Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

802results about "Cellulose material pulping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of preparing microfibrillar polysaccharide

ActiveUS20060289132A1Pulp properties modificationThin material handlingPolysaccharideOxidizing agent

The present invention relates to a method of preparing microfibrillar polysaccharide comprising treating a polysaccharide in an aqueous suspension comprising an oxidant and at least one transition metal, mechanically delaminating said polysaccharide such that microfibrillar polysaccharide is formed. The invention also relates to microfibrillar polysaccharide obtainable by the method.

Owner:KEMIRA OY

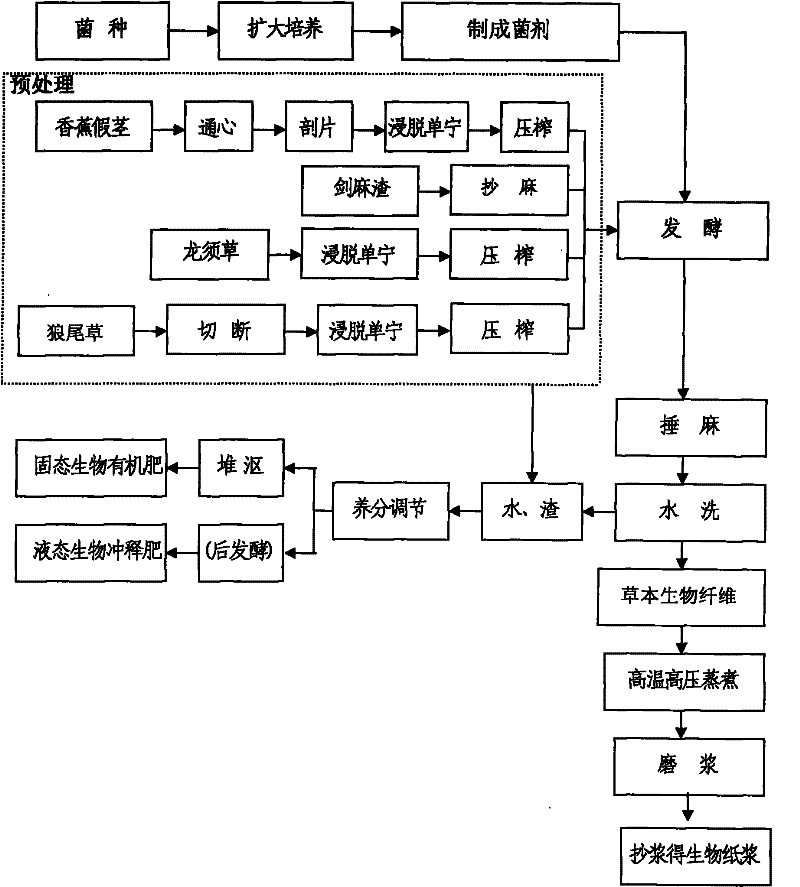

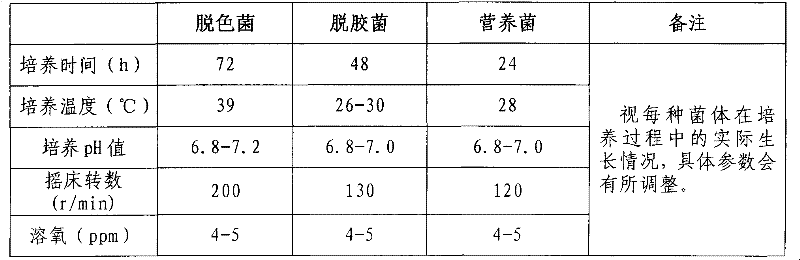

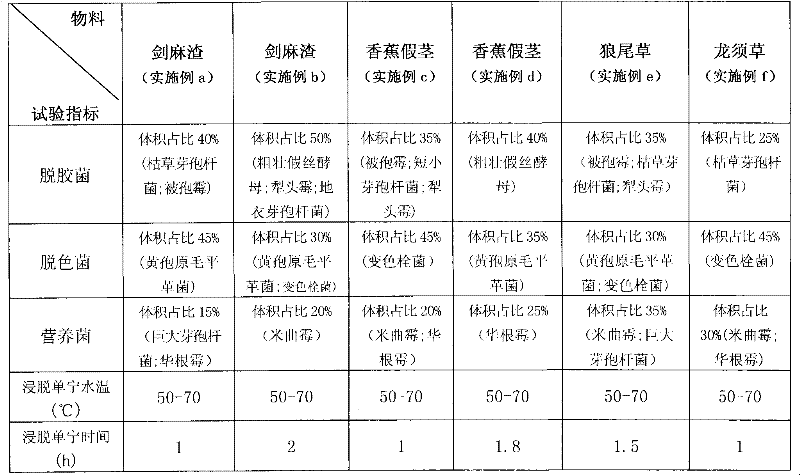

Method for preparing herbal biological fiber and biological paper pulp

InactiveCN102174399AOvercome color differenceOvercome resilienceFungiBio-organic fraction processingFiberWastewater

The invention discloses a method for preparing a herbal biological fiber and biological paper pulp, and the used microbial composite agent and a preparation method thereof. The biological fiber is prepared through pretreatment of a herbal raw material, biological degumming fermentation, and subsequent mechanical treatment of a fermentation product. The composite agent comprises degumming bacteria, nutrition bacteria and decolorizing bacteria, and various strains are synergistic without antagonistic reaction. In the method for preparing the biological fiber and the biological paper pulp, a chemical additive is not needed at all, but the high-cellulose and hemicellulose biological fiber and the biological paper pulp can be industrially produced; decolorization is complete, and the produced biological fiber and biological paper pulp have white color; a bleaching process is avoided, so investment in decolorizing production equipment is saved, and fiber extracting and pulping investment cost can be effectively reduced; in addition, waste gas and waste water are not generated in the fiber extracting and pulping process, inorganic pollutants are not generated, waste water and waste residues produced in each process step can be produced and converted into a biological fertilizer, and water is recycled.

Owner:GUANGXI SAIER PAPER IND

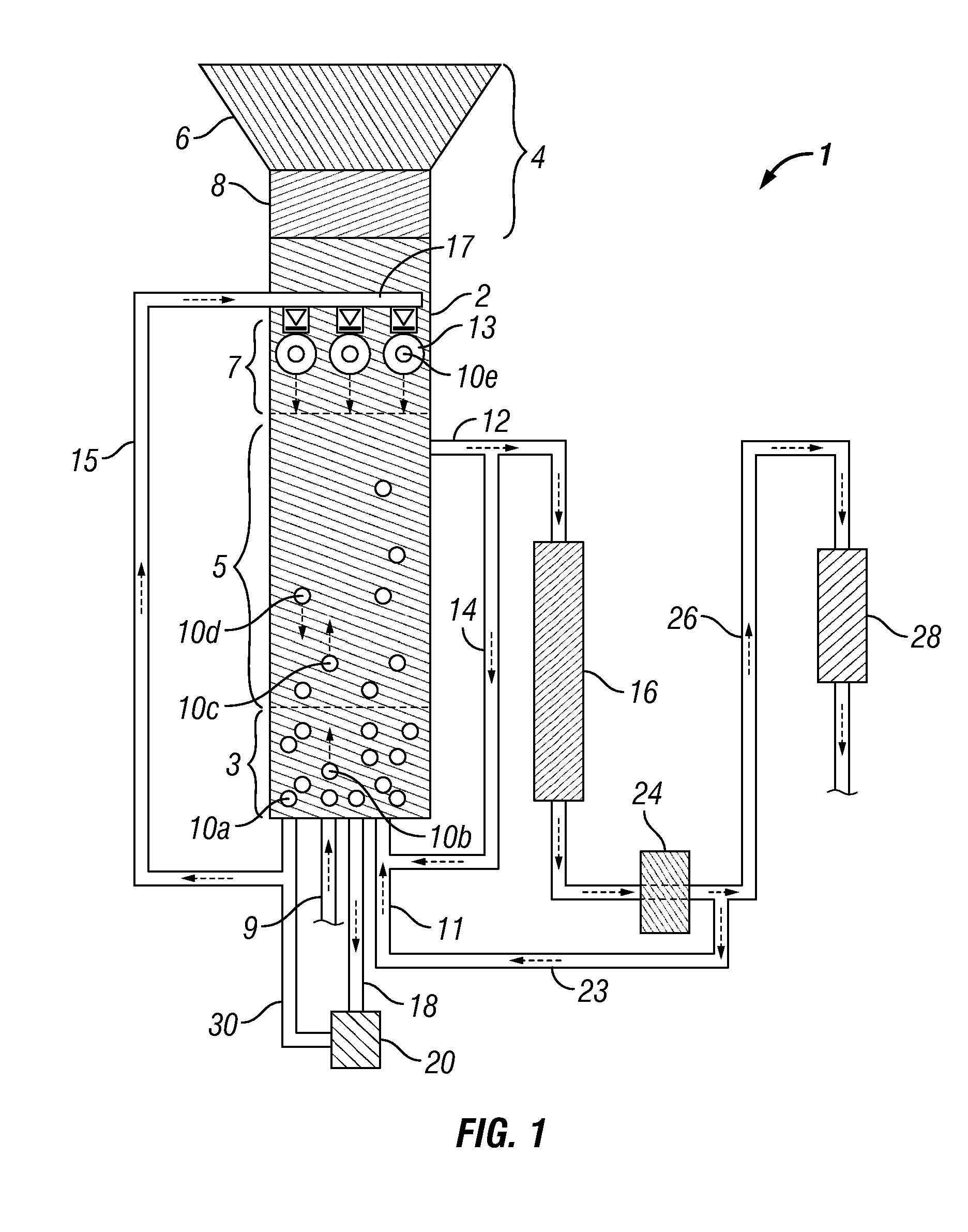

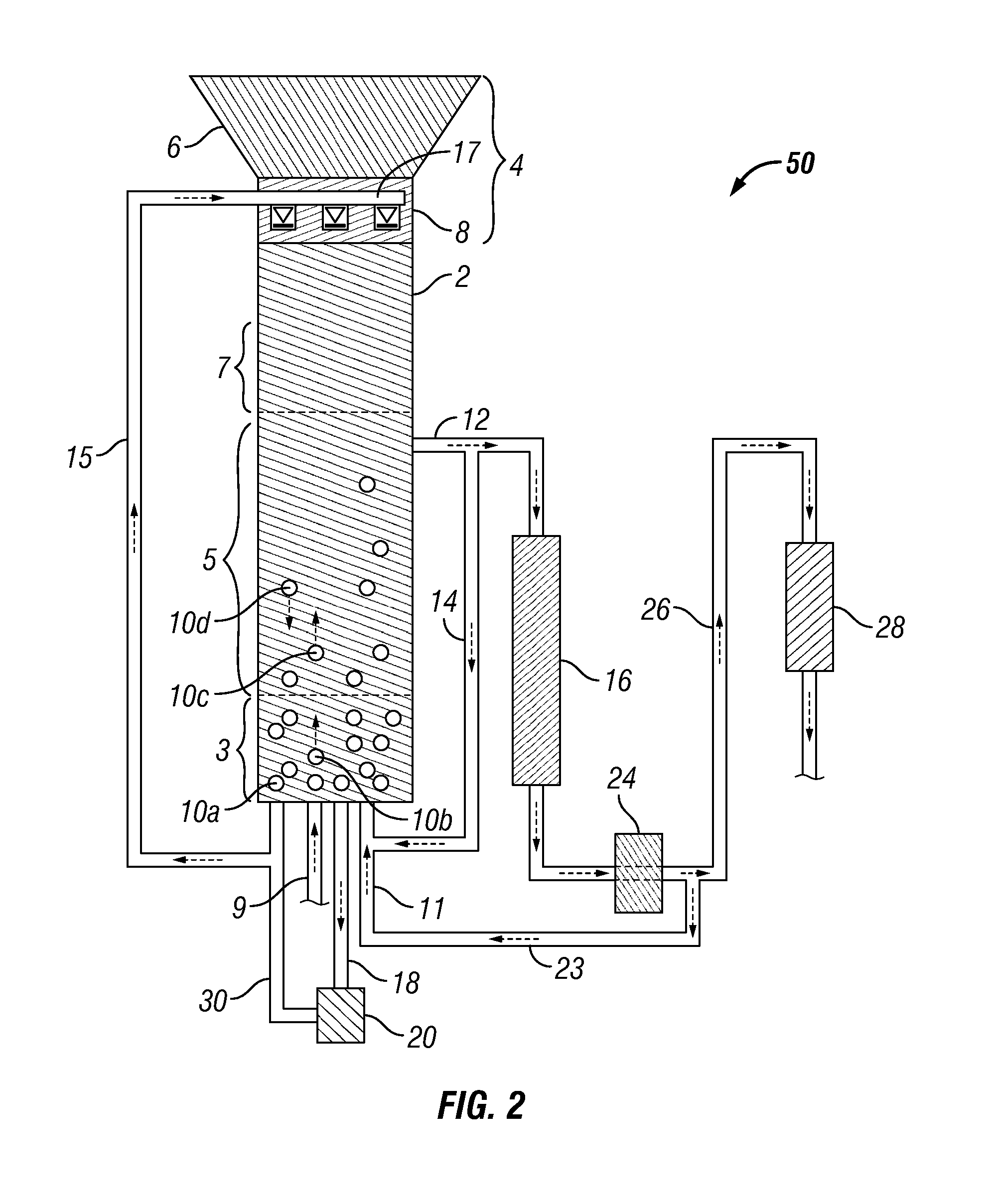

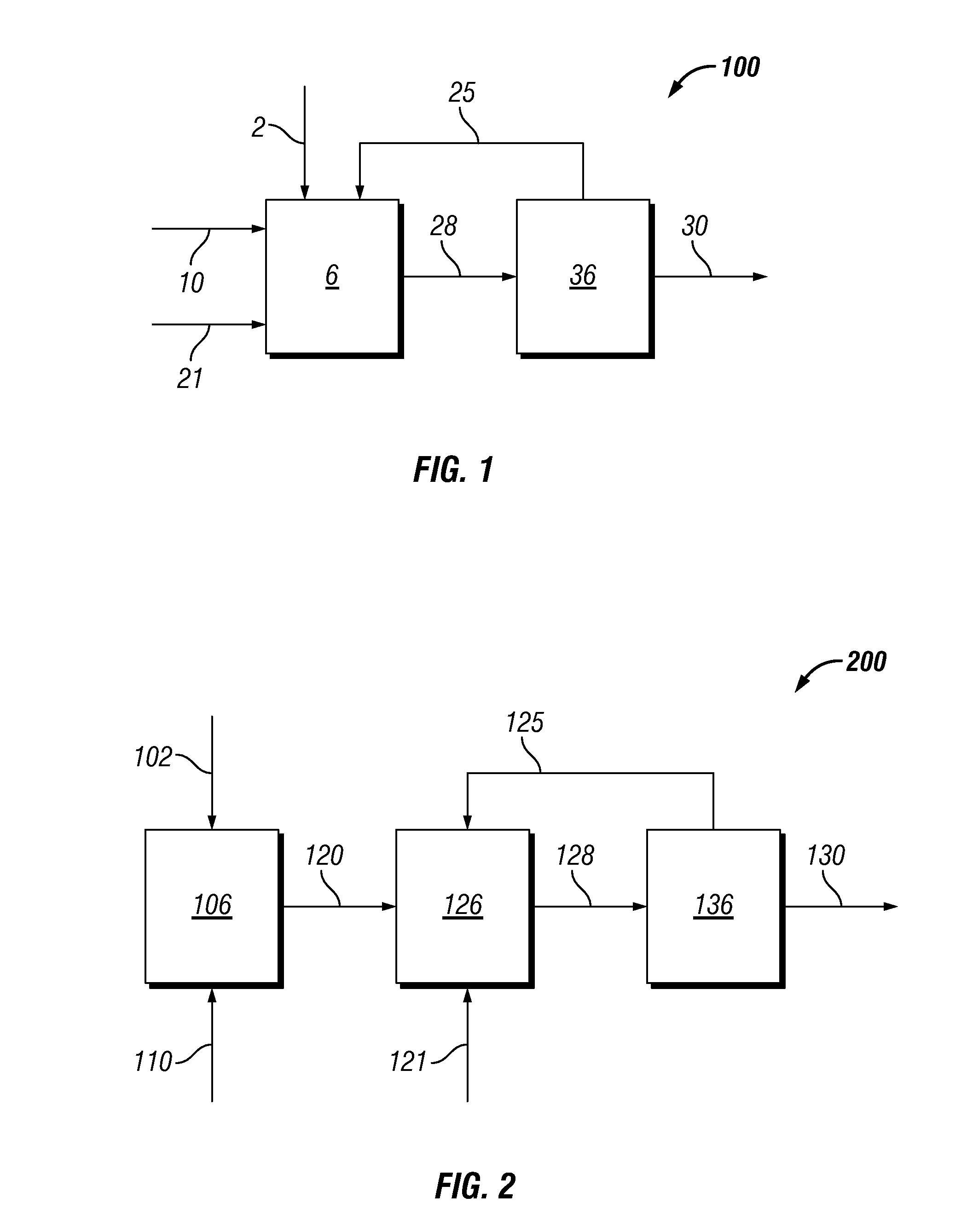

Methods for hydrothermal digestion of cellulosic biomass solids in the presence of a slurry catalyst and a digestible filter aid

Digesting cellulosic biomass in the presence of a slurry catalyst may reduce degradation product formation, but catalyst distribution and retention can be problematic. Digestion methods can comprise: providing cellulosic biomass solids and a slurry catalyst capable of activating molecular hydrogen in a digestion unit; providing a digestible filter aid in the digestion unit; distributing the slurry catalyst within the cellulosic biomass solids using fluid flow; retaining at least a portion of the slurry catalyst in a fixed location using the digestible filter aid; heating the cellulosic biomass solids in the presence of the slurry catalyst, a digestion solvent, and molecular hydrogen, thereby forming a liquor phase comprising soluble carbohydrates; and performing a catalytic reduction reaction on the soluble carbohydrates within the digestion unit, thereby at least partially forming a reaction product comprising a triol, a diol, a monohydric alcohol, or any combination thereof in the digestion unit.

Owner:SHELL USA INC

Method of preparing microfibrillar polysaccharide

Owner:KEMIRA OY

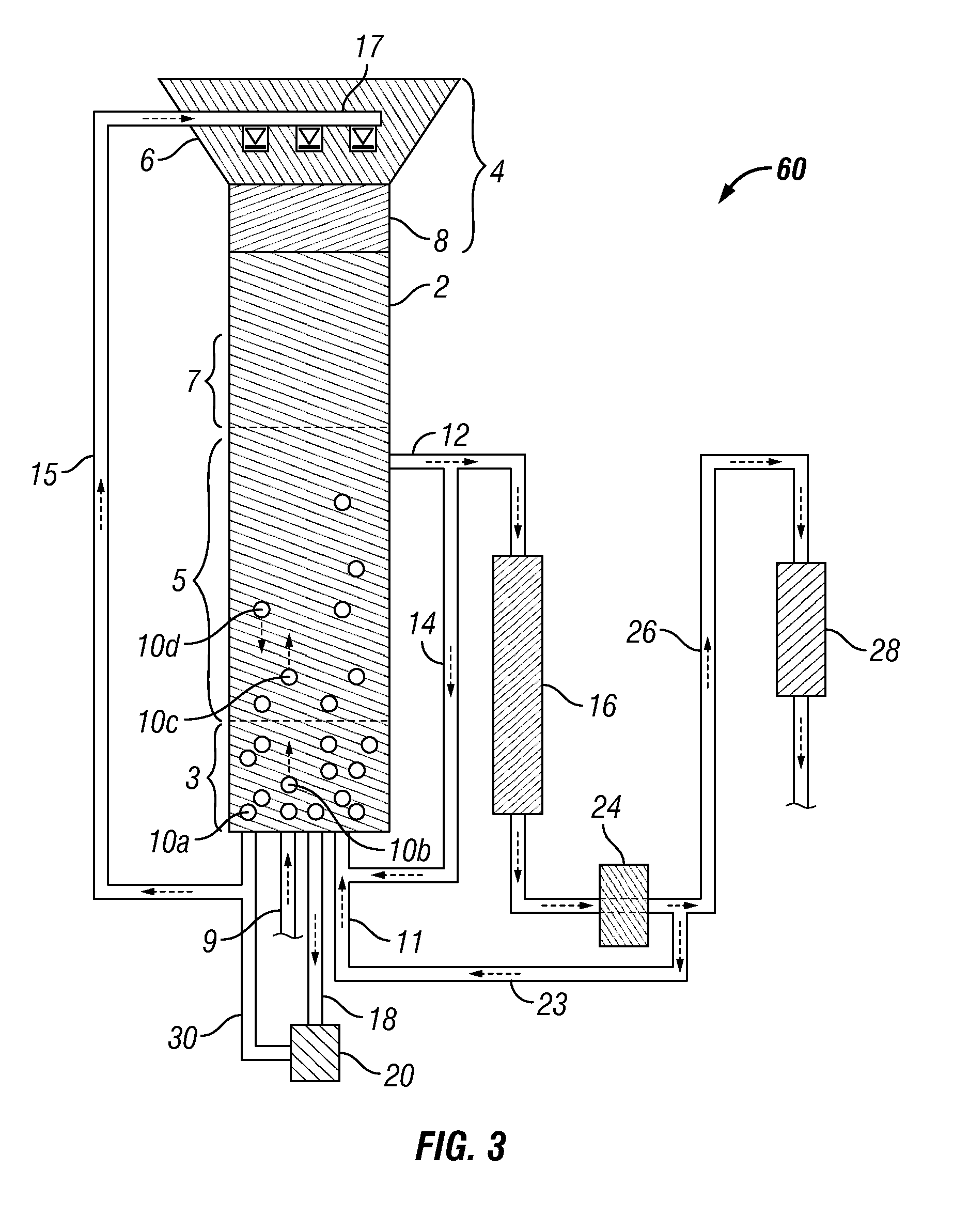

Methods and systems for distributing a slurry catalyst in cellulosic biomass solids

Digestion of cellulosic biomass solids may be complicated by release of lignin therefrom. Methods for digesting cellulosic biomass solids may comprise: heating cellulosic biomass solids and a digestion solvent in the presence of molecular hydrogen and a slurry catalyst capable of activating molecular hydrogen, thereby forming a phenolics liquid phase comprising lignin, an aqueous phase comprising an alcoholic component derived from the cellulosic biomass solids, and an optional light organics phase, the slurry catalyst being distributed in the cellulosic biomass solids and at least a portion of the slurry catalyst accumulating in the phenolics liquid phase as it forms; conveying at least a portion of the phenolics liquid phase and the slurry catalyst to a location above at least a portion of the cellulosic biomass solids; and after conveying the phenolics liquid phase and the slurry catalyst, releasing them such that they come in contact with the cellulosic biomass solids.

