574B2Uniform removalElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringDry etching

A method for conformal dry etch of a liner material in a high aspect ratio trench is achieved by depositing or forming an inhomogeneous passivation layer which is thicker near the opening of a trench but thinner deep within the trench. The method described herein use a selective etch following formation of the inhomogeneous passivation layer. The selective etch etches liner material faster than the passivation material. The inhomogeneous passivation layer suppresses the etch rate of the selective etch near the top of the trench (where it would otherwise be fastest) and gives the etch a head start deeper in the trench (where is would otherwise be slowest). This method may also find utility in removing bulk material uniformly from within a trench.

Owner:APPLIED MATERIALS INC

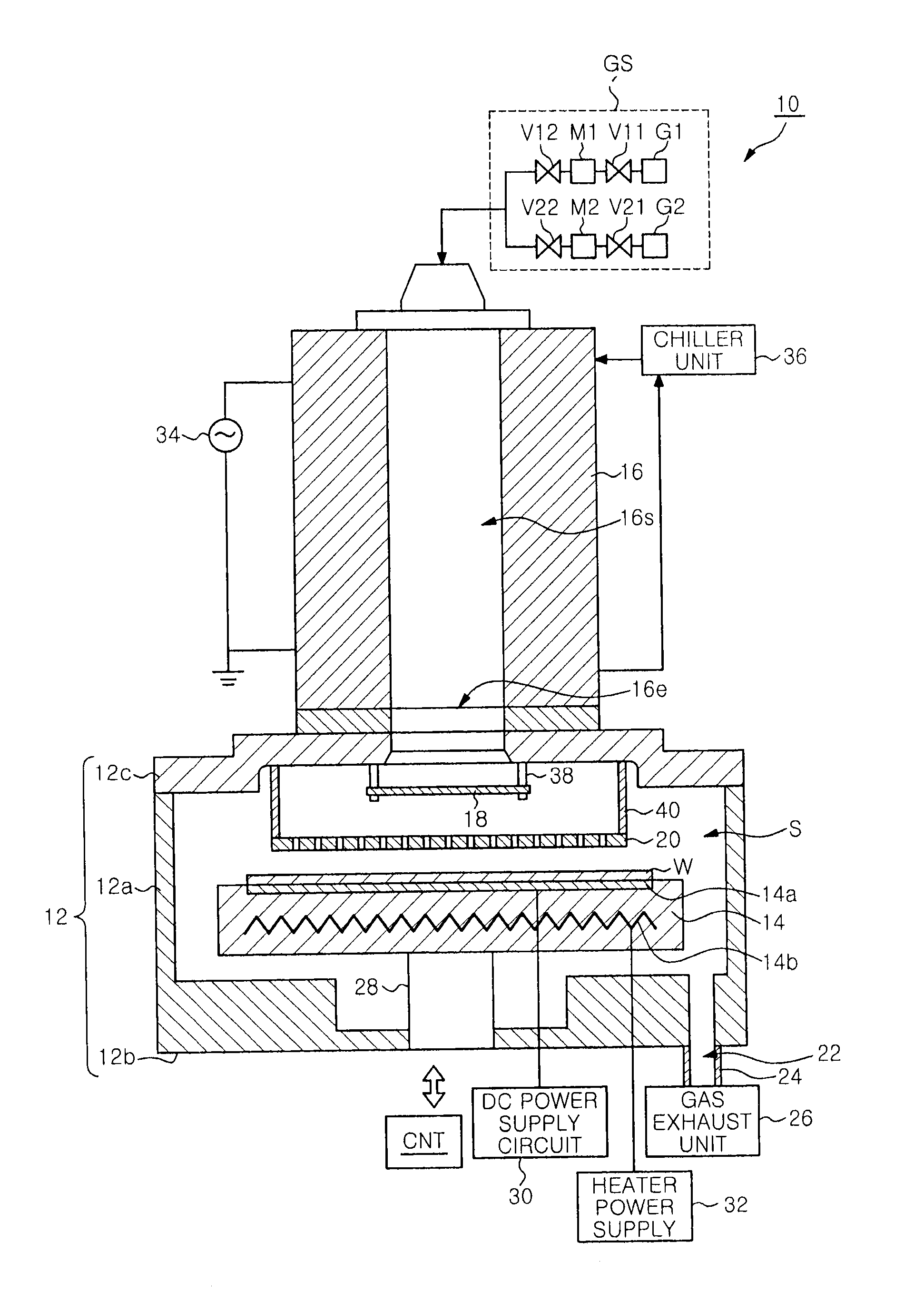

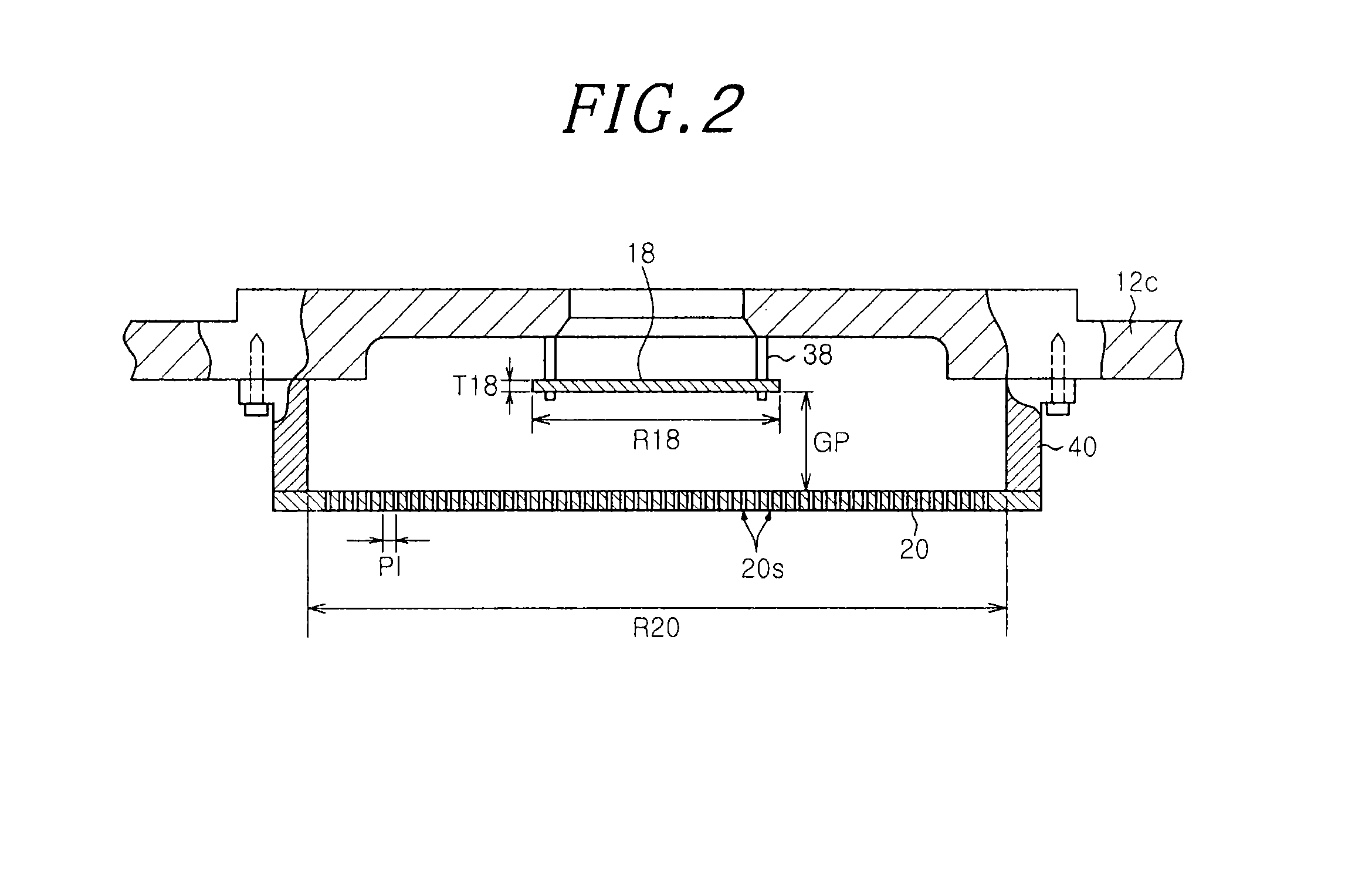

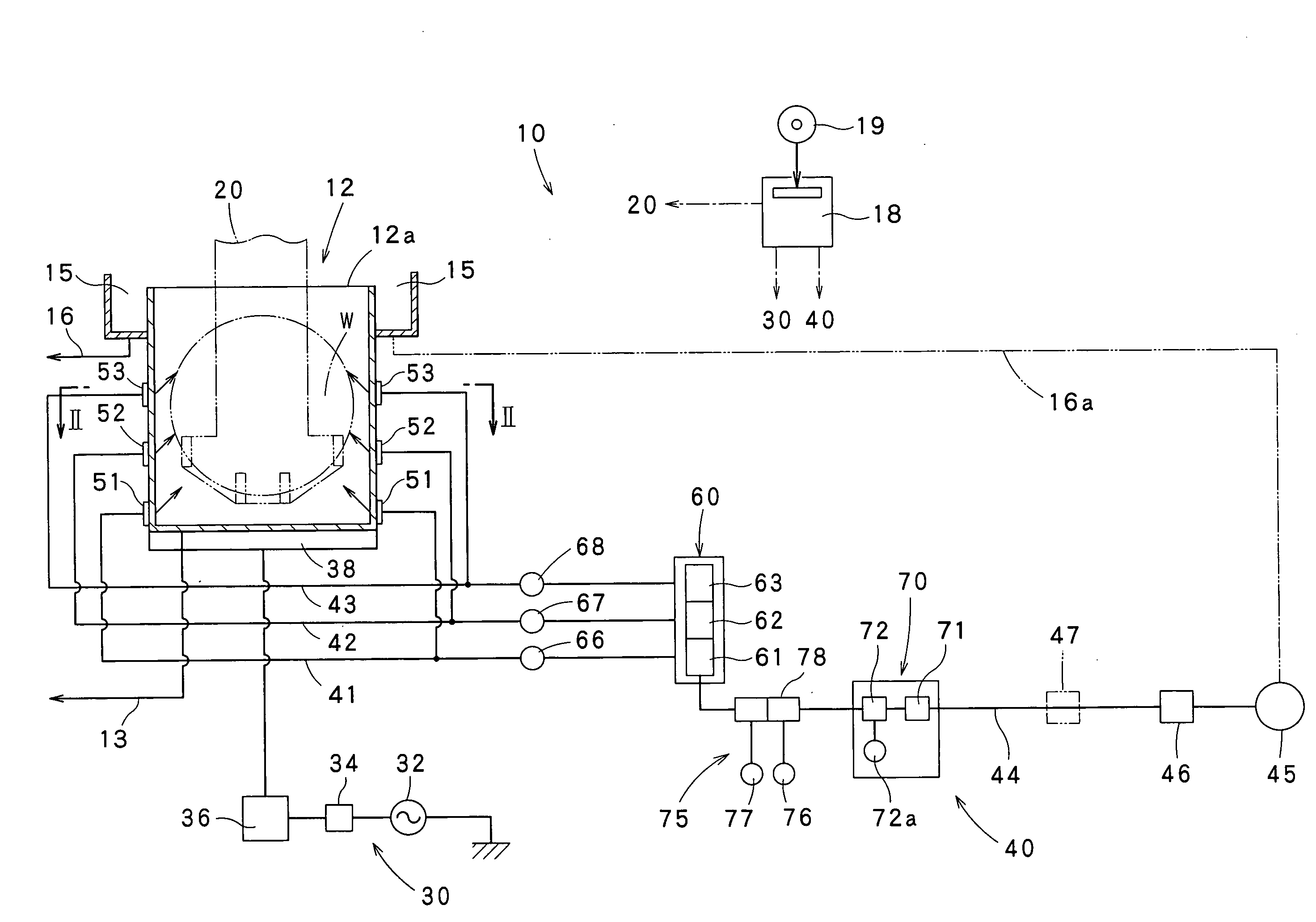

Plasma Processing Apparatus

InactiveUS20080236751A1Improve process yieldUniformity of processElectric discharge tubesSemiconductor/solid-state device manufacturingCircumferential ringsPlasma processing

A plasma processing apparatus wherein a layer structure consisting of plural layers formed in stack one upon another on a semiconductor wafer placed on the sample holder located in the process chamber, is etched with plasma generated in the process chamber by supplying high frequency power to the electrode disposed in the sample holder, the apparatus comprising a ring-shaped electrode disposed above the electrode and around the periphery of the top portion of the sample holder, an outer circumferential ring of dielectric material disposed above the ring-shaped electrode and opposite to the plasma, and a power source for supplying power at different values to the ring-shaped electrode depending on the sorts of layers of the layer structure.

Owner:HITACHI HIGH-TECH CORP

Dry etch process

InactiveUS20140134842A1Etch rate be fasterSuppress etch rateElectric discharge tubesSemiconductor/solid-state device manufacturingEtching rateAspect ratio

A method for conformal dry etch of a liner material in a high aspect ratio trench is achieved by depositing or forming an inhomogeneous passivation layer which is thicker near the opening of a trench bat thinner deep within the trench. The methods described herein use a selective etch following formation of the inhomogeneous passivation layer. The selective etch etches liner material faster than the passivation material. The inhomogeneous passivation layer suppresses the etch rate of the selective etch near the top of the trench (where it would otherwise be fastest) and gives the etch a head start deeper in the trench (where it would otherwise be slowest). This method may also find utility in removing bulk material uniformly from within a trench.

