Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1171results about How to "High softening point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

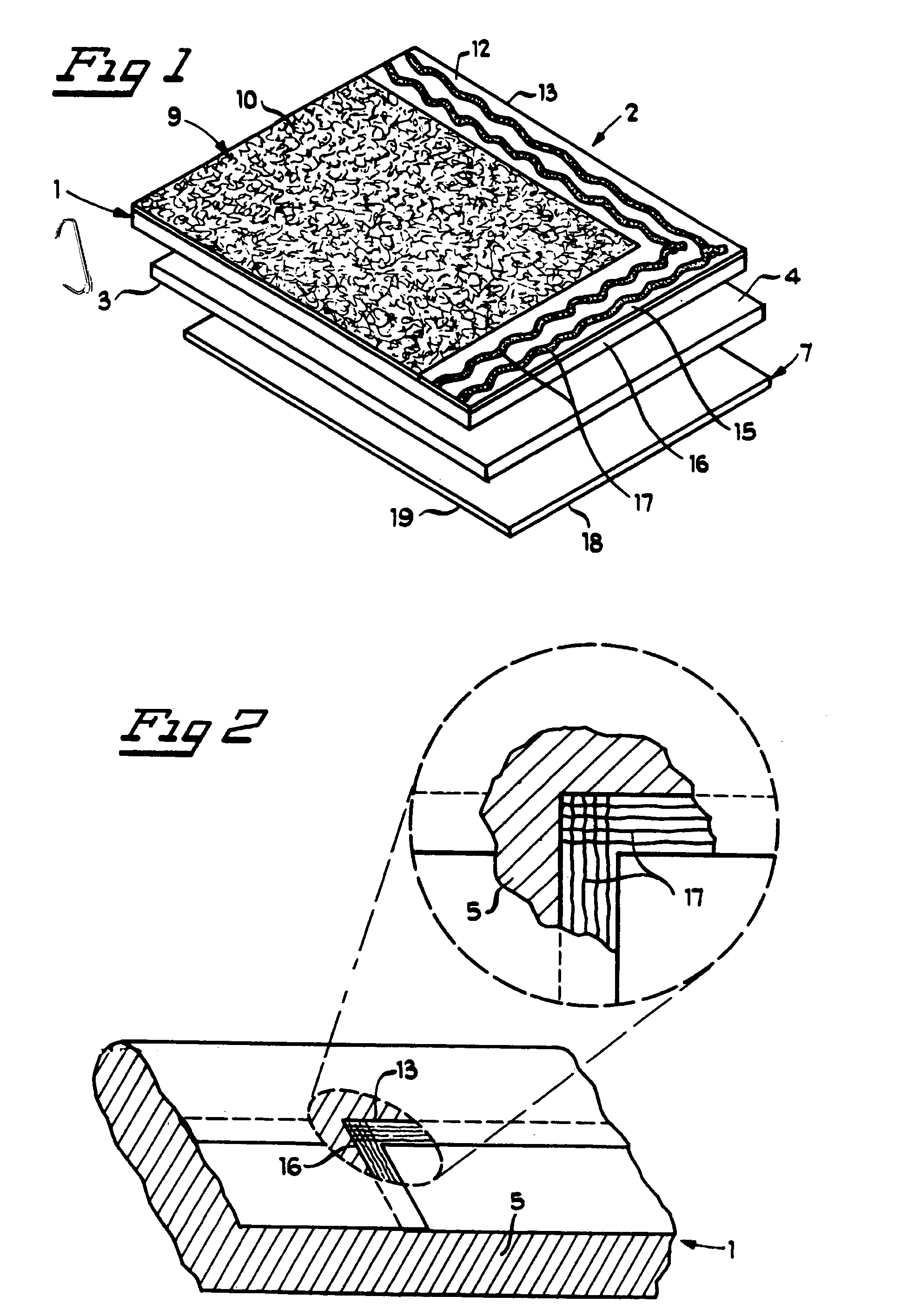

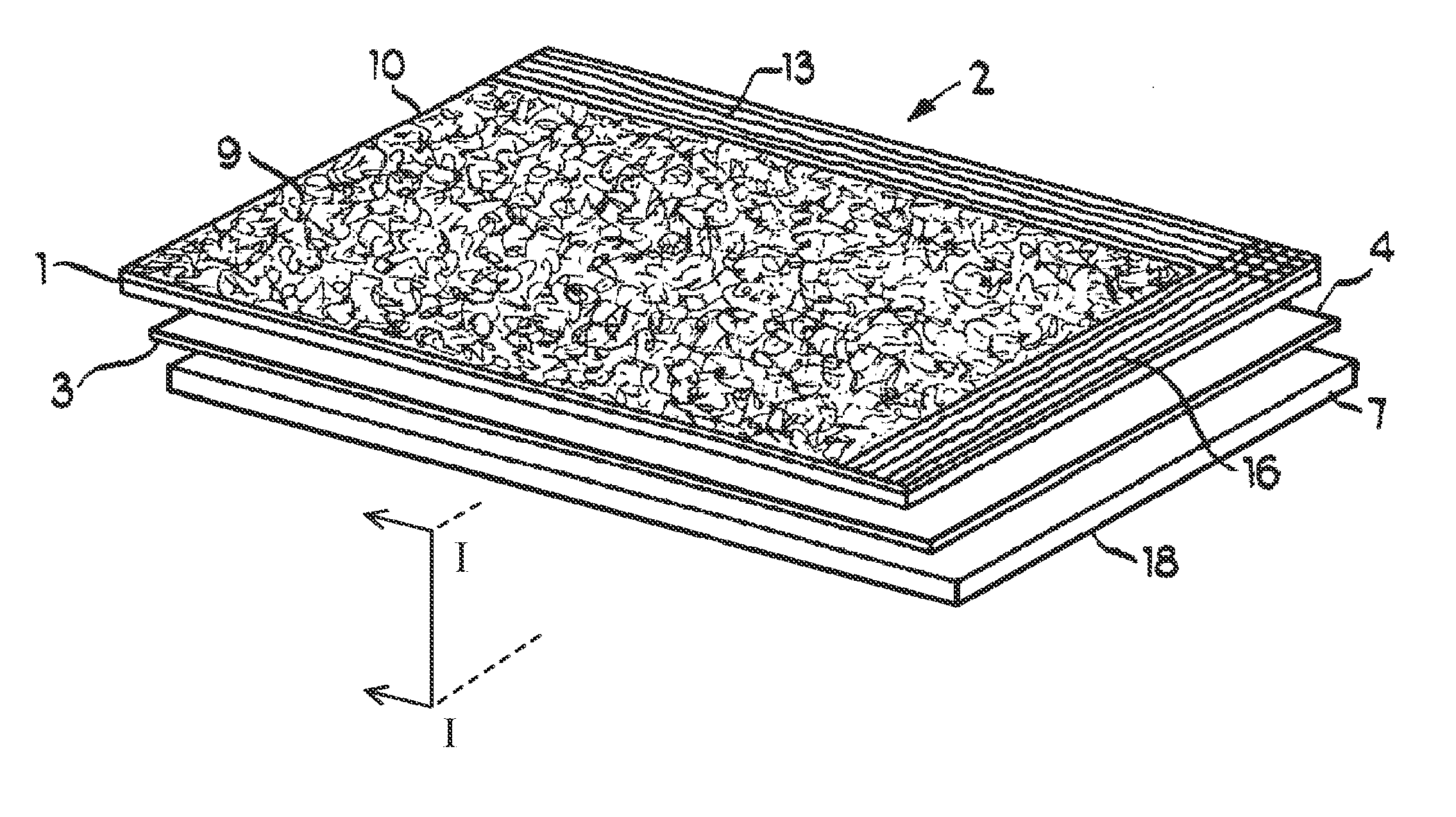

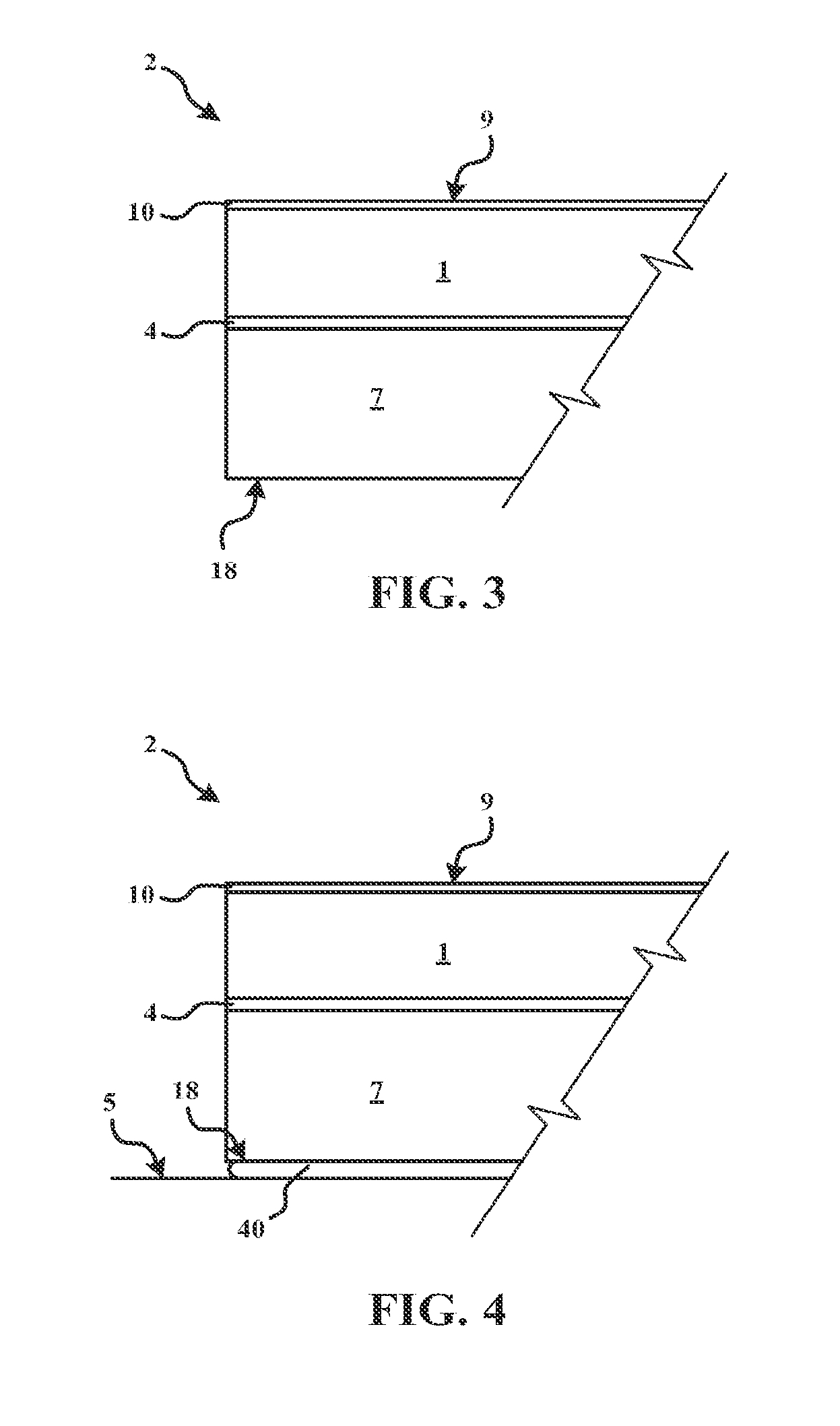

Self-adhering modified bitumen underlayment for tile roofs

InactiveUS7132143B2High softening pointHigh temperature resistanceTreadsRecord information storageEngineeringSelf adhesive

