Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1362results about "Artificial filaments from viscose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

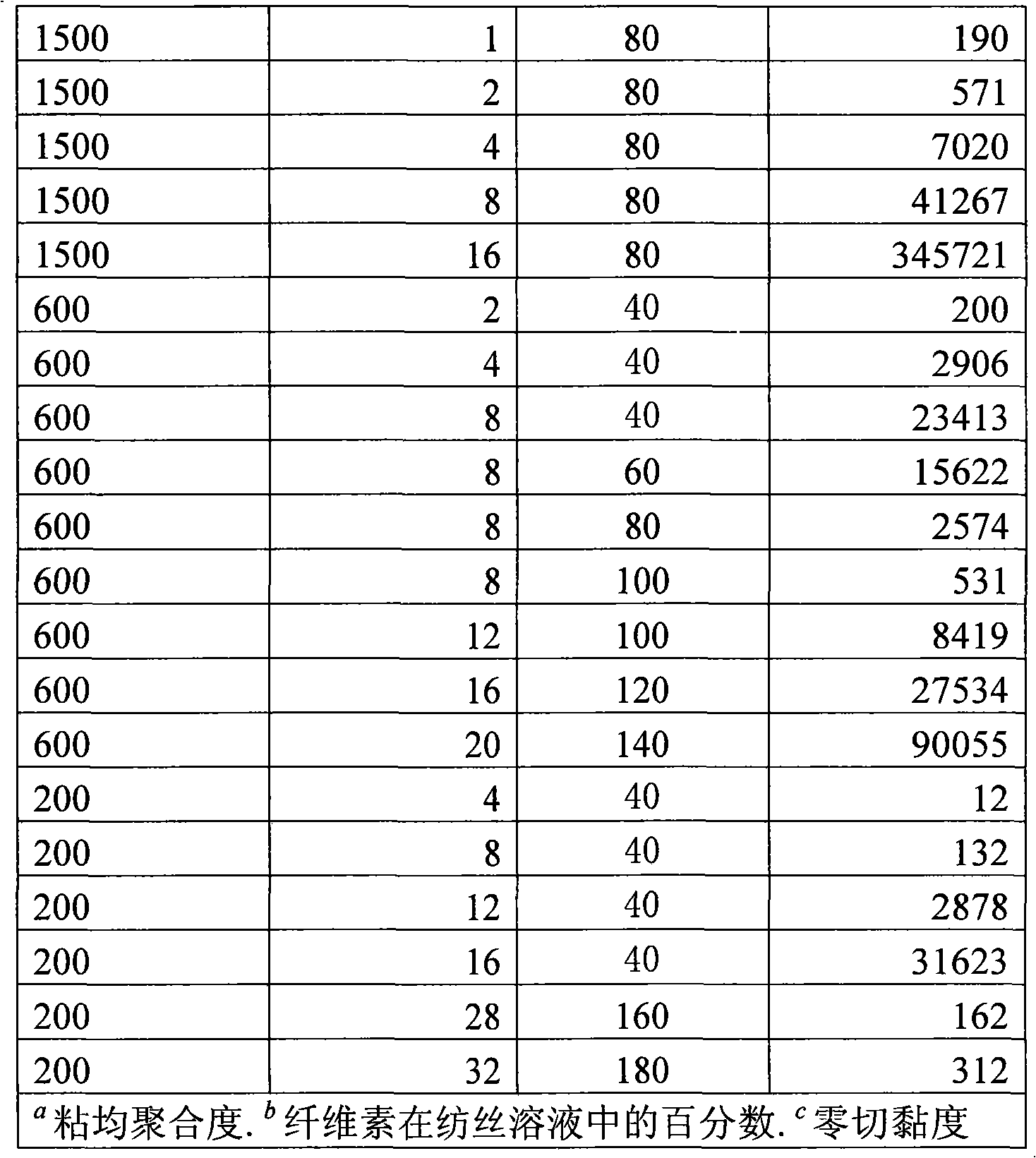

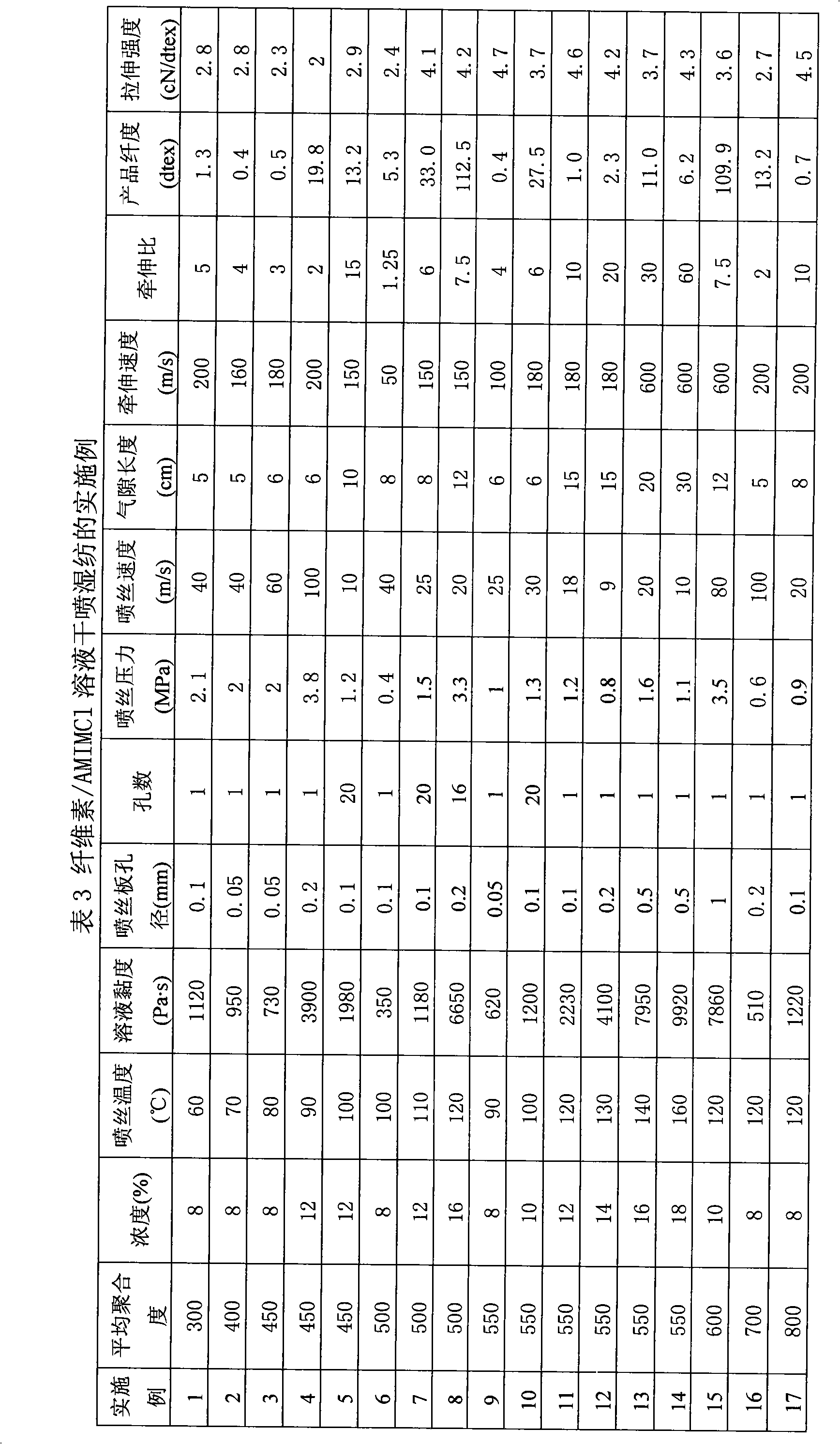

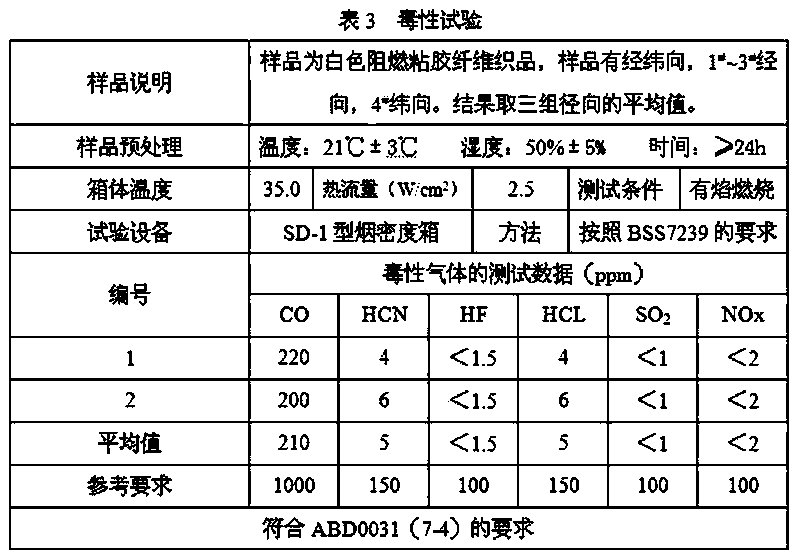

Method for continuously preparing regenerated cellulose fibre

InactiveCN101328626AReduce manufacturing costReduce the temperatureArtificial filament recoveryFibre treatmentPolymer scienceTetrafluoroborate

The invention discloses a method for continuously preparing regenerated cellulose fibers through the solvent method, comprising the following steps that: a cellulose raw material is dissolved into an ion liquid to prepare a spinning liquid; gel type regenerated cellulose fibers are obtained through spinning; and the regenerated cellulose fibers are obtained through cleaning, rear draft and drying, wherein, the ion liquid is selected from one or a plurality among the following ion liquids: a). an ion liquid with 1, 3-dialkyl imidazole as a cation and formiate radical, radical vinegar or propionate radical as an anion; and b). an ion liquid with 1-R1-3-R2- dialkyl imidazole as the cation and chlorine, bromine, iodine, formiate radical, radical vinegar, sulfate radical, nitrate radical, tetrafluoroborate radical, thiocyanate radical, hexafluorophosphate radical, p-toluenesulfonate radical or trifluoromethanesulfonic acid radical as the anion. The method has the advantages of wide technological range, mild temperature condition, adequate pressure, quick spinning speed and so on, can prepare the regenerated cellulose fibers with superior performance and complete specifications, and has low production cost, high production efficiency and wide application prospect.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

