Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180 results about "Xylanase Y" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the fractionation of cereal brans

InactiveUS20050089602A1Minimal contaminationImprove efficiencyTea extractionProtein composition from vegetable seedsUltrafiltrationHordeum vulgare

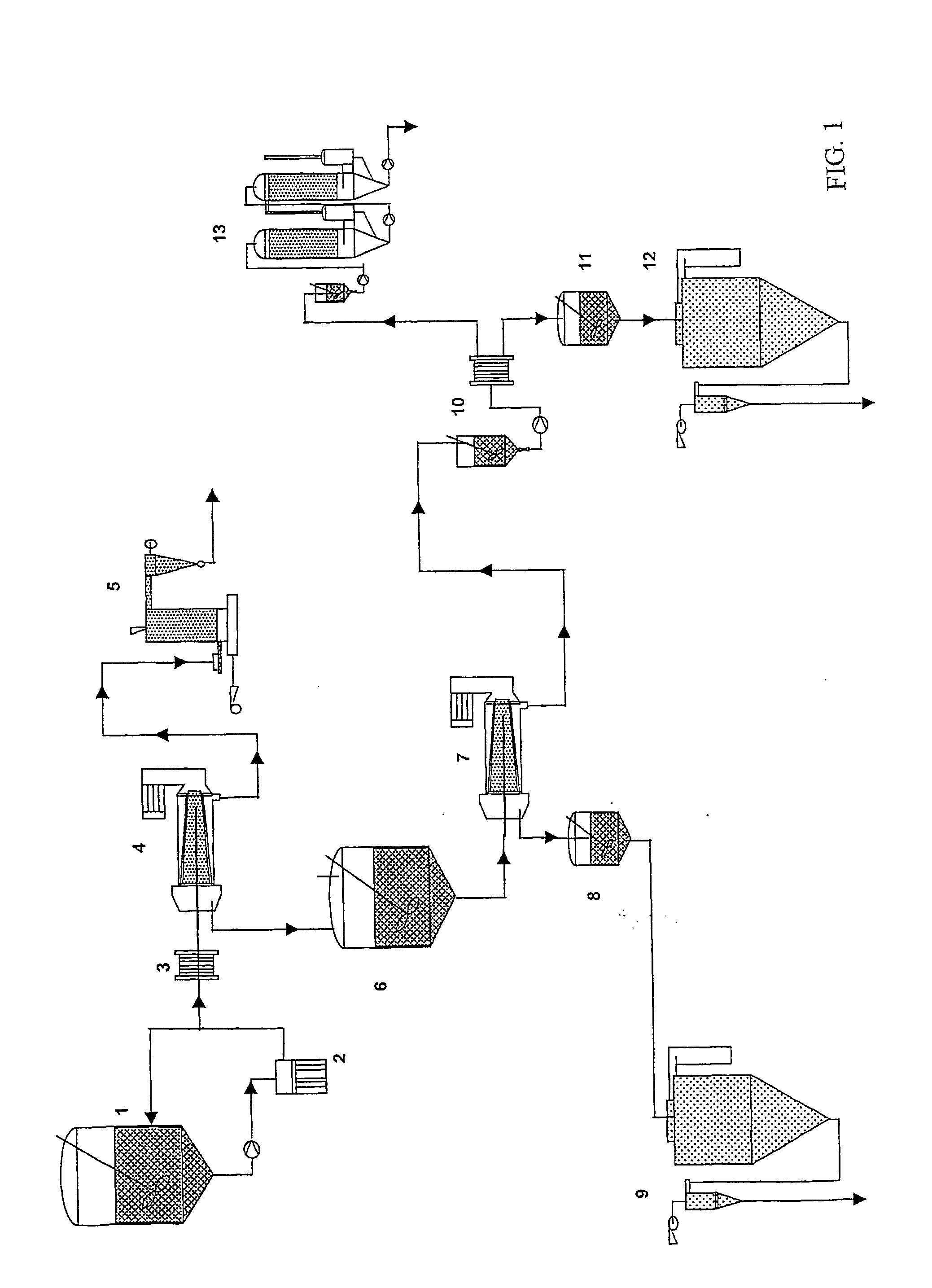

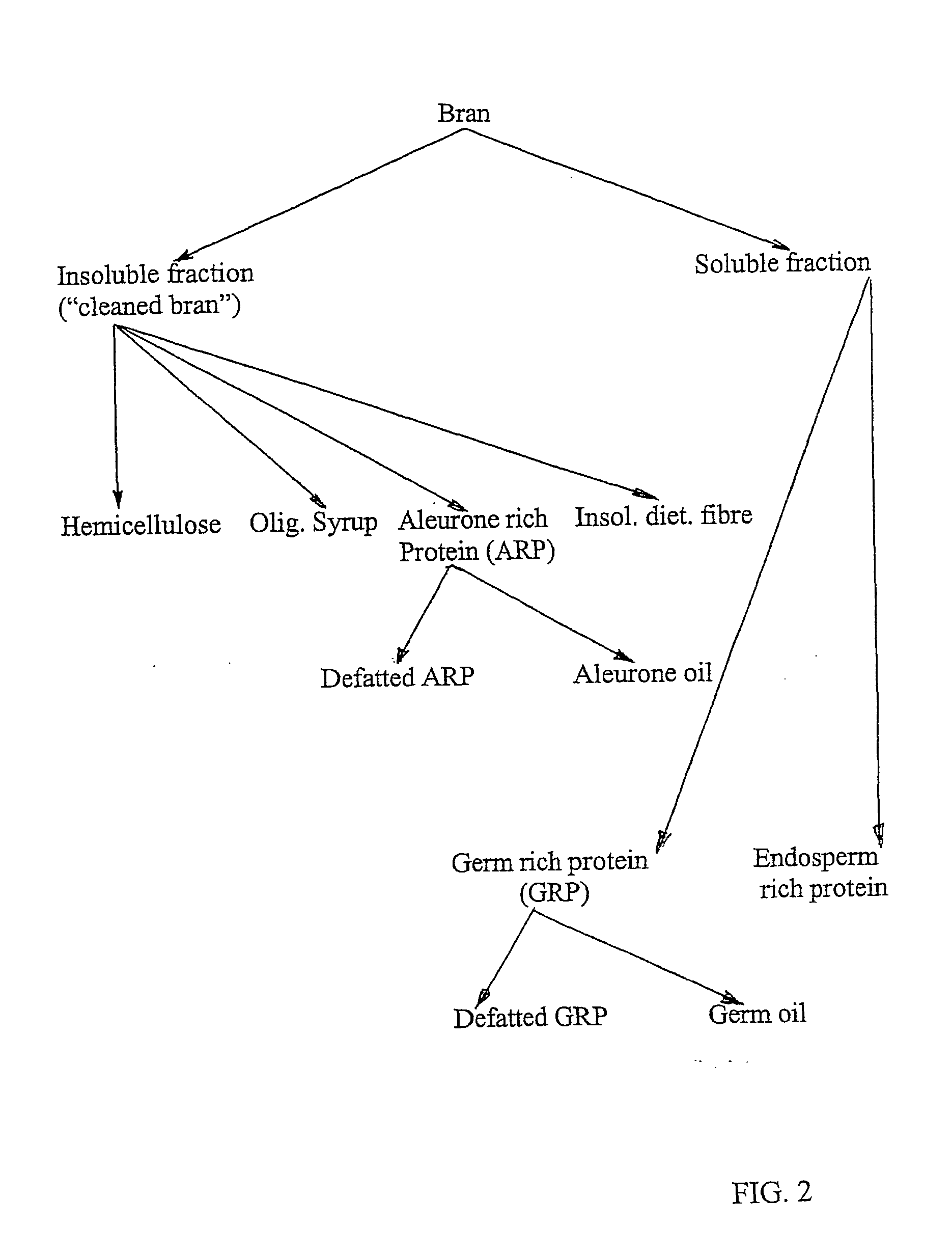

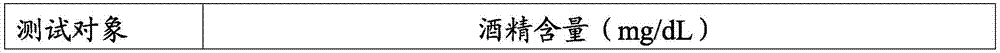

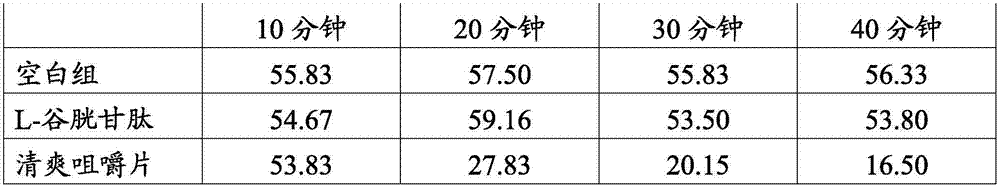

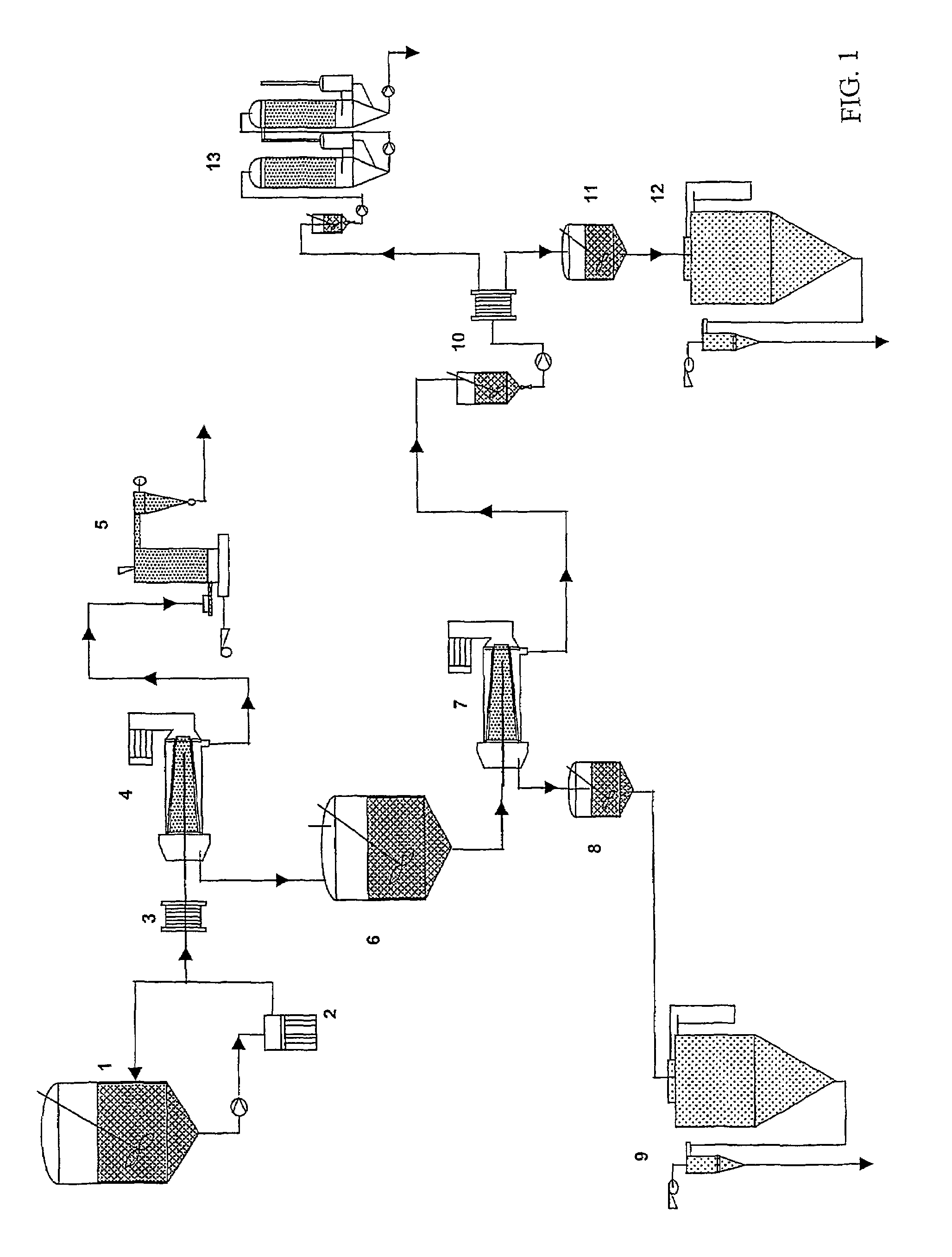

A process for the fractionation of valuable fractions from cereal brans (e.g. wheat, barley and oat brans, and rice polish) is described. In particular, this invention describes a two step process, in which the said bran is first subjected to a combination of enzymatic treatment and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich fraction, residual endosperm fraction and soluble sugars. A second step consists of fractionating cereal brans substantially free of soluble compounds, hence insoluble phase from the above-mentioned first step, by enzymatic treatment with xylanases and / or beta-glucanase and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main fractions, i.e. insoluble phase (remaining cell wall components), protein-rich fraction, soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall components and aleurone cells from previously cleaned bran.

