Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

451results about How to "Guaranteed deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super plastic forming method for plate type heat converter special titanium plate

InactiveCN101121178AHigh yield strengthEasy to processRoll mill control devicesFurnace typesPlate heat exchangerTitanium

The present invention relates to a superplastic forming method for the titanium plate specially used for the plate type heat exchanger, which belongs to the field of mechanical processing technology. The present invention comprises the following steps that spongy titanium is chosen to be the melted raw material; the spongy titanium is placed in a vacuum plasma smelting furnace to be directly cast into plate base; the plate base forms a plate of a thickness of 2.0 to 2.4 mm after the process of heating, hot rolling, acid and alkali washing; second heating, hot rolling and acid and alkali washing and annealing; the plate of a thickness of 2.0 to 2.4 mm after the annealing in the vacuum smelting furnace forms a titanium plate of a thickness of 0.5 to 0.6 mm after the process of cold rolling, cleaning, second annealing and cold rolling, acid and alkali washing and third annealing. The present invention adopts the process that the spongy titanium which contains oxygen, iron and nitrogen of comparatively high content is directly processed into the titanium plate base in the plasma smelting furnace and directly rolled into the plate without forging and pressing.

Owner:上海桦厦实业有限公司

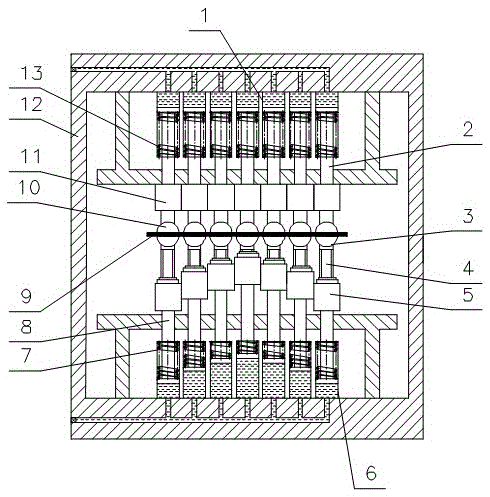

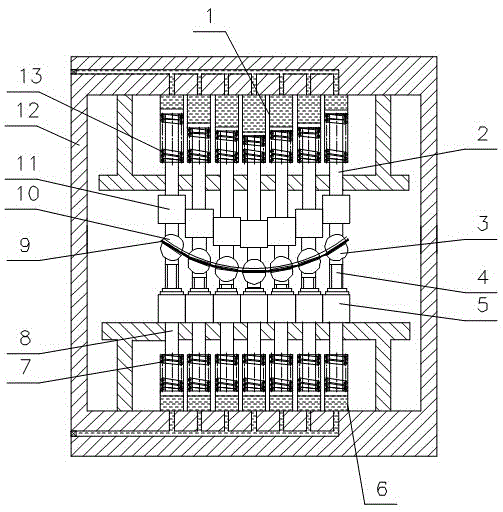

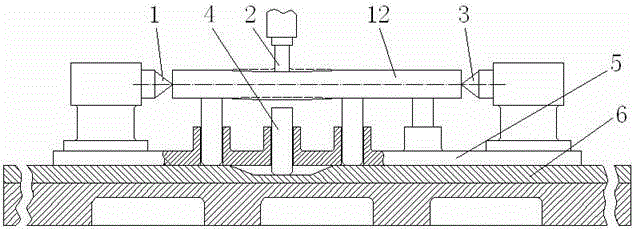

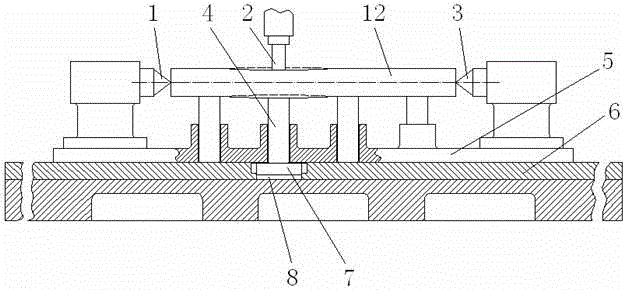

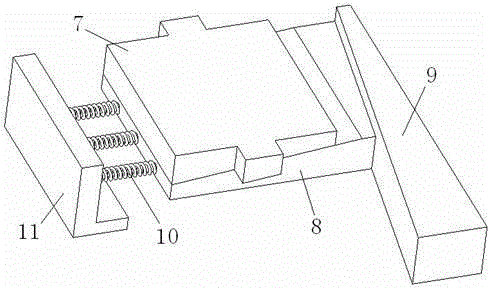

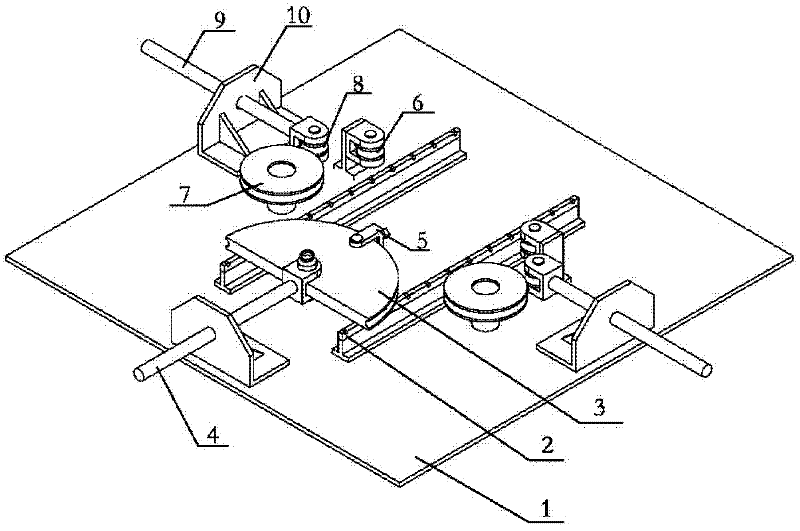

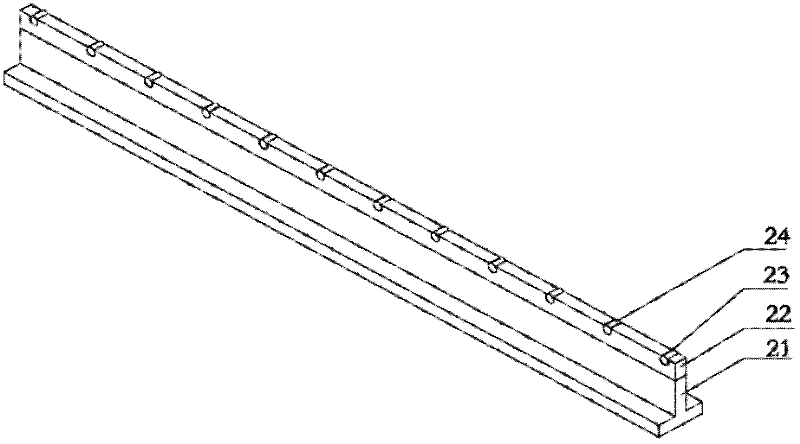

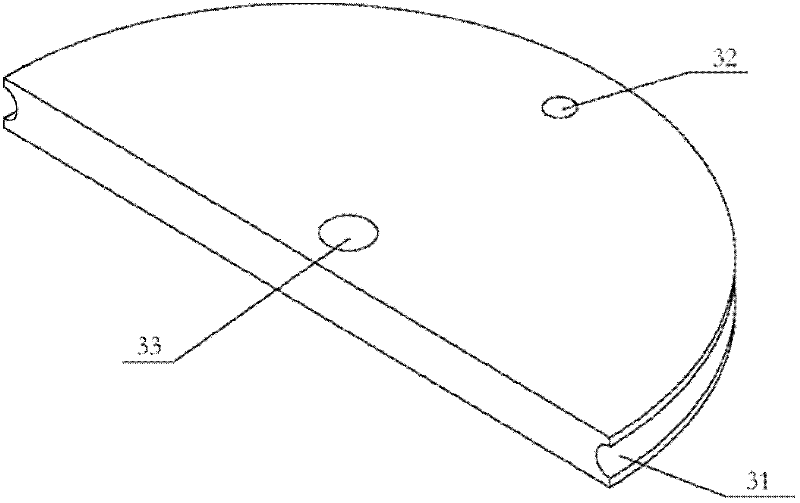

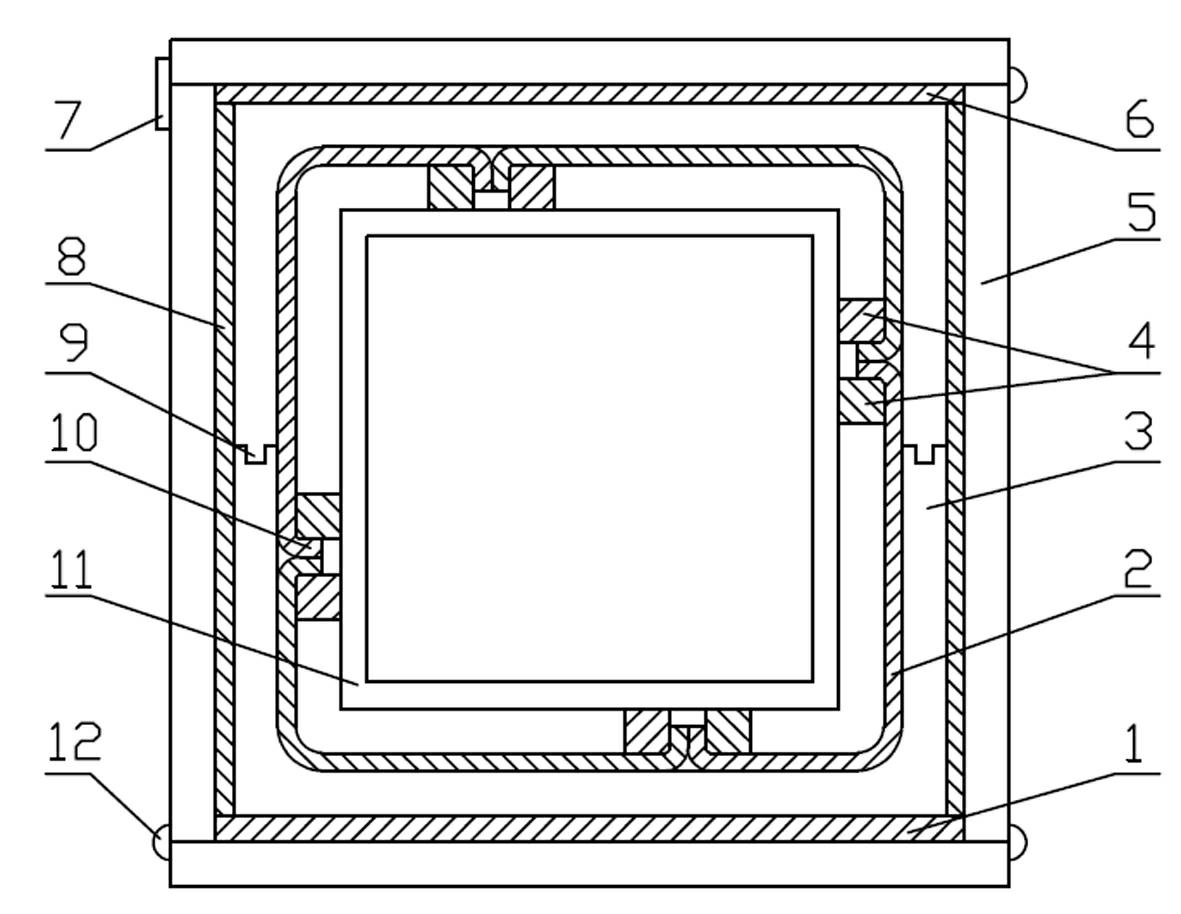

Plate multipoint progressive forming device

ActiveCN105478539AOptimal forming pathRaise the forming limitShaping toolsPress ramPistonEngineering

The invention relates to a plate multipoint progressive forming device which comprises a mould stand, a plurality of driving pressurization units and a plurality of shape adjusting and supporting units, wherein the driving pressurization units are mounted on a top plate of the mould stand; each driving pressurization unit consists of an upper pressing head, a driving basic body, a spring, a piston and a driving hydraulic cylinder; the upper pressing heads are movably mounted at the bottom ends of the driving basic bodies; the driving hydraulic cylinders are fixed to the top plate of the mould stand; the shape adjusting and supporting units are mounted on a bottom plate of the mould stand; each shape adjusting and supporting unit consists of a lower pressing head, a supporting basic body, a spring, an adjusting bolt and a supporting hydraulic cylinder; the lower pressing heads are movably mounted at the top ends of the adjusting bolts; the supporting hydraulic cylinders are fixed to the bottom plate of the mould stand; and under the action of the driving hydraulic cylinders and the supporting hydraulic cylinders, multipoint progressive forming of a plate between the upper pressing heads and the lower pressing heads is realized. The plate multipoint progressive forming device is reasonable in structure; by controlling the pressure difference between the two sides of the plate, the optimal forming effect is realized; the forming precision of the plate is high; and the surface quality of the plate is good.

Owner:HARBIN INST OF TECH AT WEIHAI

Machining process of middle-long thin-wall blades

ActiveCN103008741AReduce cumulative errorReduce processing stress deformationMilling equipment detailsEngineeringMachining process

The invention discloses a machining process of middle-long thin-wall blades, which belongs to the technical field of machining of blades. The machining process is implemented by a detailed process of integrated rough machining and integrated fine machining, wherein the integrated rough machining comprise the specific steps of rough machining of each surface of a blade tip, each surface of a blade root and a molded surface of a steam passage; and the integrated fine machining comprises the specific steps: semifinishing of each surface of the blade tip and each surface of the blade root, fine machining of each surface of the blade tip, each surface of the blade root and each residue, semifinishing of the steam passage and fine machining of the steam passage. According to the machining process of the middle-long thin-wall blades, the operation is simple and convenient, the use is convenient and fast, the cost is low, the machining efficiency is high, and the operation is easy and labor-saving; and the deformation of the middle-long thin-wall blades is controlled within 0 to 0.8mm, the normal machining of a subsequent mold correction process is facilitated, and the machining of each blade is finished once.

Owner:SICHUAN MIANZHU XINKUN MACHINERY MAKING

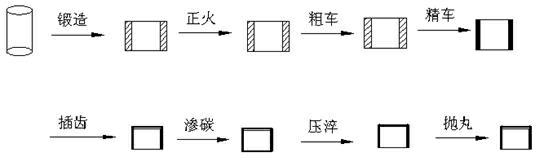

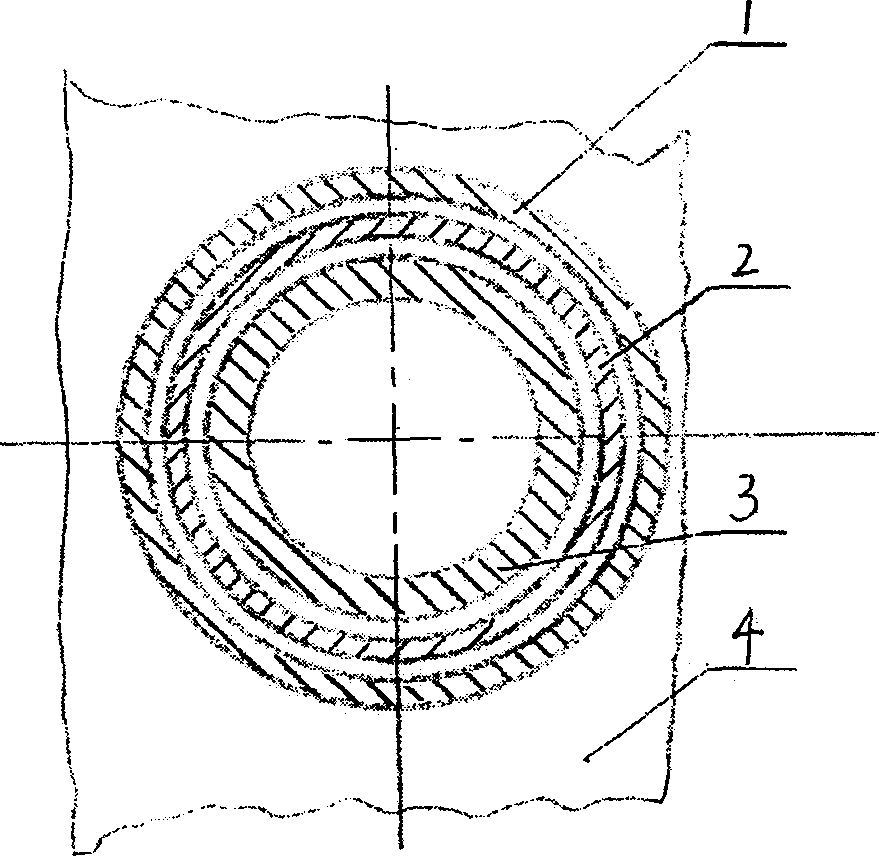

Method for machining inner gear rings

InactiveCN102581574AHigh surface hardnessReduce processing costsFurnace typesHeat treatment furnacesQuenchingHardness

The invention discloses a method for machining inner gear rings. The method includes steps of forging, normalizing, rough lathing, finish lathing, gear shaping, carburizing, pressure quenching and shot blasting. By the aid of the method, surface hardness, core structure and depth of a hardened layer of a gear ring are improved, machining cost is lowered, deformation of the gear ring is avoided assuredly, accordingly, the service life of the gear ring is prolonged, and the load capacity of a vehicle is enhanced.

