Convenient-to-adjust vegetable and fruit enzyme grinding equipment

A vegetable and fruit enzyme and powder grinding technology, which is applied in the field of vegetable and fruit enzyme powder grinding equipment, can solve the problems of general stability and single product specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

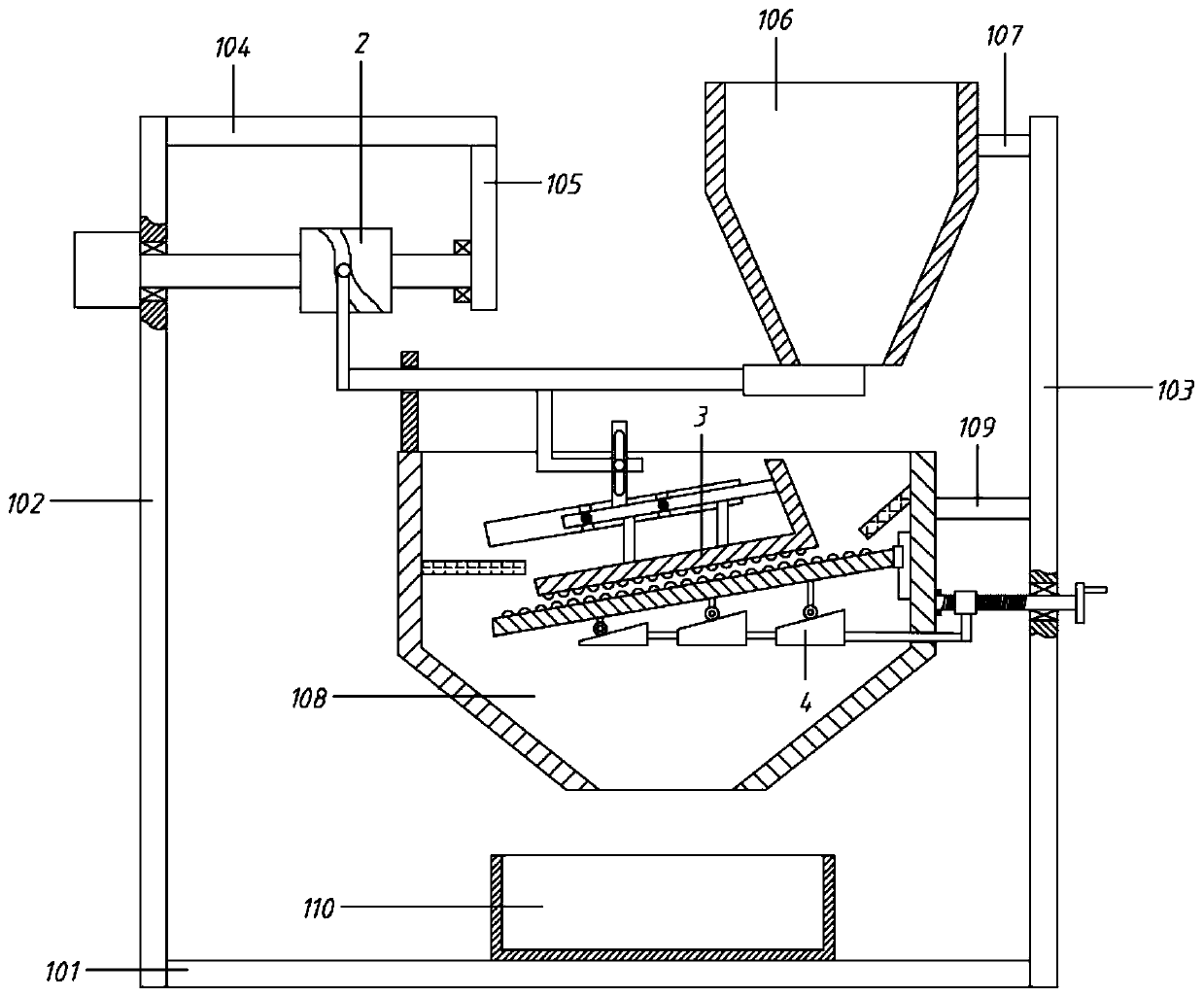

[0059] A conveniently adjustable vegetable and fruit enzyme powder milling device, comprising a frame 1, a blanking assembly 2, an upper grinding assembly 3 and a lower grinding assembly 4;

[0060] Frame 1 comprises bottom plate 101, left side plate 102, right side plate 103, material storage chamber 106, No. 1 pole 107, milling chamber 108, No. 2 pole 109 and material receiving box 110, and the left and right ends of base 101 are fixed respectively. The left side plate 102 and the right side plate 103 are connected, the left side of the top of the right side plate 103 is connected with the material storage chamber 106 through the No. The material assembly 2 is below, and the right side plate 103 is fixed through the No. 2 support rod 109;

Embodiment 2

[0062] A conveniently adjustable vegetable and fruit enzyme powder milling device, comprising a frame 1, a blanking assembly 2, an upper grinding assembly 3 and a lower grinding assembly 4;

[0063] Frame 1 comprises bottom plate 101, left side plate 102, right side plate 103, material storage chamber 106, No. 1 pole 107, milling chamber 108, No. 2 pole 109 and material receiving box 110, and the left and right ends of base 101 are fixed respectively. The left side plate 102 and the right side plate 103 are connected, the left side of the top of the right side plate 103 is connected with the material storage chamber 106 through the No. The material assembly 2 is below, and the right side plate 103 is fixed through the No. 2 support rod 109;

[0064] Wherein, the blanking assembly 2 includes a servo motor 201, a No. 1 rotating shaft 202, a No. 1 cylindrical cam 203, a No. 1 roller 204, a No. 1 connecting rod 205, a No. 2 connecting rod 206 and a blocking plate 207;

[0065] Th...

Embodiment 3

[0077] On the basis of embodiment 2,

[0078] Since the grinding plate has a certain length, in order to provide effective support, several wedge blocks 406 are arranged at intervals along the No. 7 connecting rod 405, and several correspondingly are arranged on the No. 8 connecting rod 408;

[0079] The first slide rail 411 is a T-shaped slide rail, and the second slide block 410 is a corresponding C-shaped slide block to avoid detachment; the opposite surfaces of the upper grinding plate 309 and the lower grinding plate 409 are processed with grinding protrusions 310 to ensure the grinding effect .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com