Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1074 results about "Wet oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

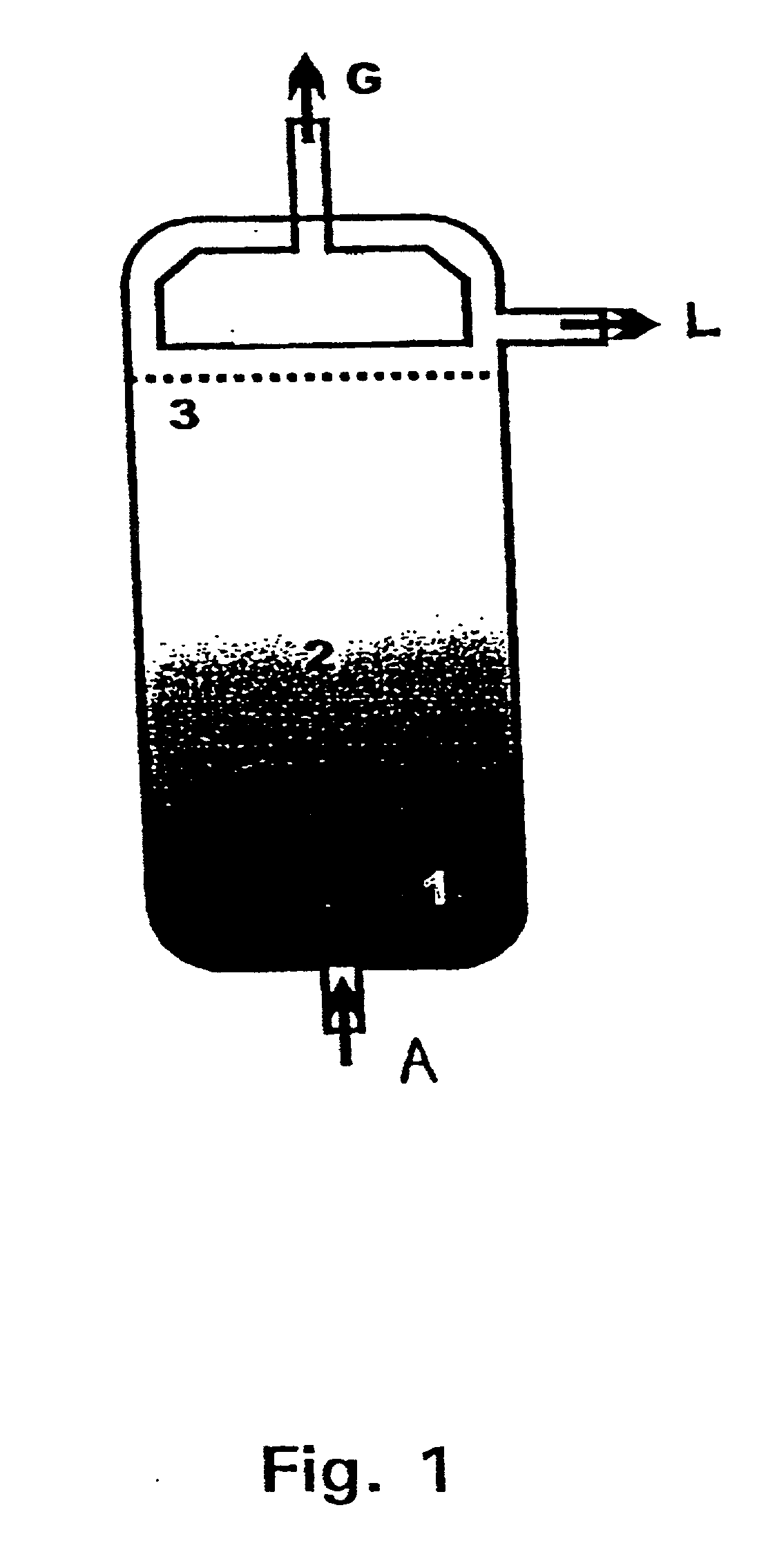

Wet oxidation is a form of hydrothermal treatment. It is the oxidation of dissolved or suspended components in water using oxygen as the oxidizer. It is referred to as "Wet Air Oxidation" (WAO) when air is used. The oxidation reactions occur in superheated water at a temperature above the normal boiling point of water (100 °C), but below the critical point (374 °C).

