Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2057results about How to "Not easy to peel off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

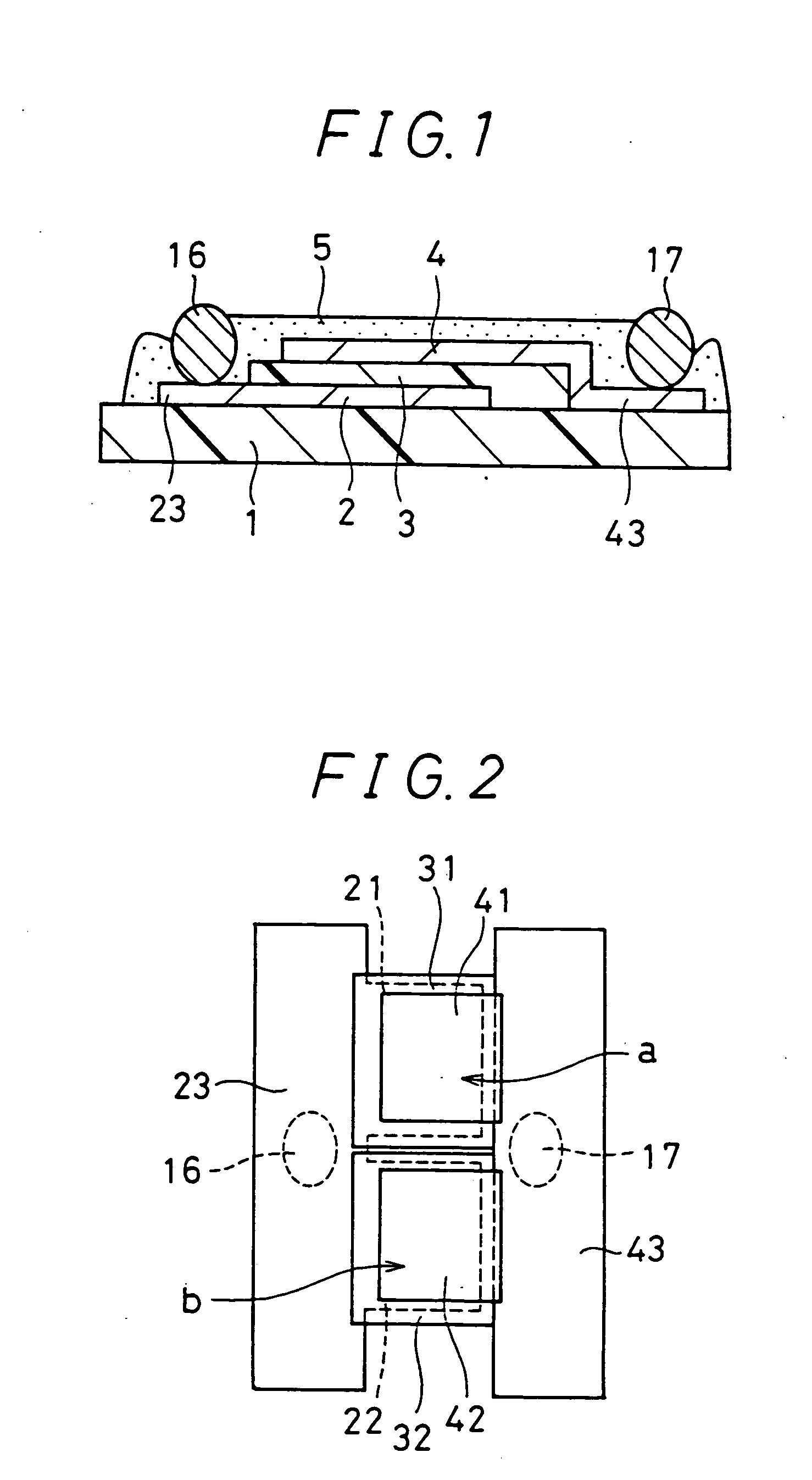

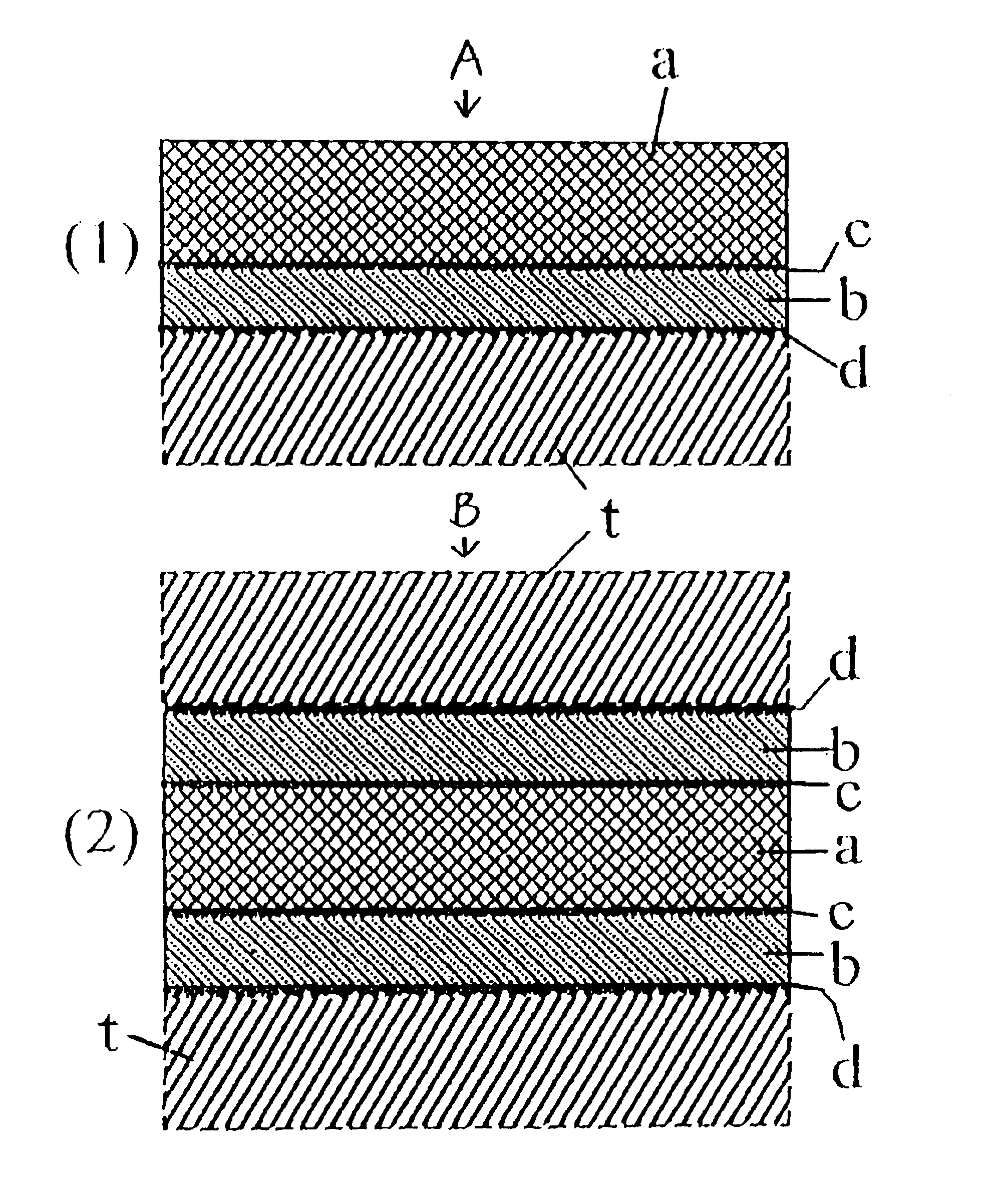

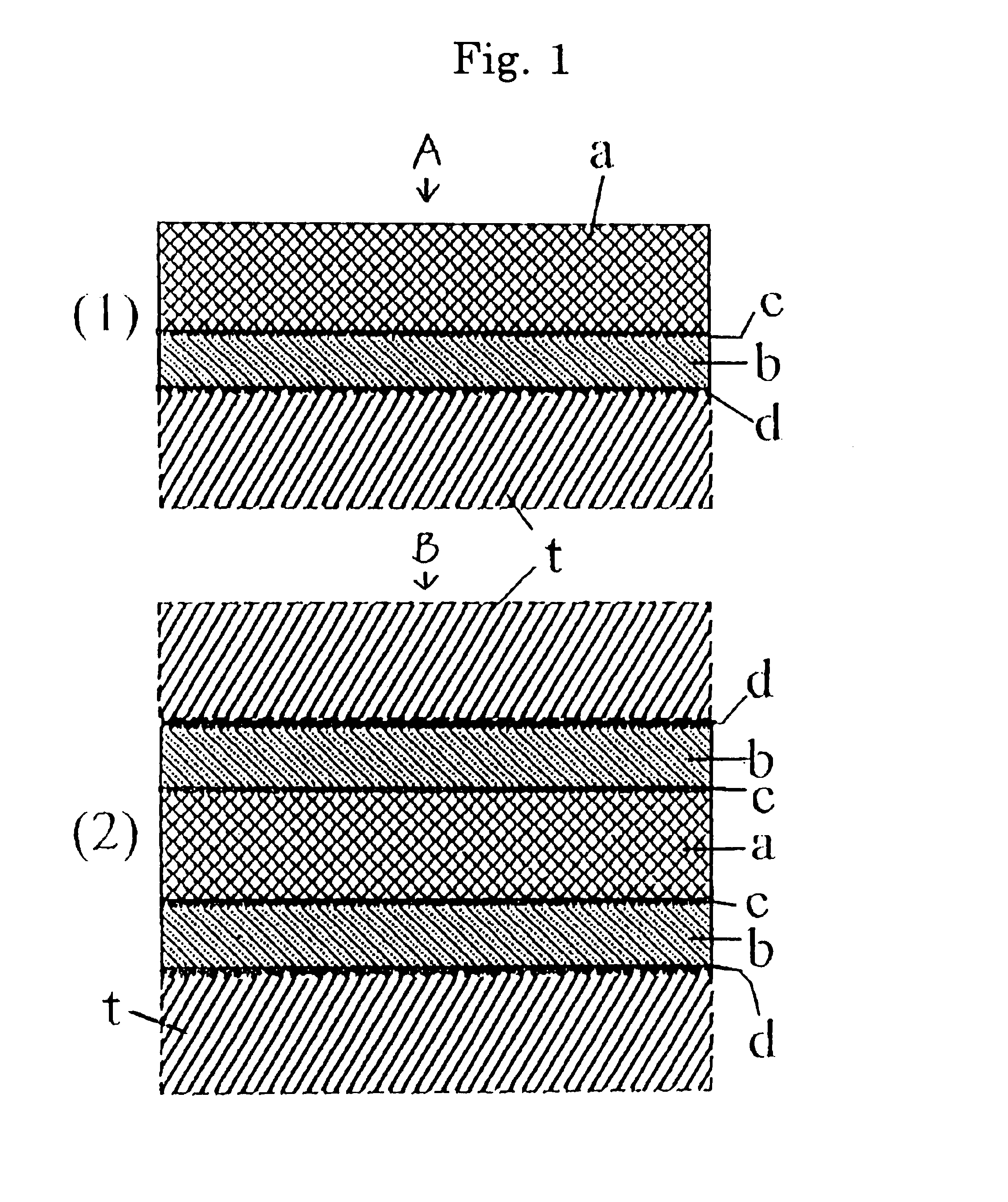

Tunable thin film capacitor

InactiveUS20050082636A1Resistance in the upper electrode layer of the capacitance can be easily loweredElectrode loss can be reducedTransistorThin/thick film capacitorCapacitanceDielectric layer