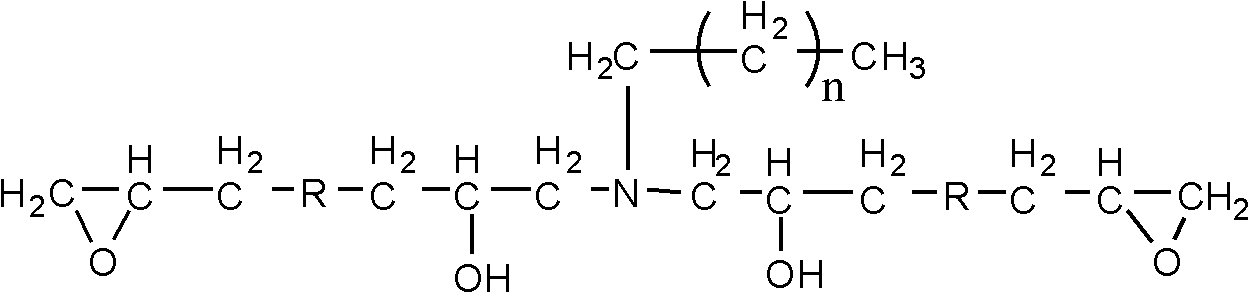

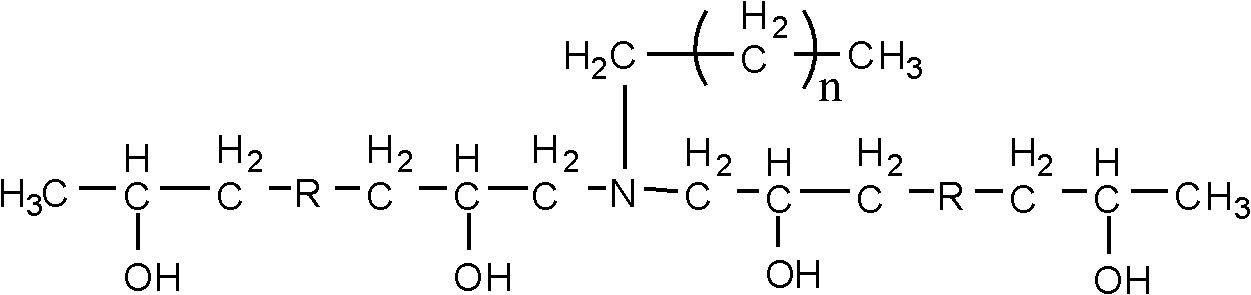

A self-adhering modified bituminous roofing tile underlayment material for tile roof assemblies that comprises an APP modified bitumen compound on the front side, and a factory-applied self-adhesive compound on the back side of a reinforcement carrier sheet, and granules embedded on the APP modified bitumen compound to provide a non-skid surface. A method of manufacturing such composite comprising coating an APP compound on the top surface and affixing a self-adhesive compound to the bottom surface of a reinforcement carrier support sheet, and applying a release liner to the tacky self-adhesive layer during manufacture, stripping the release liner, salvage release film and end lap film from the membrane immediately prior to use, subsequently placing the surface of the membrane directly on to the upper surface of the roof deck, base sheet or underlayment, and applying force directly to the sheet to enhance the bond between the composite and the underlying surface that is created by the tacky self-adhesive compound. The present invention relates generally to roofing underlayments residential roofing assemblies using tiles made of clay or concrete as the exposed surface.

Owner:POLYGLASS

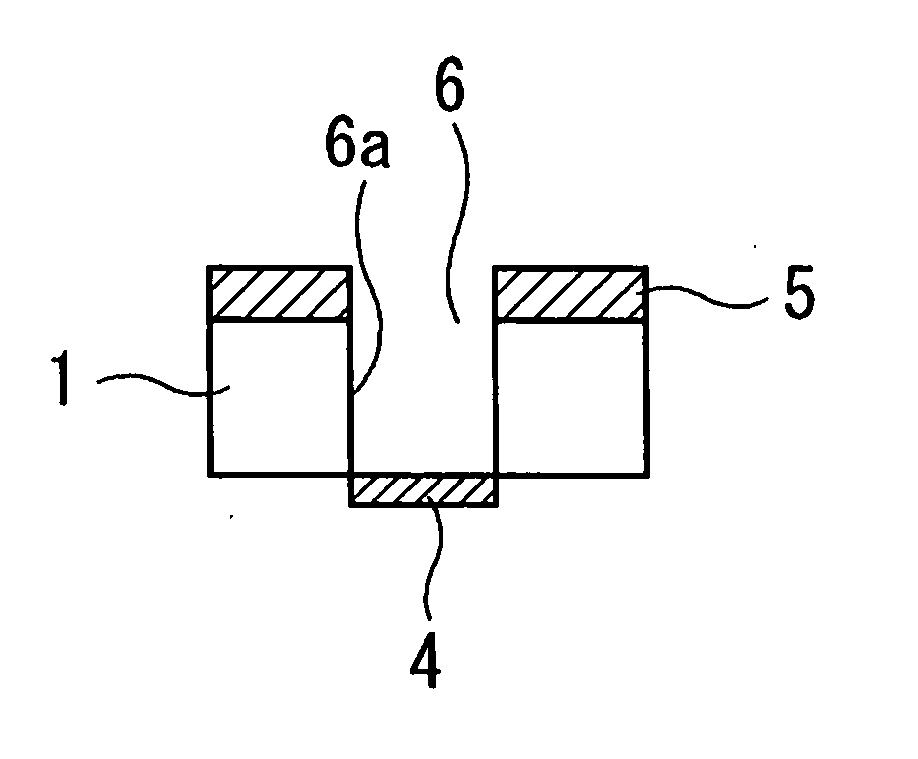

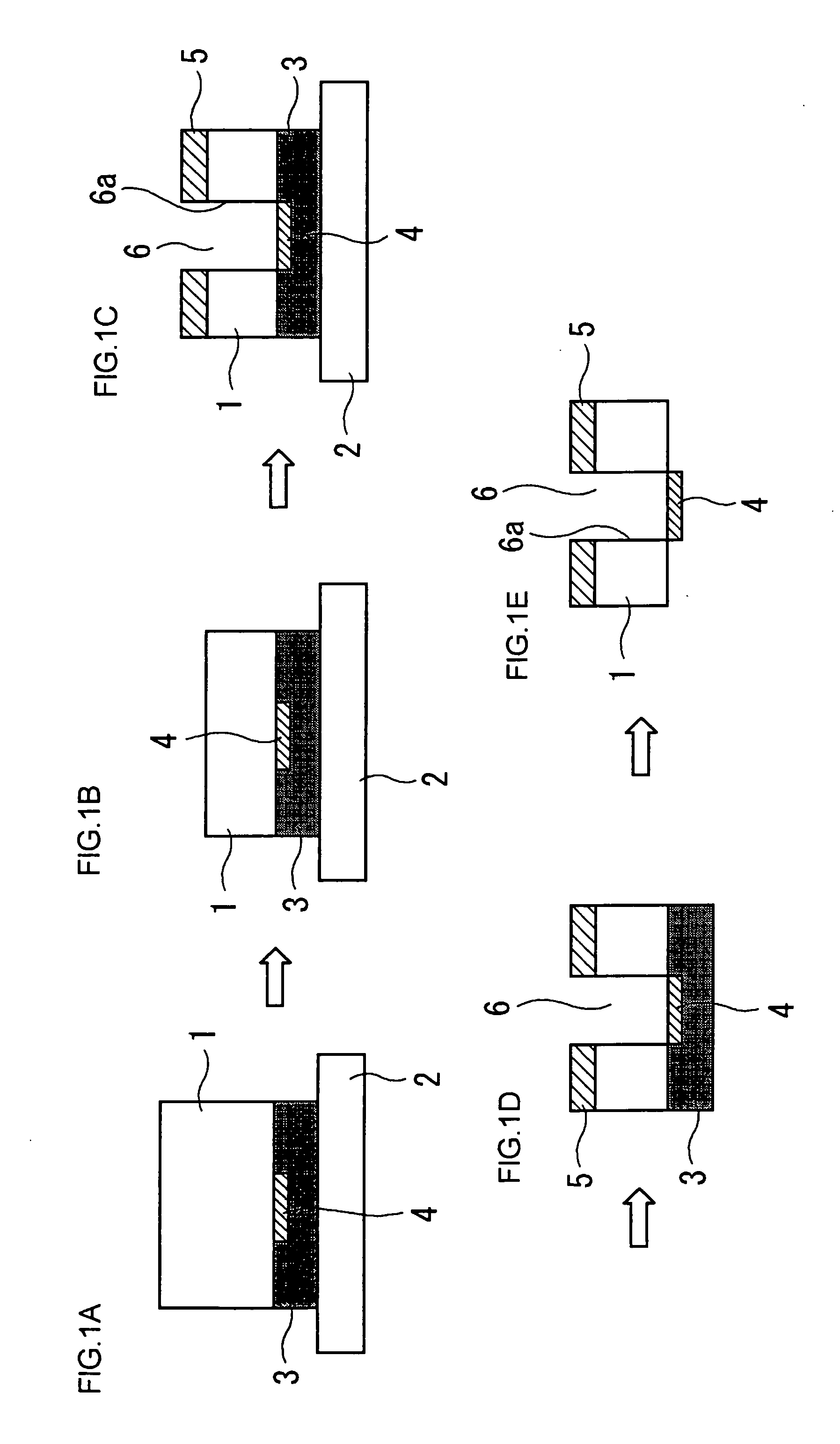

Method for manufacturing a compound semiconductor device having an improved via hole

InactiveUS20070082427A1Increase etch rateImprove verticalitySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveEngineering

In a method for manufacturing a compound semiconductor device, a principal surface of a SiC wafer, on which a compound semiconductor device is located, is bonded to a support substrate with an adhesive having a softening point higher than 200° C. A via hole is formed dry etching, including supplying a fluorine-containing etching gas to a rear side of the SiC wafer. Thereafter, the support substrate and the adhesive are removed. Preferably, the adhesive is formed by reacting one material coating the principal surface of the SiC wafer, and another material coating the support substrate.

Owner:MITSUBISHI ELECTRIC CORP

Heat-resistant glass fiber and process for the production thereof

InactiveUS6933045B2Improve heat resistanceEasy to producePolycrystalline material growthLayered productsFiberGlass fiber

Provided are a heat-resistant glass fiber which has excellent heat resistance, which is also easy to spin and less expensive and which is suitable as an acoustic material for use in an automobile muffler, and a process for the production thereof. The heat-resistant glass fiber has a composition comprising, substantially by weight %, 56 to 58.5% of SiO2, 12 to 17% of Al2O3, 16 to 27% of CaO, 1 to 9% of MgO, 0 to 1% of Na2O and 0 to 1% of K2O as the entirety of the fiber and containing neither B2O3 nor F2, and has a surface layer portion made of a silicic glass having an SiO2 content of at least 90% by weight. The process comprises treating the surface of the above fiber having the above composition with a mineral acid, to produce the heat-resistant glass fiber.

