Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2591results about How to "Improve curing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for increasing mechanical strength of dielectric film by using sequential combination of two types of UV irradiation

InactiveUS20080220619A1Enhance porogen-removing effectHigh mechanical strengthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricLength wave

A method for increasing mechanical strength of a dielectric film includes: providing an initial dielectric film containing porogen; irradiating the initial dielectric film with first UV light having a first wavelength which is substantially or nearly similar to a maximum light absorption wavelength of the porogen for removing the porogen; and then irradiating the porogen-removed dielectric film with second UV light having a second wavelength which is shorter than the first wavelength, thereby increasing mechanical strength of the dielectric film.

Owner:ASM JAPAN

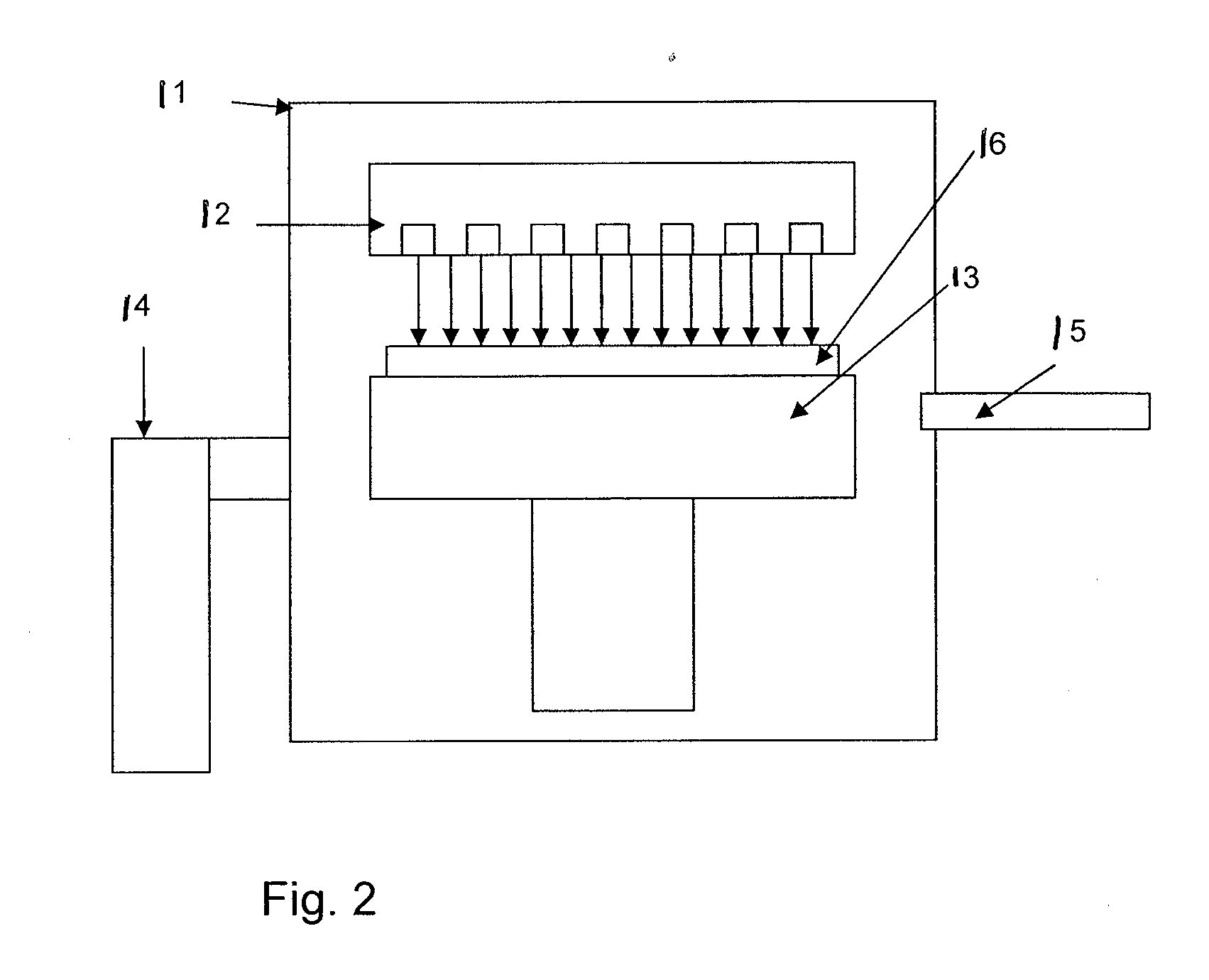

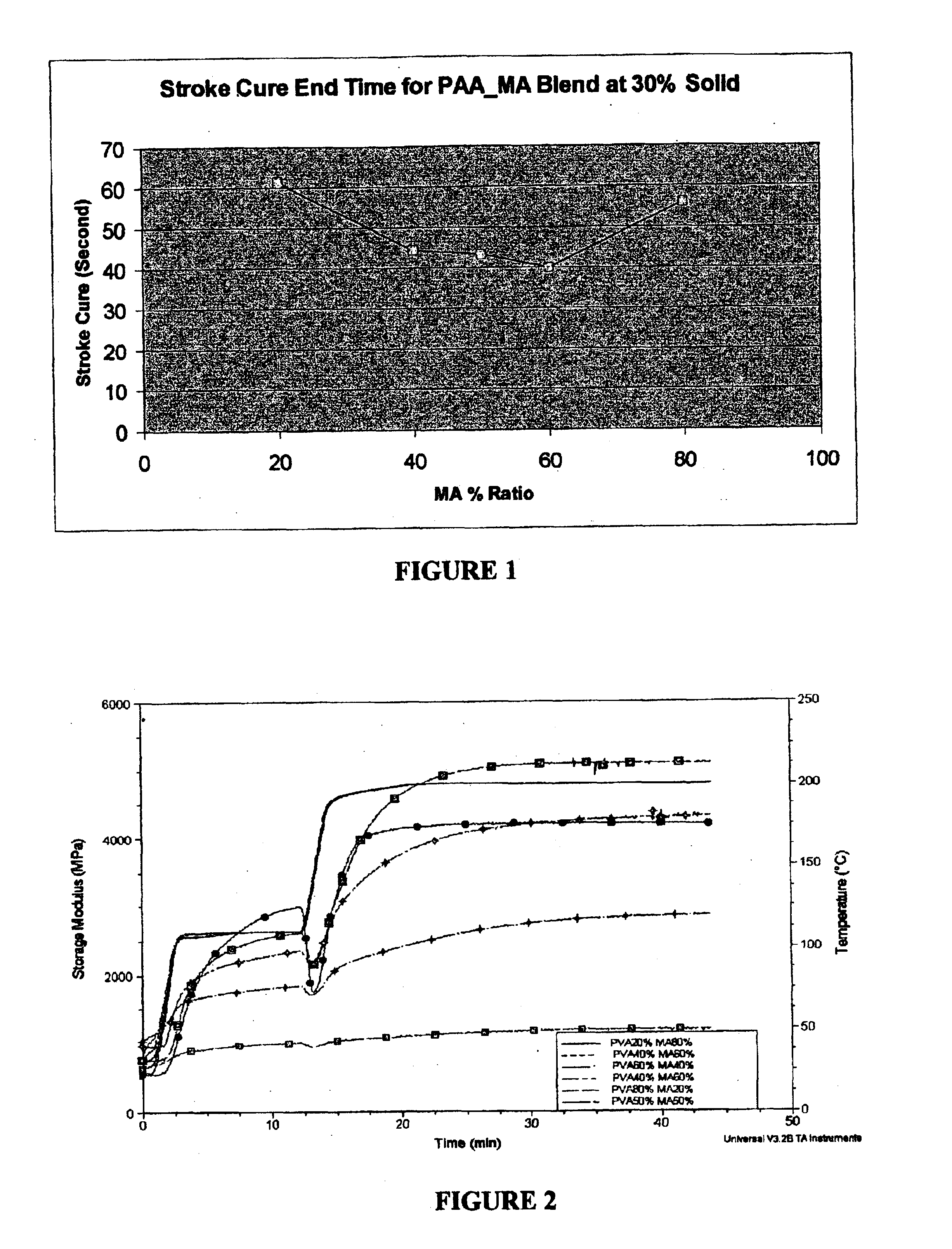

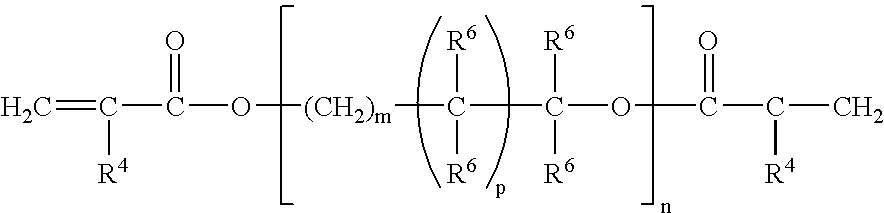

Poly alcohol-based binder composition

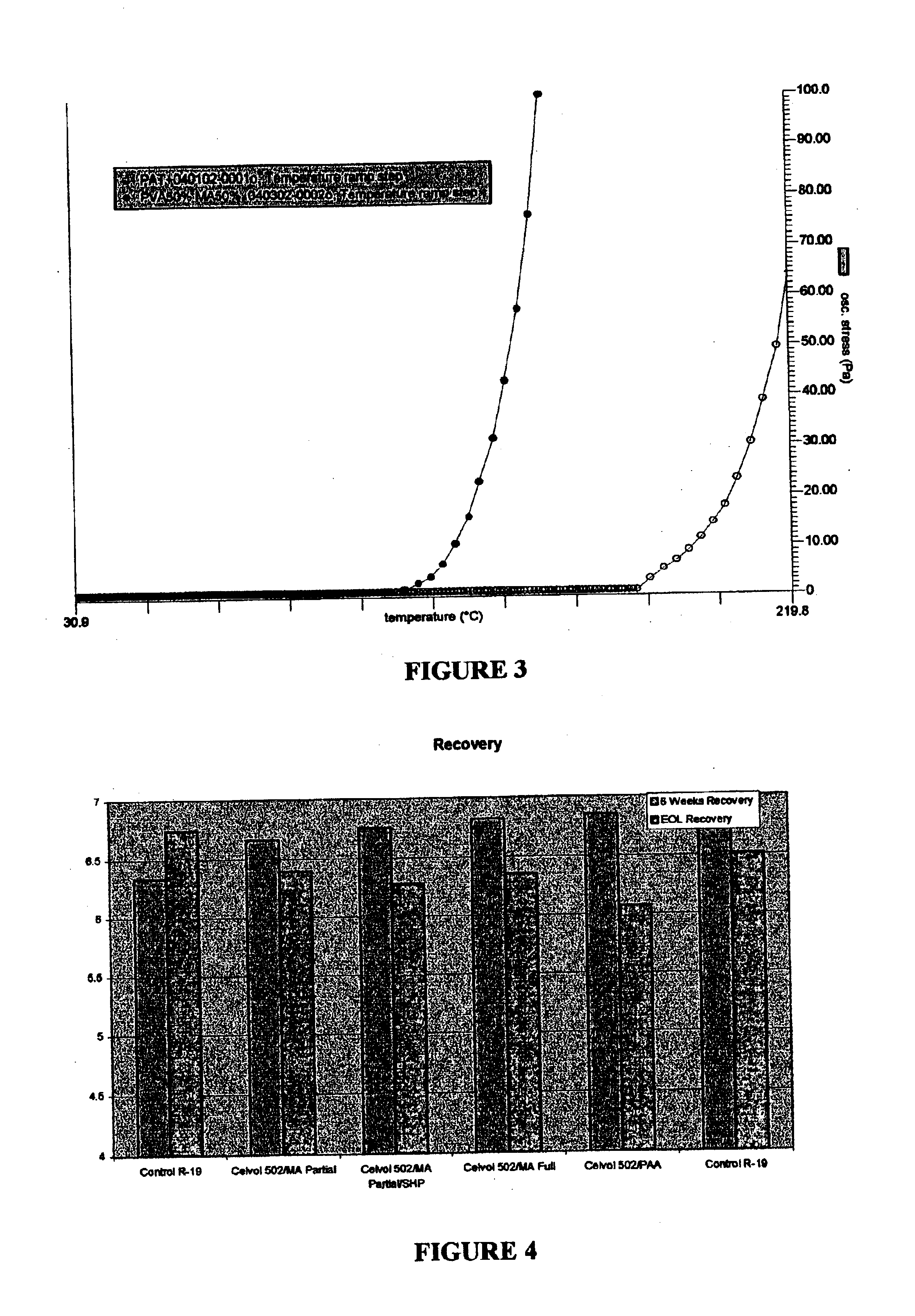

InactiveUS6884849B2Improve curing effectEmission reductionNon-fibrous pulp additionSynthetic resin layered productsAlcoholCarboxylic acid

The present invention provides a binder composition comprising a low molecular weight polycarboxylic acid, such as maleic anhydride, and a low molecular weight poly alcohol, such as polyvinyl alcohol, that exhibits improved cure performance with reduced emissions without sacrificing the performance of the final product or complication the manufacturing process. The binder composition may also incorporate a cure catalyst or accelerant such as sodium hypophosphite.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

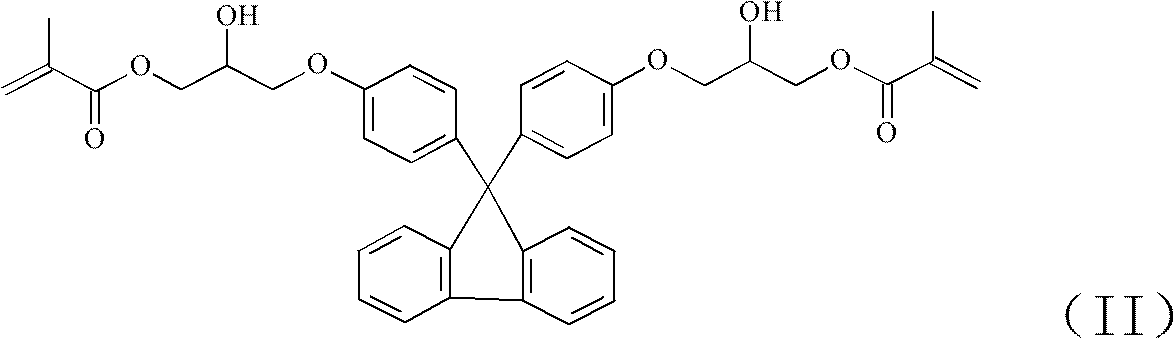

Photocurable Compositions

ActiveUS20070205528A1Reduce Shrinkage ProblemsHigh Tg cured propertyAdditive manufacturing apparatusNanostructure manufacturePhysicsRadiation exposure

An optical moulding process is disclosed comprising the sequential steps of: (a)(y) forming a layer of a photocurable composition; and (bXz) irradiating selected areas of the composition in the layer with radiation from a radiation source, thereby curing the composition in said selected areas and repeating the steps a) and b) on top of an earlier cured layer to form a three dimensional structure, wherein the radiation source used in step b) is a non-coherent source of radiation and wherein the photocurable composition comprises at least two curable components: (i) 45%-95% (and preferably at least 50%, more preferably at least 60%, e.g. at least 70%) by weight of the total curable components in the composition is a first component that is photocurable and that is such that, when cured in the presence of a photocuring initiator by exposure to UV radiation having an energy of 30 mJ / cm2, at least 90% of the component is cured within 50 milliseconds; and (ii) 5% to 55% (and preferably 10-40%, more preferably 15 to 30%, e.g. about 20%) by weight of the total curable components in the composition is a second component that results in the composition, on curing, shrinking, in a linear direction, by less than 3% and preferably that results in the composition having, after cure, a Tg of greater than 50° C., preferably at least 100° C. and more preferably at least 120° C.

Owner:3D SYST INC

Ink composition for ink jet recording and ink jet recording method

ActiveUS20140002556A1Good dispersionLow viscosityMeasurement apparatus componentsSpecial tyresLower limitSolvent

An ink composition for ink jet recording includes a coating film forming material, a polyether-modified silicone oil, and water, wherein the polyether-modified silicone oil is soluble in a solvent in which a lower limit of an SP value is 8.5 or less and an upper limit of the SP value is 18.0 or more.

Owner:SEIKO EPSON CORP

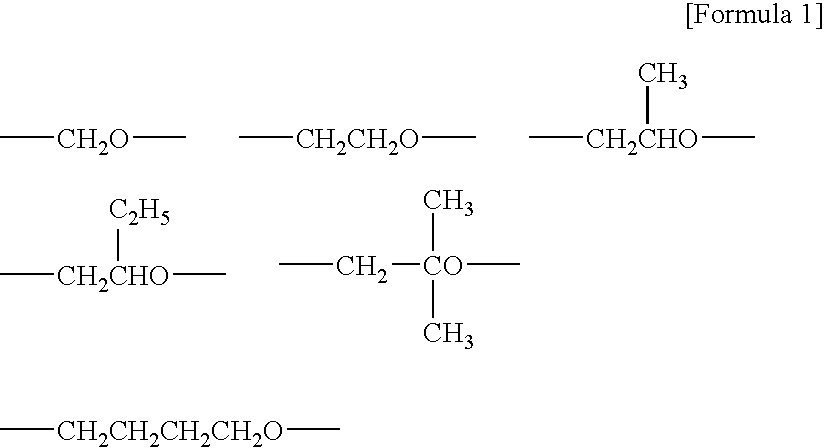

Thermopolymerizable composition for battery use

InactiveUS6562513B1Good storage stabilityHigh strengthCell electrodesFinal product manufactureMeth-Carbonate ester

The present invention provides (1) a thermopolymerizable composition containing a thermopolymerizable compound having (meth)acrylate having a moiety consisting of oxyalkylene, fluorocarbon, oxyfluorocarbon and / or carbonate group within the molecule, an electrolyte salt, an organic polymerization initiator having no benzene ring, and a polymerization retarder having vinyl group within the molecule, (2) a solid electrolyte obtained by heat-curing the composition, (3) a primary battery, a secondary battery and an electric double-layer capacitor each using the solid electrolyte, and processes for manufacturing the same.

