Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5515results about "Vehicle sealing arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

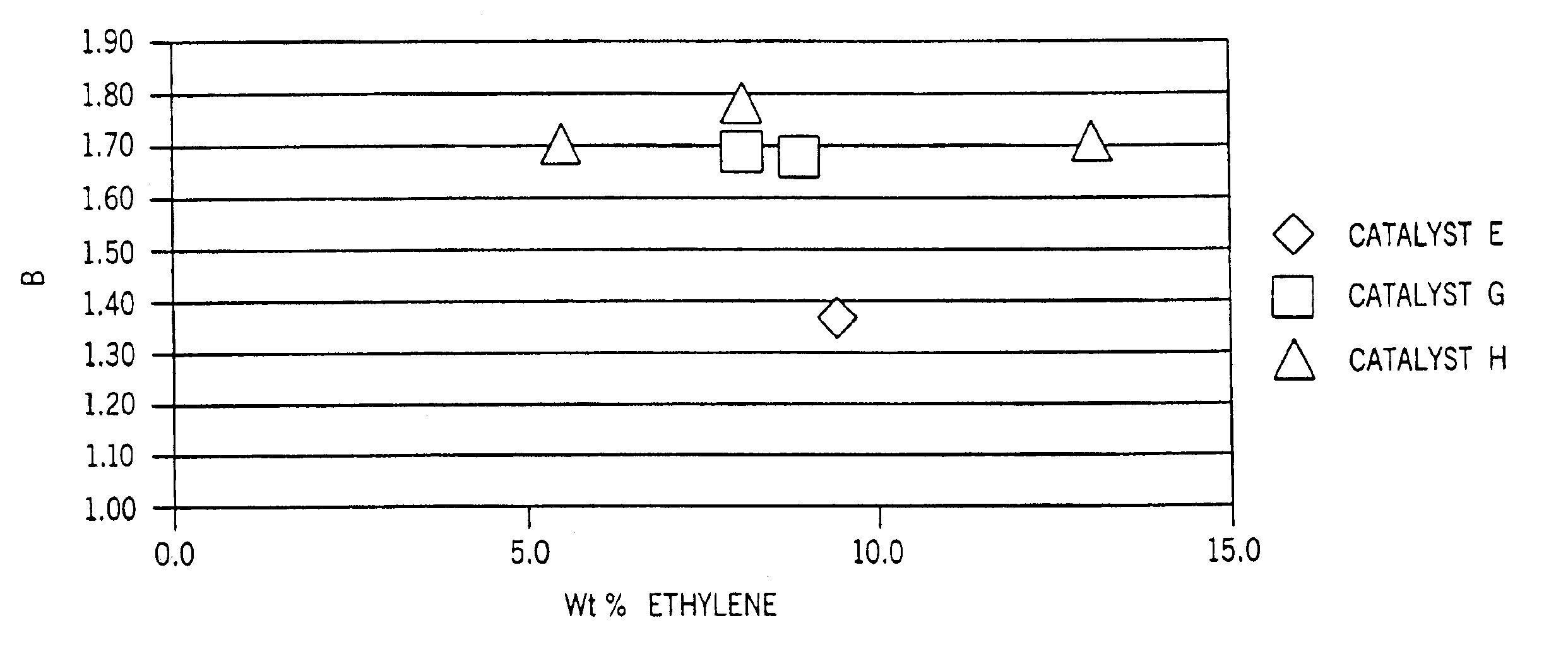

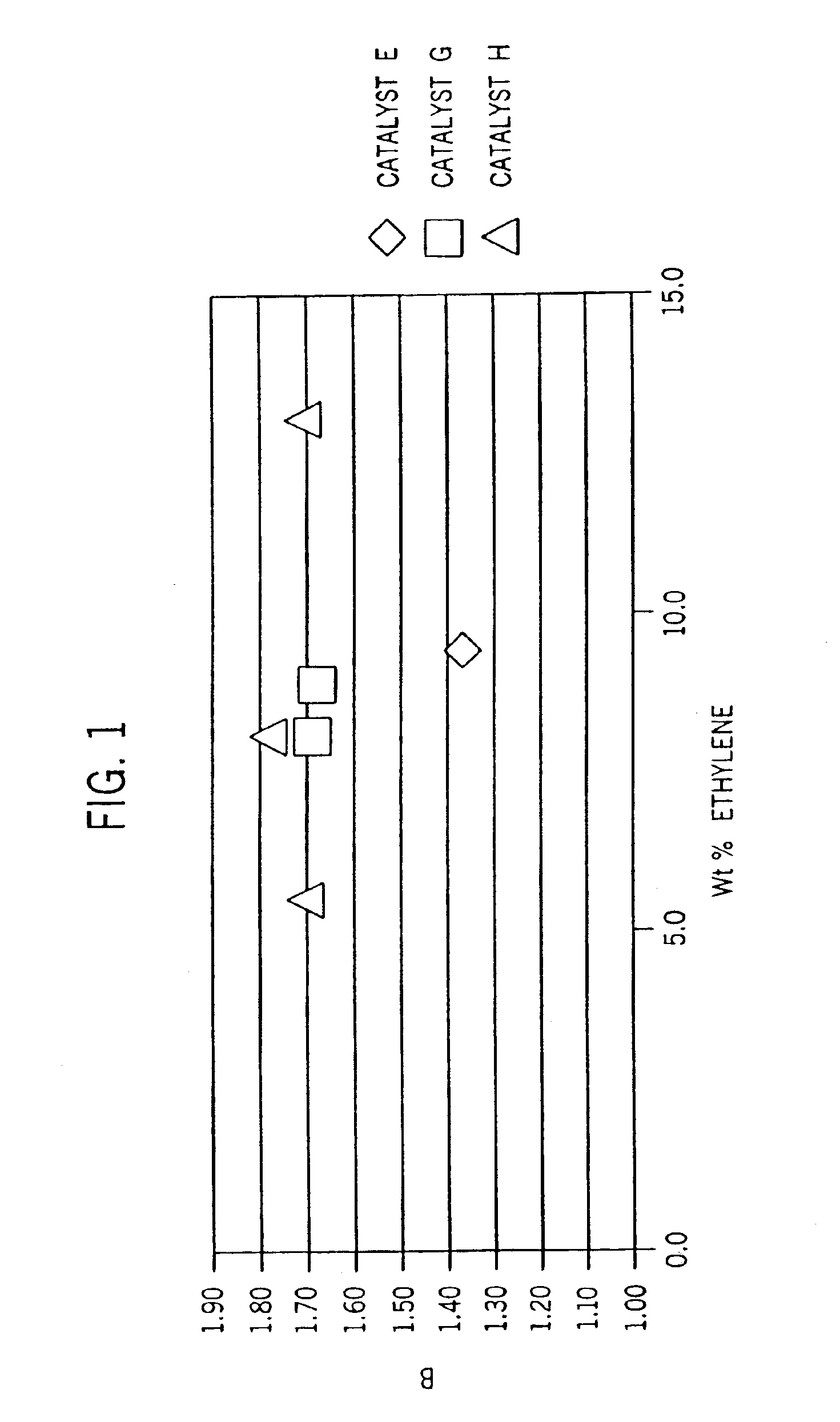

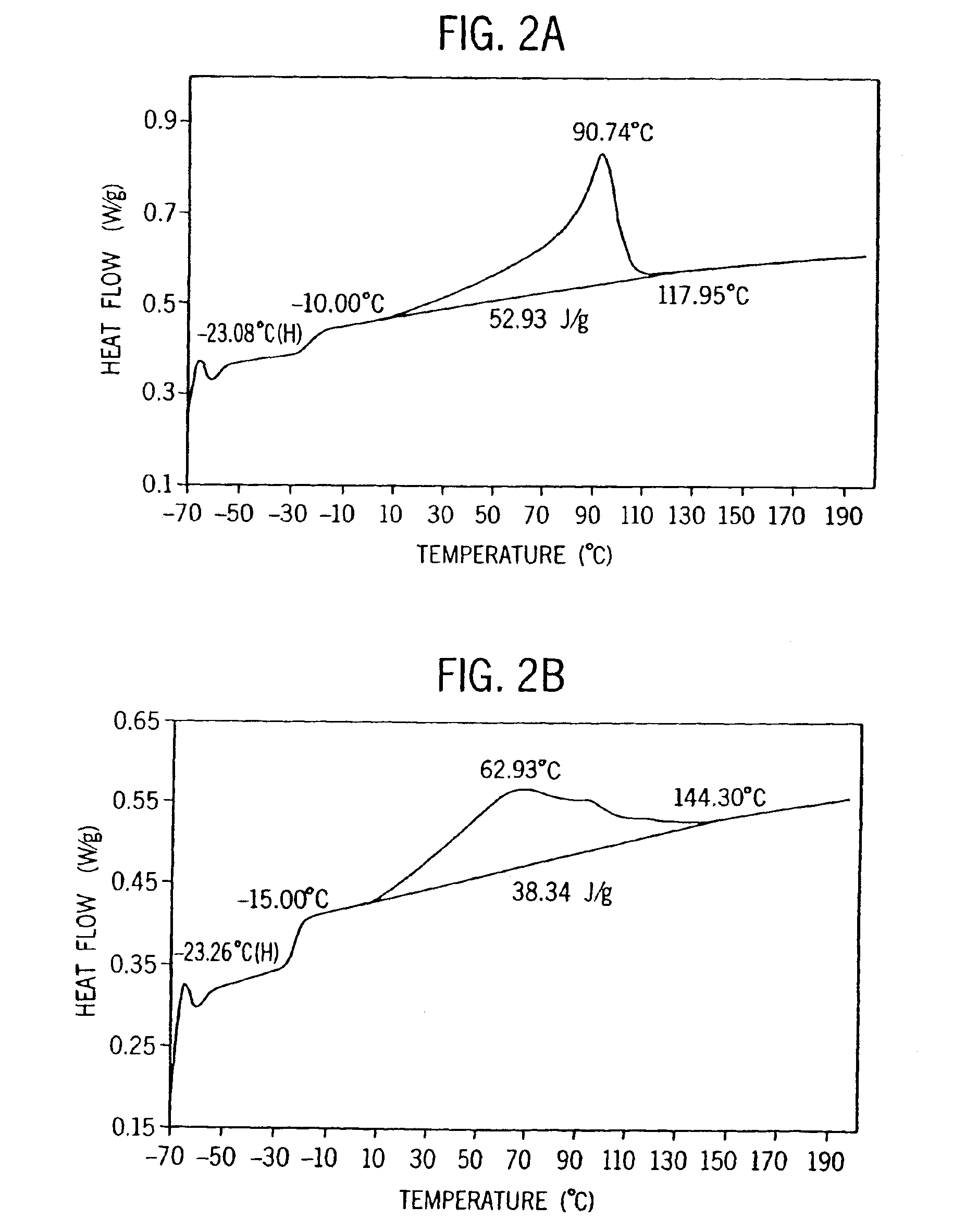

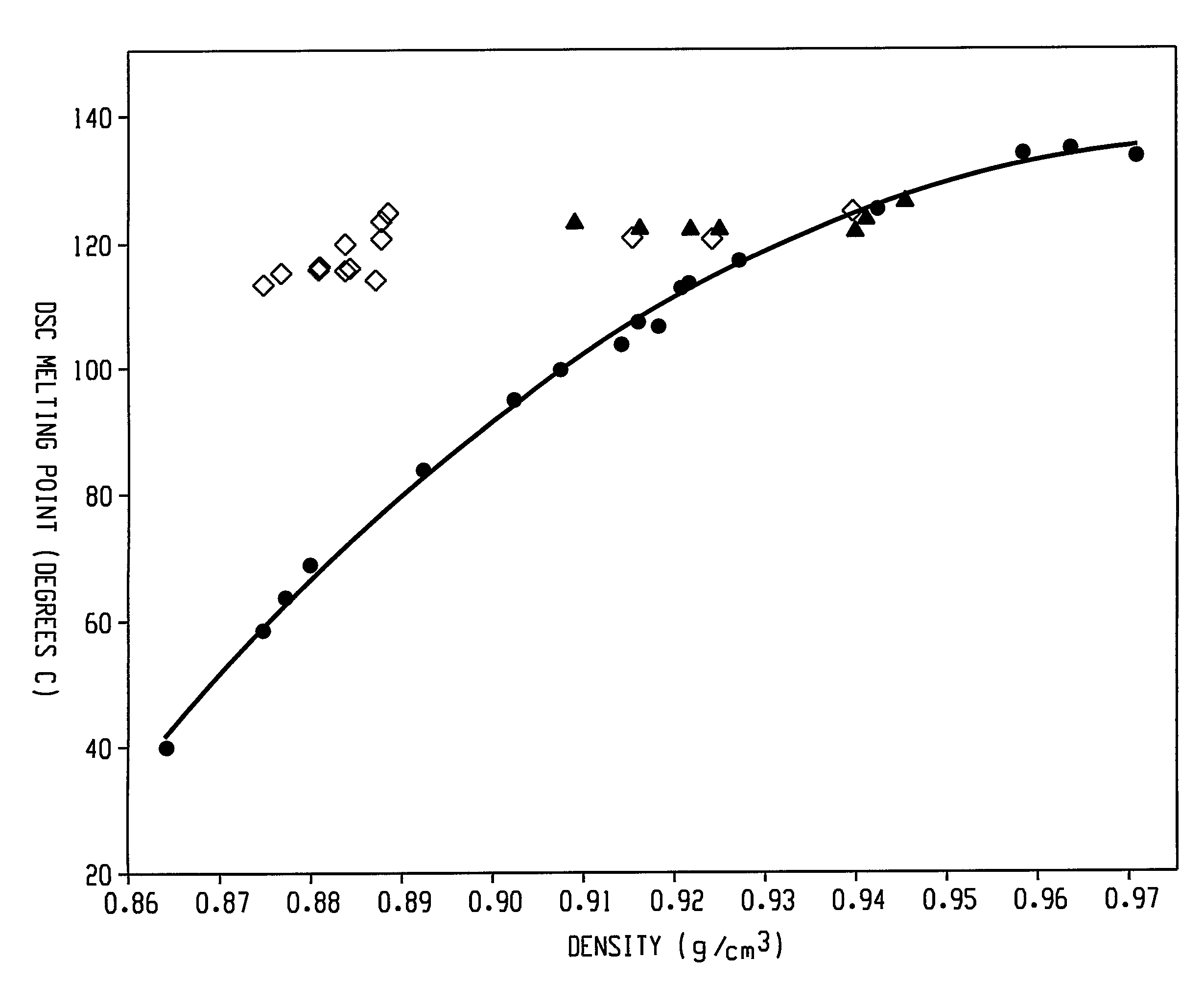

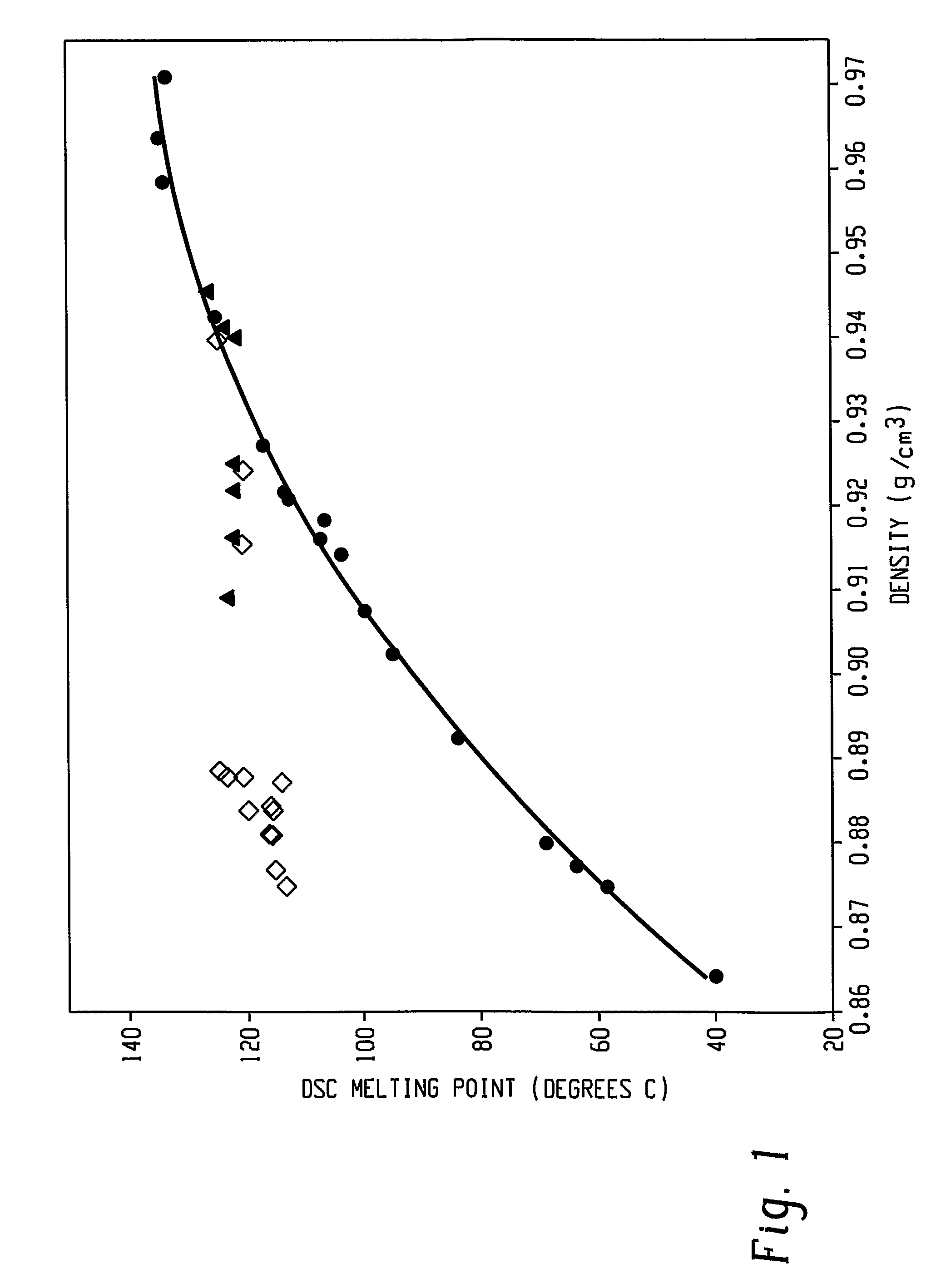

Isotactic propylene copolymers, their preparation and use

InactiveUS6960635B2Group 4/14 element organic compoundsOther chemical processesFiberZiegler–Natta catalyst

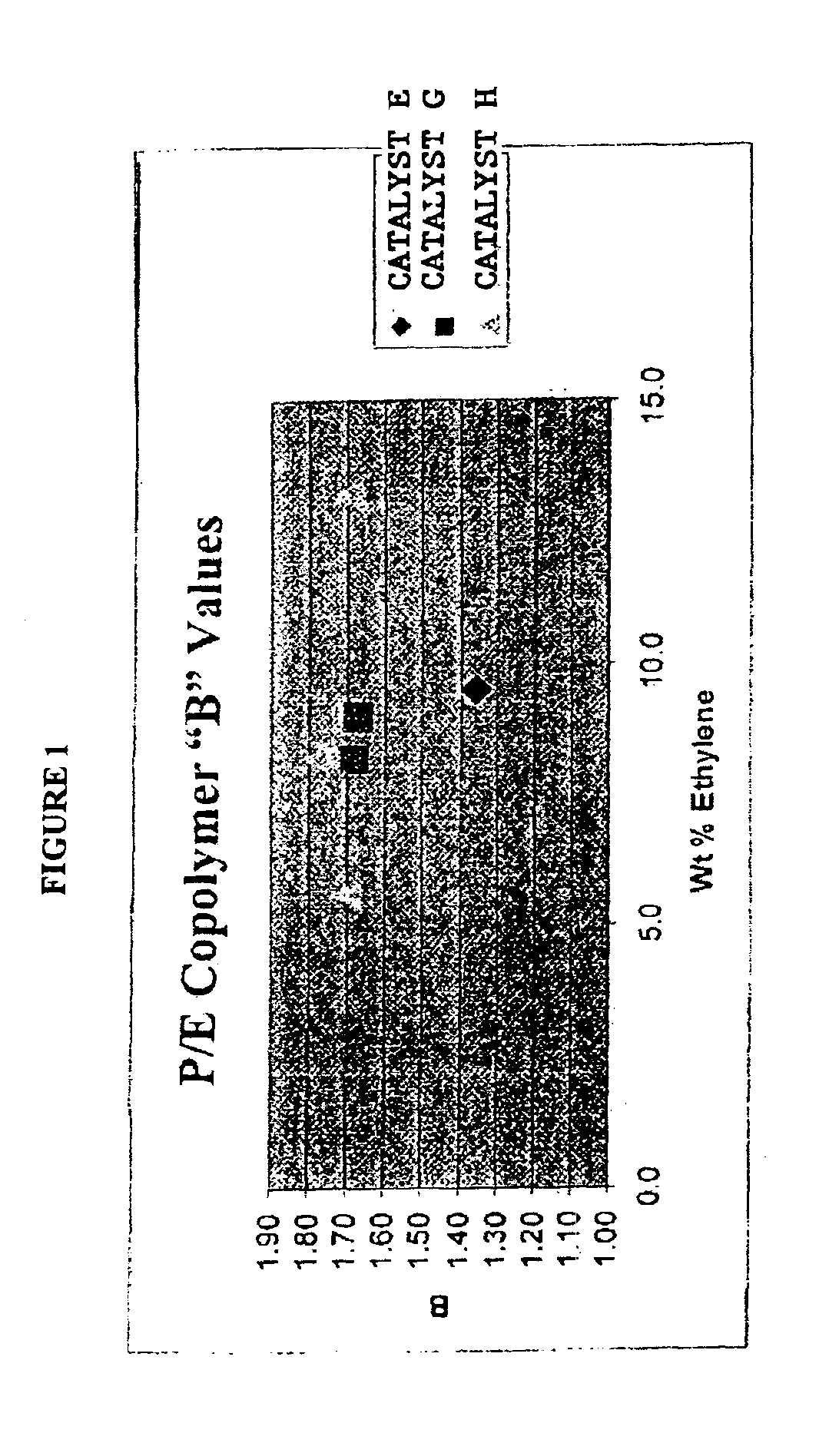

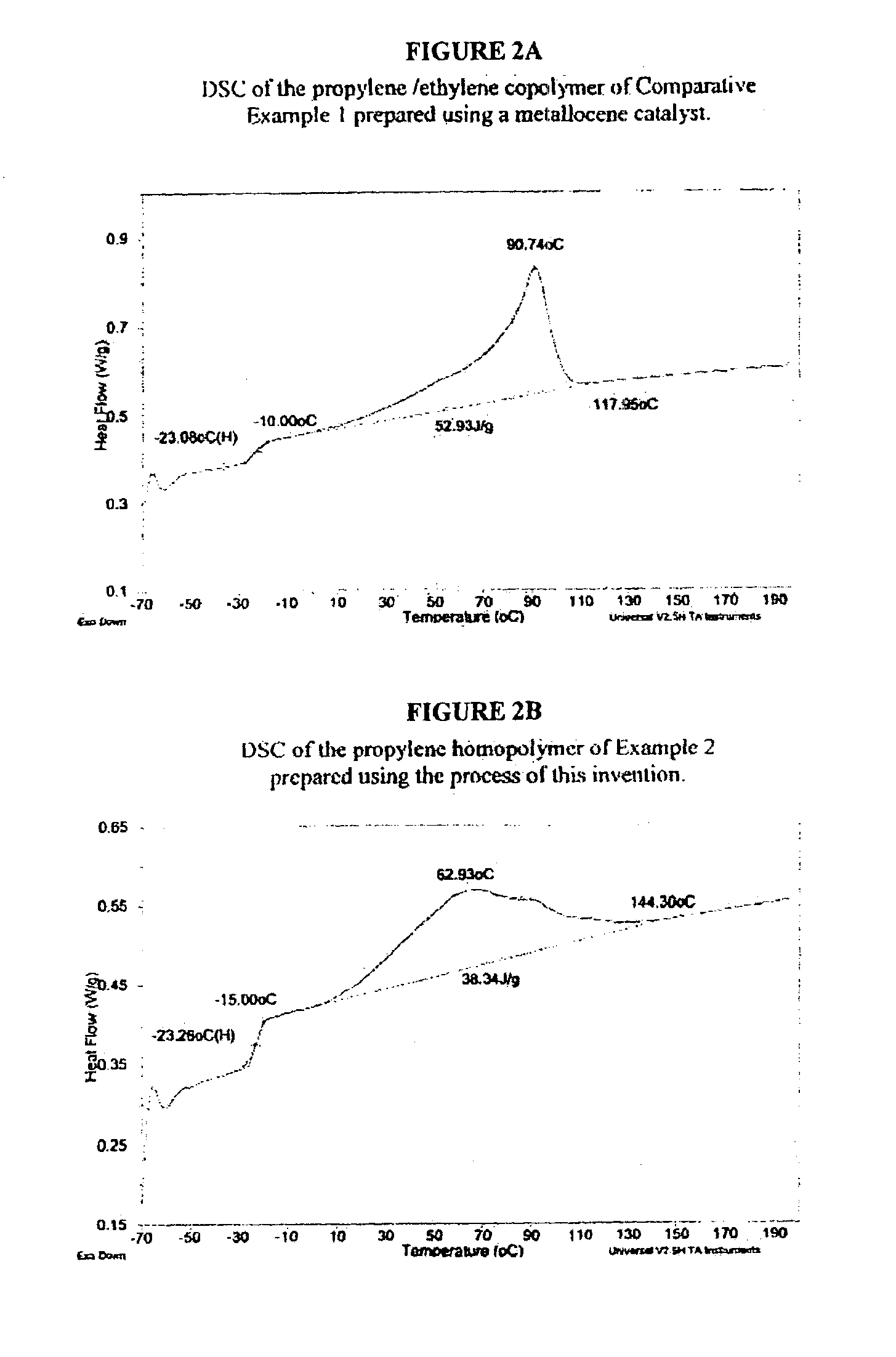

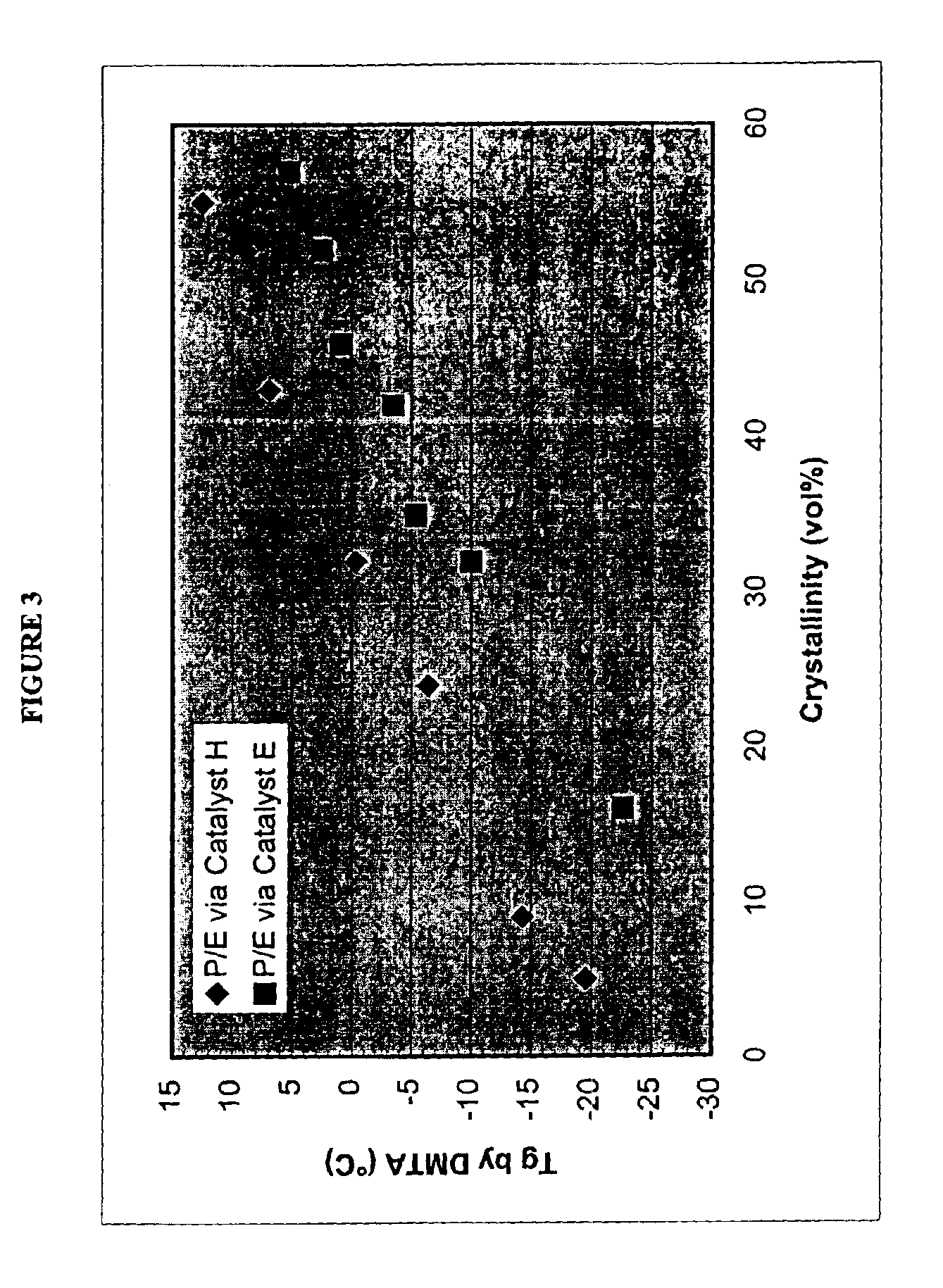

Unique copolymers comprising propylene, ethylene and / or one or more unsaturated comonomers are characterized as having: at least one, preferably more than one, of the following properties: (i) 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity, (ii) a B-value greater than about 1.4 when the comonomer content of the copolymer is at least about 3 wt %, (iii) a skewness index, Six, greater than about −1.20, (iv) a DSC curve with a Tme that remains essentially the same and a Tmax that decreases as the amount of comonomer in the copolymer is increased, and (v) an X-ray diffraction pattern that reports more gamma-form crystals than a comparable copolymer prepared with a Ziegler-Natta catalyst. These polypropylene polymers are made using a nonmetallocene, metal-centered, heteroaryl ligand catalyst. These polymers can be blended with other polymers, and are useful in the manufacture of films, sheets, foams, fibers and molded articles.

