Multi-station transfer mechanism and motor bearing assembly equipment

A load-shifting and displacement technology, which is applied in the direction of electromechanical devices, metal processing equipment, assembly machines, etc., can solve the problems of reducing the service life of motors, poor assembly compatibility of different types of products, and difficulty in meeting flexible production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

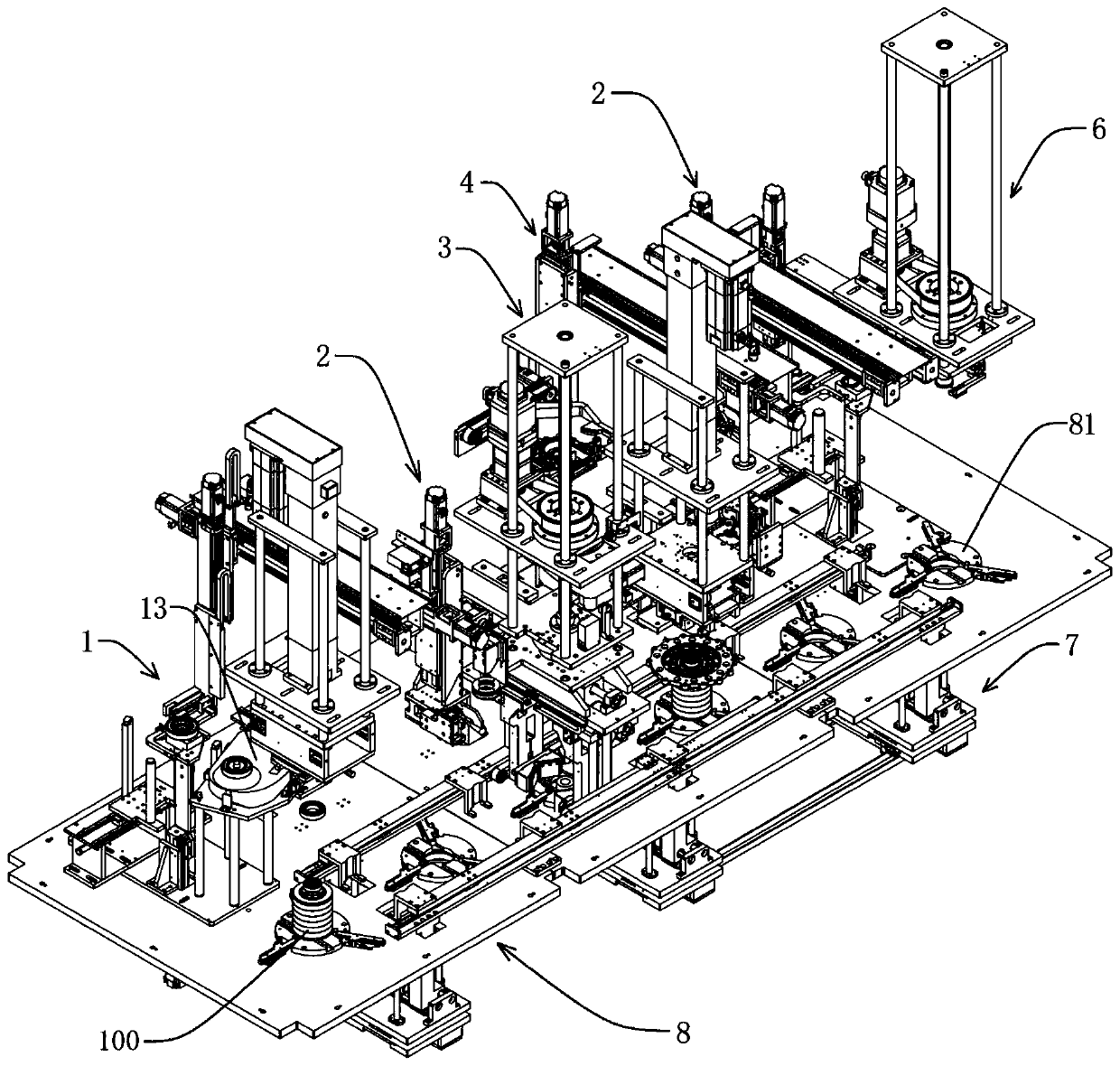

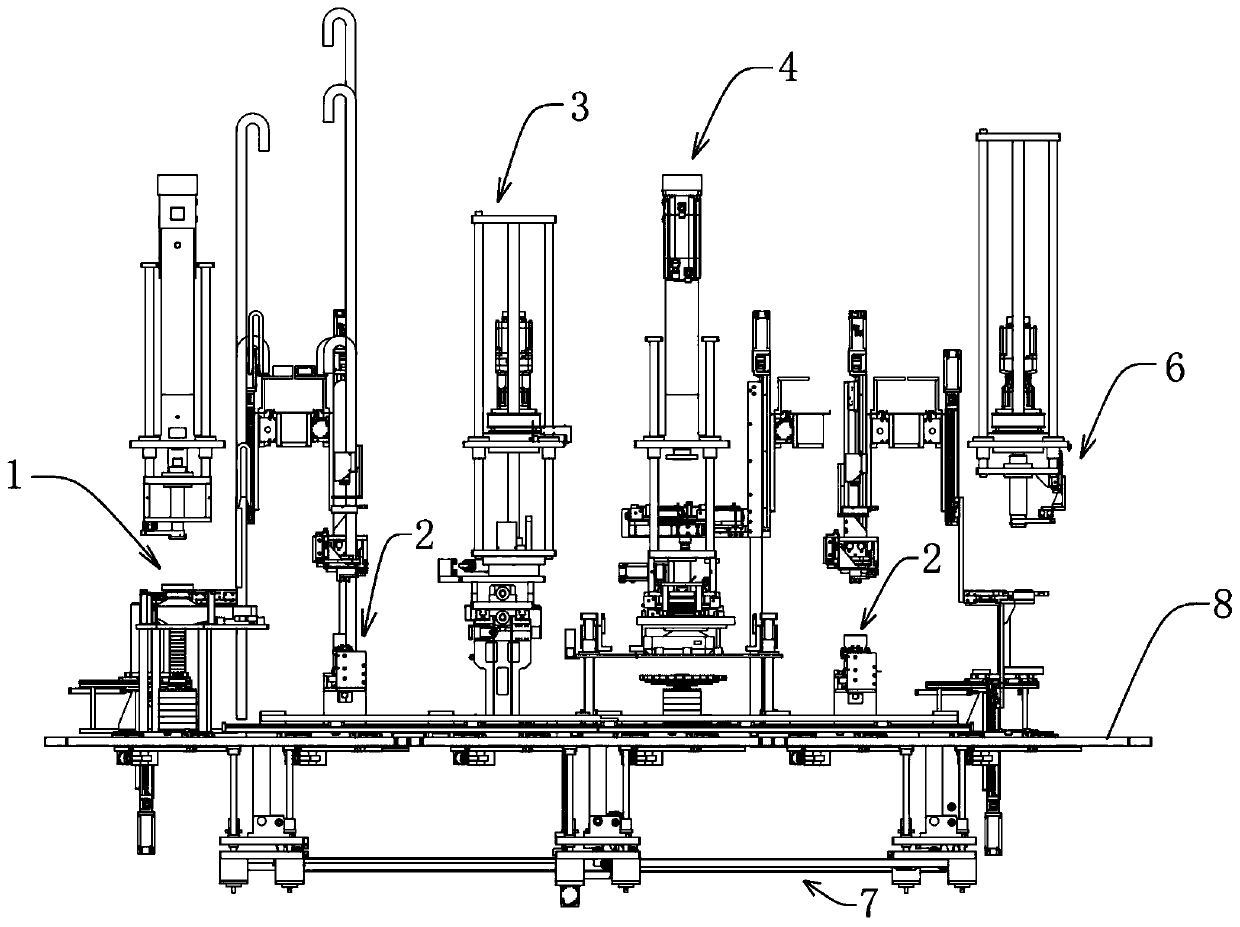

[0068] Such as Figure 1a with Figure 1b As shown, this embodiment relates to a motor bearing assembly equipment, including the first station-bearing assembly mechanism 1, the second station-circlip assembly mechanism 2, the third station-overturn mechanism 3, the