Fermentation inducement preparation method for ramee degumming composite enzyme

A technology of hemp degumming enzyme and compound enzyme, which is applied in the field of fermentation induction and preparation of ramie degumming compound enzyme, can solve the problems of not fully considering the effect of cellulose, and achieve convenient and easy price, strong controllability, and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Determination of chemical components of ramie

[0040] The test adopts the quantitative analysis method of ramie chemical composition in the national standard GB5889-86 of the People's Republic of China to analyze the raw ramie used in this test. The results obtained are shown in Table 1, which are quite consistent with the results reported in the literature.

[0041] Table 1 Quantitative analysis of chemical components of ramie

[0042] Chemical composition of ramie

The measurement results(%)

Literature (%)

Fat waxy

total gum

7.02

71.47

0.88

2.17

3.89

13.93

25.74

-

70-75

0.538

1.19

4.043

13.287

25-30

[0043] 2. Seed Culture of Trichoderma reesei

[0044] (1) Trichoderma reesei seed medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015...

Embodiment 2

[0073] 1. Seed Culture of Trichoderma reesei

[0074] (1) Trichoderma reesei seed medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N;

[0075] (2) Trichoderma reesei Rut C30 was used as the production strain, and cultured at pH 5.0, 30° C., 200 r / min for 48 hours.

[0076] 2. Fermentation of Trichoderma reesei to produce enzymes

[0077] (1) Trichoderma reesei enzyme production medium: 0.5% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N, adding 2% ramie powder, pH5.0;

[0078] (2) With 10% inoculum size, the culture without ramie powder was used as a control, and the enzyme was induced to be produced by culturing at 30° C. and 160 r / min for 7 days;

[0079] (3) The fermented broth clear liquid collected by filtration or centrifugation is the ramie degumming compound enzyme liquid.

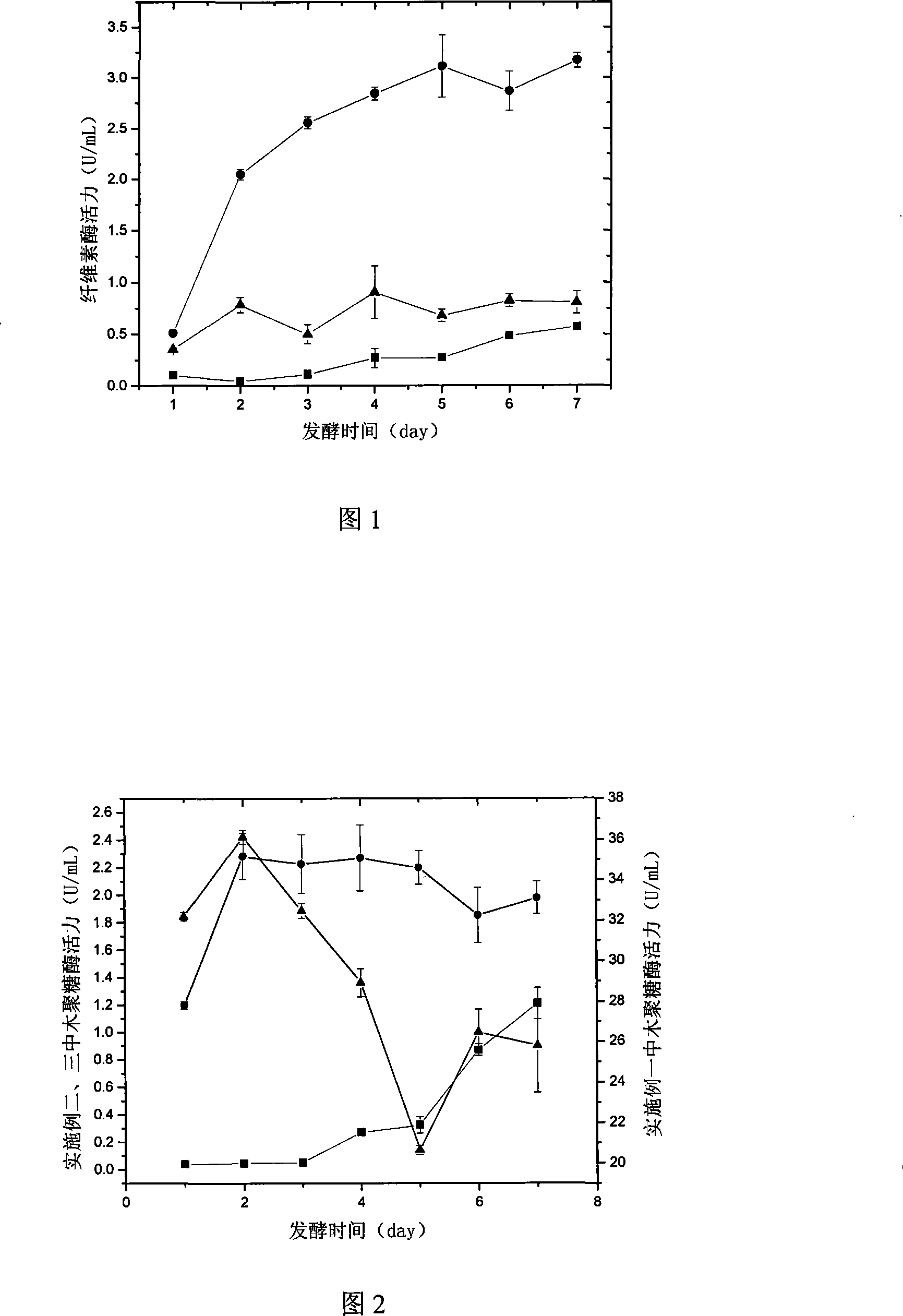

[0080] 3. Determination of cellulase activity, see Example 1 for details.