Owner:LANTMANNEN OATS AB

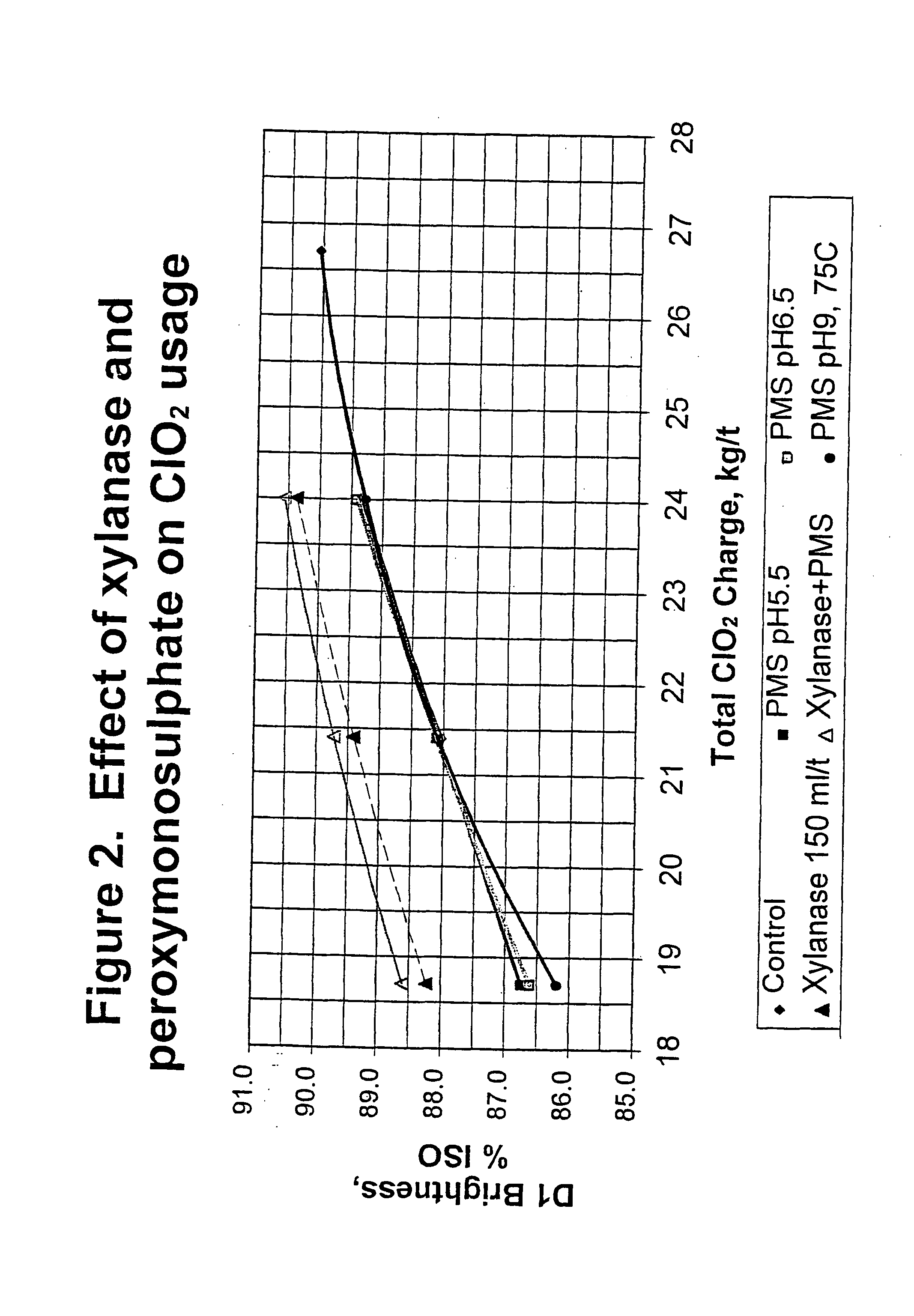

Bleaching stage using xylanase with hydrogen peroxide, peracids, or a combination thereof

InactiveUS20040112555A1Less-costly bleaching operationReduce usagePulp bleachingPulping with inorganic basesChlorine dioxideXylanase Y

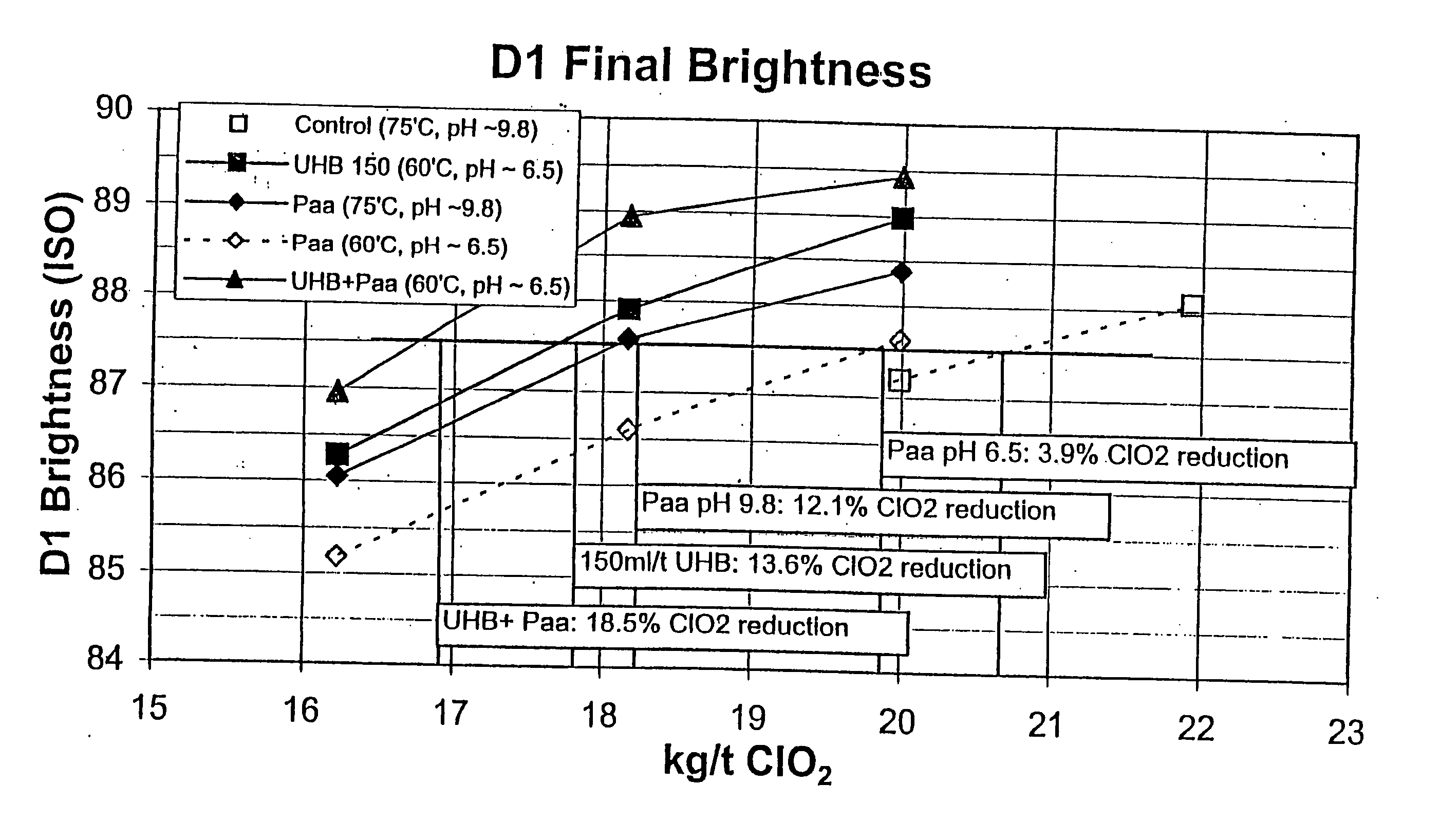

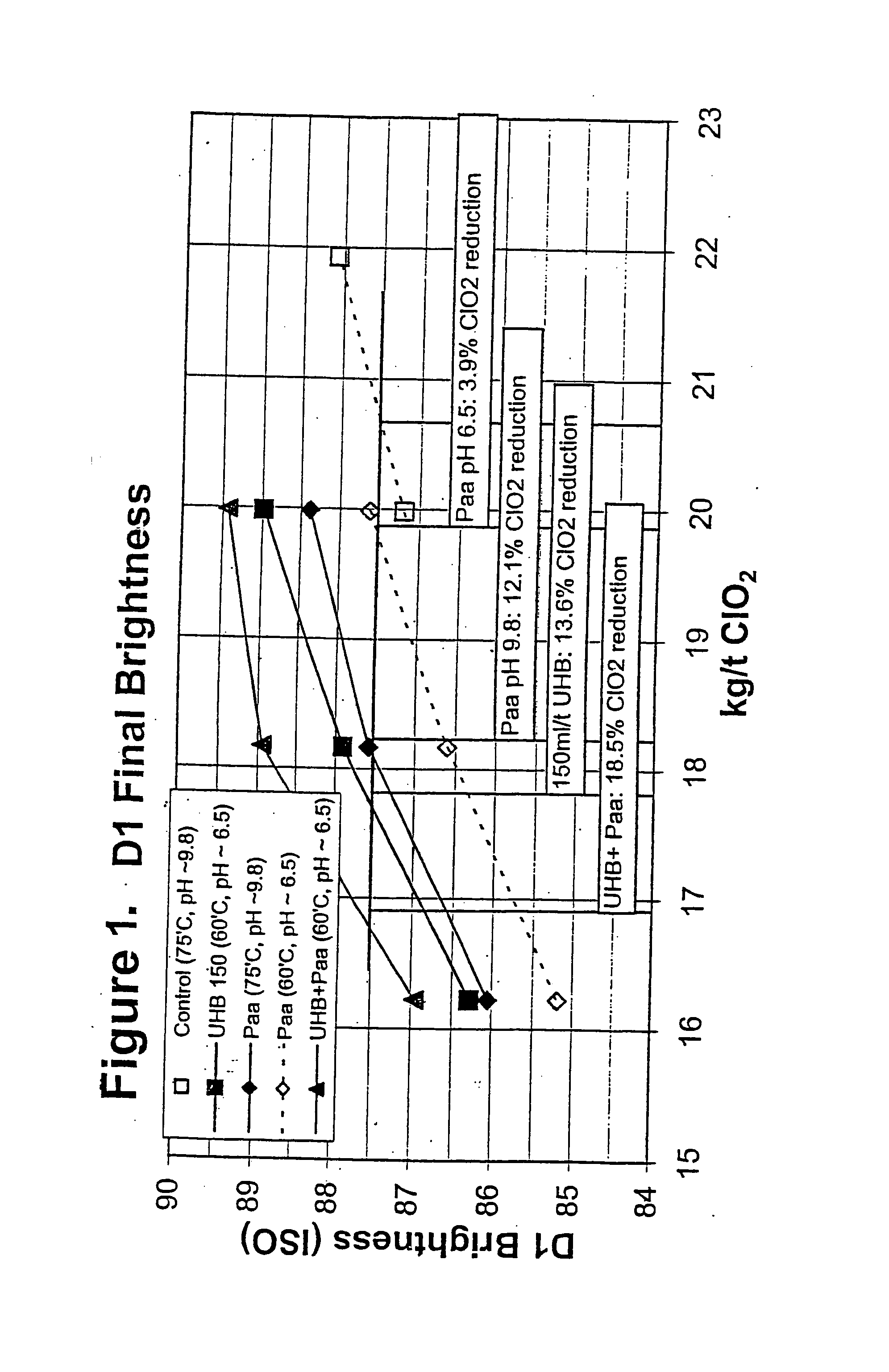

The present invention discloses methods of bleaching chemical pulp that combine xylanase enzymes with hydrogen peroxide, peracids, or a mixture. The method comprises the steps of carrying out a chemical pulping operation, optionally followed by delignifying the pulp with oxygen, then combining xylanase enzymes with hydrogen peroxide, peracids, or a mixture to bleach the pulp. The method allows the mill to use both xylanase and peracids in a single bleaching tower to decrease the usage of chlorine dioxide and other bleaching chemicals. The pulp bleaching method of the present invention may be performed in a pulp mill as part of a complex pulp bleaching process.

Owner:IOGEN BIO PRODUCKTS CORP

Xylanases, nucleic acids encoding them and methods for making and using them

InactiveUS20060003433A1Low viscosityIncrease profitBacteriaAntibody mimetics/scaffoldsXylanase YIncrease ph

The invention relates to xylanases and to polynucleotides encoding the xylanases. In addition, methods of designing new xylanases and methods of use thereof are also provided. The xylanases have increased activity and stability at increased pH and temperature.

