Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1803 results about "Ethanol fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethanol fermentation, also called alcoholic fermentation, is a biological process which converts sugars such as glucose, fructose, and sucrose into cellular energy, producing ethanol and carbon dioxide as by-products. Because yeasts perform this conversion in the absence of oxygen, alcoholic fermentation is considered an anaerobic process. It also takes place in some species of fish (including goldfish and carp) where (along with lactic acid fermentation) it provides energy when oxygen is scarce.

Method for processing lignocellulosic material

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

Method for processing lignocellulosic material

InactiveUS20020192774A1High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseEnvironmental engineering

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process. involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

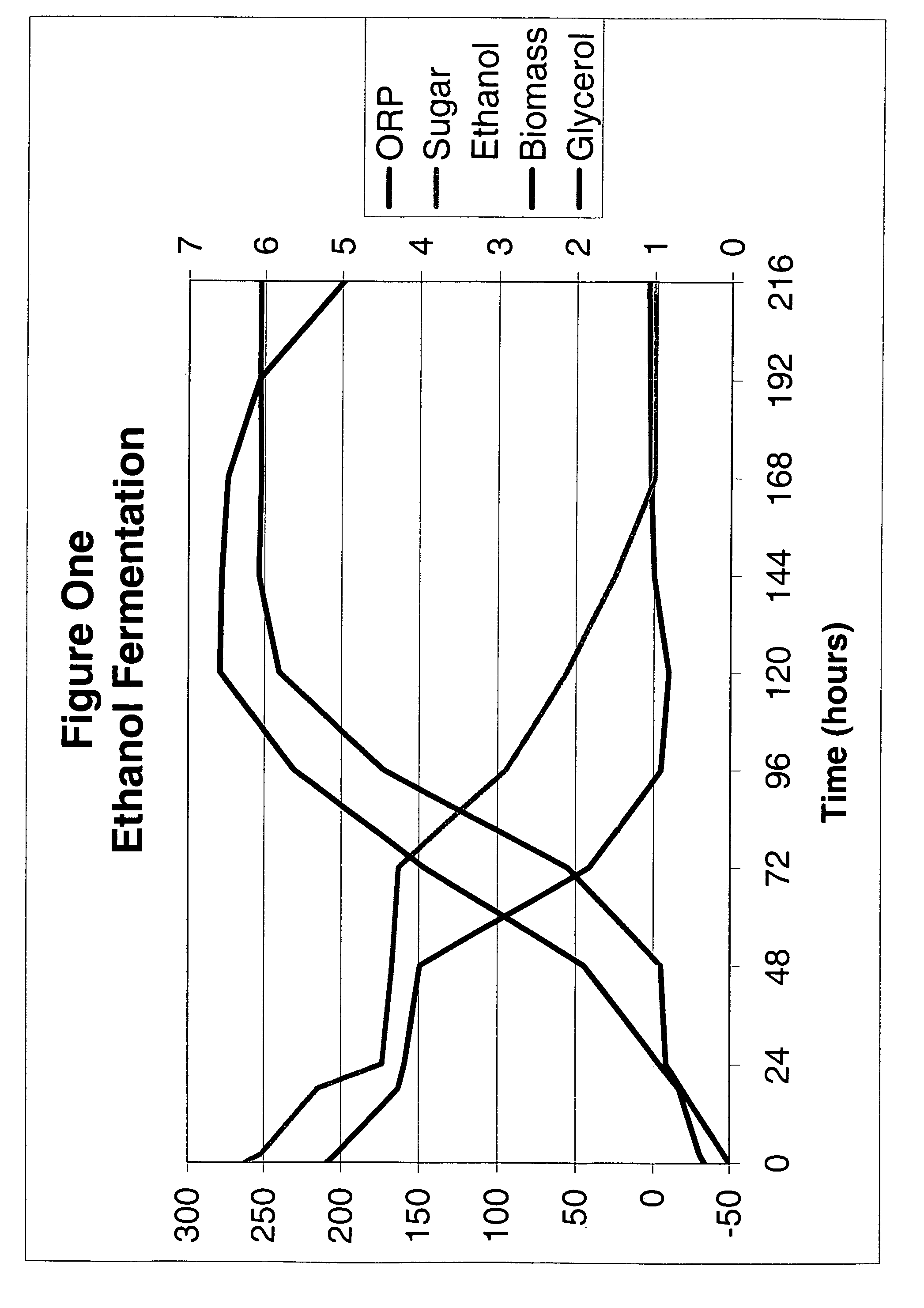

Ethanol fermentation using oxidation reduction potential

InactiveUS7078201B2Increased ethanol productionReduce formationMicrobiological testing/measurementBiofuelsOxidation-Reduction AgentRedox

A process to improve ethanol yield, decrease fermentation time and reduce byproduct formation by monitoring and controlling oxidation reduction potential (redox) of the fermentor is disclosed.

Owner:BURMASTER BRIAN M

Fermentation method for production of nutritionally balanced natural fruit enzyme

ActiveCN103609985AReduce lossesRetain activityFood ingredient functionsFood preparationLactic acid bacteriumAcetic acid

The invention relates to a fermentation method for production of nutritionally balanced natural fruit enzymes. The method comprises the following steps: (1) pretreatment on raw materials; (2) a first bacterium inoculation: inoculating a saccharomyces cerevisiae liquor with concentration of 106 CFU / ml into a pulp according to an inoculation proportion of 5%; (3) early stage fermentation; (4) a secondary bacterium inoculation: after the early fermentation, inoculating acetic acid bacterium liquid and lactic acid bacterium liquid in a weight ratio of 1:1 for a secondary bacterium inoculation according to an inoculation amount of 5%; (5) middle-term fermentation; (6) coarse filtration; (7) secondary fermentation; (8) ripening; and (9) fine filtration to obtain the natural fruit enzyme. The fermentation method provided by the invention through low-temperature sterilization and strict control on the fermentation temperature retains the enzyme activity to the maximum; and twice inoculation of dominant bacteria effectively inhibits breeding of other infectious microbes, so as to realize stable product quality.

Owner:JINYES QINGDAO BIOTECH CO LTD

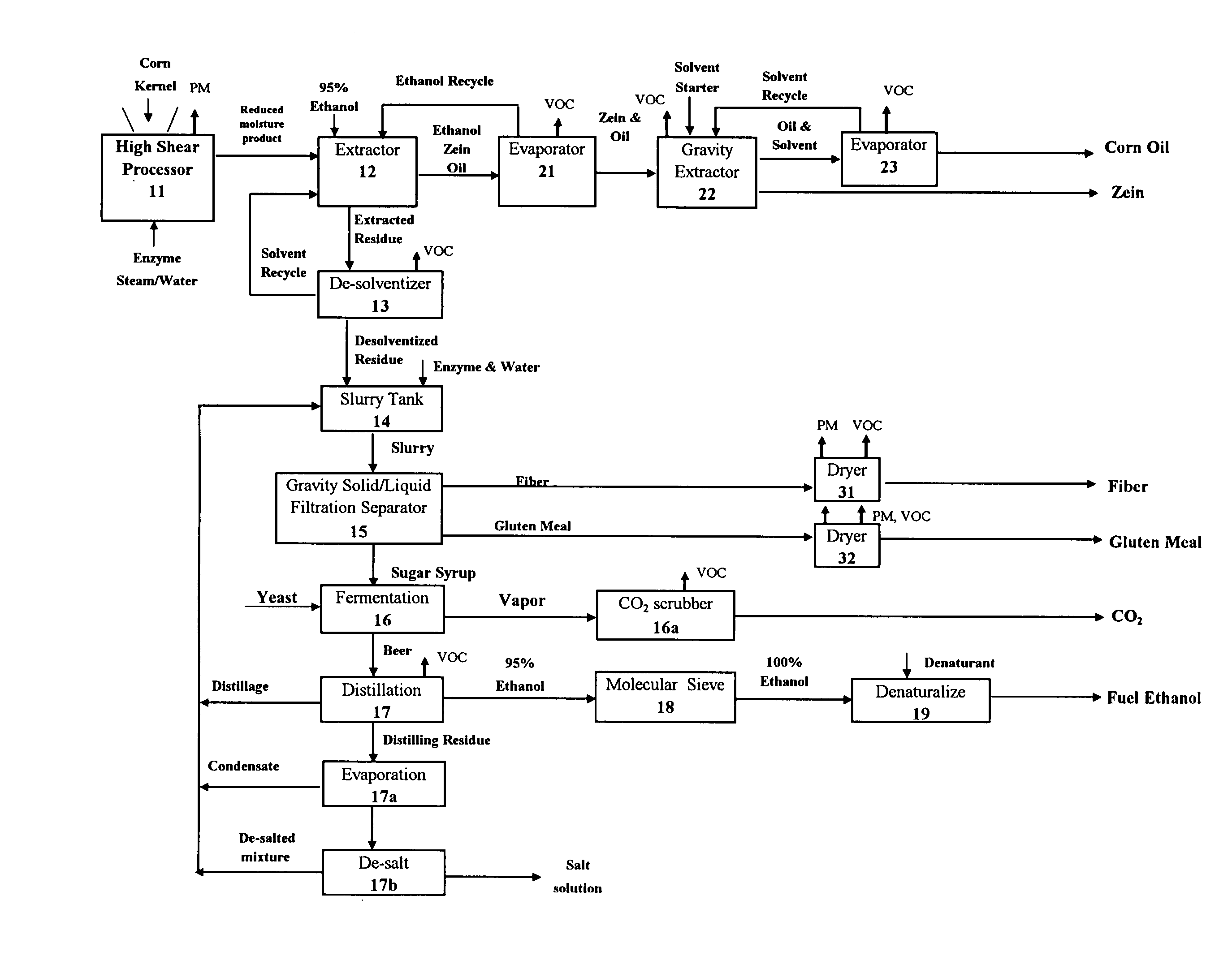

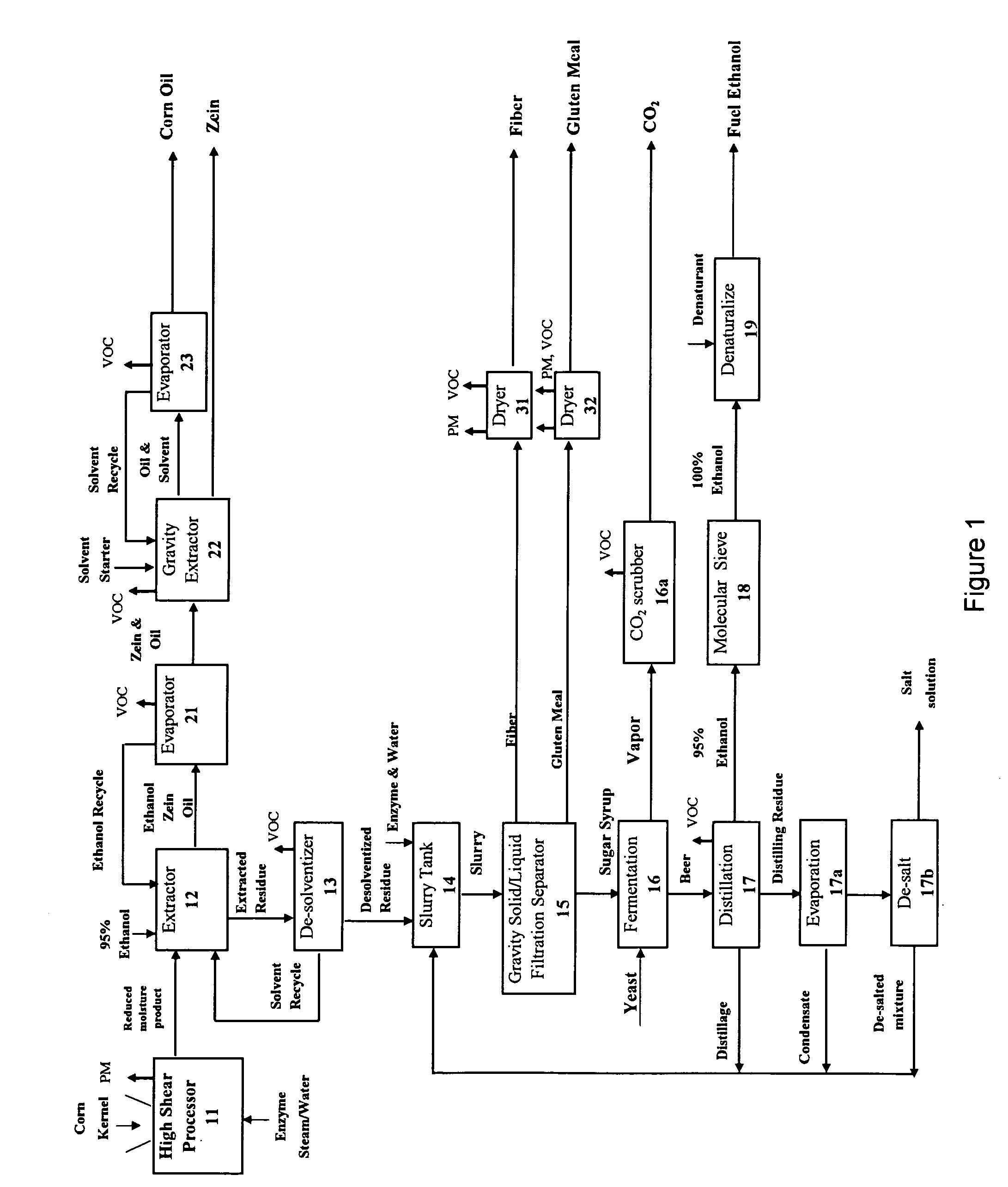

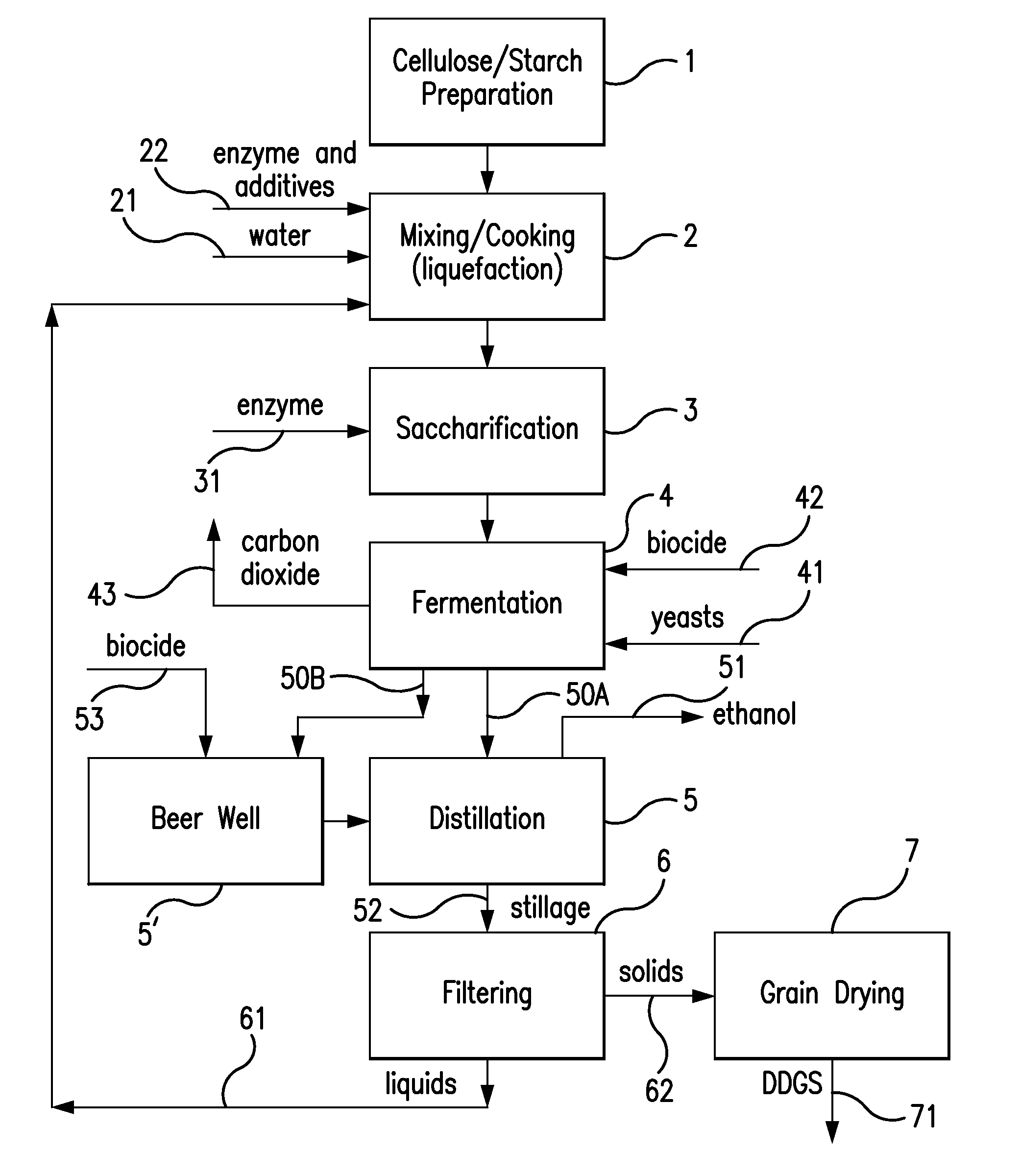

Starchy material processed to produce one or more products comprising starch, ethanol, sugar syrup, oil, protein, fiber, gluten meal, and mixtures thereof

InactiveUS20070014905A1Reduce processIncrease shearProtein composition from eggsConfectioneryFiberFood grade

The invention provides a method and system of processing a starchy material that can advantageously produce ethanol, sugar syrup, or starch as the chief products along with food-grade co-products such as, but not limited to oil, protein, fiber, and gluten meal. The invention can apply such a force to a starchy material that is at a superambient temperature with a high shear processor to mill, mix, and gelatinize some of the starch. A liquefaction enzyme can be introduced into the high shear processor to liquefy the processed product. The moisture content of the processed starchy material can be reduced, which preferably occurs in the high shear processor. Some of the co-products such as the oil, protein, fiber and gluten meal can be separated prior to the sugar syrup purification or ethanol fermentation steps.

Owner:PURDUE RES FOUND INC

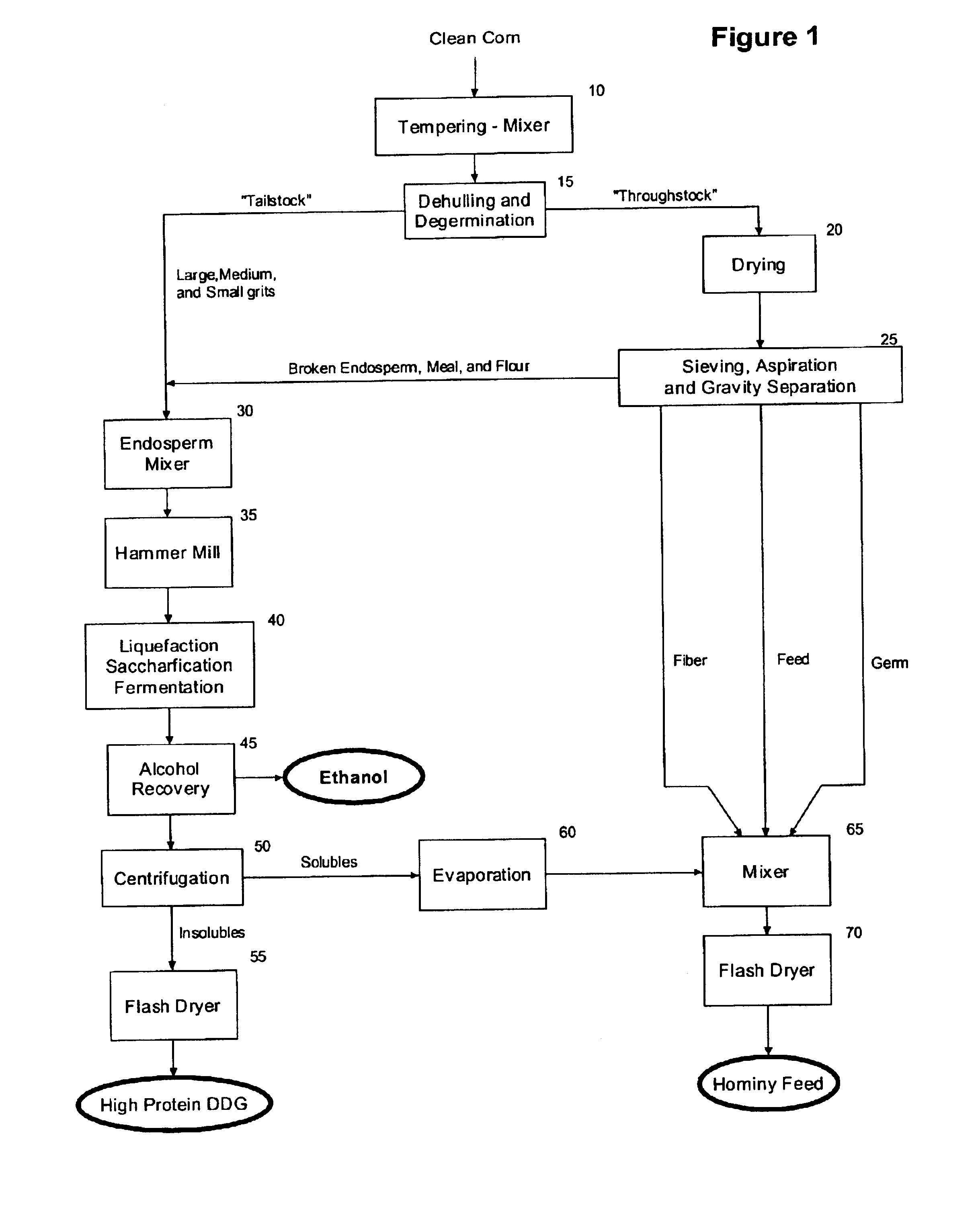

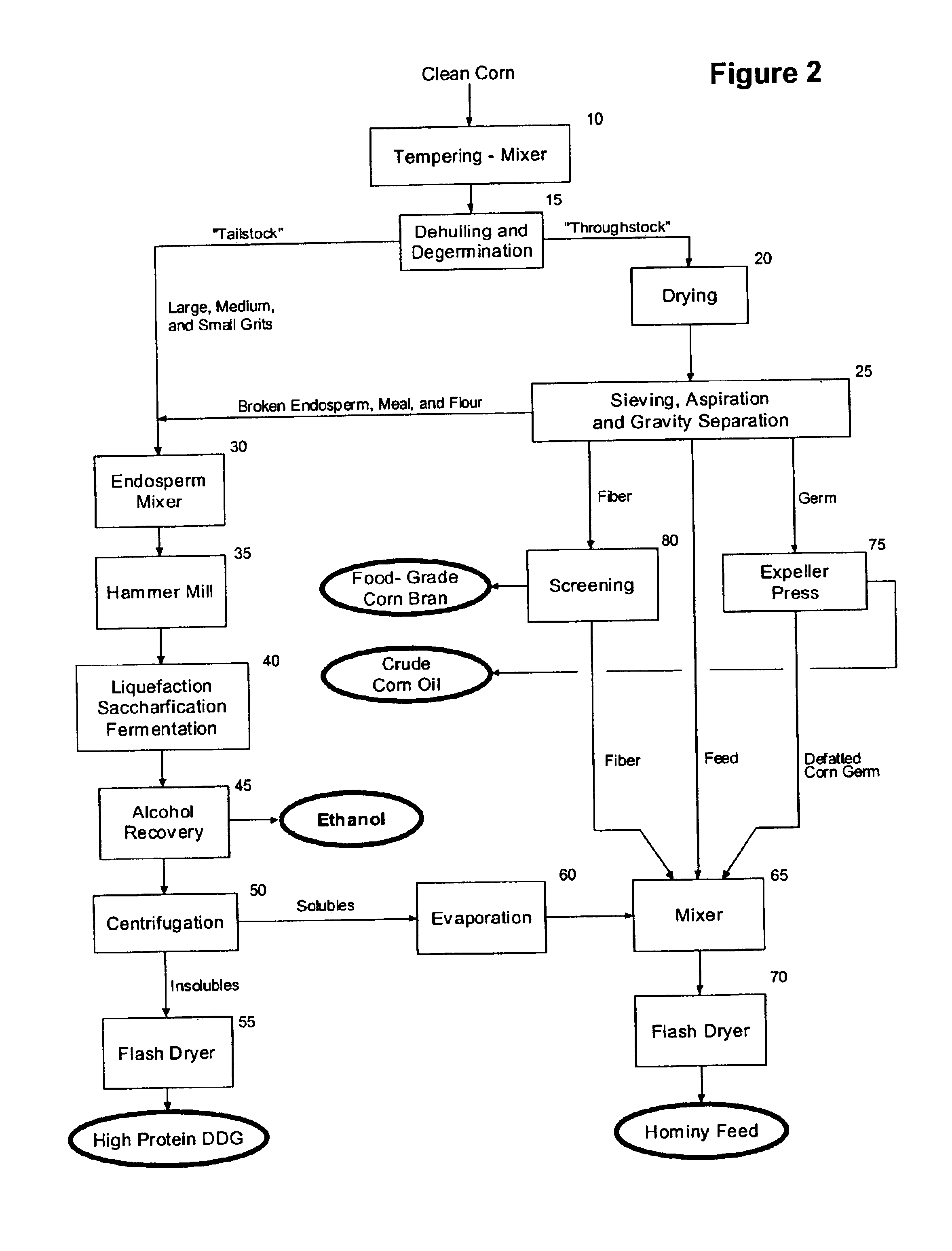

High protein corn product production and use

InactiveUS6962722B2Improve palatabilityImprove digestibilityFood processingClimate change adaptationWeight gainingFiber

