Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1810 results about "Steam temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

ANSWER; The basic steam point of water is when it is heated to a temperature of 212 degrees Fahrenheit, 100 degrees Celsius or 373 degrees Kelvin.

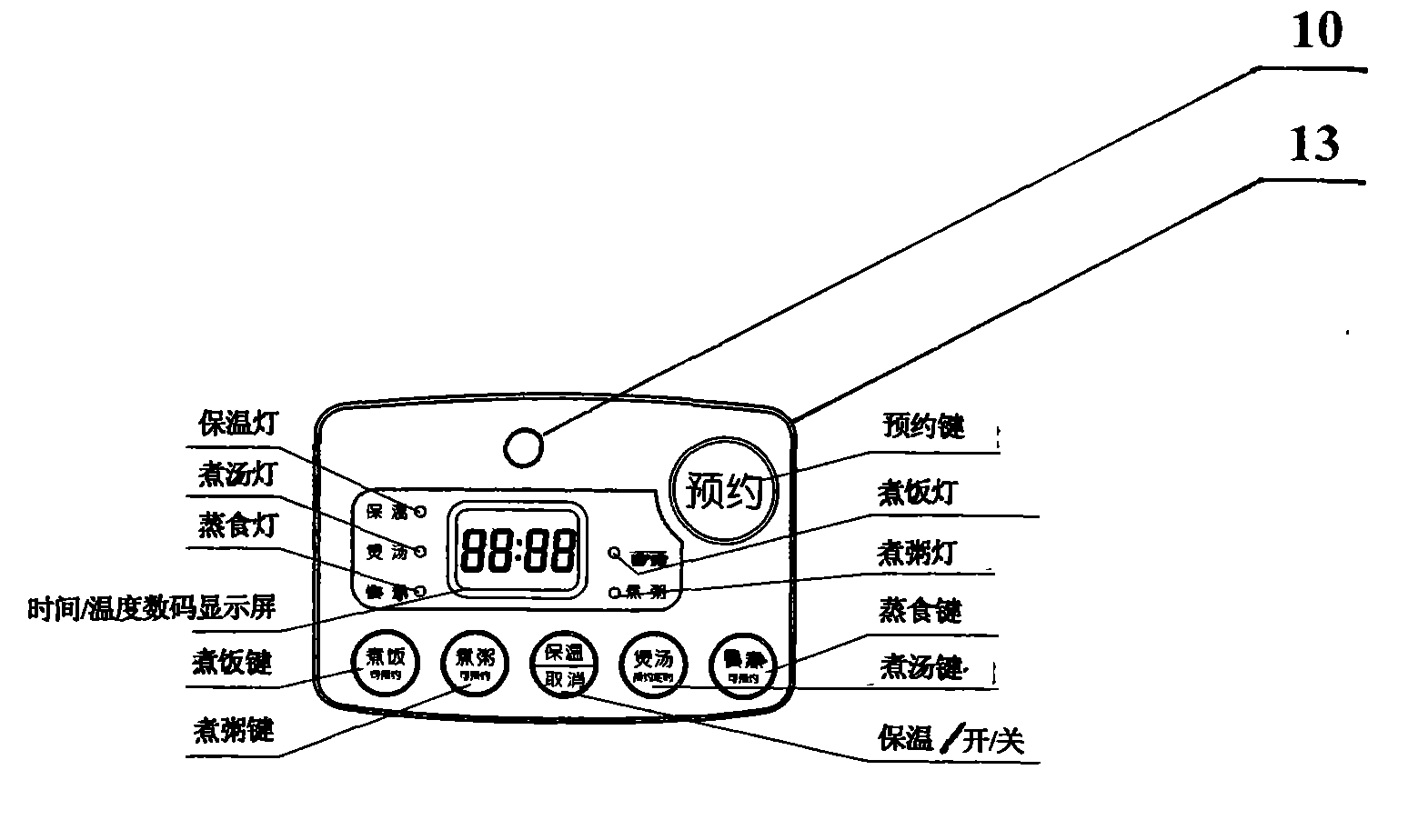

Efficient energy saving electro heating multipurpose cooker and new method of accurate temperature controlling and healthy cooking

InactiveCN101669761APlug the drainSolve technical problems that cannot withstand high temperaturesCooking-vessel lids/coversCooking utensils shields/jacketsElectricityAutomatic control

The invention discloses an efficient energy saving electro heating multipurpose cooker utilizing a new method of accurate temperature controlling and healthy cooking. The technical scheme of the invention is as follows: the outside surface of the cooker body is provided with an ambient temperature sensor; the base of the cooker is provided with an inner pot temperature sensor; the cooker body, thecooker cover and the cooker base are all set to be closed efficient heat insulation interlayers; the closed heat insulation interlayer on the cooker base is arranged between the casing of the cookerbase and the electro heating device; a hallow cavity is arranged between the casing of the cooker base and the closed heat insulation interlayer; and the purposes of energy saving, discharge reducingand healthy cooking can be realized by setting standard control values such as ambient temperature or temperature drop, cooking / steaming temperature and time and the like by an automatic control device and by comparing the ambient real-time temperature or temperature drop with the inner pot real-time temperature to control the power on and power off of the electro heating device. The efficient energy saving electro heating multipurpose cooker can be used for cooking rice, cooking congee, cooking soups and steaming food; compared with various electro rice / congee / soup cooker in the prior art, the invention can save electricity by 30%-50% and can be widely used in families, dining halls and catering enterprises in cities and towns.

