Paint coating process for wooden furniture

A kind of technology of wooden furniture and coating process, which is applied to the device of coating liquid on the surface, coating, pretreatment surface, etc., which can solve the problems of difficult plane treatment and long time for blank treatment and polishing, so as to improve value and appreciation Sexuality, saving production cost, bright and smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

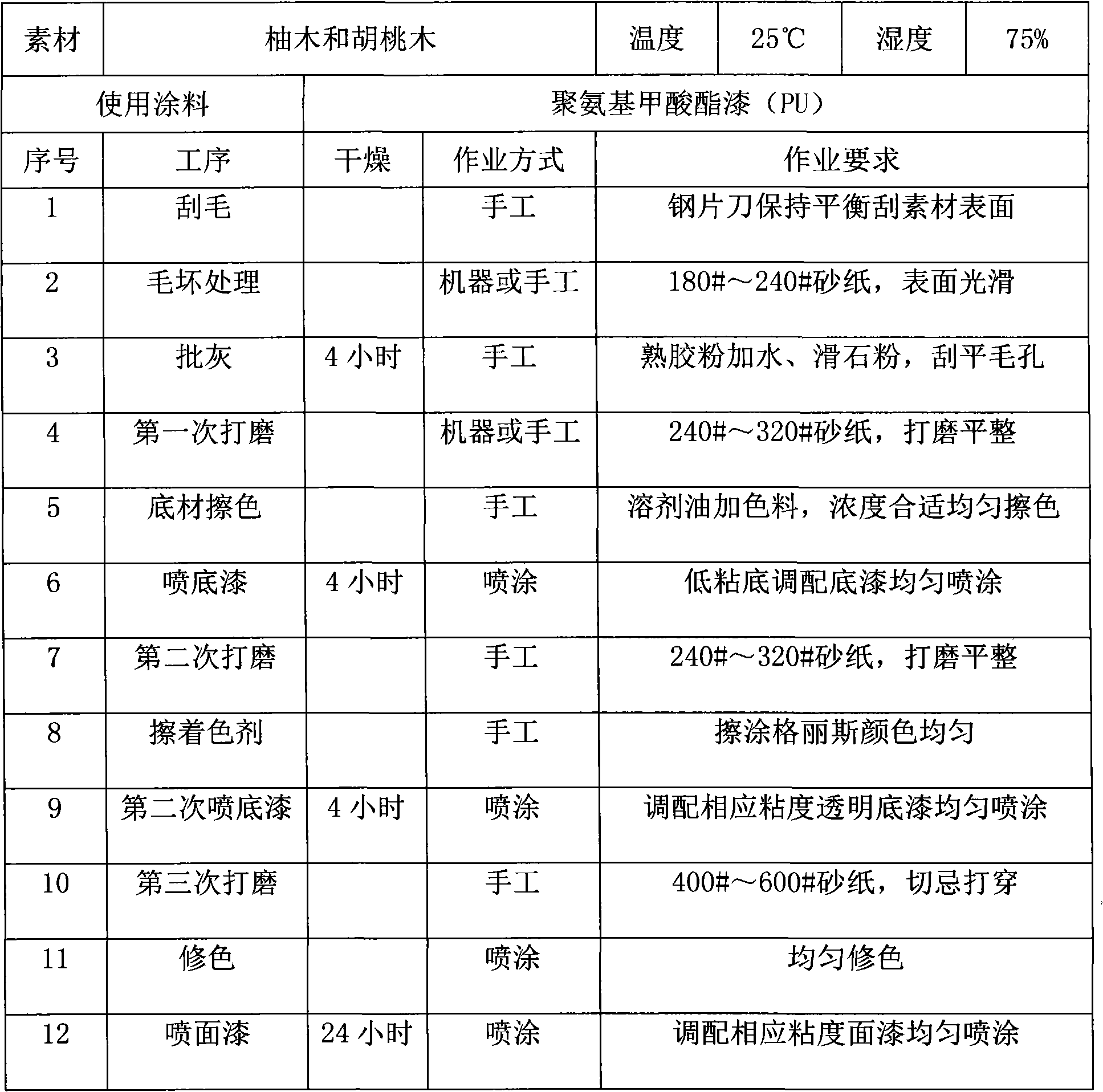

[0033] As shown in Table 1, teak is used as the wood material, polyurethane paint is used for the coating, the working environment temperature is 25°C, and the humidity is 75%. Teak furniture paint coating process, including the following processes:

[0034] In the shaving process, the surface of the wood scraper is kept balanced by hand with a steel blade;

[0035] In the blank treatment process, use 180# sandpaper to manually sand the surface of the wood to make the surface of the wood smooth;

[0036] Criticizing the dust process, using cooked rubber powder, adding water and talcum powder to scrape the surface pores manually, and then drying for 4 hours;

[0037] For the first grinding process, use 240# sandpaper to manually polish the surface to make the surface smooth;

[0038] Substrate color wiping process, using solvent oil and coloring material to evenly wipe the surface by hand;

[0039] Spray primer process, spray primer on the surface, and then dry for 4 hours; ...

Embodiment 2

[0049] Walnut is used as the wood material, the paint is polyurethane paint, the working environment temperature is 25°C, and the humidity is 75%. Walnut furniture paint coating process, including the following processes:

[0050] In the shaving process, the surface of the wood scraper is kept balanced by hand with a steel blade;

[0051] In the rough processing process, use 180# sandpaper to sand the surface of the wood through the machine to make the surface of the wood smooth;

[0052] Criticizing the dust process, using cooked rubber powder, adding water and talcum powder to scrape the surface pores manually, and then drying for 4 hours;

[0053] In the first grinding process, use 240# sandpaper to grind the surface through the machine to make the surface smooth;

[0054] Substrate color wiping process, using solvent oil and coloring material to evenly wipe the surface by hand;

[0055] Spray primer process, spray primer on the surface, and then dry for 4 hours;

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com