Owner:BP CORP NORTH AMERICA INC

Enzymatic straw material pulping process

InactiveCN1421570AWell mixedChemical/chemomechanical pulpNon-woody plant/crop pulpLignin peroxidaseXylanase Y

The enzymatic straw material pulping process includes three stages of mechanical pre-treatment, enzyme treatment and chemical pulping or chemical-mechanical pulping. After being pretreated mechanically in a pulp grinder, the straw material is treated with hemicellulase liquid or mixed enzyme liquid comprising hemicellulase and lignin peroxidase at pH 3.5-6.5 and 40-60 deg.c for 1-10 hr. In chemical pulping, the material is presoaked with waste pulp-making liquor before extruding out wastes liquor and digested; and in chemical-mechanical pulping, the material is first treated with EDTA, NaOH and H2O2 at 40-80 deg.c for 30-120 min and then ground to form the pulp. The present invention is used in papermaking enterprises with straw as material and has the advantages of low pollution load, high, paper pulp quality, easy-to-process waste liquor, etc.

Owner:SHANDONG UNIV

Composite plant enzyme containing probiotics and application of composite plant enzyme

ActiveCN103876155APromote body metabolismWide range of conditionsFood ingredient functionsFood preparationBiotechnologyLactase

The invention discloses a composite plant enzyme containing probiotics and an application of the composite plant enzyme. The composite plant enzyme comprises amylase, lipase, protease, cellulase, beta-dextranase, xylanase and lactase. The composite plant enzyme is obtained by discontinuously feeding materials and fermenting for a plurality of periods, selecting a plurality of types of fruits and vegetables, and edible and medical plants as fermentation substrates and taking a plurality of types of probiotics / yeasts as fermentation inoculation substances through a plurality of grades of deep fermentation. The composite plant enzyme contains seven enzymes needed by a human body at the same time so that the plant enzyme has the synergistic effects of promoting in-vivo metabolism and decomposing toxic substances; the plant enzyme contains a high-activity compound enzyme and has a wide acting condition, good adaptability, and good stability, acid-base resistance and high-temperature resistance; the plant enzyme can effectively and rapidly improve the biochemical reaction speed and can be used as a raw material to be applied to foods and chemicals for daily use.

Owner:田雷

Process for the fractionation of cereal brans

InactiveUS7709033B2Improve efficiencyEasy to separateTea extractionProtein composition from vegetable seedsUltrafiltrationFractionation

A process for the fractionation of valuable fractions from cereal brans (e.g. wheat, barley and oat brans, and rice polish) is described. In particular, this invention describes a two step process, in which the said bran is first subjected to a combination of enzymatic treatment and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main bran factions, i.e. insoluble phase (pericarp and aleurone layer), germ-rich fraction, residual endosperm fraction and soluble sugars. A second step consists of fractionating cereal brans substantially free of soluble compounds, hence insoluble phase from the above-mentioned first step, by enzymatic treatment with xylanases and / or beta-glucanase and wet milling, followed by sequential centrifugation and ultrafiltration, which aims at physically separating the main fractions, i.e. insoluble phase (remaining cell wall components), protein-rich fraction, soluble hemicellulose and oligosaccharide, and therefore maximizes the extraction rate of valuable cell wall components and aleurone cells from previously cleaned bran.

Owner:LANTMANNEN OATS AB

Method for producing ethanol by fermenting straws

ActiveCN101705255AOvercome stabilityOvercoming the deficiency of high residual xyloseBiofuelsMicroorganism based processesIsomerizationXylanase Y

The invention provides a method for producing ethanol by synchronizing saccharification, isomerization and fermentation of lignocellulose. In the method, cellulase, xylanase and xylose isomerase are used to enzymolyze the lignocellulose, and enzymolysis products are fermented to obtain the ethanol. The method adopts the synchronous saccharification, isomerization and fermentation of the lignocelluloses to produce the ethanol, and has the advantages of reducing the negative feedback inhibition of the enzymolysis products on the cellulase and the xylanase, increasing enzymolysis rate, shortening a fermentation period, reducing production cost and the like.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Feed additive composition

InactiveUS20150216203A1Improve performanceImprove feed conversionMilk preparationBiocideAlglucerasePentagalacturonic acid

A feed additive composition comprising a direct fed microbial (DFM), in combination with a xylanase (e.g. endo-1,4-β-d-xylanase) and a β-glucanase (and optionally a further fibre degrading enzyme), wherein the DFM is selected from the group consisting of an enzyme producing strain; a C5 sugar-fermenting strain; a short-chain fatty acid-producing strain; a fibrolytic, endogenous microflora-promoting strain; or combinations thereof. The DFM may be selected from the group consisting of: Bacillus subtilis AGTP BS3BP5, Bacillus subtilis AGTP BS442, B. subtilis AGTP BS521, B. subtilis AGTP BS918, Bacillus subtilis AGTP BS1013, B. subtilis AGTP BS1069, B. subtilis AGTP 944, B. pumilus AGTP BS 1068 or B. pumilus KX11-1, Enterococcus faecium ID7, Propionibacterium acidipropionici P169, Lactobacillus rhamnosus CNCM-1-3698, Lactobacillus farciminis CNCM-1-3699, a strain having all the characteristics thereof, any derivative or variant thereof, and combinations thereof and the further fibre degrading enzyme may be selected from the group consisting of a cellobiohydrolase (E.C. 3.2.1.176 and E.C. 3.2.1.91), a β-glucosidase (E.C. 3.2.1.21), a β-xylosidase (E.C. 3.2.1.37), a feruloyl esterase (E.C. 3.1.1.73), an α-arabinofuranosidase (E.C. 3.2.1.55), a pectinase (e.g. an endopolygalacturonase (E.C. 3.2.1.15), an exopolygalacturonase (E.C. 3.2.1.67) or a pectate lyase (E.C. 4.2.2.2)), or combinations thereof.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Pre-treating method for cotton fabric by one bath two-step enzyme method

InactiveCN1944784ANo damageImprove wettabilityBiochemical fibre treatmentNatural fibresChemical treatmentAlpha-amylase

The present invention relates to re-compounded enzyme preparation and its application in cotton fabric treatment, and is especially one bath and two step enzyme process for pre-treating cotton fabric. Alkaline pectase, cellulase, alpha-amylase, PVA degrading enzyme, proteinase, lipase, xylanase and sugar oxidase are first re-compounded, and the re-compounded enzyme preparation is then used in the one bath and two step enzyme process for pre-treating cotton fabric. The process includes the first desizing and boiling off step in the treating bath at 55 deg.c and pH 8.0 for 60-90 min, with the sugar oxidase reacting with the desizing product to produce hydrogen peroxide; and the second fabric bleaching step with the enzyme process generated hydrogen peroxide at 95 deg.c and pH 11.0 for 60-120min. The present invention has low power consumption, short technological process and environment friendship, and may be used to replace chemical process.

