Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31141results about "Grinding work supports" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

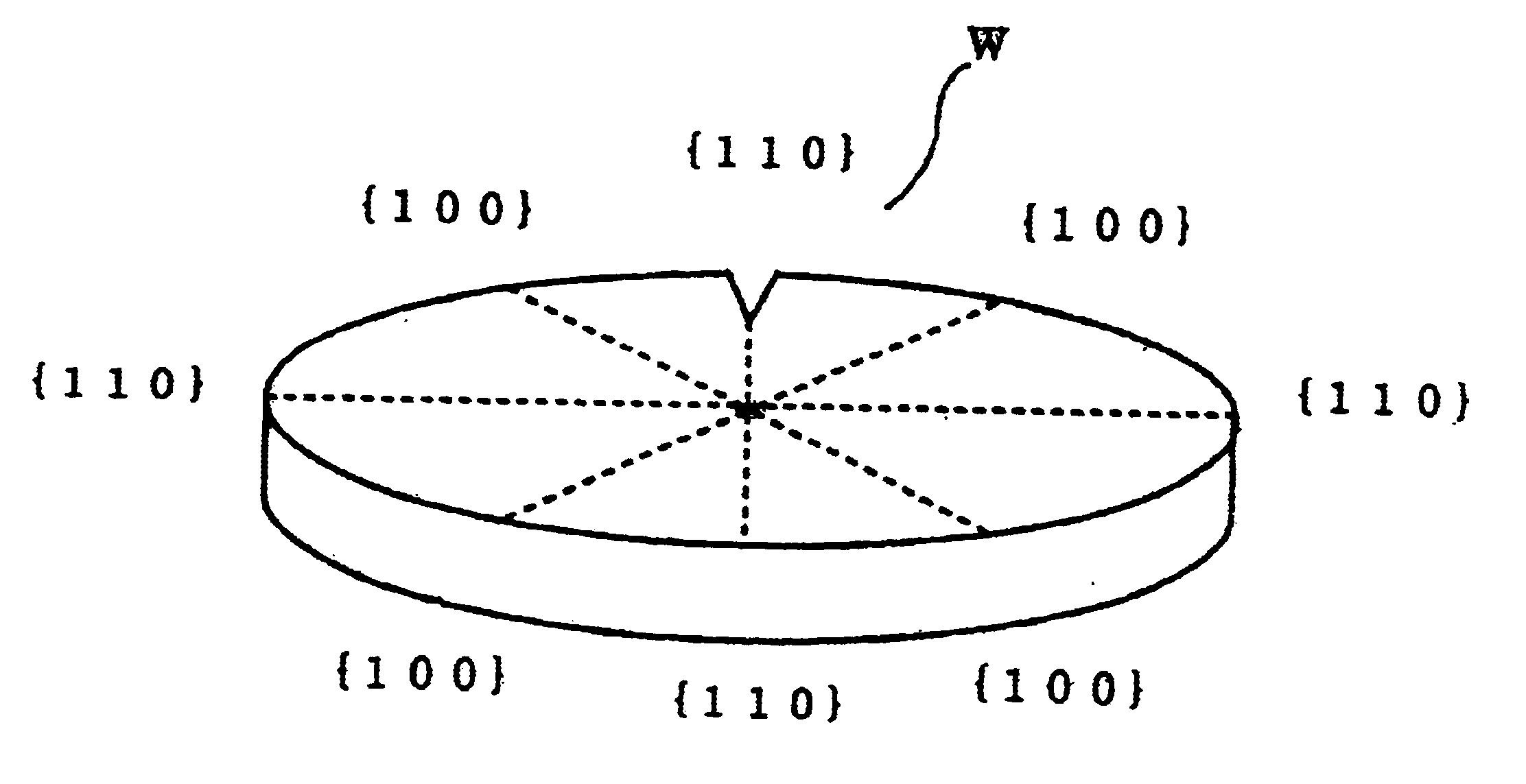

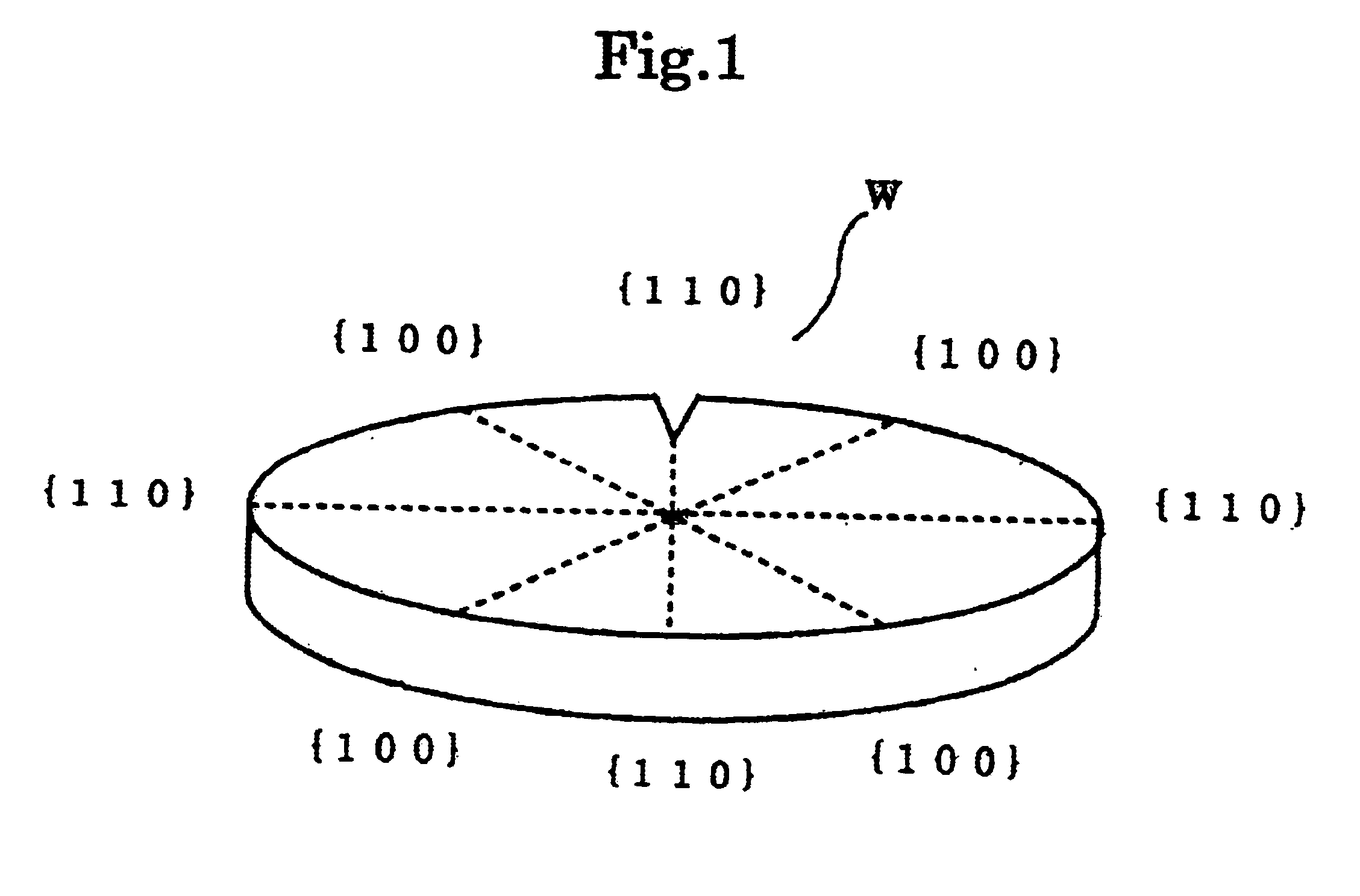

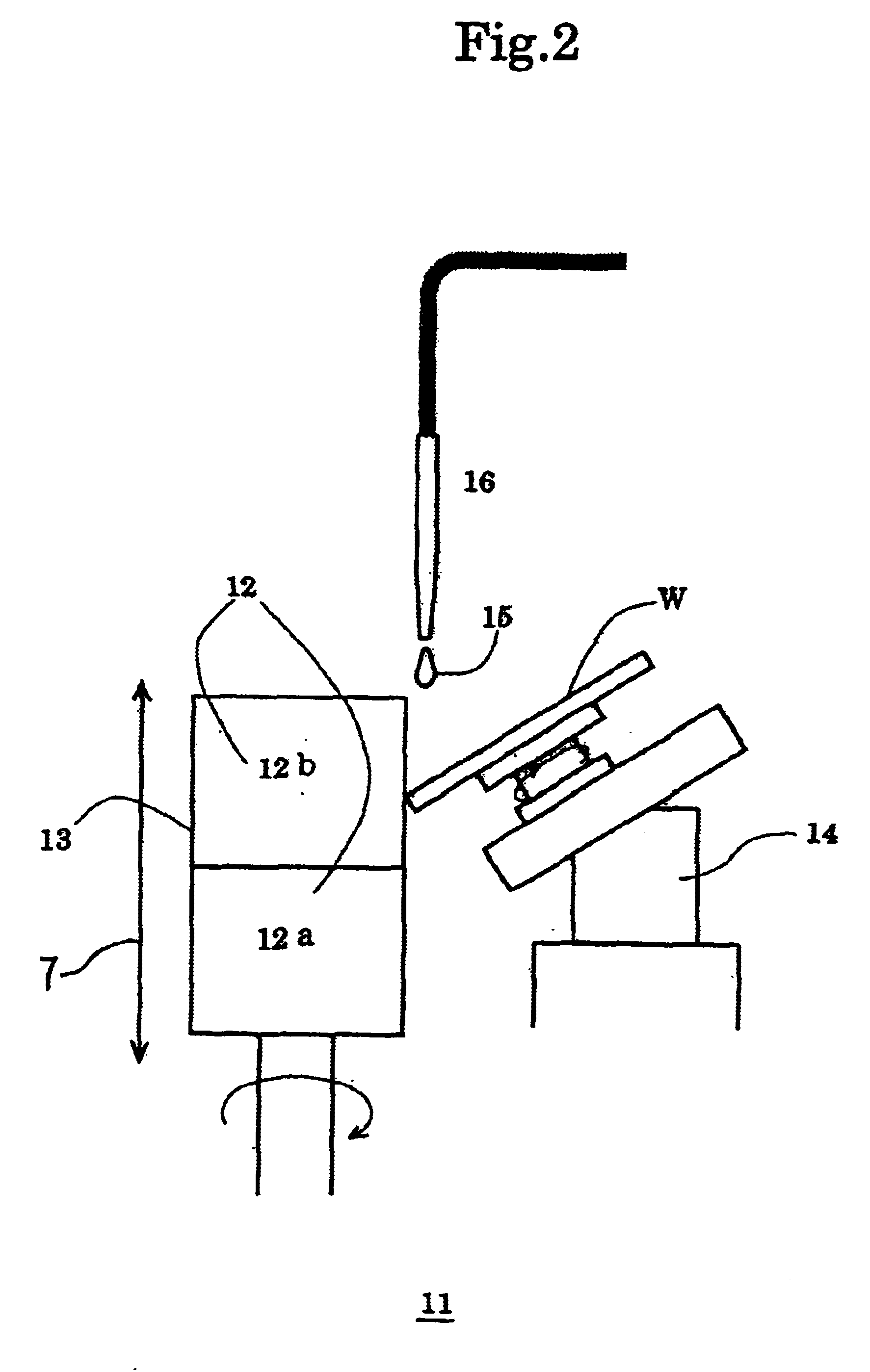

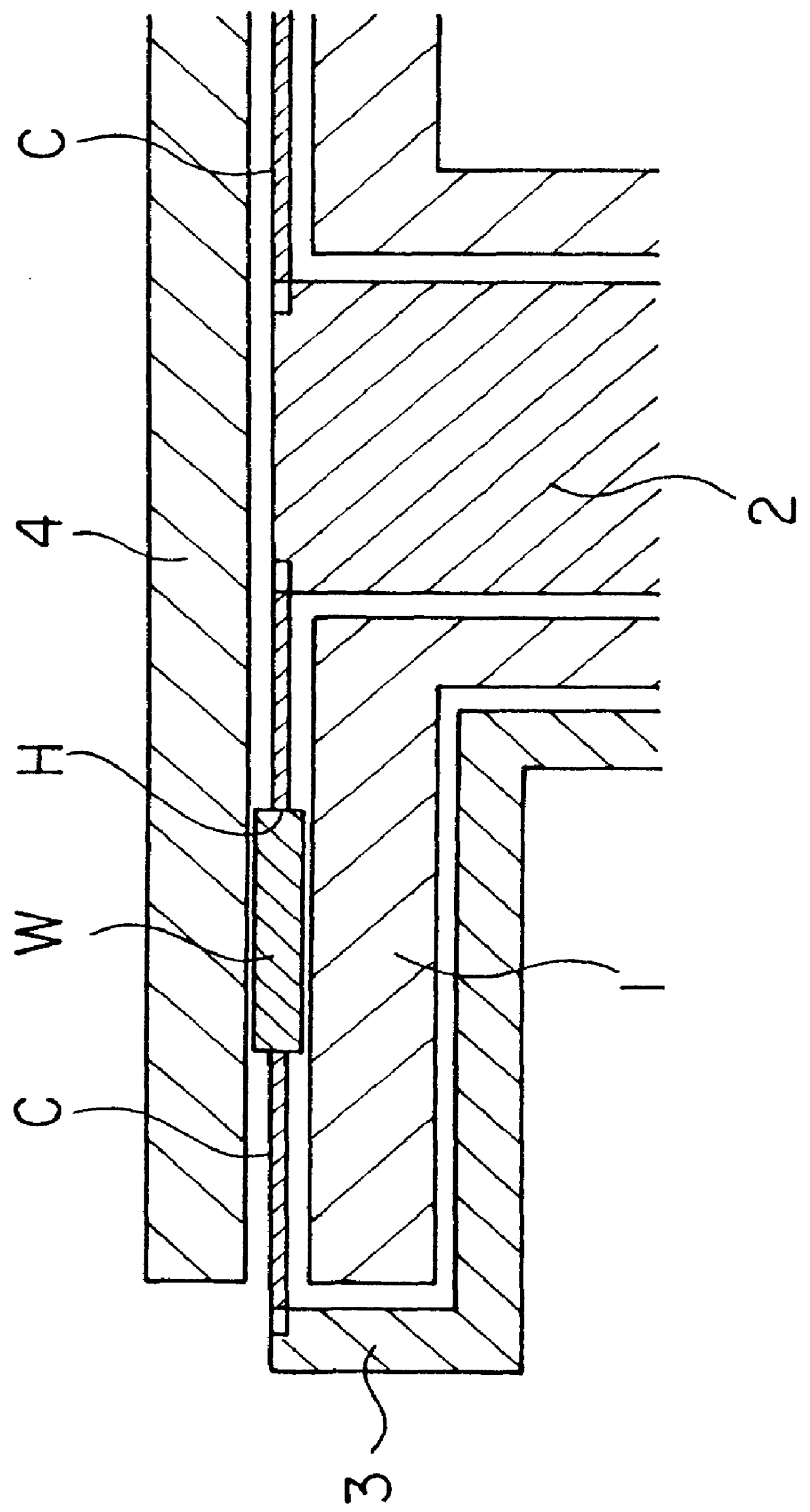

Method for apparatus for polishing outer peripheral chamfered part of wafer

InactiveUS6884154B2Improve productivityShorten polishing timeEdge grinding machinesPolishing machinesProduction rateHardness

In a process for polishing the chamfered peripheral part of a wafer using a polishing cloth while supplying a polishing slurry in order to improve productivity of the process by reducing a polishing time, at least two steps of polishing processes are performed in sequence. The process comprises a first polishing process to polish a particular part, e.g. the part corresponding to the {110} plane of a peripheral part of the wafer and a second polishing process in which the whole part of a peripheral part of the wafer is polished for finishing by means of varying a hardness of the polishing clothes and / or a particle size of abrasives in the slurry such as the hardness of the polishing cloth in the second polishing process being softer than that of in the first polishing process and a particle size of abrasives in the slurry in the second polishing process being finer than that of in the first polishing process.

