Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

234 results about "Ullage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ullage or headspace is the unfilled space in a container, particularly with a liquid.

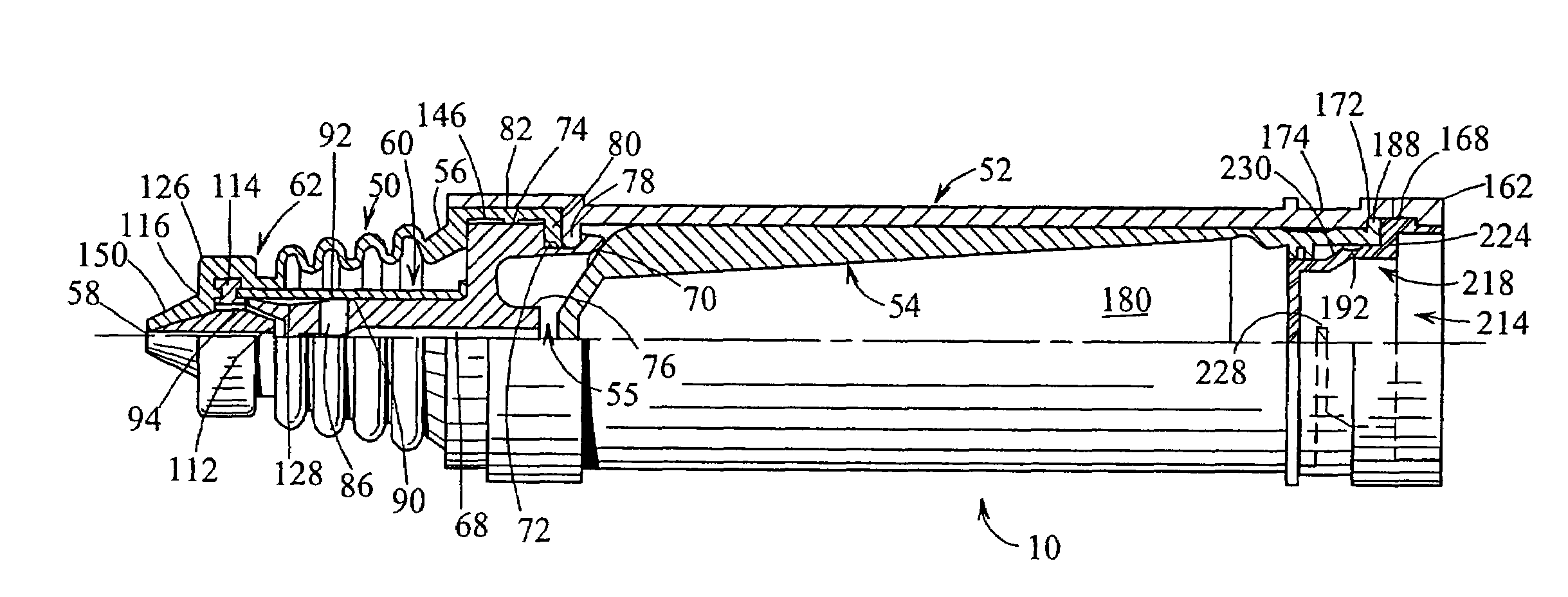

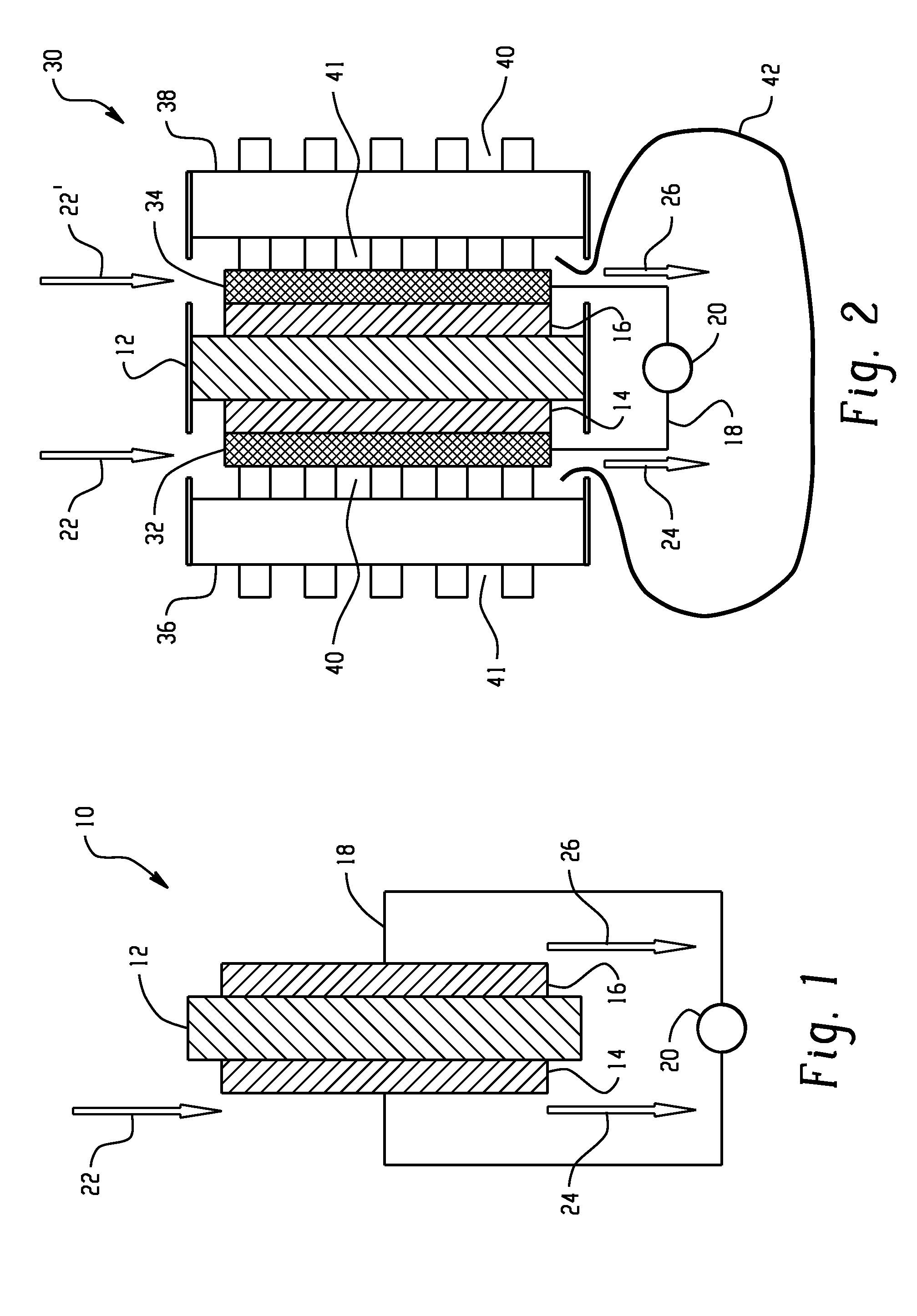

Fluid delivery device

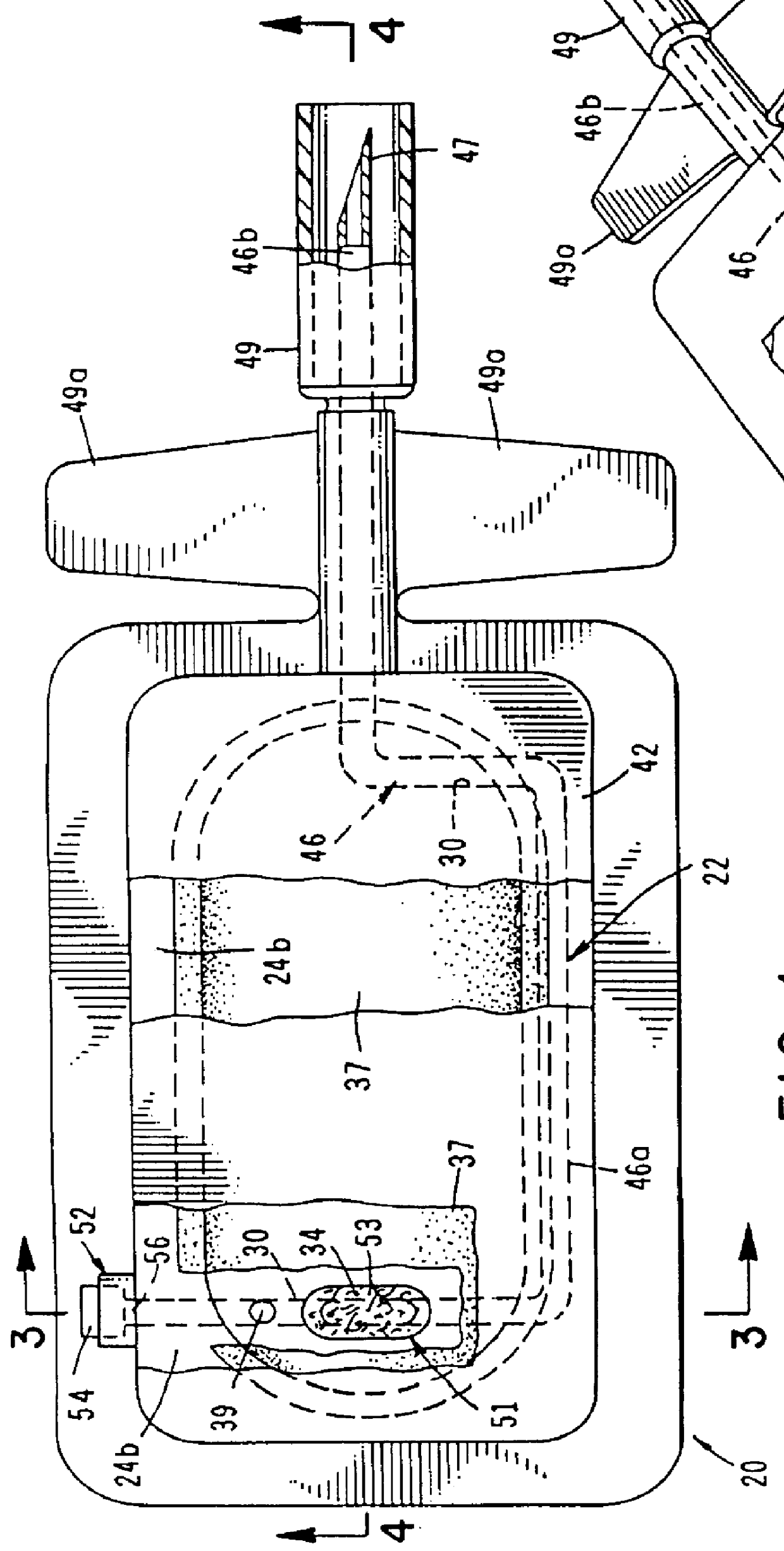

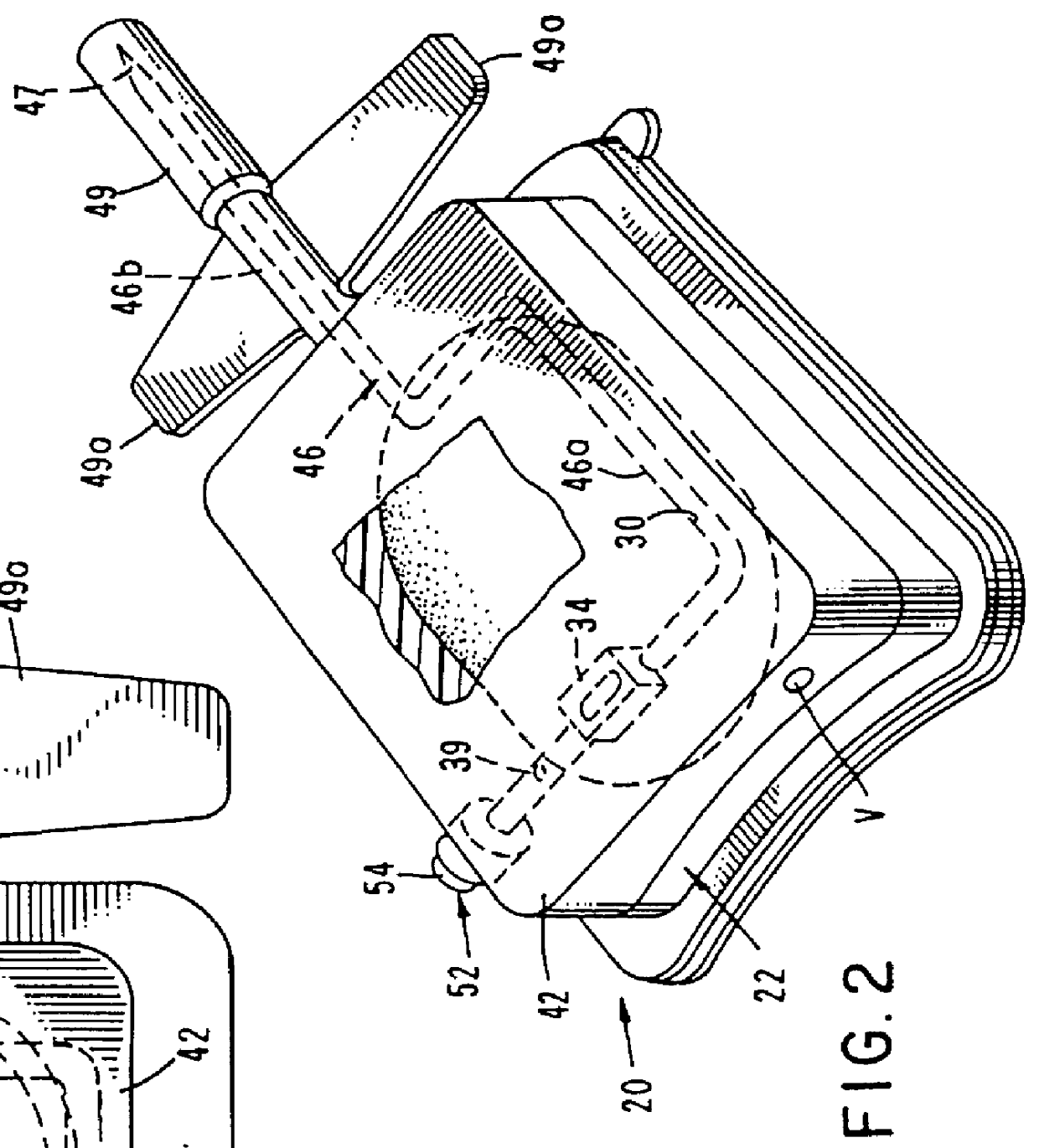

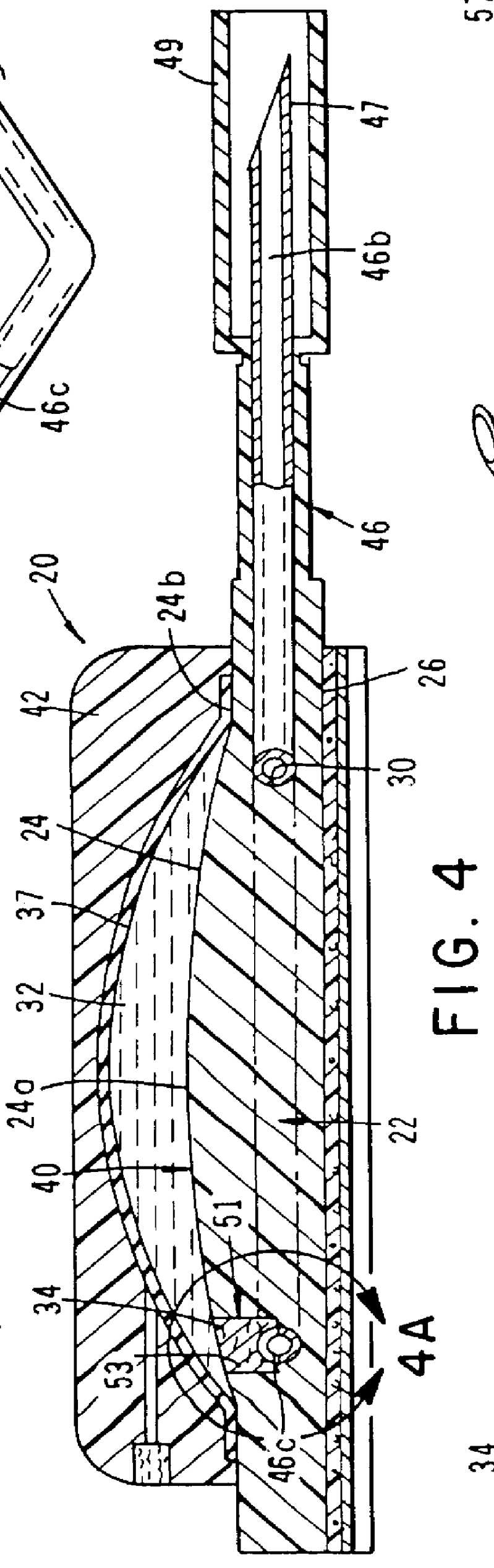

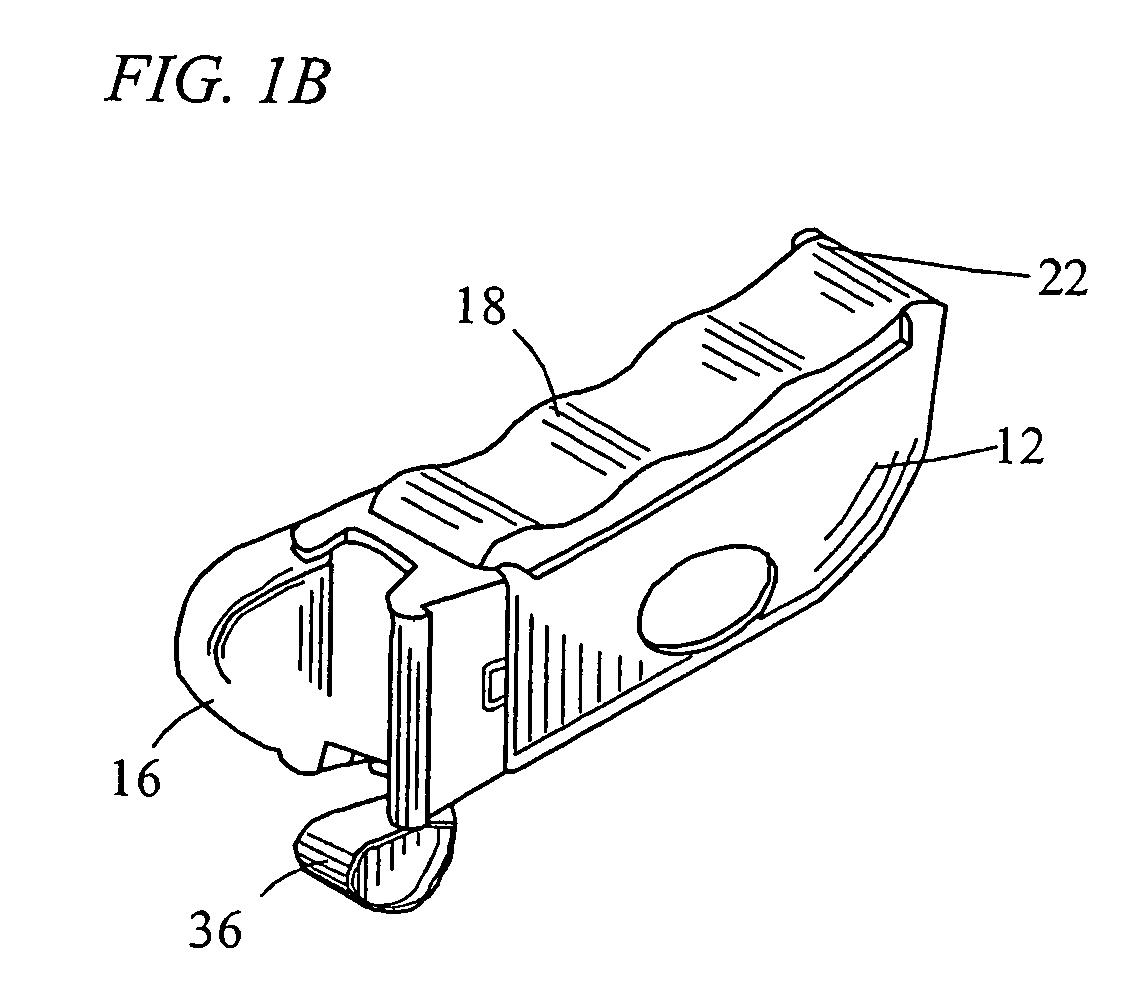

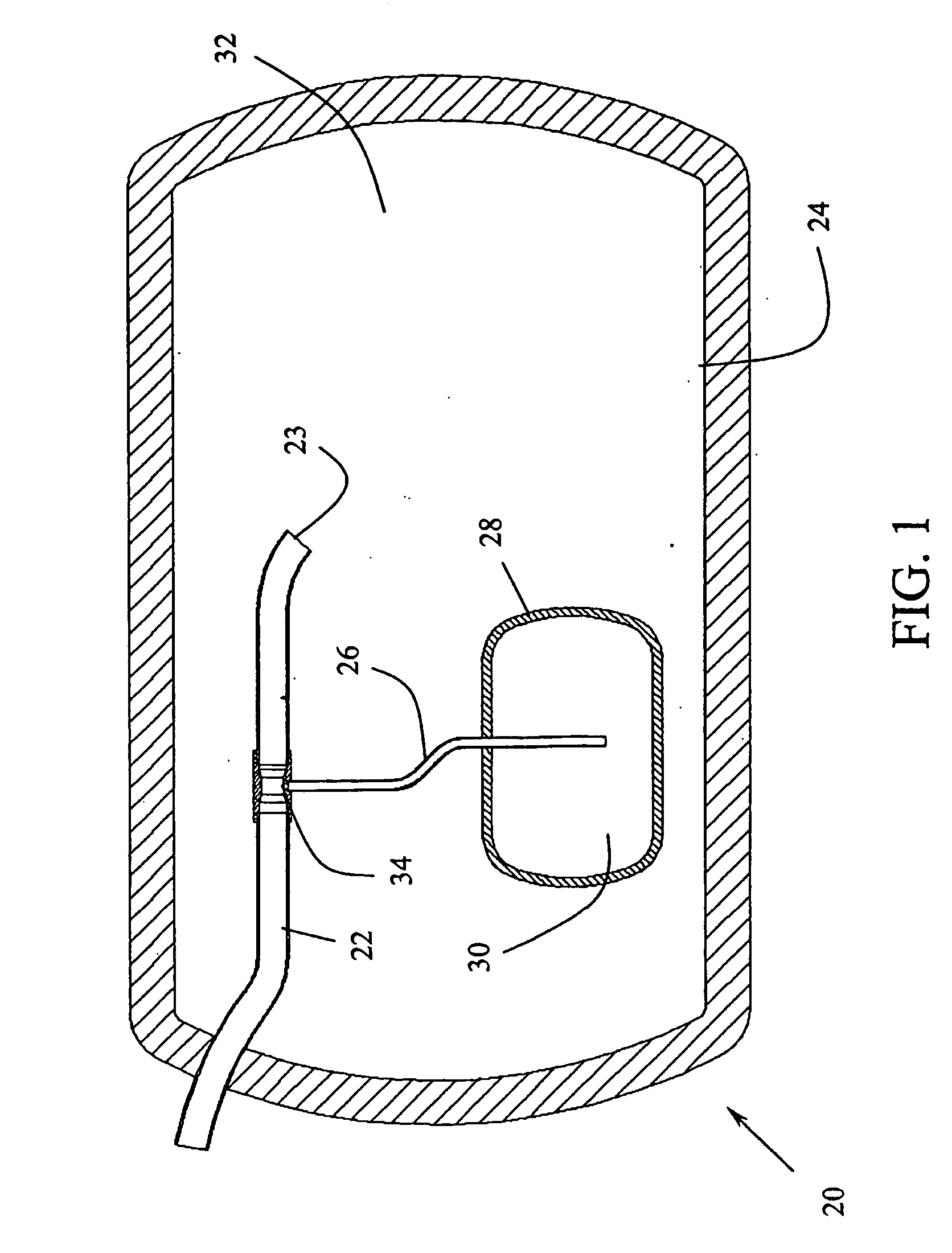

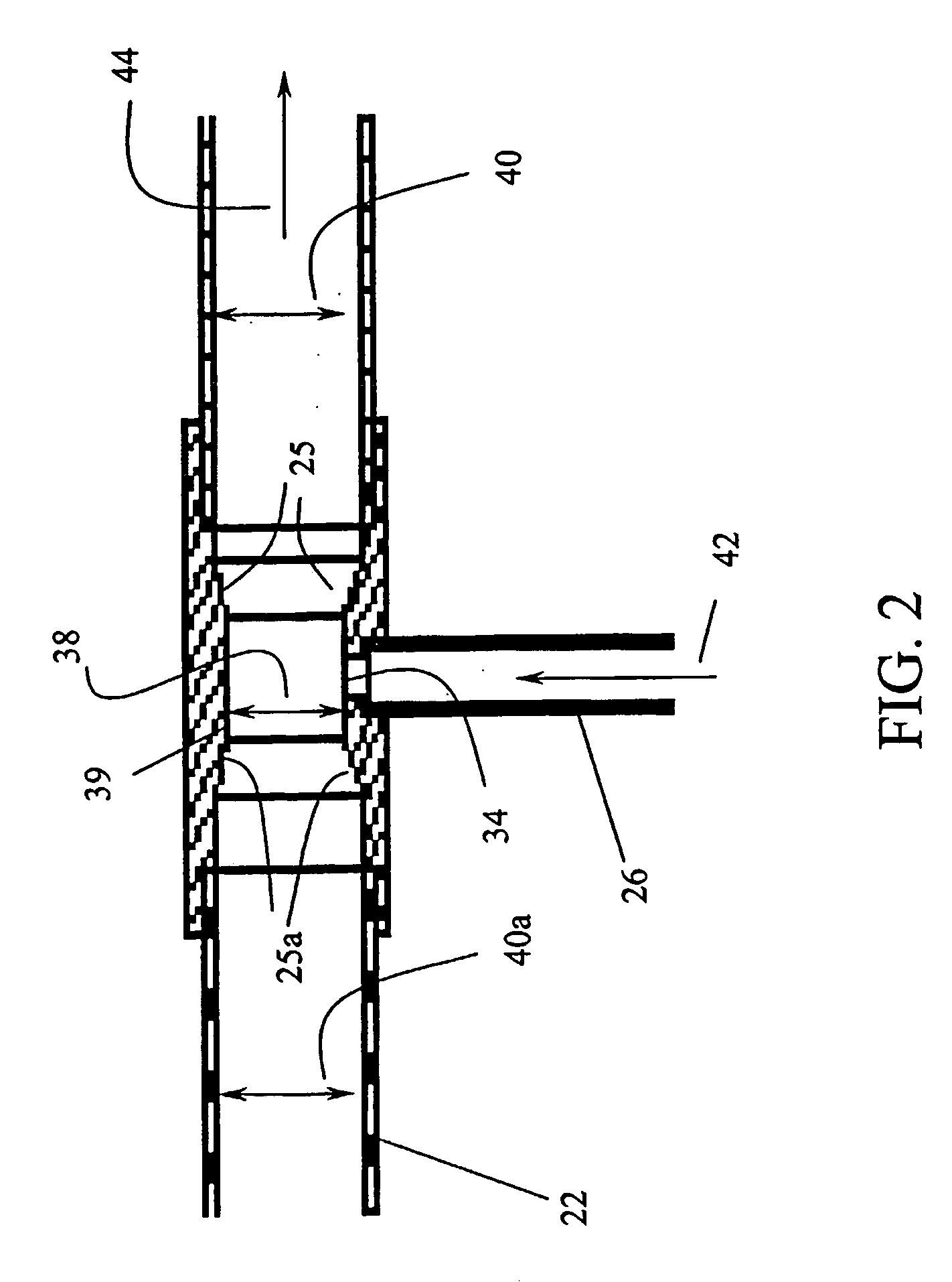

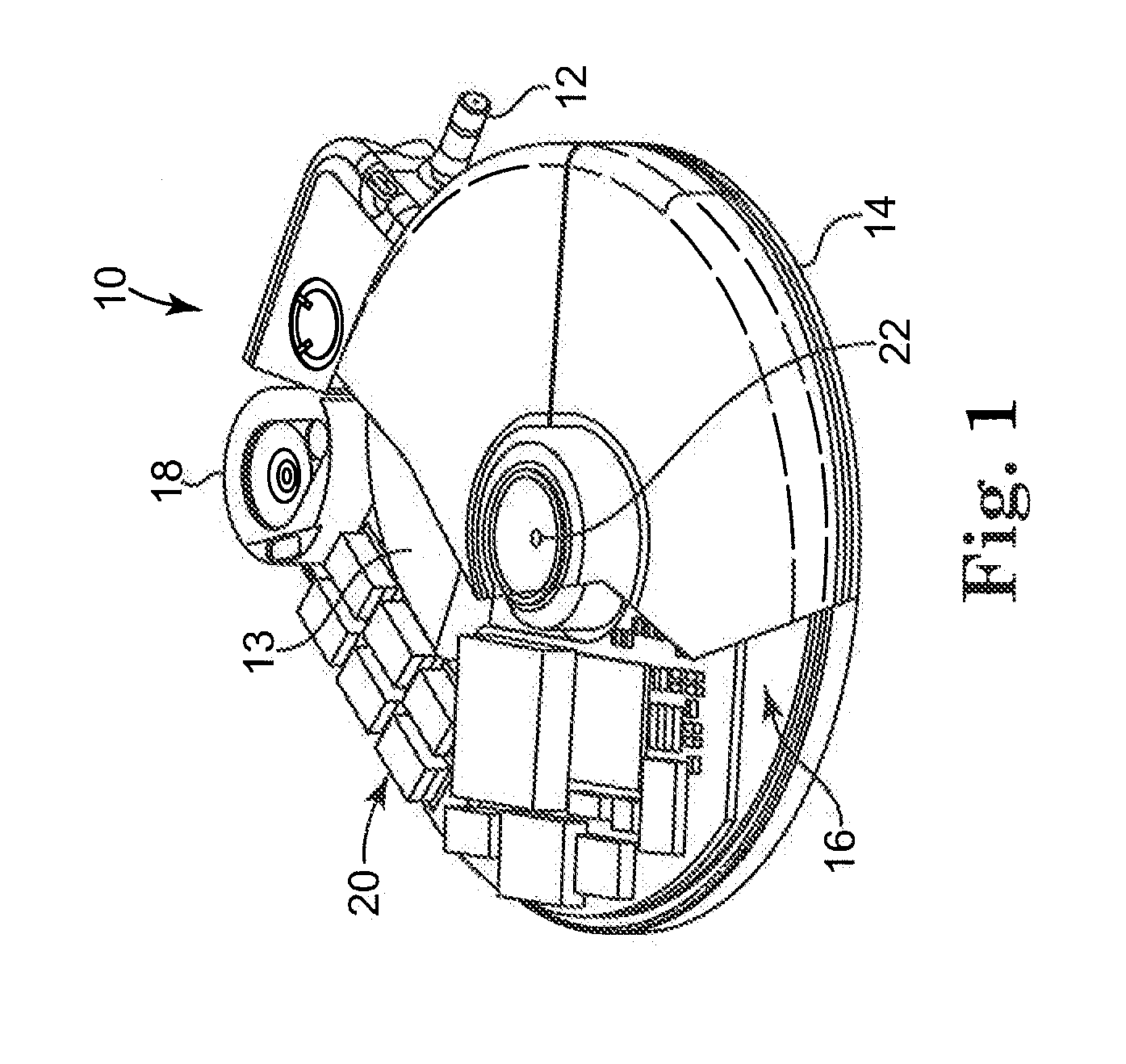

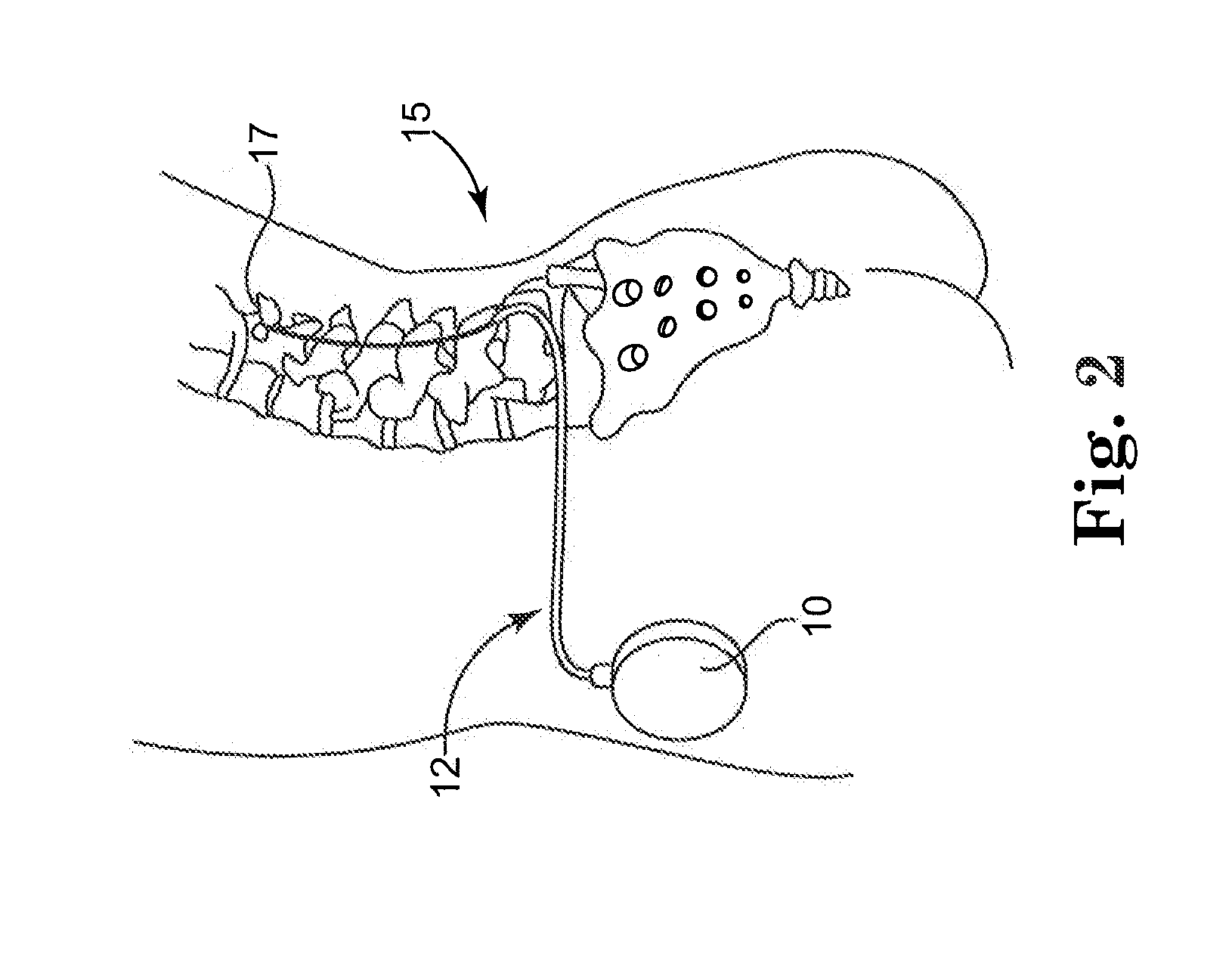

An apparatus for accurately infusing fluids into a patient at specific rates over an extended period of time. The apparatus is of a low profile, laminate construction having a stored energy source in the form of a distendable membrane, which in cooperation with the base of the apparatus defines one or more fluid reservoirs each having a fluid inlet and a fluid outlet. The apparatus further includes a novel, conformable ullage made of formable materials. The conformable ullage uniquely conforms to the shape of elastomeric membrane as the membrane returns to its less distend configuration and in so doing can move between a central chamber and a toroidal chamber formed in the cover of the apparatus. This arrangement will satisfy even the most stringent medicament delivery tolerance requirements and will elegantly overcome the limitations of materials selection encountered in devices embodying solely rigid ullage construction. Additionally, the infusion cannula of the apparatus is connected to the base in a novel manner which permits expeditious subdermal delivery to the patient via a cannula which extends generally perpendicularly relative to the base.