Owner:NITTO BOSEIKI CO LTD

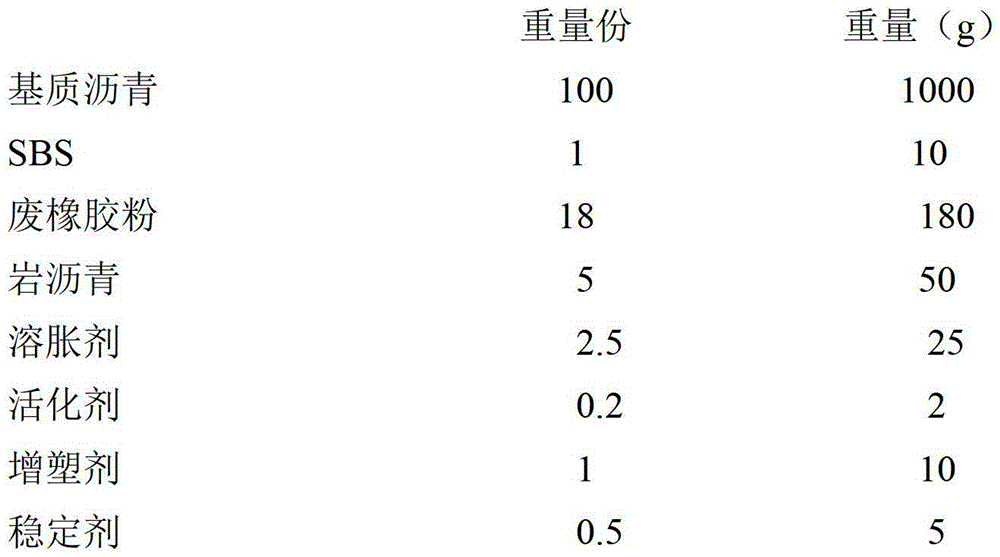

Ultraviolet aging-resistant compound modified asphalt and preparation method thereof

ActiveCN103146207AImprove anti-aging propertiesStop breakingTreatment with plural serial refining stagesBuilding insulationsPolymer modifiedPolymer science

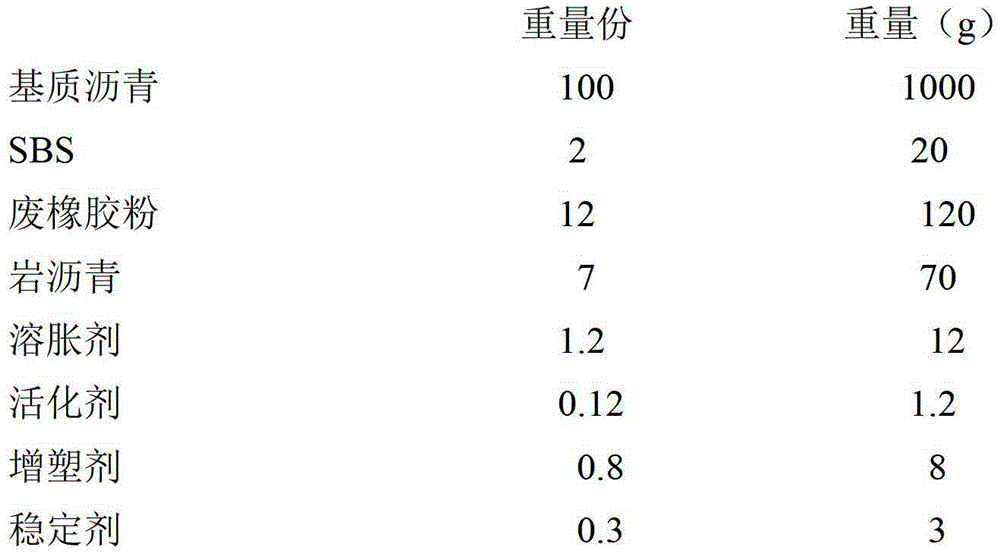

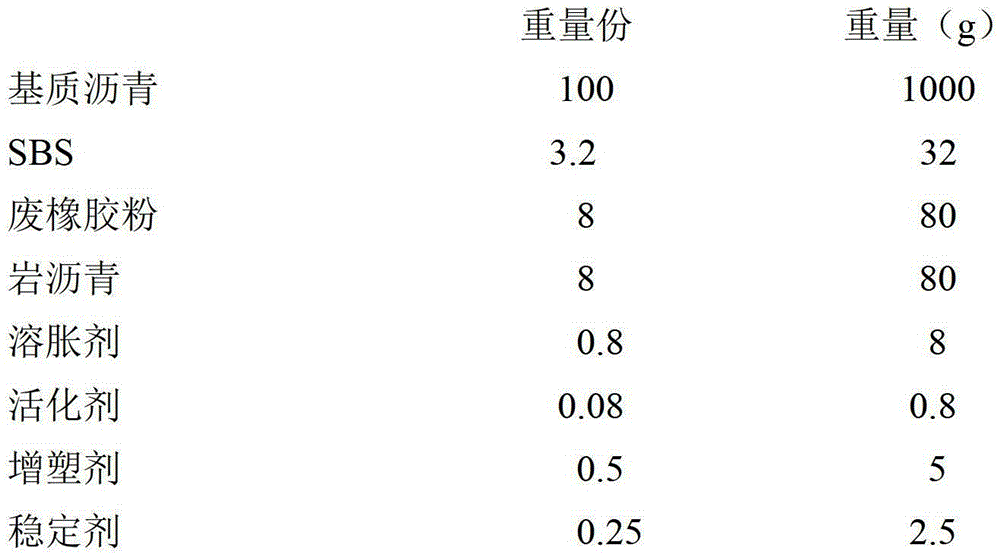

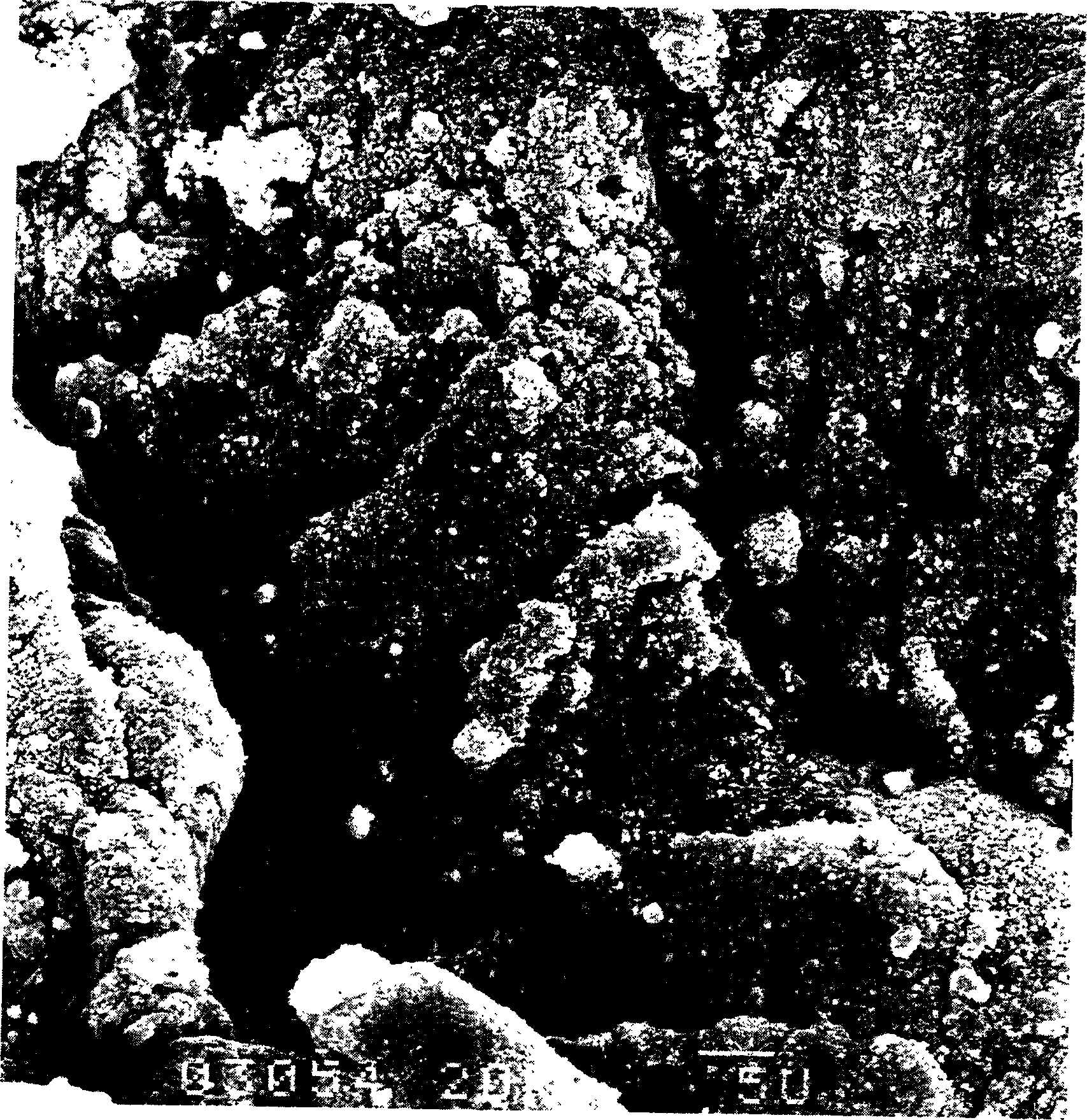

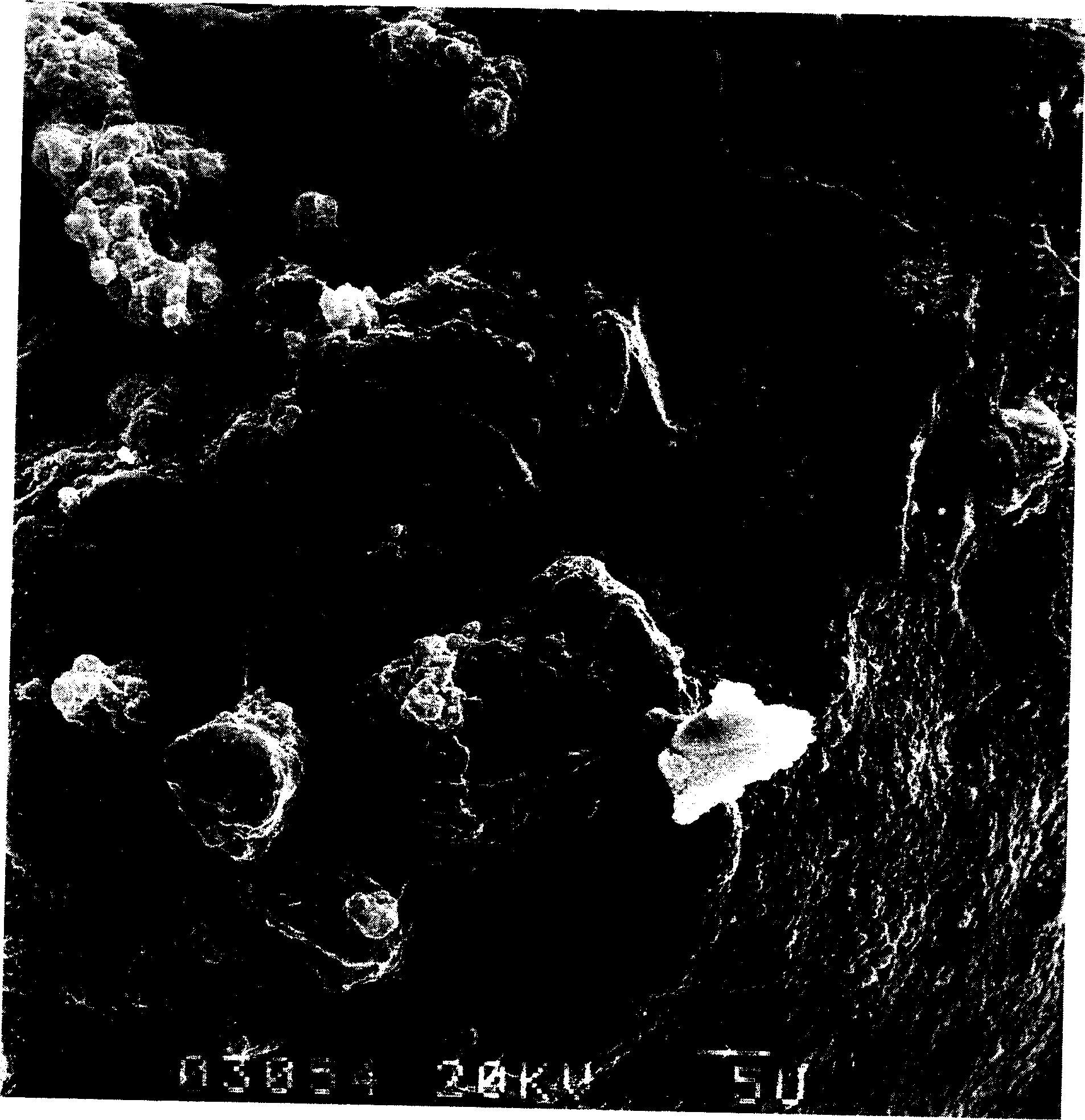

The invention belongs to the technical field of road asphalt modification and relates to an ultraviolet aging-resistant compound modified asphalt, wherein on the basis of 100 parts by weight of matrix asphalt, in parts by weight, 1-6 parts of styrene-butadiene-styrene block copolymer, 3-18 parts of waste rubber powder, 5-10 parts of rock asphalt, 0.3-2.5 parts of sweller, 0.03-0.2 part of activator, 0.1-1 part of plasticizer and 0.2-0.5 part of stabilizer are further added, wherein the sweller is furfural extract oil which is subjected to dewaxing treatment previously; the furfural extract oil contains 60wt%-88wt% of aromatic components which contain 40-65wt% of heavy aromatic hydrocarbon; and the waste rubber powder is waste rubber tire tread rubber powder having the content of carbon black between 28wt% and 58wt% and the grain diameter between 45 and 80 meshes. The ultraviolet aging-resistant compound modified asphalt provided by the invention is up to the standard of the polymer modified asphalt in performance, and the ultraviolet aging resistance of the asphalt is improved to a large extent; and waste resources are utilized.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

Composite of modified road asphalt by microwave radiating old rubber powder and its preparation process

InactiveCN1597782AGood dispersionGood physical and mechanical propertiesBuilding insulationsWaxMicrowave

The invention relates to a microwave-irradiated waste-rubber powder modified pitch combination and its preparing method, using higher-wax content pitch as a substrate, adding in powdery butadiene-styrene rubber and microwave-irradiated waste rubber powder, and making high-speed cutting and uniform commixing to make the modified pitch. The modified pitch has the characters of high-temperature stability, obviously increased low-temperature extensibility, good antiaging property, etc, has road performance synthetically improved and can act as high-grade road pitch for use.

