Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

381results about How to "Realize automatic flip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

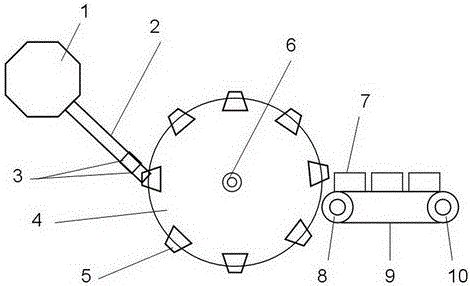

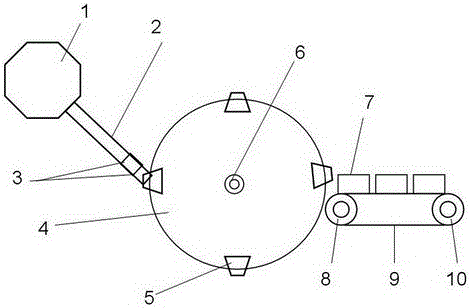

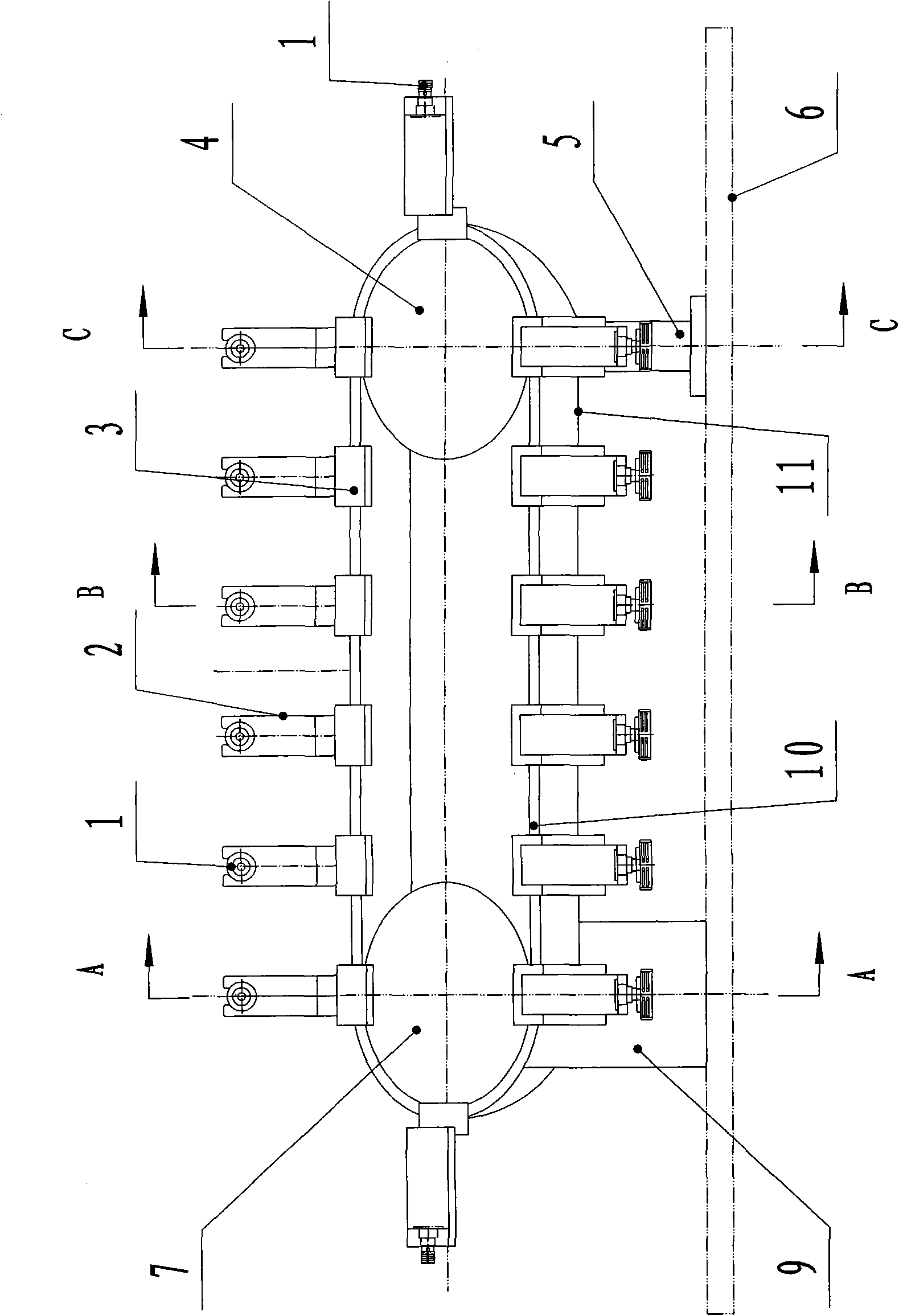

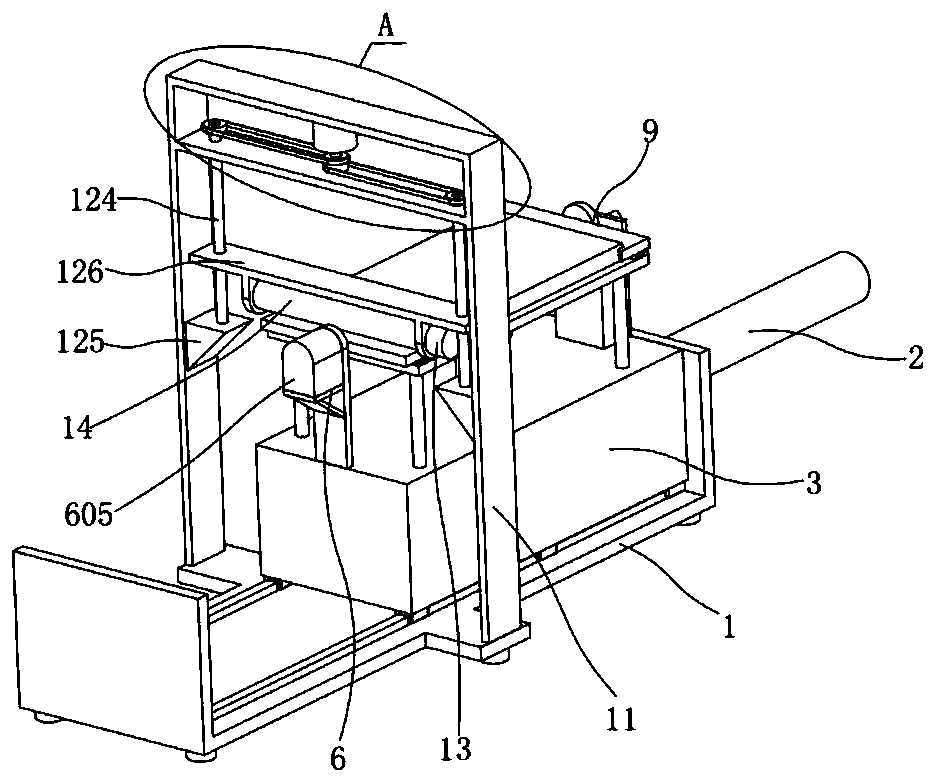

Automatic assembly machine of round capacitor

ActiveCN106847558ARealize automatic flipImprove welding efficiencyTerminal applying apparatusCapacitanceDistribution control

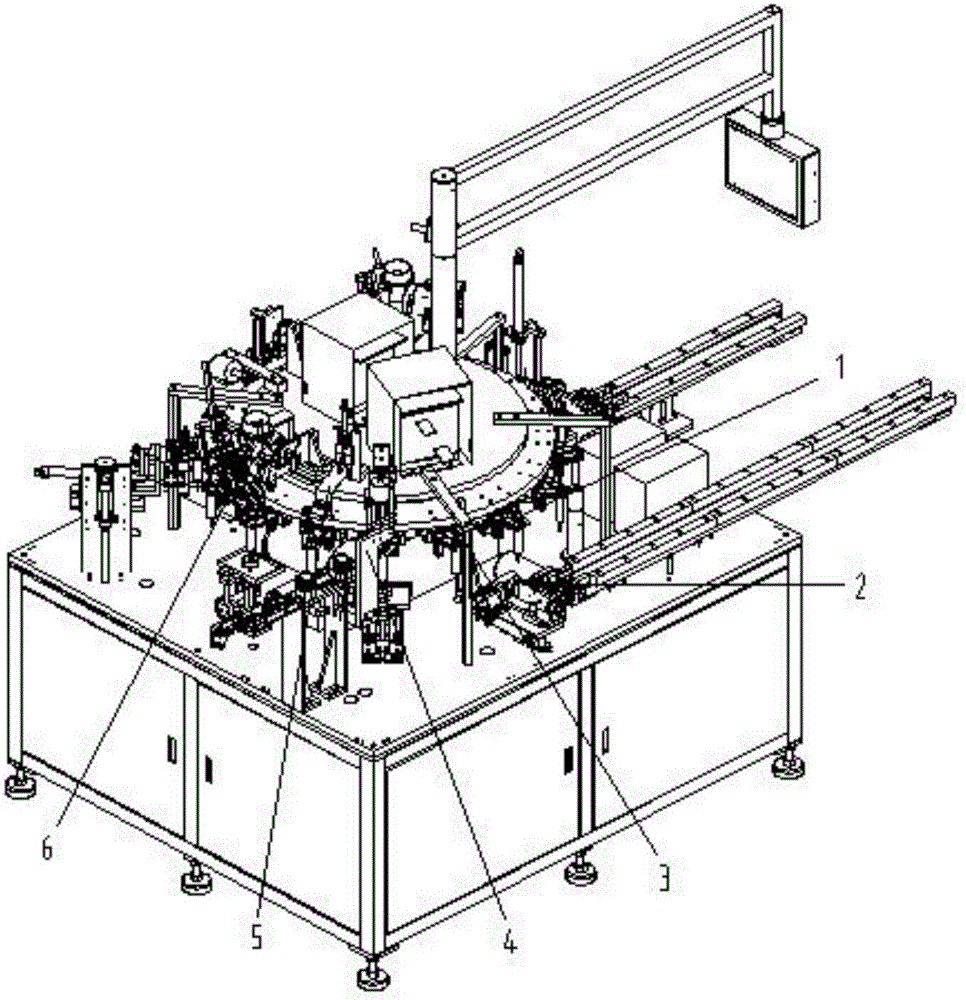

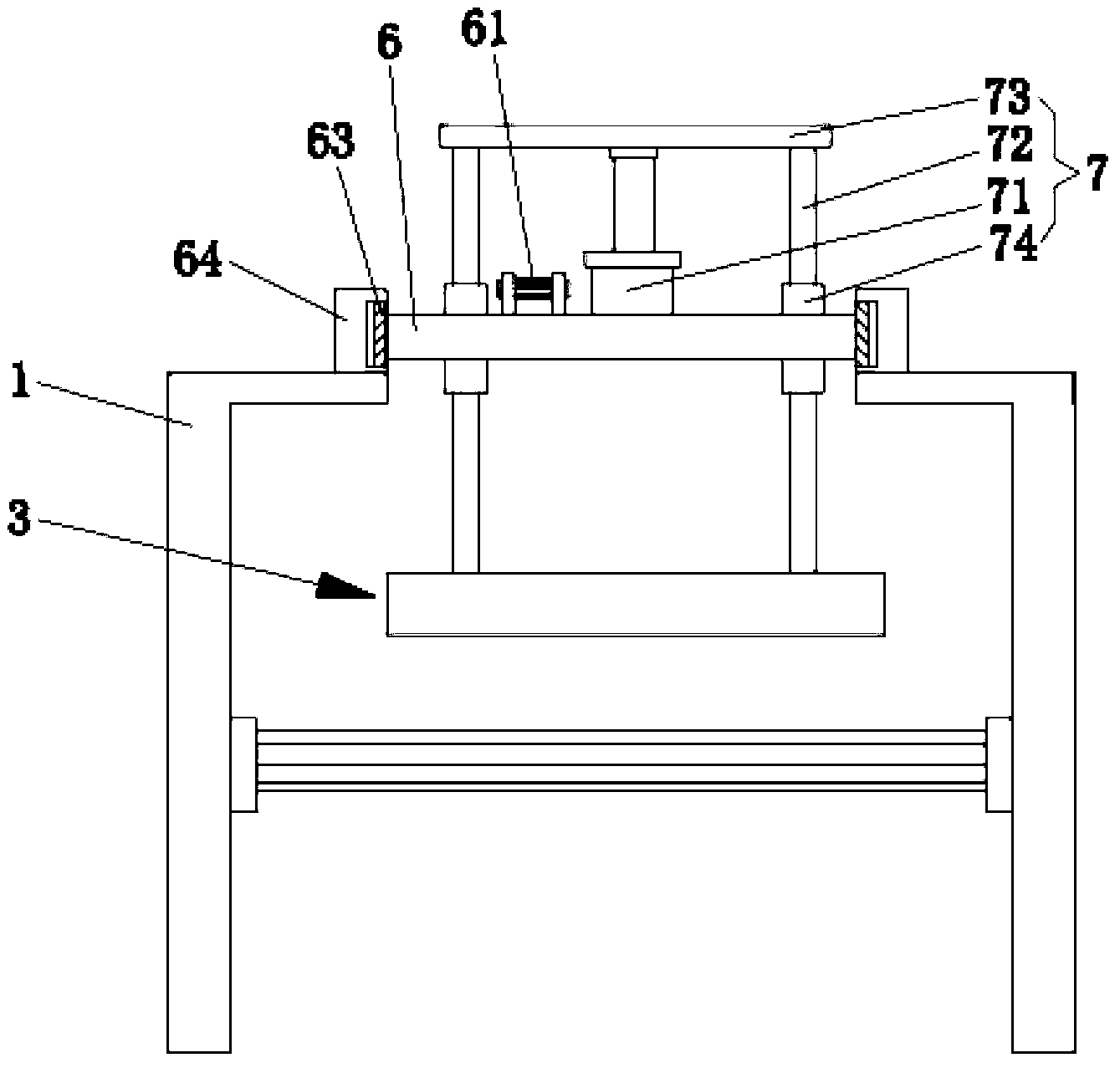

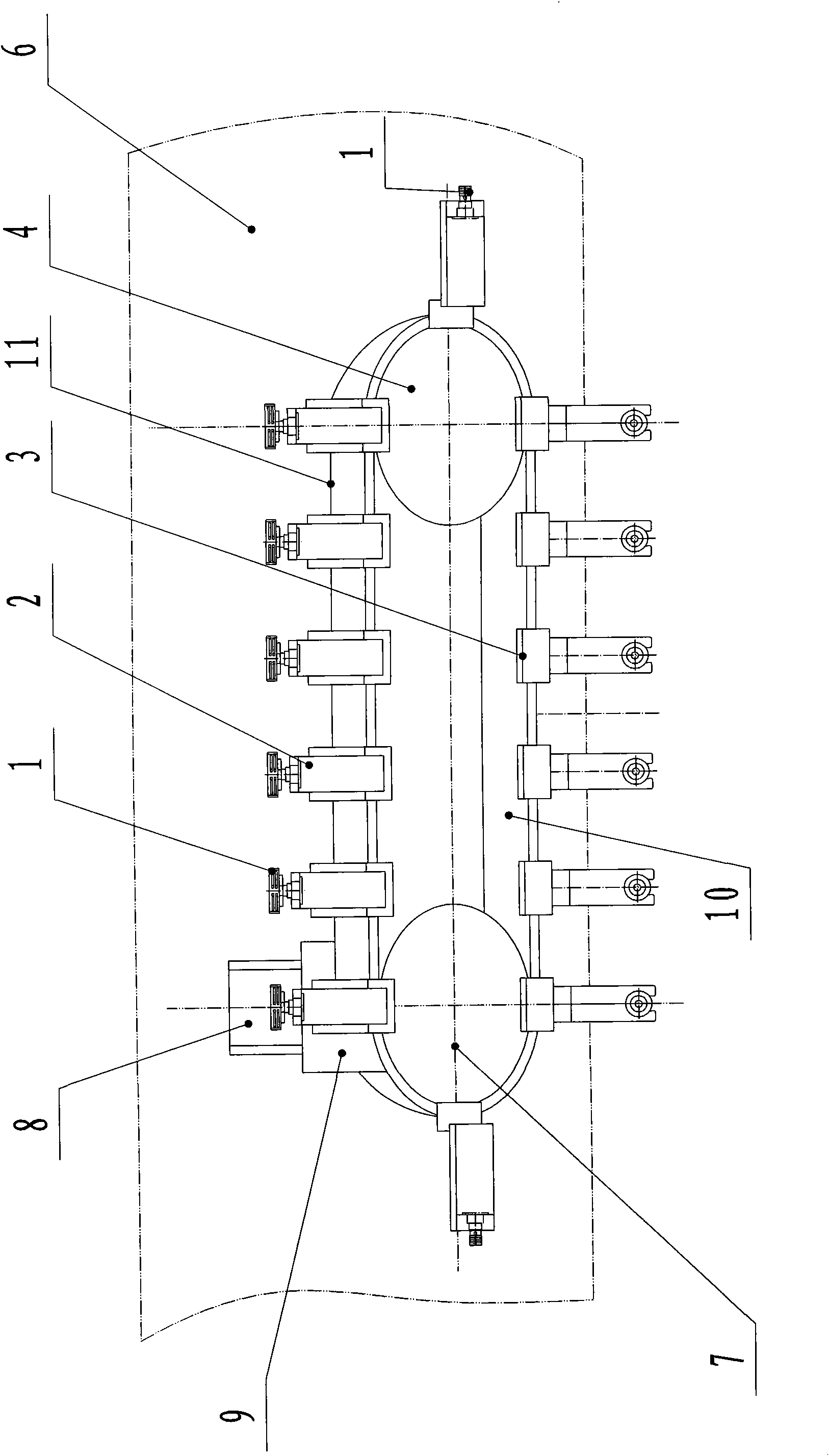

The invention relates to the field of capacitor processing equipment, in particular to an automatic assembly machine of a round capacitor. The machine includes a power distribution control box, a rotary plate and an operation screen, wherein the rotary plate and the operation screen are arranged above the power distribution control box through a bracket and communicated with the power distribution control box; clamps are uniformly arranged along a circle under the rotary plate; a feeding device, a positioning detection device, an upper tin-wire feeding device, a polarity detection device, a first tin-wire welding device, a capacitor turnover device, a lower tin-wire feeding device, a second tin-wire welding device and a discharging device are arranged in sequence on the outer side of the rotary plate in the clockwise direction and connected with the power distribution control box. The automatic assembly machine of the round capacitor has the advantages that automatic operation is adopted from feeding to discharging, the processing accuracy and processing efficiency of the round capacitor are greatly improved, and a large amount of working time is saved.

Owner:天长市中发电子有限公司

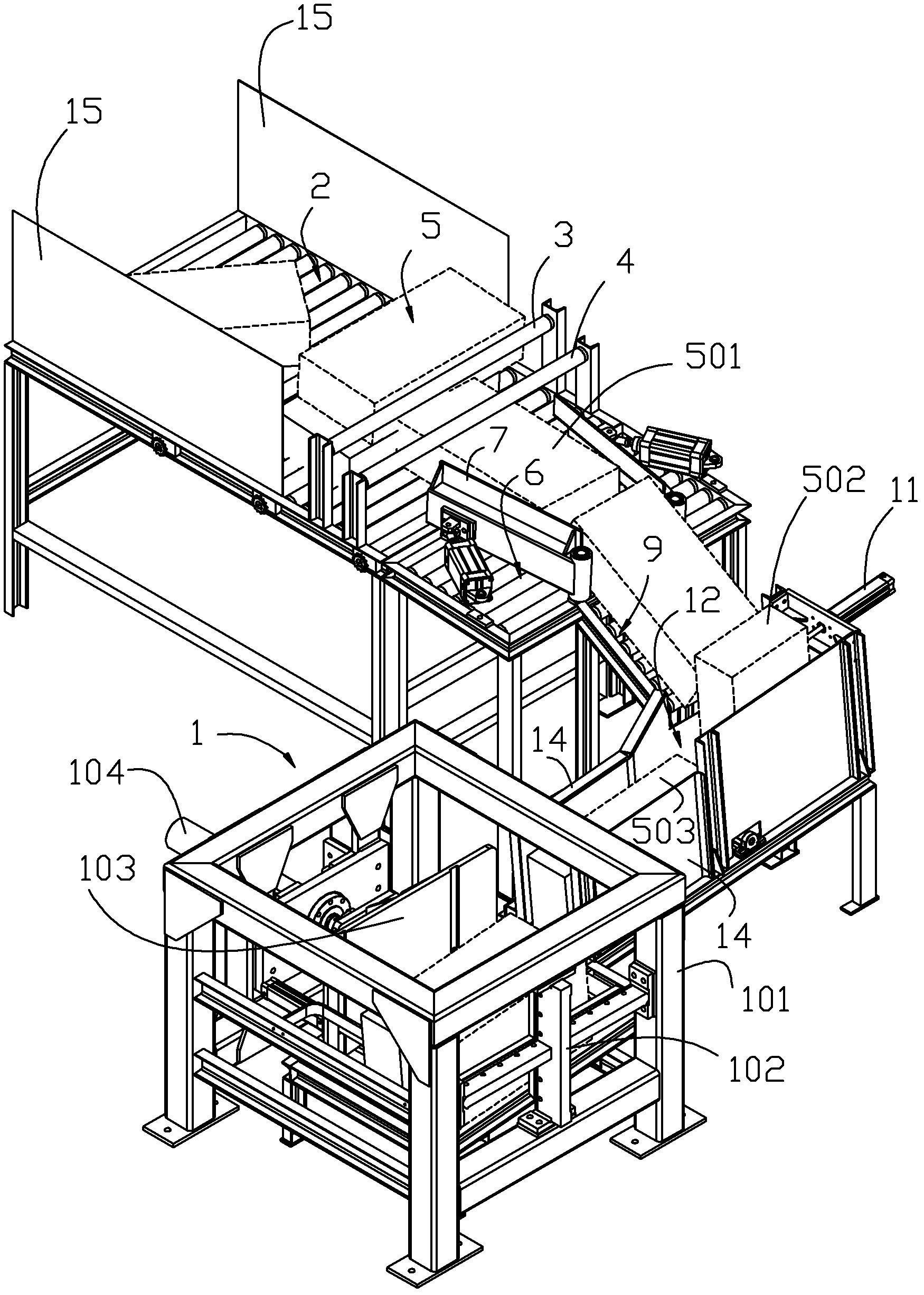

Plate overturning device with overturning wheel

ActiveCN110723513ASimple structureImprove work efficiencyConveyorsConveyor partsPush outStructural engineering

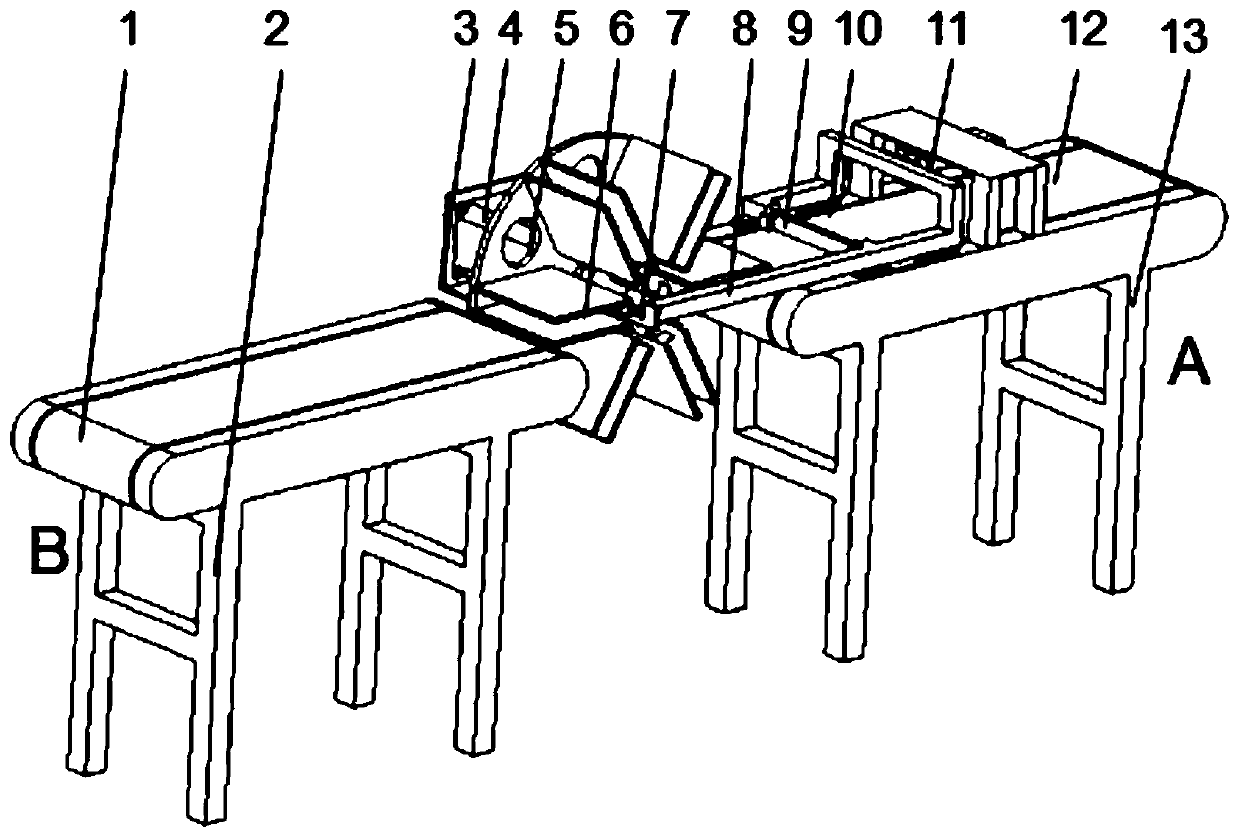

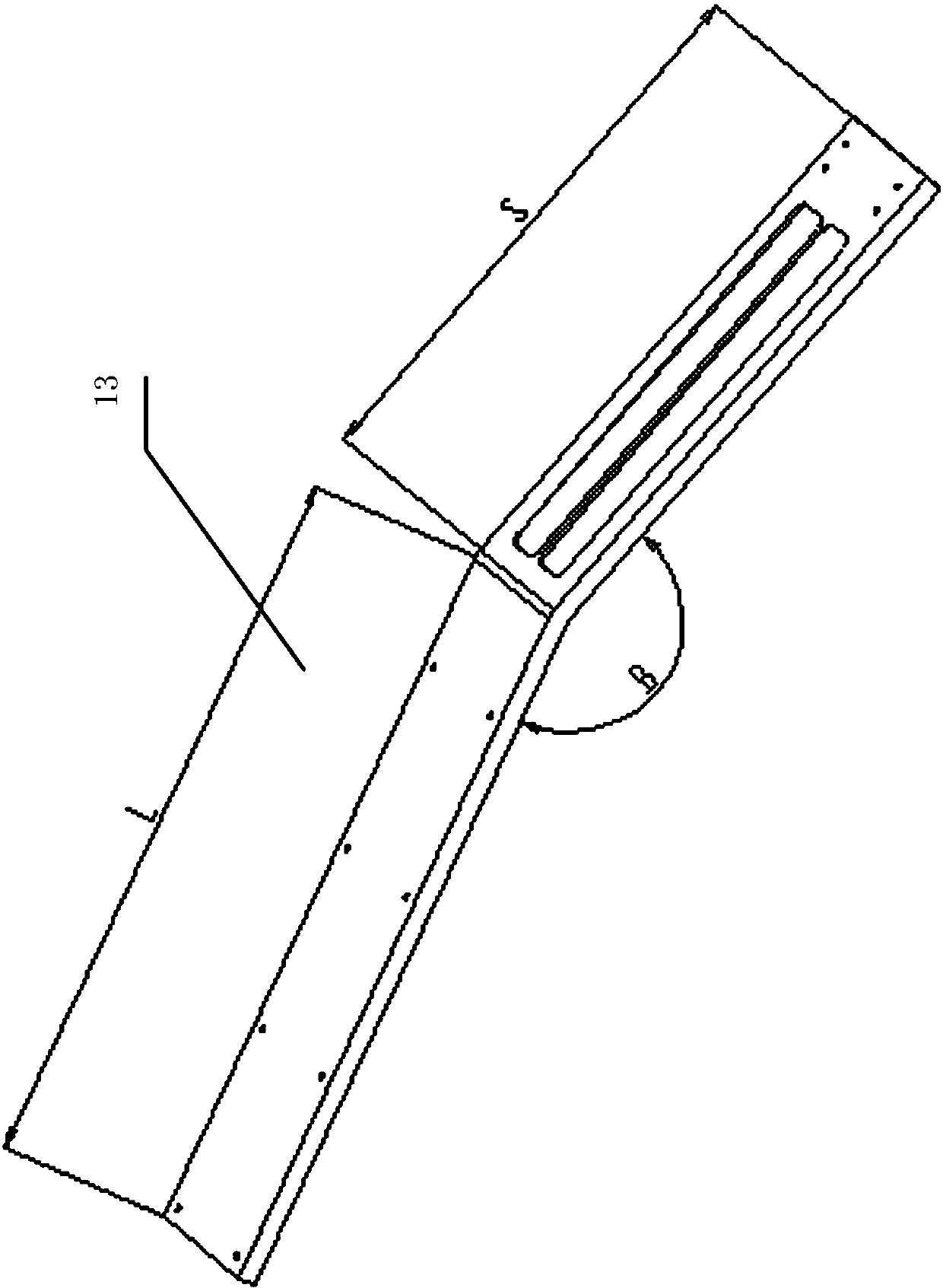

The invention discloses a plate overturning device with an overturning wheel, and relates to the field of material overturning. The plate overturning device comprises a front conveying belt, a rear conveying belt, the overturning wheel and a pushing assembly, wherein the overturning wheel is used for driving plates to be overturned between the two conveying belts, and the pushing assembly can pushmaterials into the front conveying belt and pushing the materials out of the rear conveying belt. According to the plate overturning device, the overturning wheel is arranged between the conveying belts for conveying the materials, through pushing of a one-way pushing sheet, the non-overturned plates enter positioning plates on the overturning wheel, the overturned plates in the positioning plates of the overturning wheel are pushed out from positioning blocks of the overturning wheel through pushing blocks, and therefore the plates are overturned in the conveying process, the overturning efficiency is high, the structure is simple, and the automation degree of overturning of the plates is greatly improved.

