Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

407results about How to "Avoid seal failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

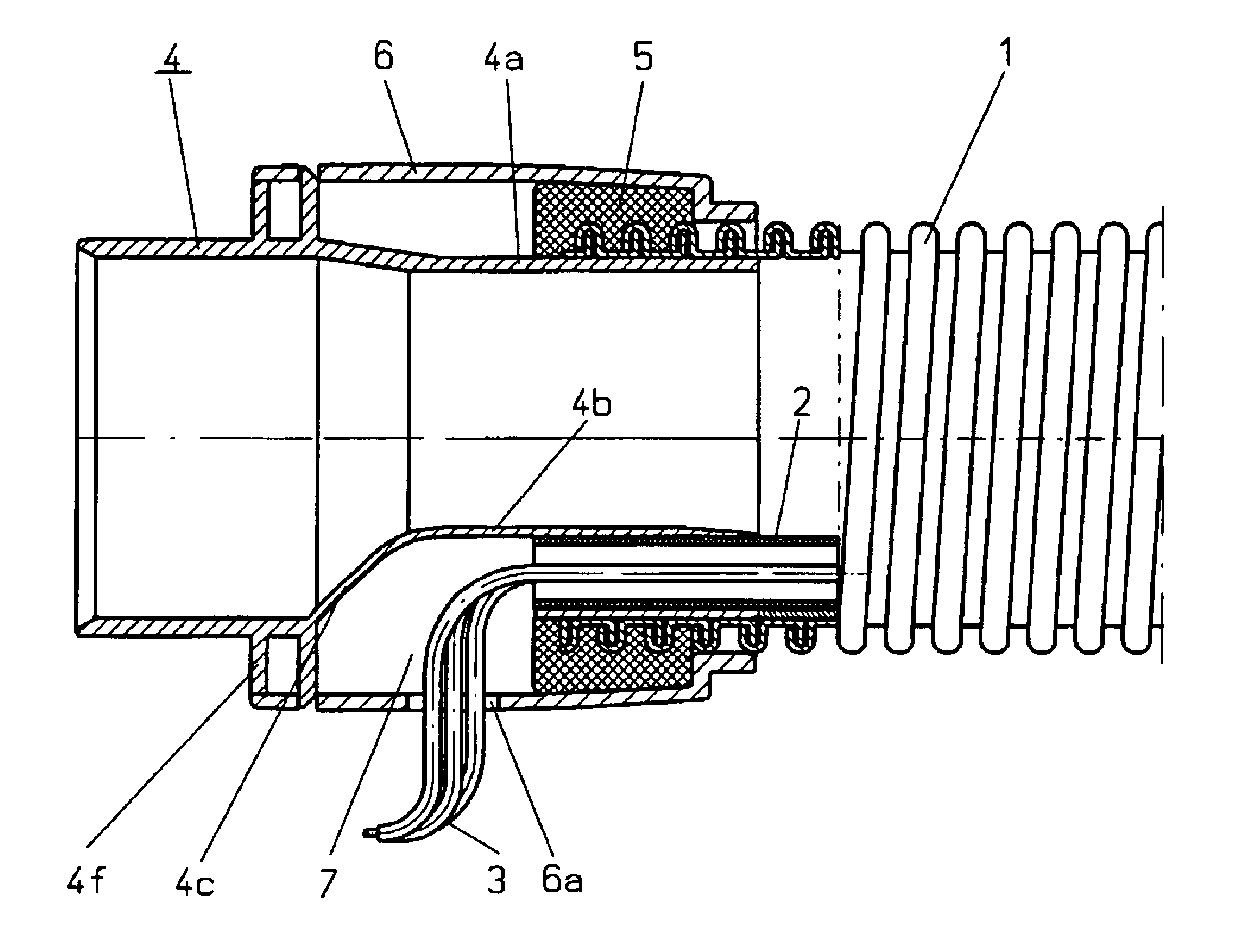

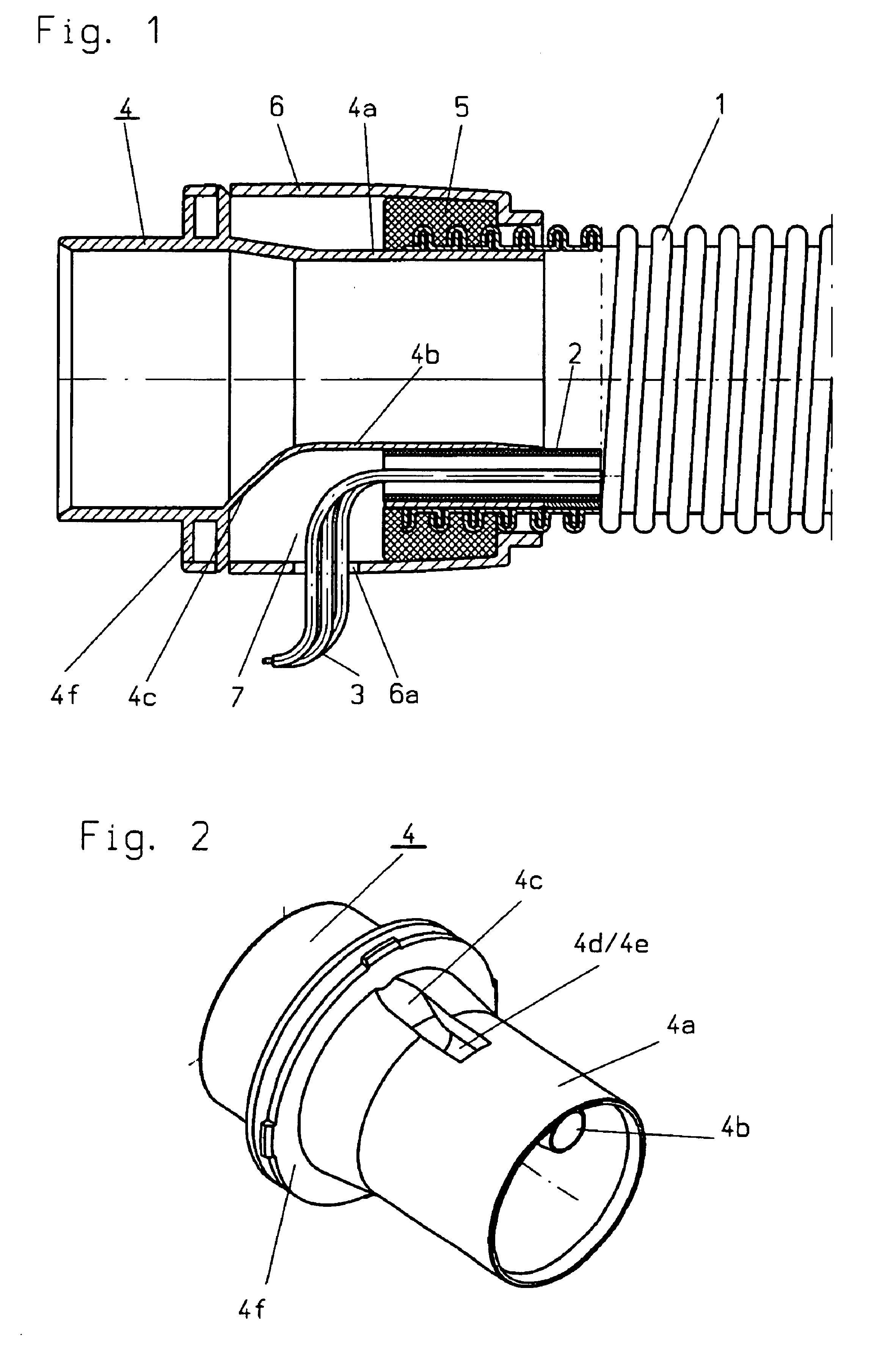

Vacuum cleaner hose with a connection sleeve

InactiveUS6722904B2Avoid seal failureSuction hosesInsulated cablesElectrical conductorVacuum cleaner

A vacuum cleaner hose with a connection sleeve includes a hose (1) having an inner wall, a protective envelope (2) for electrical conductors (3) attached at an inner wall of the hose (1), a rear connection part (4a) formed at a connection sleeve (4) and engaging partially into the hose (1), a receiver (4b) extending from the rearward end of the connection sleeve (4) and formed for an insertion of a coordinated end of the protective envelope (2), wherein an end of the receiver (4b) is disposed opposite to an end for insertion and is closed. The receiver (4b) is formed as a tube molded to the inner jacket face of the rear connection part (4). The tube exhibits a first recess (4d) directed rearwardly from the closed end of the tube.

Owner:TRUPLAST KUNST STOFFTECHNIK GMBH

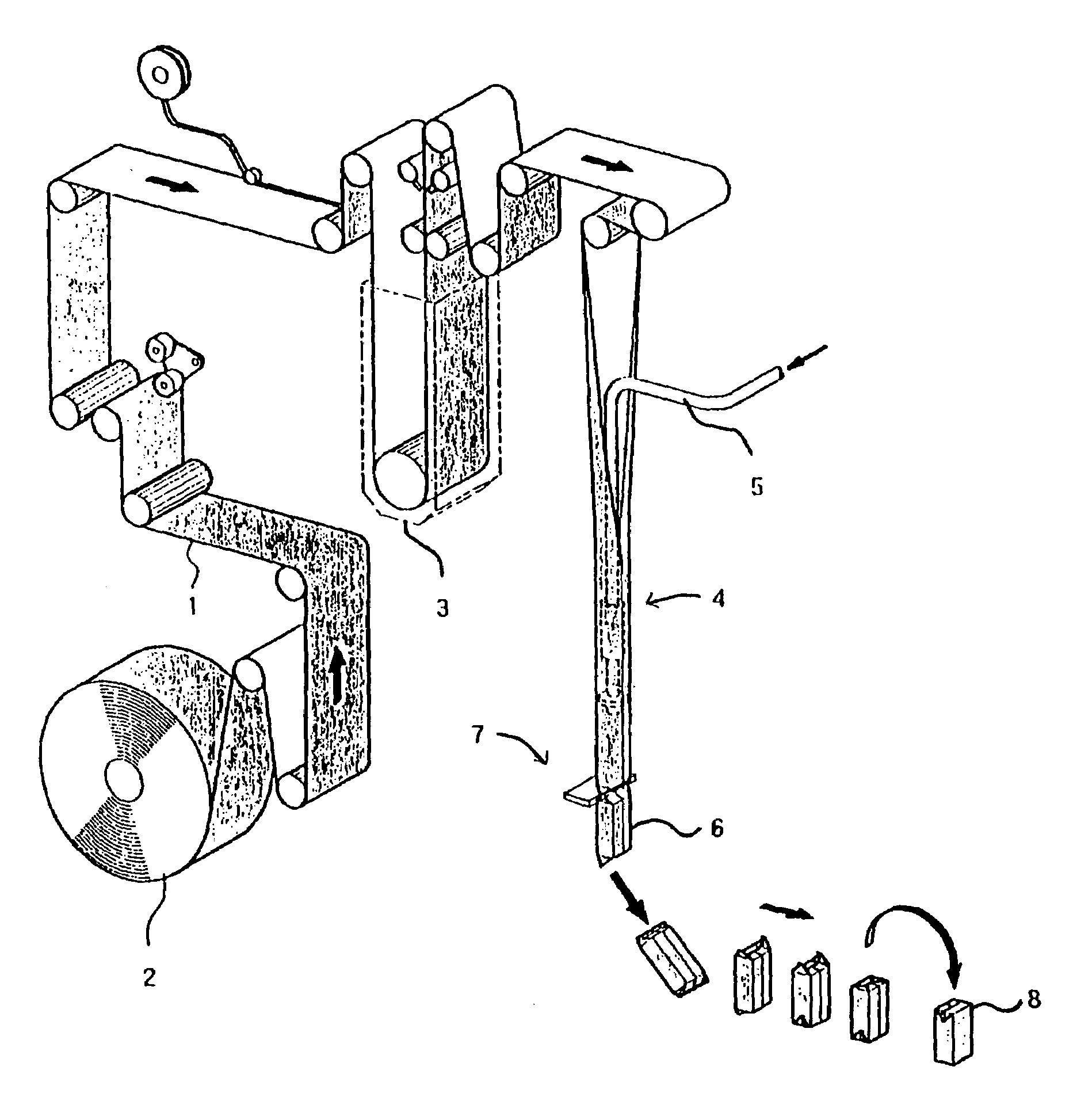

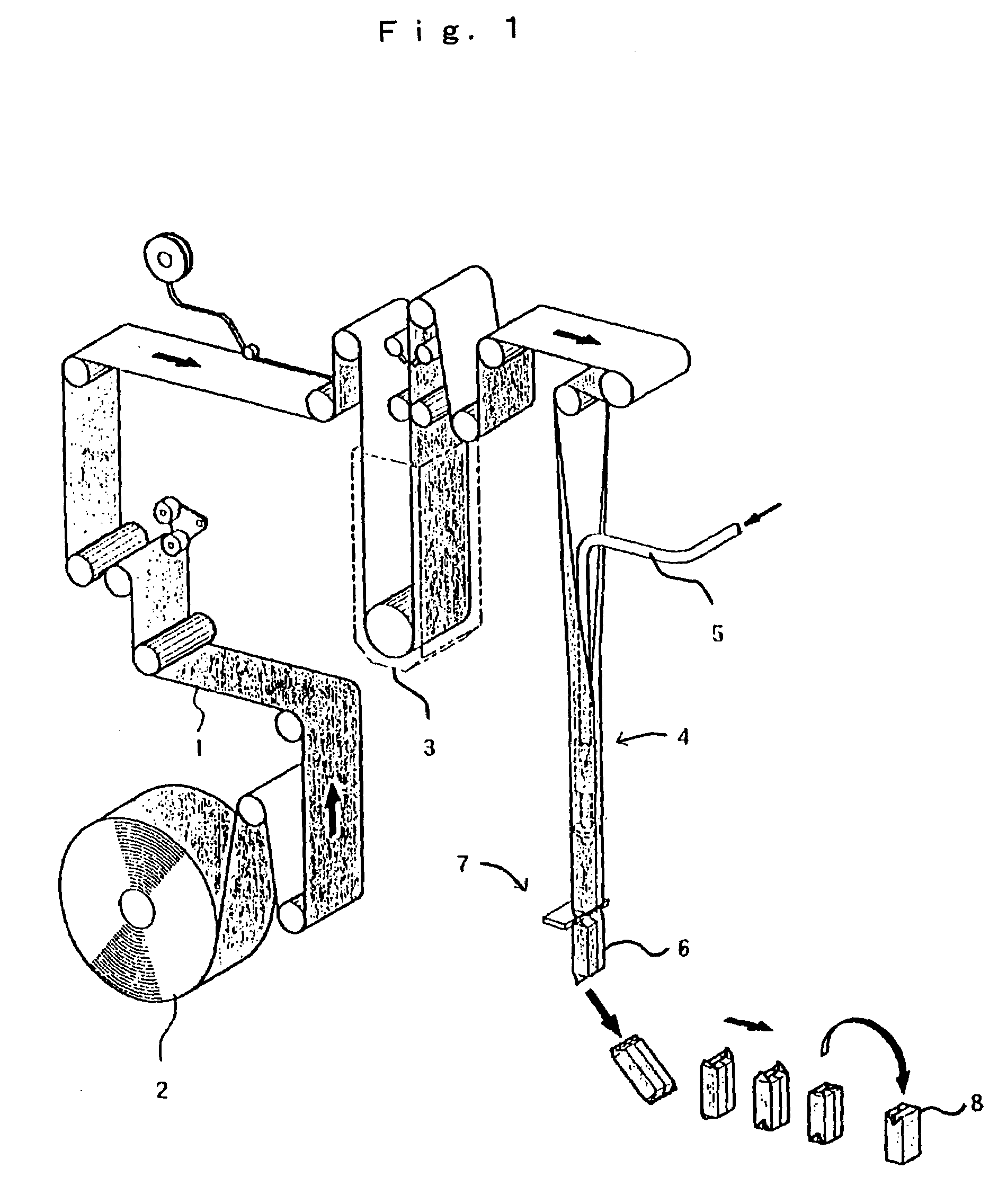

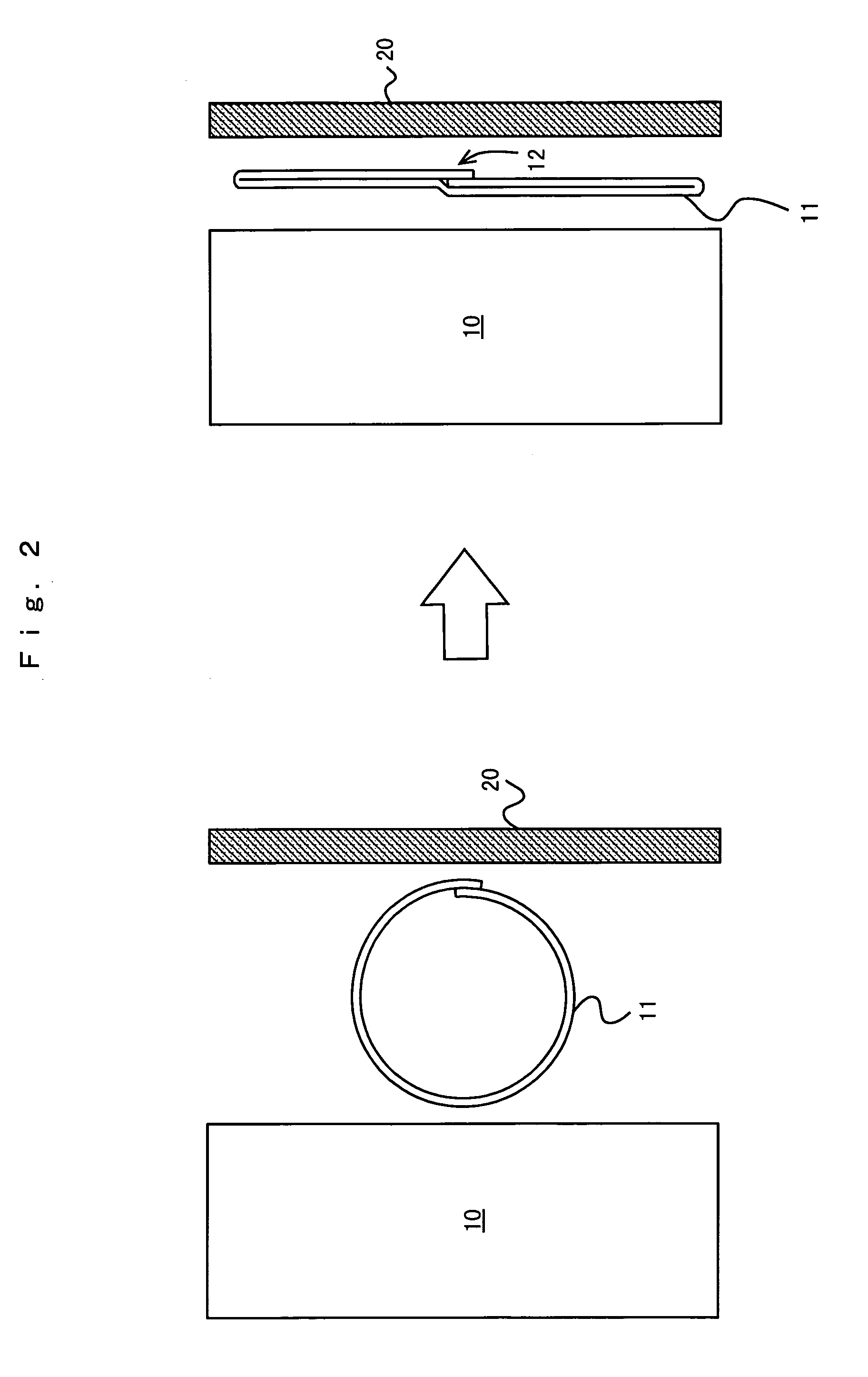

Ultrasonic sealing apparatus

InactiveUS6986232B1Sufficient pressing forceImprove sealingWrapper twisting/gatheringDomestic articlesMechanical engineeringUltrasound

An ultrasonic sealing apparatus prevents a sealing failure by preventing a tunnel (through passage) to form in the step portions in the vicinity of both end portions of longitudinally sealed portions, when the tubular laminated packaging material is transversely ultrasonically sealed. An ultrasonic sealing apparatus, in which a laminated packaging material containing a thermoplastic resin layer and a paper layer is formed into a tubular form and the tubular laminated packaging material is transversely ultrasonic sealed, includes a horn having an elongated and flat sealing face and an opposing jaw having an elongated pressing face which presses the laminated packaging material in cooperation with the sealing face of the horn, wherein the center portion in longitudinal direction of the pressing face of the opposing jaw is narrower than both end portions of the pressing face. Further, at a center portion in longitudinal direction of a pressing face of the opposing jaw, a recess having an arc shape, etc. in section is formed along a direction perpendicular to the longitudinal direction of the pressing face.