Owner:JIANGNAN UNIV

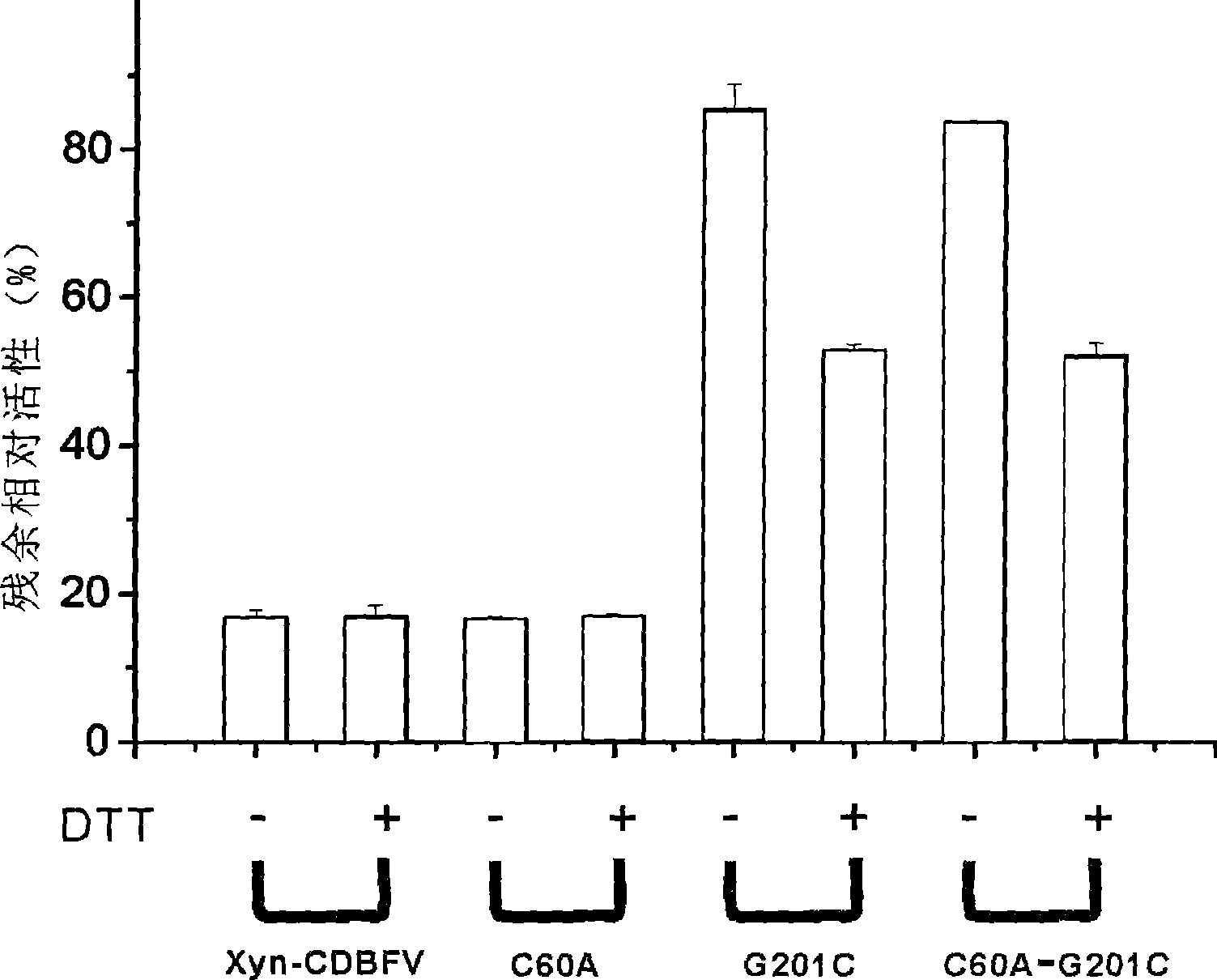

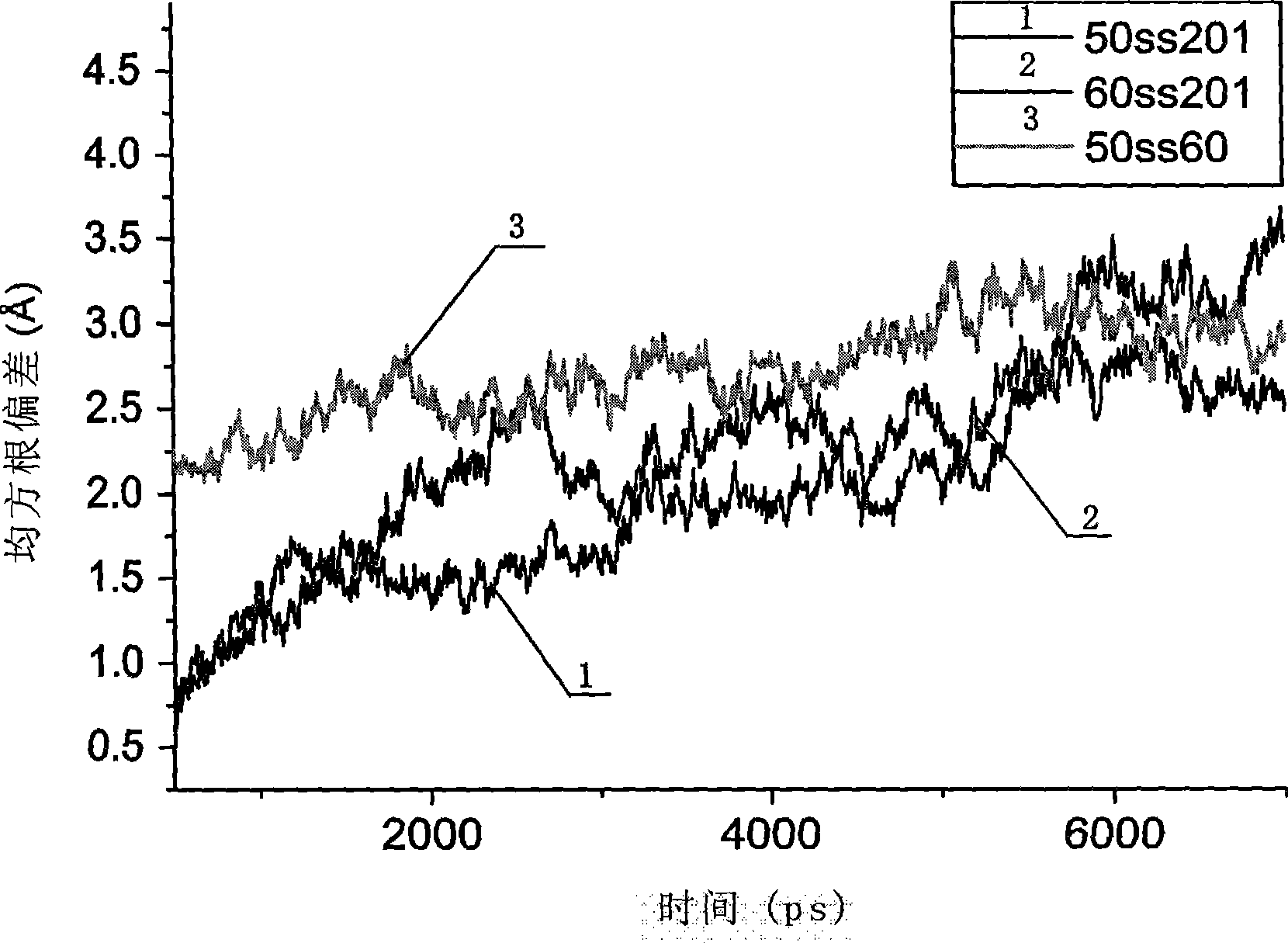

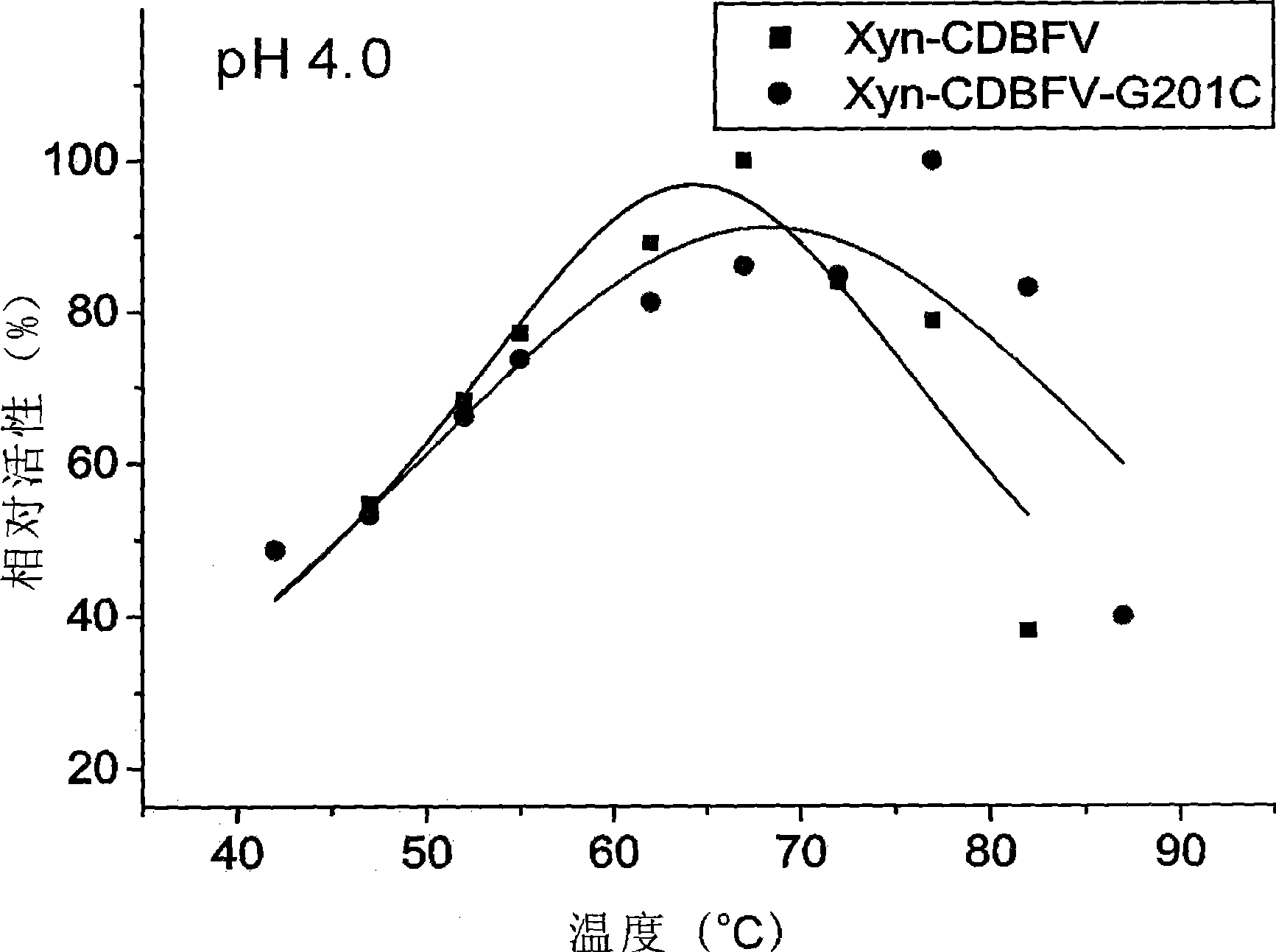

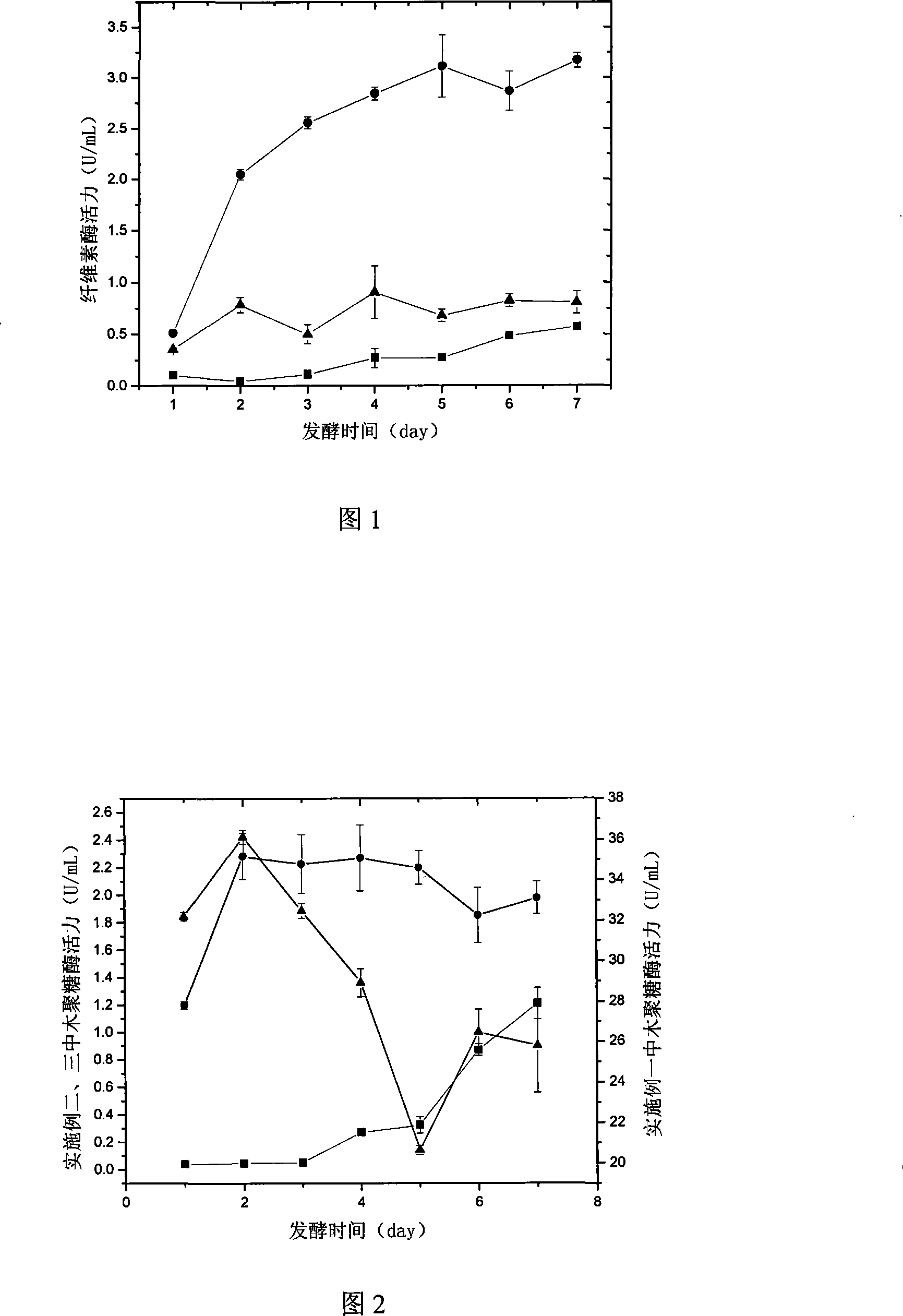

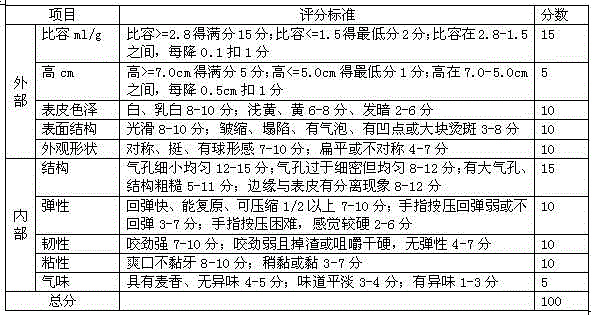

High temperature and strong alkali resistant xylanase improved gene, genetic engineering bacterial strain thereof and preparation method thereof

ActiveCN101392266AImprove thermal stabilityEasy extractionFungiMicroorganism based processesPichia pastorisXylanase

The invention provides a modified coding gene of xylanase that has high activity in the condition of high temperature and strong alkali, a recombinant plasmid thereof, a yeast recombination genetic engineering strain containing the gene and a preparation method of the gene. Compared with the original xylanase, the modified xylanase is mutated into cysteine from glycin of the 201 site of amino acid sequence of the original xylanase; and the modified xylanase has higher heat stability, after being processed for 10 minutes at the temperature of 75 DEG C, the residual activity of the modified xylanase reaches 80 percent, while that of the original xylanase is only 15 percent. The activity of the modified xylanase is 1.5 to 2 times of that of the original xylanase at the environment with high temperature and strong alkali and can decompose xylan for a long time at high temperature. The invention also provides the Pichia pastoris yeast recombination genetic engineering strain containing the modified gene. The modified xylanase can be widely applied to industries of paper making, feedstuff and food.

