Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

911results about How to "Achieve grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

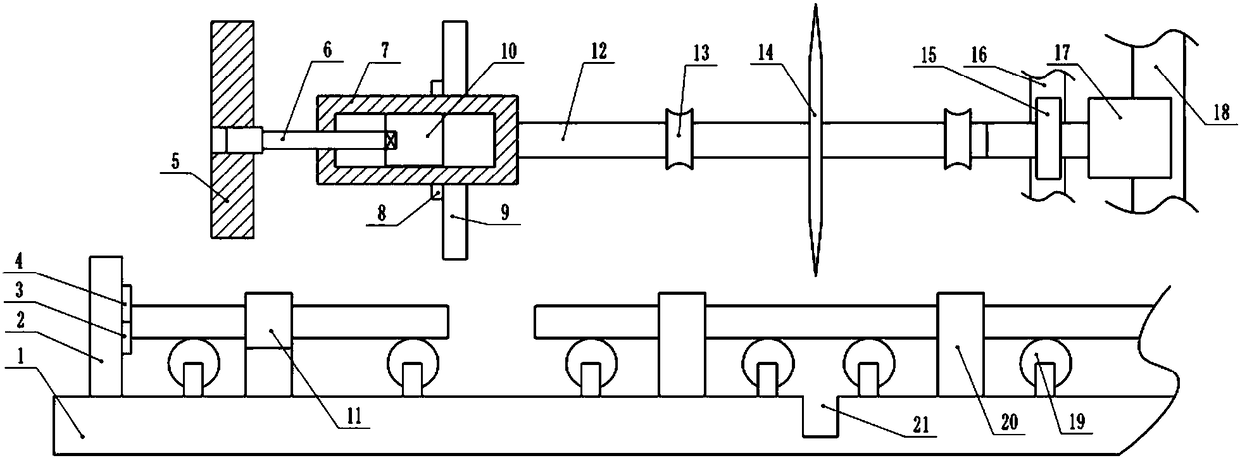

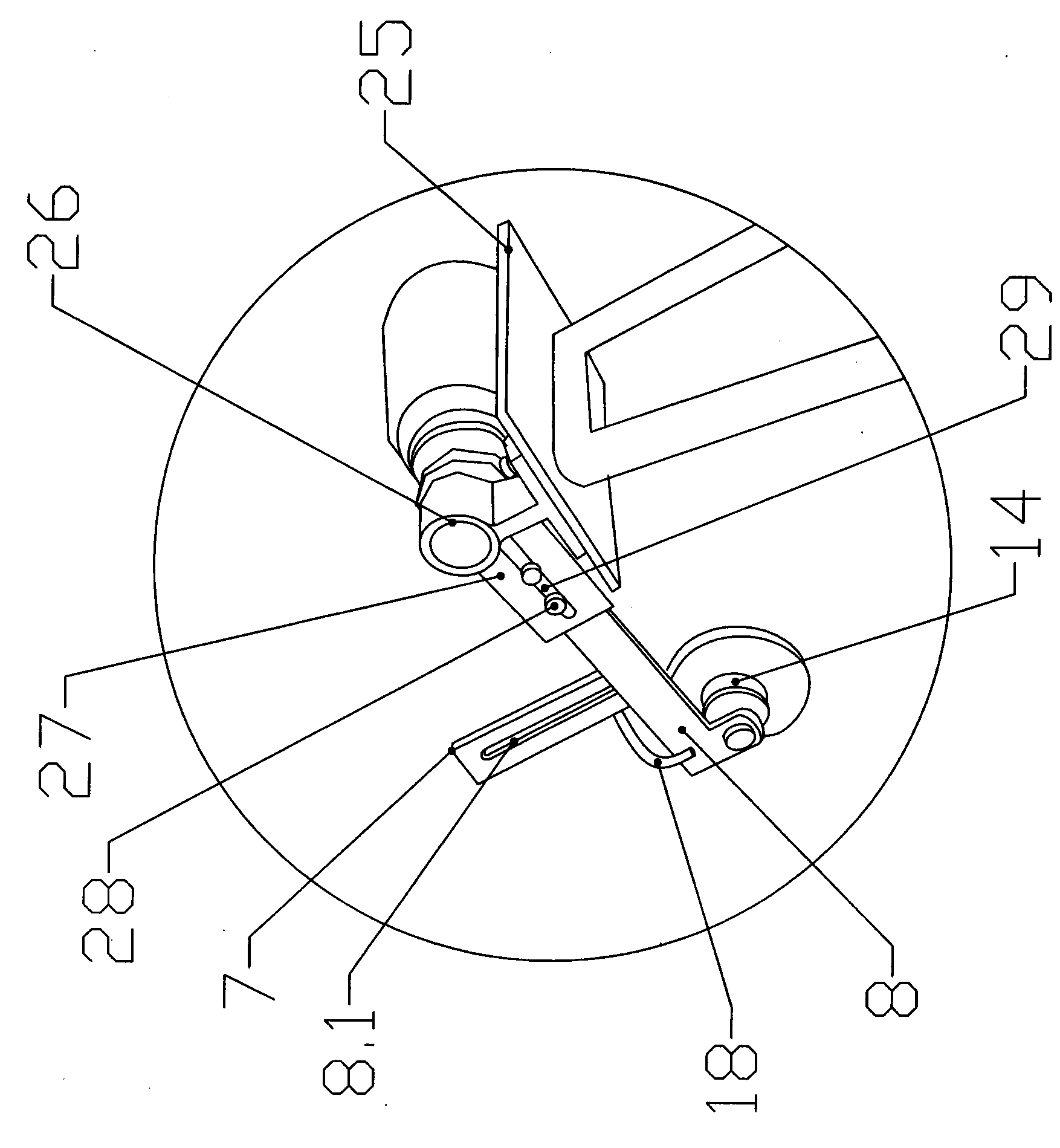

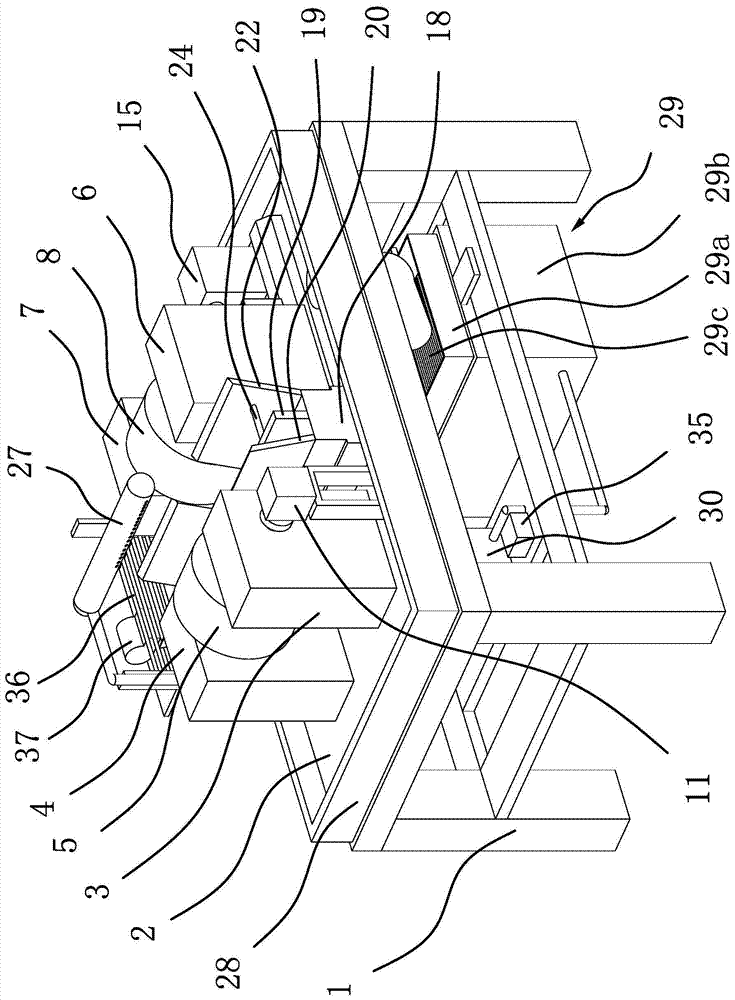

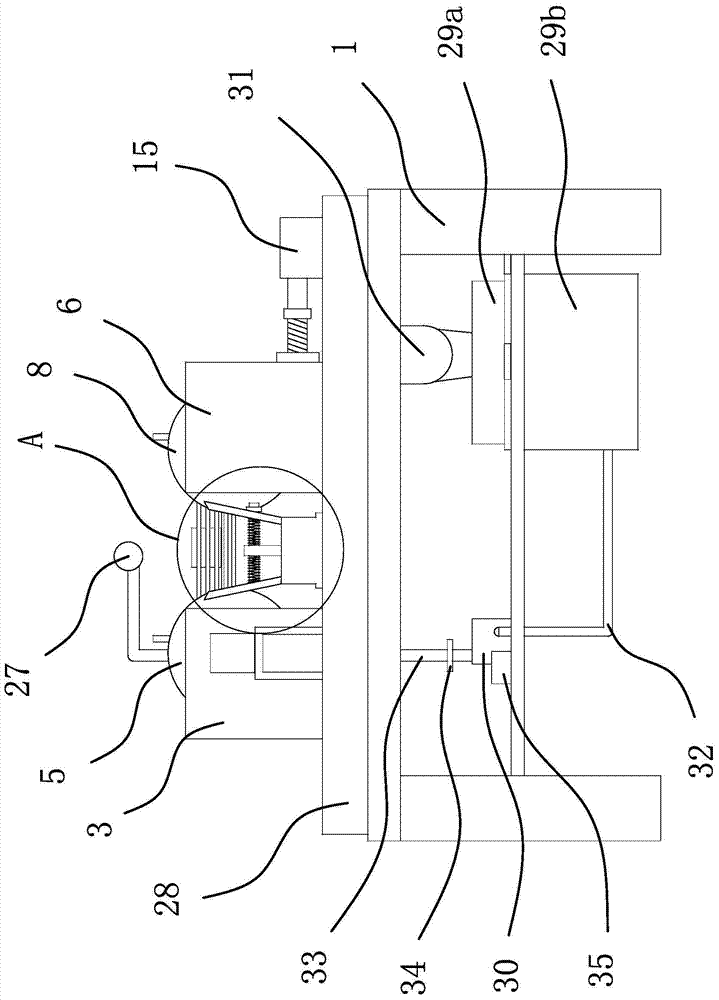

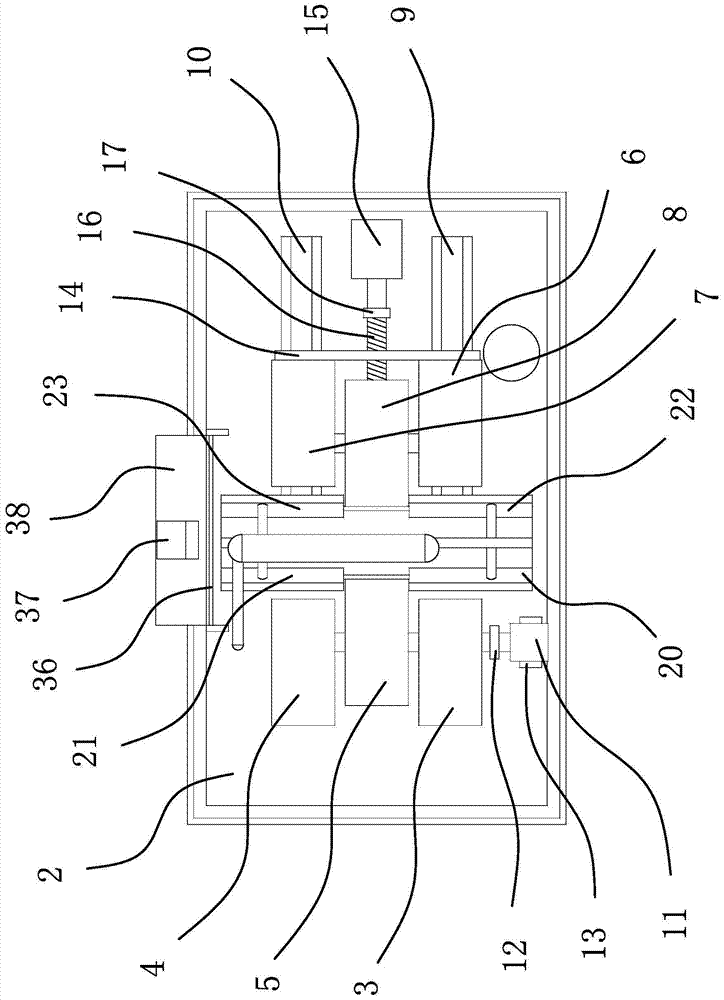

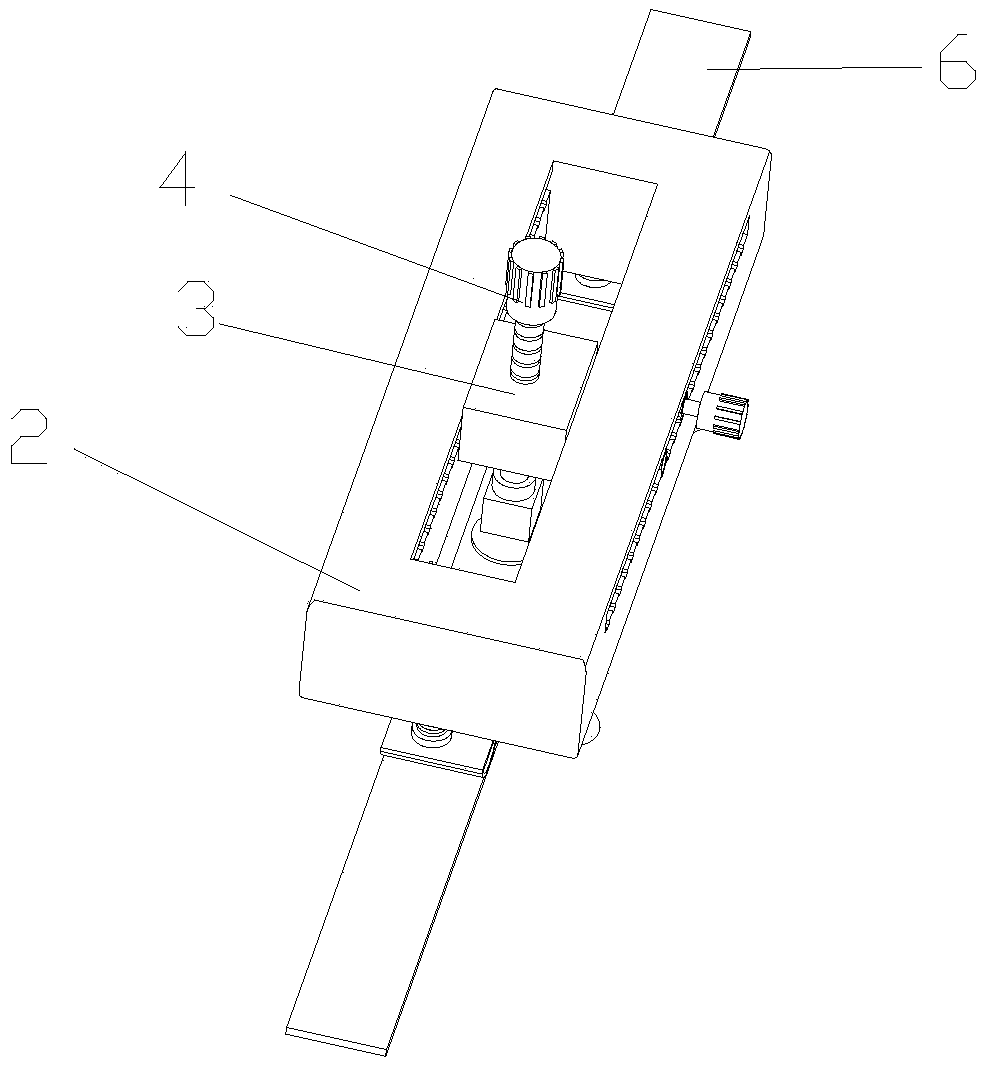

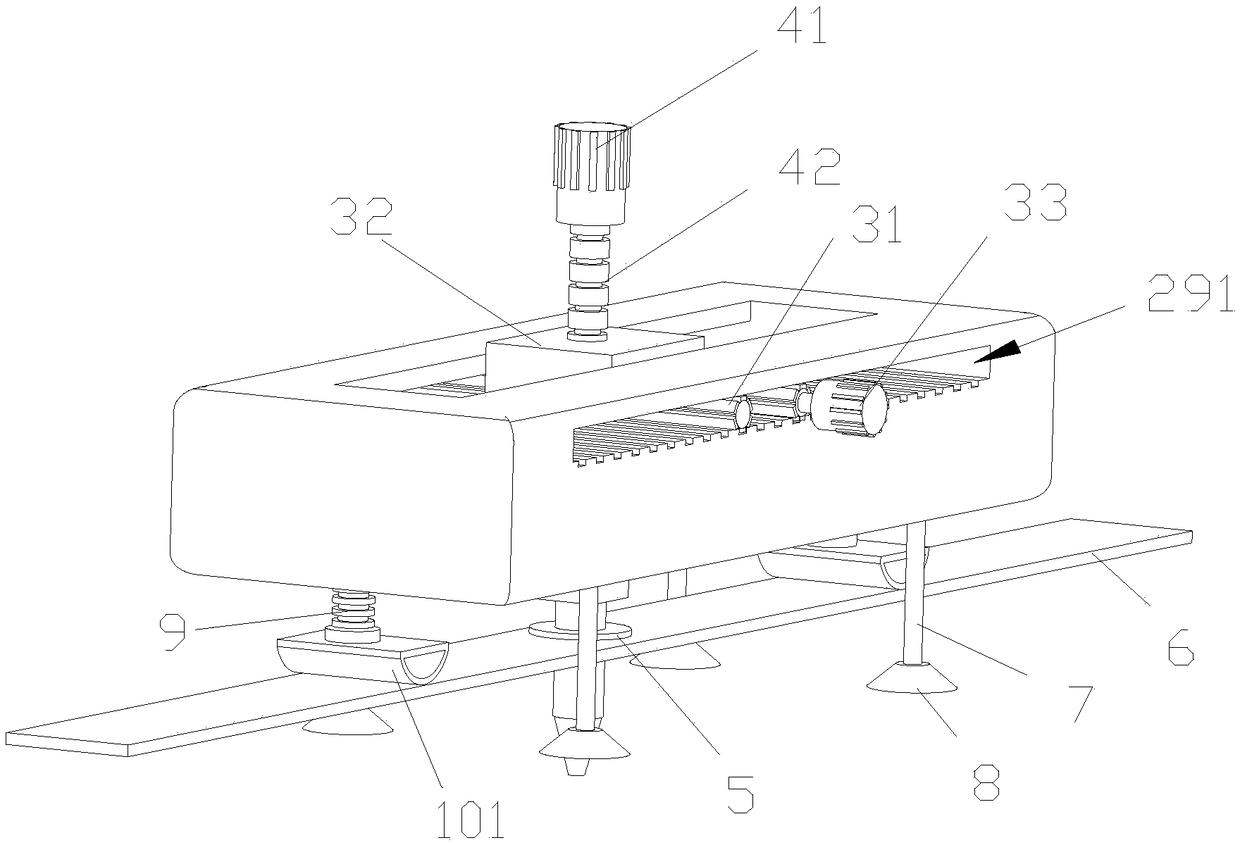

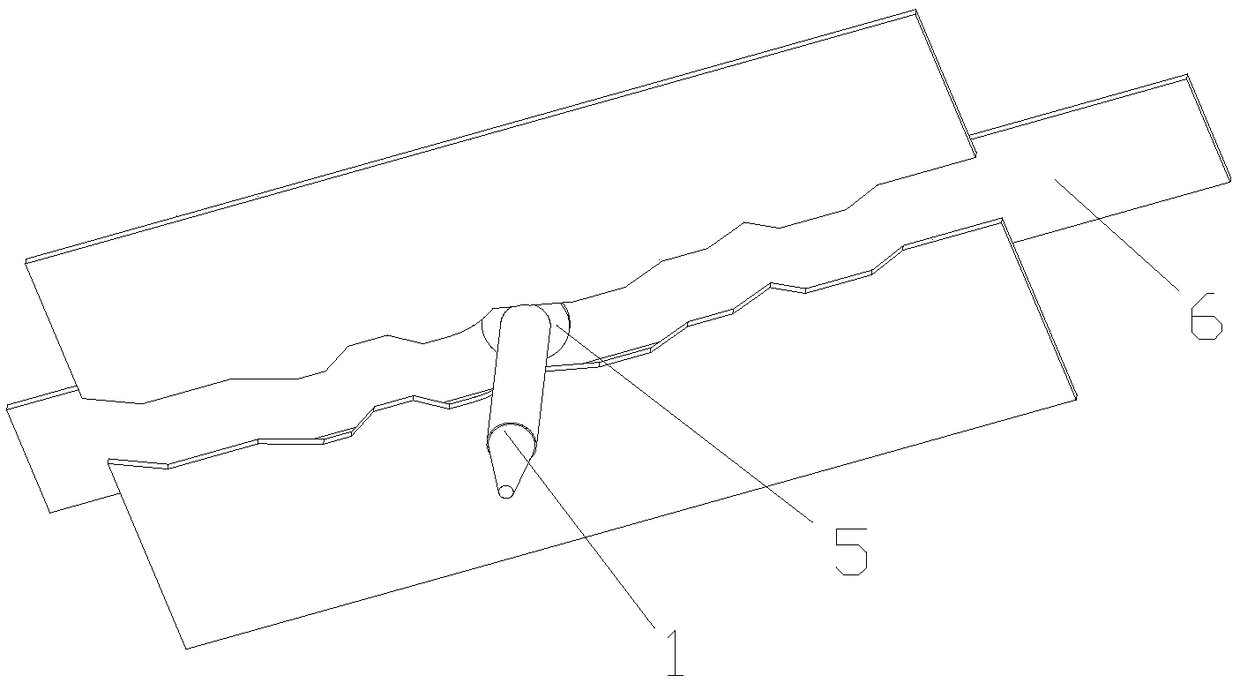

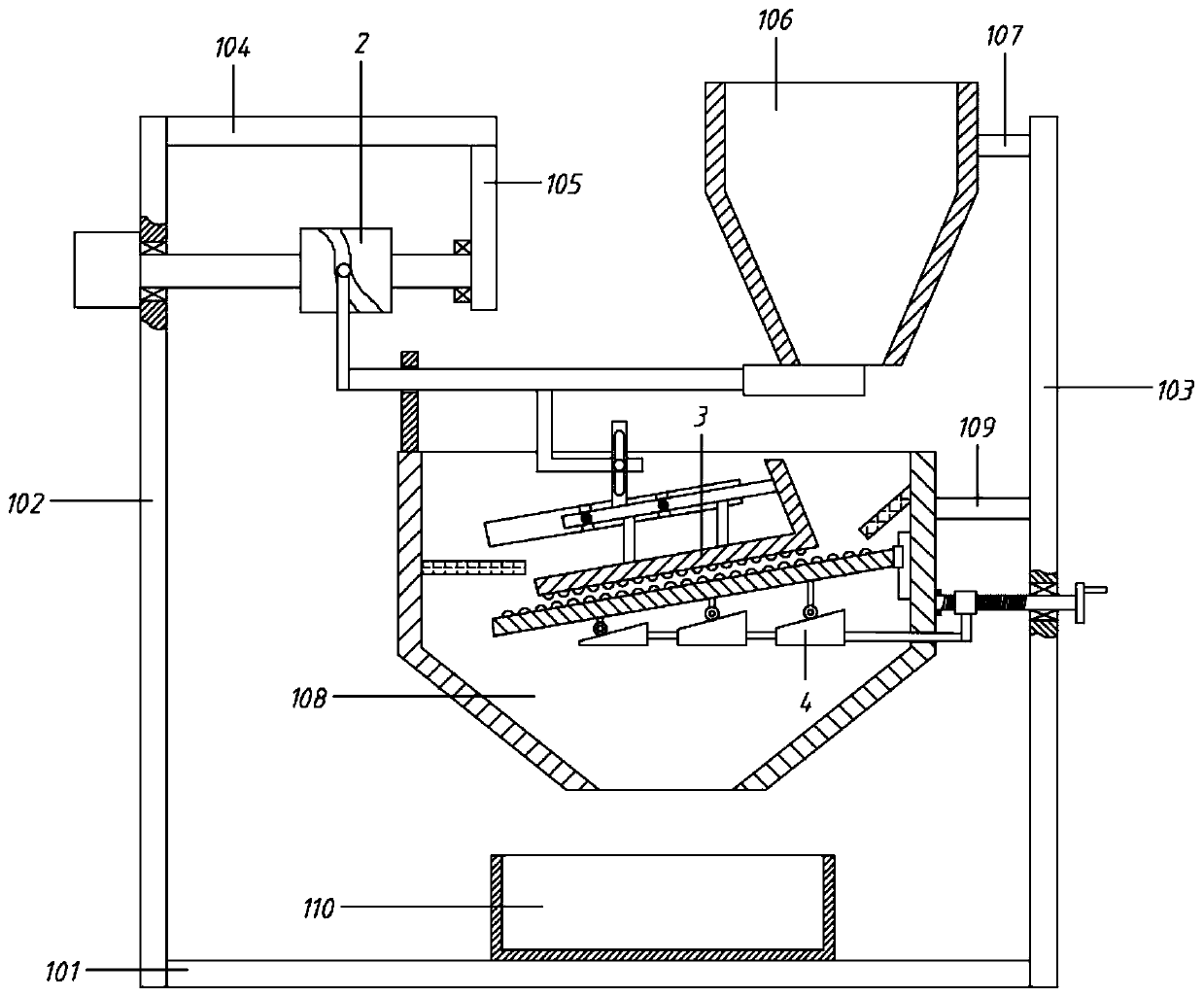

Pipe cutting and grinding device

ActiveCN108453508ARealize automatic clampingAchieve grindingEdge grinding machinesOther manufacturing equipments/toolsEngineeringSlide plate