Owner:郭卫康

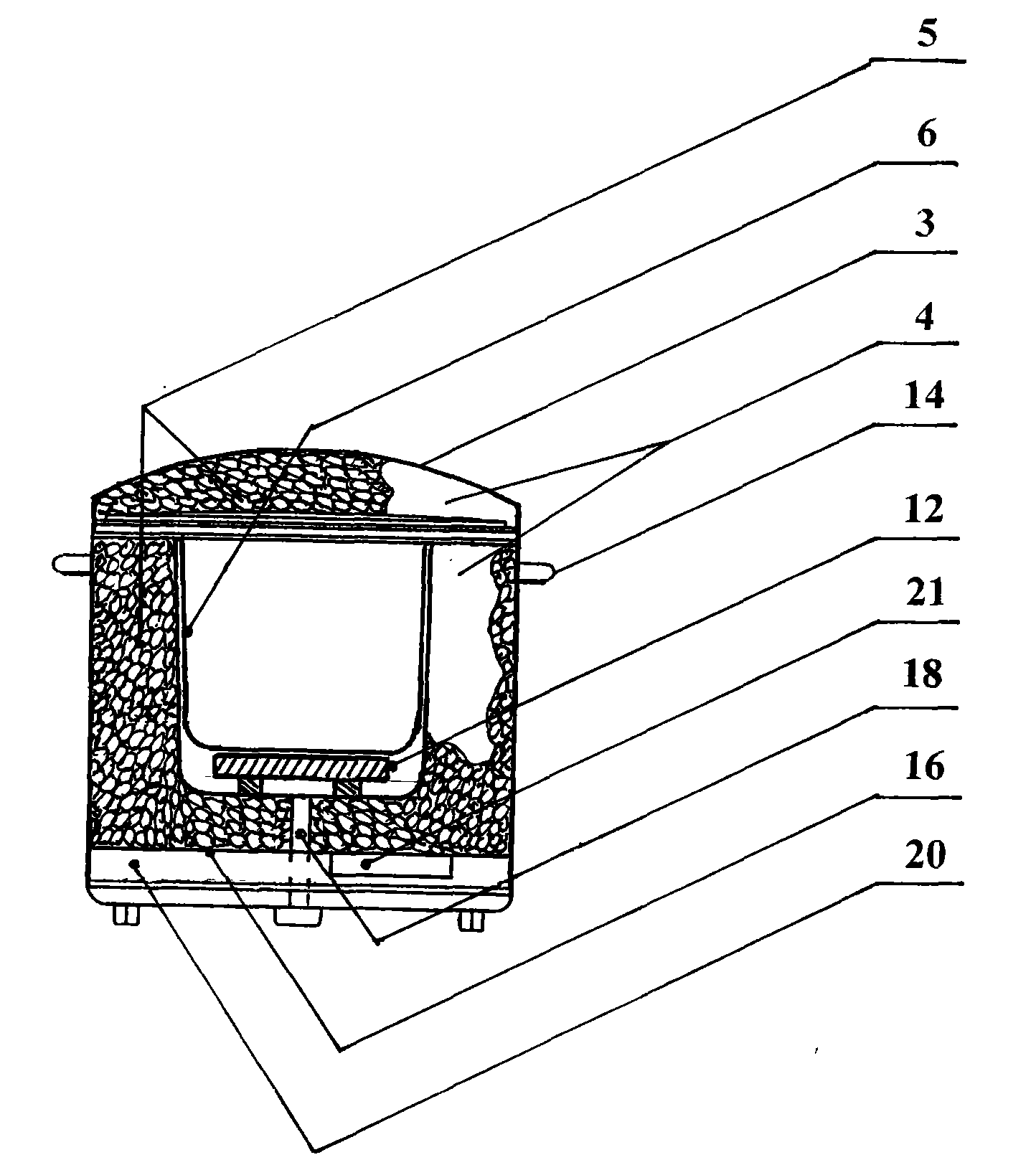

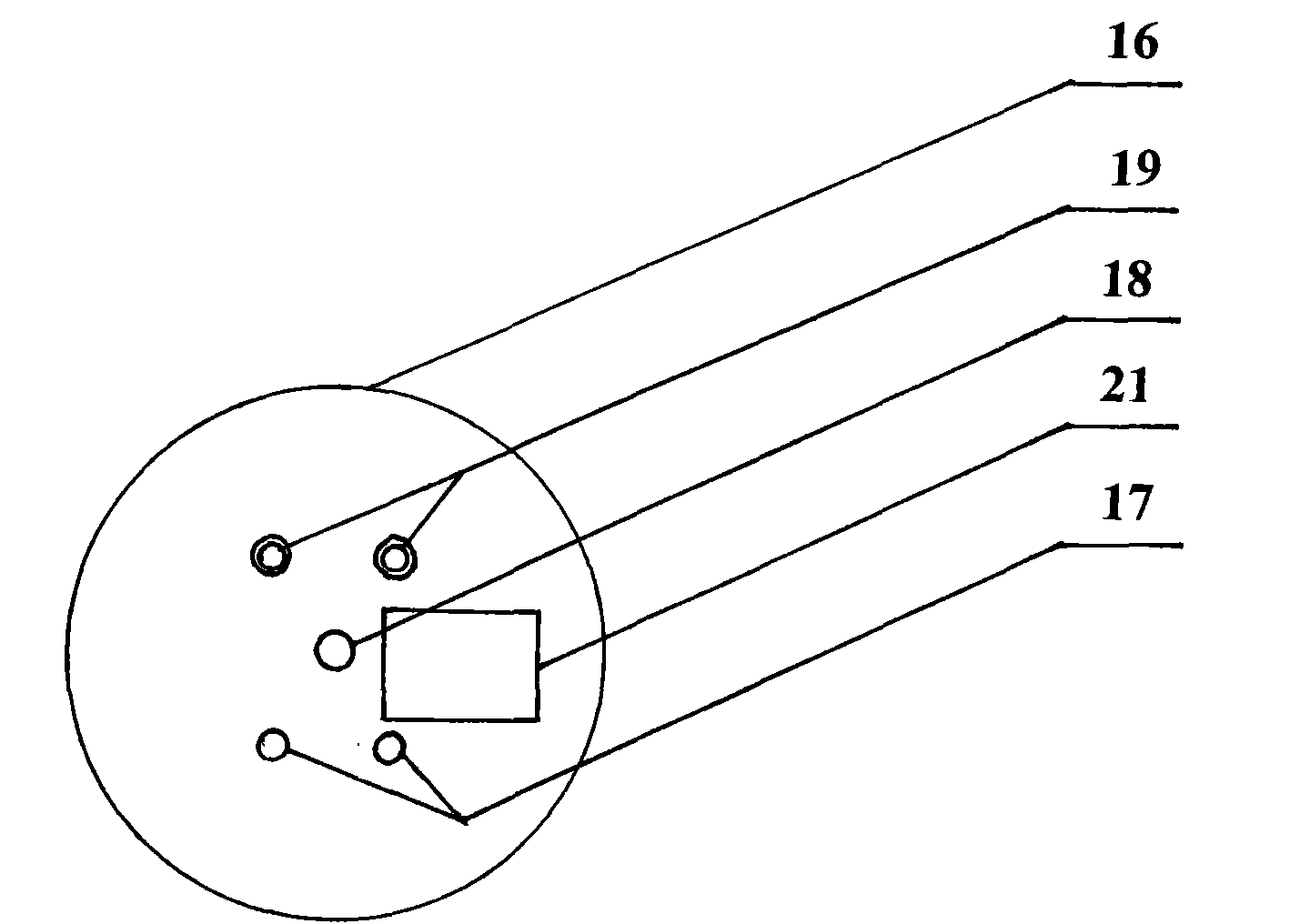

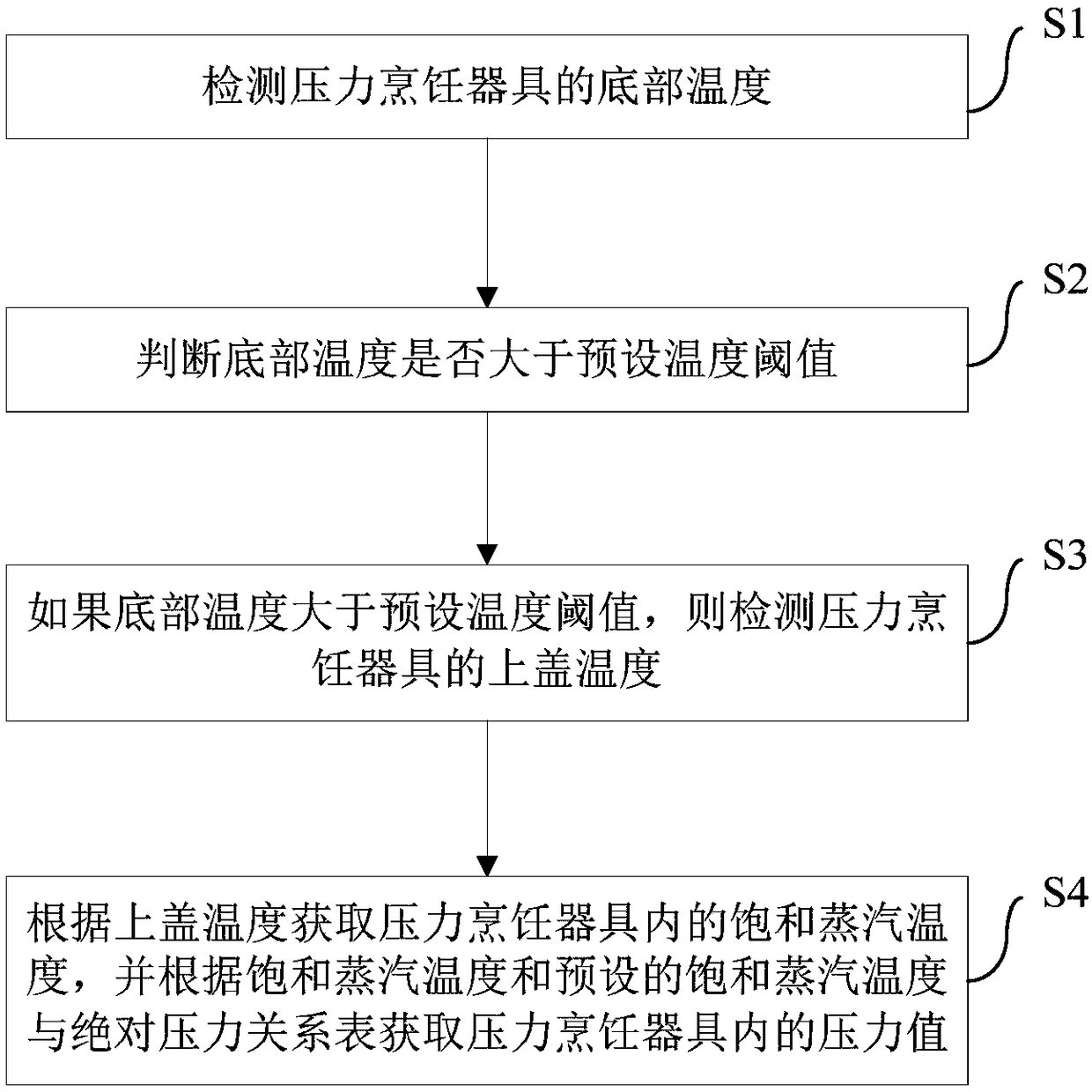

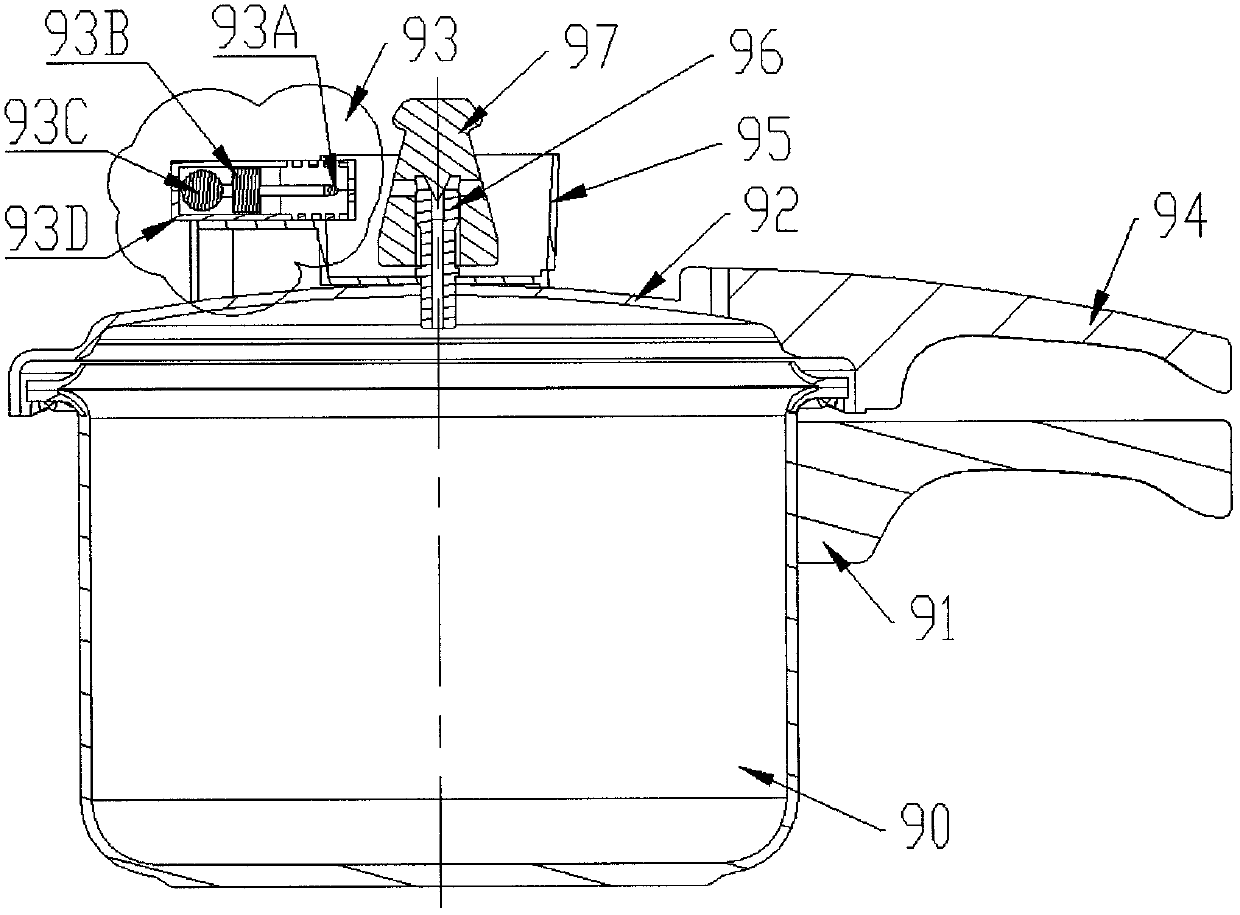

Pressure cooker and pressure detection method and device thereof

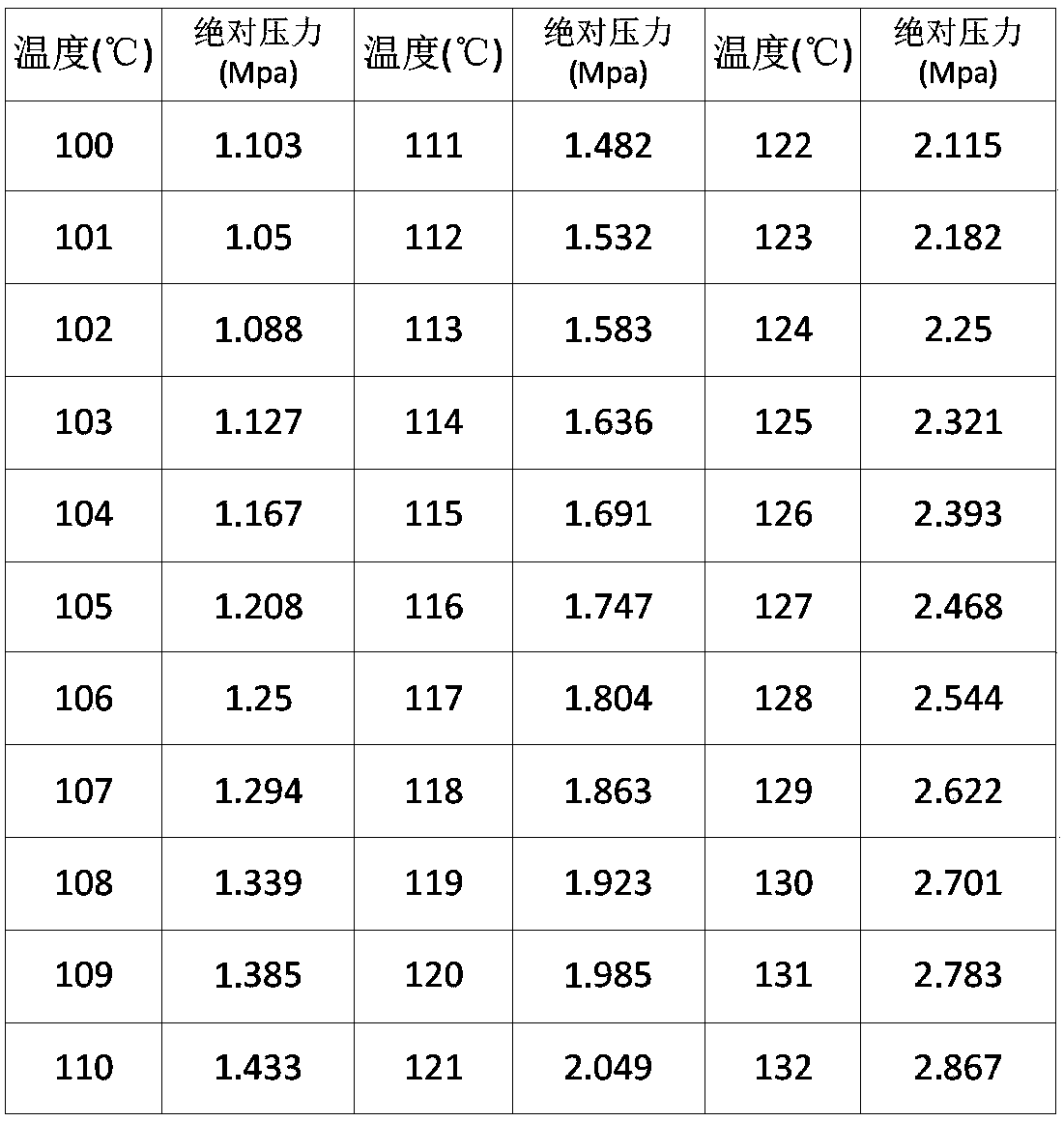

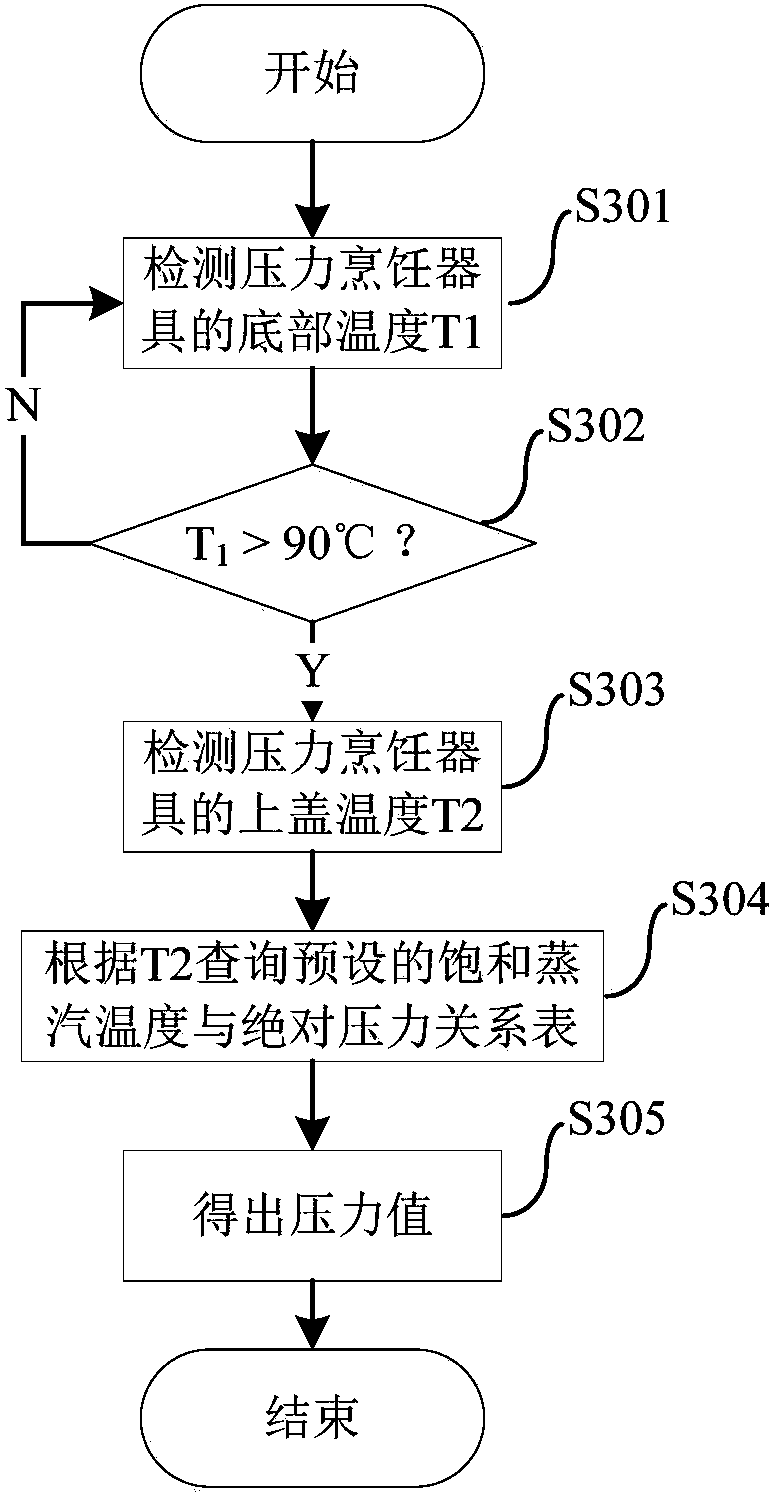

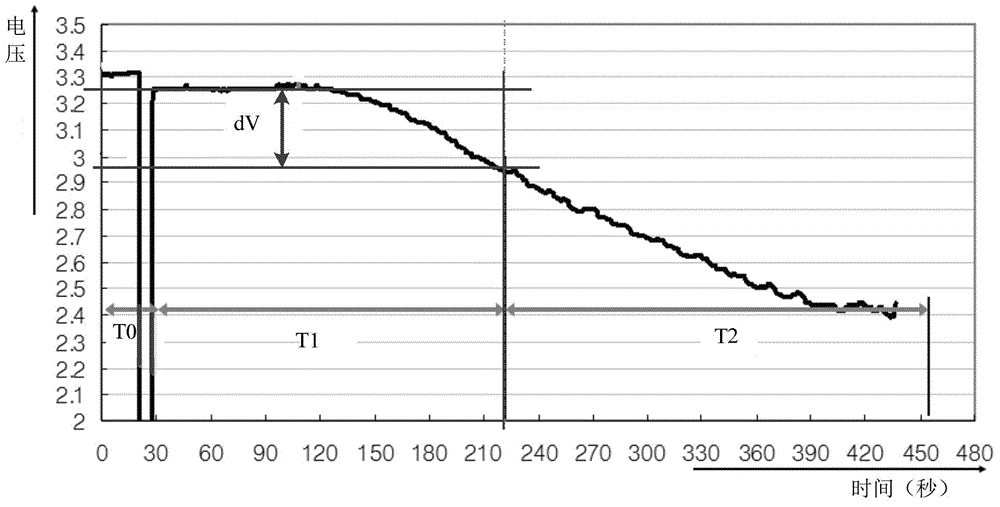

ActiveCN108272338AEasy to detect and more accurateAccurate detectionPressure-cookersEngineeringSteam temperature

The invention discloses a pressure cooker and a pressure detection method and device thereof. The method comprises the following steps that the bottom temperature of the pressure cooker is detected; whether the bottom temperature is larger than a preset temperature threshold value or not is judged; if the bottom temperature is larger than the preset temperature threshold value, the upper lid temperature of the pressure cooker is detected; the saturated steam temperature in the pressure cooker is obtained according to the upper lid temperature, and a pressure value in the pressure cooker is obtained according to the saturated steam temperature and a preset saturated steam temperature and absolute pressure relation table. According to the method, the pressure in the pressure cooker can be detected conveniently and accurately.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Cooking equipment and control method thereof

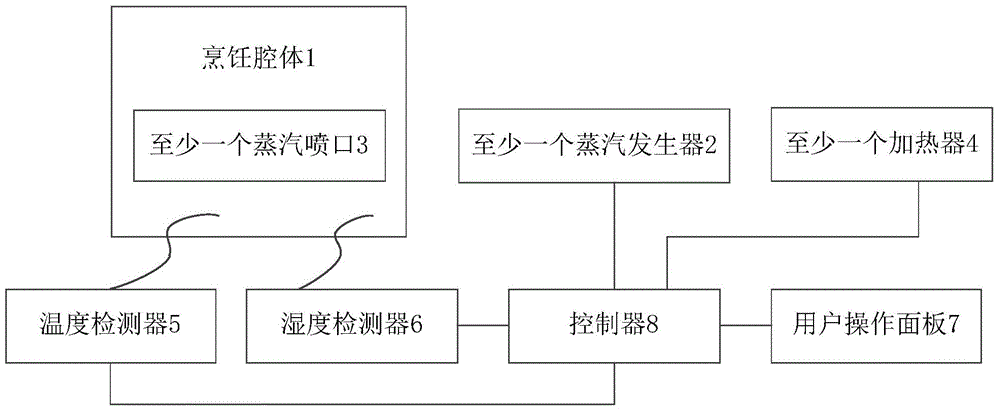

InactiveCN104665573AReduce oxygen concentrationMeet different cooking needsSteam cooking vesselsProcess engineeringSteam temperature

The invention discloses cooking equipment. The cooking equipment comprises a cooking cavity, at least a steam generator, at least steam spraying port formed in the cooking cavity, at least one heater, a temperature detector, a humidity detector, a user operation panel and a controller, wherein the temperature detector is used for detecting the current temperature in the cooking cavity; the humidity detector is used for detecting the current humidity in the cooking cavity; the user operation panel is used for receiving the target temperature and target humidity set by a user; the controller is used for controlling each steam generator and each heater according to the target temperature, the target humidity, the current temperature and the current humidity. The cooking equipment has the advantages that the steam amount and steam temperature in the cooking cavity can be controlled effectively, the dry-wet ration required by cooking can be precisely controlled, different cooking requirements of the user can be satisfied, food nutrition can be well preserved, good cooking effect is achieved, energy is saved effectively, and user cooking experience is increased. The invention further discloses a control method of the cooking equipment.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

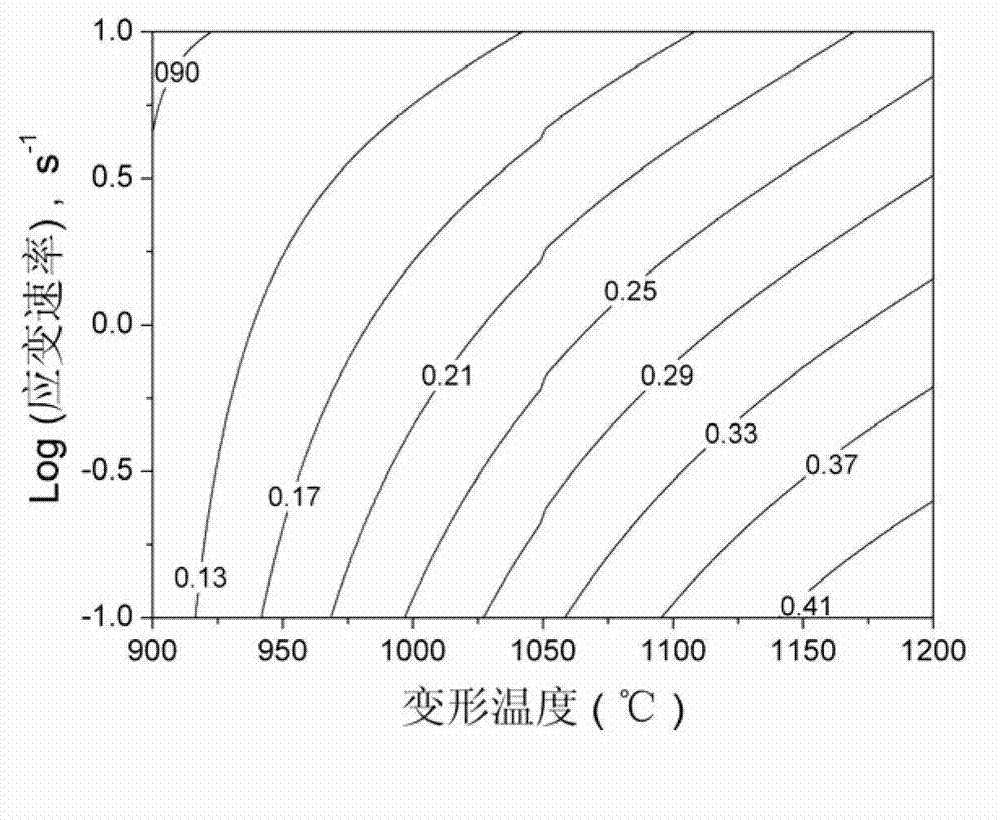

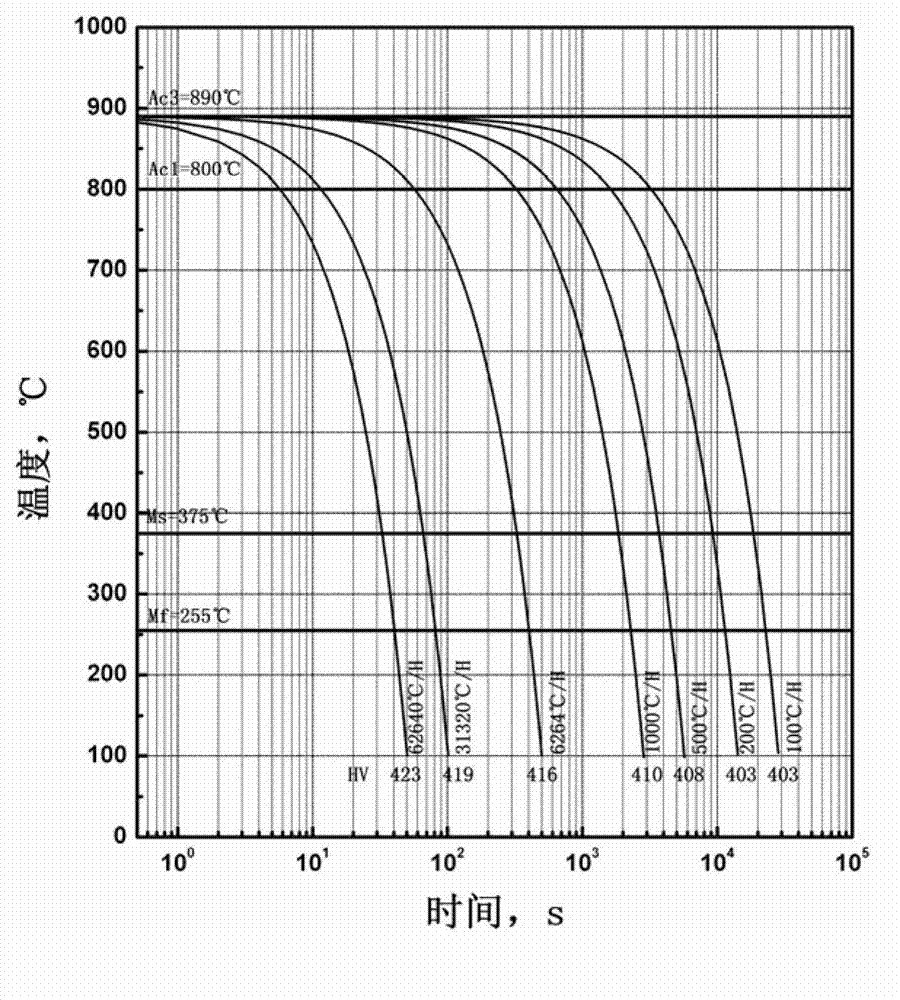

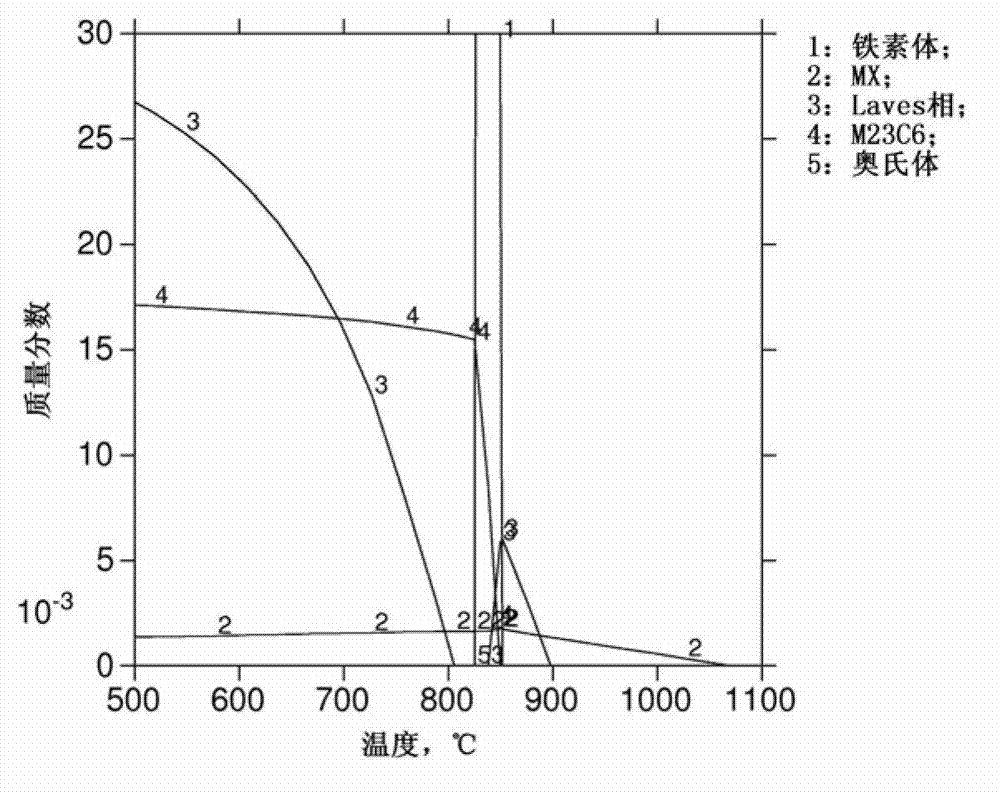

Steel for steam-temperature ultra-supercritical thermal power unit and preparation method thereof

The invention relates to steel for a steam-temperature ultra-supercritical thermal power unit and a preparation method thereof, belonging to the technical field of heat resistant steel. The steel comprises the following chemical compositions by weight percentage: 0.06-0.10 percent of carbon, 0.1-0.5 percent of silicon, 0.2-0.8 percent of manganese, not more than 0.004 percent of phosphorous, not more than 0.002 percent of sulfur, 8.0-9.5 percent of chromium, 2.5-3.5 percent of tungsten, 2.5-3.5 percent of cobalt, 0.03-0.07 percent of niobium, 0.10-0.30 percent of vanadium, 0.80-1.20 percent of copper, 0.006-0.010 percent of nitrogen, 0.010-0.016 percent of boron, 0.01-0.04 percent of rare-earth cerium, not more than 0.01 percent of nickel, not more than 0.005 percent of aluminum, not more than 0.01 percent of titanium, not more than 0.01 percent of zirconium and the balance of ferrum and inevitable impurity elements. The steel has the advantages that the steel can be used for preparing G115 steel of 650 DEG C of steam-parameter ultra-supercritical thermal power unit and a large-diameter boiler tube thereof, and the room-temperature mechanical property, the impact property, the high-temperature mechanical property and the permanence property of the steel are much higher than those of P92 steel in the Gb5310 and ASME standard.

Owner:CENT IRON & STEEL RES INST

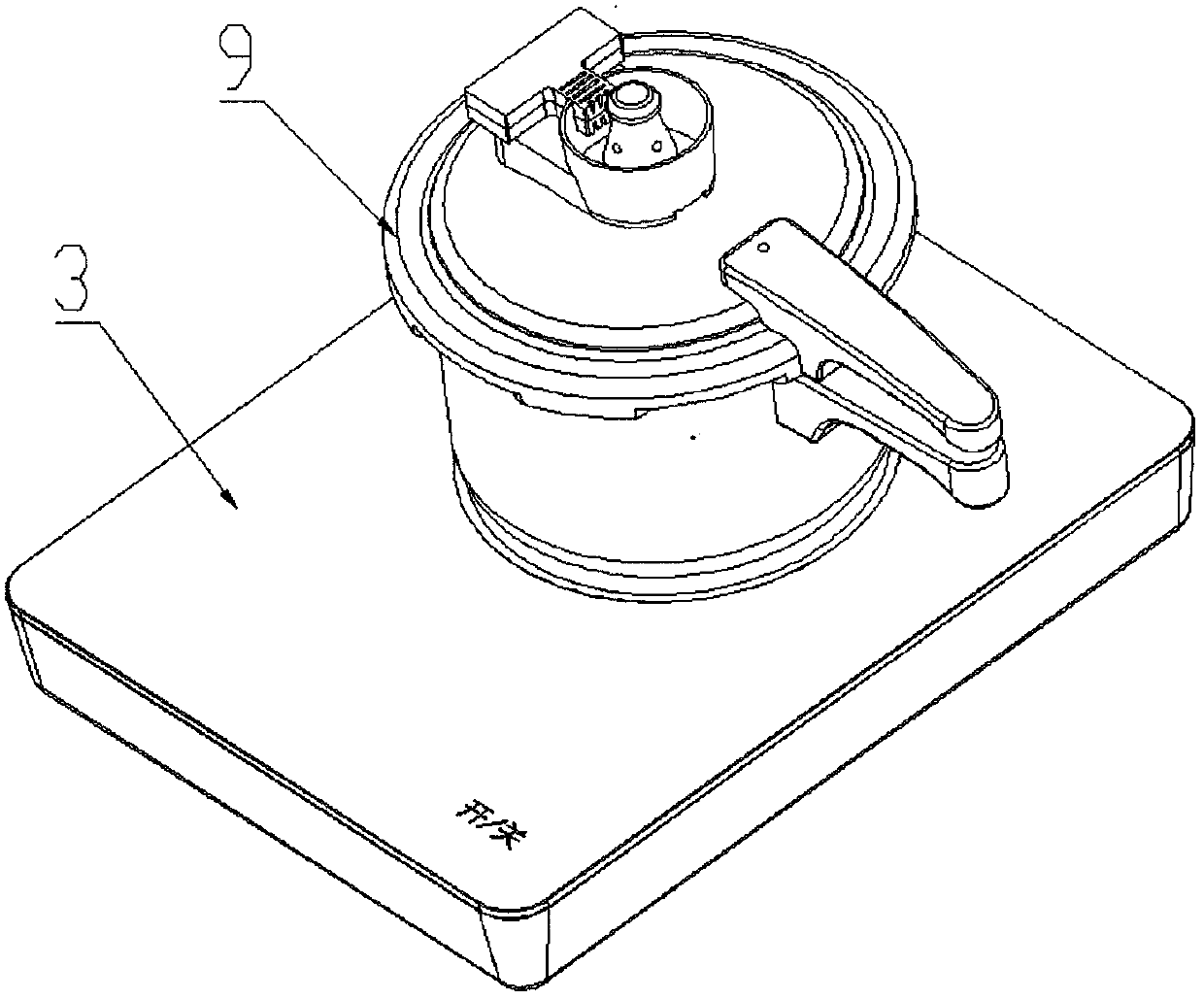

Pressure cooker with steam detector and matched electric heating stove

InactiveCN107647772ARealize matchingAvoid safety accidentsDomestic stoves or rangesLighting and heating apparatusWireless transceiverMature technology

The invention discloses a pressure cooker equipped with a steam detector and the matching electric heating stove. It combines the mature wireless transceiver technology with the steam detection technology. Detectors of temperature, humidity, flow velocity, and flow changes of steam flowing into the atmosphere through exhaust pipes and pressure limiting valves in different boiling states of liquids, providing stable, reliable, and accurate data signals for electric heating stoves equipped with matching wireless transceiver systems , realize the intelligent control when the ordinary pressure cooker is used with the electric heating stove, improve the performance of the electric heating stove, expand the application range of the electric heating stove, and effectively eliminate the safety hazard of using the pressure cooker on the electric heating stove.