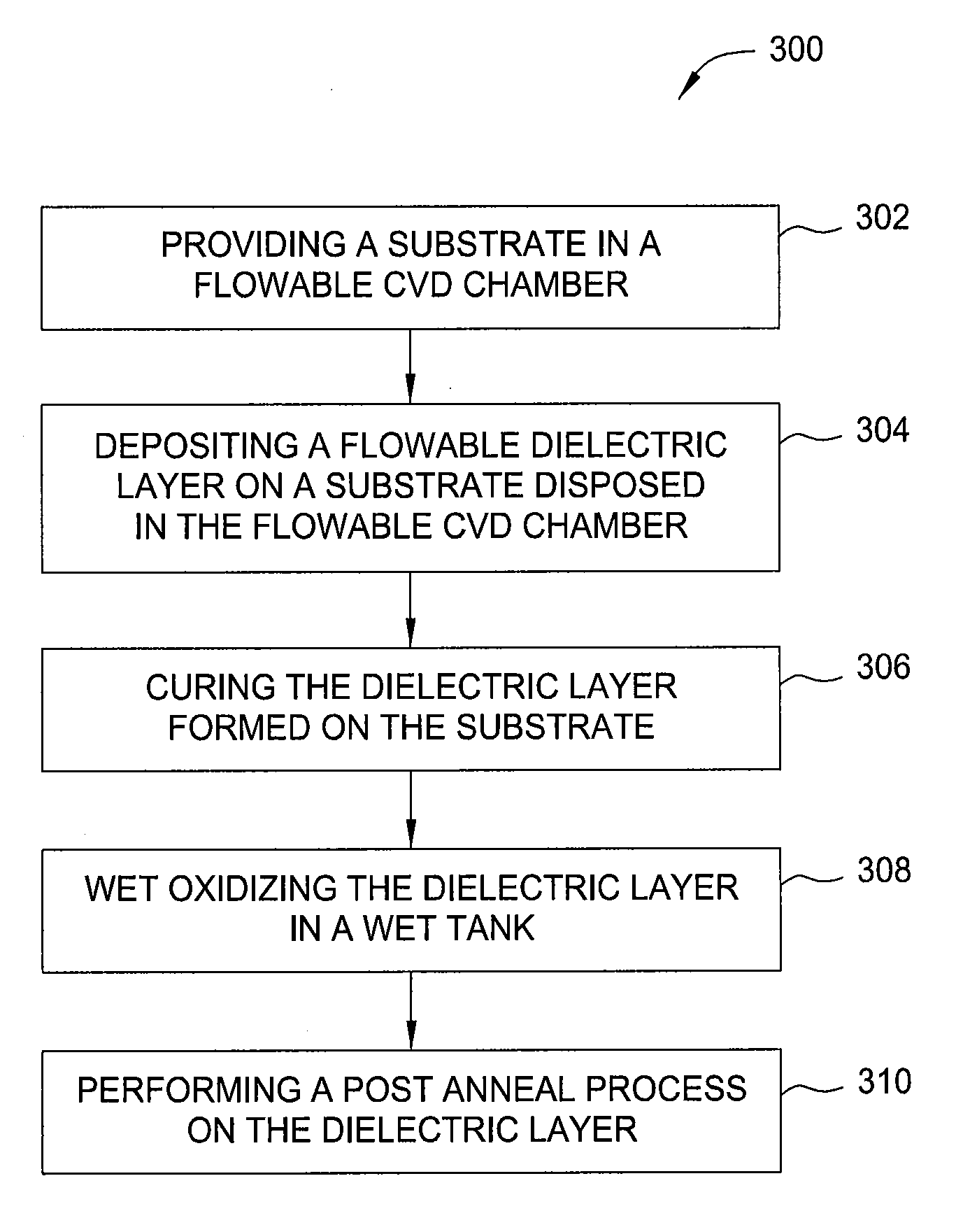

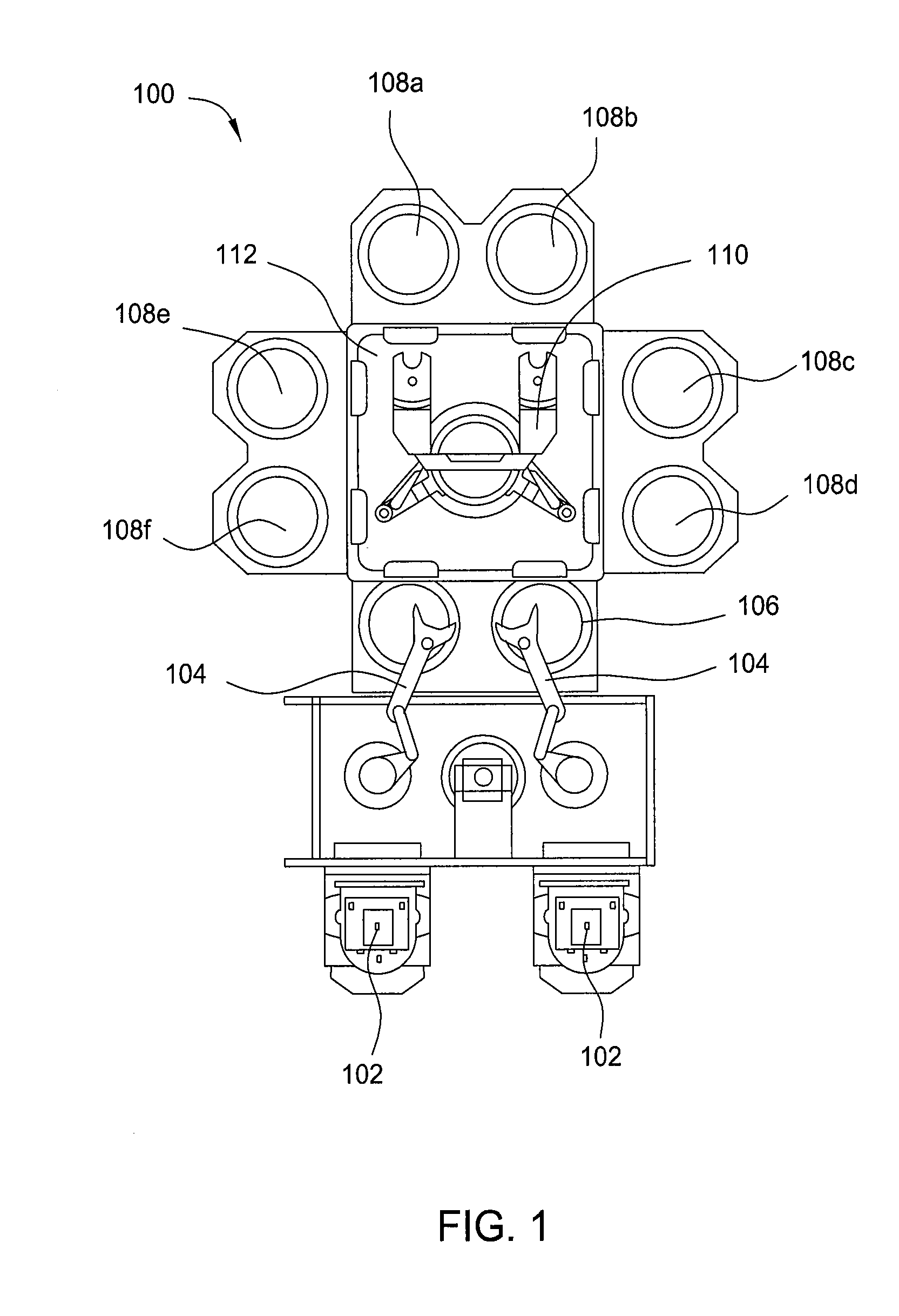

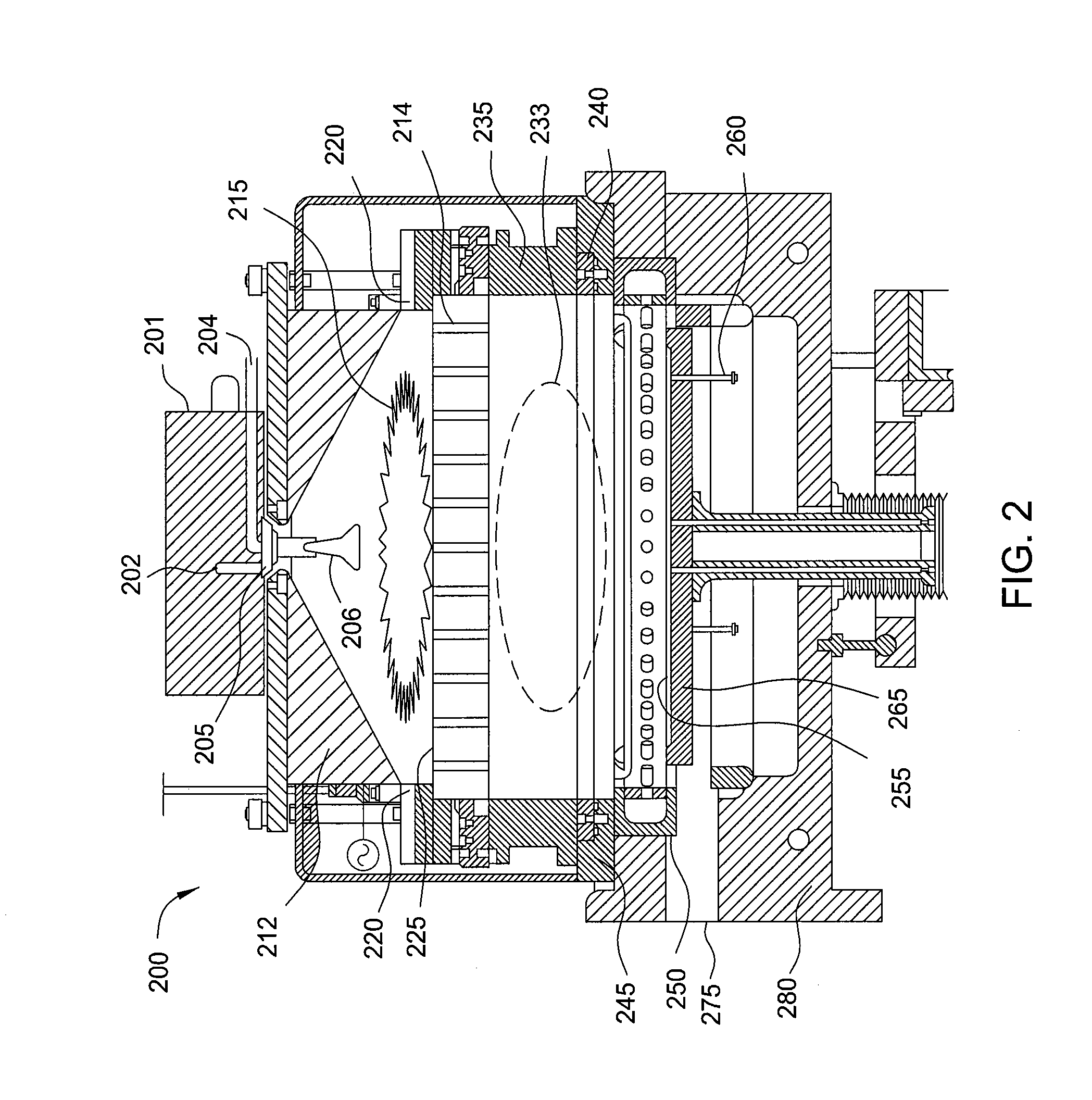

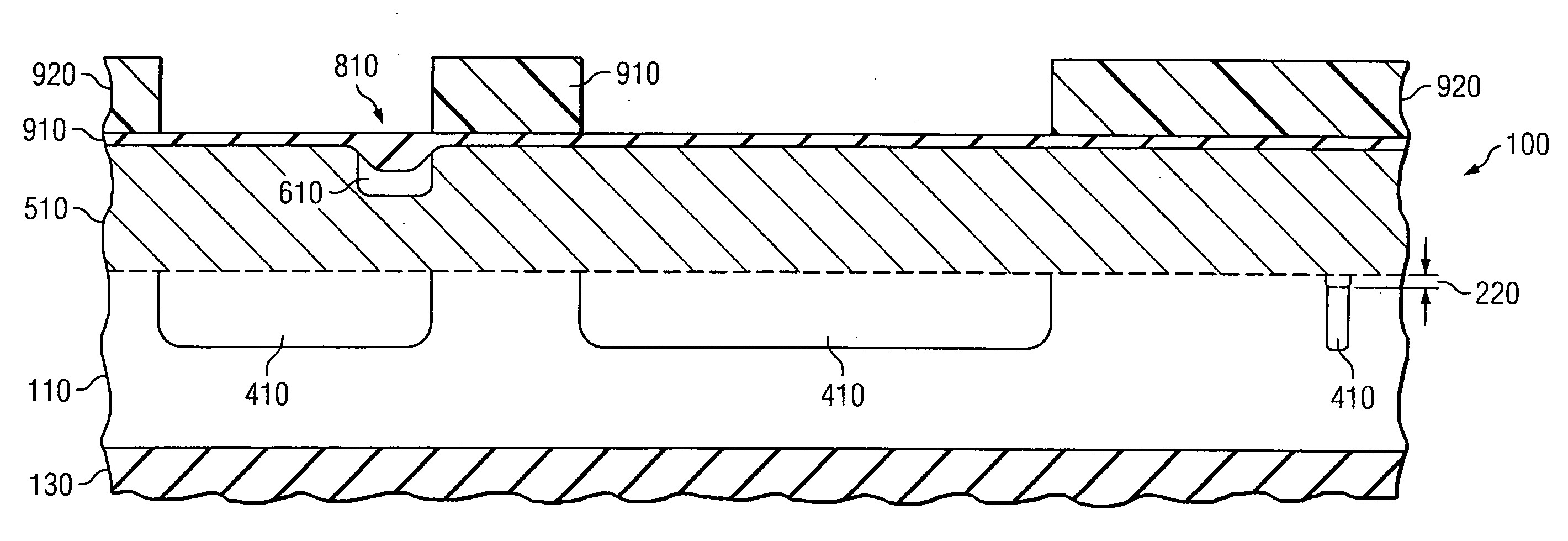

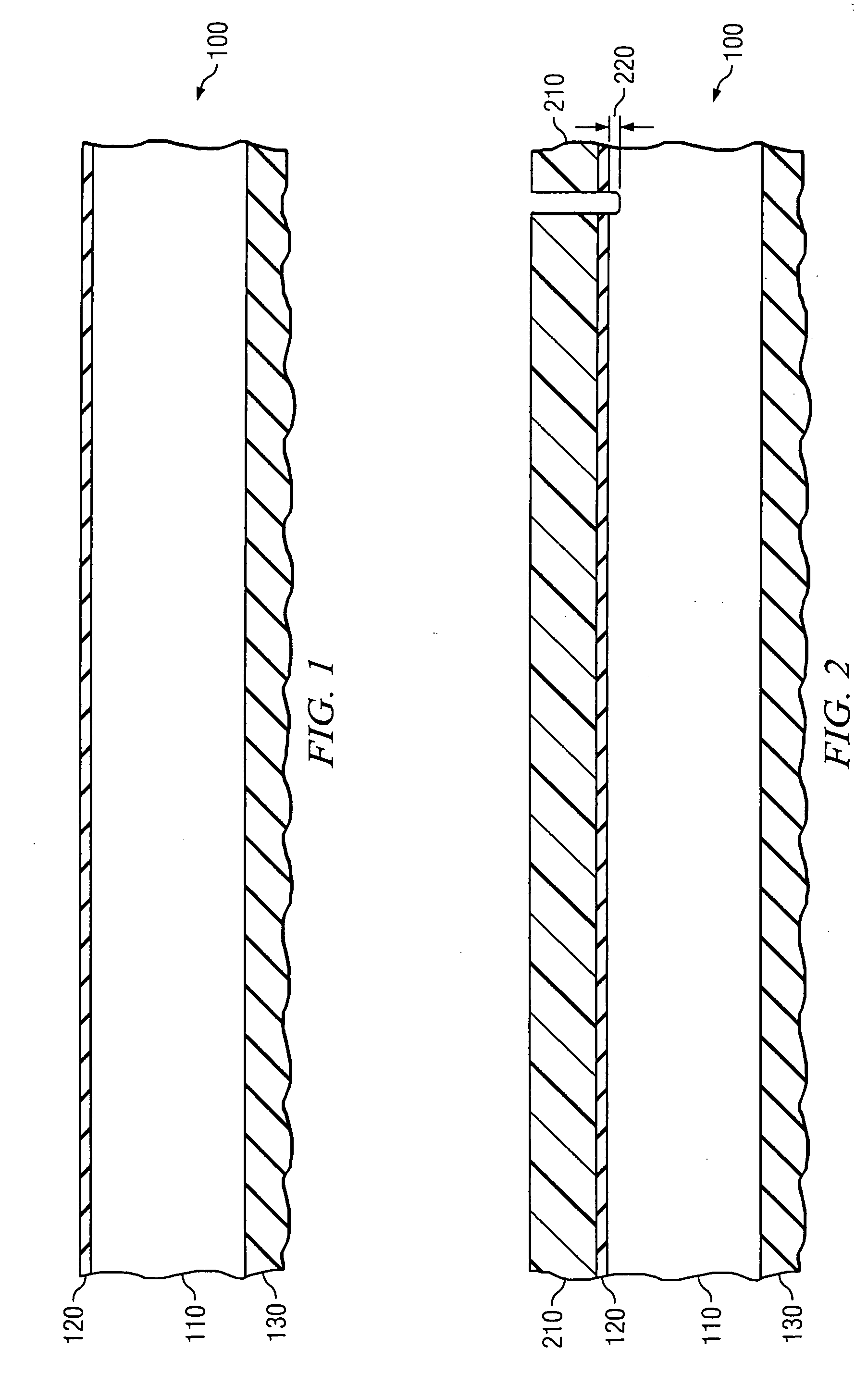

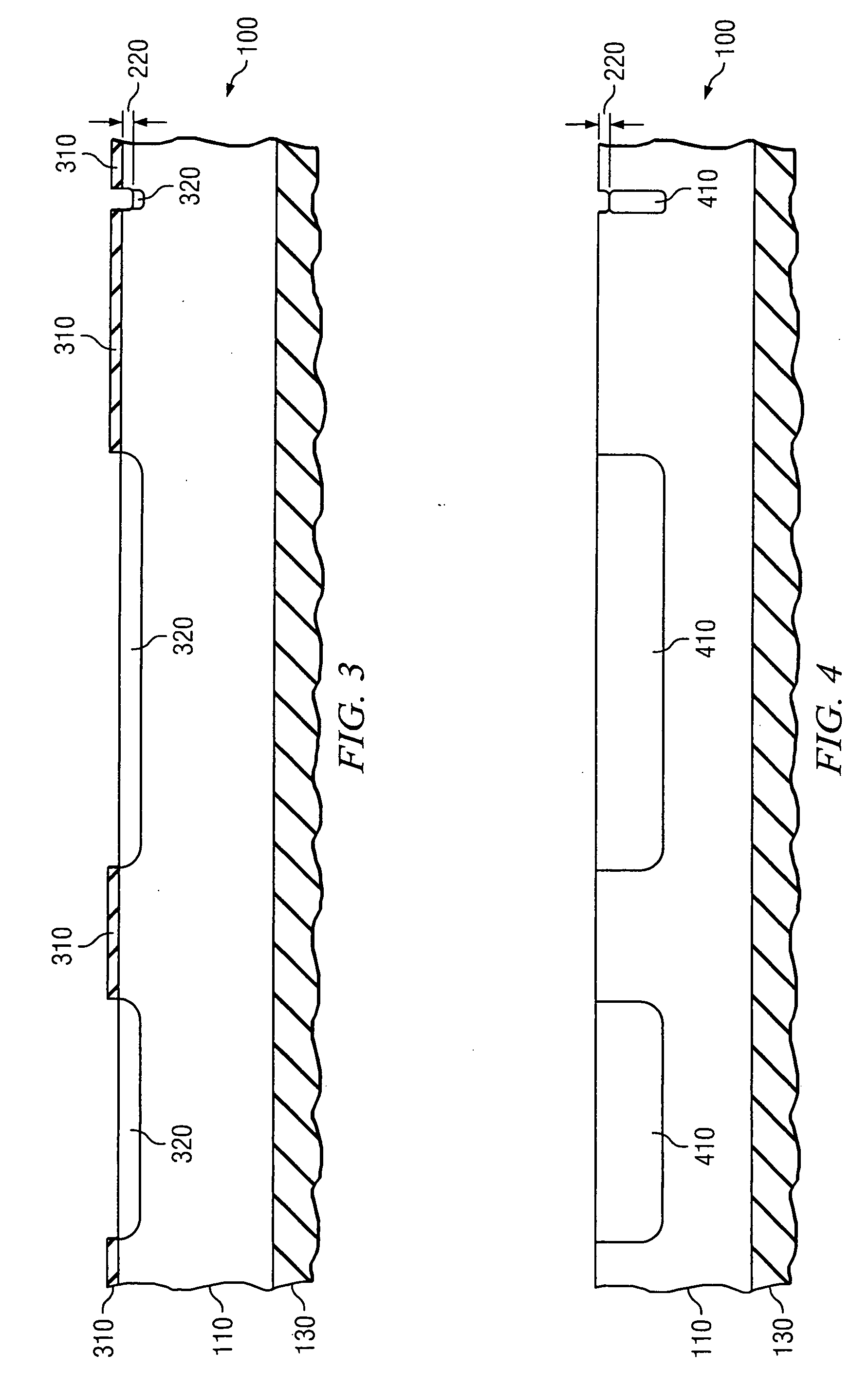

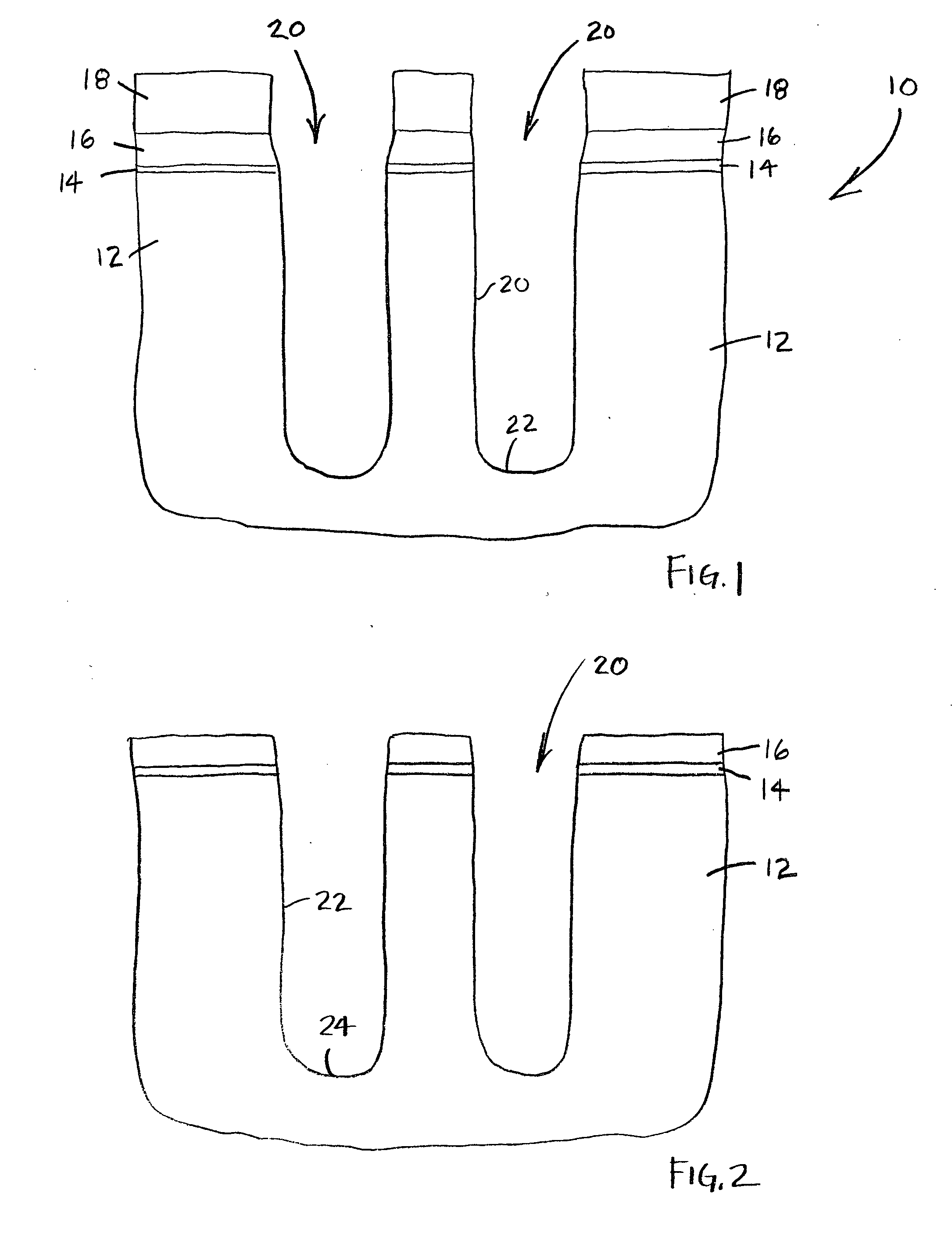

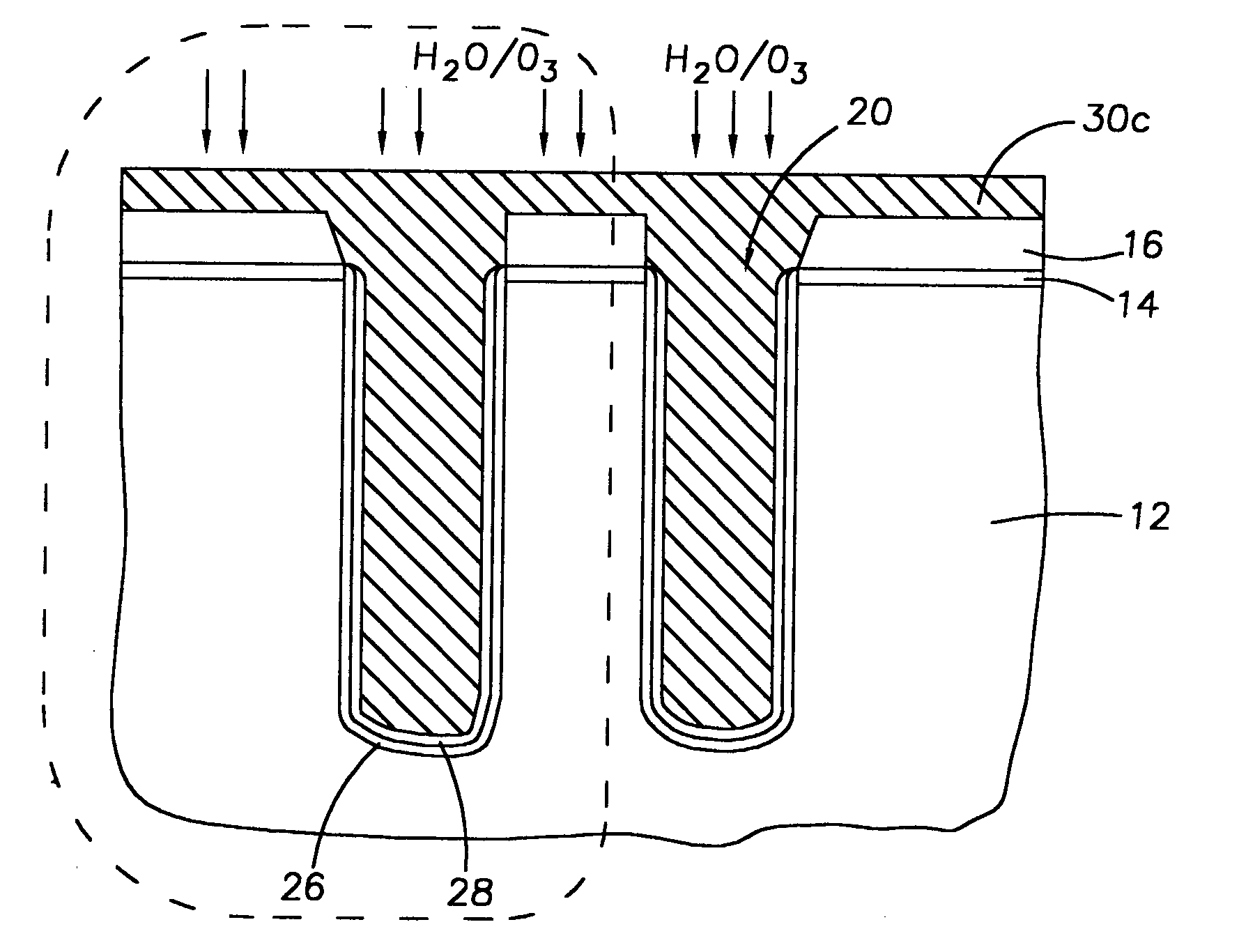

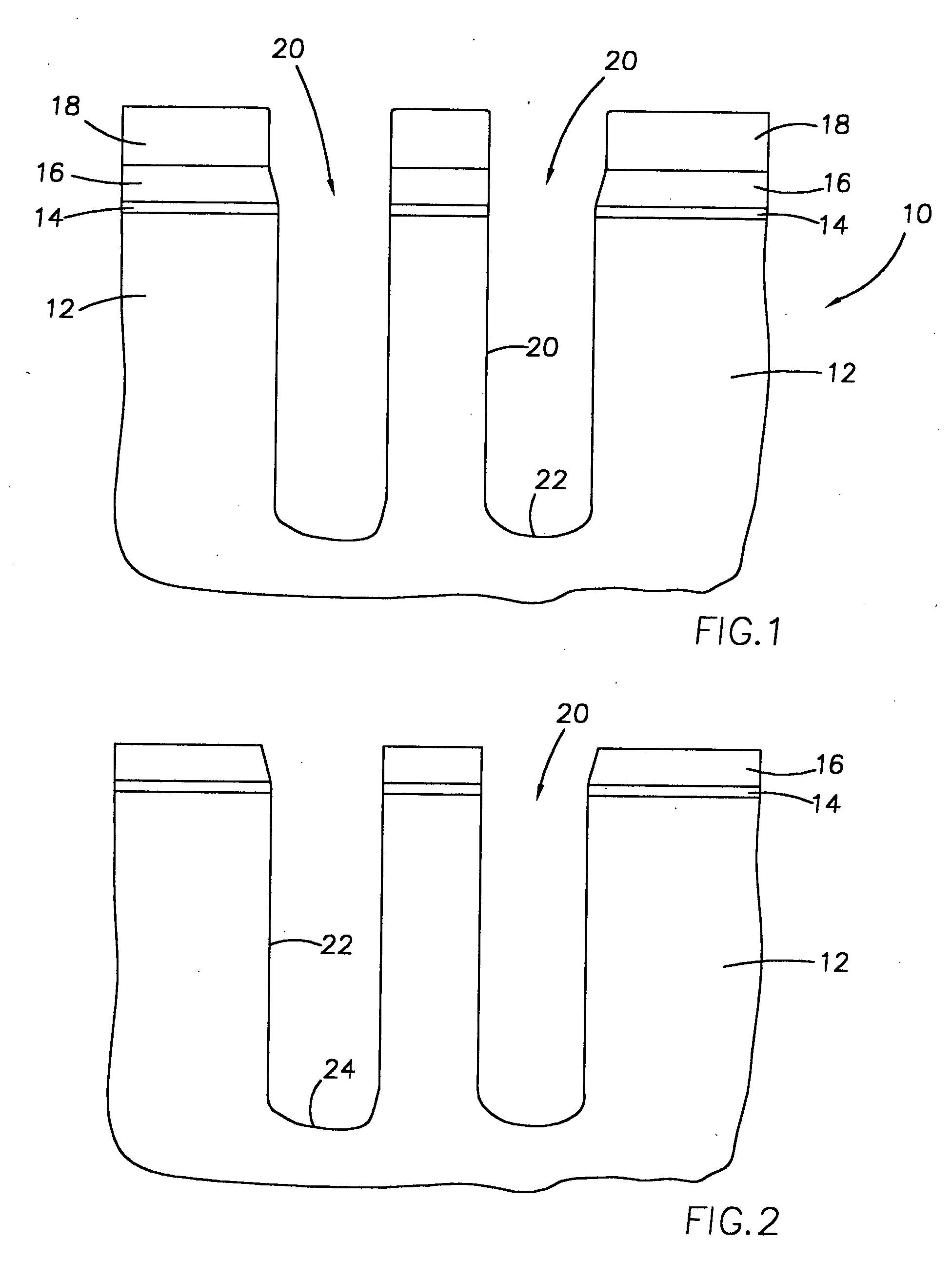

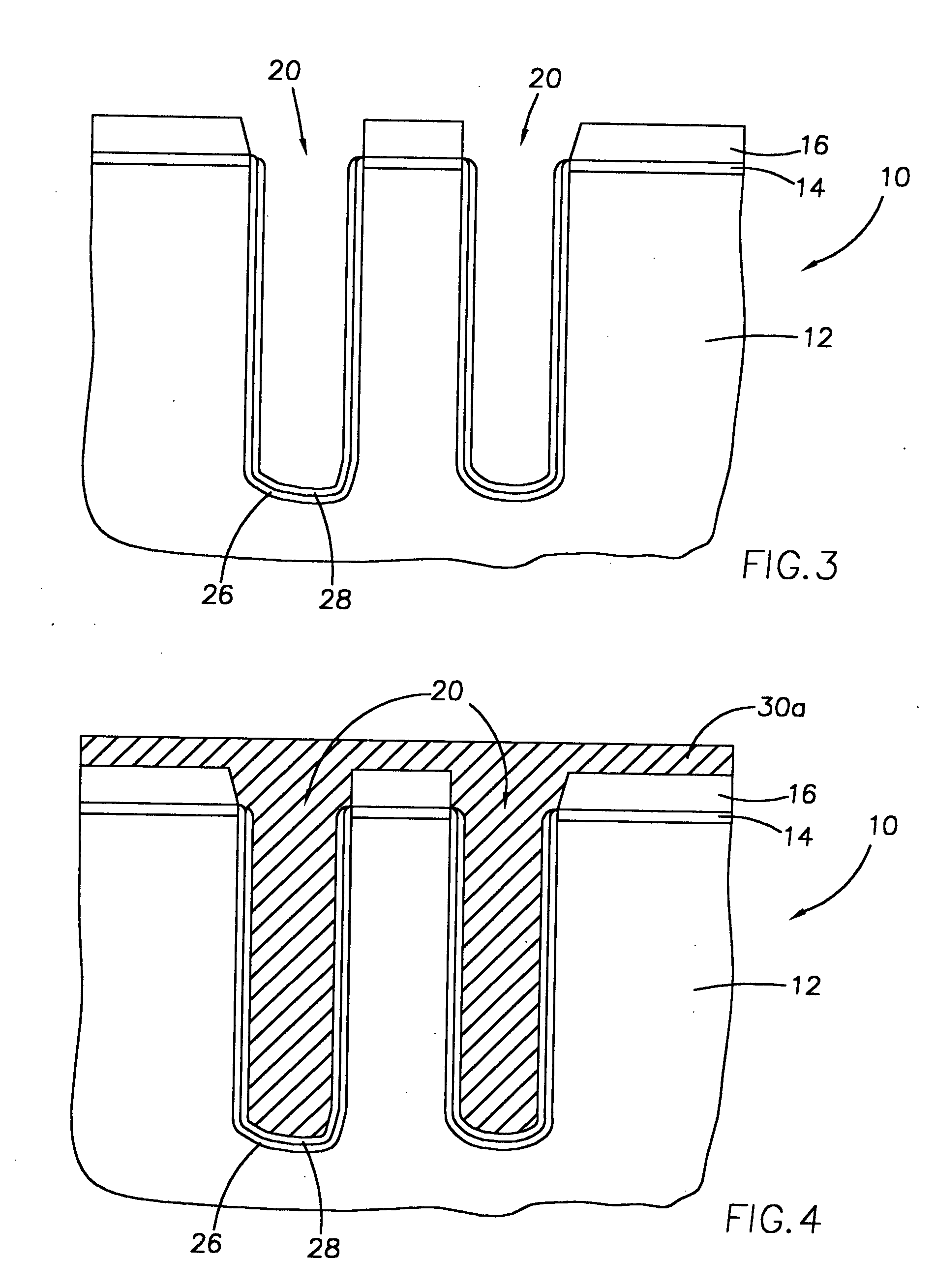

Wet oxidation process performed on a dielectric material formed from a flowable CVD process

InactiveUS20110151677A1Low costReduce process complexitySemiconductor/solid-state device manufacturingSiliconWet oxidation

Methods of performing a wet oxidation process on a silicon containing dielectric material filling within trenches or vias defined within a substrate are provided. In one embodiment, a method of forming a dielectric material on a substrate includes forming a dielectric material on a substrate by a flowable CVD process, curing the dielectric material disposed on the substrate, performing a wet oxidation process on the dielectric material disposed on the substrate, and forming an oxidized dielectric material on the substrate.

Owner:APPLIED MATERIALS INC

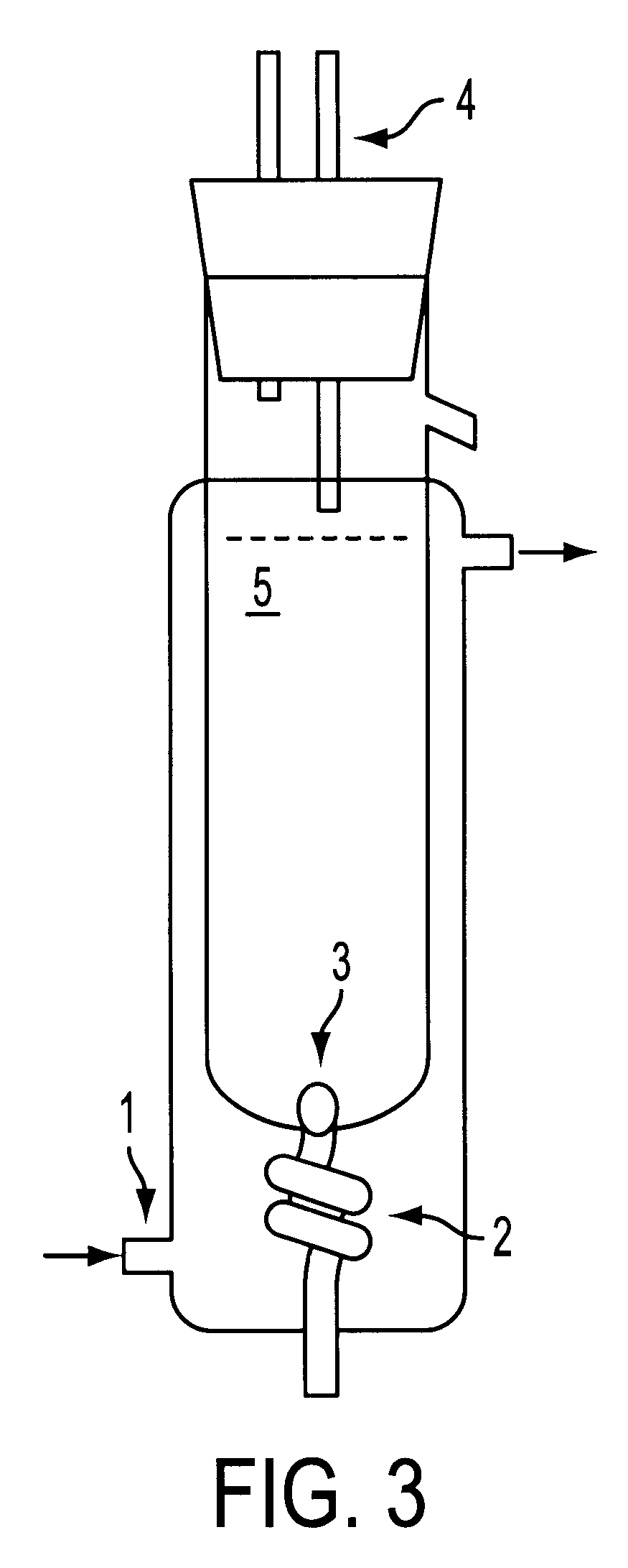

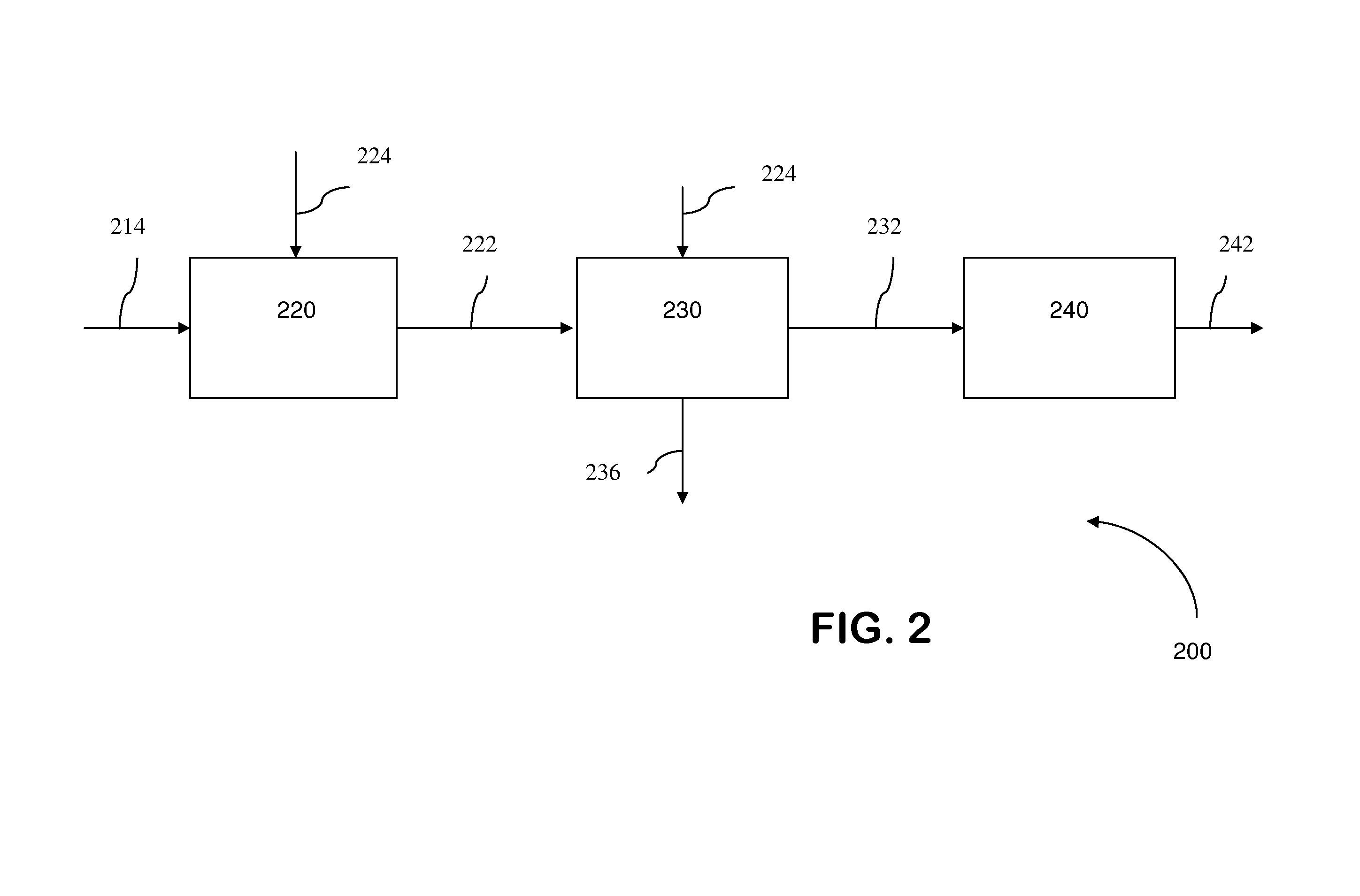

Method for processing lignocellulosic material

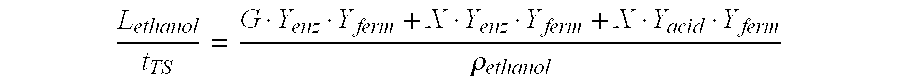

InactiveUS6555350B2High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseWater flow

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process, involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

Method for manufacturing a semiconductor device having an alignment feature formed using an N-type dopant and a wet oxidation process

The present invention provides a method for manufacturing a semiconductor device having an alignment feature. The method for manufacturing the semiconductor device, among other steps, may include implanting an n-type dopant into a substrate thereby forming an implanted region and an unimplanted region in the substrate. The method may further include oxidizing the substrate using a wet oxidation process, the wet oxidation process and n-type dopant causing a ratio of oxidation of the implanted region to the unimplanted region to be 2:1 or greater, and then removing the oxidized portions of the substrate thereby leaving an alignment feature proximate the implanted region.