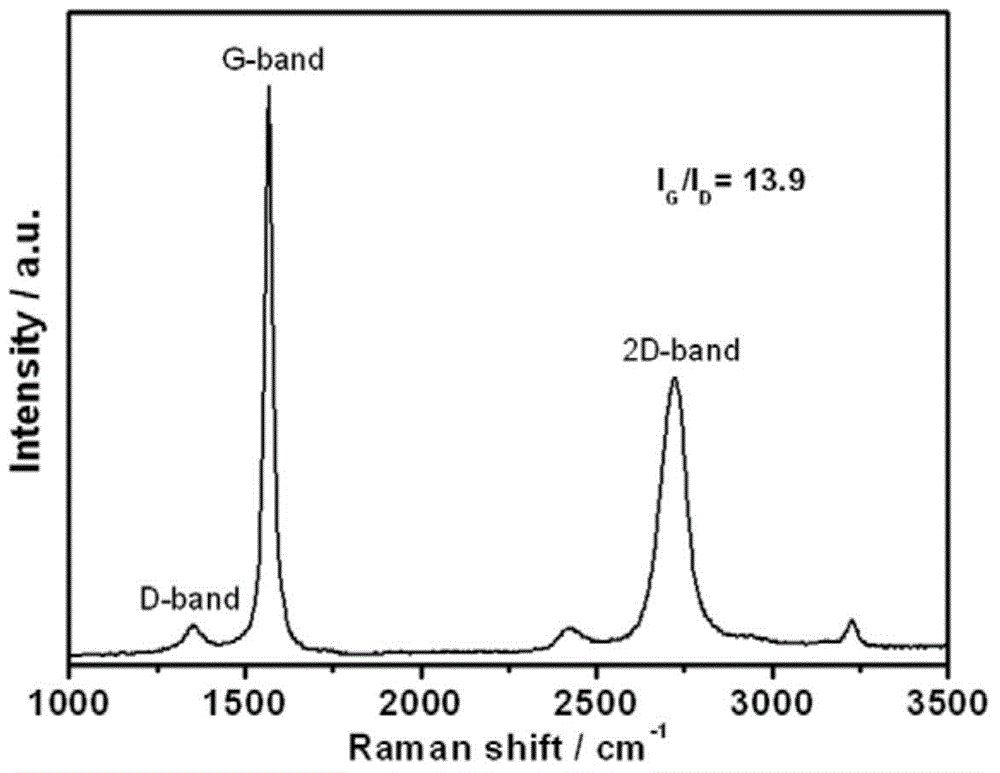

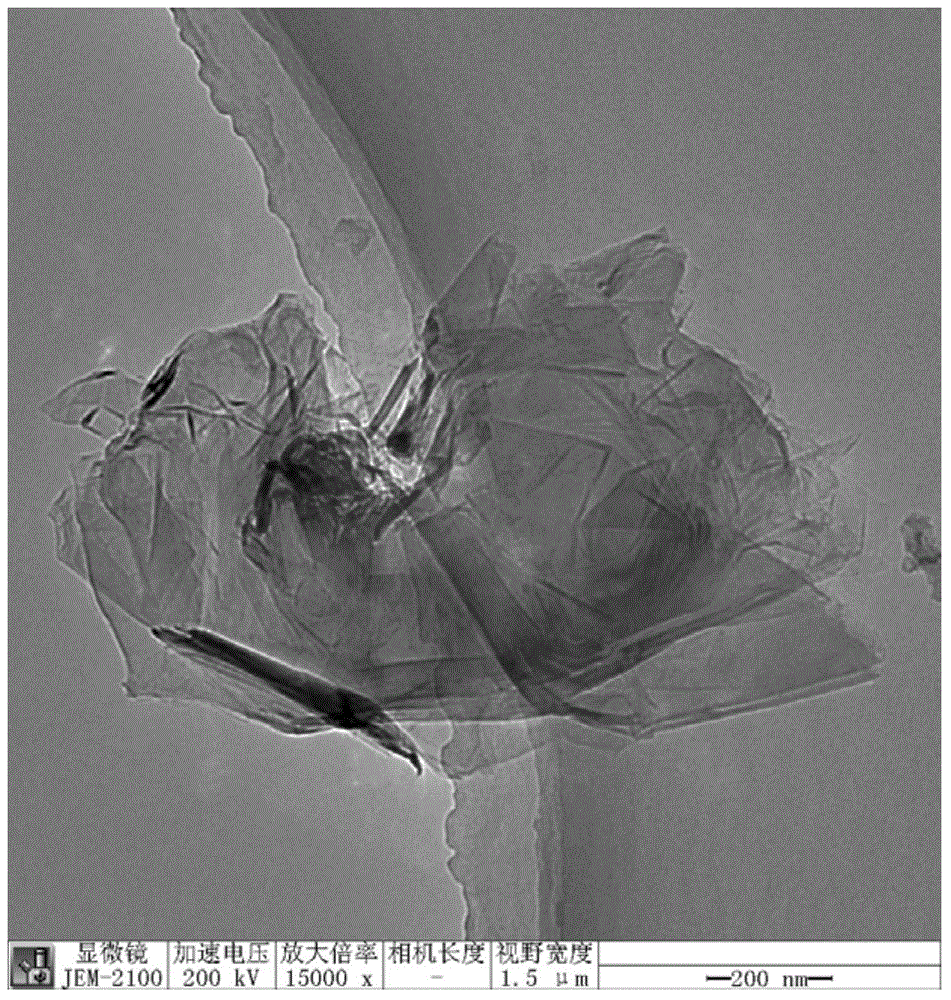

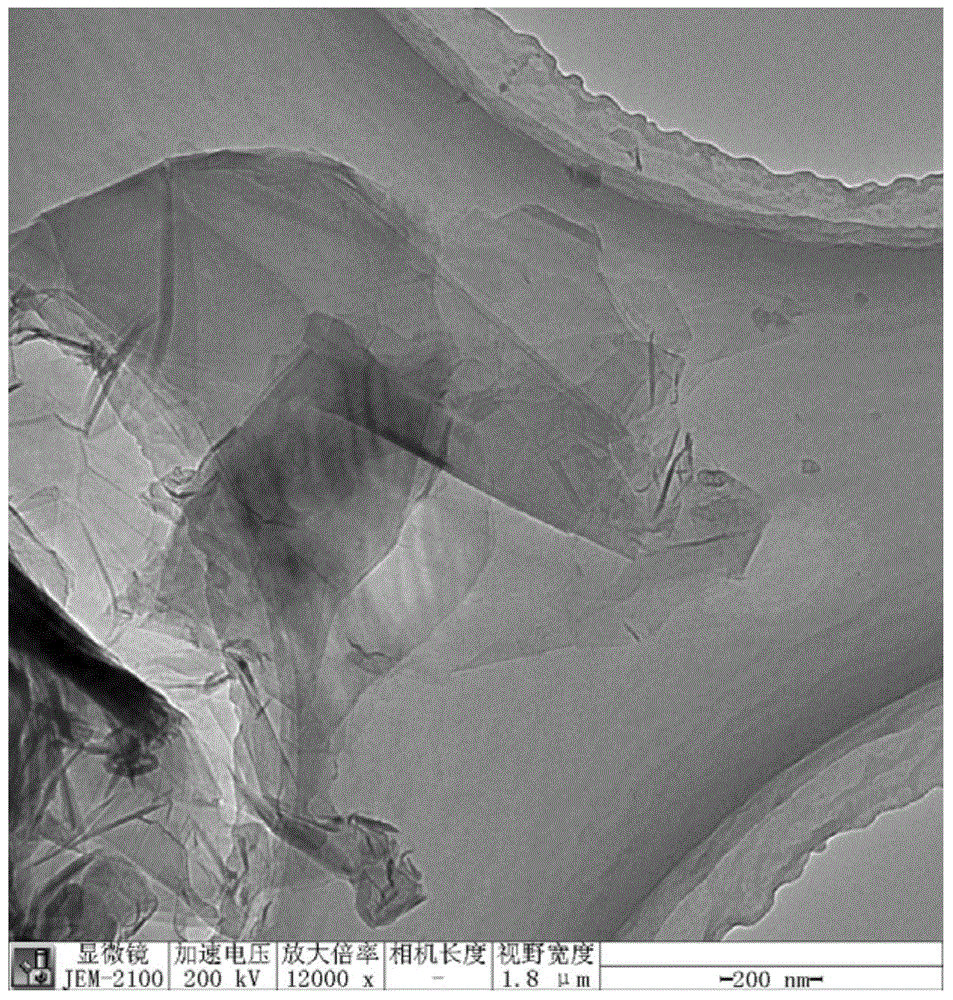

Grapheme-containing viscose fiber and preparation method thereof

ActiveCN104328523AHigh breaking strengthGrapheneArtificial filaments from viscoseViscoseUltimate tensile strength

The invention relates to a graphene-containing viscose fiber and a preparation method thereof. Graphene is non-oxidized graphene with a layer number not more than 10. The preparation method comprises the step of introducing the graphene into viscose before spinning. The viscose fiber obtained through the preparation method disclosed by the invention outstandingly enhances the fracture strength.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