Owner:APPLIED MATERIALS INC

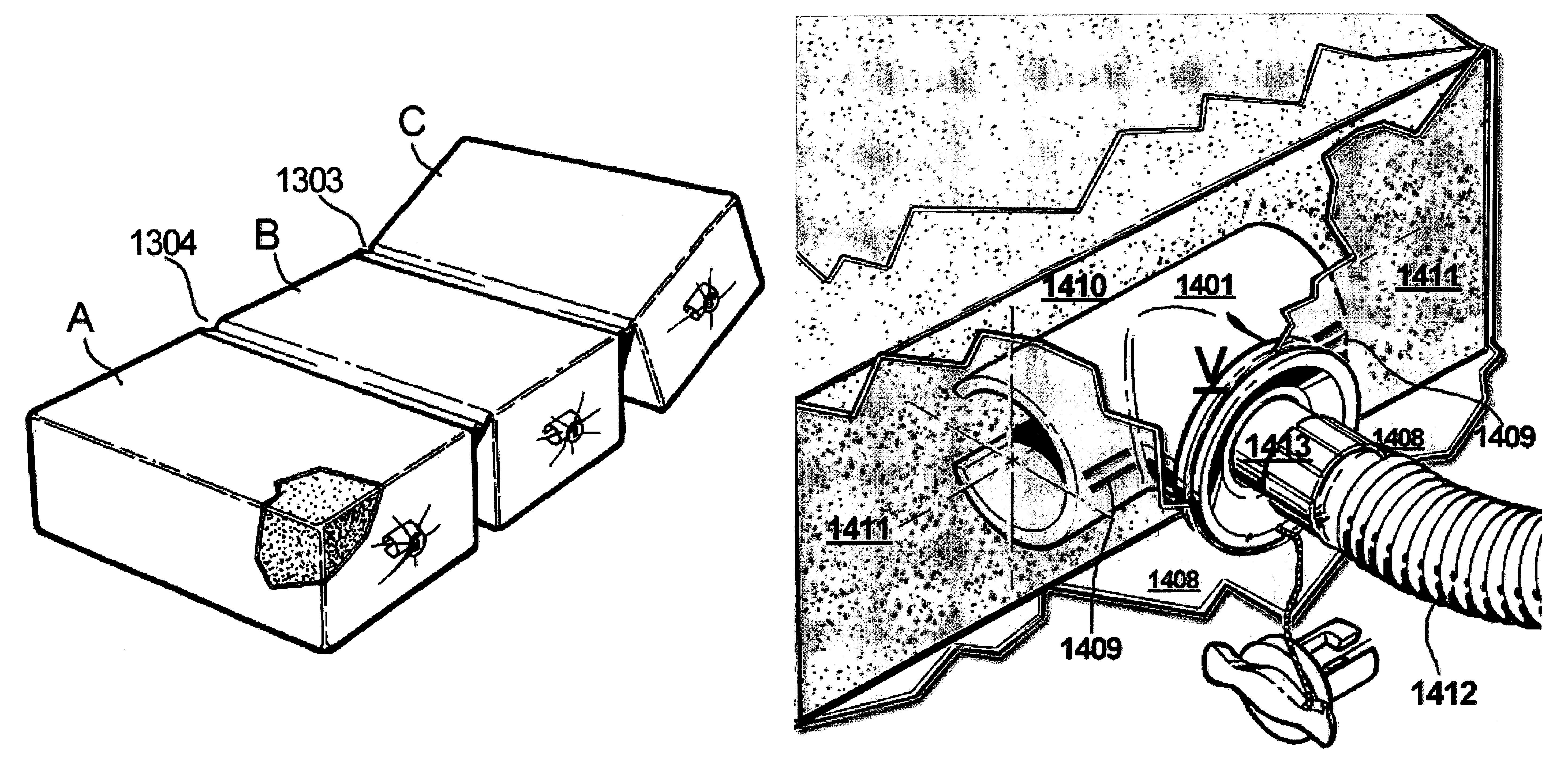

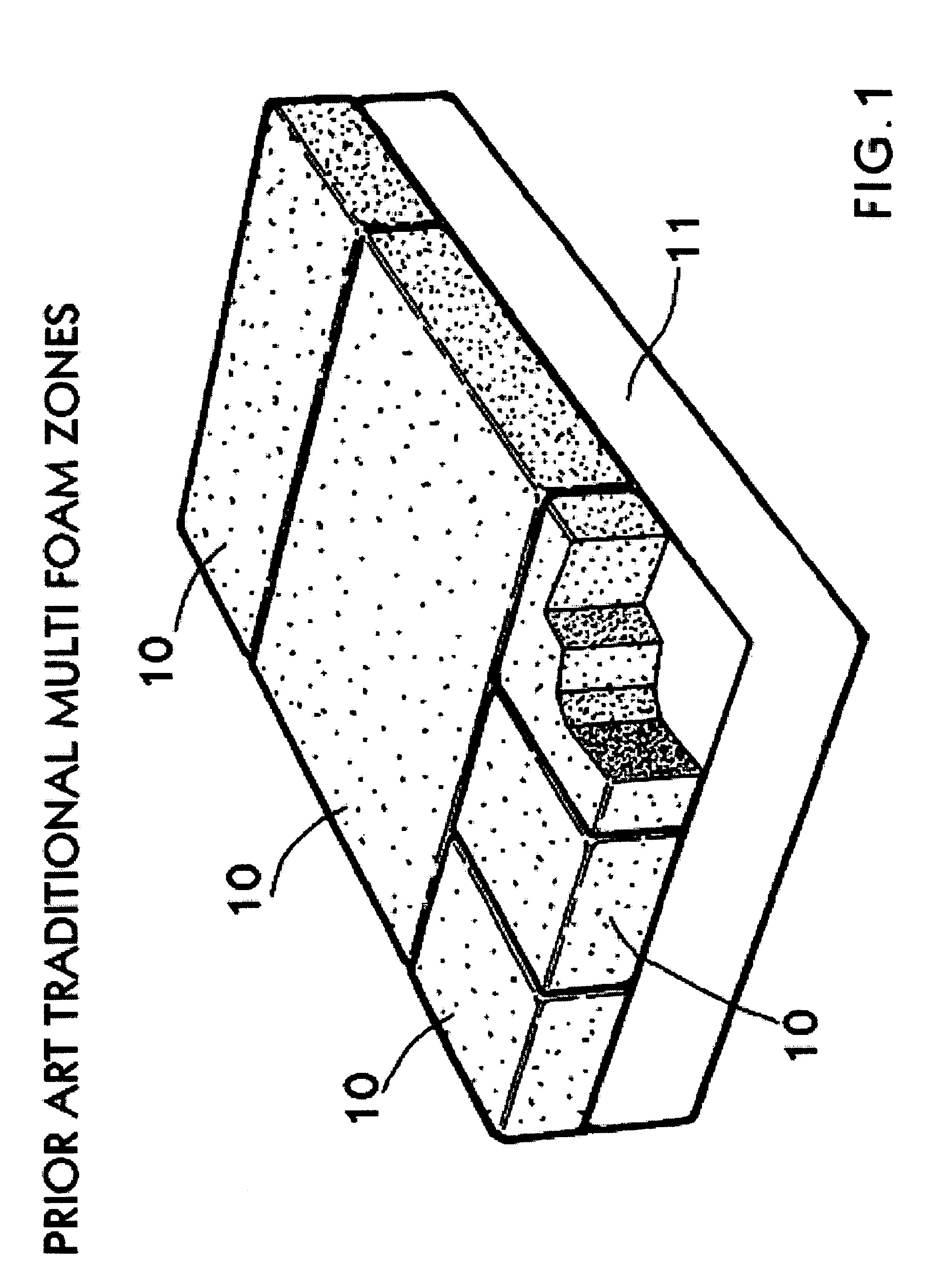

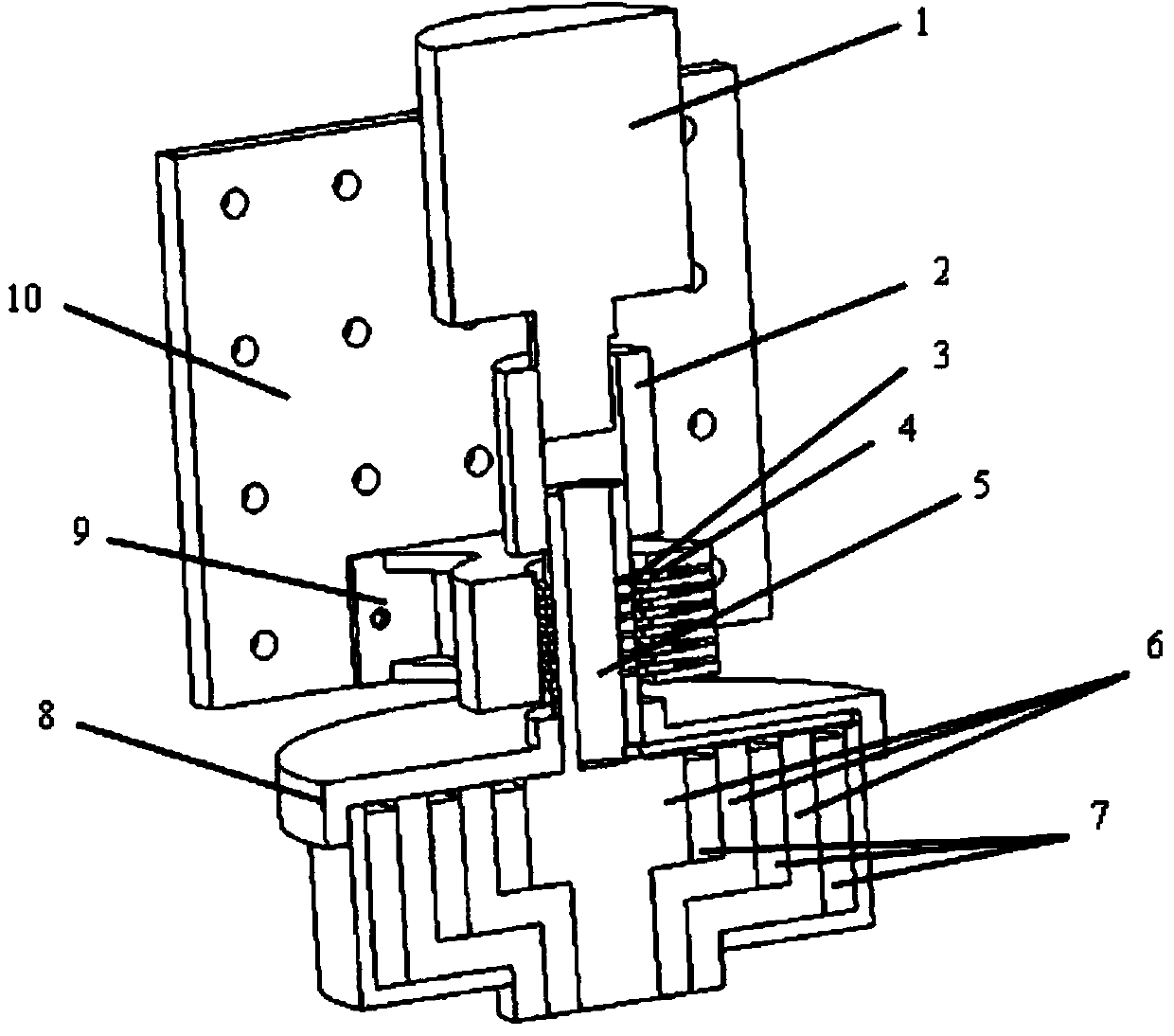

Adjustable foam mattress

InactiveUS6922863B2Improve comfortLower comparable costStuffed mattressesSpring mattressesAir volumeCoil spring

The invention modulates the air volume in foam cores of cushioning support devices and any other support apparatus using foam or similar materials. The foam core can be incrementally modulated to realize an infinite number of comfort levels as to softness and support firmness. The core consists of self-inflating open-cell flexible polyurethane foam and is completely sealed within an enclosure fitted over it, with one or more valves installed in the side walls which communicate with the outside air. Through the valves air is selectively withdrawn from the foam core, allowing the foam's density to increase. The invention uses relatively inexpensive foam, but through air volume modulation achieves a tactile feel of supreme softness for the user, without giving up the necessary firmness to support the body, as happens with very soft foam (bottoming-out or hammock-effect). When air is extracted from a self-inflating foam core, the surface of the core will soften uniformly while maintaining its support firmness. Contrary to this, when pressure is exerted on, for example, traditional coil spring core mattresses, their surface will harden. Integral part of the invention is a device using balanced springs in valve assemblies to avoid compression set, an irreversibly solid state of totally air-depleted foam.

Owner:GIORI GUALTIERO G +1

Cathode systems for electrolytically obtaining aluminum

InactiveUS20060151333A1Reduce measurementUniform removalElectrical resistance and conductanceElectrolysis

Cathode systems for the electrolytic production of aluminum, which are divided in the direction of their long axis on the side of the power conduction from the cathode into at least two parts having differing electrical resistances in such a way that the electrical resistance from the ends of the collector to the part of the marginal zone of the cathode facing the collector is at least 1.2 times the electrical resistance from the ends of the collector to the part of the middle of the cathode facing the collector, where either the contact composition or the collector is divided into zones of differing resistance, processes for producing them and their use in the electrolytic production of aluminum