fourth station, etc. Station-end cover bearing assembly mechanism 4, fifth station-circlip assembly mechanism 2, sixth station-sealing ring assembly mechanism 6, six-station loading mechanism 7 and workbench 8.

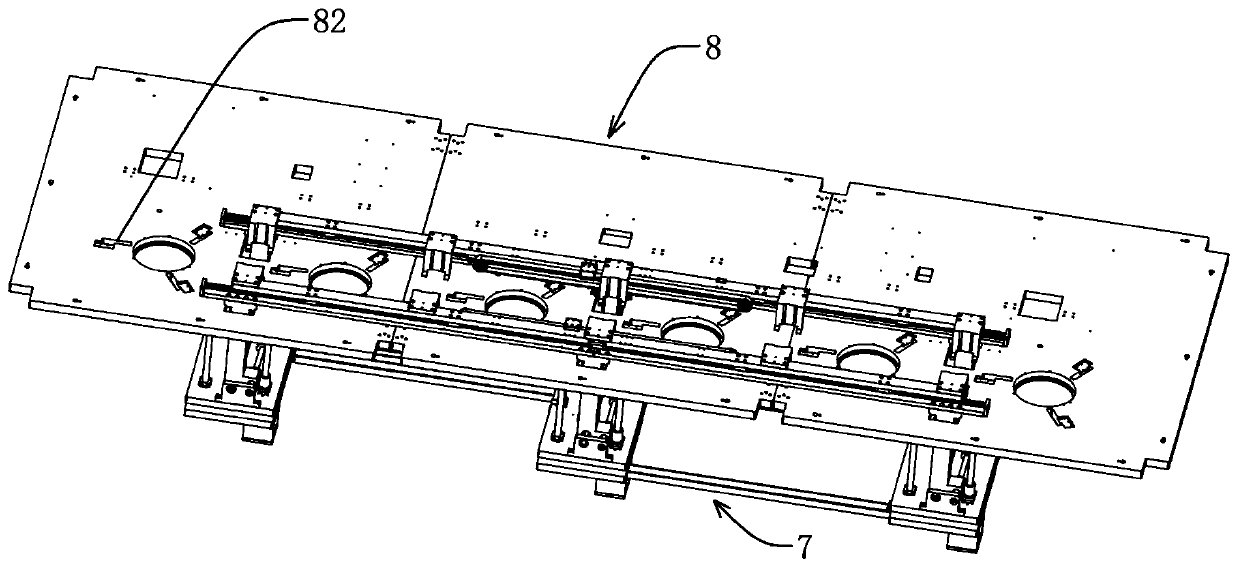

[0069] Such as figure 2 , Figure 3a , Figure 3b with Figure 3c As shown, the six-station load displacement mechanism 7 includes: an X-axis transfer assembly 71, a Y-axis spacing adjustment assembly 72, and three sets of Z-axis lifting assemblies 73. The three sets of Z-axis lifting assemblies 73 are divided into a middle group and two outer groups.

[0070] Each group of Z-axis lifting assemblies 73 includes a lifting platform 733 and two groups of ball screws 731 vertically arranged on the lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com