Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1040results about How to "Good coloring effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

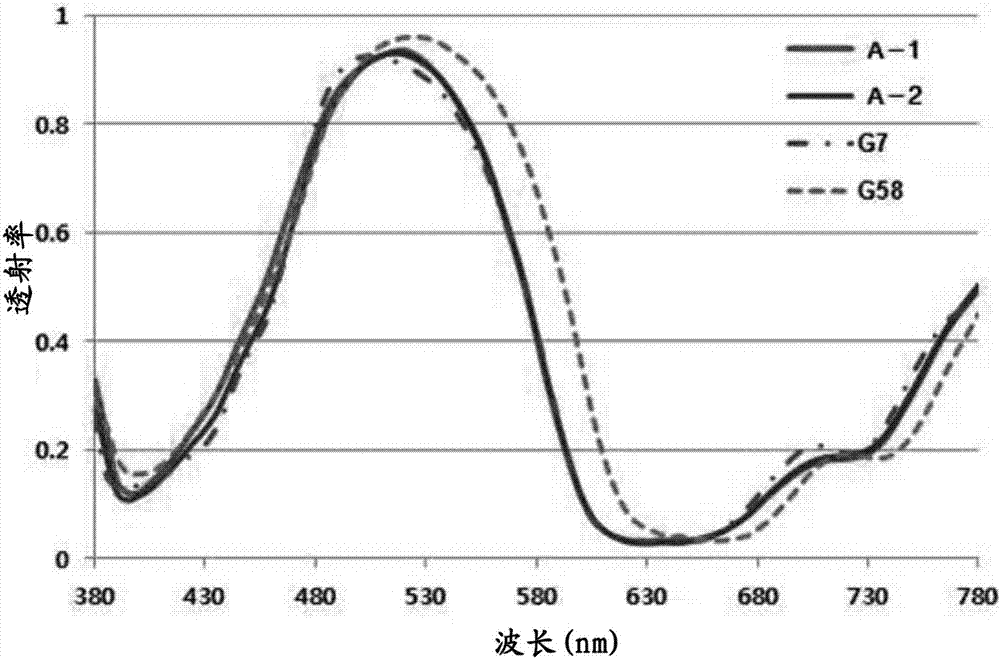

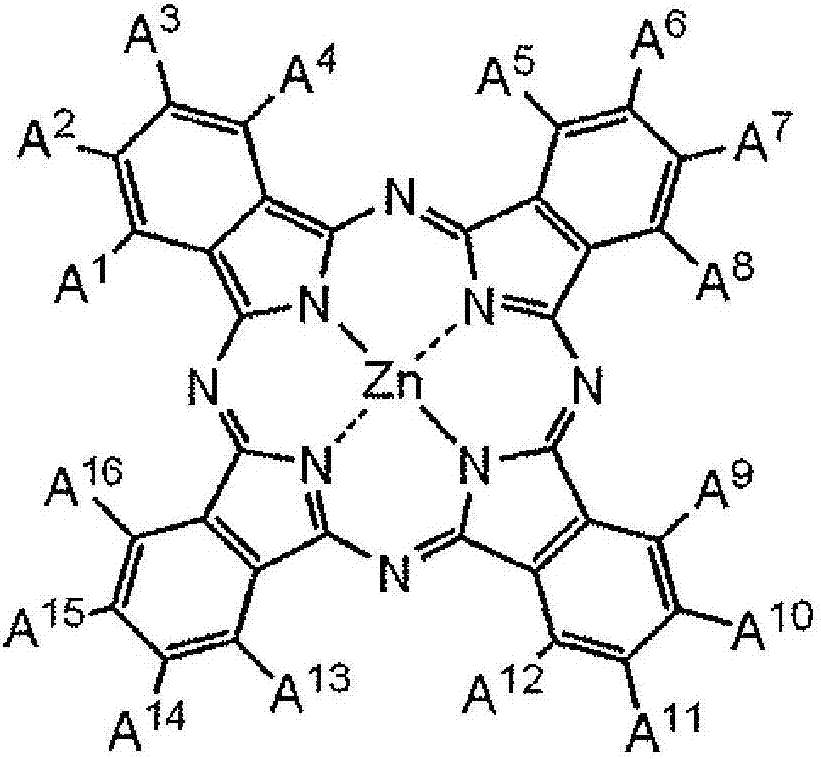

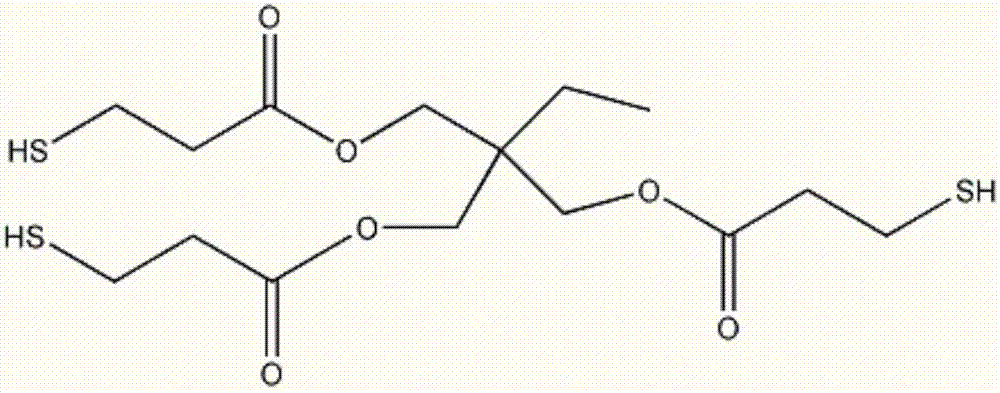

Colored photosensitive resin composition, color filter, method for producing the same, and image display device

ActiveCN106909027AExcellent adhesionPrevent peelingPhotosensitive materials for photomechanical apparatusOptical elementsSolventOrganosilicon

The present invention provides a colored photosensitive resin composition, a color filter, a method for producing the same, and an image display device, the colored photosensitive resin composition comprising: (A) a colorant, (B) an alkali-soluble resin, (C) a photopolymerizable compound, (D) a photopolymerization initiator, (E) one or more compounds selected from the group consisting of a polyfunctional thiol compound and an organosilicon compound, and (F) a solvent. The colorant (A) contains one or more of Pigment Green 59, 62 and 63 selected from C.I. and one or more selected from pigments and dyes.

Owner:DONGWOO FINE CHEM CO LTD

Acid dye composition

An acid dye compound is prepared by taking weak acid dye, natural assistant and stabilizer as raw material and mixing to obtain final product. It has higher absorptive rate, better biological degradability and washing fastness.