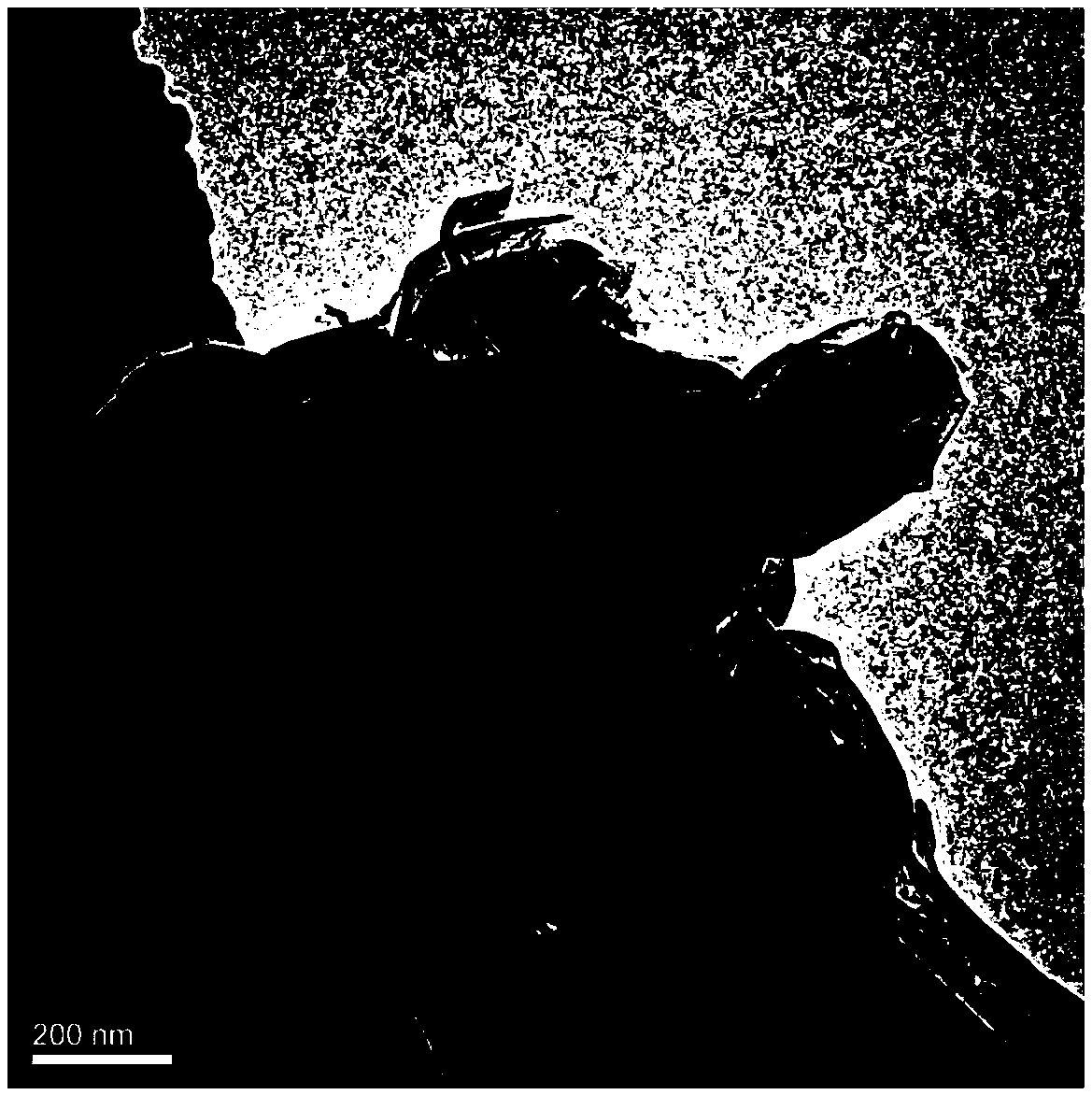

Graphene blend regenerated cellulose fiber and preparation method thereof

ActiveCN103046151AImprove conductivityImprove thermal performanceArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentMoisture absorptionCellulose fiber

The invention relates to a graphene blend regenerated cellulose fiber. The graphene blend regenerated cellulose fiber is prepared by mixing an oxidized graphene solution and a regenerated cellulose solution, molding a mixture through a viscose wet spinning process and reducing the mixture; the dry breaking strength of the graphene blend regenerated cellulose fiber is not less than 1.8 cN / dtex, the wet breaking strength of the graphene blend regenerated cellulose fiber is not less than 0.9 cN / dtex, the dry breaking elongation of the graphene blend regenerated cellulose fiber is not less than 16%, the mass specific resistance of the fiber is 1-9X106 omega.g / cm2, and the thermal decomposition temperature of the fiber is not lower than 400 DEG C; and with the regenerated cellulose fiber as a matrix, the prepared graphene blend regenerated cellulose fiber has the advantages of good moisture absorption, good air permeability, soft handle and good dyeing performance and has the characteristics of ultrahigh strength, thermal conductivity, electric conductivity, antibacterial property and the like of the graphene; the conductive and thermal properties of the fiber are both improved by being compared with those of the traditional regenerated cellulose fiber; the antibacterial property of the fiber is additionally provided; and the graphene blend regenerated cellulose fiber provided by the invention has the advantages of simple production process, easiness in operation, and higher yield. People estimate that the developed graphene blend regenerated cellulose fiber can be widely applied to the field of costumes, industrial textiles and the like.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG +1

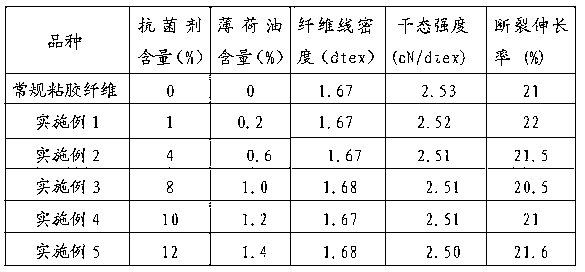

Viscose fiber with plant source anti-bacterial function and aromatic smell, and preparation method thereof

ActiveCN103225123ANo side effectsComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseSide effectMint extract

The invention discloses a viscose fiber with a plant source anti-bacterial function and aromatic smell. The viscose fiber is composed of a viscose spinning solution, an anti-bacterial agent and an aromatic agent, wherein the anti-bacterial agent is mixed powder of a mint extract and a isatis root extract, wherein the weight percentage of the mint extract accounts for 40%-80%; and the weight percentage of the isatis root extract accounts for 60%-20%; the aromatic agent is mint oil coated by microcapsules; the anti-bacterial agent accounts for 1%-8% of the mass of methyl cellulose in the viscose spinning solution; the mint oil accounts for 0.2%-1% of the mass of methyl cellulose in the viscose spinning solution; and the viscose fiber is prepared by adopting a wet spinning method by using the viscose spinning solution, the anti-bacterial agent and the aromatic agent. The plant source extracts and the plant source essential oil are used as the anti-bacterial agent and the aromatic agent; and the anti-bacterial agent and the aromatic agent are uniformly distributed in the fiber, so that the anti-bacterial function and the aromatic smell of the fiber are durable. Since the plant source extracts and the aromatic agent are natural substances extracted from the plants, so that the viscose fiber has no side effect to human body.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Viscose fiber with mint antibacterial function and preparation method thereof

InactiveCN101525777AImprove antibacterial functionPrevent adverse side effectsArtificial filaments from viscoseSocial benefitsAntibacterial agent

The invention provides a viscose fiber with mint antibacterial function and a preparation method thereof. The viscose fiber is characterized in that a natural mint extractive is used as an antibacterial agent agent, superfine powder grains or solution of the natural mint extractive are added to viscose spinning solution, and the superfine powder grains are molded to obtain the viscose fiber with the mint antibacterial function according to the traditional wet spinning and spraying technology, wherein the additive quantity (or the additive quantity of the superfine powder grains of the natural mint extractive in the solution) of the superfine powder grains of the natural mint extractive is 1 percent to 10 percent of the weight of the viscose spinning solution. The viscose fiber adopts the natural mint extractive as the antibacterial agent which is evenly distributed in the fiber, and the antibacterial agent has persistent antibacterial function and dyeing effect and does not have side effects on human body. The viscose fiber with the mint antibacterial function is suitable for preparing underdress, other clothes and bed textiles and has wide application range and large economic and social benefit. The preparation method has reasonable and simple process and is suitable for industrialization production.

Owner:张永堂

Multifunctional viscose and preparation method thereof

ActiveCN104831389AGood far infraredImproves UV resistanceGrapheneArtificial filaments from viscoseViscoseAntibacterial activity

The invention provides multifunctional viscose. The multifunctional viscose comprises viscose, graphene and nano-silver, wherein nano-silver is loaded to a graphene slice layer in situ. The invention further provides a preparation method of the multifunctional viscose. The preparation method is characterized by comprising the following steps: (a) dispersing graphene in a water solution, so as to obtain a graphene dispersion liquid; (b) dissolving silver salt into the graphene dispersion liquid, adding a reducing agent, and carrying out reduction reaction, so as to obtain nano-silver-loaded graphene dispersion liquid; and (c) uniformly mixing the nano-silver-loaded graphene dispersion liquid with viscose liquid, and carrying out spinning, so as to obtain the multifunctional viscose. An experimental result shows that compared with viscose which is not added with nano-silver-loaded graphene, the multifunctional viscose has the advantages that the far infrared temperature increase performance is increased by not less than 100%, the ultraviolet protecting coefficient is increased by not less than 70%, and the antibacterial activity reaches 99.9% and is increased by not less than 100%.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Viscose containing natural antimicrobials and preparation method thereof

InactiveCN102926013AImprove antibacterial functionNo side effectsArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentViscose fiberStock solution

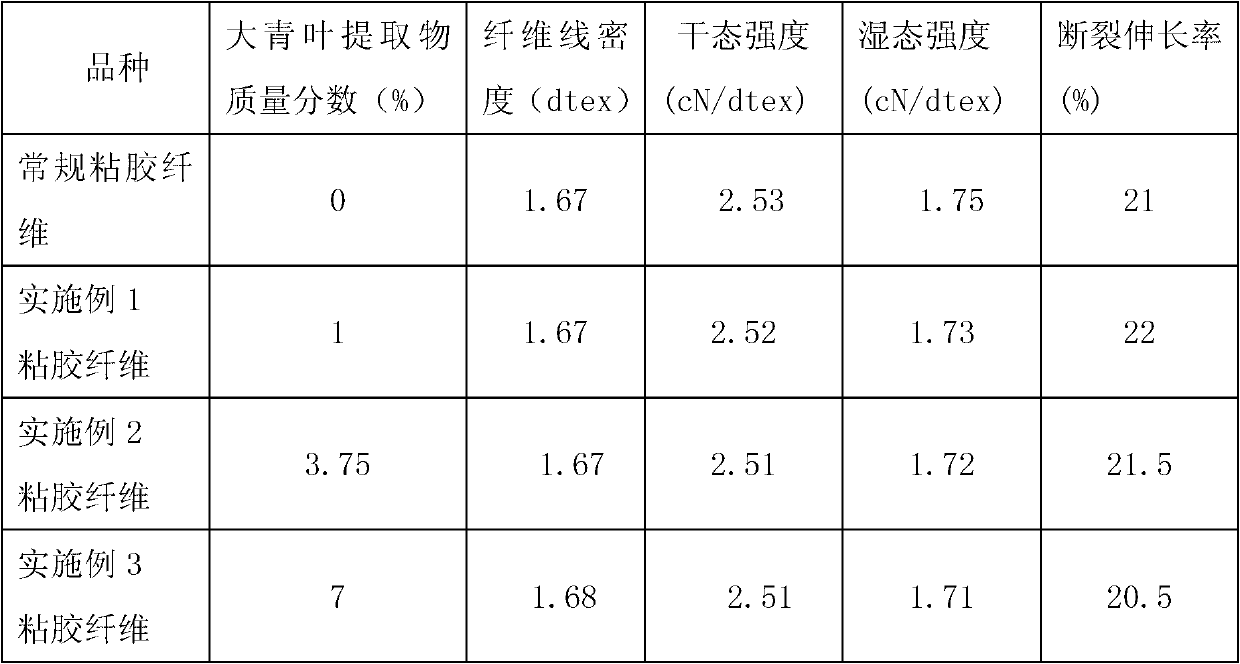

The invention provides viscose containing natural antimicrobials. The viscose containing the natural antimicrobials comprises the viscose and the antimicrobials contained in the viscose. The viscose containing the natural antimicrobials is characterized in that the antimicrobials is natural indigowoad leaf extract powder, a natural indigowoad leaf extract powder solution added with dispersing agent is added into a viscose filature stock solution, the additive amount of the natural indigowoad leaf extract powder is 1%-7% of the quality of the viscose filature stock solution, the additive amount of the dispersing agent in the natural indigowoad leaf extract powder solution is 0.1%-1.0% of the quality of water in the natural indigowoad leaf extract powder solution. The preparation method of the viscose comprises the steps of dissolving the indigowoad leaf extract powder into water and adding the dispersing agent to obtain the indigowoad leaf extract powder solution, adding the indigowoad leaf extract powder solution to the viscose filature stock solution according to a ratio of 10%-14% of the quality of the viscose filature stock solution, and then shaping a obtained solution according to conventional wet spinning jet process to obtain the viscose. The viscose has a durable antibacterial function and has no side effect on human bodies. The preparation method has reasonable and simple technology, and is suitable for industrialized production.