Owner:SHIN-ETSU HANDOTAI CO LTD

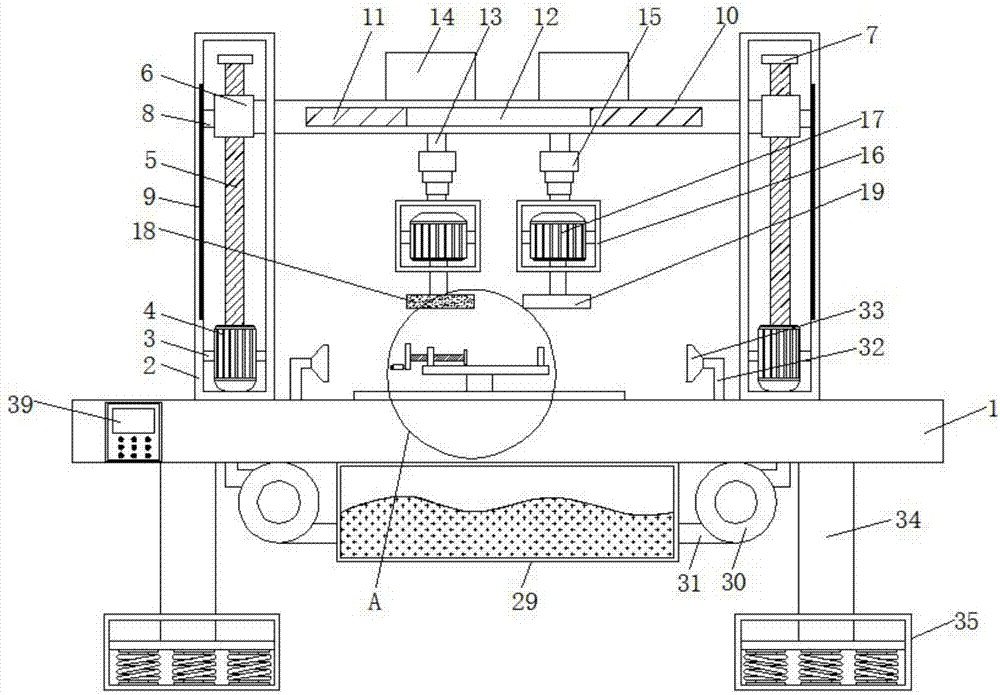

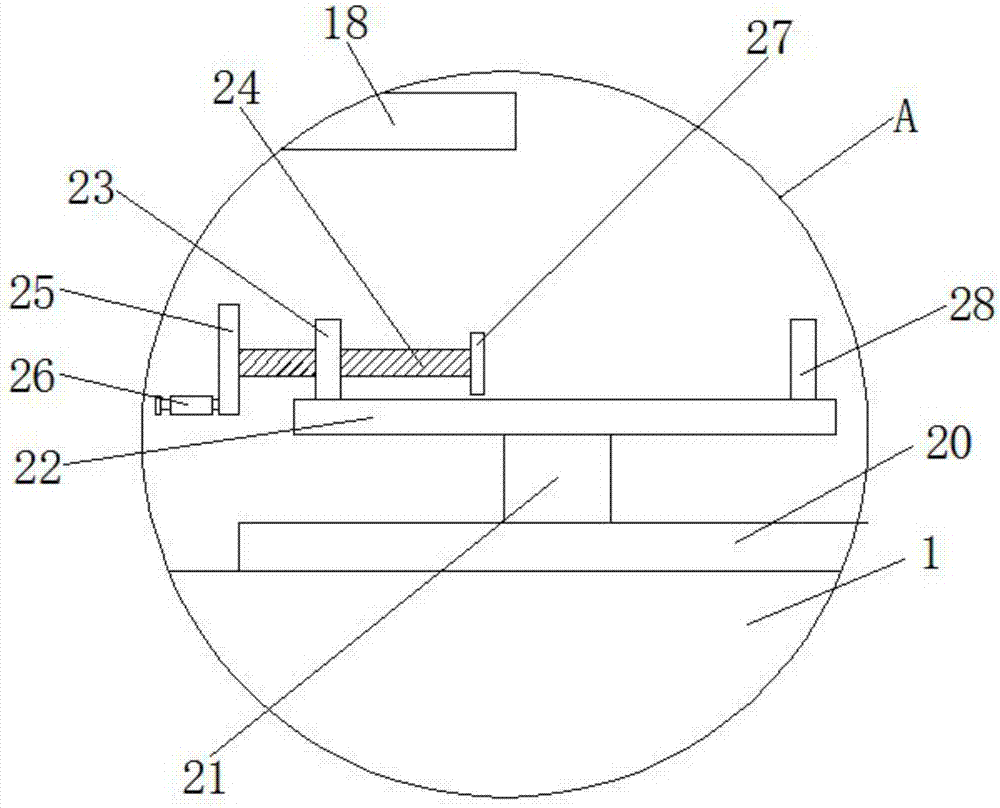

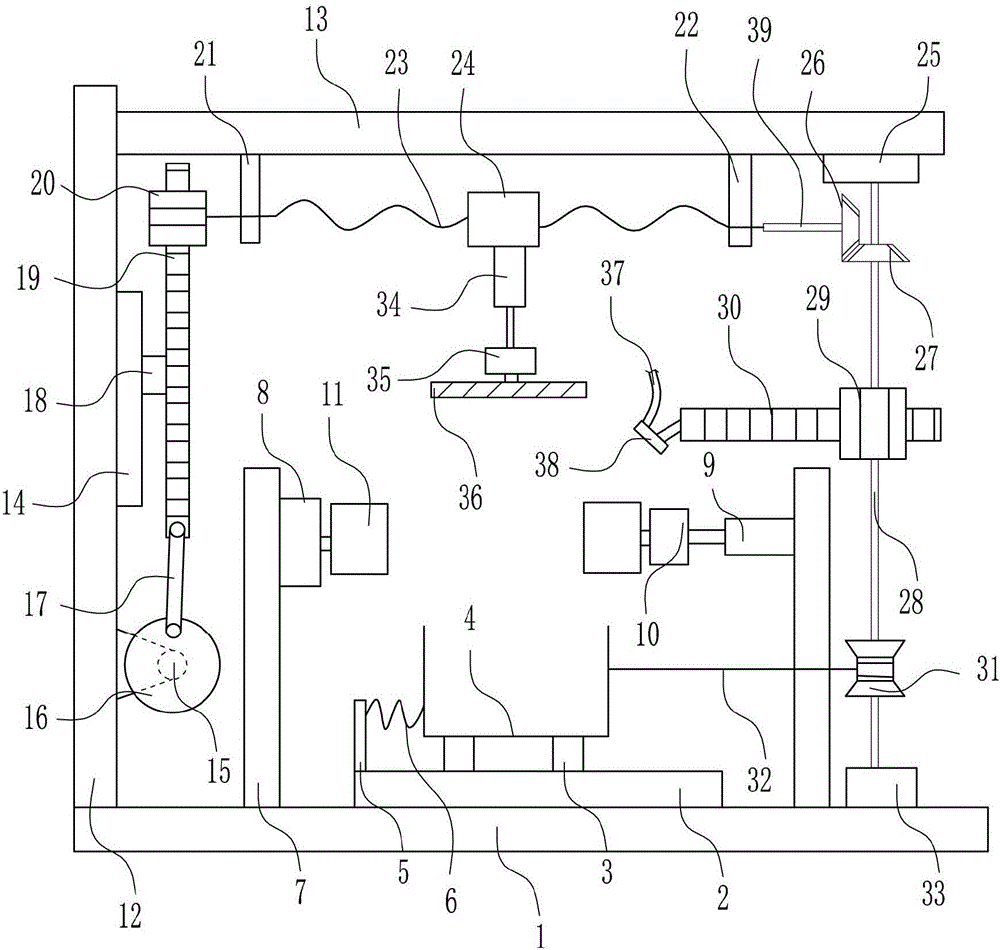

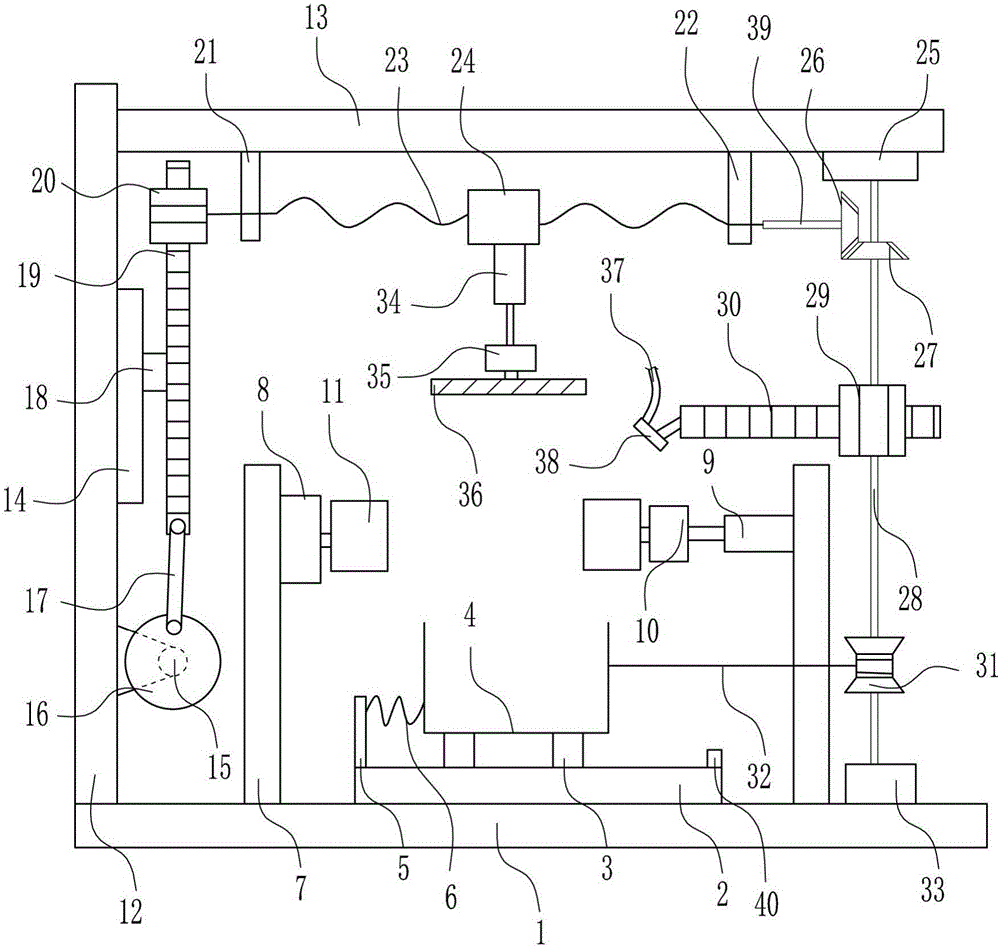

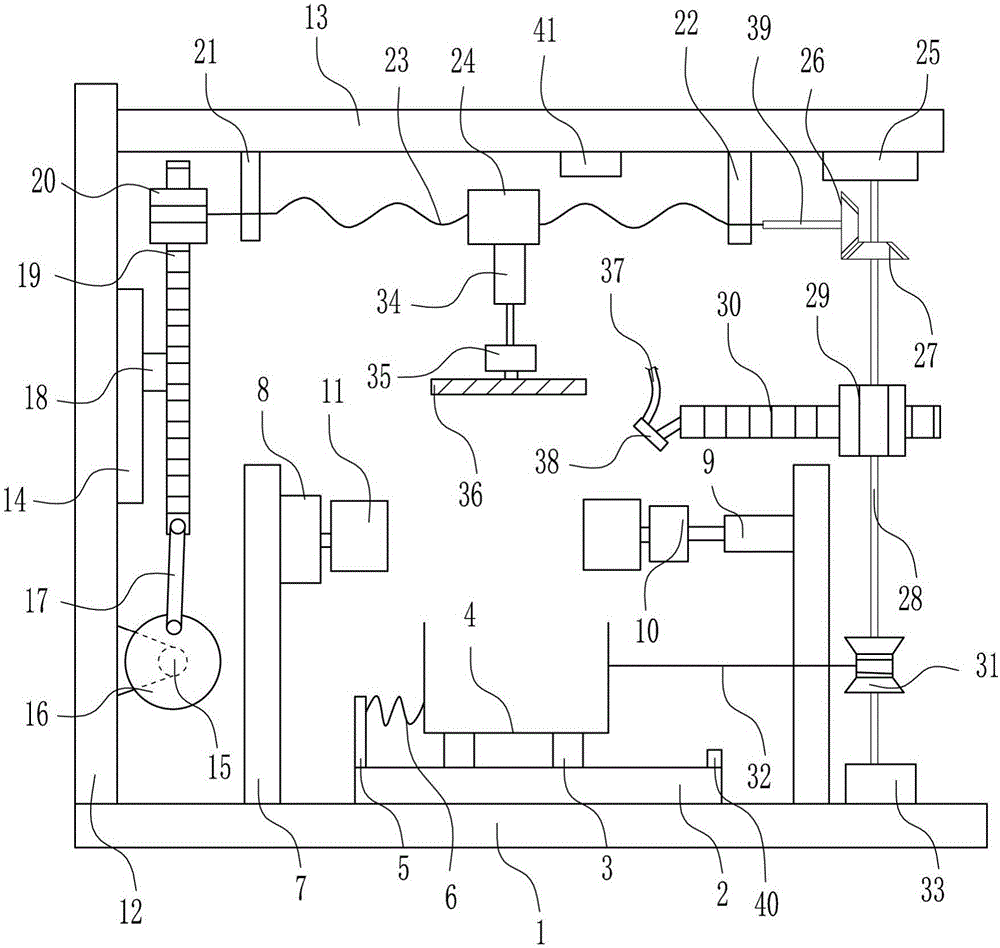

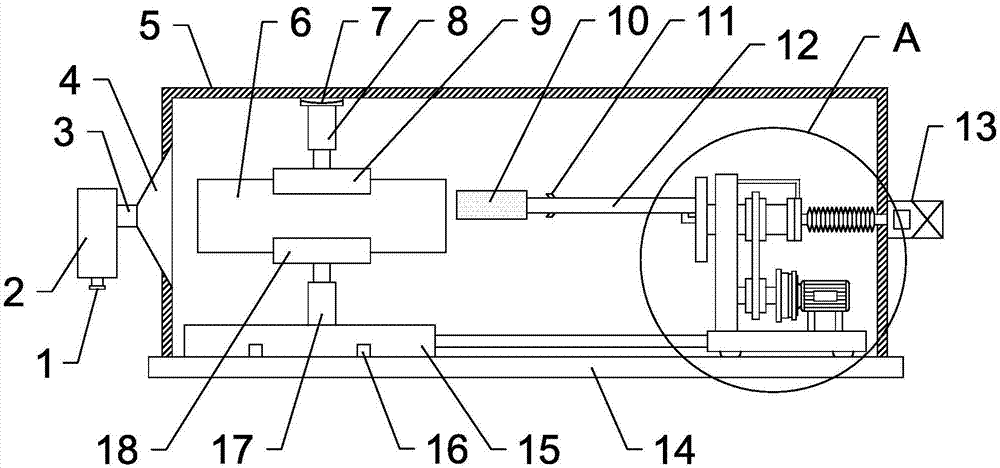

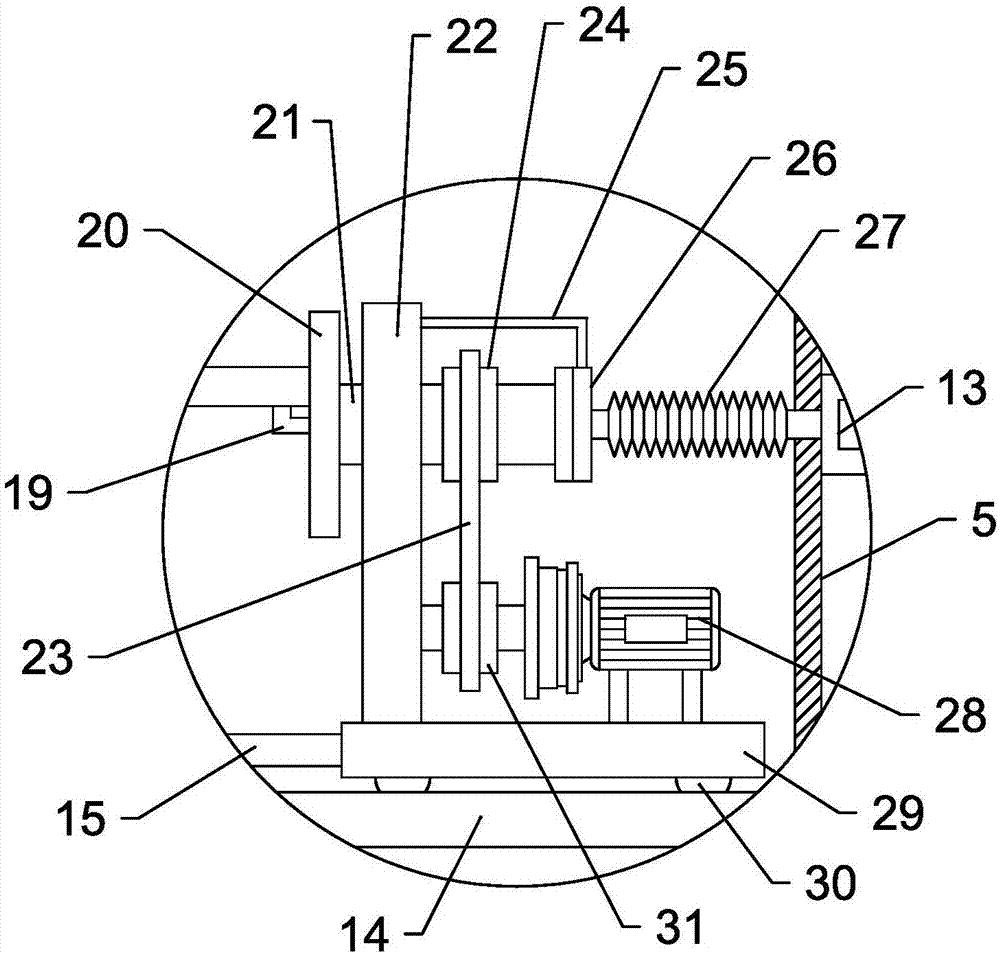

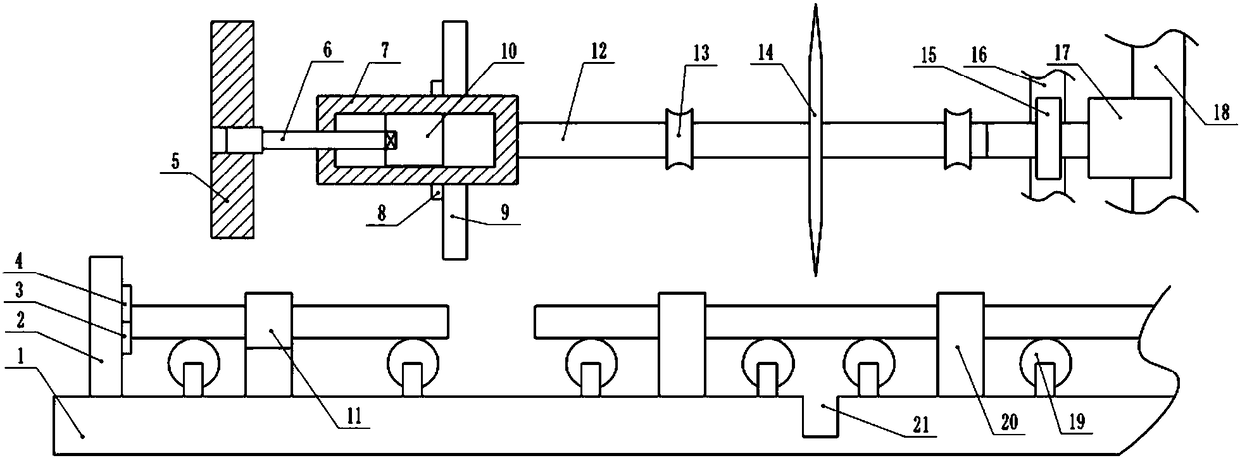

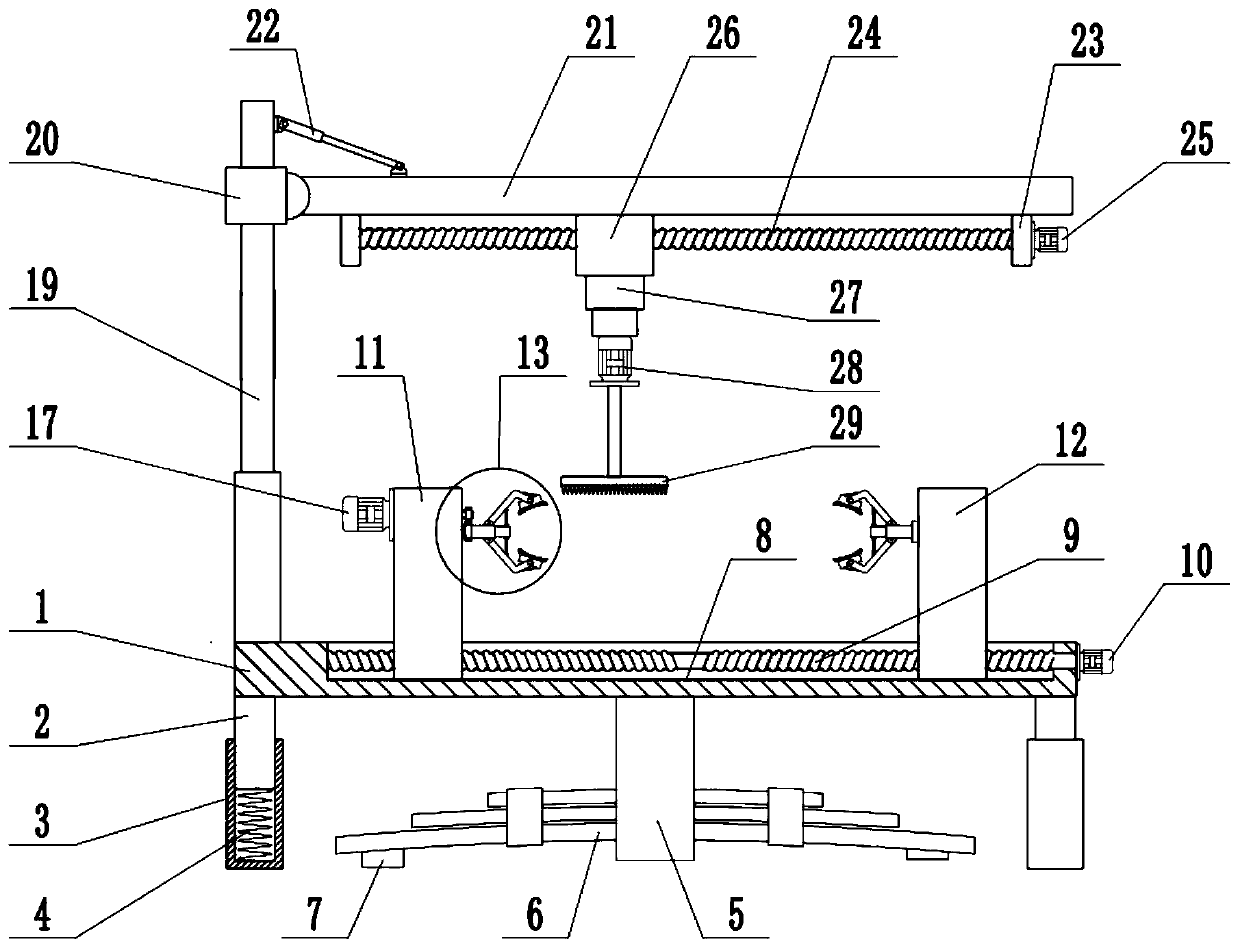

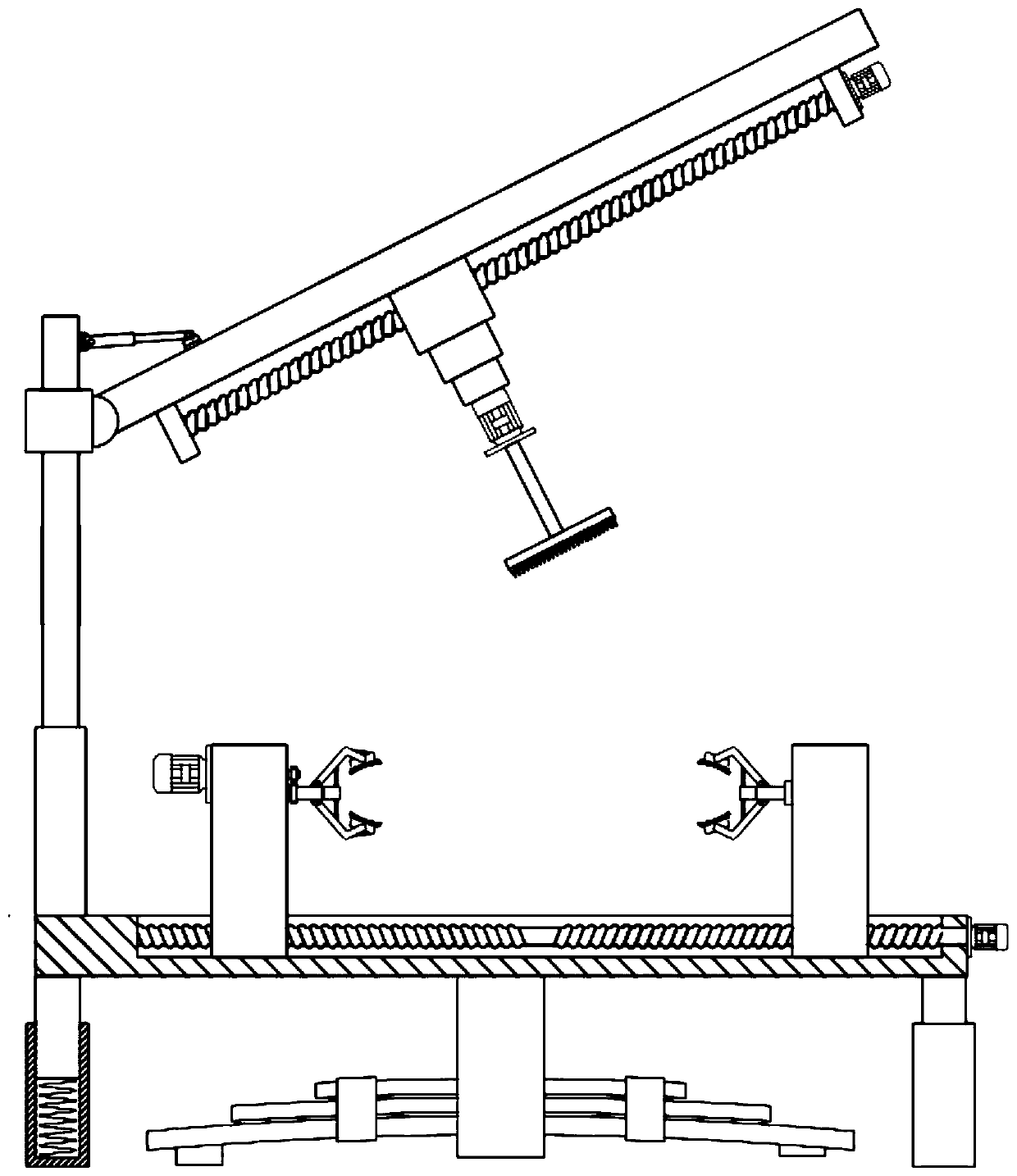

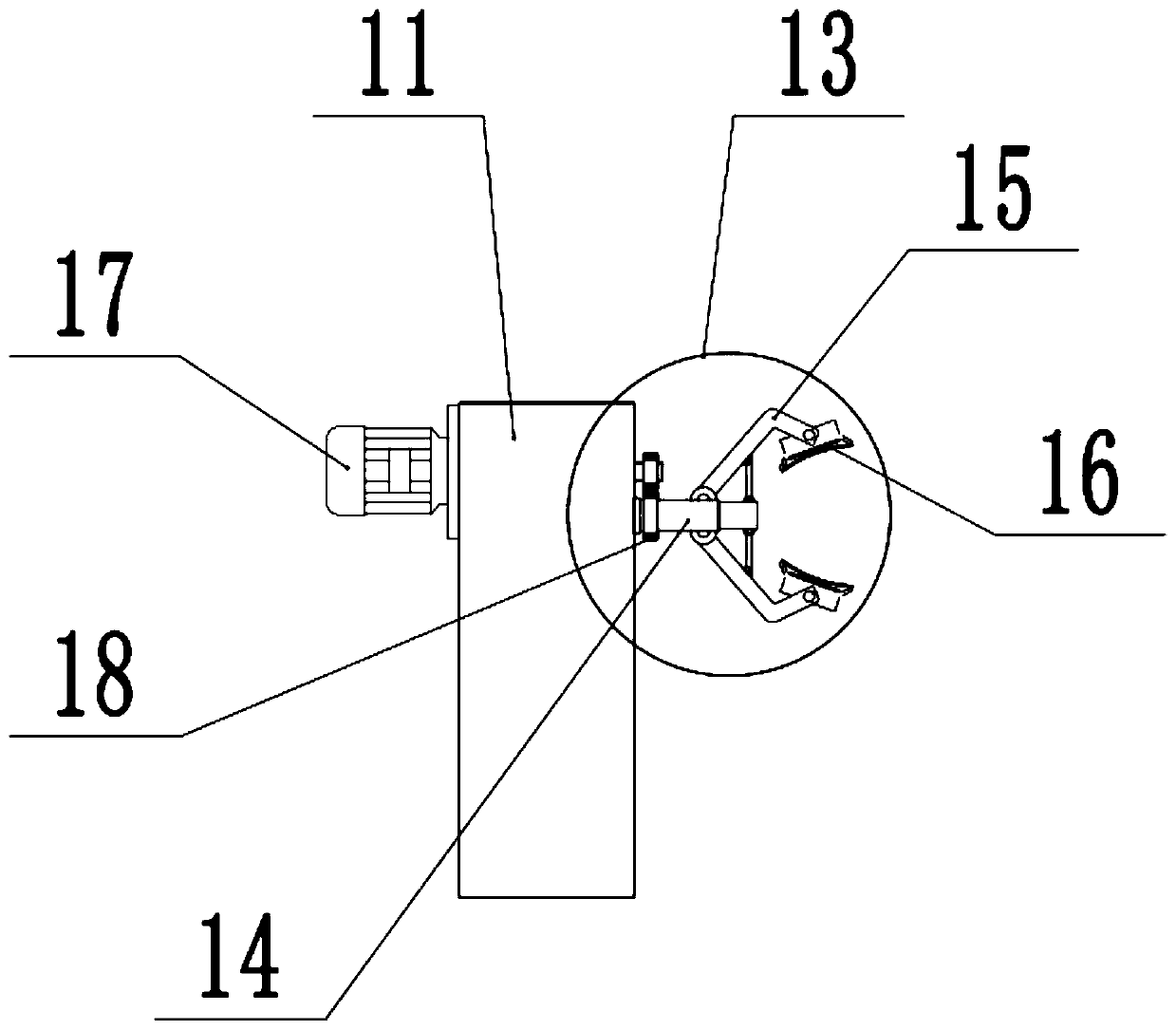

Automobile gear end surface polishing device

InactiveCN107336096AQuality improvementEasy to polishGrinding carriagesGrinding work supportsGear wheelEngineering

The invention provides an automobile gear end surface polishing device, and relates to the technical field of automobile gear polishing. The automobile gear end surface polishing device comprises a working table, standing columns are fixedly installed on both sides of the top of the working table, and motor mounting blocks are fixedly installed on both sides of the inner wall of each standing column. According to the automobile gear end surface polishing device, through arrangement of telescopic motors, threaded rods, telescopic blocks, sliding rods, a strip-shaped sliding groove and a cross plate, a polishing device body on the bottom of the cross plate can vertically move between the two standing columns under driving of the telescopic motors; through arrangement of the cross plate, the sliding groove and supports, the polishing device body on the bottom of the cross plate can transversely move on the bottom of the cross plate; through arrangement of a polishing table, a rotating rod and a clamping base, a gear to be polished which is fixed to the top of the clamping base in a clamped mode can conduct circular motion on the bottom of a polishing motor under driving of the rotating rod. In sum, by means of the automobile gear end surface polishing device, the effect that adjustment is convenient is achieved, it is convenient for people to polish the end surface of the gear from different angles, and the quality of the gear after polished is better.

Owner:姚飞

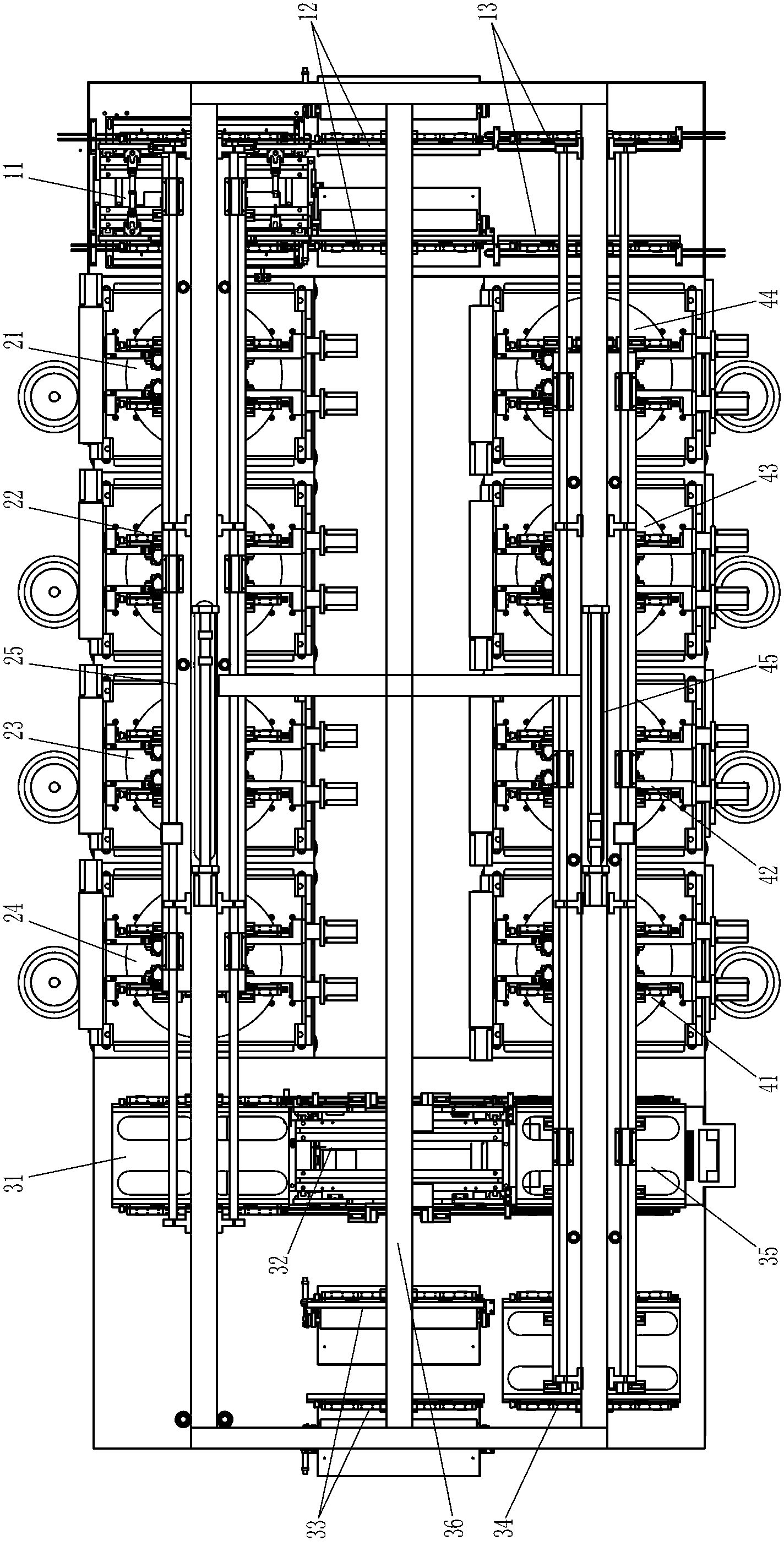

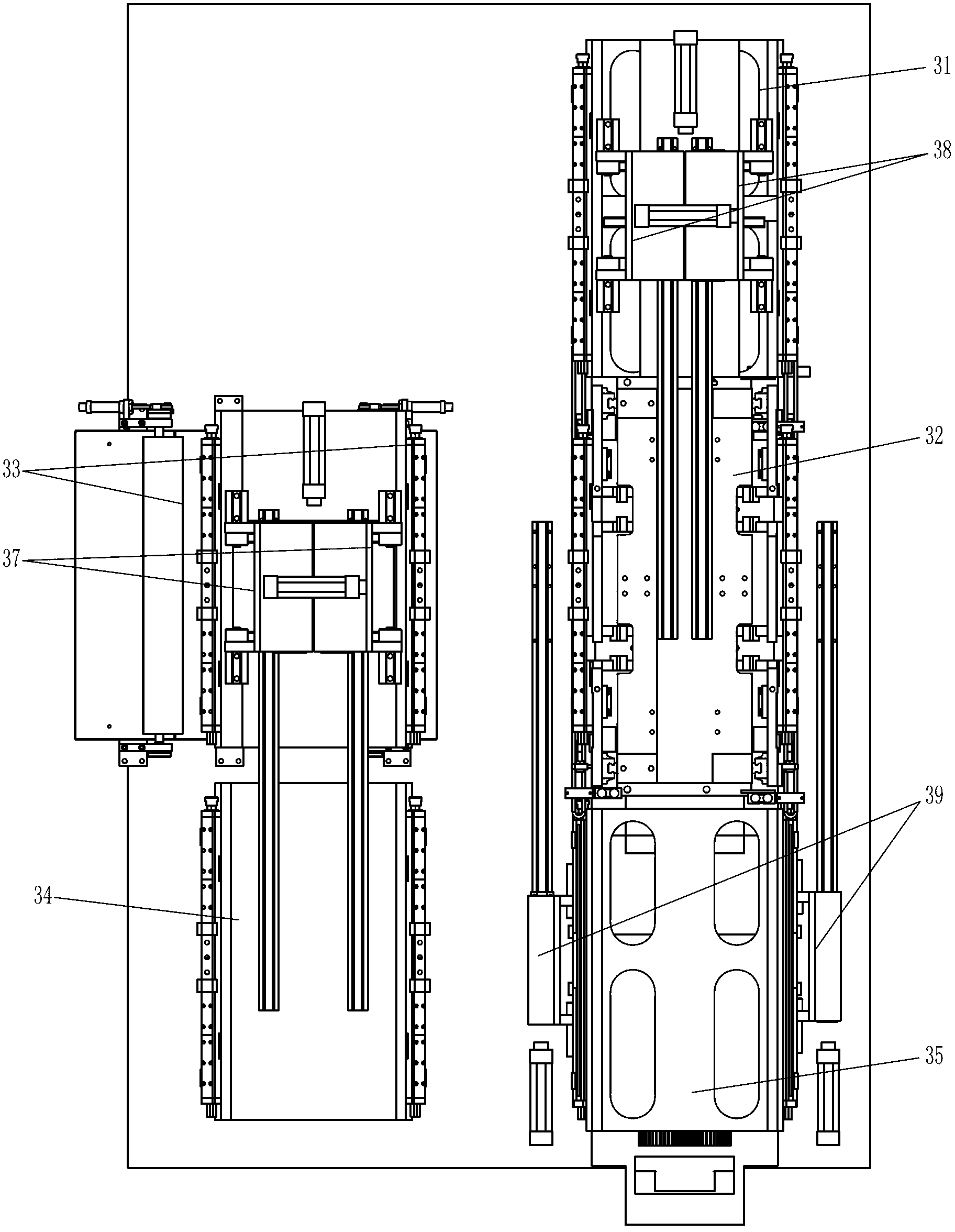

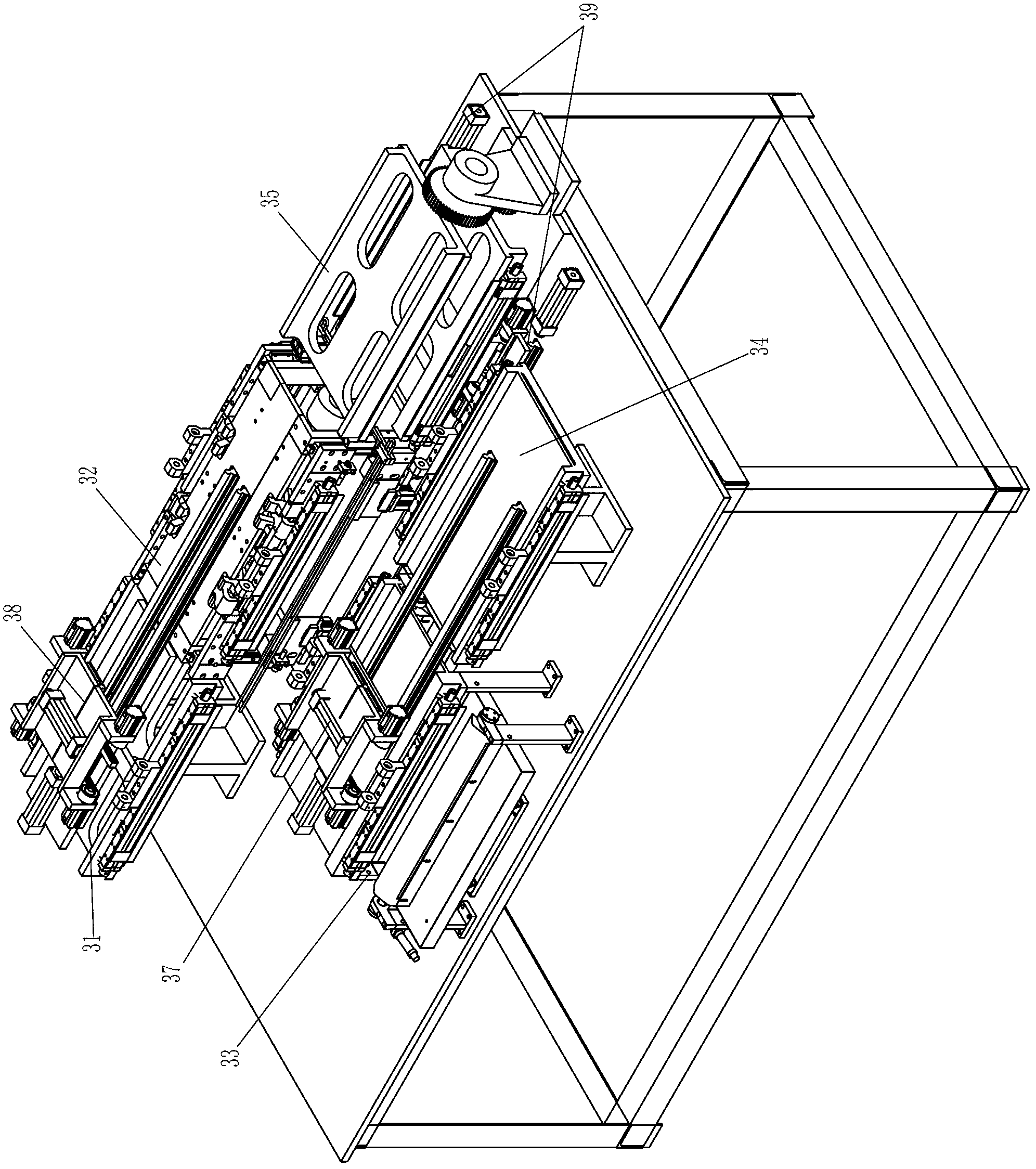

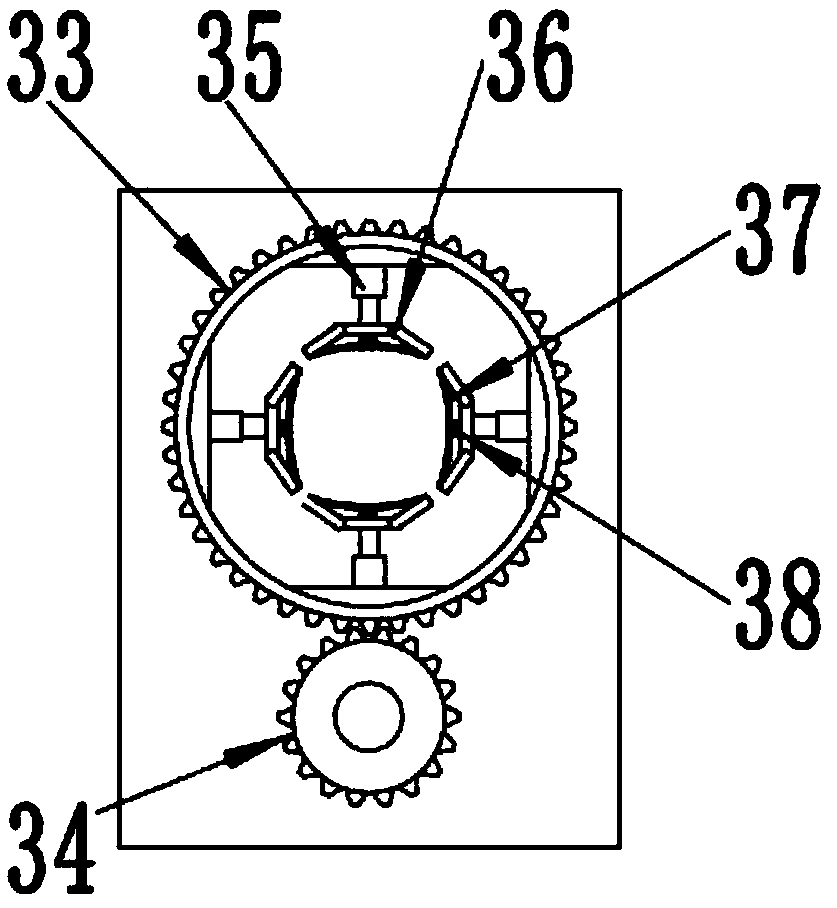

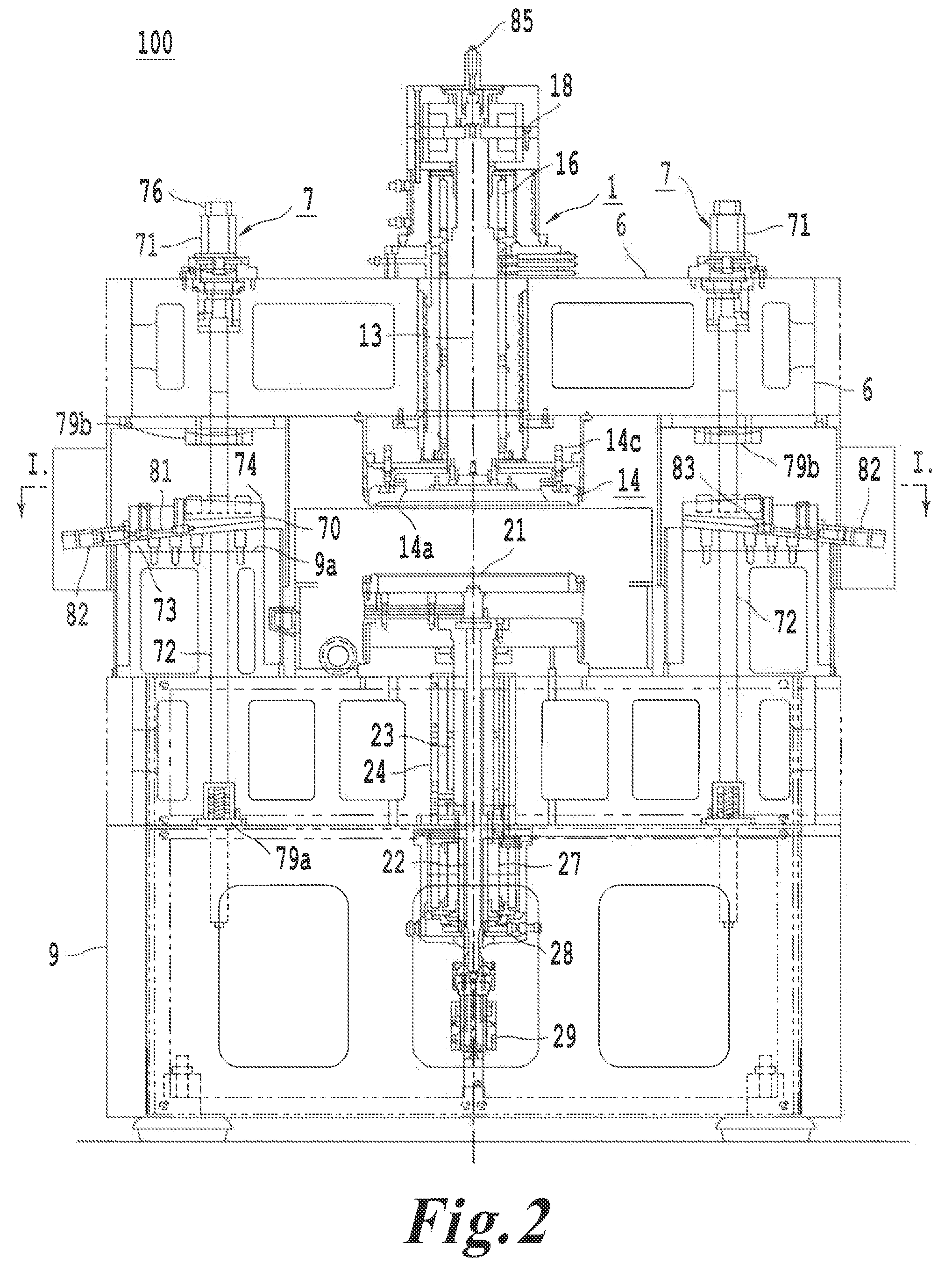

Automatic crystal blank polishing and burnishing system and docking mechanism thereof

ActiveCN103072059AExcellentExcellent efficiencySpherical surface grinding machinesGrinding work supportsEngineeringTransfer mechanism

The invention discloses a docking mechanism, comprising a docking machine frame, wherein a docking position, a switching position, a powder soaking position and a transition position are arranged on the docking machine frame; the docking bracket is fixedly mounted in the docking position, a docking component is arranged on the docking bracket, and the docking component comprises an upper sliding fixture seat and a lower fixed fixture seat; a switching bracket is arranged in the switching position, the switching bracket is driven by a switching bracket driving device to rotate around a horizontal shaft, and an upper fixture fixing part and a lower fixture fixing part are arranged on the switching bracket; a powder soaking component is arranged in the powder soaking position; a first fixture placement rack is arranged in the transition position; and the docking mechanism also comprises a first front-and-back transfer mechanism and a second front-and-back transfer mechanism. The invention also discloses an automatic crystal blank polishing and burnishing system adopting the docking mechanism. According to the technical scheme, the docking precision and the bonding firmness of crystal blanks are guaranteed, the docking working position is reasonable in structure, and the docking efficiency and the processing efficiency of the whole automatic polishing and burnishing system are improved.