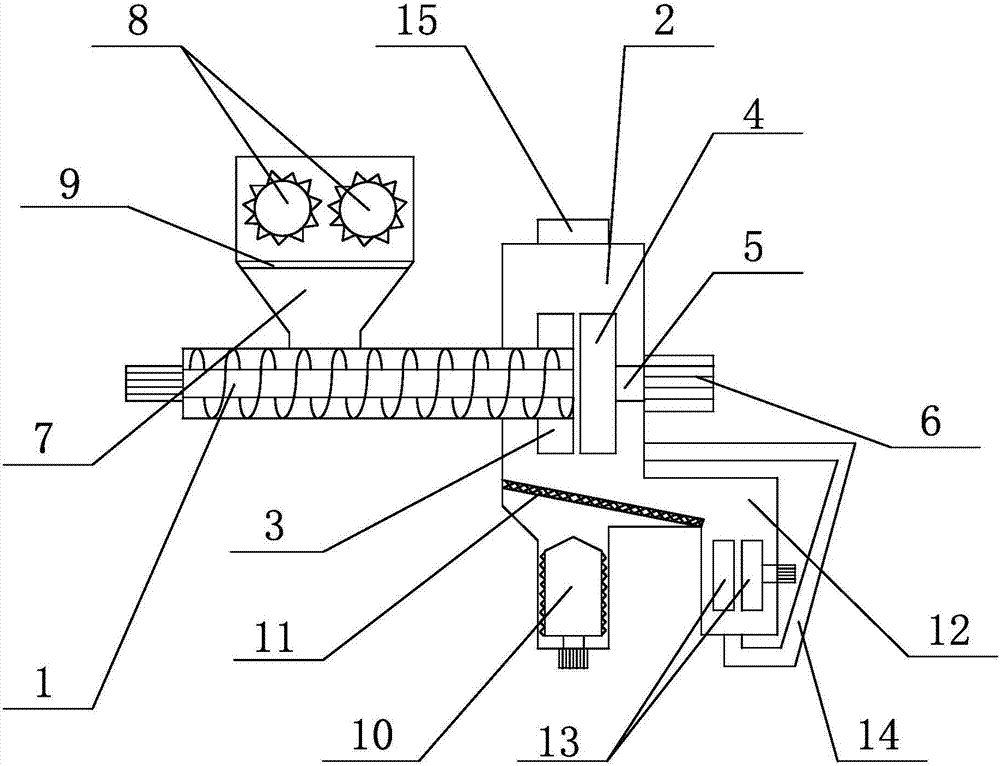

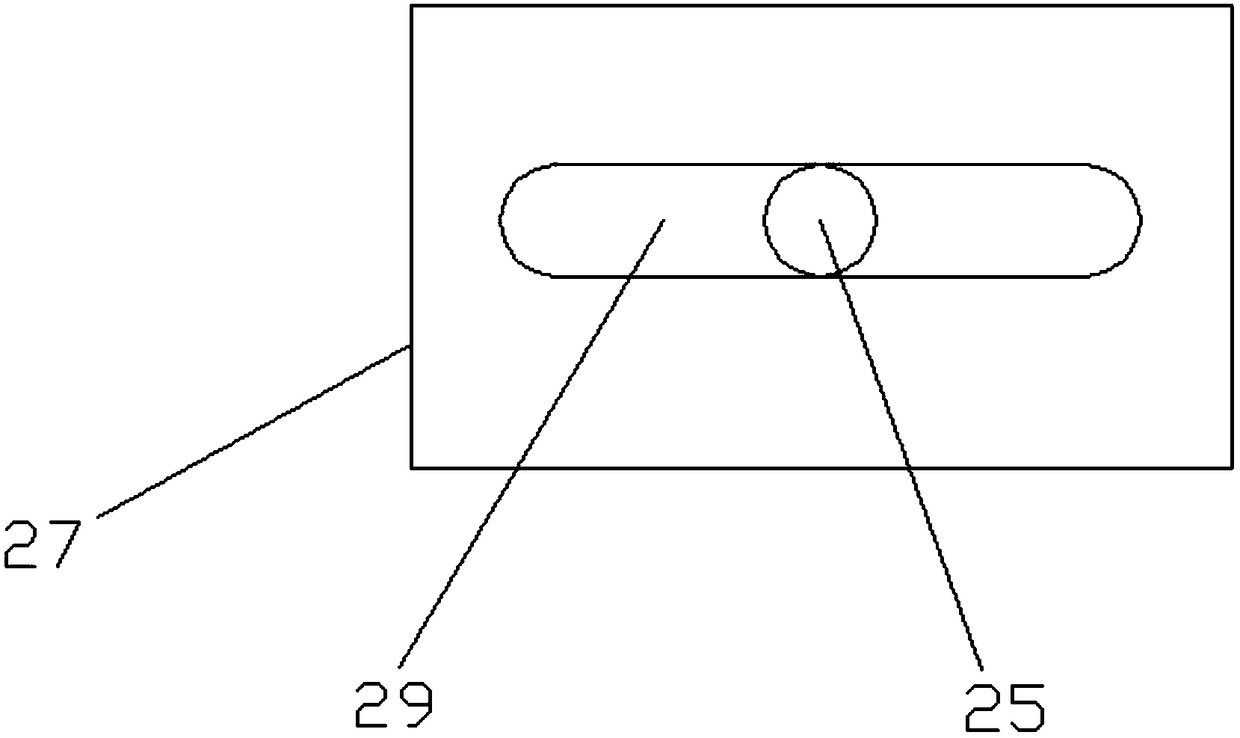

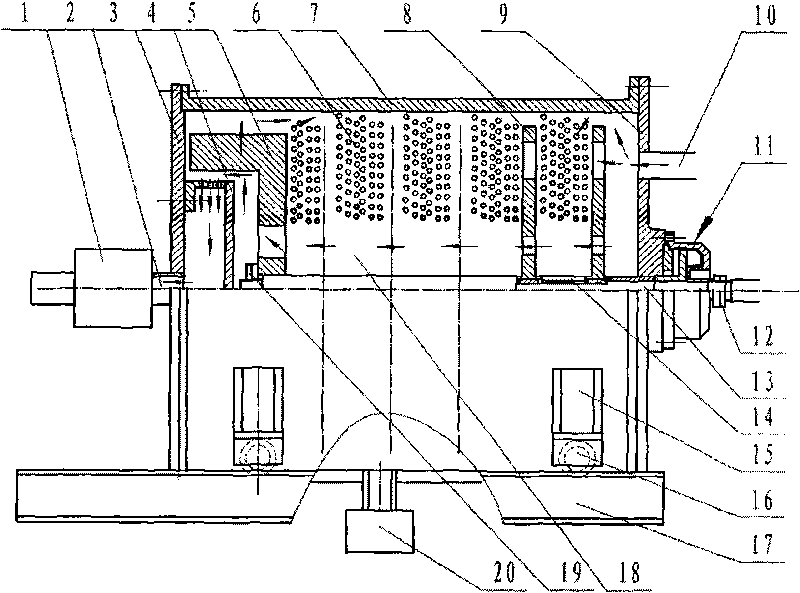

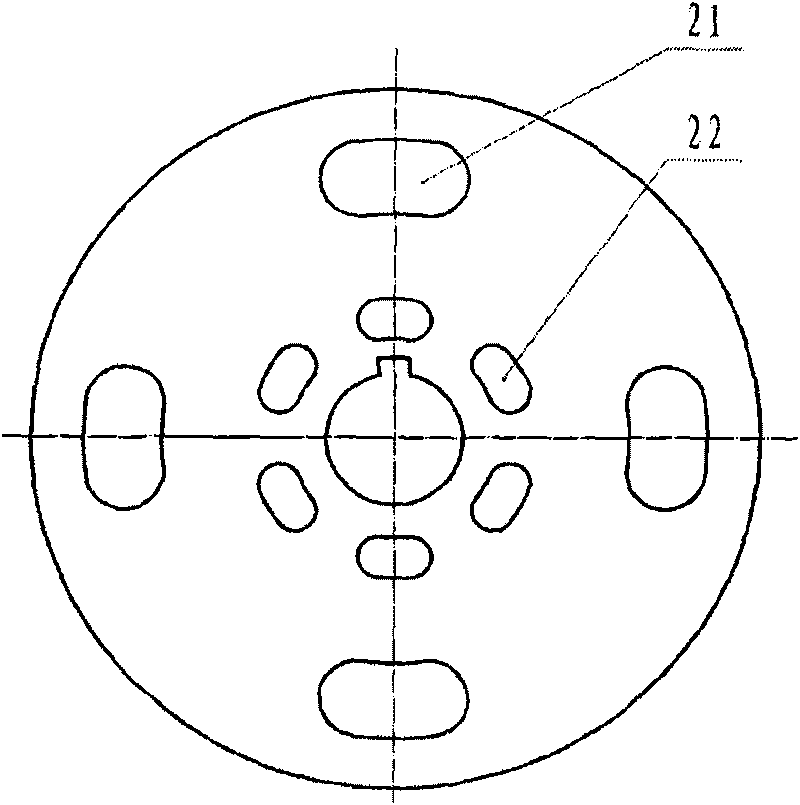

The invention belongs to the technical field of cutting equipment, and specifically discloses a pipe cutting and grinding device. The pipe cutting and grinding device comprises a cutting mechanism anda grinding mechanism which are connected to the same rotating shaft, wherein a transmission gear and two fixed pulleys are arranged on the rotating shaft; a rack which is fixed to a machine frame isengaged with the transmission gear; the grinding mechanism comprises a rotating barrel which is fixed to the rotating shaft, and a grinding plate is arranged on the rotating barrel; a square shaft isin sliding connection with the interior of the rotating barrel, and a threaded rod which is in thread connection with the rotating barrel is rotatably connected to the square shaft; and the threaded rod is in sliding connection with a sliding plate, and the sliding plate is in sliding connection with the machine frame. The pipe cutting and grinding device further comprises a conveying roller, a first clamping mechanism and a second clamping mechanism; the first clamping mechanism comprises a clamping block and a fixing block; a sliding rope is connected between the clamping block and the corresponding fixed pulley; the second clamping mechanism is in sliding connection with a working platform; a baffle plate is arranged at the left end of the working platform; and magnetic parts which areattracted to and repelled by each other are arranged between the baffle plate and the second clamping mechanism. According to the scheme, the pipe cutting and grinding device has the advantages that anotch of a steel pipe can be ground while the steel pipe is cut, so that the working efficiency is improved.

Owner:苏州市振渭城镇建设发展有限公司

Metallographic specimen grinding and polishing machine

InactiveCN102218690ASimple structureEasy to operateBelt grinding machinesManufacturing efficiencyManufacturing quality

The invention discloses a metallographic specimen grinding and polishing machine. An upper supporting plate and a lower supporting plate are arranged on a machine body; a grinding and polishing bottom plate is arranged in the middle of the upper supporting plate and is enclosed by a drainage tank; two ends of the upper supporting plate are provided with an abrasive belt driving shaft and an abrasive belt transmission shaft; a pressing plate is correspondingly arranged on the upper part of the grinding and polishing bottom plate; a screw is arranged on the pressing plate; a rotary pressing disc and a specimen fixture disc are arranged at two ends of the screw; an abrasive belt adjusting shaft is arranged in an adjusting groove on the lower part of the upper supporting plate; a water tank and a motor are arranged on the lower supporting plate; water is supplied to the grinding and polishing bottom plate through a water pump; the motor drives the abrasive belt driving shaft; and the abrasive belt is tensioned on the abrasive belt driving shaft, the abrasive belt transmission shaft, an abrasive belt supporting shaft and the abrasive belt adjusting shaft. The metallographic specimen grinding and polishing machine is simple in structure, convenient to operate and high in specimen manufacturing efficiency, and can effectively guarantee the manufacturing quality of a metallographic specimen.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