Owner:DOW GLOBAL TECH LLC

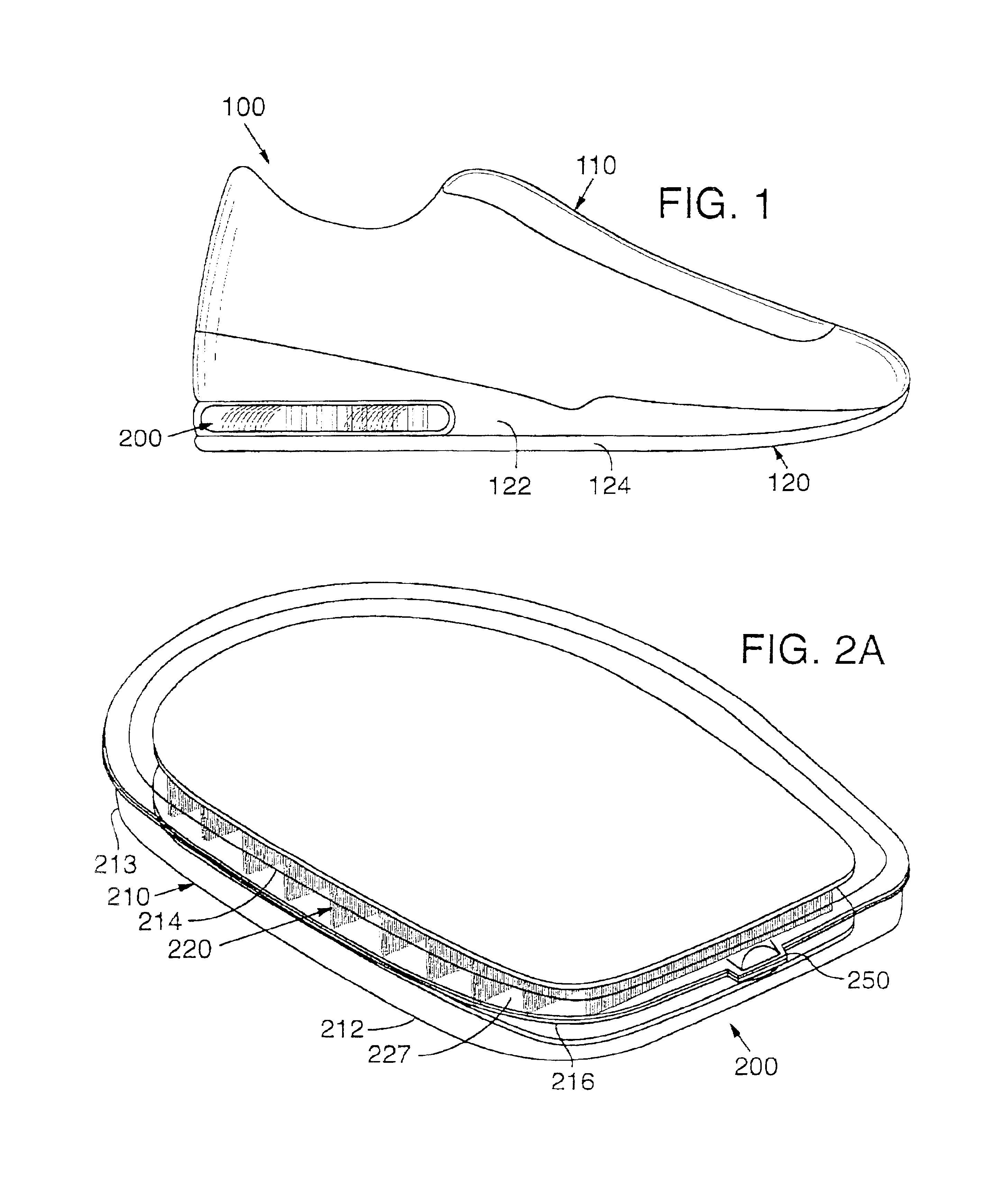

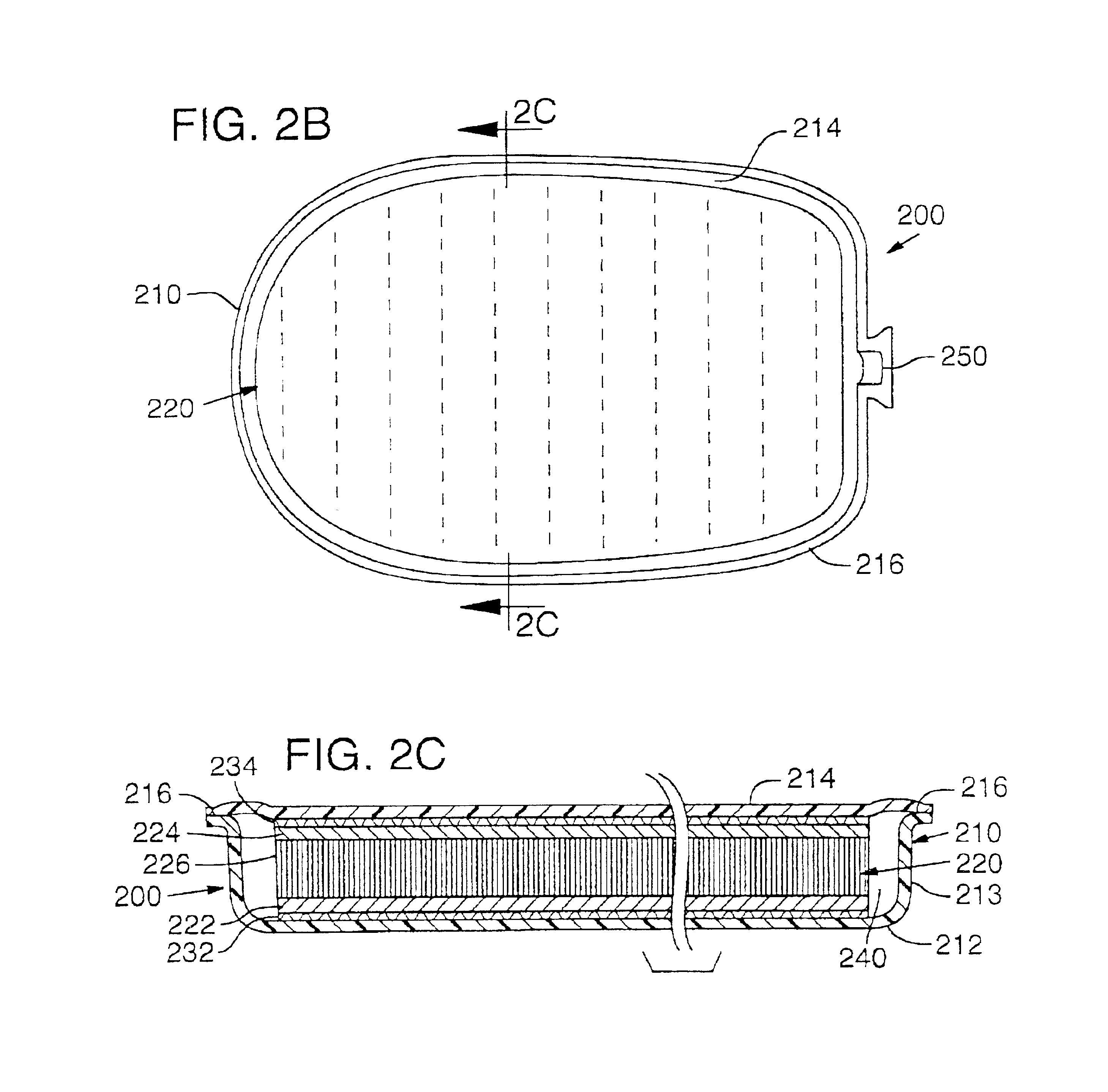

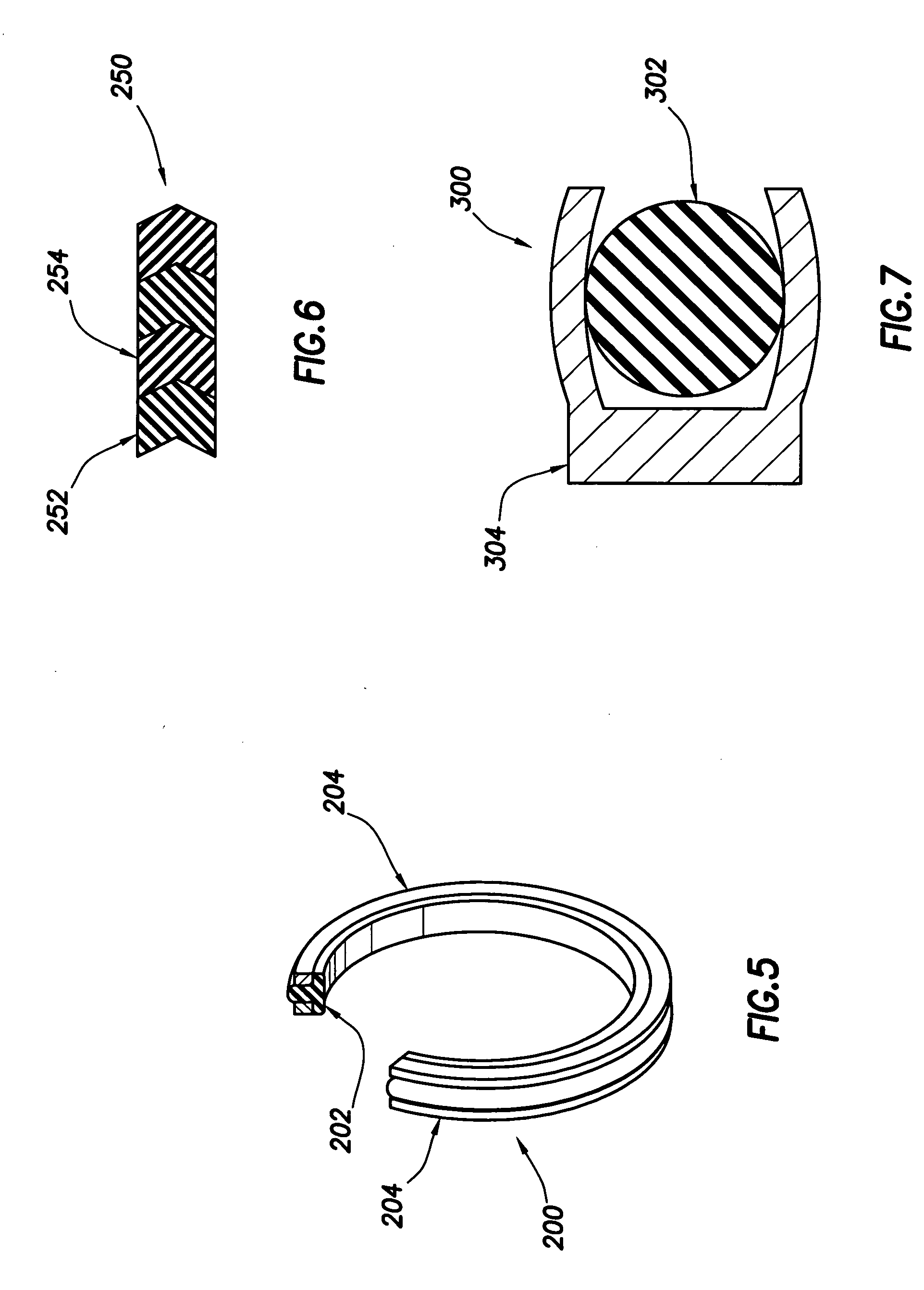

Method of thermoforming a bladder structure

InactiveUS6837951B2Increase awarenessImprove efficiencySolesOrnamental textile articlesBladder structureThermal contact

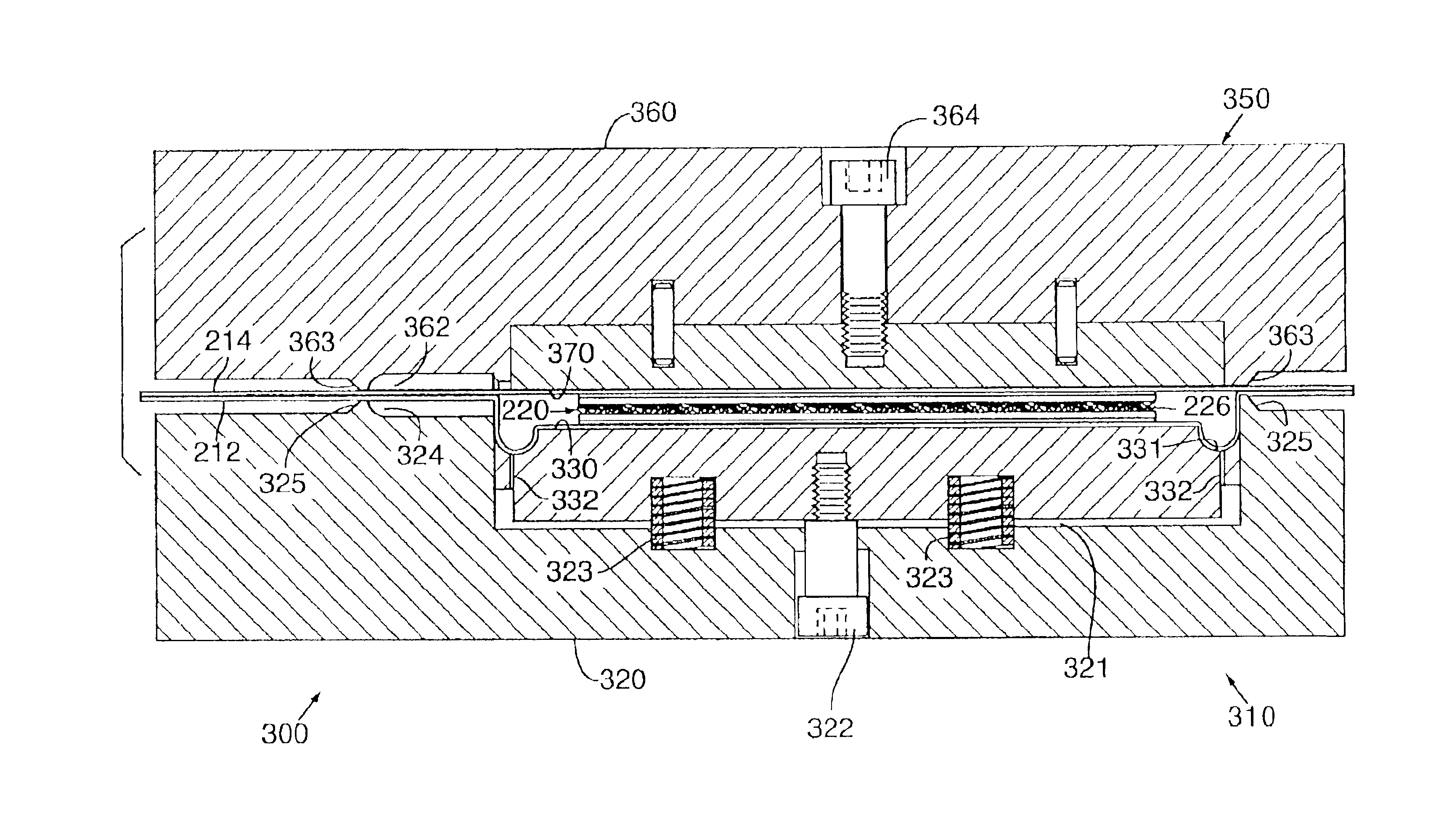

A method for thermoforming a resilient, fluid-filled bladder structure with thermal contact molding is disclosed. The bladder includes two sheets of thermoplastic material that are separated by at least one core formed of two spaced outer layers connected together by a plurality of connecting members. The bladder is formed by bonding the sheets to the core, bonding the sheets to each other around the periphery of the core and forming a sidewall between the sheets in a single mold. A fluid is then inserted into the space bounded by the peripheral bond and the two sheets such that the connecting members are extended.

Owner:NIKE INC

Aqueous dispersion of epoxy resin and blend of epoxy resin-polyoxyalkylene amines

PCT No. PCT / EP97 / 06364 Sec. 371 Date Sep. 25, 1998 Sec. 102(e) Date Sep. 25, 1998 PCT Filed Nov. 14, 1997 PCT Pub. No. WO98 / 25988 PCT Pub. Date Jun. 18, 1998A blend of epoxy-amine adducts are useful as emulsifiers of aqueous epoxy resin dispersions comprises (A-1) one or more epoxy-amine adduct(s) obtained by the reaction of (i) one or more aromatic, cycloaliphatic or novolac epoxy compound(s) and (ii) one or more amine-terminated polyalkylene glycol(s) having a molecular weight of from 700-5000 and an ethyleneoxide content of at least 60% by weight in an equivalent ratio of amine-terminated polyalkylene glycol(s) to epoxy compound(s) of from 0.01:1 to 0.9:1; (A-2) one or more epoxy-amine adduct(s) derived from the reaction of (i) one or more aliphatic epoxy compound(s) and (ii) one or more amine-terminated polyalkylene glycol(s) having a molecular weight of from 700-5000 and an ethyleneoxide content of at least 60% by weight in an equivalent ratio of amine-terminated polyalkylene glycol(s) to epoxy compound(s) of from 0.01:1 to 0.9:1; (B-1) aromatic, cycloaliphatic or novolac polyglycidyl ethers; (B-2) optionally, polyglycidyl esters of aromatic or cycloaliphatic polycarboxylic acids; and (C) optionally, at least one of reactive thinners, pigments, filler or other addtitives.

Owner:SIKA CHEM

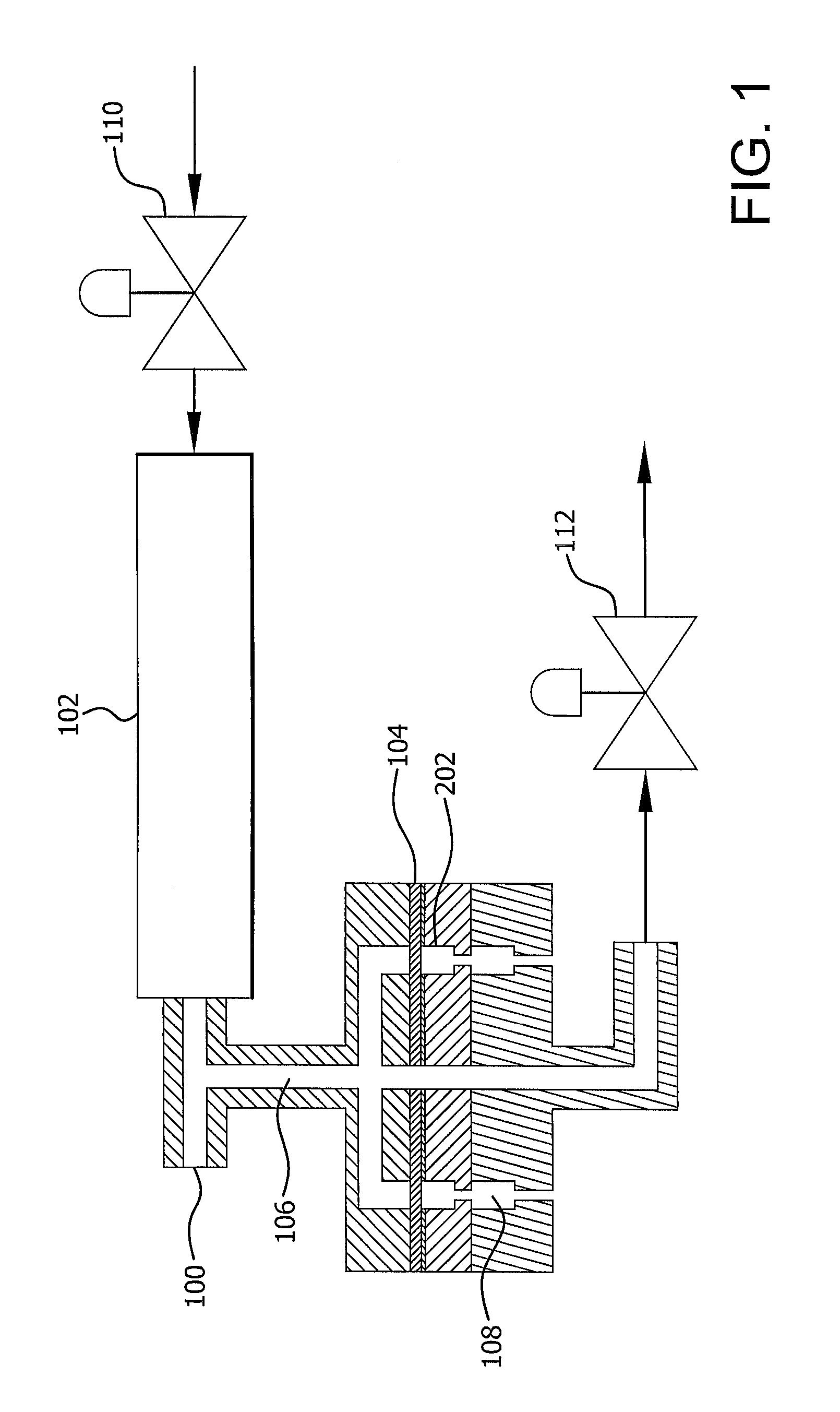

Hydrogel for use in downhole seal applications

InactiveUS20050171248A1Increase expansionAvoid seal failureOther chemical processesVehicle sealing arrangementsElastomerThermoplastic

The present invention is a composition for forming seals. The composition includes a base material and a hydrogel. The base materials is preferably an elastomer or a thermoplastic. Seals formed with the composition are particularly suited for use in a wellbore environment. The inclusion of hydrogel in the seals allows the seals to be manipulated or altered through certain environmental factors. For instance, temperature, oil / water ratio, pH and the electronic field may all be used to alter the characteristics of the hydrogel. In this way, the seal may be caused to swell in response to a specific stimulus, thereby preventing or sealing a leak without requiring additional work or input from the operator.

Owner:SCHLUMBERGER TECH CORP

Blends and sealant compositions comprising isotactic propylene copolymers

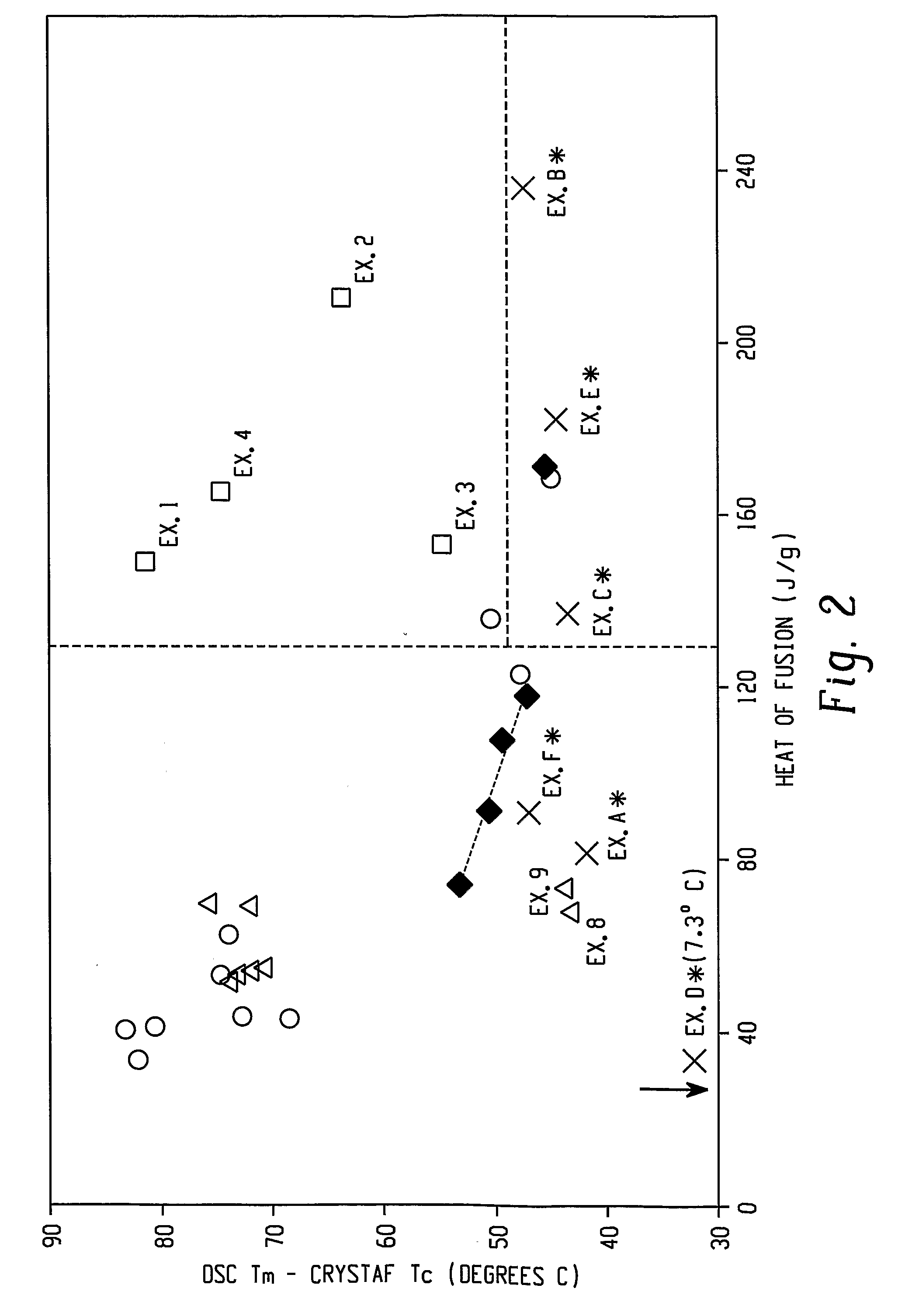

Films with excellent machine direction (MD) tear properties comprise at least one layer made from a polymer comprising:(A) at least 50 weight percent (wt %) propylene; and(B) at least 5 wt % ethylene and / or one or more unsaturated comonomers.Representative of component (B) unsatuarated comonomers are the C4-20 α-olefins, C4-20 dienes, styrenic compounds, and the like. Preferably, the film has at least one of a (i) haze value of less than about 10, (ii) 45 degree gloss of greater than about 65, and (iii) dart value of greater than about 100 g / mil. In one preferred embodiment, the layer comprises a compolymer characterized as having at least one of the following properties: (i) 13C NMR peaks corresponding to a regio-error at about 14.6 and about 15.7 ppm, the peaks of about equal intensity, (ii) a B-value greater than about 1.4 when the comonomer content, i.e., the units derived from ethylene and / or the unsaturated comonomer(s), of the copolymer is at least about 3 wt %, (iii) a skewness index, Six, greater than about −1.20, (iv) a DSC curve with a Tme that remains essentially the same and a Tmax that decreases as the amount of comonomer, i.e., the units derived from ethylene and / or the unsaturated comonomer(s), in the copolymer is increased, and (v) an X-ray diffraction pattern that reports more gamma-form crystals than a comparable copolymer prepared with a Ziegler-Natta (Z-N) catalyst.

Owner:DOW GLOBAL TECH LLC

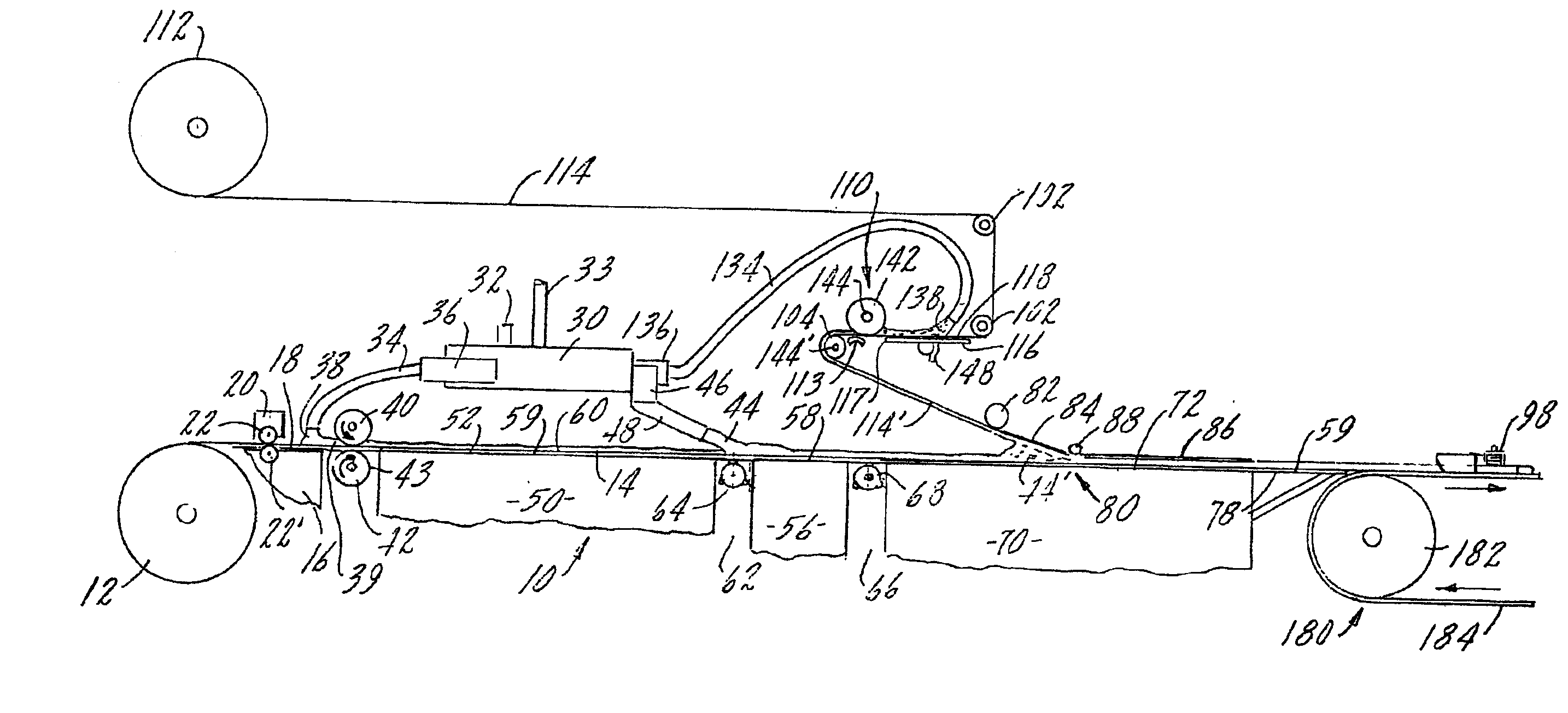

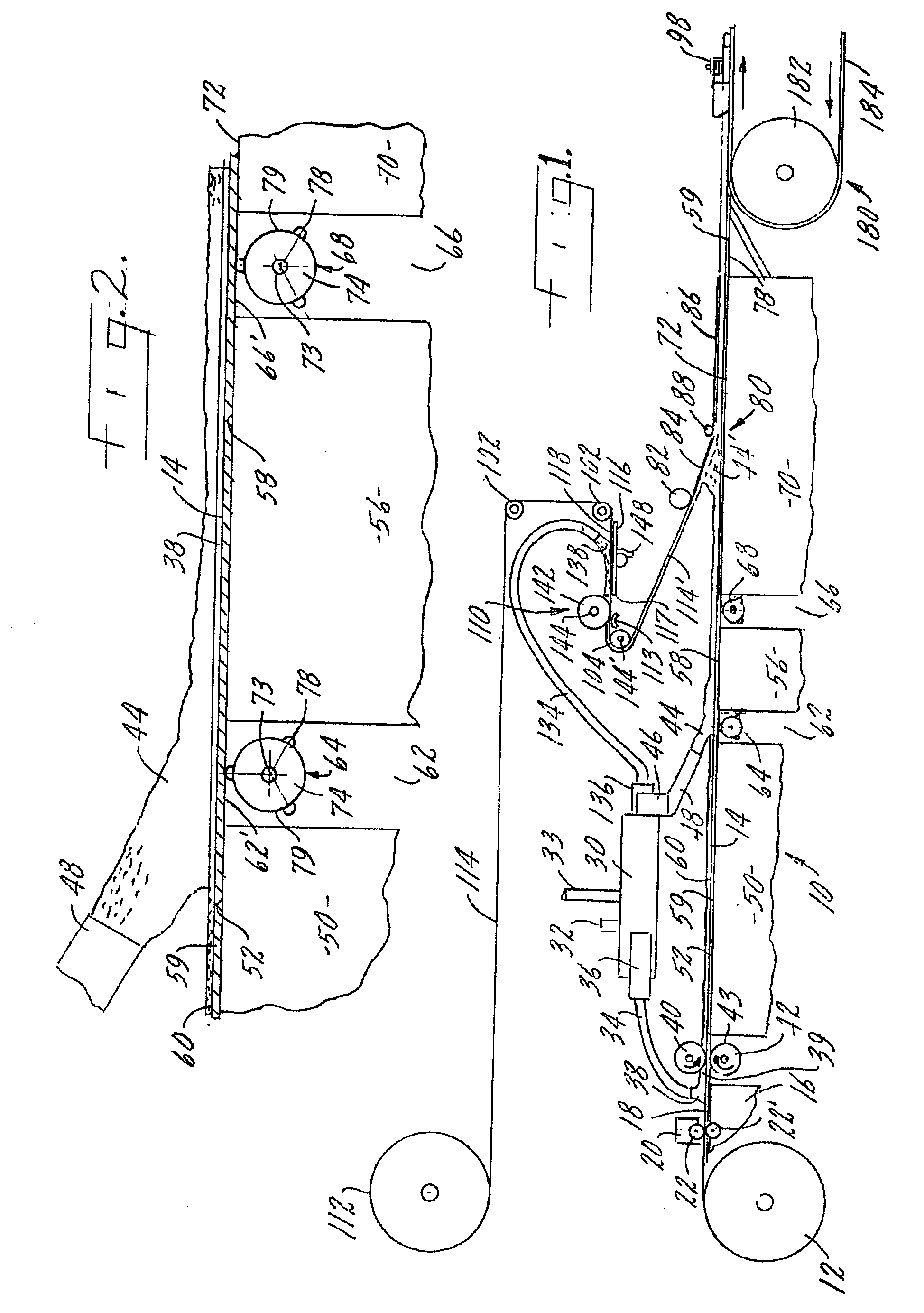

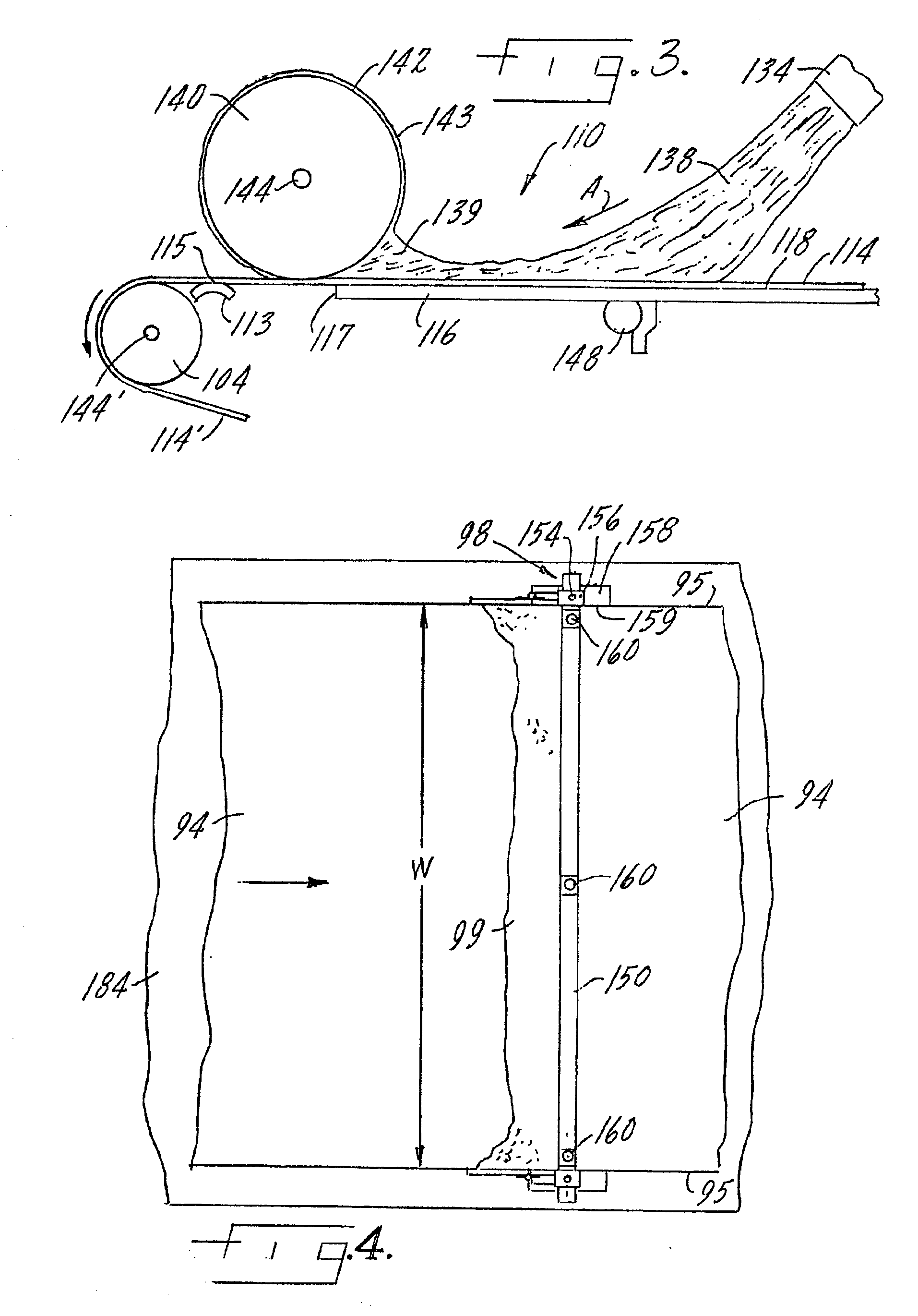

Method of manufacture of glass reinforced gypsum board and apparatus therefor

Gypsum board having inorganic fiber, preferably glass fiber, preferably glass fiber, includes providing face sheets which have been completely impregnated with a gypsum slurry so as to penetrate through said random interstices between the inorganic fibers and to thereby cover the board surfaces with gypsum slurry. The gypsum board product is formed by passing the wet gypsum board through a board forming station having double forming plates, an upper forming plate having at least a portion thereof being set at a predetermined angle relative to a lower forming plate and having a separation between the forming plates defining a predetermined dimension substantially equal to the desired thickness of the manufactured gypsum board product. The method provides a multilayer gypsum board having a polymeric compound added to unset gypsum so as to provide a gypsum board ready for finishing.