Owner:SHOWA DENKO KK

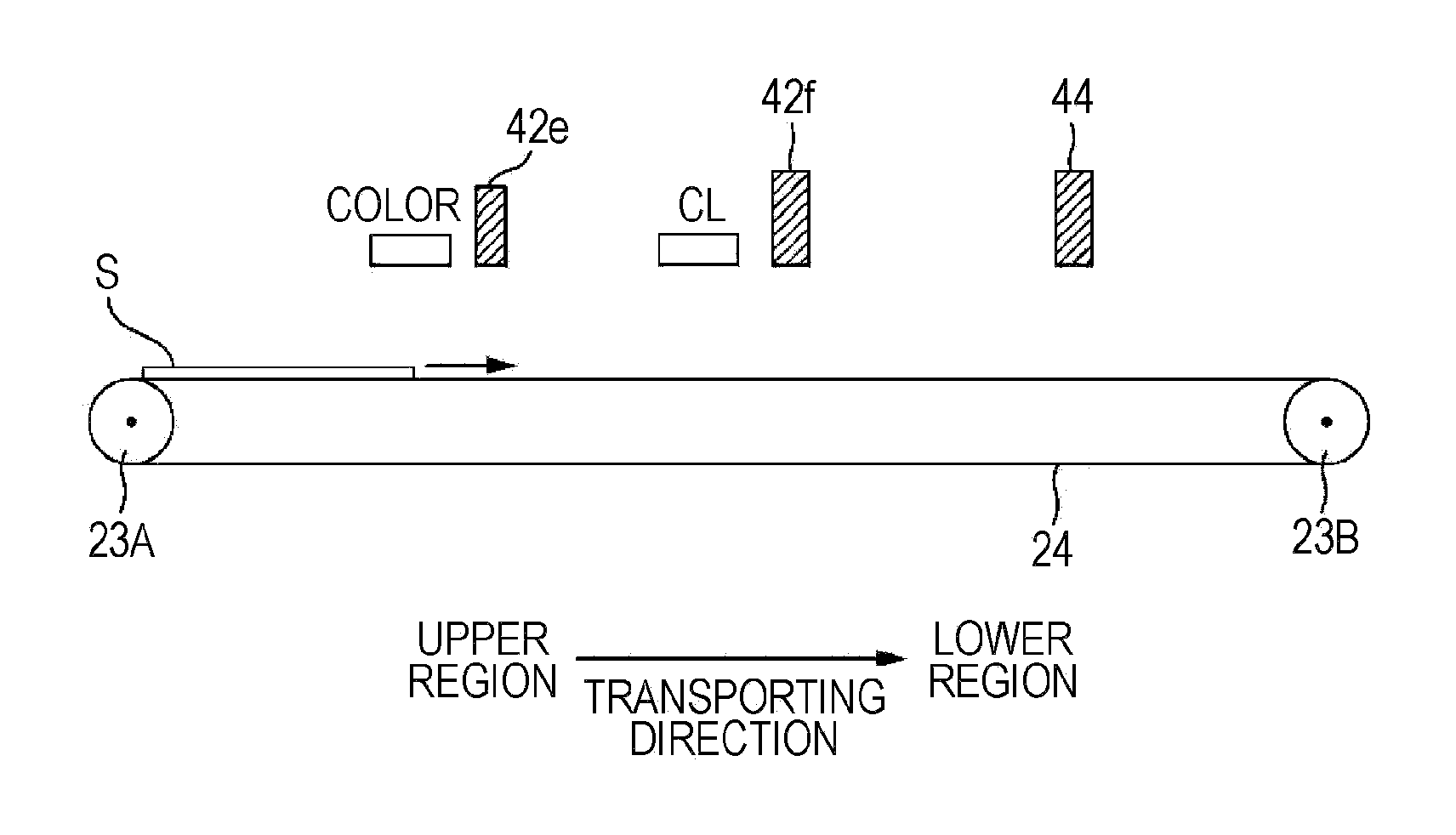

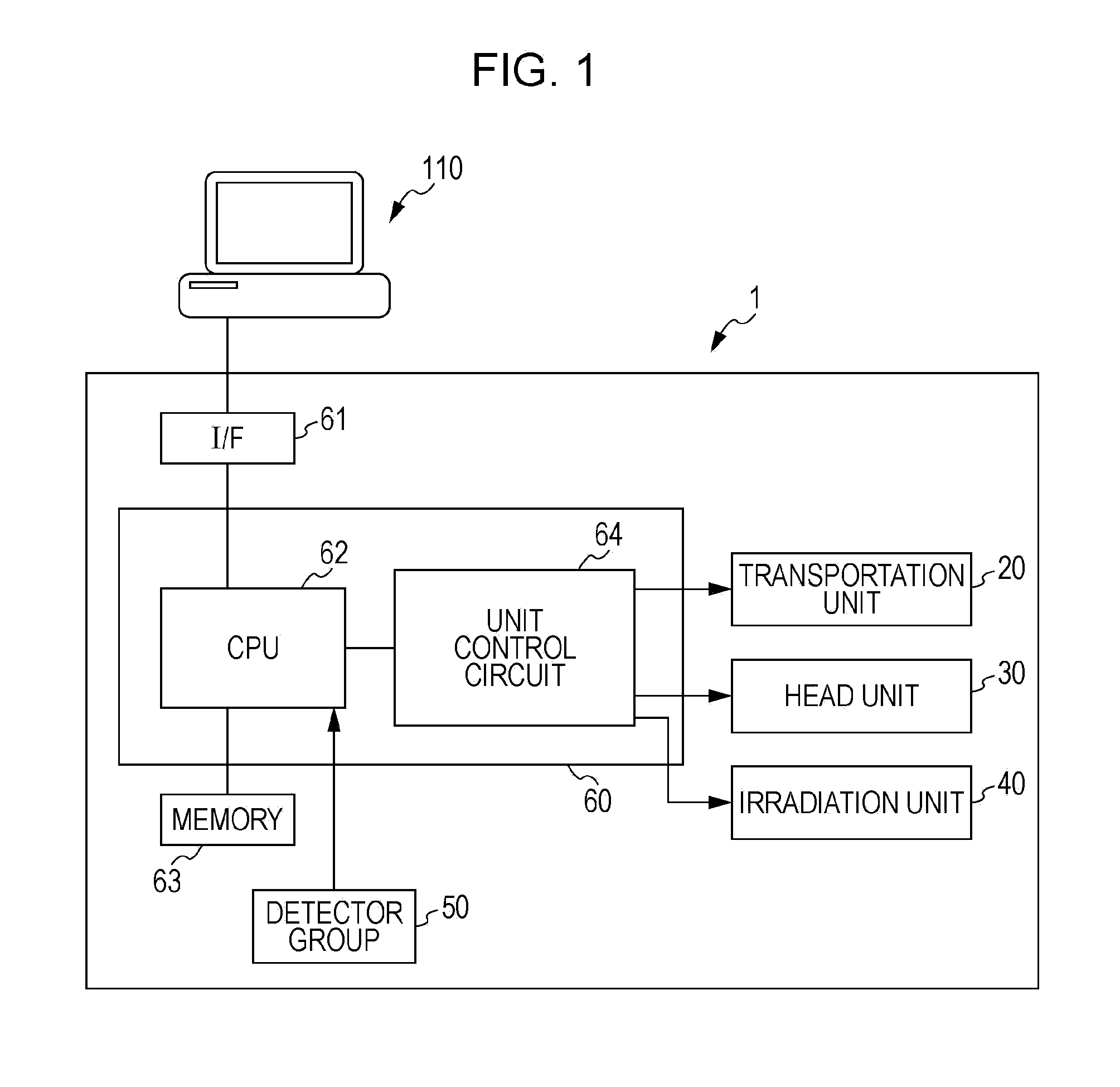

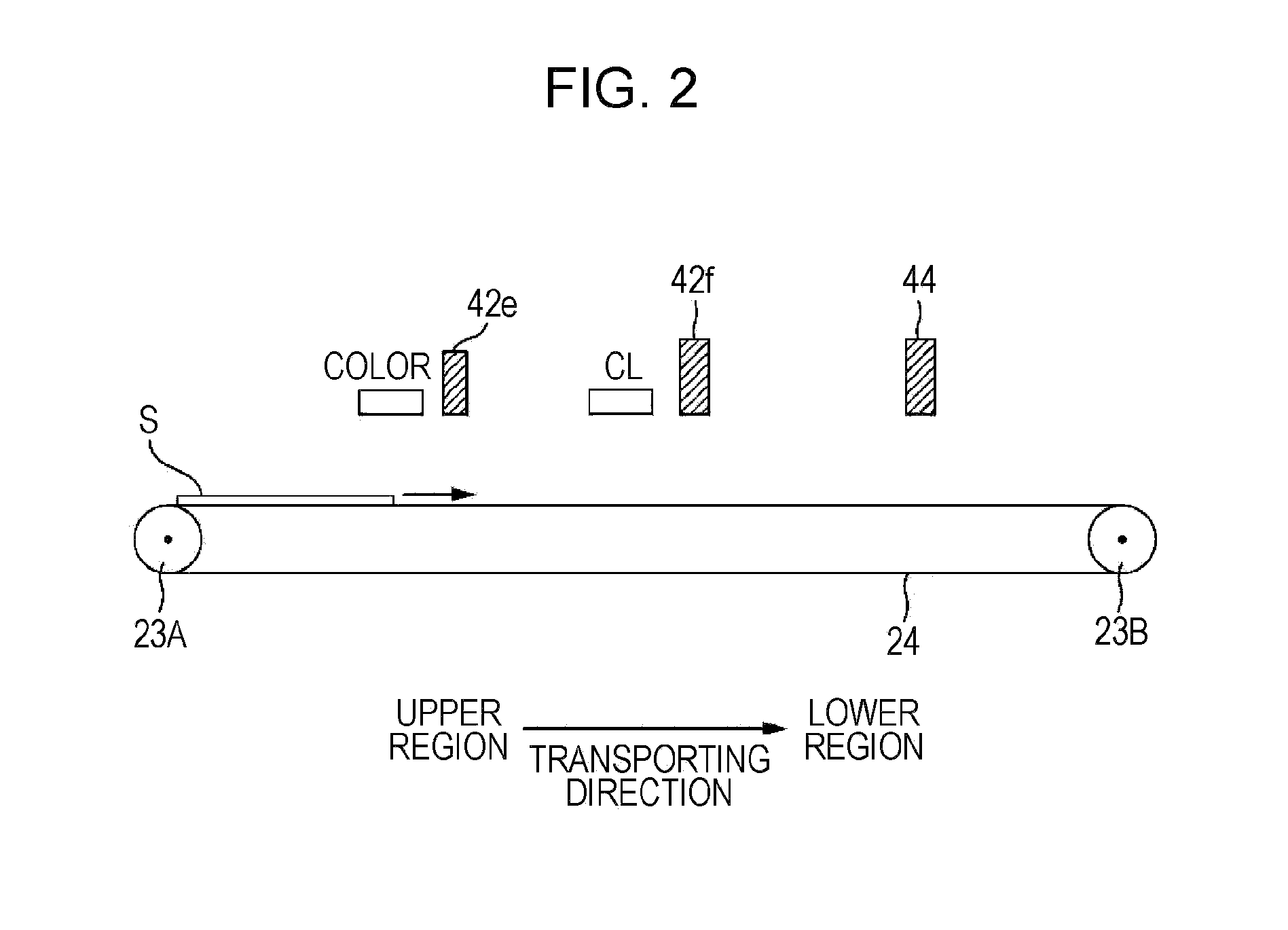

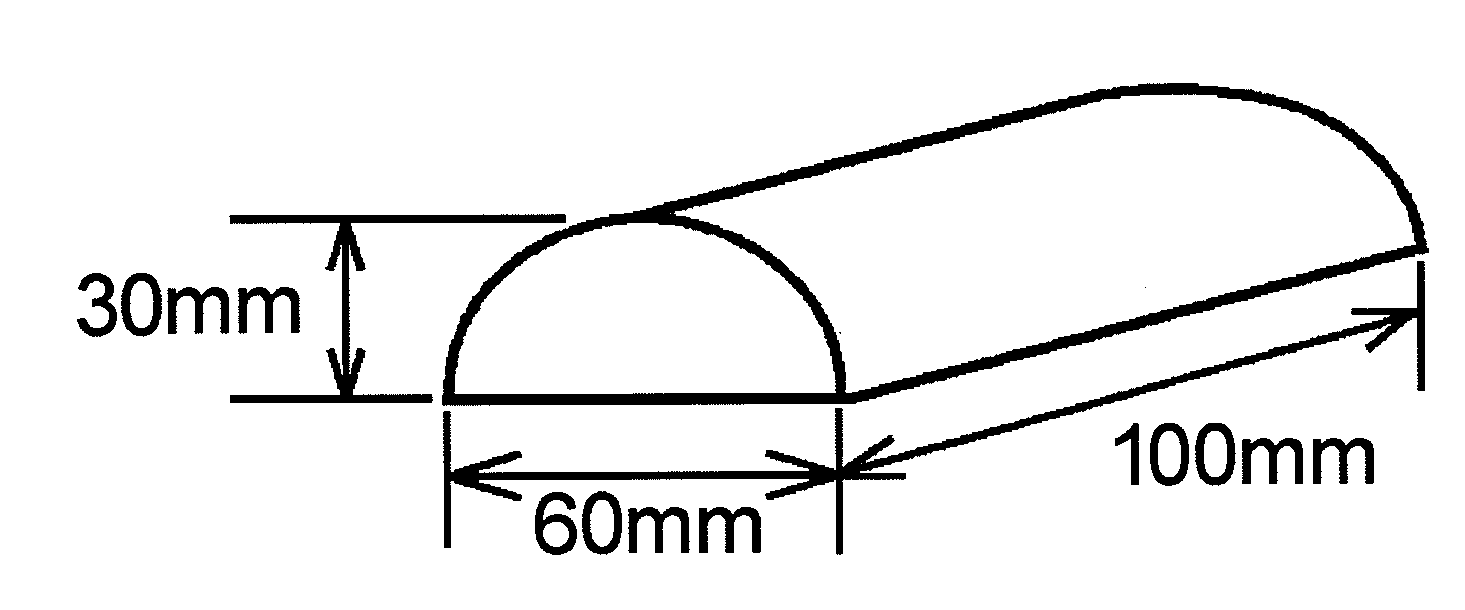

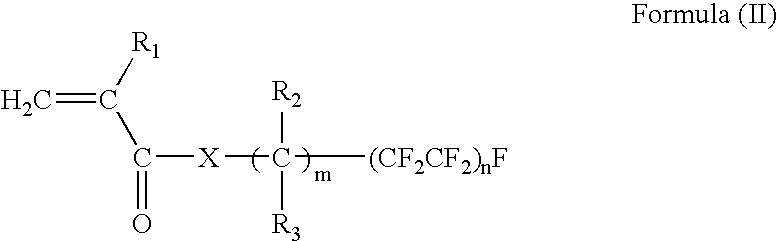

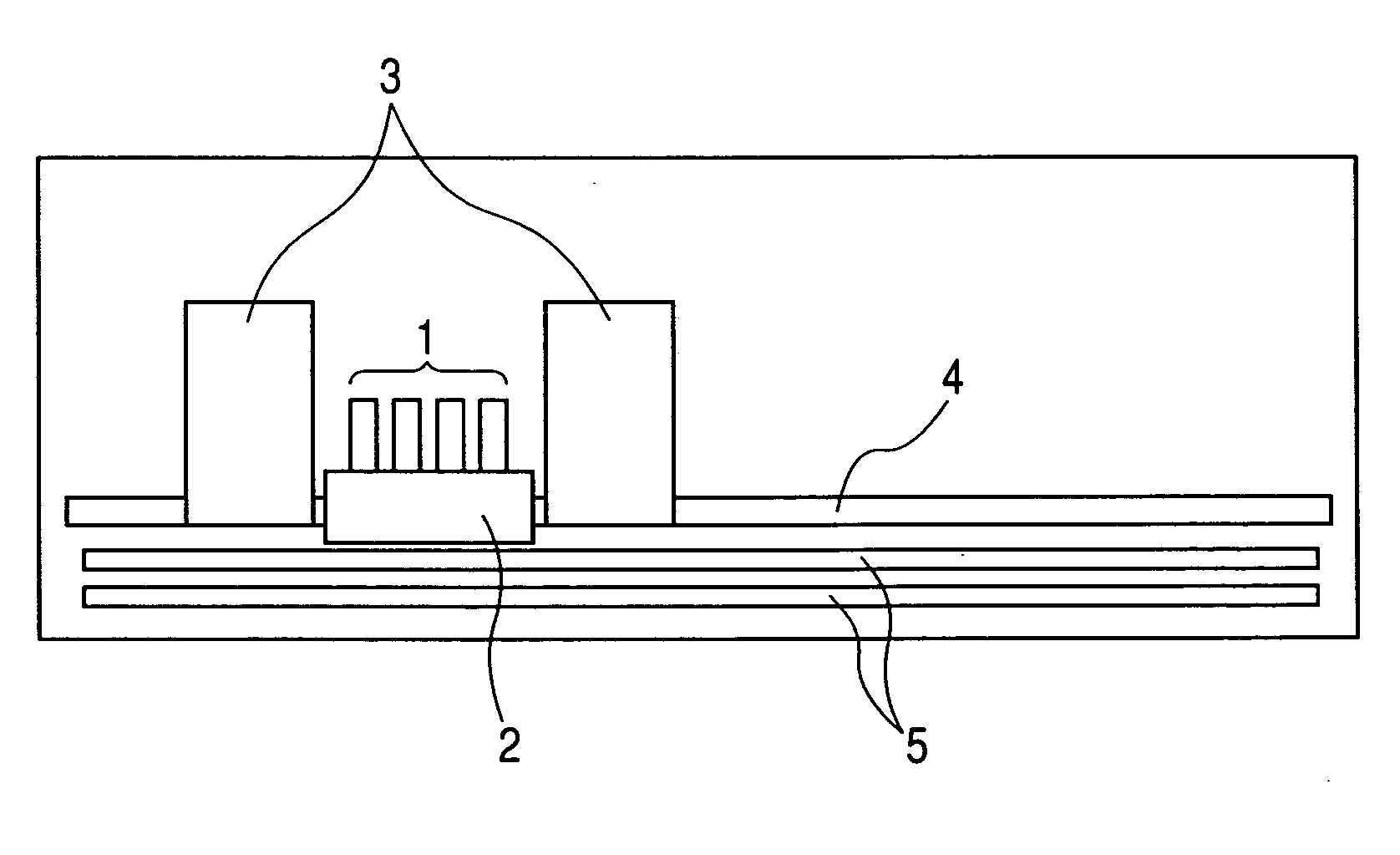

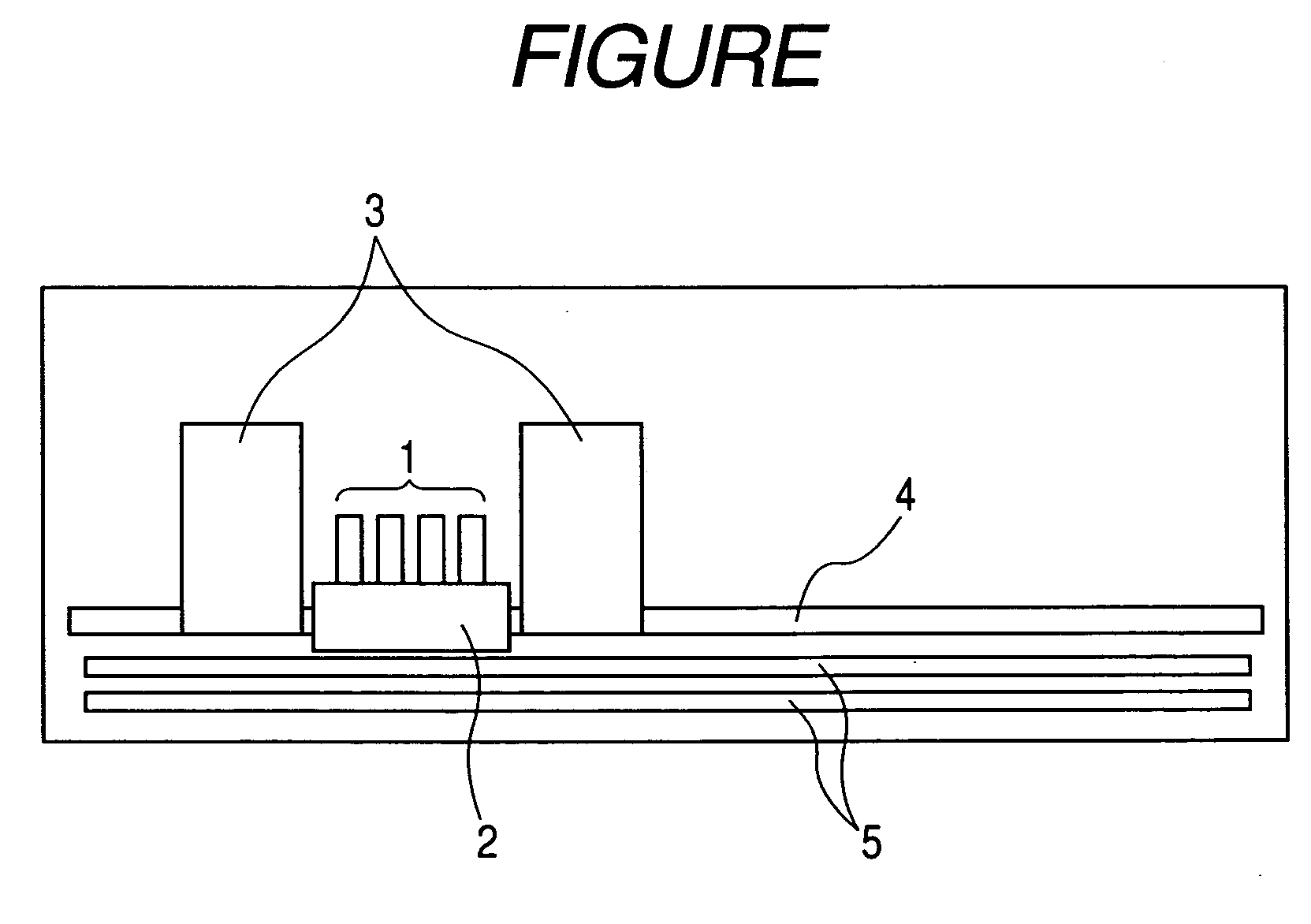

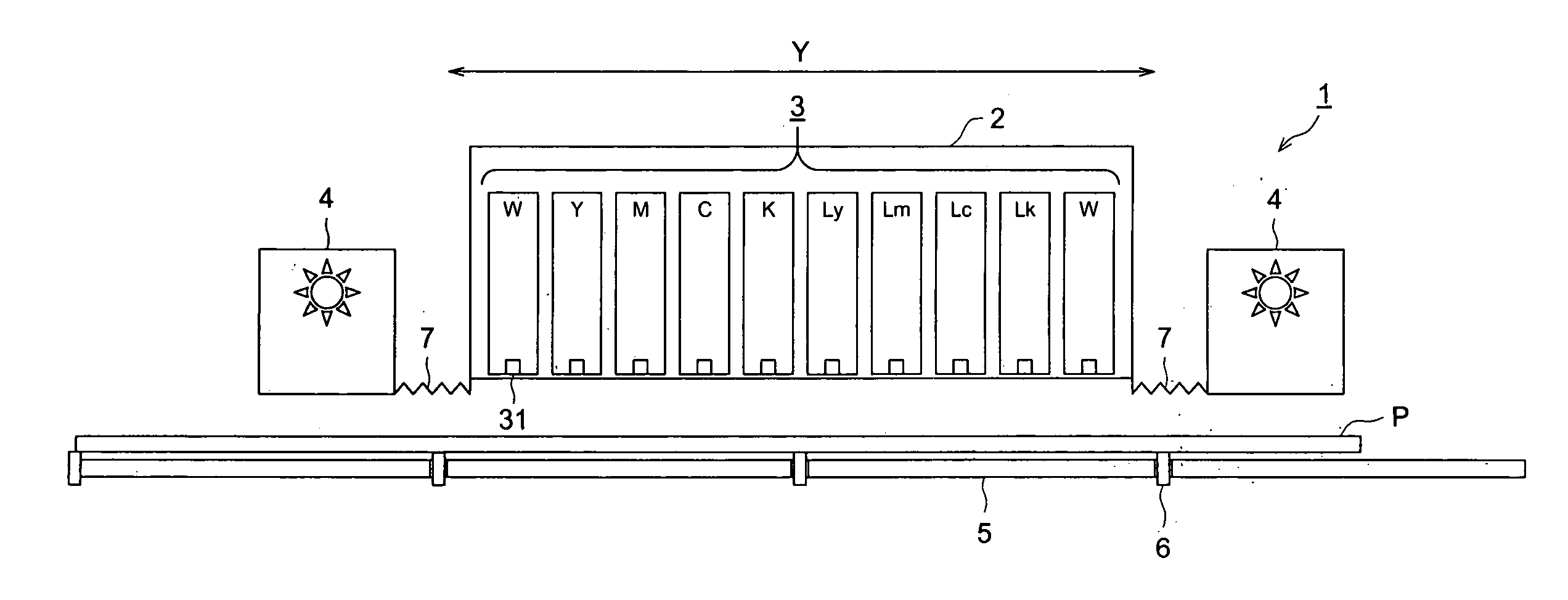

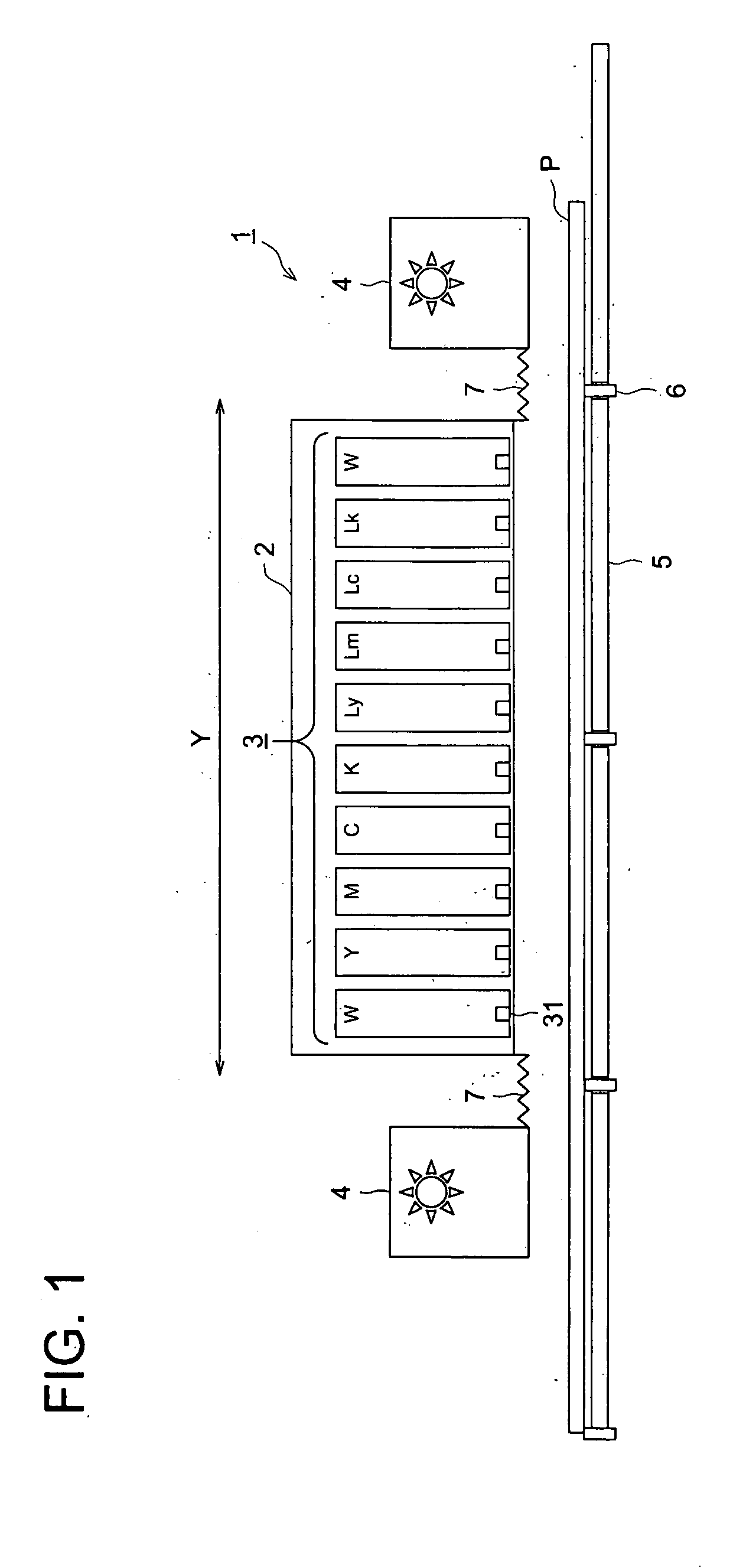

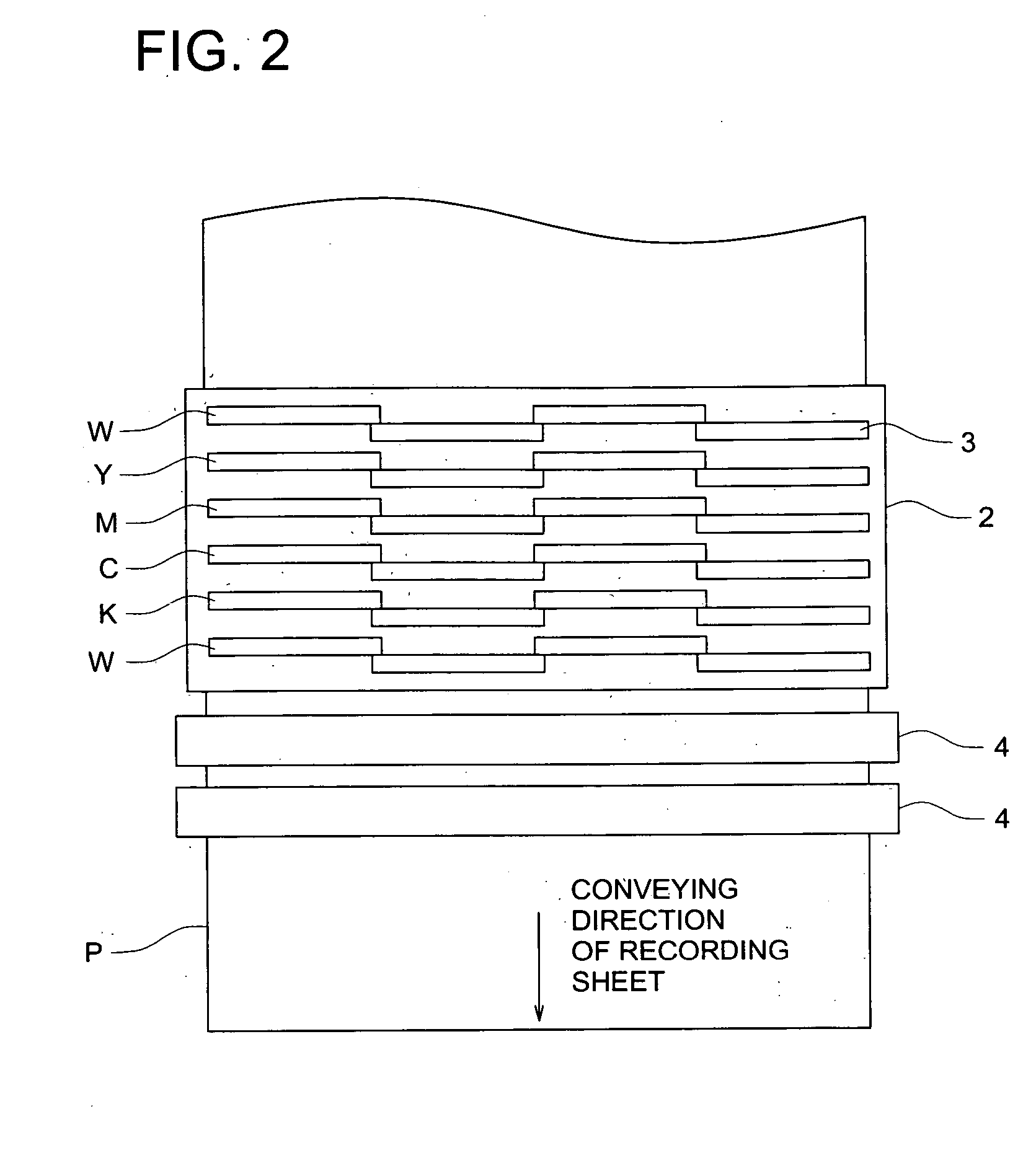

Ink jet printer and image recording method

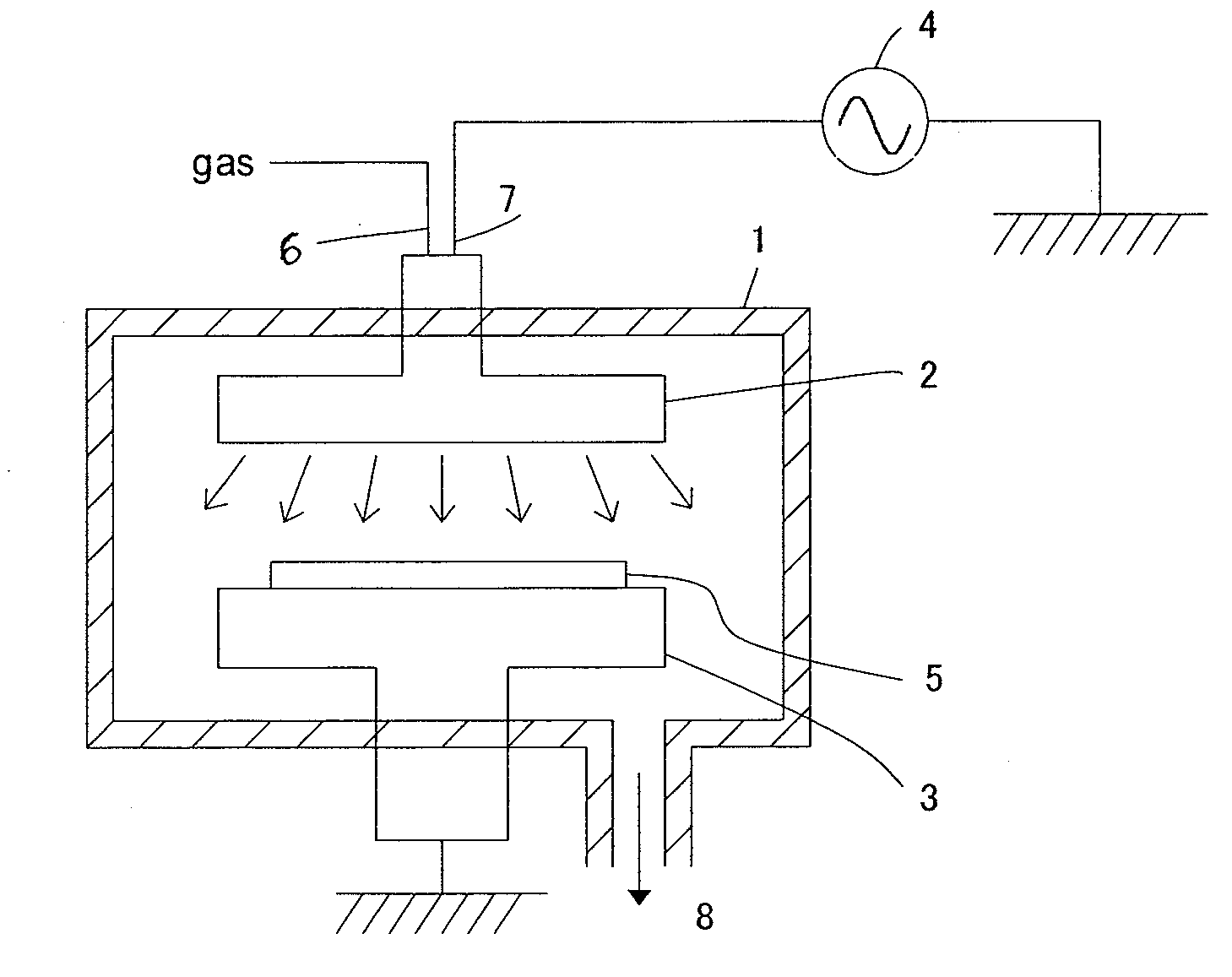

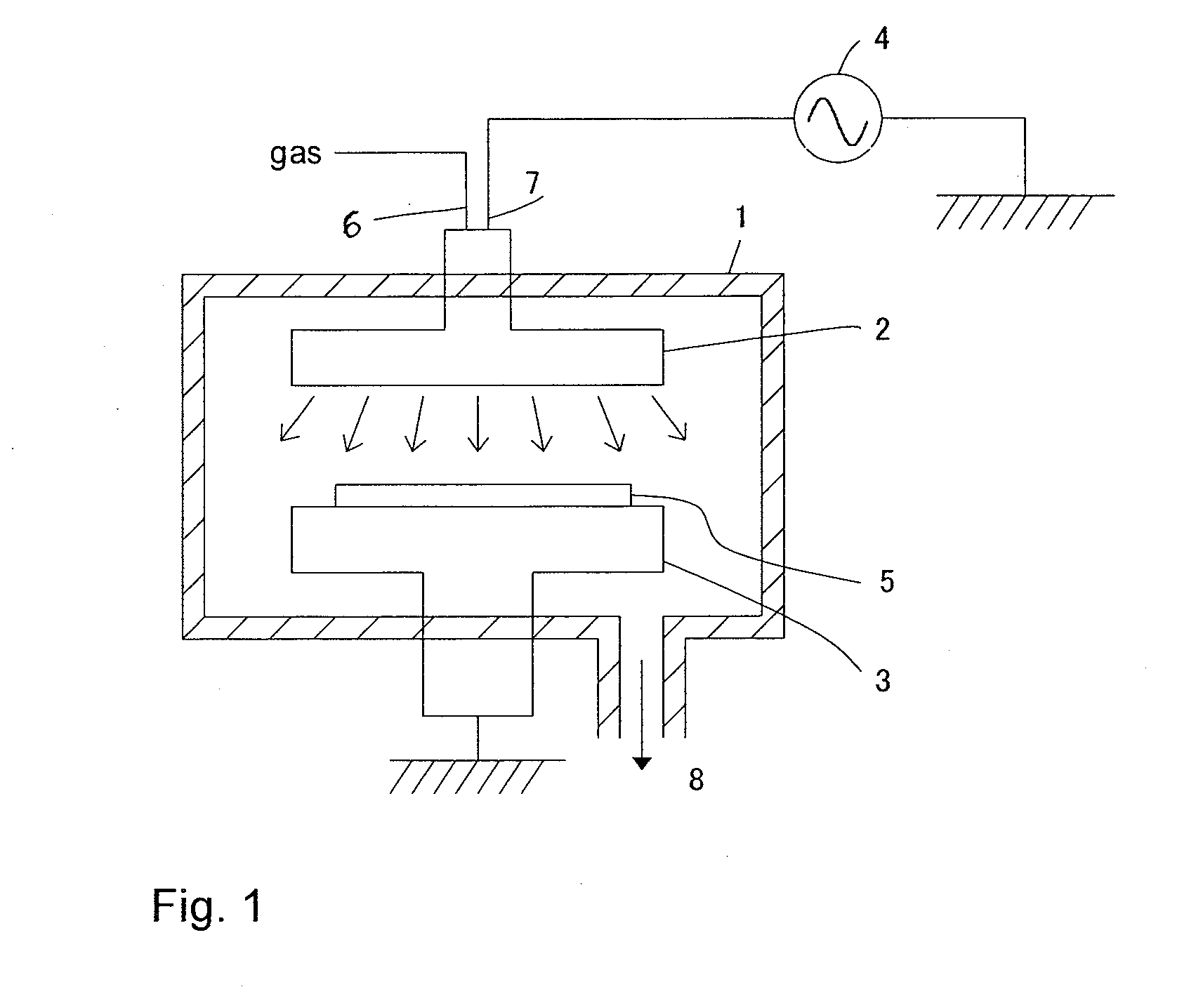

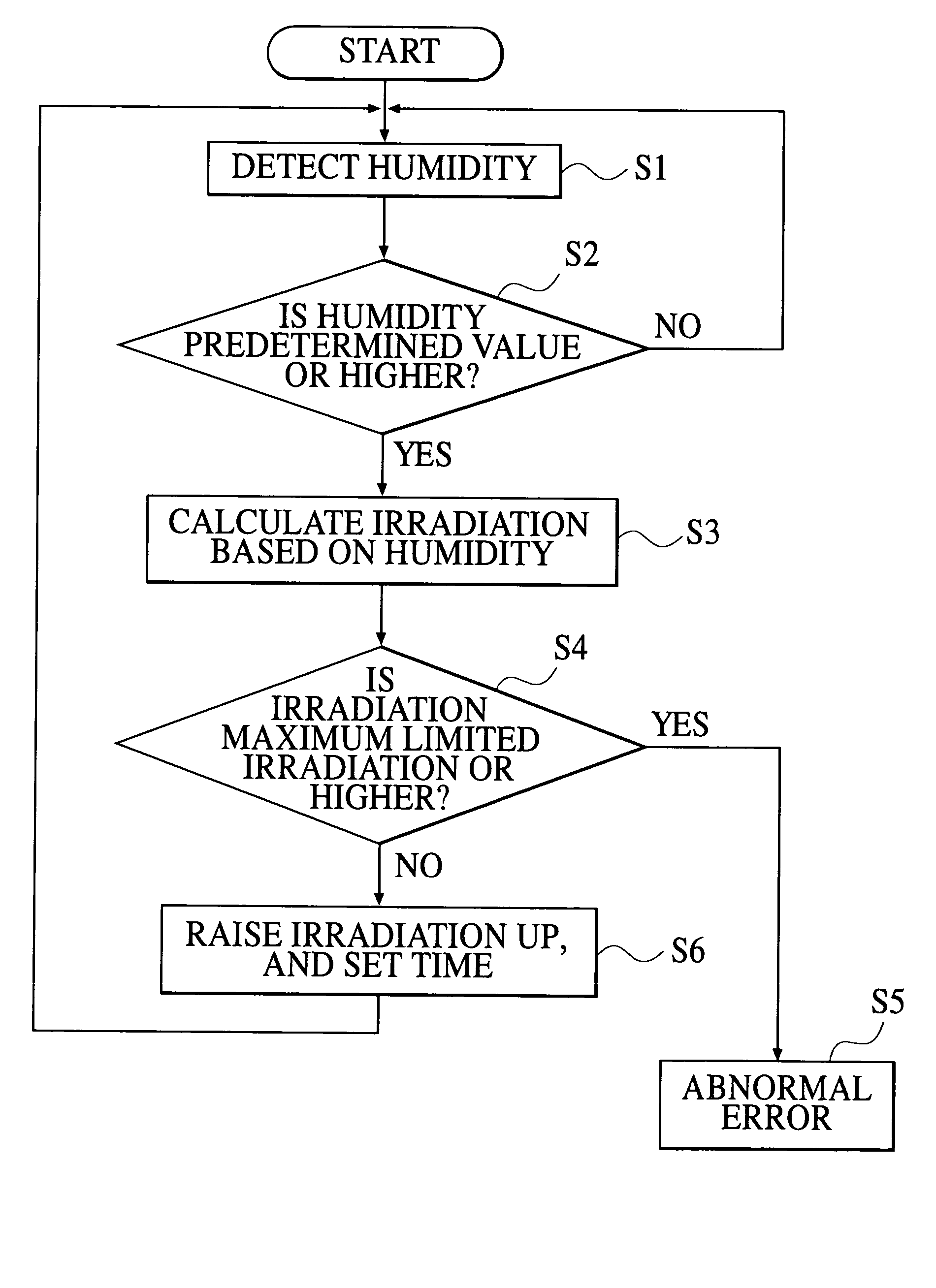

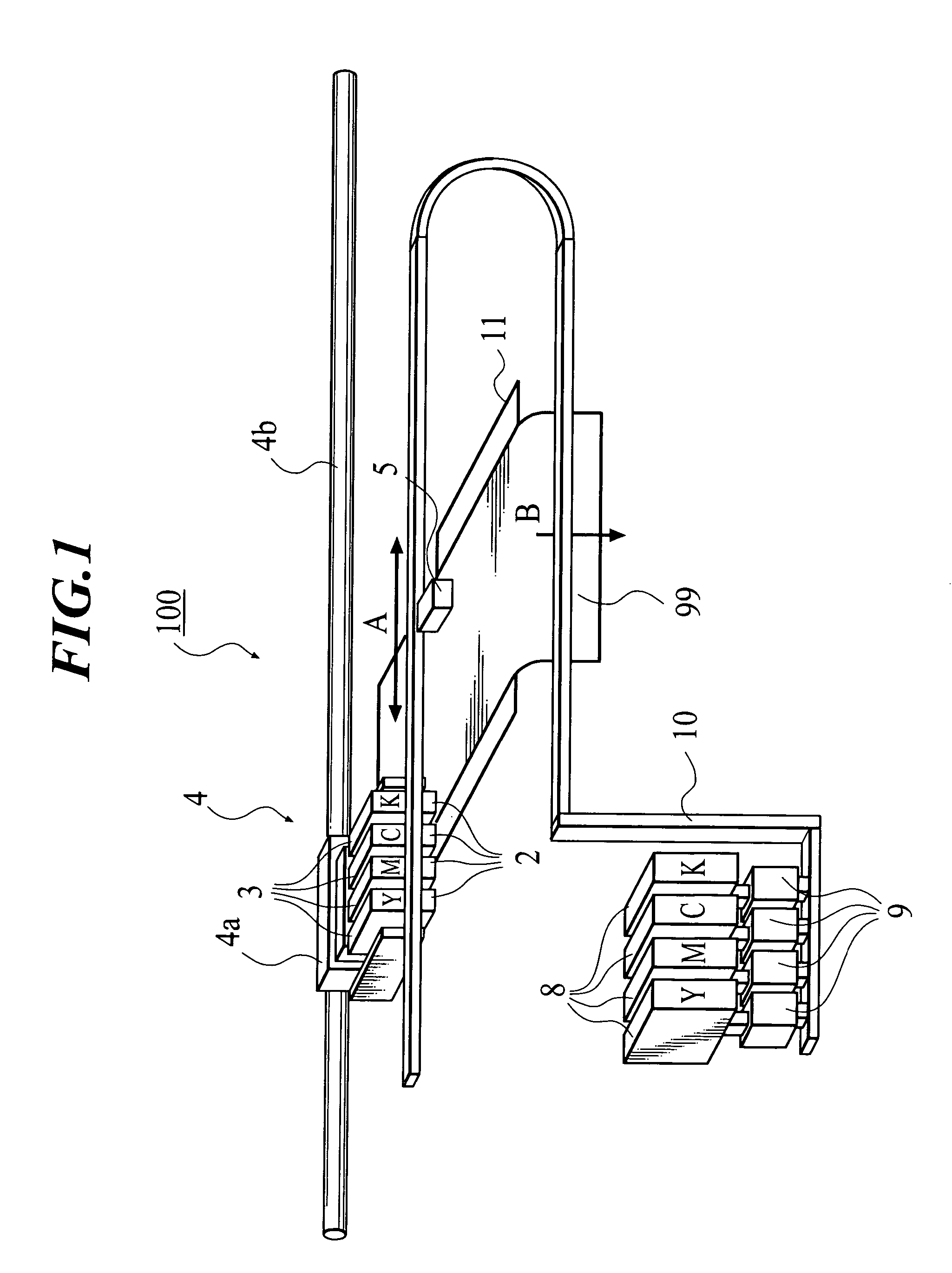

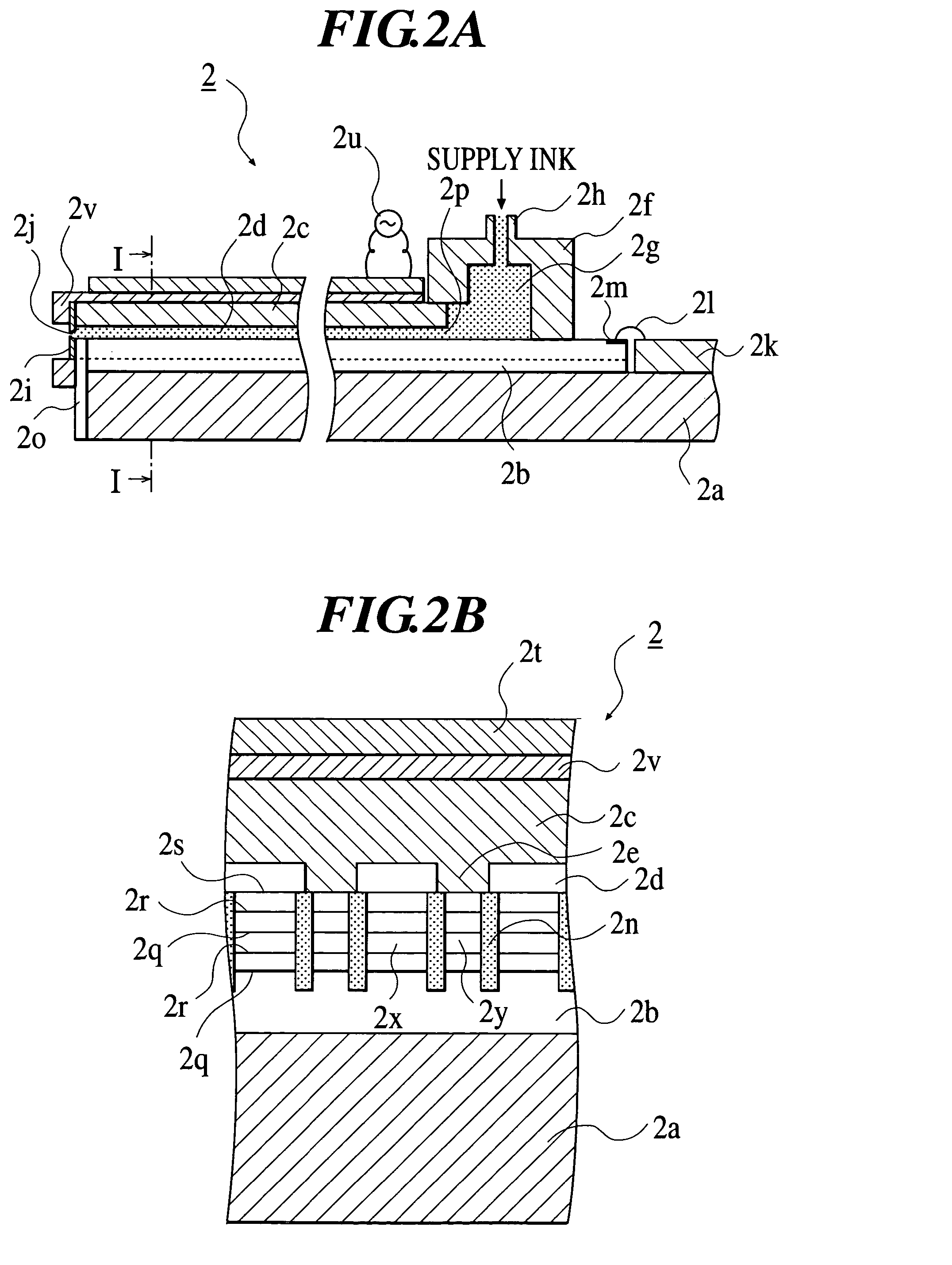

InactiveUS20040041892A1Improve curing effectIncrease temperatureOther printing apparatusPrinting after-treatmentLight irradiationCationic polymerization

An ink jet printer capable of enhancing curability of cationic polymerization ink in a state that a raise in temperature of a recording medium is prevented as possible. The ink jet printer for recording a desired image on a recording medium by ejecting ink which includes a cationic polymerization component and which is curable when irradiated with light to the recording medium, has: a recording head for ejecting the ink to the recording medium; a light irradiation section for irradiating the light to the ink placed on the recording medium; a humidity detecting section for detecting humidity around the ink placed on the recording medium; and a controller for controlling irradiation of the light to be irradiated from the light irradiation section on the basis of detected humidity detected by the humidity detecting section.

Owner:KONICA CORP

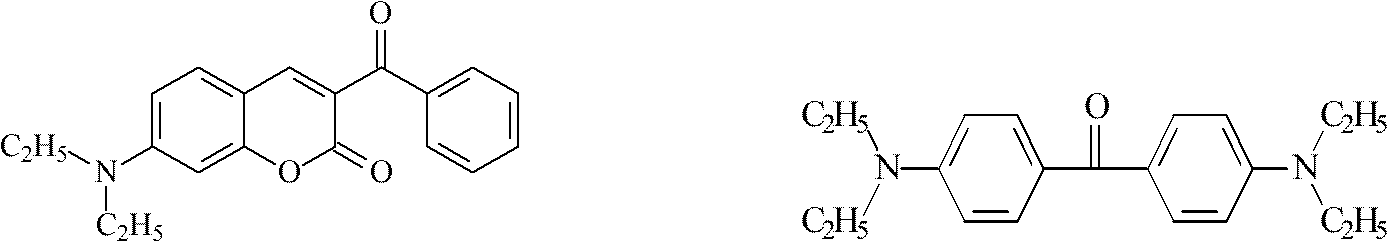

Photocurable Ink Composition for Ink Jet Recording and Ink Jet Recording Method