Owner:虞雅仙

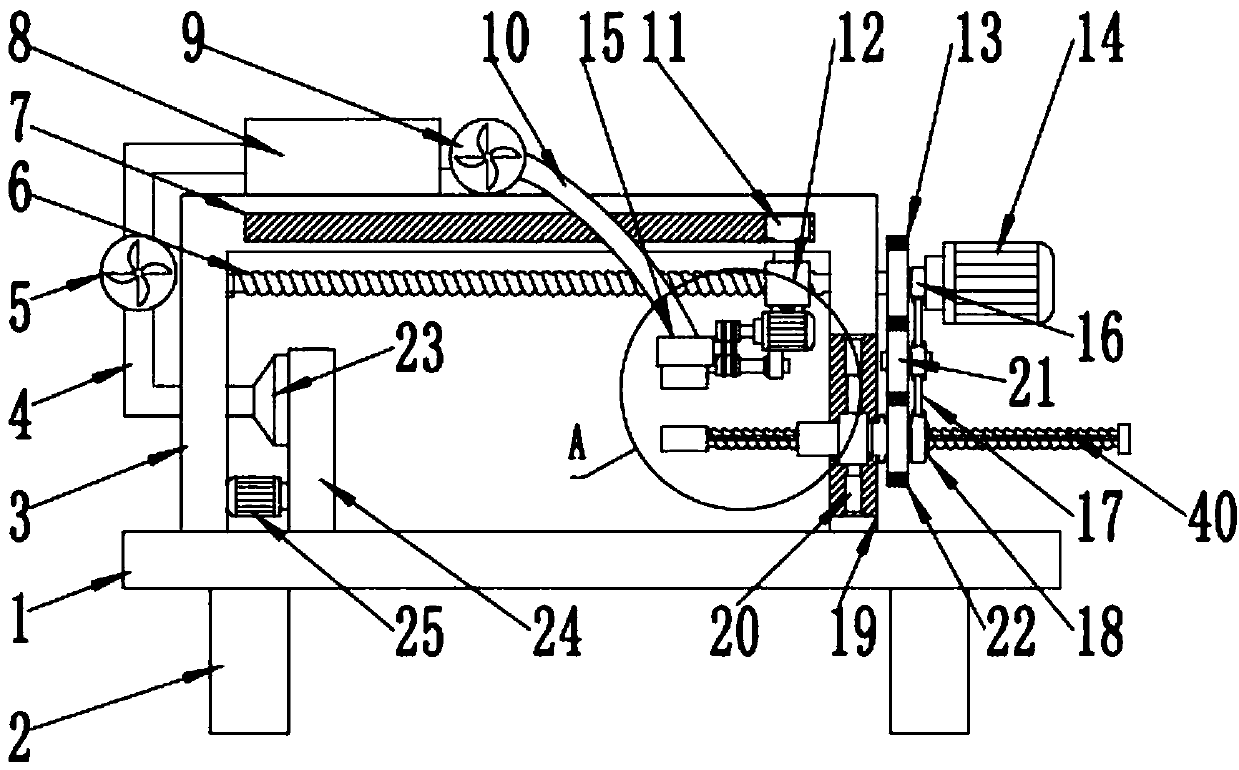

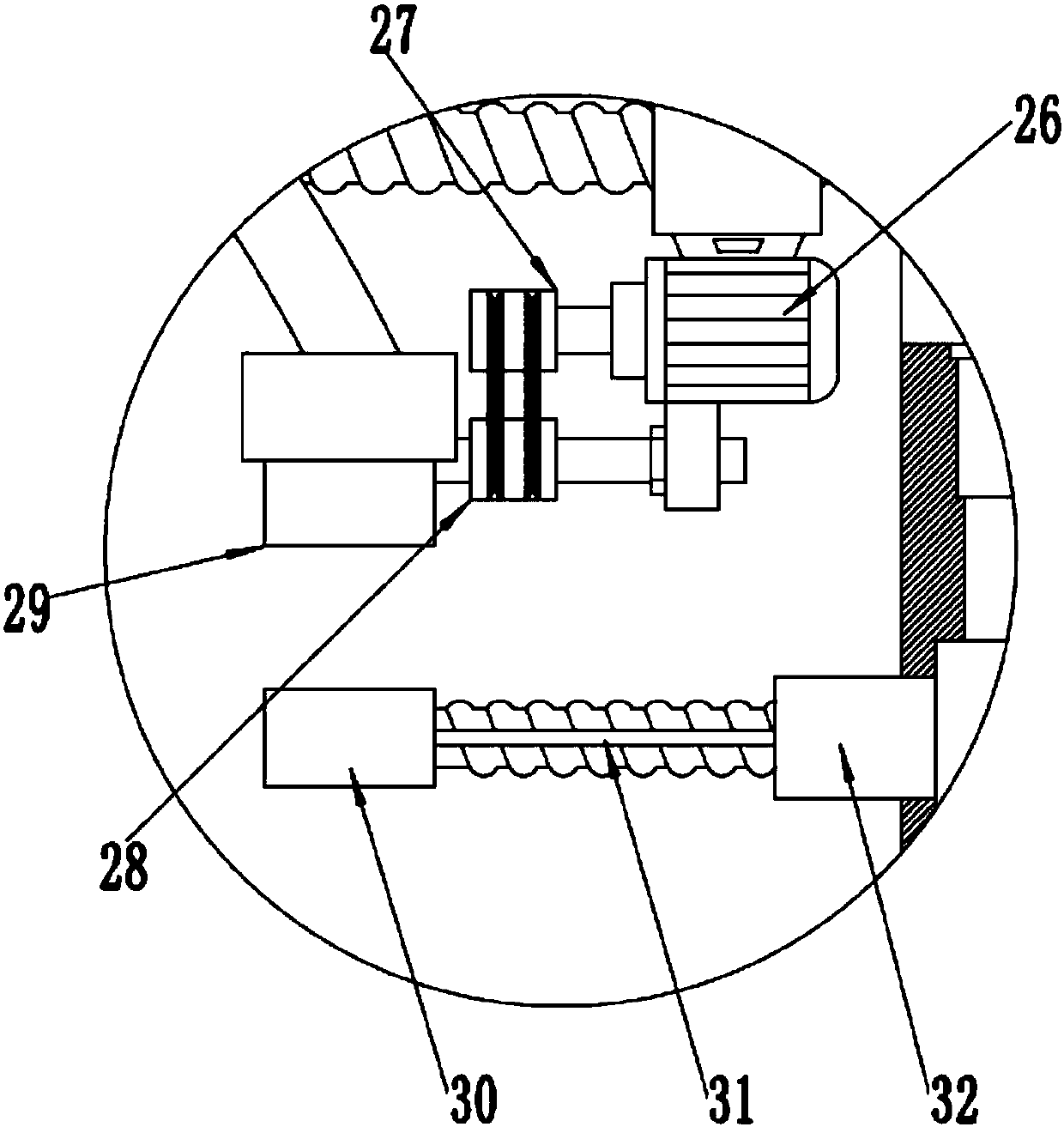

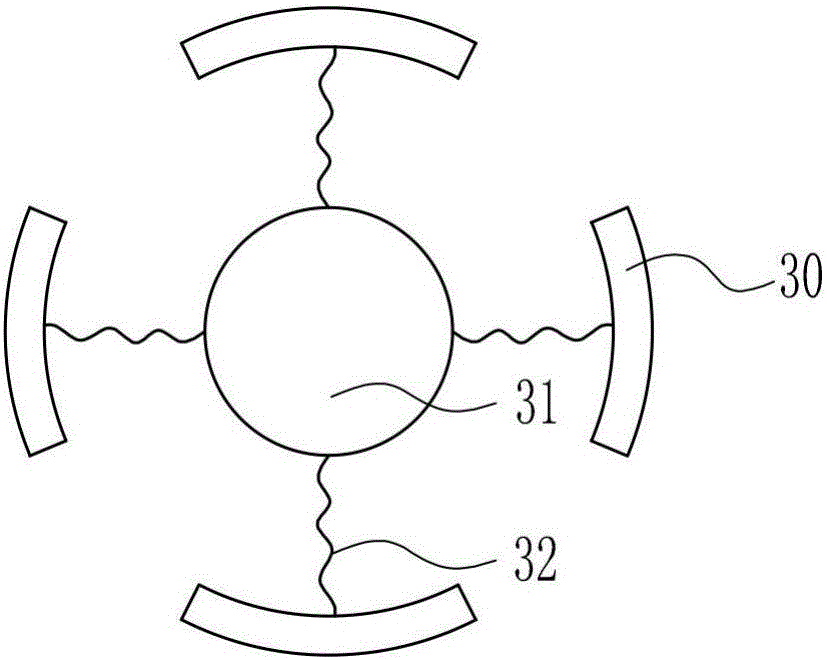

Device for simultaneously grinding inner walls and outer walls of steel pipes

InactiveCN107738167AAvoid pollutionShorten the timeGrinding carriagesRevolution surface grinding machinesHydraulic cylinderEngineering

The invention discloses a device for simultaneously grinding the inner walls and the outer walls of steel pipes. The device comprises a workbench, a support, a collecting tank, a clamping mechanism, an outer grinding mechanism and an inner grinding mechanism; the support is arranged at the upper end of the workbench, and the clamping mechanism is arranged at the left end of the inner side of the support and comprises a clamping plate, a rotating motor, an annular gear, a gear, electric telescopic rods, supporting plates, rubber pads and springs; the outer grinding mechanism is installed at thelower end of a moving block; and the inner grinding mechanism is arranged under the outer grinding mechanism and comprises an inner grinding wheel, a threaded rod B, a fixing sleeve, a threaded sleeve, a second sliding groove, an electric hydraulic cylinder, a drive gear, a driven gear A, a driven gear B, a rectangular block and a connecting rod. The device is novel in design, simple in structure, capable of simultaneously grinding the inner walls and the outer walls of steel pipes with different thicknesses, high in grinding efficiency, wide in application range, capable of effectively preventing impurities such as scrap iron from polluting the environment, high in practicality and worthy of popularization.

Owner:宁波高新区峰林化工科技有限公司

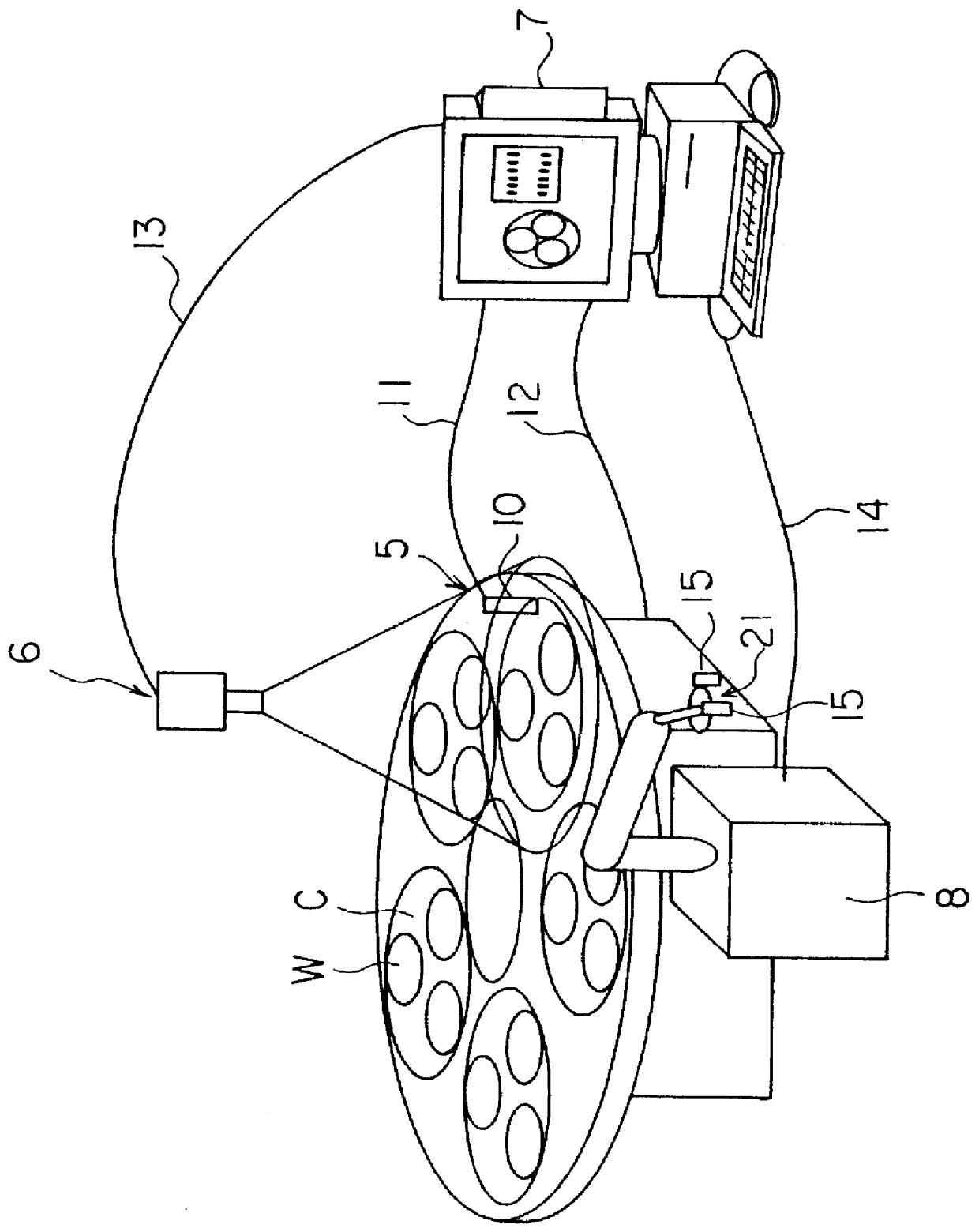

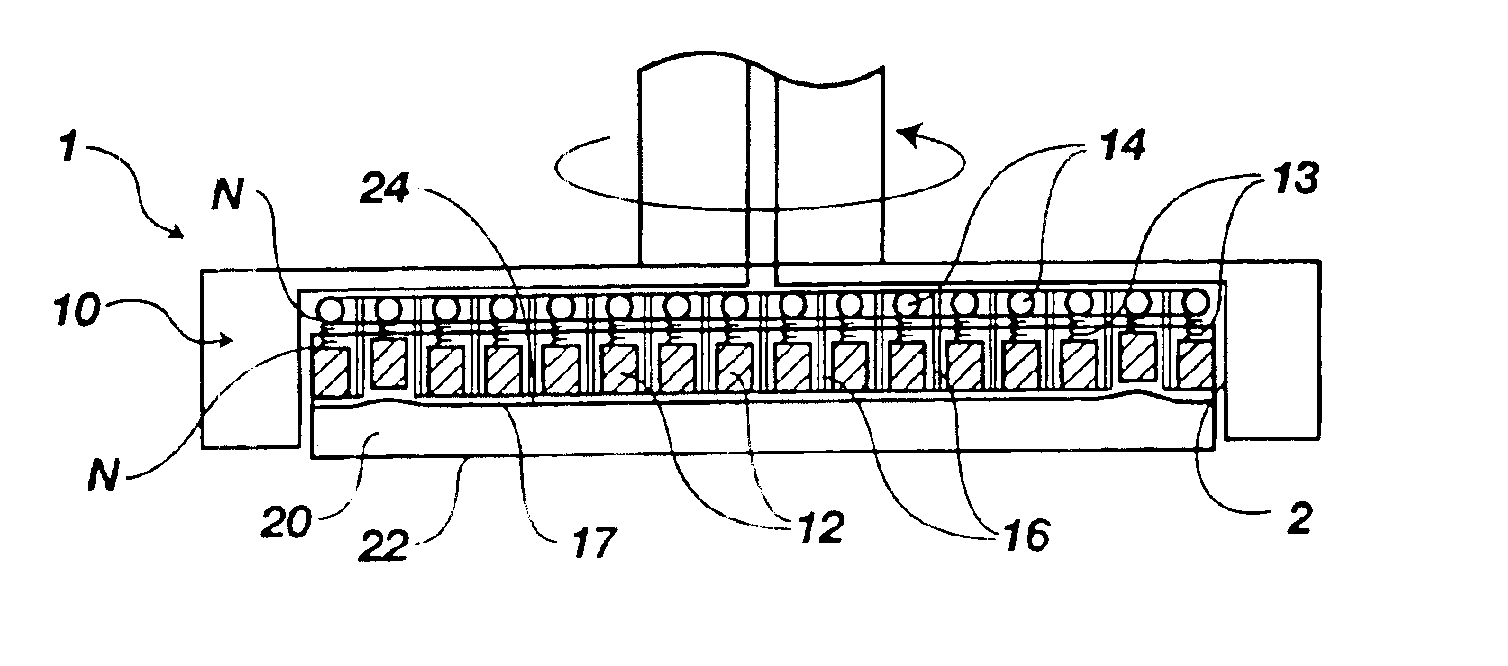

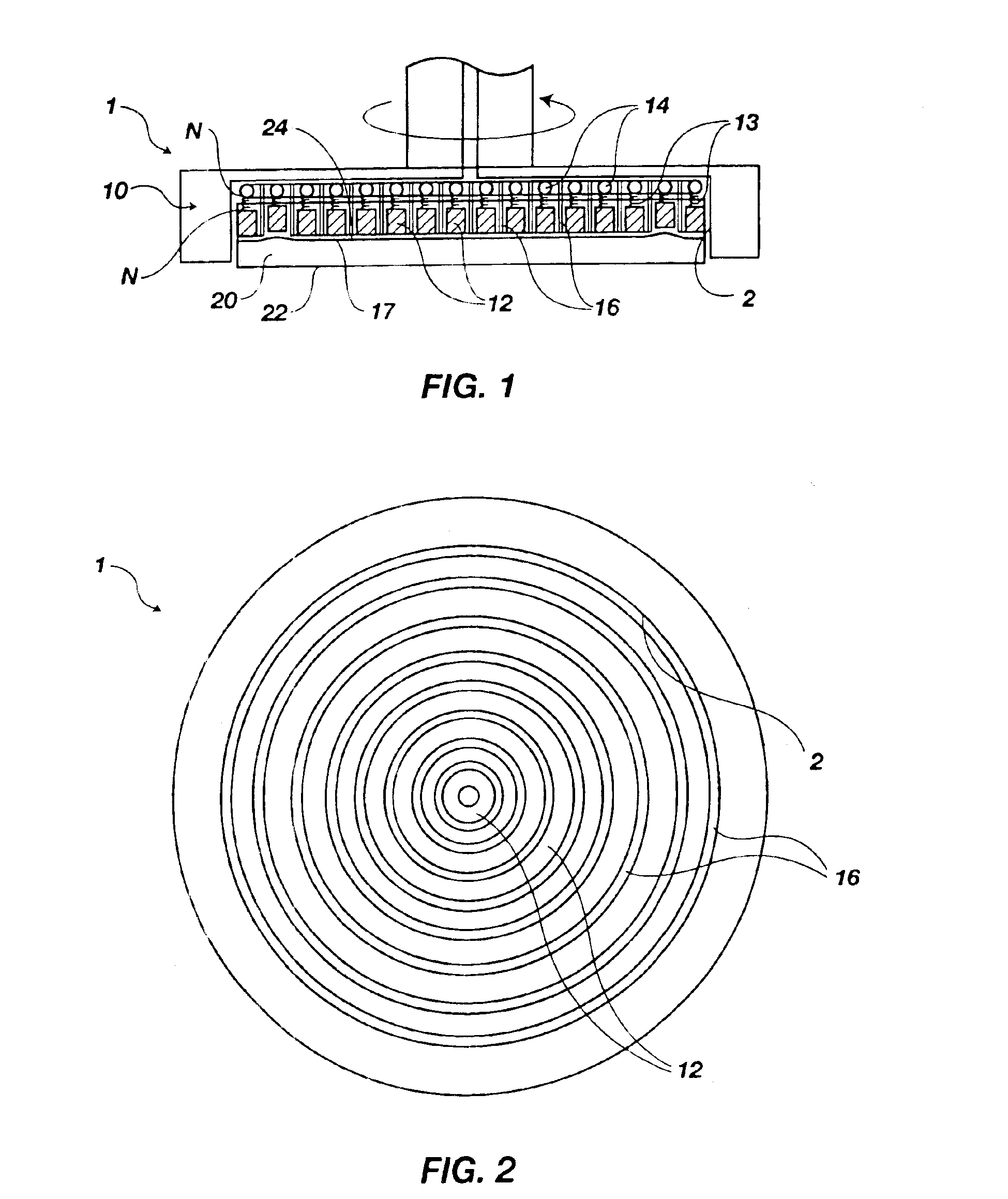

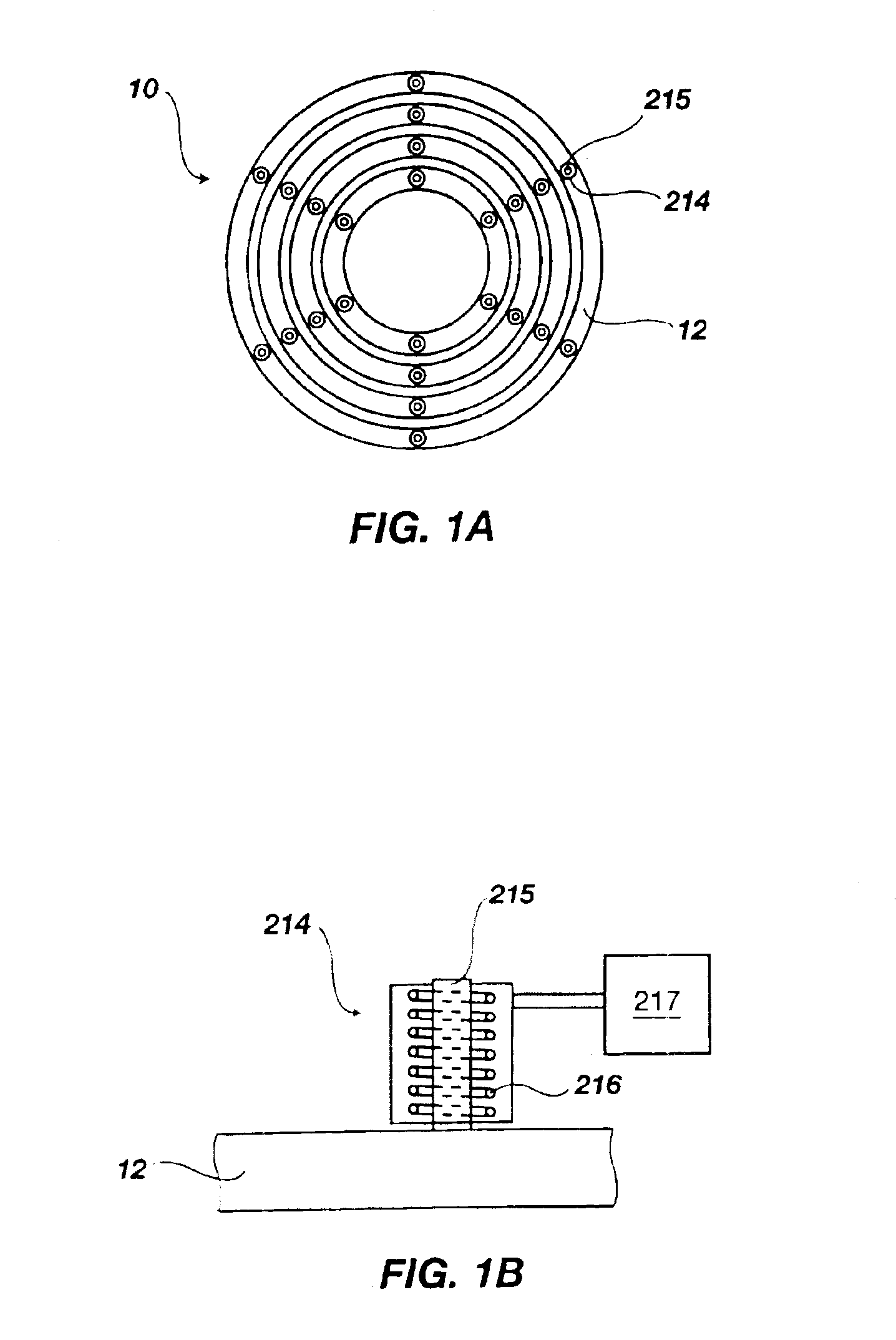

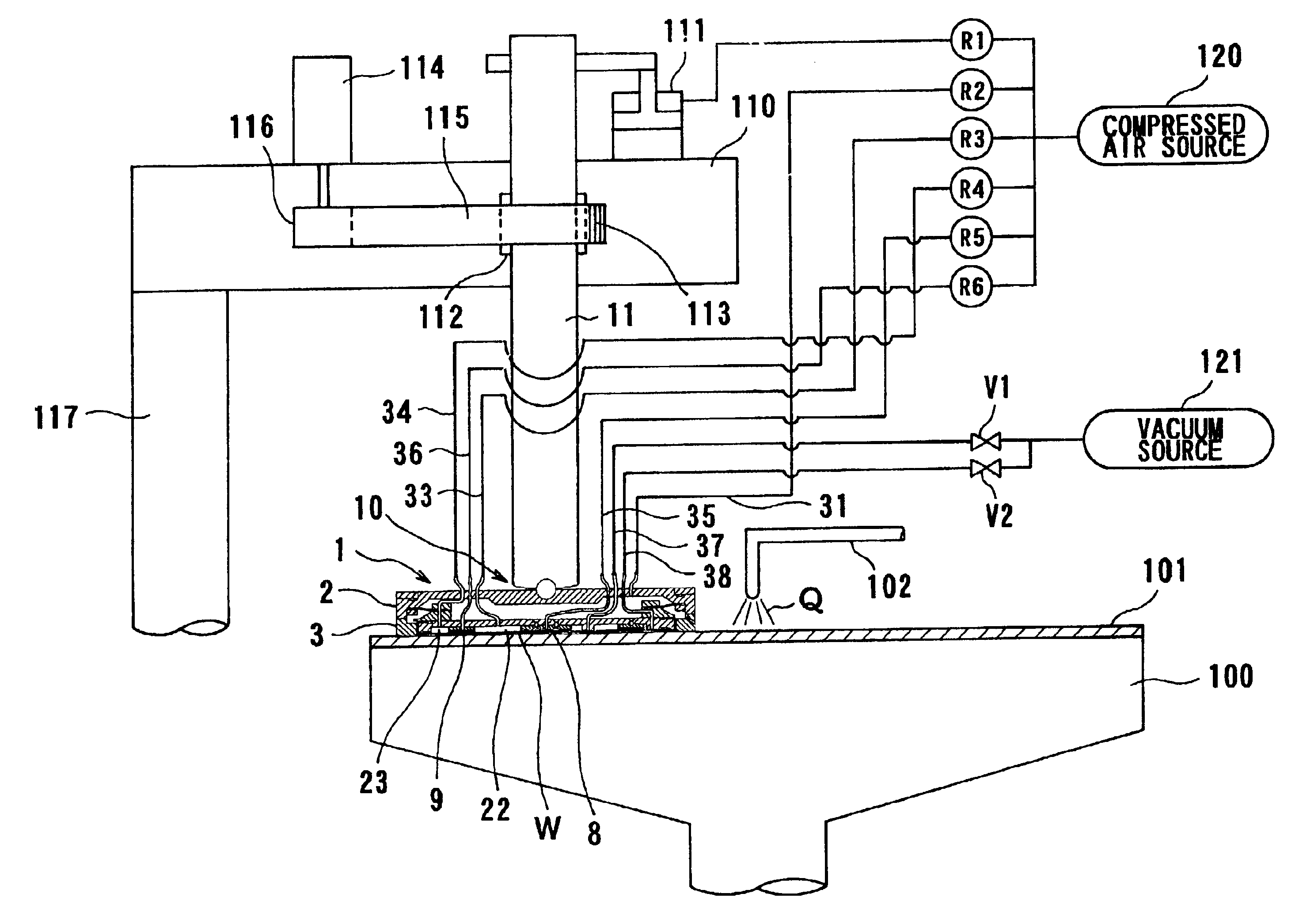

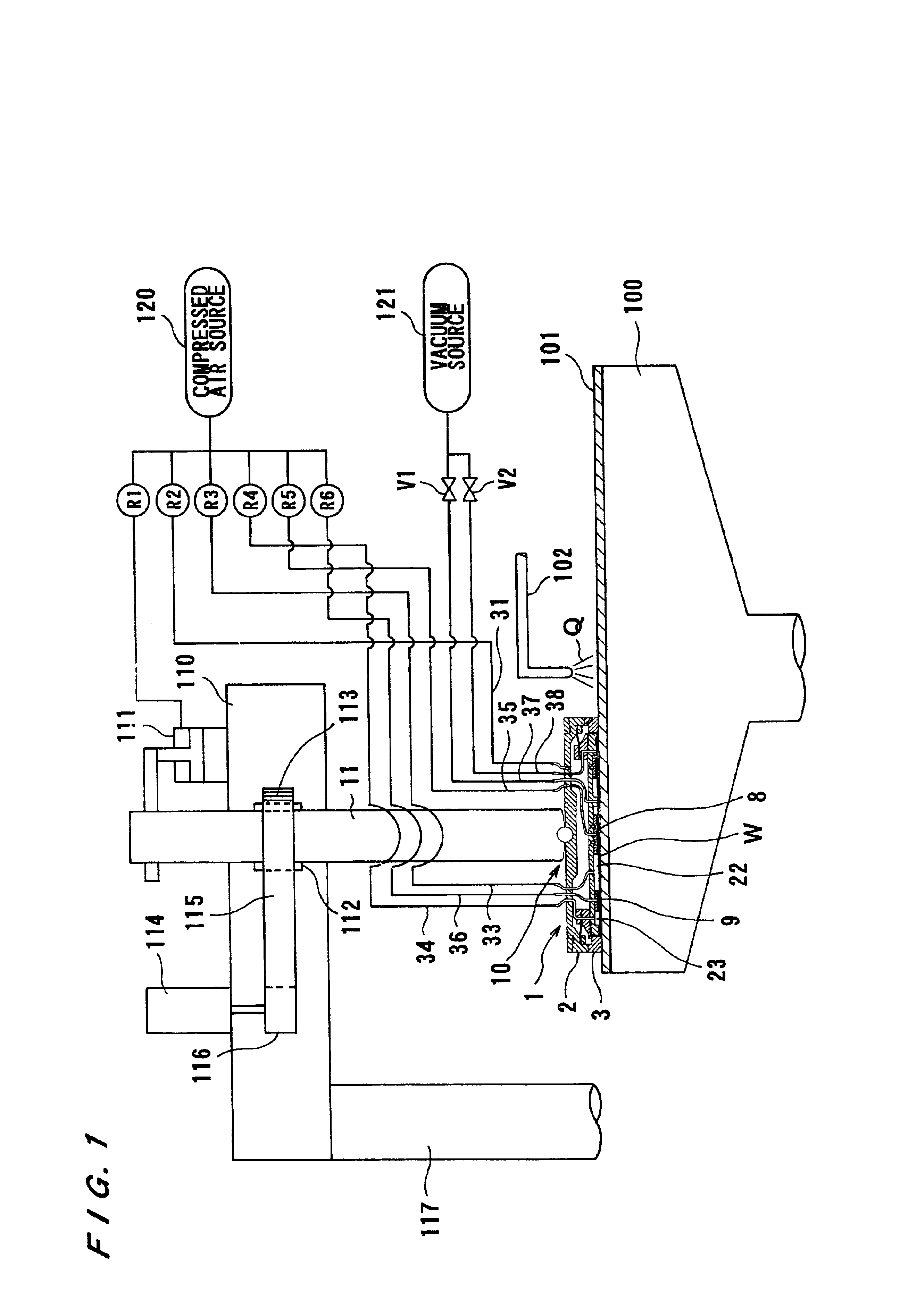

Automatic workpiece transport apparatus for double-side polishing machine

InactiveUS6135854AReliable loadingAccurate detectionRevolution surface grinding machinesGrinding drivesImaging processingEngineering

An automatic workpiece transport apparatus for a double-side polishing machine is disclosed. A carrier is positioned at a predetermined position by a positioning unit, and an image of the top surface of the carrier is captured by use of a visual sensor. A computer performs image processing to obtain the center coordinates of the wafers or the workpiece holders while reference marks or the like provided on the carrier are used as references. The transport robot is moved and controlled based on the thus-detected coordinate data in order to load the wafers into the workpiece holders or to unload the wafers from the workpiece holders. Further, two visual sensors are provided at the tip end of the arm of the transport robot. These visual sensors send to the computer an image of the peripheral portion of the held wafer. Thus, the computer performs fine adjustment in positioning the wafer and the workpiece. The automatic workpiece transport apparatus can reliably load and unload semiconductor wafers to and from the carrier that holds semiconductor substrates.