The present invention relates to the production of a highly digestible, high protein product (high protein distillers dried grains or high protein DDG) from corn endosperm, and more particularly to a method for the recovery of high protein DDG by using: (i) dehulling and degermination to isolate a low fat, low fiber corn endosperm fraction, (ii) enzymatic hydrolysis to solubilize and alcoholic fermentation to assimilate the starch and non-starch carbohydrates present in the corn endosperm, and (iii) filtration and / or centrifugation to recover the dealcoholized insoluble solids that remain after fermentation of the corn endosperm. The present invention provides an alternative to the traditional dry mill method of processing corn to produce ethanol, and results in the production and recovery of a distillers' by-product (high protein DDG) with increased value and range of use as an ingredient in feeds for farm-raised ruminants and non-ruminants and pet foods. The product of the present invention contains less than about 2.0 weight percent starch, from about 55.0 to about 65.0 weight percent protein, from about 4.5 to about 7.5 weight percent fat, from about 3.0 to about 5.0 weight percent crude fiber, and from about 78.0 to about 90.0 percent total digestible nutrients, and improves the palatability and digestibility of animal feeds and / or pet foods into which it is incorporated, and aids in the management of the health and weight gain of the animal.

Owner:GREENSTOCK RESOURCES

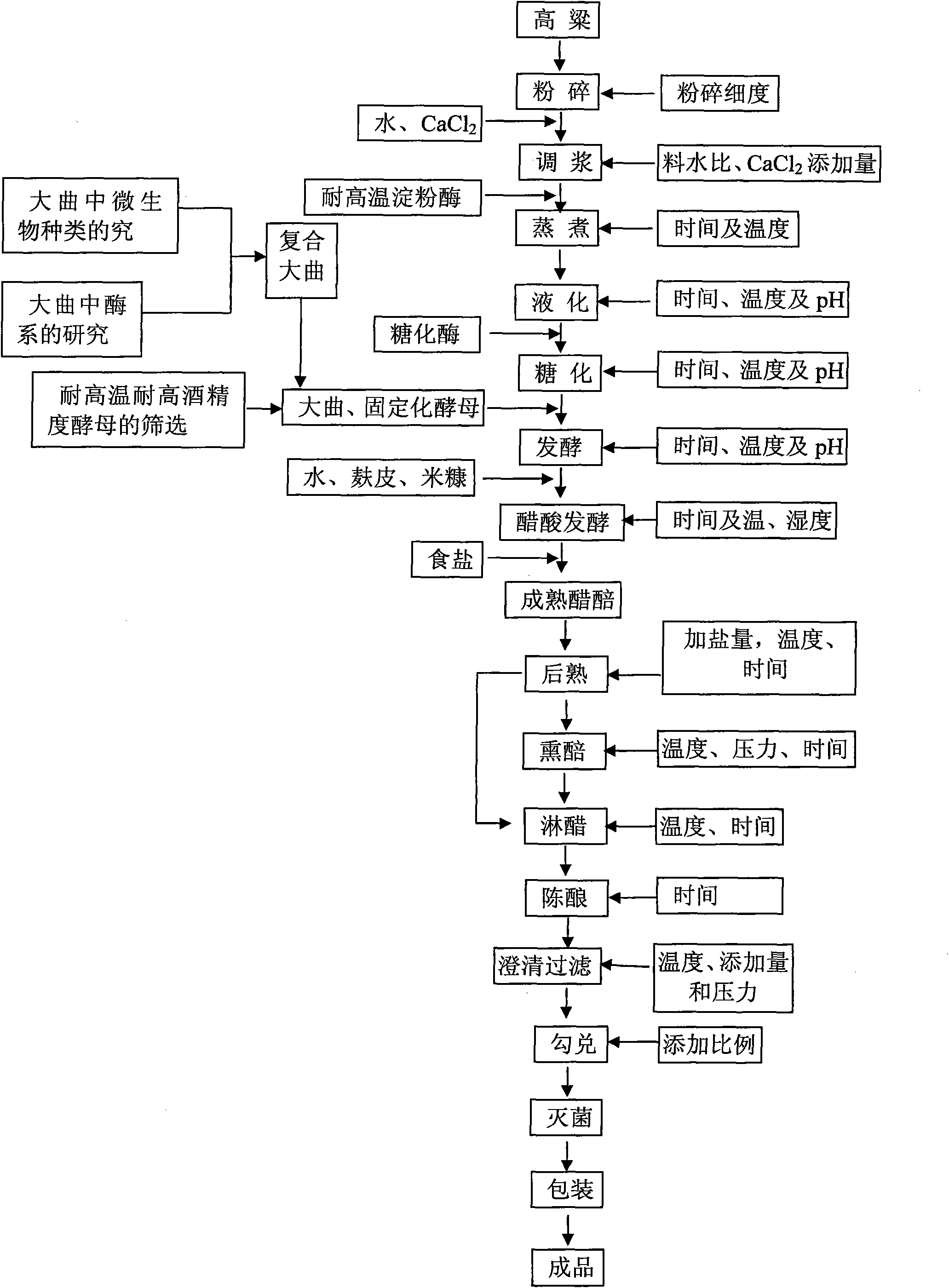

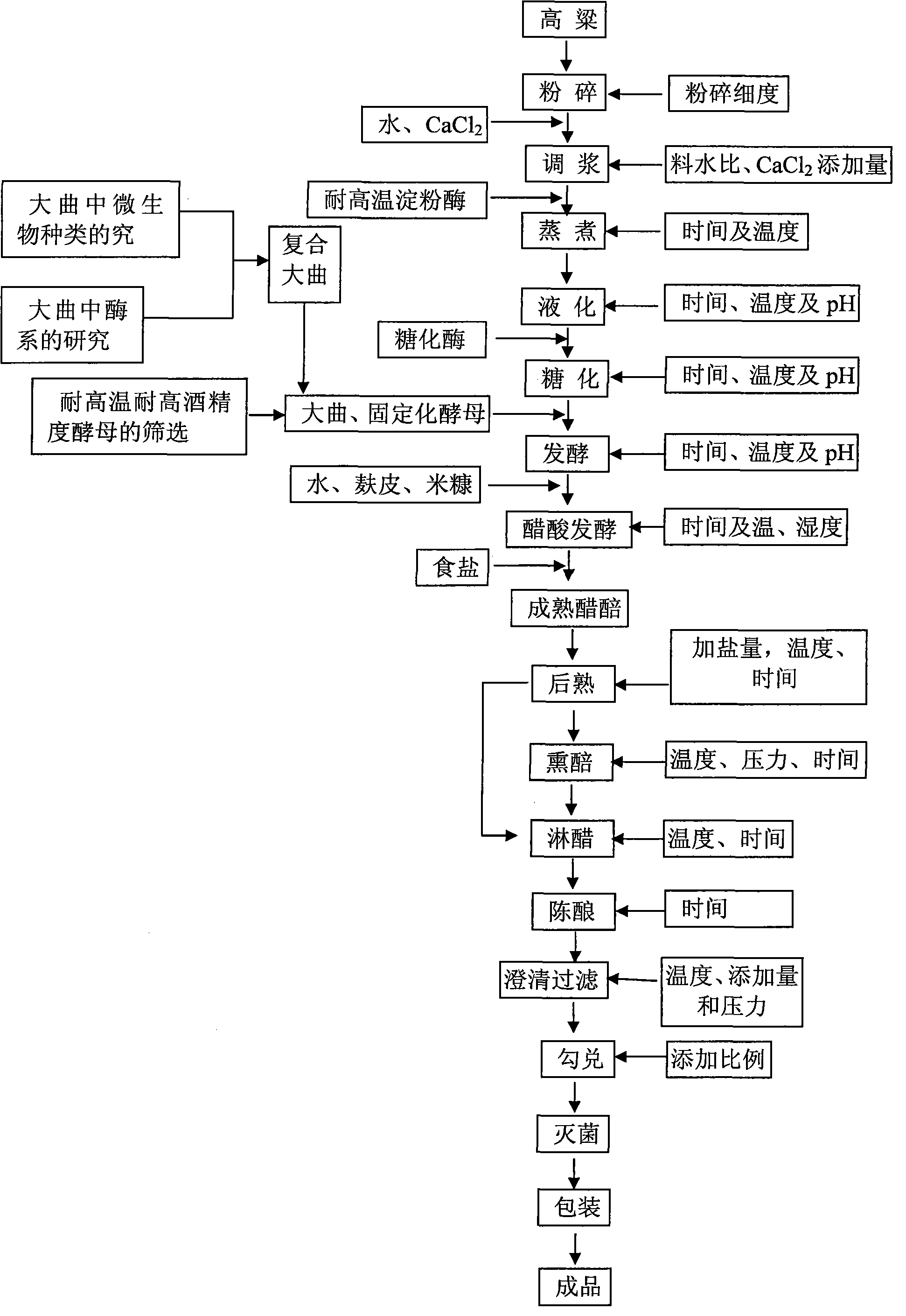

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

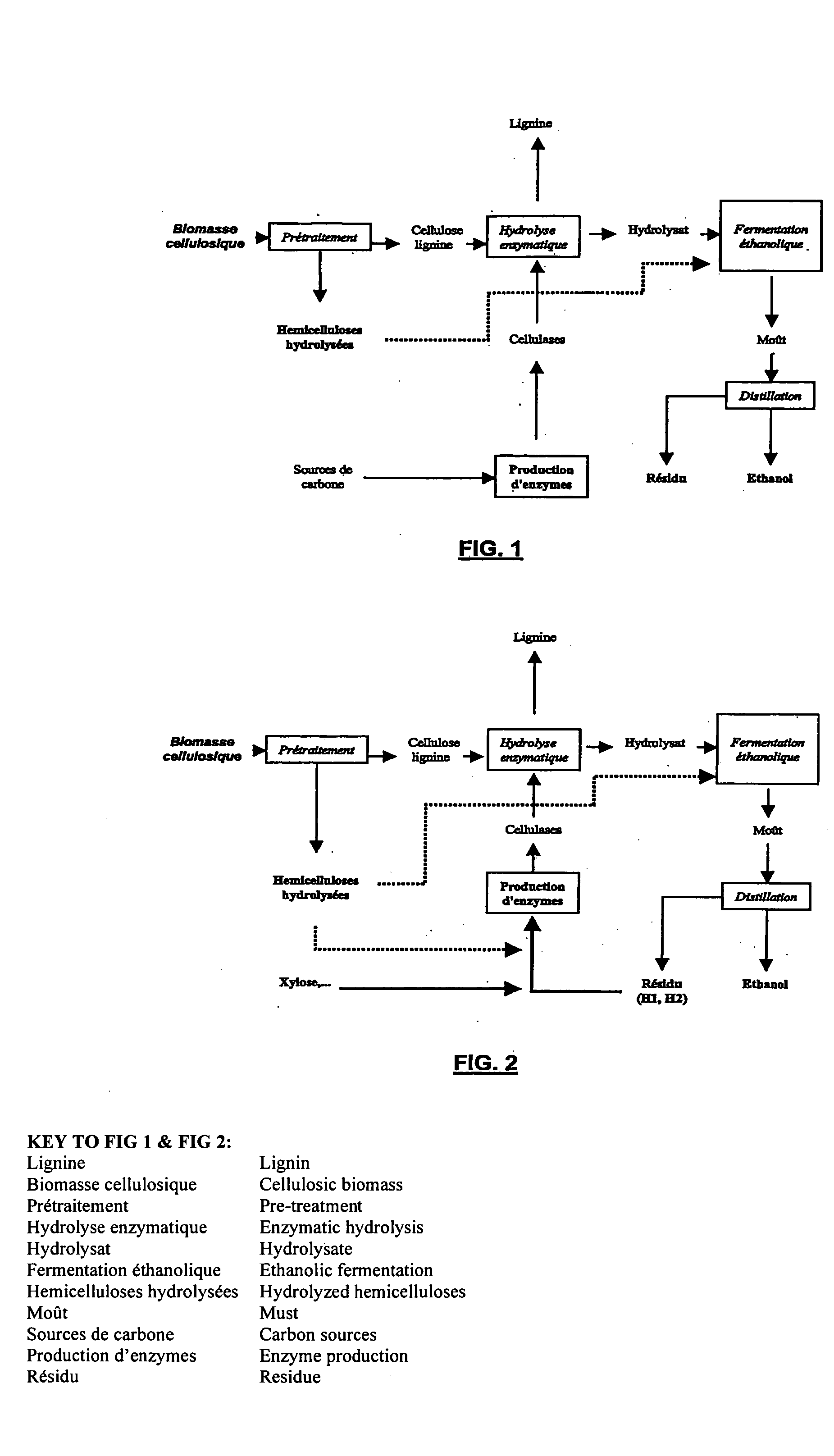

Process for the production of cellulolytic and hemicellulolytic enzymes using distillation residues from the ethanolic fermentation of enzymatic hydrolyzates of (ligno)cellulosic materials

A process for producing cellulolytic and / or hemicellulolytic enzymes uses the residue from the ethanolic fermentation of enzymatic hydrolyzates of cellulosic or ligno-cellulosic materials. This process may be integrated into a process for the production of ethanol from cellulosic or ligno-cellulosic materials which comprises the following steps: 1) chemical and / or physical pre-treatment of a cellulosic or ligno-cellulosic substrate; 2) enzymatic hydrolysis of the pre-treated substrate using cellulolytic and / or hemicellulolytic enzymes; 3) ethanolic fermentation, by a suitable alcohologenic microorganism, of the hydrolyzate from step (2) and production of a fermentation must; and 4) separation of the alcohologenic microorganism used in step (3), separation / purification of the ethanol and production of an aqueous phase constituting a residue; and in which said residue serves for the production of the cellulolytic and / or hemicellulolytic enzymes used in step 2).