Owner:PESCADERO BEACH HLDG

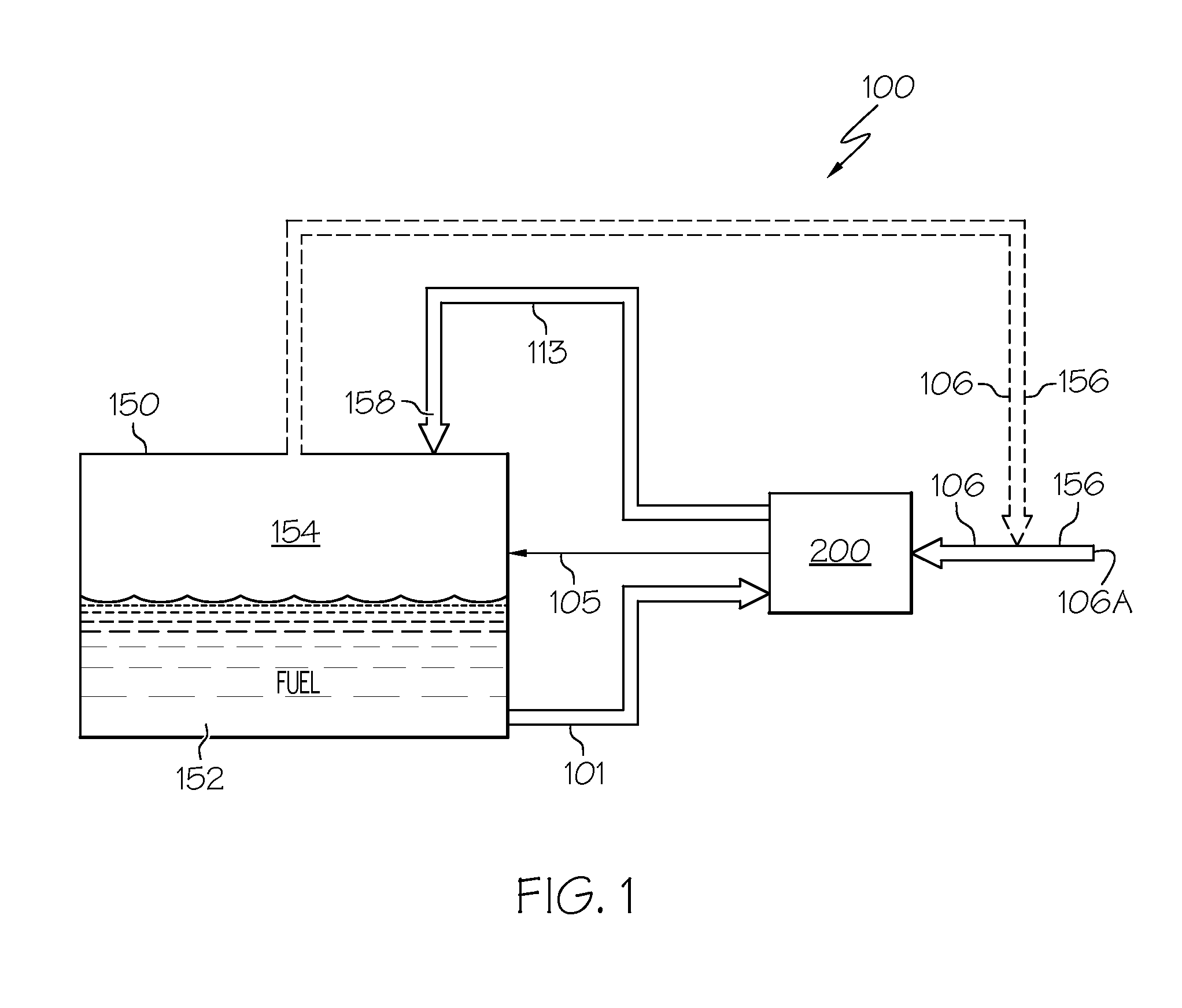

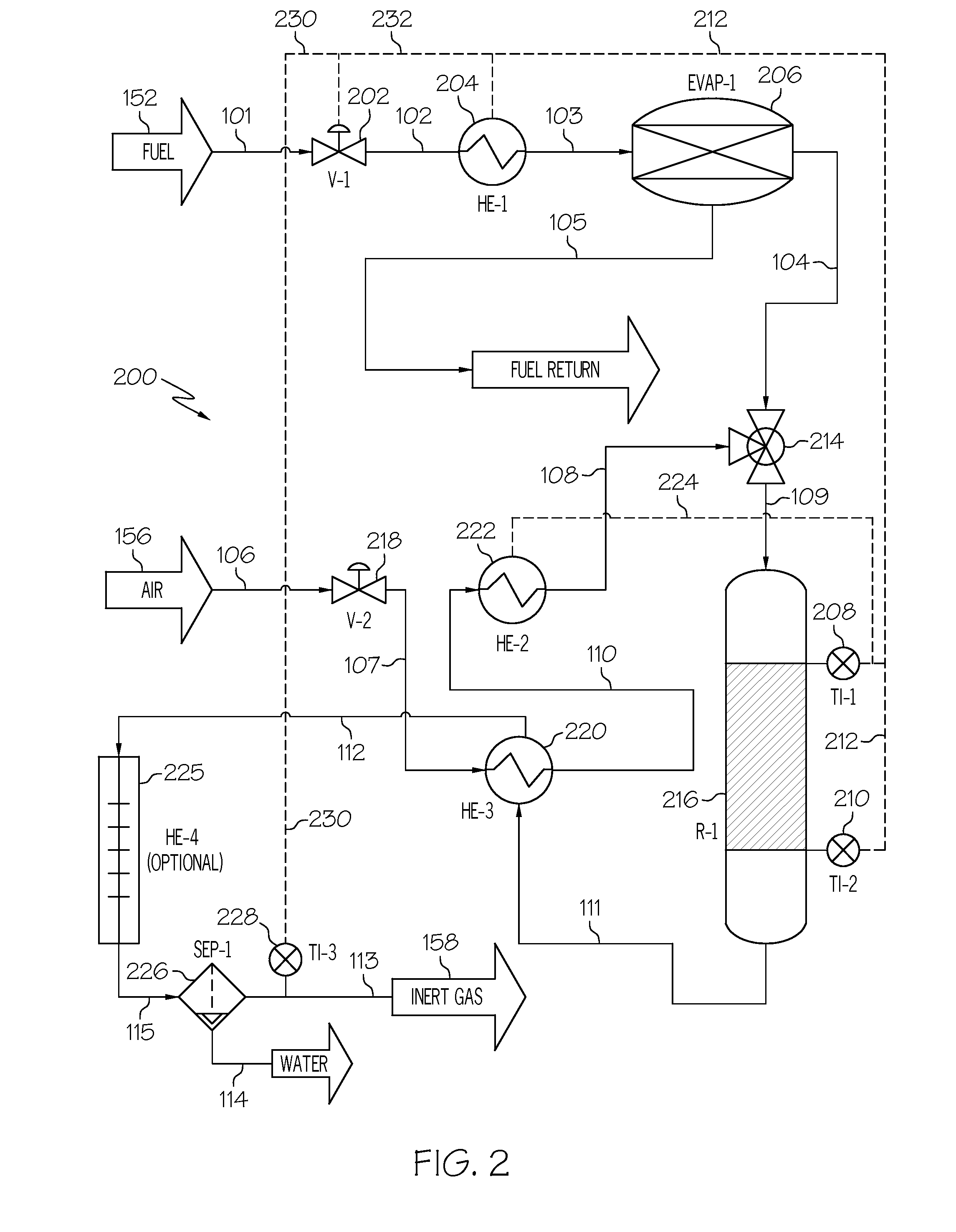

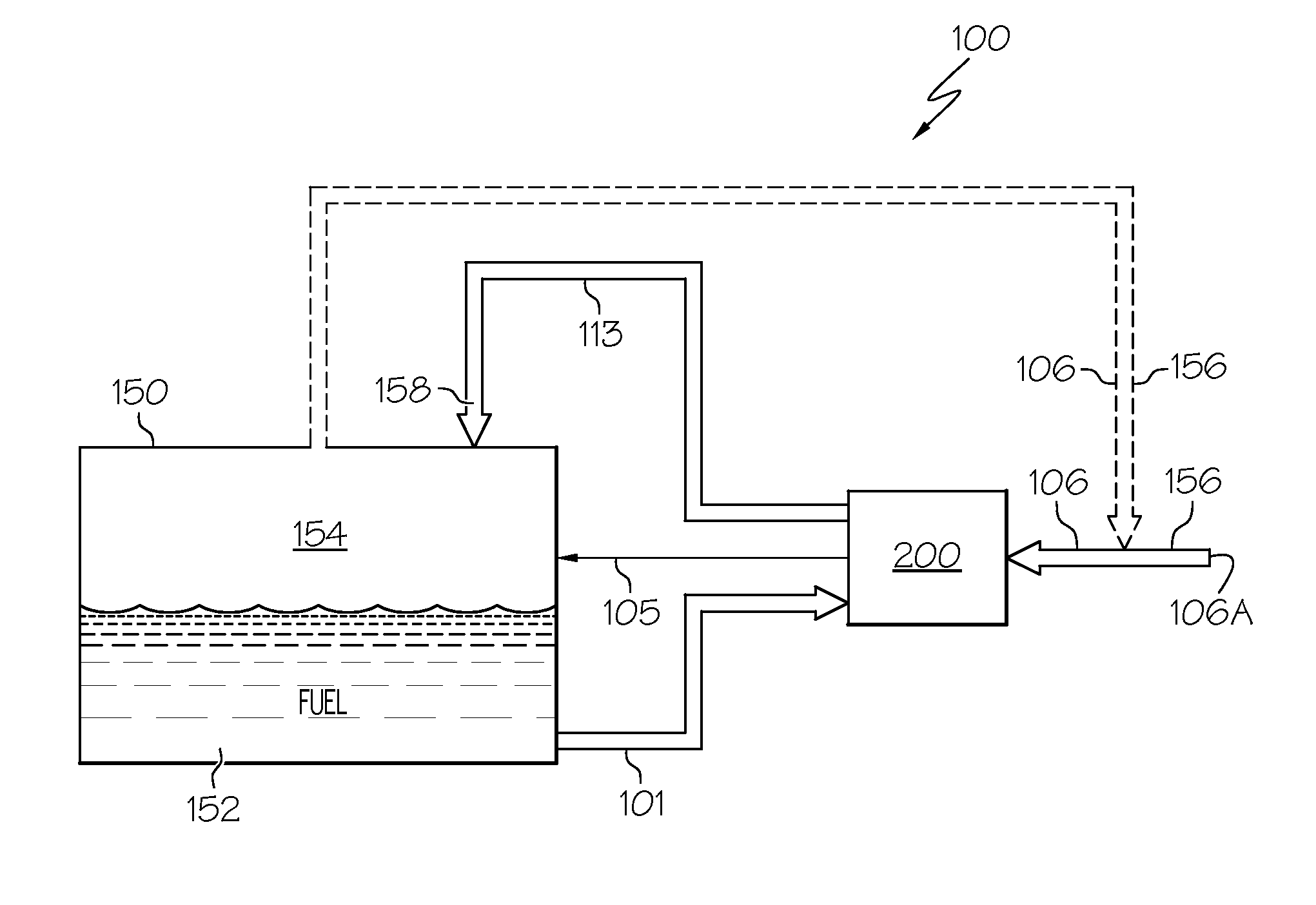

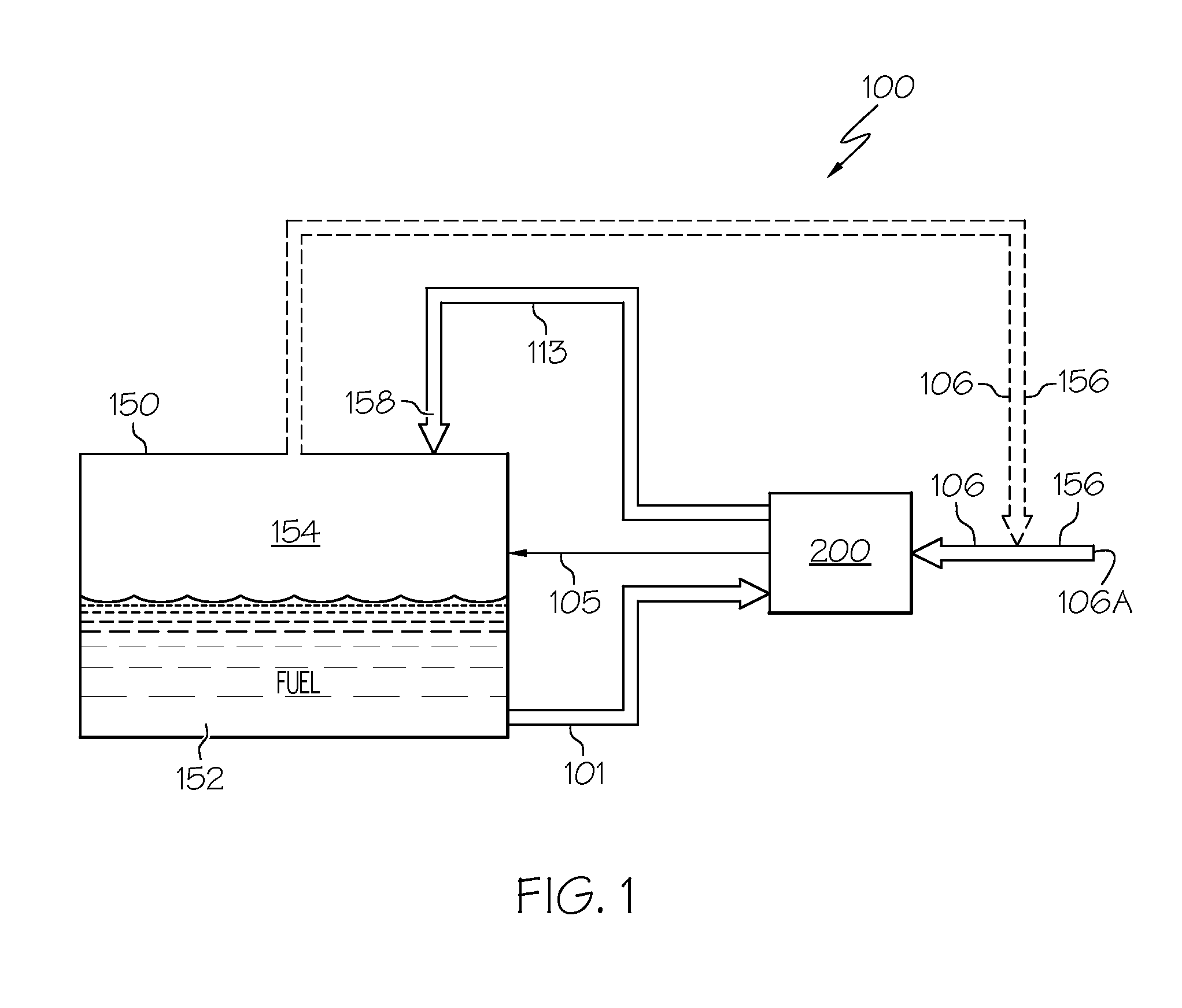

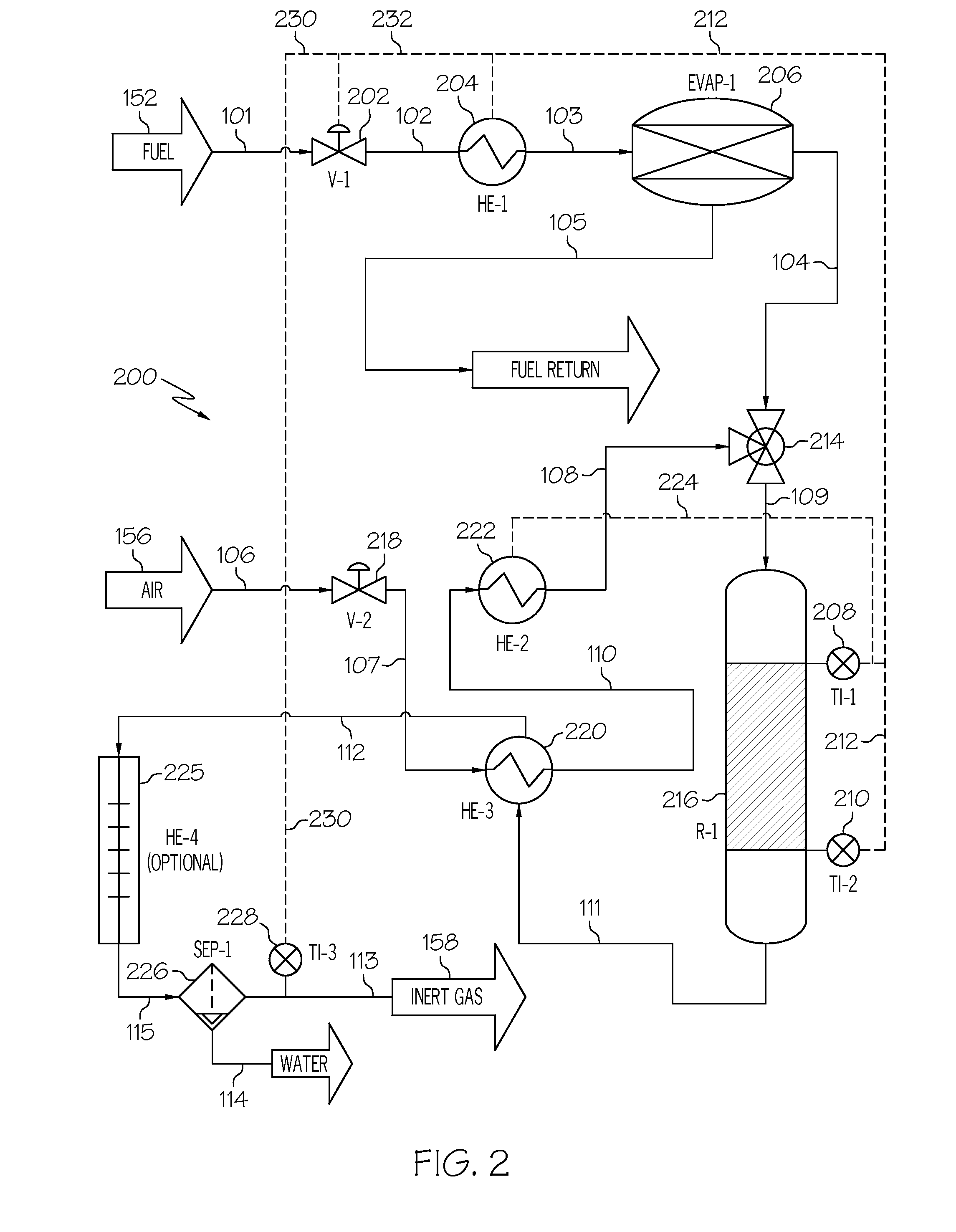

Advanced carbon dioxide fuel tank inerting system

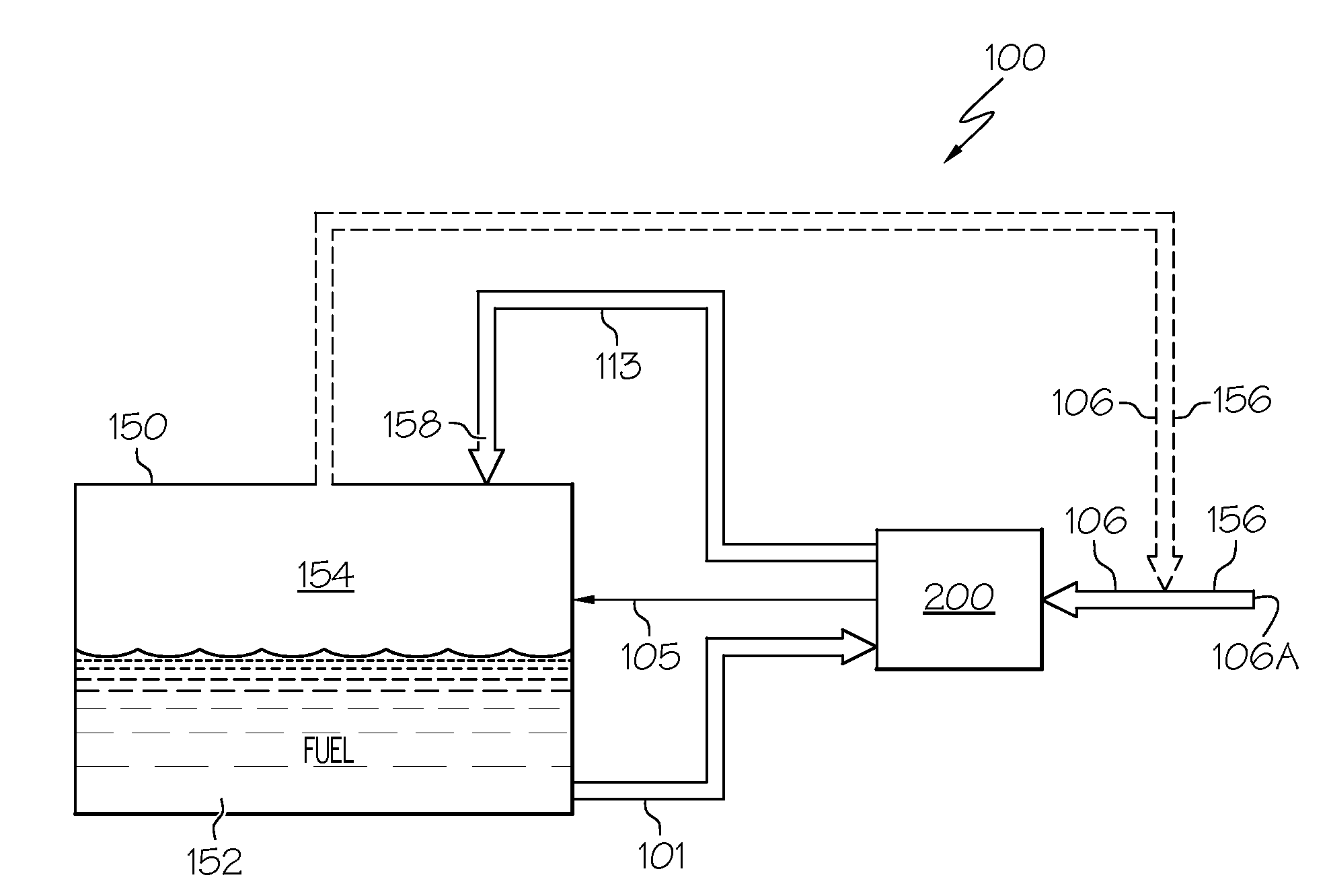

An onboard inert gas generation system includes an evaporator comprising a vessel that receives a hydrocarbon fuel from a fuel tank, separates vapor fuel components from liquid fuel components, establishes a nearly constant fuel vapor composition, and outputs the fuel vapor to be mixed with air prior to combusting the fuel vapor and air mixture in a catalytic reactor. Water is separated from the inert gas produced and the inert gas is introduced into the ullage space of the fuel tank to prevent or reduce possible hazardous conditions in the fuel tank.

Owner:HONEYWELL INT INC

Fluid dispenser having a housing and flexible inner bladder

A dispenser for dispensing a fluid includes a rigid vial that has a main fluid chamber containing a fluid, and a pump assembly that is in fluid communication with the main fluid chamber and is configured to dispense a predetermined quantity of fluid from the main fluid chamber. A flexible bladder is provided which is located within the main fluid chamber and is configured to expand to fill the ullage created within the main fluid chamber during dispensing of fluid by the pump assembly. The resilient bladder tends to force itself outwardly toward the rigid vial and, in turn, increases the pressure within the main fluid chamber in comparison to the interior of the bladder to thereby prevent the ingress of air or vapors through the bladder or otherwise into the main fluid chamber.

Owner:DR PY INST LLC

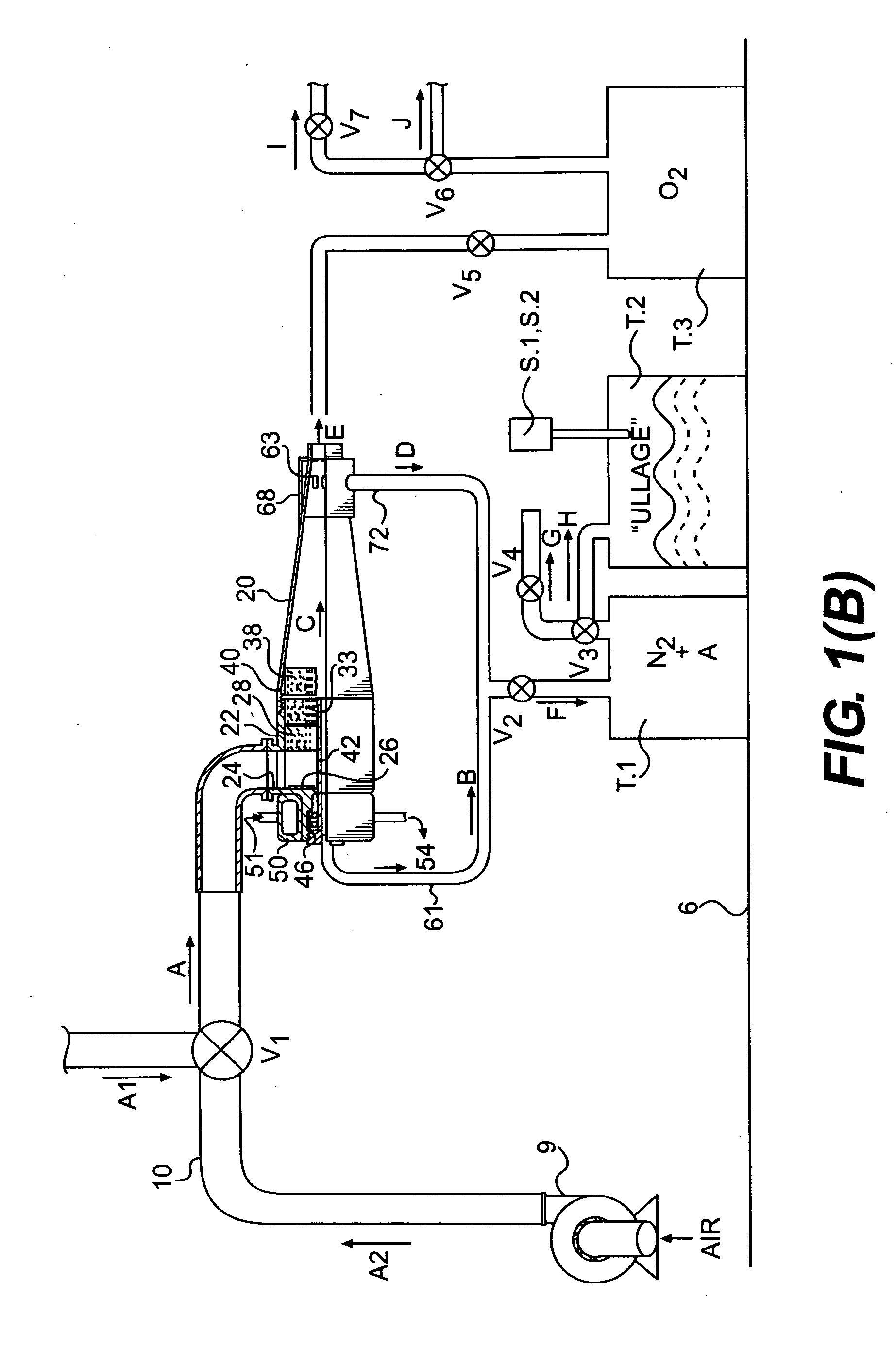

On-board fuel inerting system

InactiveUS6634598B2Effective monitoringExplosion is minimized and eliminatedPower plant fuel tanksFuel tank safety measuresUllageNitrogen gas