Owner:SGL CARBON SE

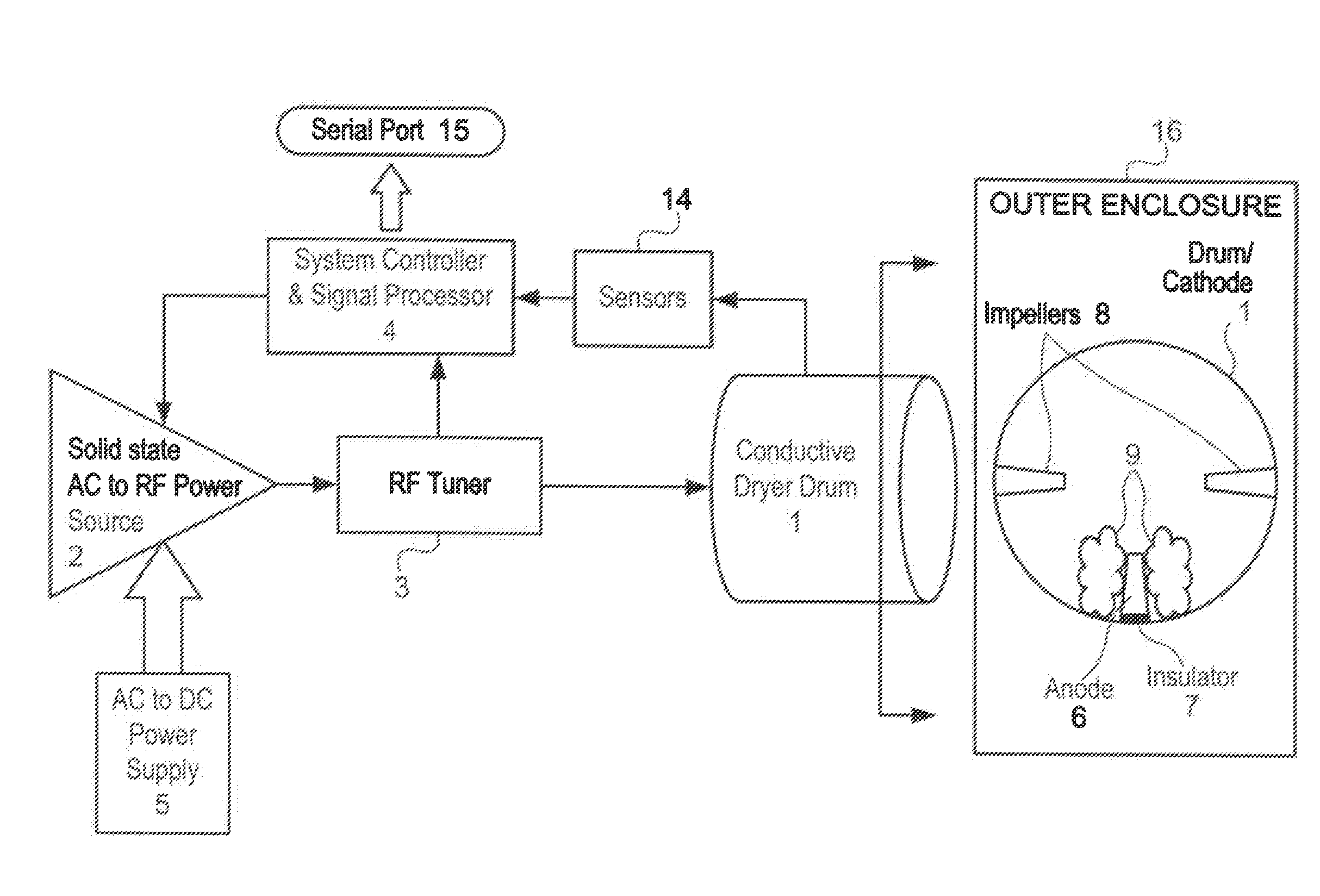

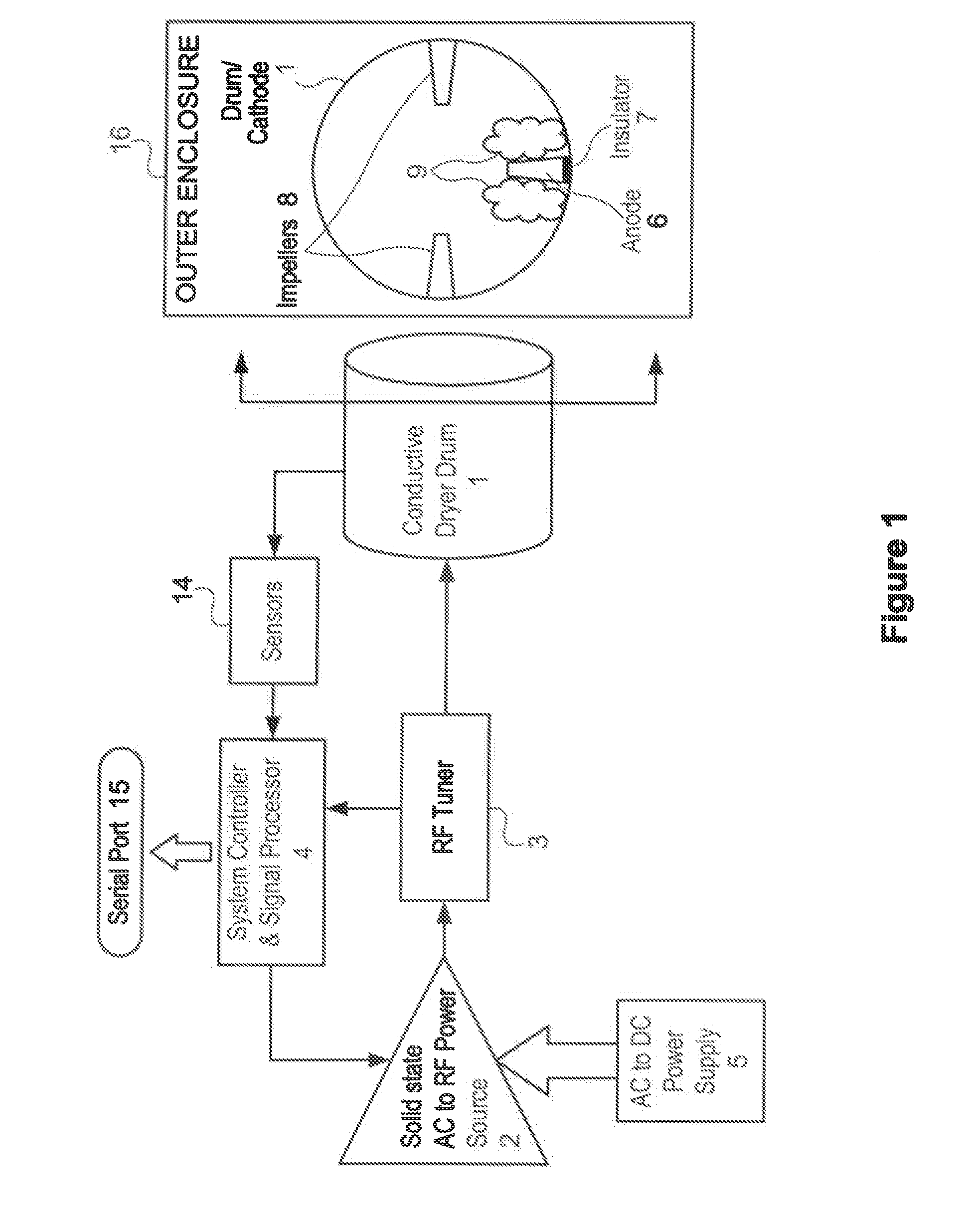

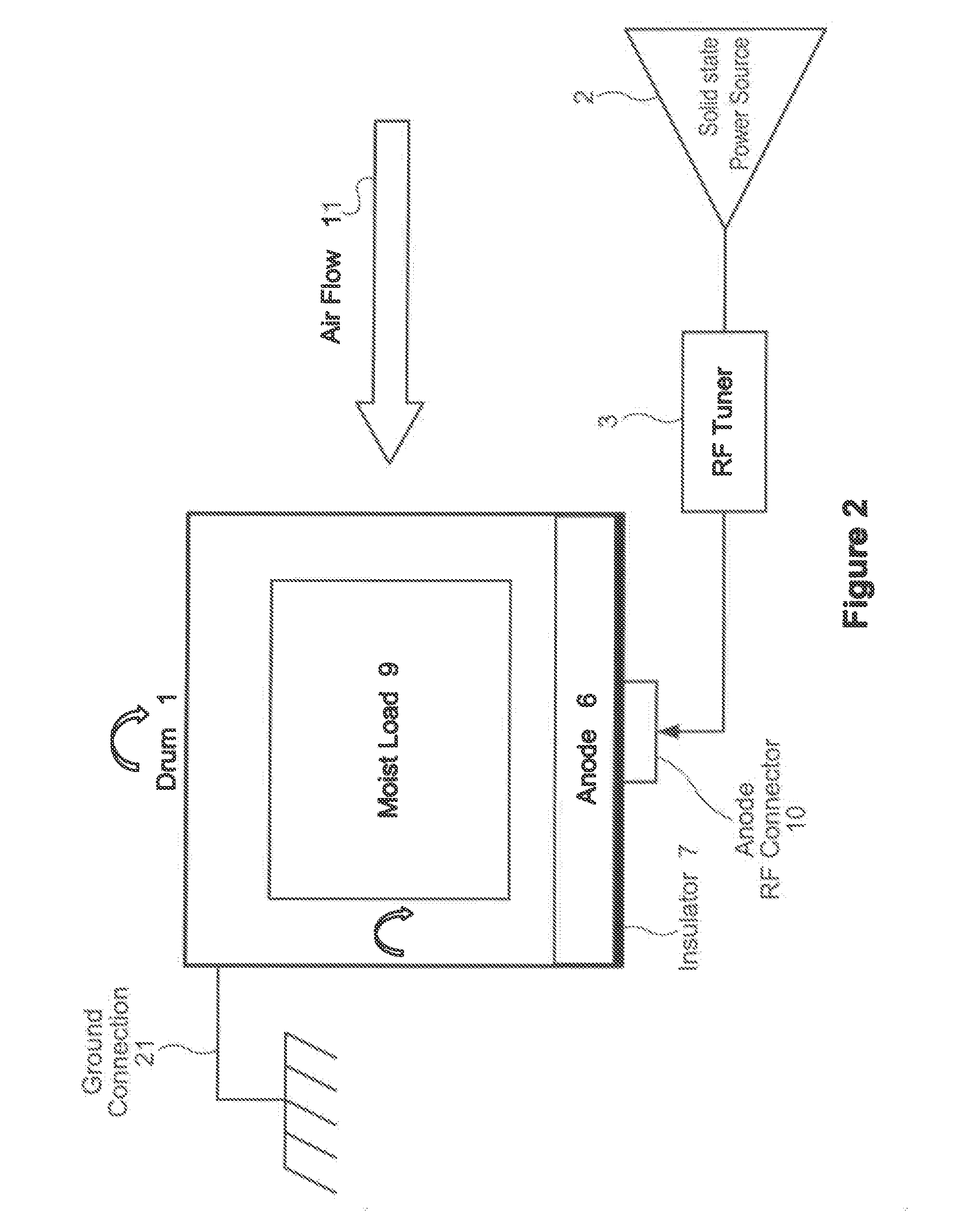

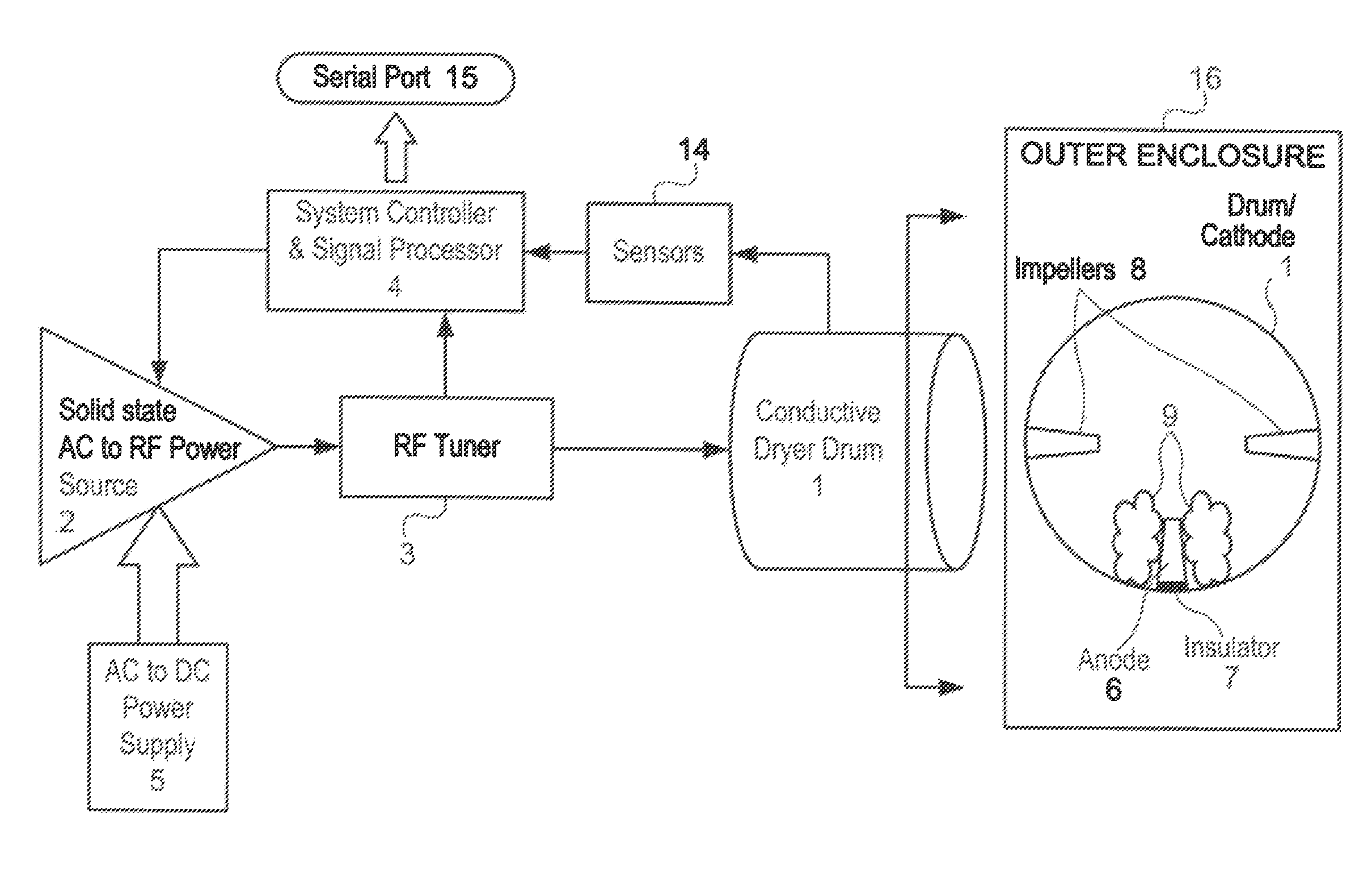

Dielectric dryer drum

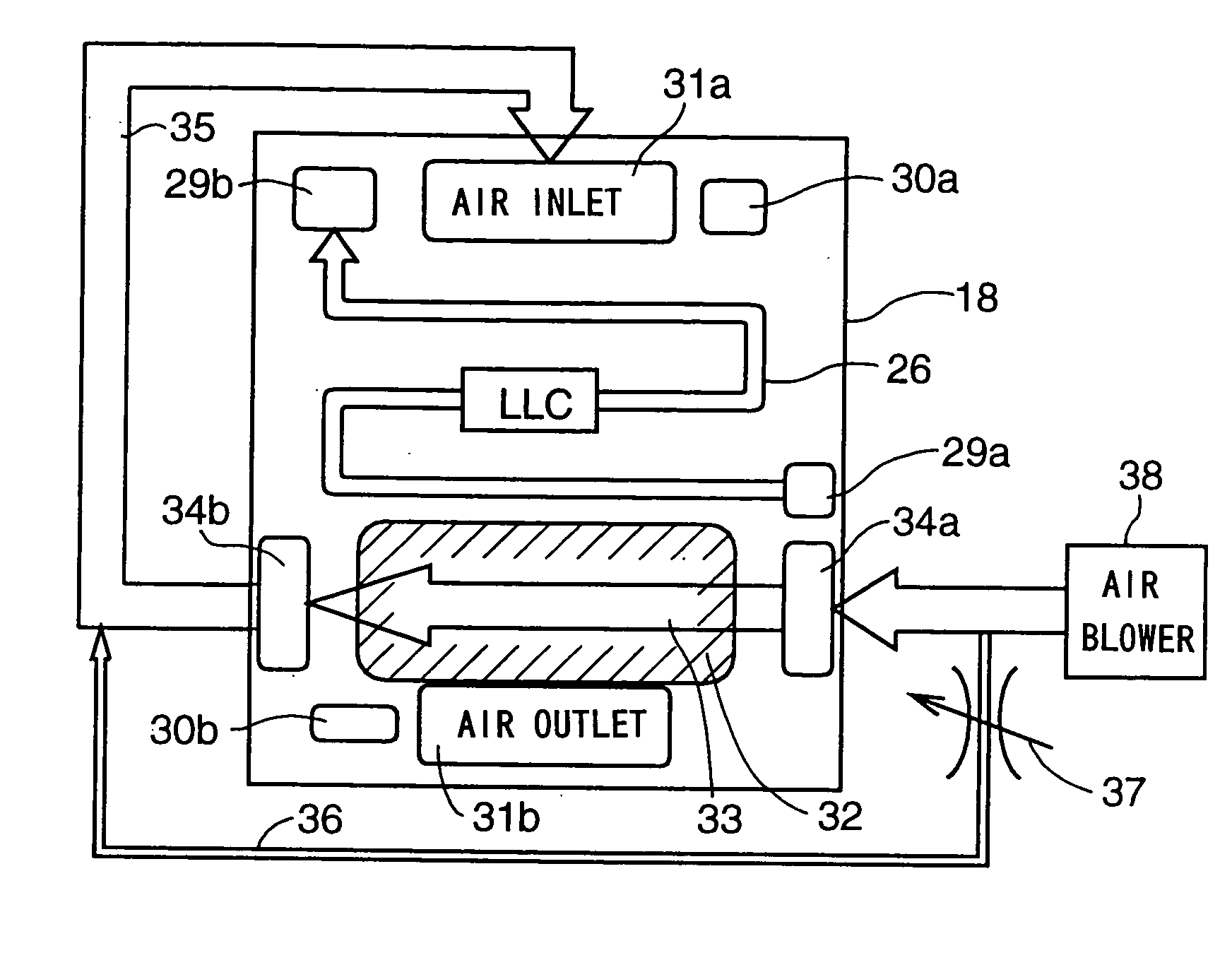

ActiveUS20140325865A1Sufficient heat energyAvoid problemsDrying solid materials with heatDrying machines with non-progressive movementsDielectricEngineering

Methods and apparatus for heating an object 9 that includes an absorbed medium. A method embodiment comprises: placing the object 9 including the medium into an enclosure 16; initiating a heating process by subjecting the object 9 and medium to a capacitive AC electrical field generated by an RF power source 2 at a single low frequency; controlling the heating process by taking real time measurements; and making real time adjustments to the RF power source 2 in response to the real time measurements. The object 9 substantially absorbs the medium in a first “cool” state, and therefore has a maximum weight in the first “cool” state. The object 9 is substantially free from the medium in a second “heated” state, due to substantial release of the medium from the object 9. The released medium is evaporated during the heating process. The heating process is completed when the object 9 is substantially transitioned into the second “heated” state. The method further comprises causing an air flow 11 inside the enclosure 16 to carry away evaporated medium out of the enclosure 16.

Owner:LG ELECTRONICS INC

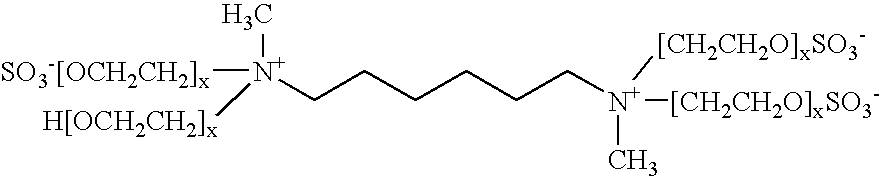

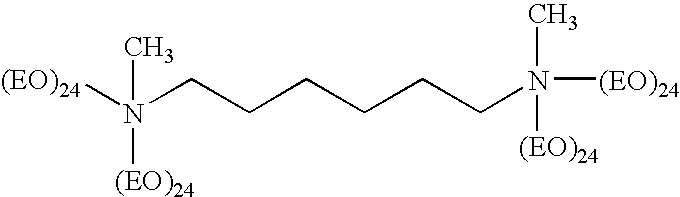

Detergent and bleach compositions

InactiveUS20060281654A1Solubility profileInhibition formationNon-surface-active detergent compositionsDetergent compounding agentsPolymerPeroxide