Owner:NORTHWEST NORMAL UNIVERSITY

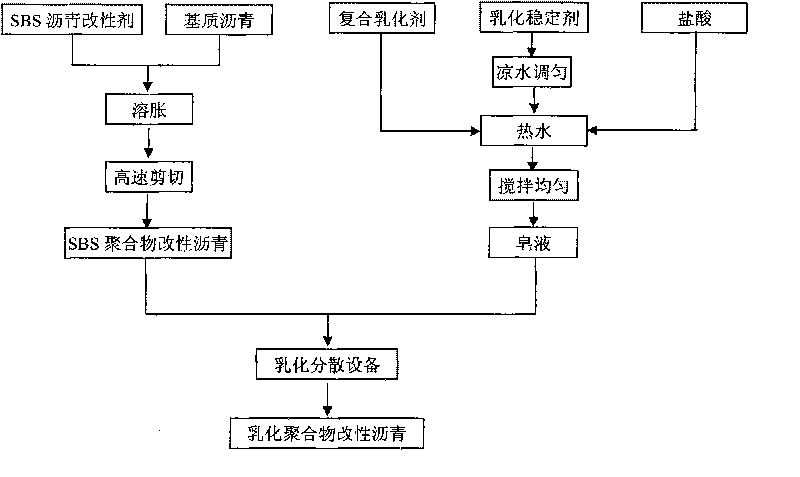

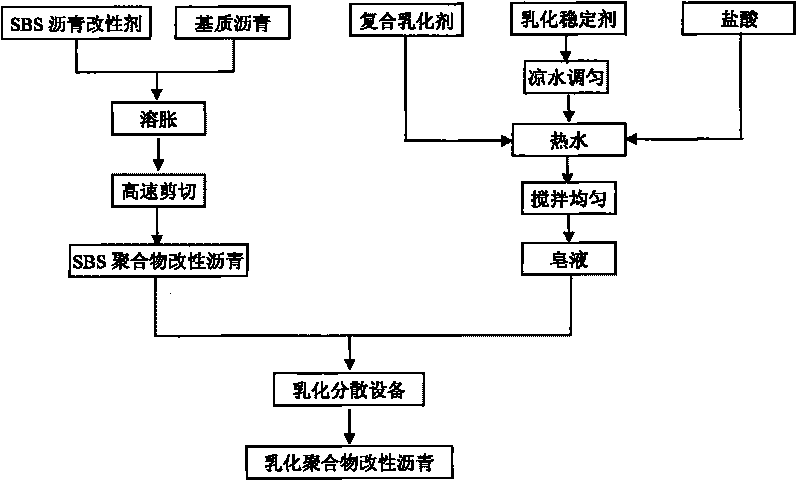

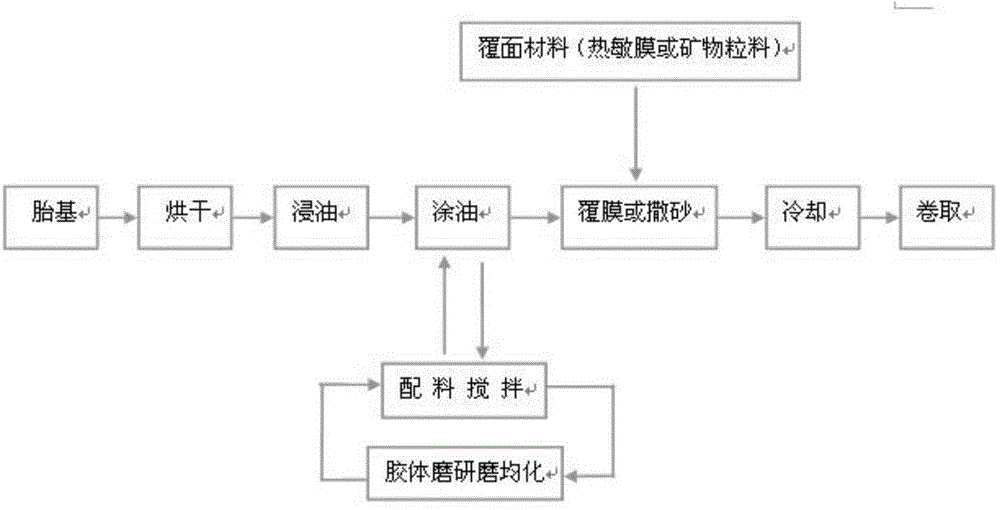

Emulsified SBS polymer modified asphalt and preparation method thereof

InactiveCN101717585AImprove performanceReduce the difficulty of productionClimate change adaptationBuilding insulationsPolymer scienceHigh-speed grinding

The invention relates to an emulsified SBS polymer modified asphalt and preparation method thereof. At present, emulsification and emulsified modified asphalt applied to surfacing is hard to produce and not stable in quality, high temperature performance improvement is not obvious. The raw materials of the invention are matrix asphalt, water, SBS asphalt modifier, compound asphalt emulsifier, emulsification stabilizer and hydrochloric acid; firstly the matrix asphalt is heated, added with SBS asphalt modifier and then stirred to be swelled, high speed grinding by colloid grinder and full dispersion are carried out, and heat preservation growth is carried out to obtain SBS modified asphalt; compound asphalt emulsifier is added into water, emulsification stabilizer smoothened by water in advance is added, and appropriate hydrochloric acid is added to adjust pH value, so as to obtain liquid soap; and finally the SBS modified asphalt is subject to temperature reduction and then mixed with the liquid soap and emulsification dispersion is carried out, thus obtaining emulsified SBS polymer modified asphalt. The invention is applicable to coat tacking, coat sealing, surface treatment, slurry sealing and asphalt pavement recycling, asphalt wet-mixing of road construction and cerement asphalt mortar layer of passenger special line plate type unballasted track.

Owner:深圳路安特沥青高新技术有限公司

Polymer lithium ion battery core outer package forming material

InactiveCN102431239AImprove shielding effectNot easy to peel offSynthetic resin layered productsMetal layered productsHigh resistancePolyvinyl alcohol

The invention provides a polymer lithium ion battery core outer package forming material, and aims at providing a battery core outer package forming material with the advantages that the blocking performance is very high, the cold punching forming performance is good, and puncture resistance, electrolyte resistance stability and organic solvent and high-volatile substance resistance can be realized. An outer resistance layer lamination layer body is formed by at least one layer of heat resistance resin film: any one material from polyethylene glycol terephthalate (PET), biaxially oriented polyamide (BOPA) and polyethylene naphthalate (PEN) or coexistence of two materials from PET, BOPA and PEN through co-extrusion compounding, aluminum foils in a resistance permeation layer lamination body at least comprise 0.9 weight percent to 1.5 weight percent of Fe, a high-resistance layer lamination body comprises a base layer, a function layer and a hot sealing layer, the base layer is a co-polymer film formed by paired compounding or the combination of at least two kinds of film substrates in polystyrene (PP), chlorinated polypropylene (CPP), polyurethane (PE), PET, polyamide (PA) or metaxylylene diamine (MPE) elastic body polymer blends, polyvinyl dichloride (PVDC), ethylene vinyl silane (EVOH), PEN and transpeptidase (GT), and a high-resistance water-resistance modified polyvinyl acetate (PVA) coating film is respectively coated on the co-polymer film substrate. The polymer lithium ion battery core outer package forming material revolutionarily solves the electrolyte resistance stability problem.

Owner:刘继福

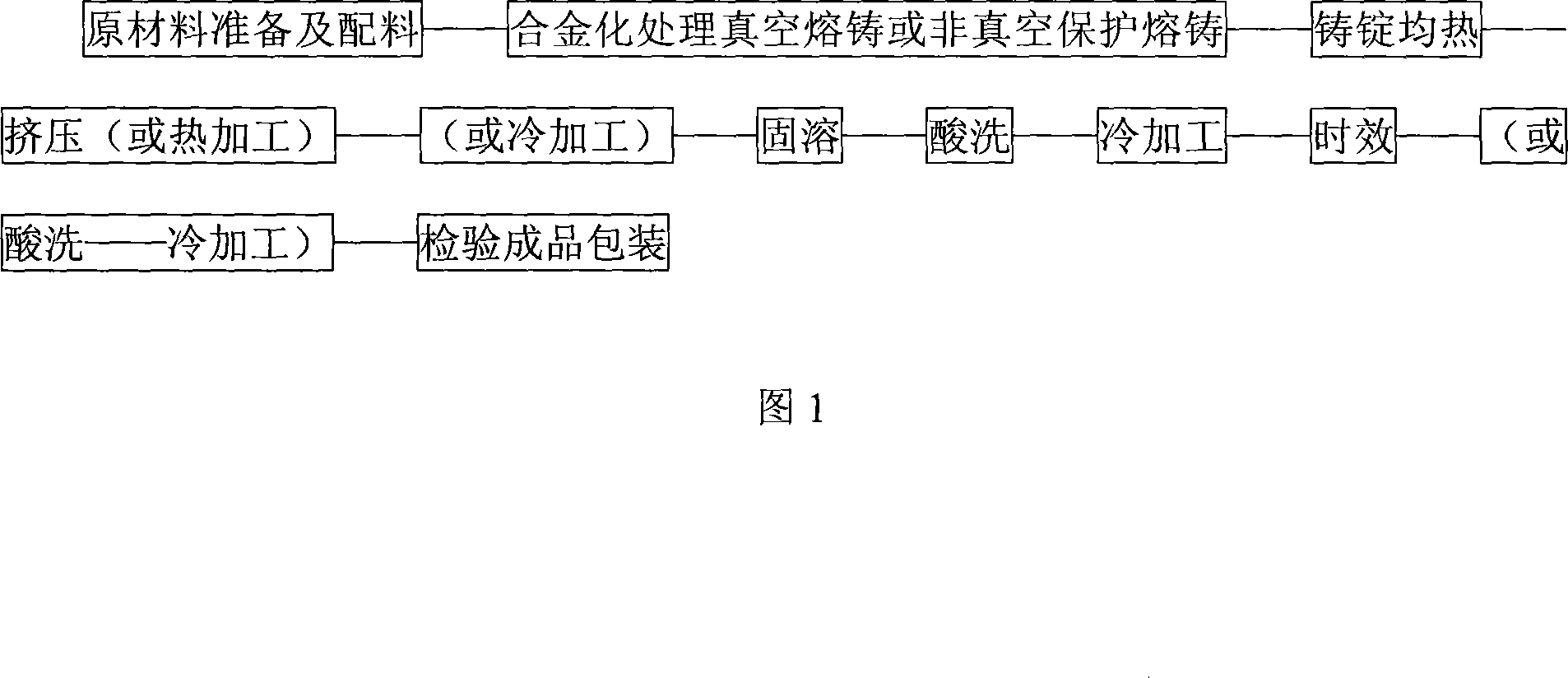

High-strength high-conductivity copper-chromium-zirconium alloy and preparation method of plate/strip thereof

The invention discloses a high-strength high-conductivity copper-chromium-zirconium alloy and a preparation method of a plate / strip thereof. This alloy comprises the chemical composition: 0.01-1.5 wt% of Cr, 0.01-0.5 wt% of Zr, 0.001-0.5 wt% of Ti, 0.01-0.5 wt% of Mn, 0.0001-0.07 wt% of Ca, and the balance of copper and unavoidable impurities; the position and process of the Cu-Cr-Zr alloy are optimized, the provided high-strength high-conductivity copper-chromium-zirconium alloy retains high conductivity (above 80% IACS), elastic modulus up to higher than 130 GPa, softening temperature resistance up to higher than 500 DEG C, yield strength up to higher than 550 MPa and hardness up to 160 HV, the copper-chromium-zirconium plate / strip is imparted high strength, high conductivity and excellent comprehensive performance, this comprehensive performance meets the requirements of products such as a lead frame and a connector upon base material stamping and machining performances, and this plate / strip material is mainly applied to electronic components such as connectors and lead frames.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

High performance SBS modified asphalt and its making method

InactiveCN1569964AHigh softening pointLow SBS contentBuilding insulationsBituminous materialsMaterials science

Owner:SHANGHAI QUNKANG ASPHALTUM TECH CO LTD

High temperature high pressure synthesis method for polycarbosilane

The invention provides a high temperature high pressure synthesis method for polycarbosilane which comprises the steps of, (1) loading small molecular PCS or LPS whose PDMS or average molecular weight is less than 2000 into hot pressing kettle, evacuating and replacing gas in the kettle with high purity nitrogen, charging 0.1-5Mpa of N2 and sealing, elevating the temperature to 430-490 deg. C, reacting time being 0.5-10 hours, (3) dissolving the crude product with xylene, filtering, and proceeding vacuum distillation to the filter liquor at 330-380 deg. C, finally cooling down to obtain the resin form product.