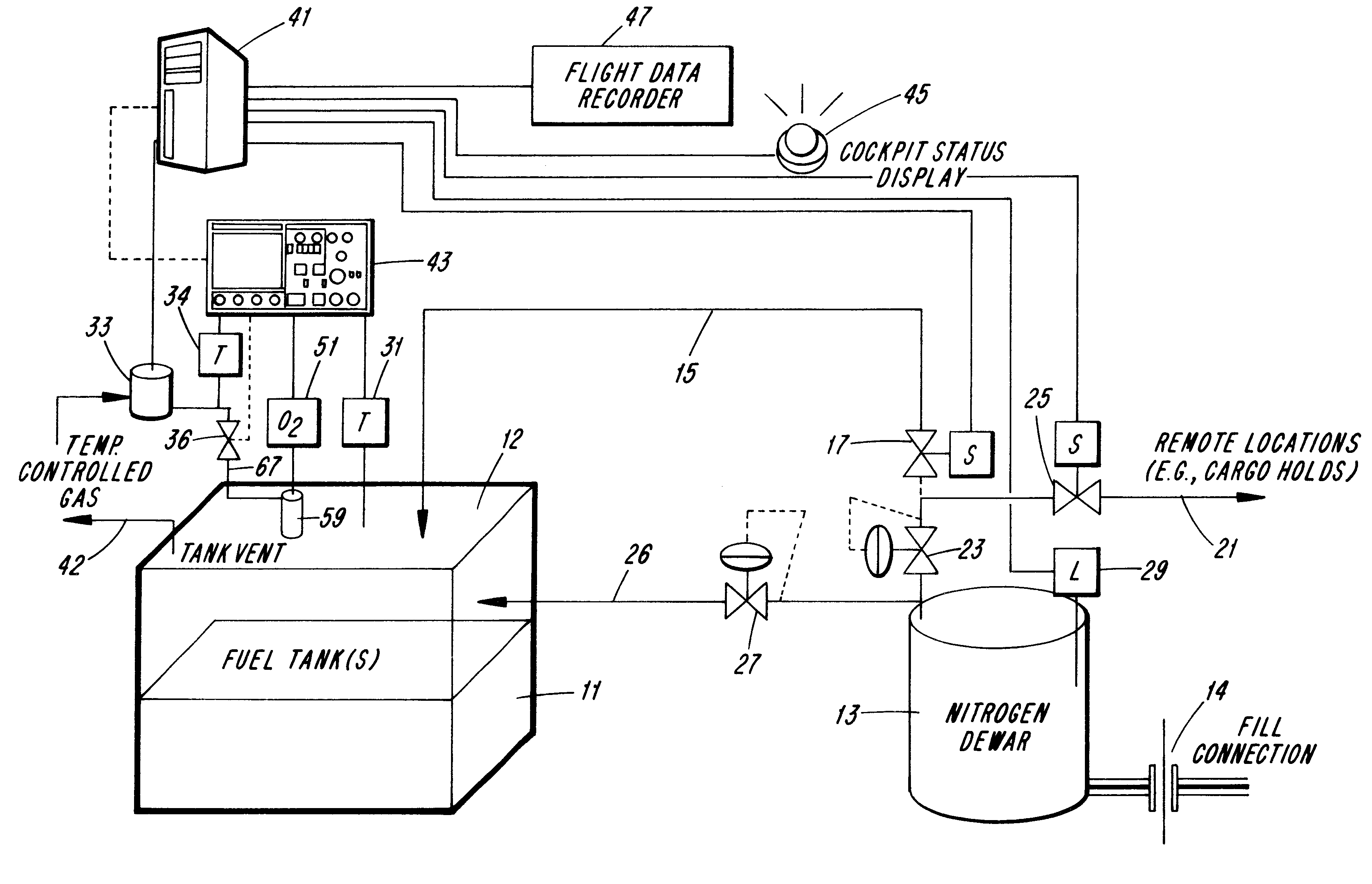

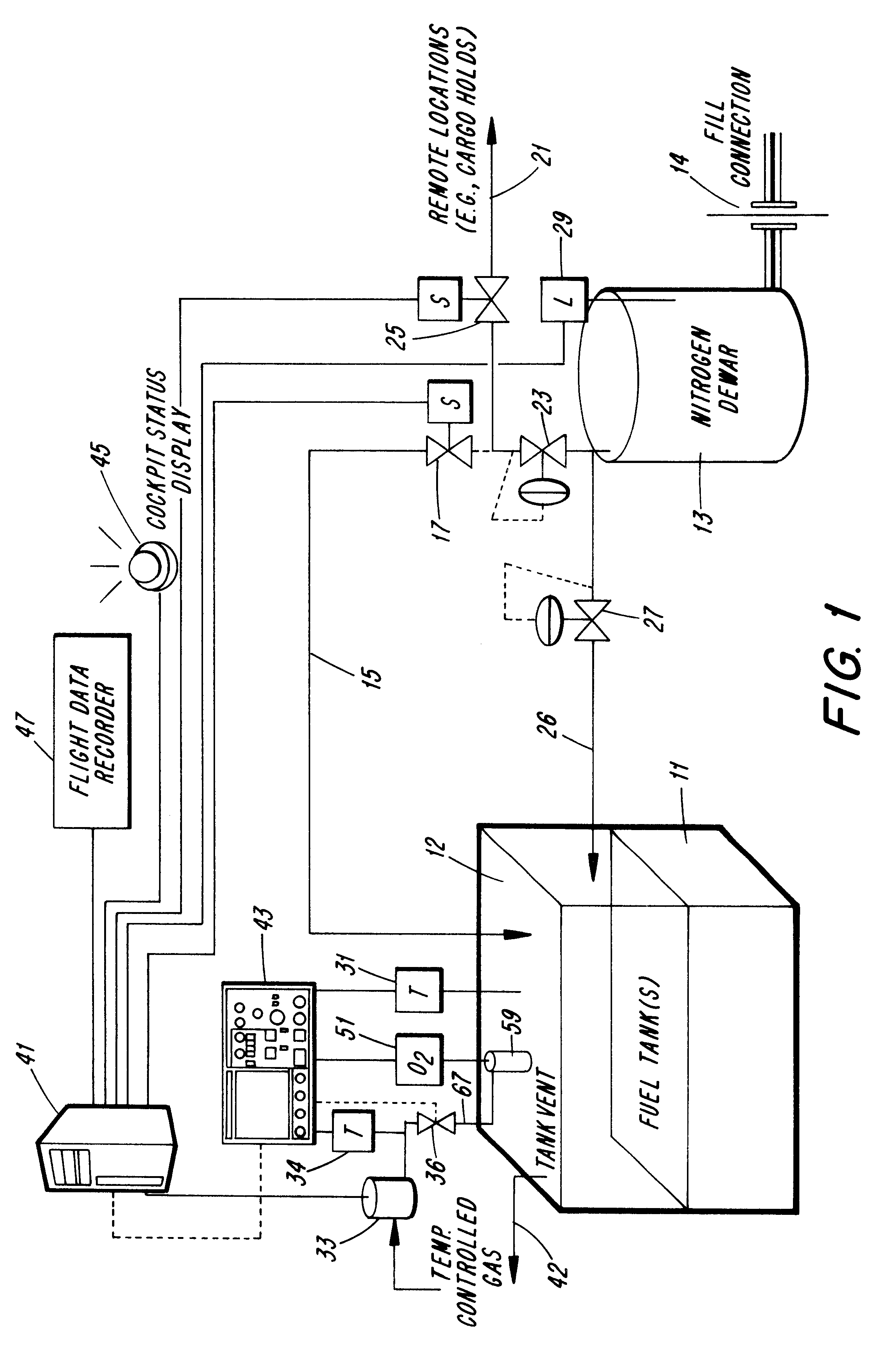

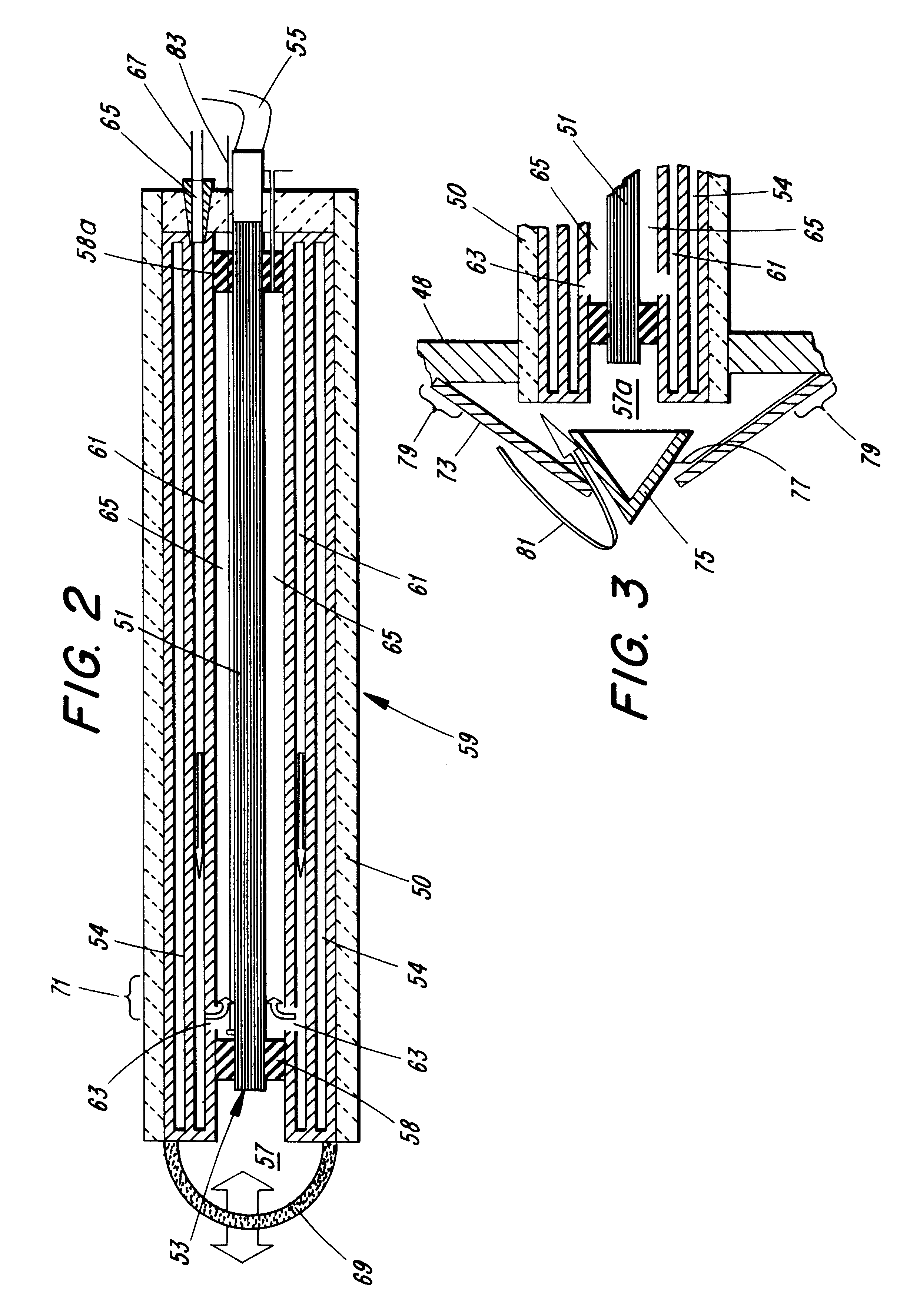

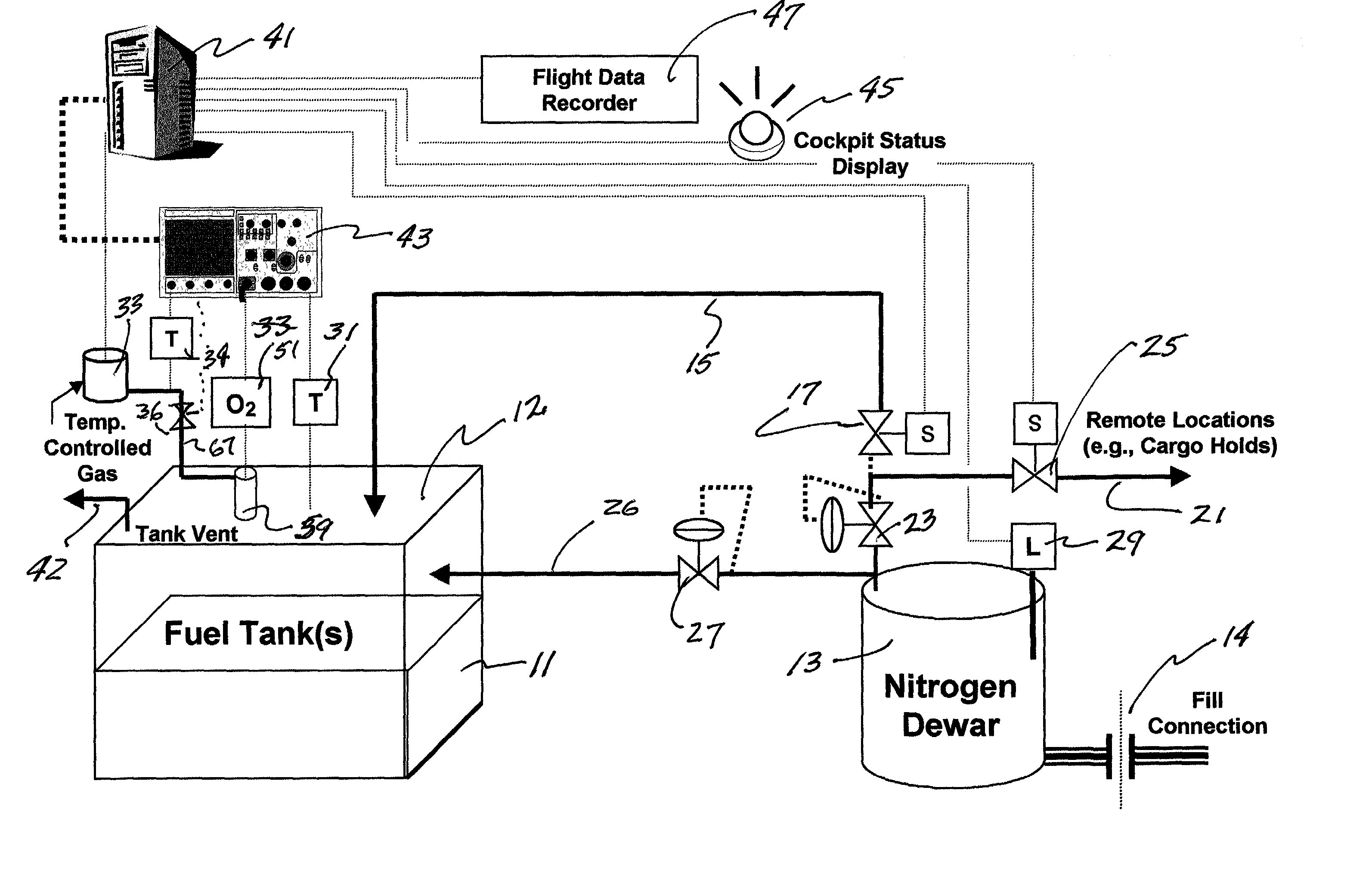

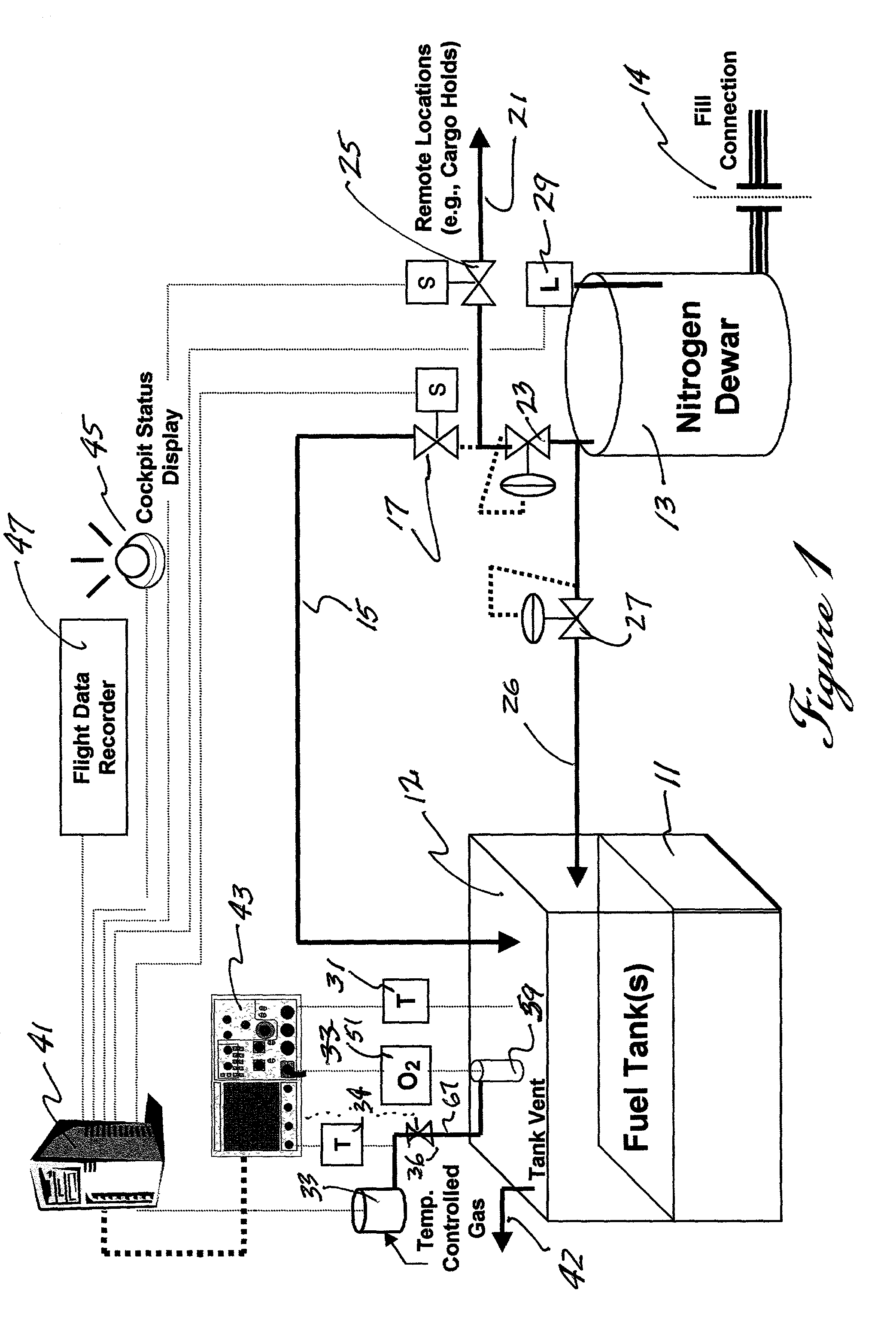

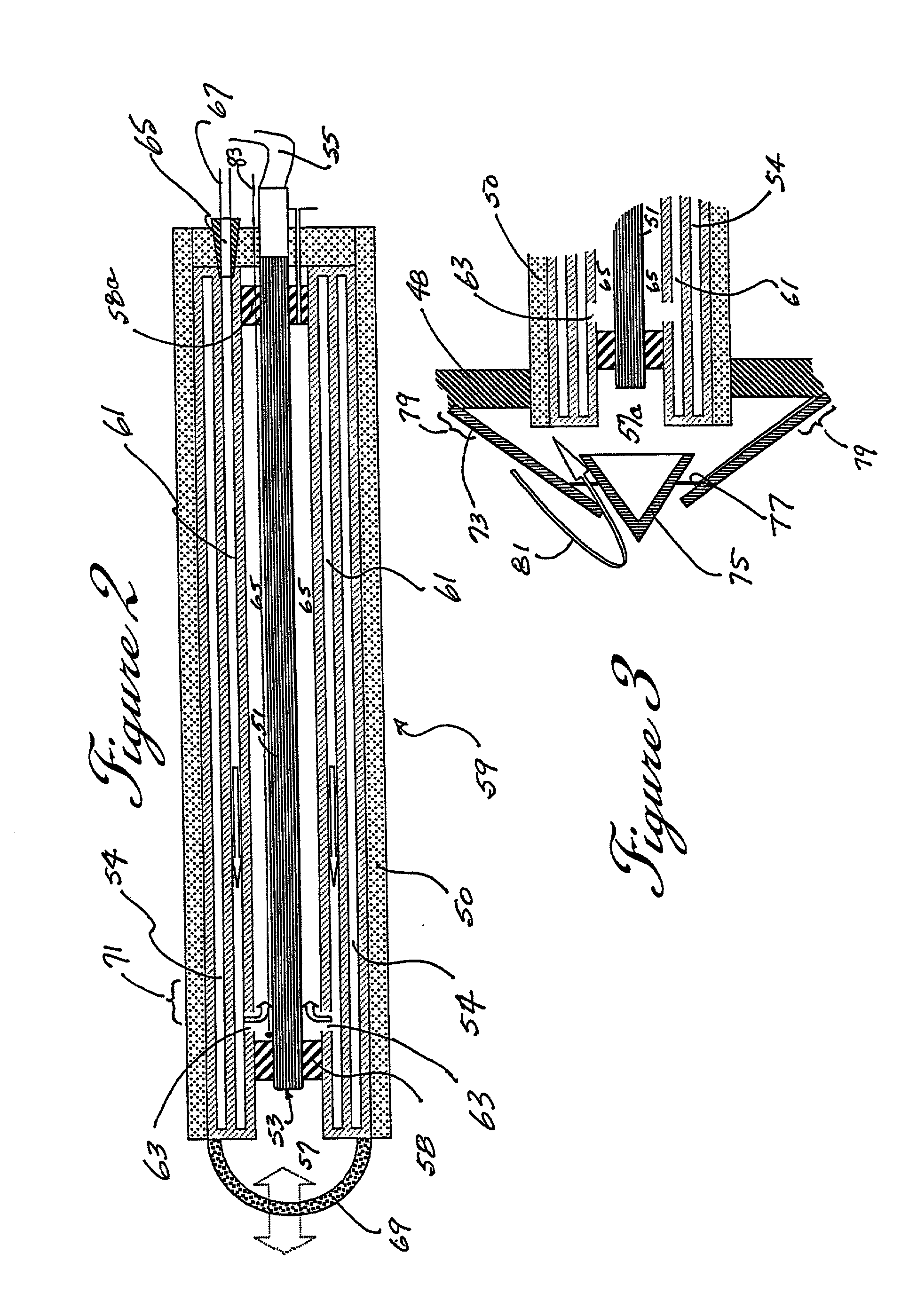

An inerting system is disclosed that is adaptable to inert the fuel tank of a vehicle, most typically an aircraft, that includes an oxygen detector to monitor the oxygen partial pressure of the vapors in the ullage (i.e., the overfuel) volume of the tank, a source of an inert gas (e.g., nitrogen) in valved communication with the ullage of the tank, and a detector for sensing the oxygen content in the ullage of the tank and controlling the flow of inert gas to the tillage to maintain that volume with a proportion oxygen that will not support combustion in the event of an ignition source or intrusion of another potentially explosive occurrence within said tank. A specific fiberoptic probe which enables monitoring oxygen content within the tank without introducing a source of electrical current within the tank is also disclosed.

Owner:SUSKO KENNETH

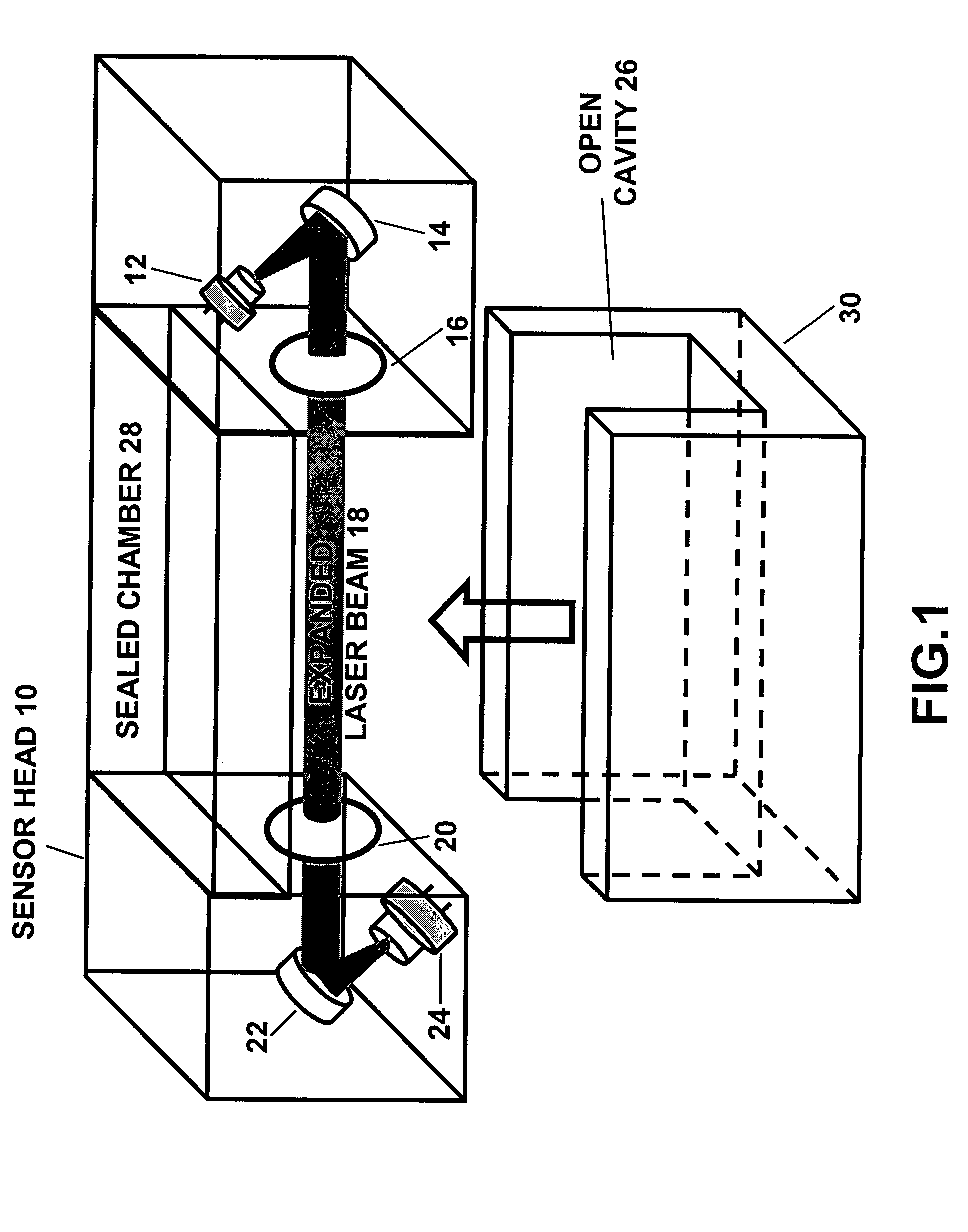

Oxygen sensor for aircraft fuel inerting systems

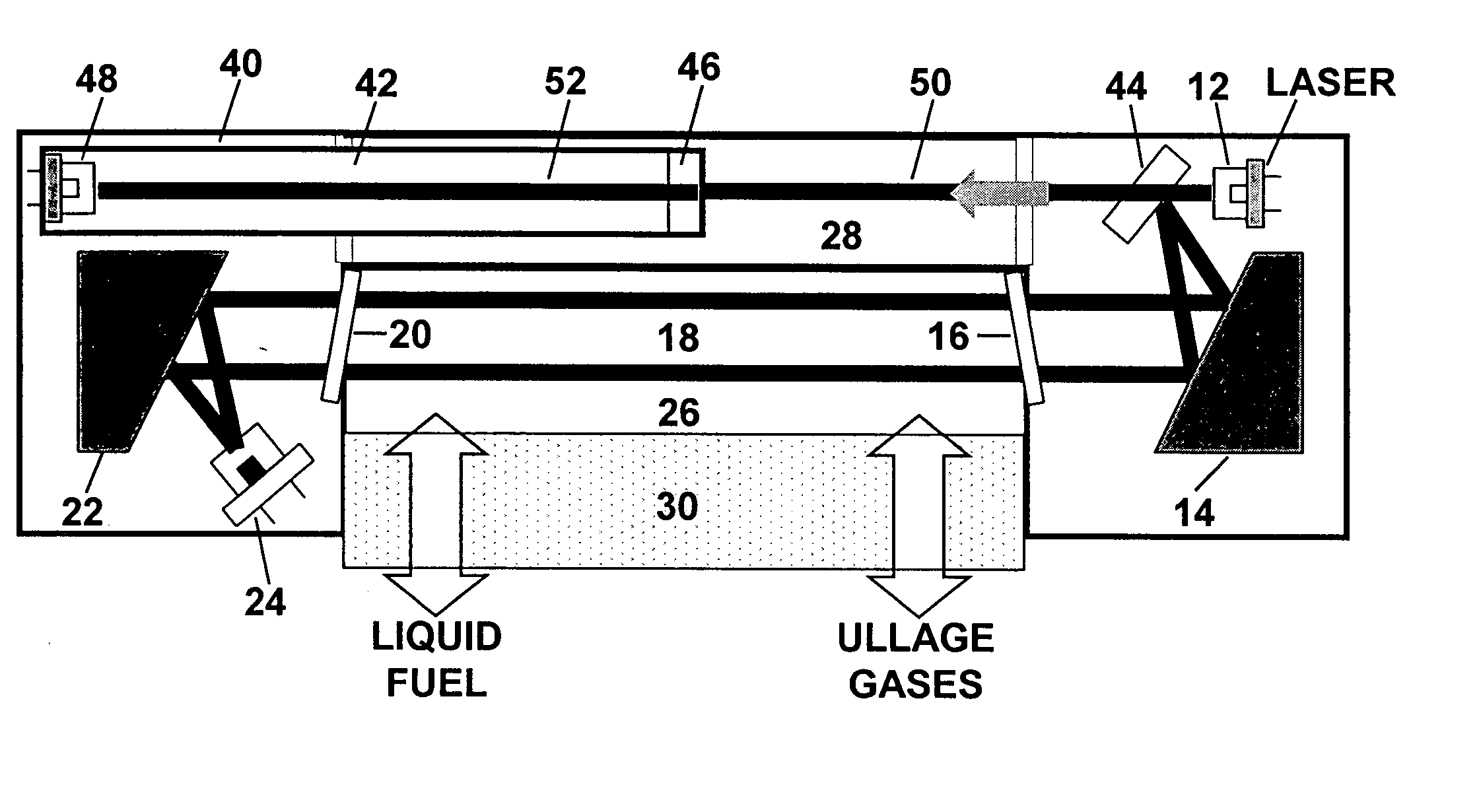

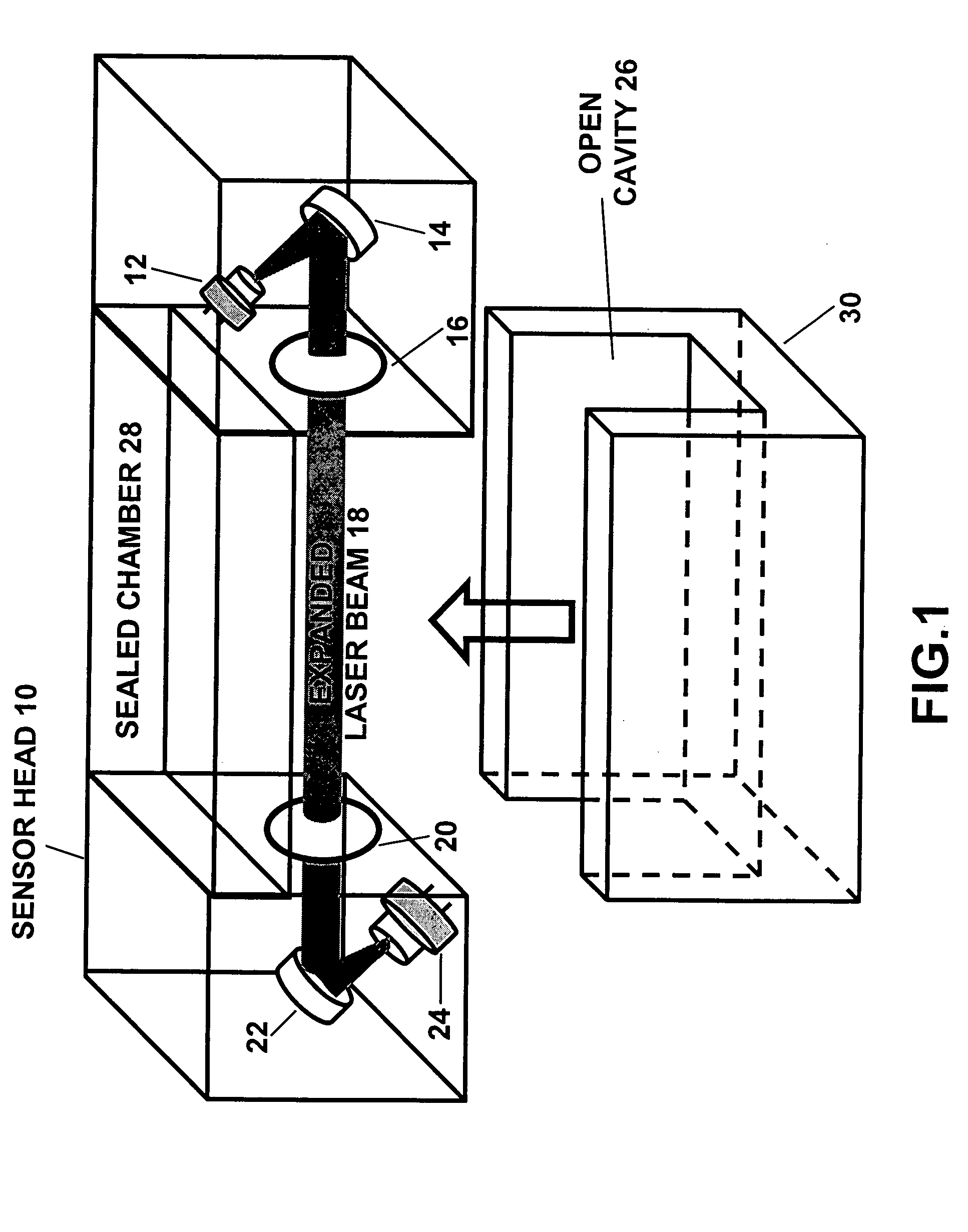

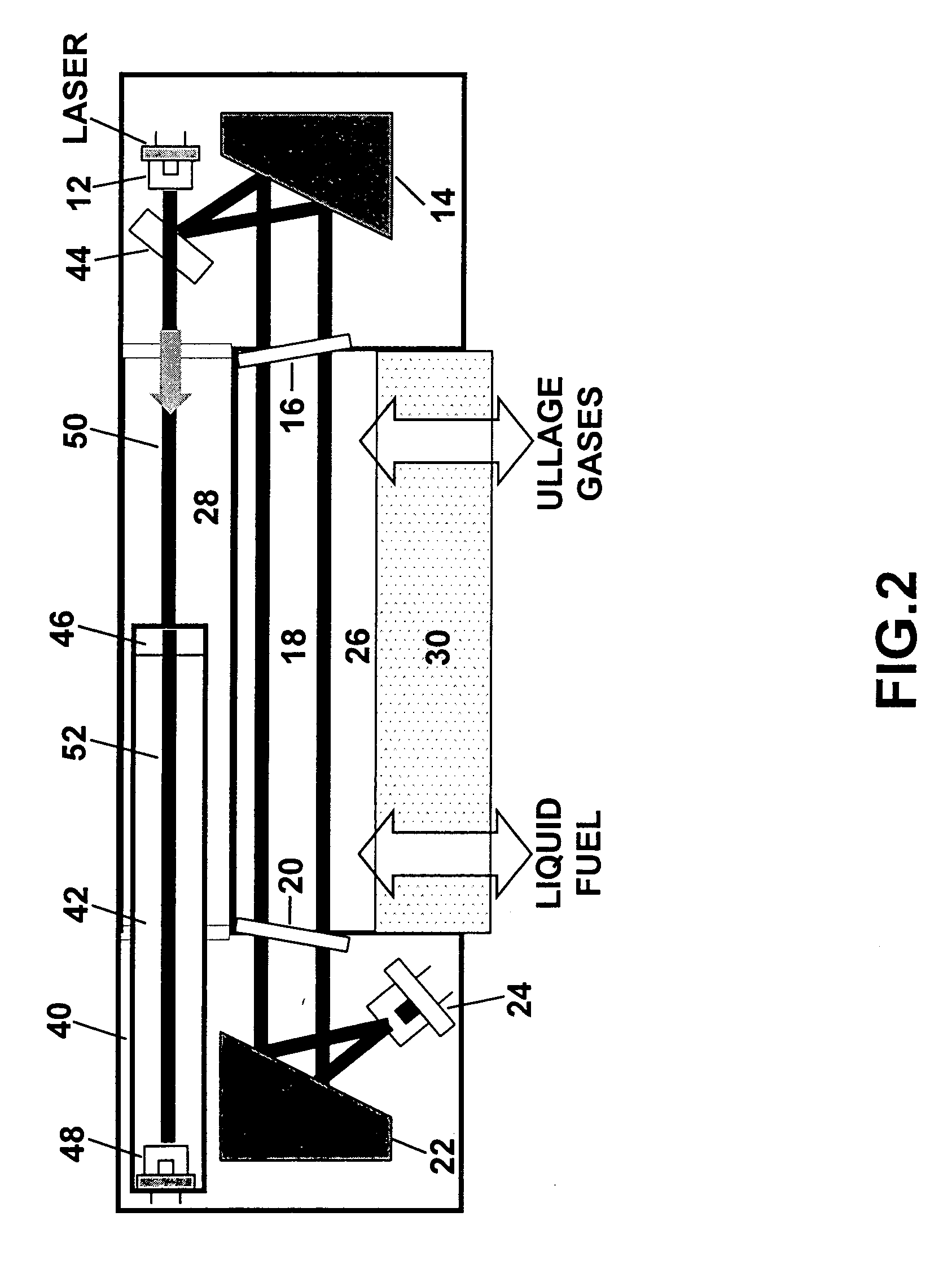

ActiveUS20050286054A1Transmissivity measurementsColor/spectral properties measurementsFuel tankEngineering

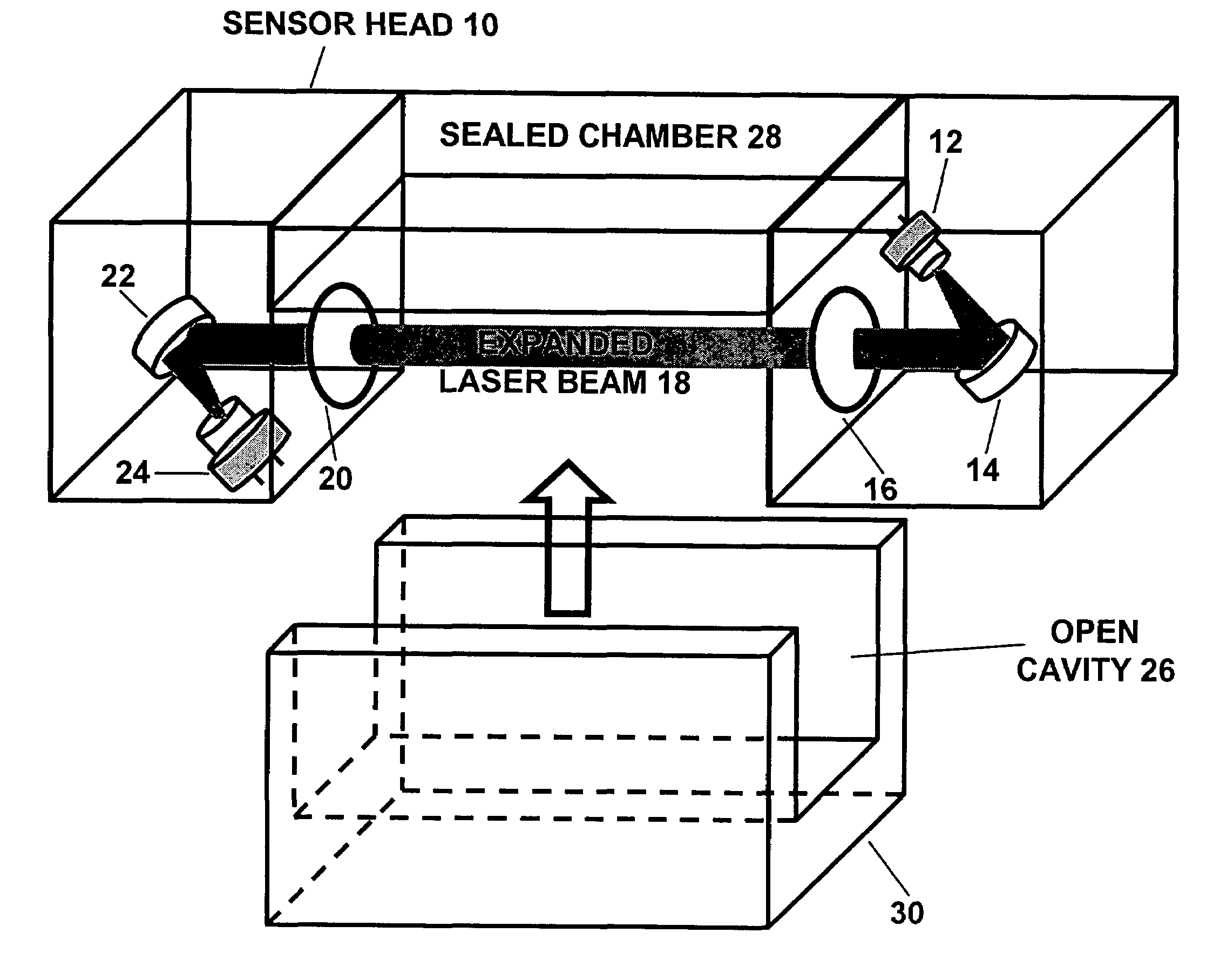

An apparatus and method for monitoring oxygen concentrations in fuel tank ullage comprising providing a sensor head comprising an optical cavity, exposing the optical cavity to an ambient gaseous environment of a fuel tank or air separation module, via a laser light source emitting wavelength modulated light through the cavity, and receiving the wavelength modulated light with a detector.