Owner:FUDAN UNIV +1

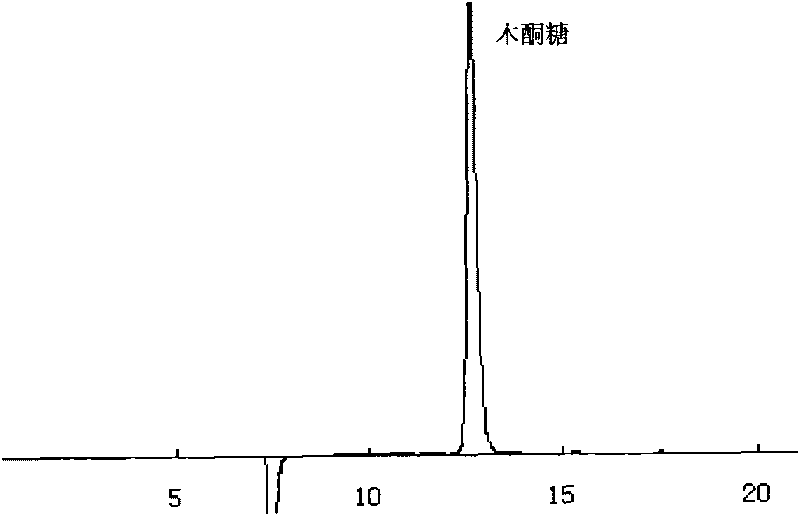

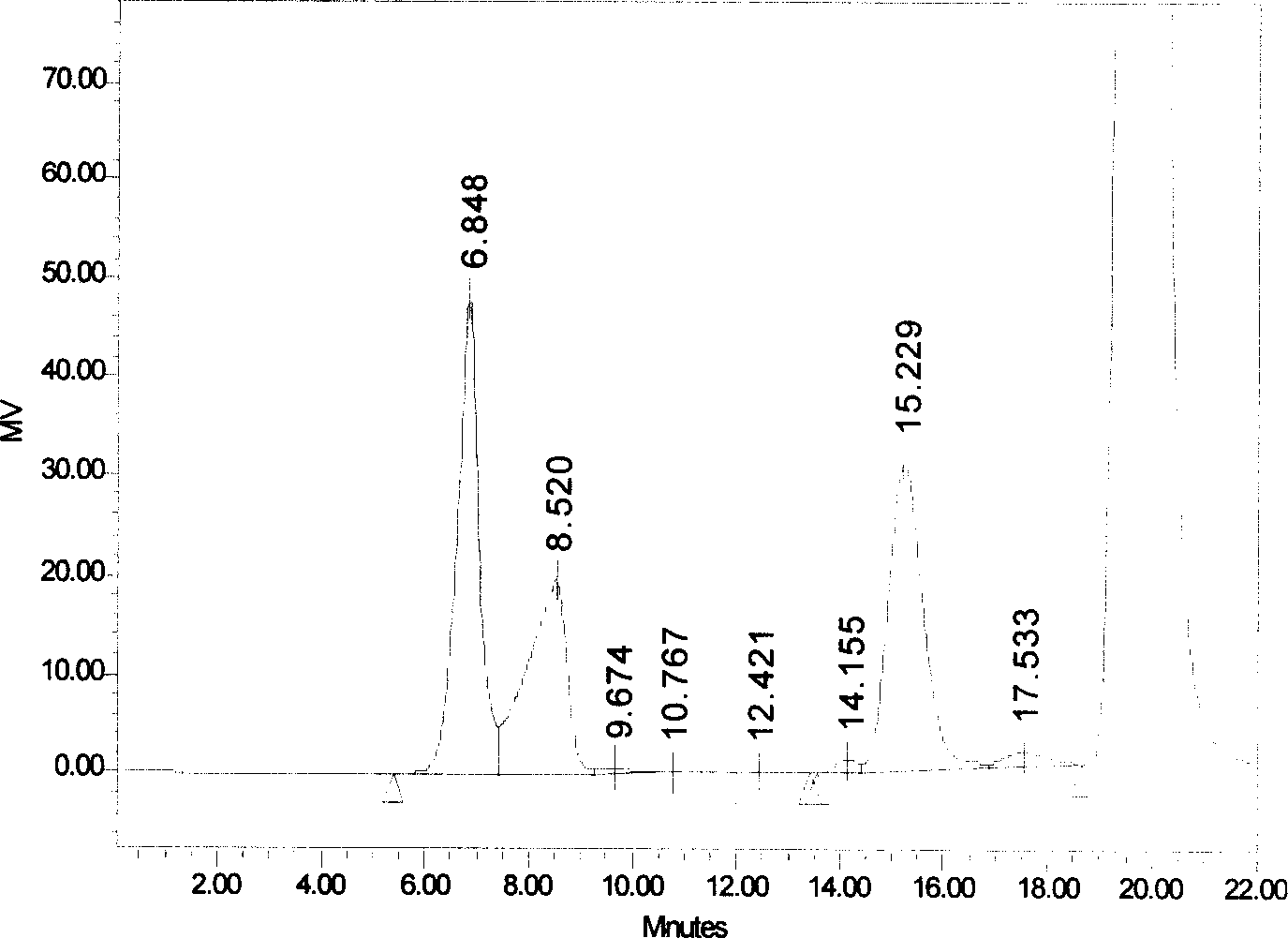

Production method for xylose by enzyme process

The technical scheme for xylose preparation with enzyme comprises: using CGMCC1476 as a Aspergillus niger strain to ferment and prepare excision xylanase that has high activity and needs mild reaction condition; enzymolyzing specially corn core and zylan in straw materail; refining to prepare single-xylose with purity more than 90%. This invention has no pollution to environment and conversion more than 80%.

Owner:JINAN GUOLI BIOLOGICAL SCI & TECH

Method for preparing bamboo primary fibre using composite biological enzyme

InactiveCN101372763AHas softnessKeep active ingredientsVegetable materialPectinaseManufacturing technology

A method for preparing a bamboo fiber by a compound bio-enzyme belongs to the technical field of manufacturing the natural cellulose fiber used for weaving. Bamboo linen is used as raw material; the bamboo linen normally processed is treated in the water liquid of the compound bio-enzyme for 1 to 5 hours, then is treated in a pectase liquid for 1 to 5 hours, then the bamboo fiber is obtained after normal processing; the water liquid of the compound bio-enzyme is any single or mixture of laccase, xylanase, the mixture of the laccase and the xylanase, the mixture of the laccase and cellulose, the mixture of the xylanase and the cellulose as well as the mixture of the laccase, the xylanase and the cellulose; the concentration of the laccase and the xylanase are respectively 20 to 50g / L; the concentration of the cellulose is 2 to 6g / L; the concentration of the pectase in the pectase liquid is 10 to 25g / L. The technique of the method is reasonably designed; the fineness, the intensity and the softness of the prepared bamboo fiber can all meet the weaving requirements.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

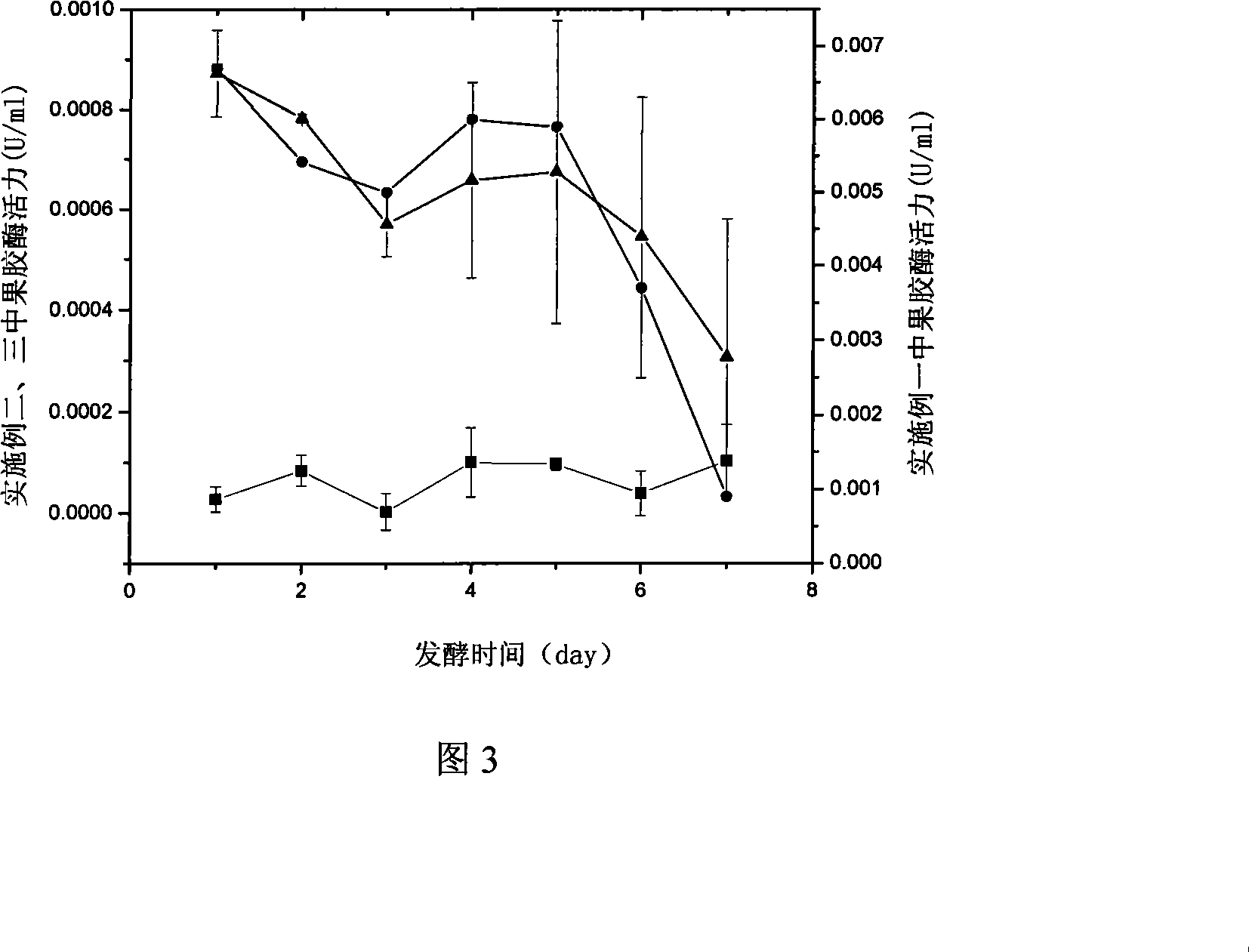

Fermentation inducement preparation method for ramee degumming composite enzyme

The invention relates to a process for preparation of fermentation and induction of ramie degumming compound enzyme, which includes the steps of (1) induction preparation of ramie degumming compound enzyme system of trichoderma reesei, (2) determination of the activity of cellulose, xylanase and pectinase and (3) the processing of ramie by crude enzyme liquid which is obtained by fermentation. The invention can obtain the higher enzyme activity, is better qualified to the compound enzyme system of the ramie degumming, and is low in costs, simple and convenient in operation and easy in industrial production.

Owner:DONGHUA UNIV

Preparation with activities of laccase xylanase, peroxidase and its nucleolide series

A preparation with the activities of laccase, xylanase and peroxidase for paper-making, environment production, food and feed industries is prepared through cloning new genes of laccase, xylanase and peroxidase, configuring their expression carrier, introducing it to yeast or mycelial fungus for expression, checking the activity of recombinant enzymes, and mixing said recombinent enzymes together.

Owner:李宝健 +1

Compound feruloyl esterase additive for feed and using method thereof

InactiveCN101228921AImprove biological transformation efficiencyFacilitated releaseAnimal feeding stuffAccessory food factorsGlucanaseVolatile fatty acids

The invention provides a feeding complex ferulic acid esterase additive, which comprises four enzymes of ferulic acid esterase, cellulase, xylanase and glucanase; among which, the enzyme activity of endo cellulose is more than 16U / g, the enzyme activity of xylanase is more than 1024U / g, the enzyme activity of beta-glucanase is more than 2.0U / g, and the enzyme activity of ferulic acid esterase is more than 2.0U / g. The feeding complex ferulic acid esterase additive of the invention has the advantages of remarkably improving the release amount of reducing sugar, the cell wall degrading rate and the vitro rumen fermentation volatile fatty acids yield in the hydrolysis process of forage plants, crop straws and bran feed, enhancing the feed biological transfer rate in an all-round way. The invention has a high practical application value in the feed industry and the ruminant breeding industry.

Owner:CHINA AGRI UNIV

Preparation method of superfine bran powder

The invention discloses a preparation method of superfine bran powder. The method comprises the following steps: (1) steam explosion, namely, feeding bran into a steam explosion tank, maintaining for 10 to 12 minutes at the temperature of 160 to 180 DEG C and under the pressure of 0.6 to 1.0MPa, and then performing instantaneous explosion; (2) enzymolysis, namely, collecting bran subjected to steam explosion in step (1), adding water, and then adding a mixture of cellulose, hemicellulase, xylanase and pectinase, wherein 0.5 to 1U / g of each of cellulose, hemicellulase, xylanase and pectinase is added to the mixture of bran and water; (3) crushing, namely, performing superfine crushing for the mixture obtained in step (2); and (4) drying, namely, drying the mixture obtained in step (3) to obtain the superfine bran powder. With the adoption of the method, cellulose, hemicelluloses, xylan, pectin and other high molecular substances with high content in the bran can be fully degraded, so that the problems of poor taste and difficult digesting of the superfine bran can be solved, and moreover, the energy consumption in the superfine bran crushing process can be effectively reduced.

Owner:北京中国科学院老专家技术中心

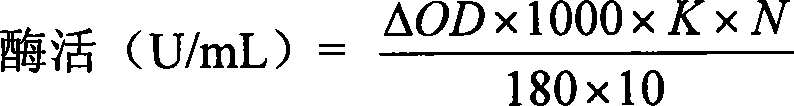

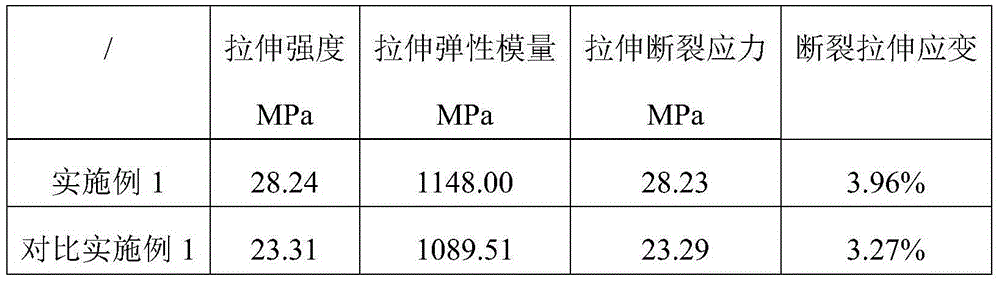

Enzyme modified paper pulp fiber, wood-plastic composite material and preparation method thereof

InactiveCN104963206AReduce productionHigh mechanical strengthBiochemical fibre treatmentPectinasePolyolefin

The invention discloses an enzyme modified paper pulp fiber, a wood-plastic composite material and a preparation method thereof. The method of the enzyme modified paper pulp fiber comprises the following steps: modifying the paper pulp fiber by adopting a compound enzyme, wherein the compound enzyme is a mixture of hemicellulose, xylanase and pectinase, wherein the mass ratio of the hemicellulose to the xylanase to the pectinase is 2:2:1 to 2:1:0, and the weight of the compound enzyme accounts for 10%-30% of the weight of the paper pulp fiber. The invention discloses the wood-plastic composite material which comprises the following ingredients: a polyolefin compound, enzyme modified paper pulp fiber, a compatilizer and a releasing agent. When being used for preparing the wood-plastic composite material, the enzyme modified paper pulp fiber has good mechanical performance, the preparation method of the enzyme modified paper pulp fiber and the wood-plastic composite material is easy to operate, environmentally friendly and suitable for industrial production.