Owner:江国辉

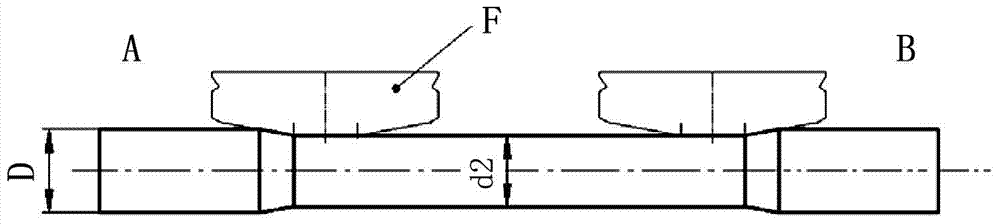

Radial forging method for high temperature alloy step shaft

The invention provides a radial forging method for a high temperature alloy step shaft. The method includes: upsetting and drawing out a steel ingot, and providing a blank to a forging machine; forging the blank in multiple passes, and pre-forging to form a first step shaft; forging the middle of the first step shaft in multiple passages so as to form a middle step shaft, and forming a transition section between the first step shaft and the middle step shaft, wherein pulling speed for forming the first step shaft is controlled to be 3-5.5m / min, deformation of each pass for forming the middle step shaft is controlled to be 10-25%, and pulling speed for forming the middle step shaft is controlled to be 3-5.5m / min. By control on forging frequency, reduction in pass and pull speed of the radial forging method and by control on final forging temperature, the property structure of a step shaft product is controlled, quality stability and structure property uniformity of the product are improved greatly while comprehensive yield and qualified rate of the product are increased greatly.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Ultraviolet curing adhesive

ActiveCN102079961ASolve the problem of unexposed initial tackHigh softening pointPolyureas/polyurethane adhesivesPhotosensitive materials for photomechanical apparatusAcrylic resinAdhesive

The invention discloses an ultraviolet curing adhesive comprising a resin main body, a dissolvent, an ultraviolet light initiator and an addition agent, wherein the resin main body is composed of a resin R and a resin H; the R resin is an active polyurethane acrylic resin with a main chain containing a polyether structure and a branch chain containing a vinyl optical active group as well as with a lower molecular weight; and the H resin is an inert polyurethane acrylic resin with a main chain containing a polydiene and aryloxide structure and with a relatively higher molecular weight. The adhesive contains no monomer or prepolymer, has high softening point, can be precoated on a base material, has super strong cohesive force on a high-oilness contact surface and has characteristics of high-temperature resistance, small internal stress and good flexibility.

Owner:LUCKY HUAGUANG GRAPHICS

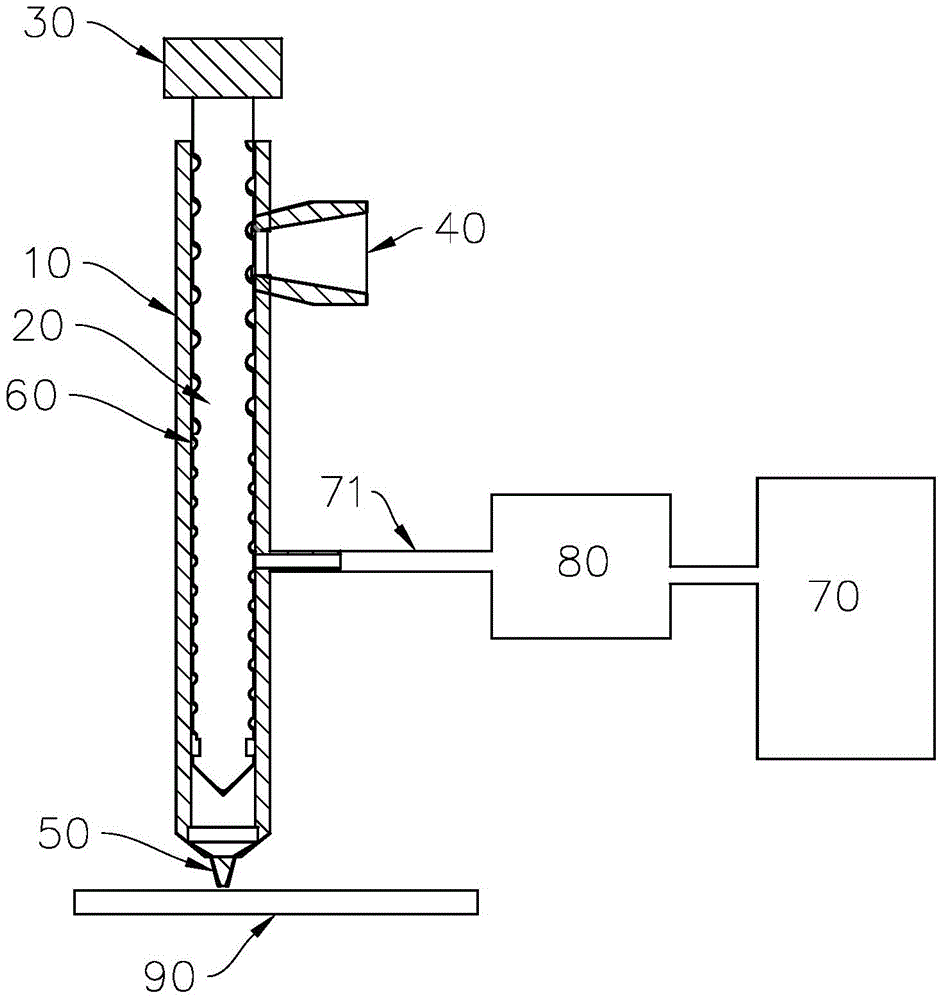

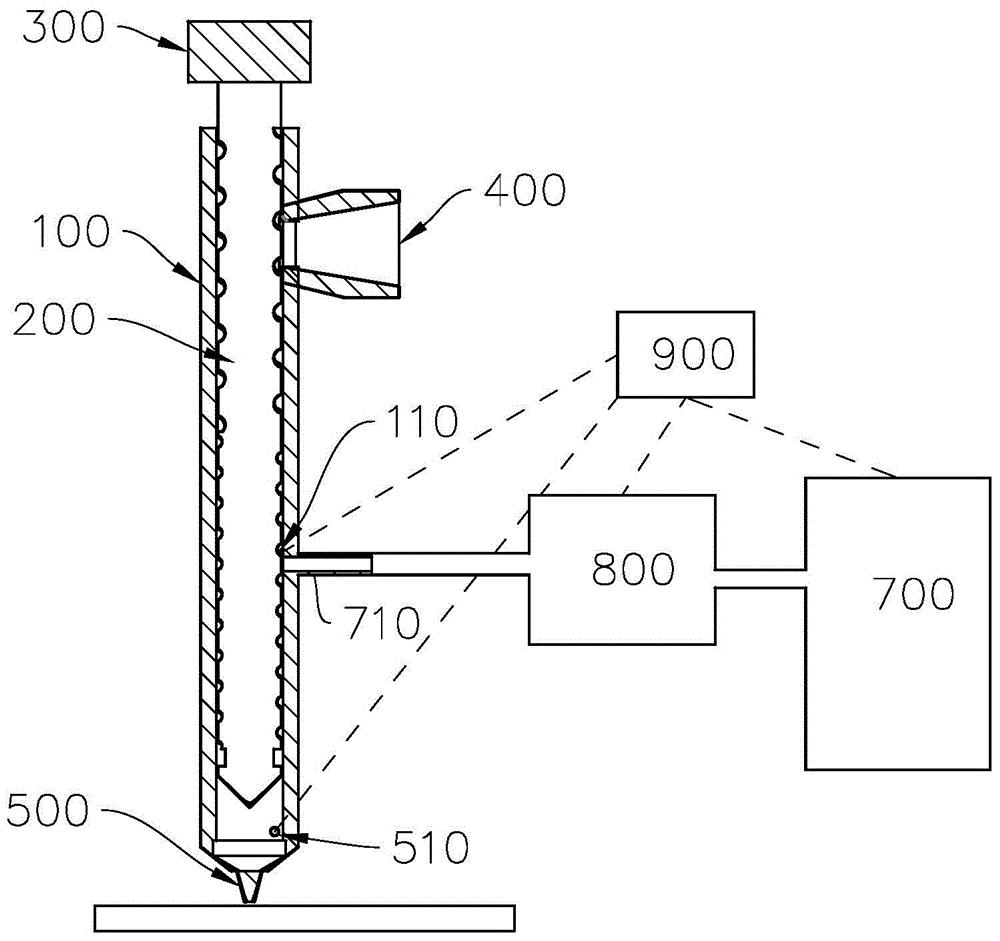

Three-dimensional printer and printing method and three-dimensional printing head

ActiveCN104875389ALow densityReduce the density valueAdditive manufacturing apparatusEngineeringVolumetric Mass Density

The invention relates to a three-dimensional printer, a three-dimensional printing head and a printing method. The three-dimensional printing head comprises a material volume cavity, wherein a screw rod is arranged in the material volume cavity, a motor is connected with the screw rod, a material supply device is communicated with the material volume cavity, a printing nozzle is arranged on the end part of the material volume cavity, a heater is arranged on the material volume cavity and positioned between the material supply device and the printing nozzle, and a supercritical fluid supply system is communicated with the material volume cavity. A molten printing material is mixed with supercritical fluid to generate a single-phase molten mixture under the mixing and stirring effect of the screw rod, and a uniform microporous bubble formation effect is formed, so that the density value of a printing object can be reduced, the size deviation of the three-dimensional printing object can be alleviated, the flatness and straightness of the three-dimensional printing object can be improved by more than 50 percent, the temperature for printing the molten printing material is effectively lowered, the energy is saved, and the operation personnel is prevented from being scalded.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

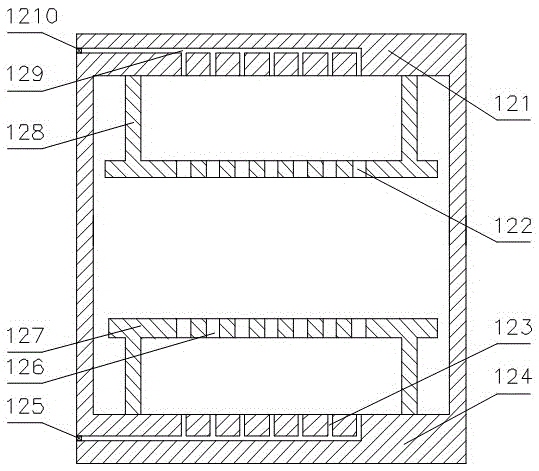

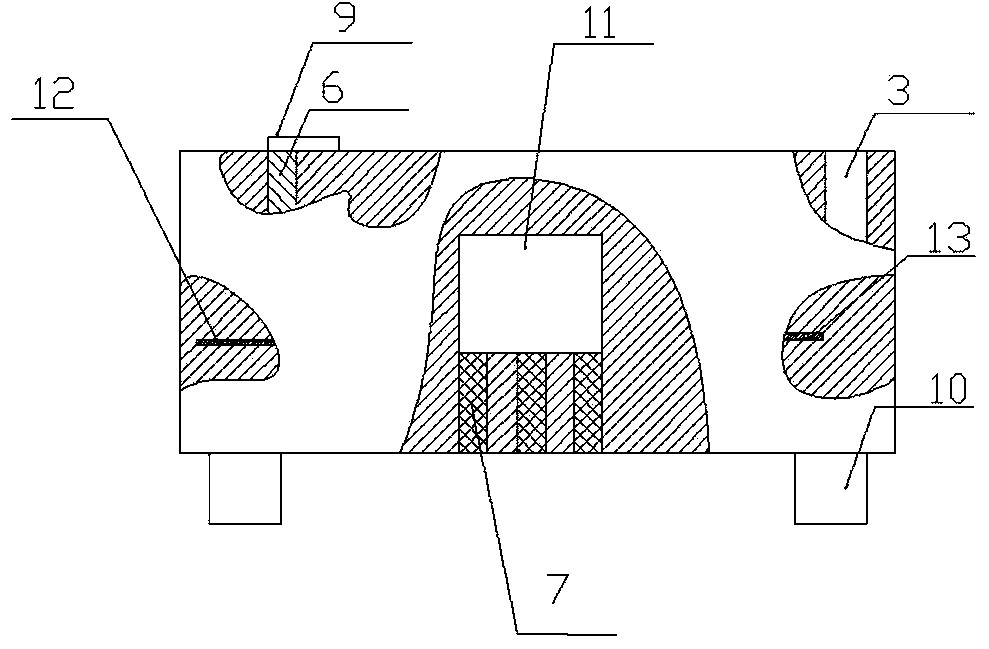

Method for preparing multilayer low-temperature cofired ceramics integrated liquid cooling circulation channel

ActiveCN103456646AGuaranteed not to deformGuaranteed deformationAntenna supports/mountingsSemiconductor/solid-state device manufacturingFilling materialsCeramic

The invention provides a method for preparing a multilayer low-temperature cofired ceramics integrated liquid cooling circulation channel. By the adoption of the method, the fact that the liquid cooling circulation channel does not collapse can be guaranteed, and the problems of layering and swelling in the sintering process can be solved. According to the technical scheme, the method is achieved through the following steps that firstly, a plurality of low-temperature cofired raw ceramic chips are divided into three layers, locating holes, via holes, heat radiating holes and the liquid cooling circulation channel are prepared respectively, then, integral lamination is conducted on the top raw ceramic chip layer with an antenna unit to form a top unit, and integral lamination is conducted on the middle raw ceramic chip layer with the liquid cooling circulation channel and the bottom raw ceramic chip layer with a TR component unit to form a pit unit; volatilizable filling materials are printed into pits of the pit unit, organic adhesive coats the surface of the pit unit, the top unit is stacked on the pit unit, and an integral module is formed in a low-temperature and low-pressure mode; the integral module which is laminated is placed in a sintering furnace for sintering, and a liquid cooling external joint is welded to a corresponding liquid cooling inlet and outlet on the surface of the top layer of the module.