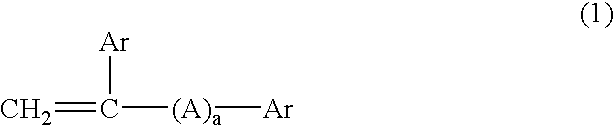

ActiveUS20130010039A1Improve curing effectPoor in curabilityMeasurement apparatus componentsInksVinyl etherHydrogen atom

The present invention provides a photocurable ink composition for ink jet recording with excellent curability. The photocurable ink composition for ink jet recording includes polymerizable compounds, a photopolymerization initiator, and a colorant, wherein the polymerizable compounds include a vinyl ether group-containing (meth)acrylate represented by general formula (I):CH2═CR1—COOR2—O—CH═CH—R3 (I)(wherein R1 is a hydrogen atom or a methyl group, R2 is a divalent organic residue having 2 to 20 carbon atoms, and R3 is a hydrogen atom or a monovalent organic residue having 1 to 11 carbon atoms) and phenoxyethyl (meth)acrylate.

Owner:SEIKO EPSON CORP

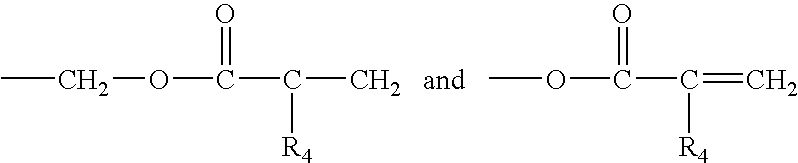

Water-based primer-topcoat braking paint and preparation method thereof

The invention relates to a water-based primer-topcoat braking paint and a preparation method thereof. The braking paint comprises the following materials by weight percentage: 30-40 of water-based acrylic resin, 2-10 of amino resin, 1-3 of neutralizing agent, 2-5 of compound rustproofing pigment, 1-3 of tinting pigment, 10-20 of filling agent, 0.1-0.5 of defoaming agent, 0.1-0.5 of flatting agent and 25-40 of deionized water, wherein the water-based acrylic resin is a free radical polymerization resultant which comprises the following materials by weight percentage: 10-30 of monomer containing hydroxy acrylic acid, 5-20 of monomer containing carboxyl acrylic acid, 2-8 of internal crosslinking monomer, 20-40 of other acrylic acid monomer, 15-30 of phenyl ethylene monomer, 1-5 of evocating agent and 40-50 of alcohol ether latent solvent. When the paint