Owner:DALIAN UNIV OF TECH

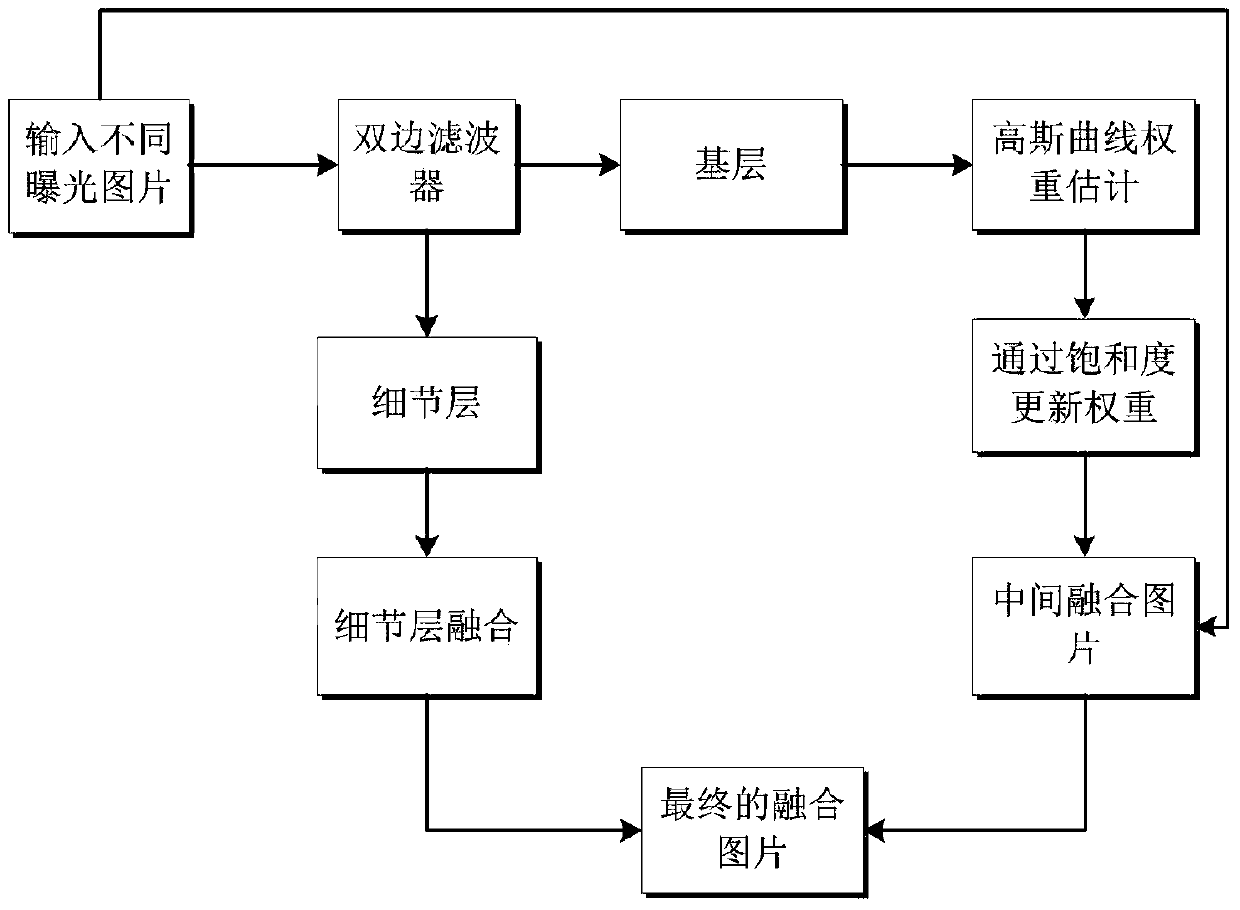

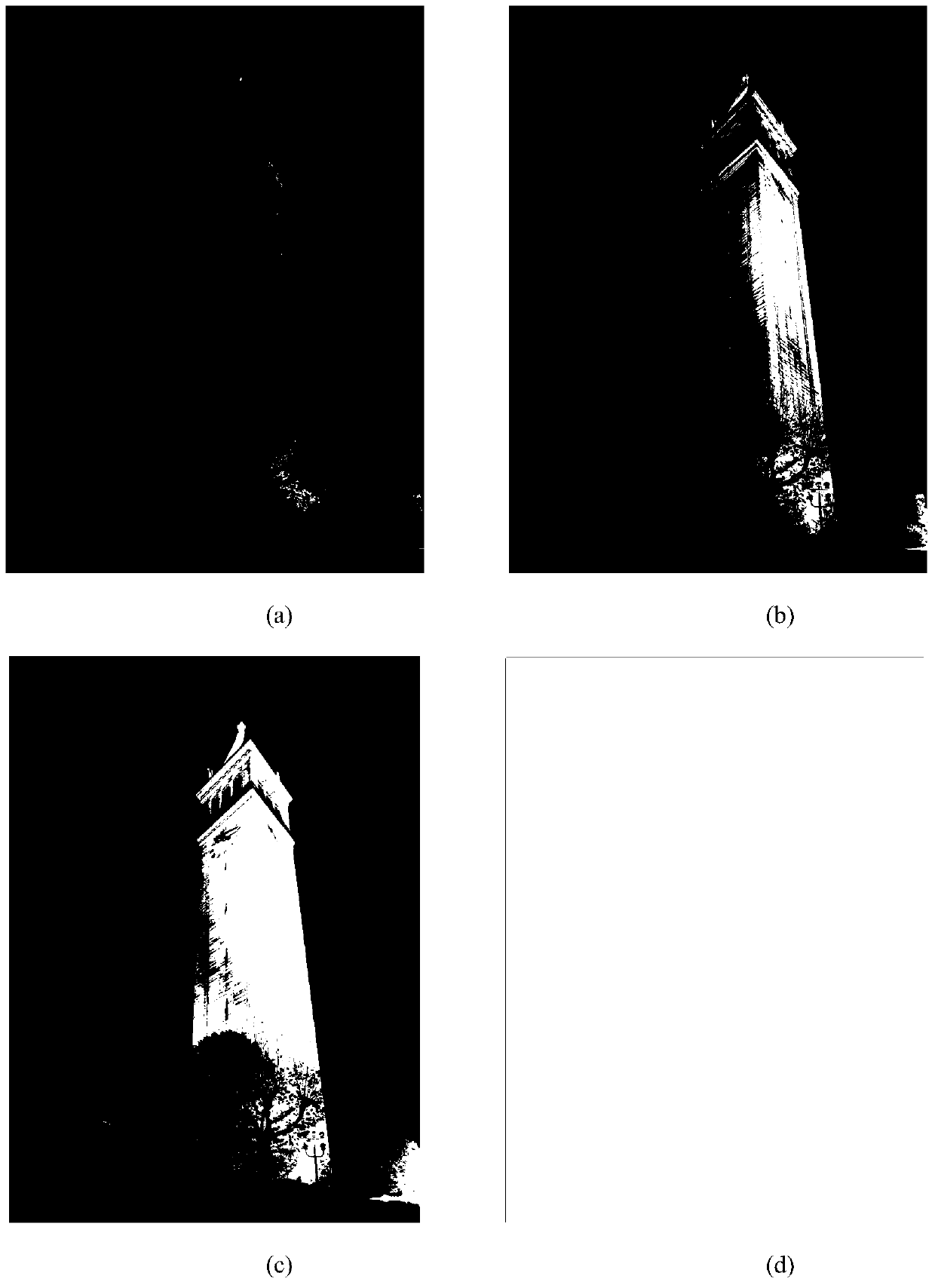

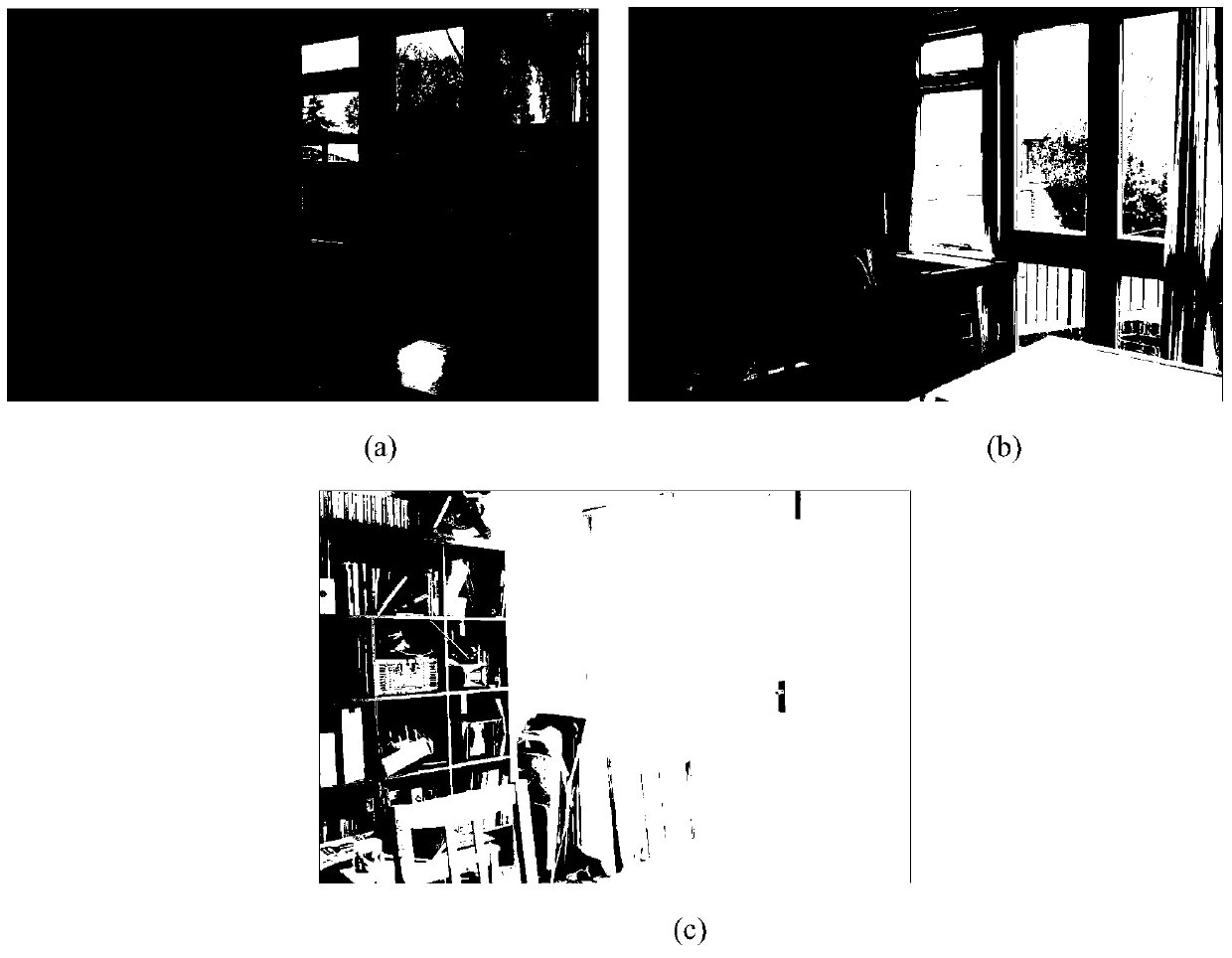

Multi-exposure image integration method based on bilateral filtering

InactiveCN105279746AImprove protectionClear edge textureImage enhancementComputation complexityImaging processing

The invention belongs to the technical field of image processing, and particularly discloses a multi-exposure image integration method based on bilateral filtering. The method comprises the steps that (1) three static pictures of the same scene of different exposures are inputted; (2) the originally inputted pictures are divided into two parts of a detail layer and a basic layer based on a bilateral filter and then the detail layer and the basic layer are processed respectively; (3) weight of the basic layer is estimated by applying a Gaussian curve and weight is updated by applying picture saturation information; (4) an intermediate integration picture is preliminarily integrated by the updated weight; (5) the maximum value of each detail layer is obtained to act as a detail picture as for the detail layer; and (6) a final integration picture is obtained by synthesizing the obtained intermediate integration picture and the detail picture. Calculation complexity is low, and the details of the picture can be fully protected in the integration picture and the picture is enabled to be more natural in the aspect of color. The multi-exposure image integration method based on bilateral filtering can be widely applied to the field of image enhancement or cameras.

Owner:XIDIAN UNIV

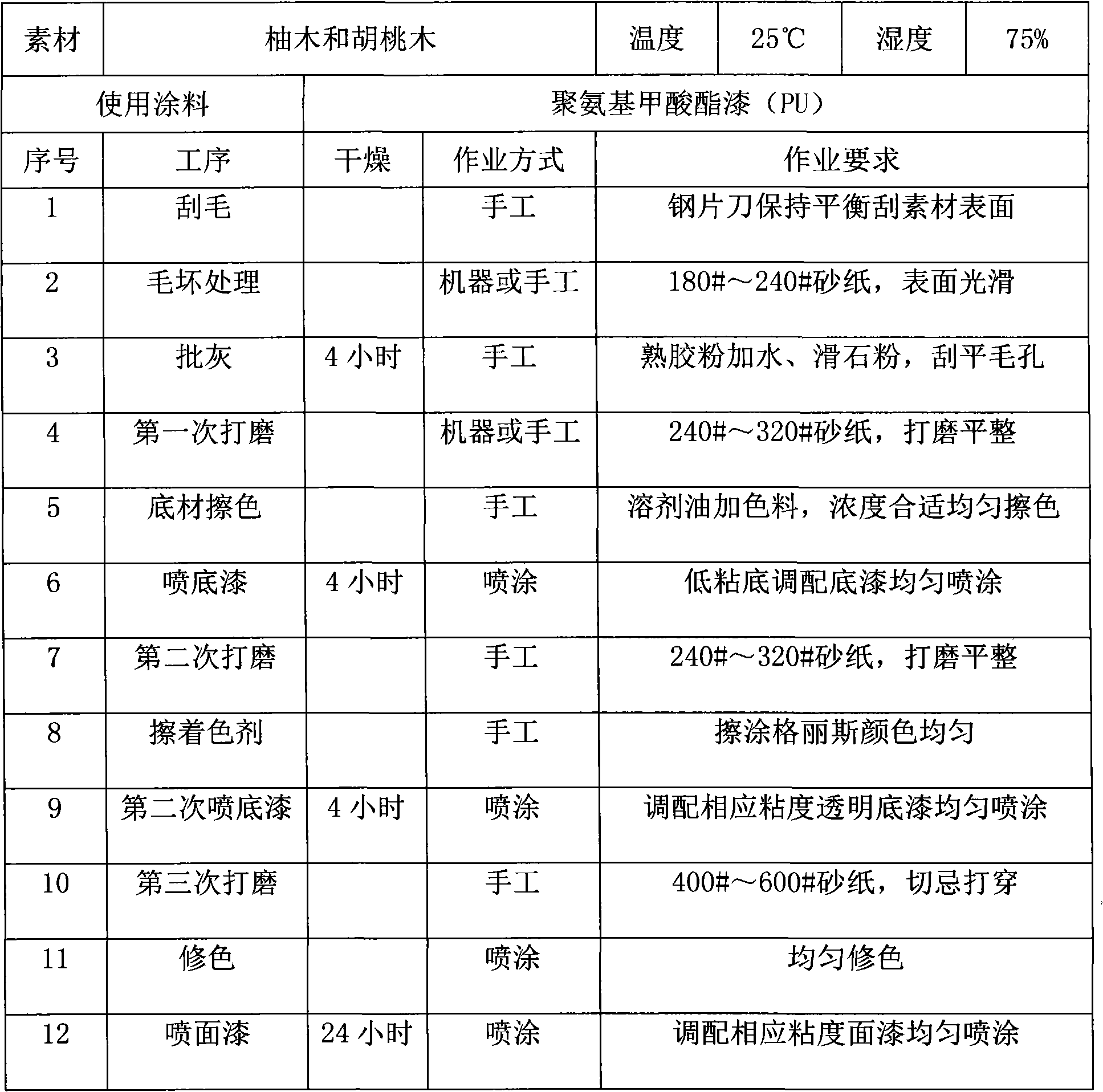

Paint coating process for wooden furniture

InactiveCN101670335AShorten the timeConsistent colorPretreated surfacesCoatingsRoughcastMaterials science

The invention relates to the field of paint coating processes, in particular to a paint coating process for wooden furniture. The paint coating process for the wooden furniture comprises the followingworking procedures: (1) scraping, (2) blank treatment, (3) plastering, (4) primary polishing, (5) base material coloring, (6) base paint spraying, (7) secondary polishing, (8) colorant coating, (9) secondary base paint spraying, (10) third polishing, (11) tinting, and (12) finish paint spraying. The paint coating process for the wooden furniture provided by the invention overcomes the defects that the blank treating and polishing time is long and the plane is not easy to be smoothened, improves the color definition of the furniture, and improves the visual effect and appreciation of the furniture.