Owner:10TH RES INST OF CETC

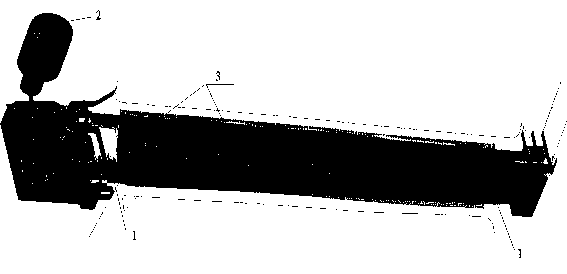

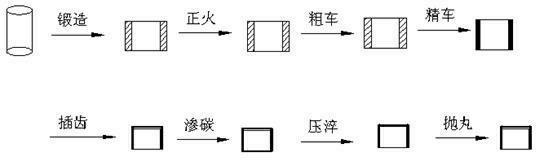

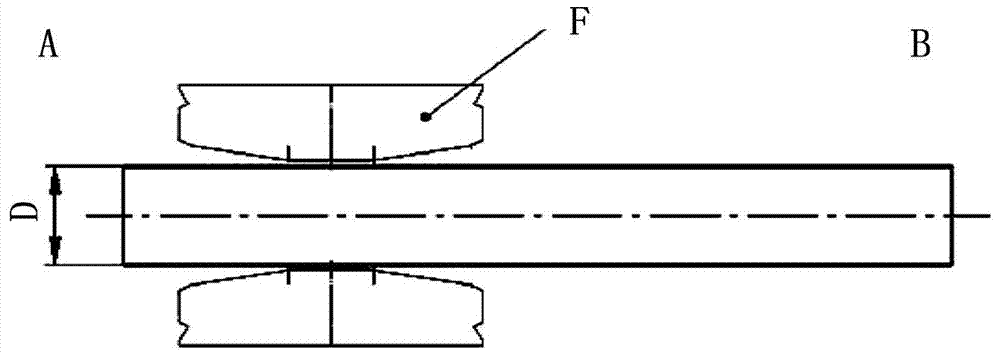

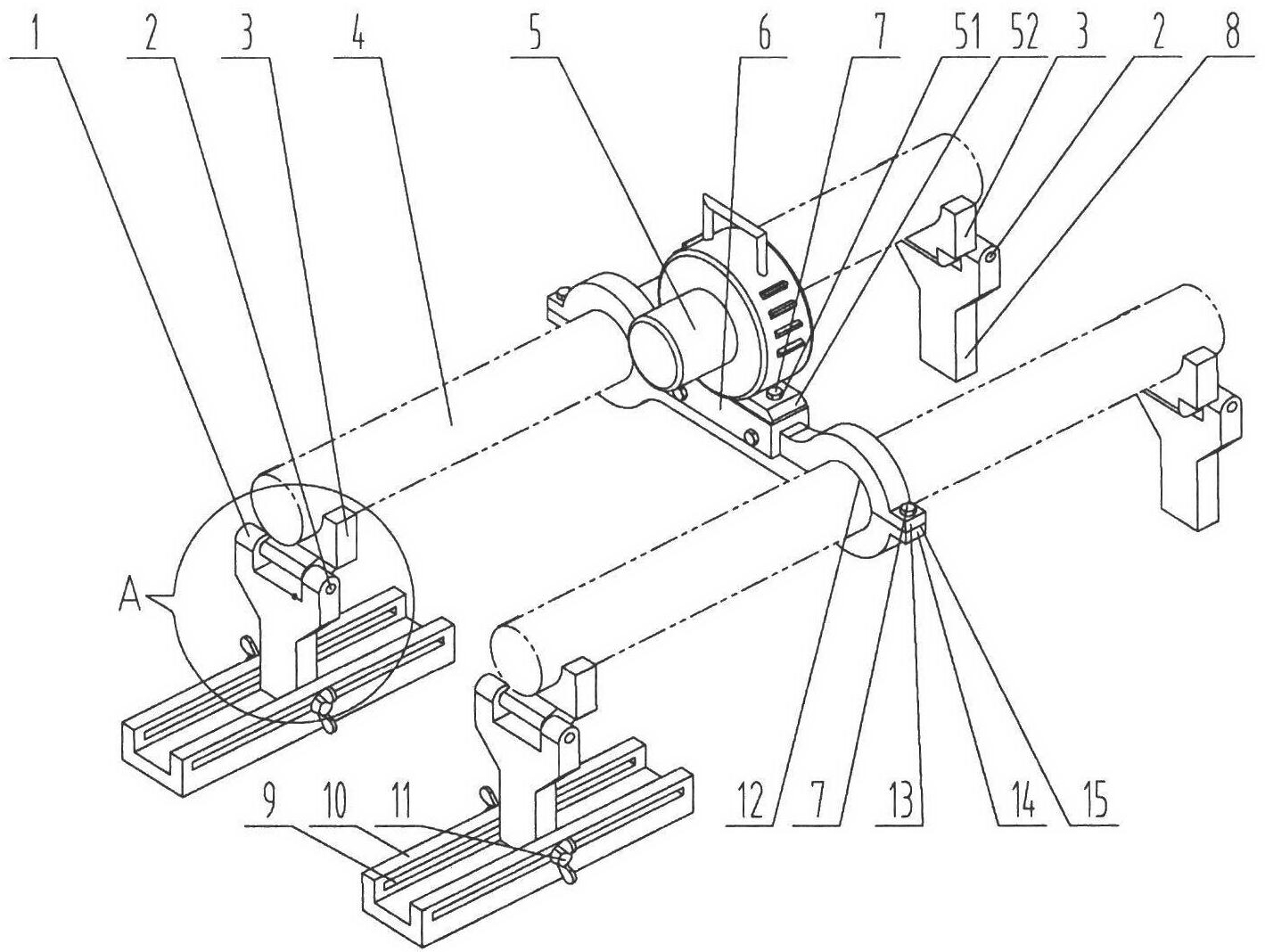

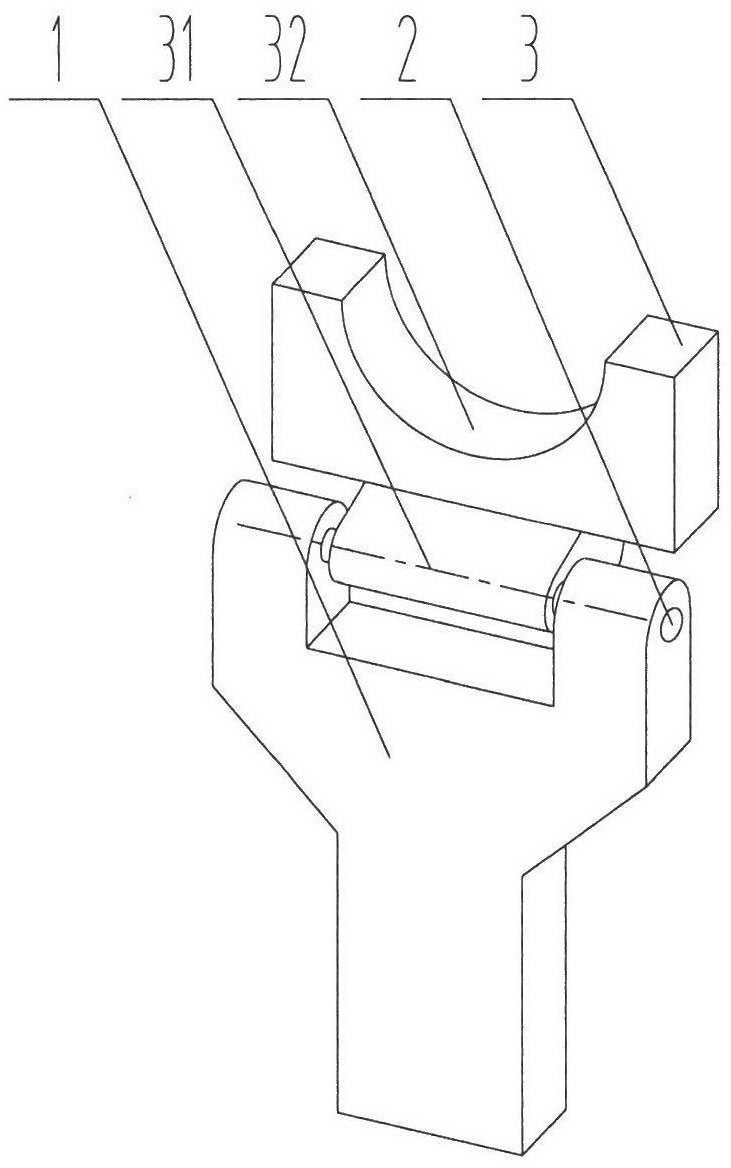

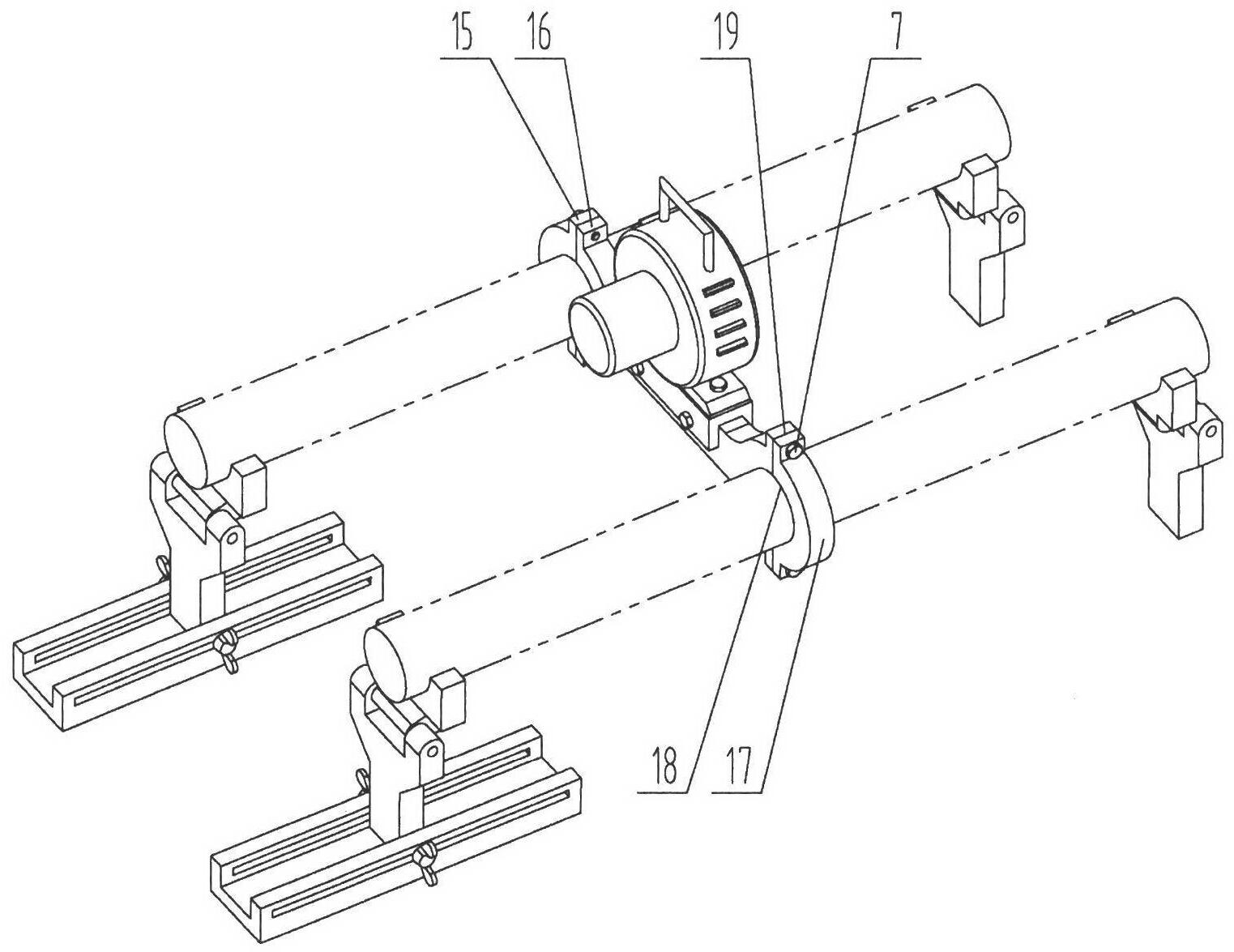

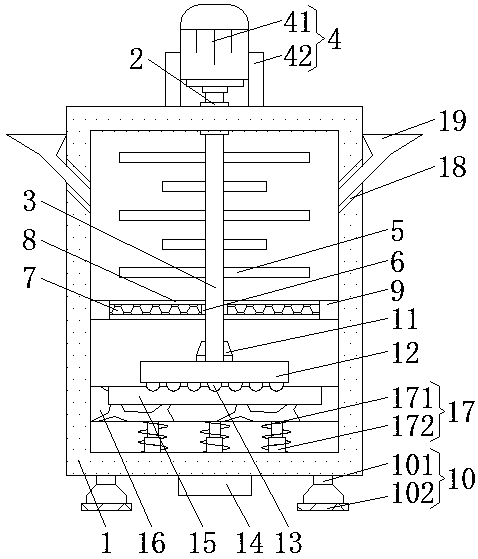

Vibratory stress relief apparatus for medium frequency and low frequency shaft type parts, and use method thereof

InactiveCN102321793AAddress effectivenessAddress stressFurnace typesHeat treatment furnacesMedium frequencyEngineering

The invention relates to a vibratory stress relief apparatus for medium frequency and low frequency shaft type parts, and a use method thereof. The apparatus comprises a vibration exciter, a support block for clamping and supporting a workpiece, and a support mechanism connected with the support block. The support mechanism comprises a pair of support frames comprising a left support frame and a right support frame, and a support seat for installing the left support frame and the right support frame, wherein the left support frame and the right support frame right are arranged relatively. Thesupport block respectively forms rotatable connections with the left support frame of the support mechanism and the right support frame of the support mechanism. The apparatus further comprises a vibration exciter base for installing the vibration exciter, wherein the vibration exciter base is arranged on the middle portion of the workpiece, the vibration exciter, the vibration exciter base and the workpiece synchronously vibrate during vibratory stress relief. According to the present invention, a simply supported beam form is adopted, the flexural vibration type primary resonance is generated by the shaft type parts under the excitation of the vibration exciter at the natural frequency adopted for shaft flexural vibration; in the prior art, the dynamic stress generated by the apparatus does not reach the requirement of residual stress decreasing, with the apparatus provided by the present invention, the problem in the prior art is solved; the deformation amounts on both ends of the shaft are substantially improved; the dynamic stress distribution of the shaft is uniform so as to effectively reduce the residual stress of the shaft part.

Owner:GUANGXI UNIV

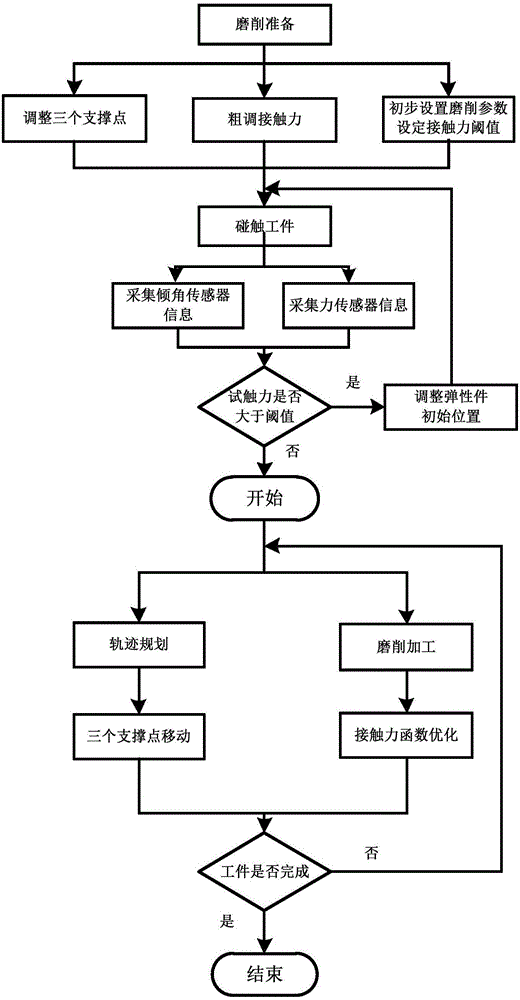

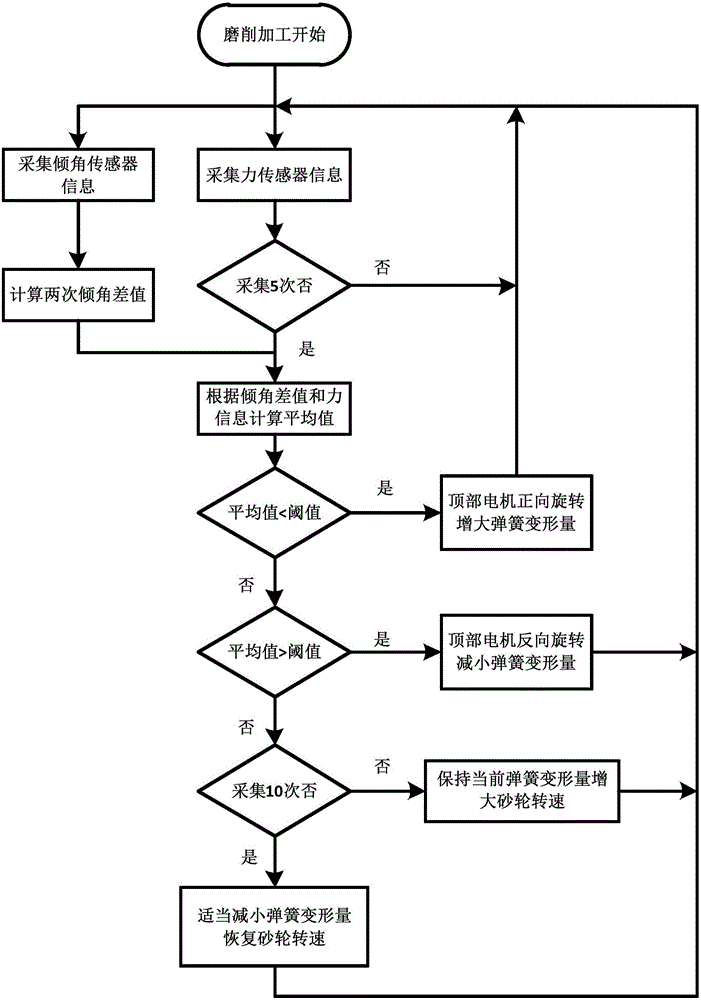

Self-adaptive control method for large-curved-surface grinding

ActiveCN105690209AGuaranteed continuityGuaranteed integrityGrinding feed controlGrinding machinesComputer moduleContact force

The invention discloses a self-adaptive control method for large-curved-surface grinding. The method adapts to workpieces with different curvatures through adjusting positions of three support points from the center, shortens the contact force adjusting time through roughly adjusting the thread pre-tightening force to improve the efficiency, acquires the contact force in the grinding process through a stated sampling period to feed back force signals, sets a contact force threshold to calculate a mean value of contact force values acquired by continuous 5 times of sampling periods, and uses a set controller for generating driving signals to continuously adjust the torque direction and magnitude of a drive in a polishing tool module to change the deformation of an elastic part, so that the magnitude of the contact force is proper, a proper numerical value range is kept, and the relatively stable polishing contact force is realized. The method comprises five steps of: (1) grinding preparation; (2) workpiece touching; (3) trajectory planning; and (4) grinding; and the method can realize relatively constant polishing contact force, and improves the machining stability.