is prepared, the dispersion and the abrading condition of the pigments and the filling agents are reasonably controlled to ensure that each component of the paint fully plays the respective function. The paint ensures the corrosion prevention effect and the decoration of a coating and realizes the combination of a primer and a topcoat.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +1

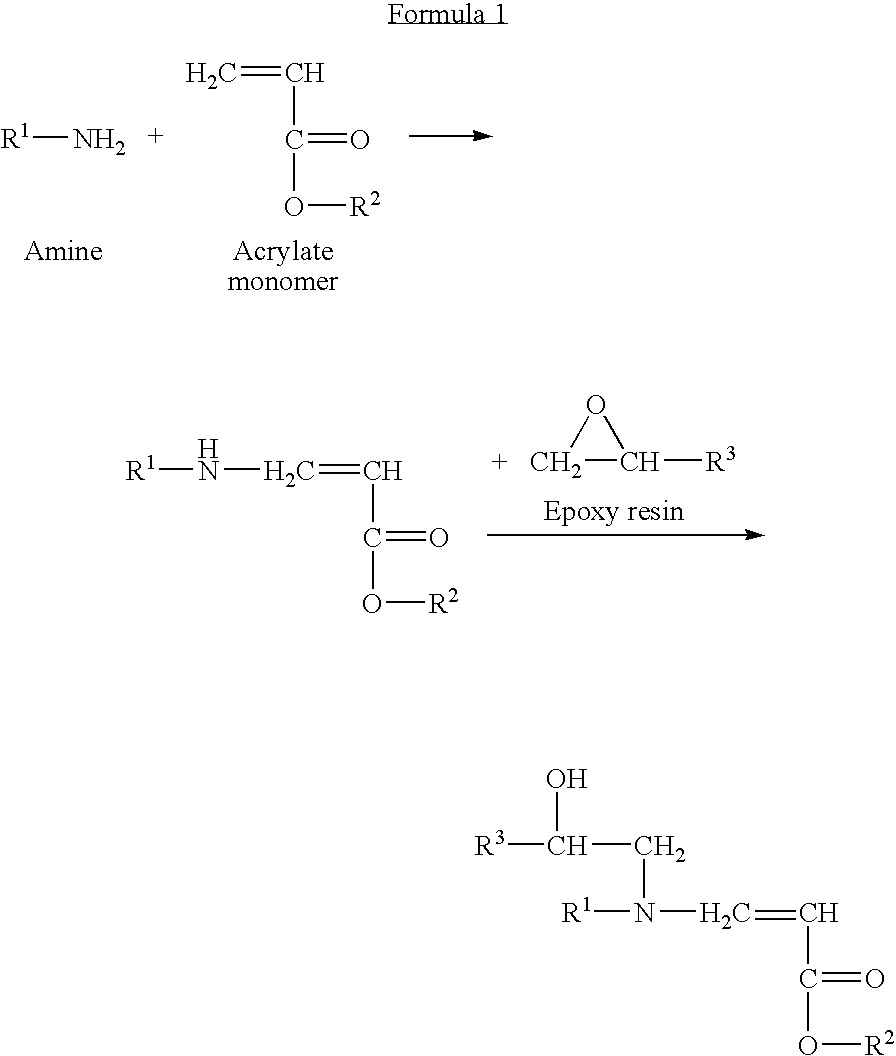

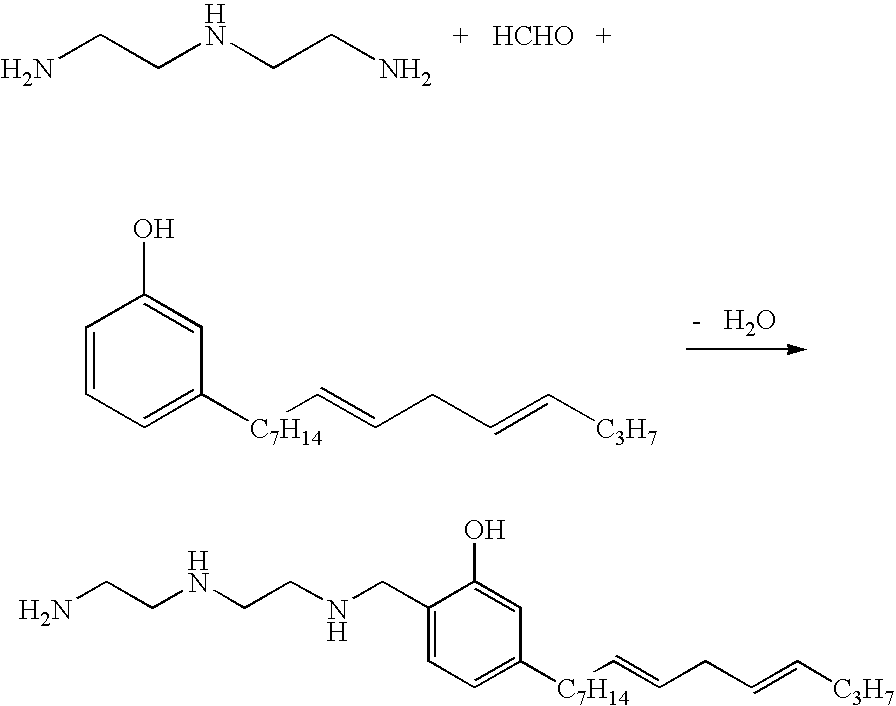

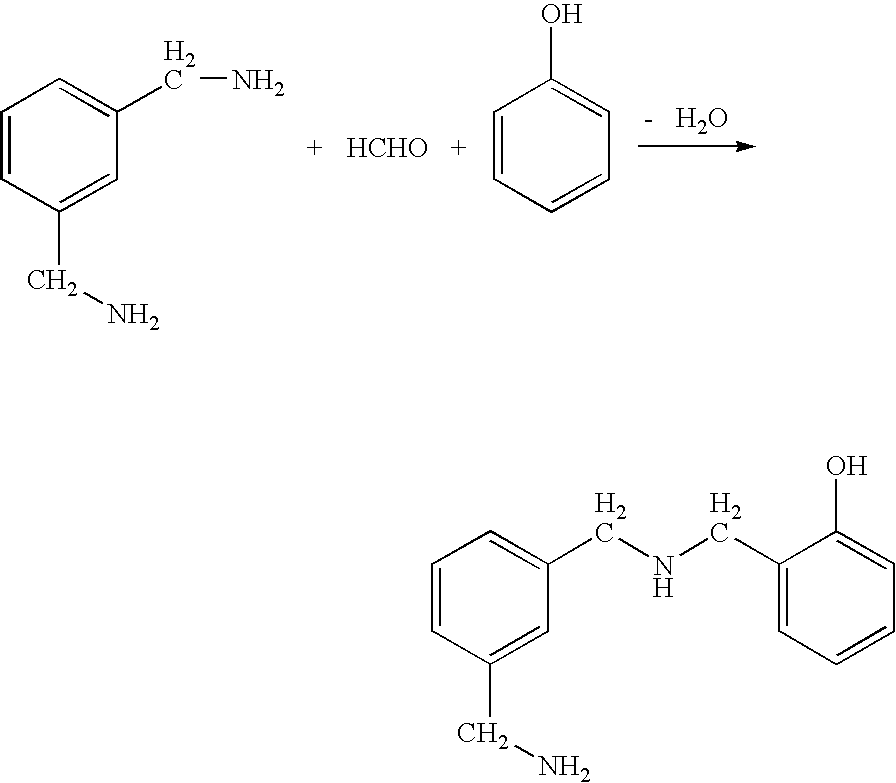

High-solid anticorrosive coating composition, high-solid rapidly-curable anticorrosive coating composition, method of coating ship or the like, high-solid anticorrosive film and rapidly cured high- anticorrosive film obtained, and coated ship and underwater structure coated with these coating films

InactiveUS20090226729A1Improve anti-corrosion performanceIncrease contentLiquid surface applicatorsAntifouling/underwater paintsOrganic solventBoiling point

A high-solids anticorrosive coating composition which comprises a main ingredient (A) comprising an epoxy resin (a1) and a hardener ingredient (B) comprising an alicyclic amine hardener (b1) and / or a Mannich type hardener (b2), the ingredient (A) and / or the ingredient (B) containing at least either of an additive (a2) selected among epoxidized reactive diluents and modified epoxy resins and a coating film modifier (ab) selected among petroleum resins, xylene resins, coumarone resins, terpene phenol resins and vinyl chloride copolymers. The high-solids anticorrosive coating composition especially of the rapidly curable type is characterized by containing a high-boiling organic solvent having a boiling point exceeding 150° C. and containing substantially no organic solvent having a boiling point of 150° C. or lower.