Owner:谢勇

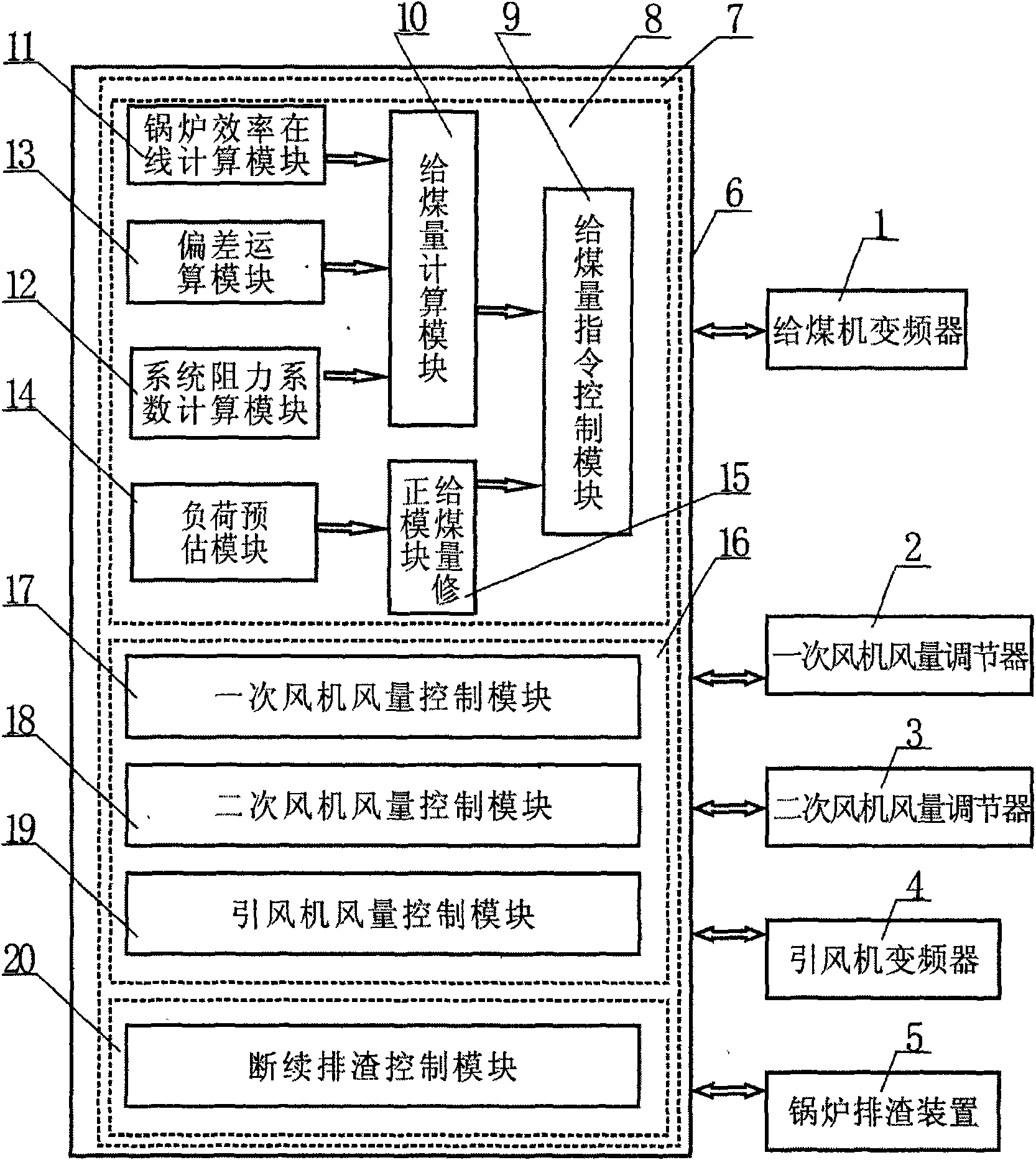

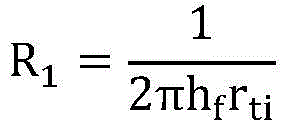

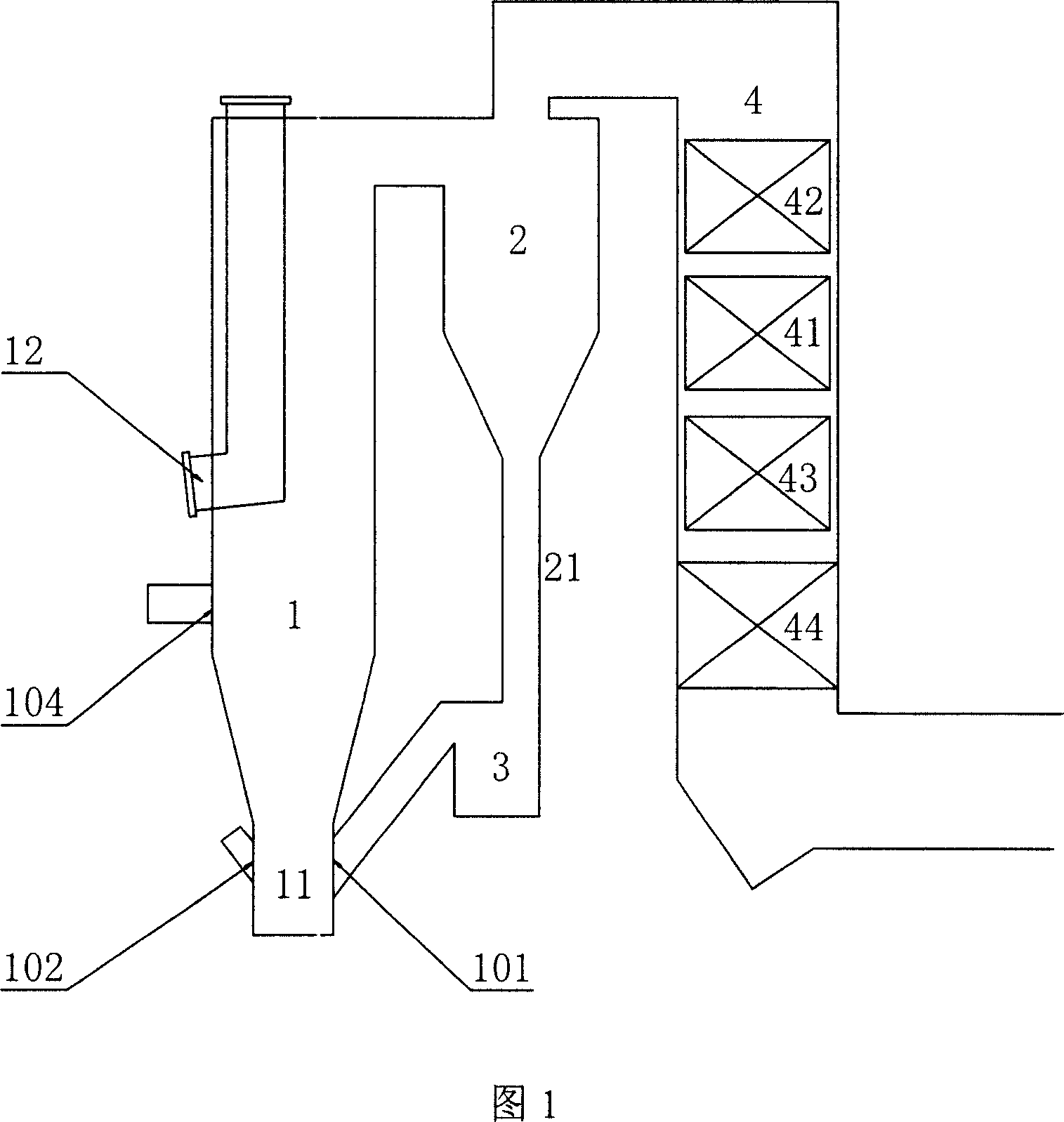

Automatic boiler combustion control system of circulating fluid bed

ActiveCN101551103AAdvanced and reasonable designImprove combustion efficiencyFluidized bed combustionProgramme control in sequence/logic controllersSteam pressureAir volume

The invention discloses an automatic boiler combustion control system of a circulating fluid bed, which is applied to machine sets for coal-fired power generation, heat supply or combined heat and power generation. The system comprises hardware and control program software, wherein the control program software comprises a fuel control part, an air volume control part and a deslagging control part, and the control program software can automatically and timely control the input quantity of boiler fuel, the oxygen content in the boiler and the boiler deslagging device. The combustion control system is applicable to all sorts of complicated operating conditions, has consistently correct and reliable reaction, advanced and reasonable algorithm design as well as good control effect, is safe and effective, has the capabilities of improving boiler combustion condition, increasing boiler combustion efficiency and reducing unburned carbon in flue dust, leads main steam pressure control to be stable, enhances the capability of tracking the change in load of the boiler and greatly improves the running safety performance, leads main steam temperature control precision to be effectively improved, avoids temperature excursion of an overheater, reduces the danger of steam turbine water slug caused by low-temperature steam, and improves the thermal efficiency and automation control degree of the steam turbine.

Owner:DONGGUAN TEXWINCA HLDG

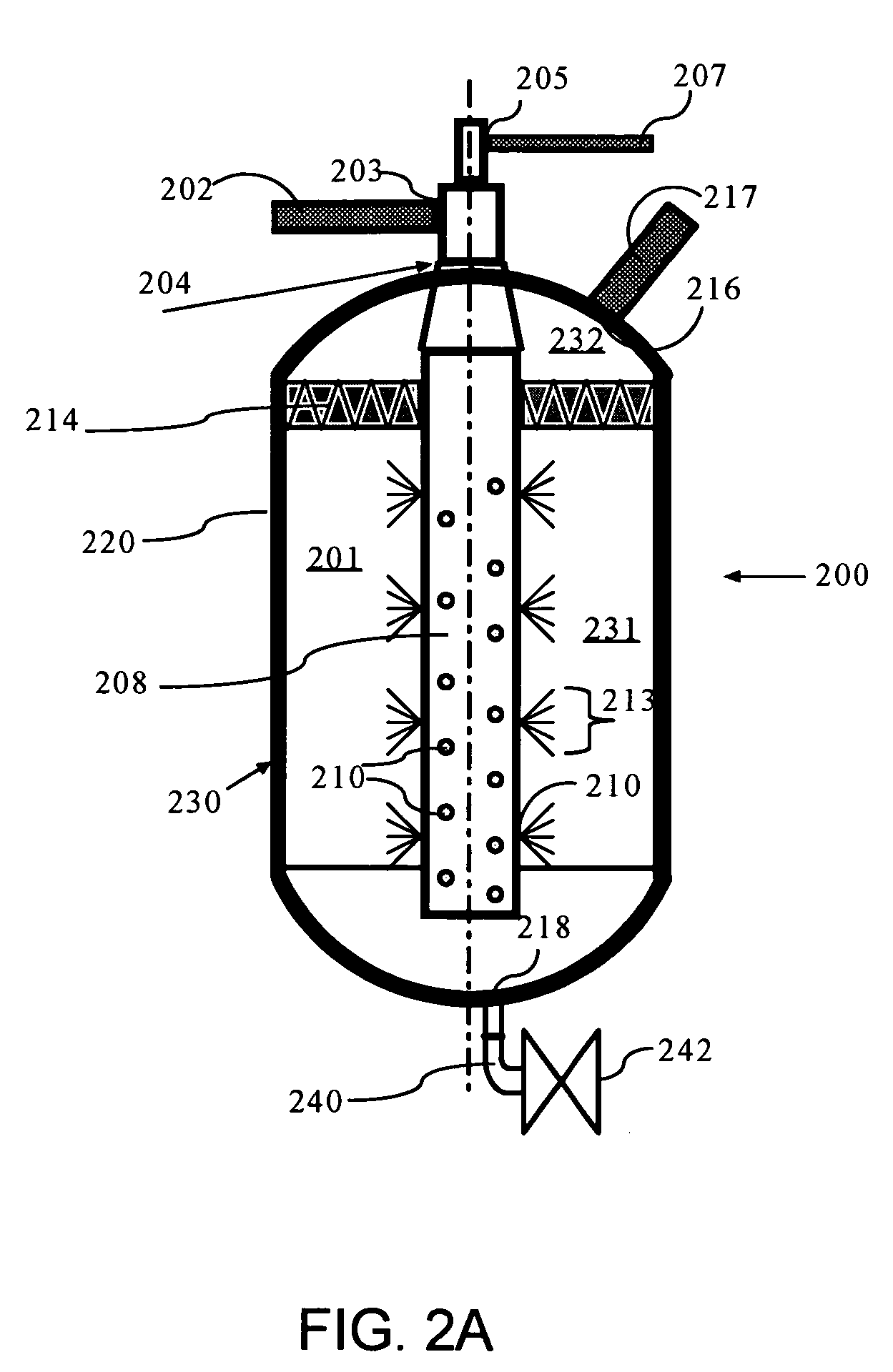

Hot to cold steam transformer for turbine systems

A steam transformer (200) receives steam through a steam inlet (203), and the steam is mixed in a mixing zone (231) with water entering through a water inlet (205). Steam cooled by contact with the water exits the steam transformer through a cold steam outlet (216). Between the mixing zone (231) and the cold steam outlet (216) is positioned a demister (214) that restricts the passage of water droplets.The steam transformer (200) is used to condition the steam temperature in steam turbine and combined cycle turbine facilities when adjustment of steam temperature is required, such as for cold starts of turbines. The steam transformer (200) may be installed into a bypass circuit or directly inline. A number of differing configurations and designs are disclosed.

Owner:SIEMENS ENERGY INC

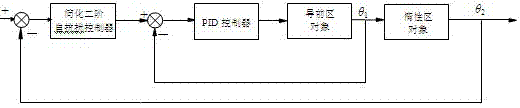

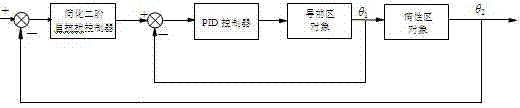

Method for controlling main steam temperature in power plant based on simplified second-order auto disturbance rejection controller

InactiveCN102360176AEasy to adjustRealize decoupling controlControllers with particular characteristicsCompensation effectControl manner

The invention discloses a method for controlling a main steam temperature in a power plant based on a second-order simplified auto disturbance rejection controller. In the method, a cascade control mode is used for forming a cascade steam temperature mediation and control system; in an inner ring, proportion integration differentiation (PID) adjustment is used for eliminating the deviation of an advance timing steam temperature to achieve a coarse tuning effect on an overheating steam temperature; in an outer ring, the simplified second-order auto disturbance rejection controller is used for controlling the outlet temperature of an overheater, so that the defects of large inertia and large delay of a temperature object in an inertia area are fully overcome; and by a disturbance compensation effect of the simplified second-order auto disturbance rejection controller, the disturbance of factors such as loads, flue gas and the like is eliminated, so that the stability of the main steam temperature is ensured. In the method, an algorithm is simple, a parameter is easy to adjust, and a higher response speed, higher steady state accuracy, higher disturbance resistance and higher robustness can be well acquired without dependence on a mathematical model with an accurate main steam temperature in the power plant.

Owner:SHANDONG ELECTRIC POWER SCHOOL

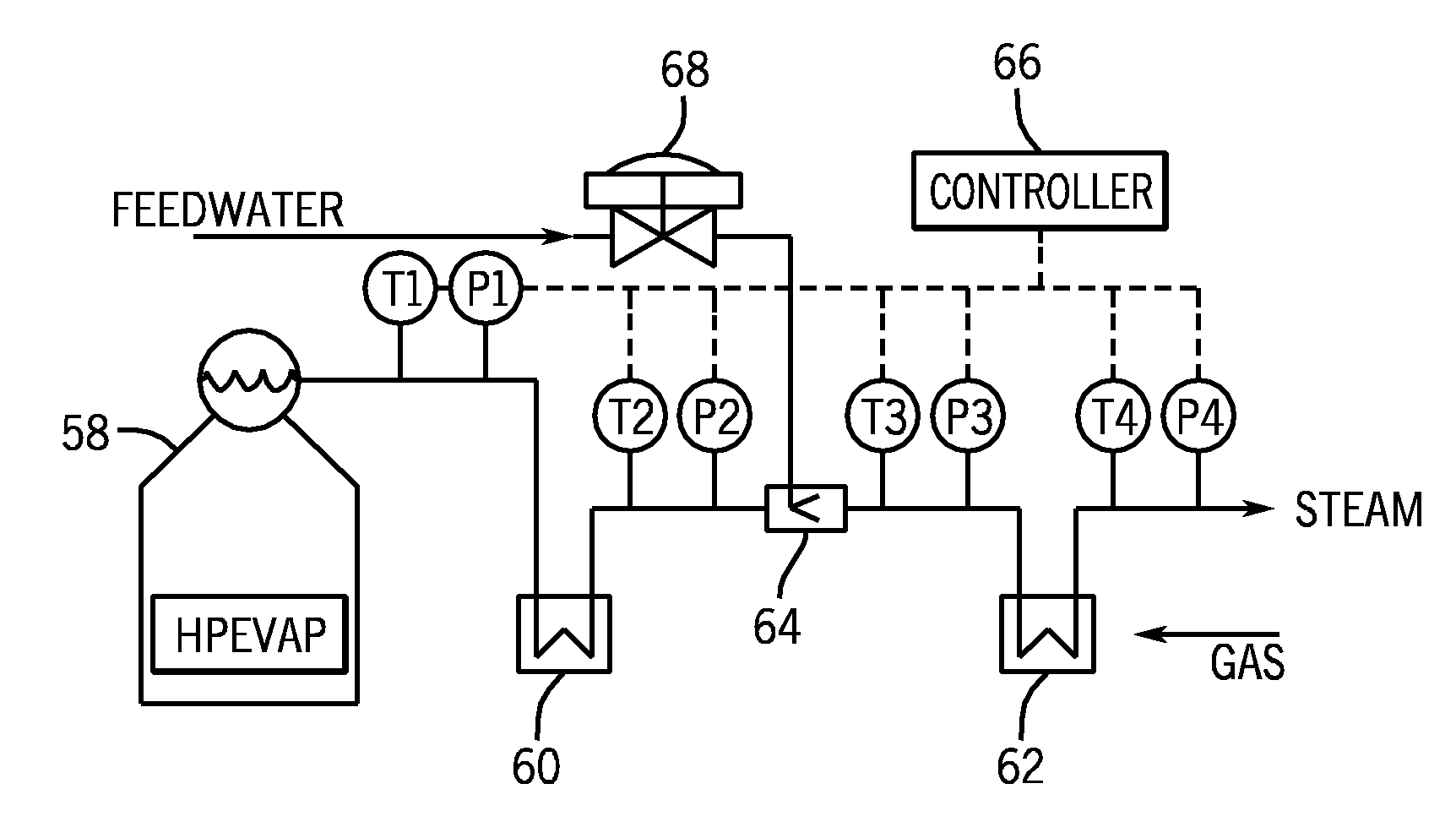

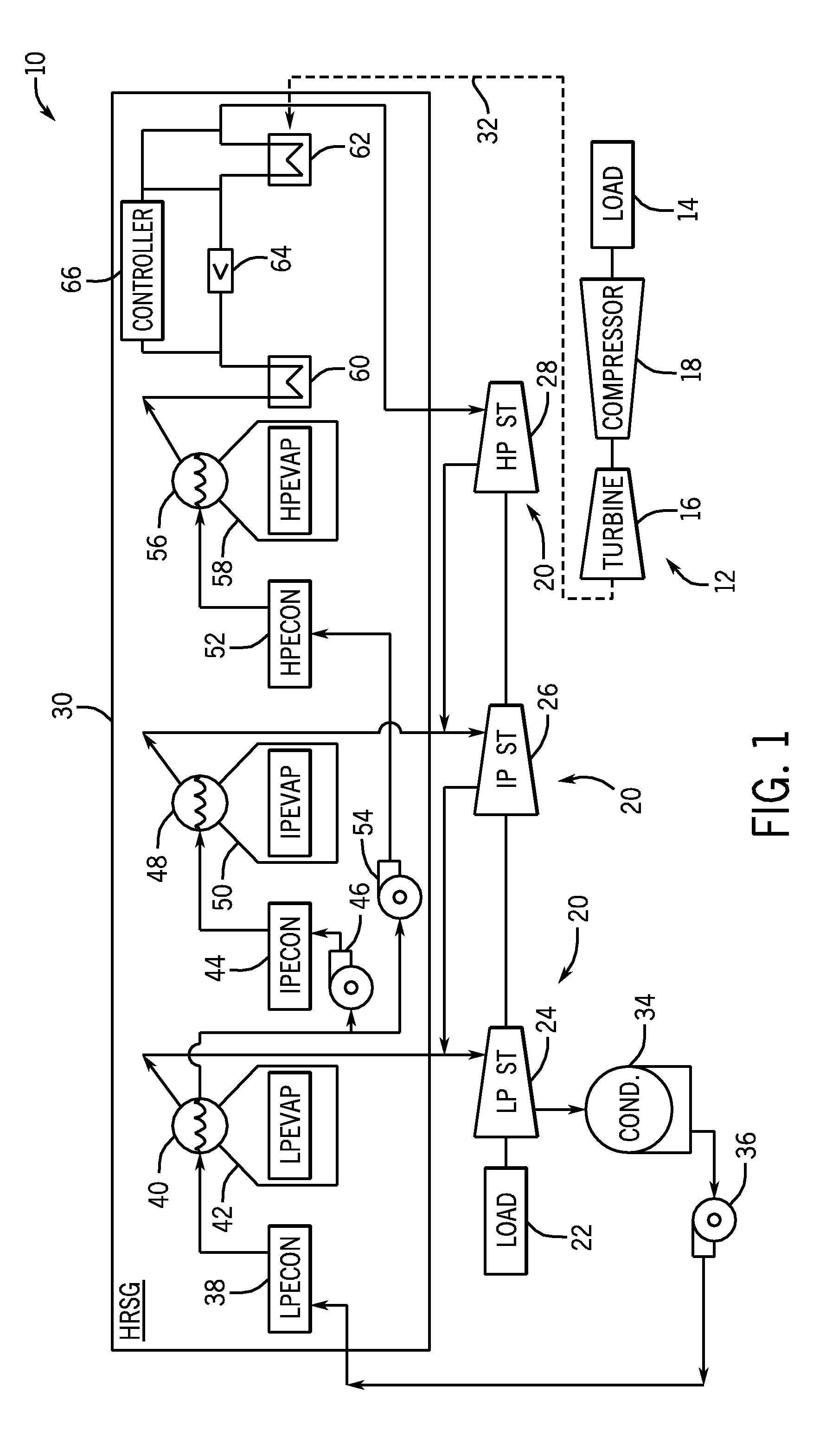

Inter-stage attemperation system and method

Systems and methods for controlling exhaust steam temperatures from a finishing superheater are provided. In certain embodiments, the system includes a controller which includes control logic for predicting an exhaust temperature of steam from the finishing superheater using model-based predictive techniques (e.g., based on empirical data or thermodynamic calculations). Based on the predicted exhaust temperature of steam, the control logic may use feed-forward control techniques to control the operation of an inter-stage attemperation system upstream of the finishing superheater. The control logic may determine if attemperation is required based on whether the predicted exhaust temperature of steam from the finishing superheater exceeds a set point temperature as well as whether the inlet temperature of steam into the finishing superheater drops below a set point temperature of steam. The attemperation system may include a characterizing function to linearize the valve operation controlled by the control logic to inject cooled, high-pressure feedwater into the steam upstream of the finishing superheater, which may, in turn, control the exhaust temperature of steam from the finishing superheater. The disclosed embodiments may also be applied to any systems where an outlet temperature of a fluid from a heat transfer device may be controlled.