Owner:TEXAS INSTR INC

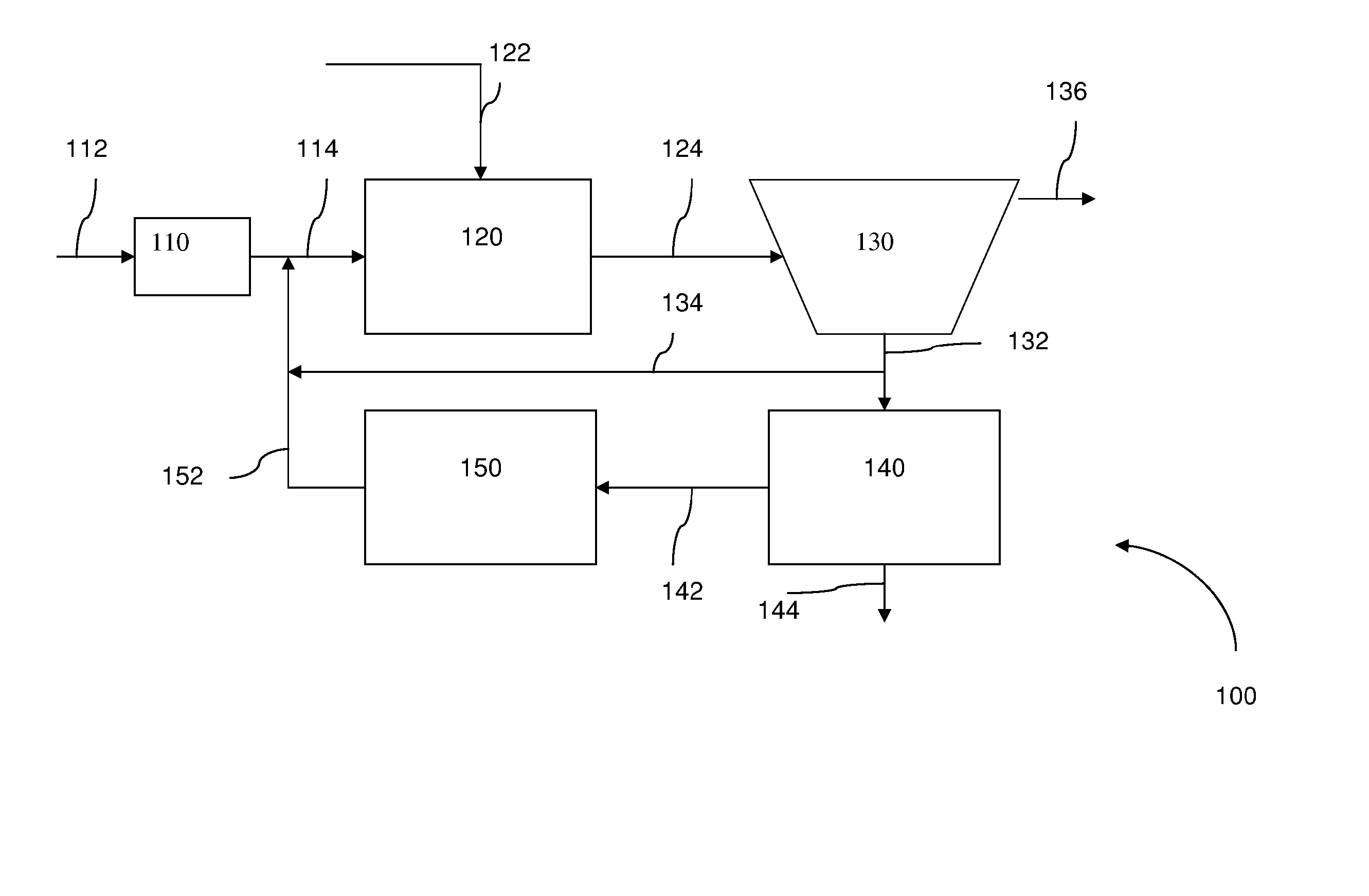

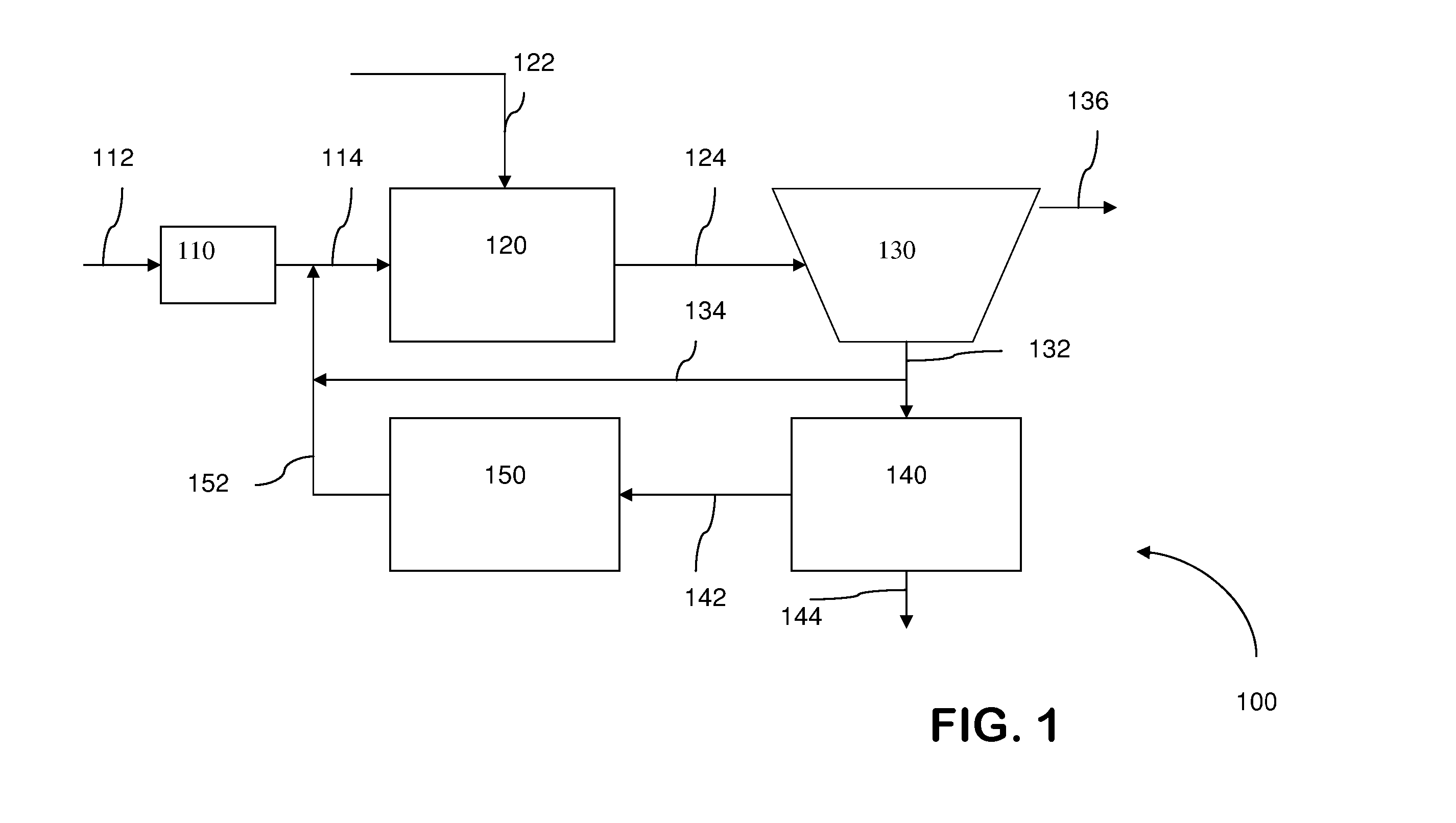

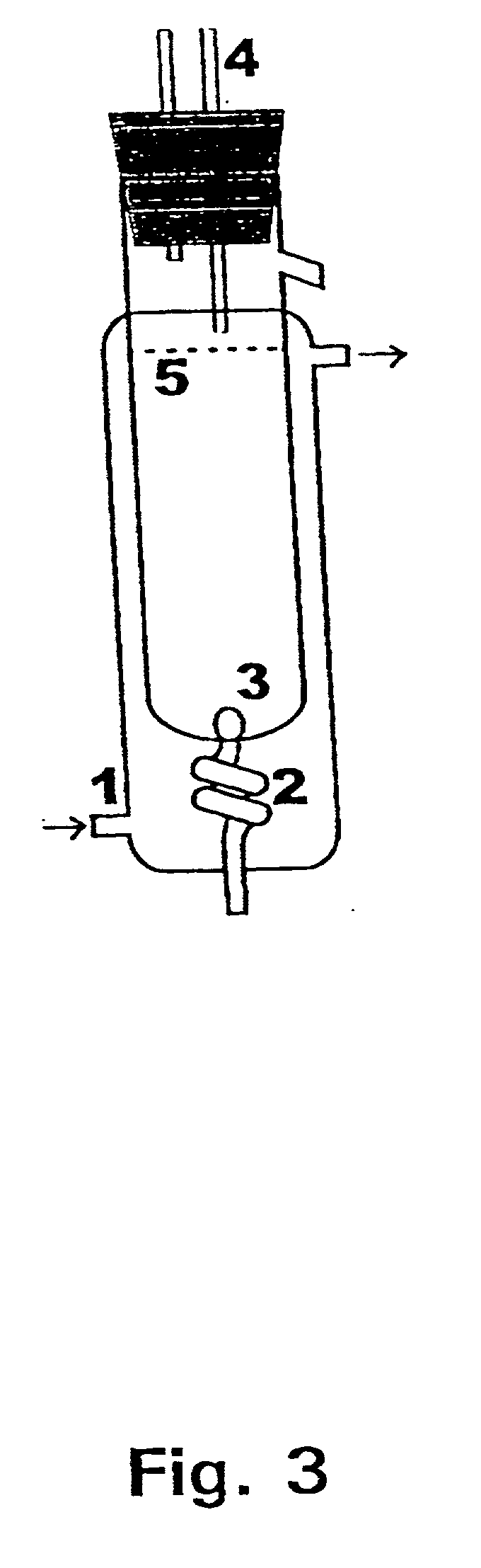

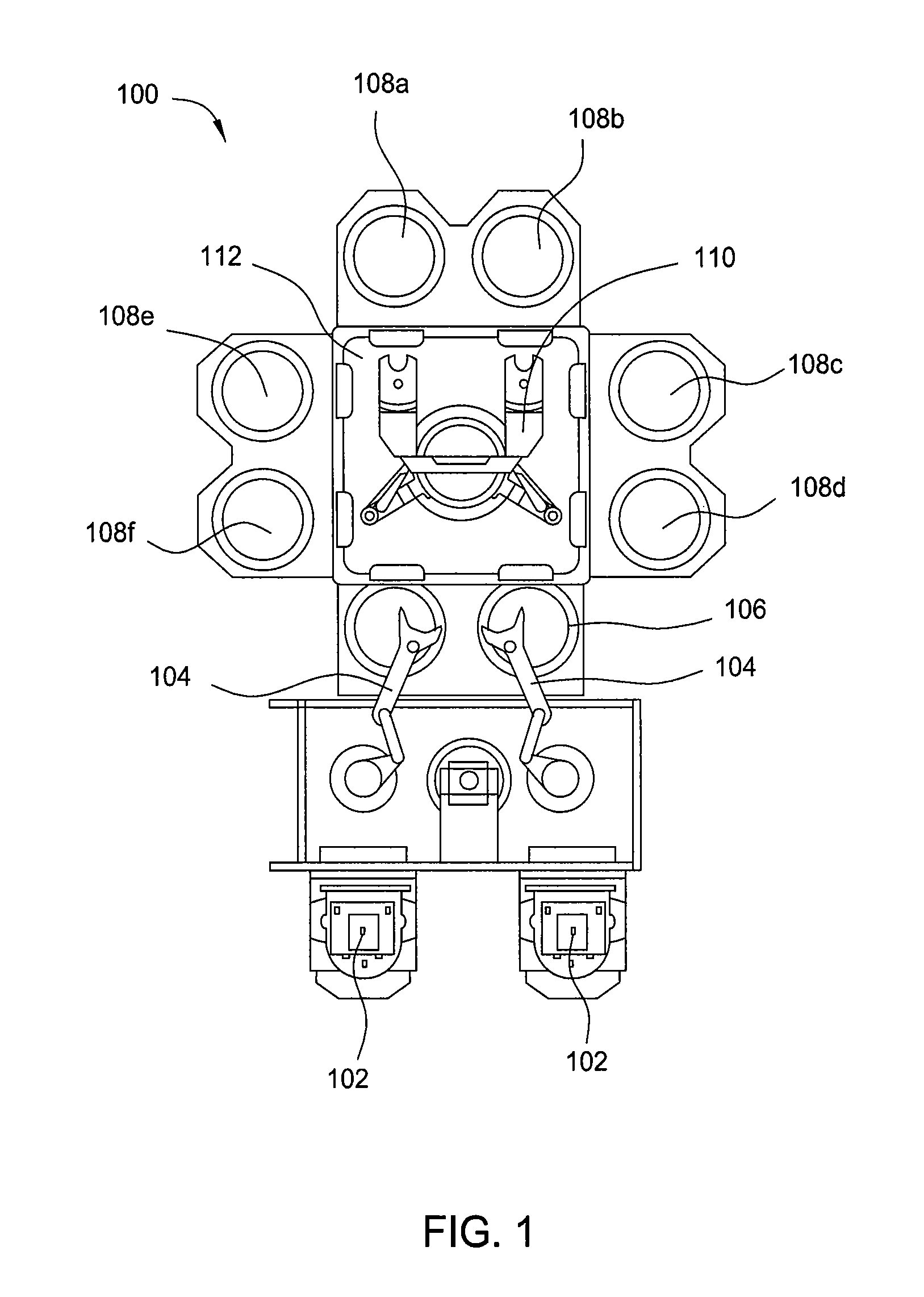

Wastewater treatment system and method

ActiveUS20070209999A1Treatment using aerobic processesTreatment involving filtrationActivated carbonWater treatment system

The invention is directed to a method and apparatus for treating wastewater. The wastewater treatment system includes a bioreactor including activated carbon and a first biological population. The wastewater treatment system may also include a membrane bioreactor and / or a wet oxidation unit.

Owner:SIEMENS ENERGY INC

Method for processing lignocellulosic material

InactiveUS20020192774A1High degreeReduce water consumptionSludge treatment by oxidationBiofuelsCelluloseEnvironmental engineering

A method wherein lignocellulosic biomass materials are converted into combustible fuel products. In particular, the method is a continuous process. involving wet oxidation or steam explosion, for fermentatively converting such biomass materials into ethanol using a process design that permits all or part of the process water from the ethanol fermentation process to be recycled to reduce the consumption of process water. The effluent from the ethanol fermentation step may be subjected to an anaerobic fermentation step generating methane and a water effluent in which the amount of potentially inhibitory substances is at a sub-inhibitory level, which in turn permits all or part of the effluent water from the anaerobic fermentation step to be recycled into the process.

Owner:POET RES INC

Low temperature process for polysilazane oxidation/densification

ActiveUS20060003596A1Easy to processHigh oxygen contentPretreated surfacesSemiconductor/solid-state device manufacturingPolysilazaneSilicon oxide

Semiconductor devices, structures and systems that utilize a polysilazane-based silicon oxide layer or fill, and methods of making the oxide layer are disclosed. In one embodiment, a polysilazane solution is deposited on a substrate and processed with ozone in a wet oxidation at low temperature to chemically modify the polysilazane material to a silicon oxide layer.

Owner:MICRON TECH INC

Catalyst for treatment of waste water, and method for treatment of waste water using the catalyst

InactiveCN102686521AStabilizationImprove purification effectWater contaminantsCatalyst activation/preparationIridiumWater use

Disclosed are: a catalyst which can exhibit an excellent catalytic activity and excellent durability for a long period in the wet oxidation treatment of waste water; a wet oxidation treatment method for waste water using the catalyst; and a novel method for treating waste water containing a nitrogenated compound, in which a catalyst to be used has a lower catalytic cost, the waste water containing the nitrogenated compound can be treated at high purification performance, and the high purification performance can be maintained. The catalyst for use in the treatment of waste water comprises an oxide of at least one element selected from the group consisting of iron, titanium, silicon, aluminum, zirconium and cerium as a component (A) and at least one element selected from the group consisting of silver, gold, platinum, palladium, rhodium, ruthenium and iridium as a component (B), wherein at least 70 mass% of the component (B) is present in a region positioned within 1000 [mu]m from the outer surface of the component (A) (i.e., the oxide), the component (B) has an average particle diameter of 0.5 to 20 nm, and the solid acid content in the component (A) (i.e., the oxide) is 0.20 mmol / g or more. The waste water treatment method uses a catalyst (a pre-catalyst) which is placed on an upstream side of the direction of the flow of the waste water and can convert the nitrogenated compound contained in the waste water into ammoniacal nitrogen in the presence of an oxidizing agent at a temperature of not lower than 100 DEG C and lower than 370 DEG C under a pressure at which the waste water can remain in a liquid state and a downstream-side catalyst (a post-catalyst) which is placed downstream of the direction of the flow of the waste water and can treat the waste water containing ammoniacal nitrogen.

Owner:NIPPON SHOKUBAI CO LTD

Preparation method of catalytic wet oxidation catalyst and treatment method of organic wastewater

ActiveCN103041818AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationHigh concentrationOrganic acid

The invention discloses a preparation method of a catalytic wet oxidation catalyst and a treatment method of organic wastewater. The preparation method comprises the following steps of: (1) taking a porous inert material as a carrier, and performing pre-impregnation treatment on the carrier by adopting an organic acid solution; and (2) preparing an impregnating solution with a water-soluble compound containing transition metal elements and a water-soluble compound containing auxiliary elements, impregnating the carrier after treatment in the step (1) with the impregnating solution, drying in shade for 12-48 hours in air at appropriate humidity, then drying and roasting to obtain a final catalyst. When the catalyst prepared by the method disclosed by the invention is used for high-concentration organic wastewater, the characteristics of high activity, good stability and the like are realized, and the energy consumption and the investment can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low temperature process for polysilazane oxidation/densification

InactiveUS20060102977A1Easy to processIncrease contentSemiconductor/solid-state device manufacturingSemiconductor devicesPolysilazaneSilicon oxide

Semiconductor devices, structures and systems that utilize a polysilazane-based silicon oxide layer or fill, and methods of making the oxide layer are disclosed. In one embodiment, a polysilazane solution is deposited on a substrate and processed with ozone in a wet oxidation at low temperature to chemically modify the polysilazane material to a silicon oxide layer.

Owner:MICRON TECH INC

Catalyst for wastewater treatment and method for wastewater treatment using said catalyst

ActiveCN101045204AHigh mechanical strengthIncreased durabilitySludge treatmentMetal/metal-oxides/metal-hydroxide catalystsIridiumCerium

The present invention relates to a catalyst for wastewater treatment and a method for wet oxidation treatment of wastewater using the catalyst, in particular, the catalyst of the present invention can suitably be used in wet oxidation treatment of wastewater, under high temperature and high pressure conditions. The present invention provides a catalyst for wastewater treatment containing a catalytic active constituent containing at least one kind of an element selected from the group consisting of manganese, cobalt, nickel, cerium, tungsten, copper, silver, gold, platinum, palladium, rhodium, ruthenium and iridium, or a compound thereof, and a carrier constituent containing at least one kind of an element selected from the group consisting of iron, titanium, silicon, aluminum and zirconium, or a compound thereof, characterized in that solid acid amount of the carrier constituent is equal to or more than 0.20 mmol / g.

Owner:NIPPON SHOKUBAI CO LTD

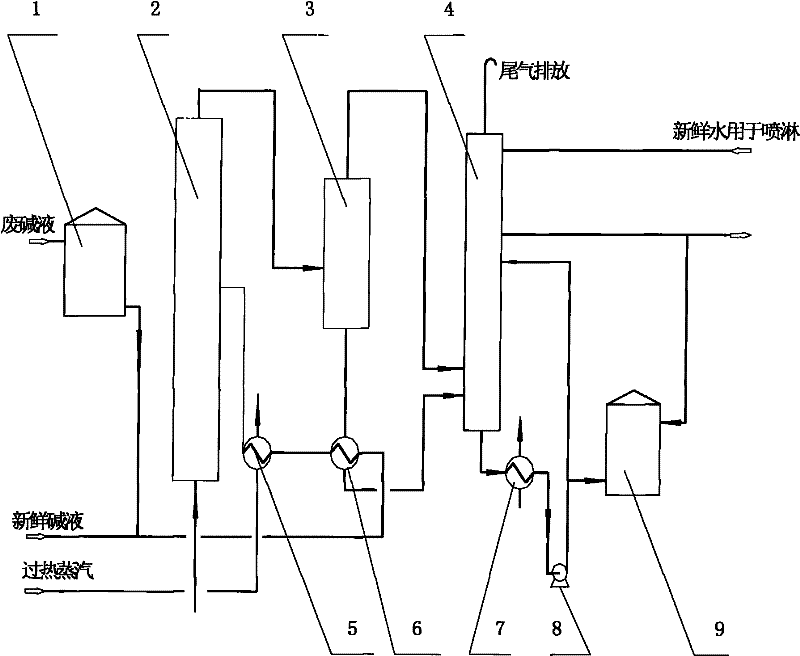

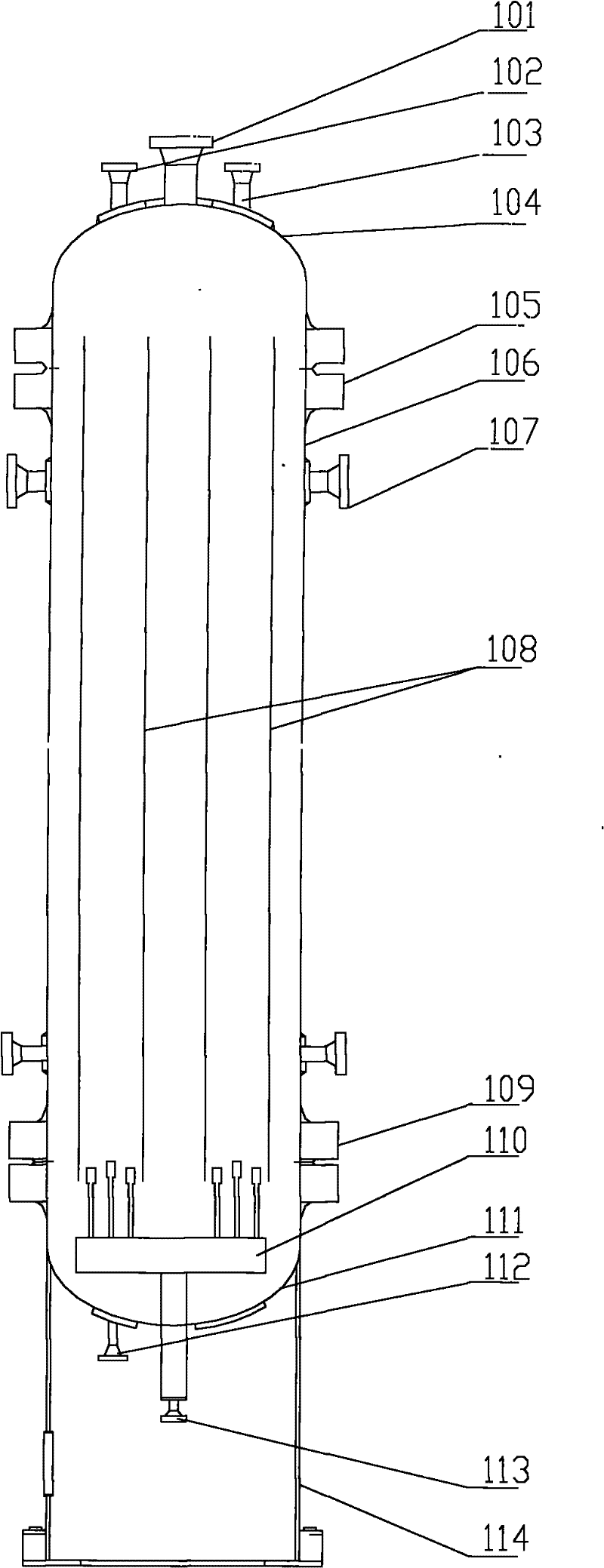

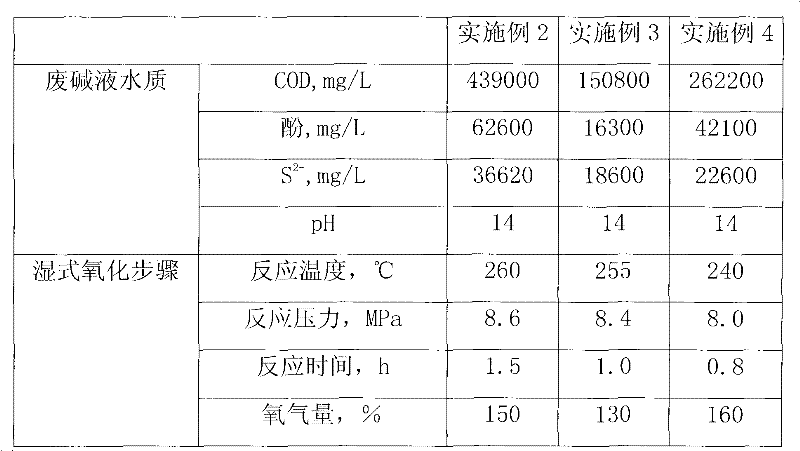

A high-temperature wet oxidation method for treating waste caustic soda

InactiveCN102285729ANo impactNo secondary pollutionMultistage water/sewage treatmentWater/sewage treatment by oxidationHigh concentrationGas phase

The invention discloses a method for treating waste lye by high-temperature wet oxidation. At 220°C to 260°C and under the pressure of keeping the waste lye in liquid phase, the waste lye is contacted with air exceeding the theoretical oxygen demand, and the waste lye is used The oxygen in the air oxidizes the inorganic sulfide and organic matter in the waste caustic so that the sulfur in it is converted into sulfate, and the organic matter is oxidized and decomposed into water and carbon dioxide; the reacted material discharged from the wet liquid phase oxidation reactor enters the high-pressure gas-liquid separator , The oxidized spent lye after gas-liquid separation and the waste lye feed are exchanged for heat, and the oxidized spent lye after heat exchange and the gas phase separated from gas and liquid enter the cooling and washing tower. Compared with the prior art, the method of the present invention has low energy consumption, the removal rate of S2- can reach 100%, the removal rate of COD can reach 75%-85%, and the waste lye after treatment can be directly discharged into the sewage treatment system, effectively alleviating the The pressure brought by the high concentration of wastewater in sewage treatment plants.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for wastewater treatment and method for wastewater treatment using said catalyst

InactiveUS20070210010A1High activityIncreased durabilitySludge treatmentWater/sewage treatment by substance additionIridiumManganese

The present invention relates to a catalyst for wastewater treatment and a method for wet oxidation treatment of wastewater using the catalyst, in particular, the catalyst of the present invention can suitably be used in wet oxidation treatment of wastewater, under high temperature and high pressure conditions. The present invention provides a catalyst for wastewater treatment containing a catalytic active constituent containing at least one kind of an element selected from the group consisting of manganese, cobalt, nickel, cerium, tungsten, copper, silver, gold, platinum, palladium, rhodium, ruthenium and iridium, or a compound thereof, and a carrier constituent containing at least one kind of an element selected from the group consisting of iron, titanium, silicon, aluminum and zirconium, or a compound thereof, characterized in that solid acid amount of the carrier constituent is equal to or more than 0.20 mmol / g.