Owner:SHIN-ETSU HANDOTAI CO LTD

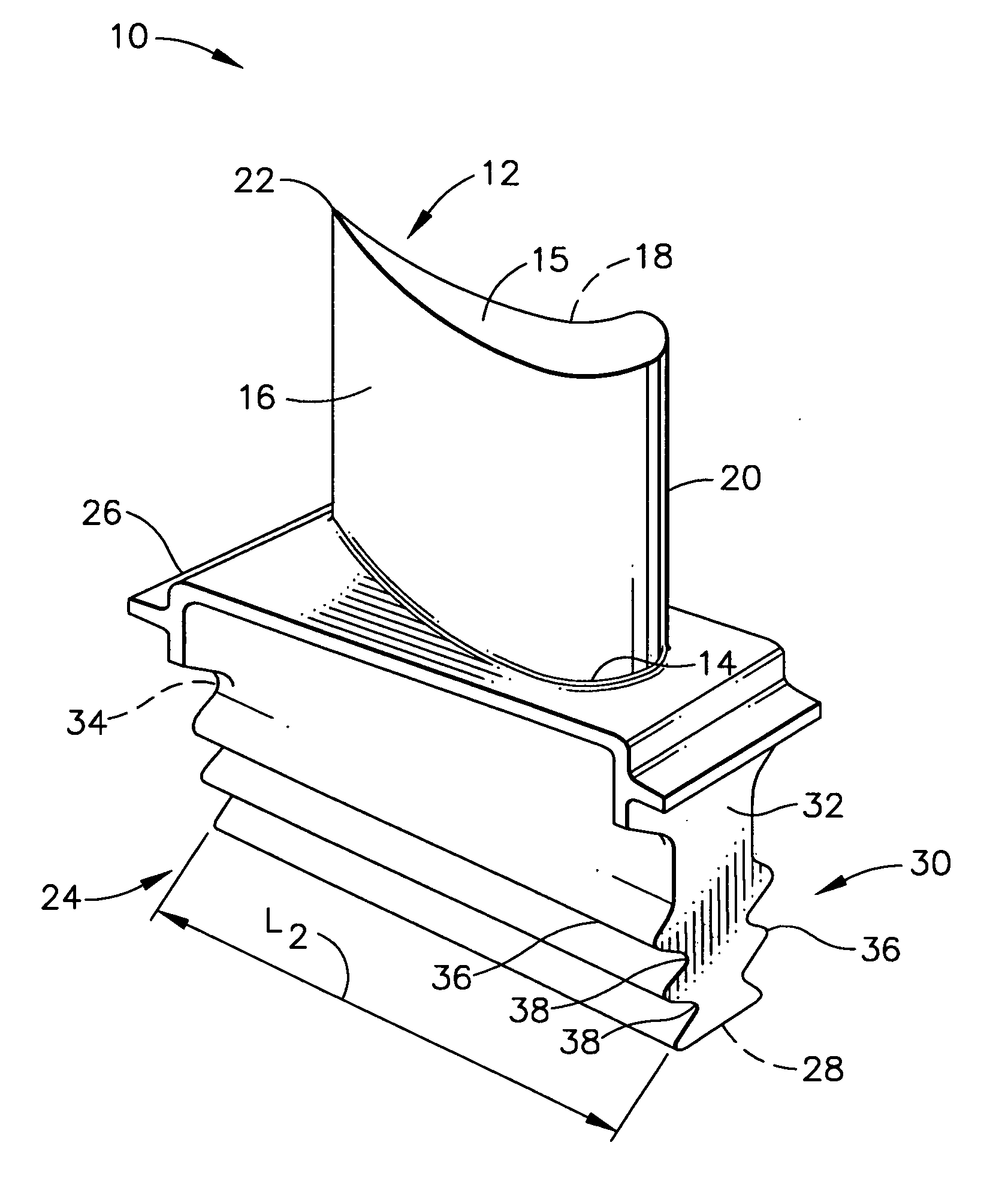

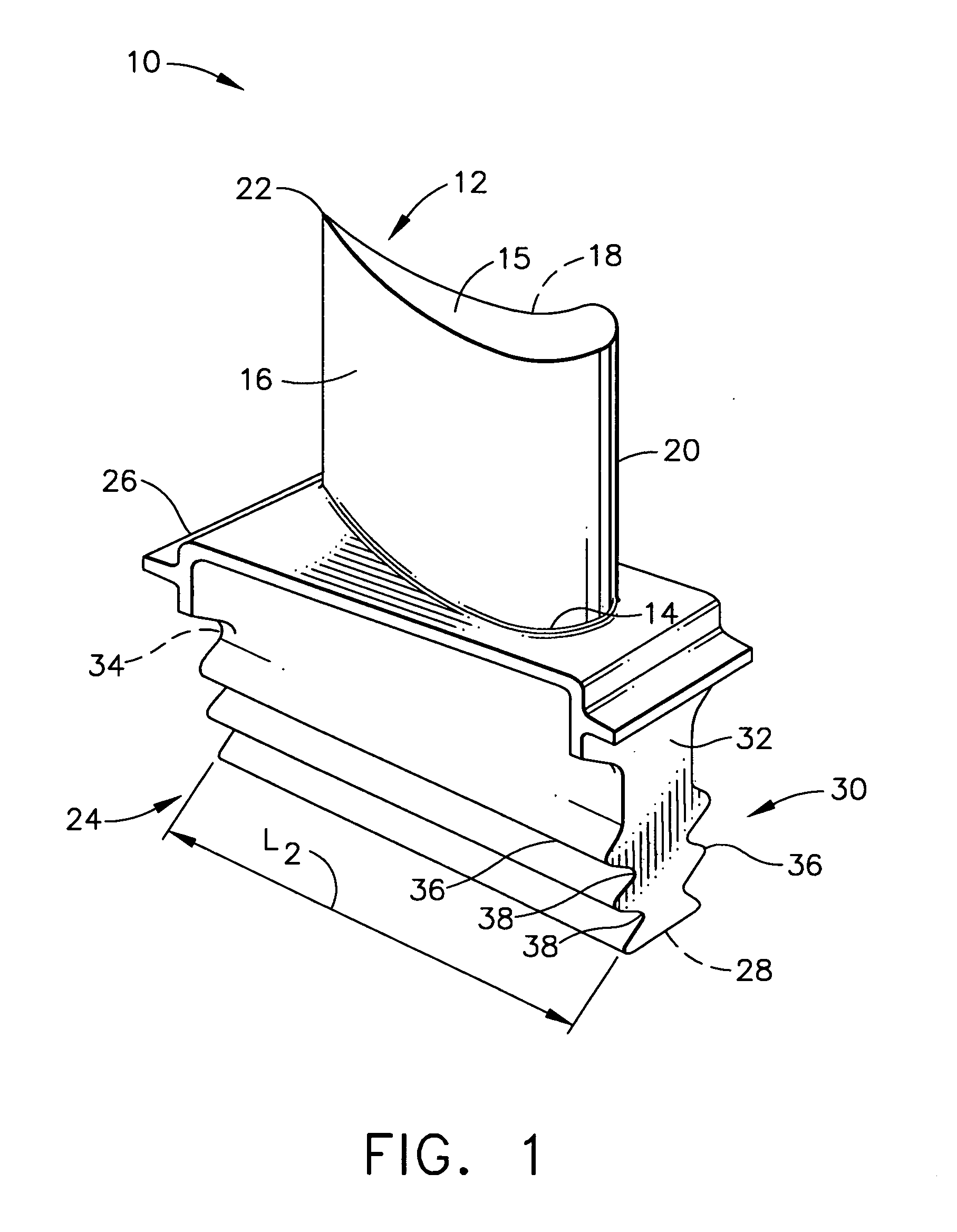

Method and apparatus for rebuilding gas turbine engines

A method for repairing a turbine blade for a gas turbine engine is provided. The method includes securing the blade into a clamping fixture, obtaining a zero reference from a gauging surface on the clamping fixture, coupling the clamping fixture to a grinding machine, and grinding the blade based on the zero reference.

Owner:GENERAL ELECTRIC CO

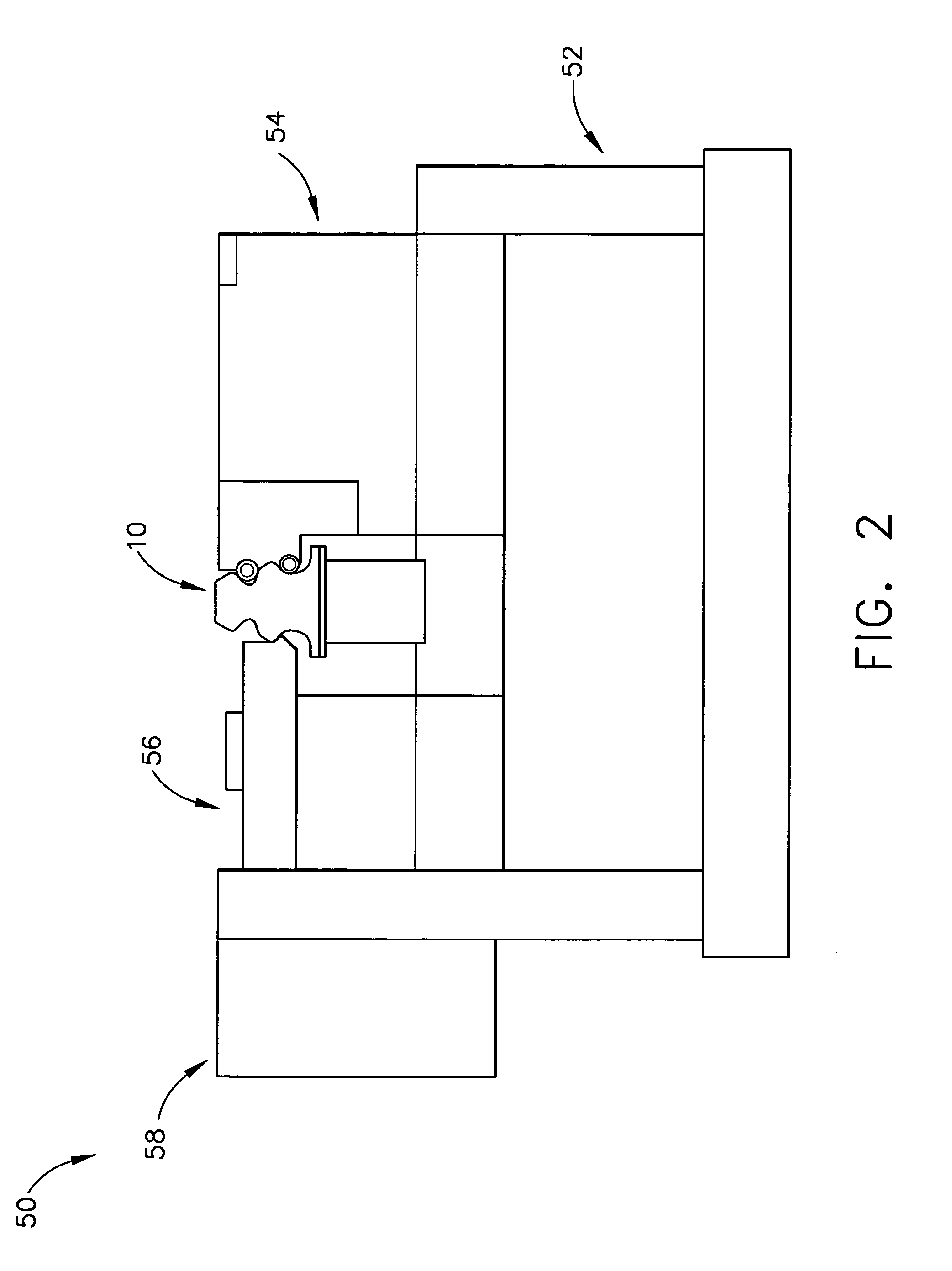

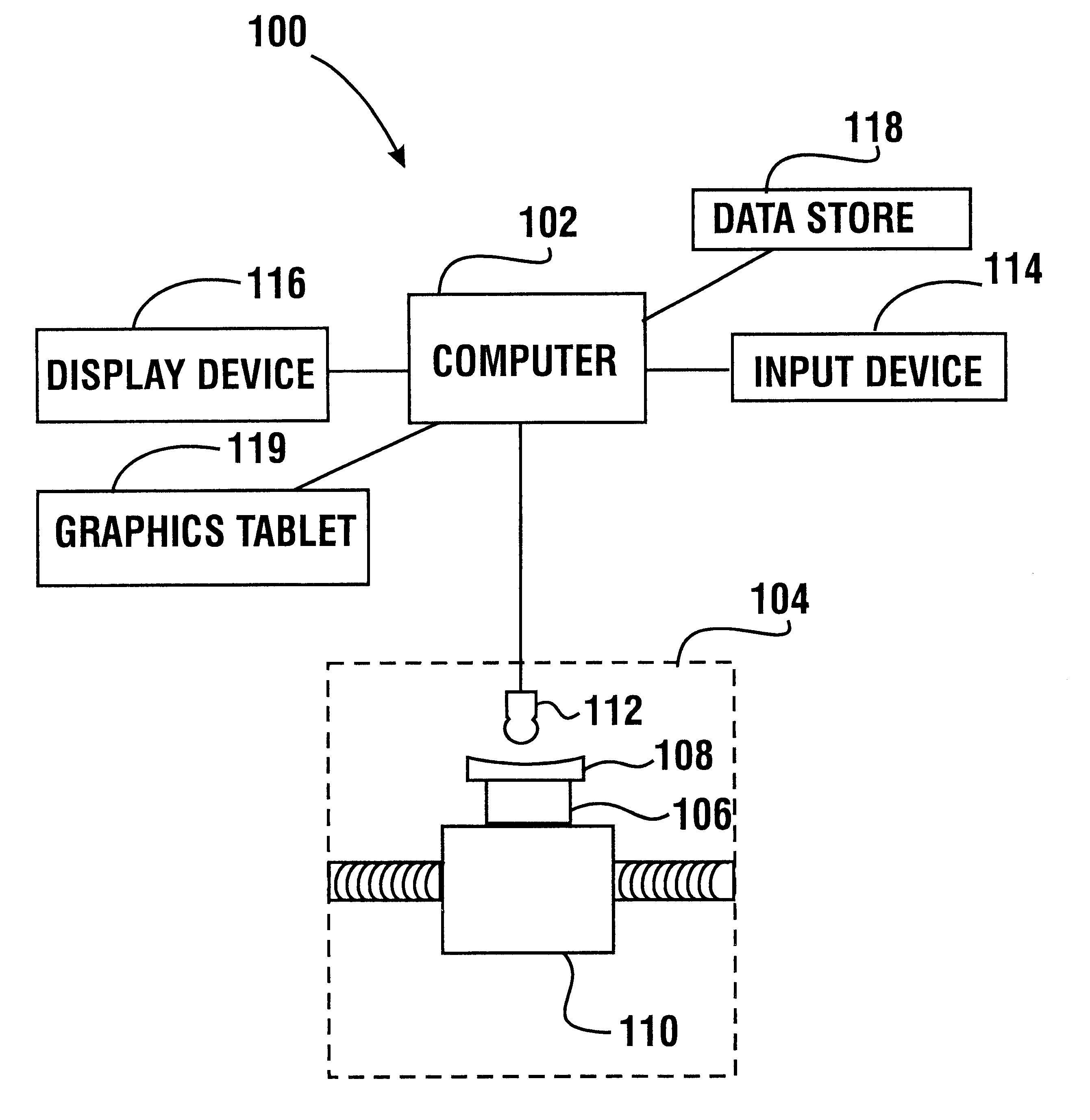

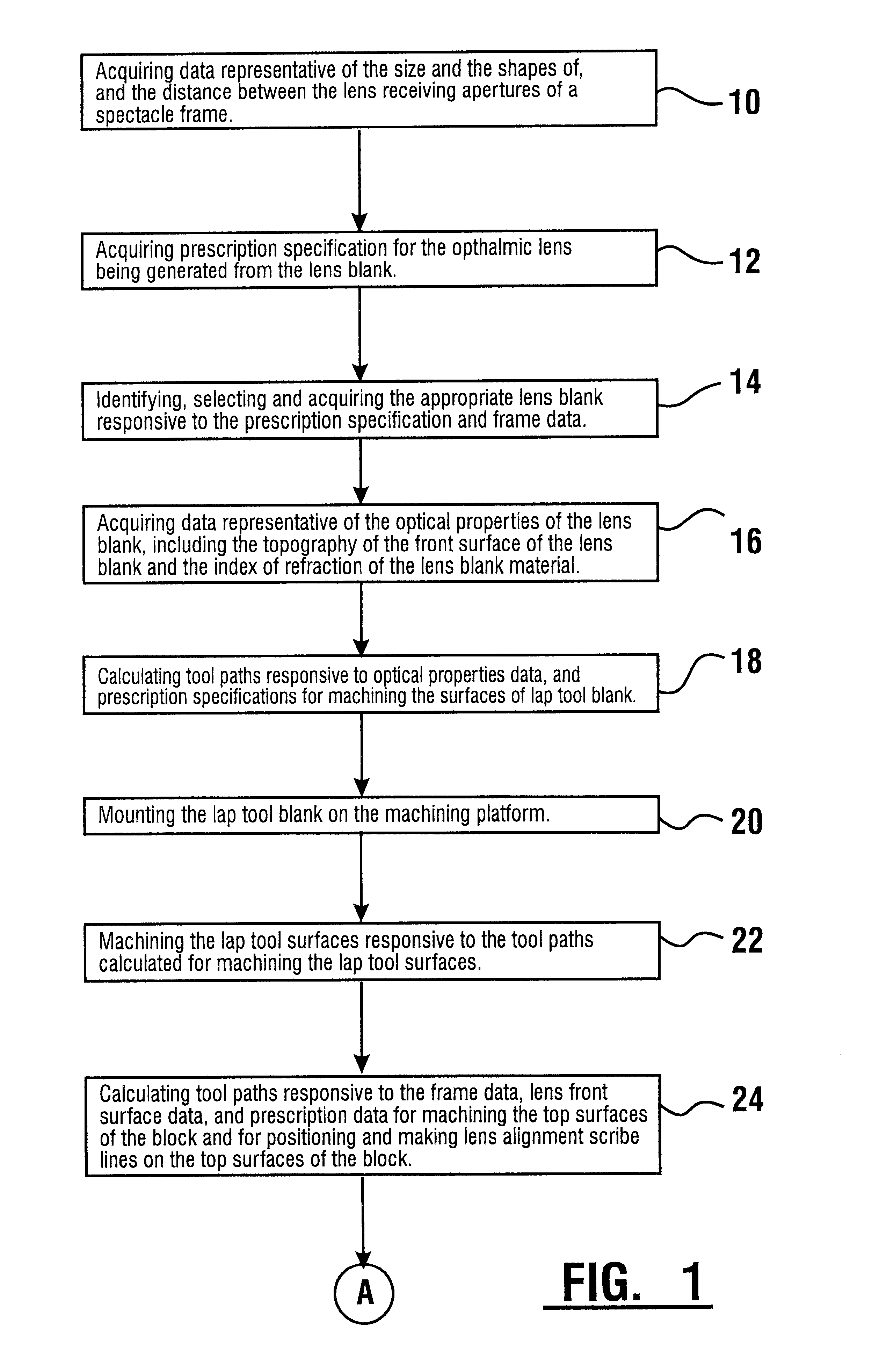

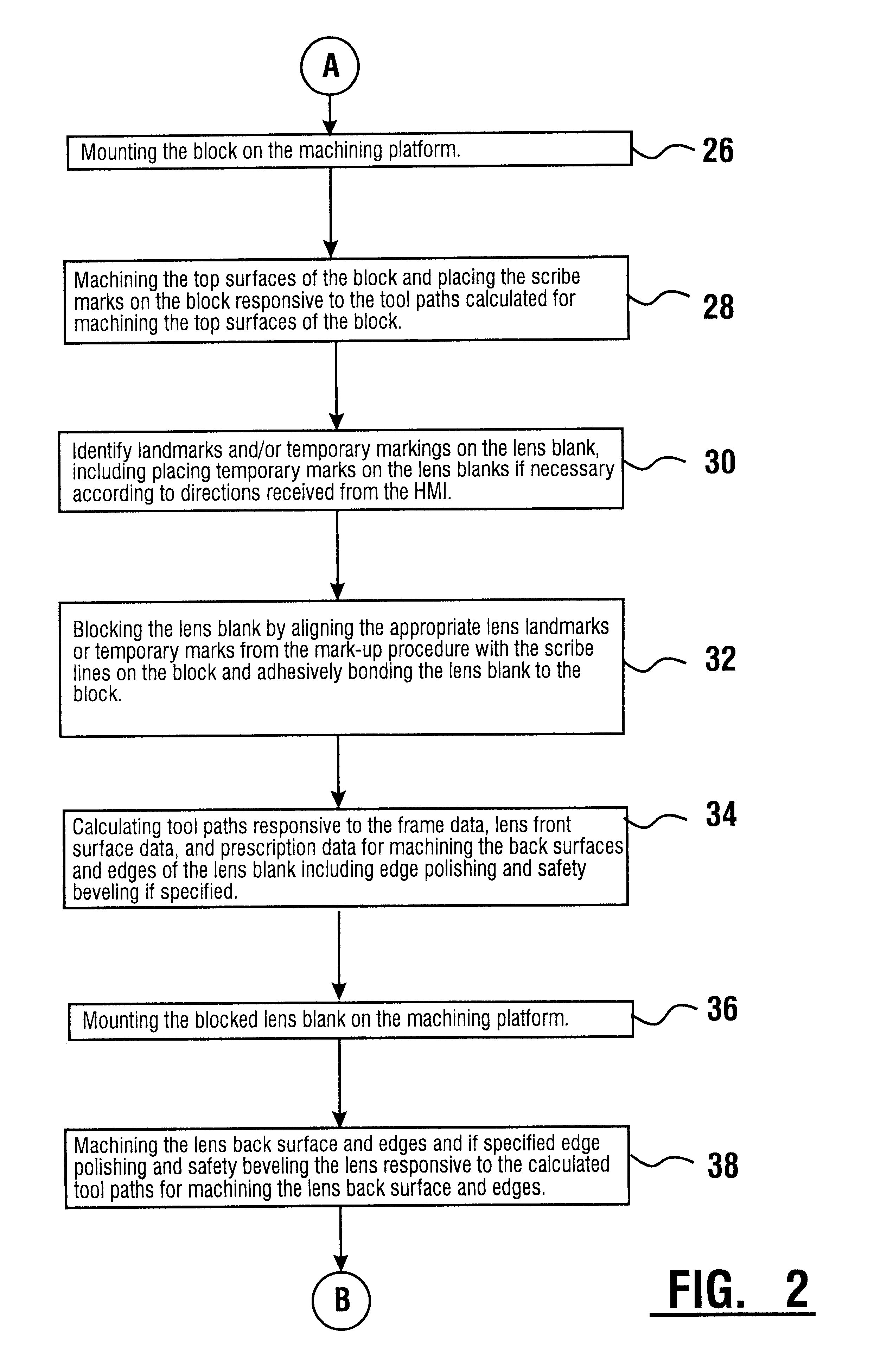

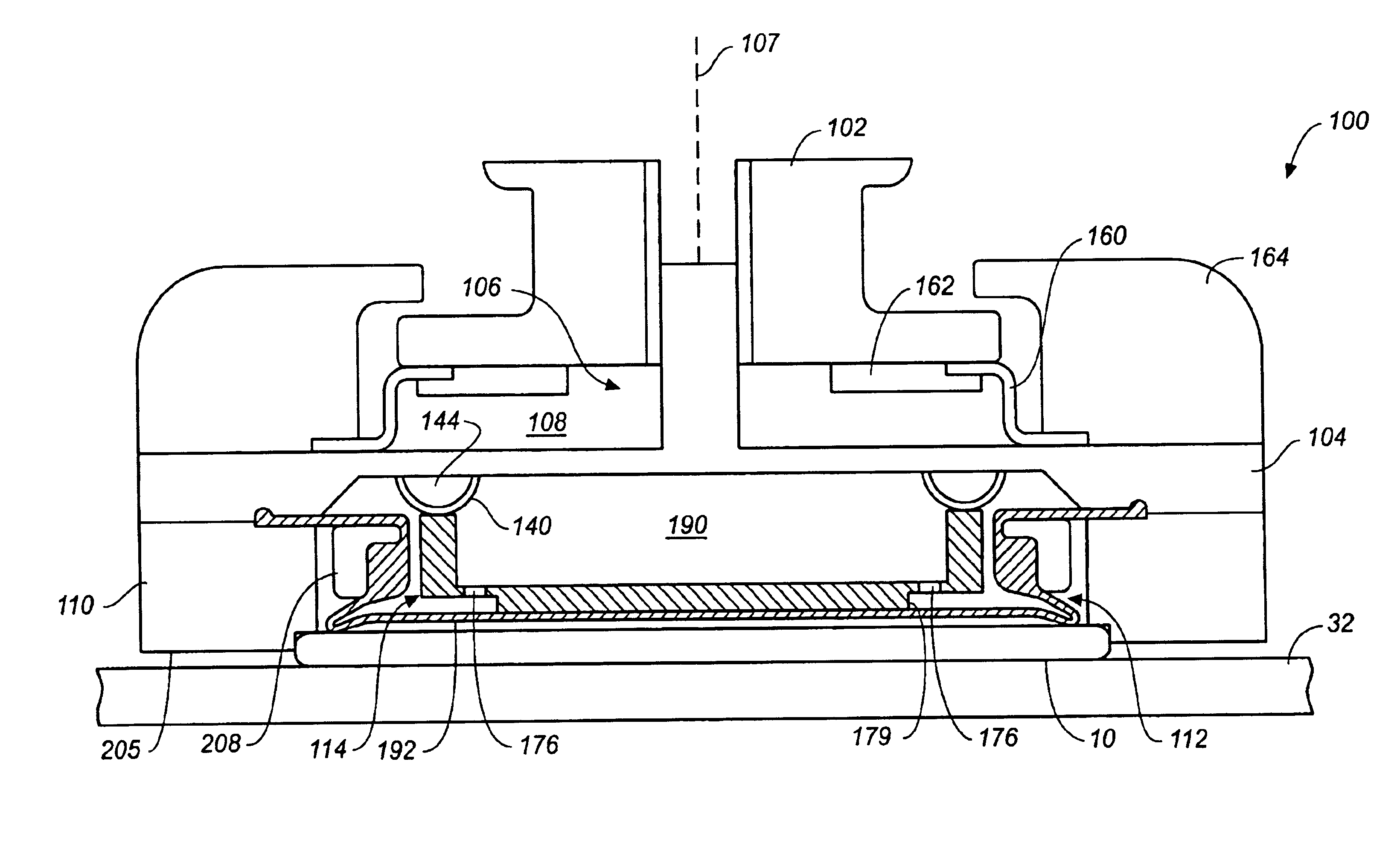

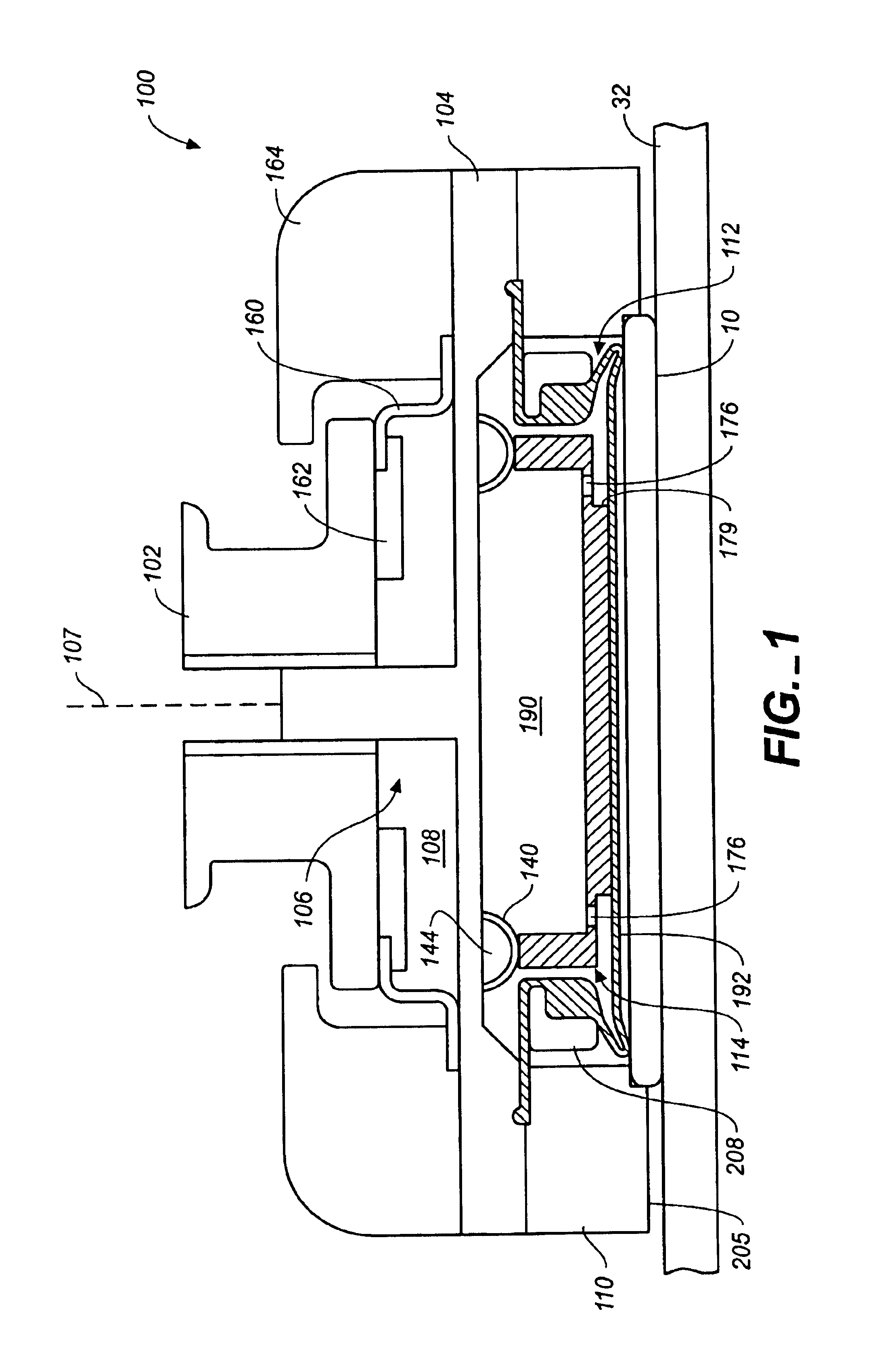

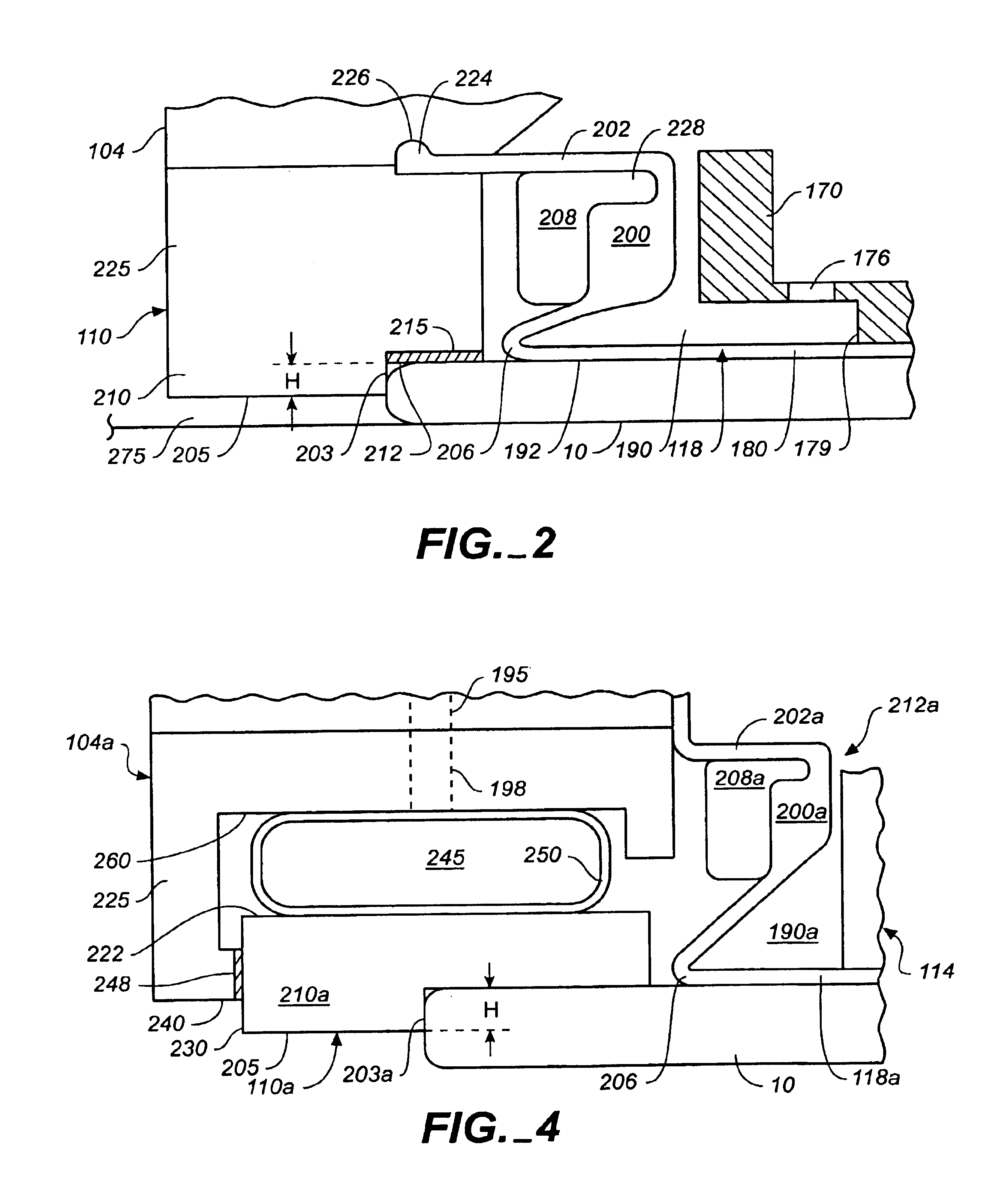

System and method for ophthalmic lens manufacture

InactiveUS6568990B2Low costAccurately derivedEdge grinding machinesOptical surface grinding machinesEngineeringLens plate

A method and system for the manufacture of ophthalmic lenses comprising a computer (102) and a CNC machining platform (104) in operative connection with the computer. The CNC machining platform includes a mounting stage (110), a block (106) in releasable connection with the mounting stage, and a machining tool (112). When an unfinished lens blank (108) is properly mounted on the block, the computer is operative to direct the CNC machining platform to perform both back surface generation and patternless edging of the lens blank in one machining cycle. The computer is further operative to direct the CNC machining platform to machine a lap tool for each lens and machine a block for receiving each lens. The block is machined by the platform to include scribe lines for facilitating proper alignment of lens blank.