Owner:BPB LTD

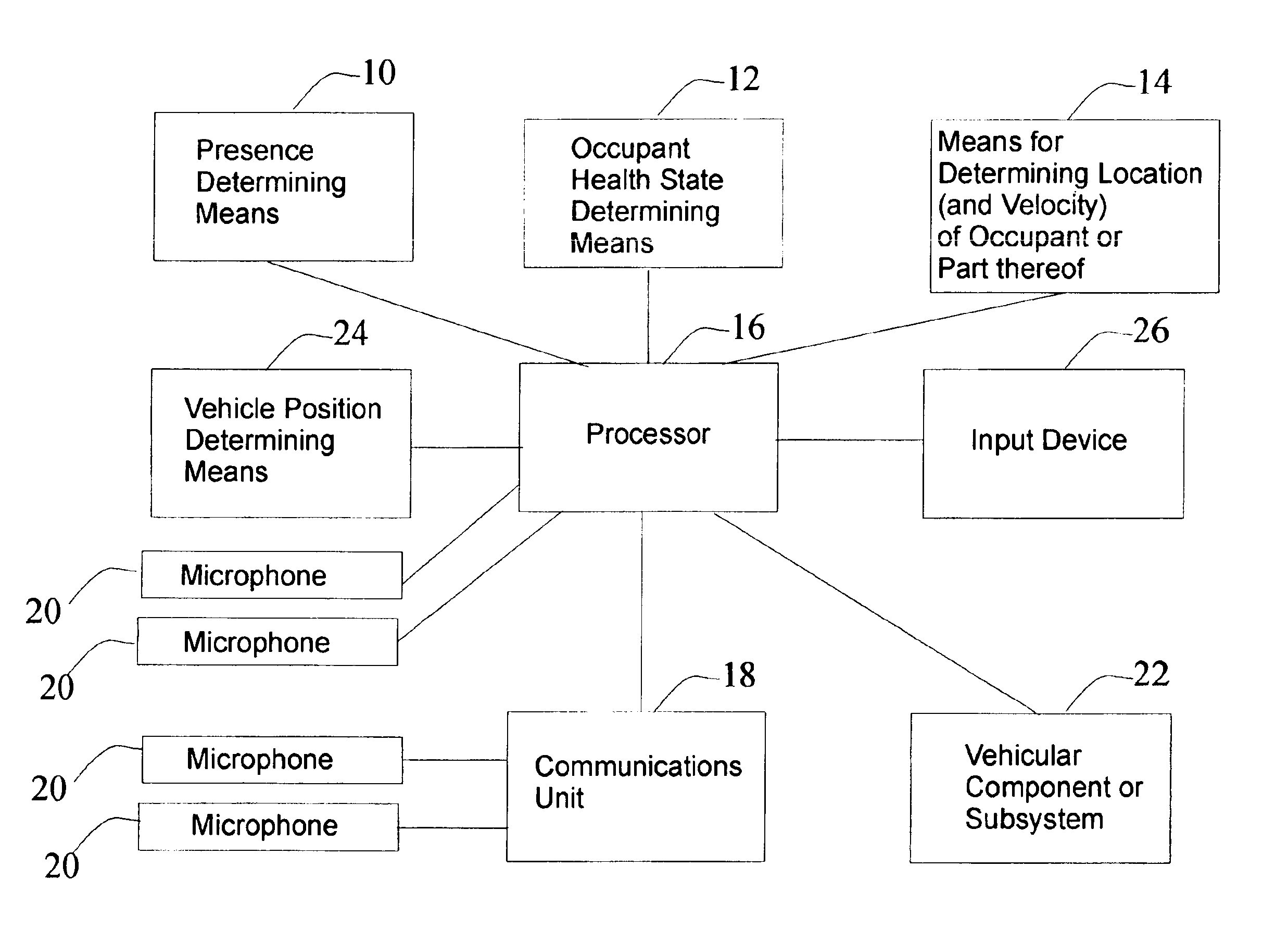

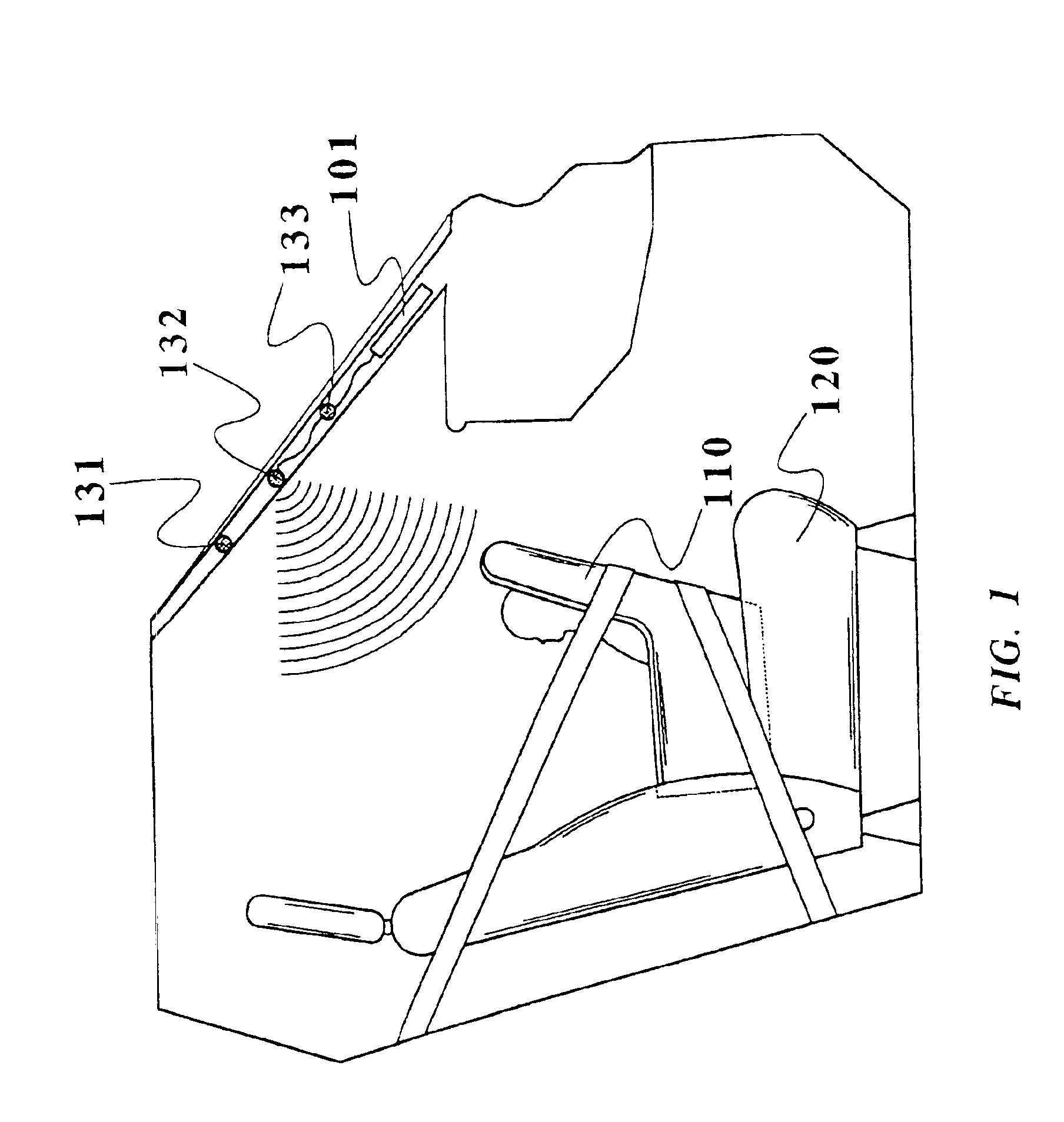

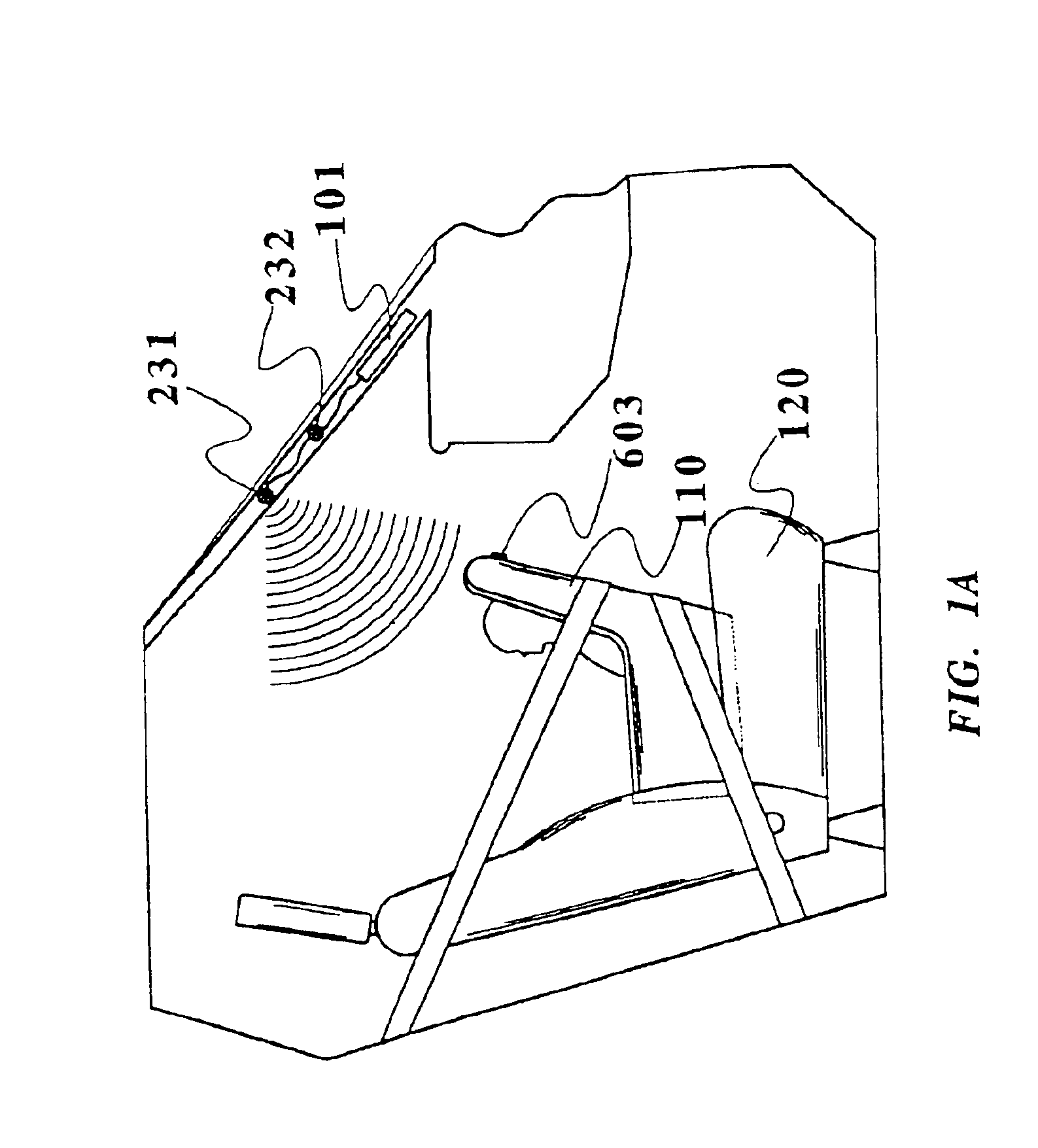

Method and arrangement for obtaining and conveying information about occupancy of a vehicle

InactiveUS6950022B2Avoid accidentsOptimize coVehicle seatsBelt control systemsElectric field sensorUltrasonic sensor

Method and arrangement for obtaining and conveying information about occupancy of a passenger compartment of a vehicle including at least one sensor for obtaining data from the passenger compartment. Information about the occupancy is generated based on the data and transmitted, e.g., through a cellular phone system, to emergency response personnel to enable them to respond accordingly. The information about the occupancy may be generated by a processor applying pattern recognition techniques so that any occupants of the seat may be classified and such classification transmitted to the emergency response personnel. The data may also be used to determine the number of occupants in the vehicle and / or whether the occupants are moving after a crash. The sensors may be a variety of sensors such as an ultrasonic sensor, an electromagnetic wave sensor, an electric field sensor, a chemical sensor, a weight sensor, a motion sensor, a microphone, a heartbeat sensor, a vibration sensor, an acceleration sensor and a capacitance sensor.

Owner:AUTOMOTIVE TECH INT

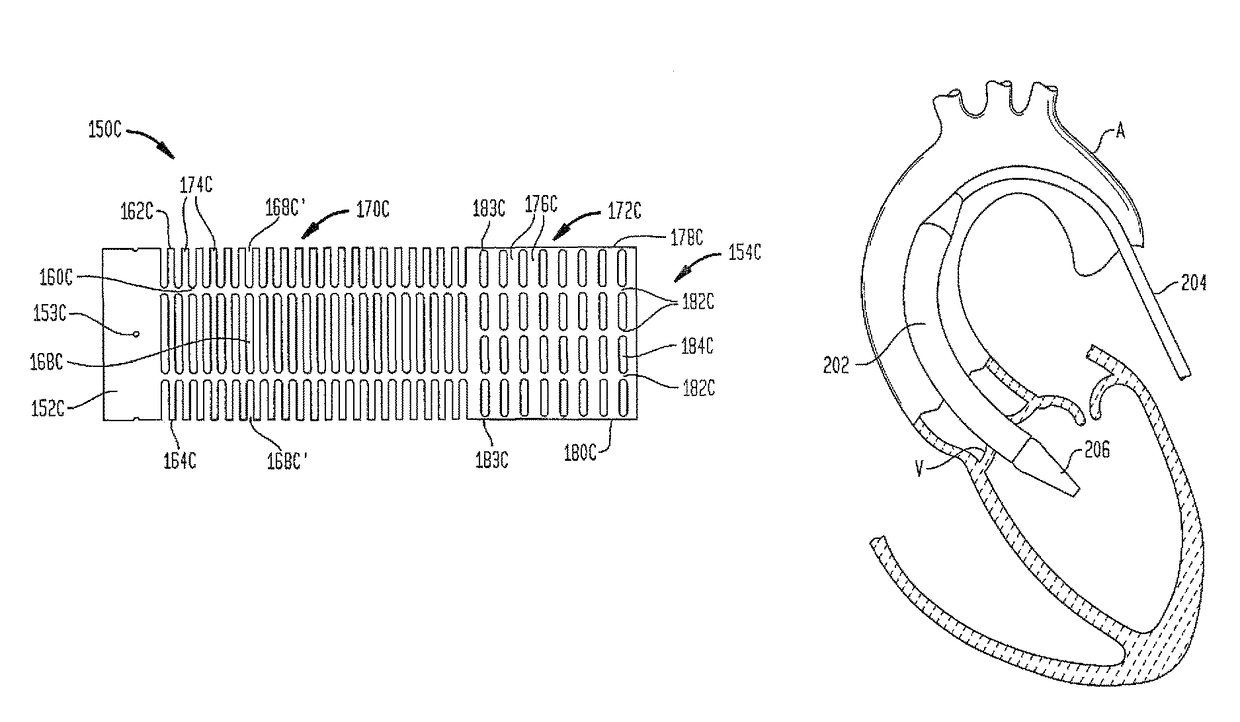

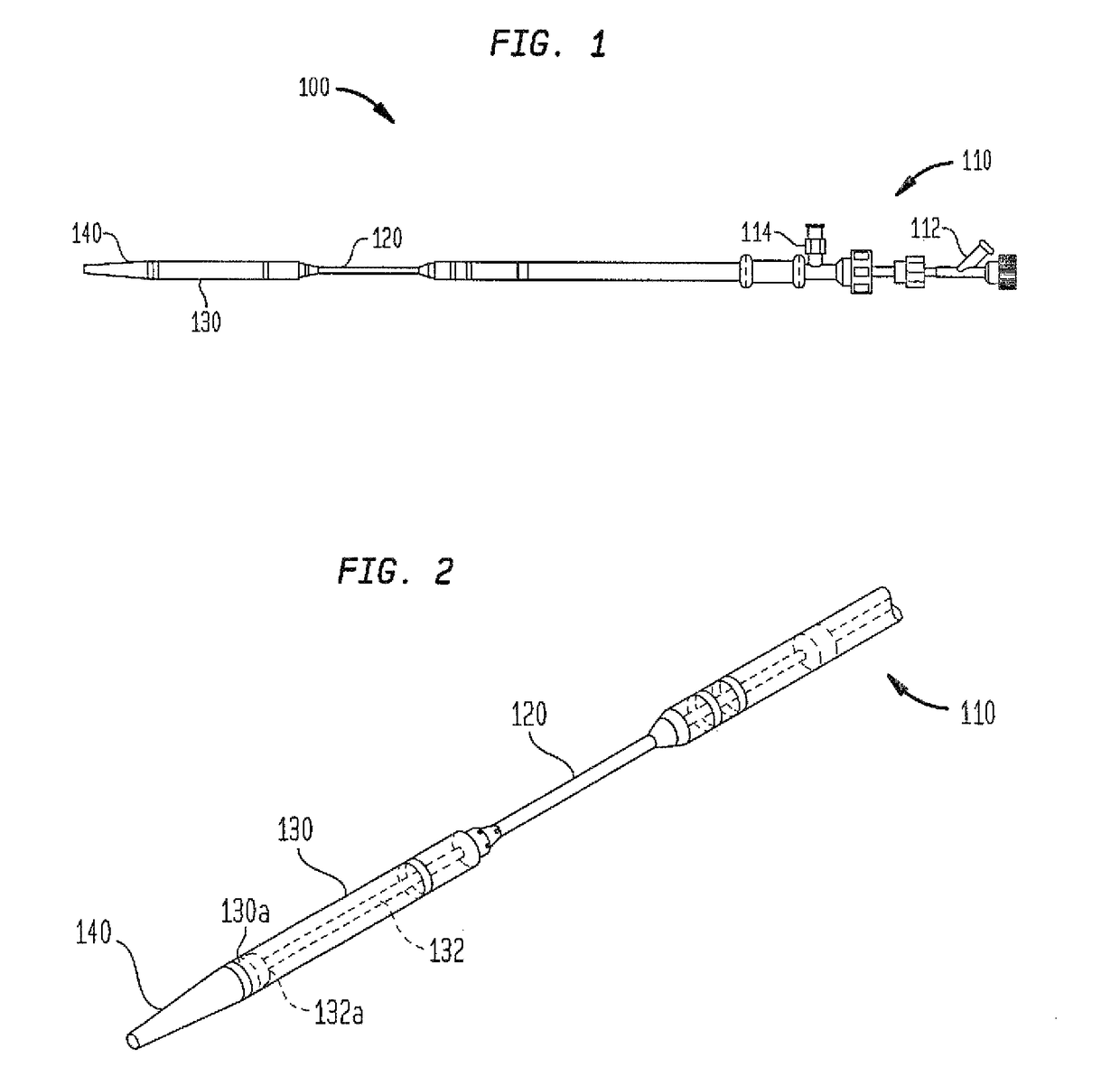

Delivery system for collapsible heart valve

Owner:ST JUDE MEDICAL LLC

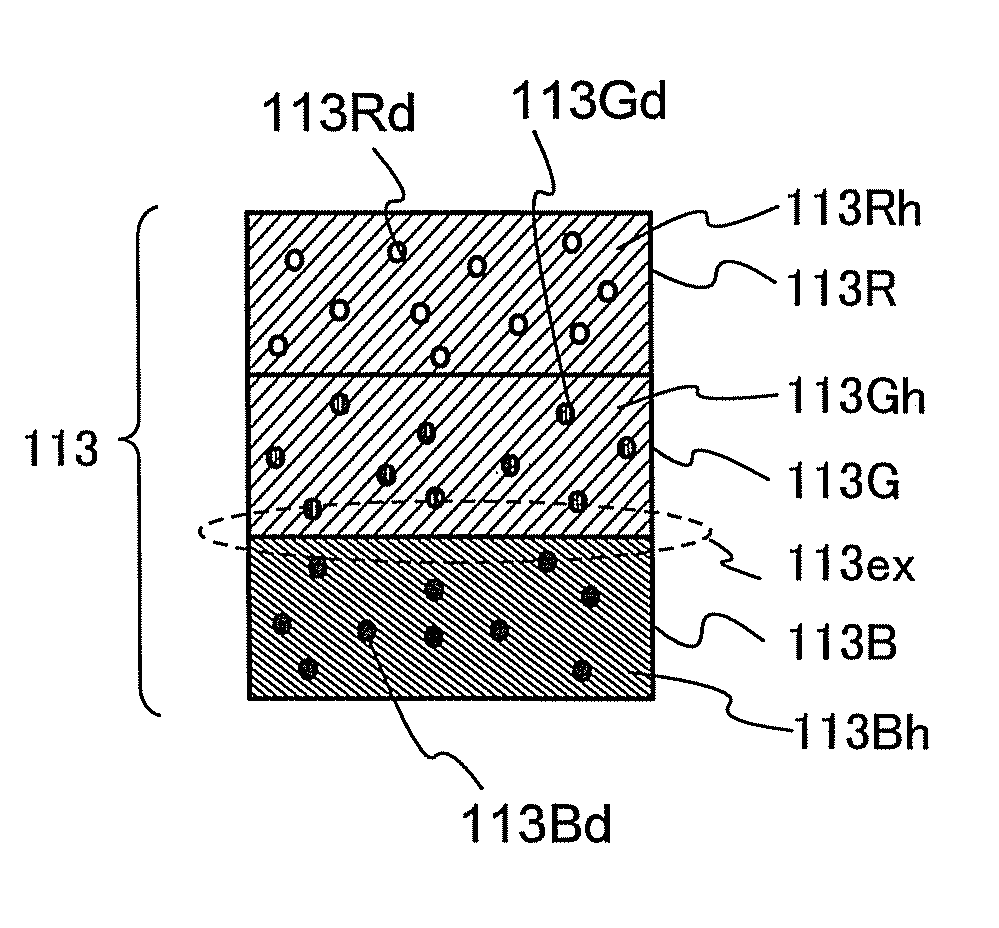

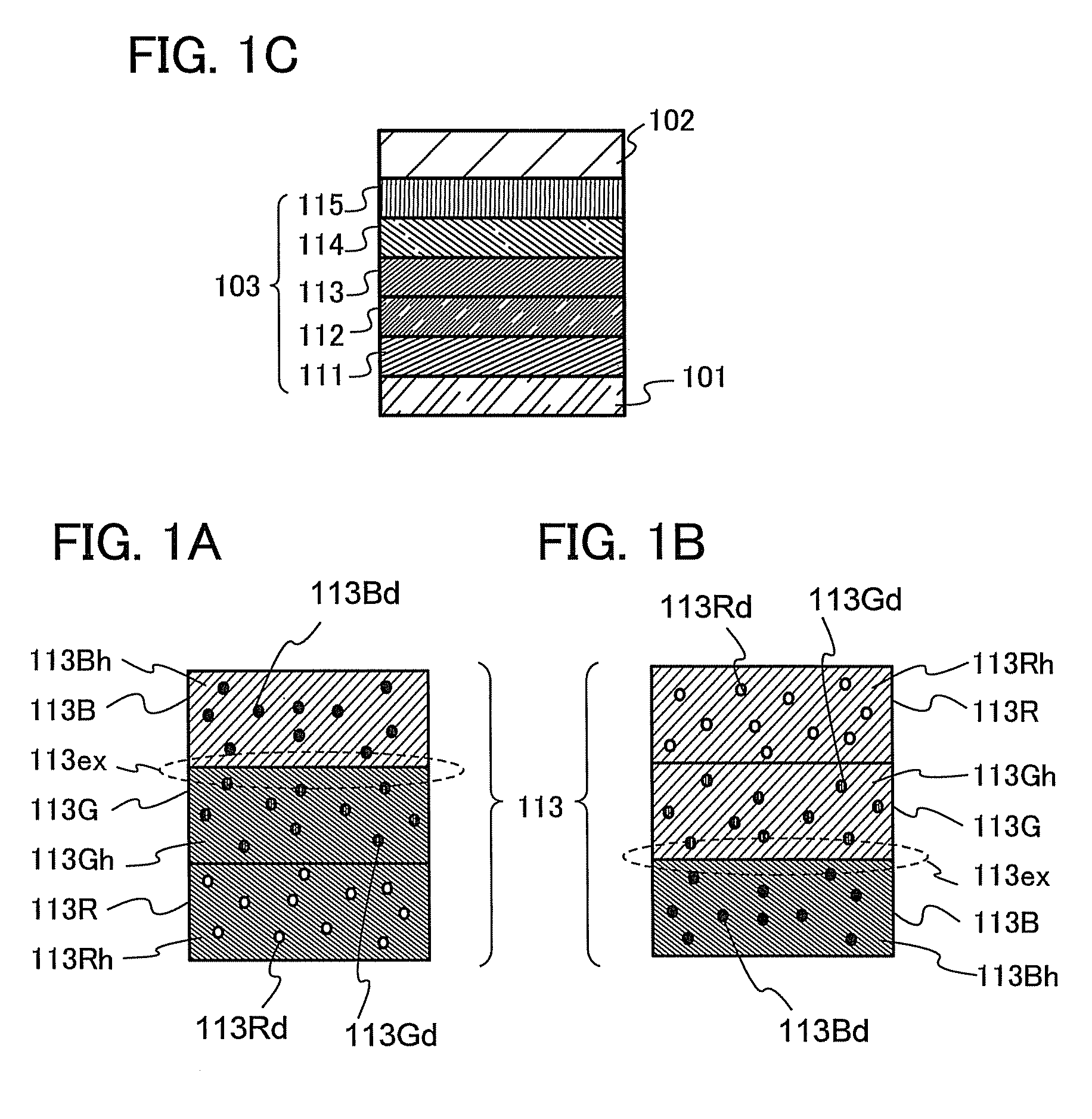

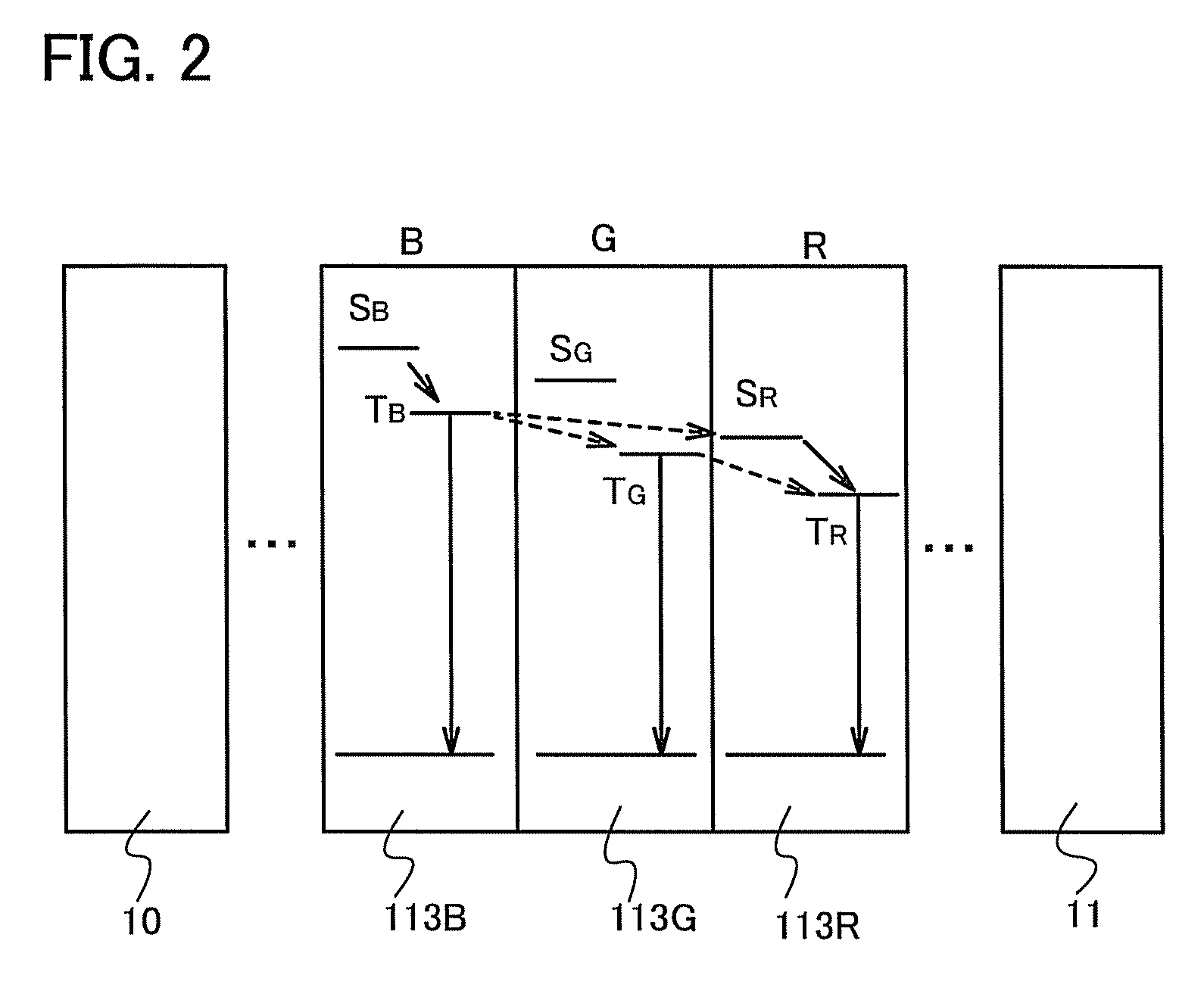

Light-emitting element, light-emitting device, display device, electronic device, and lighting device

ActiveUS8653553B2Improve efficiencyReduce power consumptionPoint-like light sourceSolid-state devicesDopantEnergy transfer

An object is to provide a light-emitting element which uses a plurality of kinds of light-emitting dopants and has high emission efficiency. In one embodiment of the present invention, a light-emitting device, a light-emitting module, a light-emitting display device, an electronic device, and a lighting device each having reduced power consumption by using the above light-emitting element are provided. Attention is paid to Förster mechanism, which is one of mechanisms of intermolecular energy transfer. Efficient energy transfer by Förster mechanism is achieved by making an emission wavelength of a molecule which donates energy overlap with a local maximum peak on the longest wavelength side of a graph obtained by multiplying an absorption spectrum of a molecule which receives energy by a wavelength raised to the fourth power.

