Automatic turnover mechanism for green ceramic tapes

A technology of automatic flipping and raw porcelain belt, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that there is no automatic implementation plan, and achieve the effect of simple structure, convenient use and installation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] In the front-end field of high-temperature co-fired ceramic production, the processed products are characterized by soft quality, easy deformation and difficult processing. The present invention is applied to the front-end process of high-temperature co-fired ceramic shell processing, that is, in the automatic processing process of green ceramic belt materials, on the premise of not affecting product quality and production tempo, it can realize automatic turning movement of belt materials, reduce labor intensity, and improve production efficiency.

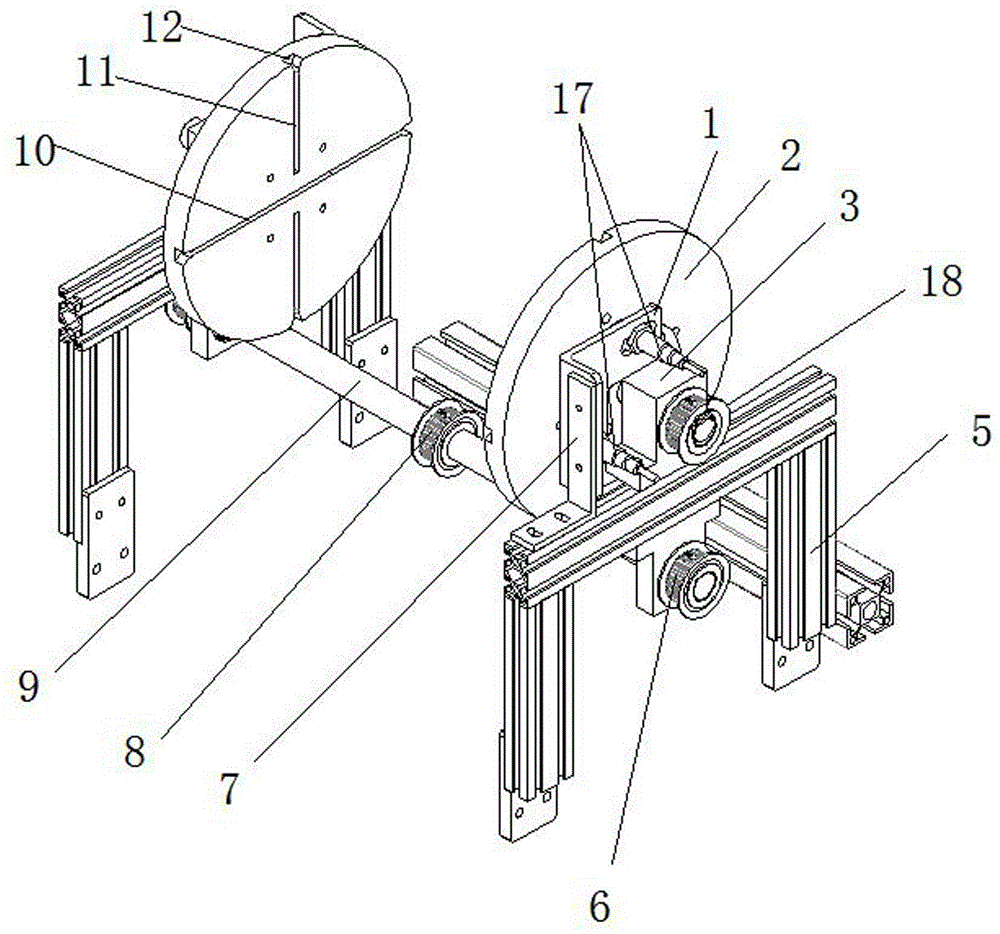

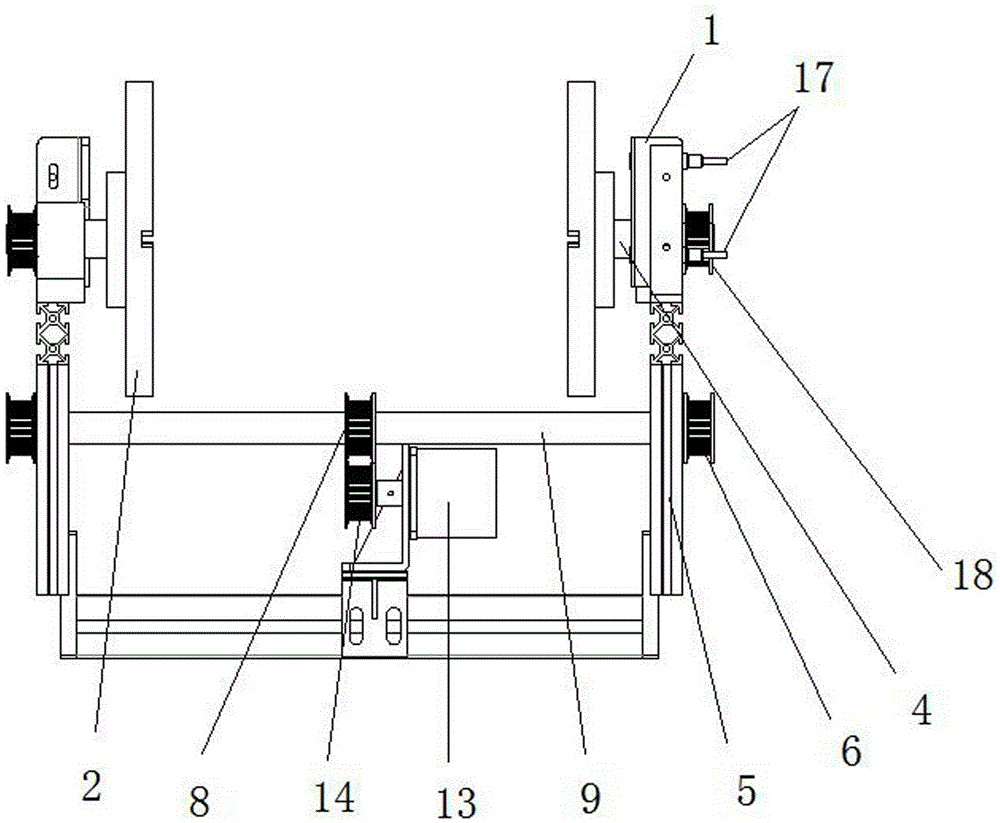

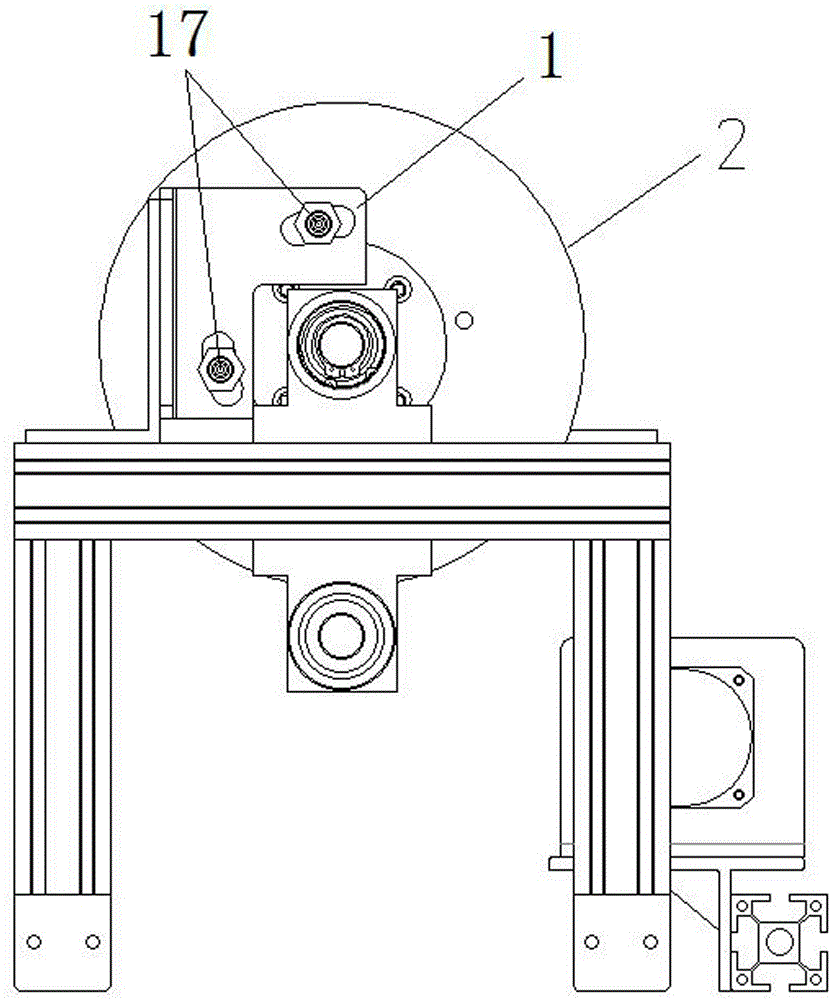

[0025] Concrete structure of the present invention sees Figure 1-Figure 3 As shown, it includes a bracket 5, a pair of synchronously rotating discs 2 symmetrically installed on both sides of the bracket 5, the disk surfaces of the two synchronously rotating discs 2 are arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com