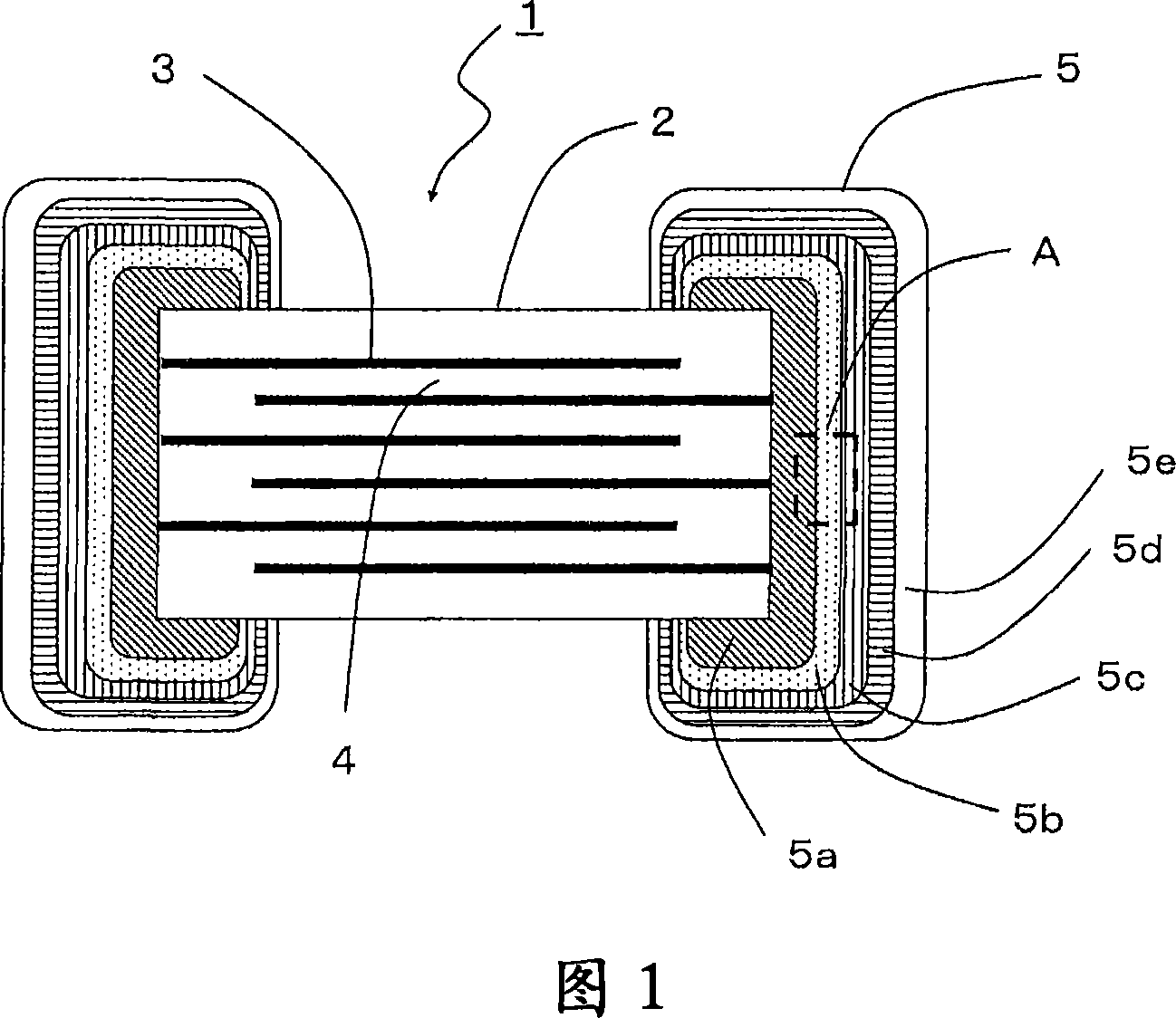

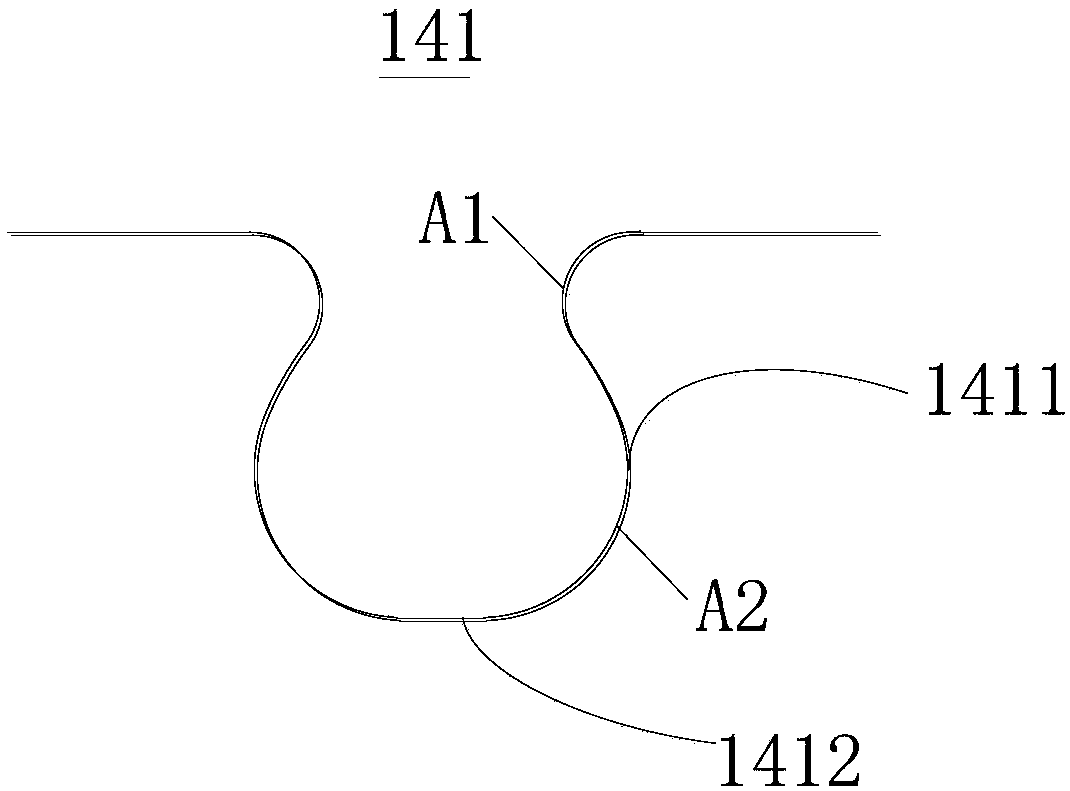

It is an object of the invention to provide a variable capacitor constituted such that, even when an external control voltage is applied, a stable dielectric constant of the dielectric layer can be obtained. A variable capacitor constituted such that a dielectric layer whose dielectric constant is changed by the application of an external voltage is held between an upper electrode layer and a lower electrode layer, wherein a plurality of capacitance-producing regions a, b are connected to each other.

Owner:KYOCERA CORP

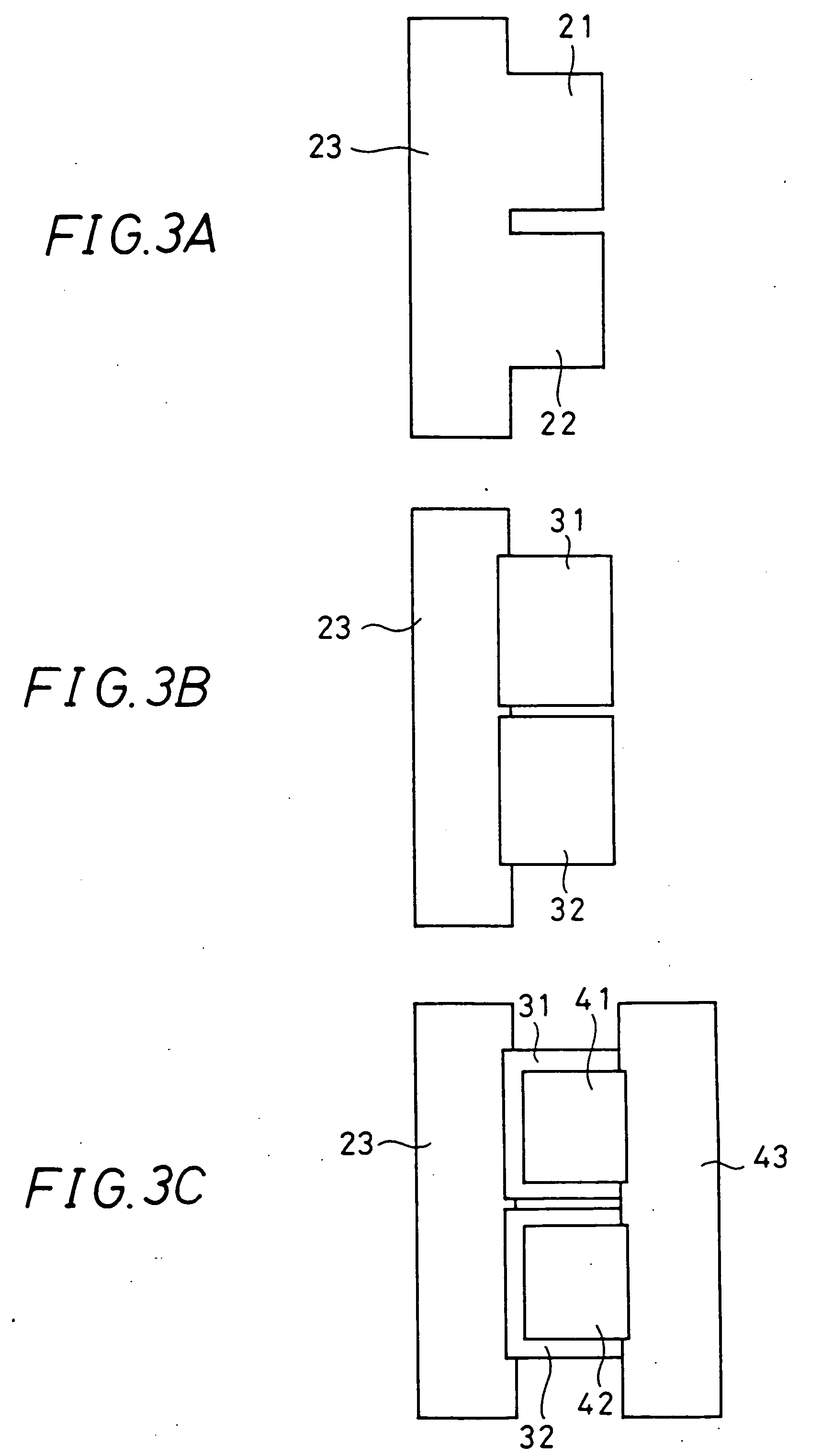

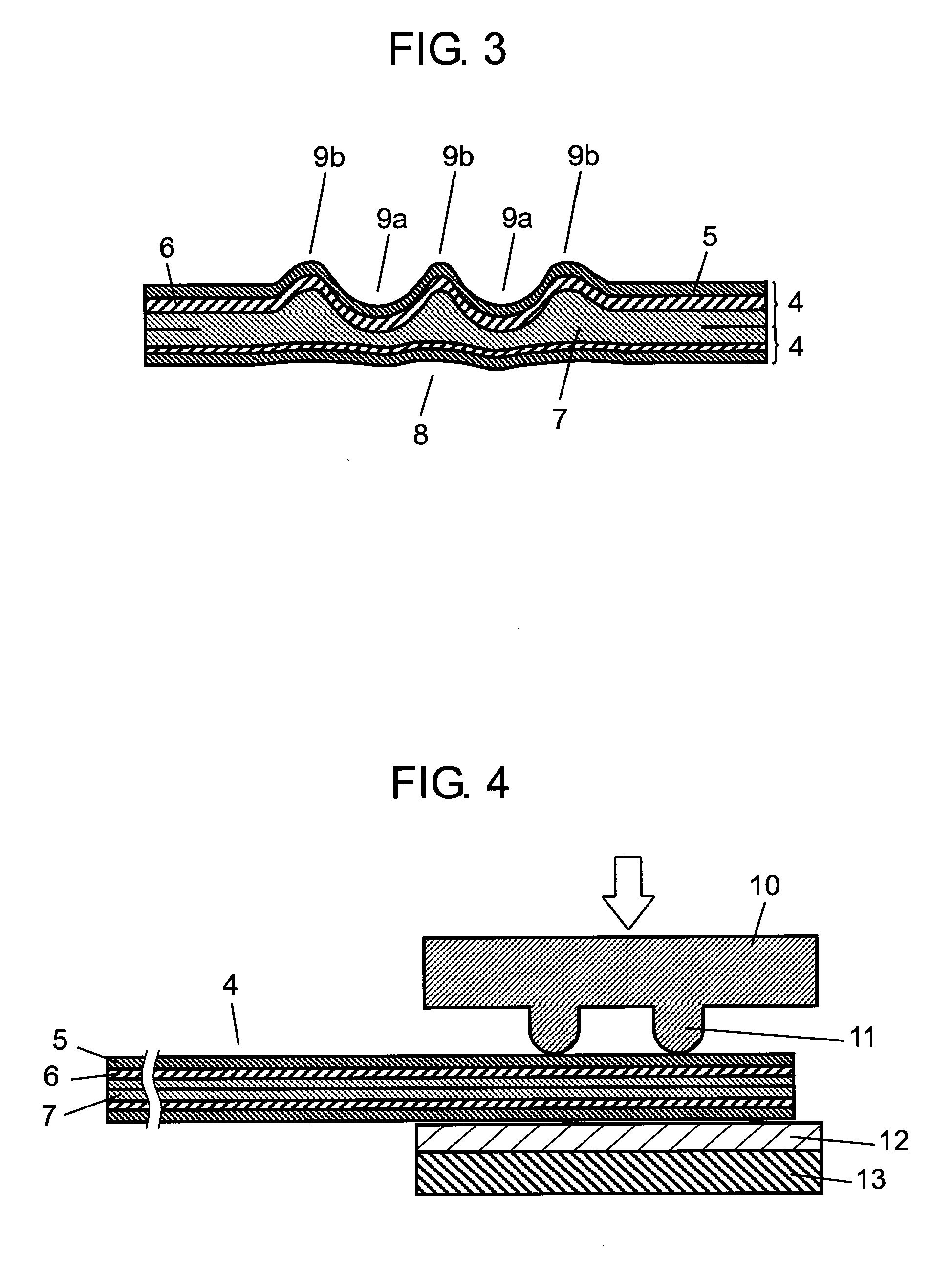

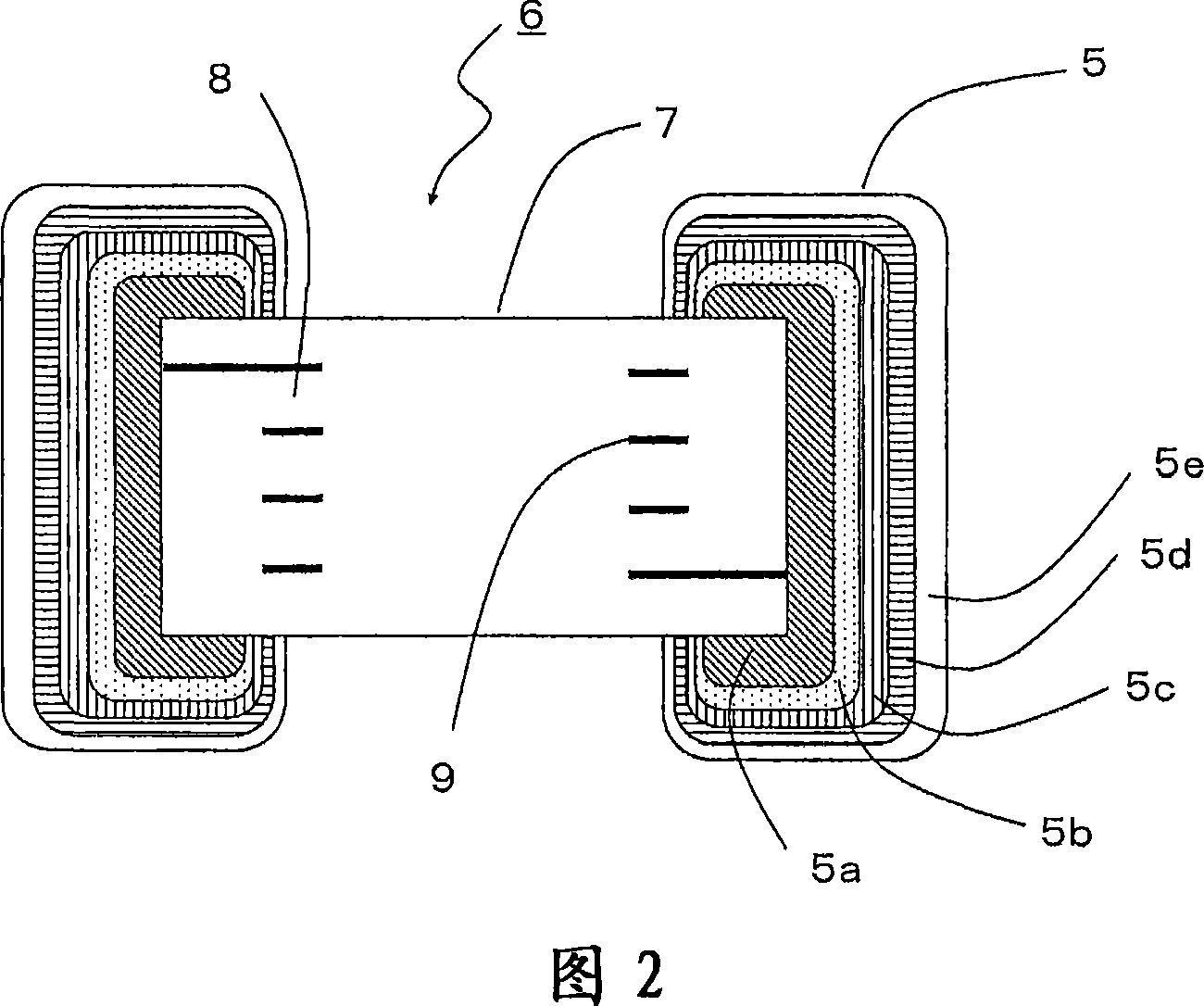

Vacuum heat insulation material and manufacturing method therefor

ActiveUS20110165367A1Avoid it happening againLimited amountThermal insulationClimate change adaptationThick wallEngineering

