Method for producing ethanol by fermenting straws

An ethanol and straw technology, applied in the biological field, can solve the problems of accumulation, coenzyme redox imbalance, affecting ethanol yield, etc., and achieve the effects of increasing ethanol yield, shortening fermentation period, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

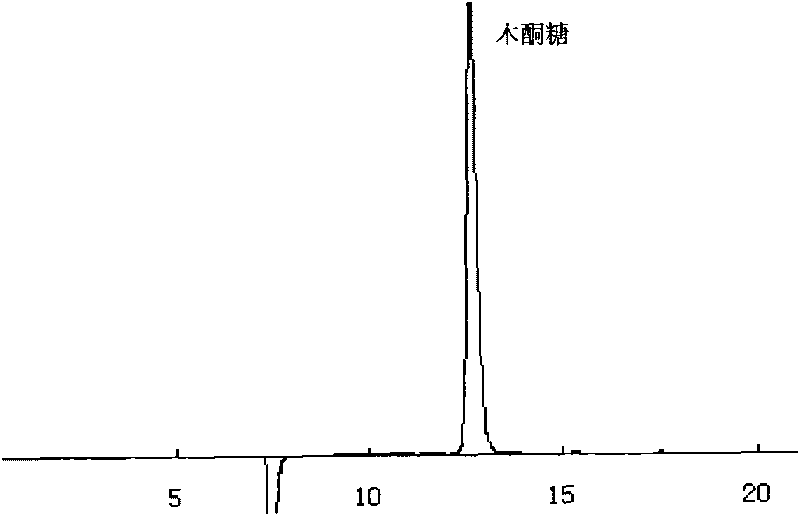

[0039] Example 1 The isomerization test of xylose

[0040] Use commercially available xylose isomerase to carry out xylose conversion xylulose test, the total reaction volume is 10L, under 120r / min stirring, the reaction system is: D-xylose 30% (W / V), CoCl 2 ·6H 2 O 2×10 -4 mol / L, MgSO 4 ·7H 2 O 2×10 -3 mol / L, the amount of adding xylose isomerase is 10 6 U / L. React at pH 5.0 and 35°C, and take the reaction solution after 12 hours for processing. The analysis was carried out by high performance liquid chromatography.

[0041] 1. Preparation of standard solution: take 500 mg each of xylose standard product and xylulose standard product respectively, and use double distilled water (ddH 2 O) dissolve and make up to 50ml.

[0042] 2. Treatment of the isomerization reaction solution: Centrifuge the reaction solution at 12,000 rpm for 20 minutes, take the supernatant for ultrasonic degassing, and filter it with a 0.45 μm organic phase filter.

[0043] 3. The chromatographi...

Embodiment 2

[0046] Example 2 Synchronous saccharification of corn stalks and xylose isomerization fermentation to produce ethanol after dilute acid pretreatment

[0047] 1. Dilute acid pretreatment of corn stalks

[0048] Take 10kg of dry corn stalks, add water at a solid-to-liquid ratio of 1:6, and then add sulfuric acid at a ratio of 1:2, heat to 120°C for 2 hours, centrifuge, and wash twice with warm water at 60°C. Take solid phase analysis: moisture is 63.46%, except moisture, cellulose in dry material is 58.64%, hemicellulose 4.37%, lignin 25.21%, ash 4.29%.

[0049] 2. Lignocellulose saccharification and xylose isomerization fermentation to produce ethanol after pretreatment

[0050] Put 1.5kg of the above-mentioned pretreated lignocellulose (dry material) into a 12L fermenter, add 4.5L of distilled water, heat to 115°C for 20min, and then add enzyme preparation when the temperature drops to 50°C, every 1g of the above Add 20U cellulase, 110U xylanase and 100U xylose isomerase to th...

Embodiment 3

[0051] Example 3 Synchronous saccharification of corn stalks and xylose isomerization fermentation to produce ethanol after alkali pretreatment

[0052] 1. Alkaline pretreatment of corn stalks

[0053] Take 10 kg of dried corn stalks, add water at a solid-to-liquid ratio of 1:6, and then add 1.5% NaOH by weight, heat to 100°C for 1 hour, centrifuge, and wash twice with warm water at 60°C. Take the solid phase analysis: water content 68.46%, except water, cellulose 62.3%, hemicellulose 23.6%, lignin 7.2%, ash content 4.7% in the dry material.

[0054] 2. Lignocellulose saccharification and xylose isomerization fermentation to produce ethanol after pretreatment

[0055] Put 1.5kg of the above-mentioned pretreated lignocellulose (dry material) into a 12L fermenter, add 4.5L of distilled water, heat to 115°C and keep it for 20min, when the temperature drops to 50°C, add enzyme preparation, every 1g of the above dry 30U cellulase, 300U xylanase and 280U xylose isomerase were adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com