Owner:GENERAL ELECTRIC CO

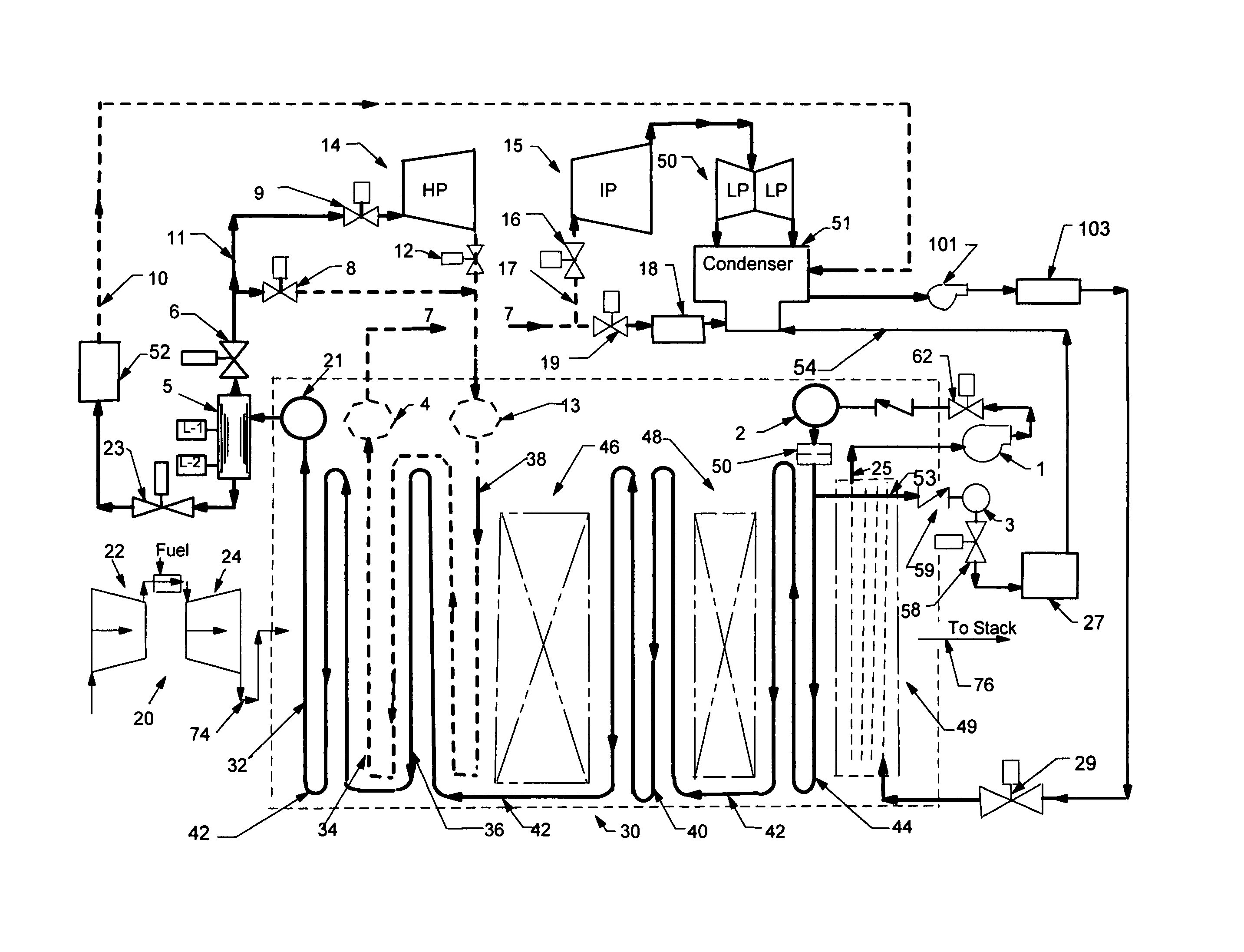

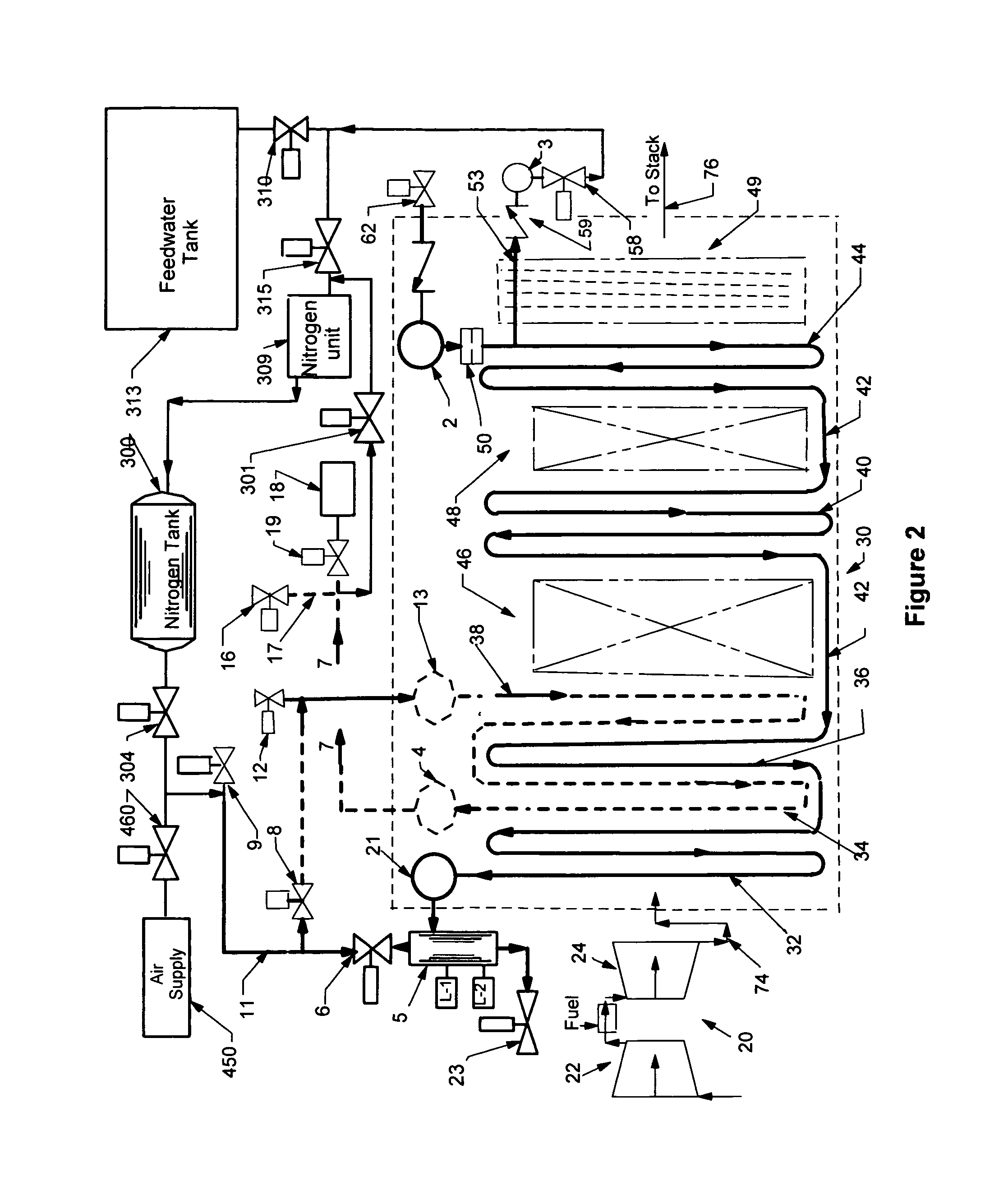

Heat recovery steam generator and method for fast starting combined cycles

ActiveUS8820078B1Control moisture contentPossible leakageLiquid degasificationSteam generation heating methodsEngineeringSuperheater

A once-through high pressure steam generator and reheater configured to eliminate the majority of components limiting cyclical life of fast start conventional HRSGs. Two remaining problematic components in conventional designs the final superheater and reheater tubes overheat while their headers remain colder in fast starts. In this inventive HRSG the critical components are arranged and started by a method that limits these damaging temperature differentials. At ignition when exhaust gas surges into a wet superheater steam flow starts minutes before conventional systems. This early steam flow cools the tubes while heating the headers, thereby reducing life damaging stresses. Steam temperature is controlled through the start and warms the rest of the plant earlier without attemperators with their problematic thermal stress history. Faster starts than conventional result without damaging fatigue life depletion with this low cost innovation.

Owner:DUFFY THOMAS EDWARD

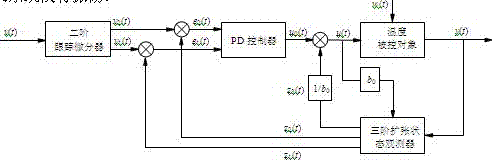

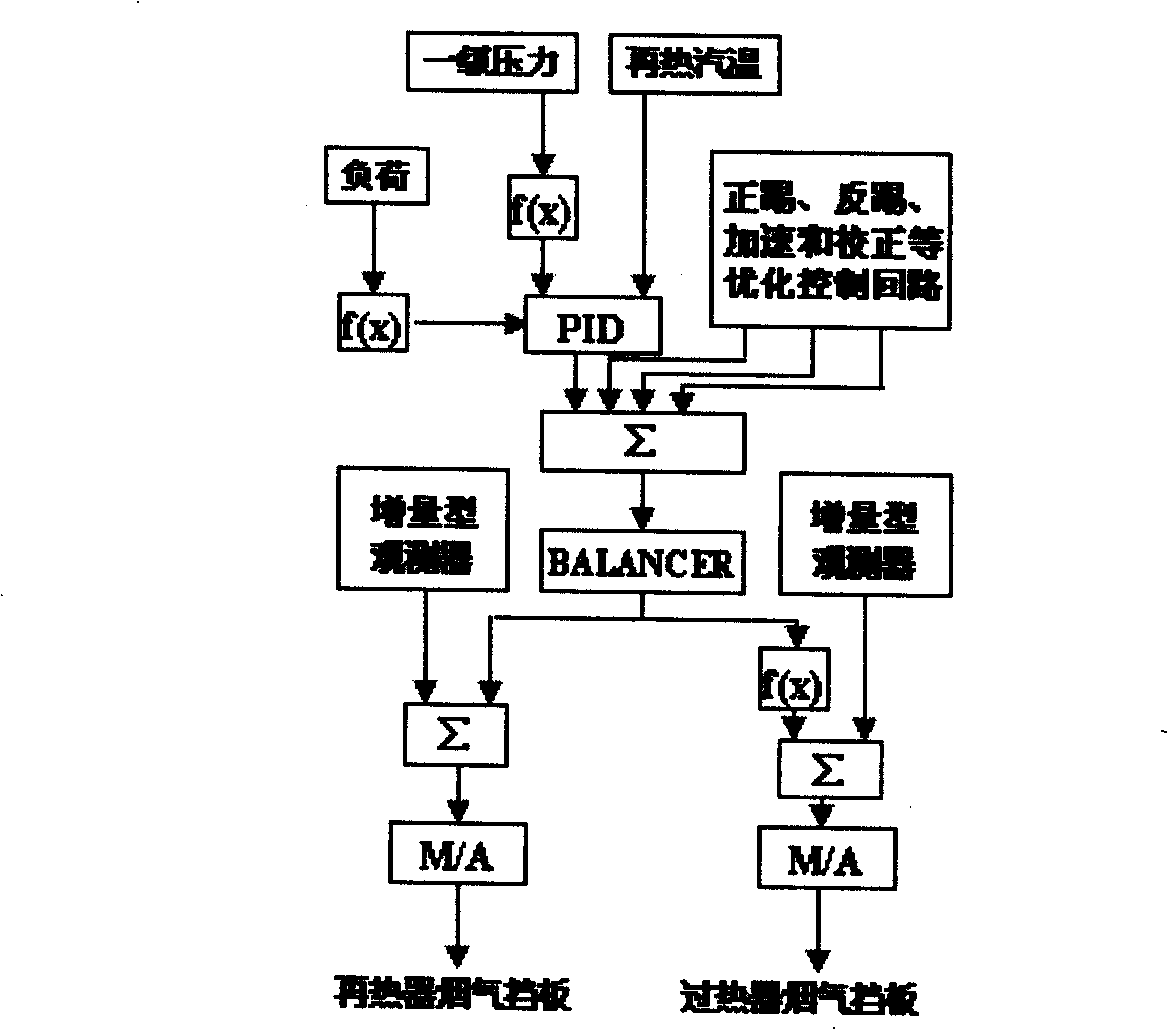

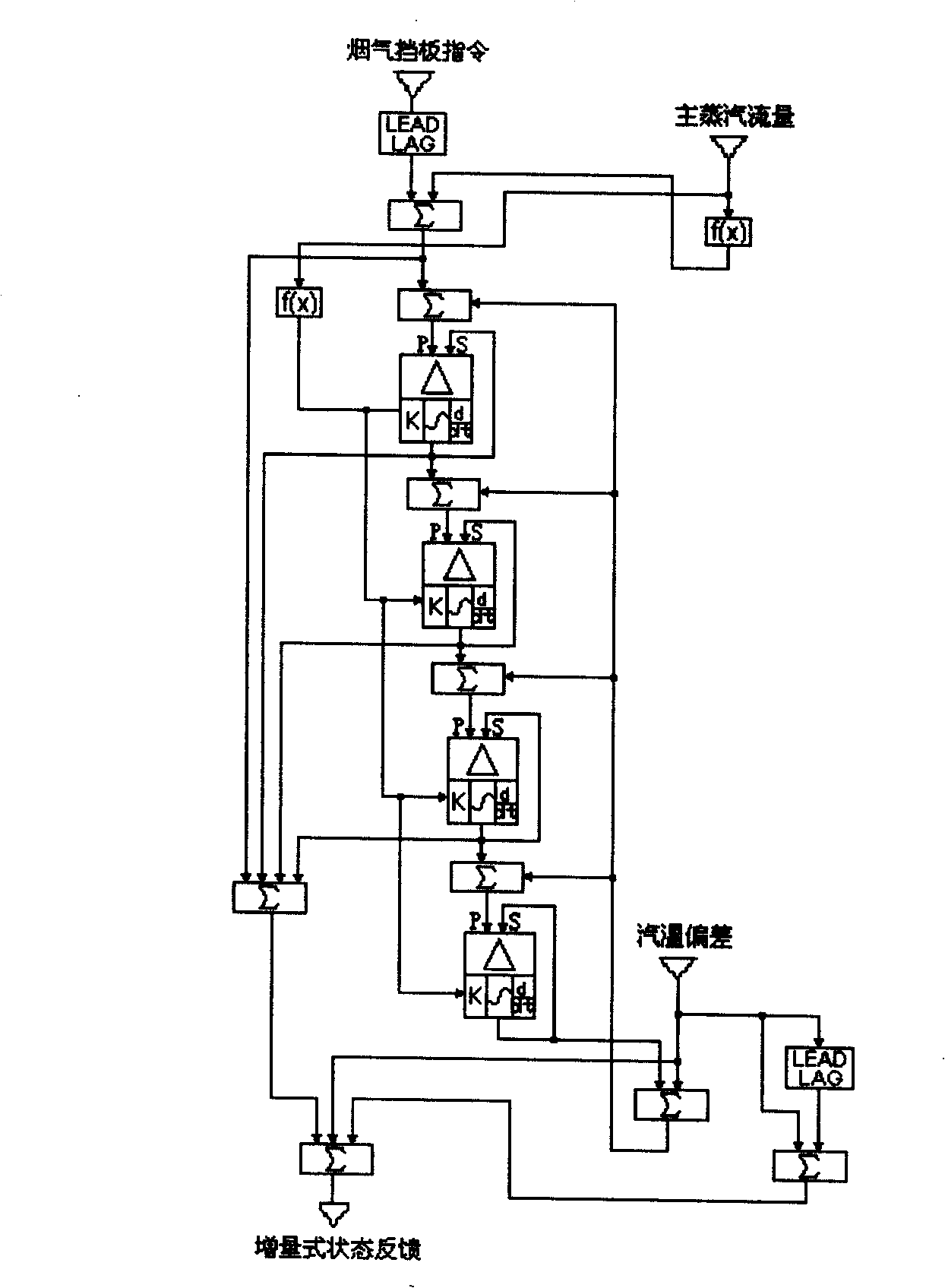

Thermal power unit reheated steam temperature control method

ActiveCN101338892APrevent overshootReduce Signal ErrorSuperheating controlTemperature control using electric meansFeedback controlLoad following power plant

The invention relates to a thermal power generating unit reheated steam temperature controlling method. According to the operating characteristics of the boiler reheater and the theoretic study on a steam-temperature control system, a state feedback control method based on incremental state observer is adopted, and the concept of an algebraically equivalence observer is used to direct the parameter setting of an incremental state observer; in addition, a special control circuit is arranged in the steam-temperature control circuit to resolve the problems that the process of steam-temperature adjustment is relatively long when the reheated steam temperature set value is changed, non-linearity exists during steam-temperature control, the process of steam-temperature variation is very slow, etc., and variation parameter PID regulator is combined to jointly form a comprehensive reheated temperature automatic adjusting system. The invention is capable to ensure reheated steam temperature control to escape spray water upon large-range load variation, and effectively overcomes the disadvantage of the poor effect of the traditional PID regulation on the control of big lagged object; the reheated temperature control effect is improved remarkably; and a sample is provided for controlling the controlled object with big inertia and serious lagging in relation to reheated steam temperature.

Owner:CHINA ELECTRIC POWER RES INST +2

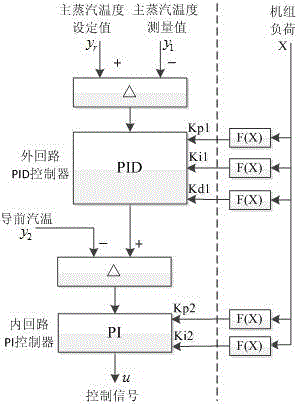

All-process control method for main steam temperature of utility boiler

InactiveCN103557511ASolve the automatic scheduling problemReduce overheatingBoiler controlProportion integration differentiationInner loop

The invention discloses an all-process control method for the main steam temperature of a utility boiler. The all-process control method comprises the following steps: firstly, partitioning the typical working condition points of the operation of the utility boiler; secondly, testing the main steam temperature mathematical models at the typical working condition points; thirdly, caculating the optimal values of PID (Proportion Integration Differentiation) adjustable parameters at the typical working condition points; fourthly, utilizing a piecewise linear function module in a DCS (Decentralized Control System) to achieve control logical configuration; fifthly, realizing the approximate optimal control of the main steam temperature at any working condition points in the DCS. The all-process control method for the main steam temperature of the utility boiler has the benefits that automatic dispatching of the optimal values of PID adjustable parameters of the inner loop and the outer loop is guaranteed when the main steam temperature system of a thermal power generating unit is within the full-load range of the unit operation, the main steam temperature adjustment quality is greatly improved, and the over-temperature probability of the unit under the condition of great load changes is lowered.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

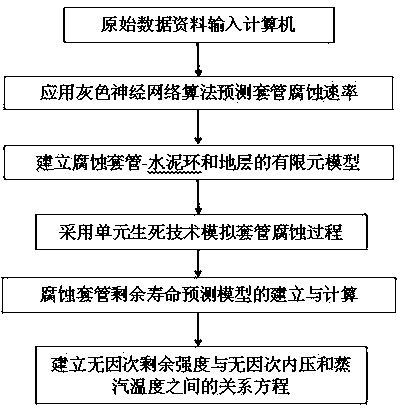

Method for predicting residual life of corroded casing of high-temperature and high-pressure well

ActiveCN103455682AGuaranteed accuracyEasy to adjust process parametersSpecial data processing applicationsInternal pressureElement model

A method for predicting the residual life of a corroded casing of a high-temperature and high-pressure well mainly comprises the following steps: (1) predicting the inner average corrosion rate and the outer average corrosion rate of the casing by adopting the gray neural network algorithm; (2) establishing an finite element model for the corroded casing, and simulating the corrosion process of the casing by utilizing the element birth-death technology, so as to acquire the critical failure wall thickness of the casing when the casing loses efficacy; (3) establishing a residual life prediction model for the corroded casing, and computing the residual life of the casing subjected to uniform corrosion, local corrosion and pitting corrosion by utilizing the approximate analytical method; (4) establishing a relation equation for zero dimension residual intensity and zero dimension internal pressure and steam temperature by utilizing the regression analysis method. Aiming at the limitation of the theoretical study, laboratory test and field data on prediction of the service life of the casing, the method can effectively predict the residual life of the casing in shorter time, and the established residual intensity relation equation enables the engineering personnel to perform comprehensive evaluation on the service capability of the casing.

Owner:SOUTHWEST PETROLEUM UNIV

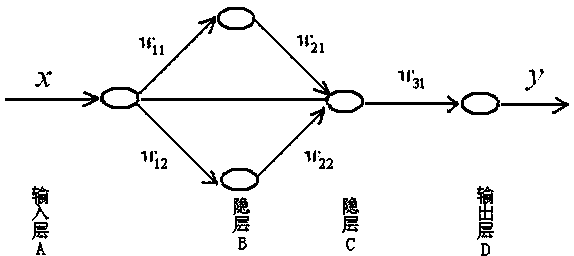

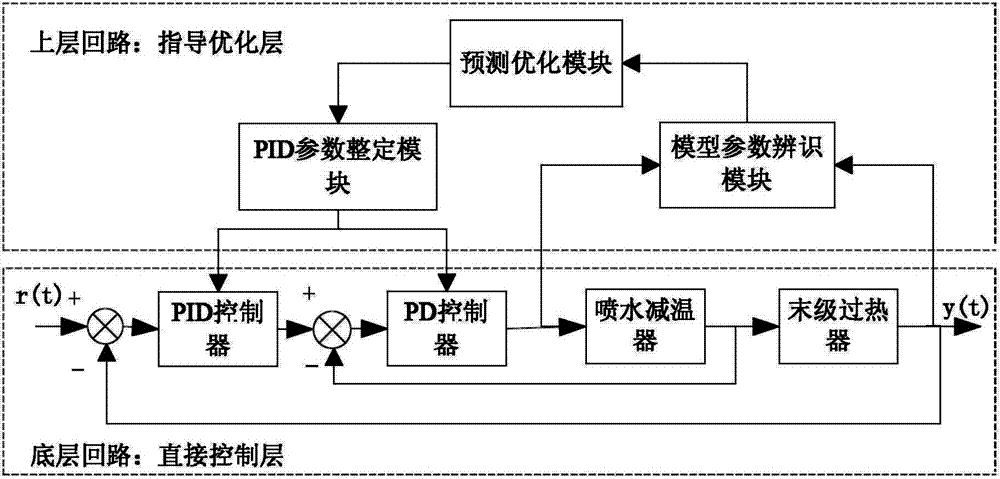

Main steam temperature predictive control method of ultra supercritical unit of thermal power plant

ActiveCN102777879ATo achieve the purpose of adaptive control of main steam temperatureImprove stabilityBoiler controlAdaptive controlComponent Object ModelOnline model

The invention relates to a main steam temperature predictive control method of an ultra supercritical unit of a thermal power plant. A layered control structure is arranged, the layered control structure consists of a bottom direct control layer and an upper guide optimization layer, and the upper guide optimization layer realizes model parameter identification, prediction optimization and PID (Proportion Integration Differentiation) parameter setting control; and the bottom direct control layer is in a cascade system structure and comprises main loop control and assistant loop control, and a PID controller orienting a DCS (distributed control system) is directly controlled. The control method can be used for replacing a control engineer to set PID parameters, on-line model identification and control parameter setting methods are directly adopted to achieve the purpose of main steam temperature self-adaptive control, the application of an advanced control technology and an intelligent optimization technology under a DCS is realized, the stability and the robustness are stronger, and a changing process of a controlled object model of the main steam temperature under a variable load can be adapted.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

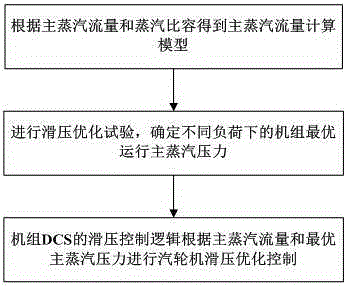

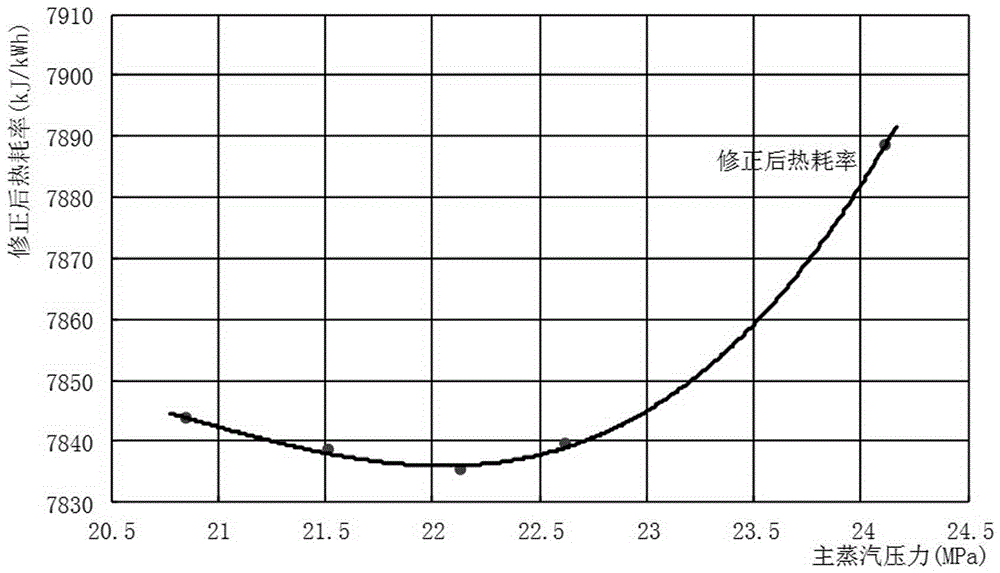

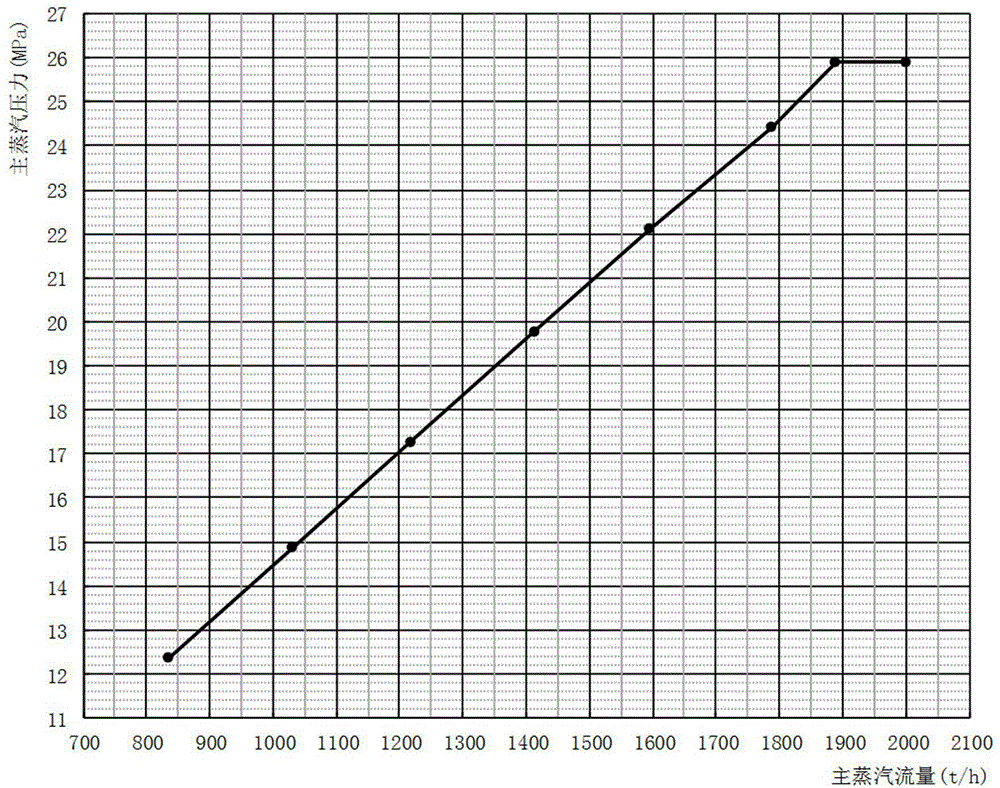

Main-steam-flow-based steam turbine sliding pressure optimization control method

ActiveCN105201564ATap into energy-saving potentialImprove operating economyMachines/enginesEngine componentsSteam pressureEngineering