Owner:莫有根

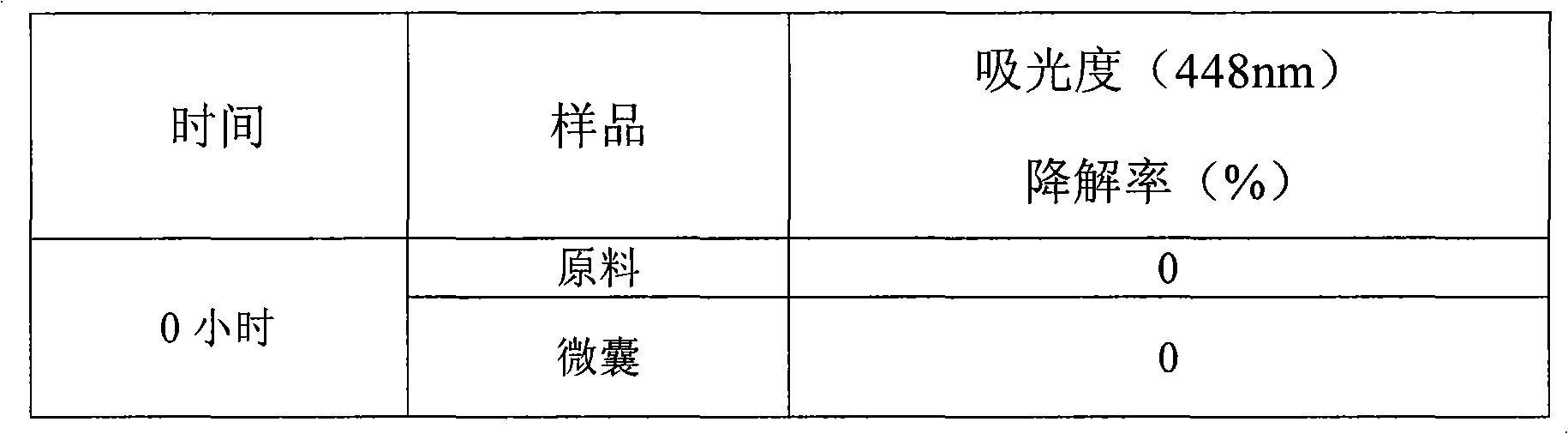

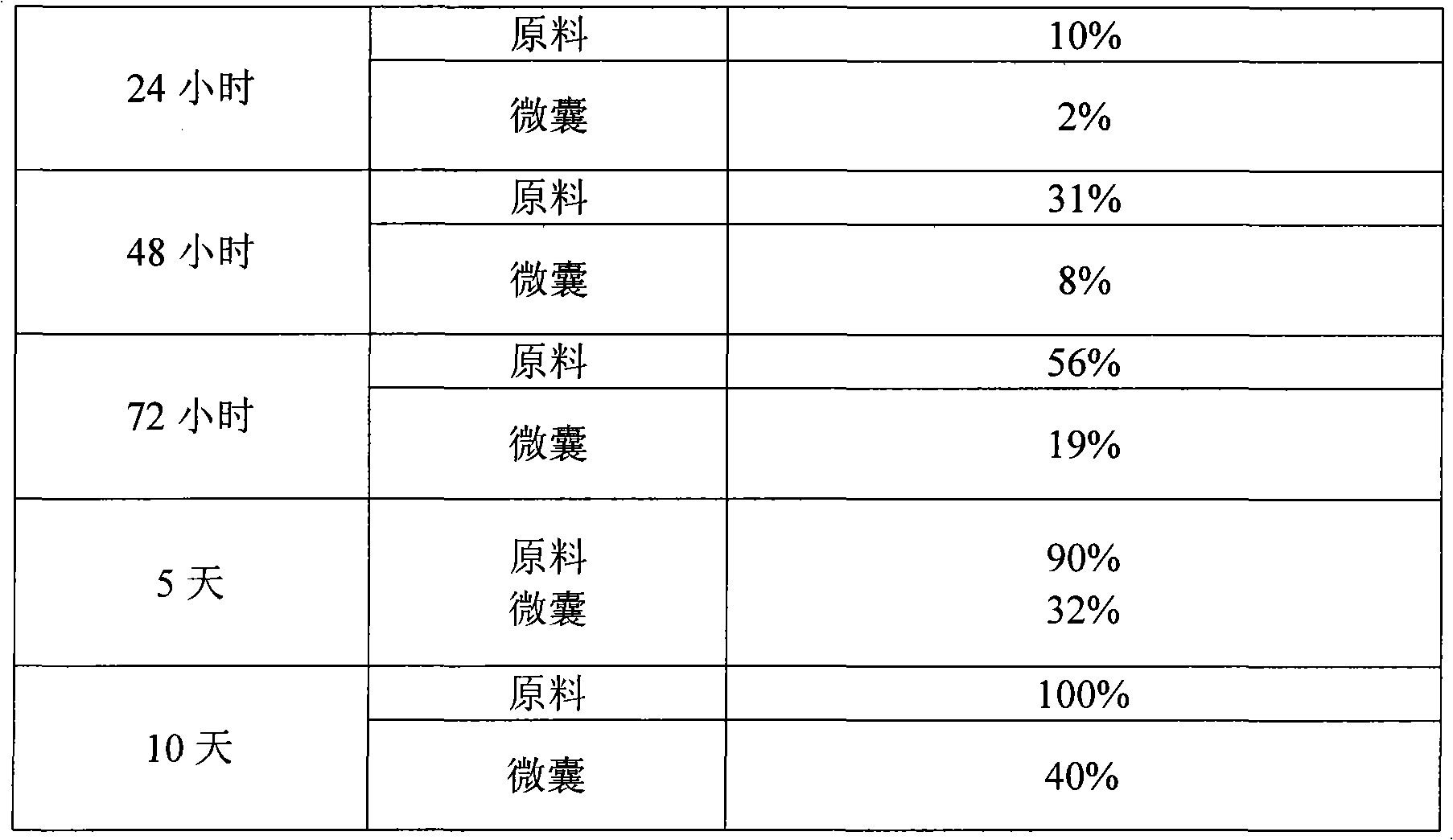

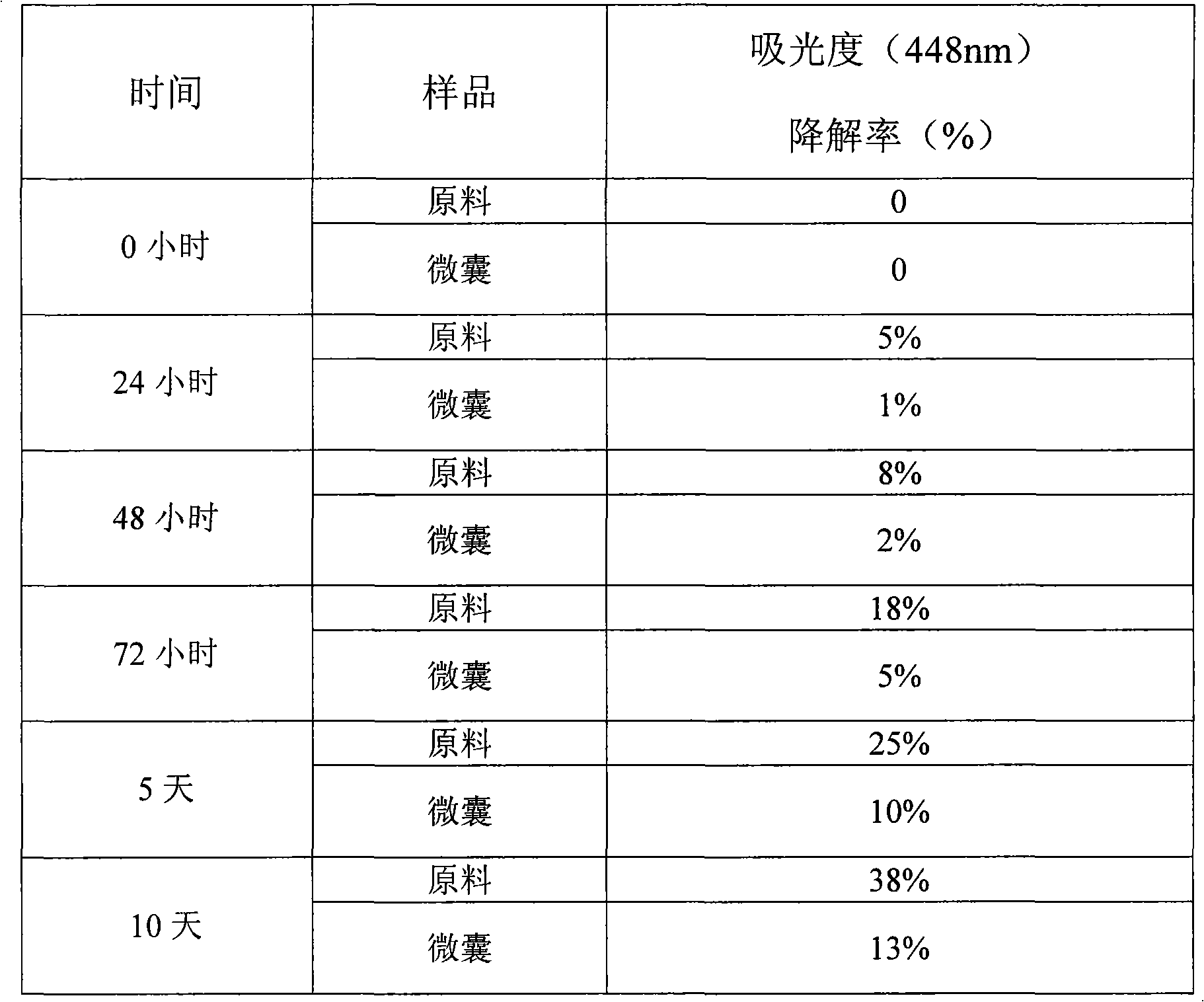

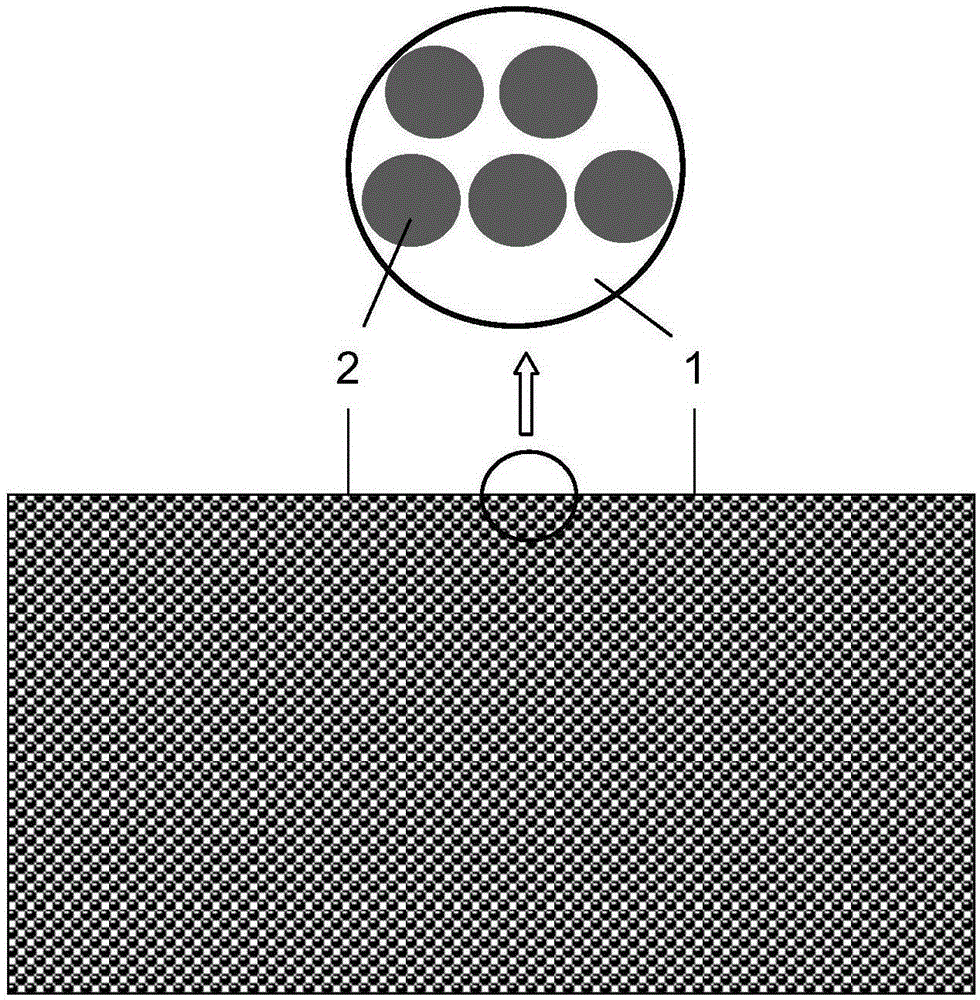

Beta-carotene microcapsule and preparing method thereof

InactiveCN101292965AImprove protectionImprove stabilityHydrocarbon active ingredientsHydroxy compound active ingredientsSolubilityLipid formation

The invention discloses a beta-carotene micro-capsule and the preparation method thereof. The beta-carotene comprises one of lycopene, lutein, zeaxanthin and astaxanthin or the mixture thereof, belonging to the fields of drugs and health care products. The beta-carotene micro-capsule is composed of the following raw materials by weight proportions: beta-carotene: lipid material: capsule material: emulsifier: water equals to 1:1-20:1-20-1-10:80-100. The invention adopts a two-phase emulsion spray drying method to prepare the beta-carotene micro-capsule, which has good light and thermal stability and water-solubility or water dispersivity.