Owner:单修铎

High-wetness modulus adhesive colloid fiber and preparing method

InactiveCN101024907AHigh strengthResistant to multiple deformationsArtificial filaments from viscoseBleaching apparatusFiberPolymer science

The invention discloses a high-humidity modulus viscose fiber with dry strength of 3.5-6.0cN / dtex, wet elastic modulus of 0.35-0.60cN / dtex and wet strength of 2.0-4.5cN / dtex, and prepared of cellulose pulp with degree of polymerization of 500-1200 and alpha-cellulose content >=95% by the steps of dip-basifying, squeezing, ageing, yellowing, dissolving, wet spinning moulding, drafting, etc. And it has features of higher intensity and wet modulus, better loop strength performance, and lower brittleness; and the fabrics made by it has features of high intensity, multiple deformation resistance, alkali resistance, etc.

Owner:CHTC HELON

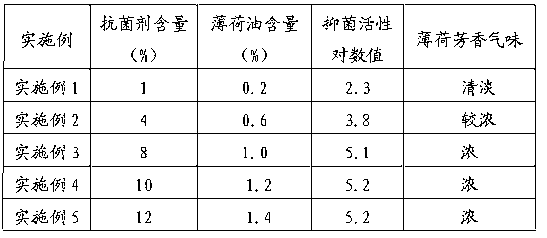

Peppermint composite cellulose fibers and preparation method thereof

ActiveCN104593893AGood antibacterial effectComfortable to wearArtificial filaments from viscosePeppermintsAntibacterial activity

The present invention provides peppermint composite cellulose fibers, which contain 1-12 wt% of a peppermint extract component and 0.5-3 wt% of peppermint odor essential oil slow-release microcapsules, wherein the dry breaking strength of the fibers is 1.0-3.0 cN / dtex, the wet breaking strength of the fibers is 0.8-1.6 cN / dtex, the dry elongation at break is 16-24%, the residual sulfur content is less than or equal to 18 mg / 100 g, the antibacterial activity logarithm value is more than 2.0, and the bactericidal activity logarithm value is more than 0. The peppermint composite cellulose fiber preparation method comprises: peppermint extract adding liquid preparation, degenerated viscose glue preparing, peppermint blending viscose glue preparing, spinning and post-treating, and filament drafting and post-treating so as to obtain the peppermint composite cellulose fibers. The peppermint composite cellulose fibers of the present invention have characteristics of good wearability, textile processability, antibacterial function, bacterial inhibition function, lasting and fresh peppermint aroma, lasting odor, good textile processing performance, and significant antibacterial function.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

Antibacterial viscose containing artemisia argyi oil component and production method of antibacterial viscose

ActiveCN103556250AHigh antibacterial rateImprove durabilityArtificial filaments from viscosePolymer scienceAnti bacterial

The invention relates to antibacterial viscose containing an artemisia argyi oil component and a production method of the antibacterial viscose. The antibacterial viscose takes an artemisia argyi oil microcapsule as an antibacterial agent and a spinning solution is composed of the artemisia argyi oil microcapsule and mucilage glue, wherein the adding ratio of the artemisia argyi oil microcapsule is 10%-30% of alpha cellulose in the mucilage glue and the antibacterial property index are as follows: the antibacterial value is more than 4.0 and the sterilization value is 2.7. The production method of the antibacterial viscose containing the artemisia argyi oil component comprises the following steps: preparing artemisia argyi emulsion, preparing the artemisia argyi oil microcapsule, preparing the mucilage glue, preparing the spinning solution, and spinning and molding. The antibacterial viscose not only has the advantages of maintaining water absorption and air permeability of common viscose and being comfort to wear, but also has high antibacterial rate and good endurance; meanwhile, the antibacterial viscose has a good skin-caring effect and can be widely applied to home textile articles, underwear, sports shirts and the like.

Owner:潍坊欣龙生物材料有限公司

Method for manufacturing modal fiber

ActiveCN101545150AHigh strengthBrightly dyedArtificial filaments from viscoseInternational standardDissolution

The invention discloses a method for manufacturing modal fiber, which comprises basification reaction, ageing reaction, yellowing reaction, dissolution of viscose glue, filter of the viscose glue, defoaming of the viscose glue, ripening of the viscose glue, wet spinning, drawing and other related process steps. The method adopts cellulose pulp with alpha cellulose content of less than 95 percent as a raw material, uses common equipment for producing common viscose glue short fiber, and adopts the technology to control a simple and practical special process formulation and a spinning drawing mode to manufacture the modal fiber capable of reaching international standards. The method has the advantages of little investment, easily obtained and low-cost raw materials, high productivity and simple process operation; and the manufactured modal fiber has good quality and stable performance.

Owner:杭州奥通新材料智能科技有限公司

Process for preparing antiseptic viscose fiber

ActiveCN1587454AGood dispersionImprove stabilityArtificial filaments from viscoseArtifical filament manufactureFiberColloid

The present invention discloses preparation process of antiseptic viscose fiber. The antiseptic viscose fiber is prepared through adding nanometer silver particle of size smaller than 100 nm as antiseptic in the form of nanometer colloid aqua into spinning liquid and subsequent conventional wet spinning process. It has lasting antiseptic effect and no side toxic effect on human body, as well as excellent mechanical performance. It may be used widely in industry, agriculture, medicine and other fields.

Owner:CHINA LUCKY FILM CORP

Manufacture of fibre containing functional mineral powder and fibre prepared by the same