Owner:THE PROCTER & GAMBLE COMPANY

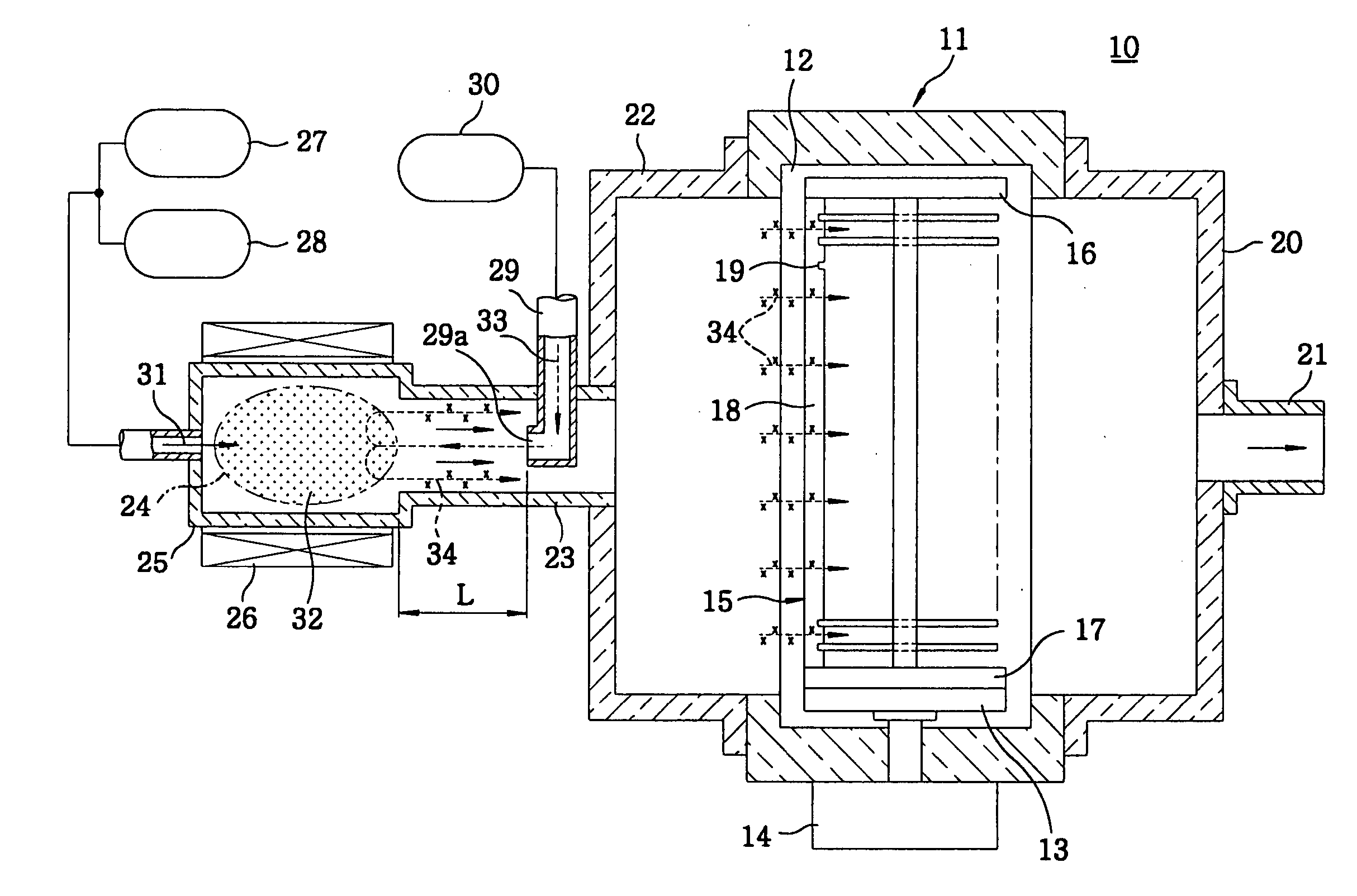

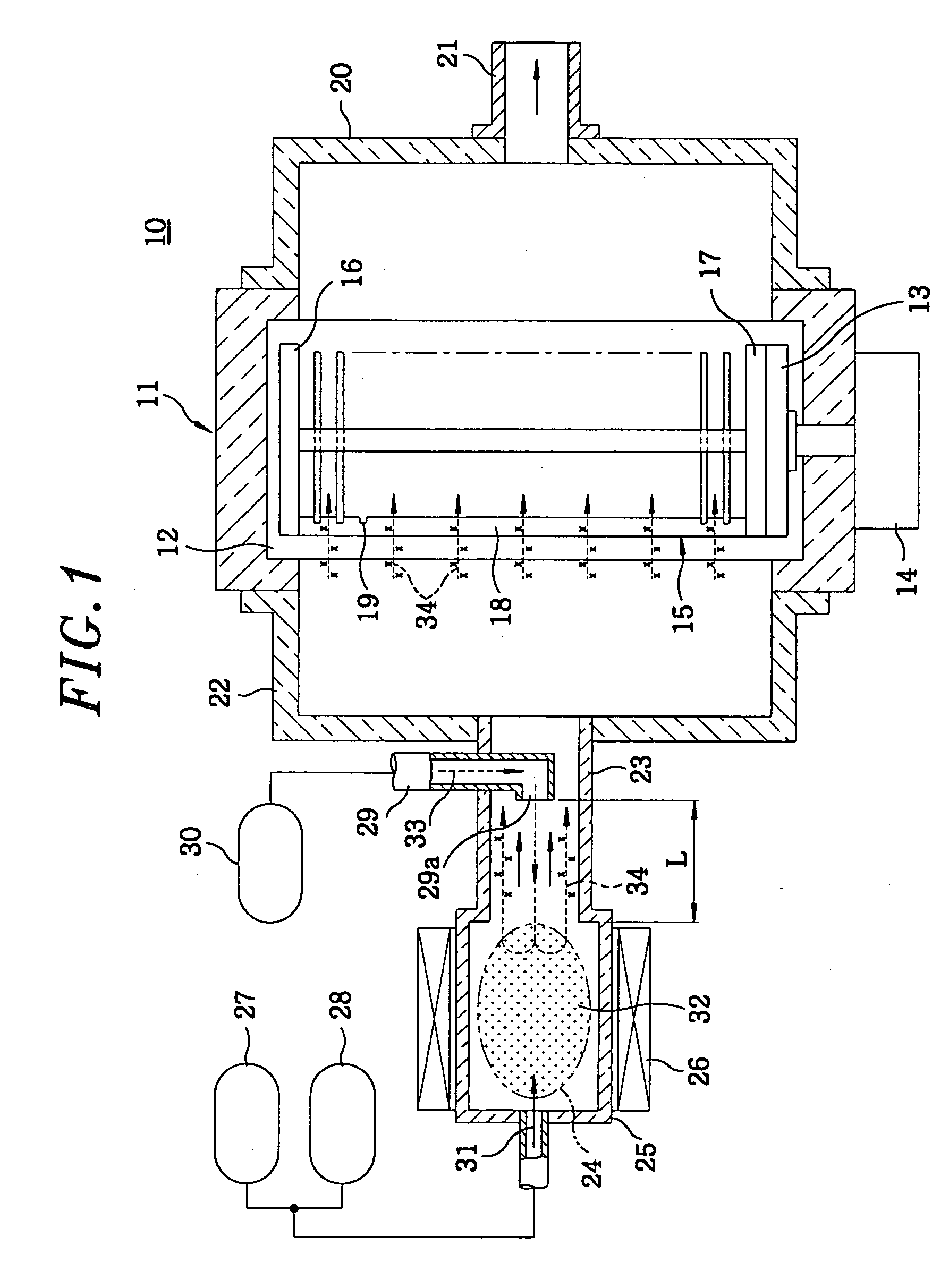

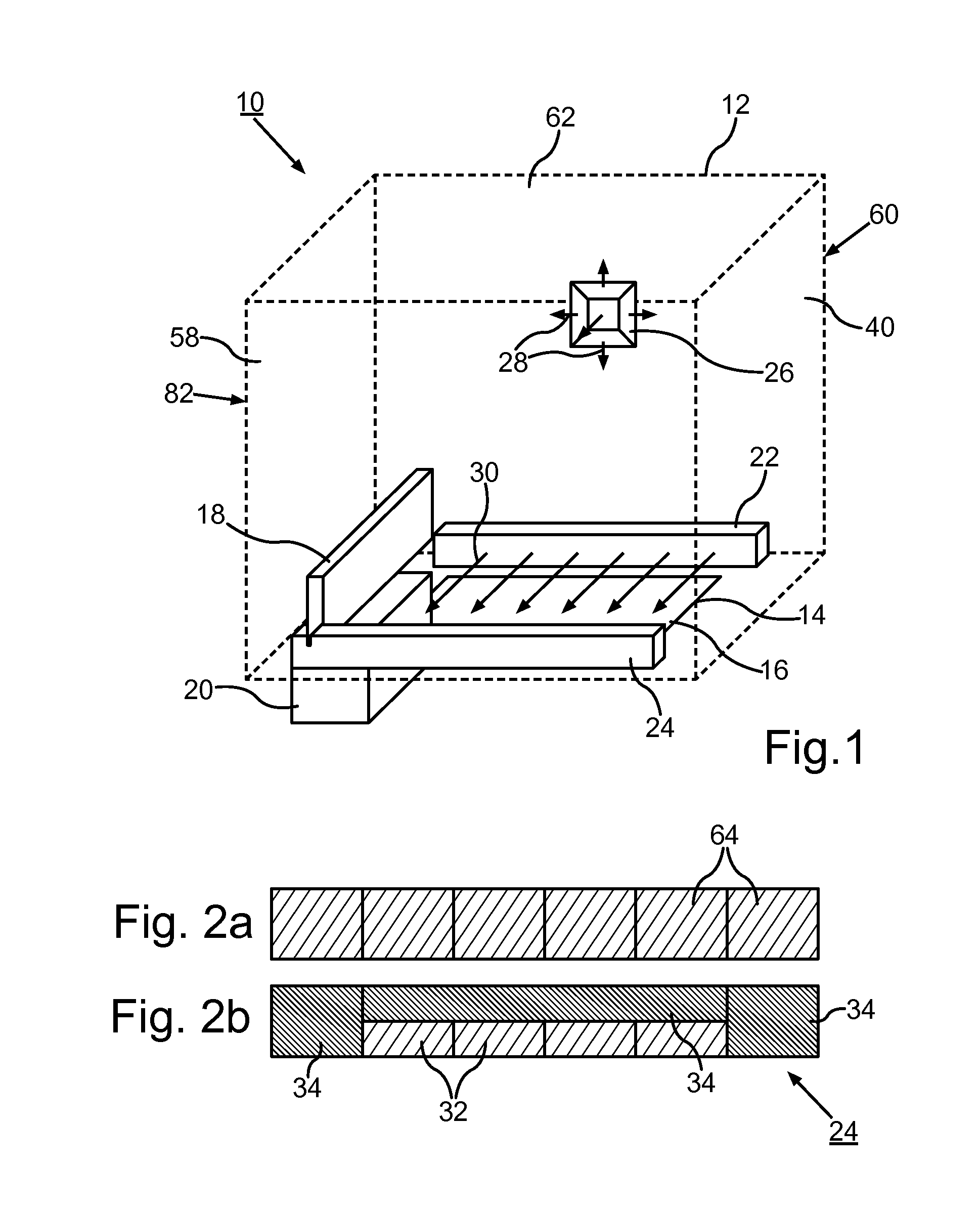

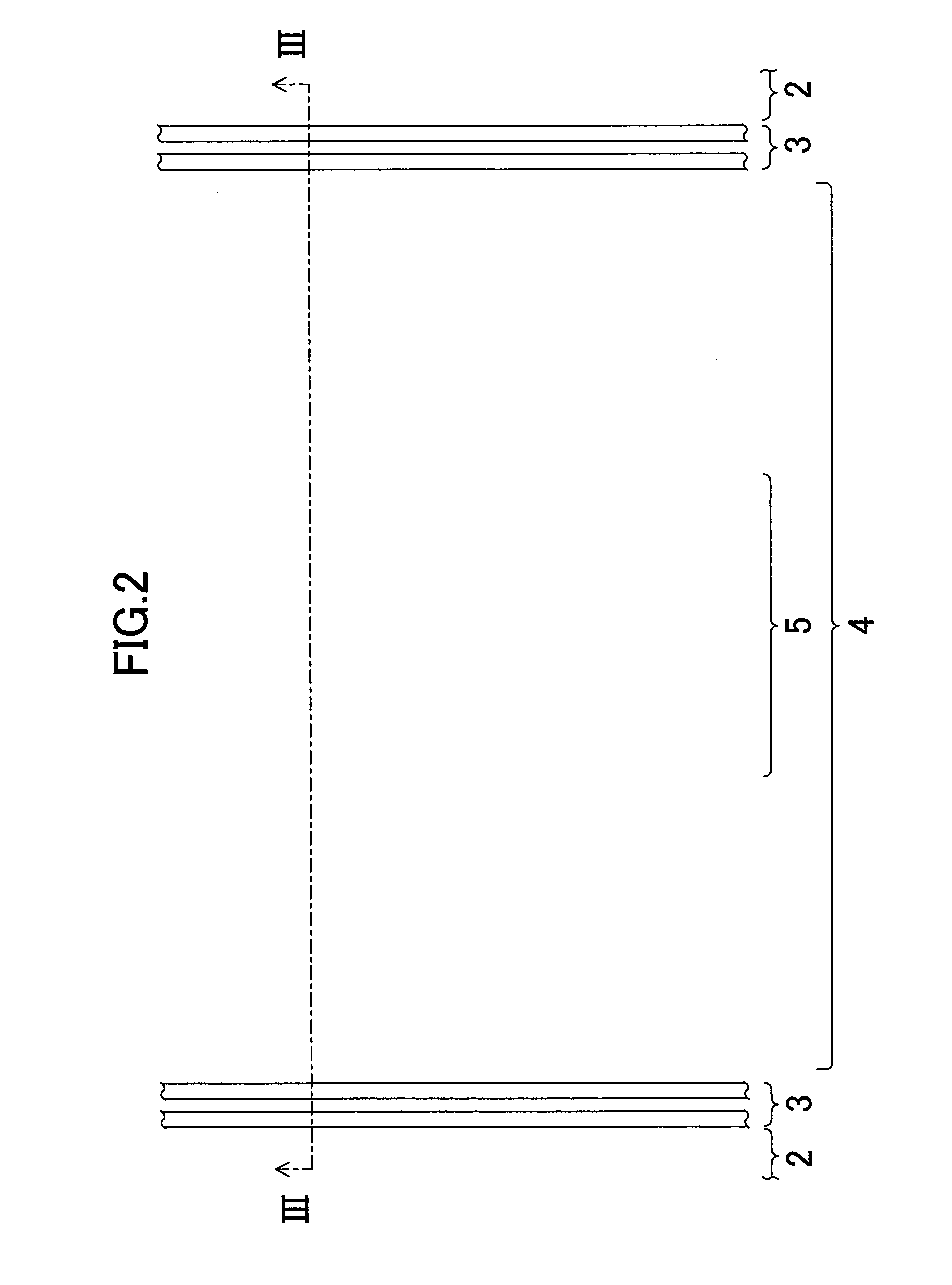

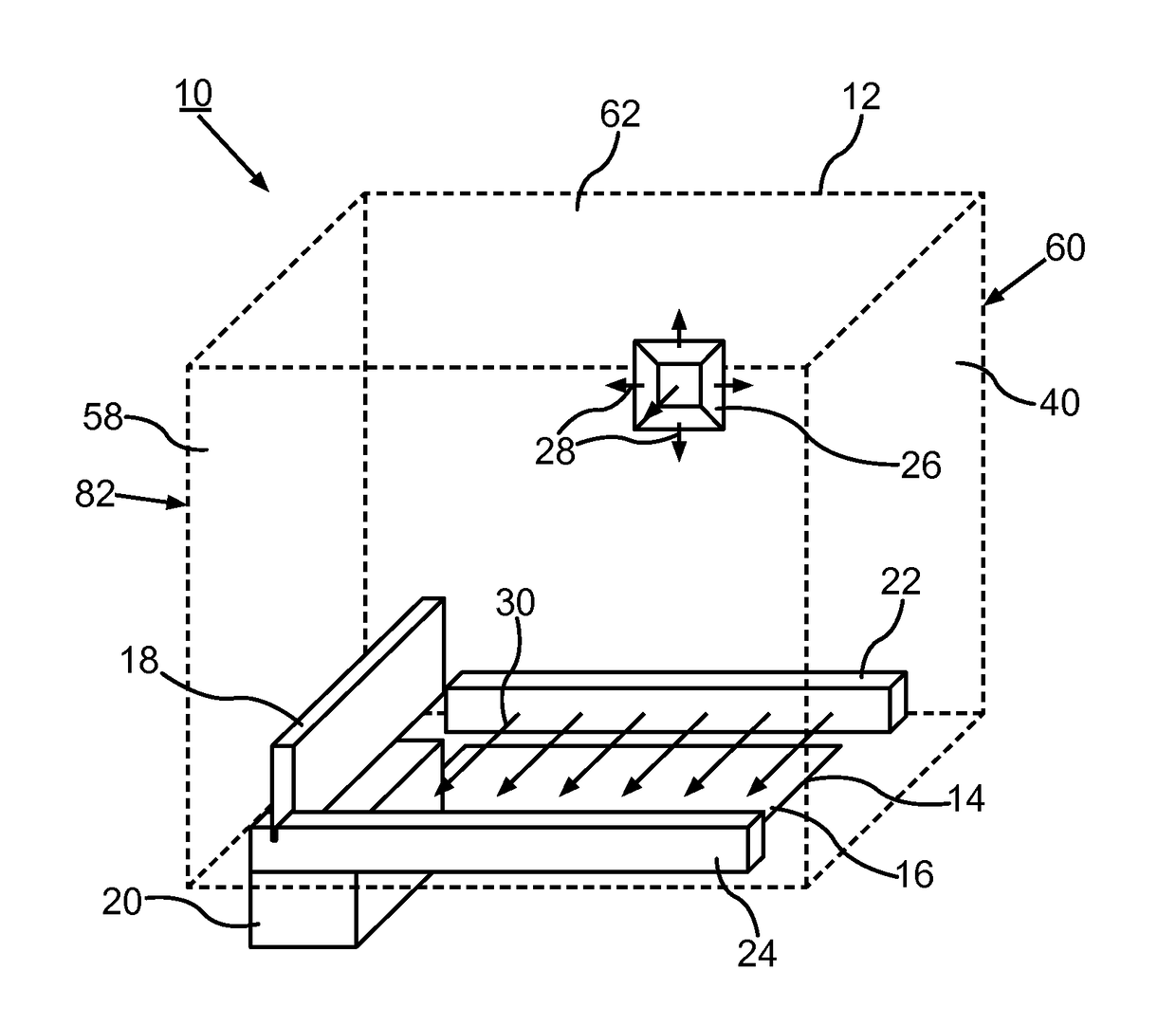

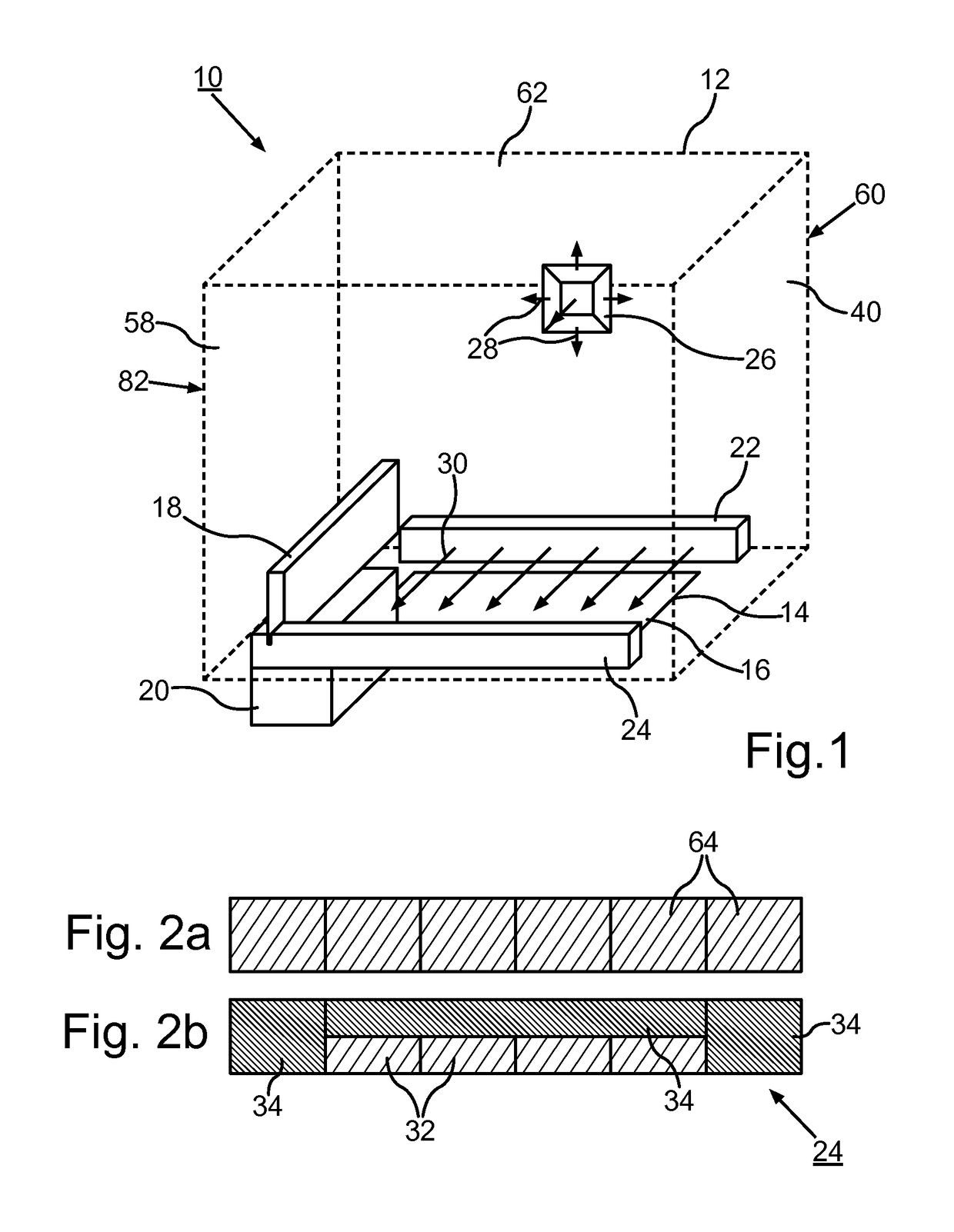

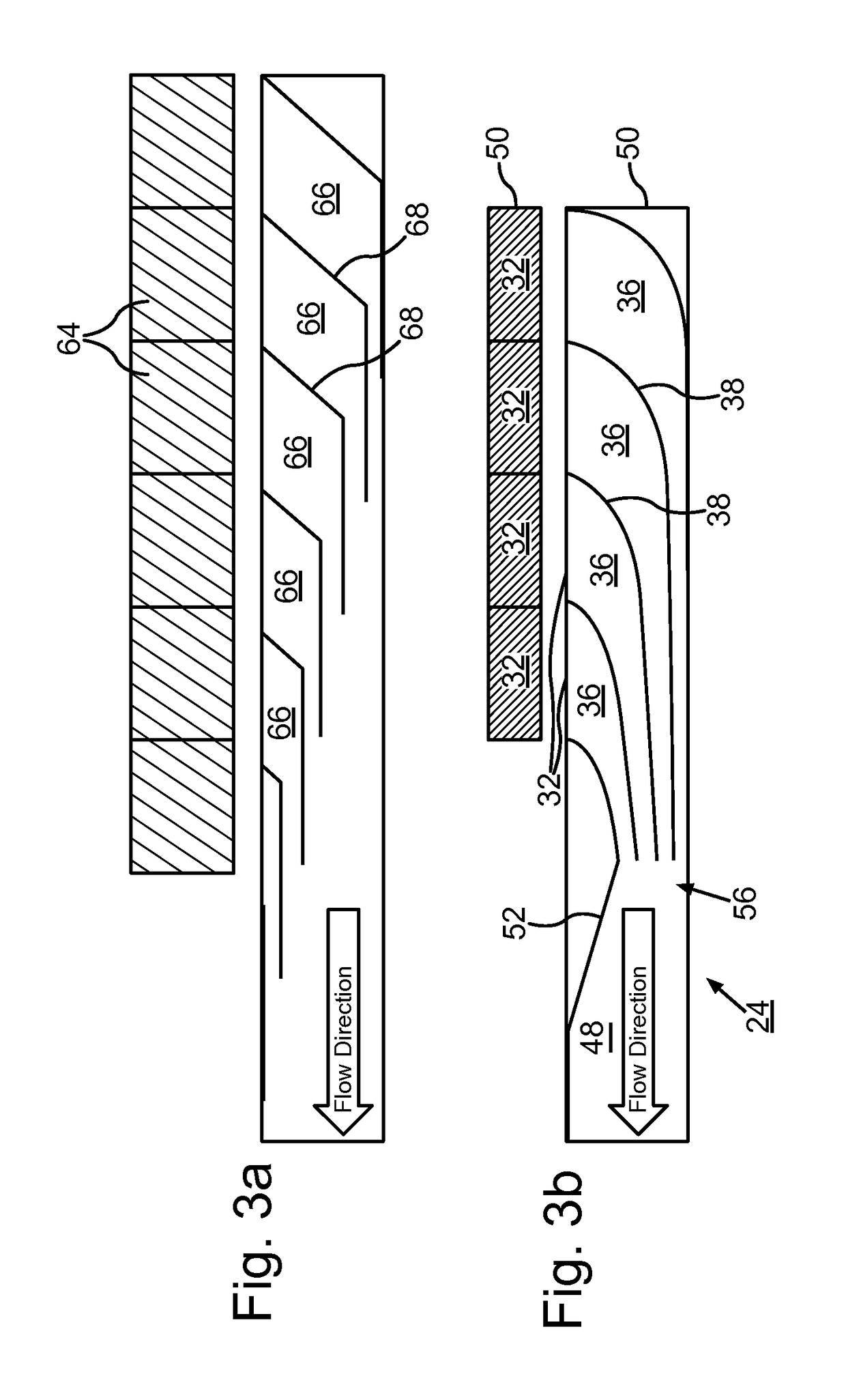

Device and method for the manufacture or repair of a three-dimensional object

ActiveUS20160121398A1Increase flow rateCompact designAdditive manufacturing apparatusTyresEngineeringBuilding construction

The invention relates to a device (10) for the manufacture or repair of a three-dimensional object, comprising at least one construction chamber (12) for a successive solidification of at least one solidifiable material layer by the layer in predefined regions for the layer-by-layer buildup of the three-dimensional object or for the layer-by-layer repair of individual regions of the three-dimensional object within the construction chamber (12), and at least one inlet nozzle (22, 26) and at least one suction nozzle (24) for a process gas, wherein the inlet nozzle (22, 26) and the suction nozzle (24) are arranged in such a way that a gas flow (30) that passes at least partially over a construction platform (14) formed in a construction chamber (12) is created.

Owner:MTU AERO ENGINES GMBH

Chemical mechanical polish process control method using thermal imaging of polishing pad

InactiveUS20050118839A1Simple methodImprove uniformitySemiconductor/solid-state device manufacturingLapping machinesMaterial removalCompound (substance)

Owner:IND TECH RES INST

Dielectric dryer drum

ActiveUS9200402B2Efficient deliverySpeed up evaporationDrying solid materials with heatDrying machines with non-progressive movementsDielectricElectricity

Methods and apparatus for heating an object 9 that includes an absorbed medium. A method embodiment comprises: placing the object 9 including the medium into an enclosure 16; initiating a heating process by subjecting the object 9 and medium to a capacitive AC electrical field generated by an RF power source 2 at a single low frequency; controlling the