Owner:SHENYANG WANJIA INST OF BIOLOGICAL TECH RES

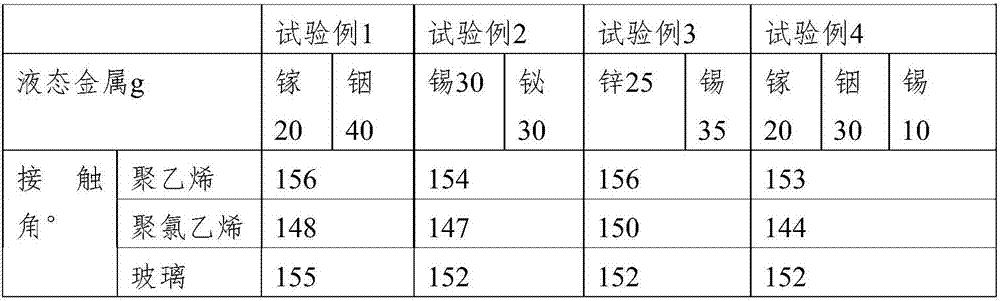

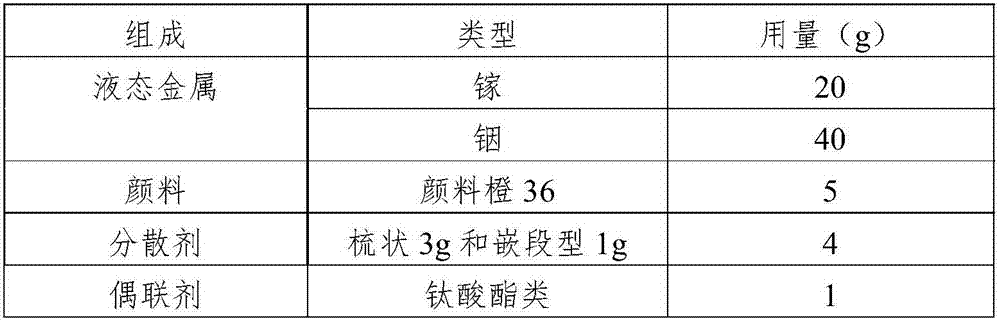

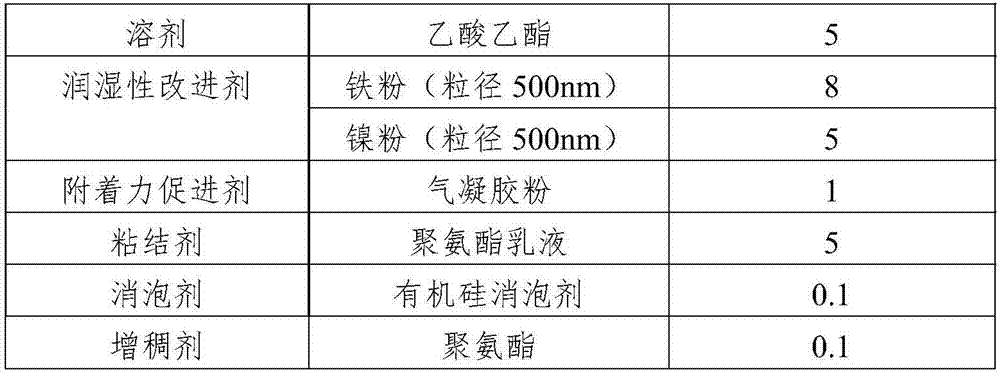

Colored liquid metal printing ink and preparation method thereof

The invention provides colored liquid metal printing ink. The printing ink is prepared from, in percentage by weight, 40%-70% of liquid metal, 2%-10% of pigment, 10%-30% of a wettability improver, 1%-5% of a dispersant, 0.5%-3% of a coupling agent, 1%-10% of a binder, 0.5%-3% of an adhesion promoter, 1%-5% of a solvent and the balance of other aids, wherein the liquid metal is a conductive nanofluid formed by low-melting-point metal or alloy or metal nanoparticles with the melting point being 300 DEG C or below and a fluid dispersant. The concept and the preparation method of the colored liquid metal printing ink are proposed for the first time, the existing application method that pigment powder is directly adopted in liquid metal is changed, color paste rather than pigment is adopted to provide colors for the liquid metal, and the color saturation and stability of a colored liquid metal composite are further improved, so that the composite has both good conductivity of liquid metal and rich colors of pigment.

Owner:BEIJING DREAM INK TECH CO LTD

PVC foaming architectural decoration material and preparation technique thereof

The invention relates to a PVC foaming construction decorative material and a preparation technique thereof. The preparation technique comprises the following steps: PVC plastics which are waste and are screened and ground, calcium carbonate, a stabilizer, an antioxidant, a lubricant, a foaming agent, a modifier, a foaming modifier, a dispersing agent, a colorant and the like are added into a high mixing machine according to the weight in sequence, mixed for 5 to 10 minutes, then placed into a low-temperature mixing machine for 5 to 10 minutes when being heated to be 120 to 125 DEG C; discharging is carried out when the temperature is 35 to 45 DEG C; the obtained materials are extruded by a parallel conical twin-screw extruder, molded, cooled in vacuum, pulled, film-stuck, cut and inspected and then the finished product of foaming plastic product is obtained. The invention is applicable to families, hotels, offices and entertainments, is the most ideal home decorative material with environment protection and is also the most practical home floor material.

Owner:胡大忠

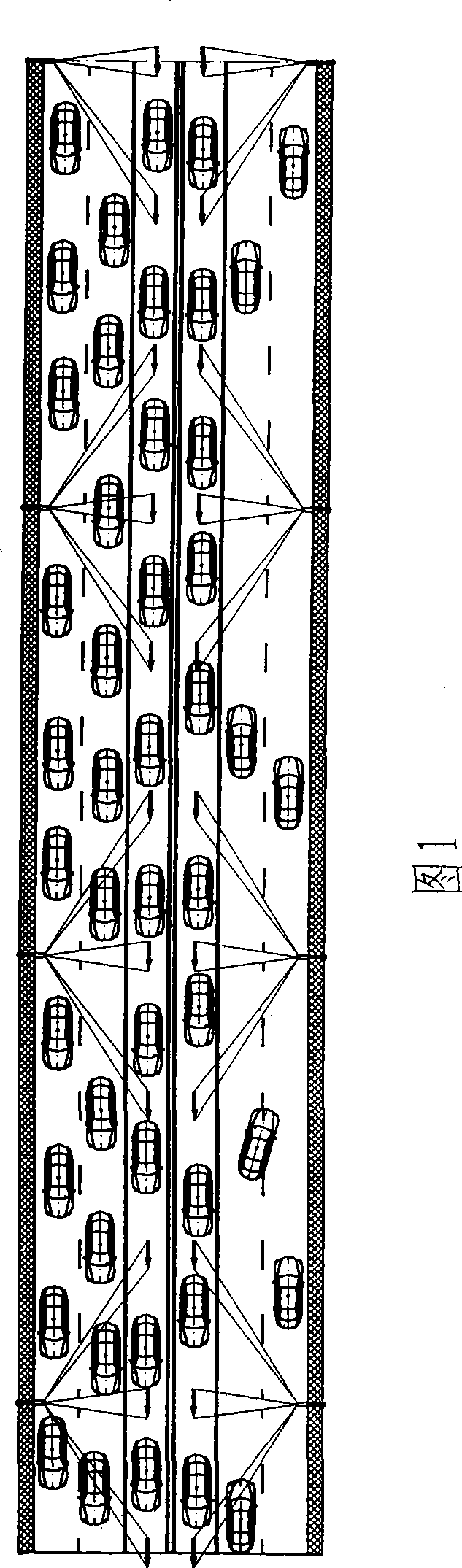

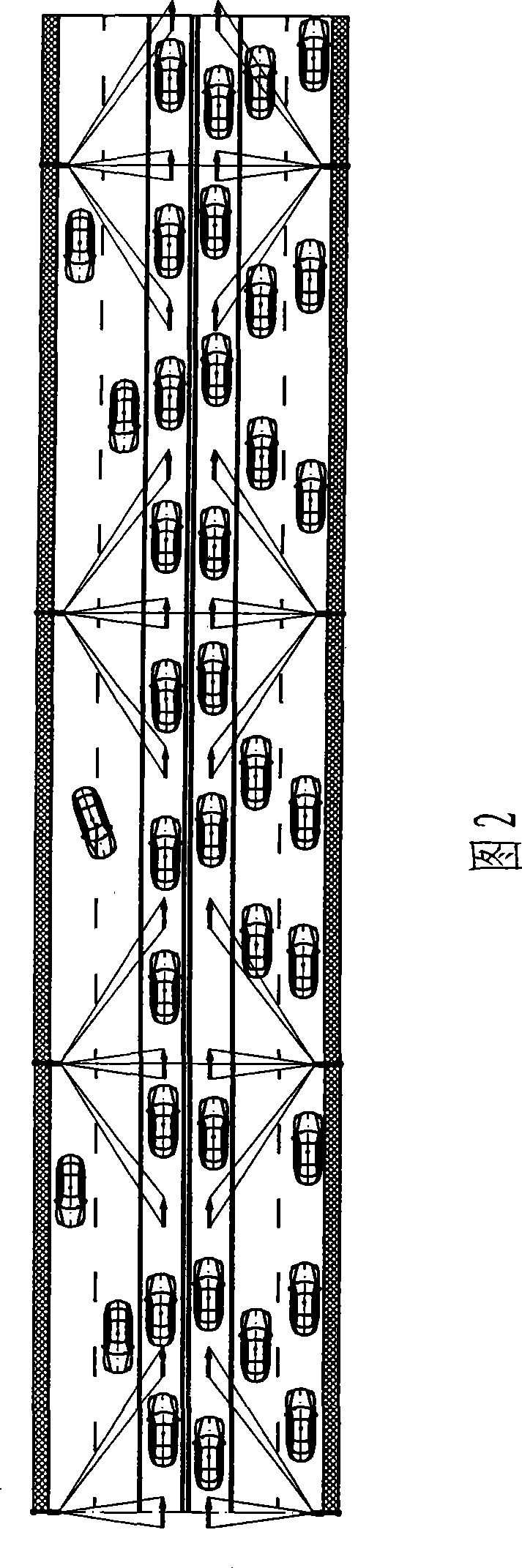

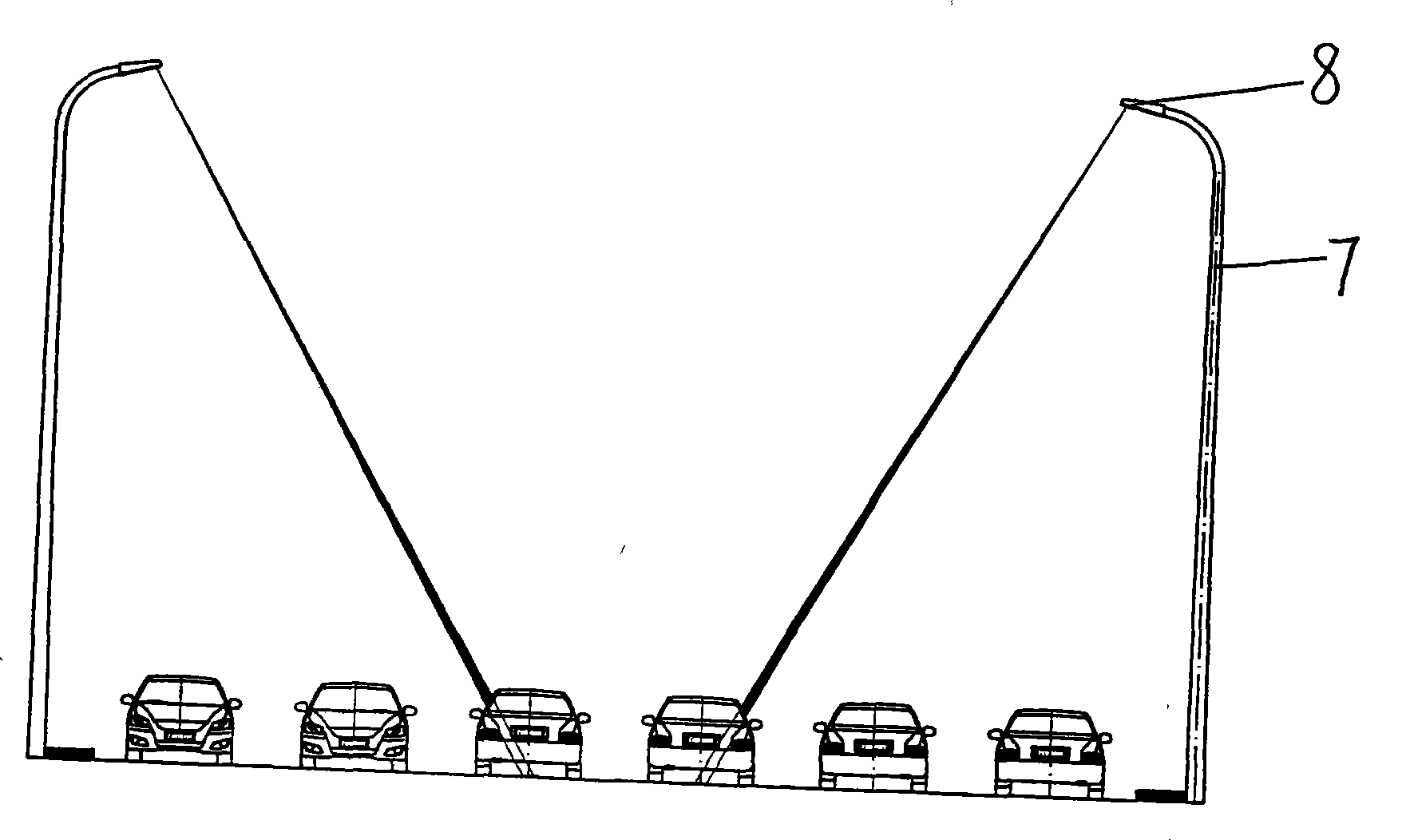

Traffic sign line labeling method and system thereof

InactiveCN101393688AIncrease brightnessImprove directionalityArrangements for variable traffic instructionsTraffic signalsLight beamEngineering

The invention relates to a method and a system for making a traffic sign marking. The traffic sign marking comprises a traffic sign and a traffic marking, and also traffic facilities; a laser generator is used for generating laser to form three-dimensional or two-dimensional traffic sign marking, and the laser beam generated by the laser generator can be adjusted to change the traffic sign marking. By adopting the method and the system, the vacant lane in the opposite direction can be utilized to relieve the pressure of traffic jam sections and solve the problem that traffic jam appears in the downtown direction and less cars go in the uptown direction when people go to work, and the traffic jam appears in the uptown direction and less cars go in the downtown direction when people get off work.