Owner:SHIKOKU KAKOOKI CO LTD

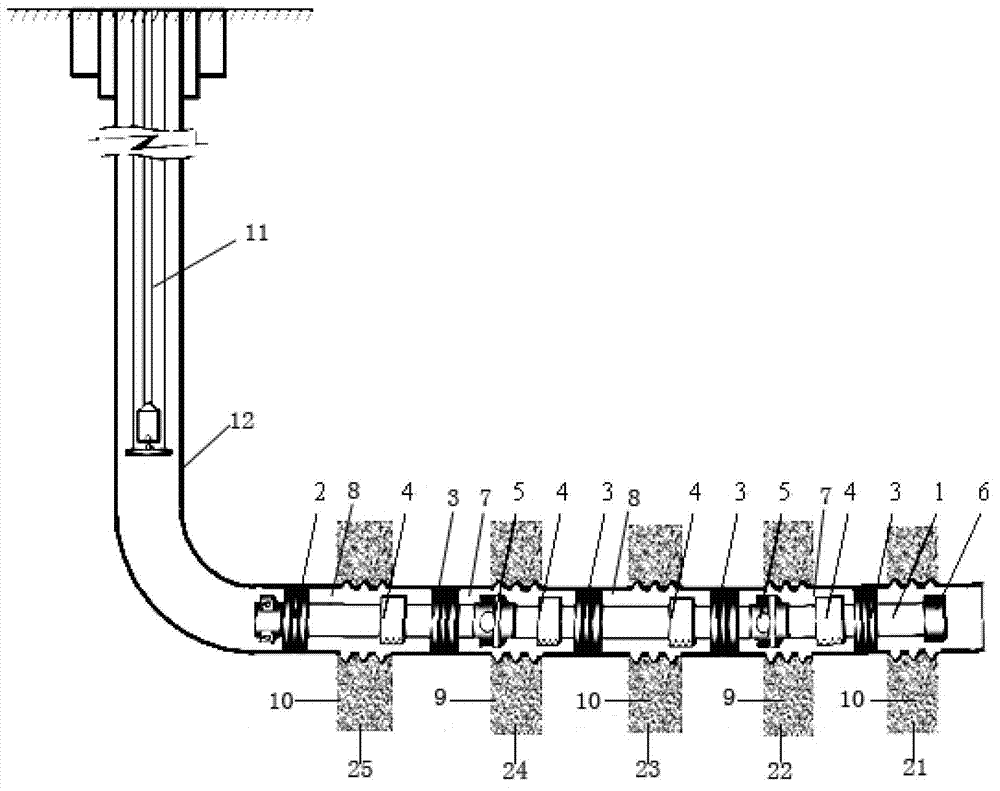

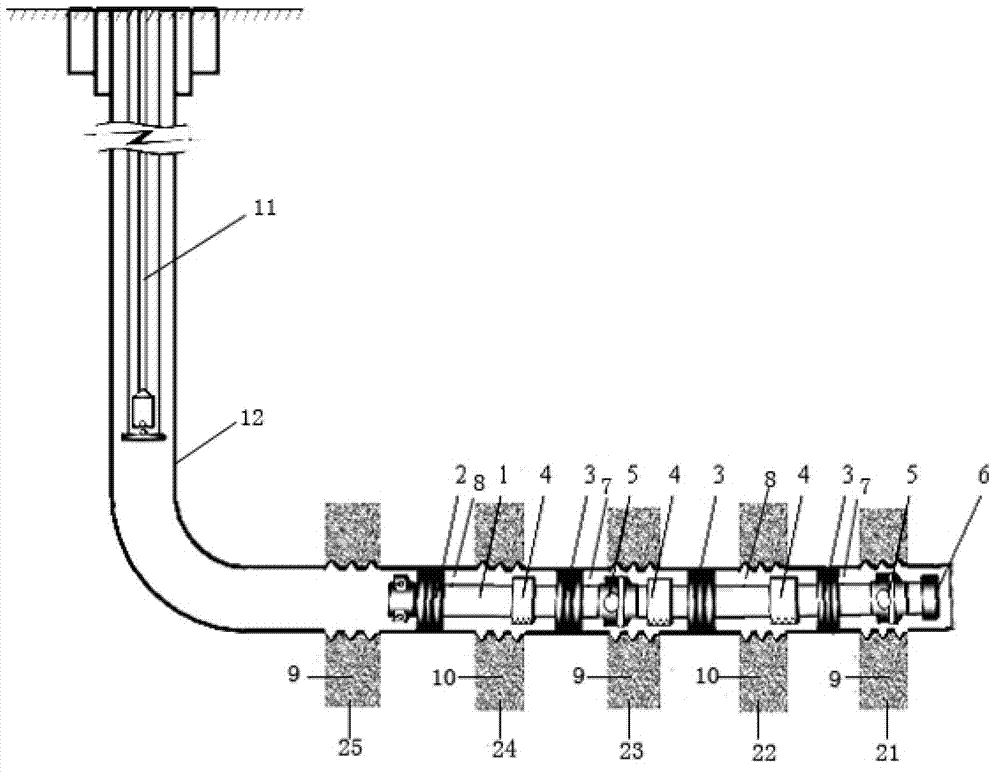

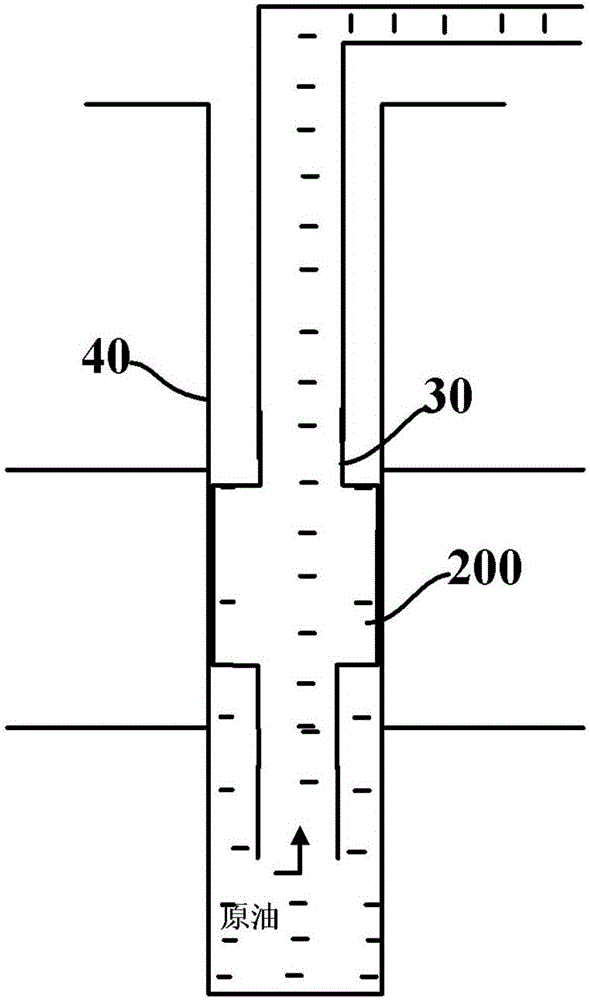

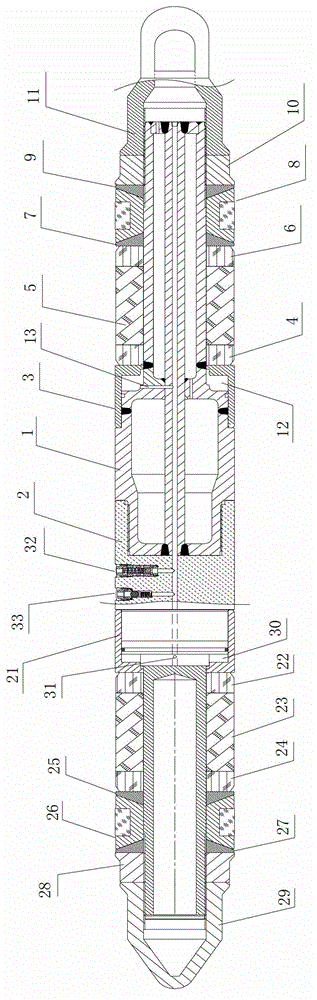

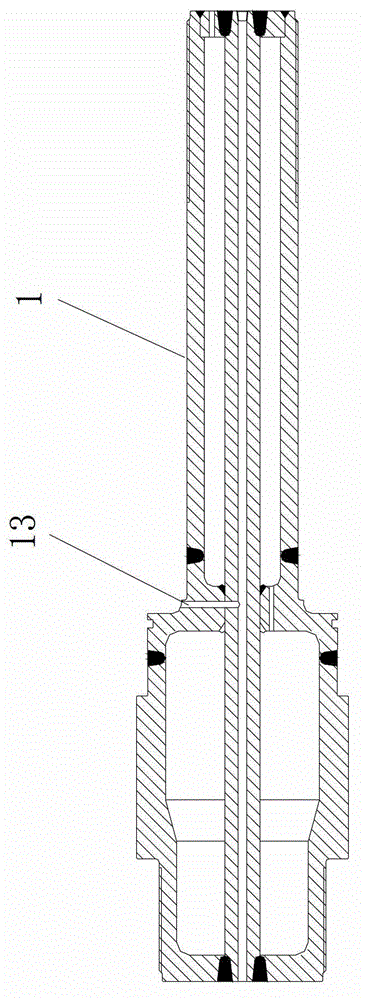

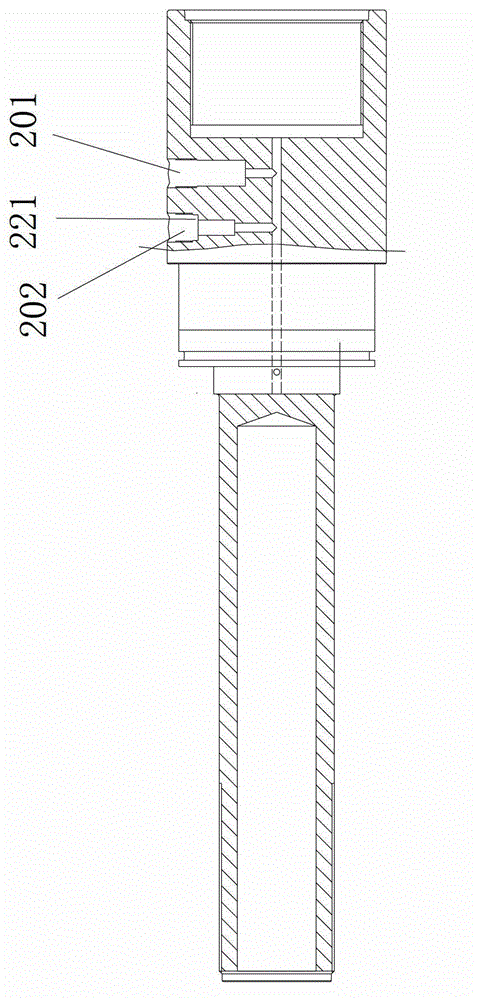

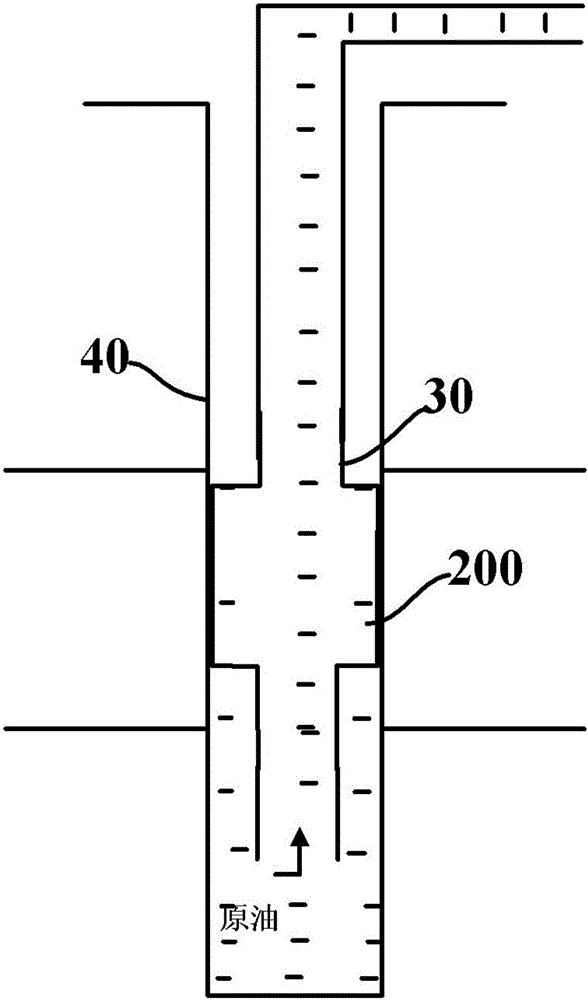

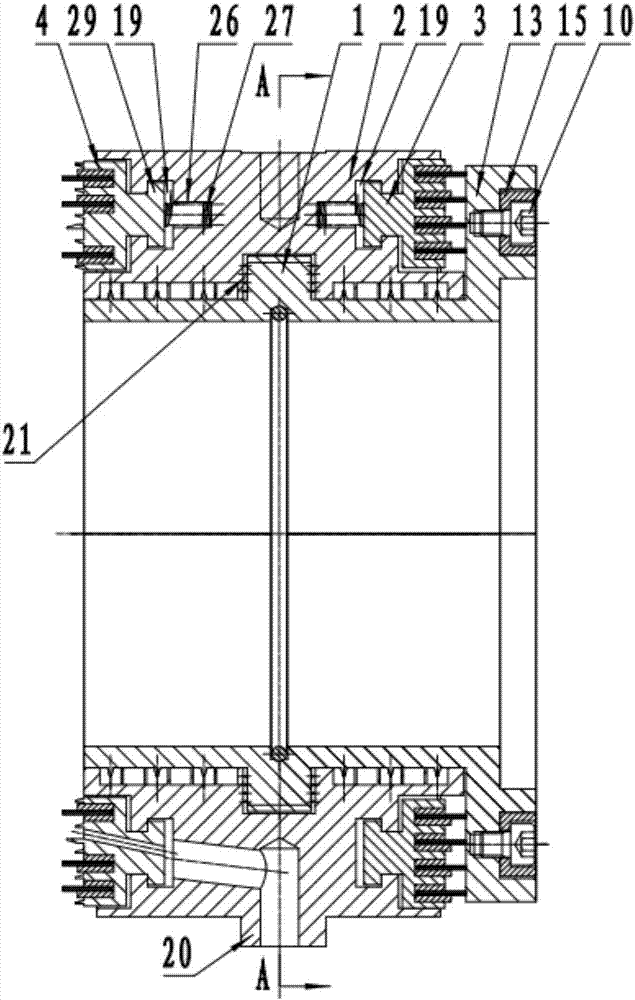

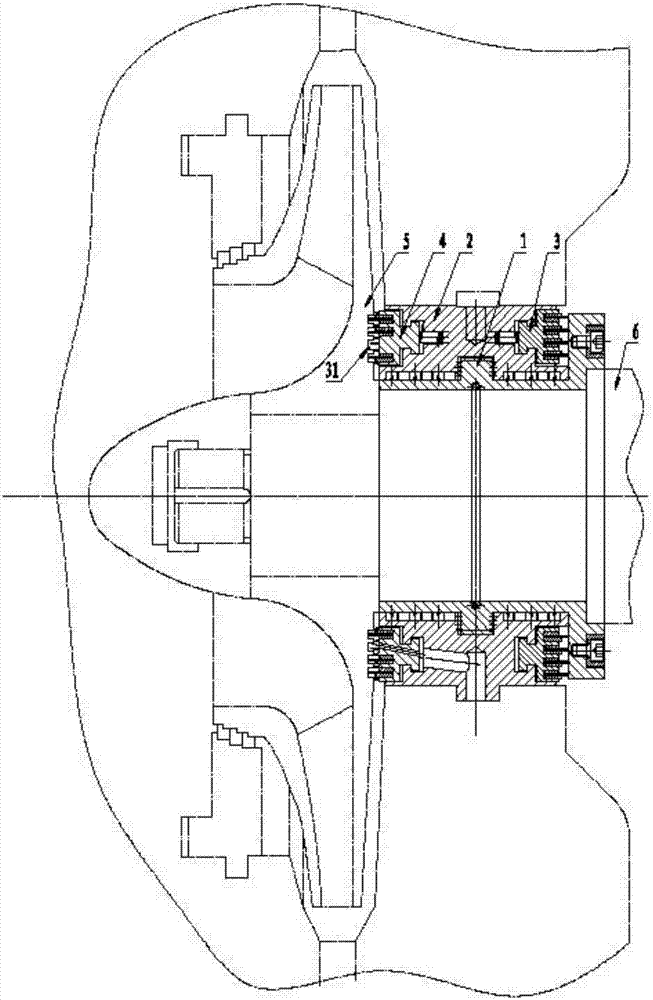

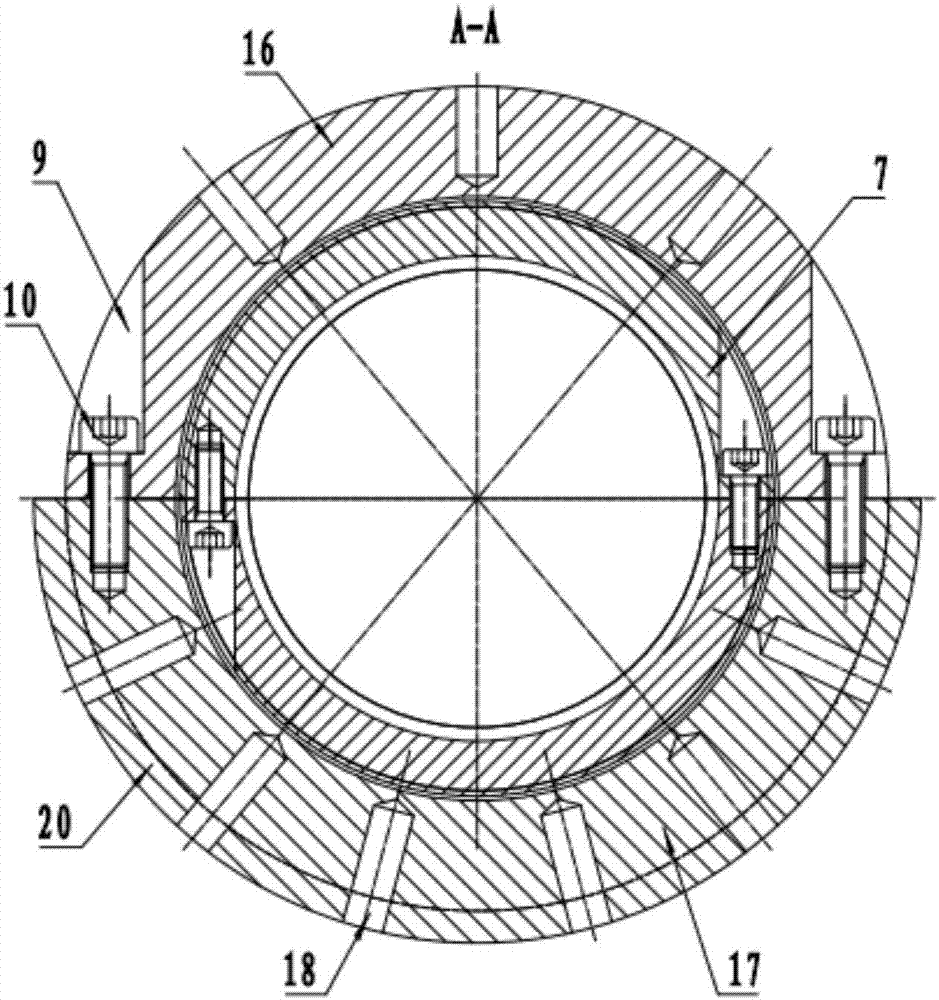

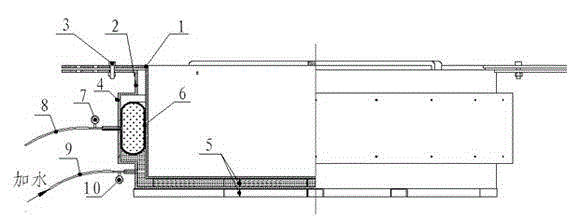

Mechanical water plugging pipe column for multi-point discharge of cased hole completion multi-section fractured horizontal well and method

ActiveCN102808584AEfficient productionAchieve the effect of water control and oil increaseDrilling rodsSealing/packingControl switchWater pipe

The invention discloses a mechanical plug pipe column for multi-point discharge of a cased hole completion multi-section fractured horizontal well and a water plugging method. The water plugging pipe column comprises a pipe plug and a Y445-type releasing packer, wherein at least three Y441-type packers are arranged between the pipe plug and the Y445-type releasing packer at intervals; sealed oil layer packing sections and water outlet layer packing sections are formed between two adjacent Y441-type packers and the inner wall of a horizontal well sleeve; a security joint and a control switch are orderly connected between the two Y441-type packers on each oil layer packing section through oil pipes in series; the security joint is serially connected between the two Y441-type packers on each water outlet layer packing section through the oil pipe; and the oil layer packing sections and the water outlet layer packing sections are connected in series through the oil pipes. According to the mechanical plug pipe column for multi-point discharge of the cased hole completion multi-section fractured horizontal well and the water plugging method, a plurality of Y441-type packers are adopted to be in multi-stage combination with the control switch, so that effective plugging of multi-point discharge of the multi-section fractured horizontal well or any point discharge is achieved; effective production of a major reservoir section is achieved, and the effects of controlling water and increasing oil are achieved.