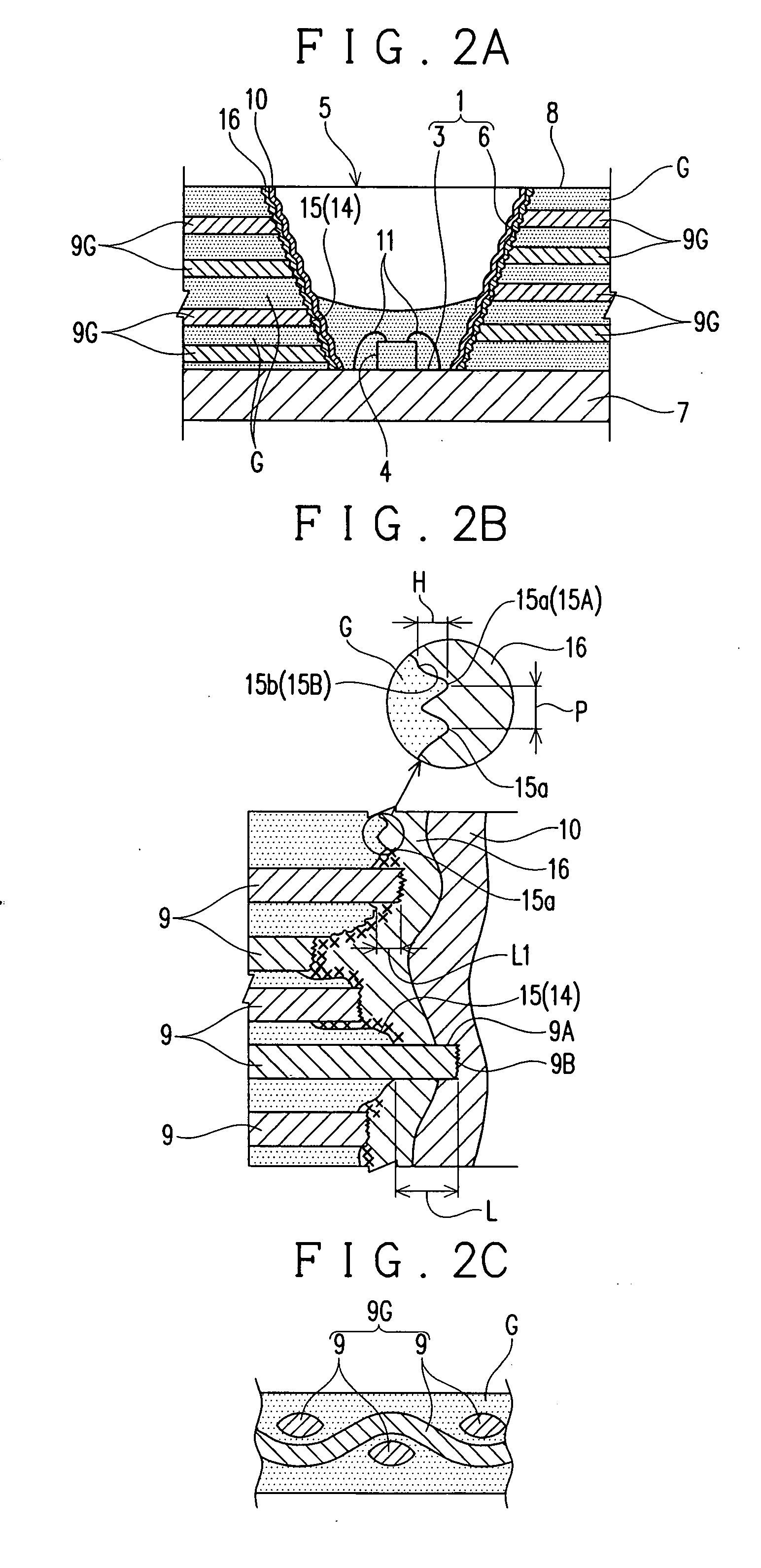

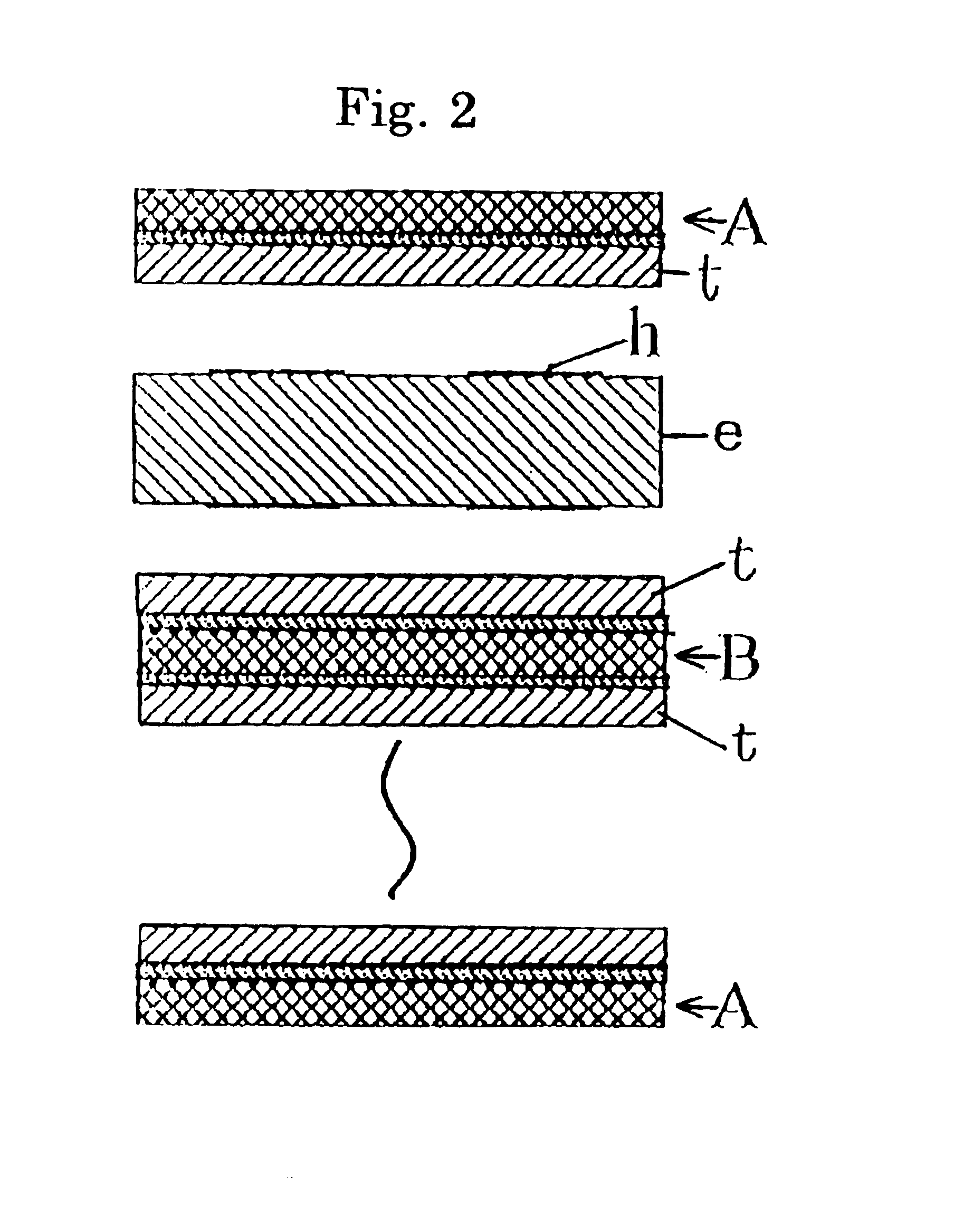

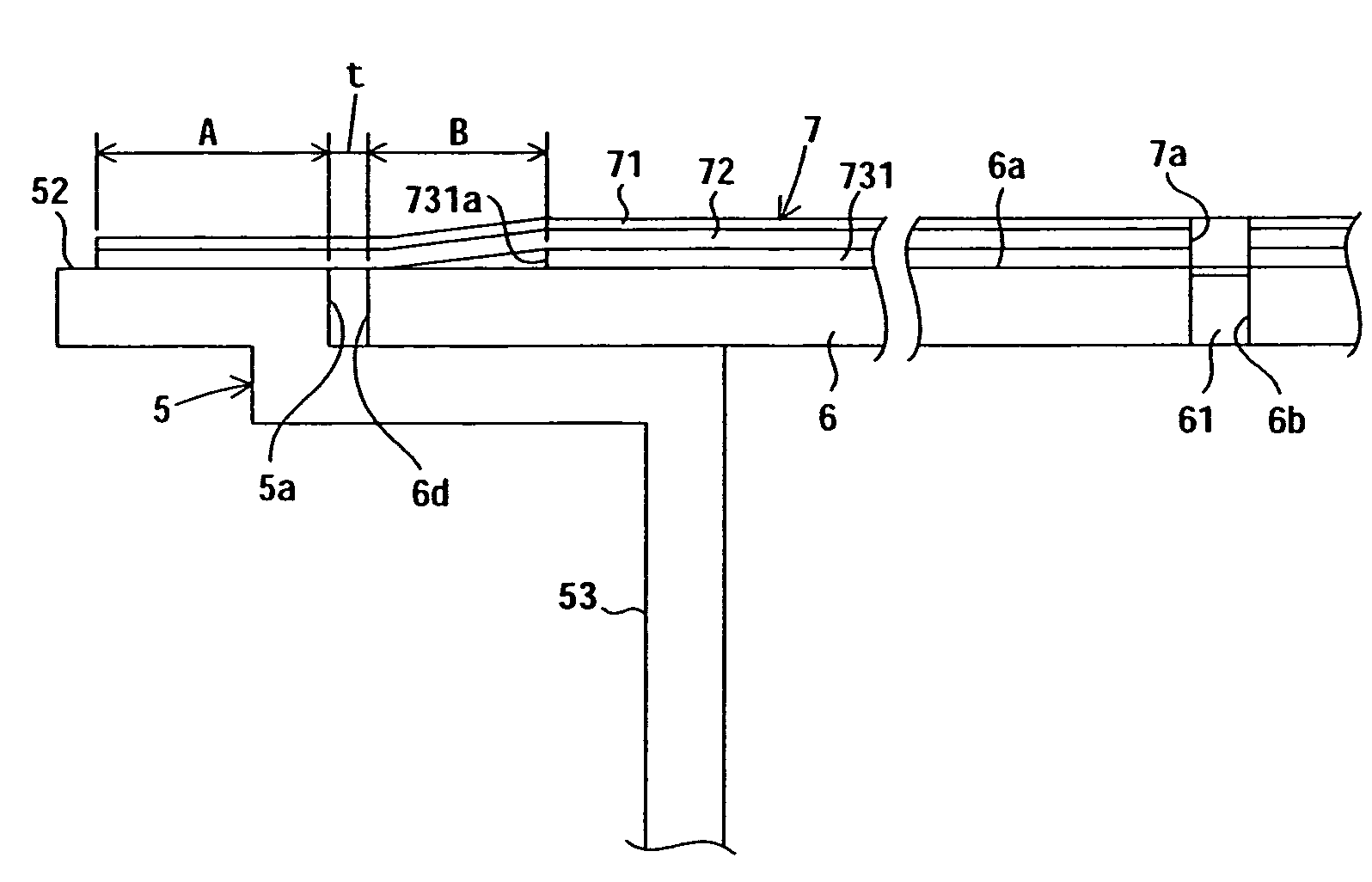

A plurality of thin-wall parts (9a) of a sealant layer (7) are formed in a portion continuously changed in the interval of one sealing part (8) and a gas barrier layer (6) of other laminate film (4). At the inner circumferential side between the adjacent thin-wall parts (9a) and the thin-wall part (9a) at the innermost circumferential side and at the outer circumferential side of the thin-wall part (9a) of the outermost circumferential side, a thick-wall part (9b) of the sealant layer (7) is formed. All of the opposing sealant layers (7) between the two adjacent thin-wall parts (9a) are mutually heated and fused, so that an excellent adiabatic performance is maintained for a long period.

Owner:PANASONIC CORP

Thermal-insulating external-wall coating of nano-composite water and its production