Owner:SHELL OIL CO

Biomass Pretreatment

A method is provided for producing an improved pretreated biomass product for use in saccharification followed by fermentation to produce a target chemical that includes removal of saccharification and or fermentation inhibitors from the pretreated biomass product. Specifically, the pretreated biomass product derived from using the present method has fewer inhibitors of saccharification and / or fermentation without a loss in sugar content.

Owner:SUSTAINABLE TECH CORP +2

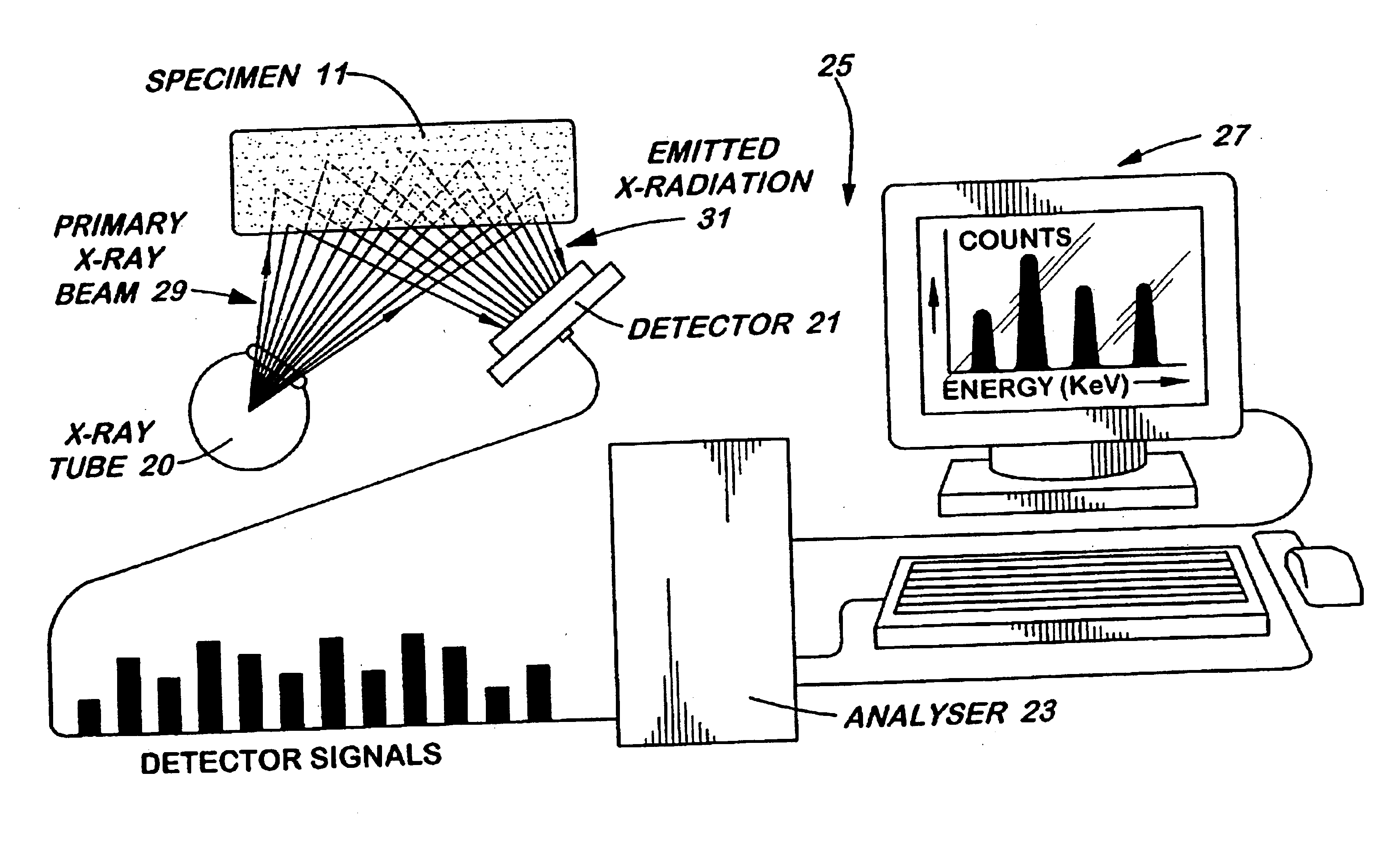

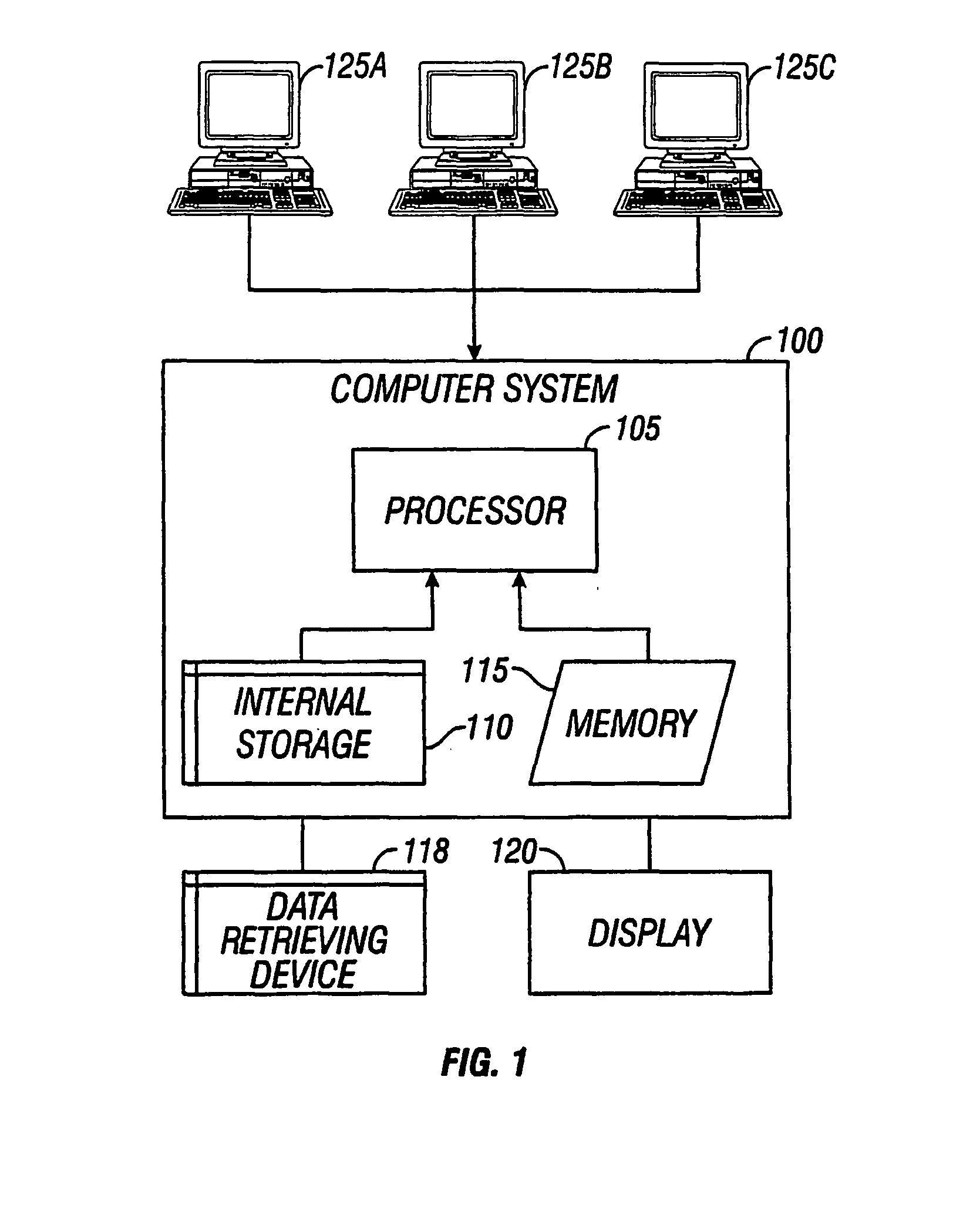

Methods for identification and verification using digital equivalent data system

Apparatus and methods in which one or more elemental taggants that are extrinsically placed in an object are detected by x-ray fluorescence analysis to identify or authenticate the object are described. The taggant is manufactured as part of the object or the taggant is placed into a coating, packaging, label, or otherwise embedded onto the object for the purpose of later verifying the presence or absence of these elements by x-ray fluorescence. The taggant is then analyzed by XRF and the analysis is then converted into a 2D symbol format that can be used in various security and authentication applications. By using x-ray fluorescence analysis, the apparatus and methods of the invention are simple and easy to use, without the limitations experience by current anti-counterfeiting technologies.

Owner:NASA +1

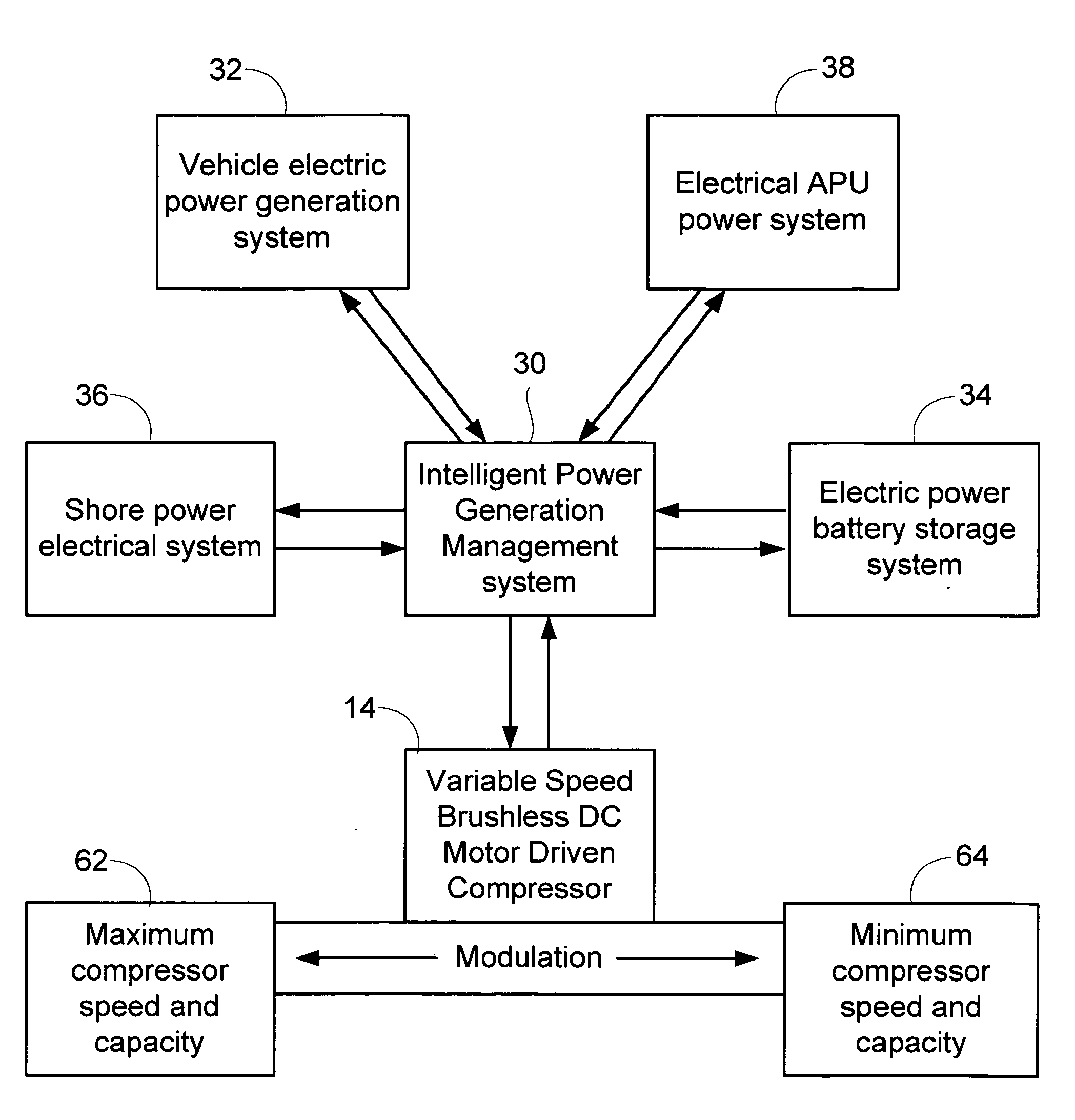

Vehicle air conditioning and heating system providing engine on and engine off operation

InactiveUS20050161211A1Solve insufficient capacityAccurate lifeAir-treating devicesCompression machines with non-reversible cycleMotor driveAir conditioning

An air conditioning system for use in an over-the-road or off road vehicle is provided that allows operation during both engine on and engine off conditions. The system utilizes a variable speed, motor driven compressor controlled by an intelligent power generation management controller. This controller selects from one of the available sources of power on the vehicle to drive the compressor, and modulates the compressor speed and capacity based on operational parameters and source availability and depletion. The controller may also operate a coolant or air heater to provide heating to the interior compartments.

Owner:BERGSTROM INC

Recyclable buffer for the hydrothermal hydrocatalytic treatment of biomass

InactiveUS20140166221A1Minimal lossMaintain activityPulp bleachingLiquid hydrocarbon mixture productionCelluloseHydrogen

A method of hydrothermal hydrocatalytic treating biomass is provided. Lignocellulosic biomass solids is provided to a hydrothermal digestion unit in the presence of a digestive solvent, at least one of ammonia or a source of ammonia, and a supported hydrogenolysis catalyst containing (a) sulfur, (b) Mo or W, and (c) Co, Ni or mixture thereof, incorporated into a suitable support. The lignocellulosic biomass solids and digestive solvent are heated in the presence of hydrogen, supported hydrogenolysis catalyst and the at least one of ammonia or a source of ammonia forming a product solution containing plurality of oxygenated hydrocarbons and ammonia. At least a portion of ammonia is separated and recycled to the hydrothermal digestion unit.