Owner:SOUTHWEST SCI

Advanced carbon dioxide fuel tank inerting system

An onboard inert gas generation system includes an evaporator comprising a vessel that receives a hydrocarbon fuel from a fuel tank, separates vapor fuel components from liquid fuel components, establishes a nearly constant fuel vapor composition, and outputs the fuel vapor to be mixed with air prior to combusting the fuel vapor and air mixture in a catalytic reactor. Water is separated from the inert gas produced and the inert gas is introduced into the ullage space of the fuel tank to prevent or reduce possible hazardous conditions in the fuel tank.

Owner:HONEYWELL INT INC

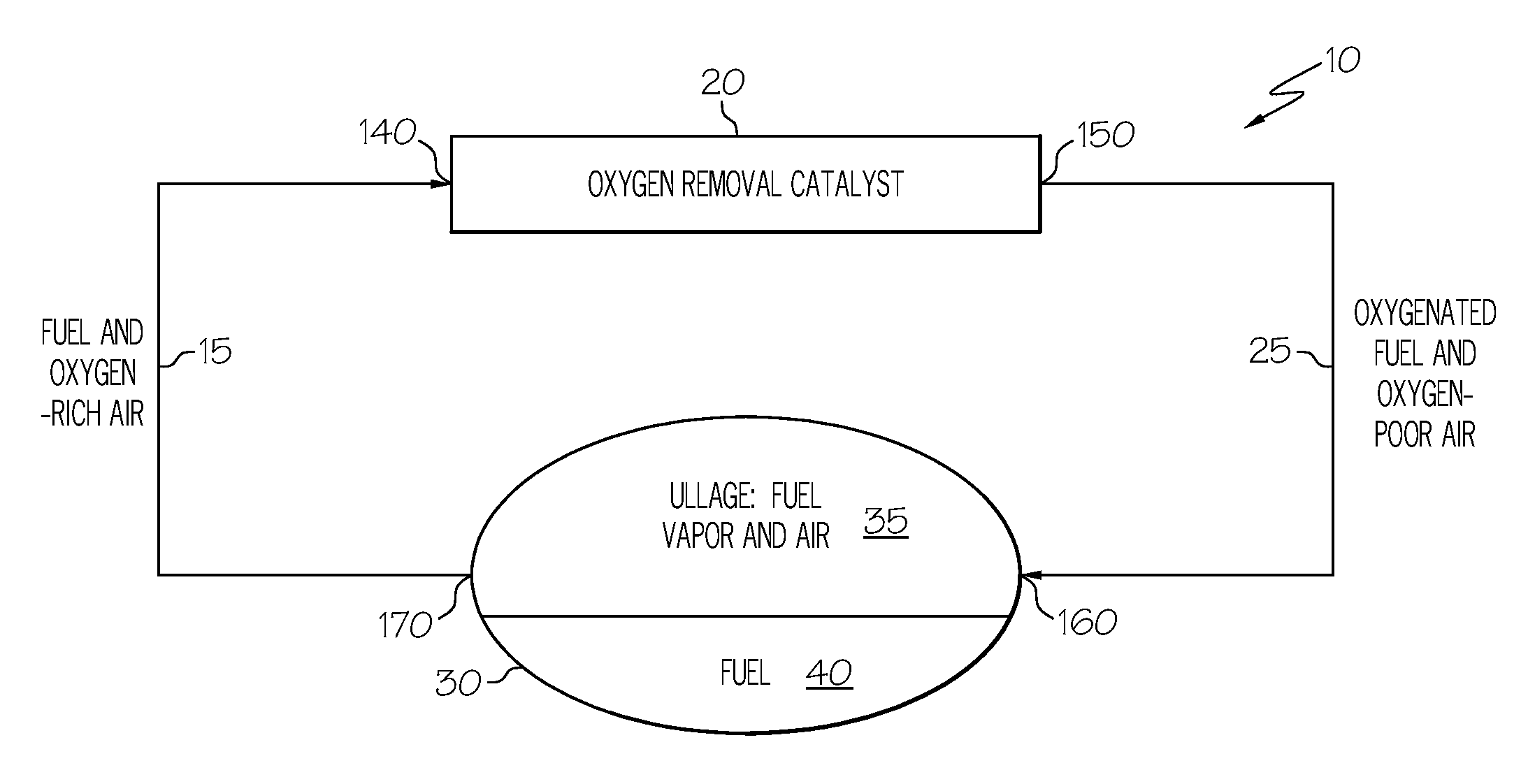

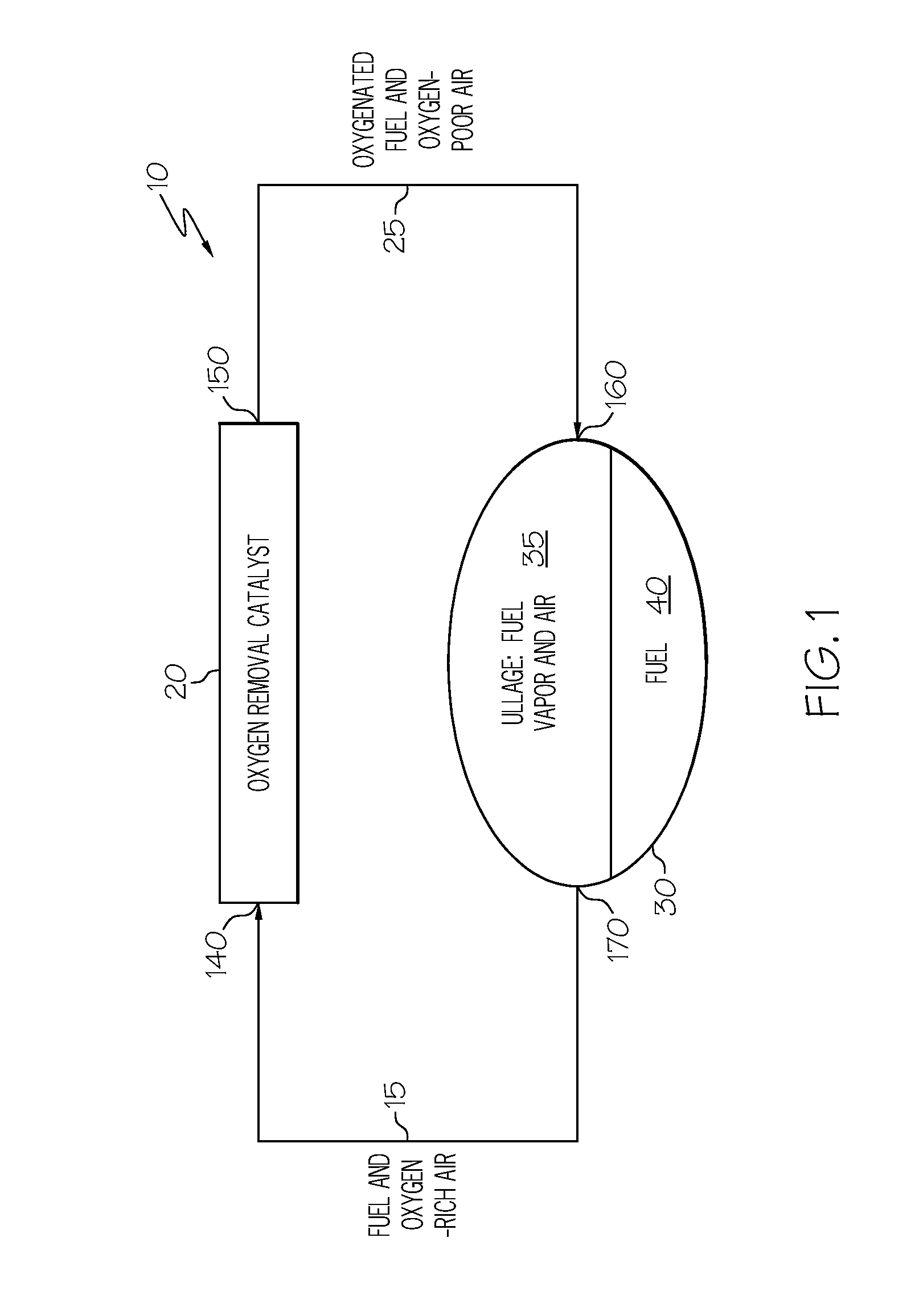

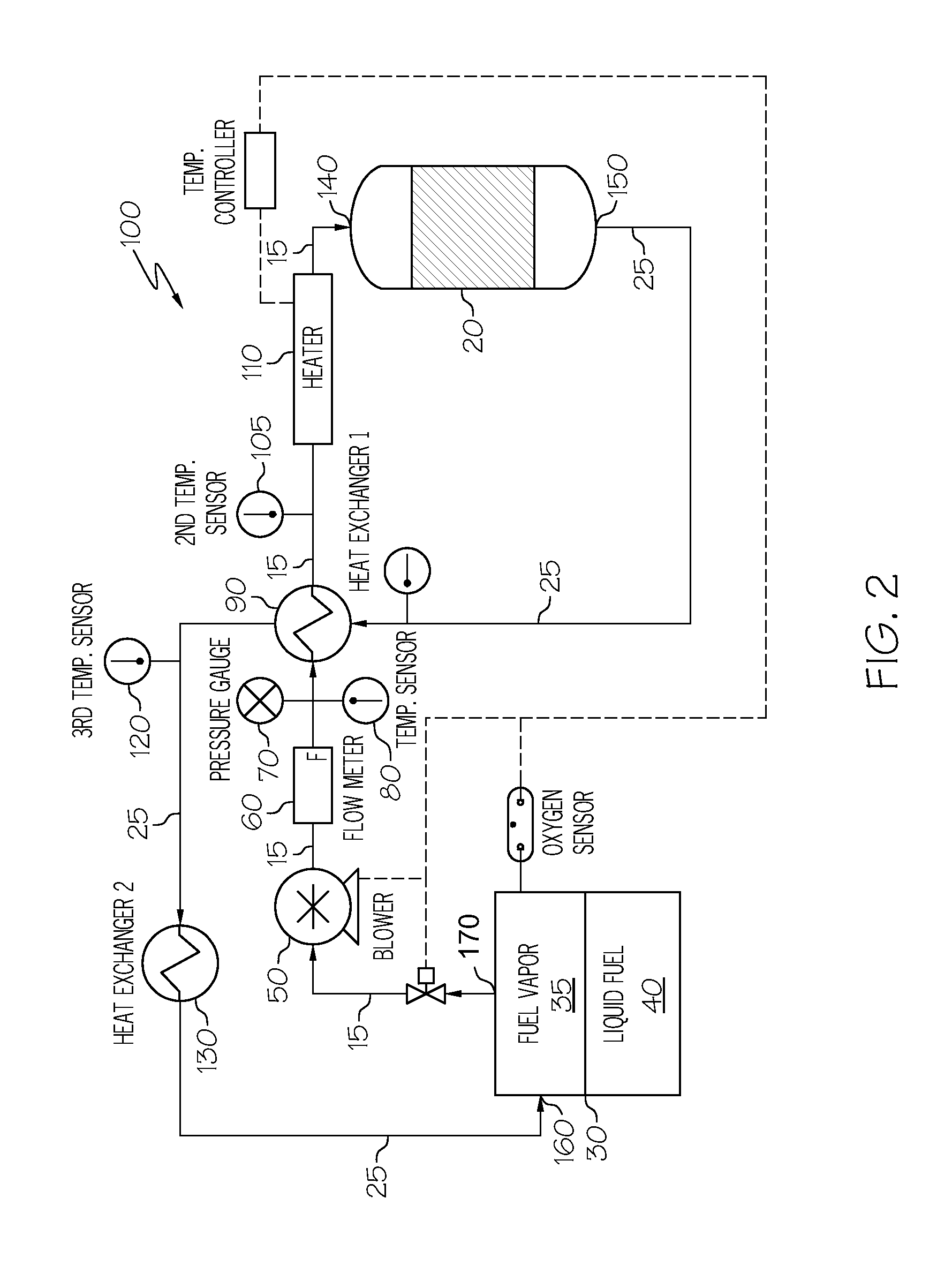

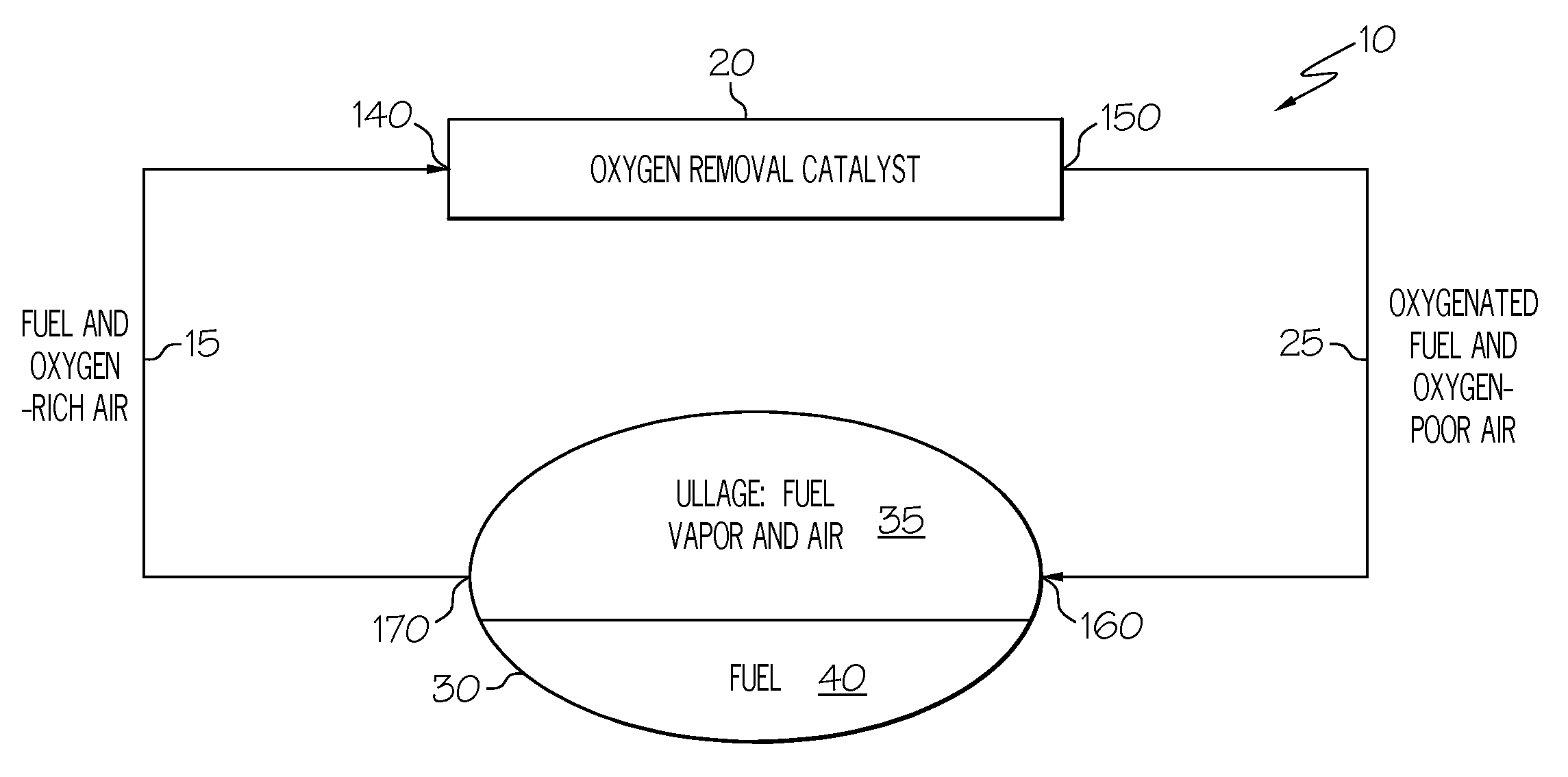

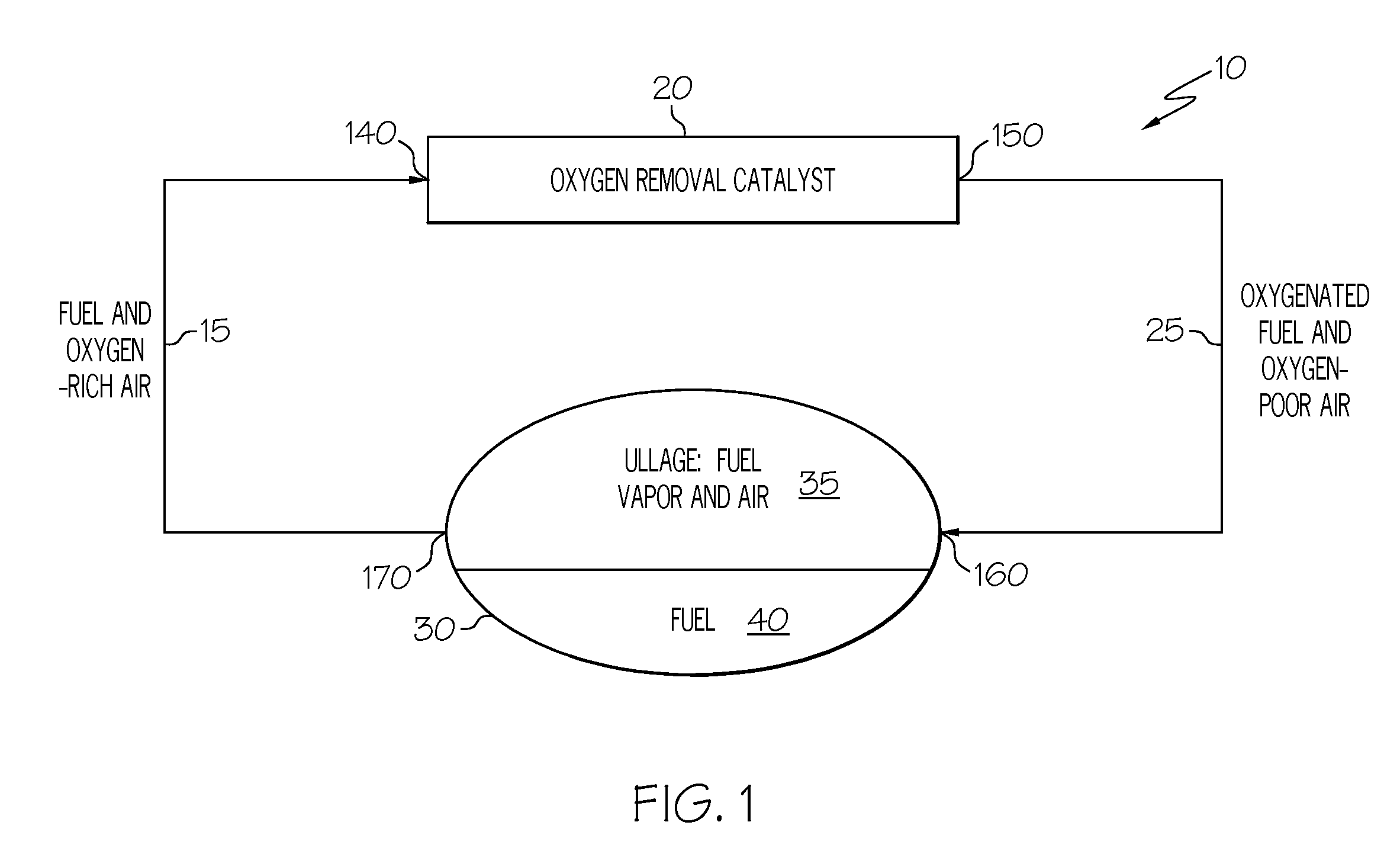

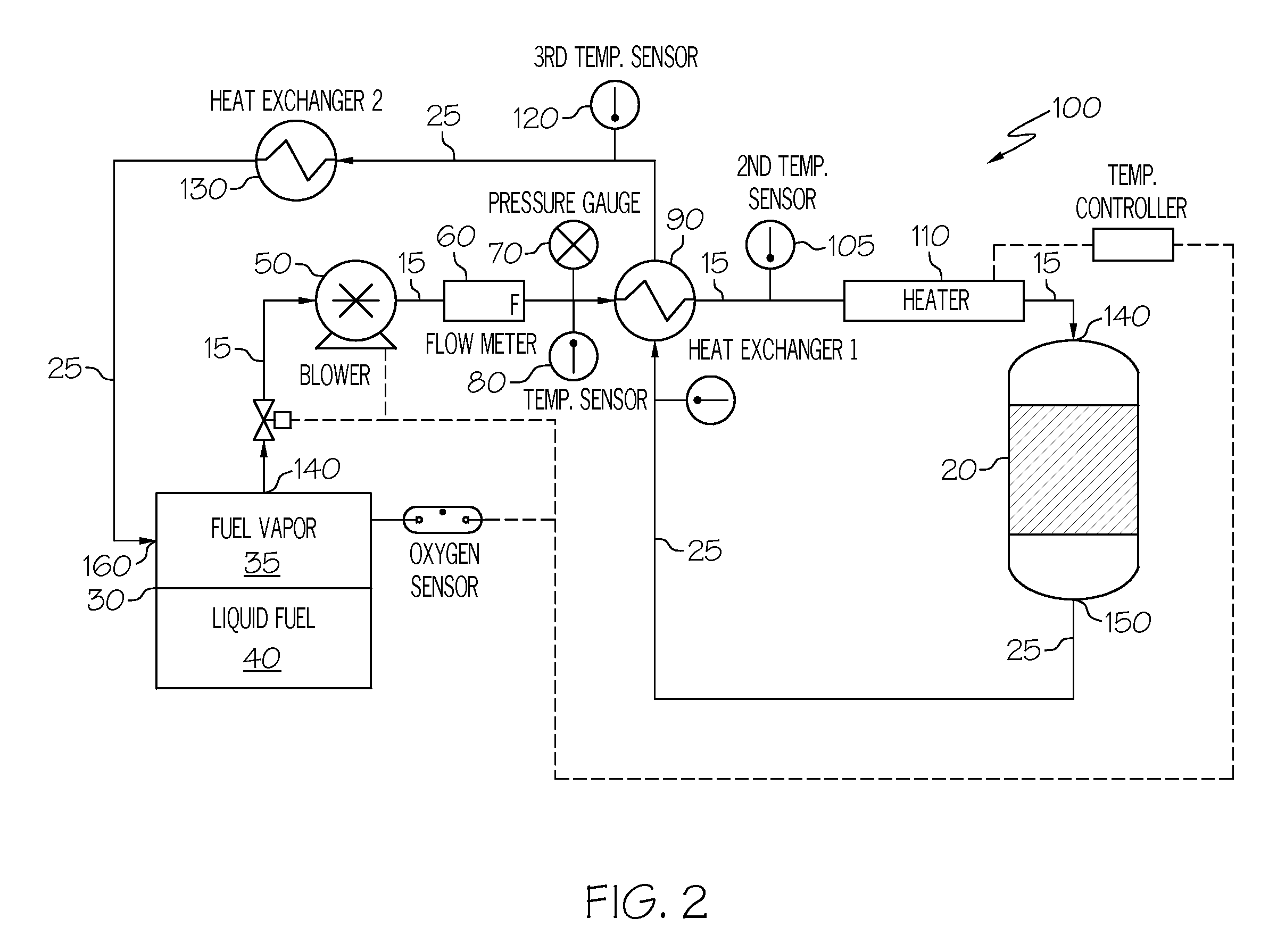

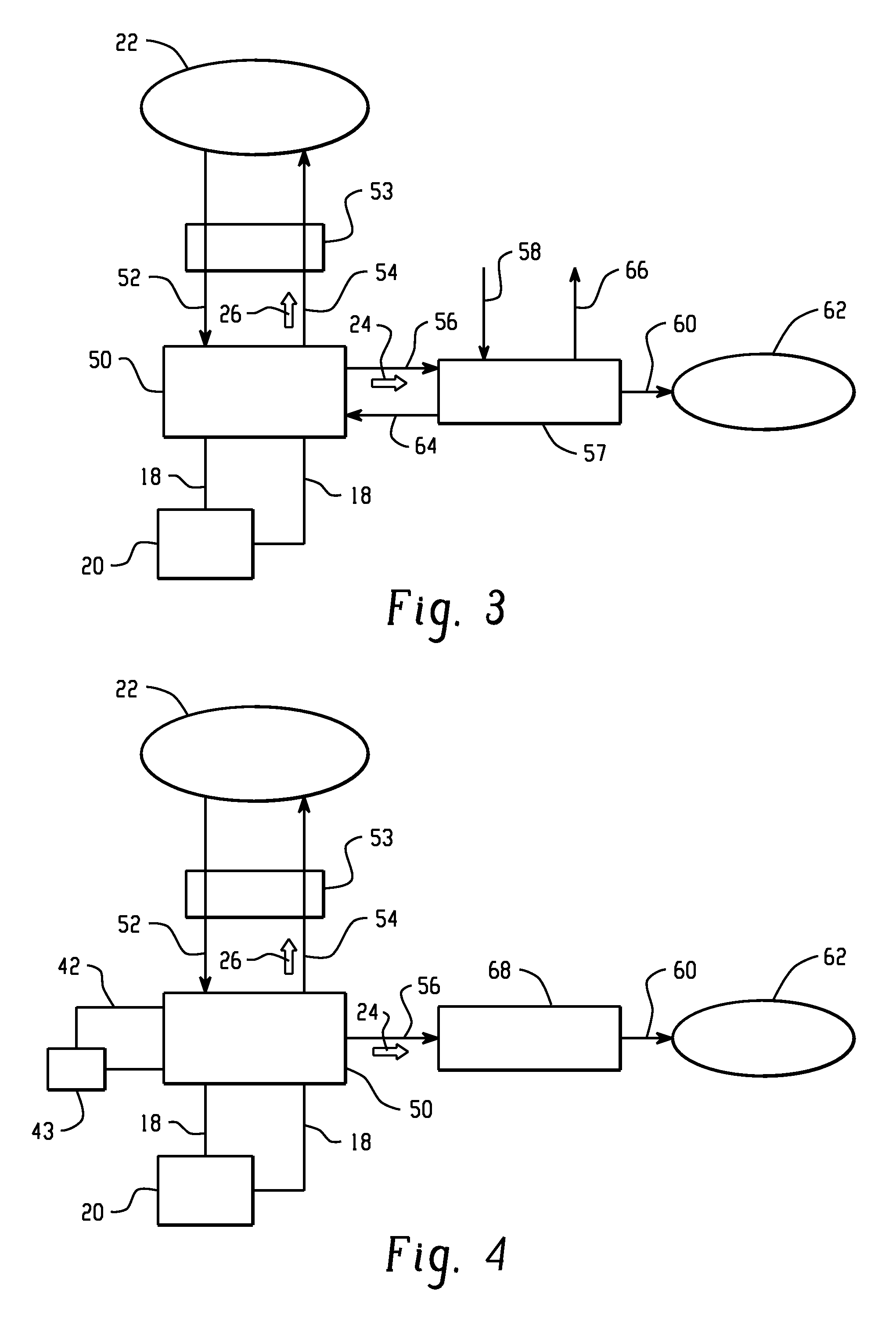

Oxygen removal system

A system and process to deplete or remove oxygen in the ullage of a fuel tank to reduce the oxygen / fuel vapor ratio below a lower explosion limit by exposing the ullage compounds to an oxygen removal catalyst active at a relatively low temperature. The oxygen removal catalyst may be a non-precious metal catalyst. A selective reaction of the oxygen by the catalyst forms primarily alcohols, aldehydes, and / or ketones and produces less than about 5% water by volume. The selective reaction, occurring at the relatively low temperature, reduces the risk of flammability of the fuel.

Owner:HONEYWELL INT INC

Oxygen removal system

ActiveUS20080099618A1Reduce riskReduce oxygen concentrationLiquid degasificationPower plant fuel tanksAlcoholKetone

A system and process is provided to deplete or remove oxygen in the ullage of a fuel tank to reduce the oxygen / fuel vapor ratio below a lower explosion limit by exposing the ullage compounds to an oxygen removal catalyst active at a relatively low temperature. The oxygen removal catalyst may be a non-precious metal catalyst. A selective reaction of the oxygen by the catalyst forms primarily alcohols, aldehydes, and / or ketones and produces less than about 5% water by volume. The selective reaction, occurring at the relatively low temperature, reduces the risk of flammability of the fuel.

Owner:HONEYWELL INT INC

On-board fuel inerting system

InactiveUS20030116679A1Effective monitoringExplosion is minimized and eliminatedPower plant fuel tanksPressure pumpsInerting systemCombustion

An inerting system is disclosed that is adaptable to inert the fuel tank of a vehicle, most typically an aircraft, that includes an oxygen detector to monitor the oxygen partial pressure of the vapors in the ullage (i.e., the overfuel) volume of the tank, a source of an inert gas (e.g., nitrogen) in valved communication with the ullage of the tank, and a detector for sensing the oxygen content in the ullage of the tank and controlling the flow of inert gas to the tillage to maintain that volume with a proportion oxygen that will not support combustion in the event of an ignition source or intrusion of another potentially explosive occurrence within said tank. A specific fiberoptic probe which enables monitoring oxygen content within the tank without introducing a source of electrical current within the tank is also disclosed.

Owner:SUSKO KENNETH

Oxygen sensor for aircraft fuel inerting systems

ActiveUS7352464B2Transmissivity measurementsColor/spectral properties measurementsOptical cavityInerting system

An apparatus and method for monitoring oxygen concentrations in fuel tank ullage comprising providing a sensor head comprising an optical cavity, exposing the optical cavity to an ambient gaseous environment of a fuel tank or air separation module, via a laser light source emitting wavelength modulated light through the cavity, and receiving the wavelength modulated light with a detector.

