Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7337results about How to "High thermal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

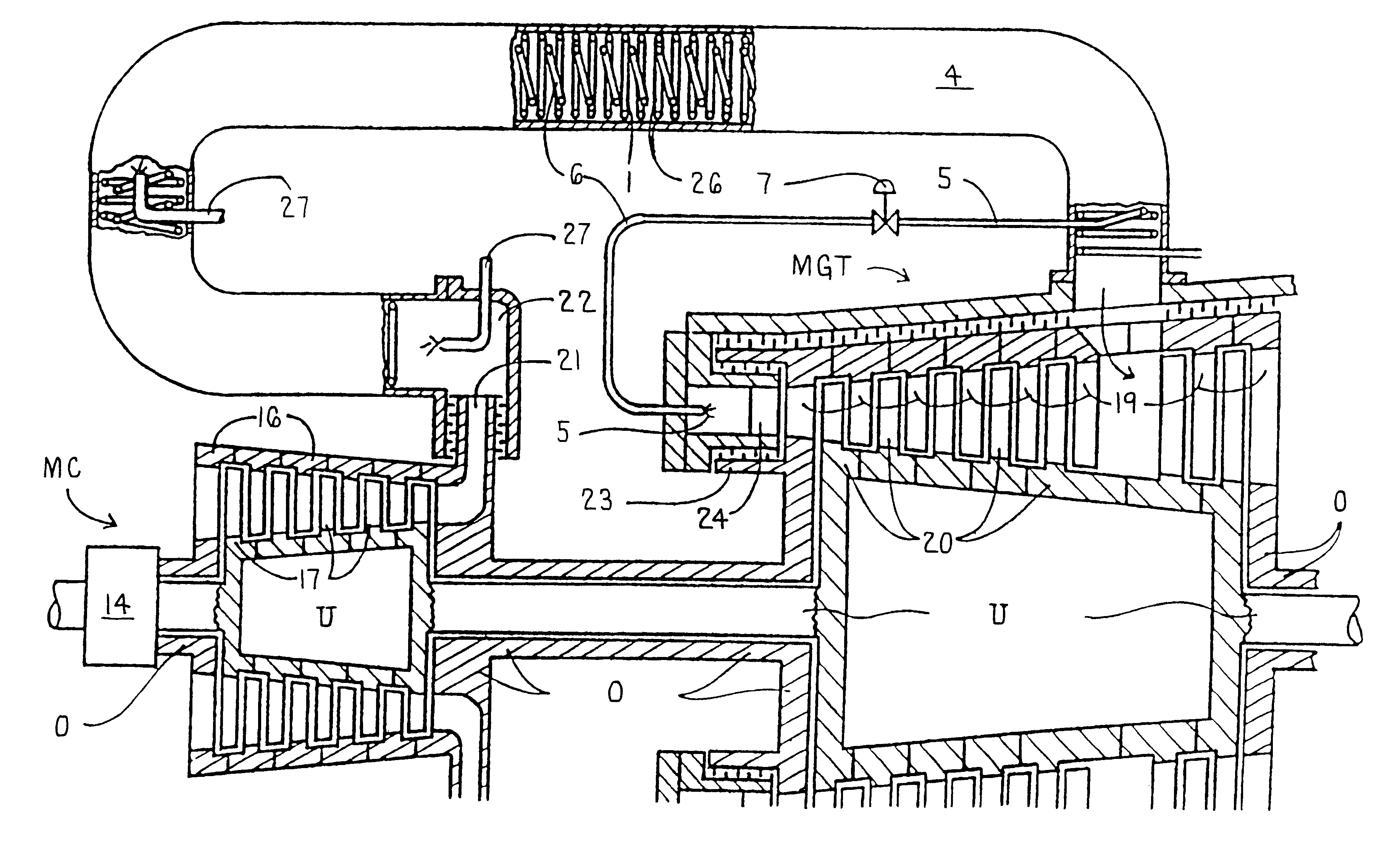

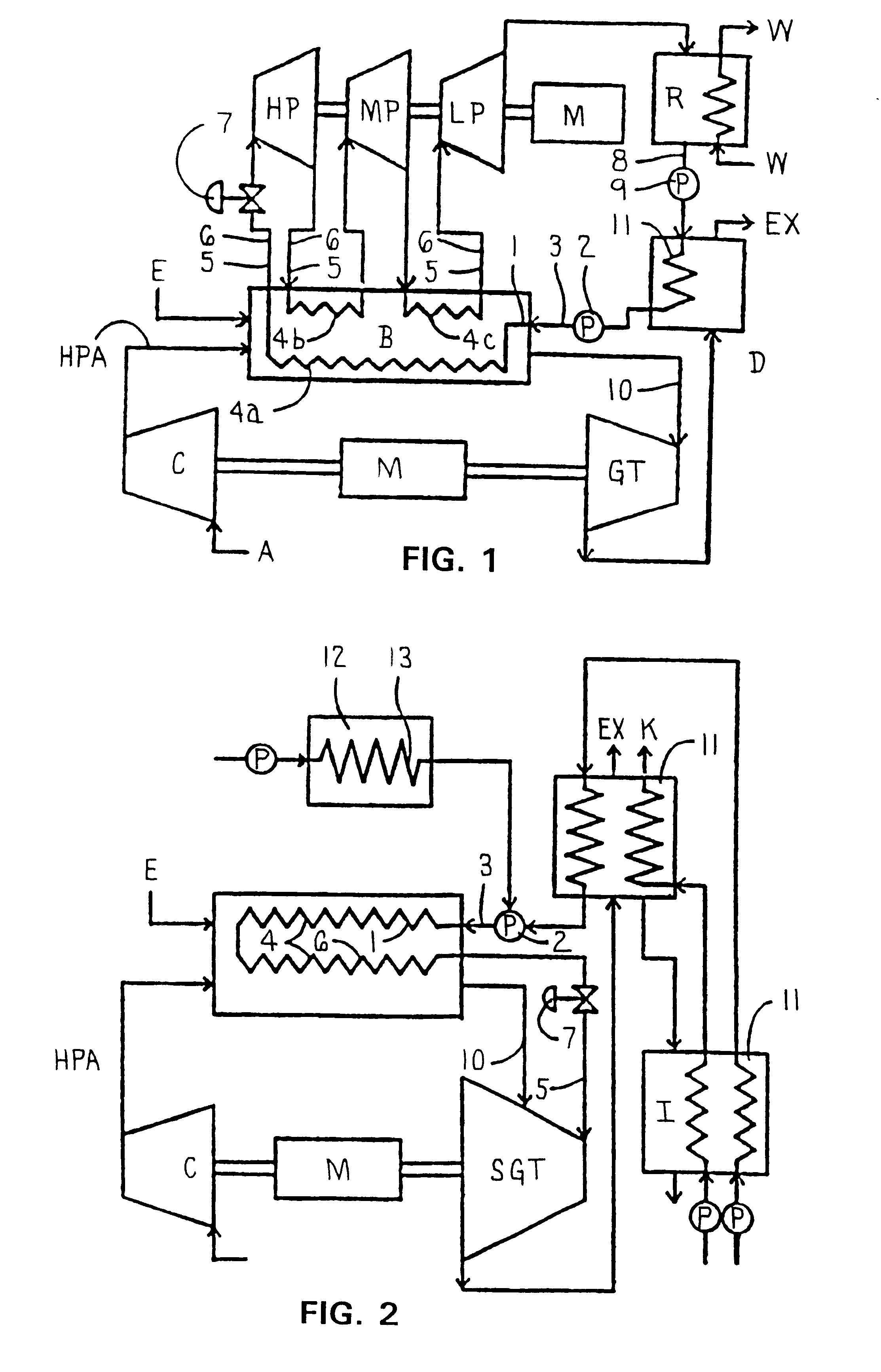

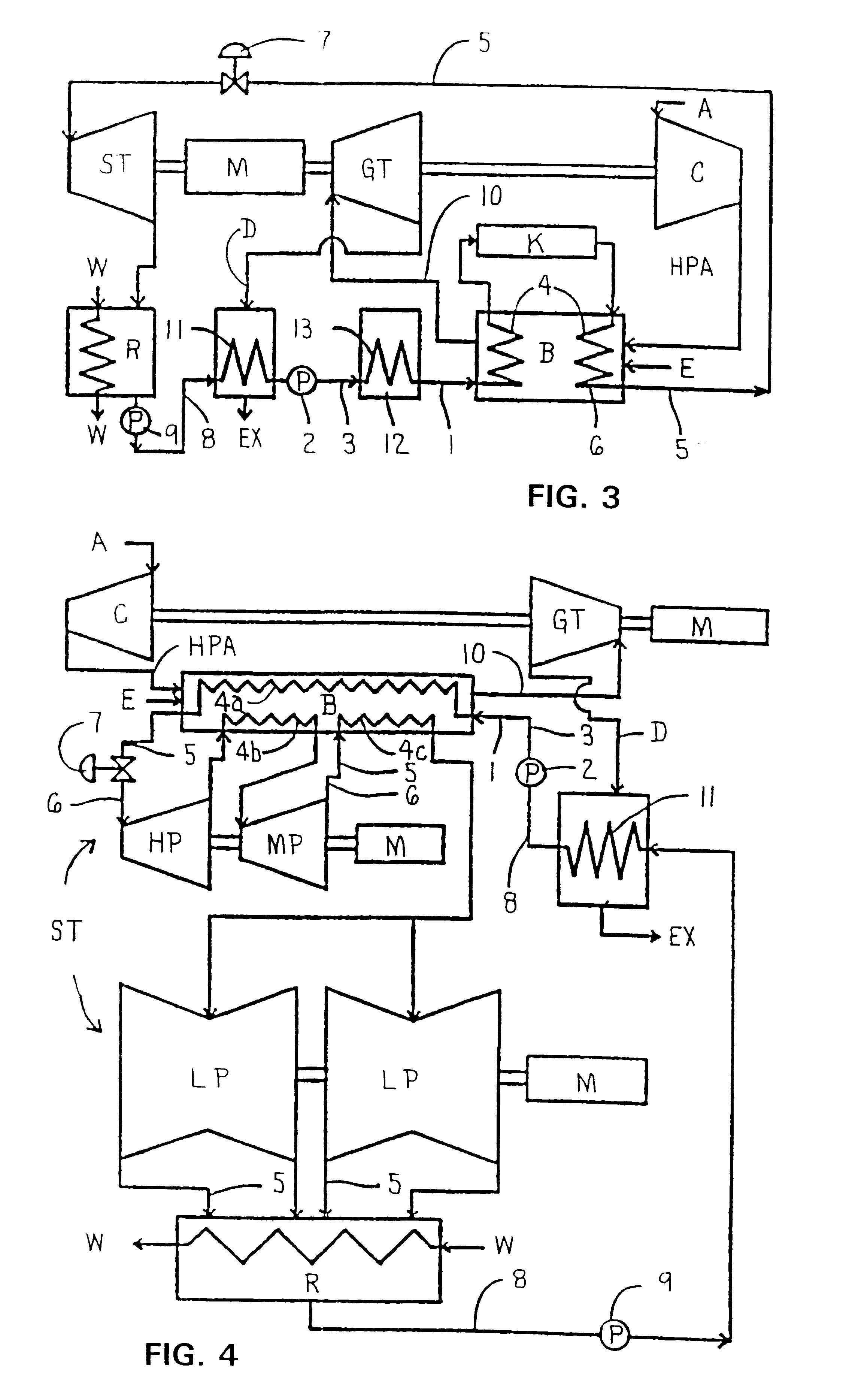

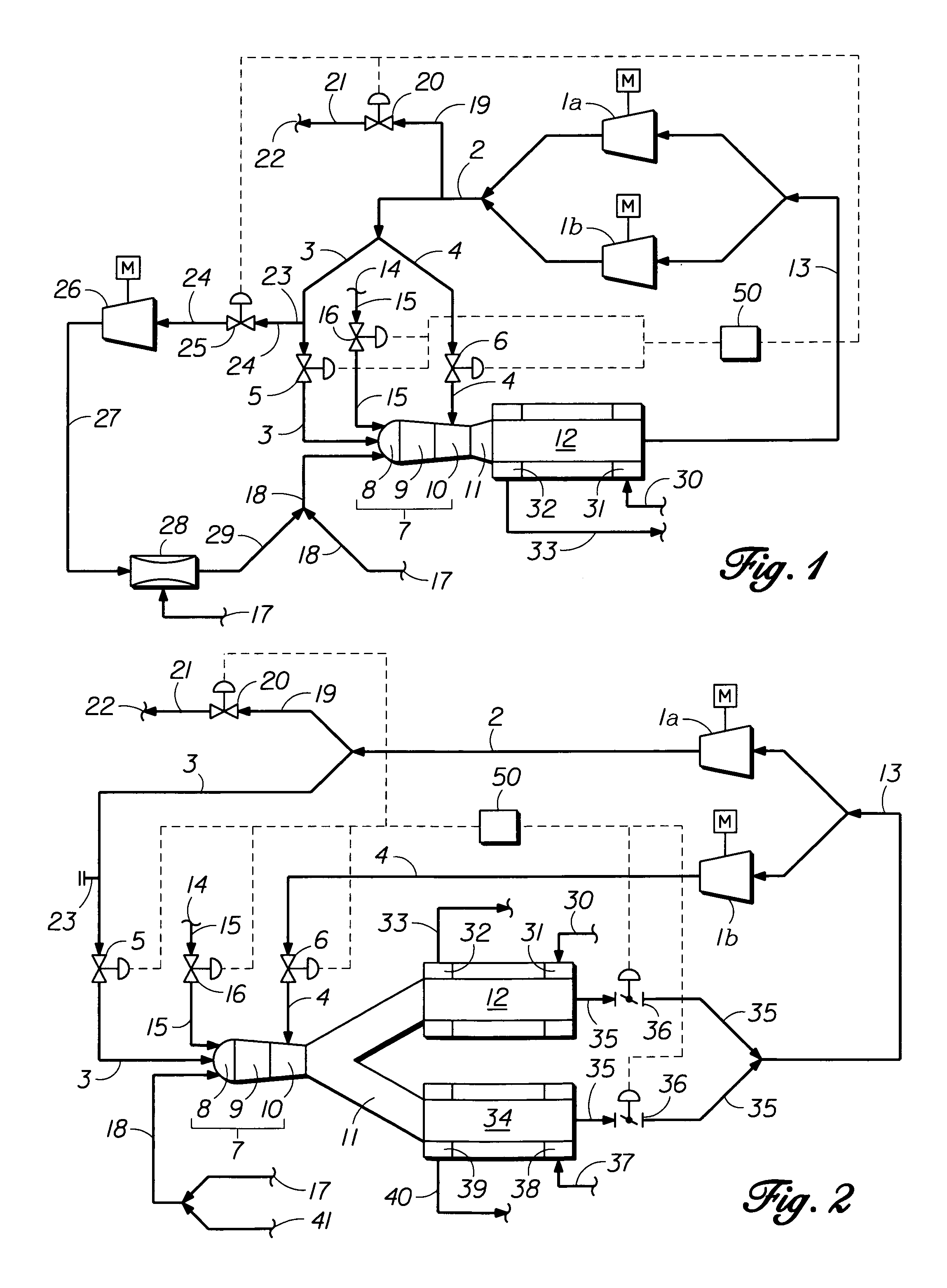

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

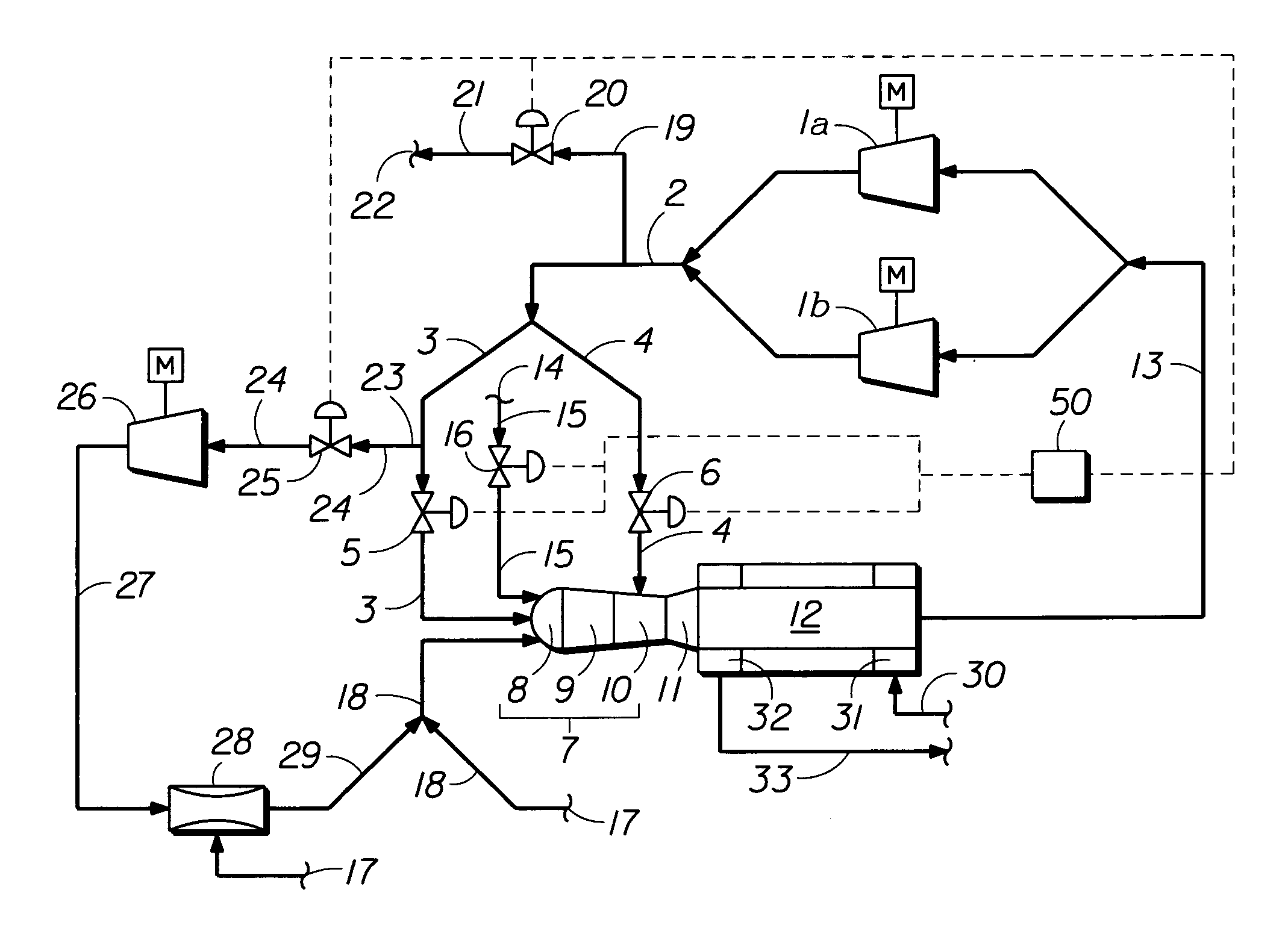

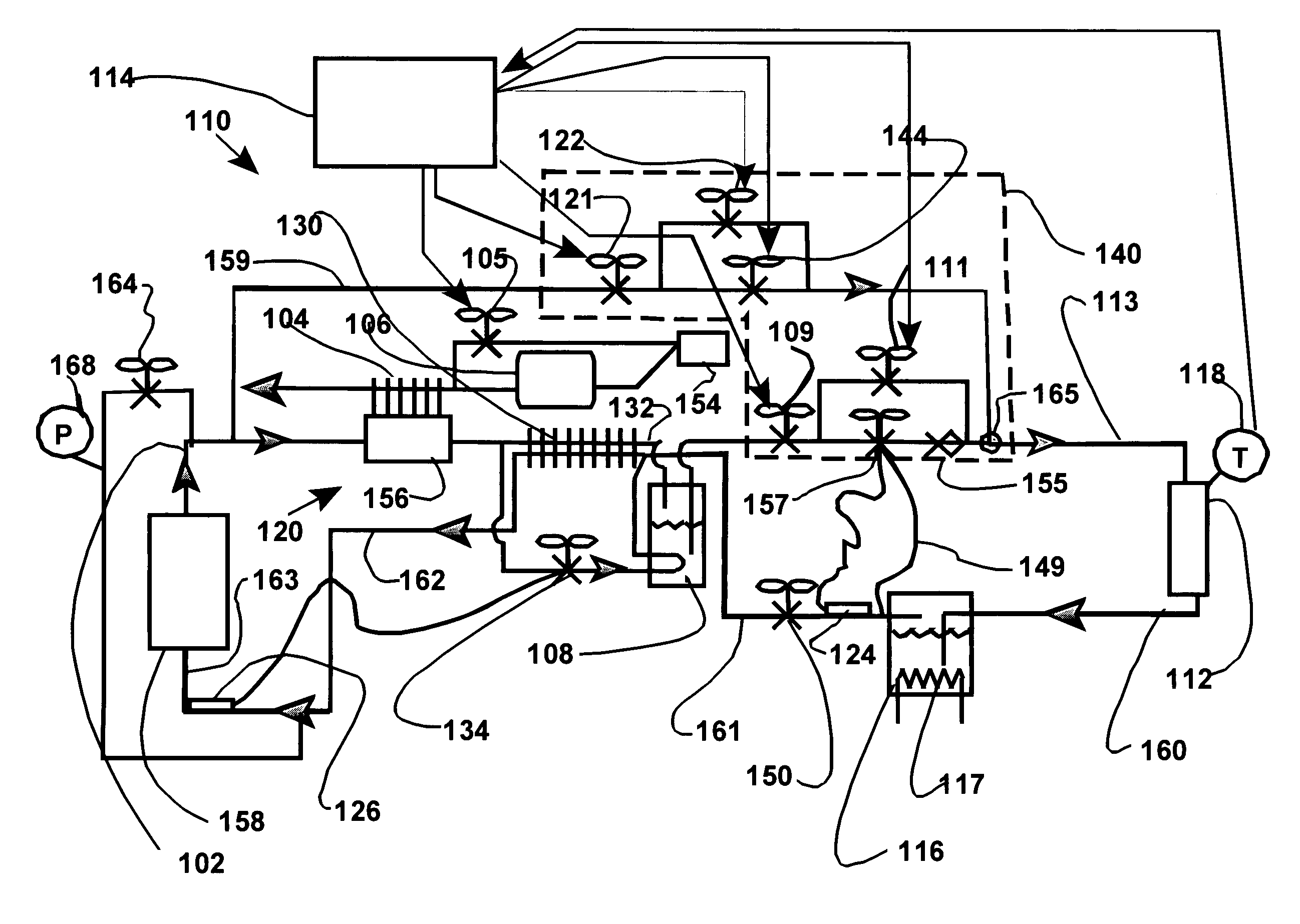

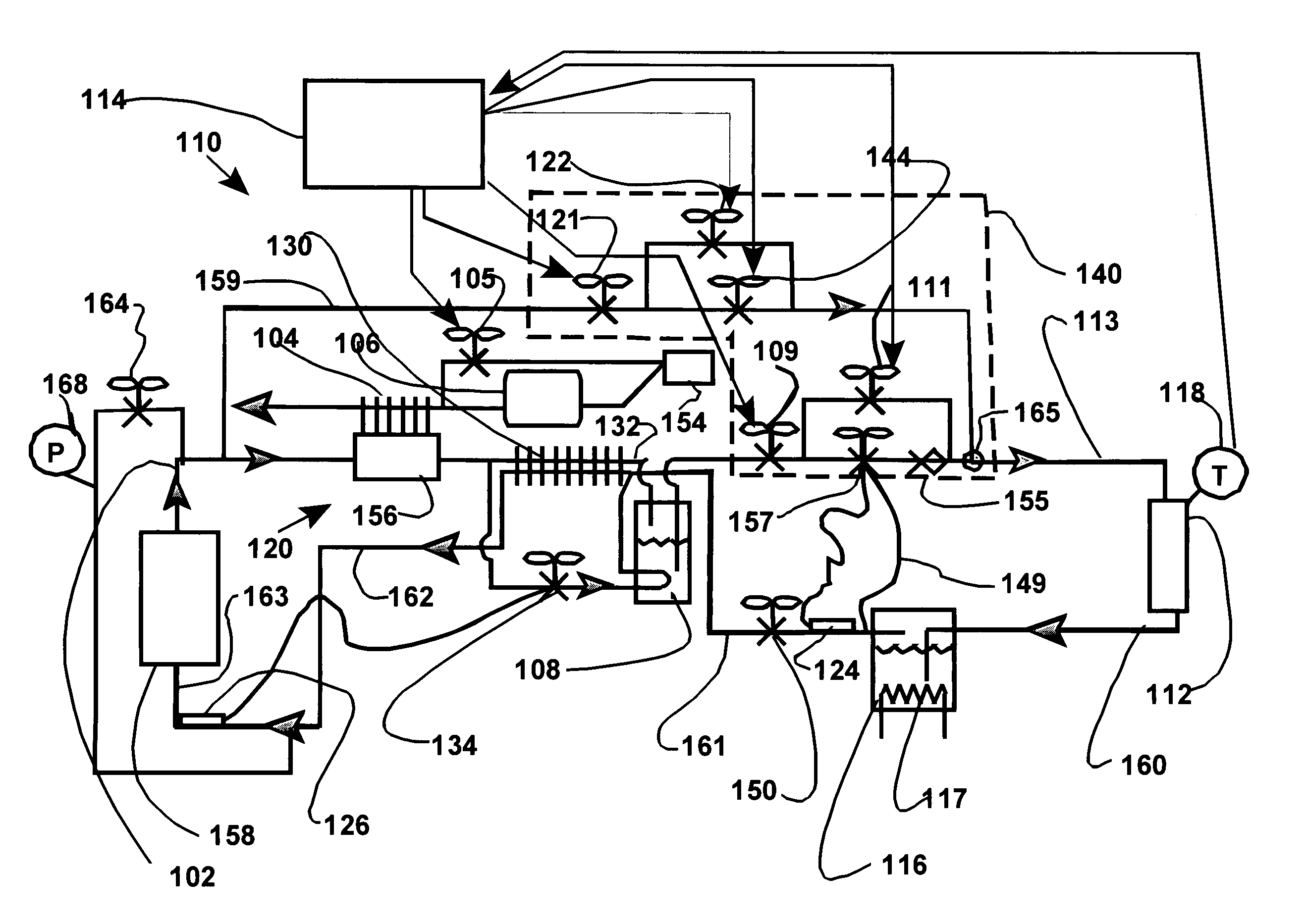

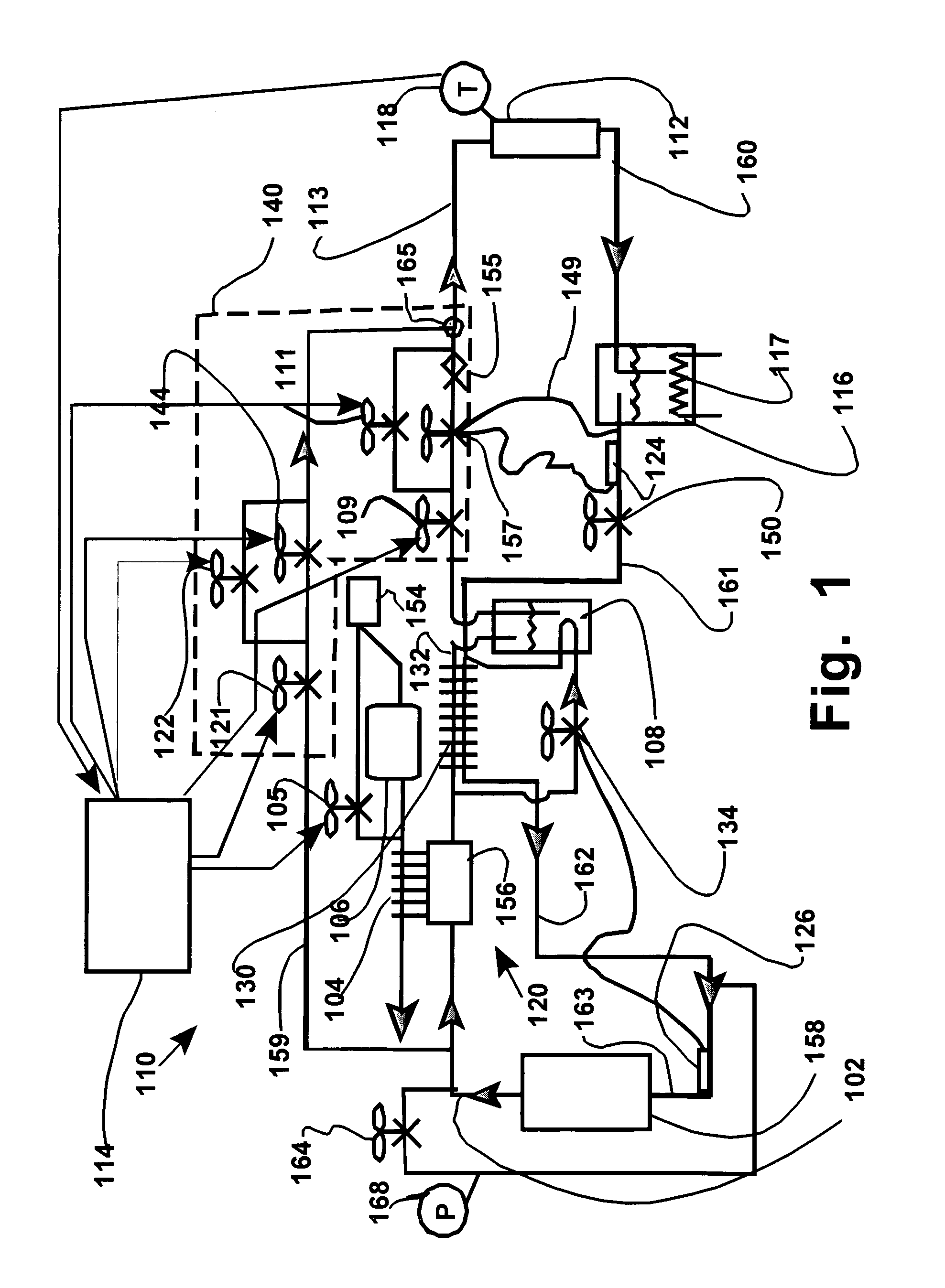

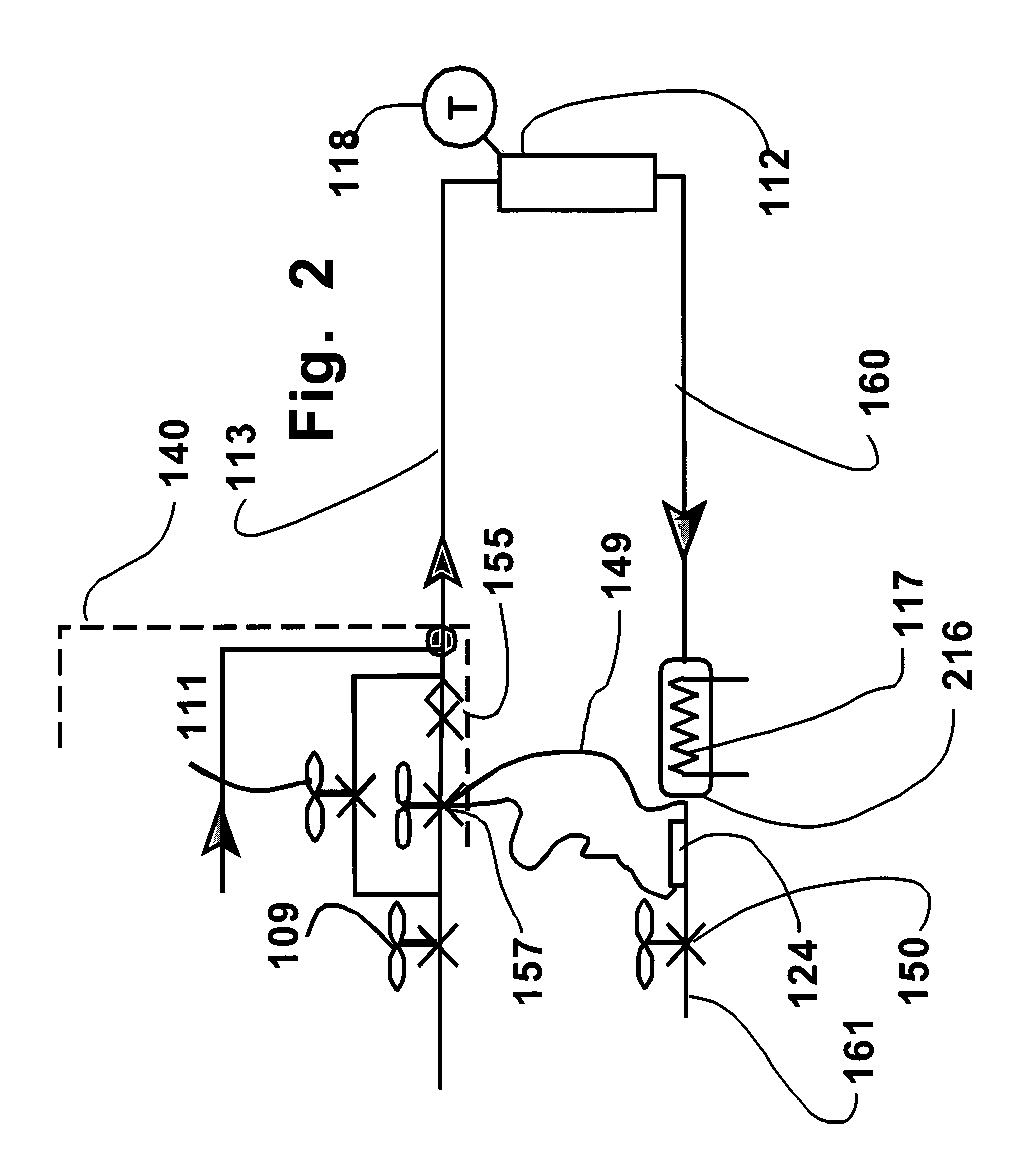

Partially-open fired heater cycle providing high thermal efficiencies and ultra-low emissions

InactiveUS7074033B2Long operate lifeLow operating temperatureFuel supply regulationGas turbine plantsNitrogen oxidesHeat transfer fluid

A partially open fired heater regenerative cycle wherein the fired industrial type heater cycle's heat transfer fluid replaces the air predominant nitrogen heat transfer fluid employed in a conventional air / fuel combustion heater. The heater cycle's method and apparatus means is susceptible to providing a 95 to 98 percent mass flow reduction of fugitive nitrogen oxide and carbon monoxide mass flow emissions as emitted by current art Low-NO.sub.x art heaters on a rated per million Btu per hour basis, and is further susceptible to developing steady-state heat transfer thermal efficiencies exceeding 124 percent.