Owner:华东理工常熟研究院有限公司 +2

Making method of soluble cereal dietary fibers

InactiveCN104719753AChange chemical structureChange the relative contentFood preparationEnzymatic hydrolysisXylanase Y

The invention discloses a making method of soluble cereal dietary fibers. The method comprises the following steps: mixing various cereal seed coats, crushing, adding water, heating for boiling to soften the various cereal seed coats, adding liquefied amylase, stirring, removing starch contained in the seed coats, adding protease, carrying out heat insulation stirring, removing proteins contained in the seed coats, adding xylanase and cellulase generated by moulds, carrying out enzymatic hydrolysis, and hydrolyzing cellulose and xylan in the cereal seed coats to form soluble cellulose and xylan in order to obtain the soluble dietary fibers. The proportion of soluble components in the dietary fibers is increased through a bioengineering technology in order to improve the physiologic functions of the dietary fibers to human body.

Owner:QINGDAO ANBEIKANG BIOLOGICAL MEDICINE TECH CO LTD

Enzyme scouring agent for linen fibers

ActiveCN103469600AImprove the effect of impurity removalReduce usageBiochemical fibre treatmentVegetal fibresFiberPectinase

The invention discloses an enzyme scouring agent for linen fibers. The enzyme scouring agent contains 2%-3% by volume of pectinase, 2%-4% by volume of glucanase, 2%-3% by volume of cellulose, as well as a 4-5g / L surfactant scouring agent and a 2-3g / L chelating agent, wherein a bath ratio is 1:30. The linen fibers are scoured by compound enzyme, so that the effect of removing impurities of pectin and lignin is very good; besides, the surfactant scouring agent and the chelating agent are added, thereby further reinforcing the impurity removing effect of the compound enzyme and effectively reducing the use amount of the compound enzyme; in addition, the scoured linen fibers achieve a degumming degree of 20%-23% and have a good handfeel, excellent whiteness and a fine capillary effect.

Owner:山东信开源科技创新发展有限责任公司

Method for producing glycyrrhizic acid through enzymolysis

InactiveCN102219824AEnhance anti-inflammatoryStrong anti virusSugar derivativesSteroidsPectinaseGlucanase

The invention provides a method for producing glycyrrhizic acid through enzymolysis. The method comprises the steps of carrying out enzymolysis on glycyrrhiza uralensis by utilizing complex enzyme, extracting glycyrrhizic acid with 10 percent volume of alcohol, separating and purification with macroporous adsorption resin, and eluting with 10 percent volume alcohol as eluent, thus obtaining glycyrrhizic acid, wherein the complex enzyme is of a mixture of pectinase, cellulose, xylanase and beta-glucanase. The extraction method has the advantages of low cost, simplicity and convenience in operation, environment friendliness, high yield and purity, and suitability for industrial production.

Owner:BIOCHEM ENG COLLEGE OF BEIJING UNION UNIV

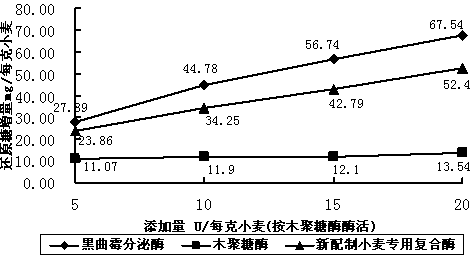

Special complex enzyme preparation for wheat for livestock and poultry and application thereof

InactiveCN102987098AIncrease stickinessGood water solubilityAnimal feeding stuffPectinaseNeutral protease

The invention provides a special complex enzyme preparation for wheat for livestock and poultry and application thereof. The special complex enzyme preparation comprises xylanase, beta-glucanase, beta-mannase, cellulase, acid protease, neutral protease, pectinase, alpha-galactosidase, glucoamylase and aspergillus niger fermentation complex enzyme; and an antioxidant, a mildew-proof agent, an insect repellant and a carrier are added. According to the invention, the special complex enzyme for wheat is prepared from xylanase for effectively reducing viscosity and mono-enzymes such as beta-glucanase, beta-mannase, cellulase, acid protease and the like; and the preparation is simpler than the operation of preparing a complex enzyme by fermenting aspergillus niger only, has low labor capacity and cost, and realizes a good enzymolysis and viscosity reduction effect. Through the invention, the anti-nutrition effect caused by adding high-proportion wheat in daily ration can be effectively overcome, the chyme viscosity is reduced, the production performance of animals is enhanced, the utilization of wheat and wheat enzyme is optimized for a feed enterprise, and the feed cost is effectively lowered.

Owner:QINGDAO GENYUAN BIOLOGICAL TECH GRP

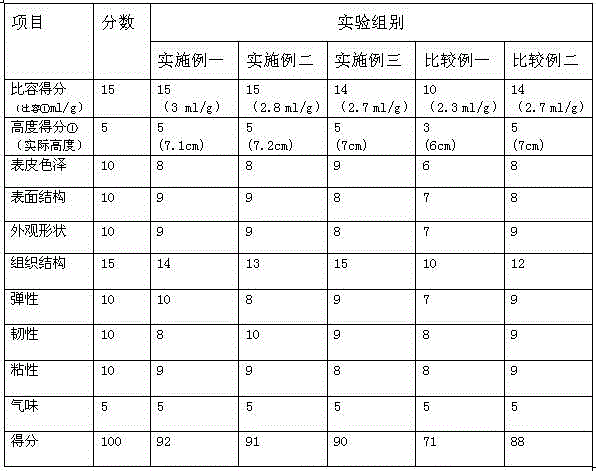

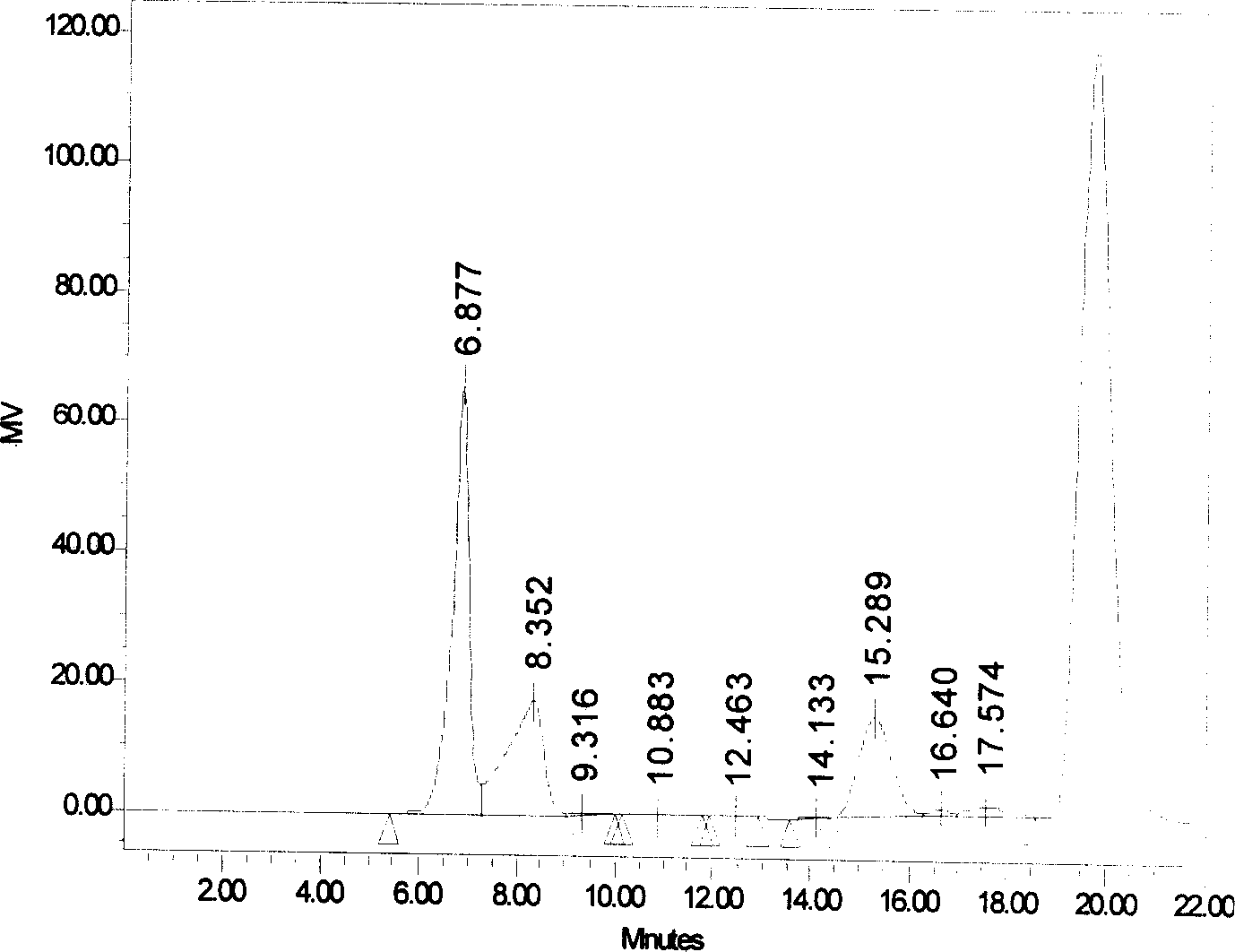

Steamed bun modifier and application method thereof in making southern steamed buns

ActiveCN104304847ASolving for Structural UniformitySolve fineFood ingredientsFood preparationBiotechnologyAmylase

The invention relates to a steamed bun modifier, which comprises following raw materials by mass percent: 90-96% of corn starch, 1-5% of monocalcium phosphate, 1-5% of calcium sulfate, 1-5% of vitamin C, 0.1-0.5% of fungus amylase, 0.1-0.5% of lipase, 0.1-0.5% of xylanase, and 0.1-0.5% of notatin. The steamed bun modifier has the advantages of containing no inhibited calcium peroxide, thoroughly solving the problem in production that the steamed bun made by the modifier without calcium peroxide has no uniform tissue, is not compact, is not soft, has poor elasticity, is not tough and soft in taste, and has short service life, improving the product quality, and also improving the production efficiency and quality of the product.

Owner:GUANGZHOU BAOTAO FOOD CO LTD

Activated Cranberry Powder

InactiveUS20110250314A1Gain color and flavor and nutrient enhancementAdd flavorAnimal feeding stuffFruits/vegetable preservation using acidsPectin esteraseAdditive ingredient

An active fruit powder is produced from fruits which include components resistant to digestion. The process includes macerating the fruit to yield a pomace slurry adding water to the process if necessary and adding enzymes to the slurry in an amount sufficient to provide the molecular breakdown of the cranberry. Examples of suitable enzymes include pectin esterase (pectinase), depolymerase, cellulase, hemicellulase, manannase, galactosidase, xylanase and glucanase. The slurry is preferably heated and agitated.

Owner:LOW TEMPERATURE DRYER

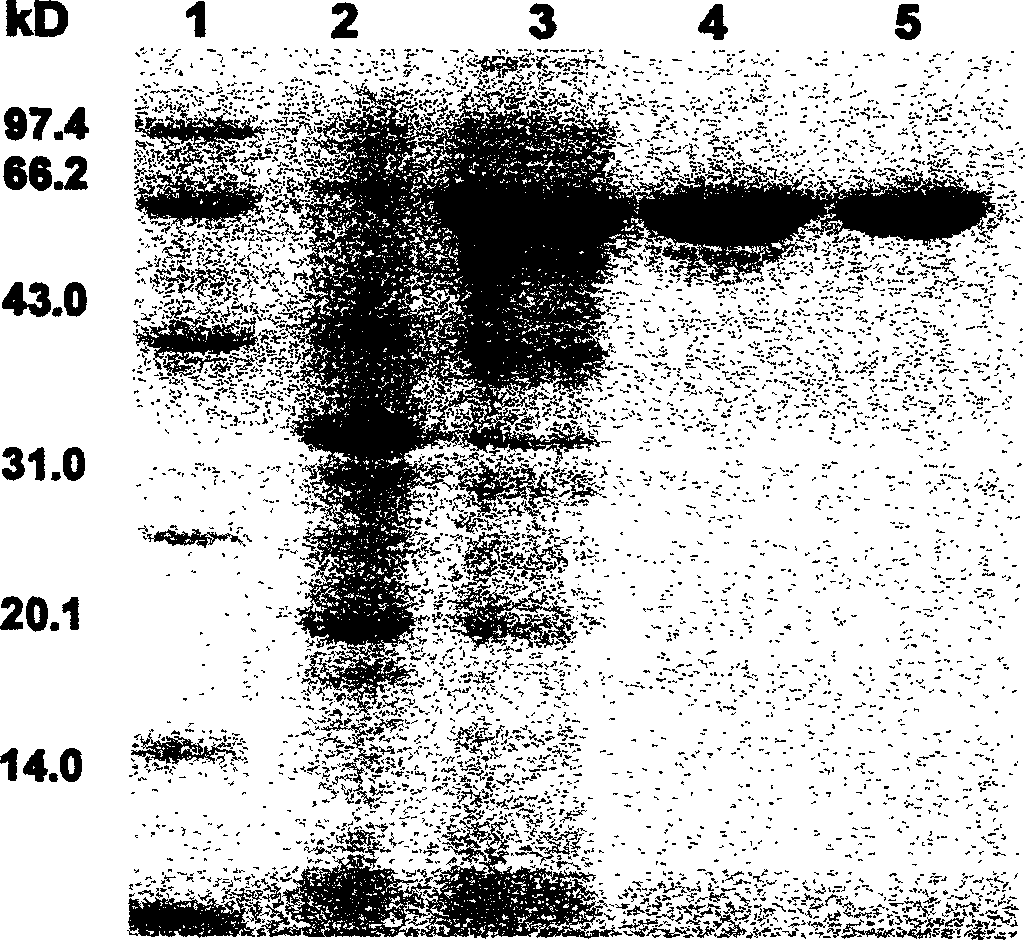

Preparation of oligomeric xylose and alpha-glucuronylic enzyme used therefor

A method for preparing oligoxylose and alpha-glucose aldehydic acid enzyme is disclosed. It includes: saccharogenic decomposing xylan by combination of xylanase and alpha-glucose aldehydic acid enzyme, expanding and obtainingalpha-glucose aldehydic acid enzyme gene from donor bacteria by PCR, inserting carrier, constructed recombinant plasmid converting into host cell and expressing it, centrifugal obtaining supernatant fluid(enzyme liquid) by centrifugal collecting cell, breaking cell and heat treating. It achieves high zymoprotein output, activity and purification.

