Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

761results about How to "Reduce oxygen concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

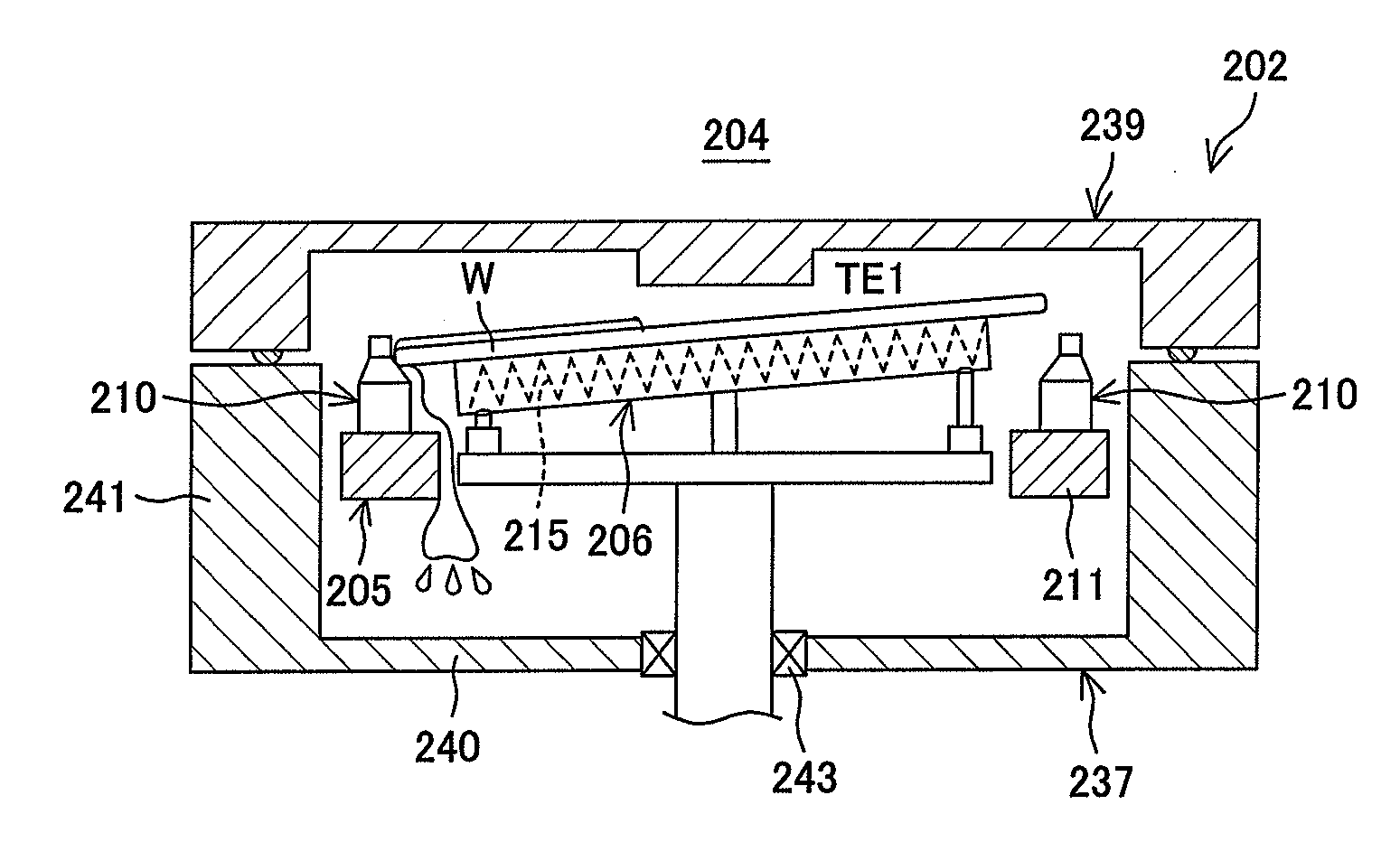

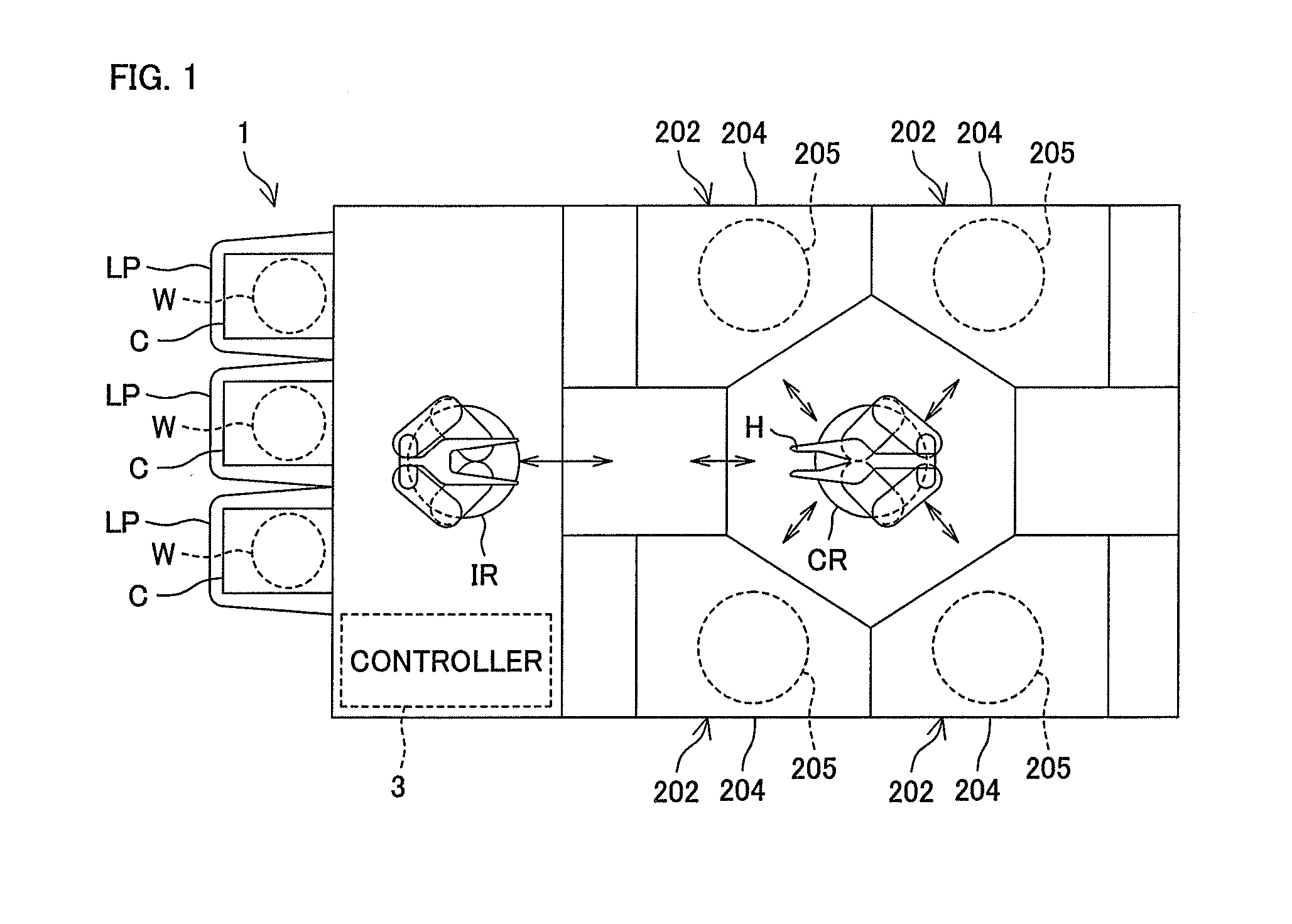

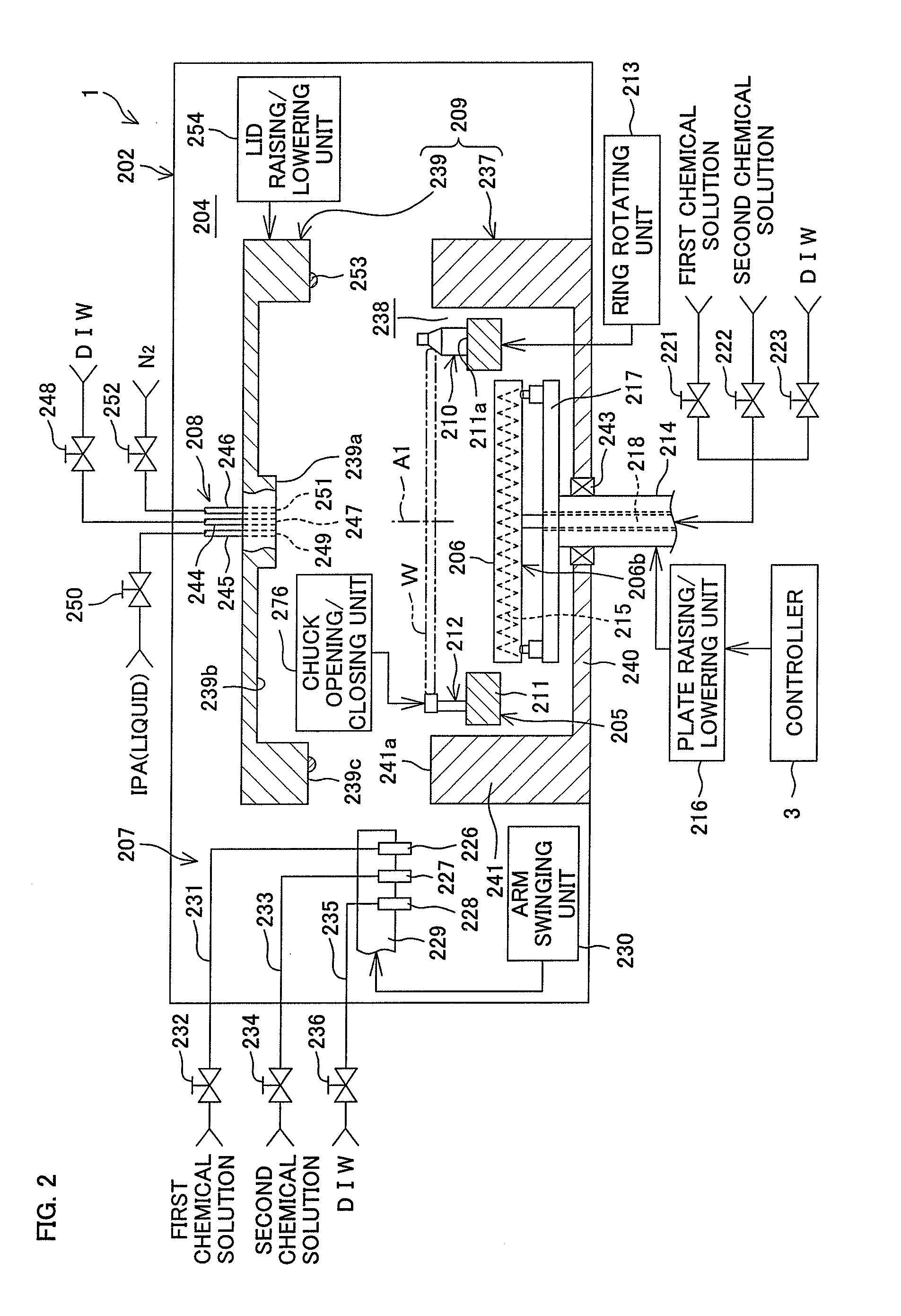

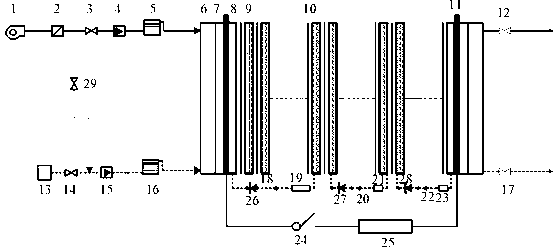

Substrate processing apparatus and substrate processing method

ActiveUS20150243542A1Short timeEasy to removeLiquid surface applicatorsLighting and heating apparatusOrganic solventEngineering

A substrate processing apparatus includes a substrate heating unit arranged to heat the underside of a substrate while supporting the substrate thereon and an attitude changing unit arranged to cause the substrate heating unit to undergo an attitude change between a horizontal attitude and a tilted attitude. In an organic solvent removing step to be performed following a substrate heating step of heating the substrate, the substrate heating unit undergoes an attitude change to the tilted attitude so that the upper surface of the substrate becomes tilted with respect to the horizontal surface.

Owner:DAINIPPON SCREEN MTG CO LTD

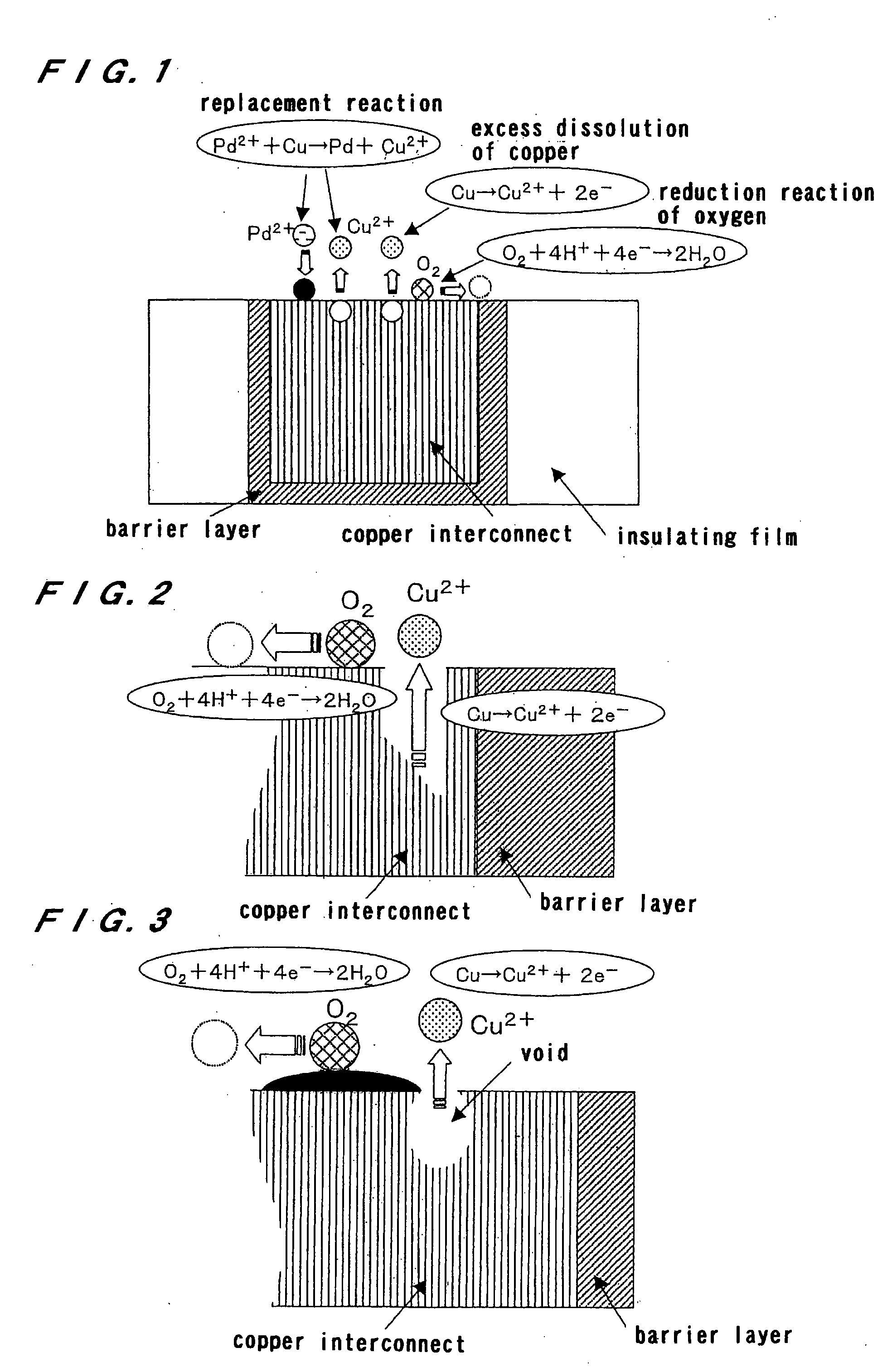

Method and apparatus for forming capping film

InactiveUS20050009340A1Suppress excess corrosionHigh characteristicSemiconductor/solid-state device detailsSolid-state devicesMetal catalystSemiconductor

A capping film serving as an interconnect protective film formed on a surface of interconnect metal on a semiconductor substrate is formed after forming a catalyst layer for electroless plating under low oxygen concentration condition. A method for forming a capping film for protecting a surface of interconnect metal includes preparing a metal catalyst solution containing a metal element nobler than interconnect metal and having dissolved oxygen concentration of 7 ppm or less, bringing said metal catalyst solution into contact with a surface of interconnect metal to form a metal catalyst layer on the surface of the interconnect metal, and performing electroless plating to form a capping film on the surface of the interconnect metal.

Owner:EBARA CORP

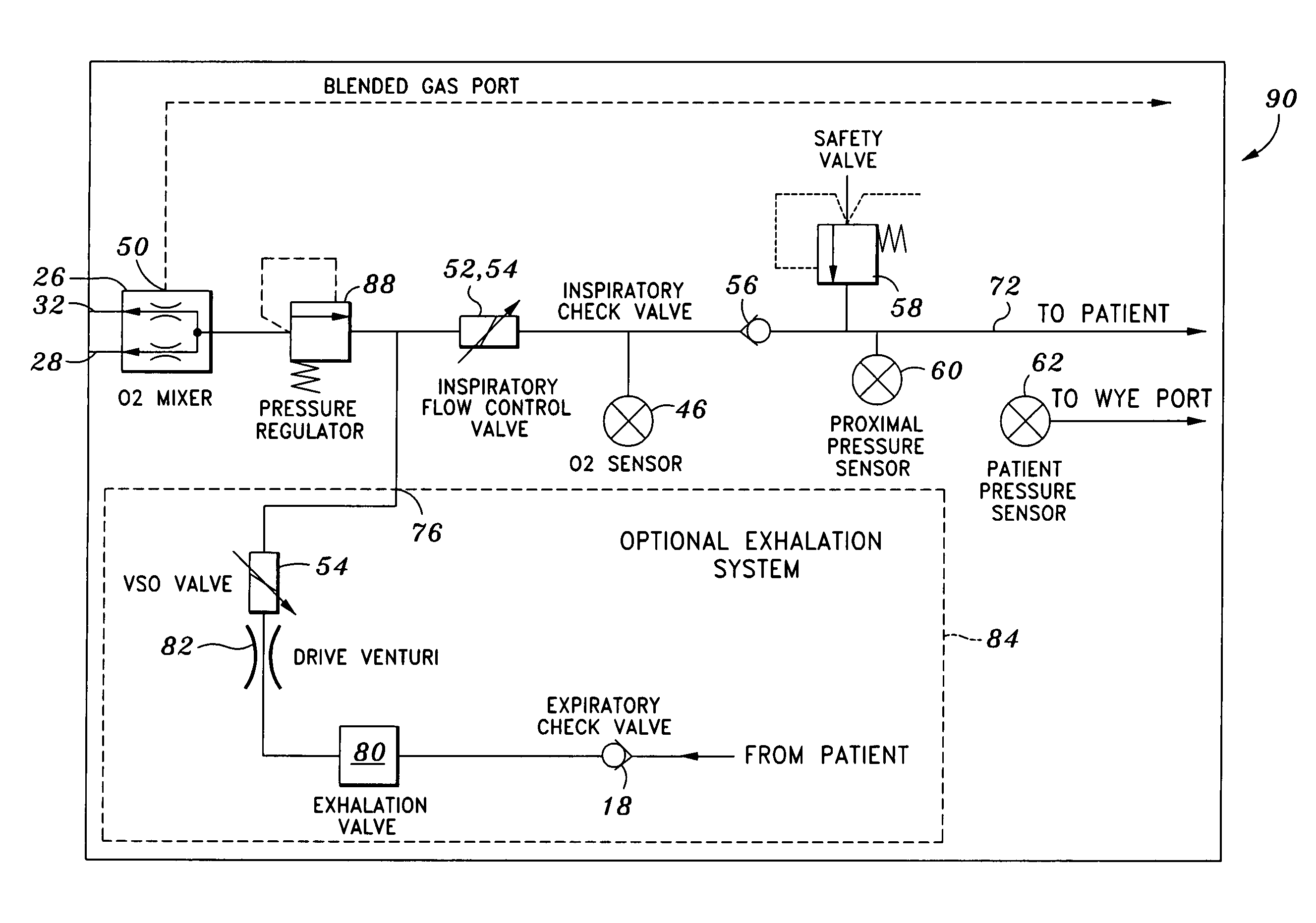

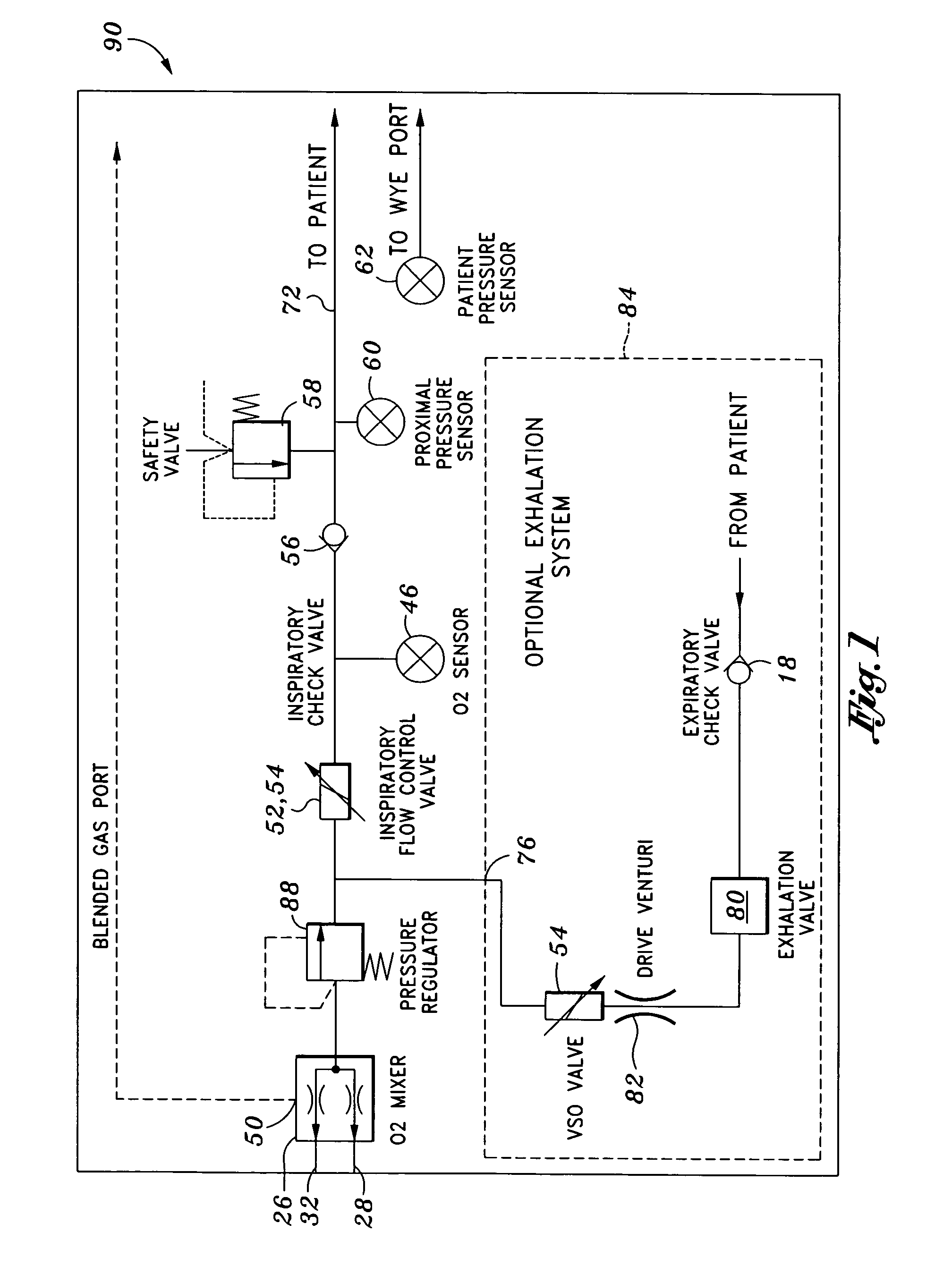

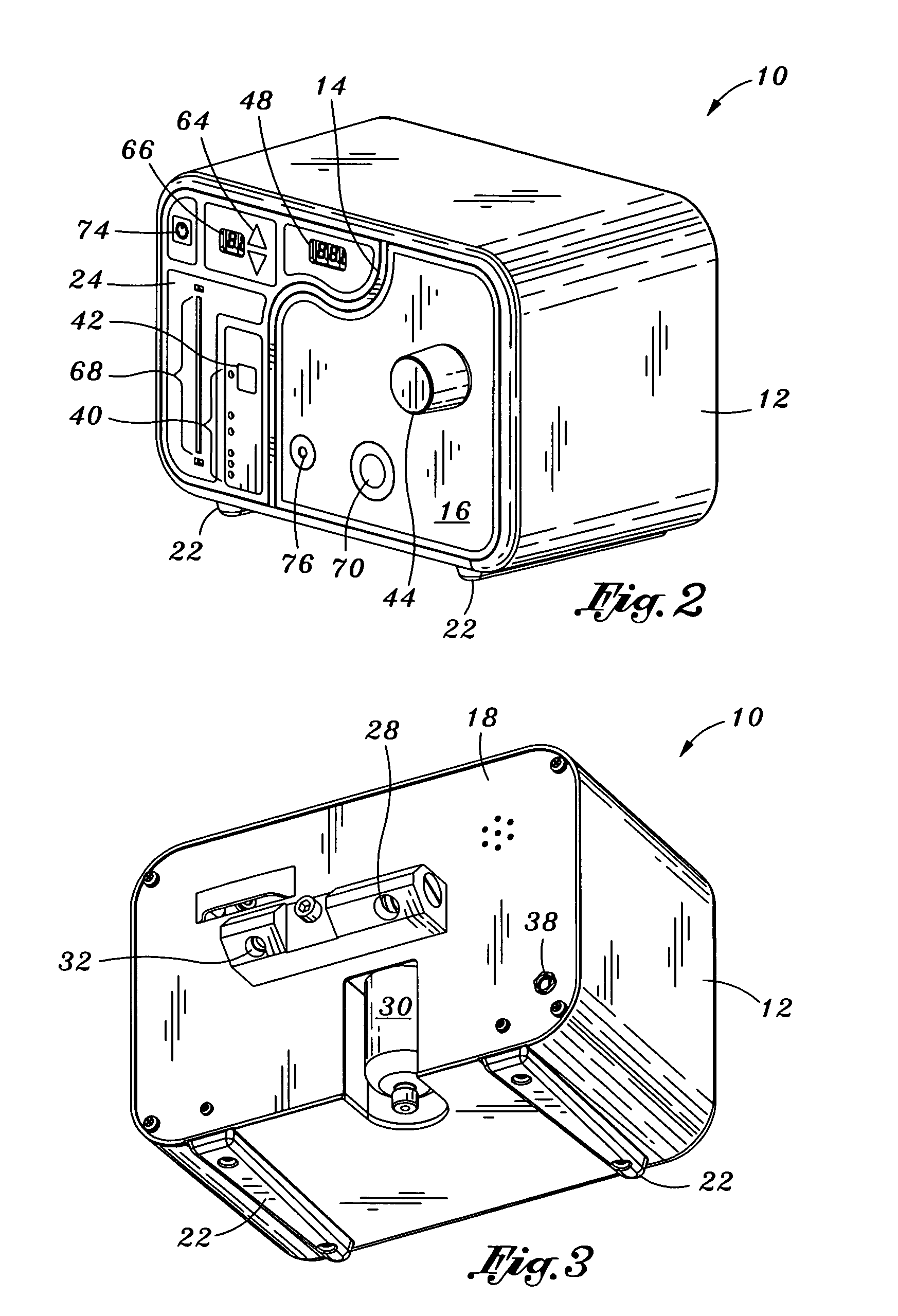

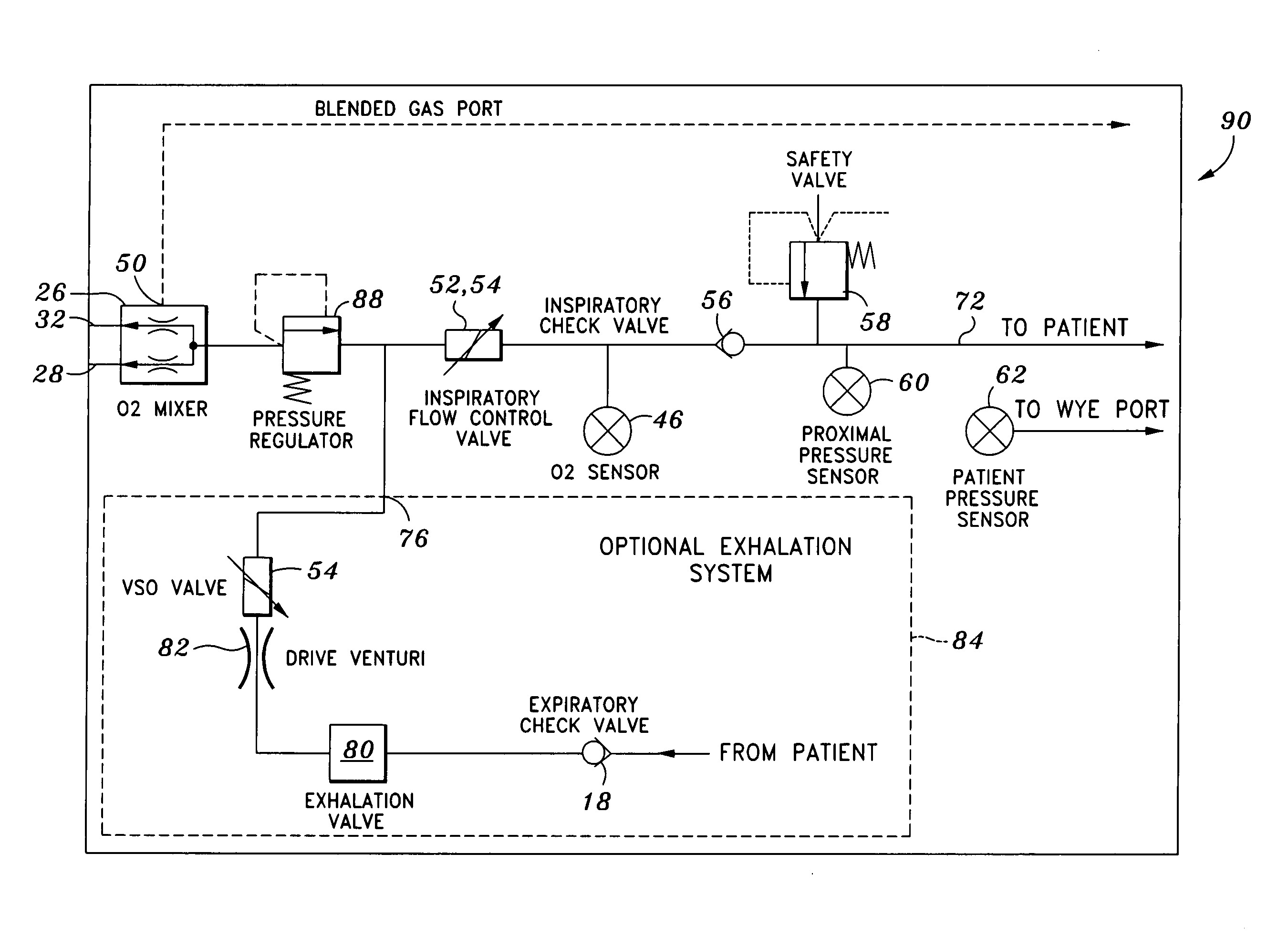

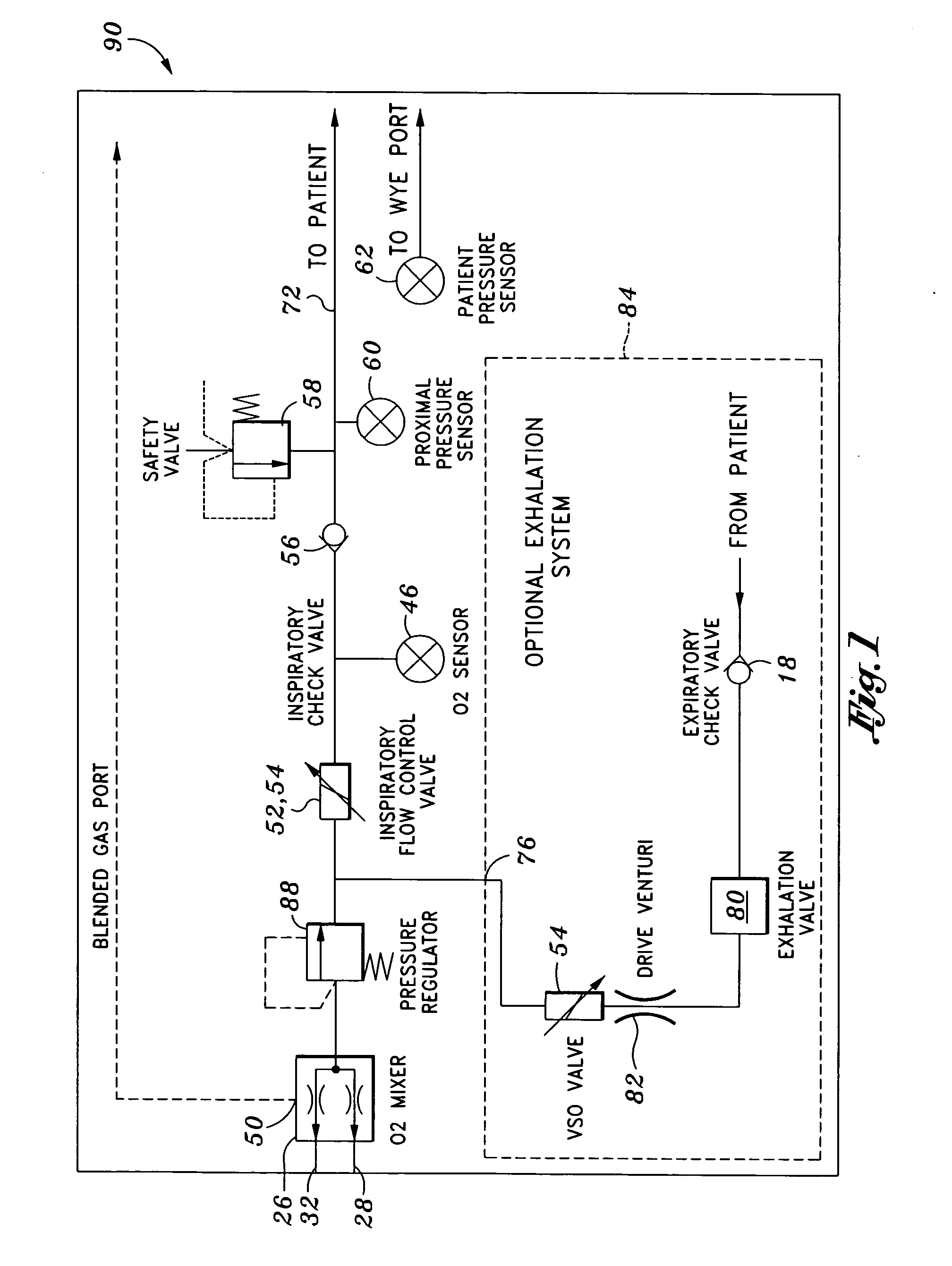

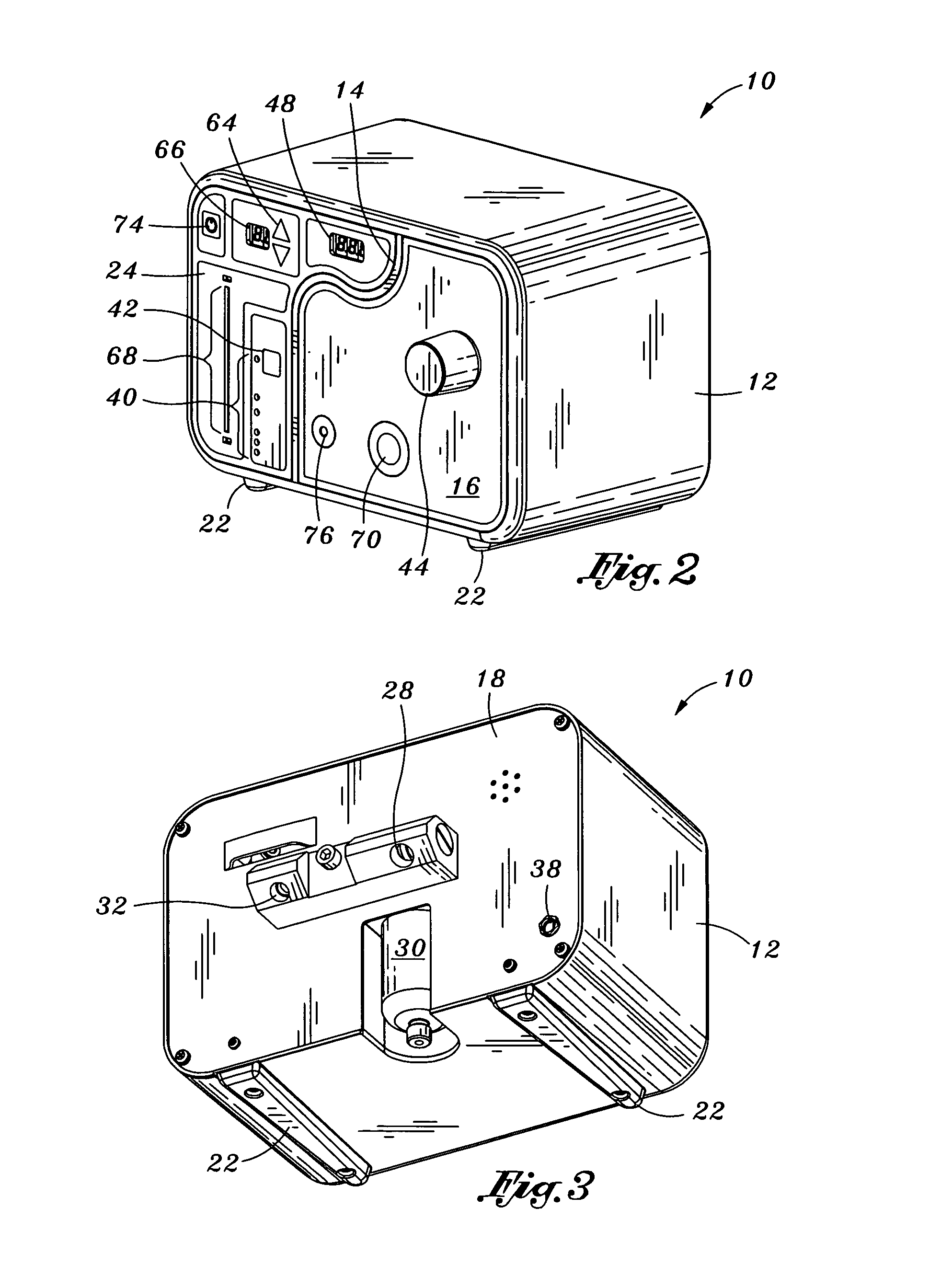

Hardware configuration for pressure driver

ActiveUS7509957B2Reduce oxygen concentrationImprove ventilationRespiratorsOperating means/releasing devices for valvesOxygen sensorControl system