Owner:AES DEV CO

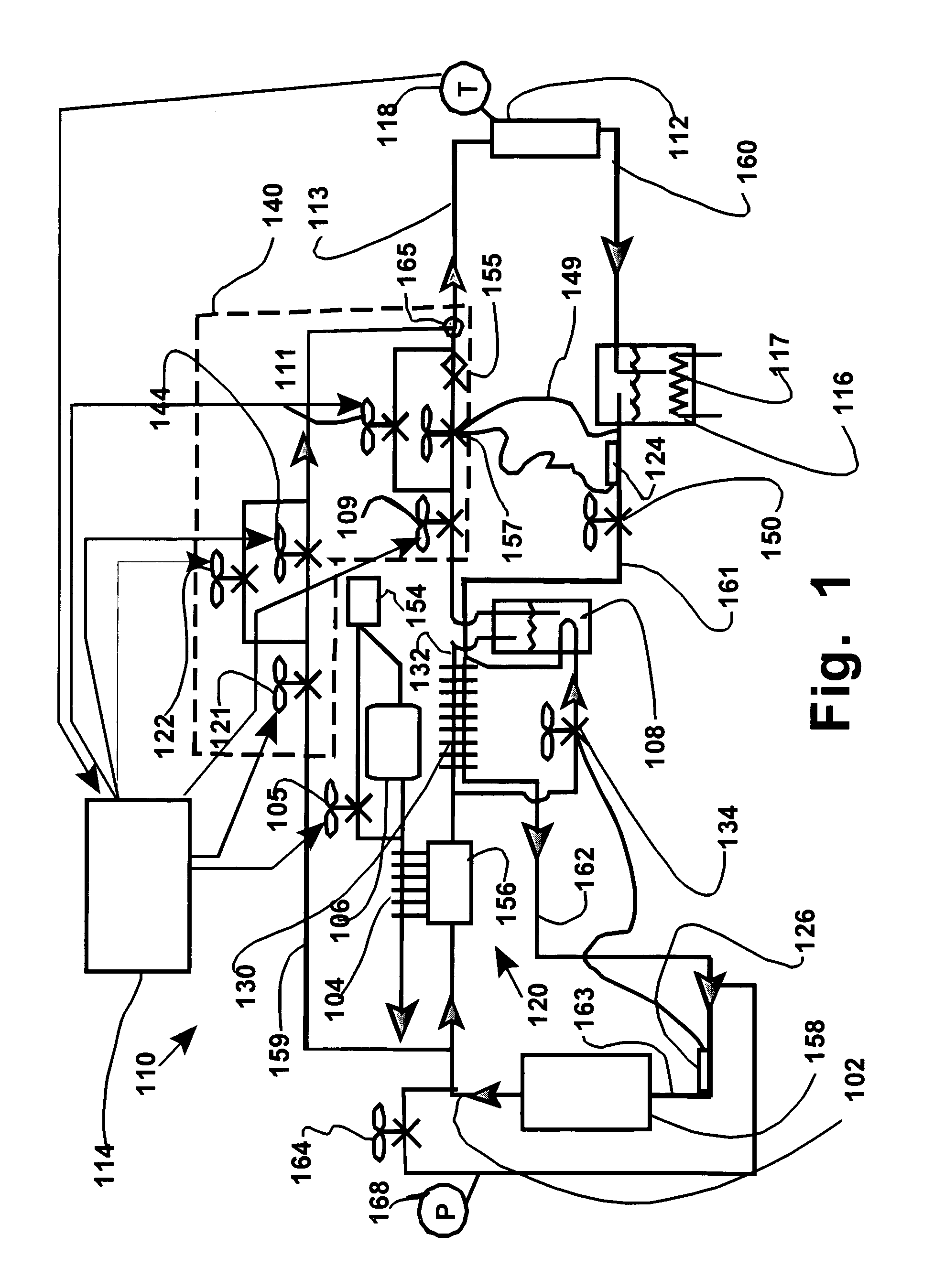

Thermal control system and method

ActiveUS7178353B2High speed responseHigh thermal efficiencyMechanical apparatusHeat pumpsProduct gasProcess engineering

A system and method for controlling the temperature of a process tool uses the vaporizable characteristic of a refrigerant that is provided in direct heat exchange relation with the process tool. Pressurized refrigerant is provided as both condensed liquid and in gaseous state. The condensed liquid is expanded to a vaporous mix, and the gaseous refrigerant is added to reach a target temperature determined by its pressure. Temperature corrections can thus be made very rapidly by gas pressure adjustments. The process tool and the operating parameters will usually require that the returning refrigerant be conditioned and processed for compatibility with the compressor and other units, so that cycling can be continuous regardless of thermal demands and changes.

Owner:BE AEROSPACE INCORPORATED

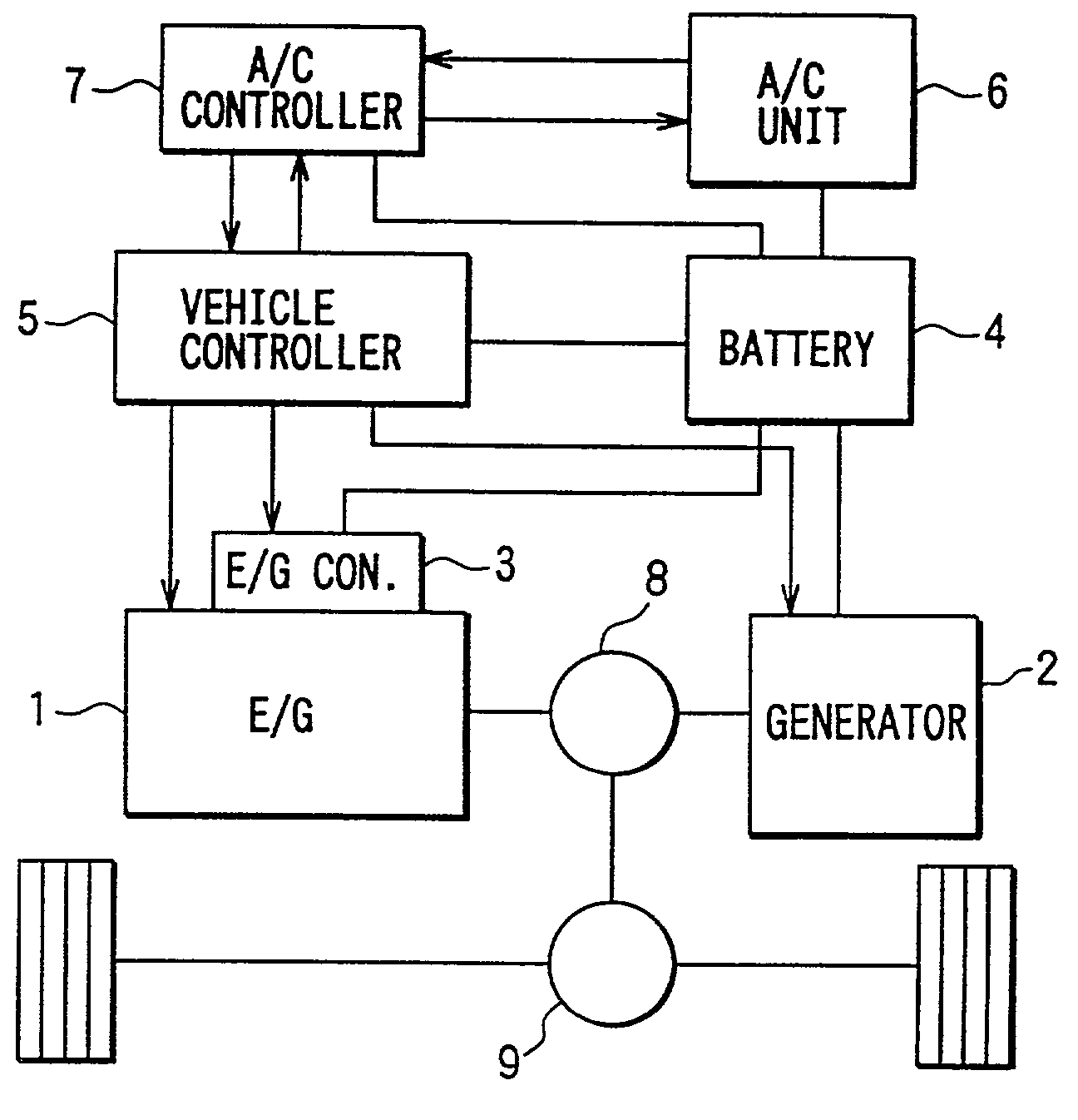

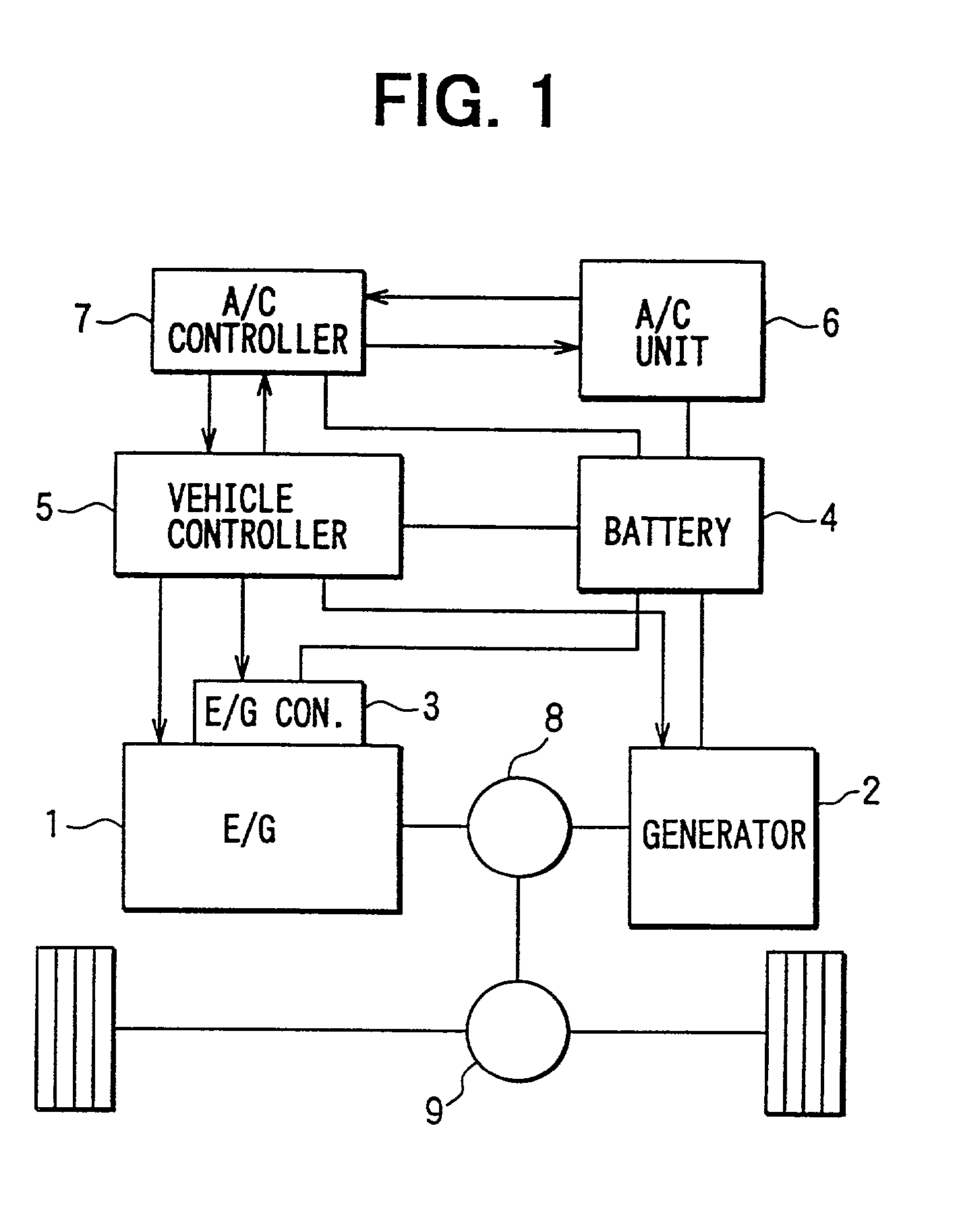

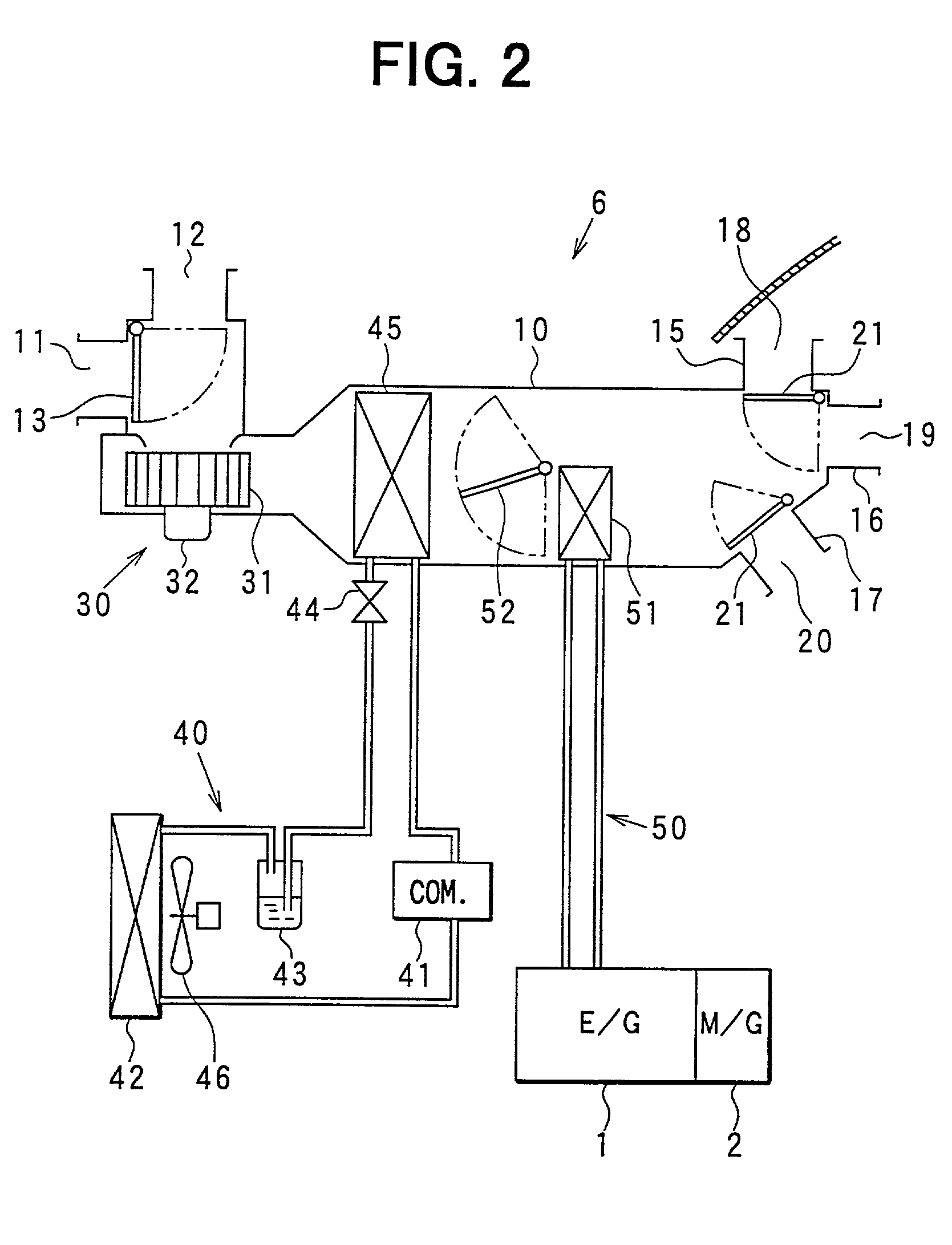

Air conditioner for hybrid vehicle

InactiveUS20020084769A1Less frequentReduce exhaustAir-treating devicesBatteries circuit arrangementsElectrical batteryHybrid vehicle

In an air conditioner for a hybrid vehicle, when a residual charging degree of a battery becomes equal to or lower than a target degree, the electrical motor generator is driven by a vehicle engine so that the battery is charged through the electrical motor generator. When the engine is driven, the target degree of the battery is set higher than that when the engine is stopped so that a charging operation tends to be required while the engine is driven. Accordingly, the frequency for starting the engine only for charging the battery is reduced.

Owner:DENSO CORP

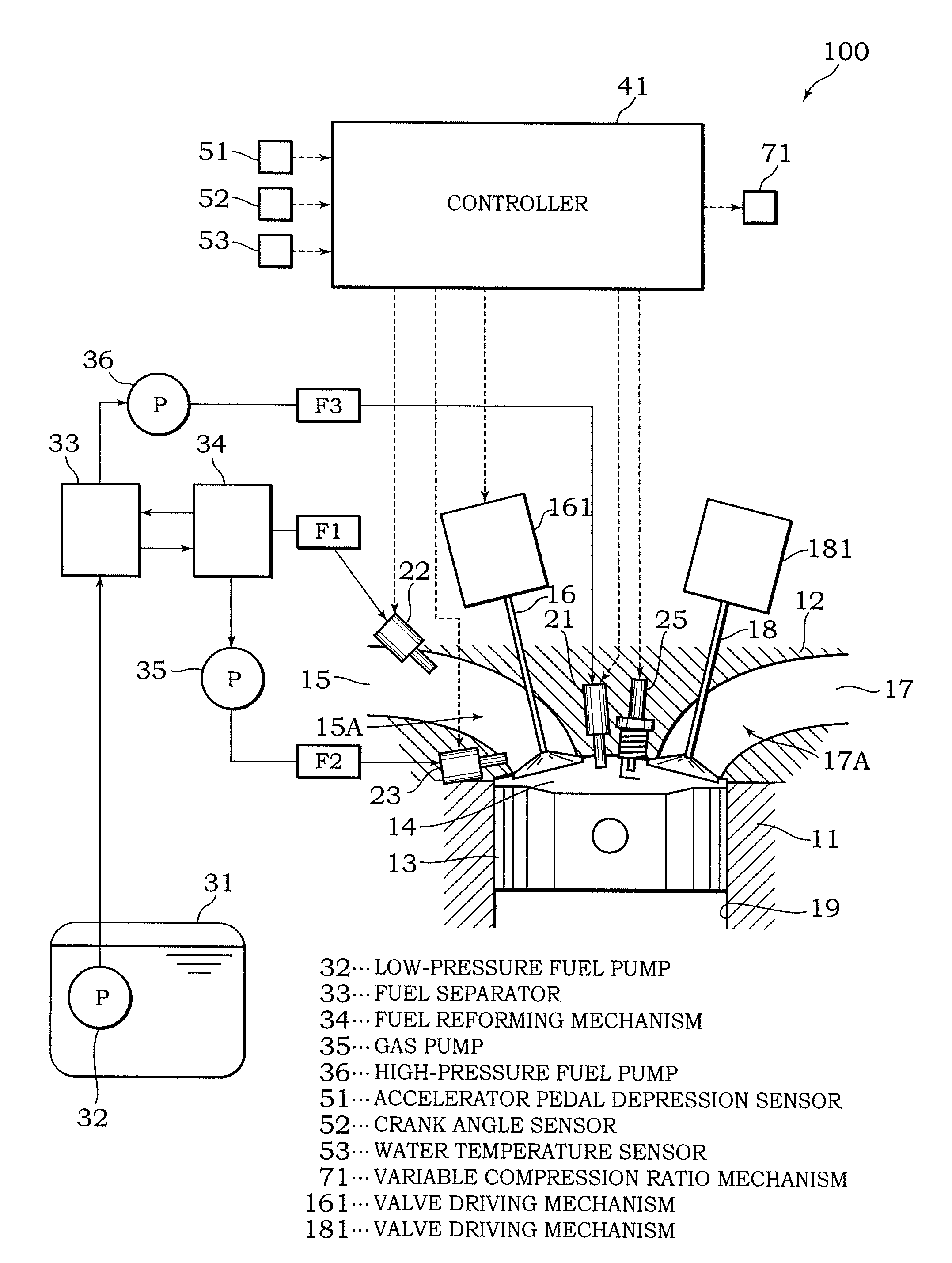

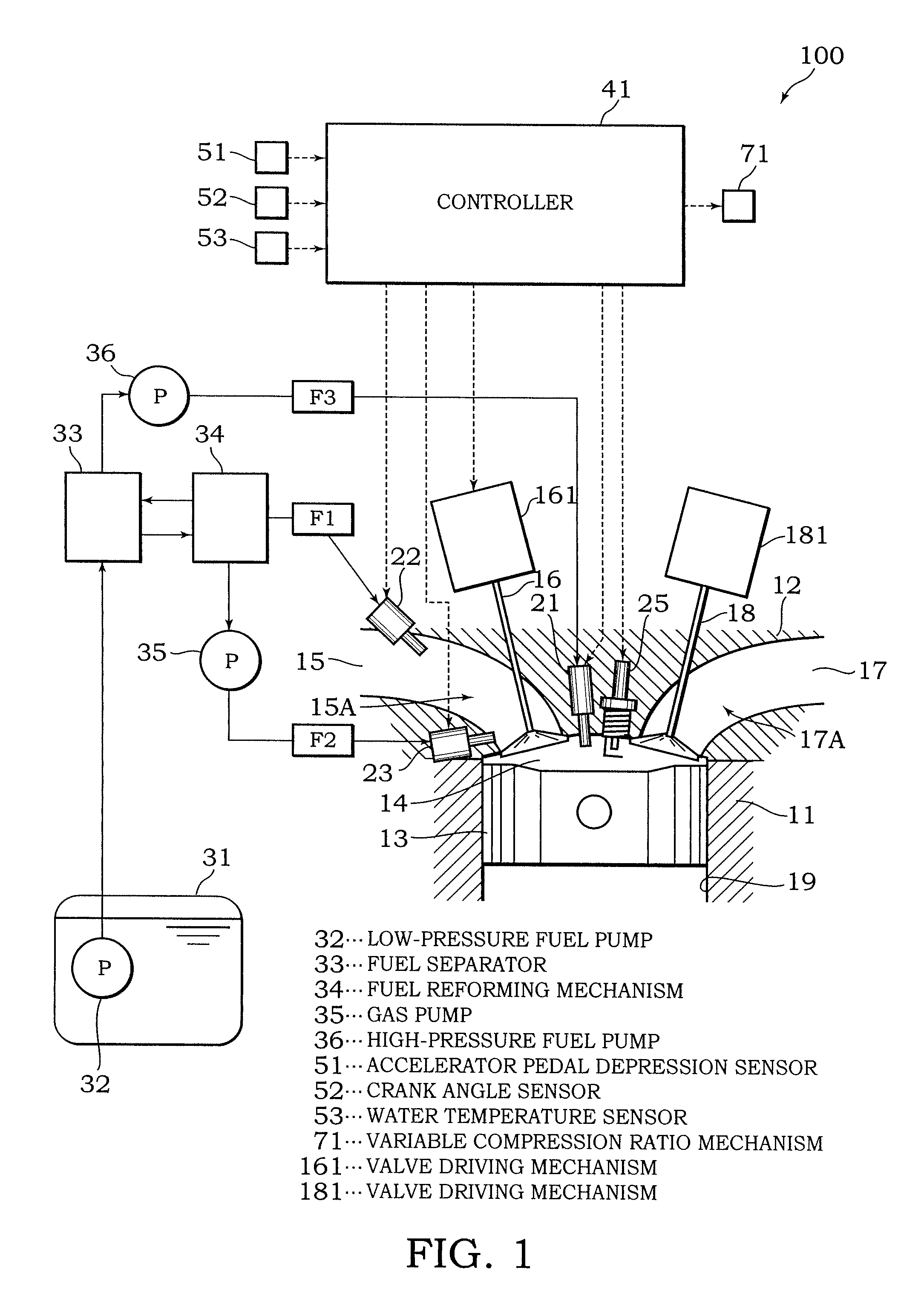

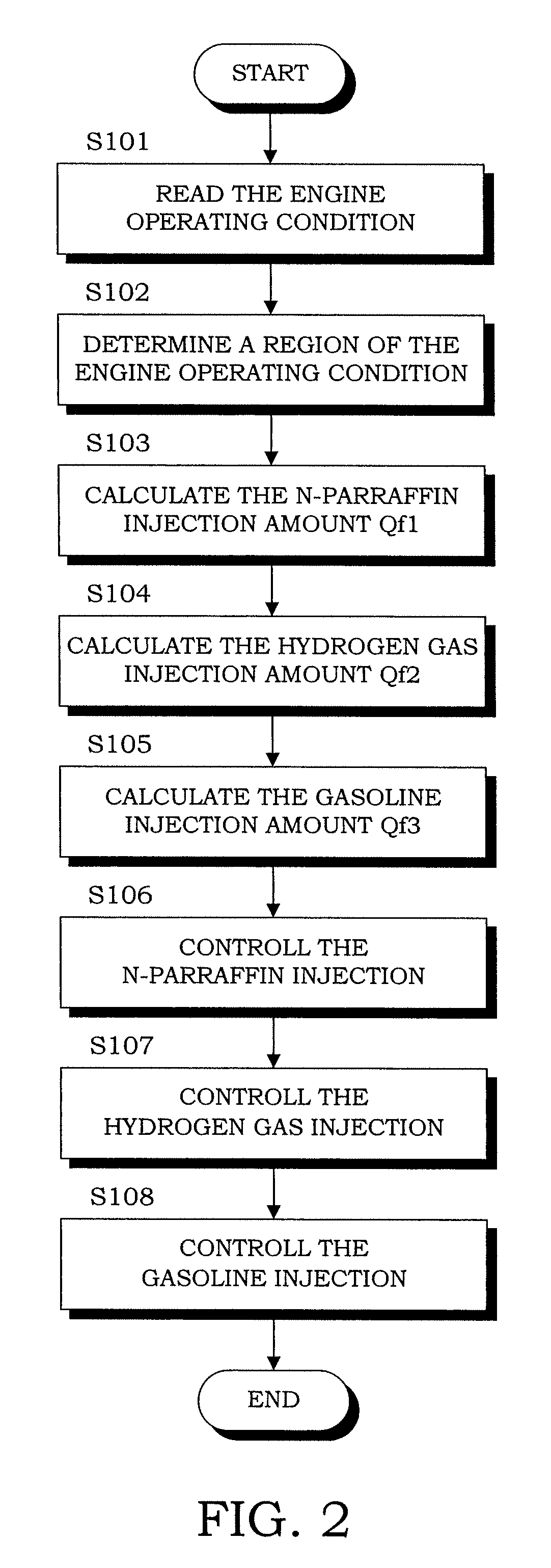

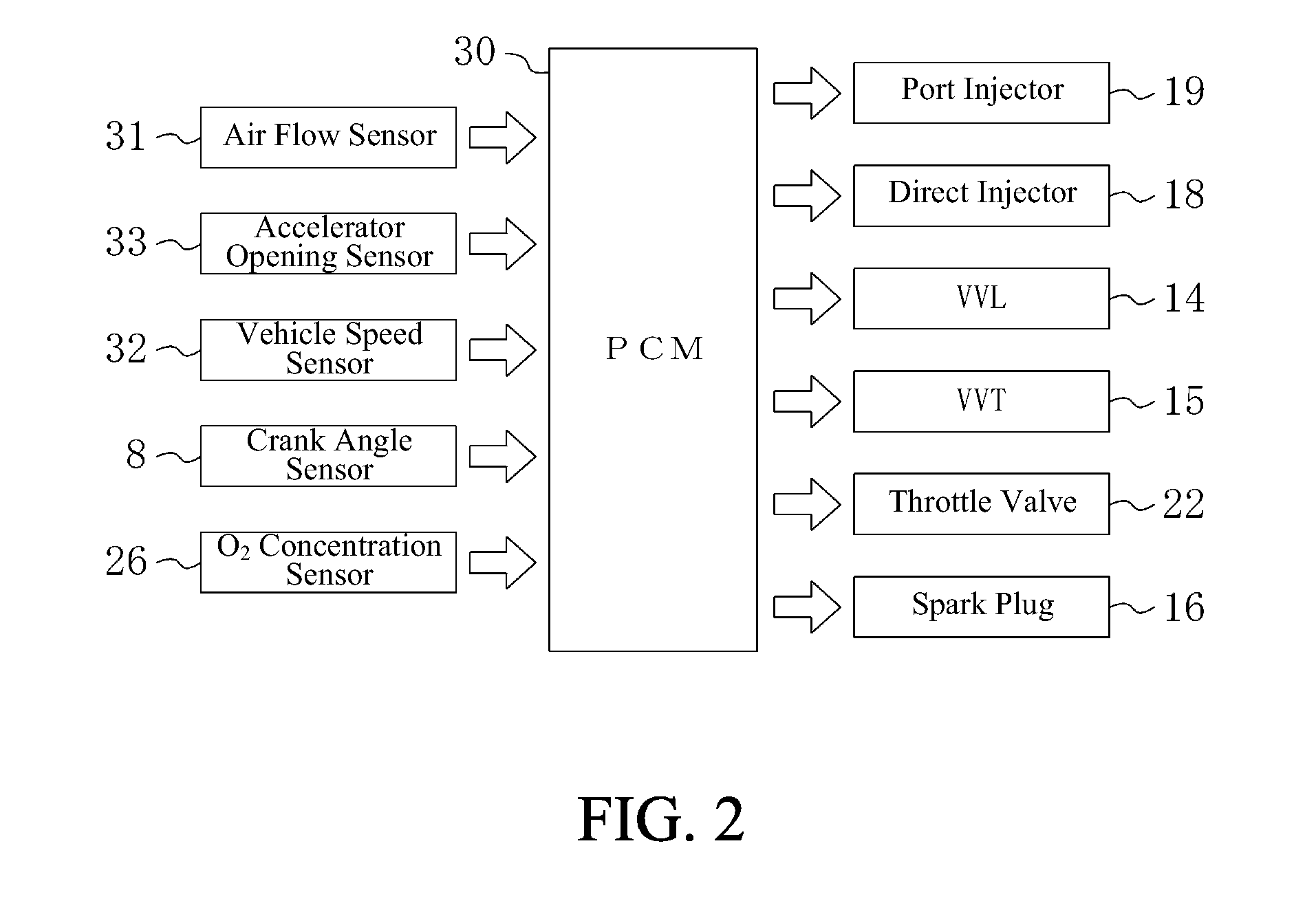

Internal combustion engine

InactiveUS20090043479A1High-temperature combustionIncrease temperatureElectrical controlInternal combustion piston enginesCombustion chamberFlame propagation

An internal combustion engine (100) comprises a fuel injection valve (21, 22) which supplies a first fuel having a higher self-ignitability than gasoline and a second fuel having a higher combustion speed than gasoline such that an air-fuel mixture containing the first fuel and the second fuel is formed in a combustion chamber (14), a spark plug (25) which ignites the air-fuel mixture, and a programmable controller (41) programmed to control supply proportions of the first fuel and the second fuel such that the ignited air-fuel mixture undergoes flame propagation combustion and then undergoes self-ignition combustion. Thus, a reduction in emissions can be achieved, and high thermal efficiency can be realized through the self-ignition combustion.