Owner:SOUTHWEST SCI

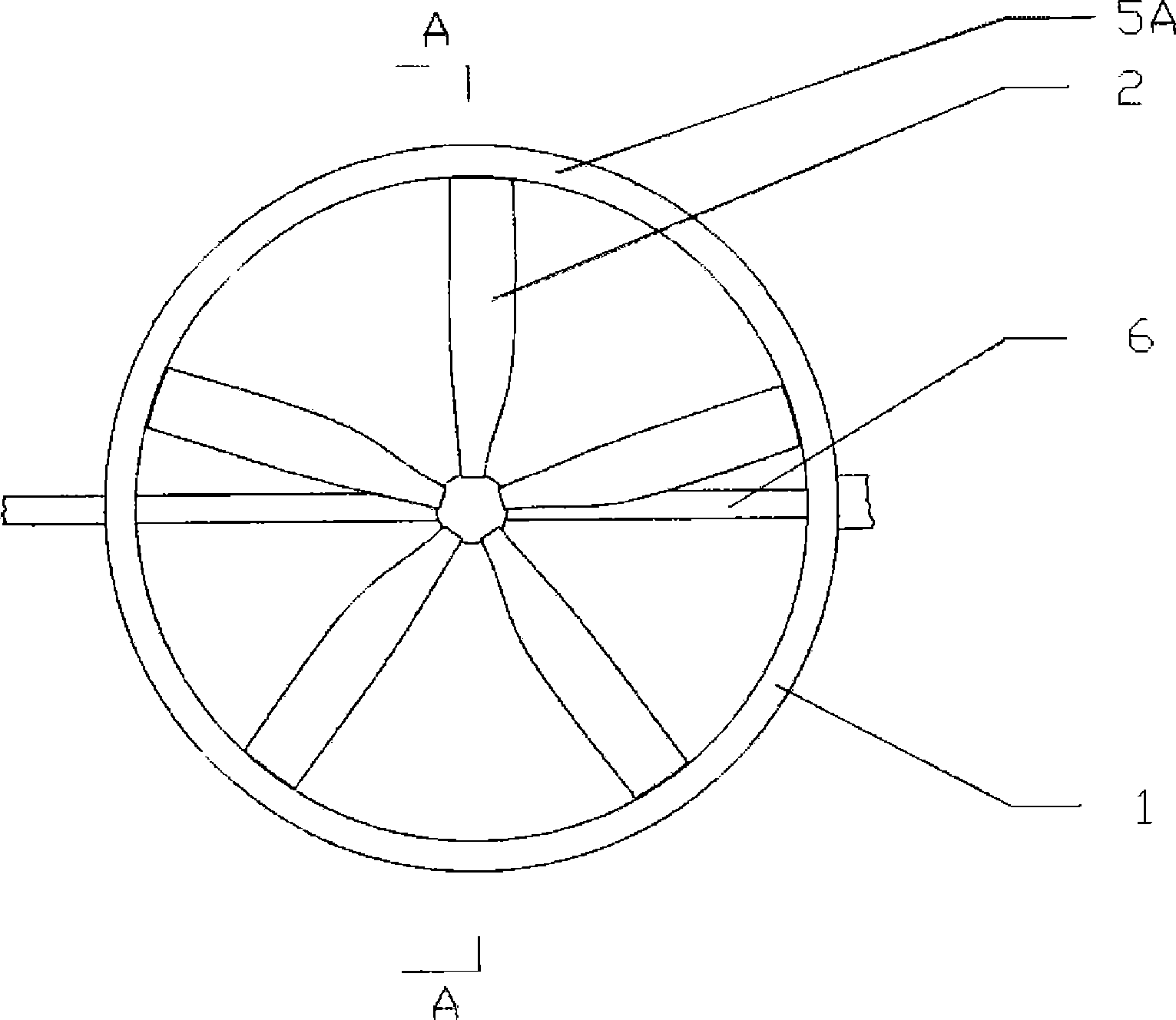

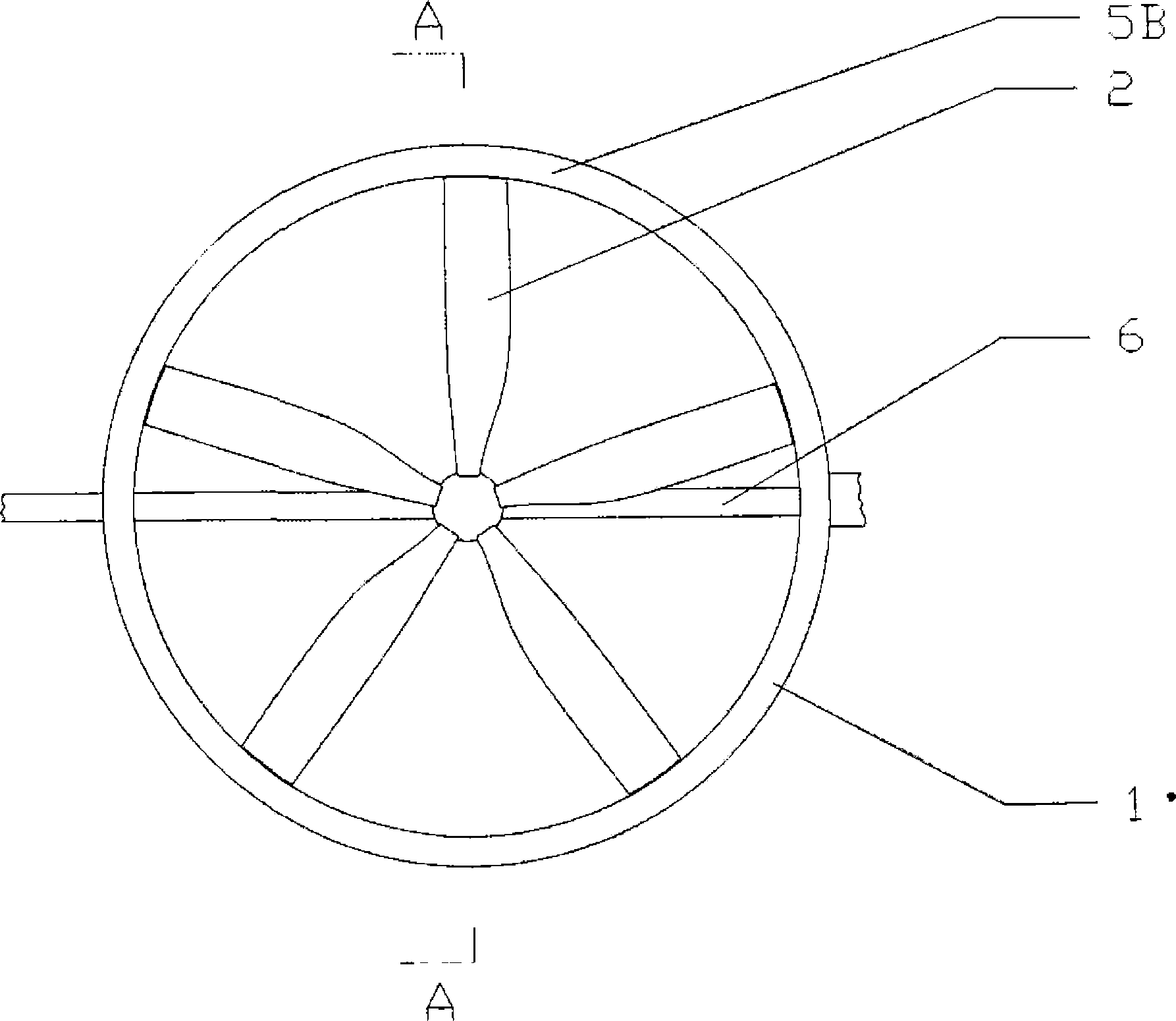

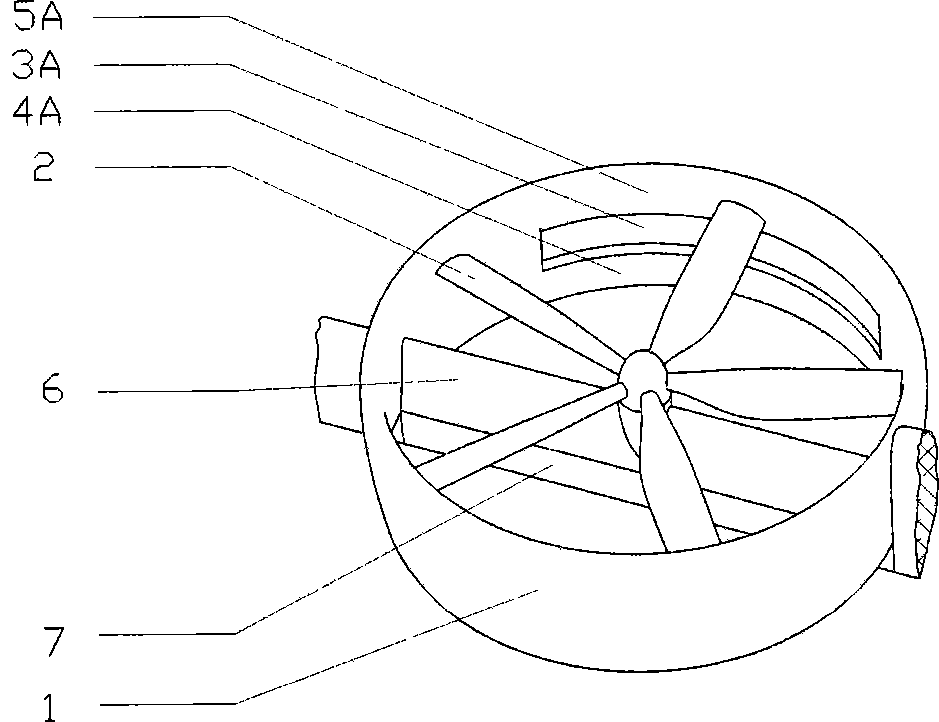

Slotting duct propeller systems and hovercar applying same

InactiveCN103395491AEasy to liftPropellersAircraft convertible vehiclesLocking mechanismVertical take off and landing

The invention discloses slotting duct propeller systems. In each slotting duct propeller system, the upper portion of a duct is provided with a seam communicated with an inner wall surface and an outer wall surface of the duct, the inner wall of the duct is provided with a controllable mechanism for controlling closing and opening of the seam, so that the seam is closed when the duct is in an approximately horizontal posture and vertical take-off and landing are carried out, so as to reduce a friction resistance of a propeller slipstream in the inner wall and reduce the loss of a direct lift force; the seam is opened when the duct tilts to an approximately perpendicular beneficial incidence angle posture and horizontal flight is carried out, lift augmentation of power is carried out, so as to increase a duct lift force. A hovercar applying the slotting duct propeller systems is provided with folding mechanisms, locking mechanisms and tilting mechanisms, so that the hovercar can be changed between a car status and an aircraft status, and the hovercar can perform vertical take-off and landing in the aircraft status and flies at a high speed.

Owner:李凤

Cavity-characteristic-based high-efficiency rough machining method of aircraft structural part

ActiveCN102922013AReduce lossImprove efficiencyAutomatic control devicesFeeding apparatusCamComputer science

The invention discloses a cavity-characteristic-based high-efficiency rough machining method of an aircraft structural part, which belongs to the technical field of CAD / CAPP / CAM (Computer Aided Design / Computer Aided Process Planning / Computer Aided Manufacturing). The method is characterized by comprising the following steps of: firstly, performing preprocessing such as input of a part and read-in of characteristic information of the part; selecting characteristic of a cavity to be subjected to rough machining, automatically generating a cavity rough machining region according to information such as rough machining margin, diameter of a tool and cutting depth of the tool, and calculating a plunge milling tool site for rough machining of the cavity; and finally, generating a plunge milling rough machining track and a saw tooth residue clear track according to a set feeding strategy. By utilization of the method, rough machining of the aircraft structural part is performed, so that the rough machining efficiency of the aircraft structural part can be greatly improved, the loss of the tool is reduced, and the cost is saved. The method has great application and promotion prospect in rough machining of a difficult-to-machine material of the aircraft structural part.

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

Fuel system for a marine vessel with a gaseous purge fuel container

InactiveUS7178512B1Lighting and heating apparatusUsing liquid separation agentGaseous elementMarine propulsion

A fuel container for a marine propulsion system is provided with a pump and a hose connected to an outlet of the pump and disposed within the cavity of the fuel container. The hose is provided with an opening, formed through its wall, through which a fluid can flow under certain circumstances. The opening is disposed in an ullage within the container and allows gaseous elements to be purged from the container when flow is induced from the container back to a fuel reservoir.

Owner:BRUNSWICK CORPORATION

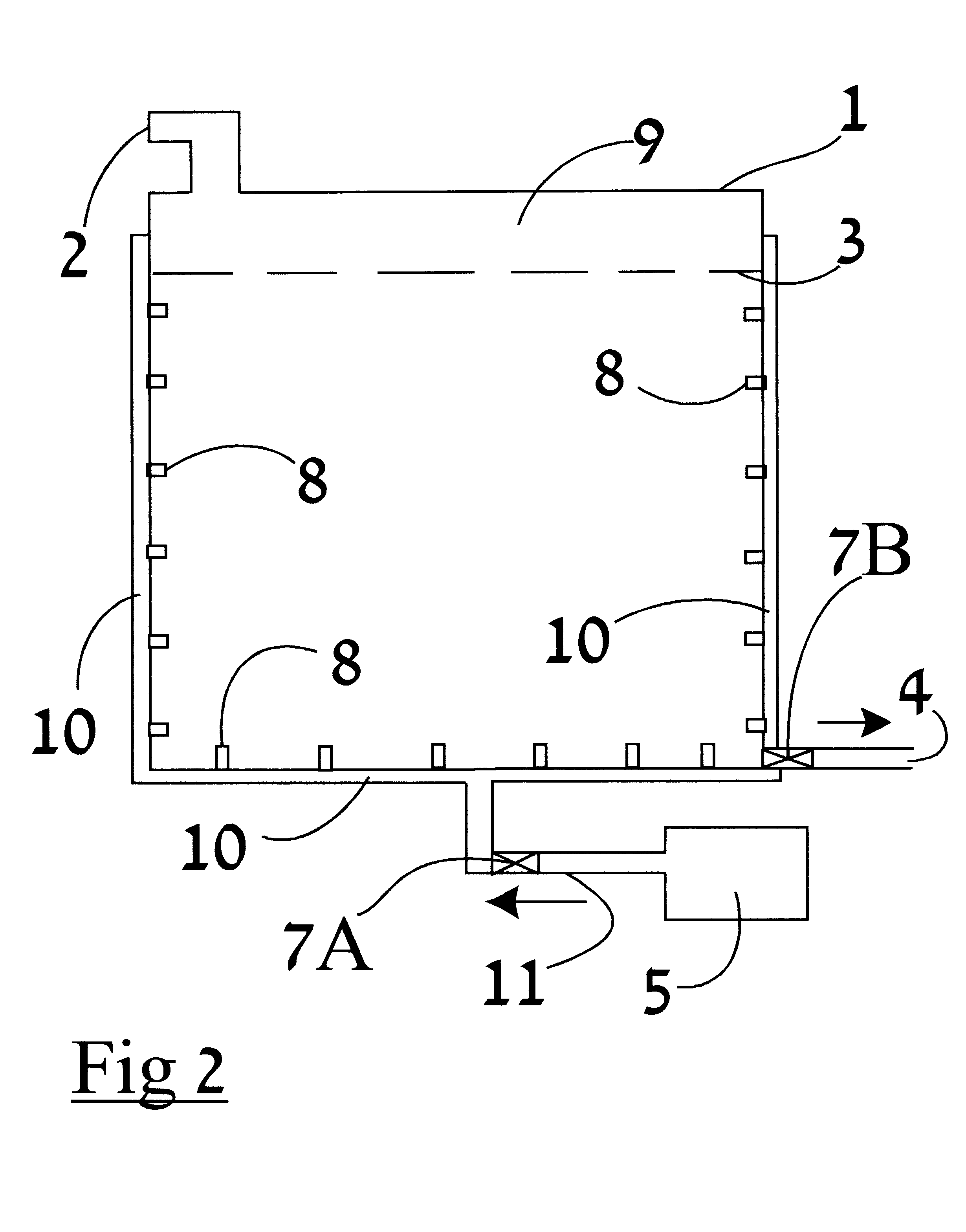

Tilting rack system

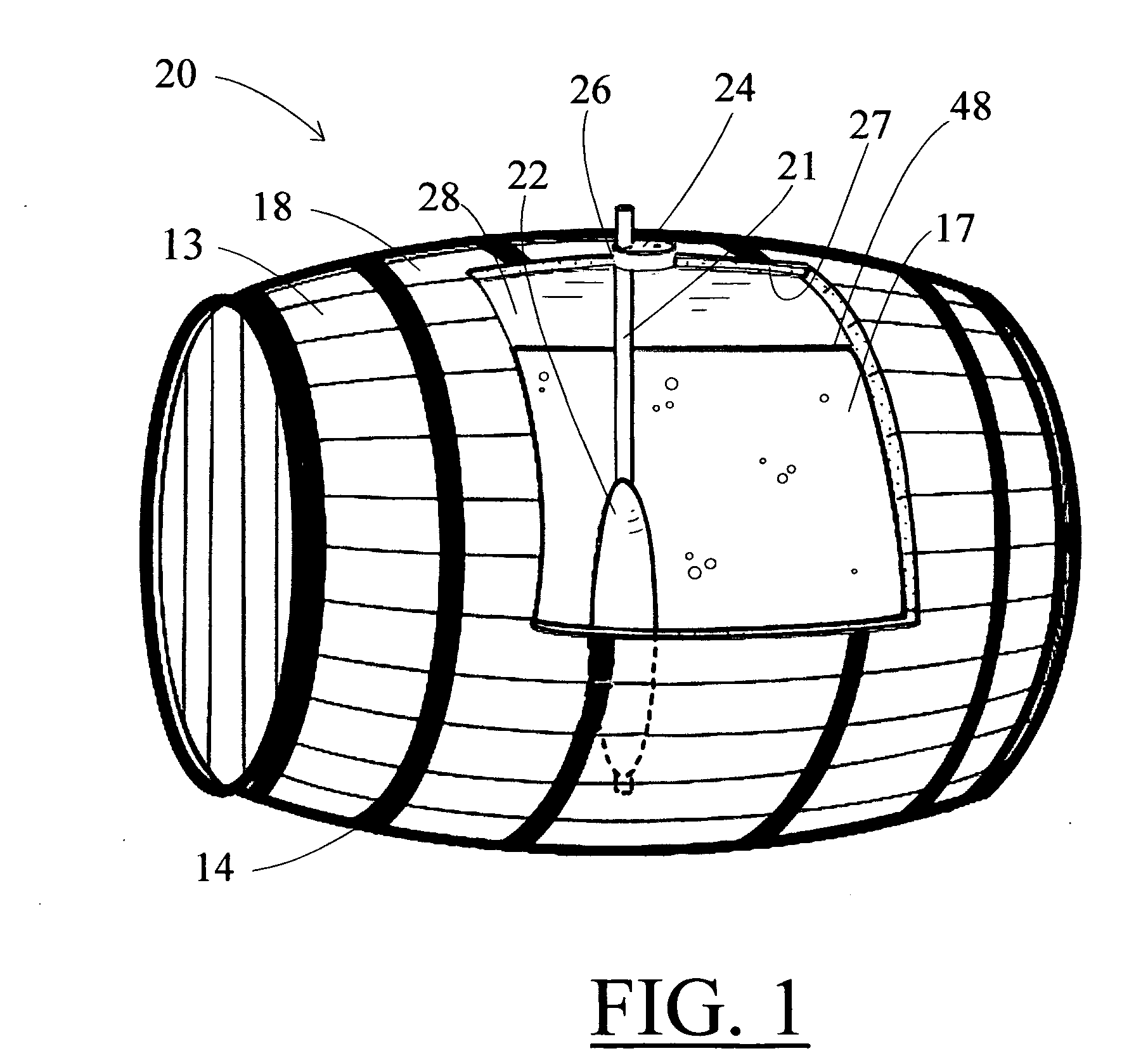

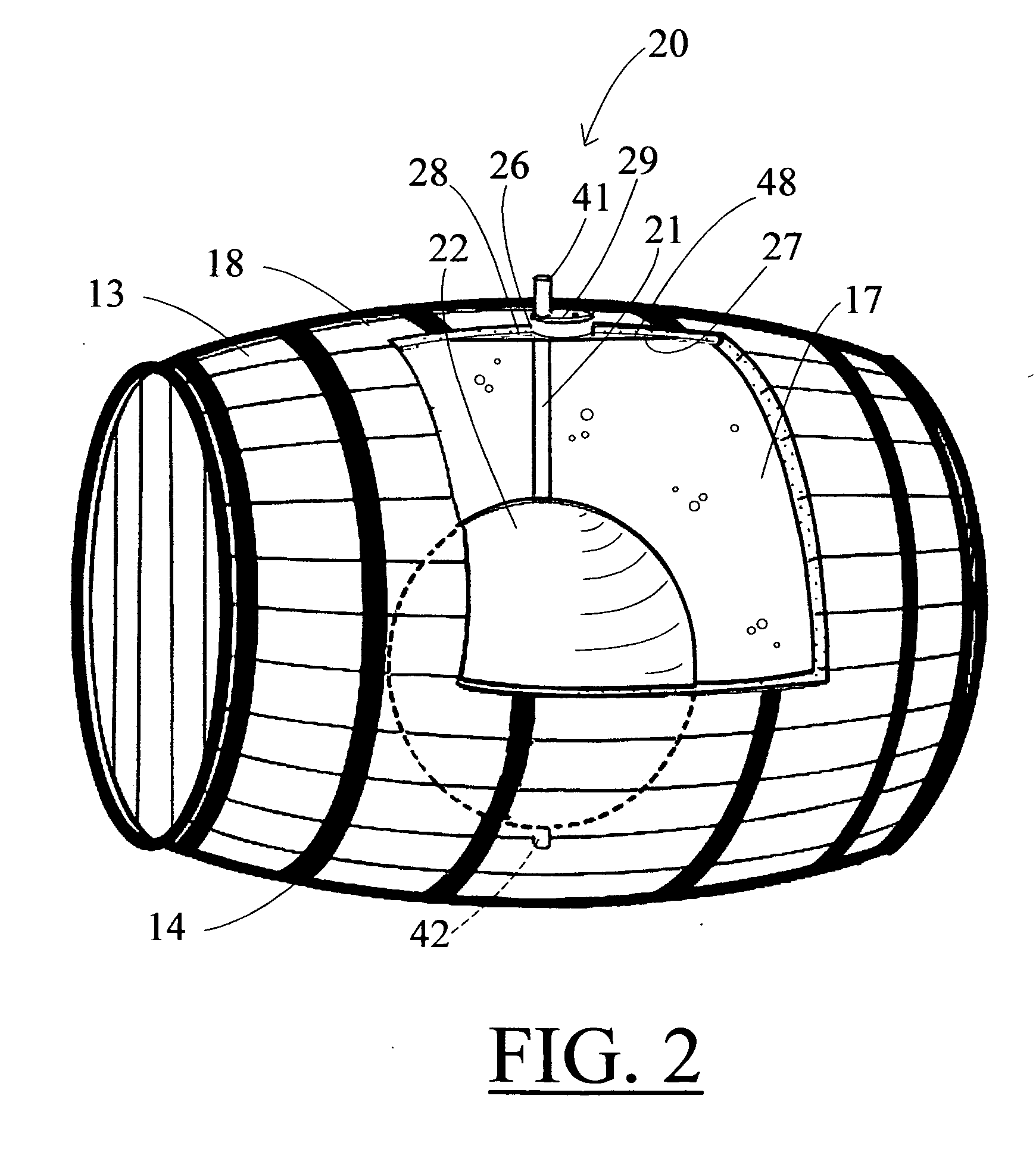

ActiveUS20110101010A1Flexible wall reciprocating enginesOperating means/releasing devices for valvesEvaporationFluid interface

A bladder system and apparatus for use with a beverage barrel or container, to reduce undesirable head-space in a wooden container of a beverage, especially a fermented beverage, such as wine. The system continuously protects the beverage contained in a wooden barrel from the harmful effects of oxidation at the air-to-fluid interface in the head-space and compensates for ullage, attributable to evaporation, leakage or sampling losses. The system includes an inflation stem connected to a barrel bladder inflatable by filling with an inflation gas. The inflation stem includes a liquid level sensor and inserts into a bung opening. The fluid level is sensed and a gas valve opens to fill the bladder, reducing head-space within the barrel. The system can combine the control of several barrels and optionally with other sensors, to create a barrel monitoring and control network.

Owner:INGENIOUS BARREL INNOVATIONS LLC

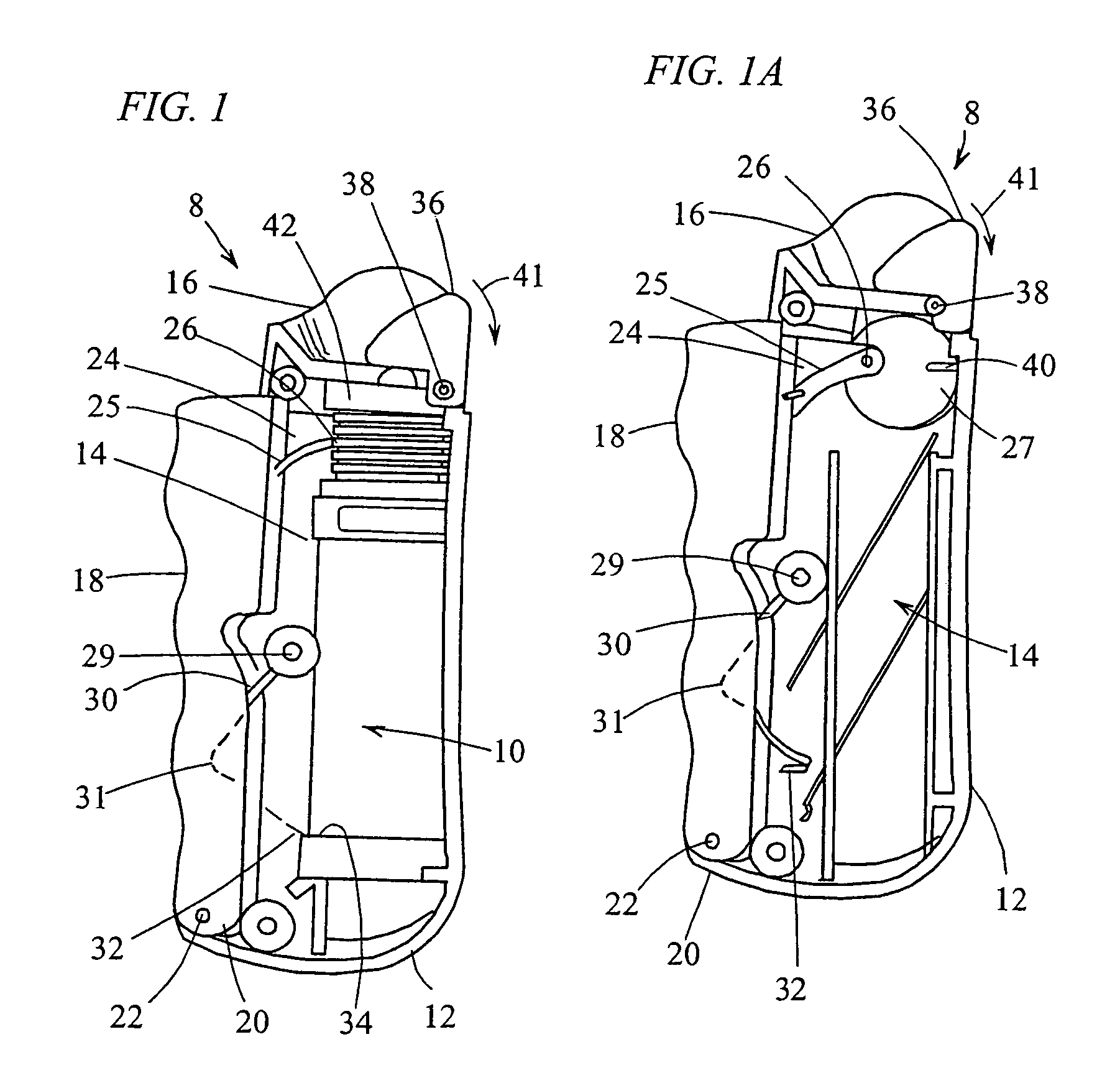

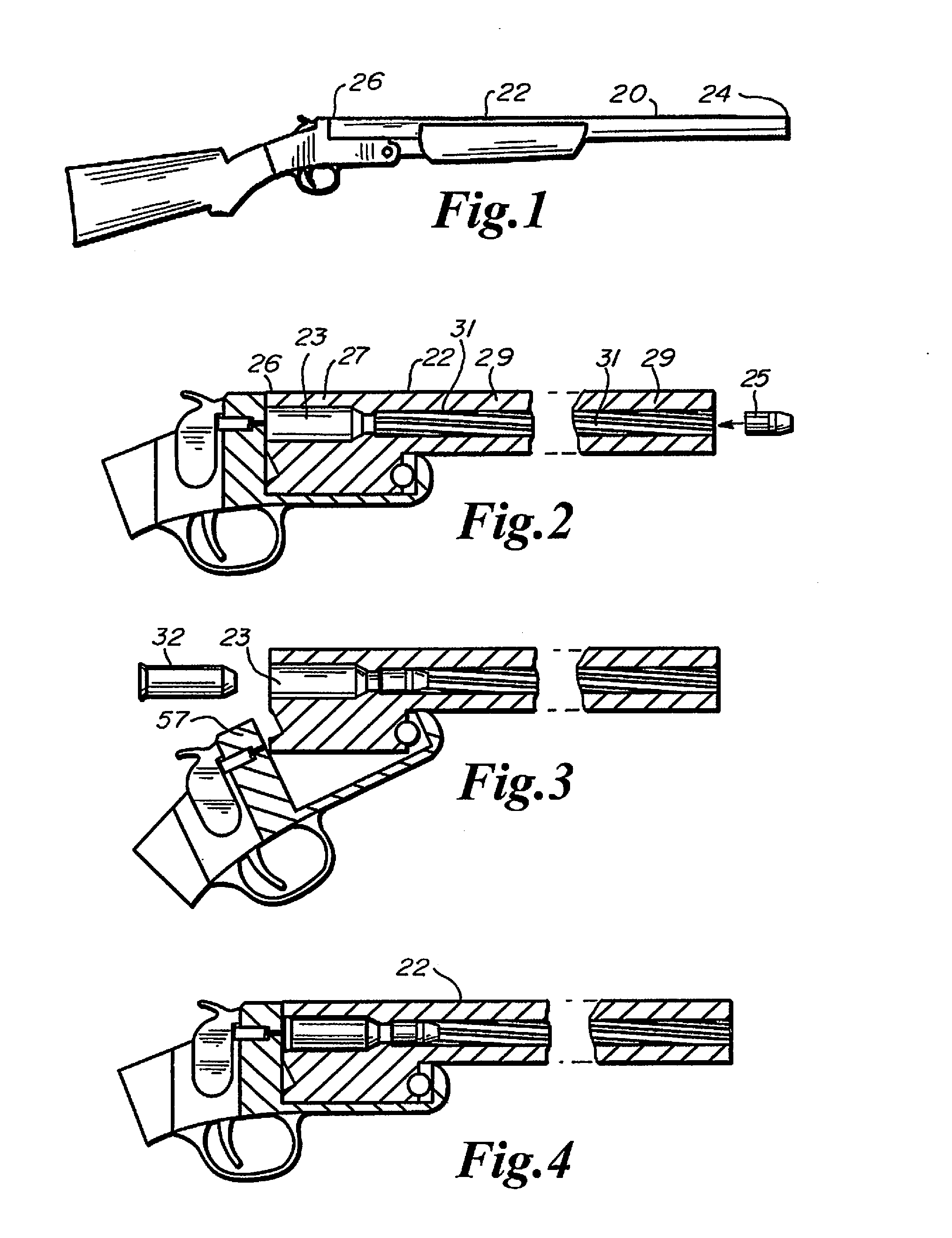

Muzzleloader systems

ActiveUS20140090284A1Efficient unloadingImprove sealing propertiesAmmunition projectilesShotgun ammunitionEngineeringUllage

Muzzleloader systems include a pre-packaged propellant charge and primer for providing efficient loading and unloading of the muzzleloader. The breech end accepts the propellant and means are provided to prevent breech loading of the projectile. A propellant cartridge conforms to a constriction portion to minimize ullage. A projectile is inserted in the muzzle end seats on the constriction portion. The propellant cartridge may be received in a removable breech plug. The constriction portion may be part of the breech plug or a separate component secured in the barrel by way of the breech plug. The cartridge may have a primer mechanism integrated into a proximal end. Projectiles have sliding components that have an axial elongate position and an axial shortened position and may be loaded with a ramrod having an engagement portion for each of the two pieces whereby the projectile doesn't prematurely collapse.