Owner:NCRX OPTICAL SOLUTIONS

Steel plate surface polishing device for hardware machining

ActiveCN106141875AImprove corrosion resistanceHigh strengthGrinding carriagesPolishing machinesSheet steelMachining

The invention relates to a steel plate surface polishing device, in particular to a steel plate surface polishing device for hardware machining. The steel plate surface polishing device for hardware machining aims to achieve the technical purposes that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of operators is small. In order to achieve the technical purposes, the steel plate surface polishing device for hardware machining comprises a bottom plate, a first sliding rail, a first sliding block, a collection tank, a fixing stop block, a spring, a supporting rod, a first bearing pedestal, a first air cylinder, a disc and the like, wherein the first sliding rail is arranged in the middle of the top of the bottom plate. Through ingenious cooperation of the components, the effects that manual labor is not needed, the requirement for professional operation skills is not high, operation is easy, the price-performance ratio is high, the safety coefficient is high, and harm of the operation environment to health of the operators is small are achieved.

Owner:如皋市通城冲压机械制造有限公司

Carrier head with non-contact retainer

A carrier head for chemical mechanical polishing of a substrate has a base and a retaining ring positioned beneath the base. The retaining ring includes a main portion with a first surface to apply a load to a perimeter portion of the back surface of the substrate and an annular projection with a second surface to retain the substrate. A bottom surface of the projection is separated from a top surface of a polishing pad by a gap.

Owner:APPLIED MATERIALS INC

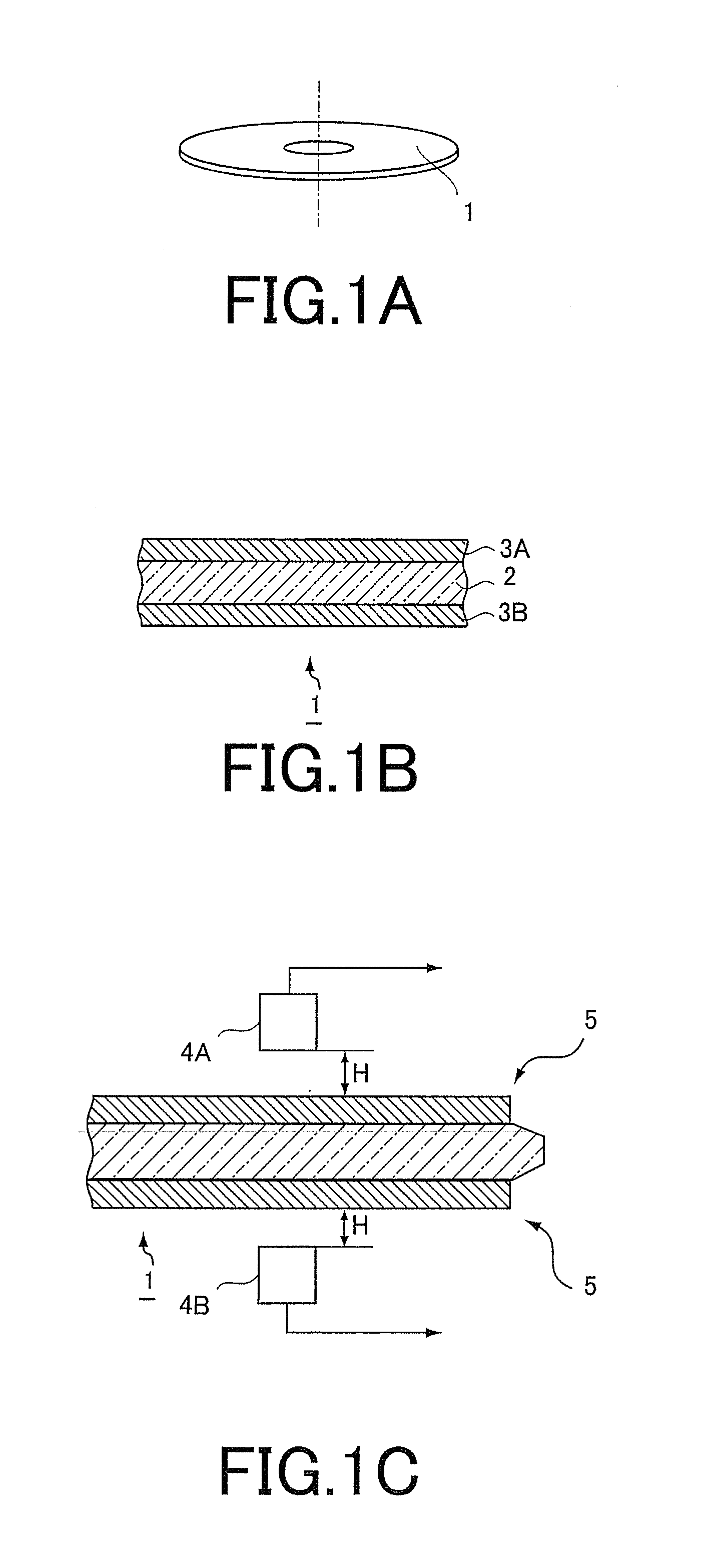

Glass substrate for magnetic disk and manufacturing method thereof

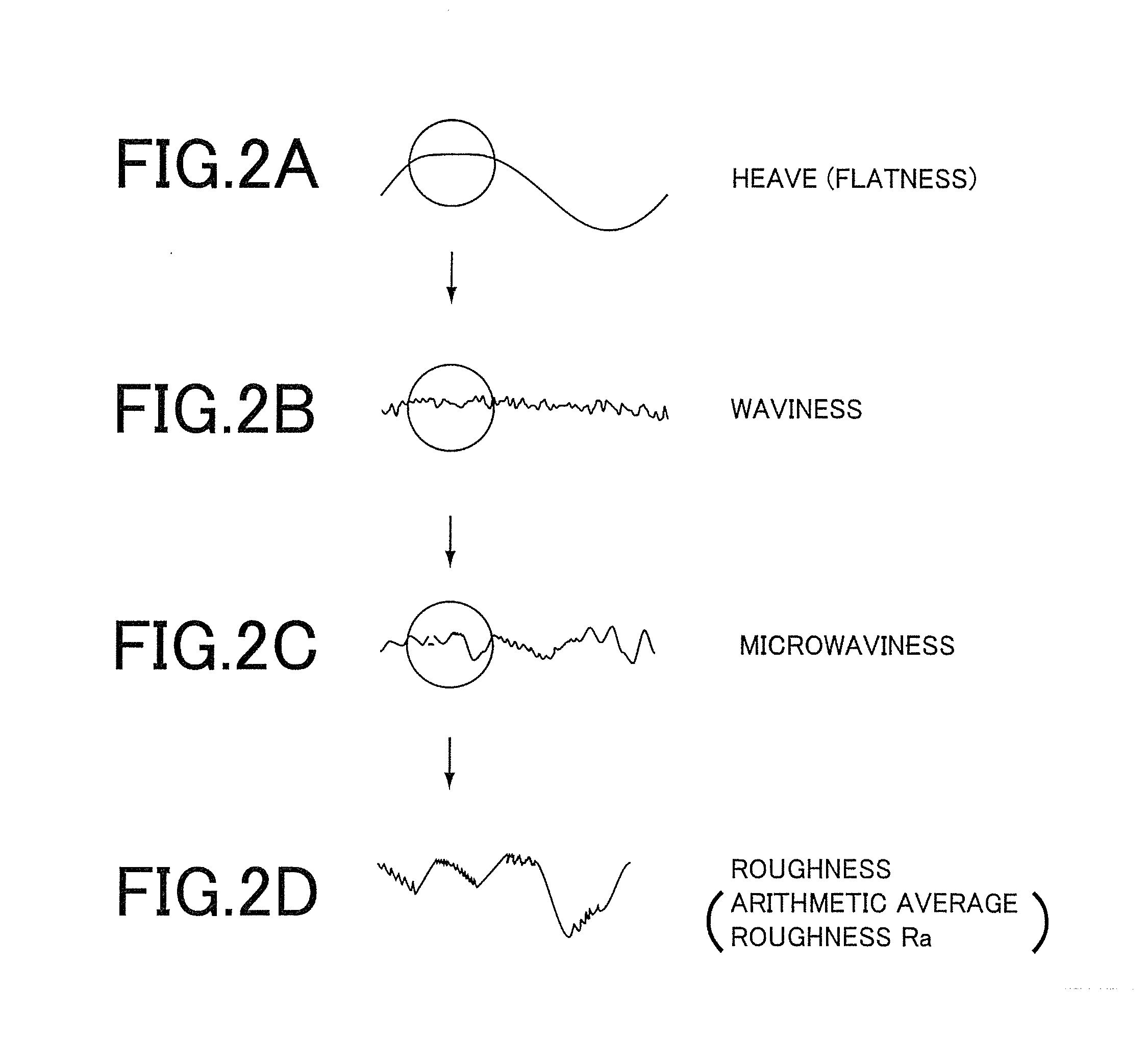

InactiveUS20110159321A1Good surface irregularity accuracyImprove impact resistanceMagnetic materials for record carriersRecord information storageFlat glassSurface roughness

The present invention provides a method for efficiently manufacturing a glass substrate for magnetic disk having good accuracy of a surface irregularity and an impact resistance. The method includes the steps of: performing press forming to molten glass to prepare a sheet glass material, the sheet glass material having a roughness of the principal surface of 0.01 μm or less and target flatness of a glass substrate for magnetic disk; chemically strengthening the sheet glass material by dipping the sheet glass material in a chemically strengthening salt, thereby preparing a disk substrate; polishing the principal surfaces of the disk substrate. A thickness of the sheet glass material prepared in the press forming step is larger than a target thickness of the glass substrate for magnetic disk by a polishing quantity of the principal surface polishing step.

Owner:HOYA CORP

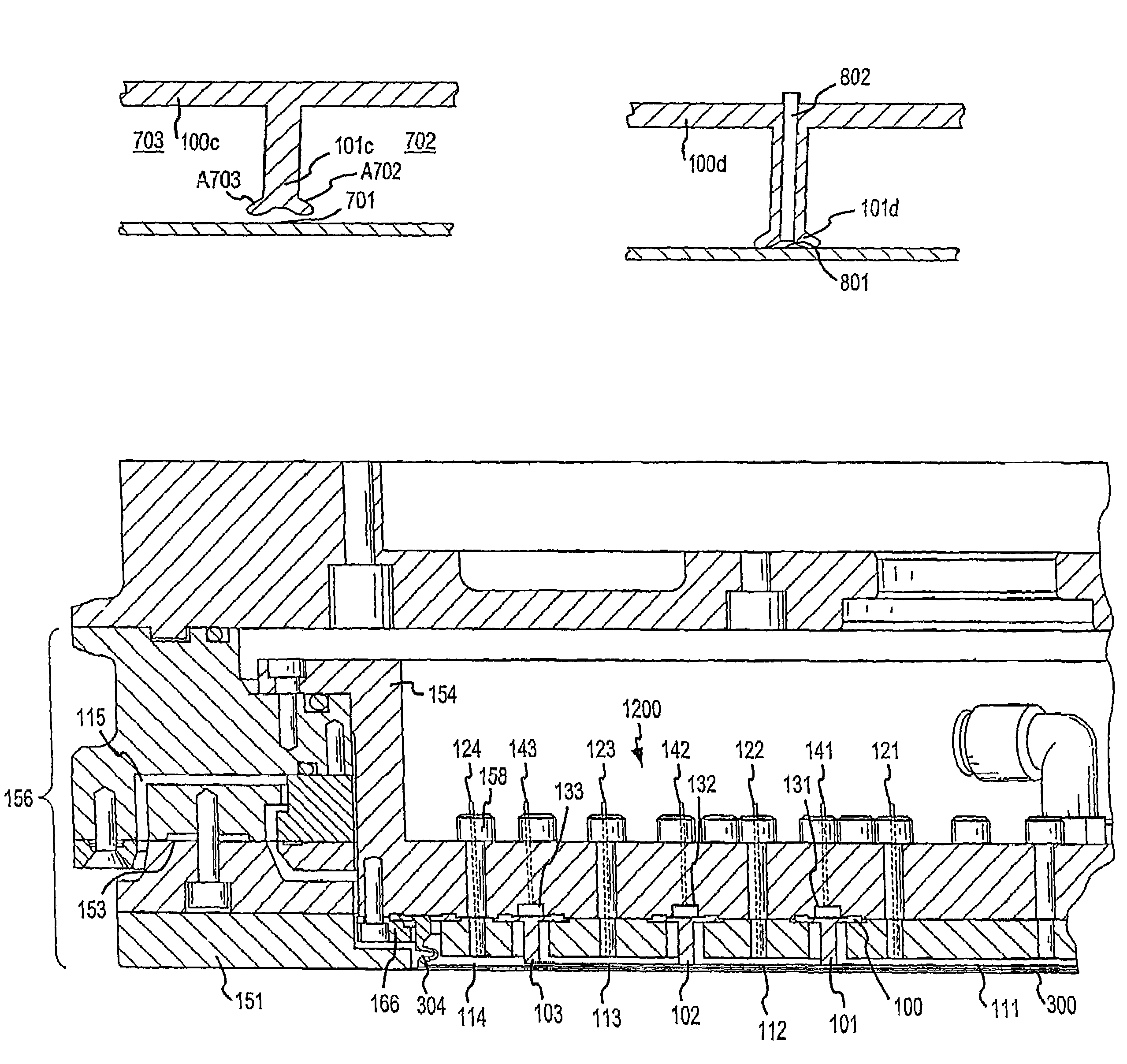

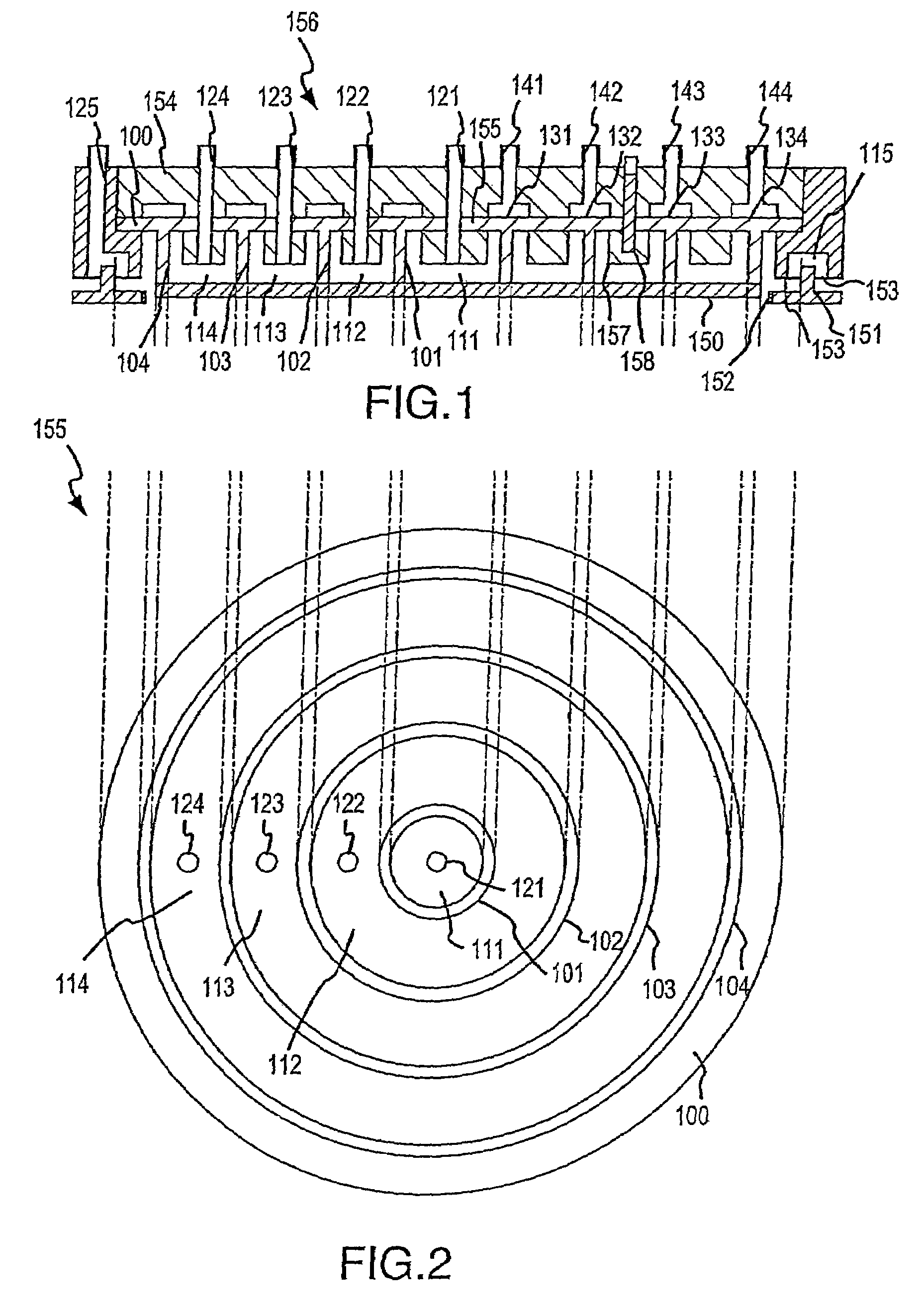

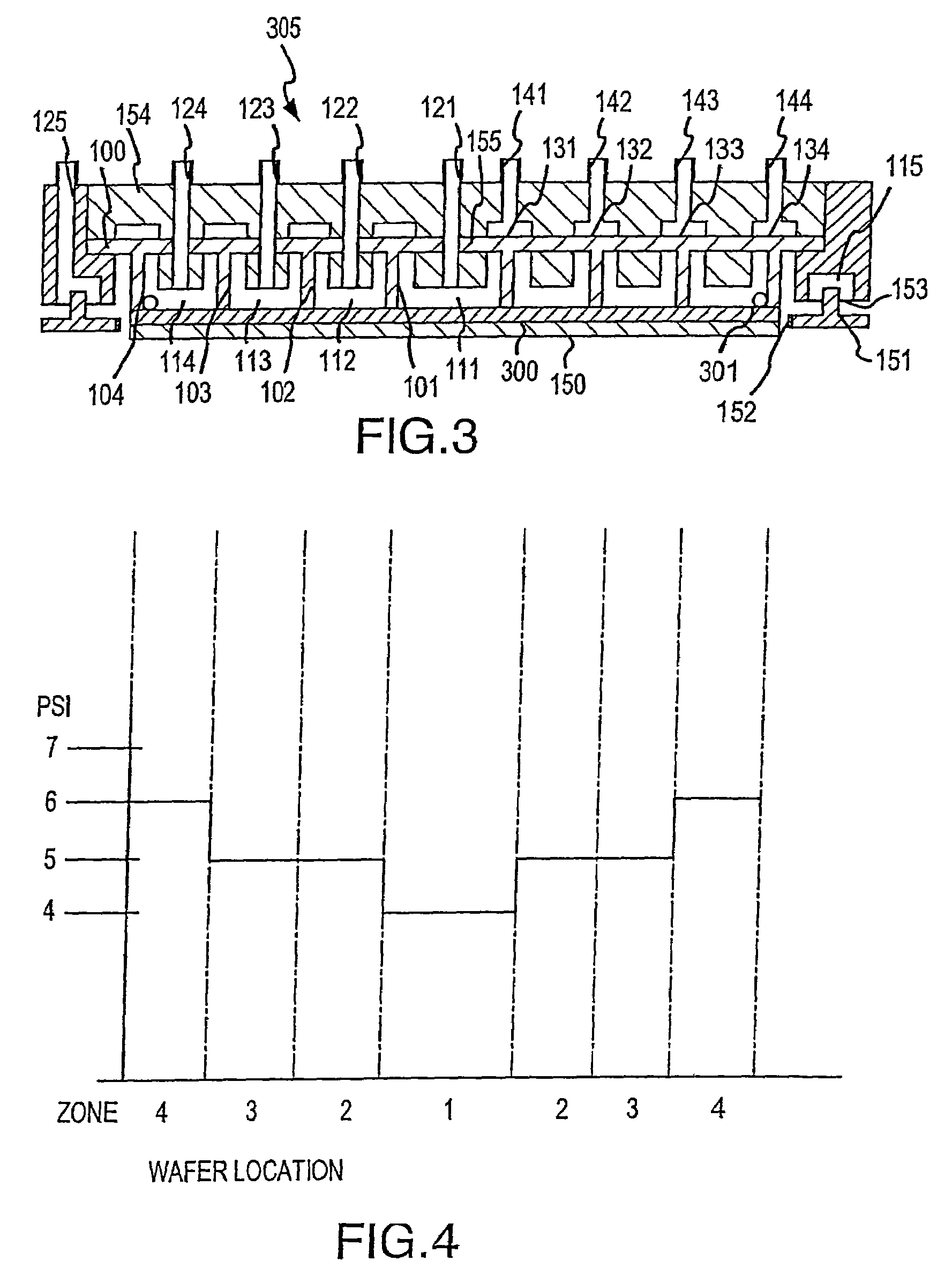

Work piece carrier with adjustable pressure zones and barriers and a method of planarizing a work piece

InactiveUS7140956B1Polishing machinesRevolution surface grinding machinesMaterial removalEngineering

An apparatus for planarizing a work piece includes an easily assembled work carrier. The carrier includes a carrier insert having a work piece bladder clamped to a carrier backing plate with a plurality of clamps to form a plurality of web plenums. The outer edge of the bladder is supported by a rib that is coupled to a carrier plenum. By adjusting the pressure in the carrier plenum, the pressure exerted on the edge of a work piece during a planarization operation can be adjusted. The carrier also includes a floating wear ring that surrounds the work piece bladder and a work piece mounted on that bladder. By adjusting the force exerted by the wear ring on a polishing pad, independently of the pressure exerted by the rib at the edge of the bladder, the material removal rate near the edge of the work piece can be controlled.