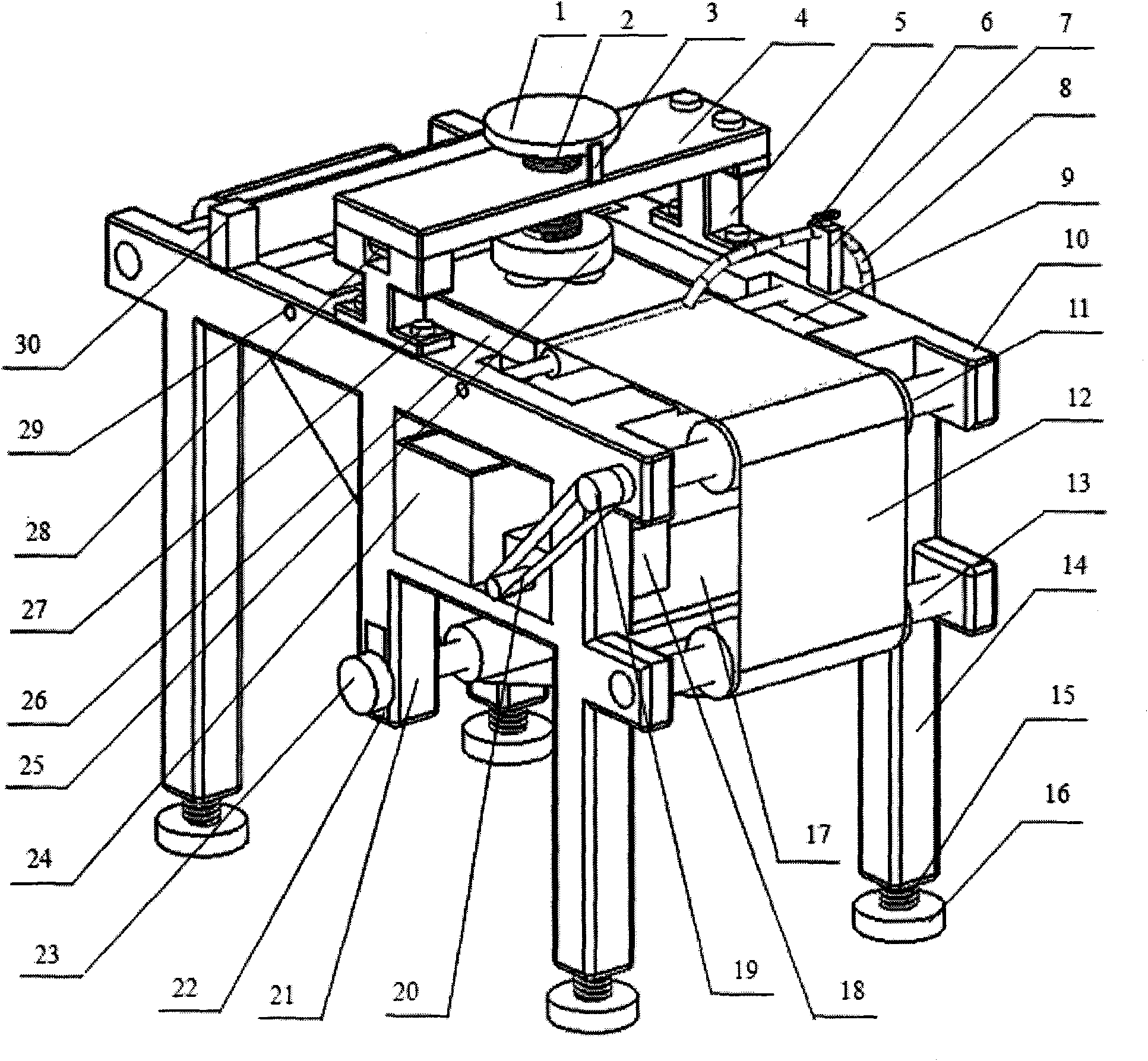

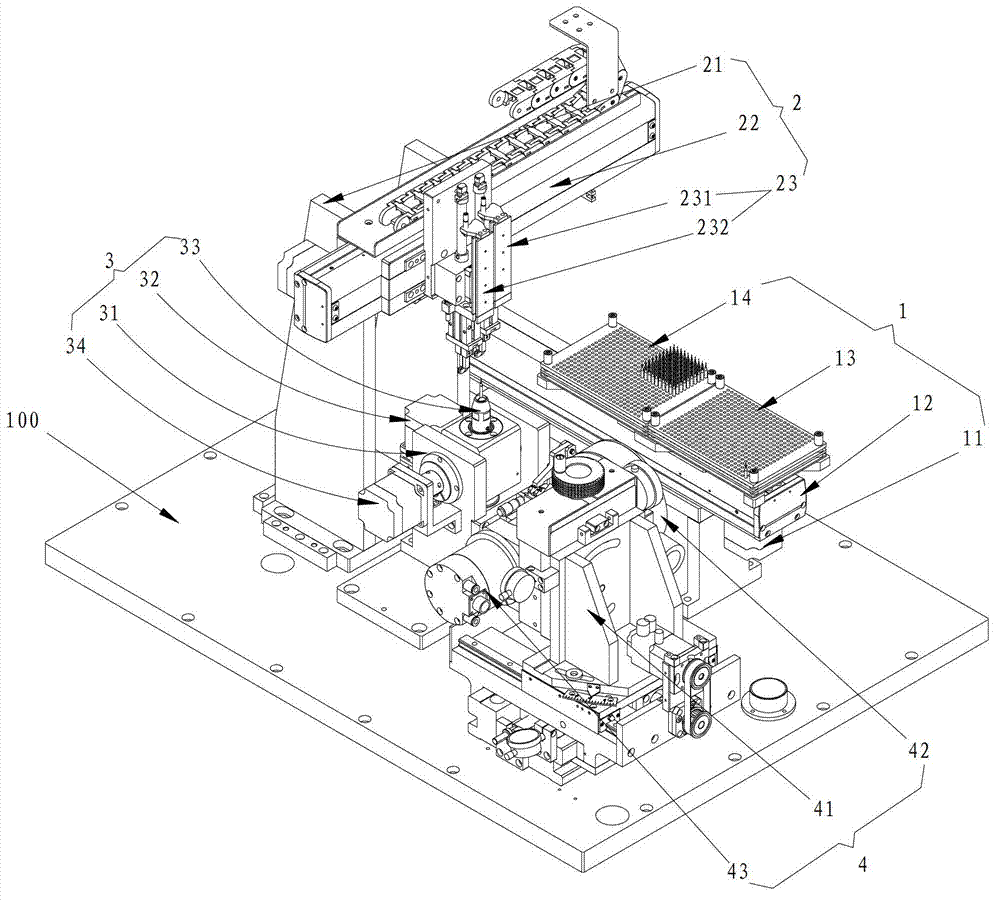

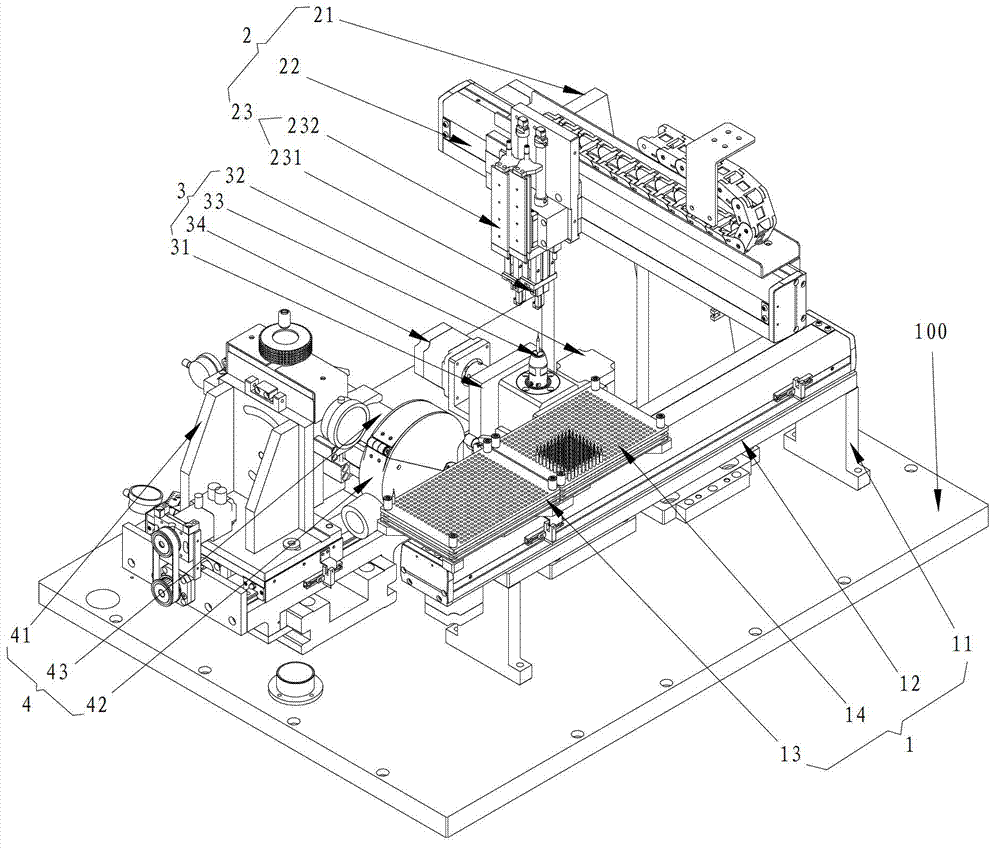

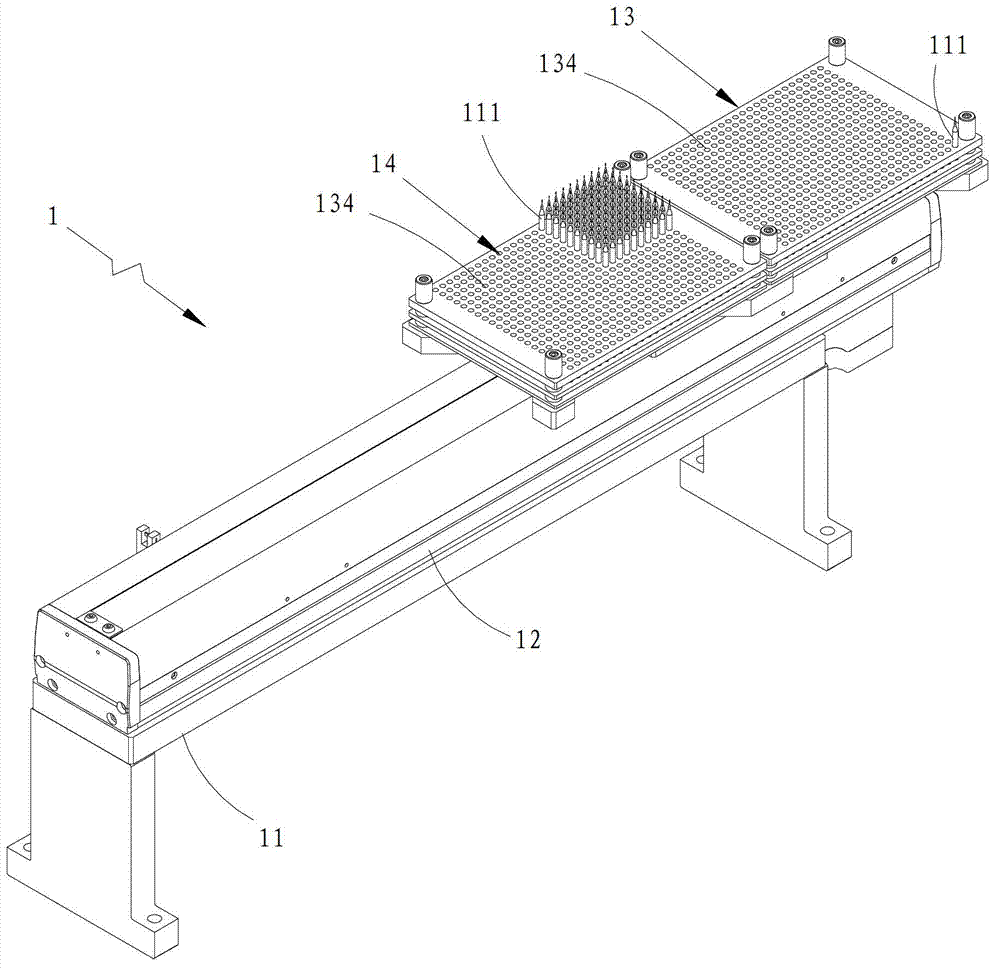

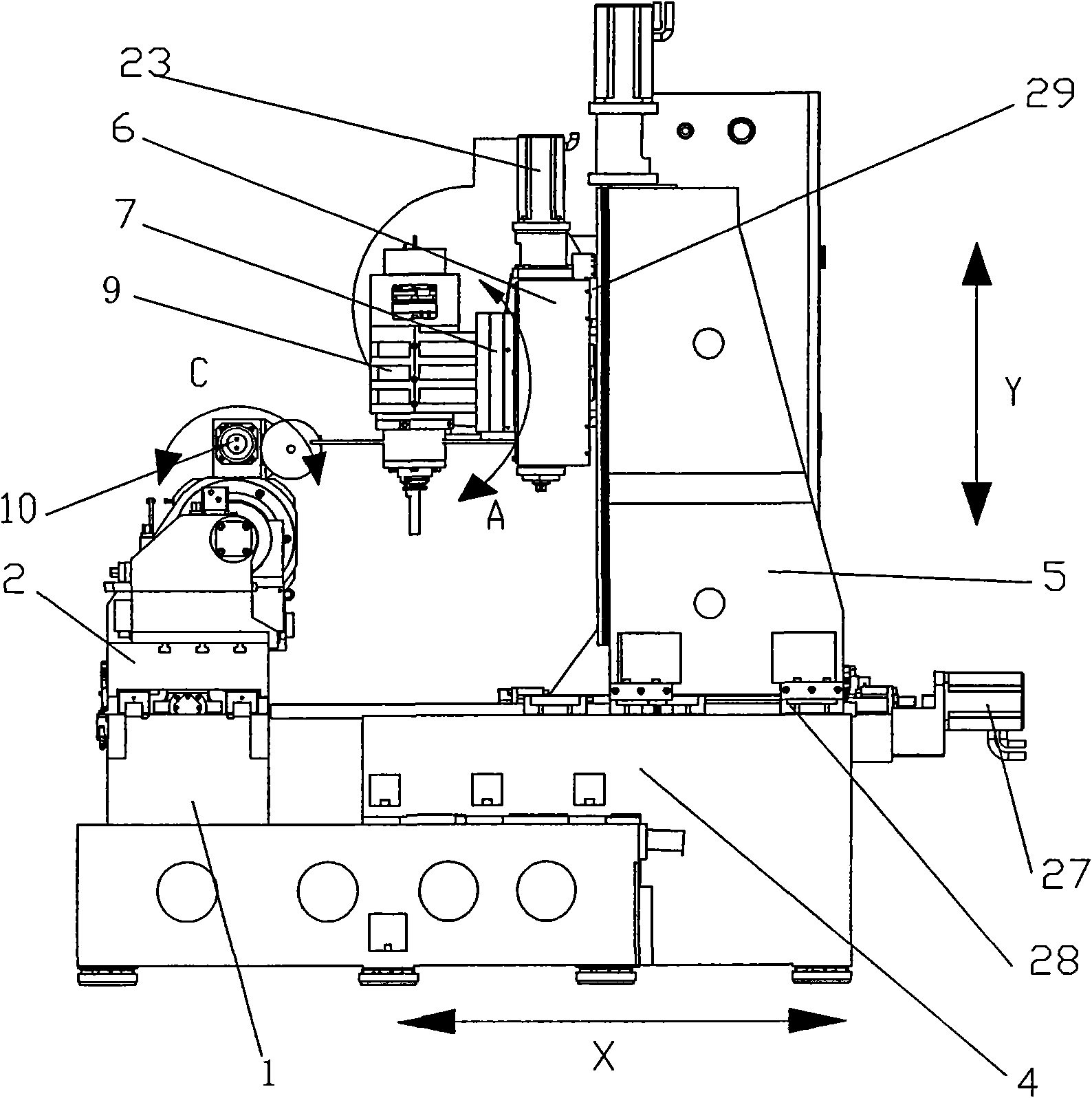

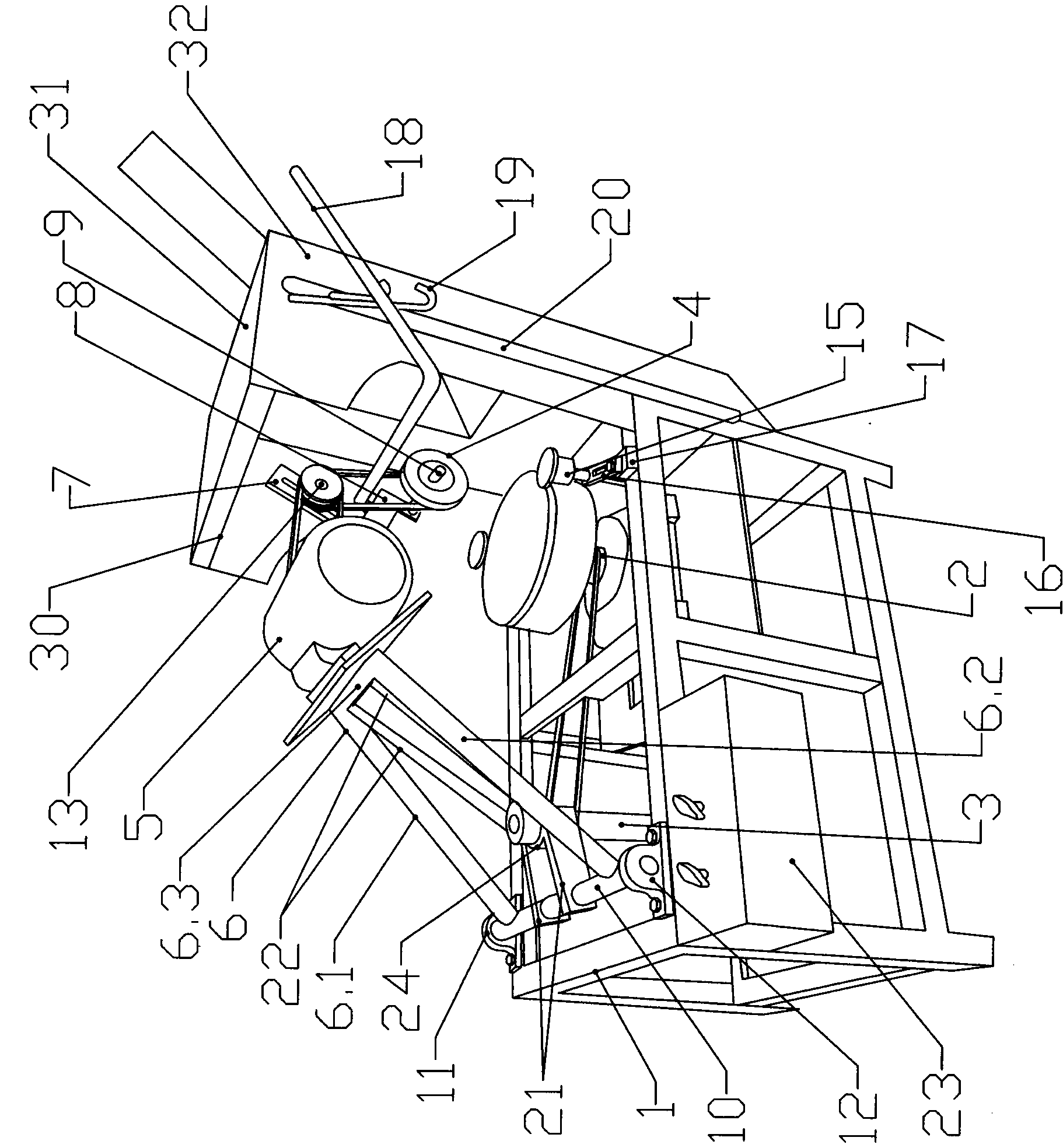

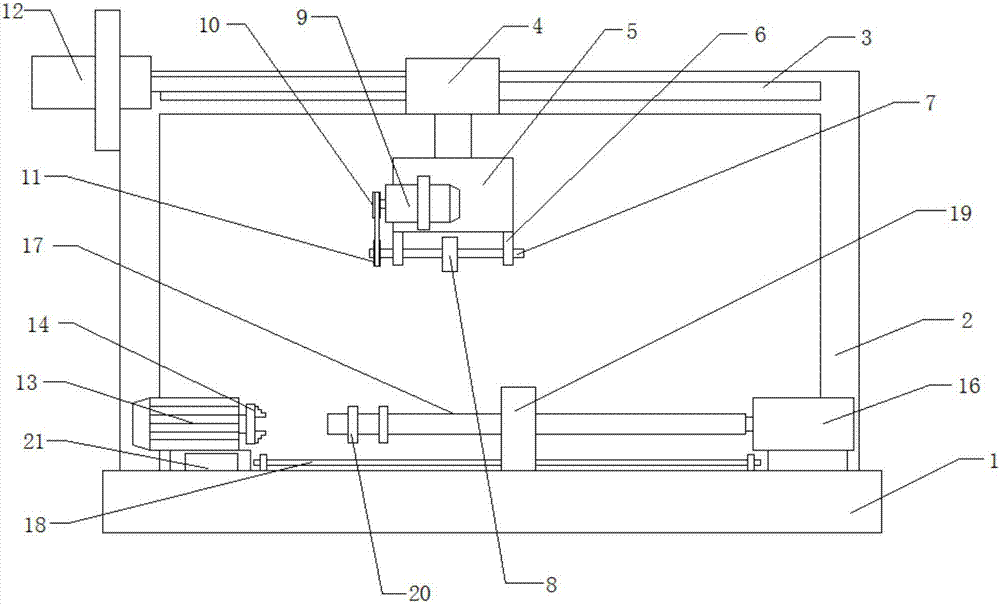

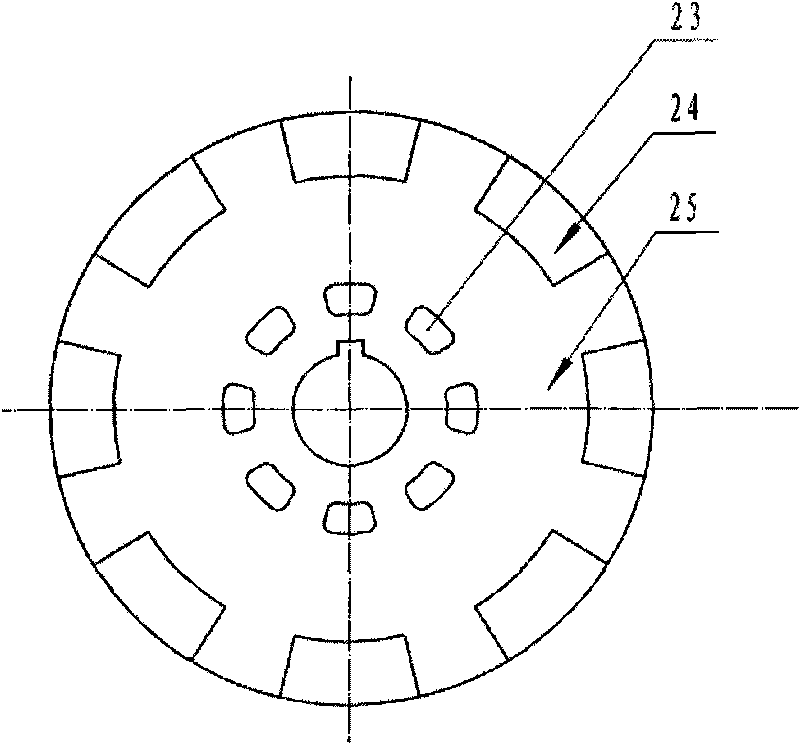

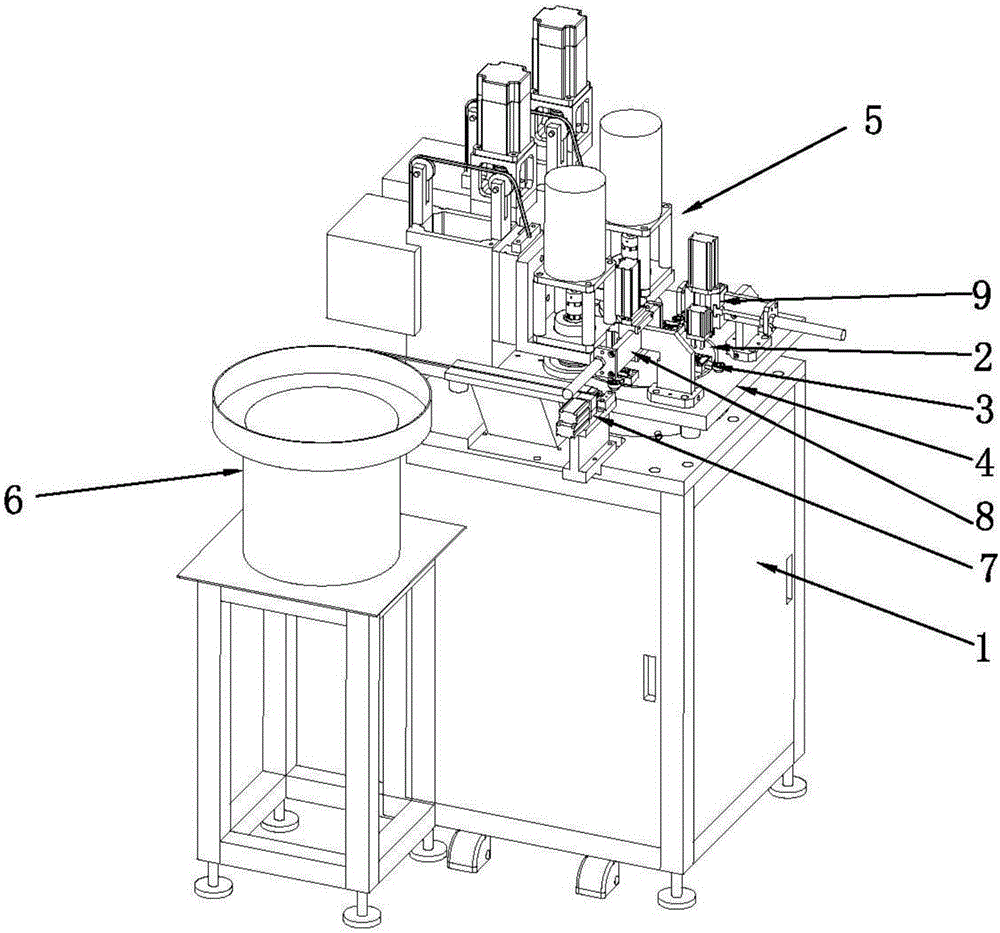

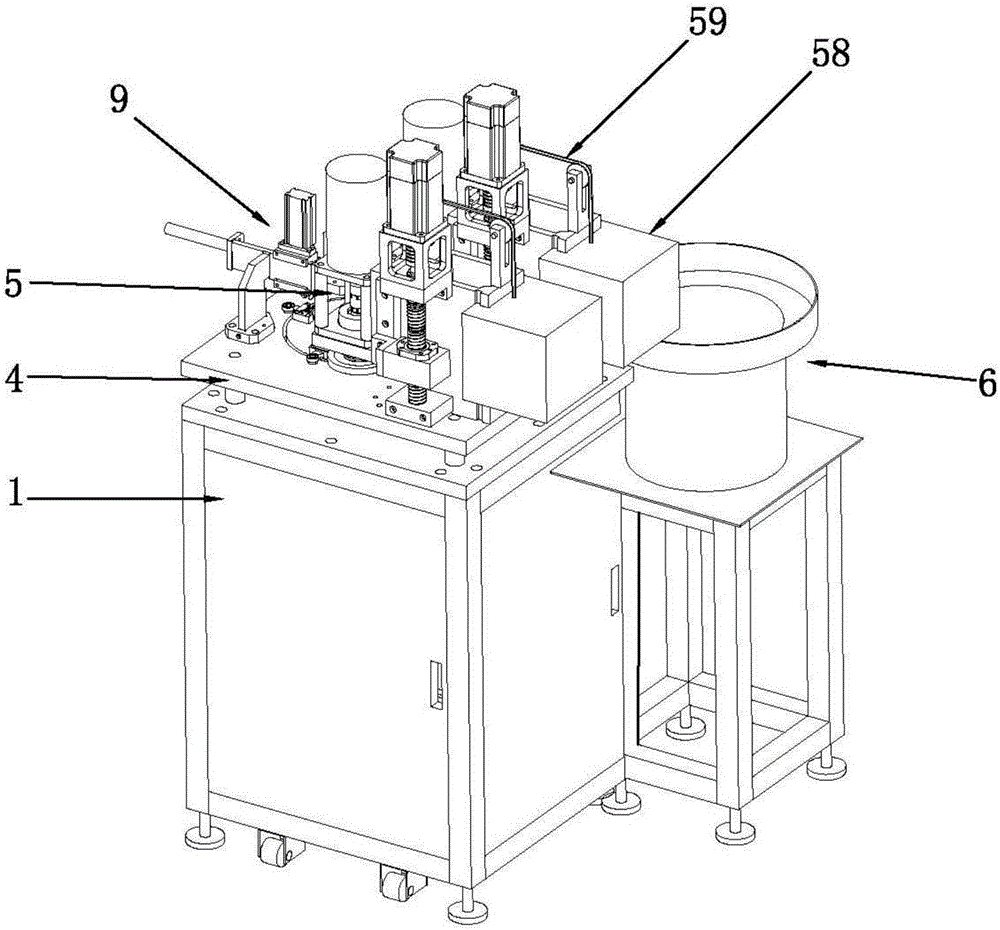

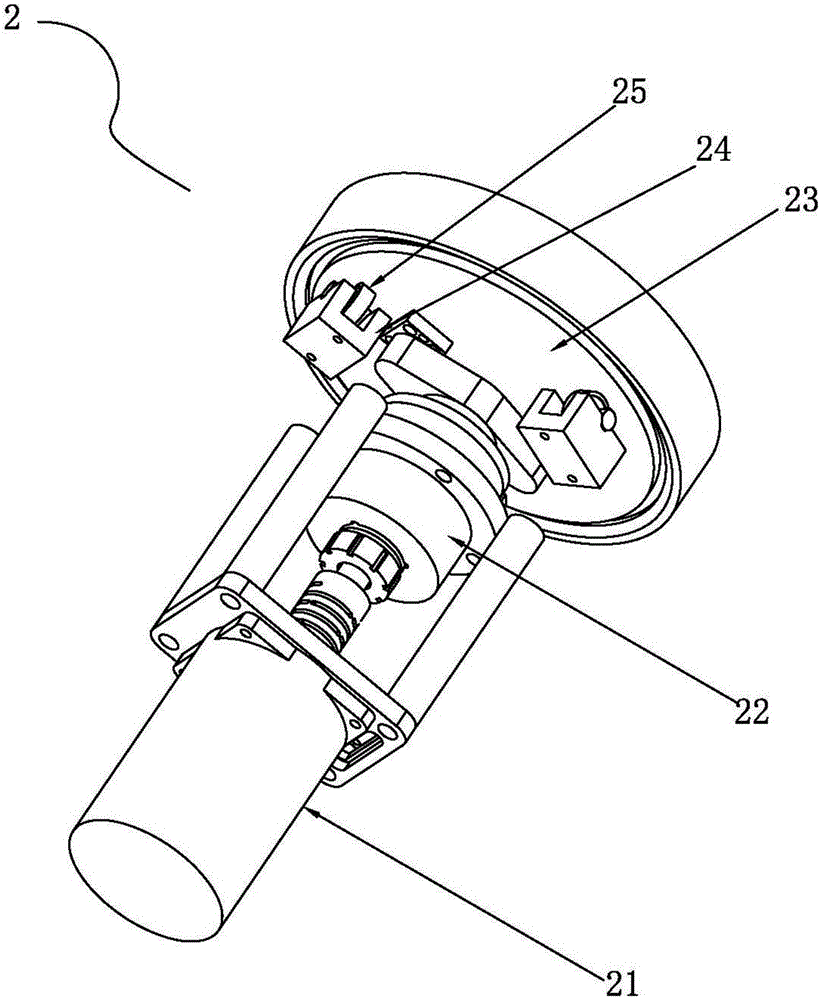

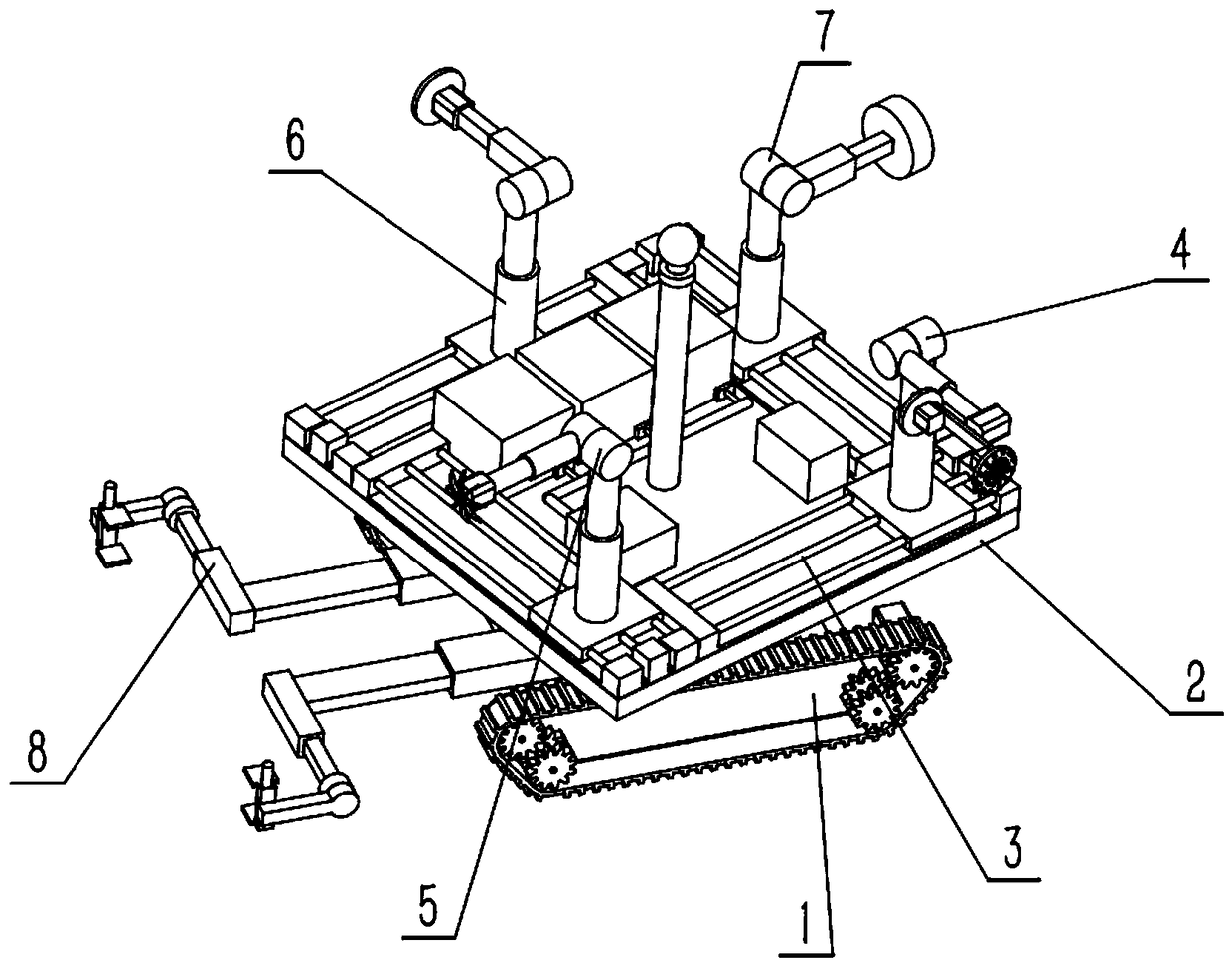

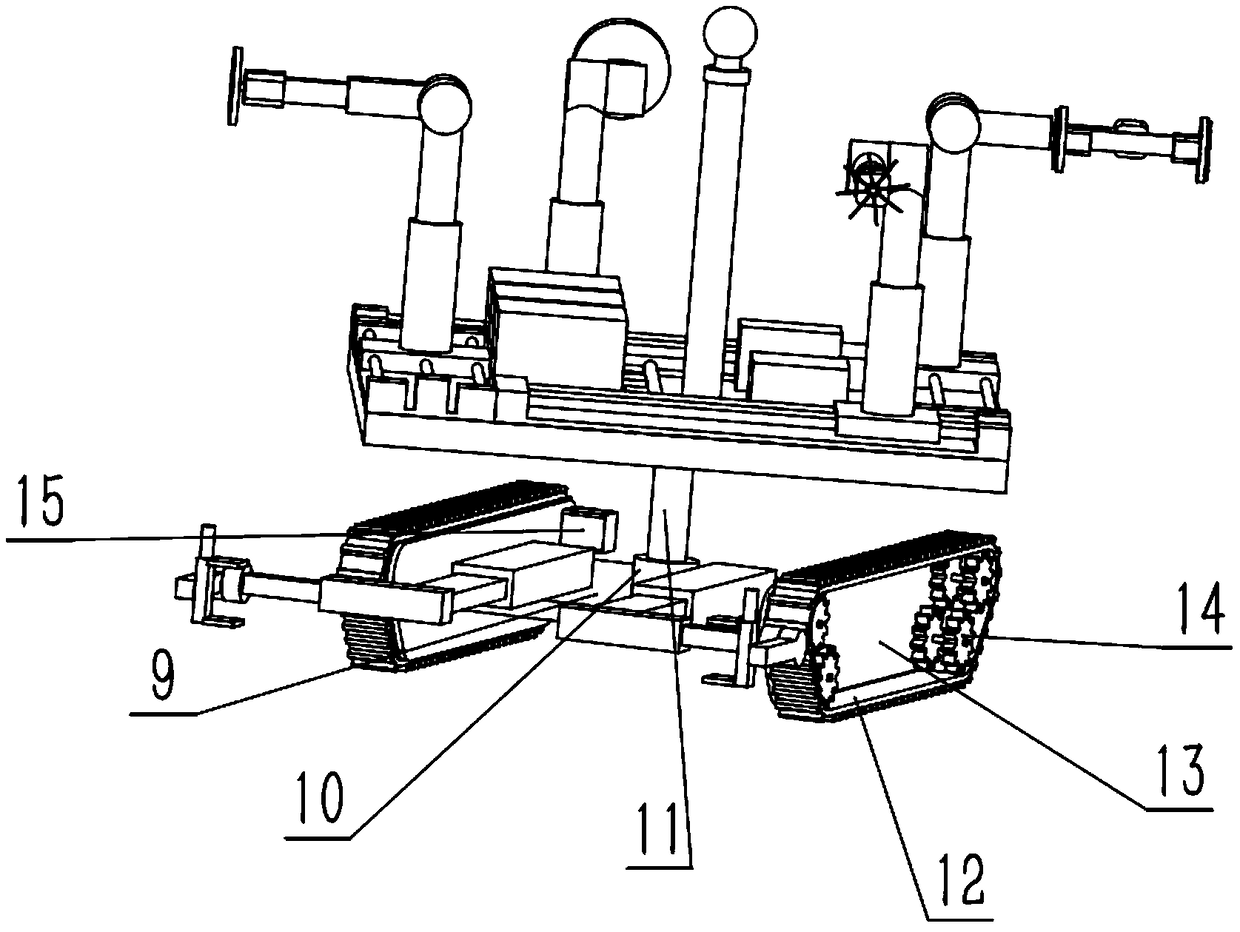

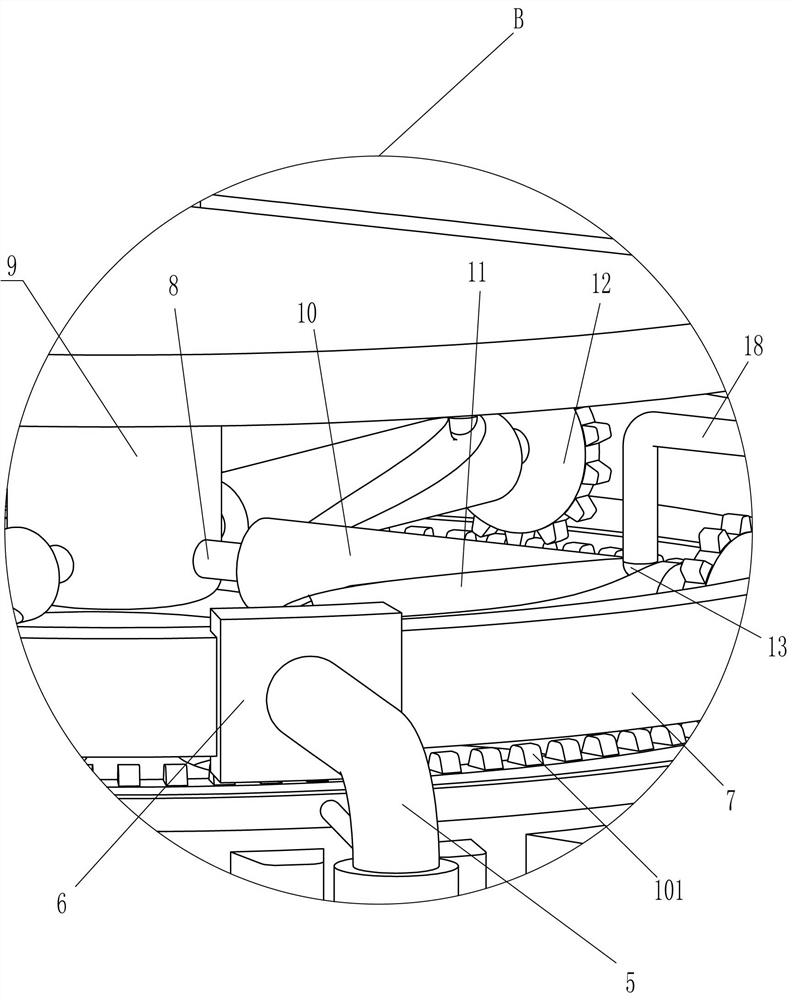

Lapping machine of milling cutters

InactiveCN102896560AAchieve grindingIntelligent grindingMilling cuttersAutomatic grinding controlProgrammable logic controllerMilling cutter

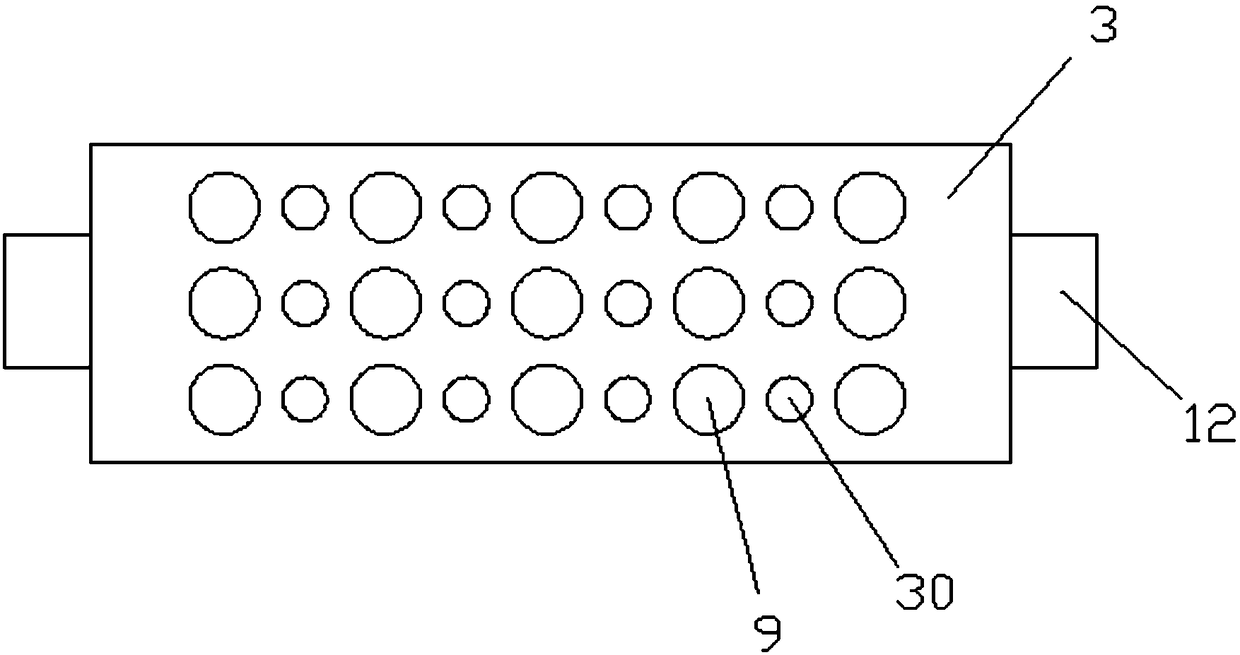

The invention is applicable to the technical field of cutter lapping equipment and provides a lapping machine of milling cutters. The lapping machine comprises a base, a programmable logic controller (PLC) control portion, a material inlet-outlet portion, a mechanical arm portion, a clamping rotation portion and an abrasive wheel grinding machine, wherein the material inlet-outlet portion, the mechanical arm portion, the clamping rotation portion and the abrasive wheel grinding machine are arranged on the base and controlled by the PLC control portion. The lapping machine of milling cutters uses a PLC to control a whole machine to operate, uses PLC pulse signals and servo motors to control positions of a mechanical arm to take and release the milling cutters, achieves automatic feeding, automatic discharging, automatic capture and automatic lapping of the milling cutters, achieves intelligentization grinding of the milling cutter, has the advantages of high manufacture speed and high lapping accuracy, is simple in equipment operation, does not need professional operators, and greatly reduces requirements for skills of the operators.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