The invention discloses a main-steam-flow-based steam turbine sliding pressure optimization control method which comprises the following steps: 1. obtaining a main steam flow calculation model according to the main steam flow and steam specific volume; 2. carrying out sliding pressure optimization testing to determine the optimal operation main steam pressure of the set under different loads; and 3. carrying out steam turbine sliding pressure optimization control by set DCS sliding pressure control logic according to the main steam flow and optimal main steam pressure obtained by the formula (3) and formula (5). In order to solve the problem that the changes of back pressure, main reheated steam temperature, heat supply and other factors influence the economical efficiency of the set in the steam turbine sliding pressure operation process, the invention provides a main-steam-flow-based steam turbine sliding pressure optimization control method, so that the steam turbine can still keep the optimal operating mode when the influencing factors change, thereby further exploring the energy conservation potential of the set.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

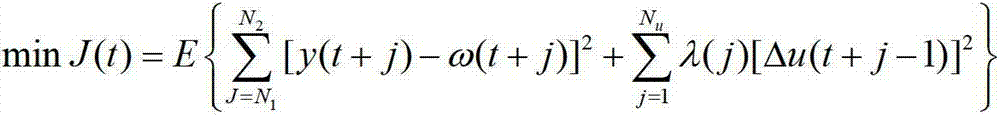

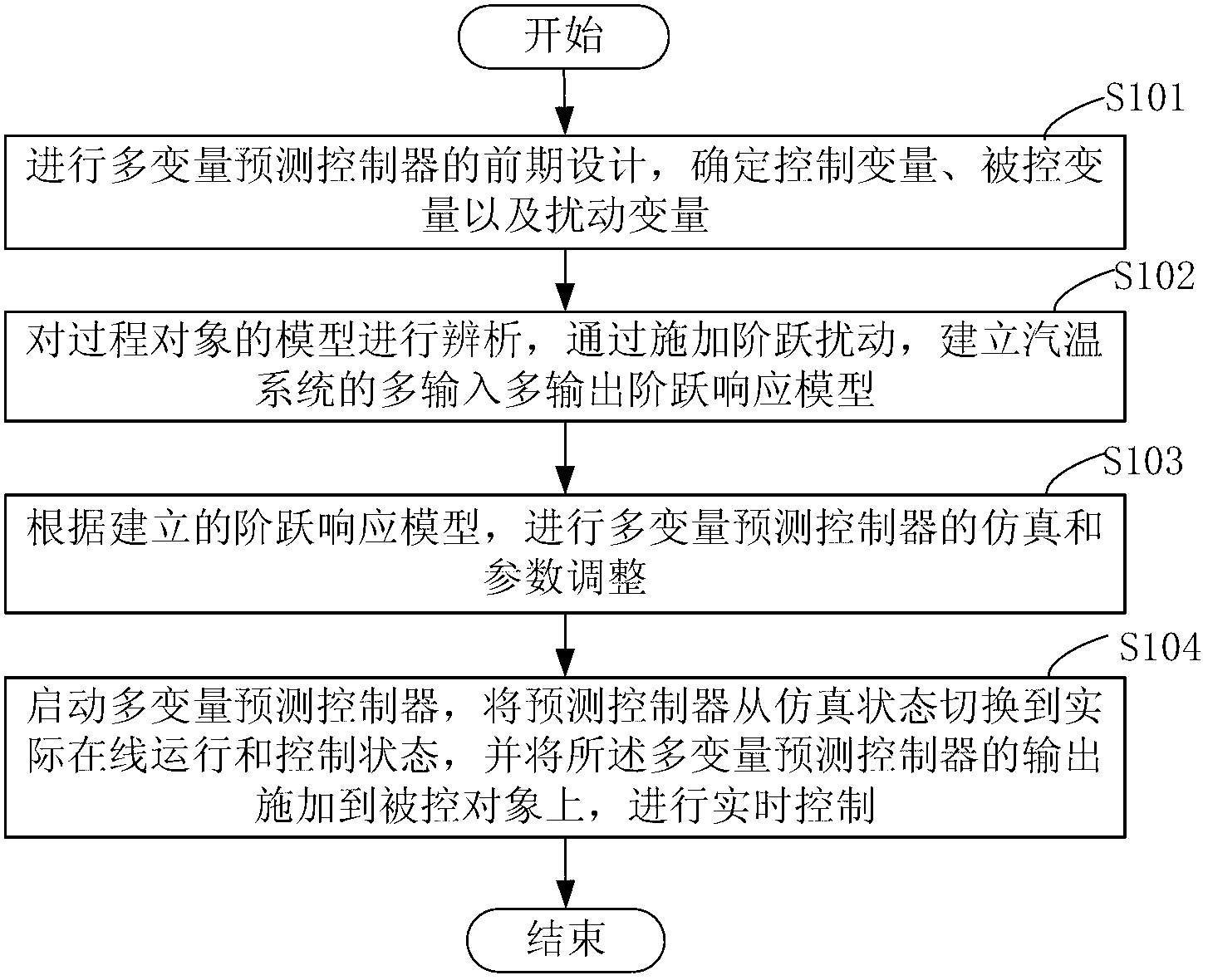

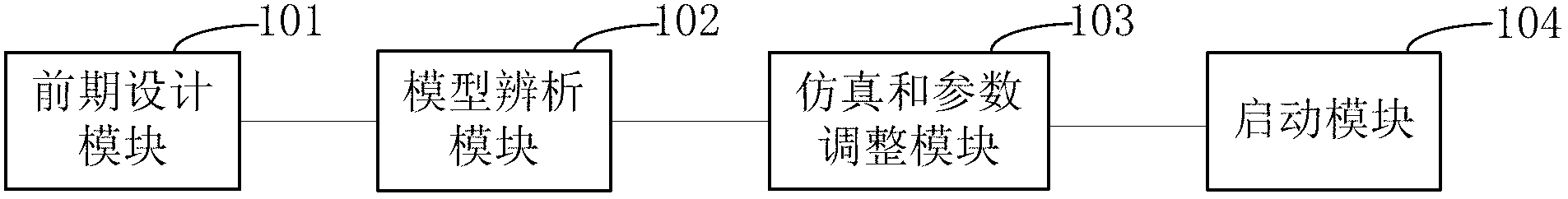

Supercritical machine set steam temperature control method and system based on multivariable predictive control

ActiveCN102707743AGuaranteed superheated steam temperatureSolve the problem of insufficient quality controlTemperature control using electric meansMulti inputPredictive controller

The invention provides a supercritical machine set steam temperature control method and system based on multivariable predictive control. The method includes the steps of: conducting pre-stage designing of a multivariable predictive controller to determine the control variables, the controlled variables and the disturbance variables, wherein the control variables include first stage temperature reducing water spray, second stage temperature reducing water spray, reheated temperature reducing water spray and the opening size of a fume gas baffle, and the controlled variables include main steam temperature and reheated steam temperature; discriminating a module of a process object and building a multi-input and multi-output step response model of the steam temperature system by applying step disturbance, simulating the multivariable predictive controller and adjusting the parameters of the multivariable predictive controller according to the built step response model; starting the multivariable predictive controller and switching the multivariable predictive controller from the simulated state to the actual online operation and control state and applying the output of the multivariable predictive controller to a controlled object to carry out real-time control. The supercritical machine set steam temperature control method and system can well ensure that the overheated steam temperature in a boiler is within the required range.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

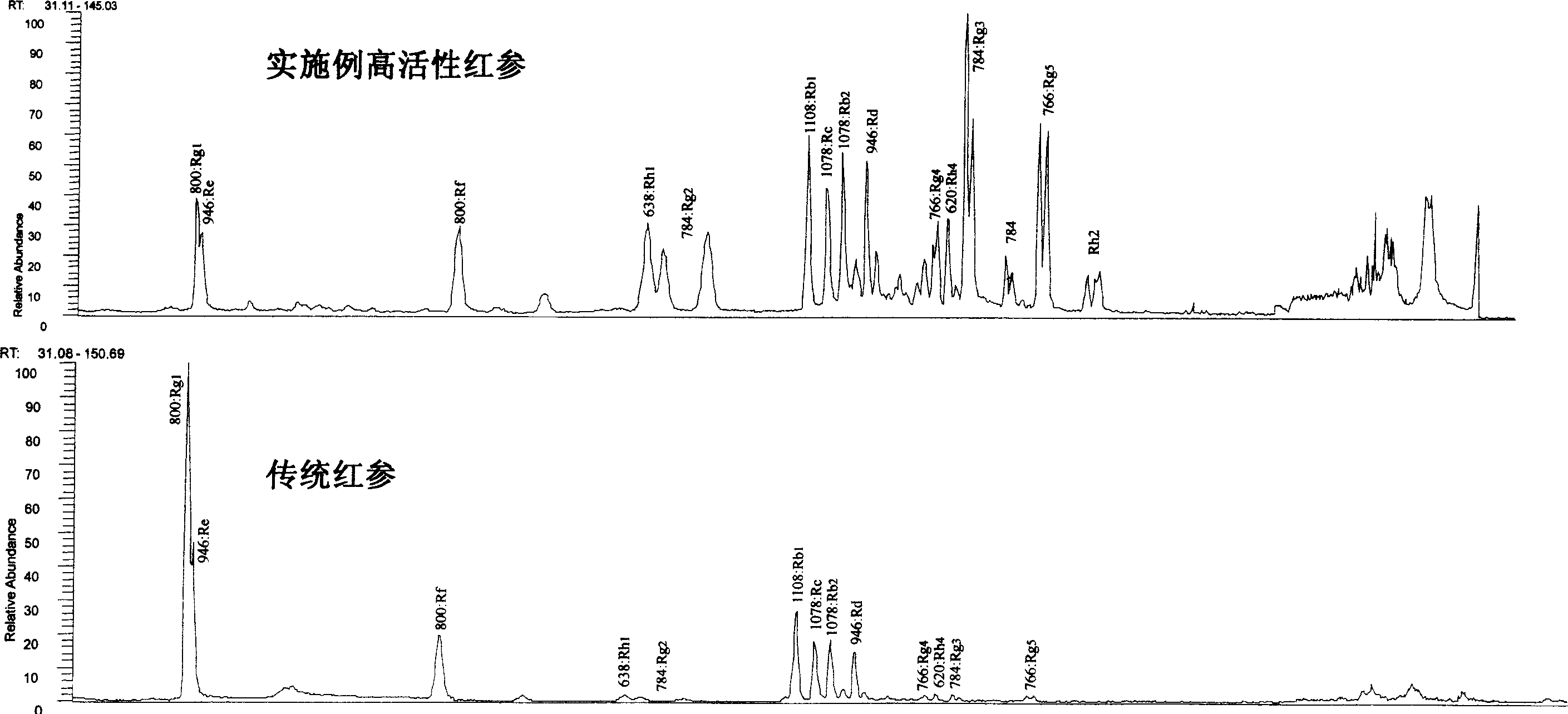

Making process of high activity red ginseng prepn

The present invention discloses high activity red ginseng treating process. By means of controlling the steaming temperature and time of ginseng and making full use of saponin enzyme and other active matters in ginseng, the treating process converts the diol type saponins Ra, Rb1, Rb2, Rb3, Rc and Rd in high contents in ginseng into Rg3, Rg5, Rh2, Rh3 and other rare saponins, converts triol type saponins Re, Rg1, Rf, etc into Rg2, Rg4, Rh1, Rh4 and other active components, and raises the contents of rare saponins greatly. The present invention is suitable for processing Korean ginseng, American ginseng, notoginseng, etc.

Owner:金凤燮

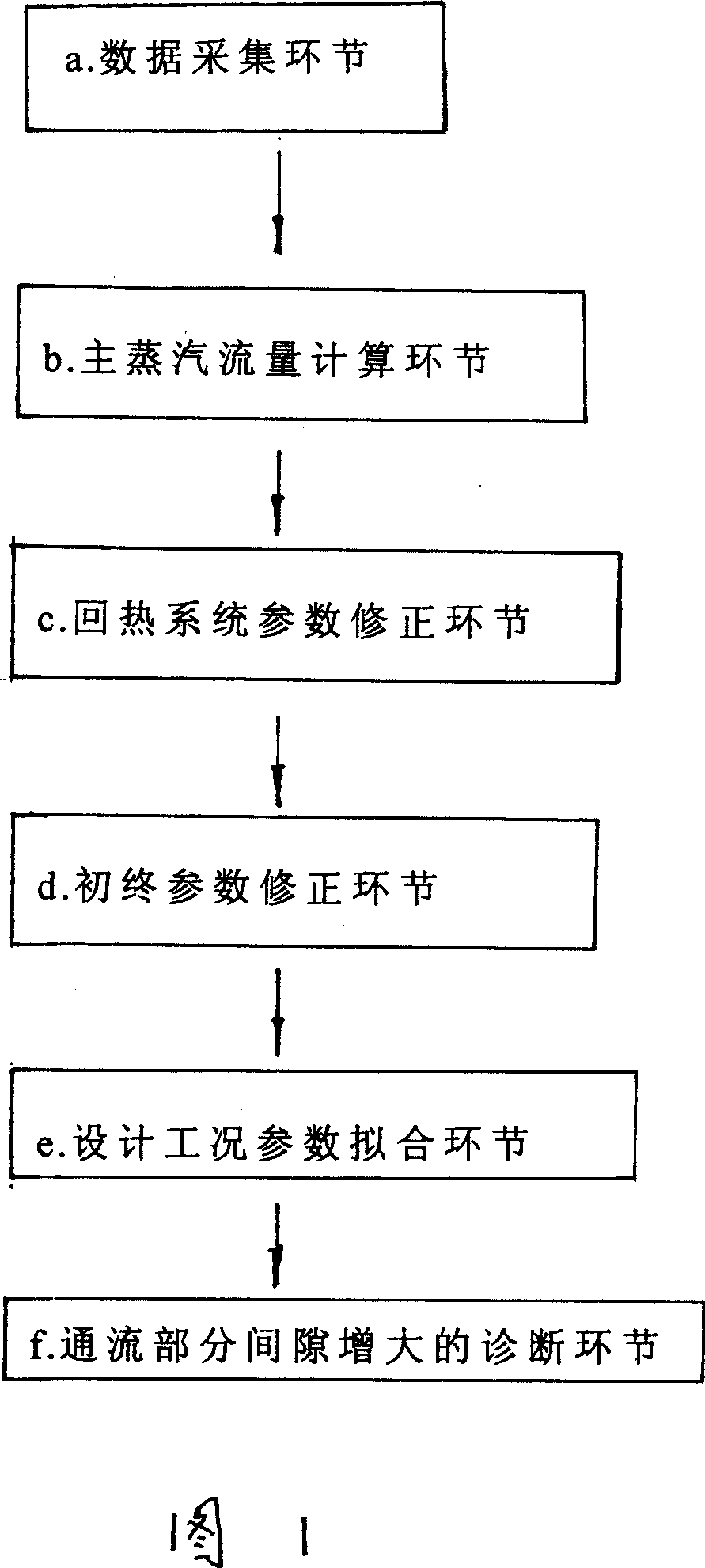

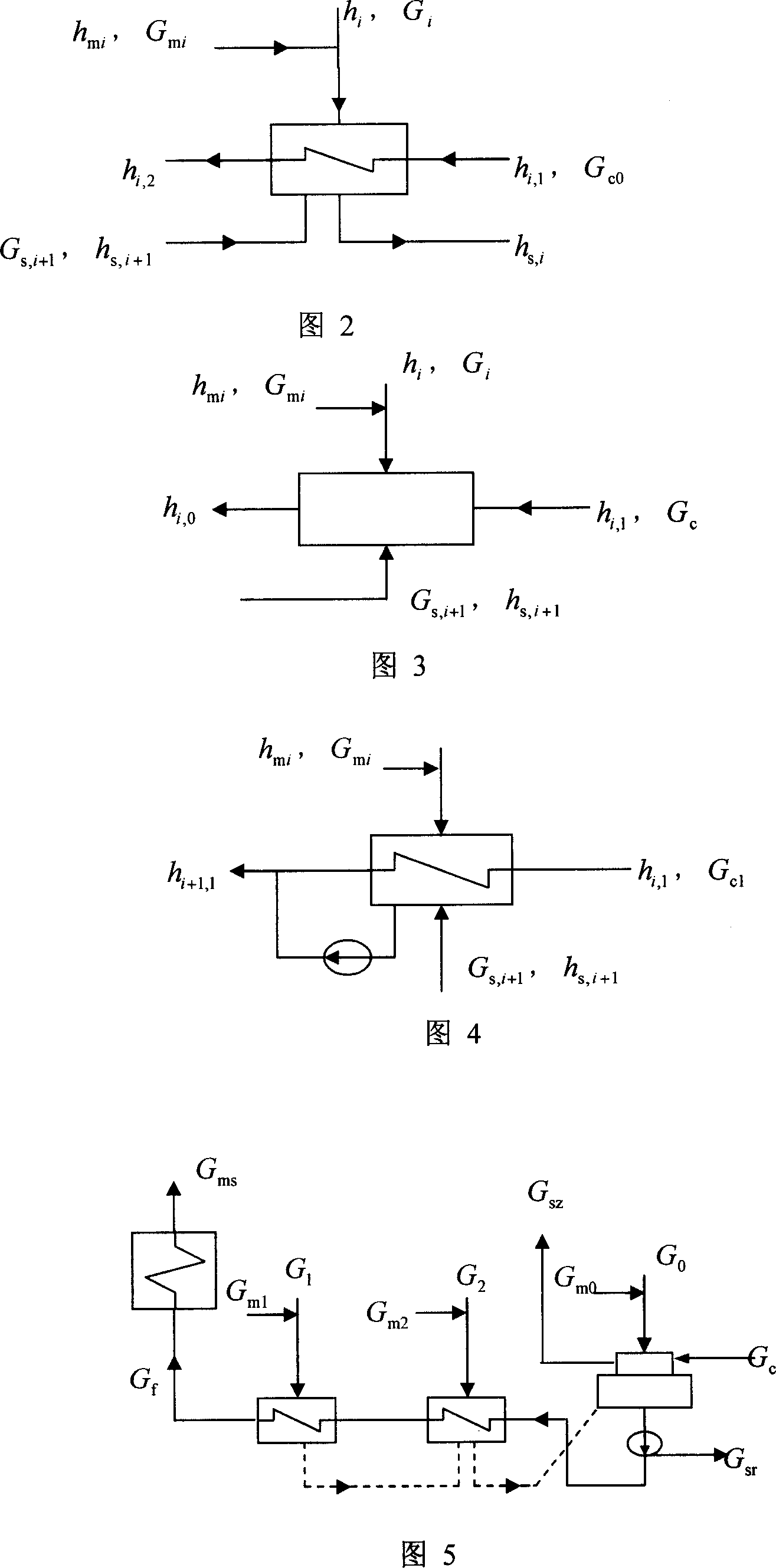

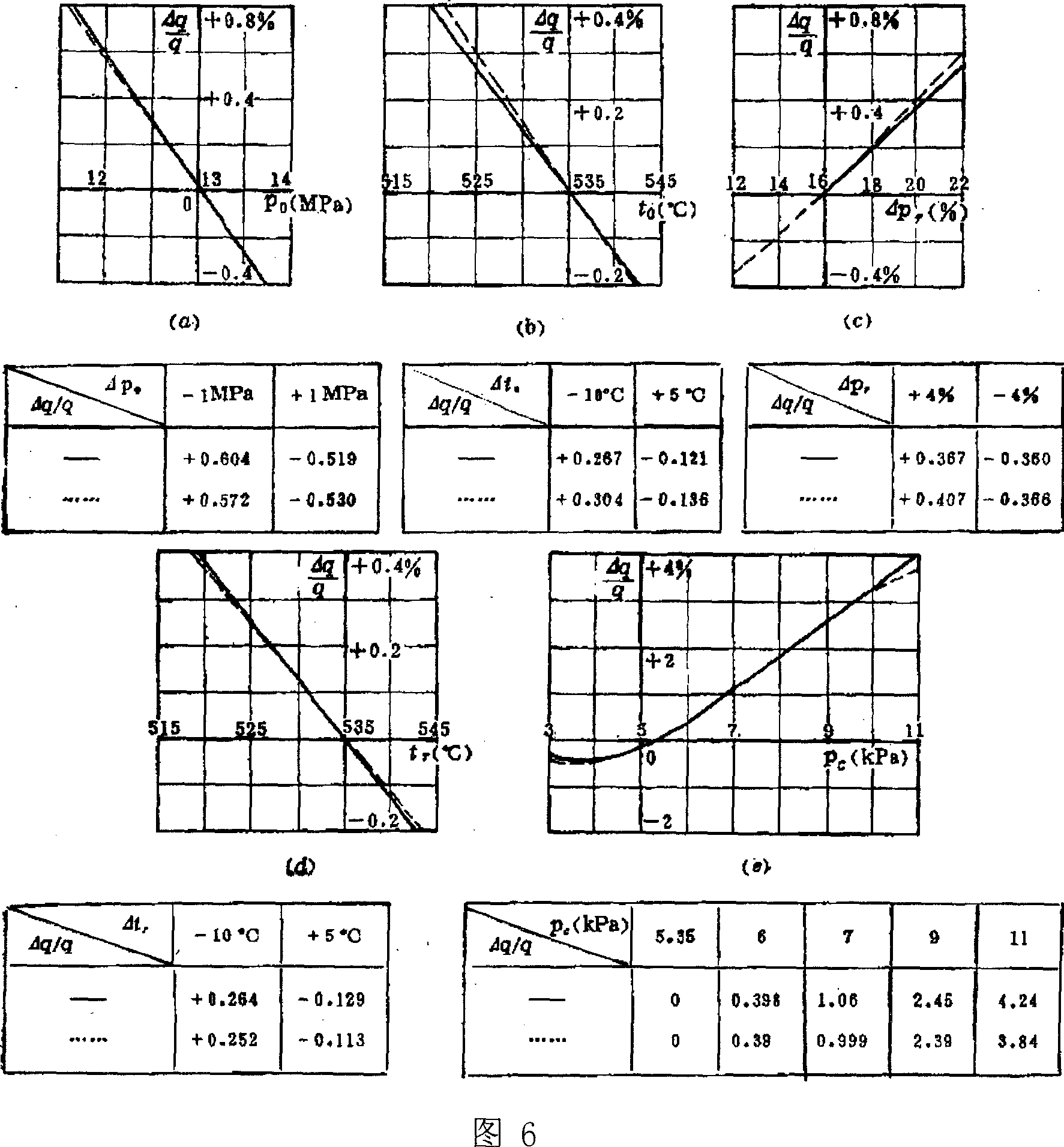

On-line monitoring method for variation of through-flow gap of steam turbine

InactiveCN1952590AMethod scienceRealize automatic online monitoringEngine testingMechanical clearance measurementsData acquisitionEngineering

An on-line monitoring method for the changing circulatation gap of the steam turbine is disclosed that comprises the steps: acquiring data, calculating the flux of the main steam, correcting parameters of the regenerative system, correcting the primary parameter and the end parameter, designing the parameter fitting in operating mode and diagnosing the augment of circulating gap. The main steam flux of the steam turbine can be obtained by computer from the main steam temperature and pressure of the main steam, the regenerative steam temperature and pressure, the vacuum condenser, the temperature and pressure in each of the regenerative exhaust points, the water temperature of the ports, the drain temperature and the water flux of condensate, the flux value of the cooling water of the superheater and the reheater when the steam turbine is running. Based on the heat balance diagram in the operating mode of the steam turbine, the temperature, pressure and the internal efficiency ratio of the regenerative ports in the condition of the main steam are contrasted with the real temperature, pressure and the internal efficiency ratio of the regenerative ports to realize the on-line monitoring for the changing circulatation gap of the steam turbine. The method is scientific to realize the automatical on-line monitoring and exact fault diagnosis.