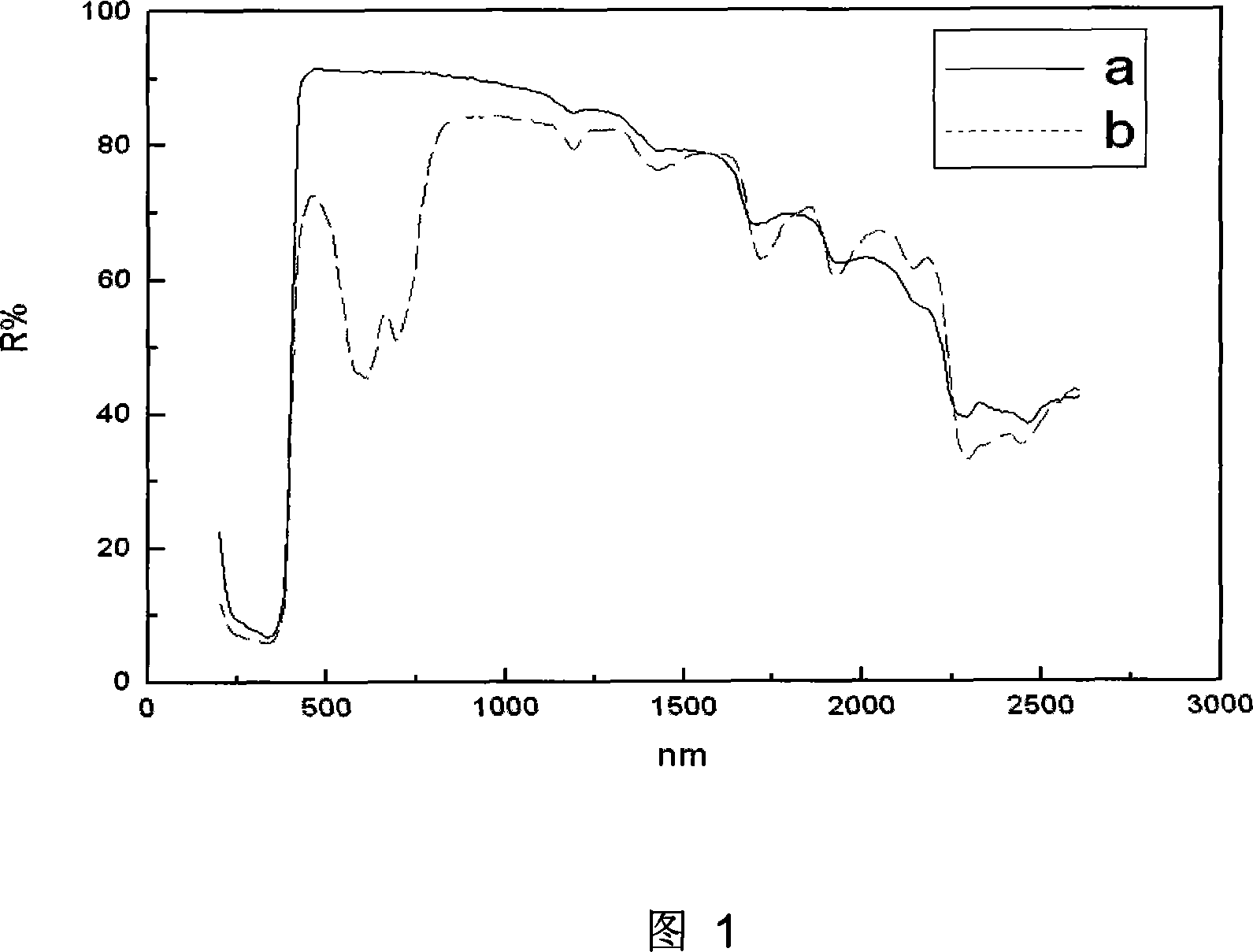

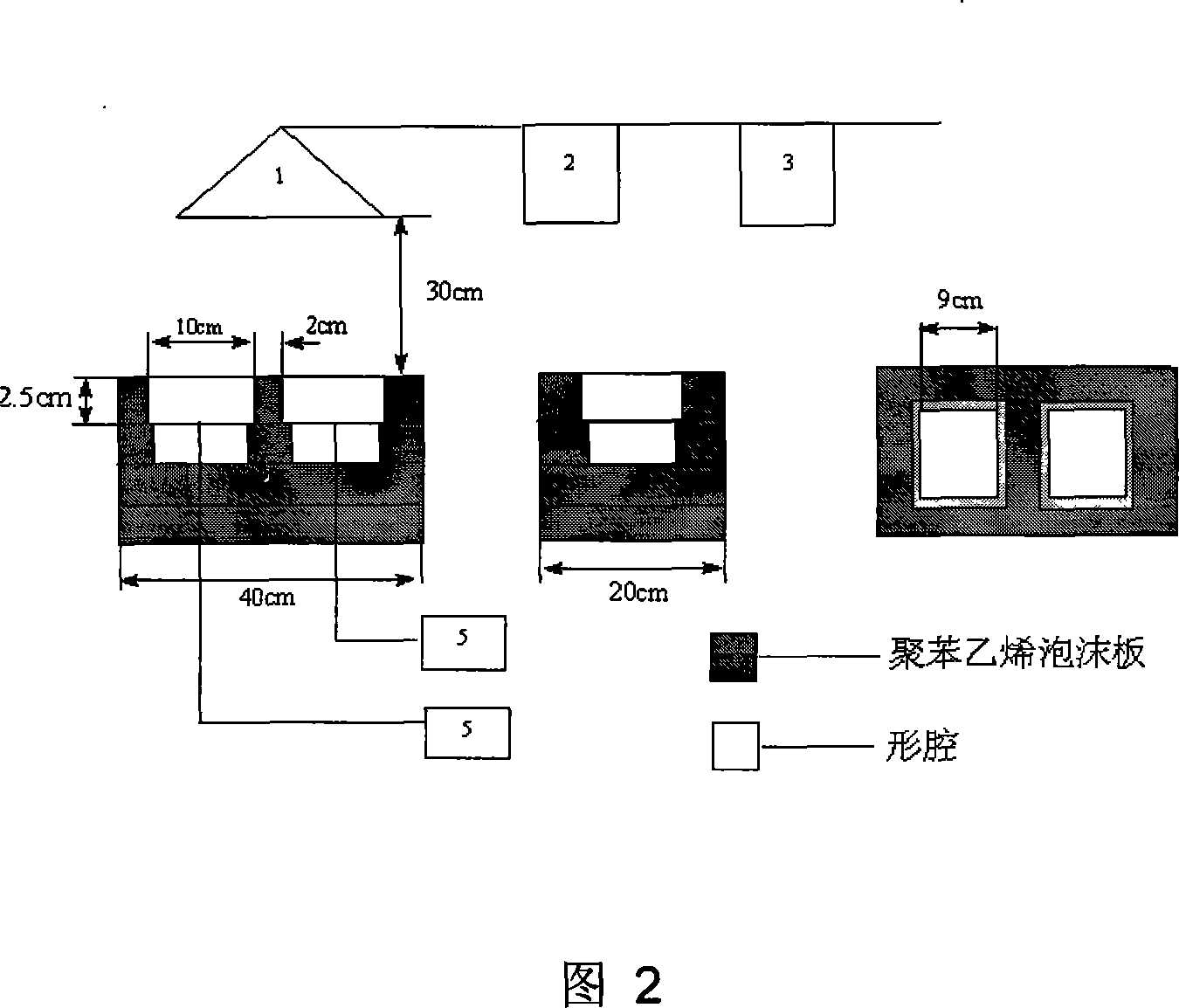

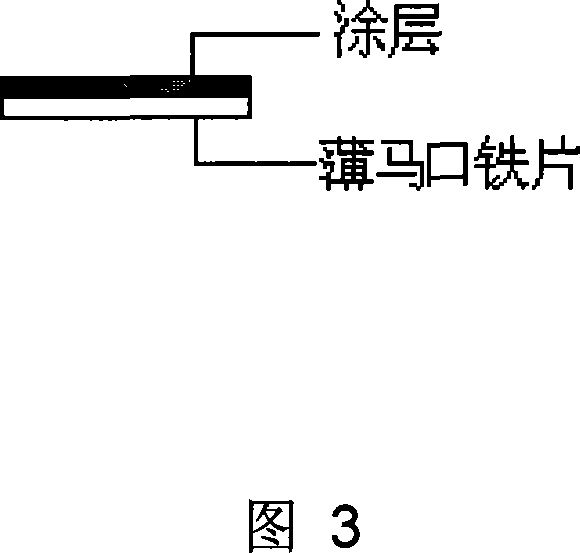

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

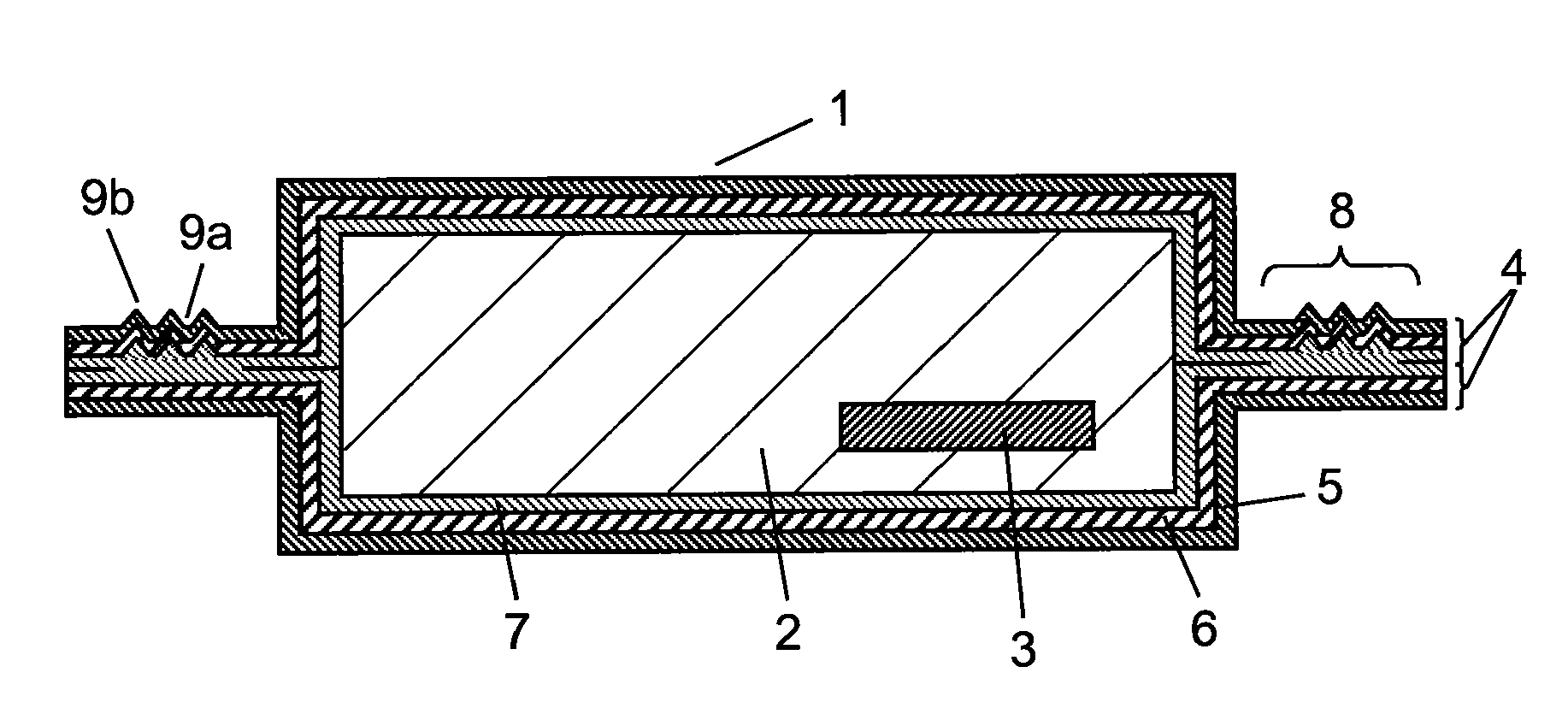

Surface-mounting ceramic electronic component

InactiveCN101051565ANot easy to peel offHigh mechanical strengthFixed capacitor electrodesStacked capacitorsFritSurface mounting

One inventive aspect relates to a surface-mounting ceramic electronic component including a terminal electrode structure which improves the mechanical strength of the electronic component. In the terminal electrode structure, an intermediate metal layer is formed on a base metal layer, and a conductive resin layer is formed thereon. A surface of the base metal layer in which a common material, an oxide film, glass frit or the like exists is covered with the intermediate metal layer, and the conductive resin layer is adhered to the intermediate metal layer as a tight metal surface.

Owner:TAIYO YUDEN KK

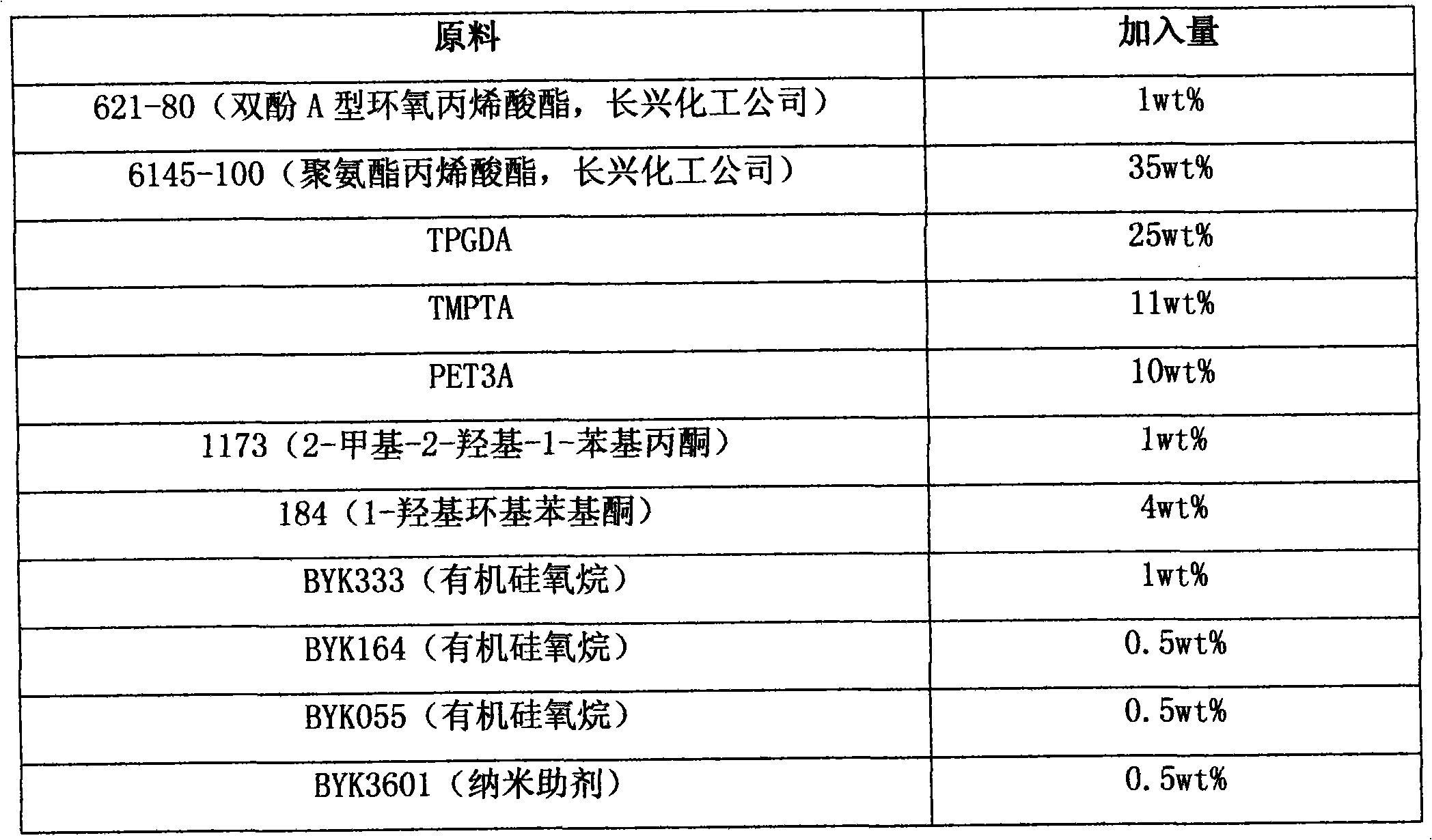

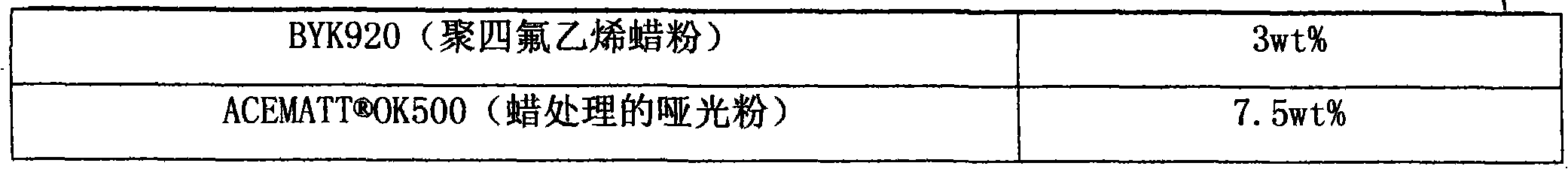

Ultraviolet curing coating

InactiveCN101638554AImprove anti-pollution performanceEasy to cleanPolyurea/polyurethane coatingsEpoxy resin coatingsUrethane acrylatePhotoinitiator

The invention relates to an ultraviolet curing coating which is characterized in that the ultraviolet curing coating comprises 1-35 wt% of epoxy acrylate, 1-35wt% of urethane acrylate, 20-50wt% of polyfunctional acrylate monomer, 1-15wt% of additive and 1-10wt% of photoinitiator. The coating formed by ultraviolet curing coating obtained by adopting the technical scheme has the advantages of good pollution resistibility, easy cleaning, high strength, strong adherence, high toughness and difficult stripping.

Owner:FOSHAN SHUNDE HEYGEY LIGHT CURING MATERIALS

Light emitting device

InactiveUS20070262336A1Small height differenceImprove adhesionDischarge tube luminescnet screensLamp detailsFiberLight emitting device

A light emitting device includes a package having a recessed portion defined by a bottom surface and a side surface and a light emitting element mounted on the bottom surface of the recessed portion, in which the package has fibrous fillers, and at least some of the fillers are projected outwards through the side surface and coated with a reflection film made of metal.

Owner:NICHIA CORP

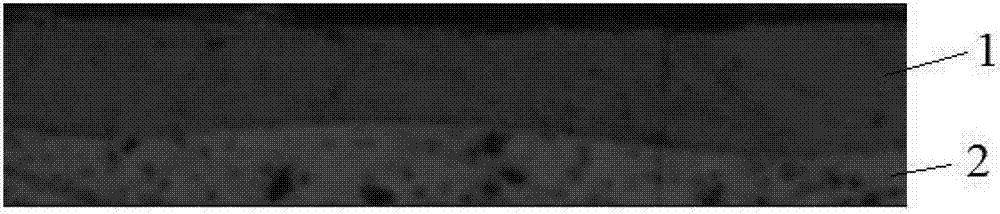

High-barrier layer flexible packaging film for isolating contents of polymer lithium battery

The invention provides a high-barrier layer flexible packaging film for isolating contents of a polymer lithium battery. The high-barrier layer flexible packaging film comprises at least two kinds of films which are combined to form a layer of composite film, wherein the composite film comprises a basic layer, a functional layer and a heat sealing layer; the high-barrier layer flexible packaging film is characterized in that: the basic layer is a copolymer film prepared by combining at least two film base materials of PP (polypropylene), CPP (chlorinated polypropylene or casting polypropylene), PE (polyethylene), PET (poly(ethylene terephthalate)), PA (polyamide) or MXD6 (aromatic polyimide), MPE (elastomer blend), PVDC (polyvinyl dichloride), EVOH (ethylene-vinyl alcohol), PEN (polyethylene naphthalate) and GT, or by complexing pairwise; and a high-barrier water-tolerant modified PVA (poly vinyl alcohol) coating film is coated on the copolymer film base materials. The high-barrier layer flexible packaging film has excellent gas barrier property, remarkably low oxygen permeability, water resistance, corrosion resistance, good high temperature resistance and great barrier property, and resists organic solvents and highly-volatile substances. In the invention, the high-barrier PVA is preferably coated on various base materials to obtain a base layer serving as a high-barrier layer which has great barrier property and excellent performance in resisting gas, water, corrosion, ultraviolet rays and the like.