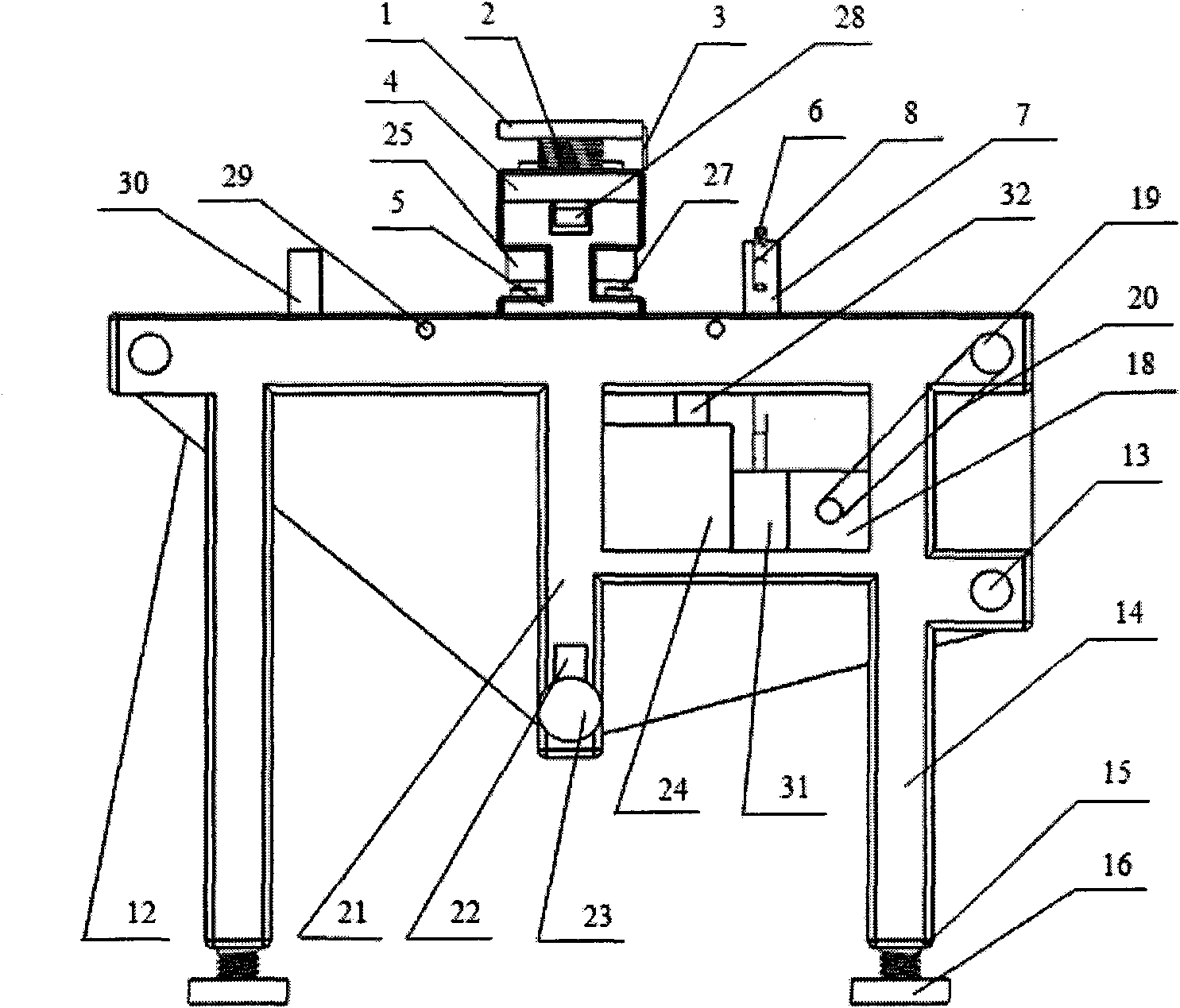

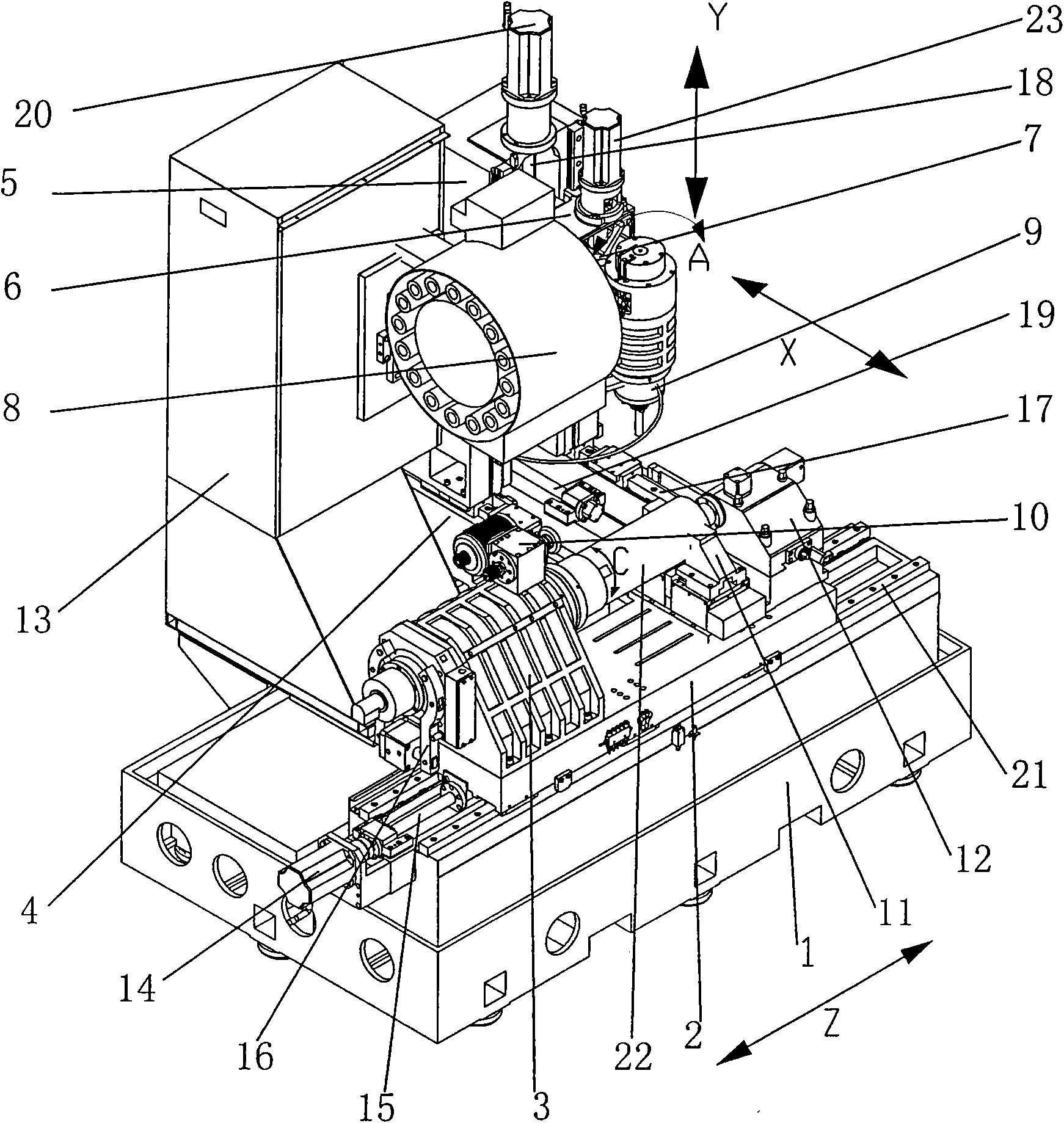

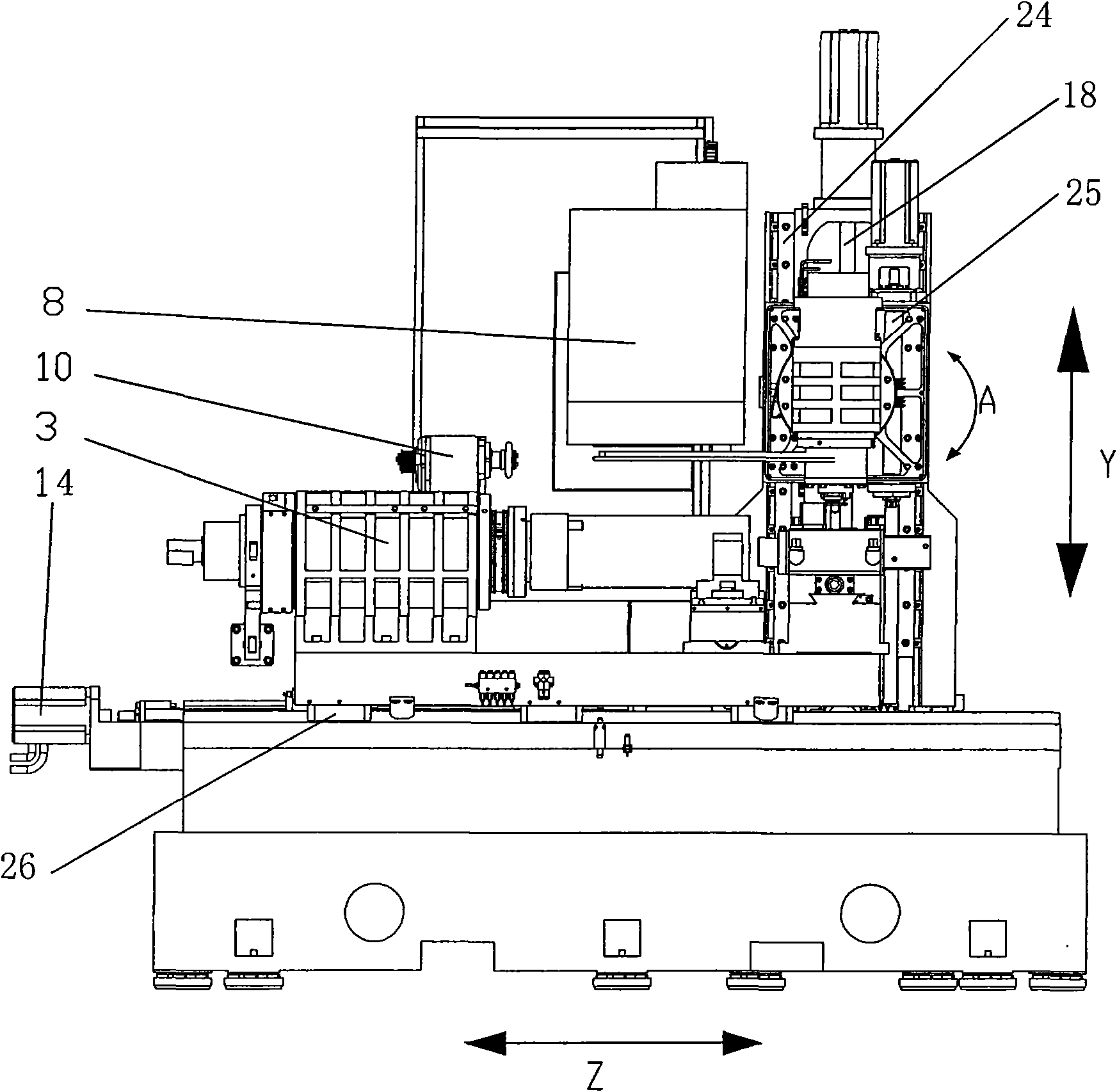

Five-axis multi-functional thread grinding machining center

ActiveCN101513686AImplement fixesSimple structureThread cutting machinesManufacturing cost reductionNumerical control

A five-axis multi-functional thread grinding machining center belongs to the numerically controlled machine tool field. The five-axis multi-functional thread grinding machining center consists of a machine tool body, a Z-direction slide plate, a workpiece electric spindle, a X-direction base plate, a post, a Y-direction slide plate, an A-axis turntable and a grinding electric spindle. A Z-direction servomotor drives a Z-direction lead screw to drive the Z- direction slide plate to perform Z-direction movement, the post is arranged on a X- direction guide rail slider, a X-direction servomotor drives an X-direction lead screw to drive the post to perform X-direction movement, a Y-direction guide rail is fixedly arranged on the post, the Y-direction slide plate is positioned on a Y-direction guide rail slider, a Y-direction servomotor drives a Y-direction lead screw to drive the Y-direction slide plate to perform Y-direction movement, the Z-direction slide plate is provided with the workpiece electric spindle, the A-axis turntable is arranged on the Y-direction slide plate and is connected with an A-axis servomotor, and the grinding electric spindle is fixed on the A-axis turntable by bolt fastening. The five-axis structure is adopted in the grinding machining center, thus simplifying machine tool structure, realizing grinding of super-long nuts, enlarging applicability of the machine tool and lowering manufacturing cost.

Owner:GUANGZHOU CITY AGILE MFG

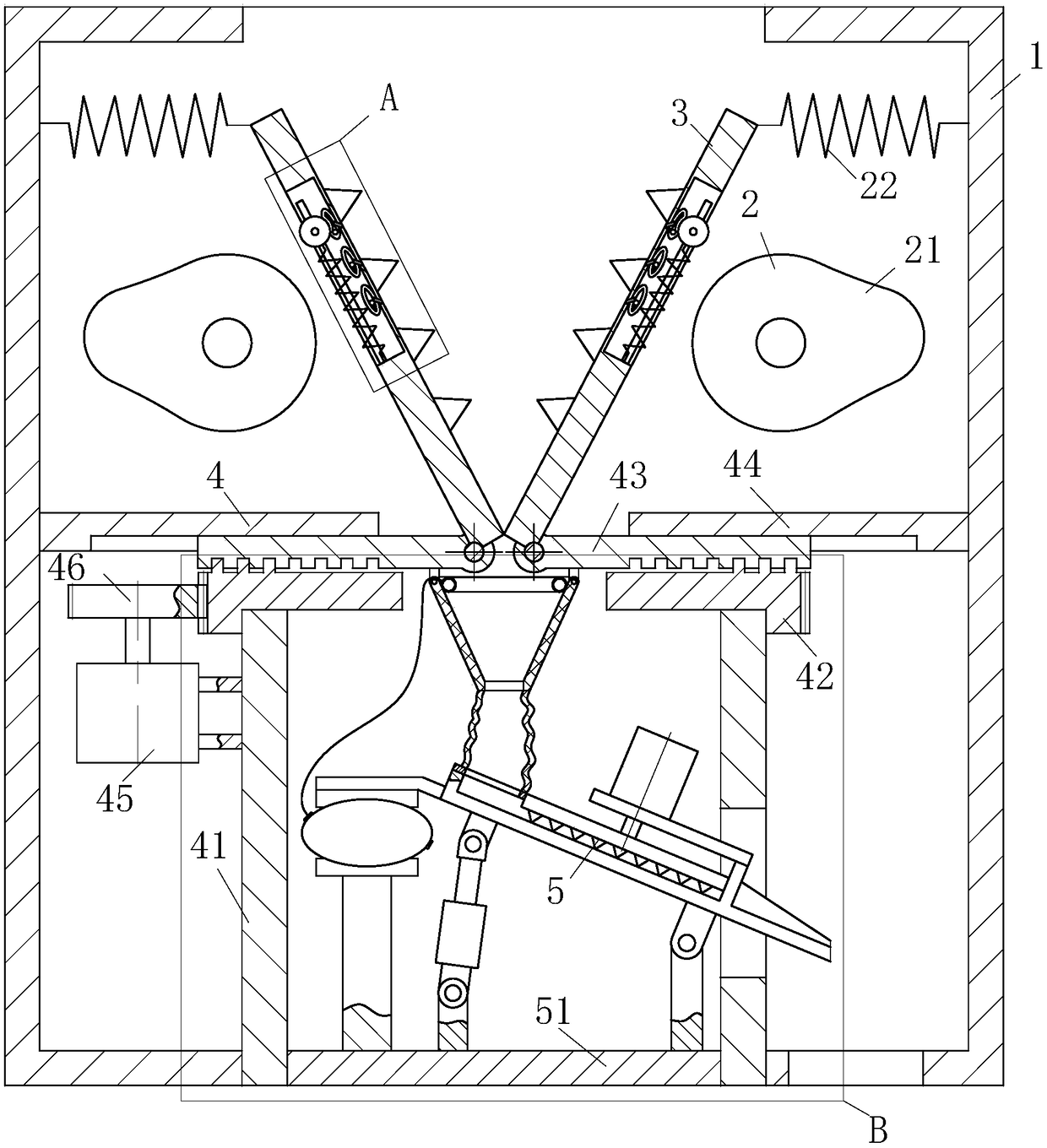

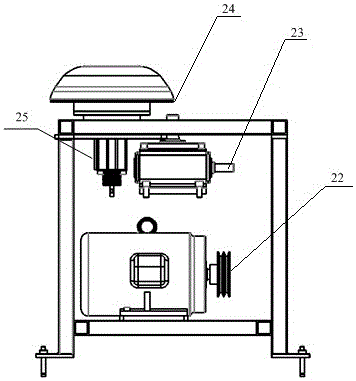

Silicone rubber production equipment

The invention belongs to the technical field of rubber production, and particularly relates to silicone rubber production equipment. The silicone rubber production equipment comprises a shell, drivingdevices, crushing plates, an opening adjusting device and a grinding device. The driving devices are used for supplying power to the crushing plate. The driving devices are matched with the crushingplates to crush talc. The opening adjusting device adjusts an opening below the crushing plates. The grinding device comprises a mounting seat, an air cylinder, a swinging plate, a grinding disc, a third motor, a corrugated pipe and an elastic funnel. The end portion of a cylinder rod of the air cylinder is rotatably mounted at one end of the swinging plate. A long rotating support on the mountingseat is rotatably connected with the other end of the swinging plate. The grinding disc is fixedly connected with the shaft end portion of the third motor. The grinding disc is used for grinding thegranular talc. The silicone rubber production equipment is mainly used for grinding the talc added in the rubber production process, and crushing, grinding and partial position cleaning of the talc are realized.