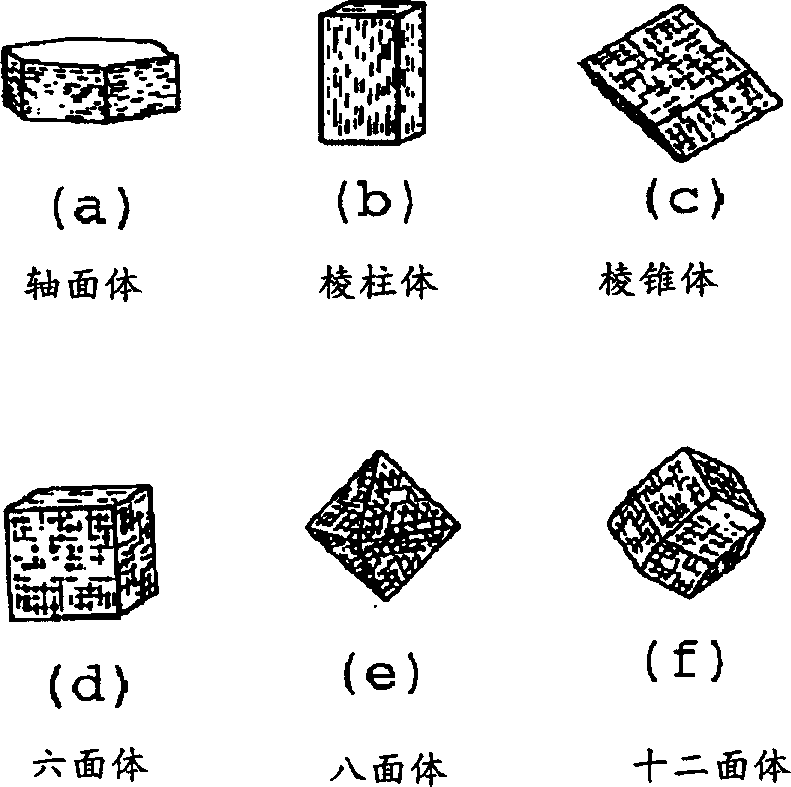

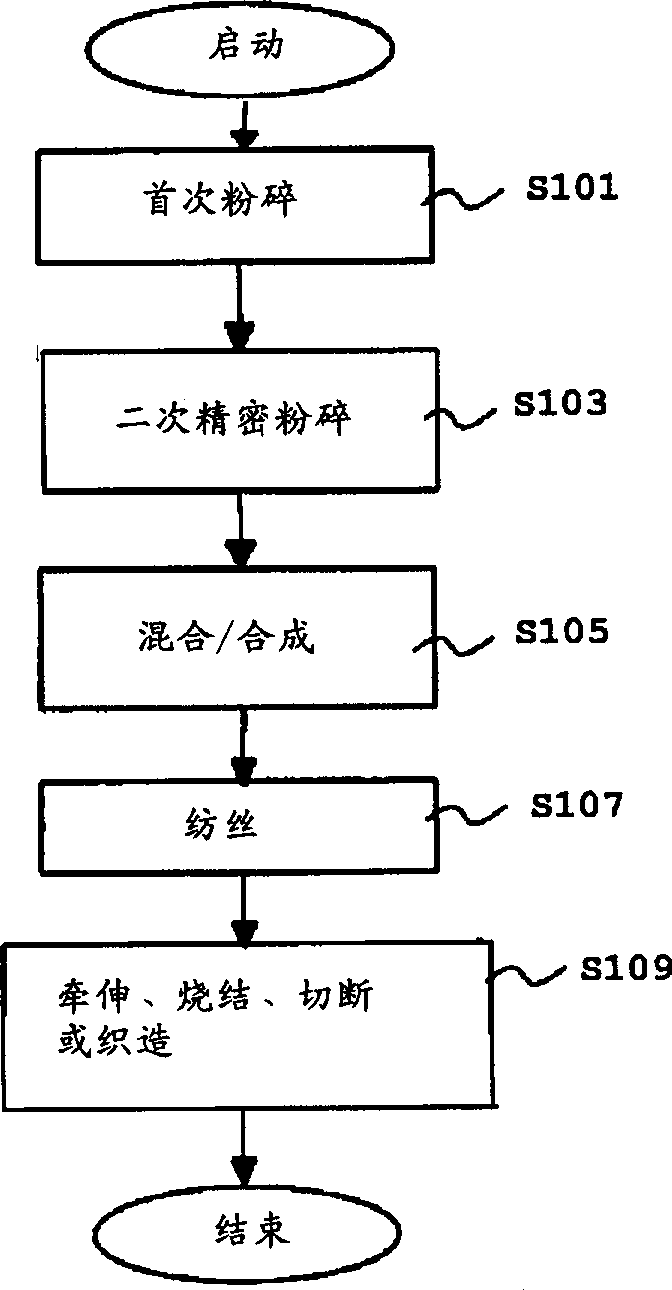

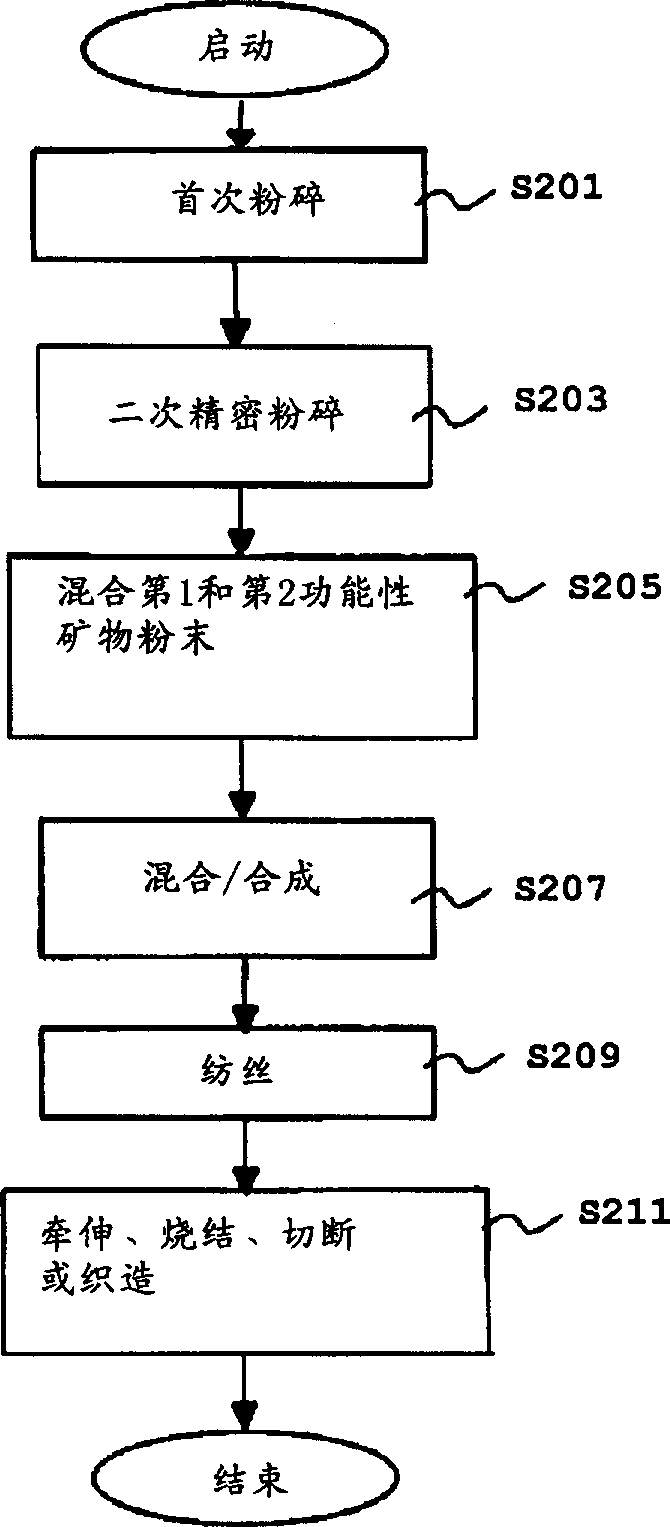

InactiveCN1318657ABlood pressure controlRelief the painArtificial filaments from viscoseArtificial filaments from cellulose derivativesGranularityPolyresin

A method of producing fiber having functional mineral powders includes the steps of a first pulverizing functional mineral which crystal form of is pinacoid, a second closely pulverizing the first pulverized functional mineral powders to be less than 1 / 3 granularity of desired fineness, mixing and synthesizing 0.1-10 weight % of the second pulverized functional mineral powders and 90-99.9 weight % of a chemical resin, and spinning the mixture of functional mineral powders and the chemical resin.

Owner:石美秀

Regenerated animal micropowder protein cellulose fiber and preparation method thereof

ActiveCN102493020AStrong sense of silkSoft touchConjugated cellulose/protein artificial filamentsArtificial filaments from viscoseViscose fiberTextile processing

The invention discloses a regenerated animal micropowder protein cellulose fiber and a preparation method thereof. The preparation method comprises the following steps of: adding nanoscale animal micropowder protein into a dispersant solution, stirring the mixture uniformly, filtering to obtain 20 to 35 weight percent of animal micropowder protein liquid; preparing viscose by using cellulose pulp as a raw material, adding denaturant in the dissolution step to obtain modified viscose; adding the animal micropowder protein liquid into the modified viscose in a weight ratio of animal micropowder to the finished fiber of (1-30):100, uniformly stirring to obtain animal micropowder compounding viscose; and defoaming and filtering, spinning molding by introducing a coagulating bath, and then drawing filament and performing aftertreatment to obtain the animal micropowder protein viscose fiber. The fabric made of the regenerated animal micropowder protein cellulose fiber is low in density, and is light; the hygroscopicity, the air permeability and the thermal insulating property of the fabric are further improved; the fiber textile processing and wearability are good; and the production process is pollution-free.

Owner:潍坊欣龙生物材料有限公司

Flax material viscose fibre pulp and preparation process of functional fibre thereof

The invention relates to a process technique of producing viscose rayon pulp and functional rayon, and the flow includes: preparing hemp materials -> cutting materials -> screening -> washing materials -> preprocessing -> cooking -> extruding -> breaking -> desanding and concentrating -> chloridizing -> alkali refining -> bleaching -> acid treating -> desanding and concentrating -> making -> dipping -> pressing -> crushing -> ageing -> etiolating -> grinding -> dissolving -> mixing -> prefiltering -> filtering -> defoaming -> filtering -> spinning -> drawing -> cutting off -> after processing -> drying -> packaging. The viscose rayon has the characters: bacteriostasis, smoothness and forcefulness, coolness, fineness, brighness, high dry-wet strength, etc, convenient for spinning and weaving processing and dying and finishing treatment, and the products have natural bacteriostasis function.

Owner:HEBEI JIGAO CHEM FIBER

A kind of production method of superfine high-strength high-modulus viscose fiber

InactiveCN102296373AIncrease contact areaIncreasing the thicknessSpinnerette packsArtificial filaments from viscoseCellulosePolymer science

The invention discloses a production method of ultra-fine, high-strength and high-modulus viscose fibers. The cellulose xanthate polymer spinning viscose which is still in a viscous flow state is provided with viscose ejection holes and coagulation baths respectively. The composite spinneret of the spray hole is sprayed out, and is solidified and formed by a low-acid, high-zinc, low-salt and low-temperature coagulation bath, and then combined with bath stretching and air stretching, and drawn by nozzles with different ratios , inter-disk drafting and plasticizing drafting, and then post-treatment to obtain a fineness of 0.44~0.78dtex, dry strength ≥ 3.1cN / dtex, wet strength ≥ 2.1cN / dtex, wet modulus ≥ 0.5cN / dtex, whiteness ≥82.0% ultra-fine high-strength high-modulus viscose fiber. The invention realizes the effective coordination of the ultrafine denier fiber spinning forming process and drafting, and the normal implementation of the spinning process, and the produced ultrafine high-strength high-modulus viscose fiber has a uniform structure, and the fiber strength and modulus are 50% higher than conventional varieties. %above.

Owner:CHTC HELON

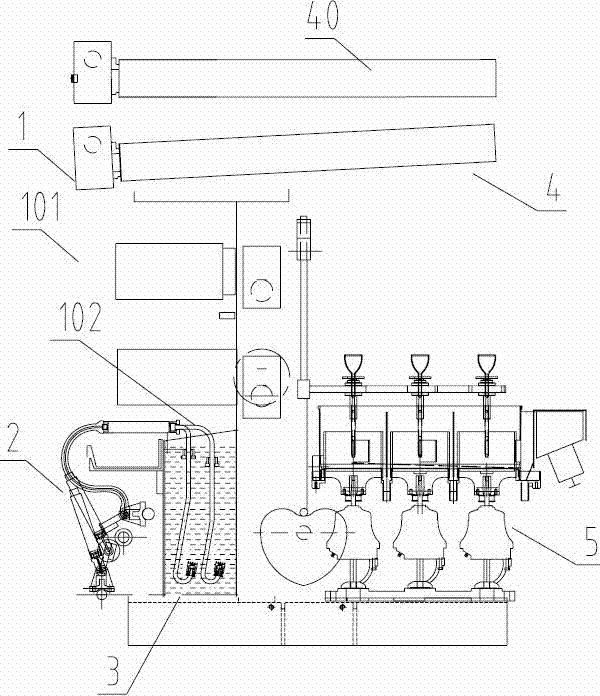

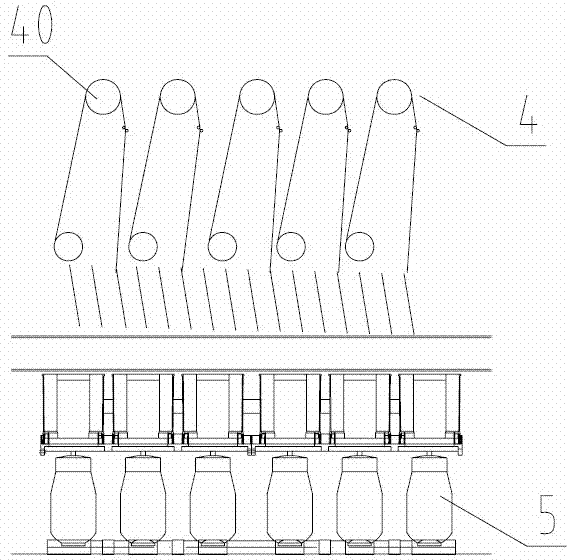

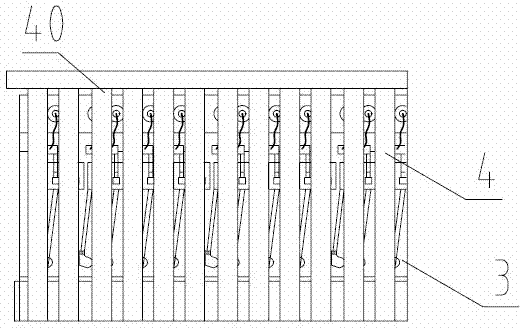

Spinning technology applied to semi-continuous high-speed spinning machine with spinning roller arranged horizontally

InactiveCN103290496ASmooth rotationNo shakingArtificial filaments from viscoseWet spinning methodsYarnSpinning

The invention relates to a spinning technology applied to a semi-continuous high-speed spinning machine with a spinning roller arranged horizontally. The spinning technology comprises glue measurement and supply, pre-spinning filtering, yarn strip forming, spinning and winding. The spinning technology aims at the specific semi-continuous high-speed spinning machine with the spinning roller arranged horizontally, under the mutual action of all processes and control of technological parameters, the spinning speed is ensured to be improved, independent walking of single yarn strips can be achieved, operations are simplified, the problems of doubling, burrs, breakage and the like are solved, the yarn strips are fully reacted and good in uniformity, the product quality is guaranteed, meanwhile, operations of workers are facilitated, and equipment maintenance is easy, overhaul costs are low, so that product costs are greatly reduced while the production efficiency is effectively improved.