Owner:CHUGOKU MARINE PAINTS

Ink composition for ultraviolet curable ink jets, ink jet recording apparatus using the same, ink jet recording method using the same, and ink set

An ink composition for ultraviolet curable ink jets including monomer A represented by a general formula (I):CH2═CR1—COOR2—O—CH═CH—R3 (I)(in the formula, ‘R1’ represents a hydrogen atom or methyl group, ‘R2’ represents a divalent organic residue having a carbon number of 2 to 20, and ‘R3’ represents a hydrogen atom or a monovalent organic residue having a carbon number of 1 to 11), and a photopolymerization initiator containing an acylphosphine oxide-based photopolymerization initiator and a thioxanthone-based photopolymerization initiator, in which the total content of the acylphosphine oxide-based photopolymerization initiator and the thioxanthone-based photopolymerization initiator is 8% by mass to 16% by mass with respect to the total mass of the ink composition.

Owner:SEIKO EPSON CORP

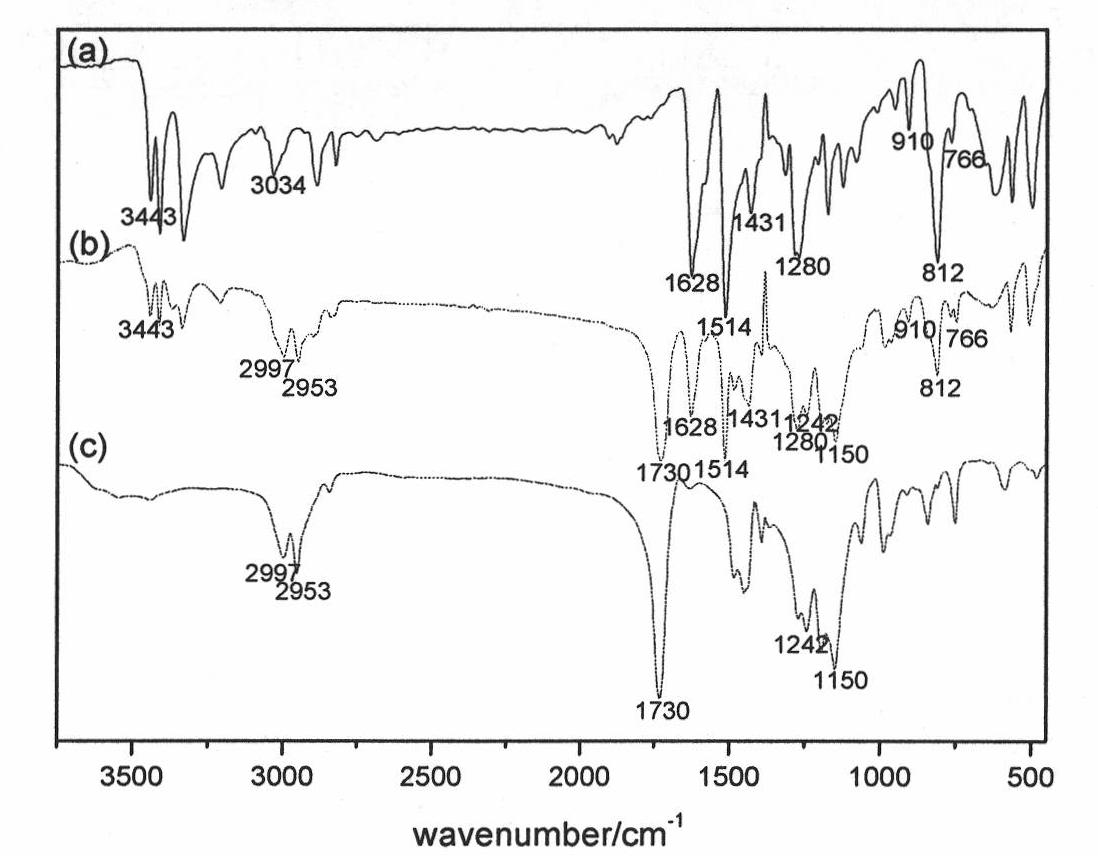

One component resin composition curable with combination of light and heat and use of the same

InactiveUS20070096056A1Improve curing effectAvoid pollutionLiquid crystal compositionsPhotomechanical apparatusEpoxyMethacrylate

A one component resin composition curable with a combination of light and heat, which comprises (1) an epoxy resin, (2) an acrylic ester monomer and / or methacrylic ester monomer, or an oligomer thereof, (3) a latent epoxy curing agent, (4) a photo radical initiator, and (5) a compound having two or more thiol groups per molecule, wherein the ingredient (5) is contained in an amount of 0.001 to 5.0 parts by weight per 100 parts by weight of this resin composition. According to the present invention, a one component resin composition curable with a combination of light and heat, which has excellent curability especially in a light-shielded area can be provided. Also, a liquid crystal sealant composition curable with a combination of light and heat, which is applicable to the one-drop-fill method and has excellent curability in light-shielded areas and adhesion reliability, especially high-temperature and high-humidity adhesion reliability, can be provided.

Owner:MITSUI CHEM INC +1

Curable composition

ActiveUS20100152373A1Good curabilityImprove curing effectOther chemical processesVehicle sealing arrangementsChemistryCompound (substance)

An object of the present invention is to provide a curable composition which is made mainly of a polymer having one or more reactive silicon groups, has good curability even when filler is used while a non-organotin catalyst is used, and is further high in industrial practicability. The object is solved by a curable composition, comprising, as constituents, a polymer (A) having one or more reactive silicon groups on average per molecule thereof, the reactive silicon group(s) being (each) a group which can be crosslinked by forming a siloxane bond, a Lewis acid and / or derivative thereof (B), an amine compound (C), a compound (D) having a reactive silicon group, and filler (E), and obtained by mixing the constituents with each other.

Owner:KANEKA CORP

Silicone resin-containing emulsion composition, making method, and article having cured film of the composition

InactiveUS6147156AImprove stabilitySatisfactory film propertySilicon organic compoundsChemical/physical/physico-chemical stationary reactorsEmulsionEmulsion polymerization

A silicone resin-containing emulsion composition is based on a silicone resin-containing emulsion obtained by emulsion polymerization of a mixture containing (A) a silanol group-bearing silicone resin and (B) a radical-polymerizable vinyl monomer. The silicone resin (A) contains 30-100 mol % of T units: R1-SiZ3, and specifically 30-80 mol % of T-2 units: R1-Si(OH)Z'2 among other T units wherein R1 is a monovalent hydrocarbon group, Z is a OH group, hydrolyzable group or siloxane residue, and Z' is a siloxane residue, and has a number average molecular weight of at least 500. The composition has a good film forming ability and cures into a flexible film having mar, weather and chemical resistance.

Owner:SHIN ETSU CHEM IND CO LTD

Latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and preparation method of adhesive thereof

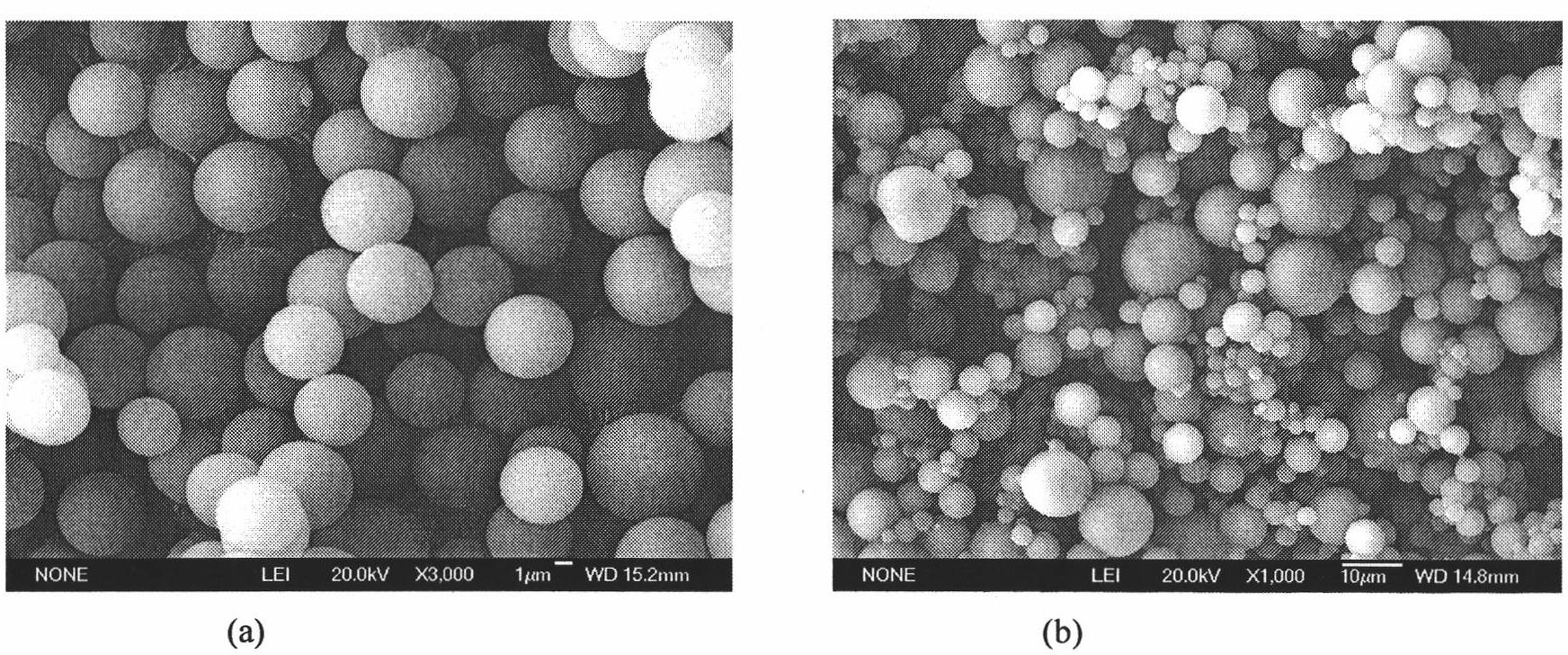

InactiveCN102423673AHigh core contentFlat surfaceMicroballoon preparationMicrocapsule preparationEpoxyMicrosphere

The invention relates to a latent microcapsule curing agent initiating thermosetting epoxy resin curing at medium temperature and a preparation method of an adhesive thereof. The latent microcapsule curing agent is technically characterized in that the high-activity medium temperature curing agent is taken as a core material, thermoplastic high polymer microspheres are taken as a wall material, the solvent evaporation technology is adopted for preparing the latent microcapsule curing agent with better curing performance and latent performance, and the latent microcapsule curing agent can be applied to an epoxy resin system for preparing the single-component medium temperature curing epoxy resin adhesive. Microcapsules prepared by the method are high in capsule core content, smooth in surfaces, narrow in particle size distribution and good in compatibility with matrix epoxy resin and can be better dispersed in the epoxy resin; and the prepared single component adhesive can realize curing at the medium temperature, the storage period at room temperature is longer and the tensile shear strength performance can be further improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

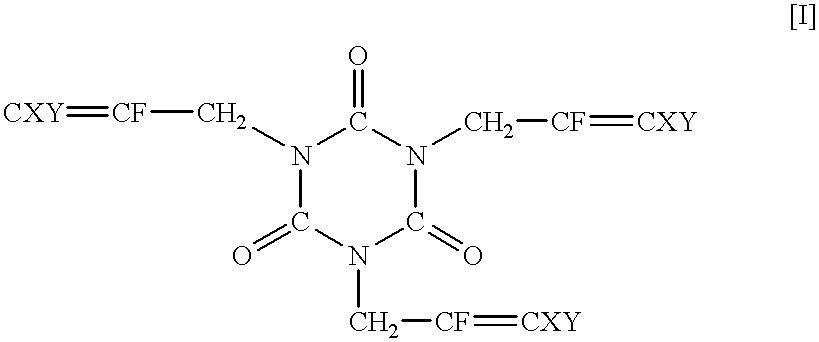

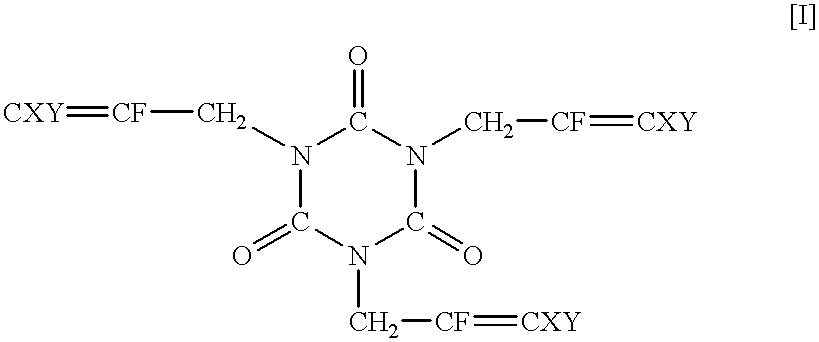

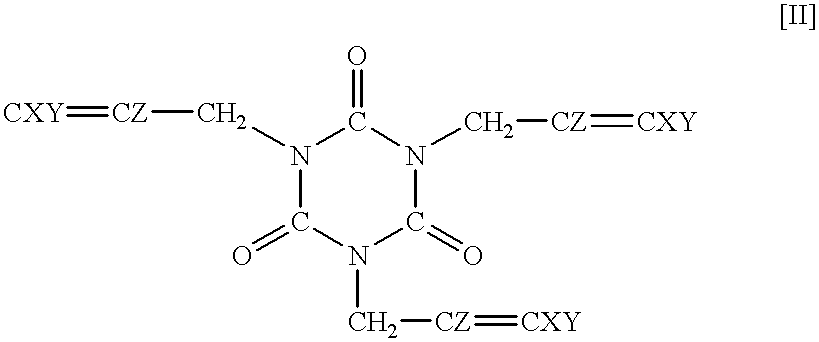

Fluorinated triallyl isocyanurates, vulcanizable elastomer compositions containing the same, and method for vulcanization

InactiveUS6191233B1Improve curing effectMaintain good propertiesOrganic chemistryElastomerHydrogen atom

A fluorine-containing triallyl isocyanurate of the formula [I]:wherein at least one of X and Y is a fluorine atom, and the other is a hydrogen atom or a fluorine atom, exhibits good curing properties even when it is used as a crosslinking aid for elastomers which are required to have good heat resistance, such as in particular, fluororubbers, and provides cured materials having good mechanical properties and heat resistance.

Owner:DAIKIN IND LTD

Ultraviolet curable type ink-jet ink composition, recording method and recording apparatus usisng same

Provided is a UV curable type ink-jet ink composition containing a monomer A which is expressed by the following general formula (I):CH2═CR1—COOR2—O—CH═CH—R3 (I)(in the formula, R1 is a hydrogen atom or methyl radical, R2 is a bivalent organic residue radical having a carbon number in a range of 2 to 20, and R3 is a hydrogen atom or a univalent organic residue radical having a carbon number in a range of 1 to 11), a compound B containing five or more (meth)acryloyl radicals per molecule, and a monofunctional (meth)acrylate C having an aromatic ring skeleton, wherein the monofunctional (meth)acrylate C which is in a range of 5 to 35 wt % with respect to the total weight of the ink composition is contained.

Owner:SEIKO EPSON CORP

Resin composition for production of clad layer, resin film for production of clad layer utilizing the resin composition, and optical waveguide and optical module each utilizing the resin composition or the resin film

InactiveUS20120077401A1Maintain good propertiesImprove stabilitySynthetic resin layered productsAnimal housingEpoxyOrganic solvent

A thermosetting resin composition containing: (A) a resin composition having an unsaturated maleimide group, produced by reacting (a) a maleimide compound having at least two N-substituted maleimide groups per one molecule and (b) an amine compound having at least two primary amino groups per one molecule, in an organic solvent; (B) a thermosetting resin; and (C) a modified imidazole compound, such as an isocyanate-masked imidazole and an epoxy-masked imidazole, and a prepreg, an insulating film with a support, a laminate plate and a printed wiring board, each containing the same.

Owner:HITACHI CHEM CO LTD

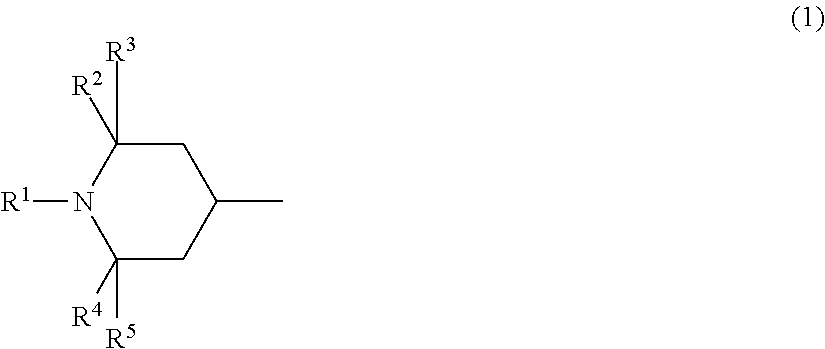

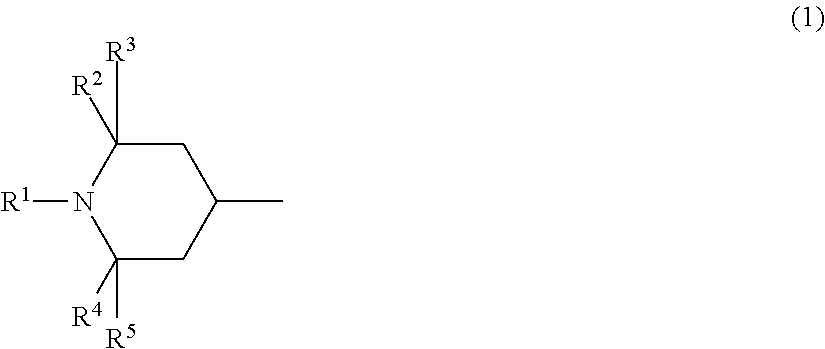

Ultraviolet ray curable ink jet composition and printed object

ActiveUS20120295076A1High glossStorage stability is degradedLayered productsDecorative surface effectsUV curingHydrogen atom

An ultraviolet ray curable ink jet composition of the present invention is characterized by being adapted to be ejected using an ink jet method and containing:a polymerizable compound;metal particles subjected to a surface treatment; anda substance A having a partial structure represented by the following formula (1),where R1 is a hydrogen atom, a hydrocarbon group or an alkoxy silyl group, and each of R2, R3, R4 and R5 is independently a hydrogen atom or a hydrocarbon group.