Owner:SHELL OIL CO

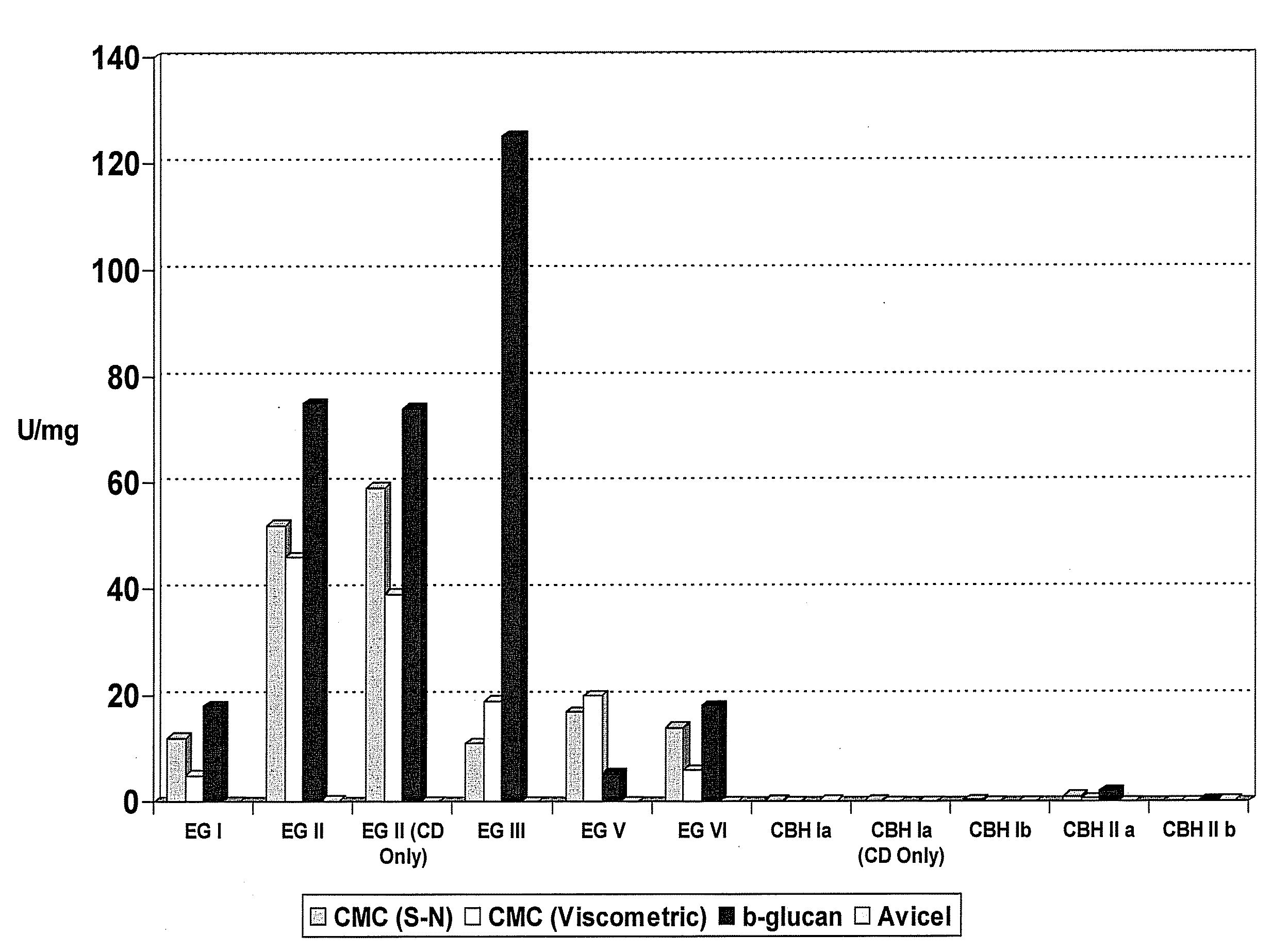

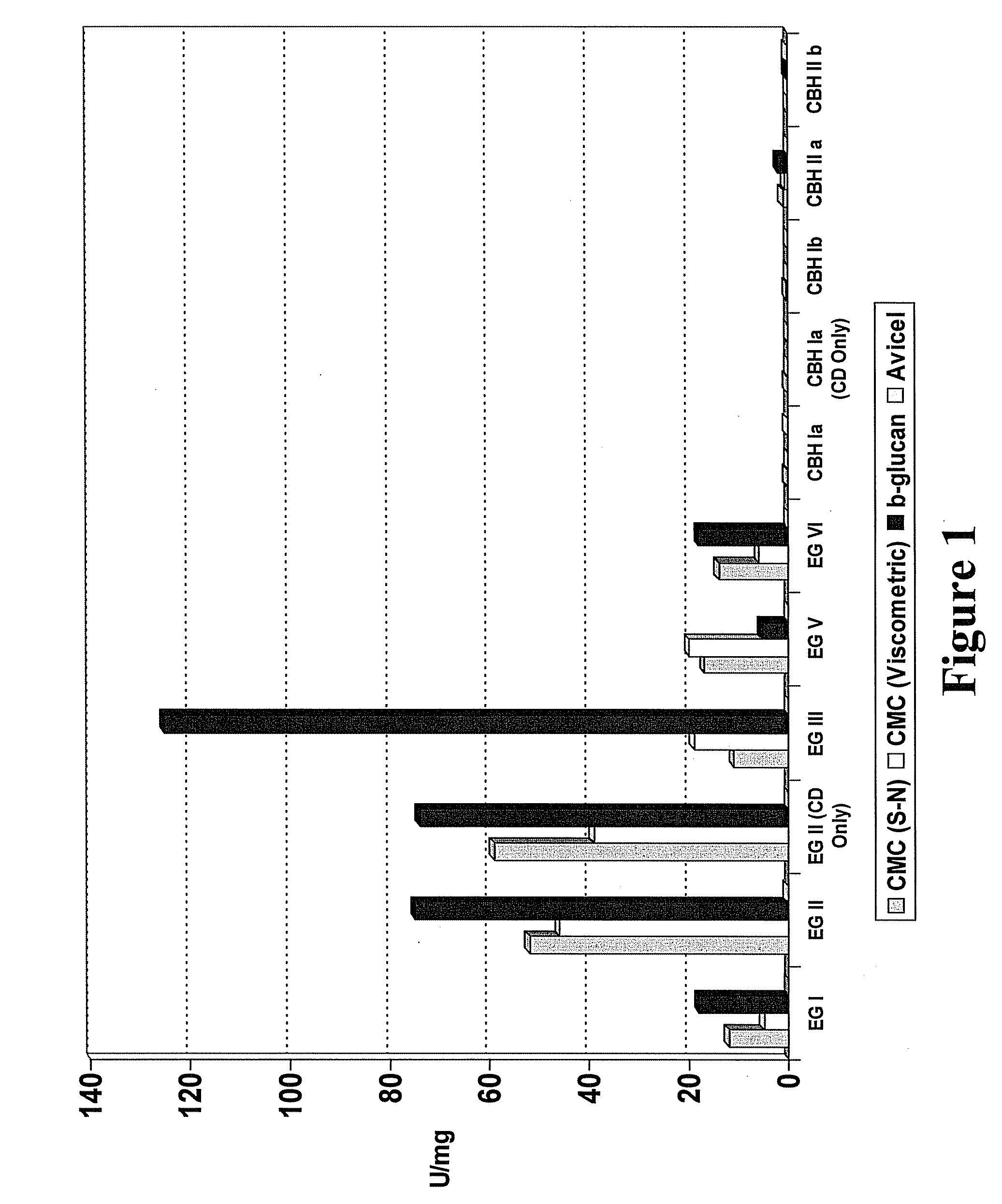

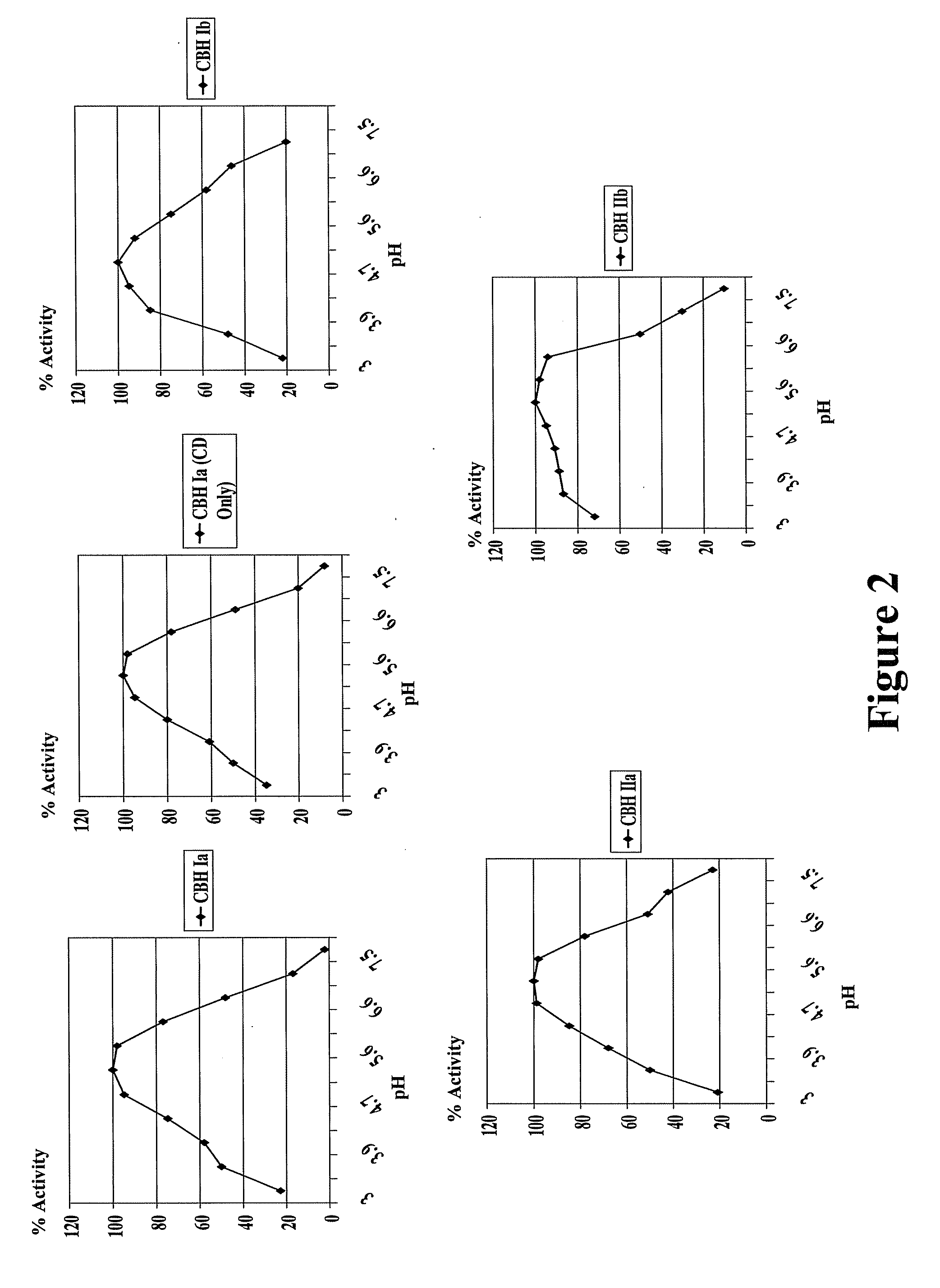

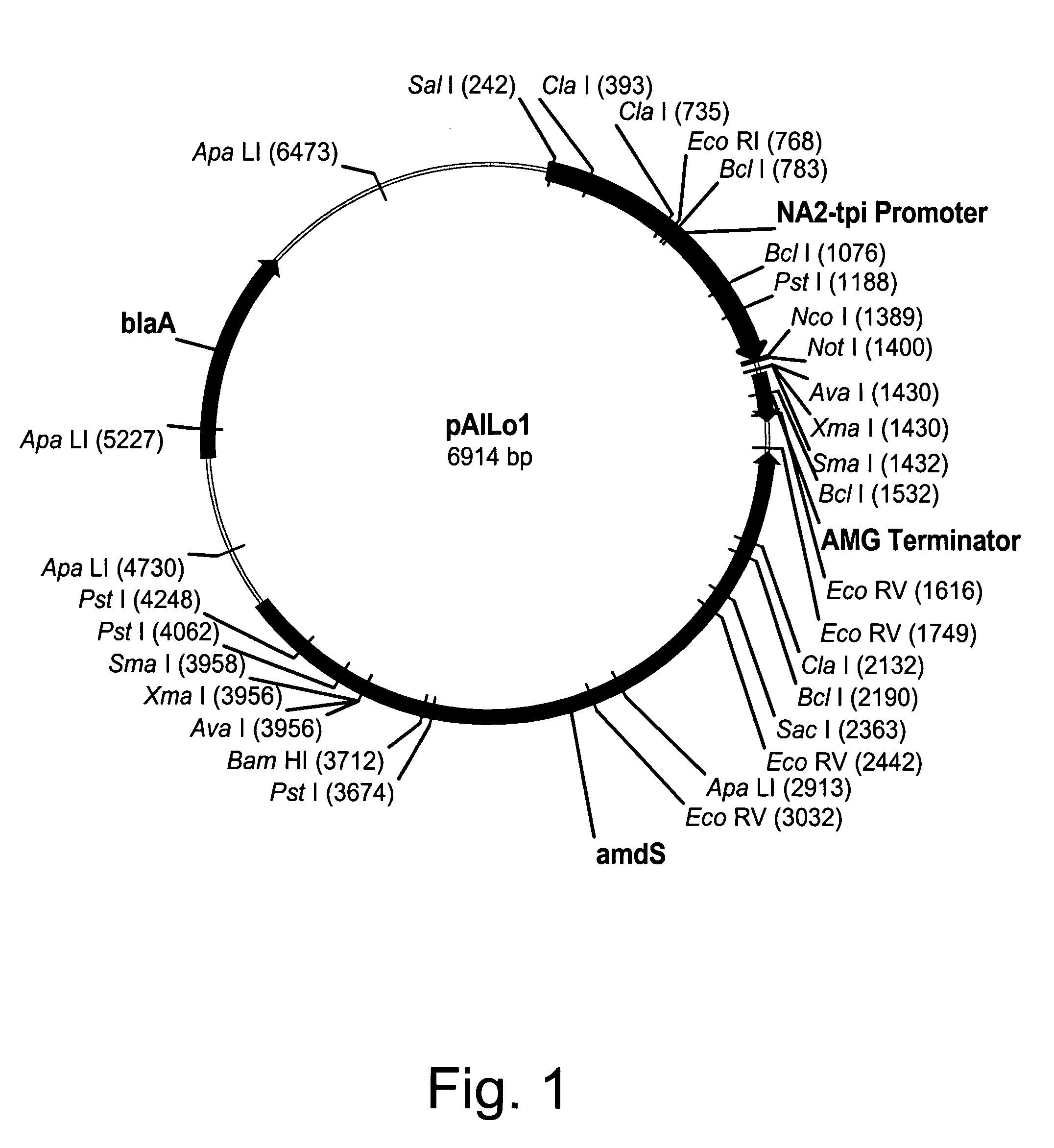

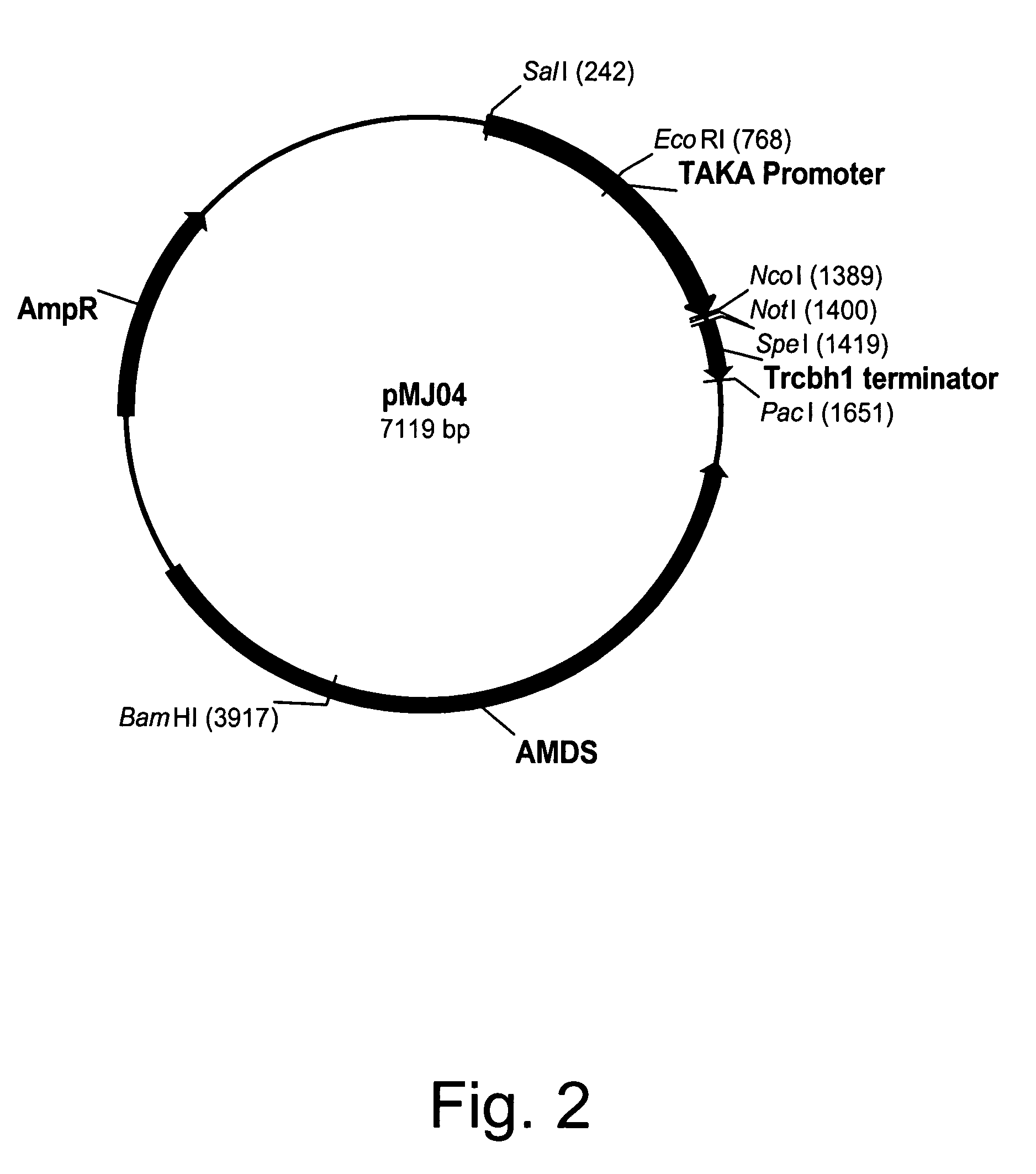

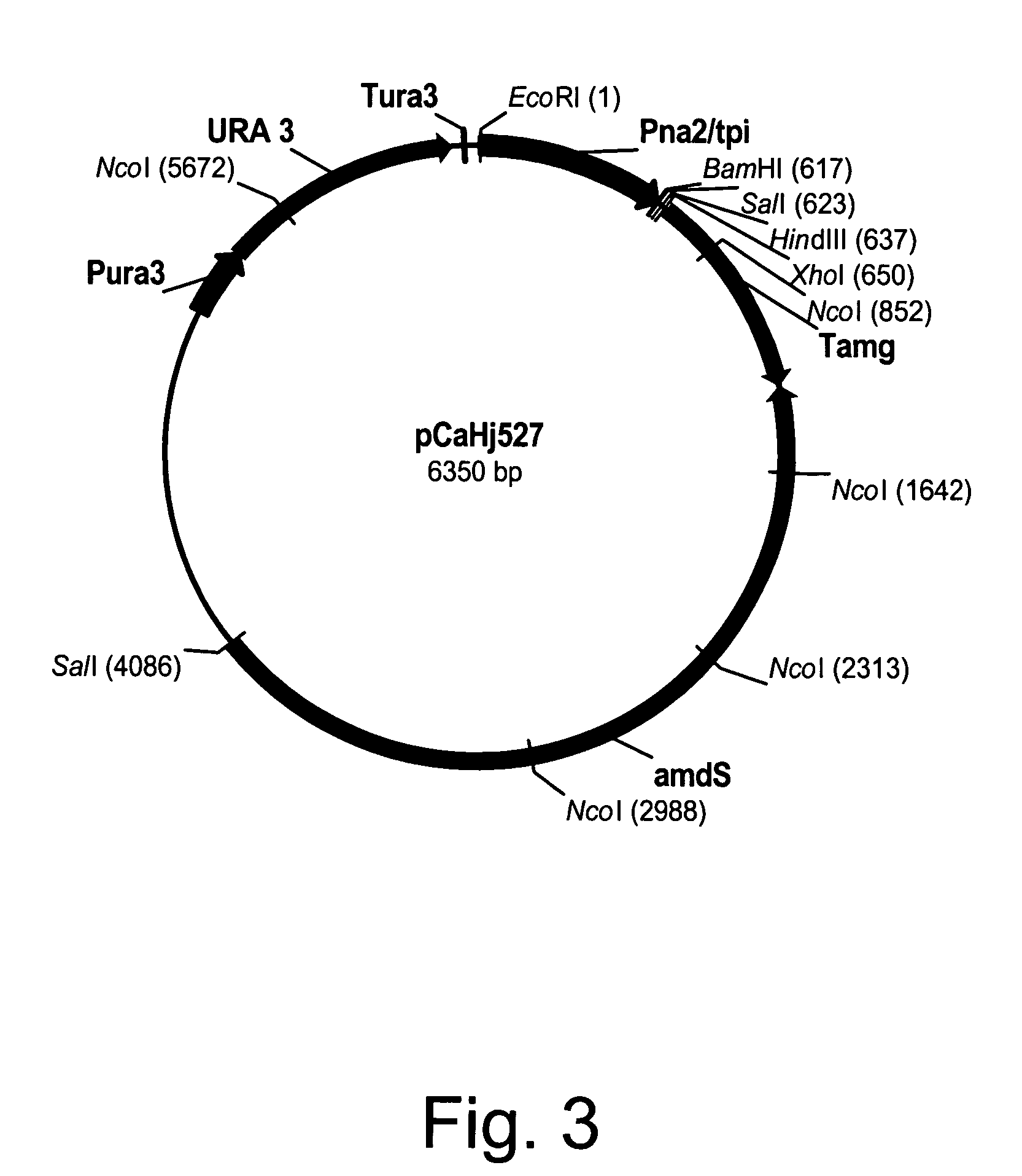

Novel Fungal Enzymes

InactiveUS20090280105A1Easy to cleanOrganic active ingredientsNon-fibrous pulp additionCelluloseWaste stream

This invention relates to novel enzymes and novel methods for producing the same. More specifically this invention relates to a variety of fungal enzymes. Nucleic acid molecules encoding such enzymes, compositions, recombinant and genetically modified host cells, and methods of use are described. The invention also relates to a method to convert lignocellulosic biomass to fermentable sugars with enzymes that degrade the lignocellulosic material and novel combinations of enzymes, including those that provide a synergistic release of sugars from plant biomass. The invention also relates to methods to use the novel enzymes and compositions of such enzymes in a variety of other processes, including washing of clothing, detergent processes, deinking and biobleaching of paper and pulp, and treatment of waste streams.