Owner:高玉宗

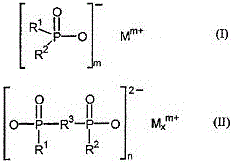

Plastics moulding composition and use thereof

ActiveUS20150175803A1Improve mechanical propertiesIncrease stiffnessSynthetic resin layered productsCasings/cabinets/drawers detailsThermoplasticBismuth

A description is given of thermoplastic, white-pigmented plastics moulding compositions having improved mechanical properties, especially for LDS applications. The thermoplastic moulding composition consists of:(A) 20-88 wt % of a mixture consisting of(A1) 60-100 wt % of a thermoplastic(A2) 0-40 wt % of a mixture of(A2_1) 0-40 wt % of a thermoplastic other than (A1);(A2_2) 0-40 wt % of impact modifiers other than (A1) and (A2_1);(B) 10-70 wt % of fibrous adjuvants;(C) 0.1-10 wt % of an LDS additive or of a mixture of LDS additives, at least one LDS additive being selected from the following group: metal oxide based on copper, neodymium, molybdenum, bismuth, antimony or tin, with the proviso that spinels are excluded; metal phosphate; metal hydroxide phosphate;(D) 0.1-20 wt % of white pigment;(E) 0-20 wt % of particulate filler other than C and / or D;(F) 0-2 wt % of further, different additives;a the sum of (A)-(F) making up 100 wt %.

Owner:EMS PATENT AG

Functional diatomite putty powder and preparation method thereof

InactiveCN105949863AImprove efficiencyShorten the timeFilling pastesInorganic pigmentsMaterials science

The invention relates to putty powder, in particular to functional diatomite putty powder and a preparation method thereof, wherein the putty powder includes in percent by weight: 10-50% of high-temperature activated diatomite, 5-30% of an inorganic binder, 30-70% of an inorganic filler, 0.01-2% of a functional aid, 0.1-5% of an inorganic pigment, 0.5-5% of an organic binder, and 0.5-5% of an organic aid. The functional diatomite putty powder meets the related standard requirements of putty powder and diatomite, and has qualified constructability and functionality, namely having standard-meeting properties such as humidity regulation, formaldehyde clarifying performance, long duration of formaldehyde purifying performance, mold-proof performance, and mold durability.

Owner:CENT SOUTH UNIV +1

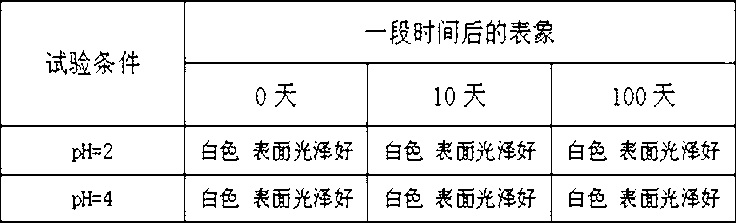

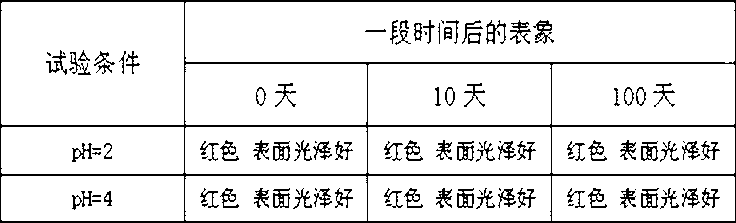

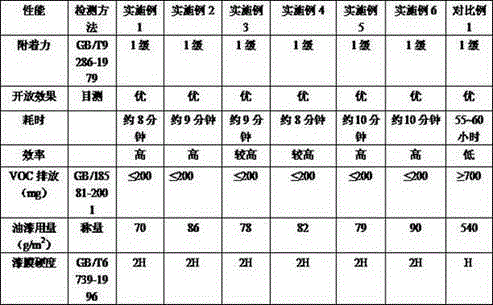

Acid-resistant anti-aging flame-retardant color masterbatch and preparation method thereof

The invention belongs to the field of polymer and relates to an acid-resistant anti-aging flame-retardant color masterbatch with excellent properties and a preparation method of the color masterbatch. The color masterbatch is prepared and processed by using a polyethylene carrier, an inorganic or organic toner, a stabilizer NOR and a dispersant. The color masterbatch has a good compatibility and a coloring effect for polyethylene products, and has an excellent flame-retardant effect with the flame-retardant level reaching V-2 level. Moreover, the color masterbatch is rich in colors and good in surface gloss. The colored products do not fade easily even in an environment with the pH value between 2 and 4.

Owner:广州保亮得塑料科技有限公司

Water-base ink composition, inkjet recording method and recorded matter

InactiveUS20070117882A1Good coloring effectBronzing can be prevented without degrading the glossiness of printed matterSpecial tyresInksWater basedWater insoluble

A water-base ink composition comprising: a chromatic color pigment covered with a water-insoluble vinyl polymer; a titanium dioxide pigment; and water; and a water-base ink composition containing, in addition to a chromatic color pigment, dispersant and water, both a titanium dioxide pigment and silica pigment.

Owner:SEIKO EPSON CORP

Coating process for coating wood veneer board with UV coatings in roll coating mode

InactiveCN104588300AEmission reductionEasy to operatePretreated surfacesSpecial surfacesWater basedInfrared

The invention discloses a coating process for coating a wood veneer board with UV coatings in a roll coating mode. The coating process comprises the following steps of 1 wood veneer board pretreatment, 2 roll coating of water-based UV transparent primer, 3 infrared drying and ultraviolet curing, 4 roll coating of UV transparent primer, 5 sand cleaning and dust removal, 6 roll coating of UV padding finishing coat, 7 laser roll coating of UV sub-gloss surface cleaning varnish, 8 infrared leveling and 9 ultraviolet curing and detection packing. The coating process for coating the wood veneer board with the UV coatings in the roll coating mode is simple, high in efficiency, low in cost and free of pollution, and the surface effect can reach a PU coating open effect.

Owner:HUIZHOU CHANGRUNFA PAINT +1

Colored liquid metal and manufacturing method thereof

ActiveCN105220013AGood coloring effectImprove conductivityAdditive manufacturing apparatusLiquid metalElectron

The invention provides colored liquid metal and a manufacturing method thereof. A colored liquid metal raw material comprises a liquid metal body, pigment and / or nanometer conductive particles. The colored liquid metal can be presented in various specific colors while achieving electrical conduction. Firstly, the colored liquid metal has good electrical conductivity of liquid metal and rich colors of the pigment, an approach to color printed electronics can be opened up, and the aesthetic property and experience of the printed electronics can be remarkably promoted; meanwhile, the oxidation resistance and rust-proof property of traditional liquid metal are improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Al-Ti-B-rare earth(RE) grain refiner and preparation method thereof

The invention relates to an Al-Ti-B-RE grain refiner and a preparation method thereof. The Al-Ti-B-RE grain refiner is used for Al-Mg-Si alloy, and is characterized by containing the following components in percentage by weight: 6.9 to 7.9 percent of Ti, 1.31 to 1.75 percent of B and 1.5 to 2.0 percent of mixed RE. The mixed RE is cerium-enriched rare earth. The preparation method of the cerium-enriched rare earth comprises: mixing the raw materials according to a weight part ratio, wherein the mixing time is controlled to be 3 to 4 hours; heating an aluminum ingot in a medium frequency induction furnace to an overhigh temperature of 700 to 750 DEG C; filling a mixed pressed block of potassium fluotitanate and potassium fluoborate and cerium-enriched rare earth into a graphite bell jar; clamping the reversed bell jar by using forceps, and pressing the bell jar into the lower middle part of aluminum melt; raising the furnace temperature to 800 to 850 DEG C, and magnetically stirring for 25 to 30 minutes with the induction furnace; after reaction, taking the graphite bell jar out; standing and keeping the temperature for 20 minutes; forcefully stirring the melt once with an artificial graphite rod every 3 minutes, and stirring for more than five times; treating molten alloy; standing and keeping temperature for 15 to 20 minutes; and performing secondary slagging off.

Owner:HUANGGANG HUAER ALUMINUM ALLOY

Preparation method for transference resistance leather dye

InactiveCN102746714ADye performance is stableExcellent migration resistanceOrganic dyesDyeing processIsocyanate compoundDyeing

The present invention discloses a preparation method for a transference resistance leather dye, wherein an active group-containing dye, an anti-yellowing isocyanate compound, a hydroxyl group-containing polymer, a compound containing a hydroxyl group and a hydrophilic functional group, a chain extender, and the like are subjected to polymerization to obtain a product of the present invention. The dye prepared by the method of the present invention has the following advantages that: performance is stable, and transference resistance of products dyed by the dye is excellent. The method of the present invention has advantages of simple synthetic route, molecular weight adjusting, easy functionality control, and the like. The dye prepared by the method of the present invention can be used for leather dyeing, and colorant components in leather coating and synthetic leather coating.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Cooking utensil controlling method and cooking utensil

ActiveCN109445485AGuaranteed MaturityImprove experienceTemperatue controlMicrowave heatingProcess engineeringCooking process

The invention provides a cooking utensil controlling method and a cooking utensil. The cooking utensil includes a control device; and the control device can adjust the cooking parameters of the cooking utensil according to the surface coloring information and internal temperature information of food in the cooking utensil. The controlling method can simultaneously consider the surface coloring information and internal temperature information of the food, so that the ripeness of the food can be judged from multiple aspects, and therefore, adjustment can be performed on the cooking parameters ofthe food, the food can have excellent coloring effects while being guaranteed to be ripe, automatic dynamic adjustment during cooking can be realized, and user experience can be enhanced.