Owner:NOVELLUS SYSTEMS

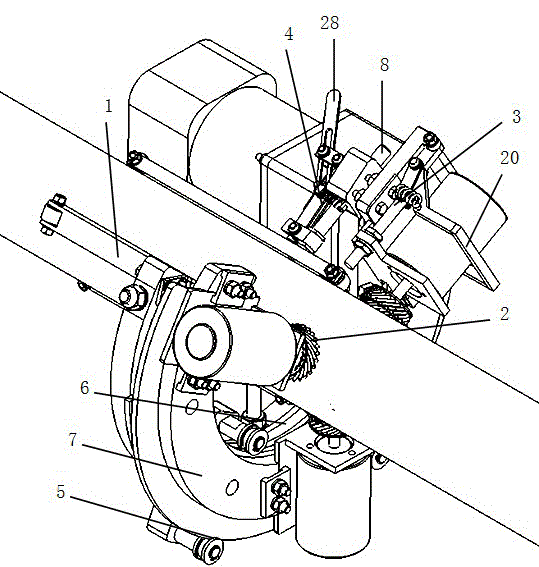

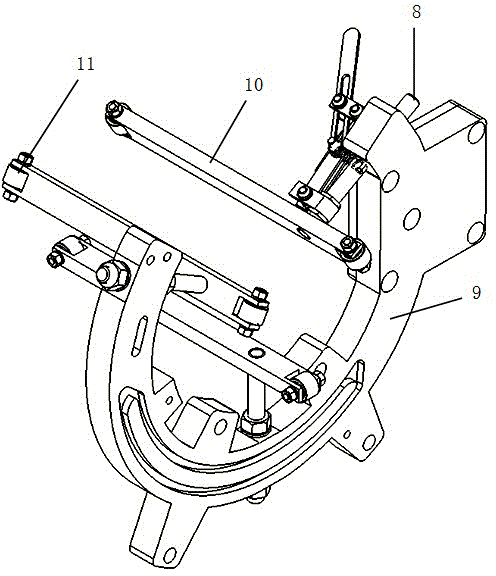

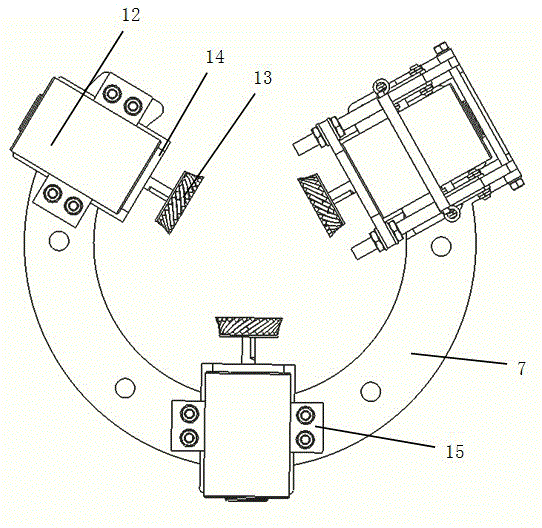

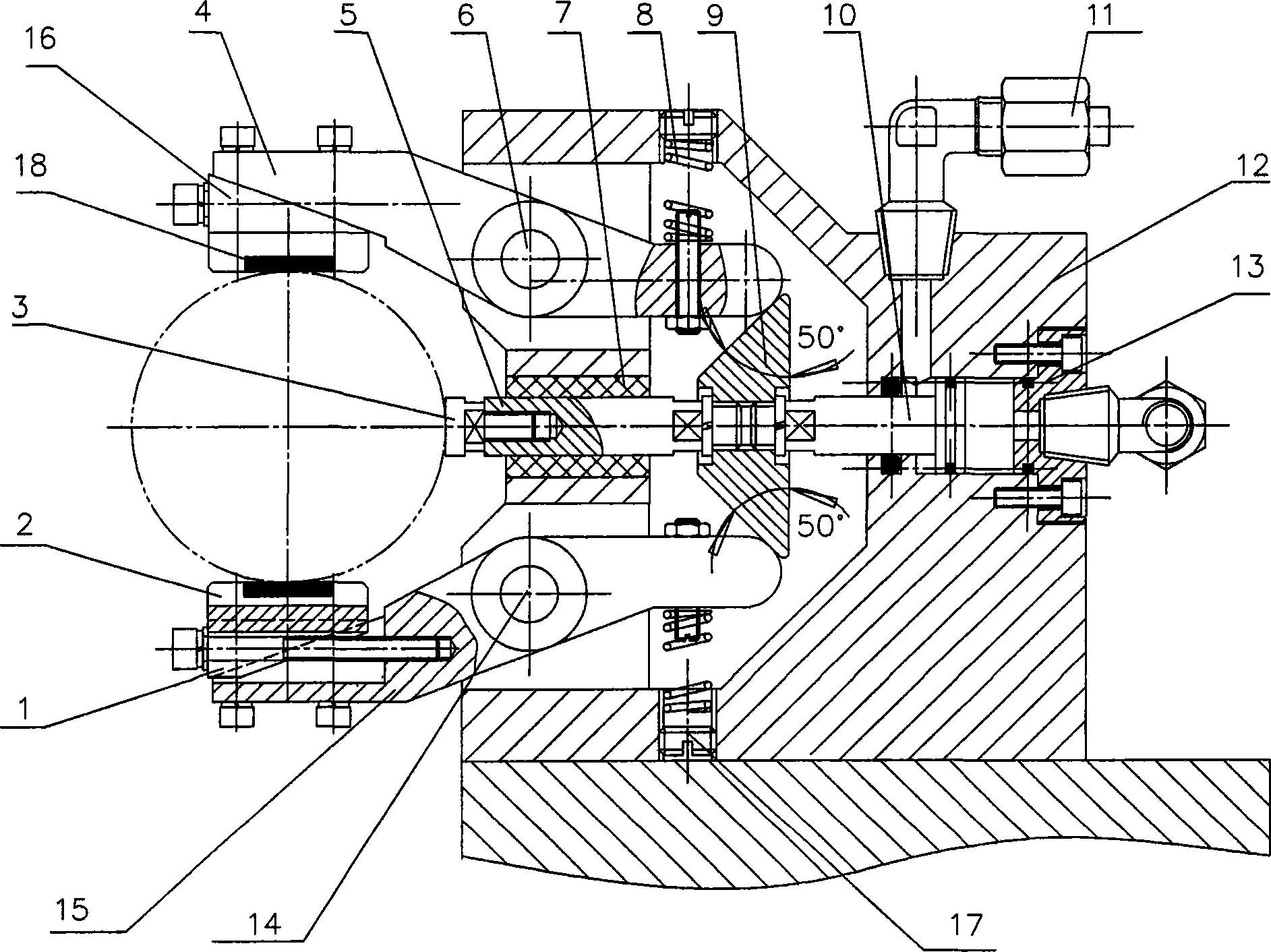

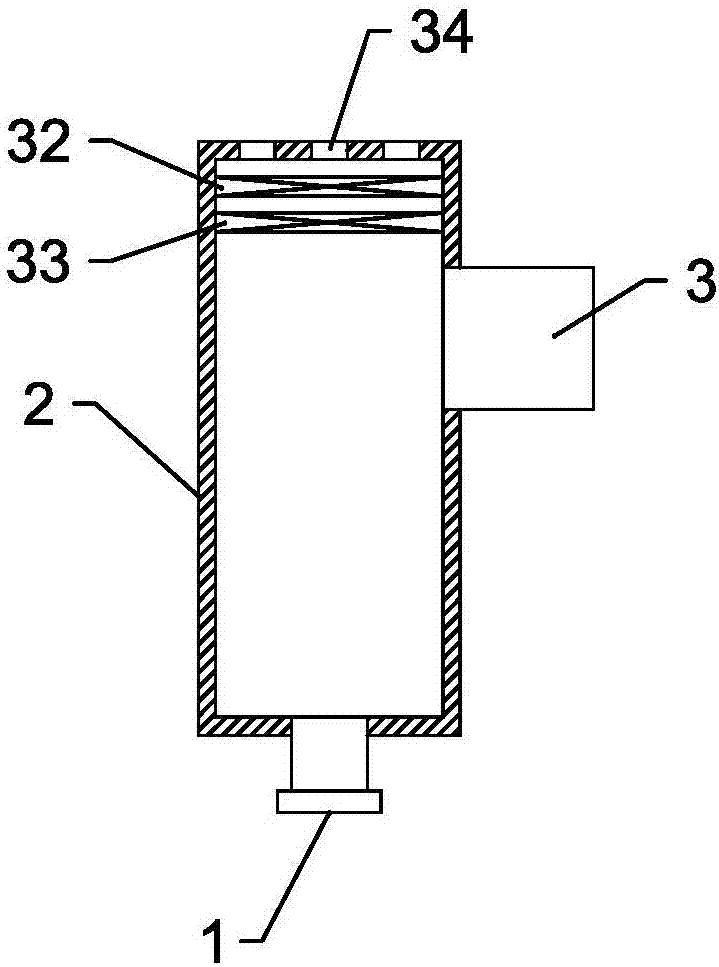

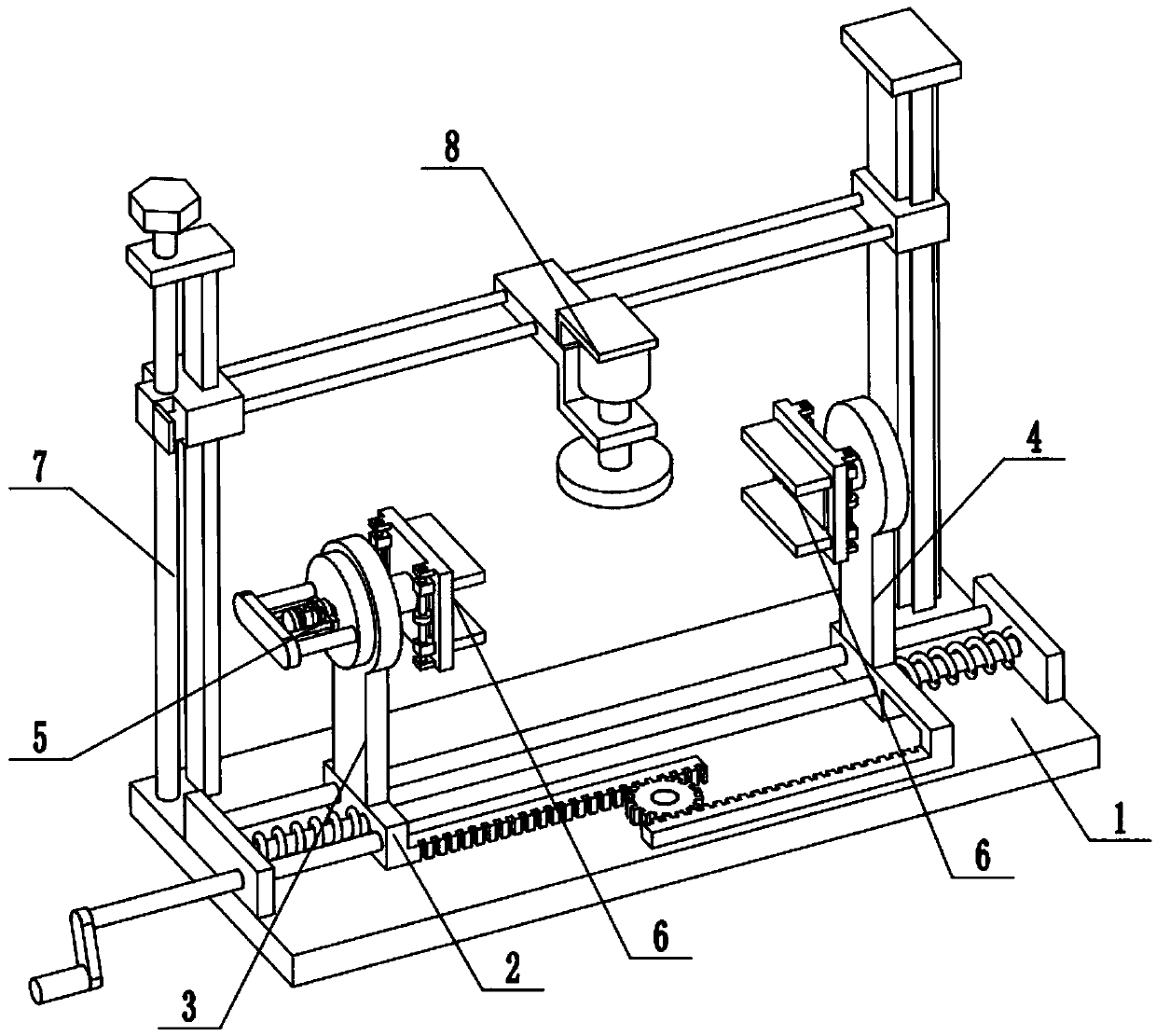

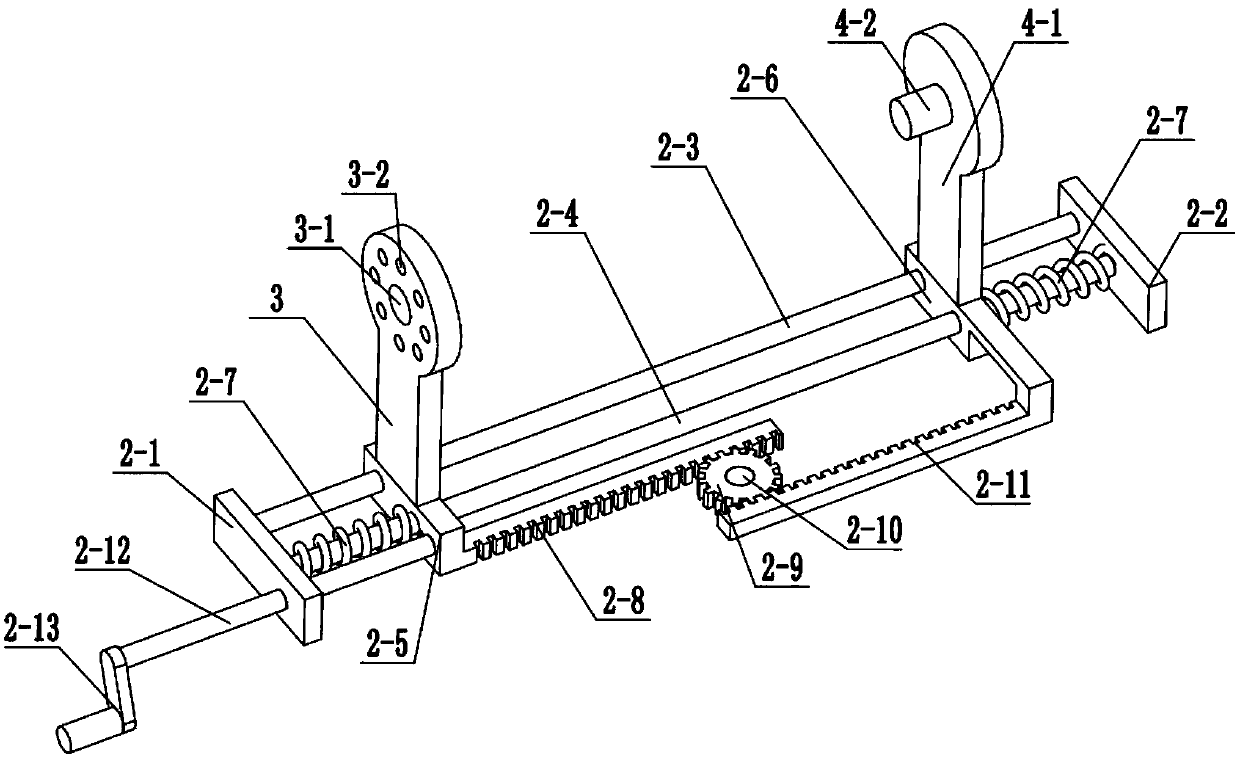

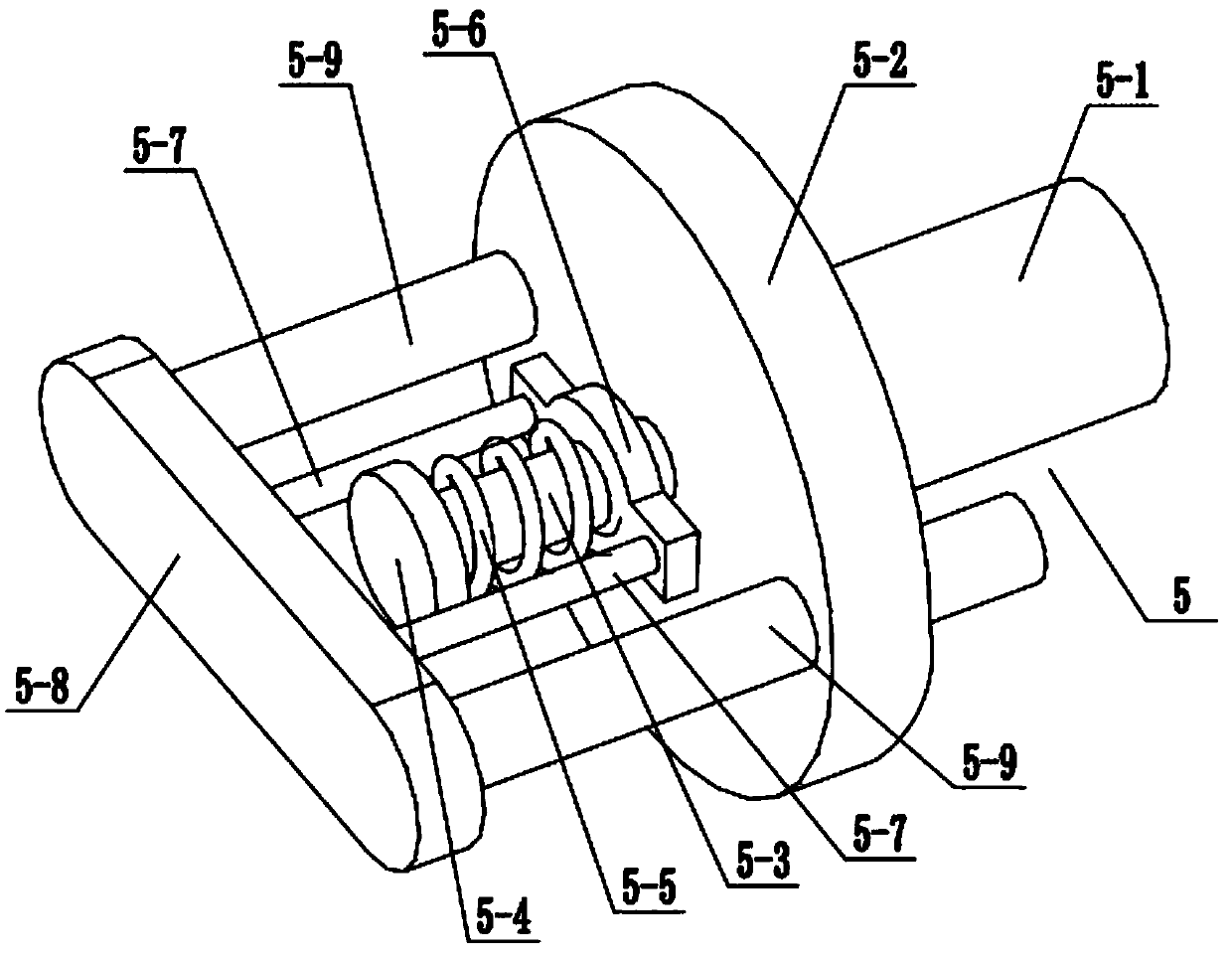

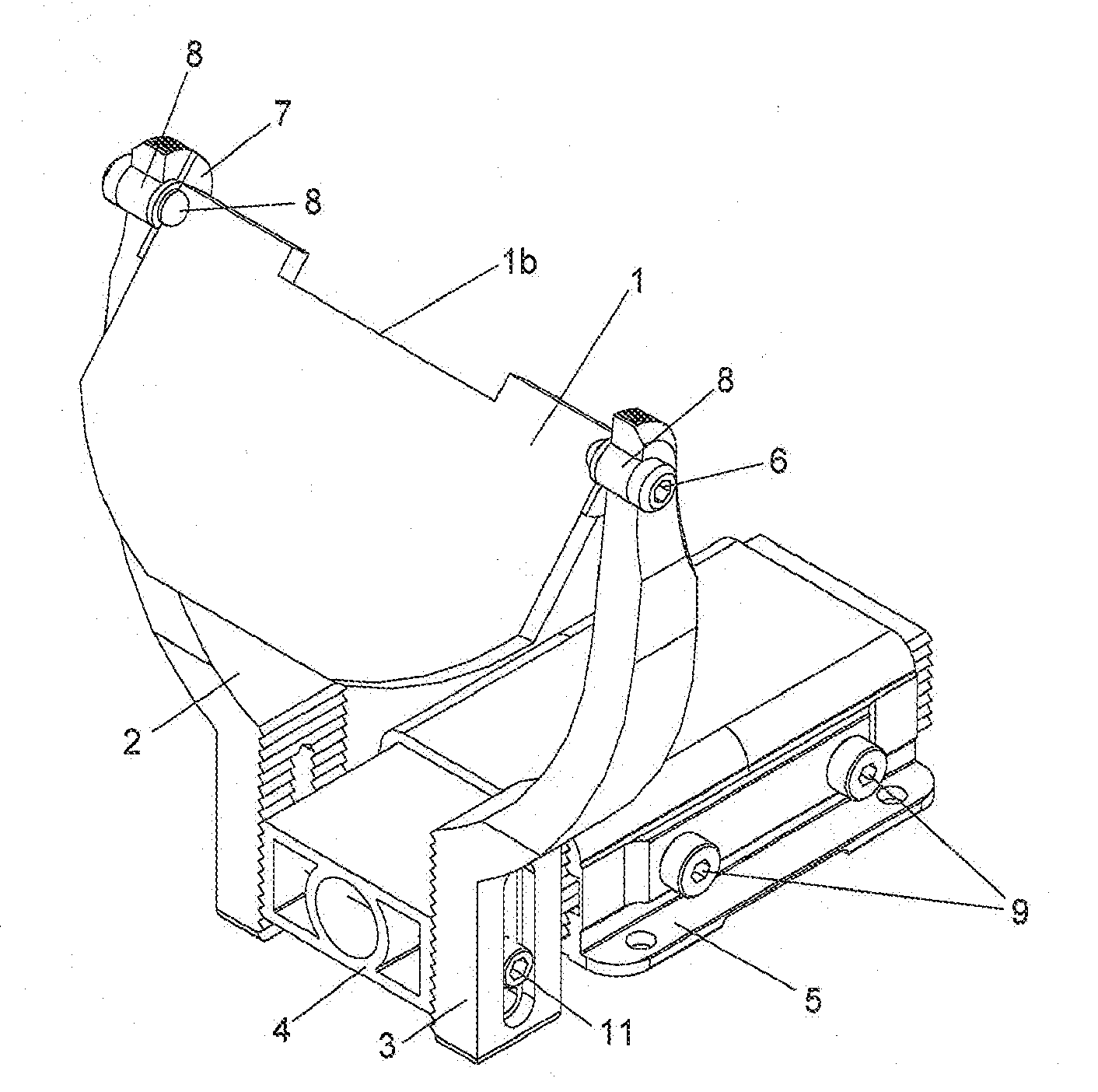

Derusting and polishing device for outer surface of steel pipe

The invention discloses a derusting and polishing device for the outer surface of a steel pipe. The device comprises a rack part (1), a polishing part (2), a polisher locking mechanism (3), a rack locking mechanism (4), a guide rail part (5) and a reciprocating mechanism (6); a high-speed motor drives a steel wire brush to rotate for polishing and derusting the outer surface of the steel pipe, and the reciprocating mechanism (6) drives the polishing part (2) to rotate around a shaft of the steel pipe in a reciprocating manner to achieve the purposes of derusting and polishing the outer surface of the whole circumference of the cylindrical steel pipe; the device is suitable for steel pipes with different diameters due to the adjustable structure; the device is convenient and quick to mount and dismount due to the arrangement of the polisher locking mechanism (3) and the rack locking mechanism (4). The device can be applied to derusting and polishing of the outer surfaces of cylindrical metal guard railings and suspended metal pipelines in public places.

Owner:GUANGDONG UNIV OF TECH

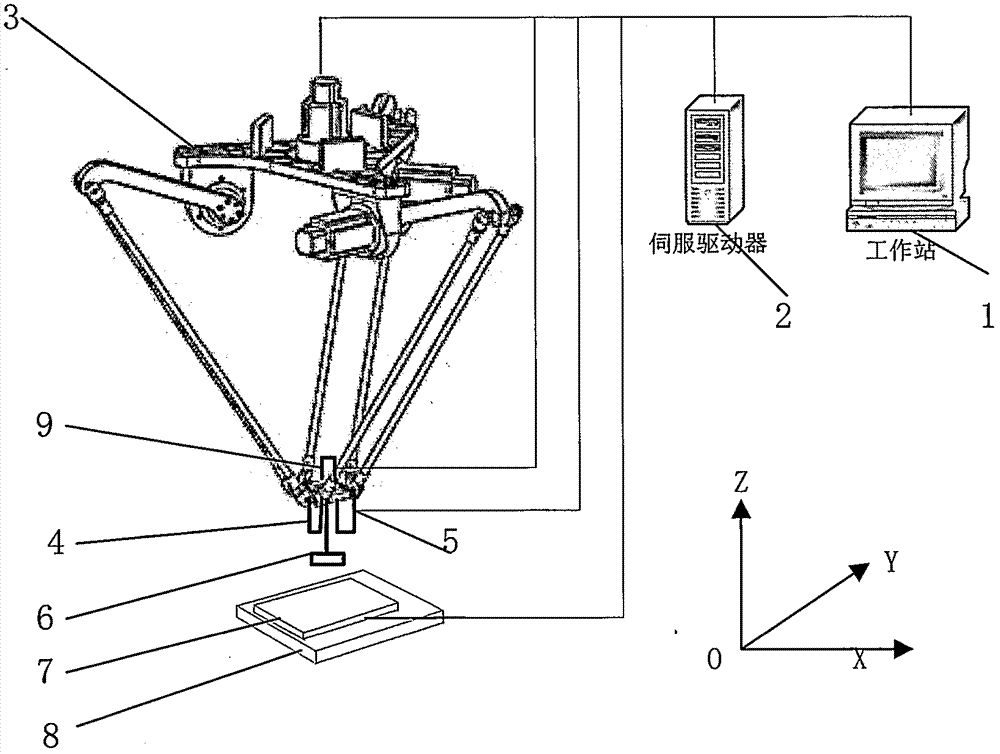

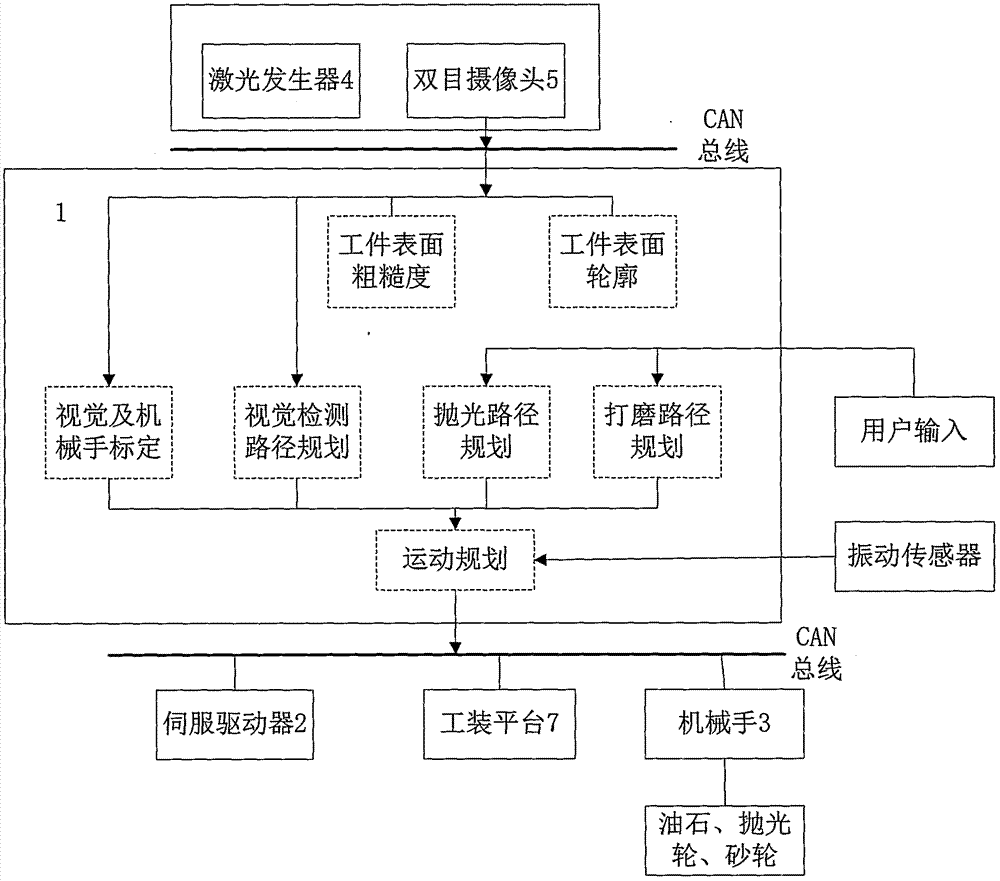

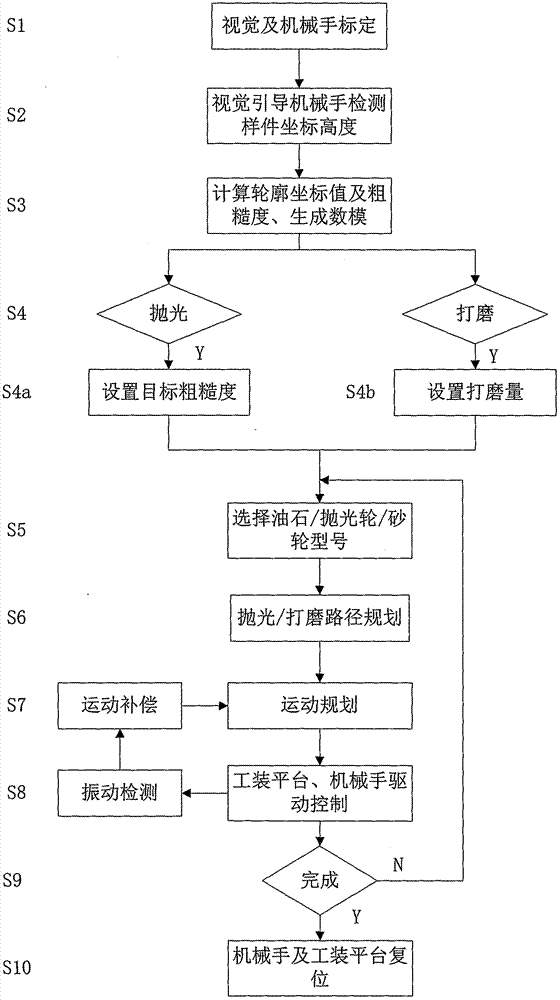

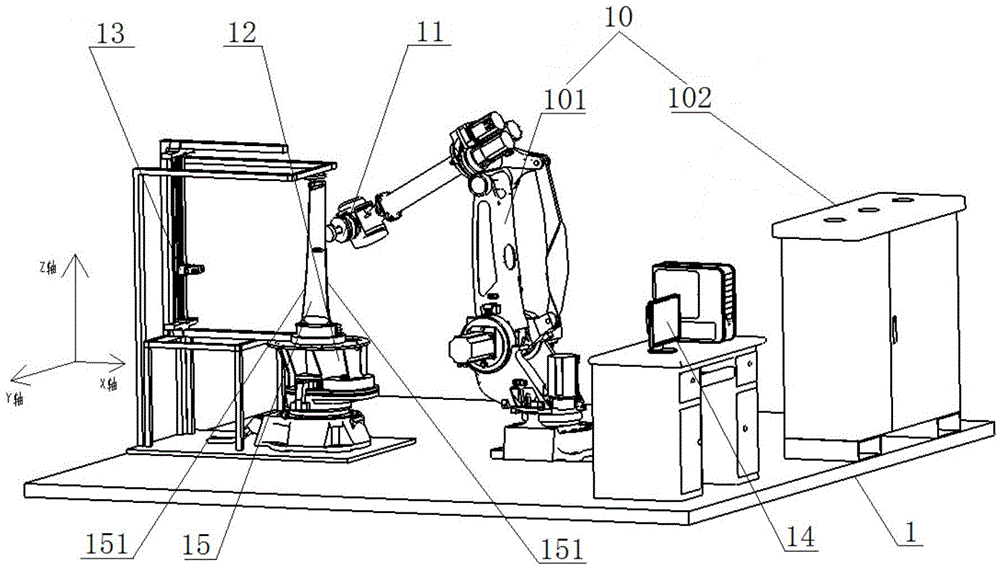

Complex curved face grinding and polishing system and method

InactiveCN107052950AFlexible setting methodHigh speedProgramme-controlled manipulatorGrinding feed controlThree degrees of freedomEngineering

The invention relates to a complex curved face grinding and polishing system and method. The system comprises a three-degree-of-freedom manipulator, a visual detection device, a vibrating sensor and a three-degree-of-freedom tool platform. An installation clamp is arranged at the tail end of the manipulator and can install an oilstone, a polishing wheel and a grinding wheel. The visual detection device comprises a laser generating device and a binocular camera, is installed on the manipulator, and detects the outline and roughness of a workpiece. During working, the workpiece is installed on the three-degree-of-freedom tool platform. The visual detection device guides the manipulator to scan the outline of the workpiece, a three-dimensional outline data model is generated, and the roughness is analyzed. Polishing or grinding setting can be conducted on a work station. During grinding, setting can be conducted in three modes that a referential three-dimensional data model is compared with an actually measured workpiece three-dimensional data model, modification is conducted on the actually measured three-dimensional data model with a drawing tool, and grinding data are directly set on the actually measured three-dimensional data model.

Owner:上海莫亭机器人科技有限公司

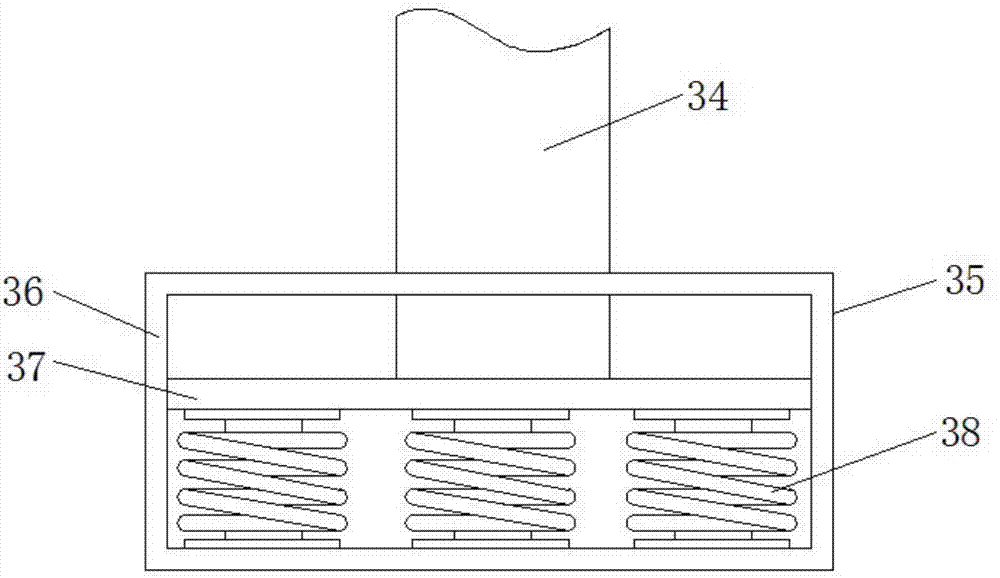

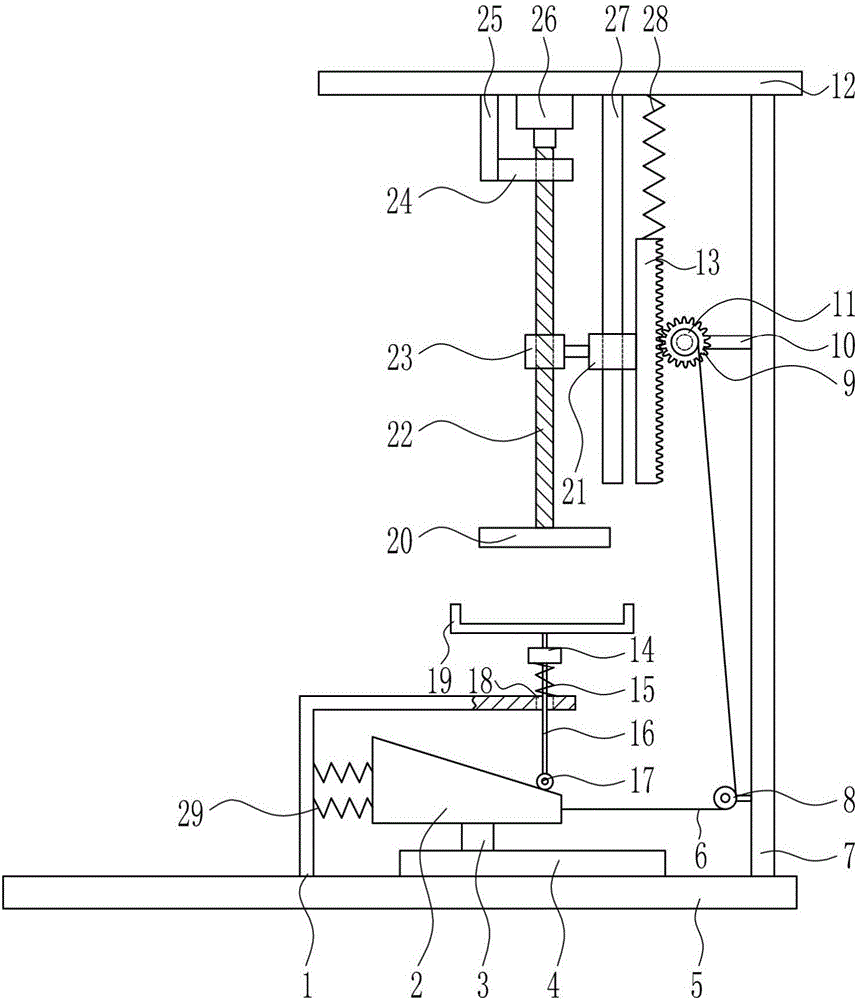

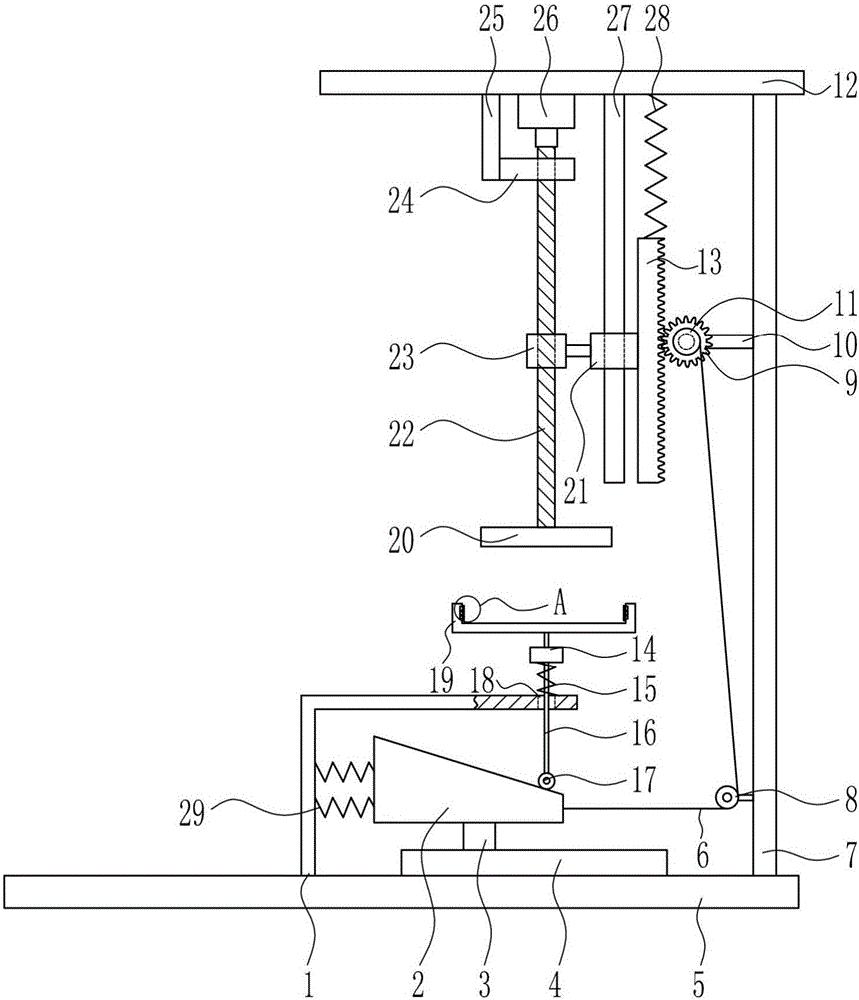

Efficient hardware kitchen ware grinding and polishing device for hardware manufacturing

ActiveCN106141877AEasy to grind and polishImprove grinding and polishing efficiencyGrinding carriagesPolishing machinesEngineeringConductor Coil

The invention relates to a grinding and polishing device, in particular to an efficient hardware kitchen ware grinding and polishing device for hardware manufacturing, and provides the high-working efficiency efficient hardware kitchen ware grinding and polishing device for hardware manufacturing which is aimed at solving the technical problem. The efficient hardware kitchen ware grinding and polishing device for hardware manufacturing provided to solve the technical problem comprises a fixing rack, a wedge block, a sliding block, a slide rail, a bottom plate, a pull wire, a first supporting rod, a fixed pulley, a gear, a second supporting rod, a wire winding wheel, a top plate, a rack, a first fixing block, a first spring, a lifting rod, a contact roller, a placing groove, a grinding device, a sliding sleeve, a screw rod, a nut, and the like, wherein the fixing rack, the slide rail and the first supporting rod are sequentially arranged at the top of the bottom plate from left to right. According to the efficient hardware kitchen ware grinding and polishing device, the grinding device is driven to grind and polish kitchen ware up and down through forward rotation and reverse rotation of a rotating motor, and the effect of high working efficiency is achieved.

Owner:江门市赞兴不锈钢制品有限公司

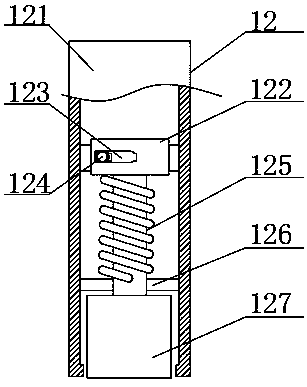

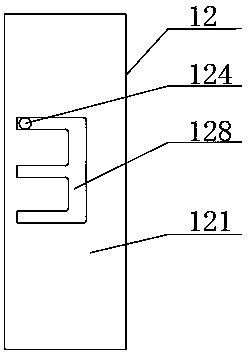

Autotracking centring clamping device for numerically controlled grinder

InactiveCN101116954AEliminate the effects of grindingEliminate the effects ofGrinding work supportsNumerical controlAxis of symmetry

The invention discloses an automatic follow centering and clamping device for a numerical control grinder. A middle clamping rod (5) is sleeved in a sliding way on a supporting body (12) which is provided with a driving mechanism which drives the middling clamping rod (5) to reciprocatingly move axially. An upper lever clamping arm (4) and a lower lever clamping arm (15) are hinged on the supporting body (12) with the middle clamping rod (5) axis of symmetry. The clamping ends of the upper lever clamping arm (4) and the lower lever clamping arm (15) are corresponding to the clamping end of the middling clamping rod (5) which is provided with a symmetric cuniform-shaped block (9) corresponding to opening ends of the upper lever clamping arm (4) and the lower lever clamping arm (15). The supporting body (12) is provided with an elastic device which keeps the clamping ends of the upper lever clamping arm (4) and the lower lever clamping arm (15) open. The invention is an automatic follow centering and clamping device applying automatic follow and moving, automatic centering and automatic compensating to a numerical control grinder.

Owner:HUNAN UNIV

Manual knife sharpener with angle control

InactiveUS6881137B2Ease of useImprove portabilityEdge grinding machinesRevolution surface grinding machinesKnife sharpenerEngineering

A sharpener for blades comprises a physical structure supporting at least one abrasive surface. A displaceable guiding plate having an integral linear structural feature of the support is disposed toward one side of the abrasive surface. The linear structural feature provides sliding contact with a face of the blade to establish the relative angle of the plane of the edge facet of the blade with the plane of the abrasive surface at the point of mutual contact as the facet is guided into contact with the abrasive surface.