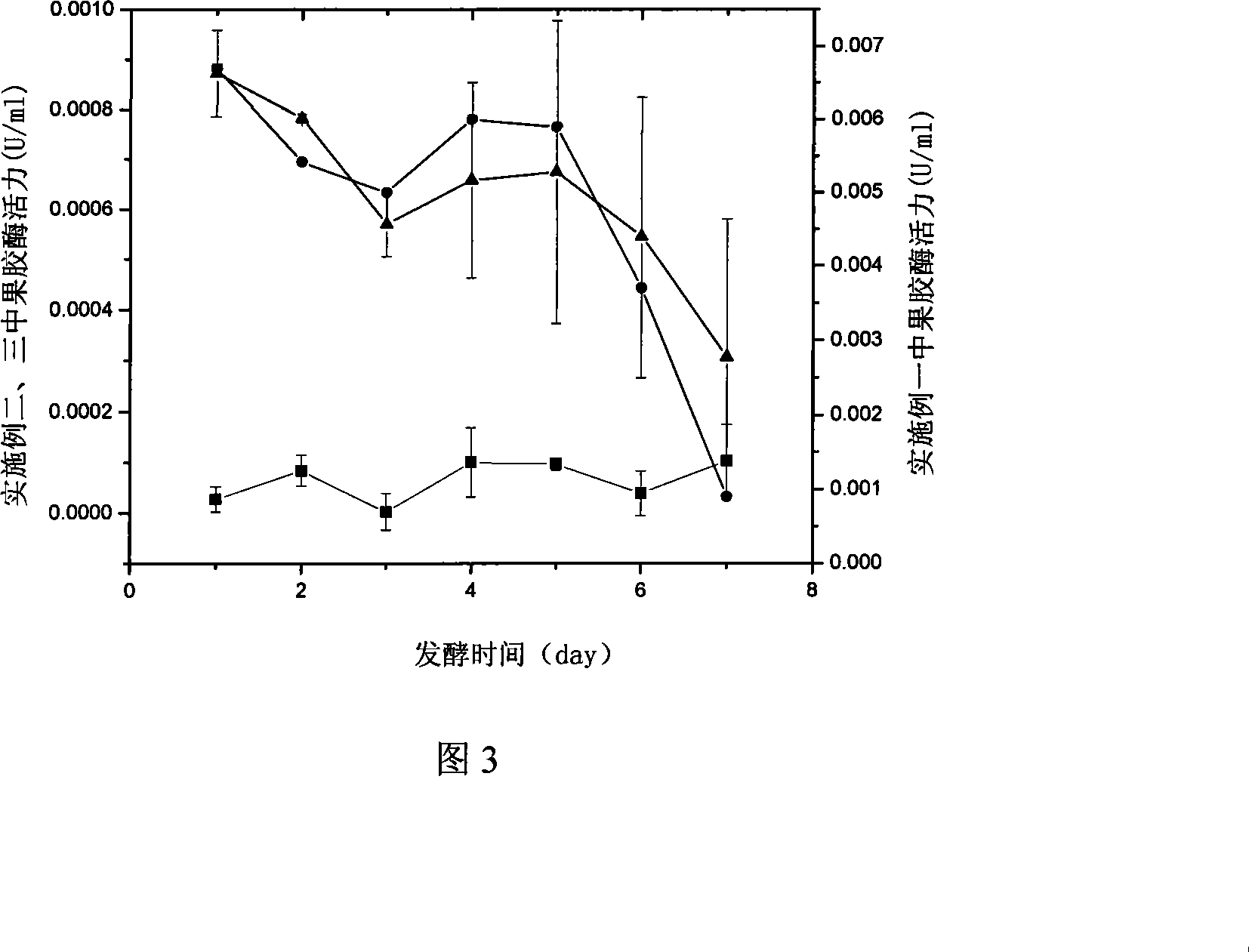

[0081] 4. Determination of xylanase activity, ...

Embodiment 3

[0085] 1. Seed Culture of Trichoderma reesei

[0086] (1) Trichoderma reesei seed medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N;

[0087] (2) Trichoderma reesei Rut C30 was used as the production strain, and cultured at pH 5.0, 30° C., 200 r / min for 48 hours.

[0088] 2. Fermentation of Trichoderma reesei to produce enzymes

[0089] (1) Trichoderma reesei enzyme production medium: 1% glucose, 0.1% peptone, 0.05% citric acid, 0.015% Tween 80, 2% Vogel's medium N, pH5.0;

[0090] (2) With 10% inoculum size, culture at 30°C and 130r / min for 7h to induce enzyme production;

[0091] (3) The fermented broth clear liquid collected by filtration or centrifugation is the ramie degumming compound enzyme liquid.

[0092] 3. Determination of cellulase activity, see Example 1 for details.

[0093] 4. Determination of xylanase activity, see Example 1 for details.

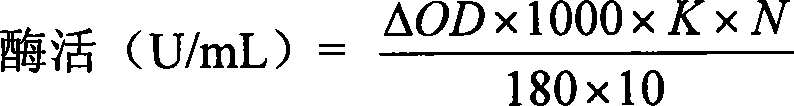

[0094] 5. Determination of pectinase activity, see Example 1 for details.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com