Owner:SEIKO EPSON CORP

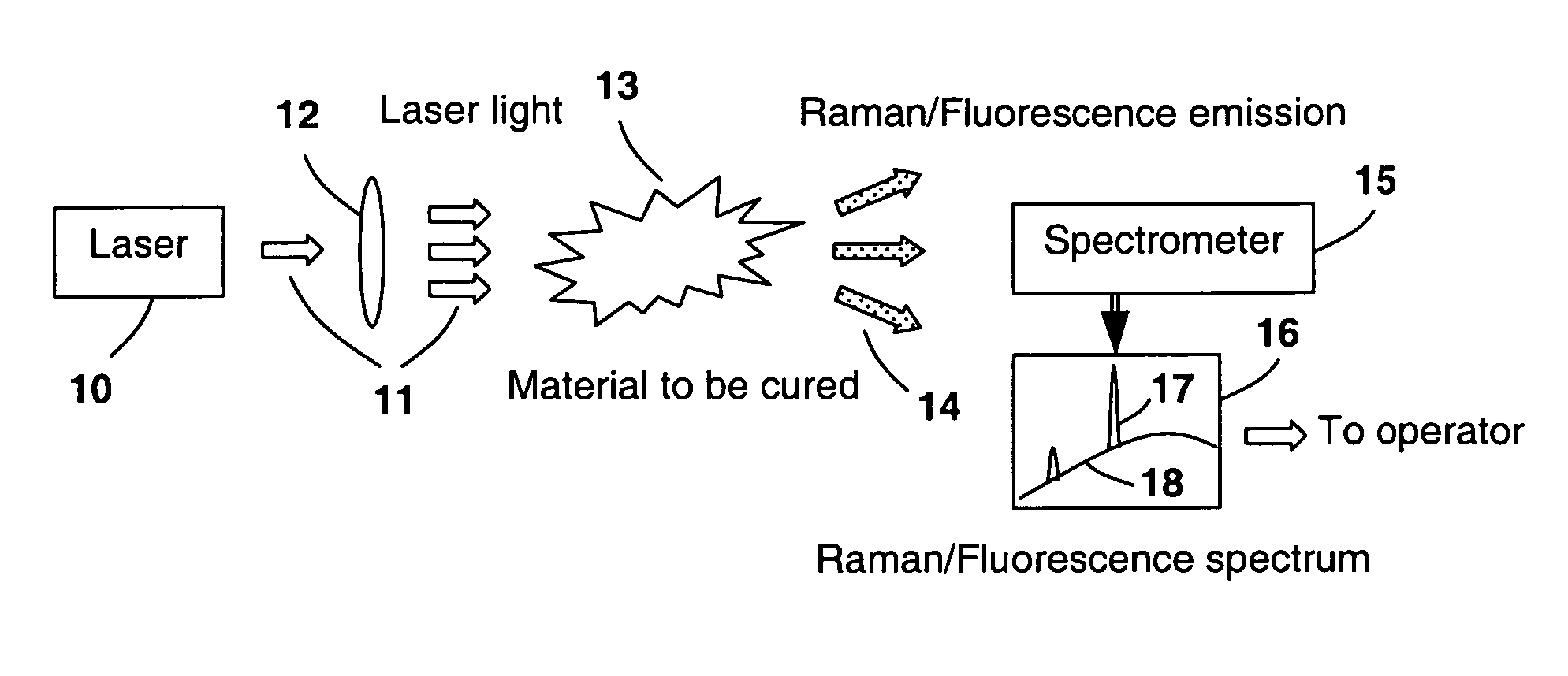

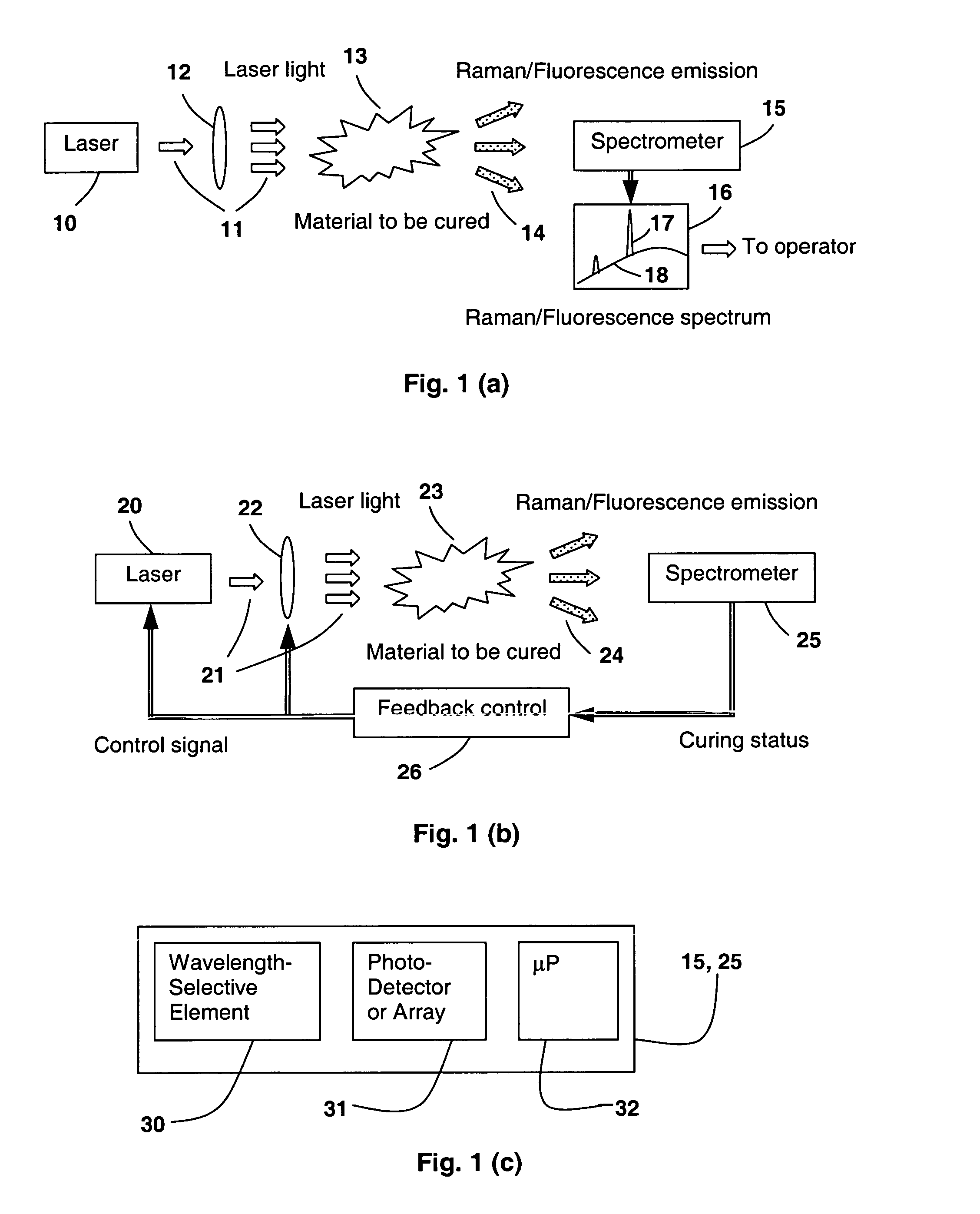

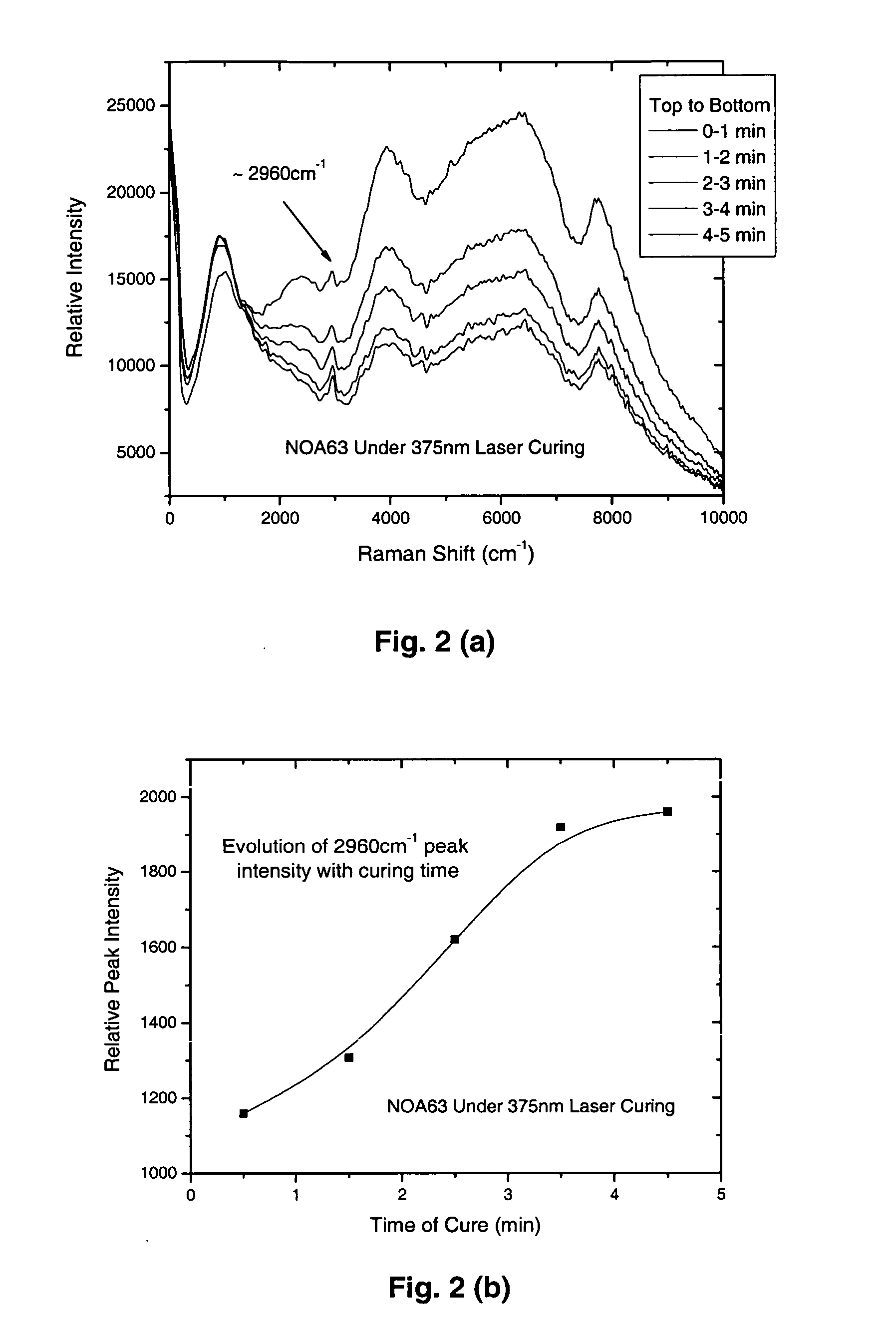

Laser curing apparatus with real-time monitoring and control

InactiveUS20060044555A1Improve curing effectAvoid over-curingRadiation pyrometrySpectrum investigationOptoelectronicsMonitoring and control

In a laser based curing apparatus, the acts both as the curing light and the excitation source for a Raman spectroscopic sensor. The spectroscopic sensor provides real-time, in situ, non-invasive curing status monitoring via Raman spectroscopy. The spectroscopic information can be further used to control the operation parameters of the laser to achieve the optimum cure result.

Owner:METROHM SPECTRO INC

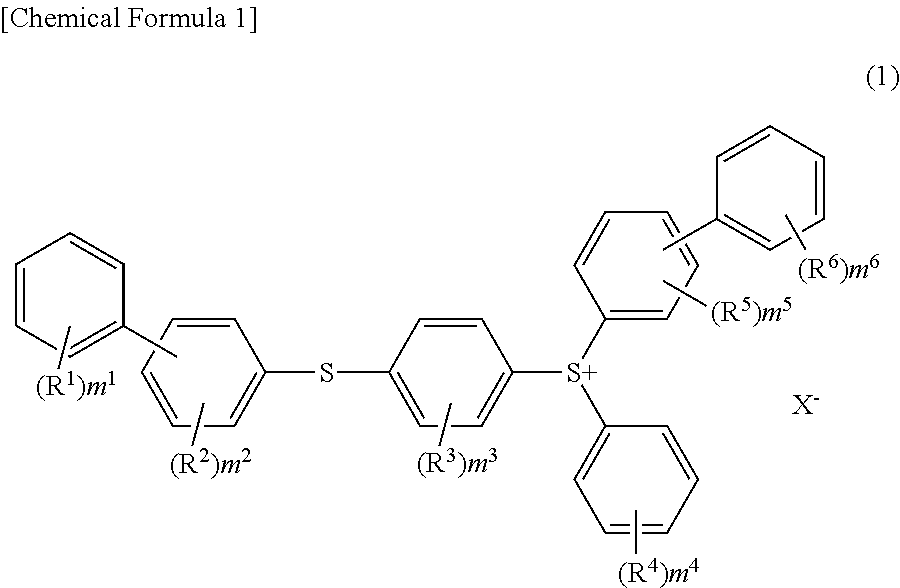

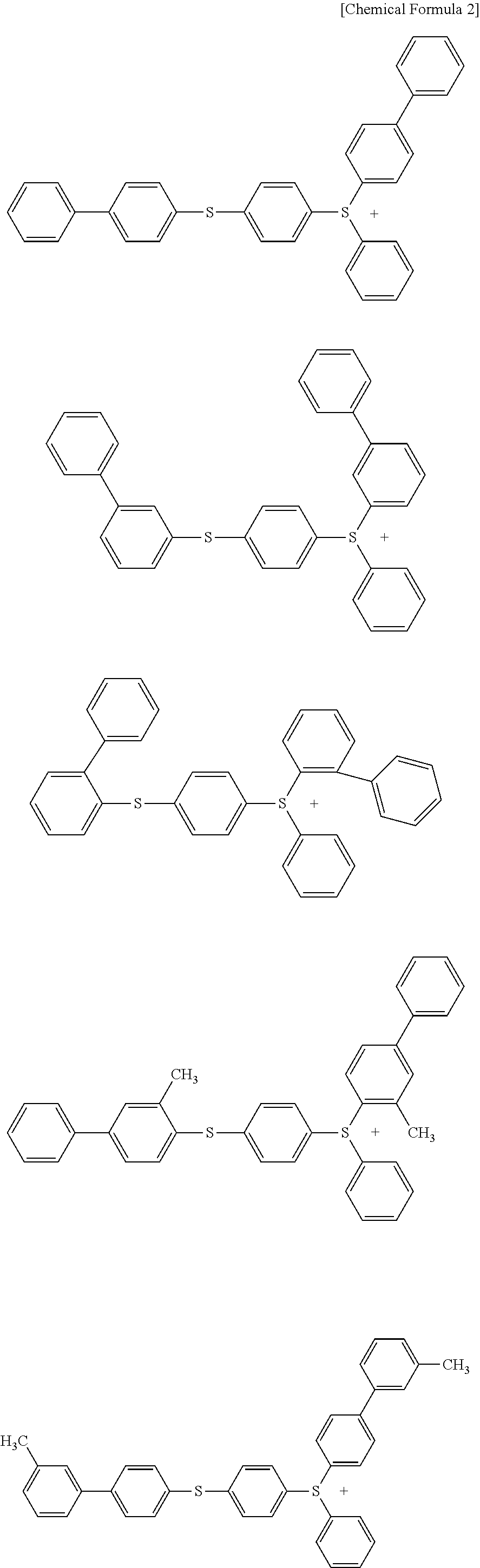

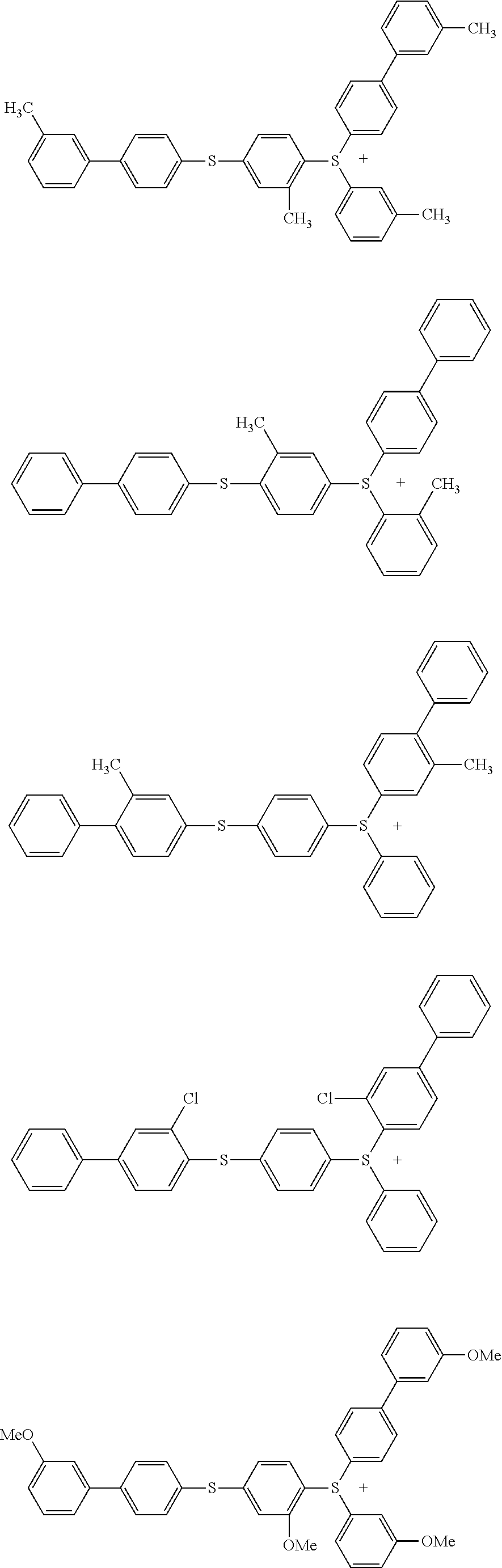

Sulfonium salt, photo-acid generator, and photosensitive resin composition

ActiveUS8617787B2Increase photosensitivityImprove compatibilityOrganic compound preparationPhotosensitive materialsHalogenAlkoxy group

There is provided a sulfonium salt having high photosensitivity to the i-line. The invention relates to a sulfonium salt represented by formula (1) described below: [in formula (1), R1 to R6 each independently represent an alkyl group, a hydroxy group, an alkoxy group, an alkylcarbonyl group, an arylcarbonyl group, an alkoxycarbonyl group, an aryloxycarbonyl group, an arylthiocarbonyl group, an acyloxy group, an arylthio group, an alkylthio group, an aryl group, a heterocyclic hydrocarbon group, an aryloxy group, an alkylsulfinyl group, an arylsulfinyl group, an alkylsulfonyl group, an arylsulfonyl group, a hydroxy(poly)alkyleneoxy group, an optionally substituted amino group, a cyano group, a nitro group, or a halogen atom, m1 to m6 each represent the number of occurrences of each of R1 to R6, m1, m4, and m6 each represent an integer of 0 to 5, m2, m3, and m5 each represent an integer of 0 to 4, and X− represents a monovalent polyatomic anion].

Owner:SAN APRO

Aqueous two-package type clear coating composition and process for the formation of multilayer finish coating film

ActiveUS20090274846A1Remarkable effectExcellent film performancePretreated surfacesPolyurea/polyurethane coatingsAcrylic resinGlass transition

The present invention provides an aqueous two-package type clear coating composition comprising: (A) an aqueous dispersion of a hydroxyl group- and acid group-containing acrylic resin having a hydroxyl value of 30 to 200 mg KOH / g, an acid value of 5 to 50 mg KOH / g, a weight average molecular weight of 3,000 to 30,000, and a glass transition temperature of −30 to +40° C. obtained by radical polymerization of 10 to 50 mass % of a secondary hydroxyl group-containing monomer (a) and 50 to 90 mass % of at least one other unsaturated monomer (b); and (B) a polyisocyanate curing agent obtained by mixing (c) a polyisocyanate compound and (d) a compound containing an anionic functional group, a polyoxyethylene group, and a hydrocarbon group, and a process for forming a multilayer topcoat film using the same.