Owner:NORTHEAST DIANLI UNIVERSITY

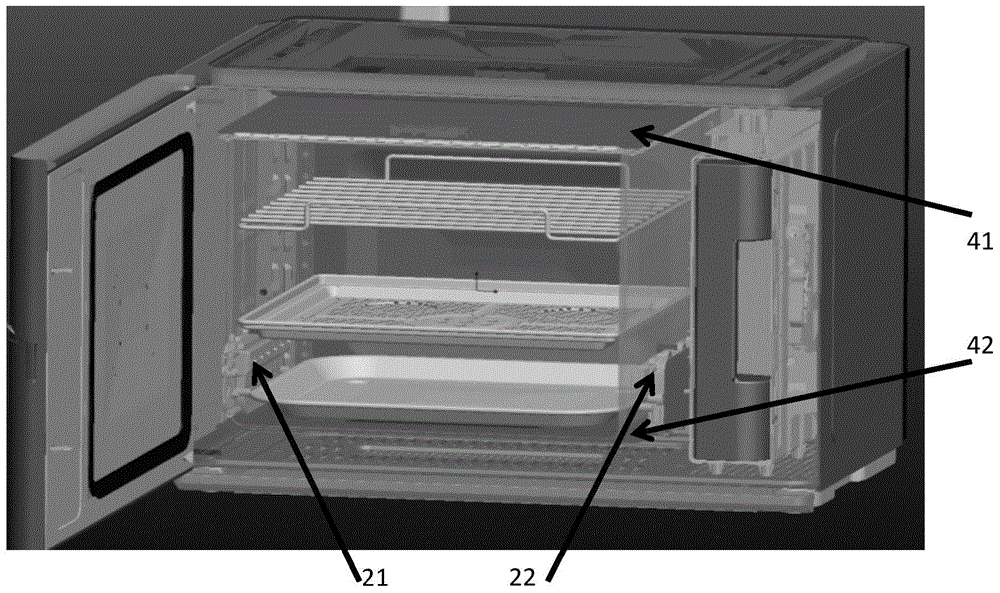

Steam cooker

InactiveUS20090007798A1Improve workabilityReduce cooking timeDomestic stoves or rangesBoiling over preventionSuperheaterEngineering

After a preheating operation is performed to raise an inner temperature of a heating chamber to a target preheating temperature (first specified temperature) by a first steam superheater of a steam temperature-raising device, a cooking operation is performed to raise, by the first steam superheater of the temperature-raising device, a temperature of steam obtained by heating of water in a steam generator by heaters 42A, 42B of the steam generator and then supply the steam to the heating chamber. In this process, when inner temperature of the heating chamber detected by an inner temperature sensor 81 during the preheating operation has come to or beyond a steam generation start temperature (second specified temperature) which is lower than a target preheating temperature, a control unit 80 decides that a steam generation start condition has been satisfied, and heats water in the steam generator by the heaters of the steam generator.

Owner:SHARP KK

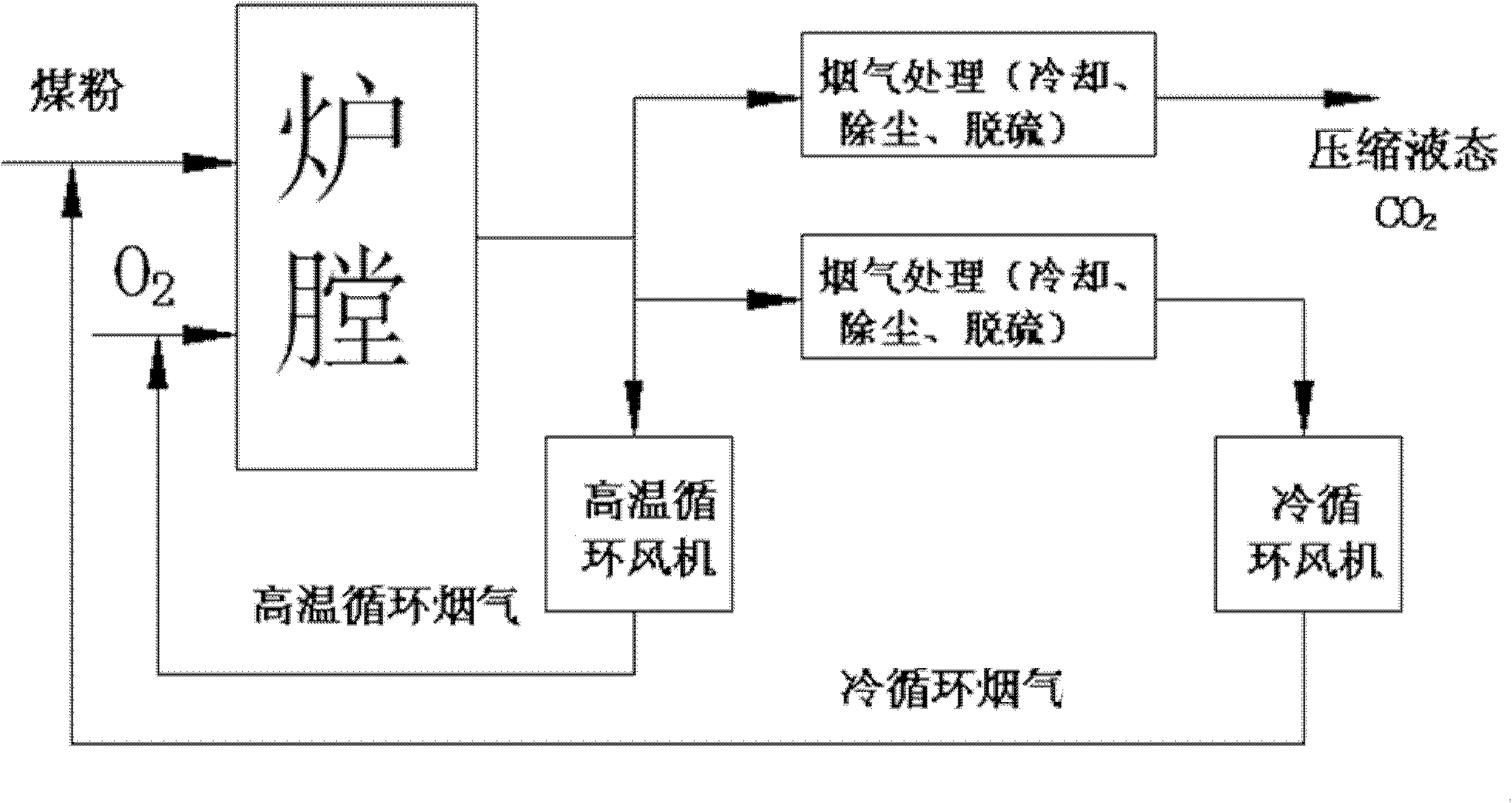

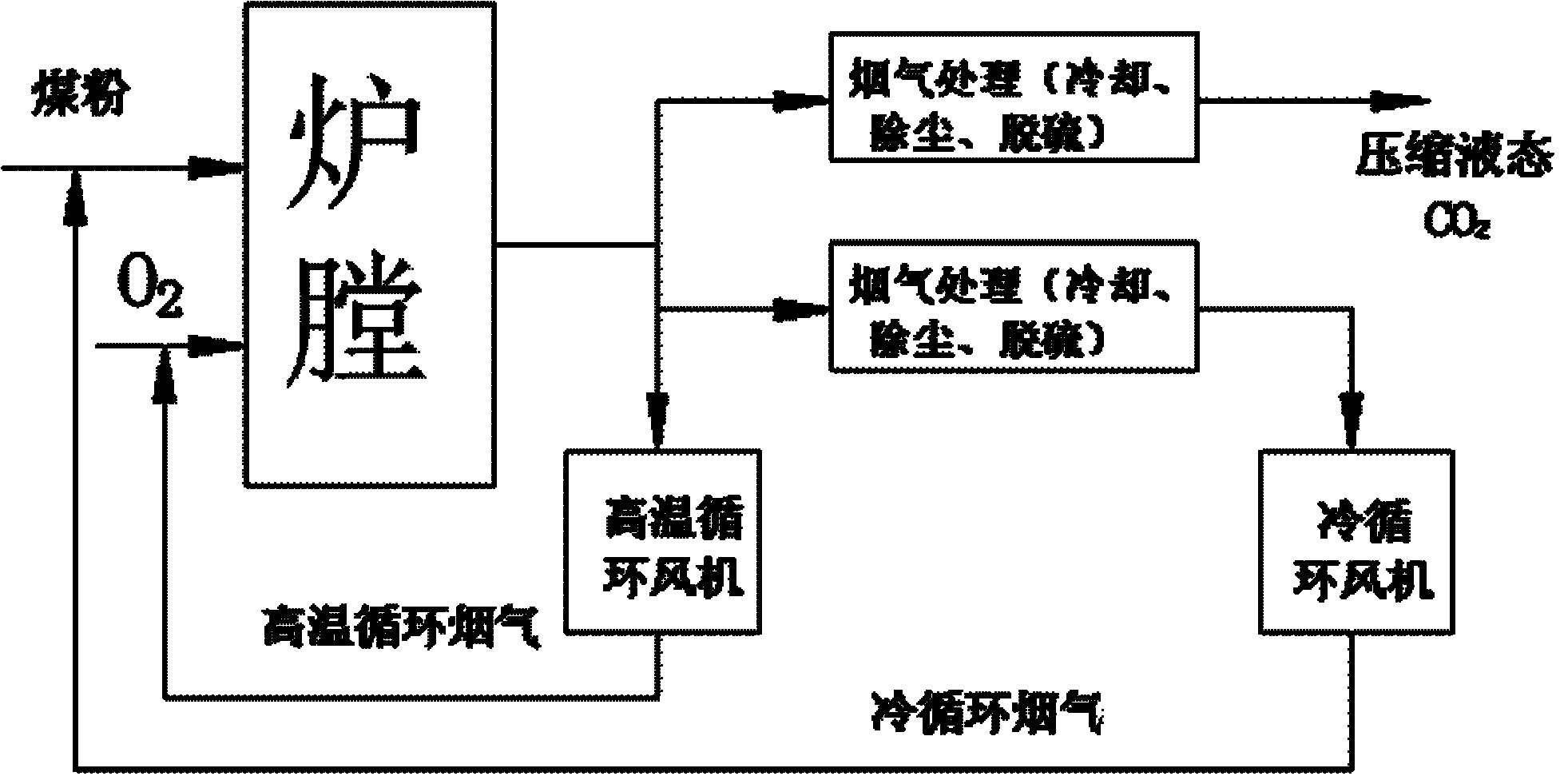

Method for re-circulating combustion of flue gas of pulverized coal fired boiler

InactiveCN101839474ASteam temperature increasedHigh thermal efficiencyFluidized bed combustionCarbon compoundsCO2 contentHearth

The invention provides a method for re-circulating combustion of flue gas of a pulverized coal fired boiler, belongs to a method for circulating combustion of oxygen gas (O2) and carbon dioxide (CO2) of pulverized coal, and aims to solve the problems of low heat efficiency and poor burn-out property existing in the conventional combustion method. The method comprises the steps of: 1,igniting and combusting: conveying the pulverized coal to a furnace hearth by using the circulation flue gas, and simultaneously conveying O2 to the furnace hearth for ignition; 2, circulating the flue gas: dividing the high-temperature flue gas generated by combustion into two parts, and performing cooling, dust removal and desulfurization compression on the first part to obtain liquid CO2; dividing the second part into two paths, conveying the first path to an entrance of the furnace hearth by using a high-temperature circulation fan, and mixing the first path of the flue gas and O2; and performing cooling, dust removal and desulfurization on the second path, and conveying the second path carrying the pulverized coal to the furnace hearth by using a cold circulation fan. The method has the advantages of adjusting the steam temperature of the boiler by using the high-temperature flue gas, enhancing convective heat transfer, increasing the steam temperature of the boiler, improving the heat efficiency of the boiler and the denitration rate, increasing the CO2 content after the high-temperature flue gas is cooled, reducing emission load of NOx, lowering CO2 capturing and collecting cost, and meeting the national energy conservation and environmental protection standard.

Owner:HUAZHONG UNIV OF SCI & TECH

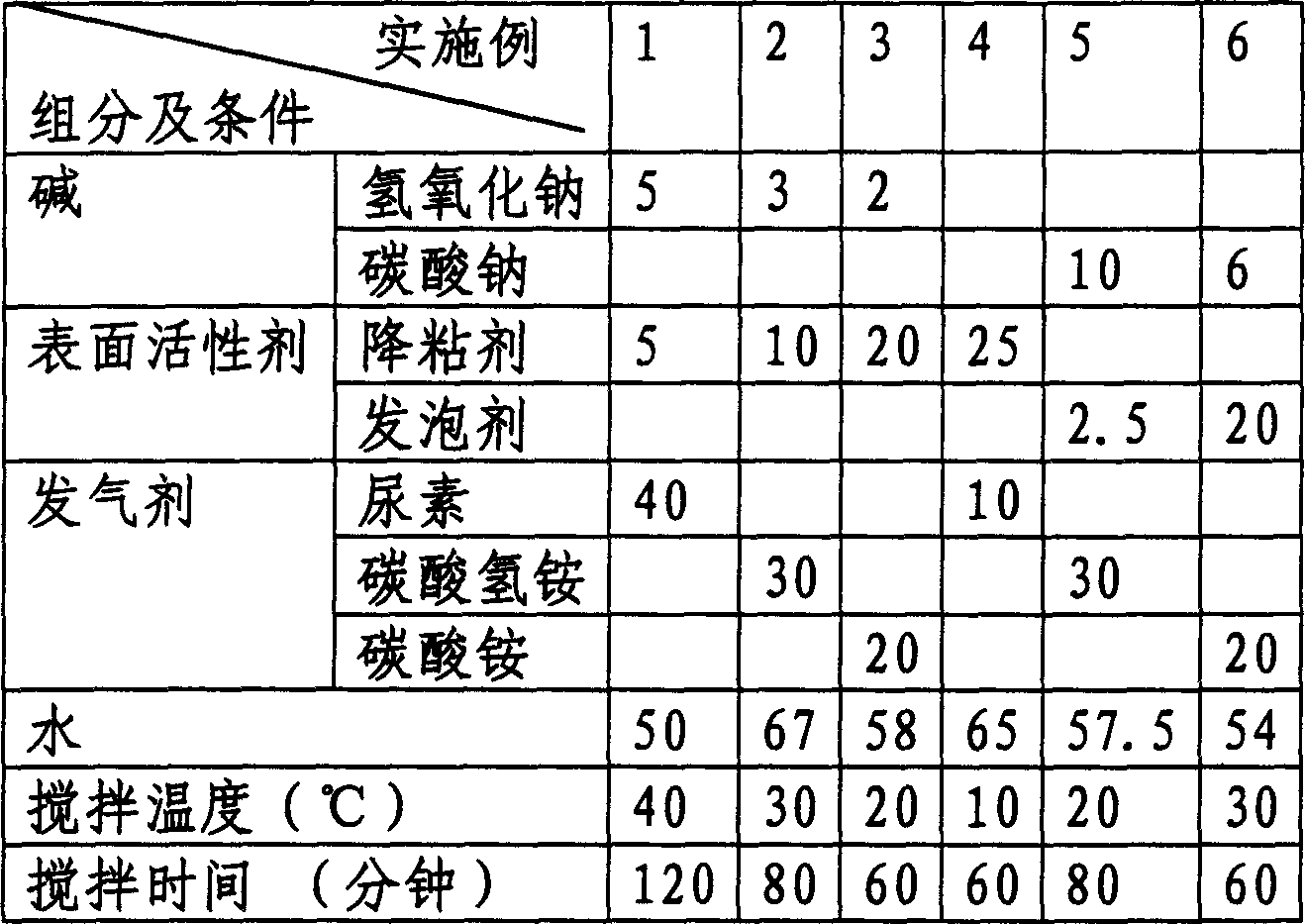

Thickened oil steam production synergist and its preparing method

InactiveCN1554725ARapid expansion of heating radiusImprove the mining effectFluid removalProduct gasSURFACTANT BLEND

The synergist for steam exploitin thickened oil consists of gas creating agent 10-40 wt%, surfactant 5-25 wt% and alkali 0-5 wt% except water. The preparation process includes the steps of: dissolving sodium hydroxide and / or sodium carbonate; adding surfactant via stirring for mixing and adding the gas creating agent via stirring. Under steam temperature urea as the gas creating agent is decomposed to generate CO2 and CO2 and the surfactant form foam to expand the steam wave and volume to raise the oil displacing efficiency and reach the synergistic effects of modifying profile and lower viscosity obviously. The present invention is suitable for exploiting shallow, thin, dense and dispersed thickened oil reservoir. The present invention can raise oil yield and steam heat efficiency.

Owner:中国石油化工股份有限公司河南油田分公司石油工程技术研究院 +1

System for controlling steam temperature

A system for controlling steam temperature that includes steam circuit including a reheater circuit, at least one reheater dilution region, at least one reheater dilution conduit, and at least one reheater supply region disposed upstream of the at least one reheater dilution region, wherein the at least one reheater supply region and the at least one reheater dilution region are associated via the reheater circuit and the at least one reheater dilution conduit.