Owner:YIBIN HIEST FIBER +2

Method for preparing Nano SiO2 fire retardant viscose fiber, and film

ActiveCN101050559ASimple processEasy to operateFlame-proof filament manufactureArtificial filaments from viscoseFire retardantSodium sulfate

The present invention relates to a preparation method of nano SiO2 fire-retardant viscose fiber and film, specially, it relates to a preparation method of fire-retardant viscose fiber formed from cellulose and SiO2 and organic-inorganic polymer nano composite membrane made of cellulose and SiO2. Said method includes the following steps: adding silicone sol with a certain mass into a viscose solution whose composition contains alpha-cellulose whose mass percentage content is 6-9% and sodium hydroxide whose mass percentage content is 5-6%; fully stirring and mixing them at 10-50 deg.C, deforming so as to obtain viscose-silicone sol solution, then adding said viscose-silicone sol into a coagulation acid bath prepared by using sulfuric acid, sodium sulfate, zinc sulfate and water, coagulating at 10-100 deg.C, spinning so as to obtain nano SiO2 fiber-retardant viscose fiber, utilizing coating process so as to obtain organic-inorganic polymer nano composite membrane of cellulose / SiO2.

Owner:QINGDAO UNIV

Functional viscose fiber containing Chinese medicinal component and its preparation method

InactiveCN1786300AKeep active ingredientsOvercome defectsArtificial filaments from viscoseAfter treatmentChinese drug

The invention discloses a traditional Chinese drug component containing functional viscose fiber and its manufacturing method. It is made up of traditional Chinese drug material, semi-finished products, finished products, part of dregs of decoction, and viscose fiber. Its components content is fiber: 85-99.9%, traditional Chinese drug: 0.1-15%. Its manufacturing method includes the following steps: dipping, mellowing, sulphidizing, dissolving, mixing, filtering, defoaming, ripening, spinning fore raw liquor mixing, traditional Chinese drug fiber spinning and drafting, and fiber after-treatment. Its traditional Chinese drug content can reach 10%. Thus the fiber has more effective health protection, sickness prevention, and auxiliary therapy. Thus it is fit for making underclothes, bedding, medical component, and so on.

