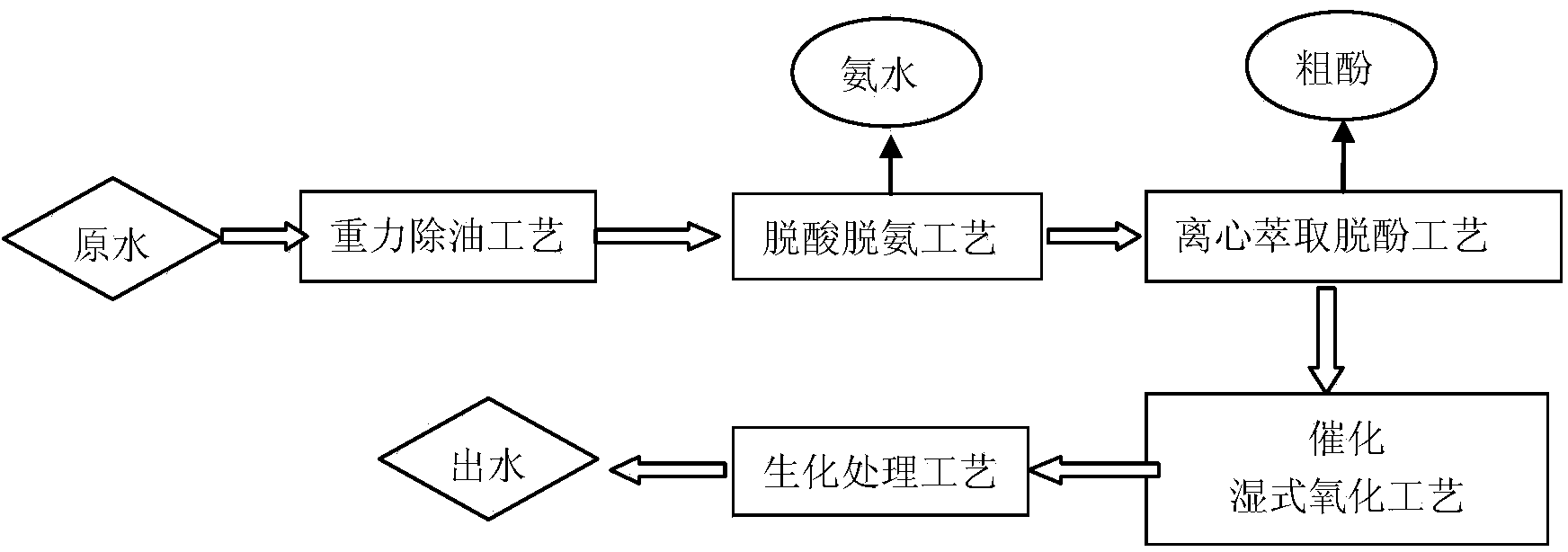

Advanced treatment process of coal chemical industry wastewater

A coal chemical wastewater and advanced treatment technology, applied in the field of coal chemical industry, can solve the problems of inability to realize the recycling of water resources, difficulty in meeting coke quenching standards for wastewater or biochemical water inflow requirements, large gas consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