Owner:HEBEI UNIV OF TECH

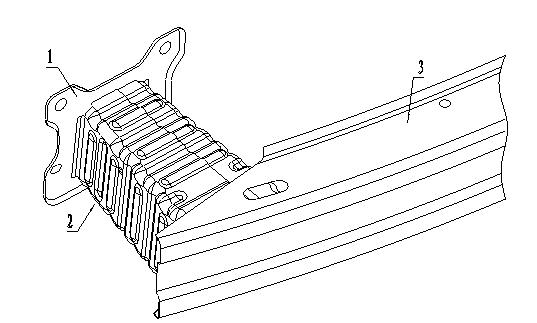

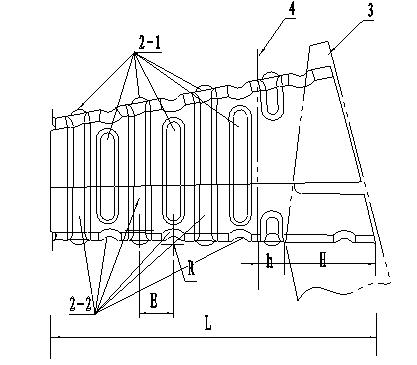

Minicar impact-proof beam energy absorption box capable of controlling impact energy absorption and residual deformation

ActiveCN101962038AImprove safety performanceGuaranteed deformationUnderstructuresBumpersAbsorbed energyEngineering

The invention relates to a minicar impact-proof beam energy absorption box capable of controlling impact energy absorption and residual deformation, which is used for solving the problem of the energy absorption of a front impact-proof beam and comprises a transverse beam and energy absorption boxes symmetrically arranged on both sides of the transverse beam, wherein the improved energy absorption boxes are provided with bulged and concave guide tendons regularly distributed; the bulged guide tendons and the concave guide tendons are alternately arranged on the side walls of the energy absorption boxes; the positions of the bulged and the concave guide tendons on the two relative side walls of the energy absorption boxes are corresponding; and the positions of the bulged and the concave guide tendons on the two adjacent side walls of the energy absorption boxes are corresponding. The invention has the advantages that the guide tendons regularly distributed are successively squashed and absorb energy when the front impact-proof beam of an automobile is impacted through the optimization design of the guide tendons arranged on the energy absorption boxes, and the front impact-proof beam presents an S-shaped squashing type when deforming; the energy absorption can be satisfied, and the height of the energy absorption boxes after deforming can be effectively overlaid and supported at the same time; the residual deformation of the energy absorption boxes after squashing can be guaranteed; and the deformation mode of the energy absorption box basically coincide to the expected design through CAE analysis and test confirmation.

Owner:LINGYUN INDAL CORP

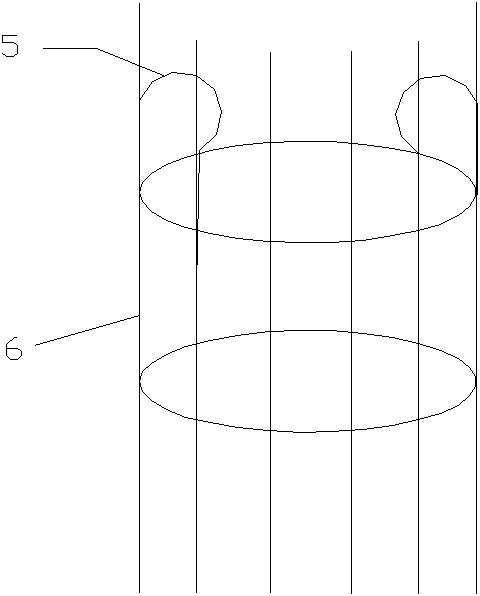

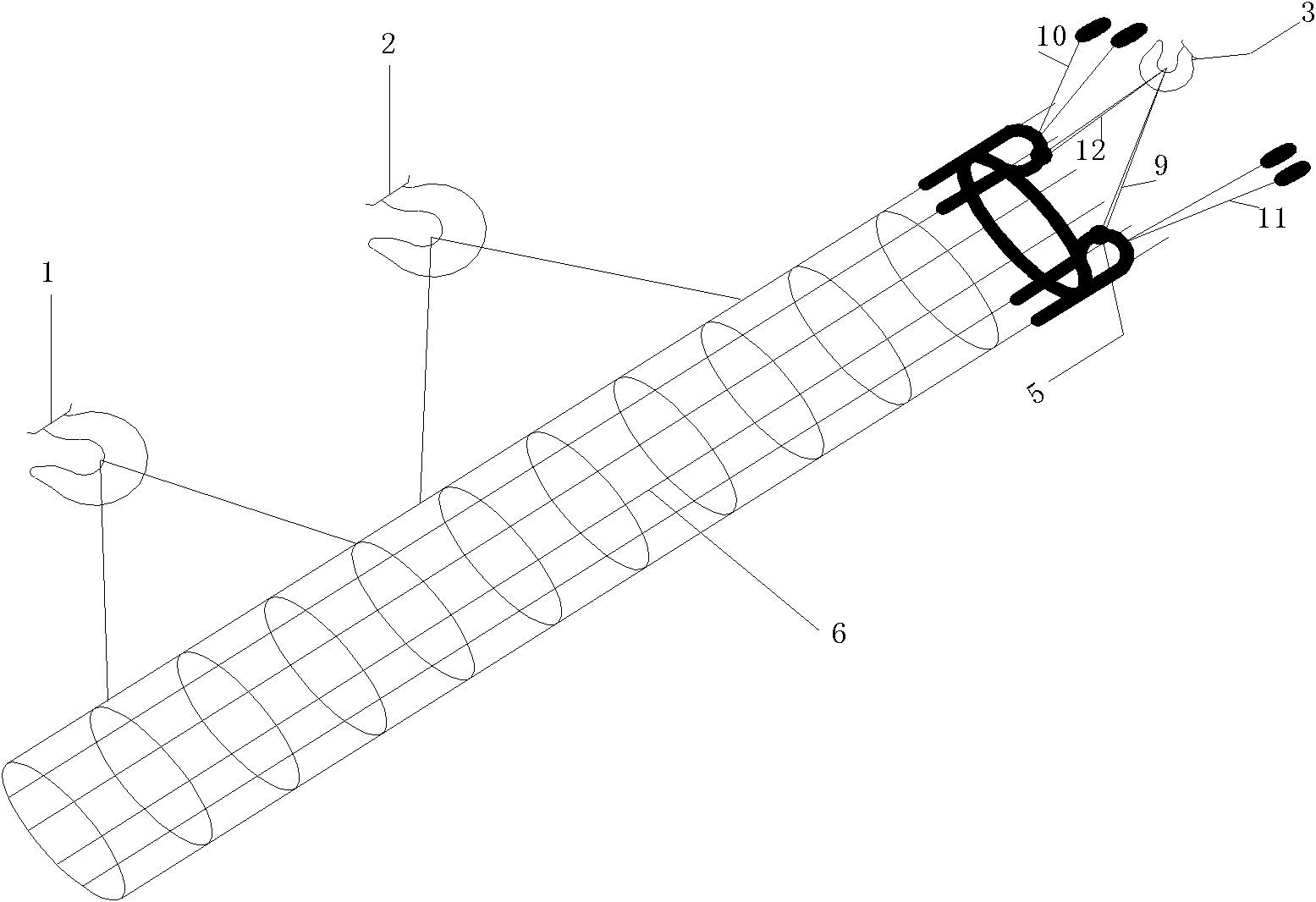

Device and method for hoisting entire oversized steel reinforcement cage in one step

InactiveCN102328881AGuaranteed deformationGuaranteed deformation controlCranesLoad-engaging elementsOperabilityRebar

The invention discloses a method for hoisting an entire oversized steel reinforcement cage in one step. The method mainly comprises the steps of: binding a steel reinforcement cage; arranging hoisting points and configuring a crane; connecting a main hoisting hook with the hoisting points; completing horizontal hoisting of the steel reinforcement cage; converting the steel reinforcement cage froma horizontal state to a vertical state; and directly hoisting the steel reinforcement cage in the vertical standing state to be in place by using a third crane. According to the invention, by jointlyhoisting the oversized steel reinforcement cage by using three hoisting equipment and by skillfully transforming the hoisting points in the angle transformation from the horizontal state to the vertical state, the oversized steel reinforcement cage is hoisted in one step without segmentation and structural variation, so that the efficiency in hoisting operation is increased, in addition, concretecan be poured, so that the advantages of construction safety, operability, capability of meeting construction period requirement and increased efficiency are achieved.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Radial truck tire air-tight layer component and preparation process thereof

InactiveCN102604243AImprove stabilityImprove thickness uniformityTyresPneumatic tyre reinforcementsVulcanizationEngineering

The invention belongs to the technical field of processing of rubber tires, and particularly relates to a radial truck tire air-tight layer component and a preparation process thereof. The radial truck tire air-tight layer component comprises the following substances in parts by mass: 100 parts of rubber substrate, 40-100 parts of reinforcing system, 1-10 parts of anti-aging system, 4.7-15 parts of vulcanization system, 0-20 parts of radiation crosslinking sensitizer and 0-50 parts of additive aid. The method comprises the following steps of: mixing other substances except a vulcanizing agent, discharging glue, and adding the vulcanizing agent for preparing a rubber compound; and rolling the prepared rubber compound to obtain an air-tight layer sheet of 3-5 millimeters in thickness, performing cobalt source radiation treatment in the air to obtain the radial truck tire air-tight layer component, wherein the radiation dosage of the air-tight layer sheet is 5-50 kGy. The air-tight layer component which is subjected to radiation pretreatment has the advantages of high Green strength, high structural size stability, high air tightness, and capability of improving the tire quality at a lower radiation dosage.