Owner:FEDERAL CARTRIDGE

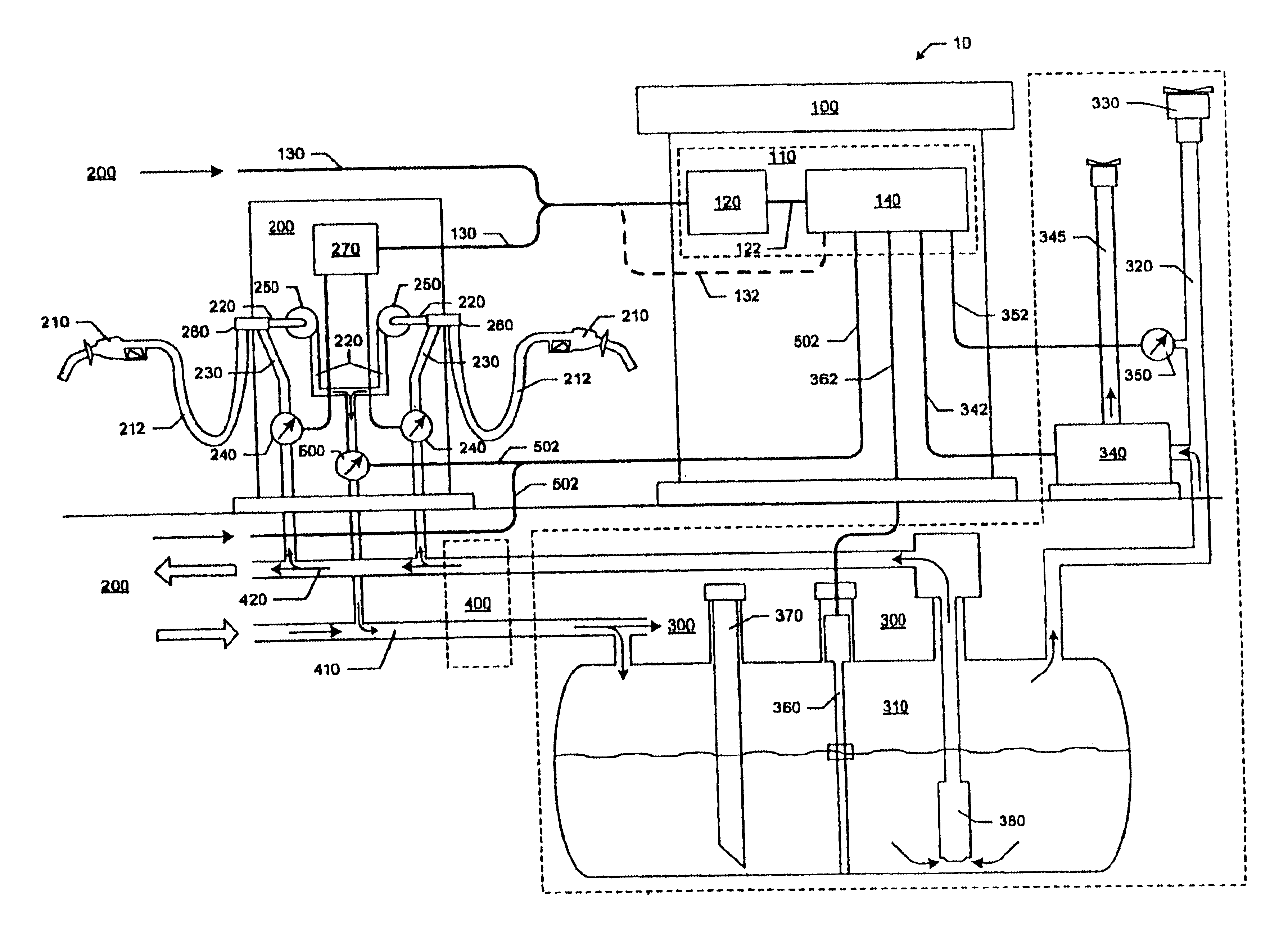

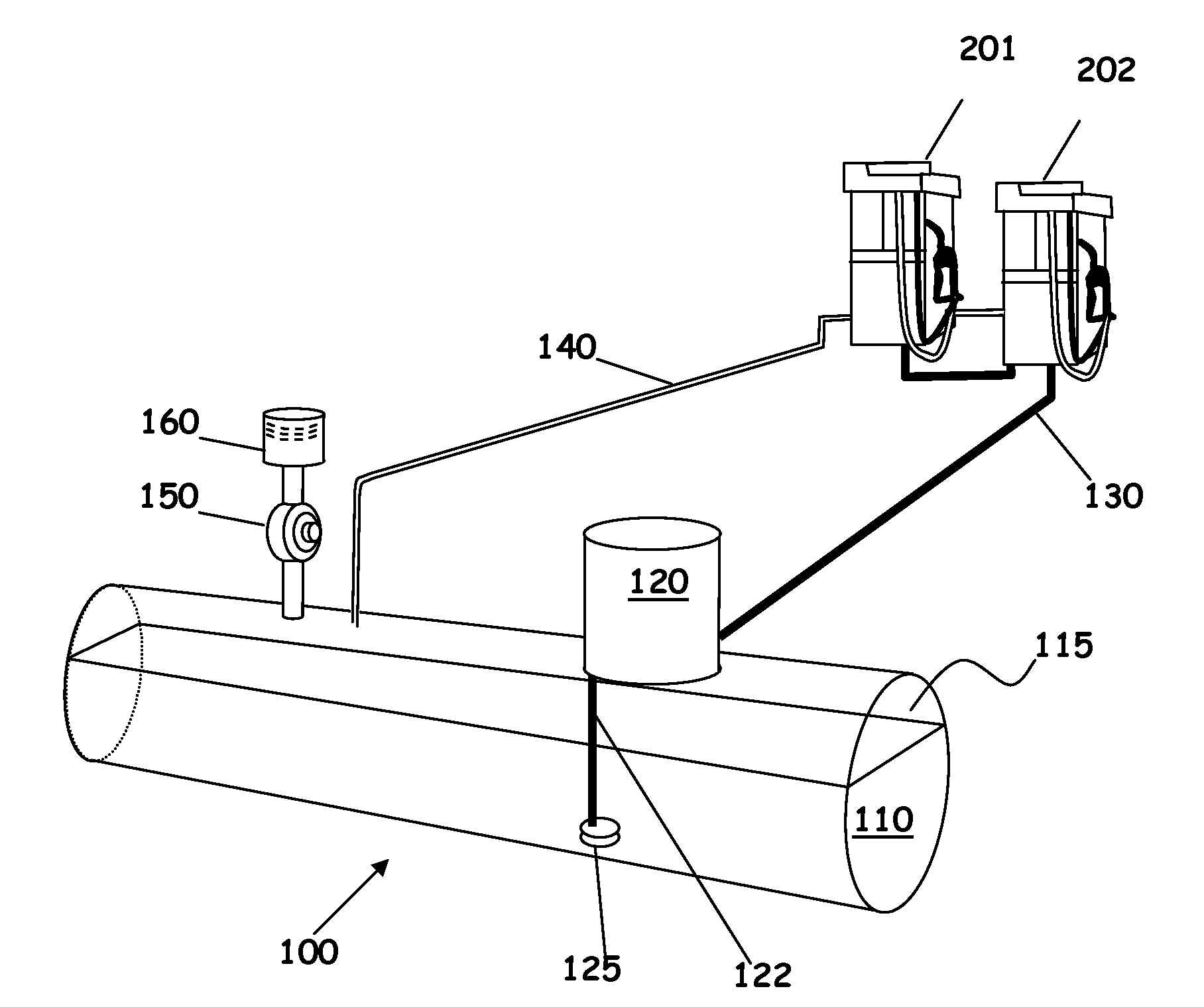

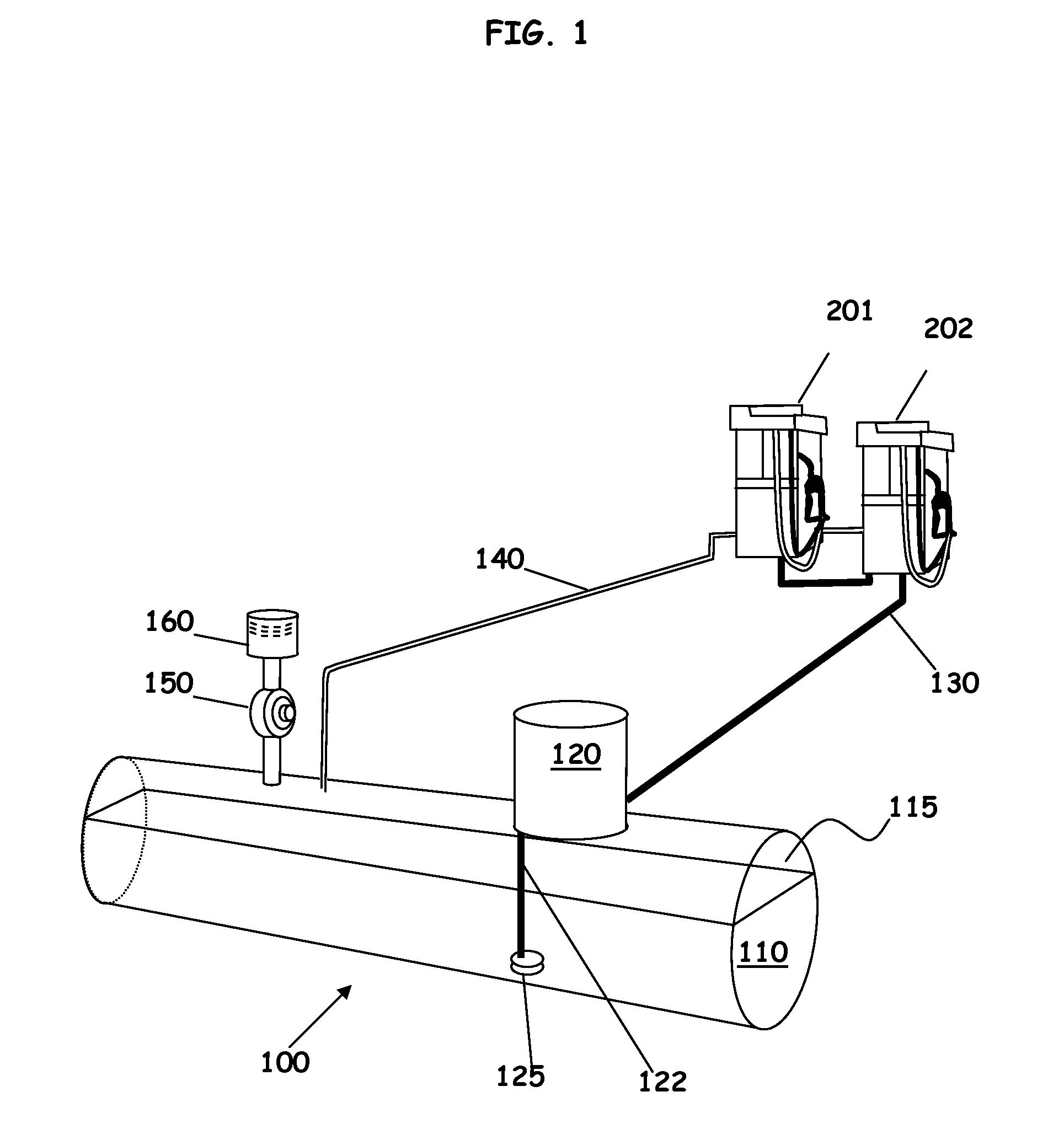

Fueling system vapor recovery and containment performance monitor and method of operation thereof

InactiveUS6880585B2Reduce in quantityMeasurement of fluid loss/gain rateLiquid fillingRecovery performanceLiquid fuel

Owner:VEEDER ROOT

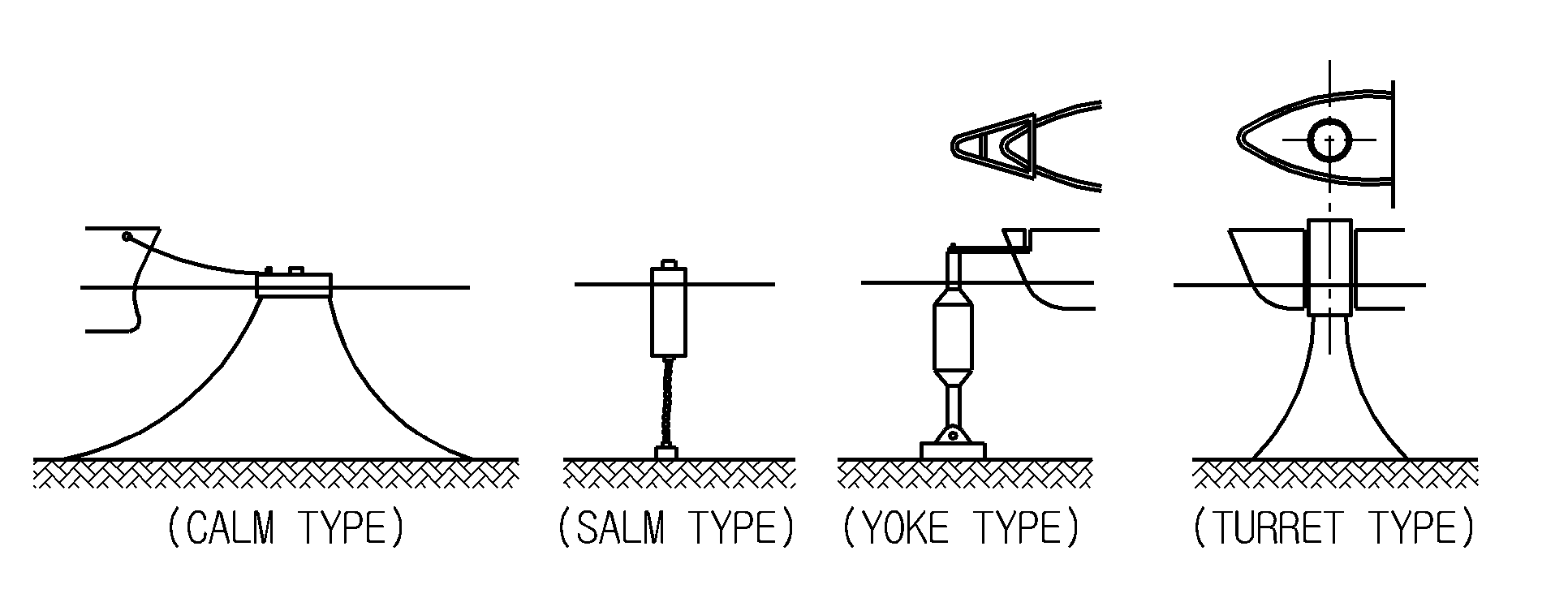

Method and system for static and dynamic positioning or controlling motion of marine structure

ActiveUS20150246711A1Prolong lifeLow costForce measurementVessel safetyOcean bottomAtmospheric temperature

Disclosed is a system and method for static and dynamic positioning or motion control of a marine structure by using real-time monitoring of at least one of a mooring line, marine environments, 6-dof movement of a marine structure, a tank state, a ship topside, the seabed, or their combinations. The static and dynamic real-time monitoring data of the mooring line is obtained and processed for positioning the marine structure or controlling and managing a motion thereof. Here, 1) a tension of a mooring line is measured by means of real-time monitoring of the mooring line, 2) various marine environment elements such as wind direction, wind speed, air humidity, atmospheric pressure, atmosphere temperature, cloud height, visibility, ocean wave, wave height, sea current speed, sea current direction, rain or the like are measured by means of real-time monitoring of the marine environments, 3) 6-dof movement of the marine structure is measured by means of real-time monitoring of the marine structure, 4) ullage and sloshing data of various tanks in the marine structure are measured by means of real-time monitoring of tank states, 5) damage and life of pipes, facilities or the like located at a ship topside of the marine structure are measured by means of real-time monitoring of the ship topside, 6) damage and life of umbilical cables, pipes, pumps and valves located on the seabed are measured by means of real-time monitoring of the seabed, and suitable static and dynamic positioning or motion control and management may be automatically performed based thereon.

Owner:CYTRONIQ

Nitrogen inerting system for explosion prevention in aircraft fuel tank & oxygenating system for improving combustion efficiency of aerospace rockets/ aircraft engines

InactiveUS20090166358A1Increase speedIncrease rotation speedCombination devicesGas treatmentAviationGas passing

Compressed Air from an aircraft rocket engine's compressed air line to its air-conditioning system, or an Auxiliary Air Compressor out-put is used, for energizing a high-speed gas turbine. The very high-speed convoluting air discharge into a vortex cone causes a first separation of the Air gas components, by stratifying into heavier (Argon), medium (Oxygen) and lighter (Nitrogen) components, where in the heavier and lighter components are non-combustible, inert gases and the medium is a combustible gas. The lighter non-combustible component (Nitrogen) exits from the turbine in one direction for storage in the Inert gas tank. The heavier (Argon) and medium (Oxygen) components together move in the opposite direction for having a second stratifying separation downstream in the vortex tube, to separate non-combustible, heavier (Argon) gas from combustible medium (Oxygen) gas components. The combustible, medium (Oxygen) component exits the vortex tube open end, to flow into an Oxygenating storage tank; whereas, the heavier, non-combustible(Argon) gas is piped into the Inert gas storage tank. Both gas storage tank in-flow lines are fitted with non-return valves. The out flow lines from the Inert tank to either Fuel Tank “Ullage” or “OBGIS” areas are fitted with electronic control valves, operated by signals received from fibre-optic Temperature / Pressure / Oxygen concentration Sensors in the Fuel tank “Ullage” or “OBGIS: areas. Likewise, the outflow lines from the Oxygenating tank are fitted with electronc control valves activated by engine “takeoff” or Passenger cabin low oxygen signals, respectively.

Owner:BOSE RANENDRA K

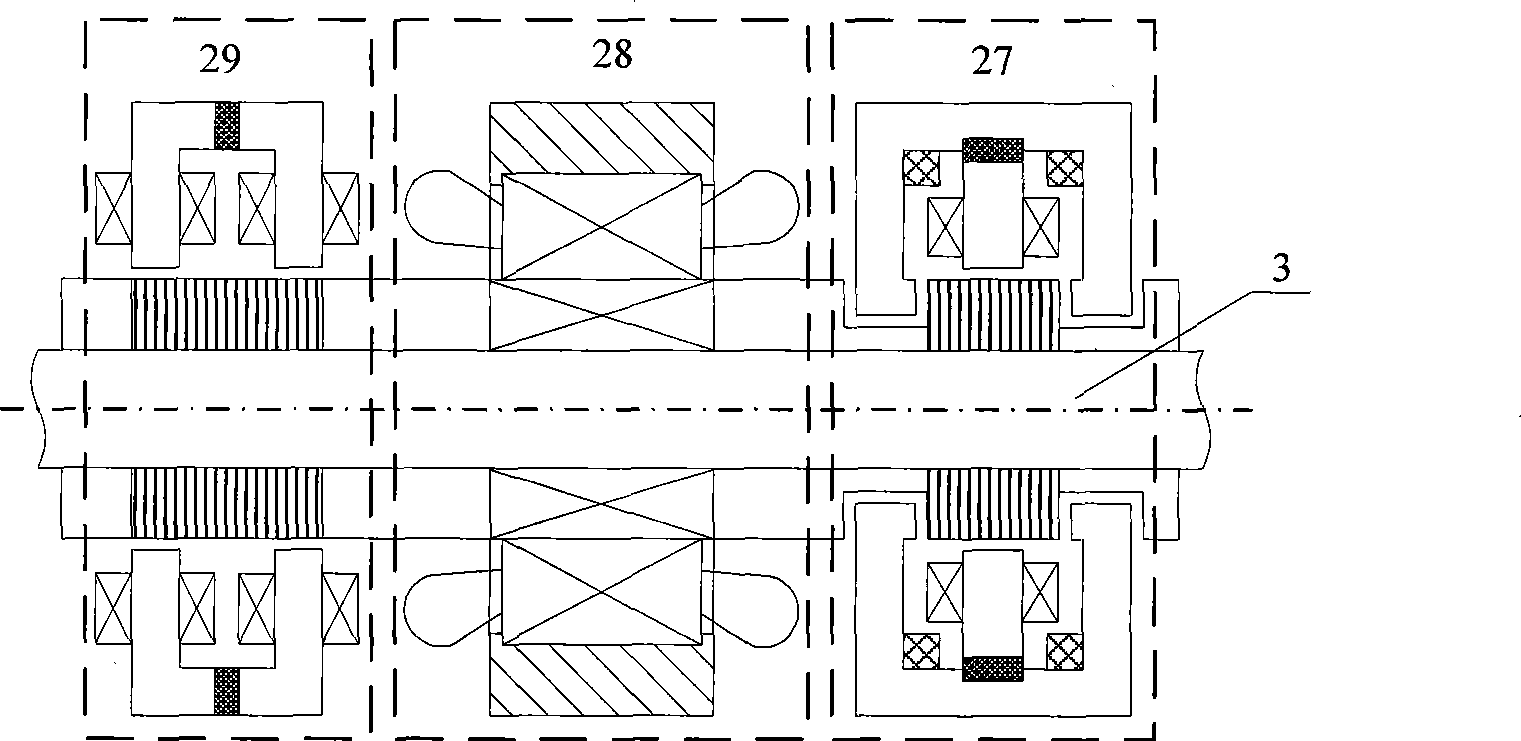

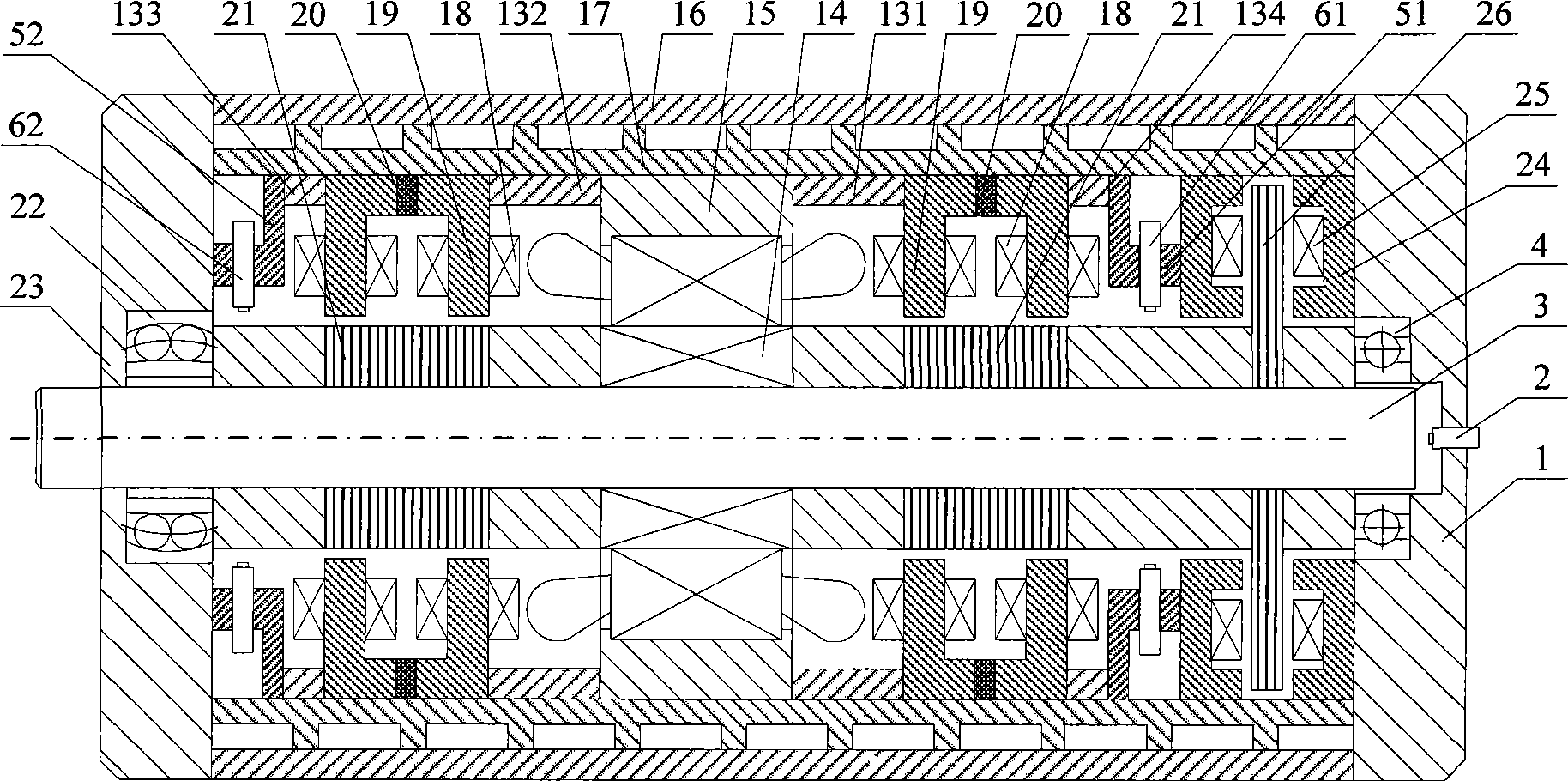

High speed electric principal shaft supported by AC mixing magnetic bearing

InactiveCN101465576AIncrease speedNo pollution in the processMechanical energy handlingMagnetic holding devicesAviationMagnetic bearing

The invention relates to a high-speed electric spindle supported by an alternating current hybrid magnetic bearing, comprising an AC / DC three freedom-degree hybrid magnetic bearing which is pressed in a steel cylinder, a high-speed spindle motor, an AC two freedom-degree hybrid magnetic bearing, a left end cover, a right end cover and a rotating shaft; the high-speed spindle motor is arranged on the rotating shaft; the AC / DC three freedom-degree hybrid magnetic bearing and the AC two freedom-degree hybrid magnetic bearing are respectively arranged on the left and right sides of the high-speed spindle motor. Static bias magnetic flux is provided for each freedom degree by adopting permanent magnet, and the radial directions of the AC / DC three freedom-degree hybrid magnetic bearing and the AC two freedom-degree hybrid magnetic bearing adopt a three pole structure and a three-phase inverter for drive control, thus remarkably reducing the loss and cost of a power amplifier. The high-speed electric spindle realizes zero intermediate transmission and has the advantages of no mechanical friction, no lubrication and sealing, high speed, high precision and low power consumption; therefore, the high-speed electric spindle has application prospect in the field of mechanical industry, space flight and aviation and the like.

Owner:JIANGSU UNIV

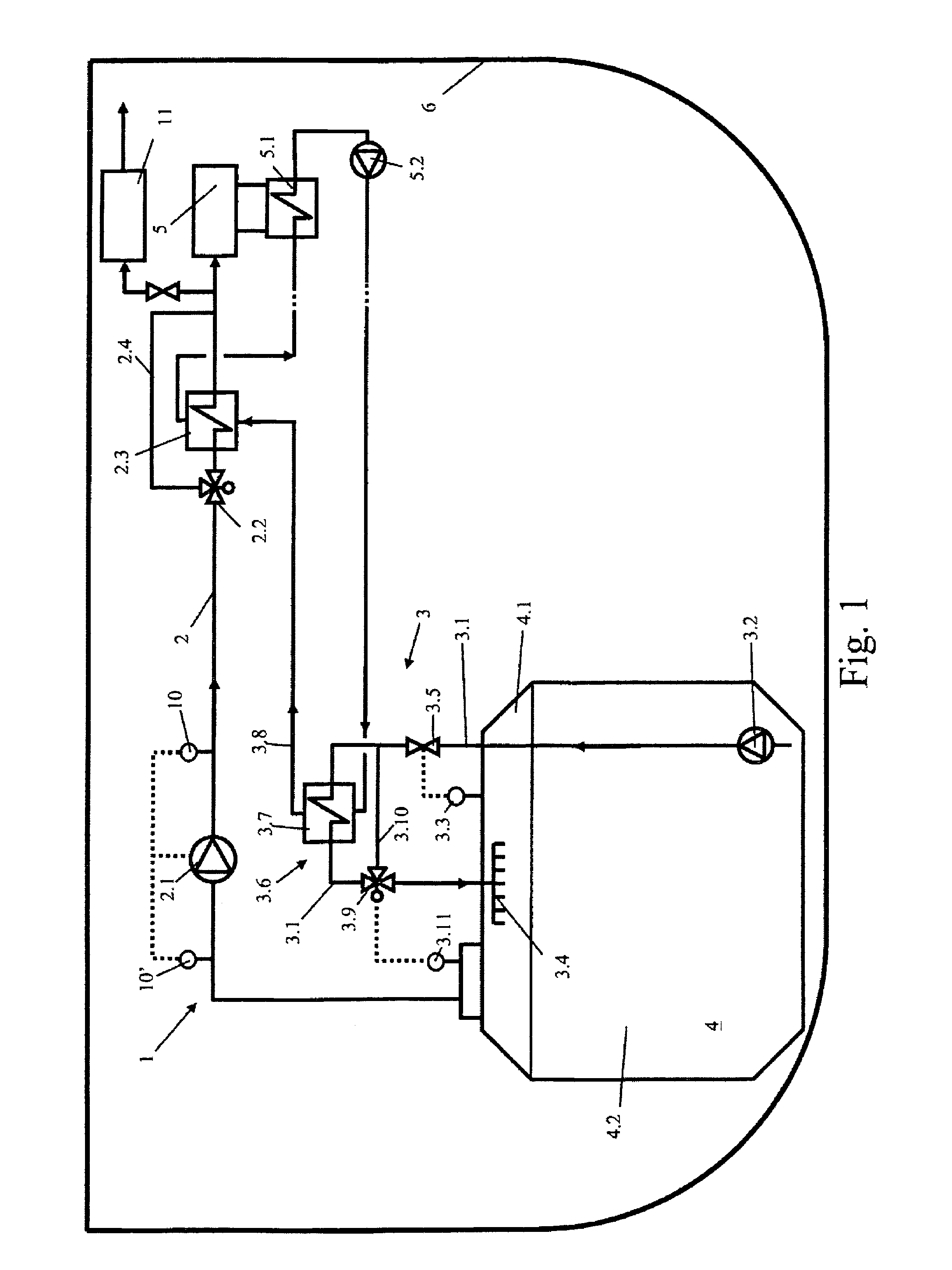

Gas supply arrangement of a marine vessel and method of providing gas in a marine vessel

ActiveUS7438012B2Easy and space-saving installationRequirement for numberAuxillariesGas handling/storage effectsProduct gasUllage

Gas supply arrangement of a marine vessel being adapted to carry liquefied gas in its gas tank having an ullage space section and a liquid phase section, which arrangement provides the gas for demands of the vessel, the arrangement comprising a gas supply line provided for delivering the gas formed in the gas tank to a consumption device, and a piping extending from the liquid phase section to the ullage space section of the gas tank being provided with at least a pump, for introducing gas into the ullage space section. The piping is provided with a heat transfer unit for effecting on the temperature of the introduced gas. The invention relates also to method of providing gas in a marine vessel with liquefied gas tank.

Owner:WARTSILA FINLAND OY

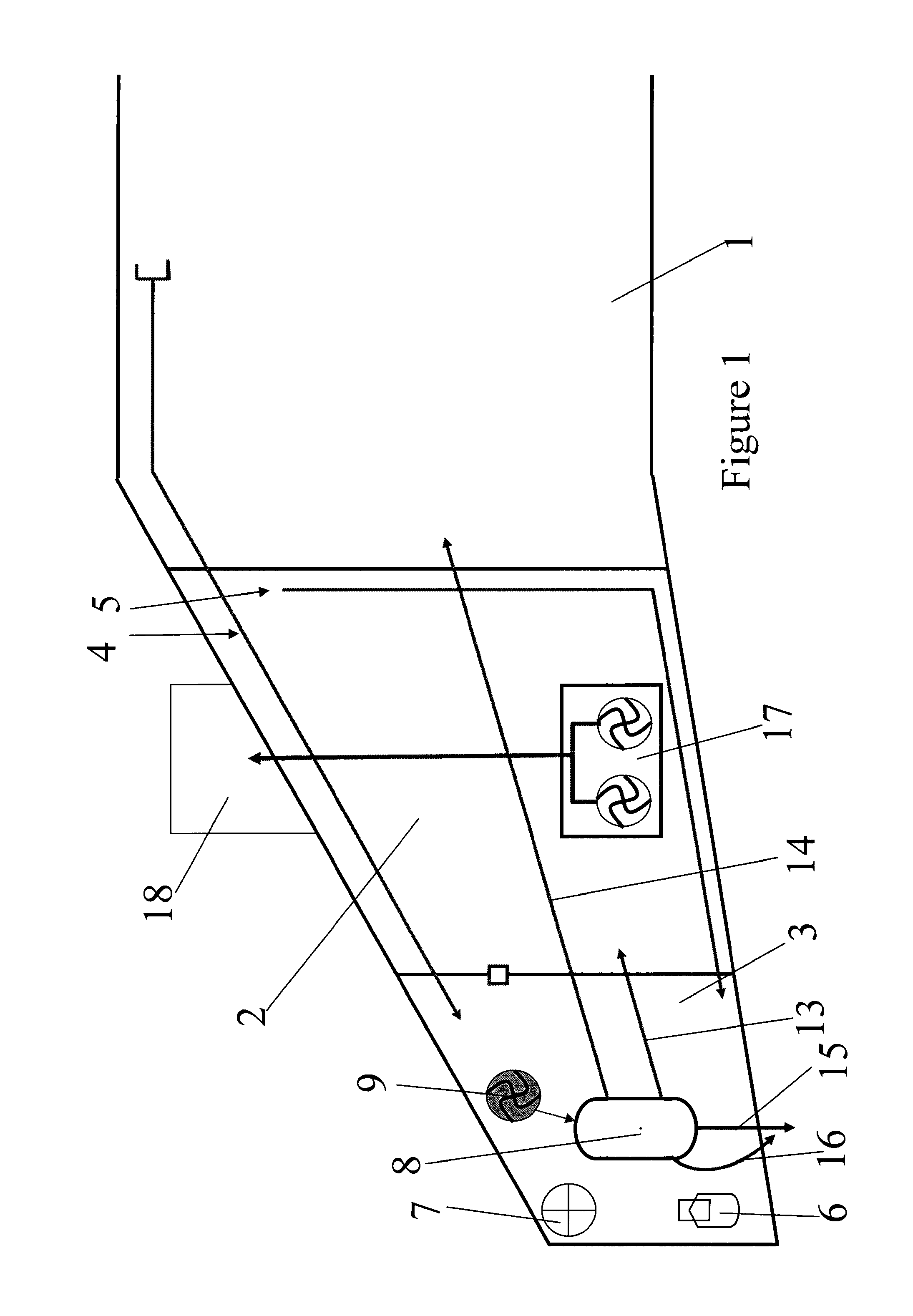

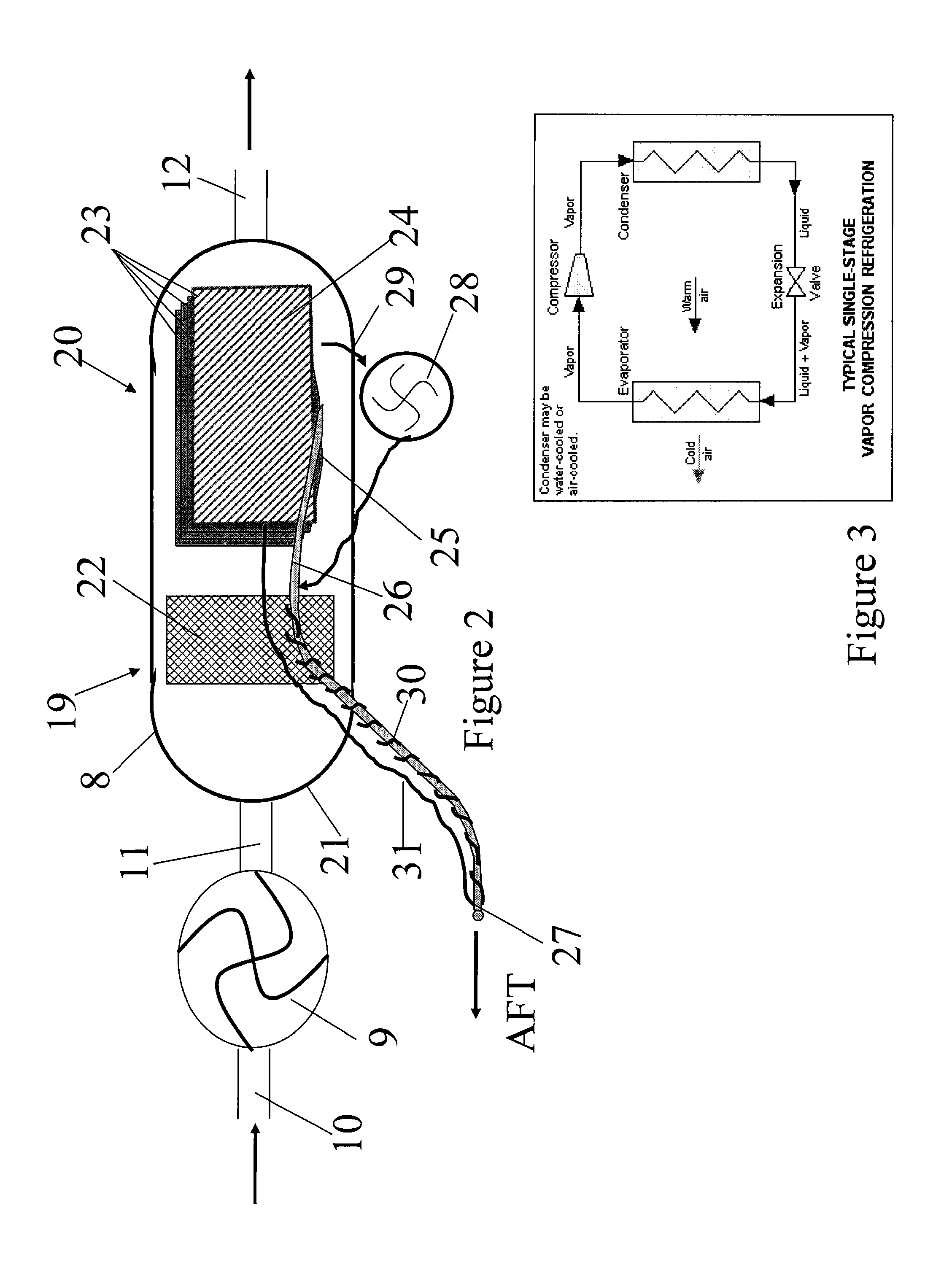

Aircraft fuel tank ullage gas management system

Owner:HAMILTON SUNDSTRAND CORP

Disabler and storage system for hazardous substances

This invention is geared at attacking the scourge of explosive fires, burns, environmental pollution, or other such hazards associated with the use, transport, and storage of fuels and other hazardous substances, before they occur, including the explosion hazard present in many automotive rear-end collisions. This is achieved by swiftly reacting a "disabler" or "neutralizer" with the hazardous substance, voluntarily or by automation, on the occurrence of predetermined events that position the hazardous substance to threaten a greater than desired risk of harm. According to one of the preferred embodiments of this invention, the formation of combustion vapors in the ullage of fuel tanks is altogether prevented.