Owner:INST FR DU PETROLE

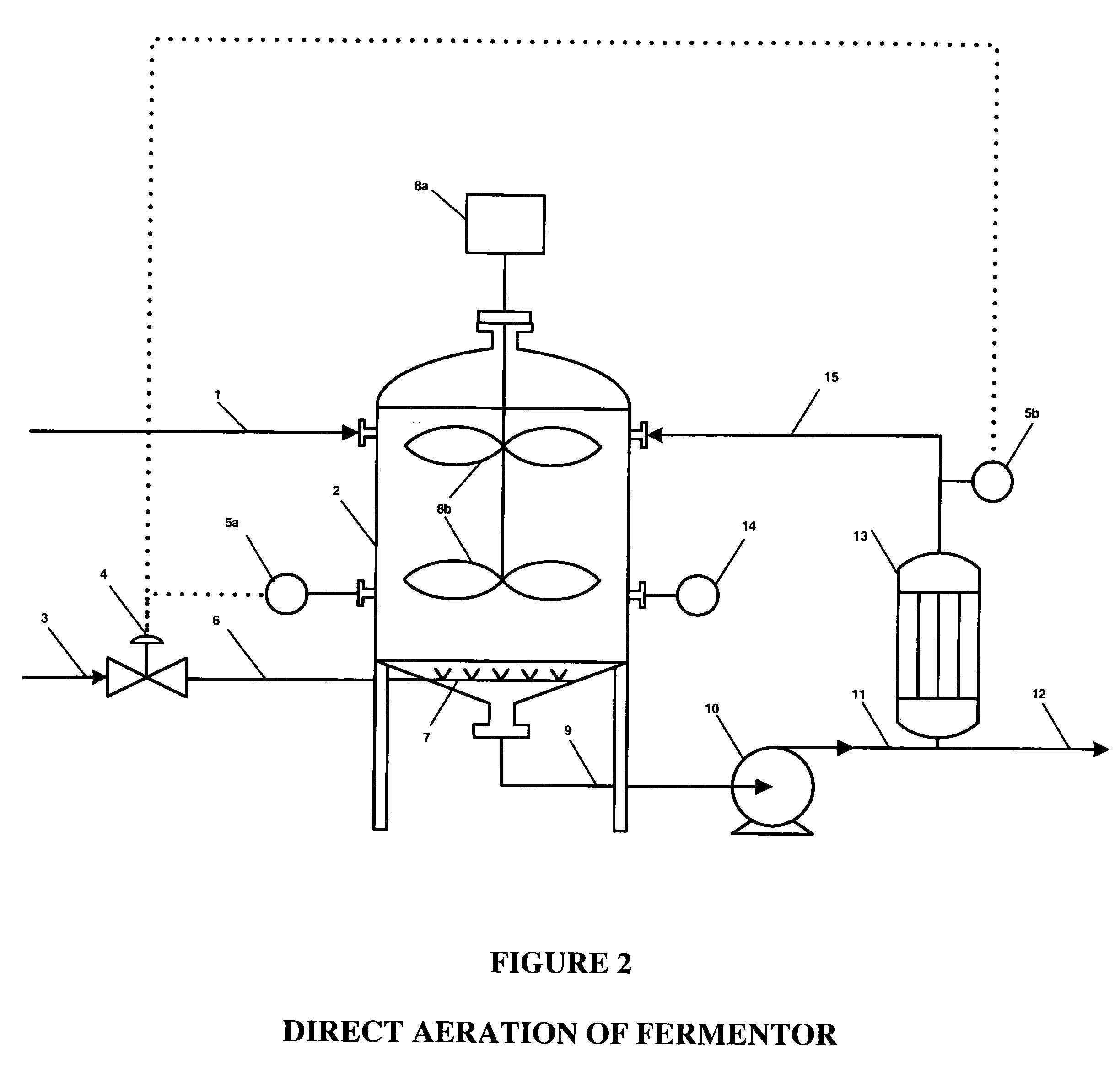

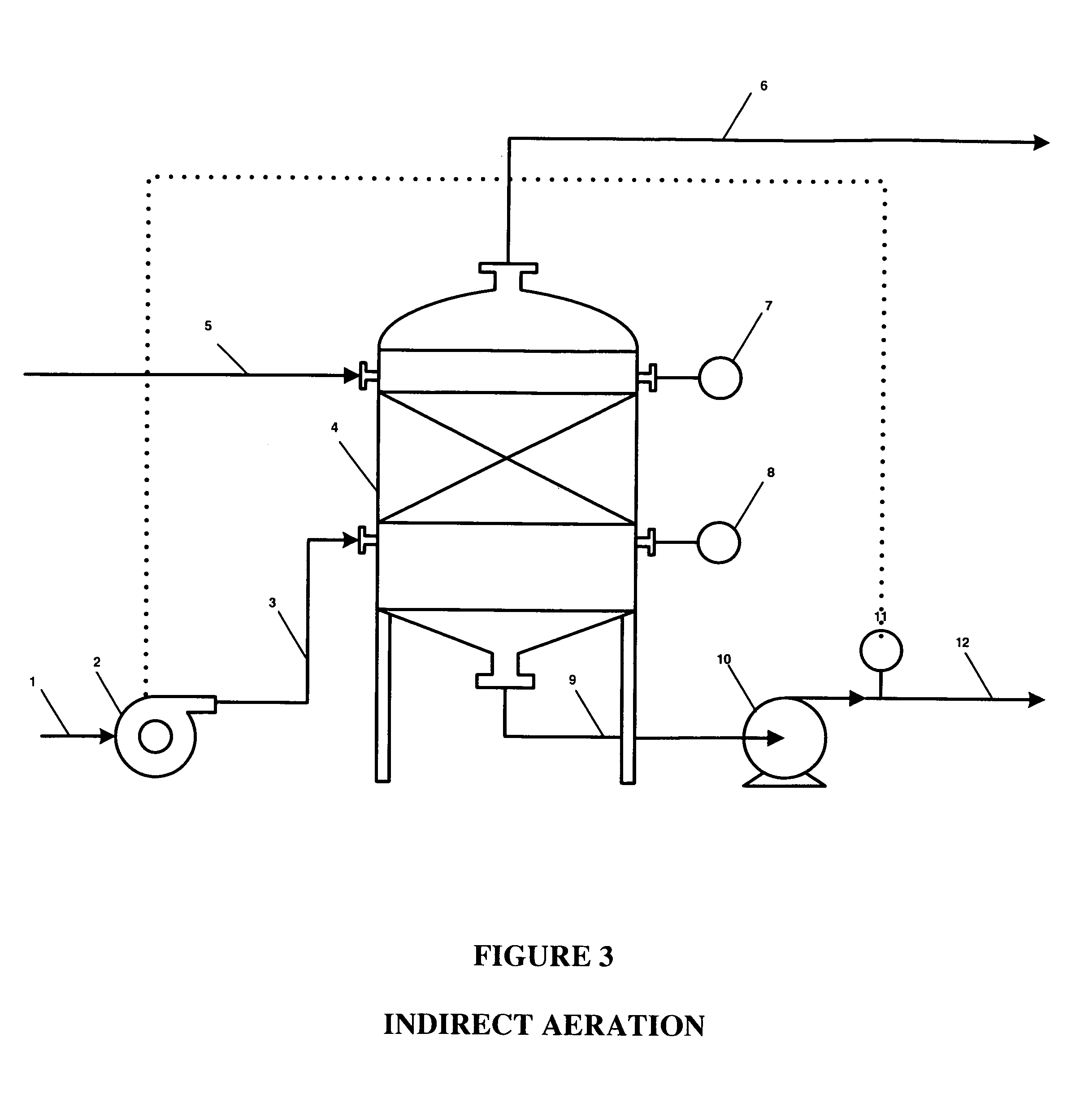

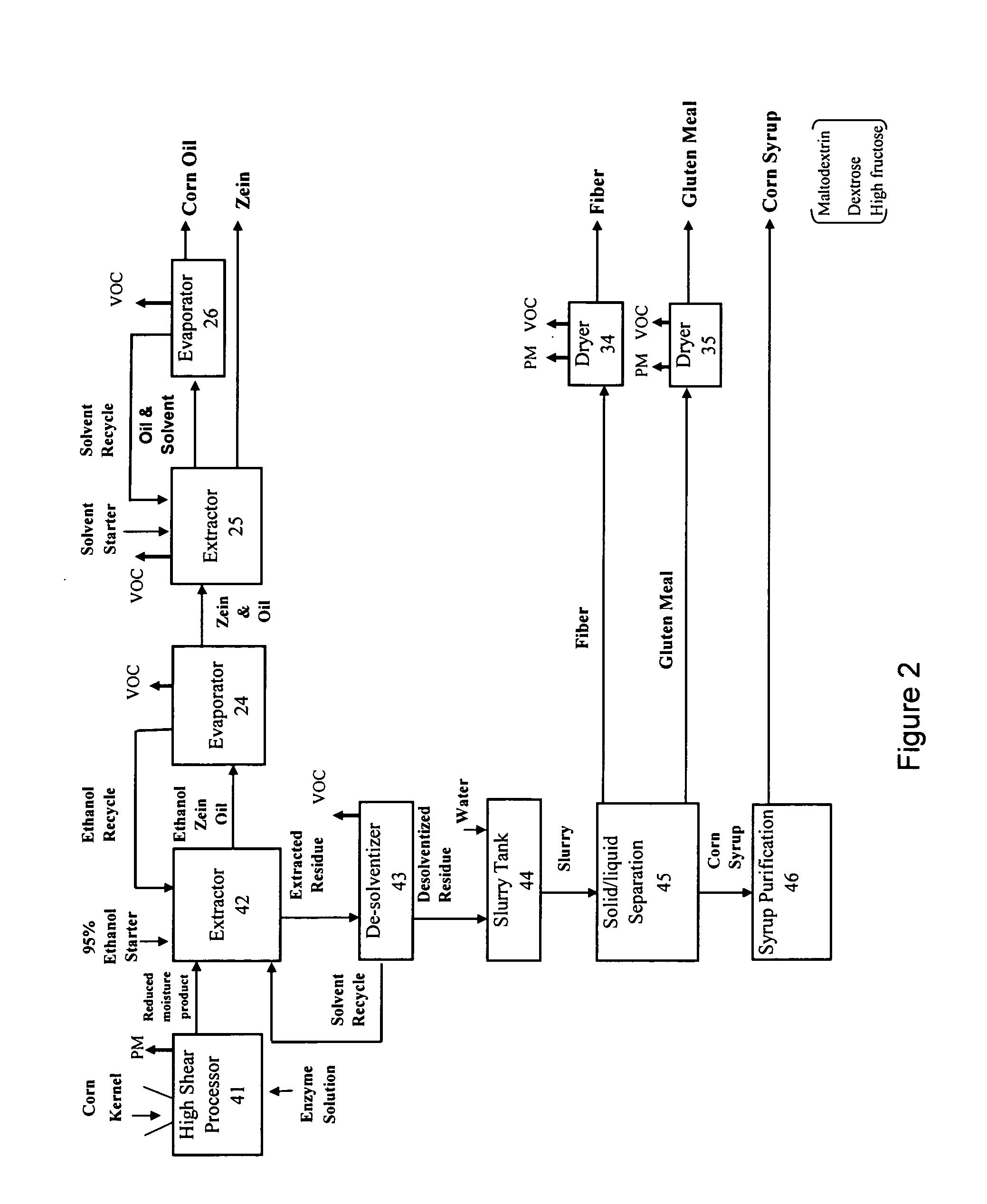

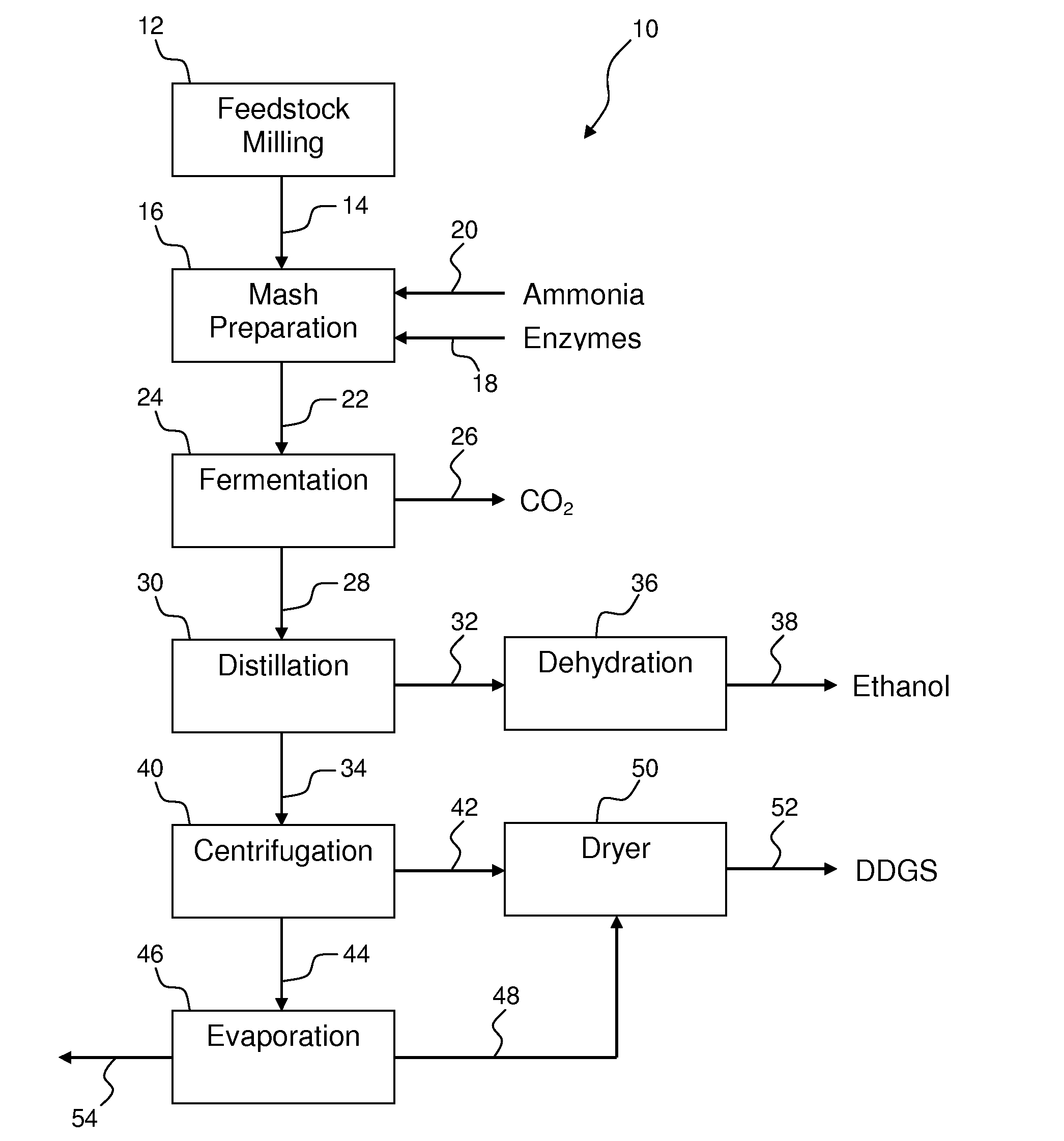

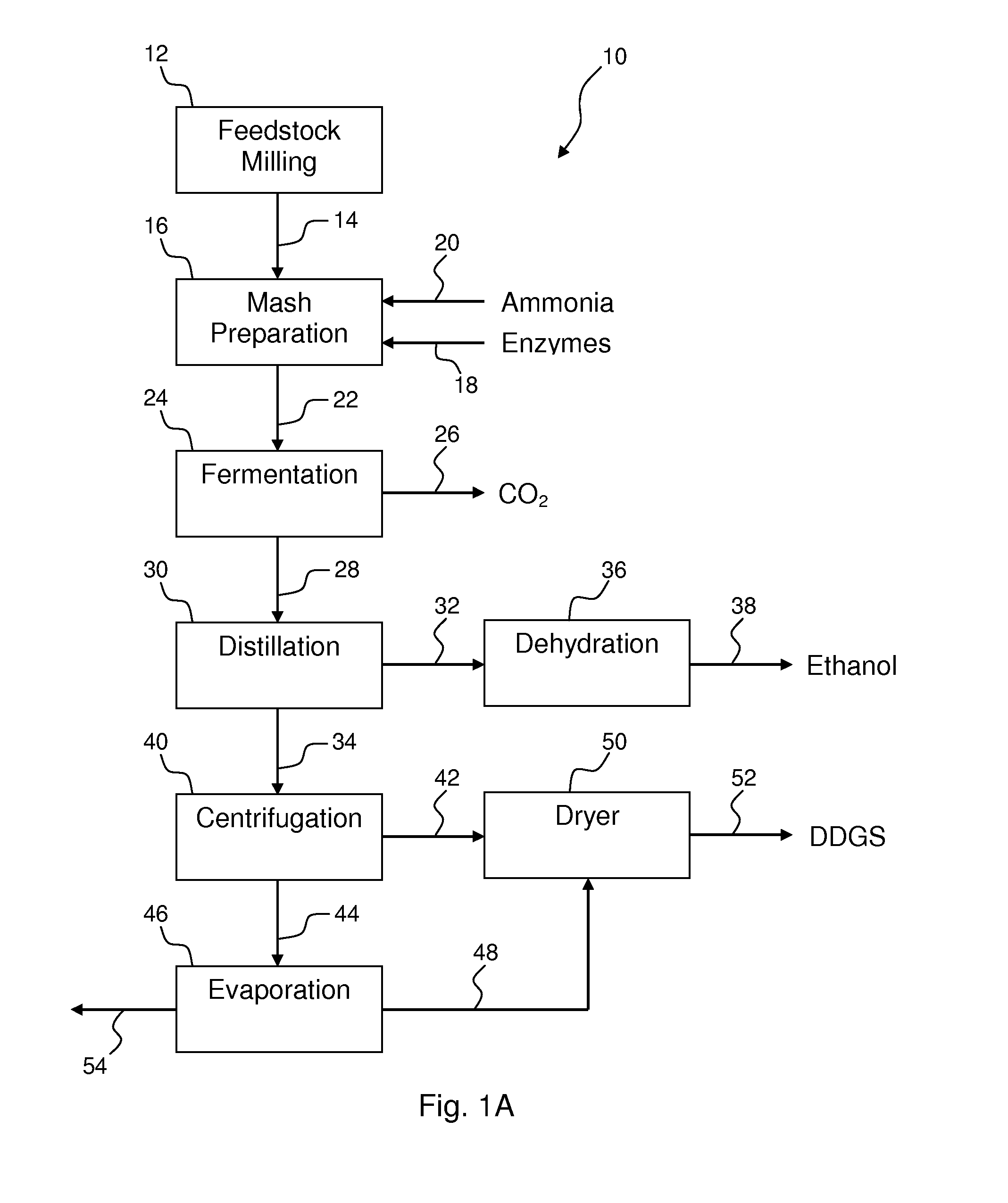

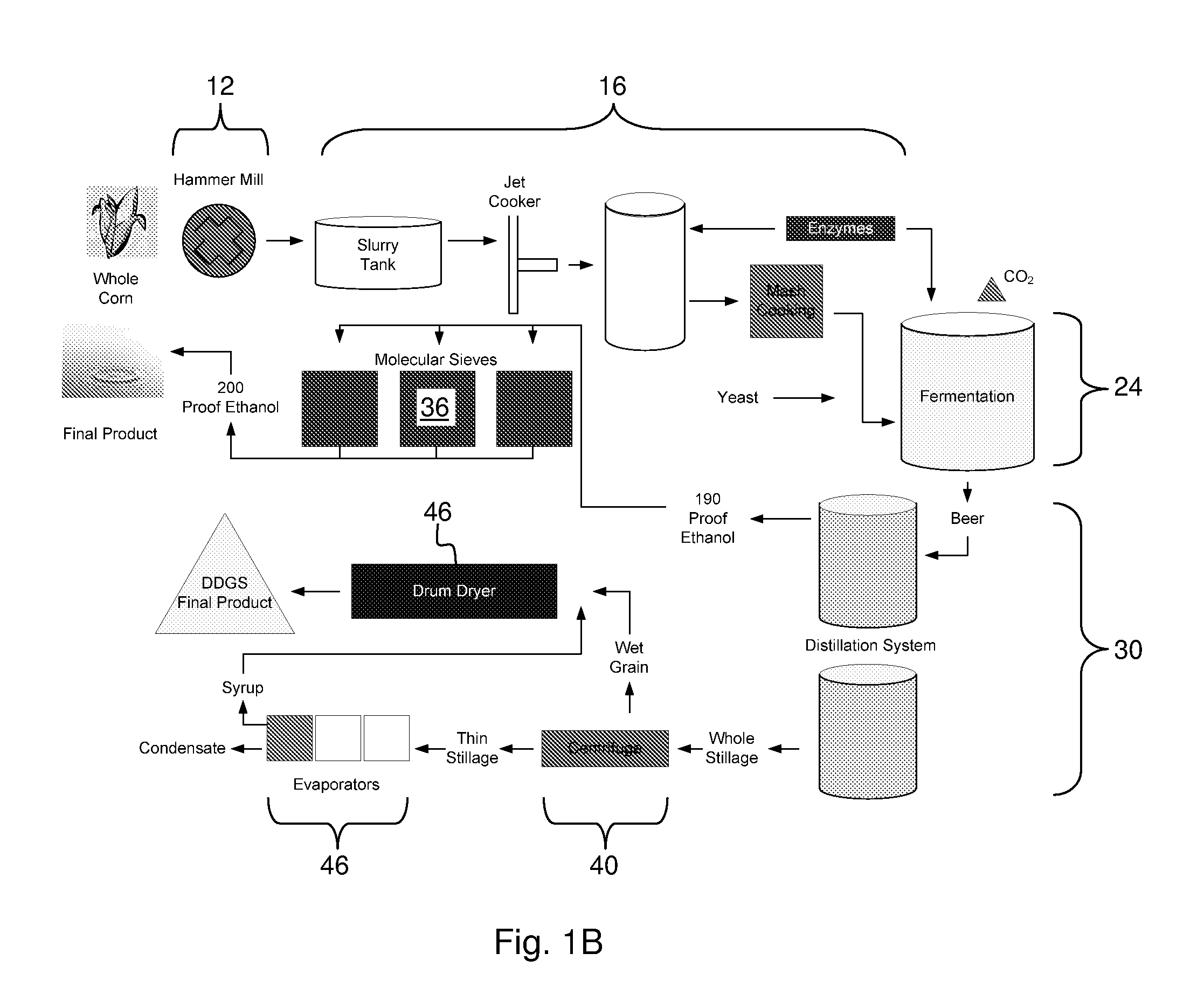

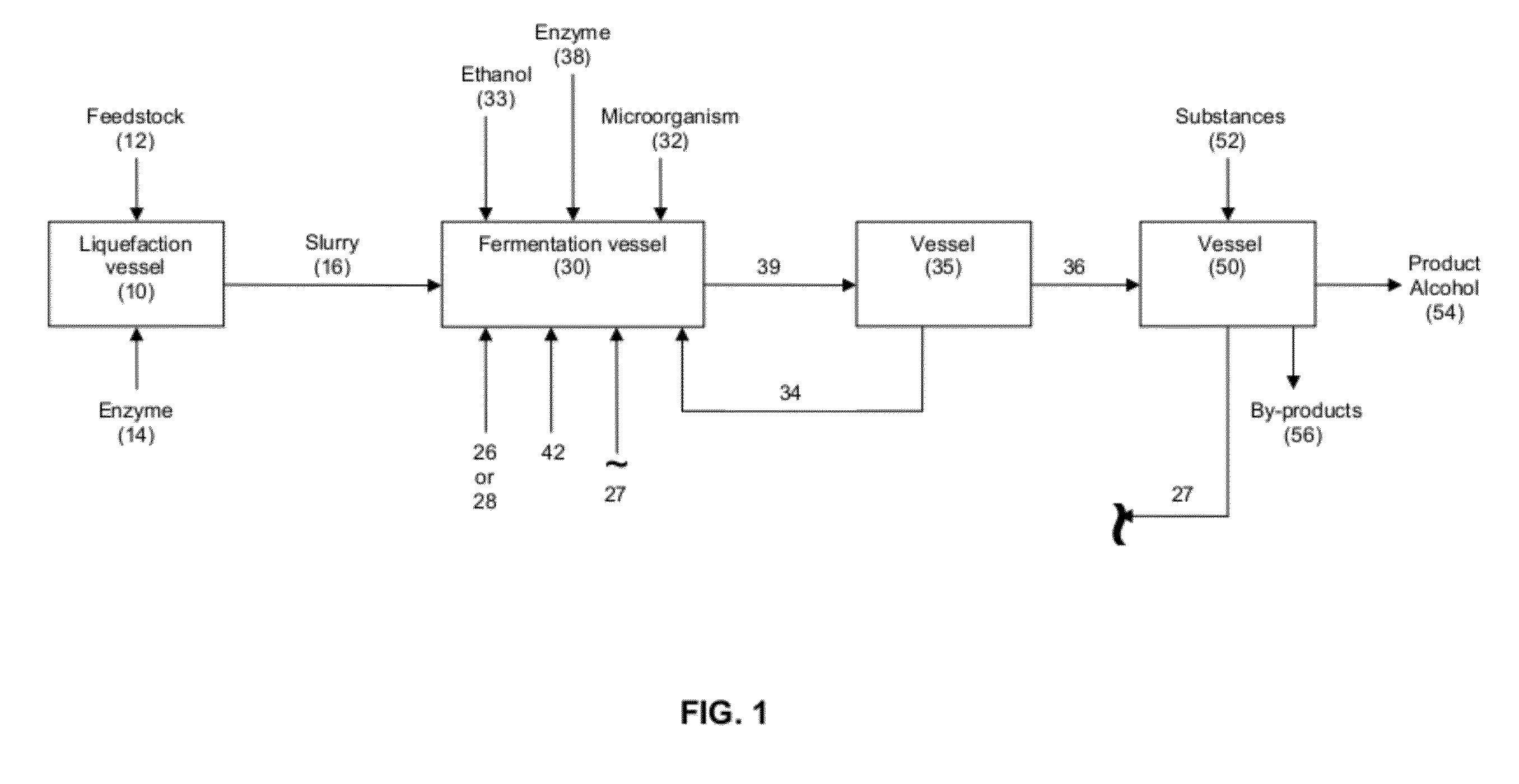

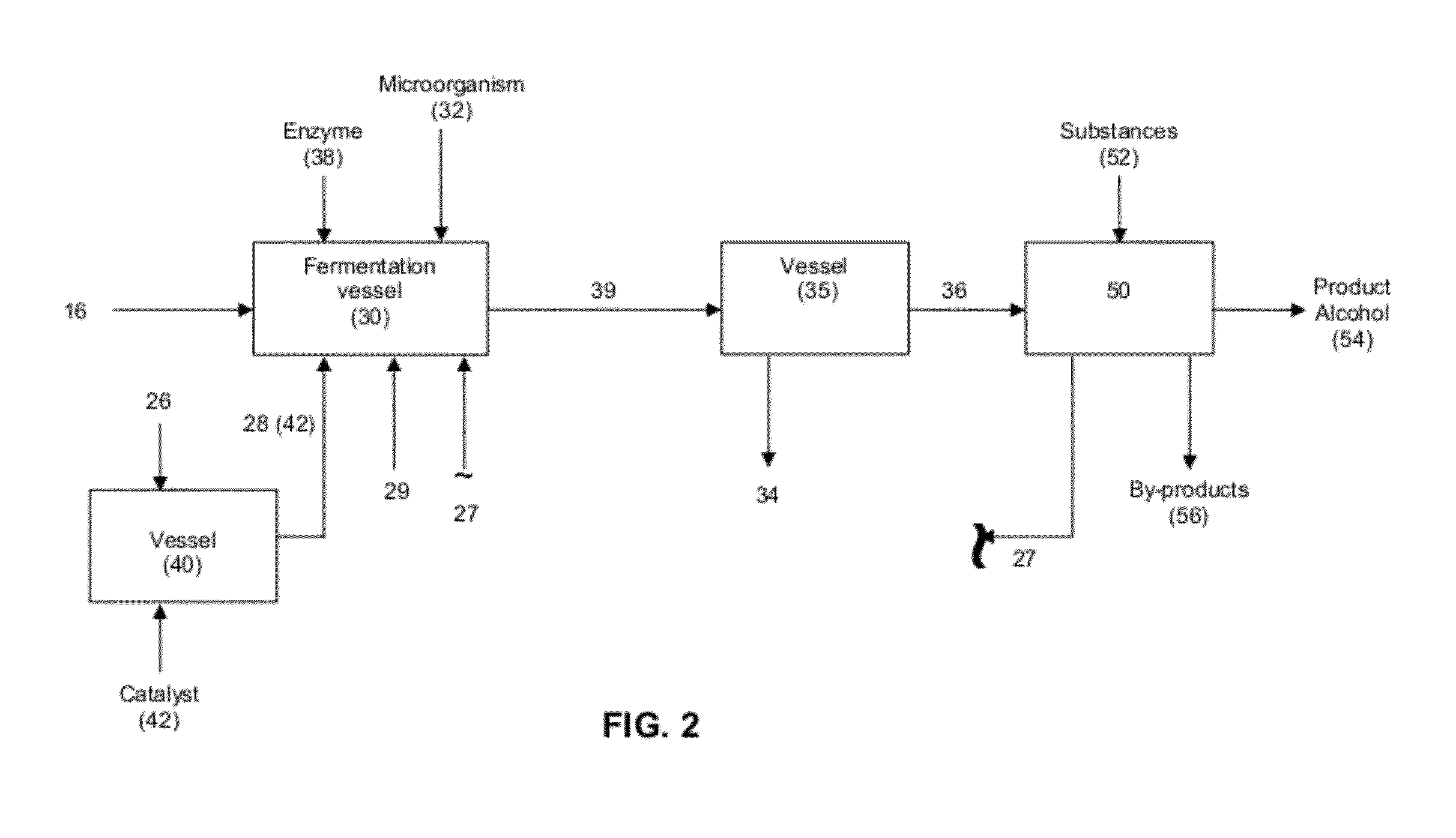

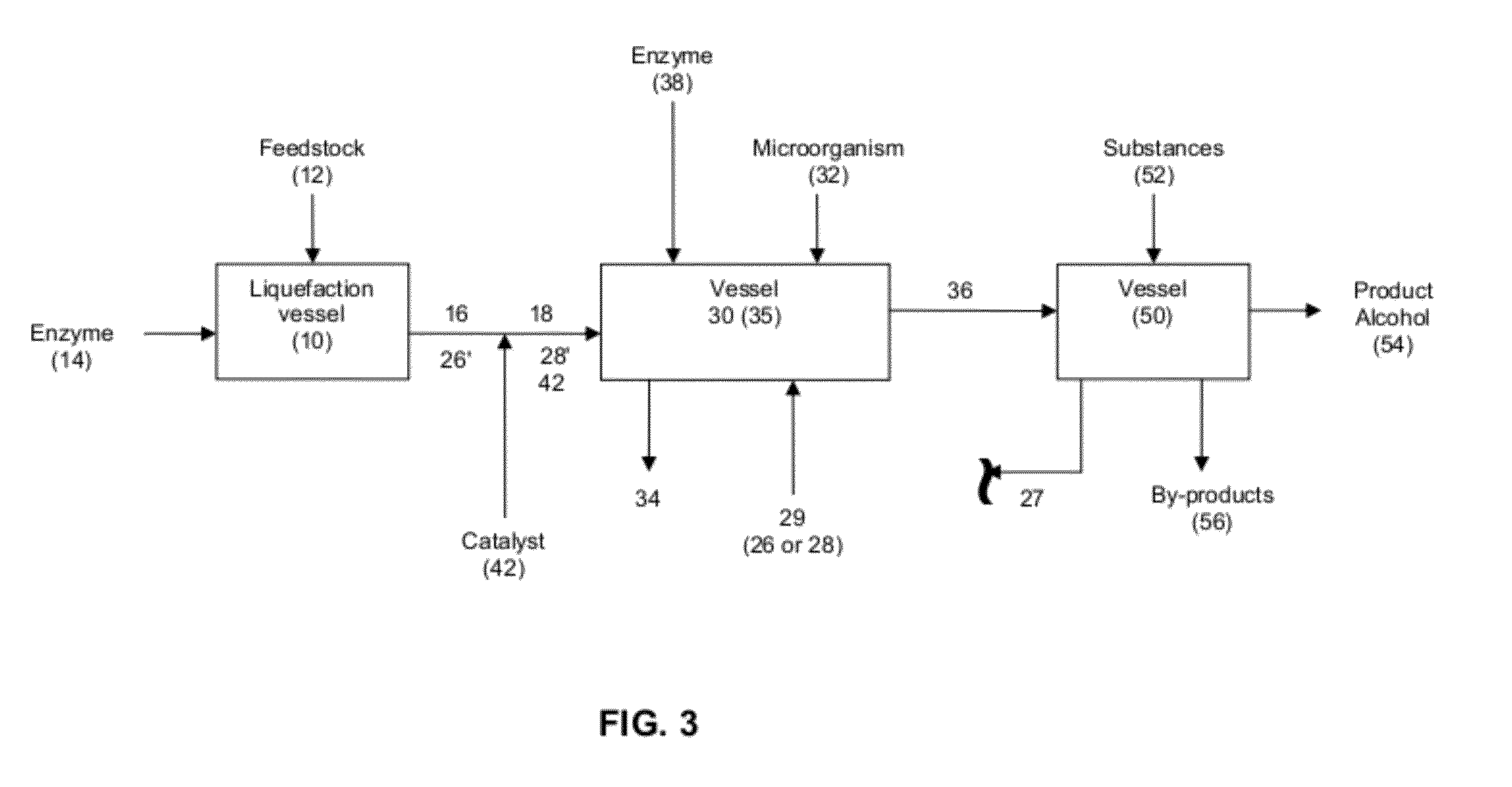

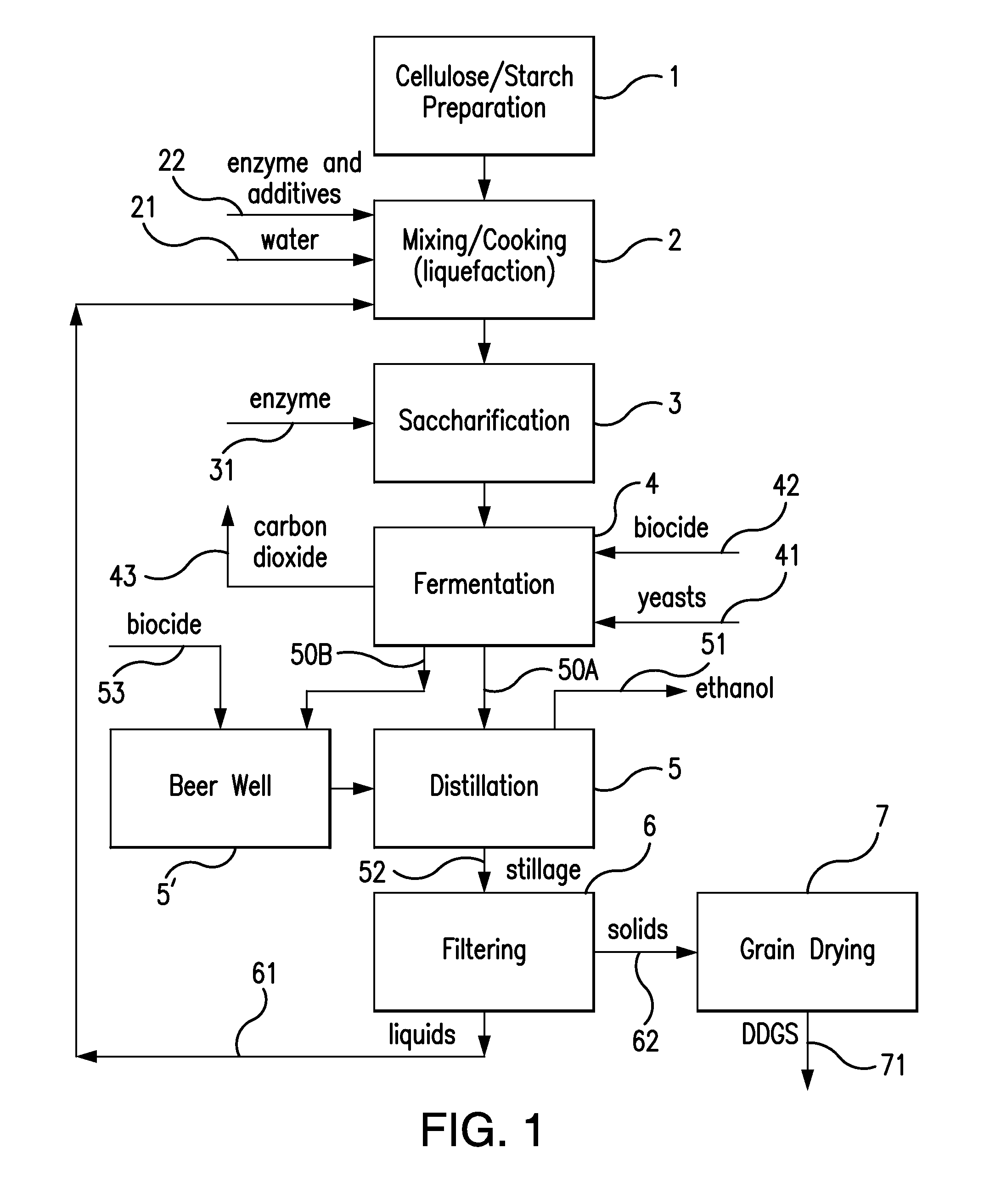

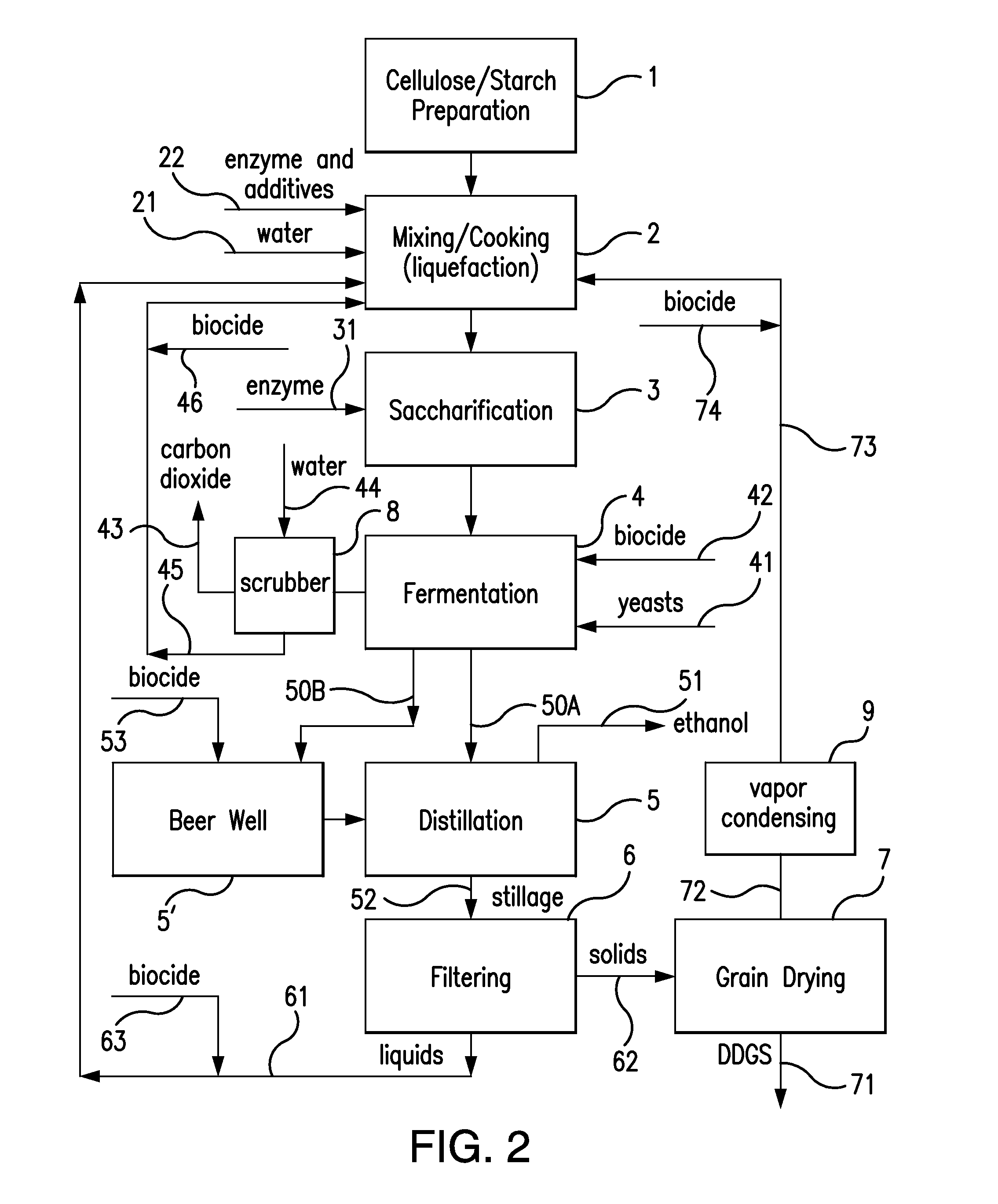

Process for improving the yield and efficiency of an ethanol fermentation plant

A process for improving the yield and efficiency of an ethanol fermentation plant that receives organic fermentable feedstock material, prepares the feedstock for fermentation, ferments the feedstock with yeast to produce ethanol, and produces stillage as a byproduct of ethanol fermentation. The process steps which can be operated independently or in combination, may include, but are not limited to, degrading fatty acids in the fermentable feedstock material prior to fermentation; degrading cellulose and hemicellulose present in the feedstock prior to fermentation; adding a surfactant to the fermentable feedstock; separating a liquid fraction from the stillage; recycling the liquid fraction to be combined with the fermentable feedstock; recovering a solid fraction from the stillage; and introducing at least a portion of the solid fraction to an anaerobic digester to produce methane.

Owner:WATER SOLUTIONS TECH LLC

Production method of aged dry red wine

The invention discloses a production method of aged dry red wine. The method is characterized by comprising the following steps of: removing the stem of grape and crushing; steeping at low temperature for 4-12 hours; after the steeping, separating part of the grape juice, and adding yeast into the pulp to perform temperature-controlled alcohol fermentation; meanwhile, centrifuging the separated grape juice for producing pink wine; after the alcohol fermentation, performing temperature-controlled micro-oxygenation on the separated raw wine; and then performing the processes of malolactic fermentation, clarification, freezing, filtering and the like to obtain the aged dry red wine. Through the invention, the chroma, tannin and total phenol of the produced aged dry red wine are obviously improved in comparison with the common aged dry red wine; moreover, the aged dry red wine produced by the method disclosed by the invention has stable color, full body, mellow and coordinative mouthfeel and strong structure sense; the aging potential is obviously enhanced; and the production method is simple and easy to control and suitable for industrial production.