Owner:NAT UNIV OF DEFENSE TECH

Multilayer modified bituminous roofing product

InactiveUS20110281094A1Reduce problemHigh coefficient of frictionProtective equipmentRoof covering using flexible materialsEngineeringCivil engineering

Owner:POLYGLASS

Waterborne epoxy resin modified emulsified asphalt and preparation and application thereof

InactiveCN102618045AGood emulsificationImprove hydrophilicityPaving detailsBuilding insulationsEpoxyRoad surface

The invention discloses waterborne epoxy resin modified emulsified asphalt, which contains emulsified asphalt and self-emulsifying waterborne epoxy resin, wherein the volume ratio of the emulsified asphalt to the self-emulsifying waterborne epoxy resin is 1: (0.2-0.8); the emulsified asphalt is nonionic emulsified asphalt, anionic emulsified asphalt or cationic emulsified asphalt, and the solid content of the emulsified asphalt is 20 to 60 percent; and the self-emulsifying waterborne epoxy resin contains waterborne epoxy resin curing agent, water and liquid epoxy resin in a mass ratio of 1: (0.8-2): (2-5). The invention also discloses a preparation method for the waterborne epoxy resin modified emulsified asphalt and application in preparation of an asphalt type waterproof coating. After the common commercial emulsified asphalt is modified by the waterborne epoxy resin, the break elongation of the emulsified asphalt can be improved, and the modified emulsified asphalt has high adhesive strength with a base plane, certain strength and high waterproof property and ageing resistance; and the modified emulsified asphalt can be used for making the asphalt type waterproof coating, and can also be used for repairing road pavements.

Owner:重庆融极环保工程有限公司

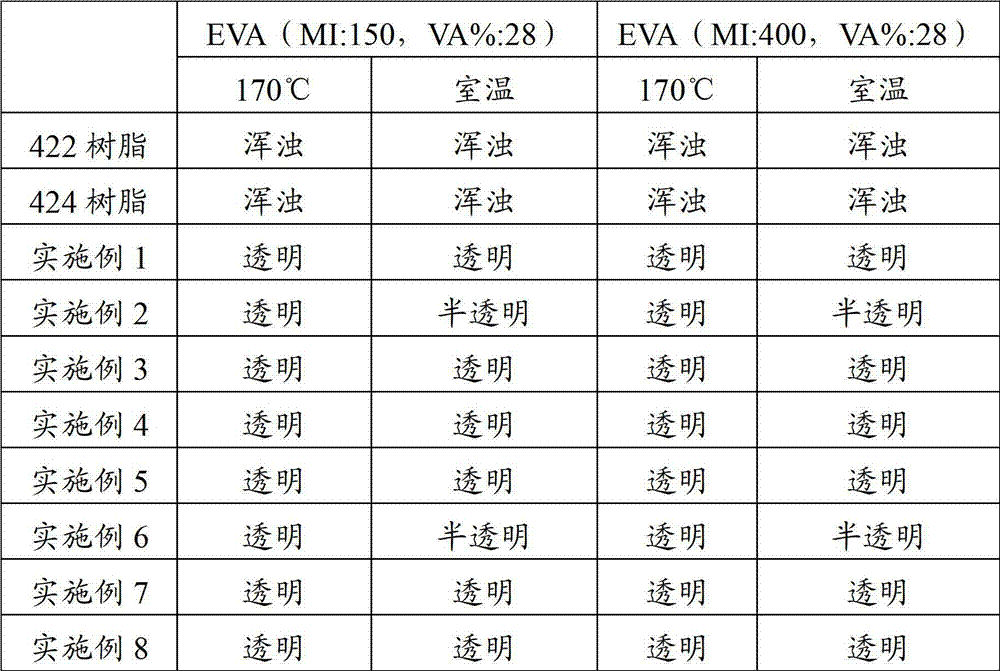

Rosin viscosified resin as well as preparation method and application thereof

ActiveCN102965024AImprove molecular structureHigh softening pointNatural resin chemical modificationRosin adhesivesElastomerDistillation

The invention discloses a preparation method of rosin viscosified resin, and the preparation method comprises the following steps of: (1) adding rosin into a distillation flask, vacuumizing, heating and distilling at the temperature of 240-280 DEG C, so that part of rosin is distilled; and (2) adding the rest rosin in the distillation flask into a reaction flask, adding a catalyst and polyalcohol into the reaction flask under the inert gas protection condition, and reacting for 4-24 hours at the temperature of 240-290 DEG C, so that the rosin viscosified resin is obtained, wherein the rosin contains pinus latteri acid. According to the preparation method disclosed by the invention, the pinus latteri acid contained in the rosin component is utilized, and the pinus latteri acid is rosin binary acid, so that the molecular structure of the resin is increased and the aim of increasing the softening point of the rosin viscosified resin is achieved. Meanwhile, the invention also provides rosin viscosified resin prepared by adopting the preparation method disclosed by the invention, and the rosin viscosified resin has higher softening point and good compatibility with EVA (ethylene vinyl acetate) elastomer and can be better used for preparing hot melt glue.

Owner:普洱科茂林化有限公司

Fusible high-performance elastomer modified asphalt waterproof roll

ActiveCN104553130AImprove construction rateExtended service lifeSynthetic resin layered productsBituminous layered productsSocial benefitsElastomer

The invention discloses a fusible high-performance elastomer modified asphalt waterproof roll. The fusible high-performance elastomer modified asphalt waterproof roll sequentially comprises a heat-sensitive fusible OPP (o-phenylphenol) isolating membrane, a fusible elastomer modified asphalt, a polyester reinforcement, fusible elastomer modified asphalt and a heat-sensitive fusible OPP isolating membrane from top to bottom. When the fusible high-performance elastomer modified asphalt waterproof roll is applied, the construction efficiency can be improved, the energy consumption is reduced, and the waterproof roll is energy-saving, environment-friendly and long in service life and has good economic benefits and social benefits. The experiment proves that the fusible high-performance elastomer modified asphalt waterproof roll disclosed by the invention has the advantage that the construction rate can be improved by 10-20 percent.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD +2

Low-melting-point colored special-shaped polyester filament and preparation method thereof

InactiveCN104532387AMeet the needs of colorReduce quality problemsMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyester

The invention relates to low-melting-point colored special-shaped polyester filament and a preparation method thereof. The low-melting-point colored special-shaped polyester filament is composed of, by mass, 20-40% of pigment, 0.1-4% of dispersing agent, 0.1-1% of antioxidant and the balance low-melting-point polyester slice. The preparation method comprises the first step of drying the low-melting-point polyester, the second step of preparing low-melting-point master batches, and the third step of preparing the low-melting-point colored special-shaped polyester filament. By means of the low-melting-point colored special-shaped polyester filament and the preparation method thereof, the phenomena of adhesion, doubling and the like which are produced in the processes of bundling and drawing of fibers are solved through lowering the spinning temperature, adopting the cross air blasting and improving the spinning speed; the low-melting-point non-ferrous special-shaped polyester filament is prepared for the first time, and the demands for colors of some hot melt adhesives are met; meanwhile, the mass of the low-melting-point polyester is reduced through using a special-shaped section.

Owner:张志明

Method for preparing magnesia carbon brick non-aluminum antioxidant coating

InactiveCN101928480AHigh strengthAvoid enteringAlkali metal silicate coatingsCarboxymethyl celluloseBrick

The invention more particularly relates to a method for preparing magnesia carbon brick non-aluminum antioxidant coating, which has the technical scheme of comprising the steps of: firstly mixing 40-60wt% of boron glass, 5-20wt% of SiC, 20-35wt% of fused quartz, 1-5wt% of MgO, 5-10wt% of CaO and 0.1-0.3% of carboxymethyl cellulose, and additionally adding ludox accounting for 20-40wt% of the mixed material or liquid water glass accounting for 40-60wt% of the mixed material, then additionally adding water accounting for 50-60wt% of the mixed material, carrying ball-milling for 20-40min, and preparing antioxidant paint; then, evenly painting the prepared antioxidant paint on the surface of a magnesia carbon brick, naturally drying and stoving at 110 DEG C; and finally, putting the stoved magnesia carbon brick in a high temperature furnace, heating up to 1150-1250 DEG C, carrying out heat preservation for 20-40min, and preparing the magnesia carbon brick non-aluminum antioxidant coating. The invention has the characteristics of simple technique and low cost, and can be glazed at the temperature range of 500-1200 DEG C; and the prepared magnesia carbon brick non-aluminum antioxidant coating has good anti-oxidation performance.