Owner:VYAIRE MEDICAL 211 INC

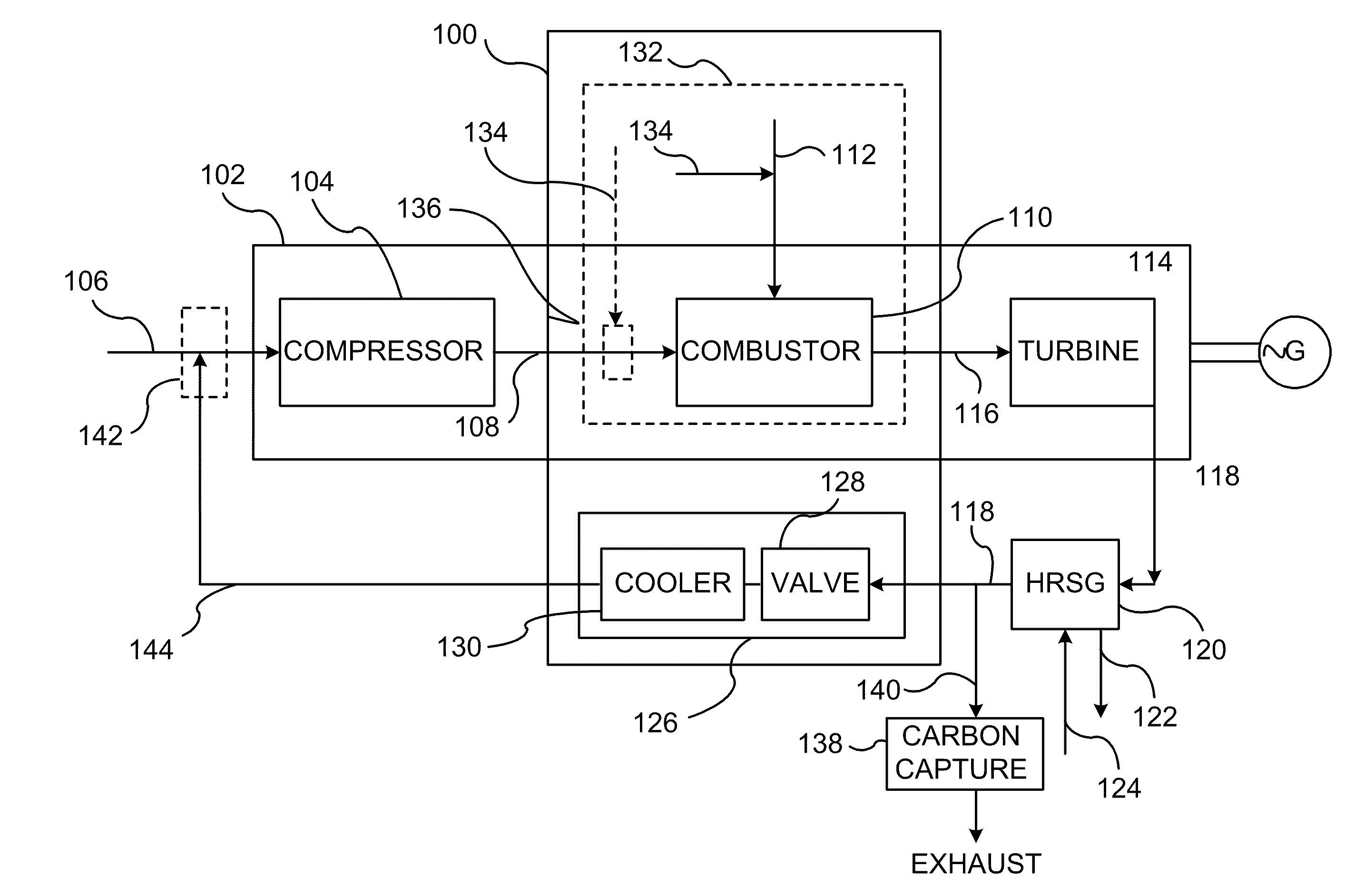

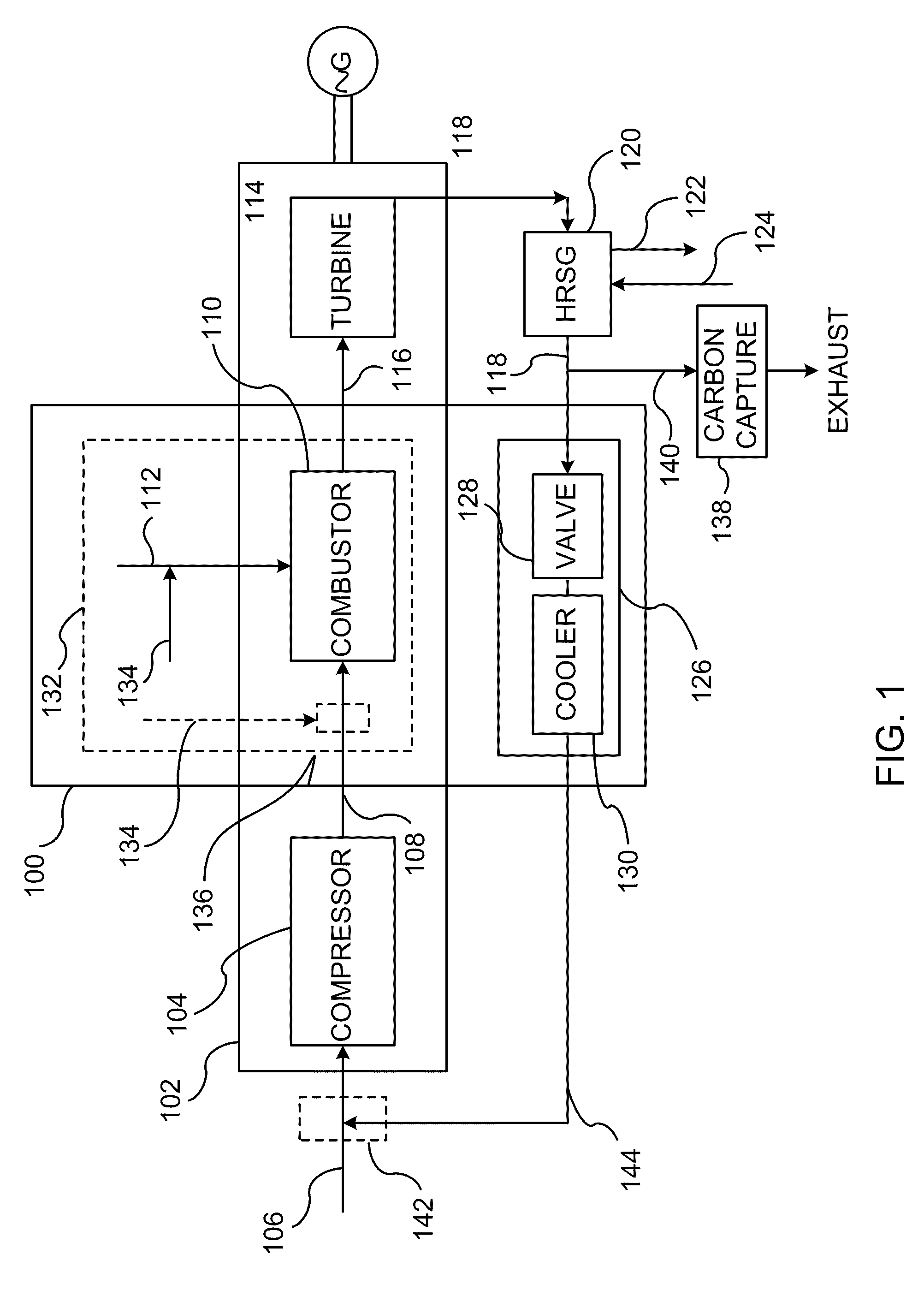

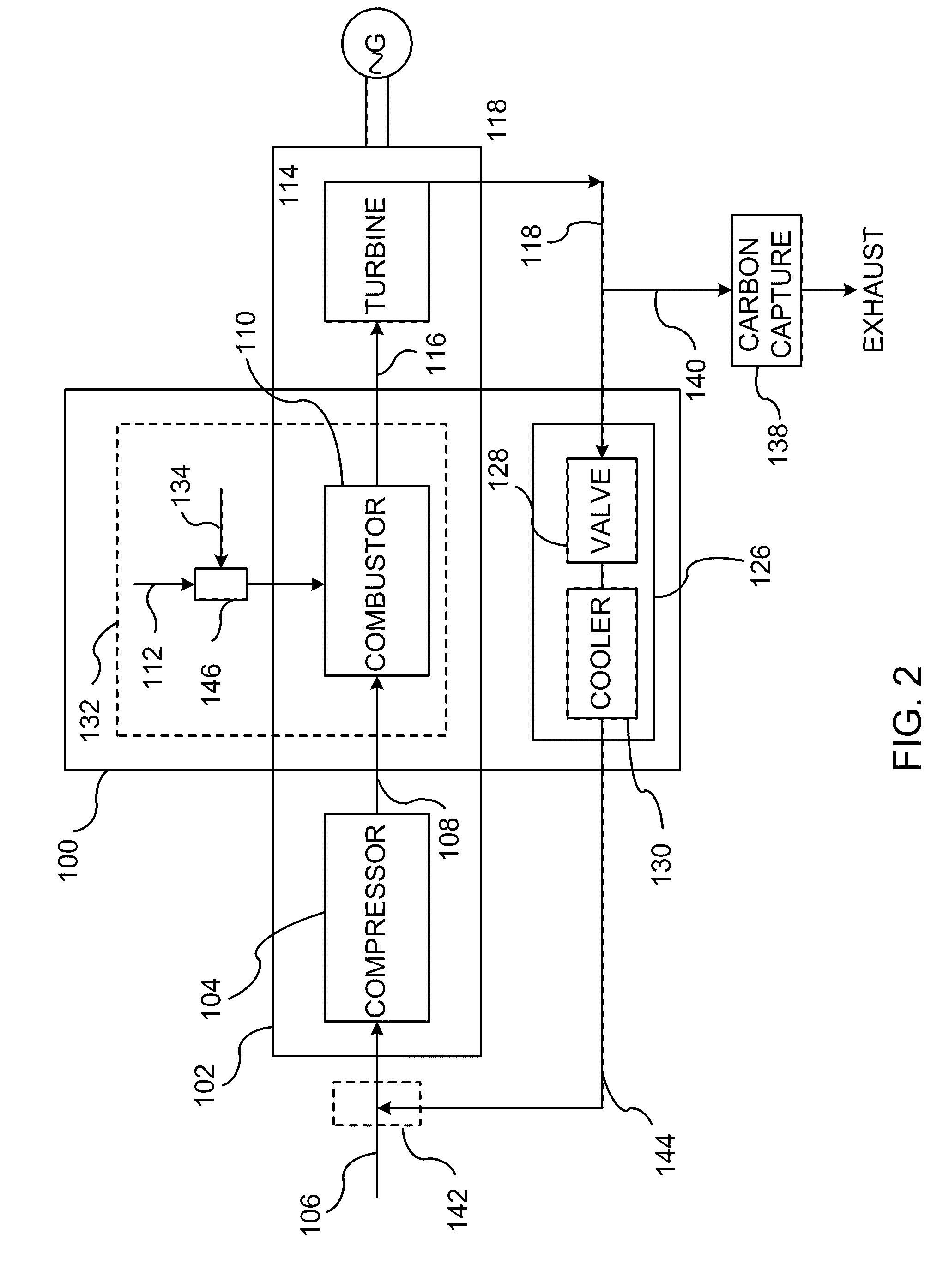

System and method of improving emission performance of a gas turbine

InactiveUS20110138766A1Improve emission effectReduce oxygen concentrationEngine fuctionsGas turbine plantsHigh pressureOxygen

A method of improving emission performance of a gas turbine is provided. The method includes recirculating a portion of an exhaust gas stream to a compressor of the gas turbine via an exhaust gas recirculating system, to reduce concentration of oxygen in a high pressure feed oxidant stream into a combustor of the gas turbine. The method further includes adding diluent to at least one of a fuel stream directed to the combustor or a low pressure feed oxidant stream directed to the compressor, to reduce concentration of oxides of nitrogen (NOx) and increase concentration of carbon dioxide in a resultant exhaust gas stream.

Owner:GENERAL ELECTRIC CO

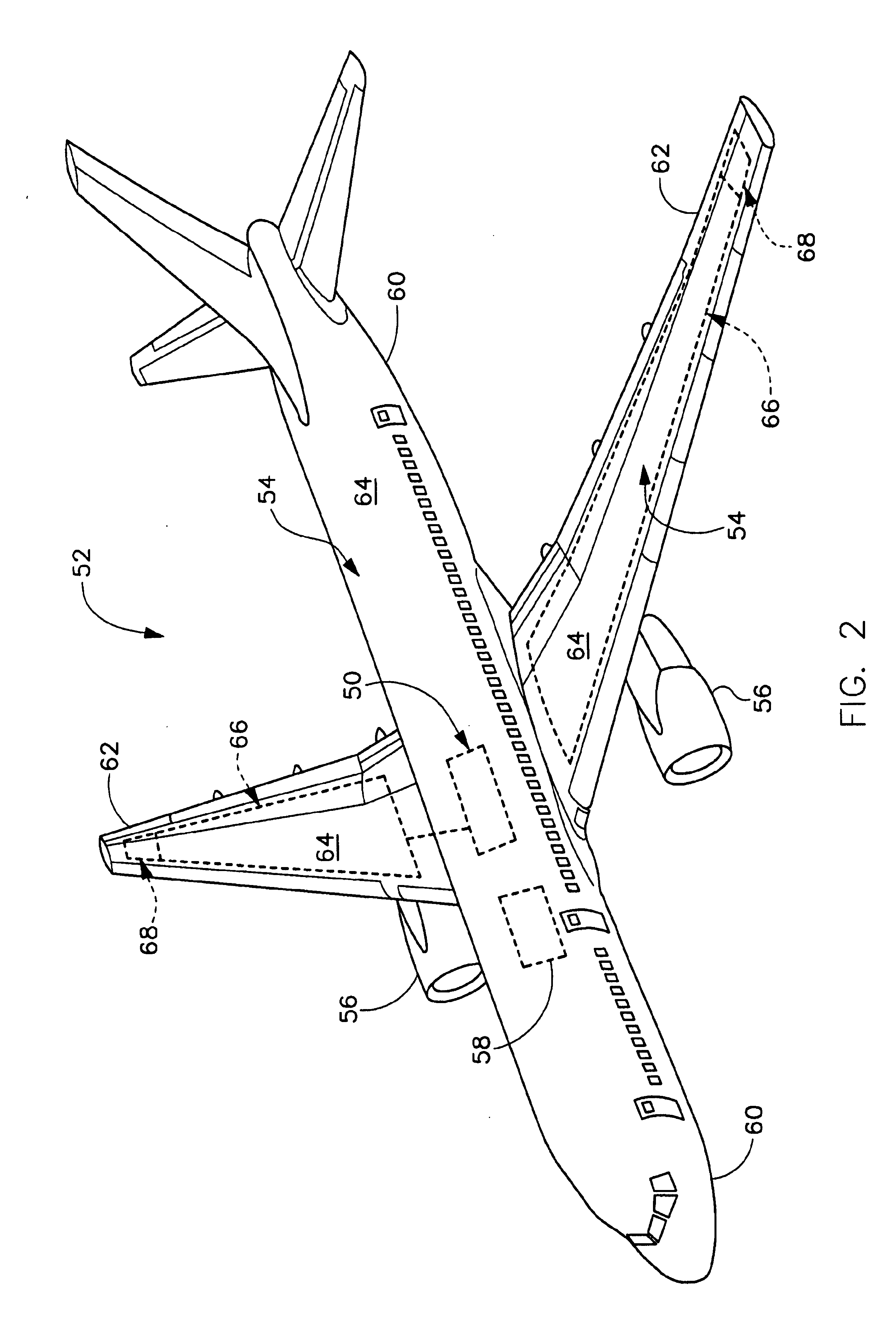

Method and apparatus for generating an inert gas on a vehicle

An inert gas generating system for generating inert gas on a vehicle having a fuel tank and a fuel tank vent. The system includes an inlet for receiving a flow of gas having a nitrogen component and an oxygen component from a gas source, a heat exchanger downstream from the inlet and in fluid communication with the inlet for cooling gas received from the inlet, and a gas separation module downstream from the heat exchanger and in fluid communication with the heat exchanger for separating gas received from the heat exchanger into a nitrogen-enriched gas flow and an oxygen-enriched gas flow. The gas separation module is adapted to deliver nitrogen-enriched gas from the nitrogen-enriched gas flow to the fuel tank without delivering the nitrogen-enriched gas through the fuel tank vent. The gas separation module is also adapted to deliver nitrogen-enriched gas from the nitrogen-enriched gas flow to the fuel tank vent.

Owner:THE BOEING CO

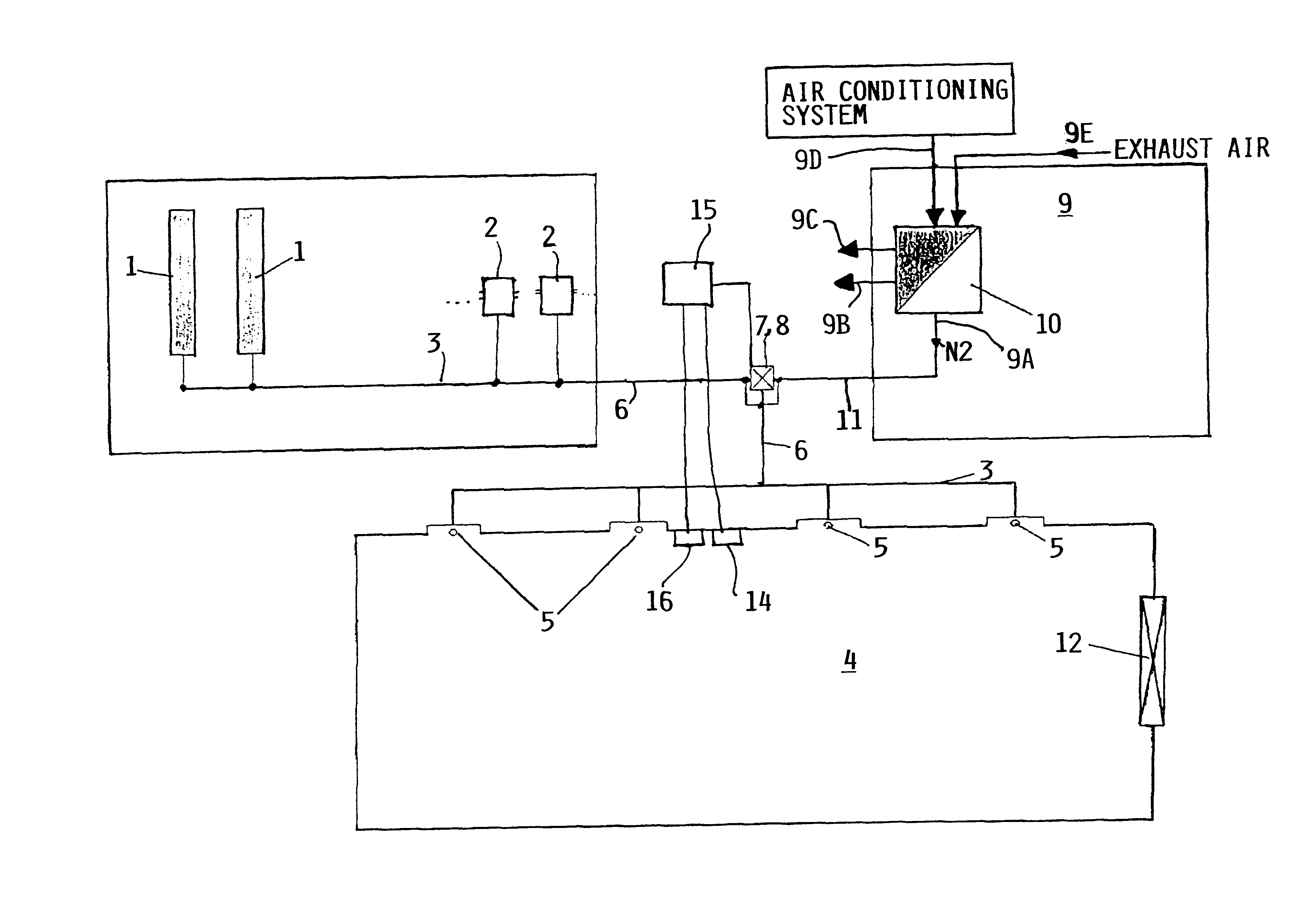

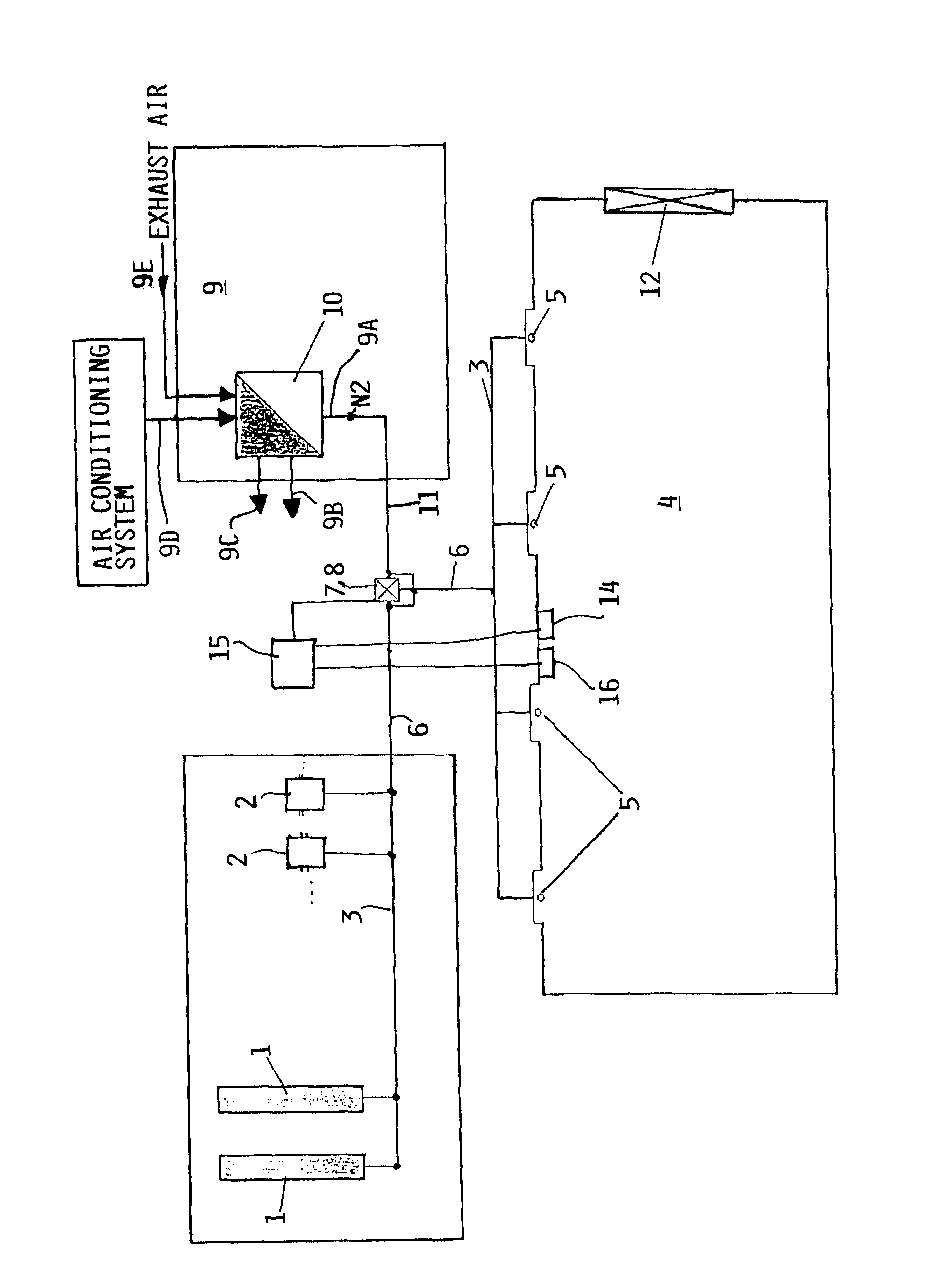

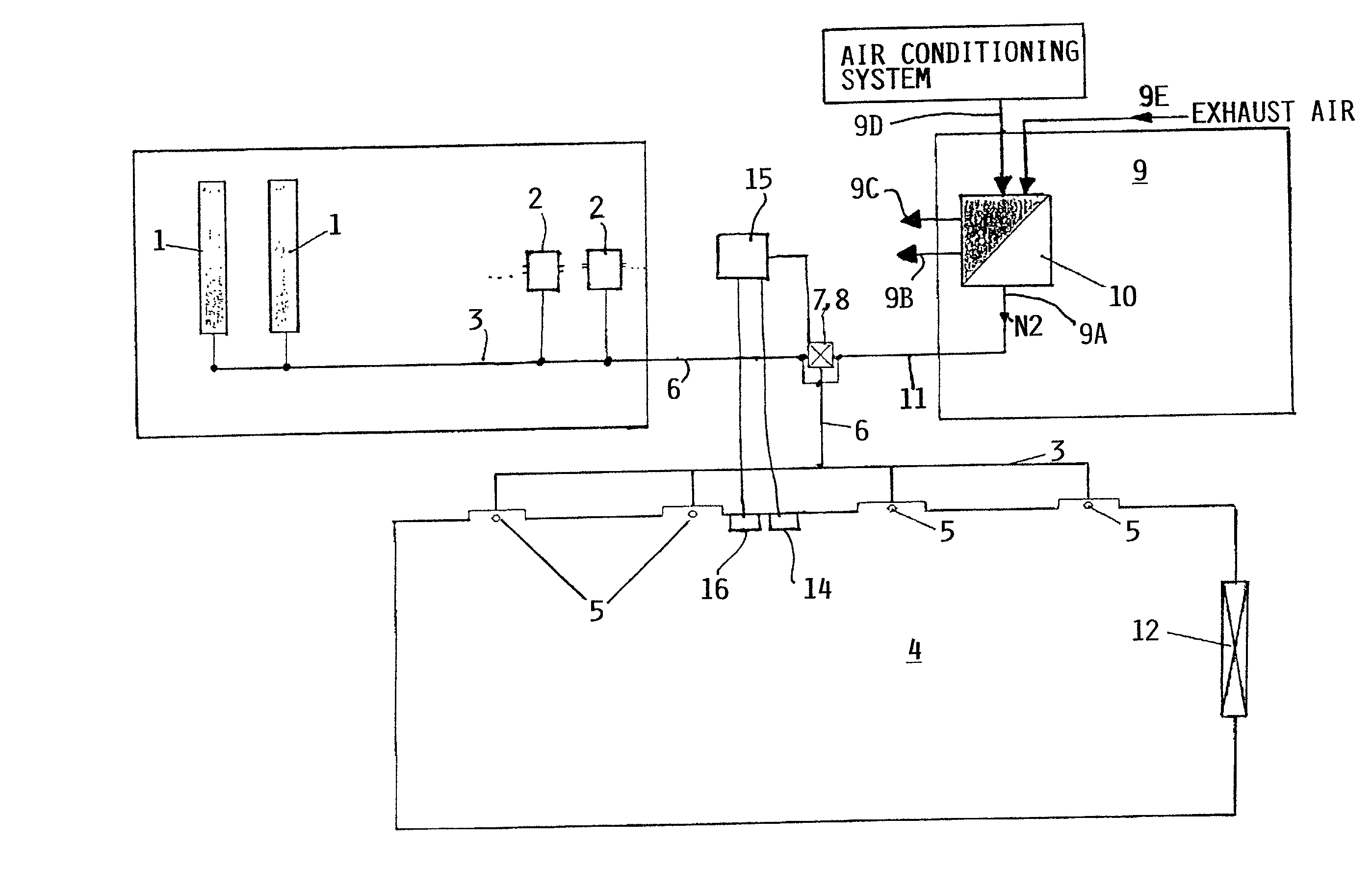

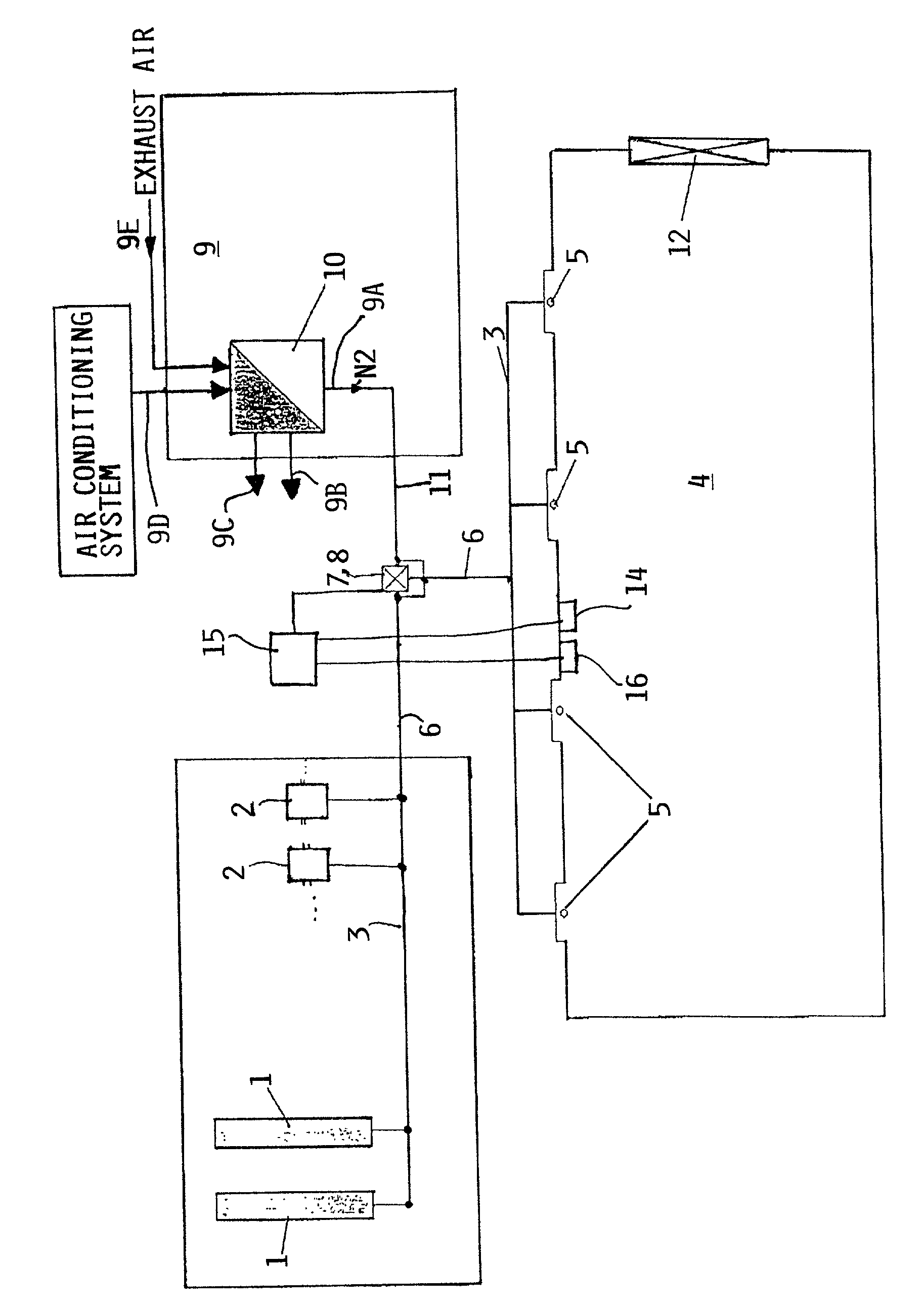

Method and system for extinguishing fire in an enclosed space

InactiveUS6601653B2Reduce oxygen concentrationImprove concentrationAir-treatment apparatus arrangementsSpraying apparatusHigh rateNitrogen

A system for suppressing fire in an enclosed space, e.g. an aircraft cabin or freight compartment, includes nitrogen tanks and / or generators to rapidly supply a limited quantity of nitrogen with-a high flow rate, and a membrane system to supply an essentially unlimited quantity of nitrogen at a lower supply rate for a long duration. The membrane system includes a selectively permeable membrane that separates nitrogen gas from ambient environmental air that is supplied into the membrane system. Once a fire is detected, nitrogen is supplied from the nitrogen gas tanks and / or generators at a high rate to rapidly increase the nitrogen concentration and establish a reduced oxygen concentration (e.g. 12 vol. %) in the enclosed space. Then, nitrogen is supplied from the membrane system at a reduced rate for a long duration to maintain the reduced oxygen concentration in the enclosed space until the fire is extinguished by oxygen starvation.

Owner:AIRBUS OPERATIONS GMBH

Fire suppression system and method

ActiveUS20100236796A1Enhanced inhibitory effectReduce oxygen concentrationFire rescueBoring toolsEngineeringHigh pressure

A fire suppression system includes a high pressure inert gas source that is configured to provide a first inert gas output and a low pressure inert gas source that is configured to provide a second inert gas output. A distribution network is connected with the high and low pressure inert gas sources to distribute the first and second inert gas outputs. A controller is operatively connected with at least the distribution network to control how the respective first and second inert gas outputs are distributed.