Owner:SEMICON ENERGY LAB CO LTD

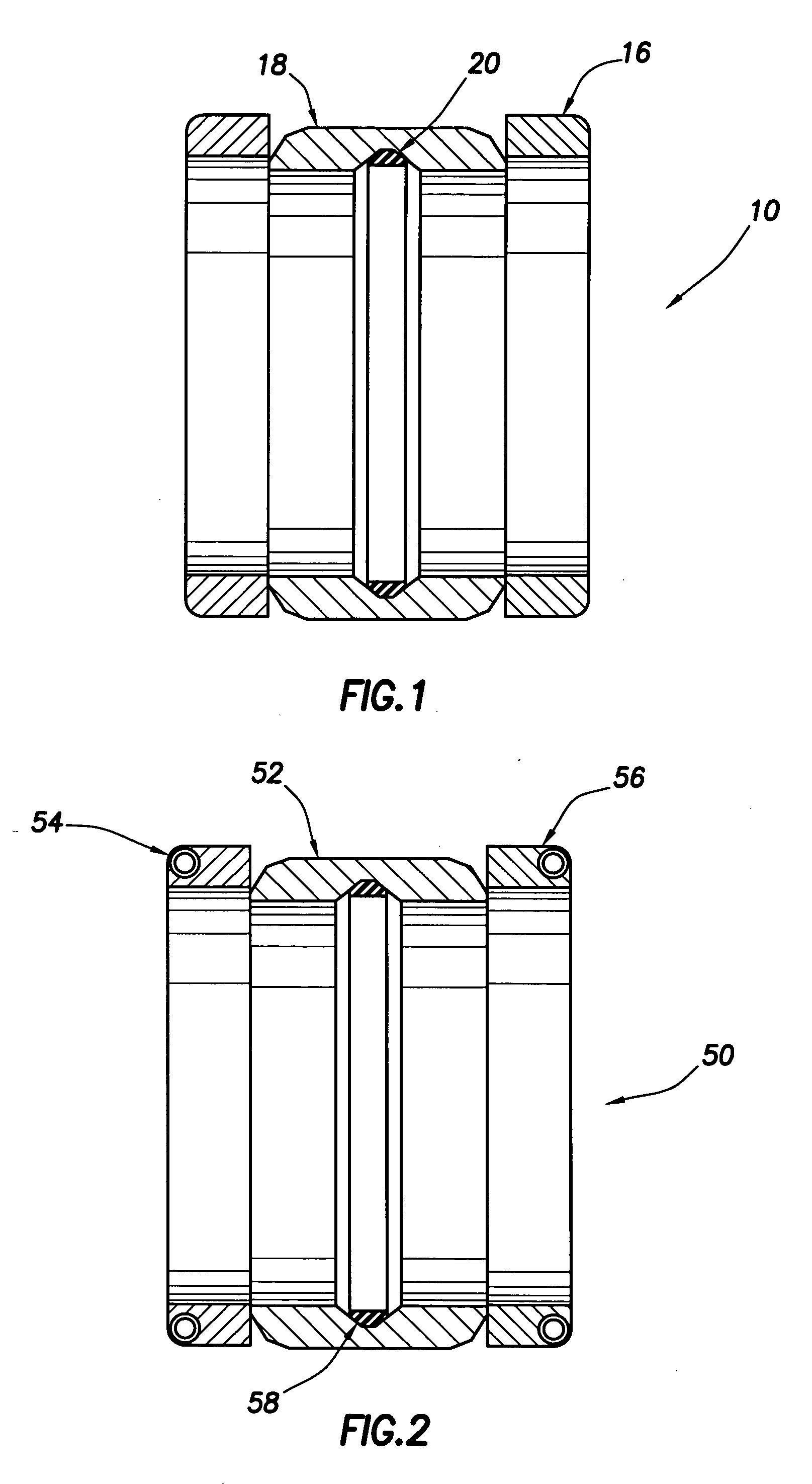

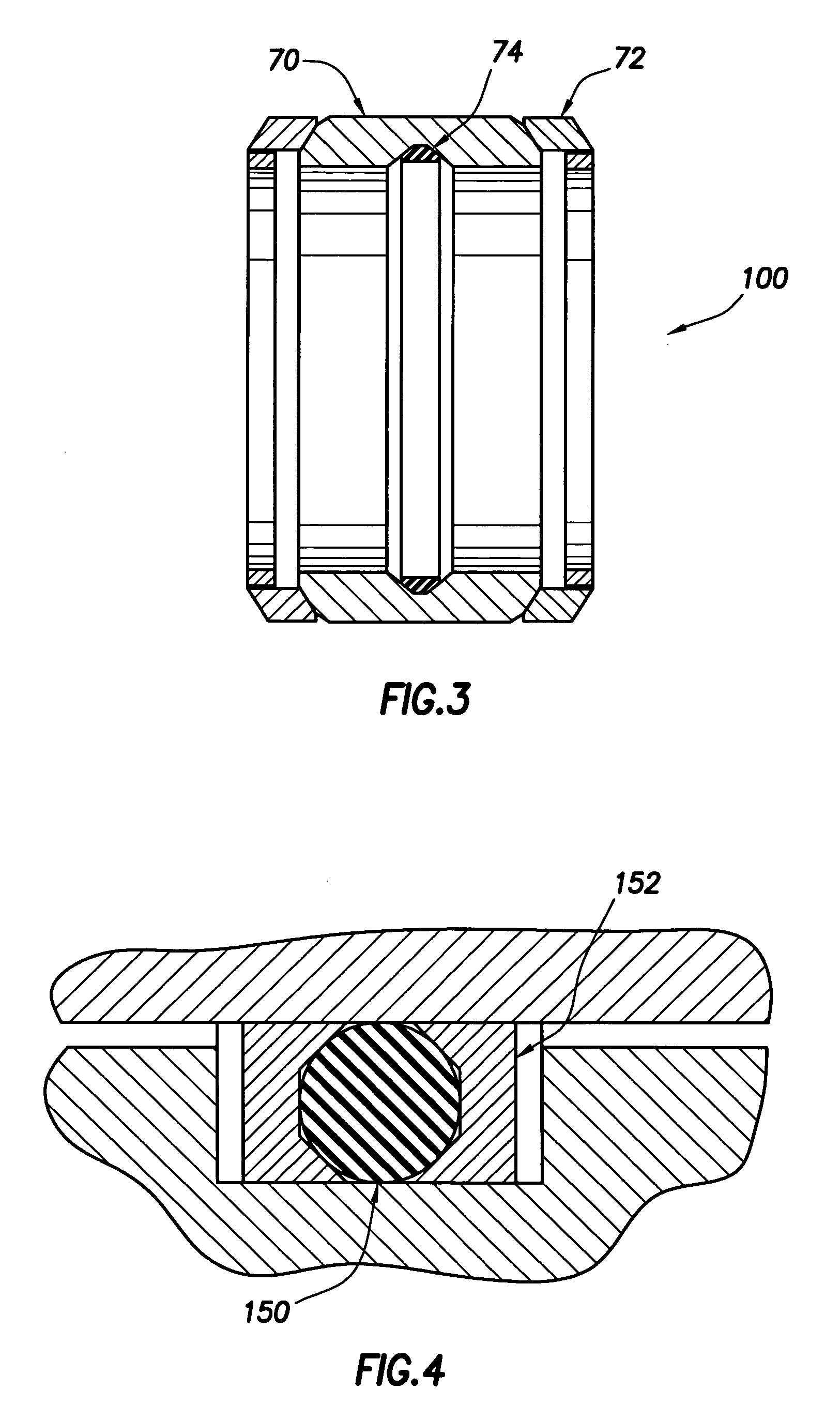

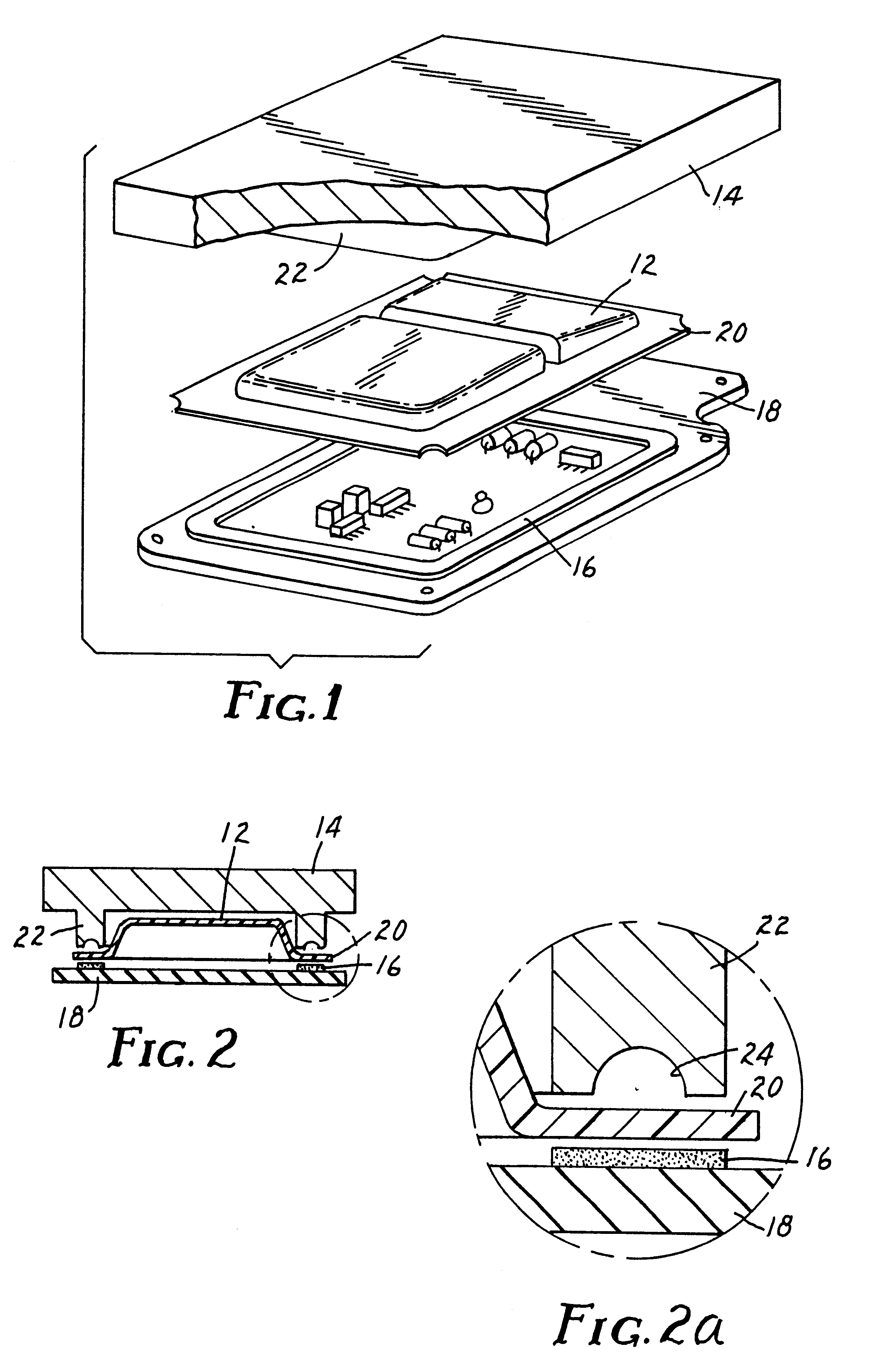

EMI shielding enclosures

InactiveUS6485595B1Maintain conductivityMaintain continuityEngine sealsMagnetic/electric field screeningFiberEngineering

An EMI shielding enclosure, for an electronic assembly, comprising a ground plane of a printed circuit connected to a shaped EMI shielding cover. The cover results from thermoforming a composite sheet of several layers, including a carrier for a fibrous metal mat that has fibers substantially surrounded by a fiber-coat. Connection of the cover to the ground plane, to form the EMI shielding enclosure, requires the fiber-coat to adhere to the printed circuit in the vicinity of the ground plane.

Owner:3M INNOVATIVE PROPERTIES CO

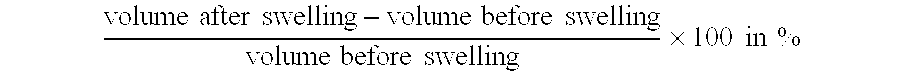

Sealing material which swells when treated with water

InactiveUS6358580B1Safely preventingRapid and sizable and controlled swellingCosmetic preparationsOrganic detergent compounding agentsElastomerCallose

The invention relates to an optionally foamed sealing composition for preformed seals which can swell when treated with water. The invention also relates to a method for the production thereof out of natural rubber and / or elastomers with a matrix comprised of natural rubber / elastomer components and particle-shaped water absorbing material stored therein. The water absorbing material is a combination of (A) polysaccharide(s) selected from cellulose, starch, starch derivatives removed from grafted starch, amylose, amylopectin, dextran, pectin, inulin, chitin, xanthan, alginic acid, alginates, carrageenan, pustulan, callose, laminarin, guluronic acid, pullulan, lichenin or mixtures of the same with (B) a highly water absorbent synthetic polymer selected from polymers based on (meth)acrylate, poly(meth)acrylic acid and the salts thereof, polyacrylamide, polyalcohols or copolymers of said synthetic polymers. The invention also relates to additional cross-linking and processing auxiliary agents and to property improving agents. It is possible to securely seal superstructures, substructures, tunnels and canals with the assistance of the inventive sealing compositions.

Owner:DAETWYLER AG CH +1

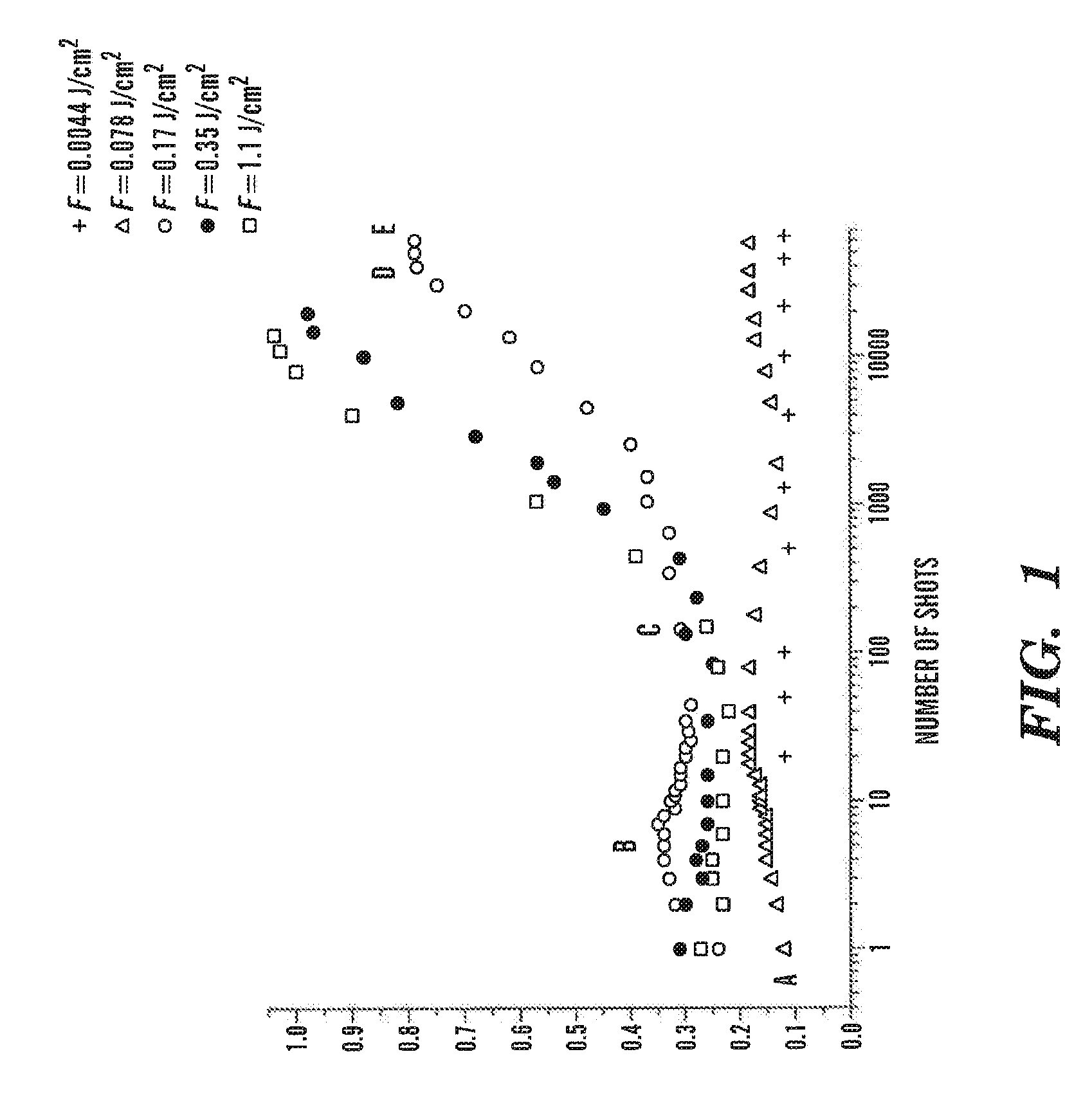

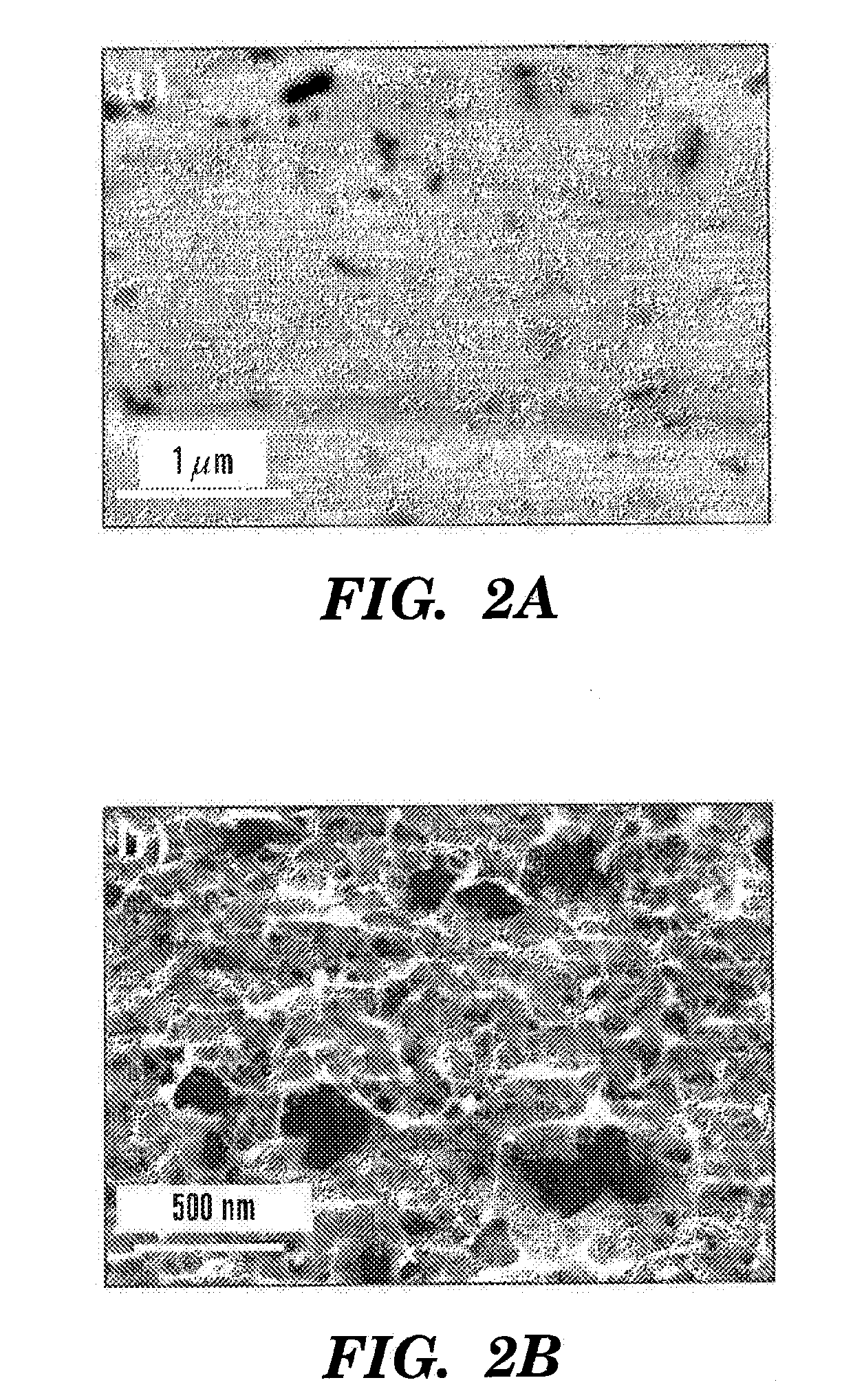

Femtosecond Laser Pulse Surface Structuring Methods and Materials Resulting Therefrom

InactiveUS20080299408A1Material nanotechnologyEngine sealsBiocompatibility TestingMaterials processing

Embodiments of the present invention are generally directed to materials processing methods using femtosecond duration laser pulses, and to the altered materials obtained by such methods. The resulting nanostructured (with or without macro- and micro-structuring) materials have a variety of applications, including, for example, aesthetic applications for jewelry or ornamentation; biomedical applications related to biocompatibility; catalysis applications; and modification of, for example, the optical and hydrophilic properties of materials including selective coloring.

Owner:UNIVERSITY OF ROCHESTER

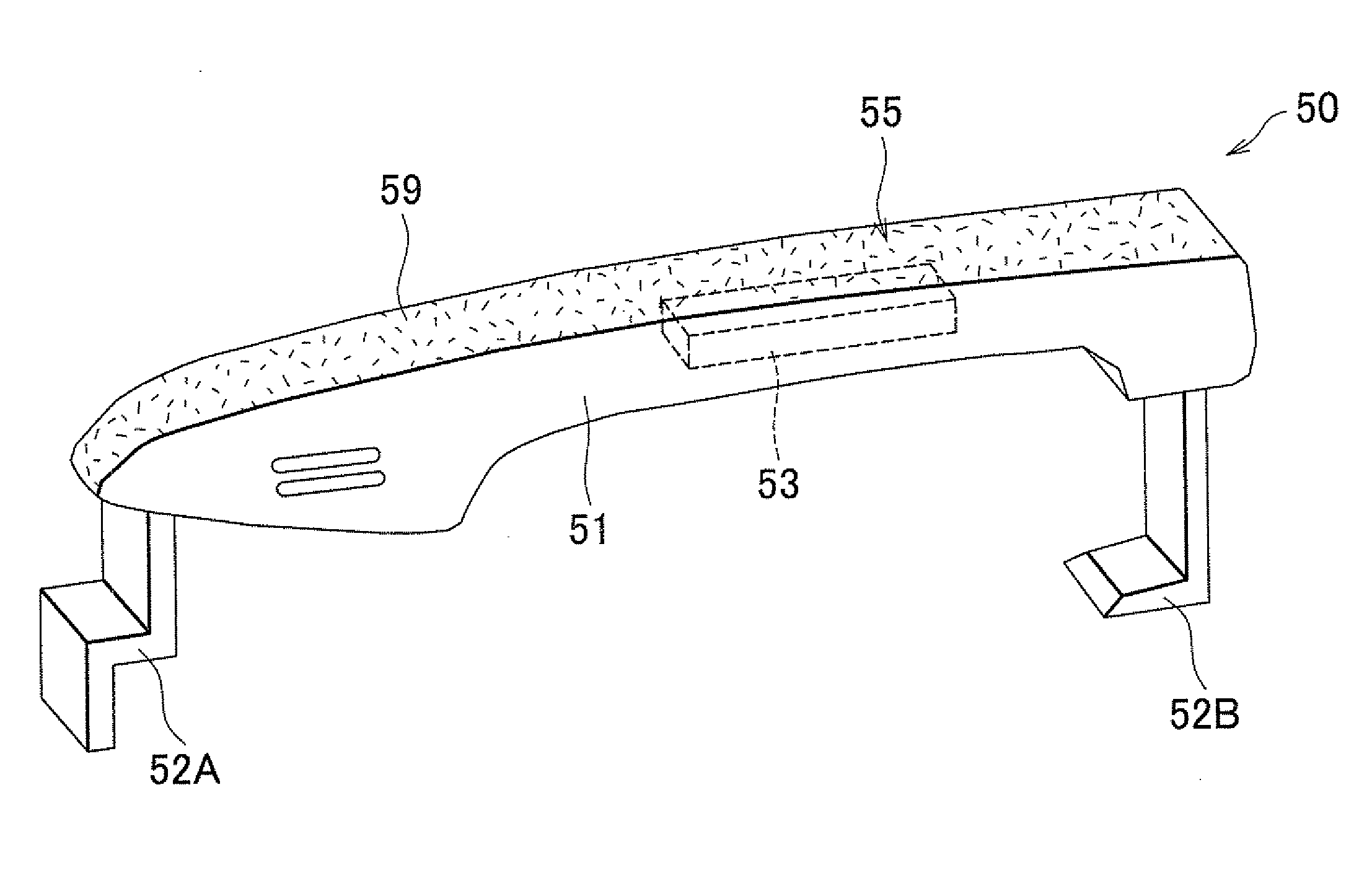

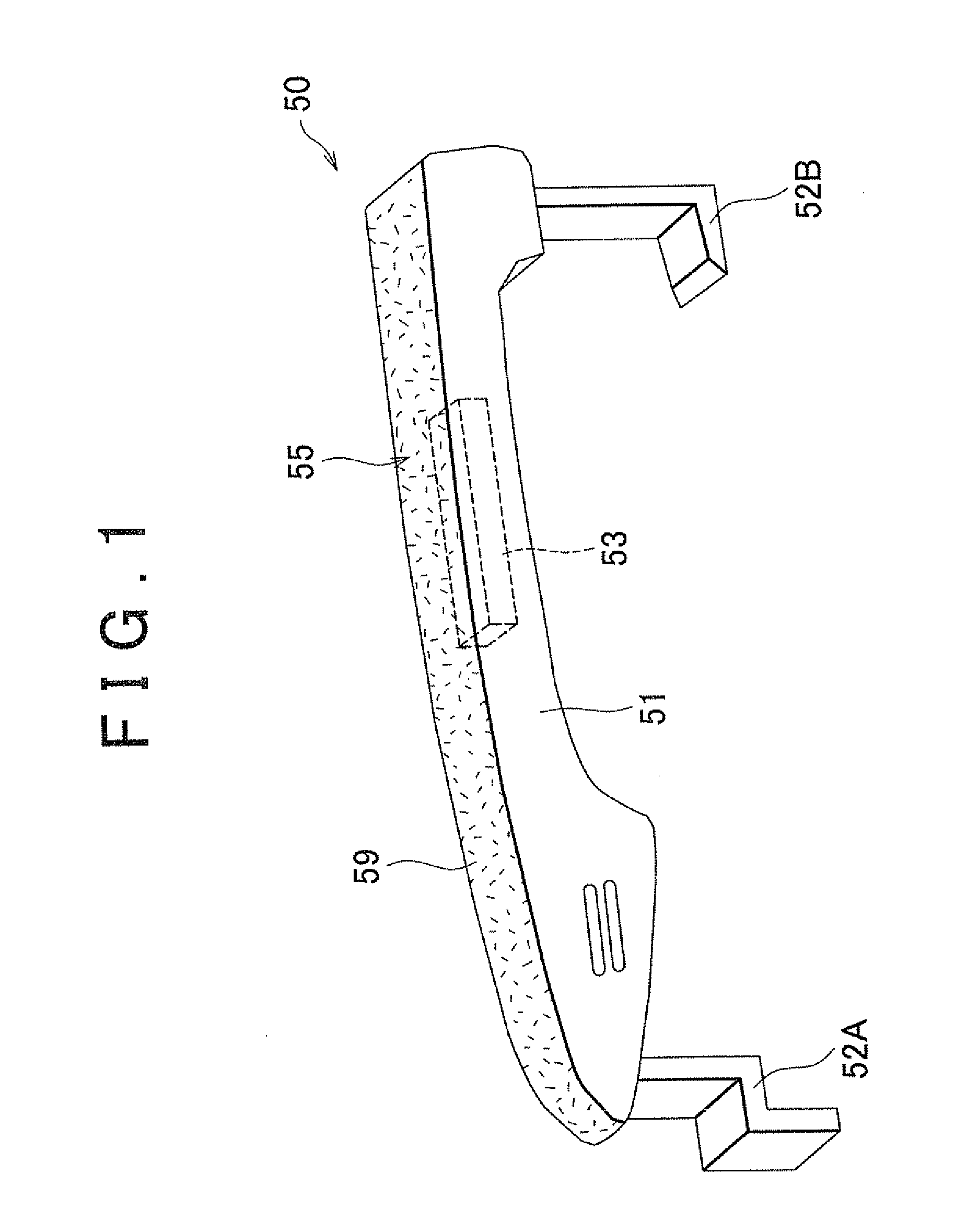

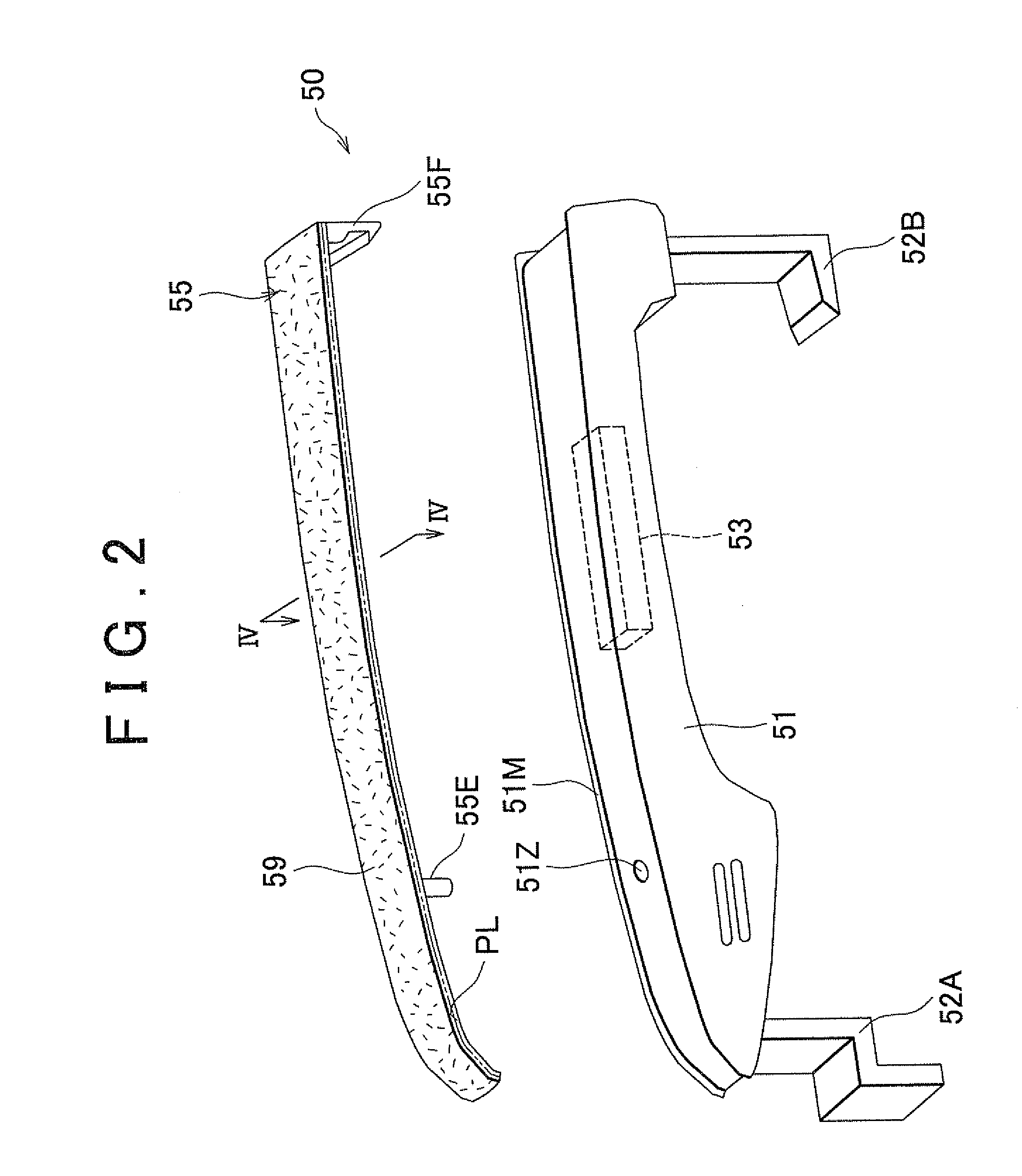

Metallic resin cover and method of producing the same, and door handle for vehicle

InactiveUS20110012378A1Improve the decorative effectReduce adverse effectsLock applicationsWing handlesCapacitance transducerBiomedical engineering

A metallic resin cover constitutes a portion of an outer wall of a human detection device in which a detection electrode of a capacitance sensor is provided, and which detects whether a human touches or approaches the human detection device. The metallic resin cover includes a covered body; and a metal layer that has a metal-object discretely arranged structure in which a plurality of metal objects are discretely arranged. The metal layer covers an outer surface of the covered body.