Owner:NISSAN MOTOR CO LTD

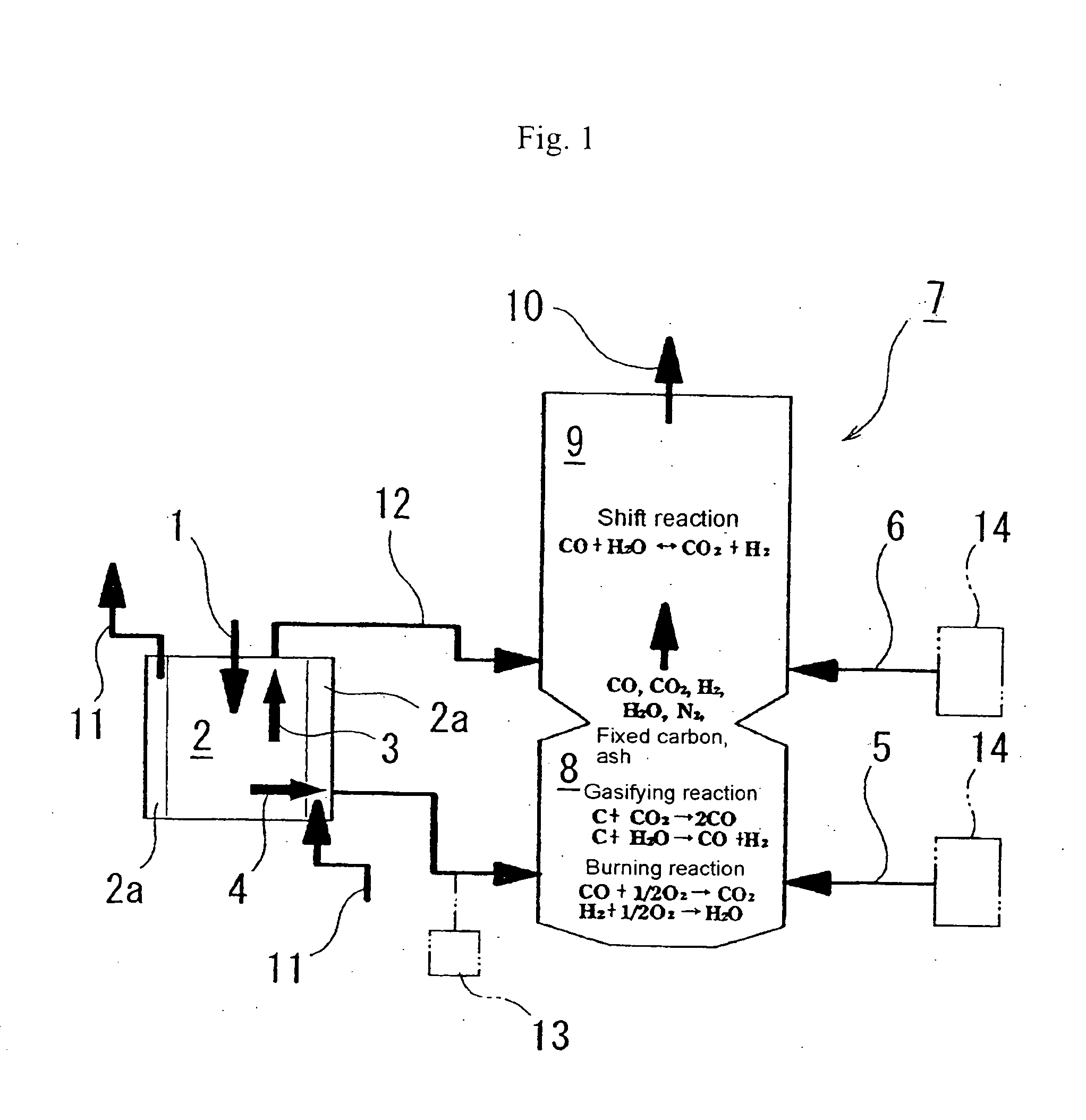

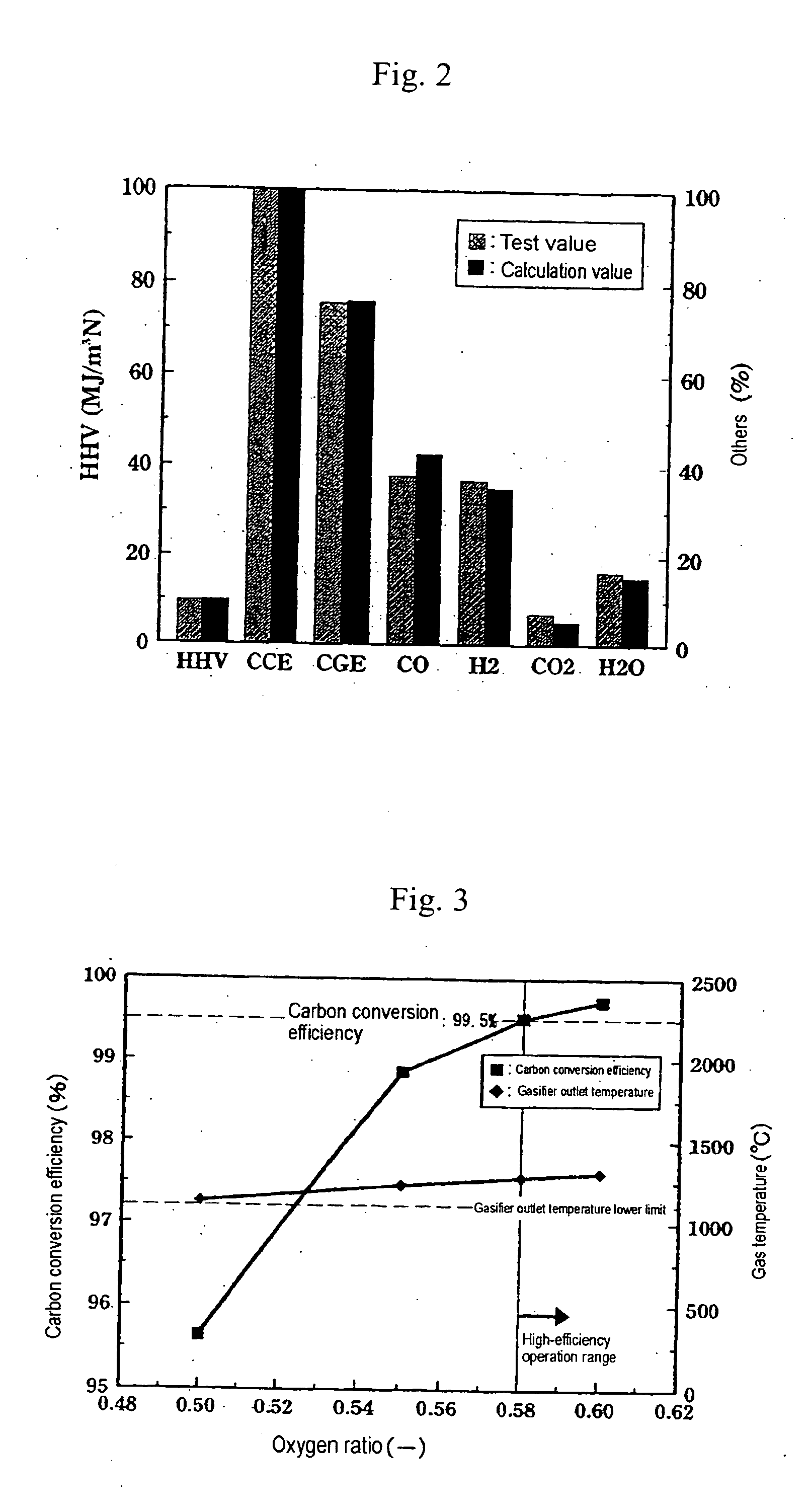

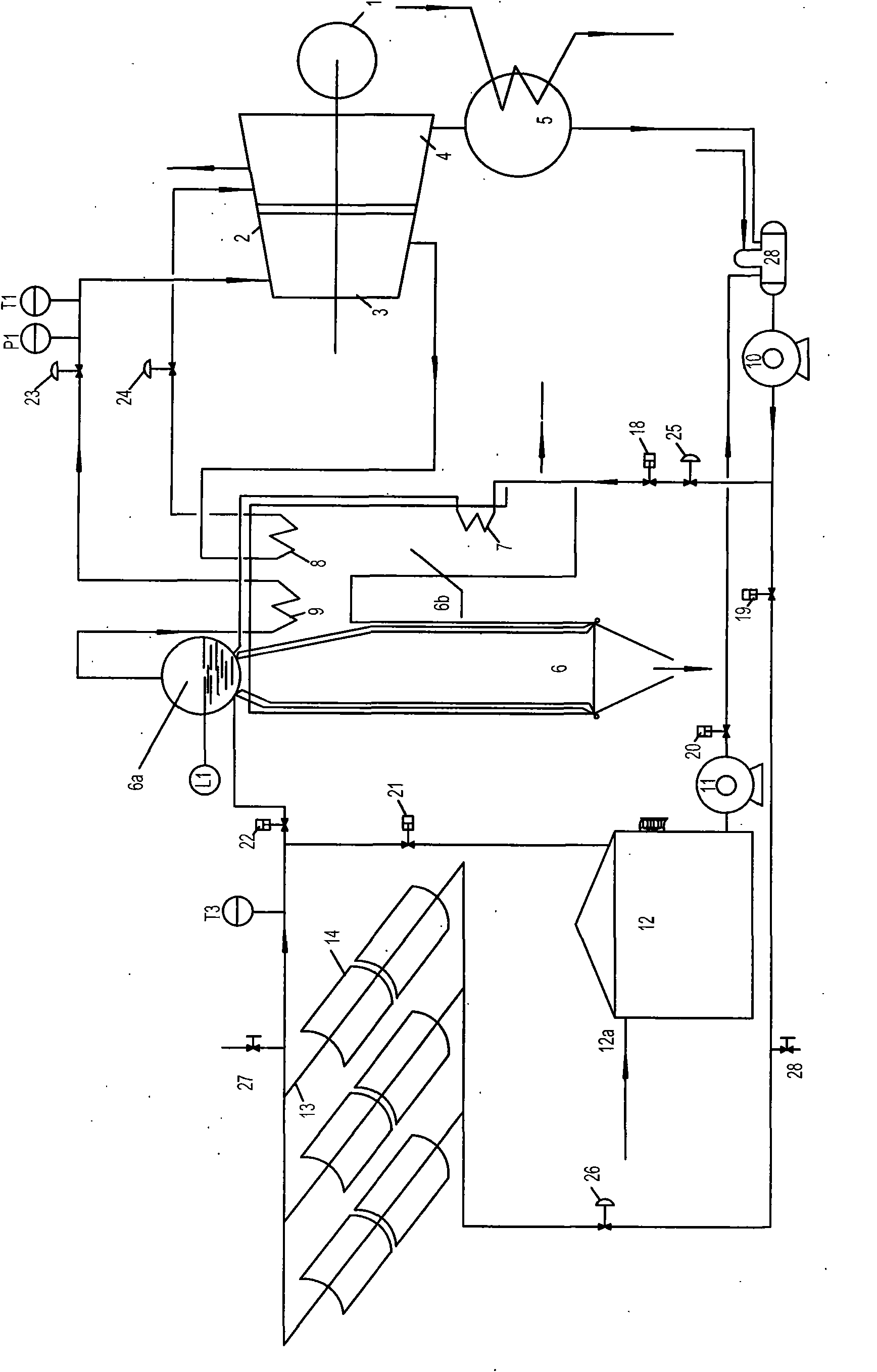

Carbonization and gasification of biomass and power generation system

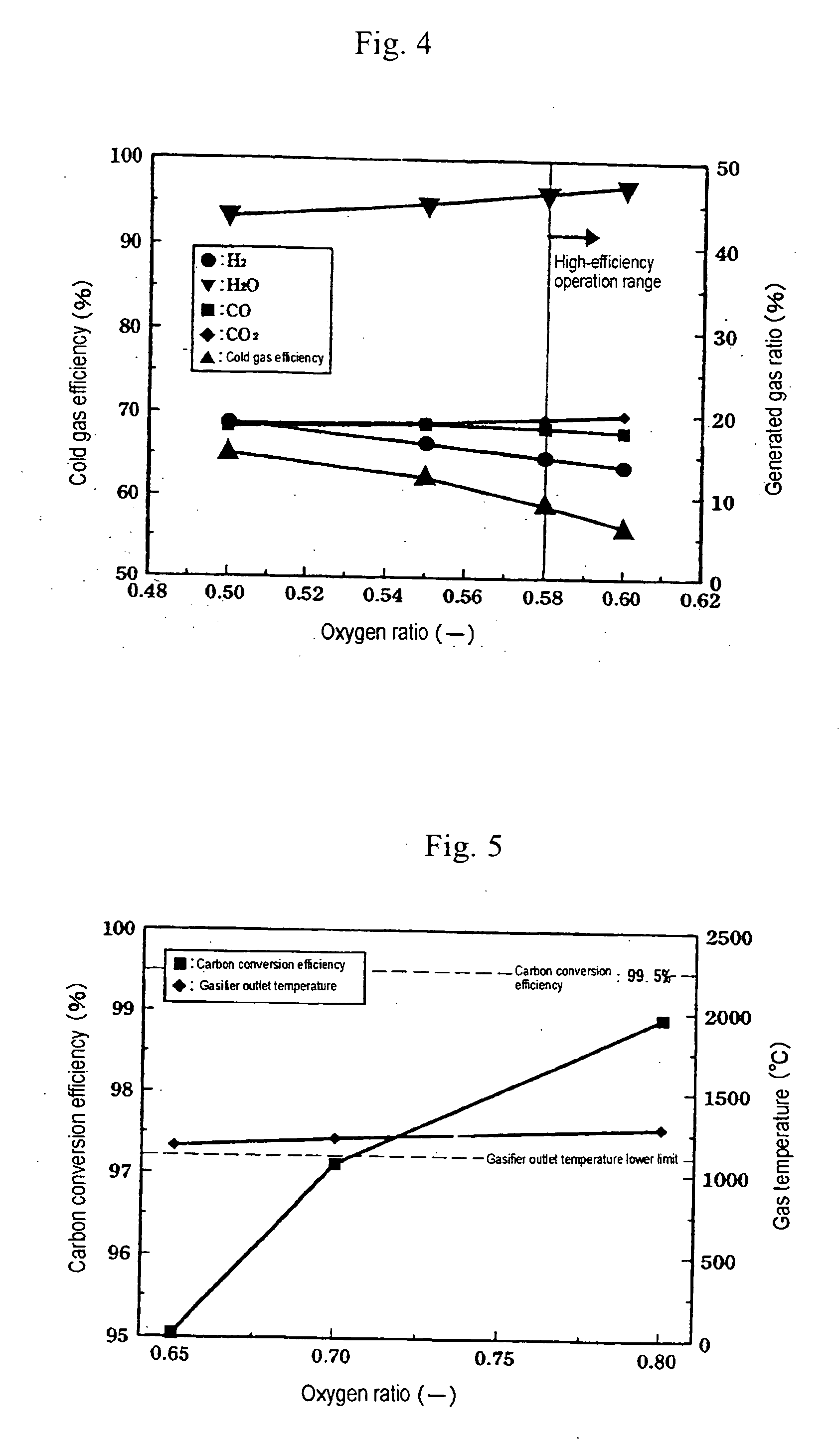

InactiveUS20050247553A1Increase temperatureHigh thermal efficiencyBeehive ovensCombustible gas catalytic treatmentCarbonizationTar

Biomass, including waste biomass, is gasified by a process in which the biomass is first carbonized, and the char and pyrolysis gas from the carbonizer are respectively fed to a high temperature gasifying part and a gas reformer part of a two-stage gasifier. A gasifying agent is continuously fed to the gasifying part, and intermittently fed to the gas reformer, to maintain the temperature required to avoid tar formation in the gas reformer stage. Multiple carbonization chambers are operated in rotation. When the carbonization / gasification apparatus is used to provide fuel to an electric power generator set, exhaust heat from the generator power plant is fed back to the carbonizer, and can be supplemented by exchange of heat from the gas delivered to generator power plant from the outlet of the gasifier.

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY +1

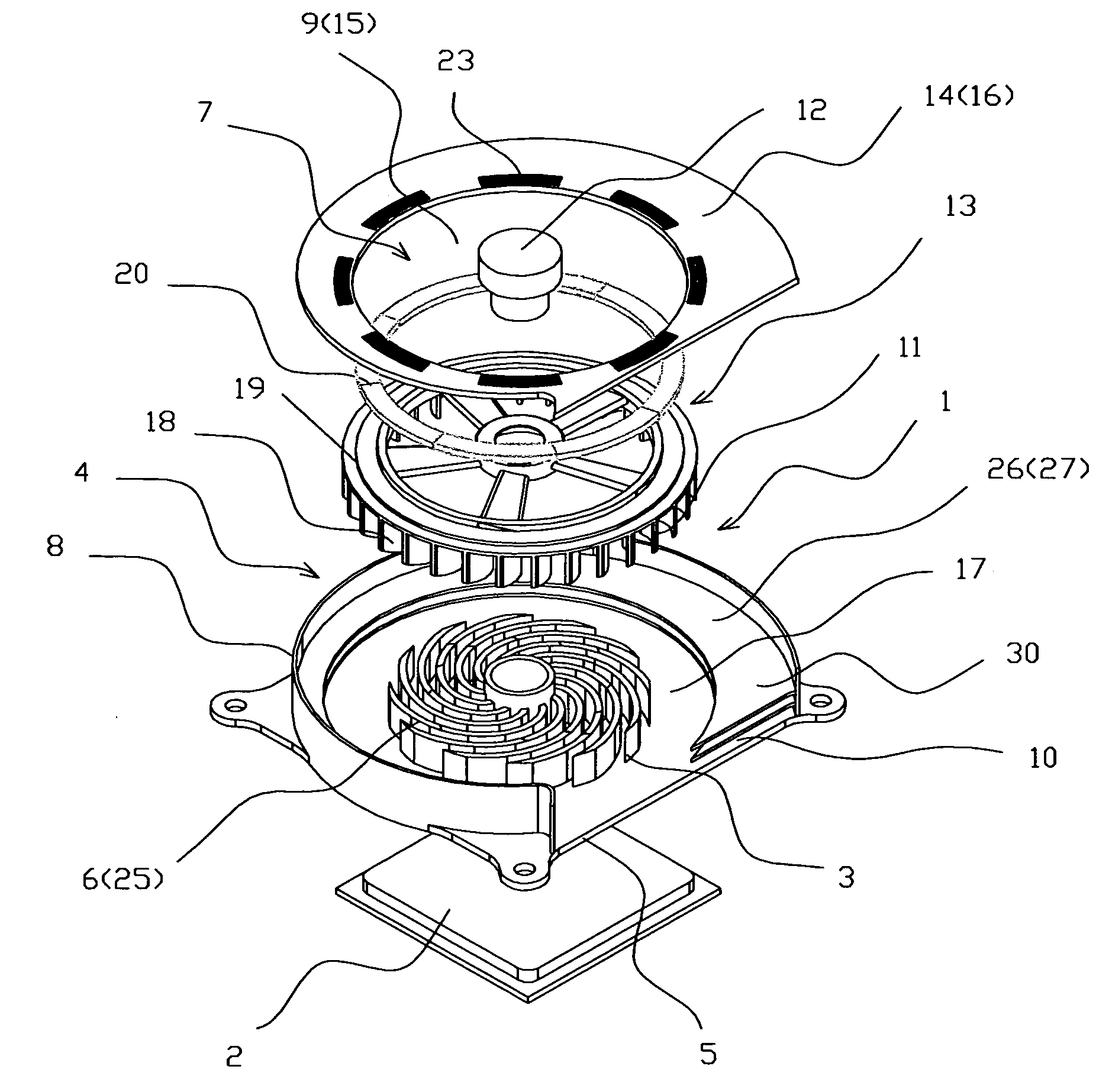

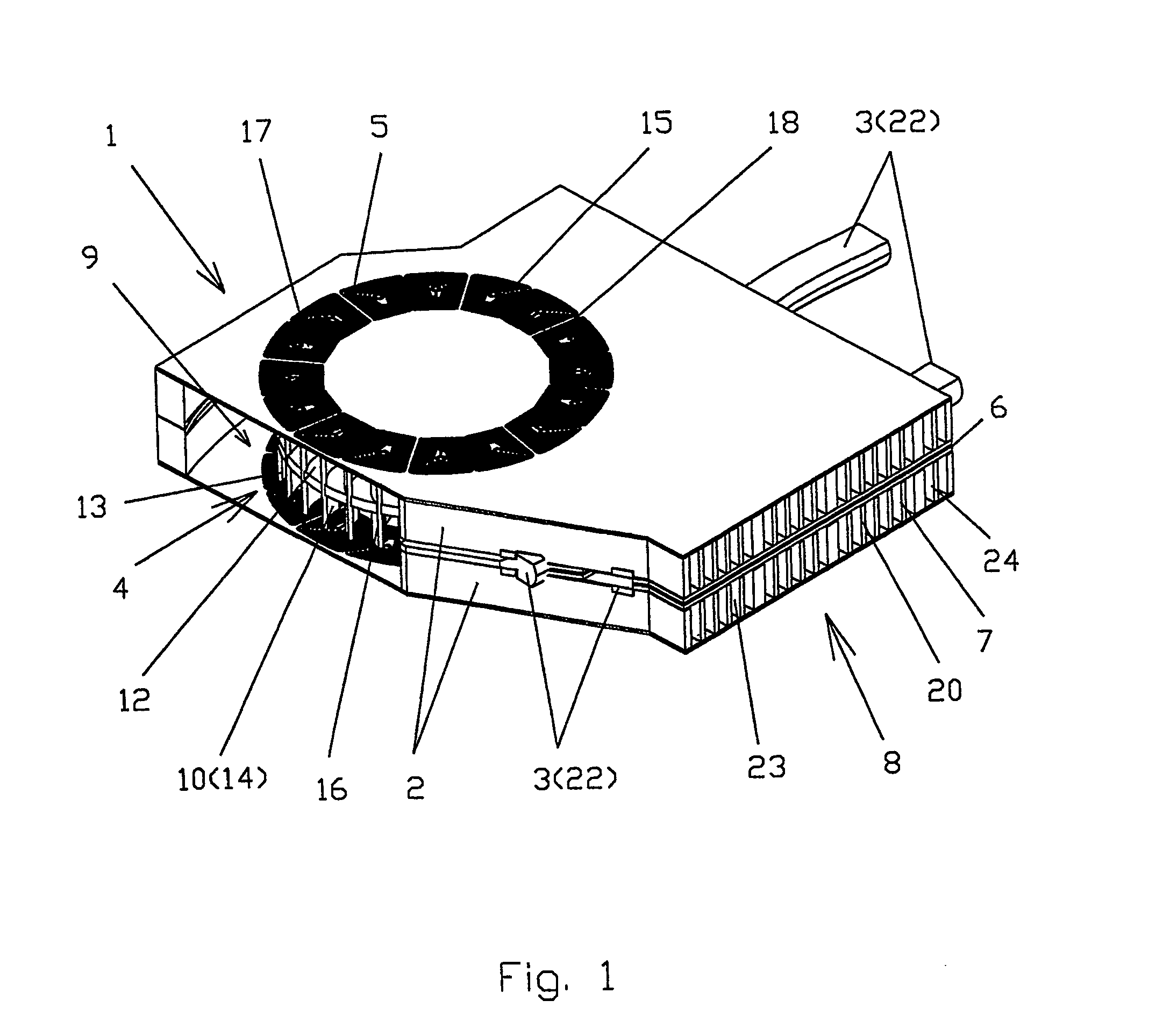

Integrated cooler for electronic devices

InactiveUS20060021735A1Improve performanceSmall spacingSemiconductor/solid-state device detailsSolid-state devicesImpellerEngineering

An integrated cooler comprises a heatsink integrated with a centrifugal blower. The heatsink comprises a base and heat exchanging means. The centrifugal blower comprises an electric motor, a casing with inlet and at least one outlet, a radial impeller and an axle. The electric motor comprises a magnetized rotor and a flat stator with an opening coincided with blower inlet thus the stator serves as an upper side of the casing. The base made as a lower side of the casing and provides thermal contact with the electronic device and the heat exchanging means. The radial impeller comprises magnetic means thus serving as the magnetized rotor. The heat exchanging means located inside of the radial impeller and surrounded by the blades thus cooling gas flows through the blower inlet, the heat exchanging means, the radial impeller and the at least one blower outlet in a series way.