Owner:河南省科学院同位素研究所有限责任公司 +1

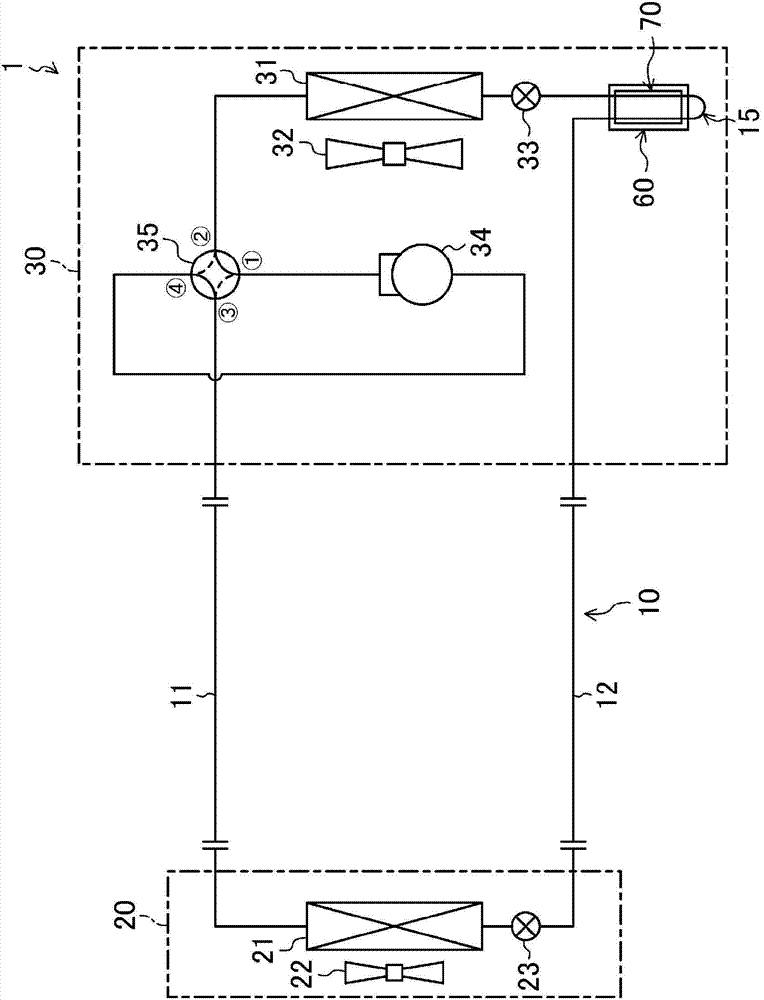

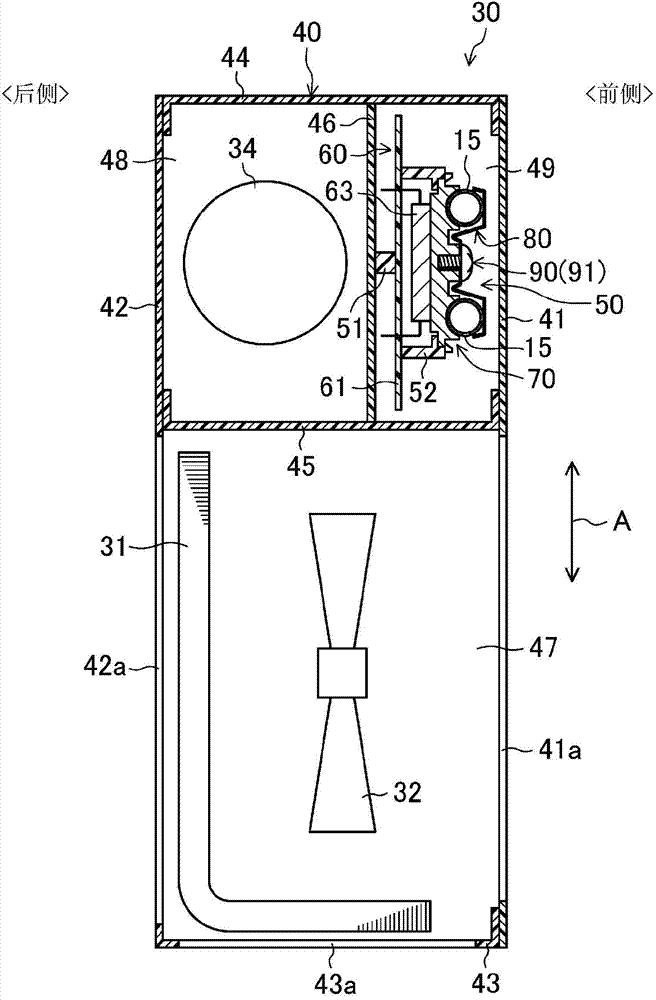

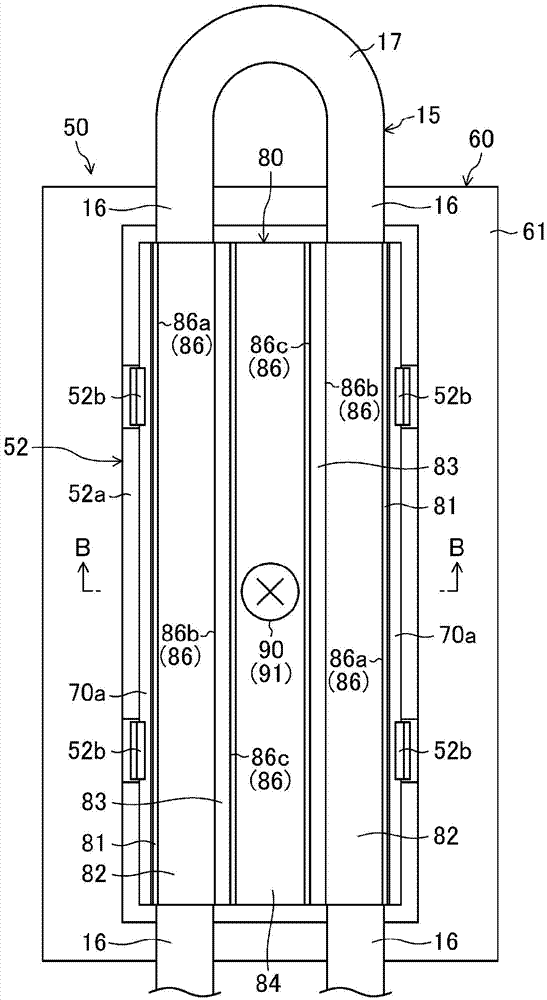

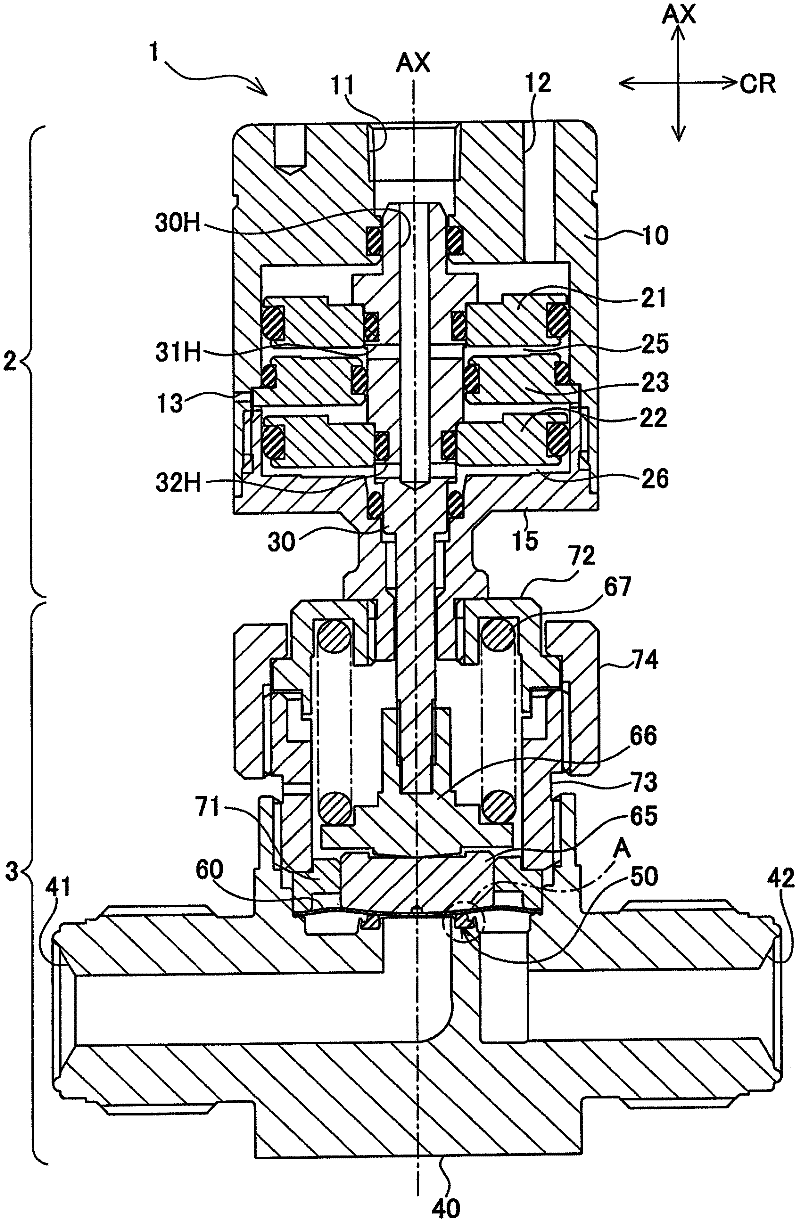

Installation structure for coolant pipe

ActiveCN103688605AIncrease contact areaReduce thermal resistanceCompressorSemiconductor/solid-state device detailsEngineeringRefrigerant

The present invention provides a coolant pipe installation structure which can reliably retain a coolant pipe and which can sufficiently decrease the thermal resistance between a coolant pipe and a heat-transmitting member. A heat-transmitting member (70) having a vertical groove part (72) into which a coolant pipe (15) fits, and which thermally contacts with a component to be cooled (63), is provided. An elastic member (80) formed in a long plate shape which extends in the extension direction of the coolant pipe (15), and having an opposing part (82) opposite the coolant pipe (15), is provided. A pushing structure (90) which pushes the elastic member (80) to the heat-transfer member (70) side is provided.

Owner:DAIKIN IND LTD

Workpiece straightening machine and straightening method thereof

InactiveCN104128396AAvoid underbendingReduce precision control requirementsHydraulic pressureIndustrial engineering

The invention discloses a workpiece straightening machine which comprises a follow-up thimble, a pressing head, a driving thimble, a bearing supporting column, a work sliding table, a bearing plate, a pressure measuring part and a bending control device. The follow-up thimble, the bearing supporting column and the driving thimble are arranged on the work sliding table, and the work sliding table is in sliding fit with the bearing plate. The bending control device comprises an upper bearing block, a lower bearing block, a feeding block, a spring and a baffle, a through hole is formed in the work sliding table, and the position, below the through hole, on the bearing plate is provided with a cavity used for arranging the bending control device. Meanwhile, the invention further discloses a workpiece straightening method. In the anti-bent straightening process of shaft and rod workpieces, the bending of the workpieces and the stroke of the pressing head can be effectively controlled. It is guaranteed that deformation of the workpieces is within a preset range, and the phenomena of insufficient bending and over bending in the workpiece straightening process are avoided. Particularly to the hydraulically-driven pressing head, the precision control demand of the pressing head strokes can be effectively lowered, operation and production efficiency is improved, and the scrappage of the workpieces is reduced.

Owner:CHONGQING UNIV OF TECH +1

A cold bending equipment and method for manufacturing U-shaped bar

The invention relates to the field of machinery manufacturing, in particular to cold bending equipment and a method for manufacturing a U-shaped rod. The cold bending equipment for manufacturing the U-shaped rod structurally comprises a guide rail device which is fixed on a bottom plate; a positive push mould capable of freely moving along the direction of a guide rail is arranged on the guide rail device; the front part of the positive push mould is in a circular arc shape; a groove is arranged on the outer edge of the circular arc shape; a driving rod is arranged on the positive push mould; the driving rod passes through a driving rod base and is connected with a driving device; sideward guiding pulley devices are symmetrically arranged on both sides of the guide rail device; sideward push pulleys capable of freely moving along the direction which is vertical to the guide rail are respectively arranged on both sides of the guide rail device; the driving rods are arranged on the sideward push pulleys, pass through the driving rod bases and are connected with the driving device; and the positive push mould, the sideward guiding pulley devices and the sideward push pulleys are arranged on the same plane. The invention can realize the once-through cold formation of the U-shaped rod, so that no danger occurs in a bending process, and the resilience problem of the U-shaped rod can be solved.

Owner:CHINA NUCLEAR POWER ENG CO LTD +1

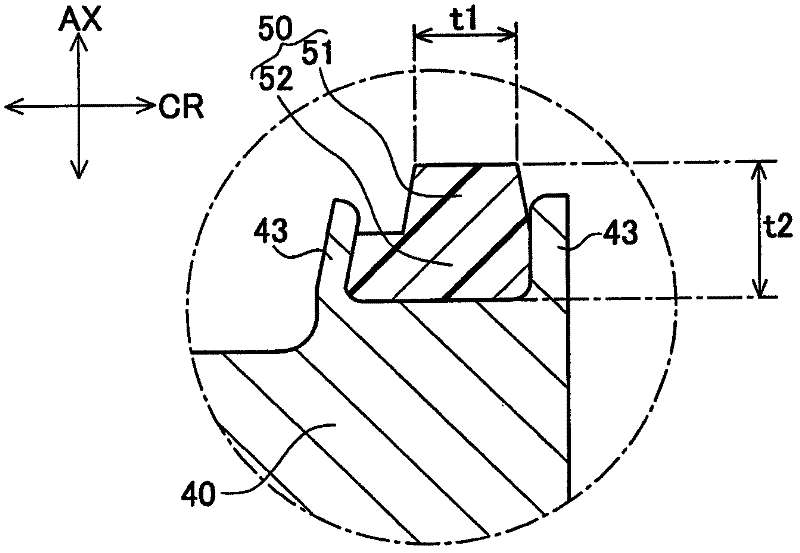

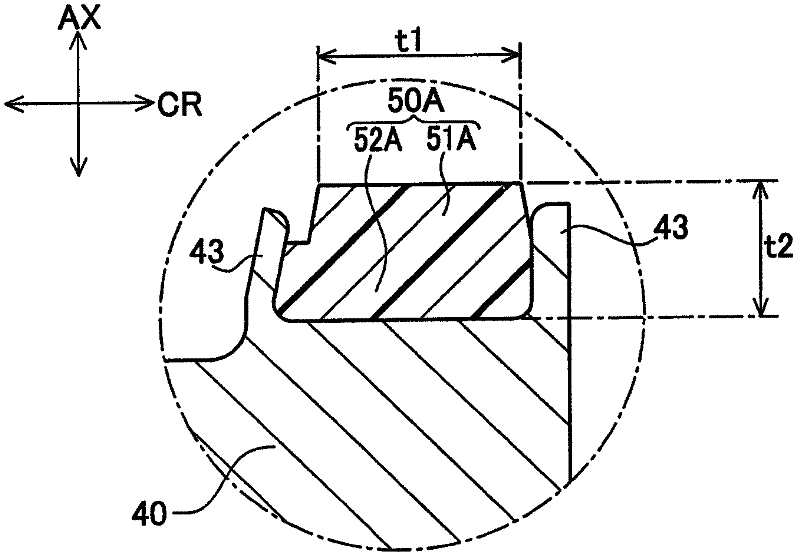

Valve seat structure of fluid control valve

ActiveCN102454808AReduce flow fluctuationSmall travel differenceDiaphragm valvesEngine diaphragmsFluid controlEngineering

In a valve seat structure of a fluid control valve comprising a valve element(60), a body formed with an inlet port (41) and an outlet port (42), and a valve seat member (50)provided in the body, the fluid control valve being configured to bring the valve element into or out of contact with the valve seat member to control the flow of a fluid, the valve seat member is formed in a ring shape and includes a valve seat portion (51) with which the valve element will come into our out of contact. Assuming that a thickness of the valve seat portion in a radial direction of the valve seat member is a first thickness t1 (0<t1), a second thickness t2 corresponding to a height of the valve seat member in a direction along an axis of the fluid control valve is determined in a range of 0.5 t1<=t2<=1.5 t1.

Owner:CKD

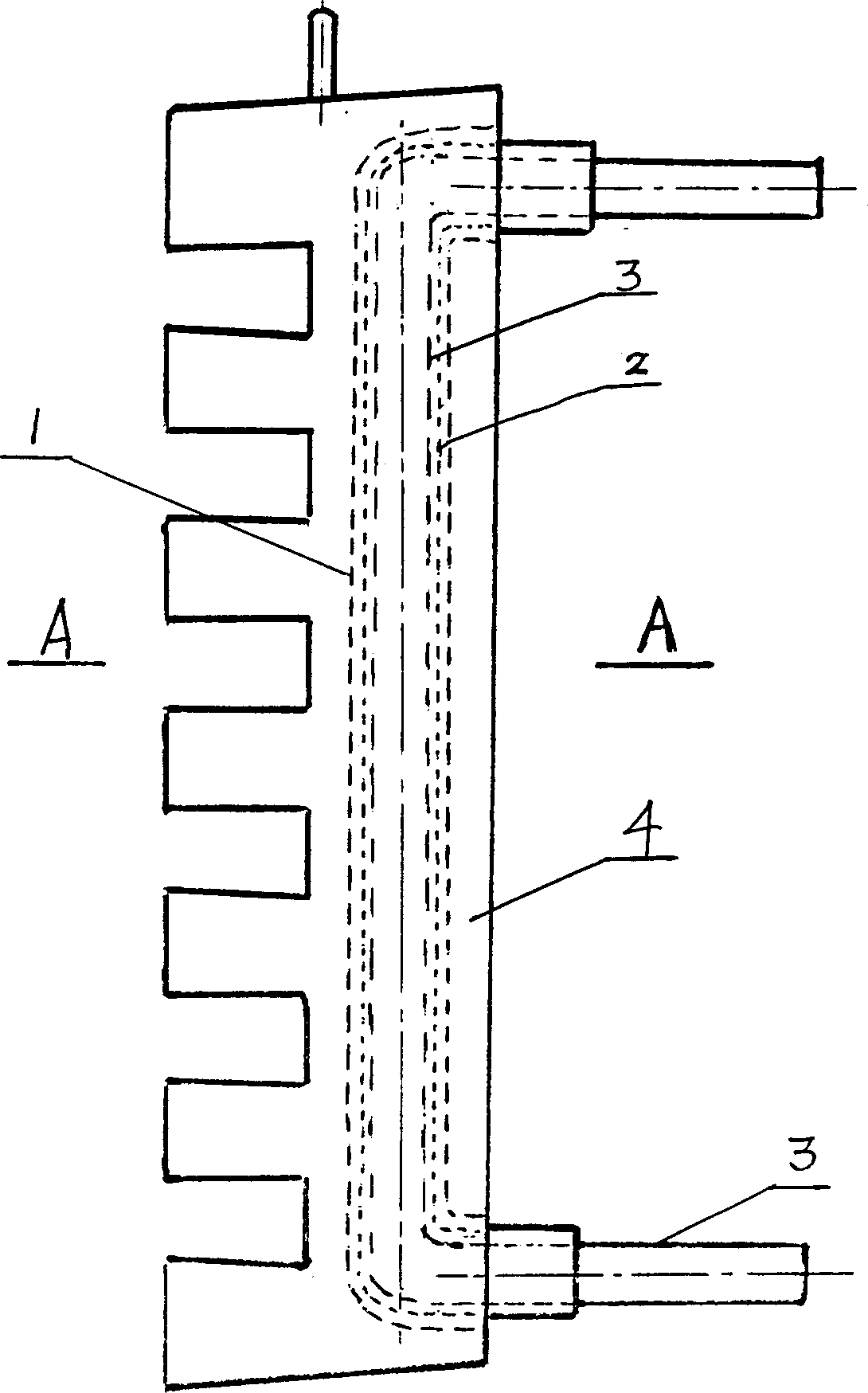

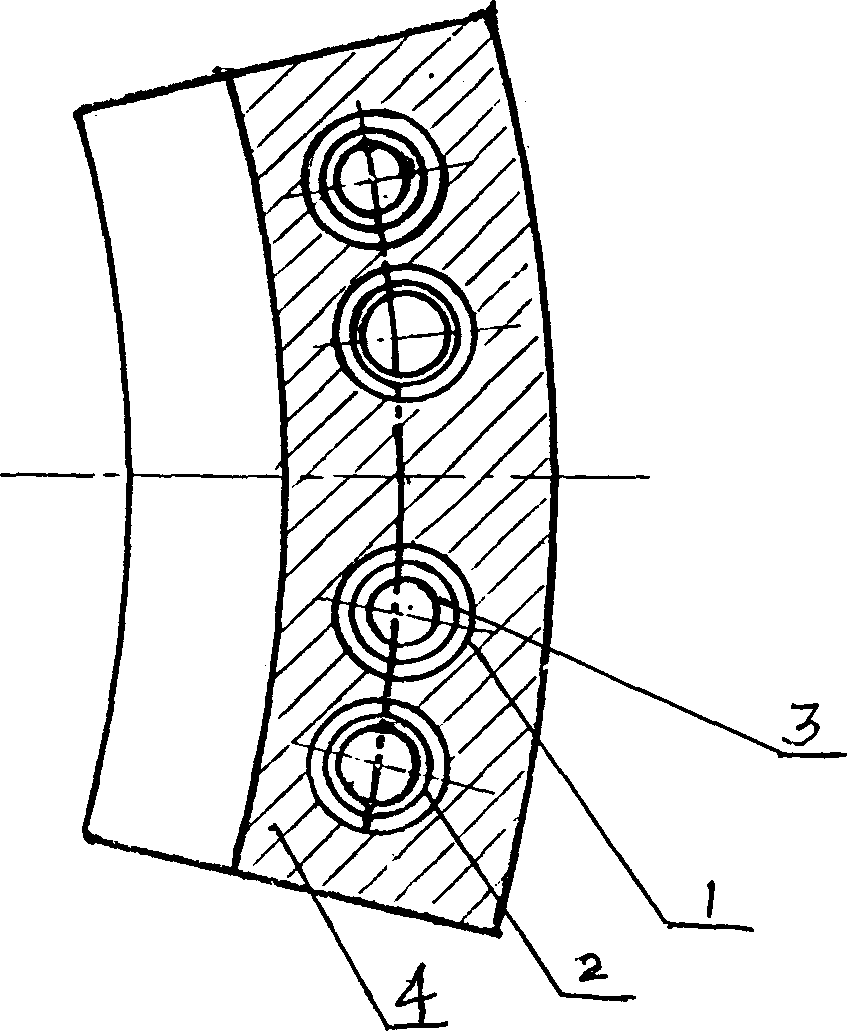

Production method of built-in water-cooling channel cast steel component

The production method of internal water cooling channel steel-casting is characterized by that two layers of spiral internal chill are winded round external periphery of steel pipe, in which first layer of spiral internal chill is winded round the steel pipe, and second layer of spiral internal chill is winded round first layer of spiral internal chill, at the same time, when it is poured, the low-temp. nitrogen gas is blown into the steel pipe, the nitrogen gas inlet temp. is -5- -10 deg.C, the nitrogen gas pressure is less than or equal to 0.2 MPa. After the pouring is completed, the low-temp. nitrogen gas is further blown into the steel pipe for 2-4 min. so that the steel pipe will not be melted through and can not be deformed when the molten metal whose melting point is identical to that of steel pipe is poured, therefore there is not gap or thermoresistance layer between steel pipe and base body.