Owner:WUHAN UNIV OF SCI & TECH

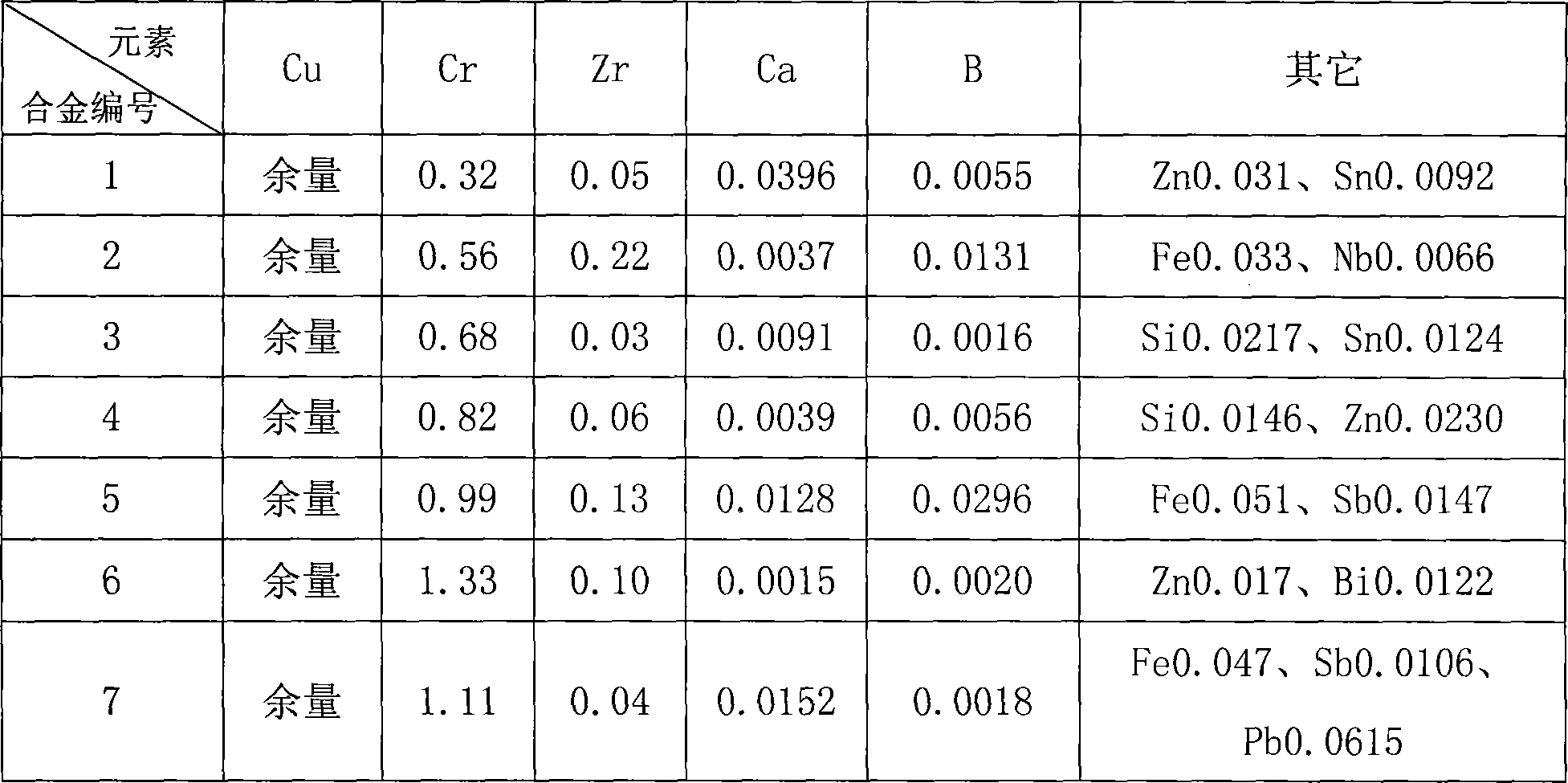

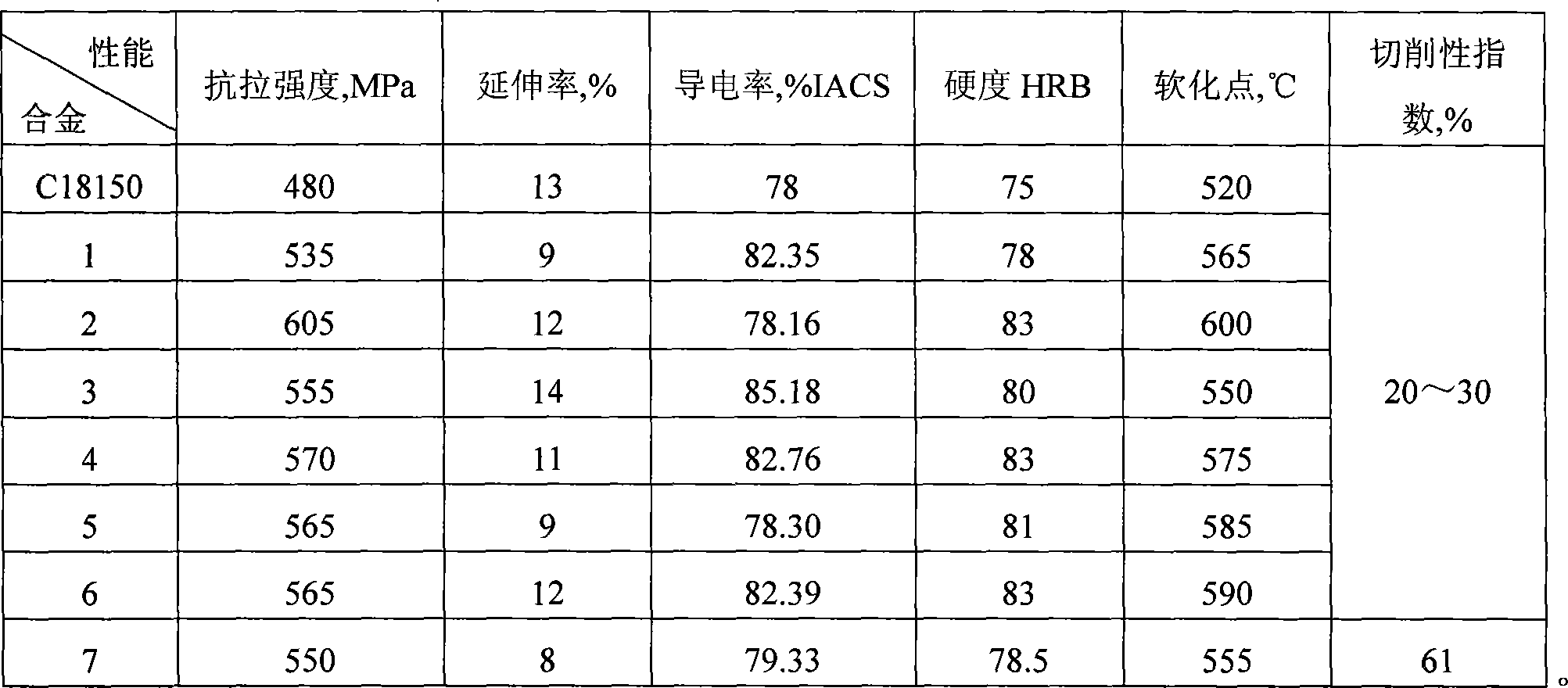

High-strength highly-conductive low-calcium boron chromic zirconium copper alloy and method for manufacturing same

The invention discloses a low-calcium boron-chromium-zirconium-copper alloy with high strength and high electrical conductivity and a preparation method thereof. The chemical components of the alloy are: 0.2-1.5wt percent of chromium, 0.02-0.3wt percent of zirconium, 0.0003-0.05wt percent of calcium, 0.0003-0.04wt percent of boron and 0.01-0.5wt percent of other components, wherein, other components are at least one of the elements of: galvanized iron, zinc, silicon, tin, niobium, antimony, bismuth and lead; the rest is copper and inevitable impurities. The preparation method comprises: alloy smelting, thermal extrusion with severe deformation, multilevel thermal treatment and multistage aging under the temperature between 320 DEG C and 480 DEG C for 1-6 hours. The obtained alloy is characterized by high intensity, high conductivity, high softening point, good wear-resistance performance, good welding ability and formability, which is applicable to the manufacturing field such as automobile, high speed train, household appliances, aerospace, electronic telecommunication, metallurgical continuous casting, motor, injection precision mold, etc.

Owner:NINGBO POWERWAY ALLOY MATERIAL

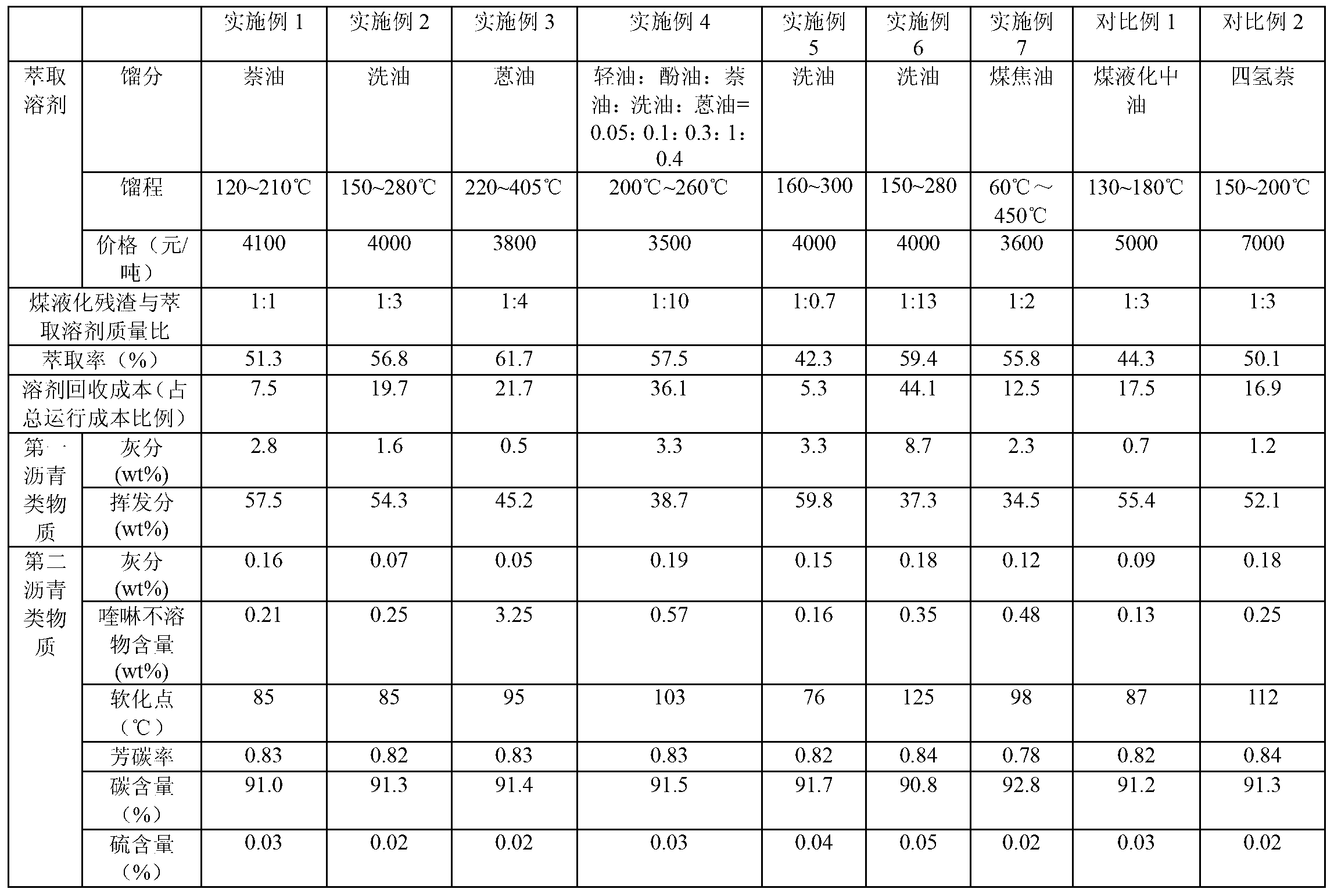

Method for separating bituminous substances from coal direct liquefaction residues

ActiveCN103242881AHigh softening pointModerate volatileWorking-up pitch/asphalt/bitumen by selective extractionSolventChemistry

The invention discloses a method for separating bituminous substances from coal direct liquefaction residues and an application thereof. The method comprises the following steps of: S1) mixing the coal direct liquefaction residues with an extraction solvent, and performing hot solution extraction to obtain a hot solution extraction mixture; S2) performing solid-liquid separation on the hot solution extraction mixture to obtain an extraction solution; and S3) performing solvent recovery on the extraction solution to obtain the bituminous substances, wherein the extraction solvent is coal tar or coal tar distillate. The coal tar or the coal tar distillate is taken as the extraction solvent for separating the coal direct liquefaction residues to prepare the bituminous substances, so that the extraction rate is improved, the cost is reduced, the mixture of the bituminous substances with appropriate volatile components and higher softening point is obtained, and the bituminous substances in the mixture can be used as raw materials of different grades of carbon materials according to different natures.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Ultraviolet curing adhesive

ActiveCN102079961ASolve the problem of unexposed initial tackHigh softening pointPolyureas/polyurethane adhesivesPhotosensitive materials for photomechanical apparatusAcrylic resinAdhesive

The invention discloses an ultraviolet curing adhesive comprising a resin main body, a dissolvent, an ultraviolet light initiator and an addition agent, wherein the resin main body is composed of a resin R and a resin H; the R resin is an active polyurethane acrylic resin with a main chain containing a polyether structure and a branch chain containing a vinyl optical active group as well as with a lower molecular weight; and the H resin is an inert polyurethane acrylic resin with a main chain containing a polydiene and aryloxide structure and with a relatively higher molecular weight. The adhesive contains no monomer or prepolymer, has high softening point, can be precoated on a base material, has super strong cohesive force on a high-oilness contact surface and has characteristics of high-temperature resistance, small internal stress and good flexibility.