Owner:WAVELOCK ADVANCED TECH +1

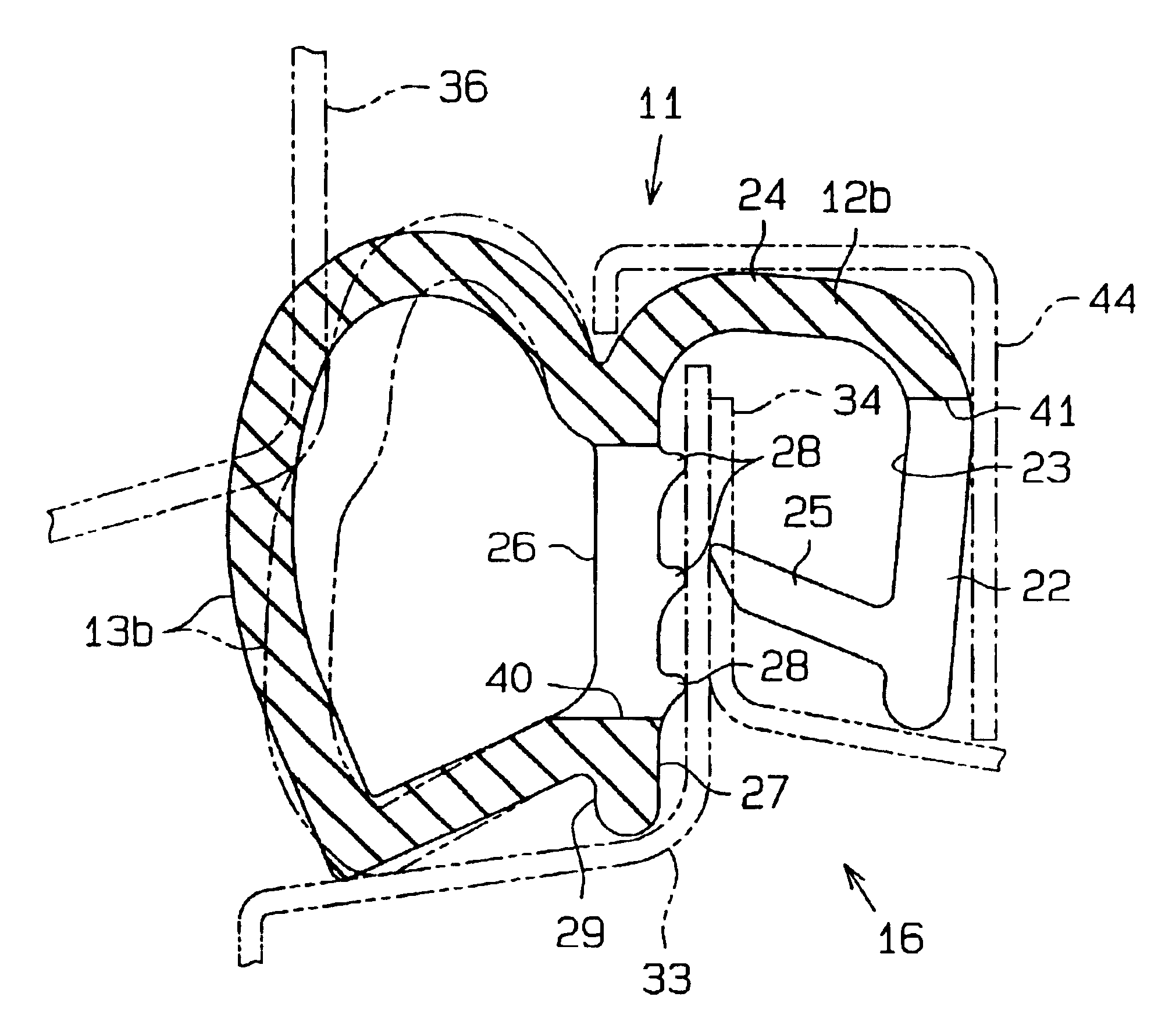

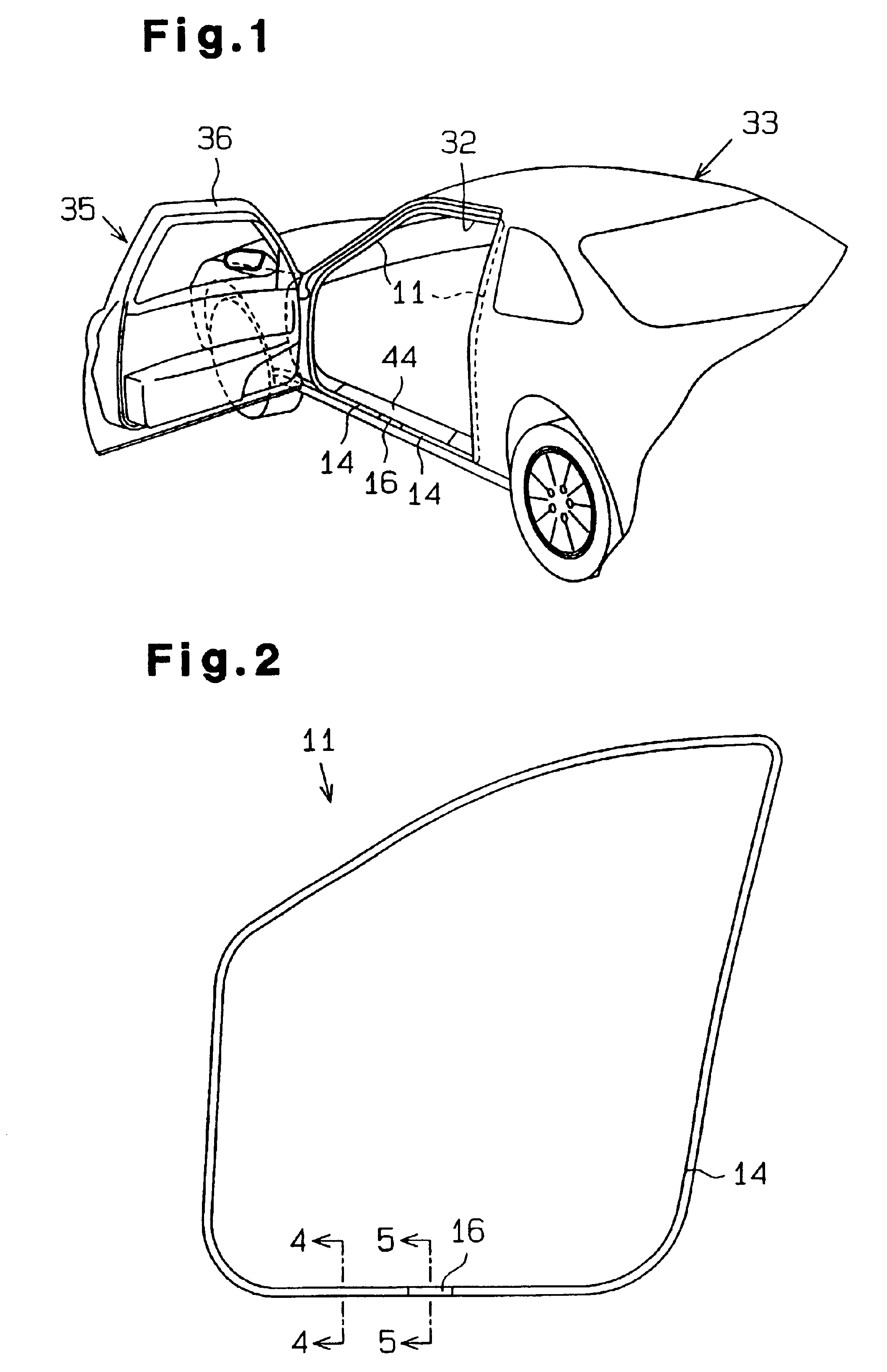

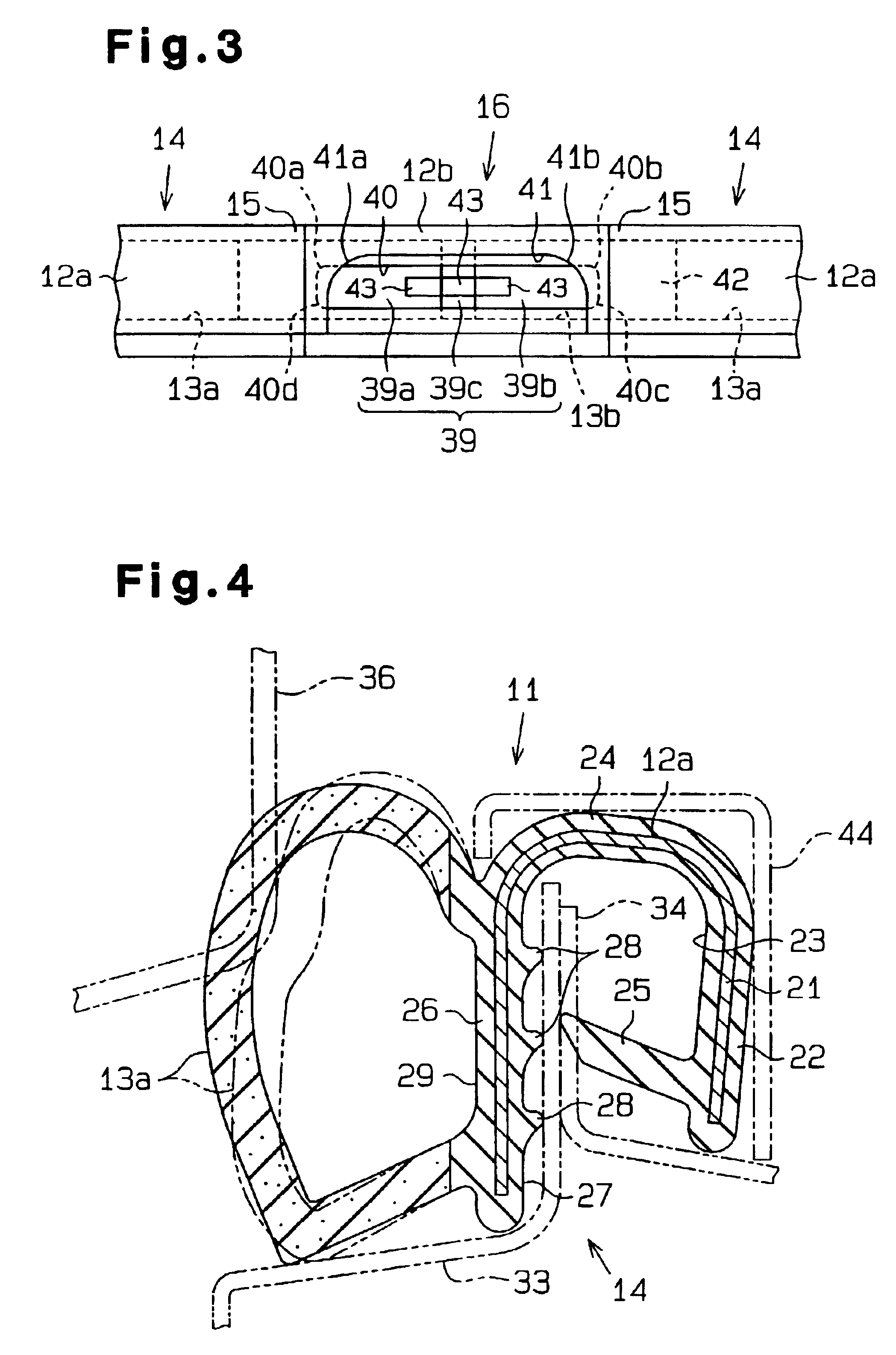

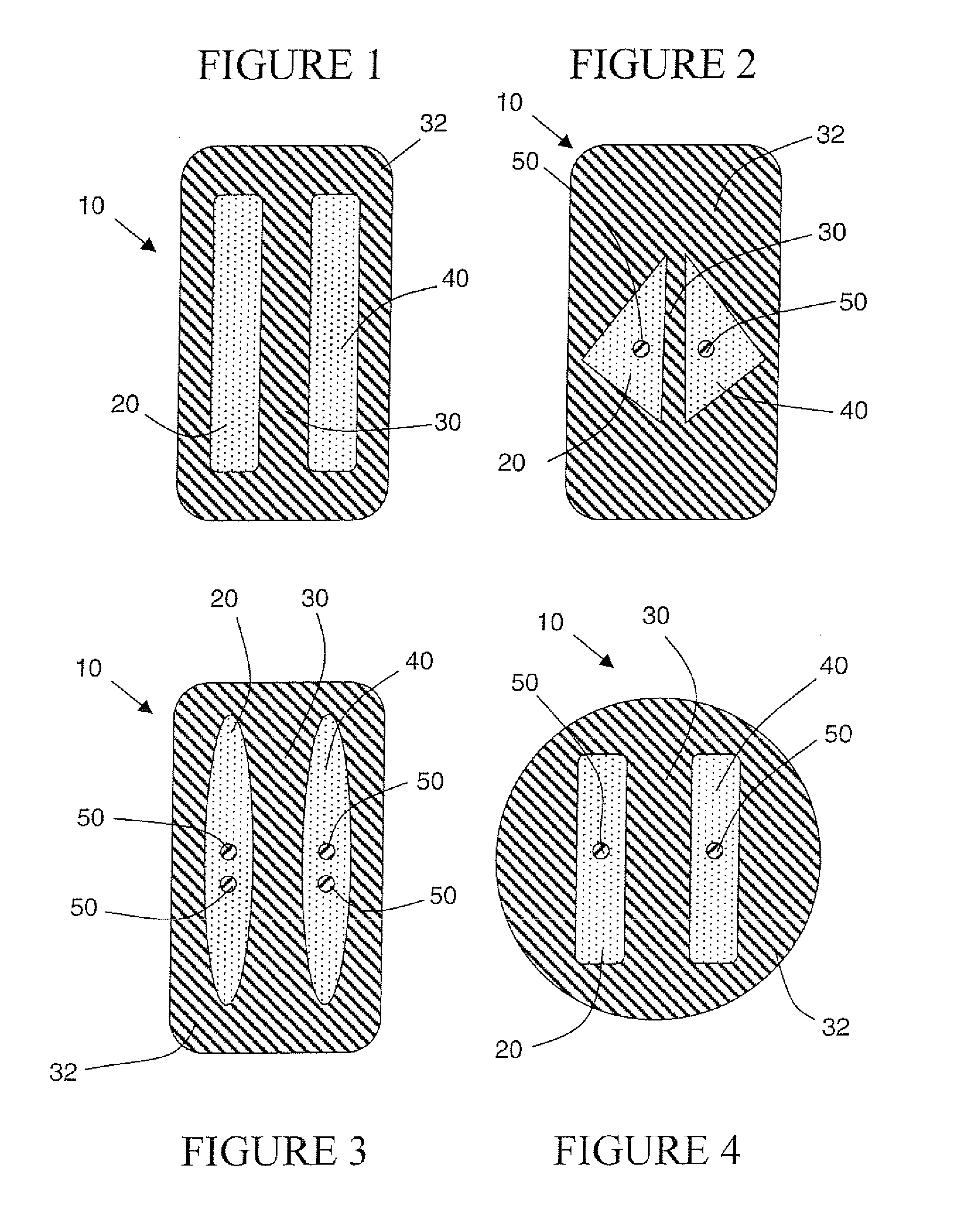

Weather strip including core-removal slot

Owner:TOYODA GOSEI CO LTD

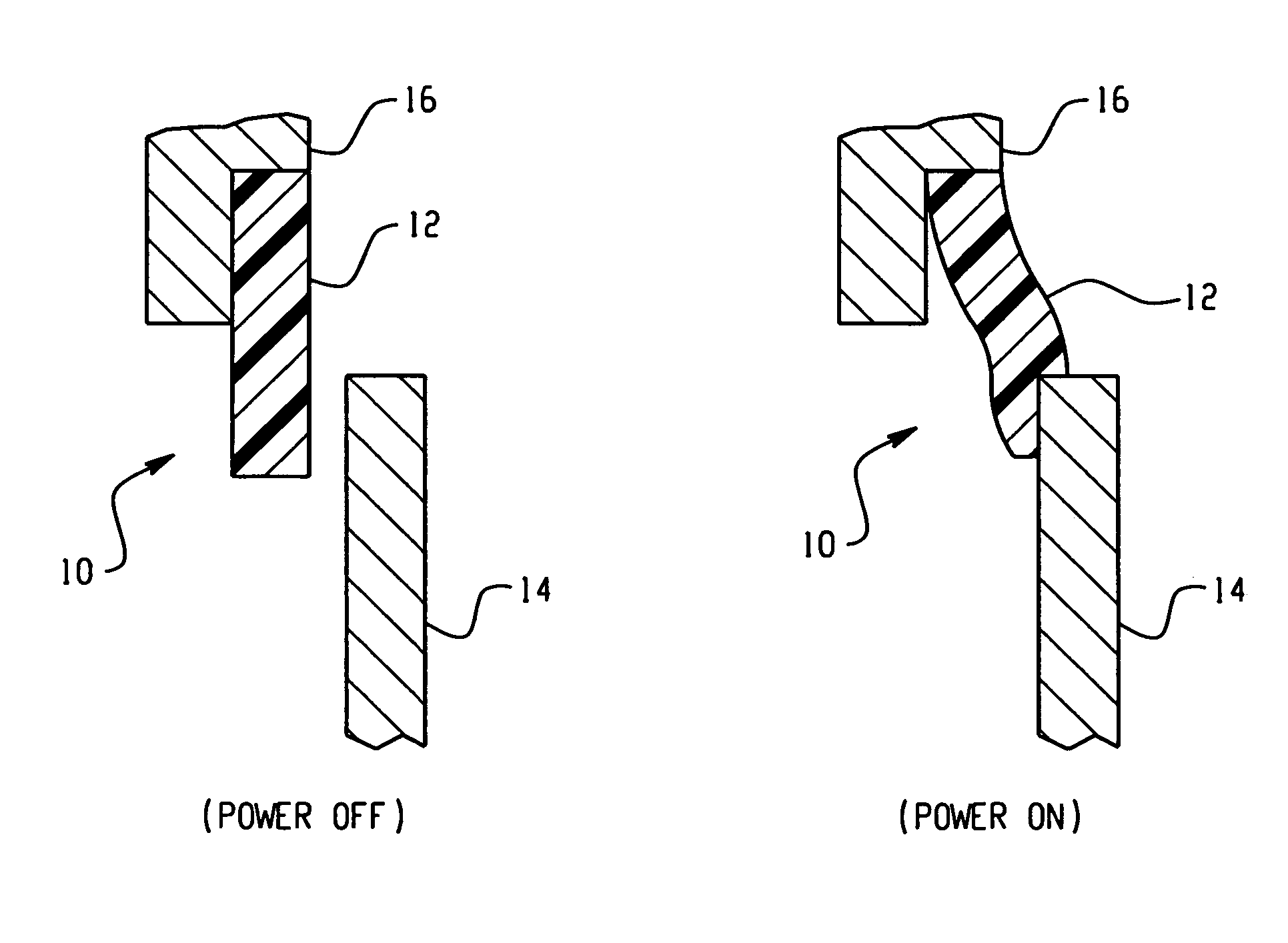

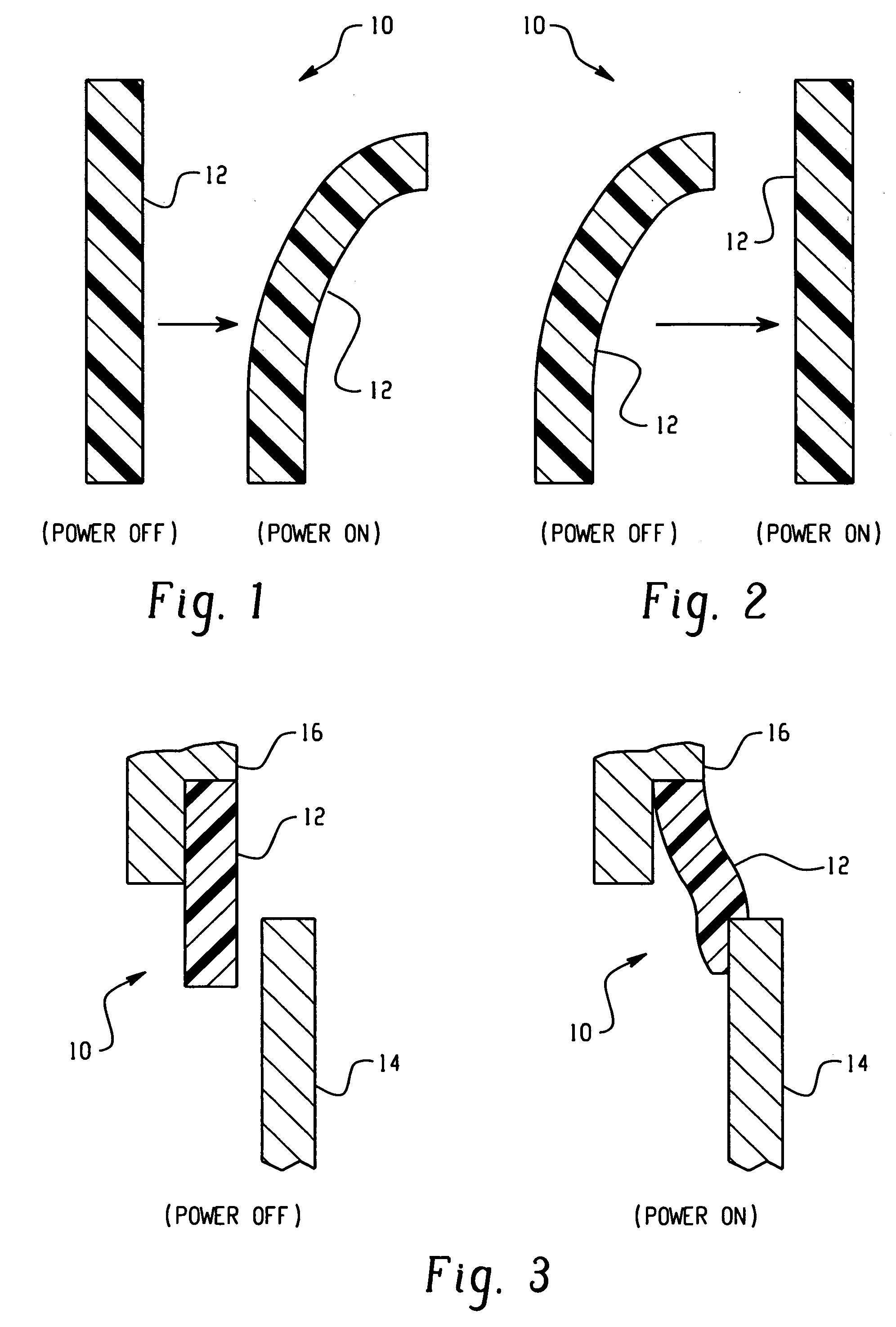

Active material based seal assemblies and methods for varying seal force

Owner:GM GLOBAL TECH OPERATIONS LLC

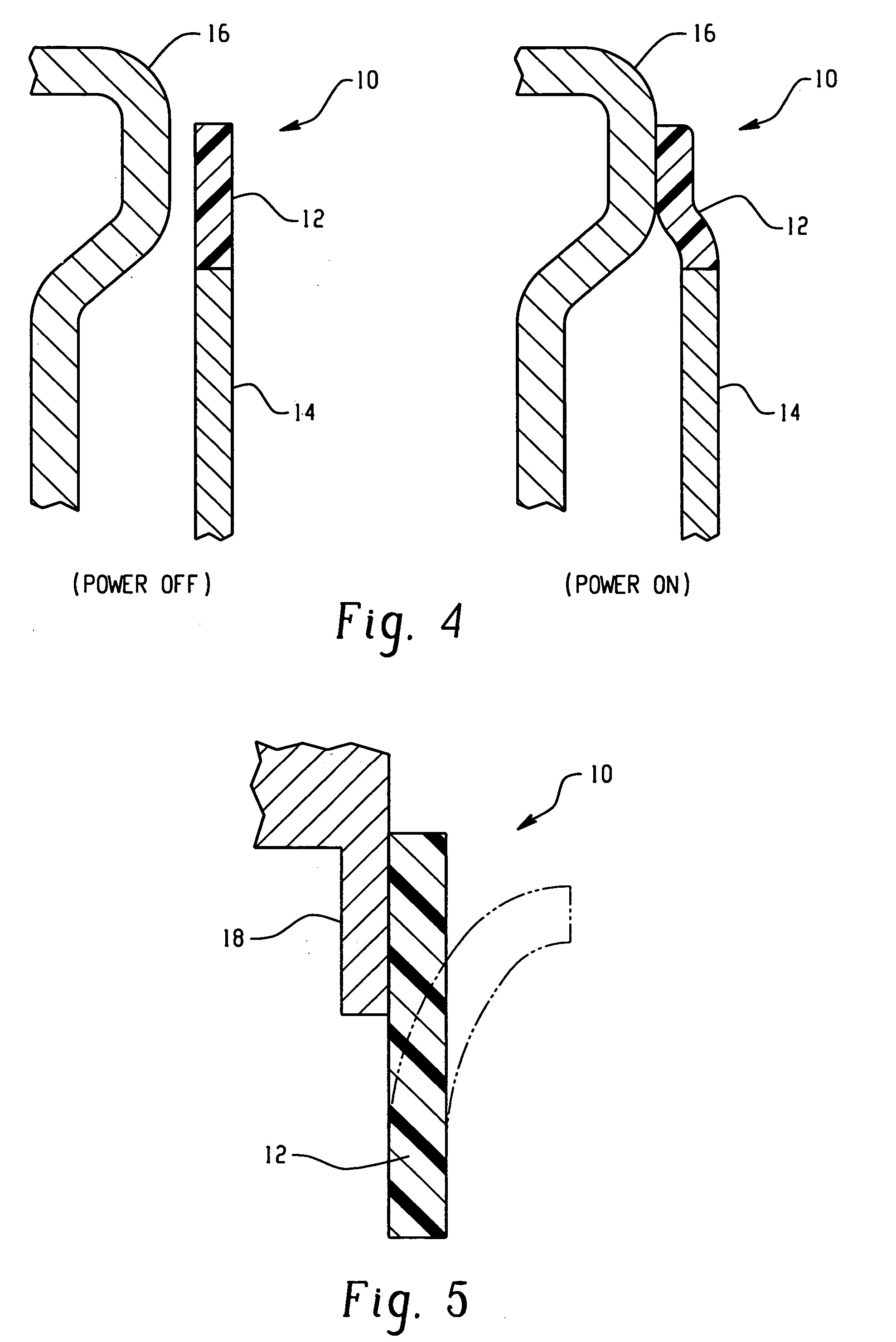

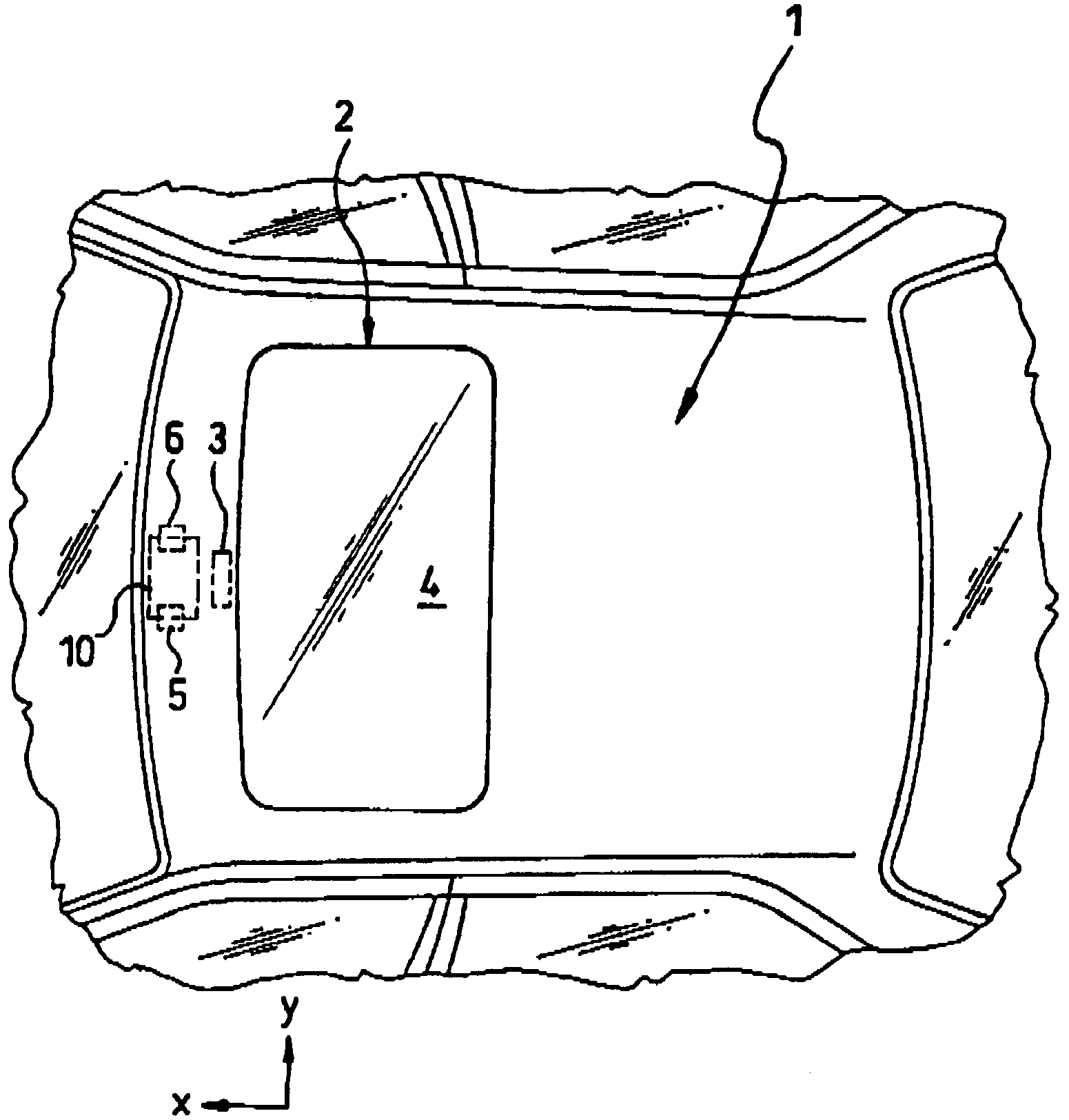

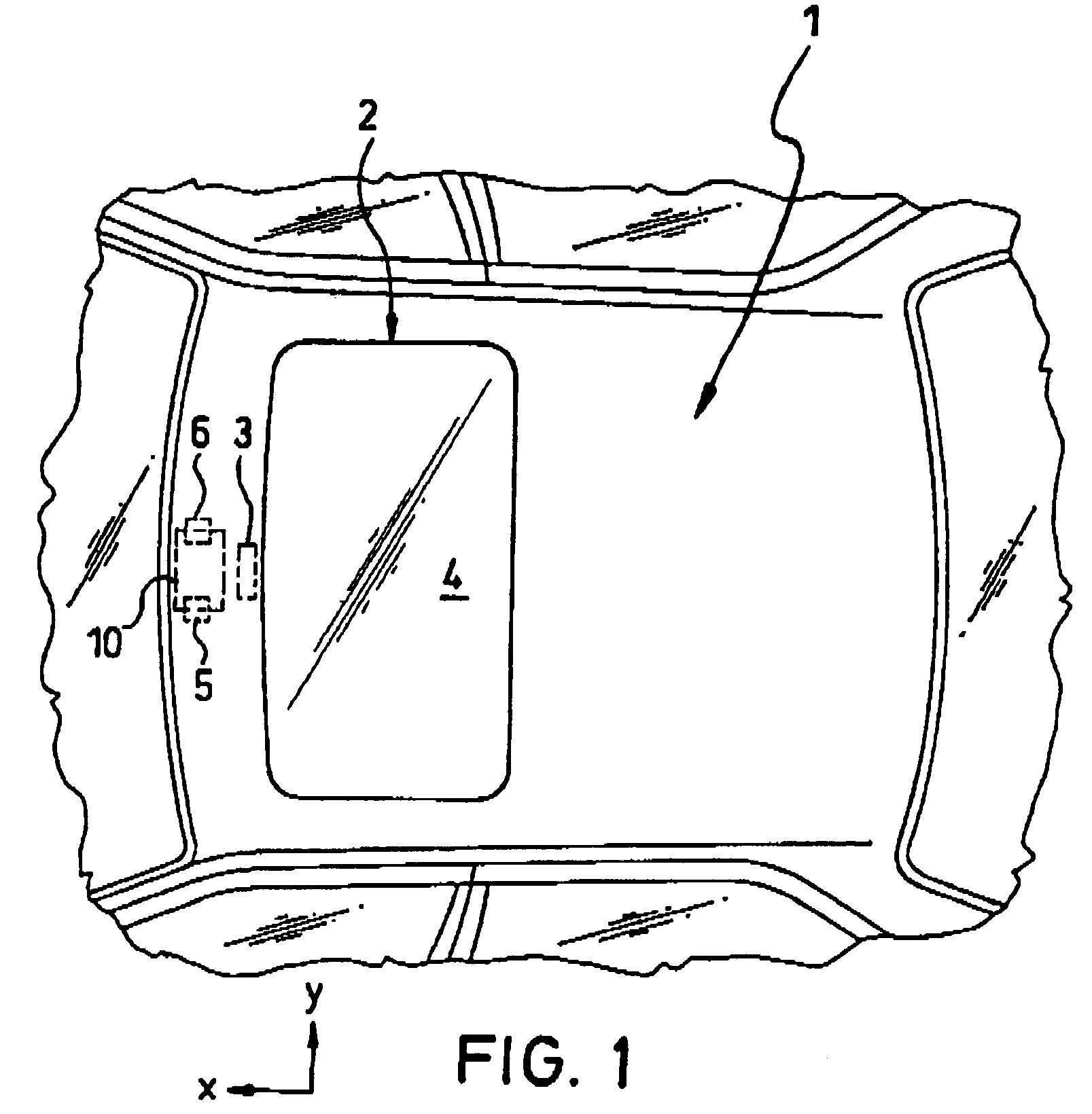

Motor vehicle roof with a control means for electrical motor vehicle components and process for operating electrical motor vehicle components

A motor vehicle roof with a control for comfortable operation of at least one motor vehicle component by a passenger of the vehicle, the control having a sensor surface arrangement (12g) for detecting the presence and / or movement of the hand or part of the hand of the passenger in a detection area of the sensor surface arrangement (12g). The sensor surface arrangement (12g) provides an electrical trigger signal based on detection of the presence and / or movement of at least part of the hand for triggering the vehicle component(s).

Owner:WEBASTO AG

Curable composition and method of use thereof

InactiveUS6706813B2Reduce penetrationLower resistanceOther chemical processesVehicle sealing arrangementsHeat resistancePliability

To provide a curable composition excellent in flexibility and heat resistance. A curable composition which comprises (A) a block copolymer having at least one kind of block formed from an aliphatic hydrocarbon compound and (B) an isobutylene polymer having a silicon group bound to a hydrolyzable group or a hydroxyl group. That composition can be used as sealants, adhesives, pressure sensitive adhesives, compositions for gaskets, double layer glazing spacers and so on.