Owner:刘继福

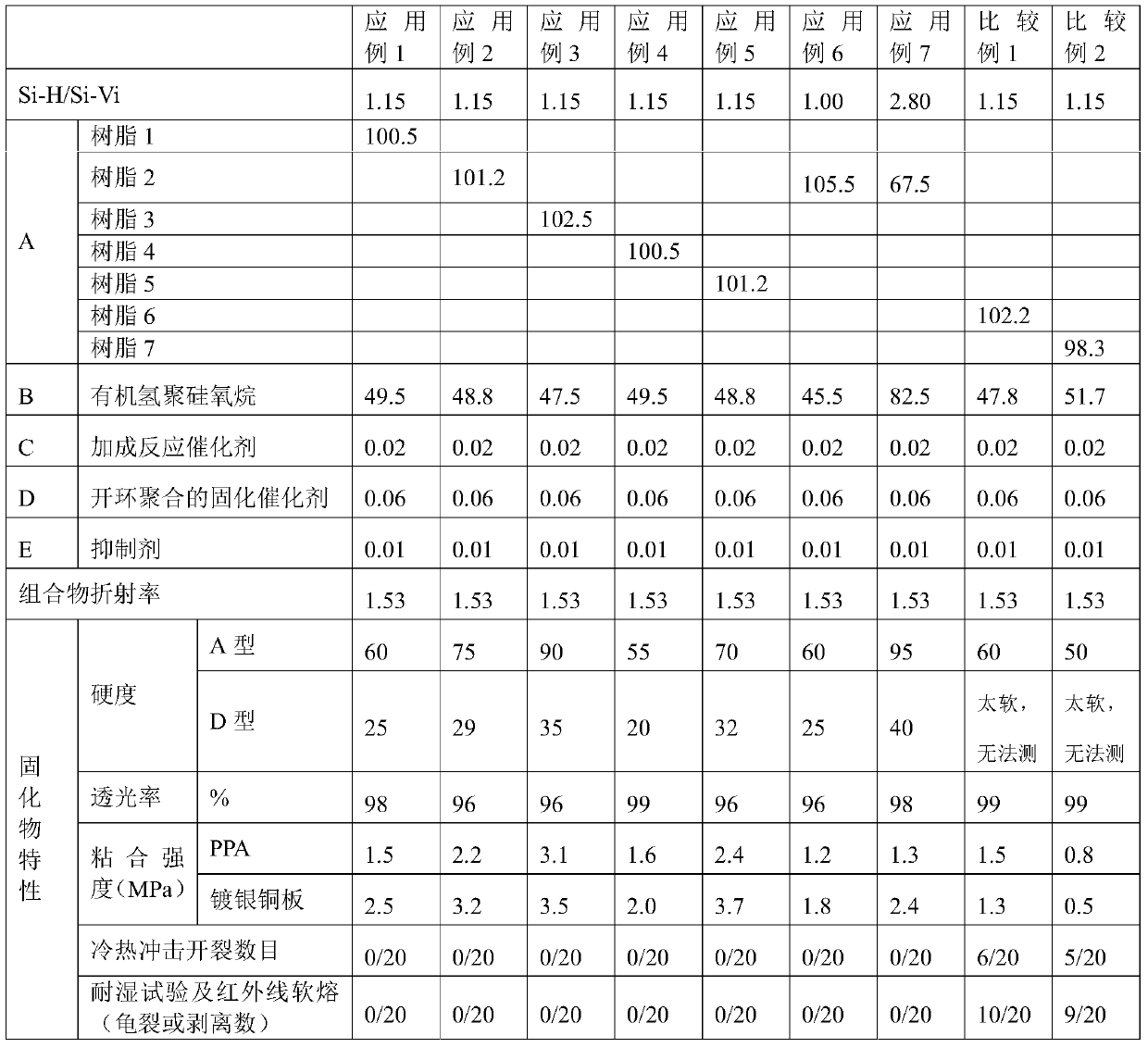

Organic silicone resin, curable organopolysiloxane composition and application

The invention discloses an organic silicone resin, a curable organopolysiloxane composition and an application. A structural formula of the organic silicone resin is shown as formula I. The curable organopolysiloxane composition is obtained by mixing the organic silicone resin with an organic silicone compound having at least two hydrogen atoms bonded with a silicone atom in one molecule. The curable organopolysiloxane composition can be applied on luminescent semiconductor package. The curable organopolysiloxane composition has the following advantages of excellent adhesive property, relatively strong hardness, excellent impact resistance, high transparency, little color change in a heat resistance test and high luminescent efficiency. Besides, the curable organopolysiloxane composition is not easy to peel off in a thermal shock test and presents excellent adhesive power in adhesive experiments with PPA and metal. The formula I is R1R22SiO(R3SiO3 / 2)a(SiO4 / 2)b(R42SiO)cOSiR22R1.

Owner:GUANGZHOU HUMAN CHEM

Underwater solventless epoxy anti-corrosive coating and preparation method thereof

InactiveCN101619189AGood flexibilityStrong adhesionAntifouling/underwater paintsPaints with biocidesEpoxyPliability

The invention relates to an underwater solventless epoxy anti-corrosive coating and a preparation method thereof. The coating contains A component and B component and comprises the following components by weight percent: 20-25% of epoxy resin E-51, 12-17% of epoxy resin E-44, 3-8% of epoxy active diluent, 3.5-5% of plasticizer, 10-16% of talcum powder, 10-15% of sericite powder, 1.0-1.6% of thixotropic agent, 2-4% of titanium dioxide, 0.5-1.0% of coupling agent, 0.5-1.2% of dispersant, 0.5-1.2% of defoaming agent, 0.1-0.5% of carbon black, 12-15% of 1085 curing agent and 5-8% of 810 curing agent; wherein, B component comprises 1085 curing agent and 810 curing agent and the remainder is A component. The preparation method comprises the following steps: separately preparing A component and B component and when using, mixing A component and B component in a weight ratio of 4:1 evenly to obtain the underwater solventless epoxy anti-corrosive coating. The invention has simple process, strong product adhesion, high mechanical strength and corrosion resistance; the coating can be especially used to coat members in water at a low temperature, has fast curing rate and good flexibility of coating film, and is hard to peel, thus being applicable to the protection of steel structures such as gates of hydroelectric power stations, sediment bottom sluices and the like and concrete structures.

Owner:QINGDAO PACIFIC OCEANEERING CO LTD

Roasting sagger for circulating type lithium battery anode material and preparation method thereof

ActiveCN103311498AGood chemical inertnessStrong alkali corrosion resistanceElectrode manufacturing processesCharge supportsMulliteCordierites

The invention discloses and provides a roasting sagger for a circulating type lithium battery anode material, which is simple in manufacturing process and structure, does not easily react with a lithium battery material, can avoid polluting the lithium battery material, does not pollute the environment and can be recycled, and a preparation method thereof. The preparation method of the roasting sagger for the circulating type lithium battery anode material comprises the following steps of: (1) uniformly mixing mullite, cordierite, aluminum oxide, corundum, kaolin, active magnesium oxide, spodumene and a bonding agent; adding the materials into a metal mould according to the weight; and pressing and molding a blank by pressing and molding equipment; (2) uniformly mixing zirconium oxide, the spodumene, cerium oxide, the corundum and the bonding agent; uniformly distributing the materials on the surface of the blank by a material distribution machine or manpower and pressing again by the pressing and molding equipment to obtain a semi-finished sagger product; and (3) drying the sagger semi-finished product and sintering. The roasting sagger disclosed by the invention can be widely applied to the field of the sagger for the lithium battery anode material.