Owner:KIDDE TECH

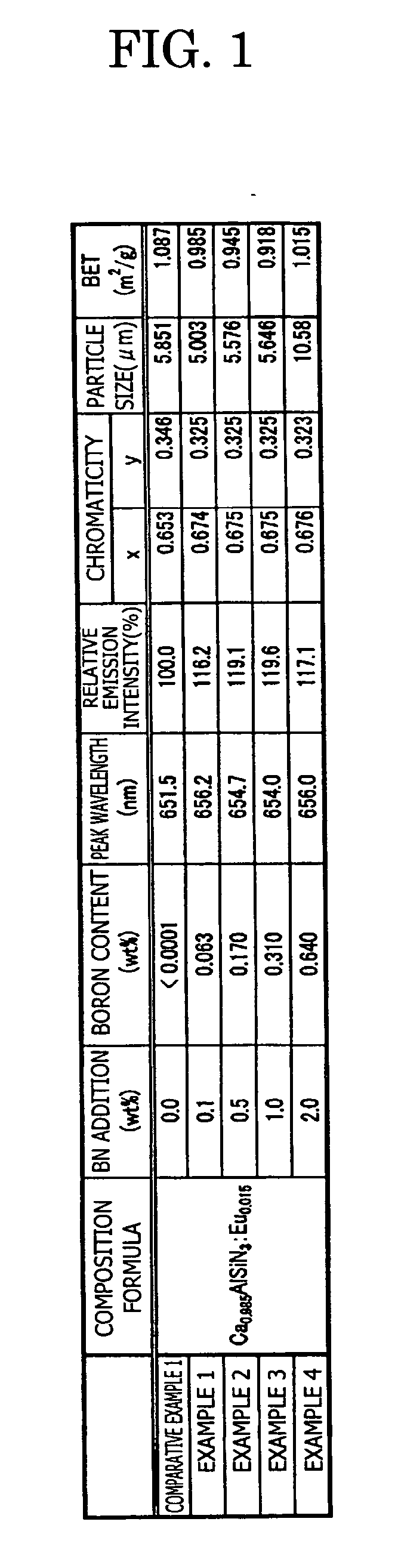

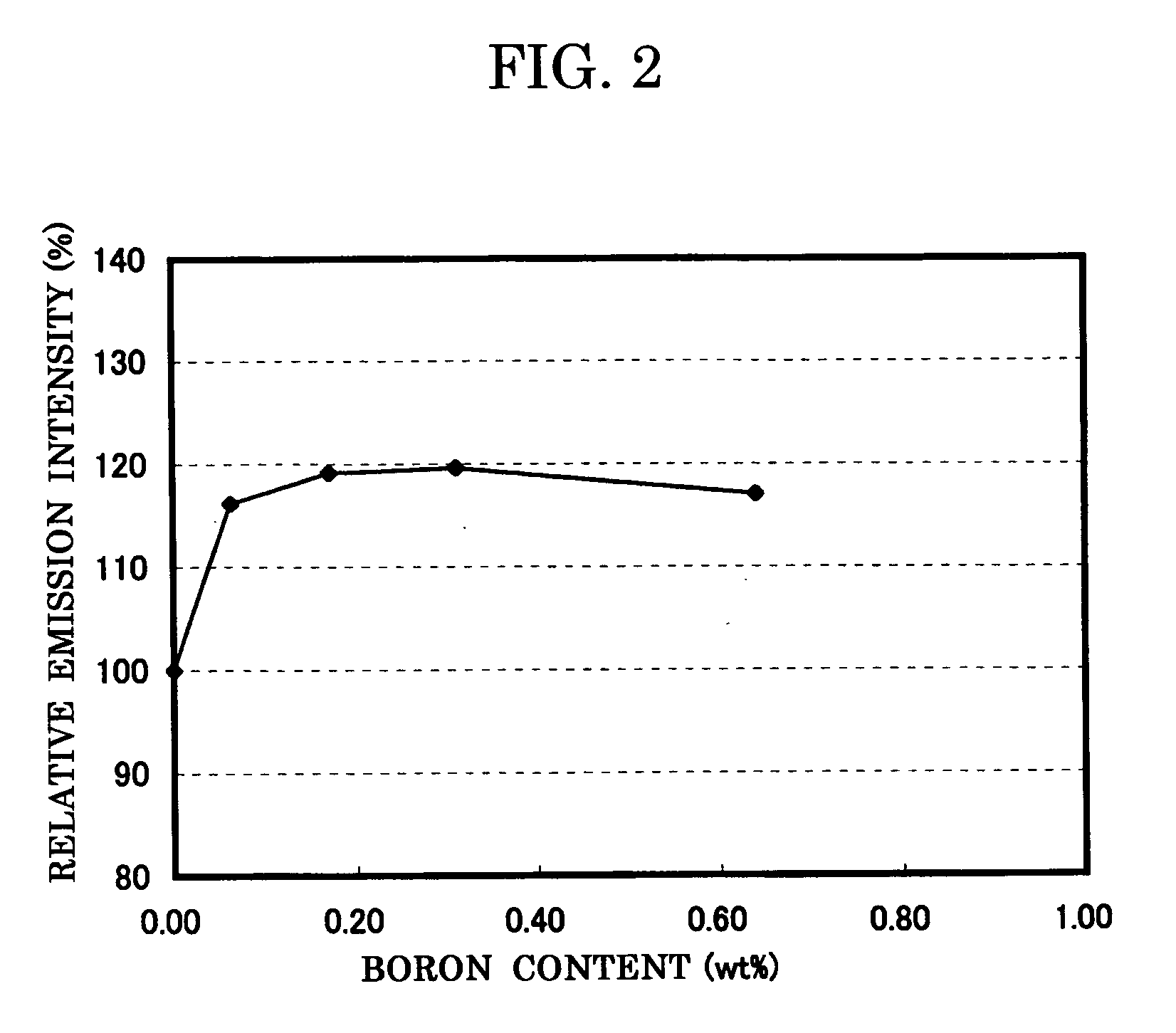

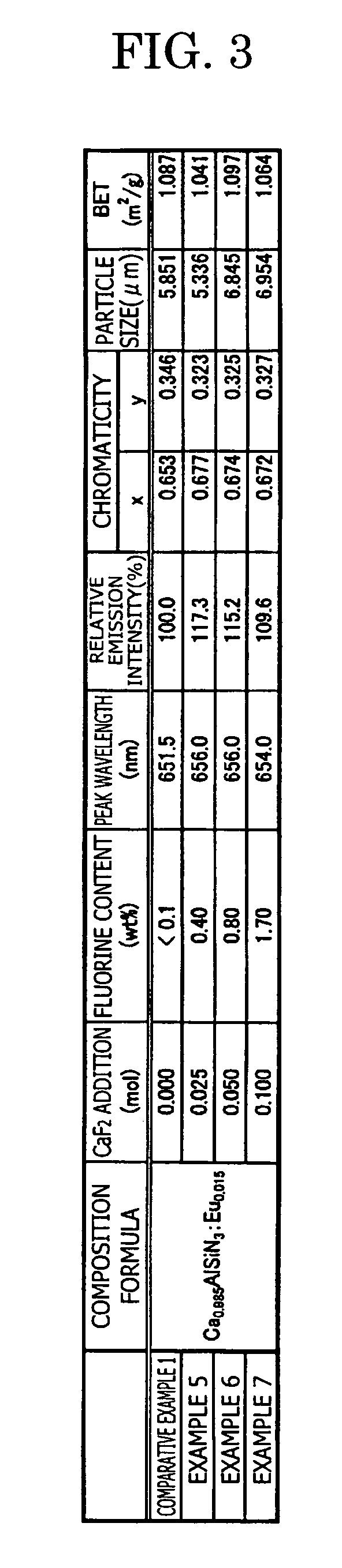

Phosphor and manufacturing method for the same, and light source

ActiveUS20060065878A1Improve emission efficiencyImprove efficiencySynthetic resin layered productsCellulosic plastic layered productsRare-earth elementUltraviolet

To provide a phosphor having an emission spectrum with a broad peak in a range from yellow color to red color (580 nm to 680 nm) and an excellent excitation band on the longer wavelength side from near ultraviolet / ultraviolet of excitation light to visible light (250 nm to 550 nm), and having an improved emission intensity. The phosphor is provided, which is given by a general composition formula expressed by MmAaBbOoNn:Z, (wherein element M is more than one kind of element having bivalent valency, element A is more than one kind of element having tervalent valency selected from the group consisting of Al, Ga, In, Tl, Y, Sc, P, As, Sb, and Bi, element B is more than one kind of element having tetravalent valency, O is oxygen, N is nitrogen, and element Z is more than one kind of element selected from rare earth elements or transitional metal elements, satisfying m>0, a>0, b>0 o≧0, and n=2 / 3m+a+4 / 3b−2 / 3o), and further containing boron and / or fluorine.

Owner:CITIZEN ELECTRONICS CO LTD +1

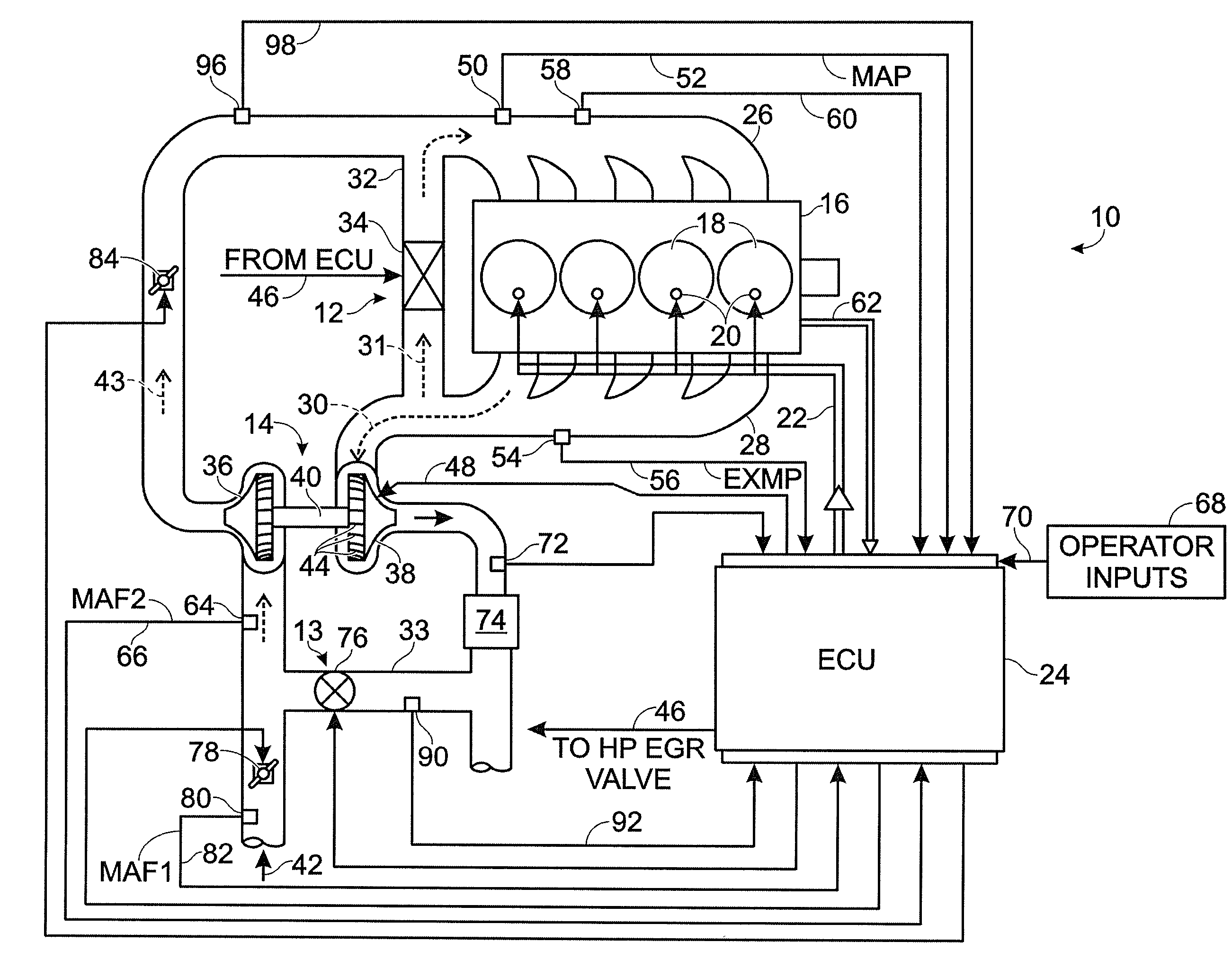

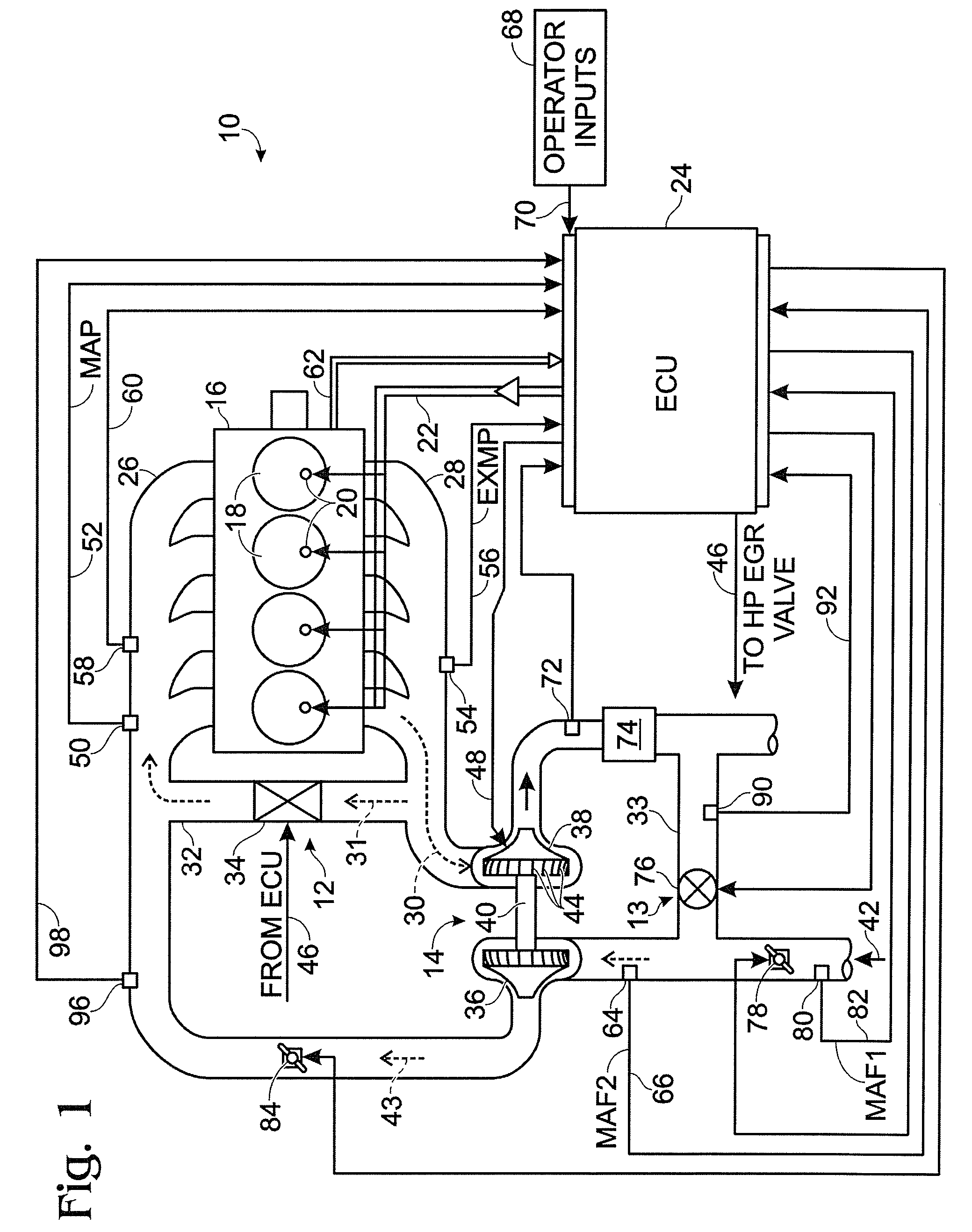

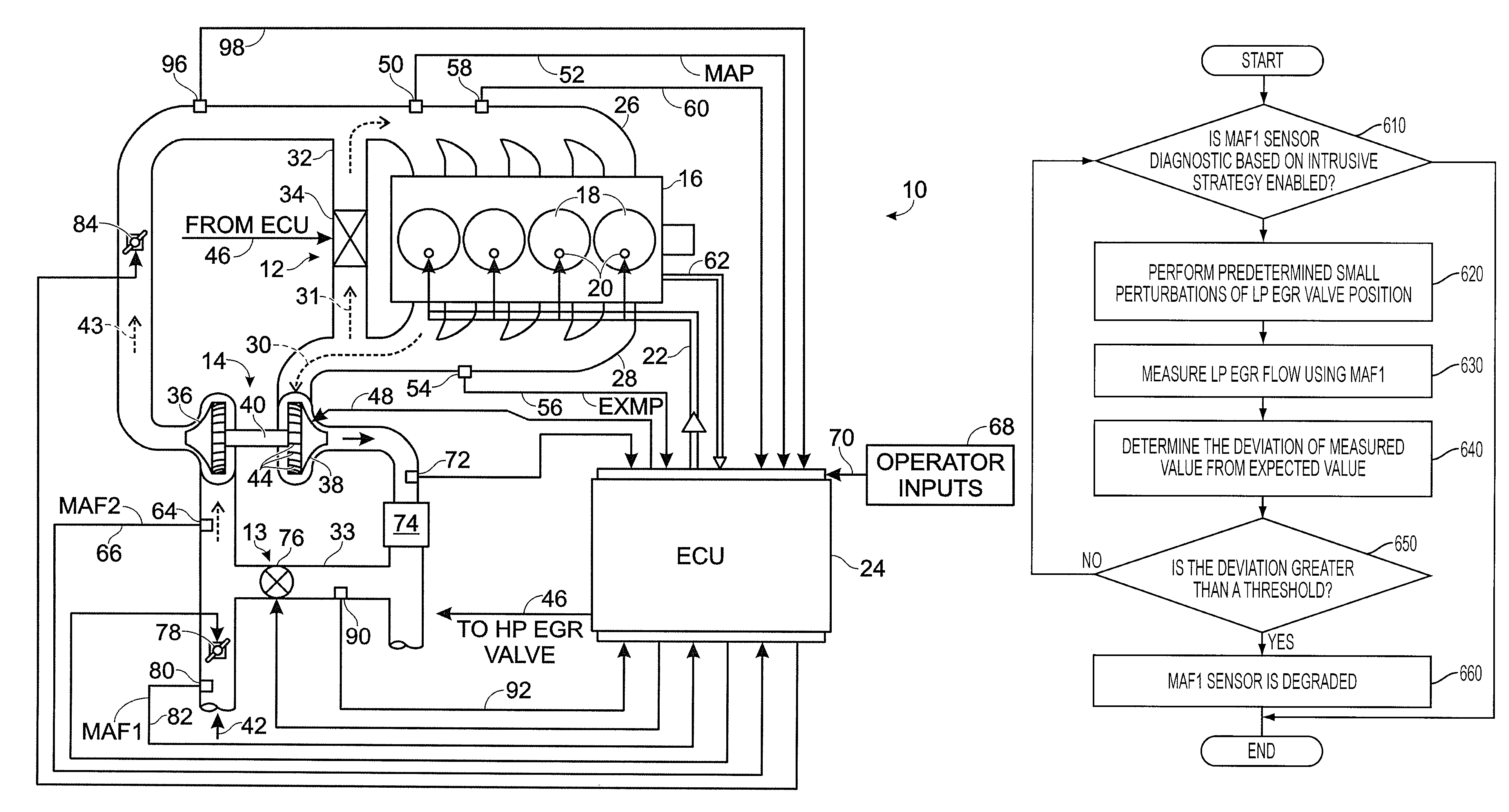

System and Method for Diagnostic of Low Pressure Exhaust Gas Recirculation System and Adapting of Measurement Devices

ActiveUS20080022677A1Reduce the formation of nitrogen oxidesImprove fuel economyVehicle testingElectrical controlMeasurement deviceTurbocharger

A system for a diesel engine having an intake manifold and an exhaust manifold, comprises a turbocharger between the intake and exhaust manifolds of the engine; a low pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold downstream of the turbocharger and a second end couple to the intake manifold upstream of the turbocharger, said low pressure exhaust gas recirculation having a first valve coupled thereto for regulating flow; a high pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold upstream of the turbocharger and a second end coupled to the intake manifold downstream of the turbocharger, said high pressure exhaust gas recirculation having a second valve coupled thereto for regulating flow; a first mass airflow sensor coupled in the engine intake manifold upstream of an inlet of said second end of said low pressure exhaust gas recirculation system; and a control system configured to diagnose the degradation of said first mass airflow sensor.

Owner:FORD GLOBAL TECH LLC

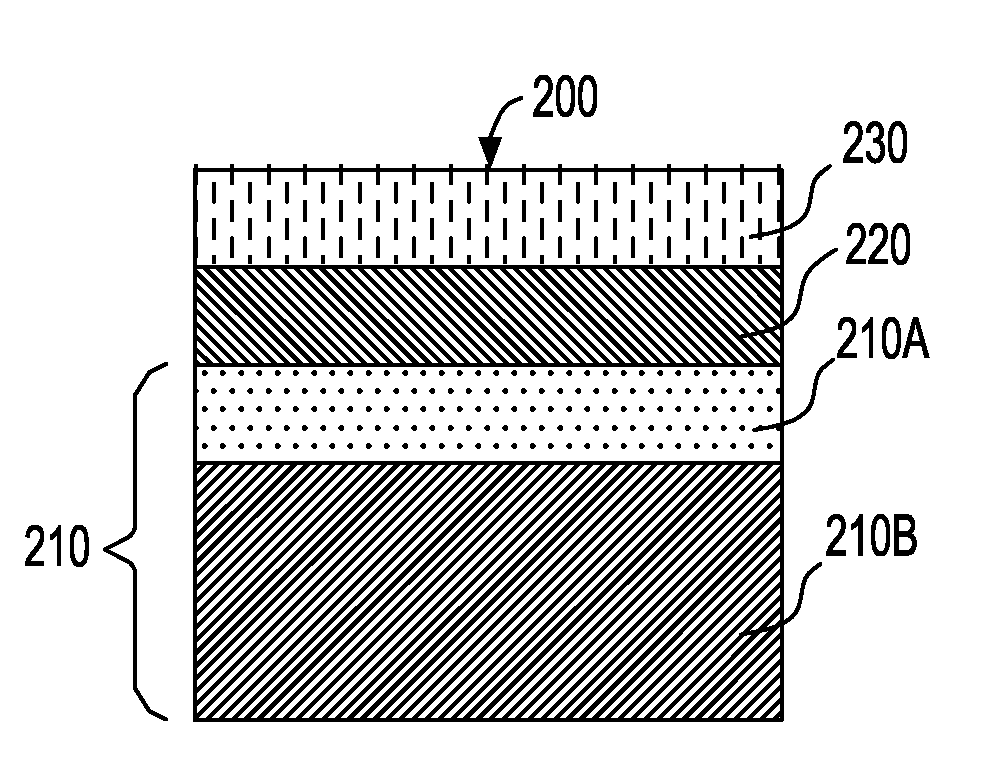

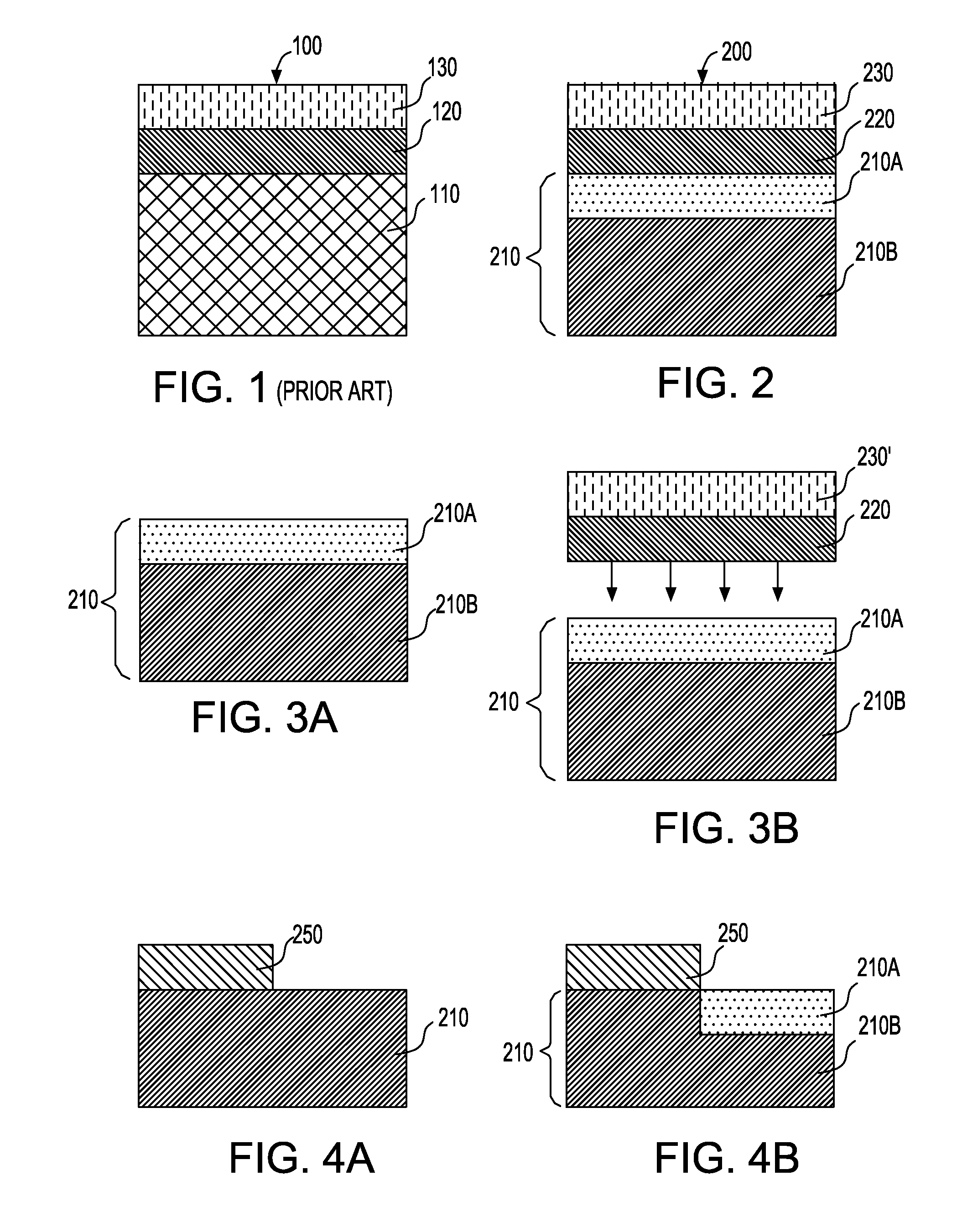

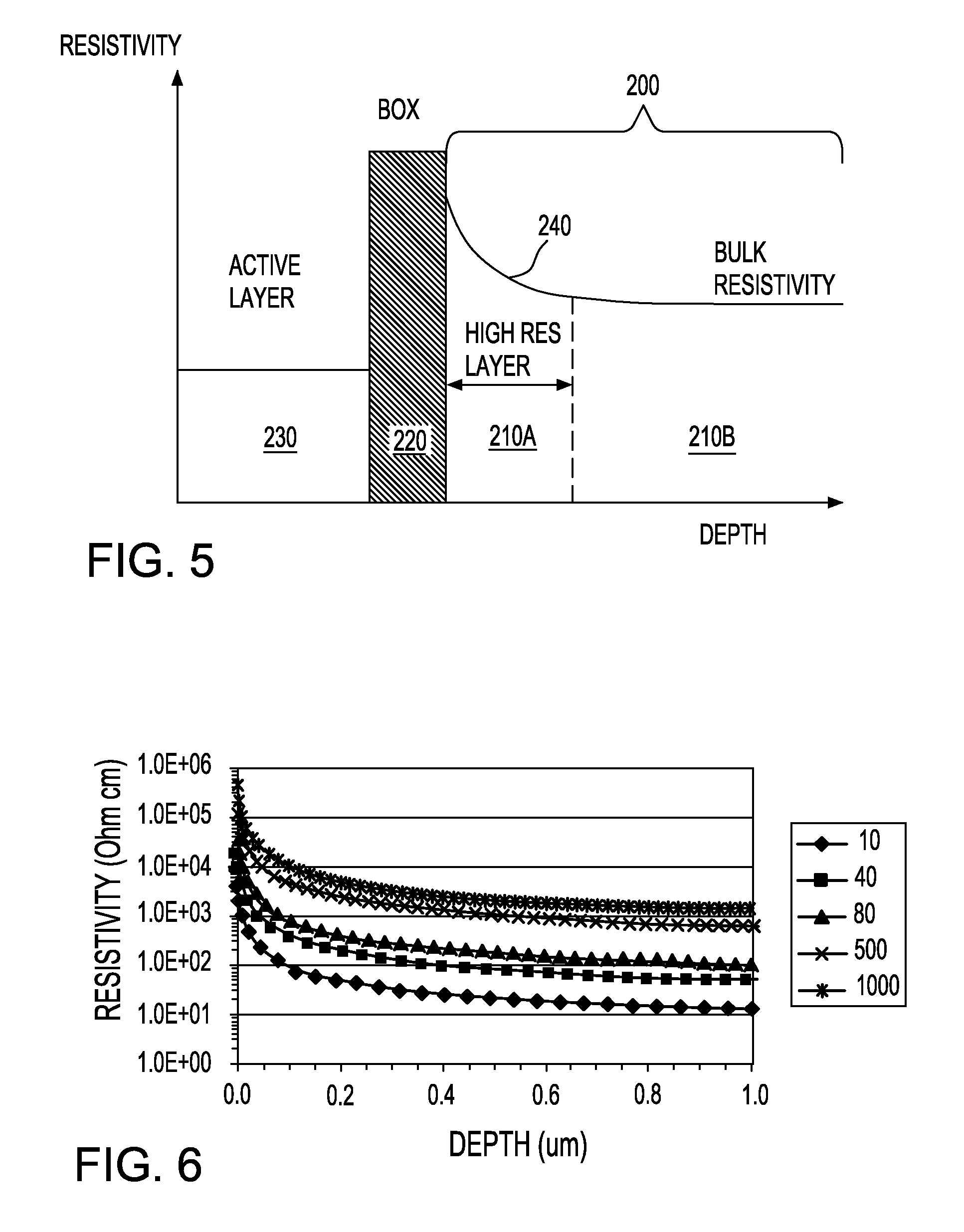

High resistivity soi base wafer using thermally annealed substrate

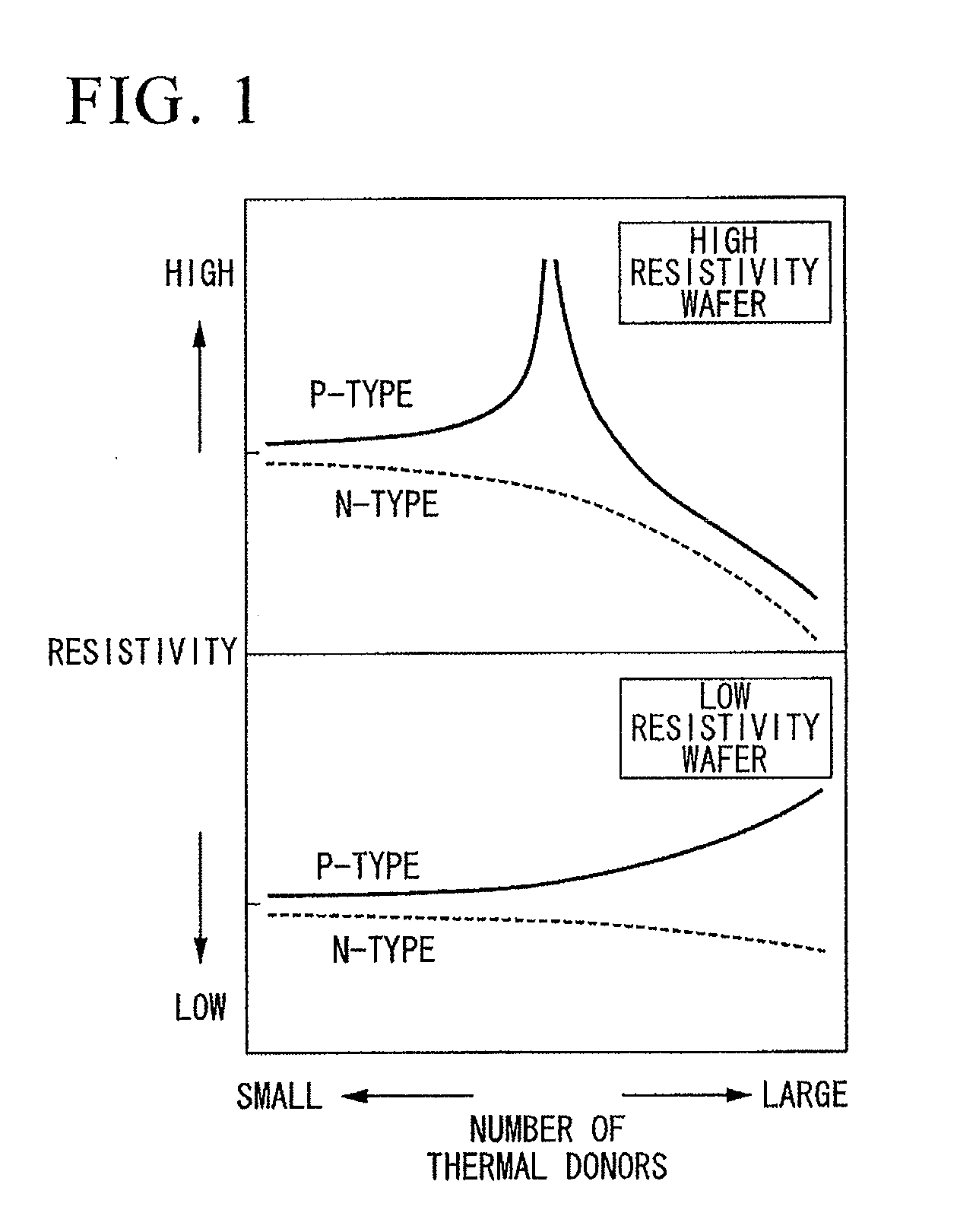

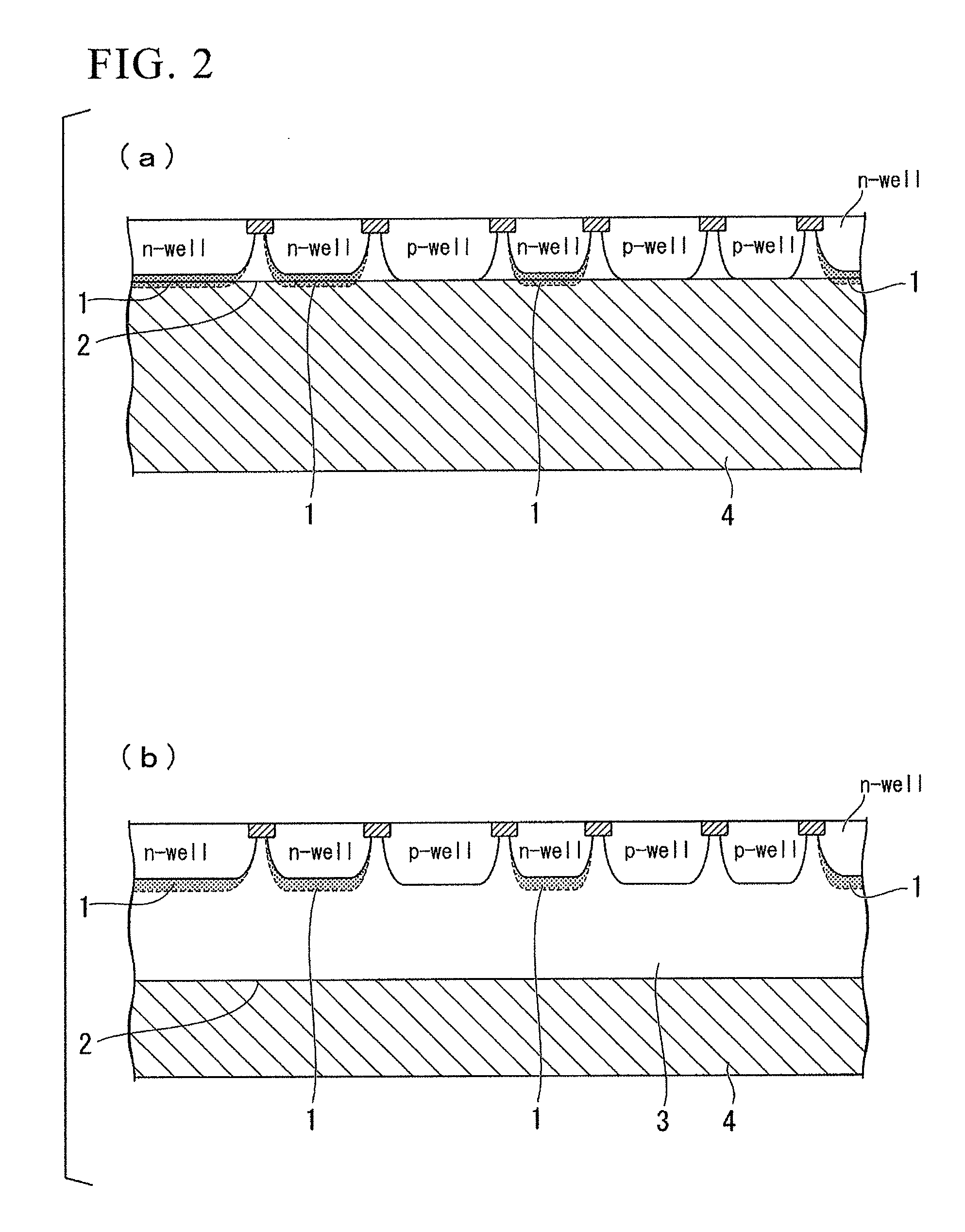

ActiveUS20090110898A1Reduces interstitial oxygen concentrationSuppresses thermal donor formationSolid-state devicesSemiconductor/solid-state device manufacturingSurface layerHigh resistivity

A method of forming a semiconductor-on-insulator (SOI) substrate using a thermal annealing process to provide a semiconductor base wafer having a thin high resistivity surface layer that is positioned at the interface with the buried insulating layer is provided. Specifically, the inventive method fabricates an a semiconductor-on-insulator (SOI) substrate having an SOI layer and a semiconductor base wafer that are separated, at least in part, by a buried insulating layer, wherein the semiconductor base wafer includes a high resistivity (HR) surface layer located on a lower resistivity semiconductor portion of the semiconductor base wafer, and the HR surface layer forms an interface with the buried insulating layer.