Owner:YANTAI CHANGYU GRP CO LTD

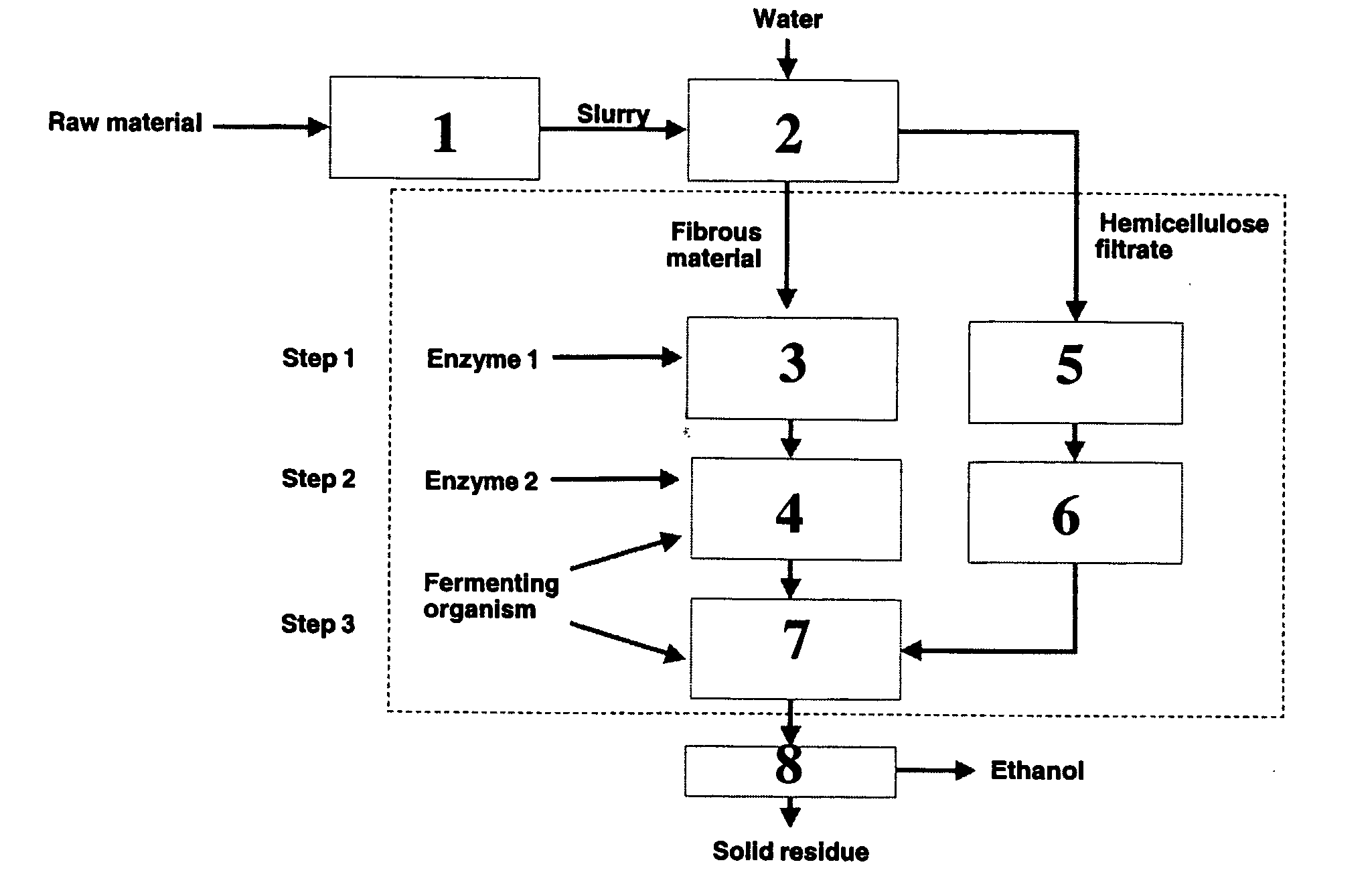

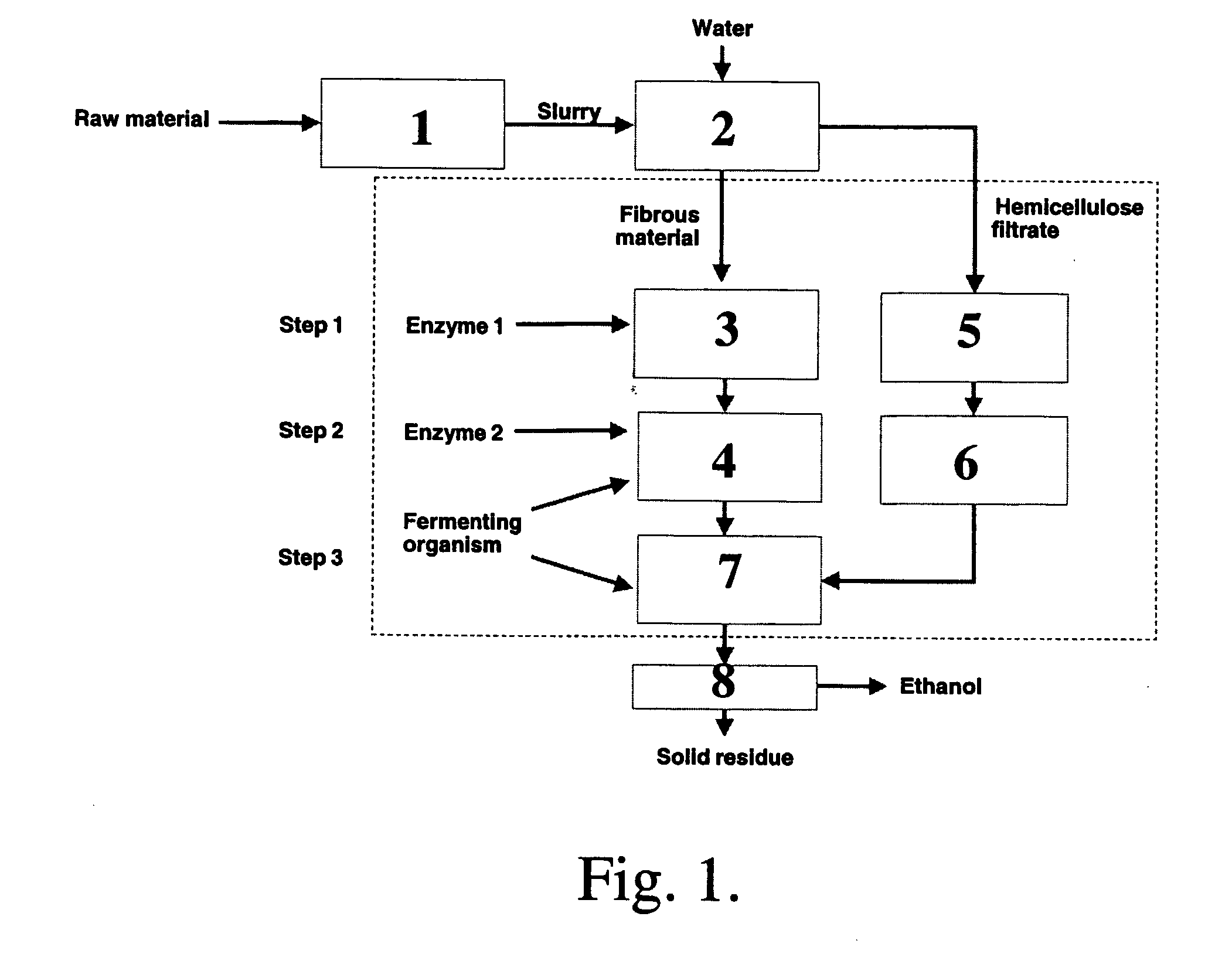

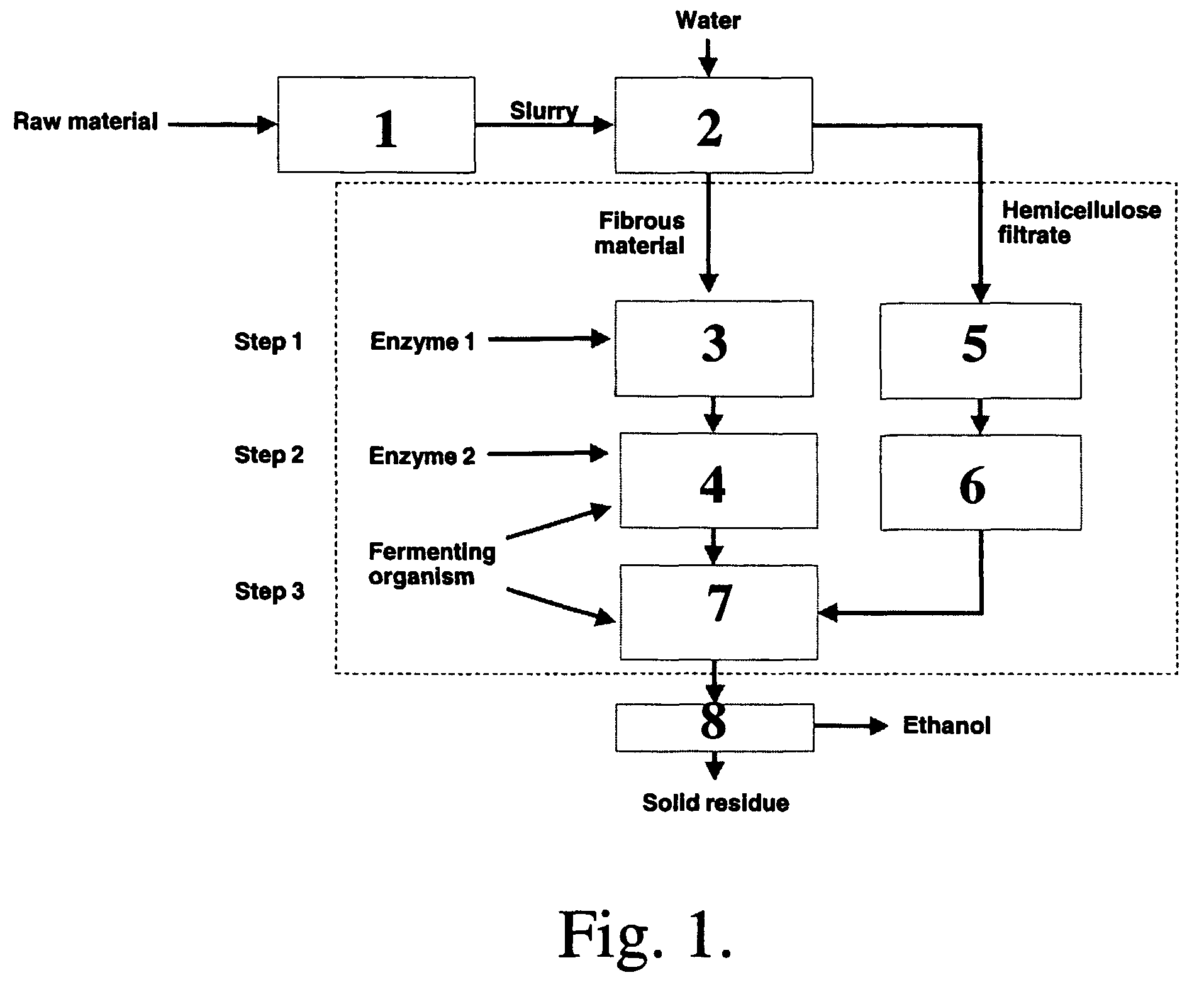

Process for Producing Ethanol

InactiveUS20080044877A1Improve efficiency and economyIncrease final ethanol concentrationBiofuelsAlcoholic beverage preparationFiberCellulose breakdown

A process for producing ethanol from a fibrous lignocellulosic raw material. After pre-treatment of the raw material, the fibrous fraction is first hydrolysed at high consistency and then the modified material is subjected simultaneously to continued hydrolysis with a cellulase and to ethanol fermentation in a fermentation mixture. Fermentation is continued to convert an essential portion of the available cellulose into ethanol, then a liquid fraction containing solubilized hemicelluloses is added to the fermentation mixture and fermentation continued. By means of the invention, high fermentation rates, high ethanol concentrations and low ethanol production costs can be attained.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

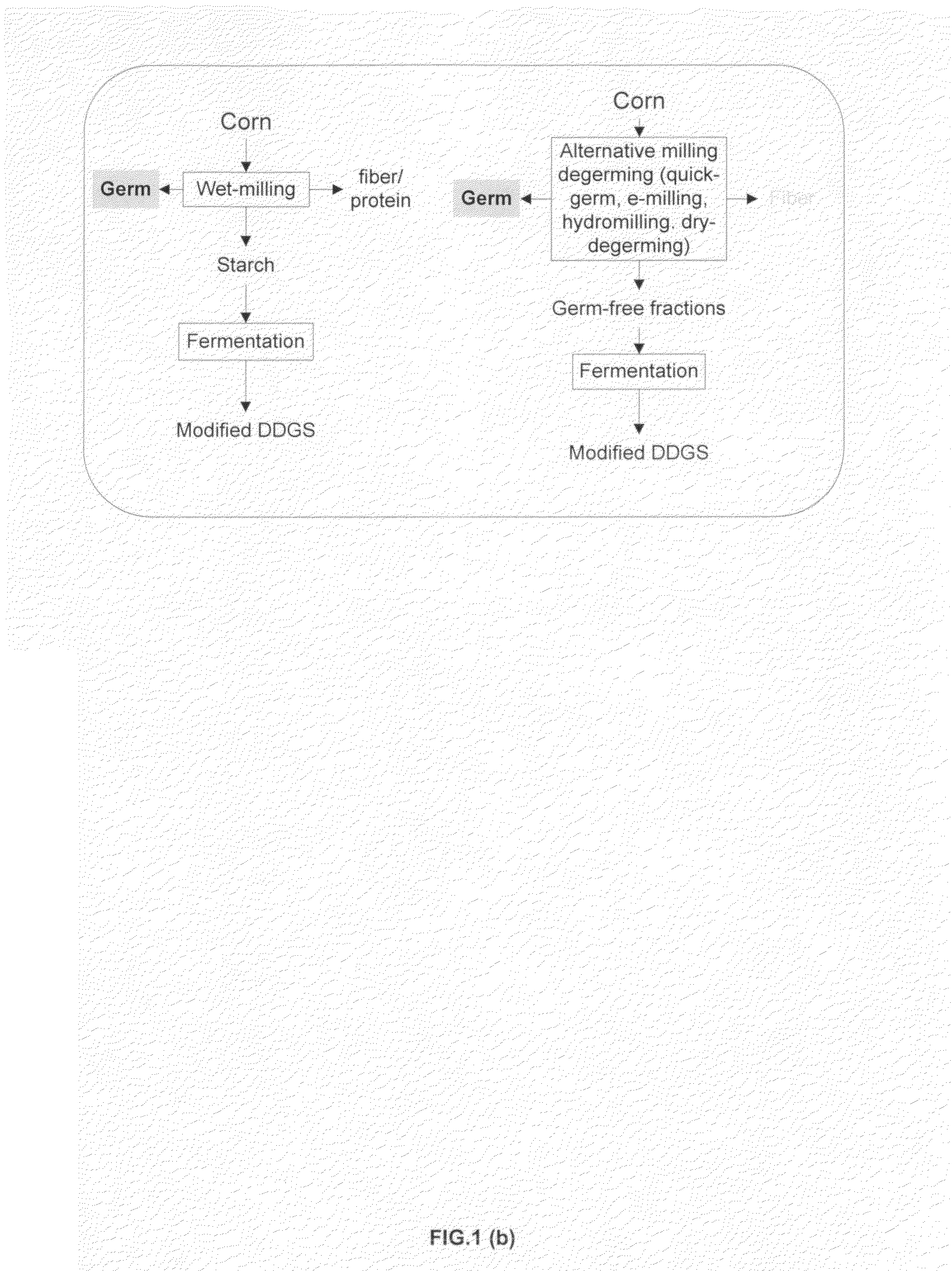

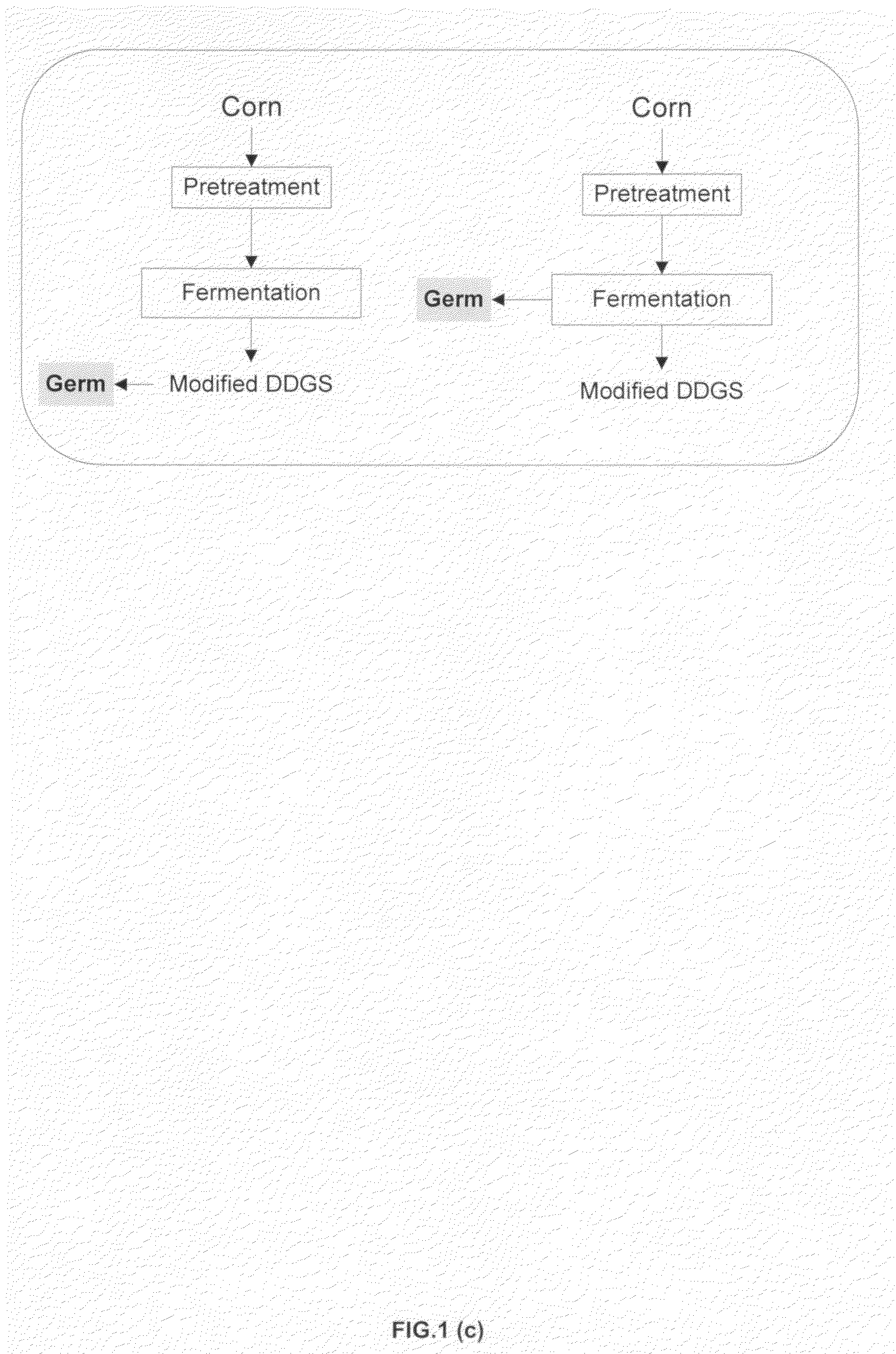

Novel corn degerming Ethanol fermentation processes

The invention presents novel corn fermentation processes that remove the oil-rich fraction either during or after fermentation instead of before fermentation as usual. Besides recovery of high value oil-rich fraction of the corn, the processes also produce other value-added co-products such as that with high fiber or high protein but low oil contents.