Owner:DANISCO US INC

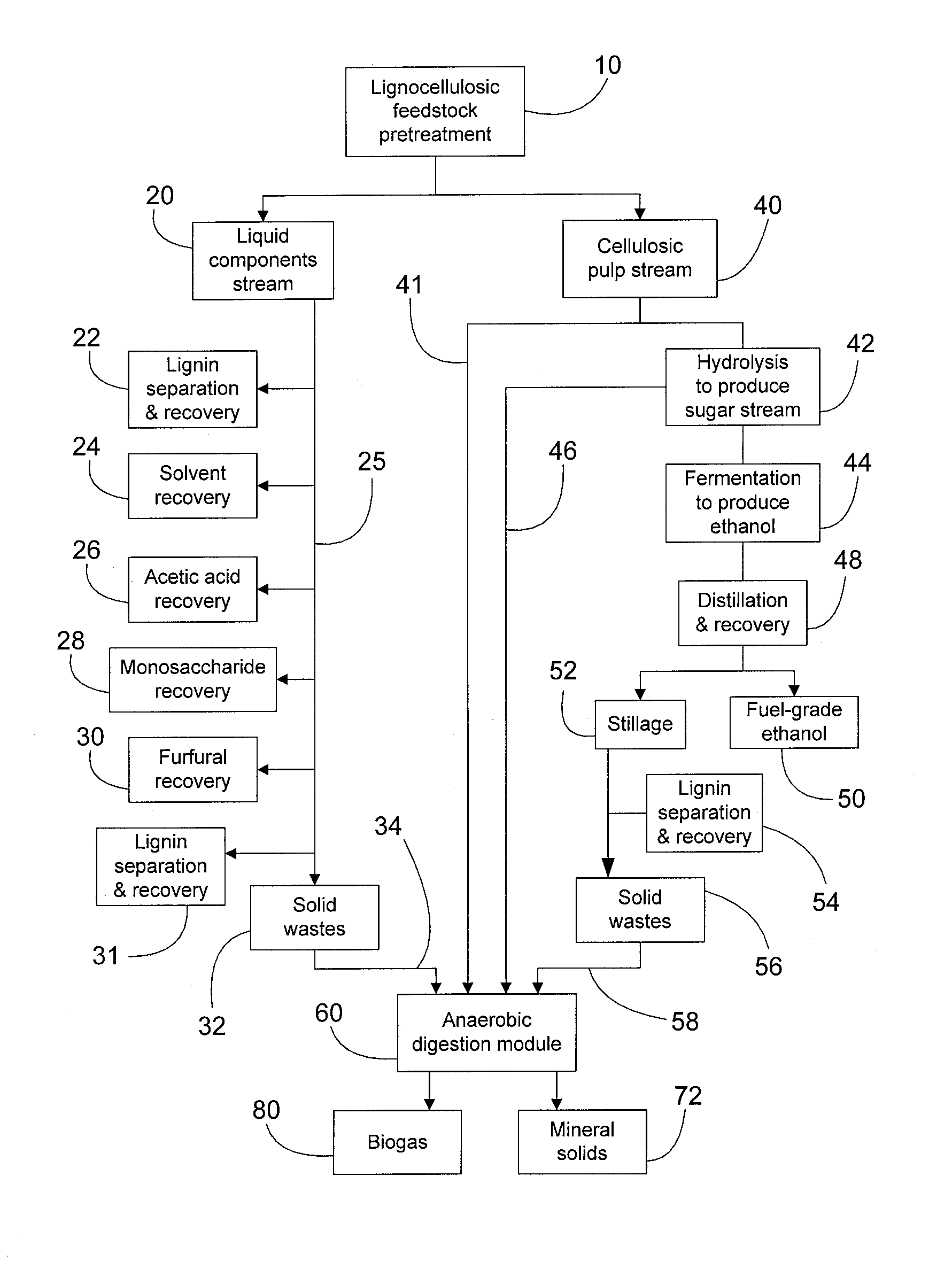

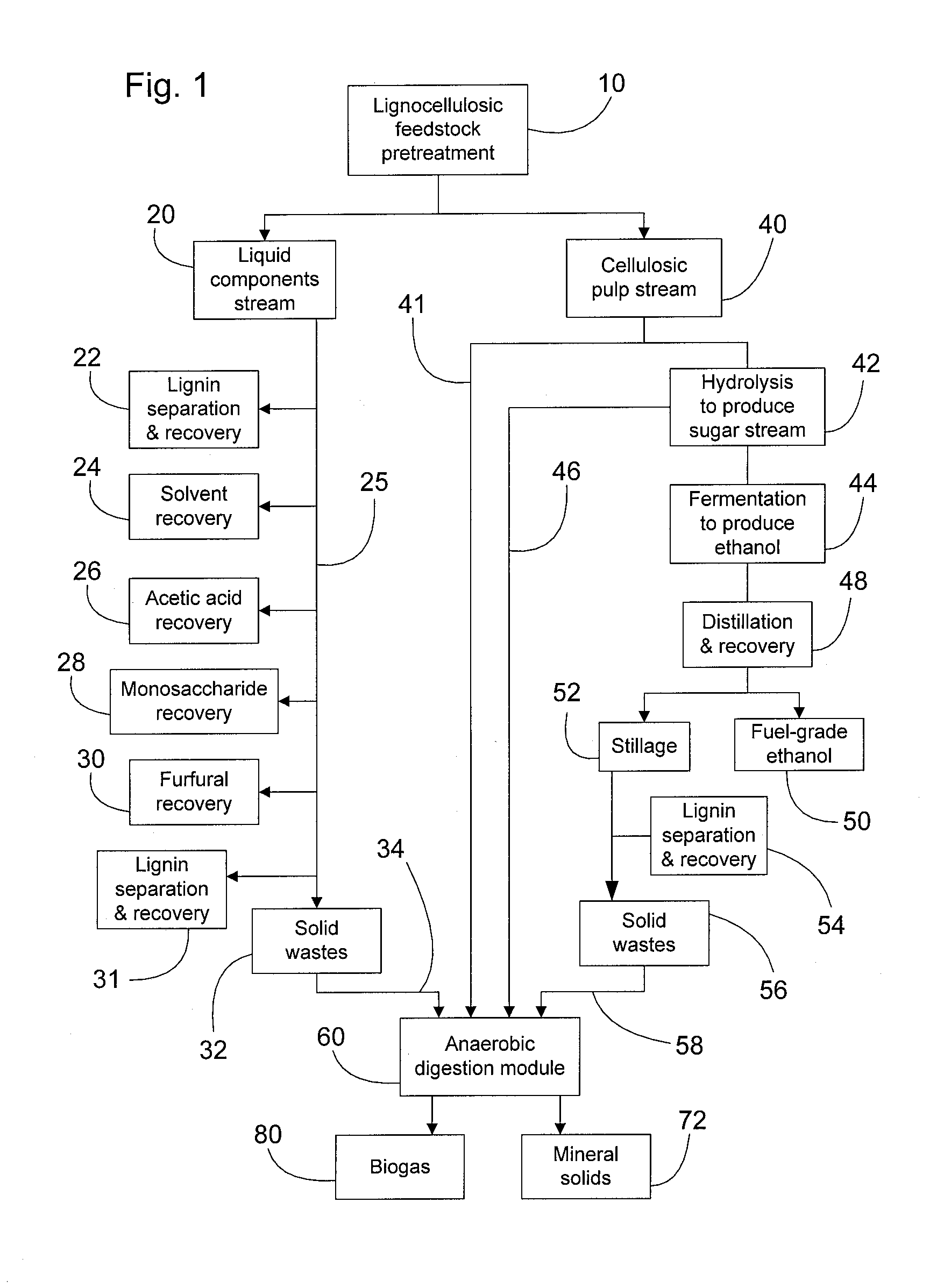

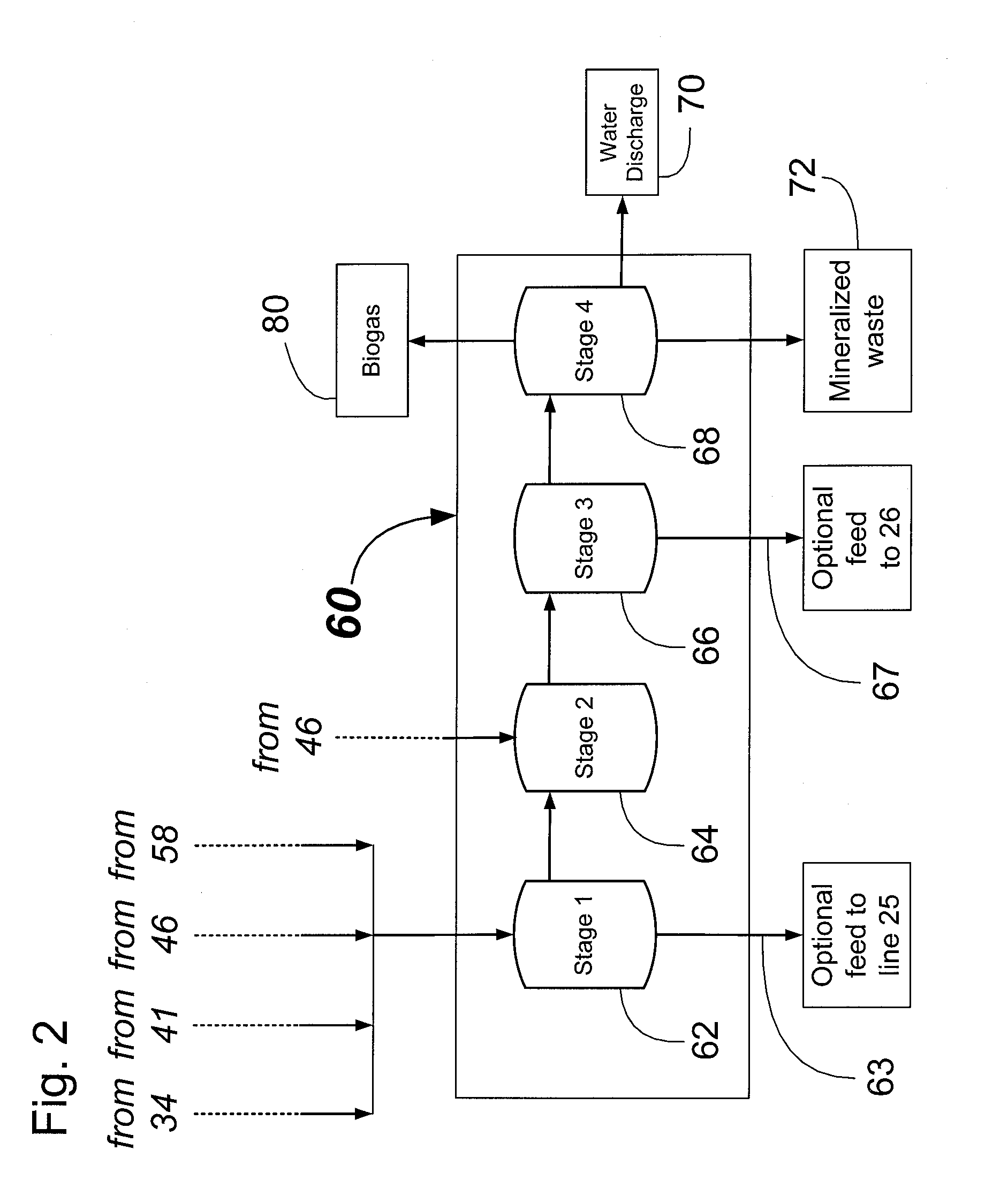

Concurrent Anaerobic Digestion and Fermentation of Lignocellulosic Feedstocks

InactiveUS20110236946A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholSemi solid

A process for concurrent production of lignins, fuel alcohol, and biogas from lignocellulosic feedstocks. The process comprises: (1) pretreating a lignocellulosic feedstock to produce a solubilised liquid components stream comprising lignins, lignin-derived compounds, and a cellulosic pulp stream, (2) separating the liquid stream from the cellulosic pulp stream, (3) processing the liquid stream to separate and recover at least lignins, lignin-derived compounds, and semi-solid waste material, (b) processing the cellulosic pulp stream to saccharify and ferment the cellulose pulp to produce a beer which is then separated into fuel-grade alcohol and a waste stillage material, (4) anaerobically digesting the semi-solid waste material from the liquid stream and the waste stillage material to produce a biogas. The rate of anaerobic digestion can be manipulated by controllably supplying a portion of the monosaccharides produced from the cellulosic pulp. The cellulosic pulp stream may also be anaerobically digested.

Owner:LIGNOL INNOVATIONS

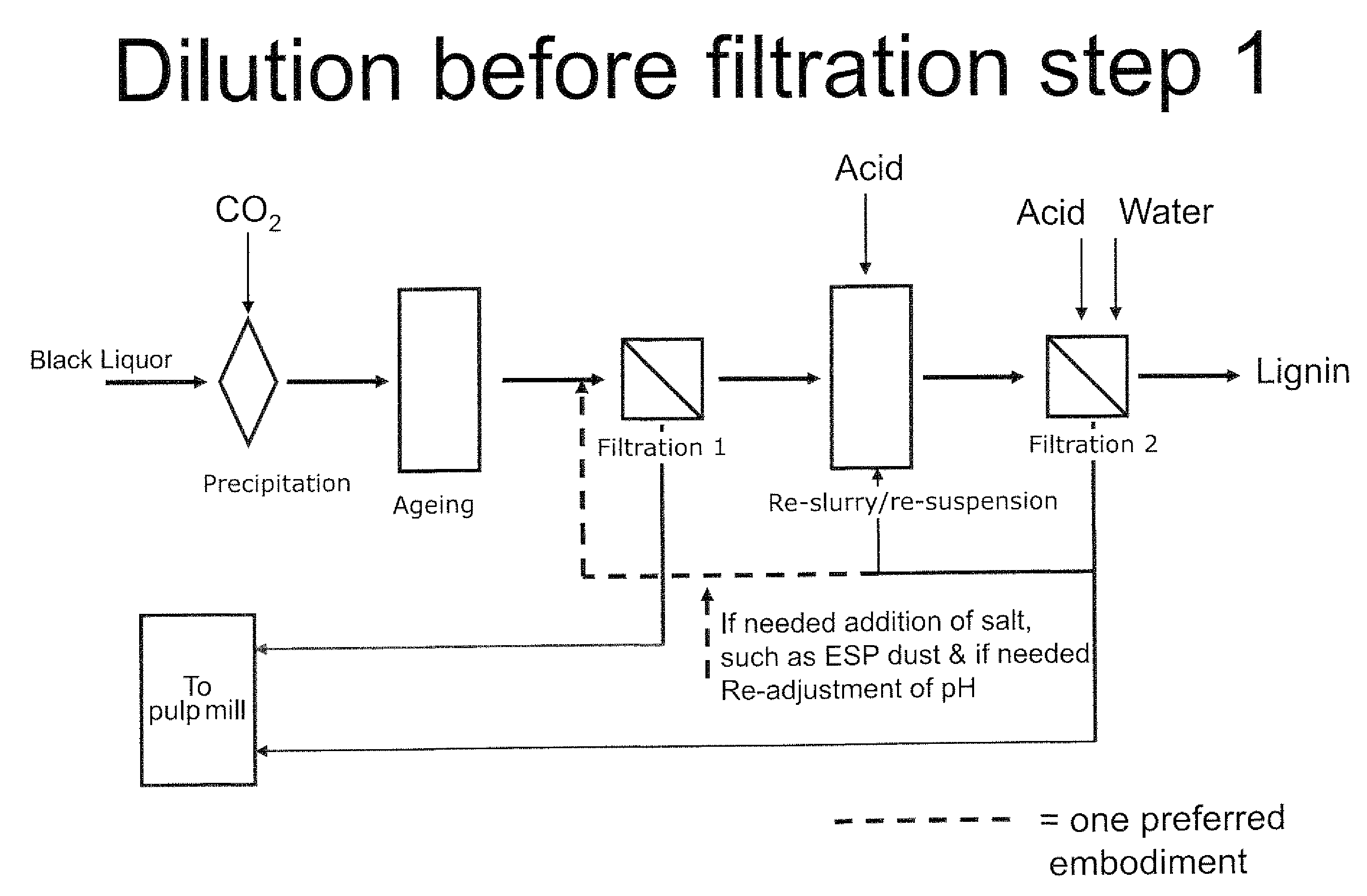

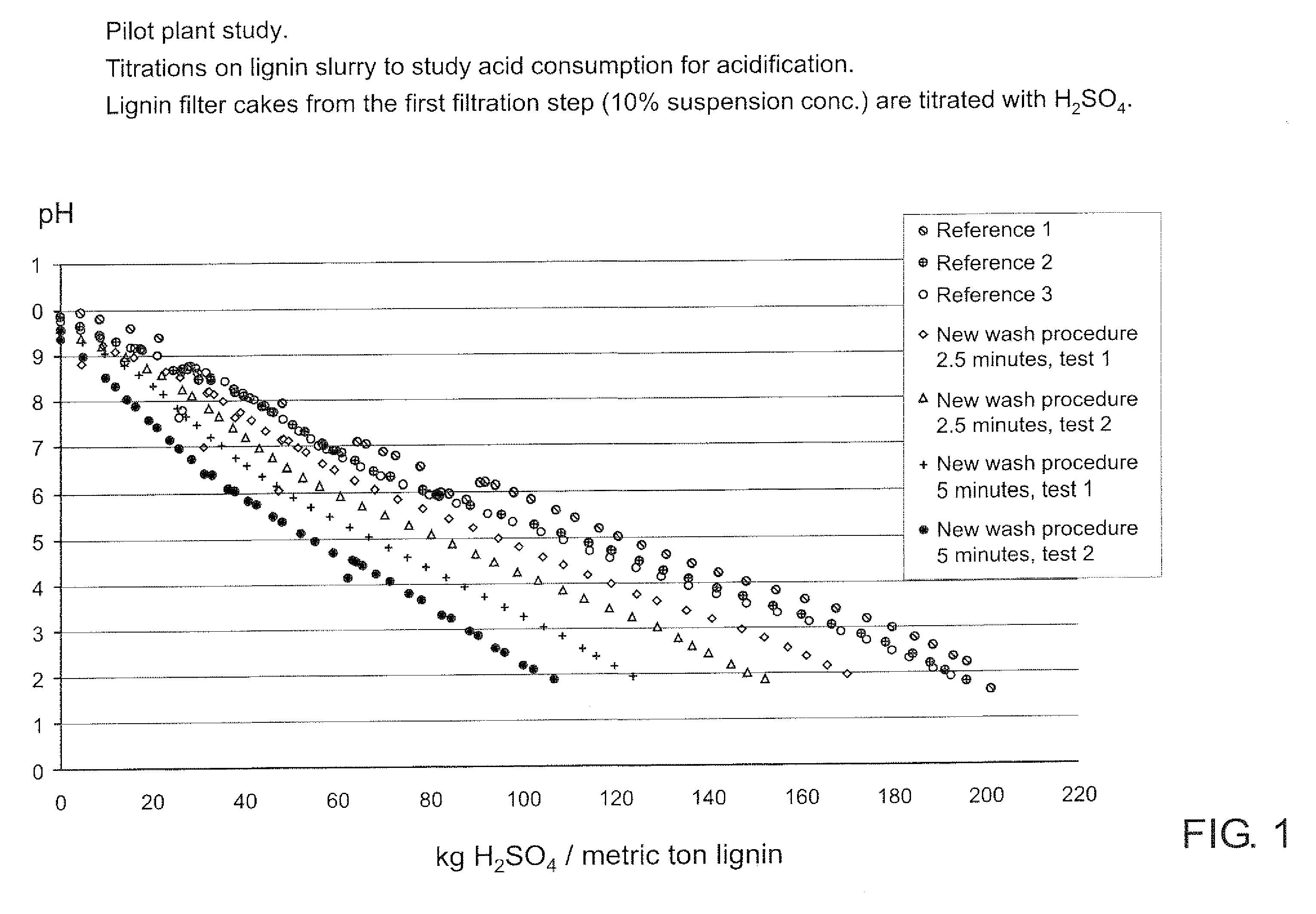

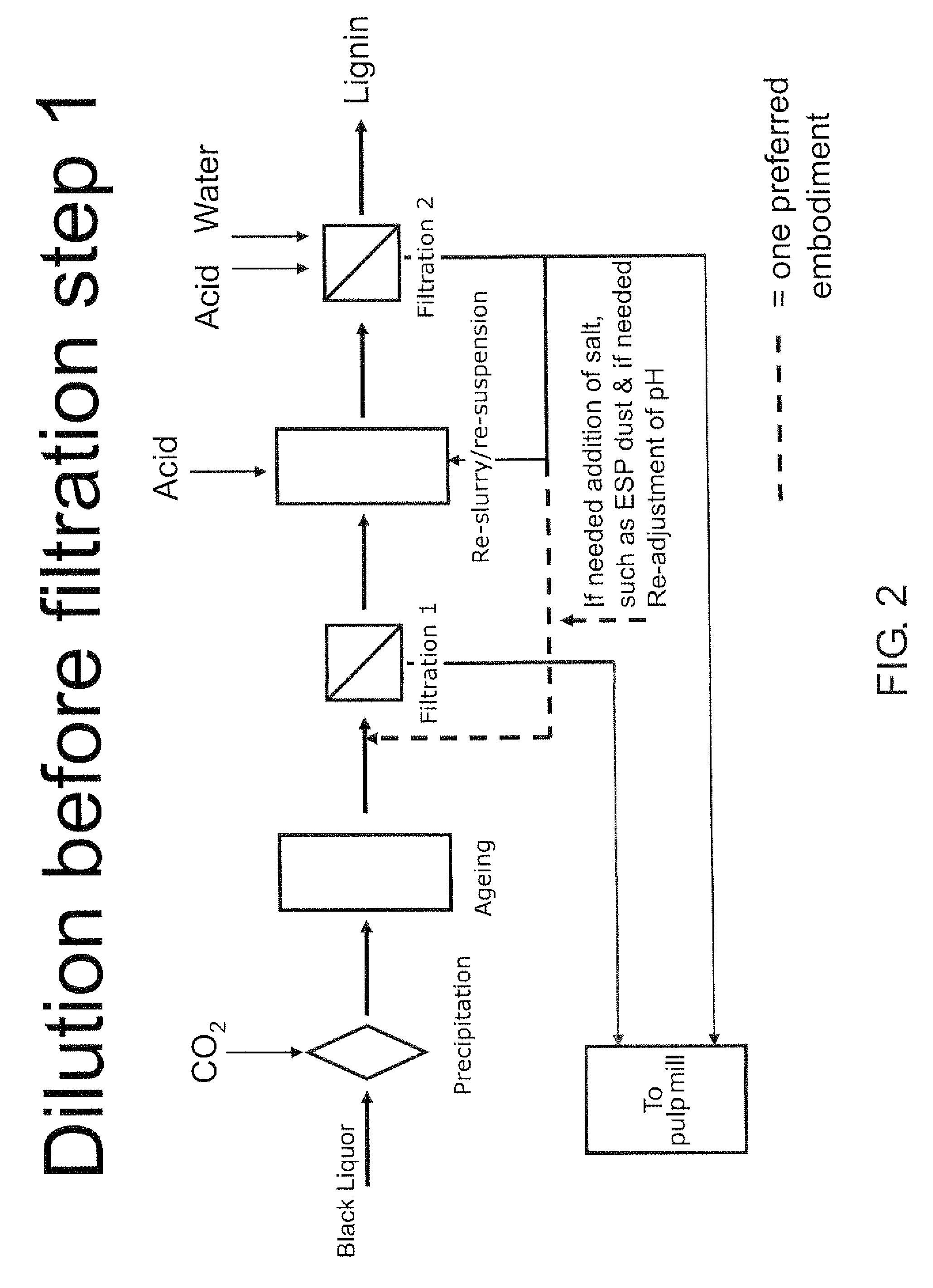

Method

ActiveUS20080214796A1Lower requirementInhibition of dissolutionLignin derivativesPulp by-products recoveryBlack liquorPulp mill

A method for controlling the sodium and sulphur balance of a pulp mill while separating lignin from black liquor, and also a lignin product or an intermediate lignin product obtainable by the method. The present invention also provides use of a lignin product or an intermediate lignin product for the production of fuel (solid, gaseous or liquid) or materials.

