Heavy metal contaminated soil remediation agent and preparation method and application method thereof

A technology of polluted soil and application method, applied in the field of heavy metal polluted soil remediation agent and preparation thereof, can solve the problems of low removal effect and remediation efficiency, poor leaching effect, high chemical cost, etc. Inhibition of leaching, improved compatibility and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

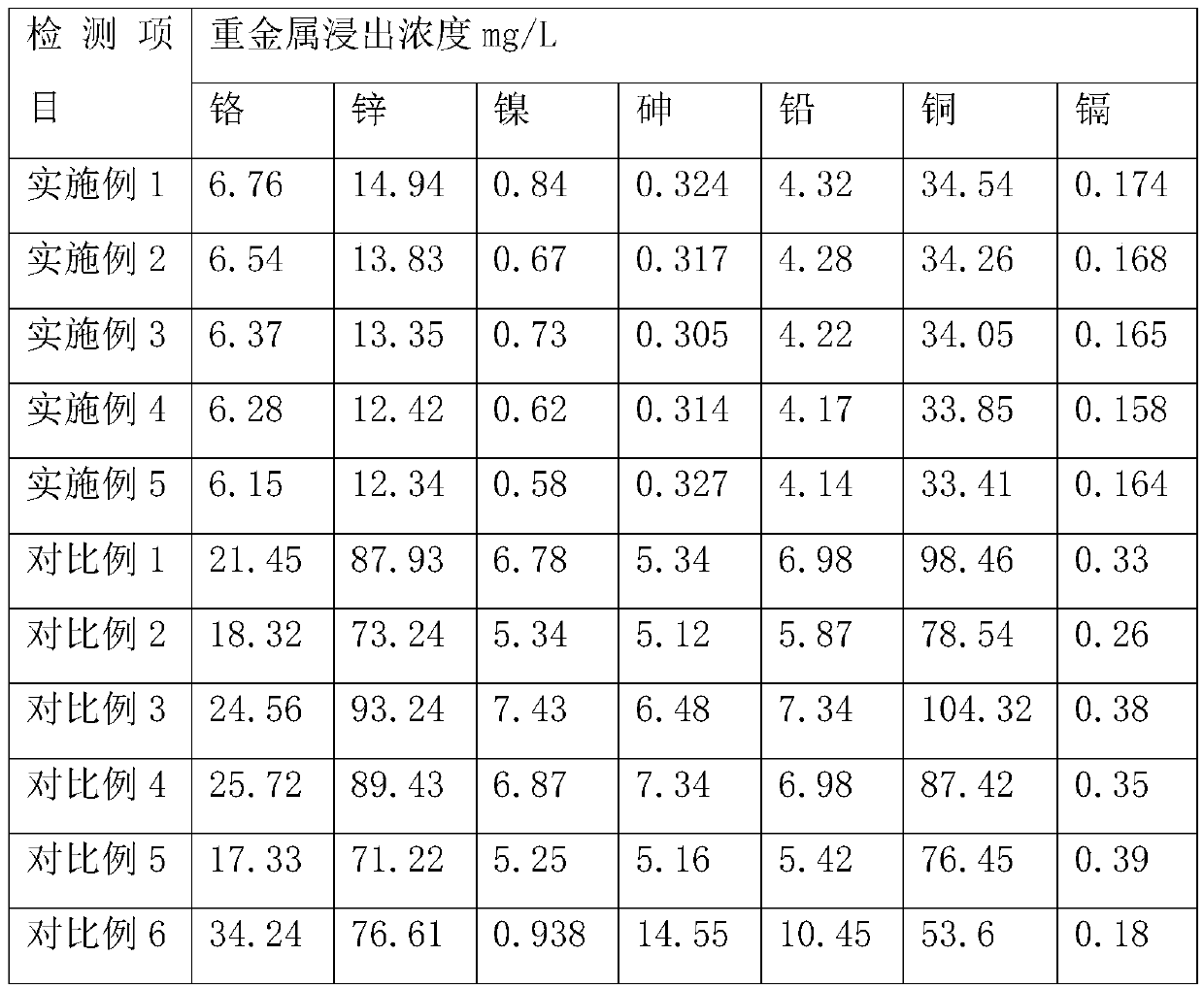

Examples

preparation example 1-3

[0046] Preparation Example 1-3 The resorcinol-formaldehyde resin is selected from the resorcinol-formaldehyde resin of the model A-250 sold by Shanghai Autong Industrial Co., Ltd., and the silane coupling agent KH-570 is selected from Guangzhou Zhongjie Chemical Industry Co., Ltd. Co., Ltd. sold the silane coupling agent KH-570 with the product number of 570, and the carbon nanotubes were selected from the carbon nanotubes with the product number of cnt700 sold by Beijing Deke Daojin Technology Co., Ltd.

preparation example 1

[0047] Preparation Example 1: (1) Put the calcium nitrate solution in a water bath at 40°C and heat it for 30 minutes. When the water bath is heated, add diamine hydrogen phosphate, keep stirring and add ammonia water, make the pH of the mixed solution 10, stir for 8 hours, transfer to a In a polytetrafluoroethylene-lined high-pressure steamer, hot-press at 100°C for 8 hours, filter, and wash the filtrate with deionized water until the conductivity is lower than 2mS·m -1 , making nano-hydroxyapatite, the mass ratio of calcium nitrate and diammonium hydrogen phosphate is 1:5;

[0048] (2) Add 0.8 kg of resorcinol-formaldehyde resin microspheres and 0.5 kg of lithium chloride to 5.5 kg of nano-hydroxyapatite, mix them at 50 ° C for 2 hours, and then add 1.2 kg of silane coupling agent KH -570 and 3.5kg carbon nanotubes, heated up to 80°C, mixed evenly, cooled to room temperature, and prepared nano-hydroxyapatite.

preparation example 2

[0049] Preparation Example 2: (1) Put the calcium nitrate solution in a water bath at 45°C and heat it for 25 minutes. When the water bath is heated, add diamine hydrogen phosphate, keep stirring and add ammonia water, make the pH of the mixed solution 10, stir for 8 hours, transfer to a In a polytetrafluoroethylene-lined high-pressure steamer, hot-press at 105°C for 7.5h, filter, and wash the filtrate with deionized water until the conductivity is lower than 2mS·m -1 , making nano-hydroxyapatite, the mass ratio of calcium nitrate and diammonium hydrogen phosphate is 1:6;

[0050] (2) Add 1.2 kg of resorcinol-formaldehyde resin microspheres and 0.8 kg of lithium chloride to 8 kg of nano-hydroxyapatite, mix and mix at 65 ° C for 1.5 h, then add 1.5 kg of silane coupling agent KH -570 and 4.5kg carbon nanotubes, heated up to 85°C, mixed evenly, cooled to room temperature, and prepared nano-hydroxyapatite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com