Owner:温州合丰胶业股份有限公司

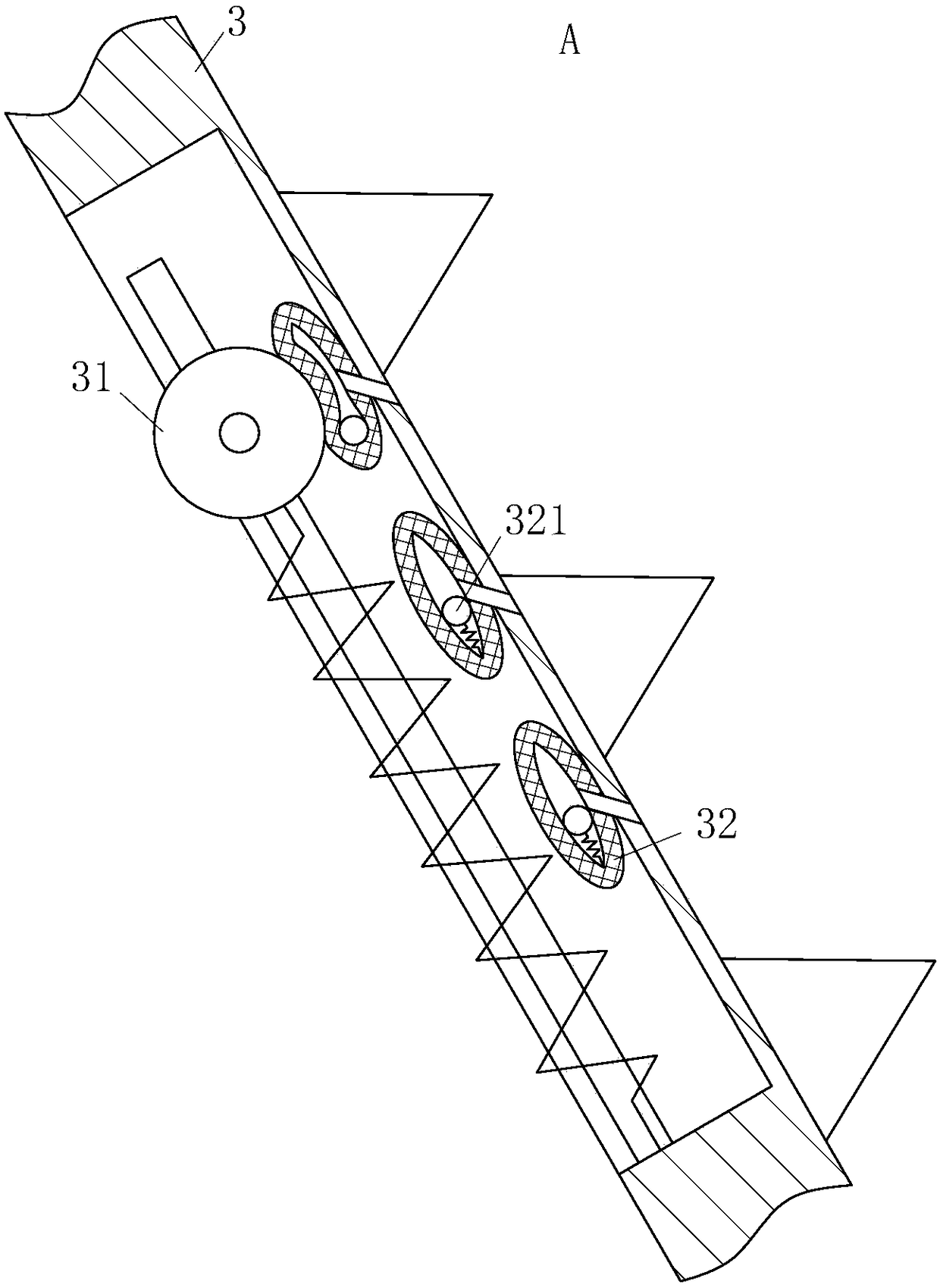

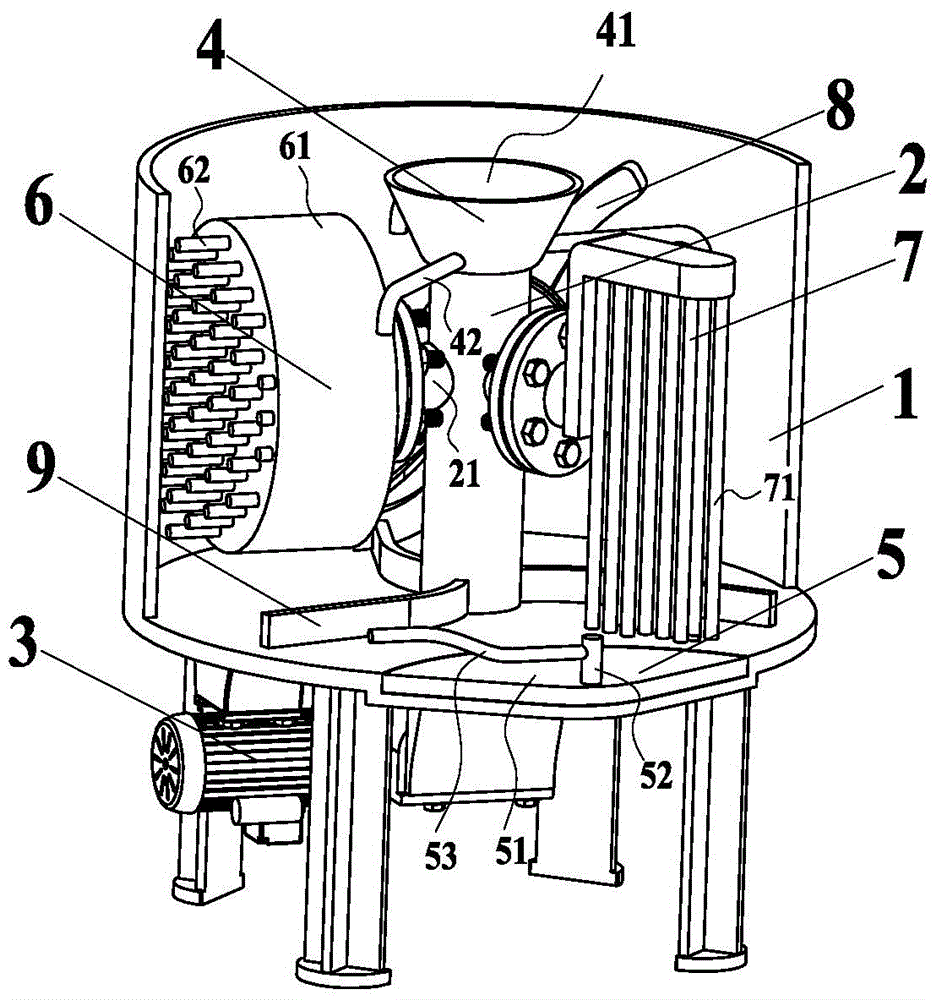

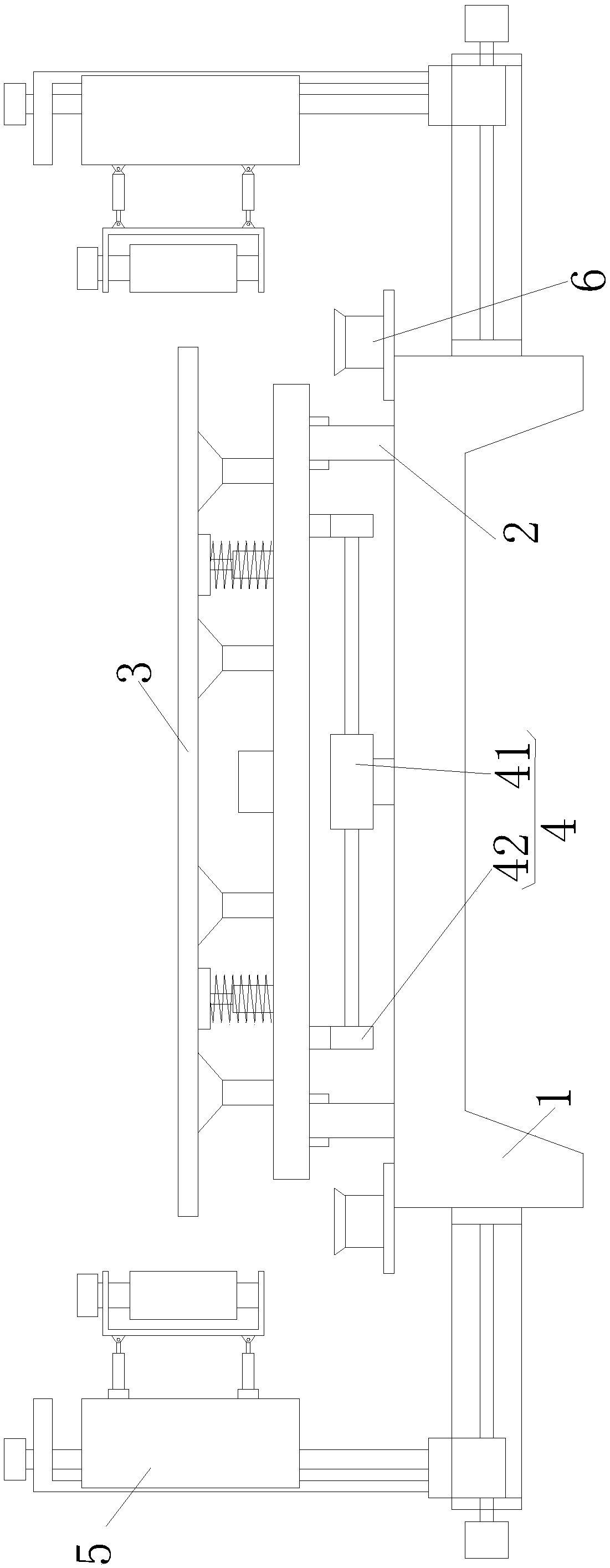

Sand mixing equipment

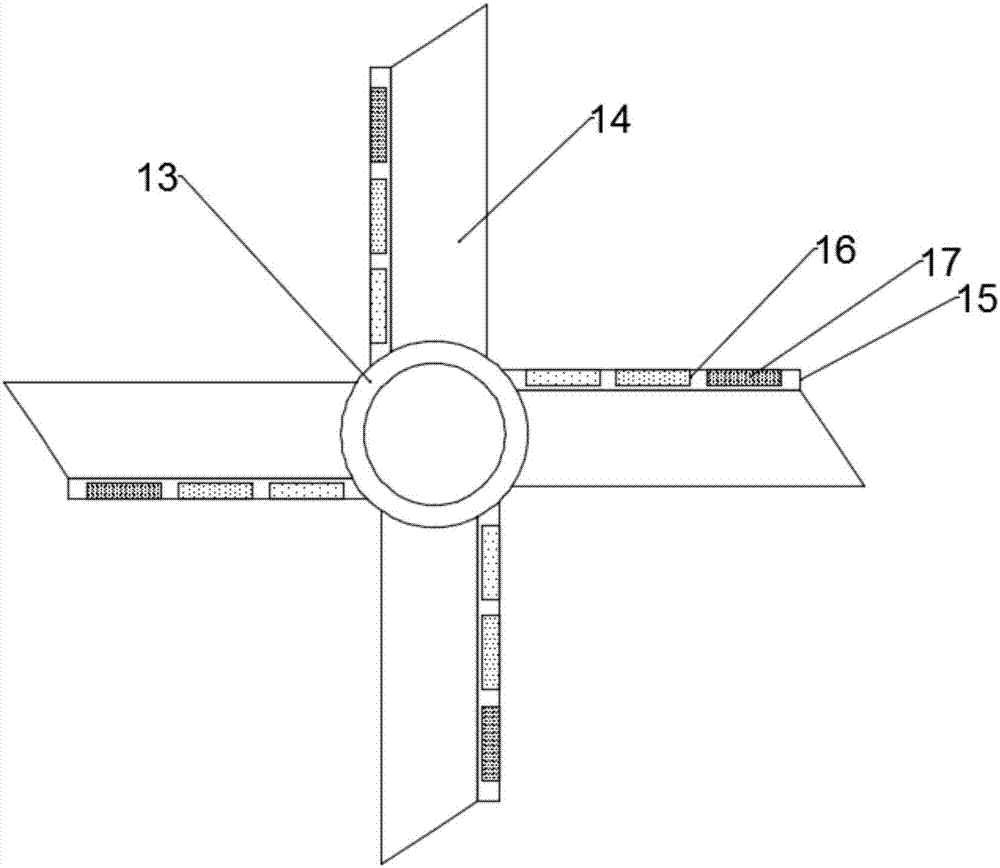

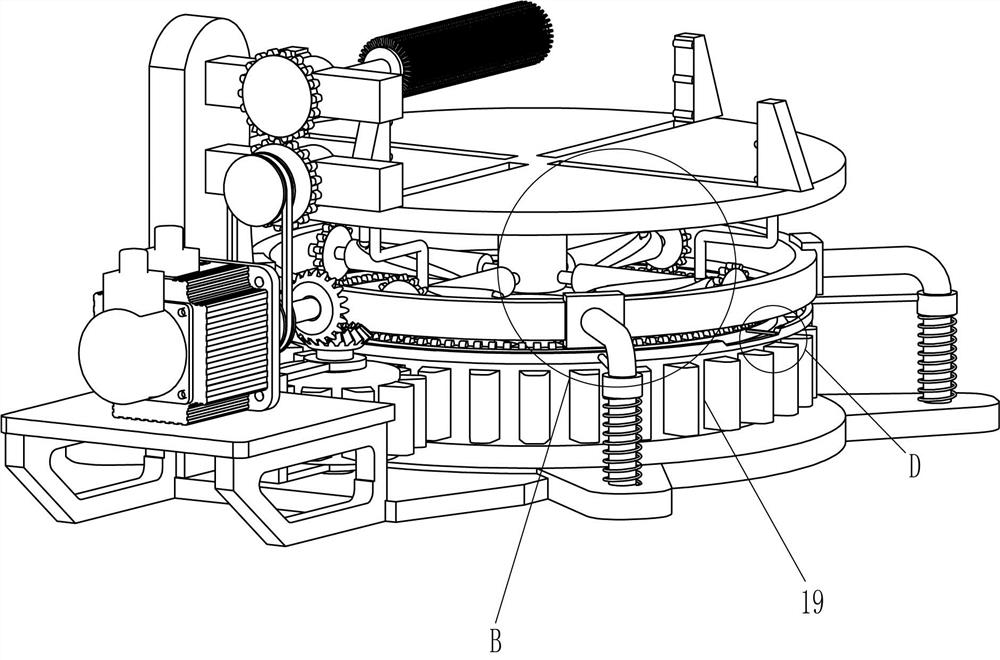

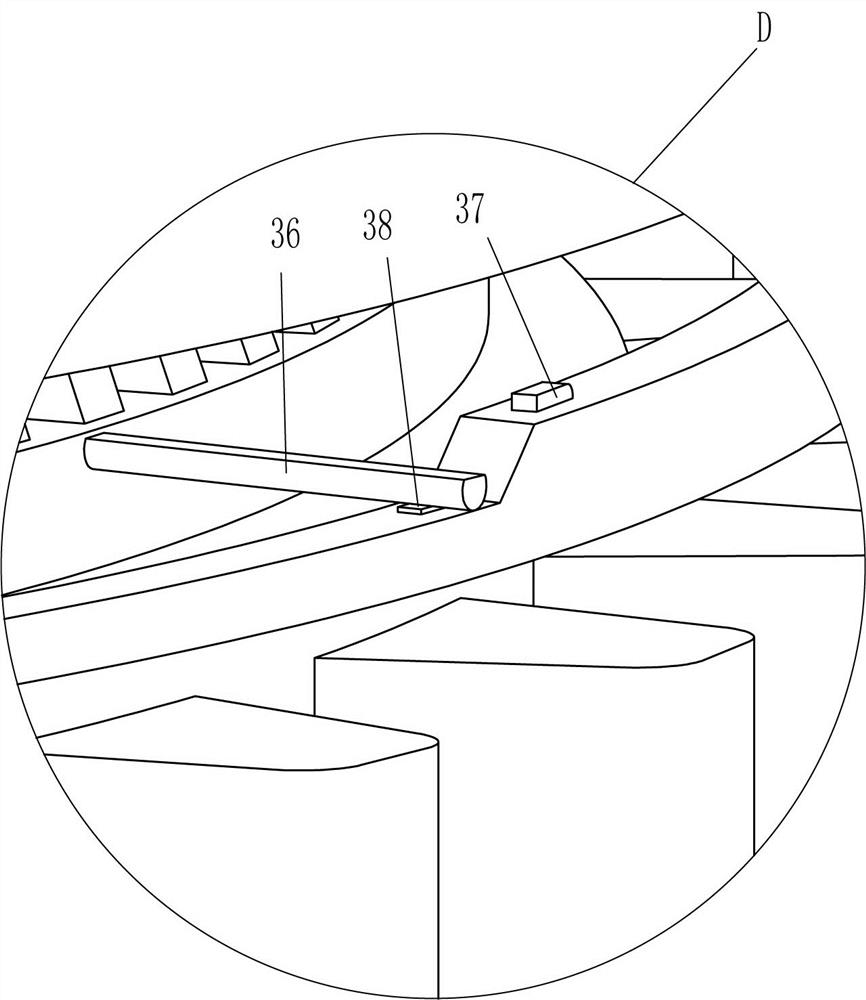

ActiveCN104815950AAchieve rollingAchieve grindingMould handling/dressing devicesDrive motorEngineering

The invention relates to foundry machinery, specifically to sand mixing equipment. The sand mixing equipment comprises a cylinder, a rotation shaft, a driving motor, a watering device, a valve device, a sand rolling device, a sand fluffing device, a sand-casting device and a scraper plate. The cylinder is a hollow cylinder structure. The bottom of the cylinder is provided with a fan-shaped opening. A support plate is arranged at the opening. The opening is used for releasing mixed sand. The support plate is provided with through-holes. The rotation shaft is installed at the middle part of the cylinder. The driving motor is positioned below the cylinder. The watering device is positioned above the rotation shaft. The valve device is installed at the bottom of the cylinder. The sand rolling device, the sand fluffing device, the sand-casting device and the scraper plate are uniformly installed on the periphery of the rotation shaft. The scraper plate is positioned at the bottom of the cylinder. The sand mixing equipment has a simple structure. By effectively integrating a muller, a sand fluffing rod, a plough and the scraper plate, rolling, grinding, stirring and turning-over of a material are realized, and sand-mixing efficiency of the sand mixer is enhanced.

Owner:南通乐士机械有限公司

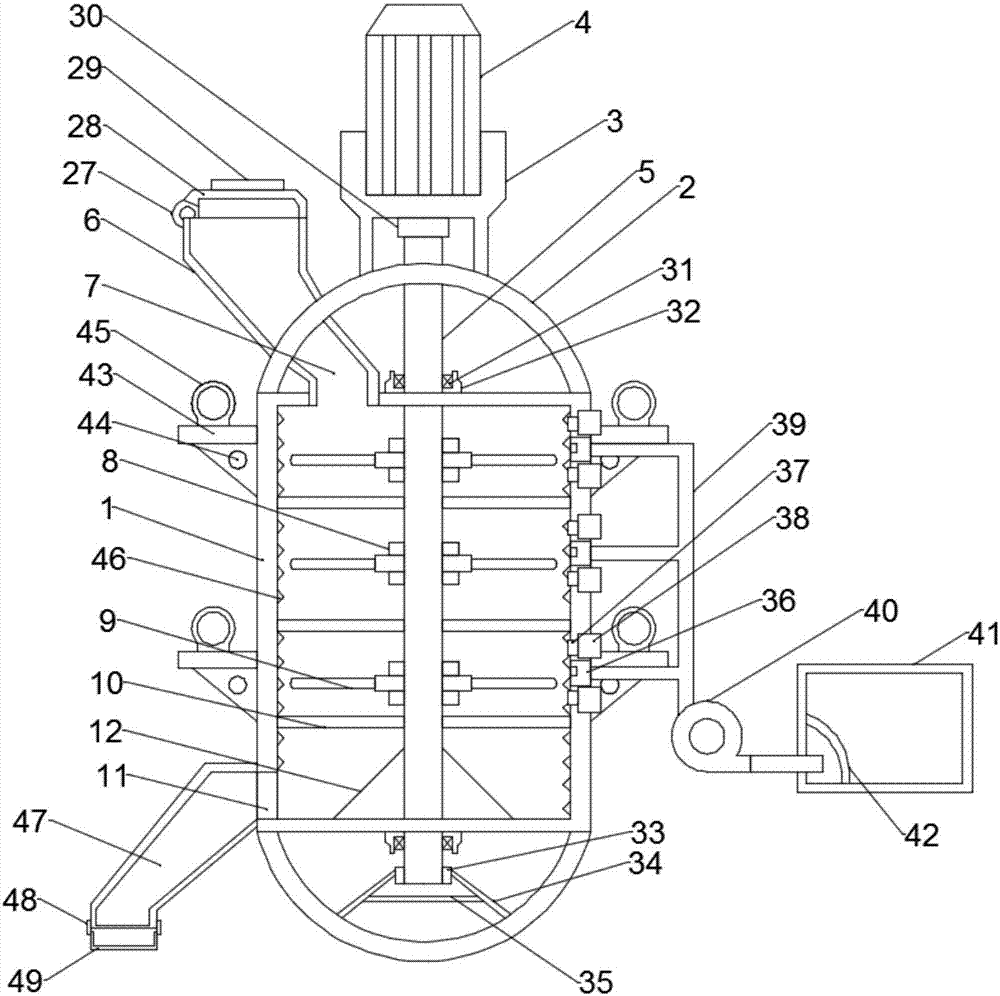

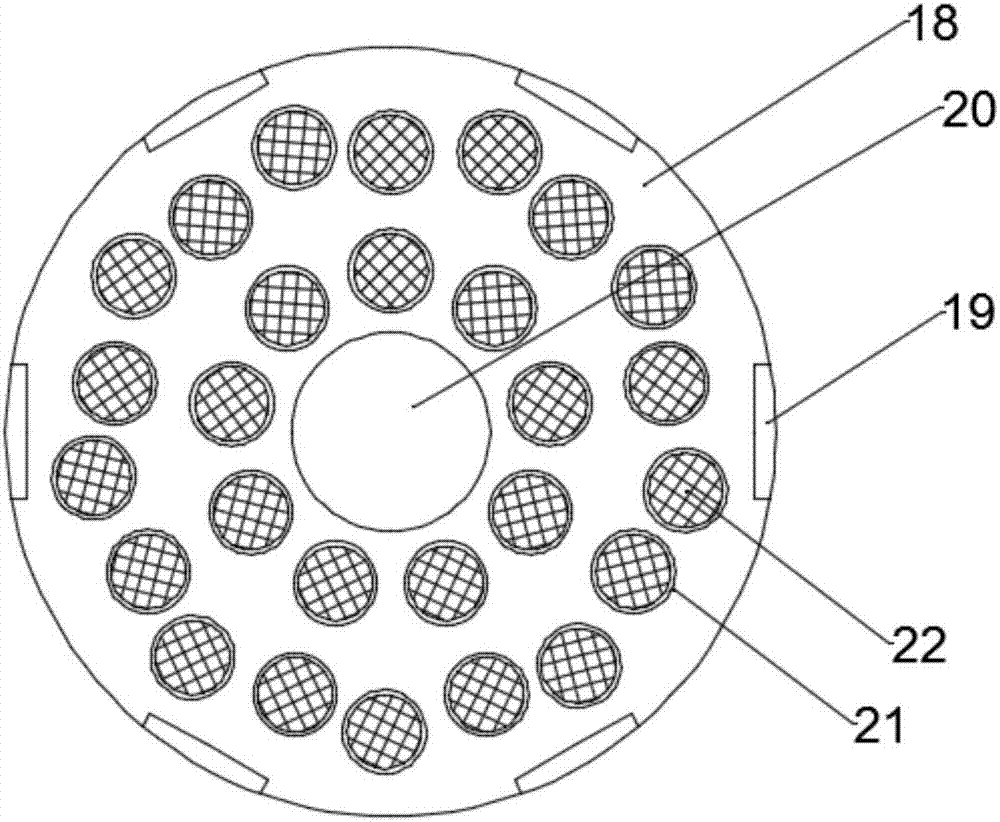

Graphene slurry multistage grinding and stirring device

The invention discloses a graphene slurry multistage grinding and stirring device which comprises a reaction kettle body. Sealing covers are mounted at the upper end and the lower end of the reaction kettle body; a motor frame is arranged at the upper end of the corresponding sealing cover; a driving motor is arranged in the motor frame; a driving main shaft is connected to the lower end of the driving motor; and a hopper-type feeding device is arranged at the upper end of the sealing cover. Three grinding and stirring mechanisms are mounted on the driving main shaft through a fixing clamping block; multistage screening plates are arranged between the grinding and stirring mechanisms; a discharging port is formed in the lower end of the reaction kettle body; a conical grinding mechanism is arranged at the right end of the discharging port; and the conical grinding mechanism is mounted at the lower end of the driving main shaft. When stirring blades rotate, grinding rods make contact with graphene slurry firstly, after the graphite slurry collides grinding particles of grinding sections, hard particles inside the slurry are well crushed and collided, thus internal slurry grinding is achieved, graphene slurry stirring and grinding integration is achieved, multistage processing is well conducted, the finer effect is achieved, and the graphene slurry multistage grinding and stirring device is worth popularizing.

Owner:徐州东创重工机械有限公司

Automatic skillet grinding machine

ActiveCN103949955AAchieve grindingReduce harmGrinding machinesGrinding/polishing safety devicesEngineeringMechanical engineering

The invention belongs to the field of a skillet grinding machine, and particularly relates to an automatic skillet grinding machine capable of automatically grinding. The grinding machine comprises a stand, a skillet rotating device and a grinding mechanism, wherein the stand is also provided with a dust collection cover; the dust collection cover is arranged at the front end of the skillet rotating device; the skillet rotating device has a cylinder-shaped structure; the skillet rotating device with the cylinder-shaped structure is connected with a vertically arranged rotating shaft II by a belt through a rotating shaft I; the lower end of the rotating shaft II is movably and fixedly arranged at the lower part of the stand, and is connected with a motor by a belt; the upper end of the rotating shaft II is fixedly arranged on the stand by a shaft sleeve I; the shaft sleeve I is movably sheathed with the rotating shaft II. The automatic skillet grinding machine is based on problems in the actual production, the aim that a plurality of grinding machines are operated by a person at the same time for grinding can be realized, and the structure of the automatic skillet grinding machine is novel; a dust prevention and removal device is additionally arranged, so that the harm of dust to the bodies of workers can be reduced to a certain extent; the automatic skillet grinding machine can be freely adjusted up and down as well as front and back, so that a pot body can be ground in an all-around way.

Owner:HENAN HUABANG ELECTRONICS COOKWARE

Pipe wall polishing and grinding treatment device

PendingCN107571104AAchieve grindingImprove work efficiencyGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

The invention provides a pipe wall polishing and grinding treatment device comprising a work table, a rack, a first air cylinder, a first motor, a second air cylinder, a second motor and a third air cylinder. The rack is arranged on the work table, the first air cylinder is slidably arranged on a first sliding rail, a lifting plate is connected below the first air cylinder through a telescopic rod, a first grinding wheel is arranged below the lifting plate. The second air cylinder stretching and retracting in the horizontal direction is arranged on the rack, and the second air cylinder is connected with the first air cylinder through a telescopic rod. A supporting plate perpendicular to a grinding rod is arranged on the work table, an annular fixing clamp is arranged on the outer side of agrinding rod hole of the supporting plate, the outer side of the fixing clamp is sleeved with a bearing, and the fixing clamp is used for fixing the other end of a pipe, so that the grinding qualityof the pipe is ensured.

Owner:TIANJIN KEEP RUNNING TECH DEV

High-strength glass edging device

InactiveCN108527062AAchieve grindingGuaranteed straightnessEdge grinding machinesHigh intensityEngineering

The invention discloses a high-strength glass edging device which comprises a rack. Two slide rails in parallel are arranged on two sides of the upper surface of the rack; a bearing assembly is arranged on the slide rails through a sliding joint way; a driving assembly for driving the bearing assembly to move is arranged between the bearing assembly and the rack, and is arranged on the rack; and two edging assemblies are symmetrically arranged on two sides of the rack. According to the high-strength glass edging device provided by the invention, through changing strokes of a No.1 electric cylinder and a No.2 electric cylinder, an included angle between a grinding roller and a glass side edge can be changed, so that the glass side edge can be ground at any angle without the need for manualoperation; and through arranging the slide rails, the moving straightness of the bearing assembly is ensured, and the edging quality is further ensured.

Owner:临泉县蓝天钢化玻璃有限公司

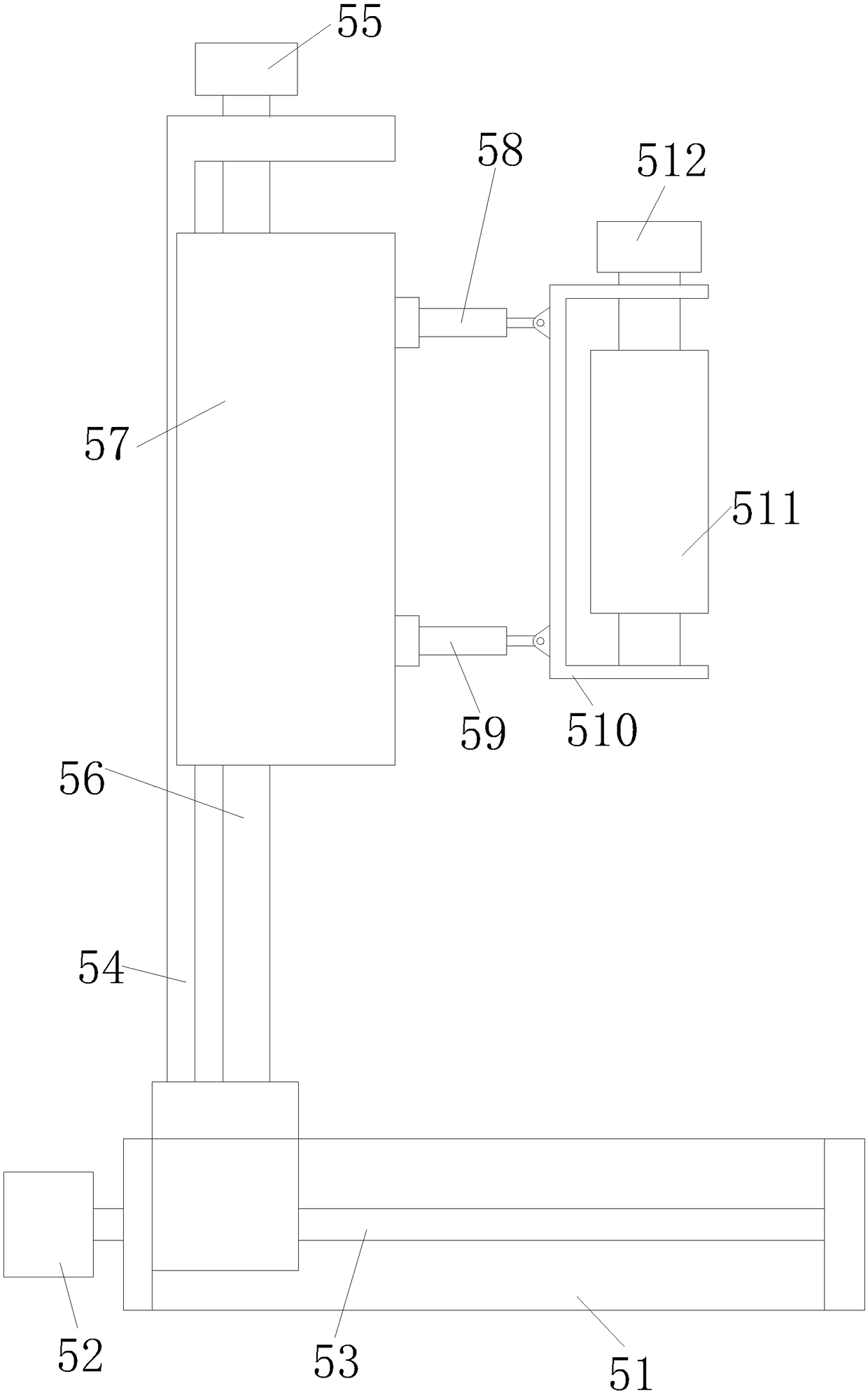

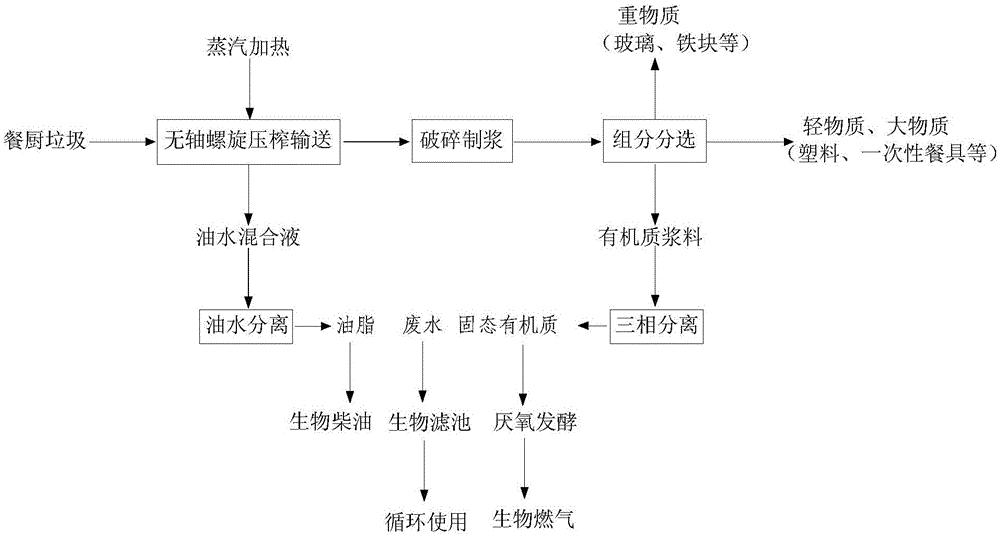

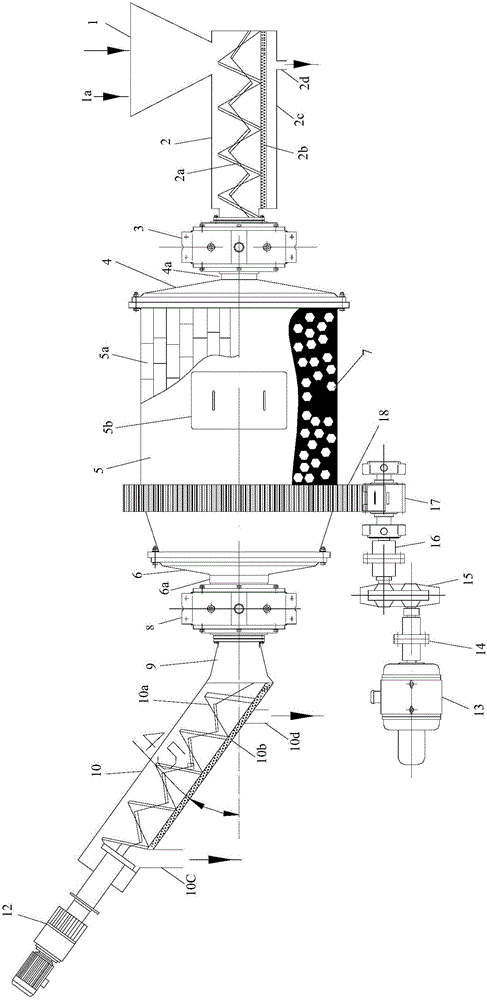

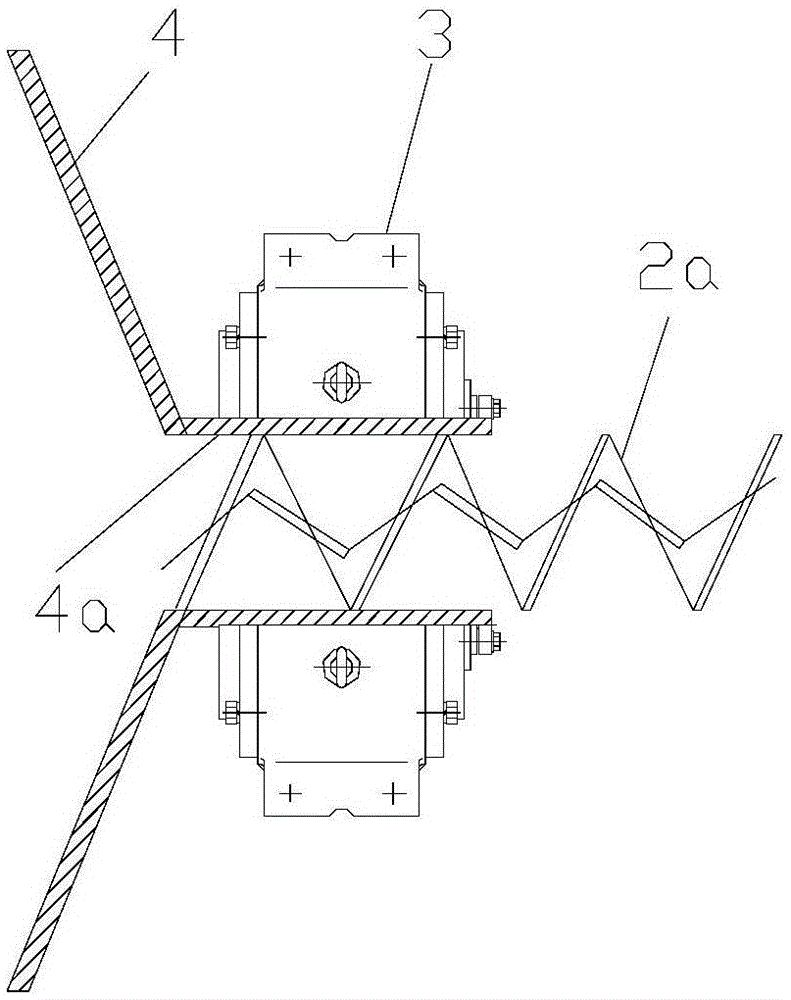

Integrated device for kitchen waste continuous crushing pulping and component sorting

ActiveCN105057305AAchieve brokenAchieve grindingSolid waste disposalDodecahedronContinuous operation

The invention discloses an integrated device for kitchen waste continuous crushing pulping and component sorting. The integrated device comprises a main driving device, and a feed oil extraction device, a feed end main bearing, a crushing cavity, a discharging end main bearing and a discharging sorting device which are sequentially connected, and the main driving device provides motive power required by operation of the crushing cavity. The integrated device has the advantages that a treatment mode of primary oil extraction, crushing and then sorting is applied, the process is simple, and the treatment efficiency is high; kitchen waste conveying and primary oil extraction can be achieved through the feed oil extraction device; a dodecahedron special for kitchen waste is used as a crushing body and performs casting motion in the crushing cavity which rotates in a decelerating mode to crush and grind raw materials, crushing effects are good, the pulping efficiency is high, and intertwining is not prone to occurrence; impurities and organic material pulps can be effectively separated by means of the discharging sorting device. The whole integrated device is reasonable in design, high in integration level and capable of performing continuous operation of kitchen waste crushing pulping and component sorting.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

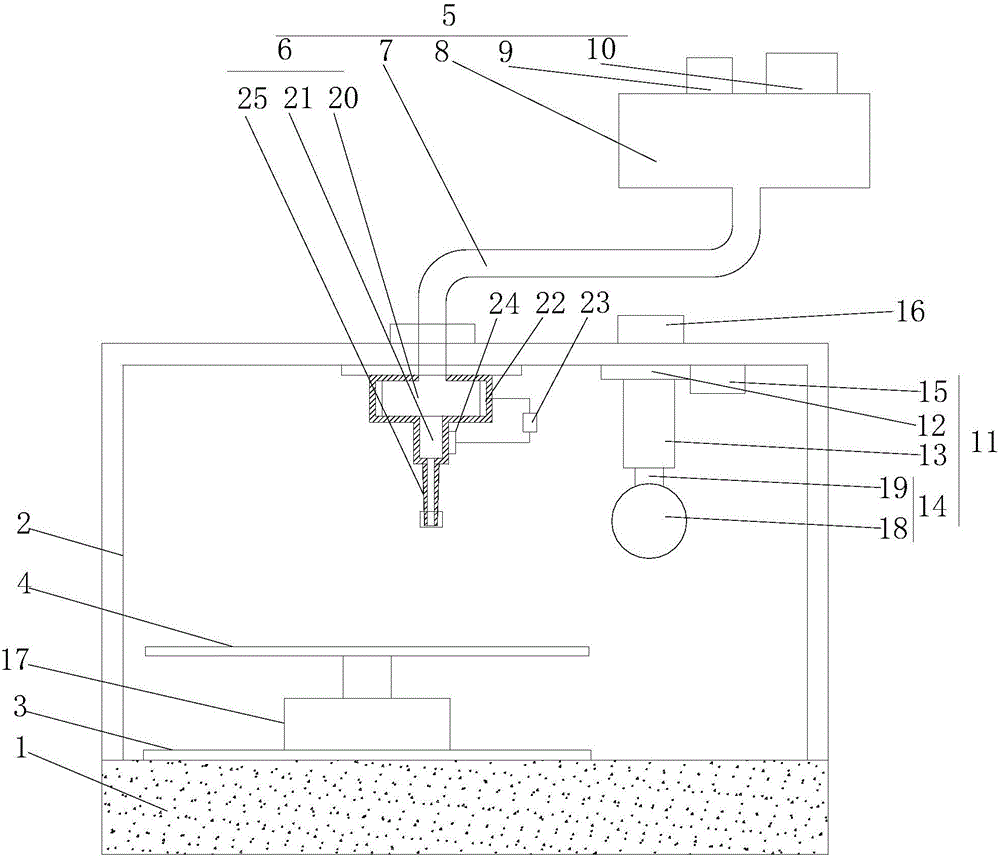

Three-dimensional printer with polishing function

InactiveCN105128334AAchieve grindingImprove product qualityAdditive manufacturing apparatusEngineering3D printing

The invention provides a three-dimensional printer with a polishing function. The three-dimensional printer comprises a base, a supporting frame, a rotary table, a lifting device, a worktable, a printing device and a polishing device, wherein the supporting frame is arranged on the base, the rotary table is mounted on the base in a rotating manner, the lifting device is arranged on the rotary table, and the worktable is horizontally arranged on the lifting device; the printing device comprises a printing nozzle, a feed pipe, a material storing box, a positive pressure device and a negative pressure device, wherein materials in the material storing box can be fed to the printing nozzle through the feed pipe by the positive pressure device, and negative pressure can be provided for the material storing box by the negative pressure device, so that the materials in the printing nozzle and the feed pipe flow into the material storing box back; the polishing device comprises a fixing base, a connecting rod, a polishing head and a first driving mechanism, wherein the fixing base is mounted at the top end of the supporting frame in a sliding manner, the first driving mechanism is connected with the fixing base, the connecting rod is positioned under the fixing base, the first end of the connecting rod is connected with the fixing base, and the second end of the connecting rod is connected with the polishing head.