Owner:JIANGSU UNIV

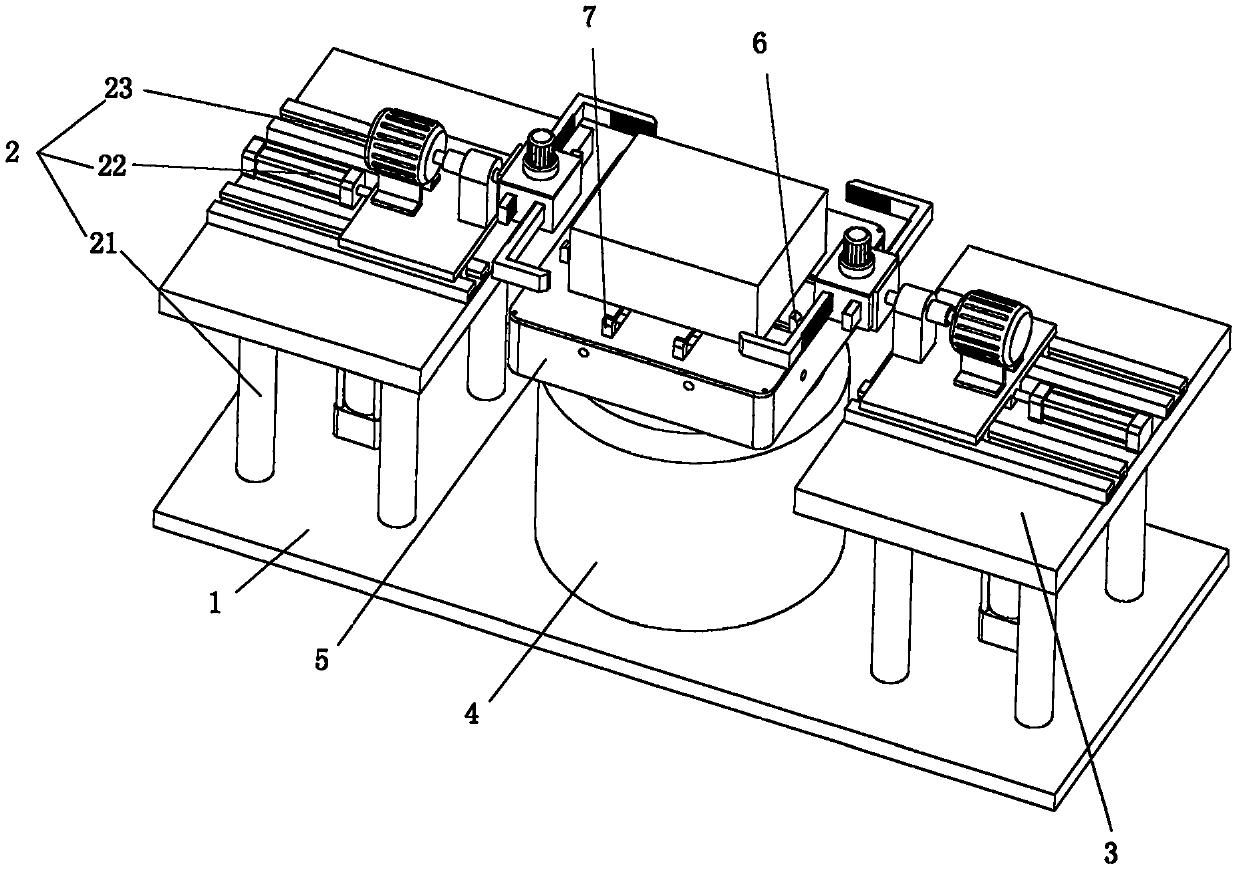

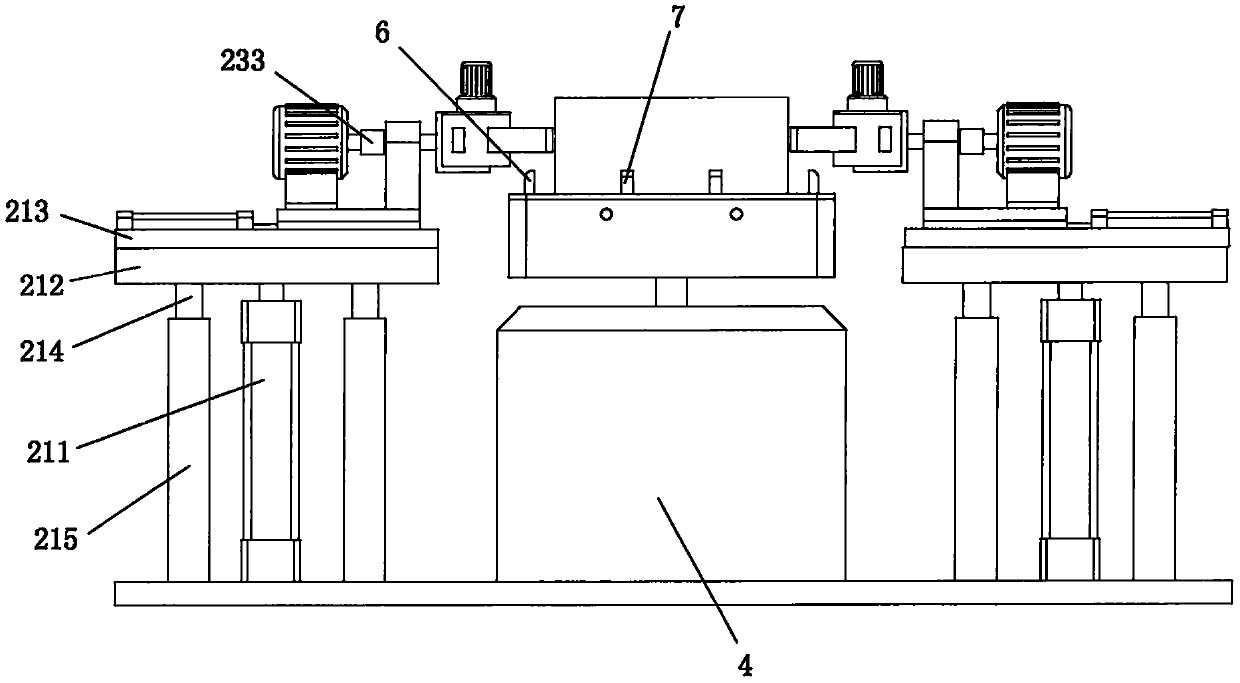

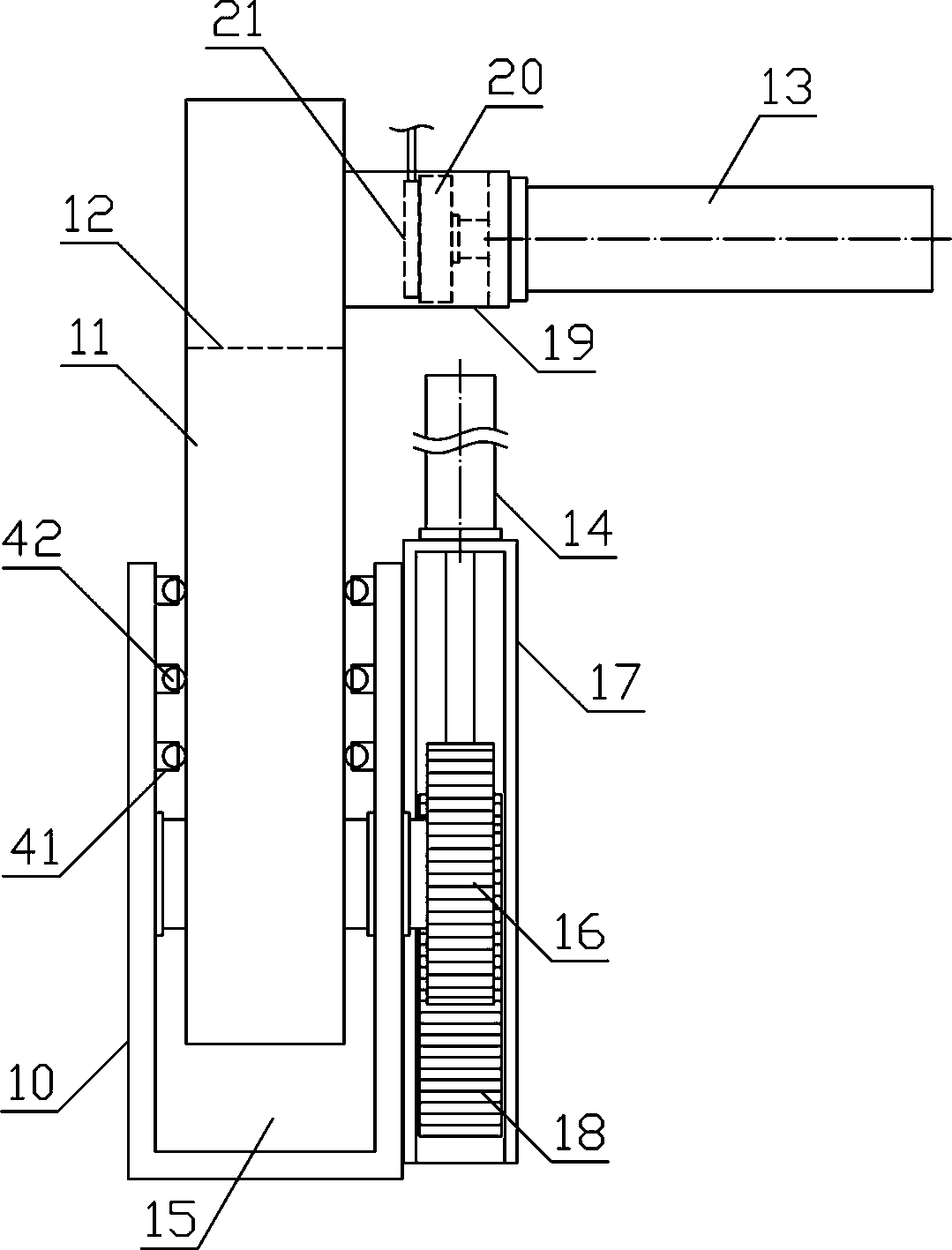

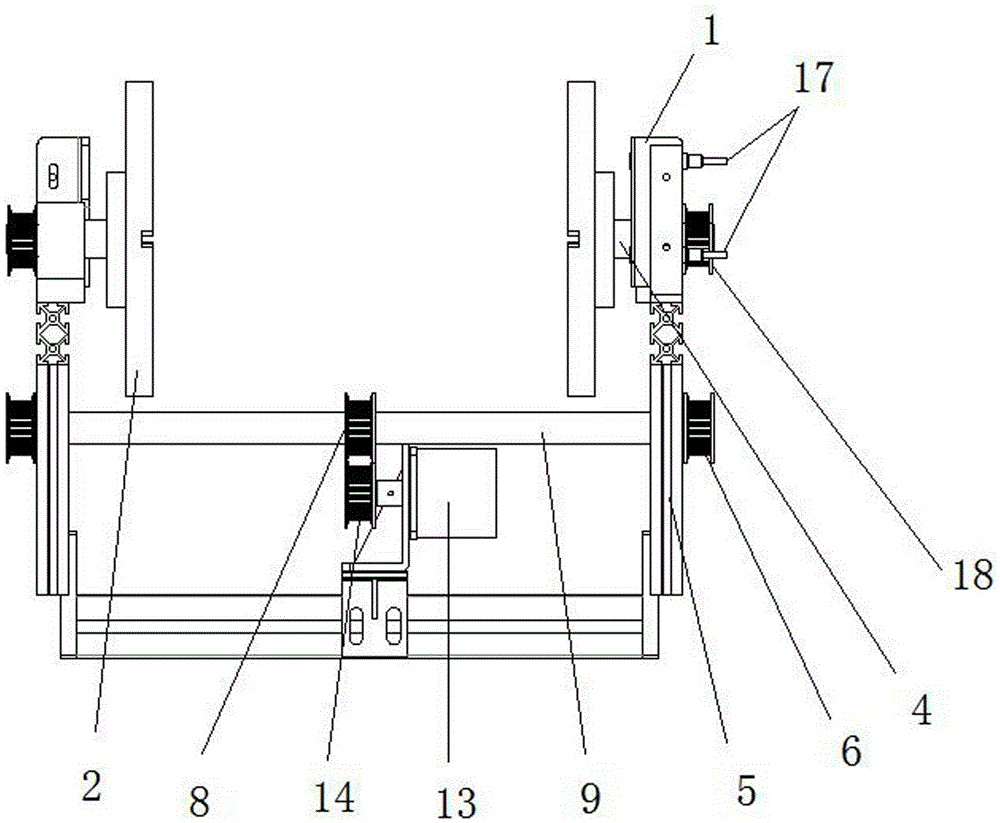

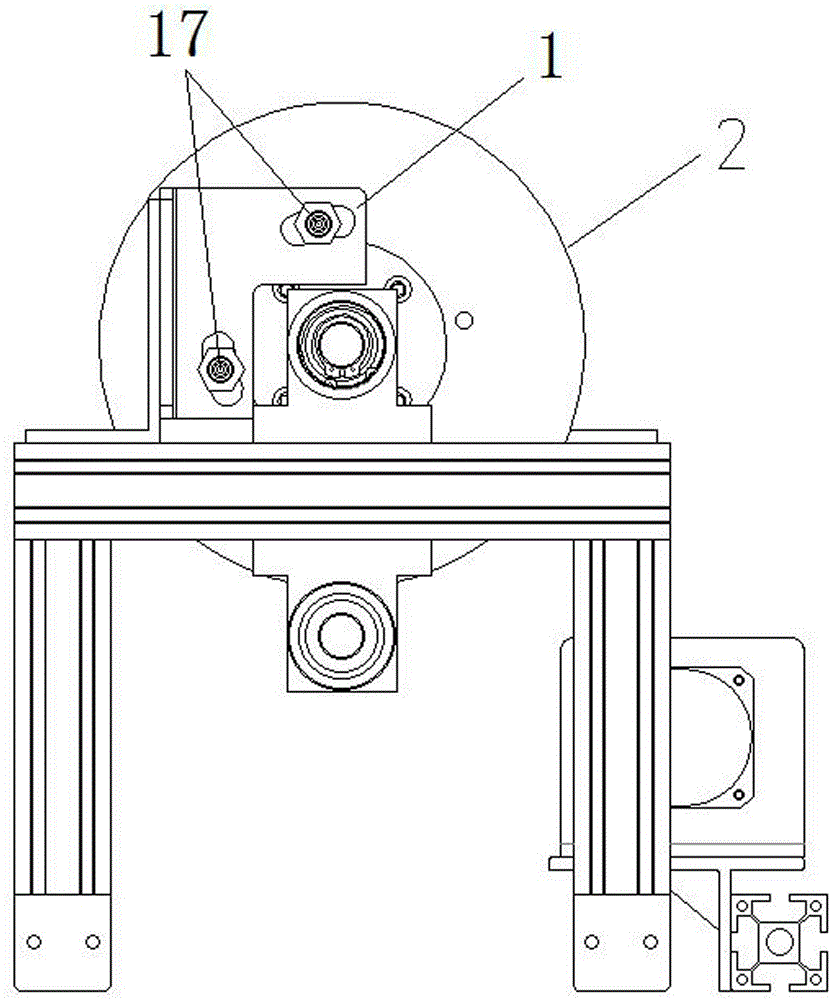

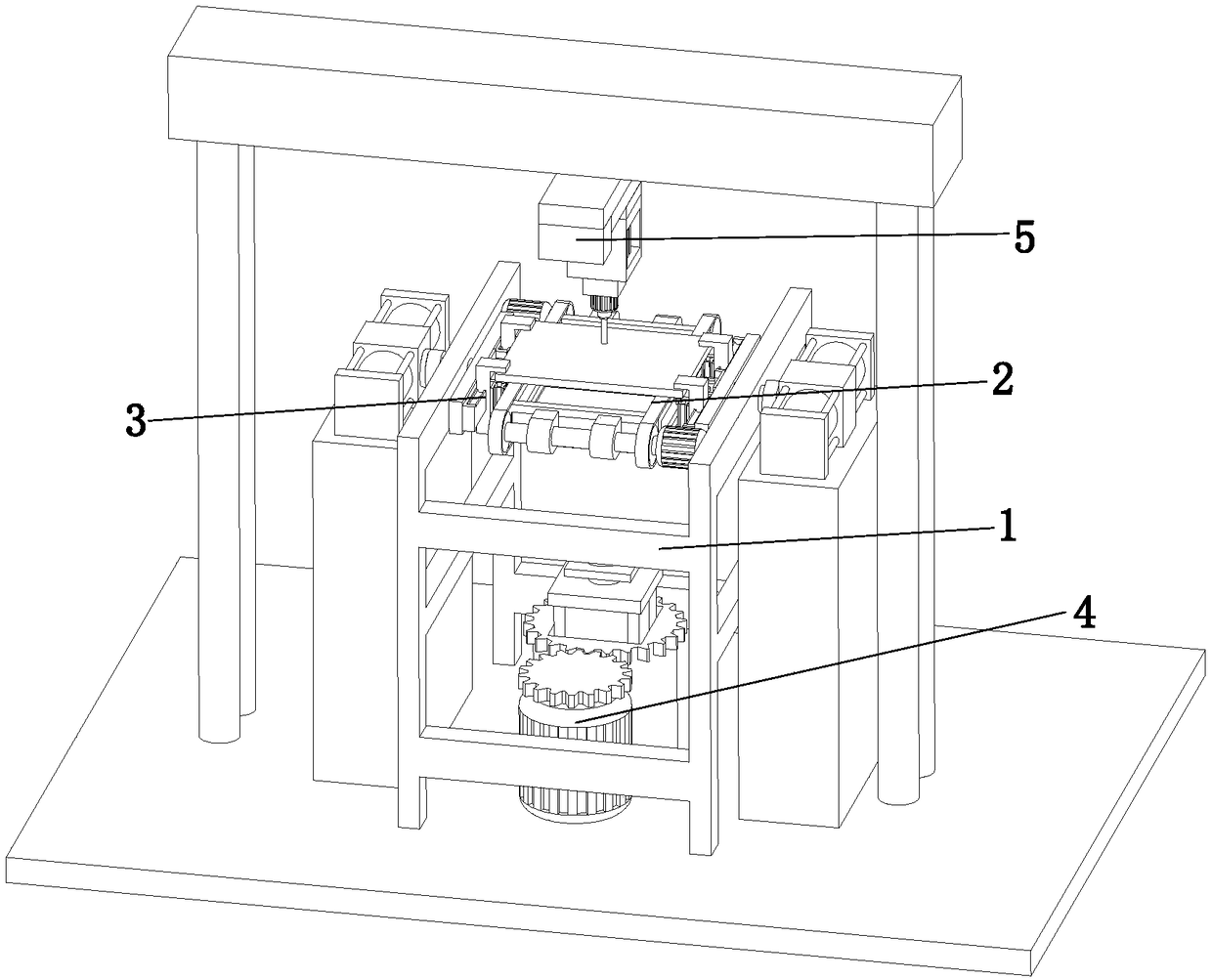

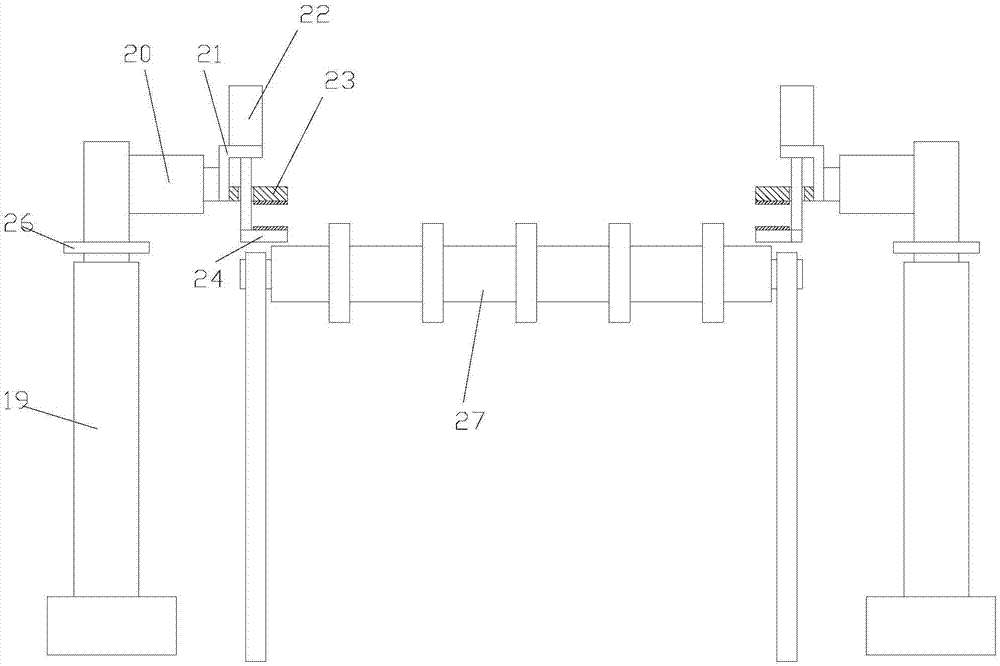

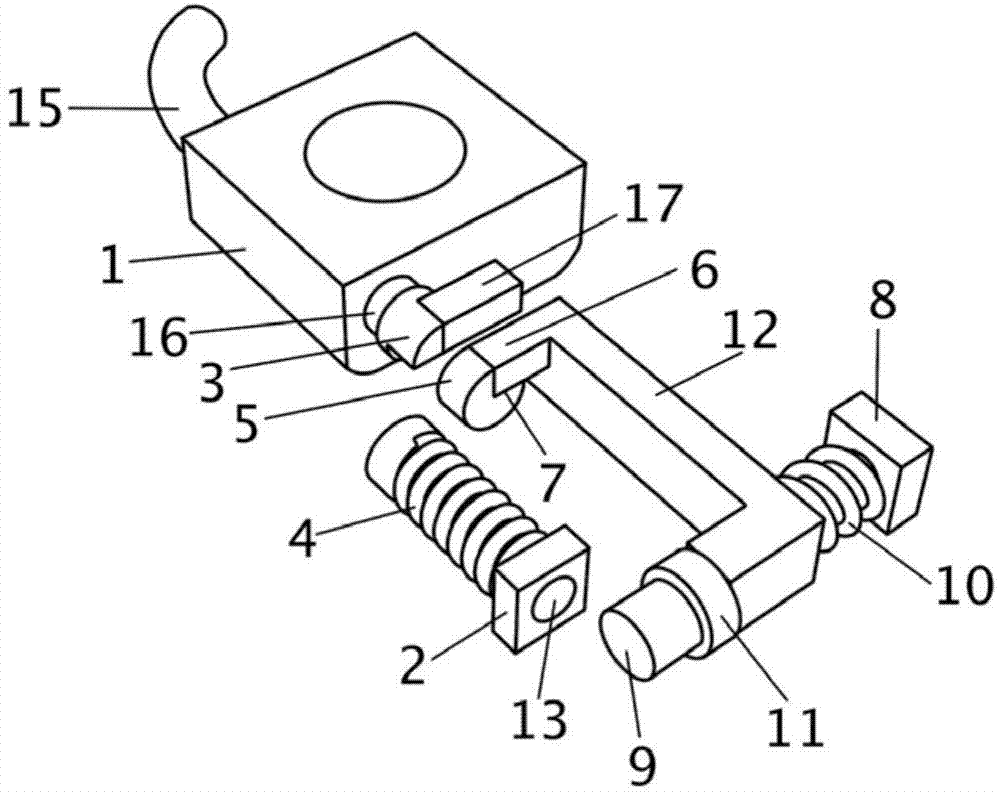

Special turnover facility for installation of electromechanical equipment

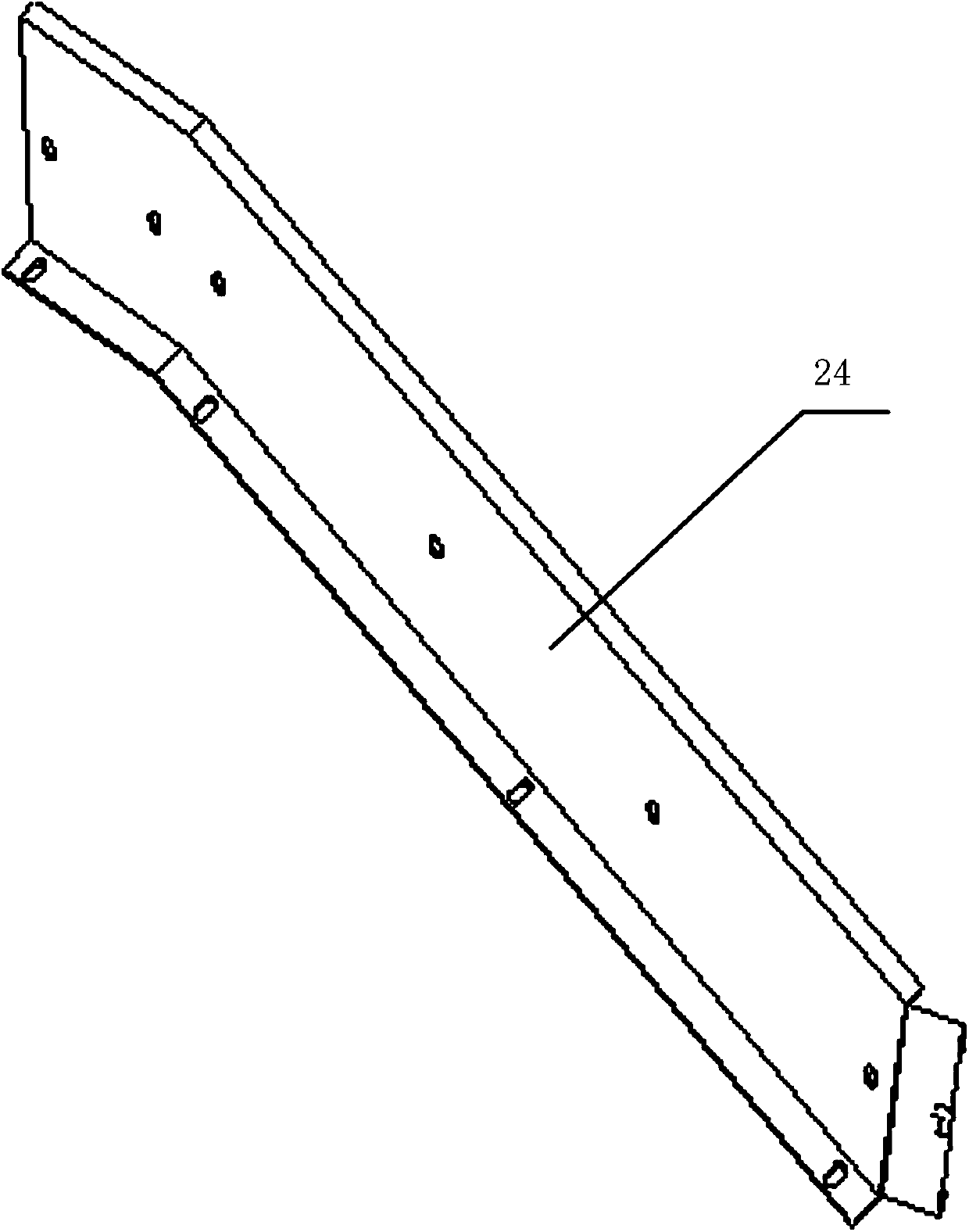

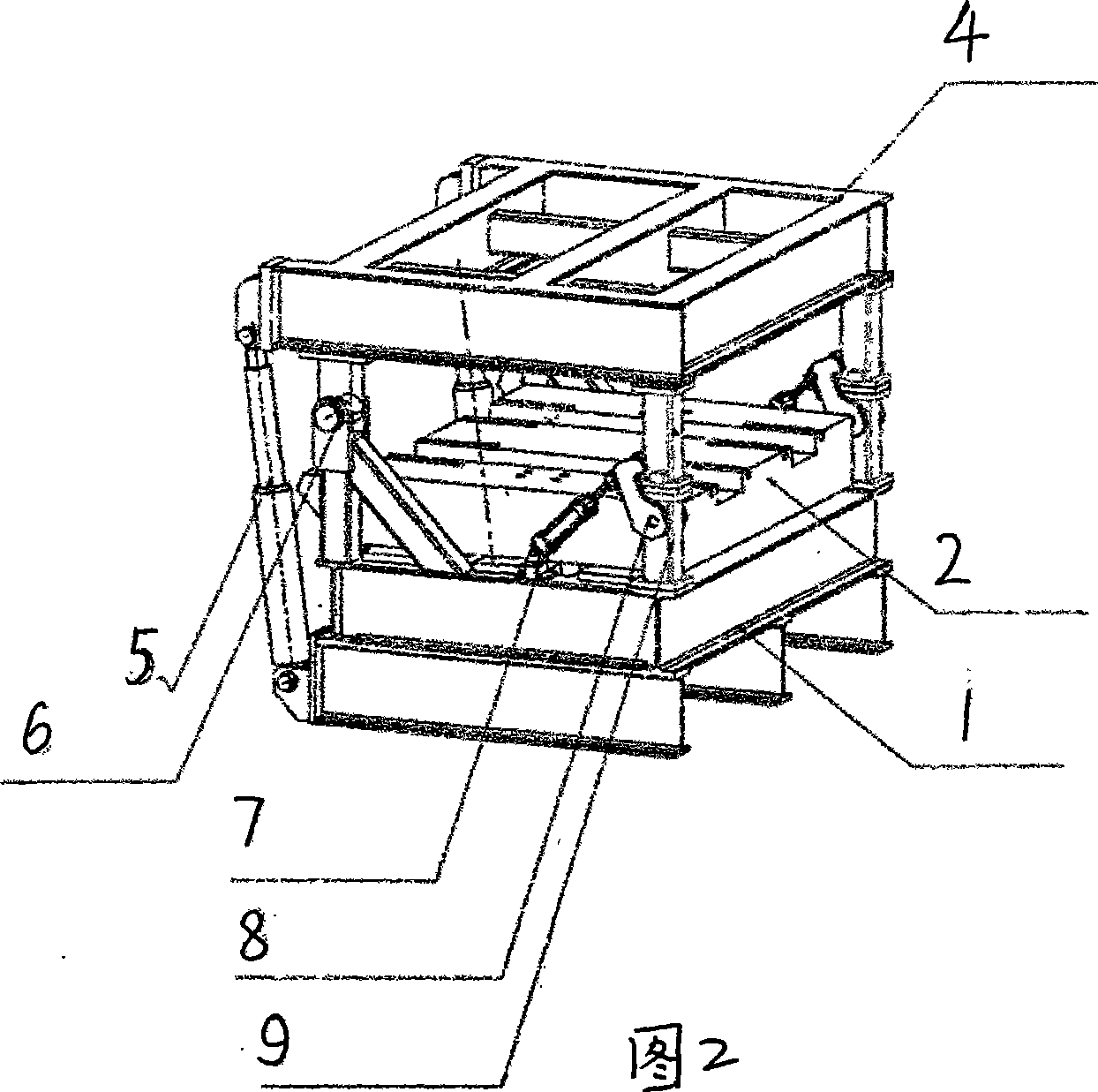

InactiveCN110193810AImprove securityRealize automatic flipWork holdersWork benchesElectric machineryEngineering