Owner:GREE ELECTRIC APPLIANCES INC

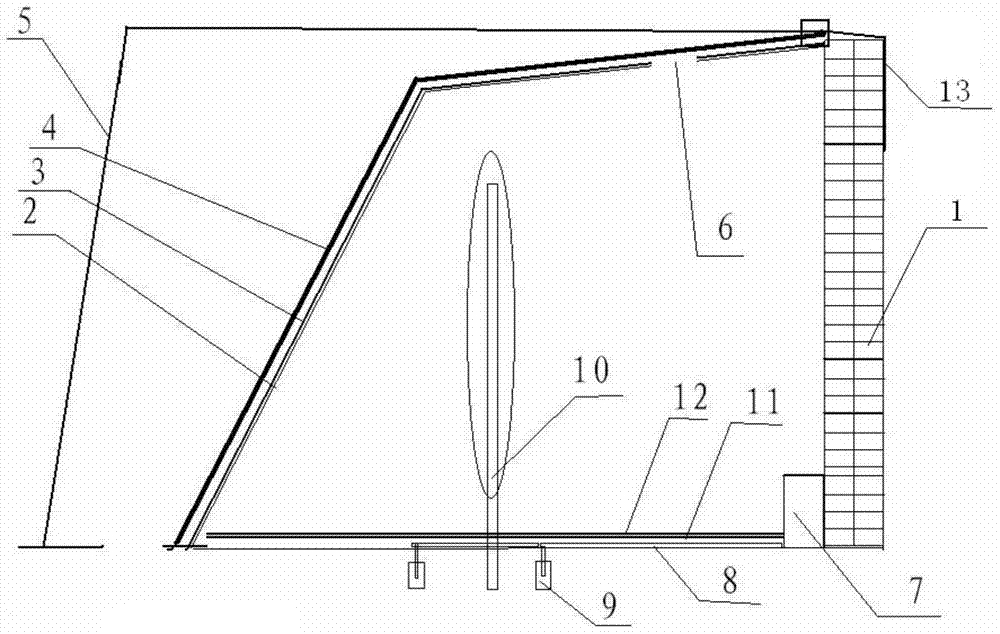

Semi-opening greenhouse cultivation technology for peach tree in low-latitude plateau area

ActiveCN104255374AGuaranteed nutritionReduce irrigationClimate change adaptationGreenhouse cultivationLow latitudeSemi open

The invention relates to a semi-opening greenhouse cultivation technology for a peach tree in a low-latitude plateau area. The technology is characterized in that a greenhouse frame is arranged on one surface of a greenhouse; a layer of inspect proof nets and a layer of heat preserving quilts sequentially cover the frame; the heat preserving quilts are controlled by a contracting and stretching bracket to the contracted and stretched, and therefore, the temperature in the greenhouse of the peach tree can be controlled in different growth periods and under the changeful air temperature condition at the low-latitude plateau area; meanwhile, the technologies like the water and fertilizer control technology and the special fruit bag utilizing technology are adopted, thus the damage factor under the natural condition is removed, and the natural growth state of the peach tree is remained to the maximum; the applied pesticide is about 20% that under the common planting condition, the applied chemical fertilizer is about 30% that under the common planting method, the water irrigated is about 40% that under the common planting condition, and the output is more than 150% that under the common planting condition; in addition, the peach quality is far more than that of common peach; the market price is the peach is more than 5 time that of the common peach.

Owner:KUNMING JINWOTU ECOLOGY CULTIVATION

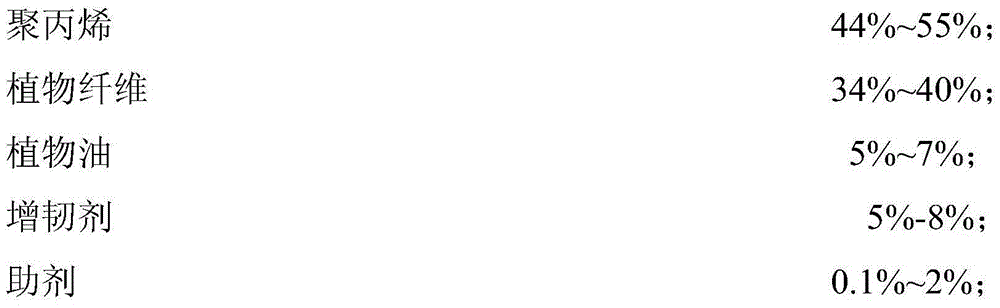

Plant fiber-reinforced polypropylene composite material and preparation method thereof, and application of plant fiber-reinforced polypropylene composite material in preparation of automobile components

The invention discloses a plant fiber-reinforced polypropylene composite material and a preparation method thereof, and an application of the plant fiber-reinforced polypropylene composite material in preparation of automobile components. The composite material is prepared from the following raw materials in percentage by weight: 40%-77% of polypropylene, 20%-40% of a plant fiber, 1%-10% of vegetable oil, 1%-10% of a flexibilizer and 0.1%-5% of an assistant, wherein the plant fibers and the vegetable oil are from renewable biomass, and conform to the requirements of low-carbon, environment-friendly and sustained economic development. In addition, a low-density biomass material is capable of further promoting light weight of automobiles, and is of great significance in energy conservation and emission reduction. The plant fiber-reinforced polypropylene composite material for automobiles can be prepared by extrusion once, so that the method is simple, easy to operate and suitable for industrialized production.

Owner:NINGBO HOMELINK ECO ITECH CO LTD

Composite mica cerium titanium pearl pigment and preparation method thereof

InactiveCN101693790AGood gloss effect and color effectHigh glossInorganic pigment treatmentTitaniumOxide

The invention relates to a pearl pigment technology, in particular to a composite mica cerium titanium pearl pigment and a preparation method thereof. CeO2-mica pearl pigment is a yellow pearl pigment which is obtained by cladding oxide CeO2 on the surface of mica pearl pigment by a liquid phase cladding method, but has poor glossiness. The composite mica cerium titanium pearl pigment comprises aCeO2-mica substrate on which TiO2 oxide is cladded, and the cladding rate of TiO2 is 1-20%. The surface glossiness of TiO2-CeO2-mica pearl pigment prepared by multi-layer cladding is much higher thanthat of the CeO2-mica pearl pigment, and the color of the yellow CeO2-mica pearl pigment is turned into bright yellow instead of being covered by the cladded CeO2, thus having better luster effect and color effect than the pearl pigment cladded with single-layer CeO2.

Owner:JIANGXI UNIV OF SCI & TECH

Jacquard acetic acid filament home textile fabric and production method thereof

ActiveCN106012214AGood coloring effectSoft touchHeating/cooling textile fabricsDry-cleaning apparatus for textilesSocial benefitsAcetic acid

The invention provides a jacquard acetic acid filament home textile fabric. Warp is semi-dull polyester filaments with the specification of 50D / 72F, and warp density is 200 pieces per inch. Weft is 75 D acetic acid filaments, and weft density is 96.5 pieces per inch. The structure is a large jacquard fabric. The breadth of the finished product is 160 cm. A production method of the fabric includes the steps that firstly, weaving is conducted, wherein weaving is conducted through warping by means of a warping machine, sizing by means of a filament sizing machine, re-beaming by means of a combining machine, leasing by means of a leasing machine, drafting and weaving by means of a rapier jacquard loom; secondly, dyeing is conducted, wherein dyeing is conducted through unwinding, desizing, dyeing, dewatering, scotching and setting. The fabric is flat, fine, smooth in cloth surface, soft in hand feeling, light, thin, cool, easy to wash, quick to dry, high in color fastness, good in air permeability, gentle and elegant. Reagents of the fabric successfully meet the requirement for comfort and cool of home textile summer quilt fabric of people, and the fabric has high addition value and wide market prospects and is remarkable in economic and social benefit.

Owner:JIANGSU YUEDA HOME TEXTILE

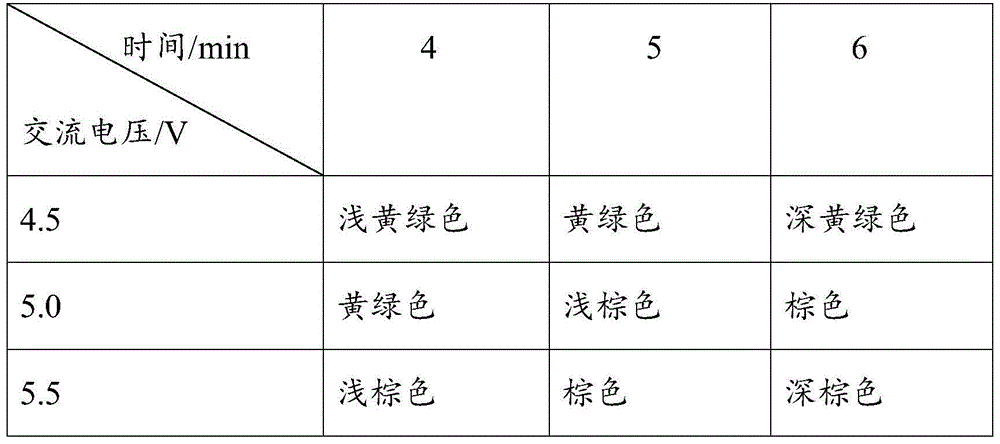

Coloring method adopting aluminium alloy alternate current electrolysis for precipitating silver and copper

The invention provides a coloring method adopting aluminium alloy alternate current electrolysis for precipitating silver and copper. The coloring method comprises the following steps: after pretreatment such as degreasing and oxidation film removing, an aluminium alloy piece is subjected to direct current electrolysis in the sulfuric acid medium to obtain the aluminium alloy piece provided with a porous oxide-film; then, the aluminium alloy piece provided with the porous oxide-film is subjected to alternate current electrolysis; a coloring liquid comprises 15-20 g / L of H2SO4, 4-7 g / L of AgNO3, 1.5-2.5 g / L of CuSO4.5H2O, 18-25 g / L of MgSO4.7H2O, 2-7 g / L of a complexing agent A or 5-10 g / L of a complexing agent B; the technological conditions of the coloring liquid are as follows: the temperature is 5-35 DEG C, the time is 3-7 min and the voltage is 4-7 V; lastly, the alternate current electrolyzed porous oxide-film aluminium alloy piece is subjected to hot water sealing treatment to obtain aluminium alloy materials. According to the coloring method, the technology is simple, the coloring is uniform and stable, the decay resistance of the aluminium alloy is improved, the antibacterial and sterilizing rate of the aluminium alloy reaches 99.0%, the duration of antibacterial and bactericidal action is long and the coloring treatment cost is low; no insoluble deposition is precipitated in the coloring liquid for long-term use and the coloring liquid is stable.