Owner:张志伟

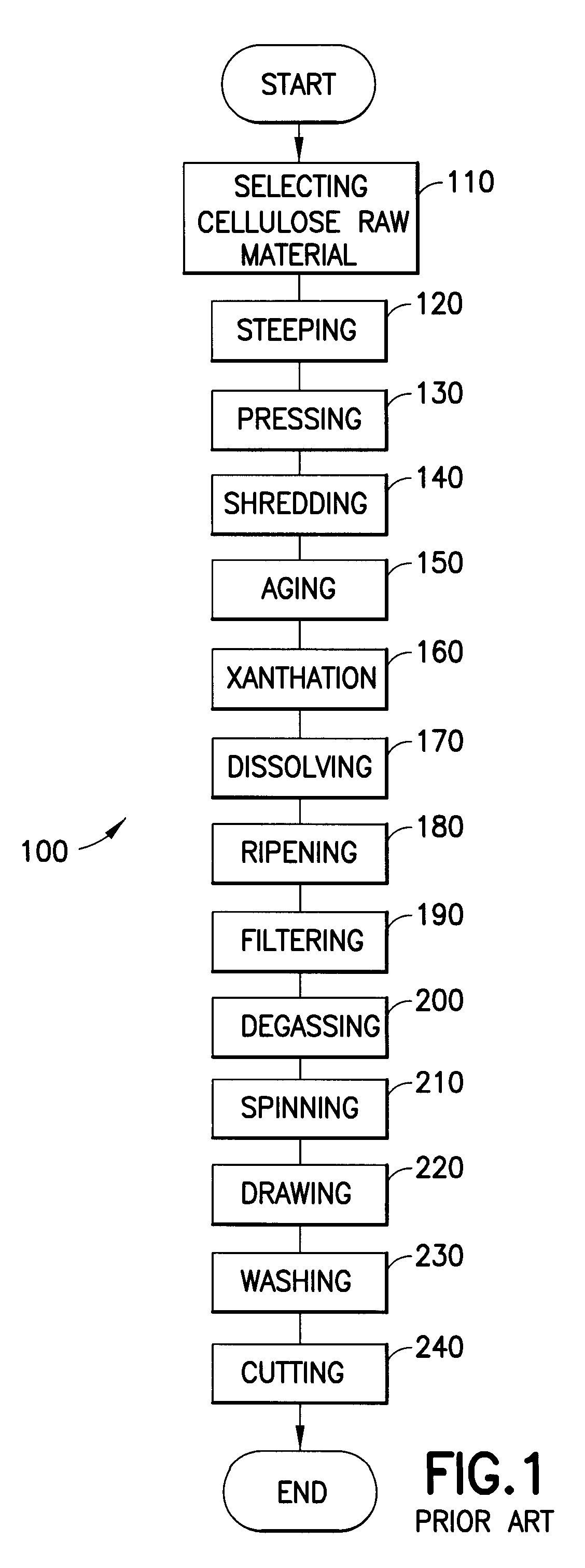

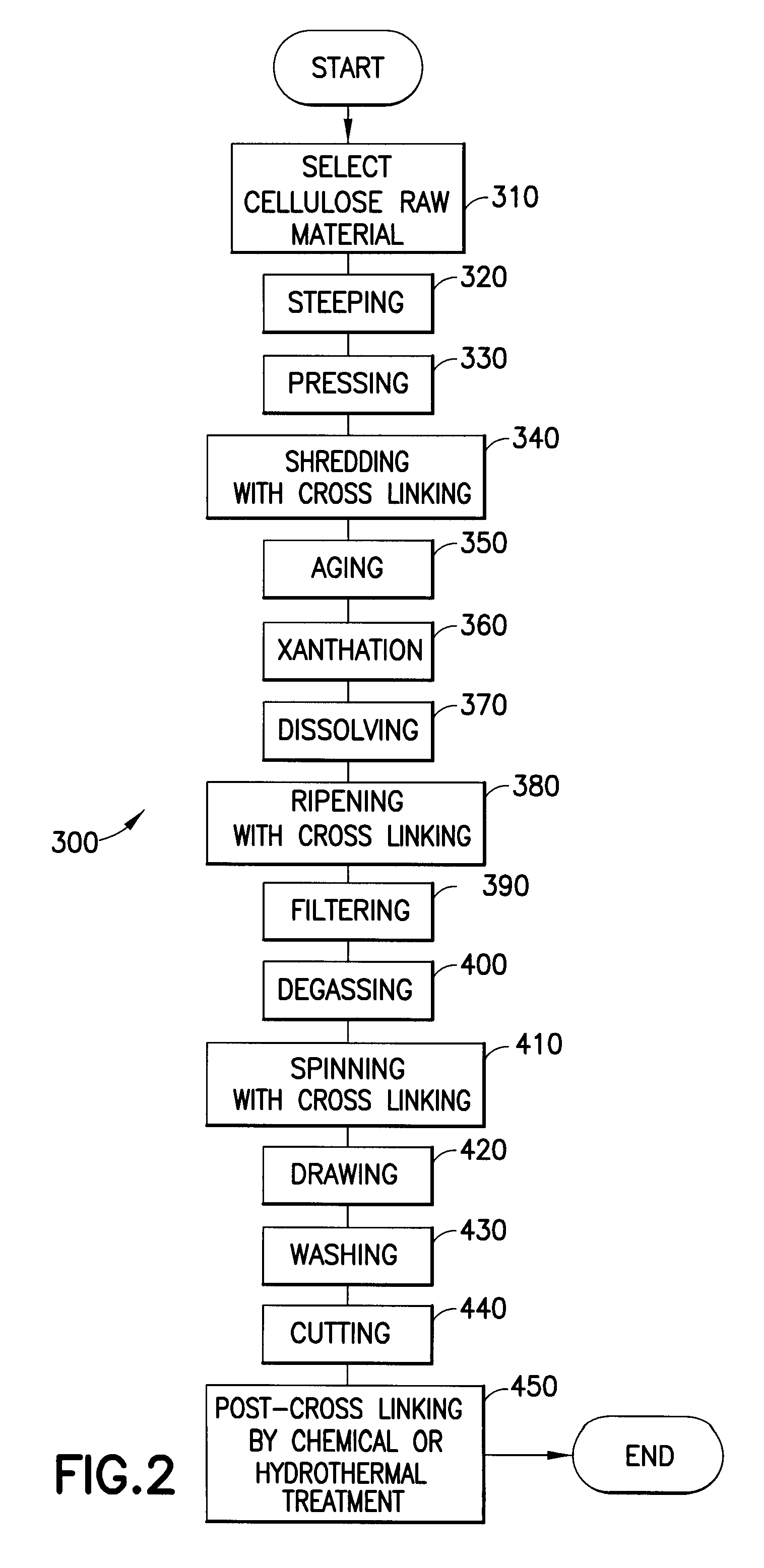

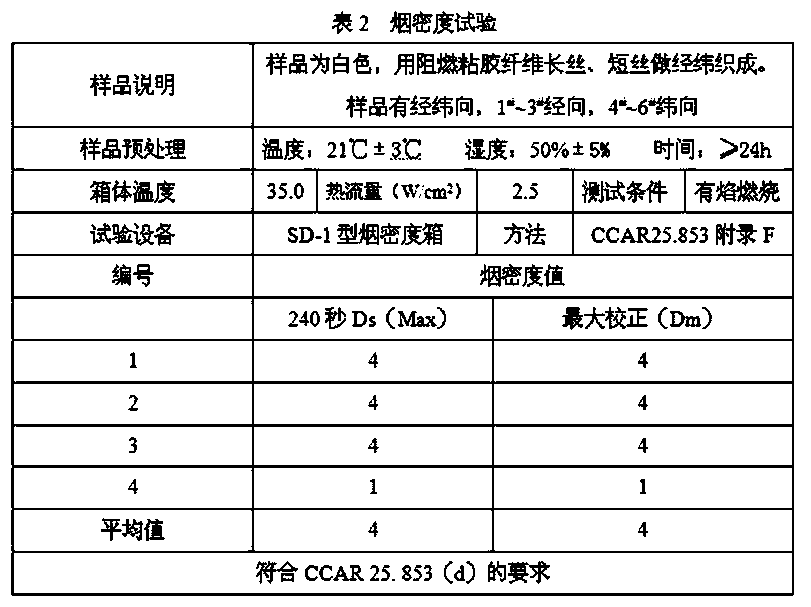

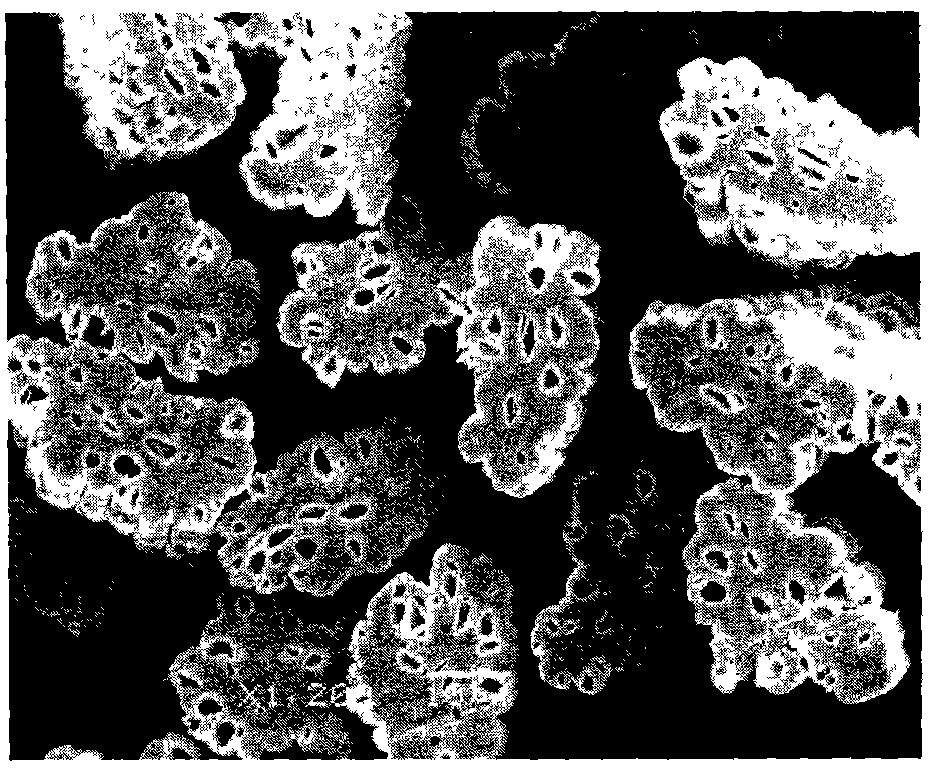

Tampon including crosslinked cellulose fibers and improved synthesis processes for producing same

InactiveUS20090227975A1Promote absorptionImprove wettabilityPulp properties modificationArtificial filaments from viscoseCellulose fiberGlyoxal

A tampon pledget includes crosslinked cellulose fibers having microstructures treated to provide improved absorbency and higher wet strength. The fibers are treated with a crosslinking agent to provide at least one of a molecular weight between crosslinks of from about 10 to 200 and a degree of crystallinity of from about 25% to 75%. The crosslinking agent includes citric acid in 1% by weight. The crosslinking agent may further include sodium hypophosphite in 1% by weight. In another embodiment, the crosslinking agent may be a difunctional agent including a glyoxal or a glyoxal-derived resin. In still another embodiment, the crosslinking agent is a multifunctional agent including a cyclic urea, glyoxal, polyol condensate. The crosslinking agent is added in an amount from about 0.001% to 20% by weight based on a total weight of cellulose fibers to be treated and, preferably, in an amount of about 5% by weight.

Owner:EVEREADY BATTERY CO INC

Compound and preparation method thereof and high-molecular material and preparation method thereof

ActiveCN105504341AEnhanced Far Infrared PerformanceGood antibacterial effectArtificial filaments from viscoseArtifical filament manufactureMolecular materialsGraphene

The present invention provides a carbon-nanostructure-containing compound comprising graphene, amorphous carbon and a non-carbon non-oxygen element, and the non-carbon non-oxygen element accounts for 0.5wt%-6wt% of the compound. Through controlling of content of the non-carbon non-oxygen element in the carbon-nanostructure-containing compound, excellent far infrared effect and antibacterial bacteriostat effect can be obtained, far-infrared property normal emittance can reach 0.85 or more, and the bacteriostasis rate can reach more than 95%. At the same time, the carbon-nanostructure-containing compound can be used in a high-molecular material in a lower amount for modifying of the high-molecular material without pre-modification and activation for achievement of significant far-infrared and antibacterial bactericidal properties.

Owner:营口圣泉高科材料有限公司

Short linen viscose fiber and preparation method thereof

ActiveCN102181956ARetain bacteriostasisHigh whitenessPretreatment with acid reacting compoundsPulp de-wateringPre treatmentUltimate tensile strength

The invention discloses short linen viscose fiber and a preparation method thereof. The viscose fiber is produced by preparing linen pulp from linen and then using the linen pulp. The preparation method comprises the following steps of: pre-processing, washing, digesting, washing, pulping, degritting, concentrating, alkali refining, whitening, performing acid treatment, washing, finely selecting, degritting, concentrating, papermaking, soaking, squeezing, smashing, aging, yellowing, grinding, dissolving, filtering, defoaming, filtering, spinning, drafting, cutting off, performing post treatment, drying, packaging and the like. The preparation method has the advantages that: the performance of bacterial resistance and bacterial resistance of the linen fiber can be kept better, a finished product has high whiteness, the production period is short, the problems of large digesting intensity, complicated digesting process and the like are solved, and the pollution generated during production is low.

Owner:潍坊欣龙生物材料有限公司

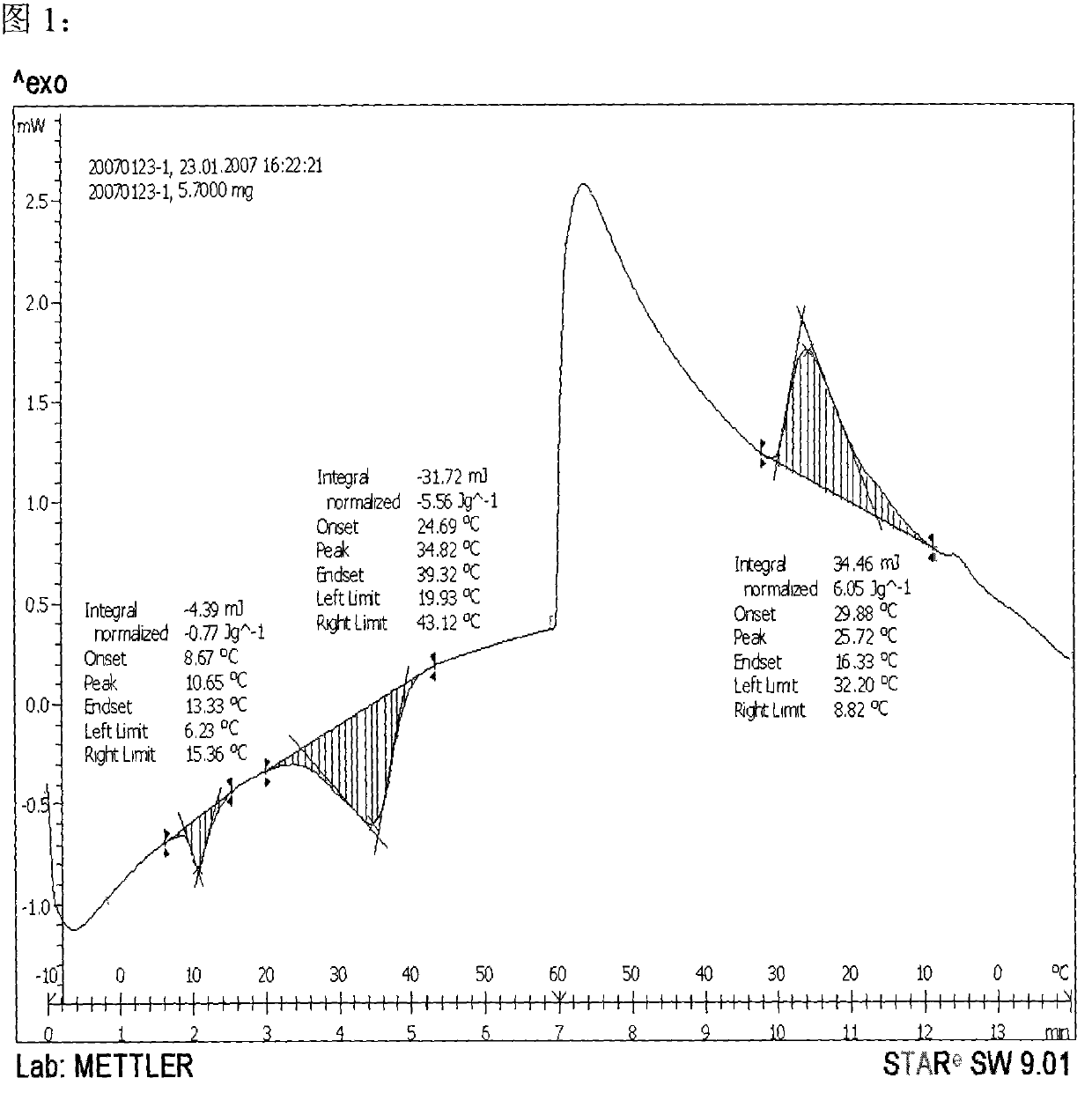

Environment-friendly type fire retardant as well as preparation method and application thereof

ActiveCN104032401AWon't gelRealize large-scale productionArtificial filaments from viscoseCellulose/protein filament chemical after-treatmentSocial benefitsSpinning

The invention discloses an environment-friendly type fire retardant as well as a preparation method and an application thereof. The fire retardant adopts a preparation method for an environment-friendly type fire retardant matched product, which takes organic silicon hydrolyzing dispersion liquid as a main component of the fire retardant and takes a fixed cross-linking agent as a post-treatment component. The other aim of the invention is to develop the application of the environment-friendly type fire retardant in spinning and post-treat of inflaming retarding viscoses and inflaming retarding synthetic fibers. Raw materials for preparing the environment-friendly type fire retardant are wide in source and low in price; the adverse effects on the environment and the safety, caused by traditional halogen-based and phosphorus based flame retardants, are overcome; the social benefits and the economic benefits are very great.

Owner:SOL FLAME RETARDANT FIBER

High whiteness and strength adhesive short fiber and process for making same

ActiveCN1632189AImprove qualityHigh whitenessArtificial filament washing/dryingArtificial filaments from viscosePolymer scienceAdhesive

The invention relates to a viscose staple fiber with high white strength and fine denier and a production process thereof, which belong to the viscose staple fiber and the production method of the textile spinning industry and the non-woven fabric industry. Its raw materials and weight percent content are: 86.7-92 percent of cellulose fiber, 7.7-13 percent of water, and 0.15-0.30 percent of oil agent. The raw materials are impregnated, squeezed, yellowed, spun, drawn, bundled, scoured, bleached twice with hydrogen peroxide, and dried to make finished products. The product of the present invention has finer denier, higher strength, higher yarn count and higher strength, and the garment fabric has higher strength, strong abrasion resistance, delicate hand feeling, wrinkle resistance and resistance to multiple deformations than ordinary viscose of the same process. Short fiber processing clothing fabrics and other advantages. High-count yarn products have thinner fabrics and lower grammage. The area of fabrics processed from raw materials of the same weight is increased and the cost is reduced.