Owner:WUHU SIRUIDI THREE DIMENSIONAL TECH CO LTD

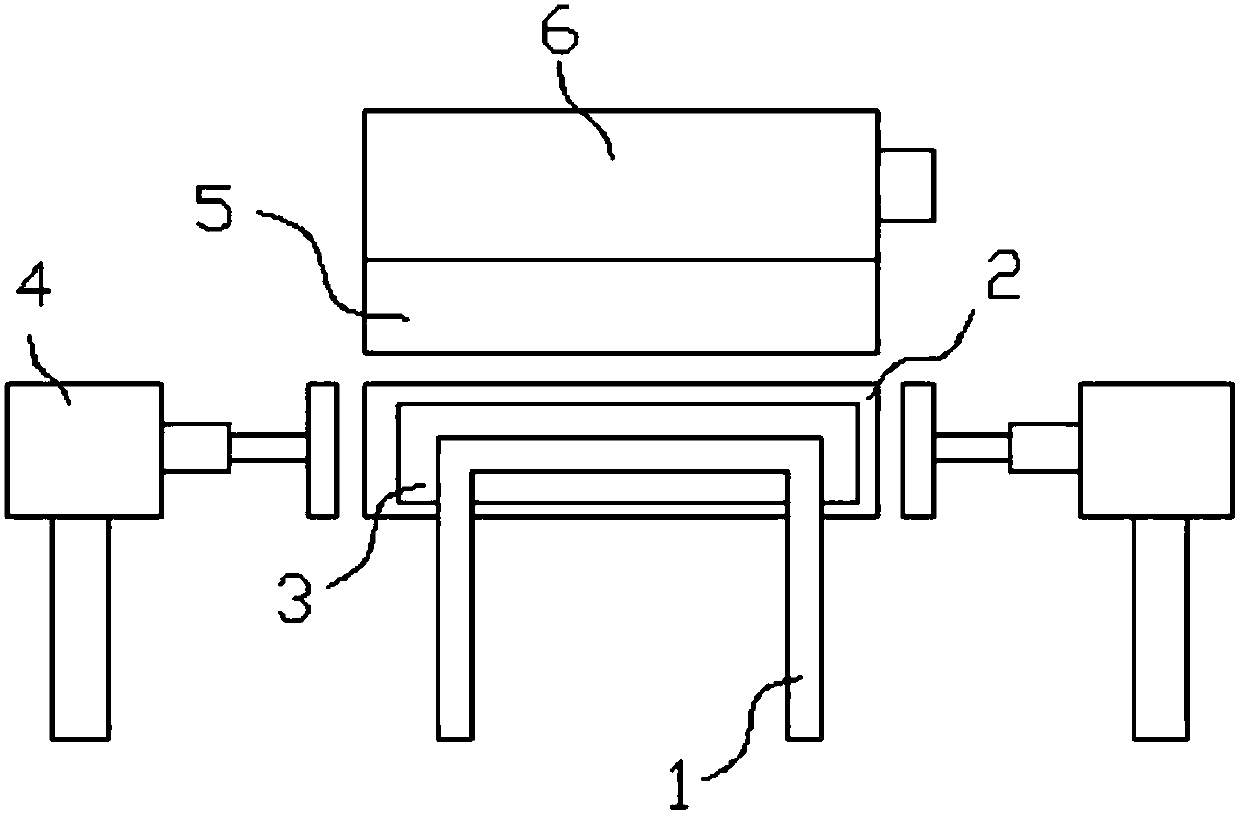

Sheet material grinding mechanism and grinding method thereof

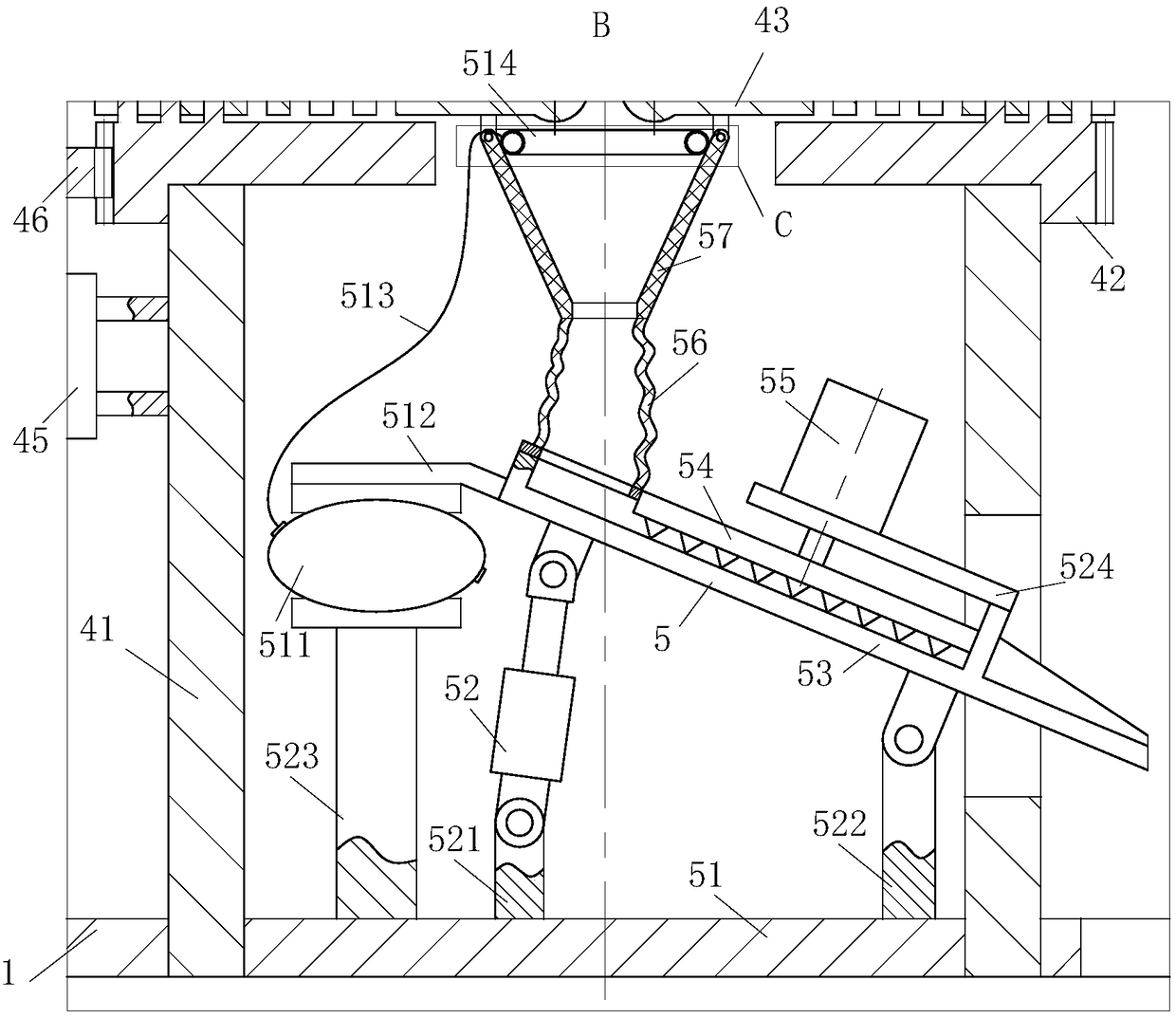

InactiveCN110977640AAchieve grindingSimple structureGrinding drivesGrinding work supportsElectric machineEngineering

The invention discloses a sheet material grinding mechanism and a grinding method thereof. The sheet material grinding mechanism comprises an upper and lower surface grinding and turning module and asheet material side end grinding device; the upper and lower surface grinding and turning module comprises a sheet material upper and lower surface grinding device and a sheet material turning device;the sheet material upper and lower surface grinding device comprises a first lead-screw, a first motor, a second motor, a third motor, a second lead-screw and a first grinding table; the sheet material turning device comprises a third lead-screw, a fourth motor, a fifth motor, a sixth motor, a first rotating block, a second rotating block, a fourth lead-screw and a rotating rod; and the sheet material side end grinding device comprises a fifth lead-screw, a seventh motor, an eighth motor, a second grinding table and a sixth lead-screw. The sheet material grinding mechanism is provided with the sheet material turning device, which can automatically lift a sheet material and rotate 180 degrees without manual turning after the upper surface of the sheet material is polished, thus the lower surface faces upward, and thereby polishing of the lower surface is realized; and the structure is simple, the practicability is high, and the sheet material grinding mechanism can be applied to a widevariety of fields such as the field of a variety of sheet material processing.

Owner:江苏国振家昌家居有限公司

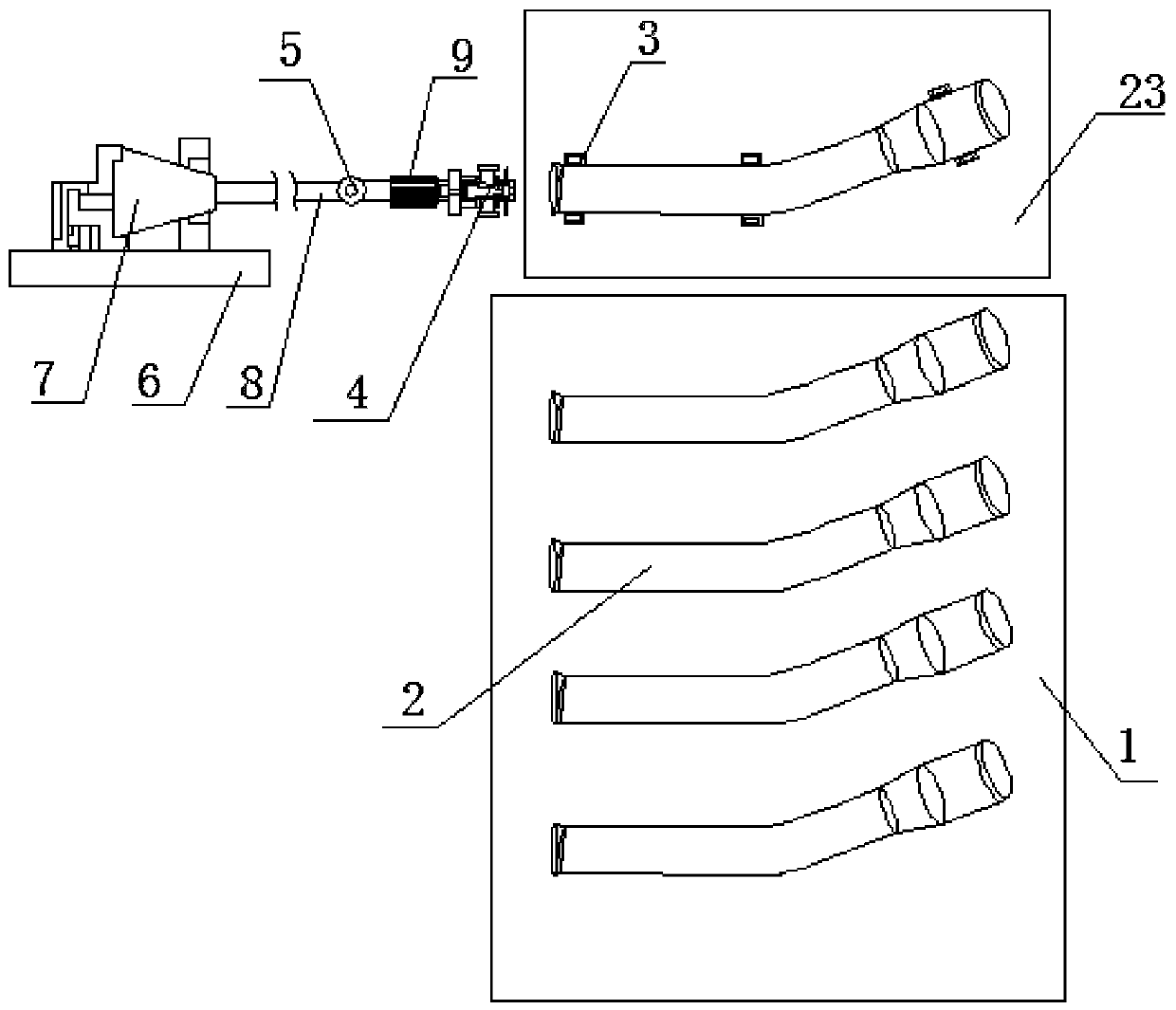

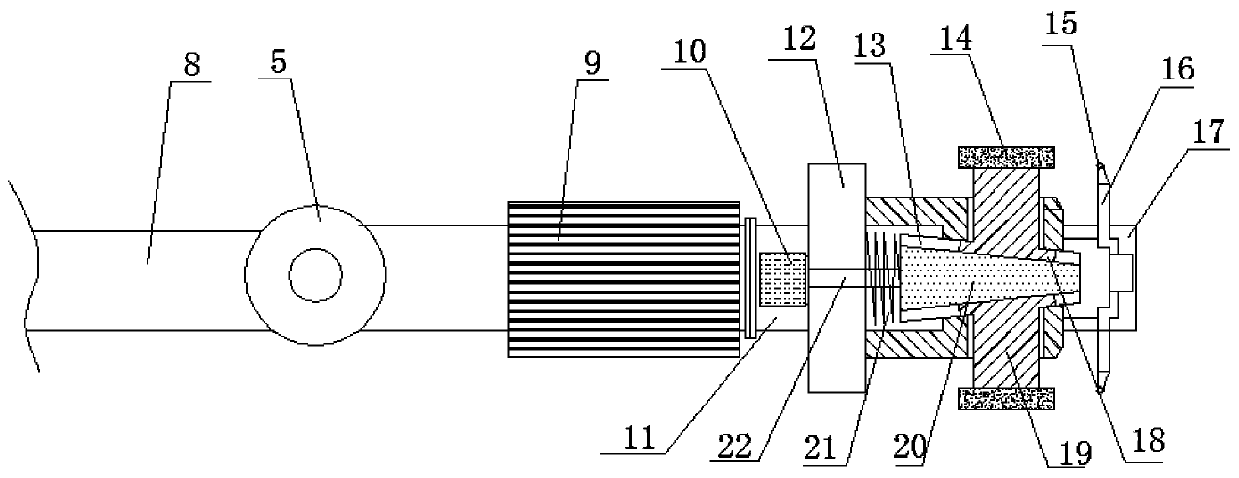

Intake pipe processing equipment for engine air intake system

InactiveCN110497284AImprove processing efficiencyImprove grinding efficiencyEdge grinding machinesGrinding carriagesAerospace engineeringBatch processing

The invention discloses an intake pipe processing equipment for an engine air intake system. According to the invention, the batch processing of intake pipes can be effectively realized. The intake pipe is placed on a positioning and locking mechanism on a processing table, and can be automatically positioned by a positioning mechanism of the positioning and locking mechanism and locked by the locking mechanism, and a grinding processing mechanism is started to extend and grind the inner wall of the intake pipe; a grinding head assembly is arranged at the end of a flexible feeding rod of an axial feeding mechanism in a way that the angle of an universal ball hinge can be adjusted, so as to effectively enable the grinding head assembly and the flexible feeding rod to adapt to the arc of theintake pipe; the intake pipe processing equipment can adapt to the grinding of different inner wall diameters of different parts of the intake pipe, the grinding is thorough, and the versatility is high; at the same time, the pressing force of the grinding can be controlled by an ejector cylinder, which is simple and convenient; and by utilizing the design of an elastic positioning piece of the locking mechanism, the intake pipe can be positioned and locked under the pressing effect of a locking pressing seat.

Owner:GUILIN UNIV OF AEROSPACE TECH

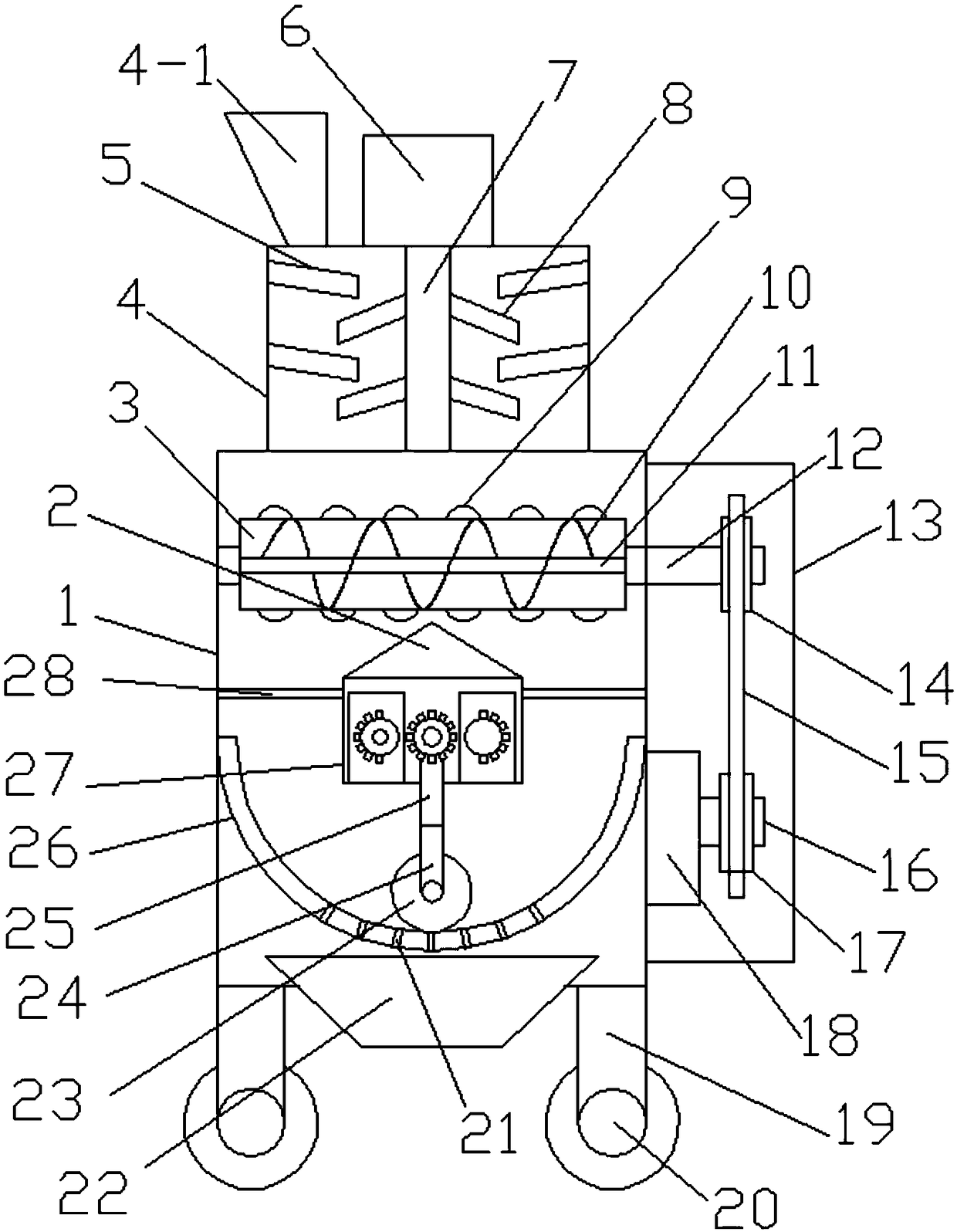

Automatic grinding machine for bamboo joints

InactiveCN107838782ARealize integrated automatic grindingImprove removal efficiencyGrinding drivesCane mechanical workingEngineeringSharpening

The invention relates to an automatic grinding machine for bamboo joints. The machine comprises a rack and a clamping and grinding device; the clamping and grinding device comprises two half clampingand grinding device bodies; the half clamping and grinding device bodies are matched with a bamboo tube through arc-shaped clamping blocks; grinding disks are arranged in positions where the arc-shaped clamping blocks are matched with the bamboo tube; bamboo joint grinding devices are matched on the left and right sides of the bamboo tube; each bamboo joint grinding device comprises a bamboo tuberotating motor, the bamboo tube rotating motor is connected with a bamboo tube rotating seat, the bamboo tube rotating seat is connected with a bamboo tube pressing air cylinder and an inner joint removal rotating motor, the bamboo tube pressing air cylinder is connected with bamboo tube pressing blocks matched with the left and right end surfaces of the bamboo tube, the inner joint removal rotating motor is connected with an inner joint removal feeding air cylinder, and an air cylinder push rod of the inner joint removal feeding air cylinder is connected with an inner joint removal grinding column. According to the machine, the clamping and grinding device cooperates with the bamboo joint grinding devices which can rotate and press the bamboo tube to grind outer bamboo joints, and the inner bamboo joints can be ground synchronously by the aid of inner bamboo joint grinding parts arranged in the bamboo joint grinding devices, so that the bamboo joint removal efficiency is improved.

Owner:DONGGUAN UNIV OF TECH

High-efficiency circulation rubber grinder

InactiveCN106903823AAchieve grindingQuality improvementPlastic recyclingGrain treatmentsImpellerEngineering

The invention discloses a high-efficiency circulation rubber grinder. The high-efficiency circulation rubber grinder comprises a feed mechanism and a first grinding chamber. A first grinding set comprises a fixed grinding disc and a movable grinding disc. The discharge end of the feed mechanism communicates with an opening in the fixed grinding disc. The movable grinding disc is connected with a first motor through a horizontal spindle. The feed mechanism comprises a spiral feed pipe and a speed adjusting motor. The spiral feed pipe is provided with a feed hopper. A crushing impeller set is arranged above the feed hopper. A vertically arranged grinding roller is arranged below the first grinding set. An obliquely arranged screening net is arranged between the grinding roller and the fixed grinding disc. A second grinding set is arranged in a second grinding chamber. A spiral feed pipe is connected to the bottom of the second grinding chamber. According to the rubber grinder, the grinding efficiency and the quality of rubber powder are improved, and the service life of equipment is prolonged, meanwhile, large particles left on the screening net can be automatically cycled and ground repeatedly, and the work efficiency and powder quality are further improved.

Owner:绵阳市奇帆科技有限公司

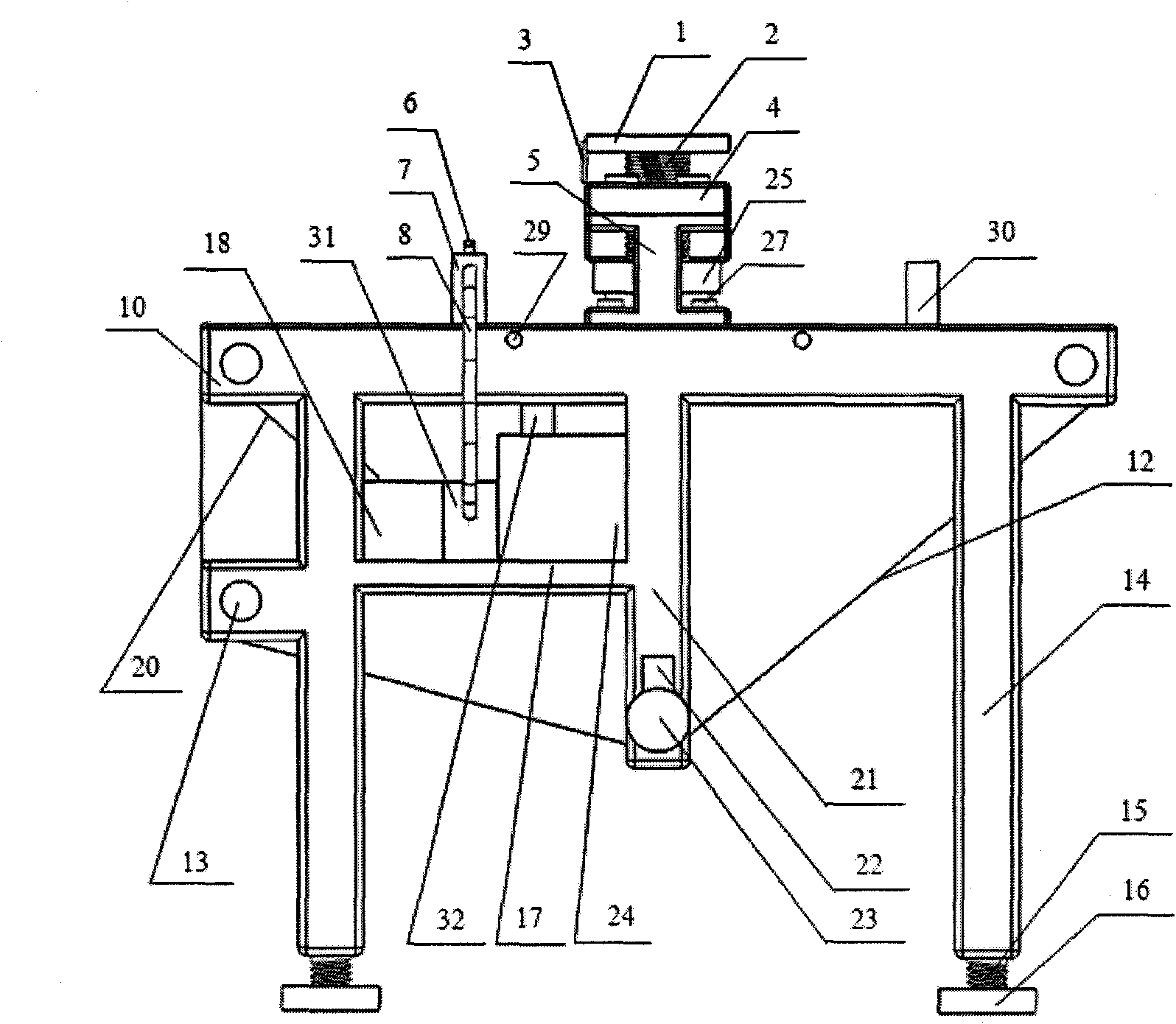

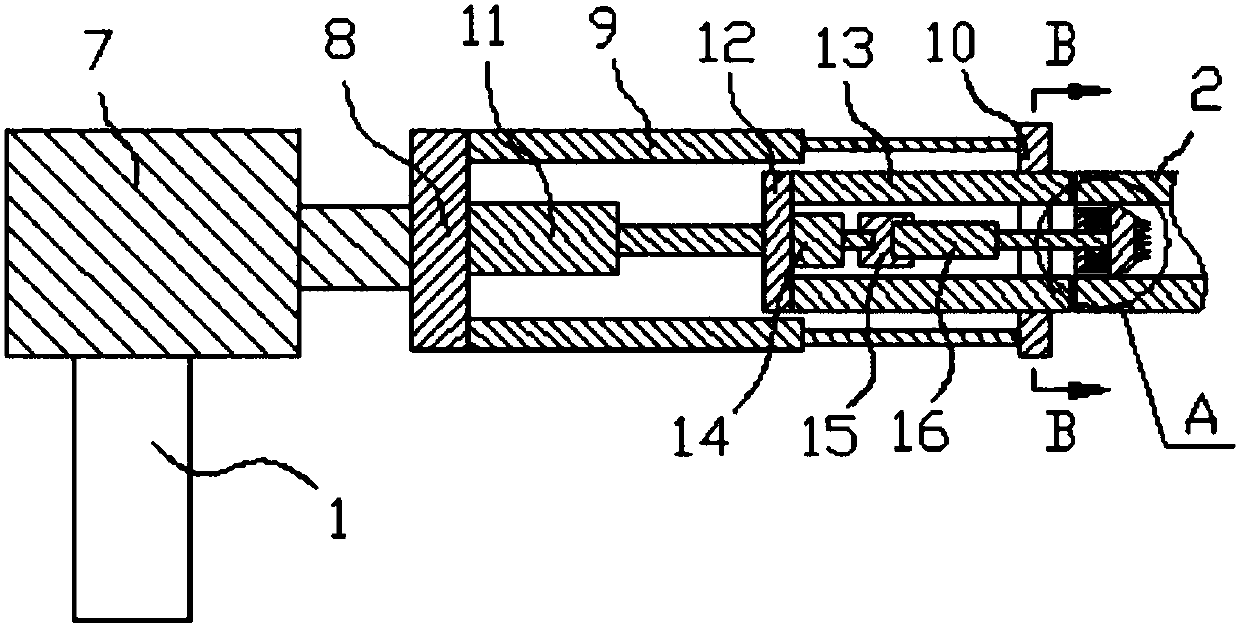

Self guiding bent pipe inner surface magnetic abrasive finishing device and method