Owner:GENERAL ELECTRIC CO

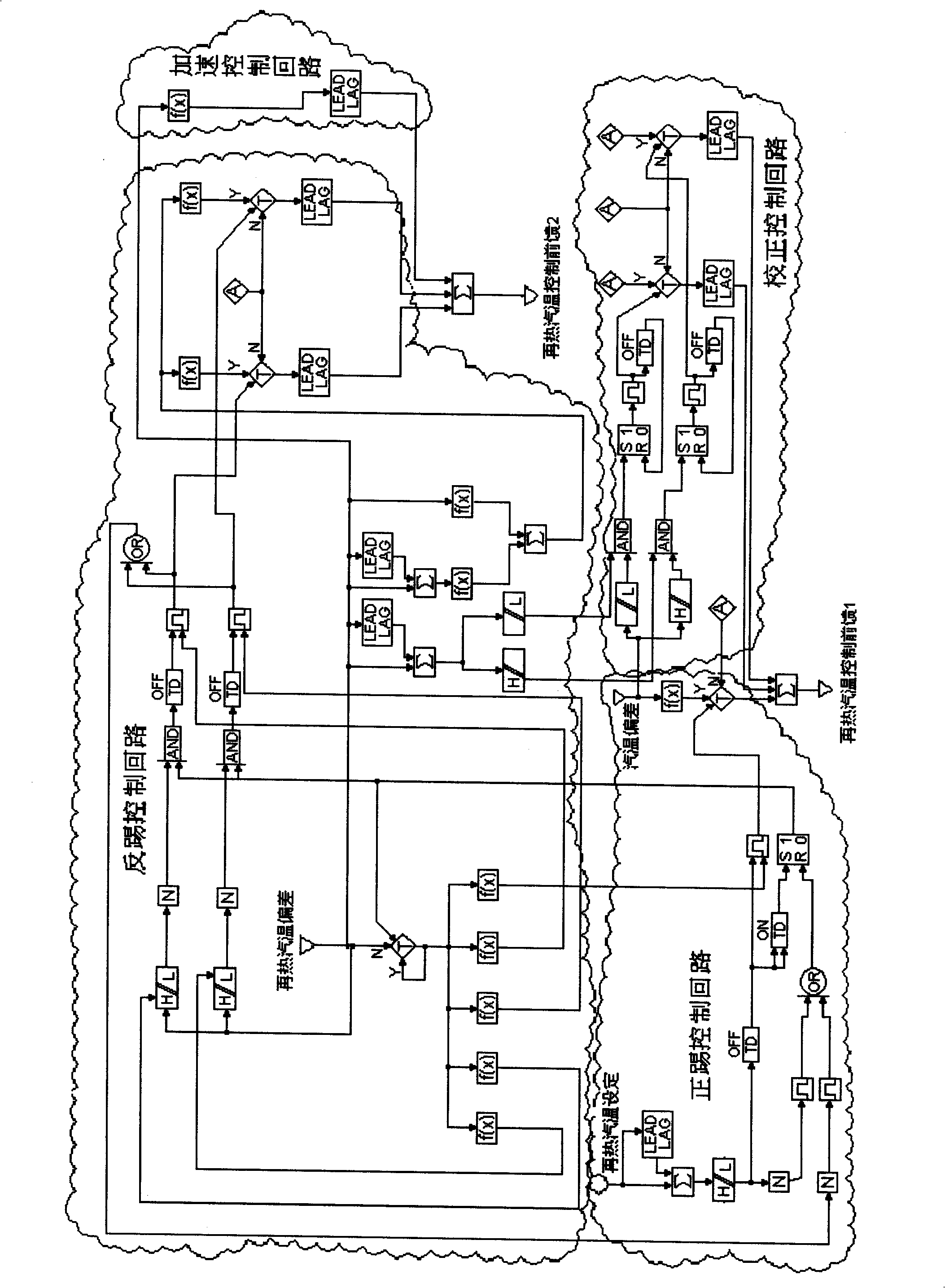

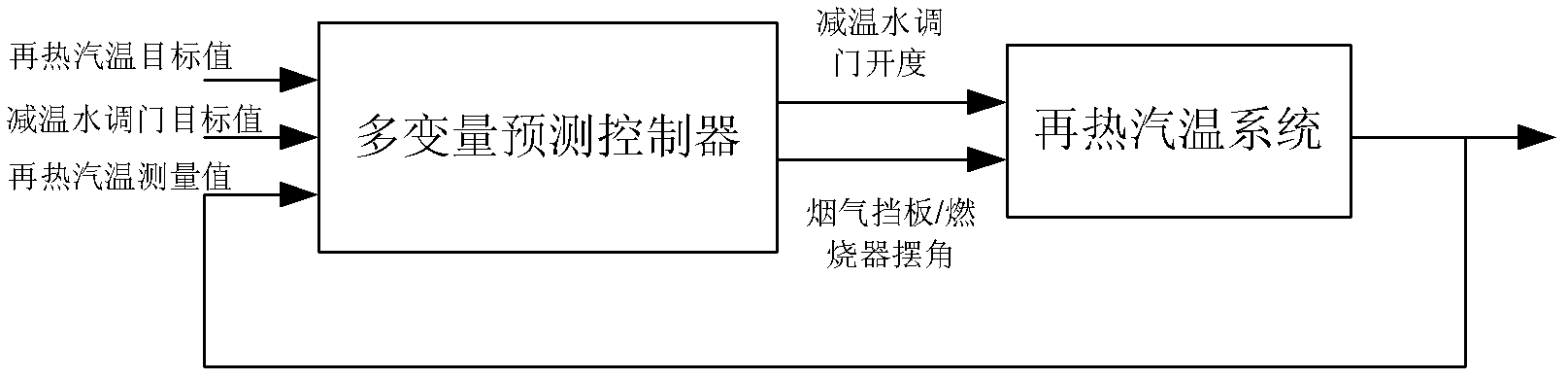

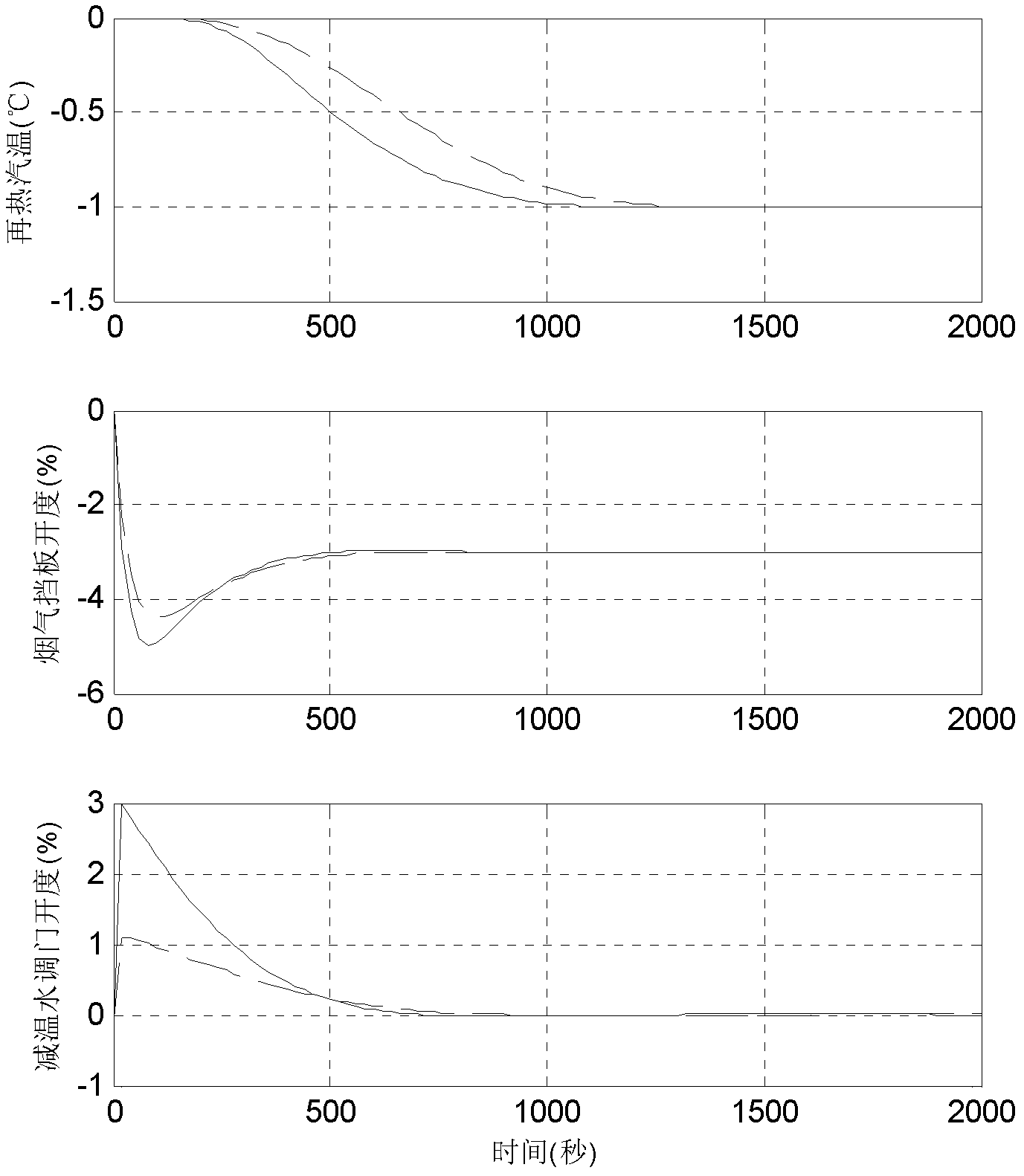

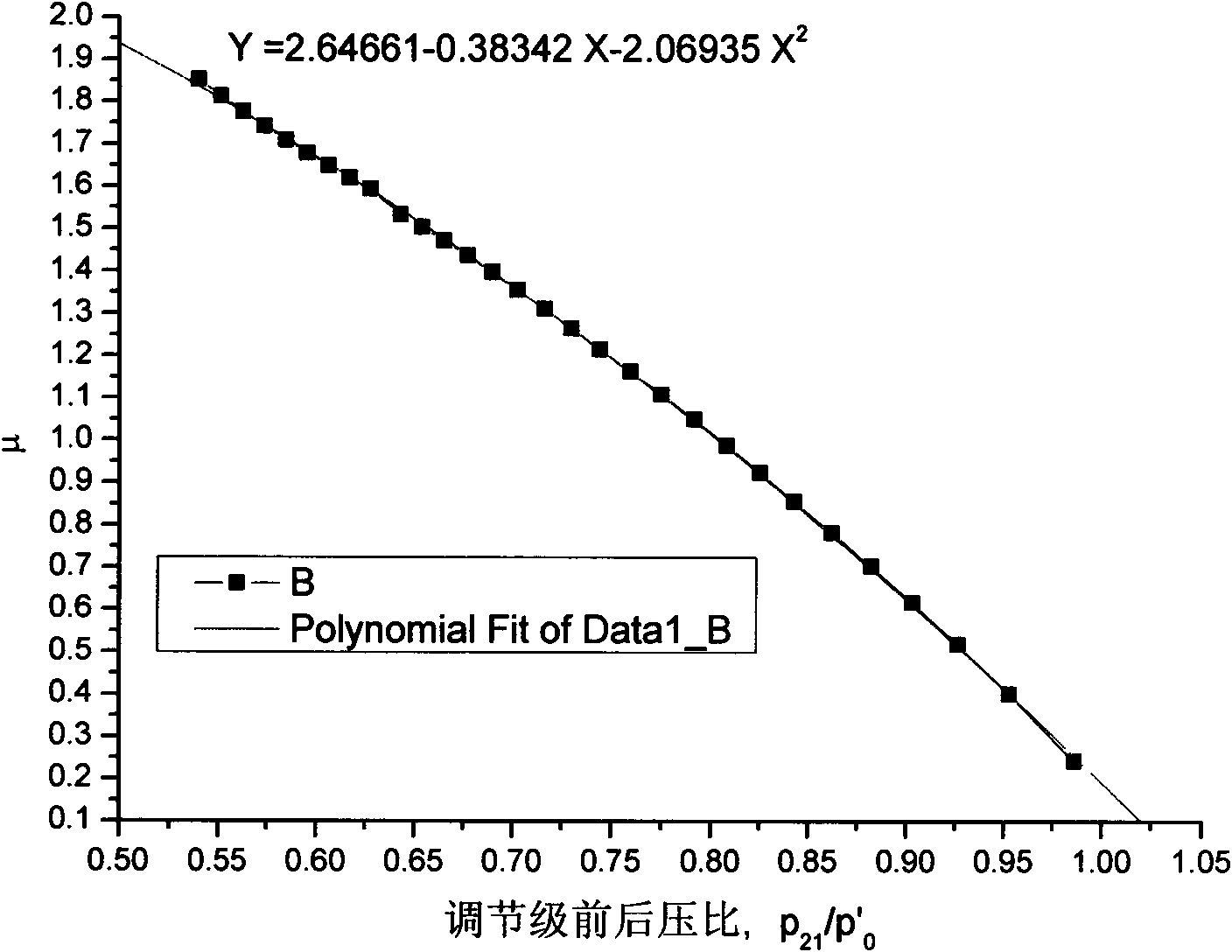

Reheated gas temperature optimization control method based on multi-variable predictive control

InactiveCN102401371AImprove economyDealing with large latency characteristicsSuperheating controlFlue gasPerformance index

The invention discloses a reheated gas temperature optimization control method based on multi-variable predictive control. According to the method, the whole hot steam temperature system is regarded as a two-in one-out multi-variable object, and the flow rate of reheated de-superheating jet water and the opening of a flue gas baffle plate are simultaneously controlled by adopting a multi-variable predictive control method; moreover, optimization of economical efficiency of the system is realized by adding a steady state target value of the opening of a reheated de-superheating jet water adjusting valve into optimization indexes of the conventional predictive control. By adopting the multi-variable predictive control method, coordination of side adjustment of flue gas and side adjustment of steam can be better realized, and the dynamic adjusting quality of the reheated steam temperature is further improved; and meanwhile, by adding the steady state target value of the de-superheating water adjusting valve into the conventional predictive control performance indexes, optimization of the de-superheating water jet quantity is realized, so that the circulating efficiency of a unit can be effectively improved.

Owner:SOUTHEAST UNIV

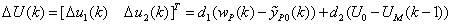

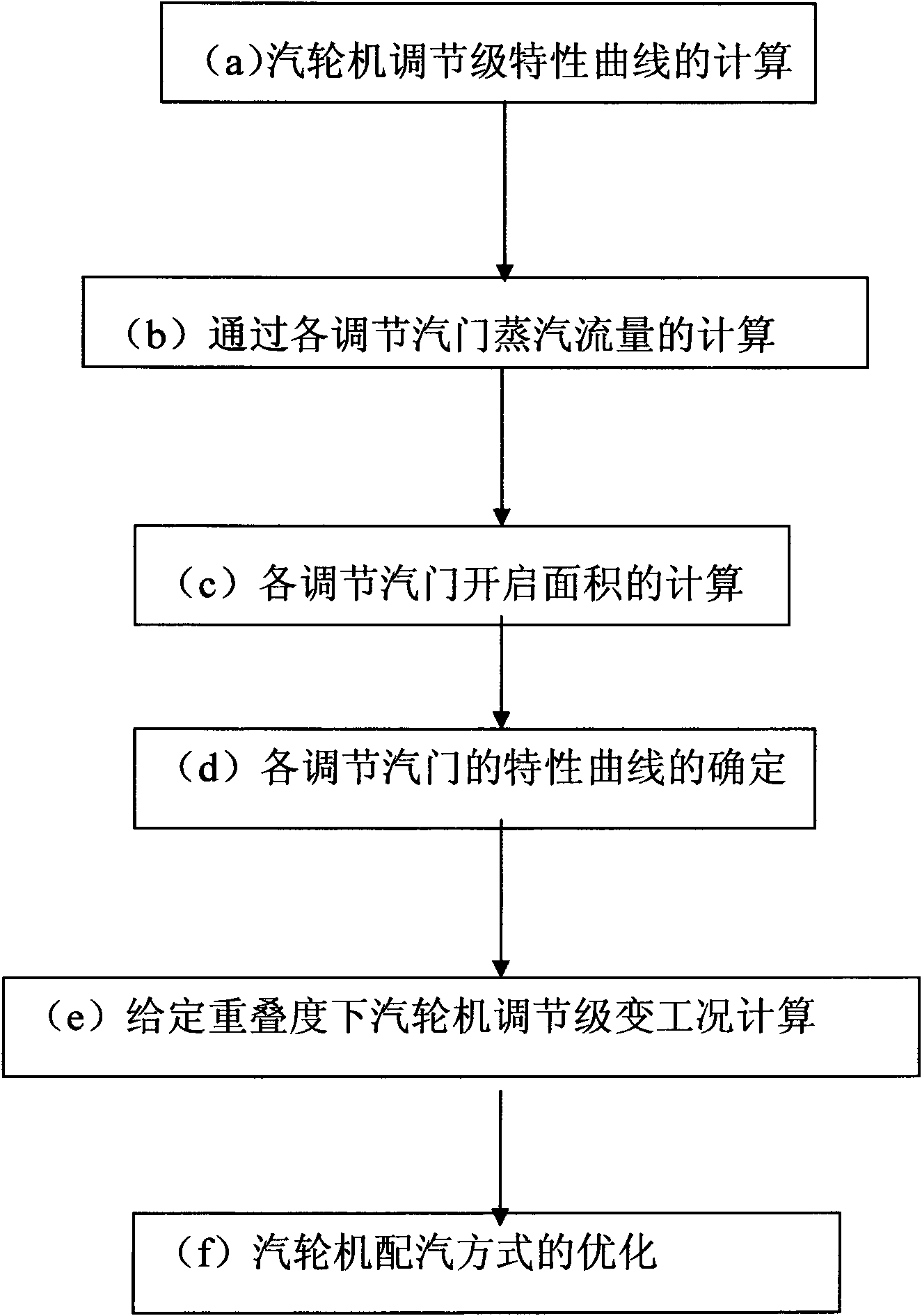

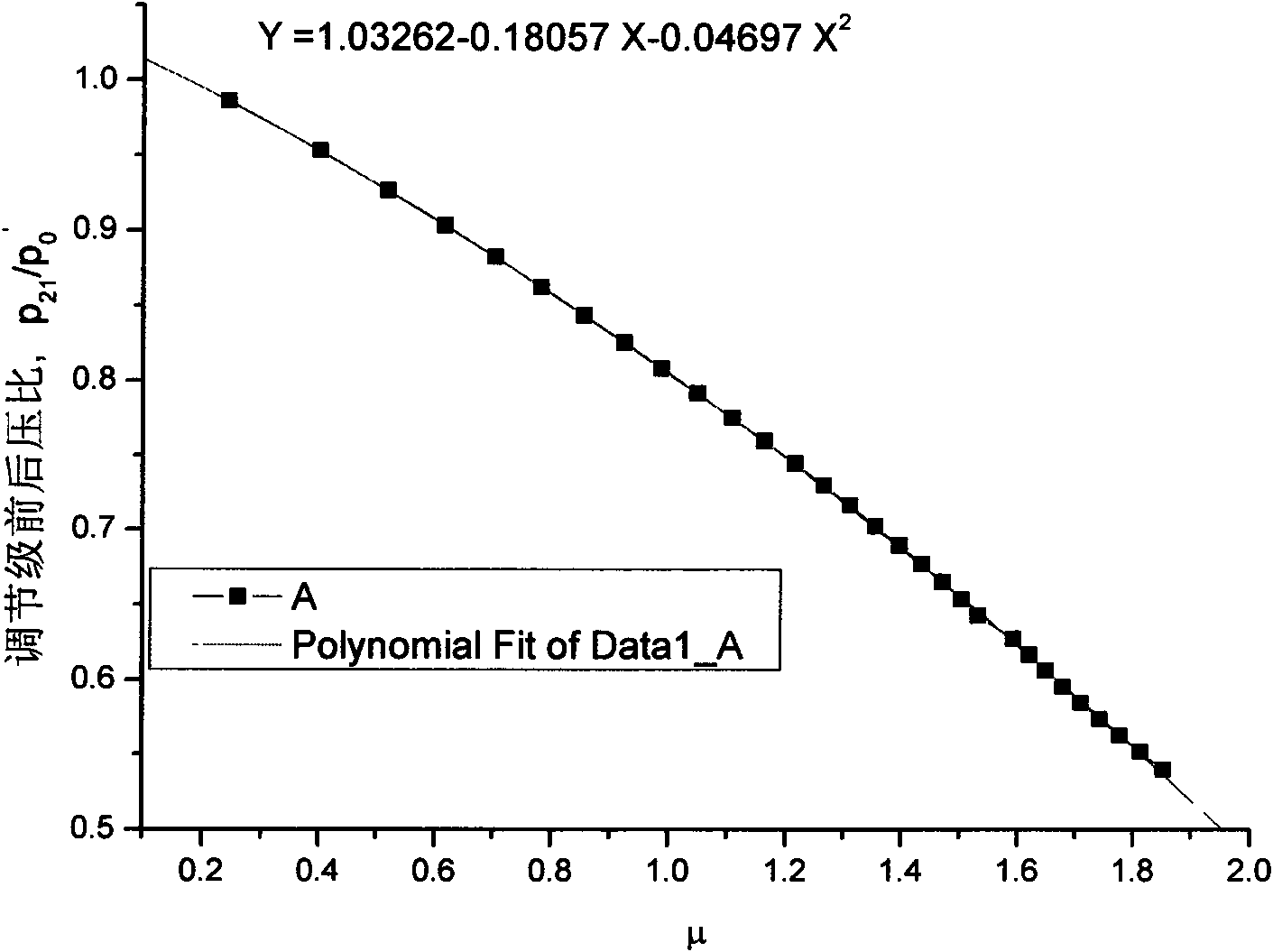

Method for optimizing steam distribution way of steam turbine

ActiveCN101644173AGood steam distributionThe method is scientific and reasonableMachines/enginesEngine componentsSteam pressureEngineering

The invention relates to a method for optimizing a steam distribution way of a steam turbine, which is characterized by comprising the following steps: calculating a regulating stage characteristic curve according to the structure parameter of a regulating stage; measuring steam temperatures and pressures in the front of all regulating air valves, steam pressures behind the regulating air valves and steam temperature and pressure behind the regulating stage in the prior steam distribution way of the steam turbine and calculating to obtain steam flows passing through all corresponding regulating air valves; calculating to obtain starting areas of all the regulating air valves by combining steam pressure specific values in the front and the rear of all the regulating air valves, the steam pressures and the temperatures in the front of the regulating air valves, and the steam flows passing through the regulating air valves; randomly giving an overlapping degree value between every two regulating air valves and giving the steam temperature and the pressure in the front of the two regulating air valves and respective opening degrees to calculate the steam pressures behind all the regulating air valves, the steam pressure behind the regulating stage, the steam flows of all regulating air valves and the relative inner efficiency of the regulating stage; and selecting the optimal steam distribution way of the steam turbine according to the principle that the relative inner efficiency is maximal and a relation curve between the lifting range and the flows of a regulating air valvegroup is a straight line.

Owner:NORTHEAST DIANLI UNIVERSITY +3

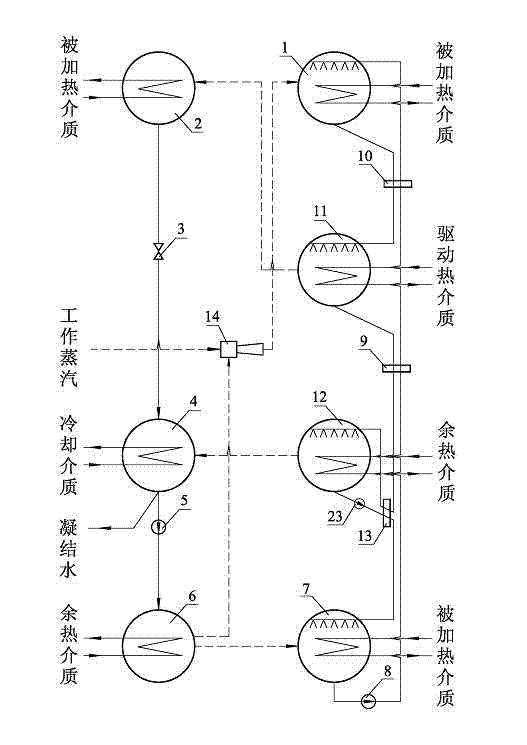

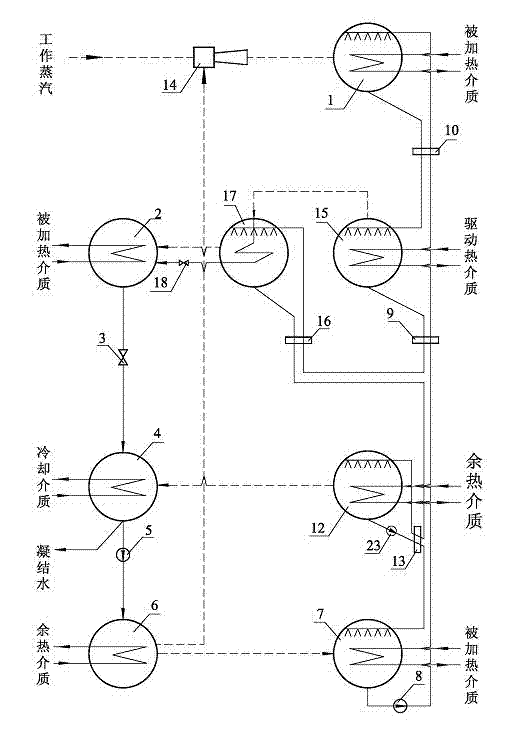

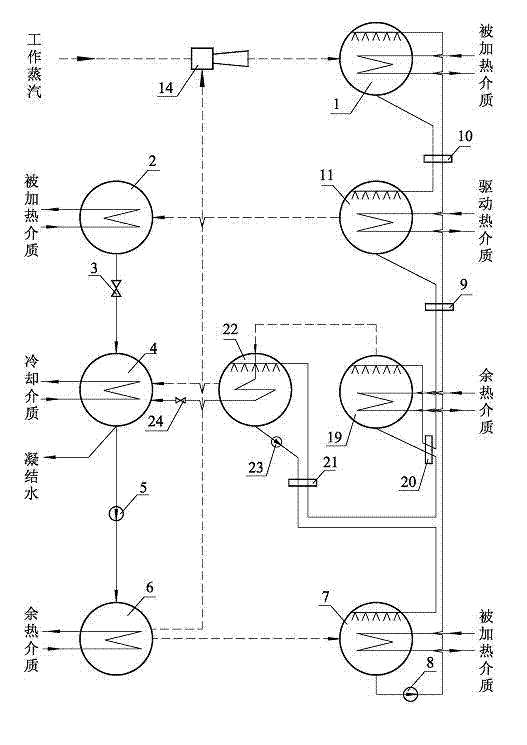

Fourth type heat pump cycle

InactiveCN103574978AEnergy efficient heating/coolingClimate change adaptationEngineeringAbsorption heat pump

The invention relates to fourth type heat pump cycle, which consists of a high-temperature absorber, a first condenser, a first throttling valve, a second condenser, a refrigerant liquid pump, an evaporator, an absorber, a first solution pump, a first solution heat exchanger, a second solution heat exchanger, a third solution heat exchanger, a second solution pump, an ejector and a plurality of generators. Jet type heat pump cycle and two types of absorption heat pump cycle are organically combined, so high-grade driving steam temperature difference and pressure difference are effectively utilized, high heat supply temperature and high-efficiency heat energy utilization ratio are obtained, high-grade driving steam can be efficiently utilized, smaller compression ratio and higher ejection coefficient are achieved, and the fourth type heat pump cycle is excellent in energy-saving efficiency as compared with the traditional heat supply method.