Owner:WANG HUI

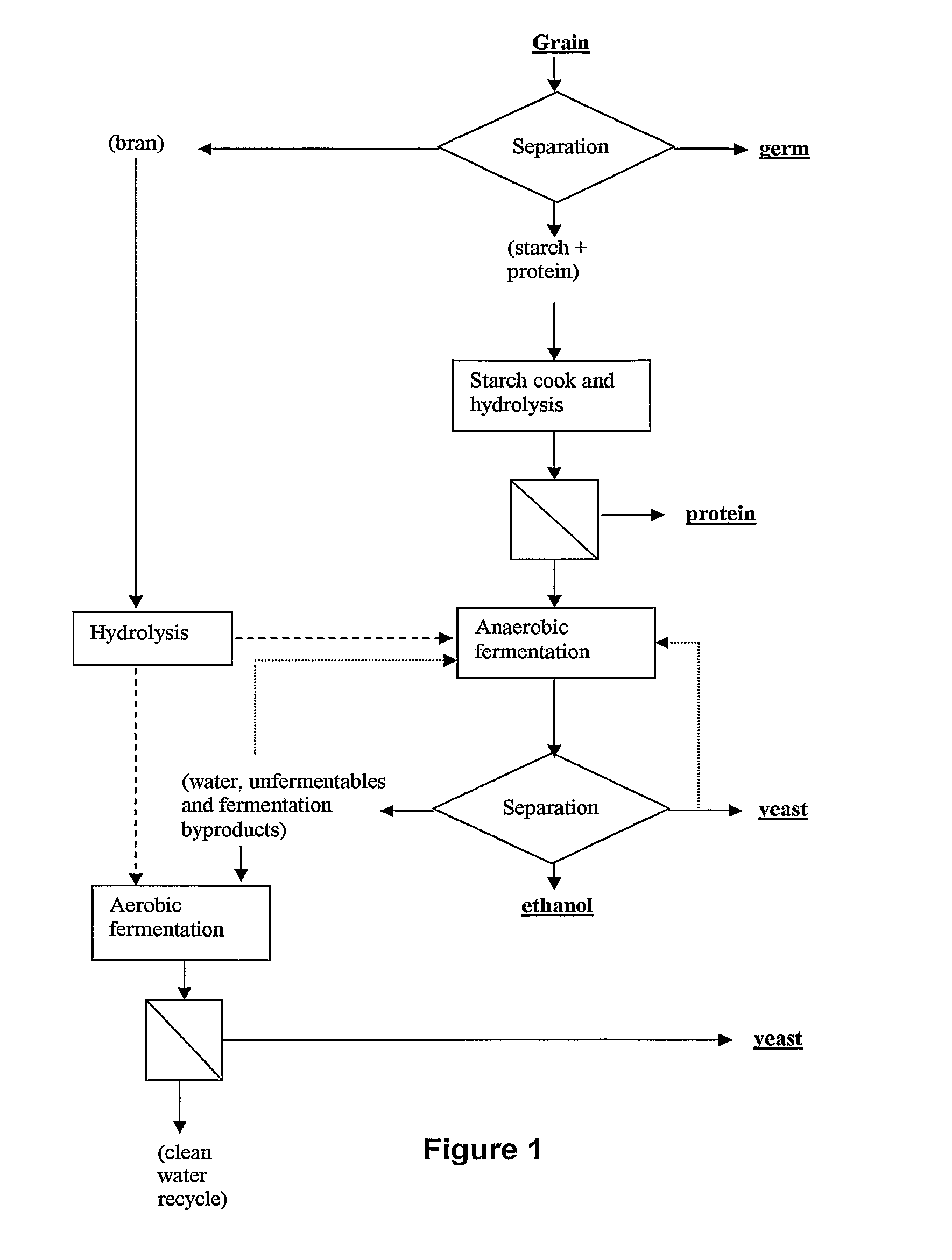

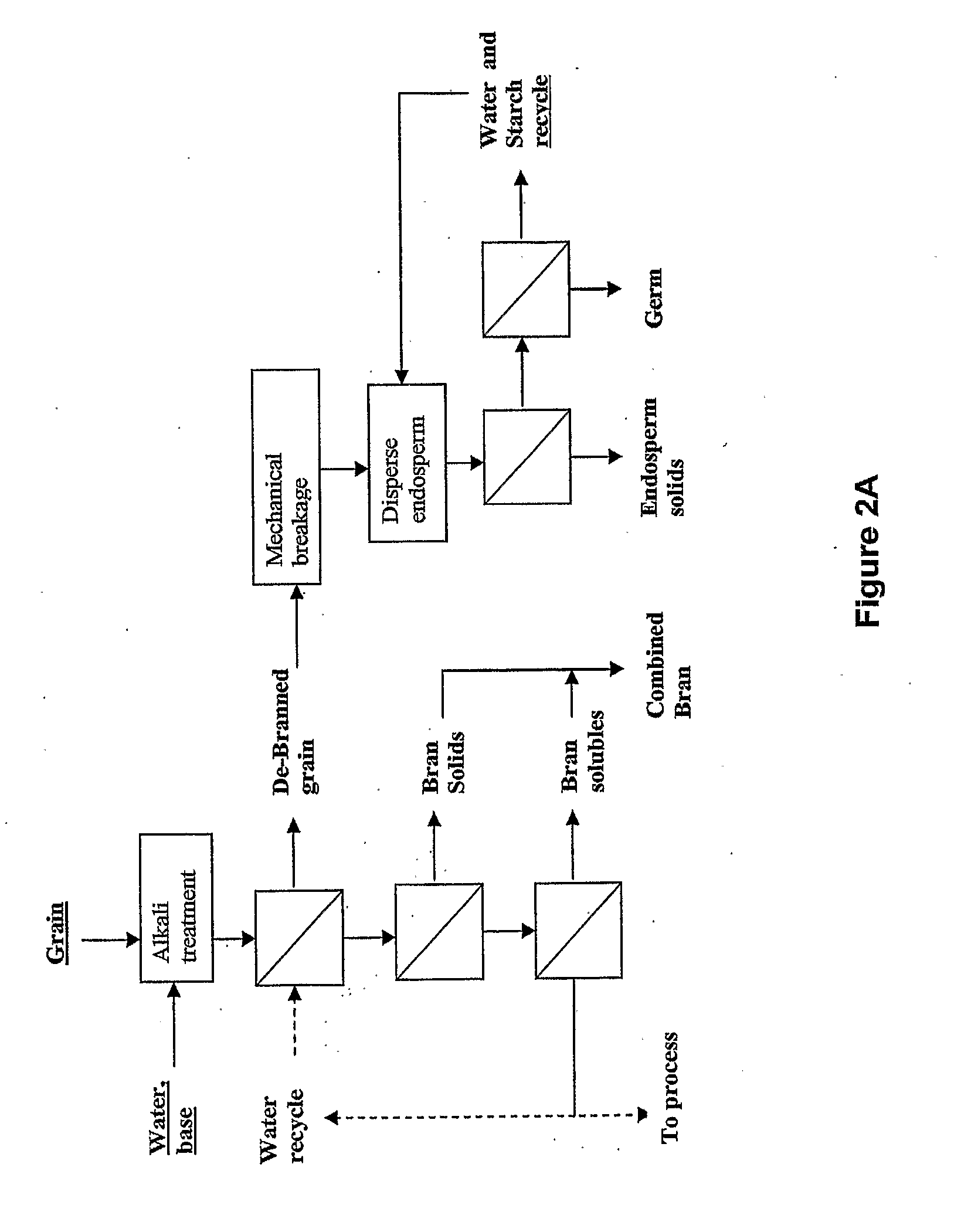

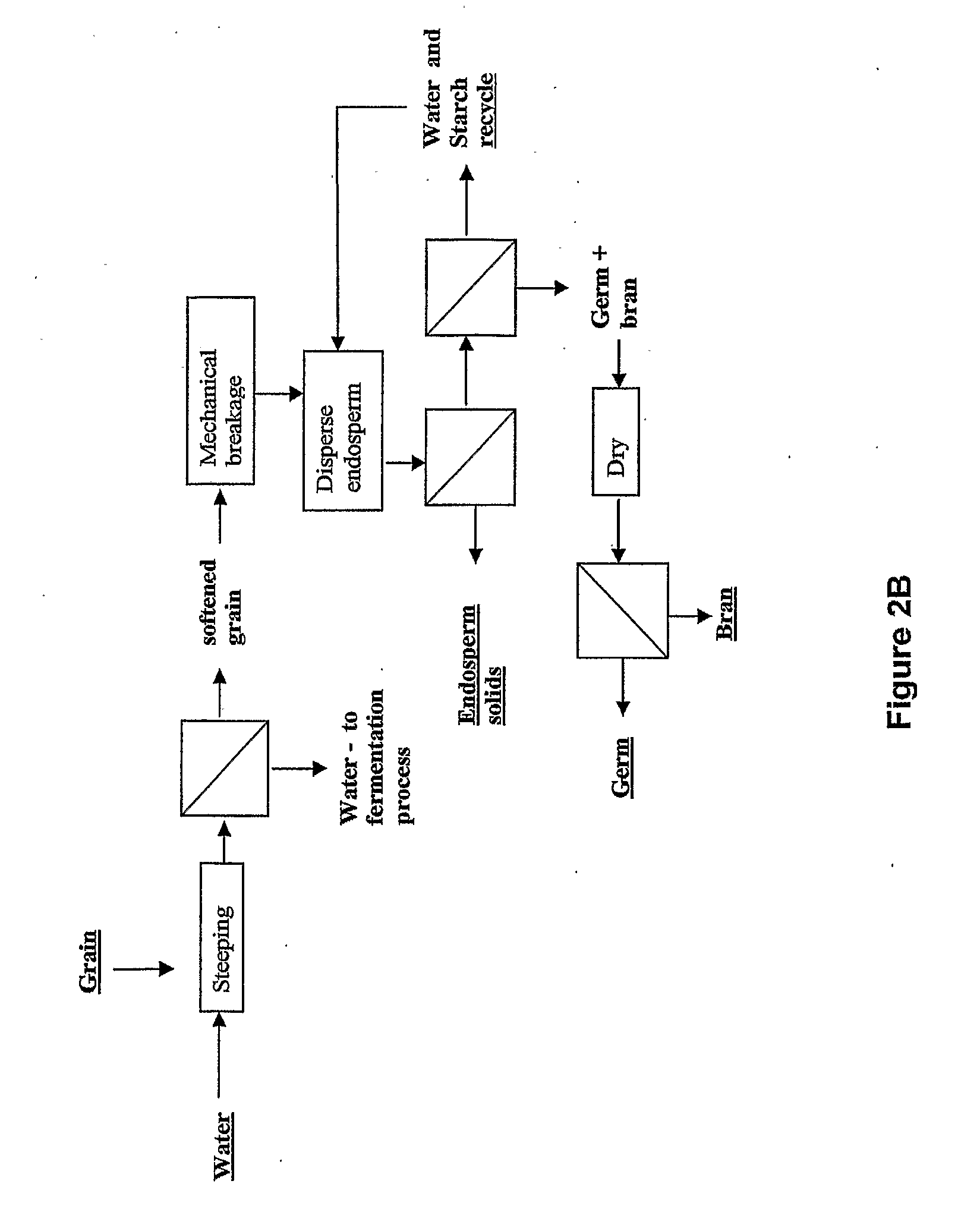

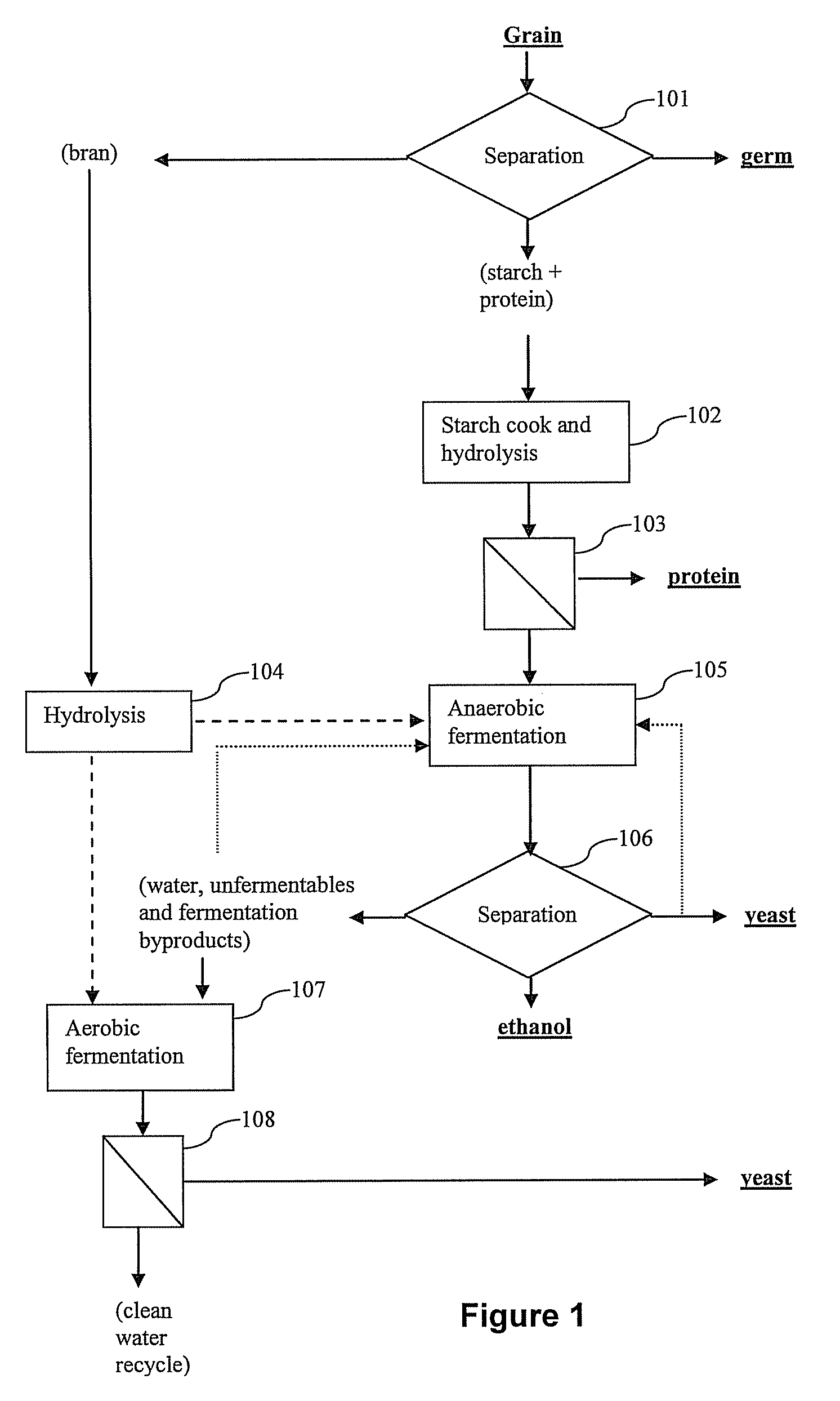

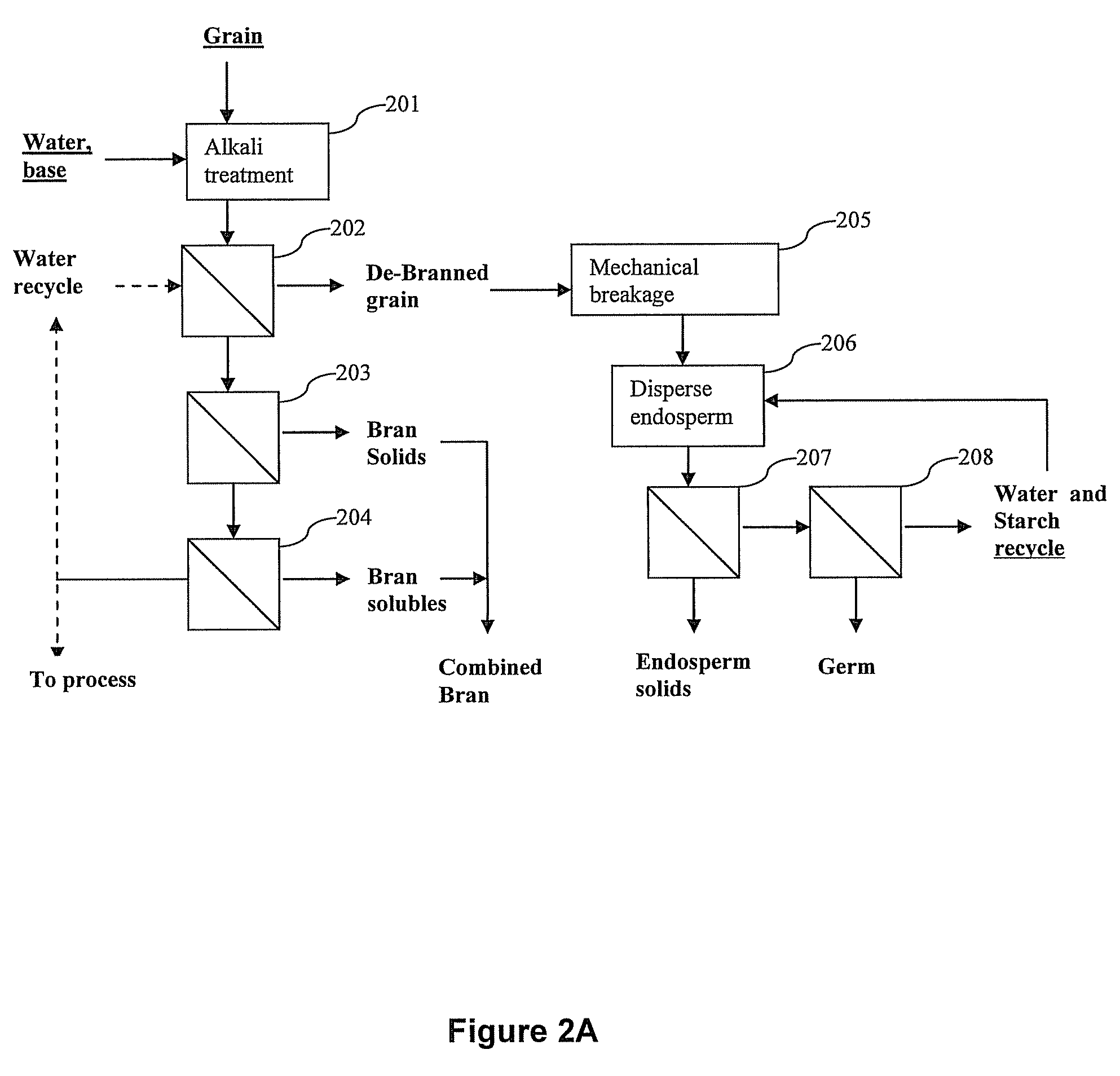

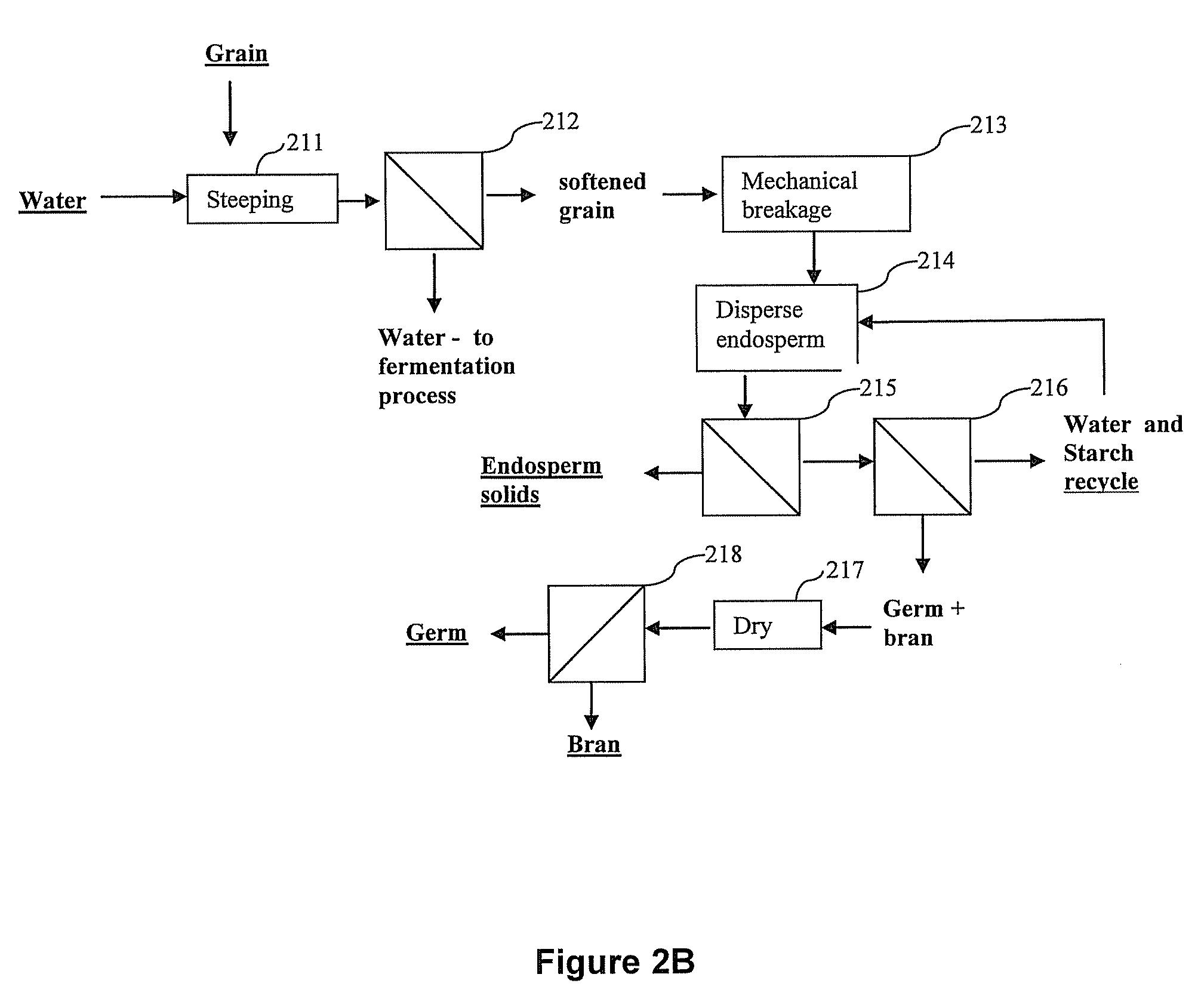

Corn fractionation method

InactiveUS20070184541A1Avoid fermentationContributing to air pollutionMicroorganismsBiofuelsFractionationFermentable sugar

An improved method for processing corn into ethanol and other valuable co-products. The invention generally involves a multi-step process which produces germ (or oil), protein, and feed yeast as its co-products while maintaining or enhancing the provision of fermentable sugar to ethanol fermentation. This is accomplished by fundamentally altering the way the corn is fractionated, disrupting the cell walls rather than the protein matrix as is done in conventional wet milling.

Owner:GRAINVALUE

Production of alcohol esters and in situ product removal during alcohol fermentation

ActiveUS20120156738A1Increase productionDecreasing rate of build-upFatty oils/acids recovery from wasteFungiAlcoholCarboxylic acid

An alcohol fermentation process and composition that includes production of alcohol esters by esterification of product alcohol in a fermentation medium with a carboxylic acid (e.g., fatty acid) and a catalyst (e.g., lipase) capable of esterifying the product alcohol, such as butanol, with the carboxylic acid to form the alcohol esters. The alcohol esters can be extracted from the fermentation medium, and the product alcohol recovered from the alcohol esters. The carboxylic acid can also serve as an extractant for removal of the alcohol esters from the fermentation medium.