Owner:ANYANG IRON & STEEL GRP

Bearing machining method

InactiveCN102518668AGuaranteed grinding precisionGuaranteed deformationBearing componentsBall bearingEngineering

The invention relates to a thin wall bearing, in particular to a heavy-duty thin wall deep groove ball bearing. A bearing machining method comprises five processes of machining an outer ring, machining an inner ring, machining a retainer, machining a seal ring, and assembling the outer ring, the inner ring, the retainer and the seal ring. The method has the advantages that: the grinding accuracy of the inner and outer rings, the deformation of the retainer and a space between the retainer and the seal ring are ensured, so that the inner and outer rings, the retainer and the seal ring are not contacted with each other and do not generate friction, and the service life of the bearing is prolonged; and moreover, noise is avoided, and the requirement on a heavy load of the bearing is met under the condition that the overall size of the bearing is not changed.

Owner:NINGBO WANFENG BEARING

Gear ring machining process

The invention discloses a gear ring machining process, which comprises the following steps of forging, rough turning, tempering, fine turning, gear shaping, fine gear broaching, carburizing, press quenching and shot blasting to obtain a finished product. According to the gear ring machining process provided by the invention, the product has the advantages of higher surface hardness, high core hardness and deep hardened layer; meanwhile, the machining cost is reduced, and the gear ring size can be ensured.

Owner:江国辉

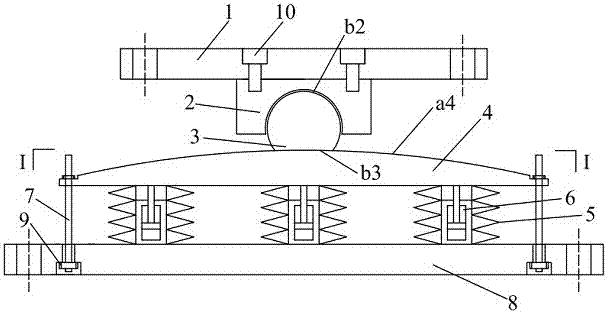

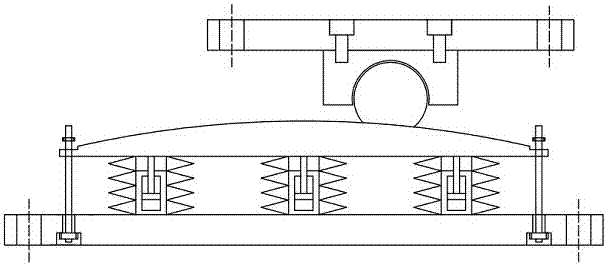

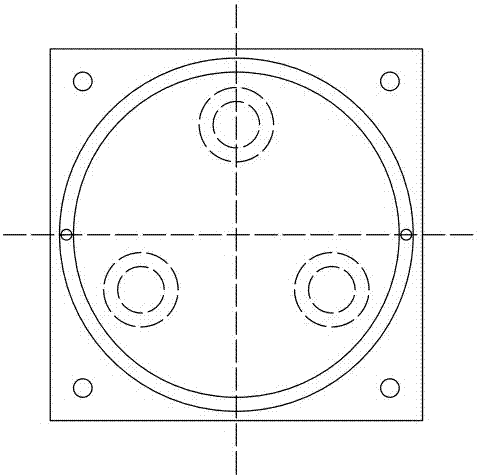

Horizontal negative stiffness device with vertical damping function

ActiveCN106968499AChange negative stiffnessMeet different design needsProtective buildings/sheltersShock proofingDamping functionNegative stiffness

The invention relates to a horizontal negative stiffness device with a vertical damping function. The horizontal negative stiffness device comprises a spherical hinge upper connecting plate, a spherical hinge lower connecting plate, a spherical hinge, an arched spherical face, pre-pressing disc springs, viscous dampers, limiting rods, a bearing base, nuts and inside hexagonal bolts; the spherical hinge upper connecting plate and the spherical hinge lower connecting plate are fixedly connected through the inside hexagonal bolts, and the spherical hinge is embedded into the spherical hinge lower connecting plate for fixation and makes contact with the arched spherical face in a pressure-bearing mode; the upper portions of the pre-pressing disc springs are in welding connection with the arched spherical face, and the lower portions of the pre-pressing disc springs are in welding connection with the bearing base. The viscous dampers are arranged at the internal diameters of the pre-pressing disc springs, the upper portions of the viscous dampers are in welding connection with the arched spherical face, and the lower portions of the viscous dampers are in welding connection with the bearing base. The viscous dampers and the pre-pressing disc springs cooperatively work, and meanwhile negative stiffness and damping force are generated; and the limiting rods are connected with the arched spherical face and the bearing base through the nuts, the pre-pressing states of the disc springs are achieved, and the limiting rods are symmetrically arranged on the two sides of the arched spherical face.

Owner:SHANGHAI UNIV

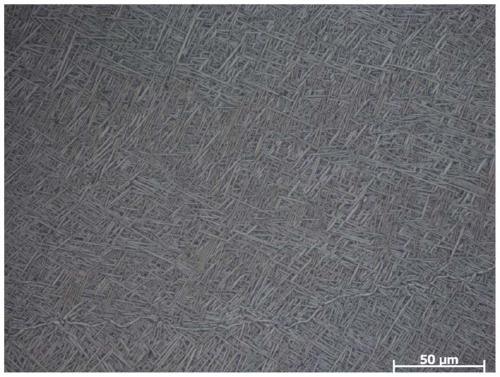

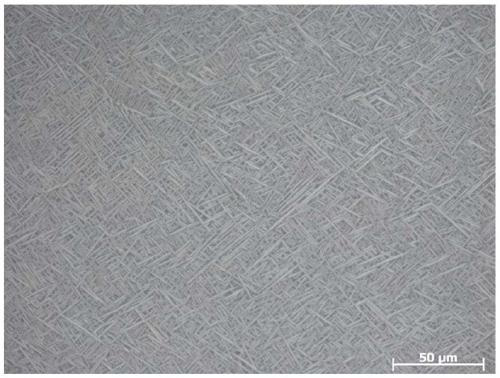

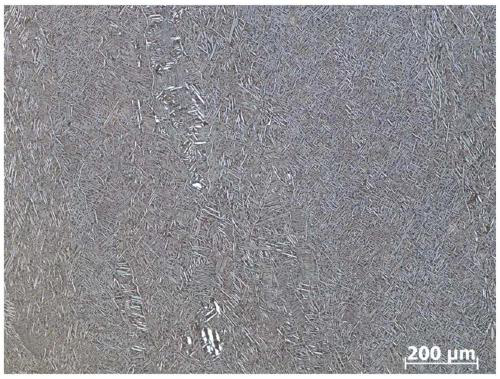

Manufacturing method for titanium alloy large-specification ring piece with basket-weave microstructure

ActiveCN111318581AGuaranteed deformationShort holding timeTemperature control deviceFurnace typesHigh fractureDamage tolerance

The invention discloses a manufacturing method for a titanium alloy large-specification ring piece with a basket-weave microstructure, in particular to a manufacturing method for an alpha + beta two-phase titanium alloy large-specification ring piece. The manufacturing method is characterized by comprising the following steps that 1) a titanium alloy blank is heated to 20-50 DEG C below a beta phase transformation point, upset, punched and shaped to obtain a ring rolling blank; 2) then the ring rolling blank is reamed at the 20-50 DEG C below the phase transformation point to the process size;and 3) then the ring rolling blank is ring-rolled and formed at 25-80 DEG C above the phase transformation point; and finally solid solution + aging dual heat treatment is carried out to obtain the titanium alloy ring piece. The titanium alloy ring piece prepared through adopting the process is the basket-weave microstructure, has high fracture toughness, durability, and creep resistance, and meets the design requirements of the high damage tolerance and durability and the creep resistance of annular components such as a machine box, and a force application cylinder for an aerospace engine ona titanium alloy material better.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

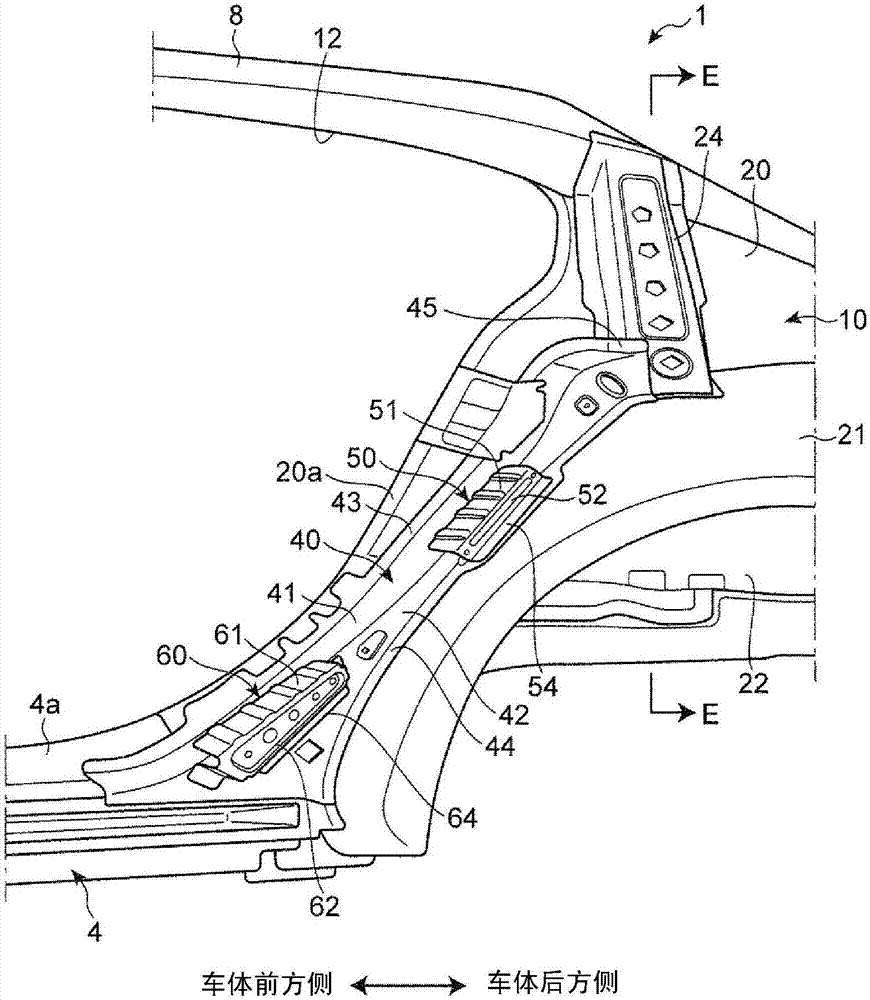

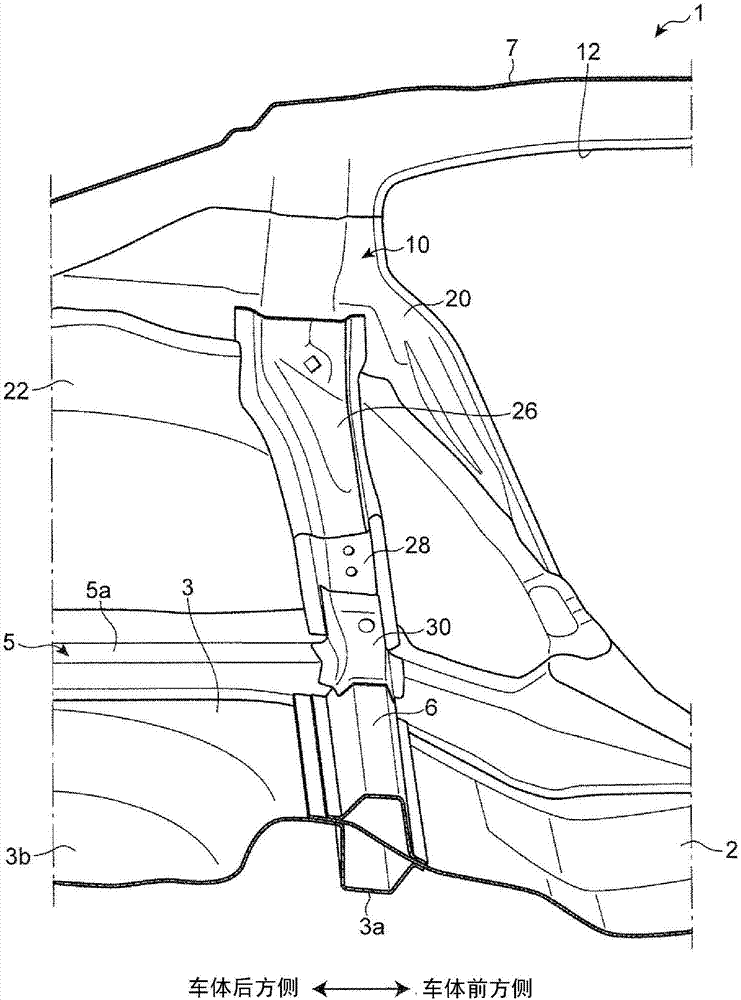

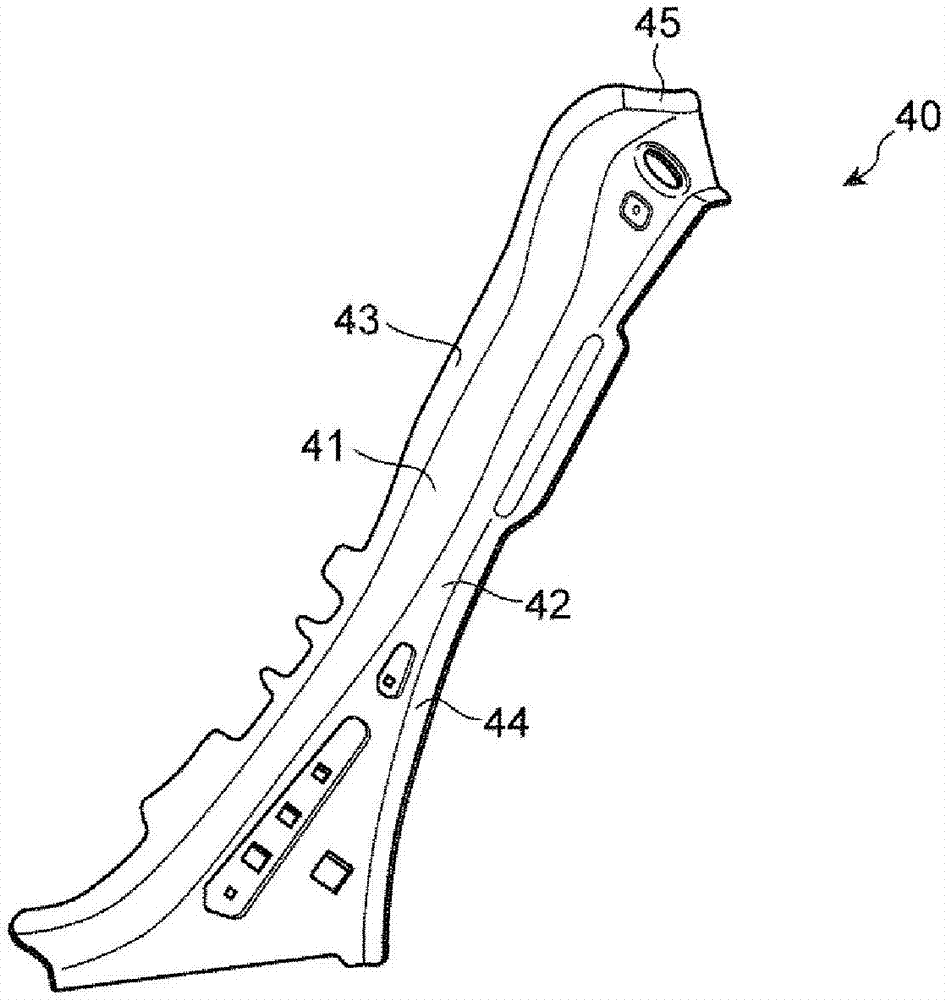

Side vehicle-body structure of automotive vehicle

ActiveCN107031731AReduce the size of the vehicle width directionInhibition of local bucklingUnderstructuresSuperstructure subunitsControl theoryMechanical engineering