Owner:EDGECRAFT

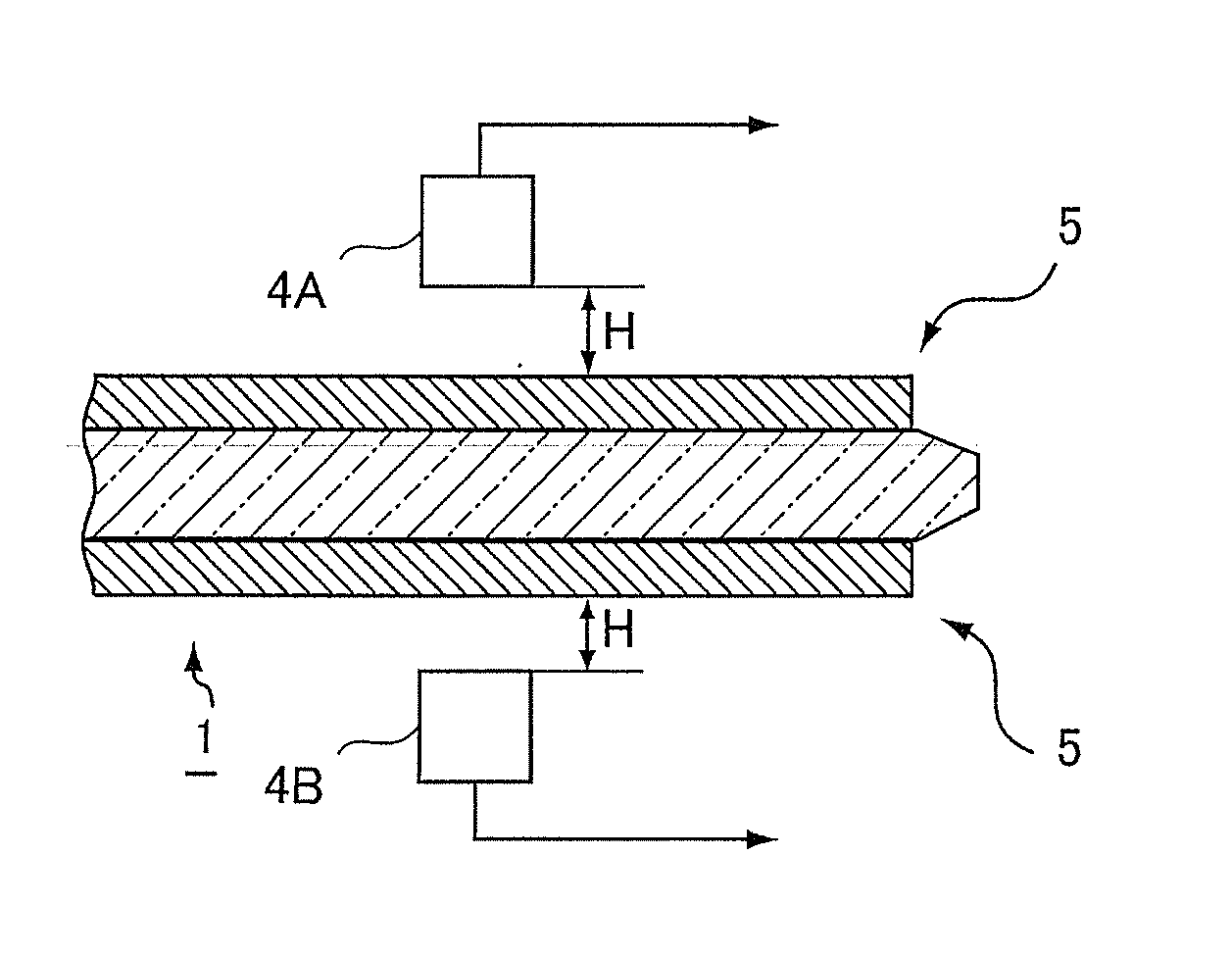

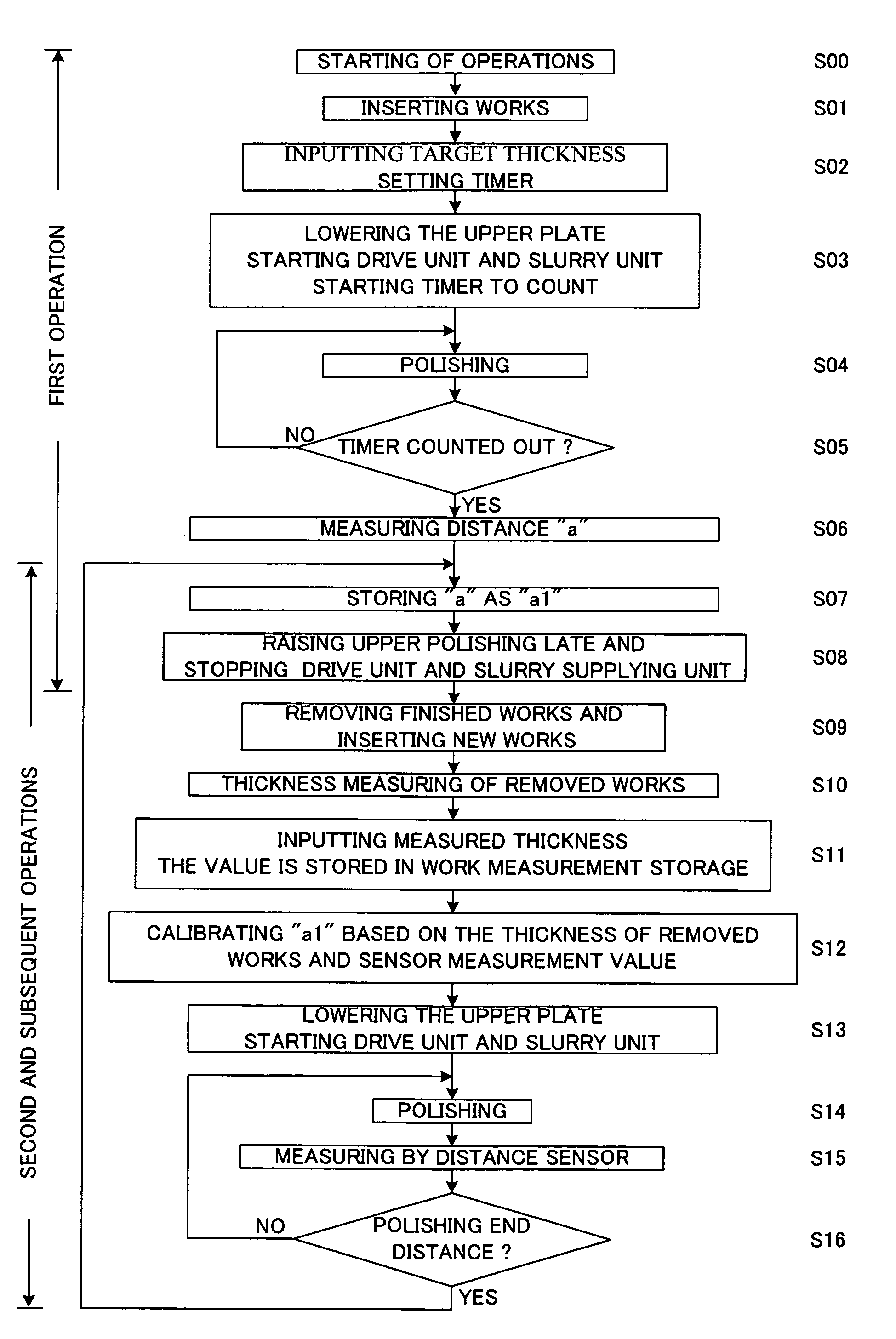

Thickness control method and double side polisher

InactiveUS7147541B2Maintaining accuracy of thickness control over a long period of timeEdge grinding machinesPolishing machinesEngineeringDistance sensors

The object of the present invention is to provide a double side polisher capable of maintaining thickness control accuracy over a long period of time without being affected by a gradual change in thickness of a polishing pad, and a thickness control method. The first polishing operation is finished based on the polishing duration time, and the second and subsequent polishing operations are finished based on the measured distance values of a distance sensor, and after each polishing operation including the first polishing, the measured value of the distance sensor is calibrated based on the measured value and target value of finishing thickness of the work piece. Since the calibration is performed for each polishing operation, it is possible to maintain thickness control accuracy over a long period of time.

Owner:SPEEDFAM CO LTD

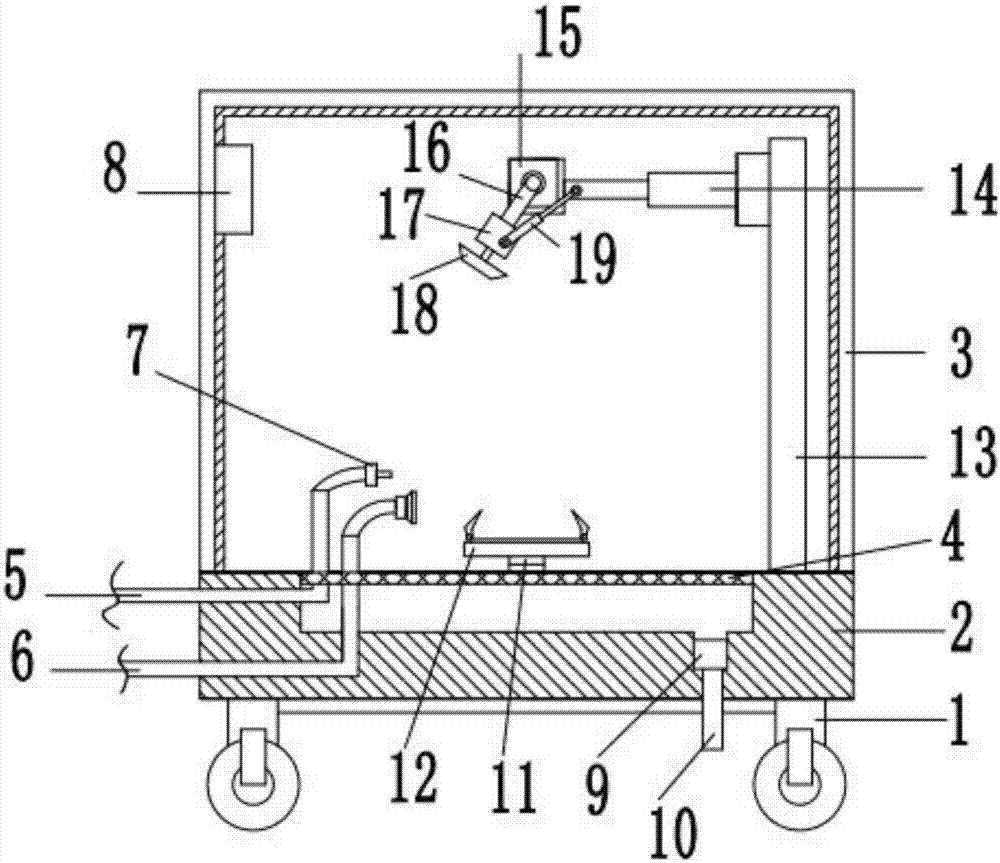

Die polishing washing equipment

InactiveCN106985025AReduce harmReduce pollutionEdge grinding machinesGrinding carriagesFiltrationEngineering

The invention discloses mold grinding and cleaning equipment in the technical field of mold processing equipment, comprising a movable support, a base is welded to the top of the movable support, a transparent cabinet is arranged on the top of the base, and the upper part of the inner wall of the transparent cabinet is There is a micro-vacuum cleaner, the top of the inner cavity of the base is fixed with a grid plate by screws, the side of the base is provided with an air inlet pipe and a liquid inlet pipe through a through hole, and through the rotating grinding wheel up and down, left and right, not only The flat surface can be polished, and the curved surface can be polished at the same time. The air inlet pipe and the liquid inlet pipe respectively use nozzles to eject air flow and liquid flow to clean the mold, and then filter out the grinding debris through the filter device to reduce pollution. The vacuum cleaner absorbs the dust generated during grinding and reduces the dust damage to the workers. The device has simple structure, convenient operation and strong practicability.

Owner:HEFEI DINGXIN MOLD

Synchronous dust extraction steel tube piece inner wall polishing device

InactiveCN106863040ASave sanding timeImprove quality and efficiencyGrinding carriagesRevolution surface grinding machinesWorking environmentDrive motor

The invention discloses a synchronous dust extraction steel tube piece inner wall polishing device which comprises an outer box and a base. A transverse support is arranged on the right side of the top of the base, a second stretchable cylinder is arranged on the left side of the transverse support, a rotary barrel is rotationally arranged on a vertical support, an eccentric gear is installed at the left end of the rotary barrel, a fixing rod is installed on the left side of the eccentric gear, and a polishing rod is installed at the left end of the fixing rod; and a driven belt wheel on the rotary barrel is connected with a driving belt wheel through a triangular belt, the driving belt wheel is fixedly installed on an output shaft of a driving motor, and the lower end of a piston rod of a first stretchable cylinder on the left side of the outer box and the upper end of a piston rod of a third stretchable cylinder are provided with an upper clamping plate and a lower clamping plate corresponding. By means of the synchronous dust extraction steel tube piece inner wall polishing device, the steel tube polishing time is greatly saved, steel tube polishing is more sufficient, the steel tube polishing quality and working efficiency are improved, synchronous dust extraction during polishing is achieved, the clean and tidy working environment is kept, and the health of workers is facilitated.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

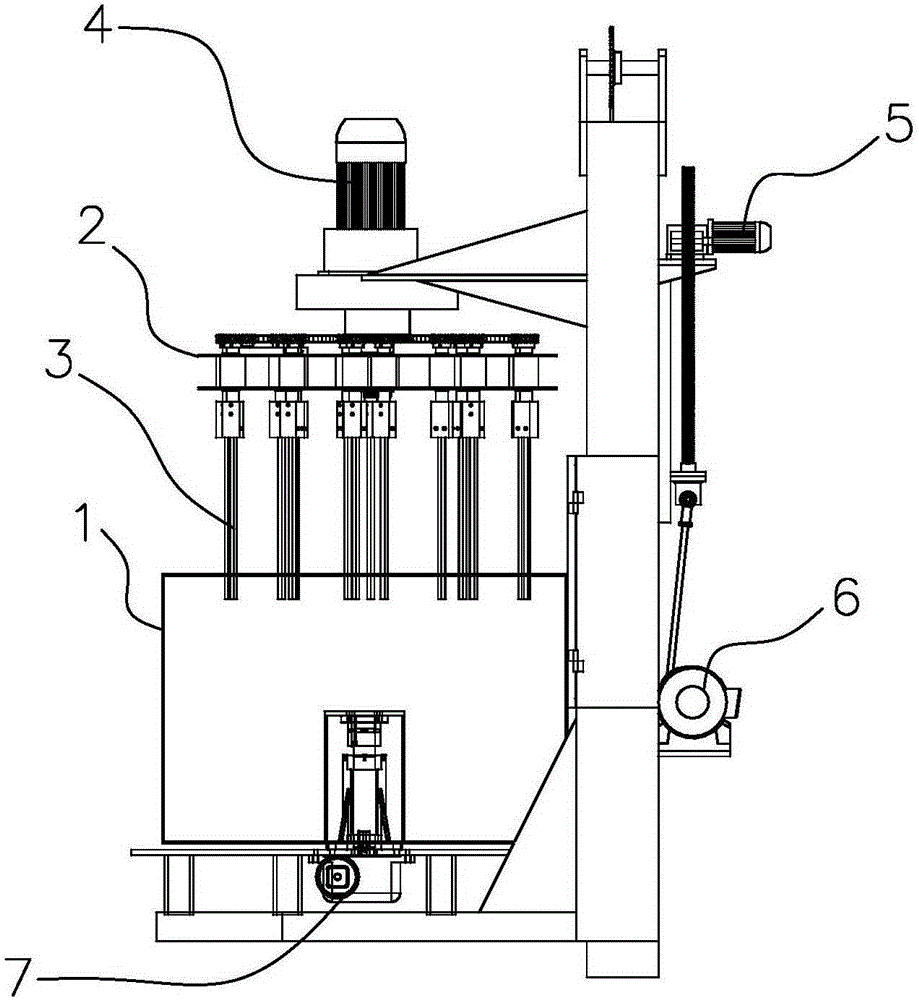

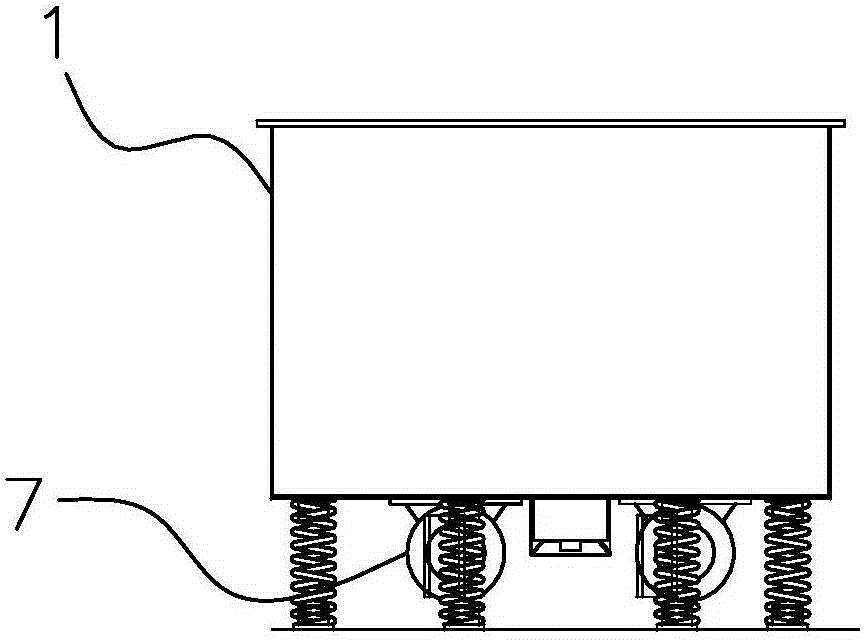

Multi-head polisher machine

The invention provides a multi-head polisher machine. The multi-head polisher machine comprises a container, a rotating plate, a rotating mechanism, a lifting mechanism and a plurality of loading sticks. An opening is formed in the upper end of the container. The rotating plate is horizontally arranged over the container. The rotating mechanism comprises a first motor, a chain, a main chain wheel, a main shaft and a plurality of auxiliary chain wheels. The main shaft is fixed to the middle of the rotating plate. An output shaft of the first motor and the main shaft are coaxially fixed. The main shaft is sleeved with the main chain wheel. The loading sticks are sleeved with the auxiliary chain wheels respectively. The main chain wheel and the auxiliary chain wheels are linked through the chain. According to the multi-head polisher machine, parts are assembled on the loading sticks, the loading sticks are driven by the rotating plate to revolve, the loading sticks unceasingly rotate, and therefore the parts can rub abrasive materials in the container, and the mirror surface effect can be generated within a certain period of time when the abrasive materials make contact with the parts at a high speed. The surface flatness can not be damaged as long as the parts do not collide.

Owner:杨一舟

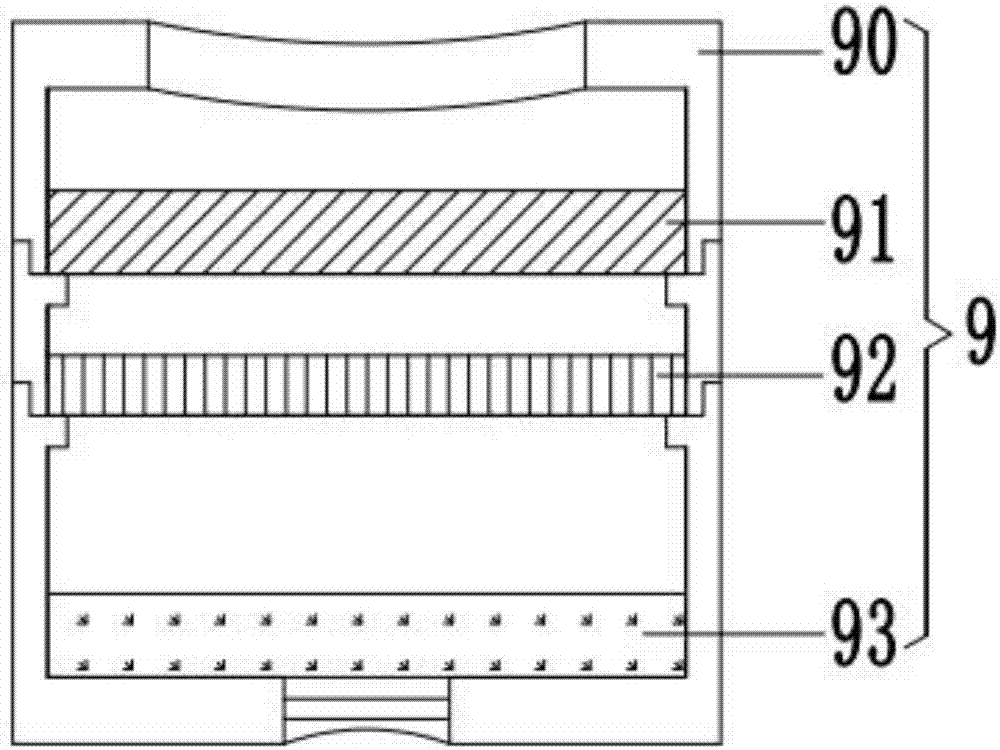

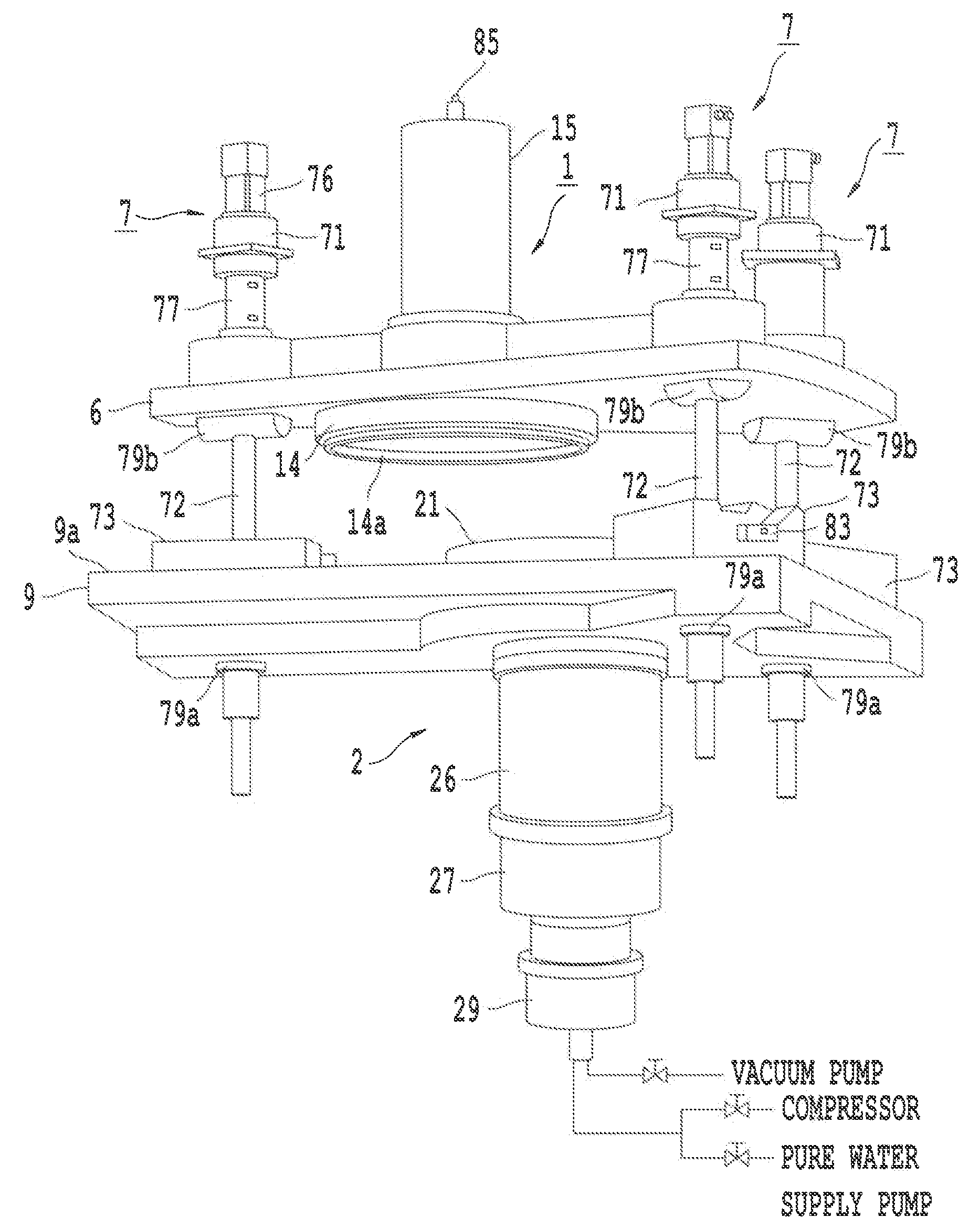

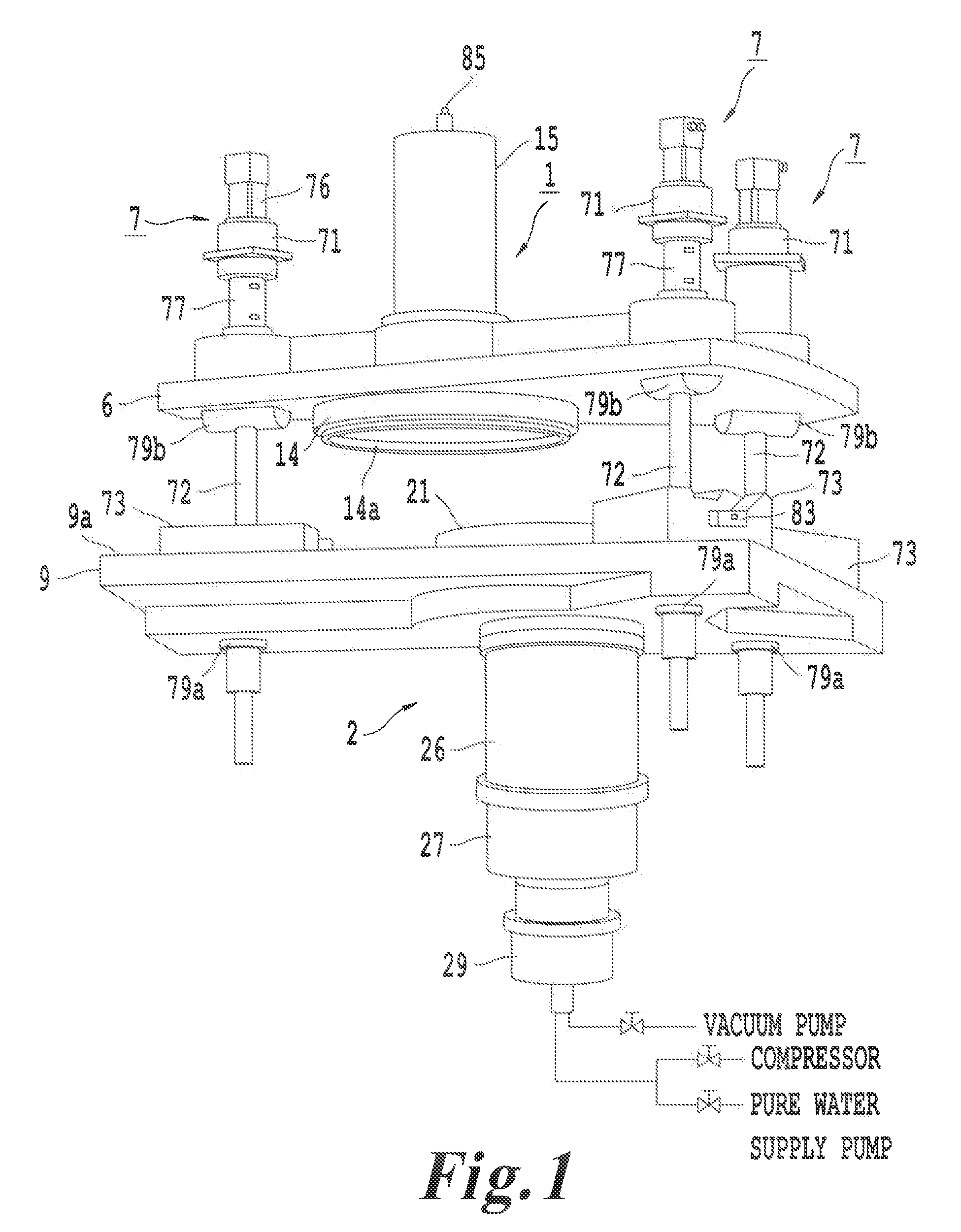

Substrate flat grinding device

InactiveUS20090203299A1Superior flat thickness distributionImprove rigidityEdge grinding machinesPolishing machinesKinematic couplingEngineering

To provide a high-rigidity flat grinding device, a substrate flat grinding device has three fastening plate lifting-and-lowering mechanisms that have kinematic couplings and a cylinder rod that move the fastening plate upward or downward. Being a high-rigidity grinding device in which the load of the fastening plate 6 also is a load on the grindstone 14 that does the grinding, there is little deflection in the thickness distribution of the substrates that are obtained, even if they are semiconductor substrates having a large substrate diameter of 450 mm.