Owner:唐山三友集团兴达化纤有限公司

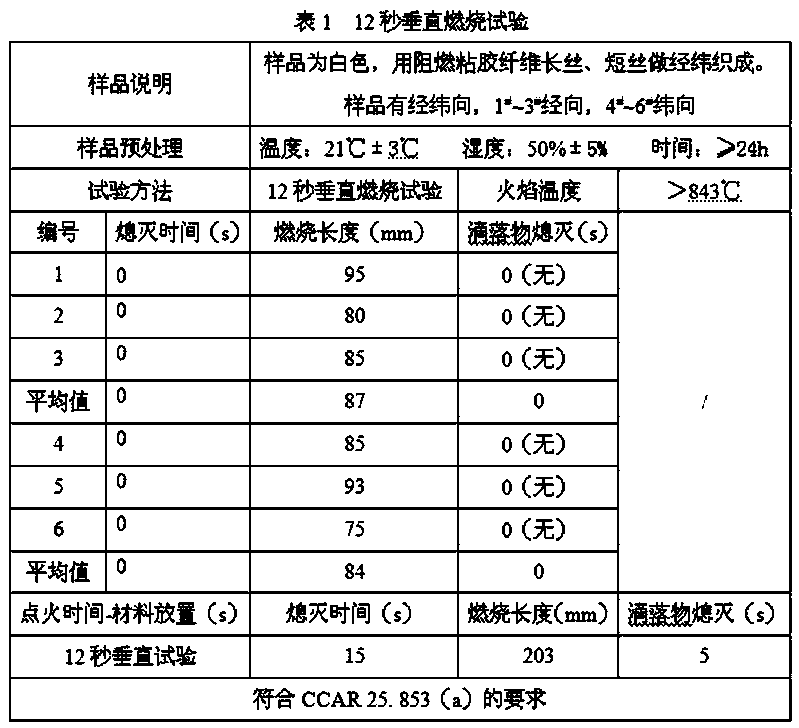

Intelligent temperature-adjusting viscose fibre and its production

InactiveCN101029421AGood textile propertiesArtificial filaments from viscoseCelluloseBreakdown strength

A phase-variable material micro-capsule as temperature-adjusting functional material, an intelligent temperature-adjusting viscose fiber and its production are disclosed. Dry breakdown strength is >=1.42CN / dtex, wet breakdown strength is>=0.64CN / dtex; It consists of cellulose 84.7-92.75wt%, micro-capsule 5-30wt% and water-content 7-15wt% and oil solution 0.15-0.30wt%. The fiber coagulation heat-liberation enthalpy valueDeltaH>=1.0J / g, melt heat-adsorption enthalpy value DeltaH>=1.0J / g. It is non-toxic, has better adaptability and no harm.

Owner:HEBEI JIGAO CHEM FIBER +1

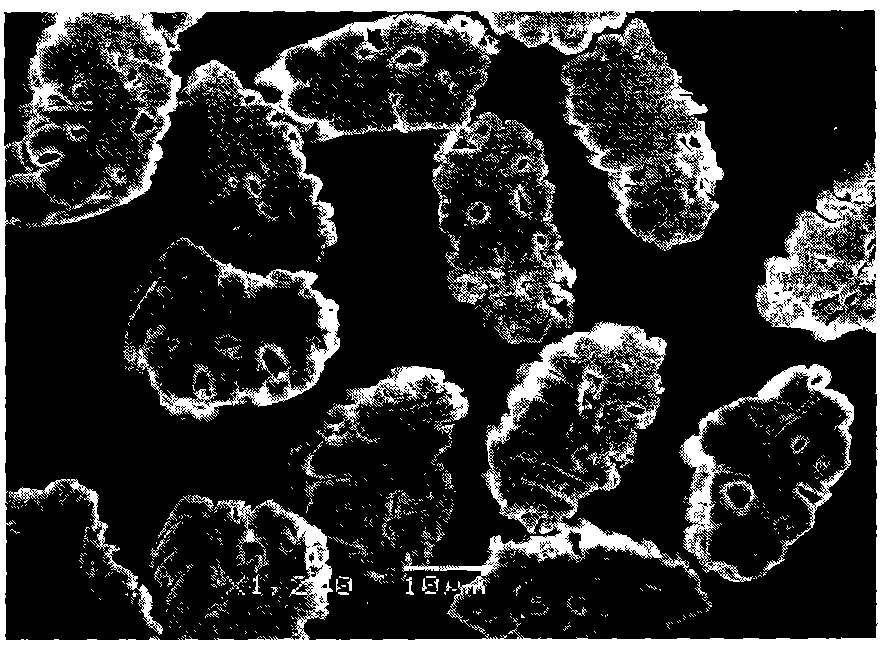

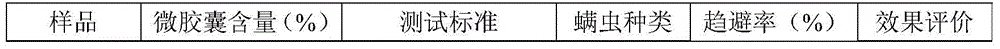

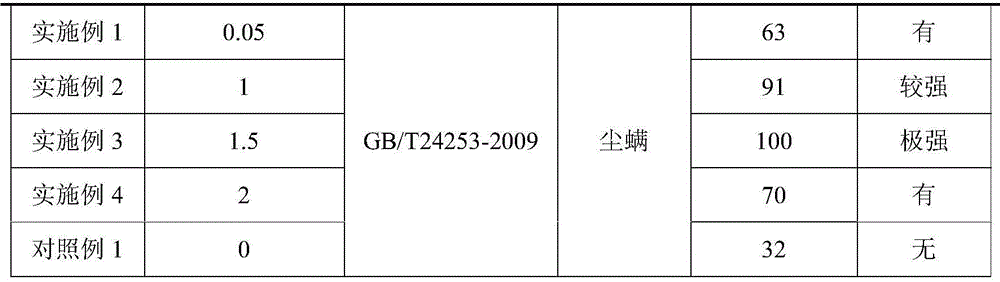

Regenerated cellulose fiber containing microencapsulated anti-mite medicine and preparation method thereof

ActiveCN104005110AStrong anti-mite effectImprove antibacterial propertiesArtificial filaments from viscoseWet spinning methodsEscherichia coliPolymer science

The invention provides regenerated cellulose fiber containing a microencapsulated anti-mite medicine and a preparation method thereof. The regenerated cellulose fiber comprises a viscose-rayon spinning solution and the microencapsulated anti-mite medicine, the microencapsulated anti-mite medicine accounts for 0.05-2% by mass of methyl cellulose in the viscose-rayon spinning solution, methyl cellulose accounts for 99.95-98% by mass of dry regenerated cellulose fiber, and borneol and argy wormwood essential oil are taken as a capsule core. The preparation method comprises: firstly preparing a solution of borneol and argy wormwood essential oil, then preparing microcapsules from the solution of borneol and argy wormwood essential oil through a microencapsulation technology, adding the microcapsules into the viscose-rayon spinning solution, mixing uniformly, and finally utilizing a viscose-rayon wet spinning technology to prepare the regenerated cellulose fiber containing the microencapsulated anti-mite medicine. The regenerated cellulose fiber containing microencapsulated anti-mite medicine has the repelling rate on dermatophagoides farina of 95% or more, and has extremely strong anti-mite effect, and has the antibacterial rate on staphylococcus aureus, escherichia coli and other pathogens of 90% or more.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Dimensionality-stable regenerated cellulose fiber and preparation method thereof

ActiveCN102586919AImprove filtering effectImprove wet modulusArtificial filaments from viscoseViscoseWet strength

The invention relates to a preparation method of a dimensionality-stable regenerated cellulose fiber. The preparation method comprises the following steps: carrying out dipping, squeezing, crushing, ageing, yellowing, continuous dissolving, filtering, and deaeration operations on a cellulose raw material to prepare a spinning viscose glue; and spinning to prepare the dimensionality-stable regenerated cellulose fiber, wherein a mixture comprising one or more of a denaturant and a crosslinking agent is added in the continuous dissolving step of the spinning viscose glue operation or before the spinning step. The dimensionality, the dry strength, the wet strength and the dry extension of the dimensionality-stable regenerated cellulose fiber are 1.4-1.72dtex, 1.6-3.0CN / dtex, 1.2-2.8CN / dtex and 10-20% respectively. The dimensionality-stable regenerated cellulose fiber prepared by adopting the method of the invention overcomes disadvantages of low fabric preparation rate and bad dimensional stability caused by the overhigh hygroscopic expansion rate and large wet tensile elongation of common viscose fibers, and has the advantages of stable transverse section and vertical dimensionality, and strong weaving strength.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Method for producing high-wet-modulus regenerated cellulose fibers from bamboo pulp

ActiveCN103556281AMeet needsReduce the degree of polymerizationArtificial filaments from viscoseAfter treatmentDegree of polymerization

The invention discloses a method for producing high-wet-modulus regenerated cellulose fibers from bamboo pulp. The method comprises a gum making step and a spinning step, and specifically comprises the following steps: with the bamboo pulp having the alpha cellulose content of greater than or equal to 90% and a degree of polymerization in the range from 400 to 500DP as a raw material, subjecting the bamboo pulp to alkali steeping, and adding BerolVisco388 which is produced by Akzo Nobel Company of Sweden and accounts for 0.1-0.2% of the weight of the alpha cellulose in the bamboo pulp in the alkali steeping step to obtain an alkali cellulose; subjecting the alkali cellulose to crushing, squeezing, aging, yellowing, dissolving, filtering, defoaming and ripening to form a spinning solution for spinning; reacting the spinning solution with a spinning bath to obtain primary filaments; and then subjecting the primary filaments to negative drafting, cutting, after treatment and drying processes to obtain finished product fibers. The method provided by the invention realizes the production of the high-wet-modulus regenerated cellulose fibers from the bamboo pulp with low polymerization degree and low alpha cellulose. Besides, the high-wet-modulus regenerated cellulose fibers are greatly improved in wet-and-dry strength and wet modulus, and meets the definition requirements of modal fibers in BISFA (Bureau International pour la Standardisation des Fibres Artificielles) standards.

Owner:唐山三友集团兴达化纤有限公司

Bamboo viscose fibre and its preparing method

InactiveCN1458306ARetain antimicrobial substancesWith delicateArtificial filaments from viscoseBleaching apparatusFiltrationPre treatment

The bamboo viscose fiber preparing process includes the steps of preparing bamboo material, cutting, screening, washing, pre-treatment, digestion, eliminating sand, concentration, chlorination, alkali refining, bleaching, acid treatment, eliminating sand and concentration, fishing, soaking, squeezing, crushing, ageing, yellowing, grinding, dissolving, filtering, defoaming, filterin,g spinning, drafting, cutting, post-treatment, drying and packaging. The bamboo viscose fiber thus prepared is antibacterial, cool, smooth, fine and bright, and the present invention creates a new field for developing viscose fiber products.

Owner:吉林化纤股份有限公司

Production of spinning stoste with cellulose base fibre

InactiveCN1818160AImprove protectionGood for healthArtificial filaments from viscoseCELLULOSE FLOURCellulose fiber

The invention opened a preparing method of the cellulose fibre spinning stock solution. The solvent is the intermixture of the [BMIM]Cl and the [BMIM]BF4. The cellulose dissolves in the solvent after breaking up to get the uniform and transparent liquid. So it can save the energy, decrease the pollution and improve the quality of the stock solution.

Owner:DONGHUA UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com