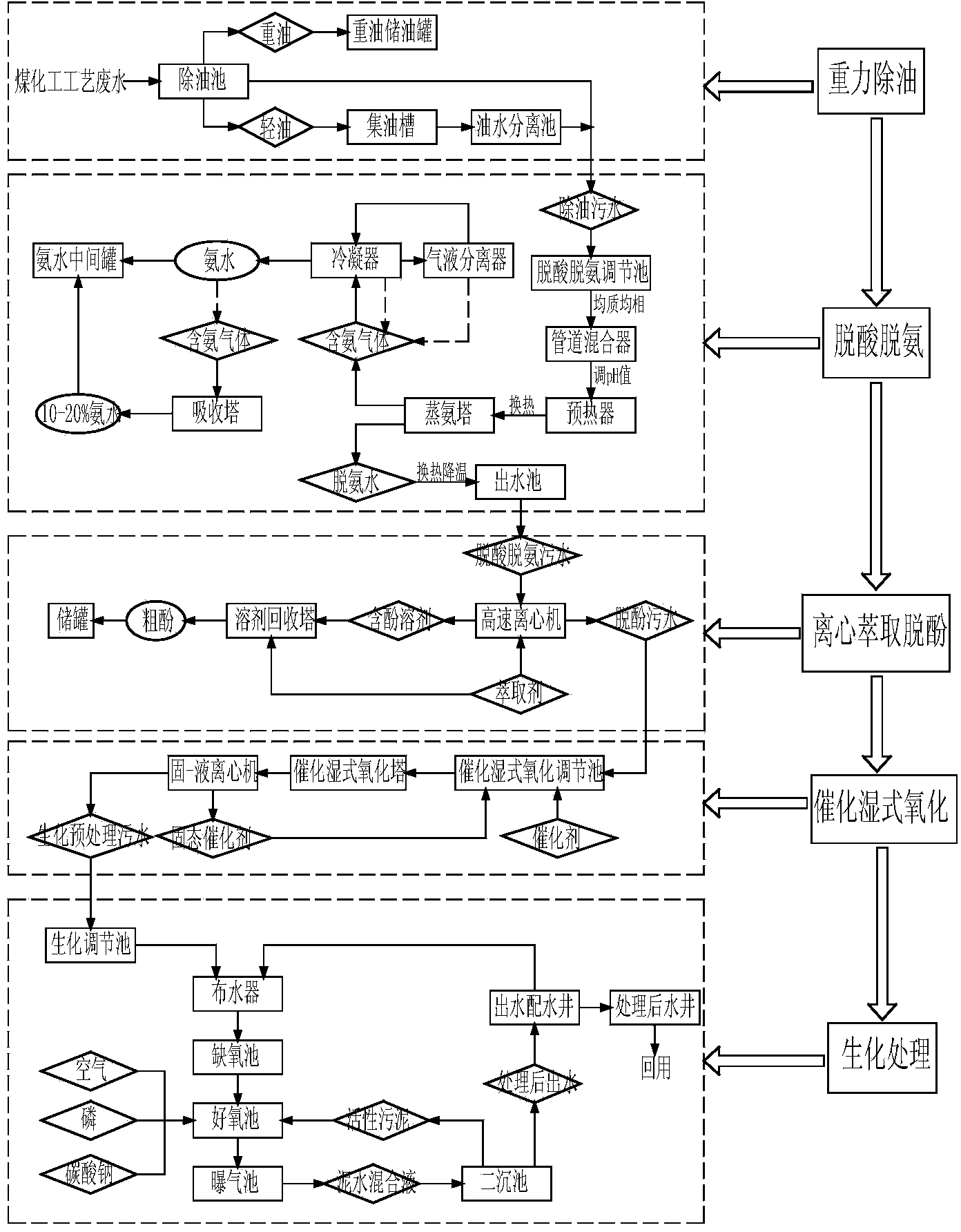

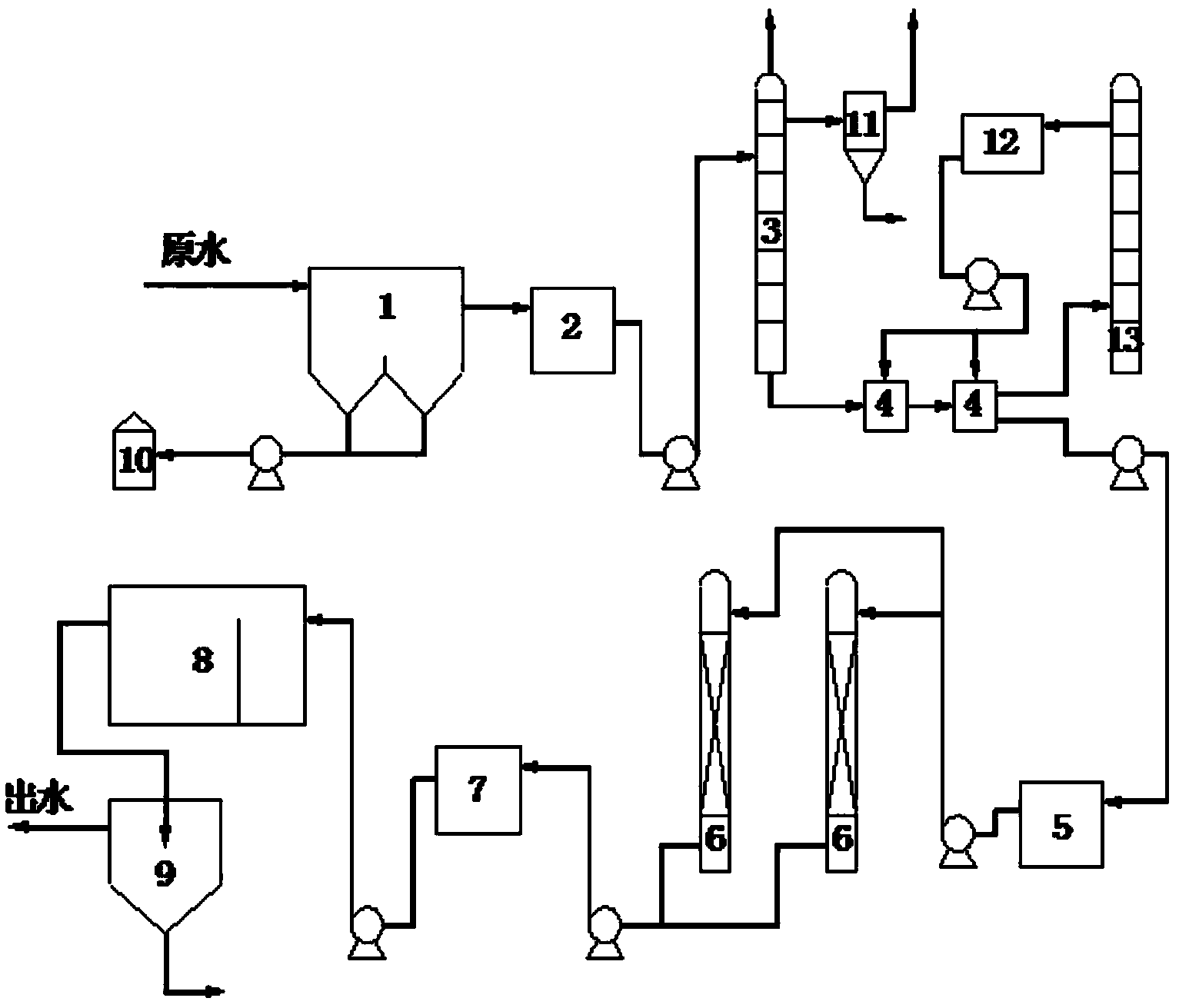

Method used

Image

Examples

Embodiment 1

[0053] [Example 1] Practical application of one of the coal chemical process wastewater advanced treatment process of the present invention, the specific process parameters are as follows:

[0054] (1) Sewage type: semi-coke production sewage, total phenol content: 8605.6mg / L, volatile phenol content: 4615.8mg / L, COD content: 25130mg / L, pH value: 8.5, ammonia nitrogen content: 3566mg / L, water temperature: 45°C;

[0055] (2) Capacity: 12m 3 / h;

[0056] (3) Deacidification and deamination process parameters:

[0057]Deacidification and deamination tower top pressure: 0.25MPa, top temperature: 102°C;

[0058] (4) Centrifugal extraction process parameters:

[0059] Solvent to sewage volume ratio: 1:5.5, solvent recovery tower top temperature: 98°C, tower bottom temperature: 185°C, reflux ratio: 0.8;

[0060] (5) Process parameters of catalytic wet oxidation process:

[0061] Reaction temperature: 150°C, reaction pressure: 1.2MPa;

[0062] (6) Biochemical treatment process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com