Owner:INDAL DESIGN LAB

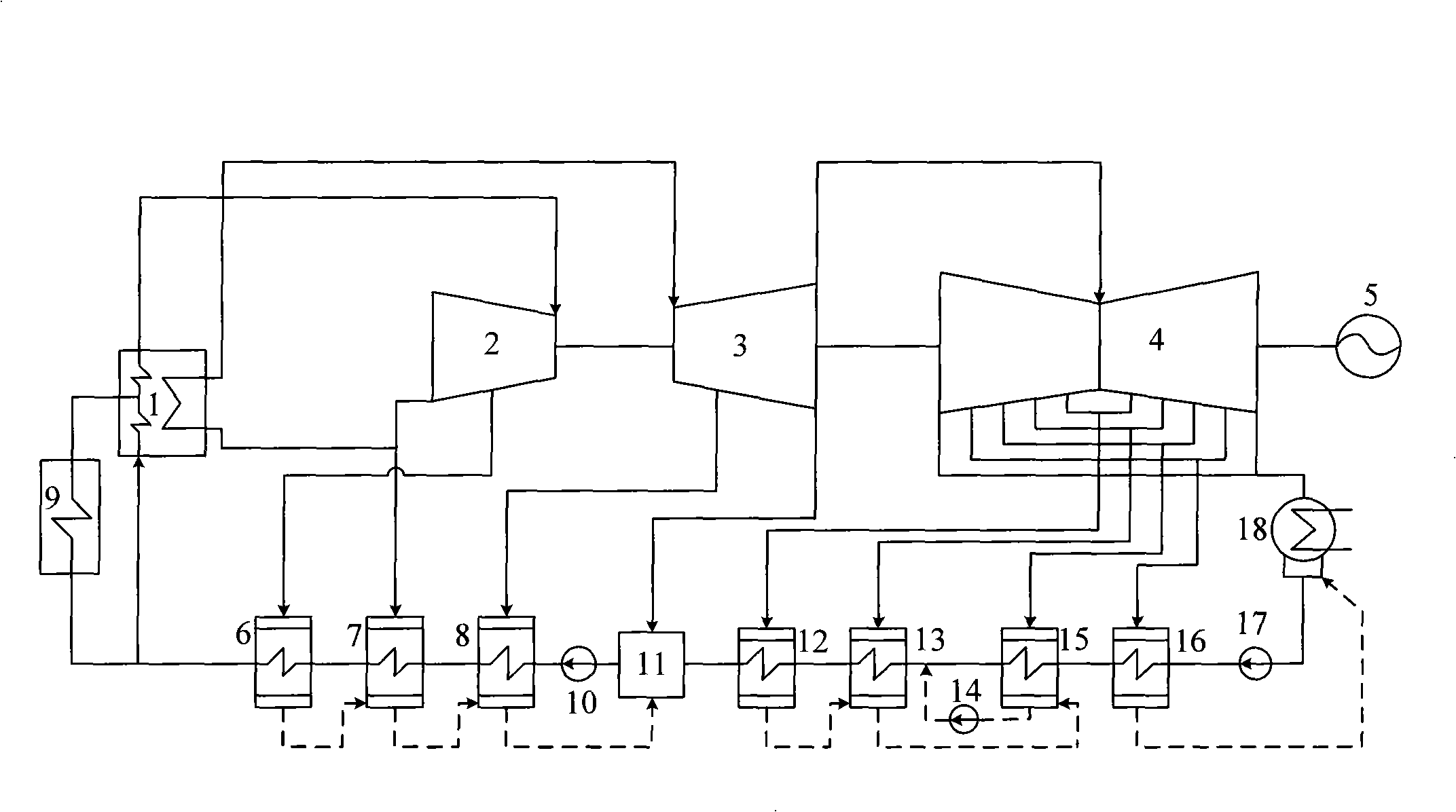

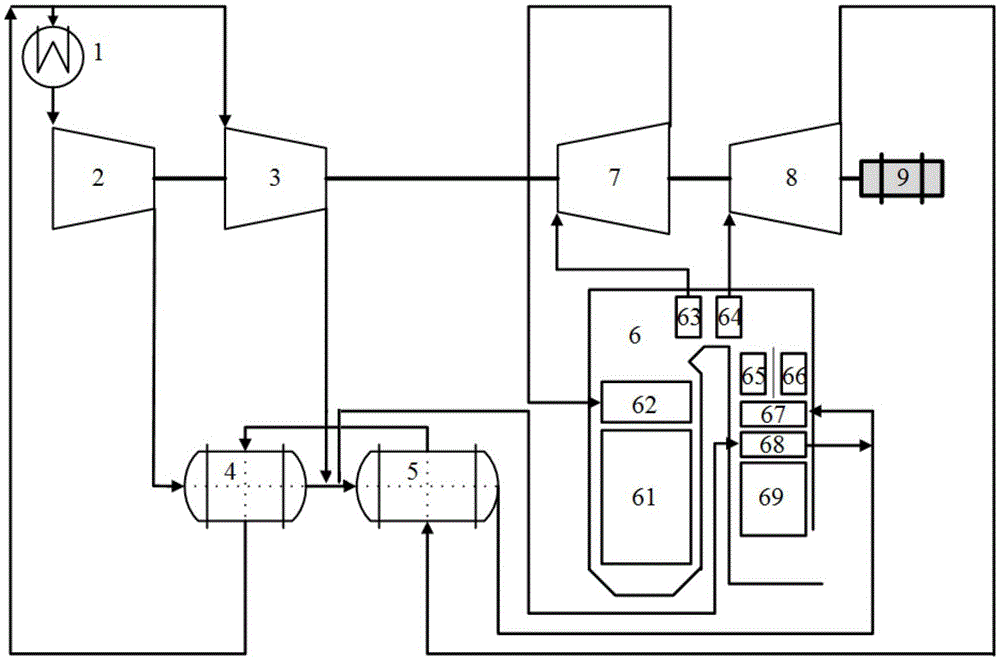

Solar energy and coal-burning unit combined thermal power generation system

InactiveCN101270675AHigh thermal efficiencyImprove thermal efficiencySteam engine plantsDeaeratorEngineering

The invention relates to a generating system, in particular to the heat generating system consisting of a solar heat collector and a coal-fired unit. The heat generating system adopts solar energy to take the place of the partial coal-fired heat energy of a coal-fired unit boiler. A condenser, an extraction pump, a low pressure heater, a deaerator, a water-feeding pump, a high pressure heater and the heat collector, a coal burning boiler and a steam turbine that are connected in parallel are connected in series. The steam turbine drives the generator and discharges gas into the condenser. Condensed water flows into a heater from the condenser to be heated up and pressurized, is deoxidized by the deaerator, then goes through the solar heat collector to be heated to be saturated vapor and goes into the coal burning boiler or directly goes into the coal burning boiler to become the steam with high temperature and high pressure. And then the steam goes into the steam turbine for applying work to drive the generator to generate electricity. The extracted steam of the steam turbine goes into each heater to finish thermodynamic cycle. The thermal efficiency of solar thermal power generation is improved, investment in the trough solar electrical energy generation of single paraboloid is reduced and the coal consumption of the coal-fired unit is decreased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

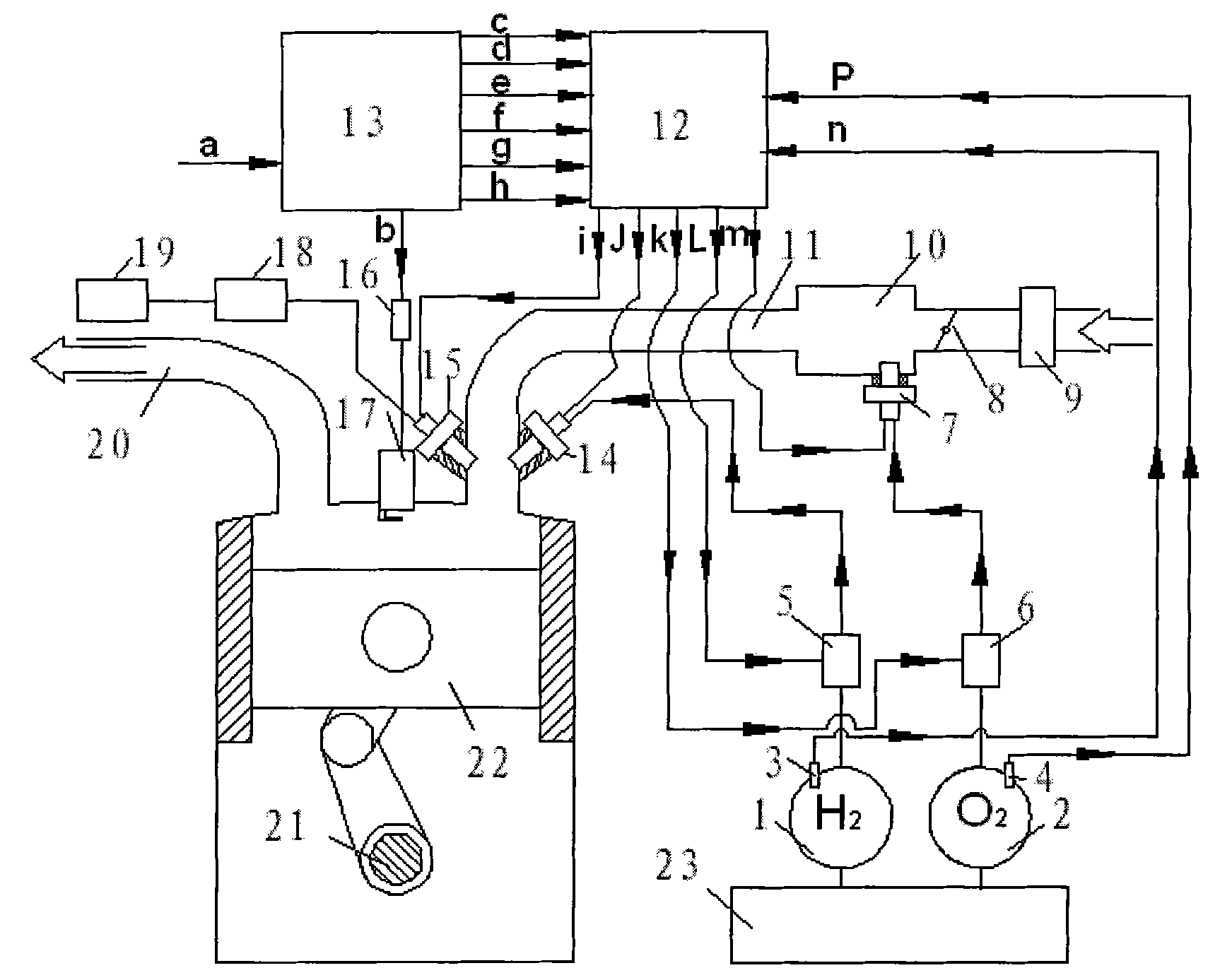

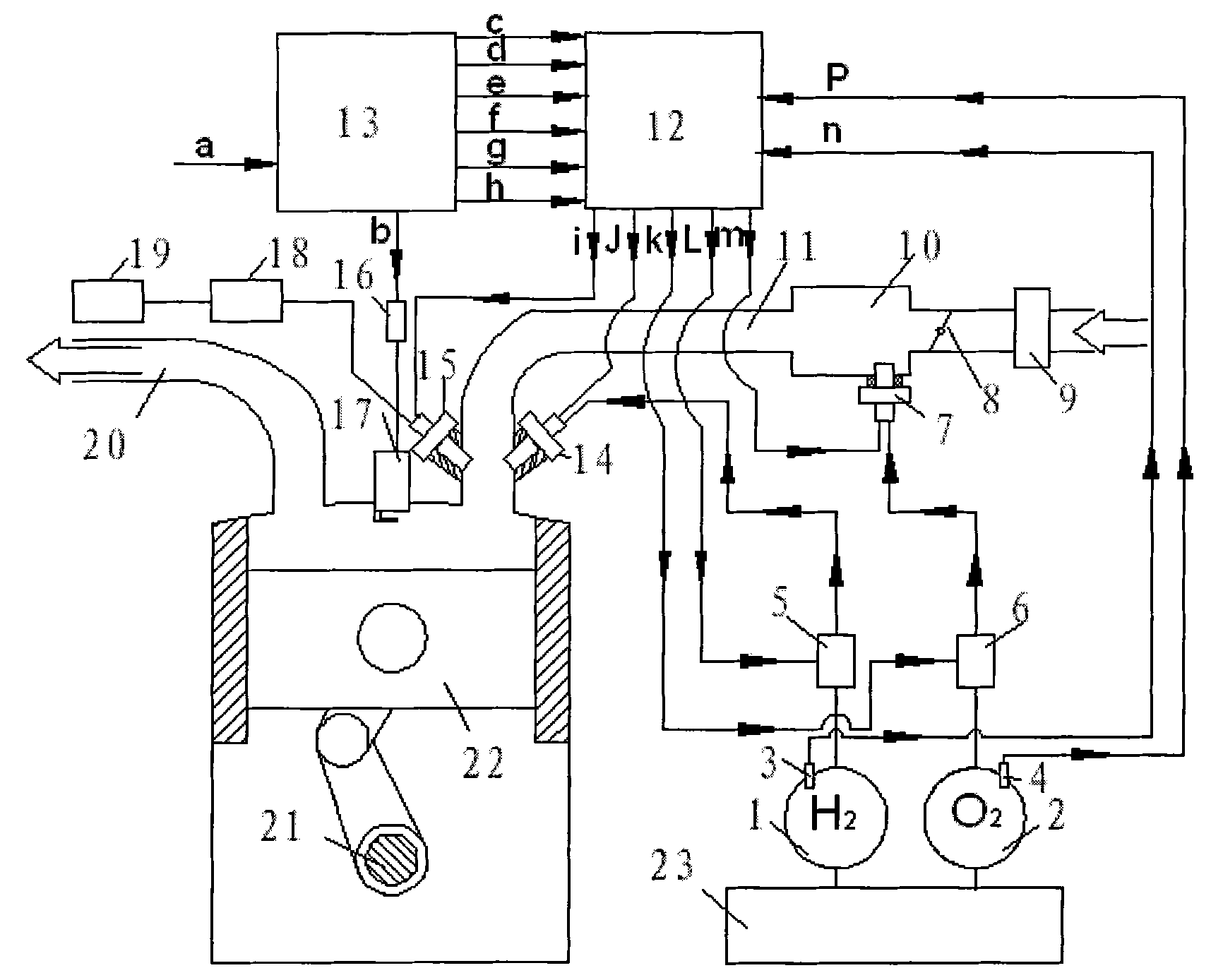

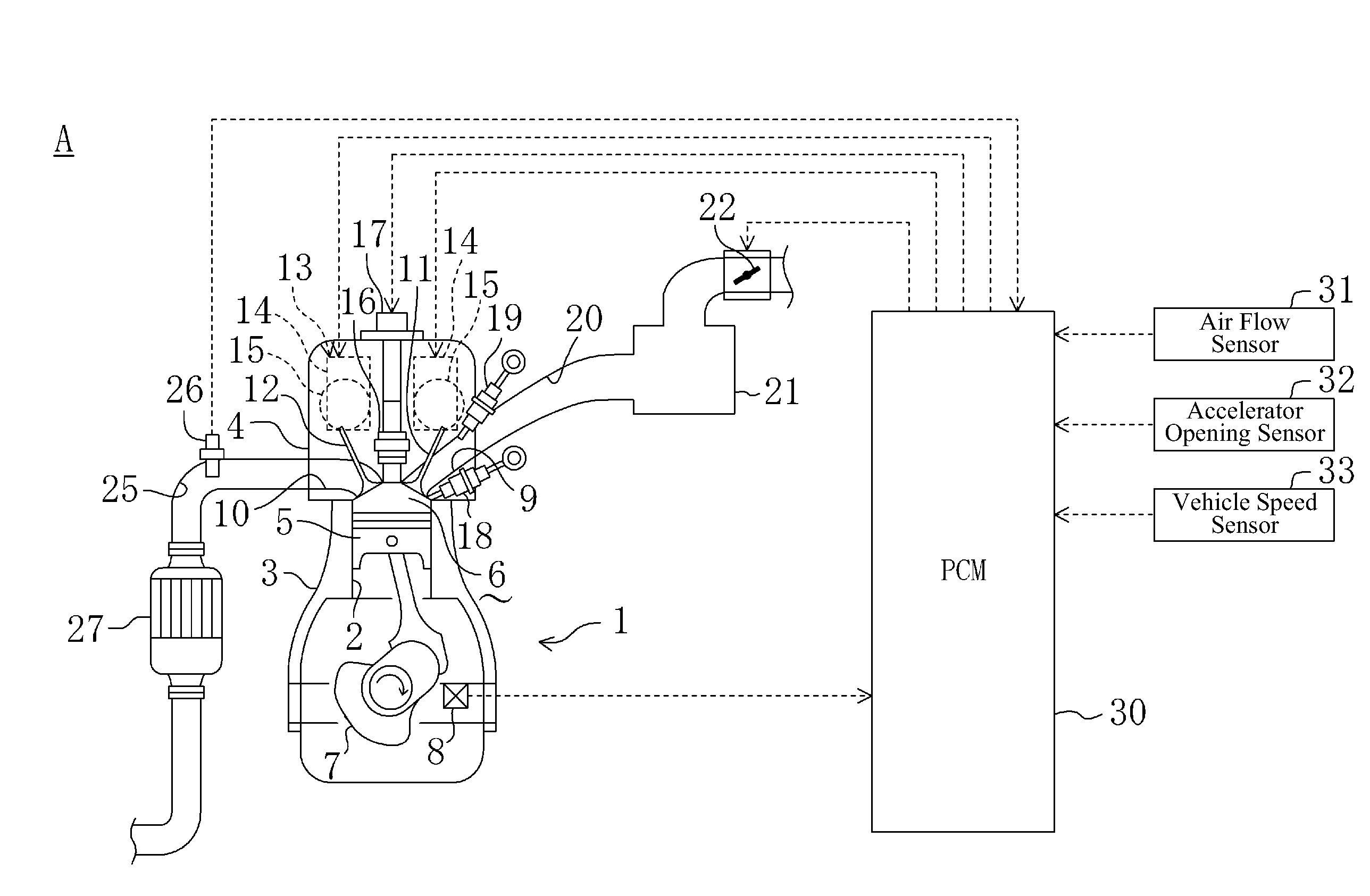

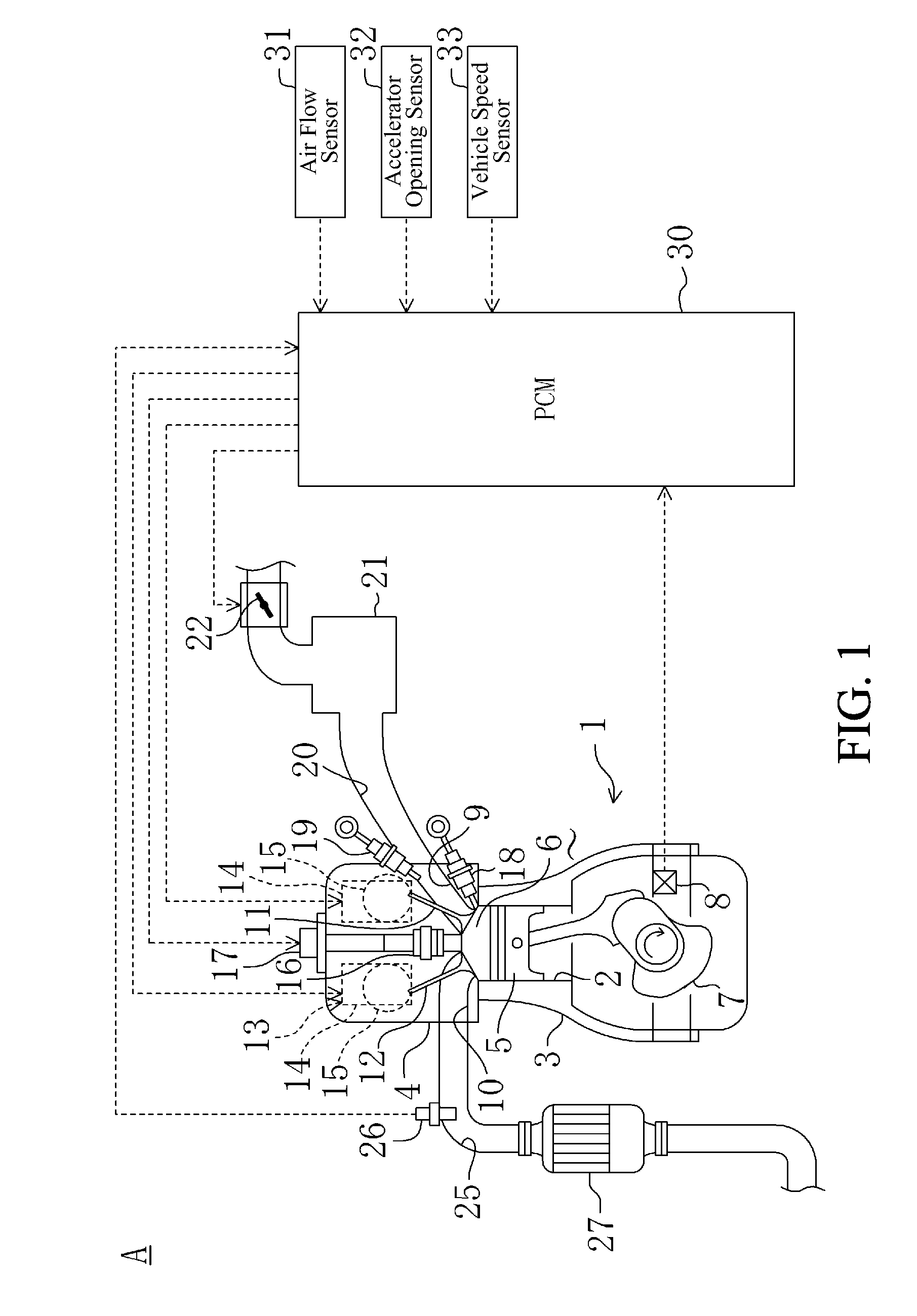

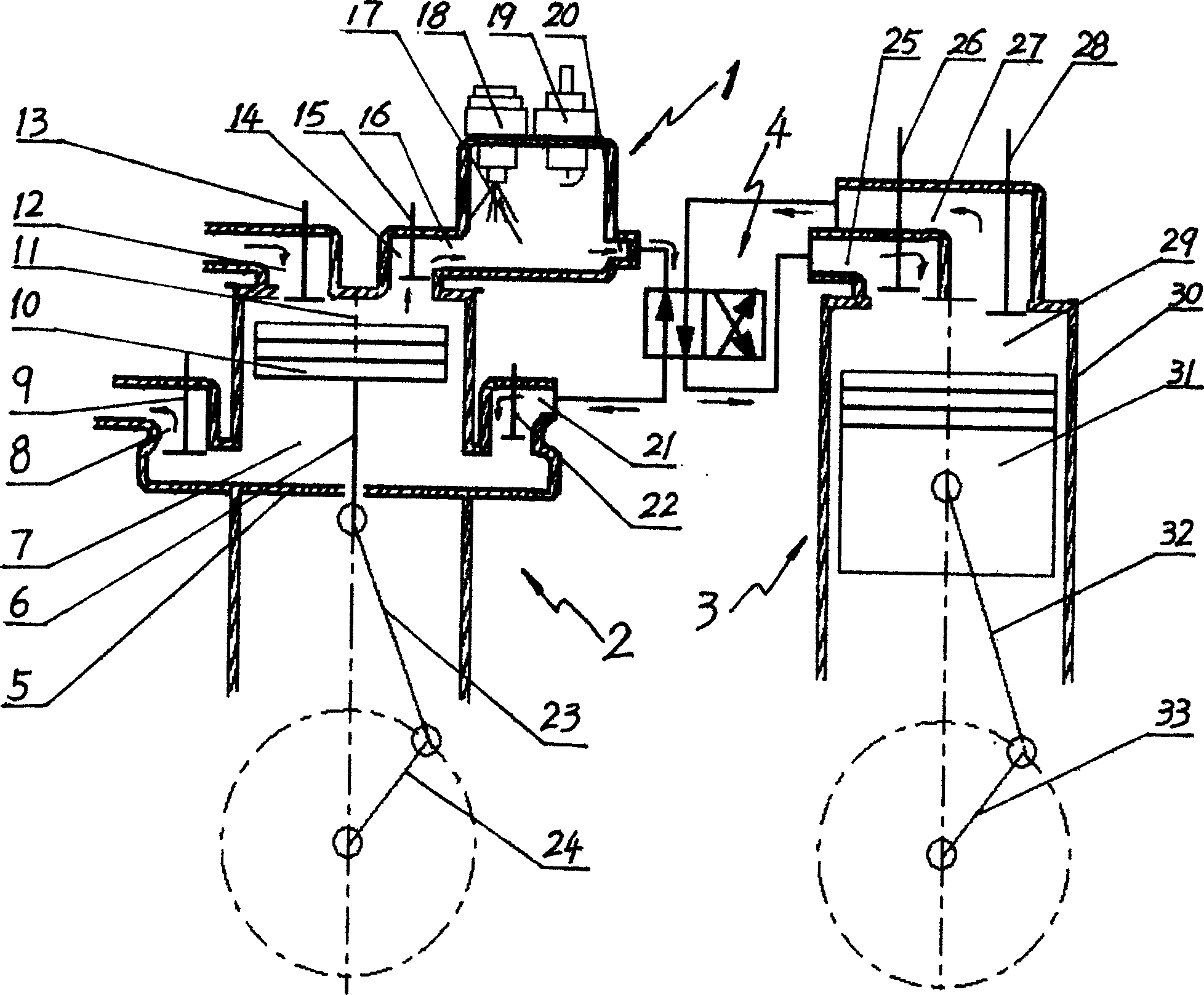

Hydrogen-oxygen-mixed high-octane fuel ignition combustion engine and control method thereof

ActiveCN101975108AReduce consumptionImprove economyElectrical controlInternal combustion piston enginesOn boardLow load

The invention provides an ignition combustion engine by the mode of mixing hydrogen and oxygen with high-octane fuel and a control method thereof, and particularly relates to a fuel storage and supply system of the ignition combustion engine by the mode of mixing the hydrogen and the oxygen with the fuel, fuel proportional distribution and combustion process control, wherein, a set of on-board hydrogen and oxygen production, a storage and supply device is added to the system on the basis of retaining main parts and an electronic control unit of the original engine. The hydrogen and oxygen mixed fuel electronic control unit (12) can control the opening and closing of a hydrogen nozzle and an oxygen nozzle according to sensor signals c-h so that the engine can run in three combustion modes such as pure hydrogen and oxygen mixed gas, hydrogen-oxygen-high-octane fuel mixed gas and pure high-octane fuel according to different operating conditions, thus greatly lowering HC and CO emission in the case of cold starting and idling of the high-octane fuel combustion engine and improving the thermal efficiency and emission level of the high-octane fuel combustion engine in middle and low load stages.

Owner:BEIJING UNIV OF TECH

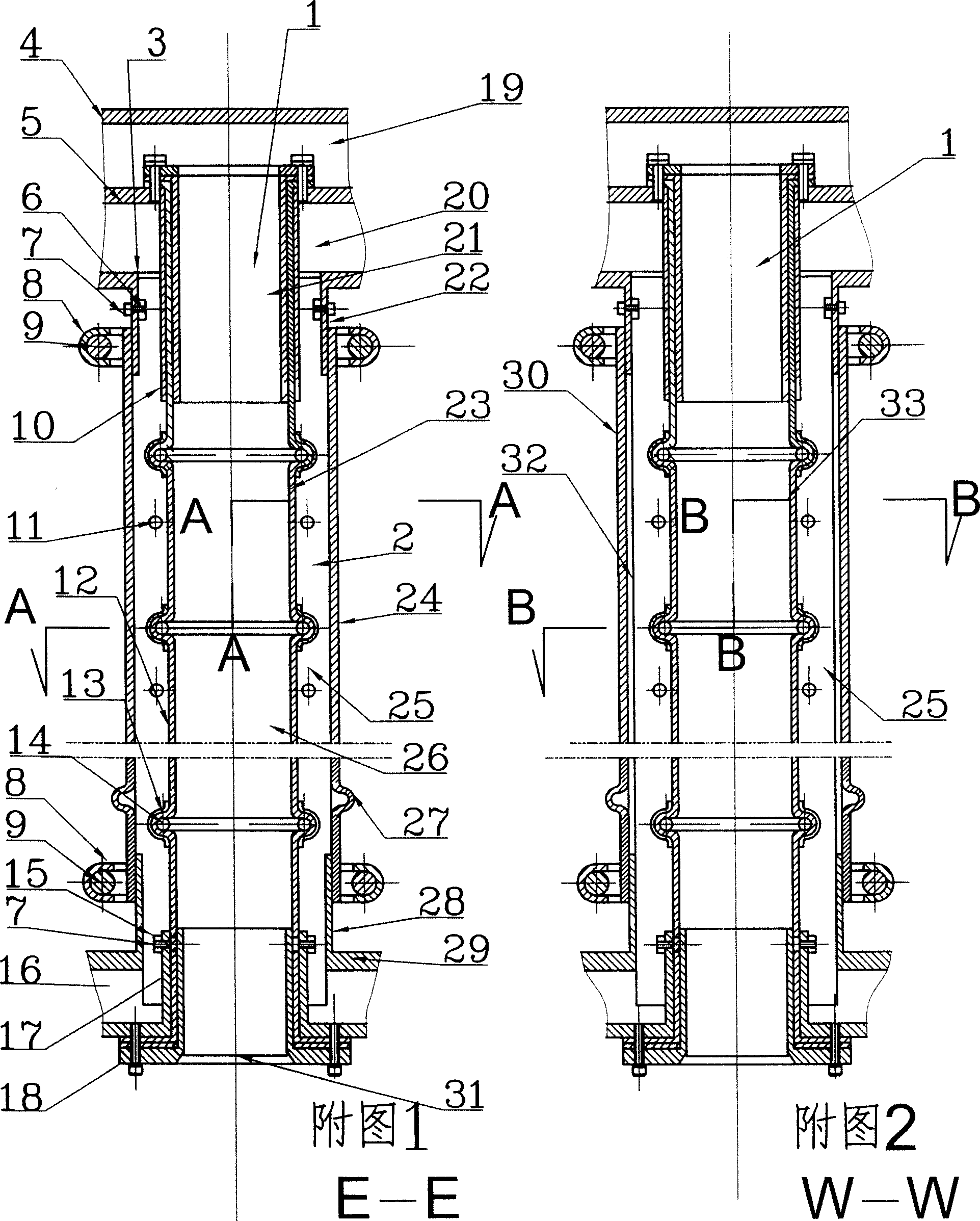

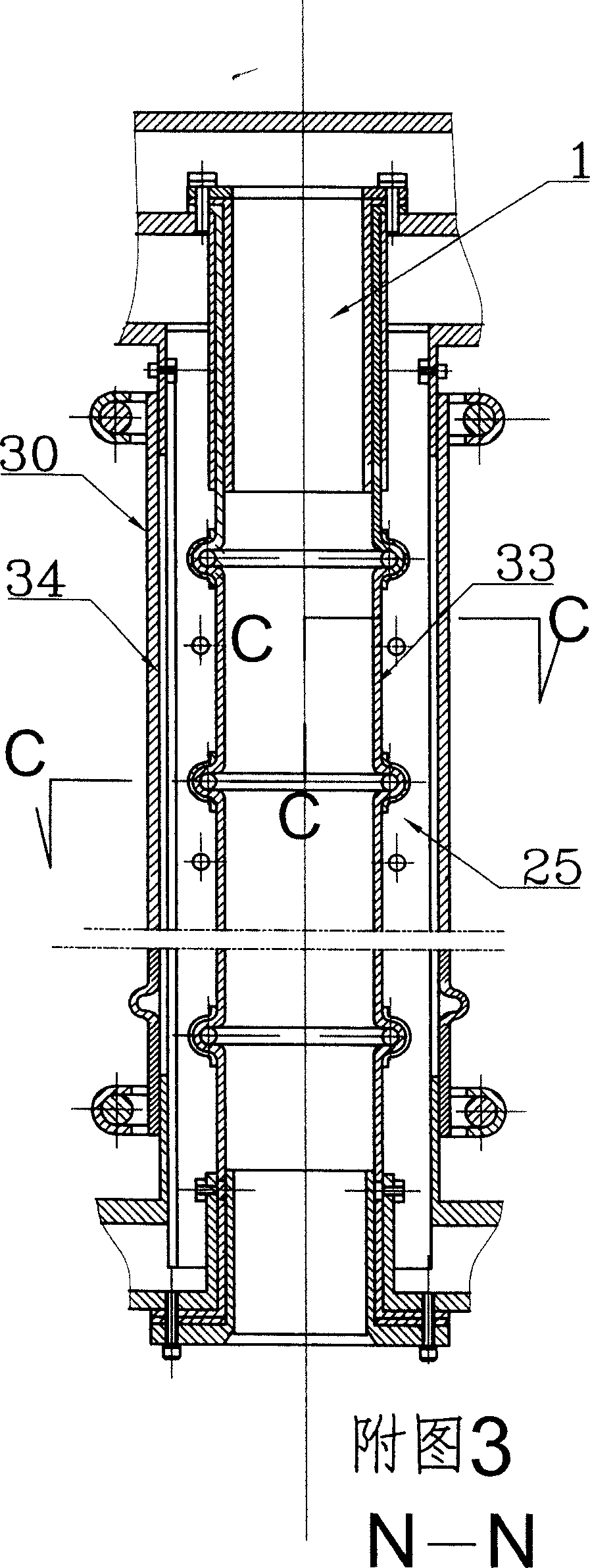

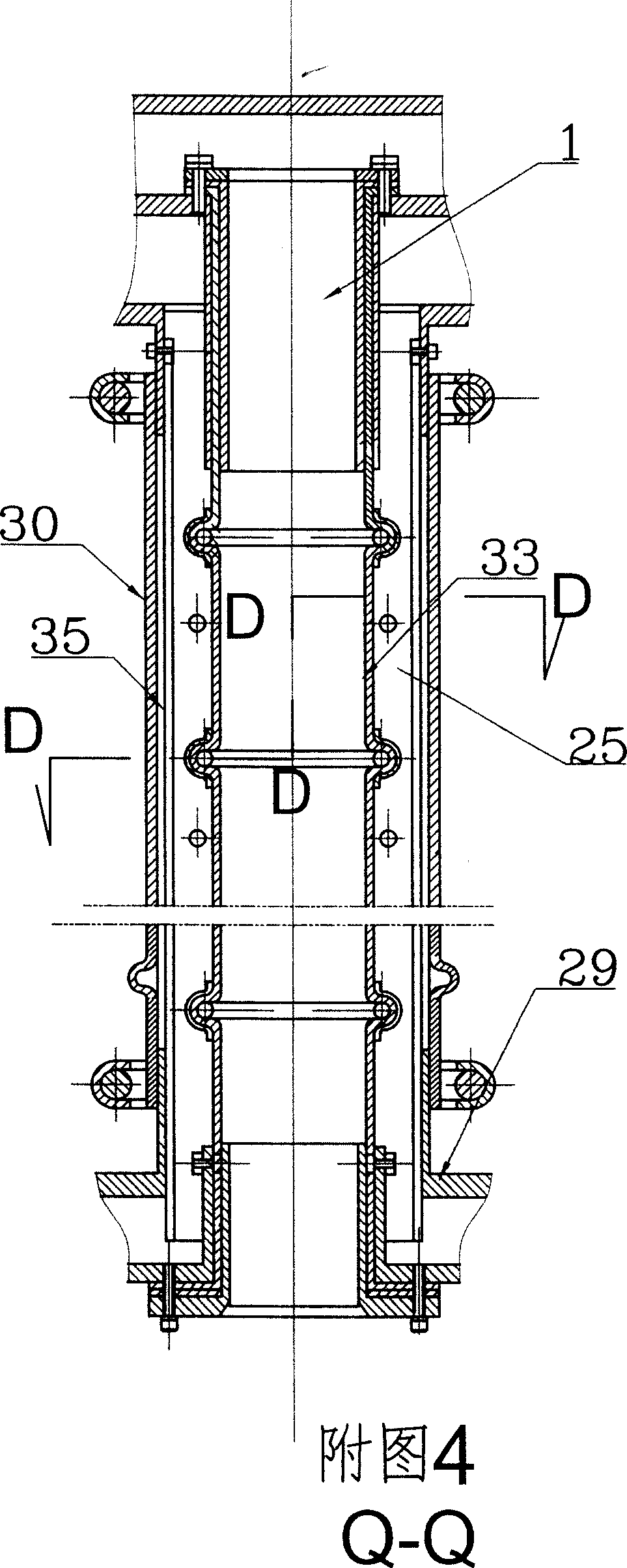

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

Process for producing fuel

InactiveUS20060027488A1Low costHigh thermal efficiencyWorking-up pitch/asphalt/bitumen by selective extractionSolid fuelsAlkaneSorbent

A fuel is produced from bitumen by precipitating a substantial portion of asphaltenes from bitumen by contacting the bitumen with a lower alkane solvent. Suitable burners include a fluidized bed boiler, a circulating fluidized bed boiler and a pitch boiler which utilize either pre-combustion sulfur sorbents or post-combustion flue gas desulfurization. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, power and sulfuric acid and meets all emission requirements for SO2, NOx and PM.