heating process by taking real time measurements; and making real time adjustments to the RF power source 2 in response to the real time measurements. The object 9 substantially absorbs the medium in a first “cool” state, and therefore has a maximum weight in the first “cool” state. The object 9 is substantially free from the medium in a second “heated” state, due to substantial release of the medium from the object 9. The released medium is evaporated during the heating process. The heating process is completed when the object 9 is substantially transitioned into the second “heated” state. The method further comprises causing an air flow 11 inside the enclosure 16 to carry away evaporated medium out of the enclosure 16.

Owner:LG ELECTRONICS INC

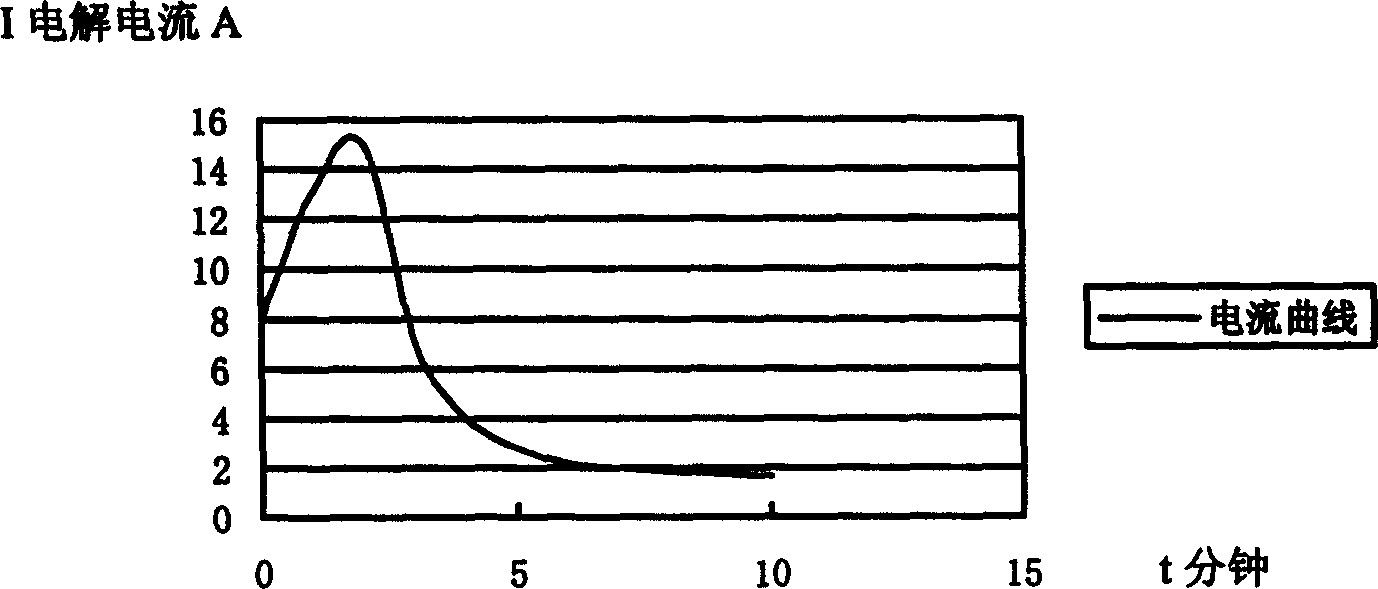

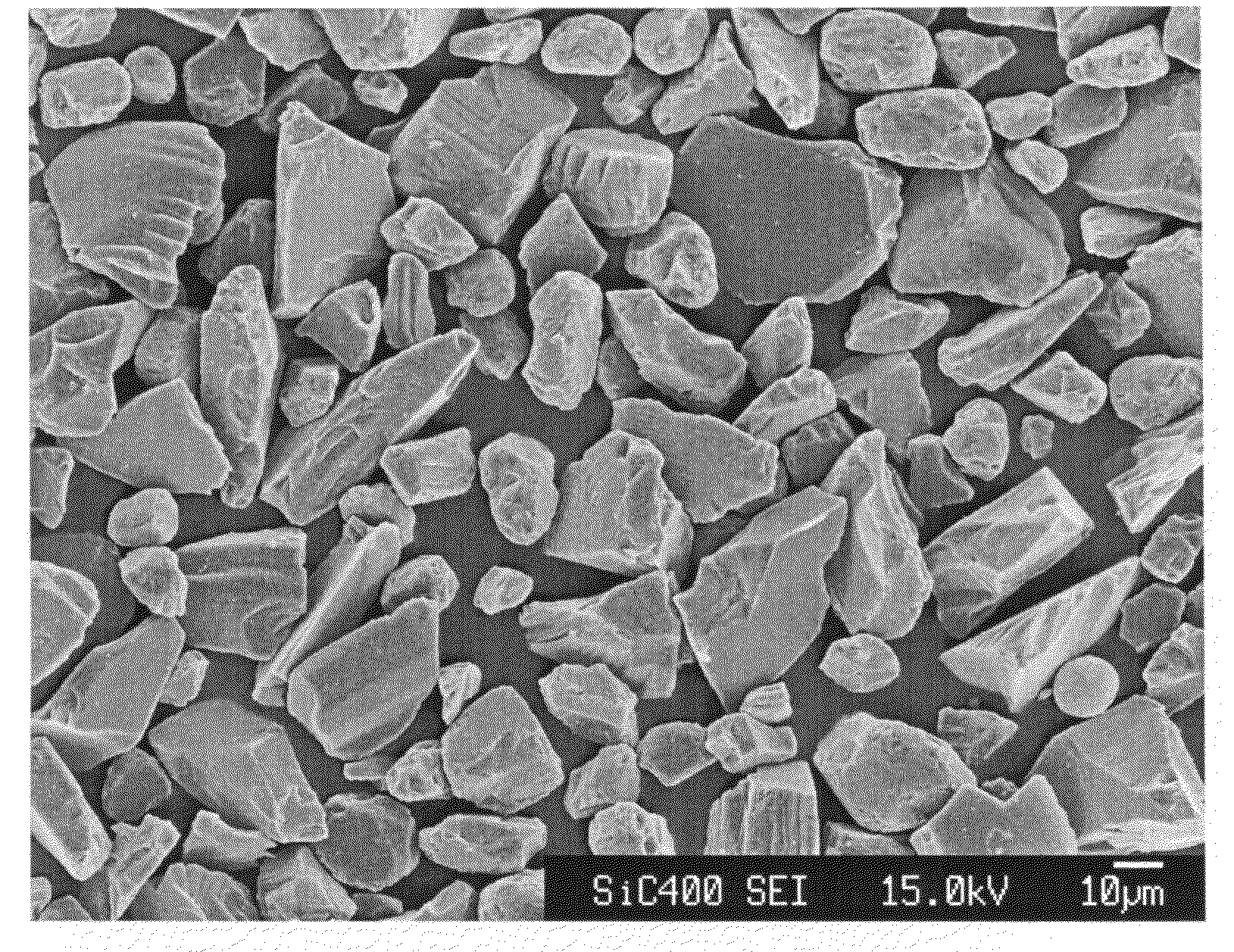

Superhard abrasive grinding wheel of metal binding agent eletrolyzable online, and preparation method

An ultrahard abrasive disk able to be in-line electrolyzed for truing it is prepared from diamond, cubic boron nitride (CBN) and the binder prepared from Fe powder, Cu powder, metal additive and non-metal additive through proportionally mixing diamond, VBN and Fe powder, stirring, adding alcohol, mixing, adding others, stirring, cold die pressing, and sintering in reductive atmosphere.

Owner:BEIJING UNIV OF TECH

Electropolishing system and process

InactiveUS20080099344A9Overcome limitationsUniform removalElectrolysis componentsSemiconductor/solid-state device manufacturingElectrolysisProcess region

The present invention provides a process for electropolishing a conductive surface of a semiconductor wafer. During the process, a contact electrode in a contact solution contacts a contact region on surface of the conductive layer with the contact solution. Further, during the process a process electrode in a process solution contacts a process region on the conductive surface with the process solution while applying an electrical potential between the contact electrode and the process electrode to electropolish the surface of the conductive layer of the process region.