Owner:GEVO INC

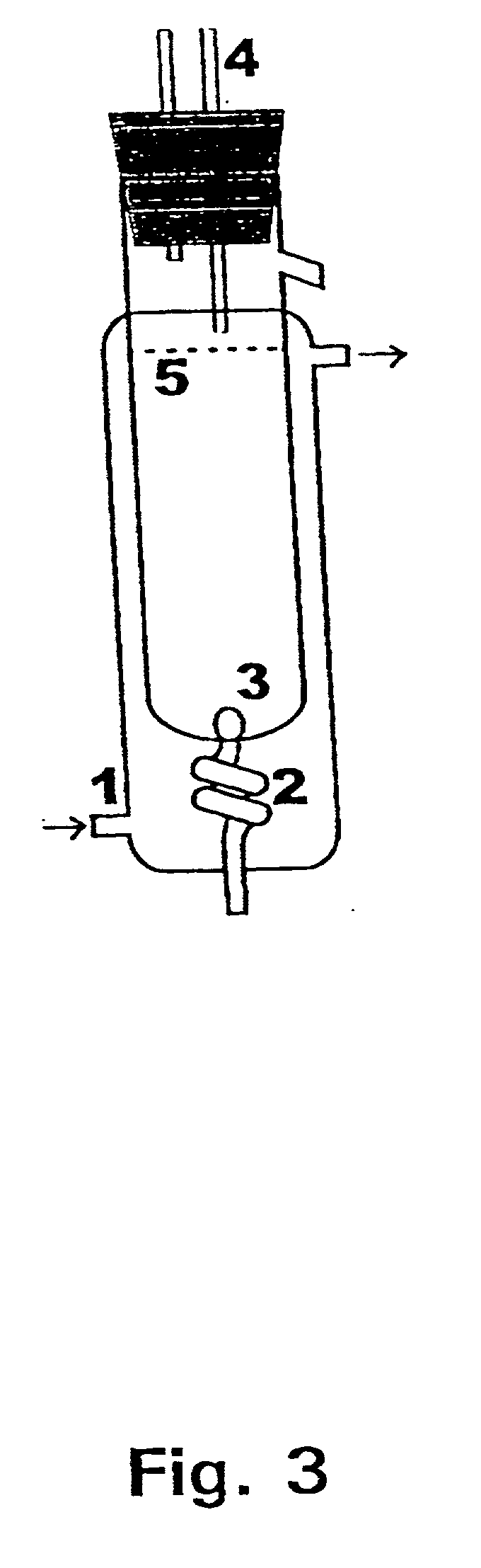

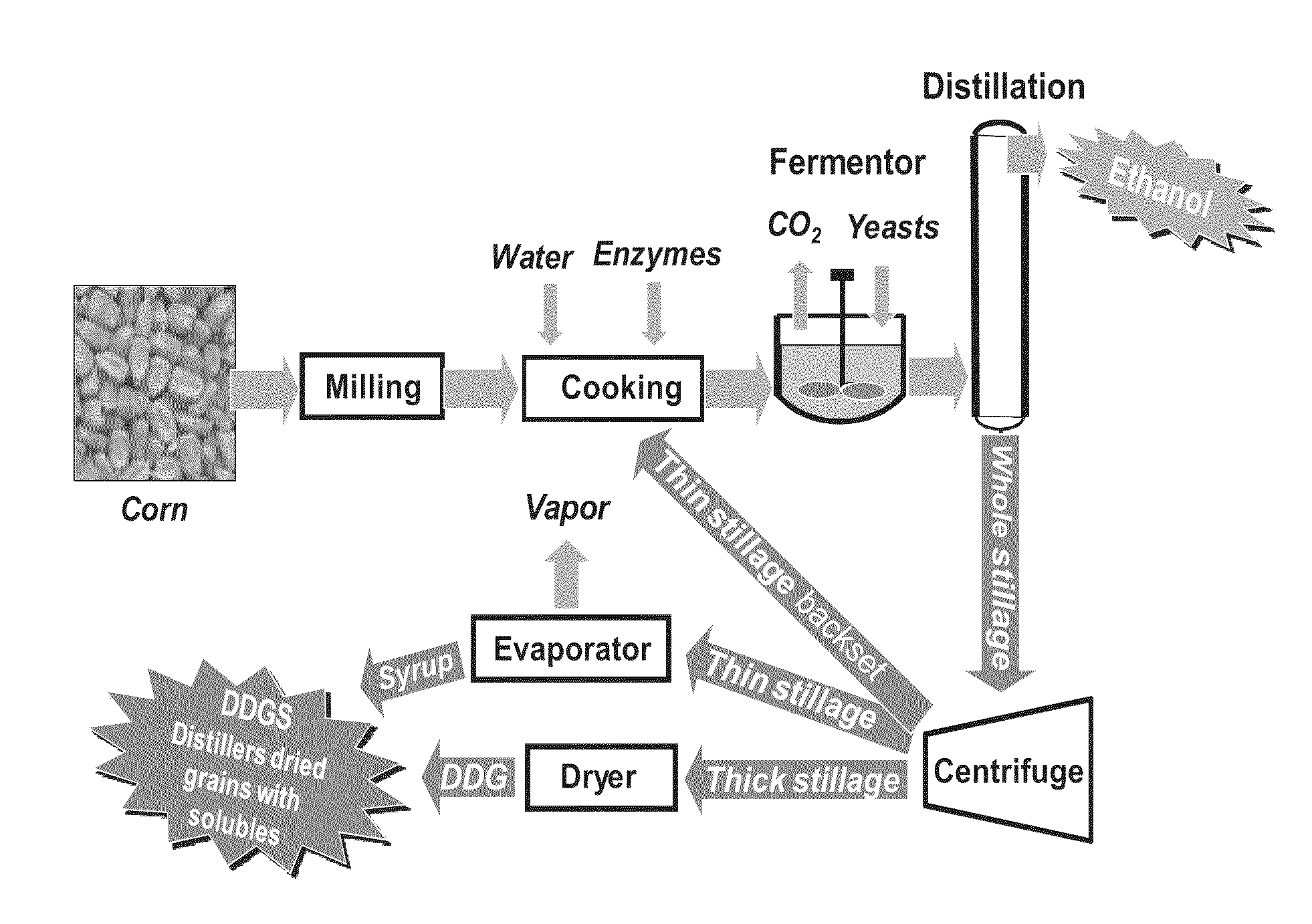

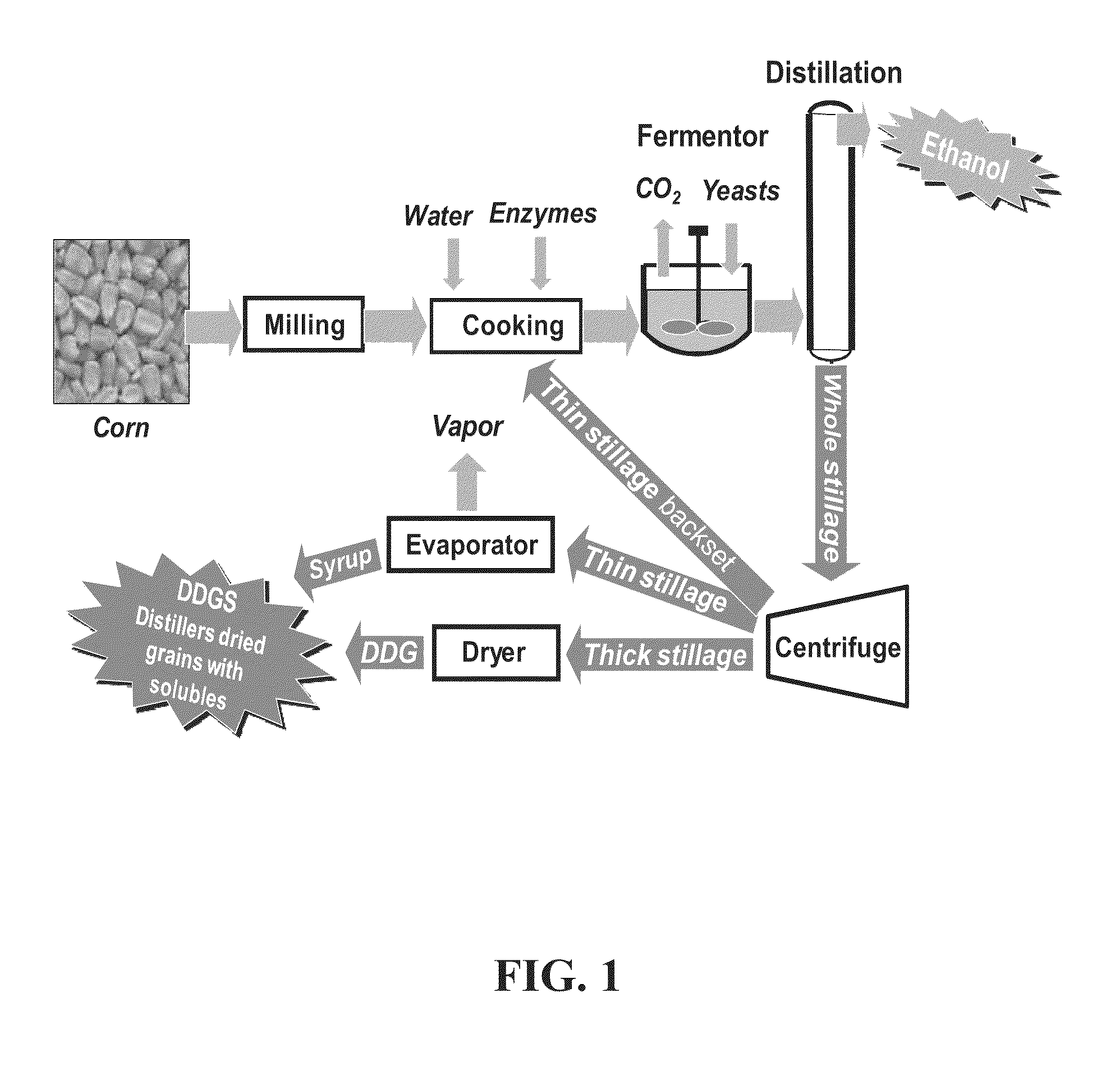

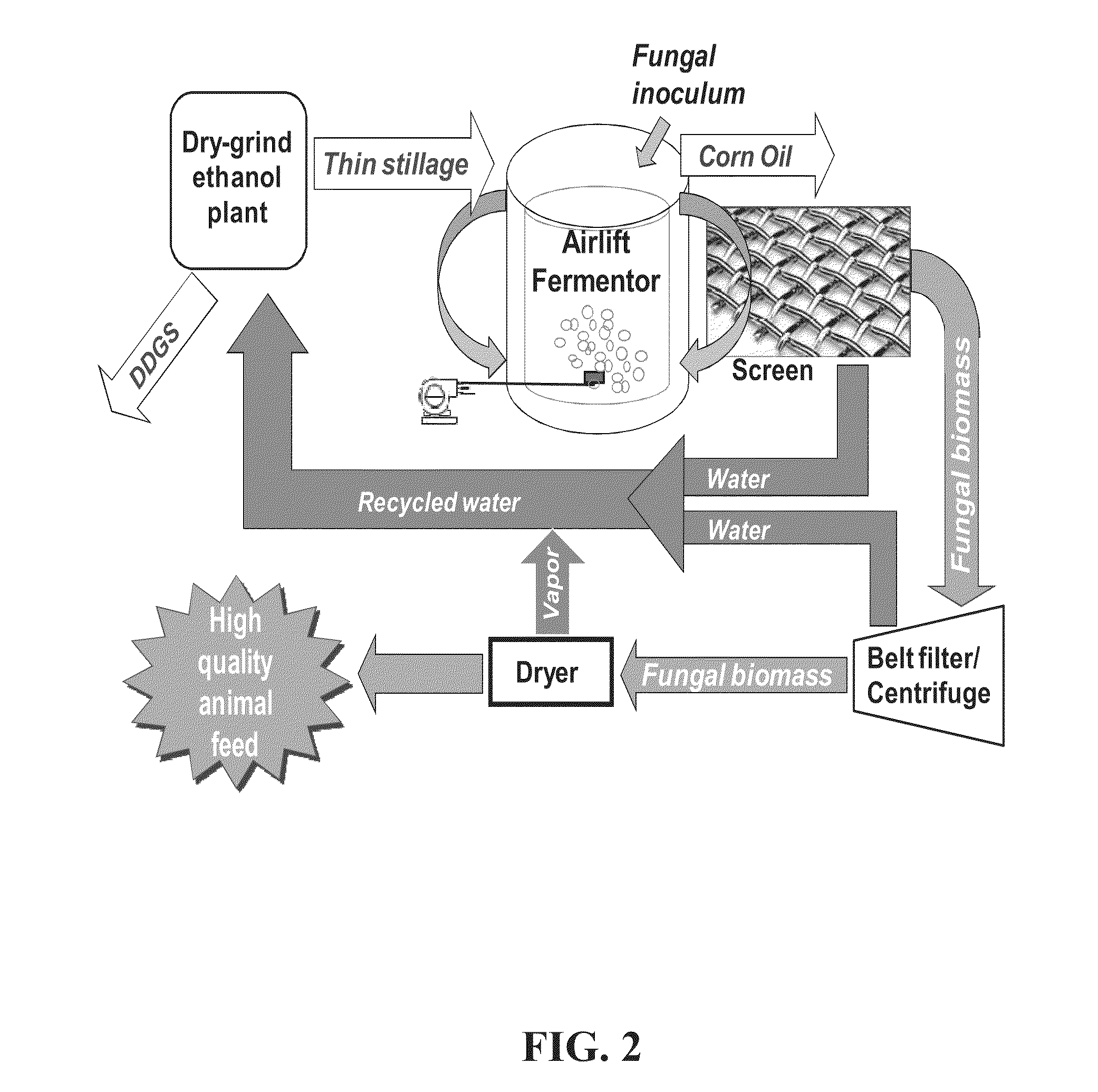

Fungi cultivation on alcohol fermentation stillage for useful products and energy savings

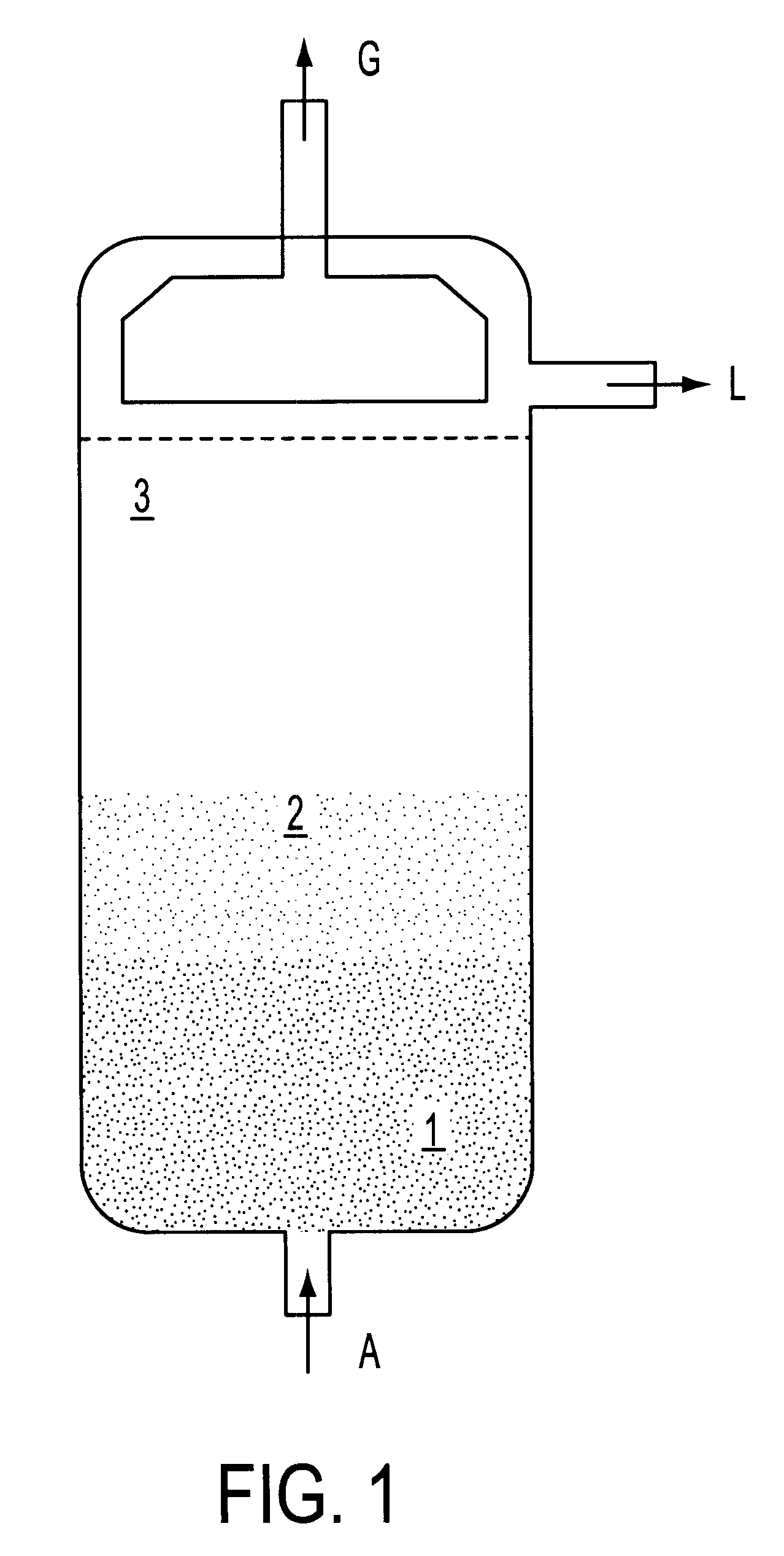

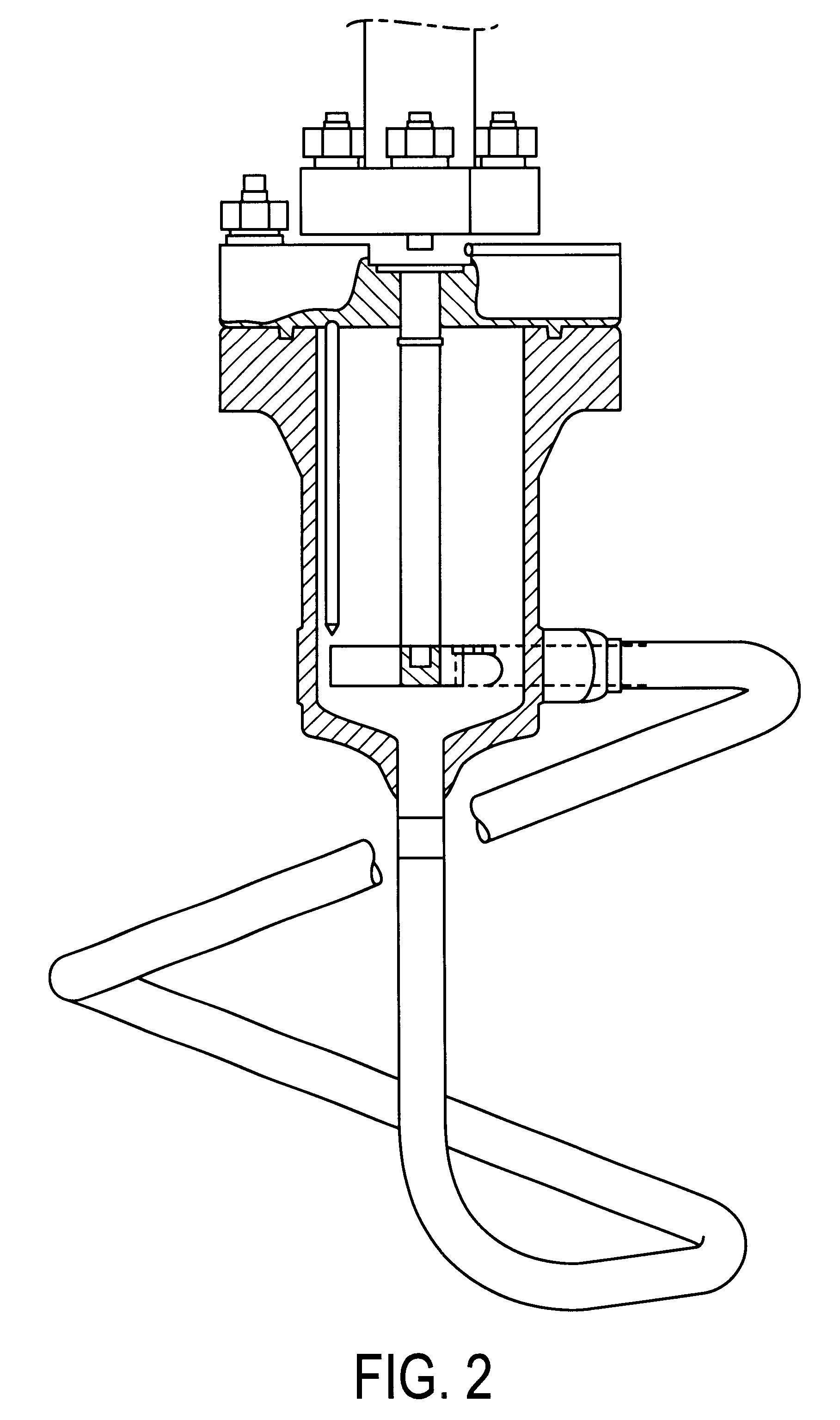

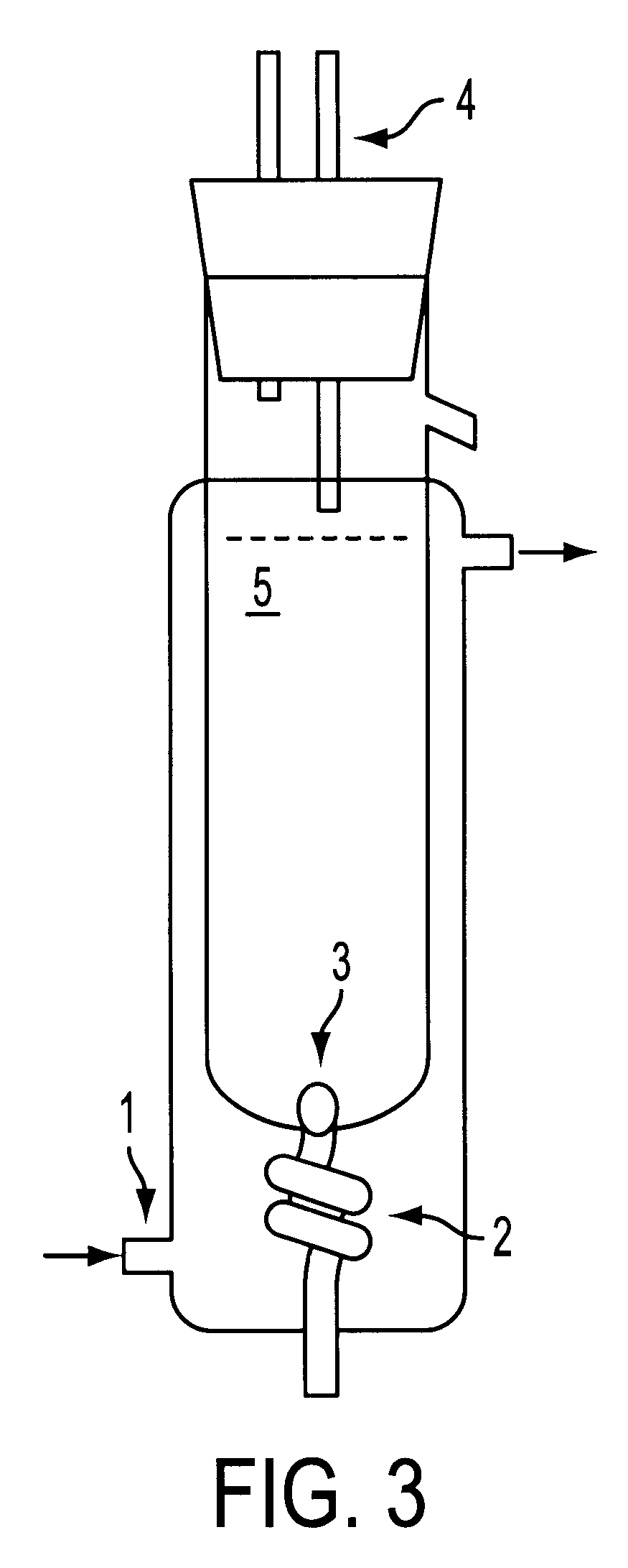

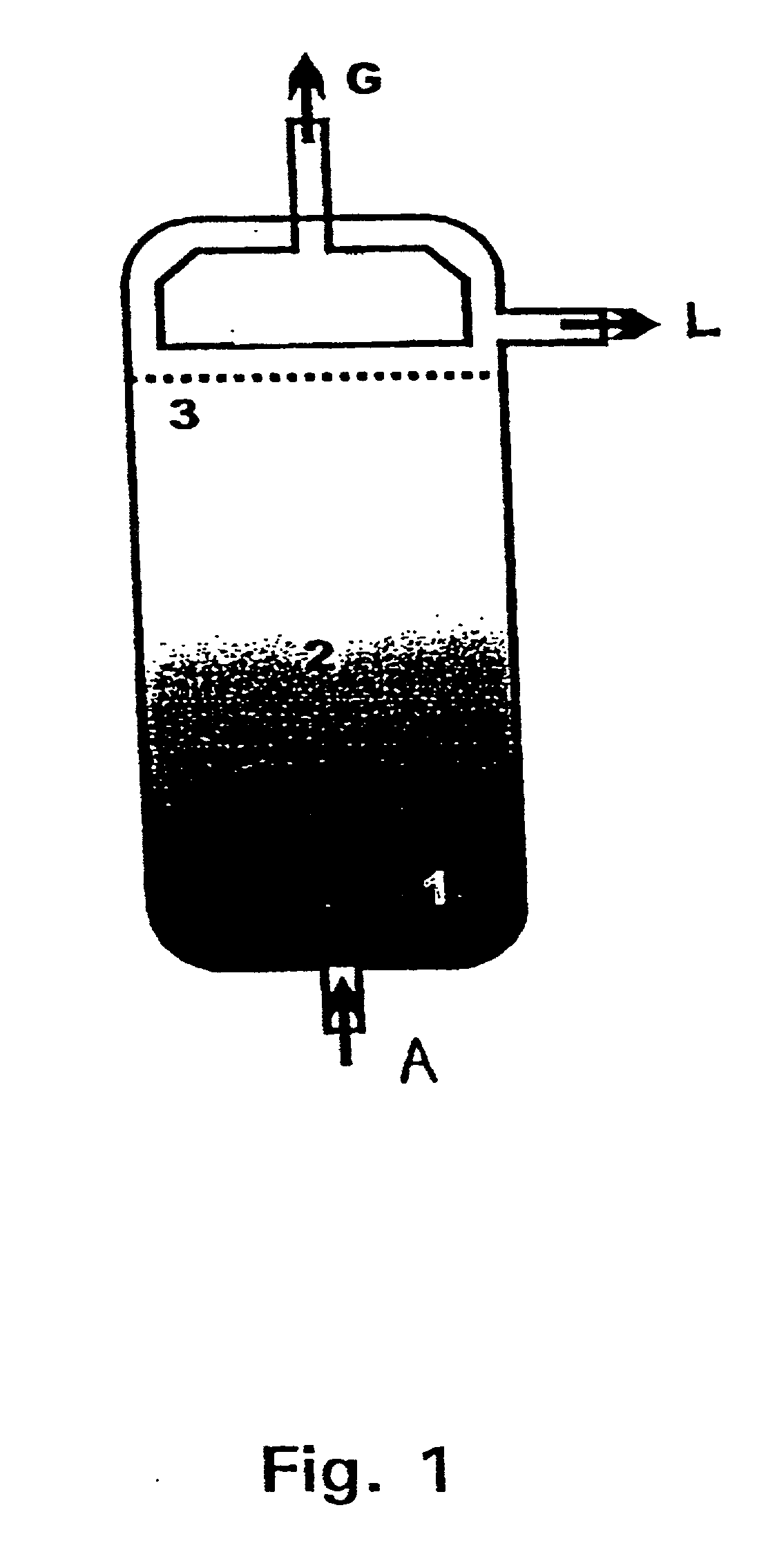

ActiveUS20100196994A1Easy to dehydrateEasy to shapeFungiEnergy based wastewater treatmentAirlift reactorGlycerol

A method of processing stillage from fermentation derived alcohol is disclosed, including dry-grind ethanol production from corn, by fermentation with filamentous fungi. This produces high-value fungal biomass that can be recovered by screening, is easily dewatered and used as an animal feed, human food or as a source of nutraceuticals. The methodology uses an airlift reactor to enhance the morphology of the fungi for easy harvesting and separation of water for recycling and reuse and to recover added enzymes and mineral acid with the water. The process also separates oil from the stillage. The fungal processing removes organic substances from the water that are otherwise inhibitory to the reuse prospects for the water, i.e. suspended and dissolved organic matter, including glycerol, lactic and acetic acids. The process also separates oil from the stillage by enmeshing the oil in the fungal biomass and can produce more oil through cultivation of oleaginous fungi. This approach generates revenue from low value thin stillage, while substantially reducing stillage processing costs, mainly by averting the need for evaporation of the thin stillage.

Owner:VAN LEEUWEN JOHANNES

Method for producing table vinegar by adopting two-step acetic acid fermentation method

ActiveCN102433255AEfficient conversionKeep the flavorMicroorganism based processesVinegar preparationAlpha-amylaseTwo step

The invention discloses a method for producing table vinegar by adopting a two-step acetic acid fermentation method and belongs to the technical field of brewing of the table vinegar. According to the method, the problems of low alcohol intolerance, long fermentation period and low acetification rate for acetic acid fermentation in a traditional method are solved. The method comprises the following steps of: uniformly stirring sorghum flour, corn flour, rice meal and water; adding thermostable alpha amylase for liquefying; after liquefying, reducing the temperature, adding Daqu, saccharifyingkoji, red starter, saccharomyces cerevisiae and aroma-producing yeast and carrying out alcoholic fermentation to obtain liquor; adopting the two-step acetic acid fermentation method: firstly, mixing the liquor; adding acetic acid bacteria subjected to liquid amplification culture for carrying out primary acetic acid fermentation; when the alcoholic strength of brewing mass is reduced to 6-5DEG C,adding wheat bran and rice husk as accessories for mixing; inoculating fire fermented liquor for carrying out secondary acetic acid fermentation; sealing the liquor; smoking the liquor; spraying vinegar; filtering; and packaging to obtain a finished product. According to the method disclosed by the invention, the high-content alcohol can be effectively converted; the acid yield and the acetification rate in unit time are improved; and the flavor of the table vinegar produced by adopting a traditional solid acetic acid fermentation method is ensured.

Owner:山西金龙鱼梁汾醋业有限公司

Fermentation pepper sauce and preparation thereof

The invention discloses a fermented pepper sauce and preparation method thereof, comprising cleaning and cutting the greenly red pepper; blanching; pulping; adding ginger, garlic, tomato, carrot, carbon source, salt as additive materials; sterilizing; and then inoculating the mold or yeast or compound bacteria of mold and yeast to perform alcohol fermentation; and then sterilizing; inoculating the acetic acid bacteria to perform acetic acid fermentation; finally adding sweeting agent and thickener to be canned. After blanching, the pulping is not necessary and the calcium salt is added to produce the products during process of preparing. The fermented pepper sauce has gentle pungent taste, delicious taste, fermentation flavor. The preparation method thereof can quickly produce the fermented pepper sauce with good and stable quality, fine flavor, safety without antiseptic, suitable for industrialized mass production with excellent market application foreground.

Owner:GUIZHOU UNIV

Dry white wine and its brewing process

InactiveCN1566312APromote fermentationStrong aromaWine preparationFruit juiceLactic acid fermentation

The invention discloses a dry white wine and its brewing process which comprises, screening grape raw material, stripping and squashing, fruit juice separating and squeezing, clarifying, alcoholic fermentation, malic acid - lactic acid fermentation, ageing, stability treatment, filtering and bottling.