Owner:JIANGNAN UNIV

Xylose enzyme method preparing method

This invention involves a kind of enzymatic production method of xylose. The specific steps are pre-treat wasted crop to produce xylan or steam exploded substance; then add xylanase, bi-activity xylose / arabinosidase and alpha-glucuronidase to buffer to generate multi- enzyme mix liquid. Mixing it and adding the xylan or steam exploded substance to multi- enzyme mix liquid to perform enzymatic hydrolysis. After hydrolysis, adds ethanol to enzymatic hydrolysis liquid and further condese and crystallize to get xylose product. The release rate of xylose can reach as much as two times of using Xylanase and xylosidase so to increase the productivity. The power consuming is low. The product can keep the natural quality. At the same time the xylose produced with enzyme has no harm to microbial species, and can be used directly in biotransformation of xylitol by yeast. It is virus free and with good fermentation performance. It is benefical for the transformation from xylose to xylitol.

Owner:NANJING NORMAL UNIVERSITY

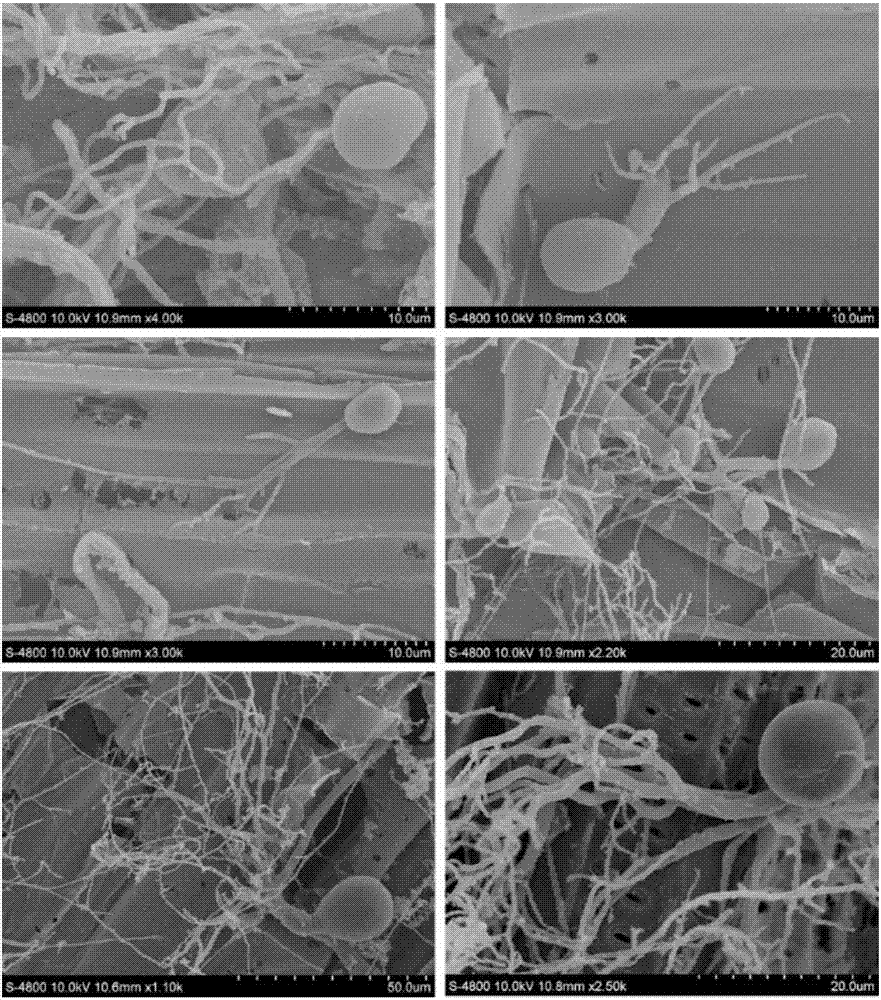

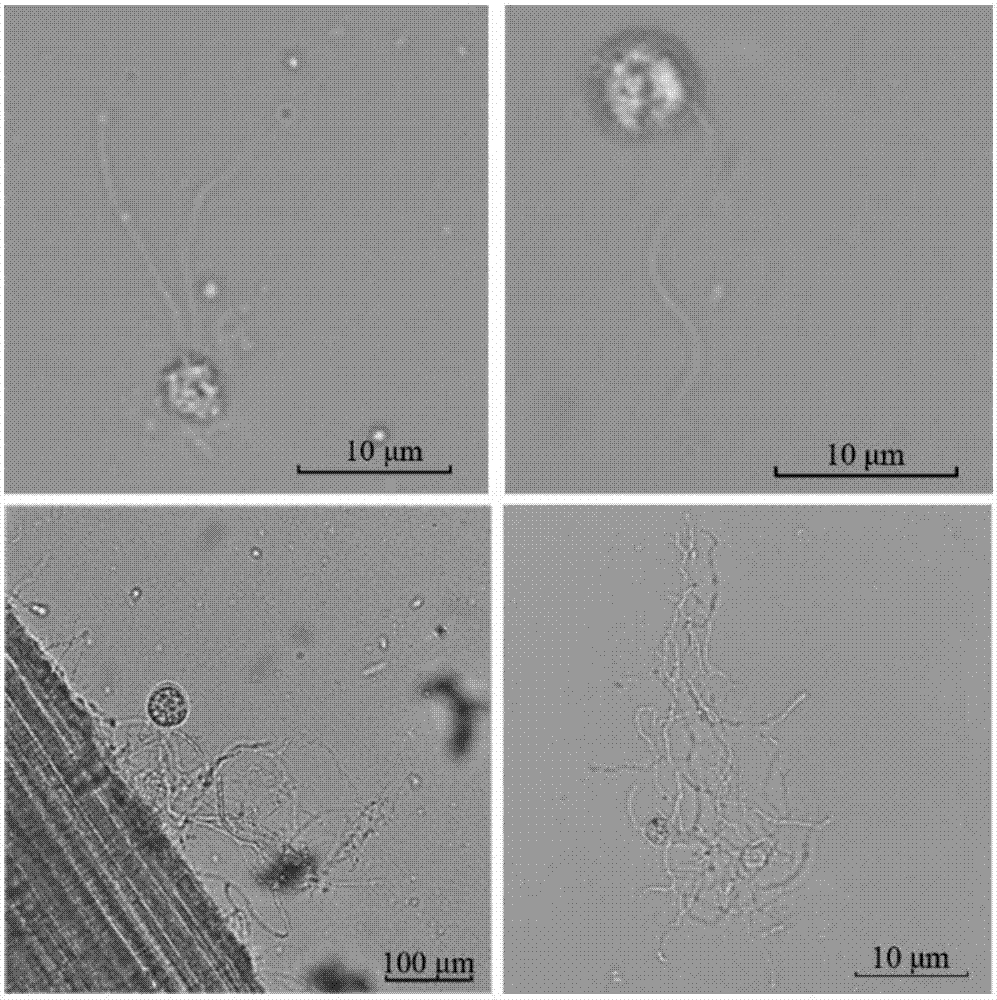

High plant cell wall degradation activity rumen fungi, and applications thereof in feed ensiling

ActiveCN107325974AImprove fermentation qualityImprove in vitro digestibilityFungiMicroorganism based processesPlant cellRumen

The invention discloses a high plant cell wall degradation activity rumen fungi, and applications thereof in feed ensiling, and belongs to the technical field of microorganism and feed processing. According to a preparation method, Hungate anaerobic roll-tube technique is adopted to obtain an anaerobic fungi with cell wall degradation enzyme activity via separating and selecting from the rumens of Xinong Saanen dairy goats, finally obtained Piromyces sp.CN6 is capable of producing xylanase and acetylesterase with relatively high activity in a wide temperature and pH range, and excellent thermal stability and acidic and alkaline stability, the preservation number is CGMCC No.14449. The bacteria strain is capable of improving fermentation quality of silage, increasing crude fiber degradation rate, and can be applied in practical production as a silage additive.

Owner:NORTHWEST A & F UNIV

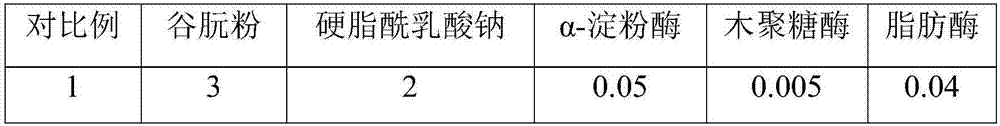

Composite modifier for whole-wheat bread, whole-wheat bread composition, whole-wheat bread and preparation method of whole-wheat bread

InactiveCN107439633AIncrease the content of dietary fiberGreat tasteDough treatmentBaking mixturesXylanase YAlpha-amylase

The invention discloses a composite modifier for whole-wheat bread, a whole-wheat bread composition, the whole-wheat bread and a preparation method of the whole-wheat bread. The composite modifier comprises 70-93wt% of vital wheat gluten, 6-28wt% of sodium stearoyl lactylate, 0.2-1wt% of alpha-amylases, 0.05-0.3wt% of xylanase and 0.3-1.5wt% of lipases based on 100wt%. The vital wheat gluten, the sodium stearoyl lactylate, the alpha-amylases, the xylanase and the lipases are mixed in a specific proportion to obtain a mixture to be used as the composite modifier, so that the mixture can cooperate with the 100wt% of the whole wheat flour for use, and the whole-wheat bread being good in mouth feel can be obtained.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Liquid complex enzyme for peeling membranes of orange segments, and compounding process and application thereof

The invention discloses a liquid complex enzyme for peeling membranes of orange segments. The liquid complex enzyme is characterized by being formed by compounding a component A, xylanase and beta-glucanase, wherein the volume of the xylanase is equal to that of the beta-glucanase; the volume ratio of the xylanase to the component A and the volume ratio of the beta-glucanase to the component A are 1:9 to 1:4; the component A is formed by mixing acidic pectinase and acidic cellulase in the volume ratio of (4-1):(1-4); and the xylanase, the beta-glucanase, the acidic pectinase and the acidic cellulose are qualified food grade liquid commodity enzymes. The invention also discloses the compounding process of the liquid complex enzyme and the application process of the liquid complex enzyme toorange can processing and production. The liquid complex enzyme for peeling the membranes of the orange segments can greatly improve production efficiency, reduce the breaking rate of the orange segments, stabilize production quality and lower production cost, has the advantages of no residue, environmental friendliness, high safety and no environmental pollution, is easy and convenient to use, efficiently and completely works on the membranes of the orange segments, decomposes thoroughly and does not damage internal pulp vesicles.