Owner:NOVELLUS SYSTEMS

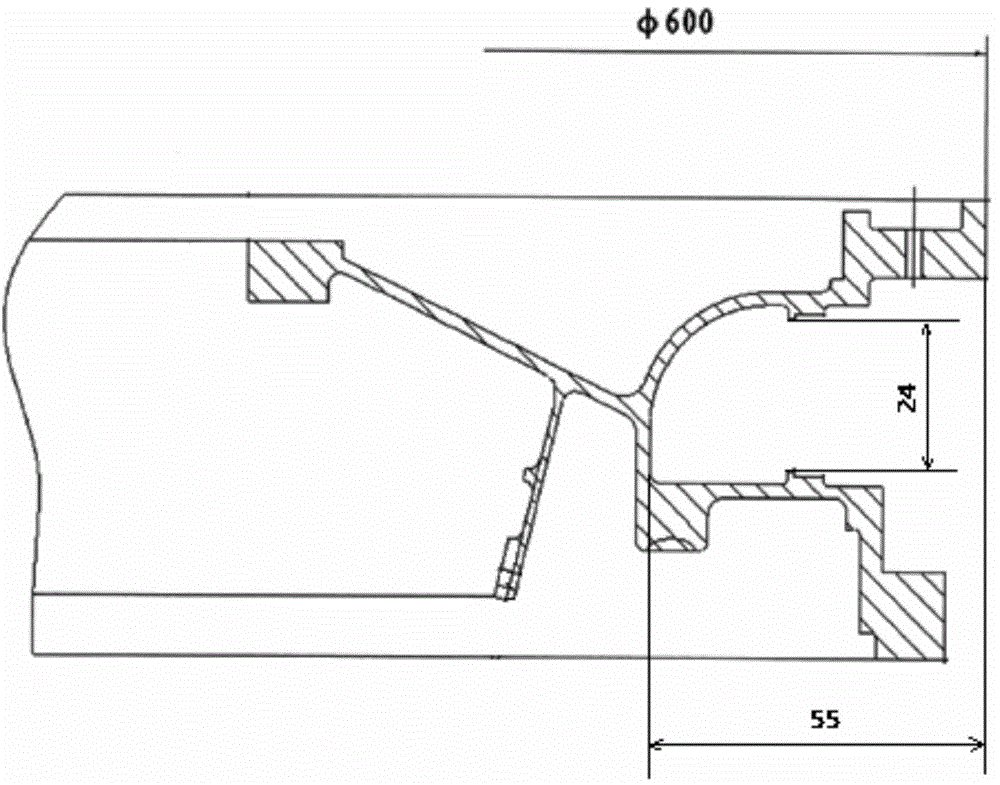

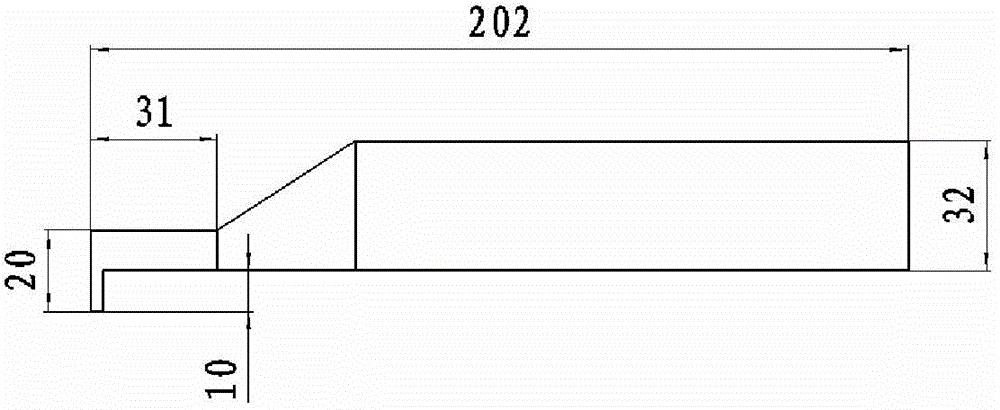

Processing method for controlling processing deformation of titanium-aluminum alloy thin-wall case

The invention relates to a processing method for controlling processing deformation of a titanium-aluminum alloy thin-wall case. The technical scheme of the processing method is as follows: the processing method comprises the steps as follows: a primary rough turning process, a primary heat treatment process, a secondary rough turning process, a secondary heat treatment process, a fine turning process, a third heat treatment process and a finish turning process. According to the processing method for controlling the processing deformation of the titanium-aluminum alloy thin-wall case, reasonable processing parameters are set, and an appropriate cutter is used, so that the processing deformation of the titanium-aluminum alloy thin-wall case is controlled, and the processing requirement is met.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

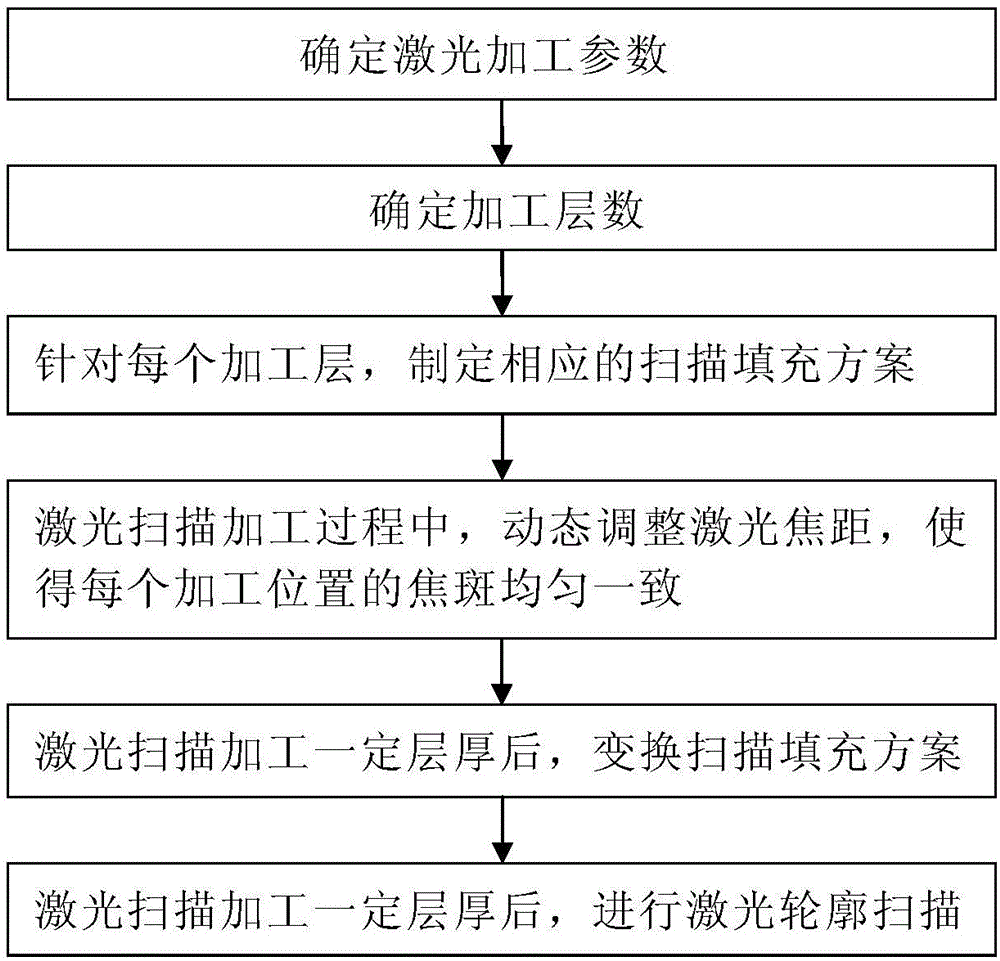

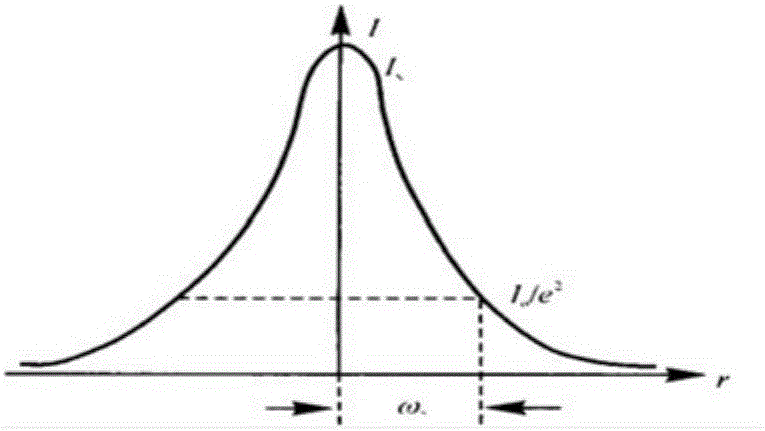

Three-dimension laser fine machining system and method for crisp and hard materials

InactiveCN107175409AGuaranteed uniformityUniform focal spotLaser beam welding apparatusLaser scanningMachining process

The invention provides a three-dimension laser fine machining system and method for crisp and hard materials. The method comprises the steps that a laser scanning machining scheme according to the model of a to-be-machined part, the model of a machining pattern and the machining requirements, specifically, the scheme comprises the process of determining the laser machining parameters and the process of determining the number of machining layers; scanning filling schemes corresponding to the machining layers are made in the pattern filling area; the laser focus is adjusted dynamically in the machining process, light spots are made to keep focusing in each machining position, and focus spots are uniform and coincident; the laser scanning filling schemes are changed every time one or more layers of materials are scanned and removed; and after one or more layers are scanned in the pattern filling area, laser contour scanning is conducted in the pattern contour area one or more times. The three-dimension laser fine machining system and method for the crisp and hard materials can achieve high-precision and efficient machining of the crisp and hard materials by making full use of the various advantages of fine light spot laser scanning machining.

Owner:苏州菲镭泰克激光技术有限公司

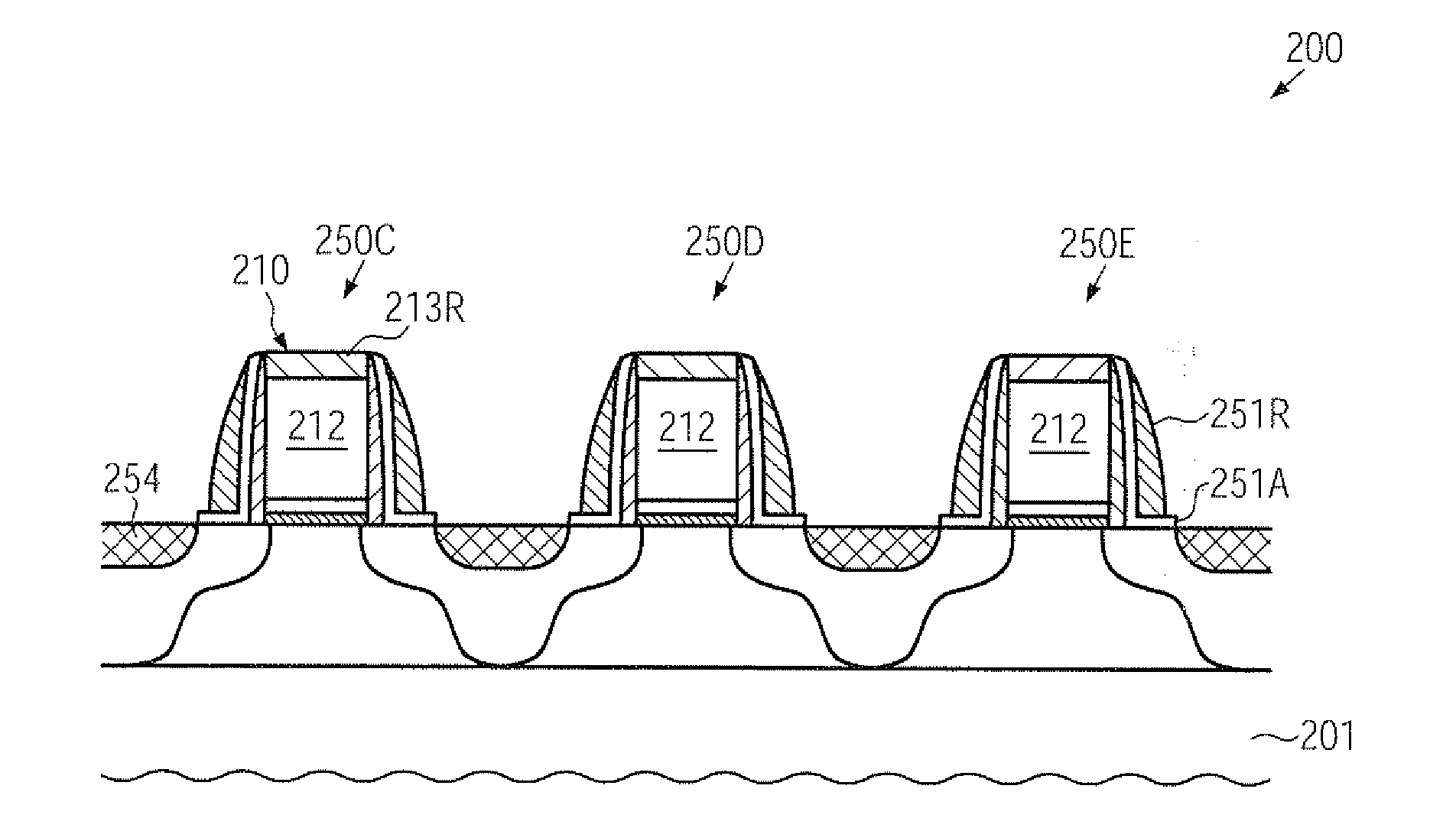

Cap layer removal in a high-k metal gate stack by using an etch process

ActiveUS20100330808A1Highly conductiveEfficiently protectSemiconductor/solid-state device manufacturingSemiconductor devicesDielectricMetal gate

In a replacement gate approach, the dielectric cap layers of the gate electrode structures are removed in a separate removal process, such as a plasma assisted etch process, in order to provide superior process conditions during the subsequent planarization of the interlayer dielectric material for exposing the sacrificial gate material. Due to the superior process conditions, the selective removal of the sacrificial gate material may be accomplished with enhanced uniformity, thereby also contributing to superior stability of transistor characteristics.

Owner:GLOBALFOUNDRIES US INC

Preparation technology of diethylene triamine pentacetic acid modified polyvinylidene fluoride separation membrane and resin

InactiveCN101537315AUniform removalImprove hydrophilicitySemi-permeable membranesFiltrationResource utilization

The invention provides a technology for preparing a diethylene triamine pentacetic acid modified polyvinylidene fluoride separation membrane by a physical blending / phase transition technology and a chemical grafting blending / phase transition technology. The technology is as follows: reagents such as diethylene triamine pentacetic acid, polyvinylidene fluoride, melamine, dimethyl sulfoxide, acrylic acid, polyvinylpyrrolidone and the like are taken as raw materials; diethylene triamine pentacetic acid polyamino and polycarboxylic acid compound is uniformly mixed in a polyvinylidene fluoride separation membrane and resin respectively by the physical blending / phase transition technology and the chemical grafting blending / phase transition technology. The technology improves the hydrophobic properties of the conventional polyvinylidene fluoride micro-filtration separation film and the resin, realizes metallic ions in waste water, and has the advantages of simple operation, uniform blending and the like. The diethylene triamine pentacetic acid modified polyvinylidene fluoride separation membrane and the resin increase the purification efficiency of drinking water, realize the resource utilization of the heavy metal in the industrial wastewater, and expand the application field of the polyvinylidene fluoride micro-filtration separation film.