Owner:GAUTHIER RICHARD

Coal-biomass co-overcritical water catalysis-gasification hydrogen production plant and method

ActiveCN1654313AMild reaction conditionsEasy to controlHydrogen productionBulk chemical productionCO2 contentHydrogen content

The present invention discloses one kind of supercritical water catalytic coal and biomass gasifying process and apparatus for producing hydrogen. The apparatus has material feeder with one inlet connected to the outlet of the material pump and the other inlet connected to the outlet of feeding tank, pre-heater with outlet connected to the preheated water inlet and inlet connected to the outlet of inner pipe outlet of the cooler, cooler with inlet connected to the inlet of water pump, water pump with outlet connected to the water tank, cooler jacket with outlet connected to the inlet of the first filter and the inlet of the second filter, and back pressure valve with inlet connected to the outlets of the first filter and the second filter. The present invention has special heating mode for fast heating of the reaction material, raised hydrogen content in the gas product, raised CO2 content in the gas product, and easy separation of CO2 and feeding of CO2 to the processing terminal. The present invention is simple, effective and feasible.

Owner:陕西中核交大超洁能源技术有限公司

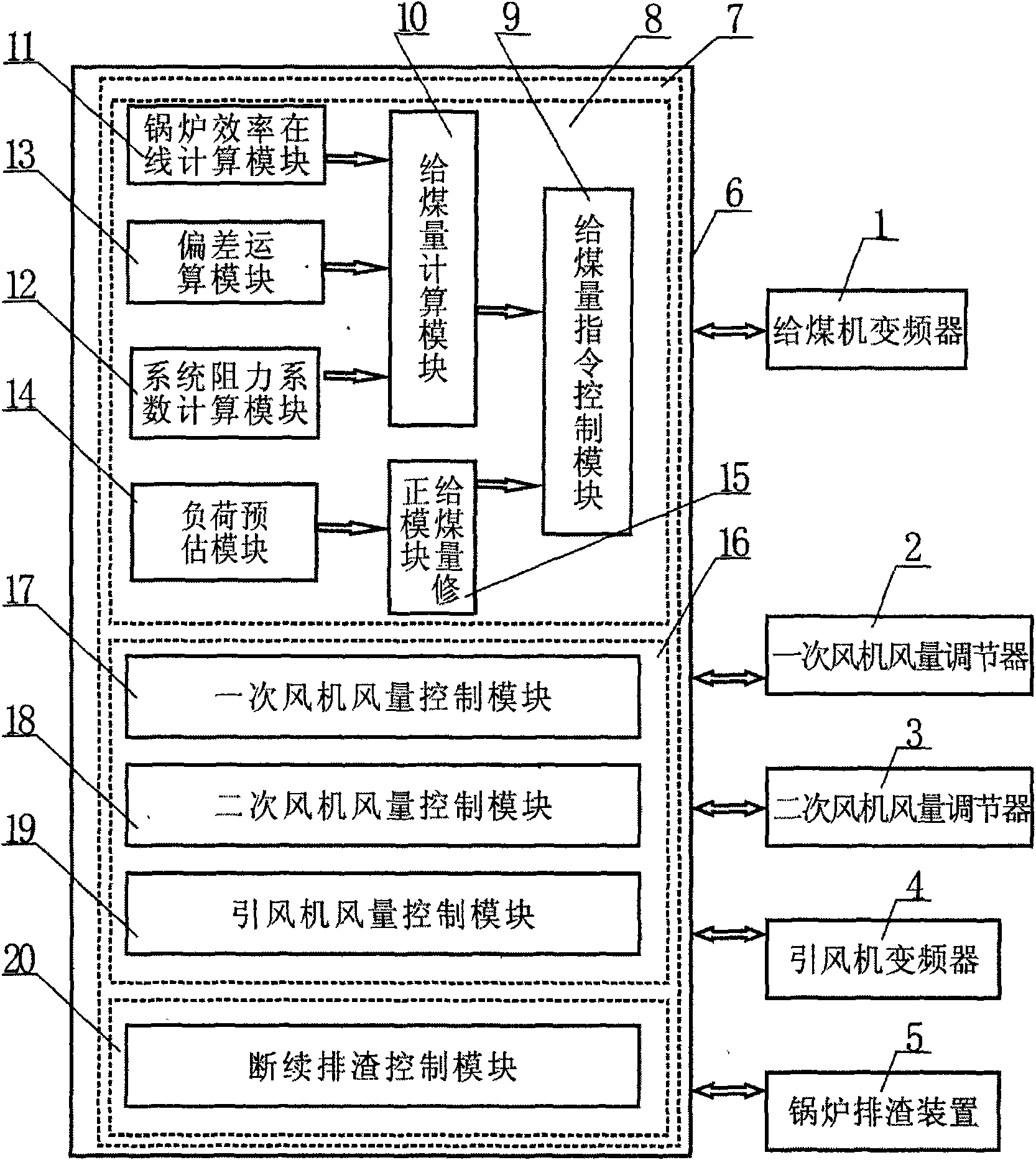

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

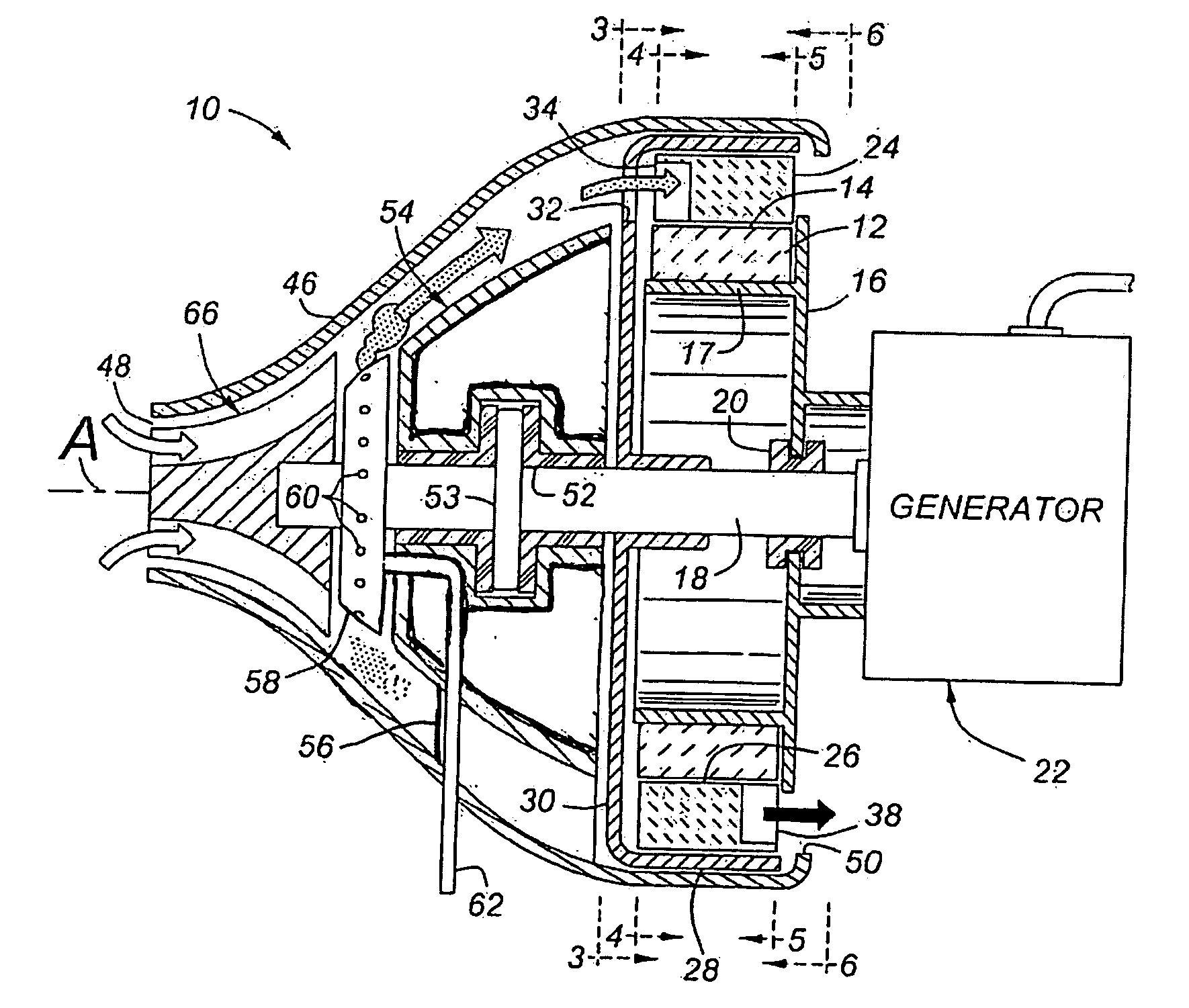

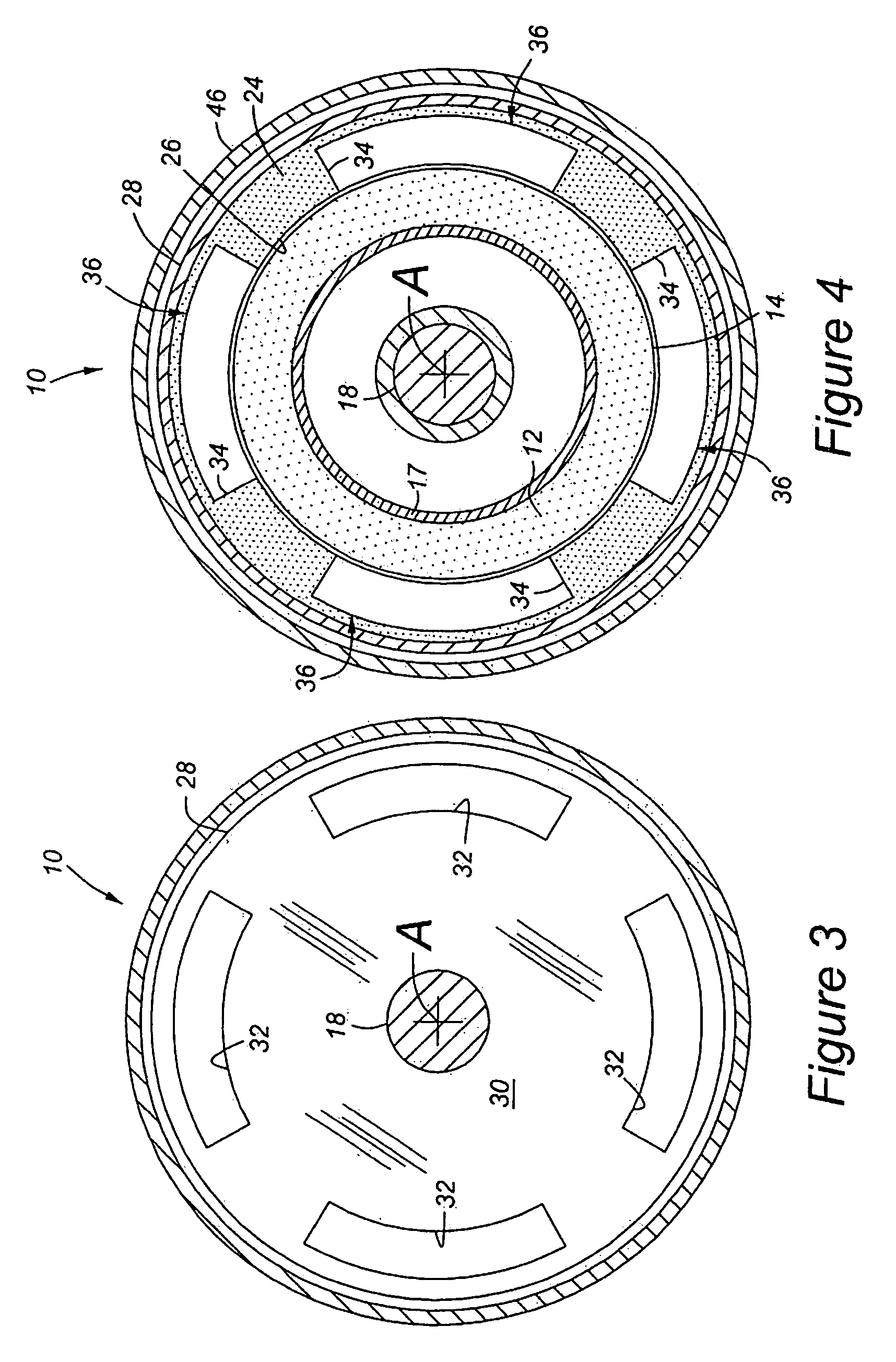

Rotary ramjet turbo-generator

ActiveUS20070056290A1MiniaturizationHigh thermal efficiencyEngine manufactureEfficient propulsion technologiesBrayton cycleElectricity

A Brayton-cycle rotary ramjet engine (10) operated within the confines of a helically elongated pass-through duct formed between a preferably stationary radially outward surface (14) and an outer rotating flow channel (36). The flow channel (36) is contoured between its inlet (34) and outlet (38) to include a supersonic diffuser (40), a combustor (42) and an expansion nozzle (44). Gaseous fuel, or liquid fuel atomized by a fuel slinger (58) within a housing (46), or solid fuel in the form of fine particulates, is inter-mixed with an oxidizer prior to being directed to the flow channel inlets (34). The air and fuel are combusted in the flow channels (36) and exhausted through the rear of the housing (46). A generator (22) can be coupled to a power shaft (18) to convert net shaft power into electricity. Preferably, the rotor (24) and stator (12) are fabricated from a ceramic or other high-temperature material so that combustor exit temperatures (T3) can be operated at highly efficient levels.

Owner:RGT UNIV OF MICHIGAN

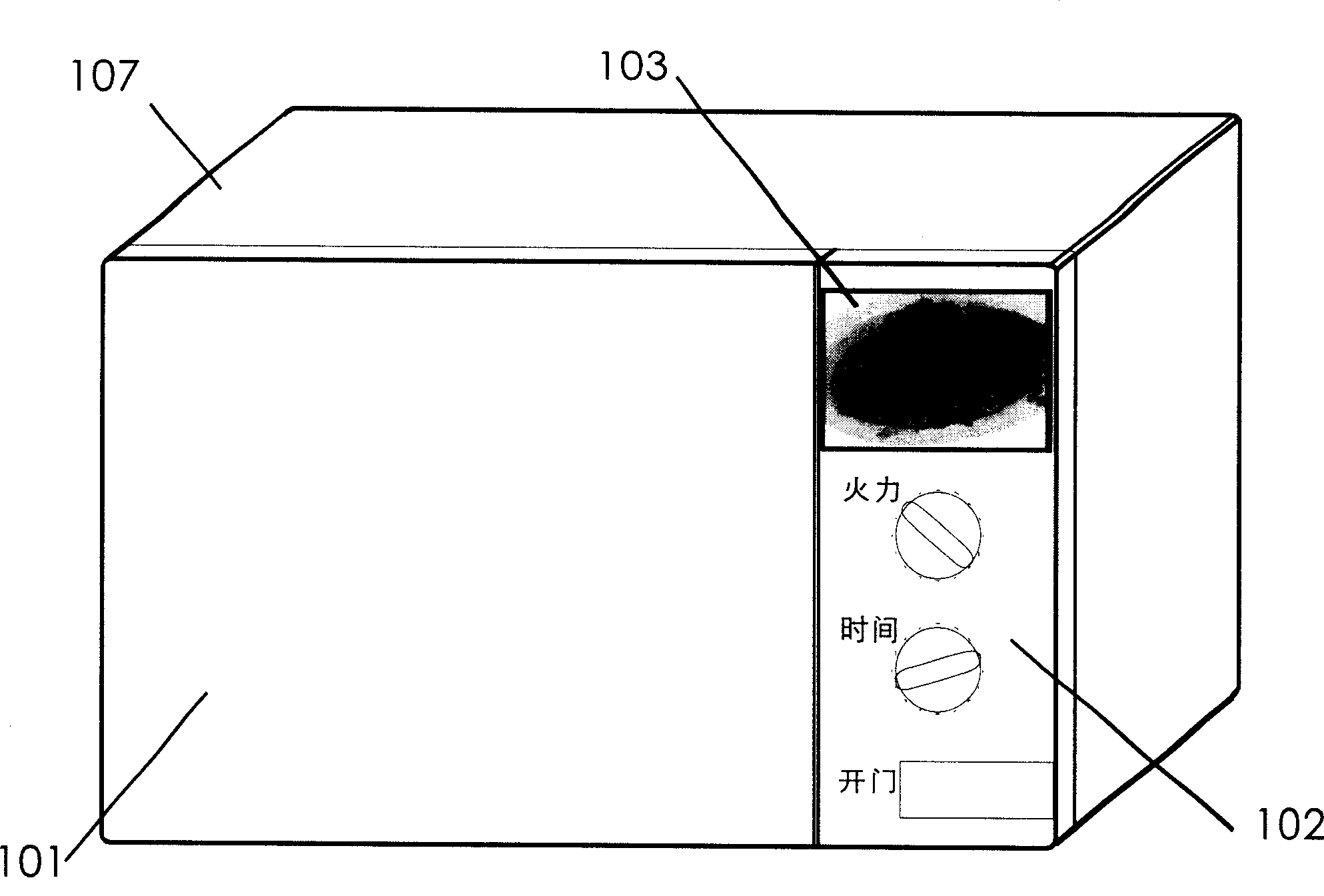

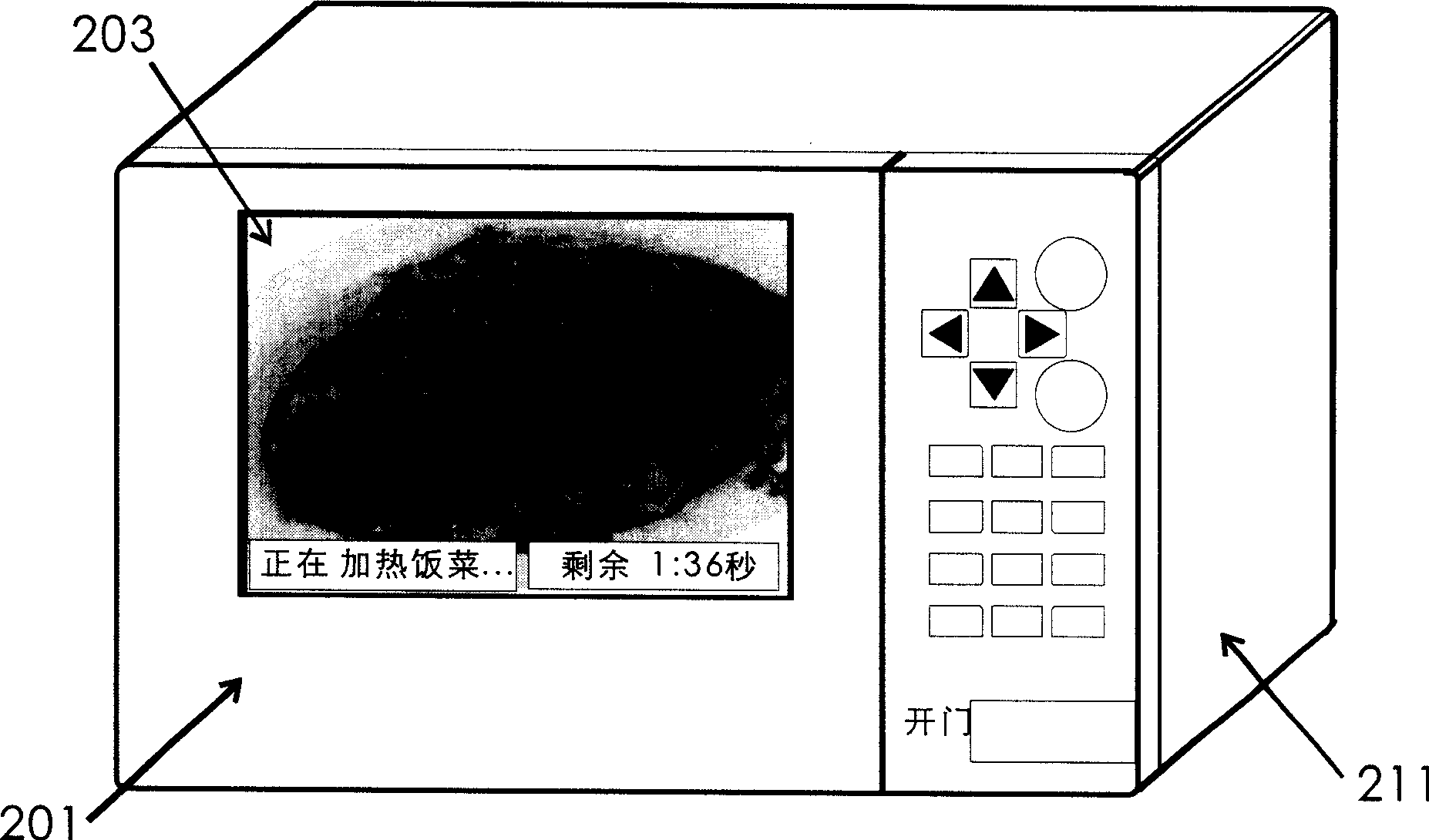

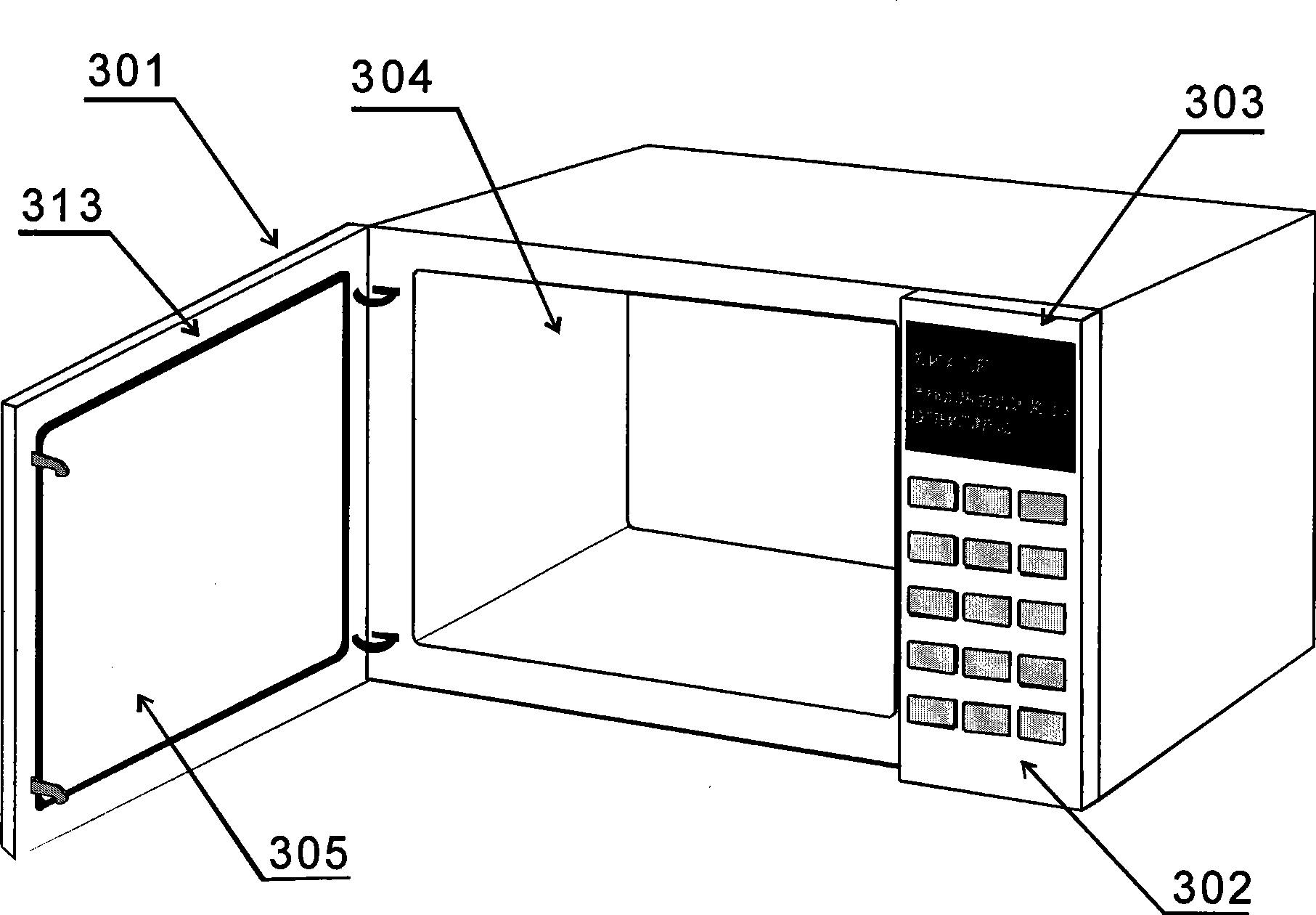

Microwave oven without microwave radiation and its operation and control method

InactiveCN101504158AProtect human healthInviolableDomestic stoves or rangesLighting and heating apparatusMicrowave ovenProcess engineering

The invention provides a microwave oven without microwave radiation. The inner side of an oven door is made of microwave reflecting materials which fully shield an opening of an oven cavity; and a transparent or semi-transparent window on the oven door, by which a user can observe the conditions of foods in the oven cavity, are not remained. The oven comprises a microprocessor used for controlling operation of the microwave oven and / or human-machine interaction, a magnetron used for generating microwaves, a wave guide used for guiding the microwaves into the oven cavity, the oven cavity accommodating the food to be cooked, of which at least one side is provided with an opening, the oven door used for fully shielding the opening, an illuminating light source used for supplying enough brightness necessary for taking video pictures, a camera for taking video pictures in the oven cavity, and a display screen used for displaying the video pictures and / or characters and graphic information; moreover, the microwave oven can also have parameterized cooking menus, and can do cooking according to parameters after a user chooses the cooking menu and adjust the parameters of the cooking menu; and the user can customize, import and export the cooking menus.