Owner:LIGNOBOOST

Methods for degrading or converting plant cell wall polysaccharides

Owner:NOVO NORDISKBIOTECH INC

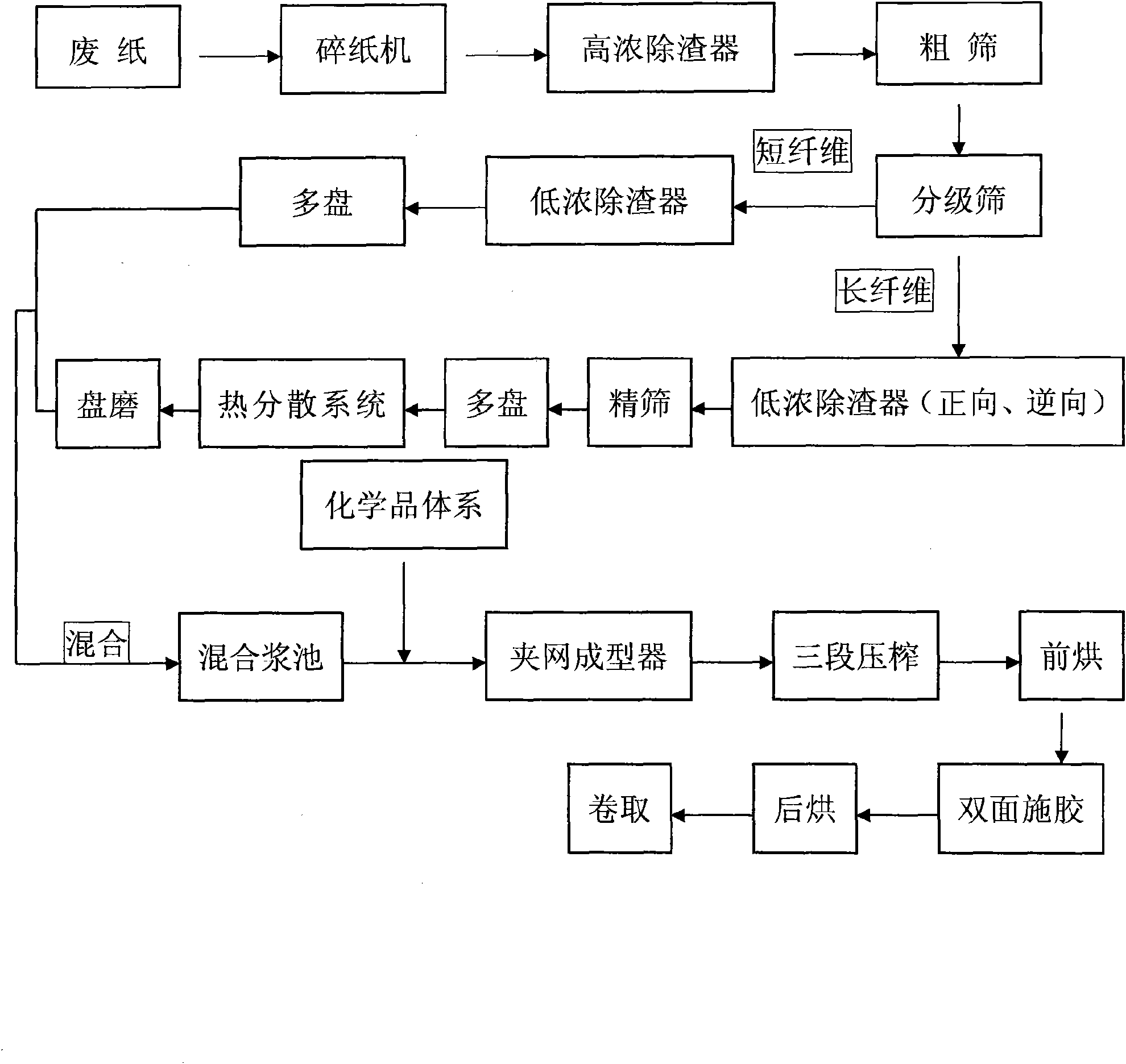

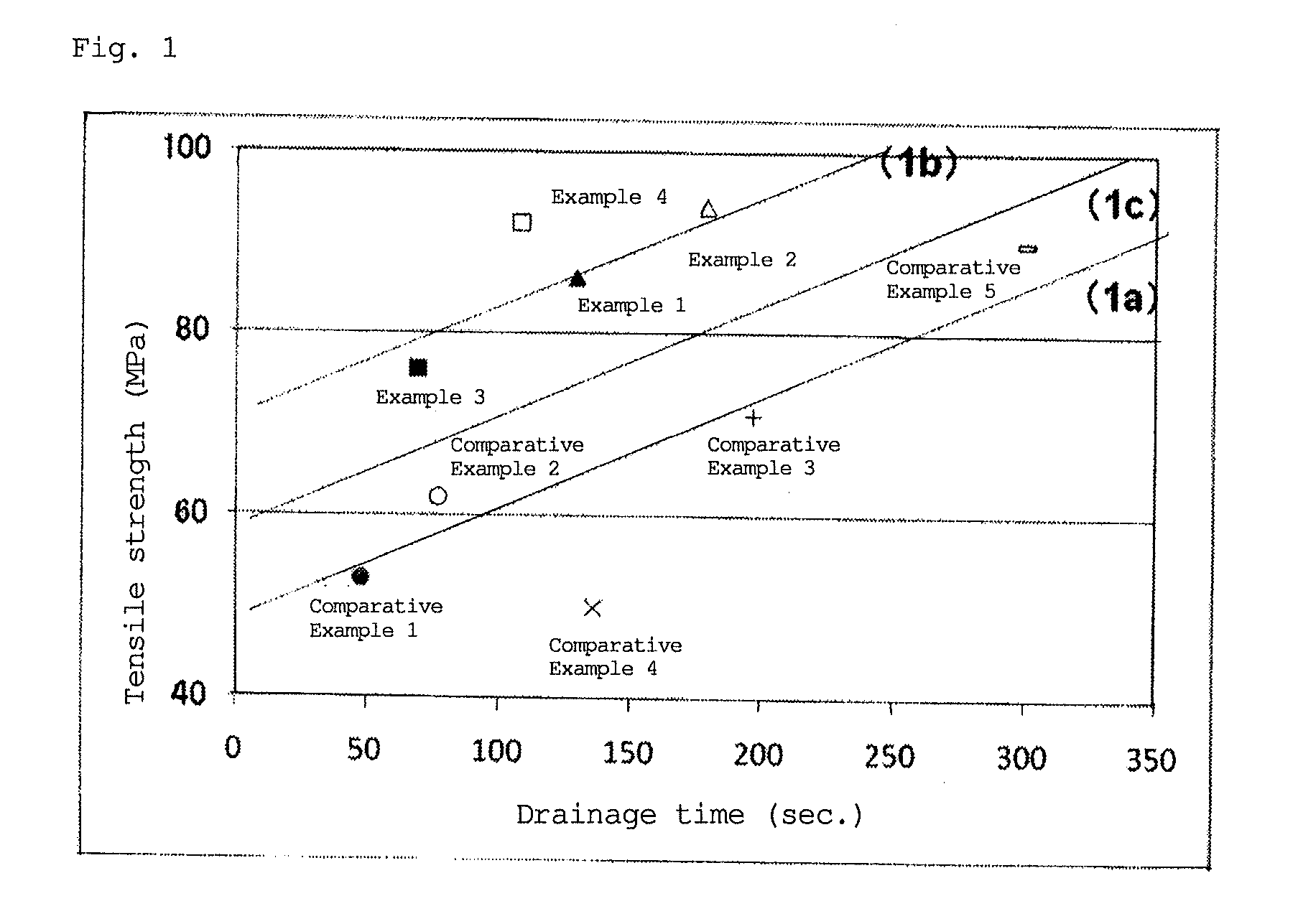

Method for producing corrugated paper with ultralow gram weight and high strength

The invention discloses a method for producing corrugated paper with ultralow gram weight and high strength. The method comprises the following technological steps: 1) mixing; 2) addition of water for size degradation to prepare pulp; 3) pulp combination and purification treatment; 4) medium-concentration pulping; 5) addition of a chemical medicine system into the pulp; 6) twin-wire forming, water filtration and paper-making with the pulp; 7) three-stage squeezing dehydration; 8) prebaking and drying; 9) double-faced sizing; 10) postbaking and drying; and 11) coiling. The method utilizes pulping and paper-making process combination and completely utilizes secondary fiber to make the corrugated paper with ultralow gram weight and high strength so as to reduce the gram weight of the corrugated paper, save the fiber amount, reduce the production cost, and simultaneously reduce the energy consumption and the discharge capacity and improve the economic benefit.

Owner:DONGGUAN NINE DRAGONS PAPER IND

Xylanases, nucleic acids encoding them and methods for making and using them

InactiveUS20060003433A1Low viscosityIncrease profitBacteriaAntibody mimetics/scaffoldsXylanase YIncrease ph

The invention relates to xylanases and to polynucleotides encoding the xylanases. In addition, methods of designing new xylanases and methods of use thereof are also provided. The xylanases have increased activity and stability at increased pH and temperature.

Owner:BP CORP NORTH AMERICA INC

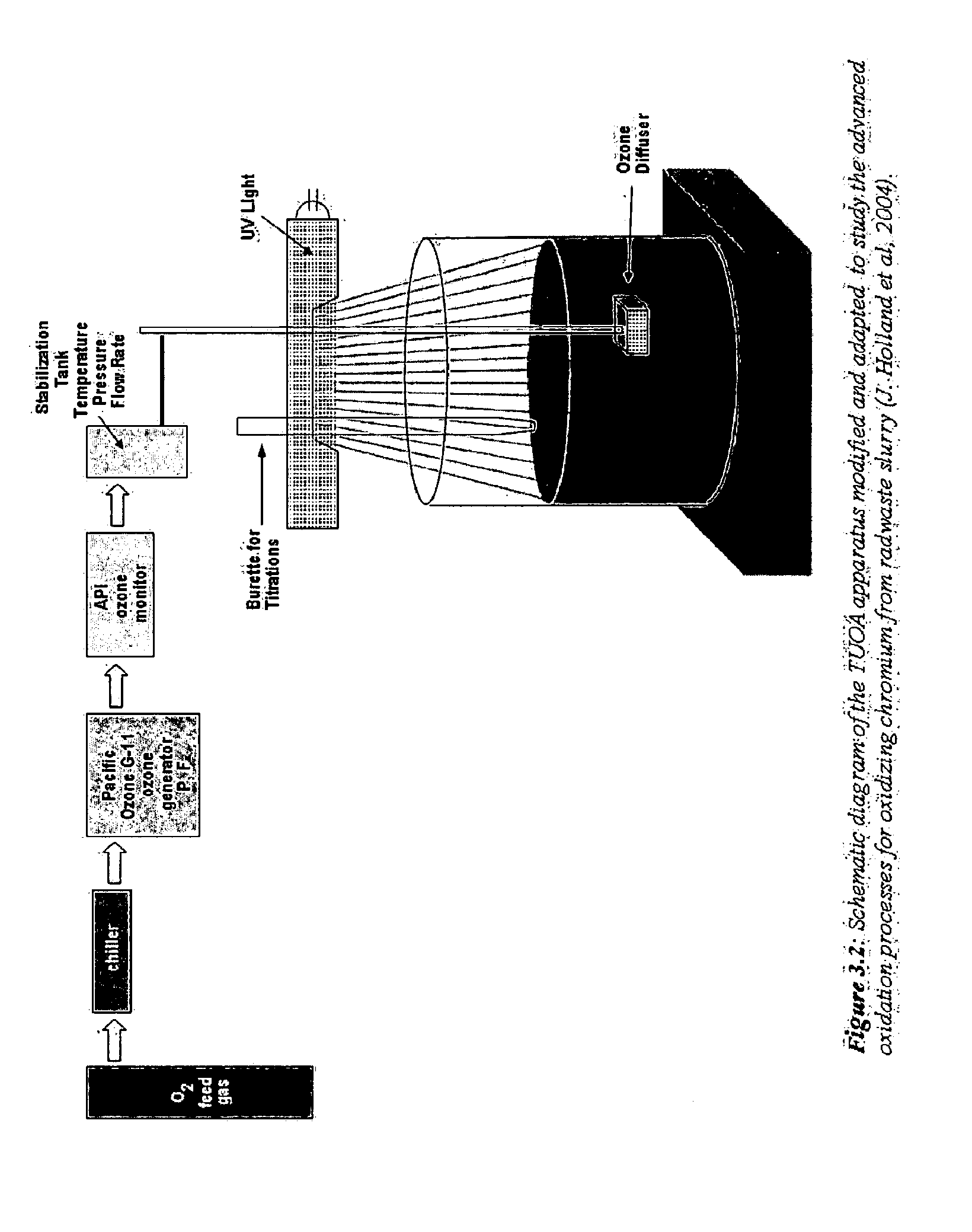

Oxidative Treatment Method

InactiveUS20100320156A1Quickly and efficiently decomposeEffective treatmentWater/sewage treatment by irradiationDecorative surface effectsElectrolysisWaste stream

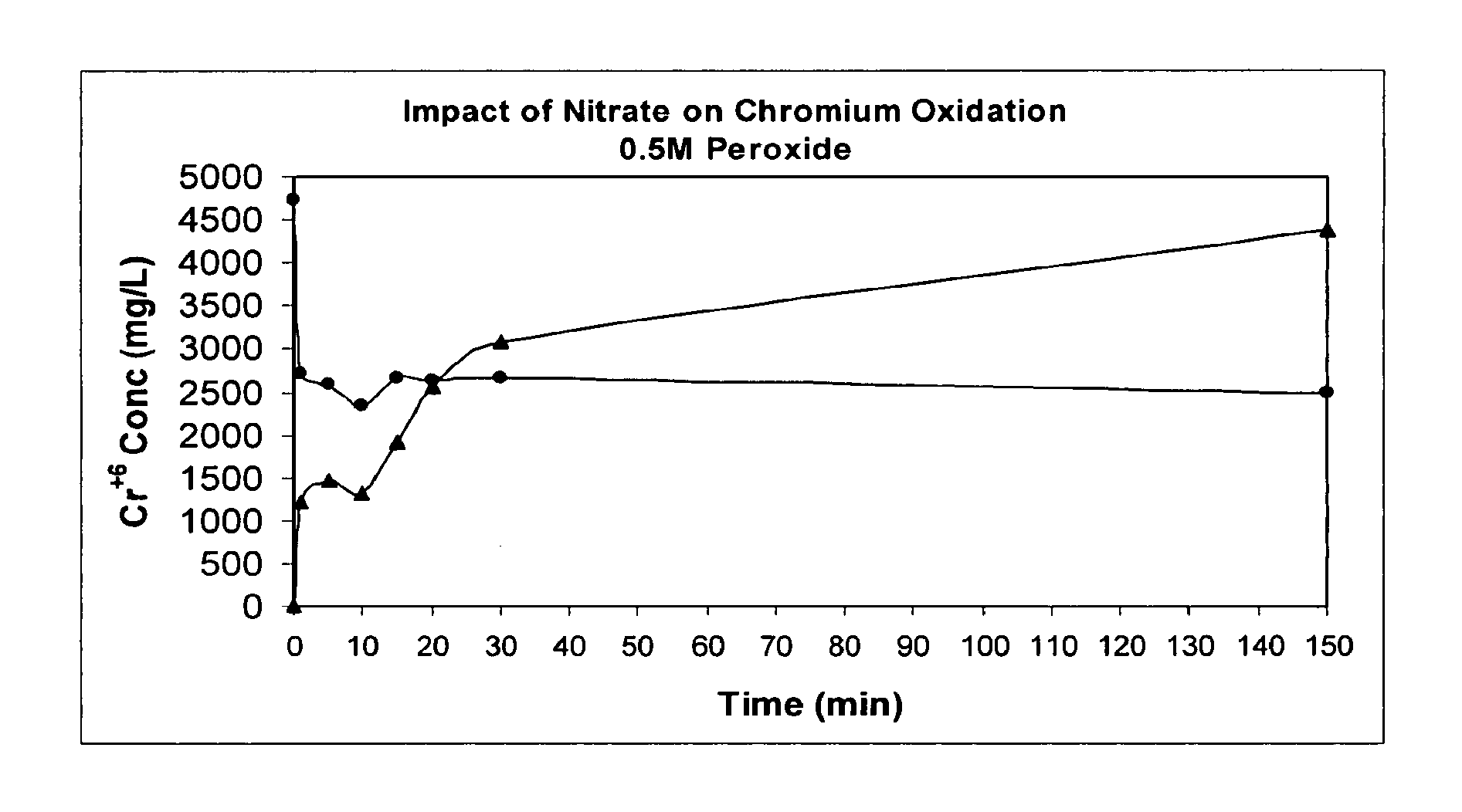

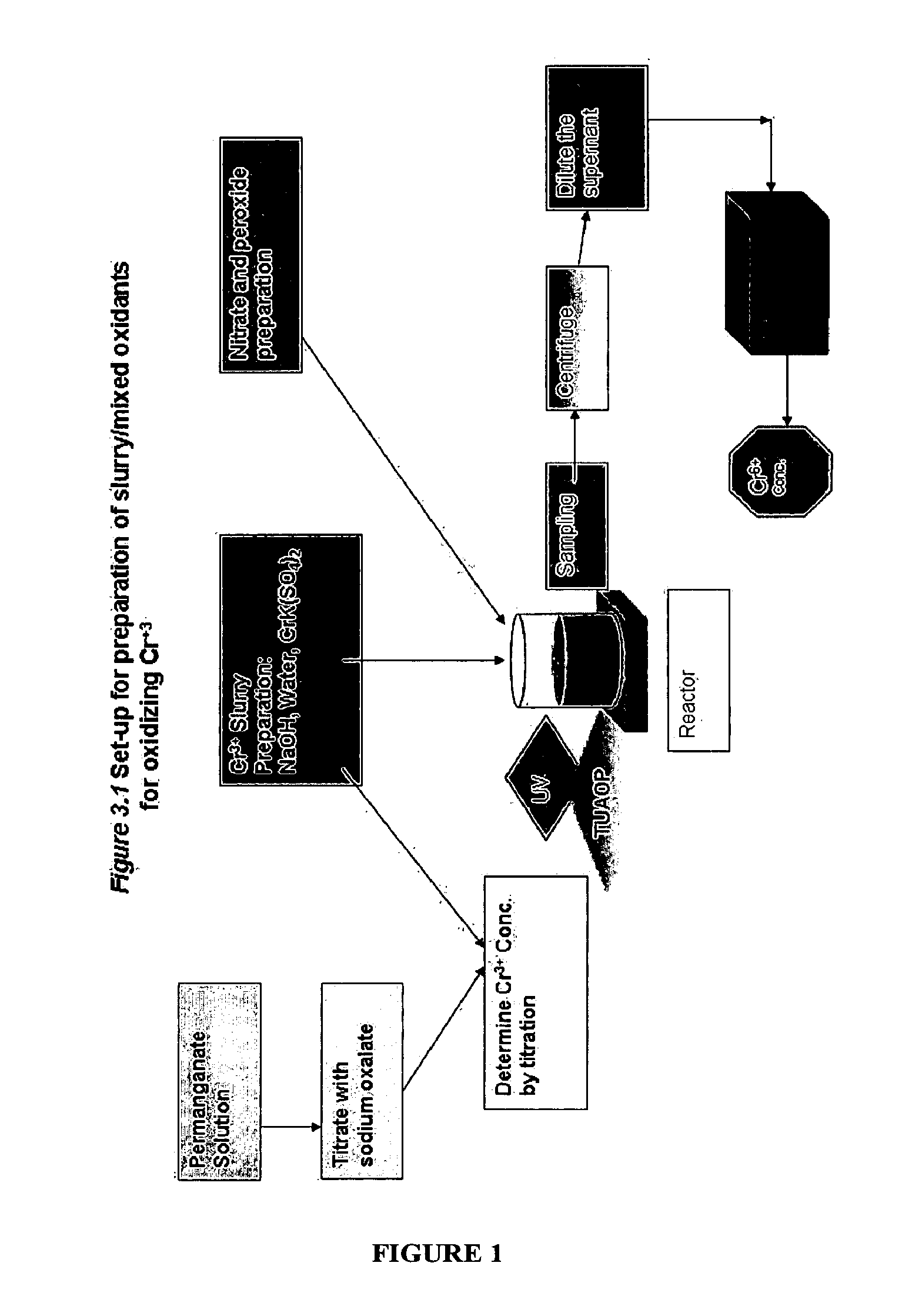

The present invention provides a method for oxidizing a substance (e.g., in a waste stream, drinking water, a paper pulp slurry, or on a surface), which uses free radicals and reactive species generated from multiple oxidants. The method comprises combining peroxynitrite or peroxynitrous acid and at least one additional oxidizing agent for a period of time sufficient to oxidize the substance of interest. The peroxynitrite or peroxynitrous acid preferably is formed by irradiation of nitrate ion and / or nitric acid (e.g., with UV or gamma rays). The yield of free radicals and reactive species, which are the intermediate species that perform the oxidation may be increased by addition of a catalysts, electromagnetic radiation, sonic waves, and / or electrolysis.

