Graphene foam film enhanced heat-conducting gasket and preparation method thereof

A graphene foam and thermally conductive gasket technology, which is applied in the fields of thermal conductivity, thermal management materials, heat dissipation, and thermally conductive interface materials, can solve the problems of high hardness of thermally conductive gaskets, increased thermal resistance of gasket applications, thermal failure, etc., and achieves good results. Compressibility and compression resilience, ensure mechanical properties, and improve the effect of resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] In this embodiment, the graphene foam film accounts for 60wt.%, and the liquid silica gel 40wt.%.

[0081] Graphene foam film thermal conductivity 50W / (m K);

[0082] Graphene foam film thickness 50μm, density 0.1g / cm 3 ;

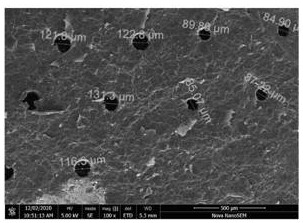

[0083] The average pore diameter of the internal pores of the graphene foam film is 10 μm, the pore diameter of the upper and lower through holes is 50 μm, and the center distance of the through holes is 300 μm;

[0084] The liquid silica gel is polydimethylcyclosiloxane, which is diluted with heptane to a viscosity of 1000mPa·s;

[0085] Curing temperature 150°C;

[0086] After testing, the porosity of the sample is 90%, and the thermal conductivity is 29W / (m K). The application thermal resistance and compression resilience of samples with different thicknesses are as follows:

[0087]

Embodiment 2

[0089] In this embodiment, the graphene foam film accounts for 95wt.%, and the liquid silica gel 5wt.%;

[0090] Graphene foam film thermal conductivity 460W / (m K);

[0091] Graphene foam film thickness 1000μm, density 0.9g / cm 3 ;

[0092] The average pore diameter of the internal pores of the graphene foam film is 100 μm, the pore diameter of the upper and lower through holes is 500 μm, and the center distance of the through holes is 1000 μm;

[0093] The liquid silica gel is polydimethylsiloxane, which is diluted with hexane to a viscosity of 30mPa·s;

[0094] Curing temperature 120°C;

[0095] After testing, the porosity of the sample is 50%, and the thermal conductivity is 326W / (m K). The application thermal resistance and compression resilience of samples with different thicknesses are as follows:

[0096]

Embodiment 3

[0098] In this embodiment, the graphene foam film accounts for 75wt.%, and the liquid silica gel 25wt.%.

[0099] Graphene foam film thickness 300μm, density 0.2g / cm 3 ;

[0100] The thermal conductivity of the graphene foam film is 102W / (m K);

[0101] The average pore diameter of the internal pores of the graphene foam film is 15 μm, the pore diameter of the upper and lower through holes is 100 μm, and the center distance of the through holes is 400 μm;

[0102] The liquid silica gel is α, ω-dihydroxy polydimethylsiloxane, which is diluted with tetrahydrofuran to a viscosity of 100mPa·s;

[0103] Curing temperature 80°C;

[0104] After testing, the porosity of the sample is 84%, and the thermal conductivity is 76W / (m K). The application thermal resistance and compression resilience of samples with different thicknesses are as follows:

[0105]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com