Owner:OSIME JOSHUA OGHENOGIEME +1

Liquid measurement system having a plurality of differential pressure probes

InactiveUS20060266111A1Reduce the possibilityCompensation changesMachines/enginesLubrication indication devicesDifferential pressureEngineering

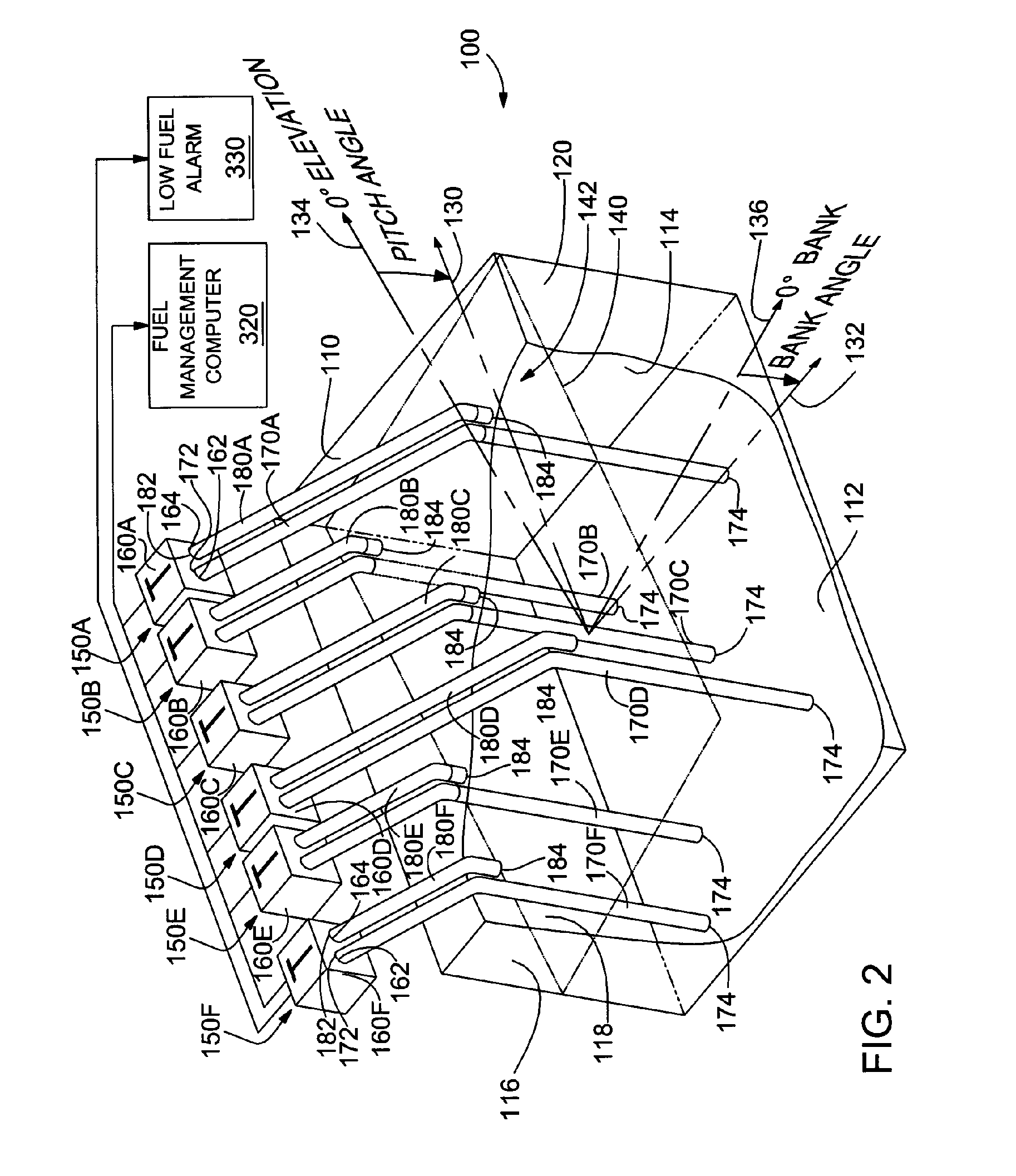

The weight of liquid in a tank subject to tilting is determined by measuring differences in air pressure in the ullage (the empty volume of the tank above the level of the liquid) and the air pressure produced by the weight of the liquid at the bottom of the tank. The pressures at the bottom of the tank are measured in a plurality of locations, and the differential pressures are combined to compensate for changes in the depth of the liquid when the tank is not level (e.g., when the tank is in an aircraft flying at an attitude other than straight and level). The electronics to measure the pressure and to process the pressure measurements are located remotely form the tanks, thus eliminating the possibility of ignition caused by the electronics when the liquid is fuel or other flammable liquid.

Owner:BAE SYSTEMS CONTROLS INC

Aircraft inerting system

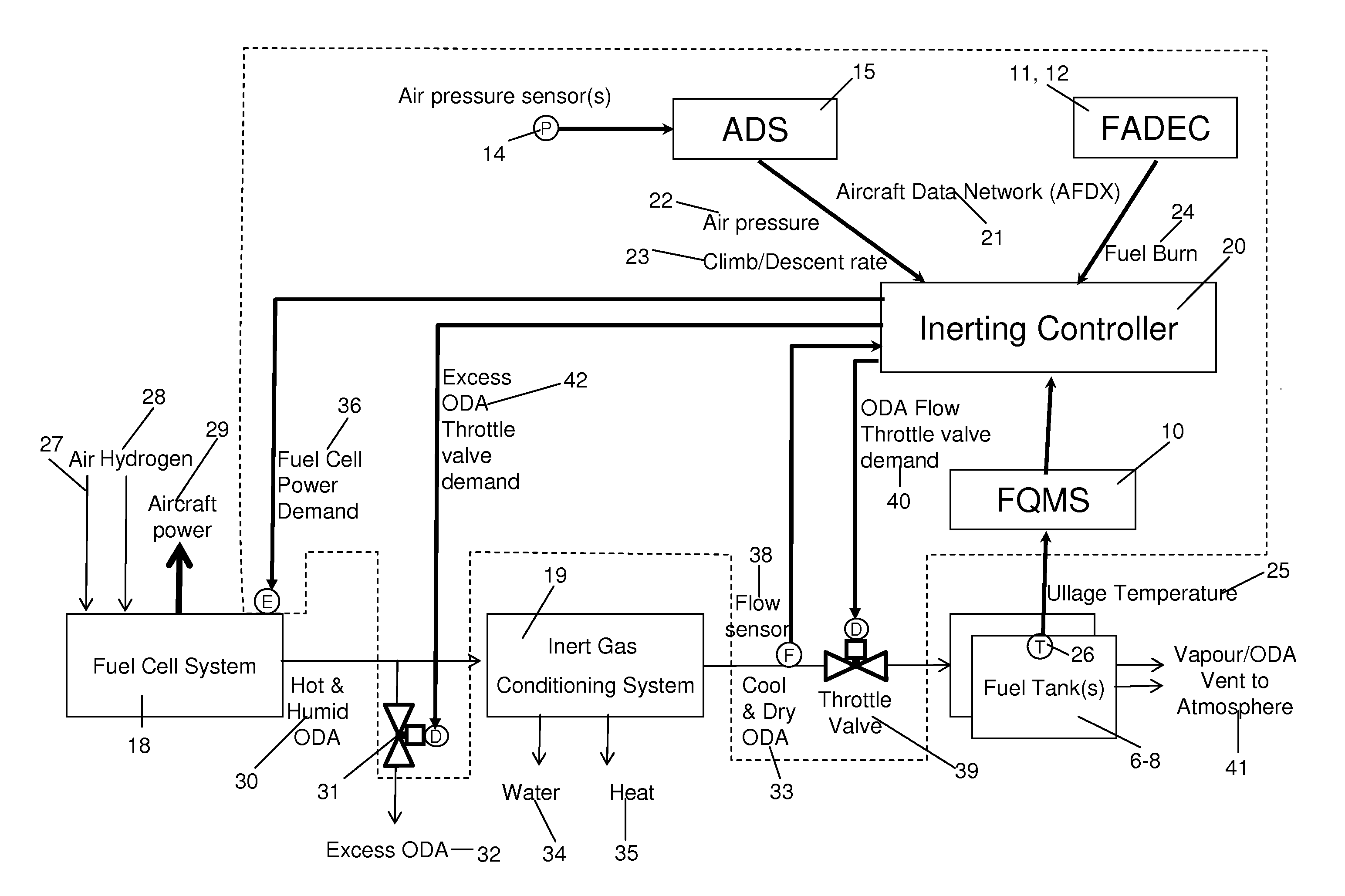

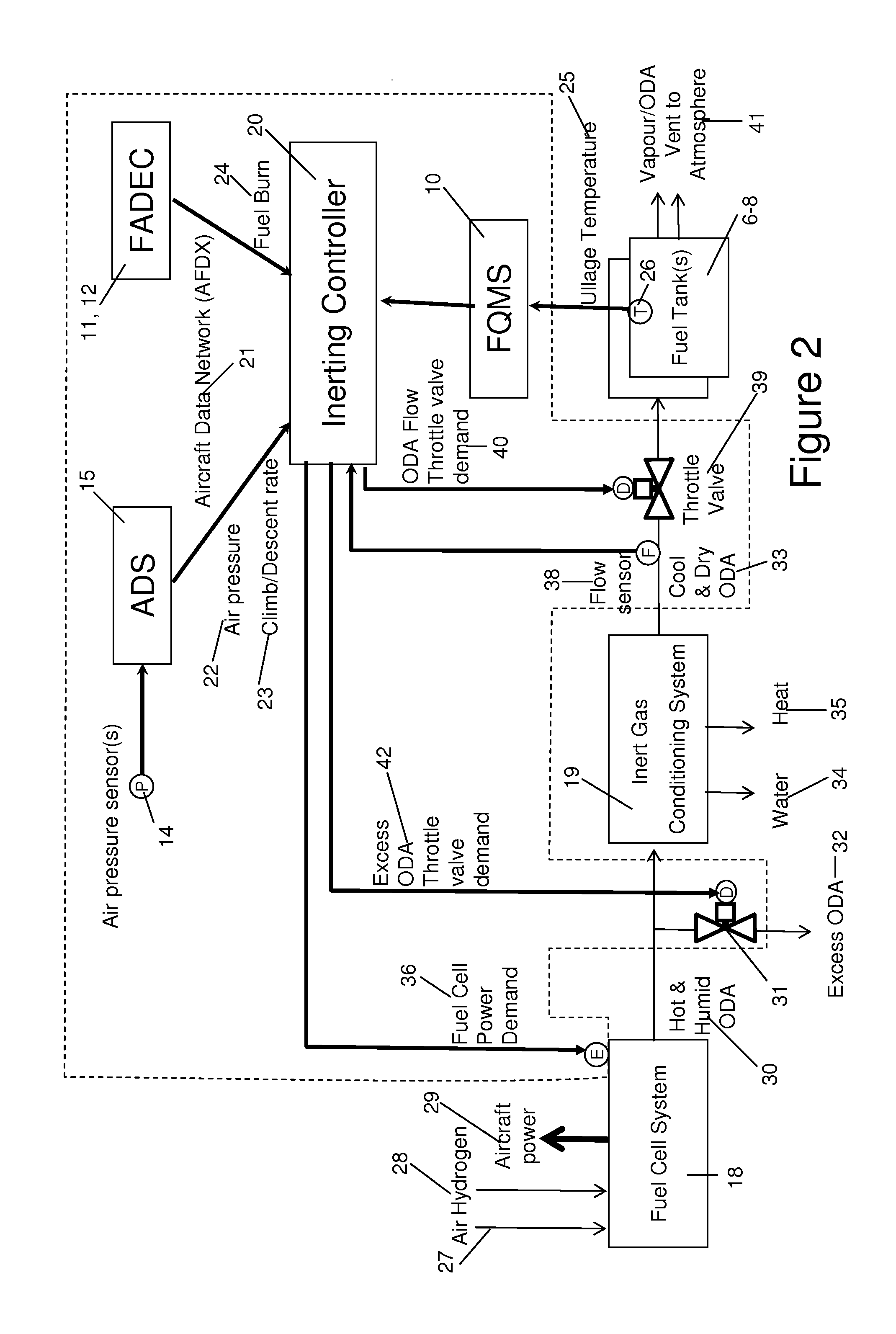

ActiveUS20140238501A1Lower the volumeEasy to usePower installationsPower plant fuel tanksInerting systemEngineering

A method of controlling a flow rate of inerting gas introduced into a vented aircraft fuel tank, the method comprising: monitoring changes in a quantity of a fuel in the aircraft fuel tank; monitoring changes in the ambient air pressure external to the aircraft fuel tank; and actively controlling a flow rate of inerting gas, {dot over (m)}(I), introduced into the aircraft fuel tank based upon changes in the quantity of fuel in the fuel tank and changes in the ambient air pressure, p. Also, an aircraft including a vented fuel tank, a supply of inerting gas for rendering inert the fuel tank ullage, and a controller for performing the method.

Owner:AIRBUS OPERATIONS LTD +1

Storage tank for cryogenic liquids

InactiveUS20050028536A1Lower the volumeFast fillGas handling applicationsPumpsLine tubingEngineering

The storage tank for cryogenic liquids incorporates an ullage vessel that provides for an ullage space. The ullage vessel is in communication through an ullage line to a fill line that provides cryogen to a cryogen space. The junction where the ullage line and fill line meet is of a certain cross-sectional area. Downstream of the junction within the fill line, measured in reference to the direction of cryogen flow during a coruse of filling the cryogen space, is of a greater cross-sectional area than is the case at the junction. This creates a pressure reduction at the junction during a course of filling that causes a net flow of material from the ullage space over the course of filling. Once the cryogen tank is liquid full causing cryogen to be redirected down the ullage line, the smaller cross-sectional area of the ullage line compared to the fill line causes a reduction in flow of cryogen which is detected by the fill pump causing filling to stop providing the ullage space. A means of draining the ullage vessel prior to and during filling of the storage tank is provided.

Owner:WESTPORT FUEL SYST CANADA INC

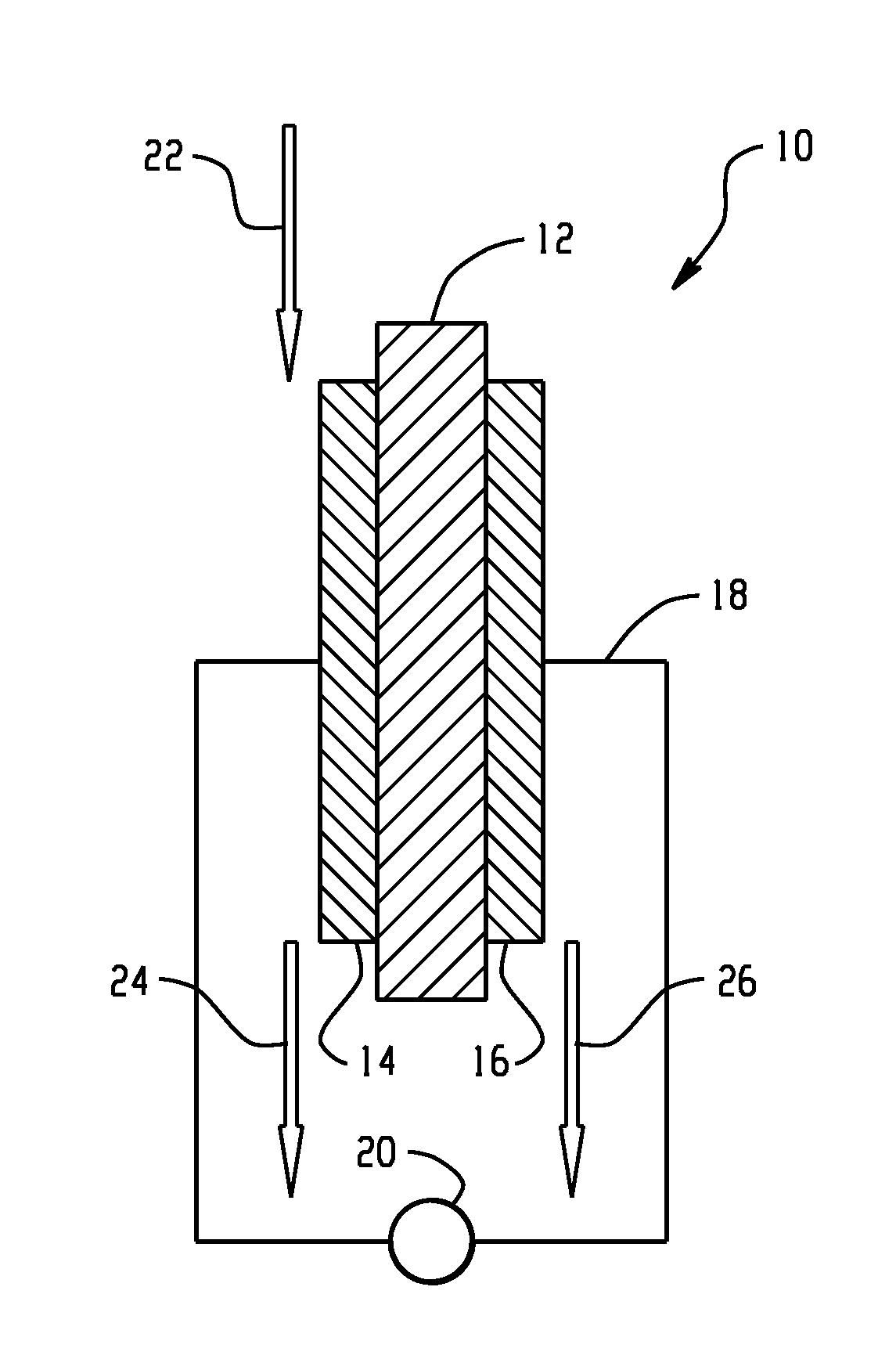

Controlling dead volume of a piston pump using an adjustment screw

InactiveUS20080287874A1Reducing and eliminating ullageIncrease volumeMetal-working apparatusMedical devicesDead volumeUllage

The present invention relates generally to infusion devices. More particularly, the present invention is directed toward an inexpensive design to adjust the dead space of a piston pump by adjusting the end position of the piston's forward stroke. The piston pump may include an actuator member with a piston that articulates between a retracted and a forward position in a piston channel. Movement between the retracted and forward position, a pumping stroke, may expel a known quantity of fluid. Because of manufacturing tolerances, the forward position may not exactly line up with the end of the piston channel, resulting in dead space, or ullage, that may result in less than desired accuracy for fluid volume pumped. Utilization of an adjustable stop or stop that contacts the actuator member at the desired forward position may allow for selective elimination of the ullage and precise adjustment of the fluid pumped.

Owner:MEDTRONIC INC

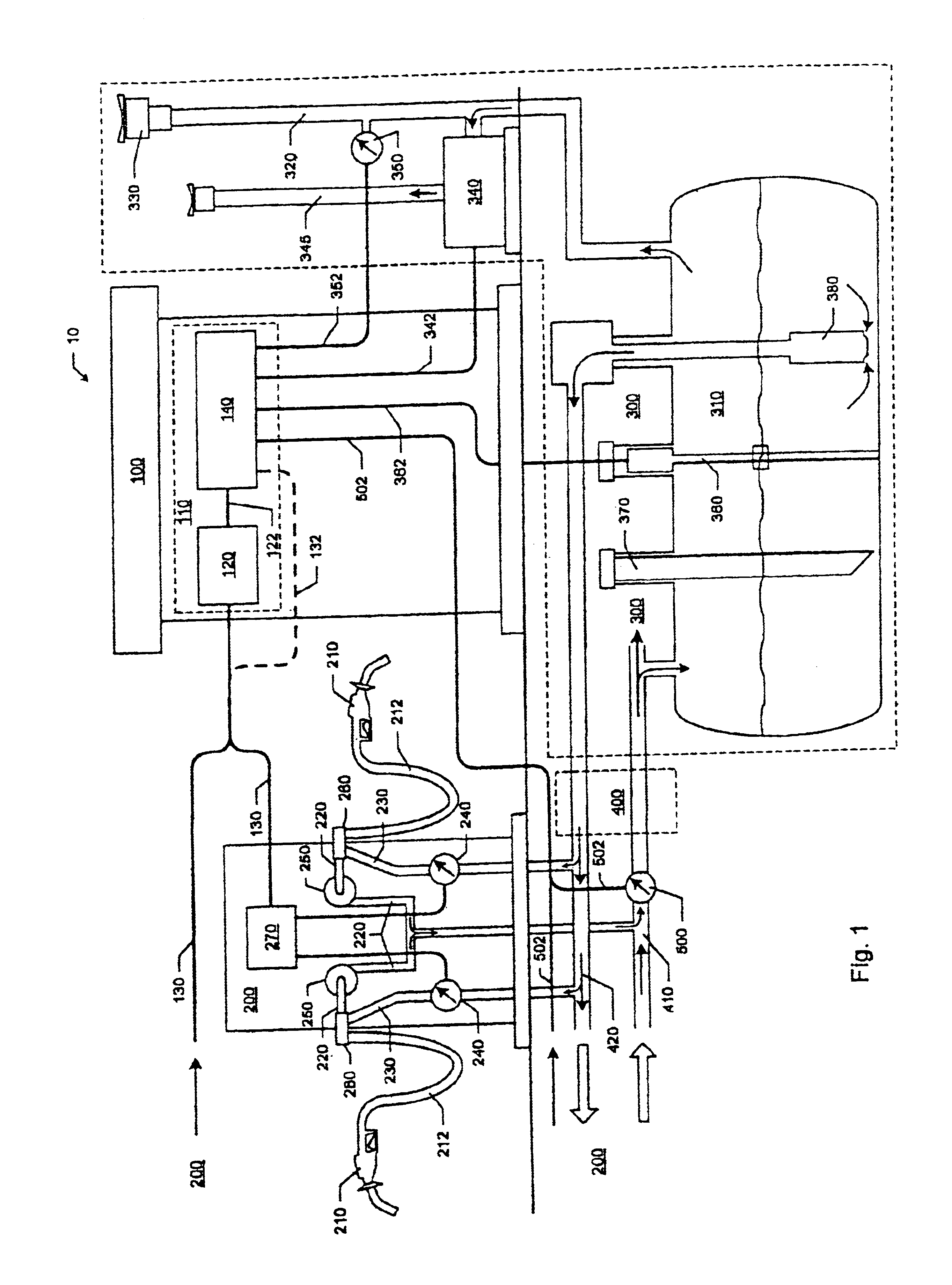

Control of vapor emissions from gasoline stations

ActiveUS20090056827A1Enhance vapor-liquid equilibriumMinimize emission levelGas treatmentIsotope separationActivated carbonSorbent

The present invention relates to a vapor recovery system for gas station that is capable of controlling vapor emission to less than 0.38 lbs / 1000 gallons fuel dispensed. The system may include at least one canister containing adsorbents such as activated carbon, zeolite, activated alumina, silica, and other adsorbents for passive removal of hydrocarbon vapors in venting air. Additionally, the system may include a means to enhance vapor-liquid equilibrium in the ullage of the fuel tank and accordingly minimize vapor emission level.

Owner:INGEVITY SOUTH CAROLINA

Fuel system and method

ActiveUS8904669B2Lower levelAccelerate evaporationLiquid degasificationDrying solid materials with heatInerting systemEngineering

A fuel system comprising a fuel tank, a vent tank having a duct open to the ambient atmosphere, a first vent line fluidically connecting the fuel tank ullage to the vent tank, a gas drying system including a pump and a dehumidifying device disposed within the vent tank, and a second vent line fluidically connecting a dry gas outlet of the dehumidifying device to the ullage, wherein the pump is operable to maintain a higher pressure within the ullage than in the vent tank so as to drive vapor rich gas from the ullage into the vent tank via the first vent line. Also, a method of operating the fuel system and a method of retro-fitting the gas drying system in an existing fuel system. The gas drying system may optionally be a gas drying / inerting system.