Owner:NIPPON SHOKUBAI CO LTD

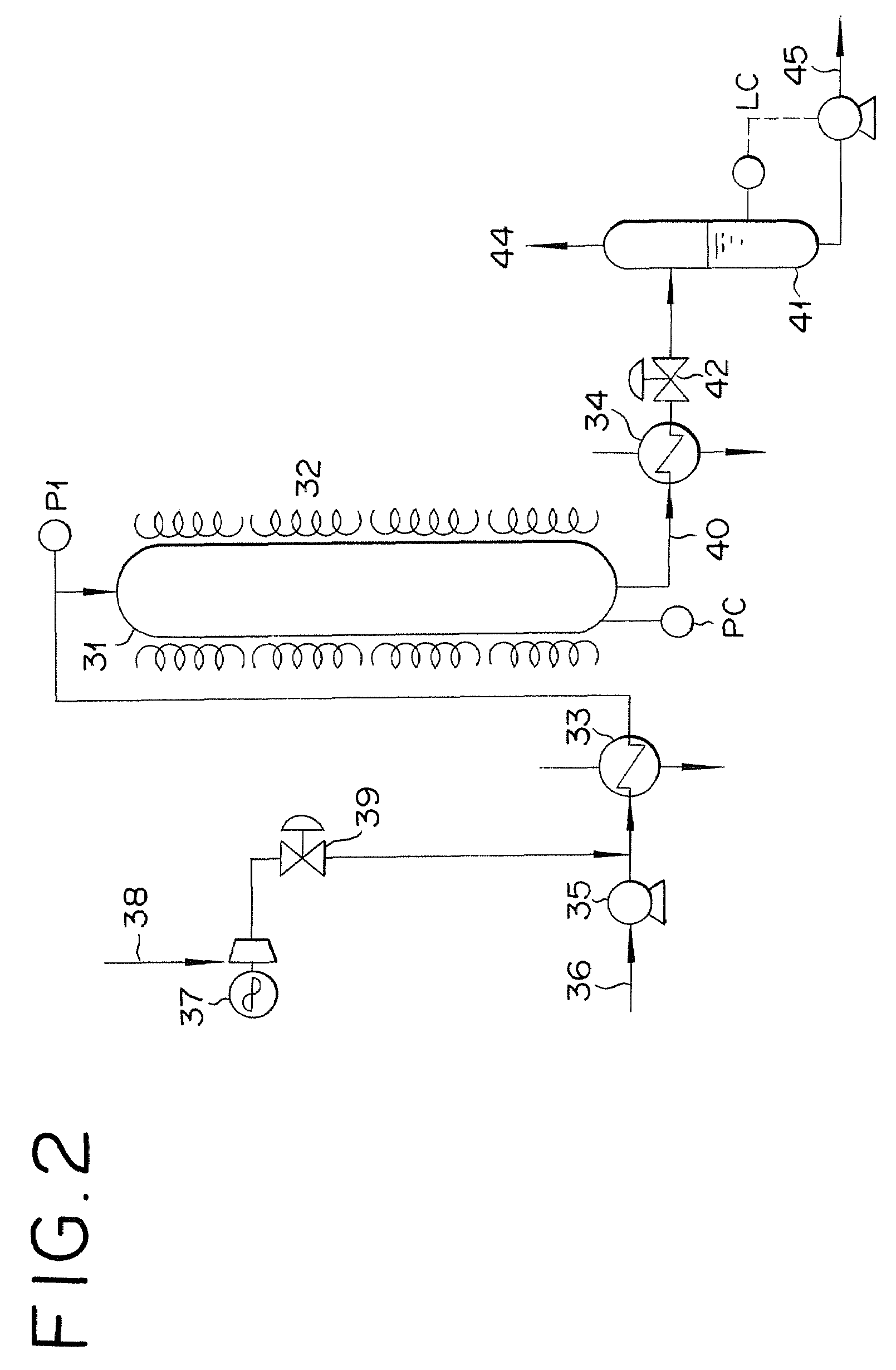

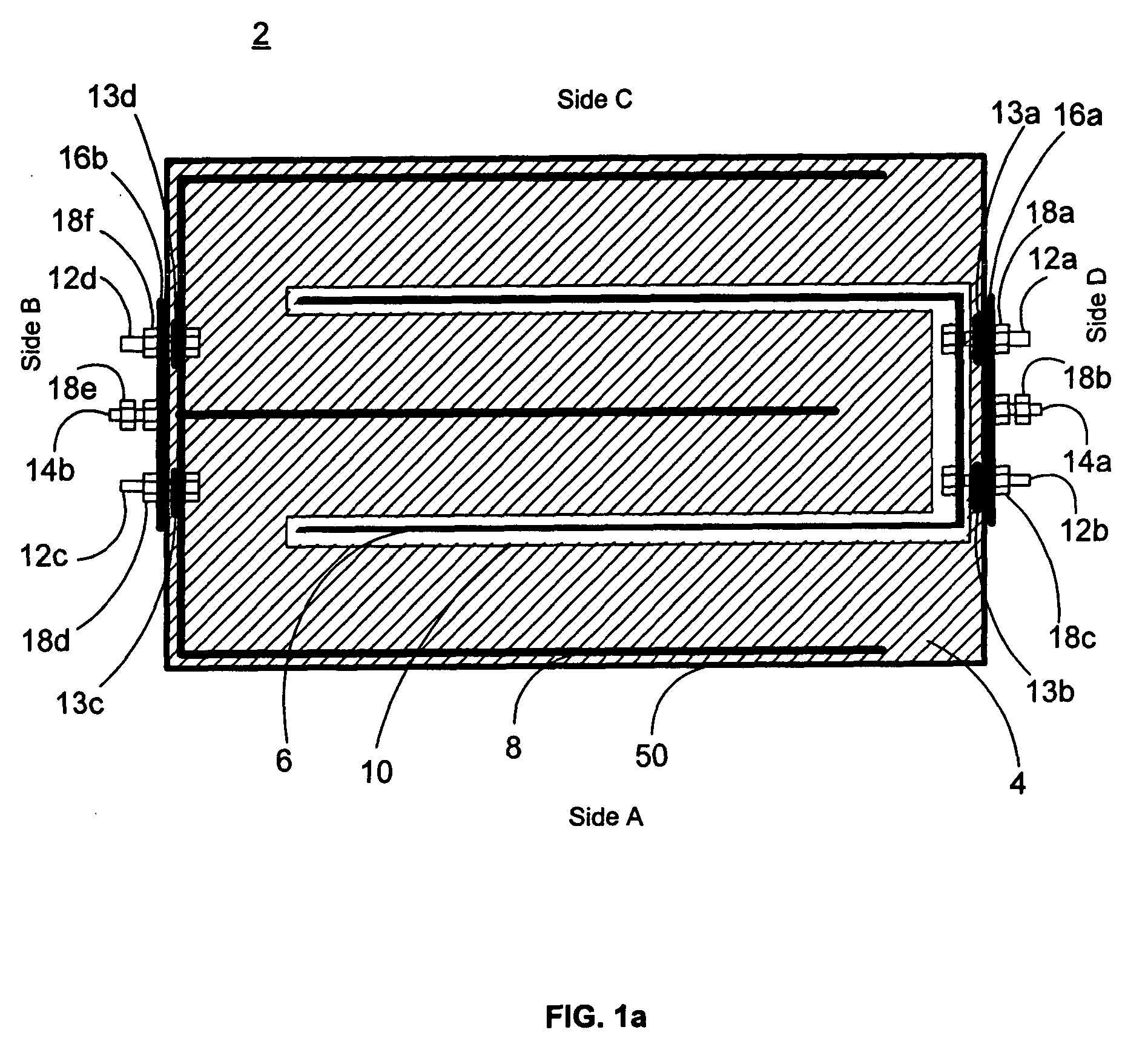

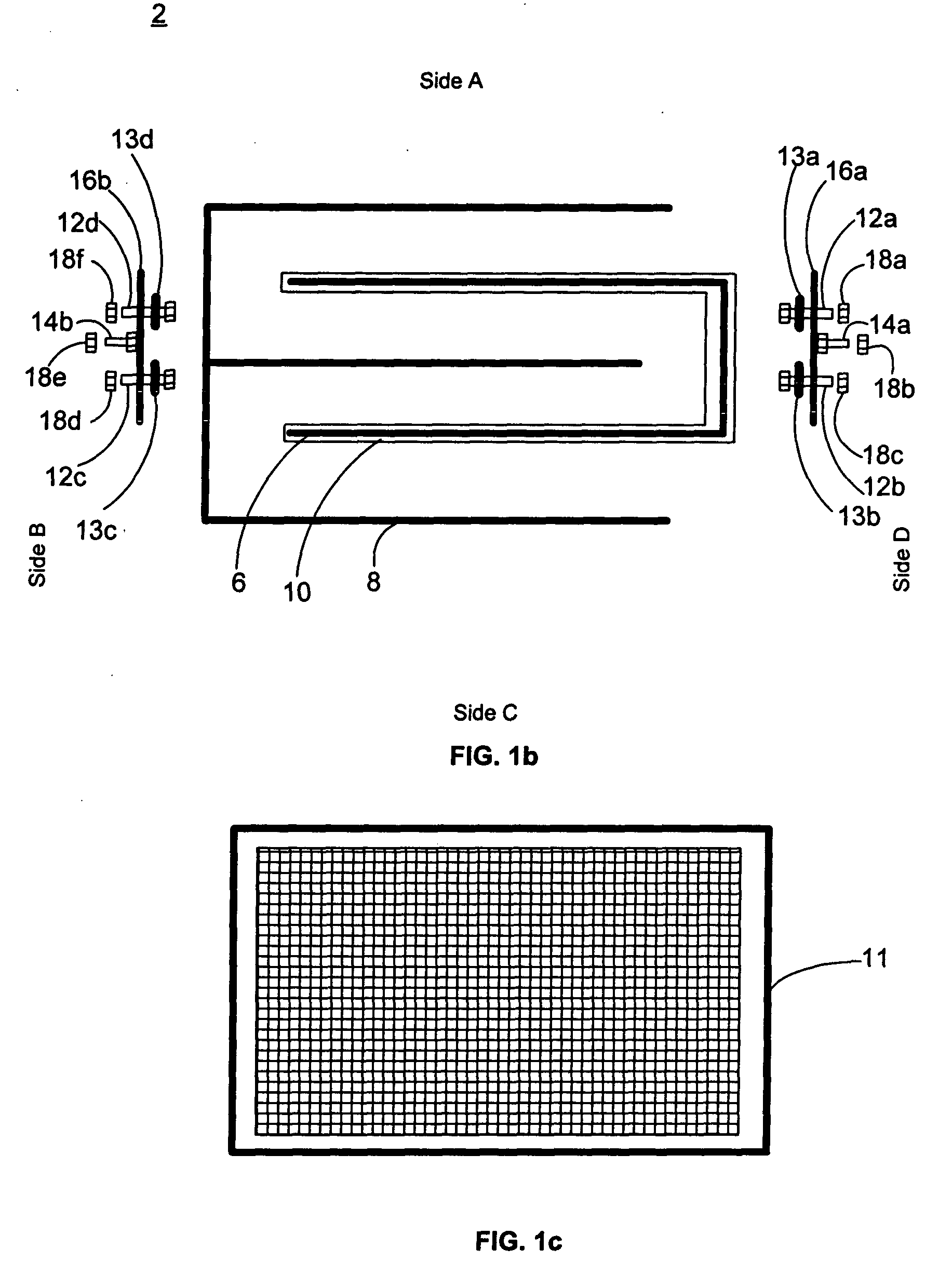

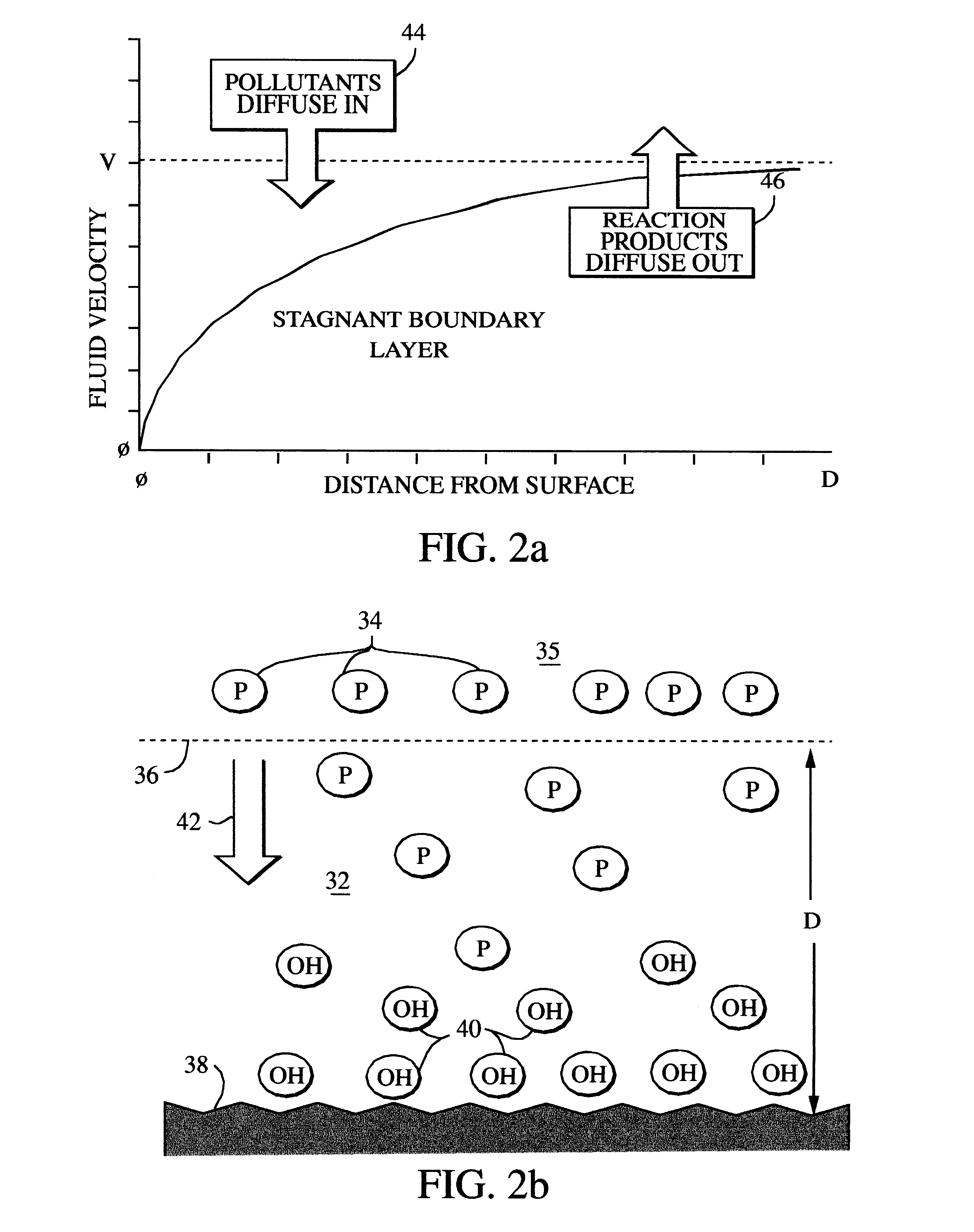

Electrolytic cell stack with porous surface active electrode for removal of organic contaminants from water and method to purify contaminated water

InactiveUS20050034978A1Overcome limitationsPromote repairCellsWater treatment compoundsWaste streamSurface water

A wet oxidation / reduction electrolytic cell stack, system, and method for the remediation of contaminated water is disclosed. A porous electrode of large surface area produces powerful oxidizing agents in situ without having to add any reagents, oxidizers, or catalysts to the water to be treated. Further, by the appropriate selection of electrode material, organic contaminants may be absorbed onto the surface of the electrode and subsequently oxidized to provide a dynamically renewable porous electrode surface. Flow rates, and power requirements may be tailored to the specific moieties to be removed, thus allowing local treatment of specific waste streams resulting in direct discharge to a publicly owned treatment works (POTW) or surface water discharge. A novel feature of this invention is the ability to remove both organic and metal contaminants without the addition of treatment reagents or catalysts.

Owner:EXTI

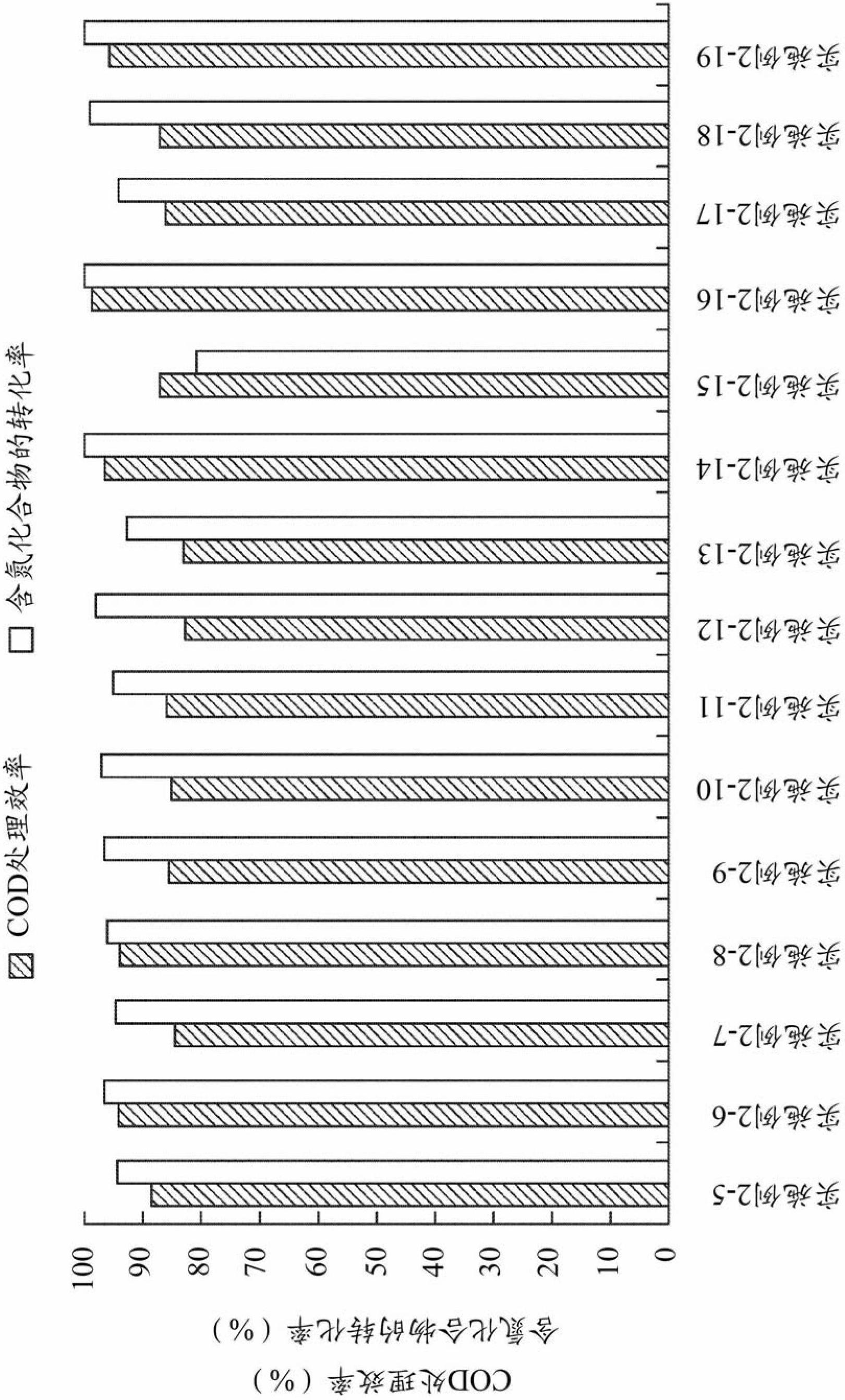

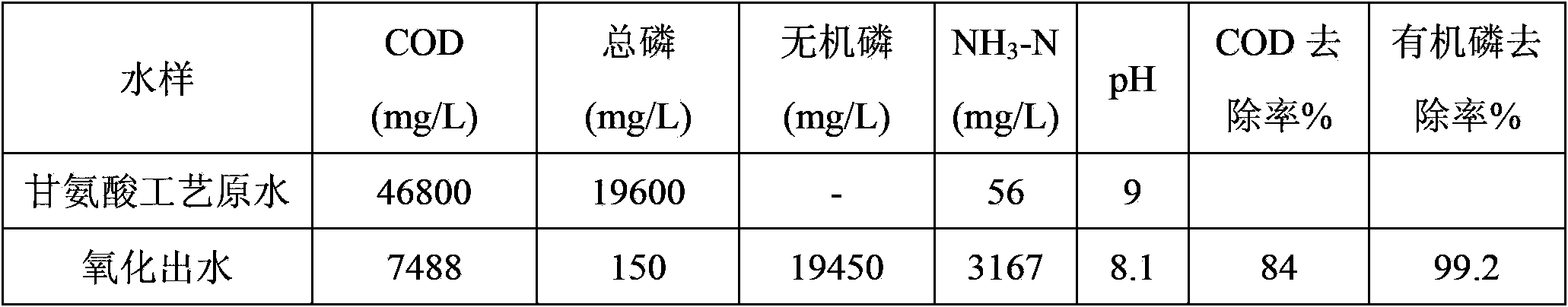

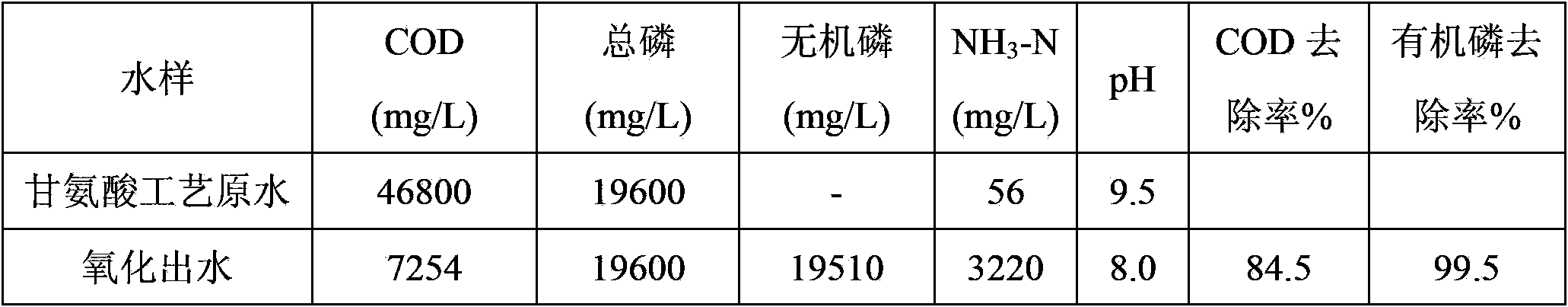

Catalytic wet oxidation pretreatment method of glyphosate production wastewater

ActiveCN103663667AHigh activityReduce dosageMultistage water/sewage treatmentWater/sewage treatment by oxidationPretreatment methodChemical oxygen demand

The invention relates to a catalytic wet oxidation pretreatment method of glyphosate production wastewater, comprises the following steps: firstly regulating pH value to be more than 8 and less than 10, adding a multi-component homogeneous catalyst and carrying out oxidative degradation on pollutants in wastewater for 0.3-2 hours by using a continuous catalytic wet oxidation device with air as an oxidizing agent at the reaction temperature of 210-230 DEG.C and the reaction pressure of 2-4MPa, wherein the catalyst is a soluble transition metal salt mixture. By adopting the method for treating the glyphosate production wastewater, the organic phosphorus conversion rate is high, the COD (chemical oxygen demand) removal rate is high, the biodegradability of the wastewater can be improved, and the secondary pollution is avoided. The method has the advantages that the catalyst activity is high, low in cost and easy to get, reaction conditions are relatively mild, and continuous operation is easily implemented; the glyphosate production wastewater can be discharged in standard through the combined process of catalytic wet oxidation pretreatment-routine technical dephosphorization and deamination-biochemistry, and the industrialized application prospect is great.