Owner:GLOBALFOUNDRIES US INC

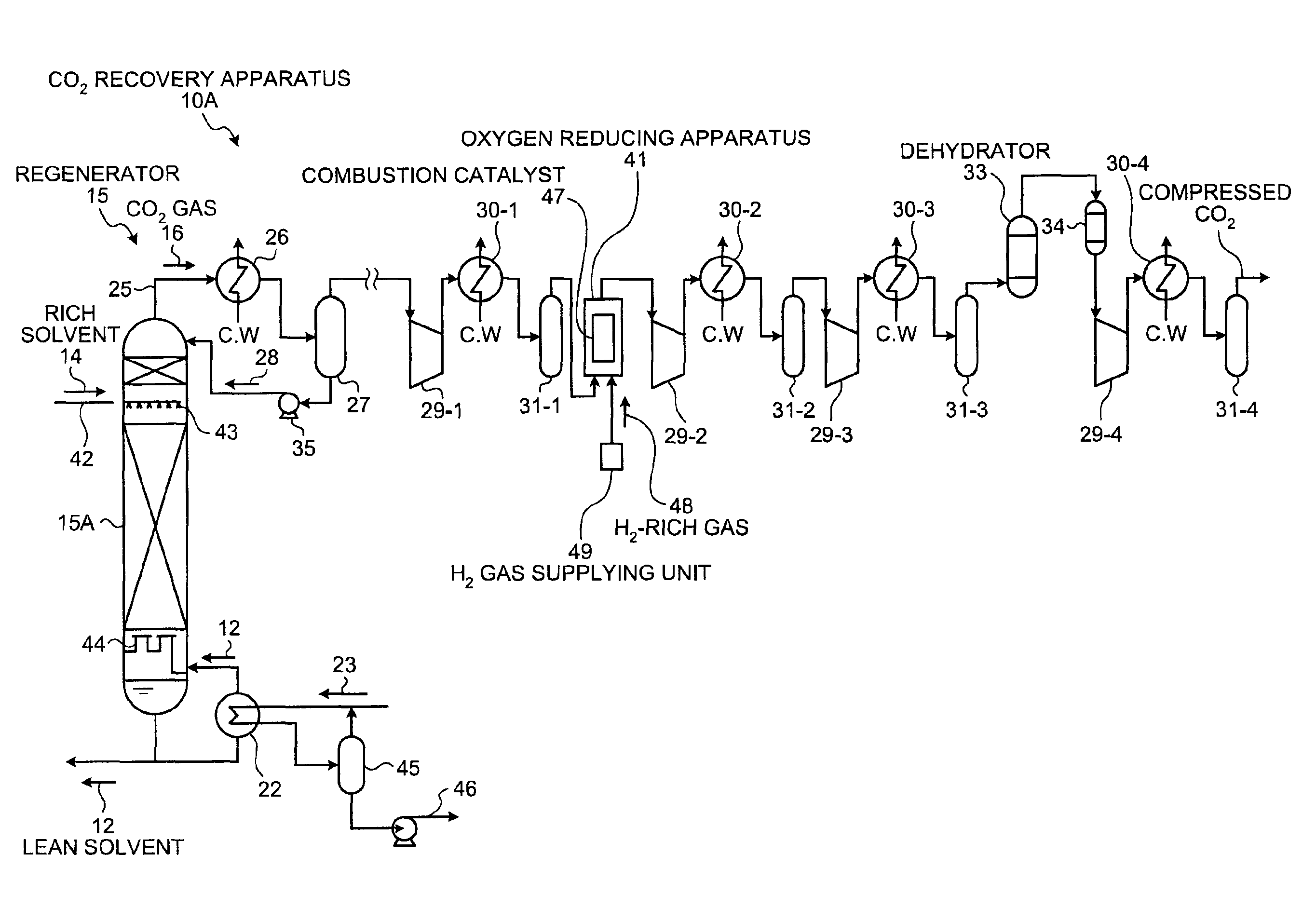

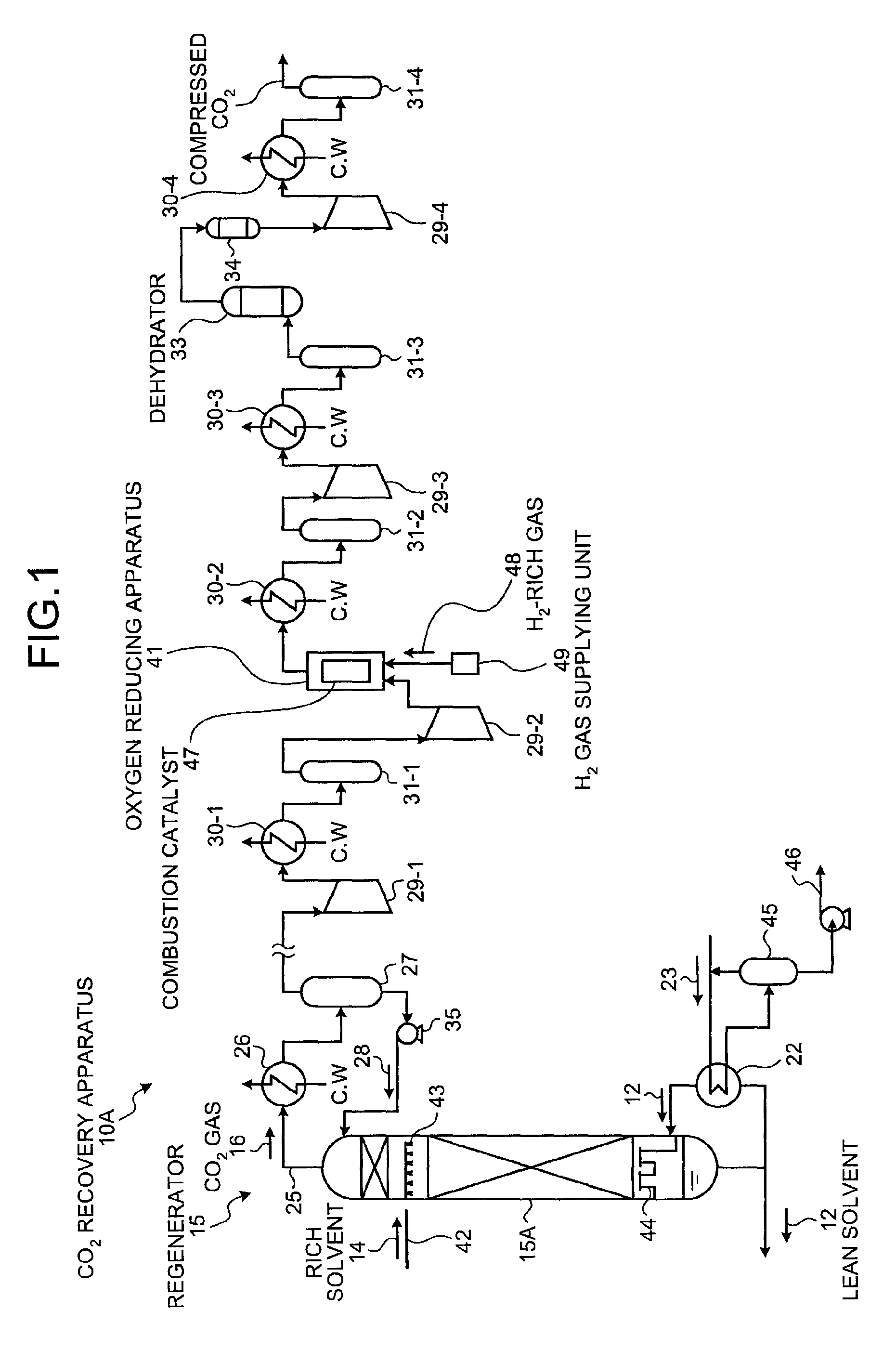

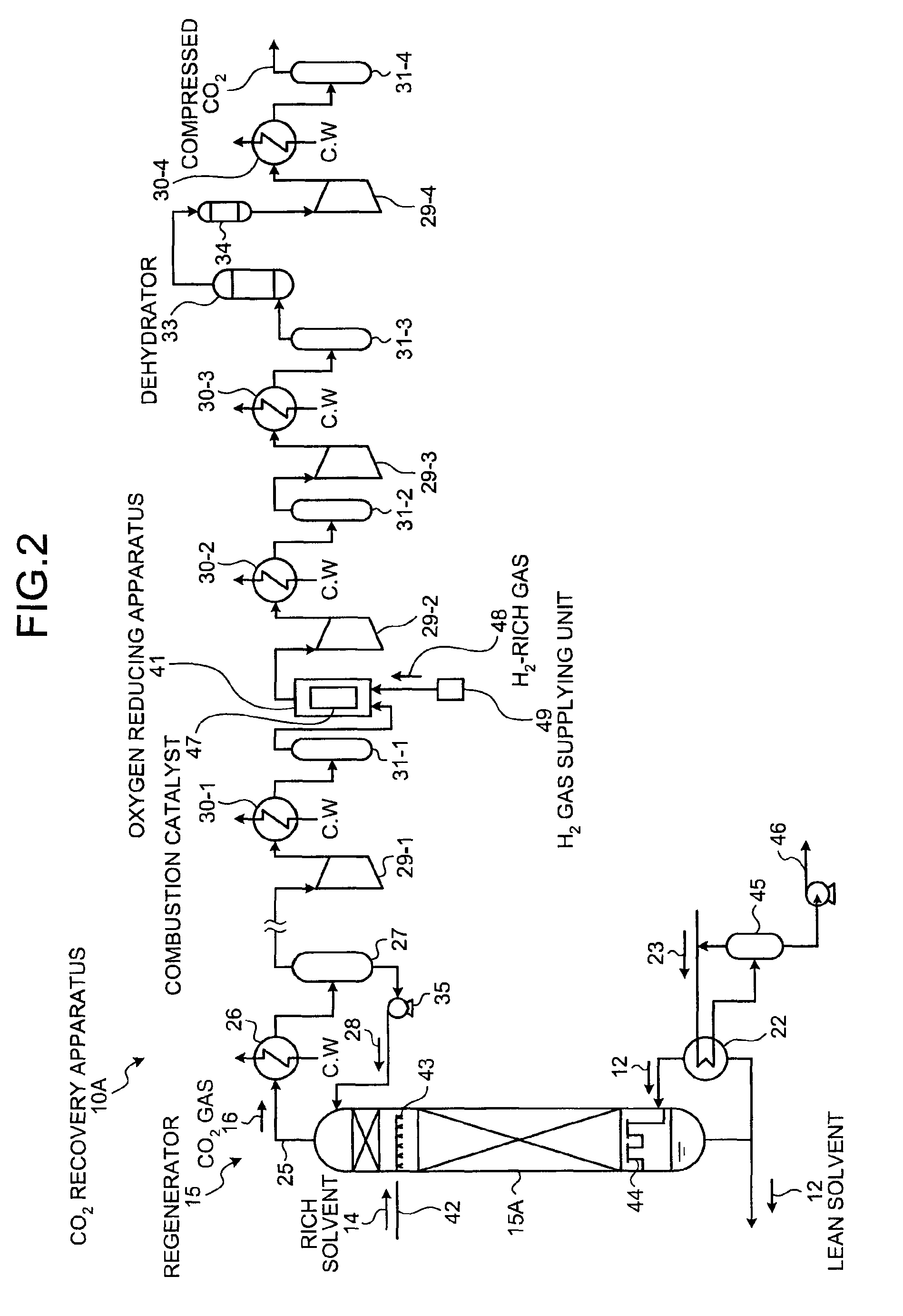

CO2 recovery apparatus and CO2 recovery method

ActiveUS8377184B2Reduce oxygen concentrationSuppression problemOxygen/ozone/oxide/hydroxideLiquid degasificationFlue gasCo2 absorption

A CO2 recovery apparatus according to a first embodiment of the present invention includes: a CO2 absorber that brings flue gas containing CO2 into contact with CO2 absorbing liquid to reduce CO2 in the flue gas; a regenerator that reduces CO2 in CO2 absorbing liquid (rich solvent) that has absorbed the CO2 in the CO2 absorber to regenerate the CO2 absorbing liquid, so that the regenerated absorbing liquid (lean solvent), having CO2 reduced in the regenerator, is reused in the CO2 absorber; a first compressor to a fourth compressor that compress the CO2 gas released from the regenerator; and an O2 reducing apparatus arranged between the second compressor and a second cooler to reduce O2 in the CO2 gas.

Owner:MITSUBISHI HEAVY IND ENG LTD

Hardware configuration for pressure driver

ActiveUS20070193579A1Reduce oxygen concentrationImprove ventilationRespiratorsOperating means/releasing devices for valvesOxygen sensorControl system

A pressure driver for a ventilation system comprises a gas source, an inspiration flow control valve and a patient pressure sensor to form a closed loop control system. The inspiration flow control valve may be mounted within a housing and is operative to open and close in response to patient pressure measurements in order to produce a desired pressure at the patient. The pressure driver may further include a mixture control for allowing selective adjustment of the oxygen concentration in pressurized gas delivered to the patient. An oxygen mixer is connected between the gas source and the mixture control and is operative to deliver the desired mixture of oxygen and air to the inspiration flow control valve for delivery to the patient. An oxygen sensor monitors the oxygen concentration in the gas provided by the oxygen mixer.

Owner:VYAIRE MEDICAL 211 INC

Method and system for extinguishing fire in an enclosed space

InactiveUS20020070035A1Reduce oxygen concentrationImprove concentrationAir-treatment apparatus arrangementsSpraying apparatusHigh rateNitrogen

A system for suppressing fire in an enclosed space, e.g. an aircraft cabin or freight compartment, includes nitrogen tanks and / or generators to rapidly supply a limited quantity of nitrogen with a high flow rate, and a membrane system to supply an essentially unlimited quantity of nitrogen at a lower supply rate for a long duration. The membrane system includes a selectively permeable membrane that separates nitrogen gas from ambient environmental air that is supplied into the membrane system. Once a fire is detected, nitrogen is supplied from the nitrogen gas tanks and / or generators at a high rate to rapidly increase the nitrogen concentration and establish a reduced oxygen concentration (e.g. 12 vol. %) in the enclosed space. Then, nitrogen is supplied from the membrane system at a reduced rate for a long duration to maintain the reduced oxygen concentration in the enclosed space until the fire is extinguished by oxygen starvation.

Owner:AIRBUS OPERATIONS GMBH

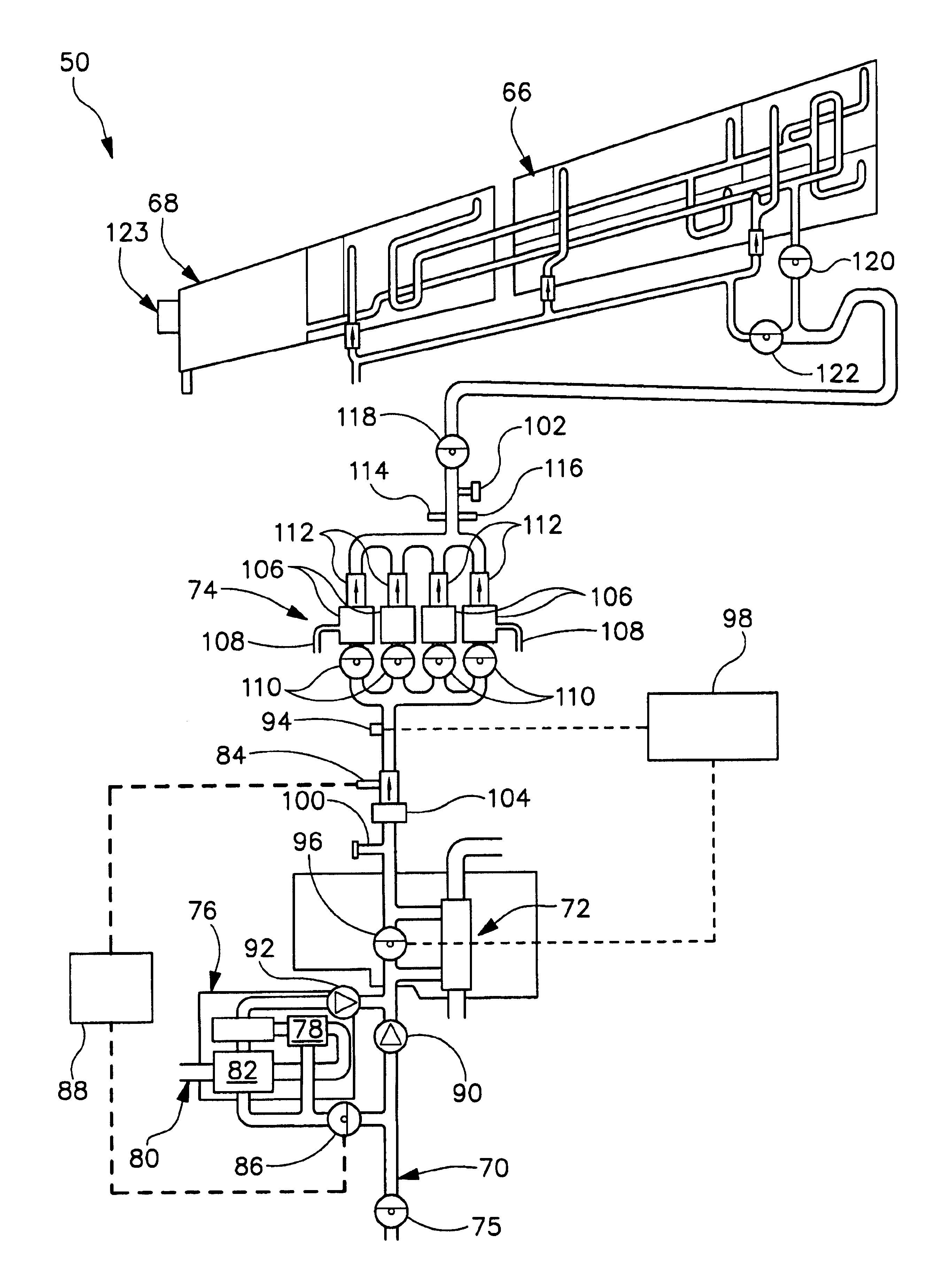

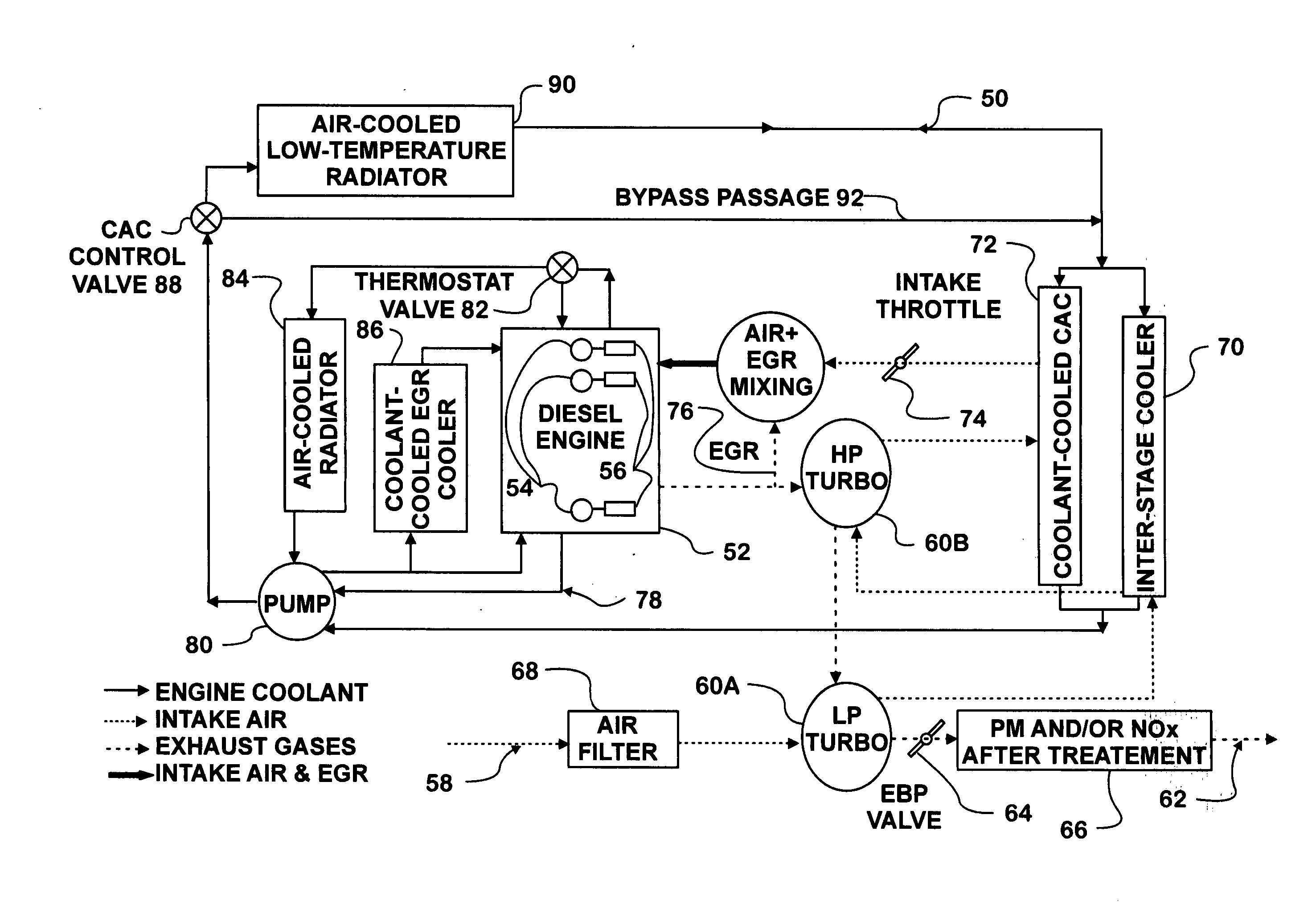

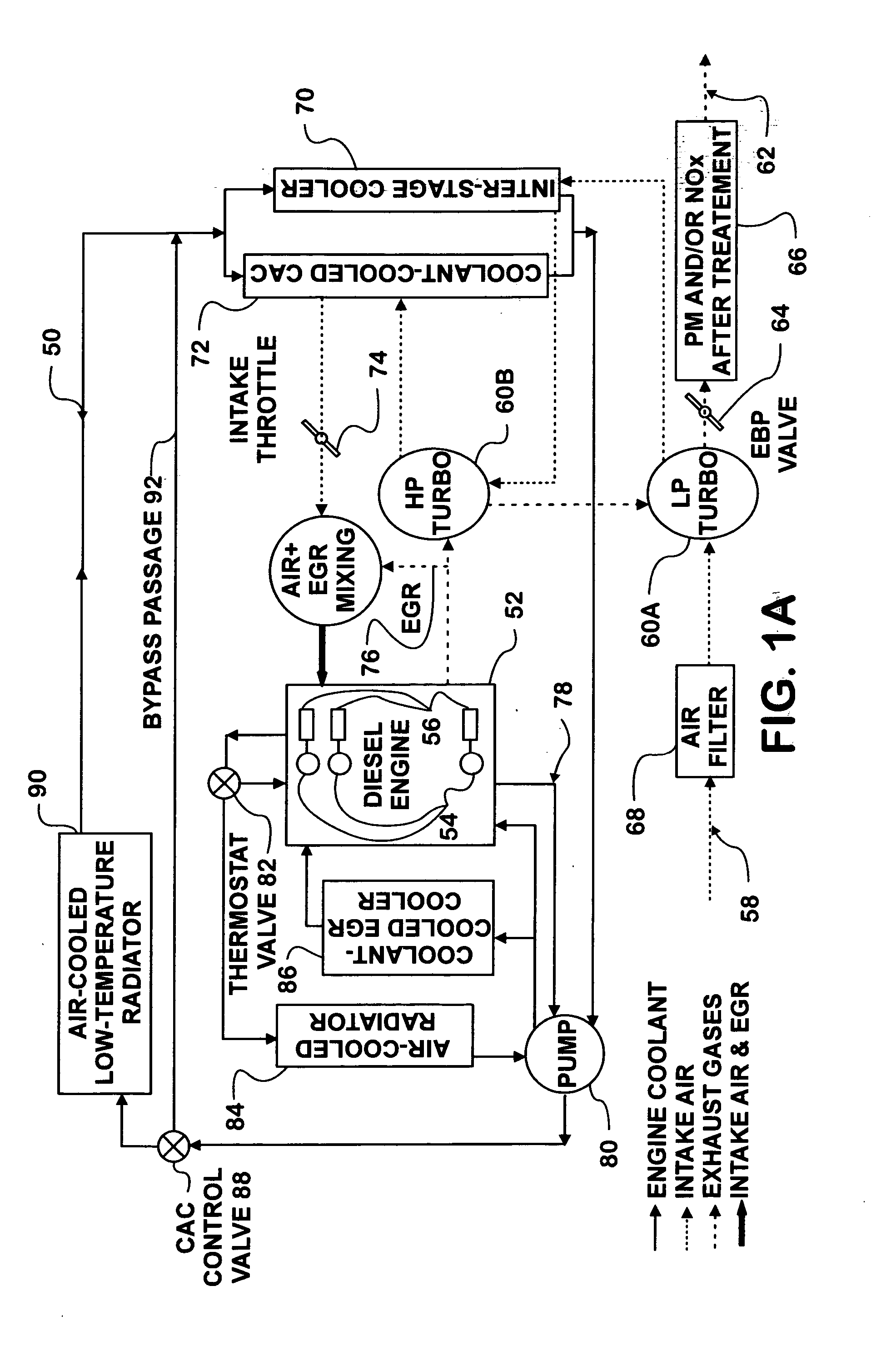

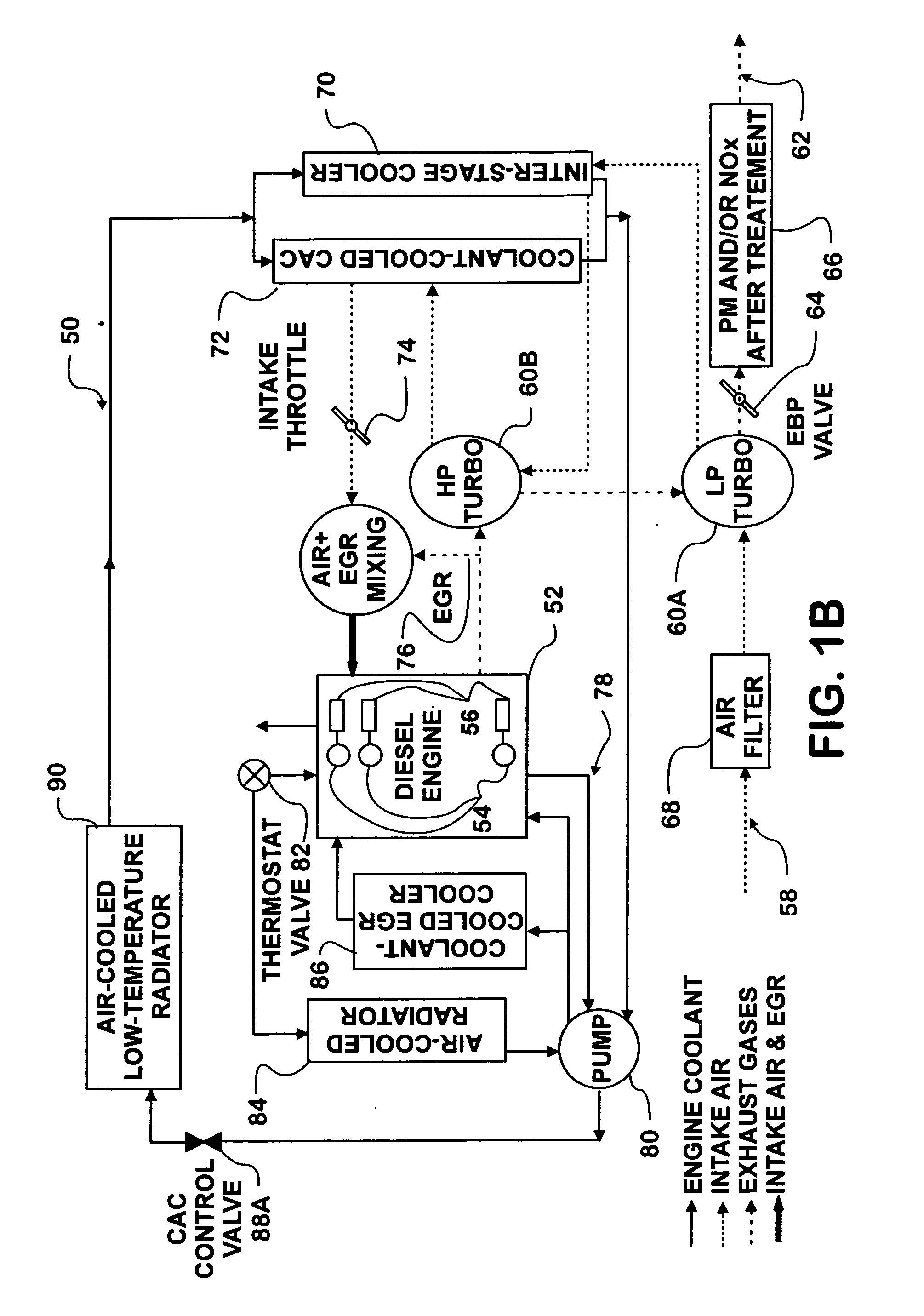

Flexible engine cooling and exhaust gas temperature controls for diesel after-treatment regeneration and engine performance improvement

InactiveUS20070199320A1Avoidance of added installationReduce Warranty CostsElectrical controlInternal combustion piston enginesTemperature controlAfter treatment

System, methods, and strategies for regulating charge air temperature in an intake manifold of an internal combustion engine (50) by controlling the flow rate and temperature of liquid engine coolant flowing through a liquid flow path of a charge air cooler (72) that is in heat exchange relationship with charge air entering the intake manifold over a range that provides for the charge air to be selectively heated and cooled by liquid engine coolant. The invention provides flexible control that is useful in controlling exhaust gas temperature for regeneration and / or efficiency restoration of exhaust after-treatment devices (66) as well as improved engine performance.