Owner:郭恒勋

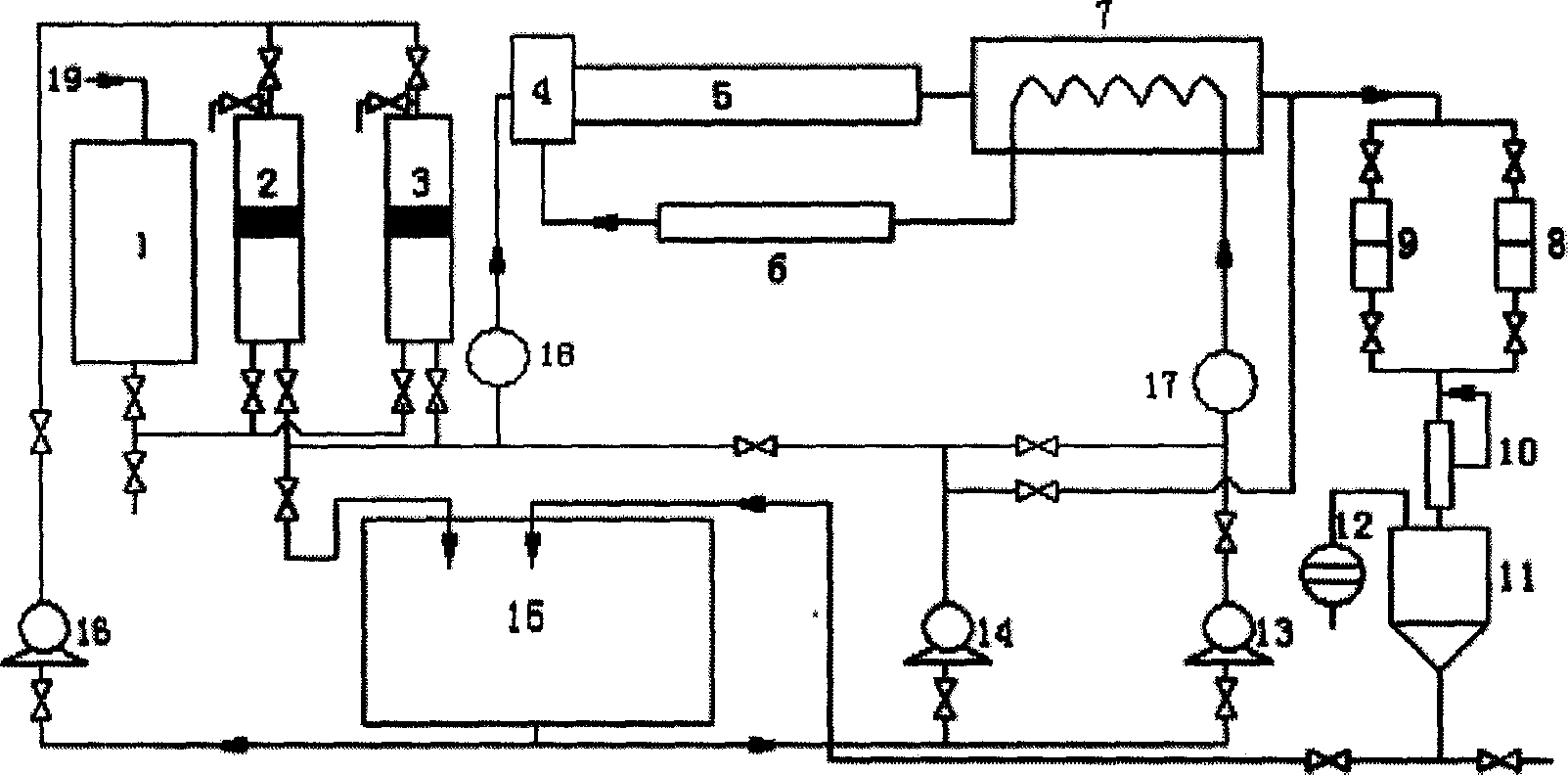

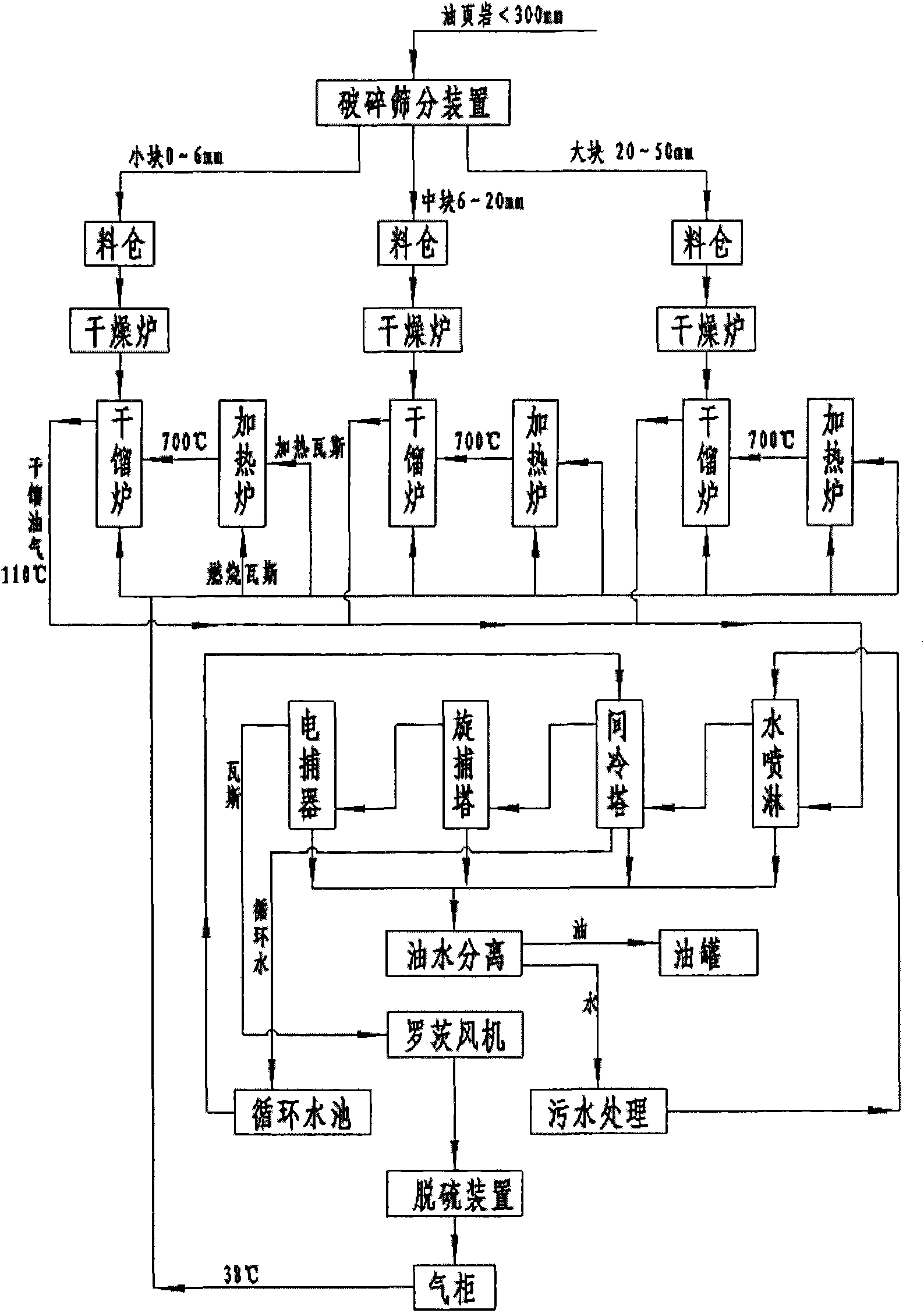

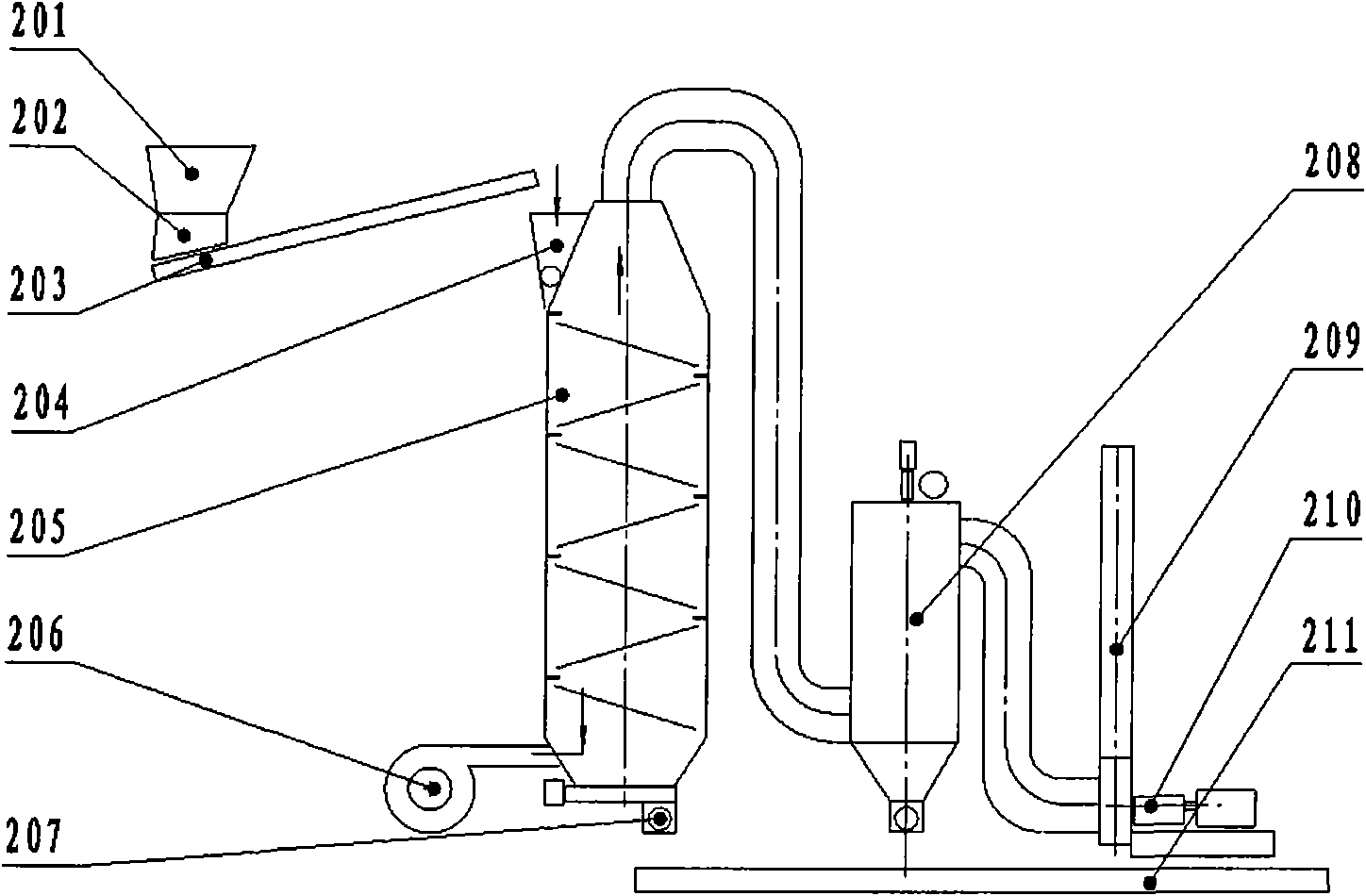

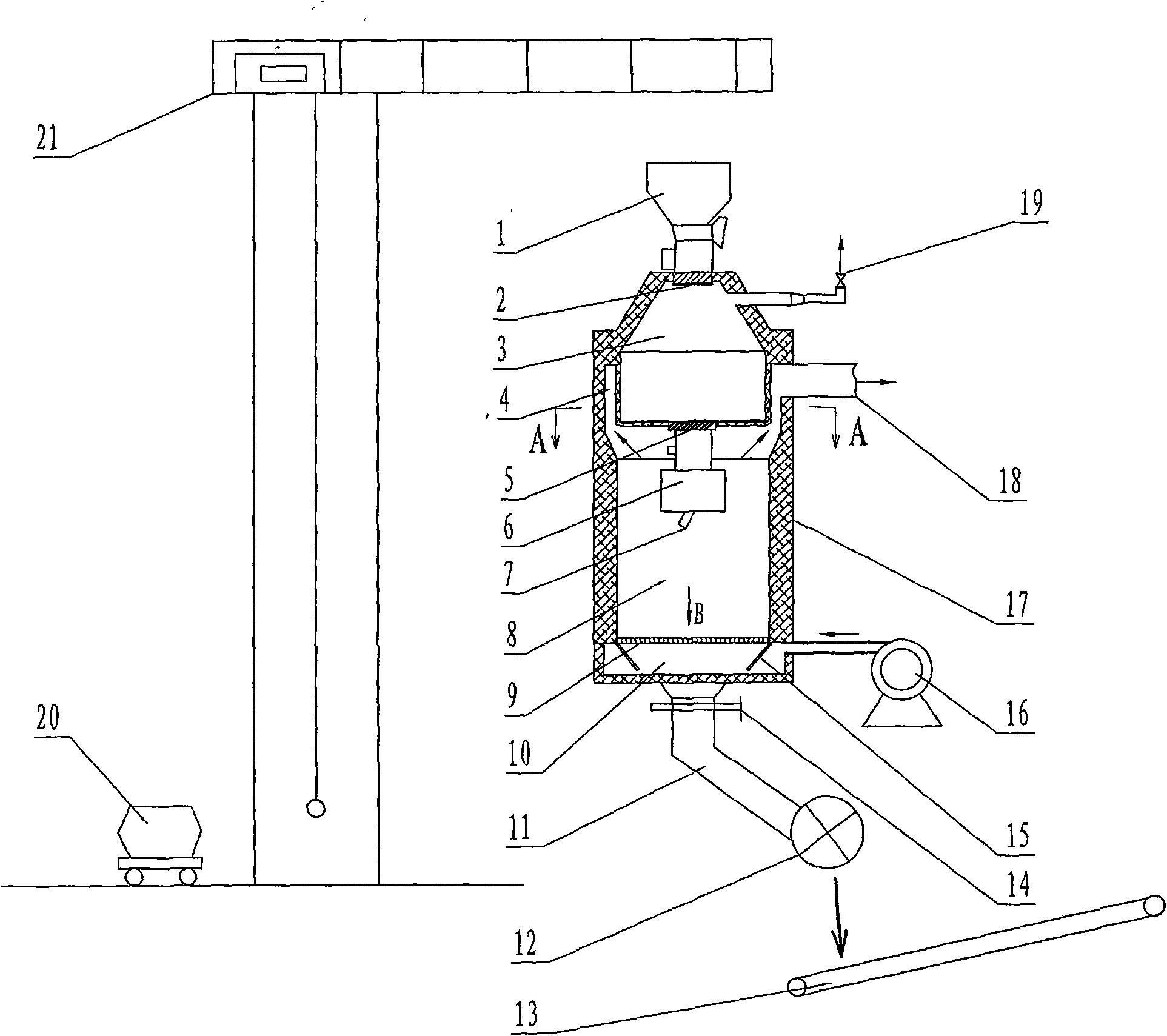

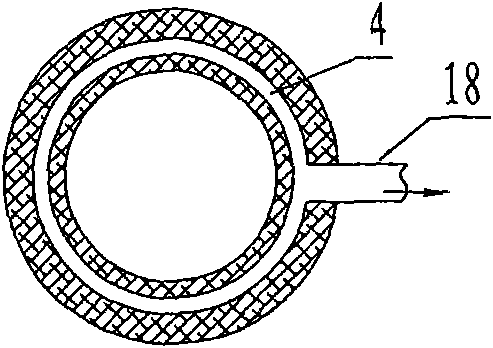

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

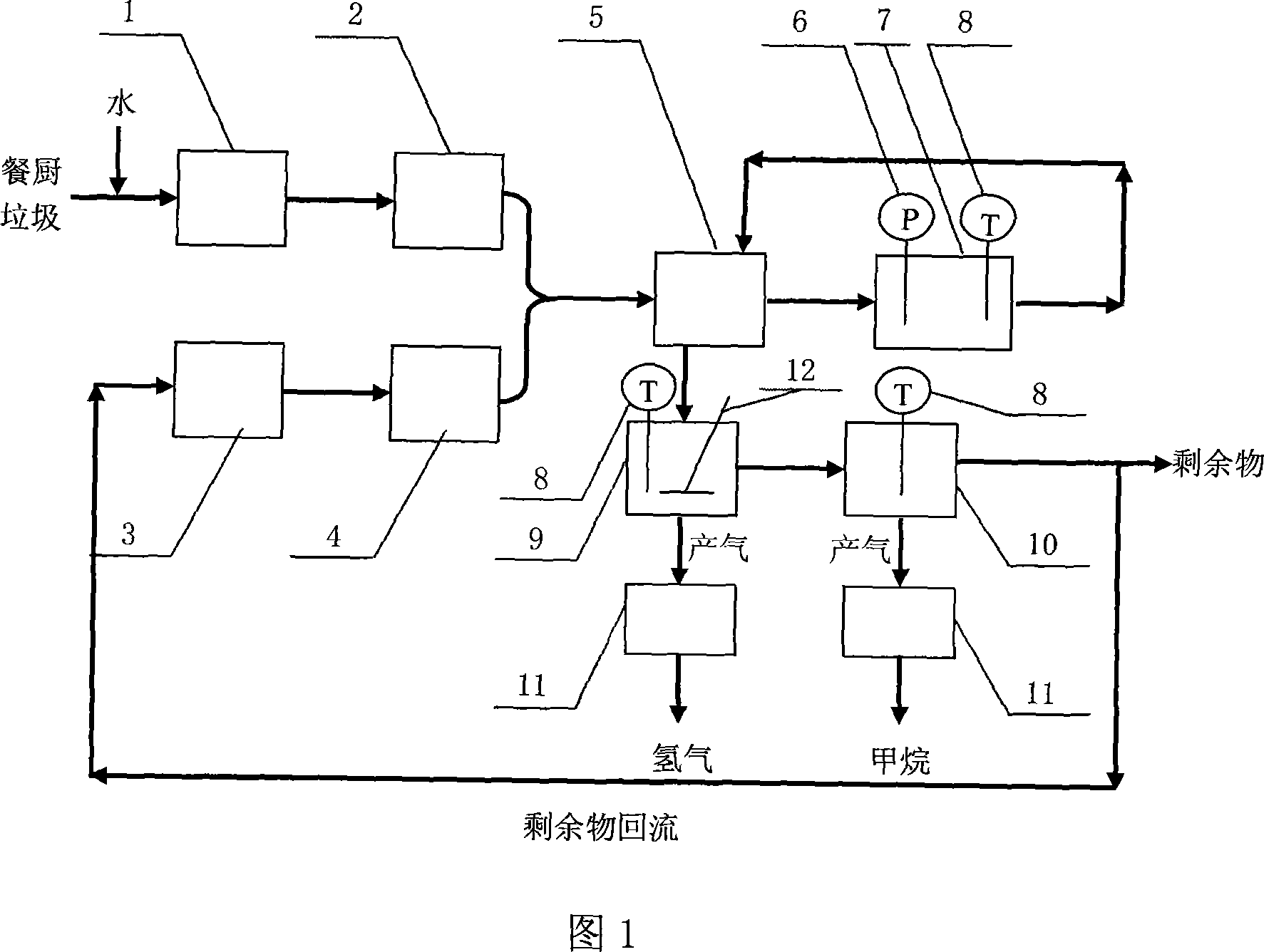

Method for producing hydrogen and methane by kitchen waste diphasic anaerobic fermentation

InactiveCN101134684APH controlLow running costBio-organic fraction processingClimate change adaptationHydrogenSludge

The biphase anaerobic fermentation process of kitchen refuse to produce hydrogen and methane includes the following steps: 1. sorting kitchen refuse and mixing with water in certain amount; 2. mixing with sludge from sewage treating yard and heat treatment; 3. heat exchange between heat treated mixture and mixture without through heat treatment; 4. anaerobic fermentation of the heat treated mixture in the first phase to produce hydrogen; 5. anaerobic fermentation of the residue from the first phase fermentation in the second phase to produce methane; and 6. using the residue from the second phase fermentation as fertilizer or returning to replace sludge serving as hydrogen producing bacteria source. The process is simple, can recover the biomass energy from kitchen refuse effectively, and has no secondary pollution.

Owner:DONGGUAN KECHUANG FUTURE ENERGY SOURCE TECHDEV

Method of operating an internal combustion engine

ActiveUS20080178836A1Overcome disadvantagesAccelerate emissionsValve arrangementsElectrical controlExternal combustion engineInternal combustion engine

A method of operating an internal combustion engine having a combustion chamber with a piston and a spark plug, comprising during a first mode, bringing the temperature of the combustion chamber to auto-ignition temperature by adjusting engine operating conditions and producing auto-ignition in said combustion chamber without requiring spark from said spark plug; and during a second mode, bringing the temperature of the combustion chamber close to auto-ignition temperature by adjusting engine operating conditions, forming a small cloud of stratified air-fuel mixture near said spark plug, igniting said fuel cloud by a spark form said spark plug, and then causing cylinder pressure to rise, thereby producing auto-ignition at other sites in said combustion chamber wherein said first mode is implemented in a first operating range and said second mode is implemented only in a second operating range where engine speed and load are lower than said first operating range.

Owner:MAZDA MOTOR CORP

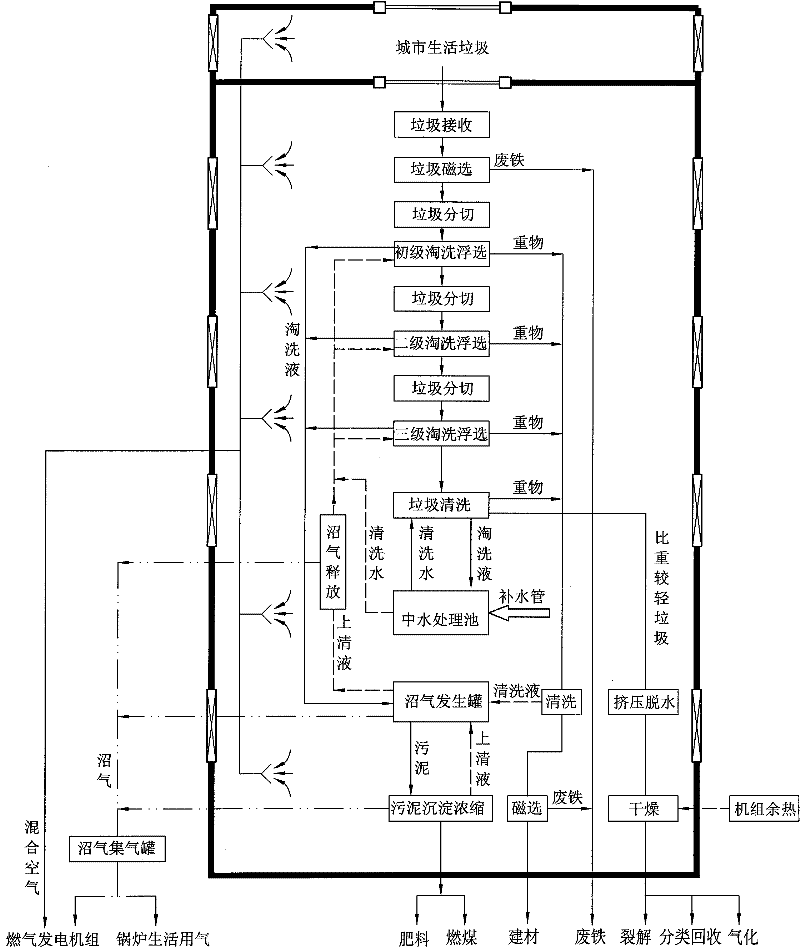

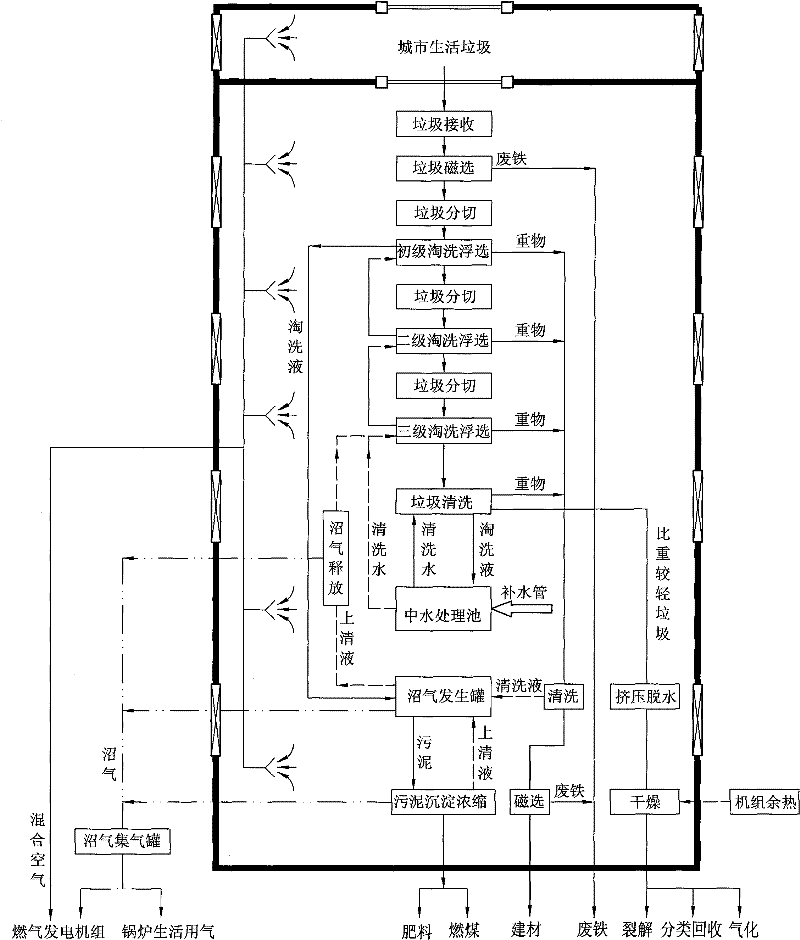

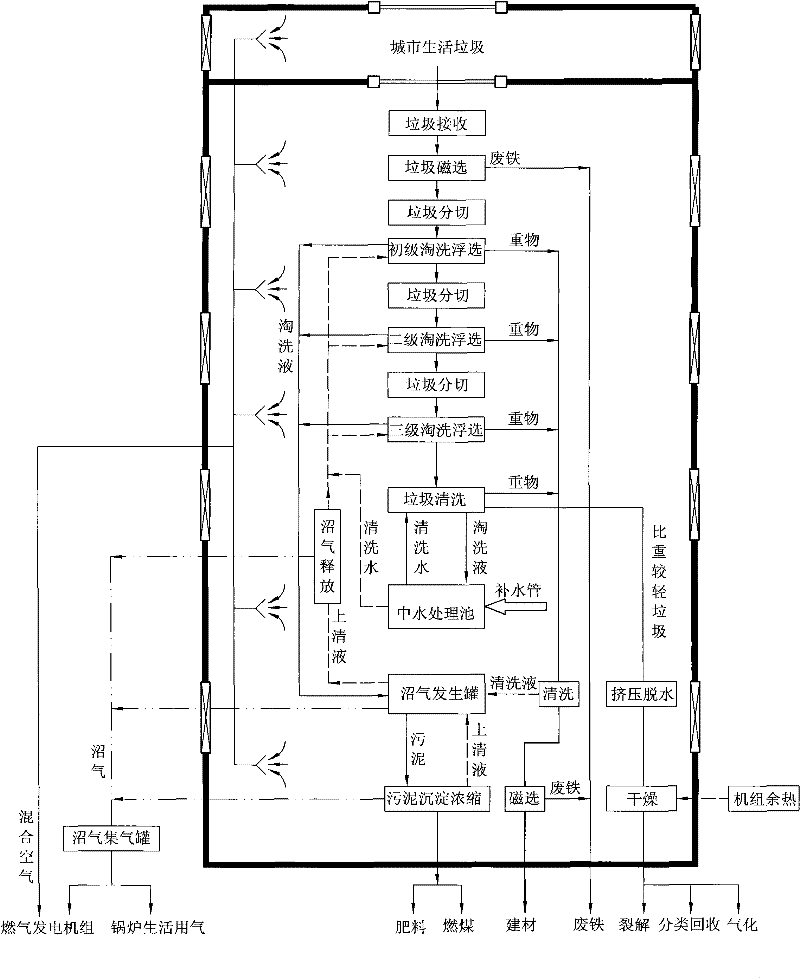

Method for resource recovery and classification utilization of urban domestic waste

ActiveCN102247969AHigh thermal efficiencyEasy to wash and separateSolid waste disposalFurniture waste recoveryEngineeringFuel oil

The invention discloses a method for resource recovery and classification utilization of urban domestic wastes, which at least comprises the following steps of: a magnetic separation step, a waste cutting step, a elutriation flotation step, a waste extrusion dehydration step, an anaerobic treatment step and a sludge deposition concentration step; scrap iron is separated by the magnetic separationstep for the recovery and utilization of the scrap iron; anaerobic organic matter is crushed by the waste cutting step; pasty organic matter and block non-anaerobic wastes are thoroughly separated bythe elutriation flotation step so as to allow the pasty anaerobic organic matter to enter a biogas generation pool or tank for an anaerobic reaction and to allow the clean non-anaerobic wastes to be extruded, dehydrated and dried for individual treatment, and the waste decrement is above 90%; after elutriation, the left 10% non-anaerobic wastes are prepared into fuel oil by a cracking reaction; or are recycled through screening with no screening difficulty being caused by dust and organic matter containing in the wastes; or are delivered into a gasifier for fuel gas production, which preventsthe energy consumption of water-containing organic matter during waste incineration treatment, and greatly increases the thermal efficiency of waste treatment.