Owner:TULANE EDUCATIONAL FUND

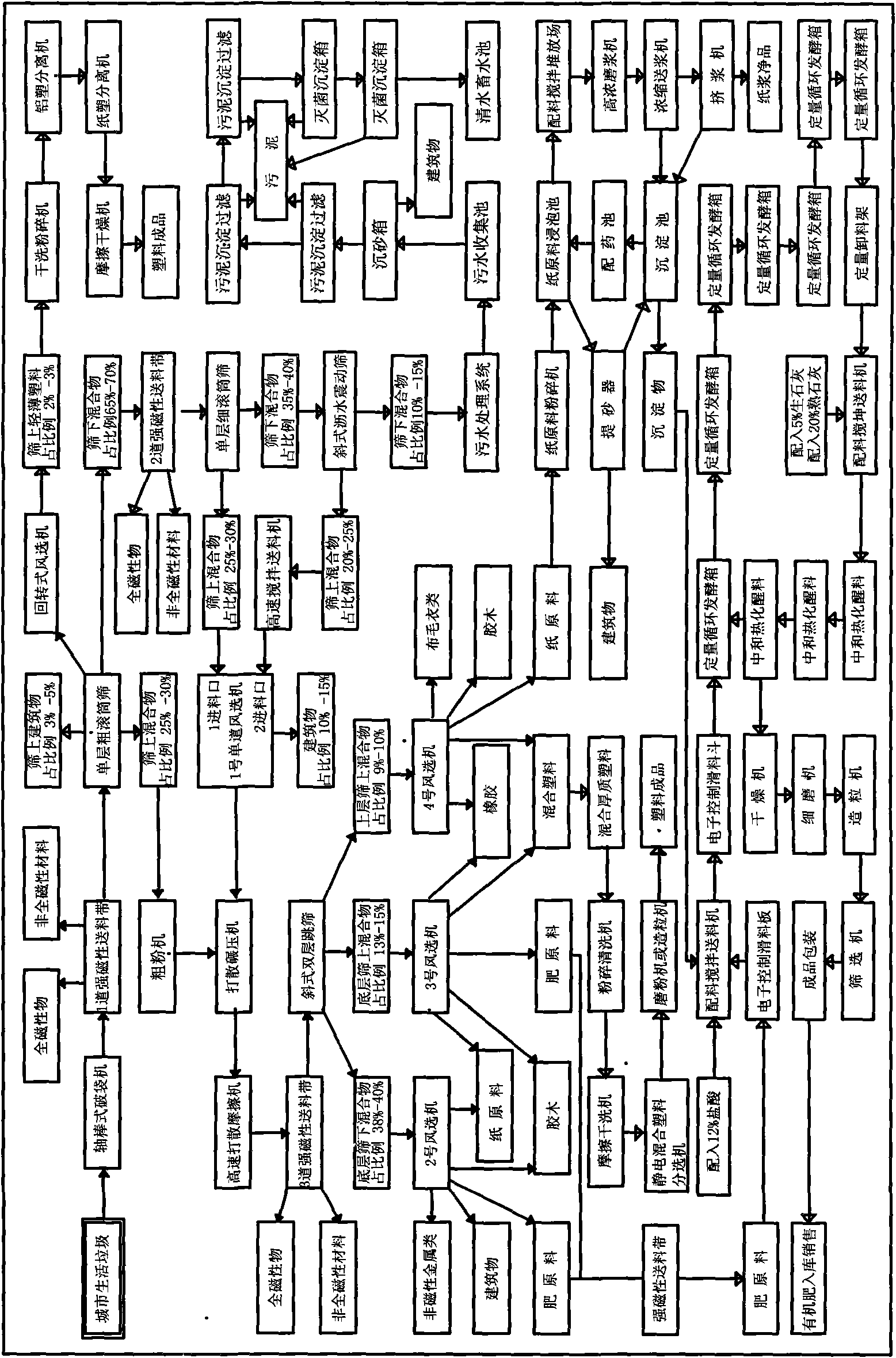

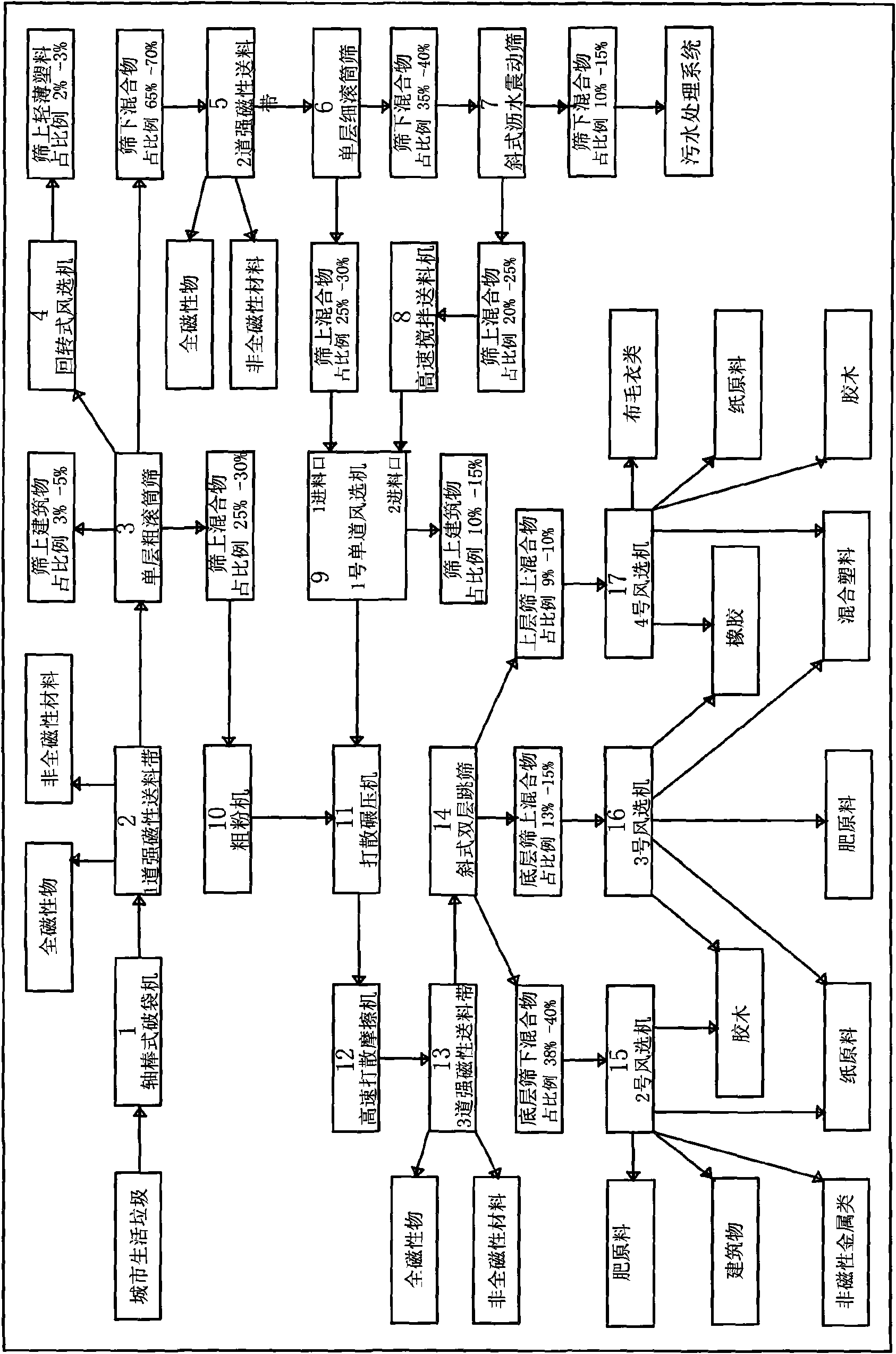

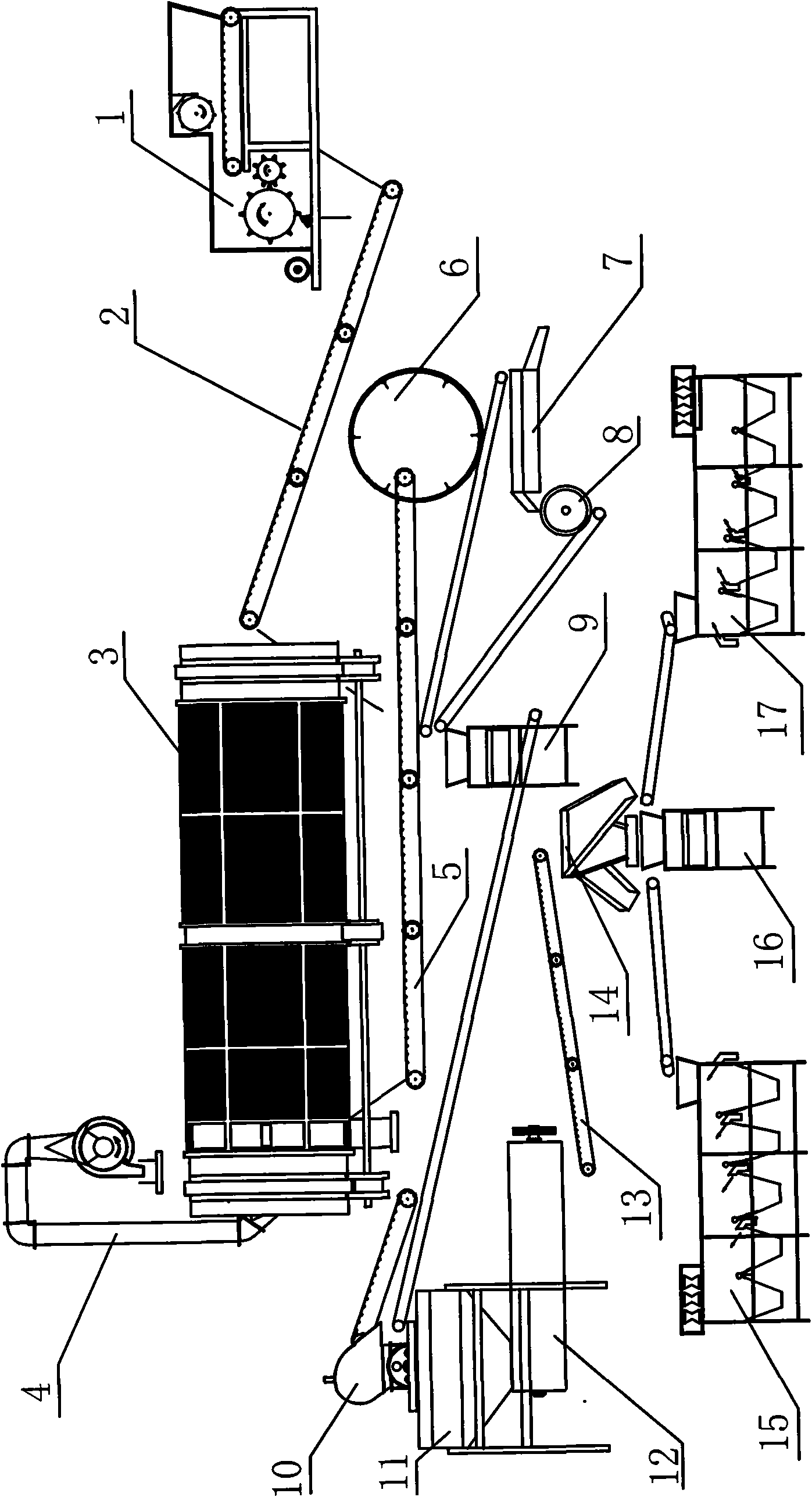

Complete system of recycling treatment of city household garbage and a method thereof

InactiveCN101579689ASolve the fragile problemSolve hanging problemsSievingGas current separationControl systemSewage treatment

The invention relates to a complete system of recycling treatment of city household garbage and a method thereof. The invention is characterized in that an electronic screen control system controls mechanical transmission and treatment condition of a garbage mechanical classification system, a fertilizer-making system, a plastic classification system, a pulping system and a sewage treatment system by a contact screen and a circuit, the recycling treatment of day treatment for day garbage, closed operation, automatic sorting, no secondary pollution and fully treatment of resources is realized finally, the city household garbage is divided into 48 types, which are combined into 15 types and seven sorts, the classification rate reaches 100 percent, the recycling rate reaches over 99 percent and the whole-range treatment needs 60 to 80 minutes.

Owner:邵道德

Chemical method for lignin depolymerization

InactiveUS6214976B1Improve efficiencyWithout major damage to cellulosePulp bleachingLignin derivativesDepolymerizationAqueous solution

A process for depolymerizing and / or chemically modifying lignin or lignin-like compounds in which a solution of copper and peroxide acts on lignin and / or lignin-like substance at a temperature of less than 100° C., characterized in that the solution is an aqueous solution containing copper or a copper complex, a coordination compound and peroxide and wherein the concentration of the copper or copper complex is between 0.001% and 5%, and wherein the concentration of the coordination compound is lower than 20% and wherein the concentration of peroxide is between 0.01% and 20%.

Owner:ANNIKKI GMBH +1

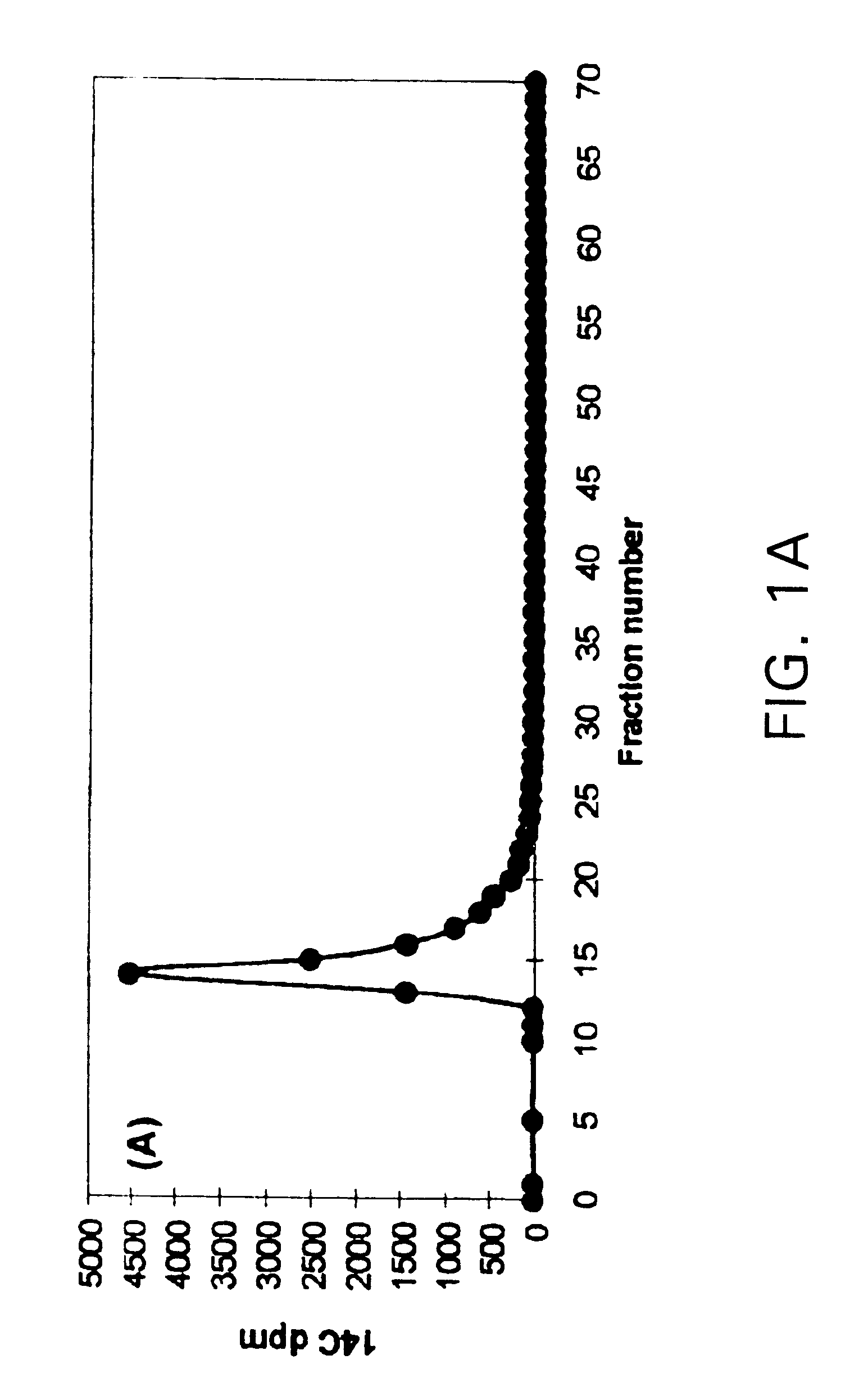

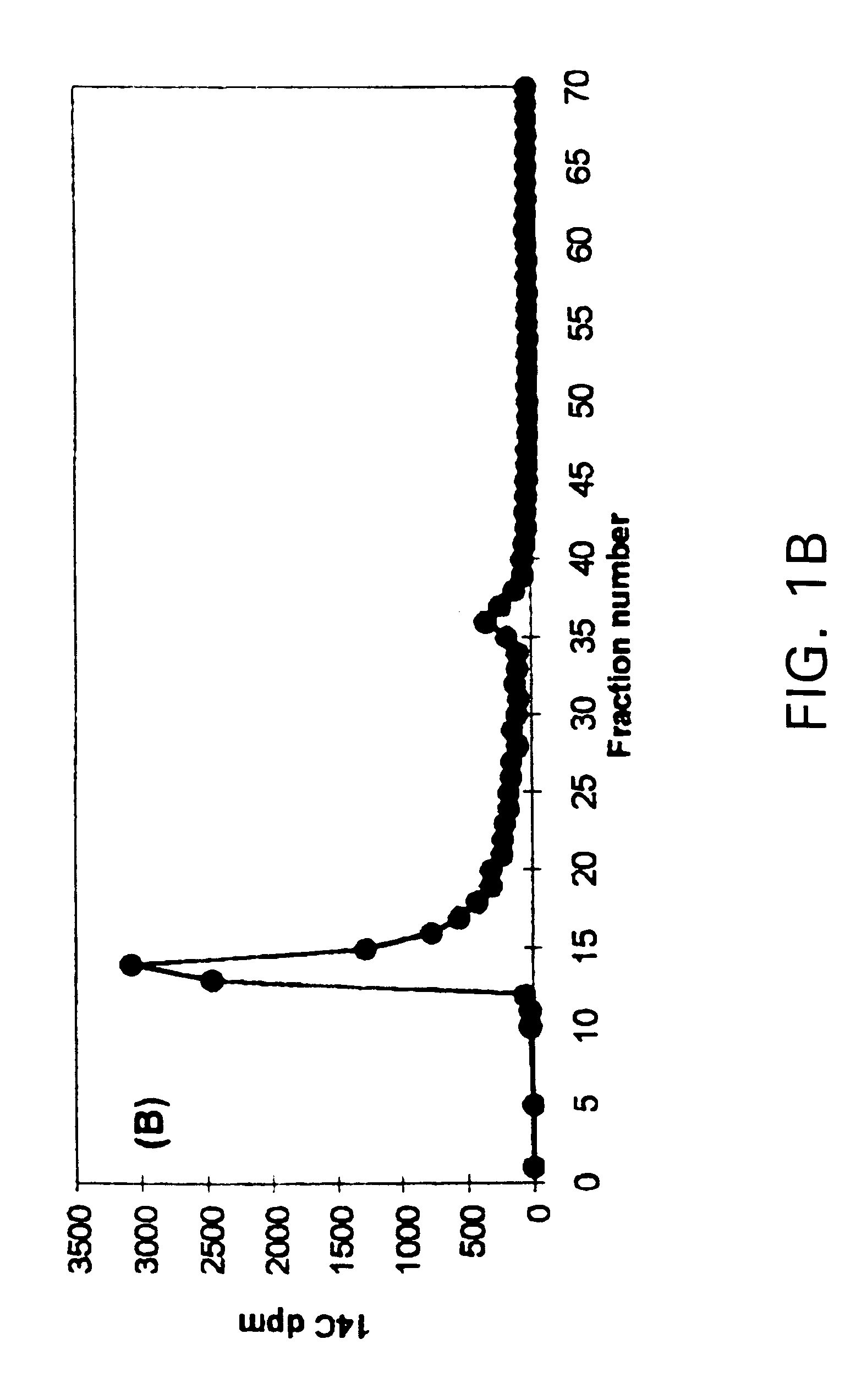

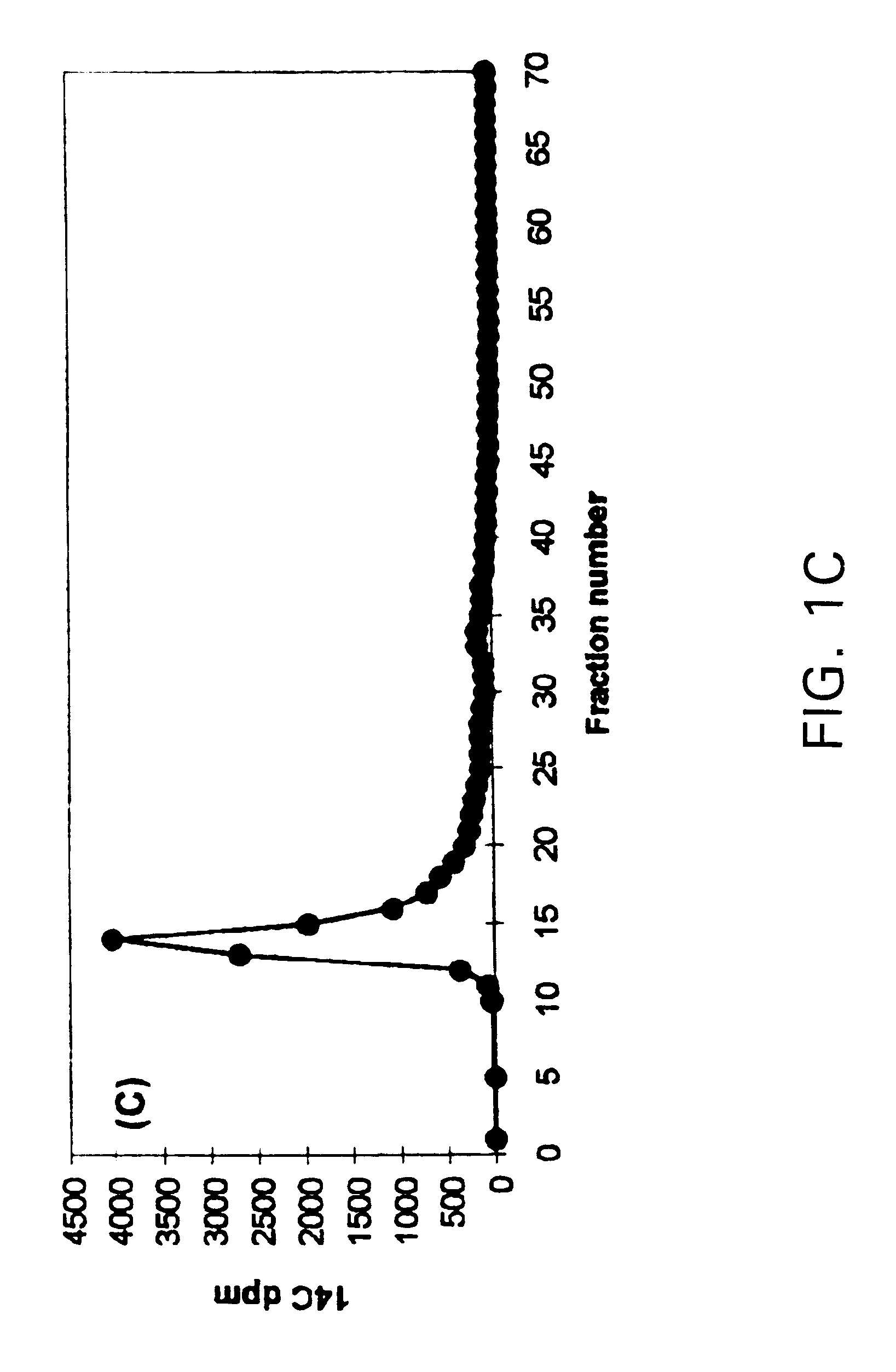

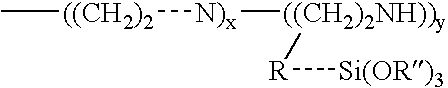

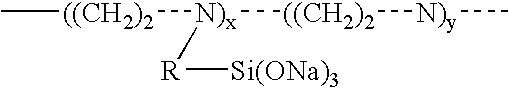

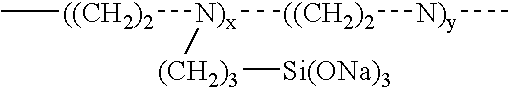

Method of preventing or reducing aluminosilicate scale in kraft pulp mills

InactiveUS20050274926A1Reduce and eliminate aluminosilicate scalingReduce and even prevent formationAluminium compoundsDigestersEnd-groupPulp mill

Materials and a method are provided whereby polymers with least 0.5 mole % of the pendant group or end group containing —Si(OR″)3 (where R″ is H, an alkyl group, Na, K, or NH4) are used to control aluminosilicate scaling in an industrial process having an alkaline process stream such as a pulping mill process stream. When materials of the present invention are added to the alkaline process stream, they reduce and even completely prevent formation of aluminosilicate scale on equipment surfaces such as evaporator walls and heating surfaces. The present materials are effective at treatment concentrations that make them economically practical.