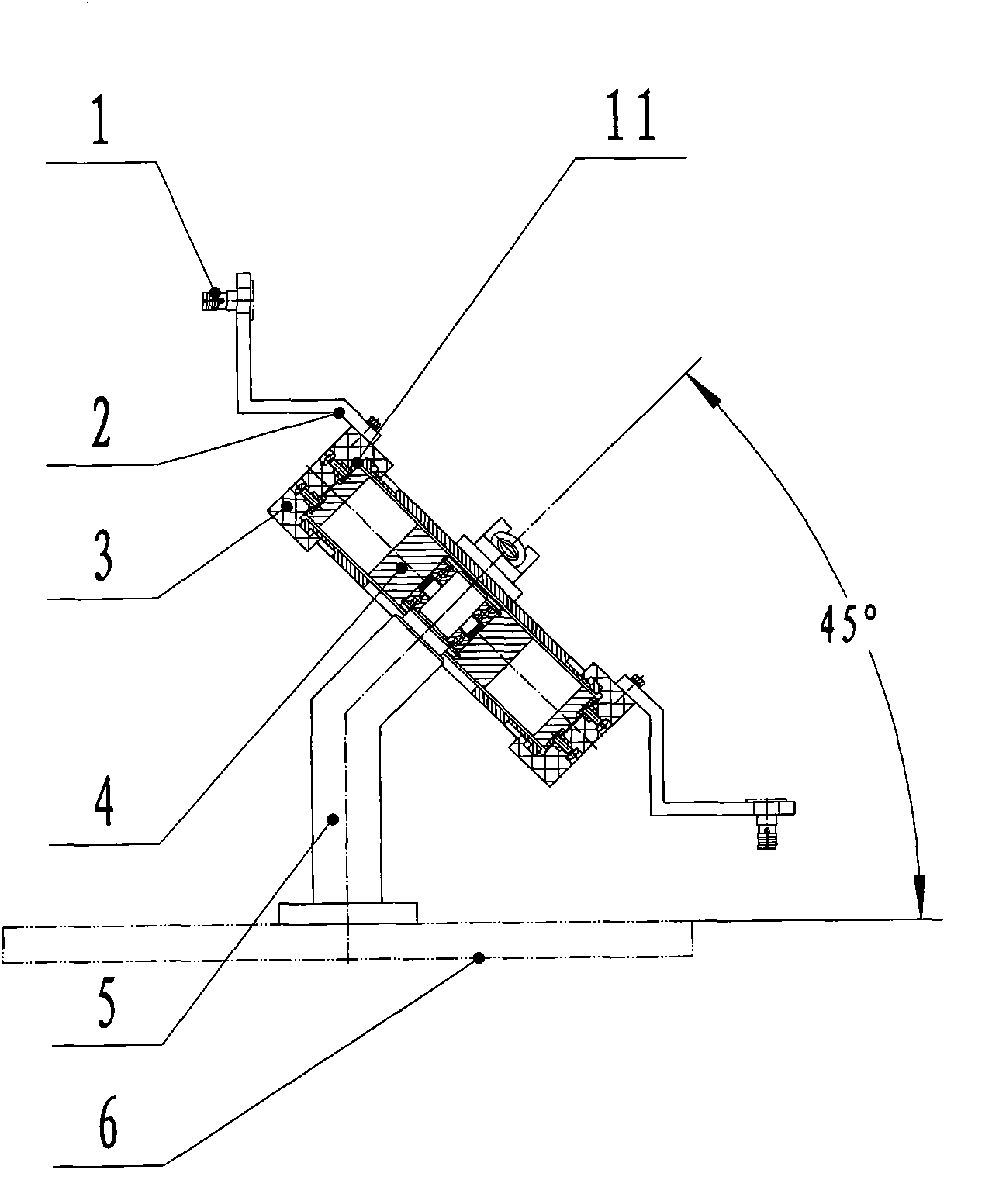

The invention relates to the technical field of electromechanical equipment, in particular to a special turnover facility for installation of the electromechanical equipment. The special turnover facility for installation of the electromechanical equipment comprises a base plate, a left clamping mechanism, a right clamping mechanism, a rotating workbench and a locating jig. The left clamping mechanism and the right clamping mechanism are symmetrically arranged on the base plate. The rotating workbench is located between the left clamping mechanism and the right clamping mechanism. A driving motor is arranged in the rotating workbench, and the output end of the driving motor penetrates through the top of the rotating workbench. The locating jig is installed at the output end of the drivingmotor. A transverse locating assembly and a longitudinal locating assembly are arranged in the locating jig and distributed in a crossed mode, and the transverse locating assembly is located over thelongitudinal locating assembly. By the adoption of the special turnover facility for installation of the electromechanical equipment, the purpose of conducting automatic turnover on the electromechanical equipment is achieved, the safety of workers is improved, and the electromechanical equipment with different sizes can be automatically located and fixed through the transverse locating assembly and the longitudinal locating assembly.

Owner:YANGTZE NORMAL UNIVERSITY

Auto-reverse camera

InactiveCN103685892ARealize automatic flipReduce manufacturing costTelevision system detailsColor television detailsTerminal equipmentEngineering

The invention discloses an auto-reverse camera which comprises a camera body and a locking module, wherein the camera body and the locking module are respectively provided with an installation end, the camera body is placed in an accommodating space of mobile terminal equipment, a limiting groove is formed in the camera body, a limiting column is arranged on the locking module, the camera body is locked in the accommodating space by the locking module when the limiting column is clamped in the limiting groove, the camera body is released by the locking module when the limiting column is disengaged from the limiting groove, and a rear camera is changed to a front camera when the camera body is reversed out automatically from the accommodating space. According to the auto-reverse camera, the camera body is mounted on the terminal equipment in a rotary mode and can be locked or released by the locking module, automatic reversing of the camera body can be achieved after the camera body is released, a front camera does not need to be arranged specially, self-photographing or video call can be realized perfectly, multiple purposes can be realized, and therefore production cost of the terminal equipment is saved.

Owner:路宽

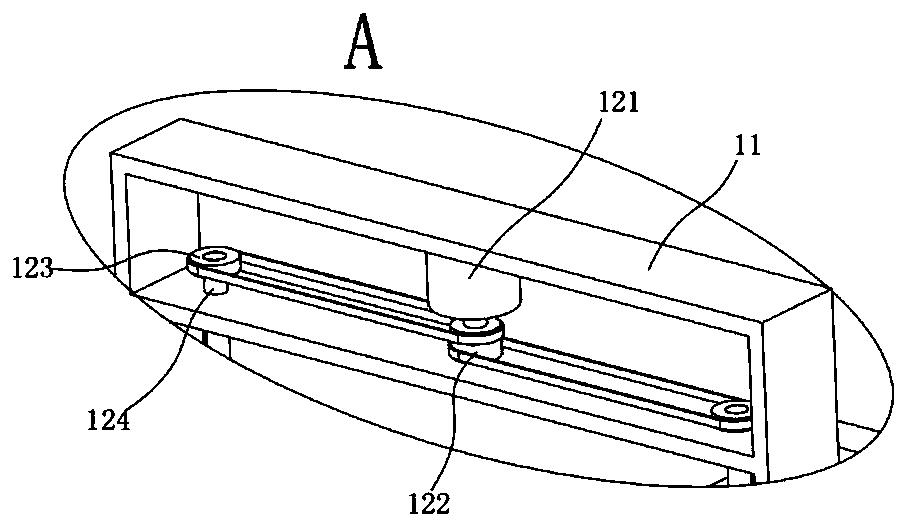

Round can shunting feeding transfer mechanism

InactiveCN108657787APrevent slidingAccurate reciprocating slidingConveyorsConveyor partsEngineeringTransfer mechanism

The invention discloses a round can shunting feeding transfer mechanism, and belongs to the field of container equipment processing machinery equipment. Two can transfer mechanisms are horizontally arranged on a fixed bracket which is located on one side of the shunting mechanism from top to bottom. The middle portion of the upper part of an upper can guiding pipe communicates with the lower end of a can bearing hopper, and the upper can guiding pipe and a lower can material pipe are integrally shaped. A shunting rotary plate is vertically arranged in a rotating clamping groove of a rotating bracket, a round can clamping groove is formed in the outer side of the shunting rotary plate in the radial direction of the shunting rotary plate, and a can pushing cylinder is horizontally fixedly arranged on a can pushing bracket on one side of the round can clamping groove. A turning rotating shaft is horizontally rotatably connected to the upper side of a turning bracket. An arc-shaped grooveplate is horizontally fixedly arranged on the outer side of a turning connecting plate, and a turning can groove is formed in the arc-shaped groove plate. According to the round can shunting feeding transfer mechanism, the design is reasonable, round cans can be transported smoothly and sequentially one by one, so that the round cans be transported in a shunting mode, and the automatic turning ofthe round cans can be realized in the process of the shunting transfer of the round cans so as to meet the needs of processing and use.

Owner:海宁市波菲特进出口有限公司

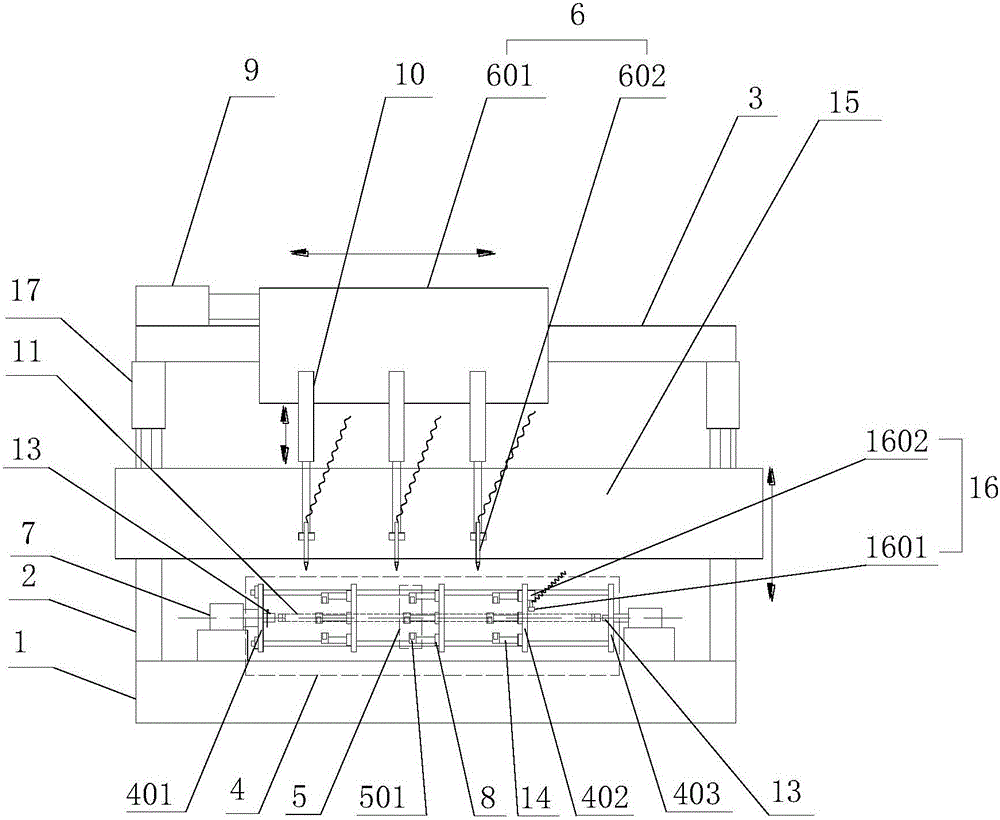

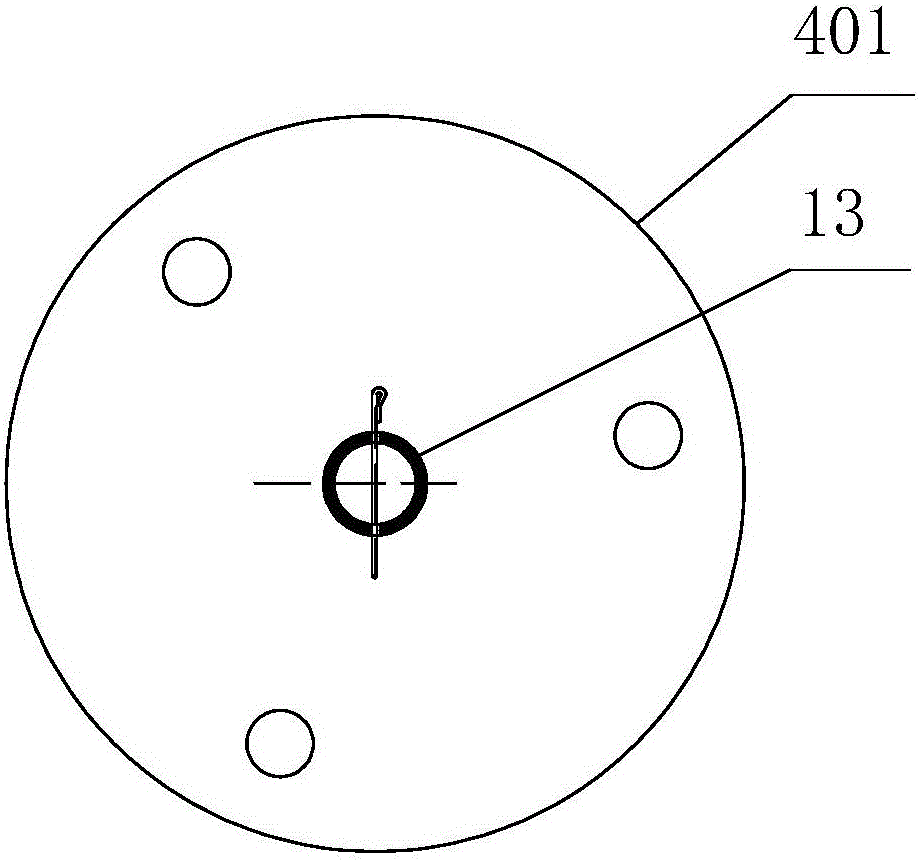

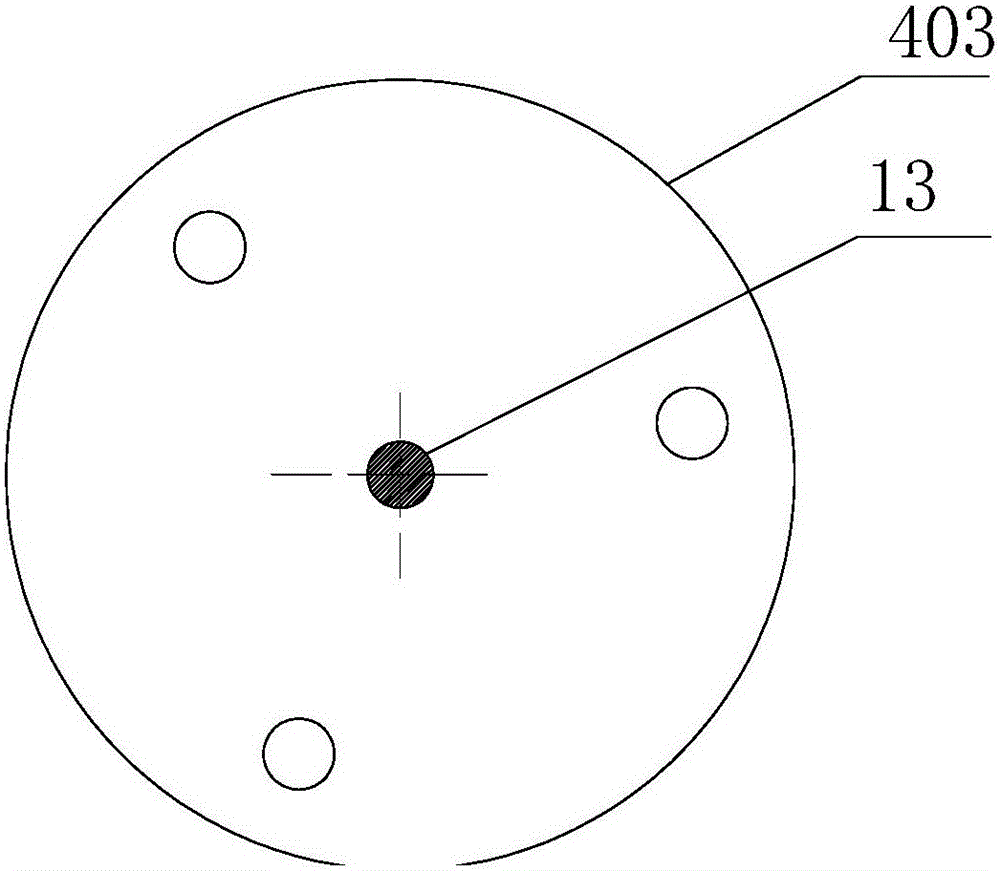

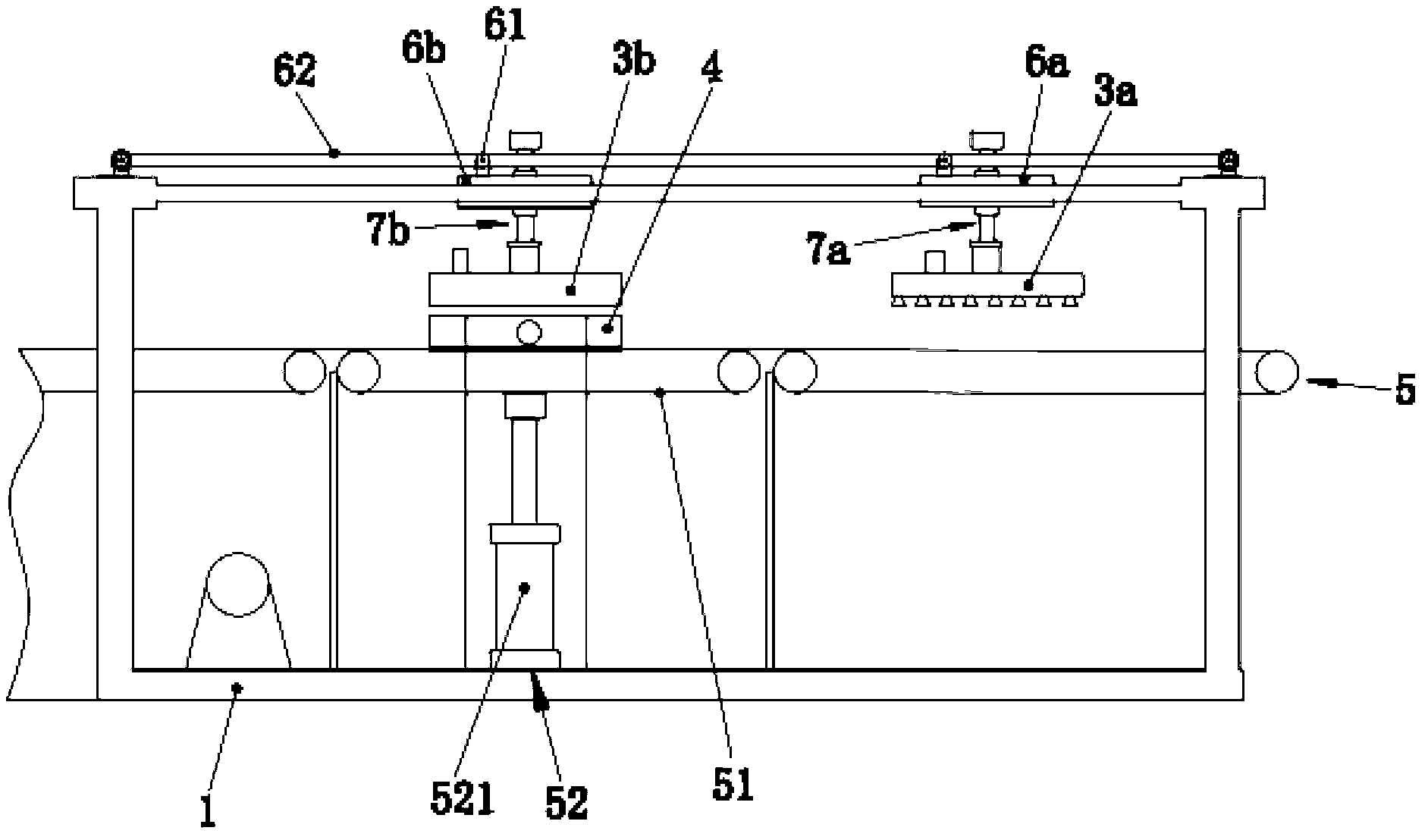

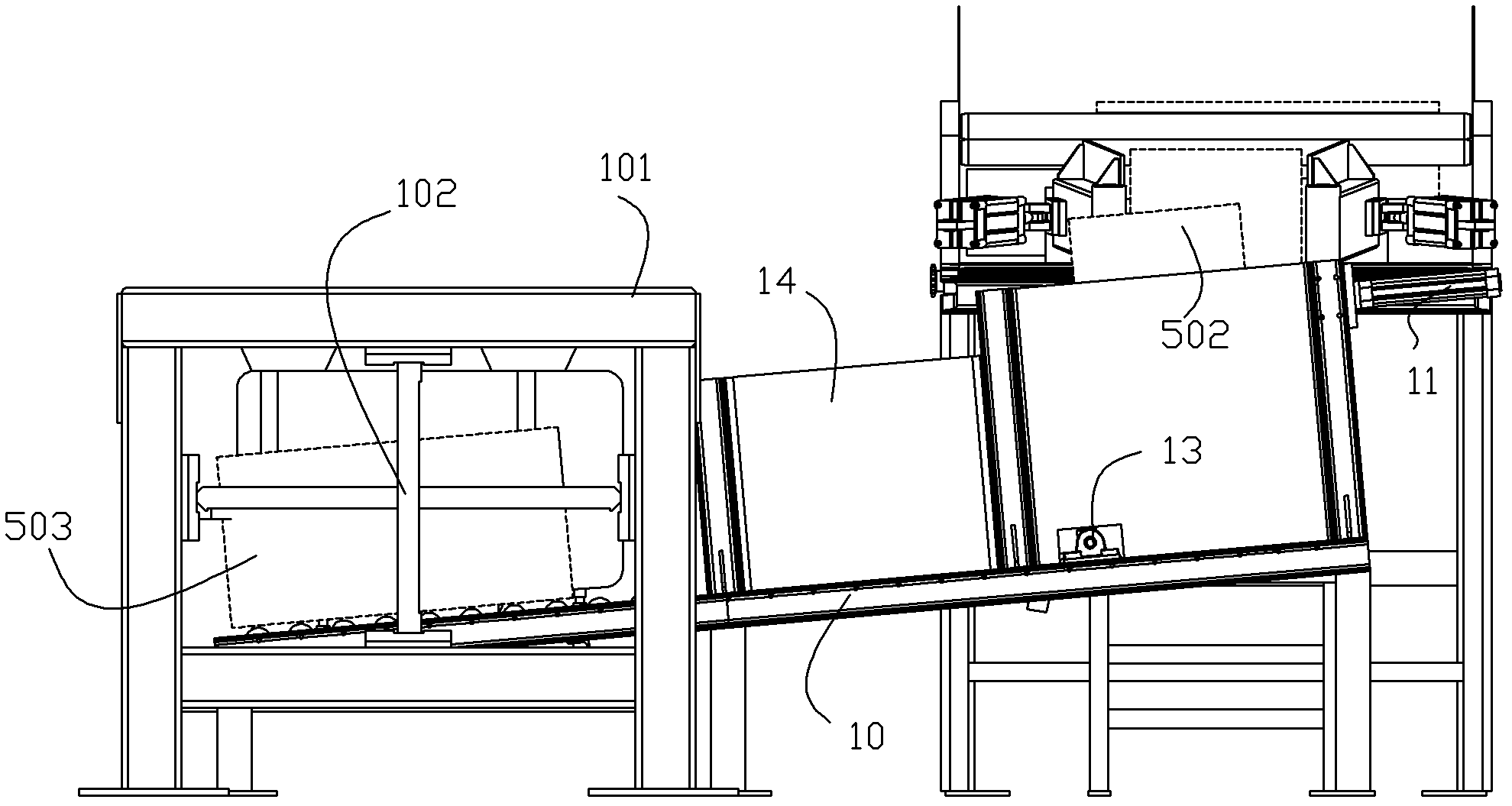

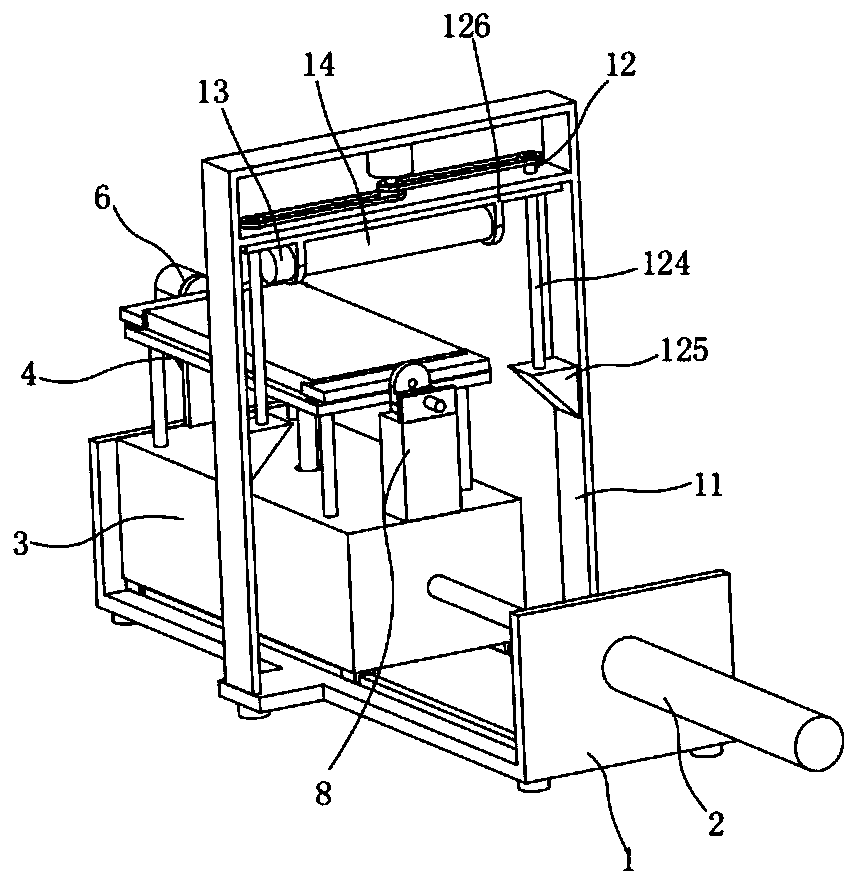

Product front face and back face appearance vision detecting device

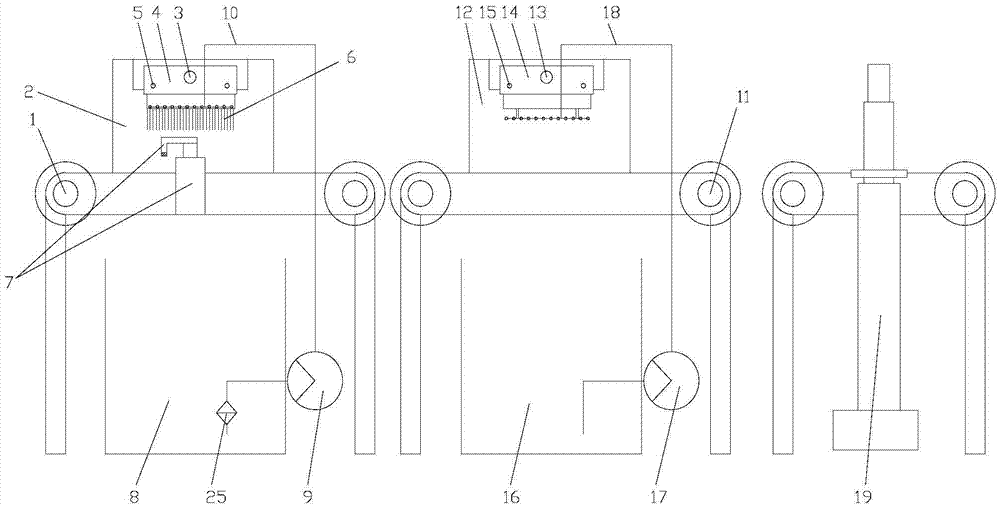

The invention relates to a product front face and back face appearance vision detecting device. According to the purpose, the provided device can automatically finish front face and back face detection, feeding and discharging of magnetic materials and also has the beneficial effects of being simple in structure and convenient to use. According to the technical scheme, the product front face and back face appearance vision detecting device is characterized by comprising a rack, a feeding conveying belt, a first detection table, a second detection table and an automatic overturning mechanism; the feeding conveying belt is arranged on the left side of the top of the rack in the front-back direction, the first detection table is arranged on the right side of the feeding conveying belt, the second detection table is arranged on the right side of the first detection table, and the automatic overturning mechanism is arranged between the first detection table and the second detection table in the left-right direction.