Owner:KANSAI PAINT CO LTD

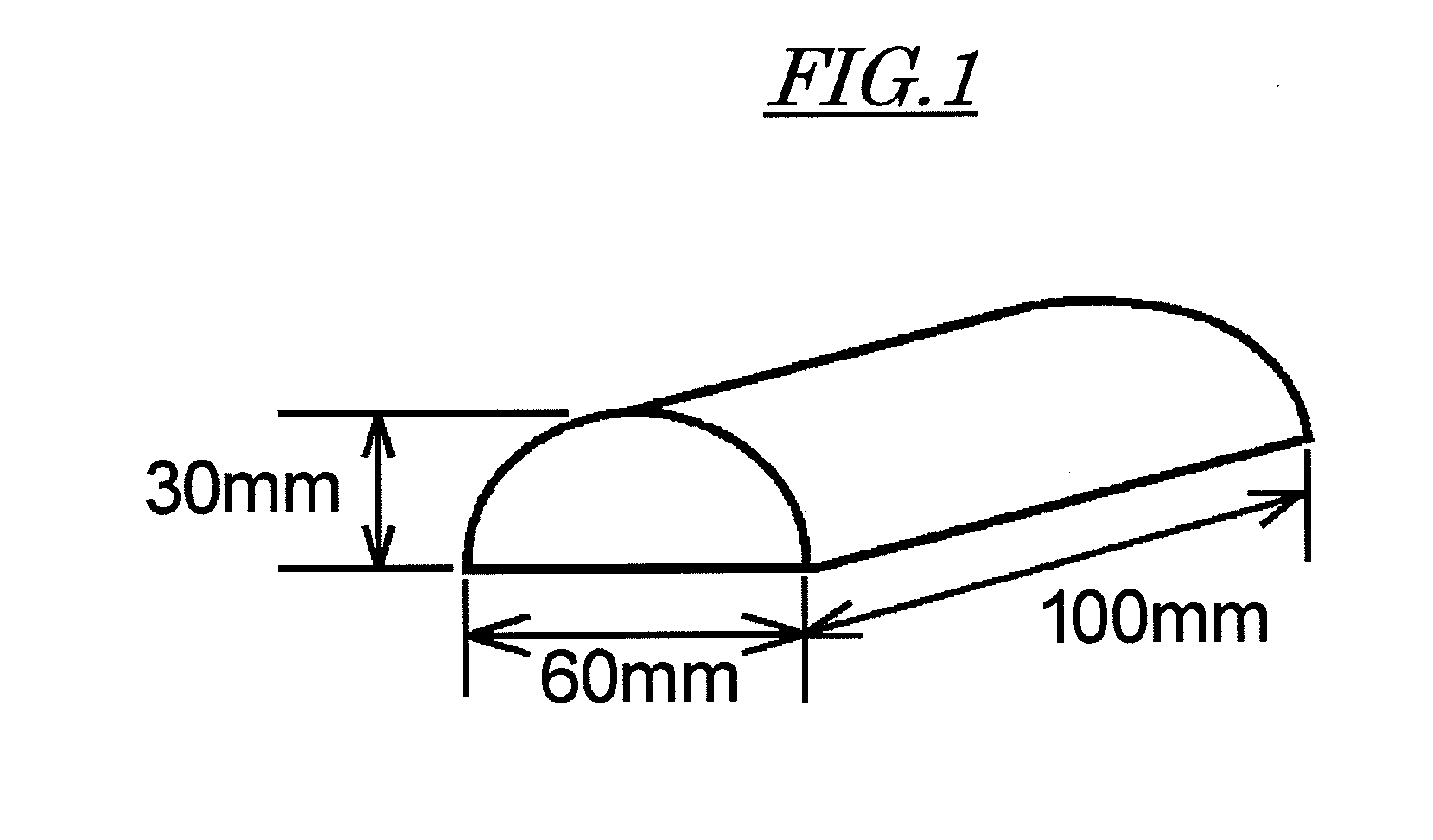

Ink composition, inkjet recording method, printed material, and process for producing molded printed material

ActiveUS20090087626A1Excellent curabilityExcellent flexibility and anti-blocking propertyDecorative surface effectsLayered productsMethacrylamideChemistry

An ink composition is provided that includes a perfluoroalkyl group-containing polymer, a polymerizable monomer, and a radical polymerization initiator, in which at least 80 wt % of the polymerizable monomer is a monofunctional polymerizable monomer selected from the group consisting of a monofunctional acrylate, a monofunctional methacrylate, a monofunctional vinyloxy compound, a monofunctional N-vinyl compound, a monofunctional acrylamide, and a monofunctional methacrylamide. There are also provided an inkjet recording method that includes a step of discharging the ink composition onto a recording medium and a step of curing the ink composition by irradiating the discharged ink composition with actinic radiation, a printed material obtained by the inkjet recording method, and a process for producing a molded printed material that includes a step of forming an image by discharging the ink composition onto a support by an inkjet method, a step of irradiating the image thus obtained with actinic radiation so as to cure the ink composition and obtain a printed material having the image cured on the support, and a step of molding the printed material.

Owner:FUJIFILM CORP

Active energy ray curable aqueous ink composition, and inkjet recording method, ink cartridge, recording unit, and inkjet recording apparatus using the same

InactiveUS20060004116A1Improve curing effectImprove responseMeasurement apparatus componentsDuplicating/marking methodsMeth-Water soluble

To provide an active energy ray curable aqueous ink composition exhibiting excellent curing performance by including a water-soluble polymerizable substance with high reactivity and a water-soluble polymerization initiator having high initiation efficiency; and an inkjet recording method, ink cartridge, recording unit, and inkjet recording apparatus all using the active energy ray curable aqueous ink composition. The active energy ray curable aqueous ink composition includes at least water; a polymerizable substance which undergoes radical polymerization by active energy rays; and a polymerization initiator which generates radicals by active energy rays, in which the polymerizable substance is a water-soluble compound having 2 to 6 (meth)acrylic groups; and the polymerization initiator is a water-soluble acylphosphine oxide compound.

Owner:CANON KK

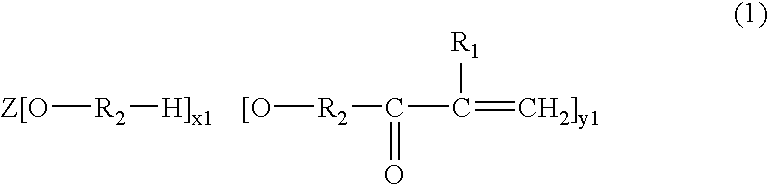

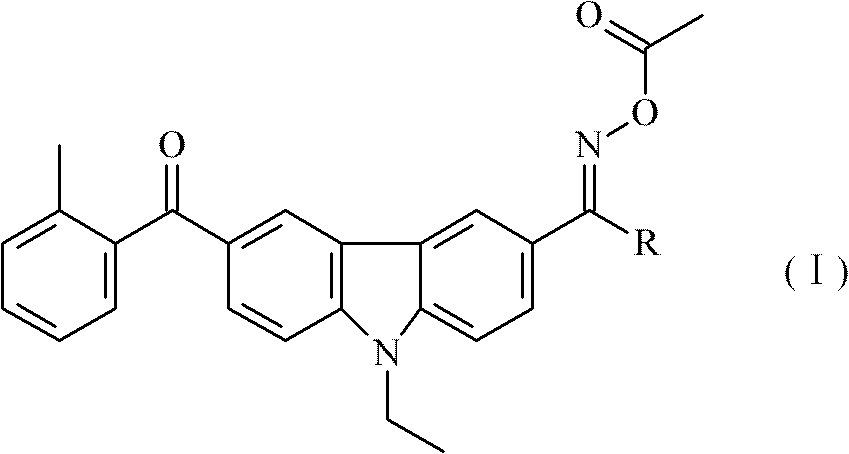

Application of carbazole oxime ester compound serving as photoinitiator in photopolymerisable acrylate composition

ActiveCN101891845AGood short wavelength sensitivityHigh short wavelength sensitivityOptical filtersPhotomechanical apparatusCarbazoleHardness

The invention relates to an application of a carbazole oxime ester compound serving as a photoinitiator in a photopolymerisable acrylate composition, the photopolymerisable acrylate composition containing the carbazole oxime ester compound and an application thereof. The composition presents excellent suitability by the combination of the specific photoinitiator and specific photopolymerisable acrylate monomer, and has high storage stability, higher light sensitivity in a short wave position, and excellent dissolvability performance; and when the composition is polymerized, the composition has the advantages of fast solidification speed, little pollution, energy conservation, high exposal efficiency and small exposal dosage, meanwhile, the solidified image pattern is fine and complete without defect and scum, and the membrane has good hardness.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS

Actinic ray curable composition, image forming method using the same and ink-jet recording apparatus using the same

InactiveUS20050196697A1Improve curing effectStable storageDuplicating/marking methodsPhotomechanical apparatusActinic RaysPhotochemistry

An actinic ray curable composition containing a quinacridone pigment; a dispersant; a cationically polymerizable monomer; a photo acid generator; and a quinacridone derivative.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

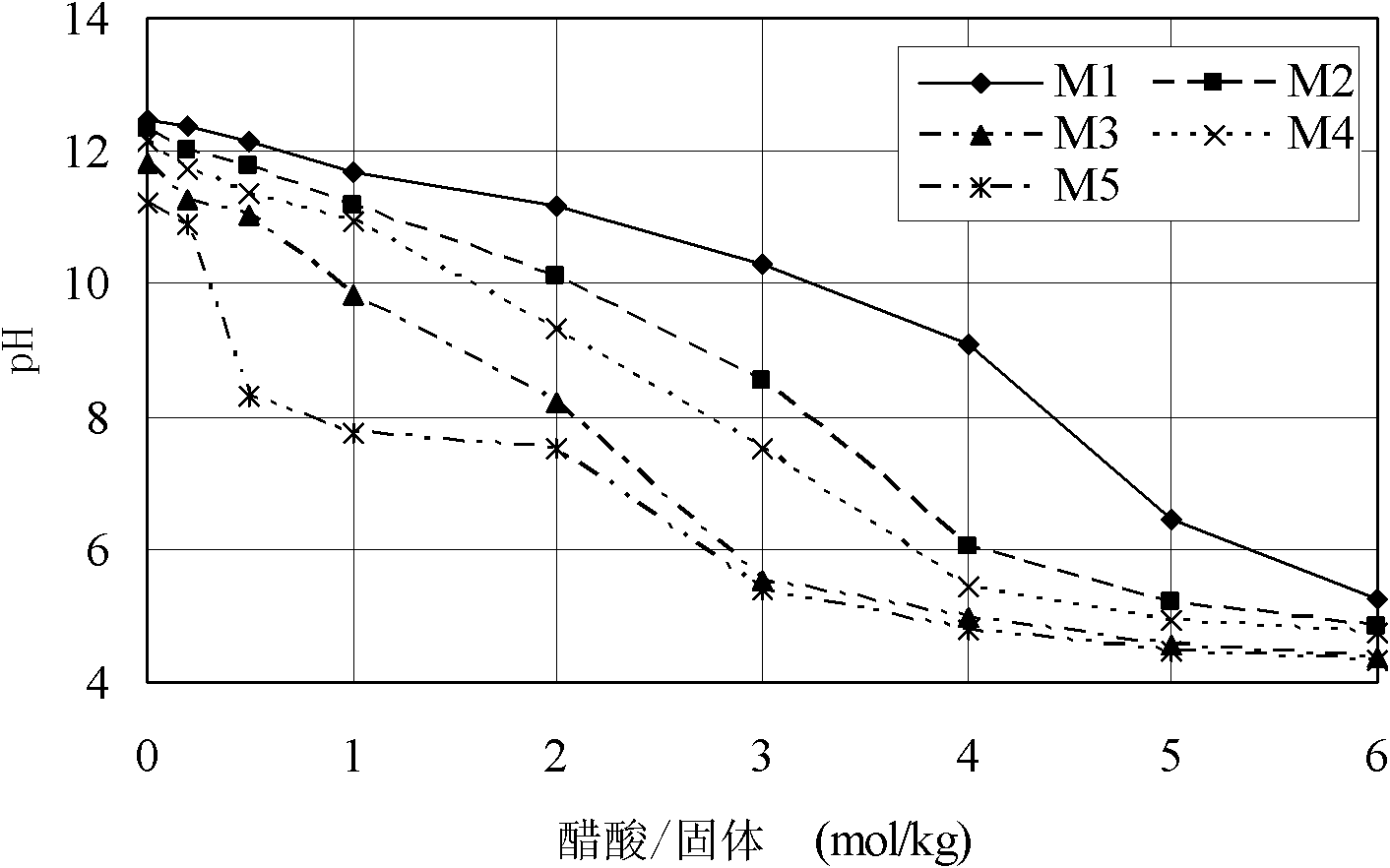

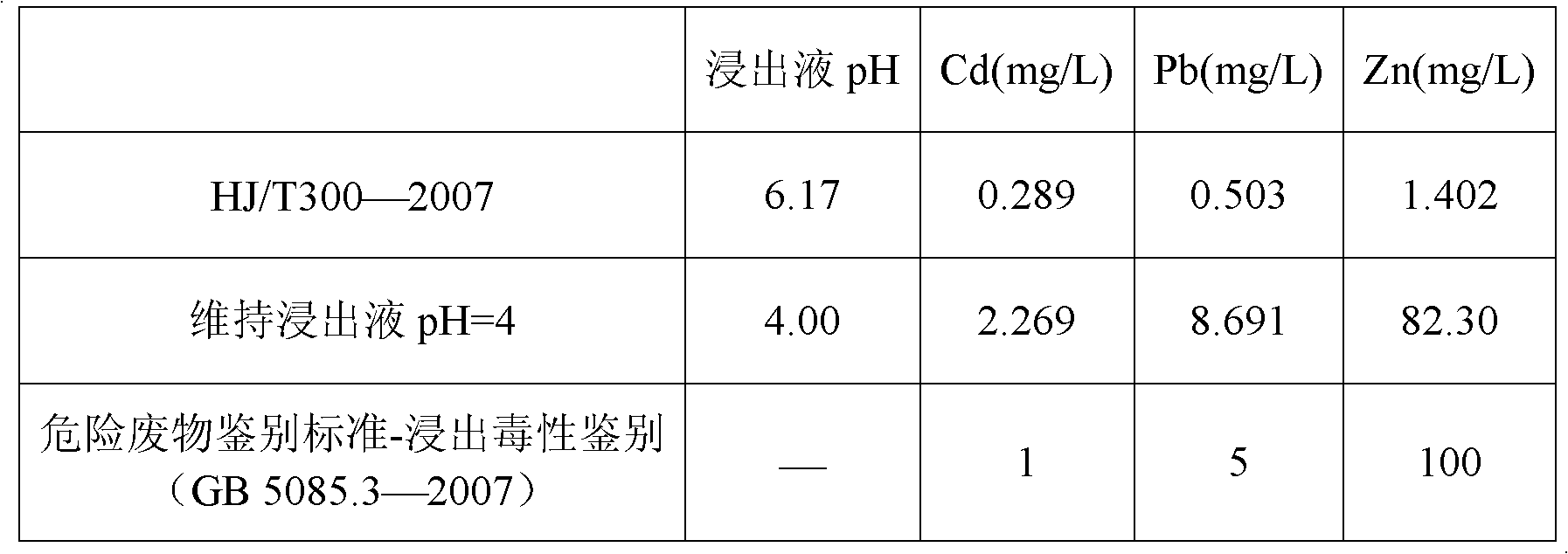

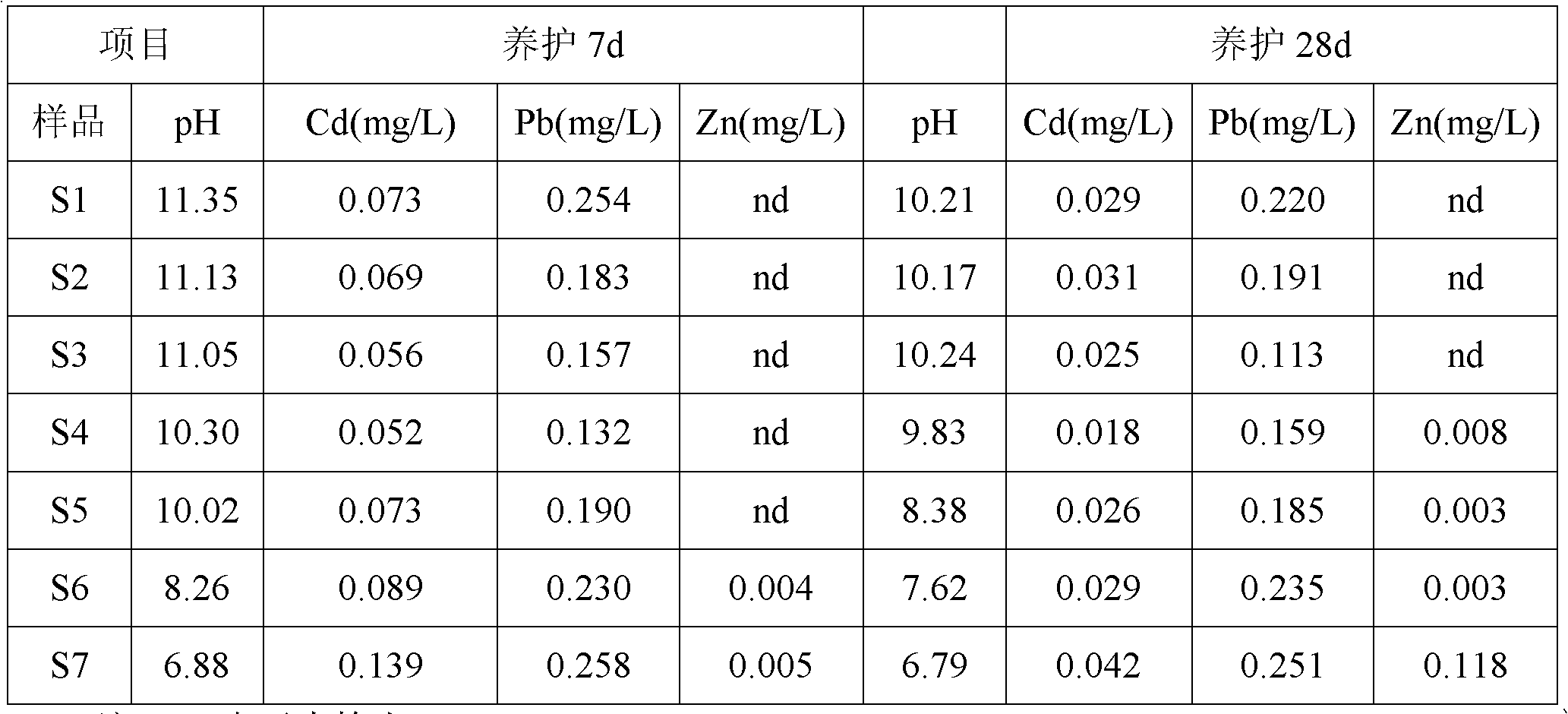

Heavy metal pollution bottle sediment curing agent and curing method thereof

InactiveCN101921090AReduce leaching concentrationWide variety of sourcesSludge treatmentSolid waste managementSludgeFirming agent

The invention relates to heavy metal sludge treated agent and a treating method thereof and in particular discloses a heavy metal pollution bottle sediment curing agent. The curing agent comprises cement and pulverized fuel ash, the mass ratio of the pulverized fuel ash to cement is 1:(0.5-11).The curing method of the curing agent comprises the following steps: directly adding the curing agent tothe heavy metal pollution bottle sediment with the use level of the curing agent being 0.4-1.5 times of the use level of the heavy metal pollution bottle sediment; maintaining the mixture after beingadded the curing agent for at least 3 days; and finally, completing the curing process.The curing agent and curing method of the invention not only has low processing cost but also ideal curing effect.