Owner:INT ENGINE INTPROP CO LLC

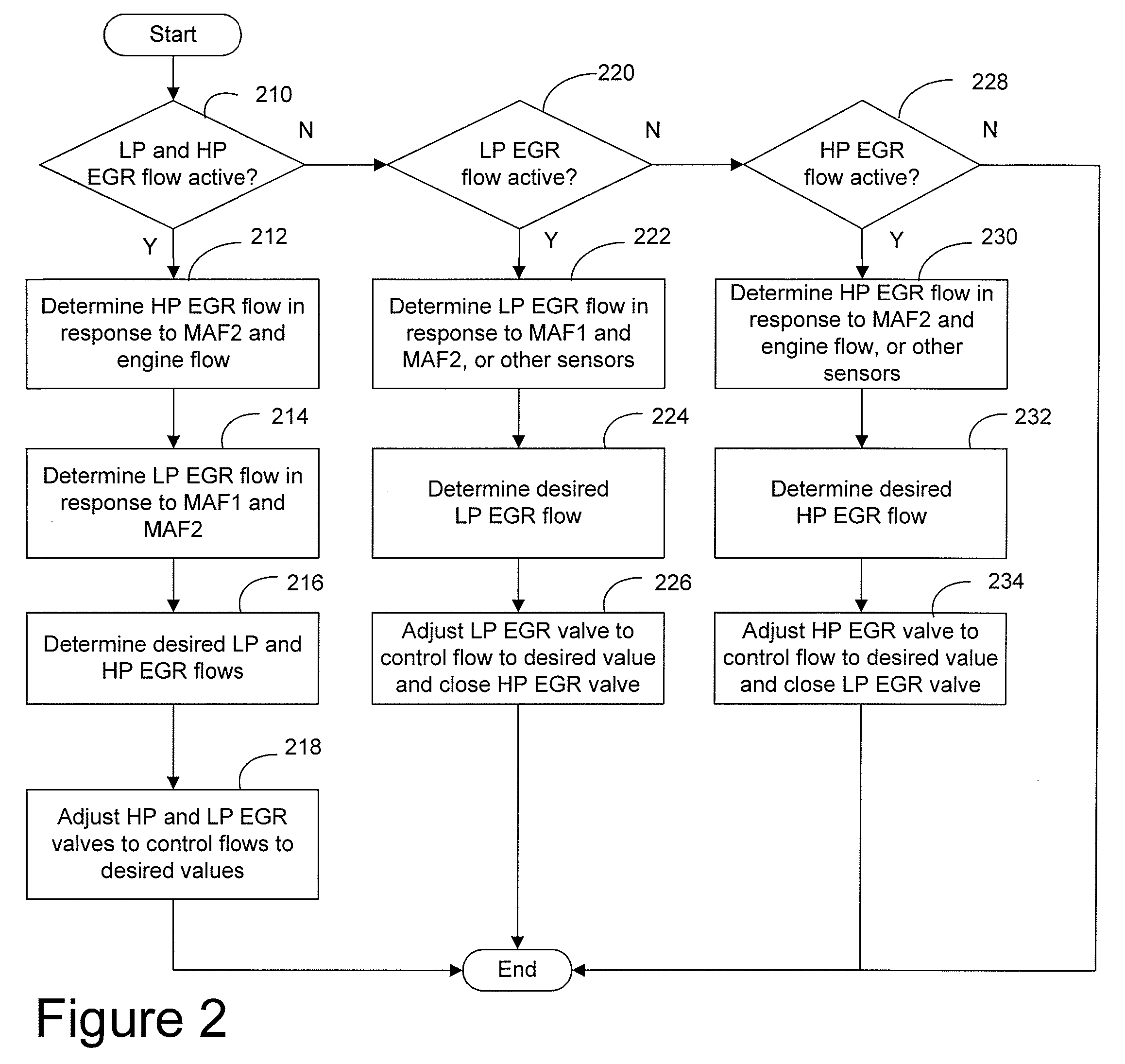

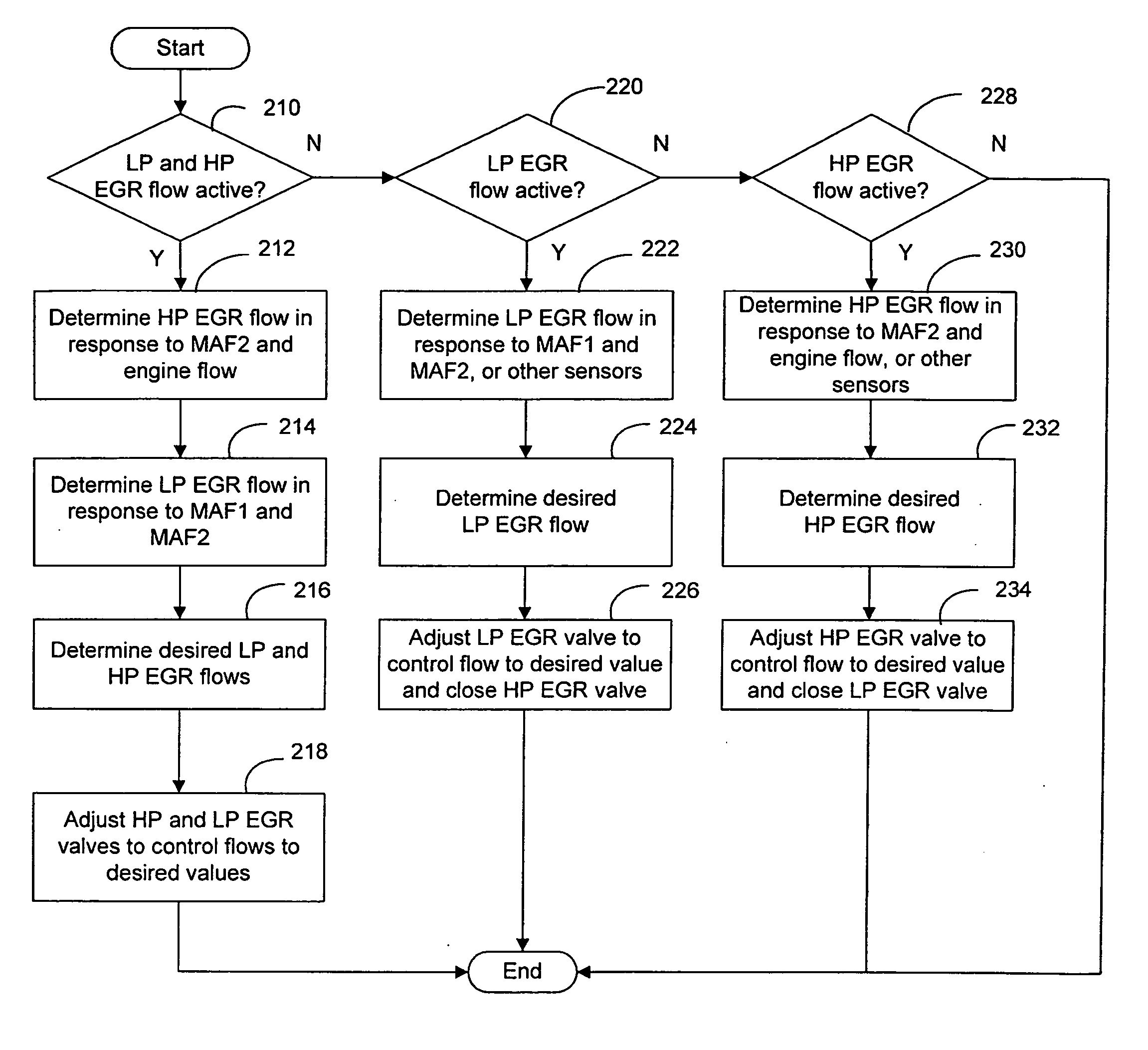

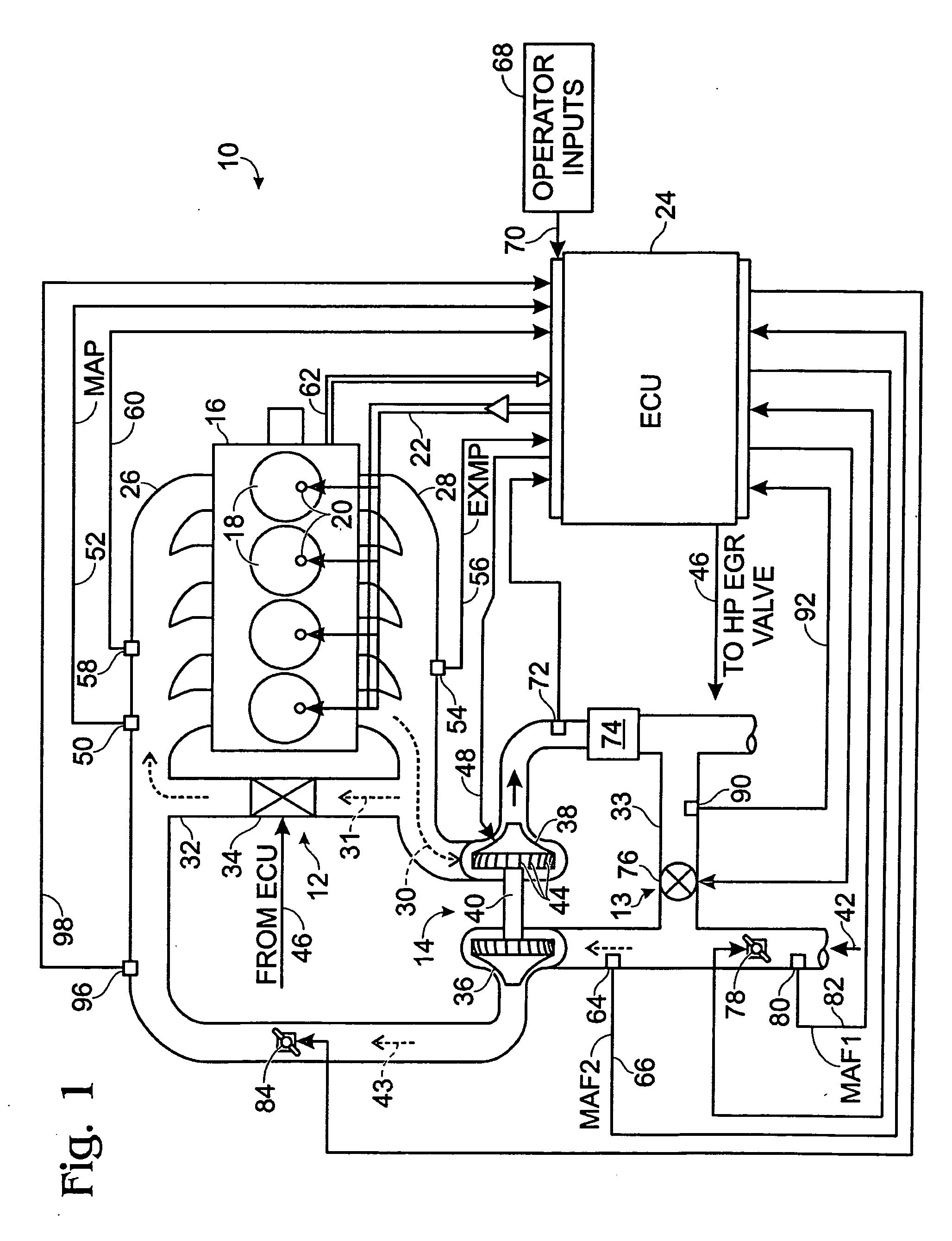

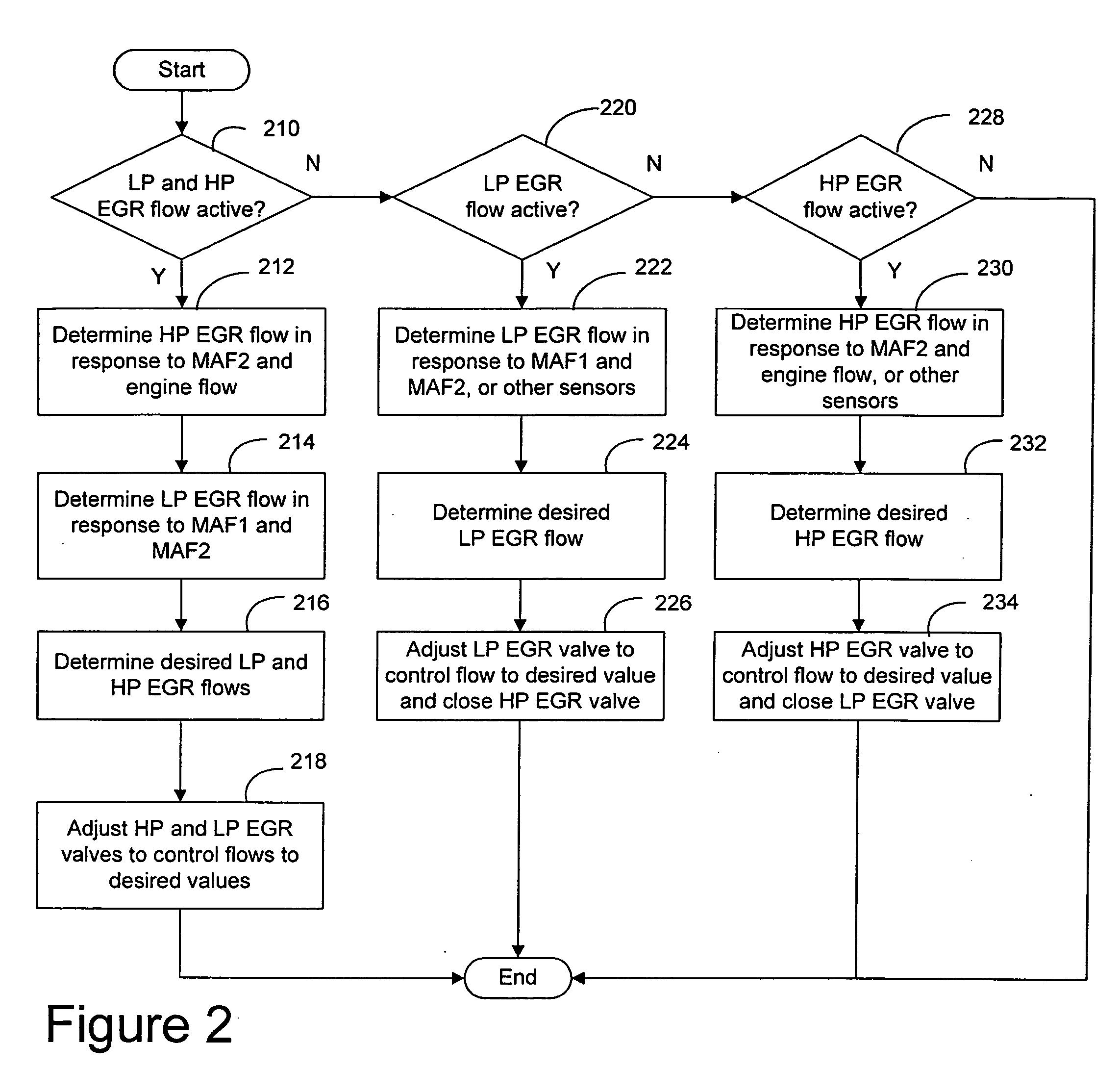

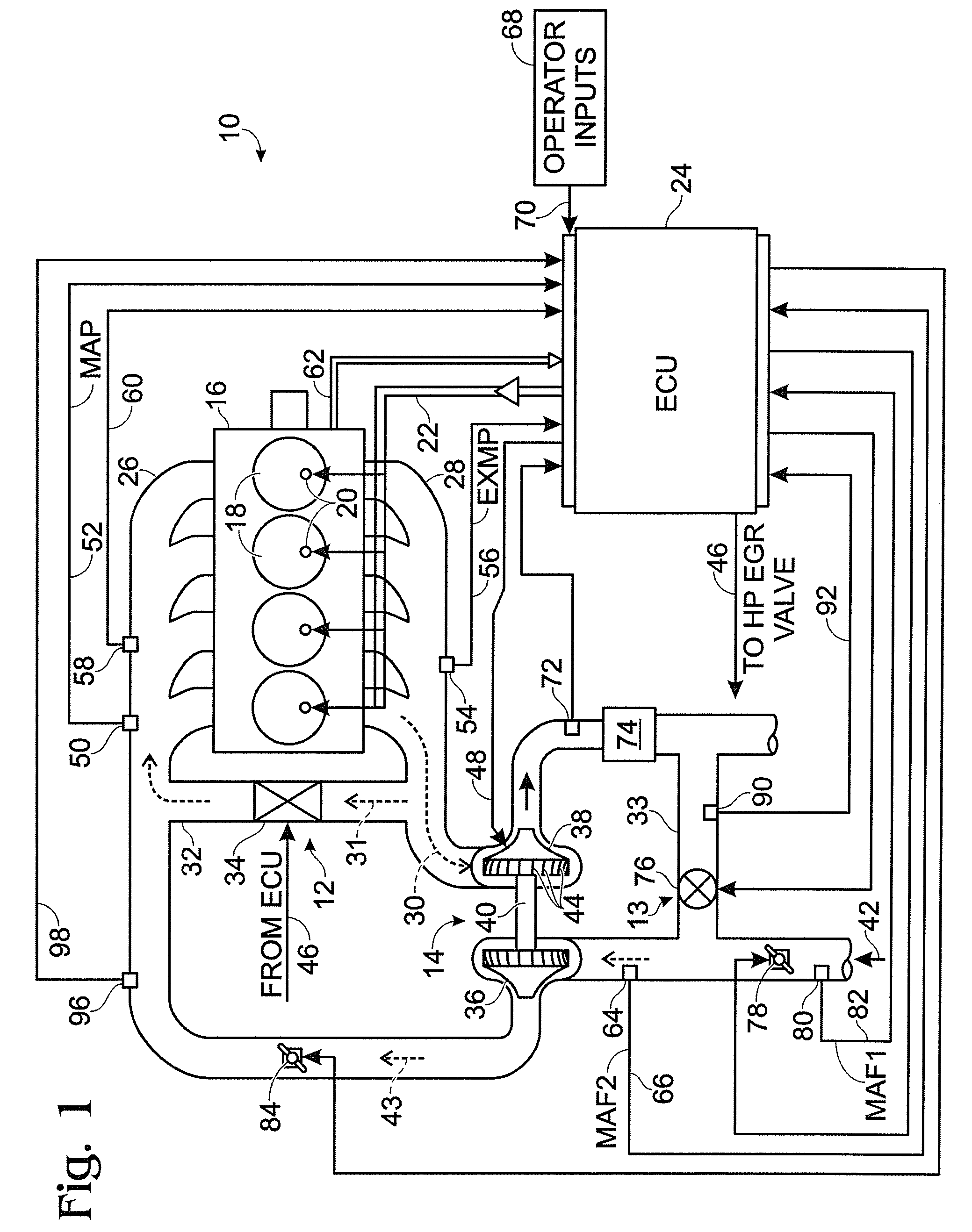

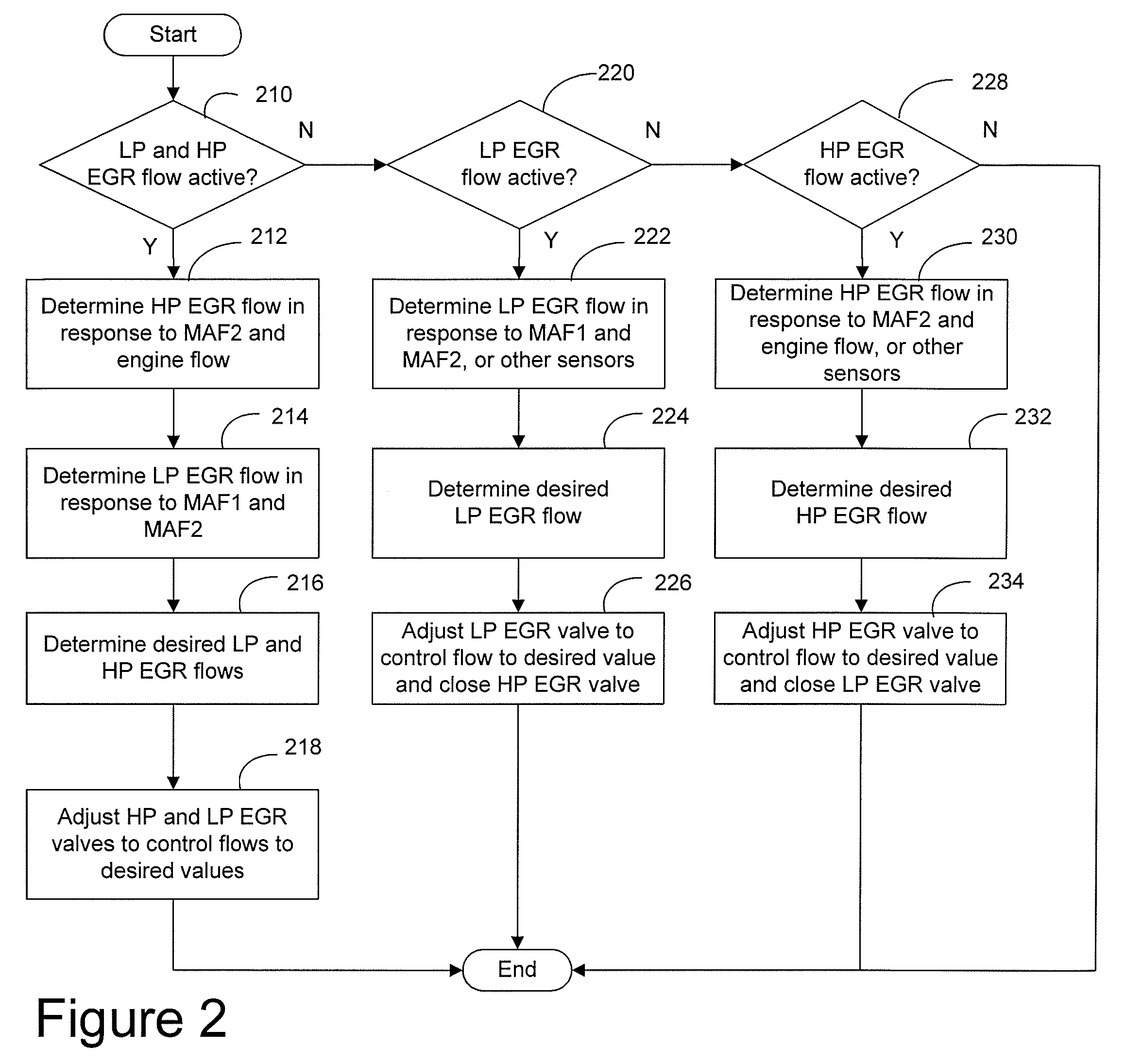

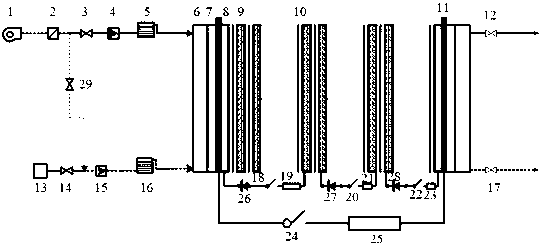

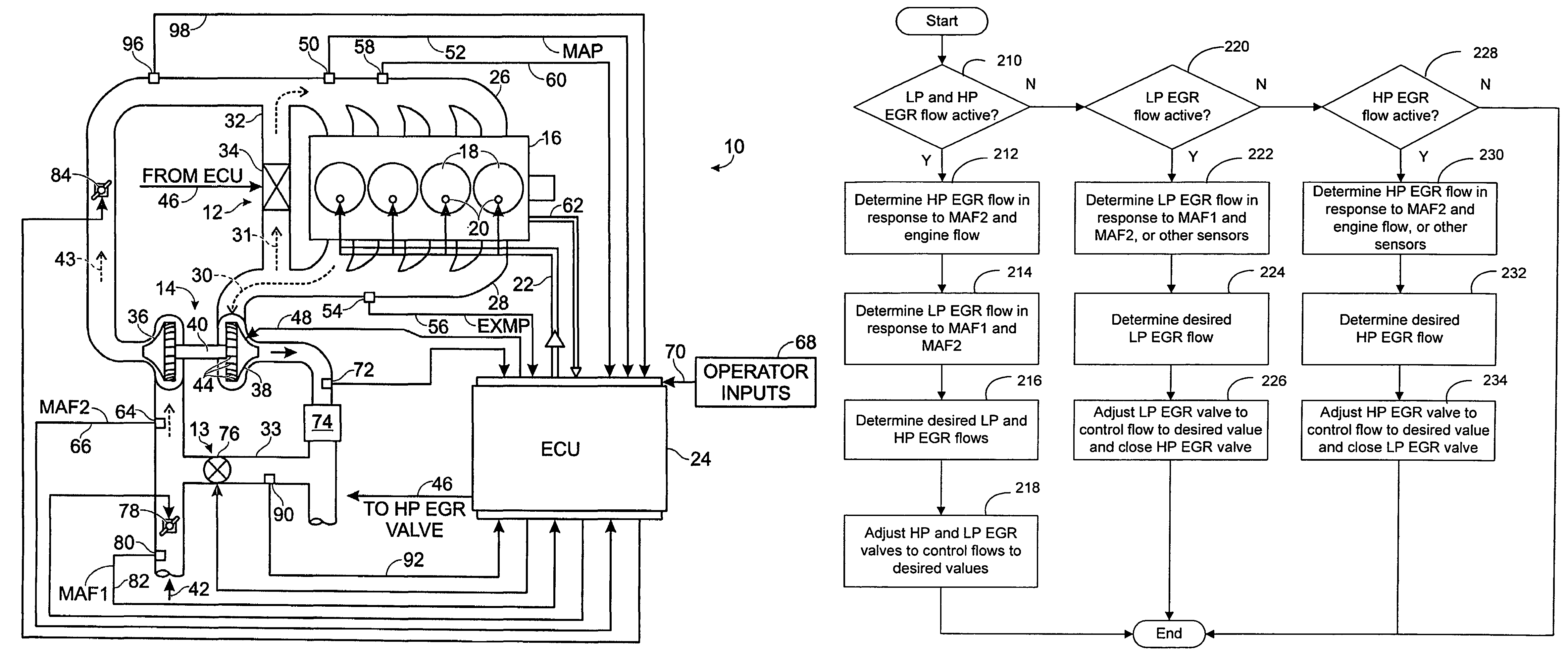

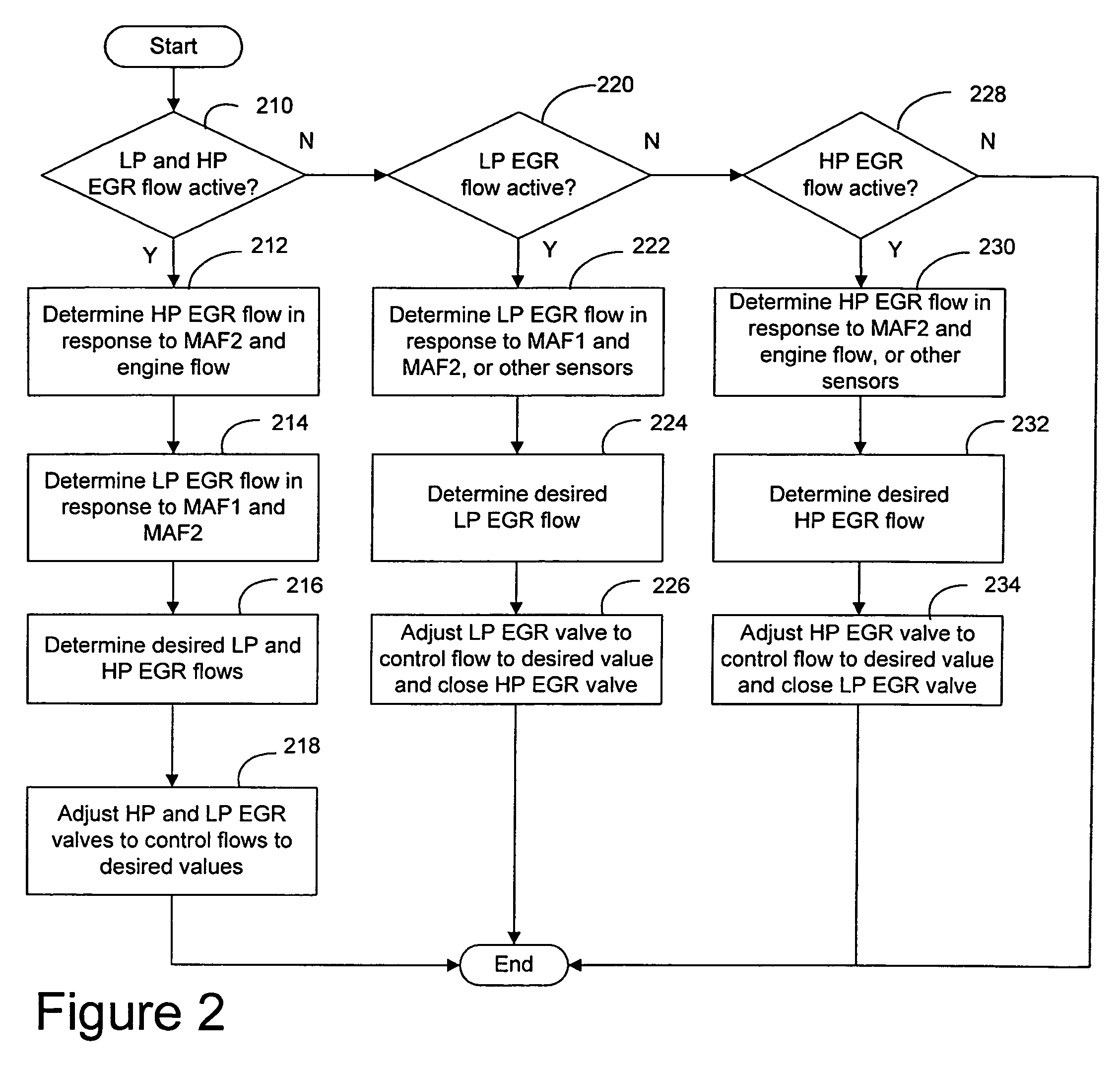

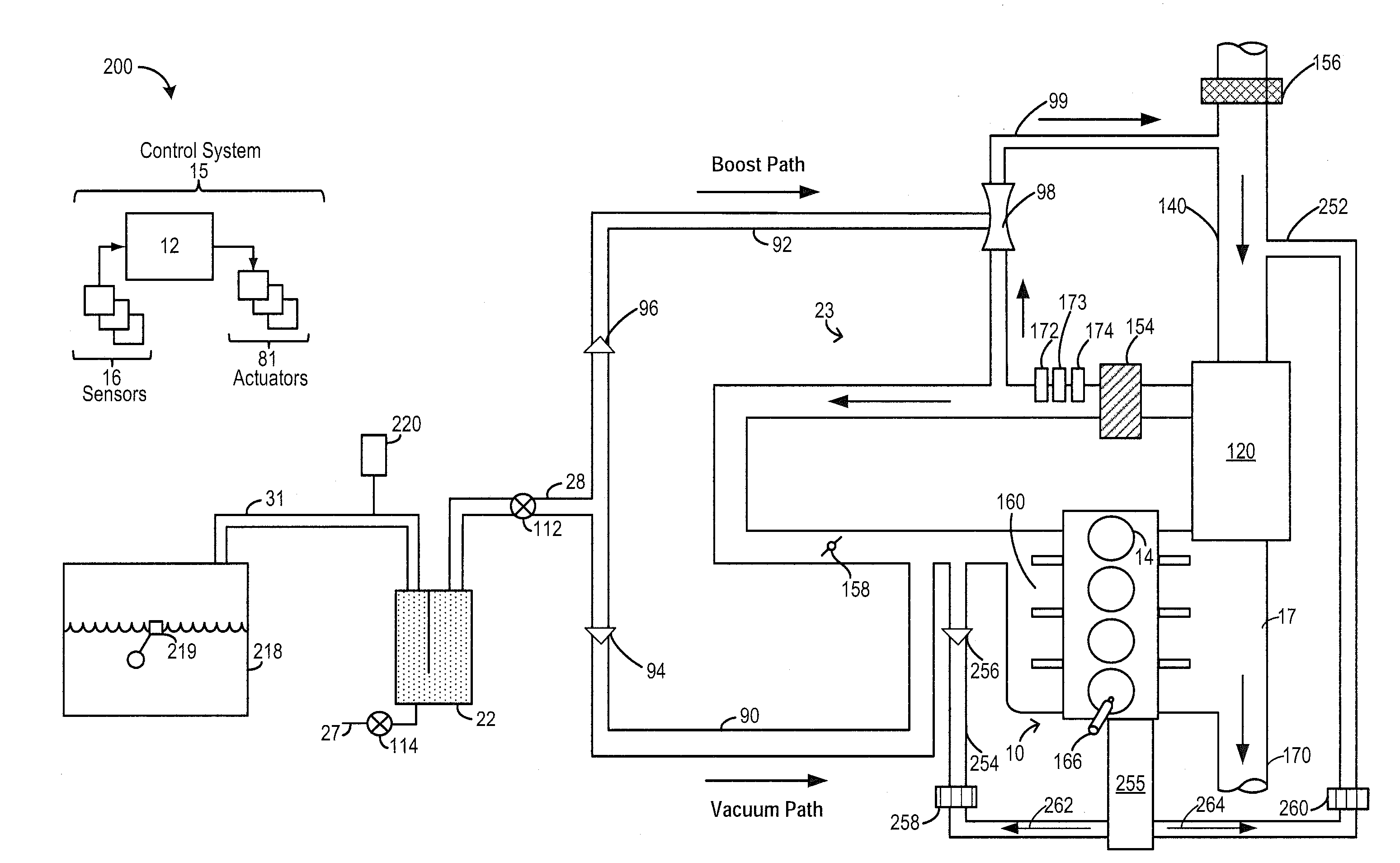

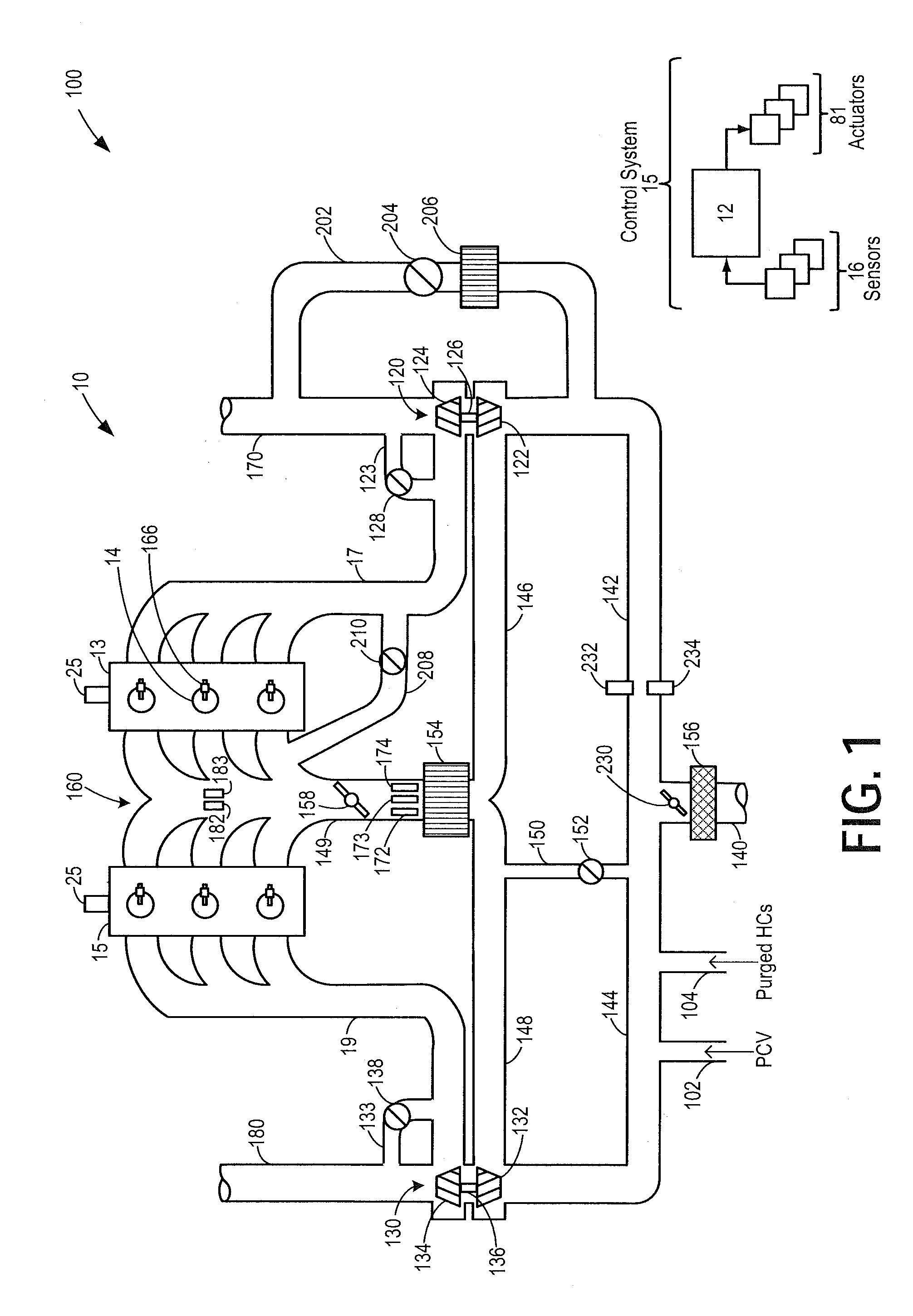

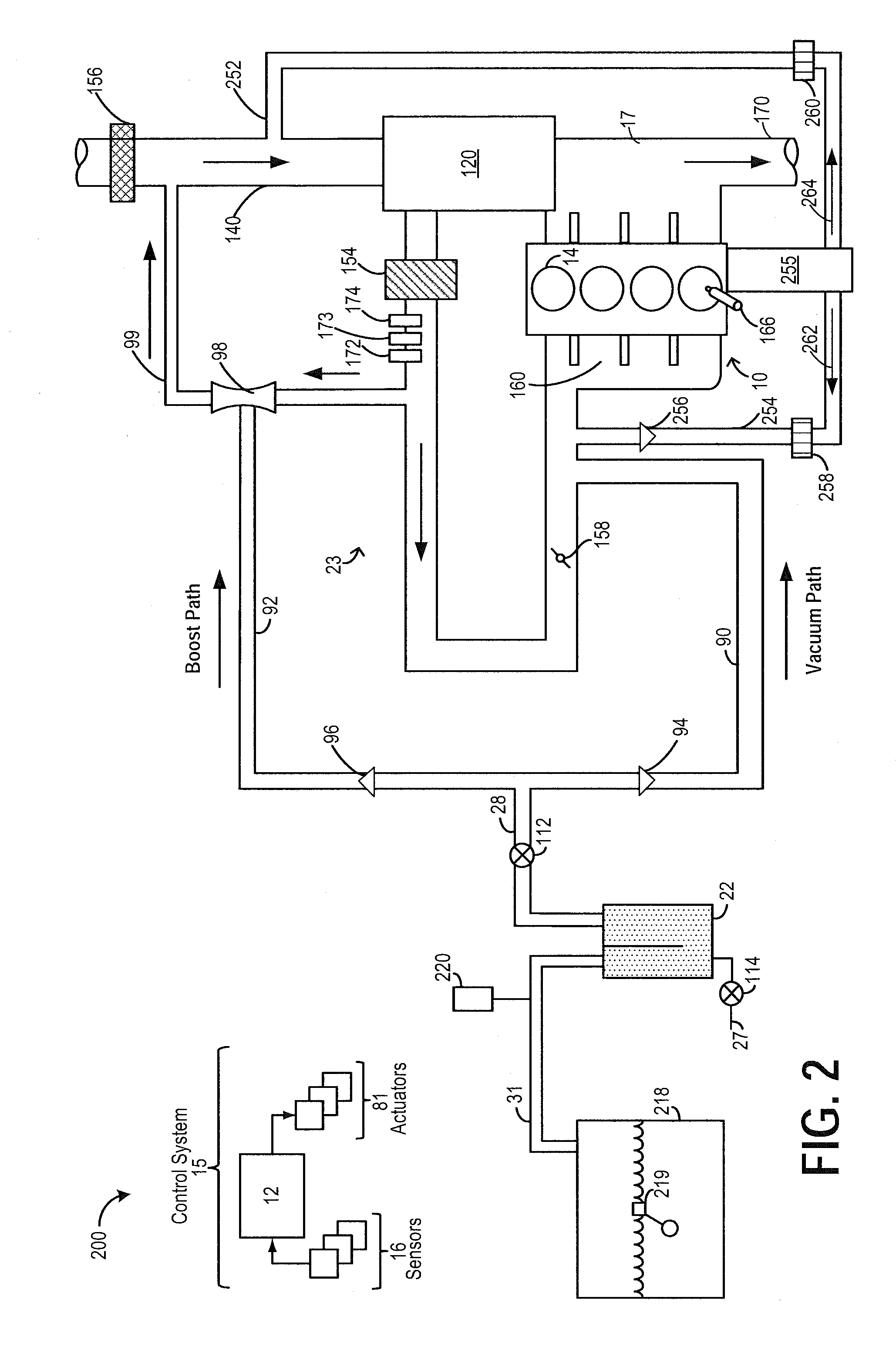

System and method for high pressure and low pressure exhaust gas recirculation control and estimation

ActiveUS20070079614A1Easy to operateReduce the formation of nitrogen oxidesElectrical controlInternal combustion piston enginesTurbochargerExhaust fumes

A system for a diesel engine having an intake manifold and an exhaust manifold, comprising a turbocharger coupled between the intake and exhaust manifolds of the engine; a low pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold downstream of the turbocharger and a second end coupled to the intake manifold upstream of the turbocharger, said low pressure exhaust gas recirculation having a first valve coupled thereto for regulating flow; a high pressure exhaust gas recirculation system with a first end coupled to the exhaust manifold upstream of the turbocharger and a second end coupled to the intake manifold downstream of the turbocharger, said high pressure exhaust gas recirculation having a second valve coupled thereto for regulating flow; a first mass airflow sensor coupled in the engine intake manifold upstream of said second end of said low pressure exhaust gas recirculation system; a second mass airflow sensor coupled in the engine intake manifold downstream of said second end of said low pressure exhaust gas recirculation system and upstream of said second end of said high pressure exhaust gas recirculation system.

Owner:FORD GLOBAL TECH LLC

System and method for diagnostic of low pressure exhaust gas recirculation system and adapting of measurement devices

ActiveUS7367188B2Reduce the formation of nitrogen oxidesImprove fuel economyVehicle testingElectrical controlMeasurement deviceTurbocharger

A system for a diesel engine having an intake manifold and an exhaust manifold, comprises a turbocharger between the intake and exhaust manifolds; a low pressure exhaust gas recirculation system having a first valve coupled thereto for regulating flow; a high pressure exhaust gas recirculation system having a second valve coupled thereto for regulating flow; a first mass airflow sensor coupled in the engine intake manifold; and a control system configured to diagnose the degradation of the first mass airflow sensor.