Owner:浙江勇创智能装备科技有限公司

Working method of H-shaped steel welding bead polishing derusting device

InactiveCN109015296AAutomatic derusting operationSubsequent polishing operation impactGrinding carriagesPolishing machinesSlide plateEngineering

The invention relates to the field of steel component machining equipment, in particular to a working method of an H-shaped steel welding bead polishing derusting device. The derusting device comprises a workbench, a polishing derusting mechanism, a turning mechanism and a limiting mechanism. The turning mechanism comprises two turning assemblies which are arranged symmetrically. The polishing derusting mechanism comprises a portal frame, a derusting assembly, a lifting assembly and a moving assembly. The derusting assembly comprises a mounting frame, a scrap suction component and a welding bead derusting component arranged at the bottom of the mounting frame. A derusting brush used for derusting workpieces is arranged at the bottom of the mounting frame. The working method of the H-shapedsteel welding bead polishing derusting device has the beneficial effects that the workpieces can be automatically turned through the turning mechanism, and the welding bead derusting component can derust welding beads of workpieces with different sizes through a derusting plate on a sliding plate; and the workpieces can be automatically limited through the limiting mechanism, so that the workpieces are not prone to deviation in the polishing process.

Owner:广东德源钢结构工程有限公司

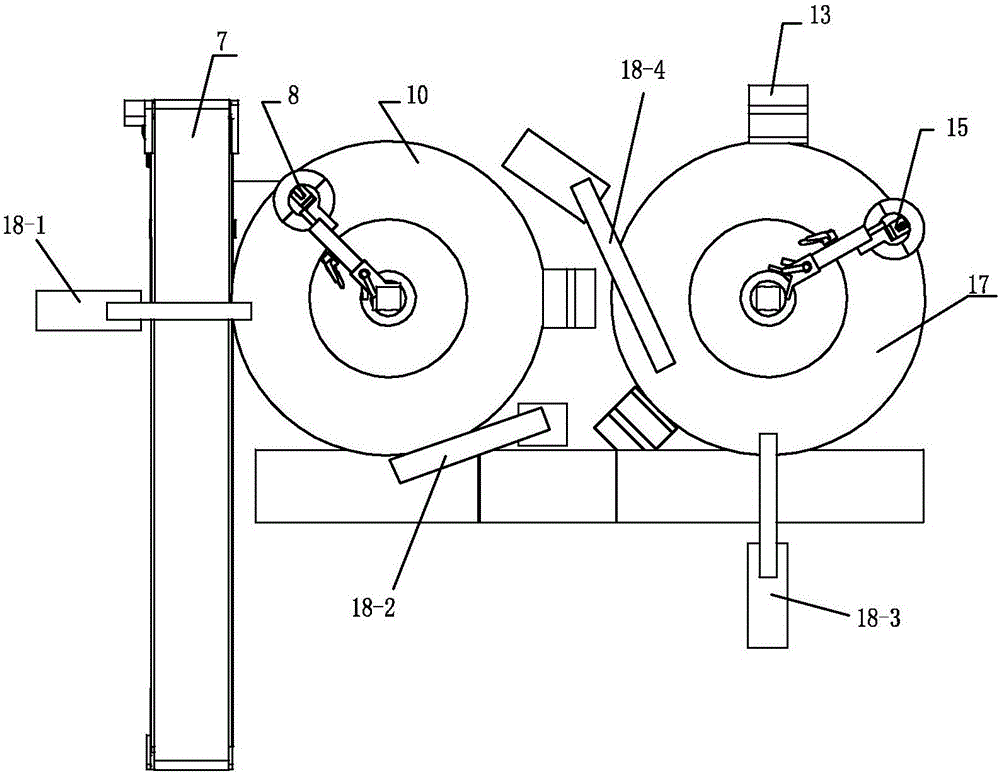

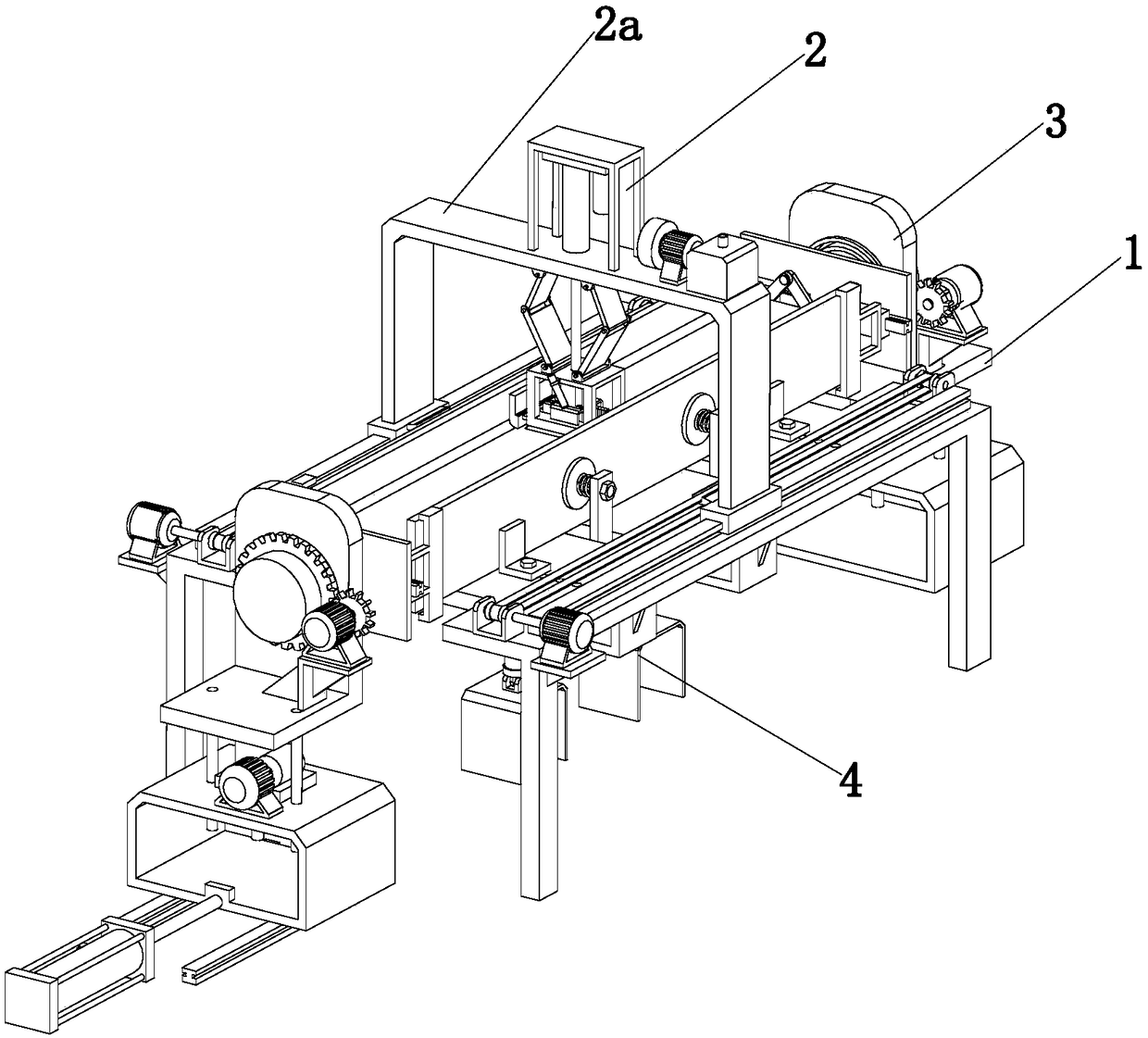

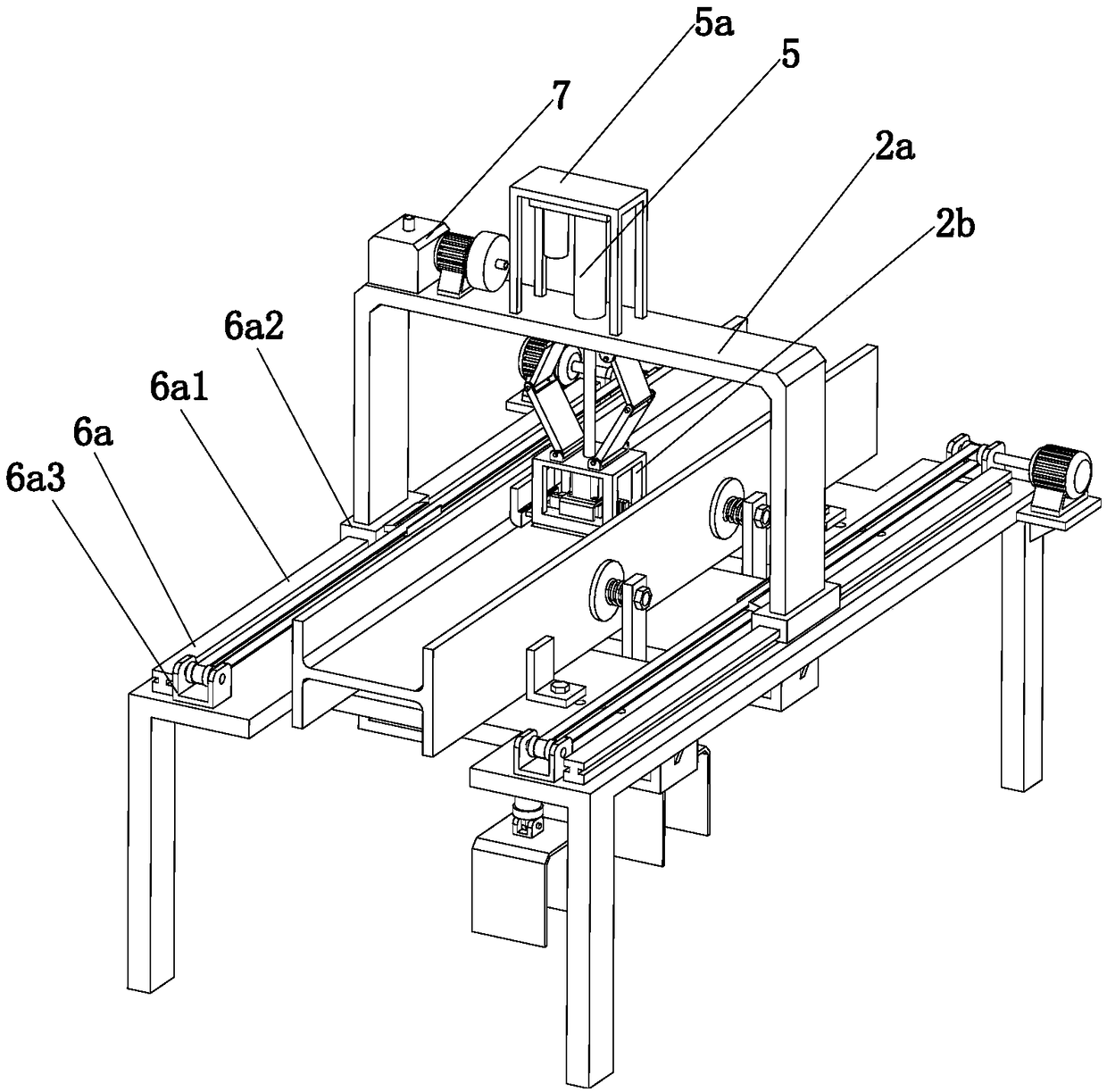

Polishing and rust removing device for H-steel welding bead

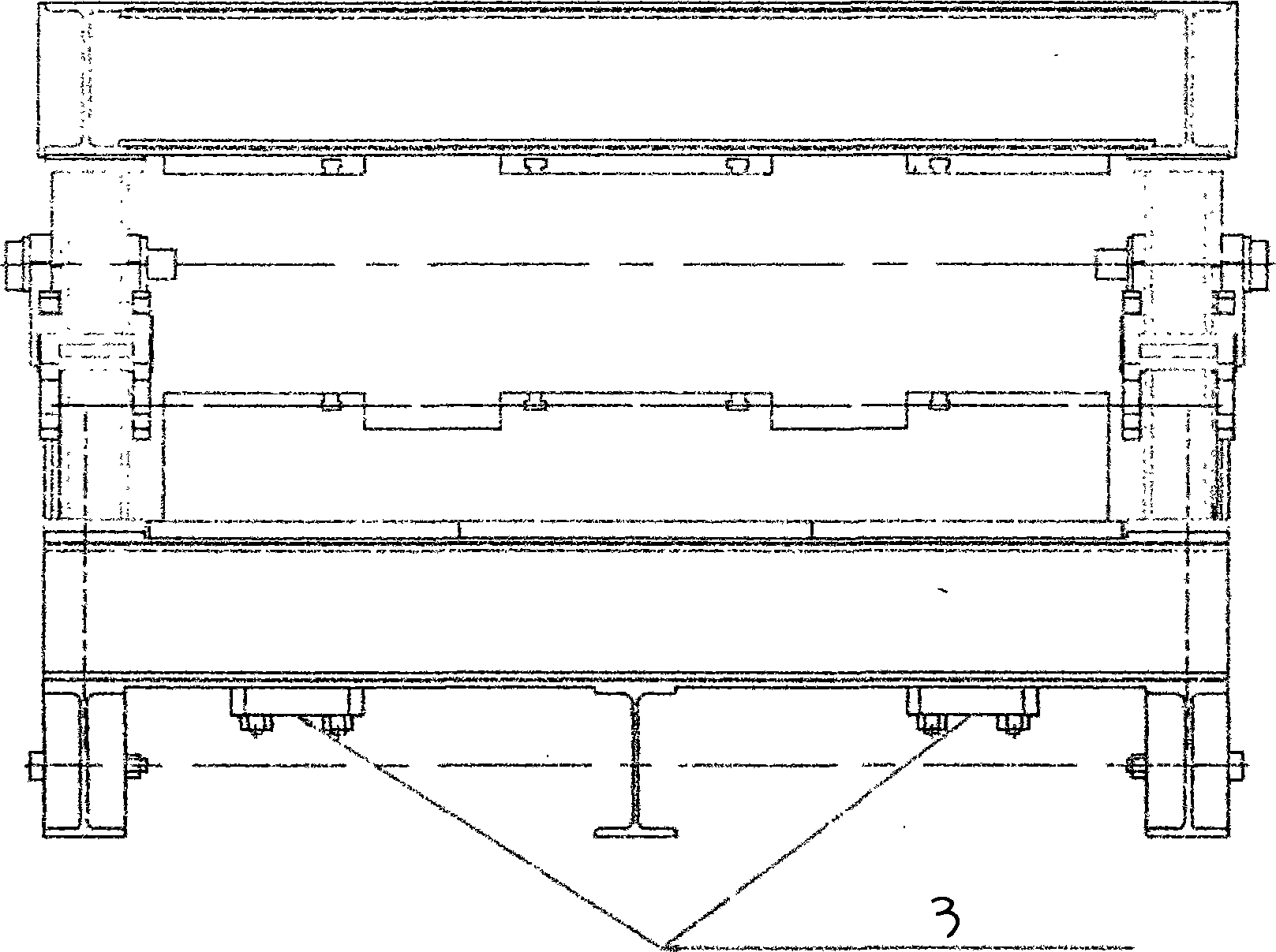

ActiveCN109015295ASubsequent polishing operation impactRealize automatic flipGrinding carriagesPolishing machinesSlide platePortal frame

The invention relates to the field of processing and handling equipment for steel components, and specifically relates to a polishing and rust removing device for an H-steel welding bead. The device comprises a working platform, a polishing and rust removing mechanism, an overturning mechanism and a limiting mechanism, wherein the overturning mechanism comprises two symmetric overturning assemblies; the polishing and rust removing mechanism comprises a portal frame, a rust removing assembly, a lifting assembly and a material transferring assembly; the rust removing assembly comprises a mounting frame, a chip absorbing part, and a welding bead rust removing part which is arranged at the bottom part of the mounting frame; and a rust removing brush for removing rust of a workpiece is arrangedat the bottom part of the mounting frame. The device has the beneficial effects that the workpiece can be automatically overturned through the overturning mechanism; the welding beads of the workpieces with different sizes can be subjected to rust removing through a rust removing board on a sliding plate under the effect of the welding beam rust removing part; and moreover, the workpiece can be automatically limited through the limiting mechanism, so that the problem that the workpiece is easily deviated during being polished.

Owner:中交二航局结构工程有限公司

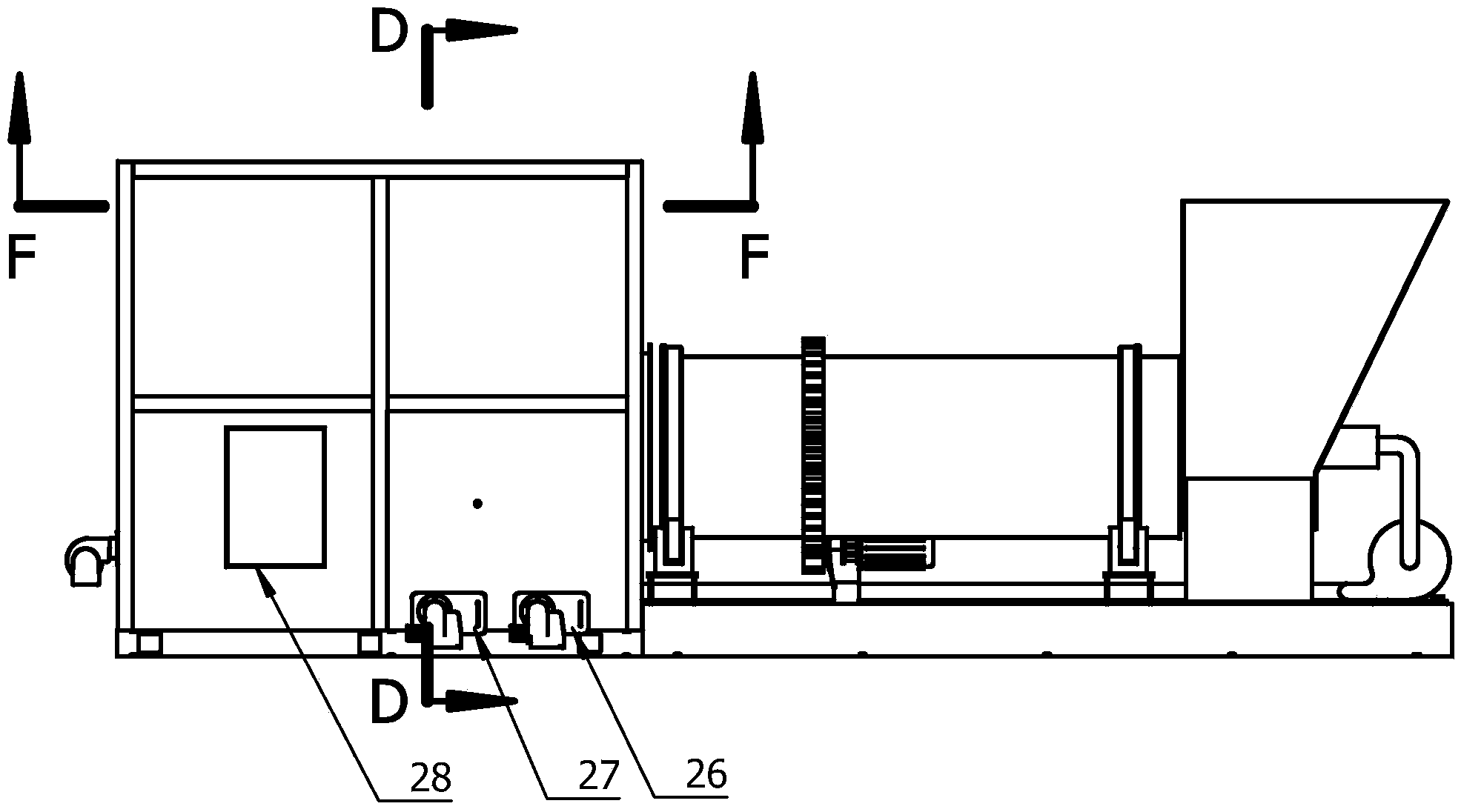

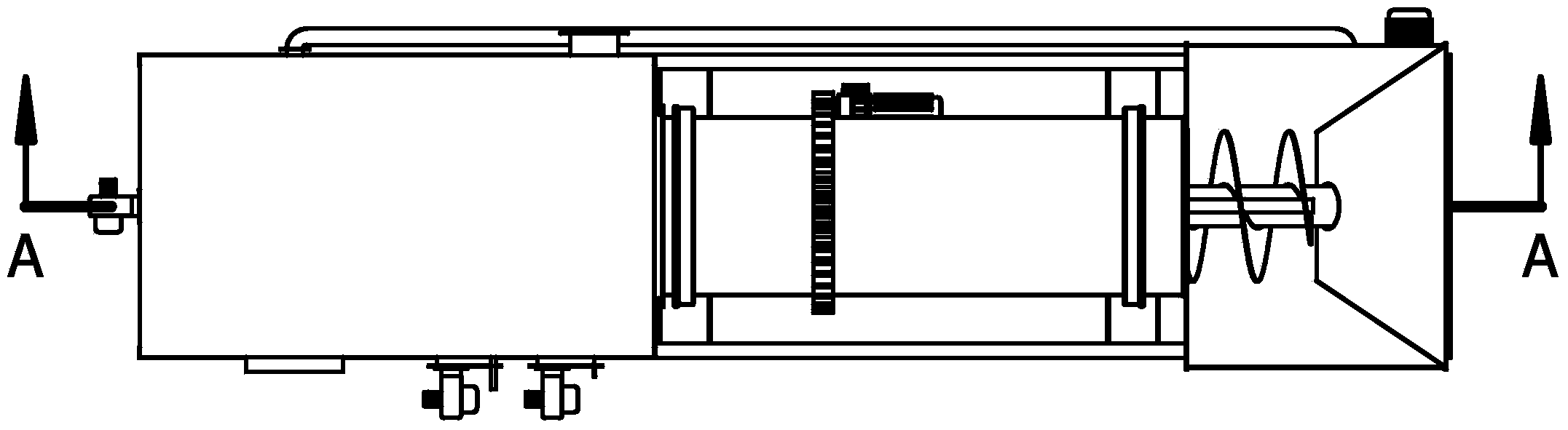

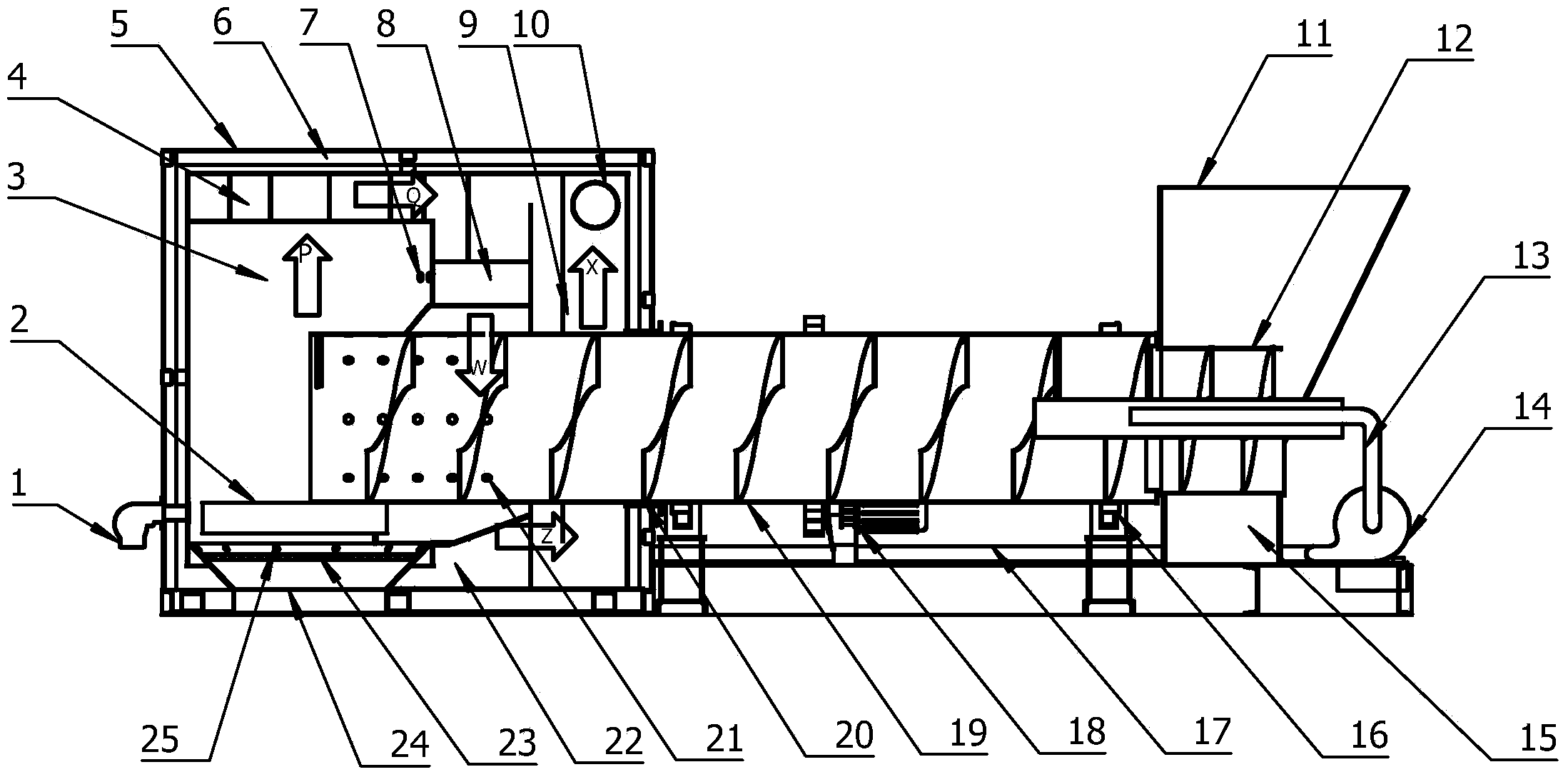

Fully-automatic production equipment for cold granulation of lead ingot

ActiveCN102328090APowertrain is reliableImprove reliabilityAutomatic controlProgrammable logic controller