Owner:LUCKY HUAGUANG GRAPHICS

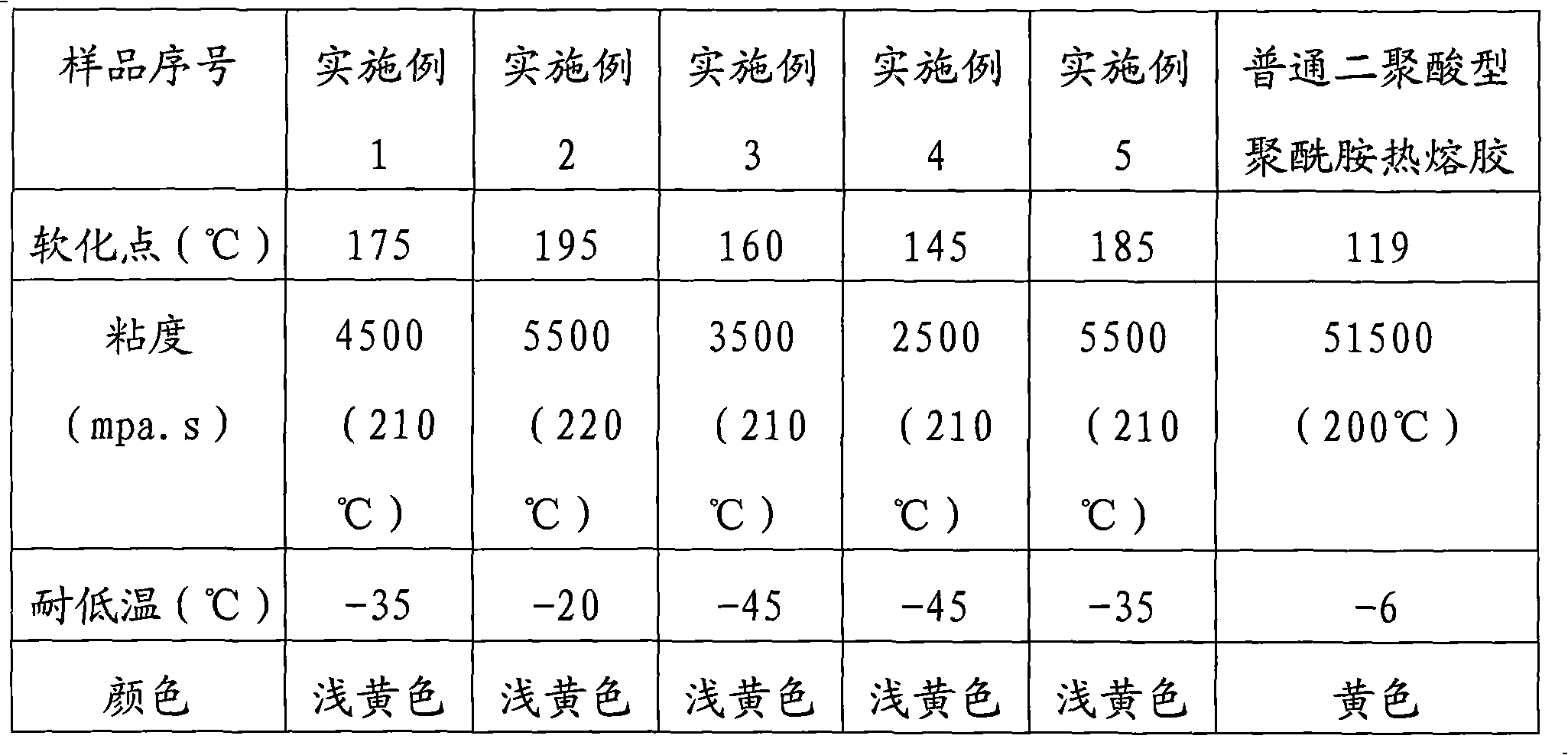

Low-viscosity dimer acid type polyamine hot melt adhesive and preparation method thereof

InactiveCN101962526AReduce high temperature viscosityLow water absorptionNon-macromolecular adhesive additivesAntioxidantNitrogen

The invention relates to a low-viscosity dimer acid type polyamine hot melt adhesive and a preparation method thereof. The hot melt adhesive consists of the following raw materials in percentage by mole: 55 to 95 percent of dimer acid, 5 to 45 percent of aliphatic dibasic acid, 60 to 95 percent of aliphatic diamine, 5 to 40 percent of polyoxypropylene polyamine, 0.1 to 5 percent of molecular weight regulator, and the balance of water and antioxidant, wherein the dosage of the water accounts for 1 to 30 percent of the total mass of the acide and the amine; and the dosage of the antioxidant accounts for 0.1 to 2 percent of total mass of the acid and the amine. The preparation method comprises the following steps: salifying in the protection of nitrogen by using the dimer acid, the aliphatic dibasic acid and the diamine, the antioxidant and the molecular weight regulator as raw materials and introducing proper water at early stage; and heating and polycondensating. The polyamine hot melt adhesive has high and low temperature resistance, low high-temperature viscosity and simple molding process, and is mainly applied in automobile and electronic industries.

Owner:YANTAI DARBOND TECH

Polyester resin for rapid curing of weather-durable powdery paint by beta-hydroxyalkylamide and preparation method thereof

InactiveCN102443148AHigh glass transition temperatureGood storage stabilityPowdery paintsPolyester coatingsChemistryPowder coating

The invention discloses a polyester resin for the rapid curing of a weather-durable powdery paint by a beta-hydroxyalkylamide. The polyester resin is obtained through carrying out a melting polycondensation reaction on the following components, by weight, 30-45% of a polyol, 45-60% of an aromatic polyprotic acid, 0-10% of an aliphatic polyprotic acid, 0-5% of a branching agent, 5-20% of an antiacid and 0.05-0.30% of an esterification catalyst. The invention also discloses a preparation method of the polyester resin. The polyester resin provided in the invention has the advantages of high glass-transition temperature and softening point, and appropriate melting viscosity and storage stability; and powdery paints prepared with the polyester resin have the advantages of excellent levelability, excellent mechanical performance, good thick film pinhole resistance and the like.

Owner:GUANGZHOU QINGTIAN INDAL

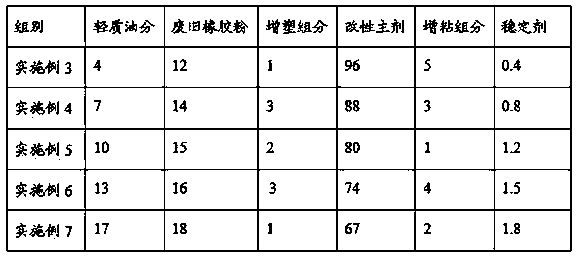

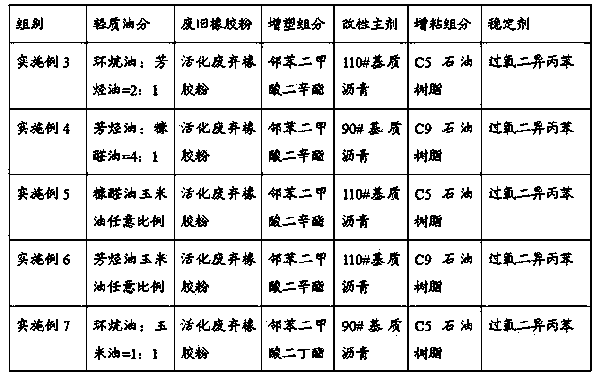

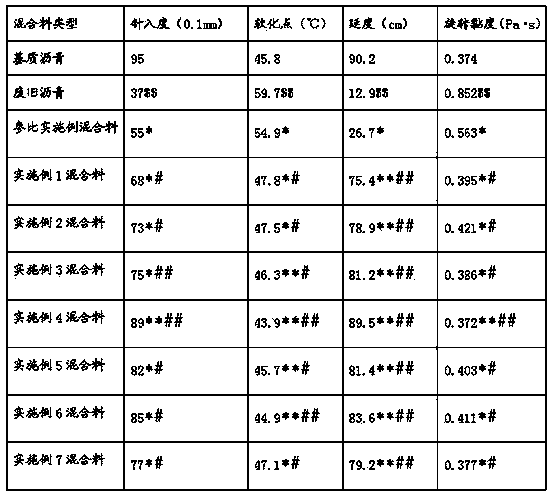

Material for waste asphalt regeneration pavement and preparation method of material

InactiveCN103468006AStrong penetrating powerHigh softening pointSolid waste managementBuilding insulationsRoad engineeringRoad surface

The invention relates to a material for a waste asphalt regeneration pavement and a preparation method of the material and belongs to the field of construction and maintenance of road engineering. For improving the property of waste asphalt and lowering the maintenance cost of the road, the invention provides a material for waste asphalt regeneration pavement and a preparation method of the material. The material for the waste asphalt regeneration pavement comprises lightweight oil, plasticized components, a modified main agent, tackifying components and a stabilizer, and the selection range and constitution of all components are specifically limited. Aging tests and low-temperature performance show that the viscoplastic performance of the regenerated asphalt and the anti-crack property and durability of the pavement can be greatly improved when the material for waste asphalt regeneration pavement is used for regeneration of the waste asphalt; therefore, the material for waste asphalt regeneration pavement has a bright application prospect.

Owner:GUANGZHOU MUNICIPAL ENG MAINTENANCE DEPT

Preparation method of near-stoichiometric silicon carbide fiber

ActiveCN102634867AHigh softening pointAvoid fusible problemsArtificial filament heat treatmentMelt spinning methodsCarbon fibersSynthetic Polymeric Macromolecules

The invention relates to a preparation method of a near-stoichiometric silicon carbide fiber, which comprises the following steps: (1) catalytically synthesizing HPCS: synthesizing high-molecular-weight polycarbosilane HPCS under the catalysis of metal by using liquid polycarbosilane or liquid polysilane as the material; (2) preparing a continuous HPCS fiber through melt spinning; (3) preparing an infusible fiber; (4) decarburizing: removing redundant carbon in the infusible fiber in a reducing atmosphere, thus forming a near-stoichiometric fiber; and (5) firing: carrying out high-temperature firing densification on the decarburized fiber under the protection of an inert atmosphere, thus obtaining a near-stoichiometric continuous SiC fiber. The preparation method can improve the performance of the composite material; the equipment and the process are simple; and the preparation method can be implemented by conventional fiber production equipment, can be easily industrialized and can promote the application of the SiC fiber.

Owner:NAT UNIV OF DEFENSE TECH

Auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and application thereof

ActiveCN101862458AReduce dosageHigh softening pointGranular deliveryMacromolecular non-active ingredientsFlavorMedicine

The invention relates to an auxiliary material combination for improving atomizing and drying process of traditional Chinese medicine granules and an application thereof. The auxiliary material combination comprises 10 to 90 percent of betadex and 10 to 90 percent of maltodextrin or dextrine. The application of the auxiliary material combination is: after being dissolved in hot water, the auxiliary material combination is added into extract obtained by extracting Chinese medicine or is directly added into extract to be uniformly mixed and to be atomized and dried; when adding the auxiliary material combination, the temperature of the extract is 50 to 100 DEG C, relative density of the extract is 1.02 to 1.20 (60 DEG C), air inlet temperature for atomizing drying is 140 to 190 DEG C, and the air outlet temperature is 75 to 100 DEG C. by adopting the auxiliary material combination, under the same atomizing and drying condition, the consumed quantity of the auxiliary material is less, the consumption quantity of the auxiliary material can be reduced by more than 30 percent, the auxiliary material with the same quantity is added for atomizing and drying, the softening point of the extract can be improved during the atomizing and drying process, the wall is difficult to be adhered during the atomizing process, the fluidity of the atomizing and drying powder is good, the atomizing and drying powder is difficult to be moistened, the dispersion of the flavor can be effectively prevented during the atomizing and drying process, and the original flavor of the extract is maintained.

