Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2707 results about "Magnetic bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A magnetic bearing is a type of bearing that supports a load using magnetic levitation. Magnetic bearings support moving parts without physical contact. For instance, they are able to levitate a rotating shaft and permit relative motion with very low friction and no mechanical wear. Magnetic bearings support the highest speeds of all kinds of bearing and have no maximum relative speed.

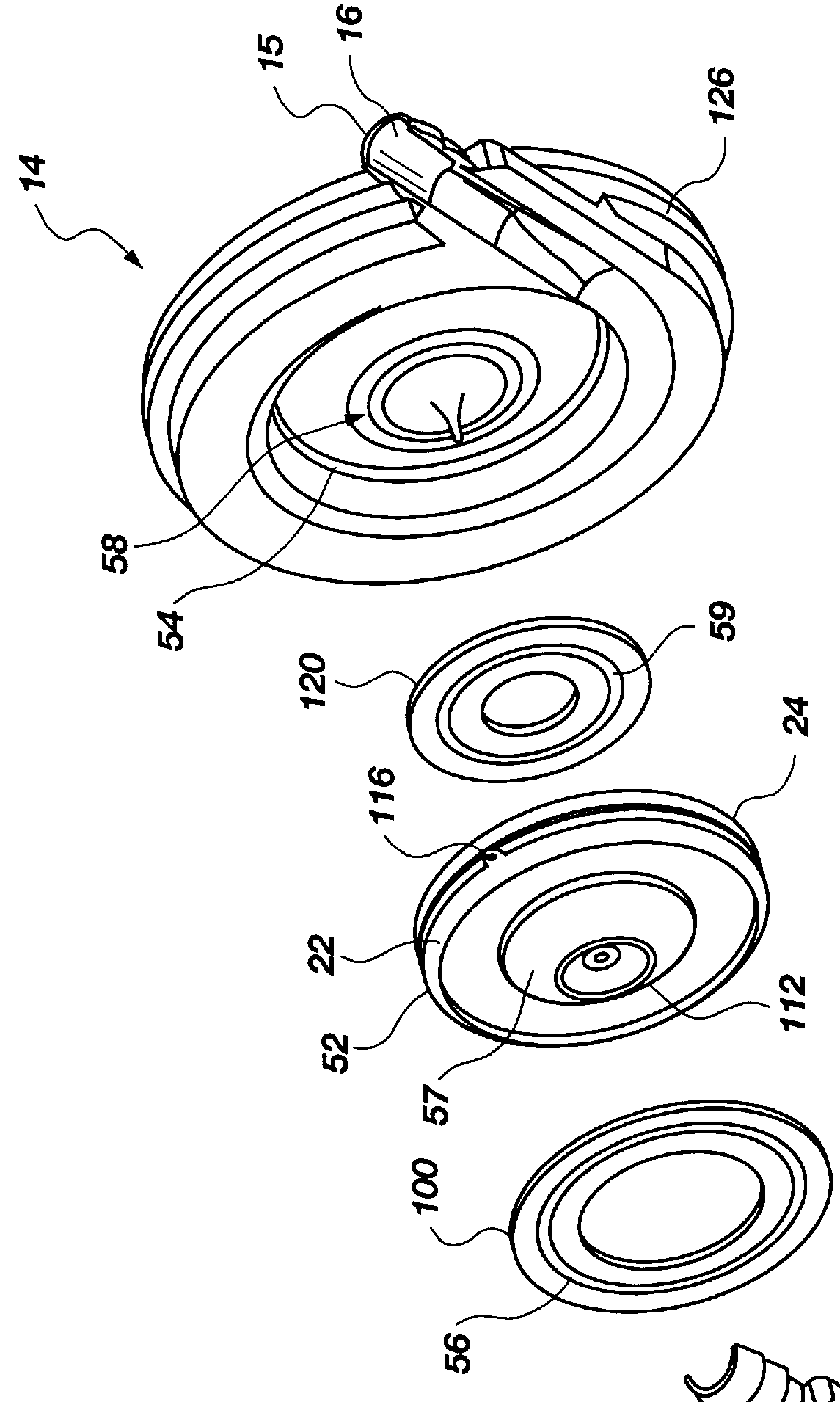

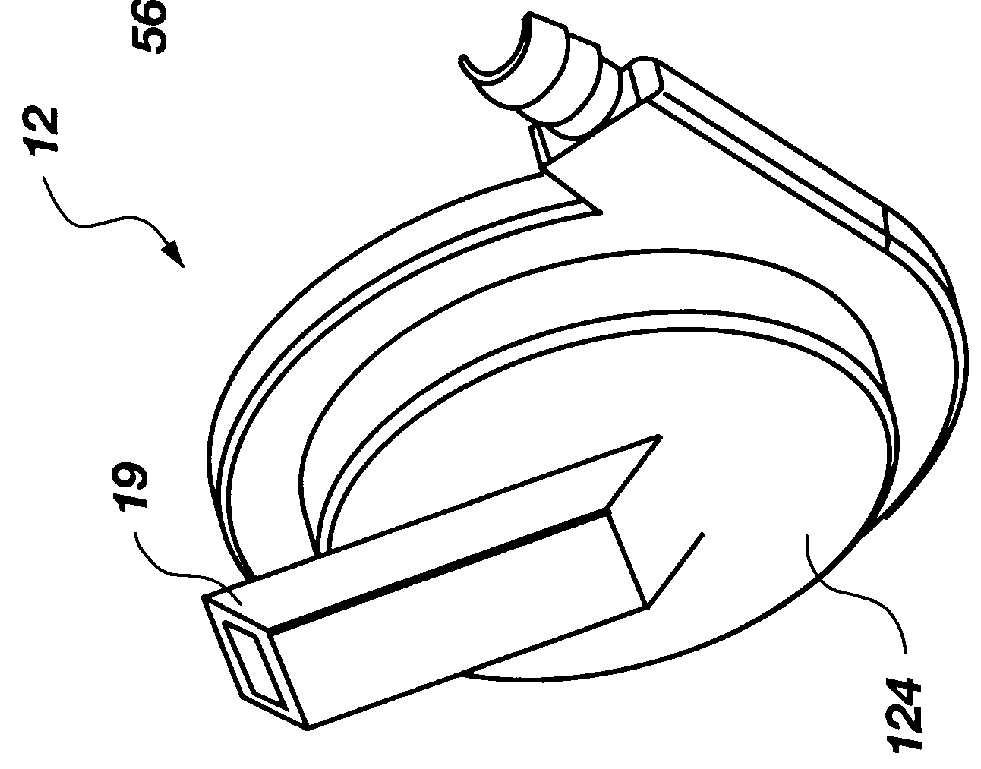