Owner:中国中化股份有限公司 +2

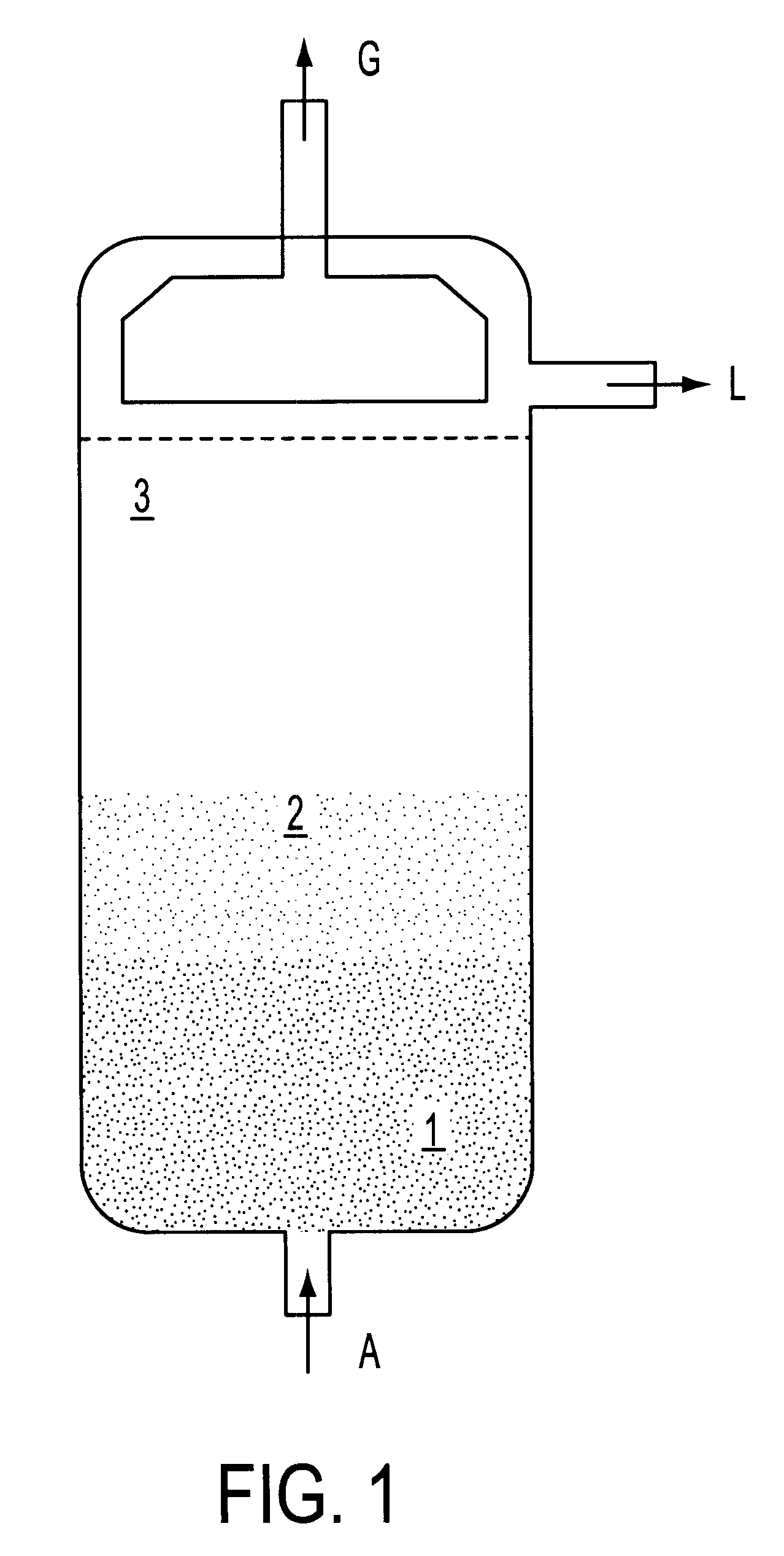

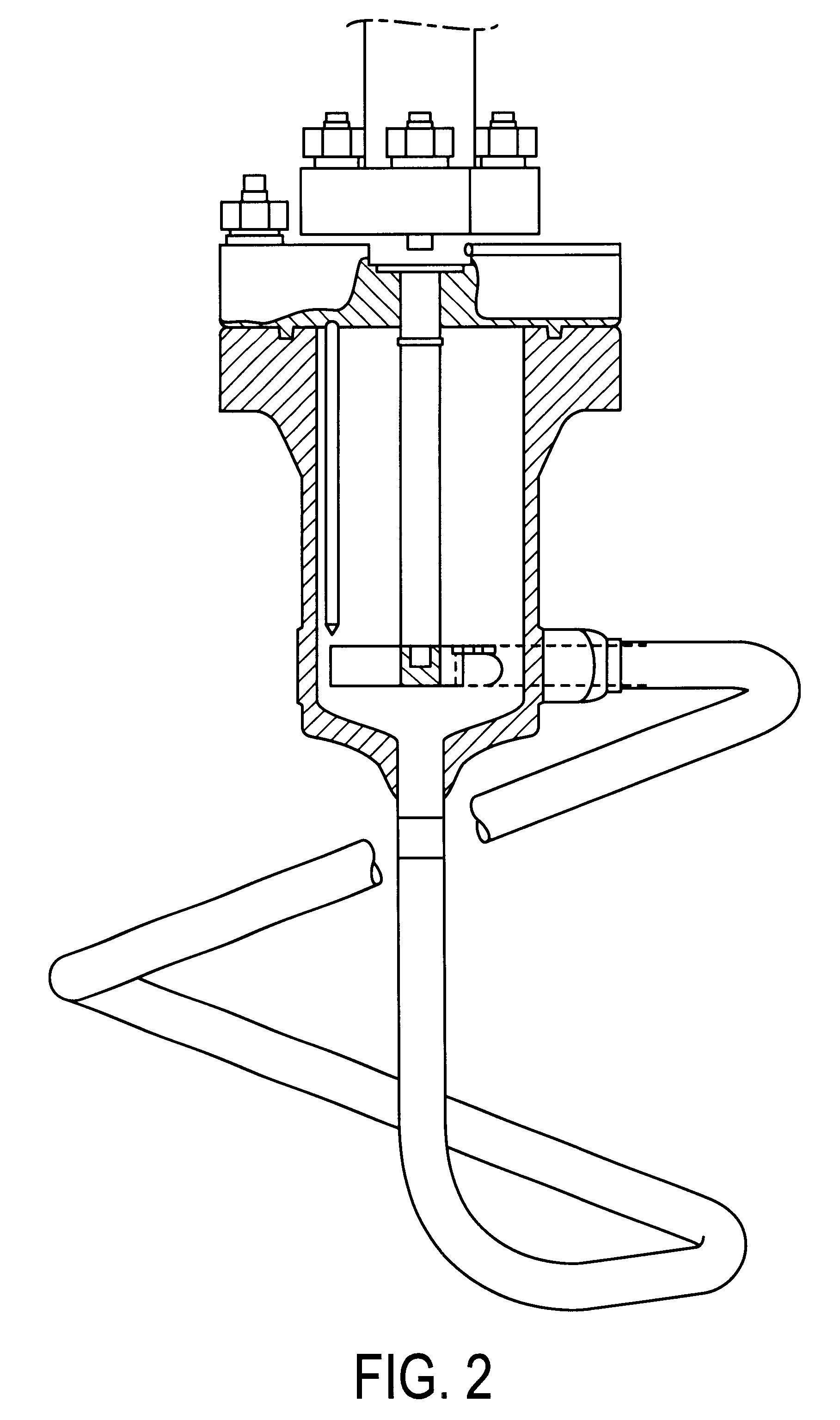

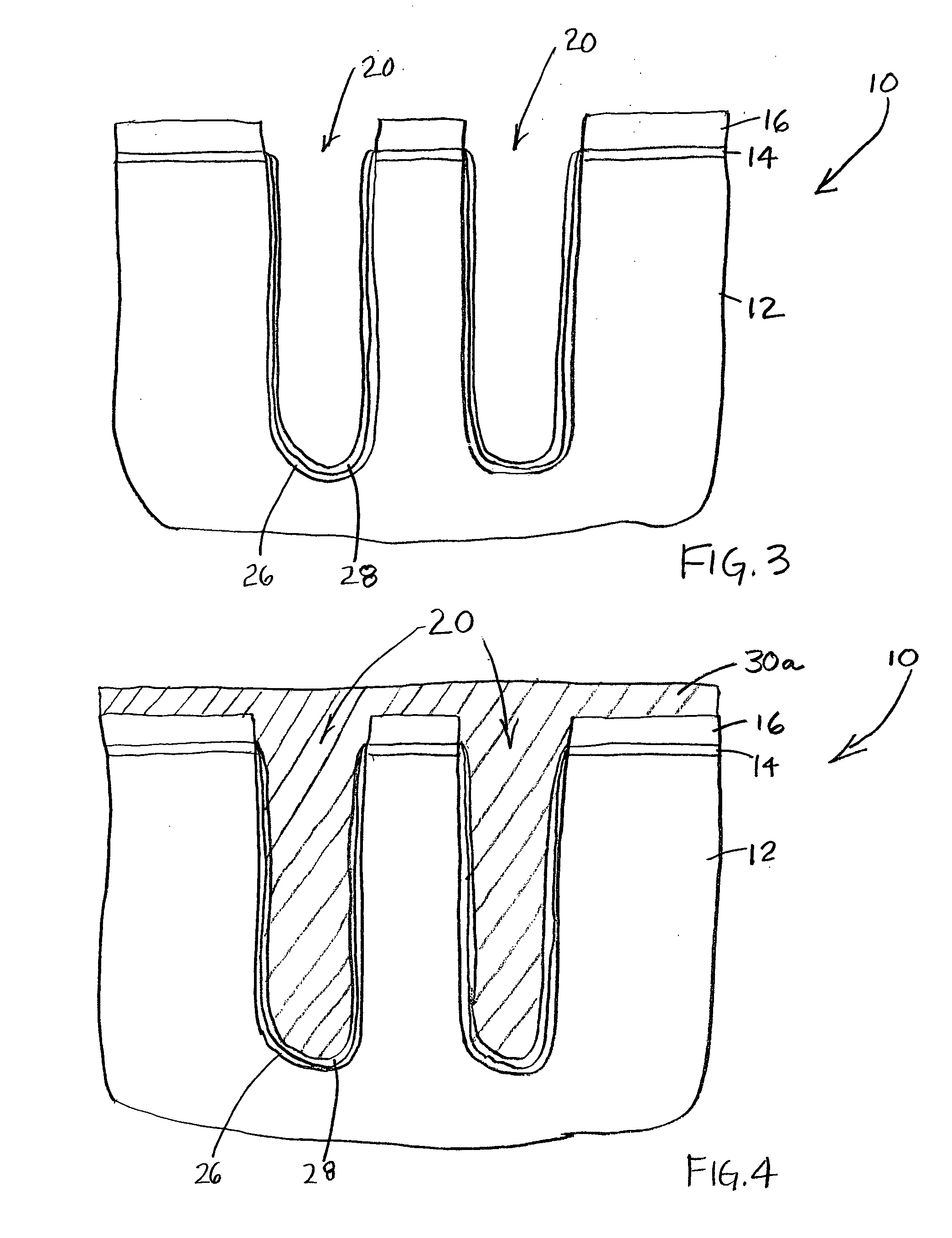

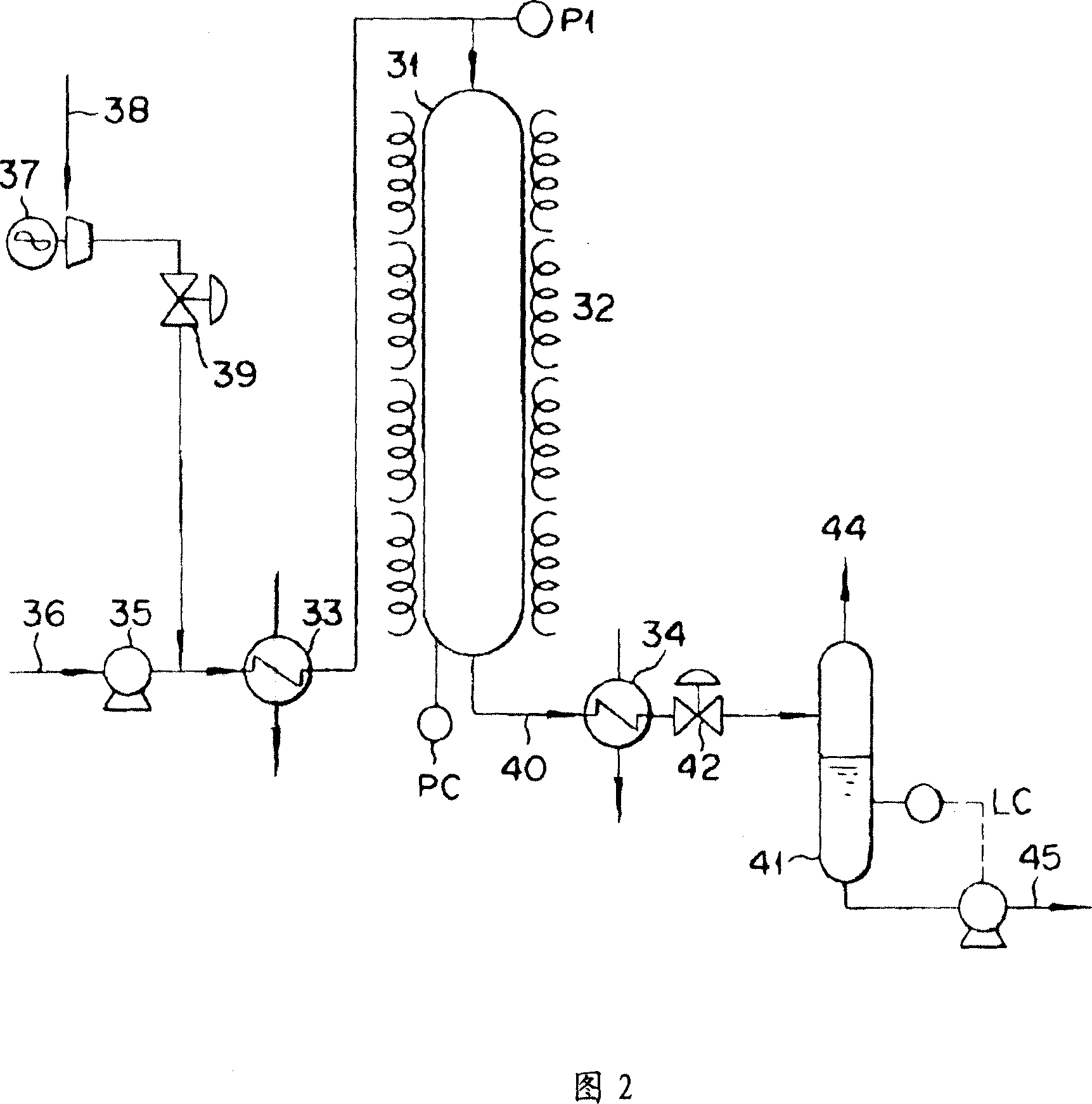

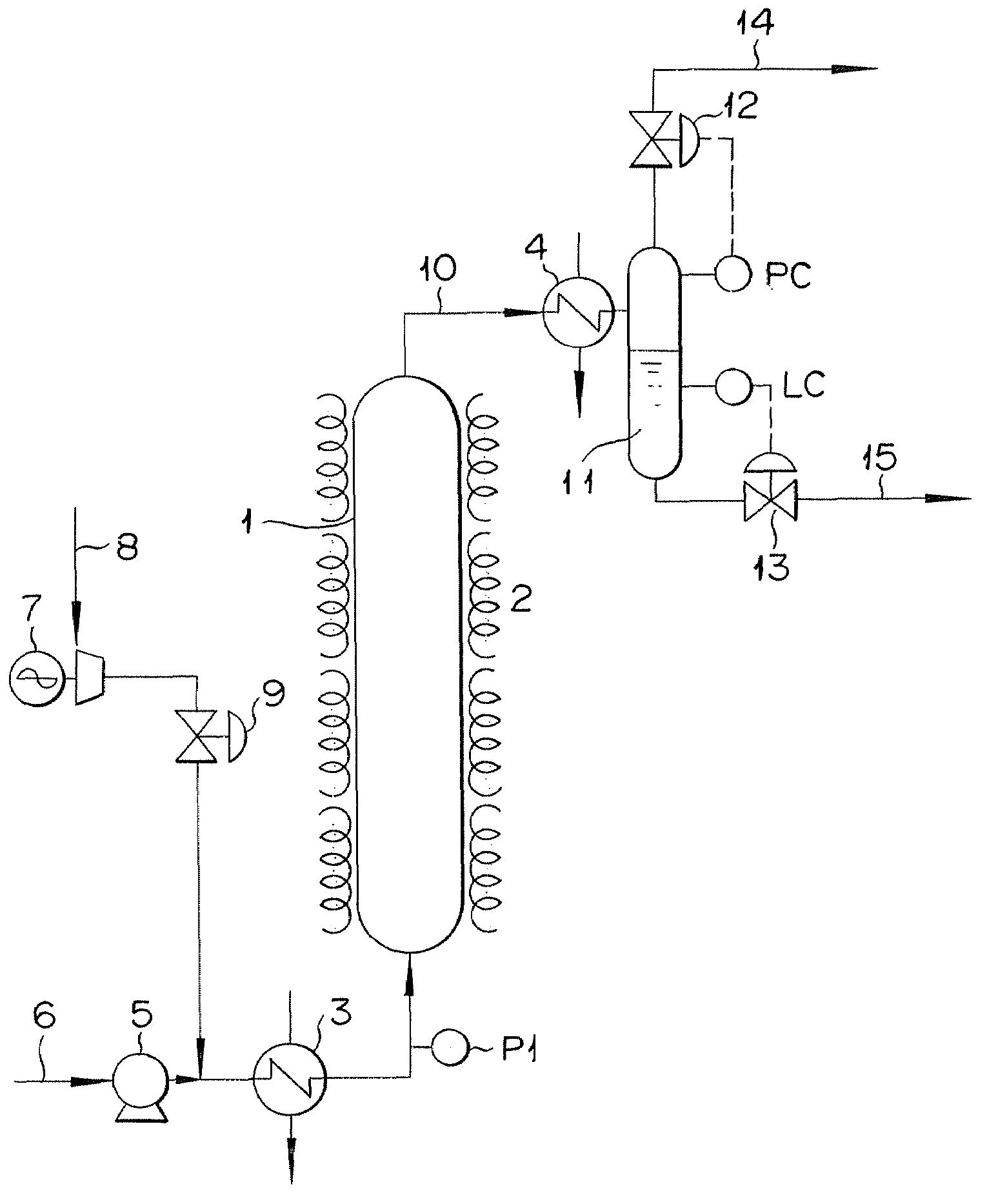

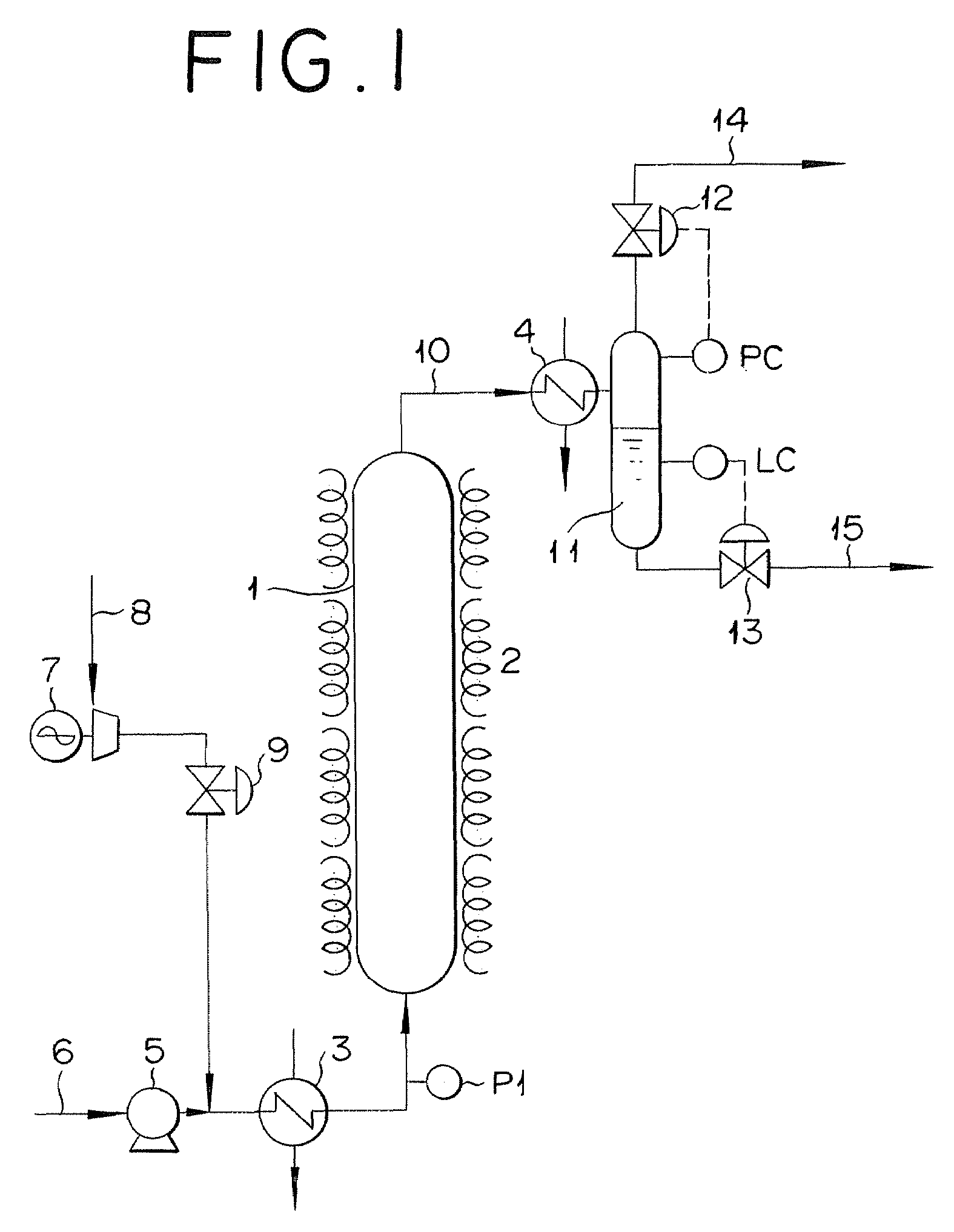

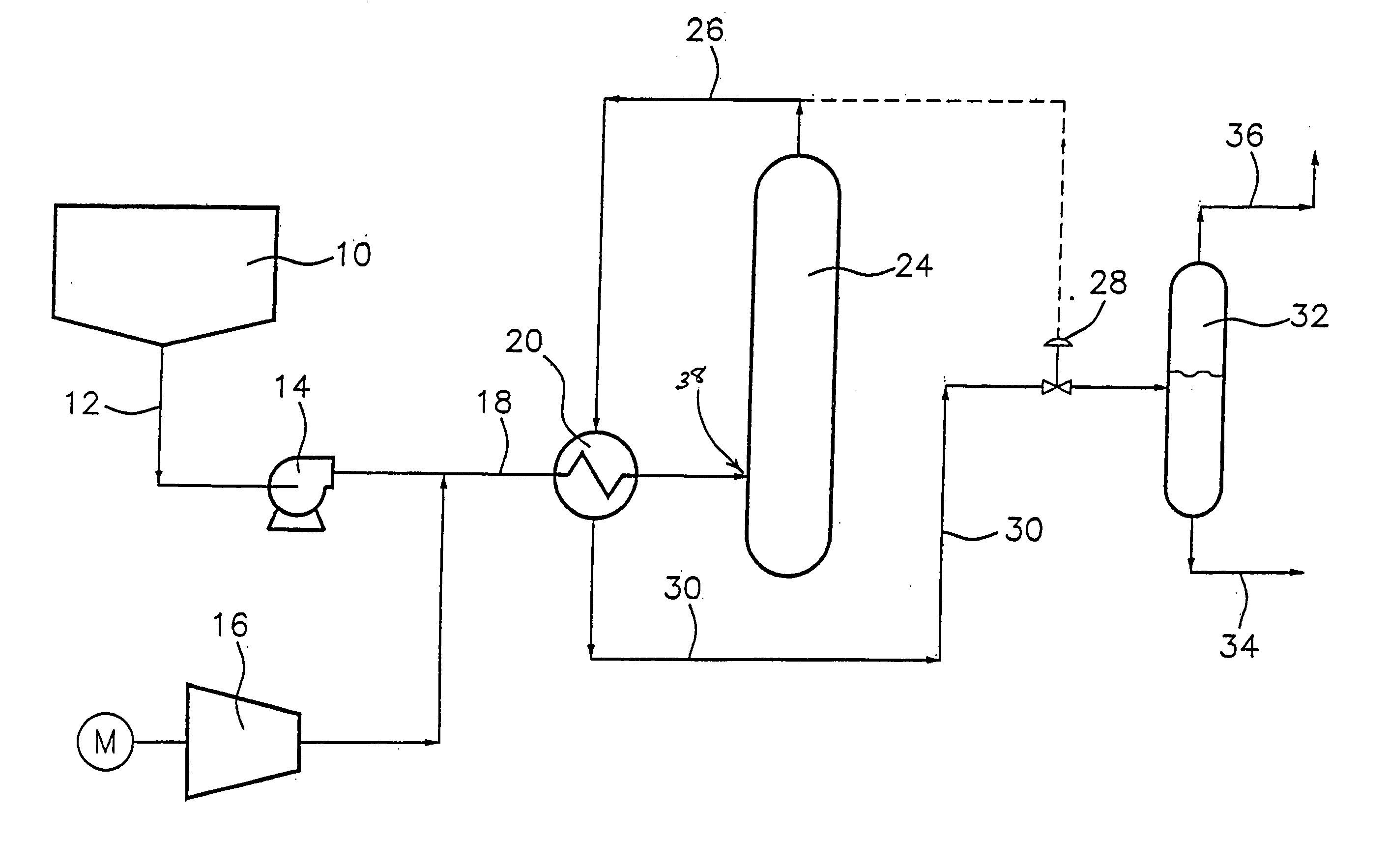

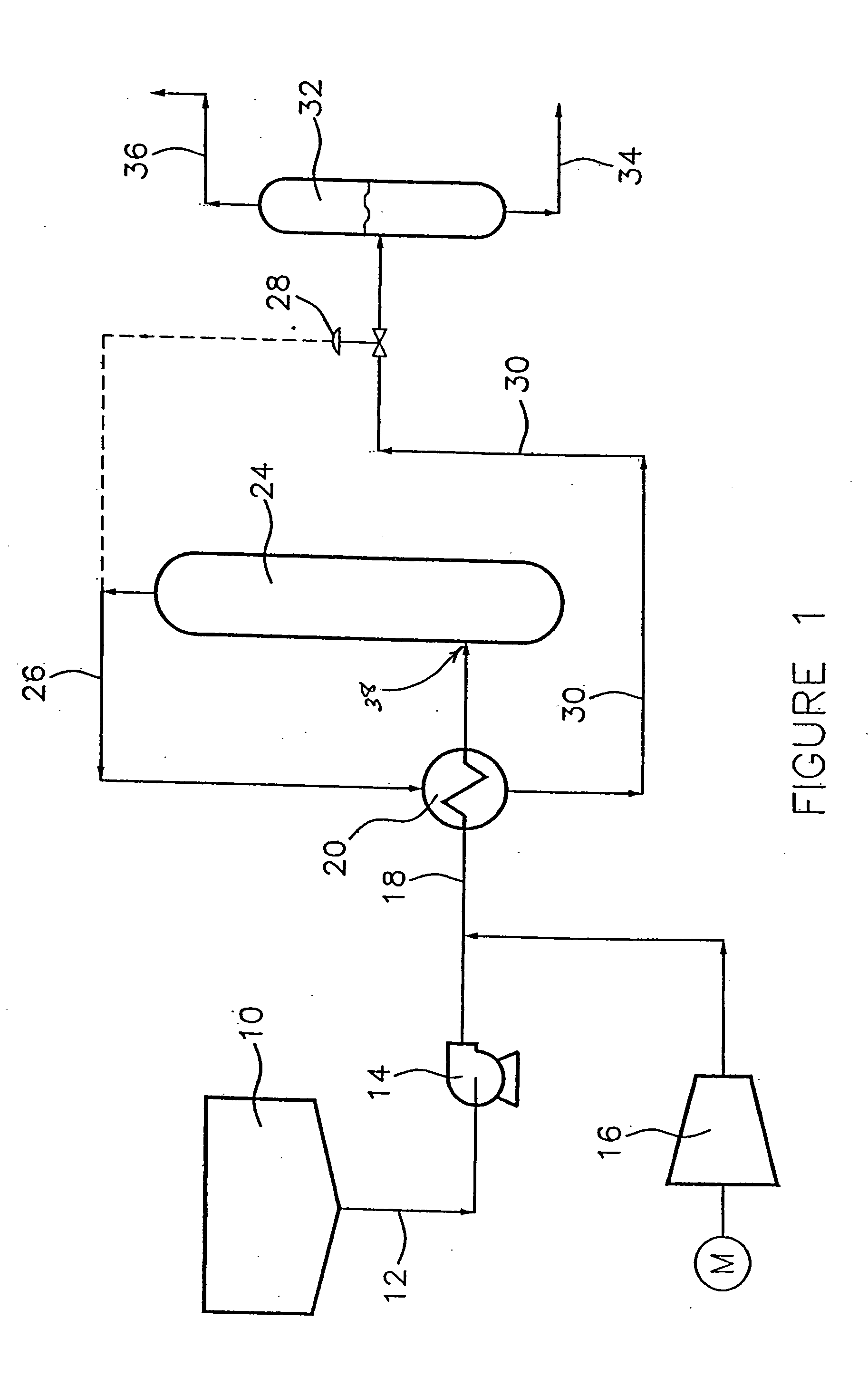

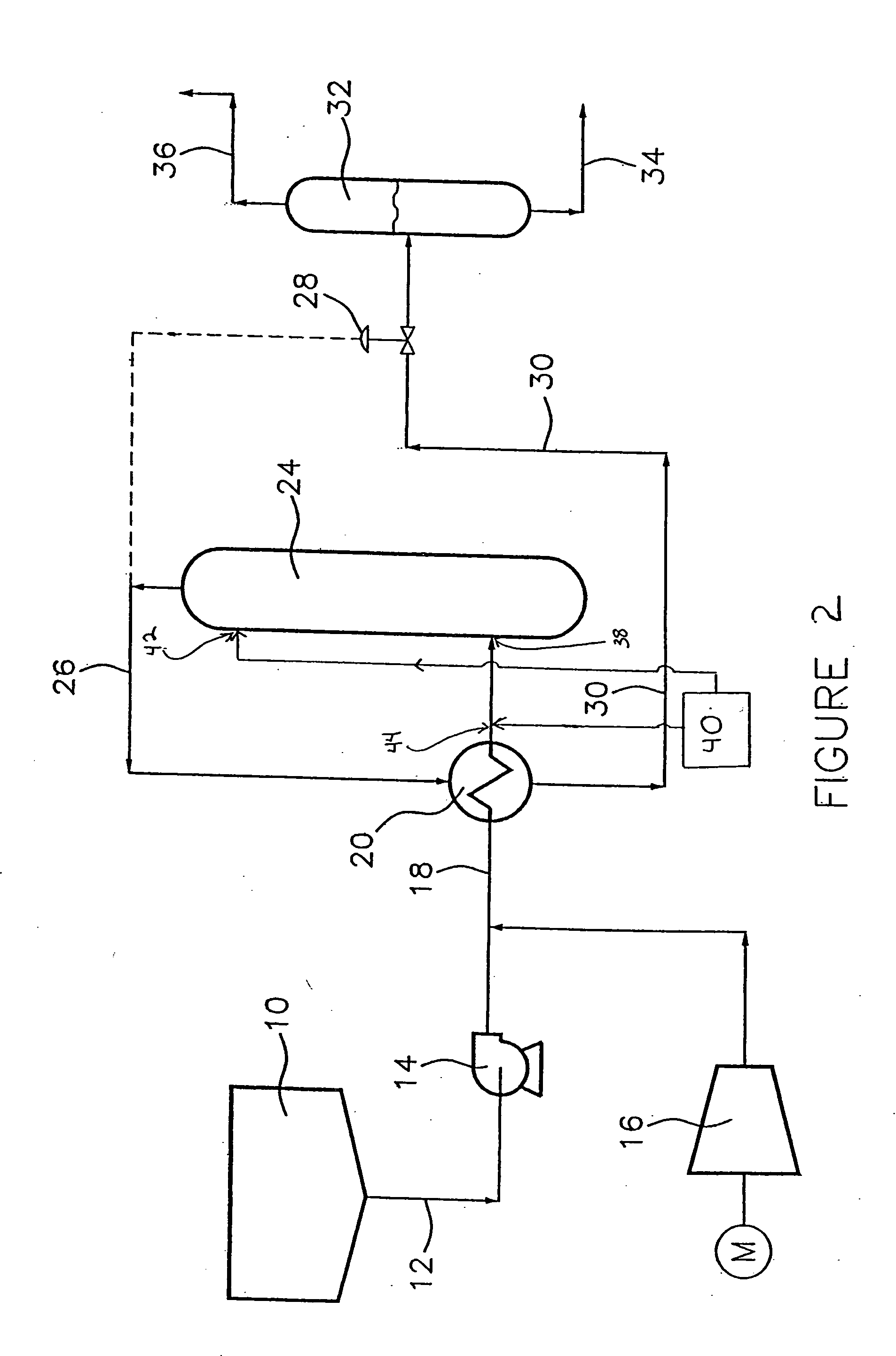

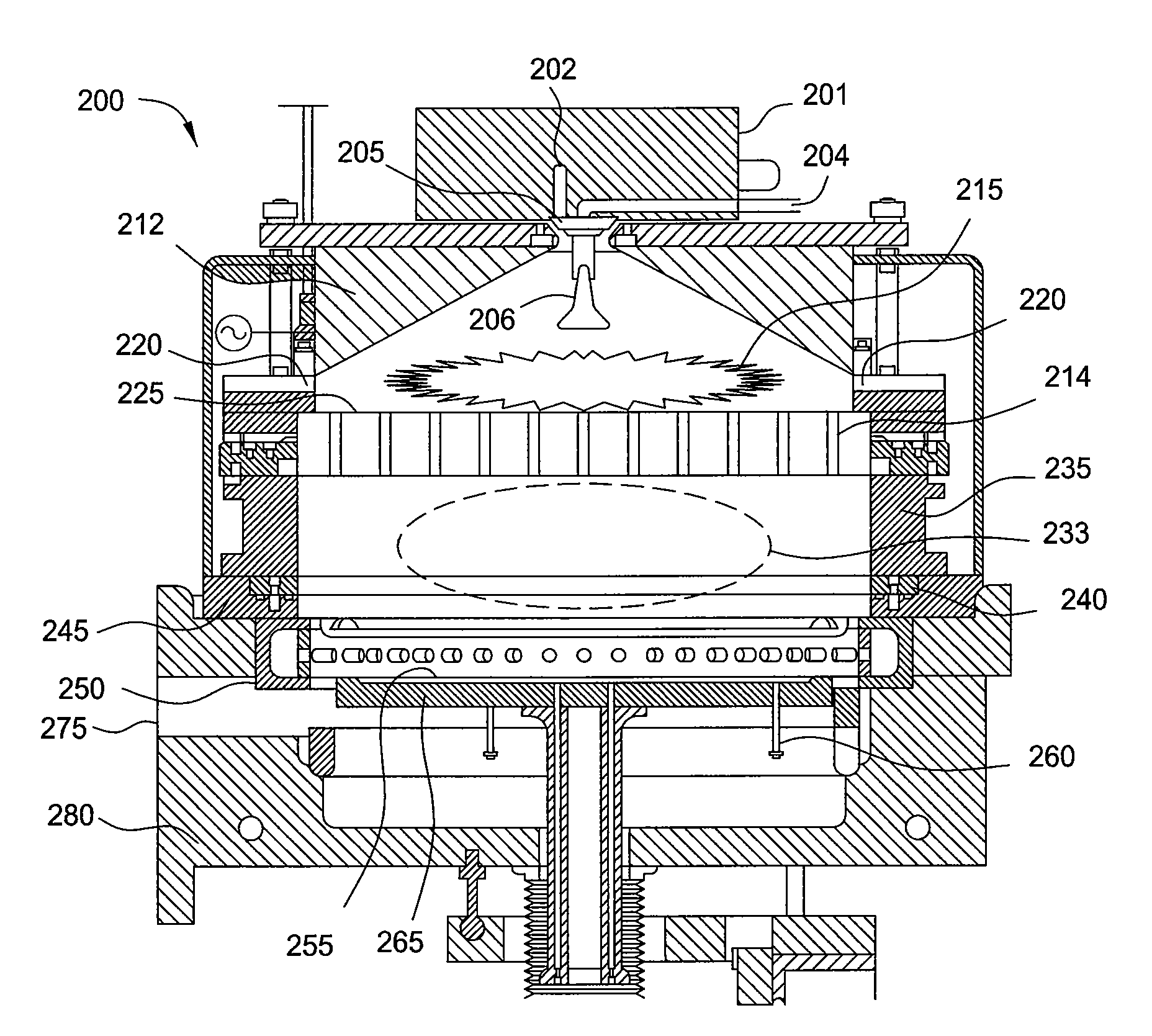

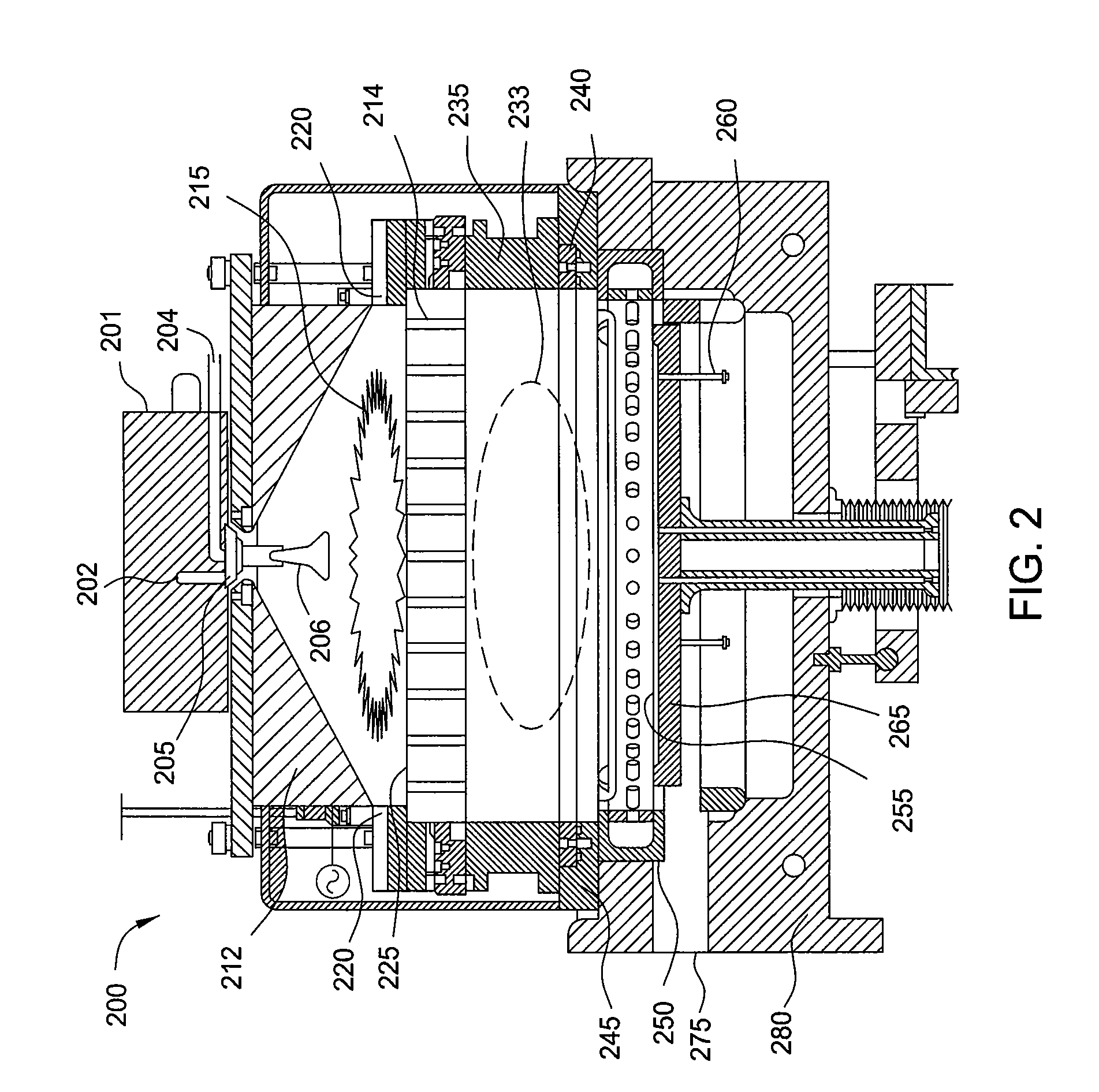

Wet oxidation process and system

InactiveUS20050171390A1Oxygen-containing compound preparationWater treatment parameter controlAdvanced oxidation processResidual carbon