Owner:CYTEC TECH CORP

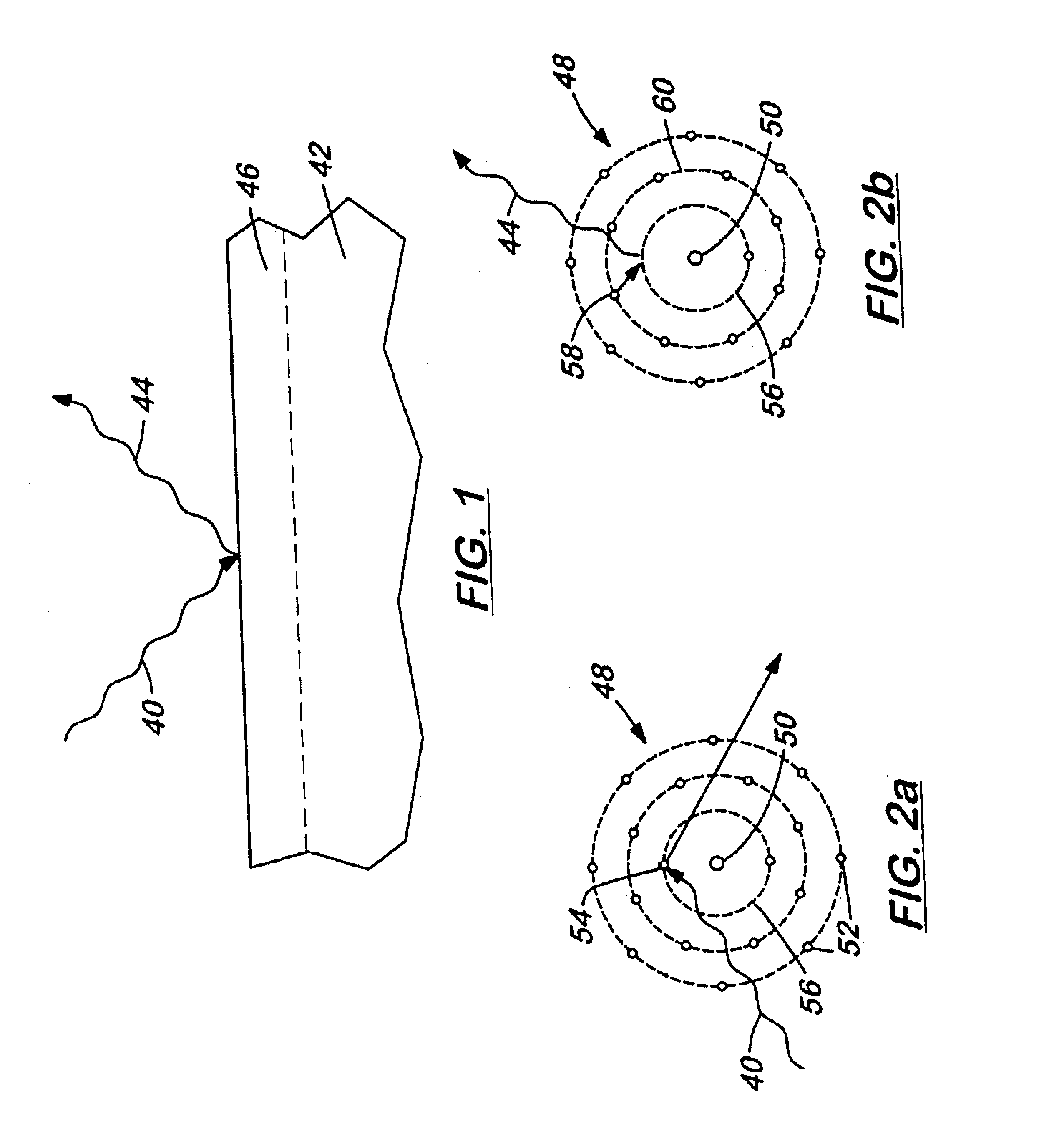

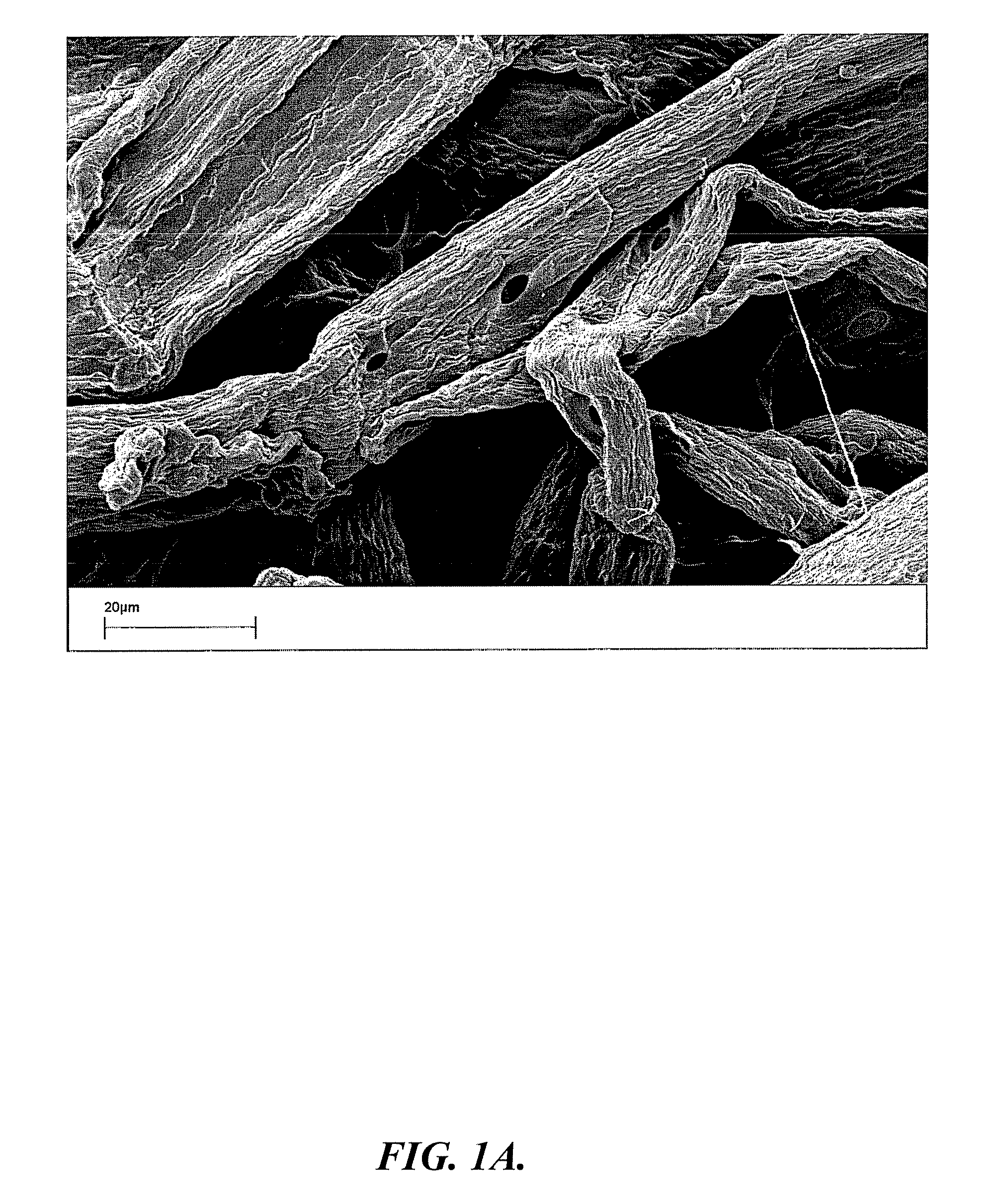

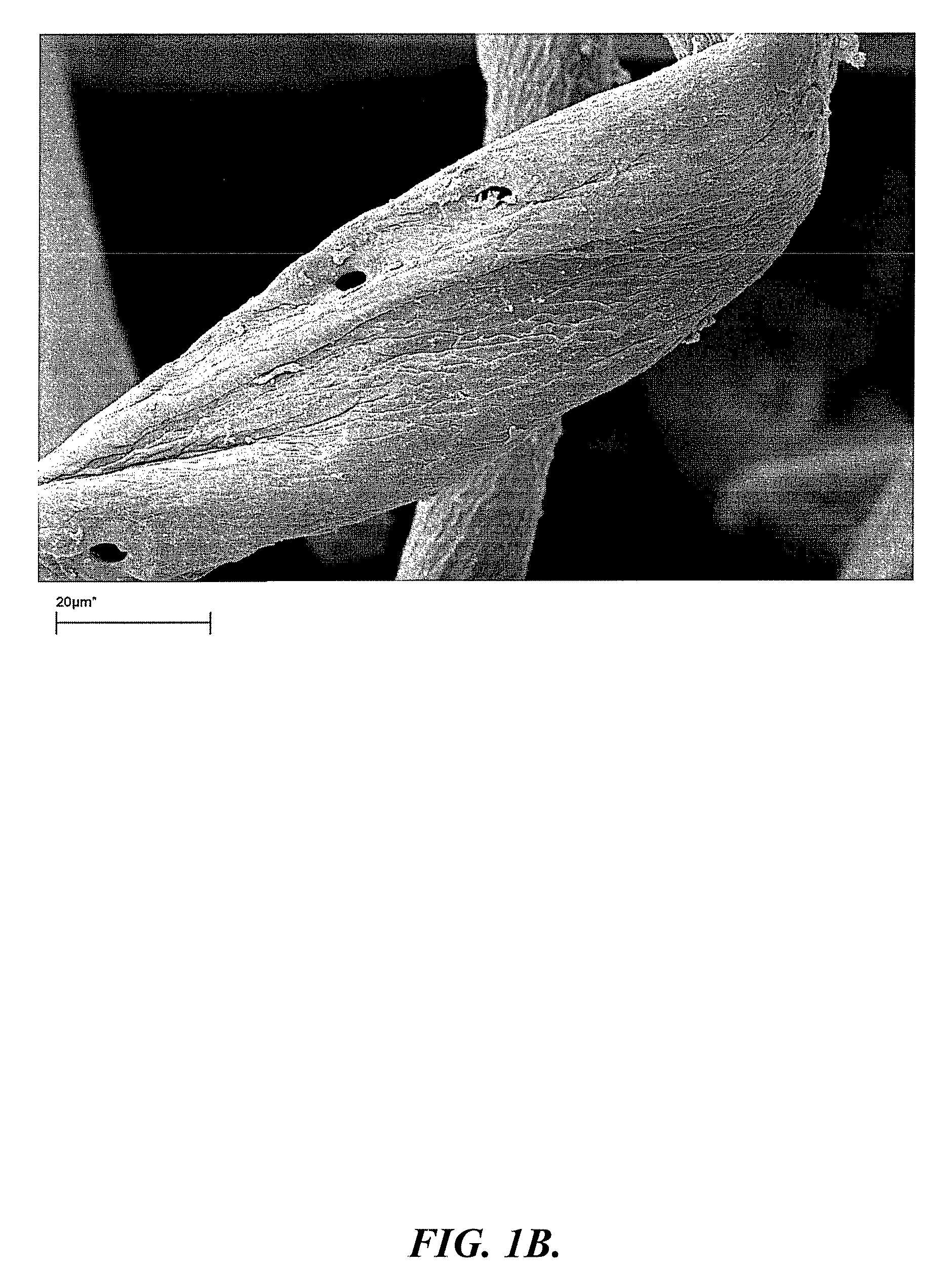

Process for making a flowable and meterable densified fiber particle

InactiveUS7201825B2Speed up the flowEasy to transportFibreboardNon-fibrous pulp additionCellulose fiberDiscrete particle

Discrete particles of cellulosic material are flowable and meterable. They are easily dispersible in an aqueous or a dry medium. The particles comprise singulated cellulose fibers that have been densified. The particles have a density of at least 0.3 g / cc.

Owner:WEYERHAEUSER NR CO

Lignocellulosic materials and the products made therefrom

A process comprising treating a lignocellulosic material preferably pulp in the presence of a transition metal catalyst with a oxidizing agent selected from a group consisting of hydrogen peroxide, hypochlorite, hypochlorous acid and any combination thereof to form a treated lignocellulosic material having a viscosity equal to or less than about 17 cp and having reducing functional groups selected from the group consisting of aldehyde and aldehyde type functional groups at the C6 and C1 positions but predominating at the C1 position.

Owner:INT PAPER CO

Method for bleaching lignocellulosic fibers

InactiveUS6136041AReduce processingSignificant to usePulp bleachingBleaching apparatusBleachPhenanthroline

PCT No. PCT / EP97 / 01865 Sec. 371 Date Dec. 30, 1998 Sec. 102(e) Date Dec. 30, 1998 PCT Filed Apr. 14, 1997 PCT Pub. No. WO97 / 39179 PCT Pub. Date Oct. 23, 1997A method of bleaching lignocellulosic fibers is disclosed which comprises the step of treating the lignocellulosic fibers with a bleaching composition comprising at least one oxidizing bleaching agent in aqueous solution in the presence of at least one additive which activates delignification or bleaching wherein the activating additive is a phenanthroline selected from the group consisting of 2,9-dimethyl-1,10-phenanthroline, 2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline, 2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline-disulfonic acid-disodium salt-hydrate, and 3,4,7,8-tetramethyl-1,10-phenanthroline.

Owner:JASCHINSKI THOMAS +1

Process to produce biofuels from biomass

A method to produce biofuels from biomass is provide by contacting the biomass with an aqueous media to form an extracted biomass, separating at least a portion of an aqueous liquor from the extracted biomass thereby providing the aqueous liquor stream comprising soluble carbohydrates; contacting the aqueous liquor stream with a purification substrate effective to remove sulfur compounds and nitrogen compounds thereby producing a treated carbohydrate stream having less than 35% of the sulfur content and less than 35% of the nitrogen content of the untreated aqueous liquor feed, based on the untreated aqueous liquor stream, then contacting the treated carbohydrate stream with an aqueous phase reforming catalyst to form a plurality of oxygenated intermediates; and processing at least a portion of the oxygenated intermediates to form a liquid fuel.

Owner:SHELL OIL CO

Enzymatic straw material pulping process

InactiveCN1421570AWell mixedChemical/chemomechanical pulpNon-woody plant/crop pulpLignin peroxidaseXylanase Y

The enzymatic straw material pulping process includes three stages of mechanical pre-treatment, enzyme treatment and chemical pulping or chemical-mechanical pulping. After being pretreated mechanically in a pulp grinder, the straw material is treated with hemicellulase liquid or mixed enzyme liquid comprising hemicellulase and lignin peroxidase at pH 3.5-6.5 and 40-60 deg.c for 1-10 hr. In chemical pulping, the material is presoaked with waste pulp-making liquor before extruding out wastes liquor and digested; and in chemical-mechanical pulping, the material is first treated with EDTA, NaOH and H2O2 at 40-80 deg.c for 30-120 min and then ground to form the pulp. The present invention is used in papermaking enterprises with straw as material and has the advantages of low pollution load, high, paper pulp quality, easy-to-process waste liquor, etc.