Owner:蚌埠市华鼎机械科技有限公司

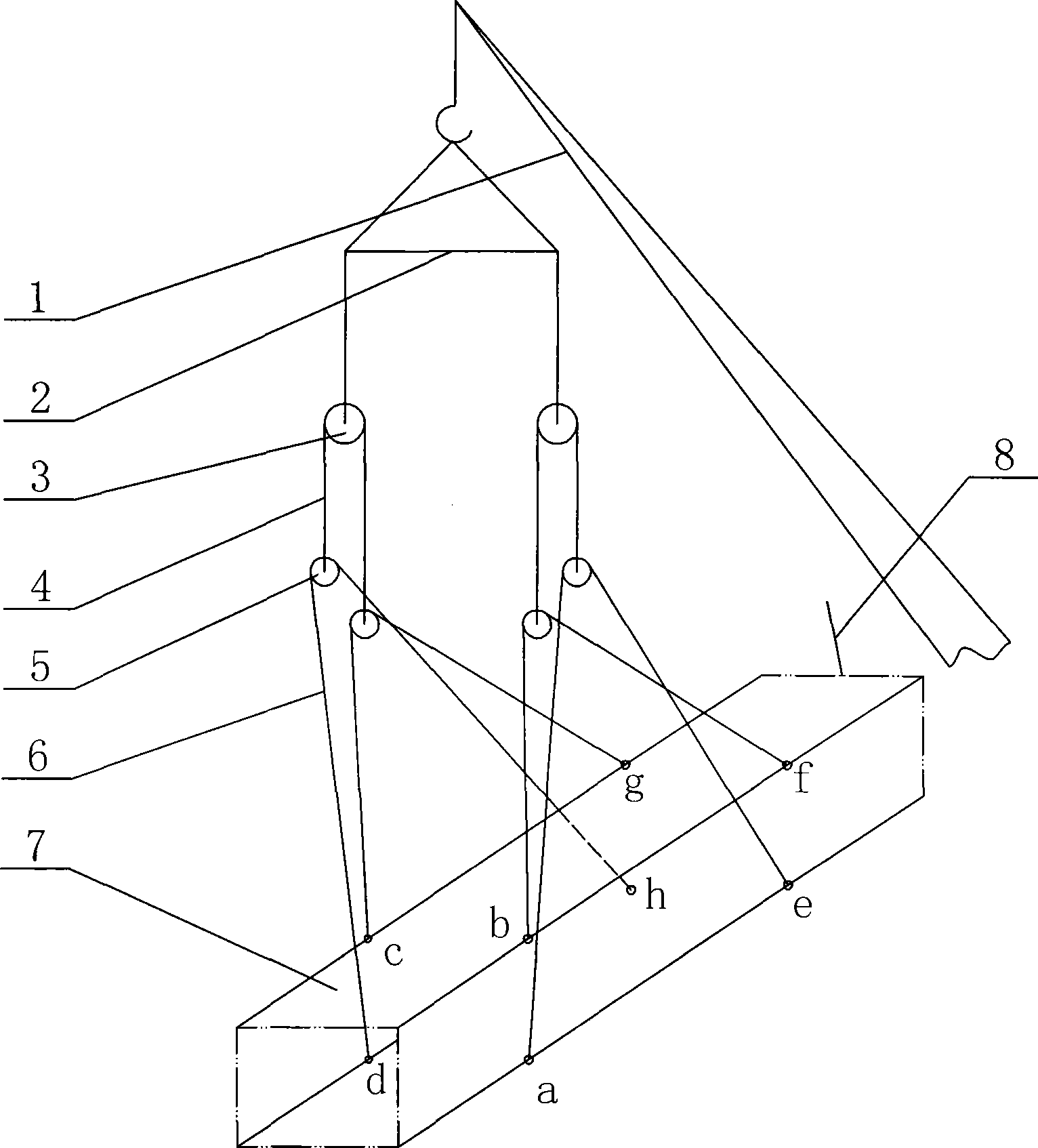

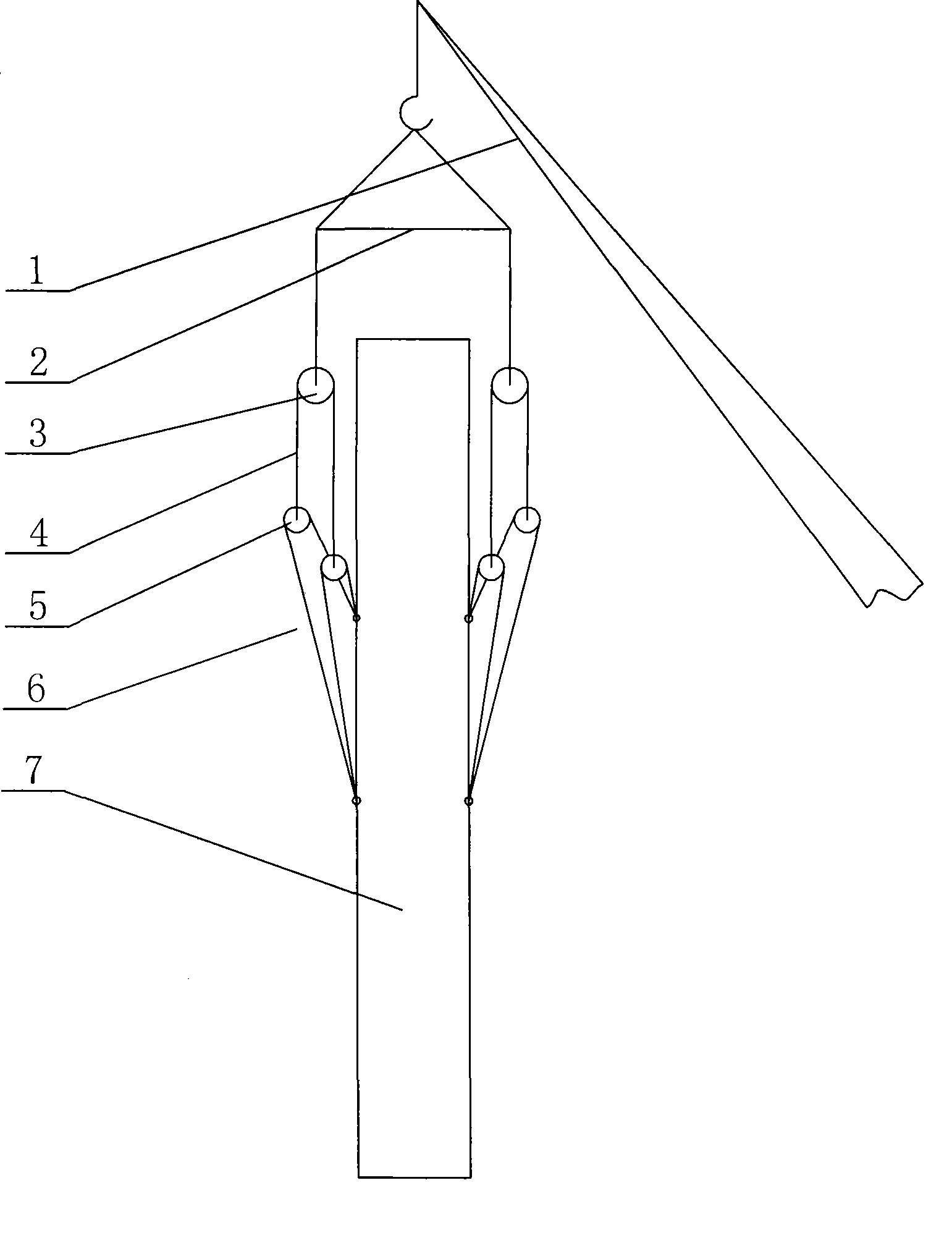

Hoisting tool and hoisting method for column component

InactiveCN101434366ARealize automatic flipImplement auto-rotationLoad-engaging elementsEngineeringIndustrial engineering

The invention relates to a lifting construction method of a large component, in particular to a lifting rig and a lifting method of a large upright column component, wherein, the lifting rig is provided with fixed pulleys respectively installed at the two ends of a lifting crossbeam, two ropes respectively roll around the fixed pulleys, and two ends of each rope are respectively provided with a pulley; the method is as follows: a main hook is connected with the lifting rig of the upright column component, and connected with the upright column component through the two fixed pulleys and four ropes rolling around the four pulleys and used for lifting on the lifting rig of the upright column component, an assisted hook is connected with an assisted suspension cable fixed at the bottom of theupright column component, and during the synchronous lifting course of the main hook and the assisted hook, the upright column component automatically turns over to be vertical to the ground from a horizontal position. The technical proposal is particularly suitable for the lifting of the large component and has the characteristics of fast construction speed and less safety risk.

Owner:宁夏送变电工程有限公司

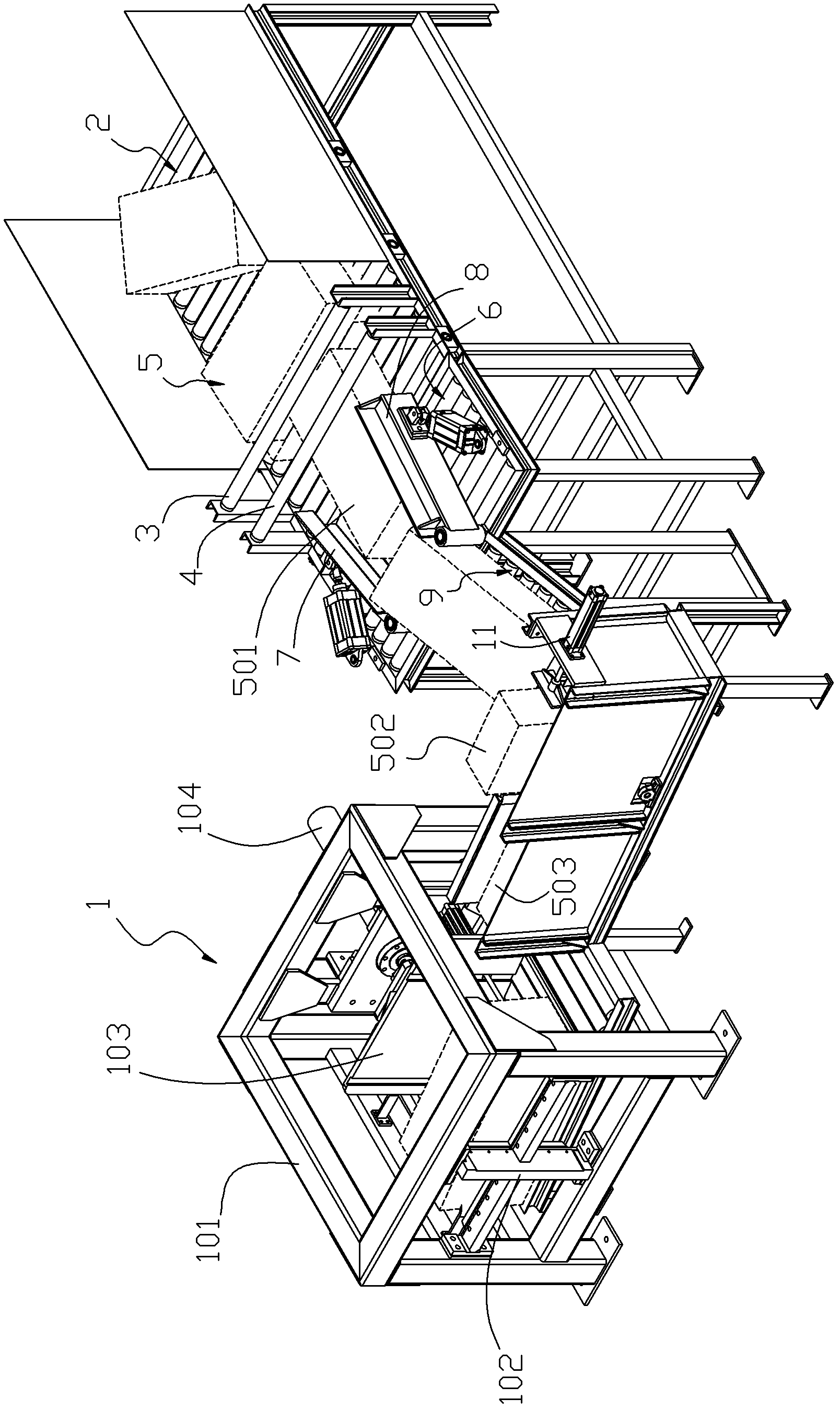

Wood tray manufacture method

InactiveCN101417452AThe nailing position is uniform and beautifulImprove the stabilityWood working apparatusProduction lineUltimate tensile strength

The invention relates to a manufacturing method of wood trays, including the following steps of: forming front components of wood trays; turning over the front components of the wood trays; forming back components of the wood trays at back sides of the front components of the wood trays to produce the wood trays; postprocessing procedures; lining up and stacking the wood trays into a block; and exporting and carrying the whole block of wood trays stacked well into a warehouse. Compared with the prior art, the invention has the advantages that only 4 to 6 operators are needed in the whole production line, which equals the production efficiency of 20 operators with manual operation; the amount of labor can be saved by 70 percent and the production efficiency can be increased by more than 5 times; the labor intensity of workers can be reduced; the wood trays are lined up in order and can be staggered positively and negatively to save space; and single-deck trays can save space by more than 40 percent, site and space can be saved, and all processing equipment can be installed on the production line.

Owner:吴继荣

Rotary vertical garbage incinerator

InactiveCN104235856AEasy to manufactureSimplify the installation processIncinerator apparatusCombustion chamberFlue gas

The invention discloses a rotary vertical garbage incinerator, and relates to waste treatment equipment. The rotary vertical garbage incinerator comprises a shell, a combustion chamber positioned in the shell, and a feeding device, wherein the combustion chamber comprises a primary combustion chamber, an annular flue gas pyrolysis chamber, a secondary combustion chamber and a tertiary combustion chamber; space between the shell and each stage of combustion chamber is filled with a vermiculite refractory material; the feeding device comprises a hopper, a rotary drying and feeding drum and a transmission system; the rotary drying and feeding drum is arranged on a drying and feeding drum support mechanism, and is connected with the output end of the transmission system; a feeding spiral plate is arranged in the rotary drying and feeding drum; one end of the drum is connected with the hopper; the other end of the drum extends into the primary combustion chamber, and is provided with drying holes, which are communicated with the primary combustion chamber, on the part in the primary combustion chamber. The rotary vertical garbage incinerator does not need separate garbage pretreatment equipment, drying equipment or secondary combustion equipment, has the advantages of simple structure, low use and maintenance costs, high incineration efficiency and wide application range, and is ideal equipment for garbage incineration.

Owner:杨学勤

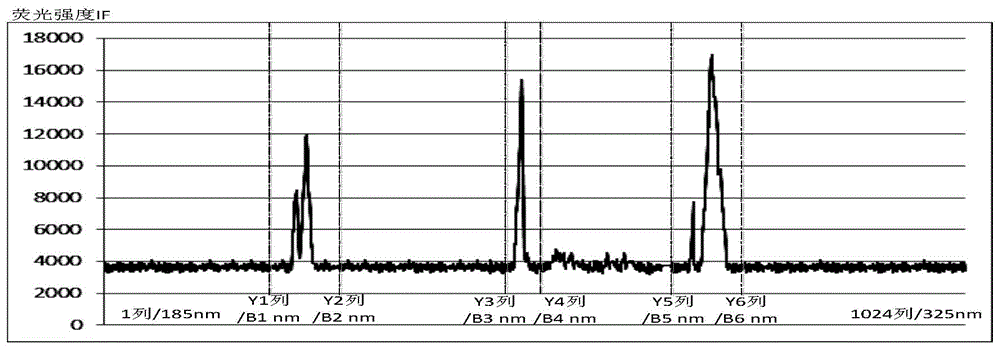

Digital micro-mirror control method suitable for atomic fluorescence chromatic dispersion detection system

ActiveCN105044056ALarge amount of data transferSimple methodFluorescence/phosphorescenceFluorescenceAutomatic control

The invention relates to a digital micro-mirror control method suitable for an atomic fluorescence chromatic dispersion detection system. The method comprises the following steps: choosing the control mode of a digital micro-mirror from three modes: an automatic control mode, a whole spectrum selection mode, and a single waveband selection mode; choosing the automatic control mode, when the element to be detected is a specific element, and controlling the digital micro-mirror to turn over according to the preset digital micro-mirror control parameters; choosing the whole spectrum selection mode, when a sample to be detected is subjected to whole spectrum detection, and controlling the digital micro-mirror to turn over according to the default values of the preset digital micro-mirror control parameters or manually-input preset values; choosing the single waveband selection mode, when the detection is carried out under a self-defined waveband, and controlling the digital micro-mirror to turn over according to the manually-input digital micro-mirror control parameter set values. The provided method has the characteristics of simple command structure, rapid control speed, and little resource utilization, and is capable of carrying out high-speed and stable atomic fluorescence chromatic dispersion detection on different elements with different characteristics for many times.

Owner:JILIN UNIV

Quick welding device for scaffold plate fastener

ActiveCN105108401AEasy to take outRealize automatic feeding processWelding/cutting auxillary devicesAuxillary welding devicesVertical tubeEngineering

The invention discloses a quick welding device for a scaffold plate fastener. The quick welding device comprises a base station, a side rack, a beam rack, a working rack, a clamping mechanism, a welding mechanism, a first drive mechanism, a second drive mechanism, a third drive mechanism and a fourth drive mechanism, wherein the base station is horizontally arranged; the side rack is mounted on the base station; the beam rack is connected with the side rack; a fixing part for axially fixing a vertical tube is arranged on the working rack; the first drive mechanism is used for driving the working rack to axially rotate; the clamping mechanism is used for clamping the plate fastener; the second drive mechanism is used for driving the clamping mechanism to move; the welding mechanism is mounted on the beam rack and is positioned above the working rack; the third drive mechanism is used for driving the welding mechanism to move back and forth in an axial direction of the vertical tube; and the fourth drive mechanism is used for driving the welding mechanism to move up and down in a radial direction of the vertical tube. The quick welding device for the scaffold plate fastener provided by the invention realizes the purpose of mechanically welding the plate fastener.

Owner:广东九为工程安全科技股份有限公司

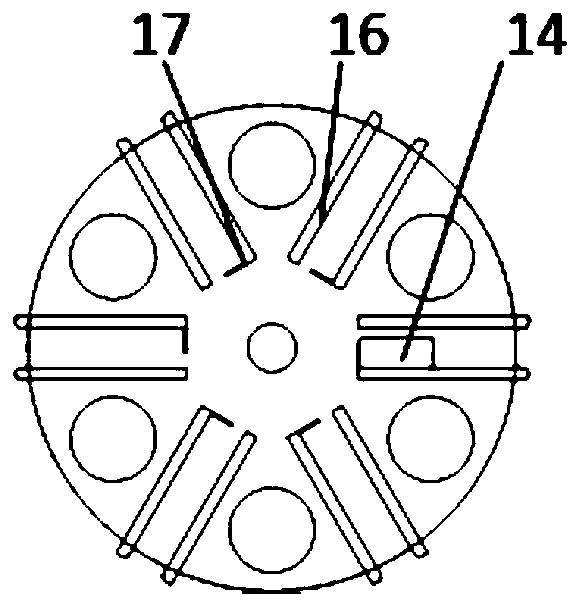

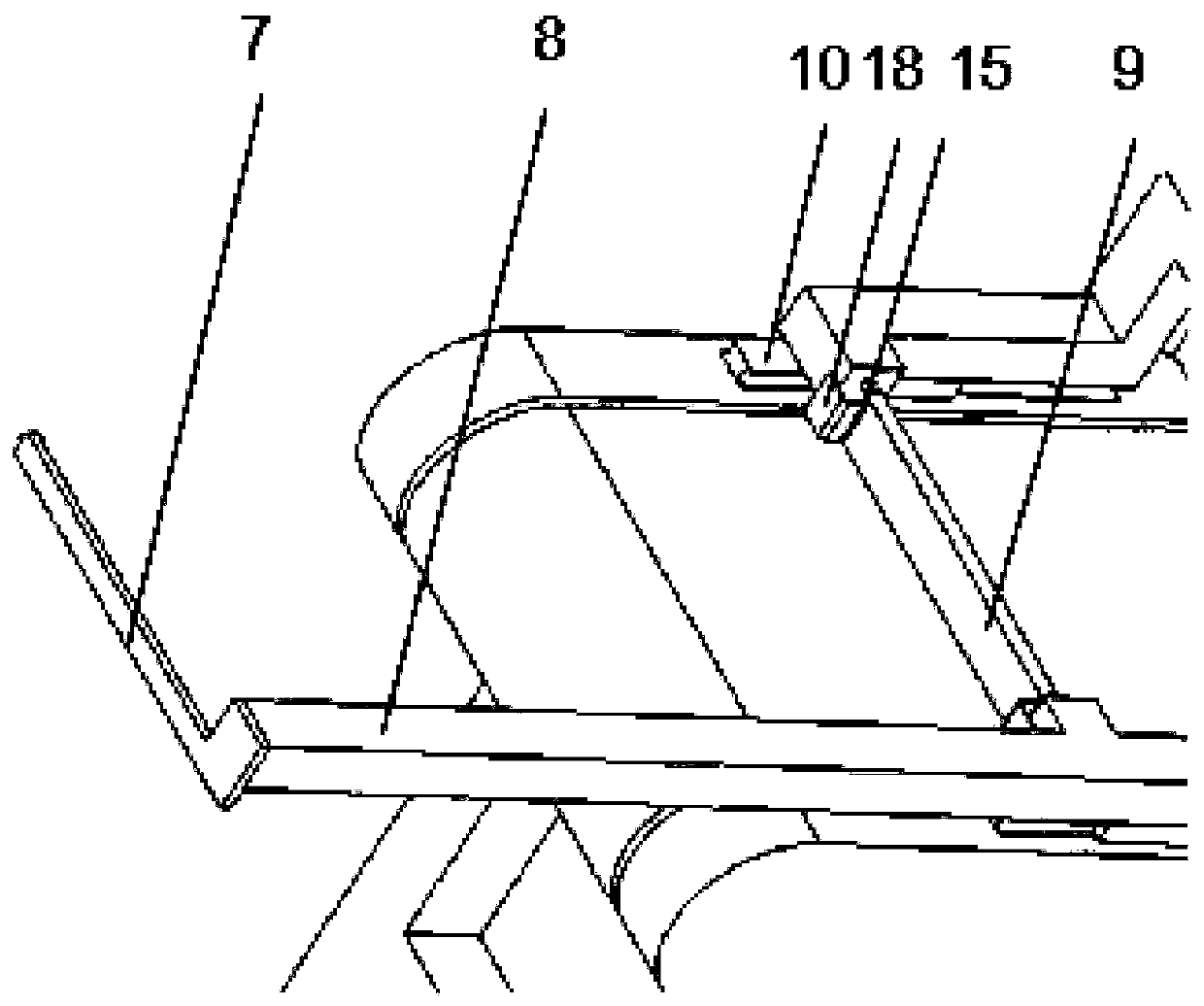

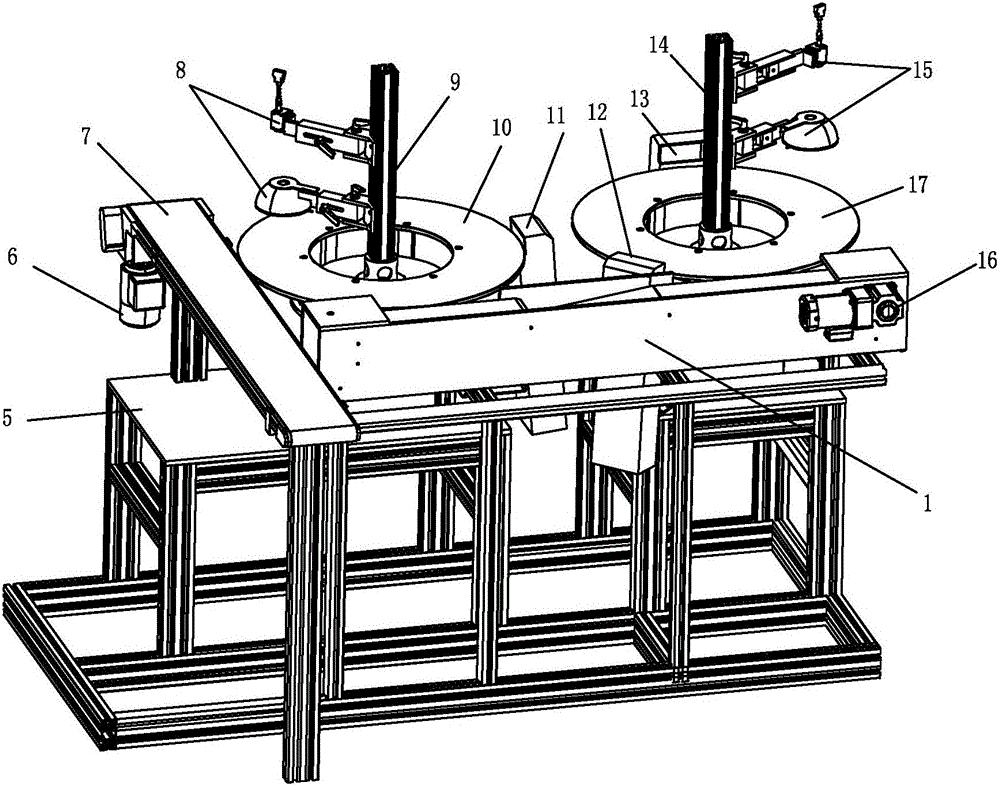

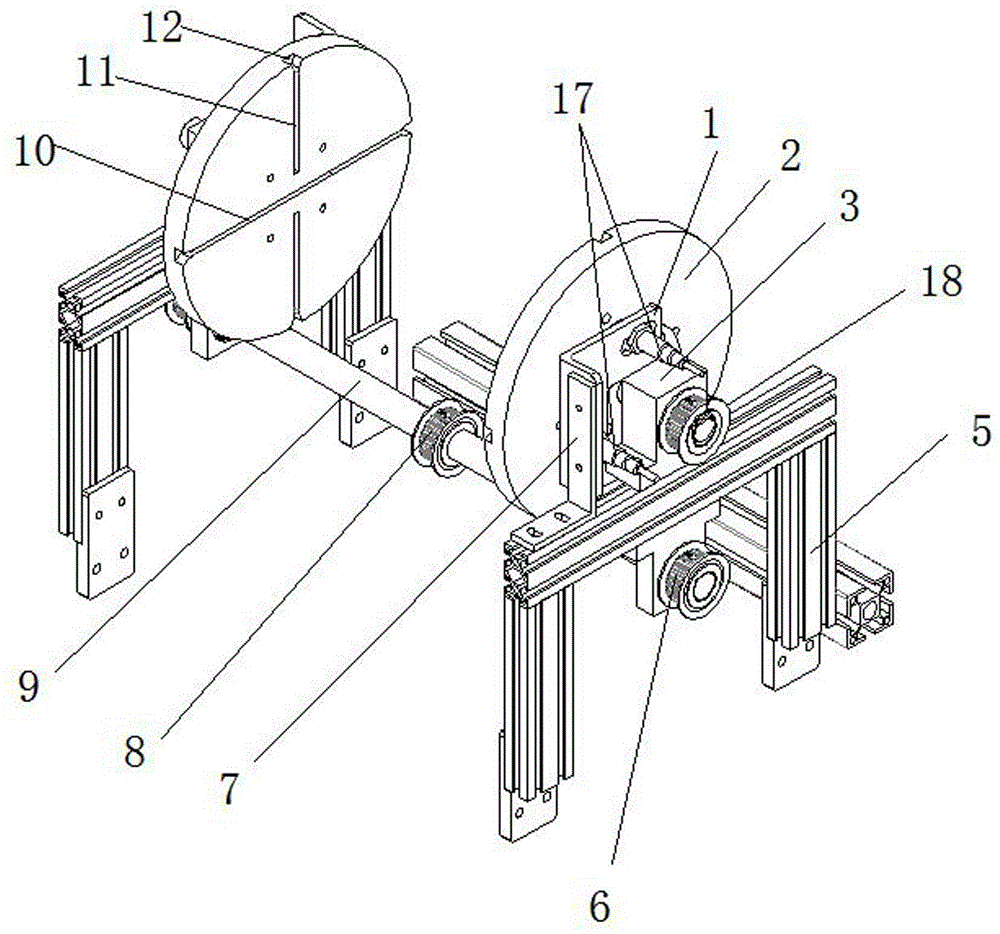

Automatic turnover mechanism for green ceramic tapes

The invention discloses an automatic turnover mechanism for green ceramic tapes, and relates to the technical field of ceramic packaging. The automatic turnover mechanism comprises a support and a pair of synchronous rotation discs, wherein the disc faces of the two synchronous rotation discs are arranged in parallel, the synchronous rotation discs are connected with synchronous rotation drive transmission devices installed on the support, and a through guide groove and two semi-through guide grooves are formed in each of the opposite faces of the two synchronous rotation discs; the groove width of the through guide grooves and the groove width of the semi-through guide grooves are equal and are equal to or greater than the width of the green ceramic tapes, and when the through guide grooves or the semi-through guide grooves in the synchronous rotation discs rotate to be horizontal, the groove walls at the lower parts of the through guide grooves or the lower parts of the semi-through guide grooves are flush with the upper surface of a conveying belt of a tape conveying mechanism; a controller and proximity switch sensors are further arranged, and the proximity switch sensors and the synchronous rotation drive transmission devices are both connected to the controller. The automatic turnover mechanism is simple in structure and convenient to use and install, automatically overturns the tapes, relieves the labor intensity and greatly improves the production efficiency.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