Owner:KANEKA CORP

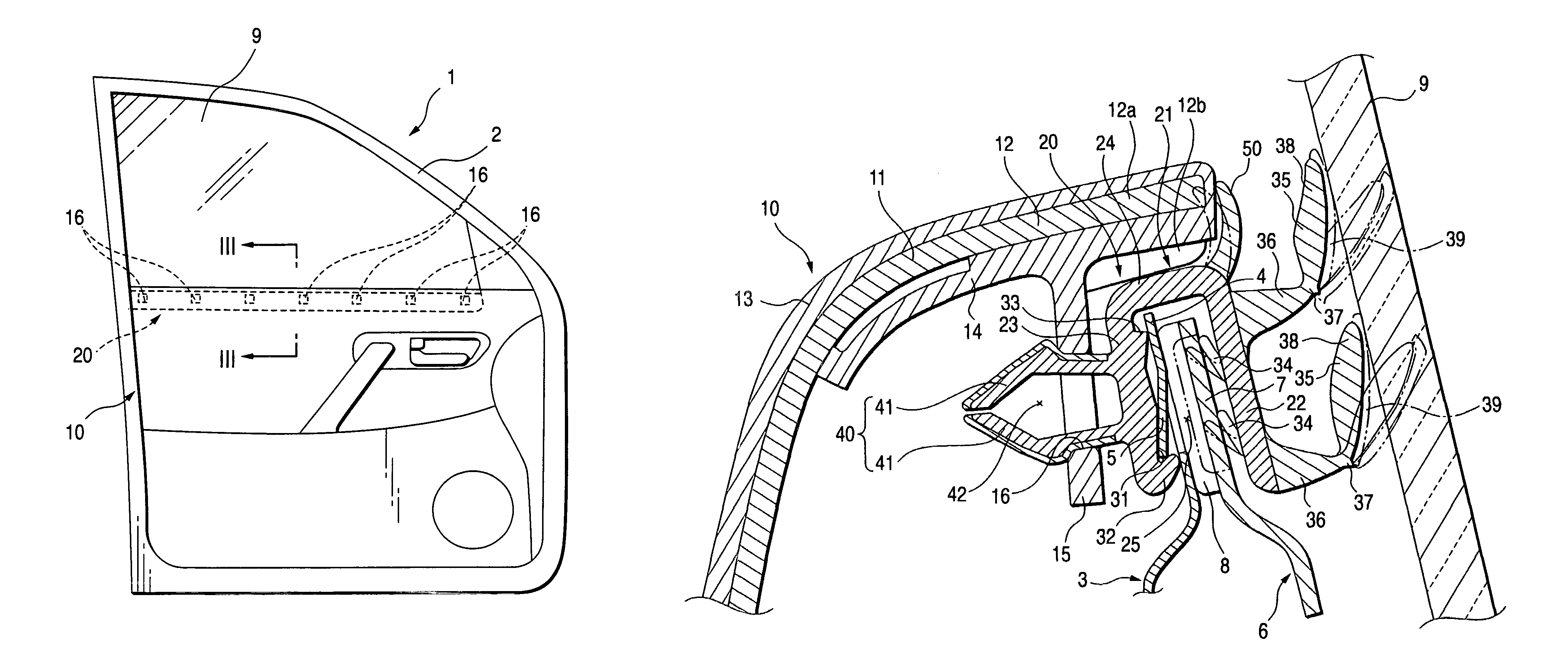

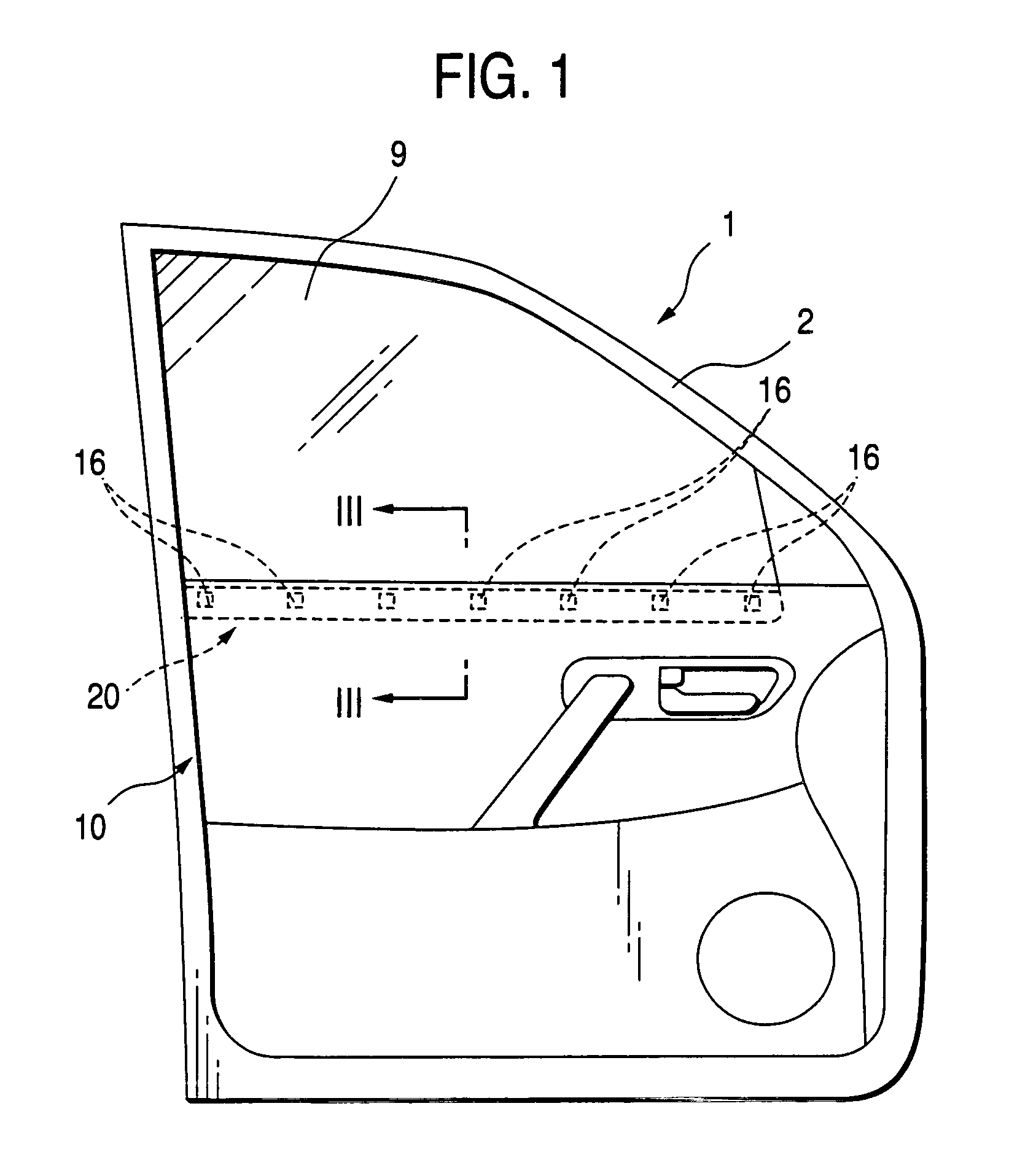

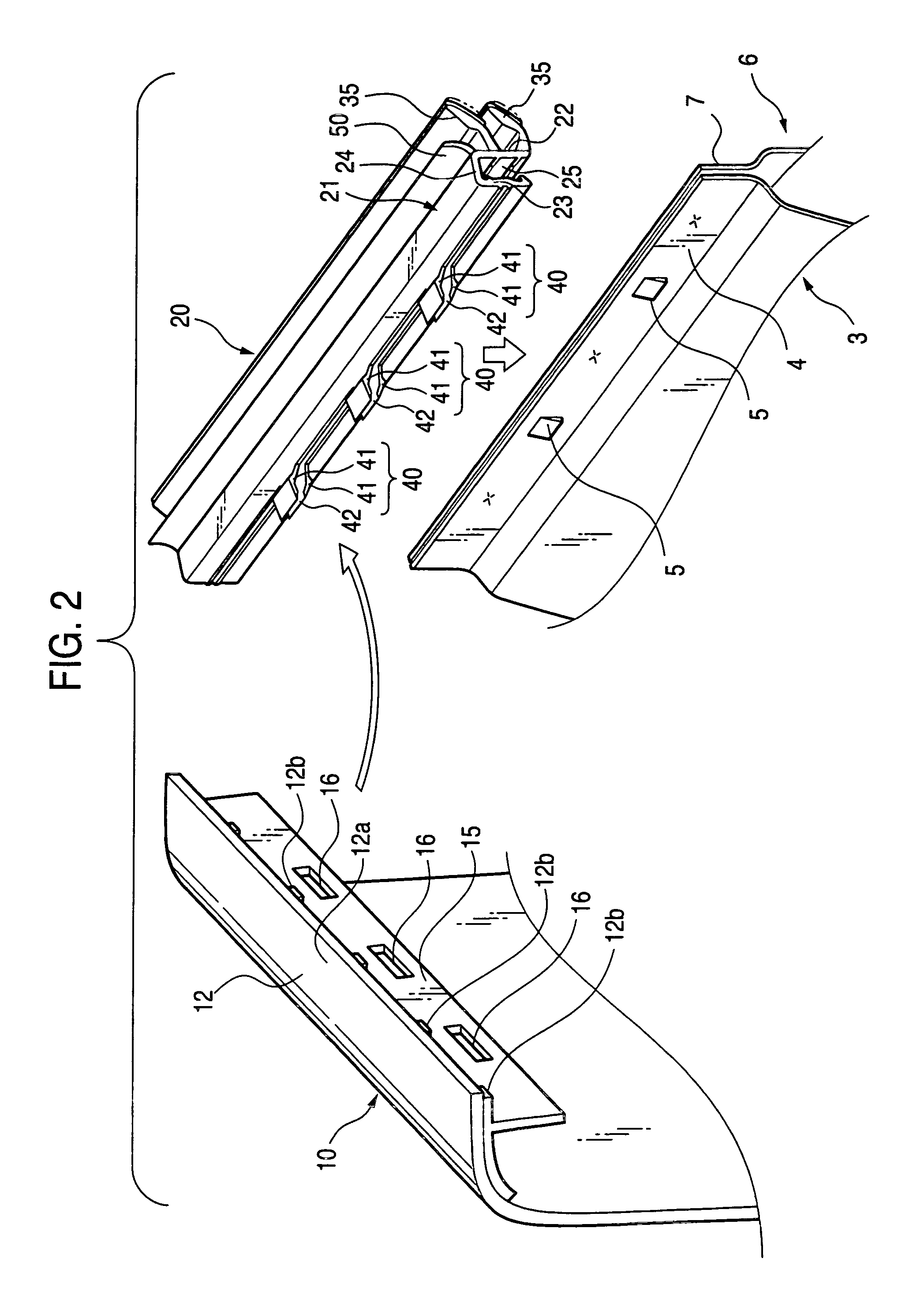

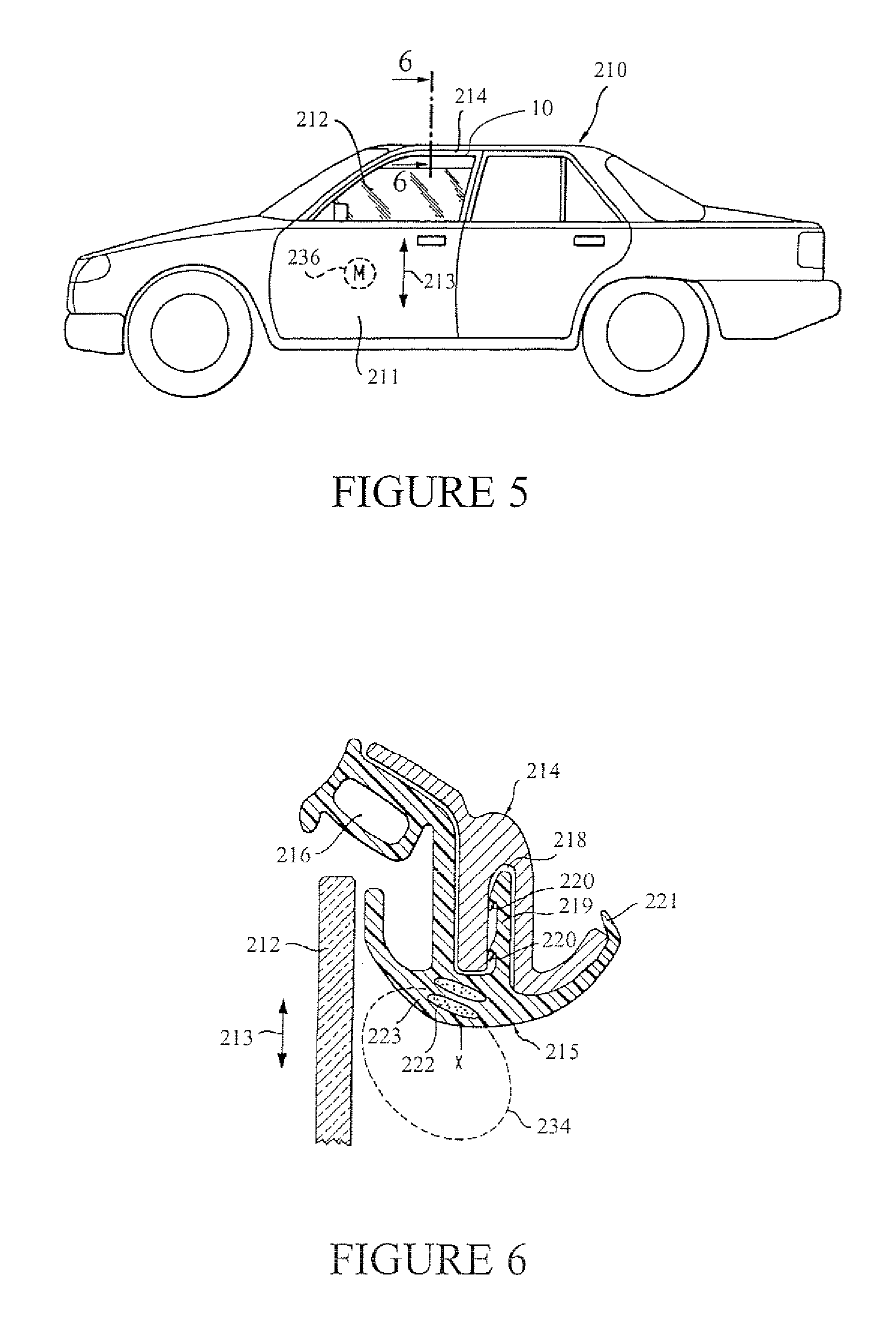

Weather strip for a vehicle door

A weather strip for a vehicle door for being fitted to an upper edge flange of a door inner panel forming a window opening edge of the vehicle door having a lifting / lowering window pane. The weather strip includes: a main body portion having an insertion groove to be fitted to the upper edge flange; a seal lip portion projecting from the main body portion to be in resilient contact with the lifting / lowering window pane; and a resilient retainer to be resiliently engaged with a door trim. The main body portion includes a fixing portion to be engaged with the upper edge flange. The resilient retainer is projected outward from the main body portion in a substantially horizontal direction and perpendicular to an attaching portion provided at an upper portion of the door trim, when the insertion groove is fitted to the upper edge flange substantially.

Owner:TOKAI KOGYO CO LTD

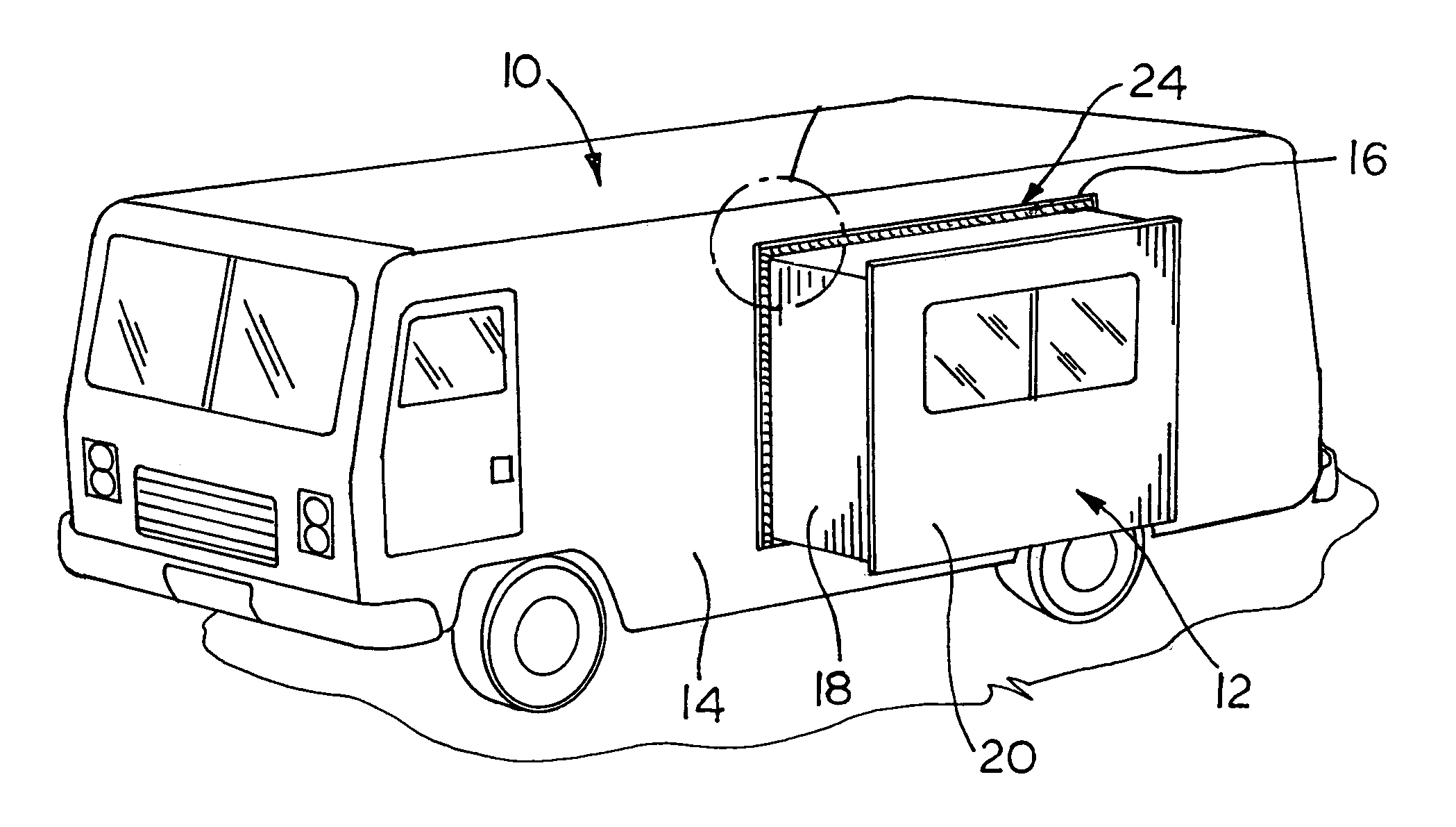

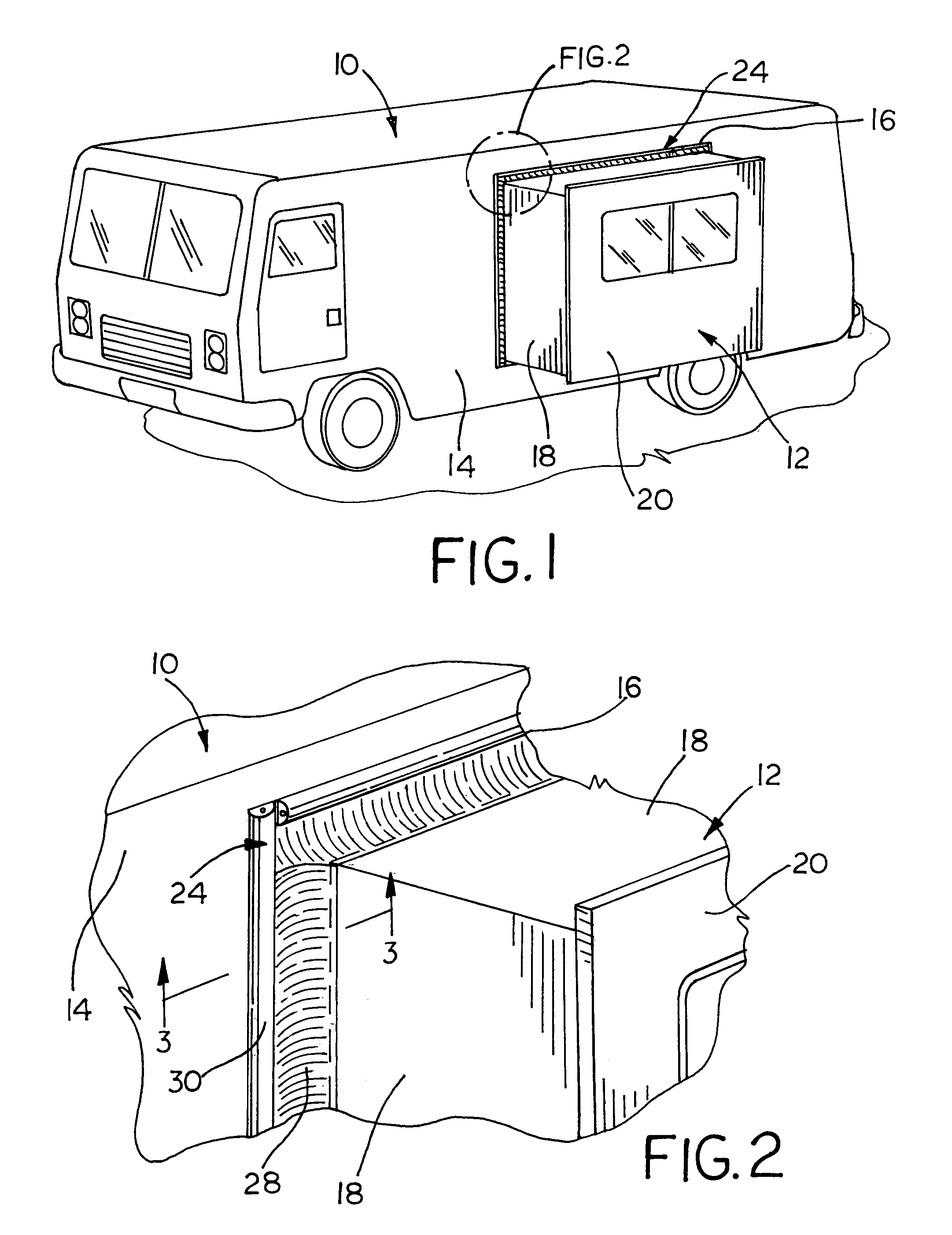

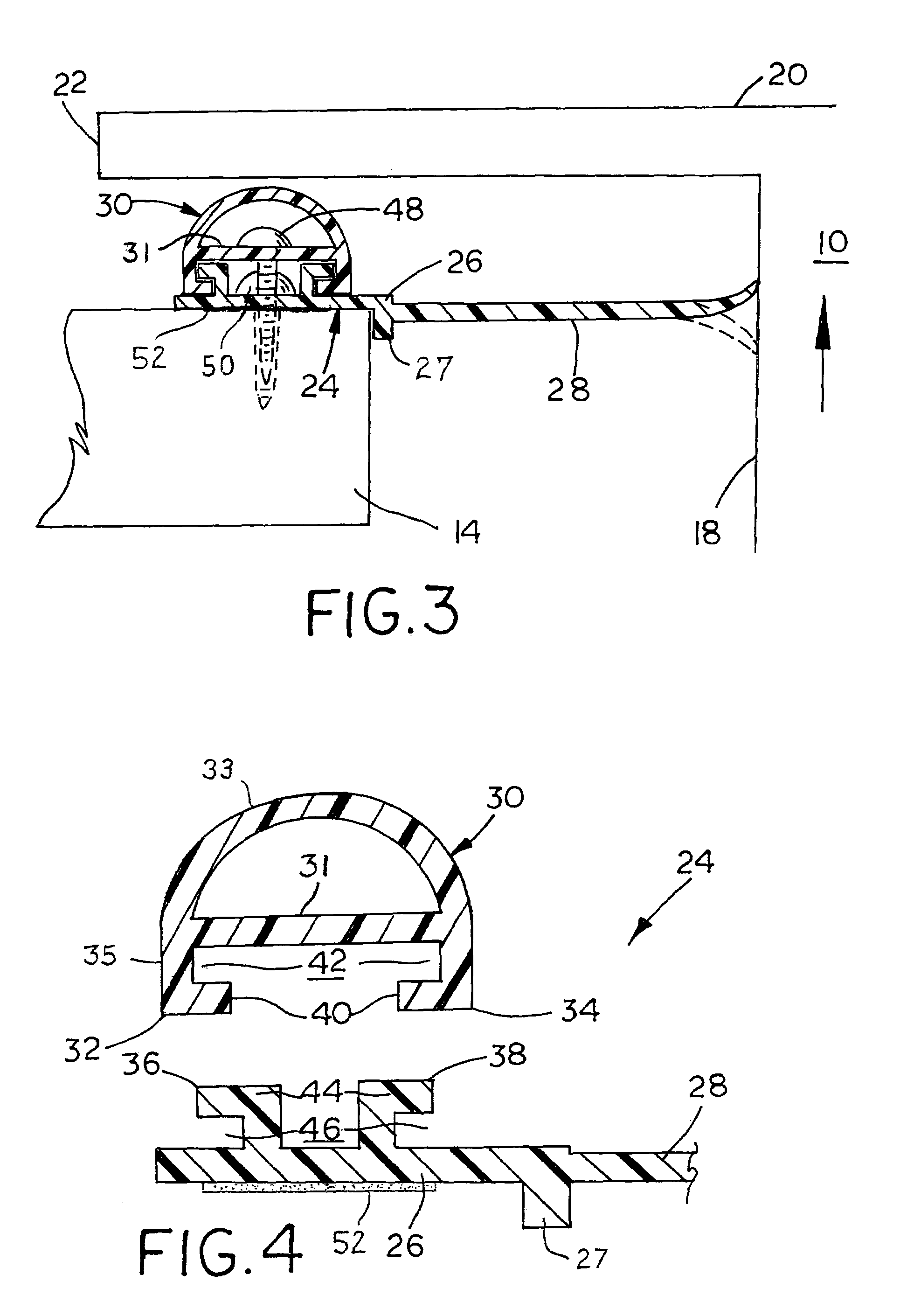

Two-part seal for a slide-out room

ActiveUS6966590B1Easy to adaptEasy to assembleBuilding roofsEngine sealsMechanical engineeringEngineering

A resilient seal is mountable around the edge of an opening in a sidewall of a mobile living quarters through which a slide-out room travels. The seal includes two parts that slide together—a mounting portion and a-bulb seal portion—with the bulb seal portion being compressed when the slide-out room is closed. A wiper seal portion extending from the mounting portion is for contacting the adjacent wall of the slide-out room.

Owner:LIFETIME INDS

Absorbent material of water absorbent polymer, thermoplastic polymer, and water and method for making same

InactiveUS20030065296A1High tensile strengthPromote absorptionInsulated cablesBaby linensFiberPolymer science

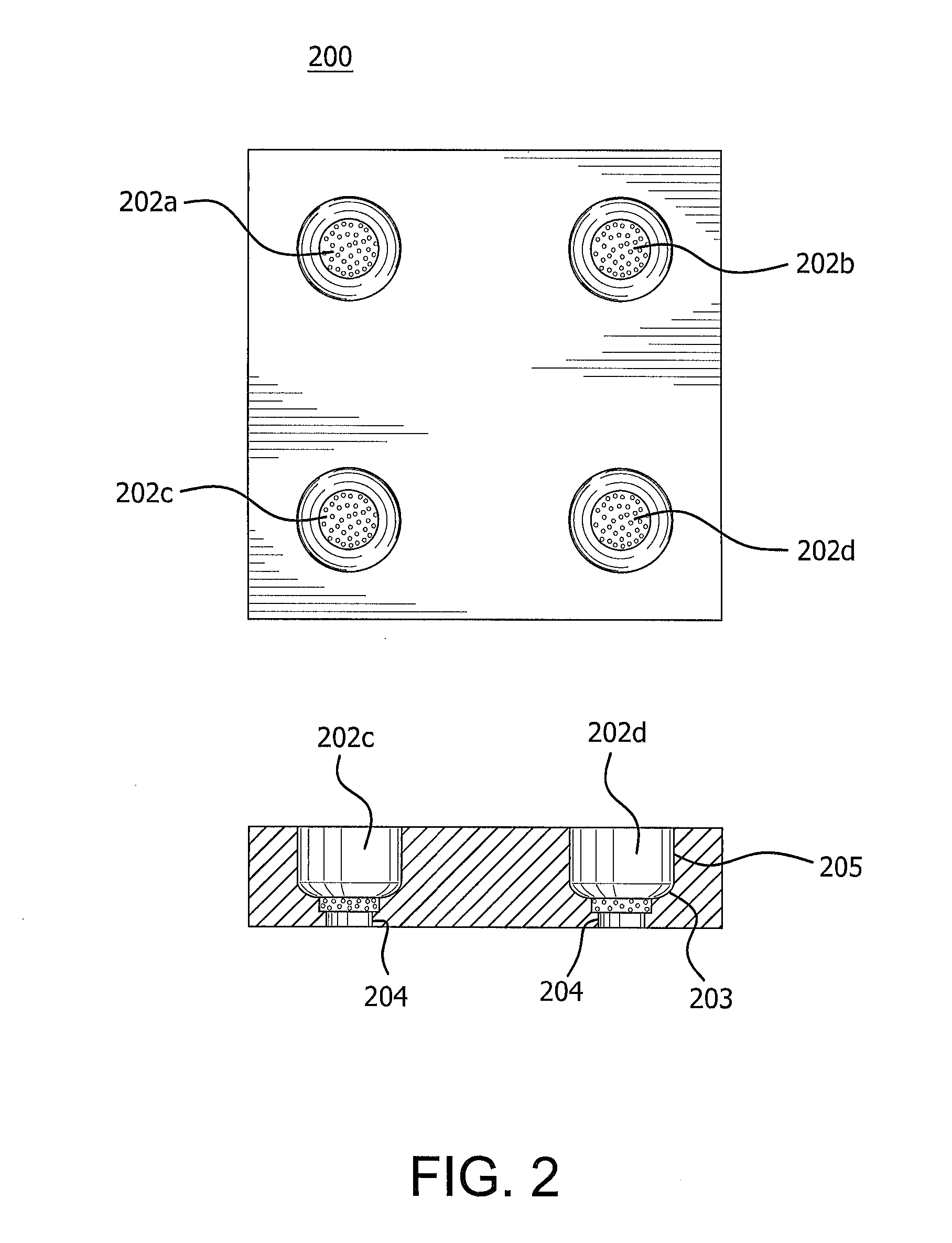

An absorbent material is disclosed, containing at least about 30 weight percent of a superabsorbent polymer, a thermoplastic polymer binder resin, and about 0.1 to about 10 weight percent water. The absorbent material absorbs deionized water to at least about 70 percent of maximum capacity within about 20 minutes after exposure to the deionized water. The method of making the absorbent material includes combining binder resin and absorbent polymer in a twin screw extrusion mechanism, compounding and driving the composition toward exit openings, extruding the composition through the exit openings, and preferably rapidly cooling the extrudate with non-liquid quenching means. The quenched or non-quenched extrudate may be made in the form of a pellet, film, or fibrous strand.

Owner:STOCKHAUSEN GMBH & CO KG DEGUSSA-HUELS AKTIENGESE

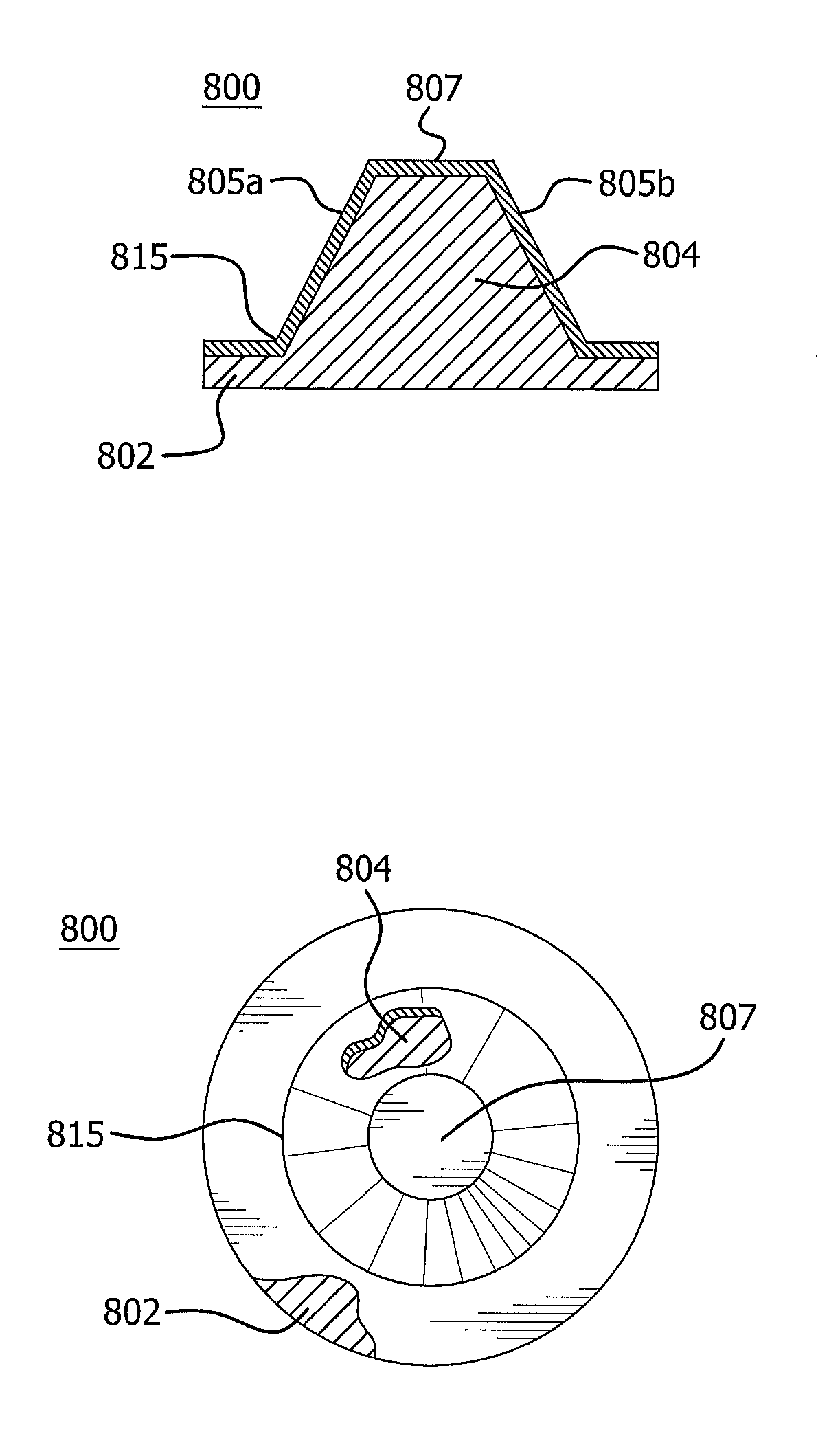

Active material based seal assemblies

Owner:GM GLOBAL TECH OPERATIONS LLC

Fluoropolymer Barrier Materials for Containers

A container having a barrier layer is provided. The container may be of thermoplastic and the barrier may inhibit materials from leaching from the thermoplastic material or from extraction of compounds from medicants by the thermoplastic. A process is also described that allows for molding thin barrier layers as container lines and for forming thermoplastic containers with barrier liners.