Owner:PETROCHINA CO LTD

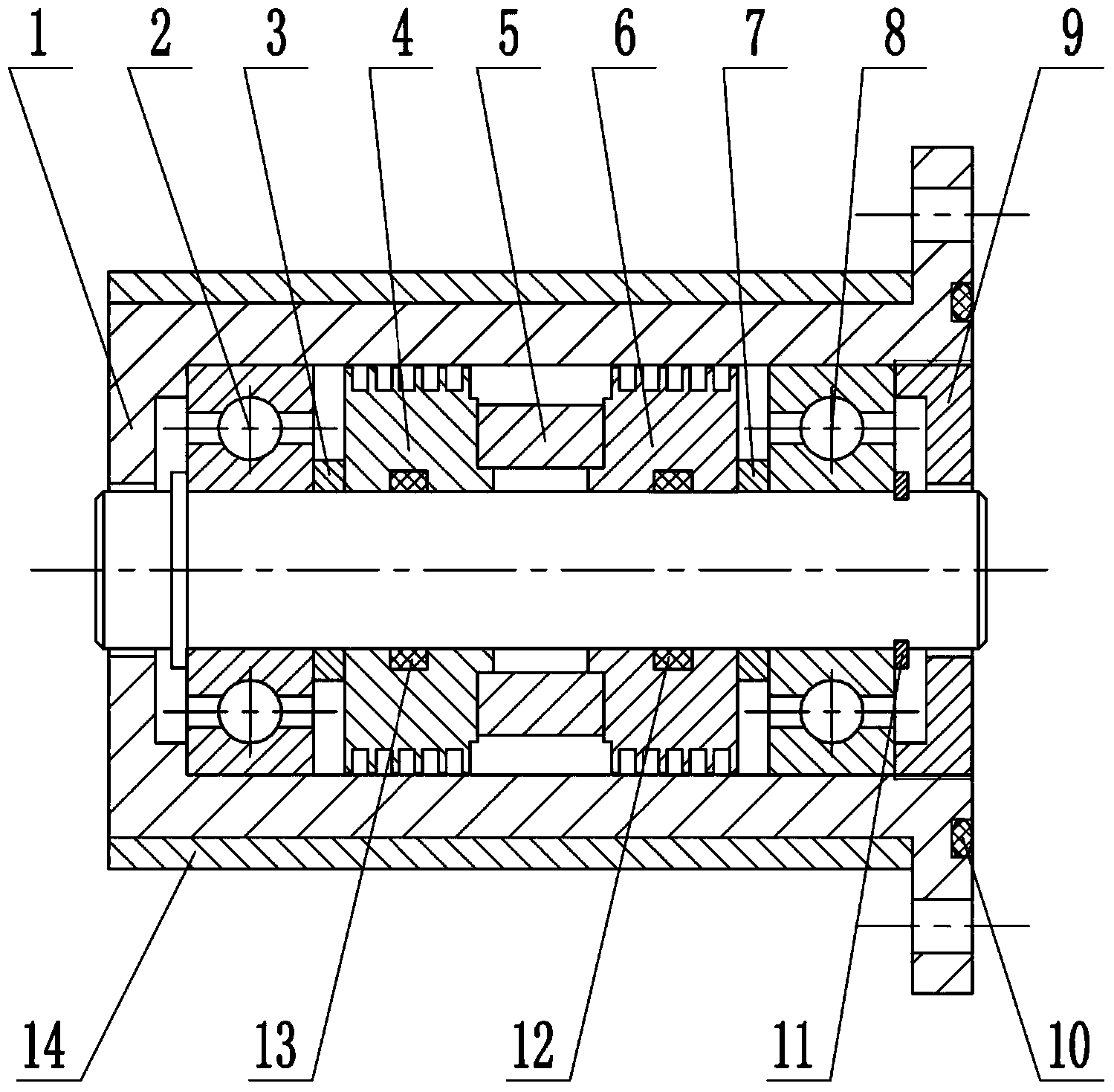

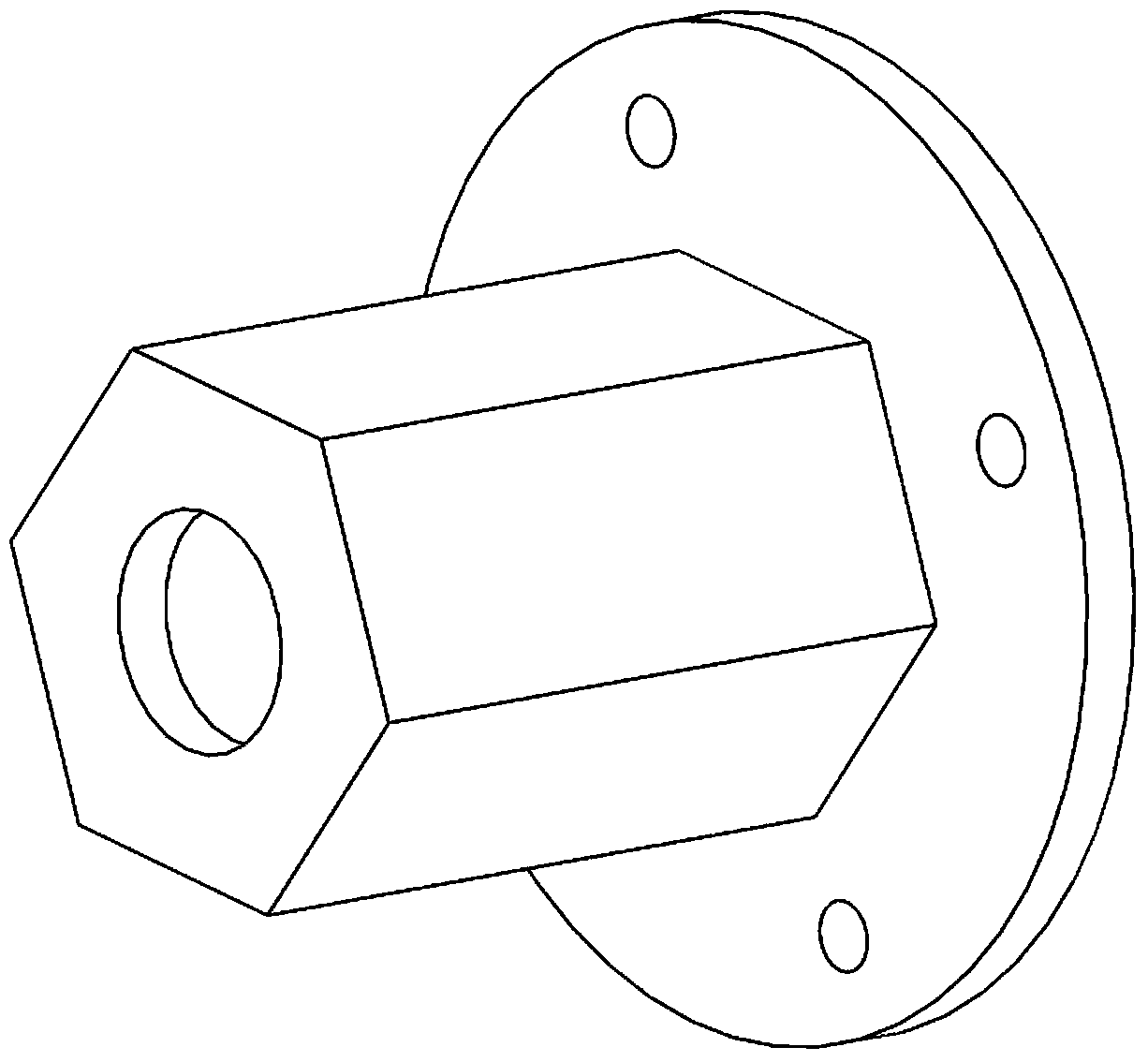

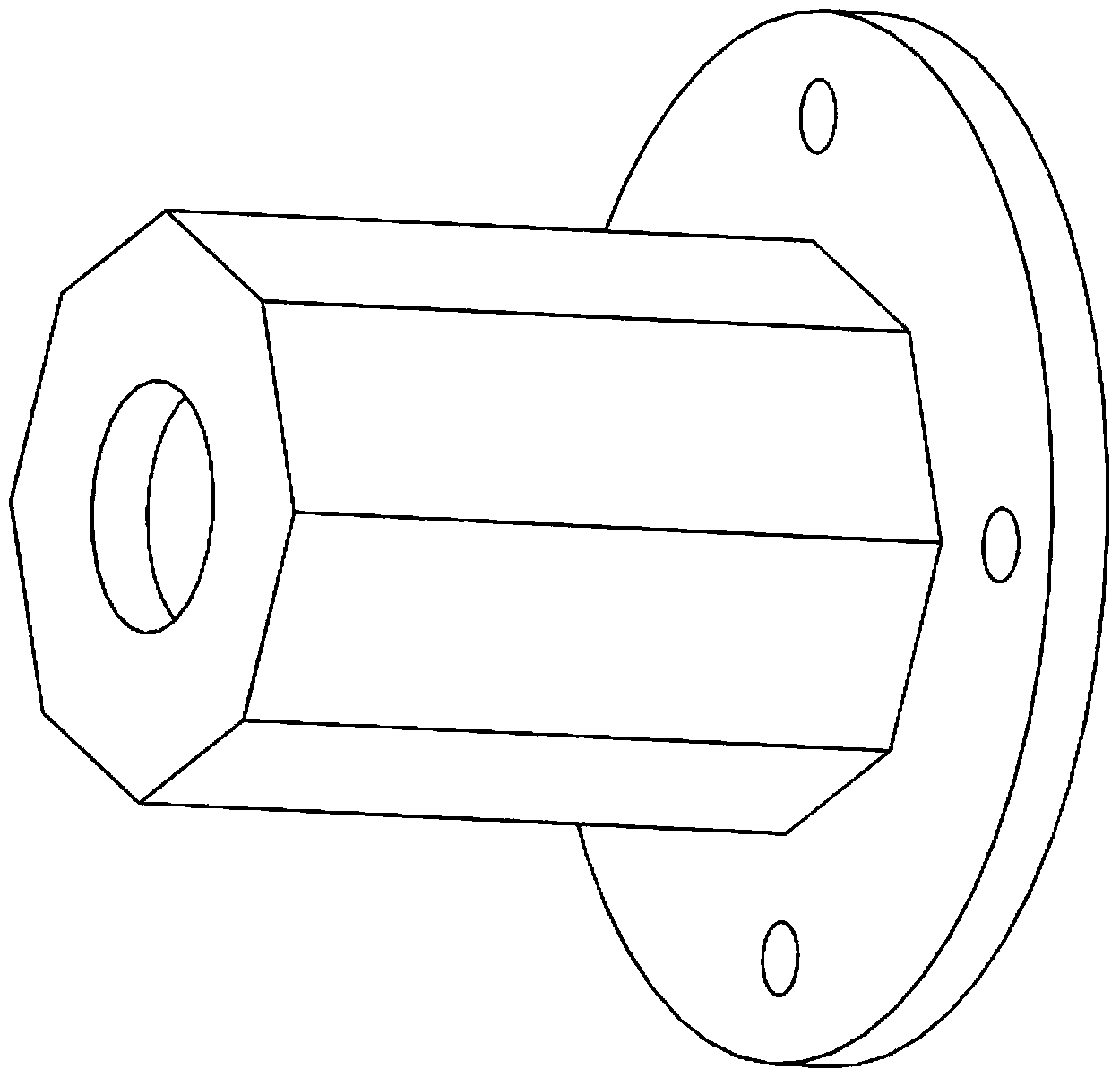

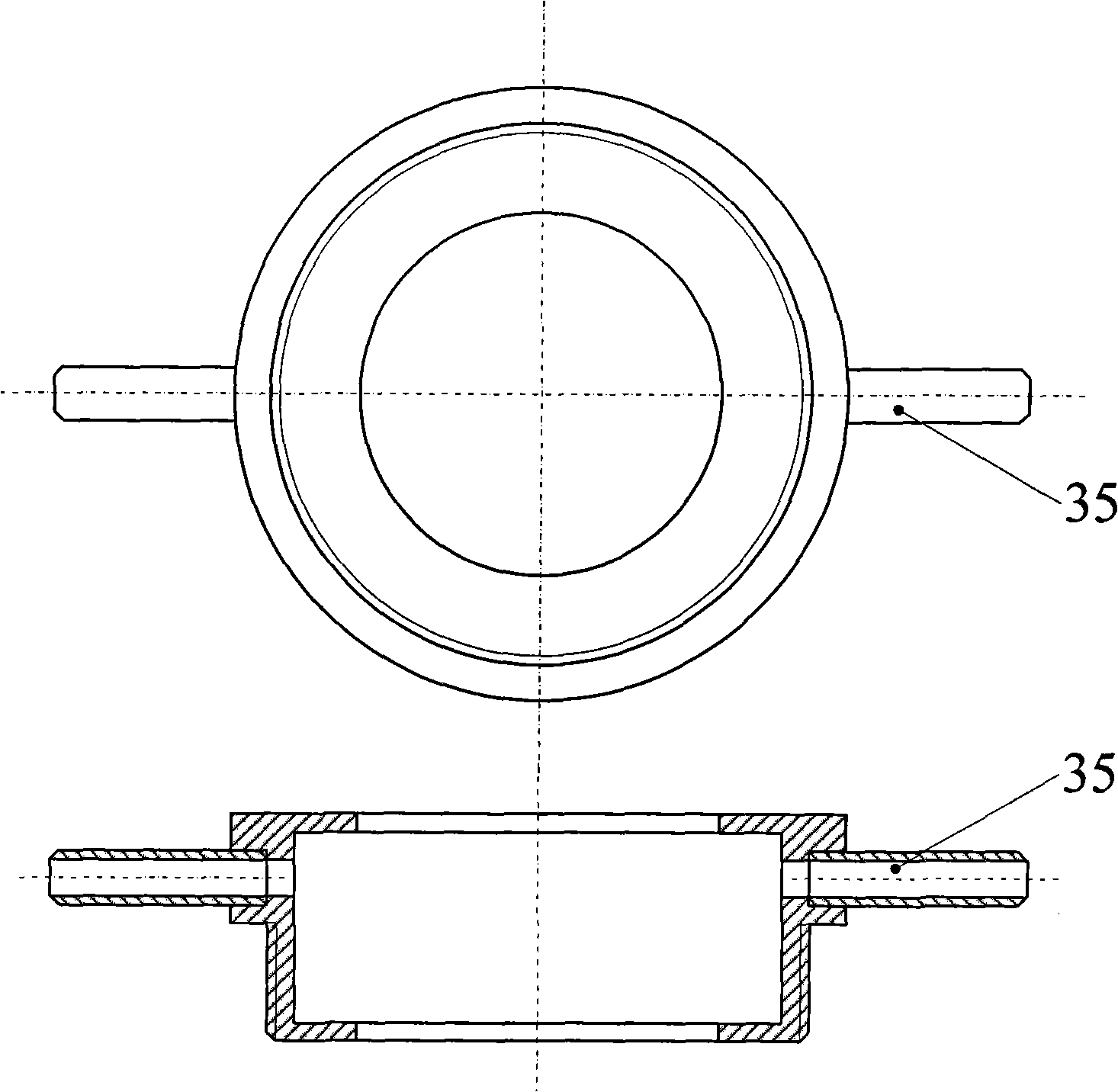

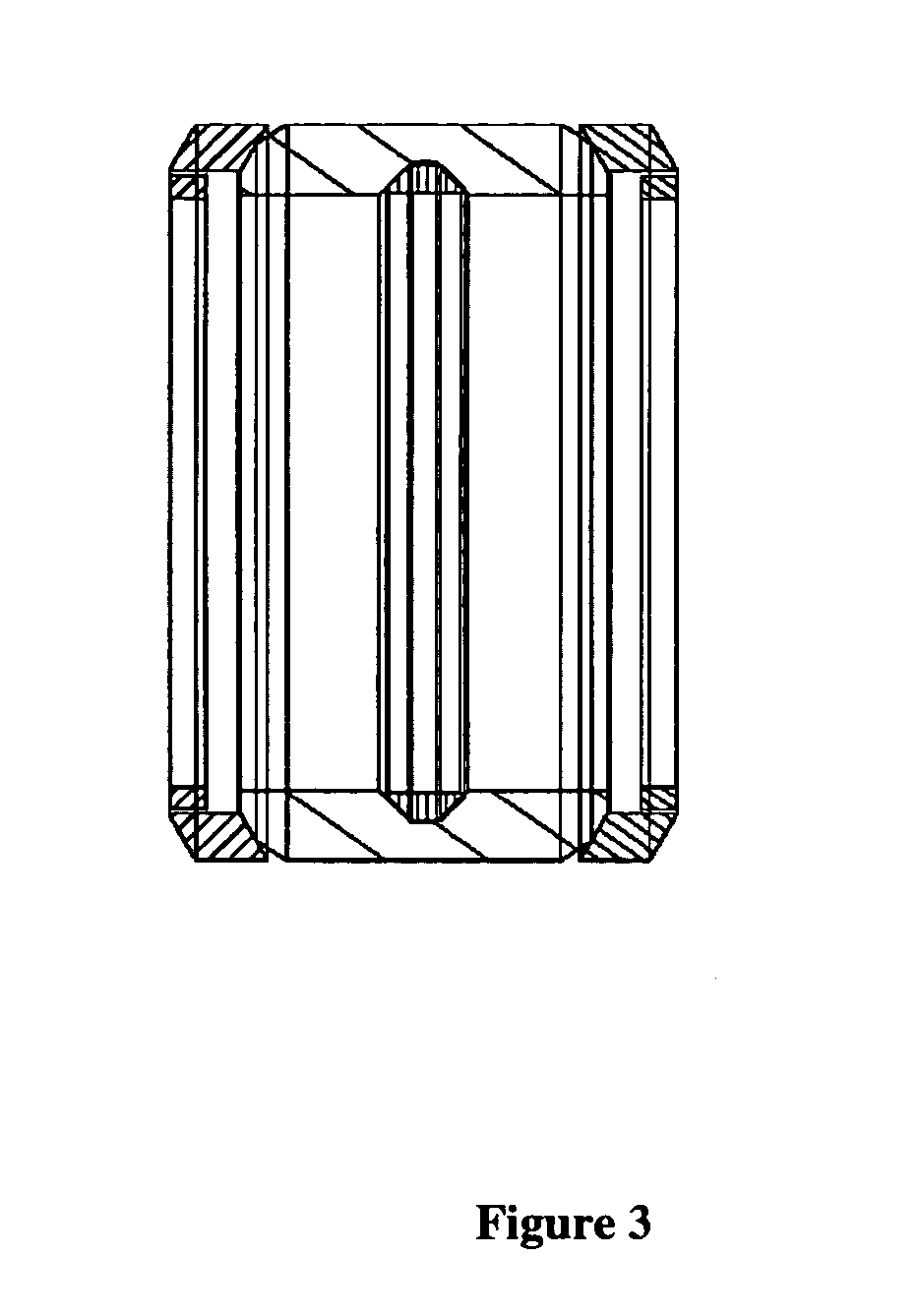

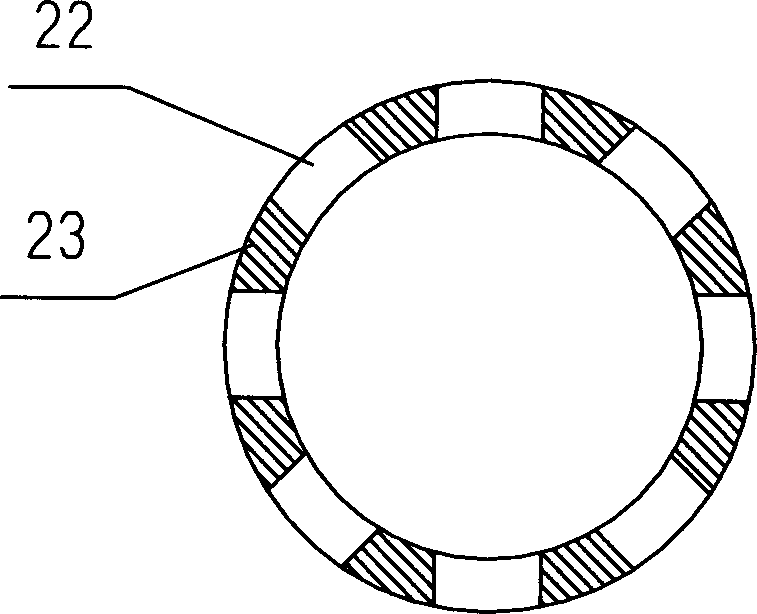

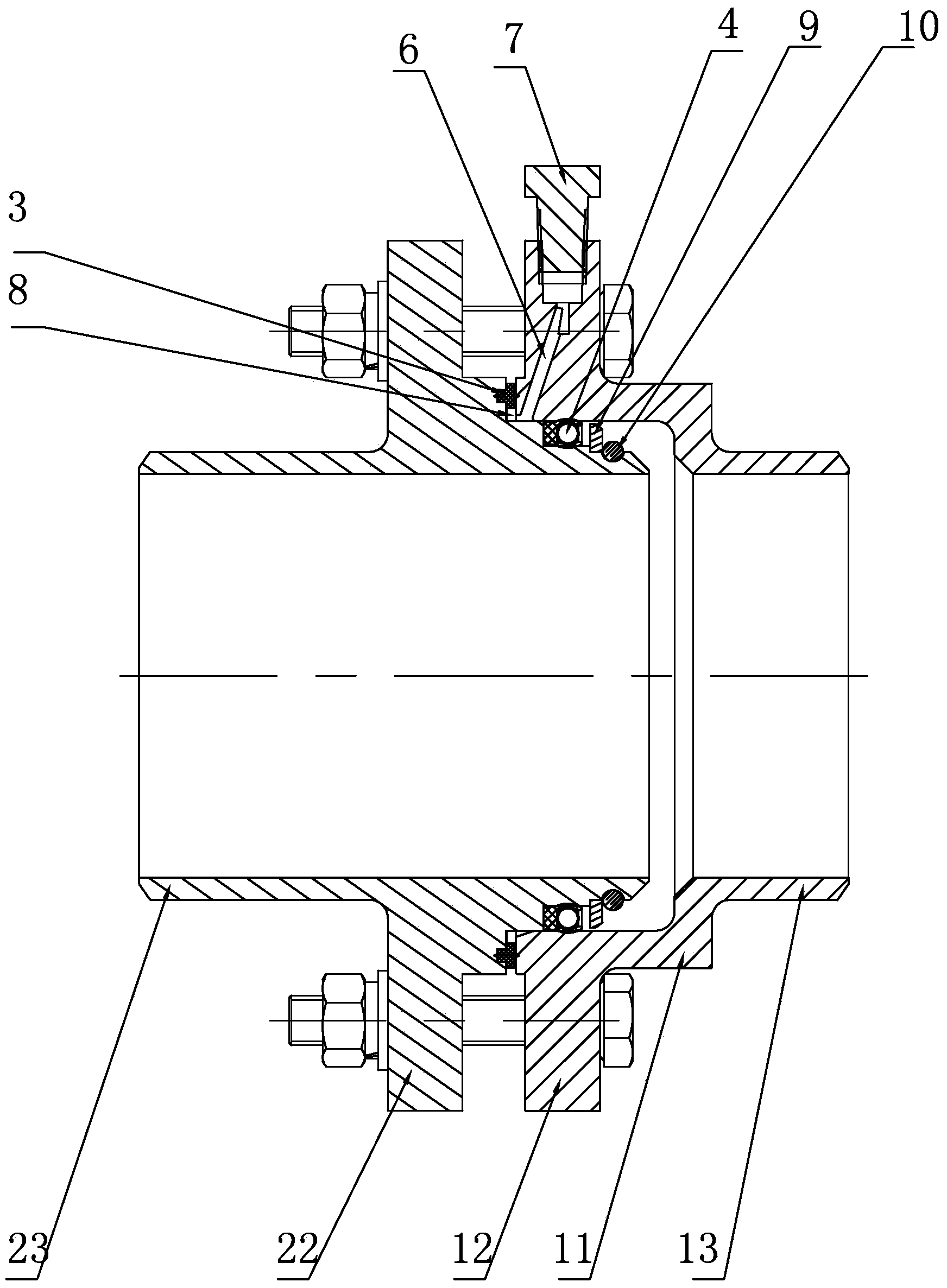

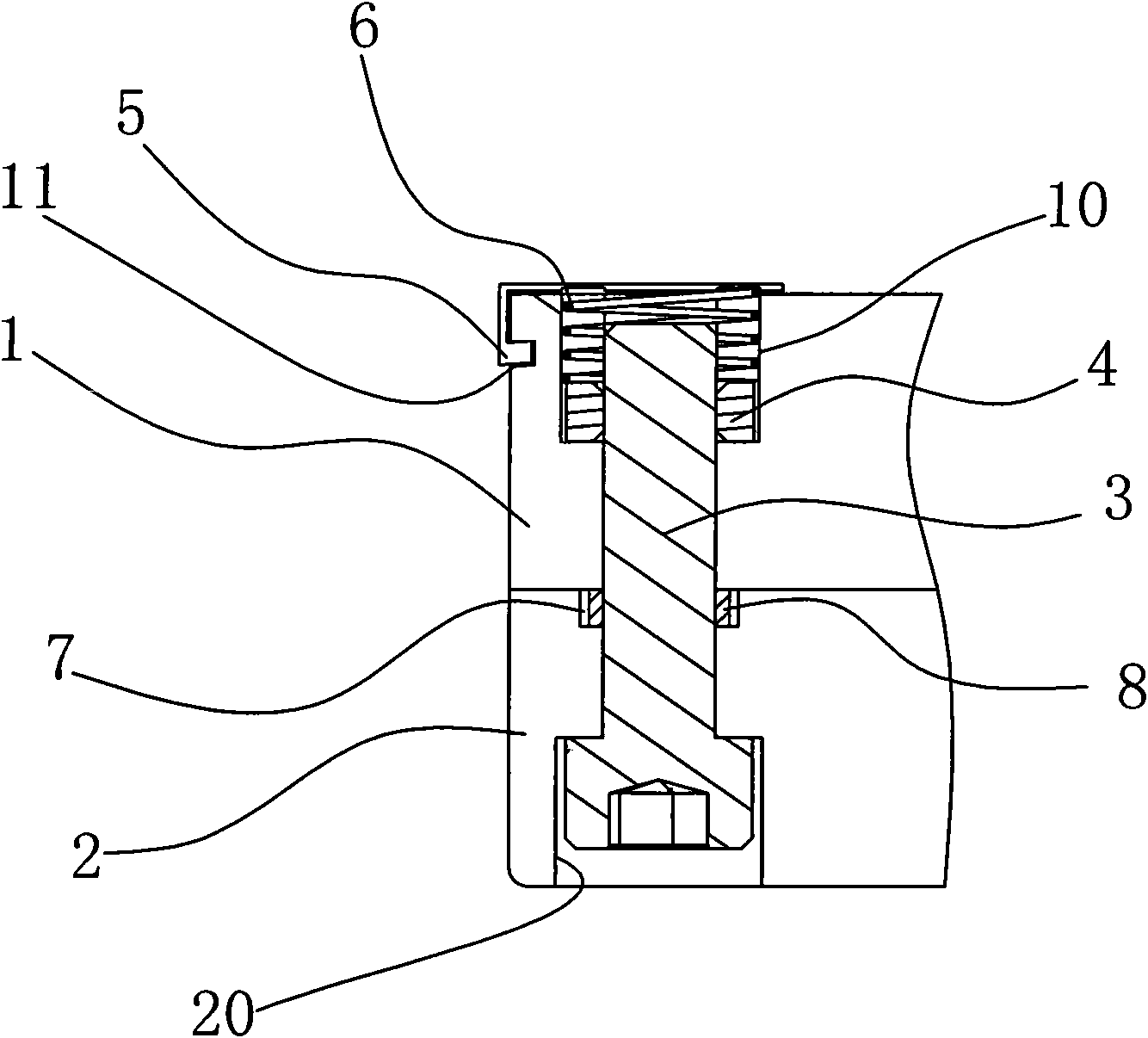

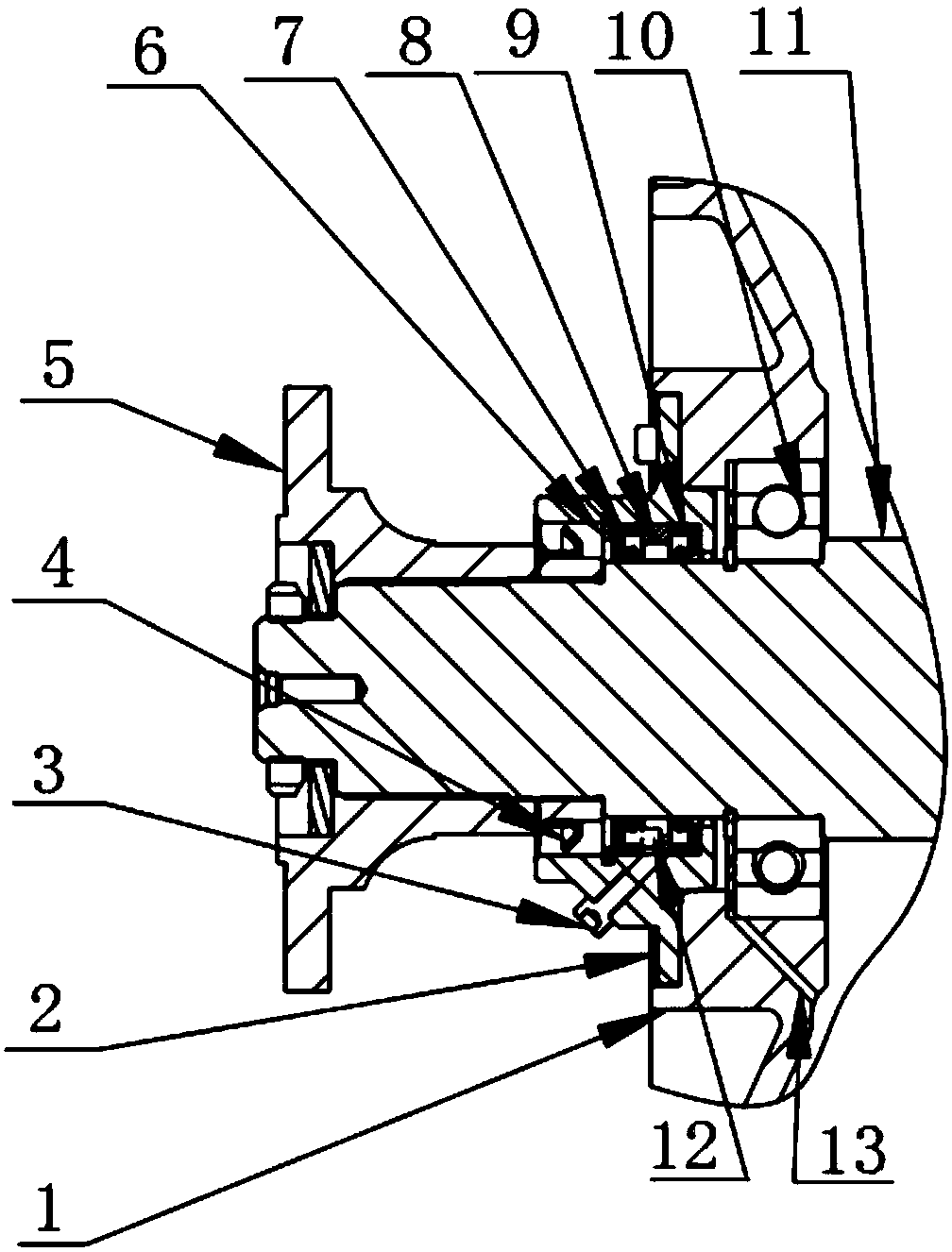

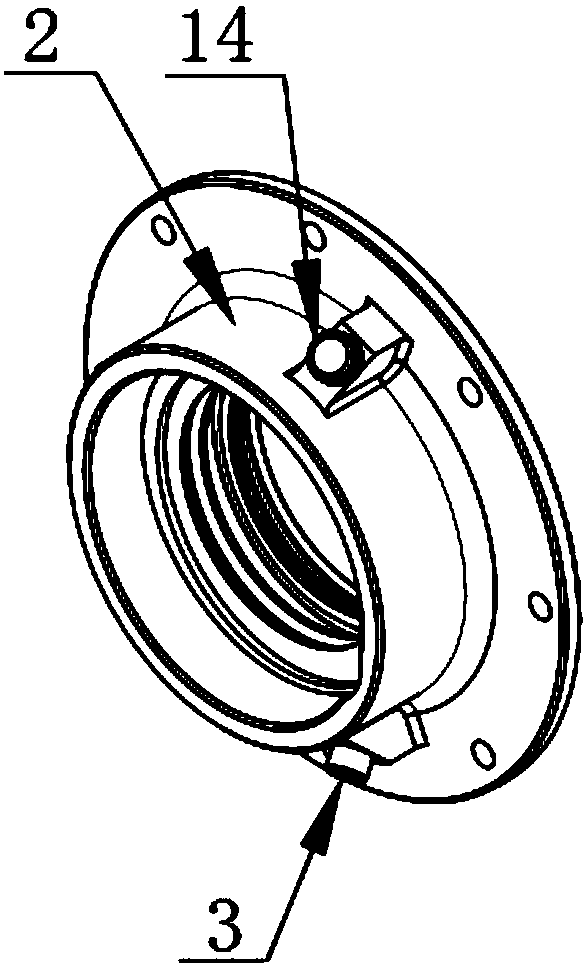

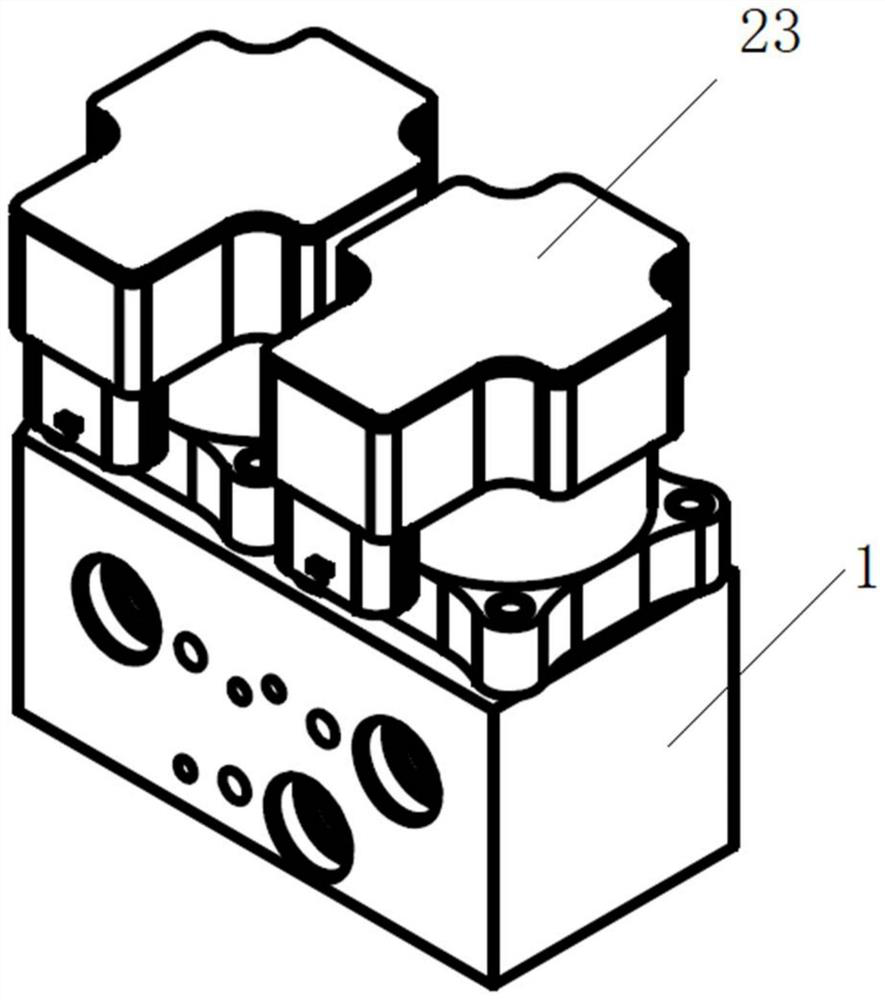

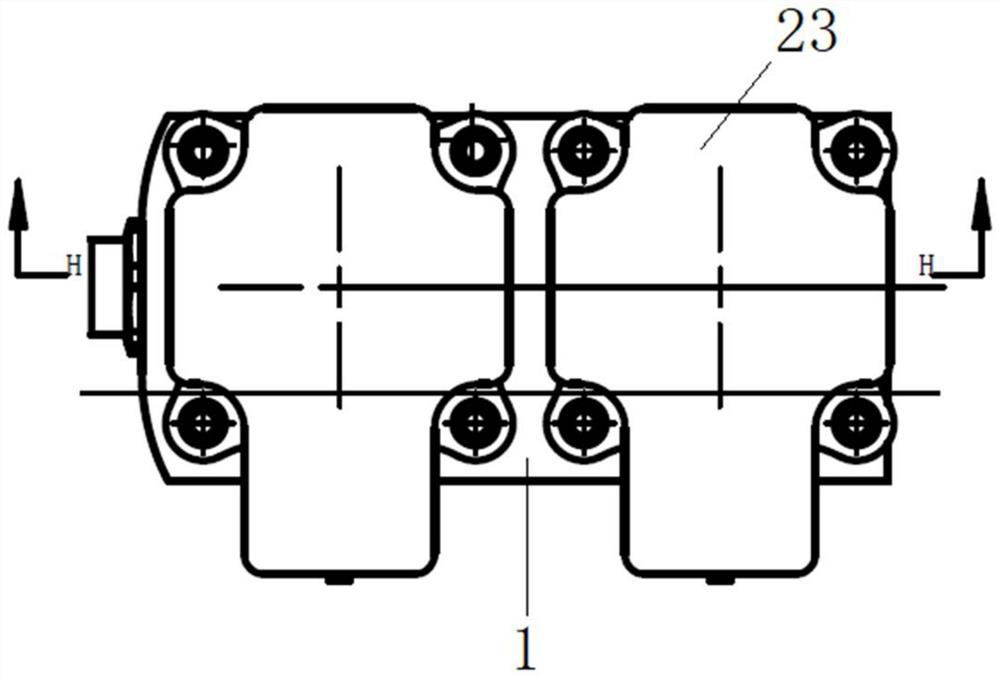

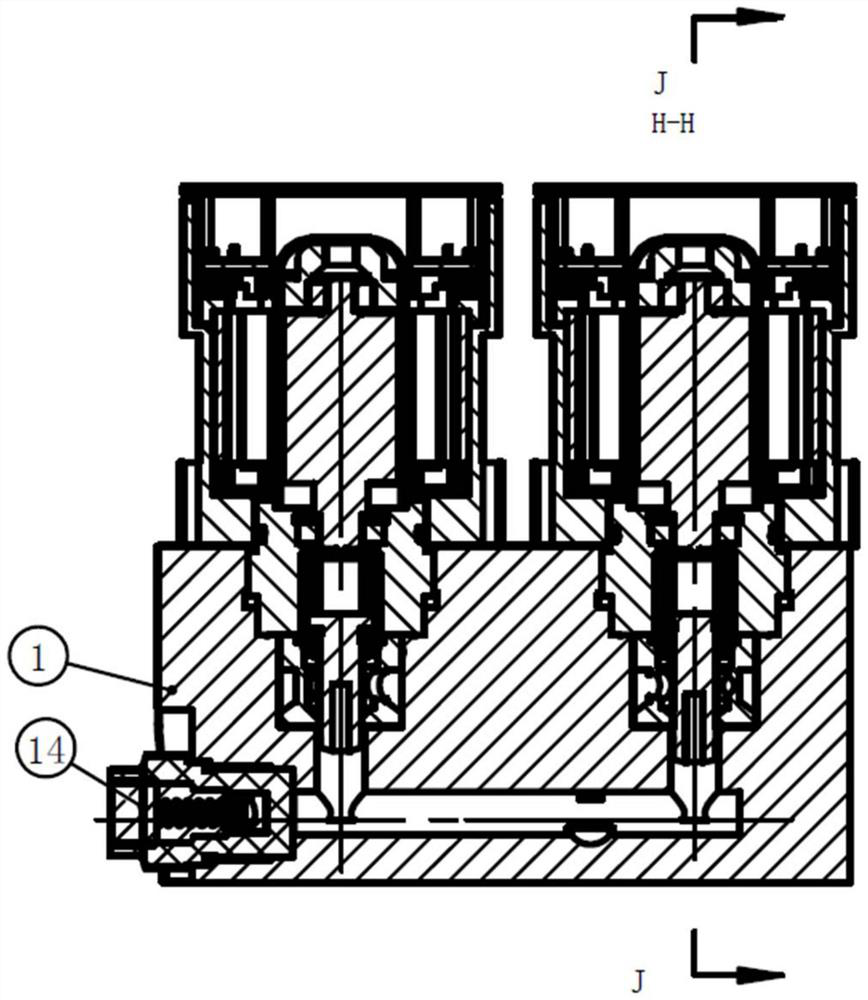

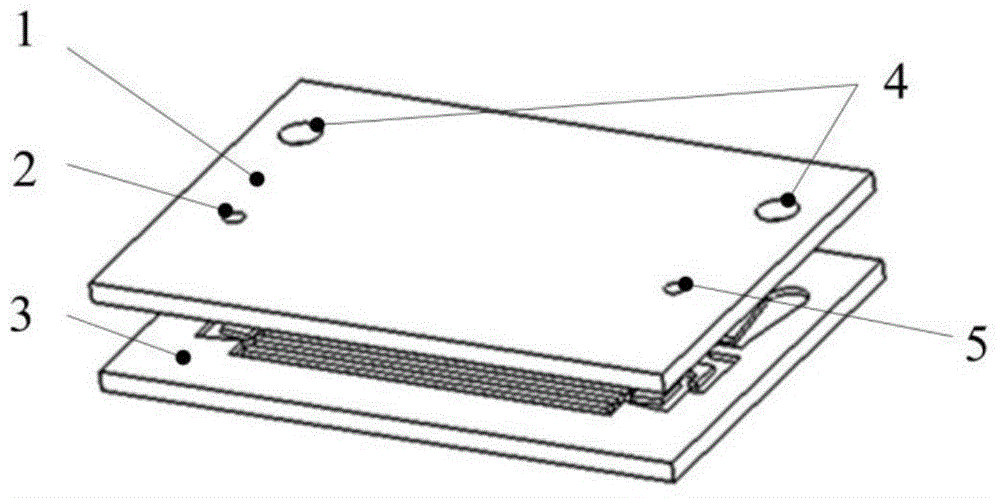

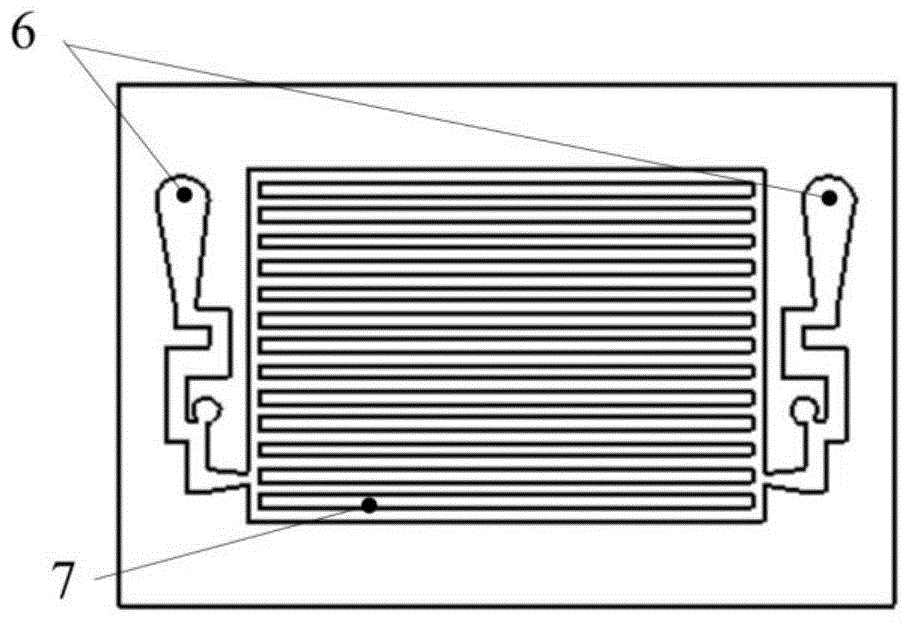

Peltier cooling type magnetic liquid sealing device

InactiveCN103925371AEasy to control temperatureAvoid seal failureEngine sealsMagnetic liquidsExtreme temperature

The invention discloses a Peltier cooling type magnetic liquid sealing device, and belongs to the field of mechanical engineering sealing. The Peltier cooling type magnetic liquid sealing device solves the problem that when an existing magnetic liquid sealing device is used in the extreme temperature occasions, the temperature of magnetic liquid in the sealing gaps is excessively high or low, so that sealing fails. The Peltier cooling type magnetic liquid sealing device comprises a case (1), a left bearing (2), a left magnetism isolation ring (3), a left pole shoe (4), a permanent magnet (5), a right pole shoe (6), a right magnetism isolation ring (7), a right bearing (8), an end cover (9), a sealing ring (10), a clamping spring (11), a right sealing ring (12), a left sealing ring (13) and a Peltier part (14). The Peltier part (14) is installed on the outer surface of the regular polygonal case (1) so that the temperature of the magnetic liquid in the sealing gaps can be controlled, and the problem that when the existing magnetic liquid sealing device is used in the extreme temperature occasions, the temperature of the magnetic liquid in the sealing gaps is excessively high or low, so that sealing fails is effectively solved.

Owner:BEIJING JIAOTONG UNIV

Direct carbon fuel cell reaction device

ActiveCN101345315AImprove performanceSolve adding waterFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsEngineering

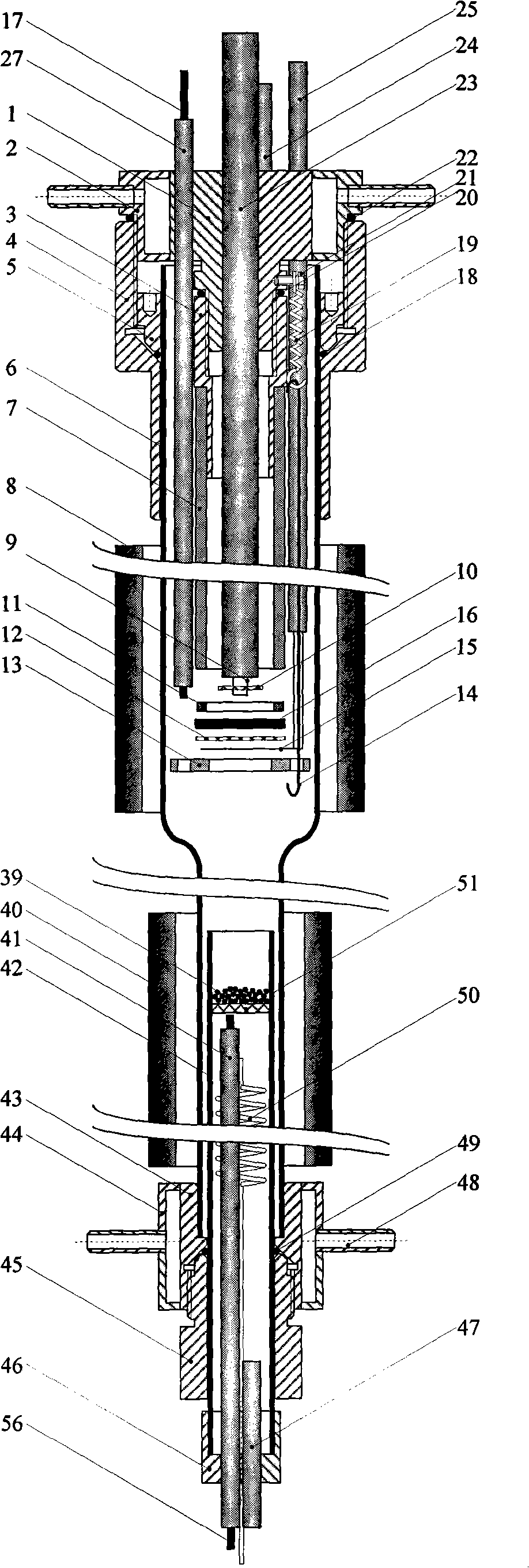

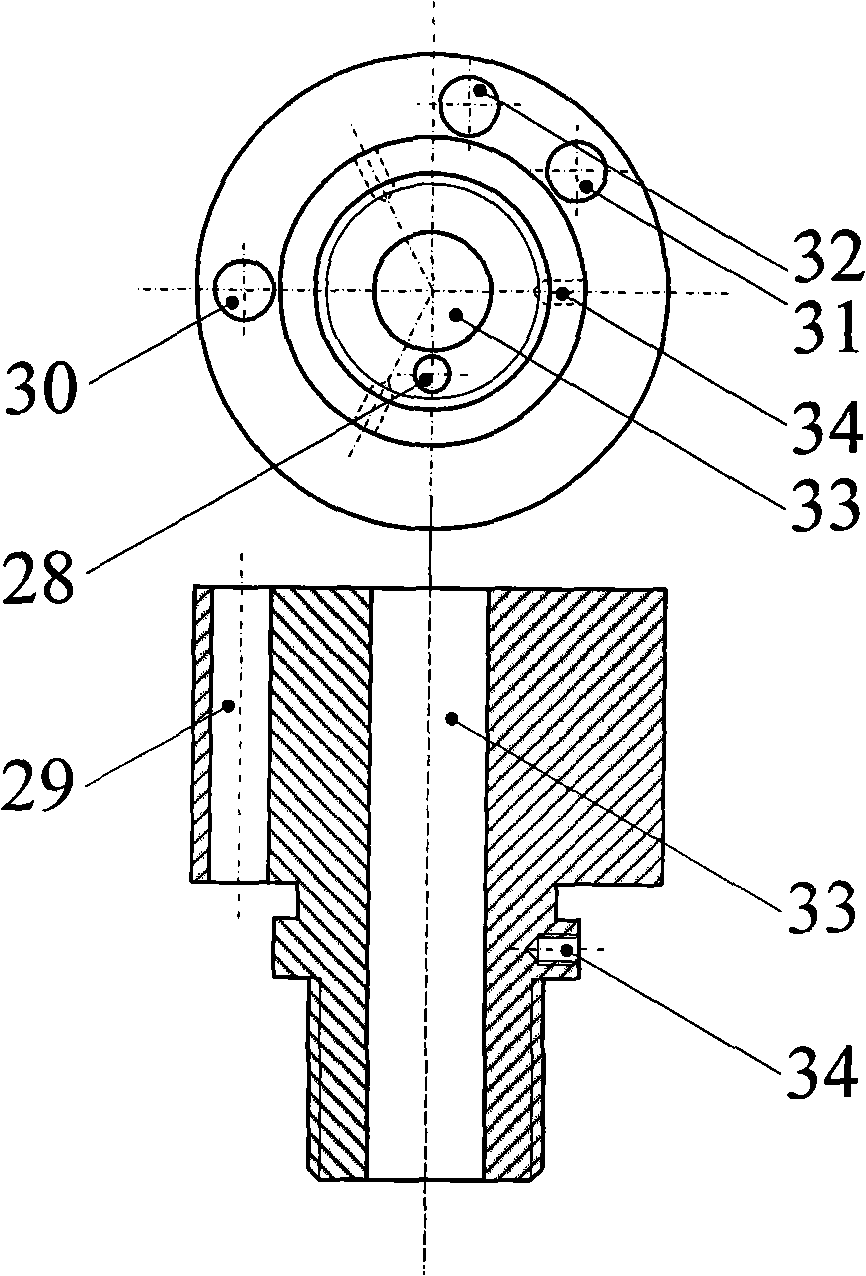

The invention provides a direct carbon fuel battery reaction device, belonging to the field of direct carbon fuel battery technique. An upper base (1) of the reaction device is coaxially arranged into a water cooling sleeve (2); the connection of the upper base and the water cooling sleeve is welded and sealed to form a water cooling chamber; an anode current collecting Pt net (12) is used for collecting current from the anode of a button-typed solid oxide fuel battery (16); two ends of an anode current collecting Pt wire (15) are respectively used as an reference electrode and a testing electrode; the temperature measuring point of a temperature measuring thermal-couple (17) and the button-typed solid oxide fuel battery (16) keep in the same height; the bottom of an anode chamber pipe (6) is inserted into the upper hole of a lower base (43); the lower surface of a quartz sand sintering plate (42) is provided with a carbon fuel thermal-couple (56); all pipes and sealing heads (46) are hermetically connected with each other. The direct carbon fuel battery reaction device of the invention solves the problem of water adding of anode chamber and the arranging of carbon fuel, realizes that the temperatures required by the running of fuel battery and the reacting of the carbon fuel are respectively controlled, avoids complex disassembly / assembly process and personnel scald, prevents the sealing invalidity and reduces the cost.