Owner:李艳晖

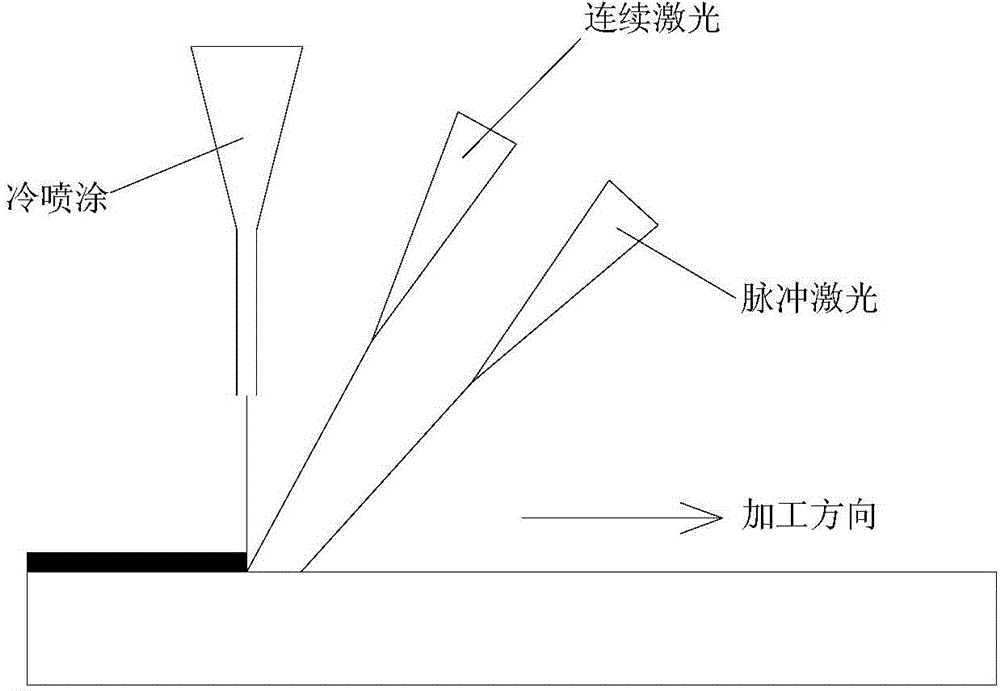

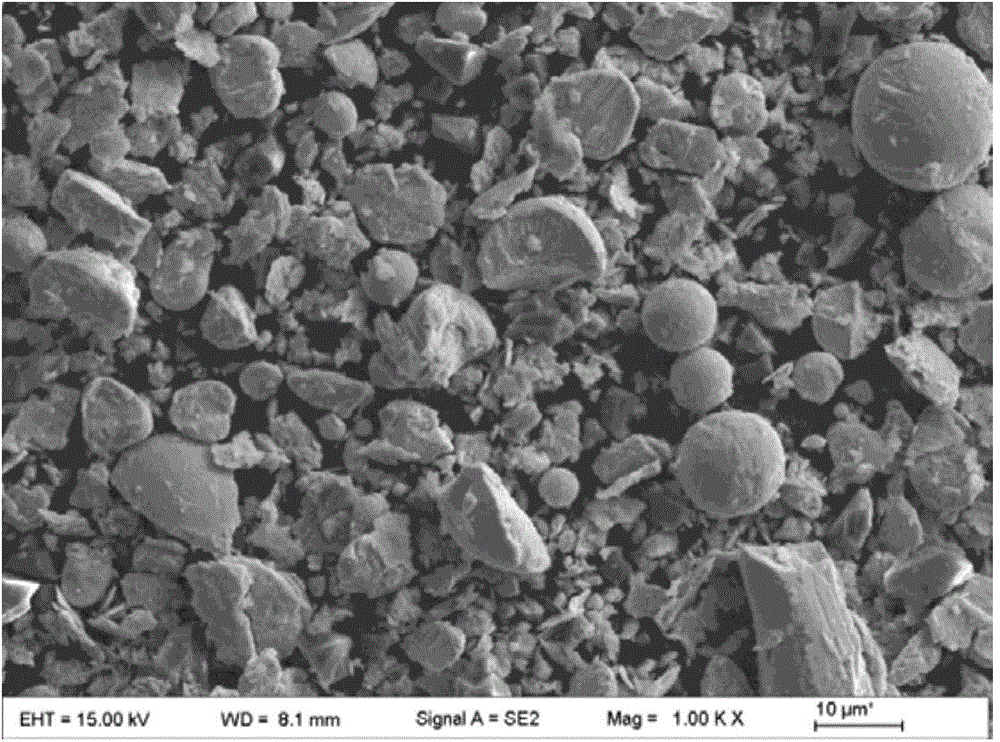

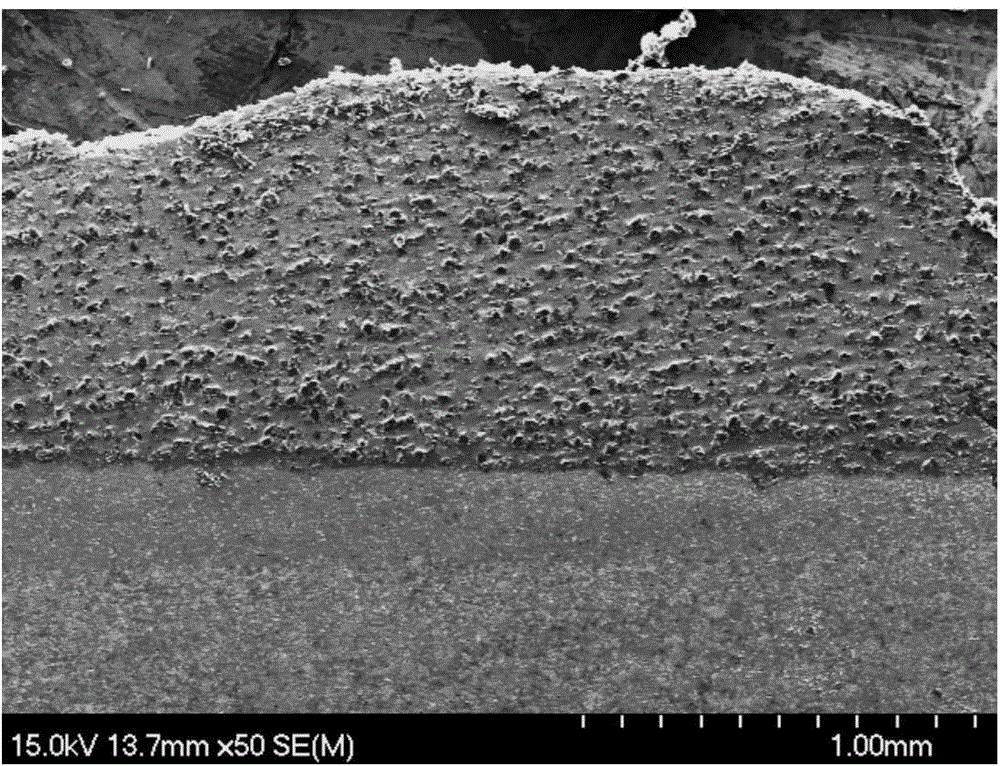

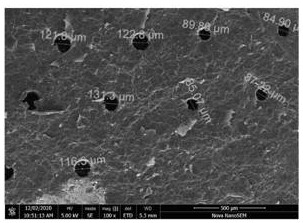

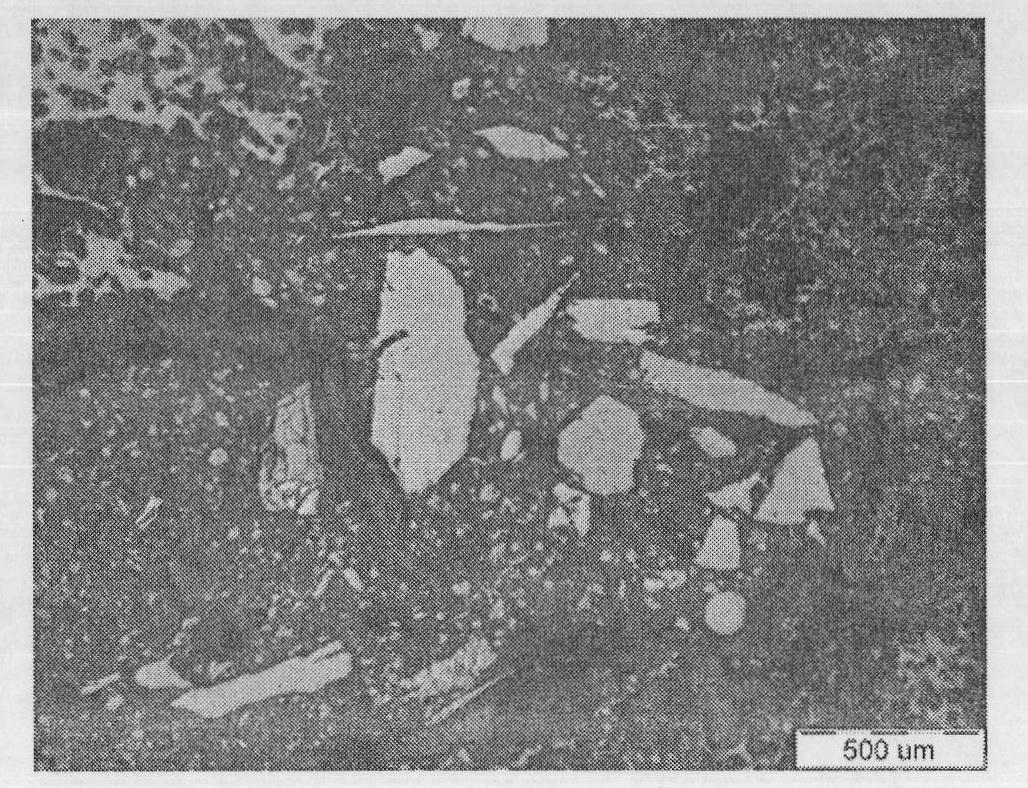

Metal-based/diamond laser composite coating and preparation method thereof

ActiveCN104018156AAvoid easy decompositionInhibition of dissolutionMovable spraying apparatusLaser beam welding apparatusCompound aHardness

The invention discloses a metal-based diamond laser composite coating and a preparation method thereof. The preparation method comprises the following steps: firstly selecting high-hardness metal powder and diamond powder with proper grain size and shape, uniformly mixing the high-hardness metal powder and the diamond powder by using a ball-milling method, and finally preparing the composite coating on a matrix by using a method of synchronously compounding a laser texturing technology, a laser heat treatment technology and a cold spraying technology. The thickness of the composite coating is over 1mm, and the diamond volume content in the coating is more than 45%. The preparation of the composite coating by using the high-hardness metal powder as the diamond binding phase is realized, and the binding strength of the composite coating and the matrix is improved through the pulse texturing treatment, and finally the stable and high-quality high-hardness metal-based / diamond composite high wear-resisting coating is prepared, and the integration, the automation and the efficiency of the matrix surface treatment and the coating deposition treatment are realized.

Owner:ZHEJIANG UNIV OF TECH +1

Method for manufacturing soft magnet silicon-aluminium magnetic powder core

InactiveCN1622236ADoes not affect electromagnetic performanceReduce curing stressInorganic material magnetismInductances/transformers/magnets manufactureAl powderBreaking strength

The production process of soft magnetic Fe-Si-Al powder core includes the steps of compounding magnetic powder in different sizes, surface treatment, mixing magnetic powder, insulating agent, adhesive and demolding agent, molding, curing, magnetic heat treatment, soaking and surface coating. The present invention has the advantages of: breaking strength after curing in radial direction of 7-12 kg, less surface stripping, small demolding force, final breaking strength in radial direction of 17-24 kg, no influence of the insulating lacquer on electromagnetic performance and capability of realizing automatic production.

Owner:王锋 +1

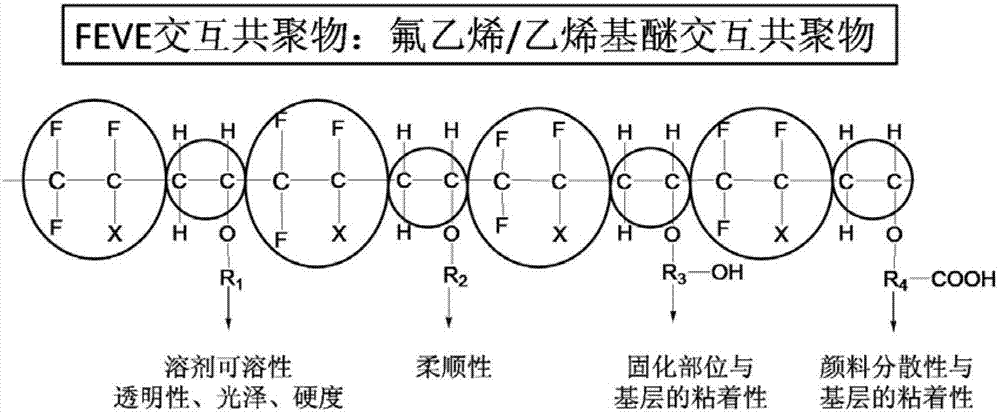

Self-cleaning super-weather-proof powder paint and preparation method thereof

ActiveCN103194140AImprove stabilityProtect against agingPowdery paintsPolyester coatingsPolyesterAging resistance

The invention belongs to the field of powder paints and particularly relates to a self-cleaning super-weather-proof powder paint. The self-cleaning super-weather-proof powder paint comprises a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system in a weight part ratio of 4:1-1:4, wherein the fluorocarbon resin particle system contains TiO2 nano-particles. As carboxyl-terminated polyester is introduced into a pure fluorocarbon paint, the phase separation occurs in a solidification process, and the fluorocarbon resin floats up to the surface of a coating to serve as coating protection and ageing resistance; the carboxyl-terminated polyester and the like and a substrate can be well wetted, so that the coating and the substrate can be well adhered and can hardly crack and spall; as the TiO2 nano-particles only exist in a fluorocarbon phase, the resin on a bottom layer cannot be broken, and the excellent stability of the system is guaranteed; and the TiO2 nano-particles are scattered in a dry blending manner, and the complex preprocessing is avoided, so that the preprocessing process can be greatly shortened, the cost is lowered, and the efficiency is improved.

Owner:NINGBO SOUTH SEA CHEM

Electromagnetic shielding heat-dissipation film and manufacturing method thereof

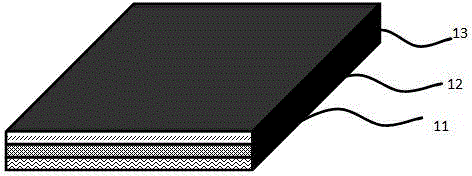

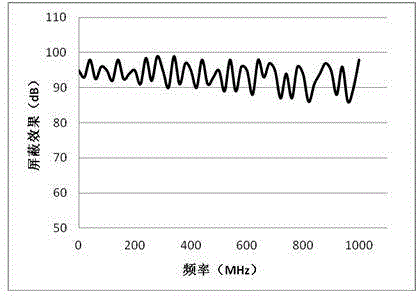

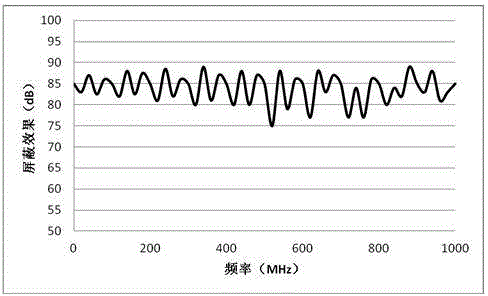

ActiveCN104981138AImprove cooling effectImprove shielding effectMagnetic/electric field screeningCooling/ventilation/heating modificationsGas phaseOptoelectronics

The invention provides an electromagnetic shielding heat-dissipation film and a manufacturing method thereof. The electromagnetic shielding heat-dissipation film comprises a heat-dissipation film layer, a shielding film layer and a wave-absorbing film layer, wherein the heat-dissipation film layer is a synthetic graphite film, the shielding film layer is a metal film, and the wave-absorbing film layer is an organic binder film mixed with soft magnetic material powders. The method for manufacturing the electromagnetic shielding heat-dissipation film comprises the following steps: 1) attaching a heat-dissipation film to a smooth high-temperature-resistant film layer to form the heat-dissipation film layer; 2) depositing the metal film onto the surface of heat-dissipation film through a gas phase method or a liquid phase method or the combination of the two to form the shielding film layer; 3) coating organic binder mixed with the soft magnetic material powders onto the surface, wherein the metal film heat-dissipation film are deposited, and carrying out solidification under the function of high temperature or a catalyst; and 4) stripping the high-temperature-resistant film layer on the surface of the heat-dissipation film to obtain the electromagnetic shielding heat-dissipation film.

Owner:SUZHOU RIDEA MATERIAL TECH

Display panel

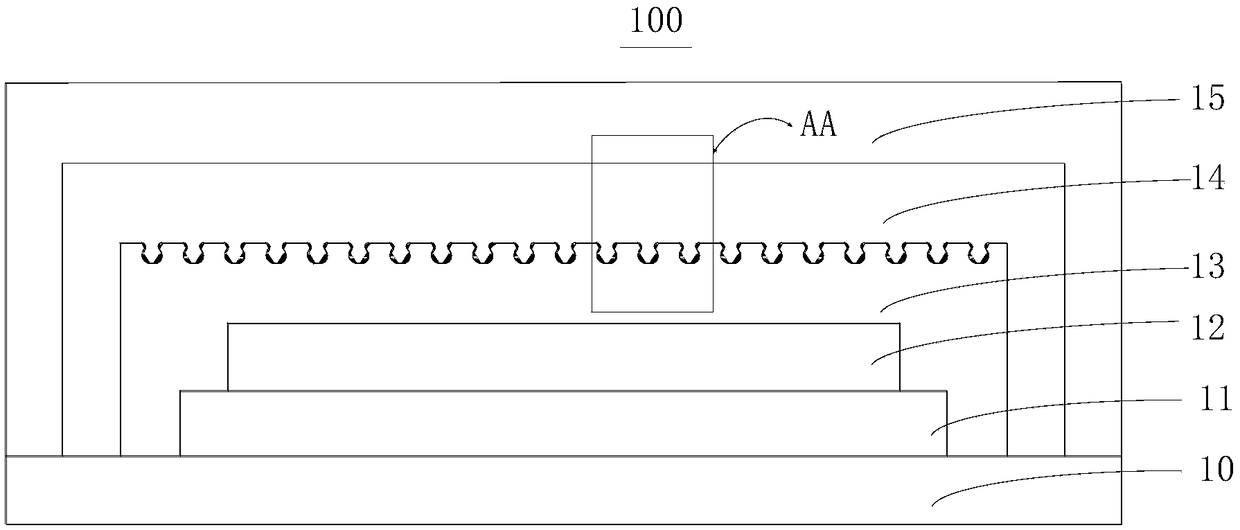

ActiveCN109273507AExtended service lifeImprove bindingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBond Force

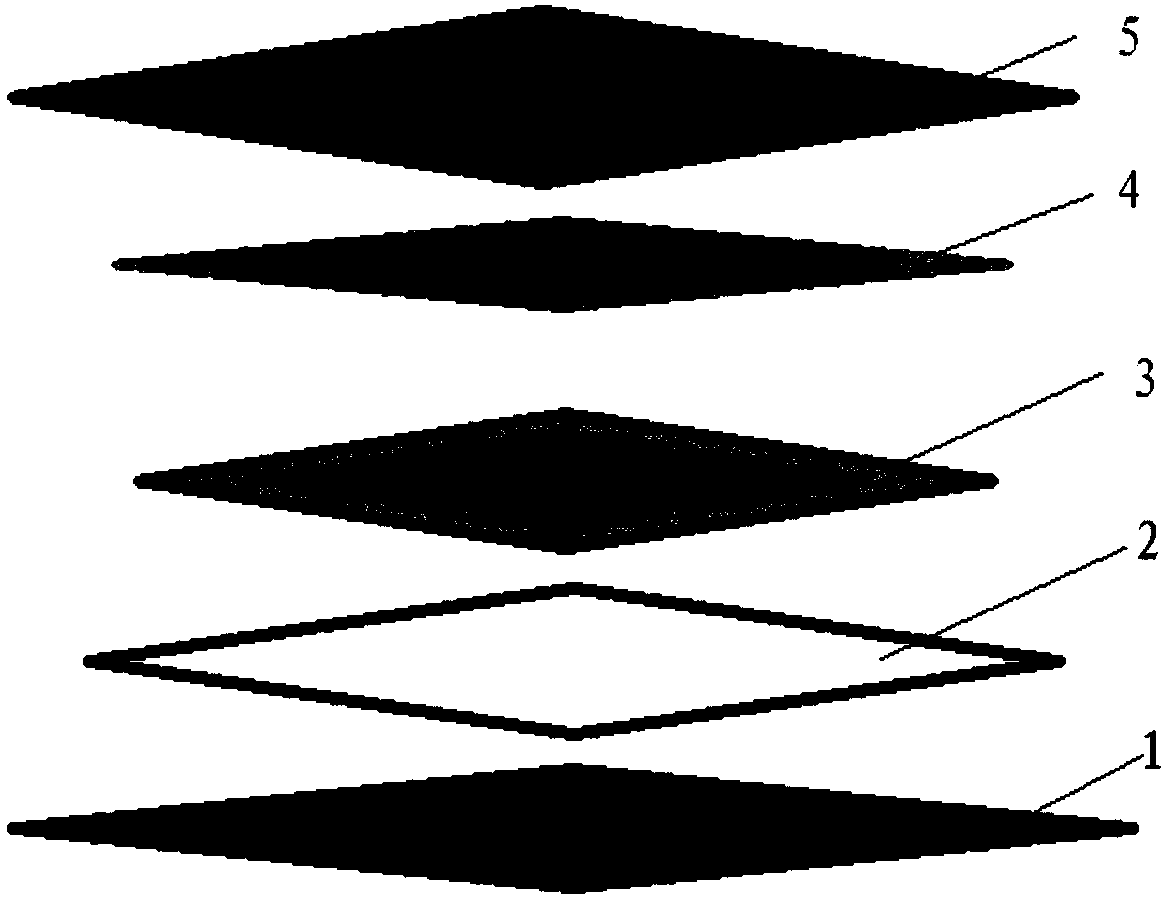

The invention discloses a display panel. The display panel comprises: a multilayer thin film layer; At least two adjacent thin film layer in that multilayer thin film layer have a concave surface anda convex surface respectively, and the concave surface and the convex surface are in concave-convex engagement, the diameter of the convex end part is larger than the diameter of the root part, and the shape of the concave inner space is matched with the convex shape. By the method, the bonding force between the thin film layers in the display panel can be improved, the thin film layers are not easy to be peeled off when the display panel is bent, and the service life of the display panel is prolonged.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

Cutting wire with composite structure, and manufacturing method and manufacturing equipment thereof

InactiveCN102310489ANot easy to peel offIncrease production speedFine working devicesThree-dimensional spaceEngineering

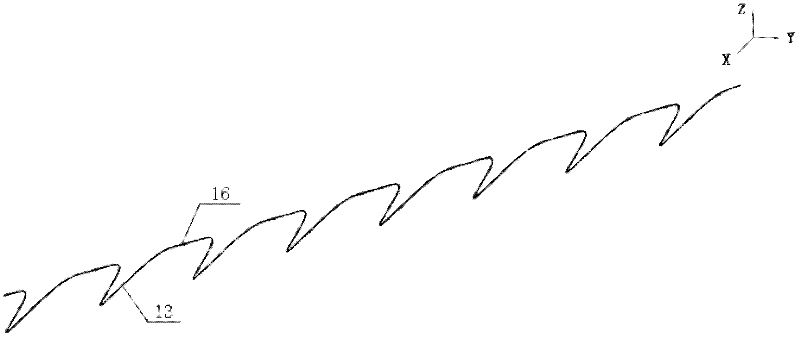

The invention discloses a cutting wire with a composite structure, and a manufacturing method and manufacturing equipment thereof. The cutting wire comprises a plurality of bent parts and curve parts, wherein adjacent bent parts are connected through the curve parts. The method comprises the following steps of: processing a metal wire into a linear metal wire; unwinding the linear metal wire along a central axis, passing through a first limiting group wheel, winding on a first deformed guide roller, applying pulling force, and bending the metal wire; and making the bent metal wire pass through a guide wheel, and unwinding the metal wire along the central axis. In the equipment, an unwinding disk, the limiting group wheel, the guide wheel, the deformed guide roller and a winding disk are arranged in sequence. In the invention, a plurality of concave regions are formed in a three-dimensional space through a three-dimensional structure of the cutting wire, thereby mortar grinding materials can be wrapped and carried efficiently and are prevented from easily falling off from the cutting wire, so that the production speed and efficiency of the cutting and fragmenting processes of silicon materials, jewels and the like are greatly increased, and the surface quality of fragmented materials can be effectively improved.