The invention provides a side vehicle-body structure of an automotive vehicle. The side vehicle-body structure can increase the effects of impact absorption when an impact load is input to a side door from a vehicle body side and the effects of load diffusion to each part of the vehicle body. The side vehicle-body structure includes: a side door which is formed on a side surface part of the vehicle body and opens and closes an opening part for getting on and off from a rear seat; an anti-collision pole which is disposed on the side door in a manner that the anti-collision pole extends along the front and rear direction of the vehicle body; a side plate internal side member which constitutes a vehicle side part which includes a peripheral part on vehicle body rear side of the opening part for getting on and off; a first reinforcing part which extends along the peripheral part on the vehicle body rear side of the opening part for getting on and off and engages the outside of a compartment of the side plate internal side member so as to form a first closed cross section with the side plate internal side member; a second reinforcing member which is configured such that the second reinforcing member is partly overlapped with the anti-collision pole when the side door is closed if viewed from the vehicle body side and the second reinforcing member engages the outside of the compartment of the first reinforcing member so as to form a second closed cross section with the first reinforcing member.

Owner:MAZDA MOTOR CORP

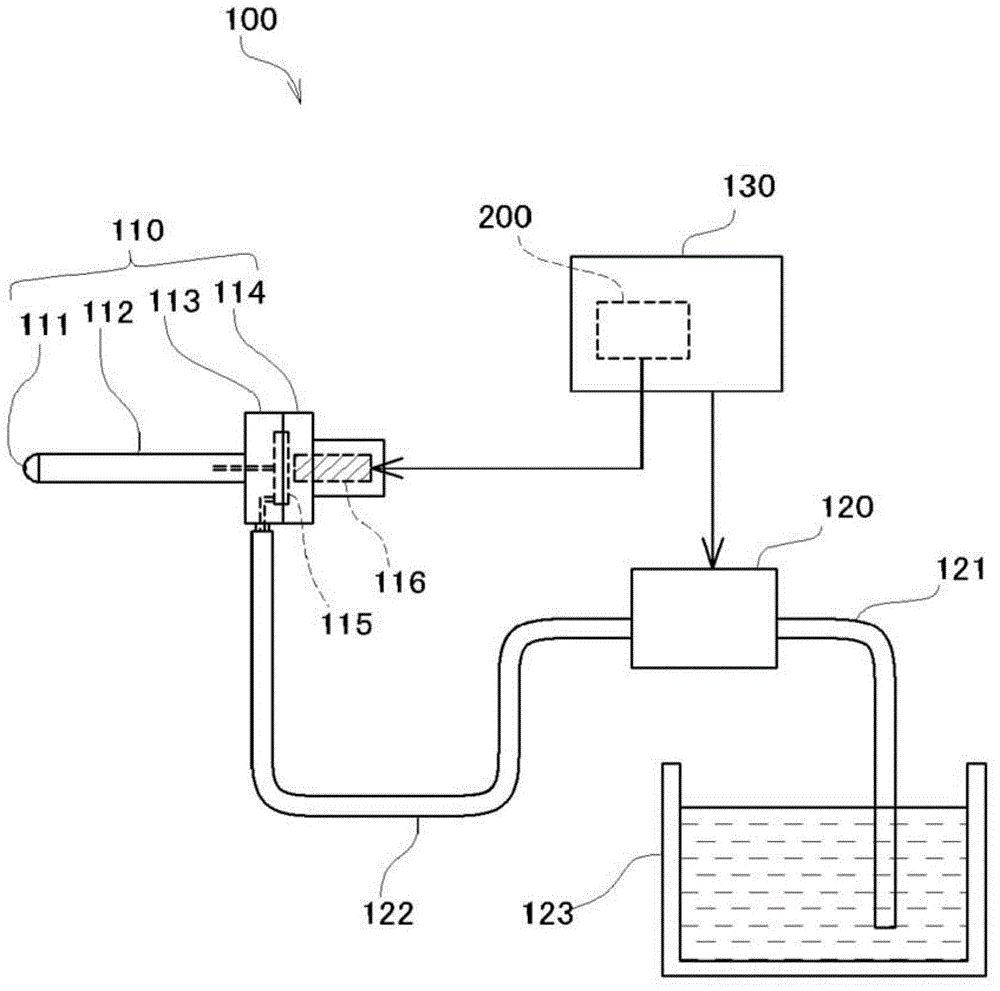

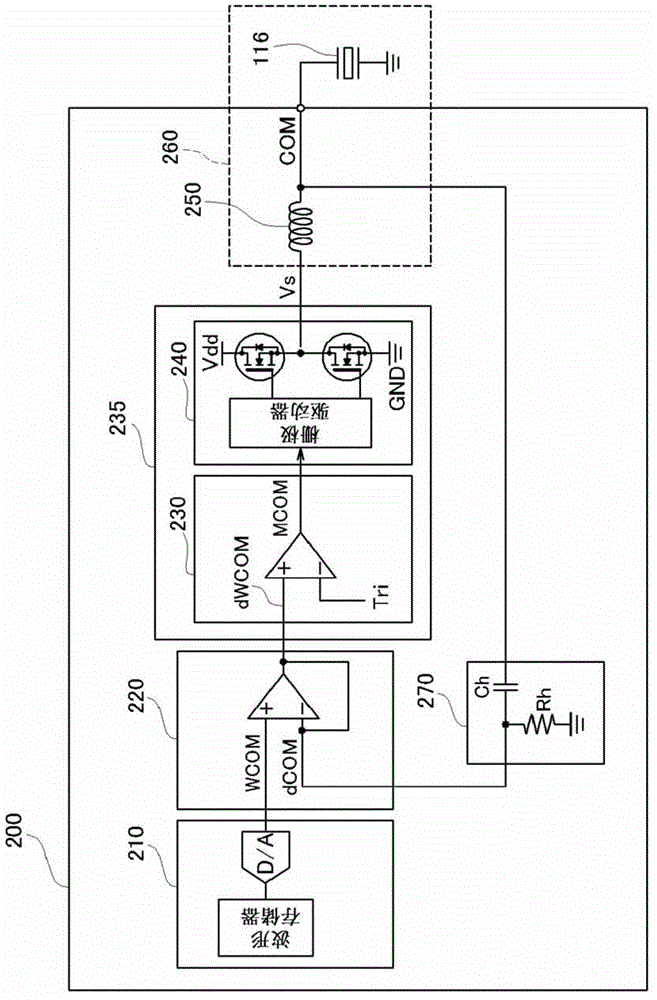

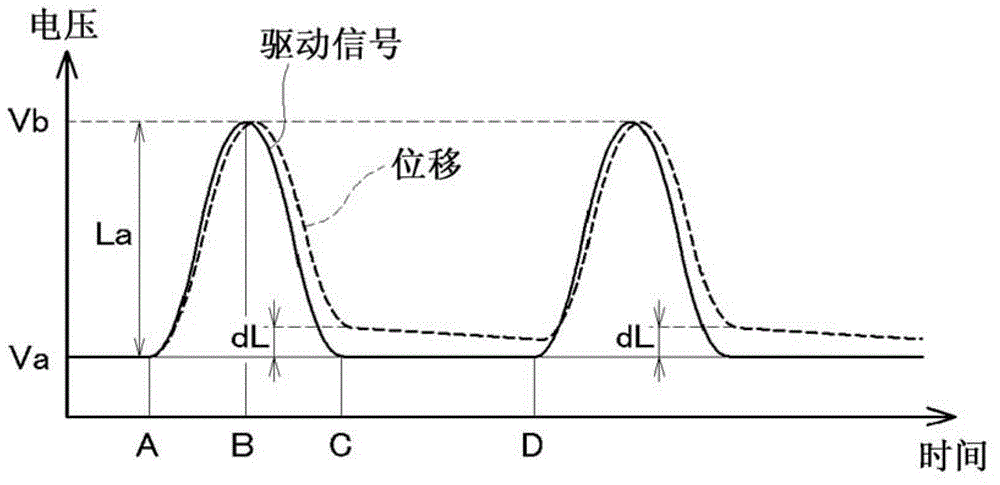

Piezoelectric element drive circuit and liquid ejecting apparatus

InactiveCN102862388AStable injection volumeGuaranteed deformationSurgeryIntravenous devicesNegative feedbackElectricity

A drive waveform signal as a reference of a drive signal to be applied to a piezoelectric element is power-amplified, and the drive signal after passing through a coil is applied to the piezoelectric element. A resonant circuit is formed of the coil and the piezoelectric element, and a resonant peak is suppressed by performing a phase advance compensation of the drive signal and by performing a negative feedback. At this time, the degree of suppression of the peak is adjusted so that a slight reverse voltage is generated. Since this can eliminate residual distortion of the piezoelectric element by the reverse voltage, even when driving is performed at a high repetition frequency, the original amount of deformation can be ensured. Besides, the circuit does not become complicated.

Owner:SEIKO EPSON CORP

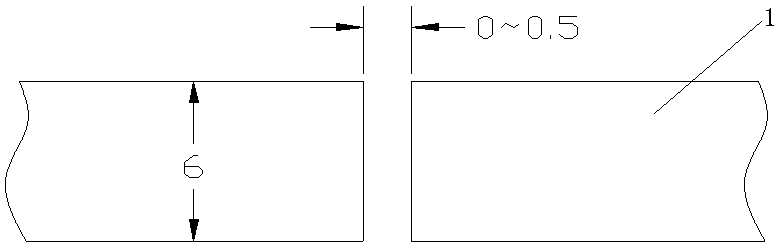

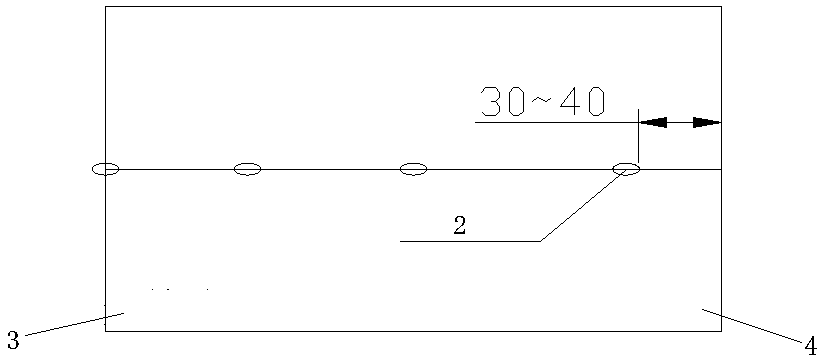

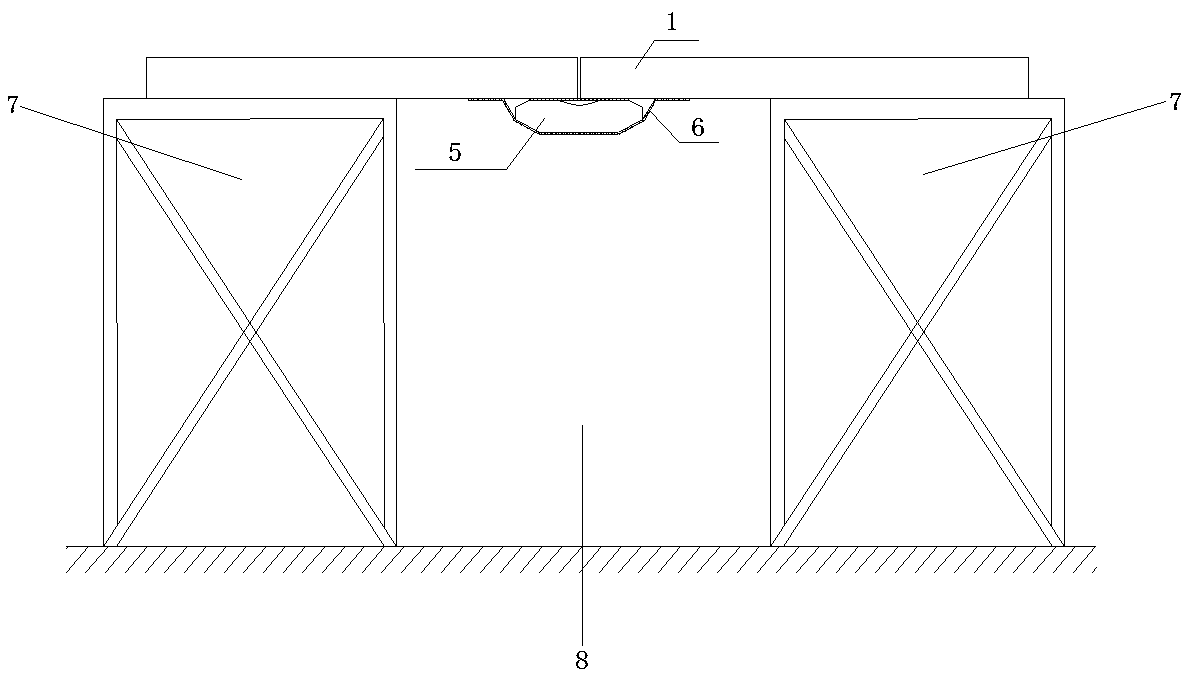

Submerged-arc automatic welding method of nuclear power plant steel lining wall plates with ceramic linings

InactiveCN108176910AAvoid hoisting and turning overGuaranteed deformationArc welding apparatusNon destructiveWall plate

The invention provides a submerged-arc automatic welding method of nuclear power plant steel lining wall plates with ceramic linings. The submerged-arc automatic welding method comprises the followingsteps: step 1, carrying out groove processing on steel lining splice plates; step 2, assembling the processed steel lining splice plates in pairs; step 3, mounting arc striking plates; step 4, pasting the ceramic linings; step 5, welding the assembled steel lining splice plates; step 6, dismounting the ceramic linings; and step 7, carrying out non-destructive testing on welds of the welded assembled steel lining splice plates, wherein the steel lining splice plates are mainly adopted as the nuclear power plant steel lining wall plates, nuclear power plant steel lining bottom walls and nuclearpower plant steel lining domes, and the thickness of each steel lining splice plate reaches 6 mm. The submerged-arc automatic welding method provided by the invention has the beneficial effects thatthrough the utilization of the ceramic linings for welding and the reasonable design of welding process parameters, the single-sided welding with double-sided formation during a submerged-arc automatic welding process can be achieved when the steel lining splice plates are shop-fabricated, spliced and welded, the steel lining splice plate turning-over procedure during a conventional double-sided welding process can be avoided, the operation risk can be reduced, and the welding efficiency can be improved.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Mould for forming prefabricated exhaust pipeline

ActiveCN102320077AEasy to assembleEasy to disassembleMouldsManufactured materialUltimate tensile strength

The invention discloses a mould for forming a prefabricated exhaust pipeline. The mould comprises an outer template and an inner template. The outer template comprises an outer bottom template and two outer lateral templates matched with the outer bottom template. An outer mould cavity is formed by encircling the outer bottom template and the two outer lateral templates. The inner template is encircled to form a core mould in the outer mould cavity. A forming cavity is formed between the core mould and the outer mould cavity. An end frame is arranged between the outer wall of the core mould at the two ends of the forming cavity and the inner wall of the outer mould cavity. Inner mould support frames are arranged at the two ends of the inner cavity of the core mould. An outer limiting device is arranged on the outer wall of the outer mould cavity. According to the mould disclosed by the invention, the production of a mechanical mould of a thin-wall exhaust pipeline can be realized; the problems of incapability of mechanical production of a prefabricated non-circular thin-wall component in the forming field and the like can be solved; products are formed at one time; the production efficiency is increased; the labour intensity of workers is reduced; the product intensity is high; the quality is good; simultaneously, the quality fluctuation and the raw material waste resulted from manual operation can be reduced.