Owner:TSINGHUA UNIV

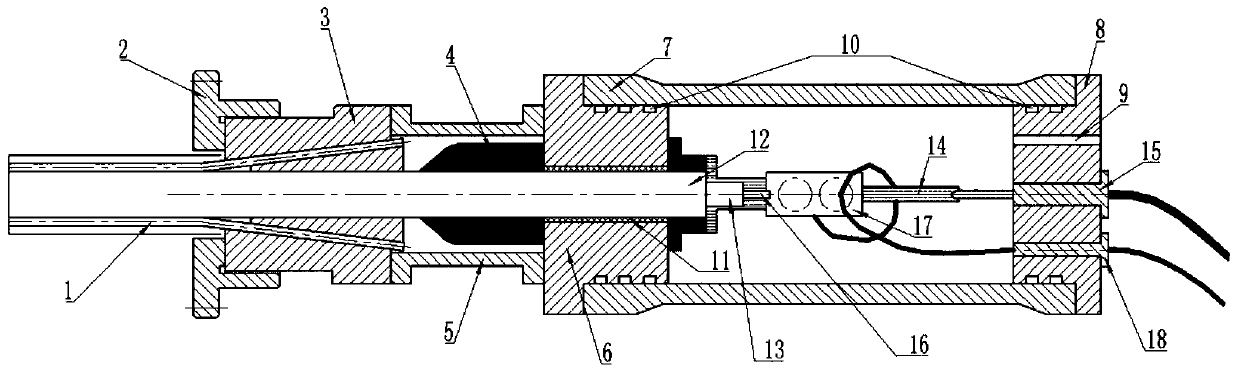

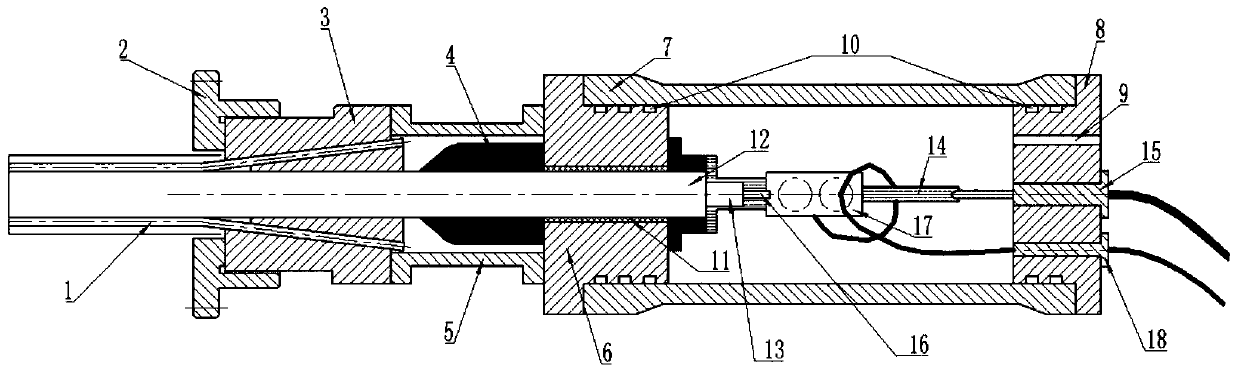

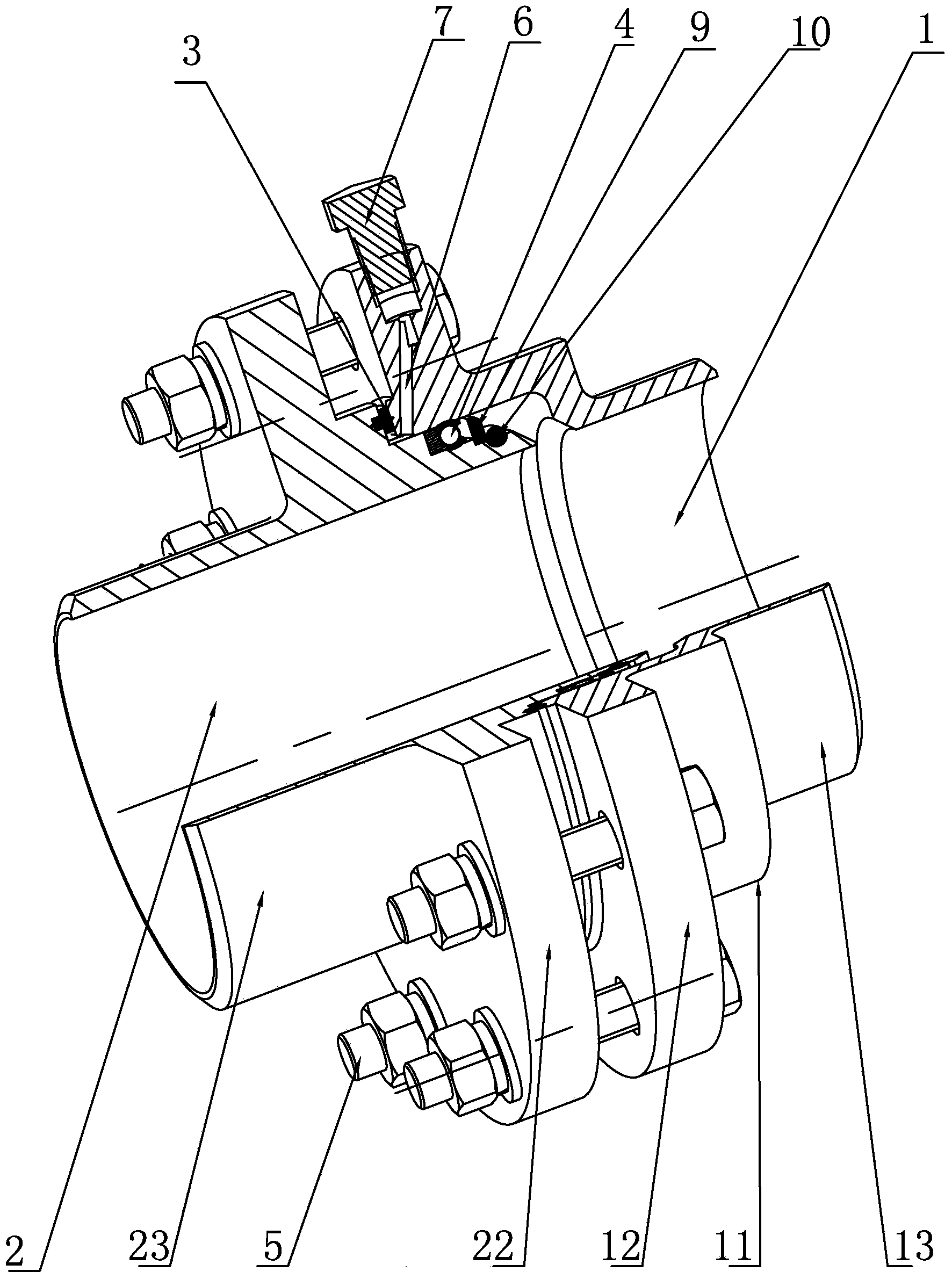

Pressure-balanced photoelectric separation device for main submarine base stations

InactiveCN109842085AImprove reliabilityPrevent creepCable fittings in presence of gas/oilCopper conductorFiber

The invention relates to the technical field of submarine observation equipment, in particular to a pressure-balanced photoelectric separation device for main submarine base stations. The device includes a submarine cable, an armored steel wire fixing mechanism, a cable core sealing protection mechanism and an oil-filled tank body mechanism. The submarine cable includes an armored steel wire (1) and a submarine cable core (12). The submarine cable core (12) is wrapped with a PE insulating layer, and a copper conductor (13) and an optical fiber unit (16) are arranged inside the submarine cablecore (12). The armored steel wire fixing mechanism is in butt joint with the cable core sealing protection mechanism, and the cable core sealing protection mechanism is in butt joint with the oil-filled tank body mechanism. The submarine cable is inserted into the armored steel wire fixing mechanism, and passes through the cable core sealing protection mechanism to the inside of the oil-filled tank body mechanism. The copper conductor (13) is connected through electrical leading with an electrical cable cabin-penetrating part (15) arranged at the end of the oil-filled tank body mechanism. Theoptical fiber unit (16) is directly welded to an optical cable cabin-penetrating part (18). The problem that a submarine cable core creeps into a photoelectric separation cabin under the pressure of deep water is solved.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

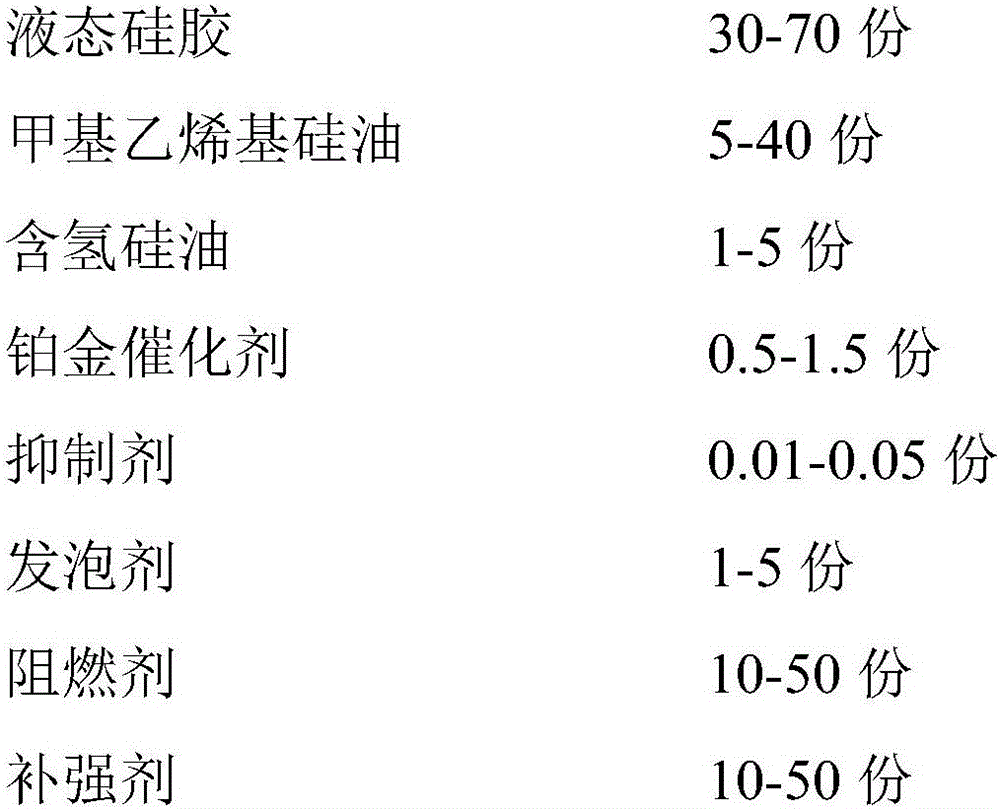

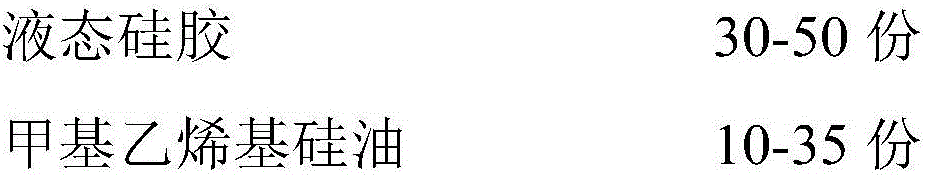

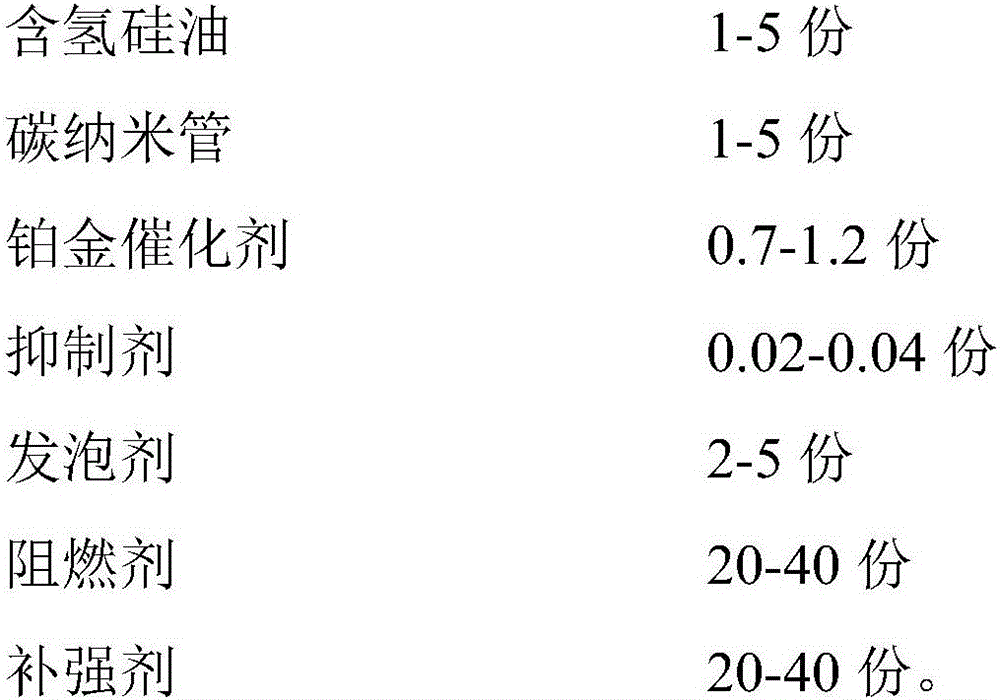

Silicone rubber foaming material and preparation method thereof

The invention relates to the technical field of silicone rubber, in particular to a silicone rubber foaming material and a preparation method thereof. The silicone rubber foaming material is prepared from the following components in parts by mass: 30 to 70 parts of liquid silicone rubber, 5 to 40 parts of methyl vinyl silicone oil, 1 to 5 parts of hydrogen-containing silicone oil, 0.5 to 1.5 parts of platinum catalyst, 0.01 to 0.05 part of inhibitor, 1 to 5 parts of foaming agent, 10 to 50 parts of flame retardant and 10 to 50 parts of reinforcing agent. The silicone rubber foaming material provided by the invention is characterized in that an Si-H bond of the hydrogen-containing silicone oil is activated by the platinum catalyst to generate a silicon hydrogenation addition reaction, so as to form an elastomer with a three-dimensional net structure, so that the silicone rubber foaming material provided by the invention has good flexibility; by adding the foaming agent, dense and uniform pores are formed inside the silicone rubber foaming material, the silicone rubber foaming material has better elasticity and smaller stress relaxation property, a sealing effect of communication equipment is guaranteed, and the maintenance cost is reduced.

Owner:昆山市硕鸿电子科技有限公司

Hydrogel for use in downhole seal applications

InactiveUS20060047028A1Increase expansionAvoid seal failureOther chemical processesVehicle sealing arrangementsElastomerThermoplastic

The present invention is a composition for forming seals. The composition includes a base material and a hydrogel. The base material is preferably an elastomer or a thermoplastic. Seals formed with the composition are particularly suited for use in a wellbore environment. The inclusion of hydrogel in the seals allows the seals to be manipulated or altered through certain environmental factors. For instance, temperature, oil / water ratio, pH and the electronic field may all be used to alter the characteristics of the hydrogel. In this way, the seal may be caused to swell in response to a specific stimulus, thereby preventing or sealing a leak without requiring additional work or input from the operator.

Owner:SCHLUMBERGER TECH CORP

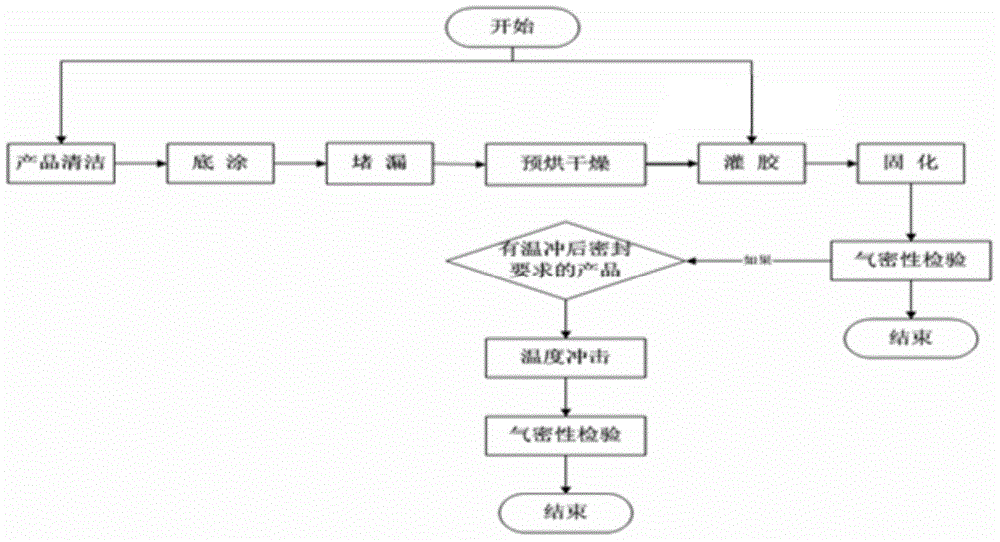

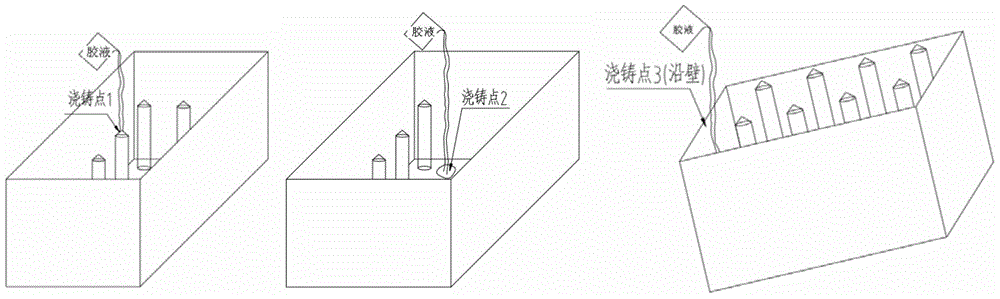

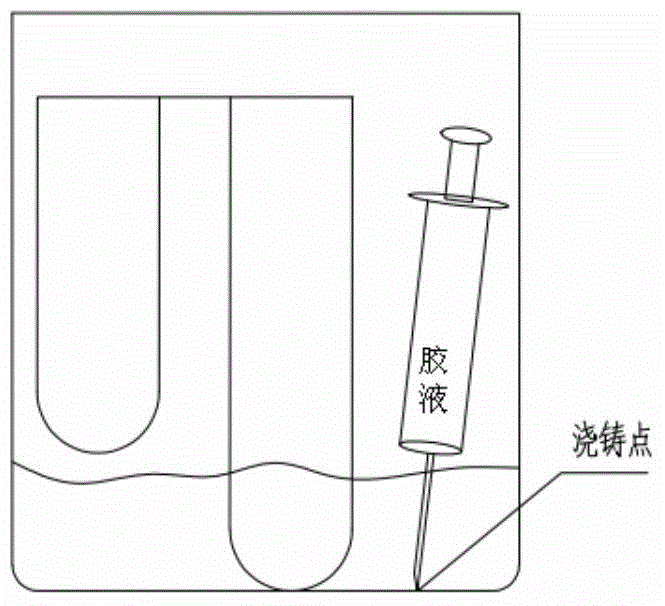

Method for using polyurethane adhesive to encapsulate electrical connector product

ActiveCN104577635AImprove airtight pass rateSolve the sealing problemContact member cases/bases manufactureElectricityPolyurethane adhesive

The invention discloses a method for using a polyurethane adhesive to encapsulate an electrical connector product. The method comprises the steps of cleaning the product, first coating, stopping leakage, pre-drying, pouring the polyurethane adhesive, solidifying, checking the airtightness, and the like, wherein the specific technologic method for each step is provided. According to the method disclosed by the invention, the airtightness qualification rate of the encapsulated product is increased, and the problem that the encapsulated product fails to be sealed or adhesive overflows after temperature shock can be solved.

Owner:杭州航天电子技术有限公司

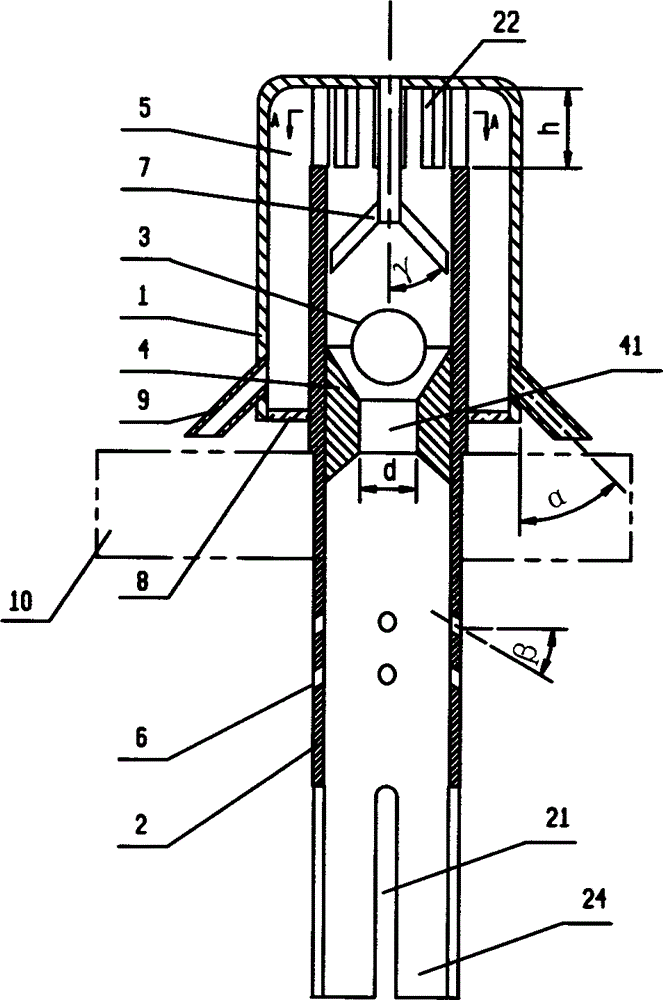

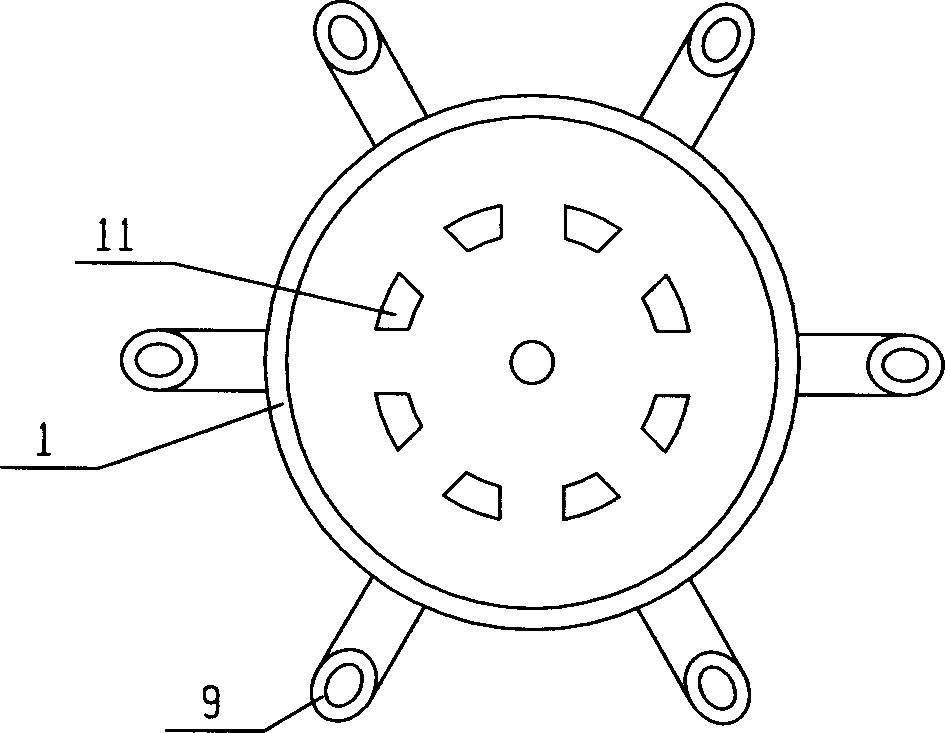

Gas-liquid distributor used for wood tar fluidized bed reactor

ActiveCN104923131AJumping up and down violentlyAvoid seal failureChemical/physical processesFluidized bedTar

The invention discloses a gas-liquid distributor used for a wood tar fluidized bed reactor, the gas-liquid distributor is mainly composed of a center pipe, a bubble cap, a non-return ball, a taper ball seat and a limit seat; the bubble cap is a cylindrical matter with a bottom opening, covers the upper end of the center pipe, and is fixedly connected with the center pipe, a material outlet is arranged on the pipe wall of the upper end part of the center pipe, the limit seat is arranged in the center pipe below the material outlet, the taper ball seat is arranged on the pipe wall of the center pipe located below the limit seat, the non-return ball is arranged on the taper ball seat; the bubble cap, the center pipe, the limit seat, the non-return ball and the taper ball seat are coaxially arranged, an annular channel is formed between the bubble cap and the center pipe, and the lower end of the center pipe is provided with a material inlet. The gas-liquid distributor can not only guarantee a gas is broken into continuous micro bubbles in a liquid, and can effectively solve or ease countercurrent congestion problem of a catalyst-carrying material when gas and liquid pressure is instable or gas and liquid material feed is suddenly interrupted, at the same time, an internal flow dead zone in the distributor is reduced, and the pressure drop is smaller.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

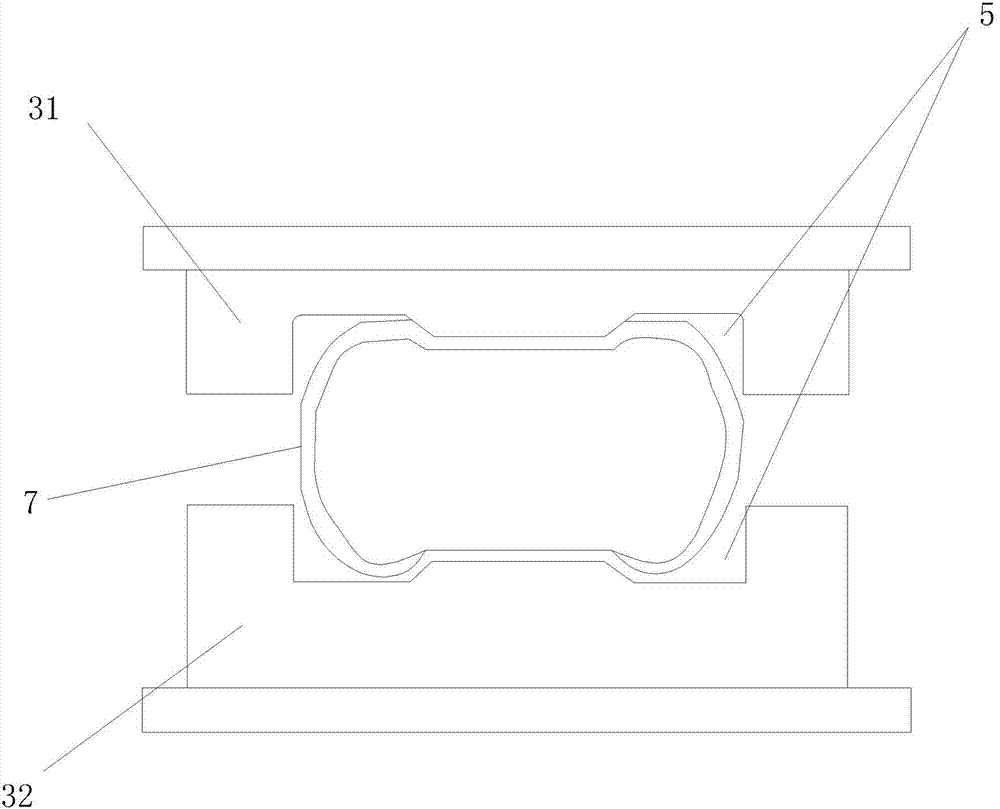

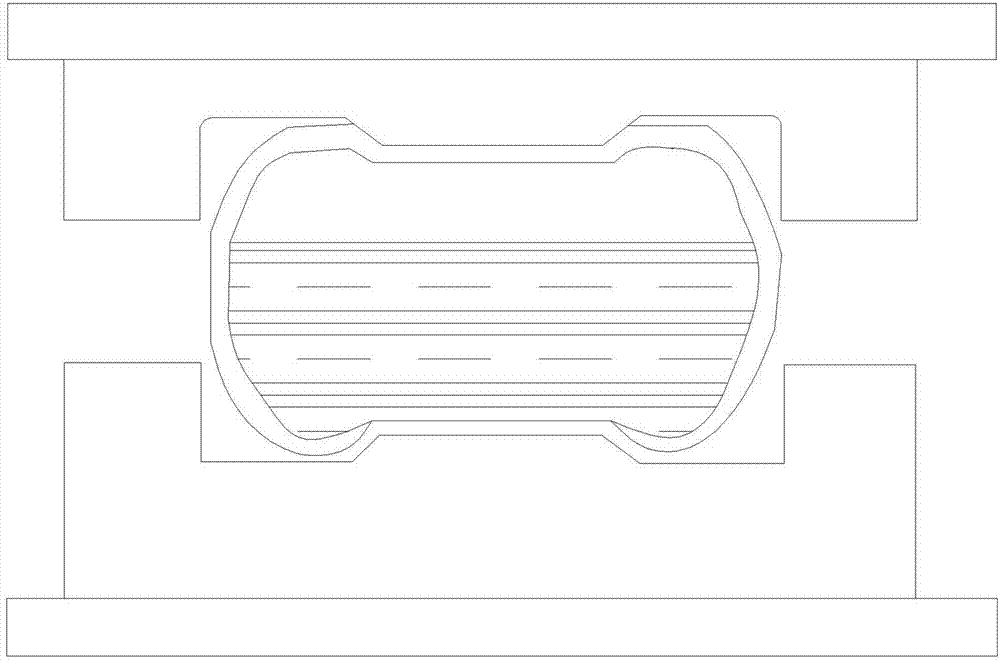

Internal high-pressure forming device and forming process

The invention discloses an internal high-pressure forming device and a forming process, and aims to provide a process and matching devices capable of forming pipes under the condition of relatively low pressure. A pipe billet is firstly formed into a pipe shape with a small R (small radian of a bent portion) by the aid of force of a press fitting die of a press machine and liquid pressure in a pipe, and forming is repeated for many times if necessary until the pipe shape is completely close to a die cavity. The press machine is driven to completely close an upper die and a lower die, internal pressurization is continued after the dies are completely closed, and the pipe shape with the small R is expanded into a pipe shape with a large R (large radian of the bent portion) by the aid of internal pressure. Besides, liquid flow channels are arranged in plugs on two sides of the die, double-end water injection can be realized, and pressurizing efficiency is improved.