Owner:SHANGHAI KDN BIOTECH

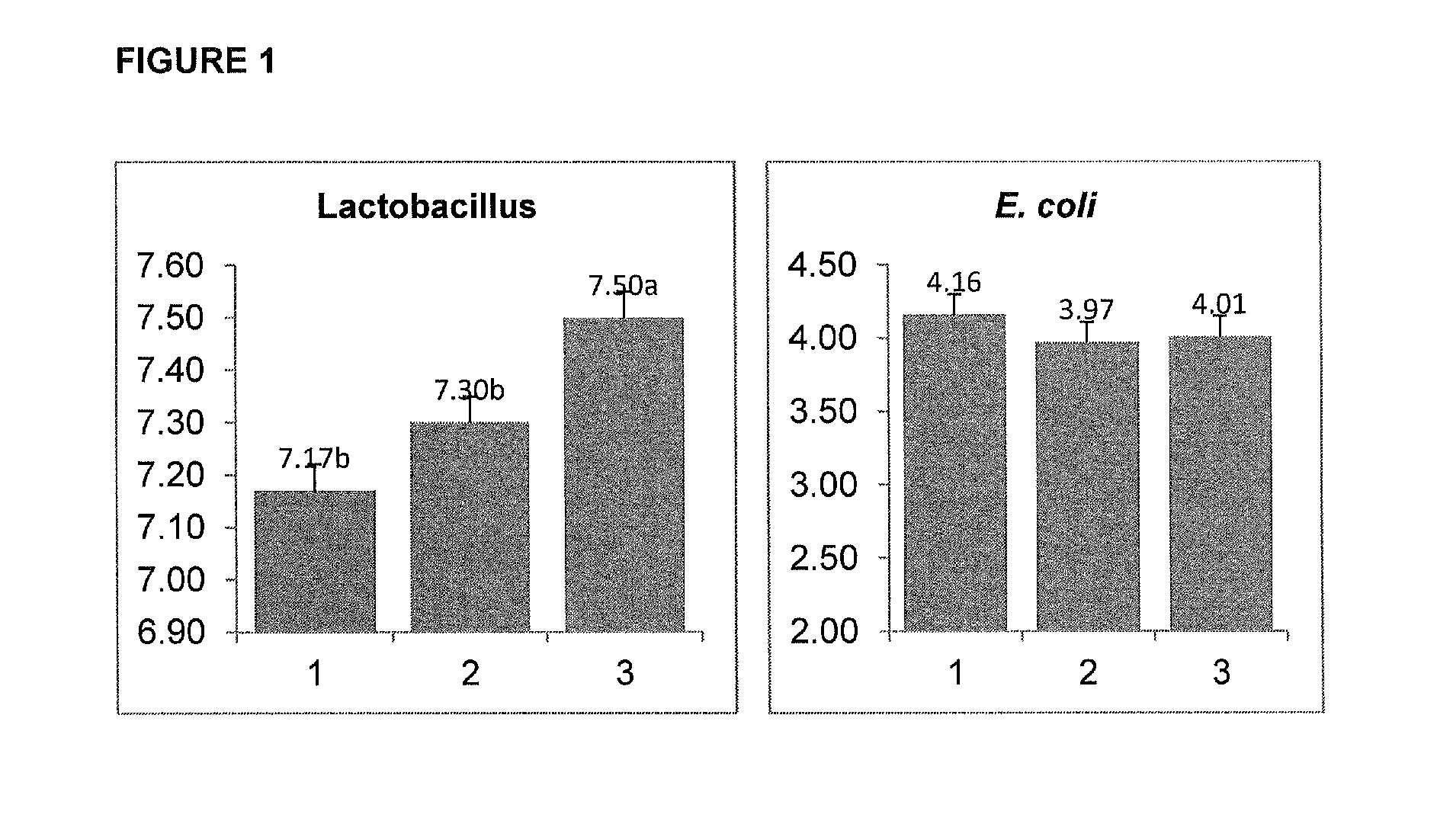

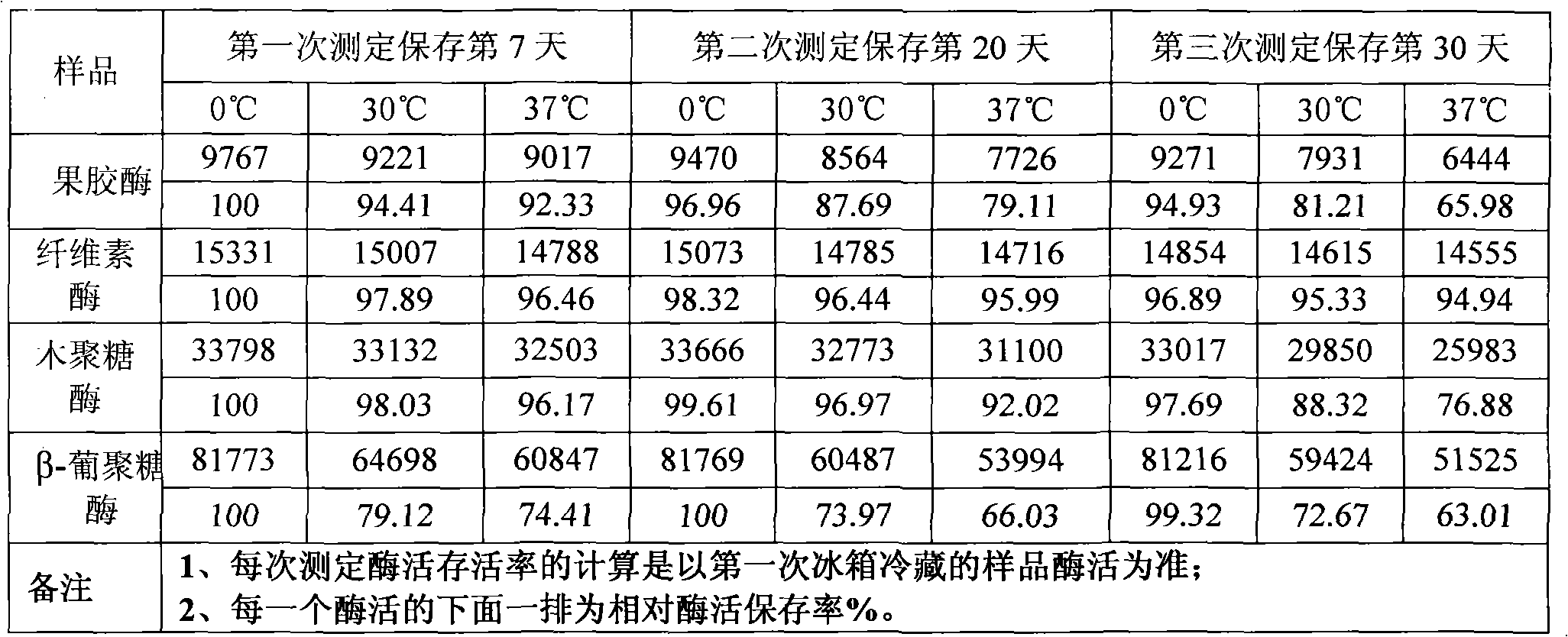

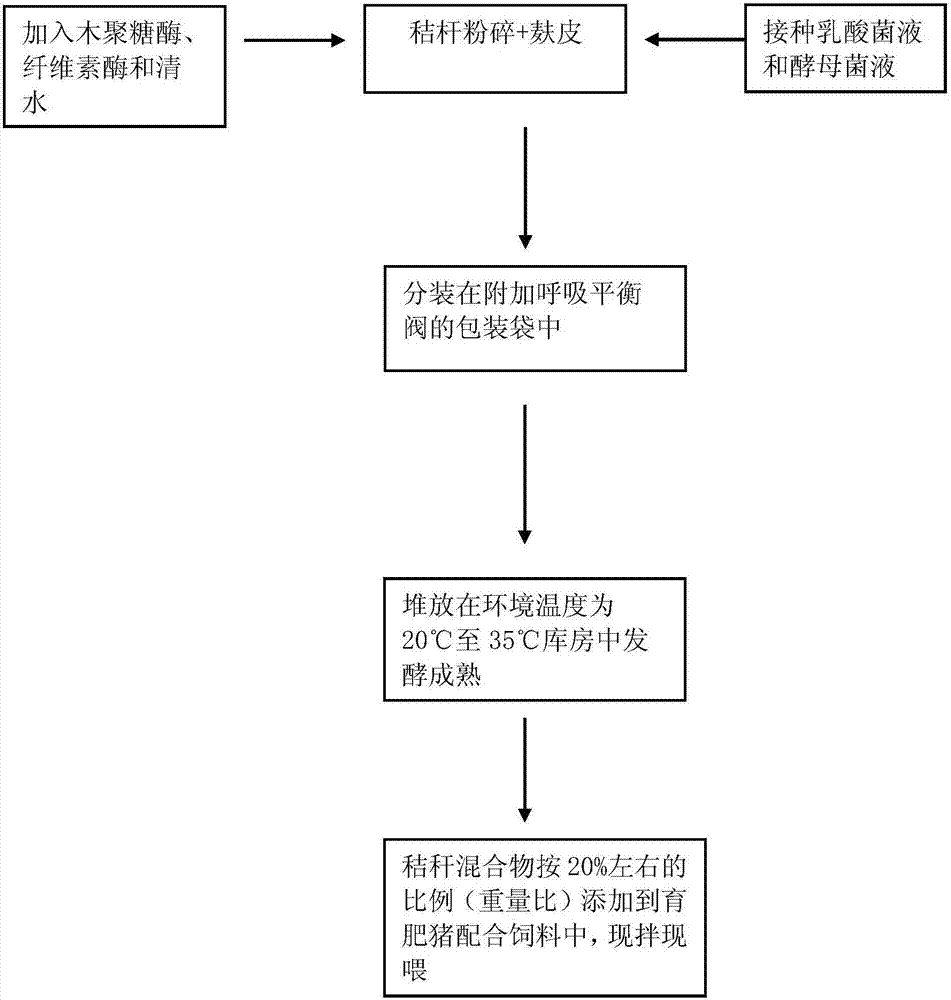

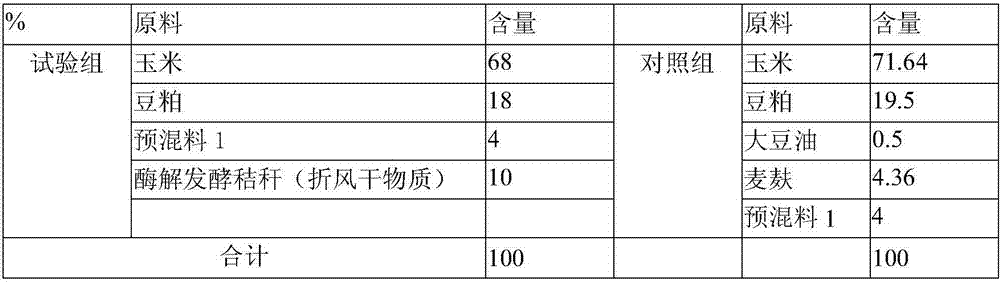

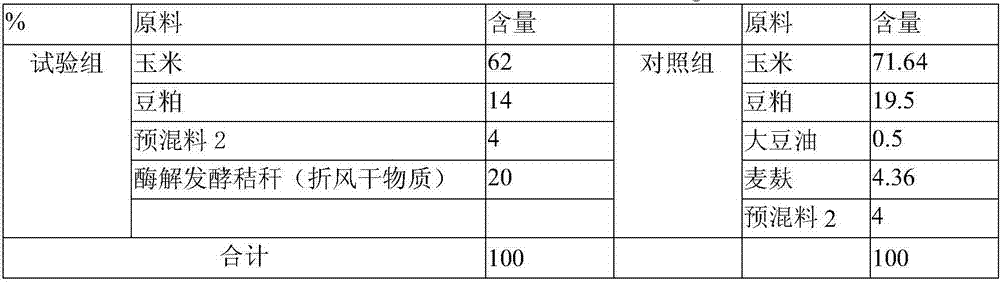

Biological feed and preparation method thereof

PendingCN107041457AReduce processing costsReduce moistureAnimal feeding stuffAccessory food factorsFeed conversion ratioCholesterol

The invention provides a preparation method of biological feed. The method comprises the following steps of crushing stalks; mixing crushed stalks with wheat bran; adding xylanase and cellulase; then, supplanting and adding water accounting for 75 to 85 percent of the weight of the stalks; then, inoculating lactobacillus liquid and yeast liquid; obtaining the biological feed after the enzymolysis and fermentation. Through the optimized enzymolysis combination, the microbial combination anaerobic fermentation is combined; the water content is reduced to a proper degree, so that the treatment cost of per ton of stalks is reduced by about 300 Yuan; the practical application values are basically realized. The prepared biological feed uses the weight ratio of 20 percent for replacing the complete formula feed; the growth speed, differences of the feed conversion ratio and the like of live pigs are not obvious, but the grain consumption and the live pig weight increase cost are obviously reduced; the contents of pork protein, amino acid and calcium can be increased; the contents of fat and cholesterol are reduced.

Owner:承德添康生物科技有限公司

Method for brewing wheat beer by using ungerminated wheat for matching with wheat malt

InactiveCN101676375AOvercome the phenomenon of blackeningLow viscosityBeer fermentationProteinase activityFiltration

The invention relates to a method for brewing wheat beer by using ungerminated wheat for matching with wheat malt, which comprises the steps of pasting, mashing, filtration of wheat juice, boiling of the wheat juice, precipitation of the wheat juice, fermentation and filtration of the beer. The pasting process adopts rice which accounts for 30-40% of total weight of dry materials and wheat which accounts for 25-35% as raw materials, and 180-200ppm of high-temperature-resistant amylase, protease pentopan, xylanase and gypsum during the pasting process. The method takes the ungerminated wheat as an auxiliary material for brewing the beer, thereby reducing the production cost. The pentopan and the protease are added during the pasting process, the temperature is rapidly increased to the temperature of inactivating oxidase for carrying out pasting and liquefaction after the transient pentosan and protein stop, thereby overcoming the phenomenon that the wheat is added in a mashing kettle, the oxidase promotes the oxidation of pigment substances because that the process is not processed at high temperature, thereby blackening the wheat juice.

Owner:王海明

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com