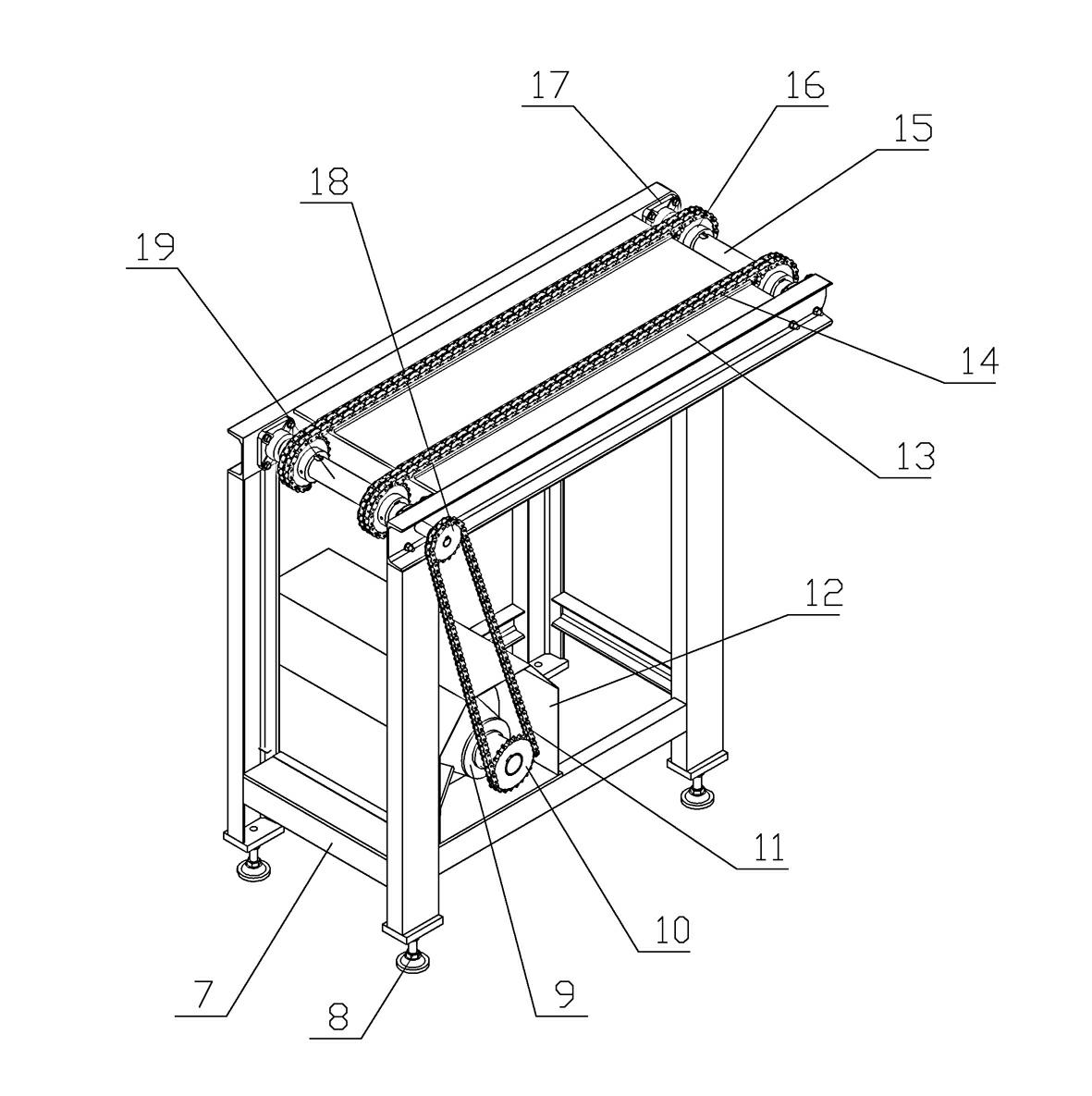

Full-automatic paving machine of ceramic colored code bricks

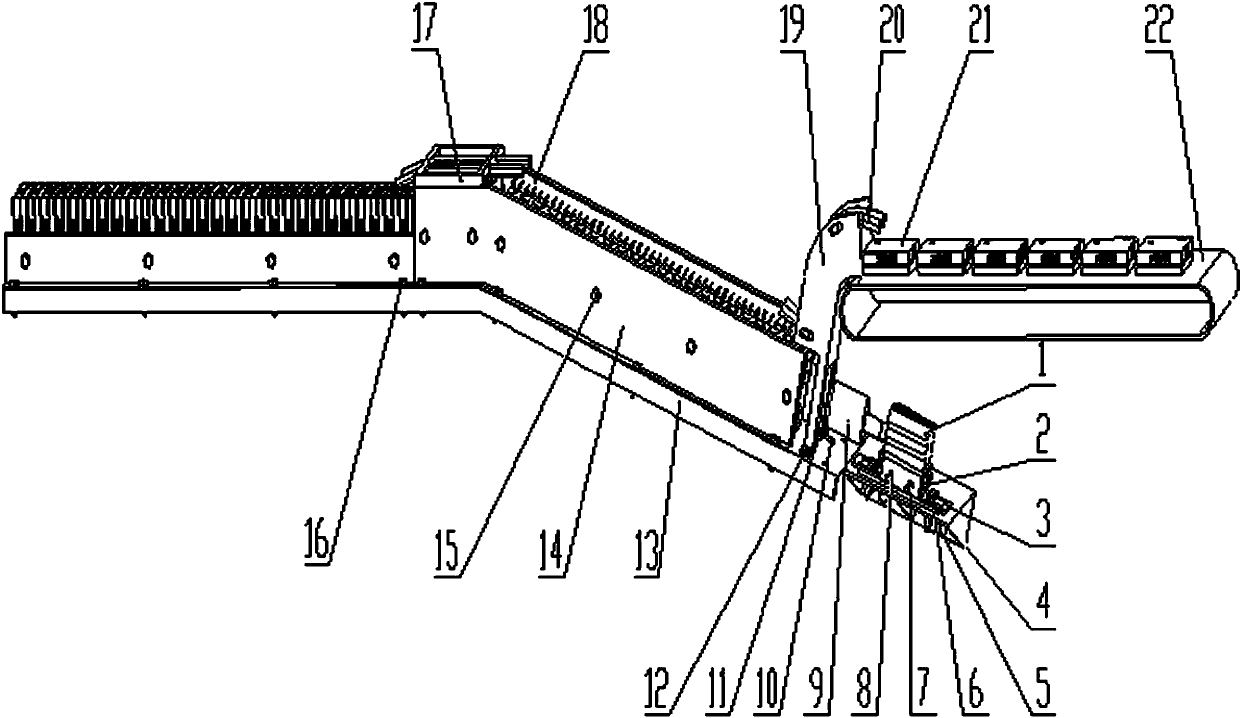

InactiveCN103171895ARealize automatic flipRealize fully automatic pavingConveyor partsBrickEngineering

The invention provides a full-automatic paving machine of ceramic colored code bricks. The full-automatic paving machine of the ceramic colored code bricks solves the problems that an existing paving machine cannot separate front faces and back faces of the colored code bricks and a mass of manual work is necessary to separate the front faces and the back faces of the colored code bricks and the like. The full-automatic paving machine of the ceramic colored code bricks comprises a rack, a vacuum pump, a sucking disc, a convey band and a shifting frame, wherein the convey band is installed on the rack, and the shifting frame is arranged on the rack in a movable mode. A sucking disc lifting mechanism is installed on the shifting frame. The sucking disc is installed on the sucking disc lifting mechanism. The full-automatic paving machine of the ceramic colored code bricks further comprises a negative pressure reversing box. The negative pressure reversing box is arranged on the rack in a rotatable mode. The sucking disc and the negative pressure reversing box are respectively communicated with an extraction opening of the vacuum pump through a pipeline. The convey belt comprises a lifting convey belt. The lifting conveying belt is connected with a convey belt lifting mechanism. The negative pressure reversing box is located over the lifting convey belt.

Owner:福建科颖工贸有限公司

Automatic overturning and transmitting device for cigarette packet

The invention relates to an automatic overturning and transmitting device for a cigarette packet, and belongs to the technical field of cigarette packing. The automatic overturning and transmitting device for the cigarette packet is installed at the tail end of a conveyer belt on a C90 packer after packet oil seal packing processes are completed, and is used for 90-degree turnover of a 'YuXi Manor' packet with 16 cigarettes to achieve close attachment of the obverse side and the reverse side of the surface of the brand of the 'YuXi Manor'. The automatic overturning and transmitting device mainly comprises a slide way, a conveying tank, a cylinder, a push rod, a photoelectric tube and the like. The cylinder and the push rod are installed on the base of the C90 packer, the upper portion of the slide way is linked with the tail end of the conveyor belt of the C90 packer, the lower portion of the slide way is linked with the conveying tank, and the photoelectric tube is installed on the side face of the bottom of the slide way. Whenever the photoelectric tube detects that the cigarette packet sliding downwards to a proper position, trigger signals enable a C90 controller to start a solenoid valve to activate the cylinder and bounce the push rod out, the cigarette packet is pushed into the conveying tank, turnover and rank ordering in the conveying tank of the cigarette packet are completed, stacking is facilitated, the cigarette packet can be loaded to a carton conveniently and manually, and packing quality and efficiency are improved. The automatic overturning and transmitting device has the advantages of being simple in structure and convenient to debug, achieving automatic overturning of the packet and smooth transmitting, and the like.

Owner:HONGTA TOBACCO GRP

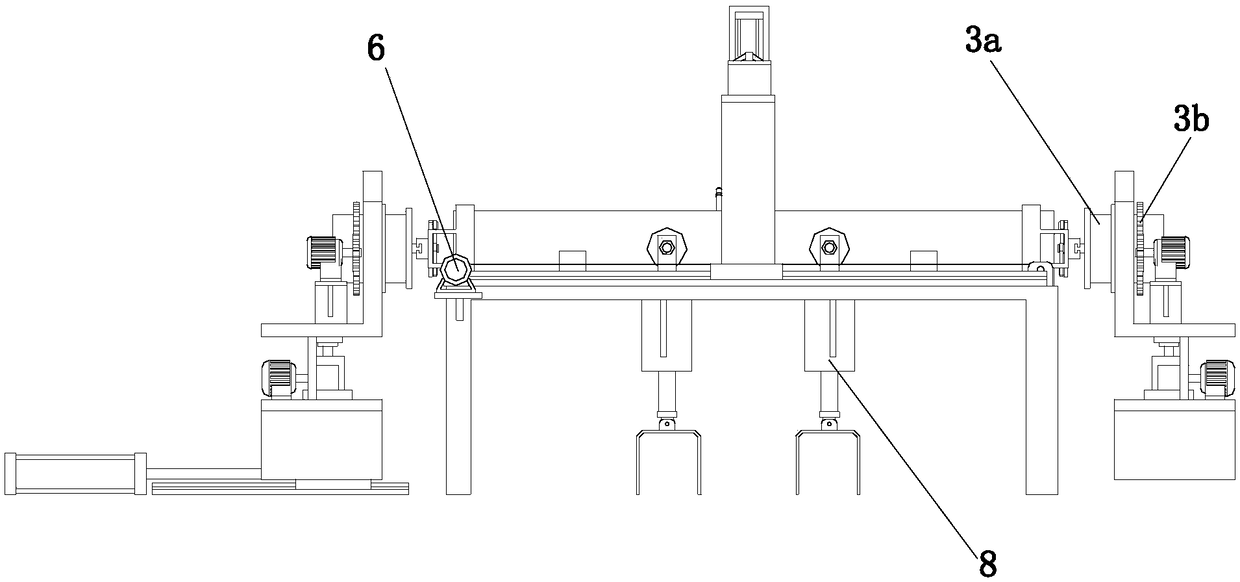

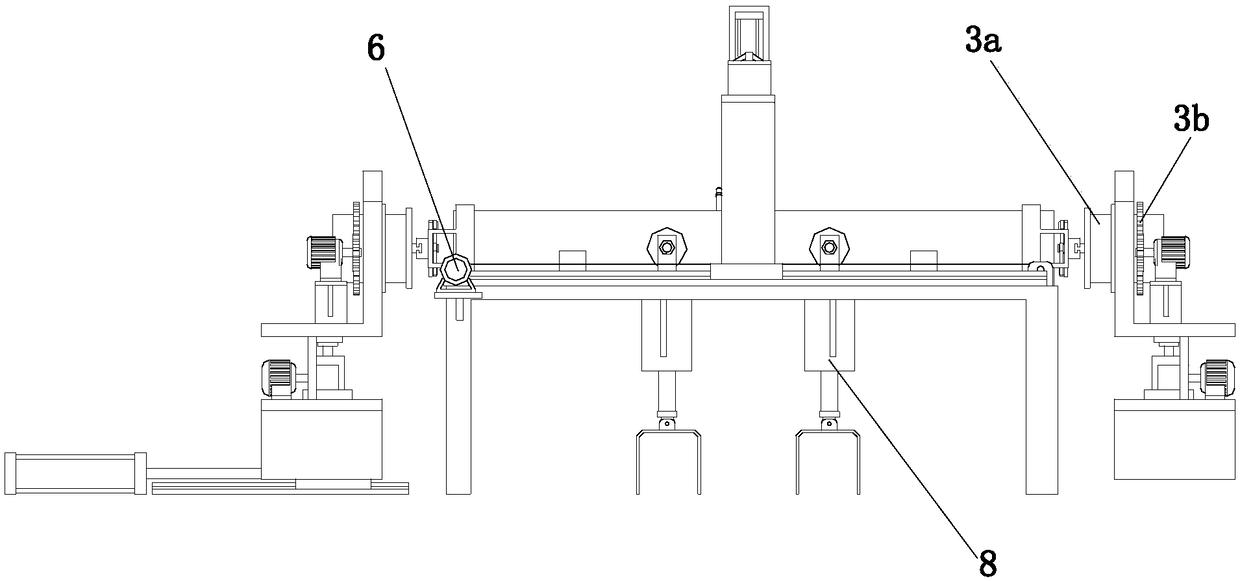

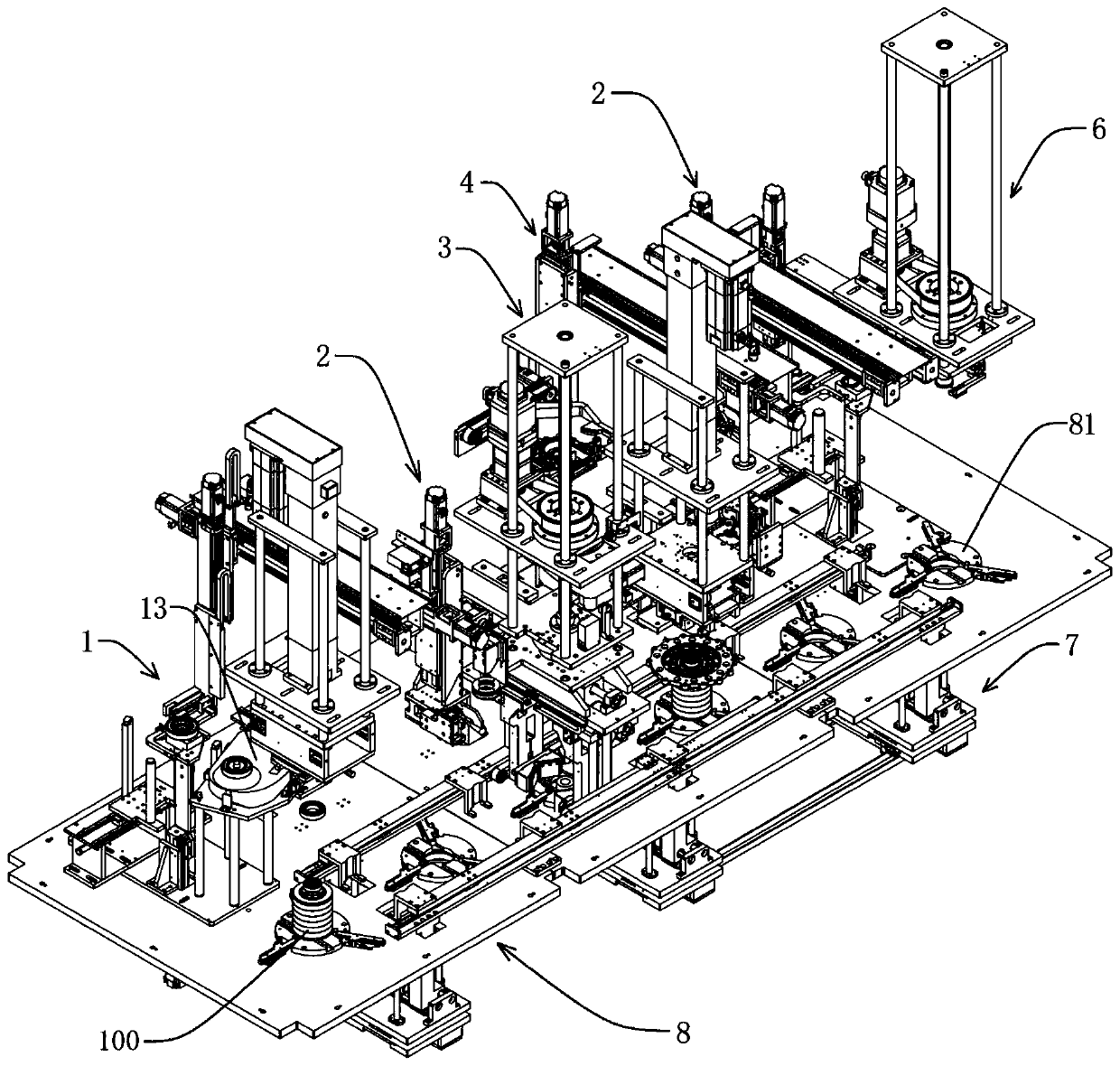

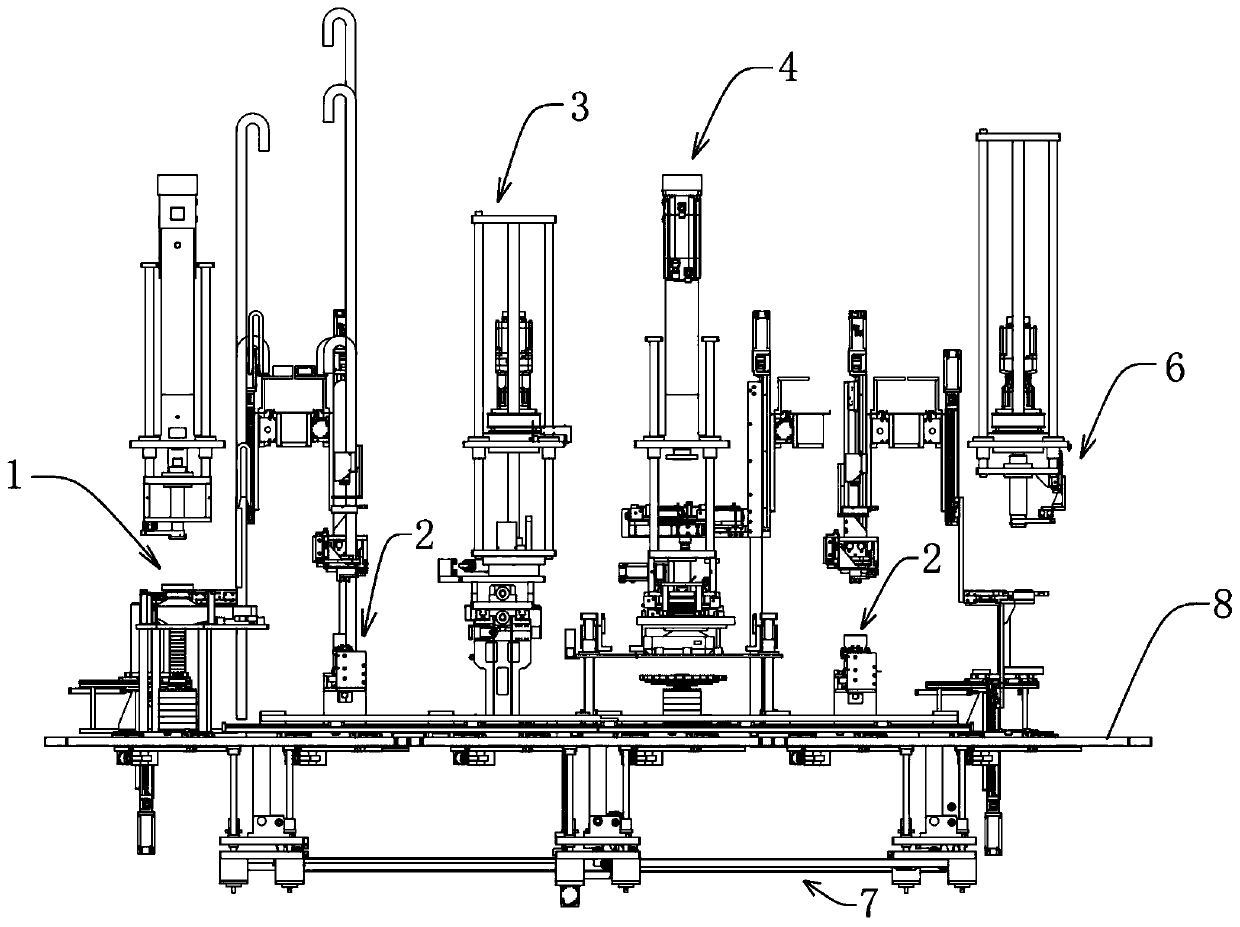

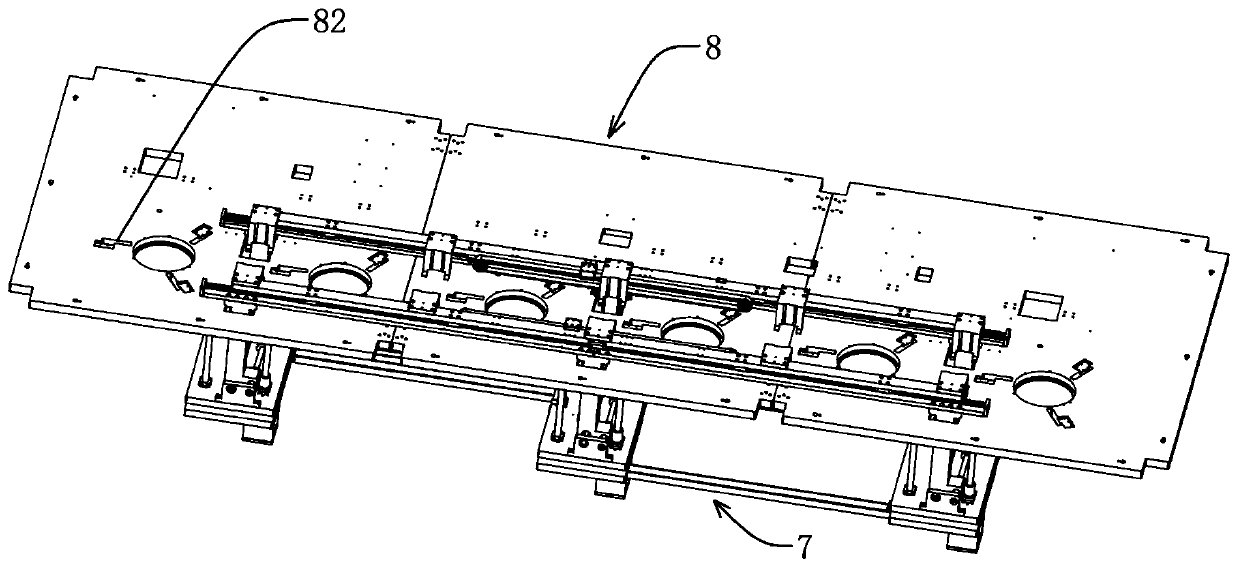

Multi-station transfer mechanism and motor bearing assembly equipment

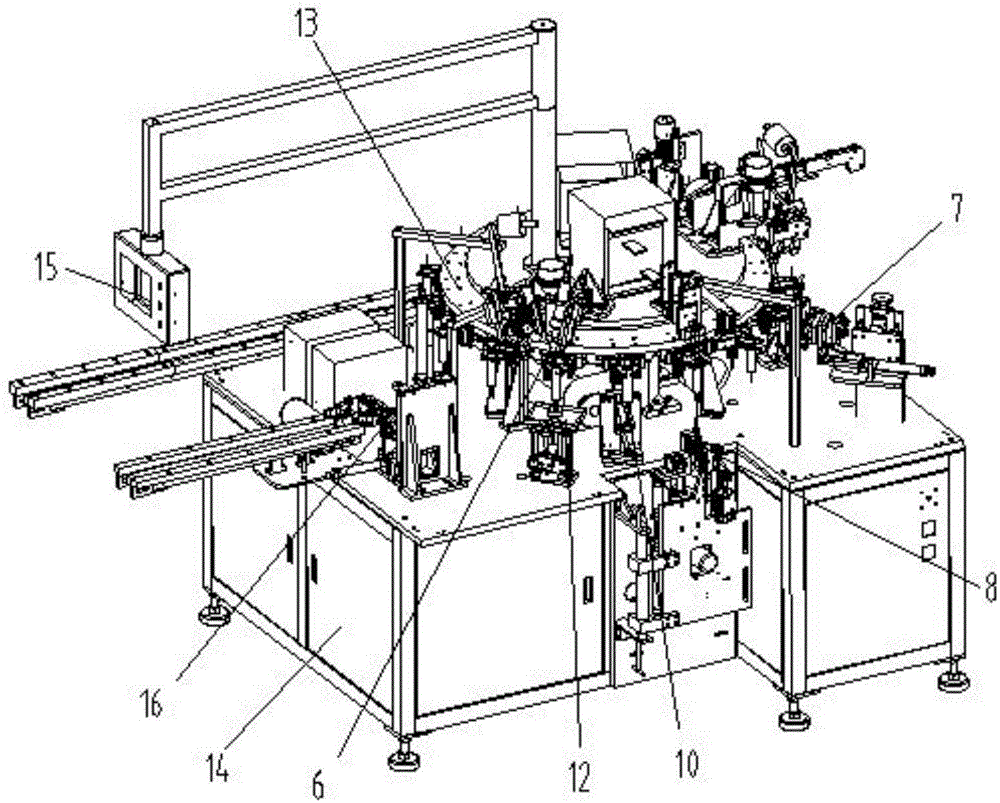

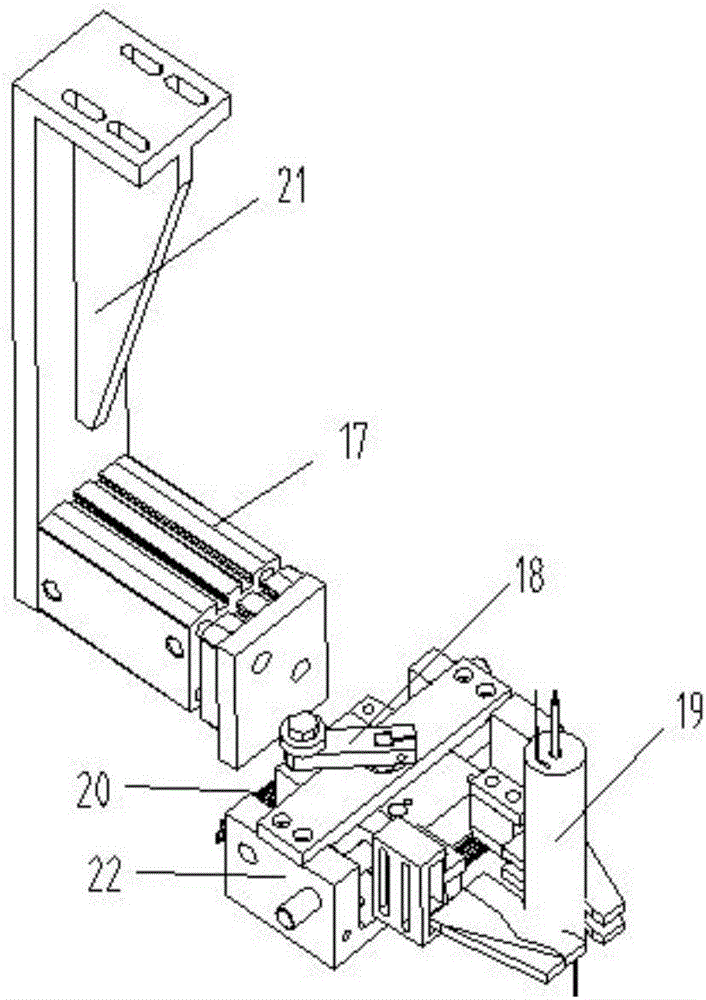

ActiveCN111300044ASuitable for transferHigh repeatabilityAssembly machinesManufacturing dynamo-electric machinesElectric machineryDrive motor

The invention discloses a multi-station transfer mechanism and motor bearing assembly equipment, and belongs to the technical field of motor assembly. The multi-station transfer mechanism comprises anX-axis transfer assembly, a Y-axis spacing regulating assembly and at least one group of Z-axis lifting assemblies; each Z-axis lifting assembly comprises a rolling ball lead screw and a lifting table which is fixedly connected to a nut in the rolling ball lead screw, wherein the upper end of the lead screw in the rolling ball lead screw is provided with an operation table, the lower end of the lead screw in the rolling ball lead screw is arranged on a support base in a penetrating mode, and the lower end of the lead screw is in transmission connection to a drive motor; the Y-axis spacing regulating assembly comprises two groups of supporting plates which are separately and fixedly connected onto supporting frames in a one-to-one correspondence mode; the supporting frames are arranged ona two-way lead screw in pair, and the two-way lead screw is in transmission connection to a drive motor; and the X-axis transfer assembly comprises transfer plates which axially extend along the X-axis, and are provided with clamping assemblies, and the transfer plates are axially arranged on the supporting plates slidably in the one-to-one correspondence mode. The multi-station transfer mechanismcan quickly take workpieces and switches to different stations, so that operation on each station is convenient.

Owner:BOZHON PRECISION IND TECH CO LTD

Automatic glue cutting machine

ActiveCN102275176AReduce labor intensityIncrease productionMetal working apparatusSide lyingEngineering

The invention discloses a full-automatic rubber cutting machine, which comprises a rubber cutting machine body and a block rubber storage and transport mechanism, and is characterized in that: the rubber cutting machine body comprises a rubber cutting knife fixed on a frame and a vertical chopping block capable of reciprocating transversely on the frame; an allowed cutting area is formed between the vertical chopping block and the rubber cutting knife; block rubber entering the allowed cutting area is positioned in a side lying posture; in the process of moving the vertical chopping block to the rubber cutting knife, the block rubber entering the allowed cutting area can be pushed to the rubber cutting knife until the block rubber is cut into at least two small rubber blocks, and the small rubber blocks fall through a knife gap and enter the next process; and the block rubber storage and transport mechanism comprises a block rubber storage unit, a block rubber horizontal passing unit,a block rubber alternative passing unit, a block rubber turning and erecting unit and a block rubber side lying conversion unit. By the full-automatic rubber cutting machine, the labor intensity of aworker can be greatly reduced, and the full-automatic rubber cutting machine has high operating safety, high yield and high production efficiency and is particularly suitable for production process automation and continuous modification.