Owner:NINGBO TRIZ AUTOMATIC EQUIP

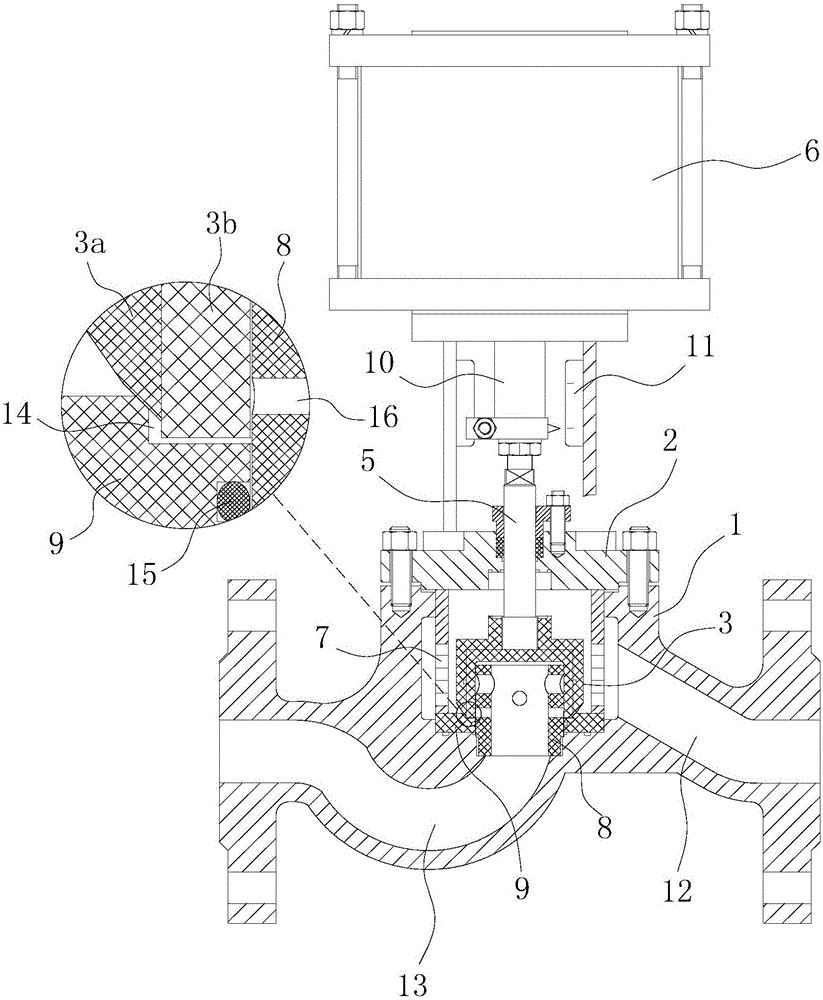

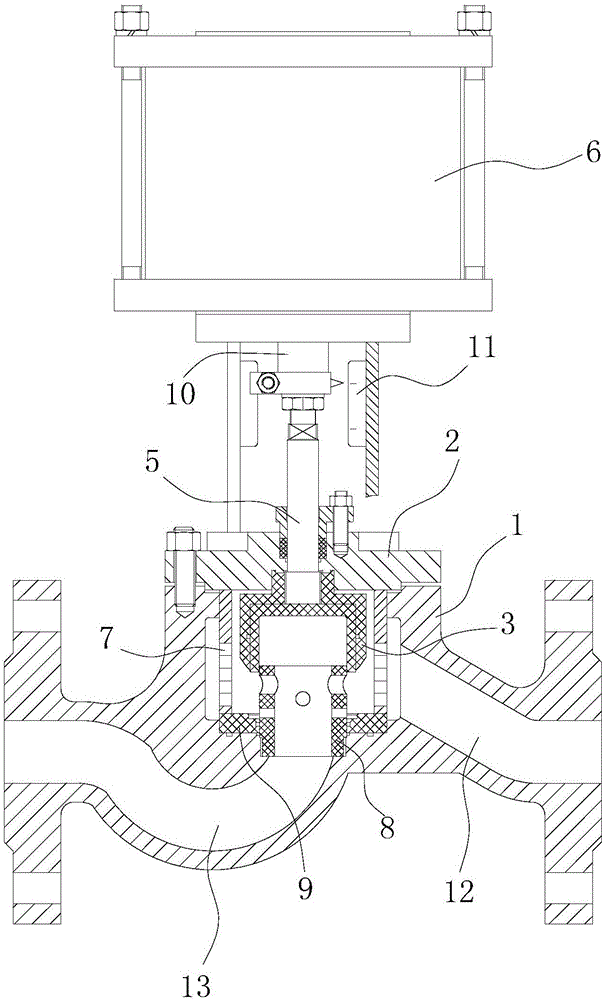

Double-valve-core double-sealing-surface adjusting valve

ActiveCN106224572AProvide service lifeAvoid direct impactValve members for absorbing fluid energyLift valveMechanical engineering

Owner:HEFEI GENERAL MACHINERY RES INST

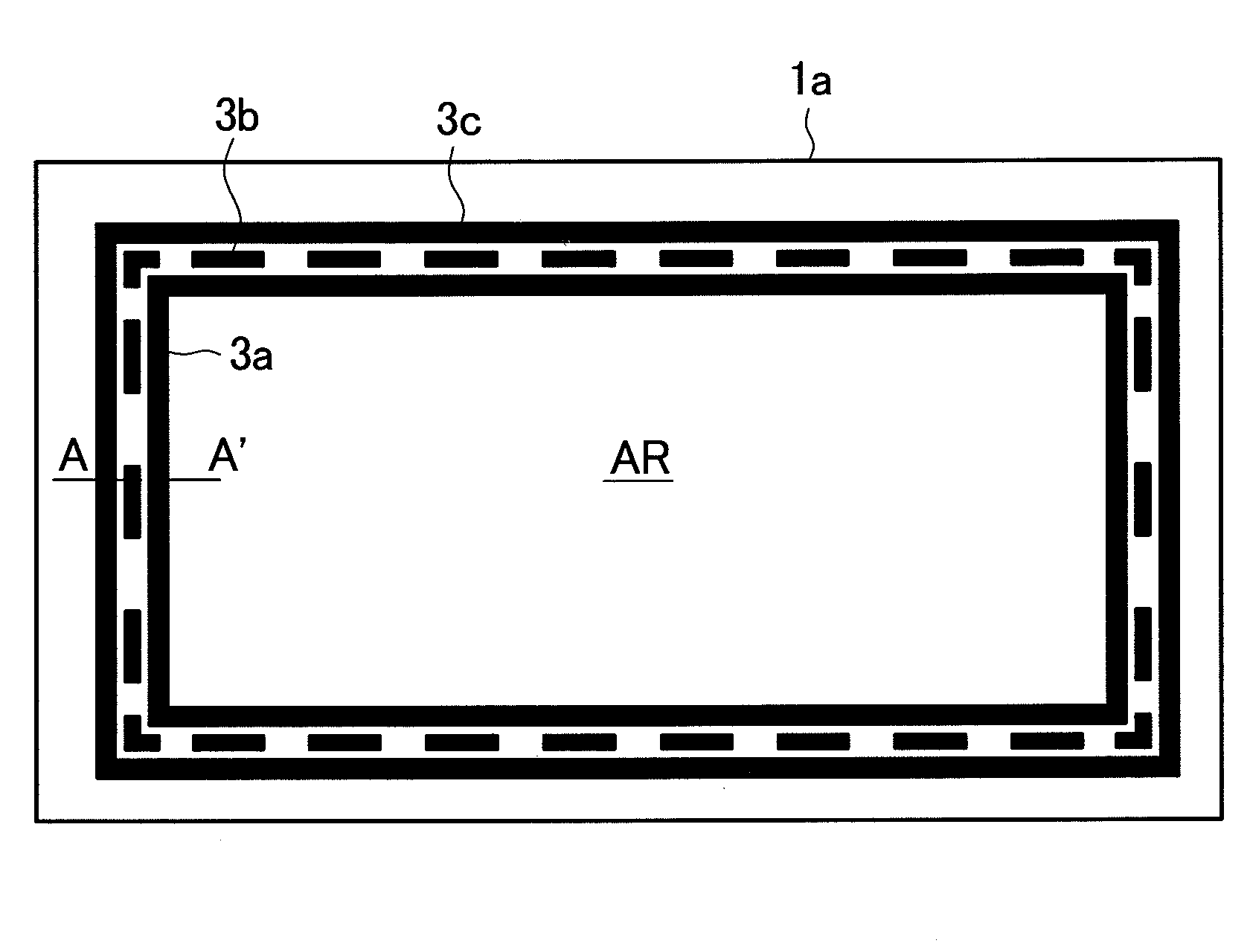

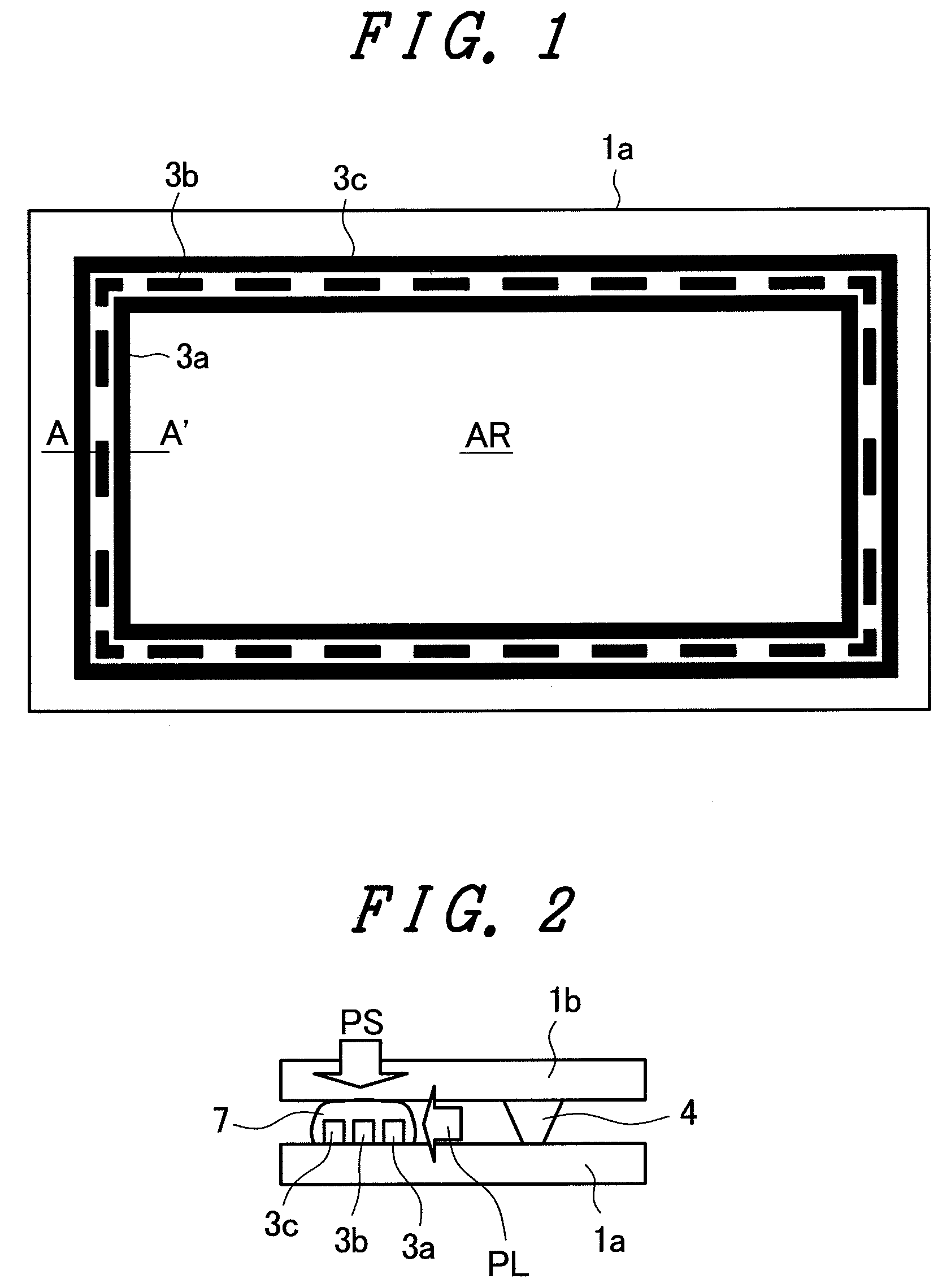

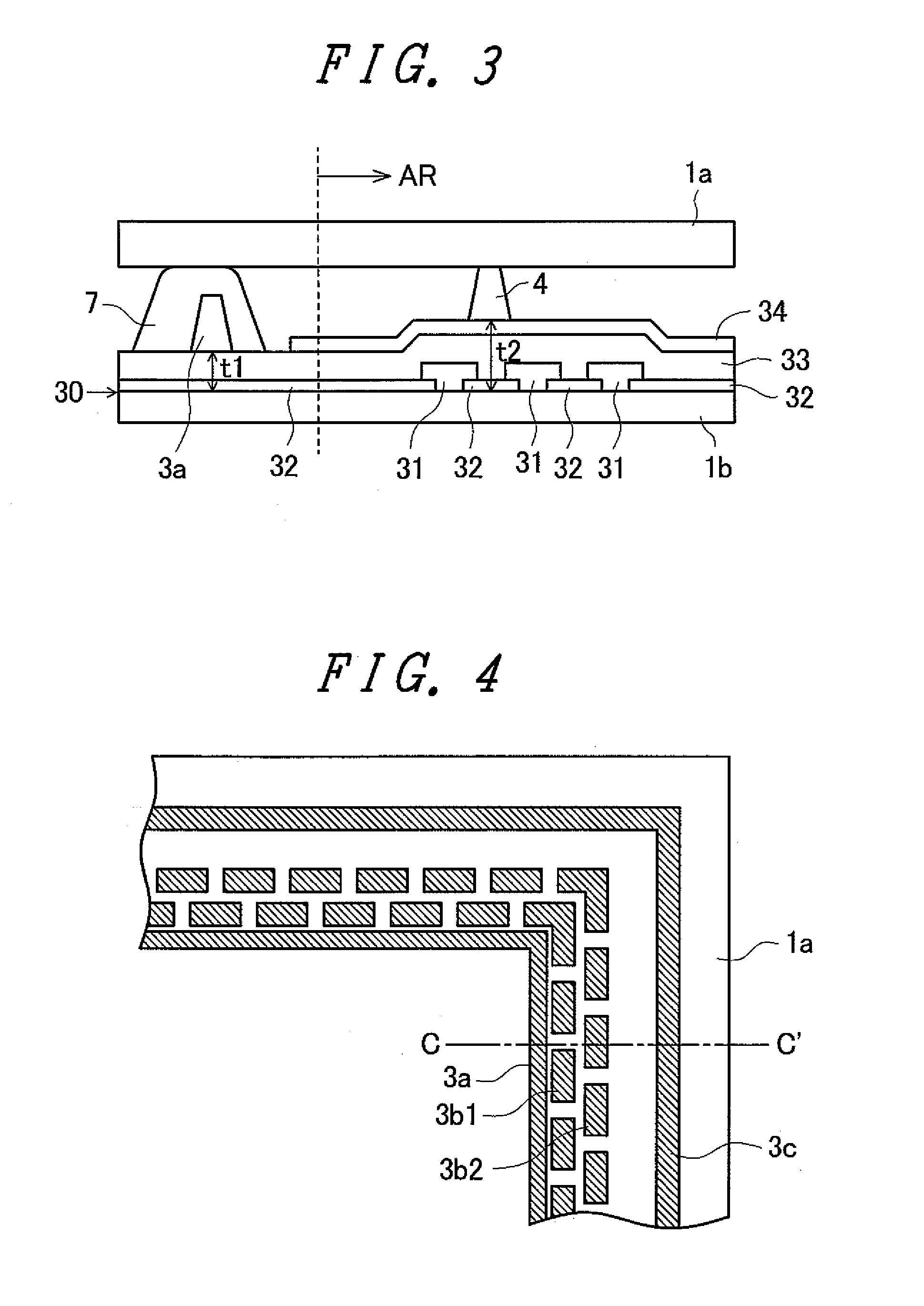

Liquid crystal display panel with a continuous weir and a discontinuous weir covered by a sealing material

ActiveUS7630050B2Reduce manufacturing stepsIncrease contact areaNon-linear opticsLiquid-crystal displayEngineering

The present invention provides a liquid crystal display panel which can prevent a leak path of a sealing material when liquid crystal is brought into contact with an uncured sealing material in a sealing step and a manufacturing method thereof. In a liquid crystal display panel which forms a display region by providing liquid crystal in a gap defined between one substrate and another substrate, a weir which is continuously formed so as to surround the display region and a sealing material which is arranged to cover the weir are arranged on a surface of one substrate.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

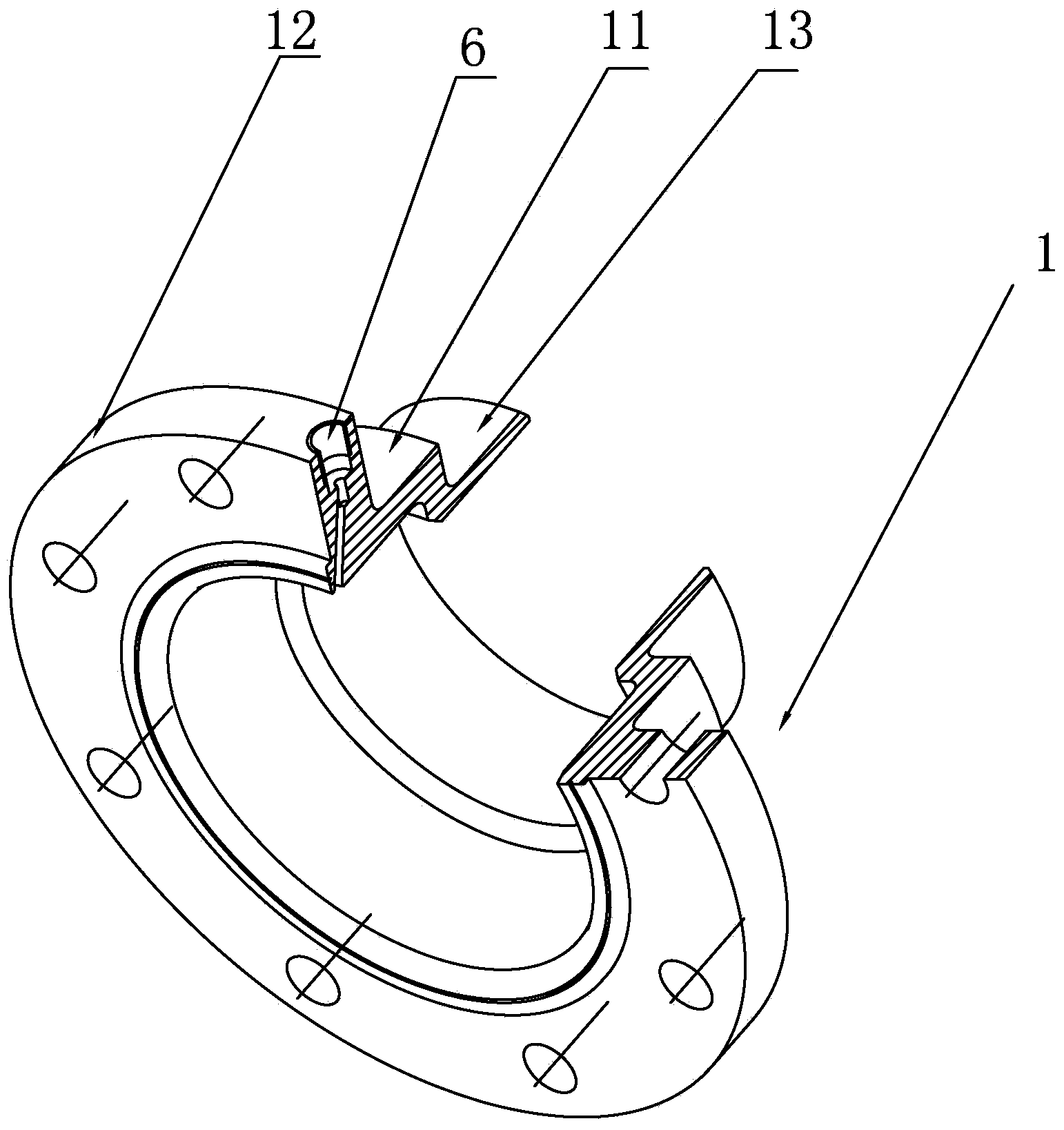

Redundant seal pipeline connector

ActiveCN104048124AEffective Radial Sealing EffectRealize online detectionDetection of fluid at leakage pointFlanged jointsButt jointFlange

The invention relates to a pipeline connector used for a filling system with higher sealing requirements, and aims to provide a redundant seal pipeline connector which has a simple structure, is reliable to seal, simple and convenient to operate, and can carry out the on-line detection on the sealing effect of the pipeline connector at the same time. The redundant seal pipeline connector comprises a seal receptacle, a seal cone, end surface sealing pieces, radial sealing pieces and fastening pieces, wherein the seal receptacle comprises a first axial bulge, a first annular flange and a first welding end, which are manufactured integrally; the seal cone comprises a second axial bulge, a second annular flange and a second welding end, which are manufactured integrally; the end surface of the second axial bulge is in butt joint with the end surface of the first annular flange; the end surface sealing pieces are positioned on the butt-joint matched surfaces; the front end of the second axial bulge is sleeved with the first annular flange; the radial sealing pieces are positioned in the radial matched surfaces; the fastening pieces are used for fixedly connecting the seal receptacle with the seal cone; a pressure measuring channel is arranged on the first annular flange; an air outlet end port of the pressure measuring channel is connected with a seal cap.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