Owner:ZHENJIANG NAISI ADVANCE MATERIALS

Separation membrane for fuel cell, and method for production thereof

InactiveUS20110244367A1Small internal resistanceHigh output voltageFinal product manufactureSolid electrolyte fuel cellsIon exchangeElectrolyte

Disclosed is a membrane for a fuel cell, which comprises: a polymer electrolyte membrane which comprises a cross-linked anion-exchange resin having a strongly basic anion-exchange group such as a quaternary ammonium salt group, a quaternary pyridinium salt group and a quaternary imidazolium salt group; and a polymer which is attached on at least one surface of the polymer electrolyte membrane and has a weakly acidic group such as a polyacrylic acid. Also disclosed is a method for producing the membrane.

Owner:TOKUYAMA CORP

Conductive fabric and preparation method thereof

ActiveCN107938369AImprove wash resistanceImprove tensile propertiesTextiles and paperSurface layerLiquid metal

The invention provides a conductive fabric and a preparation method thereof. The conductive fabric comprises, from inside to outside, an adhesive force improving layer attached to the surface layer ofa fabric substrate, a liquid metal layer, an oxygen isolation protective layer and a packaging protective layer. The preparation method comprises: applying the adhesive force improving layer to the surface layer of a fabric substrate, coating the adhesive force improving layer with the liquid metal layer, coating the liquid metal layer with the oxygen isolation protective layer, and coating the oxygen isolation protective layer with the packaging protective layer. The coating manner includes spraying, brush coating, flow coating or printing. Compared with a conductive fabric in the prior art,the conductive fabric is excellent in conductivity, fold resistance, laundering durability and tensile property. The preparation method is simple and reliable.

Owner:BEIJING DREAM INK TECH CO LTD

Graphene foam film enhanced heat-conducting gasket and preparation method thereof

PendingCN113290958ALarge poresHigh porosityLamination ancillary operationsLaminationAdhesive cementPolymer science

The invention discloses a graphene foam film enhanced heat-conducting gasket and a preparation method thereof. The graphene foam film enhanced heat-conducting gasket comprises a plurality of layers of graphene foam films and adhesives filled in the graphene foam films and among the layers, and the graphene foam films account for 60-95 wt% of the total weight of the heat-conducting gasket. The graphene is arranged in the heat-conducting gasket in the thickness direction, and the gasket has good heat-conducting performance in the thickness direction; besides, the combination of the graphene foam film and the adhesive has good compressibility and compression resilience, and the application thermal resistance is small.

Owner:CHANGZHOU FUXI TECH CO LTD

Light thermal-shield refractory castable

InactiveCN101792294ALight weightImproved thermal shock stabilitySolid waste managementCapacitanceMullite

The invention relates to a light thermal-shield refractory castable comprising the following components in percentage by weight: 40-60% of light aggregate, 10-20% of capacitance mullite, 5-10% of kyanite powder, 5-10% of high-aluminium clinker powder, 3-8% of silica micro powder, 3-8% of alpha-Al2O3 micro powder, 5-10% of high-aluminium cement, 0.5-10% of high-aluminium refractory fibre containing zirconium, 1.5-4% of thermal-shield steel fibre, 0.1-1% of melamine and 0.05-0.1% of organic anti-explosion fibre, wherein the granularity of the capacitance mullite is less than or equal to 1 mm, both the granularity of the silica micro powder and the granularity of the alpha-Al2O3 micro powder are less than or equal to 5 mu m, and the chemical modified light aggregate is obtained by drying after the light aggregate is dipped in inorganic chemical solution or sol. The light thermal-shield refractory castable of the invention can improve the service life of a furnace roller, lowers production consumption cost, reduces non-working hours caused by exchanging rollers and improves production efficiency.

Owner:武钢集团有限公司

Conductive graphite cream and preparation method thereof

ActiveCN102618107AReduce carbon additionDoes not affect conductivityCellulose coatingsConjugated diene hydrocarbon coatingsConductive polymerGraphite

The invention discloses conductive graphite cream and a preparation method thereof, which solve the technical problem of improving dispersibility of graphite cream. The conductive graphite cream comprises materials including, in weight percent, 10-30% of conductive graphite, 1-30% of matrix resin, 0.1-5% of conductive polymer auxiliaries, 0.1-5% of dispersing auxiliaries and the balance solvents. The preparation method includes the steps: adding the conductive polymer auxiliaries into the solvents to obtain solution 1; adding the matrix resin into the solvents to obtain solution 2; adding the conductive graphite into the solution 2; adding the dispersing auxiliaries into the solution 2 for ball-milling; adding the solution 1 into solution 3; and performing ultrasonic oscillation, high-pressure dispersion and stirring to obtain the conductive graphite cream. Compared with the prior art, the conductive graphite cream and the preparation method have the advantages that nano carbon materials are added, ball-milling, ultrasonic oscillation and high-pressure dispersion are performed for assisting so that the conductive graphite cream is uniformly dispersed, and the preparation method is simple and low-cost.

Owner:BTR NEW MATERIAL GRP CO LTD

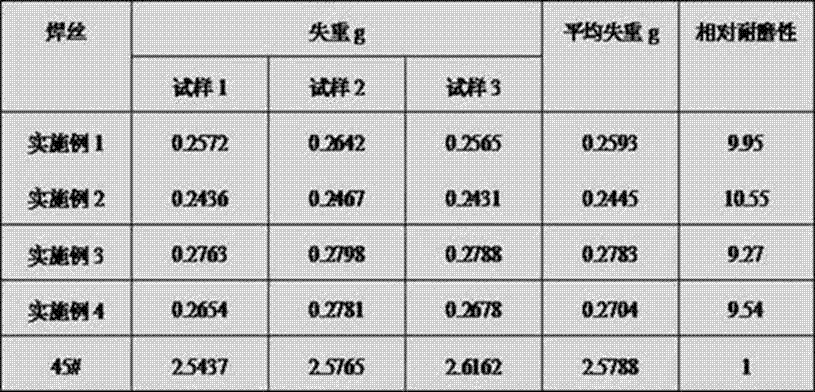

Wear-resistant overlaying flux-cored wire

InactiveCN104325232ASimple welding processA large amountWelding/cutting media/materialsSoldering mediaElectrolysisFerrosilicon

The invention relates to a wear-resistant overlaying flux-cored wire. The wear-resistant overlaying flux-cored wire comprises a low-carbon steel outer layer and a flux core inner layer, wherein the filling coefficient of a flux core is 45-55 percent, and the overlaying flux-cored wire is characterized in that the flux core comprises the following components in parts by weight: 1-6 parts of microcrystalline graphite, 1-4 parts of aluminum-magnesium alloy, 1-2 parts of fluoride, 1-2 parts of silicate, 1-3 parts of titanate, 1-2 parts of carbonate, 30-80 parts of high carbon ferro-chrome, 15-45 parts of metal chromium carbide, 5-10 parts of electrolytic chromium powder, 3-6 parts of high carbon ferromanganese, 1-4 parts of rare earth ferrosilicon, 2-6 parts of ferrosilicon, 4-10 parts of ferromolybdenum, 5-10 parts of ferrotungsten, 5-10 parts of ferrovanadium, 4-10 parts of ferrocolumbium, 4-10 parts of ferrotitanium and 1-4 parts of ferroboron. The wear-resistant overlaying flux-cored wire has the advantages of good hardness, wear resistance and anti-cracking performance.

Owner:李永锋

Threaded joint for steel pipes

InactiveUS20060197343A1Improve adhesionImprove the immunitySleeve/socket jointsPipe supportsEpoxyEngineering

A threaded joint for steel pipes comprises a pin (1) and a box (2) each having a threaded portion (3a or 3b) and an unthreaded metal-to-metal contact portion (4a or 4b) as contact surfaces which contact each other when the joint is fastened. The contact surfaces (3a and 4a and / or 3b and 4b) of at least one of the pin (1) and the box (2) are coated with a lower layer of a solid lubricating coating containing a solid lubricating powder (e.g., molybdenum disulfide, tungsten disulfide, or graphite) and a binder (e.g., an epoxy or other organic resin) and an upper layer of a solid corrosion protective coating formed by an organic resin which does not contain solid particles.

Owner:NIPPON STEEL CORP

Lead-free solder

InactiveCN1313802AHigh mechanical strengthReduce strainWelding/cutting media/materialsSoldering mediaCeramicBonding strength

A lead-free solder alloy substantially contains Sn and Ti, and has a temperature of a liquidus line of not greater than 400 DEG C. The lead-free solder alloy contains no toxic lead and has sufficient bonding strength to oxide materials such as glass and ceramics.

Owner:NIPPON SHEET GLASS CO LTD

Copper-clad board suitable for making hole with carbon dioxide laser, method of making hole in said copper-clad board and printed wiring board comprising said copper-clad board

InactiveUS6736988B1Not easy to peel offPromote absorptionInsulating substrate metal adhesion improvementLight absorption dielectricsSurface layerHigh absorption

A copper-clad board suitable for making a hole with a carbon dioxide gas laser, which copper-clad board is obtained by disposing a double-side-treated copper foil provided with a metallic-treatment layer having a high absorption rate of a carbon dioxide gas laser energy on at least one surface, at least on an outer layer of a thermosetting resin composition layer such that the metallic-treatment layer is formed on a shiny surface of the copper foil which shiny surface is to be a surface layer, and laminate-forming the double-side-treated copper foil and the thermosetting resin composition layer under heat and pressure, to make an alloy of the metallic-treatment layer and the copper by the above heating, a method of making hole in the above copper-clad board and a printed wiring board comprising the above copper-clad board.

Owner:MITSUBISHI GAS CHEM CO INC

Two-component urethane resin adhesive for polymer lithium ion battery flexible package film

InactiveCN102329594ANot easy to peel offPeeling does not affectPolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterStrong acids

The invention provides a two-component urethane resin adhesive for a polymer lithium ion battery flexible package film, and aims to provide an adhesive which has the advantages of high bonding strength, stripping resistance, excellent barrier property, impact resistance, high bonding compatibility with a nonmetallic film or an aluminum foil, resistance to swelling, dissolving, permeation and absorption of electrolyte organic solvents and high-volatility substances, resistance to strong acid and strong alkali and difficulty in breaking a molecular chain after becoming dry and hard. The two-component urethane resin adhesive consists of components, wherein a first component (A) is an emulsion waterborne Poly Urethane (PU) performed polymer which is obtained by compounding polyester and isocyanate / benzene ring-containing polyether in the mass ratio 75 / 25-55 / 45 and adding an aid for reacting; a second component (B) is a composition consisting of glycidyl ether epoxy resin with the epoxy resin 0.25-0.45 and a melamine-formaldehyde resin additional crosslinking agent; the weight ratio of the first component to the second component is 10 / 1-10 / 2; and a certain amount of additional crosslinking agent is added into a PU emulsion in a certain mass ratio.

Owner:刘继福

Hot press-formed article and method for its manufacture

ActiveCN1809650AIncrease production capacityGood lookingHot-dipping/immersion processesAbrasion apparatusSolderabilitySolid solution

The present invention provides a hot press formed product being improved in corrosion resistance and in the adhesion of a coating film, which is produced by subjecting a zinc-based metal plated steel product to a hot press forming, and has a zinc-based metal plating layer containing and, formed thereon, a zinc oxide layer, wherein the uppermost zinc oxide layer has an average thickness of 2 mum or less; and a hot press formed product being excellent in corrosion resistance, the adhesion of a coating film, the resistance to corrosion after coating, and weldability, which has a basis steel plate (1) and, formed thereon, a layer (2) consisting essentially of an iron-zinc solid solution phase and, as the uppermost layer, a zinc oxide layer (3) having an average thickness of 5 mum or less, and has substantially no iron-zinc intermetallic compound phase, wherein the iron-zinc solid solution layer (2) and the zinc oxide layer (3) contain Al in a total amount of 0.5 g / m<2> or less and / or contain Al oxides in a total amount of 5 mg / m<2> or less in terms of Al.

Owner:NIPPON STEEL CORP +2

Method for preparing carbon fiber paper for gas diffusion layer of fuel cell

InactiveCN101613982AImprove conductivityImprove breathabilitySpecial paperCell electrodesFiberPorosity

The invention discloses a method for preparing carbon fiber paper for a gas diffusion layer of a fuel cell, and belongs to the field of fuel cells. The prior carbon fiber paper cannot give consideration to air permeability and mechanical strength, and has the problems of crisp texture, low surface glossiness, easy peeling of chopped carbon fiber, high production cost, and the like. The method comprises the following steps: soaking a carbon fiber mat in an ethanol solution of phenolic resin to obtain a carbon fiber mat and phenolic resin prepreg; die-pressing the prepreg to obtain a carbon fiber paper blank, and then carrying out low-temperature carbonization treatment; soaking the carbonized carbon fiber paper blank in the ethanol solution of phenolic resin again, and curing the soaked carbon fiber paper blank; and finally carrying out high-temperature carbonization treatment to obtain the carbon fiber paper for the gas diffusion layer of the fuel cell. The carbon fiber paper prepared by the method has high porosity, air permeability, electric conductivity and tensile strength, and can be used as a substrate material for the gas diffusion layer of the proton exchange membrane fuel cell.