Owner:WL GORE & ASSOC INC

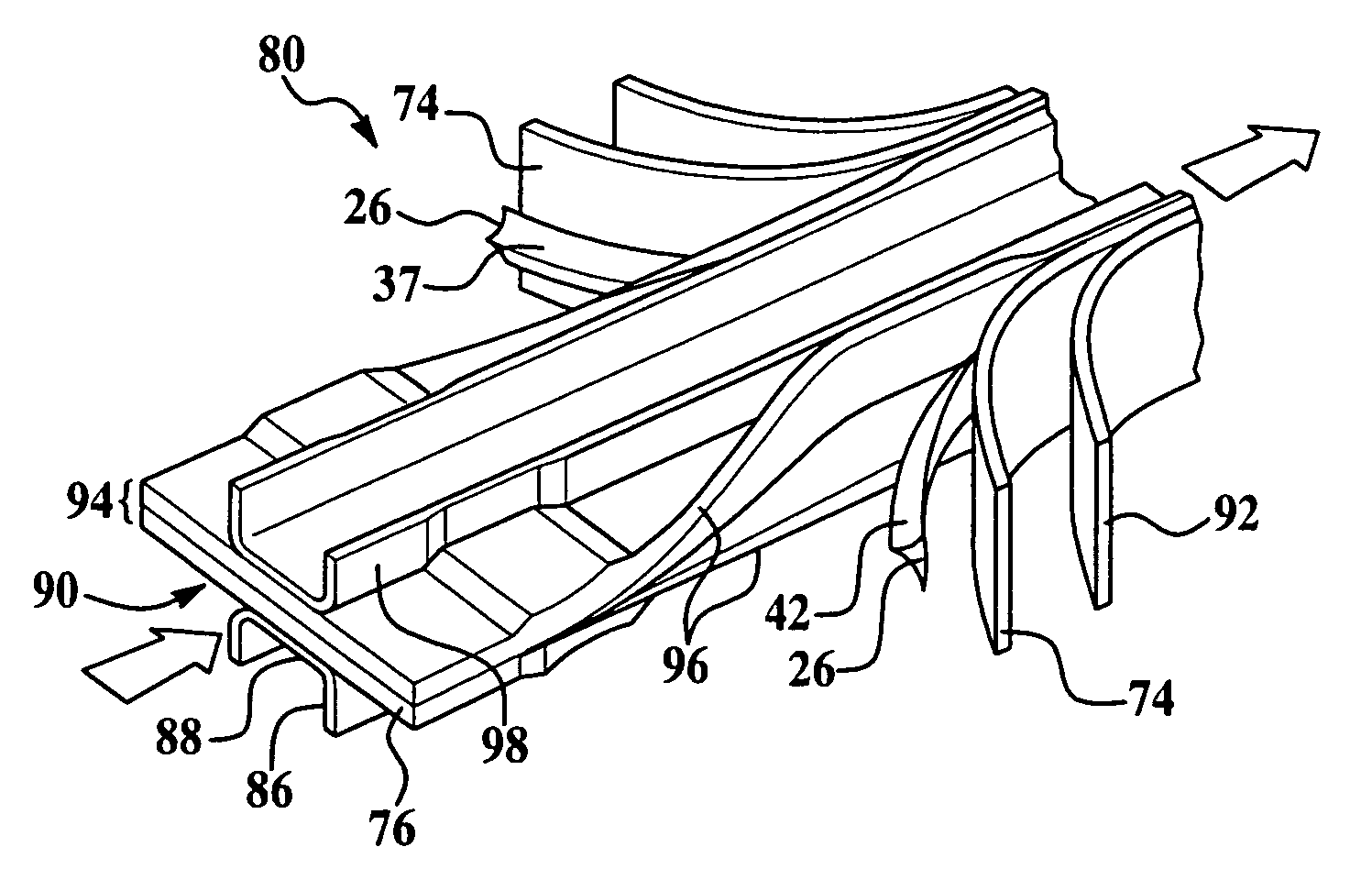

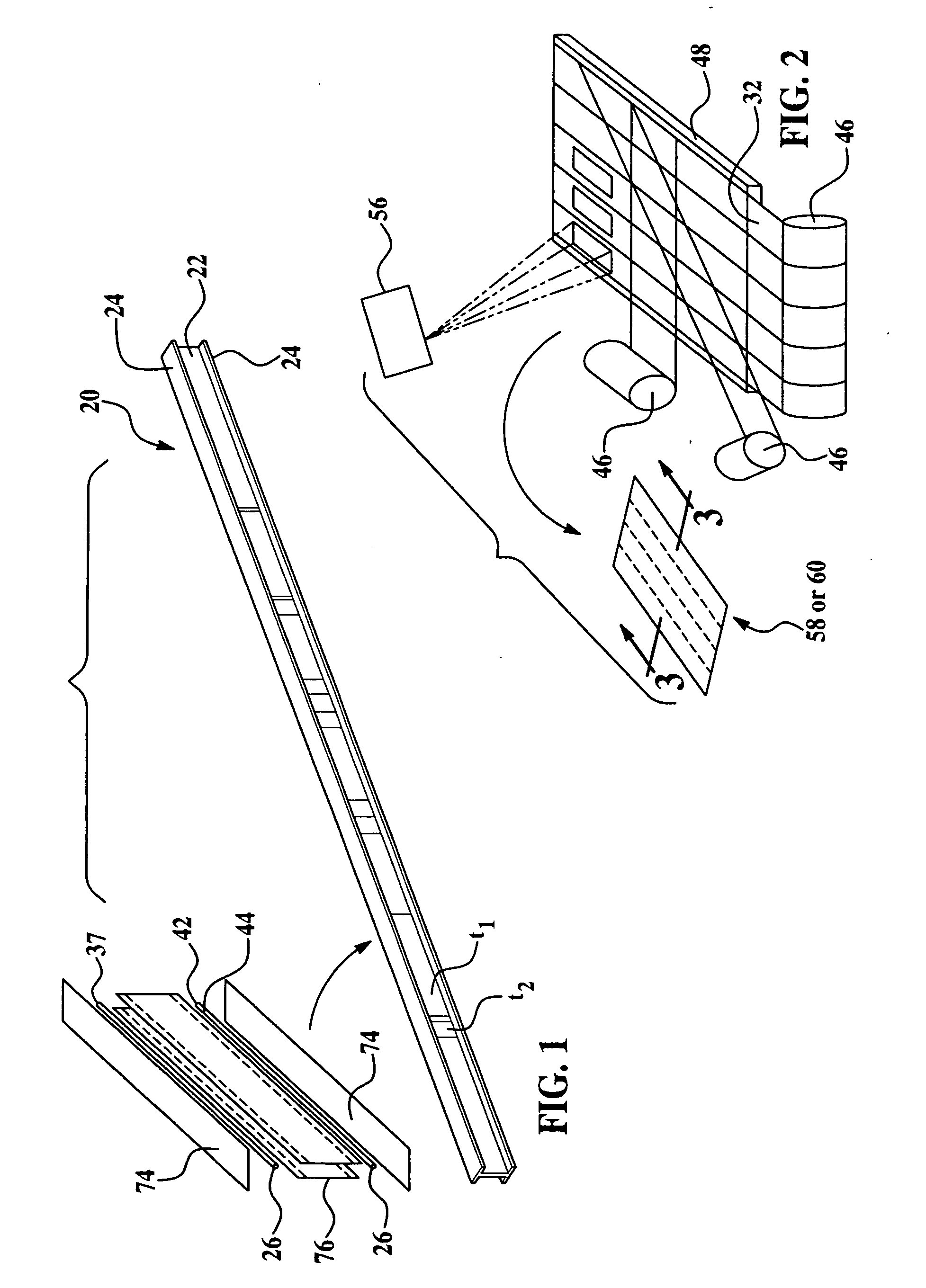

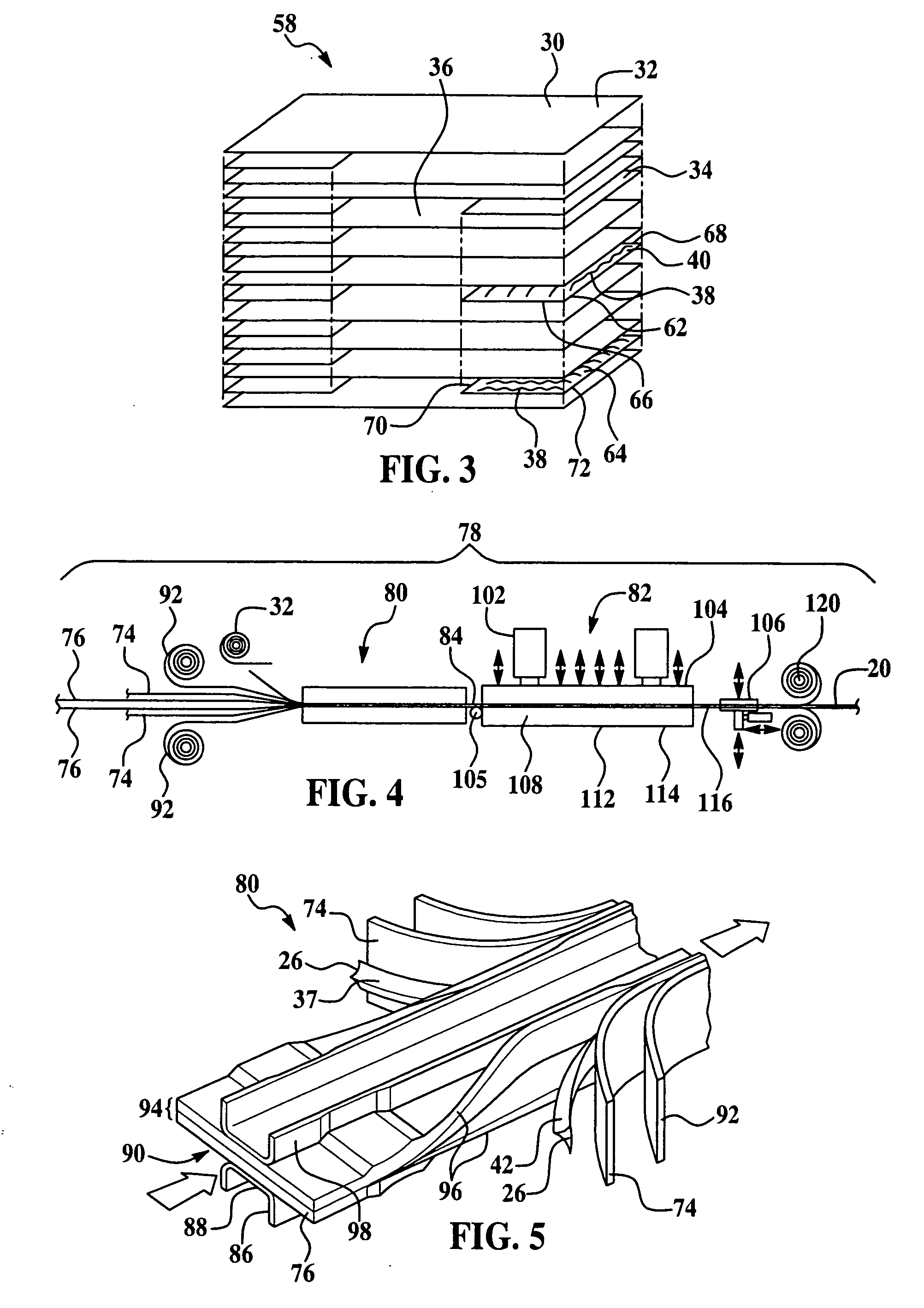

Method for fabricating curved thermoplastic composite parts

ActiveUS20070175575A1Mechanical working/deformationWood working apparatusEngineeringThermoplastic composites

A fabrication method of forming curved thermoplastic composite laminate parts with tailored and varying thickness in a continuous process. Automated equipment or hand lay-up are used to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. Ply consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from the multiple ply stacks.

Owner:THE BOEING CO

Cap Liners, Closures, and Gaskets from Multi-Block Polymers

A polymer composition comprises at least an ethylene / α-oleiln interpolymer and at least one other polymer. The other polymer can be selected from a second ethylene / α-olefin interpolymer, an elastomer, a polyolefin, a polar polymer, and an ethylene / carboxylic acid interpolymer or ionomer thereof. The ethylene / α-olefin interpolymer is a block copolymer having at least a hard block and at least a soft block. The soft block comprises a higher amount of comonomers than the hard block. The block interpolymer has a number of unique characteristics disclosed here. Also provided are gaskets, bottle cap liners, and closures that comprise or obtained from a compositon comprising at least one ethylene / α-olefin interpolymer and at least one polyolefin. The gaskets are capable of compression sealing various containers, without contaminating the contents. Liquid containers particularly benefit from the use of the novel gasket materials disclosed herein.

Owner:DOW GLOBAL TECH LLC

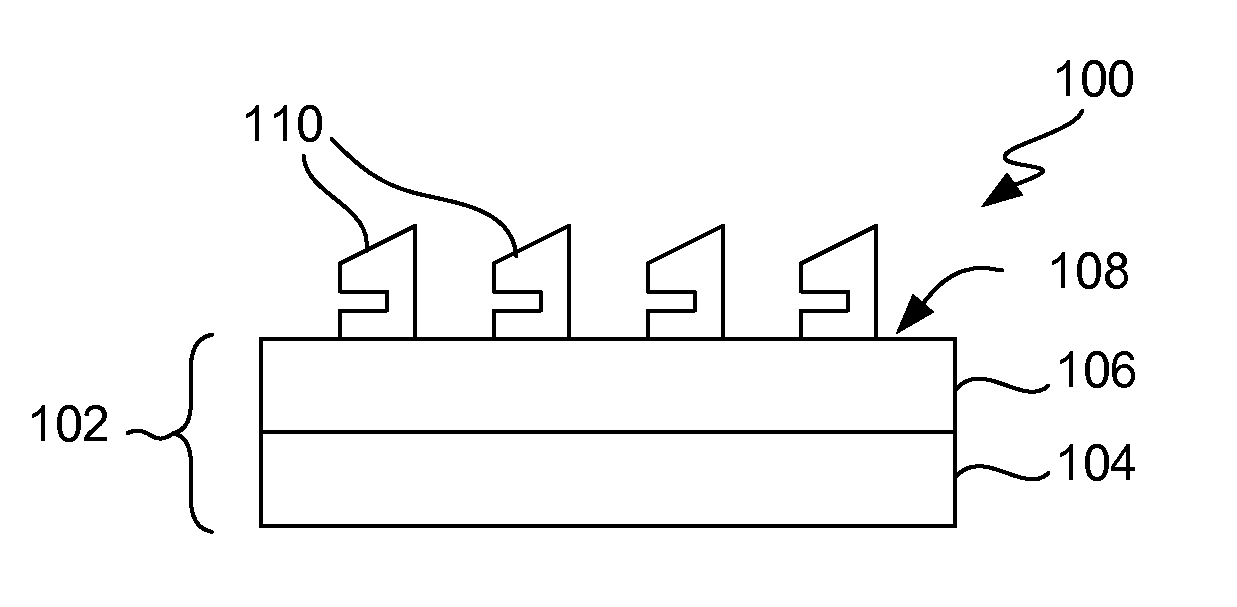

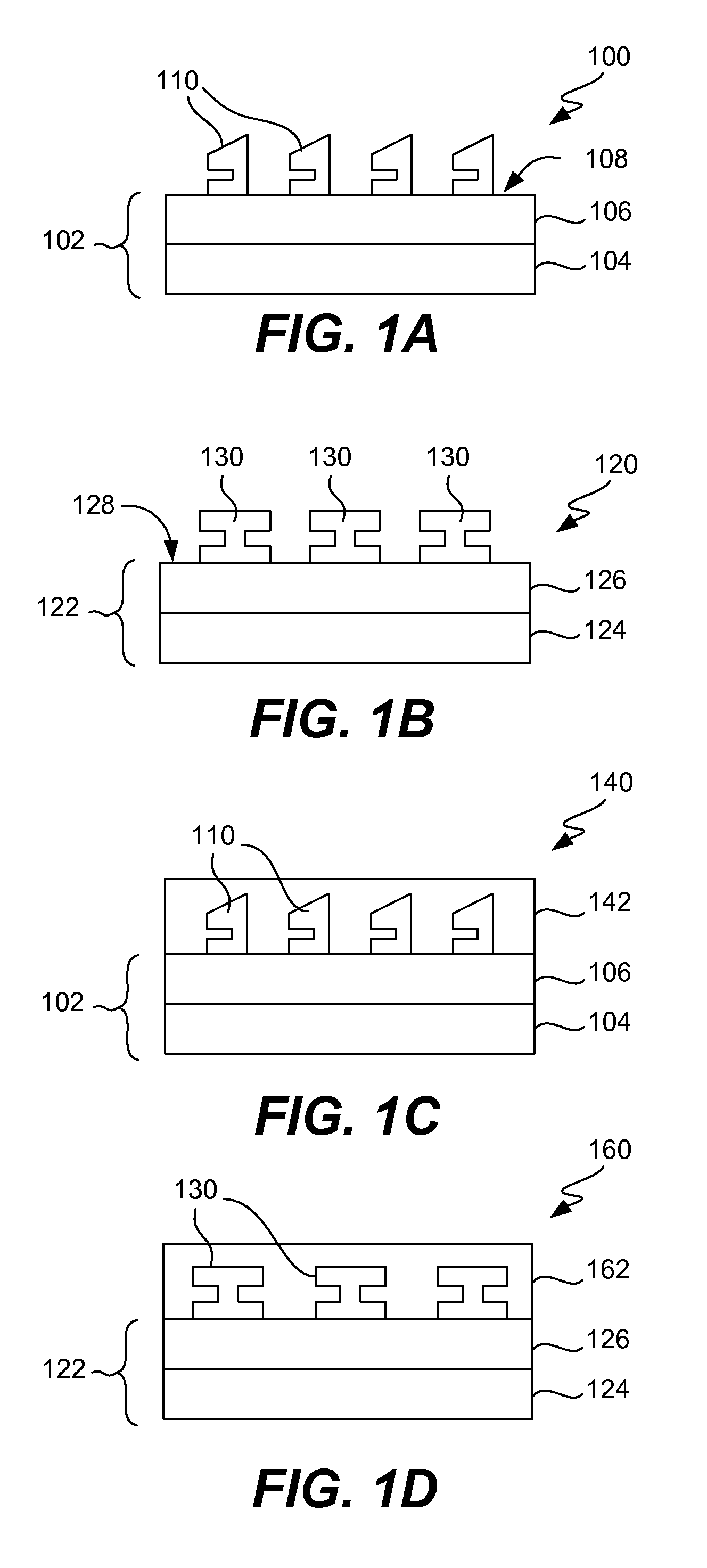

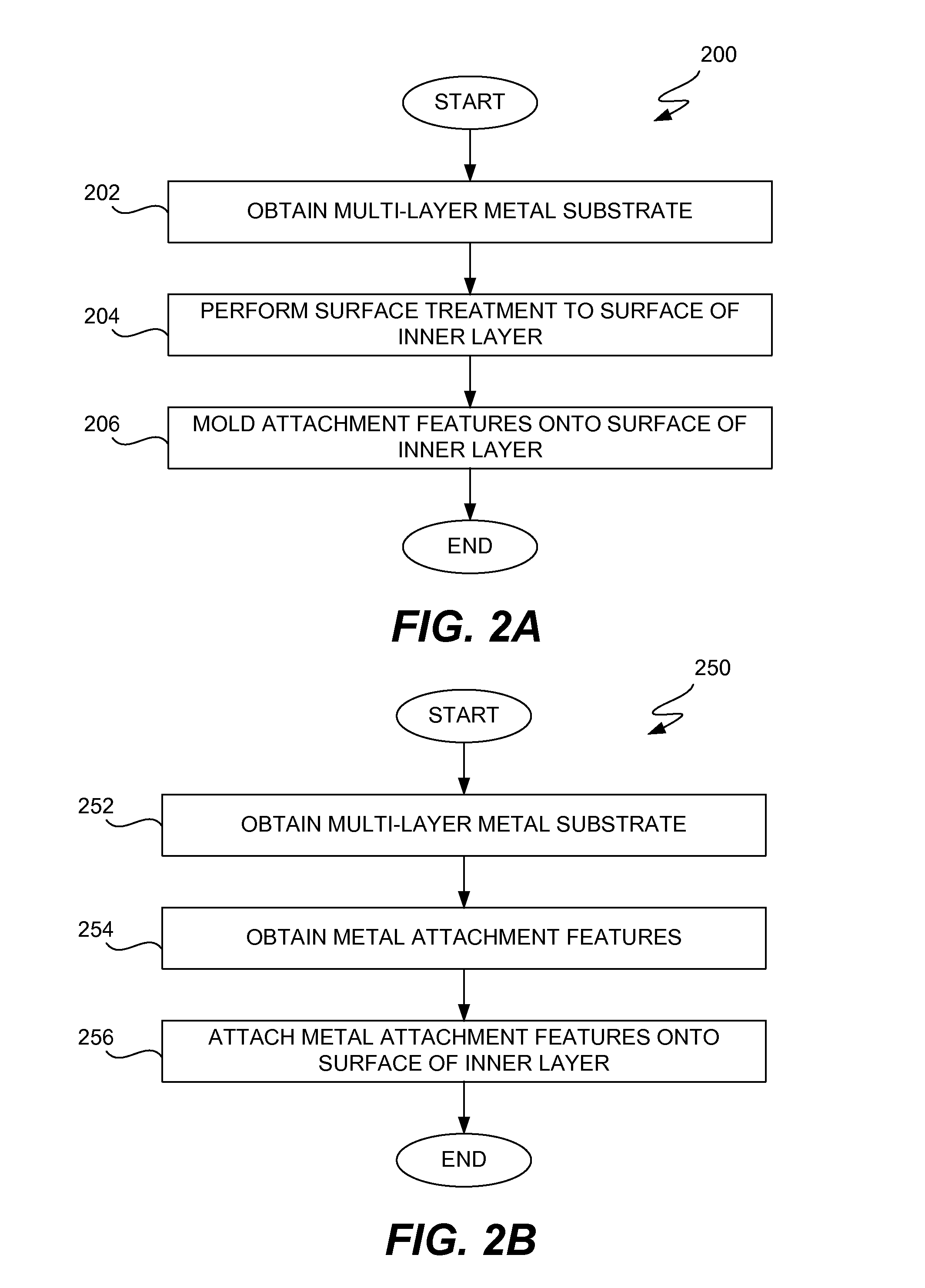

Methods and Systems for Forming Housings From Multi-Layer Materials

ActiveUS20090190290A1Easy to createFacilitate partDigital data processing detailsExtrusion containersElectronMetal

Methods and apparatus for forming a housing, such as for an electronic device, from multi-layer materials are disclosed. The multi-layer materials include at least two layers. Typically, one or more of the layers are metal. However, different layers of the multi-layer materials can be different metals. In one embodiment, an inner layer of the multi-layer materials can be provided with or form internal features that can be for attaching parts or components to the multi-layer materials. In another embodiment, processing of an inner layer of the multi-layer materials can facilitate part formation with increased curvature and / or internal part clearance. In another embodiment, the multi-layer materials can include an intermediate layer that facilitates creation of internal features that can be for attaching parts or components to the multi-layer materials. In still another embodiment, the multi-layer materials can provide a protective layer that serves to protect an outer surface of the housing during manufacturing and / or assembly.