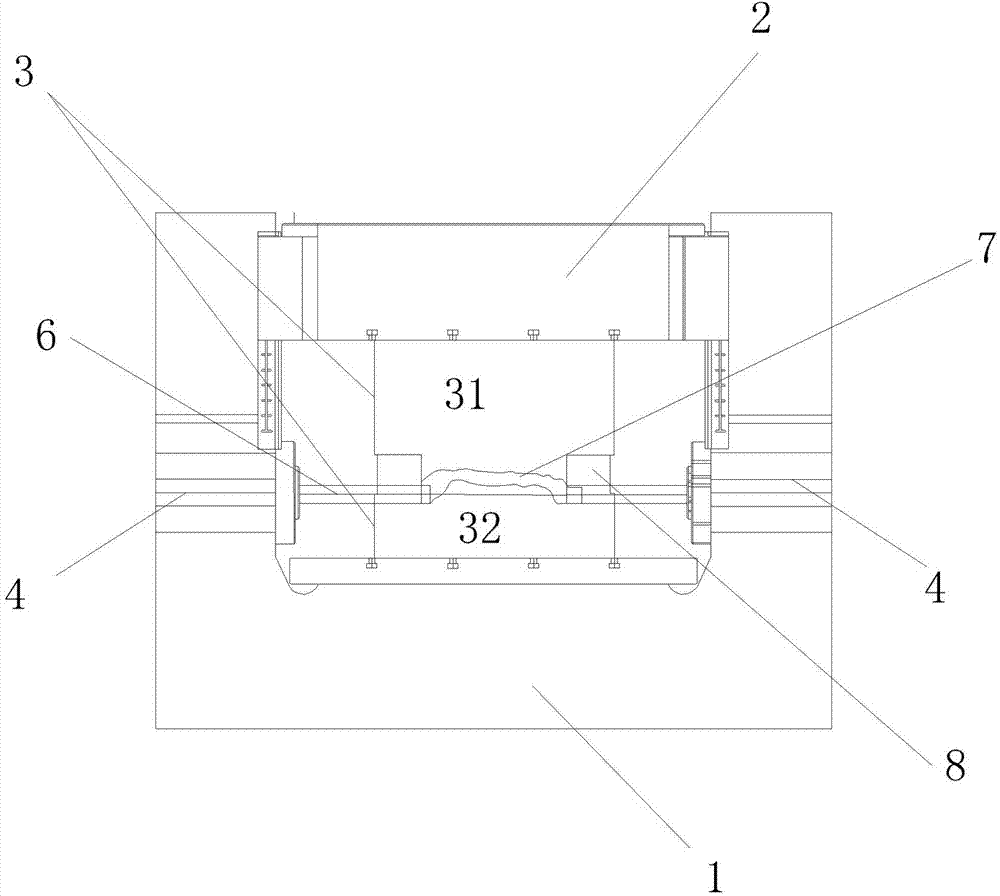

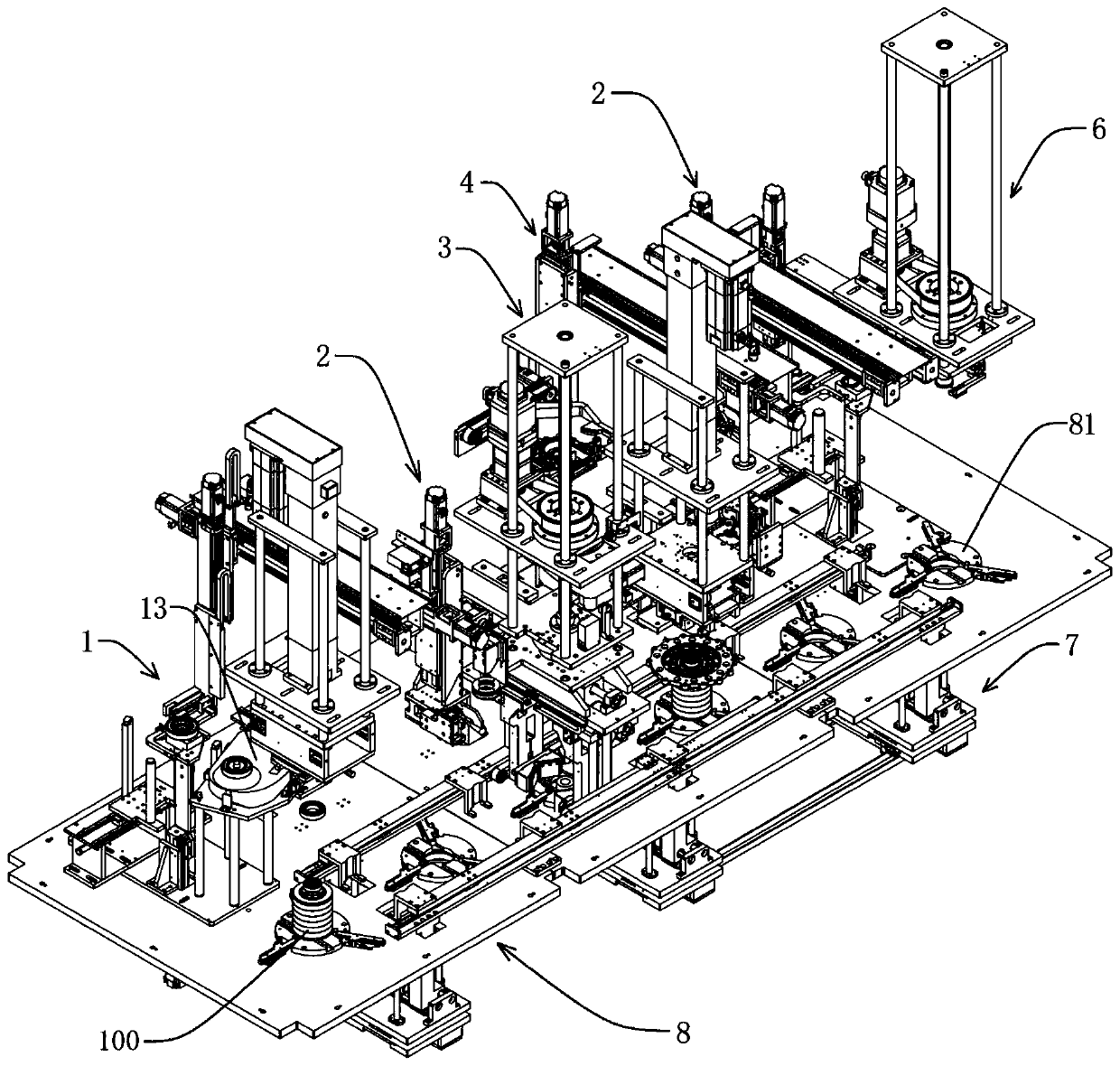

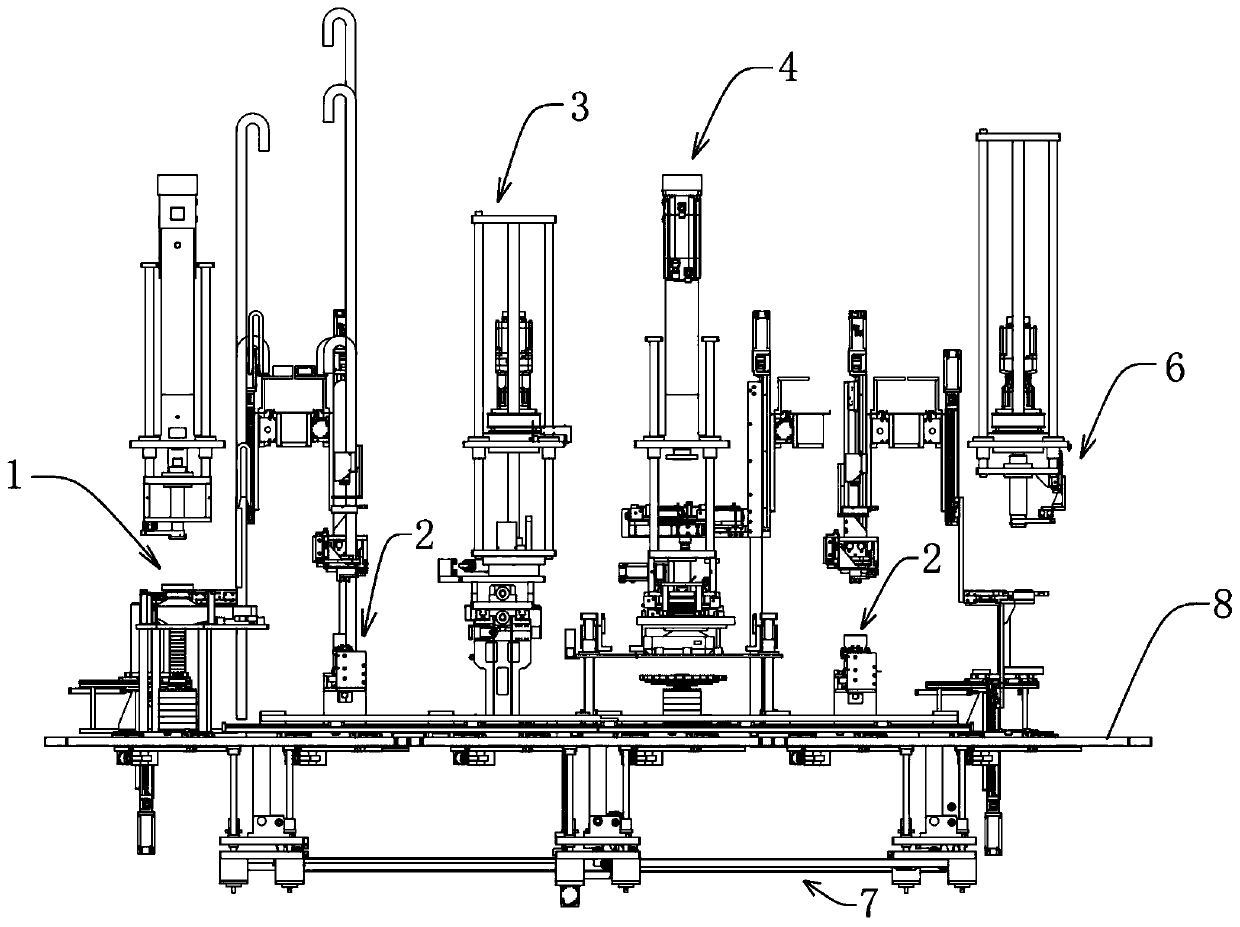

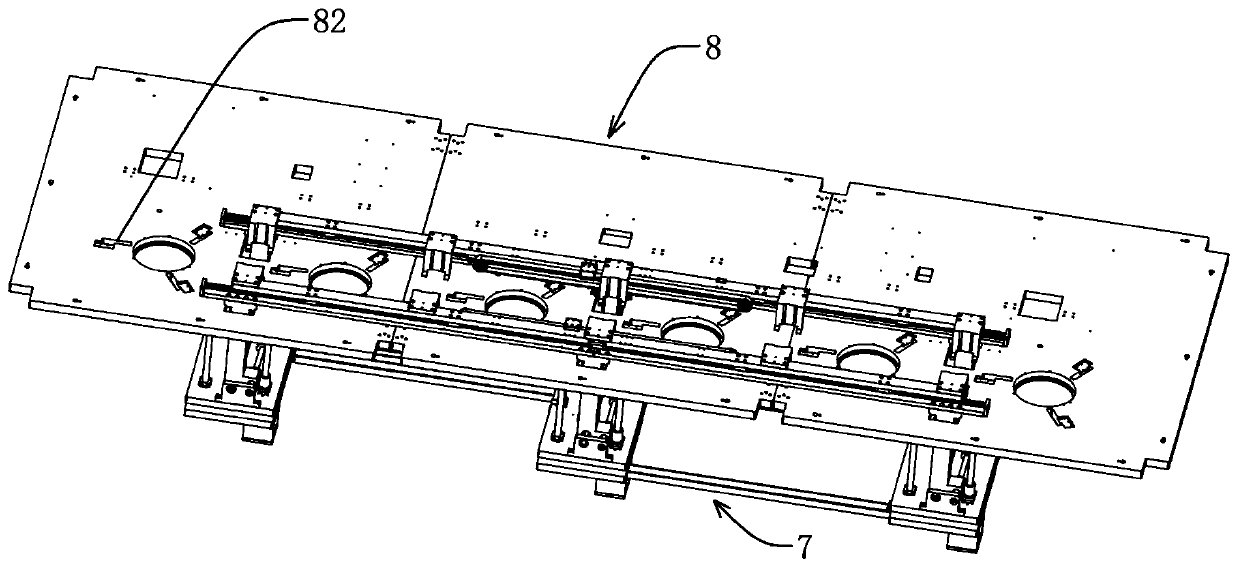

Multi-station transfer mechanism and motor bearing assembly equipment

ActiveCN111300044ASuitable for transferHigh repeatabilityAssembly machinesManufacturing dynamo-electric machinesElectric machineryDrive motor

The invention discloses a multi-station transfer mechanism and motor bearing assembly equipment, and belongs to the technical field of motor assembly. The multi-station transfer mechanism comprises anX-axis transfer assembly, a Y-axis spacing regulating assembly and at least one group of Z-axis lifting assemblies; each Z-axis lifting assembly comprises a rolling ball lead screw and a lifting table which is fixedly connected to a nut in the rolling ball lead screw, wherein the upper end of the lead screw in the rolling ball lead screw is provided with an operation table, the lower end of the lead screw in the rolling ball lead screw is arranged on a support base in a penetrating mode, and the lower end of the lead screw is in transmission connection to a drive motor; the Y-axis spacing regulating assembly comprises two groups of supporting plates which are separately and fixedly connected onto supporting frames in a one-to-one correspondence mode; the supporting frames are arranged ona two-way lead screw in pair, and the two-way lead screw is in transmission connection to a drive motor; and the X-axis transfer assembly comprises transfer plates which axially extend along the X-axis, and are provided with clamping assemblies, and the transfer plates are axially arranged on the supporting plates slidably in the one-to-one correspondence mode. The multi-station transfer mechanismcan quickly take workpieces and switches to different stations, so that operation on each station is convenient.

Owner:BOZHON PRECISION IND TECH CO LTD

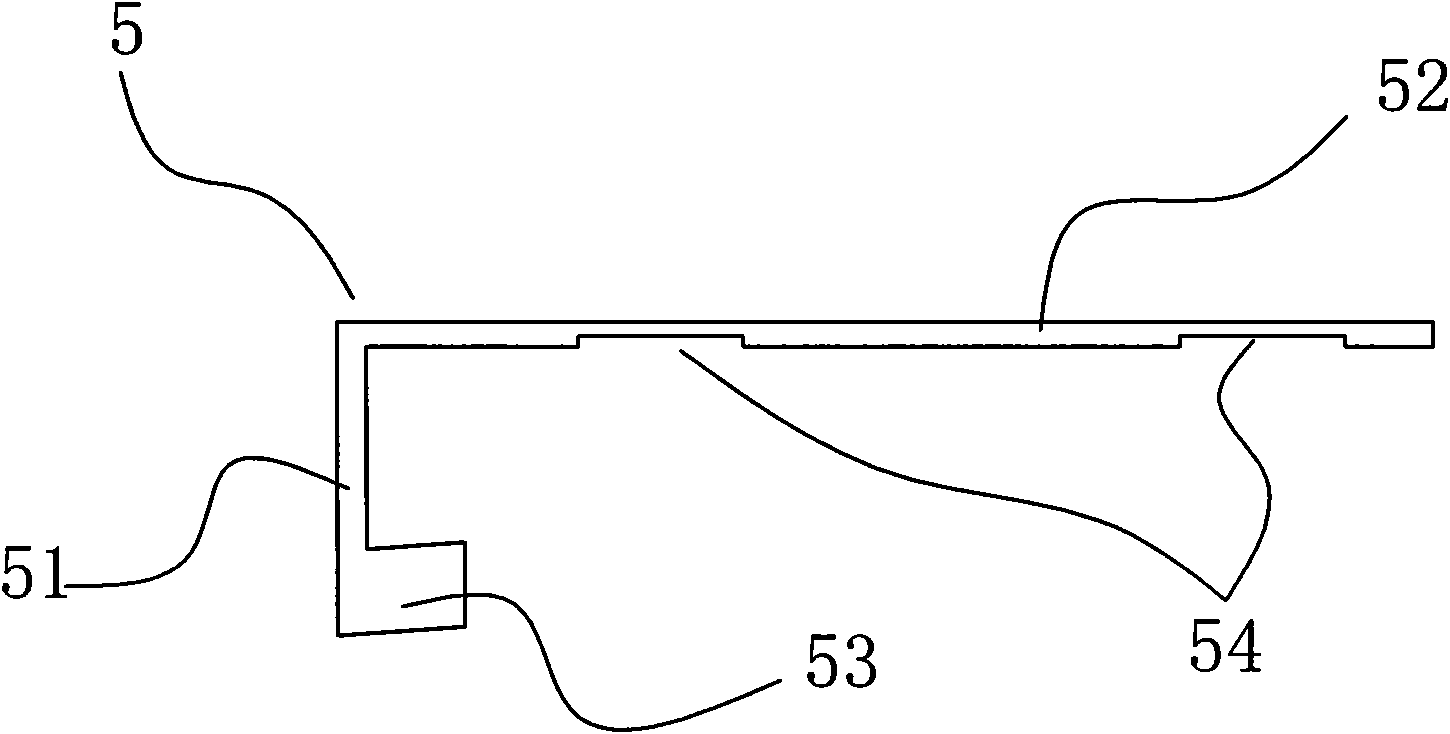

Anti-loosing locking structure and projection lamp provided with same

InactiveCN101551089AInhibit sheddingAvoid seal failureLight fasteningsFixed installationEngineeringMechanical engineering

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

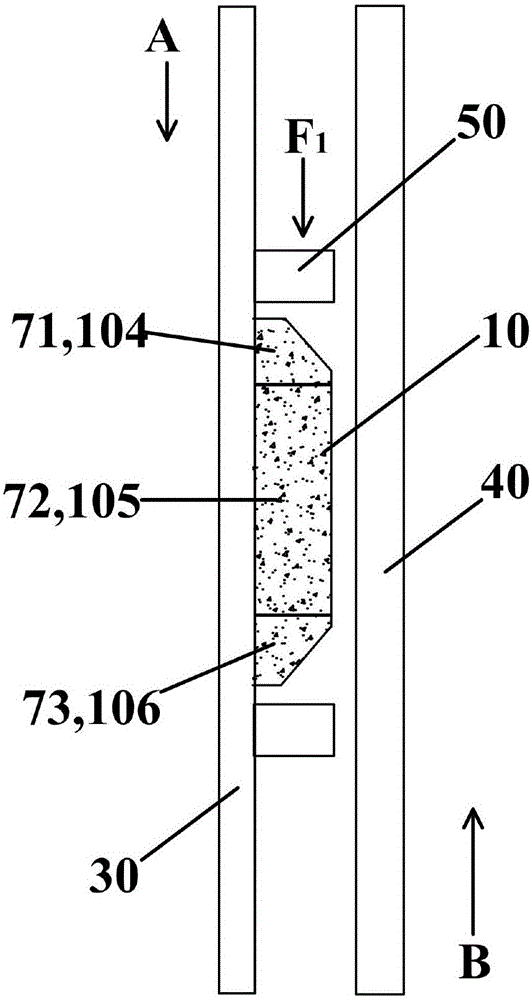

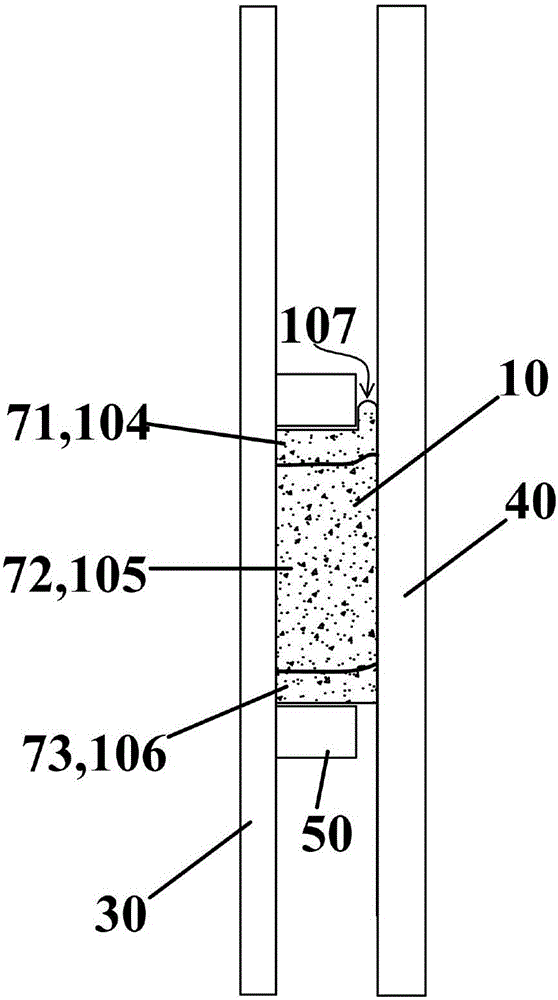

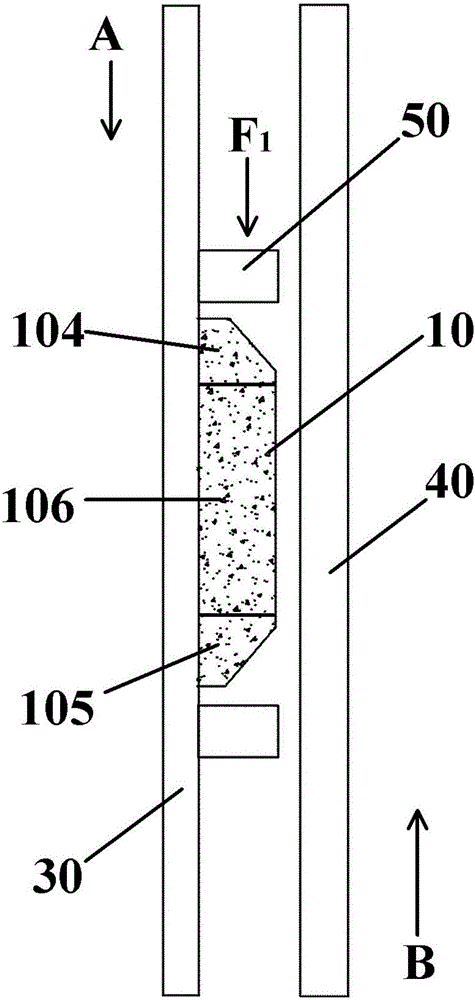

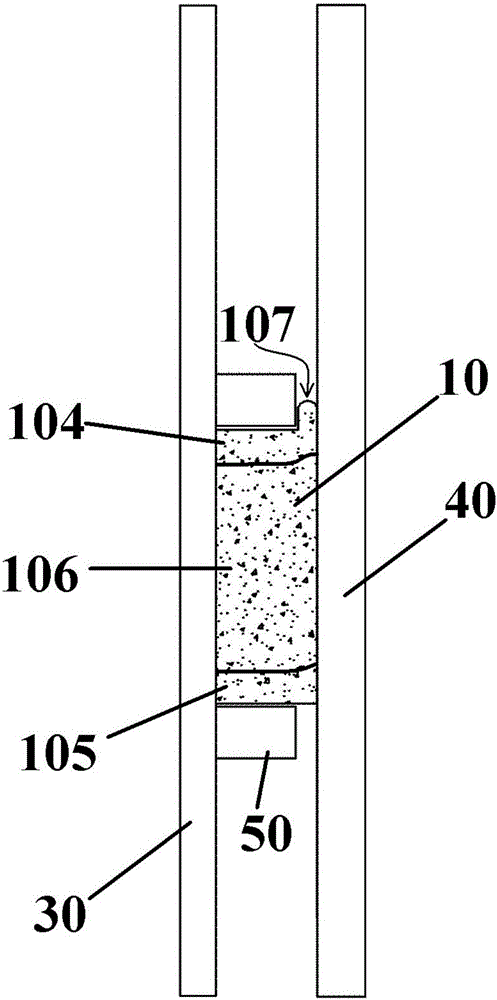

Rubber sleeve with lower end seal ring covered with opened copper sheet, packer and bridge plug

The invention relates to the field of sealing, in particular to a rubber sleeve with a lower end seal ring covered with an opened copper sheet, a packer and a bridge plug, wherein the rubber sleeve is used in the oil exploitation industry and can bearing high temperature and high pressure. The lower end seal ring of the rubber sleeve is covered with the first copper sheet, the first copper sheet covers the upper surface, the lower surface, the inner side face and the outer side face of the lower end seal ring, and the thickness of the first copper sheet is set in the mode that when the upper end bears first axial pressure, the lower end seal ring deforms in the radial direction so that the part, distributed on the inner surface of the lower end seal ring, of the first copper sheet can butt against a center tube and the part, distributed on the outer surface of the lower end seal ring, of the first copper sheet can butt against the sleeve; an annular opening is formed in the edge, located on the upper surface of the lower end seal ring, of the first copper sheet. The lower end seal ring is covered with the first copper sheet, the degradation function on the rubber sleeve by high-temperature and high-pressure steam micromolecules is reduced or prevented, and the sealing long-term effect of the rubber sleeve is improved.

Owner:TIANDING SEALING TECH BEIJING CO LTD

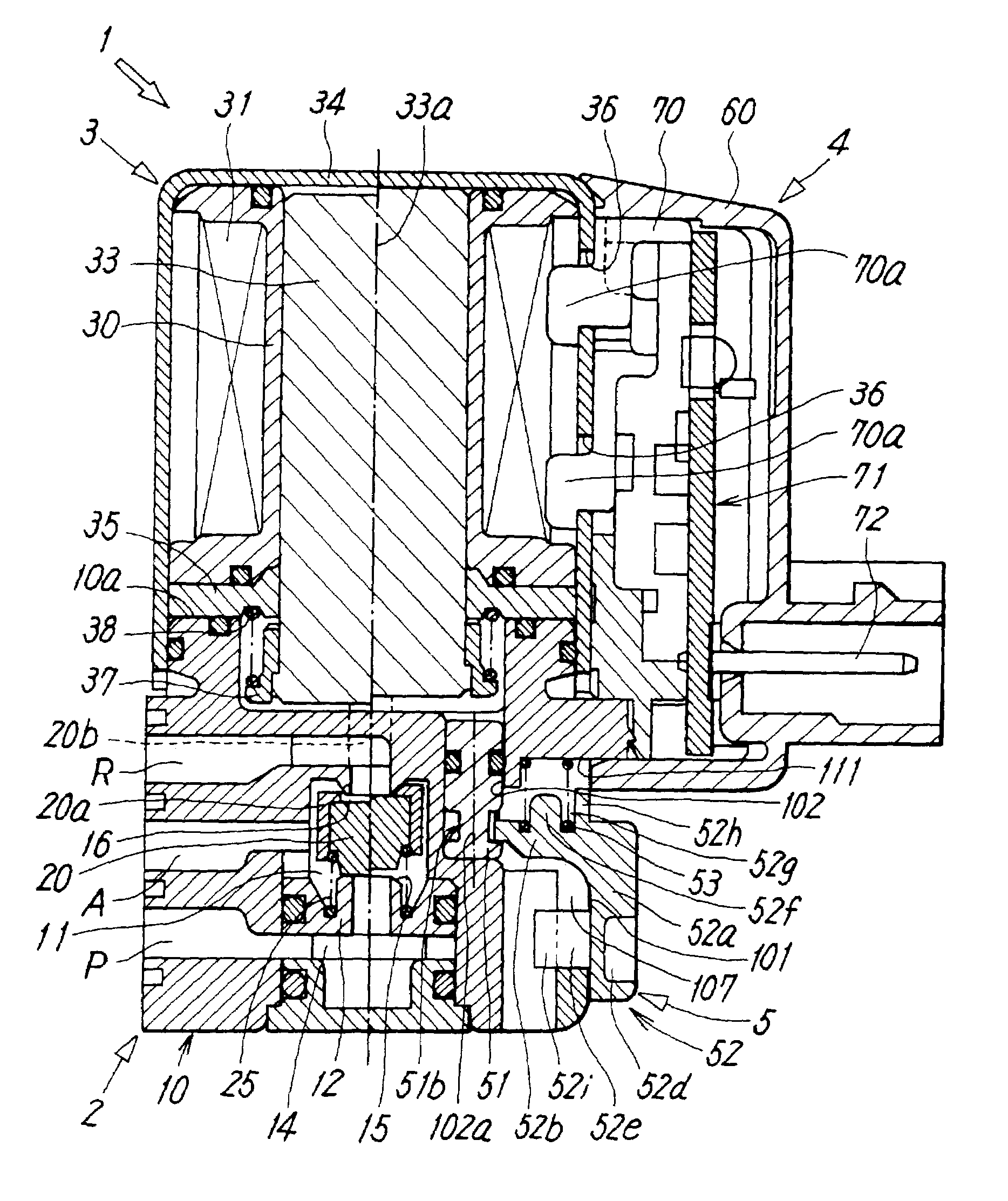

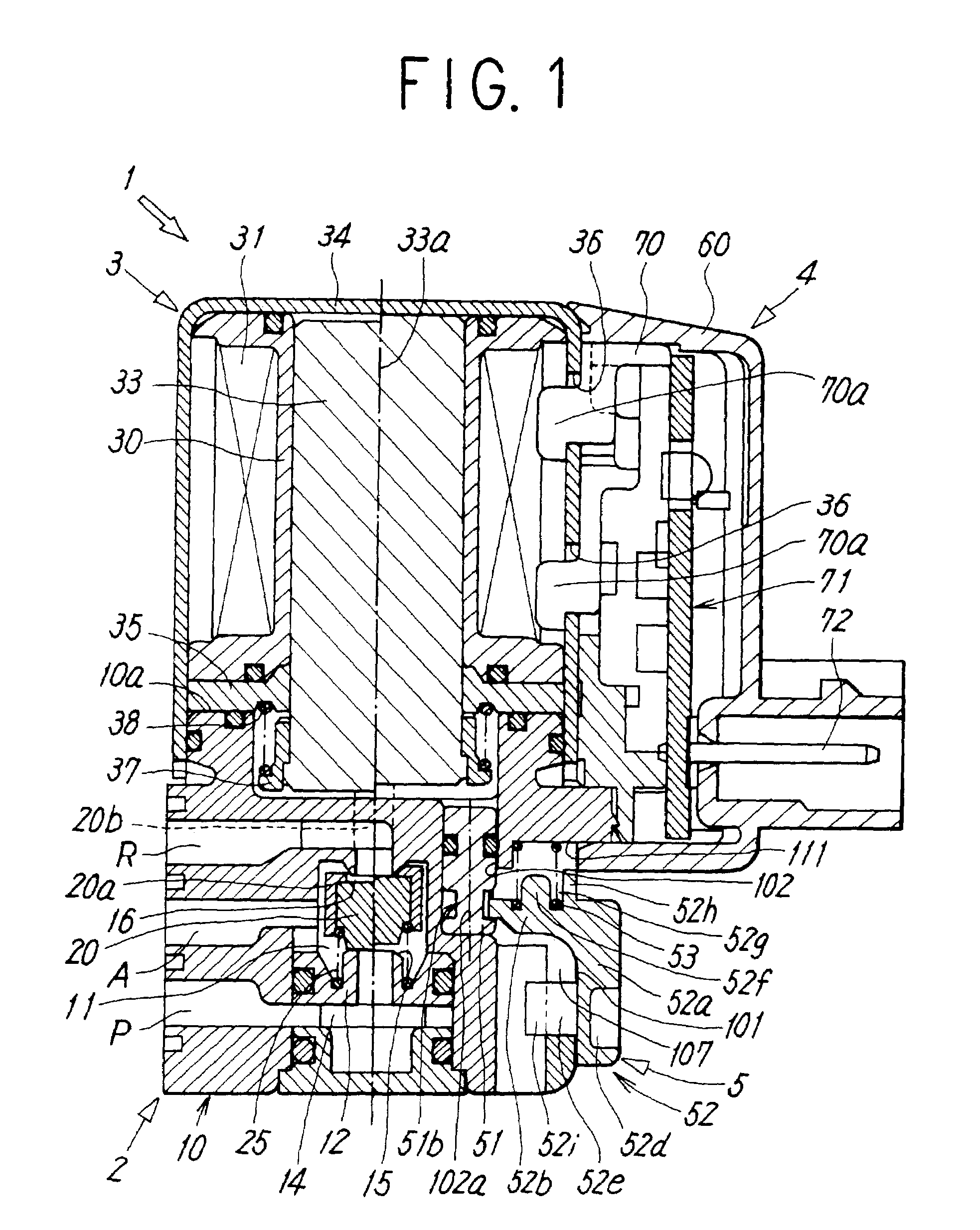

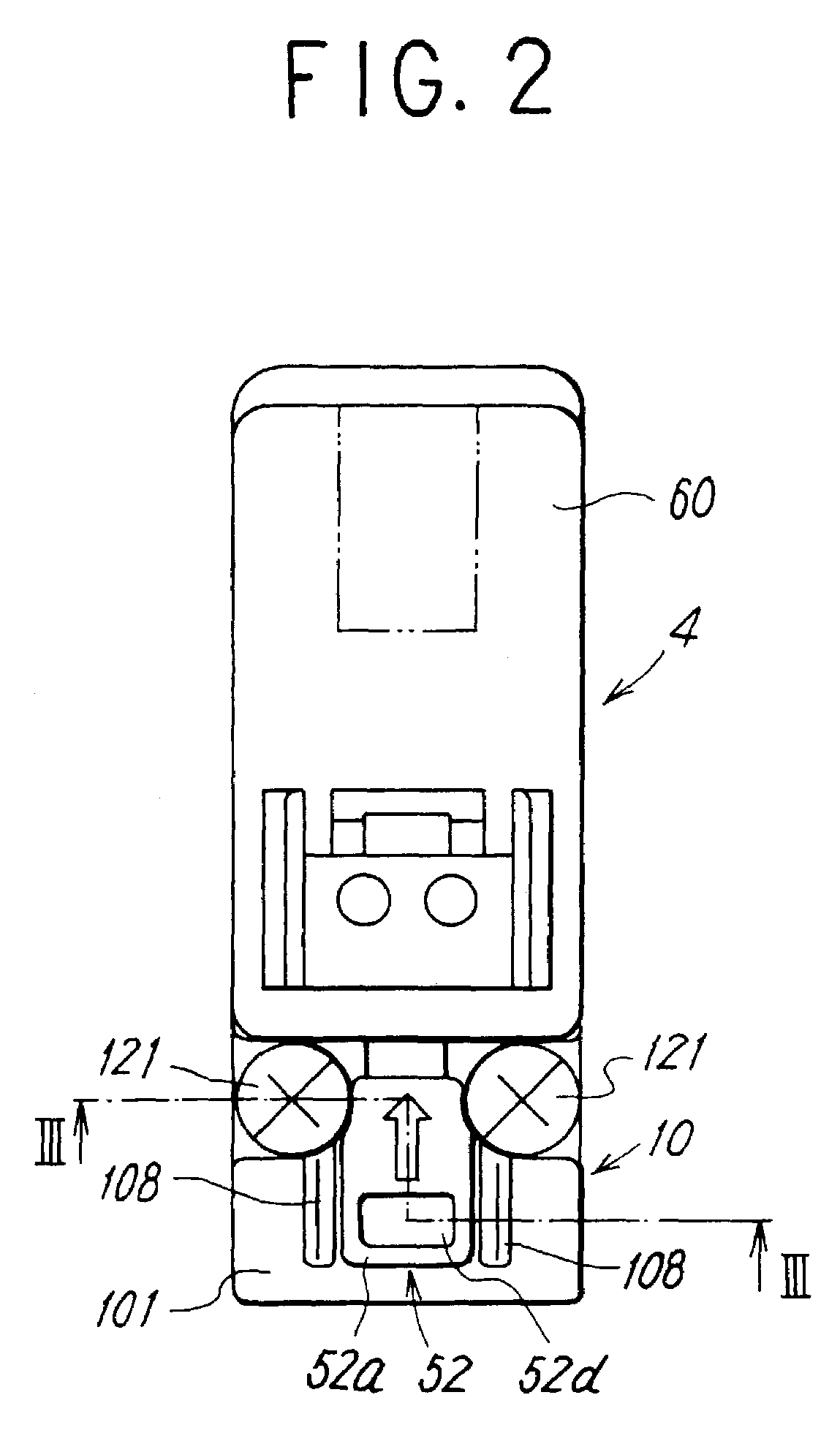

Solenoid valve having manually-operated device

ActiveUS6959910B2Simple structureAccurate transmissionOperating means/releasing devices for valvesSolenoid valveValve seat

A solenoid valve includes a main valve having a valve member which switches over flow paths by contacting with and separating from valve seats in a valve casing, a solenoid operating portion to drive the valve member, and a manually-operated device including an operation rod air-tightly and slidably accommodated in a rod-insertion hole provided in the valve casing and abuts against an end surface of a movable iron core to push the movable iron core in its axial direction, and an operating member movably mounted to a mounting surface of the valve casing to drive the operation rod.