Owner:刘振亮

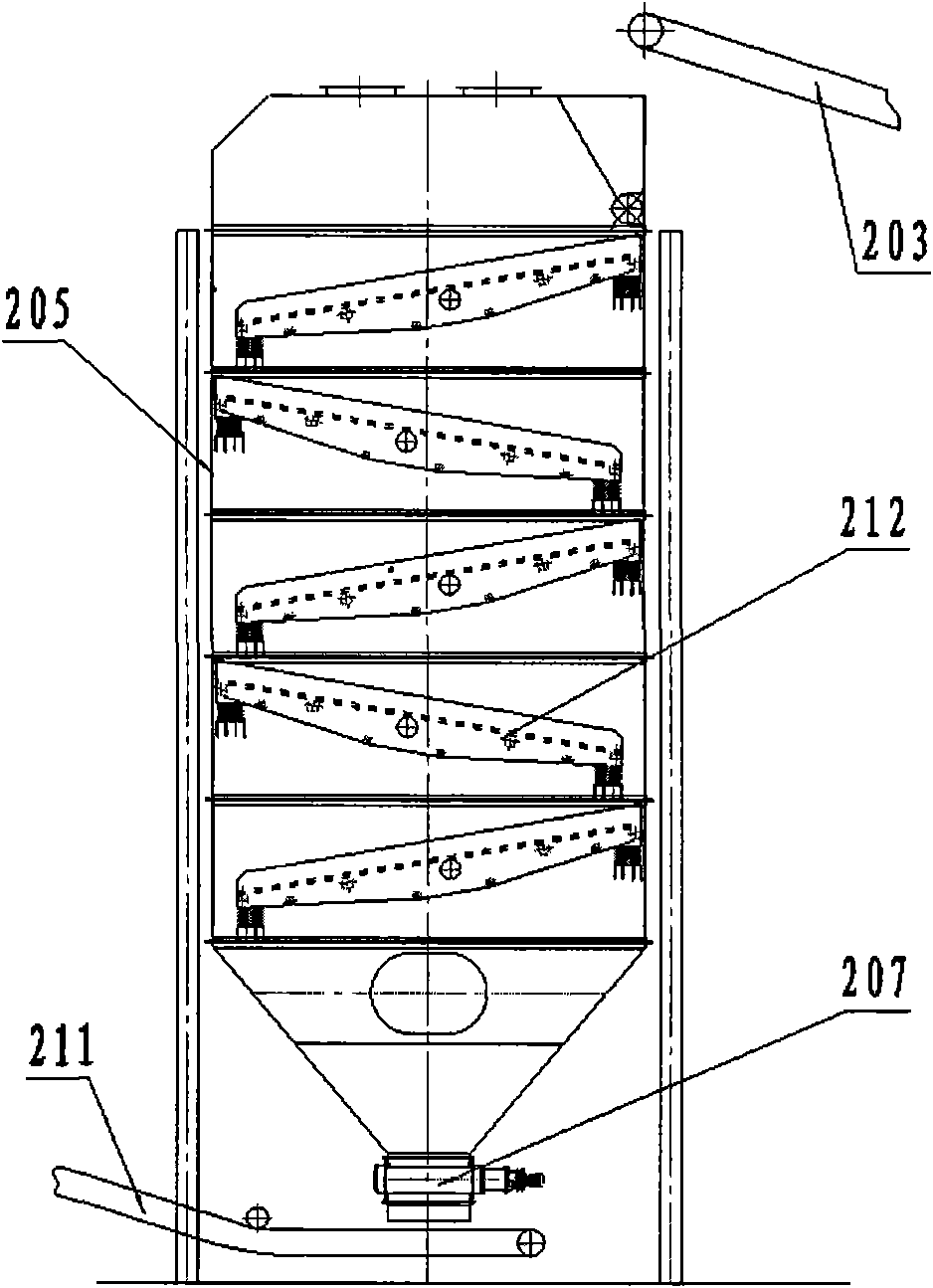

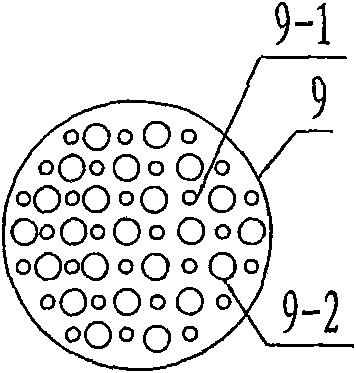

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

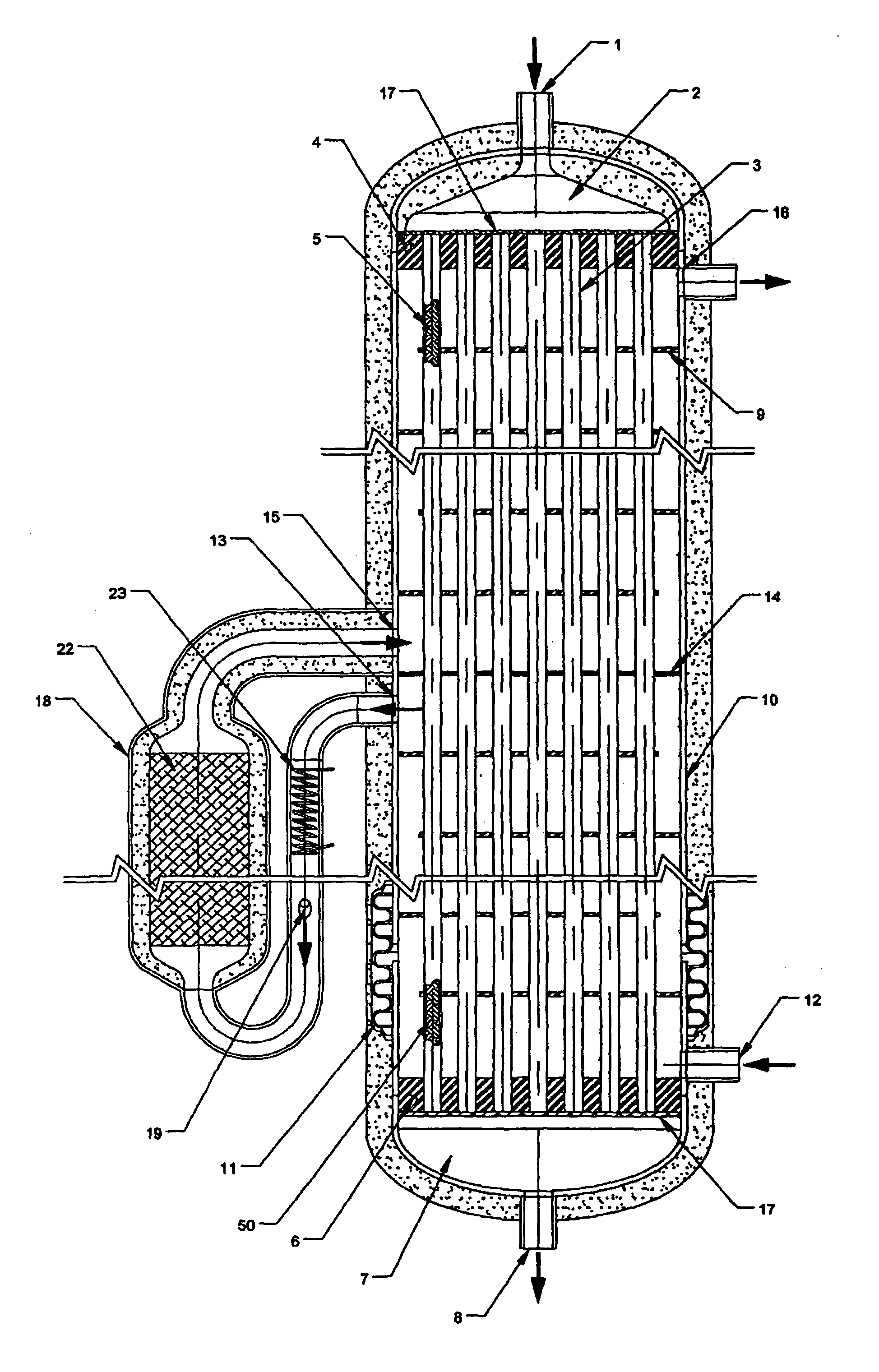

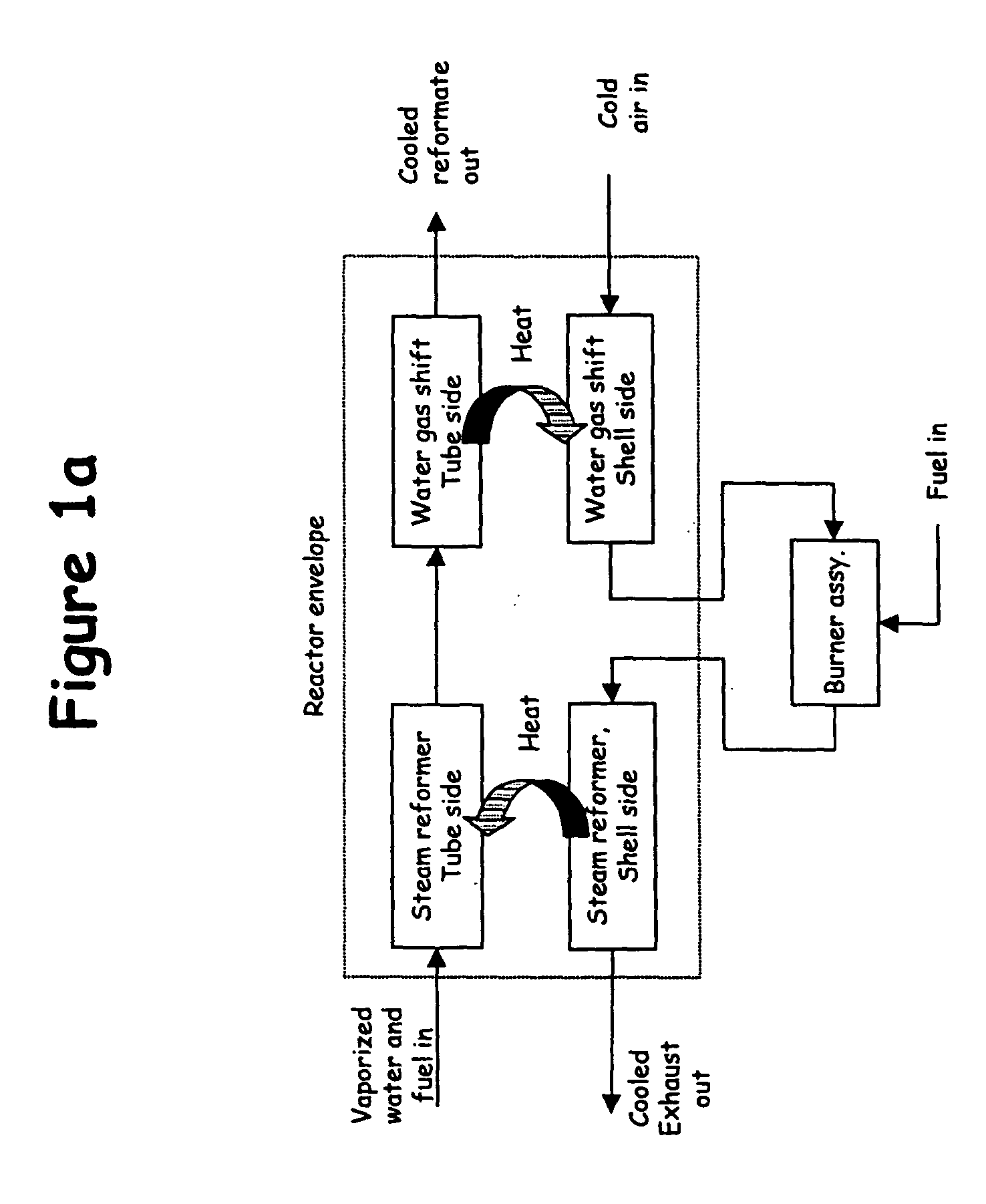

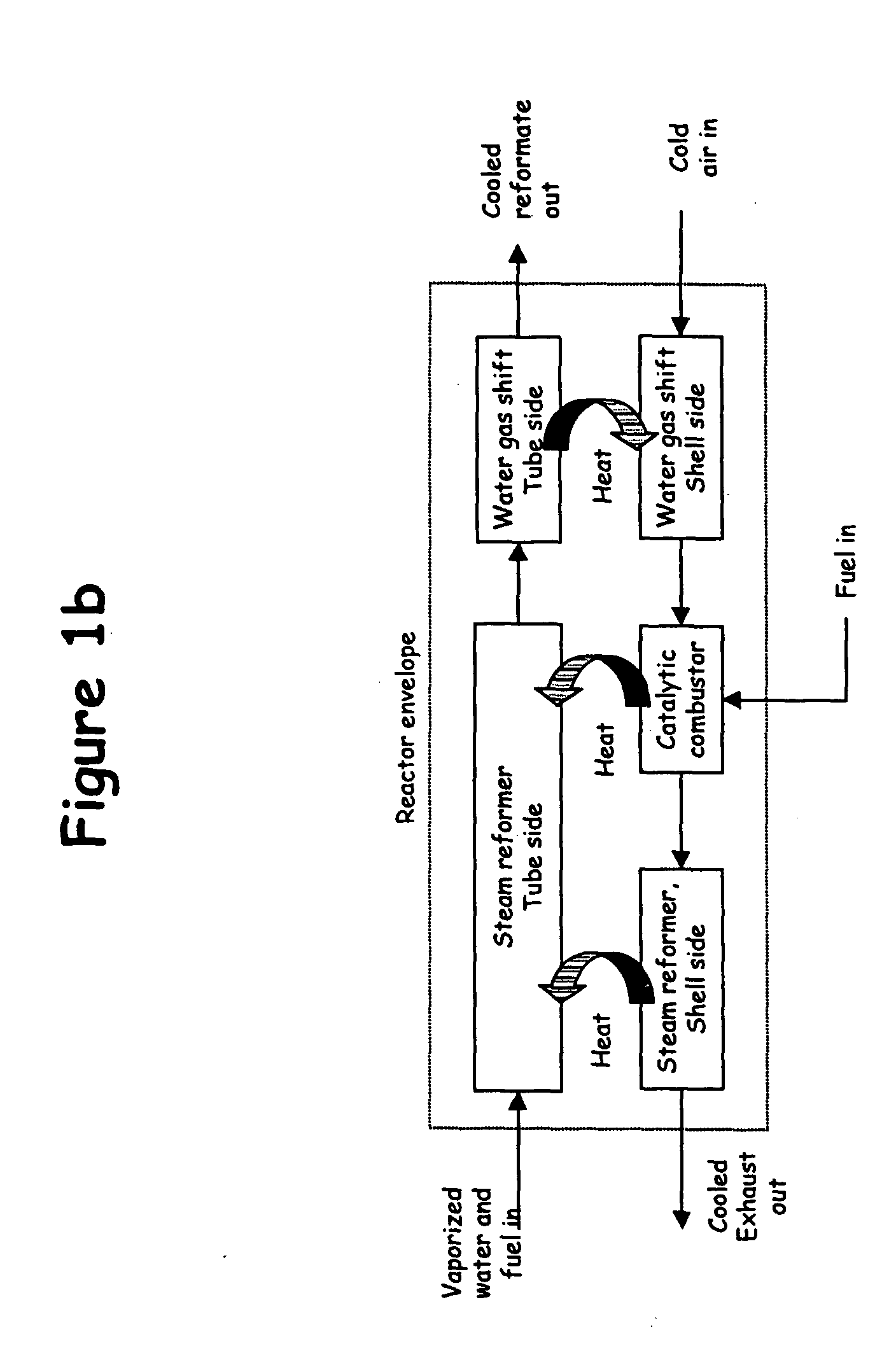

System for hydrogen generation through steam reforming of hydrocarbons and intergrated chemical reactor for hydrogen production from hydrocarbons

InactiveUS20050097819A1Avoid problemsCost efficientHydrogenHydrogen/synthetic gas productionSteam reformingEngineering

The present invention provides a reactor, which includes: a unitary shell assembly having an inlet and an outlet; a flow path extending within the shell assembly from the inlet to the outlet, the flow path having a steam reformer section with a first catalyst and a water gas shift reactor section with a second catalyst, the steam reformer section being located upstream of the water gas shift reactor section; a heating section within the shell assembly and configured to heat the steam reformer section; and a cooling section within the shell assembly and configured to cool the water gas shift reactor section. The present invention also provides a simplified hydrogen production system, which includes the catalytic steam reforming and subsequent high temperature water gas shift of low-sulfur (<100 ppm by mass) hydrocarbon fuels followed by hydrogen purification through the pressure swing adsorption (PSA). The integrated reactor offers significant advantages such as lower heat loss, lower parts count, lower thermal mass, and greater safety than the many separate components employed in conventional and is especially well-suited to applications where less than 15,000 standard cubic feet per hour of hydrogen are required. The improved system also may be started, operated and shut down more simply and quickly than what is currently possible in conventional systems. The improved system preferably employs active temperature control for added safety of operation. The hydrogen product is of high purity, and the system may be optionally operated with a feedback control loop for added purity.

Owner:H2GEN INNOVATIONS INC

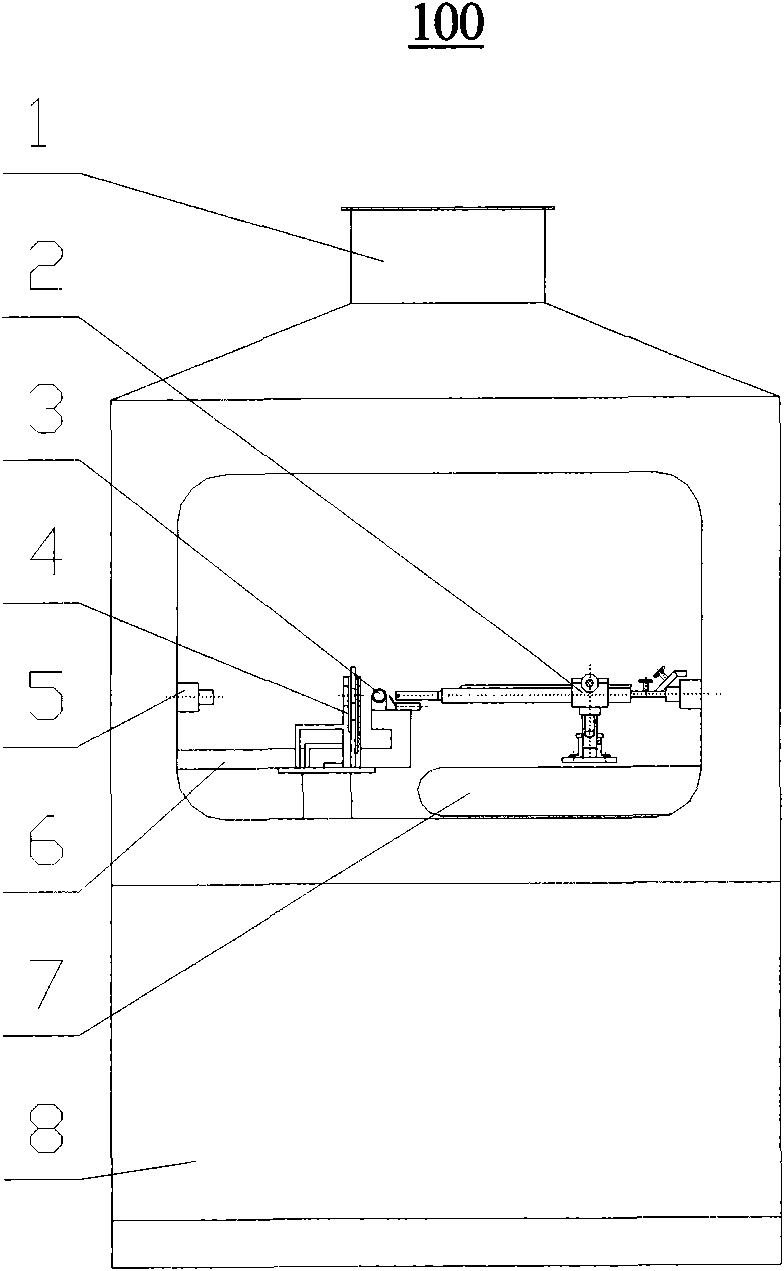

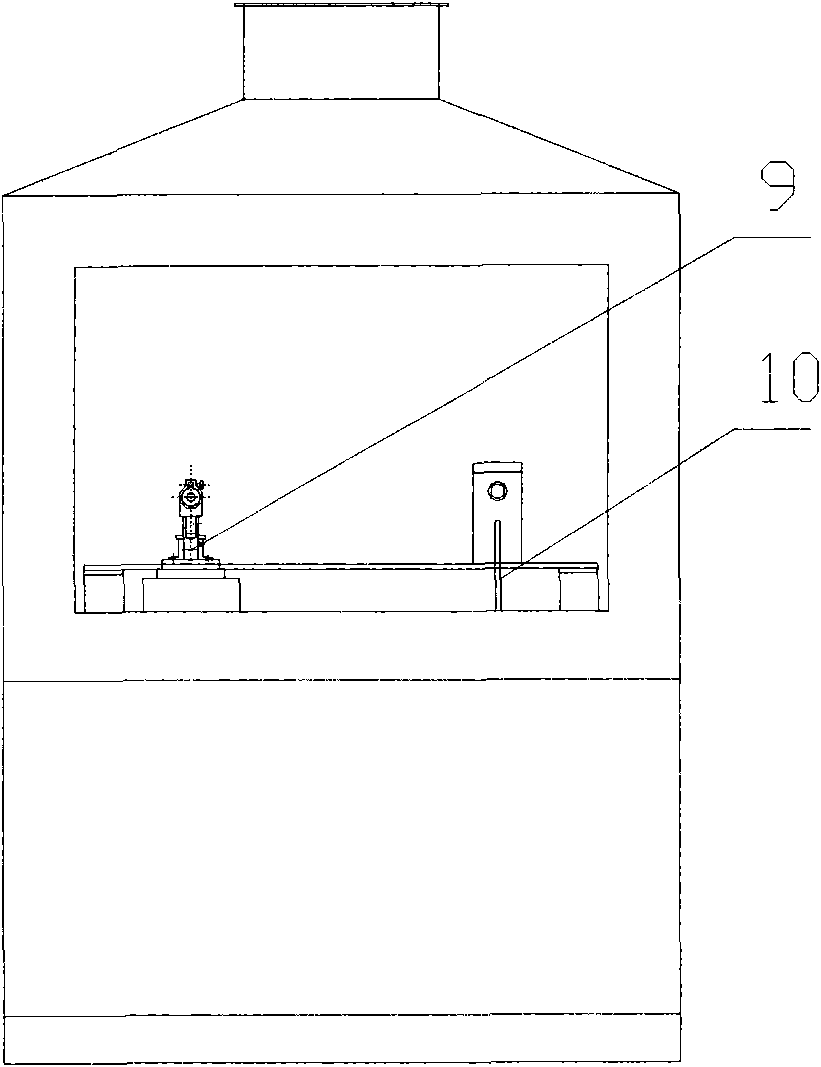

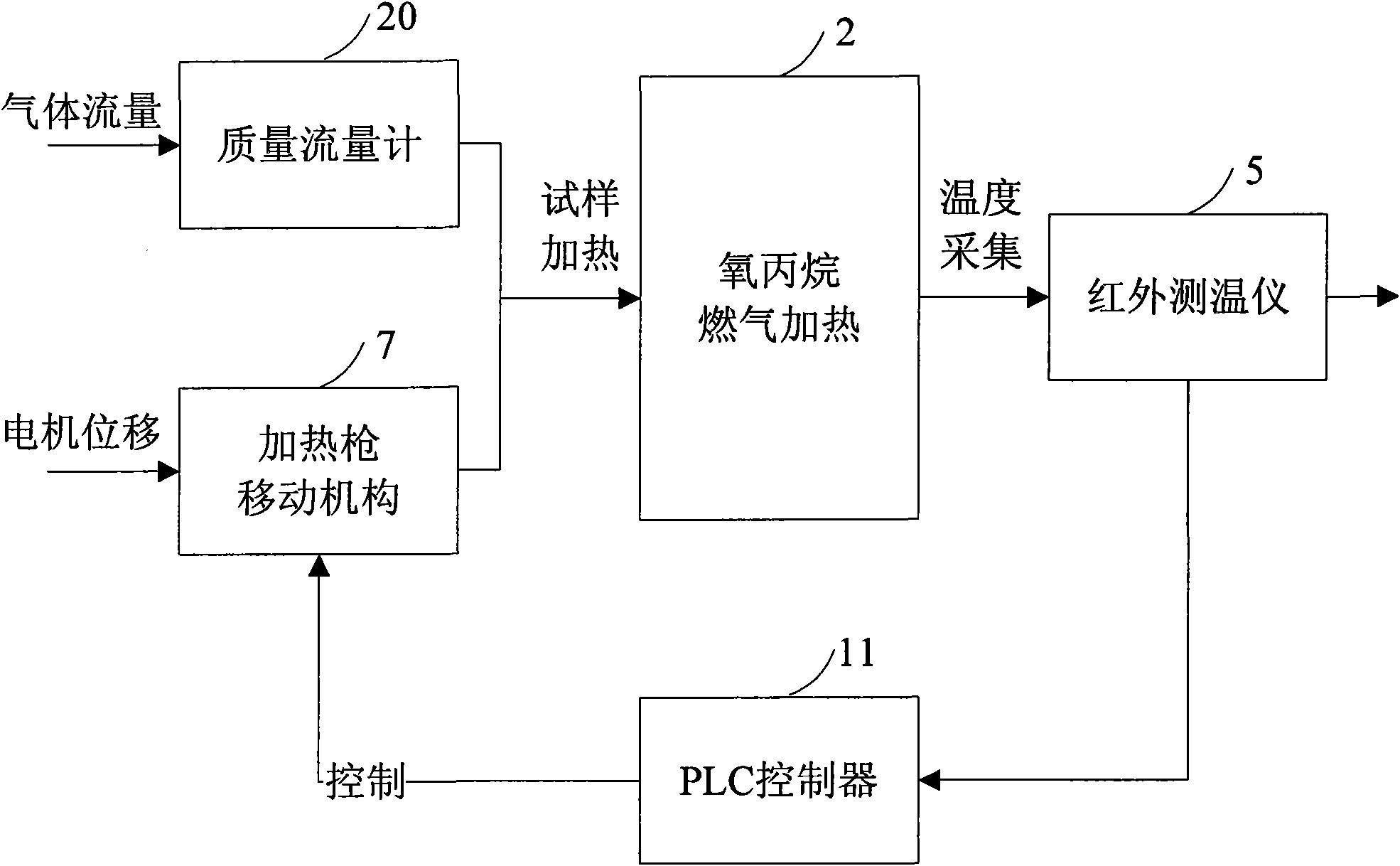

Device and method for testing thermal cycling performance of thermal barrel coating

ActiveCN101644650ATest qualityLife expectancyRadiation pyrometryStrength propertiesComputer caseHolding time

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI

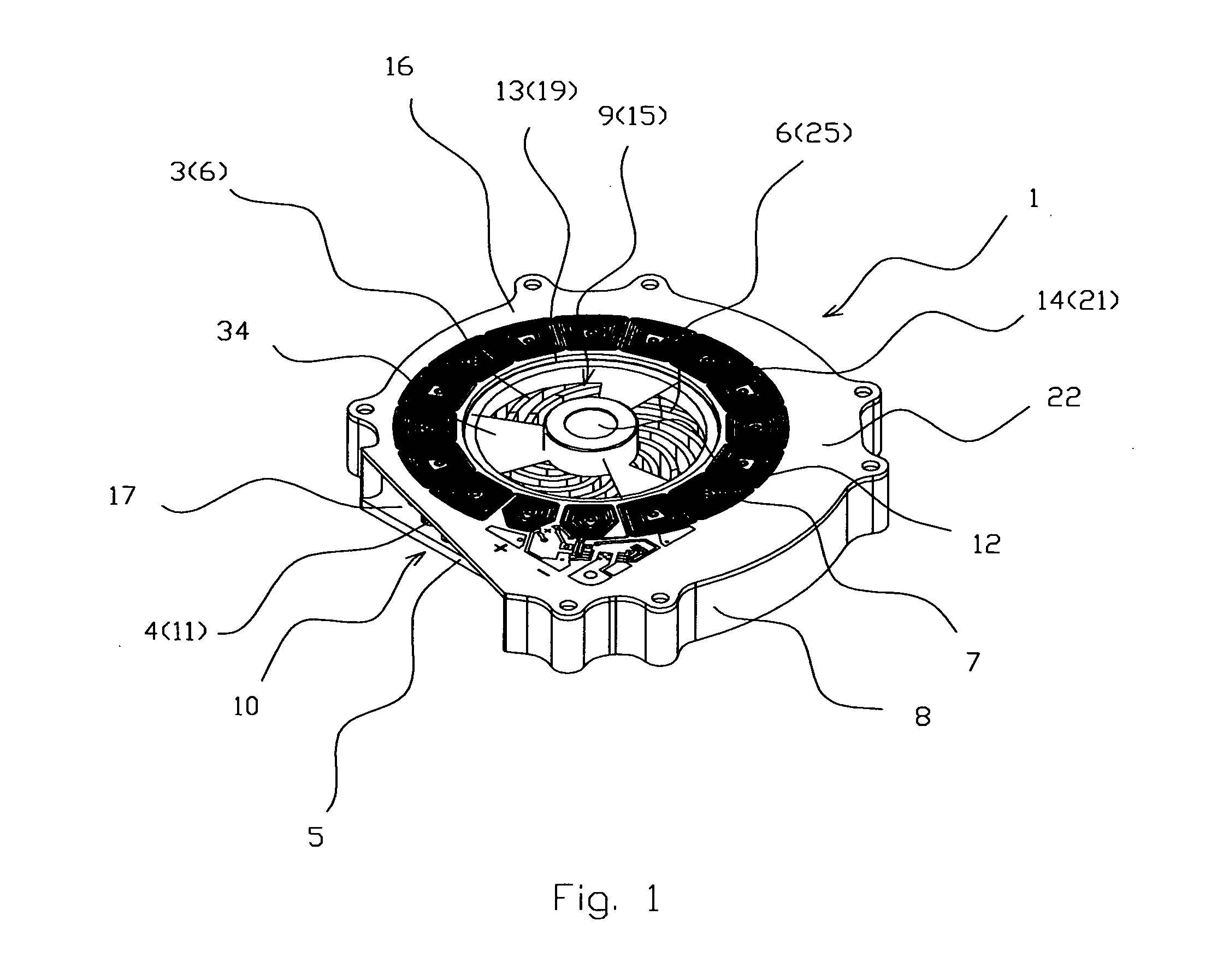

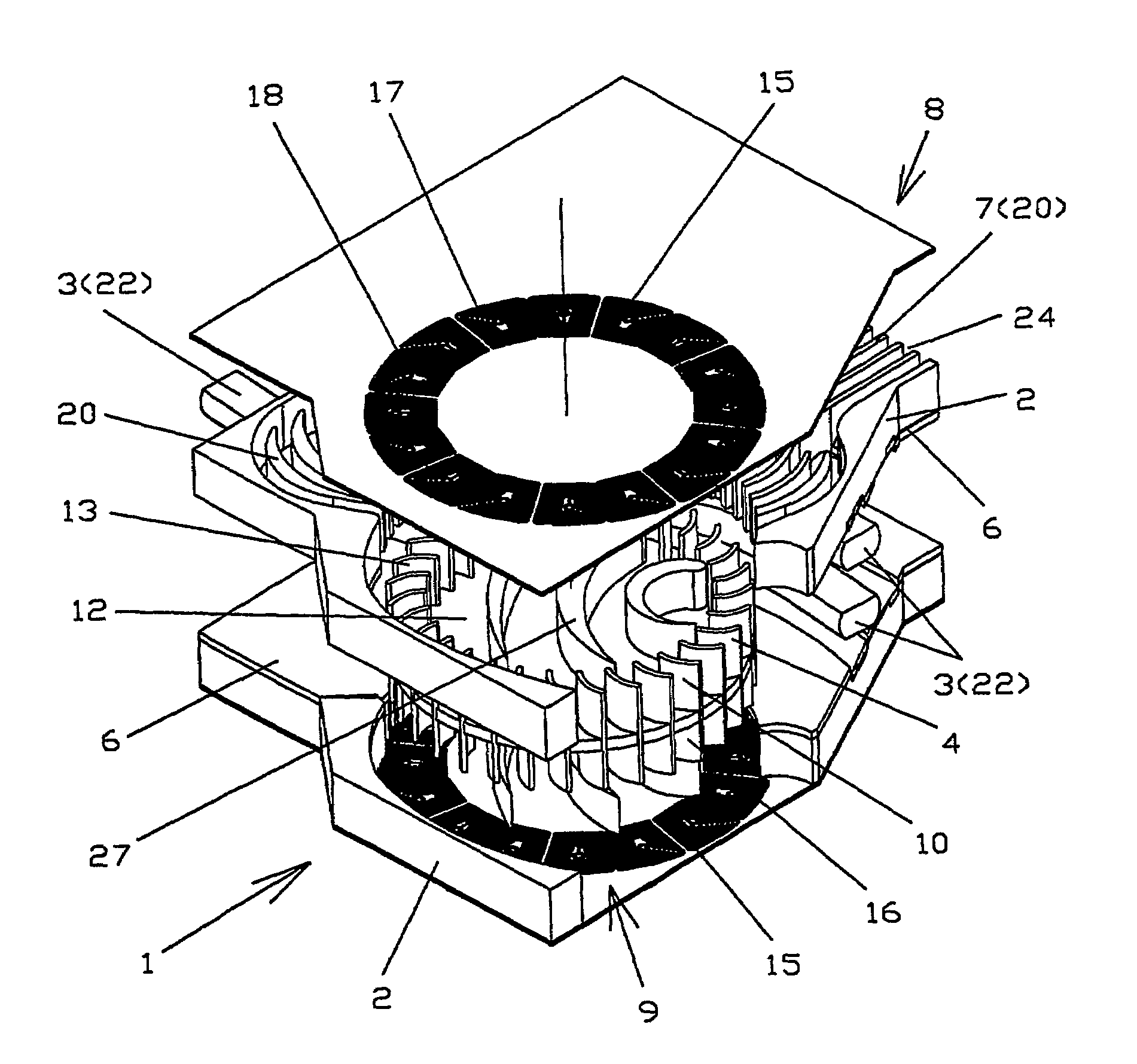

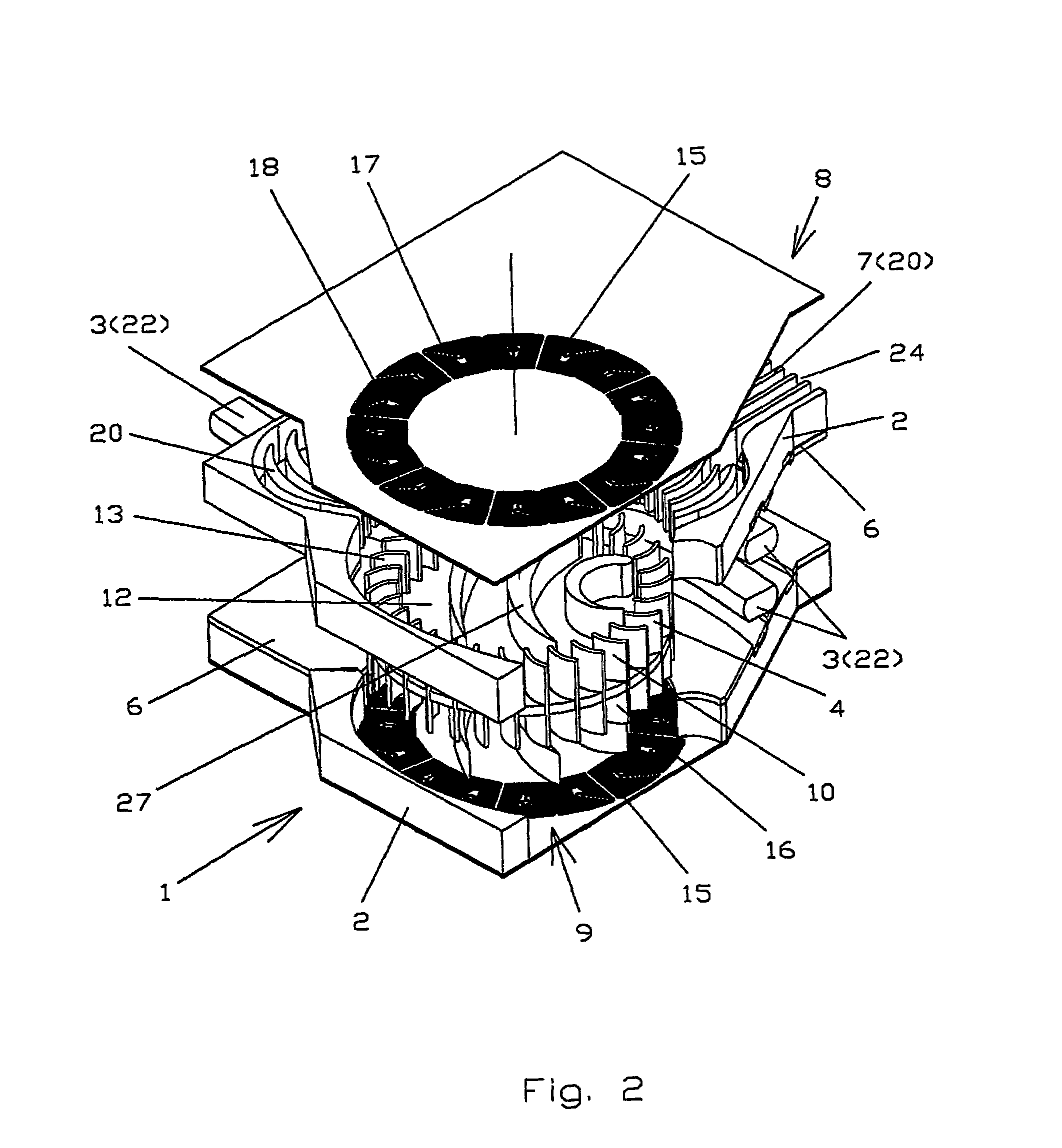

Integrated cooler for electronic devices

InactiveUS7071587B2Small dimensionHigh thermal efficiencyDigital data processing detailsSemiconductor/solid-state device detailsElectric driveImpeller

An integrated cooler for electronic devices comprises a heat exchange element, a heat transferring element and a blower with an electric drive. The heat exchange element comprises a base and heat exchanging means. The electronic device directly thermally connected with the base or the heat exchanging means by the heat transferring element. The blower comprises an inlet, an outlet and a drum type impeller comprises a disk with blades mounted on an axle fixed perpendicularly to the base. The heat exchanging means located at the inlet and / or at the outlet, thus ambient air flows through the inlet, the impeller and the outlet in a series way and in the directions perpendicular to the axle, so that the blower is a crossflow type blower. The electric drive comprises a rotor and a stator. The rotor made as the impeller having circumferential arrayed magnetic means. The stator comprises circumferential arrayed coils.