A process and system for the destruction of compounds having a carbon-hetero atom bond. The process includes wet oxidation at elevated temperature and pressure of an aqueous mixture of at least one compound having a carbon-hetero atom bond to substantially destroy the carbon-hetero atom bond of the at least one compound. The resulting oxidized material may be further treated in an advanced oxidation process to destroy any residual carbon-hetero atom bonds remaining.

Owner:SIEMENS WATER TECH HLDG CORP

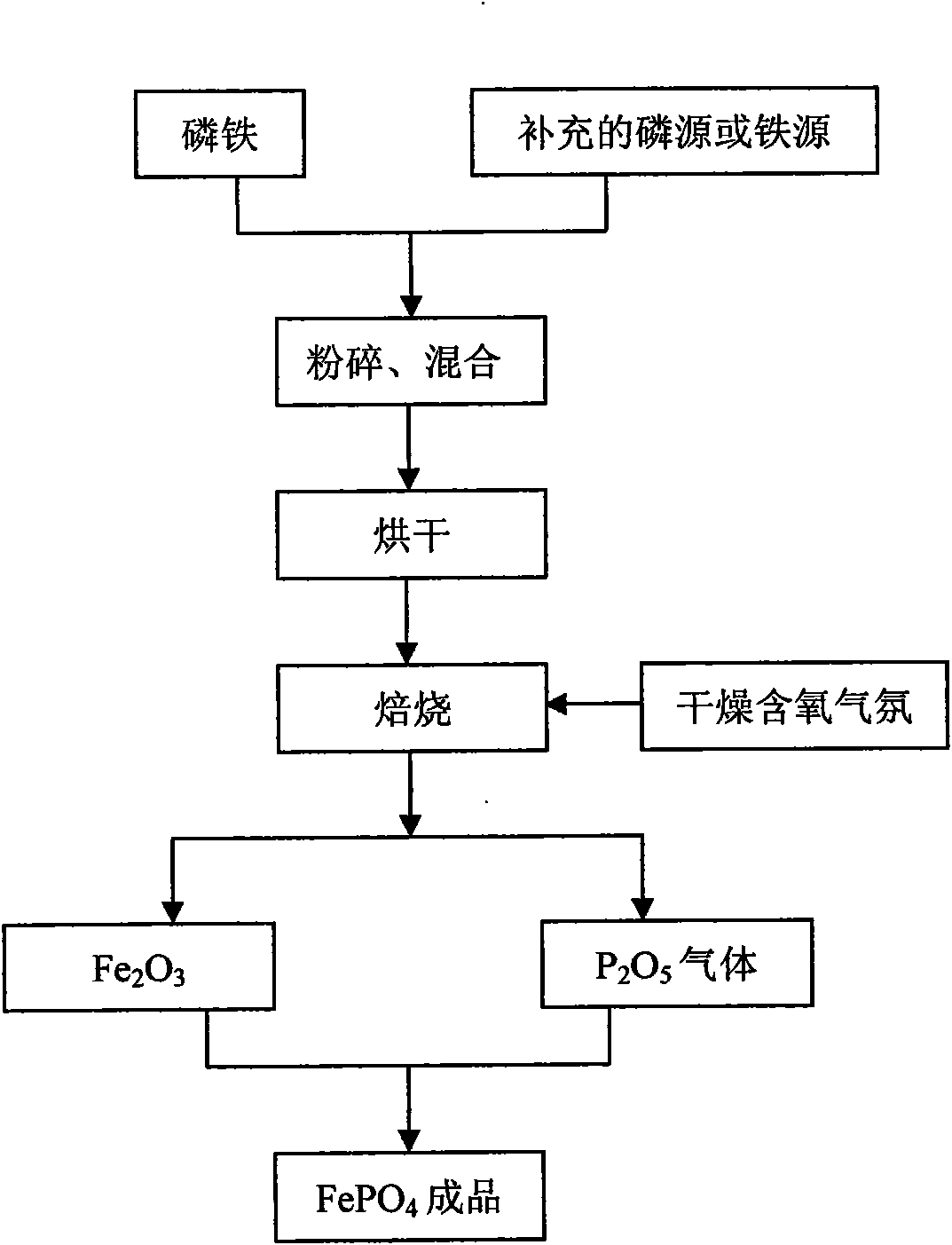

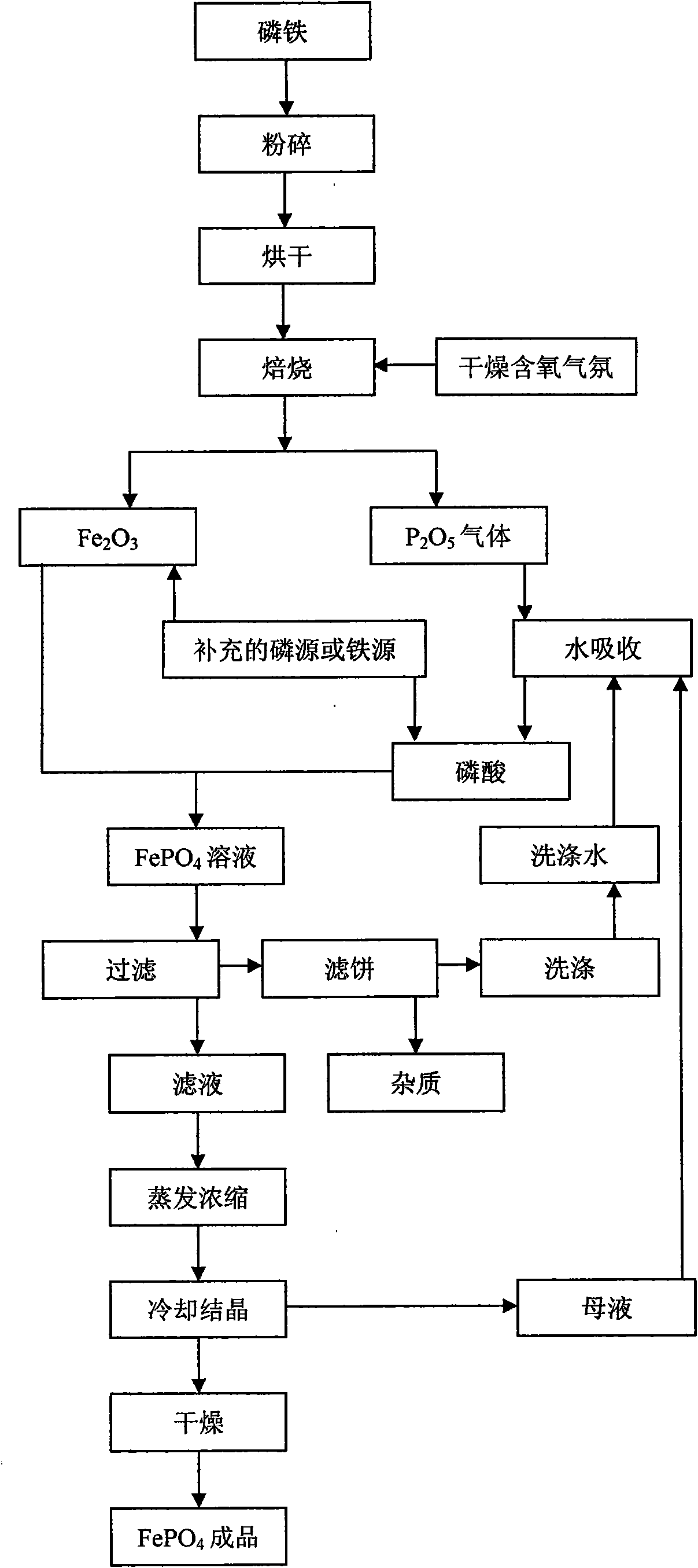

Method for preparing iron phosphate from ferrophosphorus

InactiveCN101659406AOvercome the problem of difficult ratioWide variety of sourcesPhosphorus compoundsLow demandResource utilization

The invention relates to a method for preparing iron phosphate from ferrophosphorus. The ferrophosphorus is used as a part or the whole of a phosphorus source and an iron source for preparing the ironphosphate. The phosphorus source or the iron source is supplemented according to a mol ratio of (0.8-1.2):1.0 between total phosphorus elements and total iron elements. The ferrophosphorus is roastedin a dry and oxygen-containing atmosphere. The iron phosphate product is obtained by means of dry or wet oxidation product reaction. The method adopts the ferrophosphorus as the raw material for preparing the iron phosphate, makes full use of elements in the ferrophosphorus and creates a novel preparing process of iron phosphate. In addition, as the reaction process can be used for weakening or eliminating the influence of impurity elements in the ferrophosphorus on the iron phosphate product, the method indirectly purifies the ferrophosphorus and eliminates the influence of the impurities inthe ferrophosphorus and the problem of severe corrosion caused by the existence of water during the roasting of ferrophosphorus. The reaction process has relatively low demand on apparatuses. The preparing method has simple process, short production flow and low production cost, is clean and environment-friendly, realizes high resource utilization rate, low investment and good benefit and is suitable for large-scale, industrial, low-cost and clean preparation of iron phosphate.

Owner:SICHUAN UNIV

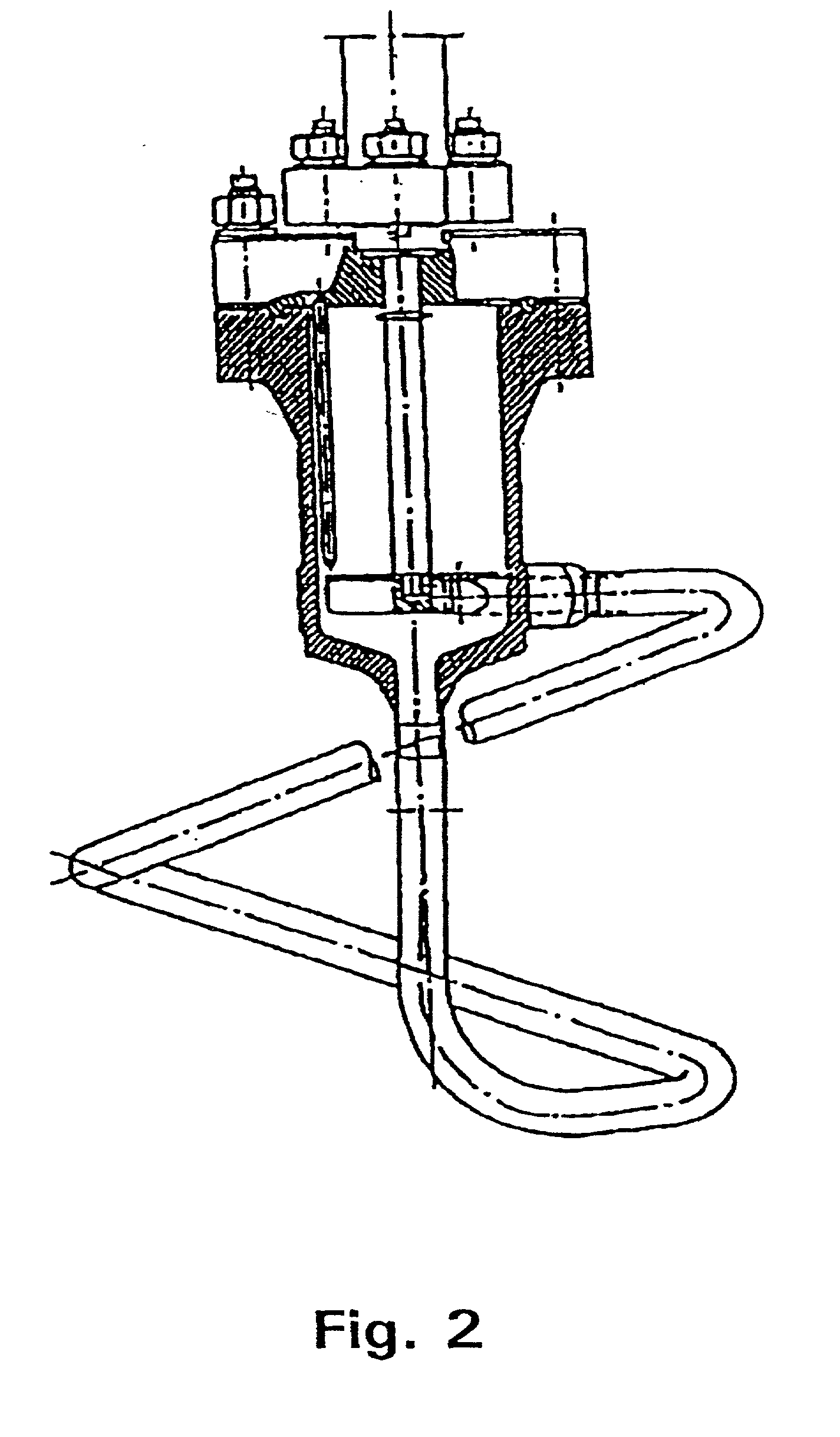

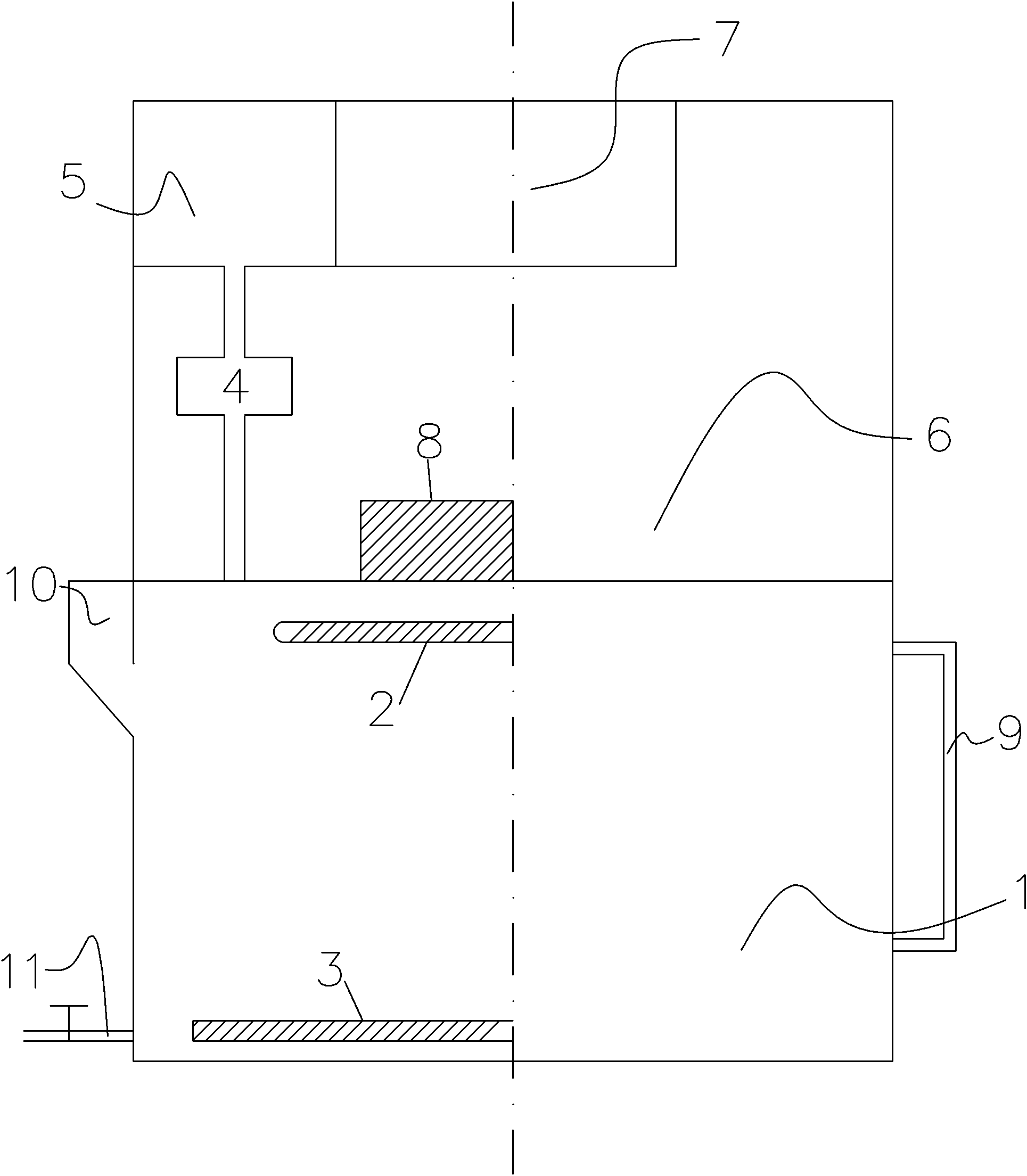

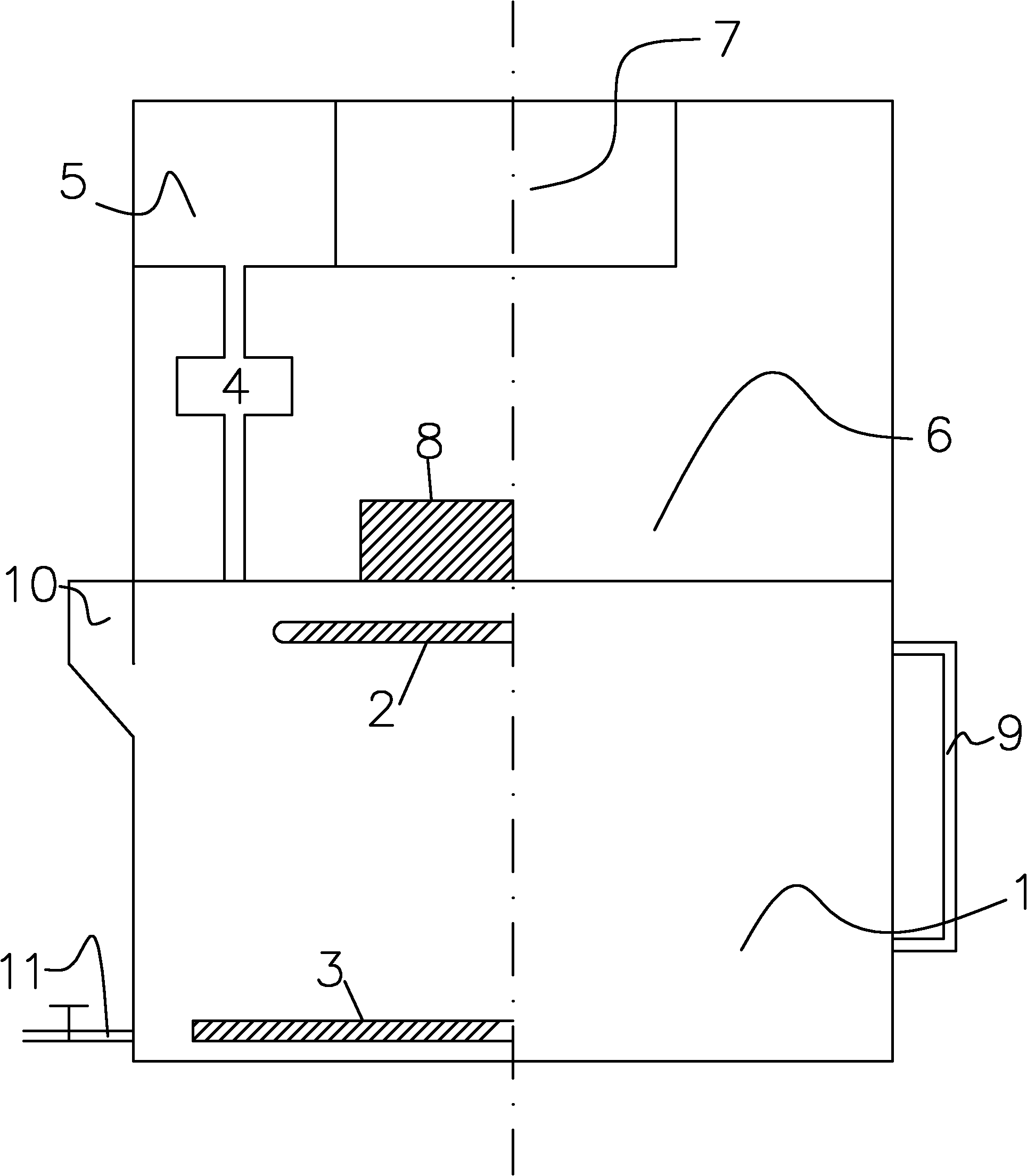

Method and device for degrading pollutants through ultraviolet catalytic wet oxidation

InactiveCN101863526AWide variety of sourcesEasy to separateWater/sewage treatment by irradiationWater/sewage treatment by oxidationHigh concentrationChemical oxygen demand

The invention discloses a method for rapidly and efficiently degrading pollutants through ultraviolet catalytic wet oxidation at the normal temperature and normal pressure and designs a typical device for implementing the method. In the method, ultraviolet light, an oxidant and a catalyst are introduced into a reaction system; and a wet oxidation reaction can be performed under the mild conditions of normal temperature and normal pressure by utilizing the synergistic catalytic oxidation of the ultraviolet light, the oxidant and the catalyst. Compared with the traditional catalytic wet oxidation method which needs to be implemented under the reaction conditions of high temperature and high pressure, the method can be implemented under the conditions of a temperature of between 25 and 80 DEG C and normal pressure, wherein organic pollutants in high-concentration toxic and hazardous waste water can be decomposed to be harmless components such as carbon dioxide (CO2), water and the like through the high oxidizing property; and the removal rate of chemical oxygen demand (COD) chromium (Cr) after the treatment of a plurality of representative high-concentration organic waste water can reach over 95 percent, and the biochemical property can be improved obviously. The method has the advantages of mild reaction, high treating efficiency, complete degradation, clean and environmental-friendly process, energy conservation and wide application prospect.

Owner:李朝林

Catalyst for wet oxidation technique and preparation method thereof

InactiveCN101185887AHigh catalytic activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationActive componentSalt solution

The invention relates to a catalyst which is used for wet air oxidation technique and the preparation method in the field of environmental protection technology. The catalyst uses Gamma-Al2O3 as a vector and the oxide of transition metal Mn or Mn and rear earth element M or the oxide of the M as active components, wherein, M is one or two kinds in La and Ce and the loading of each metal relative to Gamma-Al2O3 vector is 5wt to 8wt percent. The catalyst takes Gamma-Al2O3 as the vector, is cleaned and roasted to be a consistent weight; the obtained Gamma-Al2O3 vector is immersed into the metallic salt solution of the rear earth element M and the transition metal Mn; the loading of each metal relative to the vector is 5wt to 8wt percent; the mixture after being immersed and dried is roasted in air to get the catalyst used in the wet air oxidation. The invention does not use expensive precious metal materials and greatly reduces the cost of the catalyst; at the same time, the catalytic activity of the catalyst is enhanced; the operation condition is improved; and the reaction time is shortened.

Owner:SHANGHAI JIAO TONG UNIV

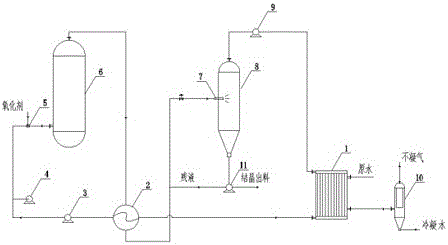

Method and device for treating high-salt refractory organic wastewater

PendingCN106495386AHigh thermal efficiencyReduce energy consumptionWater contaminantsMultistage water/sewage treatmentHigh concentrationVapor liquid

The invention discloses a method and a device for treating high-salt refractory organic wastewater, and particularly relates to a method and a device for treating high-concentration refractory COD and high-salt industrial wastewater by coupling the catalytic wet oxidation and MVR evaporation and concentration crystallization technology. The device comprises a vapor-liquid heat exchanger, a liquid-liquid exchanger, a booster pump (or a circulating pump), a compression fan, an oxidant dosing device, a wet catalytic oxidation reactor (WAO), an evaporator, a vapor compressor and a vapor-water separator. Raw water is subjected to air catalytic wet oxidation in the WAO reactor after two-stage preheating through the vapor-liquid heat exchanger and the liquid-liquid exchanger; the oxidized wastewater is evaporated and concentrated by an evaporator to obtain crystalline salt and the distilled water. The method and the device provided by the invention combine advantages of a wet oxidation technology and an MVR technology, effectively degrade organic matters, improve biodegradability of wastewater, and realize effective utilization of heat energy generated by WAO oxidation reaction and secondary vapor of the evaporator.