Owner:刘辉

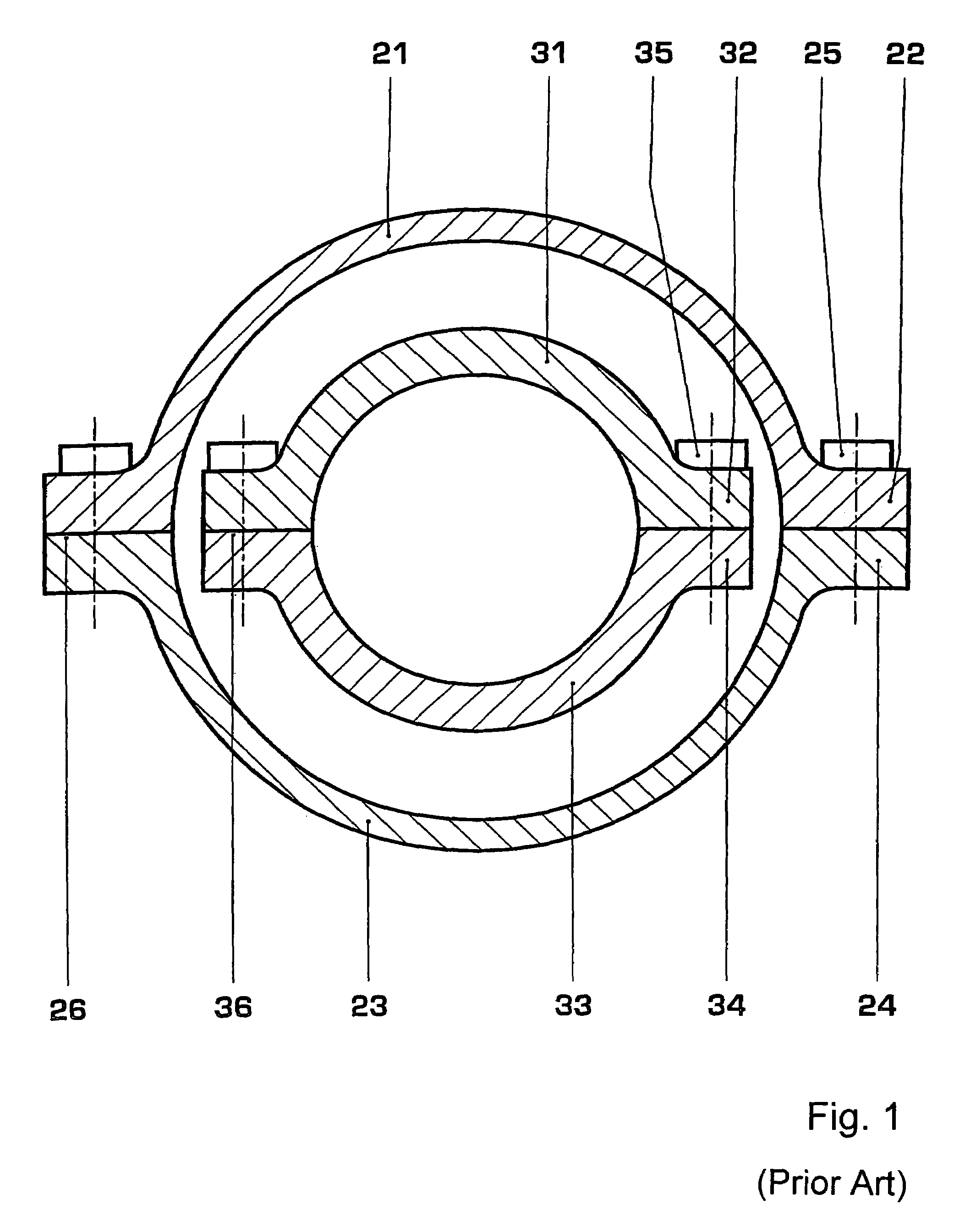

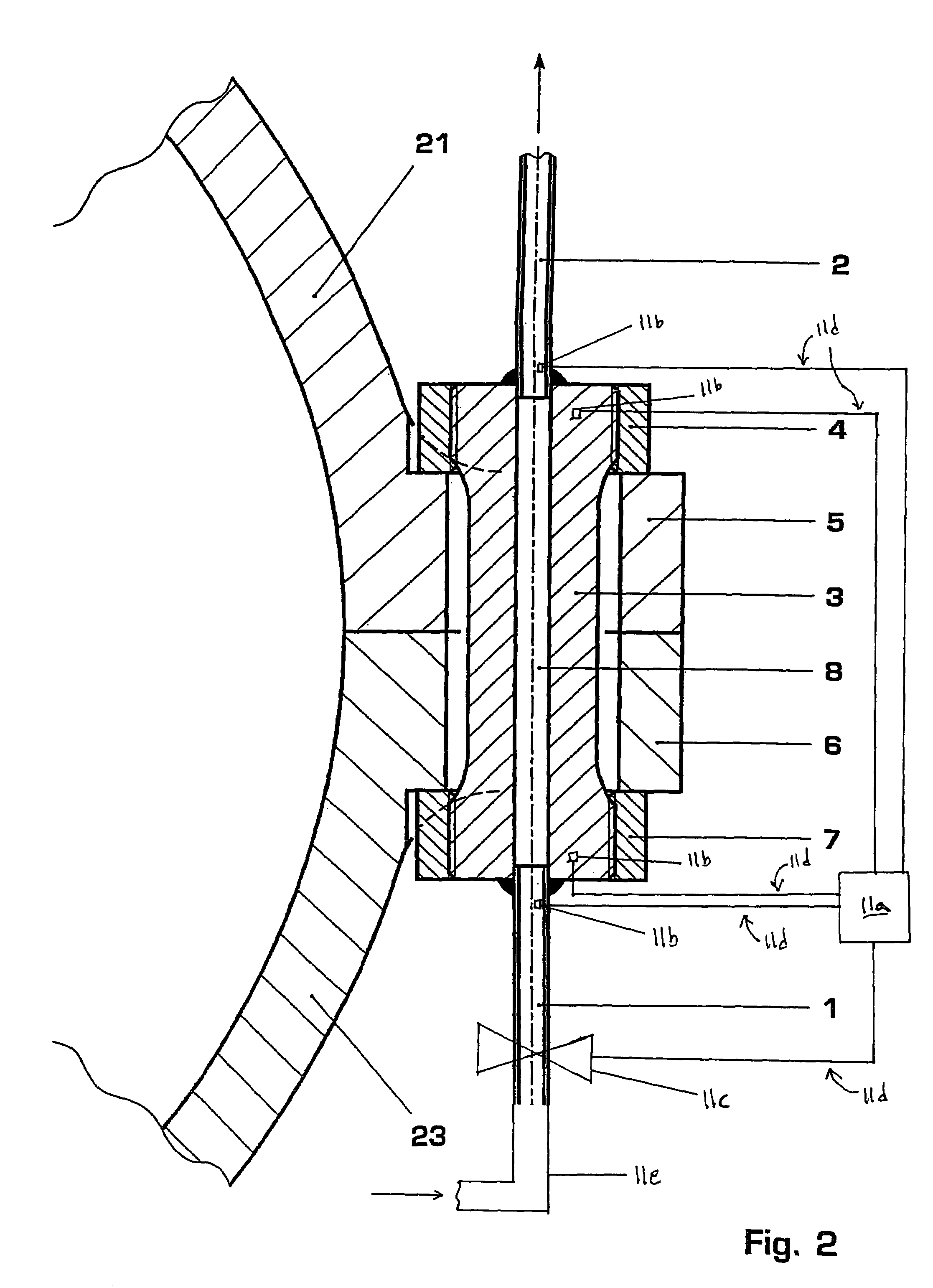

Flange bolt for turbines

InactiveUS7037065B2Improve stabilityControl changesWind motor controlPipe elementsEngineeringTurbine

An arrangement for cooling or heating of a flange bolt for turbines comprises one or more boreholes, that extend through the bolt, and inlet and outlet pipes that are connected to each end of the borehole. A cooling or heating medium such as air, steam or any other fluid flows through an inlet pipe into and through the borehole thereby cooling or heating the bolt, and exits from the borehole via an outlet pipe. The cooling or heating arrangement enables direct cooling or heating of the bolt itself and ensures stable bolting forces throughout the operation of the turbine. The flange bolts with this arrangement may be applied to gas turbines or steam turbines operated at elevated steam temperatures and pressures.

Owner:GENERAL ELECTRIC TECH GMBH

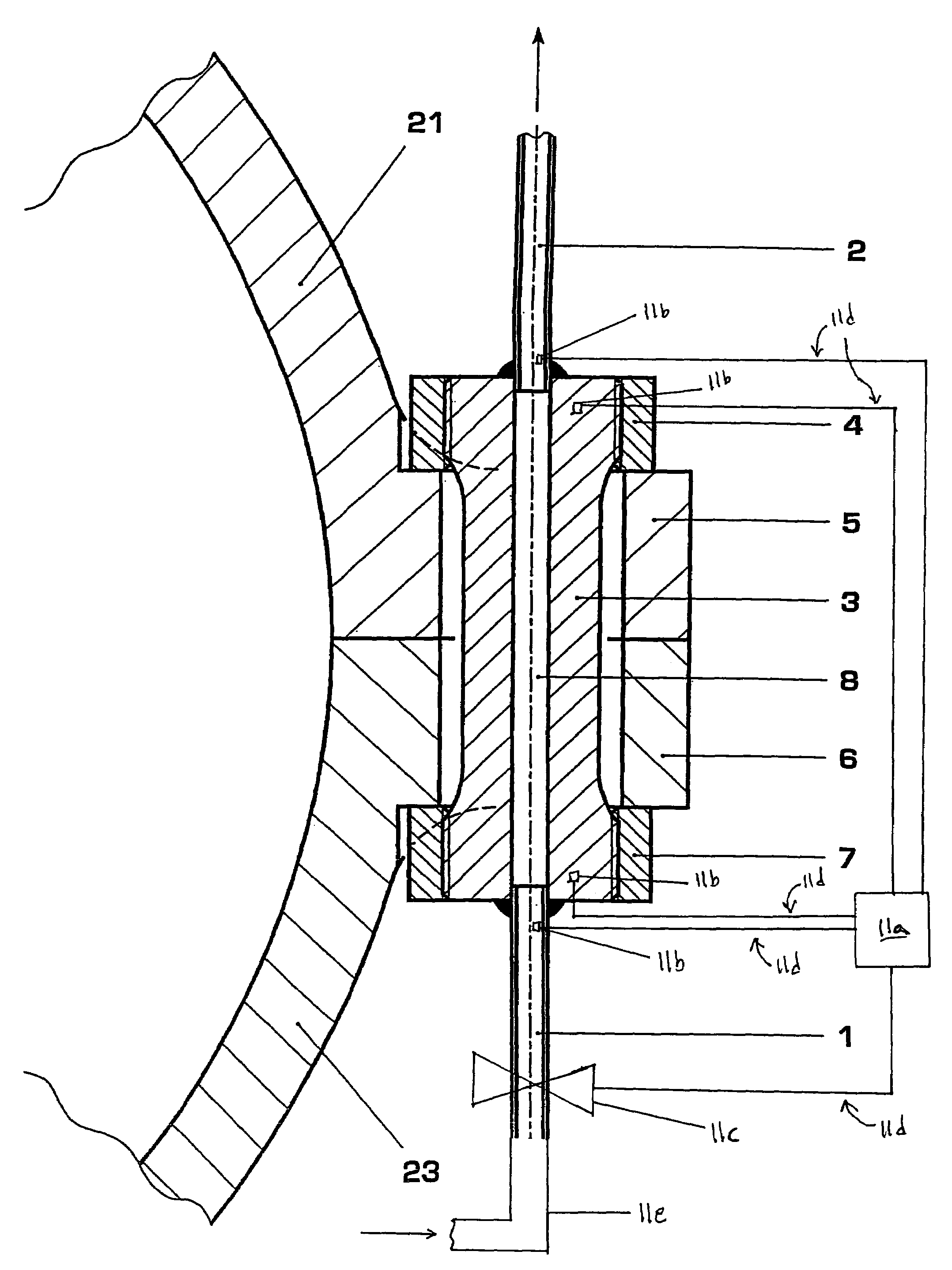

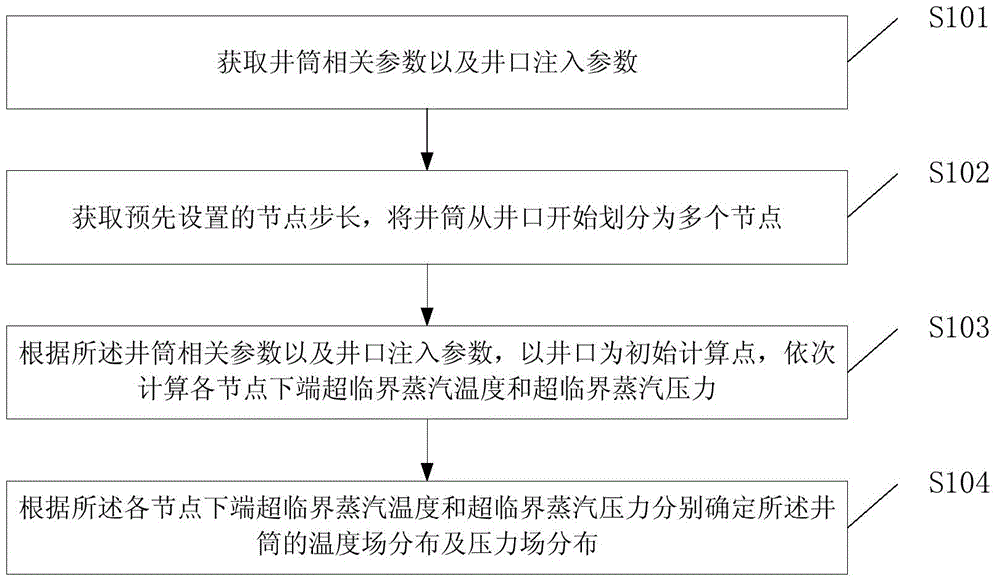

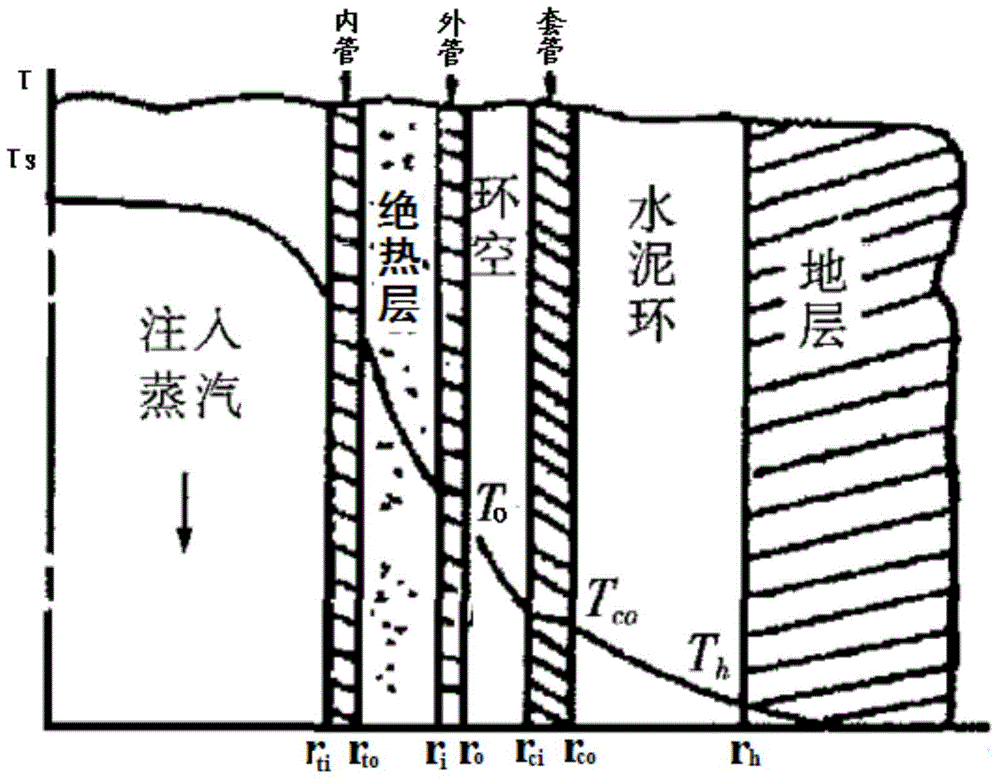

Supercritical steam injection well bore temperature field and pressure field distribution calculation method

ActiveCN104806230ASolve the mechanical propertiesSurveyConstructionsSteam pressureCalculation methods

The invention provides a supercritical steam injection well bore temperature field and pressure field distribution calculation method and relates to the field of reservoir production. The method comprises obtaining well bore relevant parameters and well head injection parameters; obtaining preset node step length, and dividing the well bore into a plurality of nodes from the well head; calculating supercritical steam temperature and supercritical steam pressure of the lower ends of all nodes according to the well bore relevant parameters and the well head injection parameters with the well head serving as the initial calculation point successively; determining the well bore temperature field and pressure field distribution according to the supercritical steam temperature and the supercritical steam pressure of the lower ends of all nodes respectively. By the aid of the method, the well bore temperature field and pressure field of the supercritical steam injection well can be calculated.

Owner:PETROCHINA CO LTD

Biomass circulating fluid bed burning method and biomass circulating fluid bed boiler

ActiveCN101113816AReduce the temperatureImprove working environmentFluidized bed combustionApparatus for fluidised bed combustionTemperature controlSuperheater

The invention discloses a biological circulation fluidized bed combustion method and a biological fueled circulation fluidized bed boiler; the fluidized bed boiler comprises a boiler cavity, a clutch, a material refeeder, a tail chimney, wherein, the boiler cavity is provided with a superheater high temperature section, and the tail chimney is provided with a superheater low temperature section. Through the arrangement of heating surfaces of the boiler cavity and the tail chimney and other auxiliary measures, the temperature of the upper part of the boiler cavity is controlled at 550 to 800 DEG C, the outlet steam temperature of the tail heating surface is controlled at 350 to 400 DEG C, so as to solve the problem that: the temperature distribution of the boiler cavity is unreasonable, and the material concentration of the lower part of the boiler cavity is too low when the biological fuels are combusted in the circulation fluidized bed based on the stable fire, complete consumption of biological fuels , so that the temperature distribution in the boiler cavity tends to be equalized and the boiler cavity can be prevented from clinkering, and the accumulated ashes on the heating surfaces can also be prevented from being clinkered, furthermore, the boiler output capacity can be ensured, and a high steam parameter can also be achieved to ensure the generation efficiency.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

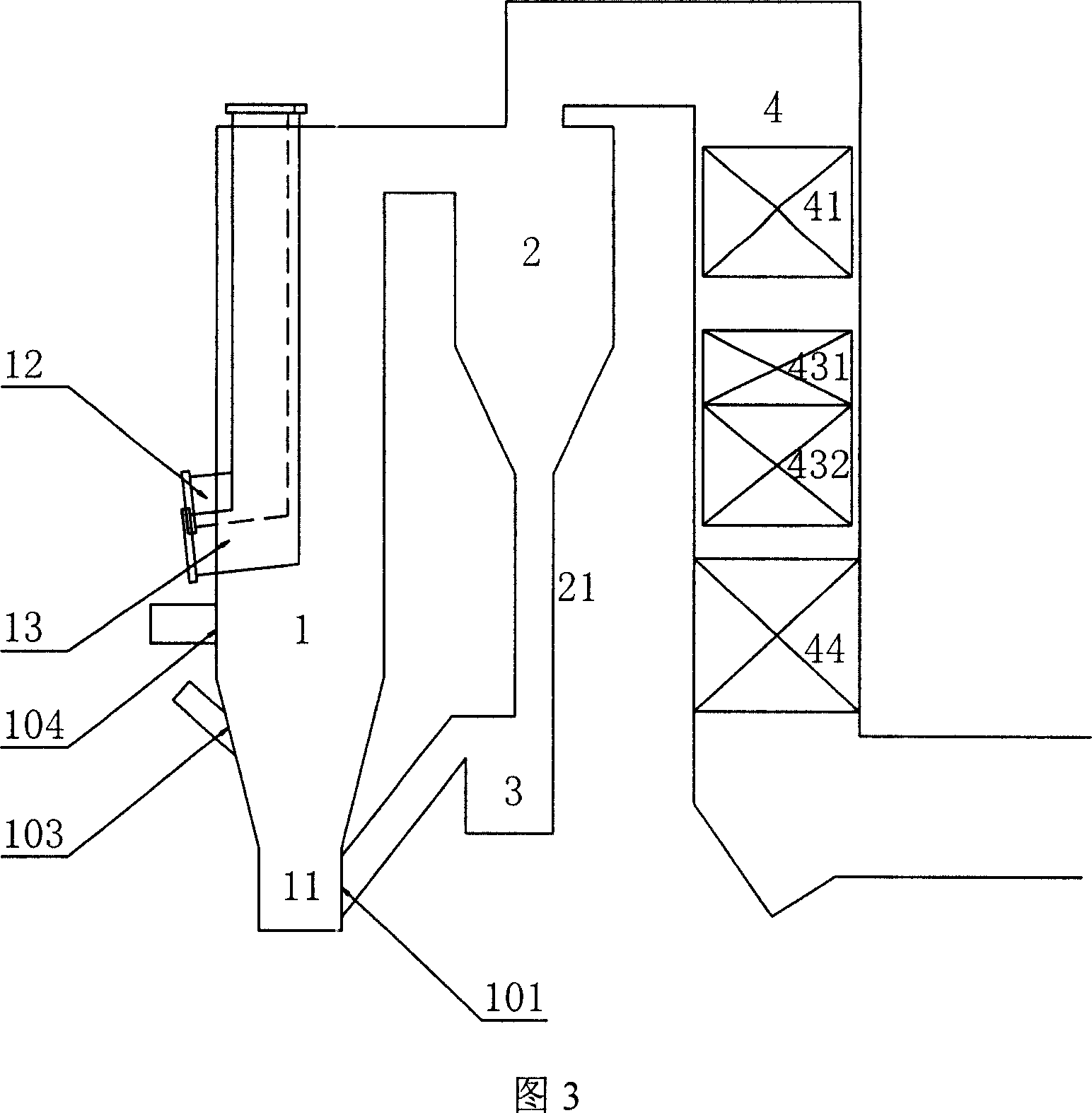

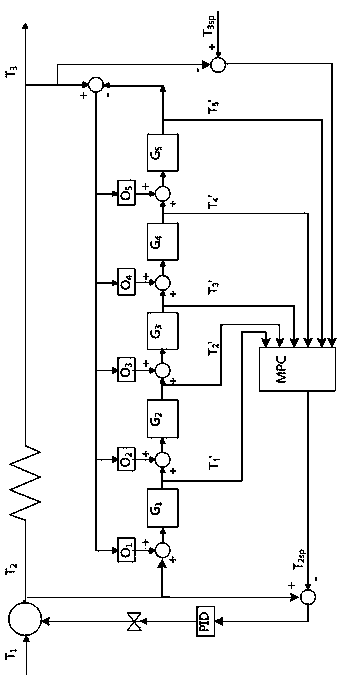

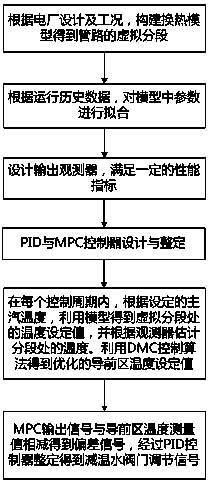

Method for predicting and controlling steam temperatures of boilers on basis of state observation model

ActiveCN103676651AReduced need for field trialsImprove object propertiesAdaptive controlControl signalMathematical model

The invention relates to a method for predicting and controlling steam temperatures of boilers on the basis of a state observation model. The method includes 1, replacing heat exchangers by multiple sections of concentration parameter links by a principle of natural segmentation or virtual segmentation, and using outlet parameters of media of various sections as representative parameters of the concentration links to build a mathematical model of enthalpy and temperature channels of the heat exchangers; 2, creating a state observer on the basis of output feedback and estimating outlet temperatures of the various sections; 3, connecting an MPC (multivariate model prediction controller) and a PID (proportion, integration and differentiation) regulator in a cascade manner to form a serial control circuit, acquiring step response coefficients according to the model of the enthalpy and temperature channels of the heat exchangers and acquiring set values of lead temperatures; 4, regulating the steam temperatures by the inner-loop PID regulator according to difference among the lead temperatures and output of the MPC and acquiring control signals of attemperation water valves. The method has the advantages that model building and verification are carried out, so that field test requirements can be reduced; states of inertial and lagged controlled objects are reconstructed via the state observer, so that characteristics of the objects can be modified; prediction and control are implemented, so that targets can be accurately and quickly controlled.

Owner:STATE GRID CORP OF CHINA +2

Feedforward signal control method in boiler steam temperature automatic control system

InactiveCN102012017AImprove qualityReduce steam temperature fluctuationsSuperheating controlSteam pressureAutomatic control

The invention discloses a feedforward signal control method in a boiler steam temperature automatic control system, which is used for improving quality of boiler steam temperature control. The technical scheme comprises the following steps of: measuring boiler furnace pressure, boiler steam pocket pressure (or steam-water separator pressure), boiler overheater outlet steam pressure, and boiler reheater outlet steam pressure; and calculating by utilizing the signals to form a combustion disturbing signal, an overheat steam flow disturbing signal, a reheat steam flow disturbing signal, an overheat steam temperature control system feedforward signal and a reheat steam temperature control system feedforward signal in turn. The method can effectively improve the quality of boiler steam temperature control, reduces steam temperature fluctuation caused by combustion disturbance and steam flow disturbance, does not need any additional hardware equipment, only needs increasing a little of software control logic, has low cost and cannot reduce the system reliability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com