Owner:HUNAN UNIV

Anaerobic adhesive compositions having microencapsulated metal ions

ActiveUS20080242764A1Improve adhesionImprove propertiesSynthetic resin layered productsOrganic non-macromolecular adhesiveCopper naphthenateCobalt(II) naphthenate

An enhanced anaerobic adhesive composition containing microencapsulated metal ions is disclosed. Microencapsulated metal ions, such as iron oxide, copper naphthenate, cobalt naphthenate, ferrocene, and ferrocene derivatives, act as bonding sites in the composition, such that the composition achieves more complete polymerization in a shorter curing time. The curing properties and the cure quality are significantly improved by the inclusion of microencapsulated metal ions. The composition can be used to bond metal and plastic substrates.

Owner:ND IND INC

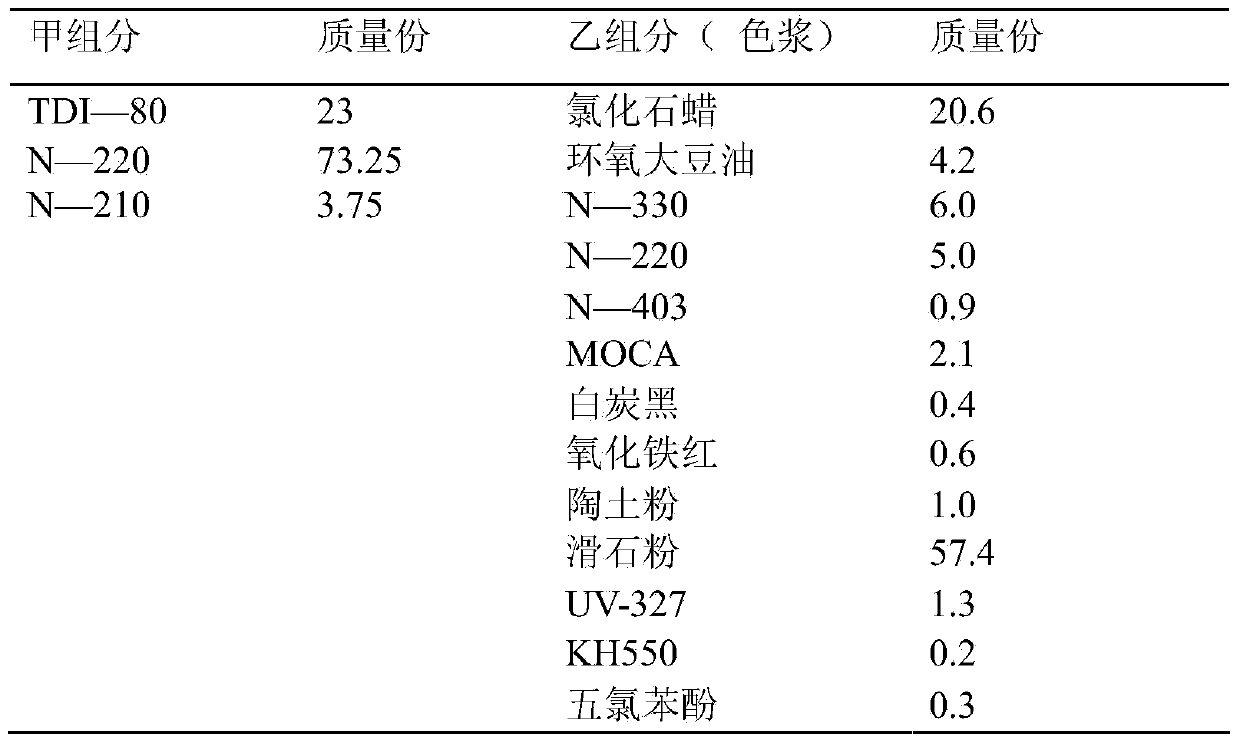

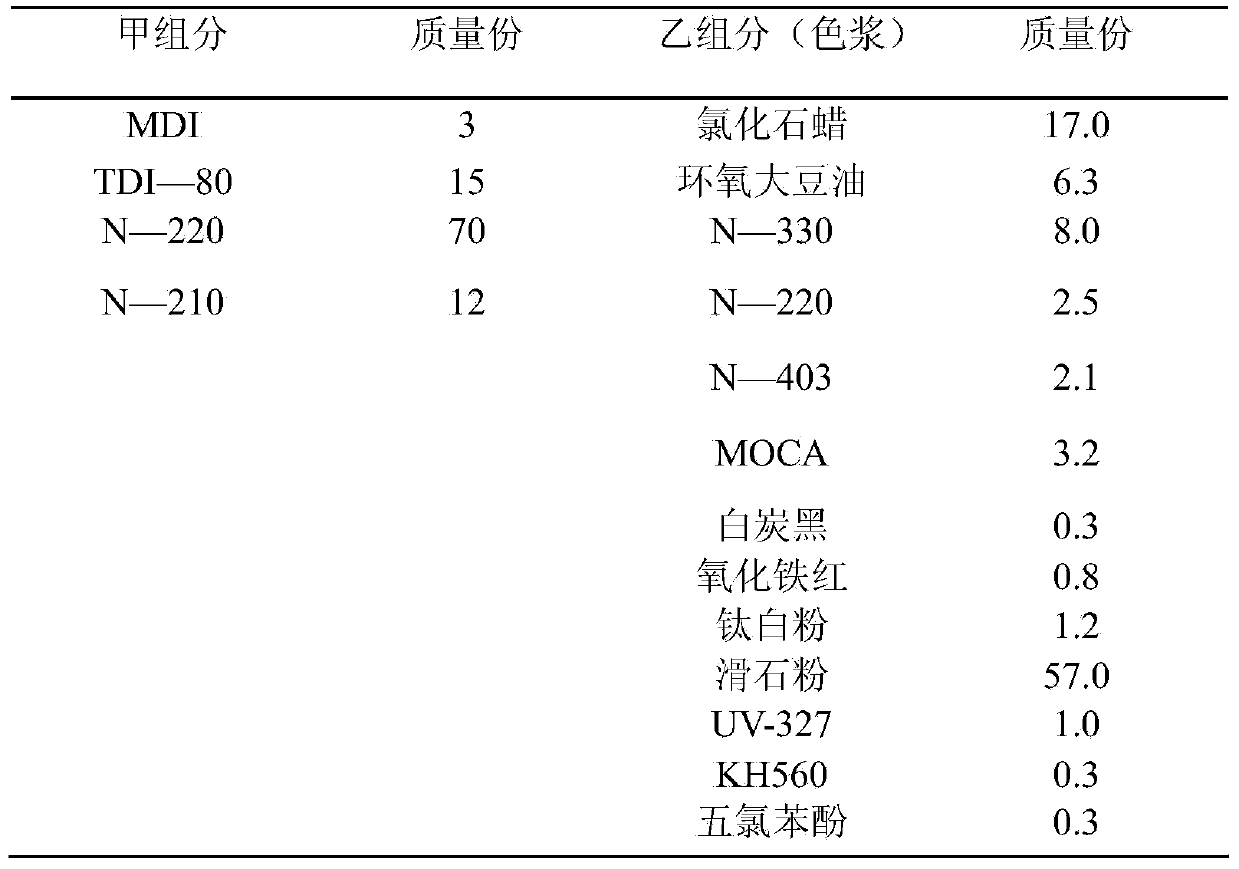

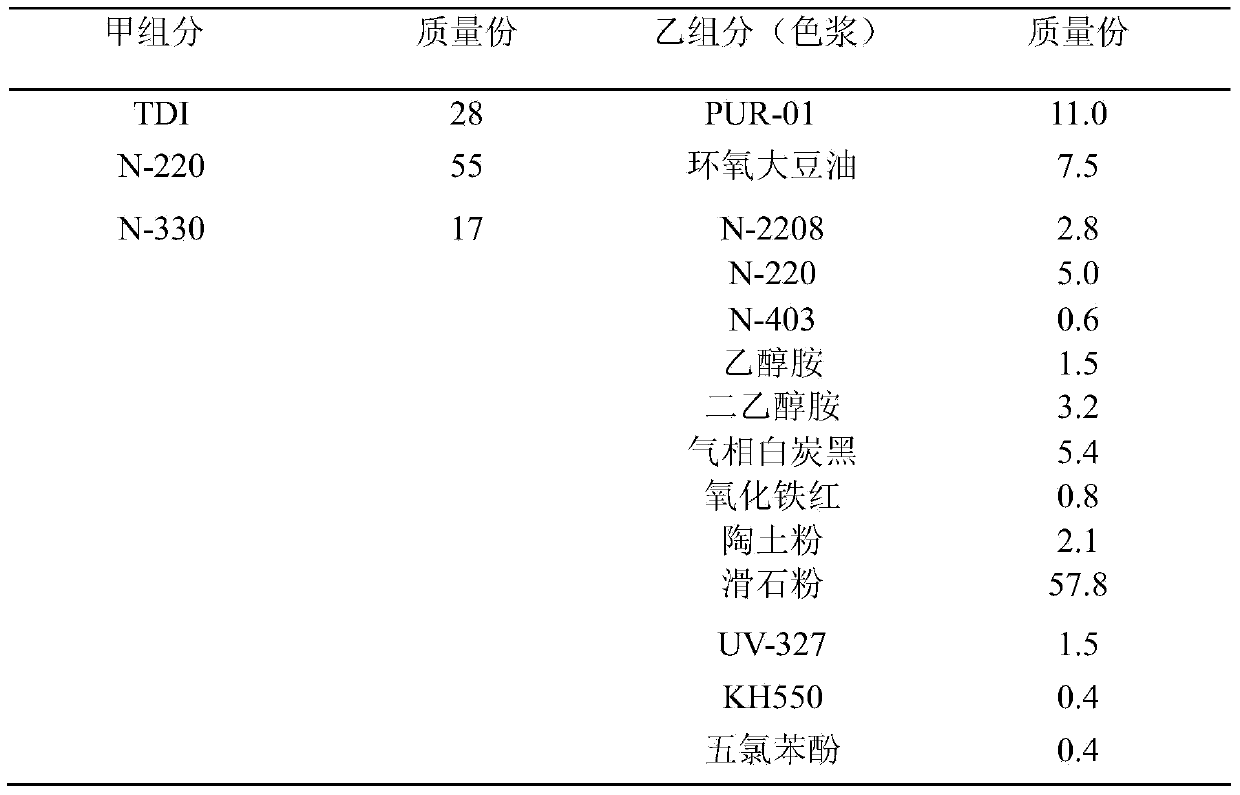

Preparation method of sprayed surface layer of environment-friendly polyurethane plastic track

InactiveCN103627310AGood curing effectRemove threatGround pavingsPolyurea/polyurethane coatingsIsocyanateSilane coupling

The invention discloses a preparation method of a sprayed surface layer of an environment-friendly polyurethane plastic track. The method comprises the steps of preparing a component A: adding polyether polyol into a reaction kettle, stirring and heating to 80-160 DEG C, dehydrating, cooling to 40-50 DEG C, adding isocyanate, stirring, and performing constant-temperature reaction at 80-85 DEG C for 2-4 hours; preparing a component B: uniformly mixing polyether polyol, a chain extender, a plasticizer, an ultraviolet light absorber anti-mildew agent, a thixotropic agent, a silane coupling agent and filler, shearing at a high speed, milling, and performing vacuum heating at 60-70 DEG C for 1-3 hours; mixing the component A and component B at a mass ratio of 1:(3-5.5); adding an inert amine dryer; stirring uniformly and spraying on the bottom layer of the polyurethane track. By adopting the method disclosed by the invention, the specific pungent smell of a conventional polyurethane track is avoided, the foaming effect is reduced, the usability of the track is improved, and the service life of the track is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

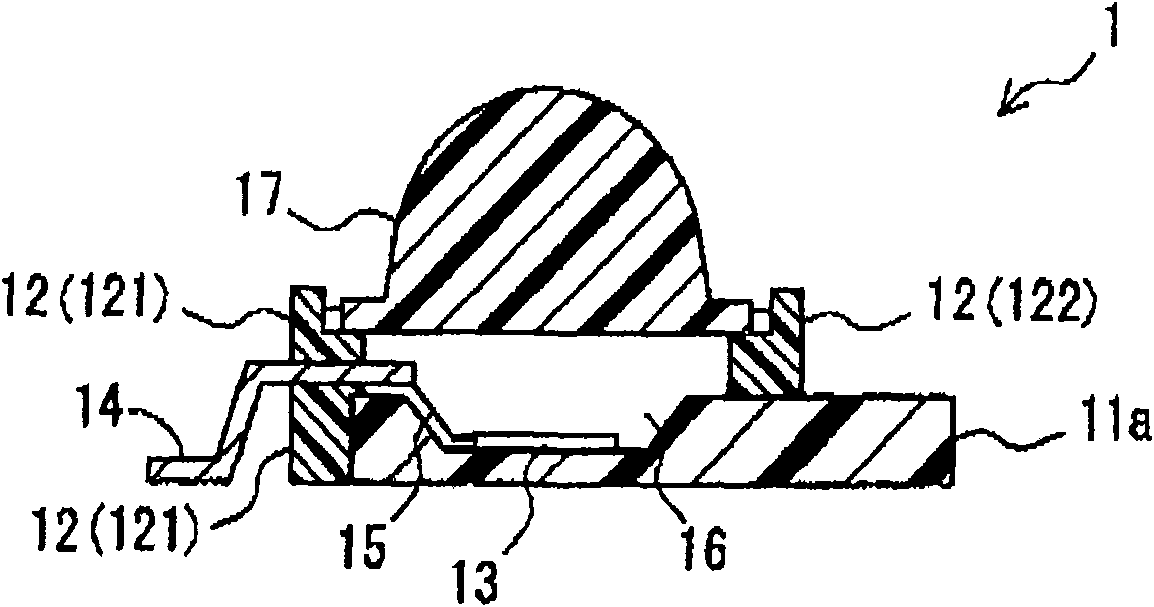

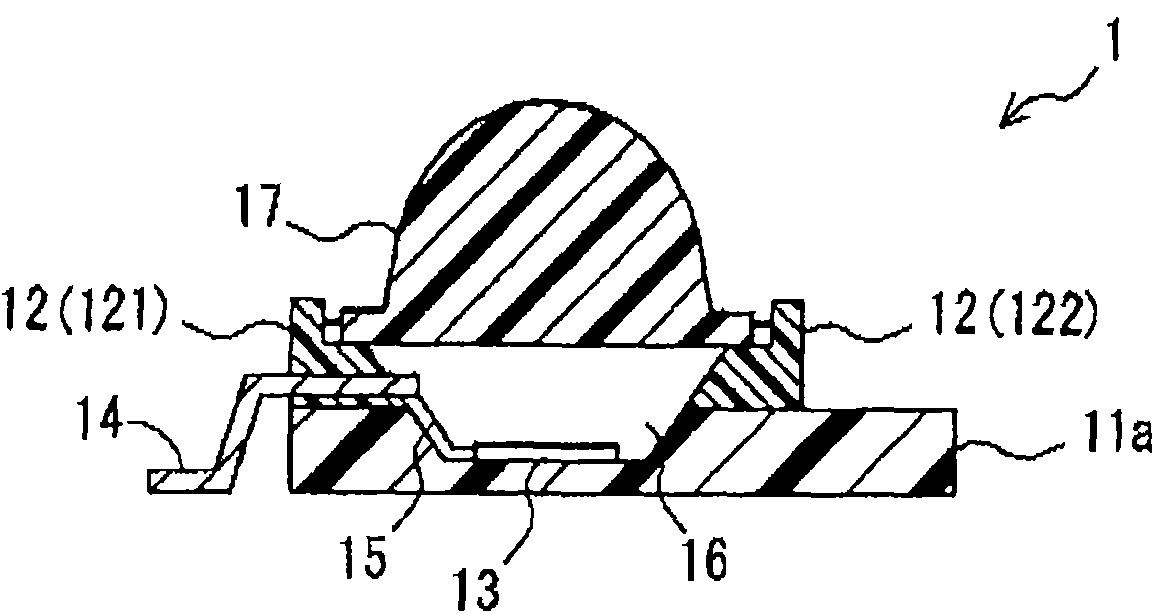

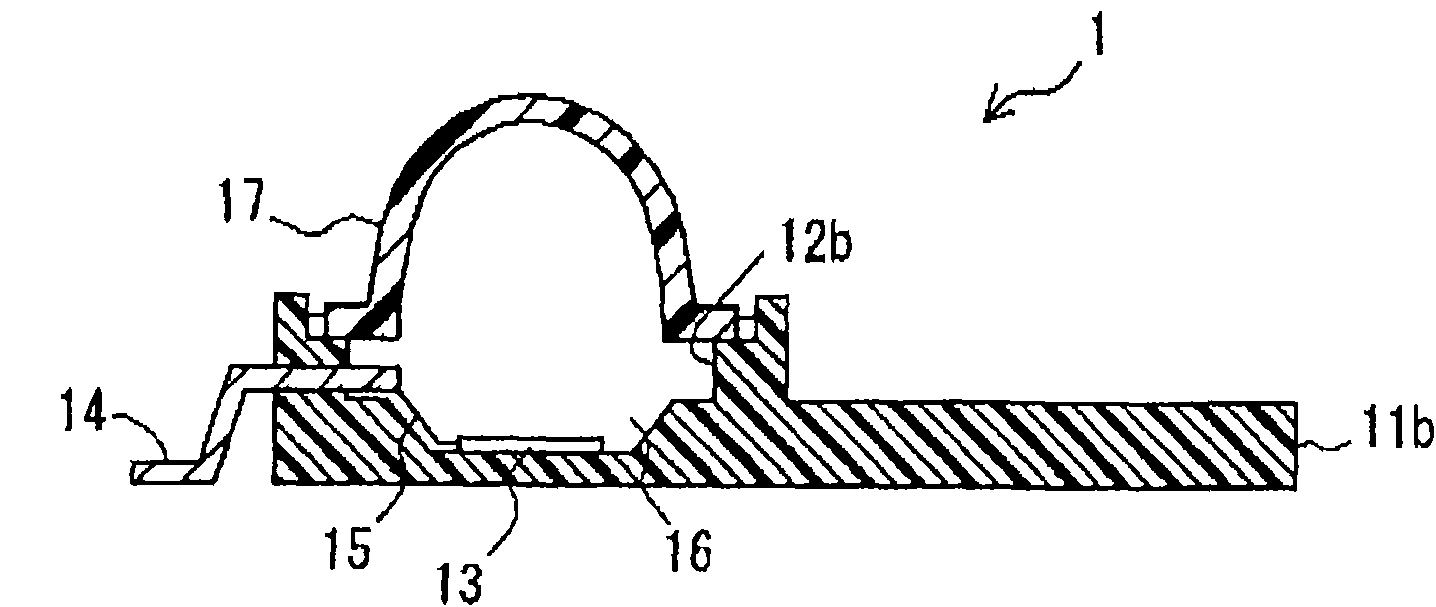

Heat-dissipating resin composition, substrate for LED mounting, reflector, and substrate for LED mounting having reflector portion

InactiveCN101583670AEasy to processImprove impact resistanceSolid-state devicesHeat exchange apparatusHeat deflection temperatureEmissivity

Disclosed is a heat-dissipating resin composition which is used for forming a substrate for LED mounting or a reflector provided on the substrate for LED mounting, and excellent in heat dissipation, electrical insulation, heat resistance and light resistance during the time when an LED element emits light. Also disclosed are a substrate for LED mounting and a reflector respectively containing such a heat-dissipating resin composition. Specifically disclosed is a composition containing a thermoplastic resin such as a modified PBT and a thermally conductive filler such as a flake boron nitride. The composition has a heat distortion temperature of not less than 120 DEG C, a thermal conductivity of not less than 2.0 W / (m K) and a thermal emissivity of not less than 0.7.

Owner:TECHNO POLYMER CO LTD

Stabilization and solidification method of highly toxic waste residues

The invention relates to a stabilization and solidification method of highly toxic waste residues containing one or more of mercury, arsenic, chromium, cadmium and cyanide. Heavy metal is stabilized through chemicals, and then the highly toxic waste residues are sequentially wrapped with gypsum plus paraffin and epoxy resin. After four times of wrapping and two times of solidification, highly toxic substances in the waste residues are fully solidified into a solidified body, and the generated solidified body is high in strength and long in stability, and can be buried conveniently later.

Owner:扬州杰嘉工业固废处置有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com