InactiveCN108161599ASimple structureEasy to operateRevolution surface grinding machinesSurface finishMagnetic poles

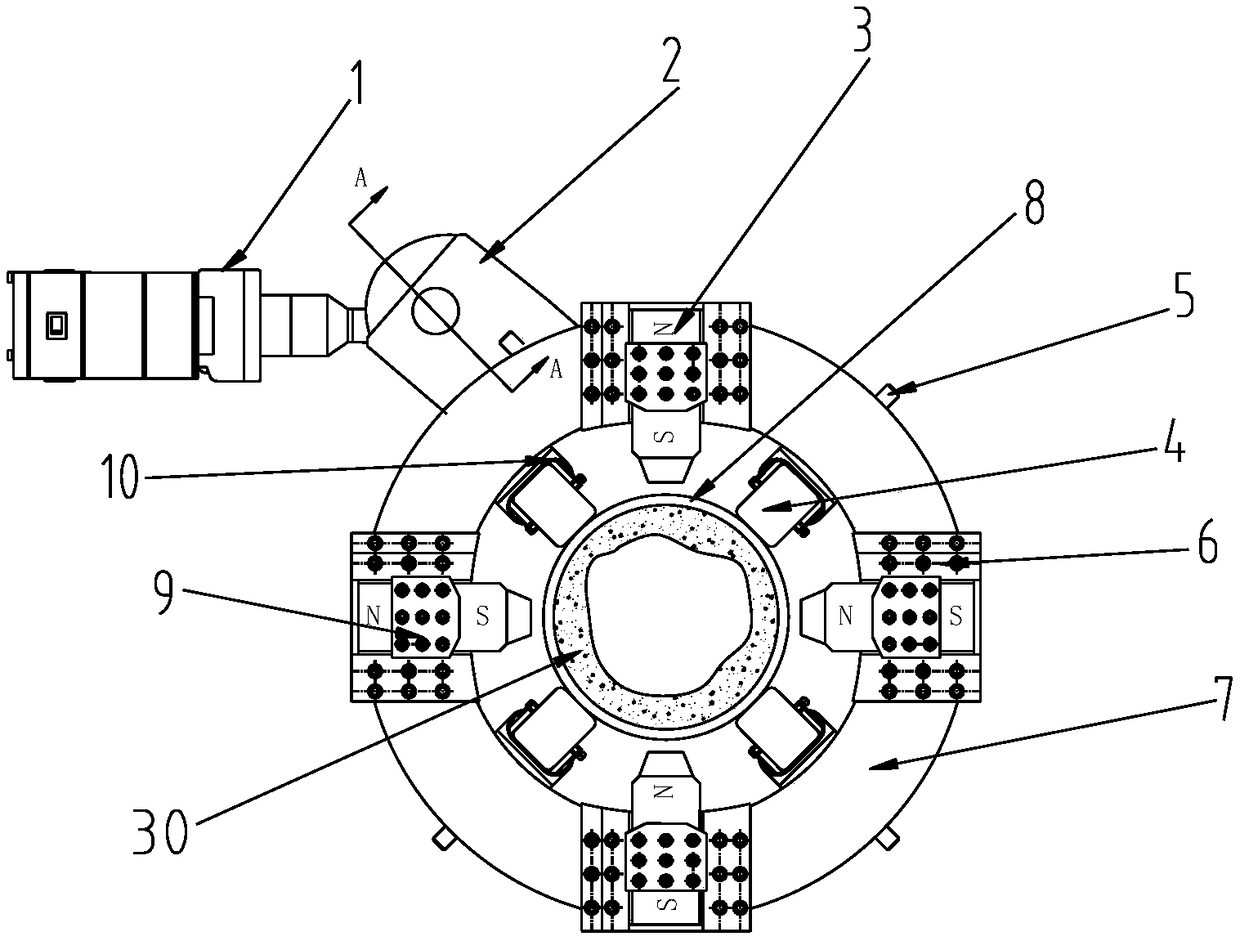

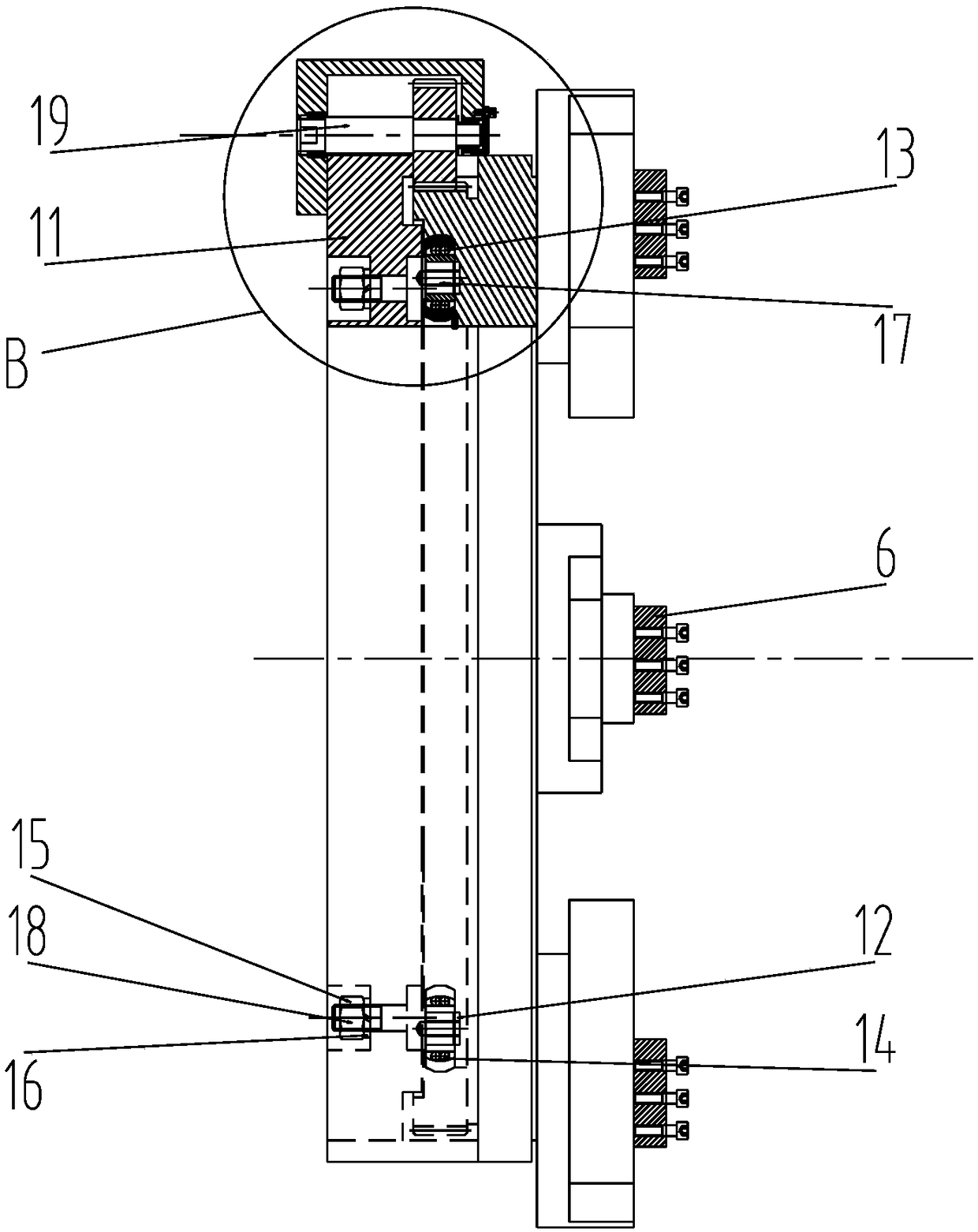

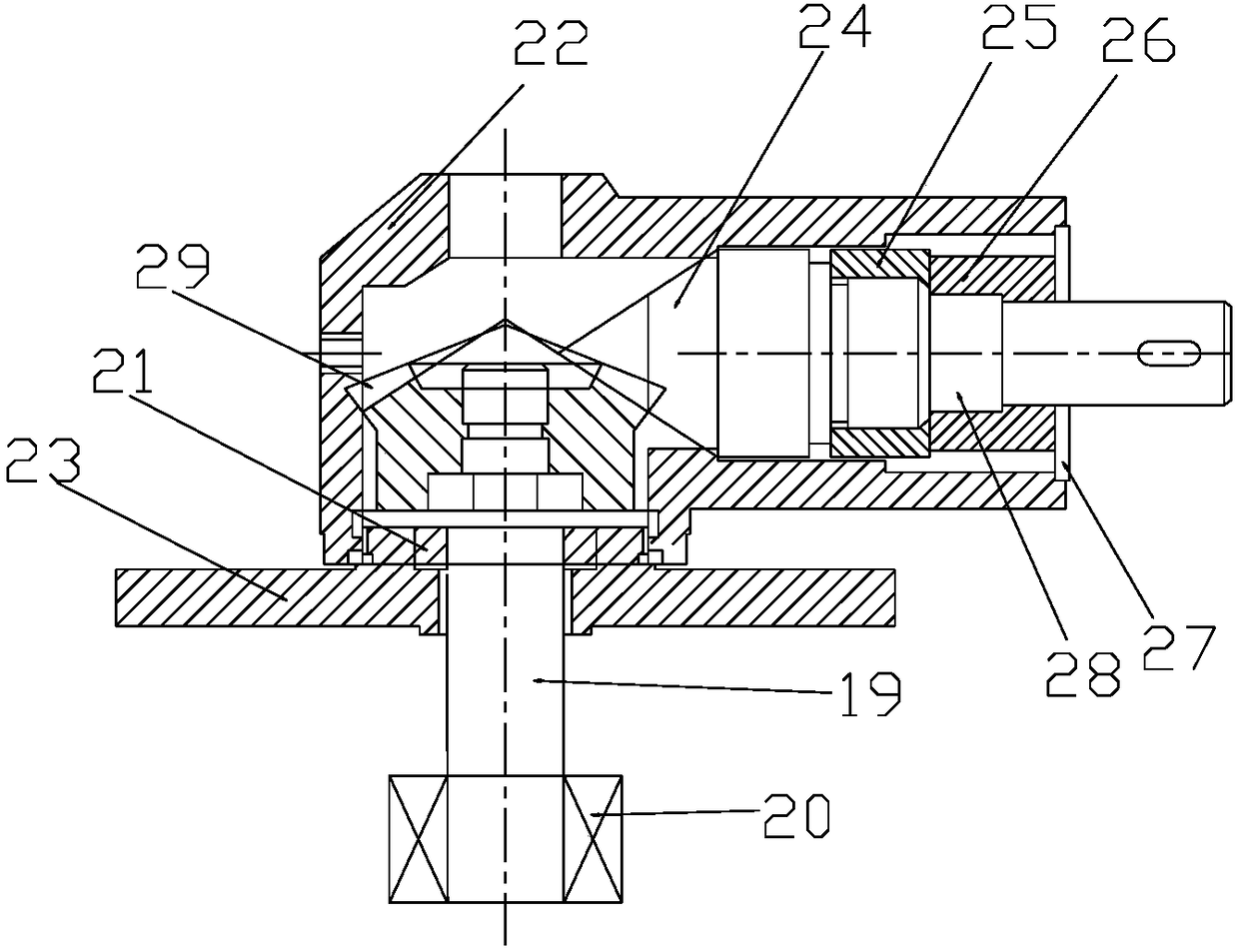

The invention relates to a self guiding bent pipe inner surface magnetic abrasive finishing device and method. The device comprises a rotating driving mechanism, a maintaining machine frame, a rotating machine frame, a magnetic pole clamping mechanism and a guiding walking mechanism. The maintaining machine frame and the rotating machine frame are both annular components, and arranged at the periphery of the bent pipe in a sleeving mode. The rotating machine frame is rotatably connected with the maintaining machine frame, and the rotating machine frame can rotate circumferentially around the bent pipe under driving of the rotating driving mechanism. The guiding walking mechanism is arranged on the maintaining machine frame, under driving of the guiding walking mechanism, the magnetic abrasive finishing device can integrally move in the axis direction of the bent pipe. The magnetic pole clamping mechanism is arranged on the rotating machine frame, and a magnetic pole in the magnetic pole clamping mechanism is matched with a magnetic abrasive material filled in the bent pipe to achieve magnetic abrasive finishing of the inner surface of the bent pipe. The self guiding bent pipe innersurface magnetic abrasive finishing device can adapt to the inner surface finishing of the bend pipes in different irregular shapes, the device is simple in structure, convenient to operate, high inmachining efficiency and low in machining cost.

Owner:UNIV OF SCI & TECH LIAONING

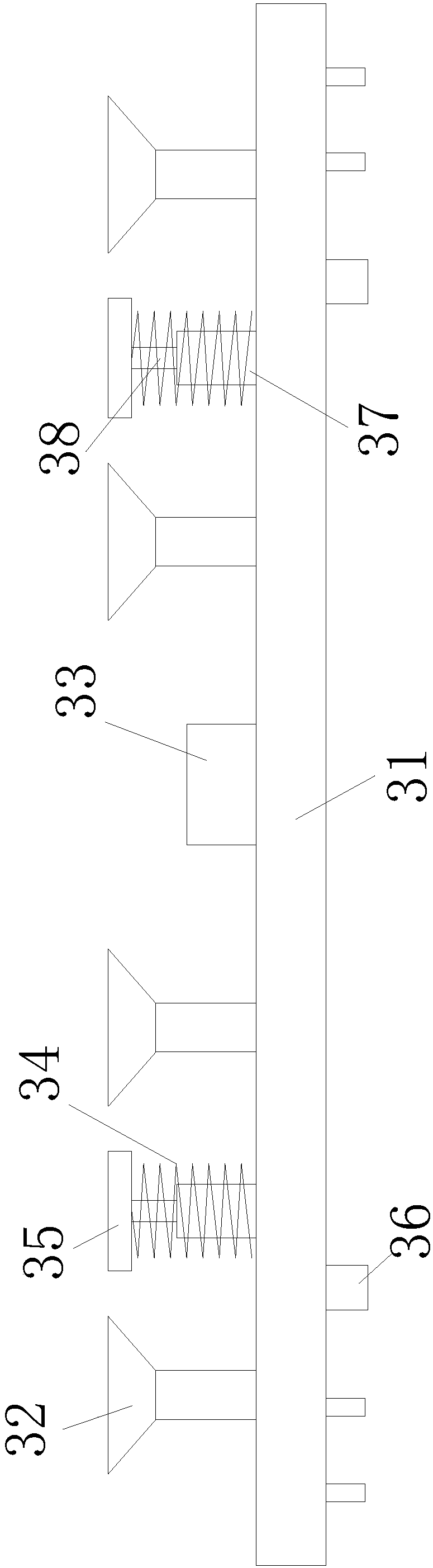

Outer peripheral face polishing machine for bearing outer ring

ActiveCN103753359AImprove grinding performanceAchieve grindingGrinding carriagesRevolution surface grinding machinesPeripheralEngineering

The invention provides an outer peripheral face polishing machine for a bearing outer ring and belongs to the technical field of machinery. The problem in the prior art that a special device for polishing the outer peripheral face of the bearing outer ring is unavailable is solved. The machine comprises a machine frame, a work table board is fixed on the machine frame, a first bearing seat and a second bearing seat which correspond to each other are fixed on the work table board, a grinding wheel is arranged between the first bearing seat and the second bearing seat through a first rotary shaft, and the first rotary shaft is connected with a power mechanism. A third bearing seat and a fourth bearing seat are arranged on the work table board, and a locating wheel is arranged between the third bearing seat and the fourth bearing seat through a second rotary shaft. A first guide track and a second guide track are fixed on the work table board, the third bearing seat and the fourth bearing seat are arranged on the first guide track and the second guide track in a sliding mode respectively, and the third bearing seat and the fourth bearing seat are connected with an adjusting mechanism. The machine can polish the outer peripheral face of the bearing outer ring and is high in efficiency.

Owner:HAINING QI SHENG BEARING

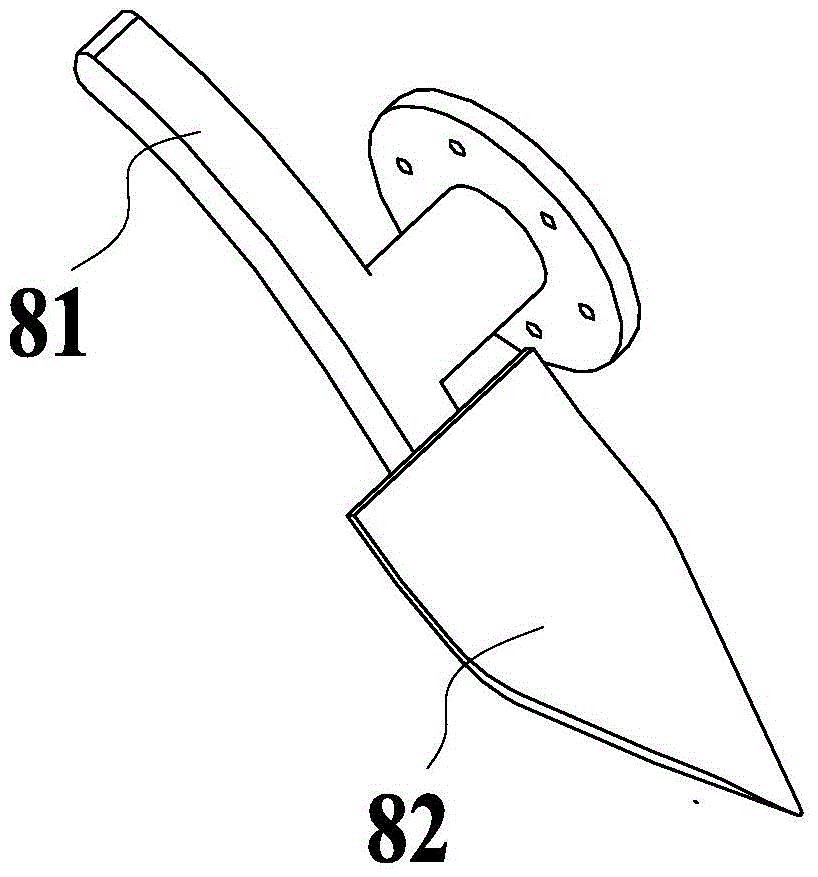

Chinese herb crushing, softening and grinding device

InactiveCN108654771ACleverly structuredReasonable arrangementGrain treatmentsFeeding tubeChinese herbs

The invention discloses a Chinese herb crushing, softening and grinding device. The Chinese herb crushing, softening and grinding device comprises a shell. A feed tube is arranged on the top of the shell. The lower end of the feed tube is of a barrel structure with an opening in the lower end. A feed hopper is arranged on the top of the feed tube. A crushing mechanism is arranged in the feed tube.A softening roller is arranged on the top of the interior of the shell. The softening roller is transversely arranged on the interior of the shell. The softening roller is of a hollow cylindrical body structure. A heating device is arranged in the softening roller. The Chinese herb crushing, softening and grinding device provided by the invention is ingenious in structural arrangement, reasonablein layout, capable of achieving crushing, softening and grinding of Chinese herbs, high in processing efficiency and good in effect. Through ingenious arrangement of the crushing mechanism, the Chinese herb crushing, softening and grinding device implements primary high-efficiency crushing of the Chinese herbs. Through ingenious arrangement of a softening mechanism, the Chinese herb crushing, softening and grinding device achieves uniform heating of the Chinese herbs and effectively prevents damage of high temperature to the Chinese herbs. Through ingenious arrangement of a grinding mechanism, the Chinese herb crushing, softening and grinding device achieves high-efficiency grinding of the Chinese herbs and facilitates discharging.

Owner:裘丹青

Horizontal grinding mill with built-in classifying turbine

InactiveCN101700504AOvercoming frictional resistanceReduce starting powerEngine sealsGrain treatmentsImpellerTurbine

The invention relates to a horizontal grinding mill with built-in classifying turbine, the technical solution of which is that a grinding chamber [18] is filled with grinding medium [6], a medium discharging valve [20] is installed on the middle of the bottom of a cylinder [7], a feeding pipe [10] is above a right end cover [9] of the grinding chamber [18] and a medium discharging pipe [2] is concentrically communicated with the grinding chamber [18] by a left end cover [3]. The length of the cylinder [7] is 1.5 to 2.5 times of the diameter thereof. A fairing [4] is fixedly installed on the left end cover [3] of the grinding chamber [18]. A classifying turbine [5] is vertically installed on the left end of a spindle [13]. A clearance between the classifying turbine [5] and the left end cover [3] is 5mm to 10mm. Five to eight mixing turbines [8] are vertically installed on the spindle [13]. The distance between the mixing turbines [8] decreases gradually from left to right and the right distance is 0.9 to 0.95 times of the left distance. The right end of the spindle [13] is connected with a driving mechanism by the right end cover [9] and a sealing device [11]. The invention has low starting power and can grind and classify with a function of selectively grinding.

Owner:WUHAN UNIV OF SCI & TECH +1

Automatic grinding machine used for grinding metal shell of USB interface

InactiveCN106737056AEasy clampingEasy to processGrinding machinesGrinding feedersAutomatic controlControl system

The invention provides an automatic grinding machine used for grinding a metal shell of a USB interface. The automatic grinding machine comprises a machine case which is internally equipped with a PLC automatic control system and a rotary workbench, wherein a supporting panel is mounted at the outer side of the rotary workbench in parallel; four product positioning devices, two perpendicular grinding devices and loading mechanical hands, which are arranged on the upper end surface of the rotary workbench, are fixedly mounted on the supporting panel; a vibrating disc used for automatically loading is arranged beside the machine case; and a quantitative feeding mechanism is arranged at one side of the discharge hole of the vibrating disc. The automatic grinding machine realizes automatic positioning and grinding for the metal shell of the USB interface, so that grinding auxiliary time is greatly reduced, heavy job of clamping workpieces during large-scale production is reduced, and clamping and processing for the workpieces can be improved, and therefore, the automatic grinding machine has the advantages of reducing labor intensity of workers, improving production efficiency, improving processing quality and the like; and moreover, the production period of the metal shell of the USB interface is shortened, so that production benefits of the enterprises are improved, and economic level of workers is improved.

Owner:XINGKE ELECTRONICS TECH

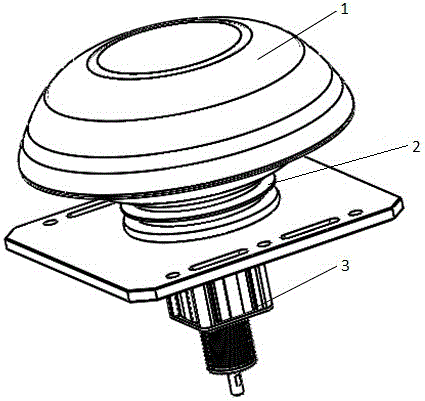

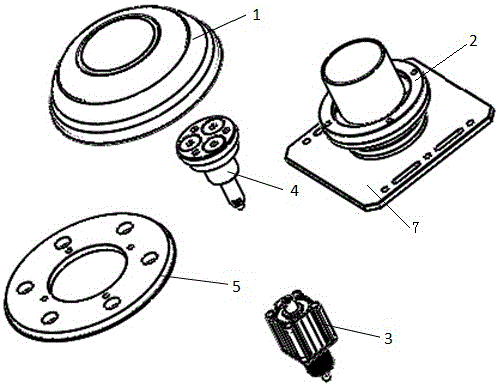

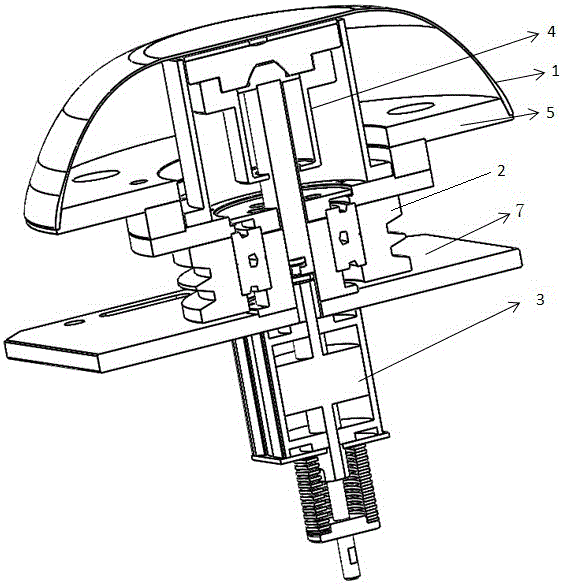

Novel jig for wok polishing

InactiveCN106346331AAchieve grindingGood effectGrinding machinesGrinding work supportsThermal insulationEngineering

The invention discloses a novel jig for wok polishing and aims to solve the problem that an existing wok blank fixing manner cannot guarantee the consistency of the rotation speed of a wok blank and the rotation speed of a roller or a profiling jig, the texture of the wok blank is affected during polishing, wok center positioning is uncertain, and the existing wok blank fixing manner has certain limitation. The novel jig comprises a base, a rotating mechanism, a wok polishing jig, a center-regulating mechanism and an air cylinder, wherein the rotating mechanism is arranged on the base and can rotate relative to the base; the wok polishing jig comprises a wok blank profiling jig for polishing the inner surface of the wok blank and an outer-surface jig for polishing the outer surface of the wok blank; the center-regulating mechanism comprises a center-regulating support, a magnet, a thermal-insulation pad and a center-regulating connecting rod connected with the center-regulating support, the thermal-insulation pad and the magnet are arranged on the center-regulating support respectively, and the air cylinder is connected with the center-regulating mechanism through the center-regulating connecting rod. The novel jig for wok polishing has the advantages that the rotation speed difference between the jig and the wok blank can be eliminated, the wok blank can be completely fixed on the jig, and the polishing efficiency and stability of the wok blank are increased greatly.

Owner:SICHUAN FUDE ROBOT

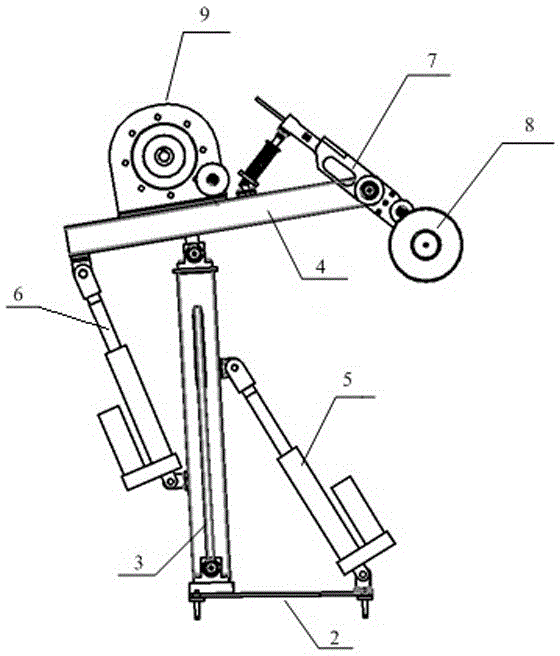

Grinding equipment and grinding method

ActiveCN105666280AAchieve grindingImplement servo controlSpherical surface grinding machinesGrinding feed controlControl systemEngineering

The invention discloses grinding equipment and a grinding method. The grinding equipment and the grinding method aim at solving the problems that at present, manpower is mainly adopted to grind a pot billet, consequently, operation efficiency is low, the requirement of an existing grinding device for the position of the pot billet is low, and certain limitation exists. The grinding equipment comprises a grinding mechanism and a control system; and the grinding mechanism comprises a grinding support, a first supporting rod, a second supporting rod, a first telescopic arm, a second telescopic arm, a third supporting rod, a grinding wheel and a grinding wheel driving device. One end of the first supporting rod is movably connected with the grinding support, and the first supporting rod can rotate relative to the grinding support; and the other end of the first supporting rod is movably connected with the second supporting rod. According to the grinding equipment, the automatic grinding requirement for workpieces with different sizes can be met, the extremely-high adaption is achieved, the grinding quality is good, efficiency is high, the production period is short, the cost is low, the good application prospect is achieved, and the equipment is worth applying and popularizing in a large-scale manner.