Owner:YANSHAN UNIV

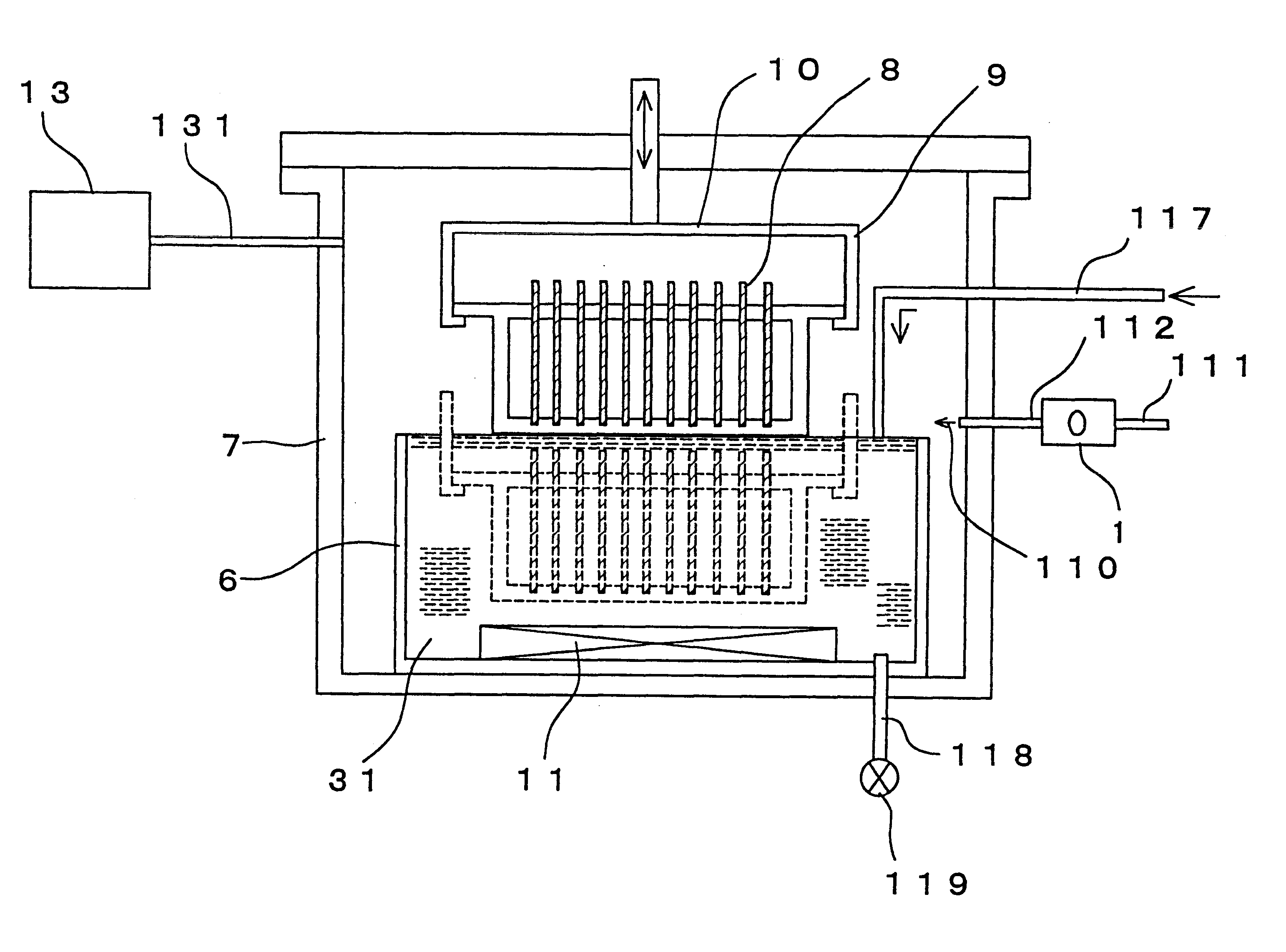

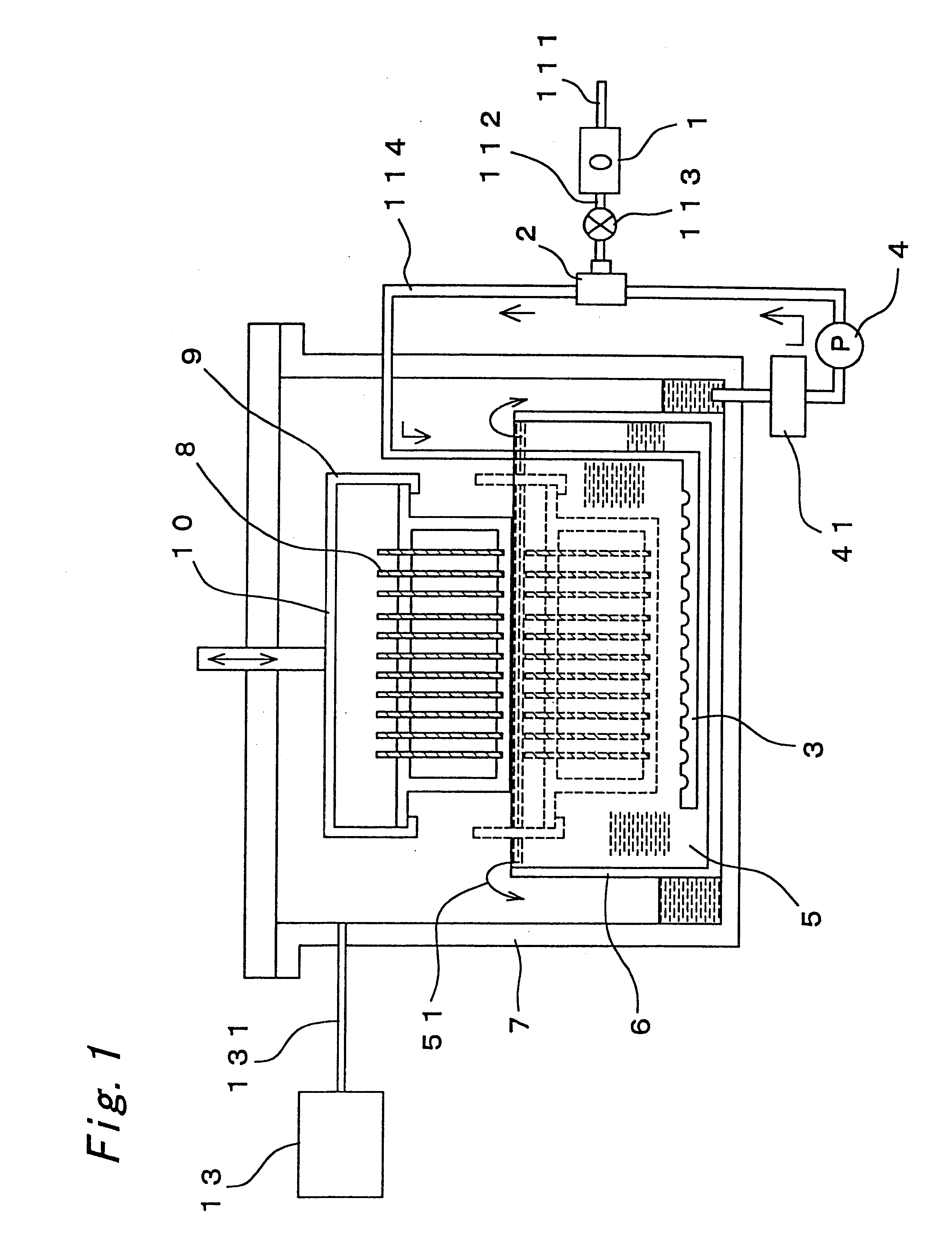

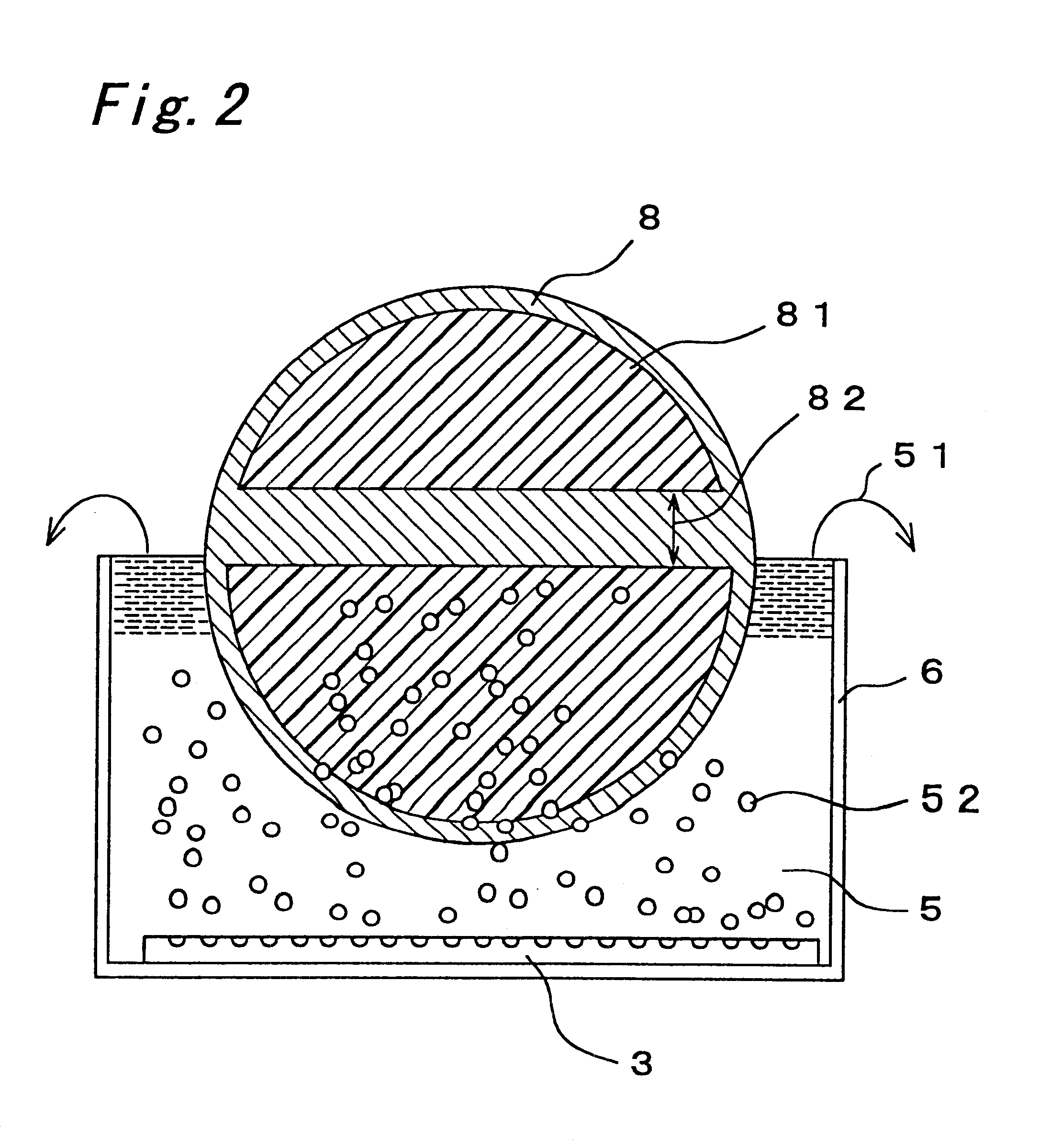

Substrate cleaning method, substrate cleaning system and program storage medium

InactiveUS20070267040A1Improve removalEnhance remove efficiencySemiconductor/solid-state device manufacturingElectrostatic cleaningEngineering

A substrate cleaning method can uniformly removing particles from substrates at a high removing efficiency. The substrate cleaning method includes the steps of immersing substrates W in a cleaning liquid in a cleaning tank 12, and generating ultrasonic waves in the cleaning liquid contained in the cleaning tank. A region in the cleaning tank toward which the cleaning liquid is supplied is varied with respect to a vertical level in the step of generating ultrasonic waves in the cleaning liquid while the cleaning liquid is being supplied into the cleaning tank.

Owner:TOKYO ELECTRON LTD

Process for Pretreating Formed Article, Bonded Article and Process for Producing Same, and Coated Article and Process for Producing Same

InactiveUS20090107629A1Good adhesionImprove adhesionAbrasion apparatusLaminationPolymer sciencePolyresin

Owner:MITSUBISHI HEAVY IND LTD

Sulfur purge control method for exhaust gas purifying system and exhaust gas purifying system

InactiveUS20090077947A1Keep warmIncrease chanceExhaust apparatusDispersed particle separationSulfurExhaust fumes

In an exhaust gas purifying system (1) which is equipped with a NOx occlusion reduction type catalyst (11) and an oxidation catalyst (12) set on the upstream side of the catalyst (11) and in which sulfur purge control for regenerating the sulfur-poisoned catalyst (11) is conducted, in conducting the sulfur purge control, the air fuel ratio control for sulfur purge is conducted after the temperature difference (ΔTIO) between the inlet side and outlet side of the catalyst (11) has been reduced to a prescribed level (ΔT0) or below by raising the exhaust temperature. According to the invention, the sulfur poison on the catalyst (11) can be uniformly removed in the sulfur-purge regeneration control, whereby the service life of the catalyst (11) can be protected from being shortened by sulfur poisoning. Further, the catalyst (11) can be protected from the thermal deterioration caused by partial temperature rise inside the catalyst (11) on its downstream side, so that the service life of the catalyst (11) can be protected from being shortened by thermal deterioration.

Owner:ISUZU MOTORS LTD

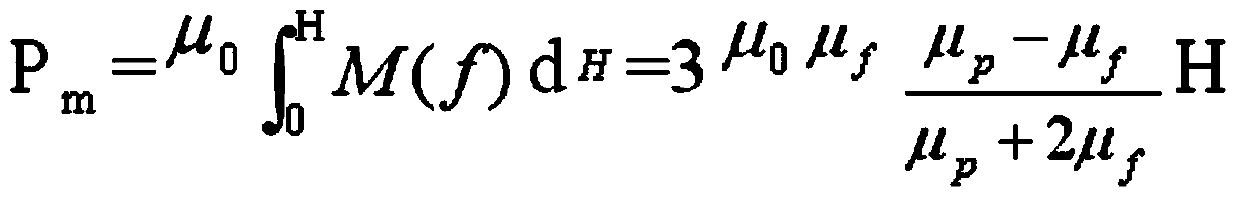

Magneto-rheological polishing method and tool

ActiveCN104191318AIndividual control of magnetic field strengthPolished evenlyMagnetic currentSurface type

The invention discloses a magneto-rheological polishing method and device. The magneto-rheological polishing method comprises the steps that surface type information of a workpiece is known; the position and polishing interval of the polishing tool are determined; the polishing interval is filled with magneto-rheological fluid; according to surface shape information of a polishing area and linear velocity distribution of all points in the polishing area, polishing pressure distribution is calculated when the removal rate is even; magnetic field distribution is obtained according to the pressure distribution through inverse solution; according to the obtained magnetic field distribution model, coil voltages of three layers of concentric circular electromagnets are changed respectively, so that magnetic field distribution in the radius direction meets the requirement; polishing is carried out. According to the magneto-rheological polishing method, the concentric circular electromagnets are of a nested structure and supply power to a collecting ring respectively, and therefore the purposes that magnetic fields at the same radius are the same in intensity and intensity of magnetic fields at different radii can be controlled separately are achieved.

Owner:ZHEJIANG FUSIDA TOOLS

Method of laser drilling

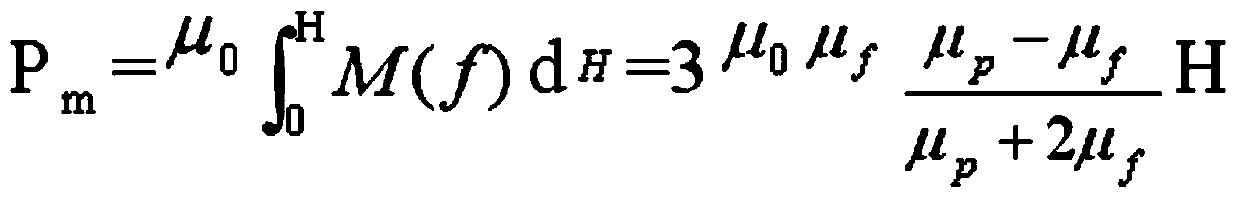

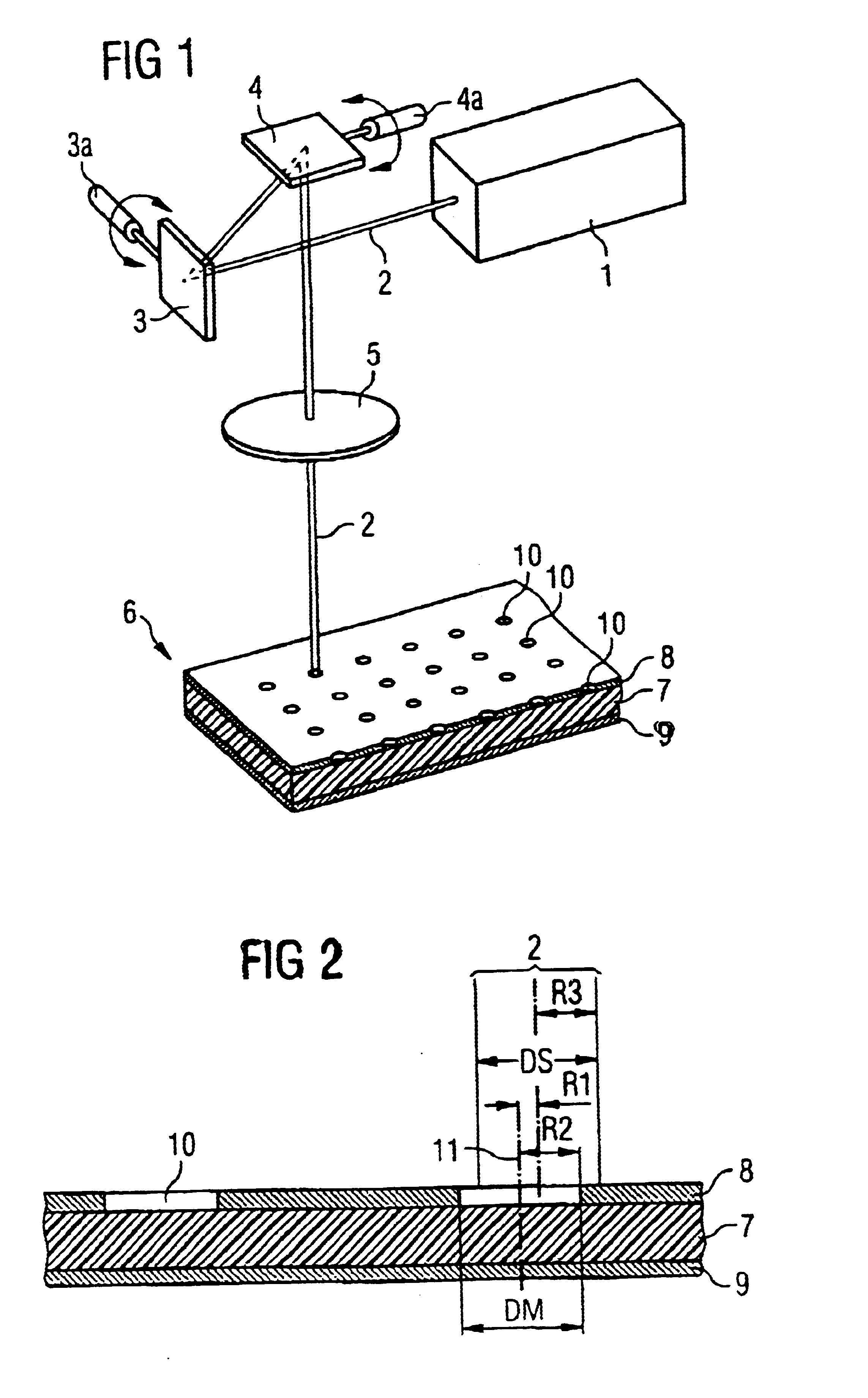

InactiveUS6649864B2Uniform removalLittle loss of laser powerLaser beam welding apparatusEtching metal masksPhysicsLaser drilling

In a method for the laser drilling of holes in a circuit substrate with the aid of a perforated mask, a laser beam is moved in the region of the perforated mask on a circular path. The center point of the region lies concentrically with respect to the set position of the respective hole in the mask. Further, the diameter of the region is smaller than the diameter of the hole. At the same time, the diameter of the laser beam spot is chosen to be large enough that it always covers the center point of the perforated mask during the circular motion. As a result, an energy distribution of the laser energy, which is as uniform as possible, is achieved in the region of the perforated mask.