Owner:HUNAN PINGAN ENVIRONMENT PROTECTION

Electrolytic cell with porous surface active anode for removal of organic contaminants from water and its use to purify contaminated water

InactiveUS6270650B1Overcome limitationsPromote repairCellsWater/sewage treatment using germicide/oligodynamic-processWaste streamEarth surface

A wet oxidation / reduction electrolytic cell, system, and method for the remediation of contaminated water is disclosed. A porous electrode of large surface area produces powerful oxidizing agents in situ without having to add any reagents, oxidizers, or catalysts to the water to be treated. Further, by the appropriate selection of electrode material, organic contaminants may be absorbed onto the surface of the electrode and subsequently oxidized to provide a dynamically renewable porous electrode surface. Flow rates, and power requirements may be tailored to the specific moieties to be removed, thus allowing local treatment of specific waste streams resulting in direct discharge to a publicly owned treatment works (POTW) or surface water discharge. A novel feature of this invention is the ability to remove both organic and metal contaminants without the addition of treatment reagents or catalysts.

Owner:KAZI ABDULLAH +2

Method for treating wastewater with high hydroxybenzene contained through catalyzing wet oxidation

InactiveCN1498861AImprove biodegradabilityEmission complianceMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationPHENOL LIQUIDActive component

A process for treating the phenol contained sewage by catalytic wet oxidizing method features that its catalyst is prepared from the active component chosen from Pt, Pd, Rh and Ru, the auxiliary component chosen from La, Ce, Pr and Nd, and TiO2-ZrO2 carrier through baking at 60-180 deg.C for 2-18 hrs and calcining at 300-800 deg.c for 2-18 hrs. It is applied under the conditions: 220-280 deg.C for reaction temp, 4-8 MPa for pressure, 50-300 for air / water ratio, and 0.5-6 / hr for space speed. Its advantages are high reaction efficiency, high removal rate of COD up to 99%, and high BOD5 / CODcr increased from 0.02 to 0.6.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

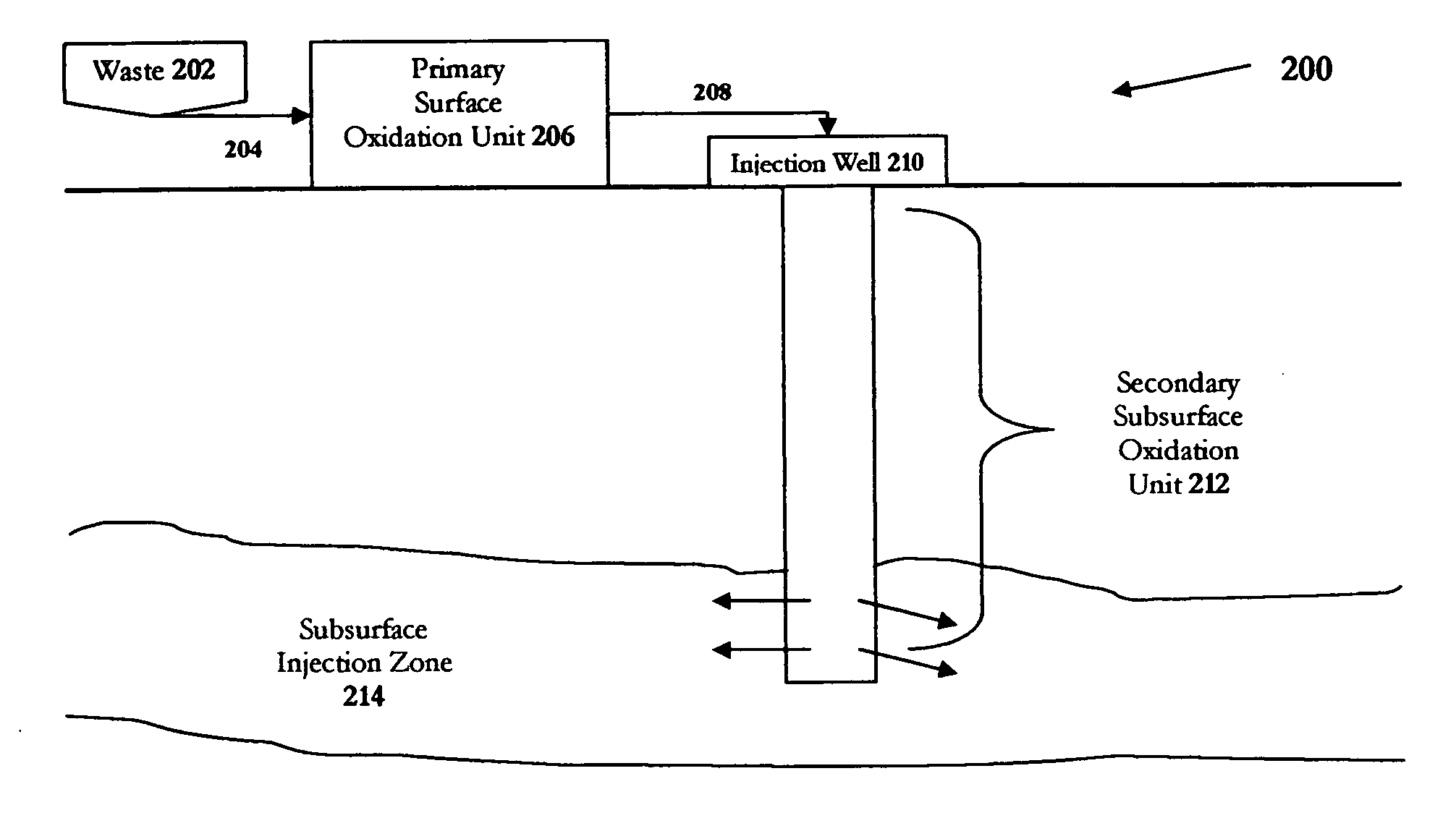

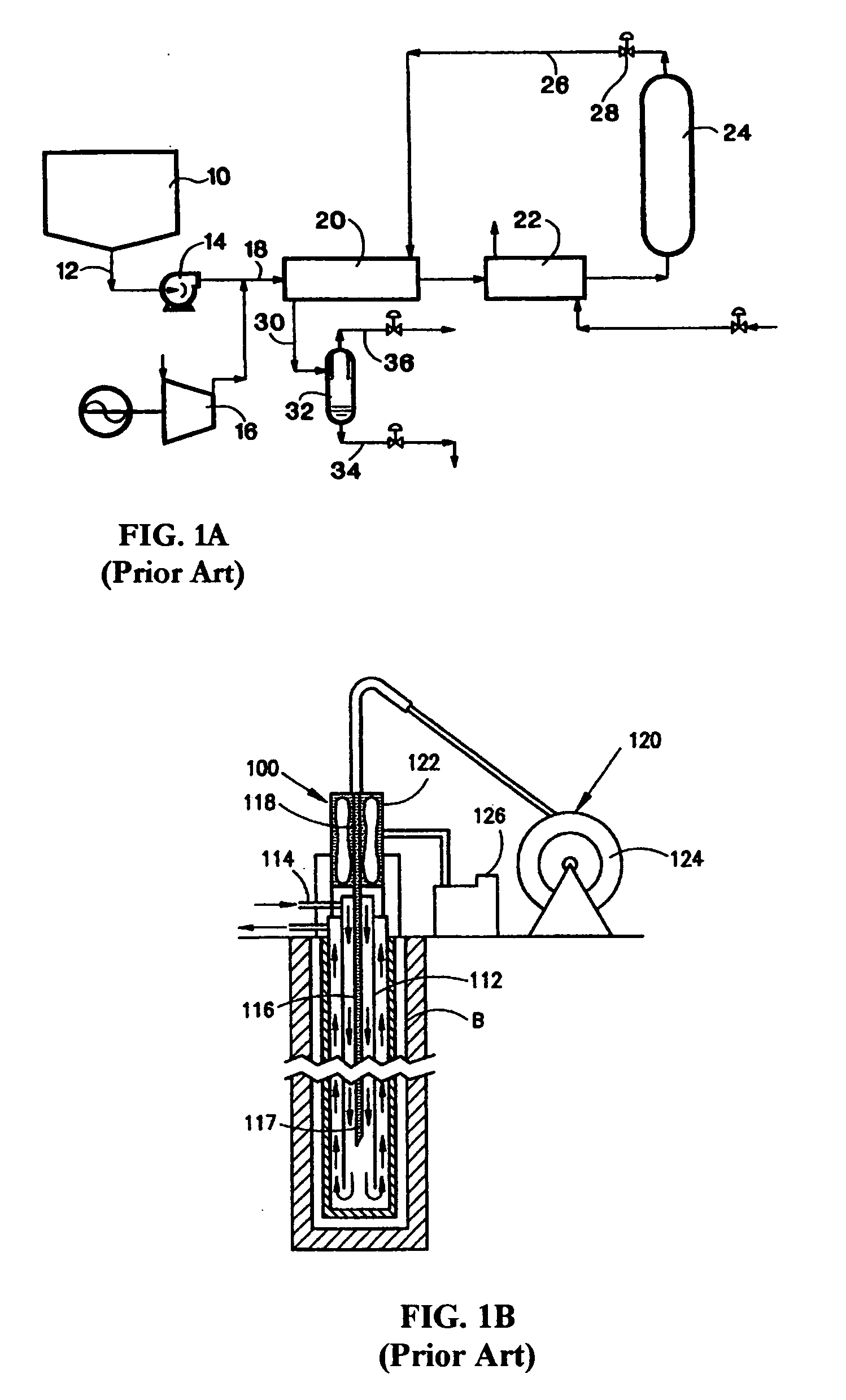

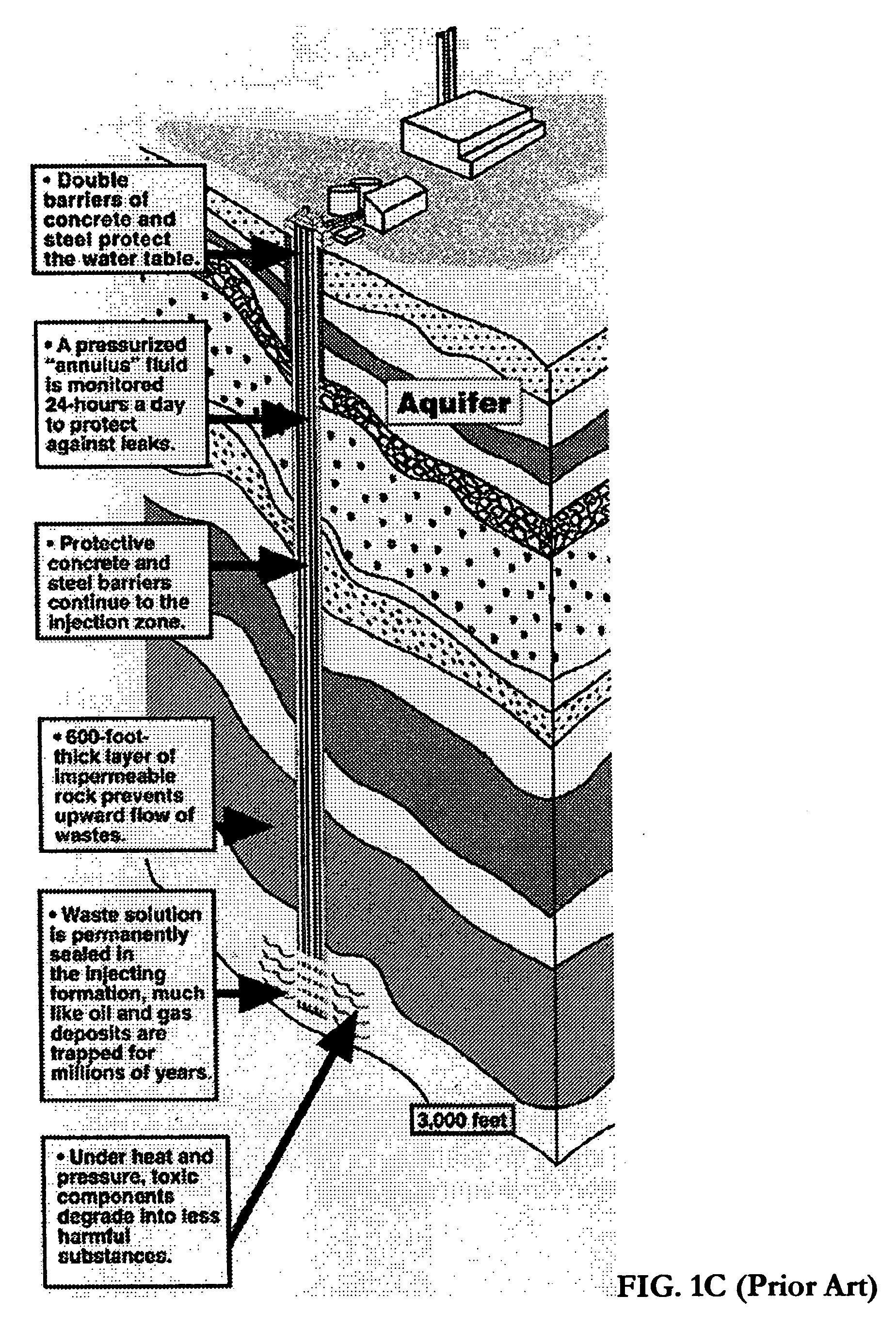

Waste disposal method and apparatus using wet oxidation and deep well injection

InactiveUS20060060541A1Sludge treatmentWater/sewage treatment by substance additionEnvironmental engineeringEngineering

The present invention relates generally to waste treatment methodologies and technologies for treatment and disposal of organic wastes. More specifically, in a preferred embodiment of the present invention, there is described a system and methodology for treating organic waste by wet oxidation processes or wet air oxidation processes (carried out on the surface or subsurface) followed by introduction of the treated waste mixture into a disposal well and injection of the mixture into a suitable geological formation. Ideally, the mixture is filtered prior to injection into the formation. The method and apparatus of the present invention provide increased waste treatment throughput as compared to conventional use of wet oxidation or wet air oxidation followed by surface biotreatment.

Owner:TM DEER PARK SERVICES

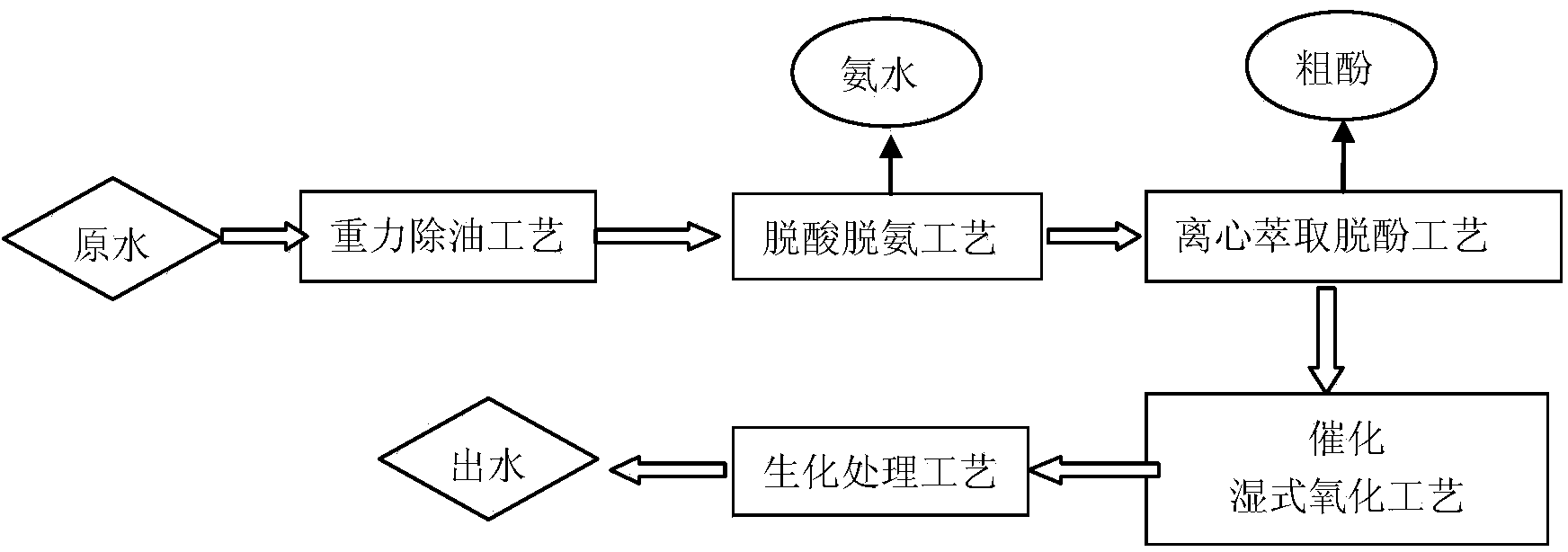

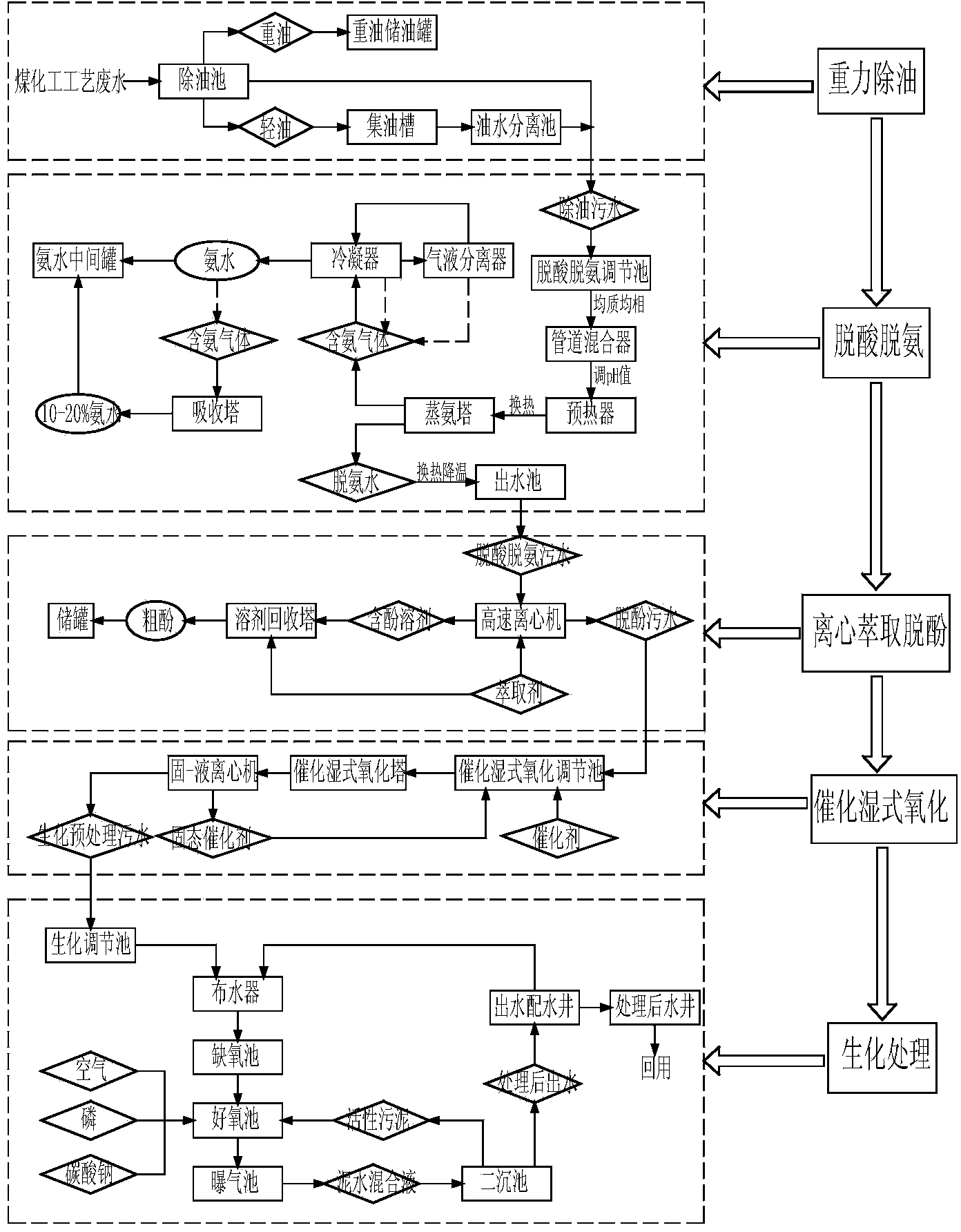

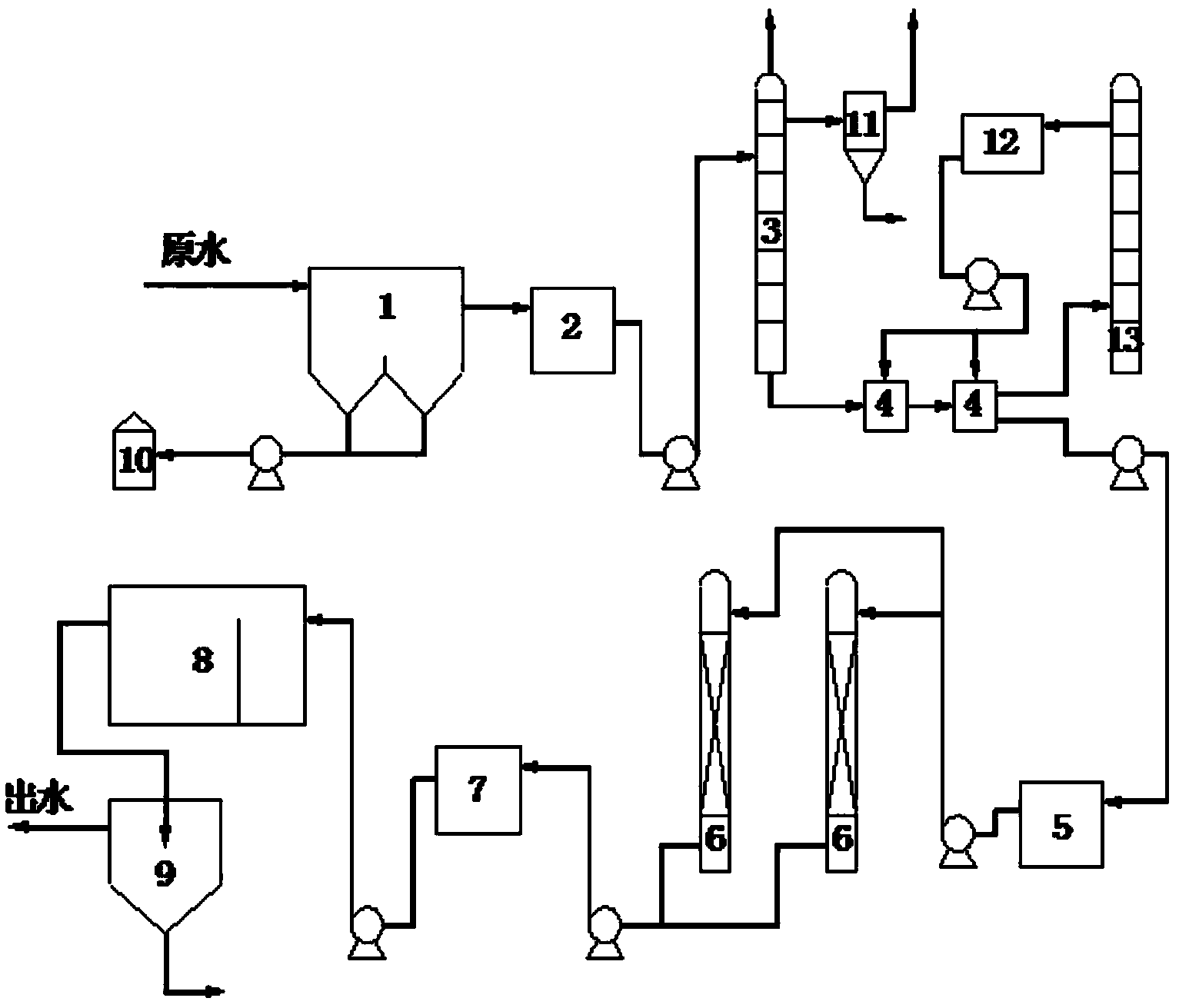

Advanced treatment process of coal chemical industry wastewater

ActiveCN103880242AAchieve water balanceMultistage water/sewage treatmentChemical industryEmission standard

The invention relates to an advanced treatment process and device of coal chemical industry wastewater. The process comprises the following steps: removing oil, performing deacidification and deamination, performing centrifugal extraction and dephenolization, performing catalytic wet oxidation and performing biochemical treatment. The device comprises an oil removal pool, a deacidification and deamination regulating reservoir, an ammonia still, a high speed centrifuge, a catalytic wet oxidation regulating reservoir, a catalytic wet oxidation tower, a biochemical regulating reservoir and an A / O biochemical system which are connected with one another sequentially. The indirect emission standard requirements in the national coking chemical industrial pollutant discharge standard (GB16171-2012) can be met after main pollutants such as chemical oxygen demand (COD), oil, ammonia nitrogen and phenol in coal chemical industry wastewater are treated, and ammonia water and crude phenol can be recovered. Compared with the prior art, the advanced treatment process of coal chemical industry wastewater has the beneficial effects that sewage produced in coal chemical industry is treated with a clear target on the basis of characteristics of the coal chemical industry production process, so that the indirect emission standard requirements are met, available resources in the sewage are recovered, and sewage resource treatment is really realized.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

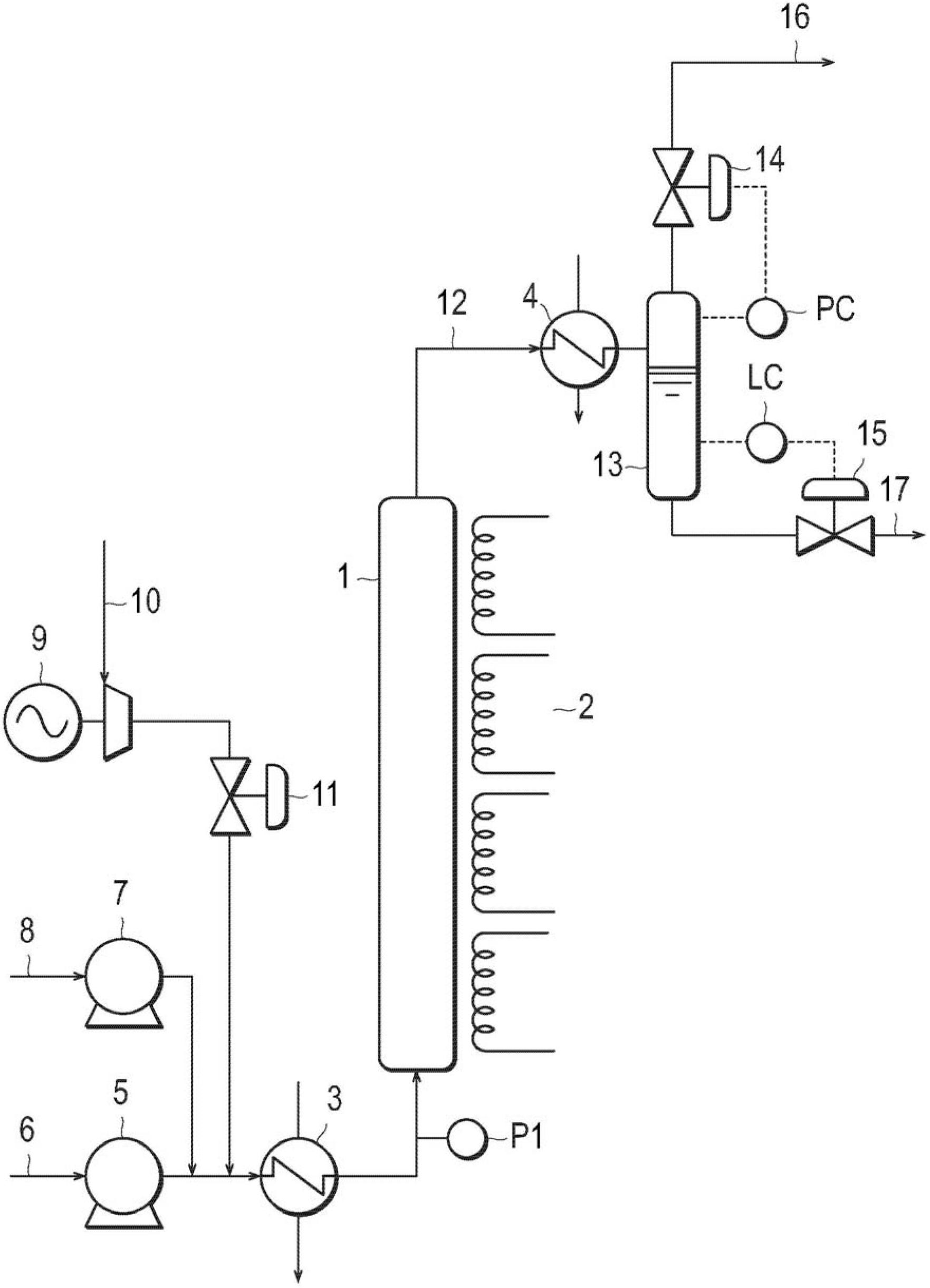

Method for treating biomass and organic waste with the purpose of generating desired biologically based products

The present invention provides a method for treatment of lignocellulosic organic waste or biomass, by which the carbohydrates are rendered more available for subsequent hydrolysis, e.g. by means of addition of enzymes or direct fermentation to one or more desired products. The invention more specifically relates to a method comprising a combination of the following process steps: thermal hydrolysis, wet oxidation and wet explosion. The method according to the present invention can operate with undivided or only poorly divided substrate having a high dry matter concentration.