Owner:BEIJING UNIV OF CHEM TECH

Magnetic disk drive with cover seal and method for fabricating same

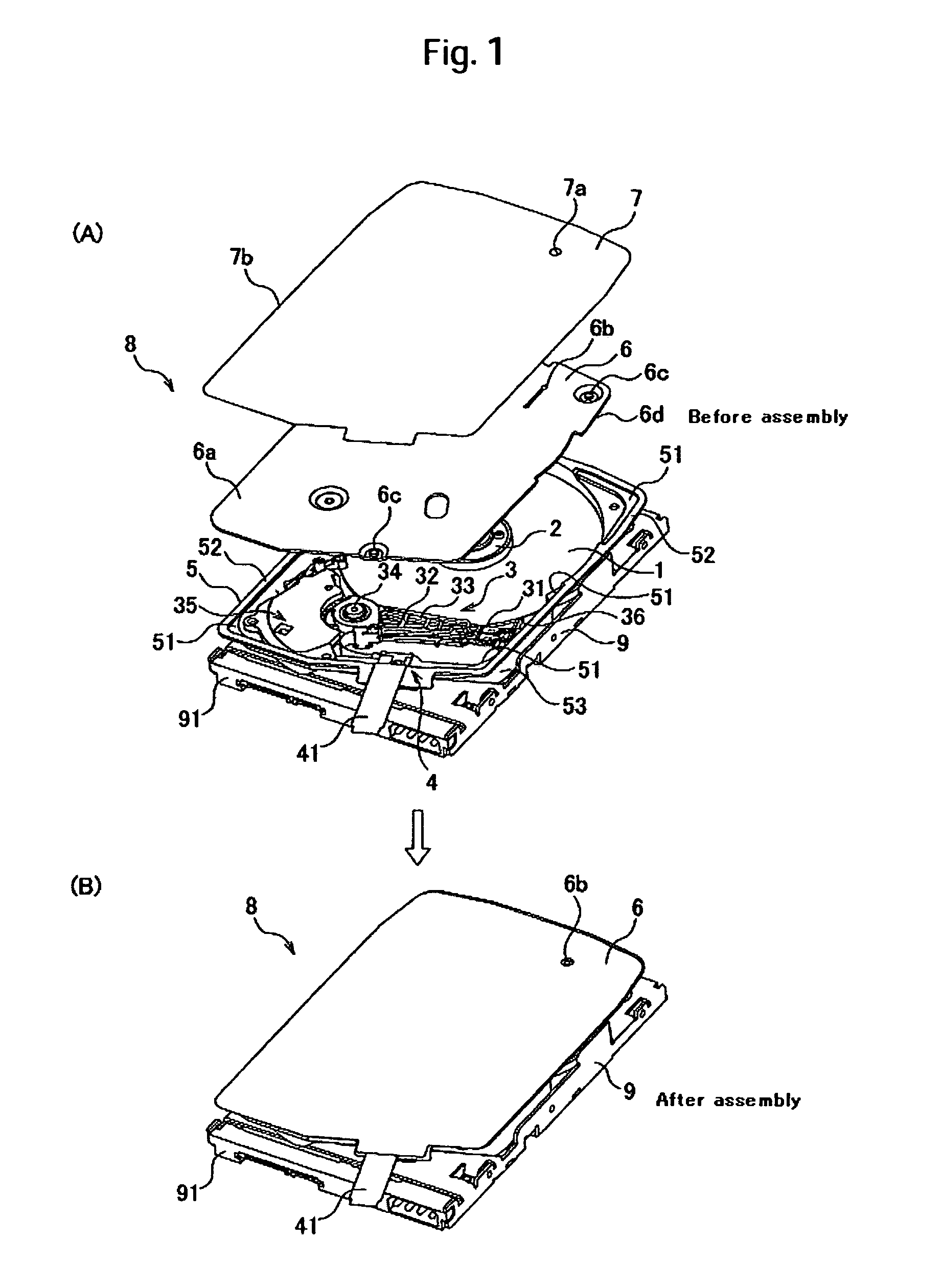

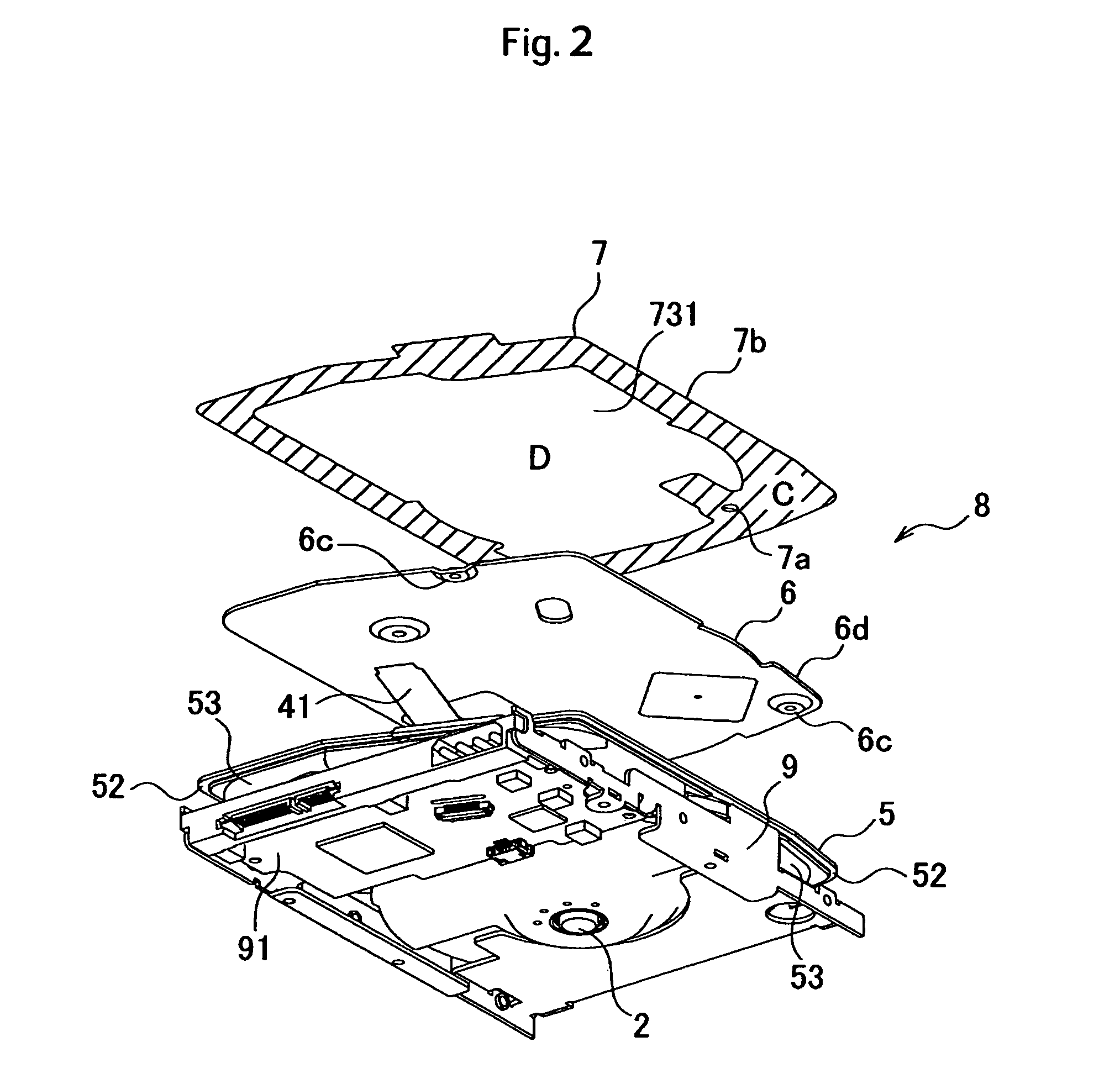

InactiveUS7522375B2Long working timeAdditional drawbackApparatus modification to store record carriersUndesired vibrations/sounds insulation/absorptionWork timeElectrical and Electronics engineering

Owner:WESTERN DIGITAL TECH INC

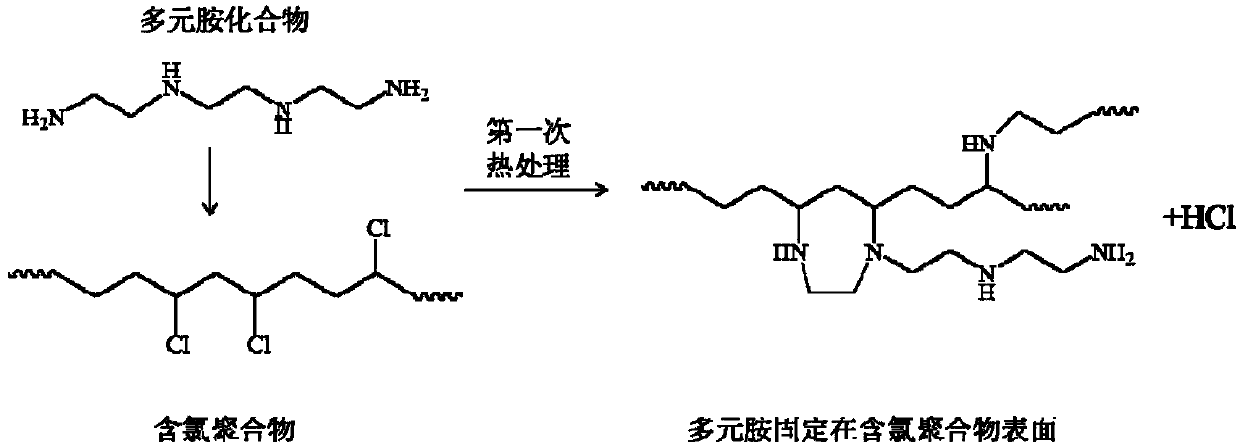

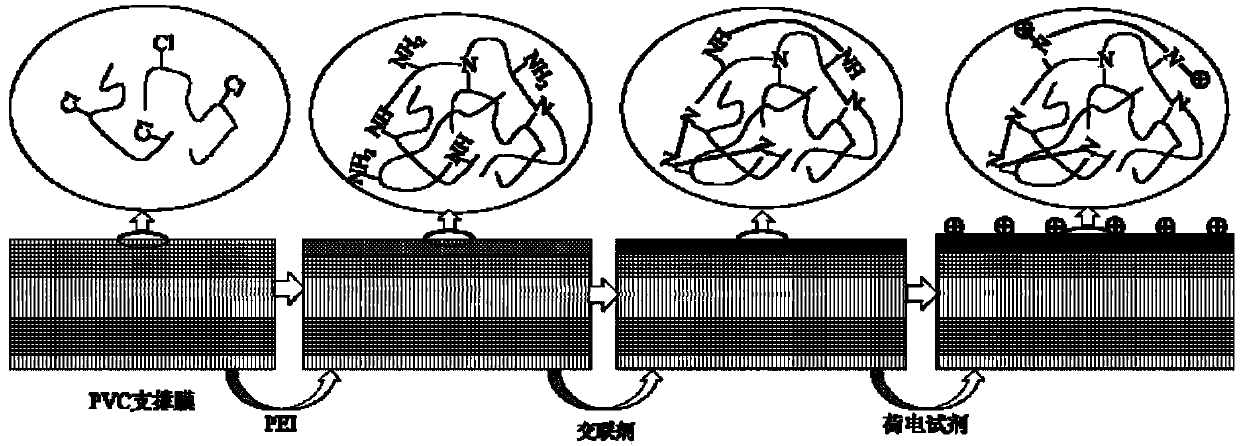

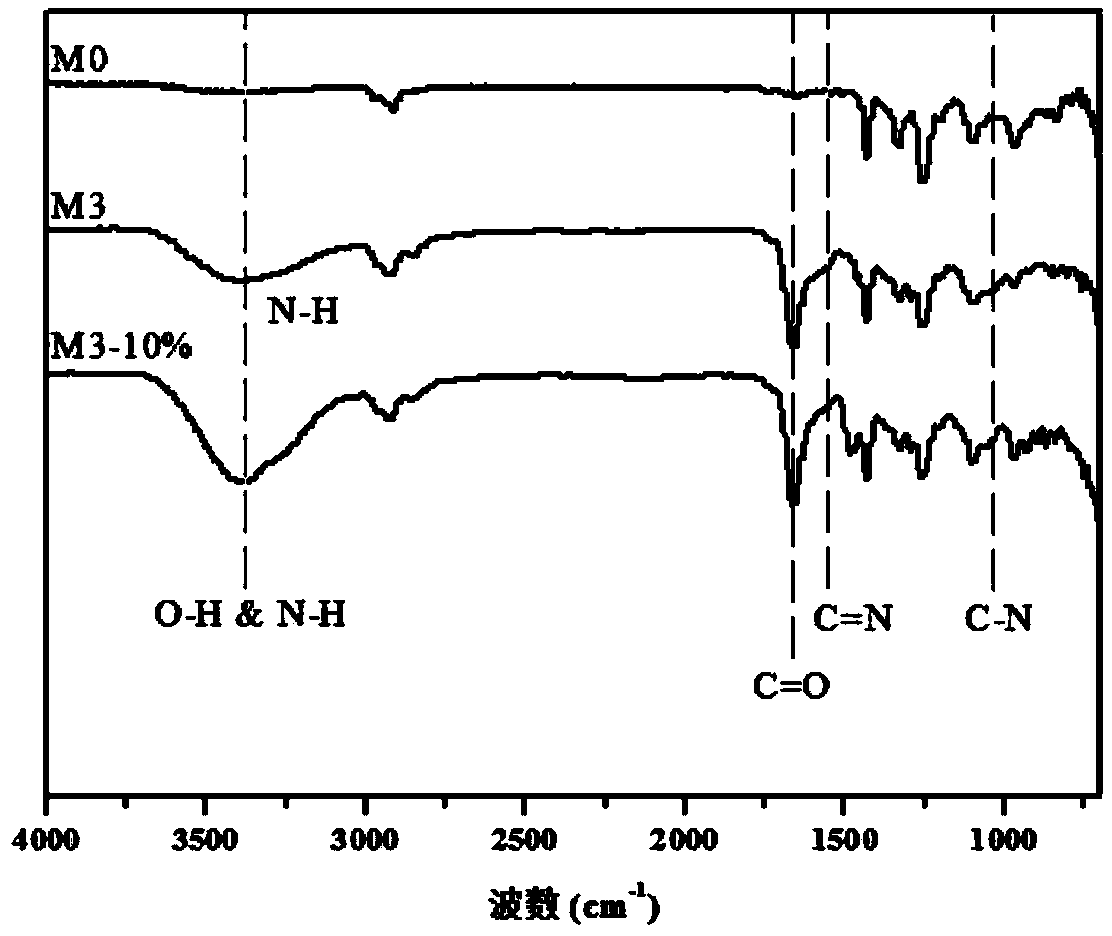

Low-pressure high-flux chlorine-containing polymer nanofiltration membrane with stable separation layer and preparation method thereof

The invention discloses a low-pressure high-flux chlorine-containing polymer nanofiltration membrane with a stable separation layer and a preparation method thereof. The nanofiltration membrane comprises a macroporous support layer and a dense function layer, wherein the macroporous support layer and the dense function layer are connected with each other by virtue of a C-N bond; the dense function layer is made of a positive, charged or amphoteric ionic cross-linking polyamine compound; the macroporous support layer is made of a chlorine-containing polymer. The preparation method of the filtration membrane comprises the following steps: firstly coating the surface of a chlorine-containing polymer ultrafiltration membrane with the polyamine compound, carrying out heat treatment, washing the ultrafiltration membrane, then dipping the ultrafiltration membrane in a mixed solution of a cross-linking agent and a charge reagent and carrying out heat treatment again. The membrane flux of the prepared polymer nanofiltration membrane can reach 60L / m<2>.h under the pressure of 0.3MPa; the retention rate on micromolecule dye and high-valence inorganic salt can reach 90%; the chlorine-containing polymer nanofiltration membrane can be in a flat fiber ultrafiltration membrane form or a hollow fiber ultrafiltration membrane form, and has good practical prospect.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com