Owner:FORD GLOBAL TECH LLC

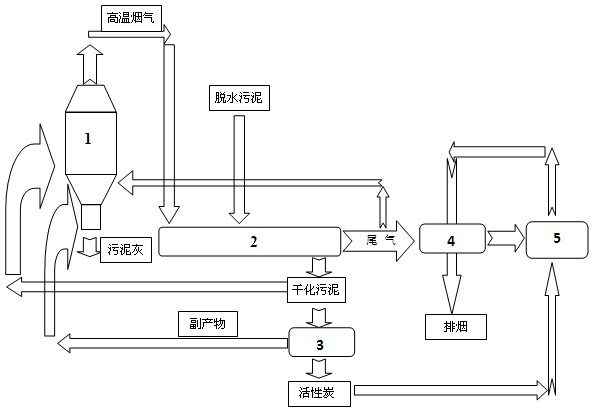

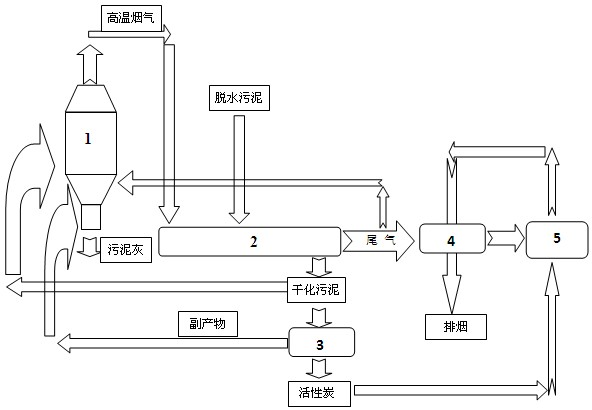

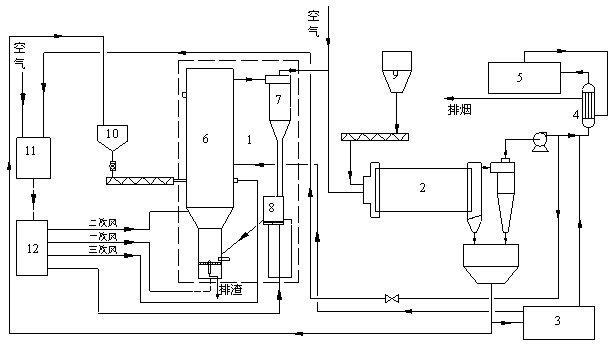

Municipal sludge drying and incineration system and treatment process thereof

ActiveCN101813316AReduce oxygen concentrationImproved Temperature UniformitySludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisExhaust gasActivated carbon

The invention discloses a municipal sludge drying and incineration system. The system comprises an incinerator, wherein a smoke outlet of the incinerator is communicated with a sludge dryer; a tail gas outlet of the sludge dryer is connected with a heat exchanger and the incinerator respectively; the heat exchanger is communicated with a tail gas treatment system; one path of a discharge port of the sludge dryer is communicated with the incinerator, while the other path is communicated with a pyrolyzing furnace; and a discharge port of the pyrolyzing furnace is respectively communicated with an activated carbon tail gas treatment system and the incinerator. The invention also discloses a process for treating the municipal sludge drying and incineration system. The system has the advantages of simple system formation, small energy consumption in sludge treatment process, no secondary pollution, concise whole processing procedure, low failure rate and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

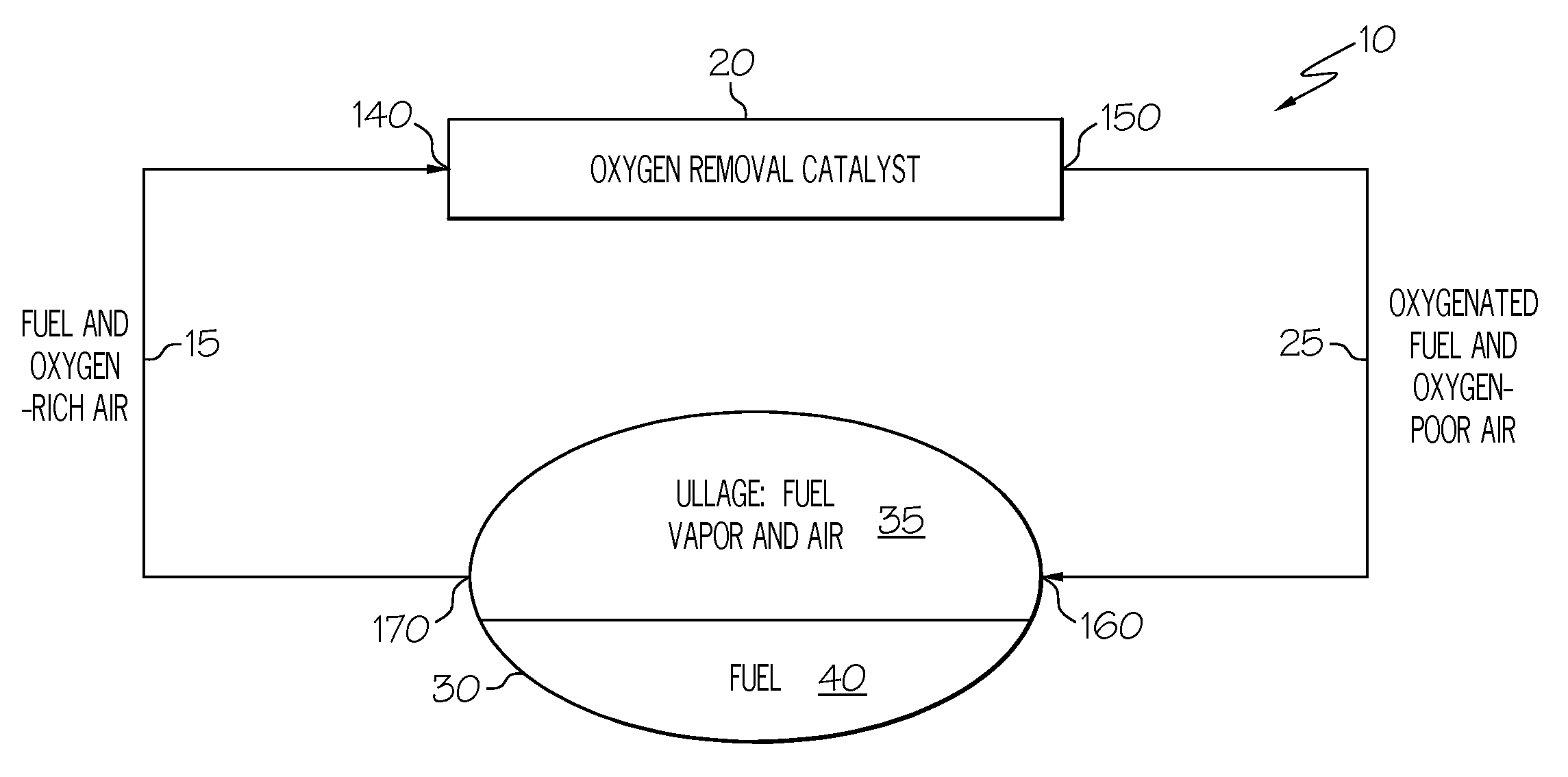

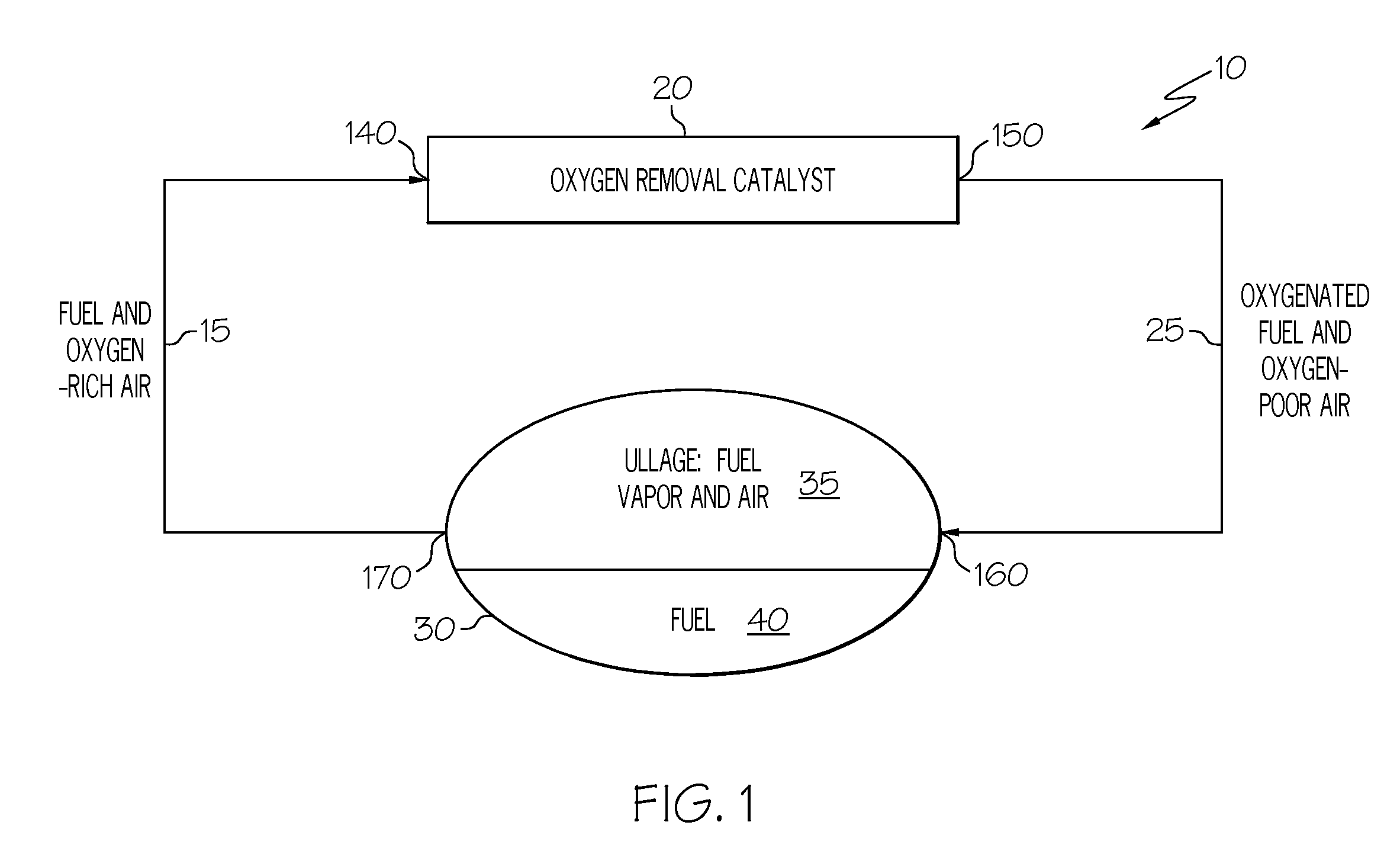

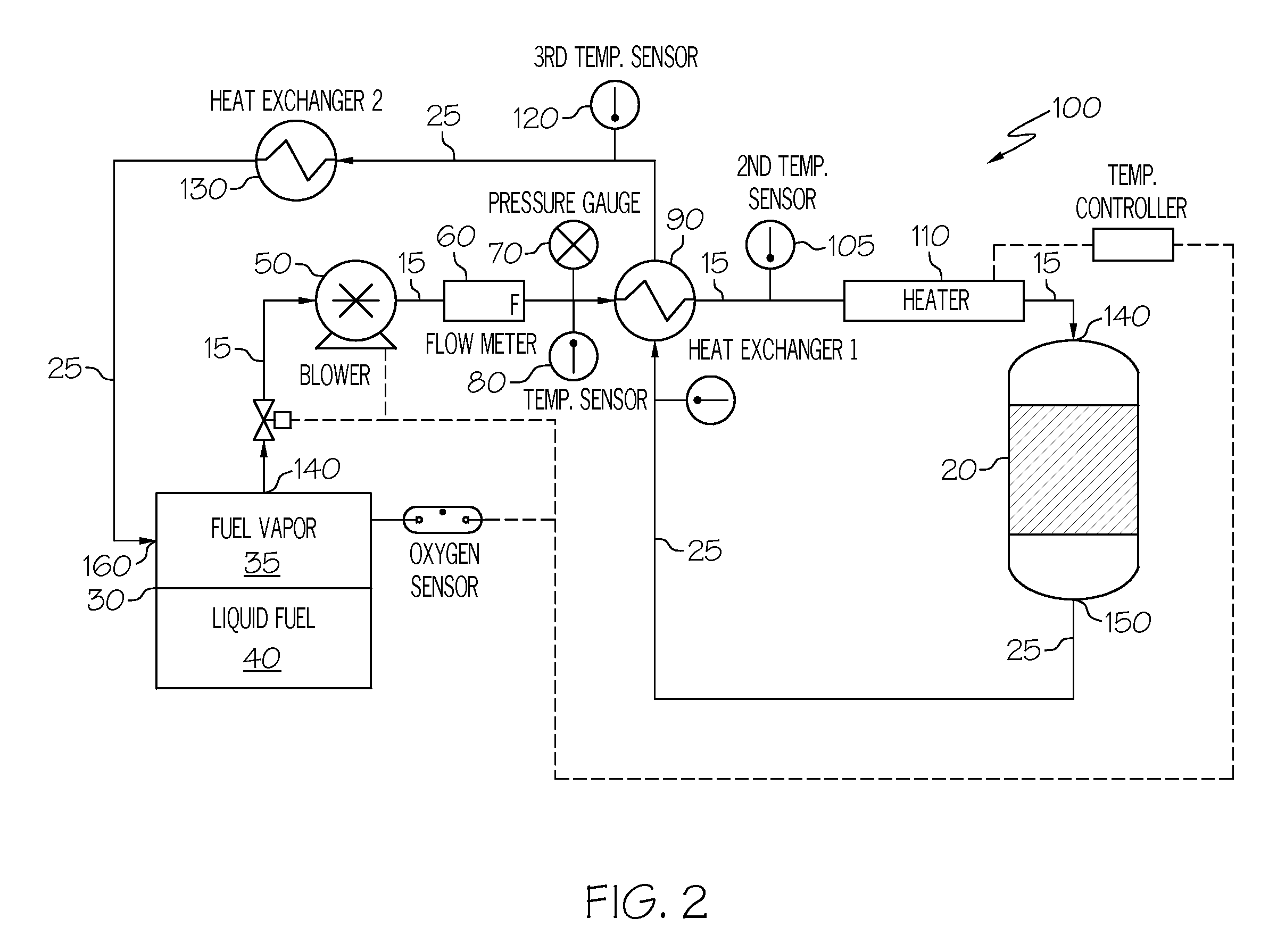

Oxygen removal system

ActiveUS20080099618A1Reduce riskReduce oxygen concentrationLiquid degasificationPower plant fuel tanksAlcoholKetone

A system and process is provided to deplete or remove oxygen in the ullage of a fuel tank to reduce the oxygen / fuel vapor ratio below a lower explosion limit by exposing the ullage compounds to an oxygen removal catalyst active at a relatively low temperature. The oxygen removal catalyst may be a non-precious metal catalyst. A selective reaction of the oxygen by the catalyst forms primarily alcohols, aldehydes, and / or ketones and produces less than about 5% water by volume. The selective reaction, occurring at the relatively low temperature, reduces the risk of flammability of the fuel.

Owner:HONEYWELL INT INC

Starting and shutdown control method for proton exchange membrane fuel cell

InactiveCN103259031AReduce voltageReduce time consumptionFuel cell auxillariesLoad circuitElectrical battery

The invention provides a starting and shutdown control method for a proton exchange membrane fuel cell. According to the method, a whole fuel cell stack is divided into a plurality of cell modules; each cell module is connected with a modularized discharging circuit which is composed of a control switch, an auxiliary load and a crystal diode in mutual series connection; each modularized discharging circuit and a main load circuit are in series connection and are respectively connected with the cathode end and the anode end of the fuel cell; an air source is connected with the anode end of the fuel cell through an air blow-down valve; and air is used to purge residual hydrogen at the anode. During starting control, hydrogen is used to purge the anode, and the auxiliary load is used to control the voltage of the cell; and during shutdown control, introduction of air and introduction of hydrogen are successively stopped, a closed system of the auxiliary load is used for discharging, and introduction of air is cooperatively used for purging of the anode. The invention has the following advantages: consumption of time during shutdown of the fuel cell is reduced; the concentration of residual oxygen at the cathode is lowered down; reversal of poles of a single cell in the modules is prevented, and the phenomenon of reversal of poles of the fuel cell in the processes of shutdown discharging and air purging is prevented; and the system of the fuel cell is more simplified and is convenient to operate.

Owner:WUHAN UNIV OF TECH

System and method for high pressure and low pressure exhaust gas recirculation control and estimation

ActiveUS7380400B2Reduce the formation of nitrogen oxidesImprove fuel economyElectrical controlInternal combustion piston enginesTurbochargerExhaust fumes

A system for a diesel engine having an intake manifold and an exhaust manifold is described. The system may include both a high pressure and low pressure exhaust gas recirculation system, as well as a turbocharger. Further, in one example, the system may include two mass airflow sensors appropriately placed to enable improved control of both the high and low pressure exhaust gas recirculation systems.

Owner:FORD GLOBAL TECH LLC

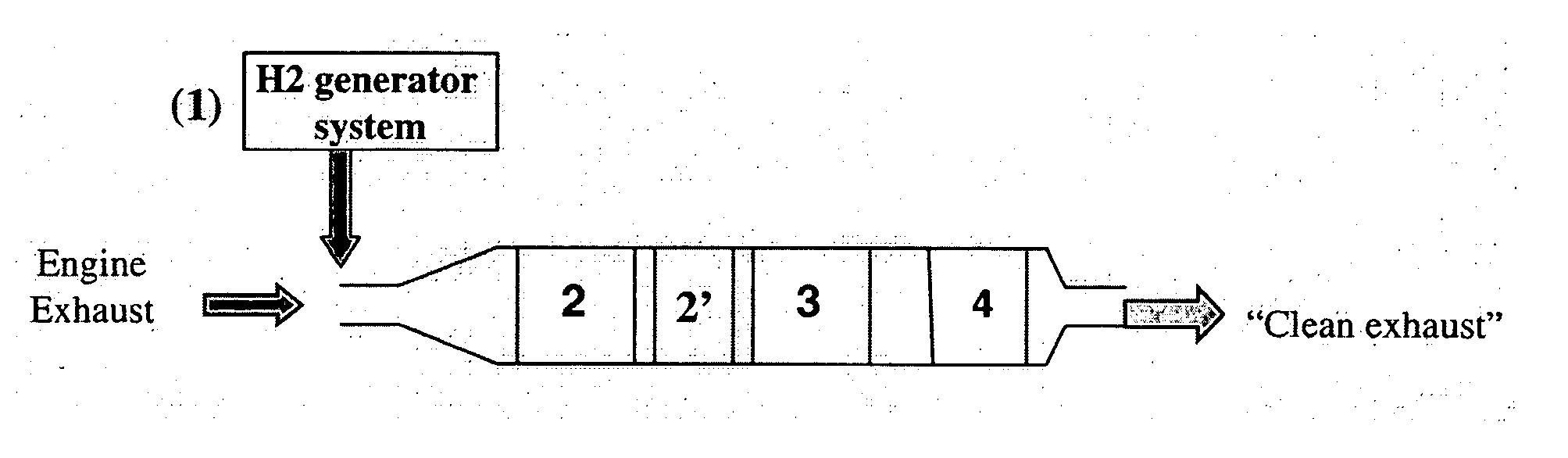

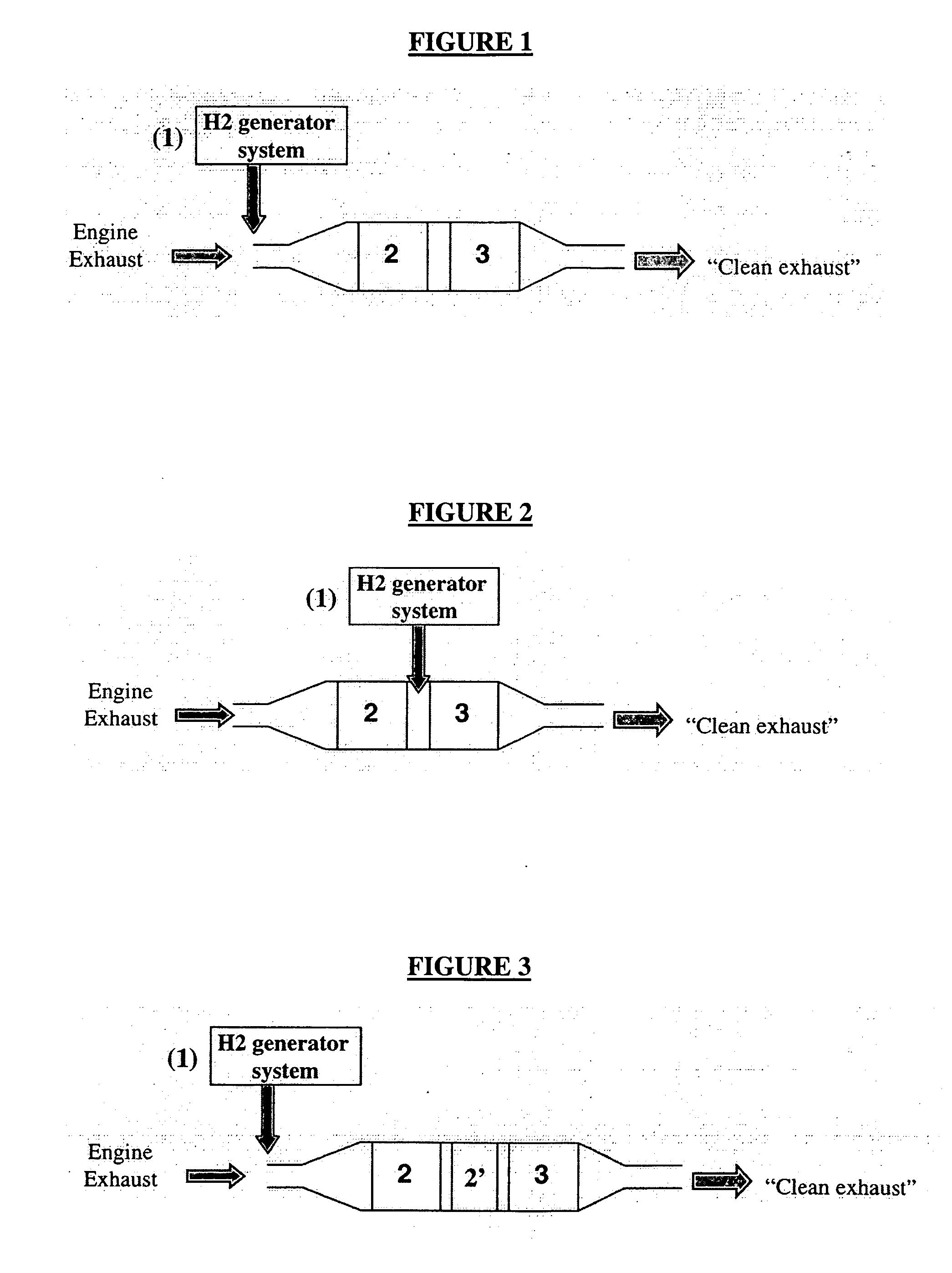

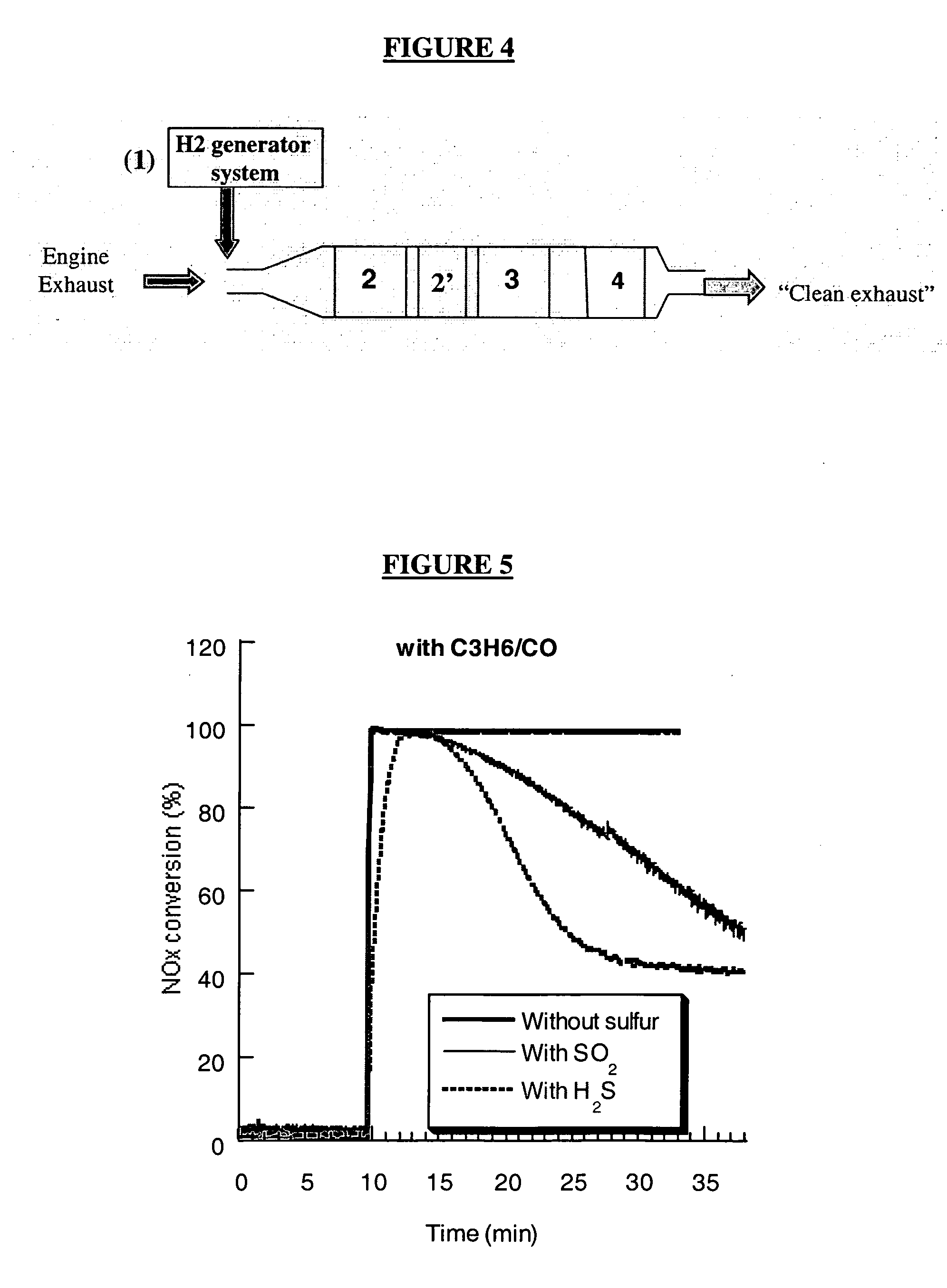

Sulfur oxide/nitrogen oxide trap system and method for the protection of nitrogen oxide storage reduction catalyst from sulfur poisoning

ActiveUS20070012028A1Improved NOx adsorption efficiencyIncreased durabilitySilencing apparatusMachines/enginesEmission standardNitrogen gas

The present invention relates to an improved exhaust gas cleaning system and method for a combustion source comprising a hydrogen generation system, a sulfur oxides trap, and a nitrogen storage reduction (NSR) catalyst trap. The improved exhaust gas cleaning system and method of the present invention also provides for a water-gas-shift catalyst between the sulfur oxides trap and the NSR catalyst trap, and a clean-up catalyst downstream of the NSR catalyst trap. The invention provides also a sulfur trap regenerable at moderate temperatures with rich pulses, rather than at high temperatures. The improved exhaust gas cleaning system of the present invention provides for the sulfur released from the sulfur trap to pass through the nitrogen oxide trap with no or little poisoning of NOx storage and reduction sites, which significantly improves NSR catalyst trap lifetime and performance to meet future emissions standards. The disclosed exhaust gas cleaning systems are suitable for use in internal combustion engines (e.g., diesel, gasoline, CNG) which operate with lean air / fuel ratios over most of the operating period.