Owner:HITACHI SEIKO

Method of removing photoresist film

InactiveUS6517999B1Increase contact frequencyIncrease ratingsElectrostatic cleaningSemiconductor/solid-state device manufacturingResistGas phase

A method of removing photoresist film with high efficiency of removal and friendliness with the environment while reducing the material consumption and the cost for the ventilation facility, and an apparatus used for the method are provided. Particularly the present invention provides a method of removing a photoresist film provided on a surface of a substrate, comprising steps of in a sealed system, disposing the substrate surface having the photoresist film to contact with a photoresist film removing solution, making ozone exist in gas phase and / or solution phase in the vicinity of the liquid surface of the photoresist film removing solution, and changing a relative position between the surface of the substrate and the liquid surface of the solution to decompose or remove the photoresist film from the substarate, characterized in that the relative position is changed continuously or intermittently within a range between a position where a bottom edge of the substrate is present above the liquid surface of the solution, and another position where a top edge of the substrate is present below the liquid surface of the solution. The present invention also provides an apparatus used for the method.

Owner:MITSUBISHI ELECTRIC CORP +1

Semiconductor device

InactiveUS20090108410A1Avoid it happening againUniform removalSemiconductor/solid-state device detailsSolid-state devicesLaser lightSemiconductor

A semiconductor device includes a semiconductor substrate, a diffusion layer conductive film formed on the semiconductor substrate, an interlayer insulating film layered on the semiconductor substrate, an interconnect pattern and a via pattern formed in the interlayer insulating film, a plurality of circuit regions formed in the semiconductor substrate, and a scribe region formed around the circuit regions and separating the circuit regions from each other. The diffusion layer conductive film is not formed at least in a region to which laser light is emitted in the scribe region.

Owner:PANASONIC CORP

Fuel cell

InactiveUS20050118490A1Add featureUniform removalFuel cell heat exchangeSolid electrolyte fuel cellsEngineeringPorosity

In a fuel cell, a porous portion is formed in a separator. At a surface of the porous portion opposite to a surface where a reactant gas passage is formed, a cooling gas passage is formed. The cooling gas passage may be fluidly connected to a reactant gas supply passage for supplying reactant gas to the fuel cell. The cooling gas passage is controllable in flow amount. The porous portion is formed only in a separator portion where a downstream portion of the reactant gas passage is located. At a separator portion where an upstream portion of the reactant gas passage is located, a coolant passage is formed. A rib and a rib-bottom portion have a great porosity. A groove may be filled with porous material. The porous portion may be replaced by a water exchange portion. A portion of the separator other than the region of the porous portion may be made by porous material. Due to these, a fuel cell can be obtained where removal of product water is improved, product water can be utilized for humidifying gas, and product water can be uniformly removed.

Owner:TOYOTA JIDOSHA KK

Device and method for the manufacture or repair of a three-dimensional object

ActiveUS10112236B2Increase flow rateCompact designAdditive manufacturing apparatusCeramic shaping apparatusEngineeringBuilding construction

The invention relates to a device for the manufacture or repair of a three-dimensional object, comprising at least one construction chamber for a successive solidification of at least one solidifiable material layer by the layer in predefined regions for the layer-by-layer buildup of the three-dimensional object or for the layer-by-layer repair of individual regions of the three-dimensional object within the construction chamber, and at least one inlet nozzle and at least one suction nozzle for a process gas, wherein the inlet nozzle and the suction nozzle are arranged in such a way that a gas flow that passes at least partially over a construction platform formed in a construction chamber is created.

Owner:MTU AERO ENGINES GMBH

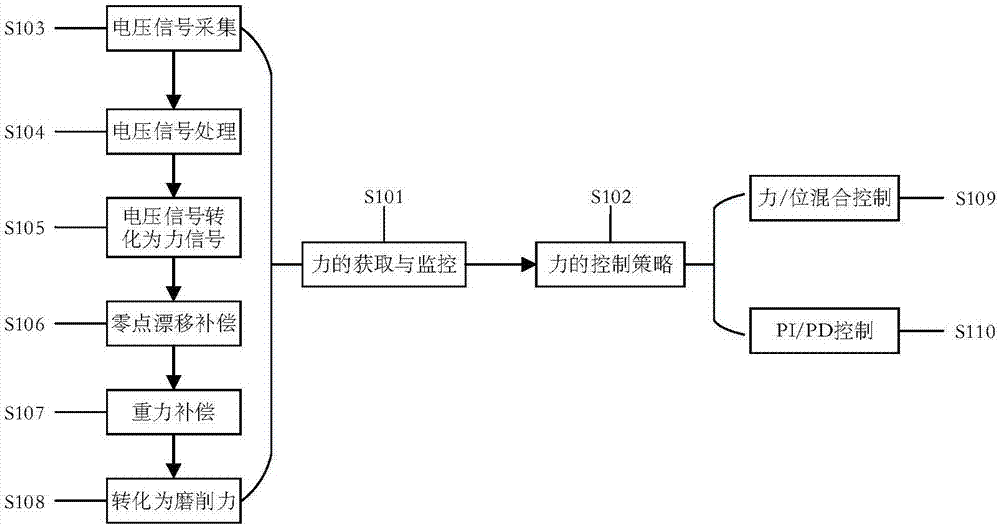

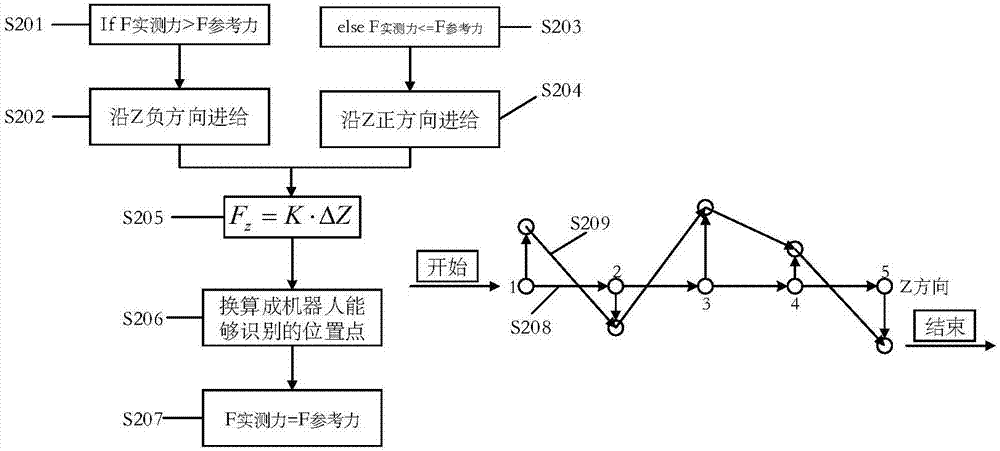

Force control method for robotic abrasive belt grinding machining for blade

ActiveCN107962480AUniform removalImprove grinding efficiencyBelt grinding machinesGrinding feed controlConstant forcePosition control

The invention discloses a force control method for robotic abrasive belt grinding machining for a blade. The force control method for robotic abrasive belt grinding machining for the blade comprises the following steps: modulation and processing for voltage signals; compensation for a converted force; and a force control strategy. The modulation and processing for the voltage signals comprises thefollowing steps: acquiring the voltage signals of six channels of a sensor; carrying out software filtering on the acquired voltage signals; and converting the filtered voltage signals to force signals. The compensation for the converted force comprises the own zero drift compensation of the sensor and gravity compensation for a robotic end load. The force control strategy comprises hybrid force-position control and PI / PD control. The force control method for robotic abrasive belt grinding machining for the blade is capable of increasing the efficiency of the grinding machining, avoiding thecase of low consistency of manual grinding machining, realizing constant-force grinding machining, and keeping a uniform and consistent removal amount of a surface material, thereby improving the surface consistency of the blade while improving the machining accuracy and surface quality.

Owner:HUAZHONG UNIV OF SCI & TECH

Method of manufacturing organic electroluminescence display device

InactiveUS20120252149A1Highly efficient, long-life, and high-definitionImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceWater soluble

Provided is a method of manufacturing an organic electroluminescence display device including an emission region, the emission region including multiple organic compound layers arranged therein, each of the organic compound layers being provided between a pair of electrodes and including at least an emission layer, the method including: forming in the entire emission region an organic compound layer which is insoluble in water; forming on the organic compound layer a mask layer containing a water-soluble material in a predetermined pattern; removing a part of the organic compound layer which is formed in a region which is not covered with the mask layer; removing the mask layer; drying the organic compound layer; and forming a common layer on the organic compound layers, in which the steps from the drying of the organic compound layer to the forming of a common layer are carried out in a vacuum.

Owner:CANON KK

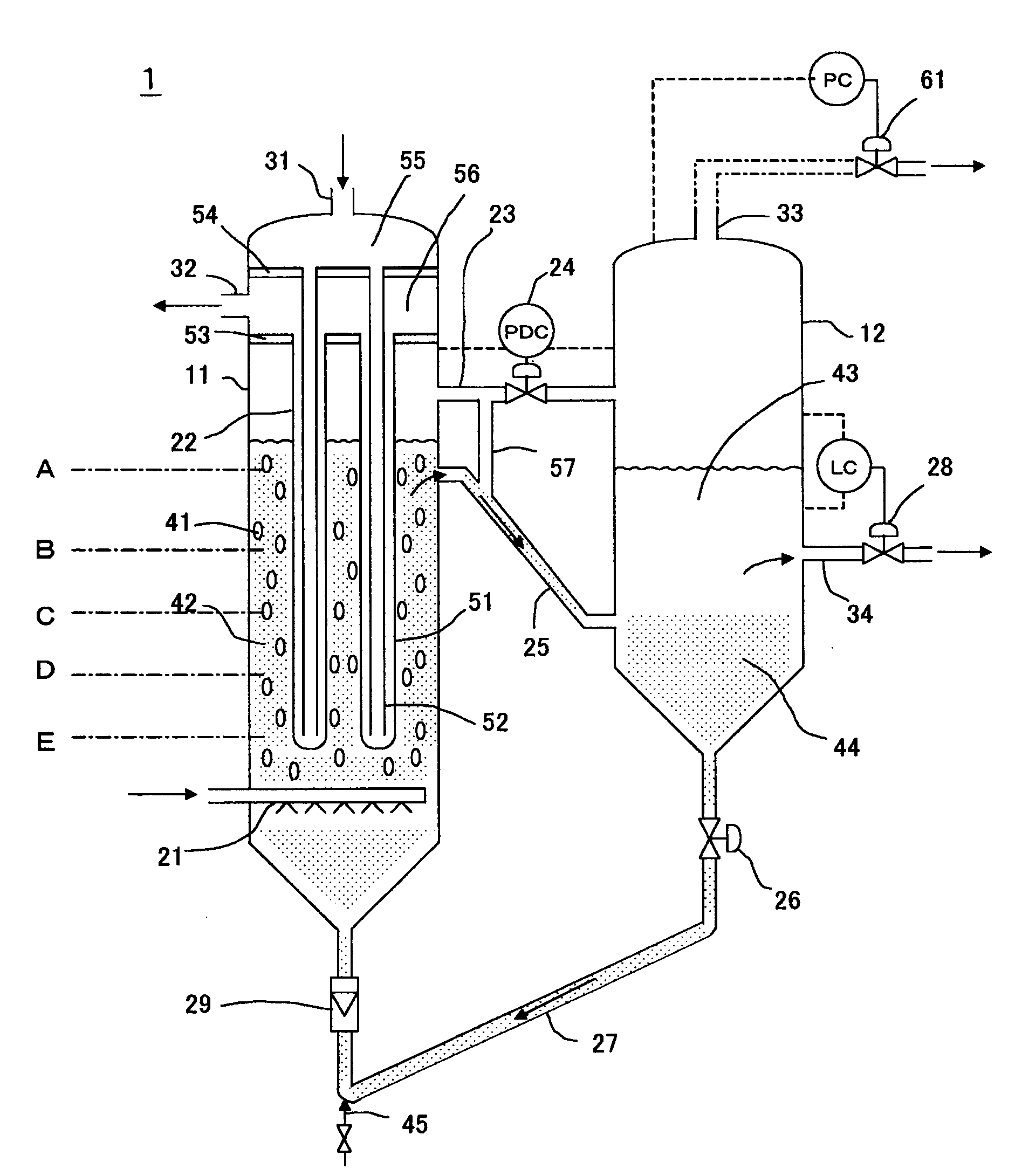

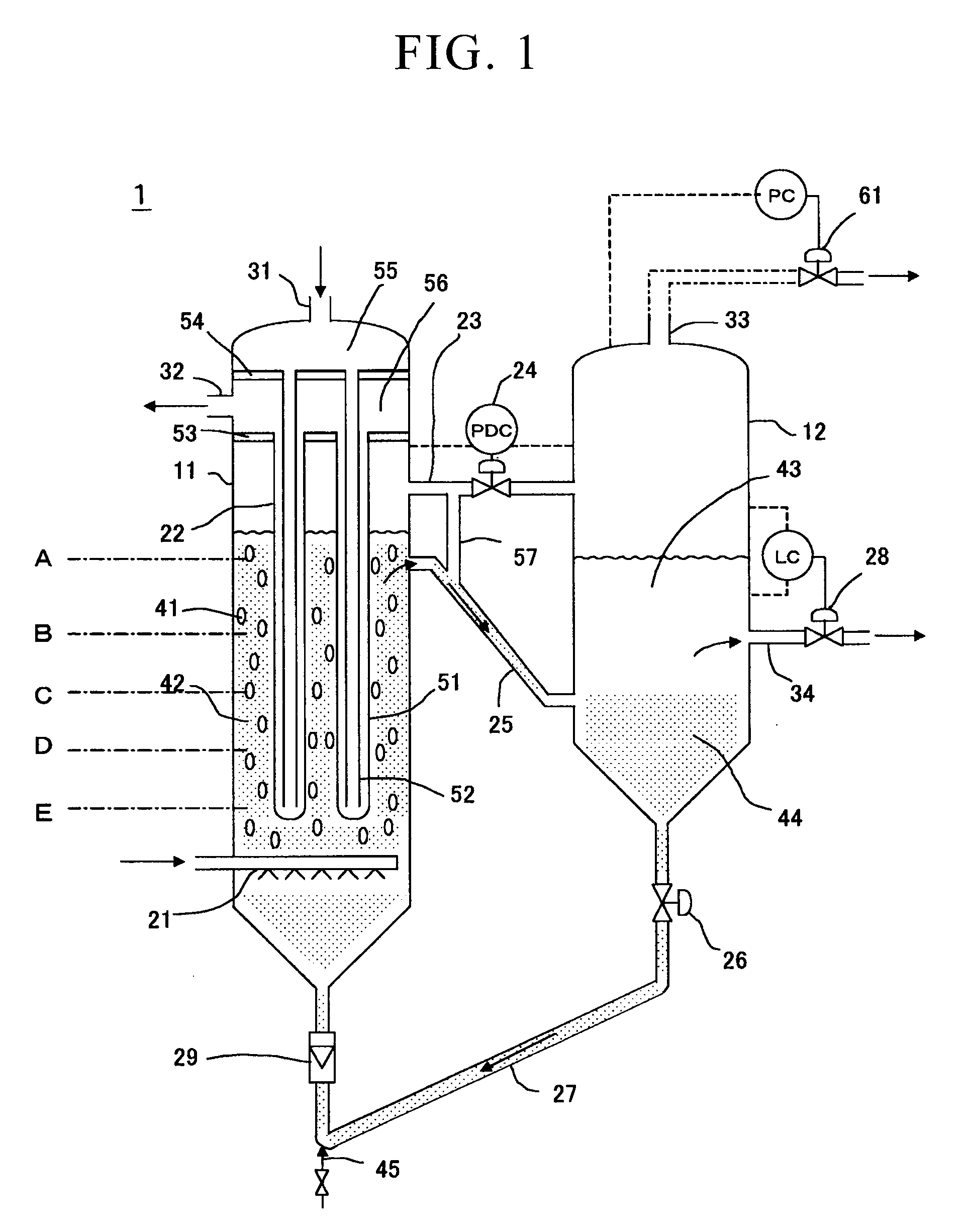

Bubble column-type fischer-tropsch synthesis slurry bed reaction system

InactiveUS20090220389A1Easy to monitorEasy to exportLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesLiquid productSyngas

A bubble column-type slurry bed reaction system is provided in which an operating system, which synthesizes liquid hydrocarbons by the Fischer-Tropsch (FT) synthesis reaction and separates and derives a catalyst and liquid hydrocarbon products from a slurry composed of gas, liquid and solid phases, can be simplified, and deterioration of catalyst particles caused by attrition and so forth can be reduced. In this FT synthesis reaction system, a bubble column-type slurry bed Fischer-Tropsch synthesis reaction process, in which synthesis gas supplied continuously from the bottom of a reactor and suspended catalyst particles are contacted to form liquid hydrocarbons, gaseous hydrocarbons and water, a process in which a slurry of suspended liquid products formed in the Fischer-Tropsch synthesis reaction process and catalyst particles moves from the reactor to the lower portion of a separation vessel through a downwardly inclined transfer pipe to separate the catalyst particles and gaseous products, a process in which the liquid products formed in the Fischer-Tropsch synthesis reaction process is sent to the separation vessel through a horizontal connecting pipe installed above the downwardly inclined transfer pipe and derived from its apex, a process in which liquid products are derived from the separation vessel, and a process in which aslurry in which catalyst particles are concentrated is derived from the bottom of the separation vessel and circulated to the bottom of the reactor, are driven by the driving force of synthesis gas introduced from the bottom of the reactor and which rises through the slurry bed reactor without using an external drive power source for circulation, and the formed liquid hydrocarbon products, gaseous hydrocarbon products and water are separated and derived without using an external drive power source for separation.

Owner:INPEX CORP +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com