Owner:CAMBI BIOETHANOL APS

Catalyzer for catalyzing wet oxidation in treating wastewater of sensitization glue, and its application

InactiveCN1498860AImprove biodegradabilityEmission complianceMulticolor photographic processingMetal/metal-oxides/metal-hydroxide catalystsActive componentReaction temperature

A catalyst for treating the photoresist sewage by catalytic wet oxidizing process is prepared from the active component chosen from Pt, Pd, Rh and Ru, the auxiliary component chosen from La, Ce, Pr and Nd, and TiO2-ZrO2 carrier through baking at 60-180 deg.c for 2-18 hrs and calcining at 300-800 deg.C for 2-18 hrs. It is applied under the conditions: 220-280 deg.c for reaction temp, 4-8 MPa for reaction pressure, 50-300 for air / sewage ratio and 0.5-6 / hr for space speed. Its advantages are high reaction efficiency, high removal rate of COD up to 99%, and high BOD5 / CODcr ratio increased from 0.02 to 0.6.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

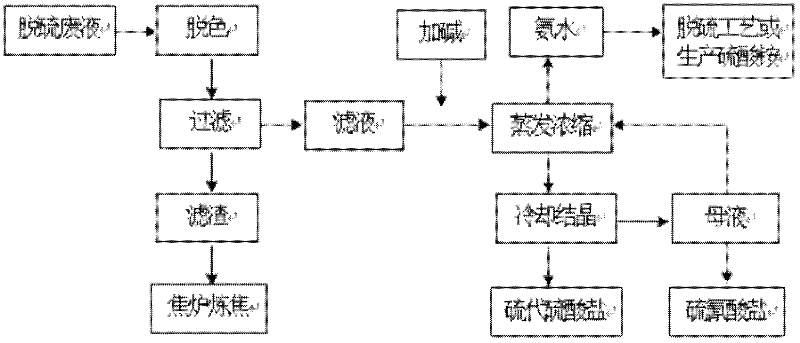

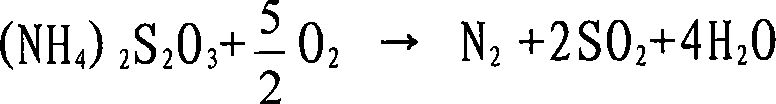

Method for treating desulfurization waste liquid of wet oxidation method

ActiveCN102295379AReduce manufacturing costNot easily decomposed by heatThiosulfates/dithionites/polythionitesThiocyanic acidSodium thiocyanateEvaporation

A method for treating desulfurization waste liquid of a wet oxidation method. The method comprises the following steps: firstly adding a decolorant into desulfurization waste liquid for decolorizing treatment, filtering after decolorization, adding alkali into the filtrate, controlling the PH to be 8-9, performing evaporation concentration under a condition with a negative pressure, condensing the evaporated ammonia gas and water vapor to obtain concentrated ammonia liquor which can be returned to the system for recycle or be used to produce ammonium sulfate, performing fractional crystallization of the concentrated desulfurization liquid to respectively obtain high-purity sodium thiocyanate and sodium hyposulfite. The invention has a simple process, and stable operations, and effectively solves the problem of difficult HPF desulfurization waste liquid treatment in coking enterprises; the method not only reduces the discharge of the waste liquid, but also recovers a lot of chemical products with economic value, and the method has quite significant economic benefits and environmental benefits.

Owner:SHOUGANG CORPORATION

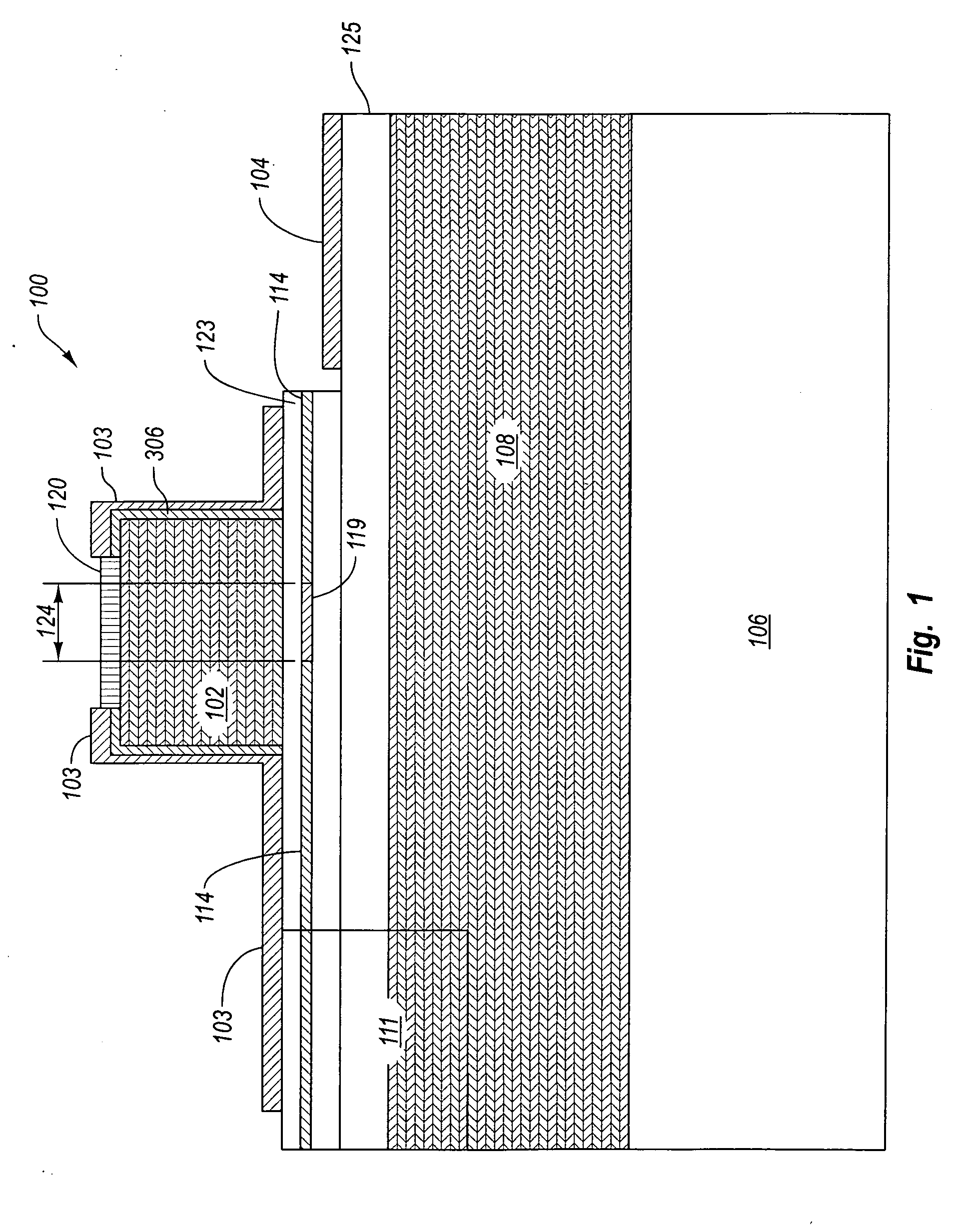

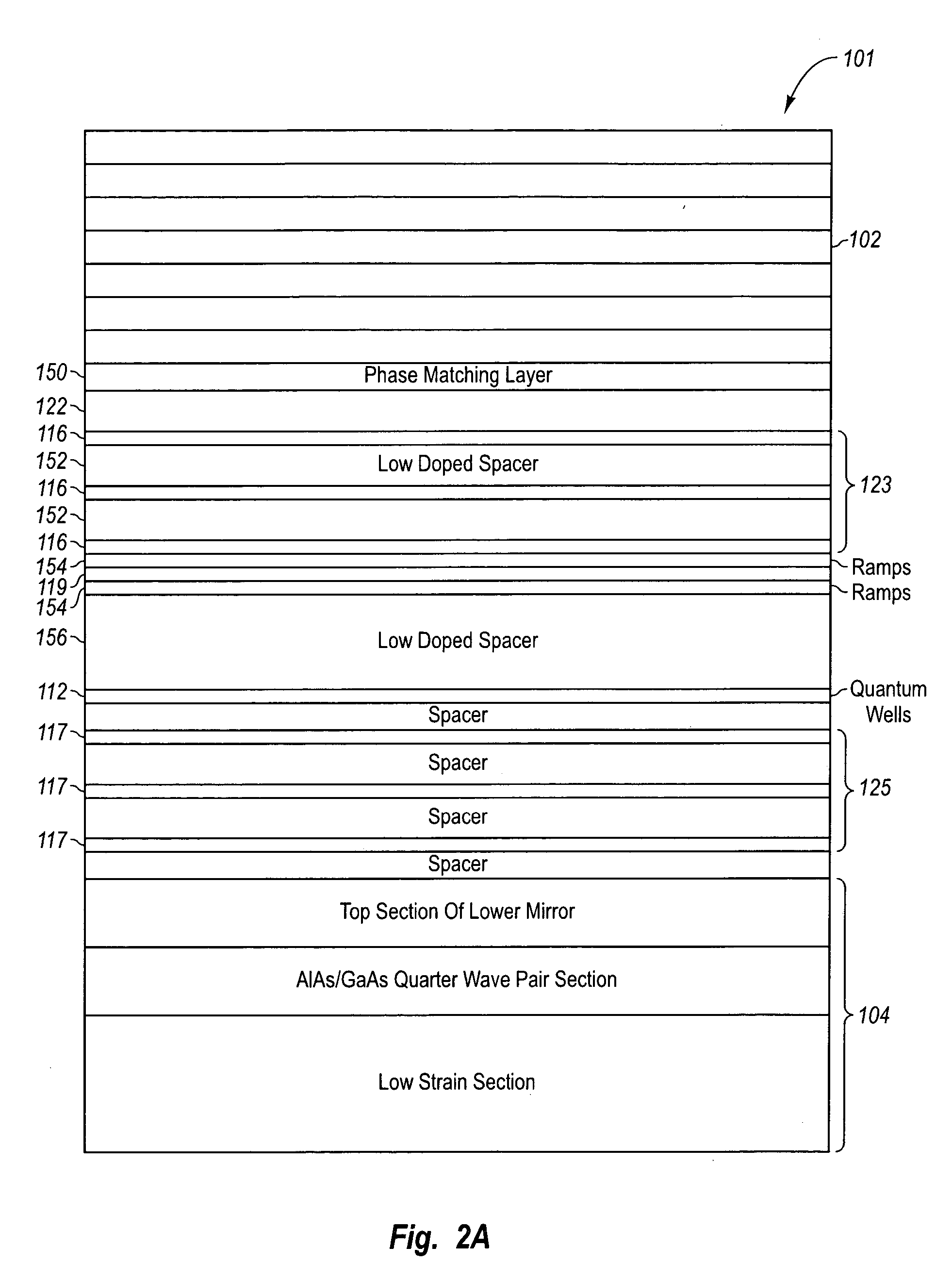

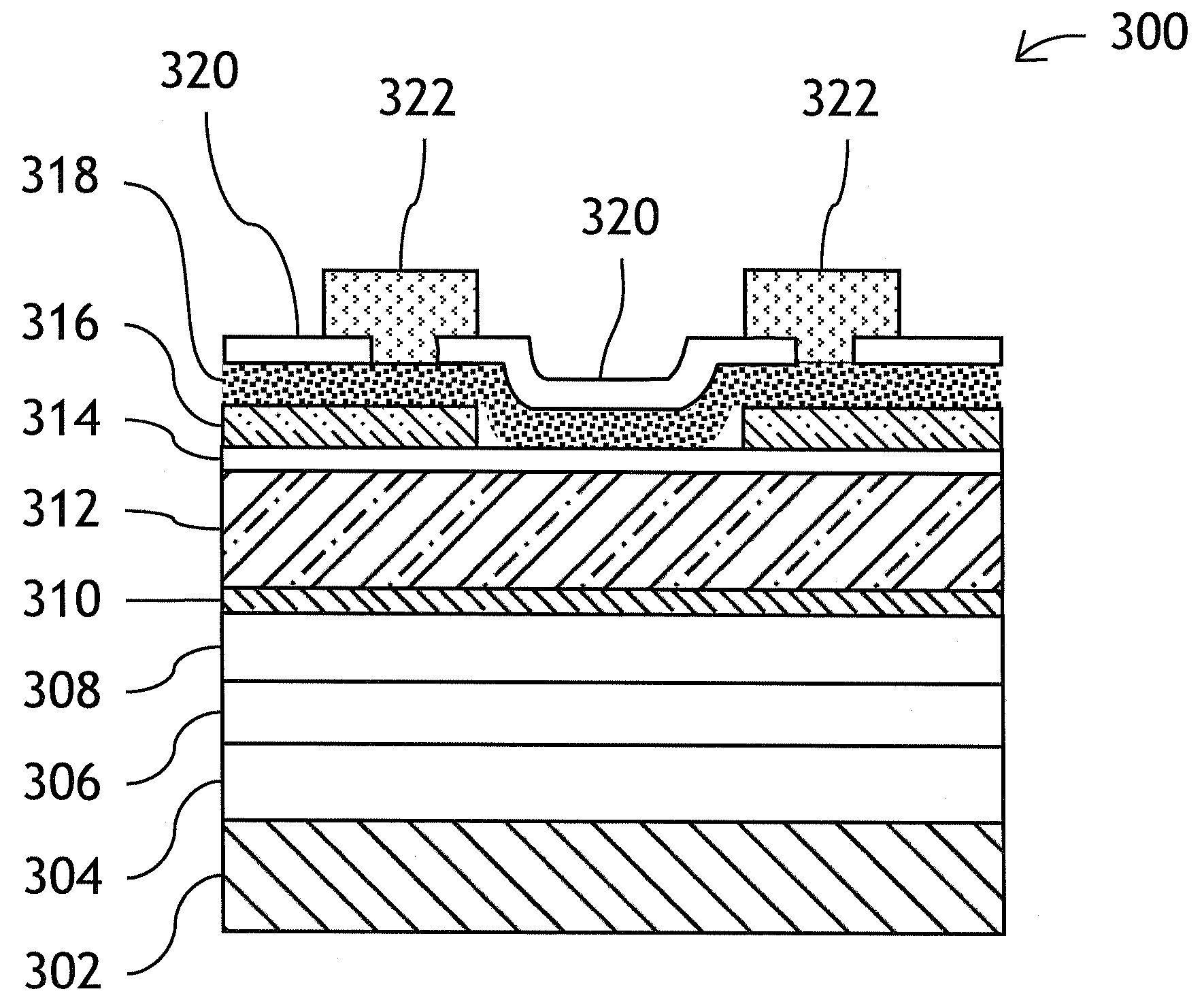

Vertical cavity surface emitting laser having multiple top-side contacts

ActiveUS20060072640A1Reduce absorptionGood performance of certainSemiconductor lasersLaser cooling arrangementsVertical-cavity surface-emitting laserQuantum well

A VCSEL with undoped mirrors. An essentially undoped bottom DBR mirror is formed on a substrate. A periodically doped first conduction layer region is formed on the bottom DBR mirror. The first conduction layer region is heavily doped at a location where the optical electric field is at about a minimum. An active layer, including quantum wells, is on the first conduction layer region. A periodically doped second conduction layer region is connected to the active layer. The second conduction layer region is heavily doped where the optical electric field is at a minimum. An aperture is formed in the epitaxial structure above the quantum wells. A top mirror coupled to the periodically doped second conduction layer region. The top mirror is essentially undoped and formed in a mesa structure. An oxide is formed around the mesa structure to protect the top mirror during wet oxidation processes.

Owner:II VI DELAWARE INC

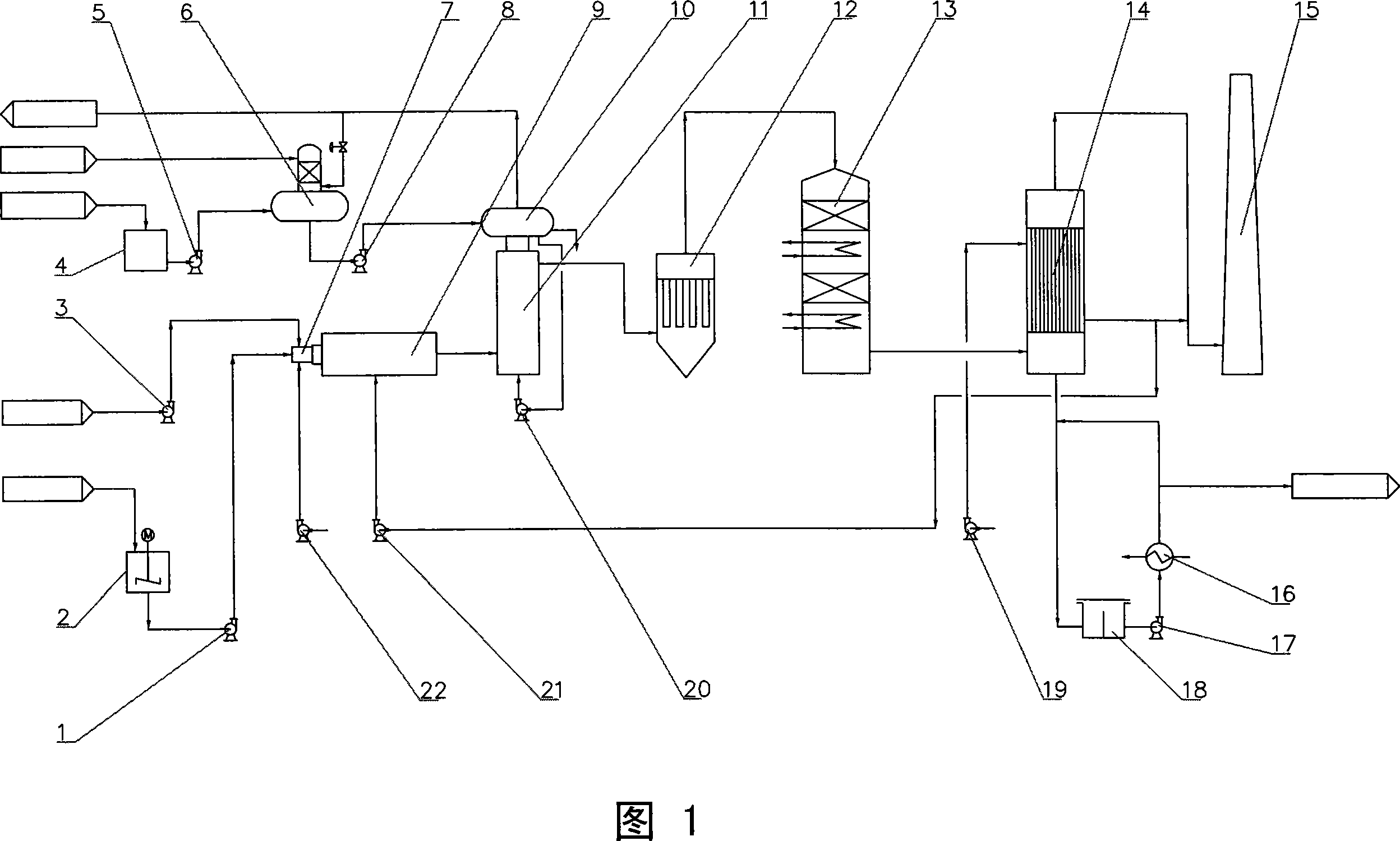

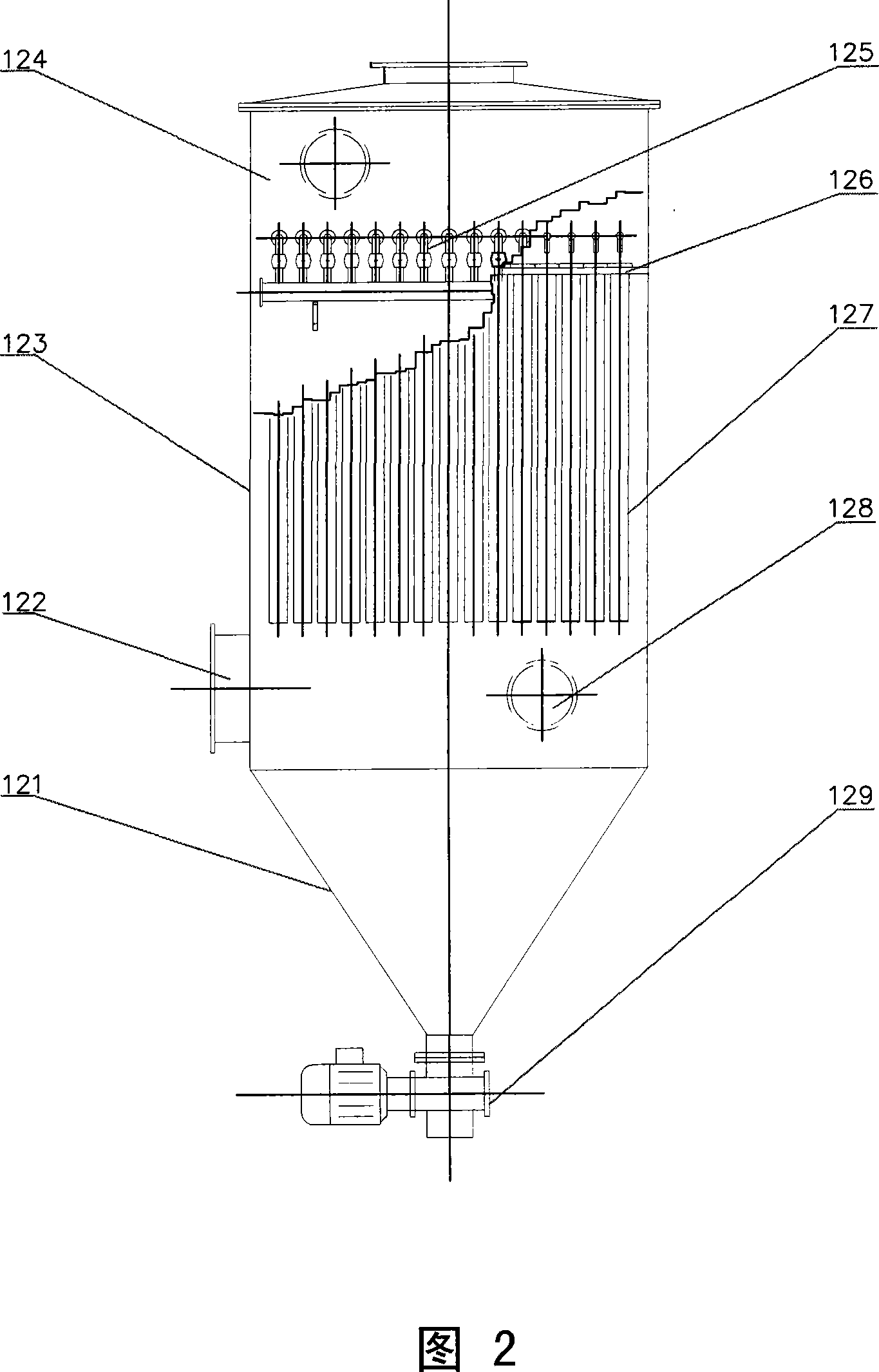

Technique and equipment for preparing sulfuric acid by using sulfur and waste liquid generated from coal gas wet type oxidation sweetening technique

ActiveCN101092577ASimple processSimplify Process Gas Cleaning ProcessSulfur compoundsEnergy inputLiquid wasteSulfur containing

This invention relates to method and apparatus for preparing sulfuric acid by using sulfur and waste solution generated in wet oxidation desulfurization of coal gas. The method comprises: mixing sulfur and sulfur-containing salt solution, incinerating wastewater, recovering waste heat, dry-cleaning, wet-contact-converting, and condensing. The apparatus comprises: an incineration unit, a waste heat recovery unit, a dry-type purification unit, a wet-type contact conversion unit, and a condensation unit, while does not comprise drying unit or tail gas treatment unit. Only one dry-type high-temperature purification deduster is used for dry purification, thus the purification process is simplified. The method has low cost, and no waste solution discharge.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Semiconductor Photodiode And Method Of Manufacture Thereof

ActiveUS20090242933A1Reduce manufacturing stepsImprove reliabilitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationDopantEngineering

A method of manufacture of an avalanche photodiode involving a step of making a recess in a top window layer of an avalanche photodiode layer stack, such that a wall surrounding the recess runs smoothly and gradually from the level of the recess to the level of the window layer. Further, diffusing a dopant over the entire window layer area so as to form a p-n junction at the bottom of the recess, and providing a first electrical isolation region around the recess by buried ion implantation or wet oxidation in order to limit the flow of electrical current to the p-n junction. Forming an isolation trench around the photodiode and a second electrical isolation region by ion implantation into the trench such that the second electrical isolation region runs through the absorption layer of the photodiode.

Owner:LUMENTUM OPERATIONS LLC

Wet oxidation process performed on a dielectric material formed from a flowable CVD process

ActiveUS20120142198A1Low costReduce process complexitySemiconductor/solid-state device manufacturingSiliconWet oxidation

Methods of performing a wet oxidation process on a silicon containing dielectric material filling within trenches or vias defined within a substrate are provided. In one embodiment, a method of forming a dielectric material on a substrate includes forming a dielectric material on a substrate by a flowable CVD process, curing the dielectric material disposed on the substrate, performing a wet oxidation process on the dielectric material disposed on the substrate, and forming an oxidized dielectric material on the substrate.

Owner:APPLIED MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com