Owner:AIRBUS OPERATIONS LTD

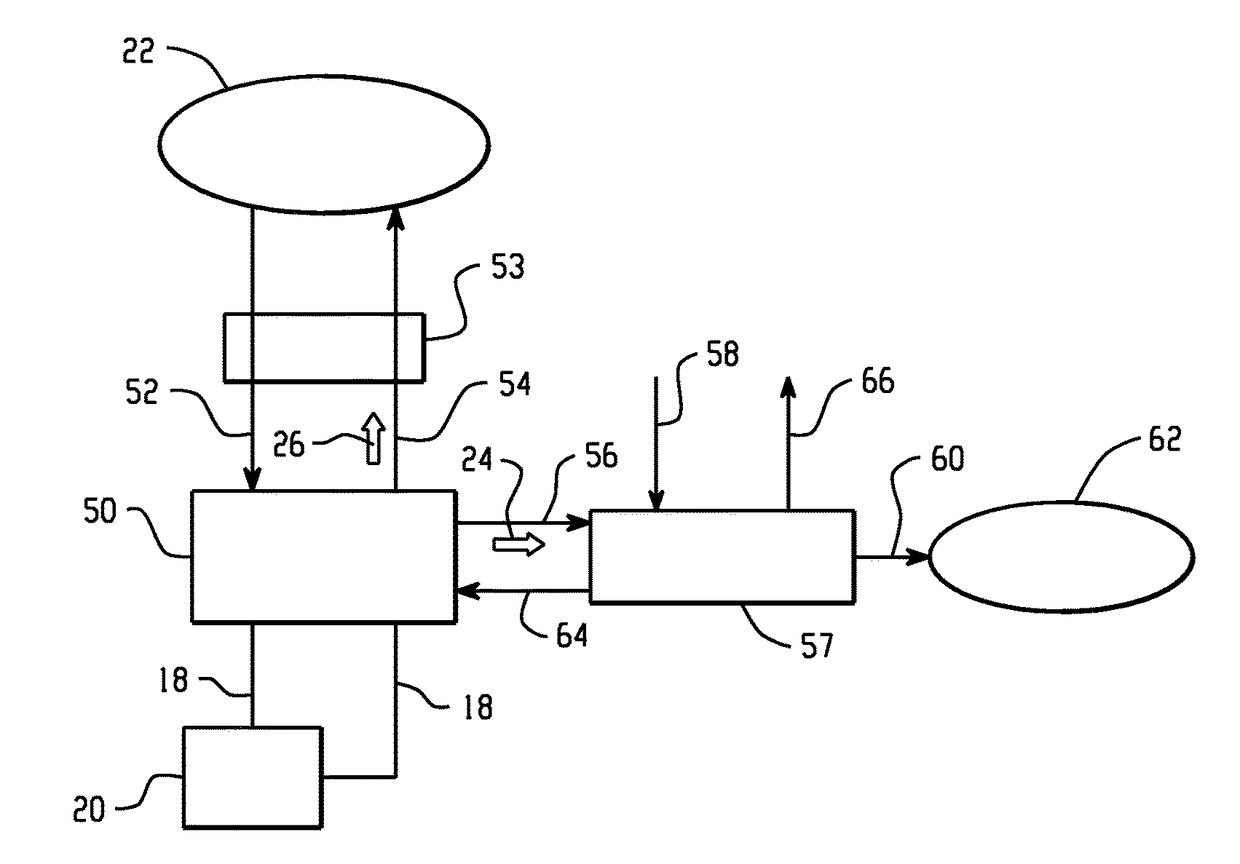

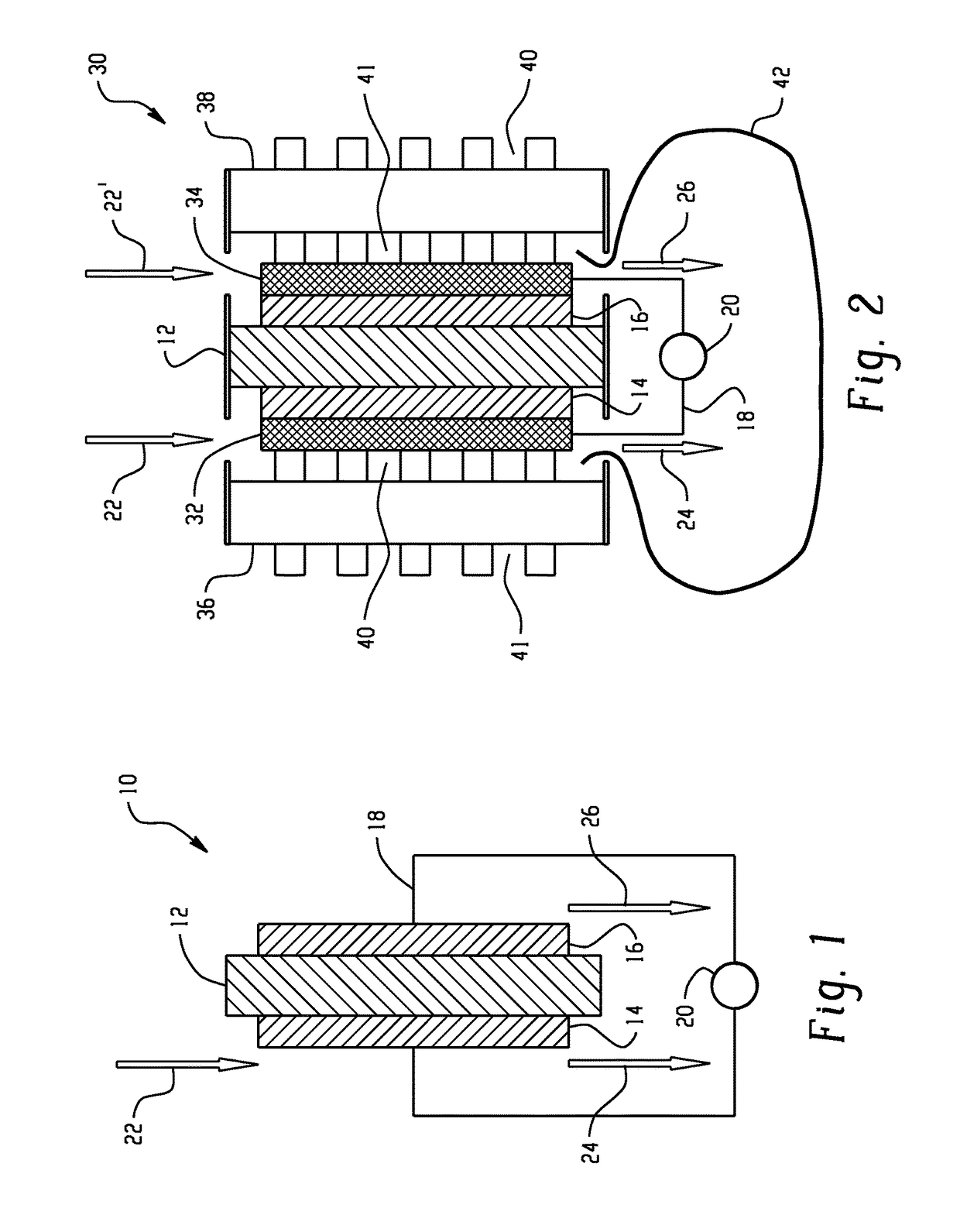

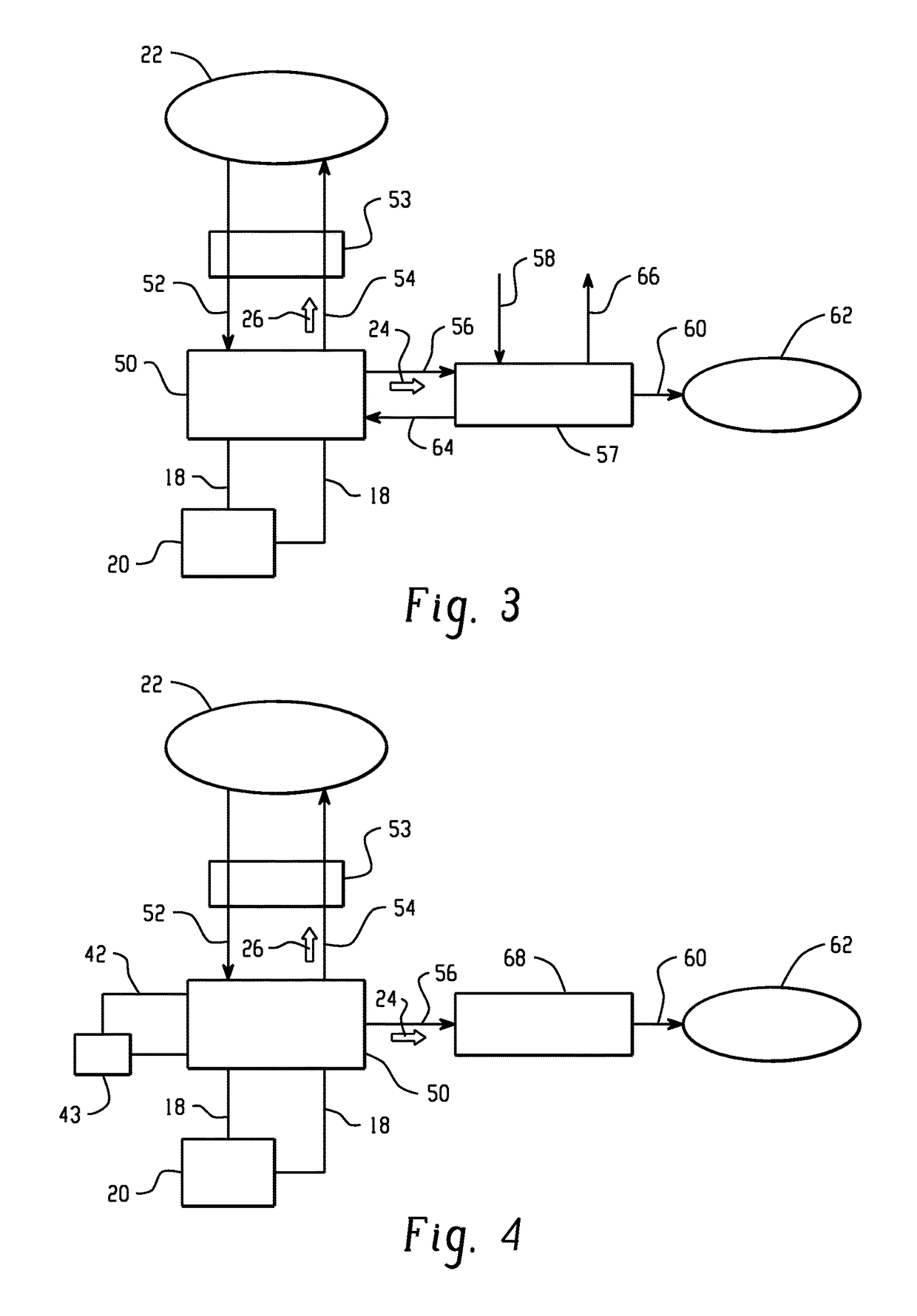

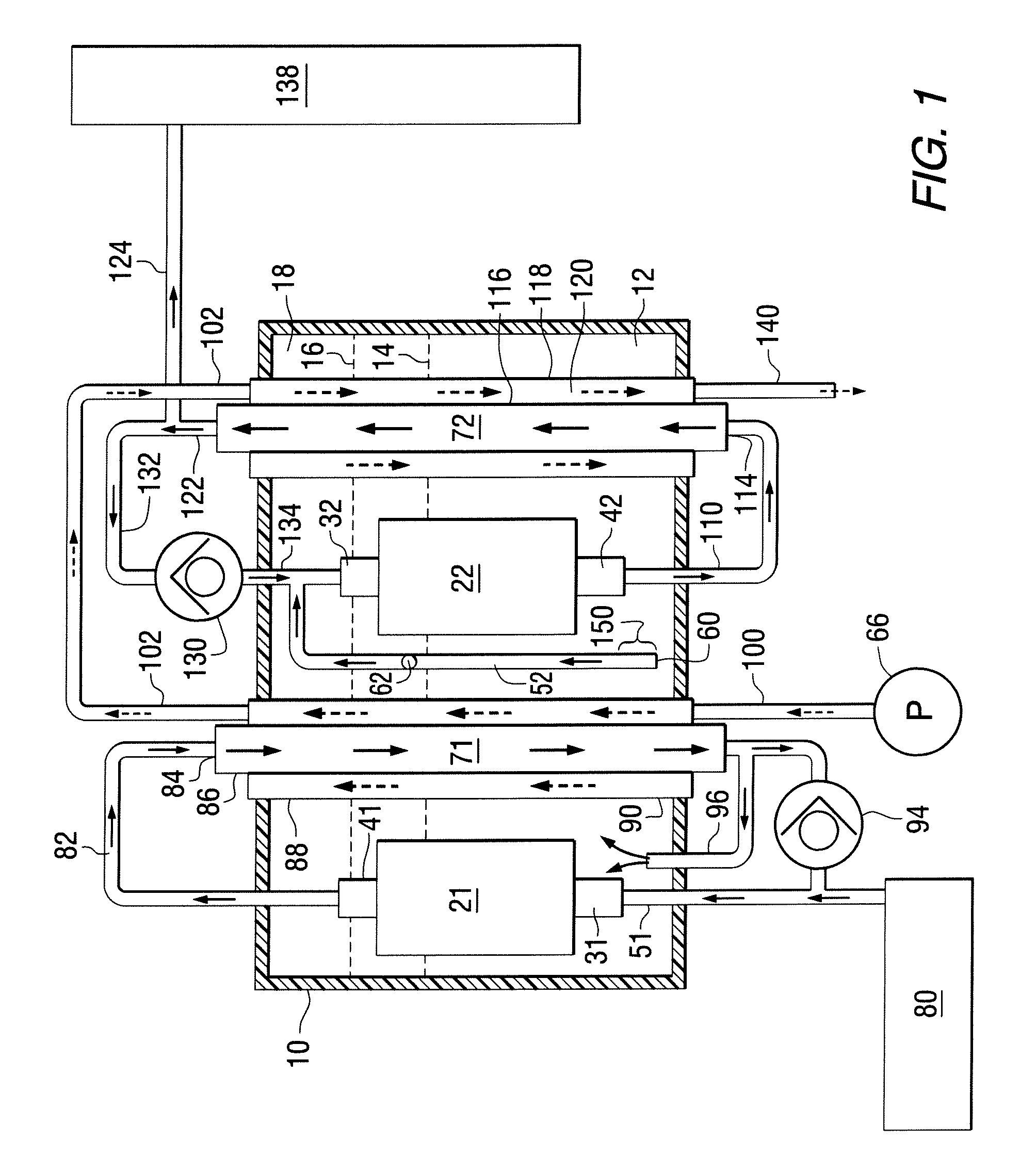

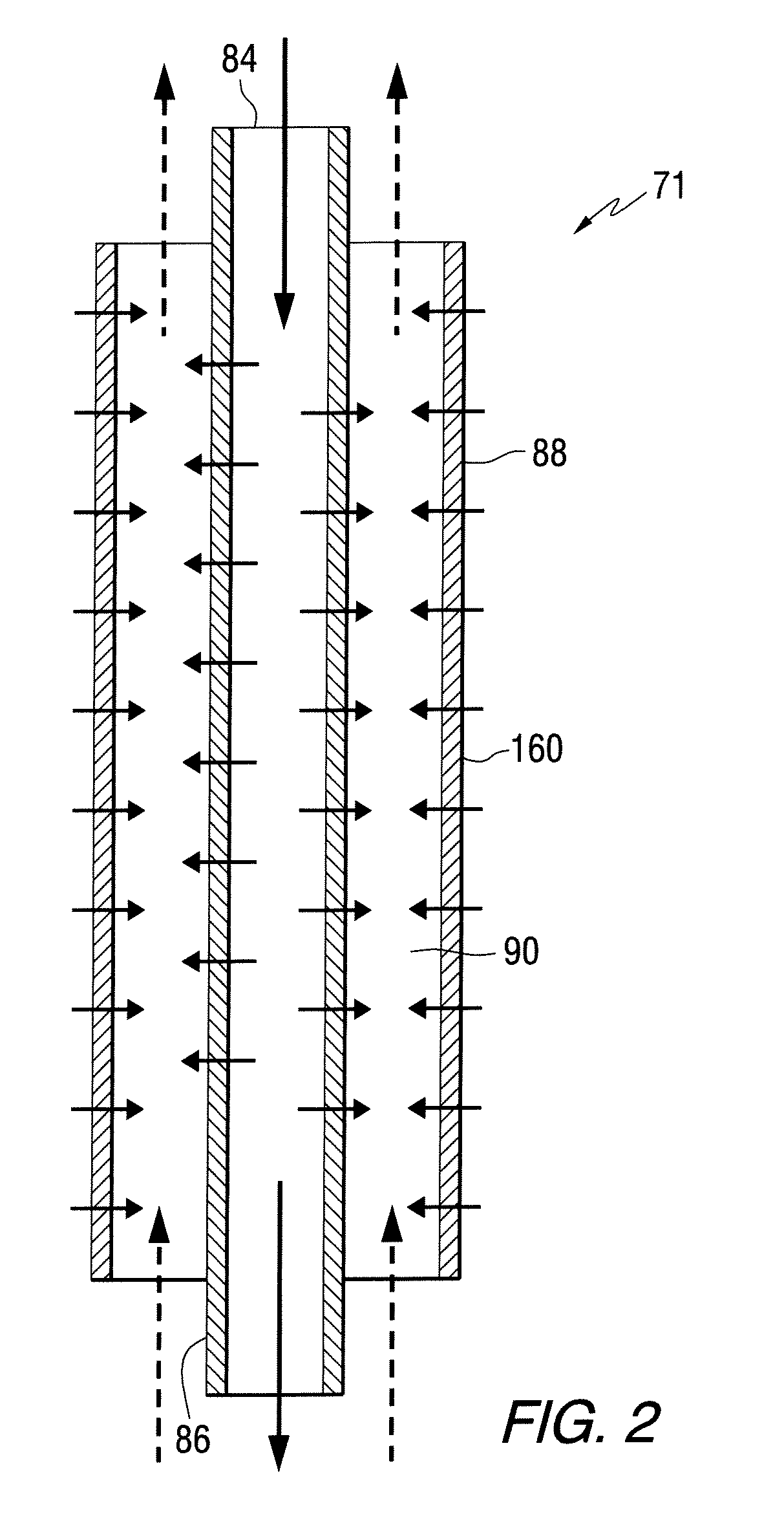

Aircraft fuel tank ullage gas management system

An aircraft fuel tank ullage gas management system is disclosed. The system includes an electrochemical cell having a membrane electrode assembly that includes a cathode and anode separated by an electrolyte separator. A cathode fluid flow path is in fluid communication with the cathode, and receives the flow of cabin air from the cabin air fluid flow path and discharges nitrogen-enriched air. An anode fluid flow path is in fluid communication with the anode, and discharges oxygen or oxygen-enriched air. The electrochemical cell also includes water in fluid communication with the anode. The system includes an electrical power source and electrical connections to the anode and cathode for providing an electric potential difference between the anode and cathode. An ullage flow path receives nitrogen-enriched air from the cathode fluid flow path and delivers it to the fuel tank. An optional flow path delivers humidified oxygen-enriched air back to the cabin.

Owner:HAMILTON SUNDSTRAND CORP

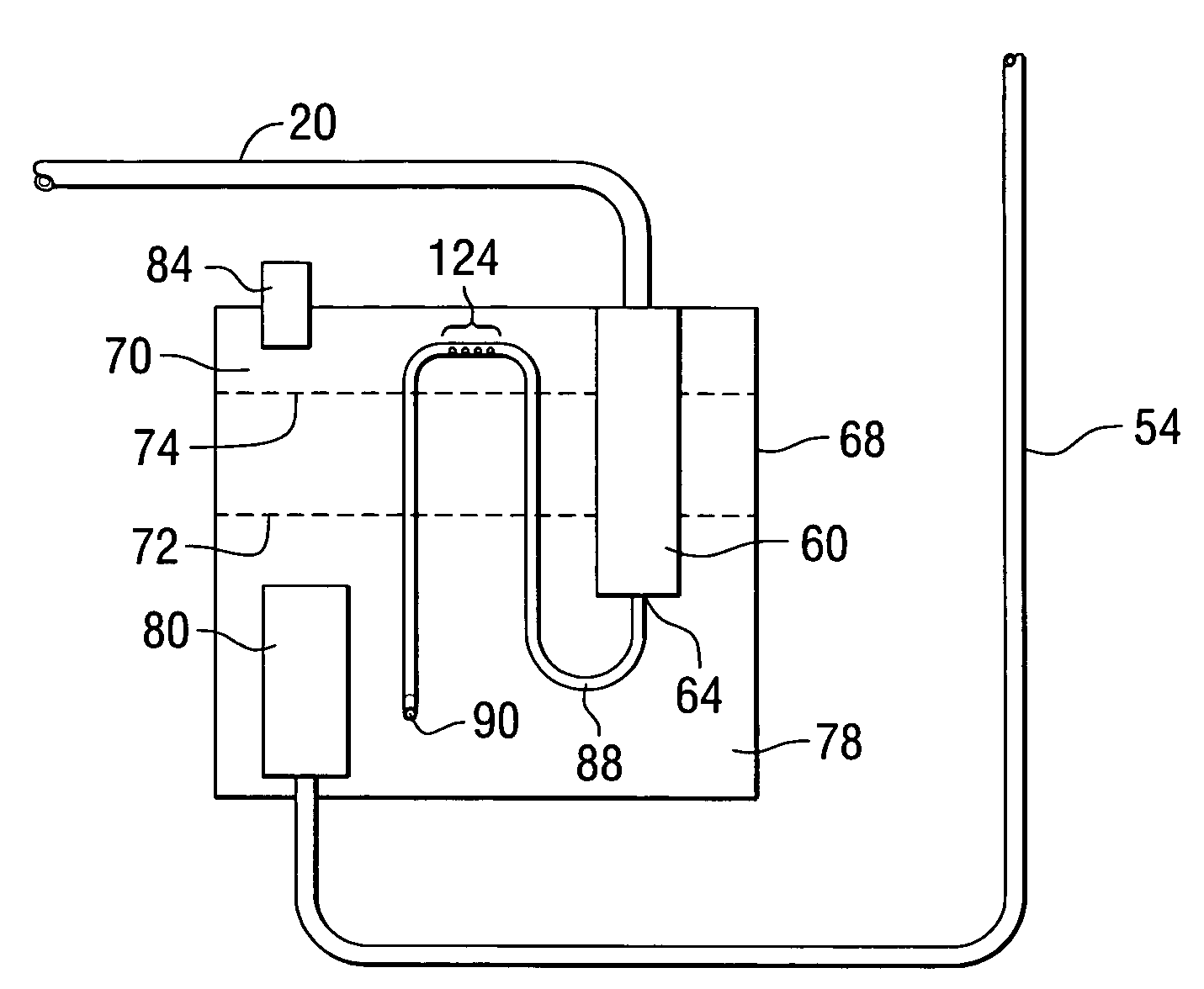

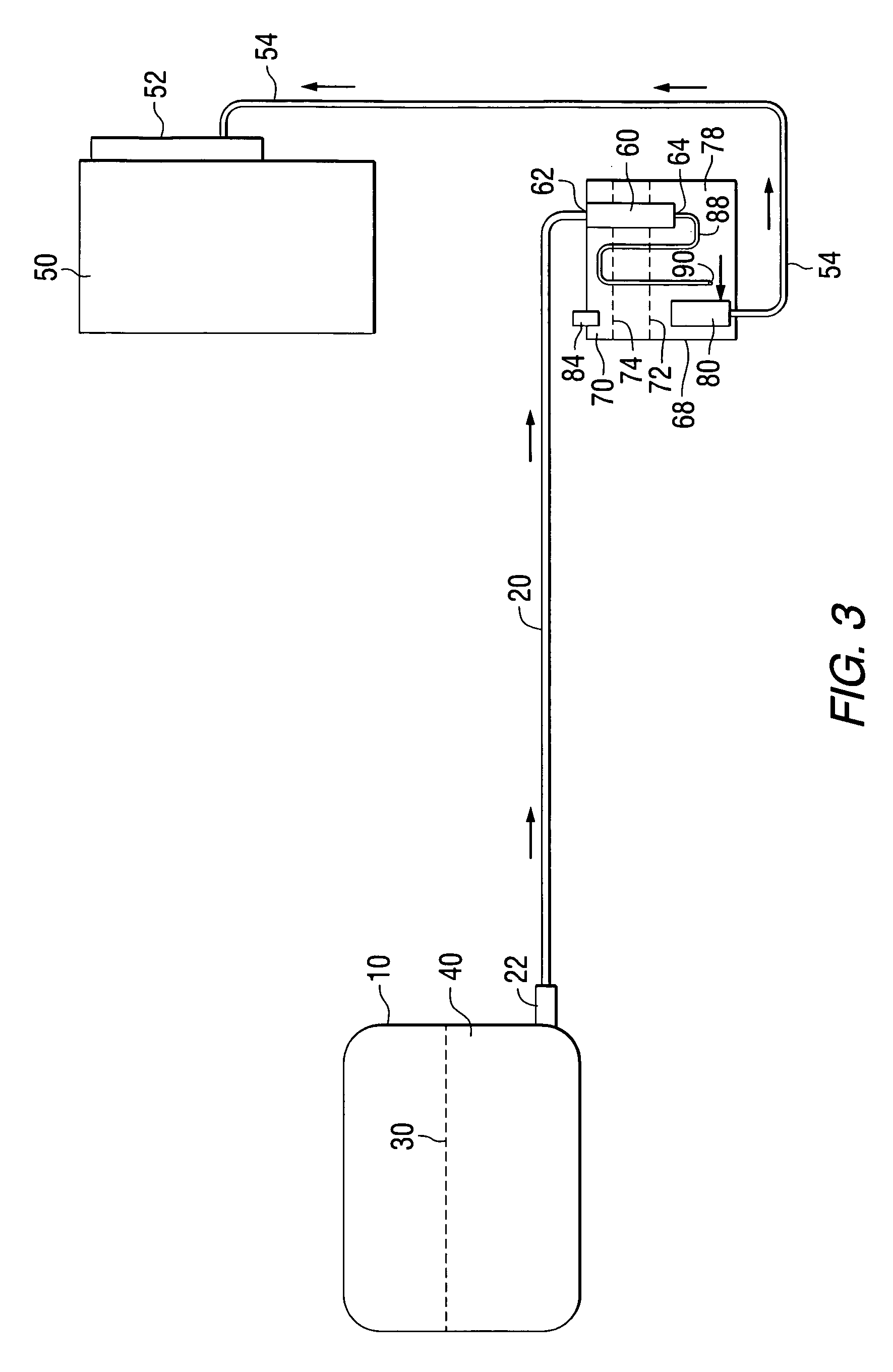

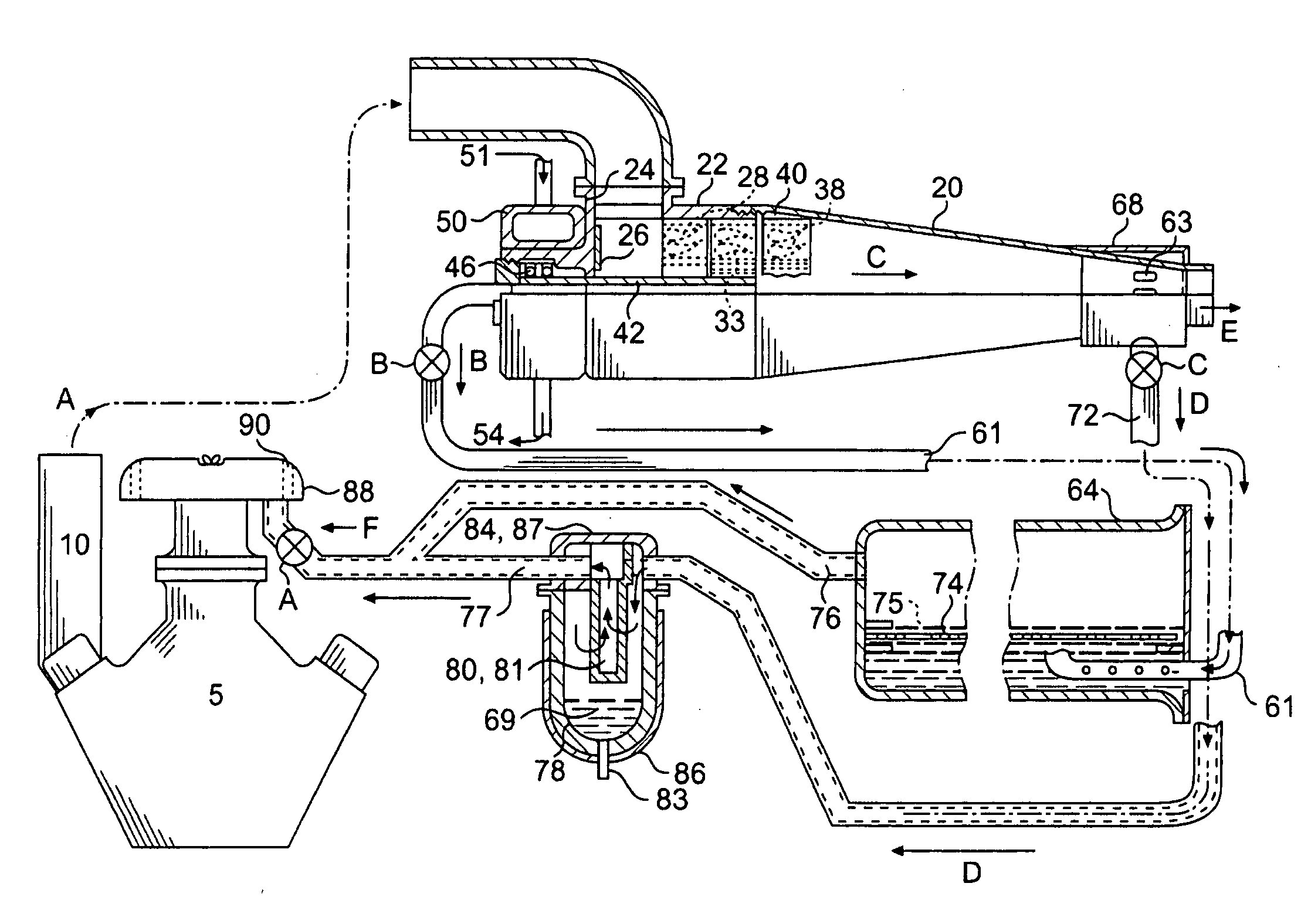

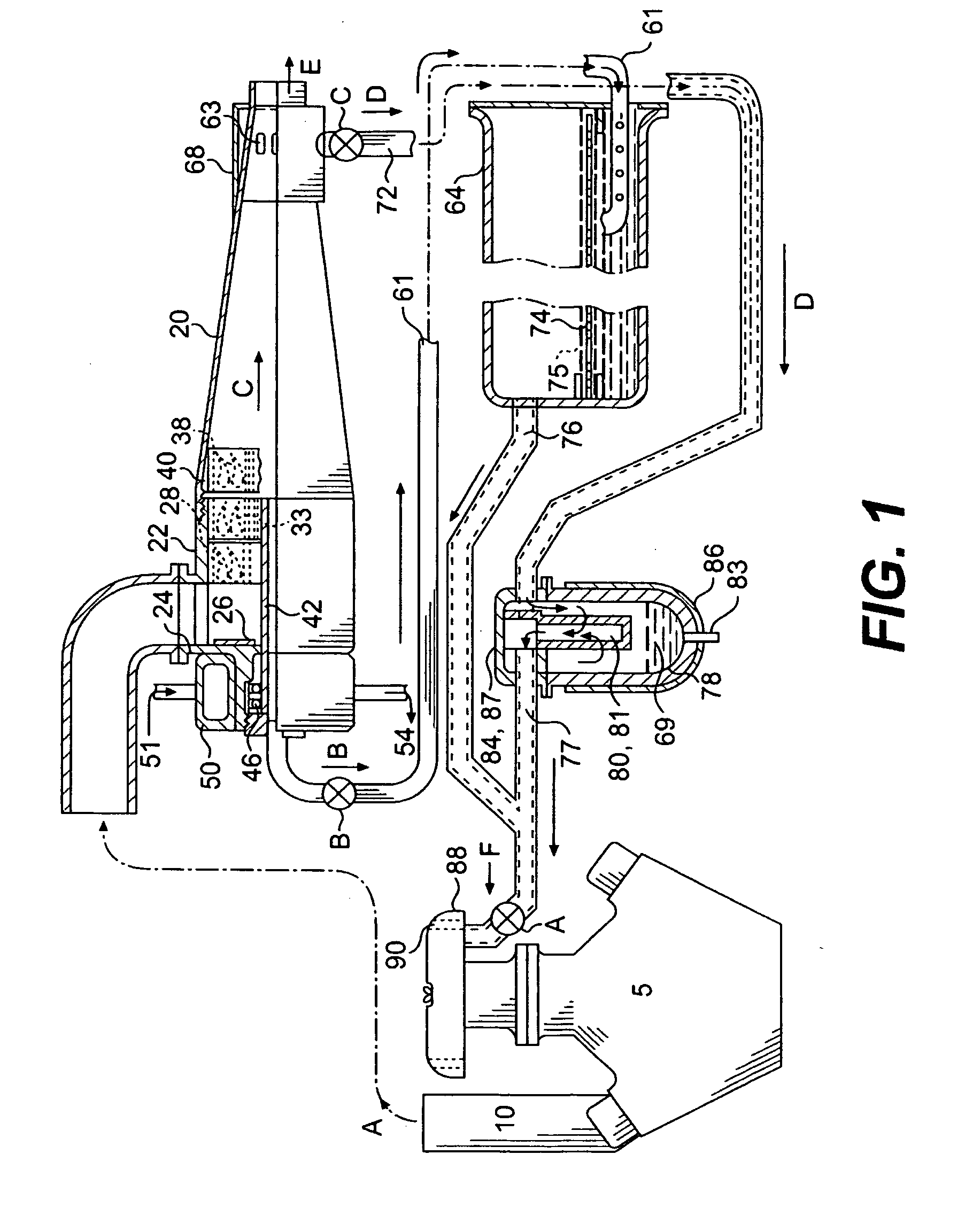

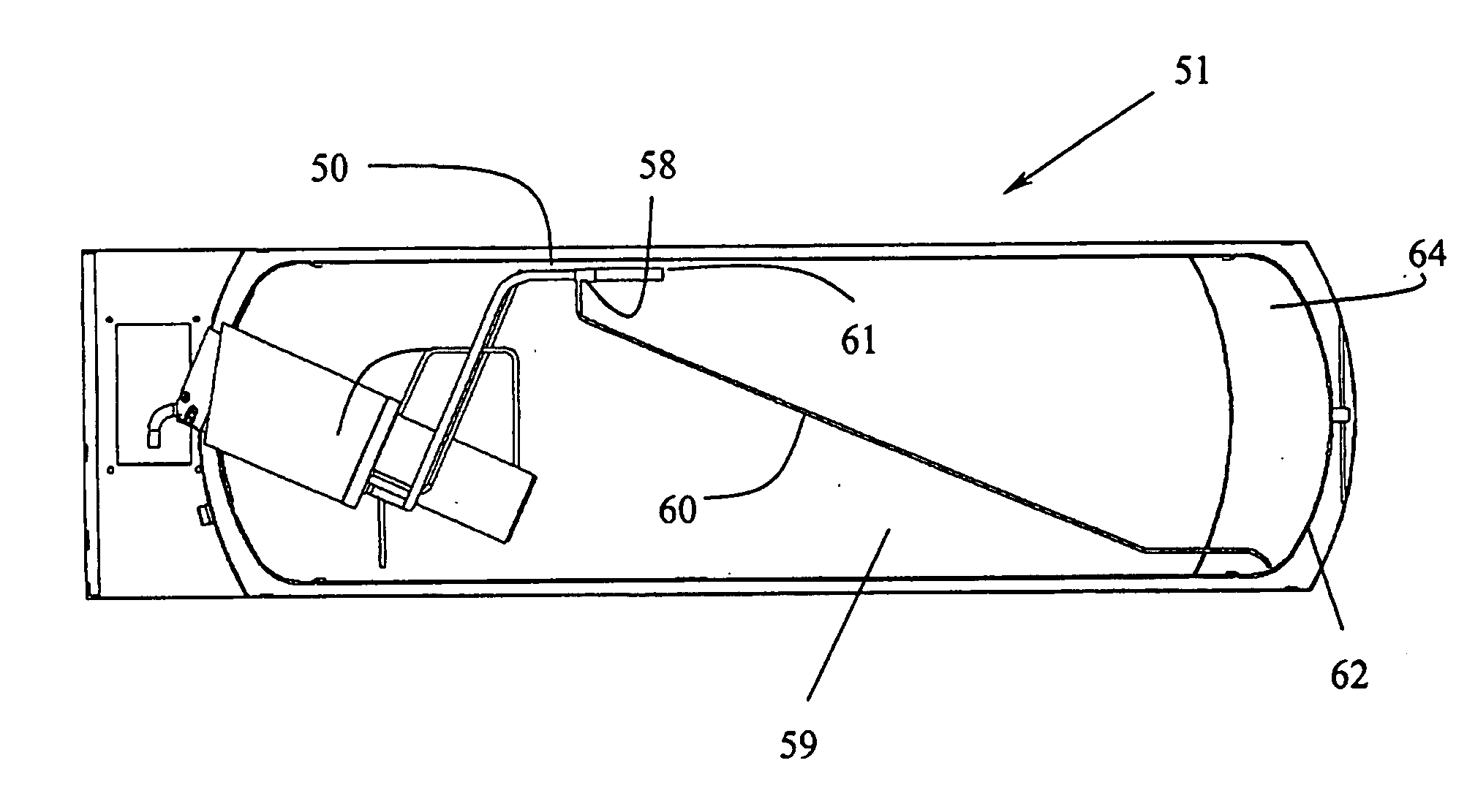

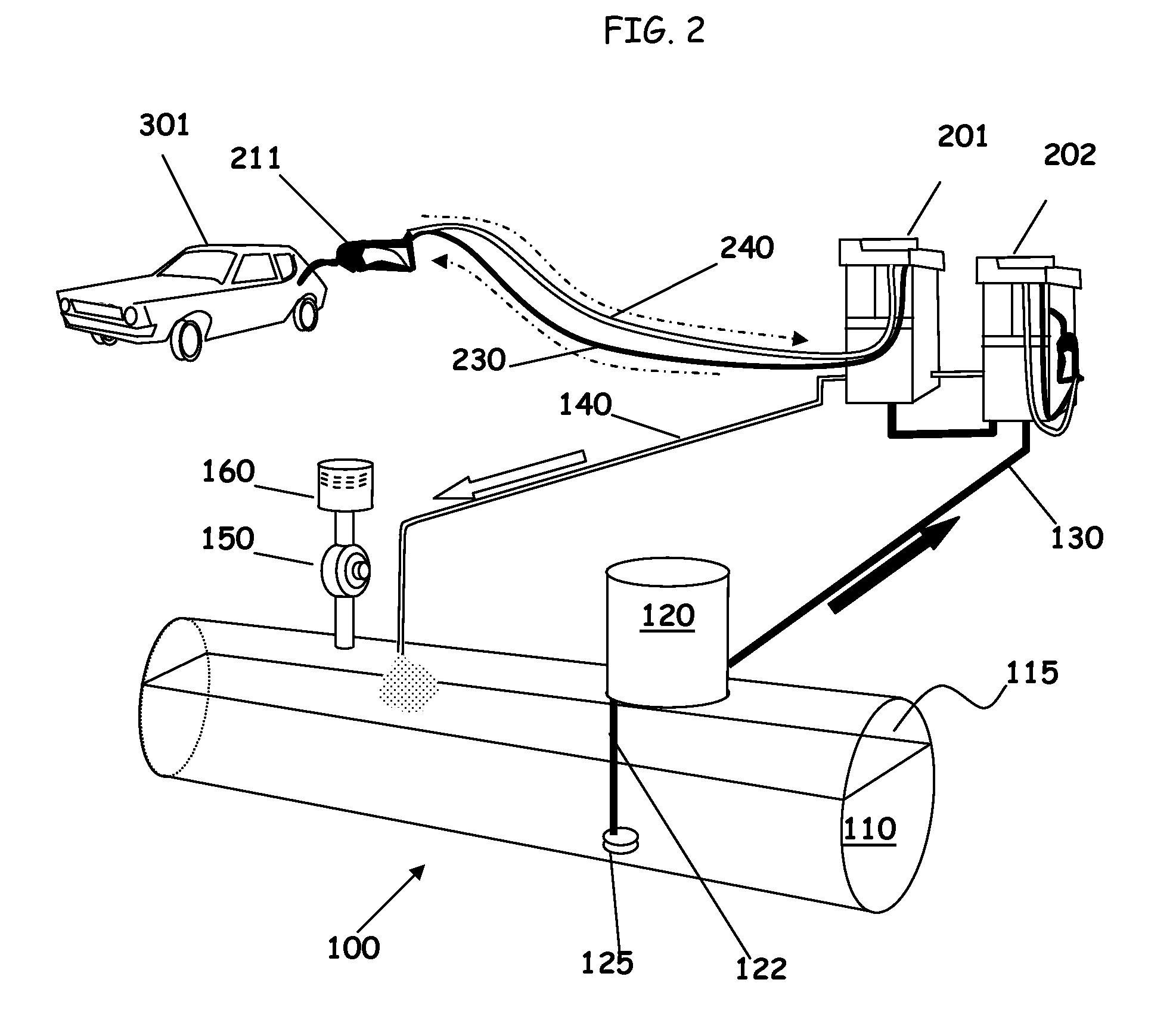

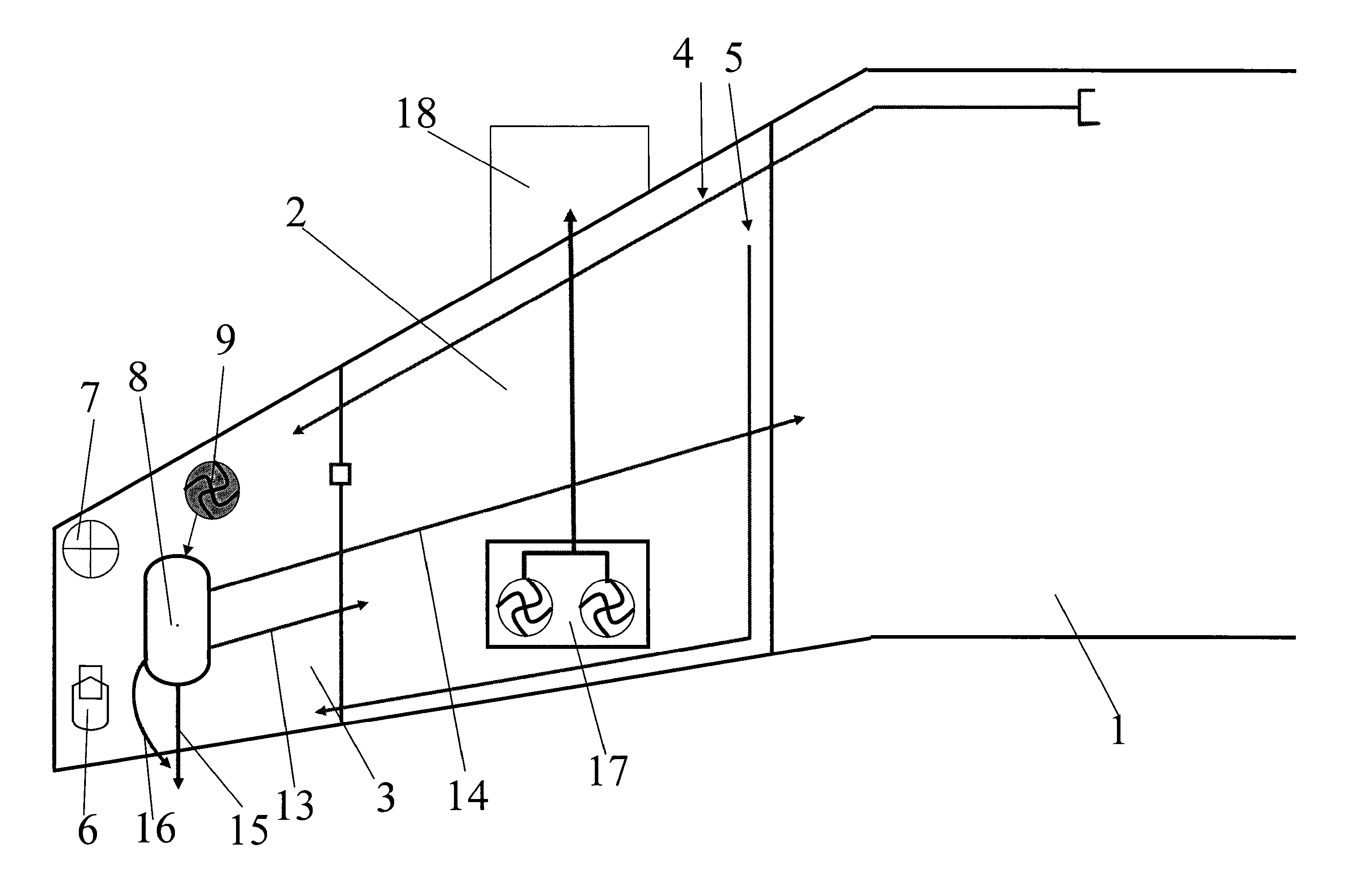

Marine fuel system with an ullage control device

A marine engine fuel system provides a low pressure lift pump to draw fuel from a fuel tank and cause the fuel to flow into a reservoir and a high pressure fuel pump which draws fuel from the reservoir and provides it to a fuel rail. An inlet conduit of the high pressure fuel pump is provided with a primary and a secondary opening. The secondary opening can be an orifice formed through a wall of the inlet conduit. The secondary opening is positioned, relative to the primary opening, at a location which assists in controlling the fuel level within the reservoir and the quantity of gaseous fuel contained within an ullage above the liquid pool of fuel.

Owner:BRUNSWICK CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com