Owner:SHANDONG UNIV

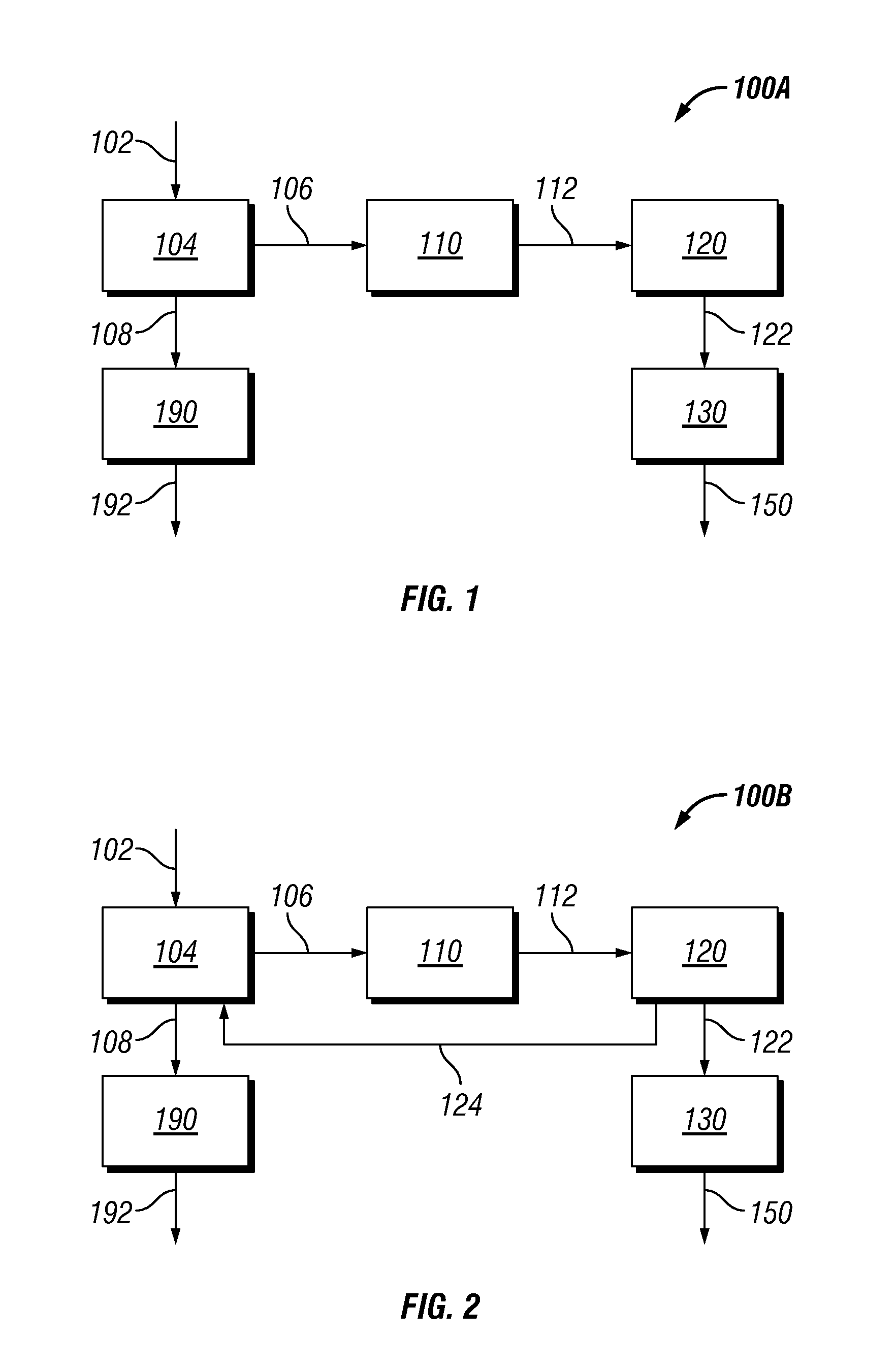

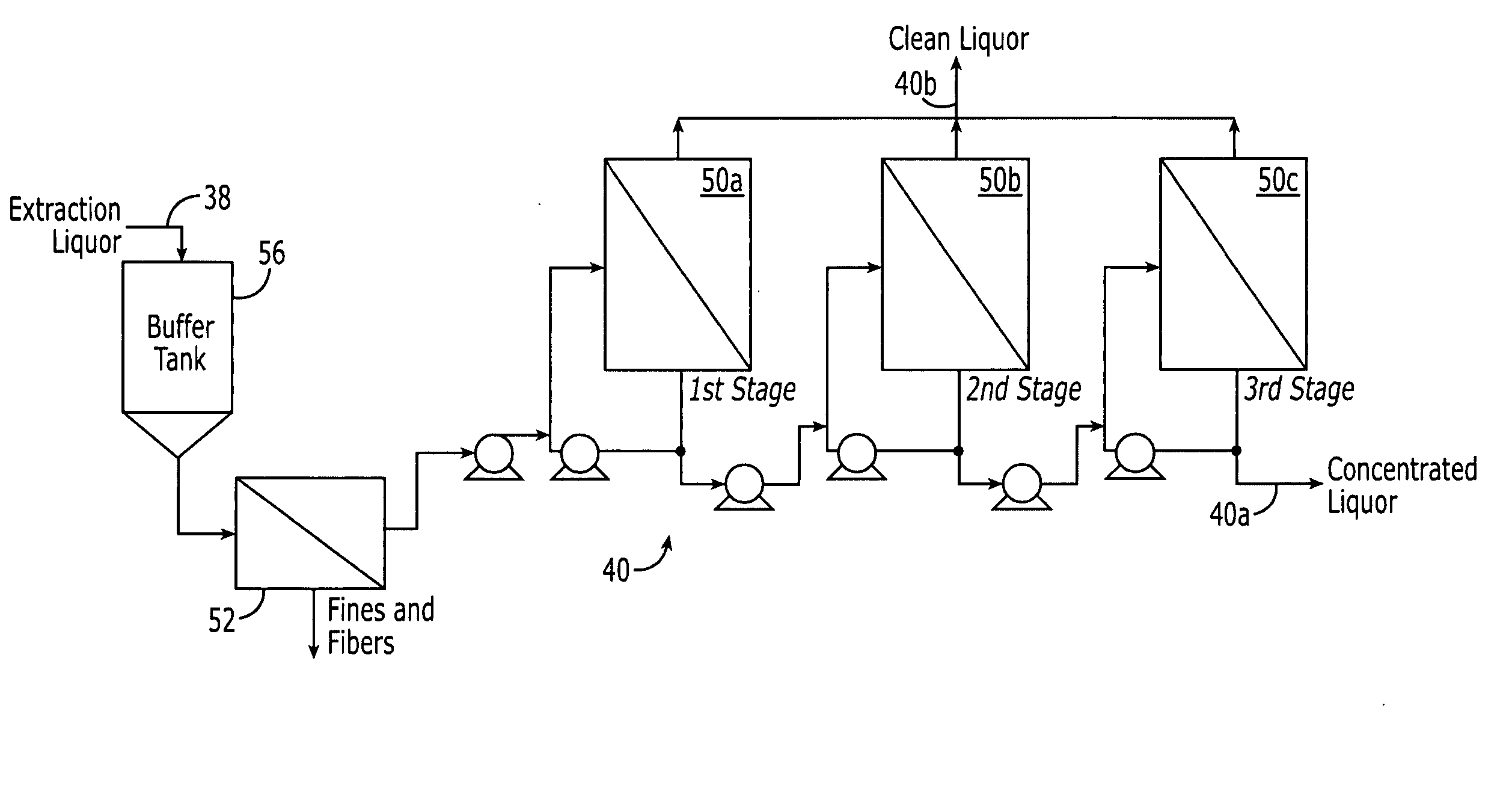

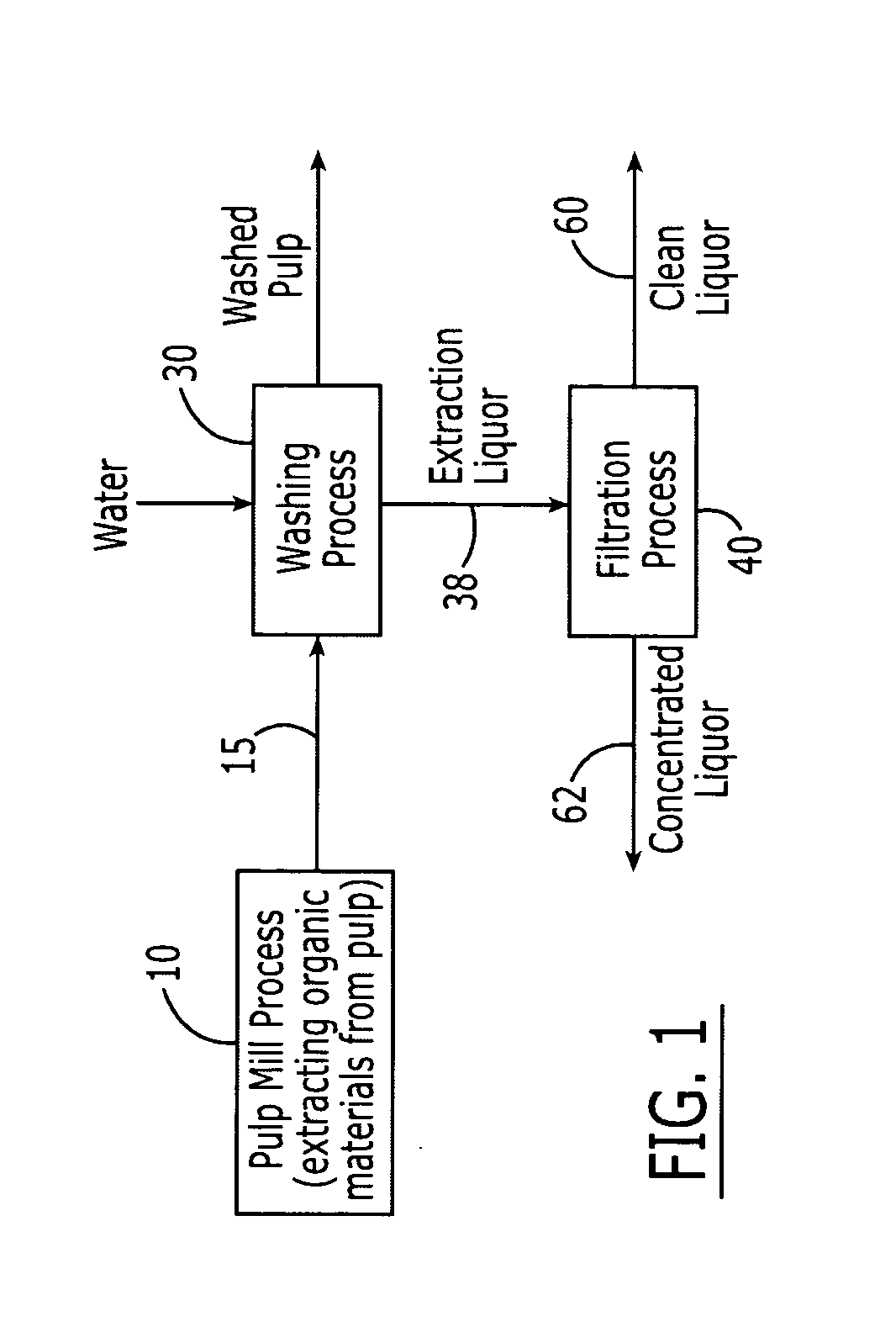

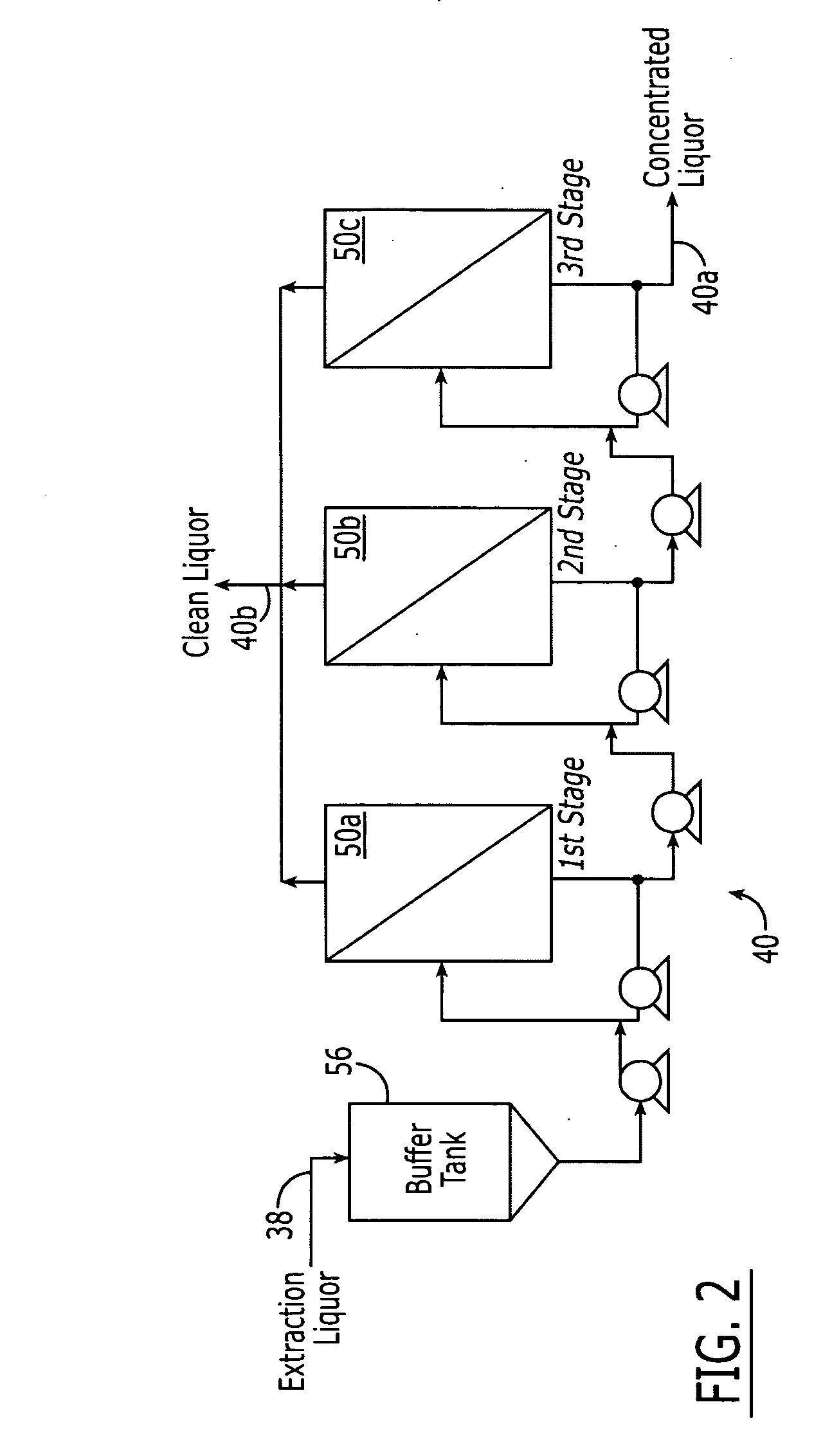

Method of concentrating pulp mill extracts

InactiveUS20060016751A1Reduce loadReduce processMembranesPulp liquors combustionWaste streamPulp mill

A process for separating organic components from a pulp mill waste stream comprising the steps of washing a cellulose pulp to obtain an aqueous extraction liquor containing organic components, and separating at least a portion of said organic components from the extraction liquor by passing the extraction liquor through at least one nanofiltration membrane. The process may be used in conjunction with a variety of pulp mill processes, including kraft cooking processes, hot caustic extraction processes, sulfite cooking processes, and bleaching processes.

Owner:RAYONIER PRODUCTS AND FINANCIAL SERVICES COMPANY

Pulp using rice grass and wheatgrass as raw material and preparation method thereof

ActiveCN101089292AHigh mechanical strengthChemical/chemomechanical pulpNon-woody plant/crop pulpPulp and paper industryHardness

The present invention relates to a paper pulp prepared by using rice straw and wheat straw as raw material. The breaking length of said paper pulp is 4500-8100 km. and its tearing strength is 180-280 mN. Besides, said invention also provides its preparation method and concrete steps.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

Ligno cellulosic materials and the products made therefrom

ActiveUS20110287275A1Maintain good propertiesHigh strengthBiocideAnimal repellantsCellulosePolymer science

A process comprising treating a lignocellulosic material preferably pulp in the presence of a transition metal catalyst with a oxidizing agent selected from a group consisting of hydrogen peroxide, hypochlorite, hypochlorous acid and any combination thereof to form a treated lignocellulosic material having a viscosity equal to or less than about 17 cp and having reducing functional groups selected from the group consisting of aldehyde and aldehyde type functional groups at the C6 and C1 positions but predominating at the C1 position.

Owner:INT PAPER CO

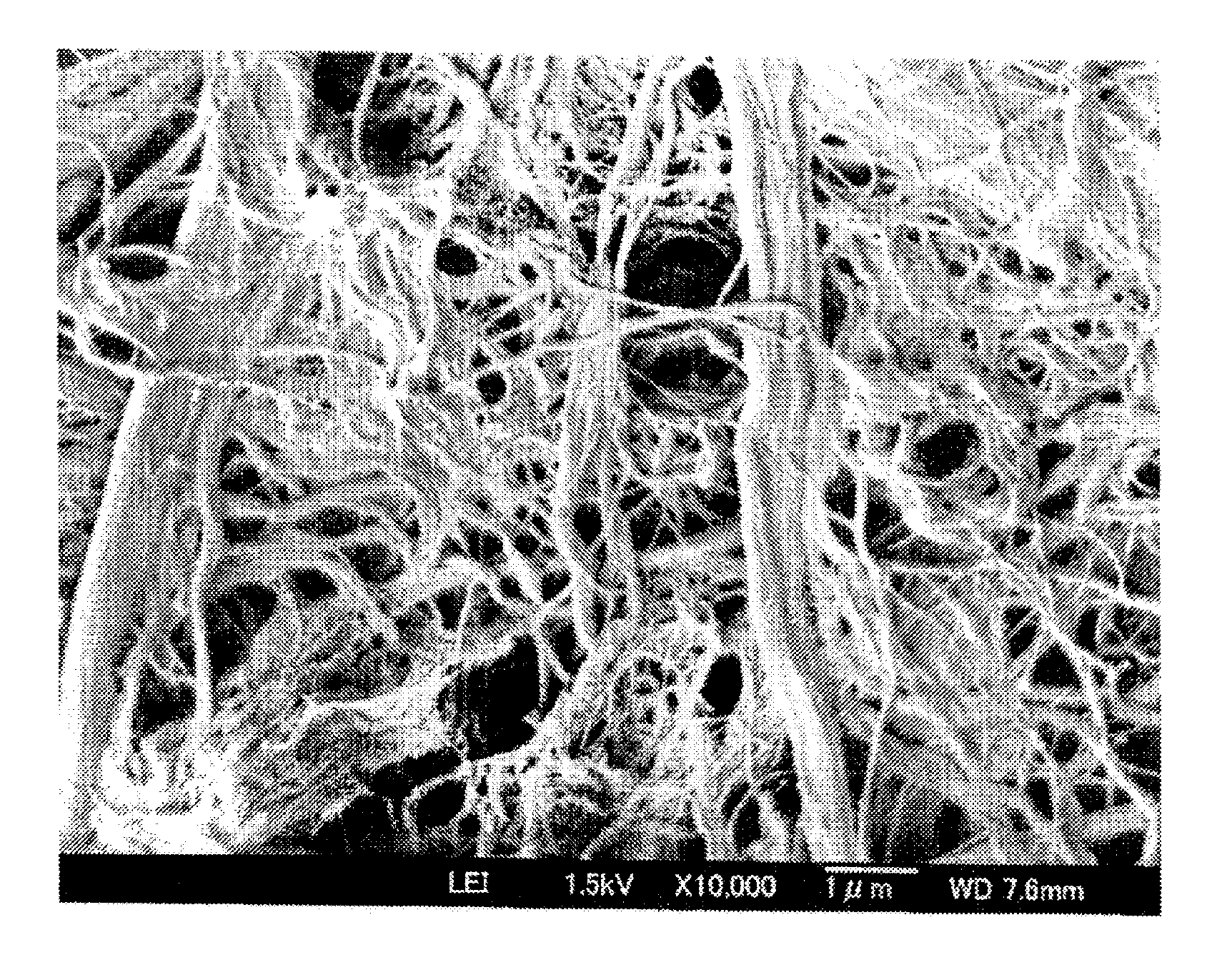

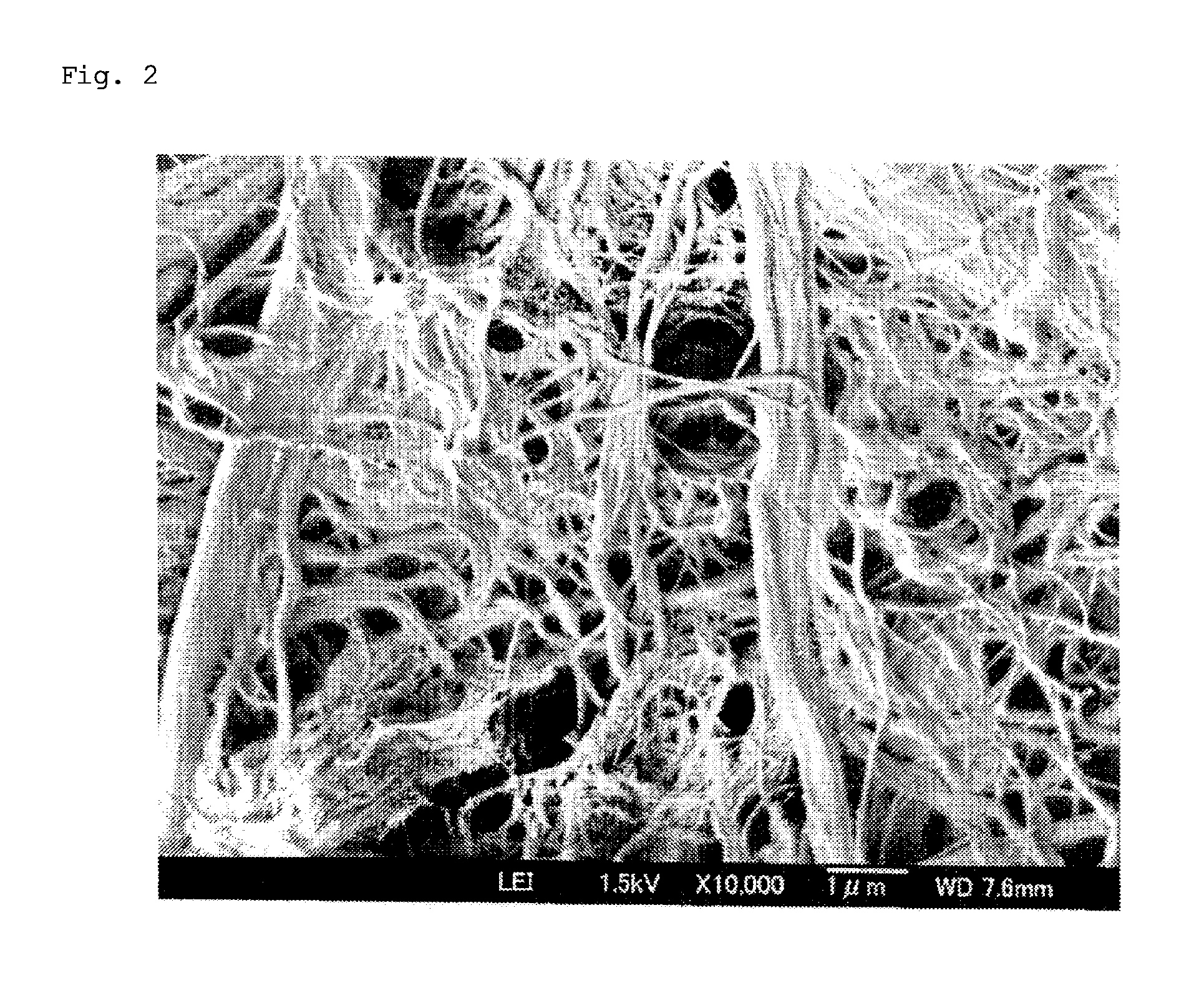

Cellulose nanofibers

ActiveUS20120277351A1Excellent water filtering propertyIncrease shear rateCellulosic pulp after-treatmentDigestersFiberCellulose

The present invention provides a novel production method of a cellulose nanofiber and a novel cellulose nanofiber.A method for producing a cellulose nanofiber comprising defibrating pulp by a single- or multi-screw kneader in the presence of water, the single or multi-screw kneader having a screw circumferential speed of 45 m / min. or more.

Owner:MITSUBISHI CHEM CORP +3

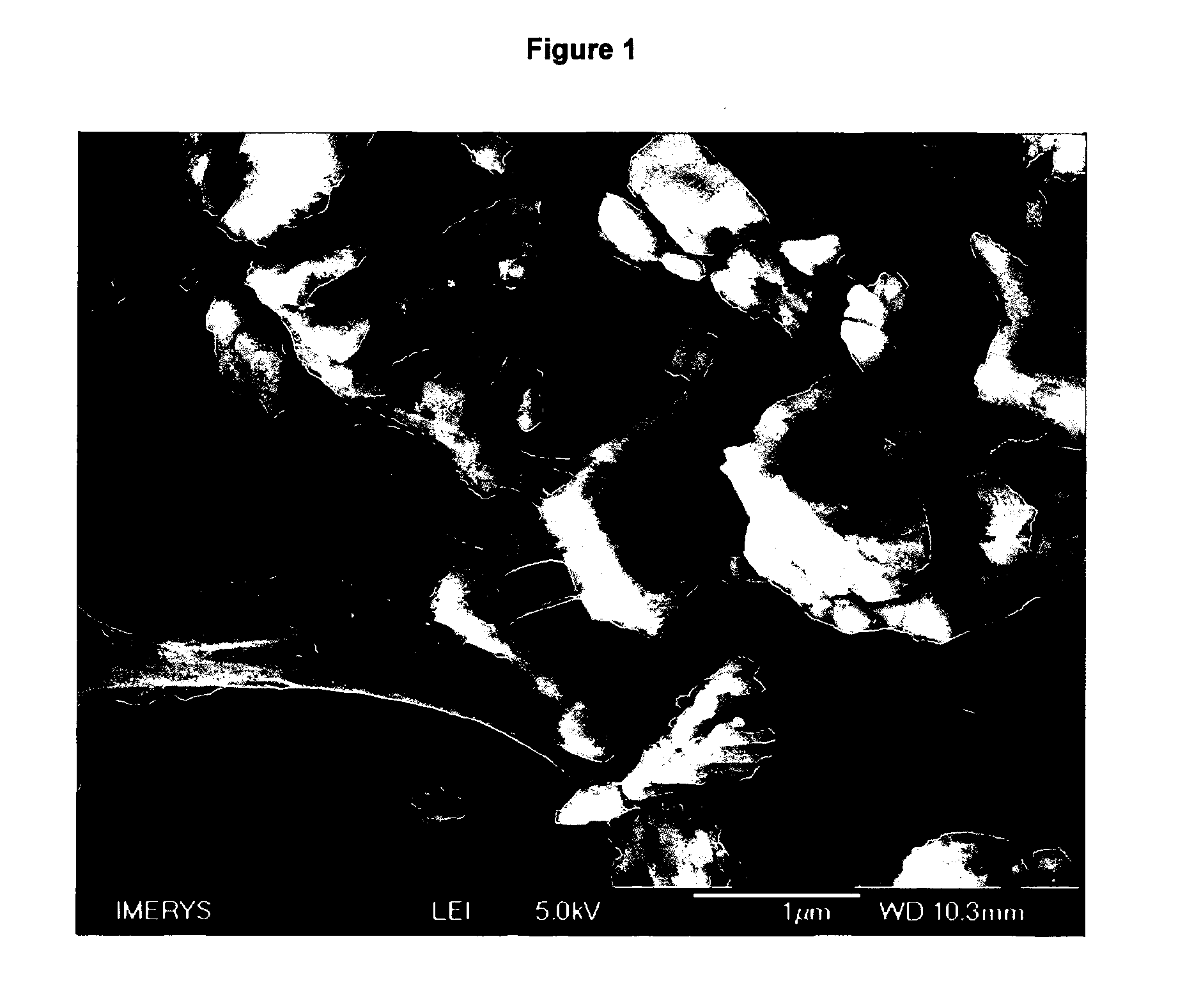

Paper filler composition

A method for preparing an aqueous suspension comprising microfibrillated cellulose and inorganic particulate material, the method comprising a step of microfibrillating a fibrous substrate comprising cellulose in an aqueous environment in the presence of an inorganic particulate material.

Owner:FIBERLEAN TECH LTD

Crosslinked carboxyalkyl cellulose fibers having permanent and non-permanent crosslinks

Substantially water-insoluble, water-swellable, non-regenerated, carboxyalkyl cellulose fibers, wherein the fibers have a surface having the appearance of the surface of a cellulose fiber, and wherein the fibers include a plurality of non-permanent intra-fiber metal crosslinks and a plurality of permanent intra-fiber crosslinks; and fiber bundles that include the fibers.

Owner:INT PAPER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com