Electromagnetic shielding heat-dissipation film and manufacturing method thereof

An electromagnetic shielding and heat-dissipating film technology, applied in the fields of magnetic field/electric field shielding, cooling/ventilation/heating transformation, electrical components, etc. Effect of heat dissipation and electromagnetic shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

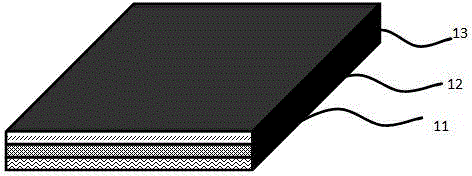

[0037] Example 1: as figure 1 As shown, the electromagnetic shielding heat dissipation film includes a heat dissipation film layer 11, a shielding film layer 12 and a wave-absorbing film layer 13, wherein the heat dissipation film layer 11 is a 25um graphite film with a thermal conductivity of 1600 W / m·k, and the shielding film layer 12 is a copper foil with a thickness of 20um, and the wave-absorbing film 13 is a film containing 80% by weight iron-nickel alloy powder and 20% by weight epoxy resin adhesive, with a thickness of 50mm and a magnetic permeability of 120 at 1MHz. .

Embodiment 2

[0038] Example 2: as figure 1 As shown, the heat dissipation film layer 11 in the electromagnetic shielding heat dissipation film is a 10um graphite film, and its thermal conductivity is 1900 W / m·k. The shielding film layer 12 is an aluminum foil with a thickness of 40um. The thin film of iron-nickel alloy powder and 30% by weight epoxy resin adhesive has a thickness of 30mm and a magnetic permeability of 90 at 1MHz.

Embodiment 3

[0039] Example 3: as figure 2 As shown, the electromagnetic shielding heat dissipation film includes a heat dissipation film layer 11, a shielding film layer 12 and a wave-absorbing film layer 13, wherein the heat dissipation film layer 11 is a 25um graphite film with a thermal conductivity of 1600 W / m·k, and the shielding film layer 12 is a copper foil with a thickness of 20um, and the wave-absorbing film 13 is a film containing 80% by weight iron-nickel alloy powder and 20% by weight epoxy resin adhesive, with a thickness of 50mm and a magnetic permeability of 120 at 1MHz. . A 25um PET protective film 14 (polyethylene terephthalate) is attached to the wave-absorbing film 13, a 10um acrylic adhesive double-sided adhesive 15 is attached to the surface of the graphite film 11 and PET coated with silicone oil on the contact surface. The release film layer 16 has a thickness of 50um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com