Owner:EXXON RES & ENG CO

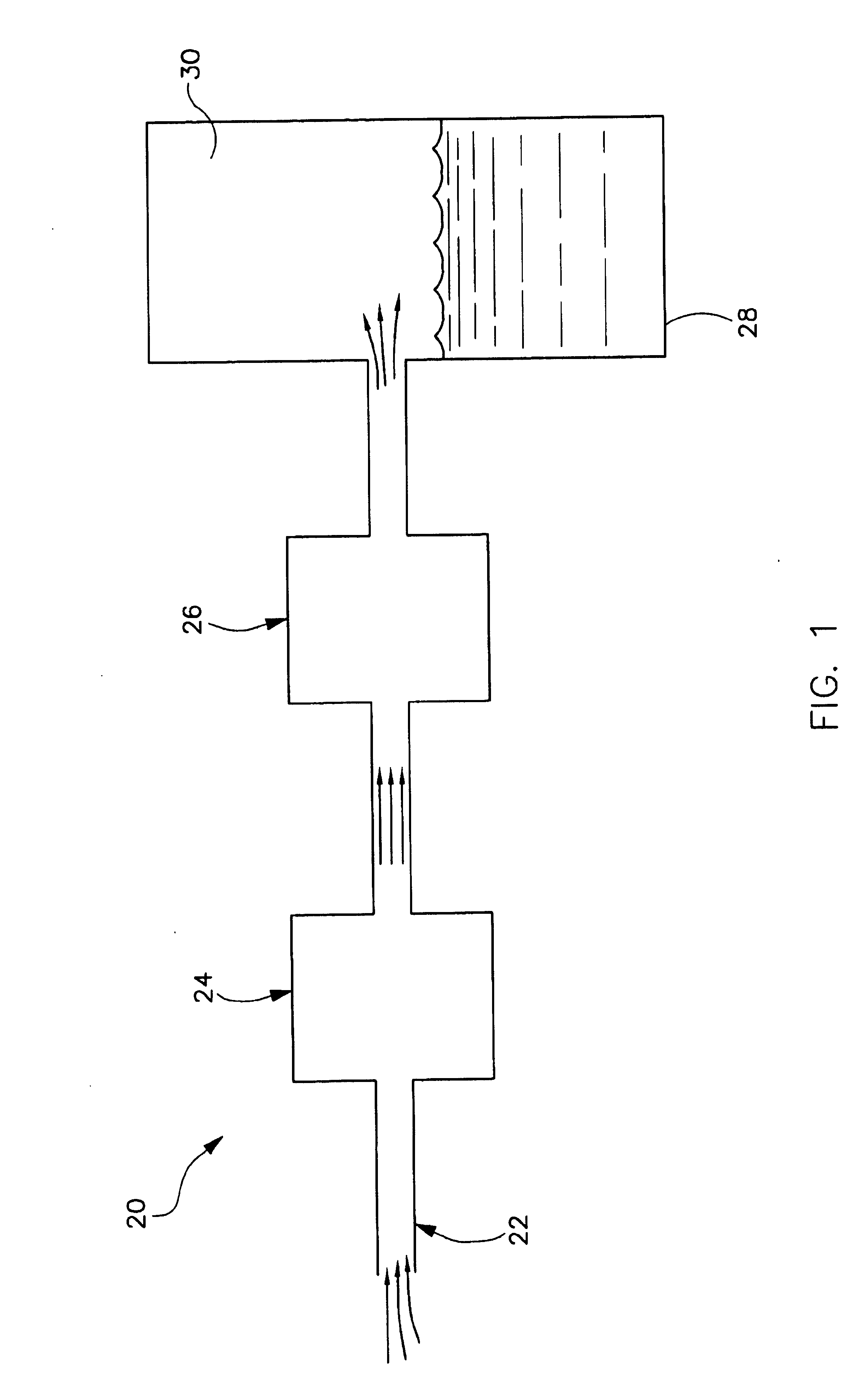

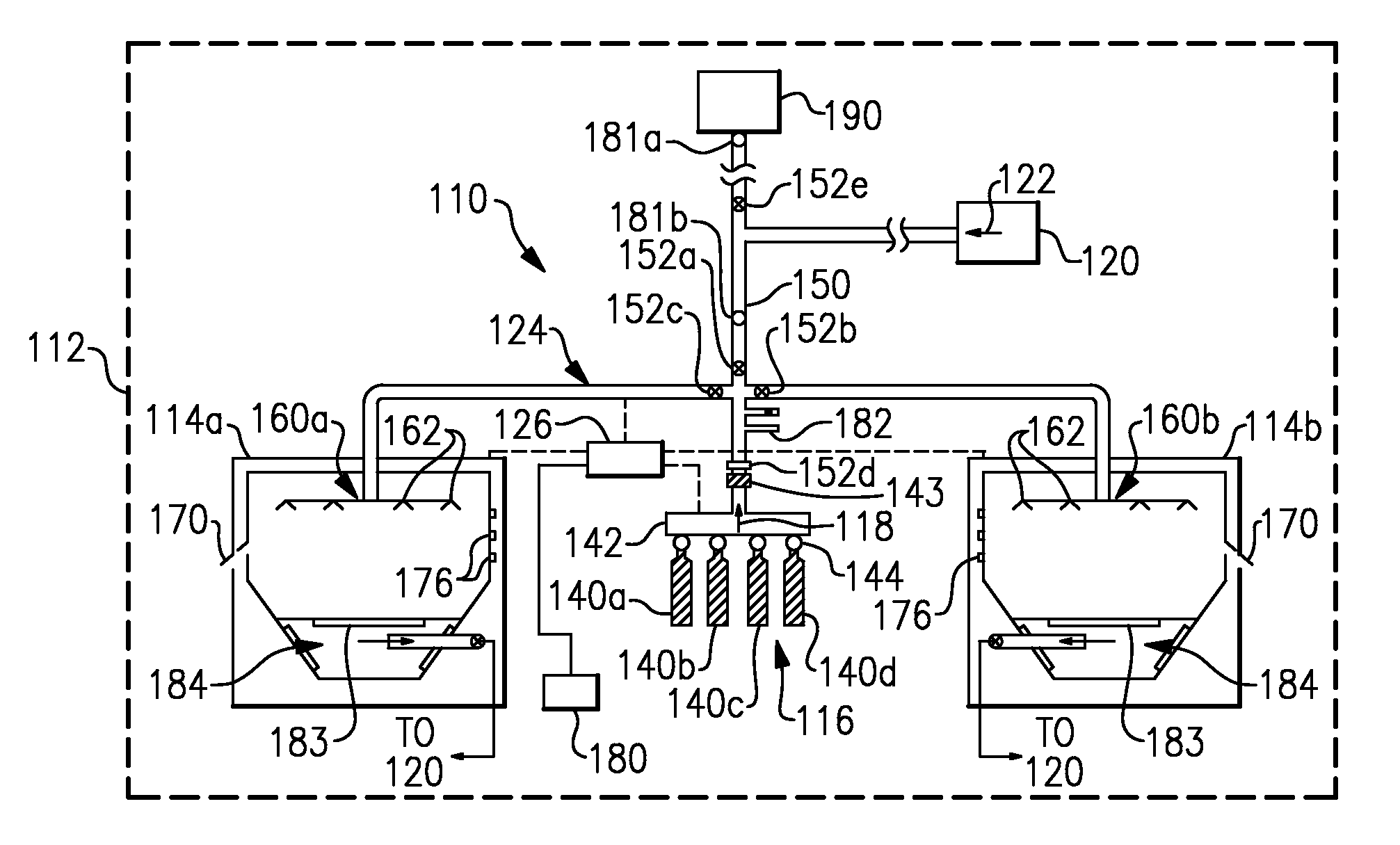

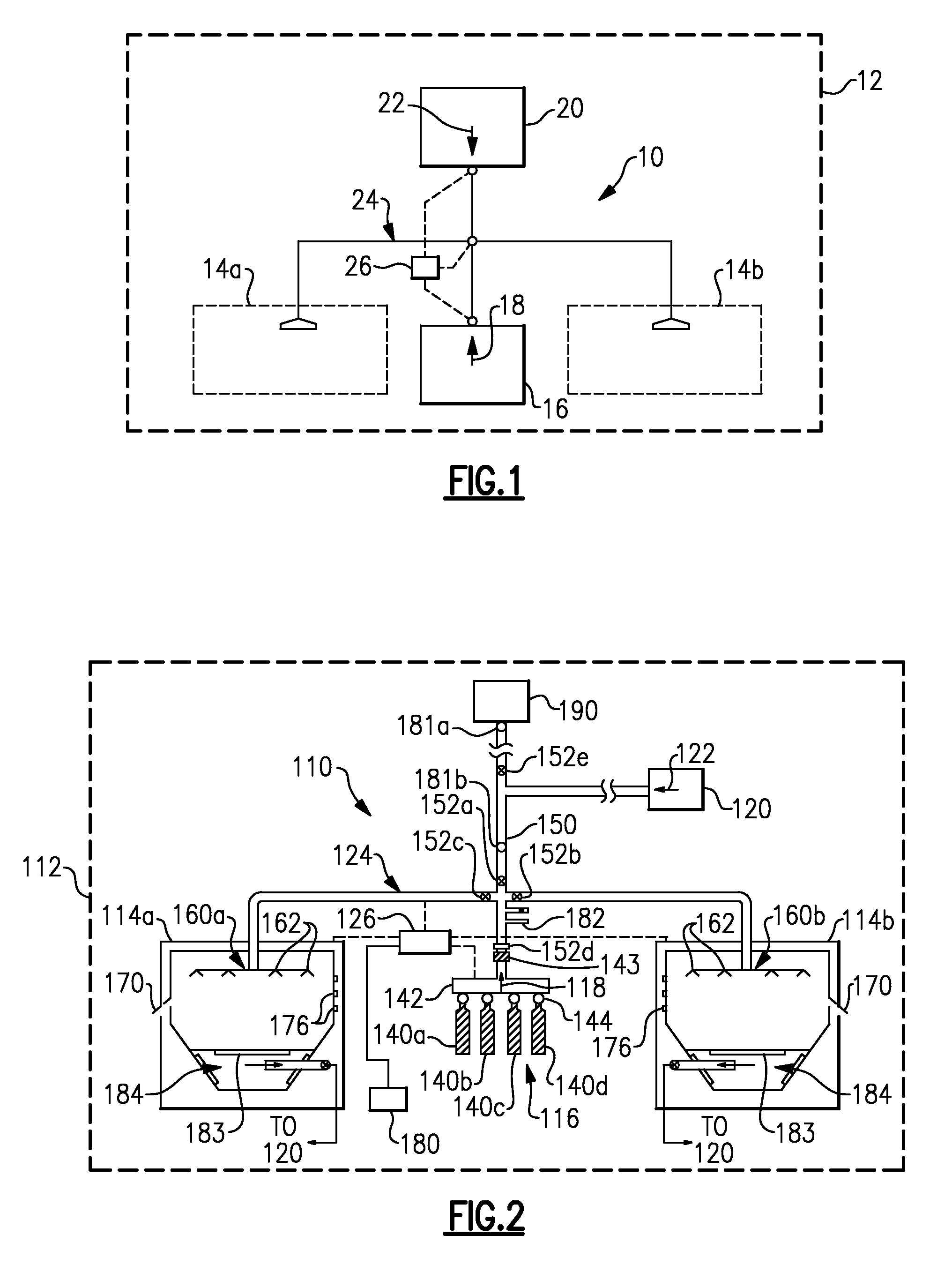

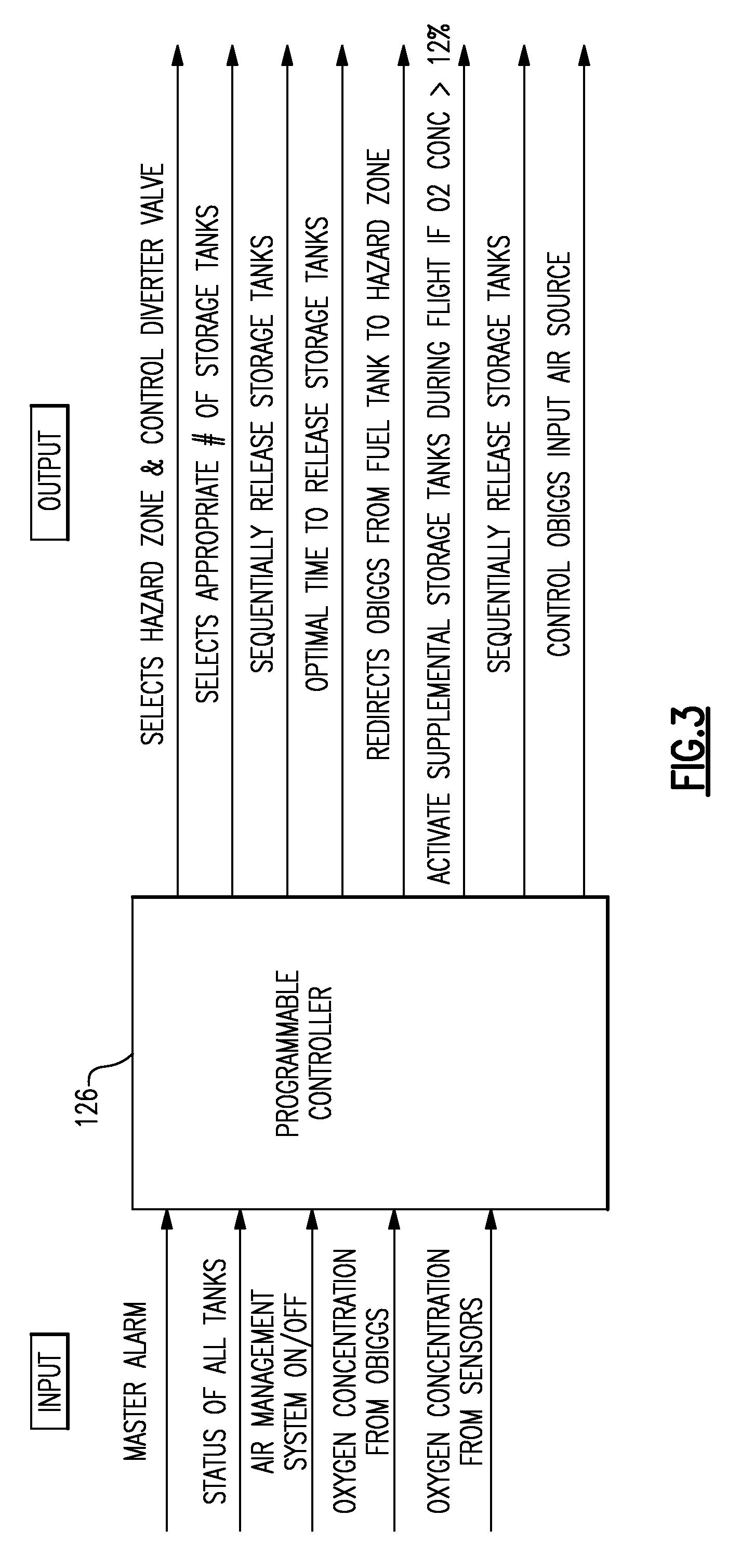

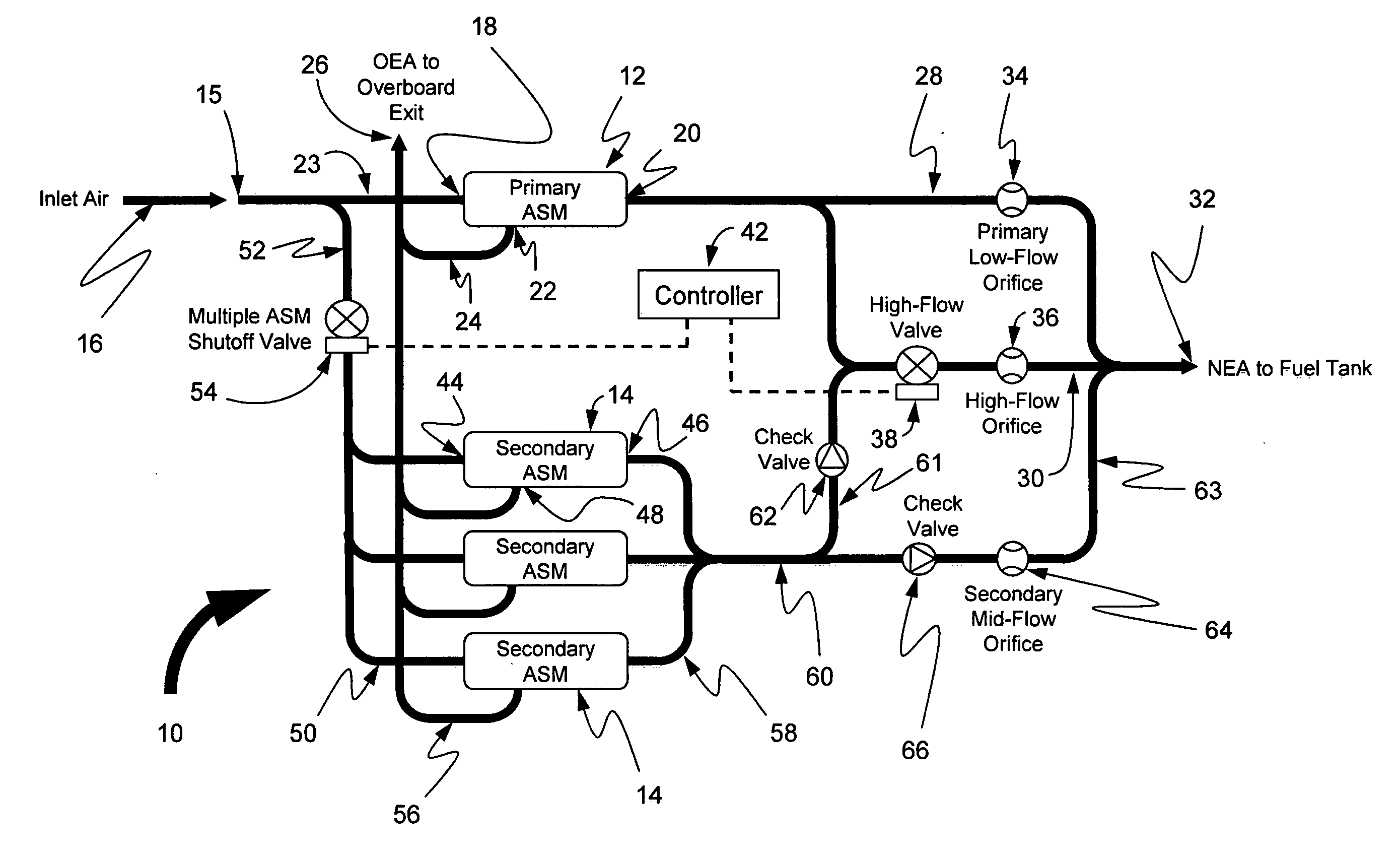

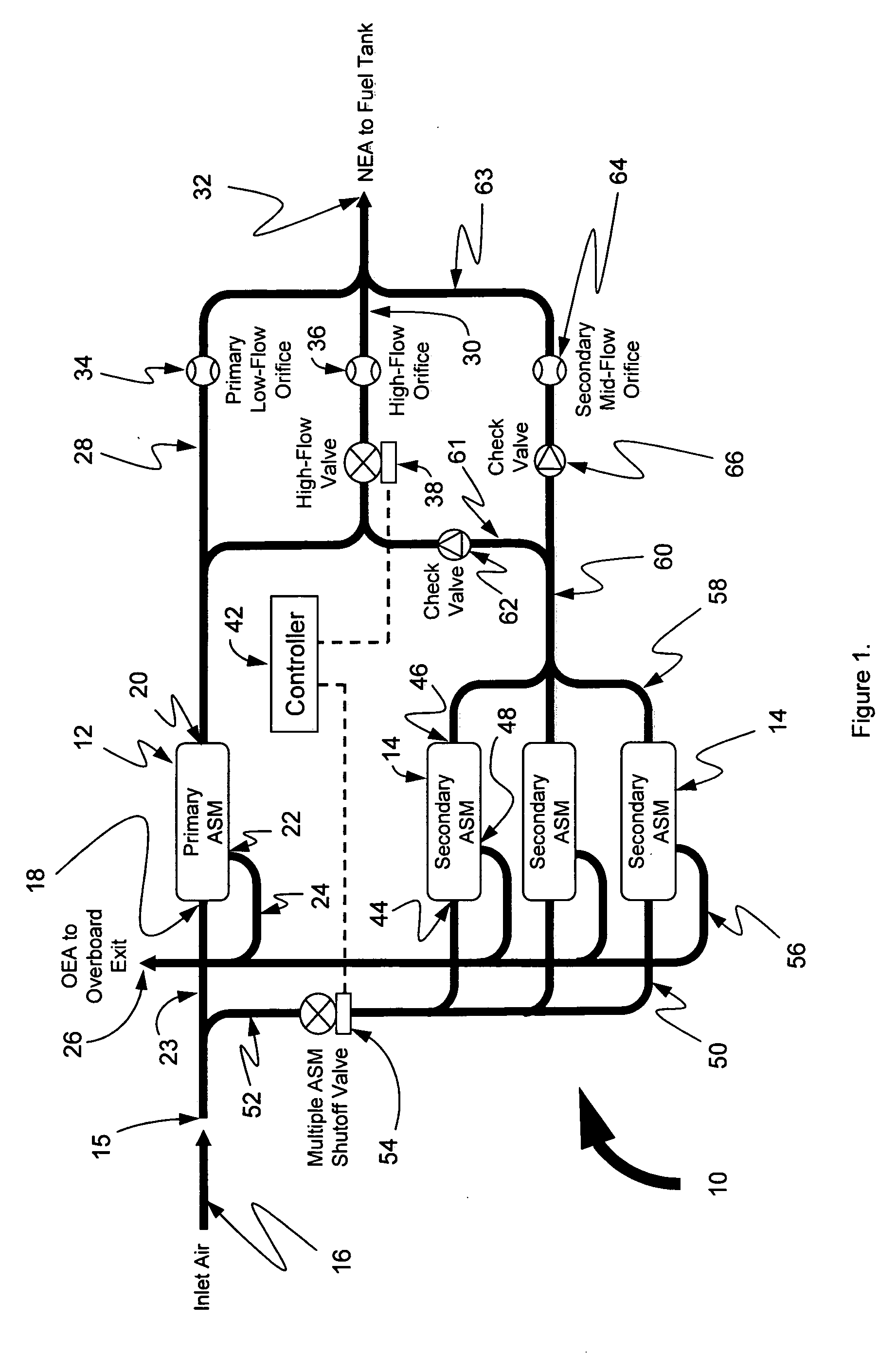

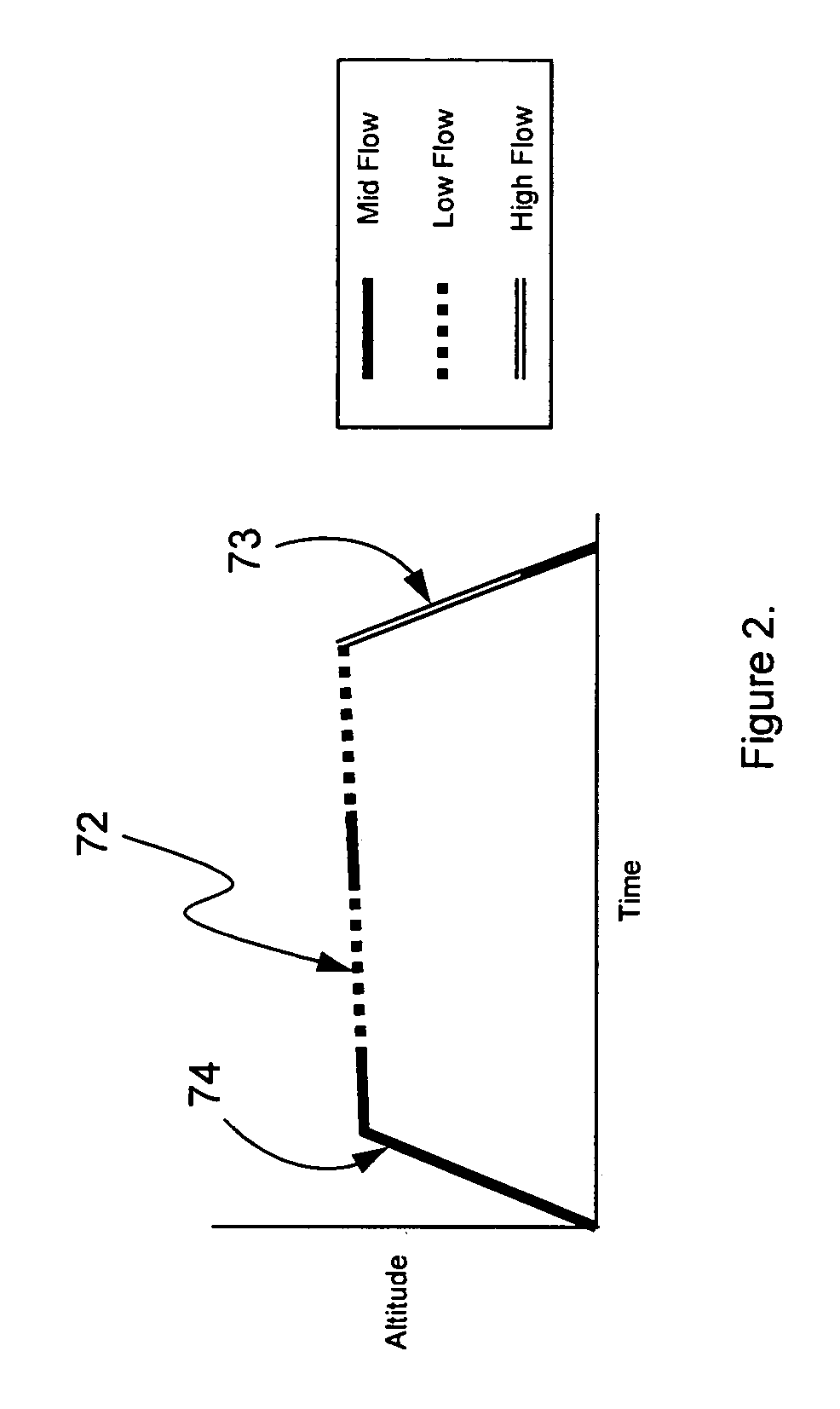

Three flow architecture and method for aircraft OBIGGS

ActiveUS20070054610A1Rapid inertingReduce oxygen concentrationDispersed particle filtrationAir-treatment apparatus arrangementsFiberEngineering

An air separation system and method wherein the outlet of a primary air separation module (one or more modules or bundles of fiber membranes) is split into two flow paths, a low flow path and a high flow path. The outlet of a secondary air separation module (one or more modules or bundles of fiber membranes) is split into two flow paths, a mid flow path and a high flow path, the latter being joined with the high flow of the primary air separation module. Flow along the primary low flow passes through a low-flow orifice, flow along the secondary mid-flow path passes through a mid-flow orifice, and flow along the high flow paths of both the primary and secondary air separation modules is joined together for passage through a shutoff valve and a high flow orifice. This configuration allows for three different flow modes of operation.

Owner:PARKER INTANGIBLES LLC

Composite sanitary napkins with heating element and method for preparing and packing thereof

ActiveCN101273938ARelieve dysmenorrheaImprove antibacterial effectAbsorbent padsBaby linensActivated carbonMelt blowing

The invention relates to a heater composite sanitary napkin and a preparation and packaging method thereof. The heater composite sanitary napkin is composed of a conventional sanitary napkin and a heater combined layer, the heater combined layer is composed of upper and lower surface layers of air-permeable layers with the same structures and materials and a middle heating substance sheet layer, the middle sheet of the air-permeable layers is melt blowing nonwoven fabric, the upper and lower layers are nonwoven fabric which is made by the composite technology; and the heating substance sheet layer is formed by mixing and pressing metal signal substance, sodium chloride and activated carbon according to the proportion. The heating sheet layer is firstly arranged in the heater combined layer which is provided with seven layers and is formed between the two pre-made air-permeable layers by hot rolling and then is fixed between an absorption layer and a mesh surface layer of the sanitary napkin by binding or hot rolling, the vacuum pumping is carried out or protective gas is introduced, the exterior thereof is packaged by an oxygen isolating thin film, and the formed package body can be stored for a long time. The reaction is activated by tearing the thin film. The product has the effects of waterproof, anti-leakage, convenient and long-term stable heating, warming uterus and reducing dysmenorrheal. The preparation method is simple and the packaging effect is good.

Owner:DONGHUA UNIV +1

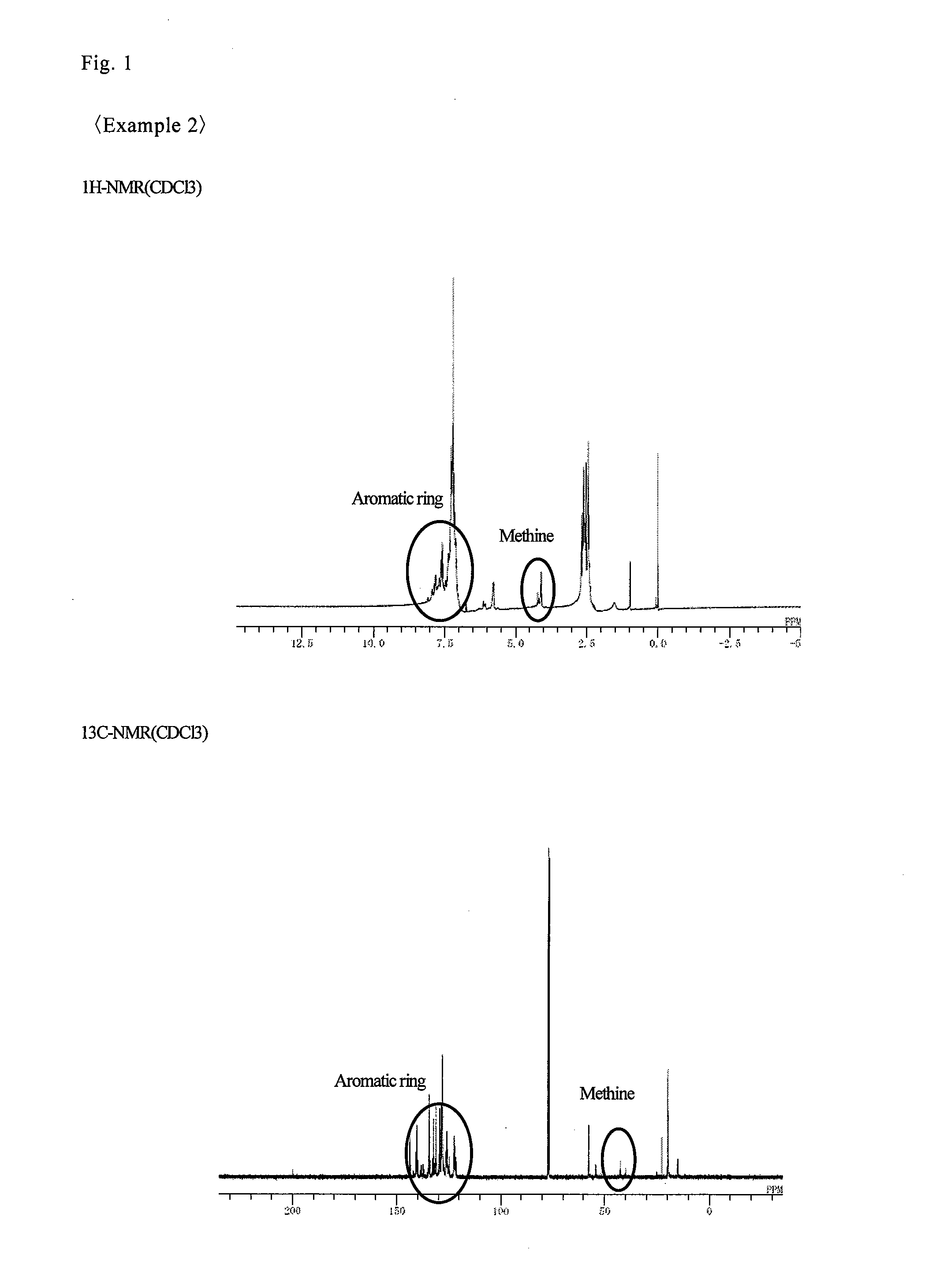

Aromatic hydrocarbon resin and composition for forming underlayer film for lithography

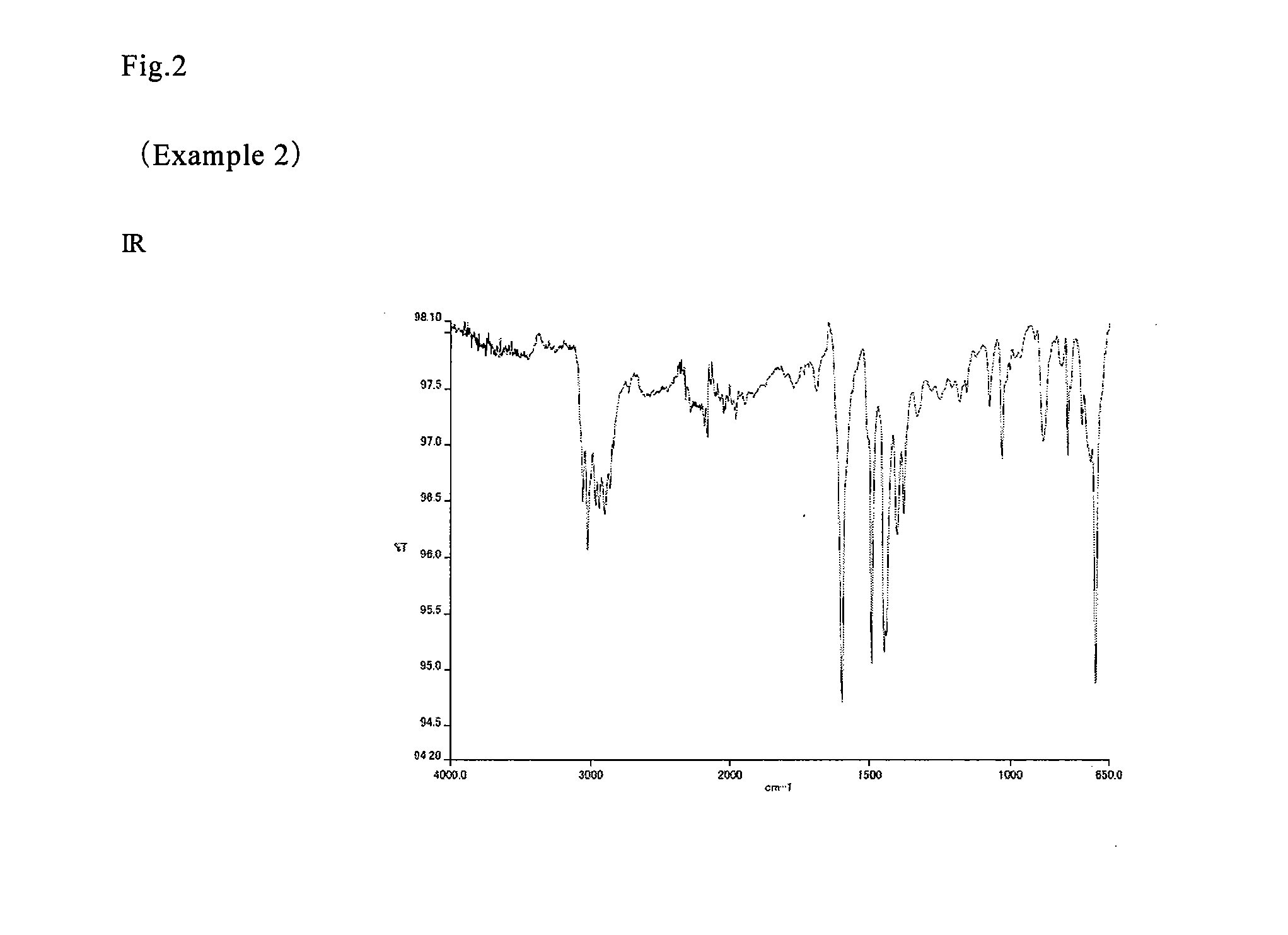

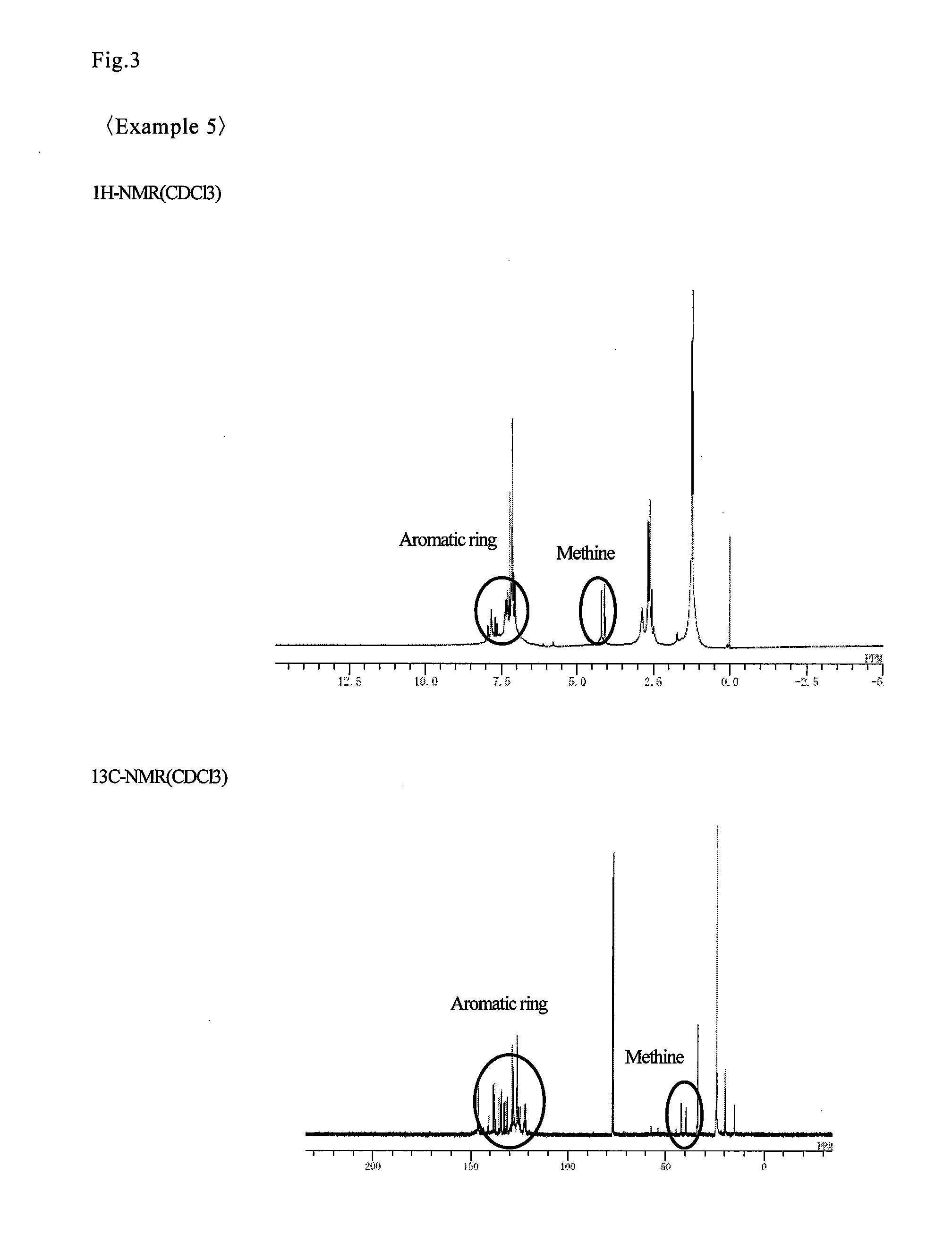

ActiveUS20120171611A1Increase carbon concentrationReduce oxygen concentrationPhotosensitive materialsPhotomechanical exposure apparatusPolymer sciencePtru catalyst

The aromatic hydrocarbon resin can be used as a coating material and a resist resin for a semiconductor, and has a high carbon concentration and a low oxygen concentration. A composition for forming an underlayer film for lithography that has excellent etching resistance as an underlayer film for a multilayer resist process, an underlayer film formed with the same, and a pattern forming method using the same are disclosed. An aromatic hydrocarbon is reacted with an aromatic aldehyde in the presence of an acidic catalyst, thereby providing an aromatic hydrocarbon resin that has a high carbon concentration of from 90 to 99.9% by mass and a low oxygen concentration of from 0 to 5% by mass. A composition for forming an underlayer film for lithography contains the resin and an organic solvent, an underlayer film is formed with the same, and a pattern forming method uses the same.