Owner:韩青

Grinding device for finish machining of ores

InactiveCN108993682AImprove work efficiencyIncrease grinding rateCocoaGrain treatmentsEngineeringMachining

The invention discloses a grinding device for finish machining of ores. The grinding device for finish machining of the ores comprises a grinding box body; a bearing is clamped in the middle part of the upper surface of the grinding box body; a rotating shaft is sleeved with the bearing; the top of the rotating shaft is fixedly connected with an output shaft of a driving device; the lower surfaceof the driving device is fixedly connected to the upper surface of the grinding box body; a plurality of crushing blades are fixedly connected to the left and right side surfaces of the rotating shaft; and the crushing blades are positioned in the grinding box body. The grinding device for finish machining of the ores, disclosed by the invention, has the advantages that ore raw materials penetratethrough small holes in a screening plate to fall into a grinding groove by arranging the driving device when the ore raw materials are small to a certain degree; a grinding disc can also be driven torotate at a high speed in the rotating process of the rotating shaft so that the ore raw materials in the grinding groove can be ground and machined; the ore raw materials entering the grinding box body are crushed and ground in sequence so that the grinding effect and the grinding efficiency of the grinding disc can be both guaranteed.

Owner:周佩龙

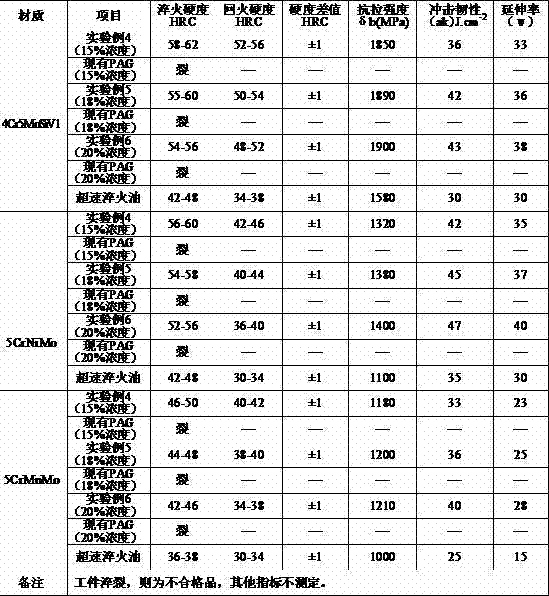

Water-soluble quenching medium for hot die steel

The invention discloses a water-soluble quenching medium for hot die steel. The water-soluble quenching medium is prepared by mixing polyalkylene glycol, polyvinyl pyrrolidone, rust inhibitor, bactericide, pH regulator, settling agent, defoaming agent and water uniformly in a ratio. The water-soluble quenching medium is low in production cost, non-flammable and environment-friendly. The water-soluble quenching medium replaces oil quenching media, and fully meets the quenching requirements of the hot die steel such as 4Cr5MoSiV1, 5CrMnMo and 5CrNiMo.

Owner:LIAONING HAIMING CHEM PROD

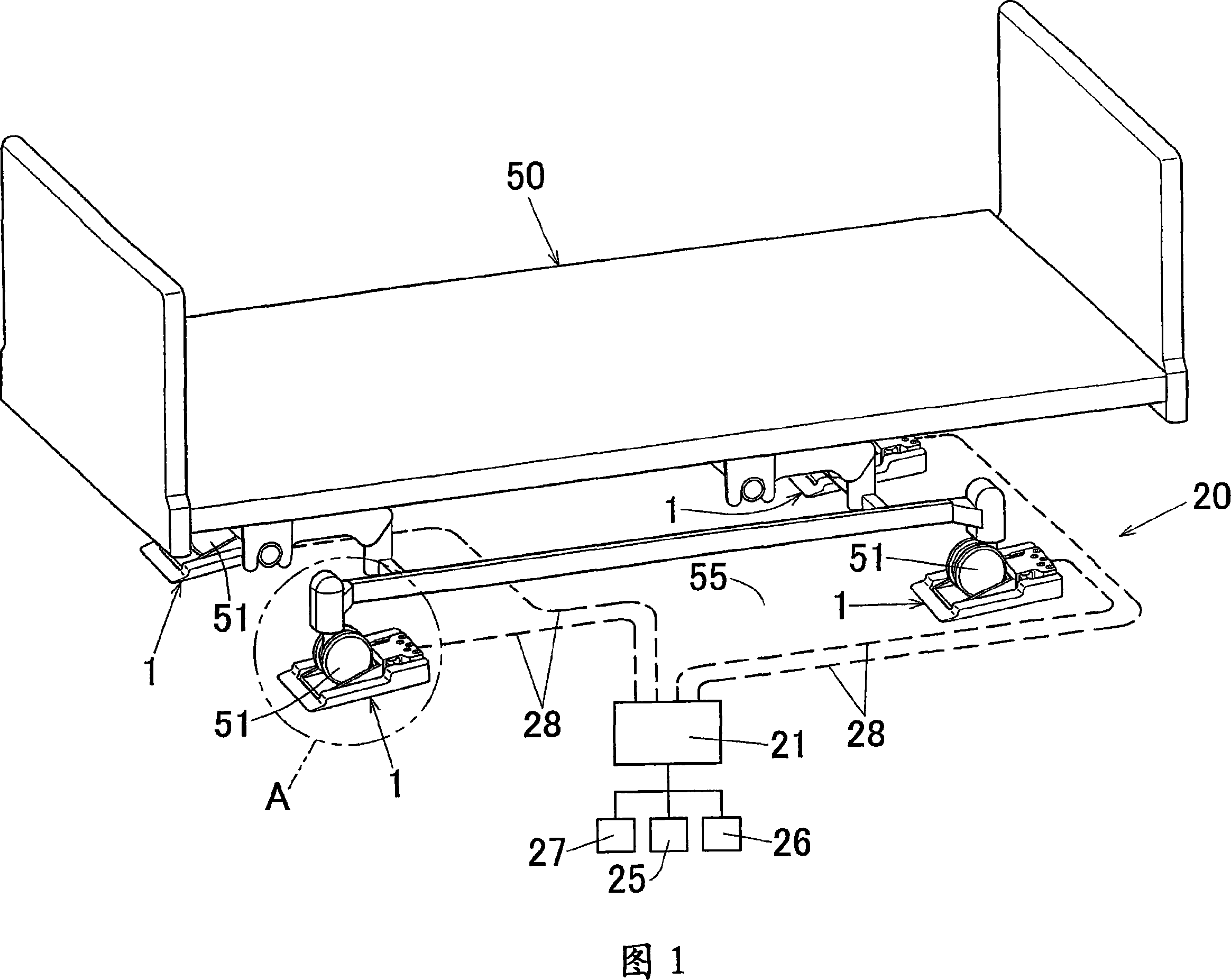

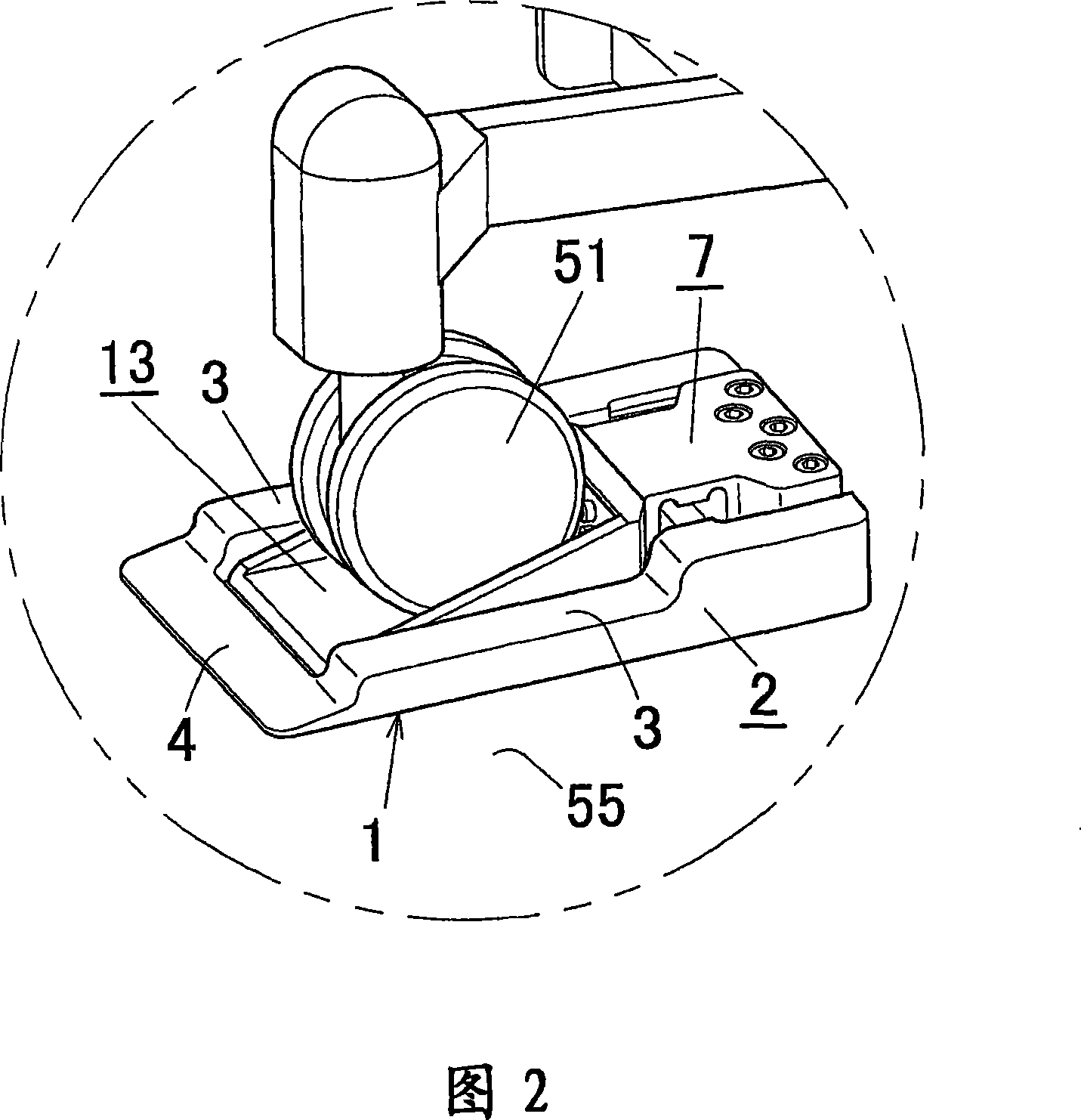

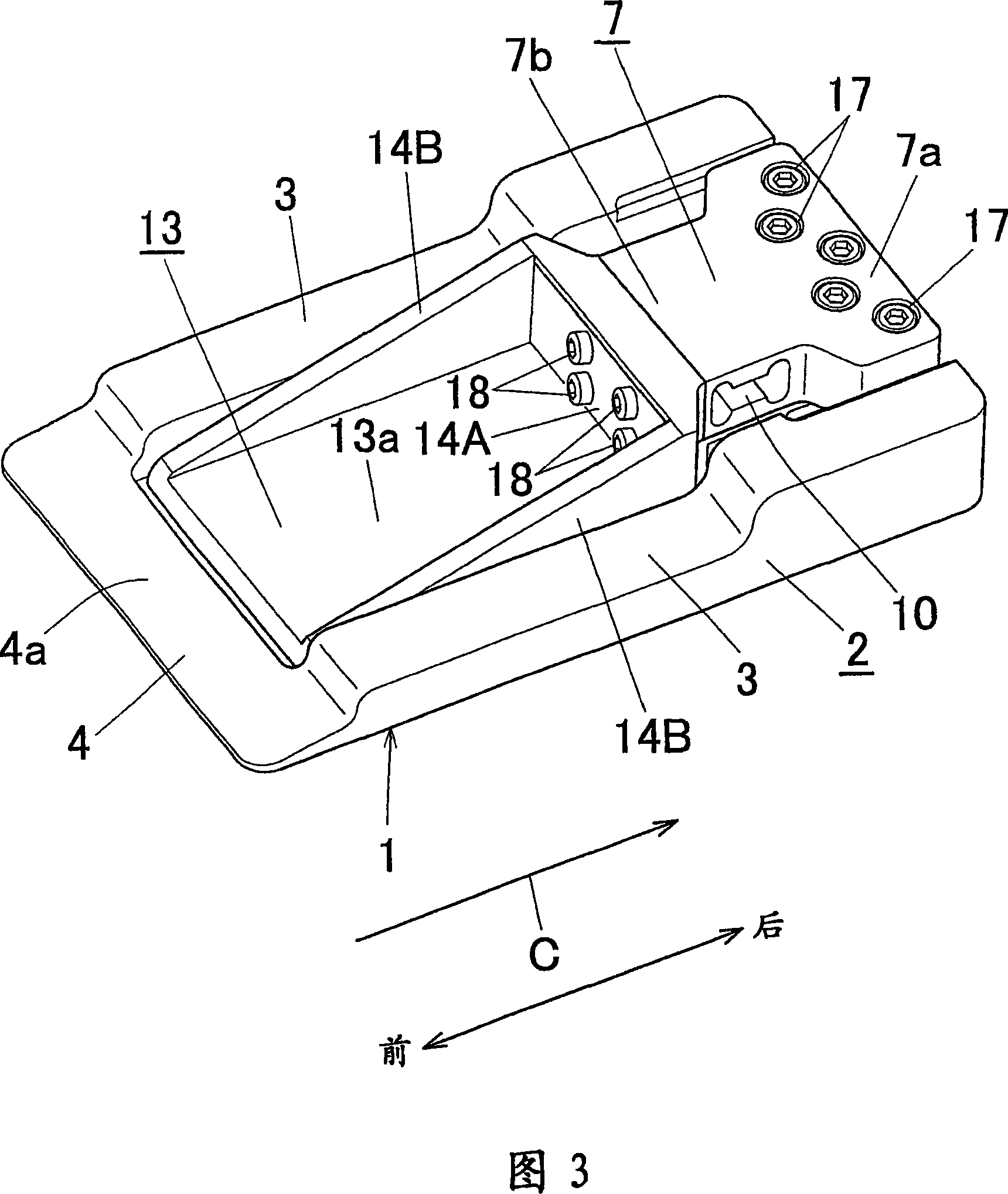

Bed load detector

InactiveCN101147179AEasy to set upPrevent accidental slippingNursing bedsAlarmsDistortionEngineering

A load detector 1 is provided with a base plate portion 2 to be disposed on a bed installation surface 55, a leg disposing plate portion 13 on which a caster 51 as a leg portion of a bed is to be disposed, the leg disposing plate portion 13 being provided at a tip end portion of a cantilever portion 7 supported generally horizontally in a state in which the leg disposing plate portion 12 is away from the bed installation surface 55, and a distortion detection sensor R attached to the cantilever portion 7, the distortion detection sensor R detecting a distortion of the cantilever portion 7 and outputting a signal to be used to detect a bed load.

Owner:SHOWA DENKO KK

Foamed aluminum composite board and manufacturing method thereof

PendingCN110481116ANot easily oxidizedImprove rigiditySoldering apparatusWelding/soldering/cutting articlesUltimate tensile strengthAluminum composites

The invention discloses a foamed aluminum composite board and a manufacturing method thereof, and relates to the technical field of foamed aluminum composite board forming. The foamed aluminum composite plate comprises a foamed aluminum plate, brazing layer aluminum plates and sandwich plates, the foamed aluminum plate is square, the brazing layer aluminum plates are arranged on the upper surfaceand the lower surface of the foamed aluminum plate, the sandwich plates are arranged on the upper surface of the brazing layer aluminum plate on the upper layer and on the lower surface of the brazinglayer aluminum plate on the lower layer, the sandwich plates being stainless steel plate. The connecting strength is improved, falling off in the using process is avoided, the rigidity of the plate can be enhanced, and the plate is not prone to deformation.

Owner:黄超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com