Owner:双星东风轮胎有限公司

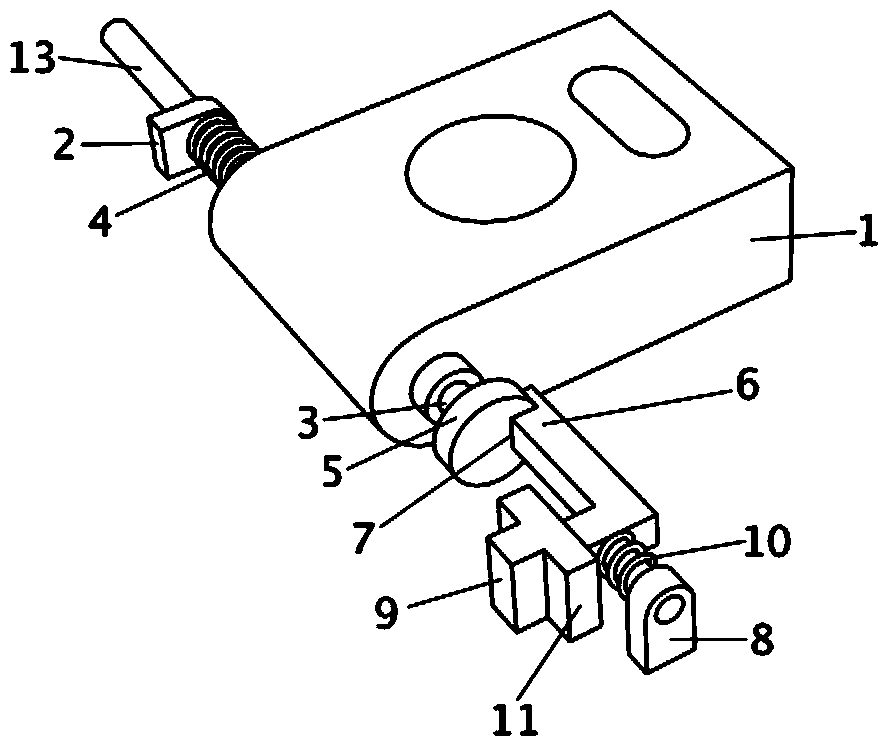

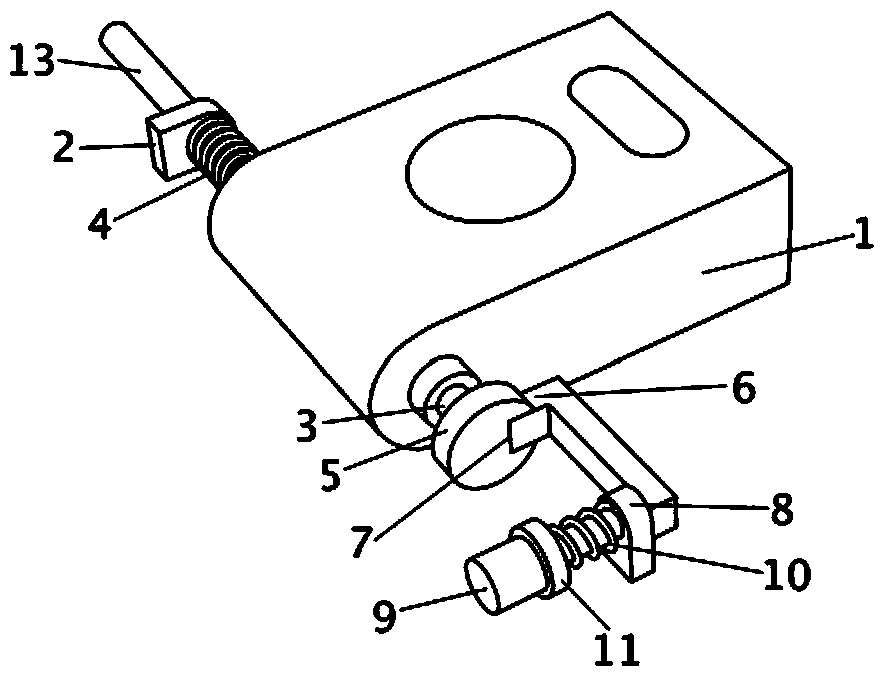

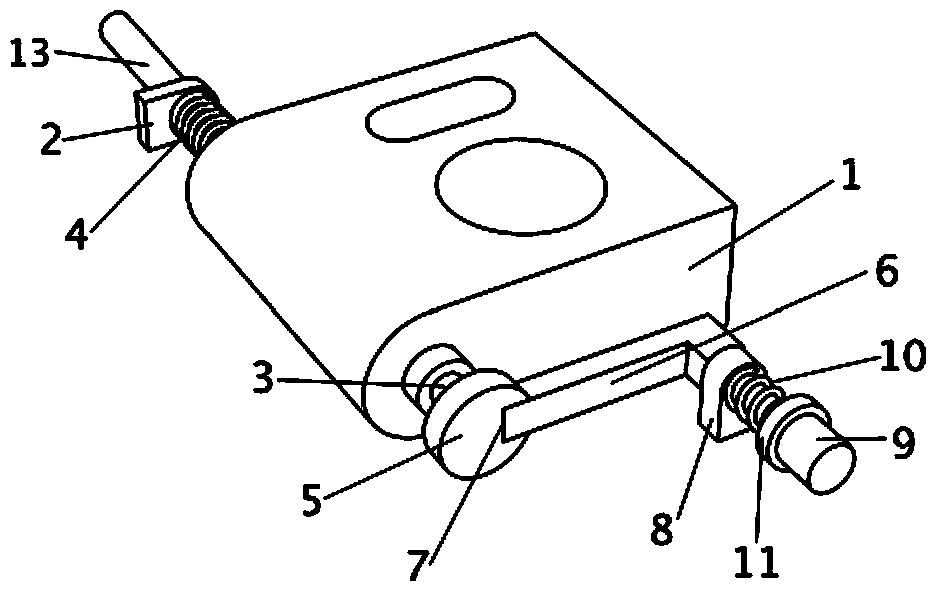

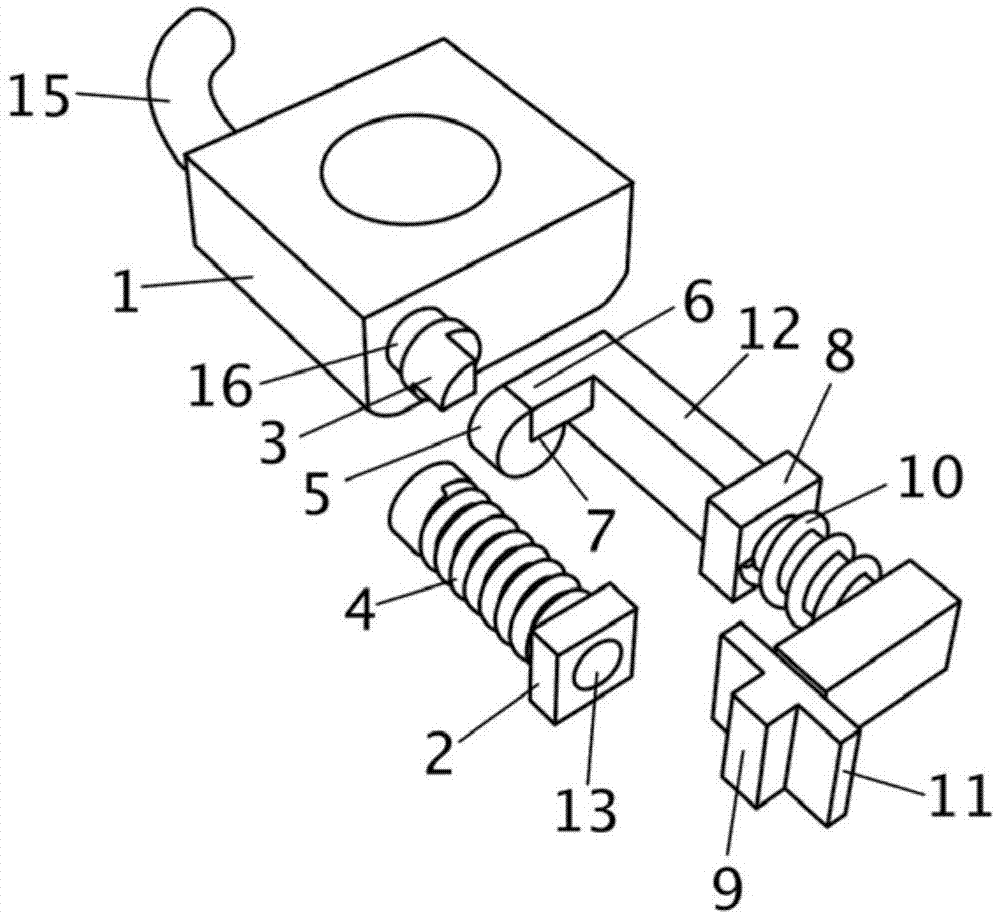

Weighting test instrument device and manufacturing method thereof

InactiveCN106493088AAccurate rotation positioningRealize automatic flipWeighing apparatus for materials with special property/formSortingTester deviceEngineering

The invention provides a weighing test instrument device and a manufacturing method thereof. The weighing test instrument device comprises a feeding unit, a weighing sorting unit, a discharging unit and a control unit. The control unit controls the feeding unit to deliver to-be-weighed materials to overturning balances of the weighing sorting unit separately; the overturning balances weigh the materials separately and feed weighing data back to the control unit; and the control unit controls a rotary table to rotate to the positions above target material receiving cases according to sorting standards, the overturning balances are overturned, and weighed and sorted materials are placed into the target material receiving cases separately. By adoption of the weighing test instrument device and the manufacturing method thereof, the technical problems that when an existing weighing test instrument device is used for weighting, testing and sorting batch materials, time and labor are wasted, and much manpower is needed for sorting out the materials are solved, and accordingly, the technical effects that the batch materials are automatically fed separately, rapidly weighed, precisely sorted and discharged in a batched mode in time through the weighing test instrument device are achieved.