Owner:SMC CORP

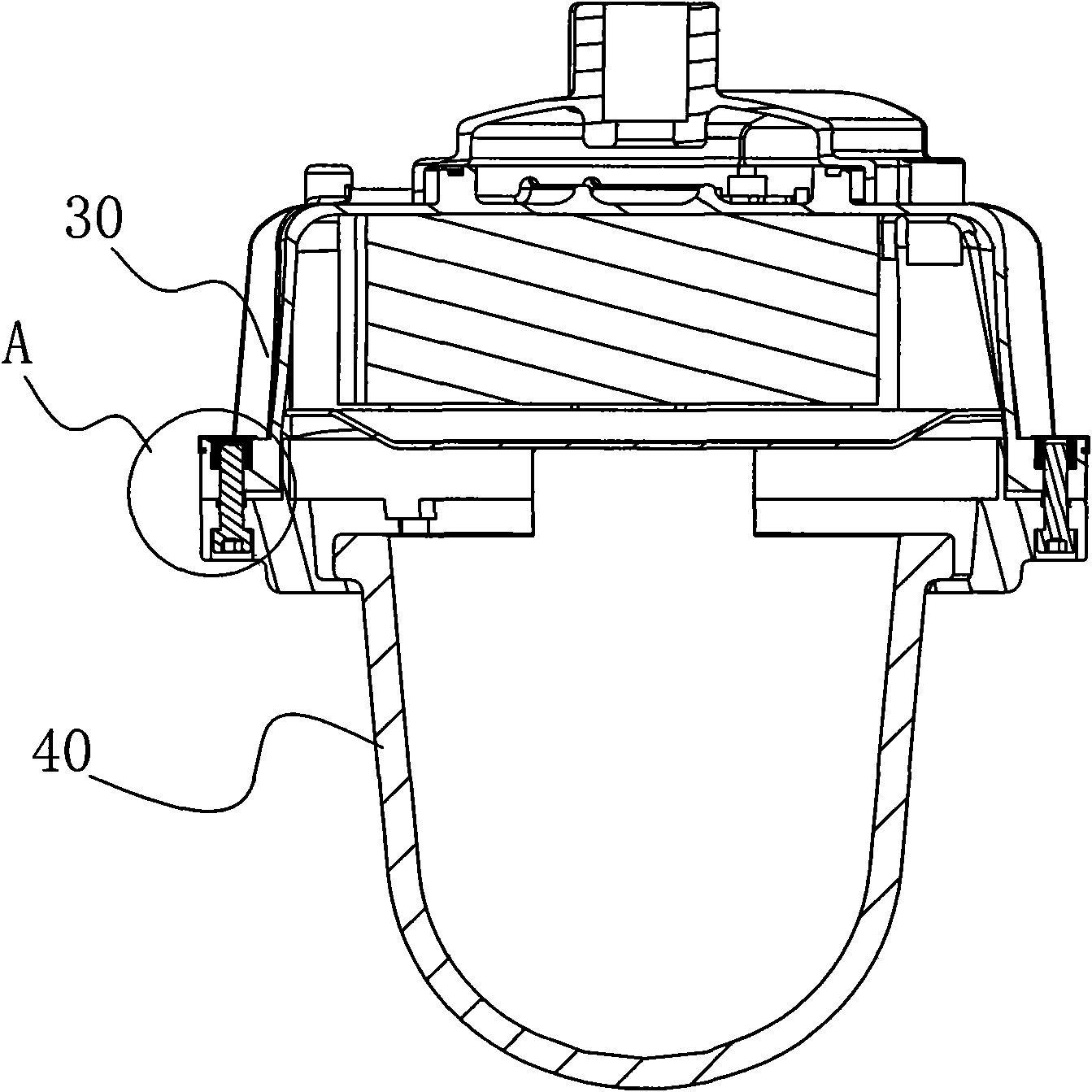

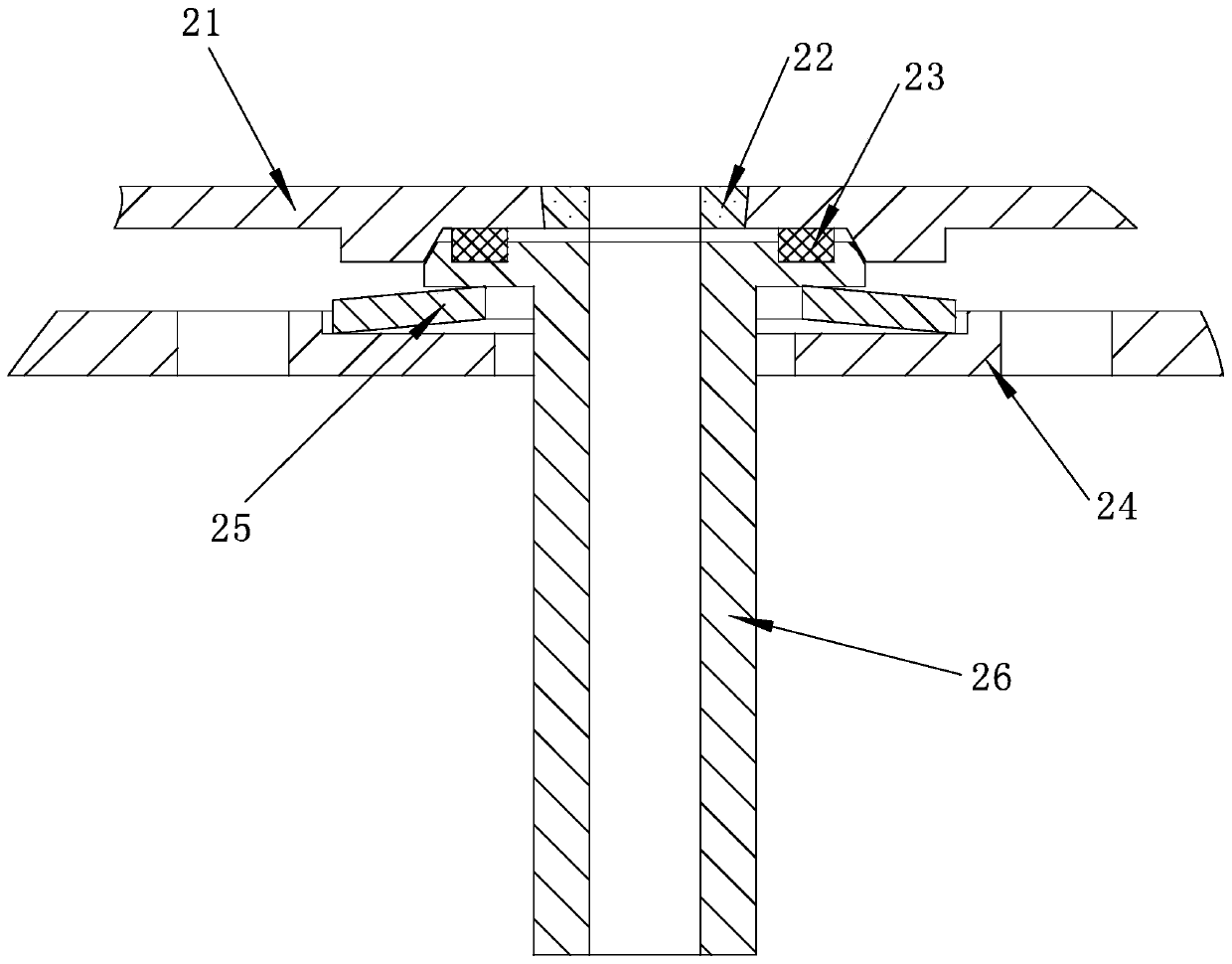

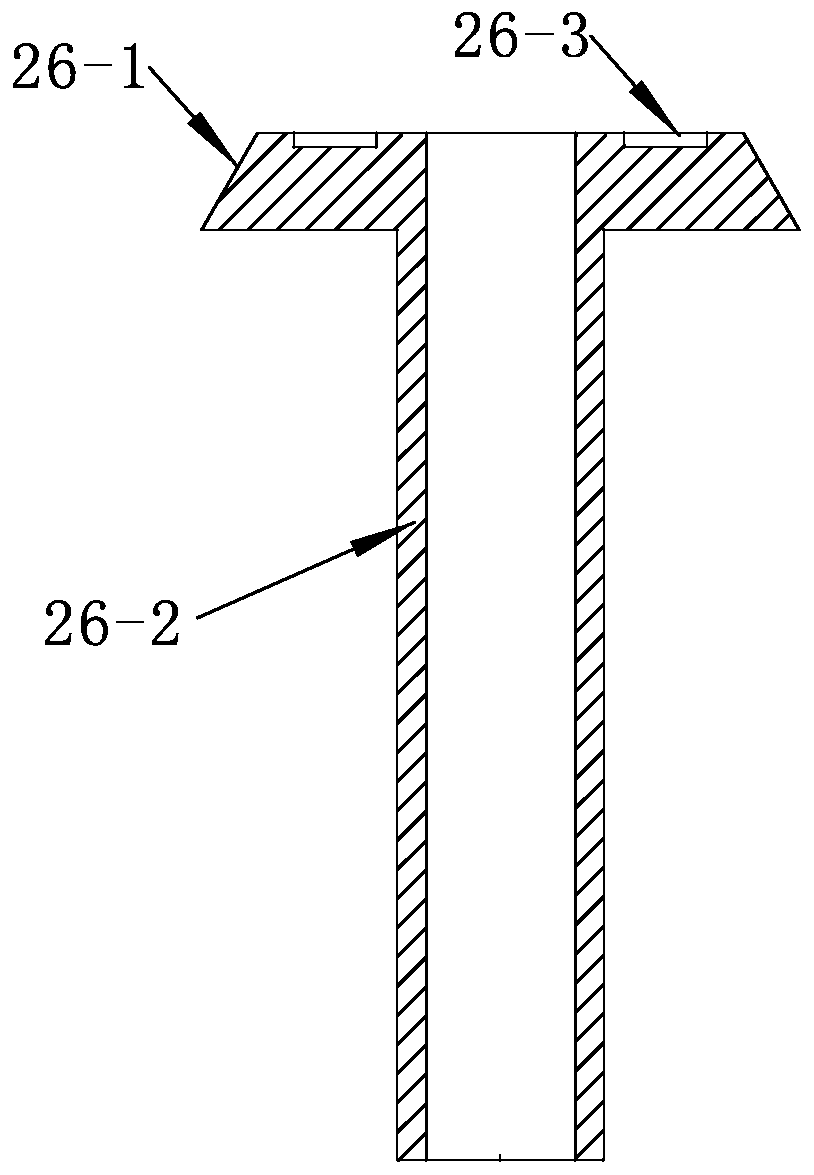

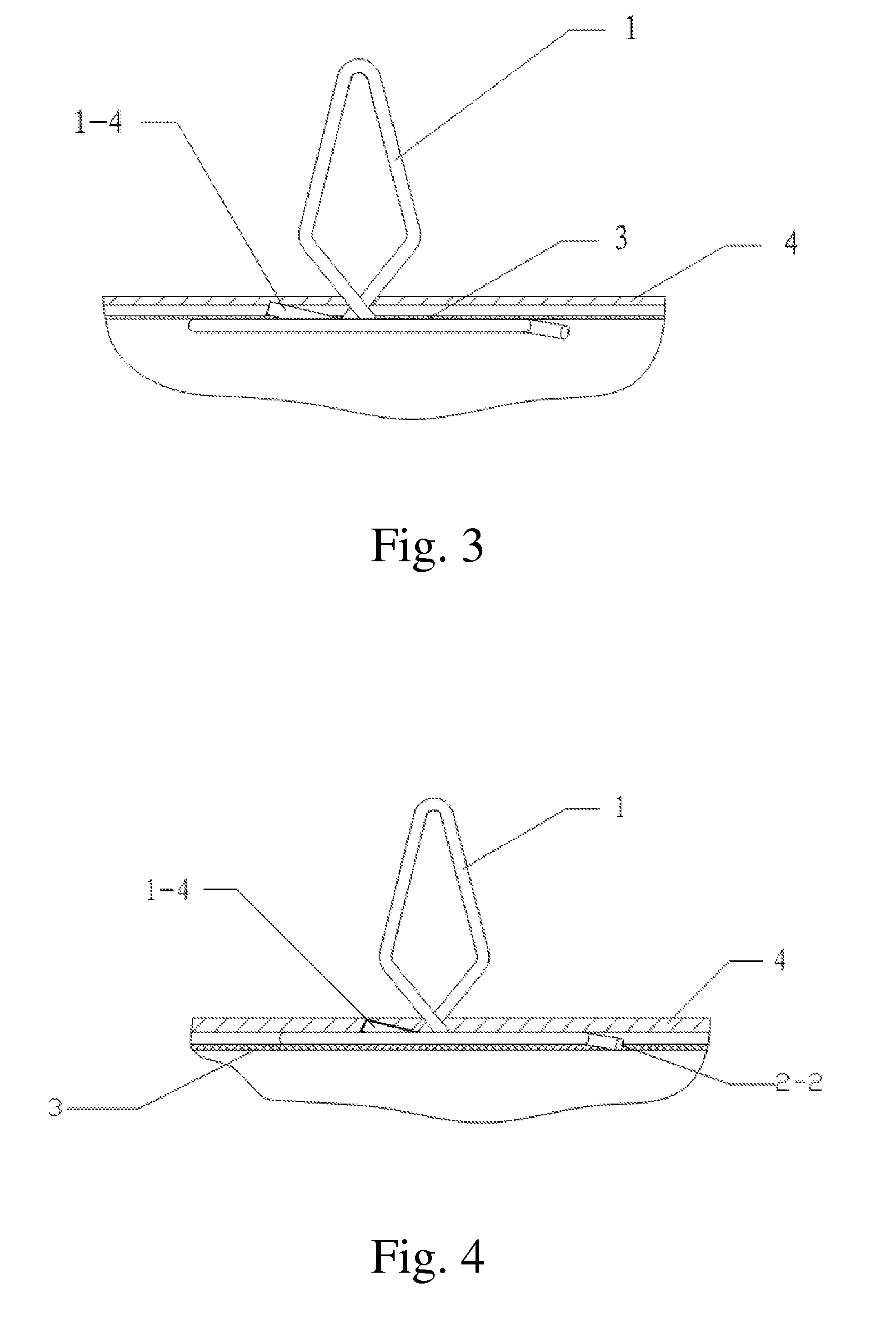

Automatic adjusting and sealing mechanism for uplift riser tube of antigravity casting machine

The invention relates to a sealing mechanism, in particular to an automatic adjusting and sealing mechanism for an uplift riser tube of an anti-gravity casting machine, which comprises a riser tube and a middle partition plate, wherein the riser tube is integrally formed by a flange and a tube body from top to bottom. The mechanism further comprises a sealing gasket, a riser tube supporting plateand an elastic element, wherein an insertion hole is formed in the middle of the riser tube supporting plate; the elastic element with a through hole is arranged on the upper end face of the riser tube supporting plate; the tube body is arranged in the insertion hole and the through hole in a penetrating mode; the tube body is fixedly connected with the riser tube supporting plate; the flange makes contact with the elastic element; the middle partition plate is inserted into the upper end face of the flange; and the middle partition plate is connected with the flange in a sealed mode. The problem that sealing of the riser tube fails due to deformation of the middle partition plate is solved, and smooth differential pressure pouring can be guaranteed.

Owner:HARBIN INST OF TECH

Flanged connection component

The invention provides a flanged connection component which comprises a first annular flange plate, a second annular flange plate. The first flange plate and the second flange plate are connected through a fastening piece, are aligned relative to a central shaft, and are respectively provided with base planes which are far from each other and butt joint faces which are matched with each other. Each butt joint face comprises at least one oblique plane, and a certain angle is formed between the oblique planes and the base planes. The two flange plates can shift in the axial direction in a driven mode, so that the too small or too large pressing force due to the fact that bolts extend due to thermal expansion and difference of thickness expansion amounts of the flange plates is compensated, the purpose of effective sealing is achieved, moreover, pre-tightening force borne by the bolts can be reduced on the premise of not increasing the number of the bolts, and reliability and economy of the flanged connection component are improved.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Pressure device for airtightness detection of casing and manufacturing method thereof

ActiveCN102944370AEasy to useEasy to carryDetection of fluid at leakage pointEngineeringHigh pressure

The invention discloses a pressure device for airtightness detection of a casing, and a manufacturing method of the pressure device. The pressure device for the detection comprises a casing body formed in a manner that a first casing is connected with a second casing, wherein the tail end of the second casing is closed; two packer components set by the action of high pressure gas and pressure energy storage rings are arranged on the first casing and the second casing correspondingly; a first one-way valve and a second one-way valve that are opposite in conduction direction are arranged on the casing body between the two packer components; the first casing is provided with an annular hollow structure; and the second casing is provided with a hollow structure. The pressure device for the detection is convenient to use and carry, and can detect the airtightness of the casing on a construction site.

Owner:通奥检测集团股份有限公司

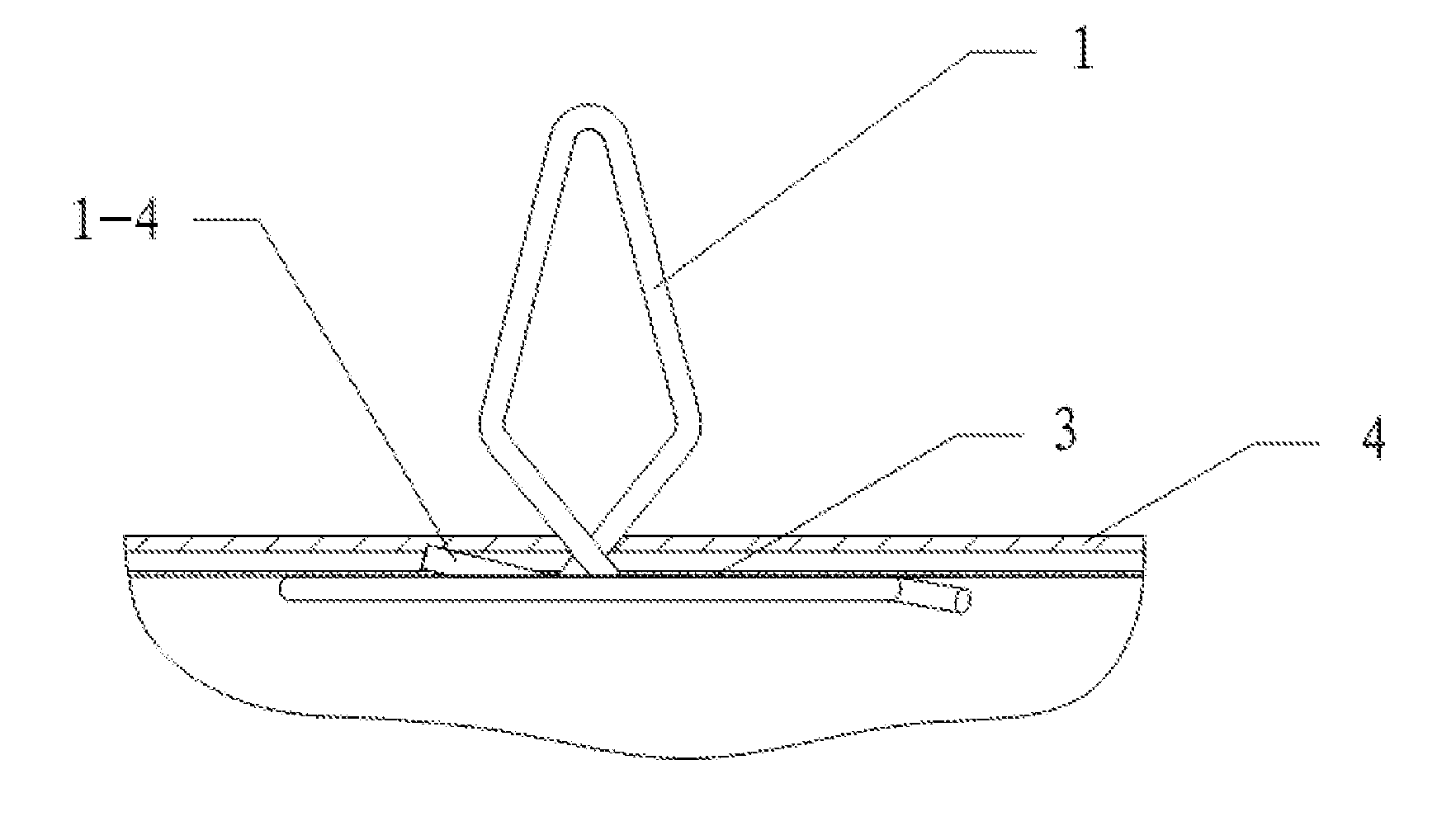

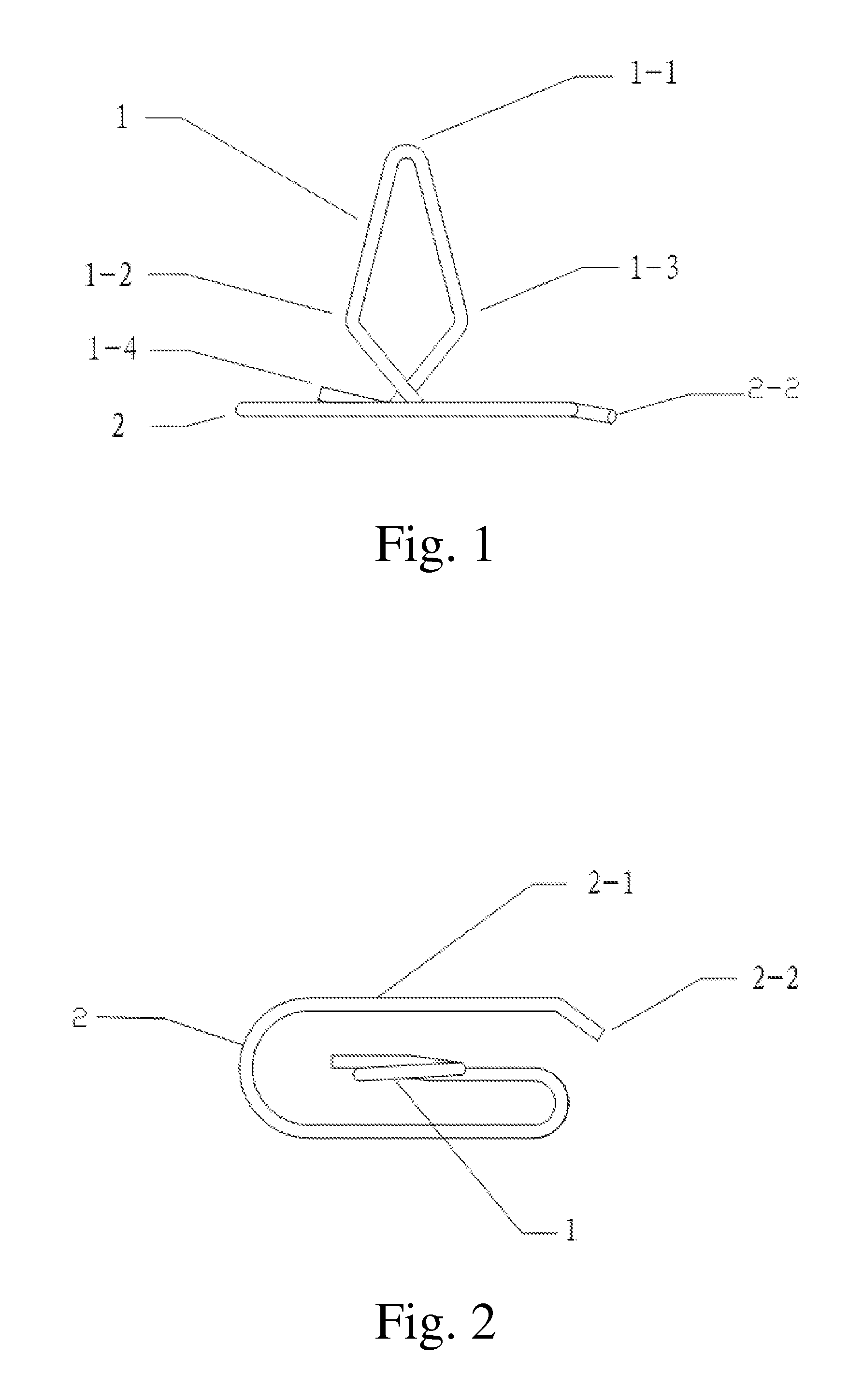

Steel wire hook

ActiveUS8601646B2Effective preventionAvoid seal failureSnap fastenersEngine sealsEngineeringLeft shoulder

A steel wire hook includes a head and a base which are made of metallic wire. The head is connected with the base. A plane where the head is provided is perpendicular to a plane where the base is provided. The head includes a circular-arc-shaped top end portion, a left shoulder, a right shoulder and a short leg. The left shoulder and the right shoulder are extended from the circular-arc-shaped top end portion and are symmetrical to each other. The short leg is provided at a lower end of the head and is tilted towards the circular-arc-shaped top end portion. An angle is provided between the short leg and the base. The base, having an approximately oval-shape and formed by coiling a metallic wire at a horizontal direction, includes a long leg which has a larger gap from the main body of the base.

Owner:WANG ZHANGJIAN

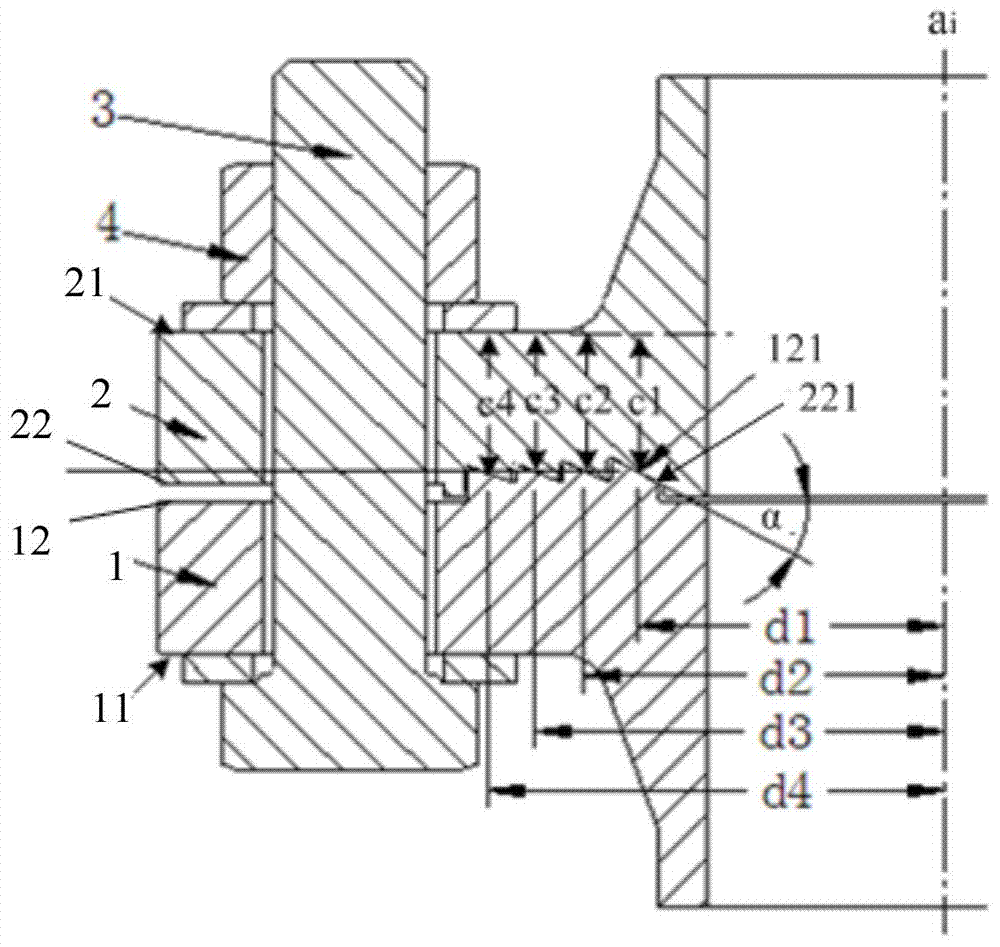

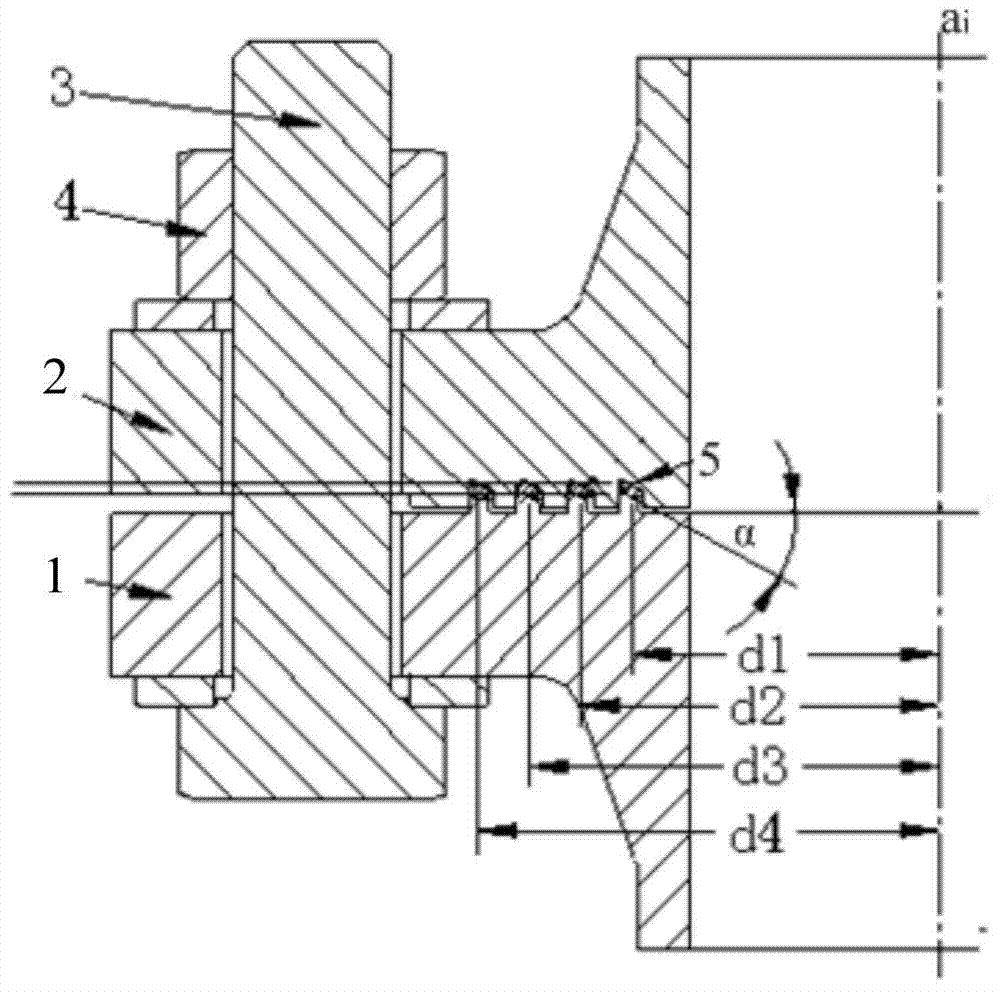

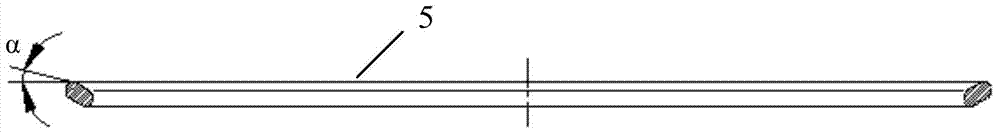

Sealing structure for extension end of motor shaft

PendingCN108429384AExtended service lifeImproves sealing reliabilityEngine sealsSupports/enclosures/casingsMotor shaftOil storage

The invention belongs to the technical field of shaft sealing, in particular to a sealing structure of an extension end of a motor shaft. The structure comprises a motor end cover and a motor shaft extension end. The motor shaft extension end is arranged on the motor end cover through a bearing. A double oil sealing structure is arranged between the motor end cover and the motor shaft extension end. The double oil sealing structure comprises an oil sealing seat connected with the motor end cover and an outer oil sealing and an inner oil sealing arranged in the oil sealing seat. The outer oil sealing and an inner oil sealing are arranged opposite with each other and are matched with the oil sealing seat in interference mode. An oil storage chamber is arranged between the outer oil sealing and the inner oil sealing and an oil sealing ring is accommodated in the oil storage chamber. By designing two oil sealings, when there is no lubricating medium inside the motor, an oil storage space is formed in the middle of the two oil sealings and lubricating oil is injected into the middle of the two oil sealings, so that the lubricating environment necessary for normal operation of the oil sealing can be provided, so that the service life and the sealing reliability of the oil sealing are prolonged.