Owner:OKAMOTO MACHINE TOOL WORKS LTD

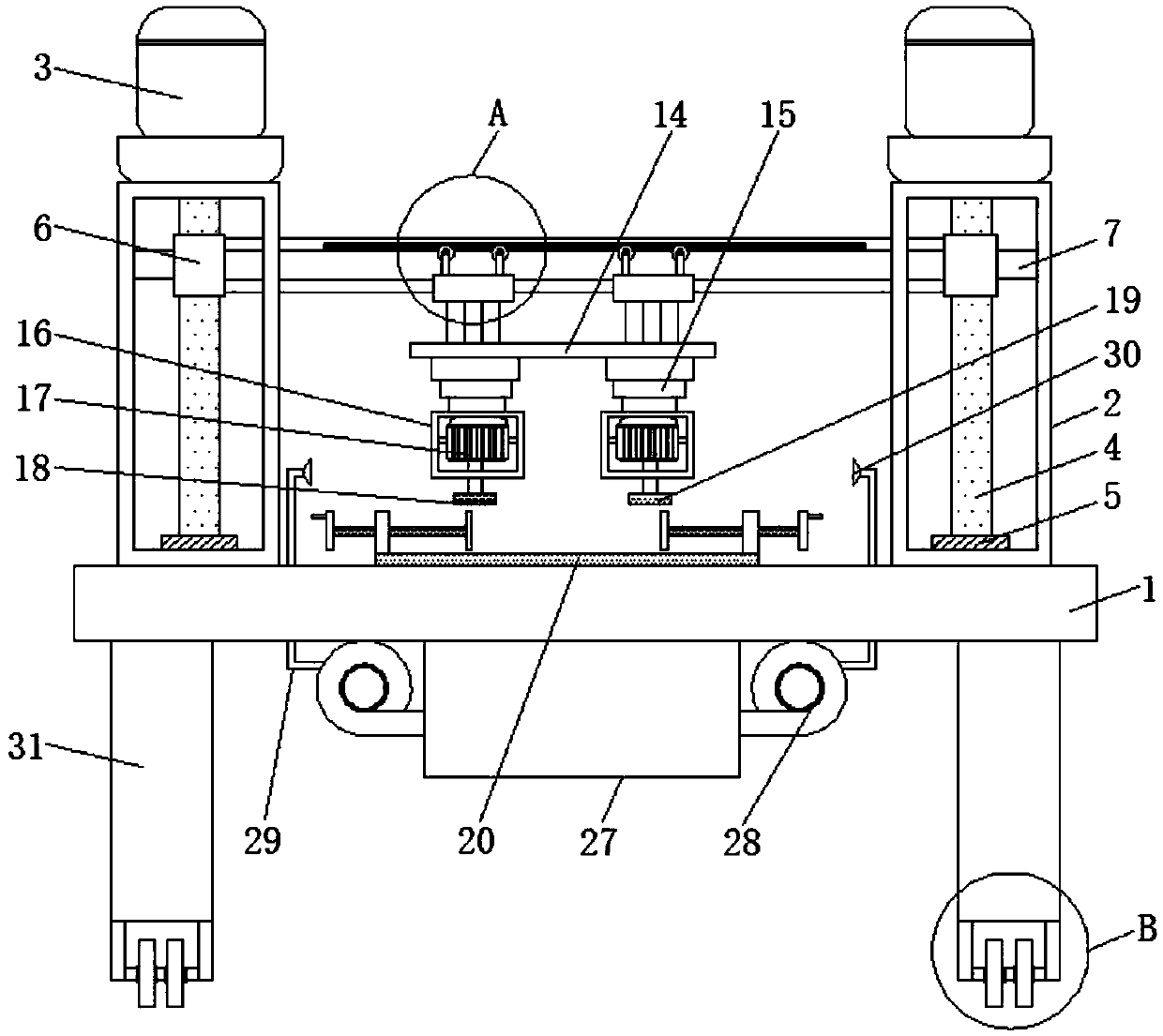

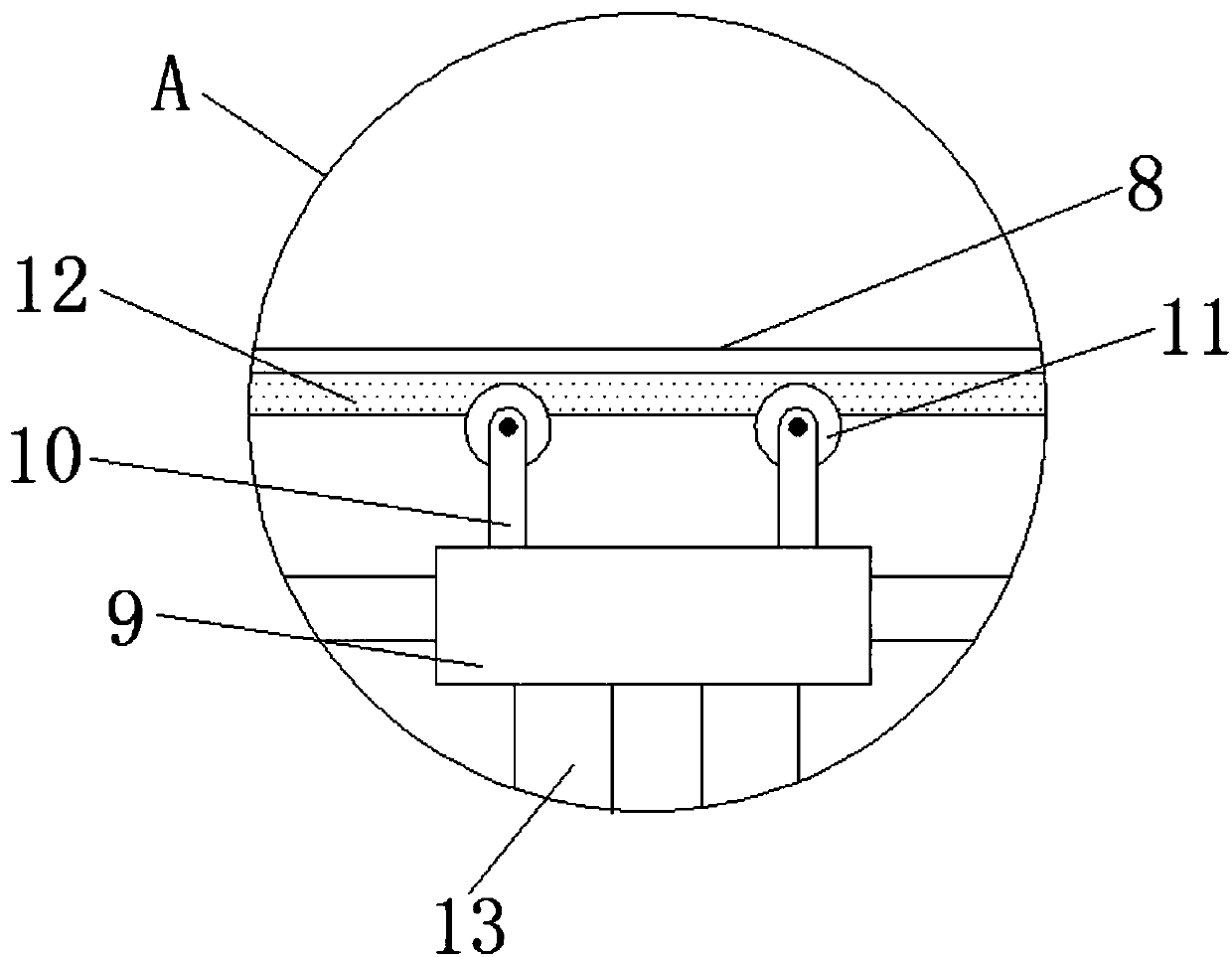

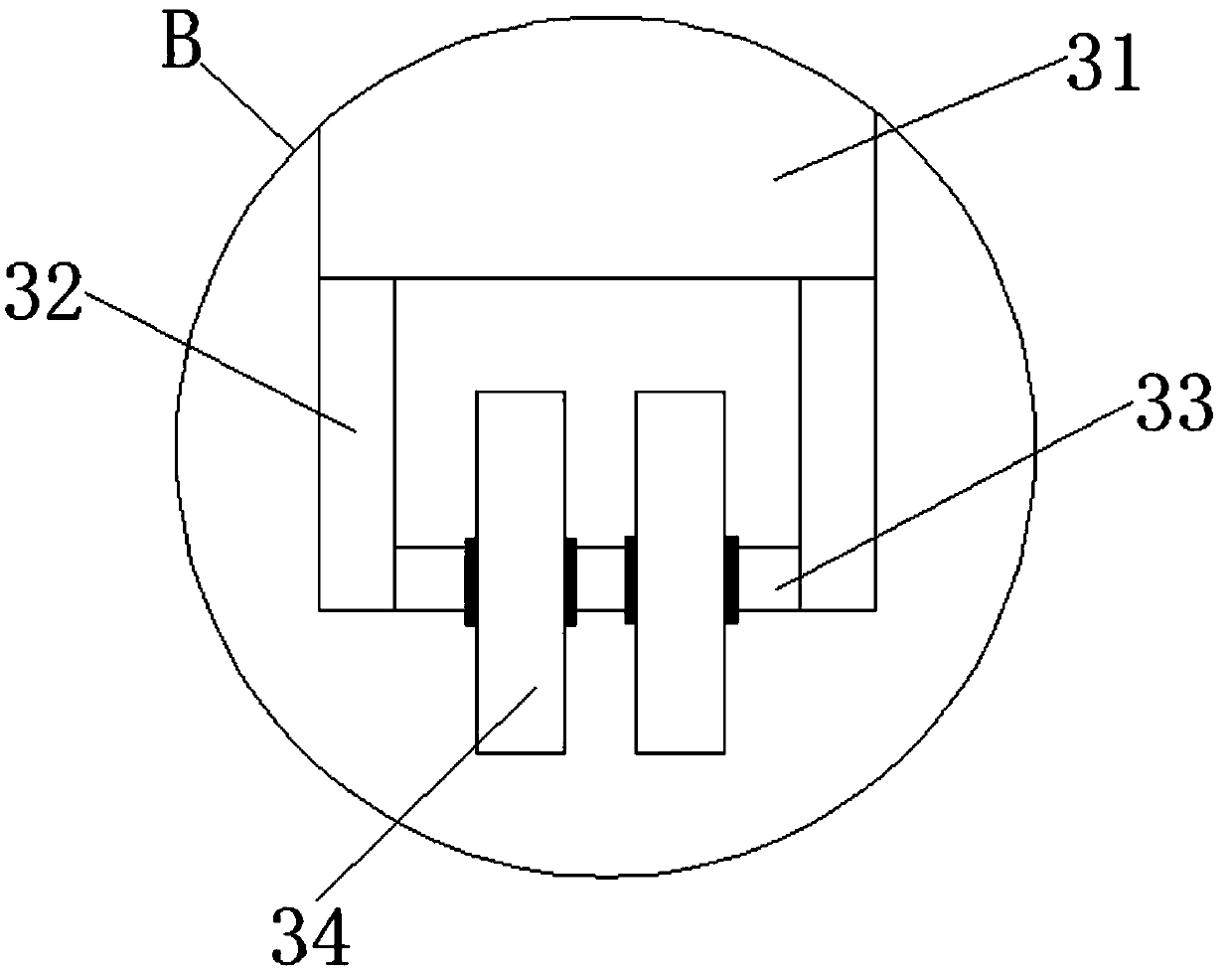

Polishing device for bearing machining

InactiveCN107695881AQuality improvementEasy to adjustGrinding carriagesGrinding machinesEngineeringMachining

The invention provides a grinding device for bearing processing, which relates to the technical field of bearing processing. The grinding device for bearing processing includes a processing table, a lifting box is fixedly installed on both sides of the top of the processing table, a lifting motor is fixedly installed on the top of the lifting box, and a screw rod is movably connected to the output end of the lifting motor. The grinding device for bearing processing is equipped with a processing table, a lifting box, a lifting motor, a screw, a bearing body, a telescopic block, a slider, a guide rod, a slip ring, a wheel shaft, a pulley, a wheel groove, a bracket, a horizontal plate, and a hydraulic telescopic rod. And the grinding motor, after the lifting motor is started, the grinding device including the grinding motor can be driven to move up and down on the top of the processing table through the rotation of the driving screw, and the grinding motor can be driven on the top of the processing table by sliding on the guide rod through the slip ring Moving left and right, in summary, the bearing processing and grinding device achieves the effect of easy adjustment, which is convenient for people to operate, saves time and effort, and is conducive to grinding out bearings with better quality.

Owner:郑艳峰

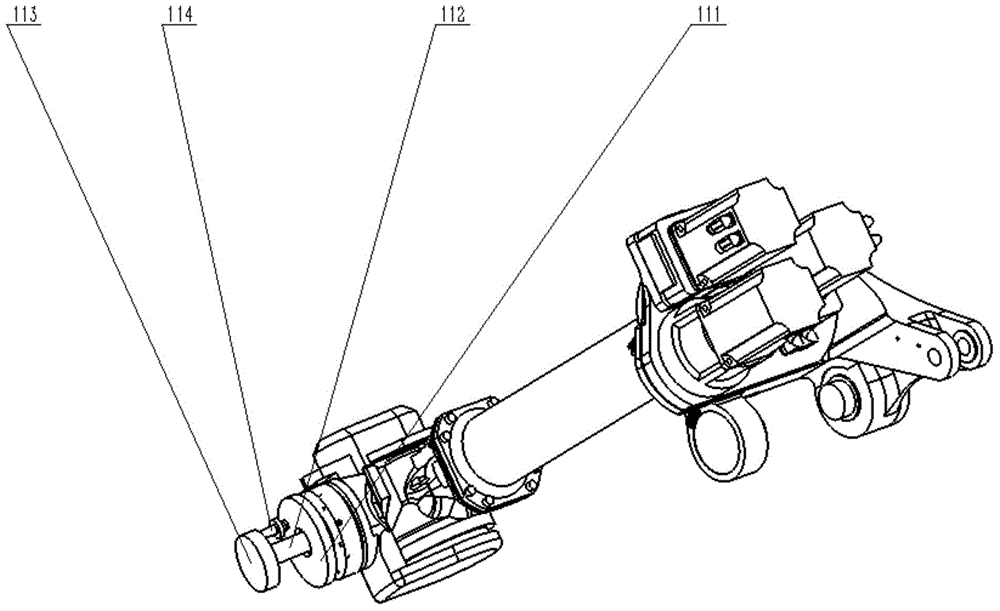

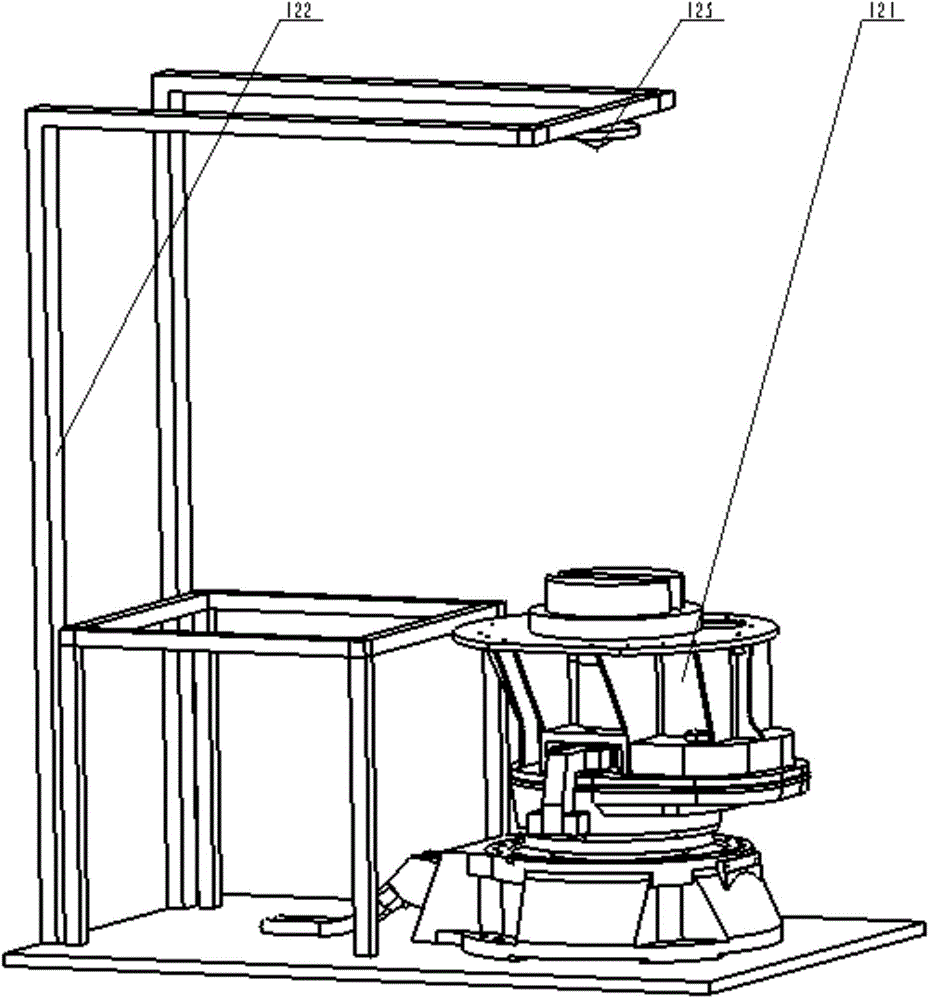

Automatic robot device for grinding air feeding and discharging edges of blade

ActiveCN104858748AGuaranteed machining accuracyGuaranteed grinding accuracyGrinding feed controlAutomatic grinding controlMeasurement deviceEngineering

The invention discloses an automatic robot device for grinding air feeding and discharging edges of a blade. The automatic robot device comprises a base station, a six-freedom-degree robot, a grinding device, a position changing machine, a three-dimensional laser measurement device and a system control host. The six-freedom-degree robot is arranged on the base station. The grinding device is used for grinding the air feeding and discharging edges of the blade. The position changing machine is arranged on the base station. The three-dimensional laser measurement device is arranged on the position changing machine and comprises a triaxial movement platform and a three-dimensional laser measurement device body. The three-dimensional laser measurement device body comprises two three-dimensional laser outline scanners. The system control host is connected with the six-freedom-degree robot and the three-dimensional laser measurement device. The system control host is used for planning the machining path of the grinding device and a moving path of the three-dimensional laser measurement device and sending the paths and commands to the six-freedom-degree robot to be executed. The automatic robot device integrates self-adaptive grinding and measurement functions, and can guarantee the machining precision of the outlines of the air feeding and discharging edges of the blade.

Owner:HUST WUXI RES INST

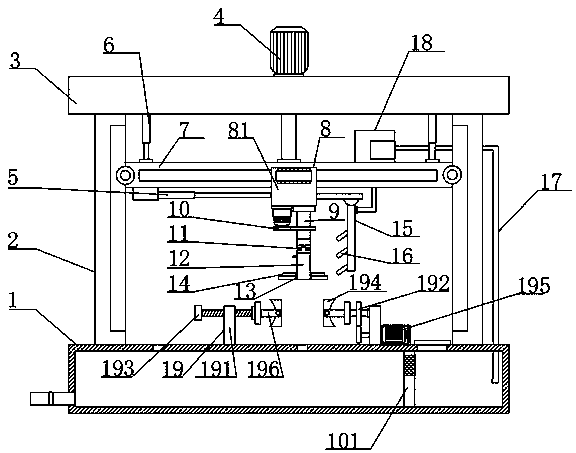

Automatic grinding machine for industrial machinery and grinding method

InactiveCN108789087AIncrease flexibilityImprove stabilityGrinding carriagesGrinding drivesHydraulic cylinderCoupling

The invention discloses an automatic grinding machine for industrial machinery and a grinding method. The automatic grinding machine comprises a base box body, wherein left and right sides of the topof the base box body are symmetrically equipped with stand columns; a top plate is arranged on the tops of the two groups of the stand columns; the outer wall of a bearing rod is movably equipped witha slide assembly; the bottom of the slide assembly is sequentially equipped with a grinding motor and a rotary rod from left to right; the bottom of the rotary rod is equipped with a universal shaftcoupler; the top of the base box body is equipped with a fixed clamp; and the right side of the top of the base bottom box is spliced with a water conveying hose I. The grinding machine for industrialmachinery is high in flexibility and is good in stability; a hydraulic cylinder drives the bearing rod to lift through a pushing rod, so that a grinding disc in grinding can lift; and an electric telescopic pole extends and shortens to drive the slide assembly to move left and right, so that the grinding disc in grinding can move left and right, and therefore, the automatic grinding machine has relatively high flexibility, and improves grinding working efficiency.

Owner:CHENGDU PUJIANG KEXIAN TECH

Polishing systems for use with semiconductor substrates including differential pressure application apparatus

InactiveUS6899607B2Reduce rateImprove material removal ratePolishing machinesRevolution surface grinding machinesDifferential pressureEngineering

An apparatus for applying different amounts of pressure to different locations of a backside of a semiconductor device structure during polishing thereof. The apparatus is configured to be associated with a wafer carrier of a polishing apparatus and includes pressurization structures configured to be biased against the backside of the semiconductor device structure during polishing thereof. The pressurization structures are independently movable with respect to one another. The amount of force or pressure applied by each pressurization structure to the backside of the semiconductor device structure is controlled by at least one corresponding actuator. The actuator may magnetically facilitate movement of the corresponding pressurization structure toward or away from the backside of the semiconductor device structure. The actuator may alternatively comprise a positive or negative pressure source. Systems including the pressure application apparatus, as well as differential pressure application methods and polishing methods are also disclosed.

Owner:ROUND ROCK RES LLC

Multi-angle plate polishing device

InactiveCN109571180ARealize multi-degree-of-freedom grindingImprove grinding limitationsEdge grinding machinesGrinding carriagesMulti degree of freedomEngineering

The invention relates to the field of plate processing, in particular to a multi-angle plate polishing device. The multi-angle polishing device is characterized in that a length adjusting component isfixedly connected to the front end of a base; a left plate and a right plate are separately fixedly connected to the two ends of the length adjusting component; an angle adjusting component is connected to the upper end of the left plate; the number of plate clamping pieces is two; the two plate clamping pieces are separately fixedly connected to the inner sides of the angle adjusting component and the right plate; a grinding plate sliding seat component is fixedly connected to the rear end of the base; and a grinding component is connected onto the grinding plate sliding seat component in asliding manner. A plate can be polished from multiple angles and in multiple directions according to the self characteristics and the grinding requirements of a product, the multi-degree of freedom polishing of the plate is realized, or the omni-directional polishing and local polishing of the plate are realized, the polishing limitation of an existing automatic polishing machine is improved, andmanual operation is replaced with mechanical automatic processing, so that the production efficiency is improved, and the production quality of the product is ensured; and the multi-angle plate polishing device is applicable to plates of different sizes or shapes.

Owner:张馨文

Pipe cutting and grinding device

ActiveCN108453508ARealize automatic clampingAchieve grindingEdge grinding machinesOther manufacturing equipments/toolsEngineeringSlide plate

The invention belongs to the technical field of cutting equipment, and specifically discloses a pipe cutting and grinding device. The pipe cutting and grinding device comprises a cutting mechanism anda grinding mechanism which are connected to the same rotating shaft, wherein a transmission gear and two fixed pulleys are arranged on the rotating shaft; a rack which is fixed to a machine frame isengaged with the transmission gear; the grinding mechanism comprises a rotating barrel which is fixed to the rotating shaft, and a grinding plate is arranged on the rotating barrel; a square shaft isin sliding connection with the interior of the rotating barrel, and a threaded rod which is in thread connection with the rotating barrel is rotatably connected to the square shaft; and the threaded rod is in sliding connection with a sliding plate, and the sliding plate is in sliding connection with the machine frame. The pipe cutting and grinding device further comprises a conveying roller, a first clamping mechanism and a second clamping mechanism; the first clamping mechanism comprises a clamping block and a fixing block; a sliding rope is connected between the clamping block and the corresponding fixed pulley; the second clamping mechanism is in sliding connection with a working platform; a baffle plate is arranged at the left end of the working platform; and magnetic parts which areattracted to and repelled by each other are arranged between the baffle plate and the second clamping mechanism. According to the scheme, the pipe cutting and grinding device has the advantages that anotch of a steel pipe can be ground while the steel pipe is cut, so that the working efficiency is improved.

Owner:苏州市振渭城镇建设发展有限公司

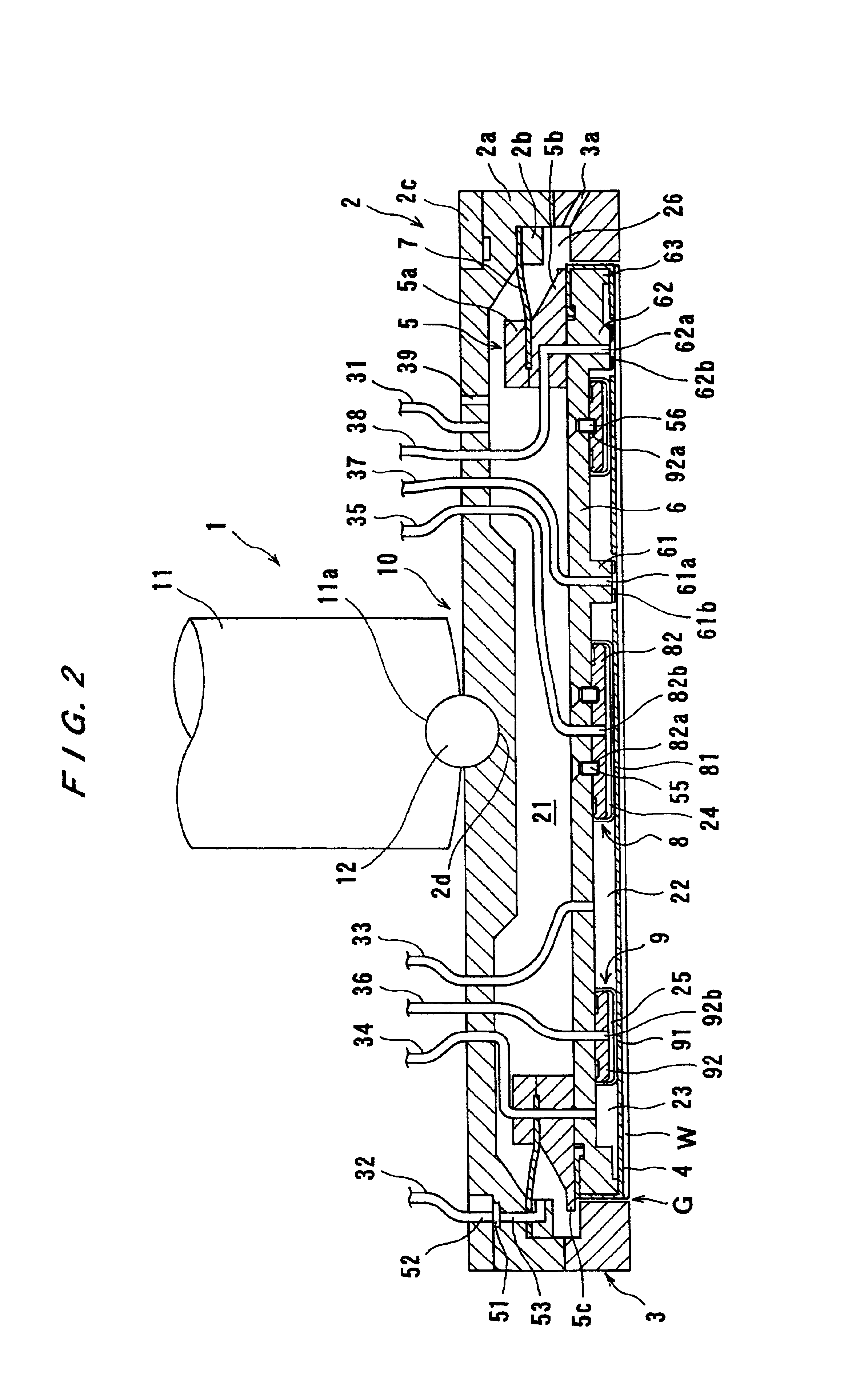

Substrate holding apparatus

InactiveUS6852019B2Uniform film thicknessSmooth movementPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

The present invention relates to a substrate holding apparatus for holding a substrate to be polished and pressing the substrate against a polishing surface. The substrate holding apparatus comprises a top ring body for holding a substrate, an elastic pad for being brought into contact with the substrate, and a support member for supporting the elastic pad. The substrate holding apparatus further comprises a contact member mounted on a lower surface of the support member and disposed in a space formed by the elastic pad and the support member. The contact member has an elastic membrane for being brought into contact with the elastic pad. A first pressure chamber is defined in the contact member, and a second pressure chamber is defined outside of the contact member. The substrate holding apparatus further comprises a fluid source for independently supplying a fluid into, or creating a vacuum in, the first pressure chamber and the second pressure chamber.

Owner:EBARA CORP

Overturning grinding rust removal device for metal plate

InactiveCN110142678AFast clamping speedEasy to remove rustGrinding carriagesGrinding drivesEngineeringMechanical engineering

The invention relates to the field of metal processing equipment, and more specifically relates to an overturning grinding rust removal device for a metal plate. The overturning grinding rust removaldevice for the metal plate comprises a workbench, a left clamping block, a right clamping block and a rust removal brush plate, wherein a slide groove is formed in the upper surface of the workbench;a bidirectional screw rod is installed in the slide groove; the left clamping block and the right clamping block sleeve the bidirectional screw rod; a second telescoping mechanism is fixedly connectedto the upper surface of the workbench; a lifting block sleeves a stretching end of the second telescoping mechanism; an installation plate is hinged to the sidewall of the lifting block; a displacement screw rod is arranged below the installation plate; a movable block sleeves the middle part of the displacement screw rod; a fourth telescoping mechanism is fixedly connected to the lower surface of the movable block; and a rust removal motor is fixedly connected to the lower end of the fourth telescoping mechanism. The metal plate is clamped by virtue of the clamping plate to keep fixed, and high clamping speed is achieved; in a rust removal process, the rust removal brush plate moves to left and right, so that a rust removal range is expanded; and through arrangement for a rotary motor, rust removal can be conveniently carried out on the front surface and the back surface of the metal plate.

Owner:蒋艳红

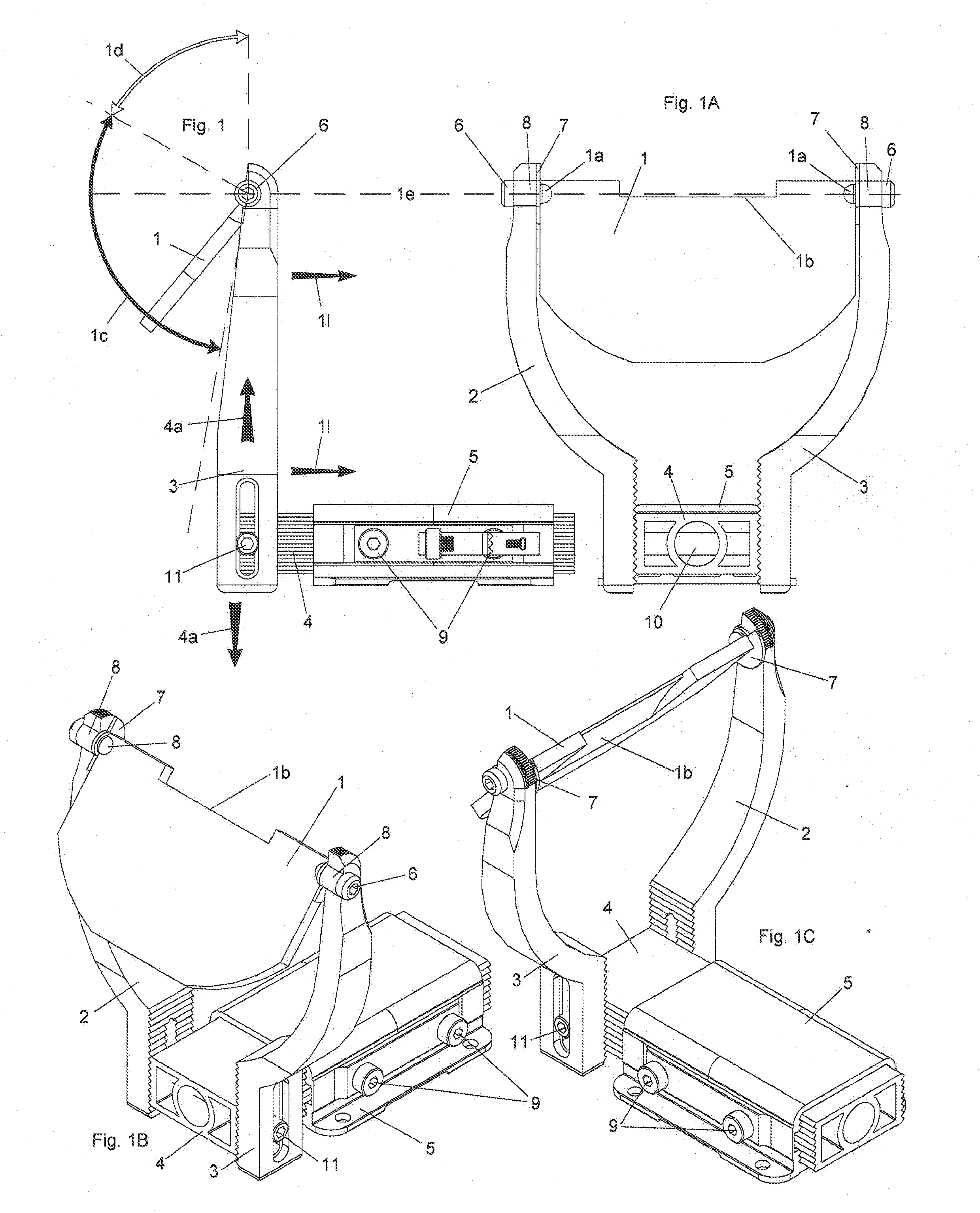

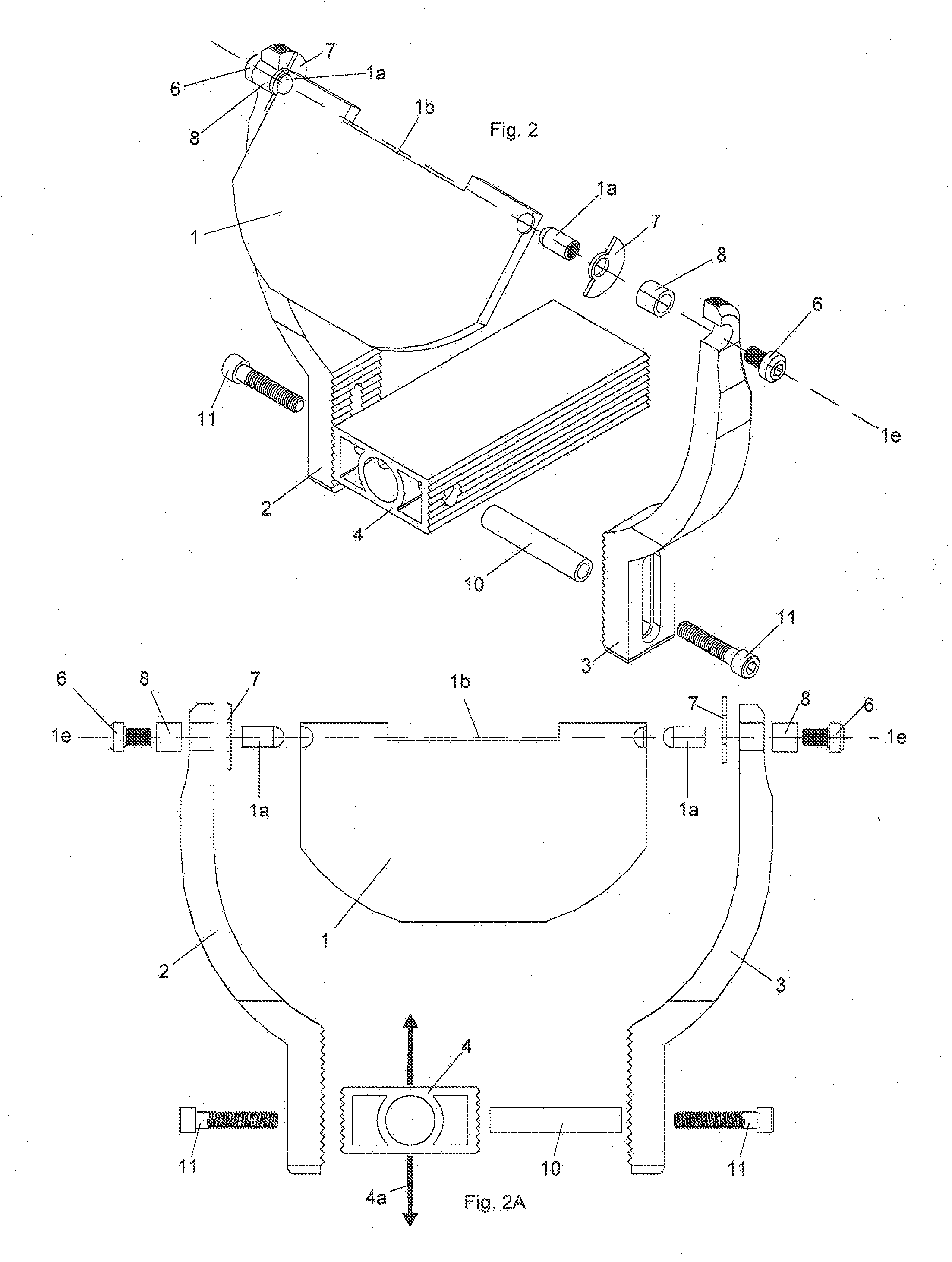

Adjustable Grinding Platform and Mounting Assembly

InactiveUS20120270479A1Accurately determineBelt grinding machinesGrinding feed controlVernier scaleEngineering

Owner:BATTY STUART

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com