Owner:SHISHI XINGHUO ALUMINUM PROD CO LTD +1

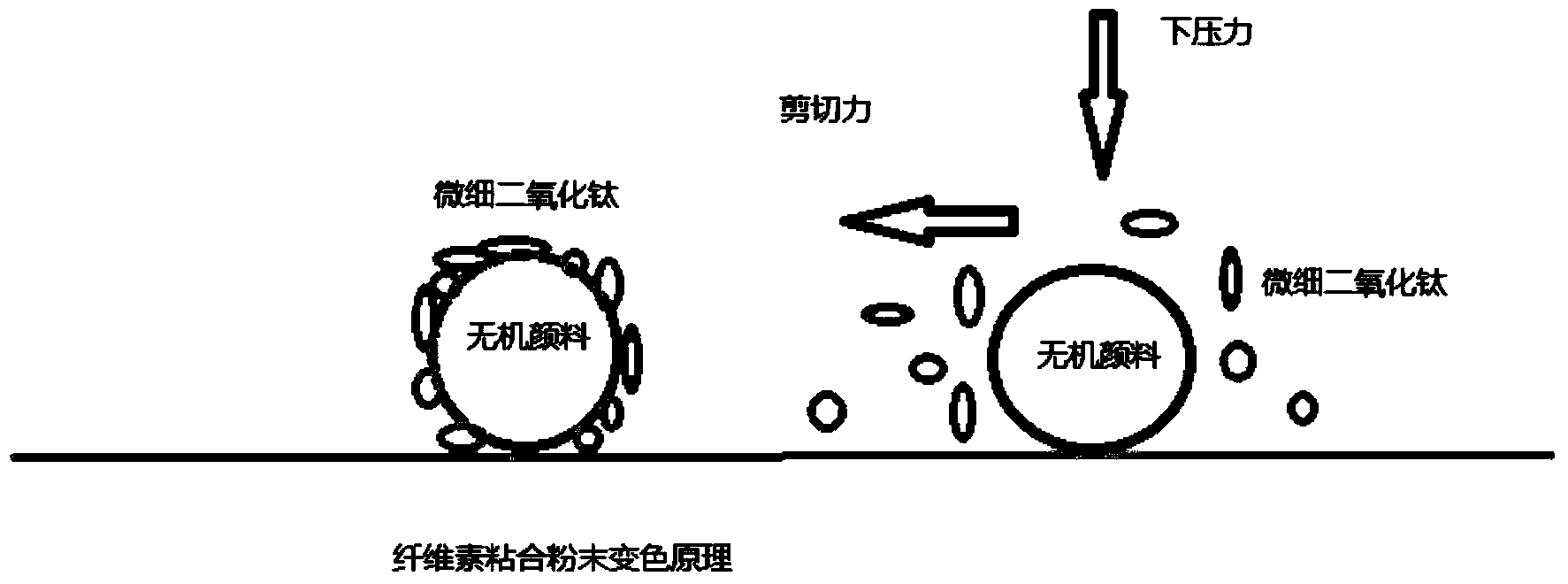

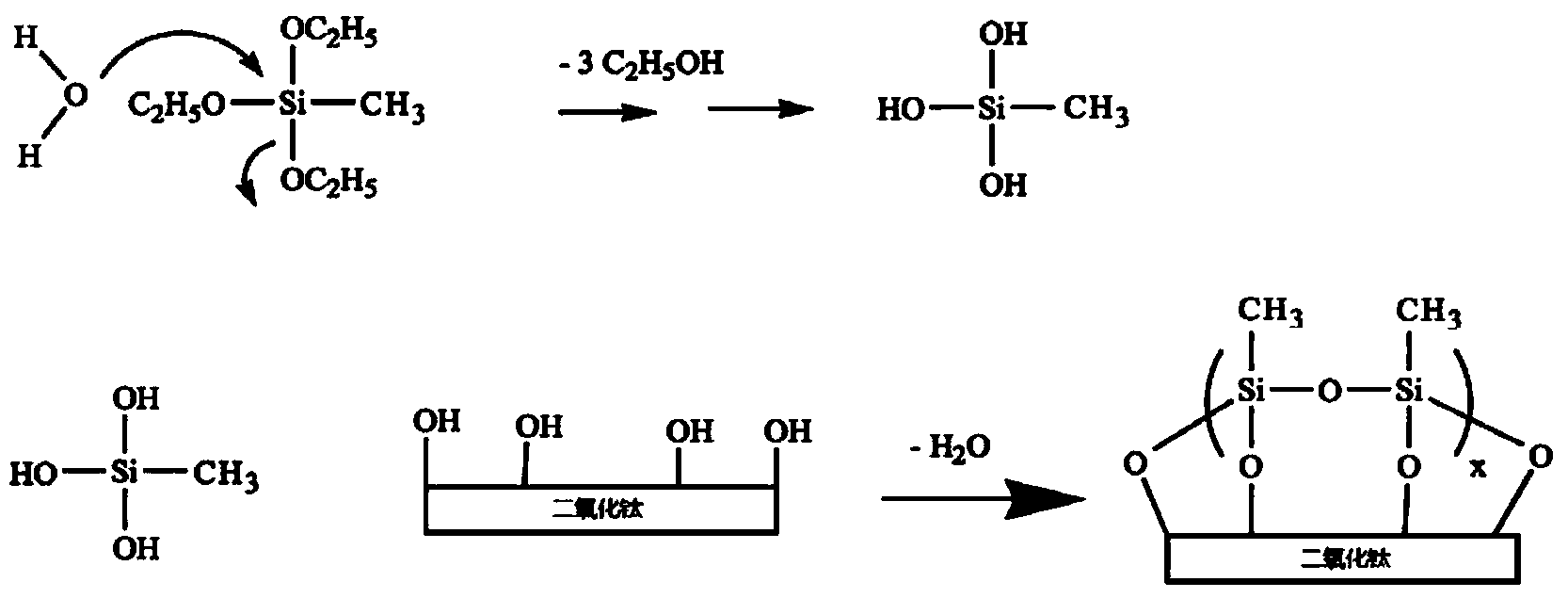

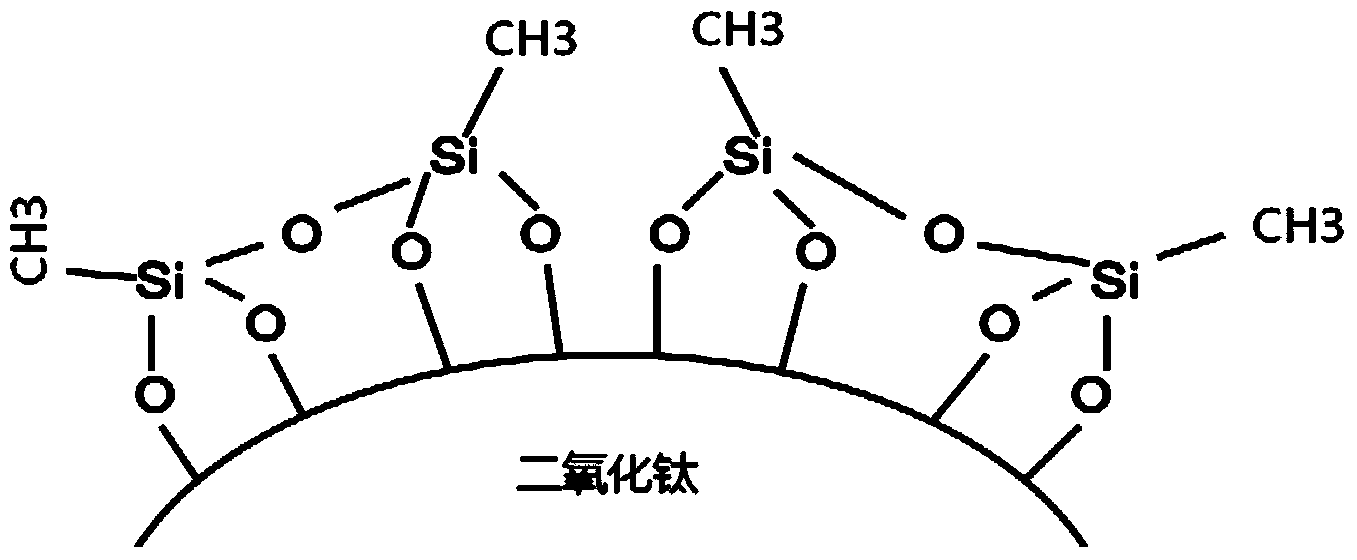

Controllable discolouring foundation cream/liquid foundation

ActiveCN104069014AFast discolorationWith discoloration effectCosmetic preparationsBody powdersSilylationIron oxide

The invention relates to controllable discolouring foundation cream / liquid foundation and a preparation method thereof. The preparation method of the controllable discolouring foundation cream / liquid foundation comprises the following steps: providing a powder premix compound containing titanium dioxide and inorganic pigment, for the coloured foundation cream / liquid foundation, wherein the titanium dioxide is subjected to triethoxy methyl silylation surface treatment, and the inorganic pigment is subjected to triethoxy octyl silylation surface treatment. The controllable discolouring foundation cream / liquid foundation has the advantages that completely different surface treatment methods are adopted for the titanium dioxide and inorganic pigment (ferric oxide) in the foundation cream / liquid foundation, so that surface properties of the two powders are obviously different;the discolouring foundation cream / liquid foundation prepared by utilizing the titanium dioxide and inorganic pigment is controllable and quick in discolouring effect; covering power is high; colours are diverse; the discolouring foundation cream / liquid foundation is safe and harmless; a production process is simple.

Owner:SHANGHAI CO FUN BIOTECH

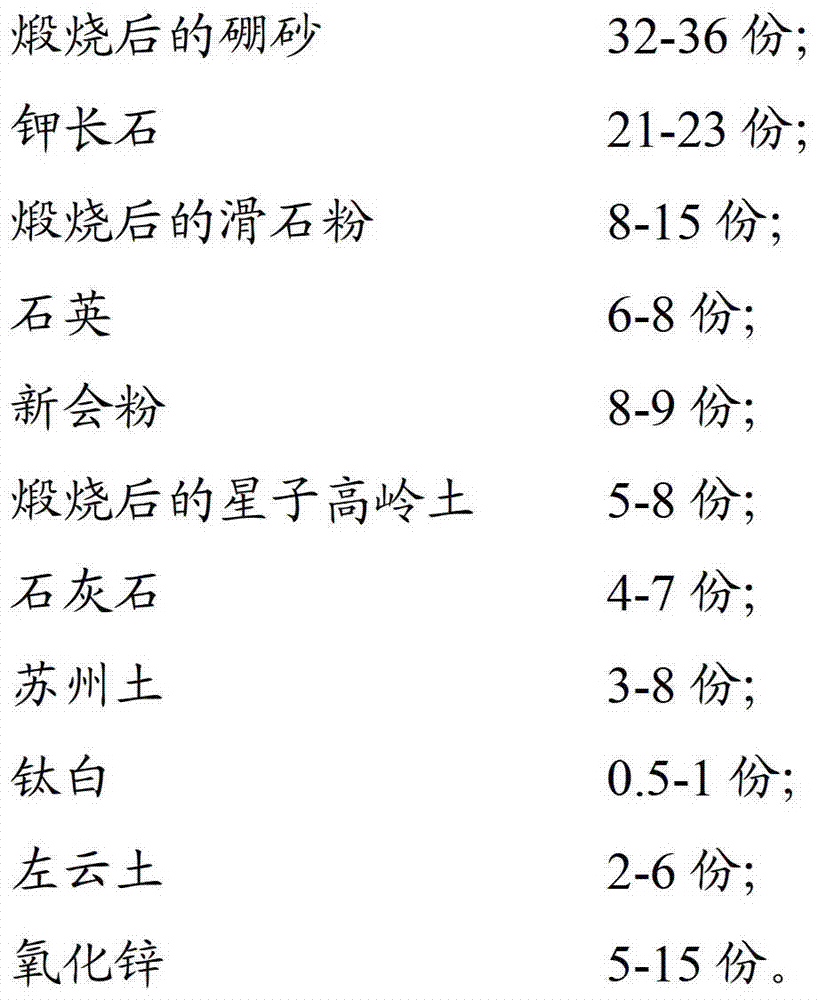

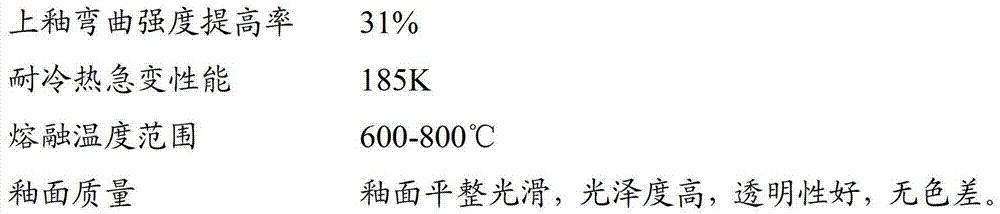

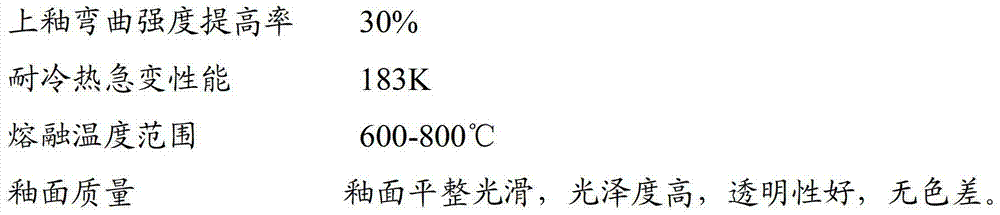

Formula and preparation method of ultralow temperature glaze

The invention discloses a formula of ultralow temperature glaze. The formula comprises 32-36 parts of calcined borax, 21-23 parts of potash feldspar, 8-15 parts of calcined talcum powder, 6-8 parts of quartz, 8-9 parts of Xinhui powder, 5-8 parts of calcined Xingzi kaoline, 4-7 parts of limestone, 3-8 parts of Suzhou soil, 0.5-1 part of titanium dioxide, 2-6 parts of Zuoyun soil and 5-15 parts of zinc oxide. The invention simultaneously discloses a preparation method of the ultralow temperature glaze. The preparation method comprises the following steps of material preparation, material mixing, wet grinding, glazing, drying and calcining. The ultralow temperature glaze prepared by the formula and the preparation method is used for retouching various porcelain blanks and porcelain bodies; a favorable intermediate layer can be formed after glazing; the ultralow temperature glaze can be favorably combined with the porcelain bodies and has excellent mechanical property, and the bending strength of porcelain is more than 30 percent; meanwhile, the porcelain glaze surface is smooth, is of a pale grey and transparent color and luster, has no defect on the surface and meets the market requirements.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Semi-aromatic copolyamide resin and copolyamide molded composition consisting of same

The invention discloses semi-aromatic copolyamide resin. The semi-aromatic copolyamide resin comprises a repetitive unit derived from the following components: (A) diamine, including 30mol%-100mol% of 1,11-undecane diamine and 0-70mol% of other C4-C36 diamine based on the amount of diamine; and (B) diacid, including 30mol%-100mol% of terephthalic acid and 0-70mol% of other C6-C36 diacid based on the amount of diacid, wherein the semi-aromatic copolyamide resin contains three or more monomers, and the monomers do not contain lactam or amino acid monomers. According to the semi-aromatic copolyamide resin, C11 diamine is taken as a copolymerization component, and the proportion of diamine to diacid is controlled to met specific requirements, so that the semi-aromatic copolyamide resin with improved color performance, low water absorption rate and good dimensional stability, and a copolyamide molded composition consisting of the semi-aromatic copolyamide resin also has improved color performance, low water absorption rate and good dimensional stability.