Owner:JING JIN ELECTRIC TECHNOLOGIES (BEIJING) CO LTD

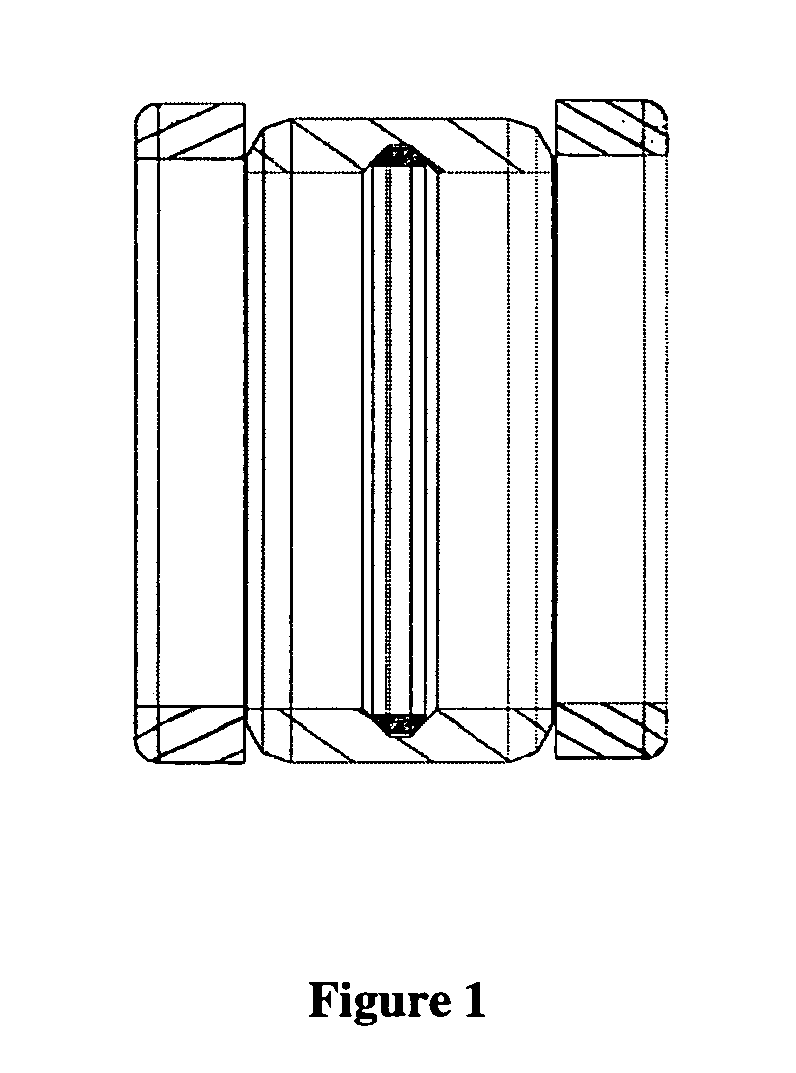

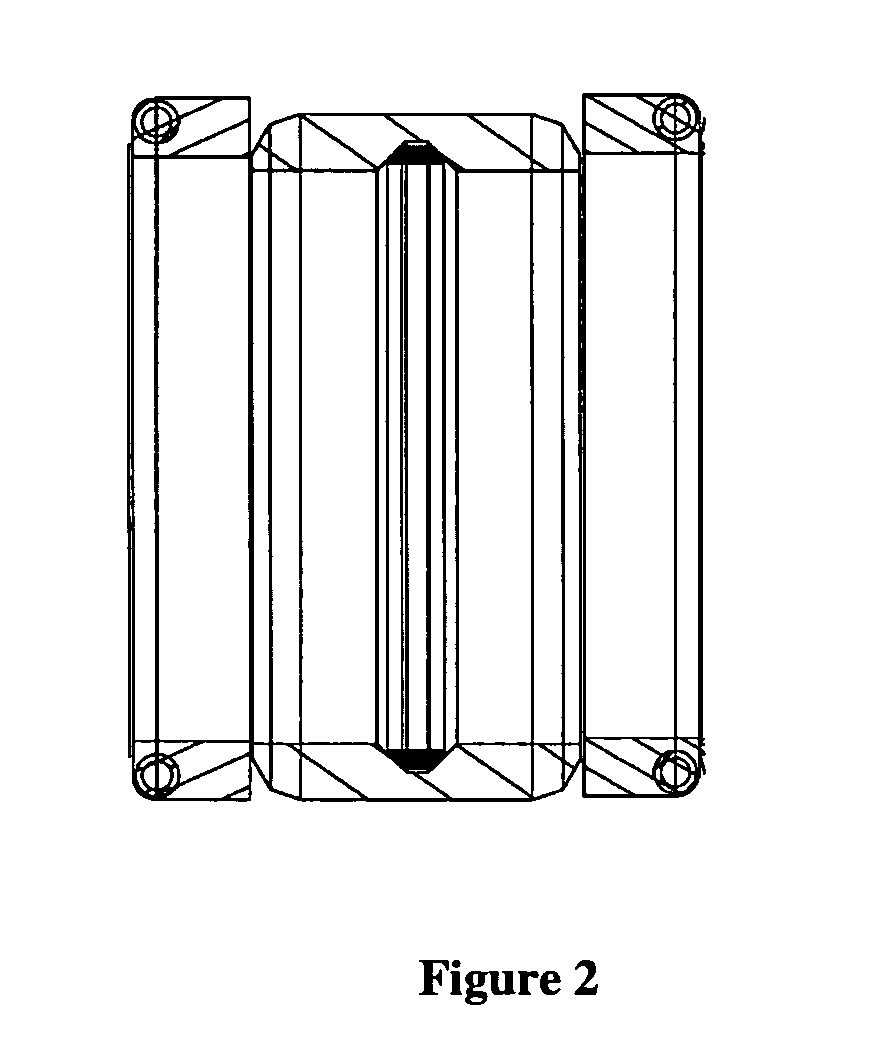

Rubber barrel with relatively hard upper and lower end parts, packer and bridge plug

The invention relates to the field of sealing and particularly relates to a rubber barrel with relatively hard upper and lower end parts, which is used in an oil exploitation process and can bear high temperature and high pressure, a packer and a bridge plug. According to one aspect of the invention, the rubber barrel is provided; and the hardness of the upper end part of the rubber barrel is greater than that of the middle part of the rubber barrel, so that the deformation of the middle part in the radial direction is greater than that of the upper end part in the radial direction when the upper end part bears first axial pressure. The hardness of the upper end part of the rubber barrel is greater than that of the middle part of the rubber barrel, so that the upper end part is almost used for transmitting the first axial pressure to the middle part and the lower end part, but not utilizes the first axial pressure to self radial deformation when the upper end part bears the first axial pressure. Therefore, the middle part and the lower end part have the radial deformation when the relatively small first axial pressure is used, and the sealing of the whole rubber barrel is realized.

Owner:TIANDING SEALING TECH BEIJING CO LTD

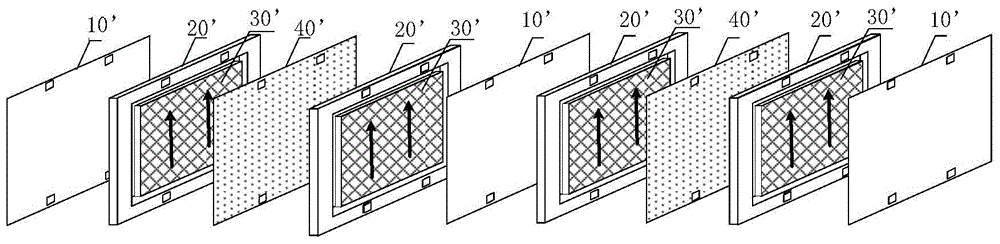

Flow cell ion exchange membrane assembly, preparing method of flow cell ion exchange membrane assembly and flow cell comprising flow cell ion exchange membrane assembly

InactiveCN105140543AReduce processing costsReduce the difficulty of assemblyRegenerative fuel cellsFuel cell detailsChemical physicsFlow cell

The invention discloses a flow cell ion exchange membrane assembly, a preparing method of the flow cell ion exchange membrane assembly and a flow cell comprising the flow cell ion exchange membrane assembly. The flow cell ion exchange membrane assembly comprises a porous membrane, an iron exchange area coating arranged in the middle area of the porous membrane, and a sealing area coating arranged in the area, outside the ion exchange area coating, of the porous membrane. The preparing method includes the following steps that firstly, the porous membrane serves as the base material, the middle area of the porous membrane is coated with the ion exchange area coating; secondly, the area, outside the ion exchange area coating, of the porous membrane is coated with the sealing area coating. By means of the technical scheme, due to the existence of a sealing area, sealing rings or sealing gaskets do not need to be embedded or added to liquid flow frames on the two sides of the flow cell ion exchange membrane assembly when a cell stack is assembled, the processing cost and the assembling difficulty of cells are lowered, and meanwhile the problem of the sealing failure caused by water absorption swelling of the iron exchange membrane in conventional design can also be solved.

Owner:中国东方电气集团有限公司

Electromagnetic valve with hard sealing structure

PendingCN112361671AReduce sealReduce usageOperating means/releasing devices for valvesCompression machinesReciprocating motionElectromagnetic valve

The invention relates to an electromagnetic valve with a hard sealing structure. The electromagnetic valve comprises a valve body internally provided with a fluid channel and an accommodating cavity,and a valve module mounted in the accommodating cavity, wherein the fluid channel is communicated with the accommodating cavity; the valve module comprises a liquid inlet base, a valve element matchedwith the liquid inlet base and used for closing or opening the fluid channel, and a driving mechanism for driving the valve element to do reciprocating motion; the liquid inlet base is provided witha guide hole allowing the lower end of the valve element to extend in; the middle section of the liquid inlet base is provided with a plurality of liquid inlet holes formed in the circumferential direction of the liquid inlet base; the lower section of the liquid inlet base is provided with a valve element fluid channel and a flow channel slope located on the upper portion of the valve element fluid channel and used for adjusting flow; and the valve element sequentially comprises a large-diameter section, a slope section, a small-diameter section and a valve element end slope from top to bottom. Compared with the prior art, the electromagnetic valve has the advantages that a hard sealing assembly mode is adopted, so that leakage is not likely to be caused, and the service life of the electromagnetic valve is greatly prolonged.

Owner:SHANGHAI ZHONGYUAN FUEL RAIL MFG +1

Honeycomb spiral radial brush-type labyrinth split seal

ActiveCN107060900APrevent separationAvoid cloggingPump componentsLeakage preventionImpellerPolymer science

The invention relates to a honeycomb spiral radial brush-type labyrinth split seal. The honeycomb spiral radial brush-type labyrinth split seal comprises a shaft sleeve assembly, a honeycomb seal body assembly, a driving end brush-type seal assembly and an impeller end brush-type seal assembly, wherein the driving end brush-type seal assembly and the impeller end brush-type seal assembly are arranged at the two ends of the honeycomb seal body assembly. An original seal length is nearly doubled, and the sealing effect is effectively enhanced. The shaft sleeve assembly, the honeycomb seal body assembly, the driving end brush-type seal assembly and the impeller end brush-type seal assembly are all of a split structure. Due to the fact that all the assemblies are of the split structure, the applied range is made wider. A shaft sleeve is in a split type and is closed at the outer circle position and the end face position of the shaft sleeve, so that strength of the shaft sleeve is increased, and the phenomenon that the shaft sleeve can be split due to insufficient closing force in the high-speed rotating process is prevented. Moreover, the middle part and the driving end of the shaft sleeve are both provided with bosses, due to the facts that a spiral groove and seal teeth arranged in the middle section boss are matched, and a groove formed in the back of an impeller and the impeller end brush-type seal assembly are also matched, the original seal length is nearly doubled, and the sealing effect is greatly enhanced. The structure is novel and the practicality is high.

Owner:沈阳北碳密封有限公司

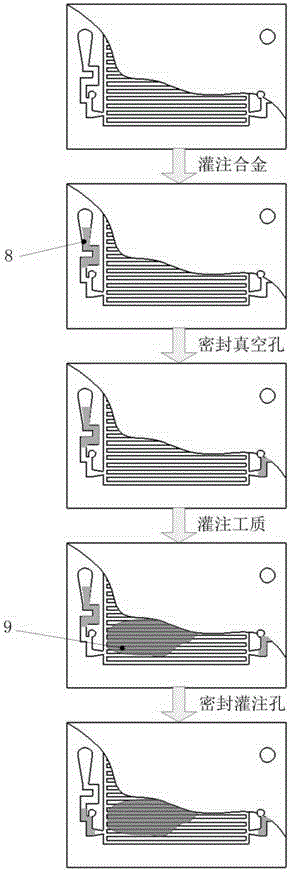

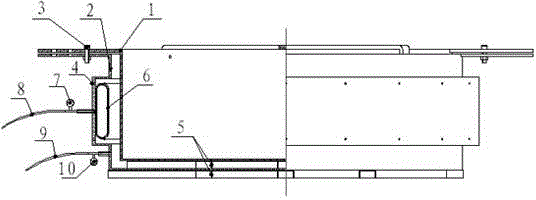

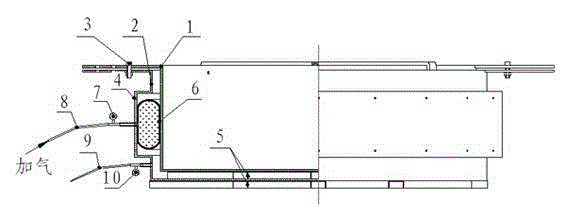

Method using low-melting-point alloy for sealing micro heat pipe filling hole

ActiveCN104961093AReduce the effect of vacuumAvoid seal failurePrecision positioning equipmentDecorative surface effectsAlloySolvent

The present invention discloses a method using a low-melting-point alloy for sealing a micro heat pipe filling hole, and the method is used for heat pipe packaging manufacturing and device heat dissipation, and belongs to the field of device packaging and heat dissipation. Before a working medium is filled, the low-melting-point alloy is preset in a silicon-based micro heat pipe, after completion of vacuumizing operation, a vacuumizing hole is sealed by low-melting-point alloy melting and solidification; and after the working medium filling proceeds, a working medium filling hole is sealed by low-melting-point alloy melting and solidification to complete the entire micro heat pipe filling operation. A micro heat pipe sealed with the method is free of a sealant, the method is suitable for solvents such as ethanol, acetone and the like as the filling working medium, the micro heat pipe has long-term sealing effect; and by use of the low-melting-point alloy for sealing, impact on micro heat pipe heat transfer properties due to material gas release can be reduced.

Owner:DALIAN UNIV OF TECH

Tool and method for detecting sealing performance of water stop capsules for bearing platform construction

ActiveCN105738044ARealize air tightness detectionAvoid seal failureMeasurement of fluid loss/gain rateEngineeringAtmospheric pressure

The invention discloses a tool and method for detecting sealing performance of water stop capsules for bearing platform construction. The tool for detecting sealing performance of water stop capsules for bearing platforms comprises an inner steel sleeve, an outer steel sleeve, an adjusting bolt, an extensible air pipe, an inlet end pressure gauge, an extensible water pipe, and a water inlet end pressure gauge; a space is kept between the inner steel sleeve and the outer steel sleeve; the inner steel sleeve and the outer steel sleeve are connected through the adjusting bolt; the extensible air pipe and the extensible water pipe are both connected to the outer steel sleeve. The detecting method comprises following steps: installing the water stop capsule; detecting the sealing performance of the device; detecting the air-tightness and sealing performance of the water stop capsule; performing eccentric detection. By means of the tool and method, not only sealing performance of water stop capsule with large diameter can be detected, but also the air pressure inside the water stop capsule can be determined and detected in real time as the judgment basis and experience results for sealing effect of the water stop capsule through the air inlet device which is connected to the outer part of the water stop capsule and the water inlet device which is connected to the outer steel sleeve.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

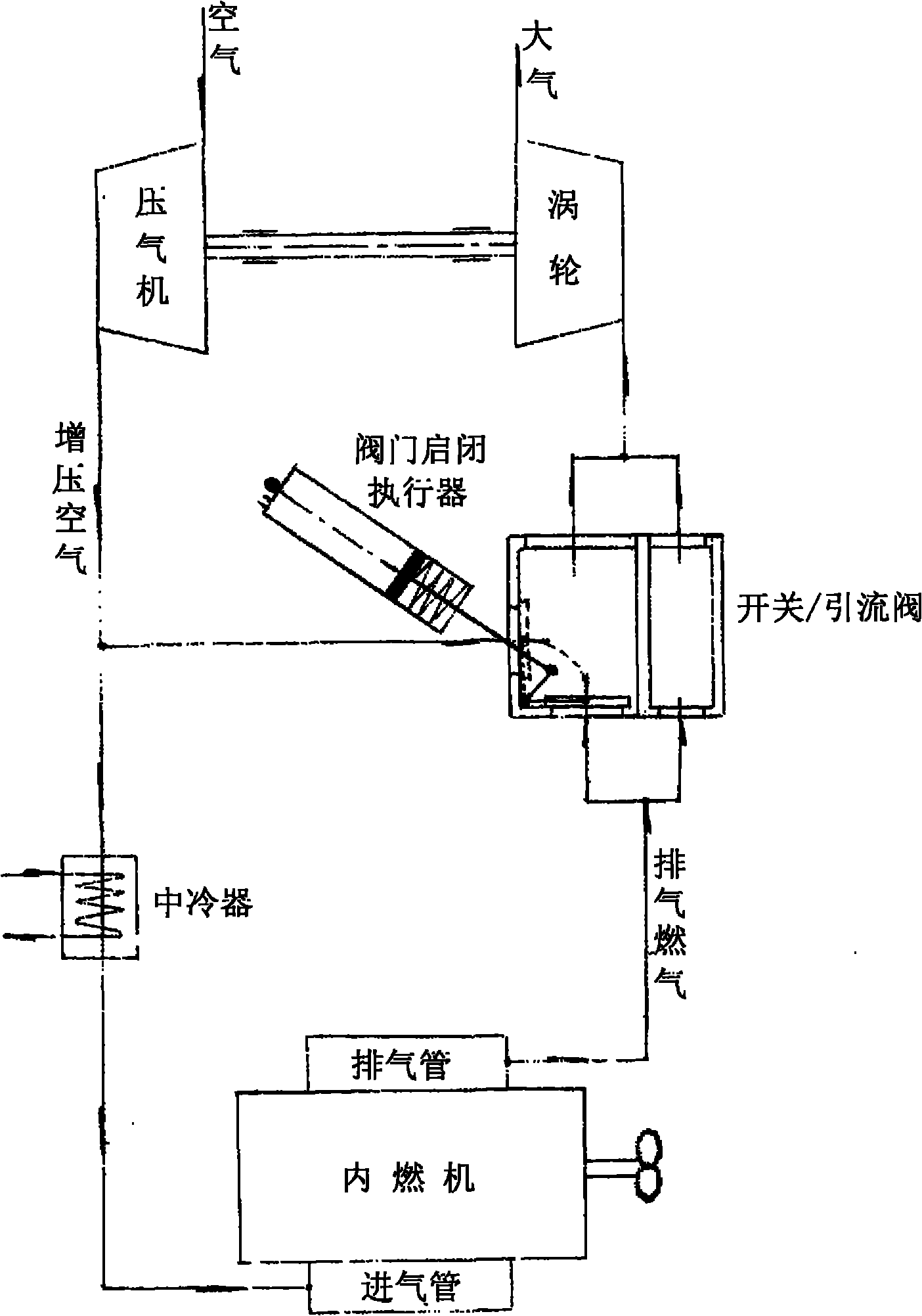

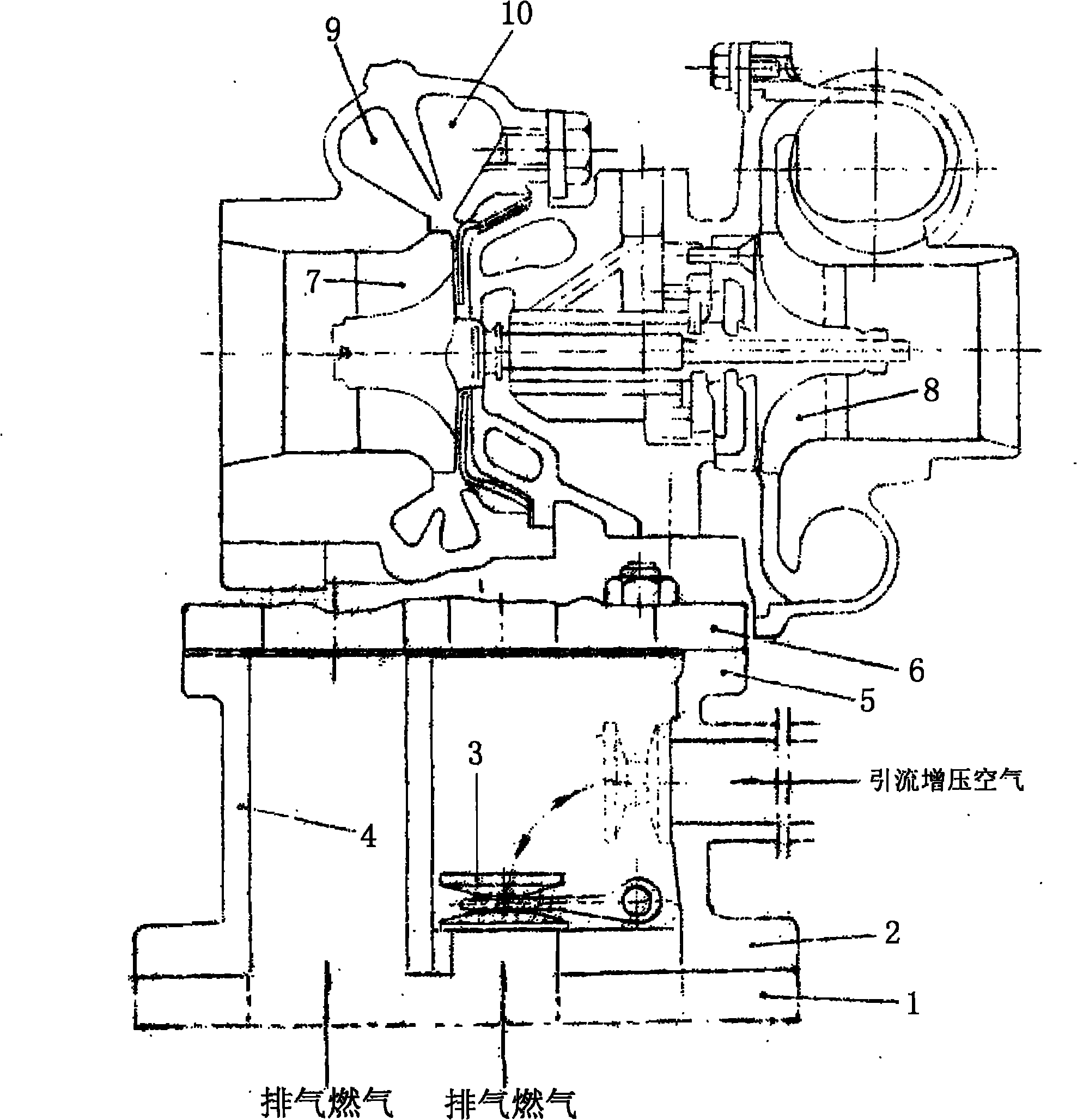

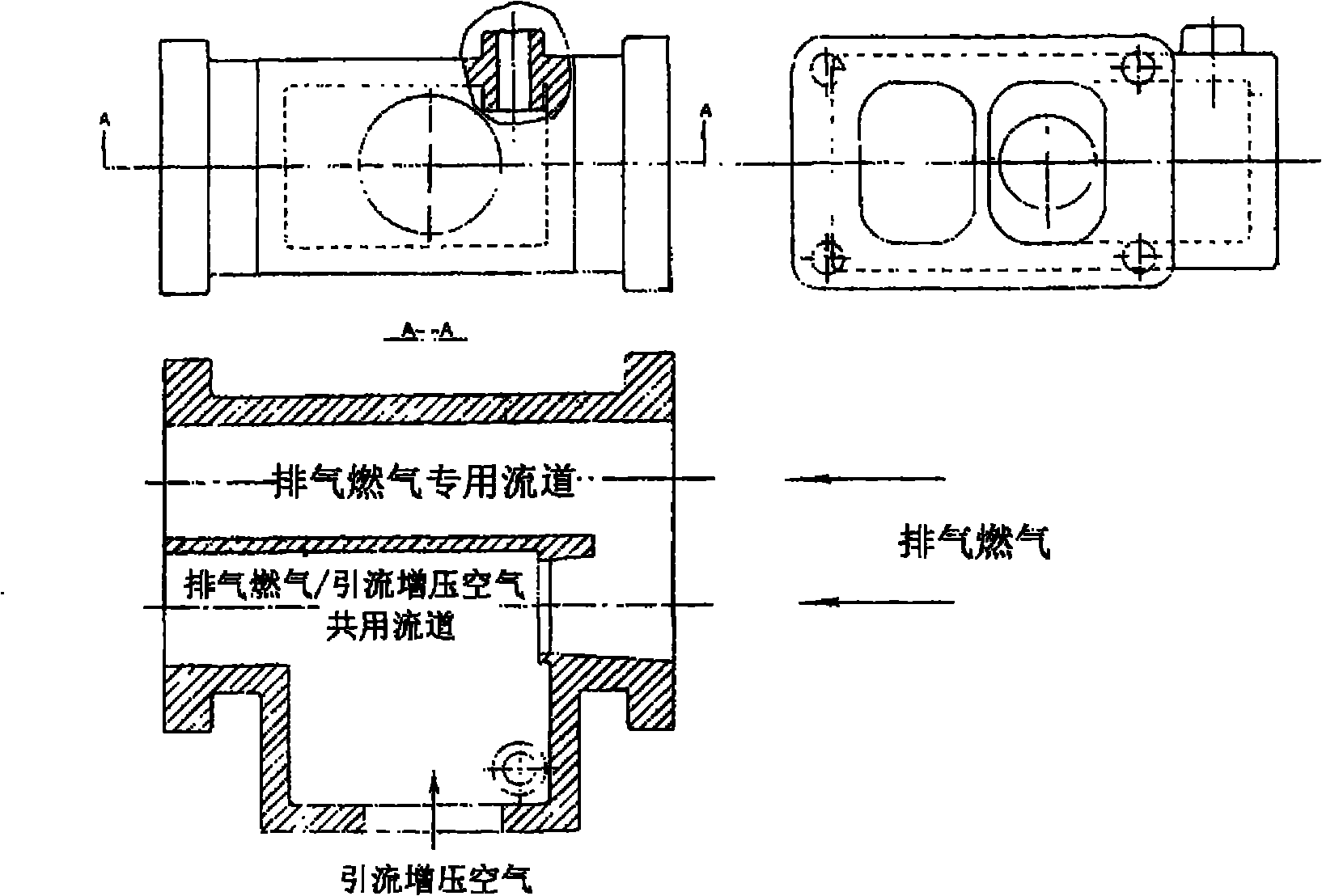

Turbocharger with variable turbine cross section and variable flow control function

InactiveCN101943052ASimple structureFusion simpleInternal combustion piston enginesGas turbine plantsTraffic capacityTurbocharger

The invention discloses a turbocharger with a variable turbine cross section and a variable flow control function, which is suitable for improving low working condition performance and transient characteristics and can meet the requirement on full-speed working condition characteristics of a supercharging internal combustion engine for vehicles / ships / engineering machinery. The turbocharger mainly comprises the ordinary conventional structure turbocharger with a double-flow channel inlet turbine volute, a switch / drain valve and a corresponding connecting pipeline. Due to linked conversion and switching of the opening and closing actions of the valve in a valve box, the configuration relationship between the flow rate of exhaust fuel gas flowing into the turbine and a through-flow cross section can be changed. Control can be performed accordingly, so that supercharging pressure can be increased greatly under a low (rotating speed / load) working condition and the increase of the supercharging pressure is suppressed under a high (rotating speed / load) working condition. Compared with the prior art, the turbocharger has the advantages of complete function, high control degree, mature technology, simple structure, low cost, easy combination with the current technology, large development potential and high popularization and application value.

Owner:孙敏超 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com