Owner:MITSUBISHI GAS CHEM CO INC

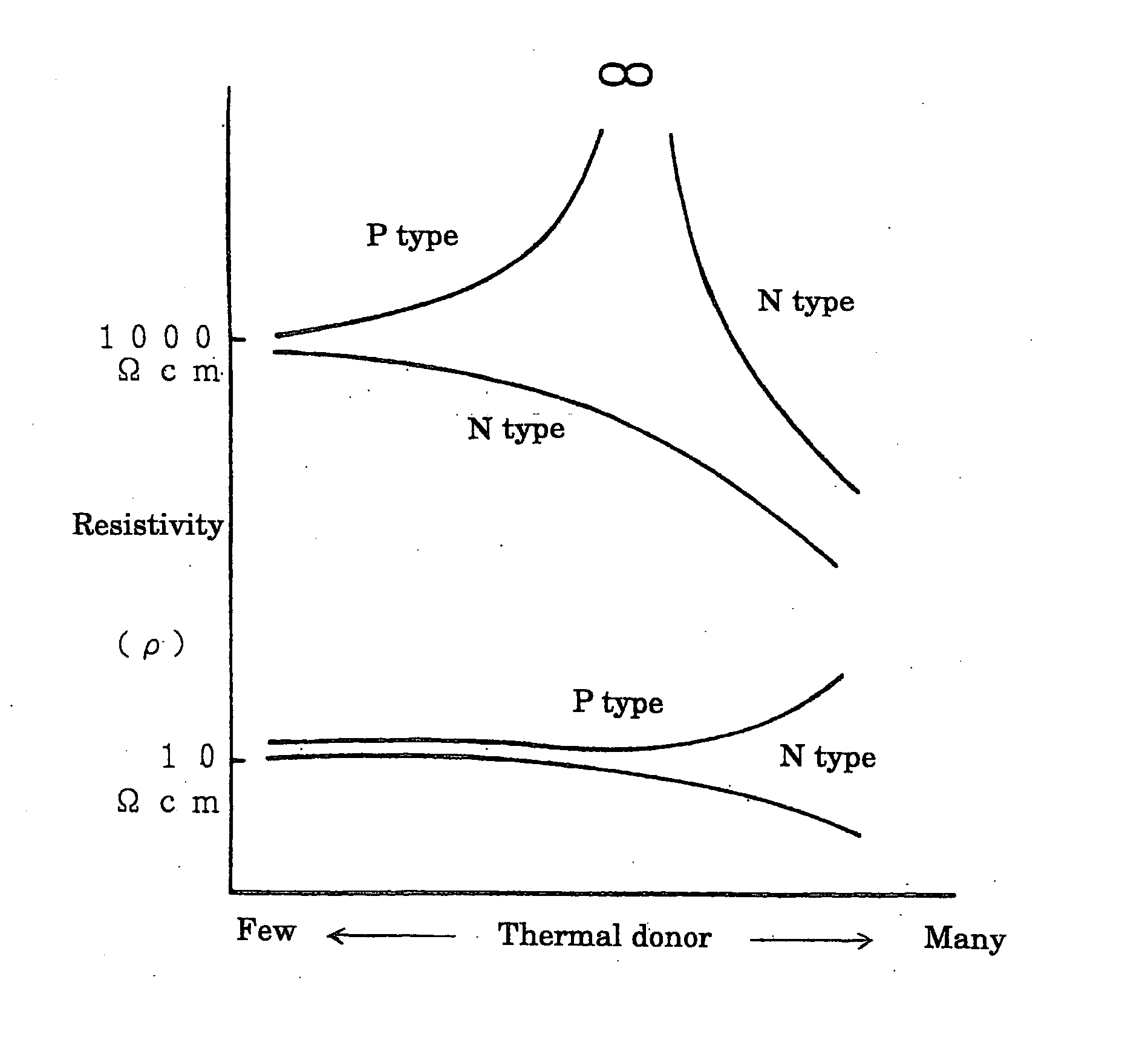

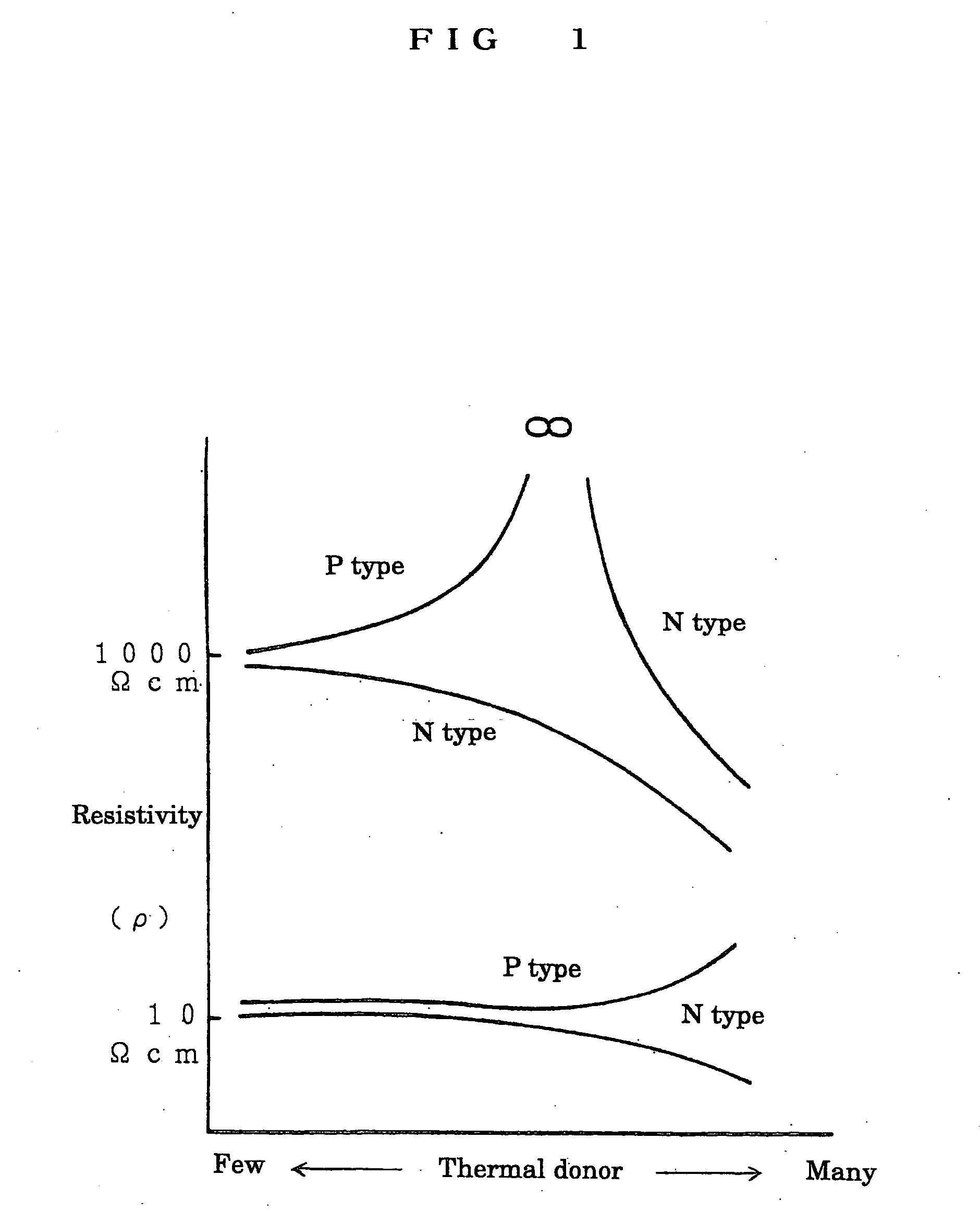

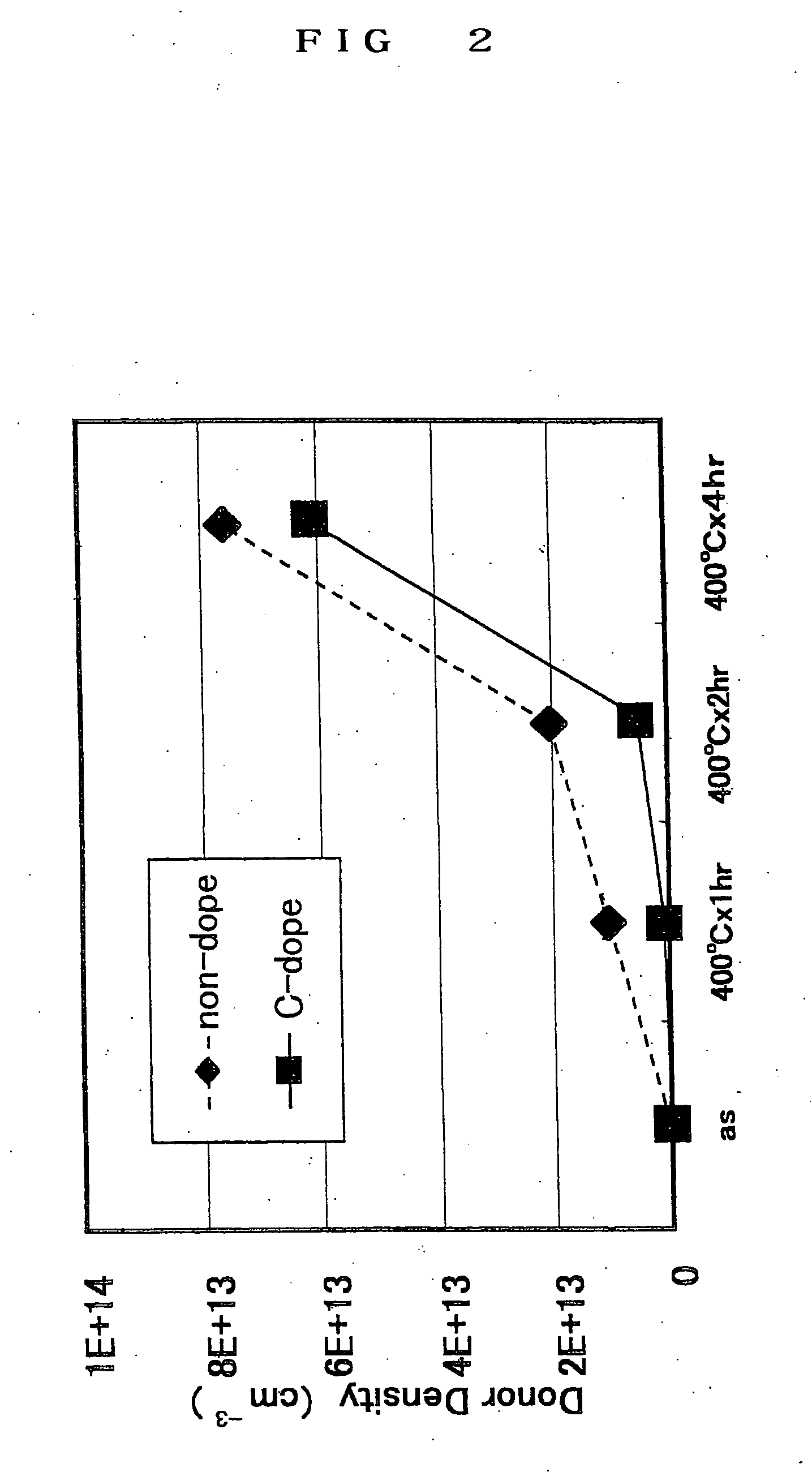

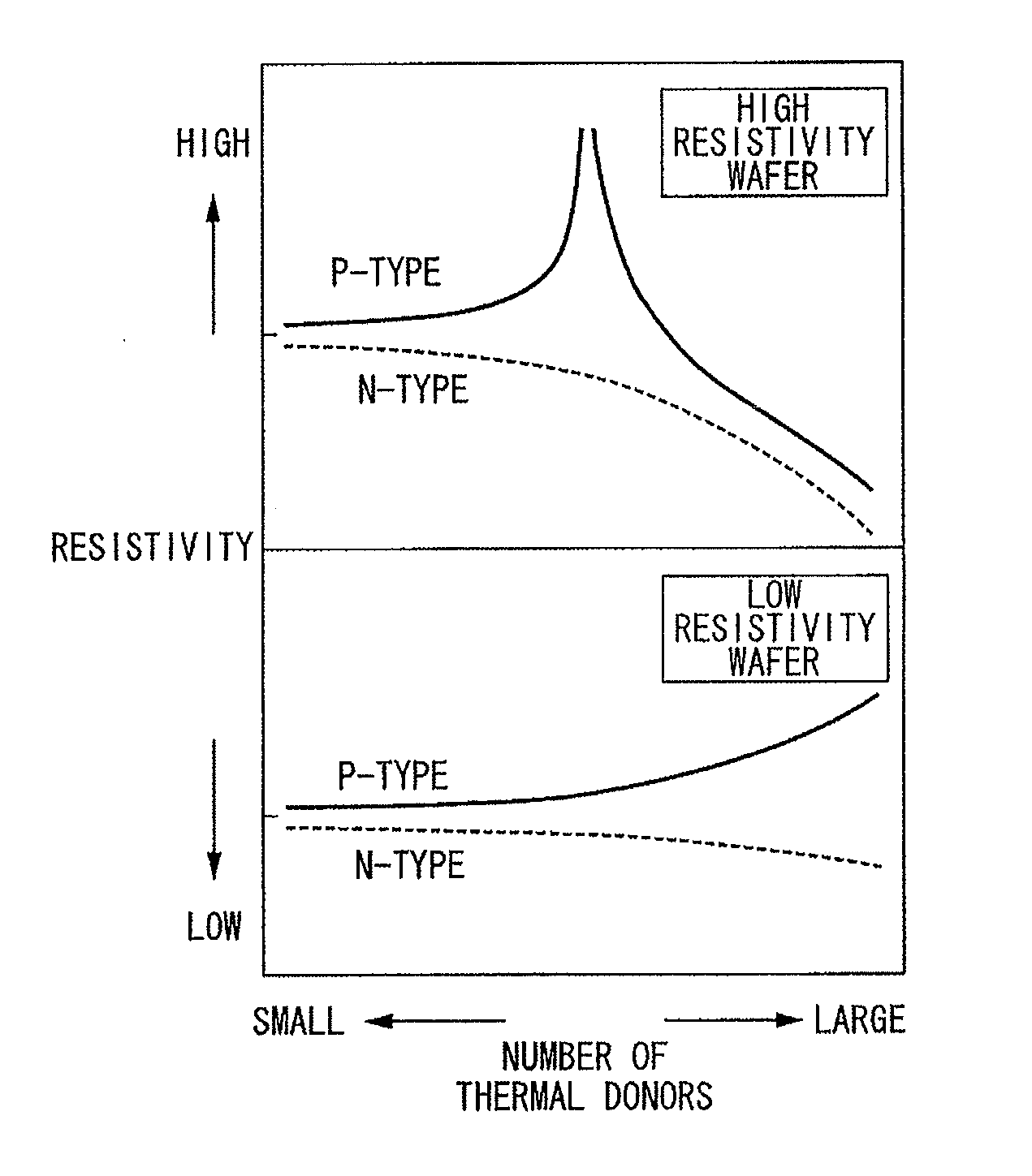

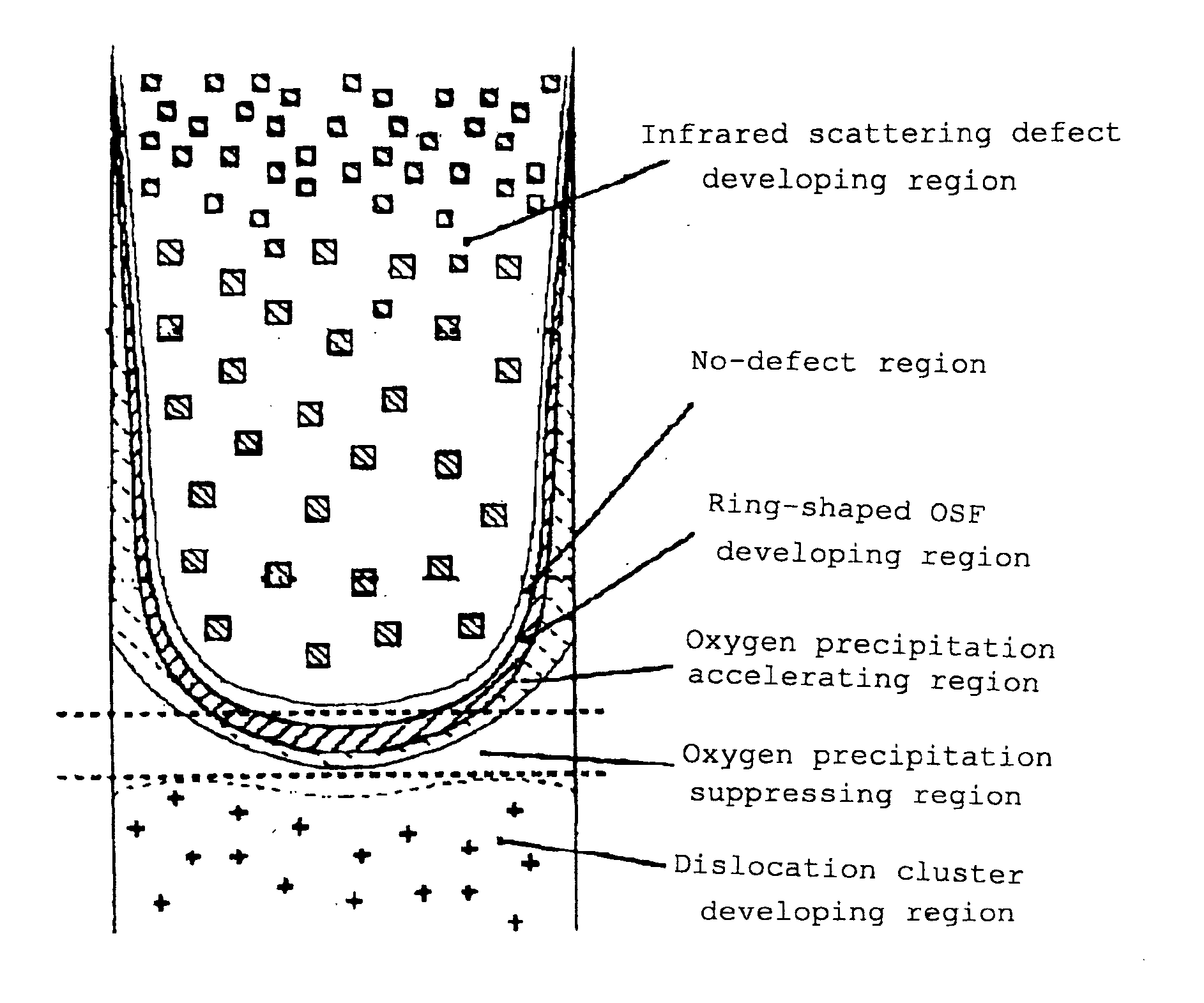

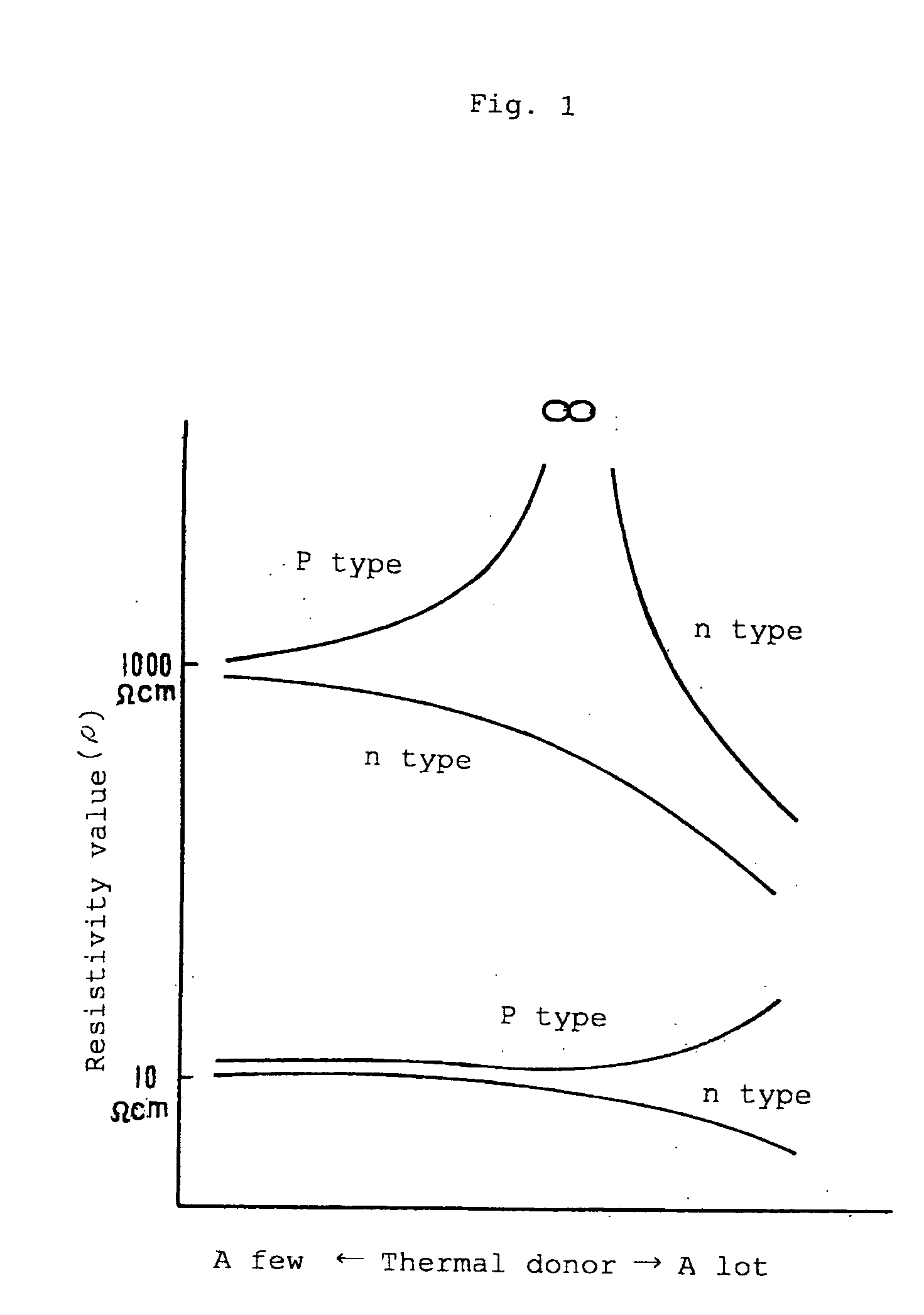

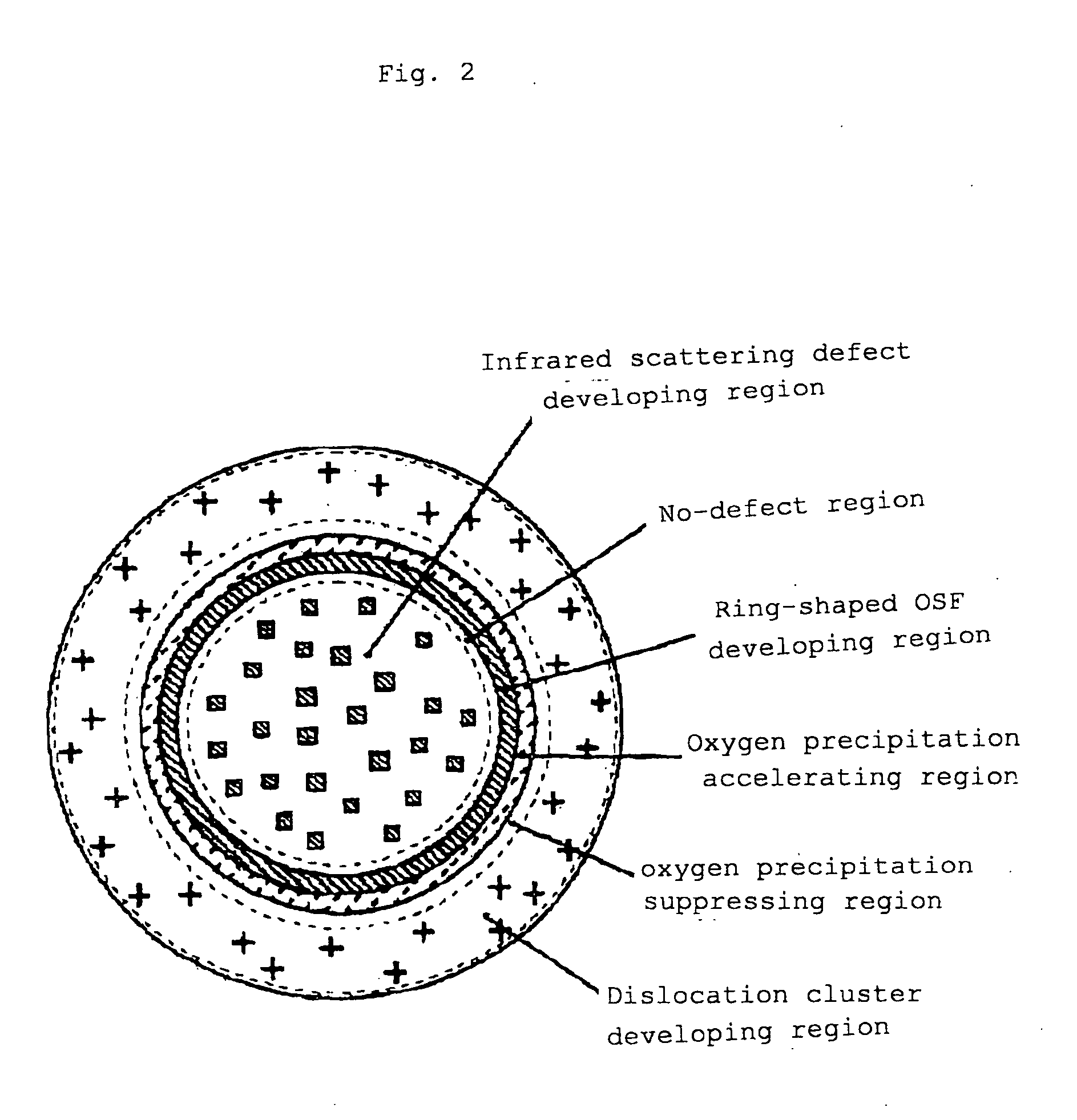

High-resistance silicon wafer and process for producing the same

ActiveUS20050250349A1Avoid it happening againEconomical efficiencyPolycrystalline material growthAfter-treatment detailsHigh resistanceSurface layer

A high-resistance silicon wafer is manufactured, in which a gettering ability and economical efficiency is excellent and an oxygen thermal donor is effectively prevented from being generated in a heat treatment for forming a circuit, which is to be implemented on the side of a device manufacturer. In order to implement the above, a high-temperature heat treatment at 1100° C. or higher is performed on a carbon doped high-resistance and high-oxygen silicon wafer in which specific resistivity is 100 Ωcm or more and a carbon concentration is 5×1015 to 5×1017 atoms / cm3 so that a remaining oxygen concentration becomes 6.5×1017 atoms / cm3 or more (Old-ASTM). As this high-temperature treatment, an OD treatment for forming a DZ layer on a wafer surface, a high-temperature annealing treatment for eliminating a COP on the surface layer, a high-temperature heat treatment for forming a BOX layer in a SIMOX wafer manufacturing process and the like can be used.

Owner:SUMCO CORP

Methods and systems for an intake oxygen sensor

ActiveUS20150101564A1Emission reductionImprove fuel economyElectrical controlInternal combustion piston enginesOxygen sensorEngineering

Methods and systems are provided for correcting an EGR rate determined based on an intake manifold oxygen sensor based on an air-fuel ratio of EGR. The output of the sensor is corrected to compensate for extra fuel in rich EGR or extra air in lean EGR and used to reliably estimate the EGR rate. One or more engine operating parameters are adjusted based on an uncorrected output of the sensor.

Owner:FORD GLOBAL TECH LLC

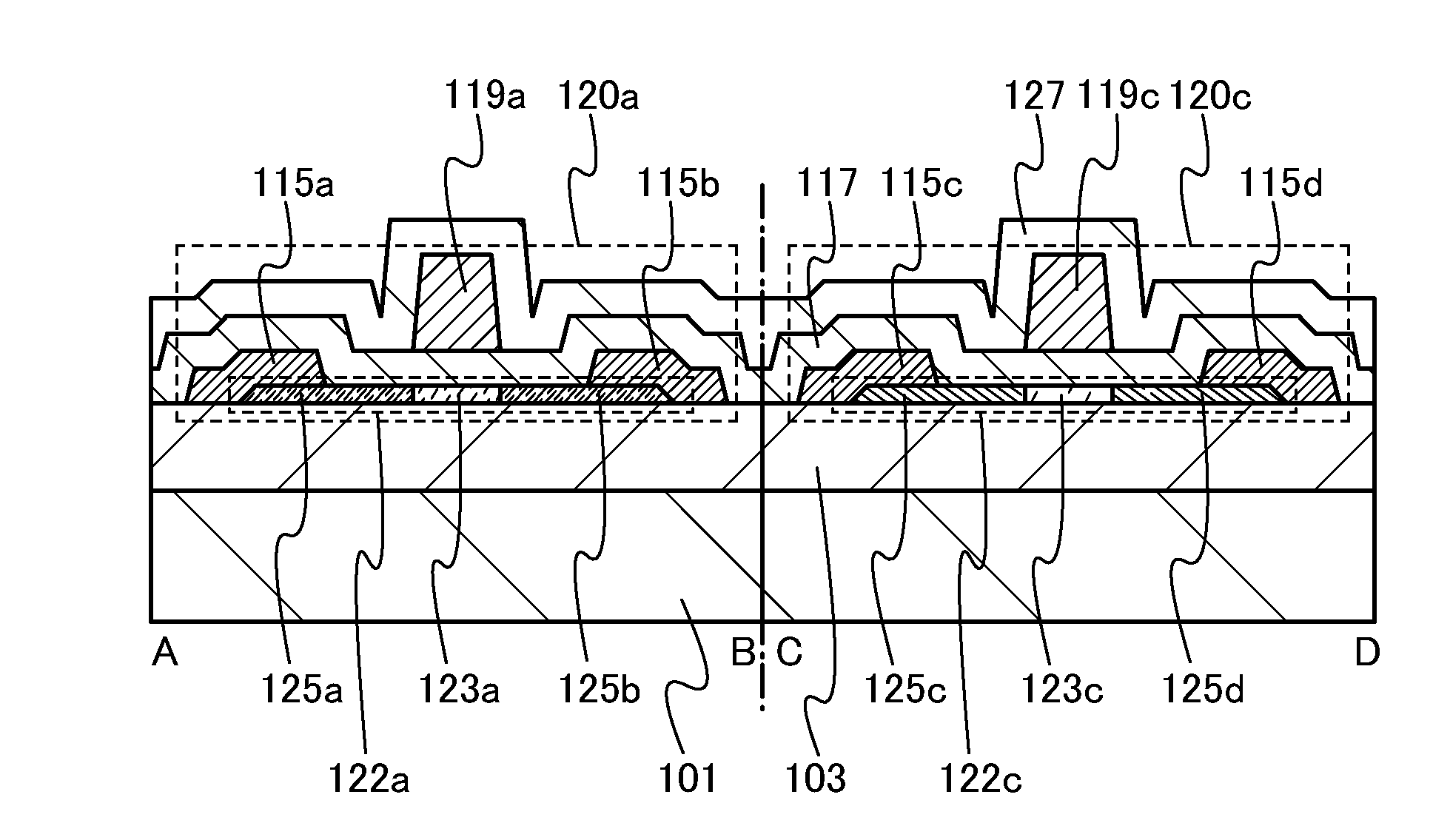

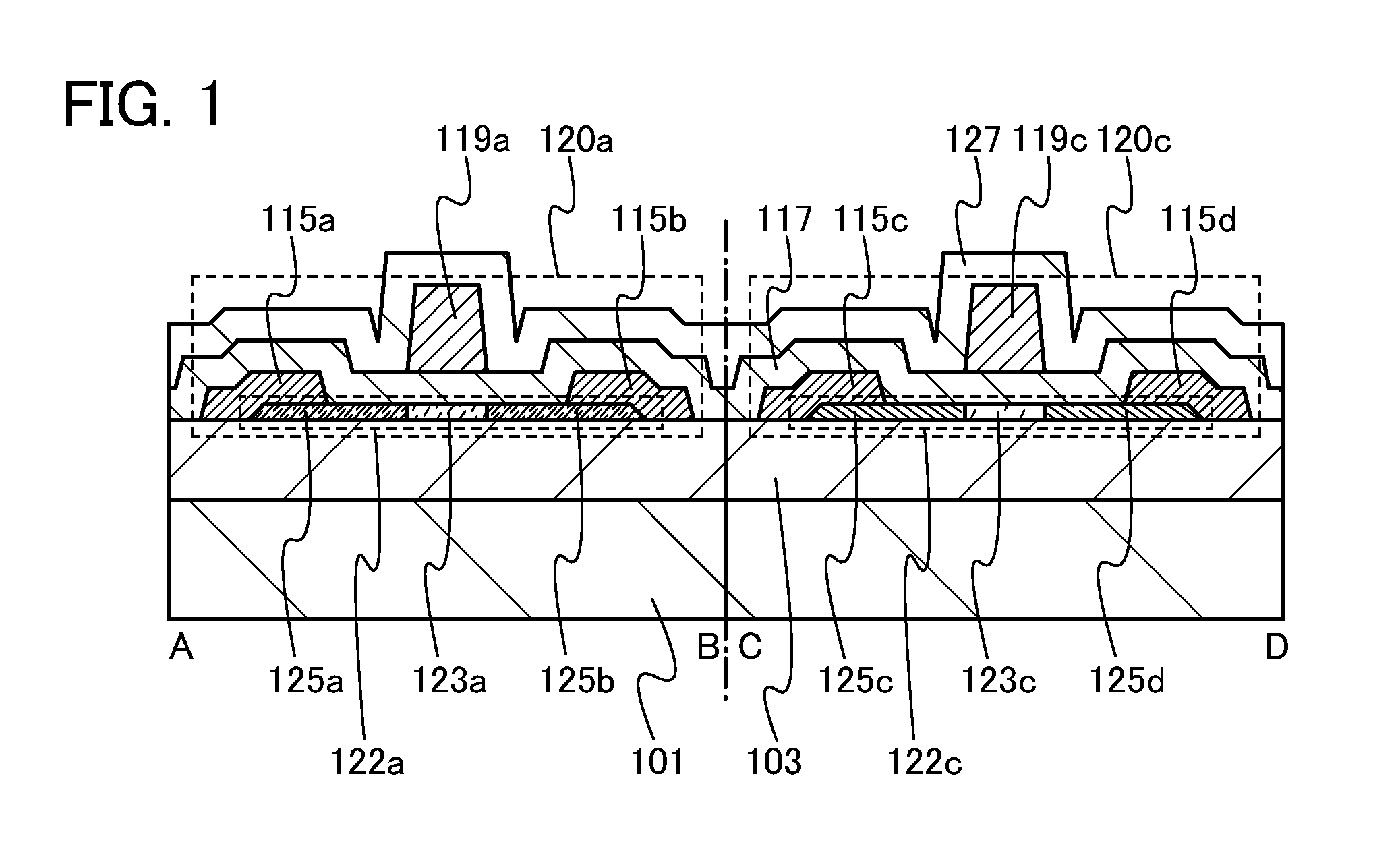

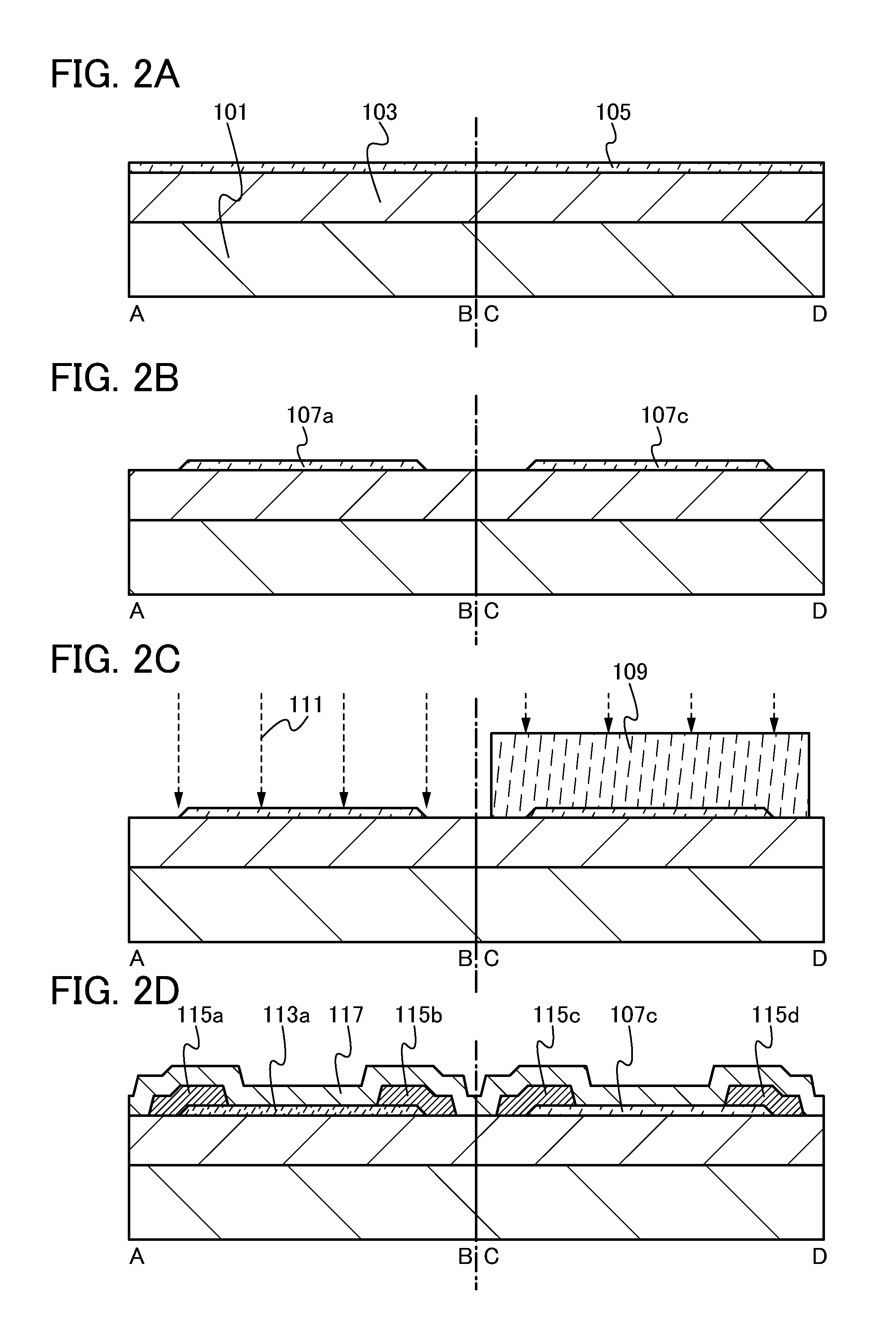

Semiconductor device

ActiveUS20130020569A1Solve the large consumptionIncrease speedSolid-state devicesSemiconductor devicesPower semiconductor devicePower flow

A semiconductor device which can operate at high speed and consumes a smaller amount of power is provided. In a semiconductor device including transistors each including an oxide semiconductor, the oxygen concentration of the oxide semiconductor film of the transistor having small current at negative gate voltage is different from that of the oxide semiconductor film of the transistor having high field-effect mobility and large on-state current. Typically, the oxygen concentration of the oxide semiconductor film of the transistor having high field-effect mobility and large on-state current is lower than that of the oxide semiconductor film of the transistor having small current at negative gate voltage.

Owner:SEMICON ENERGY LAB CO LTD

High resistivity silicon wafer and method for manufacturing the same

ActiveUS20100224968A1Avoid it happening againHigh mechanical strengthPolycrystalline material growthSemiconductor/solid-state device manufacturingDopantCzochralski method

This method for manufacturing a high resistivity silicon wafer includes pulling a single crystal such that the single crystal has a p-type dopant concentration at which a wafer surface resistivity becomes in a range of 0.1 to 10 kΩcm, an oxygen concentration Oi of 5.0×1017 to 20×1017 atoms / cm3 (ASTM F-121, 1979), and either one of a nitrogen concentration of 1.0×1013 to 10×1013 atoms / cm3 (ASTM F-121, 1979) and a carbon concentration of 0.5×1016 to 10×1016 atoms / cm3 or 0.5×1016 to 50×1016 atoms / cm3 (ASTM F-123, 1981) by using a Czochralski method, processing the single crystal into wafers by slicing the single crystal, and subjecting the wafer to an oxygen out-diffusion heat treatment process in a non-oxidizing atmosphere. A peak position of a resistivity serving as a boundary between a p-type region of a wafer surface side and a p / n conversion region of an inner side of a thickness direction is adjusted by the nitrogen concentration or the carbon concentration such that the peak position is set to a boundary depth in a range of 10 to 70 μm from the wafer surface.

Owner:SUMCO CORP

High resistance silicon wafer and method for production thereof

ActiveUS20050253221A1Promote formationUniform gettering abilitySemiconductor/solid-state device manufacturingSemiconductor devicesHigh resistanceHigh density

A high-resistance silicon wafer is manufactured in which a gettering ability, mechanical strength, and economical efficiency are excellent and an oxygen thermal donor is effectively prevented from being generated in a heat treatment for forming a circuit, which is implemented on the side of a device maker. A heat treatment for forming an oxygen precipitate nucleus is performed at 500 to 900° C. for 5 hours or more in a non-oxidizing atmosphere and a heat treatment for growing an oxygen precipitate is performed at 950 to 1050° C. for 10 hours or more on a high-oxygen and carbon-doped high-resistance silicon wafer in which resistivity is 100 Ωcm or more, an oxygen concentration is 14×1017 atoms / cm3 (ASTM F-121, 1979) or more and a carbon concentration is 0.5×1016 atoms / cm3 or more. By these heat treatments, a remaining oxygen concentration in the wafer is controlled to be 12×1017 atoms / cm3 (ASTM F-121, 1979) or less. Thus, there is provided a high-resistance, low-oxygen and high-strength silicon wafer in which resistivity is 100 Ωcm or more and an oxygen precipitate (BMD) having a size of 0.2 μm is formed so as to have high density of 1×104 / cm2 or more.

Owner:SUMITOMO MITSUBISHI SILICON CORP

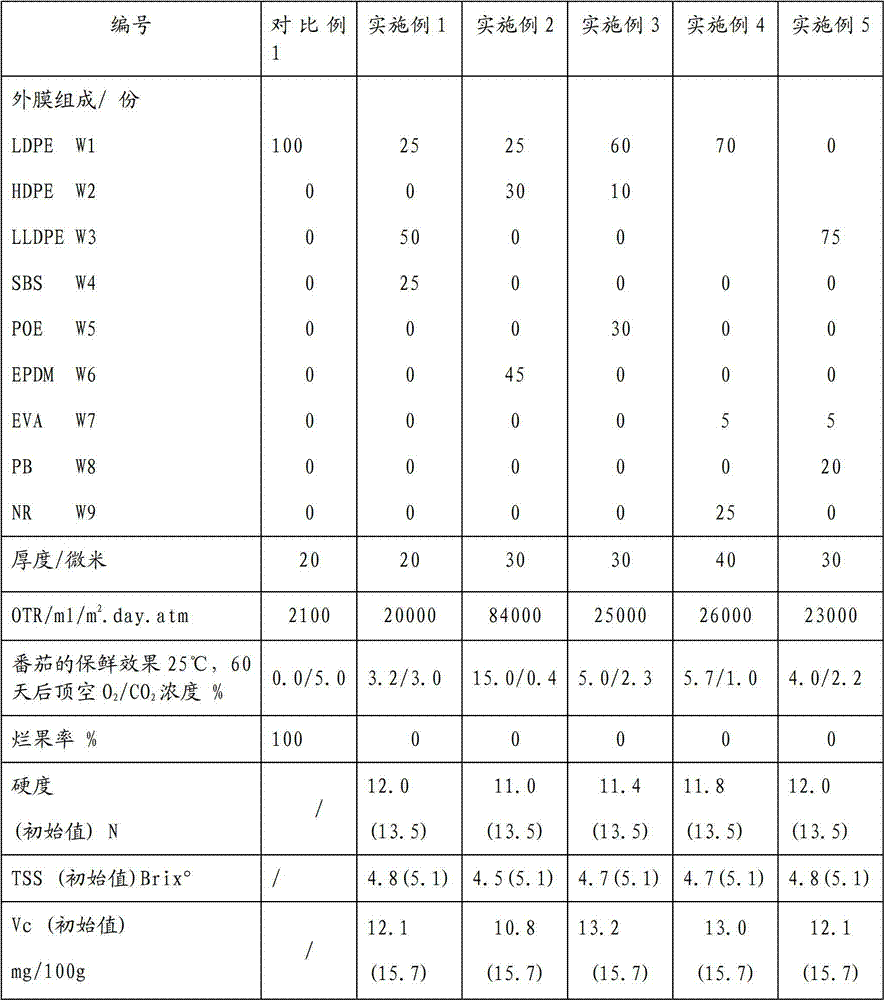

Fresh-keeping packaging material for tomatoes

ActiveCN102863685AHas a single layer structureSimple preparation processFruit and vegetables preservationLow-density polyethyleneLinear low-density polyethylene

The invention relates to a fresh-keeping packaging material for tomatoes and belongs to packaging materials. The packaging material is of a single-layer structure and is a film formed by melt blending of one or more of LDPE (low-density polyethylene), LLDPE (linear low-density polyethylene) and HDPE (high-density polyethylene) serving as matrix resin with 15-50wt% of amorphous polymers prior to blow molding, wherein the amorphous polymers are one or more of styrene-butadiene segmented copolymers, ethylene propylene diene monomer rubber, ethylene / octene copolymers, polybutadiene, natural rubber and ethylene-vinyl acetate copolymers. The fresh-keeping packaging material for the tomatoes has special fresh-keeping effect for the tomatoes and can enable the tomatoes to turn red completely but still keep hard, and the storage life of the tomatoes in a full ripe stage at the normal temperature (25 DEG C) can be longer than 60 days.

Owner:北京鉴真保鲜科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com