Owner:ZHUHAI WANTONG SPECIAL ENG PLASTICS CO LTD

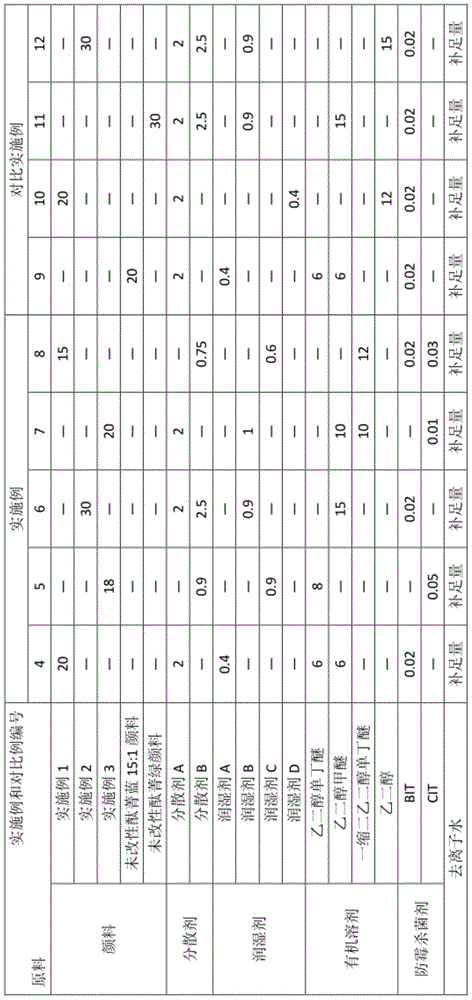

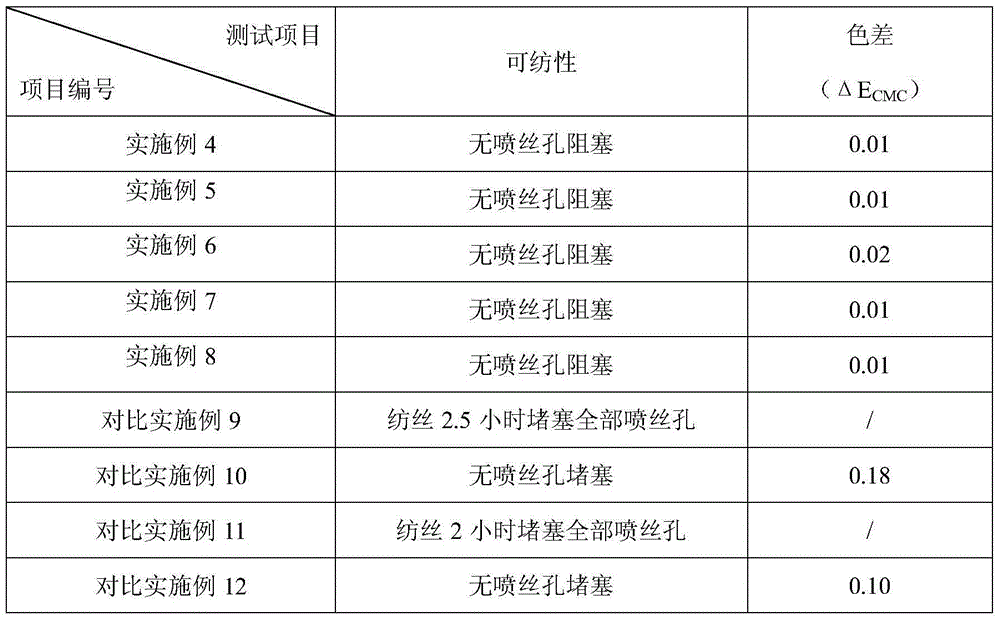

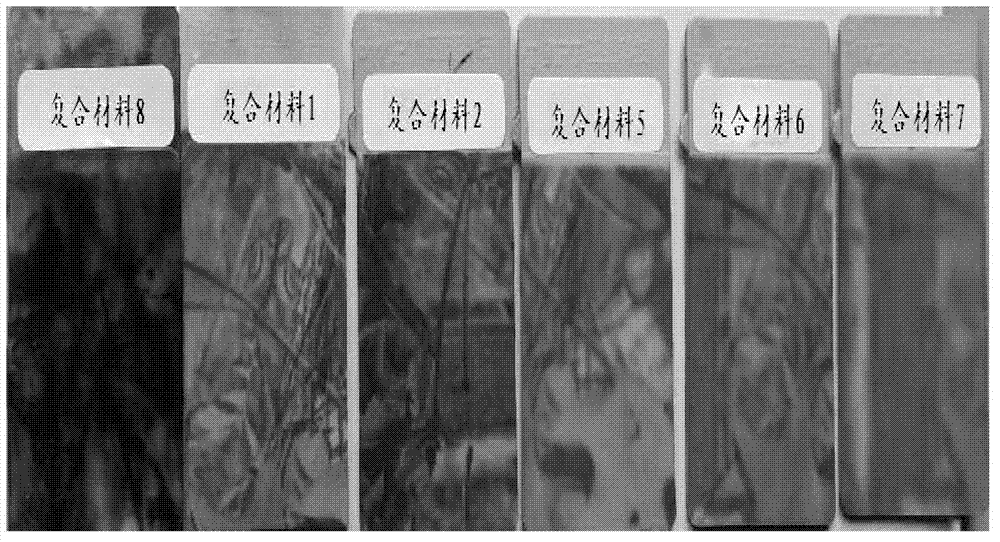

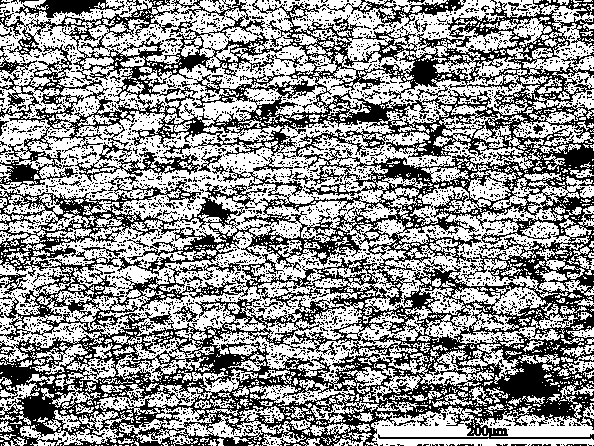

Phthalocyanine pigment water-based color paste for coloring viscose stock and preparation method thereof

ActiveCN103980766AUniform coloringGood coloring effect and spinnabilityArtificial filaments from viscosePigment pastesViscoseWetting

The invention relates to phthalocyanine pigment water-based color paste for coloring viscose stock. The color paste is prepared from a surface-modified phthalocyanine pigment, a dispersing agent, a wetting agent, an organic solvent, a mildew-proof bactericide and de-ionized water through such processes as dispersing, mixing, grinding, de-aerating and filtering. The color paste disclosed by the invention is used for coloring the viscose stock, and has such advantages as being uniform to color and capable of preventing a spinning jet from being blocked; and a coloring effect and a spinning property are excellent.

Owner:SUZHOU SUNMUN TECH CO LTD

Glass fiber reinforced PP/PA6 (Polypropylene/Polyamide6) composite material and preparation method and application thereof

InactiveCN103194023AHigh heat distortion temperatureImprove mechanical propertiesGlass fiberAntioxidant

The invention provides a glass fiber reinforced PP / PA6 (Polypropylene / Polyamide6) composite material, and a preparation method and an application thereof. The glass fiber reinforced PP / PA6 composite material is prepared by mixing 30-50 parts by mass of polypropylene, 25-35 parts by mass of polycaprolactam, 3-6 parts by mass of compatilizer, 8-15 parts by mass of flexibilizer, 0.5-1.2 parts by mass of lubricant, 0.1-0.3 part by mass of antioxidant, 0.1-0.3 part by mass of coupling agent and 0.2-0.6 part by mass of surfactant, and subsequently preparing with 20-35 parts by mass of glass fiber by using an extruder. The glass fiber reinforced PP / PA6 composite material has ordinary and easily accessible raw materials, the preparation method is simple and easy to operate, and the mechanical property is good; and when the material is applied to a vacuum heat conduction printing technique, the image is clear and vivid, and the effect is good.

Owner:深圳市比克新材科技有限公司

Universal fully-biodegradable color masterbatch and preparation method thereof

The invention belongs to the technical field of high-molecular materials, and relates to a universal fully-biodegradable color masterbatch and a preparation method thereof. The universal fully-biodegradable color masterbatch comprises the formula compositions in parts by weight: 30-80 parts of biodegradable polyester, 10-40 parts of a pigment, 10-30 parts of a filler, 0.5-3 parts of a compatilizer, 5-20 parts of a lubricant and 0.1-0.6 part of an anti-oxidant. The fully-biodegradable color masterbatch is obtained through melt blending, extrusion, strip pulling and pelletizing by employing a double screw extruder. The fully-biodegradable color masterbatch is completely biodegradable, good in processing performance and good in dispersing effect in a matrix, and has extremely good compatibility with a polyester matrix even a masterbatch carrier and a biodegradable polyester matrix are different polyesters. The masterbatch gives play to extremely good coloring effect on a product when being applied to a biodegradable polyester.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Color metallography coloring method of aluminum alloy

InactiveCN103471897AThe method steps are simpleGood coloring effectPreparing sample for investigationMetallographyAlcohol

The invention discloses a color metallography coloring method of an aluminum alloy. The color metallography coloring method comprises the following steps of (1) pre-etching, namely immersing a polished aluminum alloy metallographic specimen in an etching liquid for 1-10 minutes, after ending etching, washing with running water, cleaning with ethyl alcohol, and drying, wherein the etching liquid is a solution obtained by dissolving potassium chloride or sodium chloride in phosphoric acid or a solution prepared by phosphoric acid, nitric acid and water; and (2) coloring. The color metallography coloring method has the advantages that steps are simple, the coloring effect is good, and a clear grain structure can be obtained, namely, the clear microstructure can be obtained without adopting polarized light and sensitive hue for observation.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

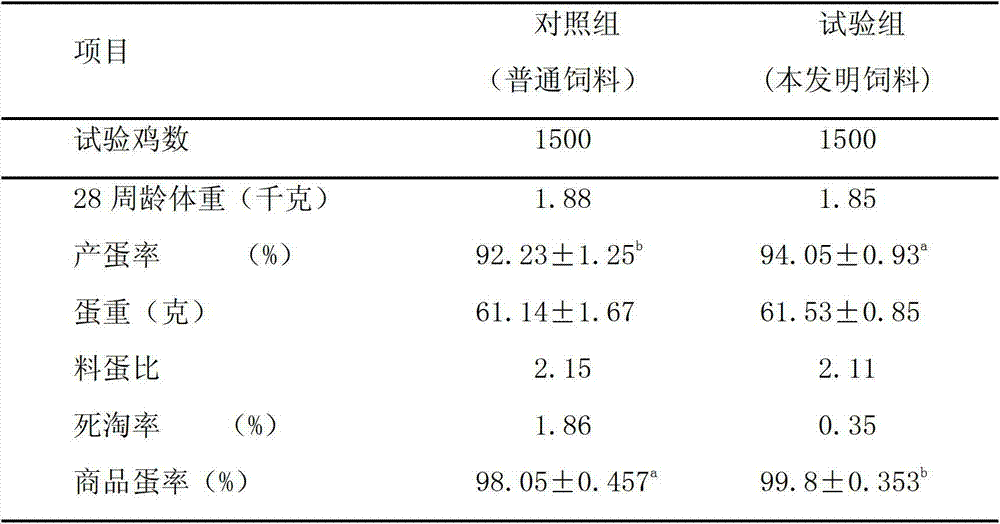

Wheat daily ration feed for promoting yolk pigmentation of laying hen

The invention discloses a wheat daily ration feed for promoting yolk pigmentation of a laying hen. The feed comprises the following materials in parts by weight of: 50-65 parts of wheat, 8-15 parts of bean pulp, 3-9 parts of chrysanthemum meal, 1-5 parts of corn gluten meal, 1-3 parts of bentonite, 5-10 parts of corn DDGS, 1-3 parts of corn oil, 1-6 parts of cottonseed meal, 5-10 parts of mountain flour, 0.5-1.5 parts of calcium hydrophosphate, 0.2-0.4 part of salt, 0.05-0.1 part of probiotics, 0.3-0.8 part of synthetic amino acid, 0.02-0.05 part of glycine betaine, 0.05-0.1 part of choline chloride, 0.04-0.08 part of a multi-enzyme preparation, 0.6-1 part of a compound premix, and 0.01-0.03 part of 50% of vitamin E. The chrysanthemum meal and combined nutrition of the chrysanthemum meal are added to the feed at the egg production period for improving the health state of the intestinal tract of the laying hen; the yolk pigmentation effect is obviously improved; the egg feed cost is reduced; and the egg producing performance of the laying hen is improved.

Owner:LIAONING WELLHOPE AGRI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com