Owner:陇西一方制药有限公司

Wood pulp non-woven fabrics in use for tobacco

InactiveCN101003925AExcellent adsorptionImprove filtering effectTobacco smoke filtersNon-woven fabricsPulp and paper industryNonwoven fabric

The present invention relates to a wood pulp nonwoven fabric for manufacturing filter tip of cigarette. Said invention uses wood pulp fiber and high-melting point synthetic fiber or / and artificial fiber as raw material and adopts air laying mode to make them into fiber web, then utilizes adhesive to make crosslinking reaction so as to obtain the invented nonwoven fabric for manufacturing filter tip of cigarette.

Owner:DARE TECH

Preparation method of hydrogenated C9 petroleum resin

The invention relates to a preparation method of hydrogenated C9 petroleum resin, which is characterized by comprising the following steps of: (1) preparation of supported noble metal hydrogenated catalyst: preparing by using a coating method, selecting noble metal palladium and platinum and transition metal cobalt or nickel as metal active components, preparing a spherical alumina supporter, then coating the active components of palladium and platinum and transition metal on the alumina supporter, and activating to obtain a hydrogenated catalyst; (2) selective hydrogenation: desulfurizing and denitrifying; (3) high pressure hydrogenation reaction: controlling the weight ratio of resin to solvent to ensure that the concentration of resin is 20-40% by weight, taking chain-like or annular saturated hydrocarbon or aromatic hydrocarbon or hydrocarbon mixture as a solvent, and taking a supported noble metal hydrogenated catalyst as a catalyst, wherein the temperature of the high pressure hydrogenation reaction is 250-350 DEG C, the pressure is 8.0-20.0 MPa and the liquid volume space velocity is 0.5-2h<-1>. The properties of the final product hydrogenated C9 petroleum resin are as follows: Gardner is not more than 1, and the softening point is not smaller than 100 DEG C.

Owner:CHINA NAT OFFSHORE OIL CORP +1

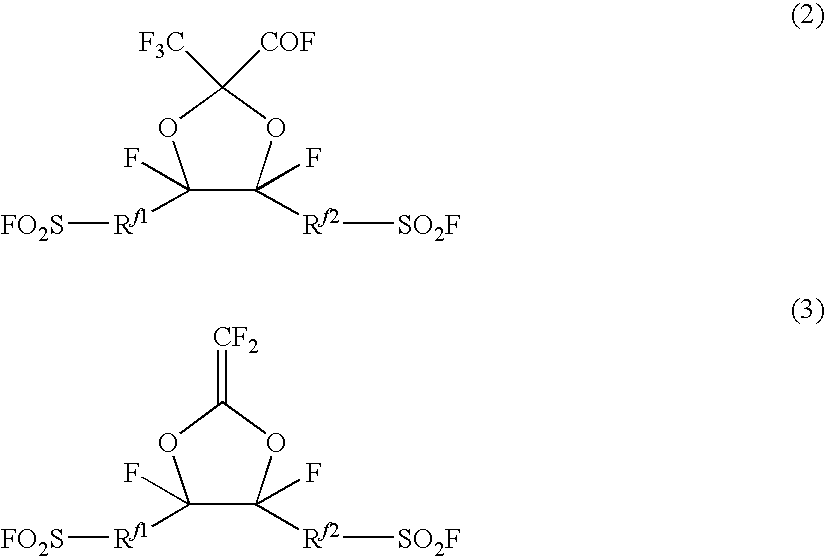

Fluorosulfonyl group-containing monomer and its polymer, and sulfonic acid group-containing polymer

InactiveUS20090048424A1Easy to getHigh polymerization reactivityOrganic chemistryPolymer scienceOxygen atom

To provide a fluorosulfonyl group-containing monomer having a high polymerization reactivity and plural fluorosulfonyl groups. Further, to provide a fluorosulfonyl group-containing polymer and a sulfonic acid group-containing polymer, obtained by using the monomer.A perfluoro(2-methylene-1,3-dioxolane) derivative which is represented by the following formula (3) and which has two fluorosulfonyl groups, and its production process and its synthetic intermediate. A fluorosulfonyl group-containing polymer having monomer units represented by the following formula (3U) obtained by polymerizing the compound (3) by itself or with a comonomer, and a sulfonic acid group-containing polymer having the following units (5U) obtained by hydrolyzing a fluorosulfonyl group of the polymer. In the following formulae, each of Rf1 and Rf2 which are independent of each other, is a C1-8 perfluoroalkylene group which may have an etheric oxygen atom between carbon atoms.

Owner:ASAHI GLASS CO LTD

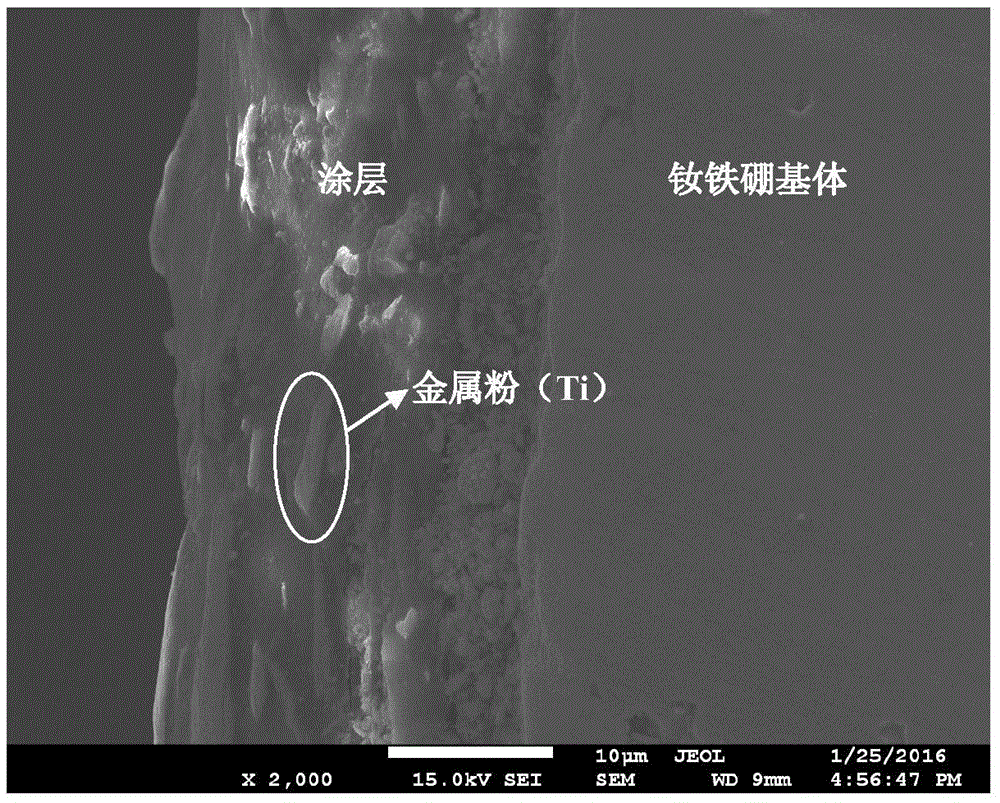

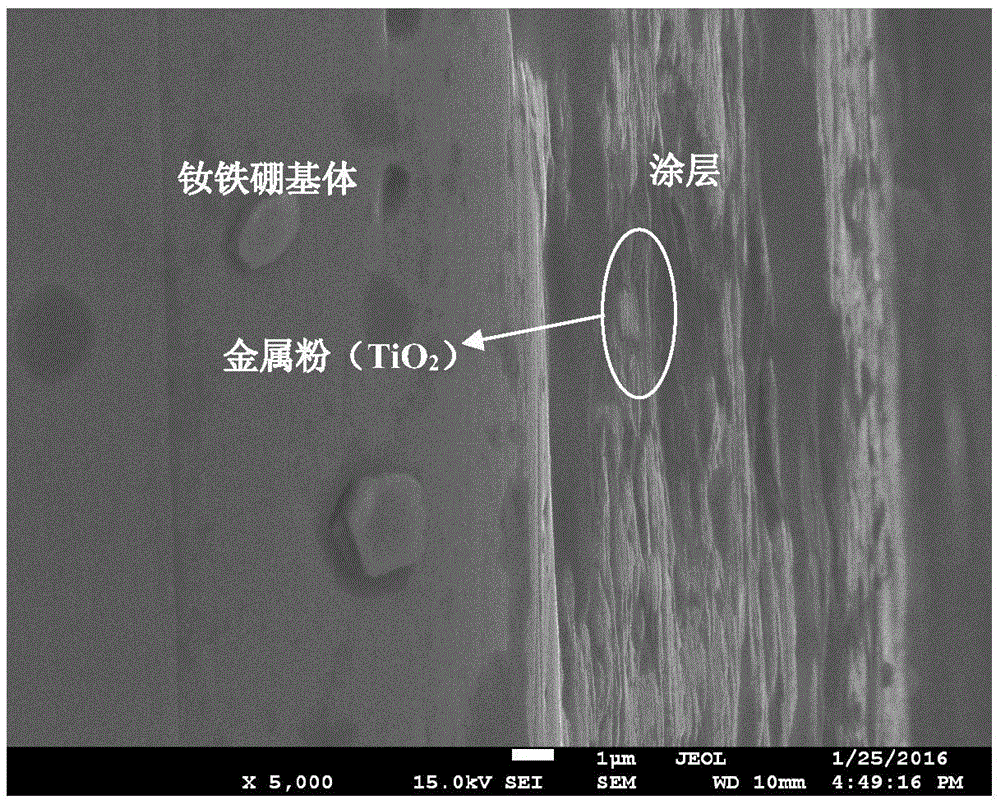

Fluorine-containing metal coating on surface of NdFeB rare-earth permanent magnet and preparation method of fluorine-containing metal coating

The invention discloses a fluorine-containing metal coating on the surface of an NdFeB rare-earth permanent magnet and a preparation method of the fluorine-containing metal coating, and belongs to the technical field of anticorrosion surface treatment. The fluorine-containing metal coating has the thickness of 5-40 microns and is prepared from polytetrafluoroethylene, solid powder and adhesive according to the mass ratio of (1-30):(2-30):(20-40). The preparation method includes the steps of firstly, preprocessing the surface of the NdFeB rare-earth permanent magnet through an oil removal and acid pickling or sand blasting method; secondly, preparing the coating through a centrifugal soaking and throwing or spraying method. Polytetrafluoroethylene contained in paint for preparing the coating has excellent corrosion resistance, and the corrosion resistant capacity of the surface of the NdFeB rare-earth permanent magnet can be improved; in the coating process, no acid bath is used, the fresh surface of the magnet is not damaged after preprocessing, and the surface adhesion force between the coating and the magnet can be effectively improved; no acid waste liquid exists, the environment is not polluted, and the preparation method belongs to the green and environment-friendly coating process.

Owner:NORTHEASTERN UNIV

Polyester resin for hydroxyalkyl amide cured powder paint and process for preparing the same

InactiveCN1544505AHigh softening pointHigh glass transition temperaturePowdery paintsPolyester coatingsPropylene glycolIsopropylene glycol

The invention discloses a polyester resin for hydroxyalkyl acidamide solidified powdery paints whose constituents and proportion by weight are, terephthalic acid 75-100, m-phthalic acid 5-25, adipic acid 3-25, neopentyl glycol 50-80, 2-methyl-1, 3- propylene glycol 0-20, 1, 6-hexandiol 0-20, 1, 4-cyclohexane dimethanol 2-20, trimethylolpropane 1-3, dibutyl tin oxide 0.1-0.2, water 2-5. The invention also discloses the process for preparing the polyester resin.

Owner:GUANGZHOU QINGTIAN INDAL

Wide temperature range modified asphalt for roads and preparation method thereof

The invention relates to wide temperature range modified asphalt for roads. The asphalt is composed of, by weight, 80-90 parts of matrix asphalt, 1-6 parts of SBS (styrene-butadiene-styrene) modifier, 10-30 parts of activated waste tire rubber powder, 2-6 parts of light oil, 0.1-0.5 part of terpene resin and 0.1-0.5 part of elemental sulfur. The wide temperature range modified asphalt for the roads has good performances of being free of flowing at high temperature and being free of cracking at low temperature, usage temperature range can reach higher than 100 DEG C, the preparation method is simple, and production can be directly performed on original SBS modifier production devices, so that cost investment of production equipment is reduced.

Owner:甘肃交通规划勘察设计院有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com