Owner:YANTAI CHANGYU GRP CO LTD

Corn fractionation method

InactiveUS7820418B2Good amino acid balanceAvoid fermentationMicroorganismsBiofuelsFractionationFermentable sugar

An improved method for processing corn into ethanol and other valuable co-products. The invention generally involves a multi-step process which produces germ (or oil), protein, and feed yeast as its co-products while maintaining or enhancing the provision of fermentable sugar to ethanol fermentation. This is accomplished by fundamentally altering the way the corn is fractionated, disrupting the cell walls rather than the protein matrix as is done in conventional wet milling.

Owner:GRAINVALUE

Process for alcoholic fermentation of lignocellulosic biomass

InactiveUS20100159552A1Lower cost of capitalReduce operating costsBiofuelsFermentationCelluloseHydrolysate

A process for the production of ethanol wherein a hydrolyzed lignocellulosic biomass is fermented in the presence of a stillage residue. The fermentation of cellulosic hydrolysates is improved by adding prior to and / or during fermentation a stillage residue side stream from a corn starch-to-ethanol process as a nutrient source for the yeast organisms used in the fermentation. Stillage residues from the grain dry mill ethanol producing process, including the whole stillage, wet cake, thin stillage, and / or syrup are added to assist as a nitrogen and nutrient source for the fermentive processes. The stillage residue is produced by any grain-to-ethanol process.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Method for preparing chitosan magnetic micro-sphere and method for immobilizing yeast by using the magnetic micro-sphere

InactiveCN101240075AGood biocompatibilityUniform particle sizeOrganic/organic-metallic materials magnetismOn/in organic carrierMicrosphereEmulsion polymerization

Preparation of chitosan magnetic microsphere and preparation of immobilized yeast for magnetic microsphere. The invention adopts suspended emulsion polymerization to prepare chitosan magnetic microsphere. The invention immobilize yeast cell to magnetic microsphere by swelling absorption. The inventive chitosan magnetic microsphere has characteristics of both magnetic particle and macromolecular material. Immobilized yeast cell is not discharged out of the system with fermentation broth, so that consumption is avoided, concentration of yeast cell in the fermentor is kept, rate of alcoholic fermentation is enhanced, fermentation time is shorten, resource consumption is reduced, while reducing discharge of waste water, and hardness to process the waste water.

Owner:HARBIN INST OF TECH

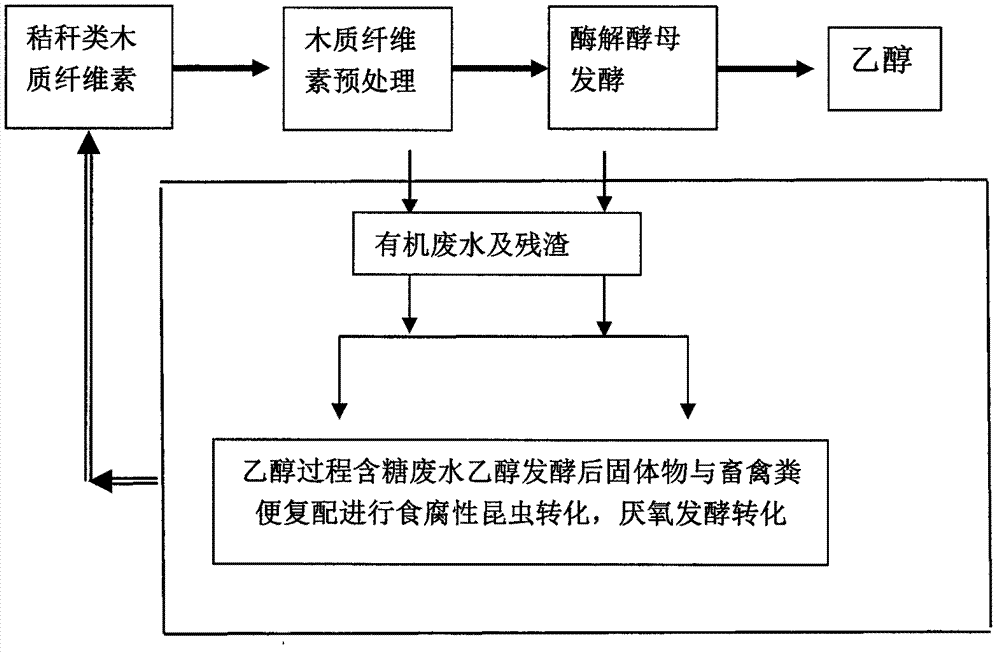

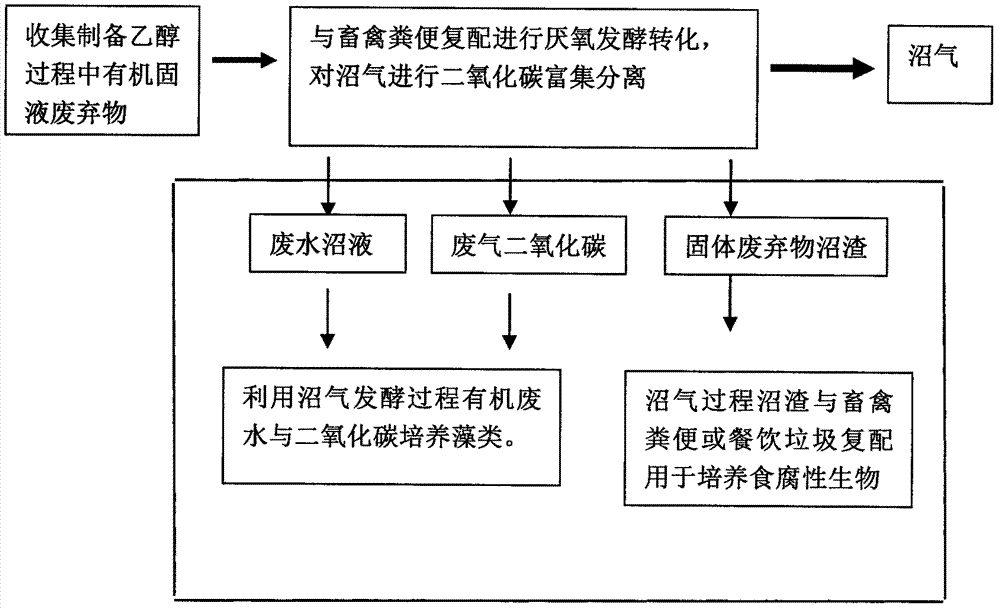

Co-production method for preparing ethanol, biogas and biodiesel by using organic waste

ActiveCN103923948AHigh yieldAbundant raw materialsBio-organic fraction processingClimate change adaptationCelluloseBiodiesel

The present invention provides a method for co-producing ethanol, biodiesel, biogas and other biological energy sources by using organic waste as a raw material. The method comprises that: a lignocellulose raw material is pretreated, enzymolysis sugar production and ethanol fermentation are performed, livestock and poultry manure is added to the enzymolysis residue, anaerobic fermentation is performed to produce biogas, the biogas residue is converted through saprophagous insects, organic wastewater is adopted to culture microalgae, and the insects and the microalgae are adopted to prepare the biodiesel; and an energy source plant conversion and utilization system is adopted to collect the process wastewater, the biogas liquid, the waste gas, the biogas residue and other solids and separate and enrich the biogas process carbon dioxide so as to be used for culture of sweet sorghum, sugar cane and other sugar-containing energy source plants, purple sweet potato and other starch-containing energy source plants, aspen and other cellulose-containing energy source plants, and sapium sebiferum and other grease-containing energy source plants, and the biomass produced by the energy source plants can further be used for extracting sugar sources, starch, fat and cellulose for biological energy source production.

Owner:HUAZHONG AGRI UNIV +1

A preparation method for a ferment type fruit tobacco flavor

InactiveCN102719313AIncrease contentIncrease cigarette aromaTobacco preparationEssential-oils/perfumesFlavorMicroorganism

The invention relates to a preparation method for a ferment type fruit tobacco flavor, comprising the following steps: uniformly mixing an apple juice and a banana juice in a weight ratio of 1:0.5-2 to obtain a complex fruit juice; adding a sugar and an acid into the complex fruit juice and adjusting a sugar degree and an acid degree of the fruit juice to ensure a sugar content of 11 DEG C to 12 DEG C and a acid degree of 3.5 to4.0 in the complex fruit juice; adding an active saccharomyces cerevisiae into the obtained complex fruit juice in a mass ratio of the juice to the active saccharomyces cerevisiae being 1000-100 : 1 and uniformly mixing the obtained product for alcoholic fermentation; after the fermentation, filtering out the saccharomyces cerevisiae, subjecting the obtained product to acetic fermentation in an acetic fermentation tank; and filtering the fermented fruit juice and storing the obtained product in an airtight container. The method, through microbial fermentation, can increase a content of various aroma materials in the fruit juice and is of great importance for cigarette aroma improvement. Adding the tobacco flavor produced through the method into cigarettes can lead to rich cigarette smoke and aroma, with taste of the cigarettes obviously improved.

Owner:HUBEI CHINA TOBACCO IND +1

Method for brewing pomelo peel vinegar

The invention discloses a method for brewing pomelo peel vinegar. According to the pomelo peel vinegar, the pomelo peel which is not eaten by people is used as raw material. The method for brewing the pomelo peel vinegar comprises the steps of steaming for removing water, pulping and separating, stewing sticky rice, fermenting ethyl alcohol, fermenting acetic acid, ageing, filtering, sterilizing, filling, inspecting and storing. Due to the adoption of the pomelo peel which is not eaten by people as the raw material, the production cost is reduced; additional values of products are increased; the pomelo peel is steamed to remove water, so that bitter taste in the pomelo peel can be removed; the taste of the finished vinegar can be improved; the finished pomelo peel vinegar has effects of assisting for digestion, warming stomach, eliminating phlegm and quenching thirst, wetting whistle, regulating qi and removing stasis and the like.

Owner:安徽杨府锦调味食品股份有限公司

Production method of fermented beef jerky

The invention discloses a production method of fermented beef jerky. The production method is characterized by comprising the steps of: cutting fresh beef into 3-4cm strips, soaking the strips by a mixing solution of CaCl2, composite phosphate and ginger juice for a whole night, adding glucose and a fermenting agent in the mixture, fermenting for 8 hours and roasting for 12 hours, boiling in boiling water and roasting for 1 hour, and implementing vacuum packaging and high-pressure sterilization to obtain the fermented beef jerky. The production method makes use of the acid production capacity of acid kumiss from natural fermentation and lactobacillus which is excellent in growth property, and is easy to control a fermentation process and short in fermentation cycle; the production method changes conventional processes of boiling twice, frying and the like, so that the deterioration of a later product due to over oxidation in the frying process is avoided and the shelf life is prolonged; and by adding a tendering pickling process and the fermentation process, the fermented beef jerky is unique in flavor, and has soft lactic acid taste and good color, reflects the fermentation property of lactobacillus, is soft and tender in texture, and is applicable to people of all ages.

Owner:贺银凤 +1

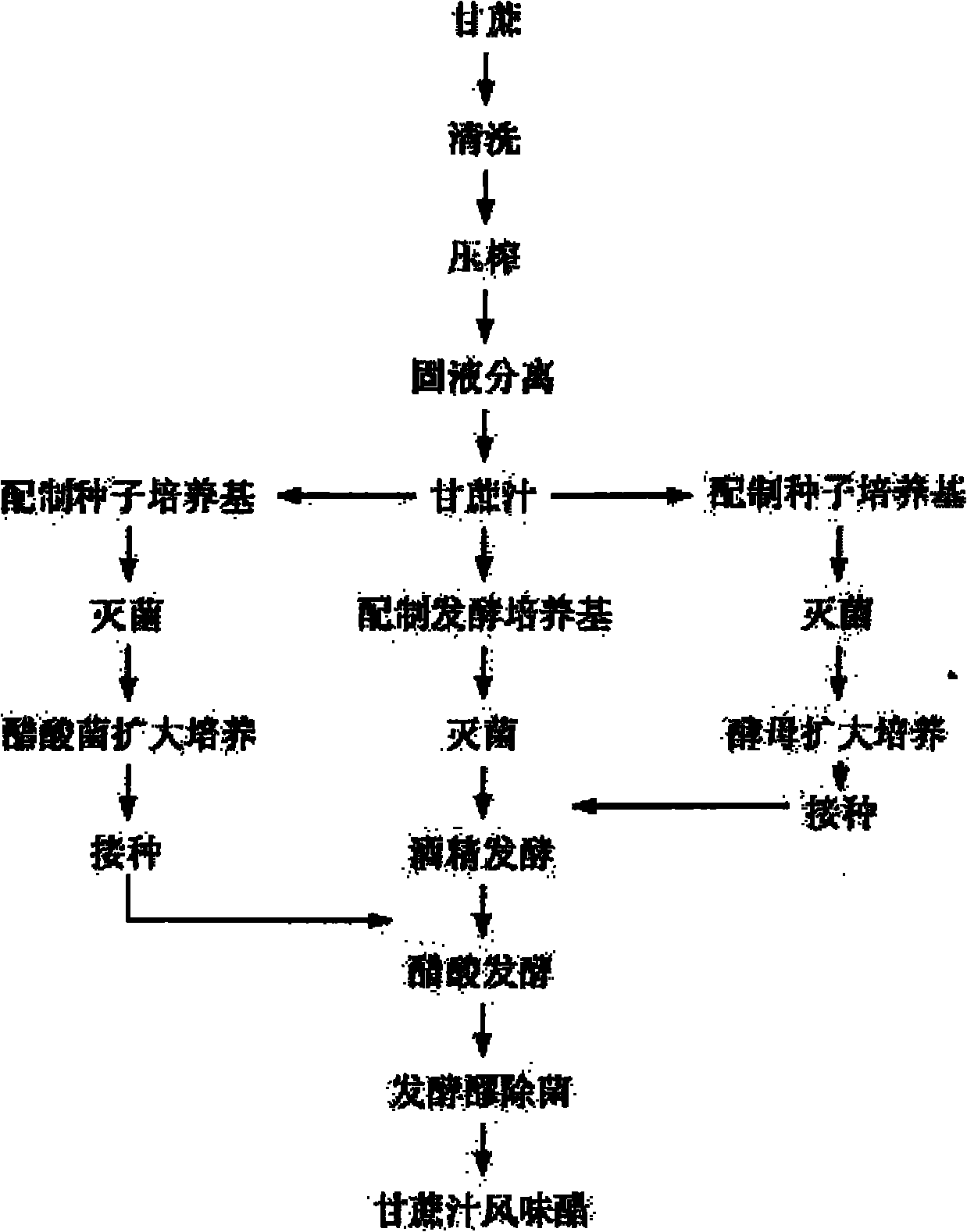

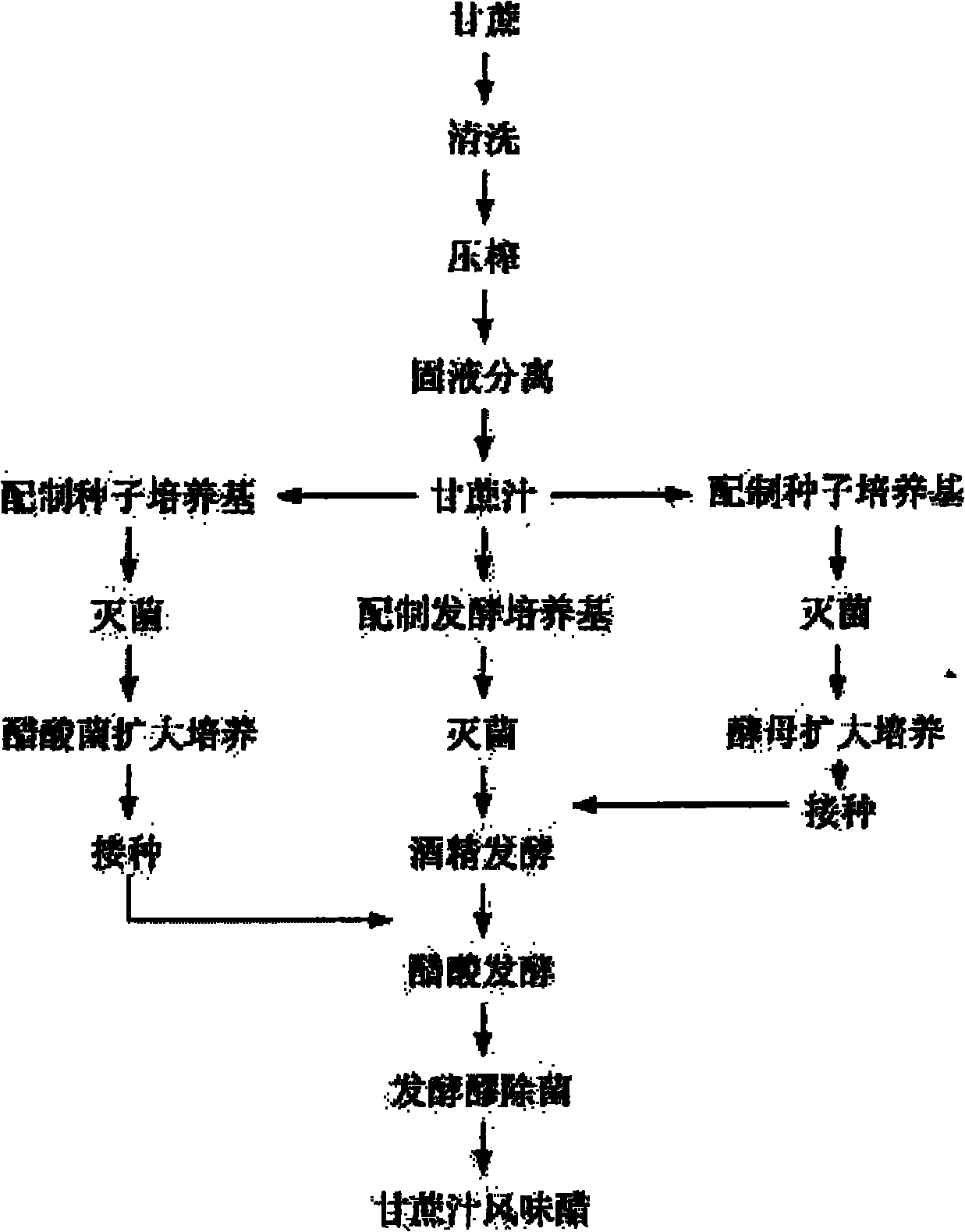

Method for preparing sugarcane juice flavor vinegar

ActiveCN101955879ASolving new utilization problemsStrong aromaMicroorganism based processesVinegar preparationFood flavorGrowth point

The invention discloses a method for preparing sugarcane juice flavor vinegar, which comprises the following steps of: cleaning sugarcane, pressing, and performing solid-liquid separation and other treatment to obtain clarified sugarcane juice, and preparing into a fermentation medium; introducing yeast culture solution for alcoholic fermentation, wherein the introduced volume is 2 to 10 percent based on an initial volume of the alcoholic fermentation, and fermenting at the temperature of between 28 and 32 DEG C for 72 to 120 hours; finishing the alcoholic fermentation and introducing acetobacter culture solution, wherein the introduced volume is 5 to 10 percent based on the initial volume of acetic fermentation, performing submerged aeration fermentation, controlling the aeration amount to be 0.06 to 0.12L / (L*min), controlling the temperature to be between 28 and 32 DEG C, fermenting for 144 to 240 hours and finishing the acetic fermentation; and finally performing solid-liquid separation on fermenting mash, and conventionally sterilizing to prepare the sugarcane juice flavor vinegar. The prepared sugarcane juice flavor vinegar has the characteristics of rich aroma, soft sour, full mouthfeel and the like, can be used as a novel leading product of a sugarcane resource, and brings a novel economic growth point to the sugarcane industry.

Owner:广东茂德公食品集团有限公司

Preparation method of medlar fruit vinegar and medlar fruit vinegar drink

InactiveCN1995317AIncrease added valueIncrease incomeVinegar preparationFood scienceHorticultureLycium chinense

The invention discloses a making method of boxthorn fruit vinegar and boxthorn fruit vinegar beverage, which comprises the following steps: adopting fresh and ripe boxthorn as raw material; washing; squeezing; fermenting under low temperature; ageing; filtering; sterilizing; modulating to obtain the product.

Owner:赵广涛

Process for producing ethanol

InactiveUS7754456B2Improve efficiency and economyIncrease final ethanol concentrationBiofuelsAlcoholic beverage preparationFiberCellulase

A process for producing ethanol from a fibrous lignocellulosic raw material. After pre-treatment of the raw material, the fibrous fraction is first hydrolysed at high consistency and then the modified material is subjected simultaneously to continued hydrolysis with a cellulase and to ethanol fermentation in a fermentation mixture. Fermentation is continued to convert an essential portion of the available cellulose into ethanol, then a liquid fraction containing solubilized hemicelluloses is added to the fermentation mixture and fermentation continued. By means of the invention, high fermentation rates, high ethanol concentrations and low ethanol production costs can be attained.

Owner:VALTION TEKNILLINEN TUTKIMUSKESKUS

Processes Using Antibiotic Alternatives In Bioethanol Production

ActiveUS20110230394A1Increase productionLow and no adverse environmental impactAntibacterial agentsBiocideEthanol yieldAntibacterial peptide

Methods for controlling the growth of bacteria in ethanol fermentation systems with antibiotic alternatives, which can be nonoxidizing biocides, stabilized oxidizers, or any combinations thereof, are described. As an option, a process or composition of the present invention can include one or more polycyclic antibacterial peptides. The methods can provide improvements, such as increased ethanol yields with minimal carryover of biocide into co-products of the processes.

Owner:BUCKMAN LAB INT INC

Complex bacterium for bean pulp fermentation and application of complex bacterium

The invention provides a complex bacterium for bean pulp fermentation. The complex bacterium is composed of bacillus subtilis, bacillus coagulans, aspergillus niger, aspergillus oryzae, lactobacillus plantarum and saccharomyces cerevisiae. The complex bacterium provided by the invention is obtained through repeated scientific experiment and reasonable combination based on physiological metabolism feature of the microorganism, the complex bacterium is vigorous in growth metabolism, is capable of secreting a plurality of enzymes, acids and other metabolites, and is capable of efficiently decomposing macromolecule protein, anti-nutritional factors and sensitization factors in the bean pulp, obviously increasing content of soluble protein, small peptide, organic acid, protease and vitamin and the number of probiotics and antibacterial peptide, improving the digestion utilization rate, inhibiting the growth of pathogenic bacteria and reducing the use of antibiotic; and meanwhile, the complex bacterium has acid fragrance of fermentation and is good in food attractant effect. The bacteria strains forming the complex bacterium are included in a feed additive variety catalogue (2013) issued by the department of agriculture, the complex bacterium is safe and reliable, and can be directly used for the industrial production for the bean pulp fermentation.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com