Owner:SICHUAN FUDE ROBOT

Automatic paint spraying robot

The invention discloses an automatic paint spraying robot which comprises walking mechanisms, a square plate, lead screw mechanisms, a grinding mechanism, a blowing mechanism, a paint spraying mechanism, a drying mechanism, a clamping mechanism, a bottom plate, a rotary disc and a first supporting column. The walking mechanisms are mounted on the two sides of the bottom plate. The lead screw mechanisms are fixedly mounted on the four sides of the upper end face of a square plate. The grinding mechanism, the blowing mechanism, the paint spraying mechanism and the drying mechanism are all mounted on the lead screw mechanisms. The clamping mechanism is mounted at the front end of the bottom plate. According to the automatic paint spraying robot, a metal plate can be polished through the grinding mechanism on the lead screw mechanisms, and air can be blown to the polished metal through the blowing mechanism on the lead screw mechanisms; paint can be sprayed to the metal through the paint spraying mechanism on the lead screw mechanisms; the paint can be dried through the drying mechanism on the lead screw mechanisms; a metal workpiece can be clamped through the clamping mechanisms; andmultiple paint boxes are arranged and can contain paint in different colors.

Owner:陕西亿青诚环保科技有限公司

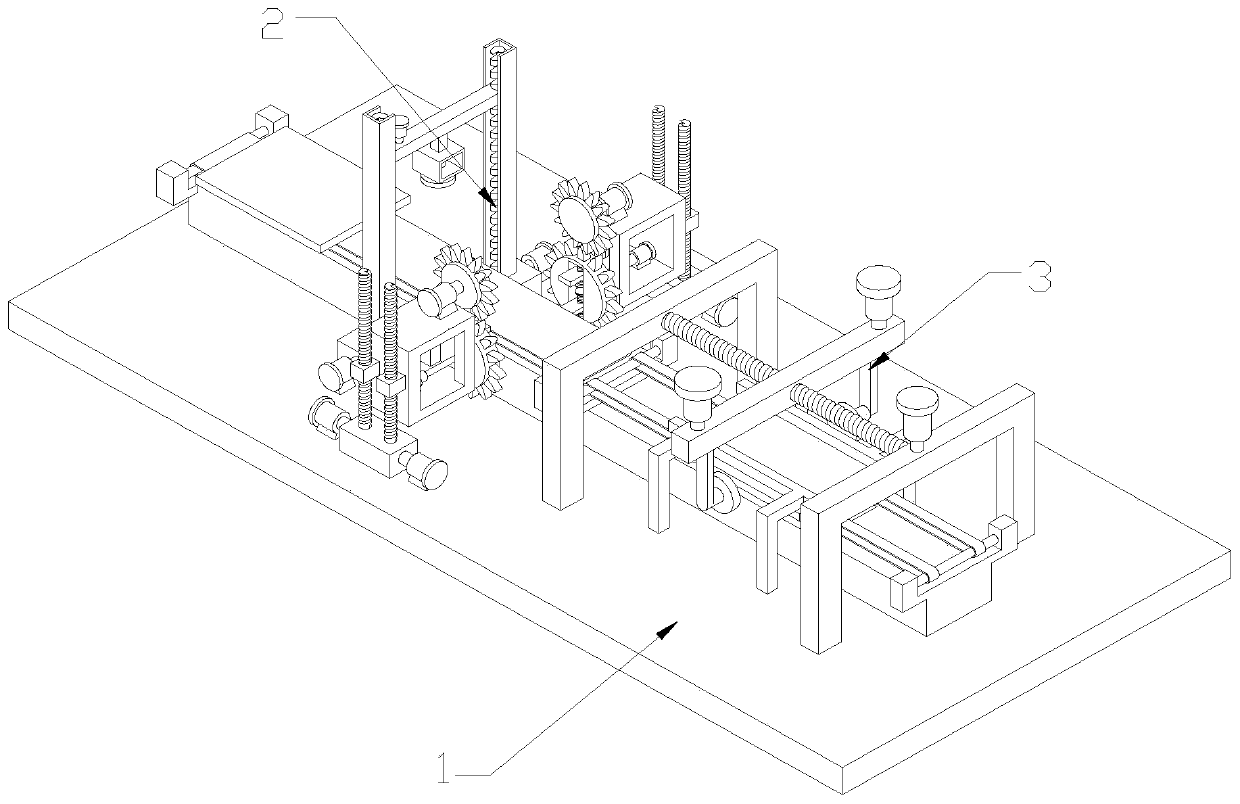

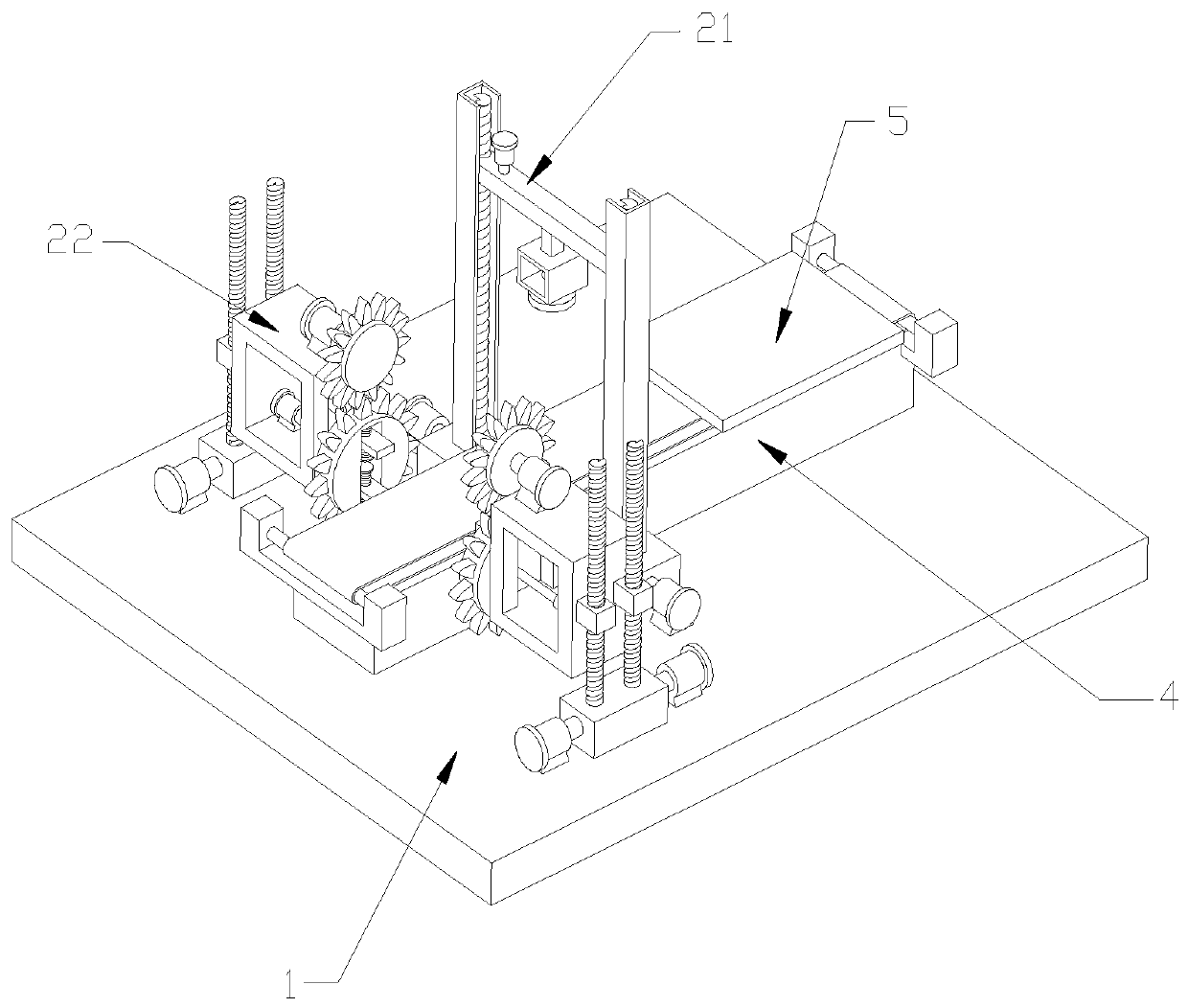

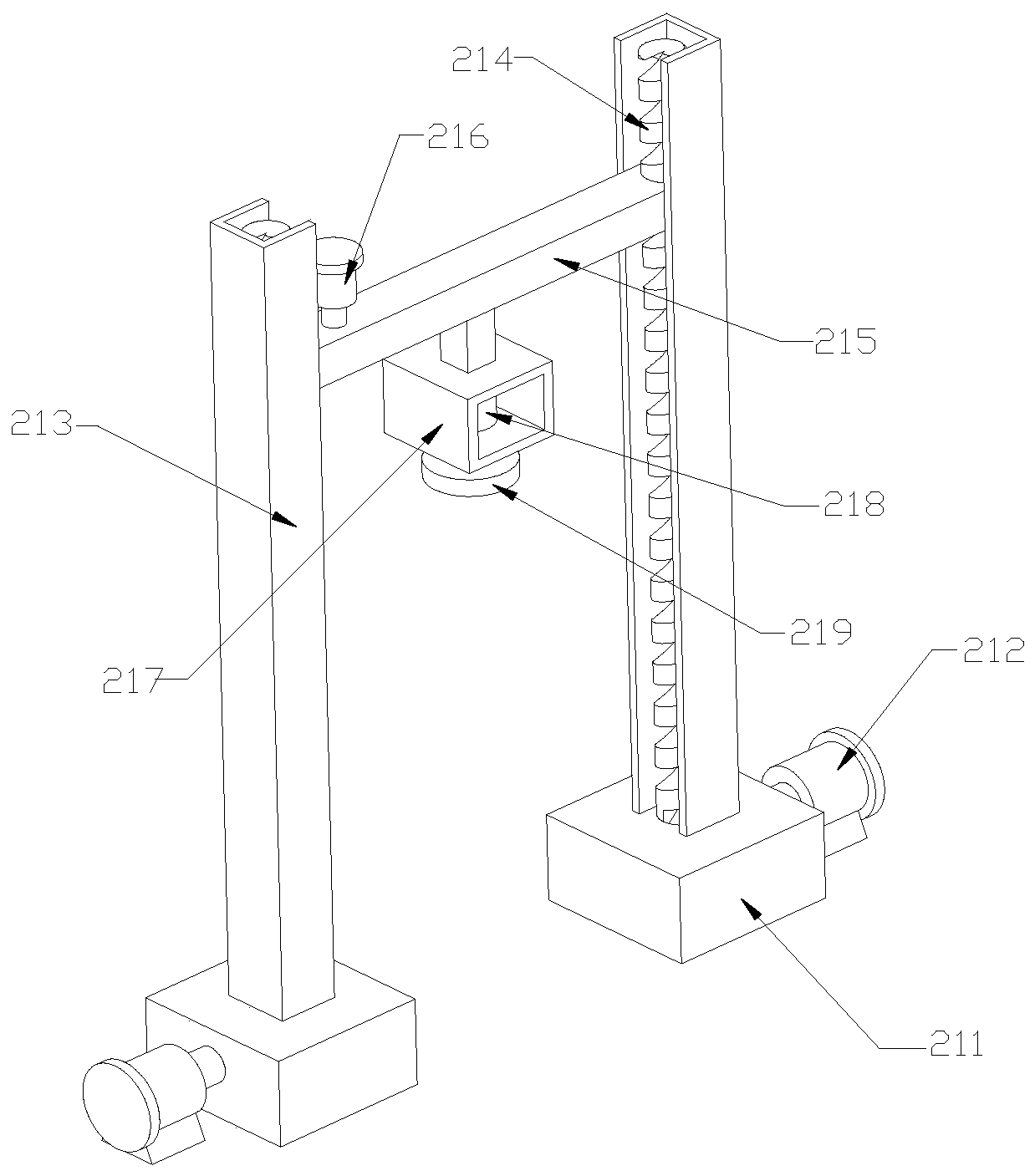

Cutting board grinding device

The invention relates to a grinding device, in particular to a cutting board grinding device, and aims at achieving the technical purpose of providing a cutting board grinding device capable of automatically clamping a cutting board, driving the cutting board to rotate forwards and reversely and conducting secondary grinding on the cutting board. According to the technical scheme, the cutting board grinding device comprises a base, an installing frame, a containing plate, a grinding mechanism, a clamping rotation mechanism and a drive mechanism; and the installing frame is arranged on one sideof the top of the base, the clamping rotation mechanism is arranged on the top of the base, the installing frame is located on one side of the clamping rotation mechanism, the top of the clamping rotation mechanism is connected with the containing plate, and the top of the base is provided with the drive mechanism. Through cooperation of the drive mechanism, the clamping rotation mechanism and the grinding mechanism, the cutting board can be automatically clamped, the cutting board can be automatically driven to rotate as well, the surface of the cutting board can be ground in the process that the cutting board is driven to rotate, and convenience and rapidness are achieved.

Owner:吴燕灵

Gravure water-based ink and preparation method thereof

The invention provides gravure water-based ink which comprises the following ingredients: 40-60wt% of modified acrylic resin emulsion, 15-35wt% of color paste, 3-15wt% of polyethylene wax, 1-5wt% of an antifoaming agent and 10-30wt% of a diluent, wherein the color paste comprises the following ingredients: 35-60wt% of dye, 30-45wt% of a wetting dispersant, 1-10wt% of a pH value modifier, 0.5-5wt% of a antifoaming agent and 5-15wt% of water. When the gravure water-based ink provided by the invention is grinded, materials have good viscidity with rollers, the gravure water-based ink is uniform in particle size and good in color can be prepared, and good color generation effect is achieved.

Owner:HUNAN FURUI PRINTING CO LTD

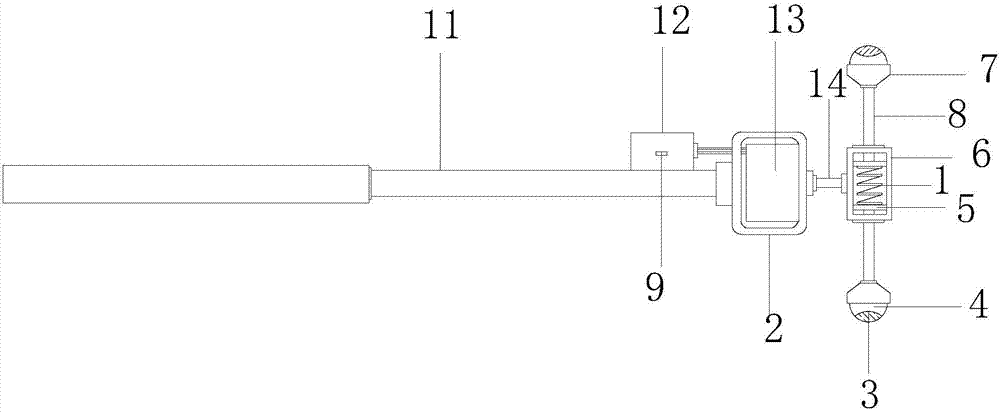

Automatic slurry filling device for concrete crack defect with high adhesion strength

The invention discloses an automatic slurry filling device for a concrete crack defect with high adhesion strength, which comprises a slurry filling pipe, wherein the concrete slurry is injected intothe concrete crack through the slurry filling pipe; and also comprises a machine frame, an electric sliding element, an electric lifting element, a rubber sleeve, a trowel, a first supporting rod, a first sucking disc, a second supporting rod and a abutted element; the electric sliding element is in sliding fit with the machine frame, the electric lifting element is arranged on the electric sliding element, the lifting end of the electric lifting element is connected with the slurry filling pipe, and the trowel is sleeved at the periphery of the slurry filling pipe through the rubber sleeve. The first sucking disc is arranged on the end part of the first supporting rod; the connecting end of the abutted element is slidably mounted on the end part of the second supporting rod, and the abutted end of the abutted element can be contacted with the trowel. The device has the advantages that the crack can be fully filled, the slurry leakage condition is reduced, the flatness of the surface after filling the slurry is high, the slurry filling pipe can achieve sliding and grouting in the crack, and the installation stability of a bracket is high, no damage is caused on a wall body or the adhesion strength of a plate body is high.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

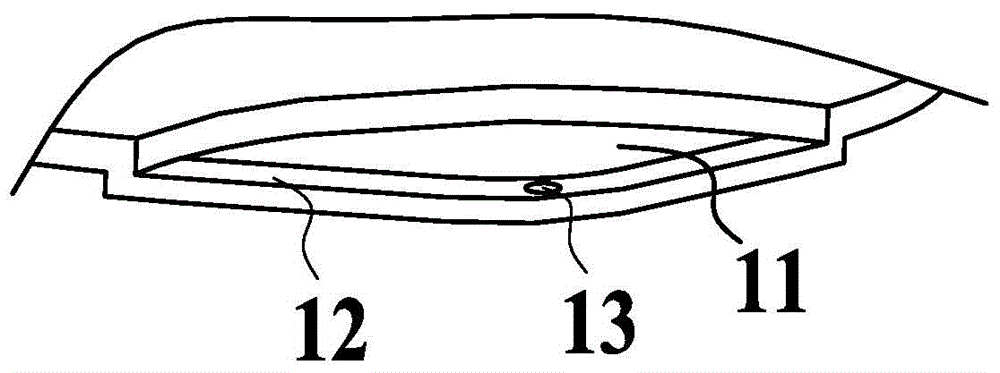

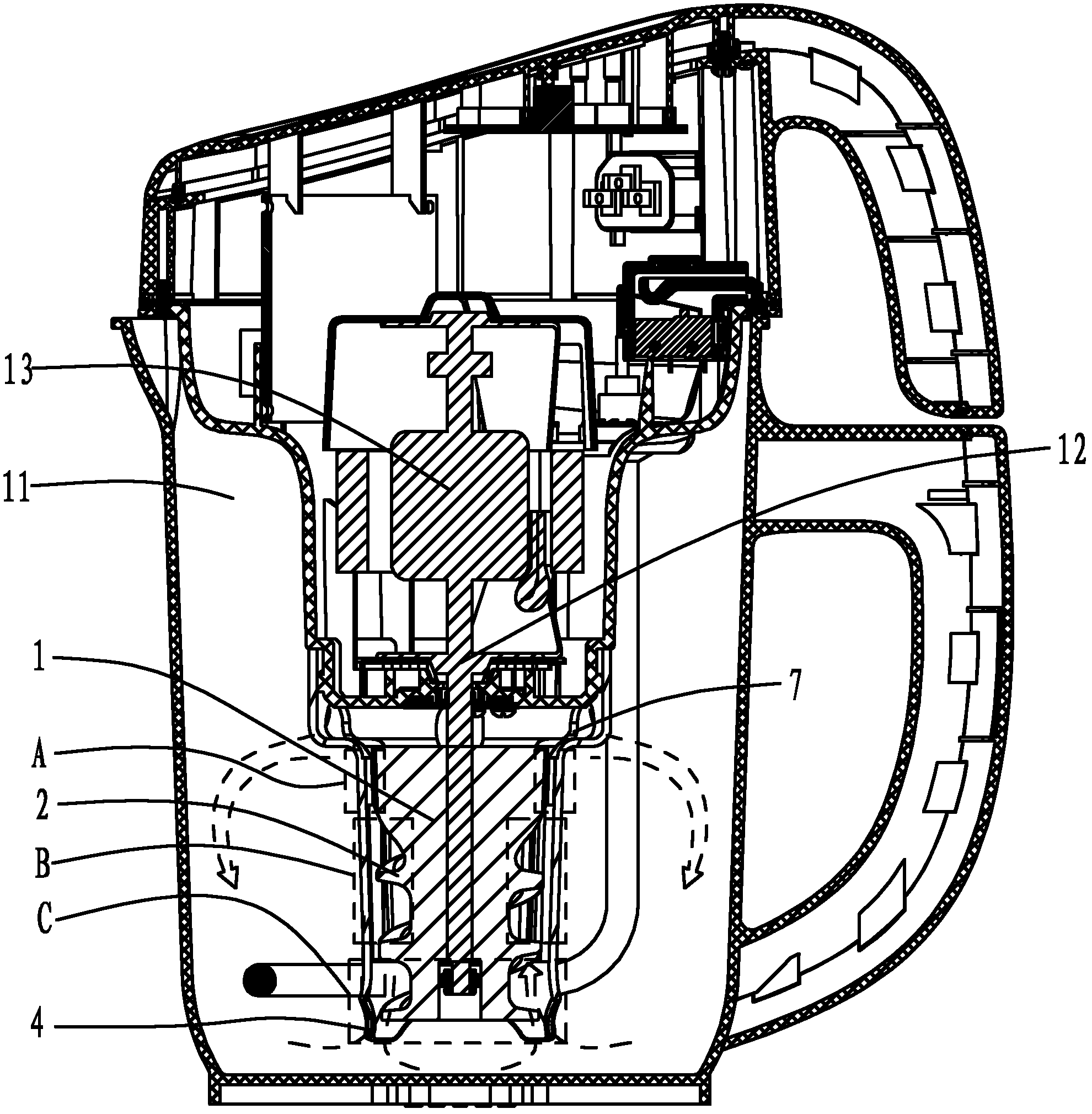

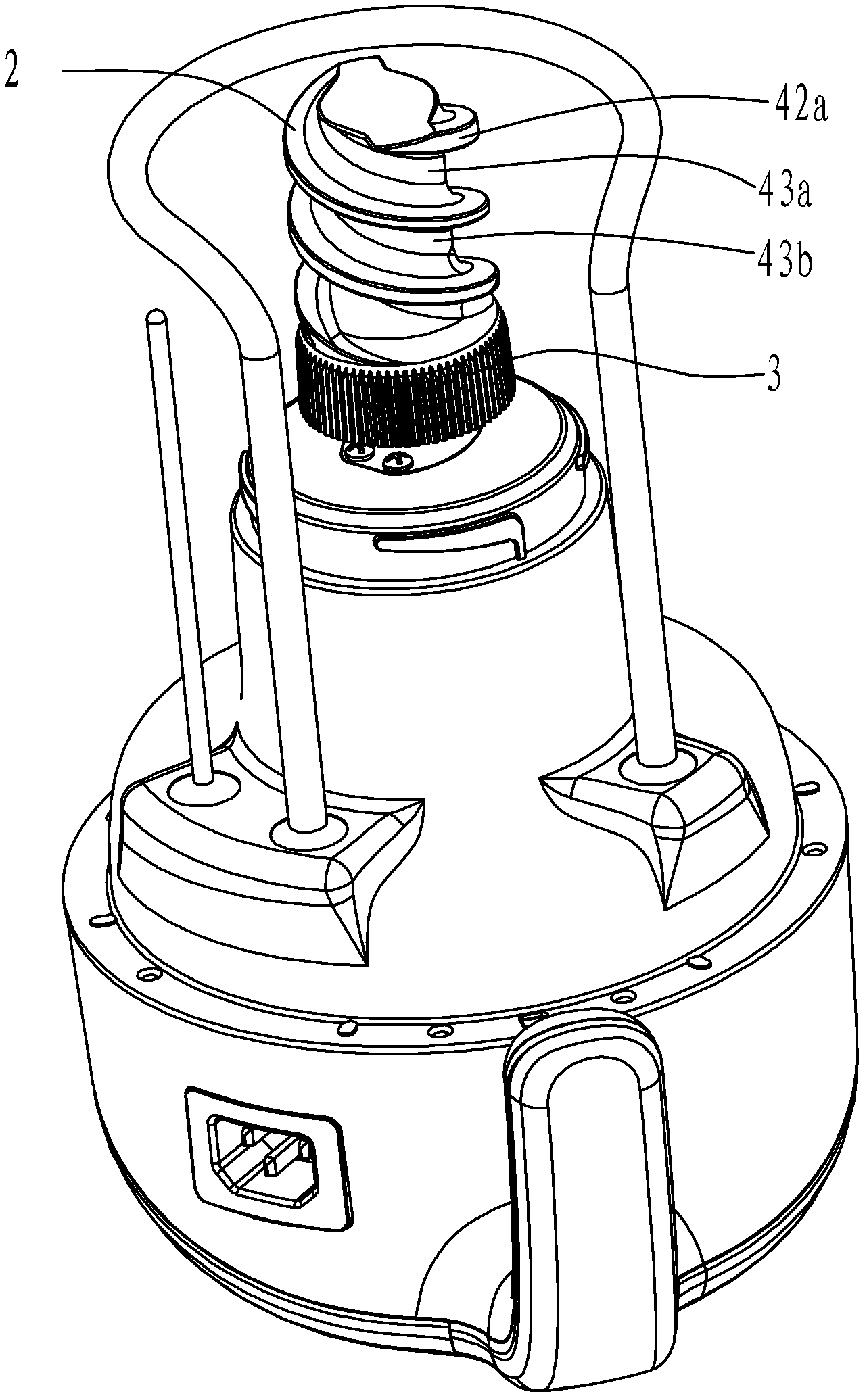

Soybean milk machine

ActiveCN102188157AAchieve mechanical mass productionEasy to cleanBeverage vesselsMilk substitutesWear resistantEddy current

The invention belongs to the field of small kitchen appliances, and particularly relates to a soybean milk machine. The soybean milk machine comprises a movable grinding head arranged on a motor shaft, wherein the movable grinding head comprises a liquid flow driving device which is provided with at least one screw tooth, and a movable grinding tooth arranged at the upper end of the liquid flow driving device; and the liquid flow driving device has a rough shape of a cylinder or rod or inverted cone. When a material is prepared, the movable grinding head rotates at a high speed in a static grinding material guiding cavity to form driven liquid flow so as to produce rotary suction eddy current, and the material is rotatablely sucked into the liquid flow driving device, is coarsely ground and further is subjected to fine grinding by using the movable grinding tooth. The gap gradually becomes smaller from the bottom to top, and the grinding process in which the coarse material is ground into the fine material is realized at the same time. A grinding mechanism of the soybean milk machine has a good grinding effect, and the grinding head is easy to process and is wear-resistant.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

Derusting device for inner wall of hollow steel pipe

InactiveCN107263264AAchieve grindingQuick removalGrinding machine componentsPortable grinding machinesMotor controllerDrive motor

The invention discloses a rust remover for the inner wall of a hollow steel pipe, which comprises a handle. Controlled by a motor controller, the motor controller is installed on the handle, the motor controller has a built-in lithium battery, which supplies power for the entire drive motor, and is also provided with a button for controlling the switch of the motor, and the motor shaft of the drive motor passes through the machine. The shell protrudes from the outside of the casing, and a rotary box is fixedly installed on the motor shaft of the drive motor. A buffer chamber is arranged inside the rotary box, and a telescopic grinding mechanism is respectively set at both ends of the rotary box. The grinding mechanism is pressed against the inner wall of the steel pipe. The invention can realize the grinding of hollow steel pipes with different inner diameters, quickly removes rust by using grinding balls, has high work efficiency, and solves the problem of low grinding efficiency of the inner wall of the hollow steel pipes.

Owner:林南平

Convenient-to-adjust vegetable and fruit enzyme grinding equipment

The invention belongs to the technical field of vegetable and fruit enzyme production equipment and relates to convenient-to-adjust vegetable and fruit enzyme grinding equipment. According to the equipment, a servo motor is adopted for driving a first rotating shaft to rotate, so that a first cylindrical cam rotates along with the first rotating shaft; a second connecting rod drives a blocking plate to move leftwards and rightwards, and therefore, an outlet in the bottom of a material storage cavity is blocked or opened for intermittent discharging. A bending rod moves along with the second connecting rod; a sliding shaft is matched with a linear hole, so that a third connecting rod drives a fourth connecting rod to move in the direction of a sliding groove; and therefore, an upper grinding plate reciprocates to be matched with a lower grinding assembly below the upper grinding plate to grind enzyme blocks. A gap between the upper grinding plate and a lower grinding plate is convenientto adjust; an adjusting screw rod is rotated through a hand wheel, so that a movable nut drives a seventh connecting rod to move through a sixth connecting rod; and therefore, a wedge-shaped block moves leftwards or rightwards. Since the inclined surface of the wedge-shaped block is matched with a third roller, the lower grinding plate moves upwards or downwards, so that the gap between the uppergrinding plate and the lower grinding plate is changed; and therefore, the size of ground particles can be adjusted.

Owner:安徽易码数据科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com