Owner:SUZHOU SICHUANGYUANBO ELECTRONICS TECH CO LTD

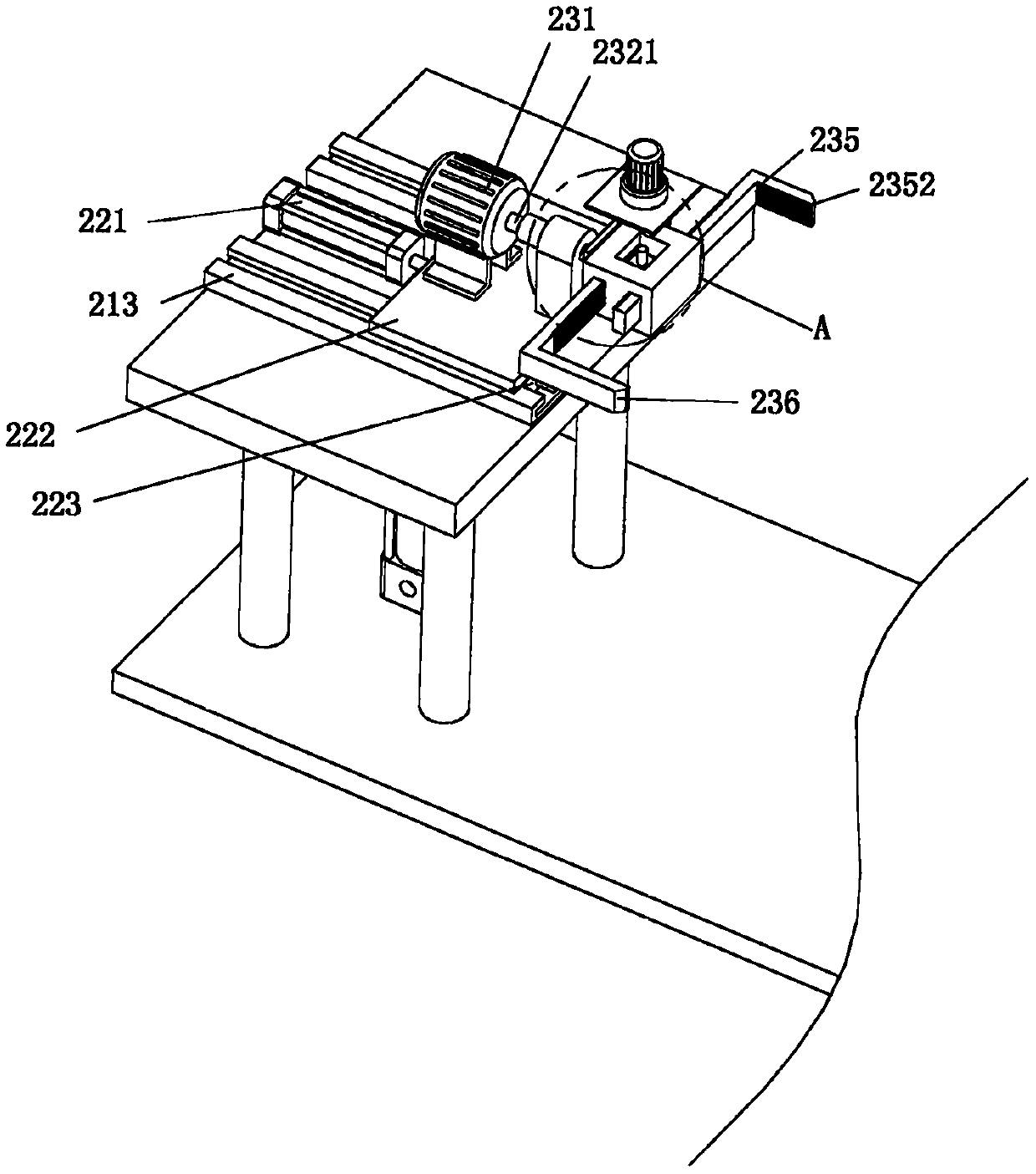

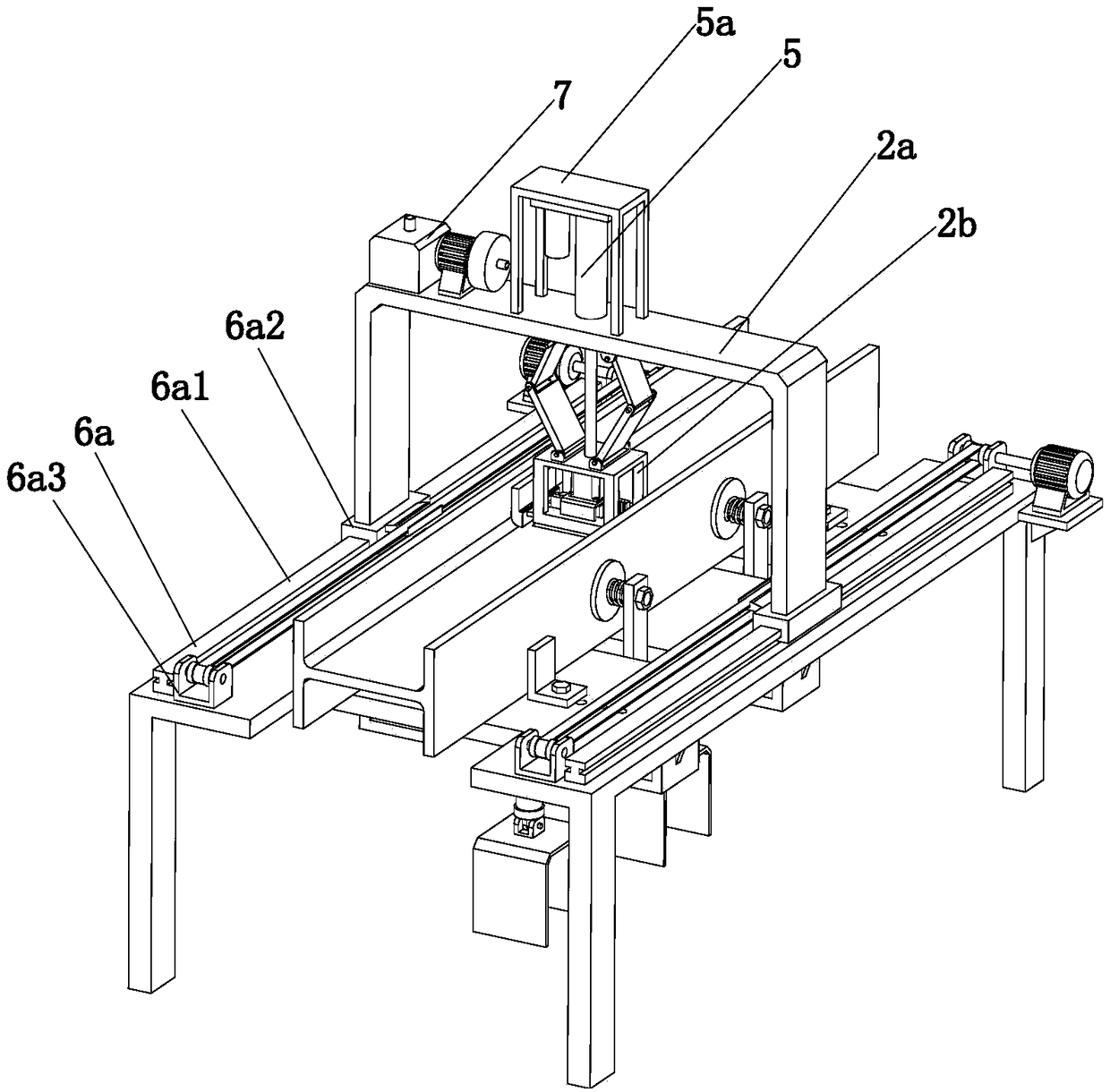

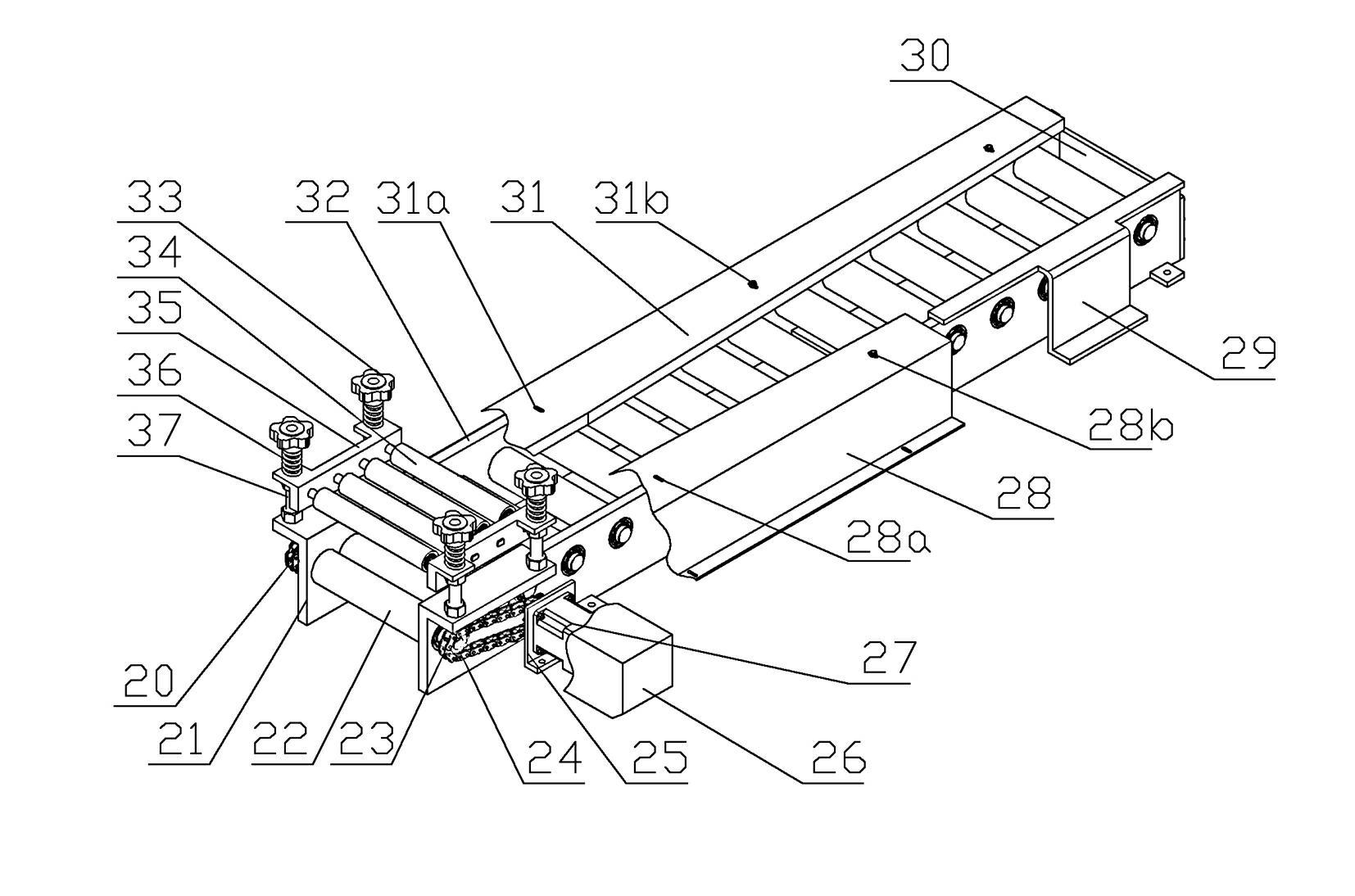

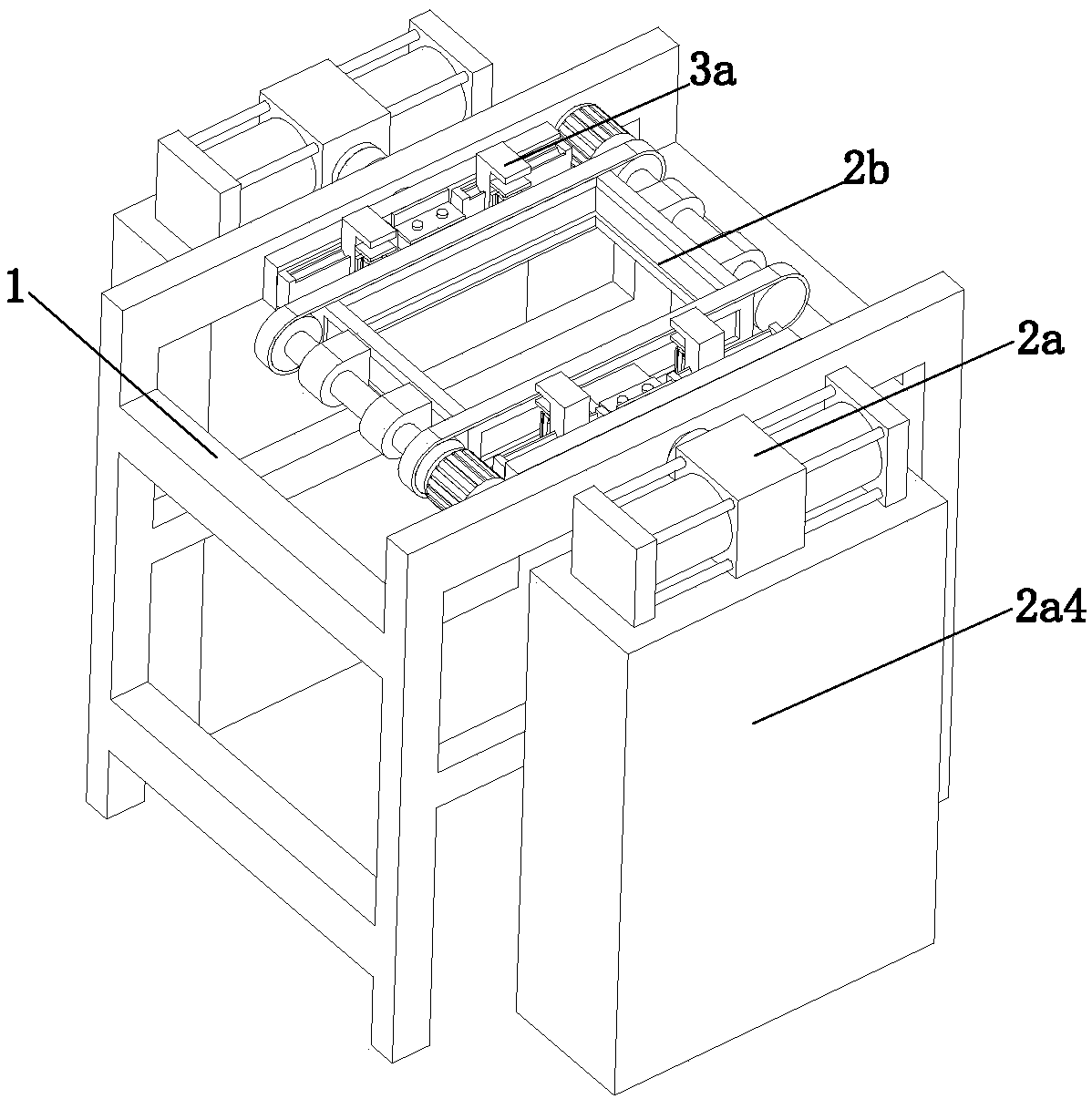

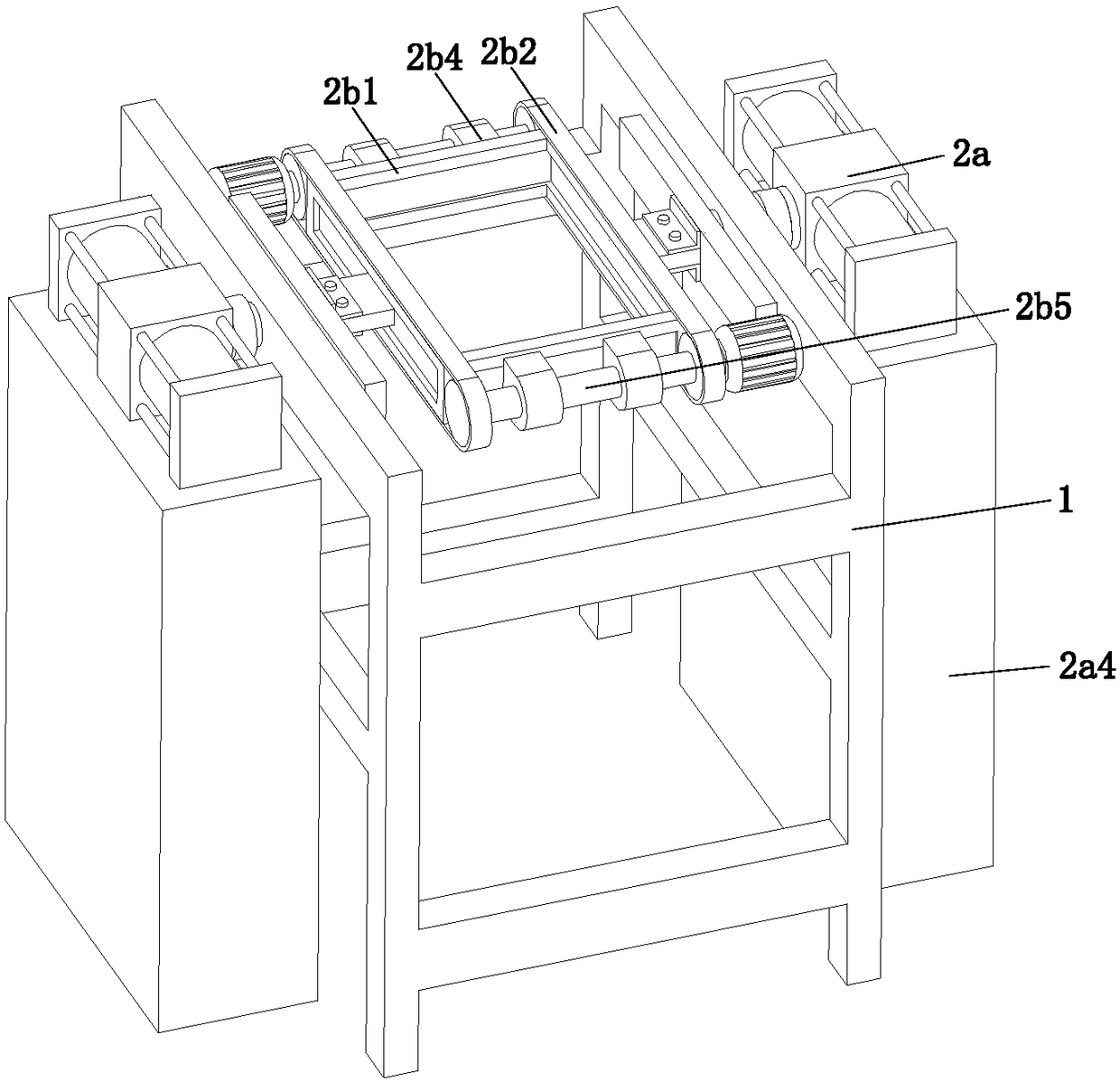

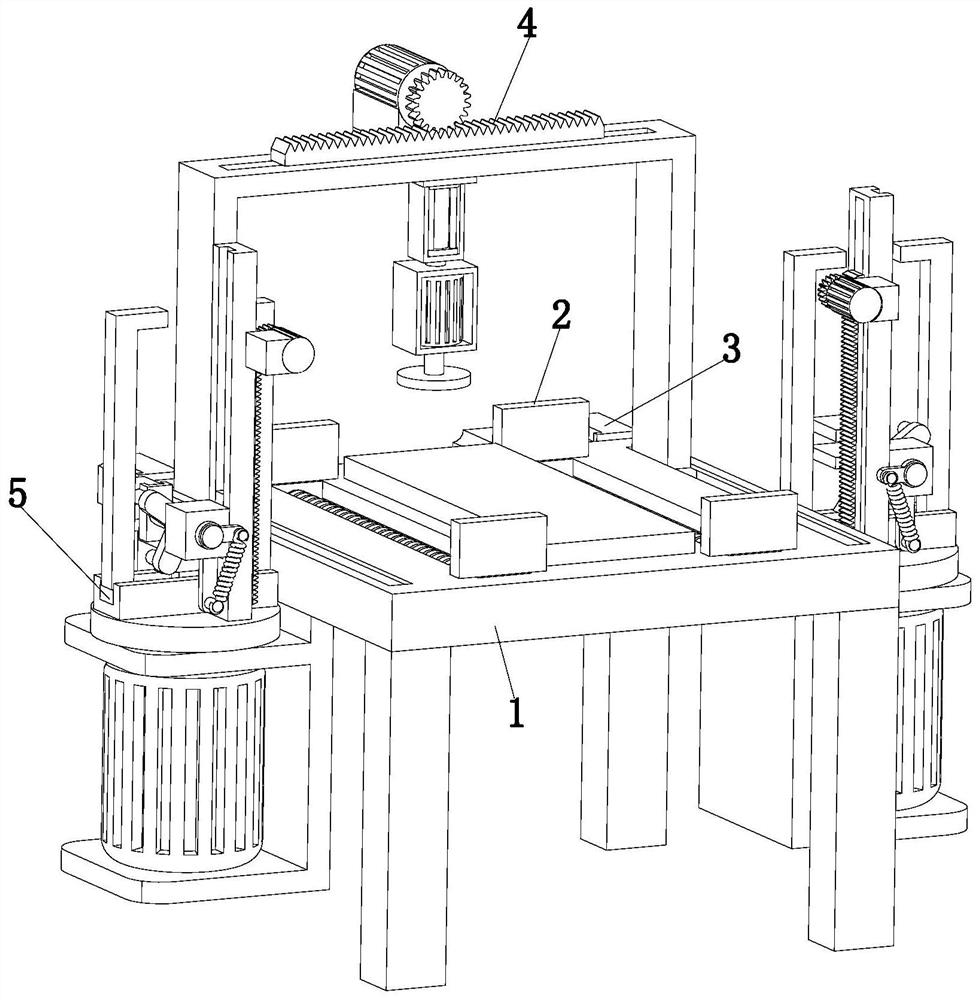

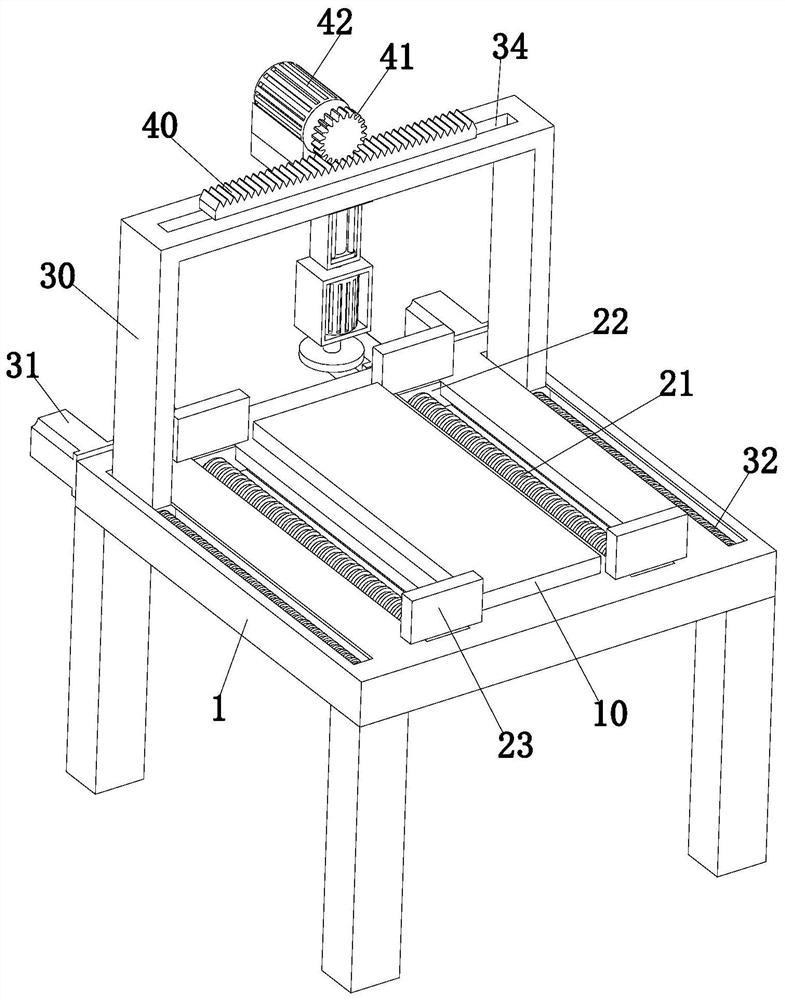

Double-faced notching device for boards

InactiveCN108161089ARealize automatic flipReduce manufacturing costMachine tool componentsWork clamping meansMechanical equipmentEngineering

The invention relates to the field of mechanical equipment, in particular to a double-faced notching device for boards. The double-faced notching device comprises a mounting rack, an overturning mechanism, a positioning mechanism, a rotating mechanism and a notching mechanism. The overturning mechanism comprises two driving assemblies and an overturning assembly. The overturning assembly comprisesa connecting frame and two conveying belts. The connecting frame is of a rectangular framework structure, and the two conveying belts are symmetrically arranged at the two sides of the connecting frame. The upper ends and the lower ends of the two sides of the connecting frame are both attached to the conveying belts. The two sides of the connecting frame are both provided with connecting blockswhich are fixedly connected with the connecting frame. The front end and the rear end of the connecting frame are both provided with fixing blocks. The front ends and the rear ends of the two conveying belts are both provided with connecting rods. The two ends of the two connecting rods are fixedly connected with conveying wheels located at the two ends of the two conveying belts correspondingly.The two connecting rods are connected with the fixing blocks at the front end and the rear end of the connecting frame through bearings separately. The boards can be overturned automatically in the machining process, double-faced notching machining of the boards can be completed quickly, production efficiency is improved and production cost is reduced.

Owner:东莞市史雷帝三维数控科技有限公司

Transmitting device for big soft infusion bag production line

The invention discloses a transmitting device for a big soft infusion bag production line, comprising a main transmission driving mechanism, a driving pulley, more than one port fixing clamping chucks, a driven pulley and a transmitting belt; wherein, the transmitting belt is arranged around the driving pulley and the driven pulley, the port fixing clamping chucks are fixed on the transmitting belt, the driving pulley is connected with the output end of the main transmission driving mechanism, and the axial line directions of the driving pulley and the driven pulley are both not vertical to the horizontal direction. The transmitting device for the big soft infusion bag production line of the invention has simple structure and low cost, and can shorten the length of the big soft infusion bag production line under the same technical parameters.

Owner:TRUKING TECH LTD

Polyurethane foaming platform

InactiveCN101422941ARealize closed mold pouringRealize automatic opening and closingLocking mechanismMaster cylinder

The invention discloses a turnover platform, in particular to a full automatic turnover platform used for manufacturing polyurethane foaming products. The platform comprises a host computer fixedly installed on a machine body and a program-controlled operation system connected with the host computer and is characterized in that the host computer mainly consists of an upper die carrier, a lower die carrier and a movable platform arranged between the two die carriers; one end of the upper die carrier and one end of the lower die carrier are mutually connected through two hinge posts, the other end of the upper die carrier and the other end of the lower die carrier are connected through a locking mechanism in a locked way; the movable platform is connected on the lower die carrier through a master cylinder; a turnover cylinder is respectively on the machine body outside the two hinge posts and a piston rod of the turnover cylinder is fixedly connected with the upper die carrier. The turnover platform has the advantages of high automation degree, good product stability, low labor intensity, high production efficiency and the like.

Owner:YANTAI ZHENGHAI HIGH TECH

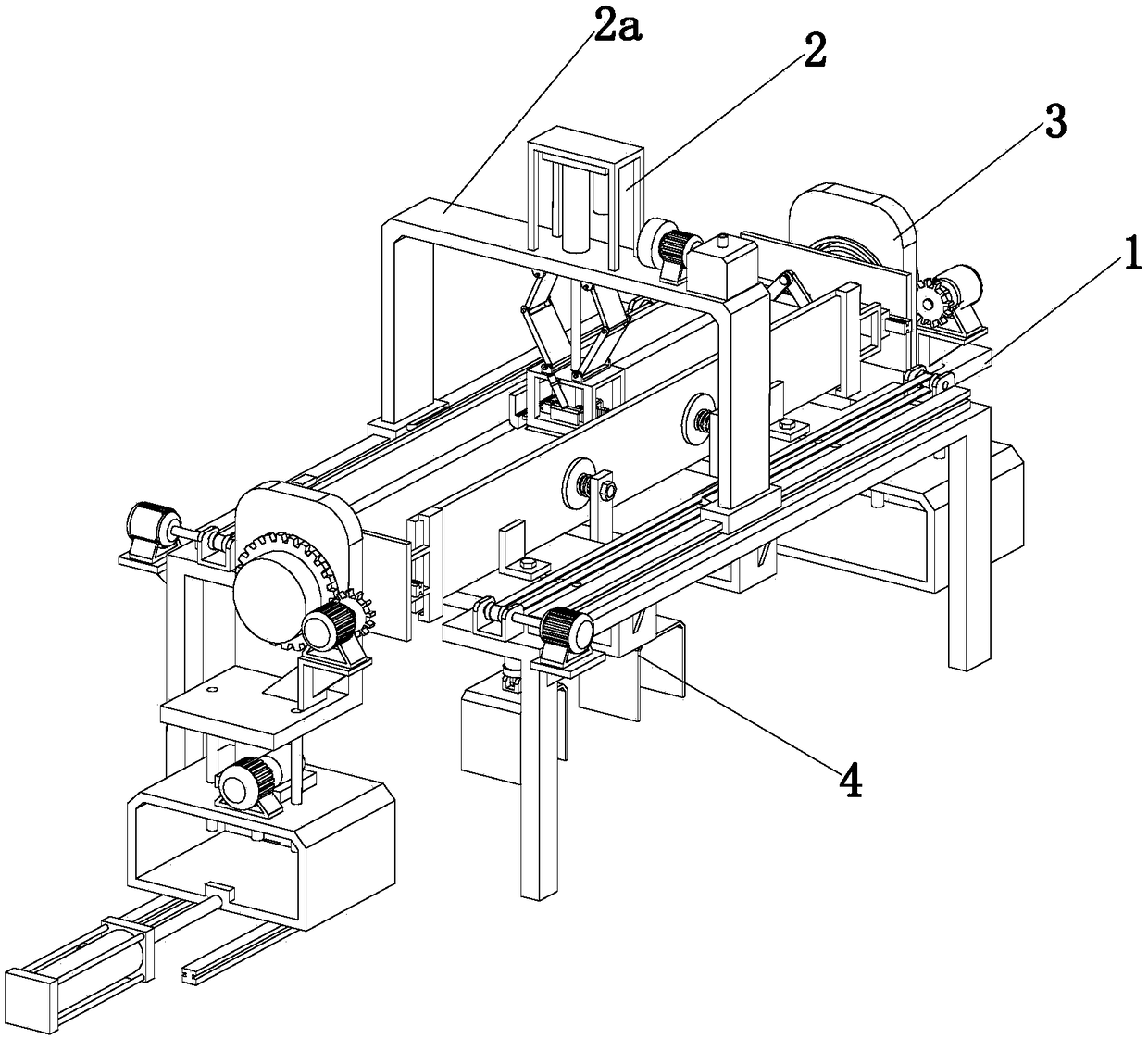

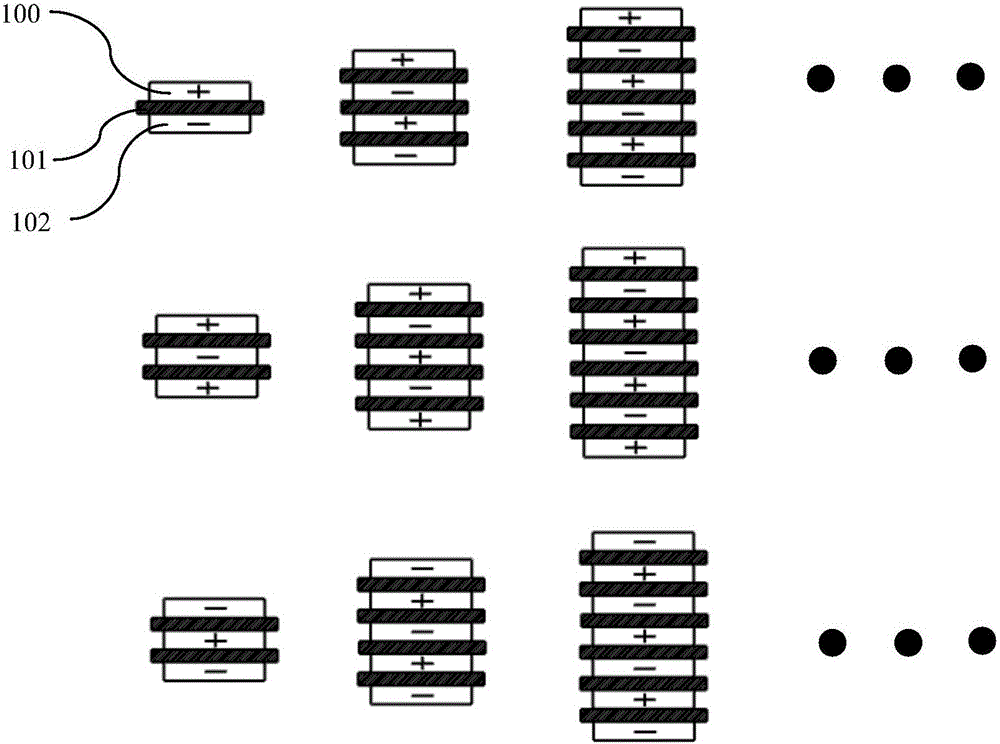

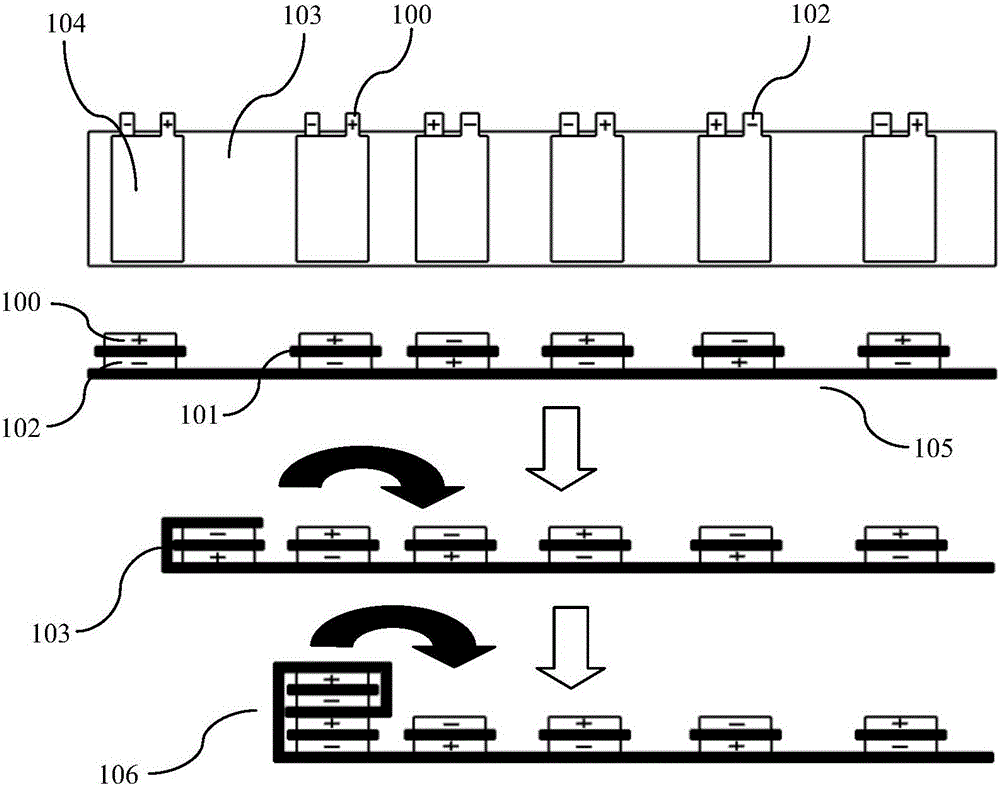

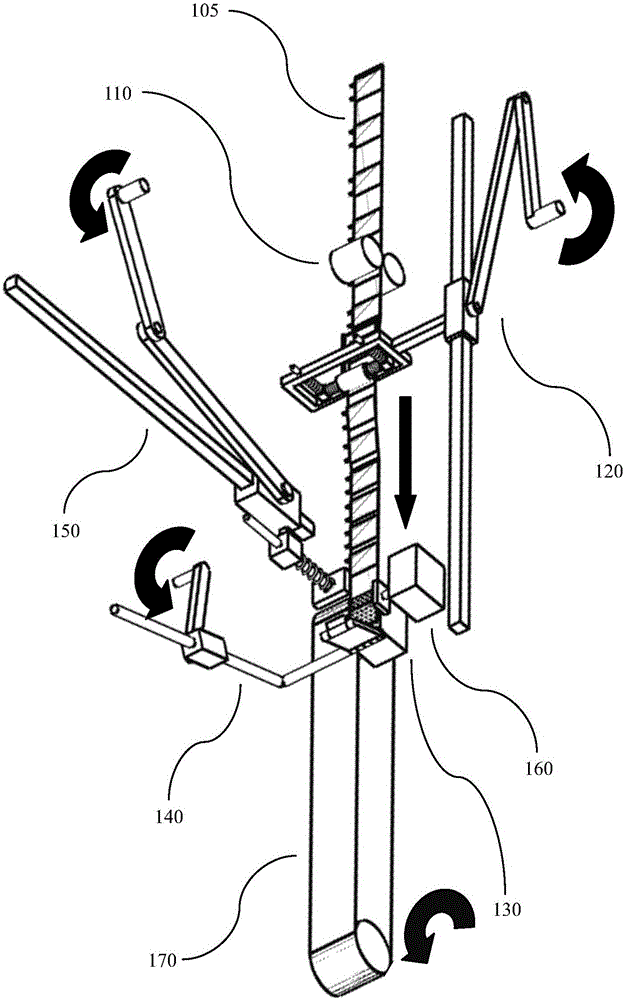

Device for automatically winding wound laminated battery

ActiveCN105742688AHeight adjustableAchieve clampingAssembling battery machinesFinal product manufactureMechanical engineeringSingle electrode

The invention relates to a device for automatically winding a wound laminated battery. The device comprises a tension mechanism, a feeding mechanism, a sucking cutting mechanism, a turnover mechanism, a pressurizing mechanism, a jacking mechanism and a conveying mechanism, wherein the tension mechanism is used for keeping certain tension for a material strap; the feeding mechanism is used for clamping the material strap or a wingding core and used for achieving intermittent feeding; the sucking cutting mechanism is sued for sucking the material strap and cutting the material strap after winding is competed so as to dissociate the material strap from the winding core; the turnover mechanism is used for turning over the material strap or the winding core; the pressurizing mechanism is used for pressurizing the surface of the winding core so as to tightly overlapping single electrode components; the jacking mechanism is used for jacking out the winding core from a working station after winding is completed; the conveying mechanism is used for conveying the jacked winding core. By adopting the device, intermittent feeding and automatic turnover of the material strap are achieved, the tension of diaphragms inside the winding core is uniform, moreover the surface of the winding core can be pressurized once when winding is performed each time, the single electrode components can be overlapped relatively tightly, good performance can be achieved even after long-time use, and the production efficiency can be greatly improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Panel polishing device for square reading bookshelf production

InactiveCN111098217AAchieve contactAchieve separationGrinding carriagesPolishing machinesHydraulic cylinderPiston rod

The invention discloses a panel polishing device for square reading bookshelf production. The panel polishing device comprises a mounting frame, a hydraulic cylinder is fixed to one side of the mounting frame, a mounting box is fixed to the end of a piston rod of the hydraulic cylinder, the mounting box is slidably connected with the bottom end of the mounting frame through a linear rail, and a supporting mechanism is arranged on the mounting box; a first fixing block is fixed to one side of the top end of the mounting box, a steering mechanism is arranged on the first fixing block, a first clamping plate is arranged on the steering mechanism, and a second fixing block is fixed to the side, away from the first fixing block, of the mounting box; a jacking mechanism is arranged at the upperend of the second fixing block, and a second clamping plate is arranged on the jacking mechanism; and a panel is clamped between the first clamping plate and the second clamping plate, a supporting frame is fixed to the two sides of the middle of the mounting frame, a lifting mechanism is arranged on the supporting frame, a first servo motor is arranged on the lifting mechanism, and a grinding roller is fixed to an output shaft of the first servo motor. The panel polishing device has the advantages that automatic overturning and automatic polishing are achieved, and the working efficiency is high.

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

Aluminum alloy door and window machining deburring device

InactiveCN112440179AImprove polishing effectEasy to install laterEdge grinding machinesGrinding carriagesStructural engineeringManufacturing engineering

The invention relates to the technical field of aluminum alloy door and window machining, and particularly relates to an aluminum alloy door and window machining deburring device. The aluminum alloy door and window machining deburring device comprises a machining table, clamping devices, a moving device, a polishing device and overturning devices, wherein a cushion plate is arranged on the machining table; the machining table is provided with a rectangular groove and a sliding groove which are symmetric; the clamping devices are symmetrically arranged on the machining table; the moving deviceis arranged beside the clamping devices; the polishing device is arranged on the moving device; the two overturning devices are arranged; and each overturning device comprises a rotation component, alifting component and an overturning component, wherein the rotation component is arranged beside the machining table, the lifting component is arranged on the rotation component, and the overturningcomponent is arranged on the lifting component. Through the mutual cooperation work of the arranged devices, the double faces of a door and a window can be polished, the polishing effect is improved,subsequent installation is convenient, manual assistance is not needed, the door and the window are automatically overturned, and the polishing efficiency is improved.

Owner:安徽黎搏装饰工程有限公司

Glass cleaning machine with automatic overturning function

InactiveCN105436178ARealize automatic flipRealize clear water washingFlexible article cleaningMotor driveEngineering

The invention discloses a glass cleaning machine with an automatic overturning function. The glass cleaning machine comprises a first face cleaning device, a second face cleaning device and a glass overturning device which is arranged between the first face cleaning device and the second face cleaning device, and the first face cleaning device and the second face cleaning device are the same in structure. In the first face cleaning device, a first motor drives a brush head to carry out reciprocating brushing in the transverse direction of a glass plate, the brushing speed is high, and after brushing is over, the glass plate is conveyed to a second conveying machine. A second motor drives a second sliding block to reciprocate in the transverse direction of the glass plate, and therefore the glass plate is thoroughly cleaned through clean water, and the glass plate cleaning speed is high. After the first face is cleaned, the glass plate is conveyed to a third conveying machine, and the glass overturning device overturns the glass plate by 180 degrees at the moment, so that automatic face overturning in the glass plate cleaning process is achieved, and the cleaning work efficiency of the glass plate is greatly improved.

Owner:CHONGQING HUARUI GLASS CO LTD

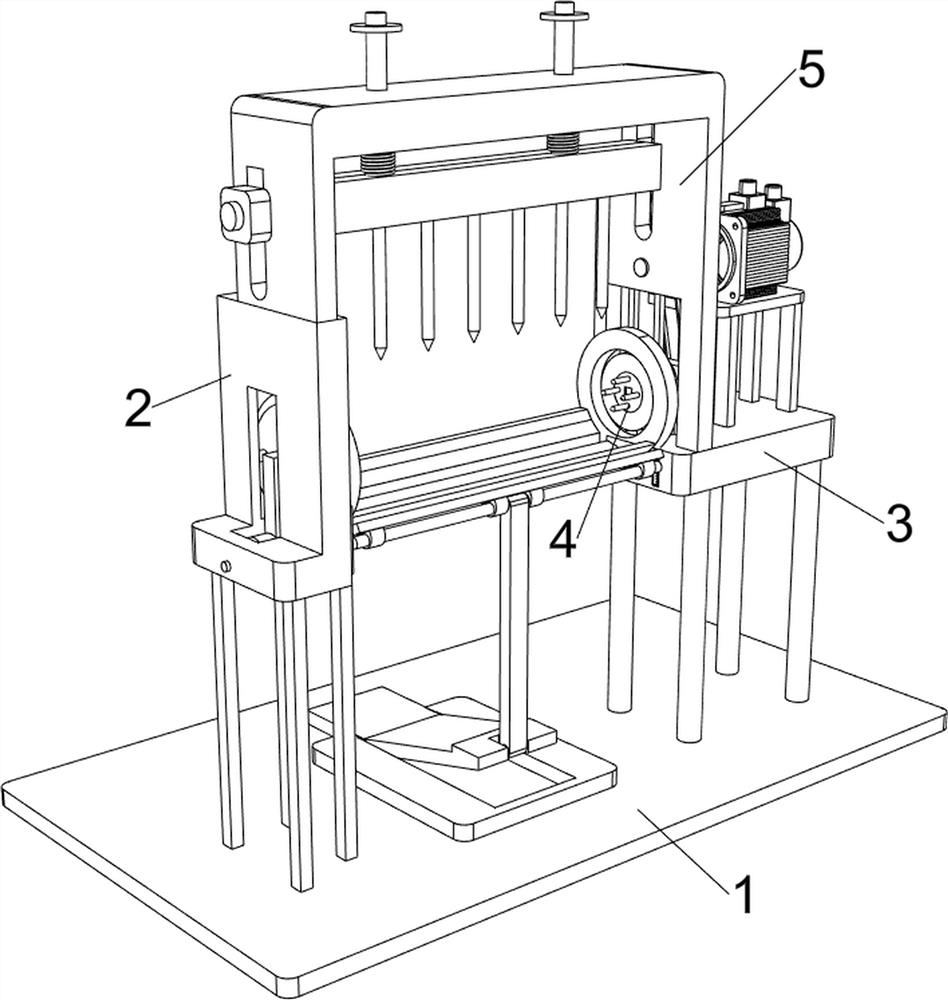

Fungus bag punching machine for agricultural planting

The invention relates to a punching machine, in particular to a fungus bag punching machine for agricultural planting. The invention provides a fungus bag punching machine for agricultural planting, which is simple in operation and convenient to pick and place, and can automatically carry out punching. The fungus bag punching machine for agricultural planting comprises a bottom plate, a support seat, a clamping mechanism and a punching mechanism, wherein a rack is arranged at one side of the bottom plate; the support seat is arranged at the other side of the bottom plate; the clamping mechanism is arranged between the rack and the support seat; the punching mechanism is arranged between the rack and the support seat; and the clamping mechanism is located below the punching mechanism. The fungus bag punching machine clamps a fungus bag through the clamping mechanism and can quickly punch the fungus bag in the cooperation of the punching mechanism at the same time, and the punched holesare consistent in depths and uniform in positions; up-and-down movement of second inserting rods is achieved through the cooperation of shifting blocks and second fixing blocks, so that turnover of the fungus bag is facilitated; automatic turnover of the fungus bag when a second sliding block moves upwards is achieved through the cooperation of a clamping block and a ratchet wheel, so that manualturnover by people is not needed.

Owner:刘小红

Intermittent material splashing device

InactiveCN106956943ASolve technical problems of intermittent feedingRealize automatic flipConveyorsLoading/unloadingEngineeringSilo

The invention provides an intermittent material splashing device, which includes a frame, a hopper, a silo, a buffer spring, a reset mechanism and a feeding pipe. Spring connection, when the grain in the silo is increasing, the silo will continue to descend along the vertical sliding part of the chute. The grains in the machine are splashed on the vibrating screen to realize intermittent feeding, which replaces the means of induction device to control intermittent feeding.

Owner:奥林精密机械科技(长兴)有限公司

Automatic turnover camera

ActiveCN103945099ARealize automatic flipReduce manufacturing costTelevision system detailsColor television detailsTerminal equipmentComputer science

The invention discloses an automatic turnover camera which comprises a camera body and a locking module. The camera body and the locking module are respectively connected with a mounting end, the camera body is arranged in a containing space of mobile terminal equipment, the camera body is connected with a limiting groove, the locking module is provided with a limiting column, when the limiting column is clamped in the limiting groove, the locking module locks the camera body in the containing space, and when the limiting column is separated from the limiting groove, the locking module releases the camera body, and the camera body is turned out from the containing space automatically and is turned into a front-facing camera from a rear-facing camera. According to the automatic turnover camera, the camera body is mounted on the terminal equipment in a turnover mode, the locking module is arranged to lock or relieves the camera body, the camera body can be turned over automatically after being released, the front-facing camera does not need to be arranged specially, self-photographing or video calling can be achieved perfectly, the automatic turnover camera is multifunctional, and therefore the production cost of the terminal equipment is saved.

Owner:GUANGDONG XIANGXIU RUI IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com