Owner:APPLE INC

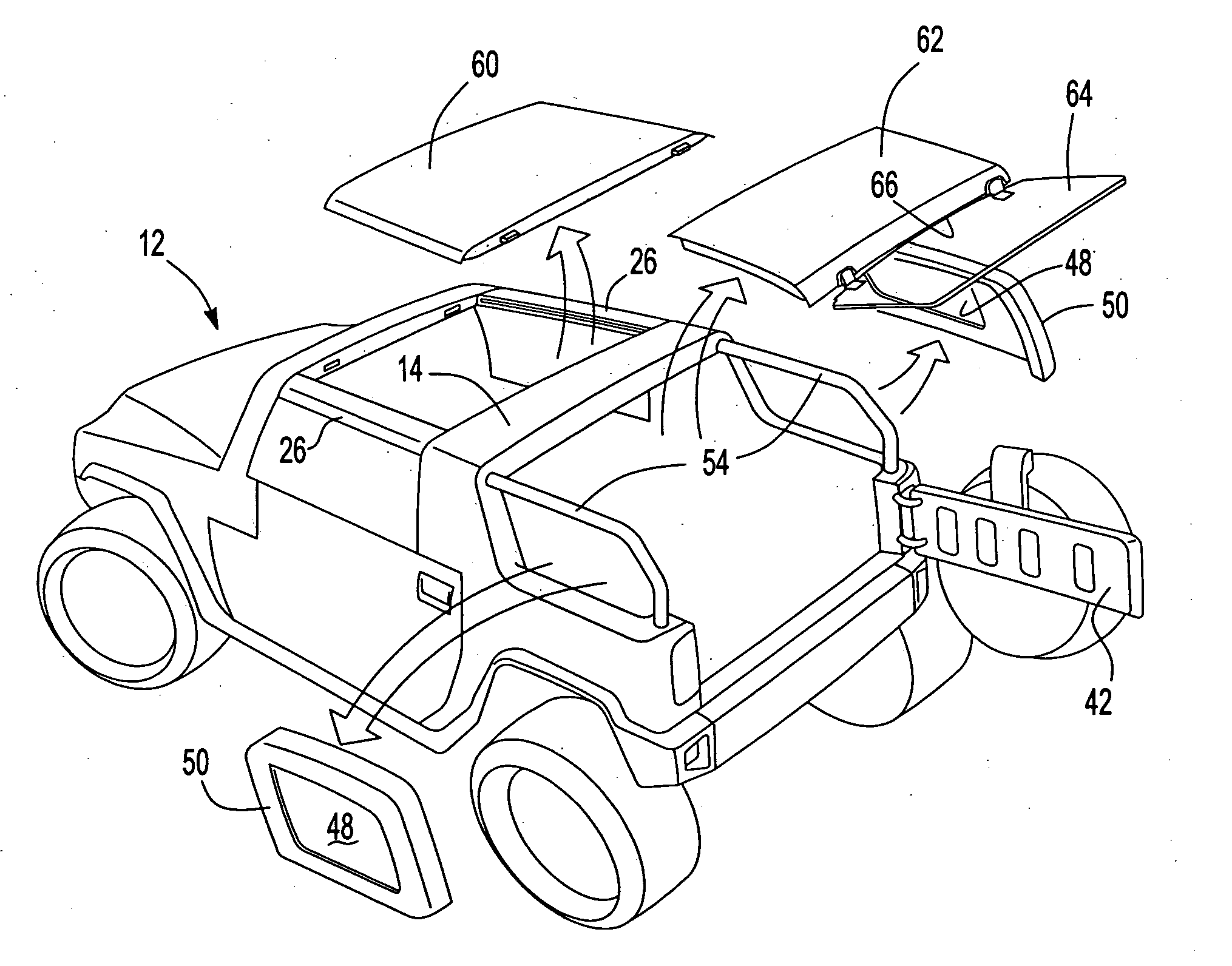

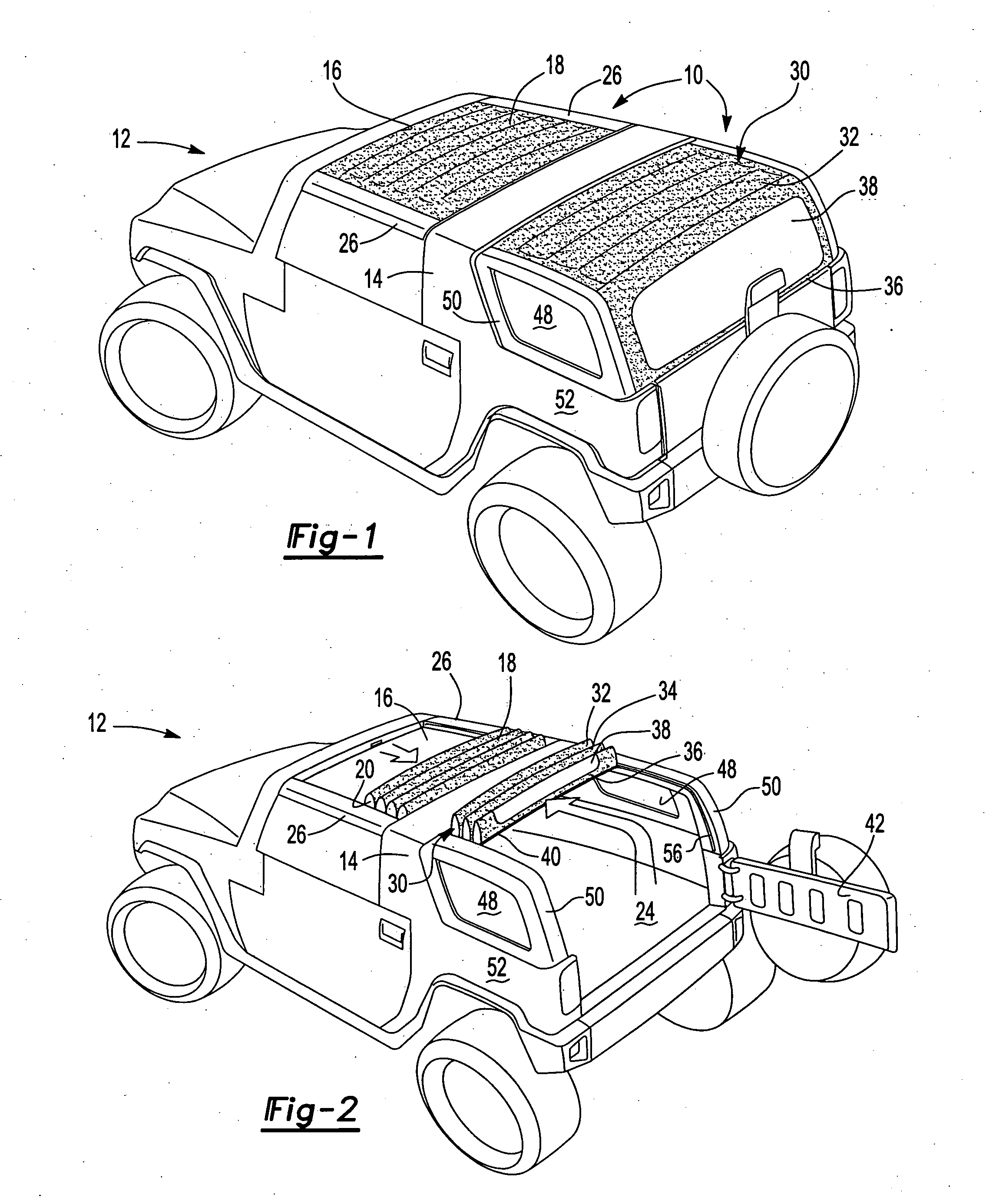

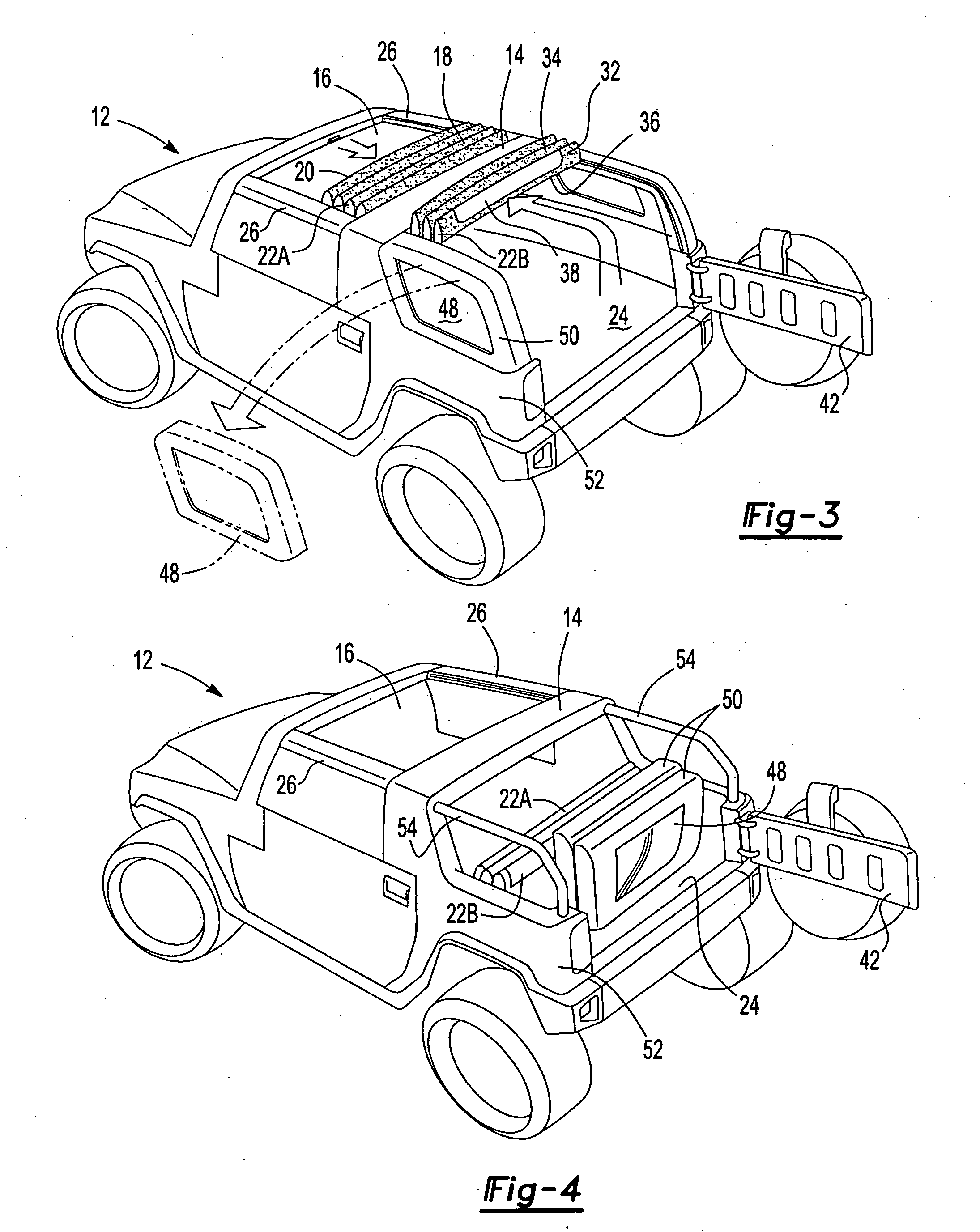

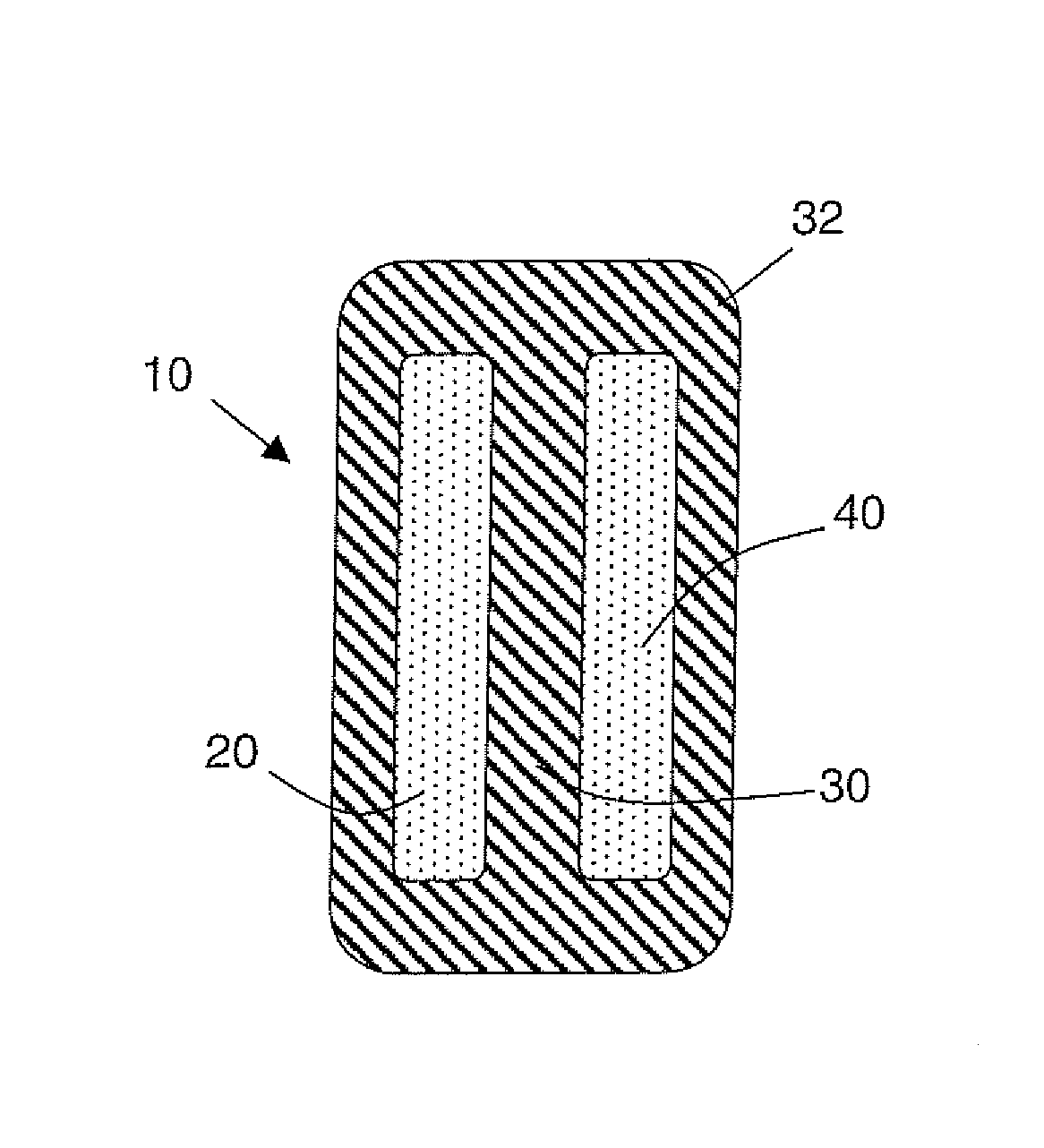

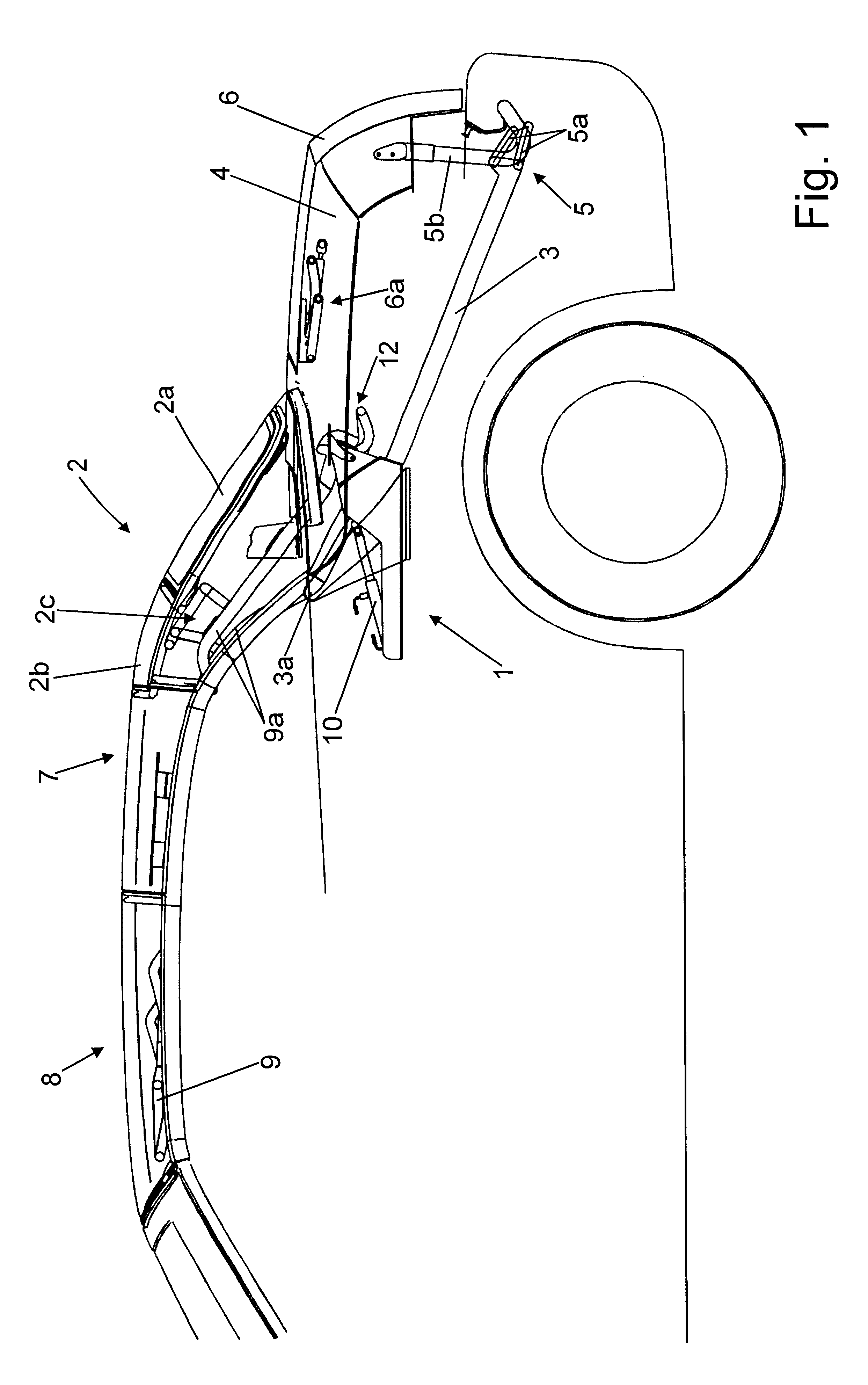

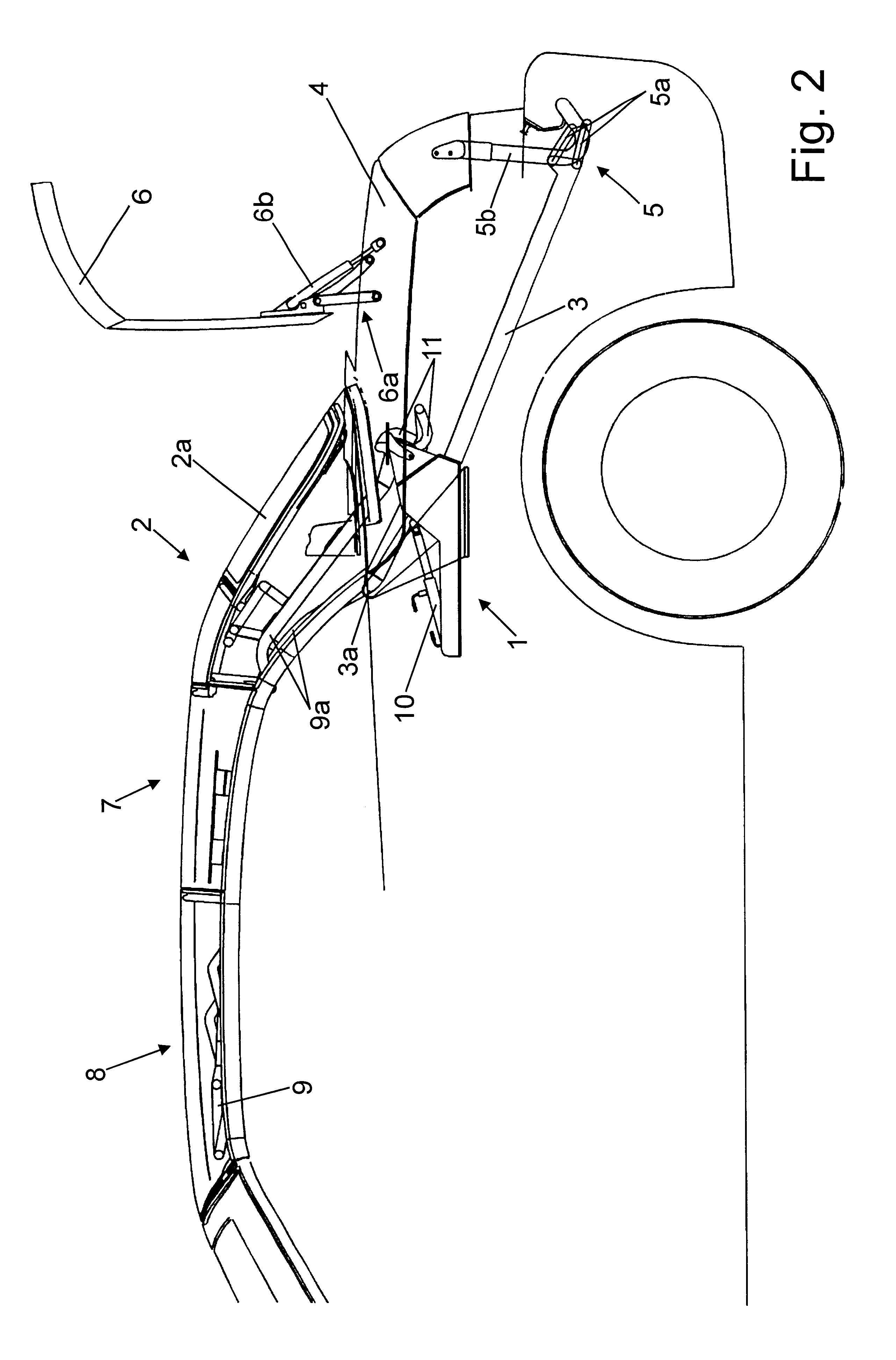

Modular convertible top

A removable top system for a vehicle having a front removable roof section and a rear removable roof section. Different removable roof coverings may be interchangeably combined to provide a complete roof for a sport utility vehicle having a permanent hoop dividing the front and rear roof sections. Soft top and hard top roof coverings are selectively provided. Different retraction mechanisms are disclosed for retracting and storing the removable roof sections.

Owner:MAGNA CAR TOP SYST GMBH

Capacitive sensor having flexible polymeric conductors

InactiveUS7215529B2Avoid displacementConstant separationAnti-noise capacitorsEngine sealsElectrical conductorCapacitive sensing

A capacitive sensor having a first and a second polymeric conductor are embedded within a non conducting body, wherein the body maintains a fixed separation distance between the first and the second polymeric conductor. The body can include a non conducting web, wherein the web substantially precludes variation in the spacing of the polymeric conductors during use in the intended operating environment.

Owner:SCHLEGEL

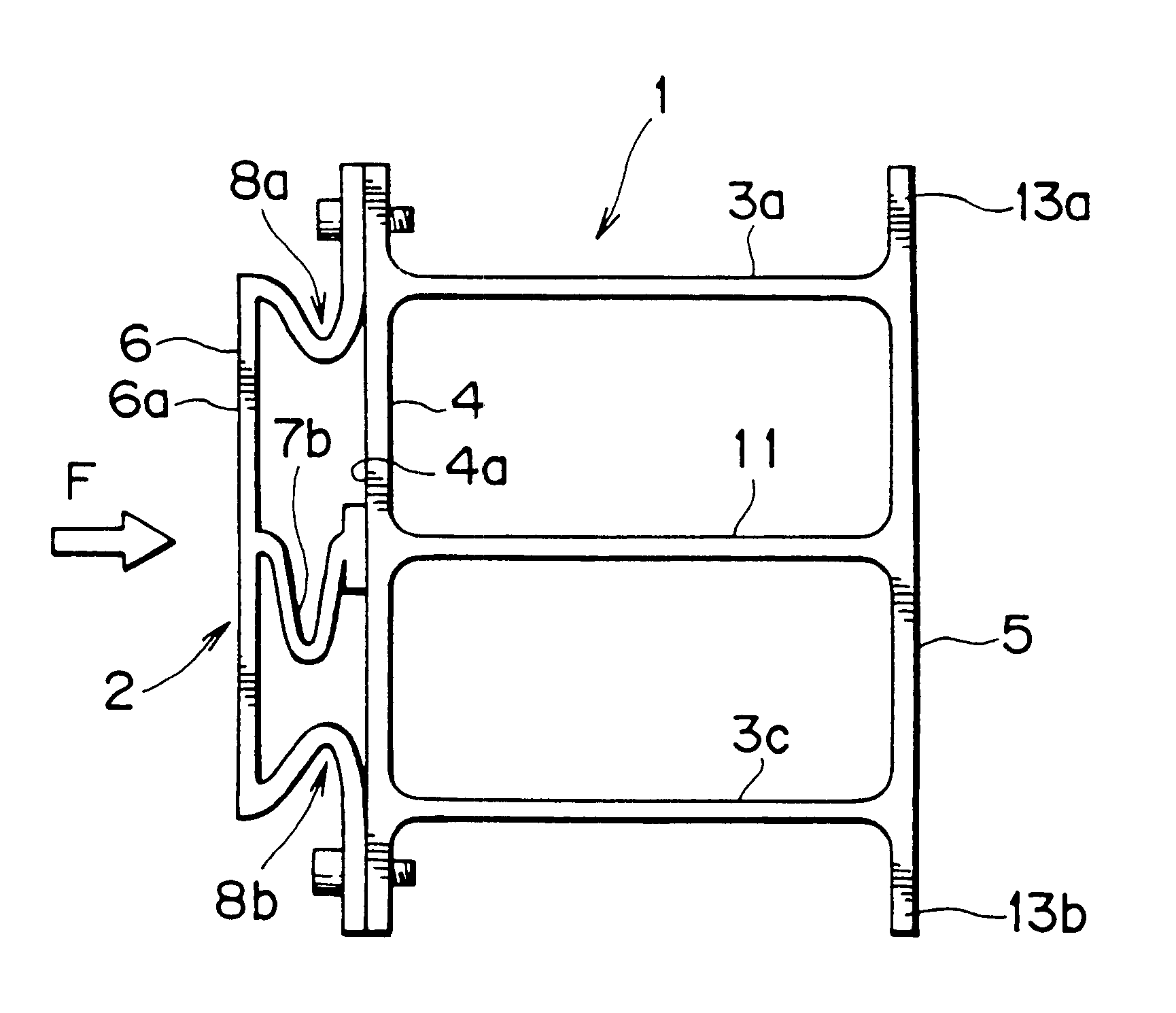

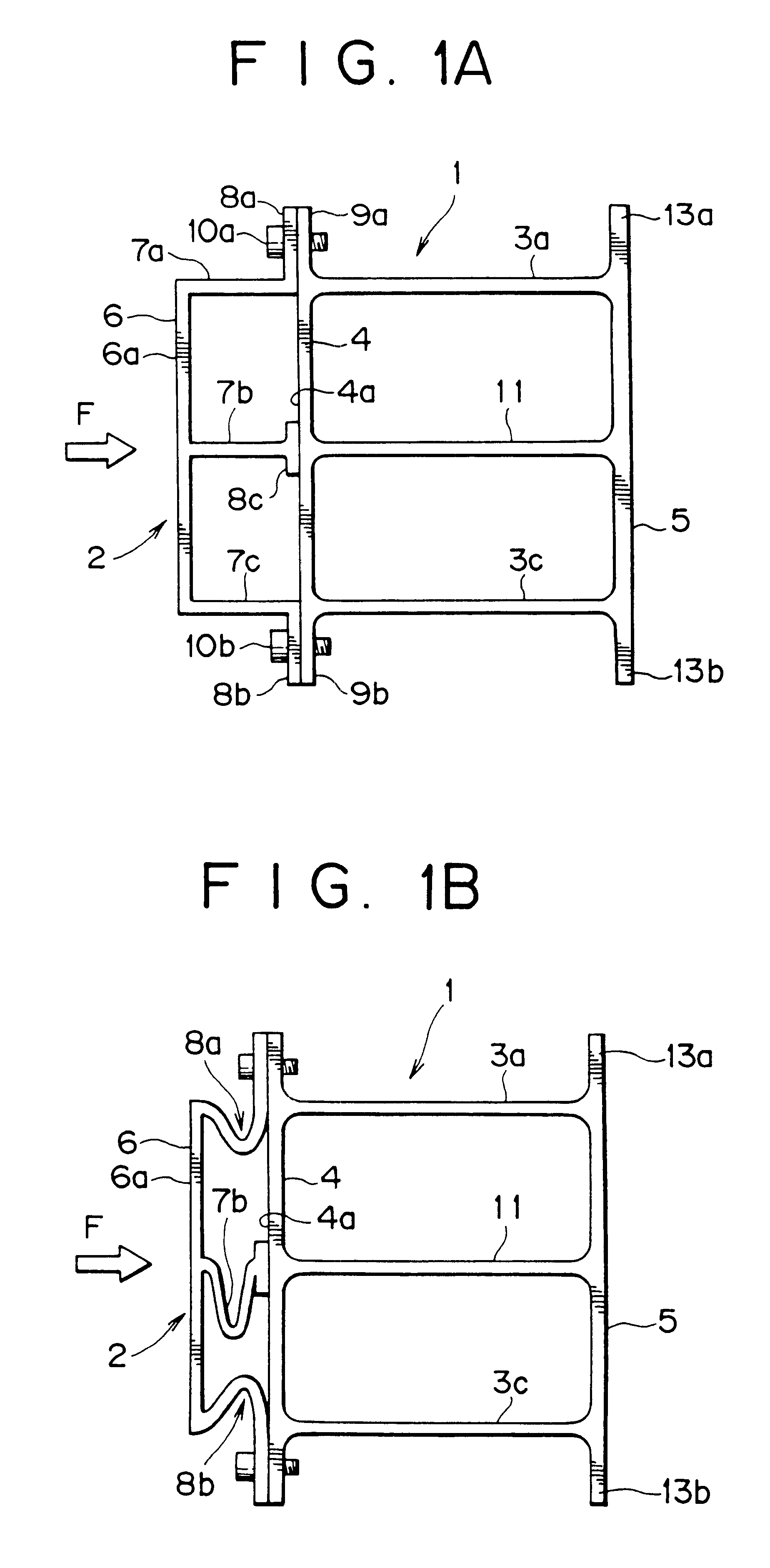

Car body energy absorber and bumper stay

InactiveUS6481690B2Reduce weightWeight increaseVehicle seatsEngine sealsHigh energyMaterials science

A lightweight car body energy absorber made of Al alloy which provides a high energy absorption performance. The car body energy absorber comprises a hollow shape with a rectangular sectional profile and a reinforcing shape attached to the front face of the collision plane of the hollow shape, where the hollow shape and the reinforcing shape are aluminum alloy extruded shapes. The reinforcing shape has a hat-shaped open sectional profile, which is composed of a collision wall almost parallel to the collision plane of the hollow shape, plural mutually parallel horizontal ribs which support the collision wall, and vertical flanges provided at the tips of these ribs. The reinforcing shape is joined to the collision plane of the hollow shape through the vertical flanges.

Owner:KOBE STEEL LTD

Top for a convertible vehicle

A top for a convertible vehicle, comprising a roof part, said roof part at least partially covering the vehicle in a closed state and being pivotable about a main bearing; a frame element, said frame element being arranged in a rear area of the vehicle; a rear element, said rear element at least partially covering said rear area of the vehicle in a closed state, and a loading lid; said rear element being fixed on said frame element, in such a way as to be pivotable relative to said frame element, by means of a rear bearing arranged at a distance from said main bearing; said frame element being fixed on the vehicle in such a way as to be pivotable relative to the vehicle about an axis arranged in the region of said main bearing; said roof part being pivotable relative to the vehicle about said axis together with the frame element in an open, deposited position of said roof part; said main bearing being firmly connected to said frame element, and said loading lid being fixed on the rear element in such a way as to be pivotable relative to the rear element.

Owner:WEBASTO EDSCHA CABRIO

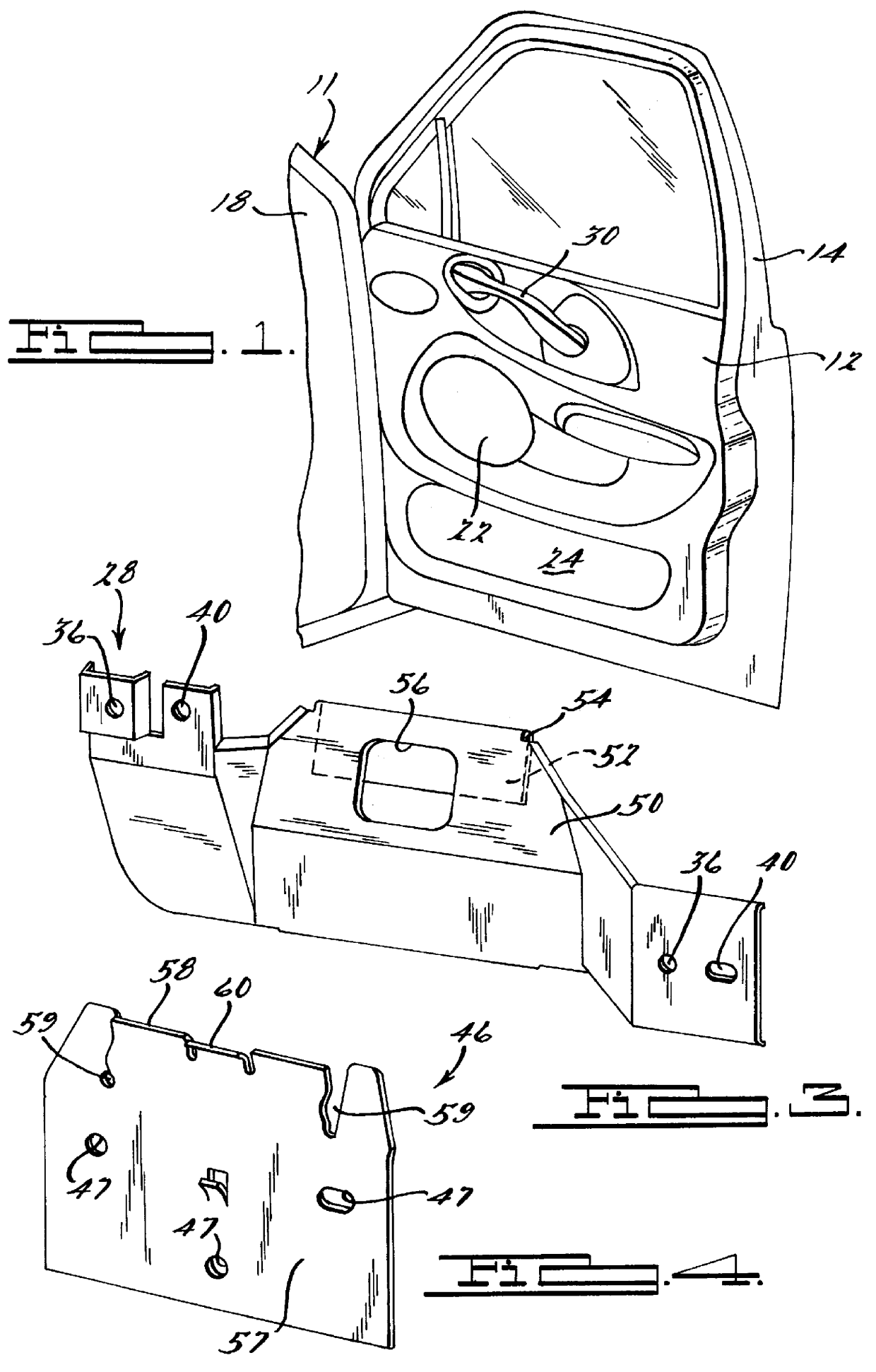

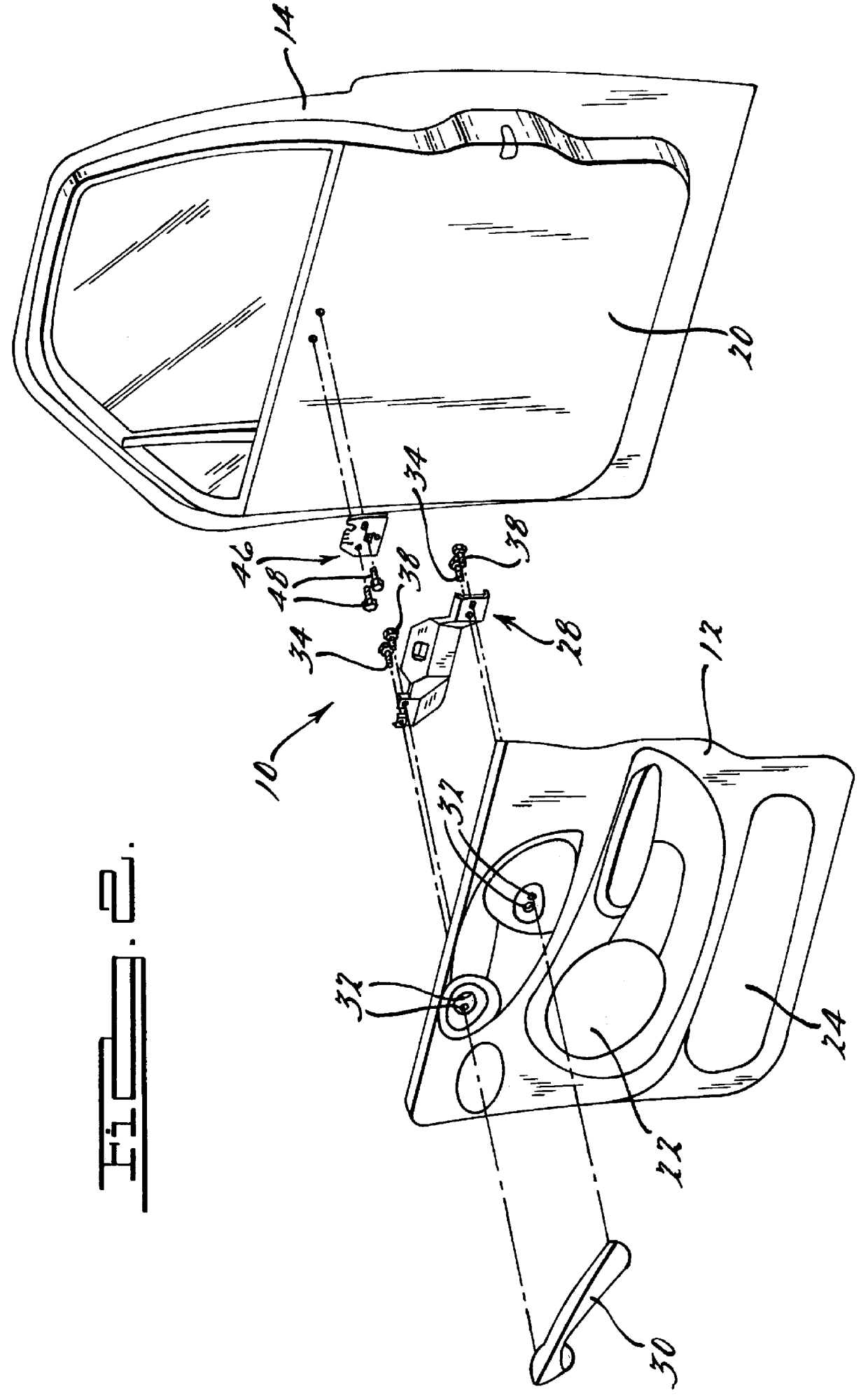

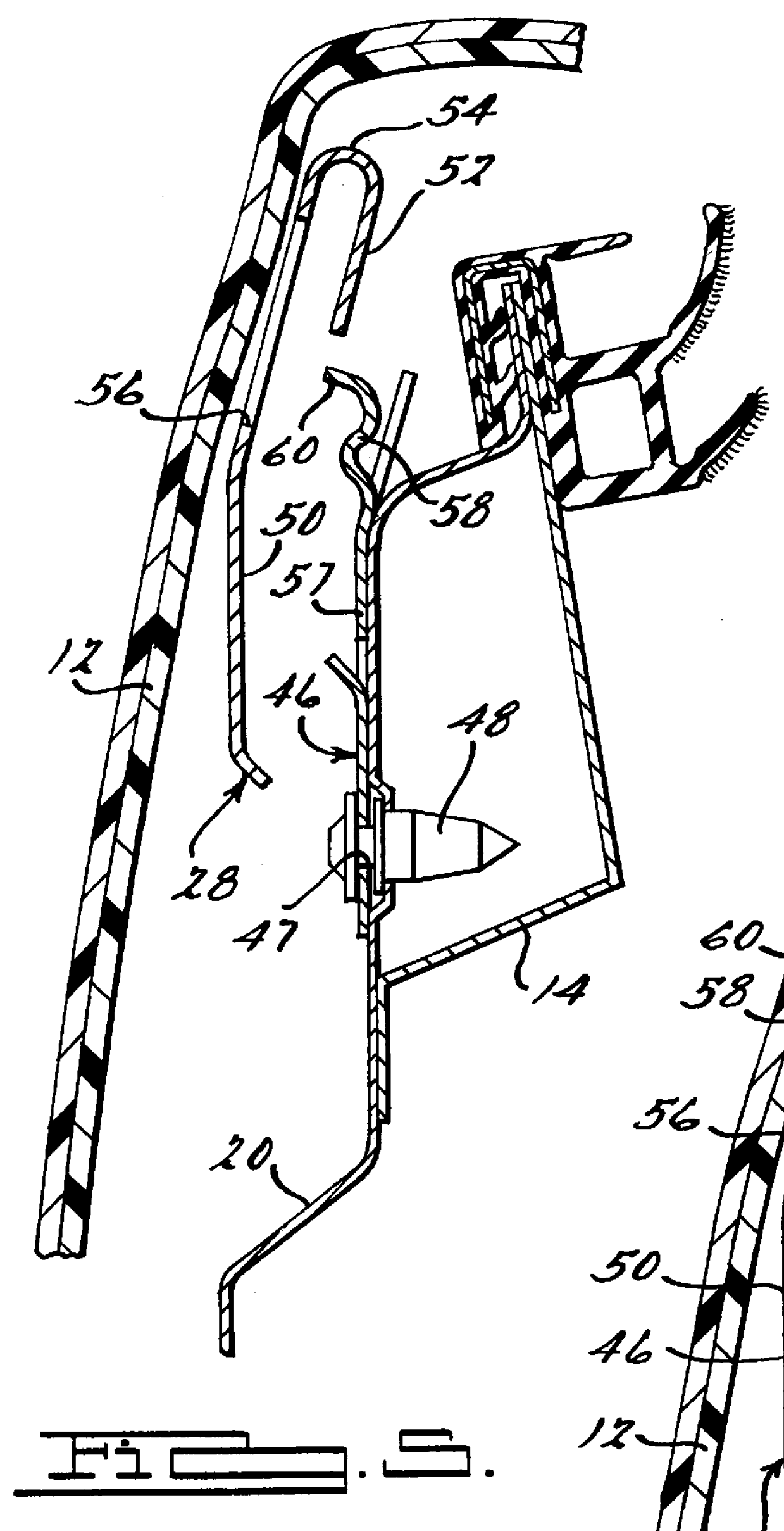

Trim panel mounting assembly

A trim panel mounting assembly for a motor vehicle includes a trim panel bracket mounted to one side of a trim panel opposite an interior of the motor vehicle and a support bracket mounted to an inner door panel opposite the trim panel bracket. The trim panel mounting assembly also includes a structure for allowing the trim panel bracket and the support bracket to self-align when the trim panel bracket and the support bracket are brought into proximate position for installation.

Owner:VISTEON GLOBAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com