Owner:ROTYS

Continuous combustion constant power engine

InactiveCN1821557ATroubleshoot hard-to-start issuesEmission reductionInternal combustion piston enginesDetonationCombustor

The present invention relates to continuous combustion constant power engine. There are one independent continuous combustor outside the cylinder, two sets of link rod-piston mechanisms with gas compressing device and expansion device, and one gas exchange valve for connecting these two mechanisms to the continuous combustor, to constitute one complete thermal engine. The present invention can reach ideal low temperature multiple fuel clean combustion with less noise, no smoke and no combustion detonation, and has raised compression ratio, raised expansion ratio, high heat efficiency, and reduced exhaust of harmful gas. The independent combustor of the present invention can realize fast ignition and self starting without compression and in the condition of low temperature.

Owner:李岳

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

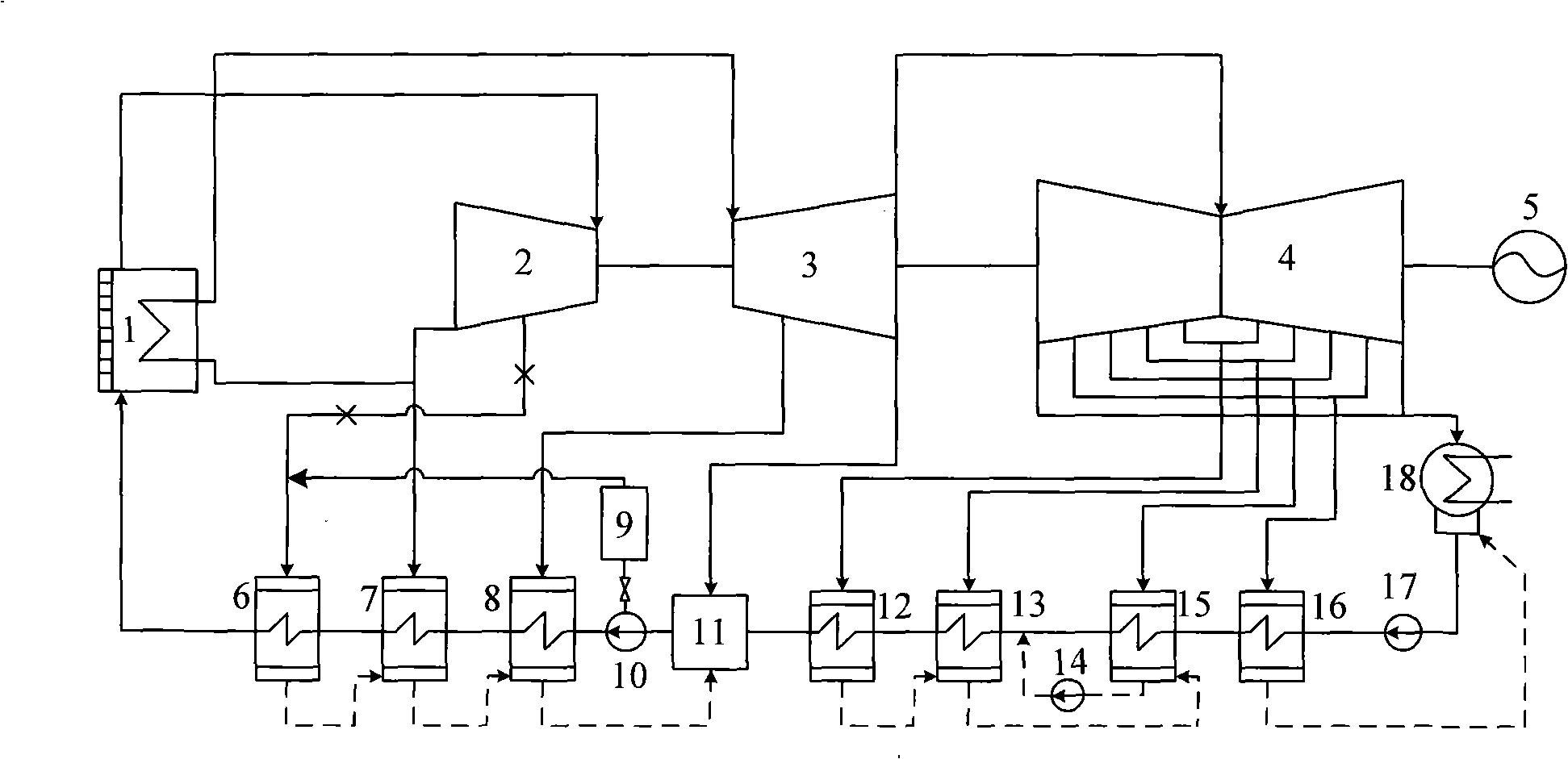

Solar power generation method and system taking biomass boiler as auxiliary heat source

ActiveCN101968041ASolve the problem of antifreeze in winterHigh thermal efficiencySolar heating energyFrom solar energyWater storage tankEngineering

The invention discloses a solar power generation method and a solar power generation system taking a biomass boiler as an auxiliary heat source. The system comprises a solar condensation heat collecting device, a biomass boiler device and a steam turbine generator system, wherein the solar condensation heat collecting device takes water as a medium and is combined by adopting medium-pressure solar vacuum heat collecting pipes in a series-parallel matrix; the outlet of the solar condensation heat collecting device is communicated with the bottom of a steam pocket of the biomass boiler; and the steam outlet of the steam pocket of the biomass boiler is connected with a cylinder of a steam turbine generator. A de-aerator and a water supply pump are connected in series in the water inlet pipeline of the solar condensation heat collecting device. A steam re-heater is connected in series in the connected pipeline of the steam outlet of the steam pocket of the biomass boiler and the cylinder of the steam turbine generator; the steam re-heater is connected to the cylinder of the steam turbine generator; and the steam re-heater is placed in a flue of the biomass boiler. A water supply tank is a desalting water storage tank, and the desalting water storage tank is connected with the de-aerator through the water supply pump and connected with the outlet of the solar condensation heat collecting device through a first control valve.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

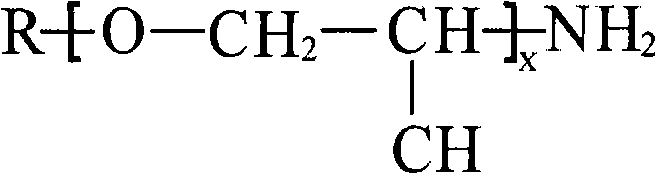

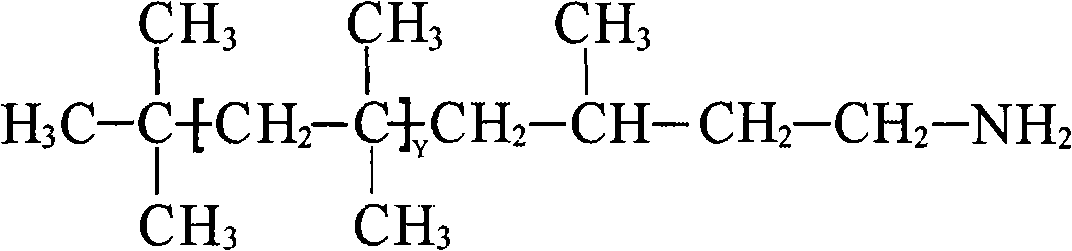

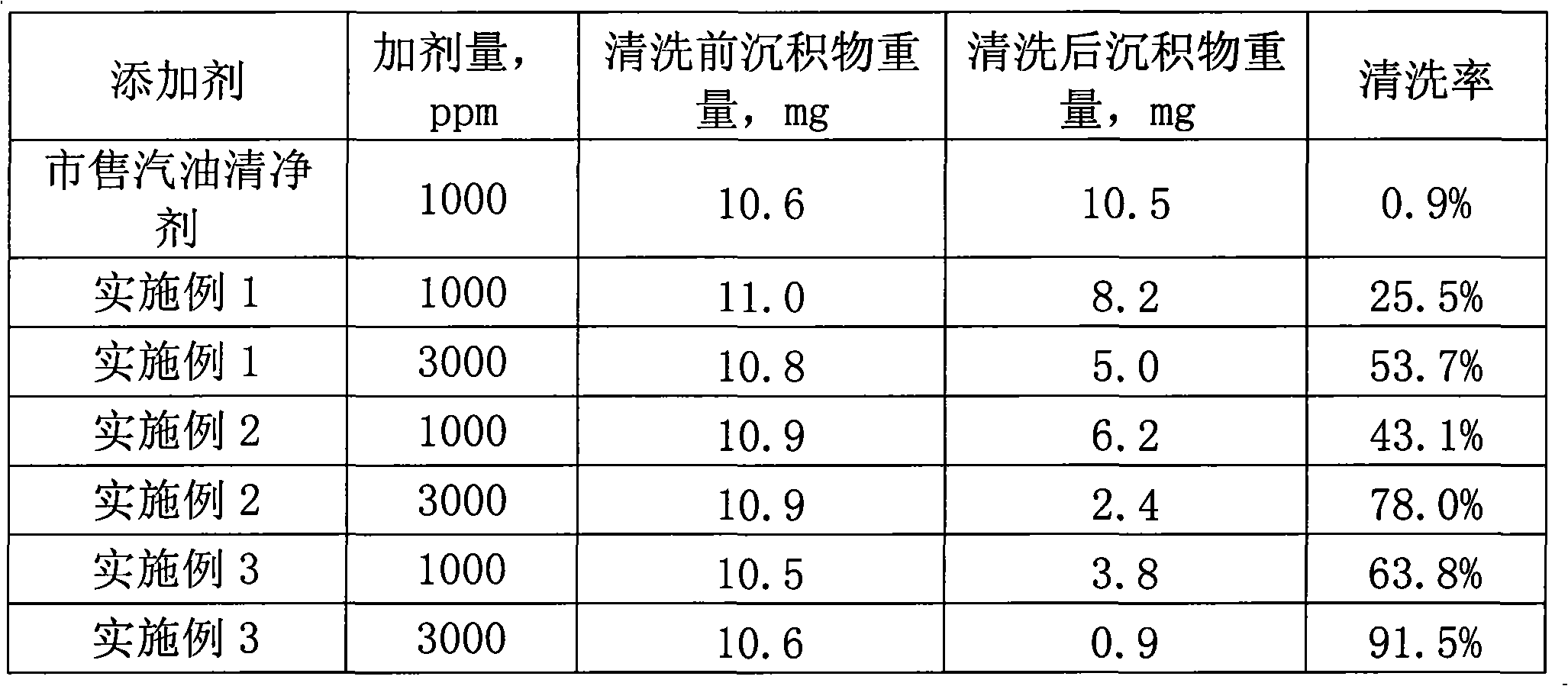

Gasoline detergent with cleaning function and preparation method thereof

InactiveCN101962584AEasy to cleanBurn fullyLiquid carbonaceous fuelsFuel additivesCombustion chamberPreservative

The invention relates to a gasoline detergent with cleaning function and a preparation method thereof. Gasoline containing the detergent can clean deposits in an oil injection nozzle, an air inlet valve and a combustion chamber of a gasoline engine. The detergent comprises at least one type of high-activity polyetheramine, at least one type of high-activity polyisobutene amine, base oil serving as carrying oil, other solvent oil and functional agents such as an antioxidant, an anti-rusting agent, a preservative and a demulsifying agent. Specifically, the detergent comprises the following components in percentage by mass: 10 to 80 percent of polyetheramine, 5 to 20 percent of polyisobutene amine, 5 to 35 percent of carrying oil and 5 to 35 percent of solvent oil and other functional agents. After being added into commercially available motor gasoline according to the dosage of between 1,000 and 3,000 ppm, the detergent of the invention can suppress and clean the deposits of the oil injection nozzle, the air inlet valve and the combustion chamber of an oil-fired air inlet system of the gasoline engine. The motor gasoline containing the detergent of the invention can clean the deposits of the oil injection nozzle, the air inlet valve and the combustion chamber in which the deposits are generated.

Owner:深圳市超美化工科技有限公司

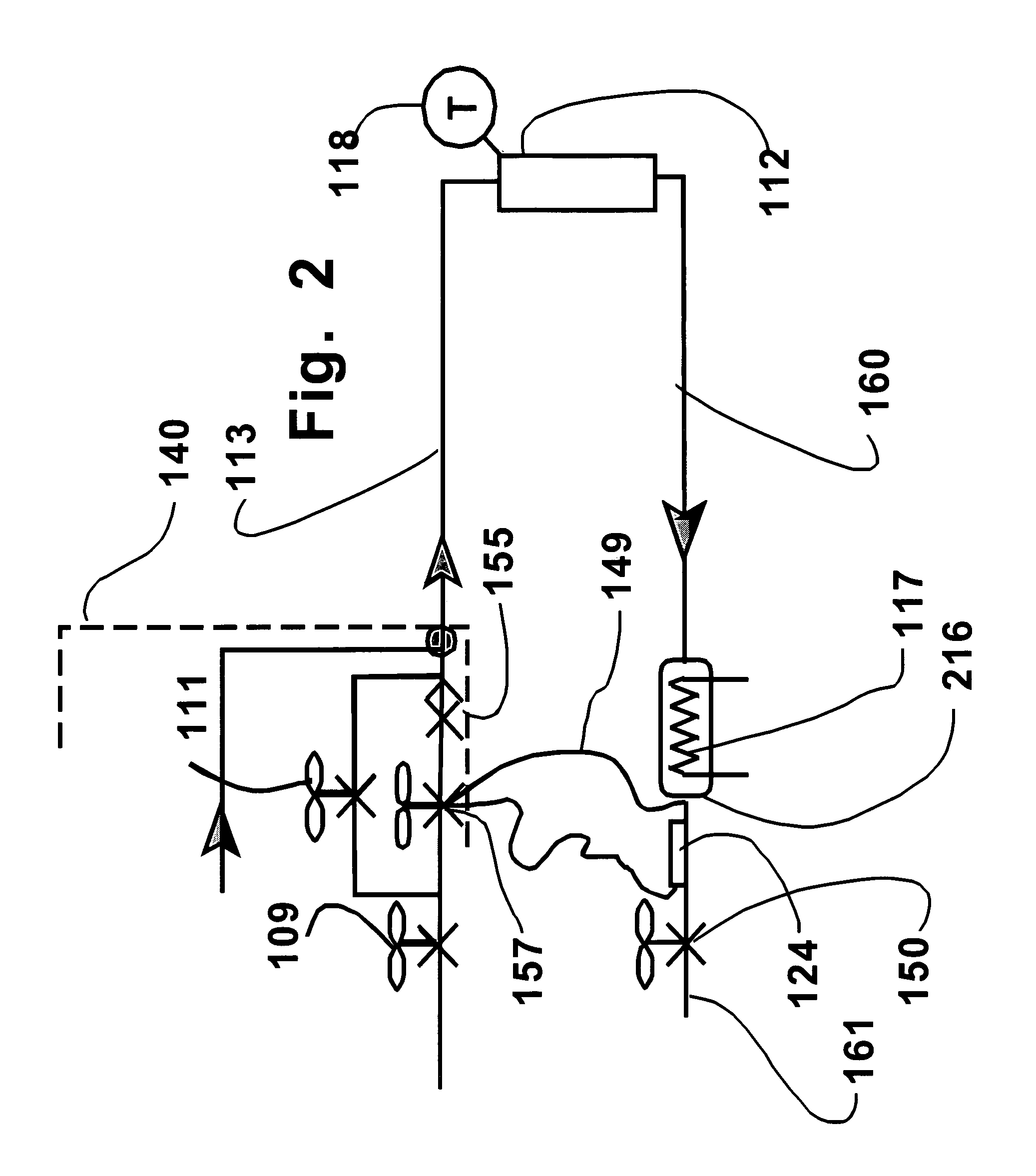

Thermal control system and method

ActiveUS20050183432A1High thermal efficiencyQuick adjustmentMechanical apparatusHeat pumpsRefrigerantProcess engineering

A system and method for controlling the temperature of a process tool uses the vaporizable characteristic of a refrigerant that is provided in direct heat exchange relation with the process tool. Pressurized refrigerant is provided as both condensed liquid and in gaseous state. The condensed liquid is expanded to a vaporous mix, and the gaseous refrigerant is added to reach a target temperature determined by its pressure. Temperature corrections can thus be made very rapidly by gas pressure adjustments. The process tool and the operating parameters will usually require that the returning refrigerant be conditioned and processed for compatibility with the compressor and other units, so that cycling can be continuous regardless of thermal demands and changes.

Owner:BE AEROSPACE INCORPORATED

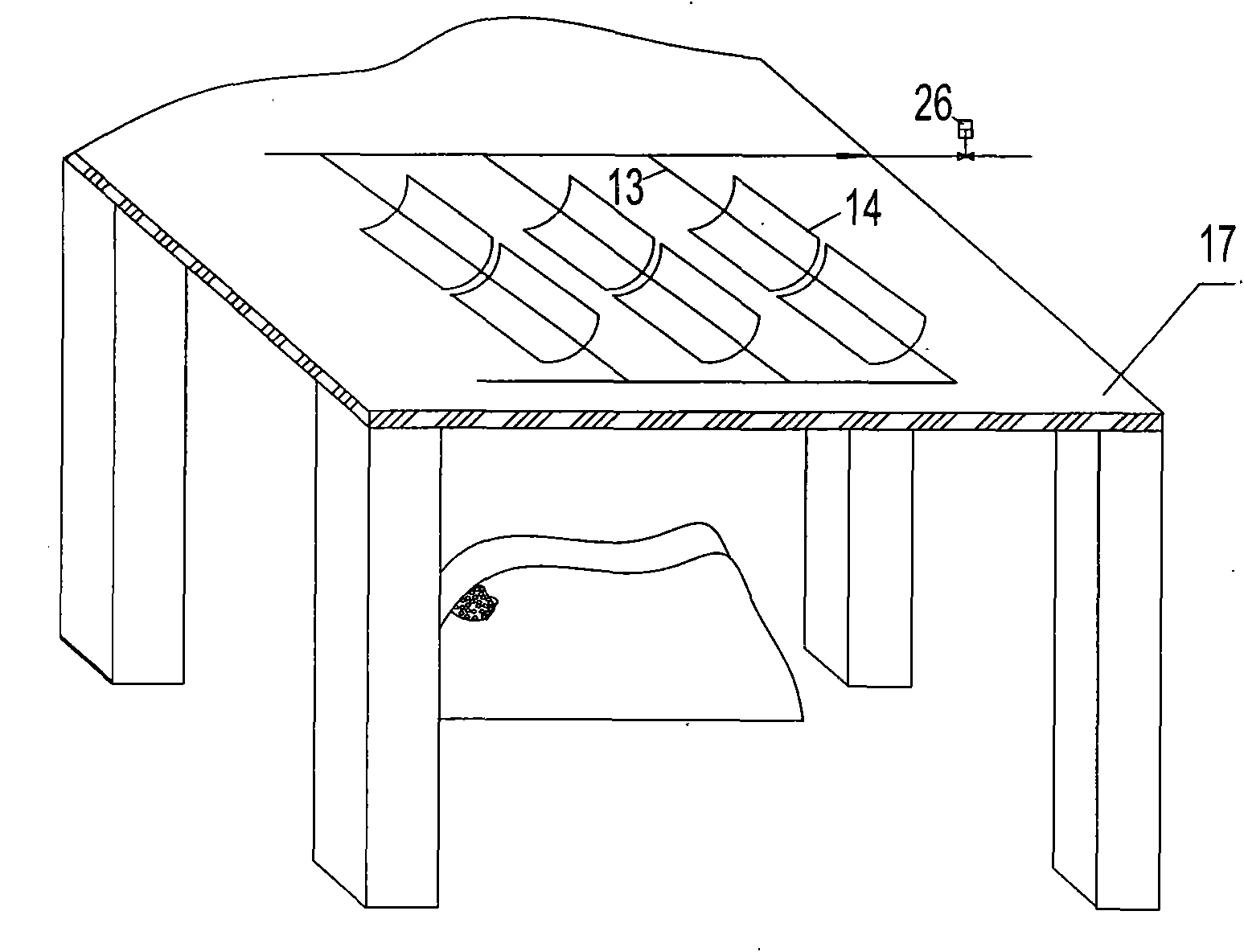

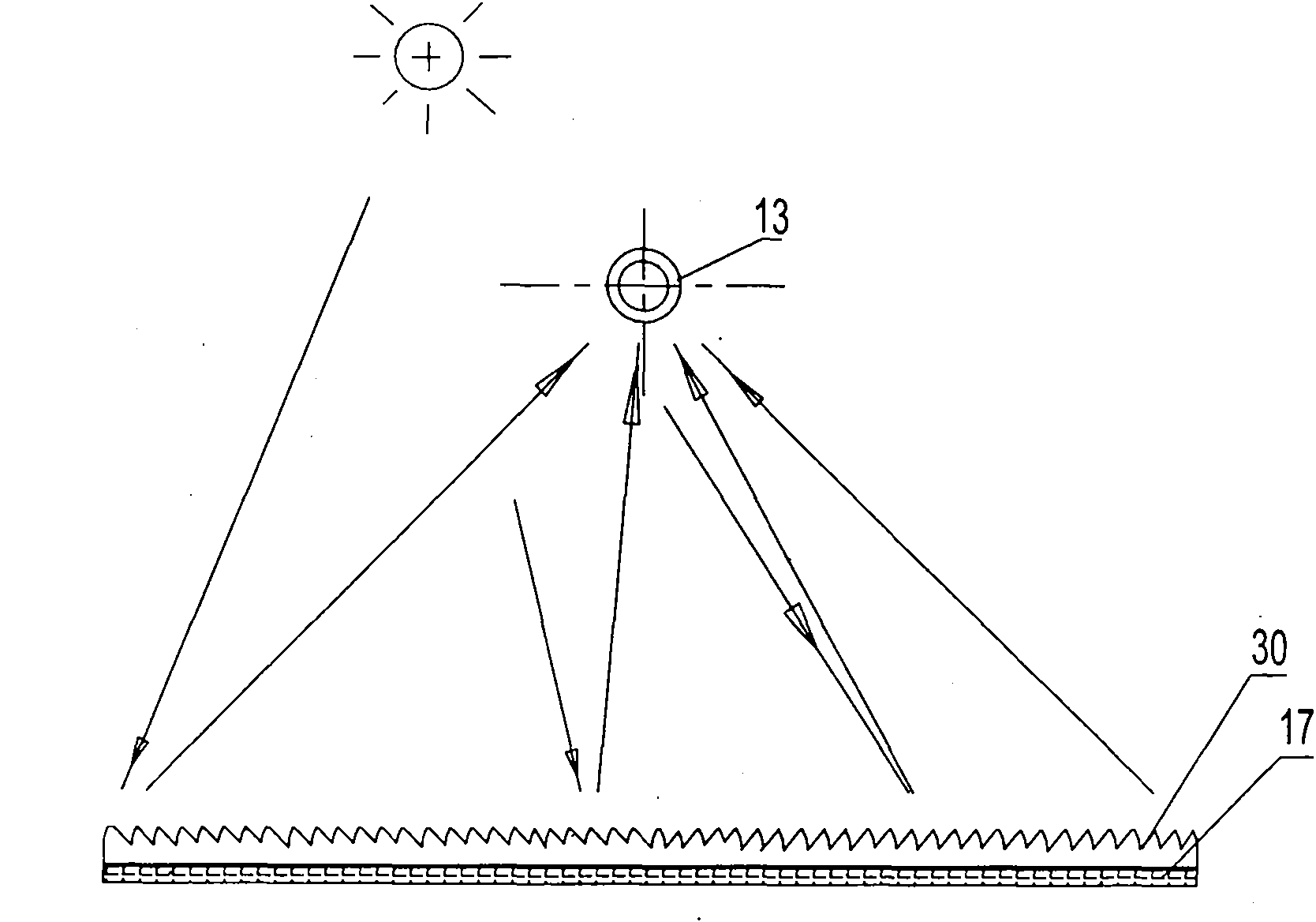

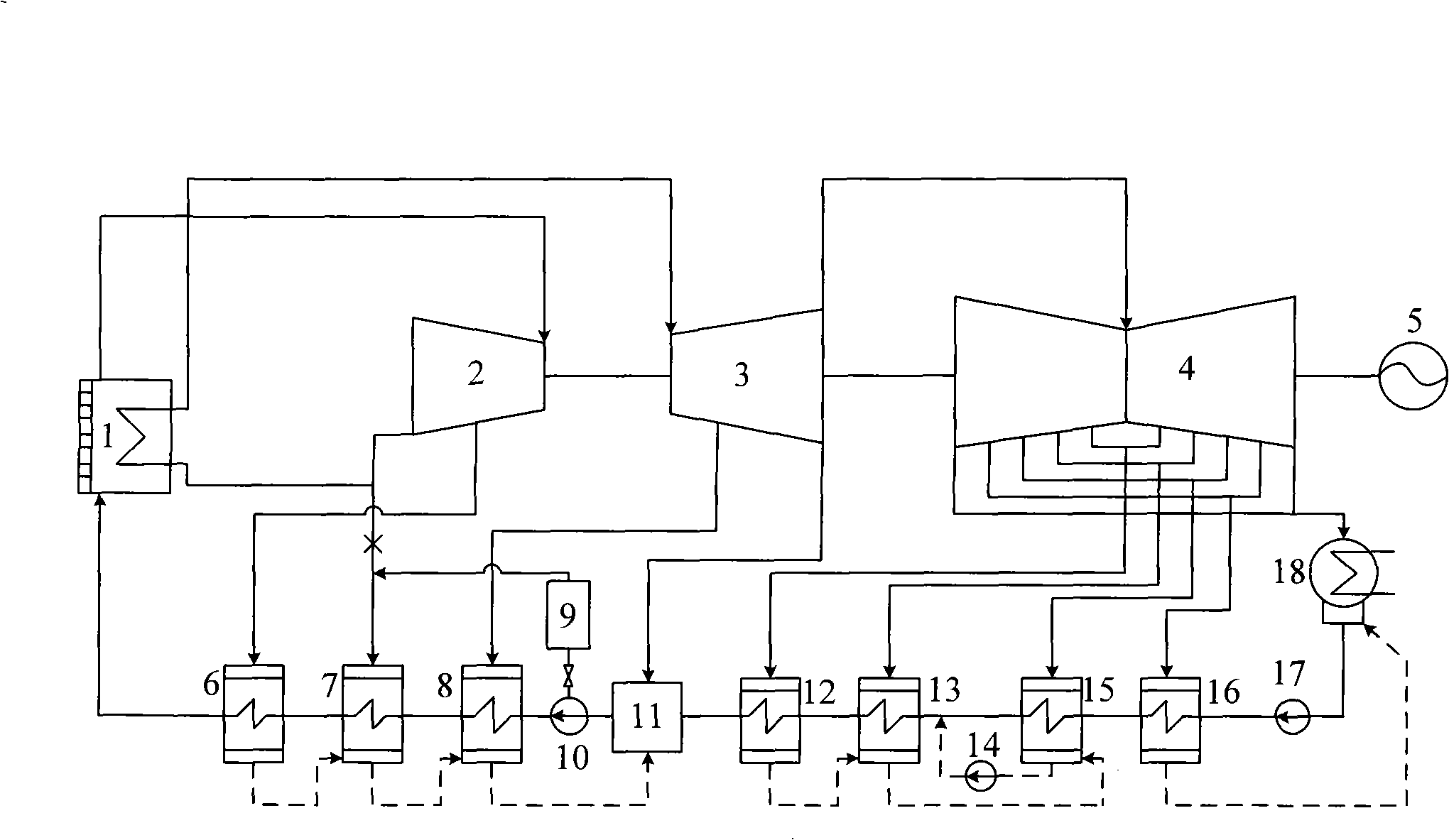

Paraboloid trough type solar heat-collector auxiliary coal-burning boiler mixing heat power generation system

InactiveCN101260815AHigh thermal efficiencyLess coal consumptionSteam engine plantsDeaeratorEngineering

The invention belongs to the generating equipment scope and in particular relates to a mixed heat power generating system with a paraboloid groove type solar heat collector to assist a coal burning boiler. A solar heat collector field is connected with a feed pump and a second or a third high-pressure heater; a condenser, an extraction pump, a low-pressure heater, a deaerator, the feed pump, the high-pressure heater, the coal burning boiler and a steam turbine are connected in series in turn; and the steam turbine drives a dynamo and discharges steam to the condenser. Condensed water flows out from the condenser and is heated up and pressurized up by a the low-pressure heater, deoxidized by the deaerator, fed with water by a leading-out part of the feed pump and enters the solar heat collector field for heat absorption; after reaching a stream drawing parameter of a certain stage high-pressure heater, the condensed water returns and joins the drawing gas of the corresponding stage heater; the other part of feeding water enters the coal burning boiler through the high-pressure heater and becomes steam with high temperature and high pressure; and the steam enters the stream turbine, applies work and flows into the condenser to complete a thermodynamic cycle. The mixed heat power generating system with the paraboloid groove type solar heat collector to assist the coal burning boiler reduces coal consumption of a coal burning unit, improves thermal efficiency of the solar heat power generation and reduces the investment on the simple paraboloid groove type solar heat power generation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com