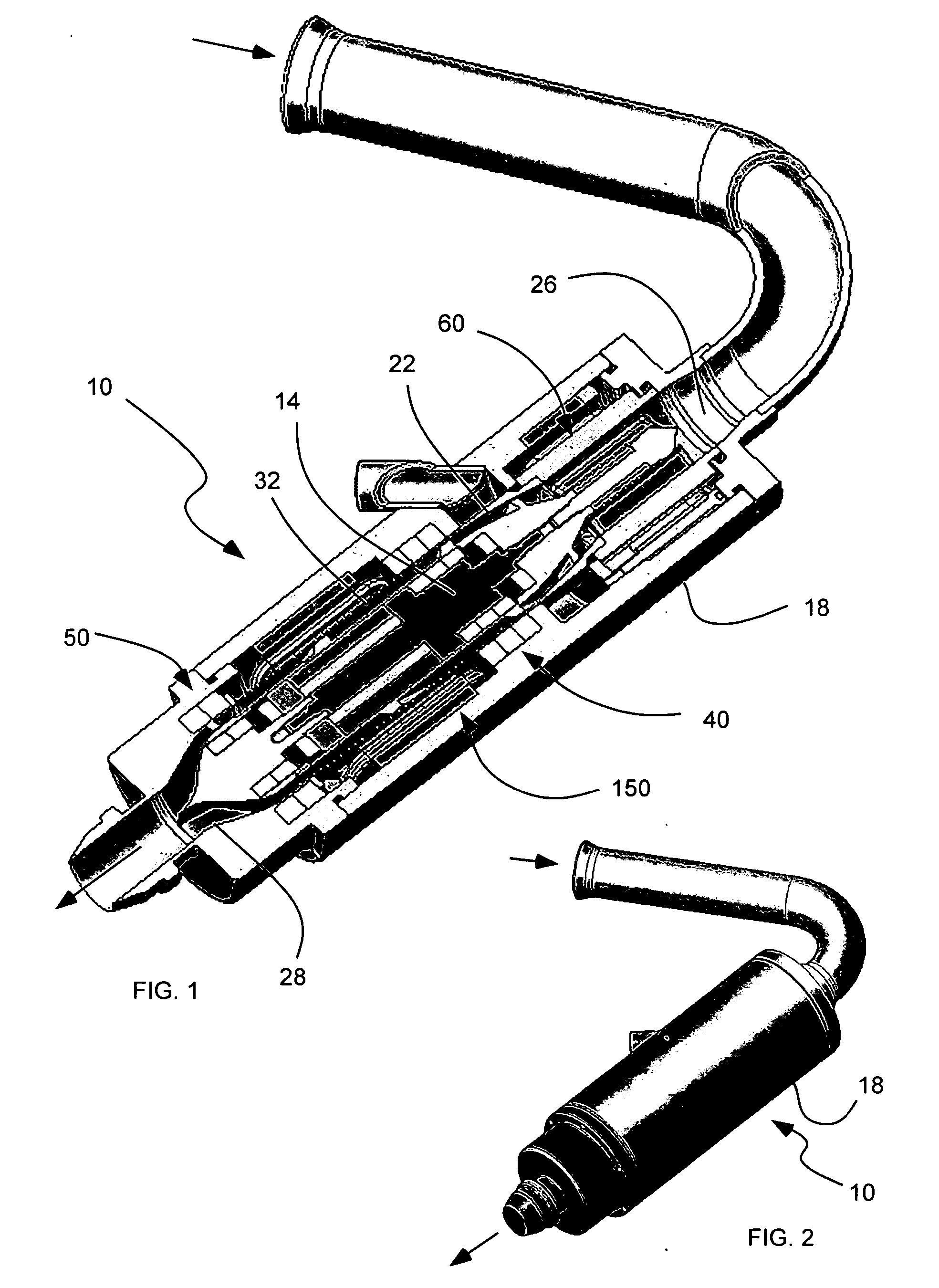

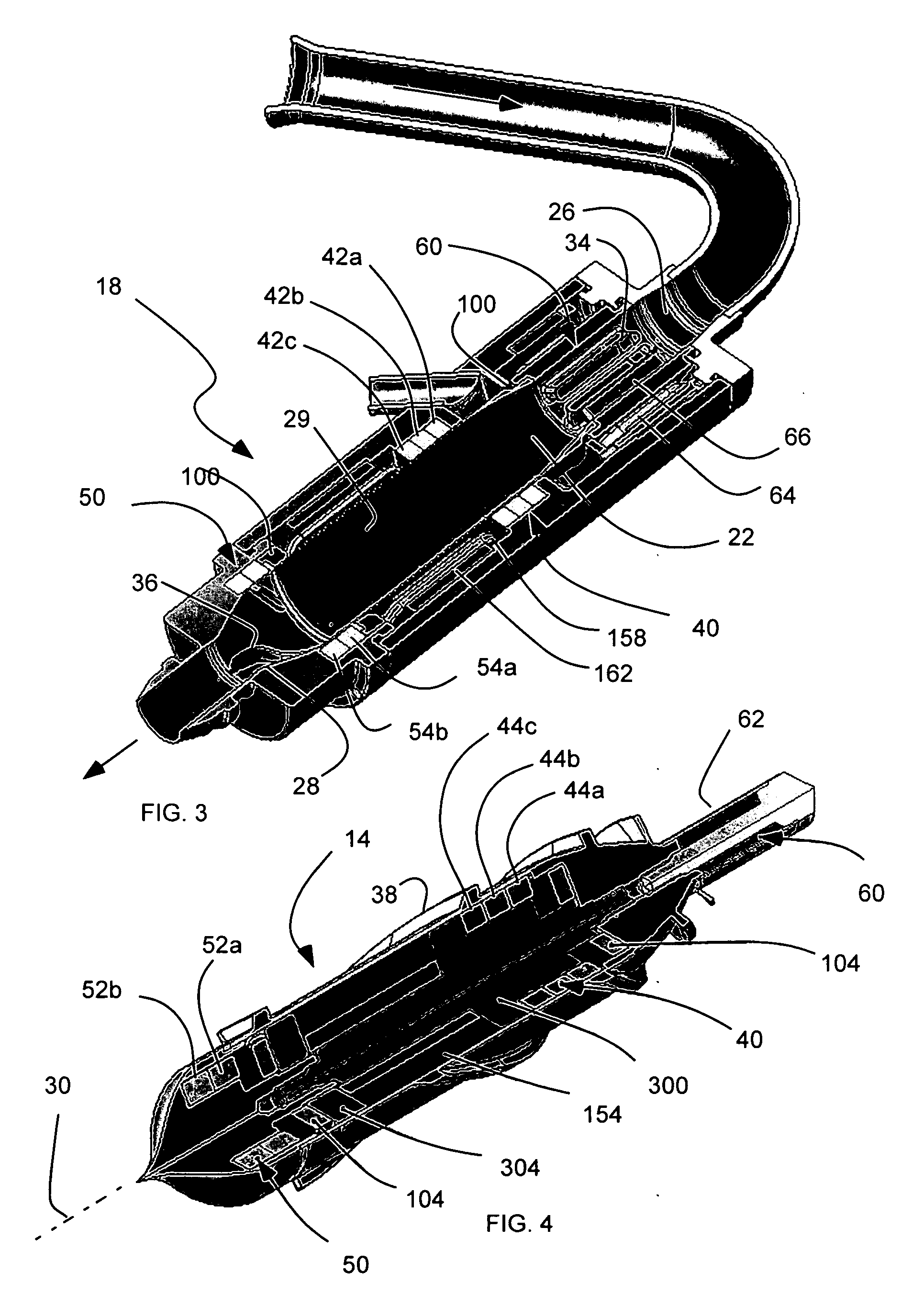

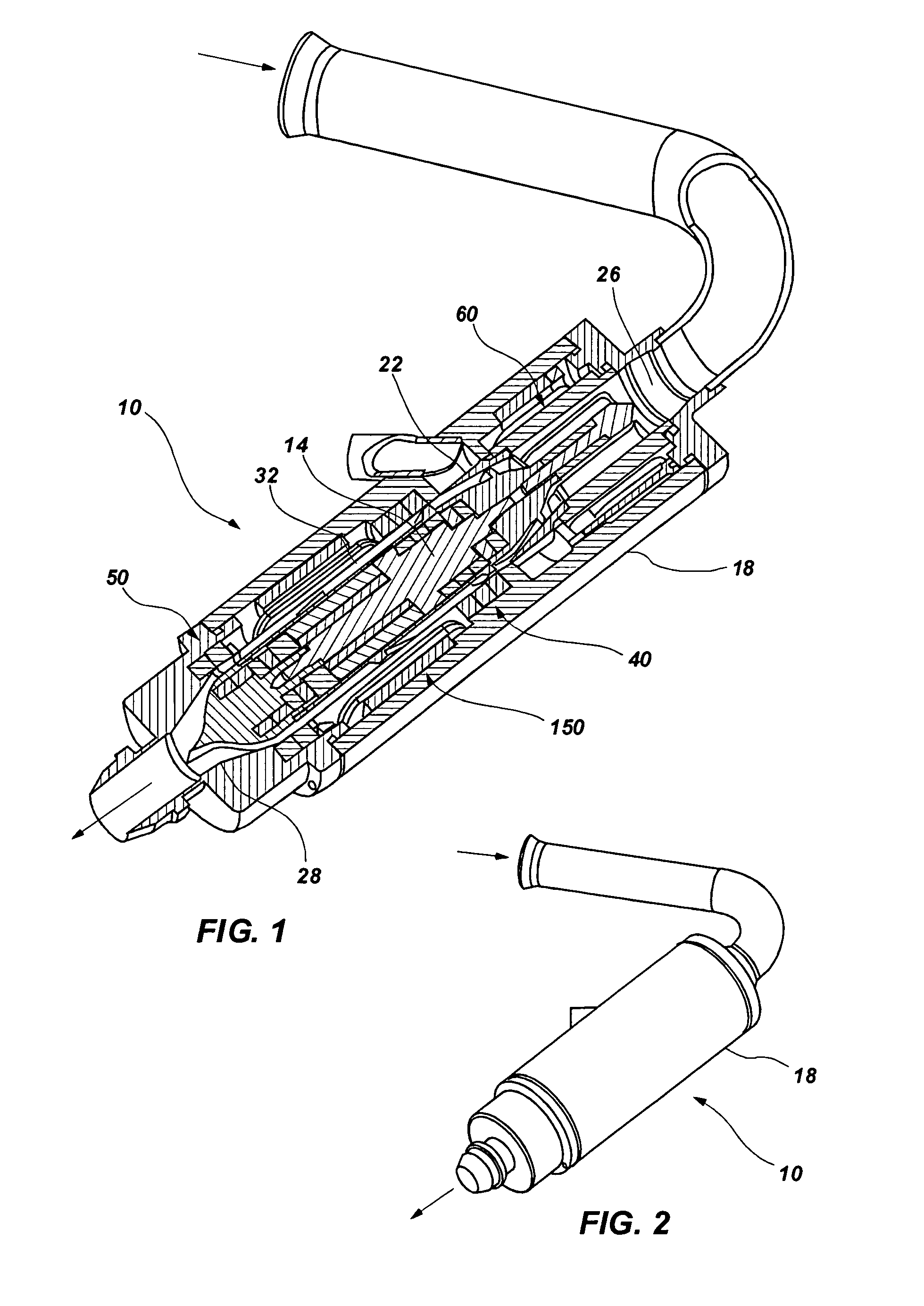

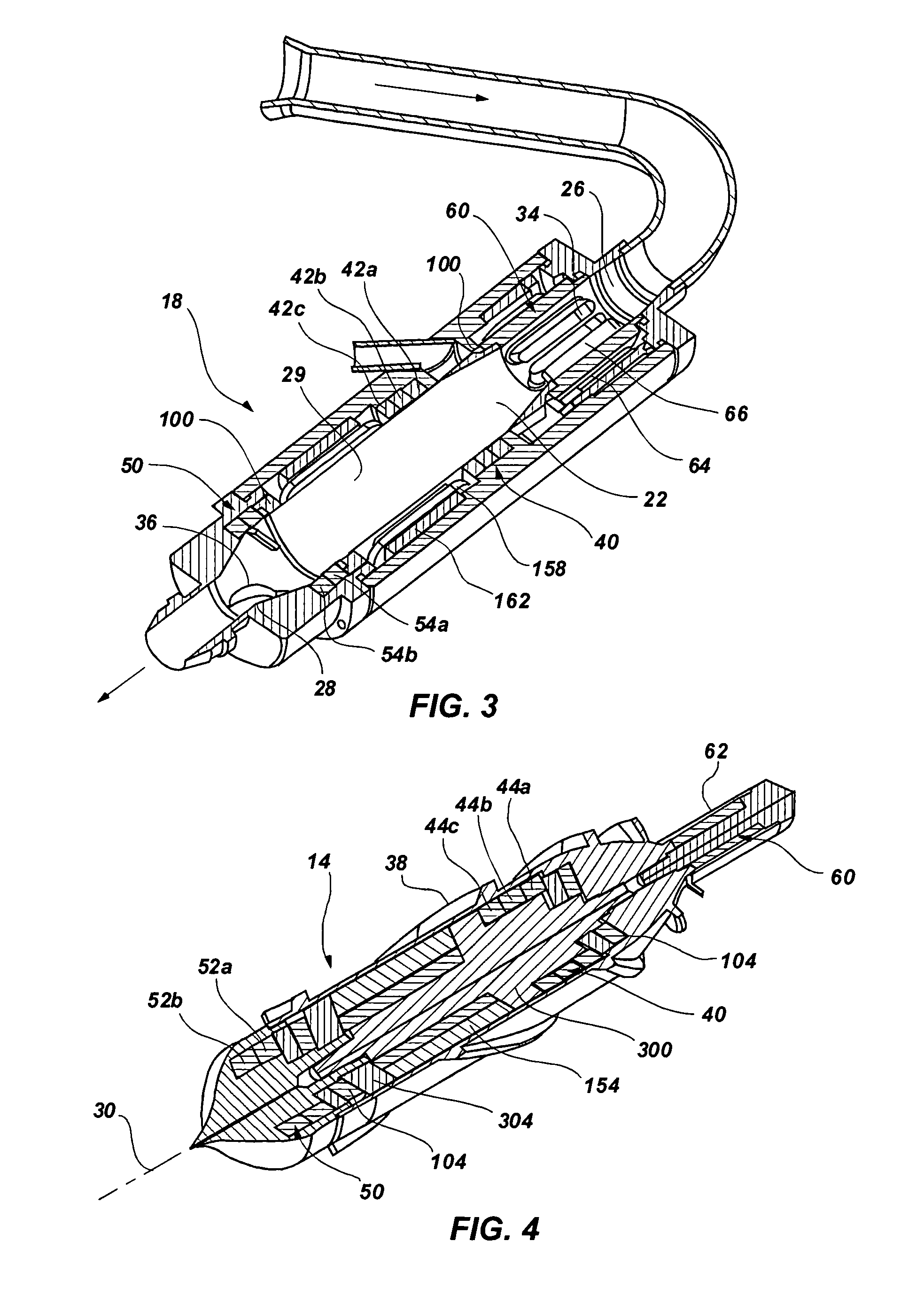

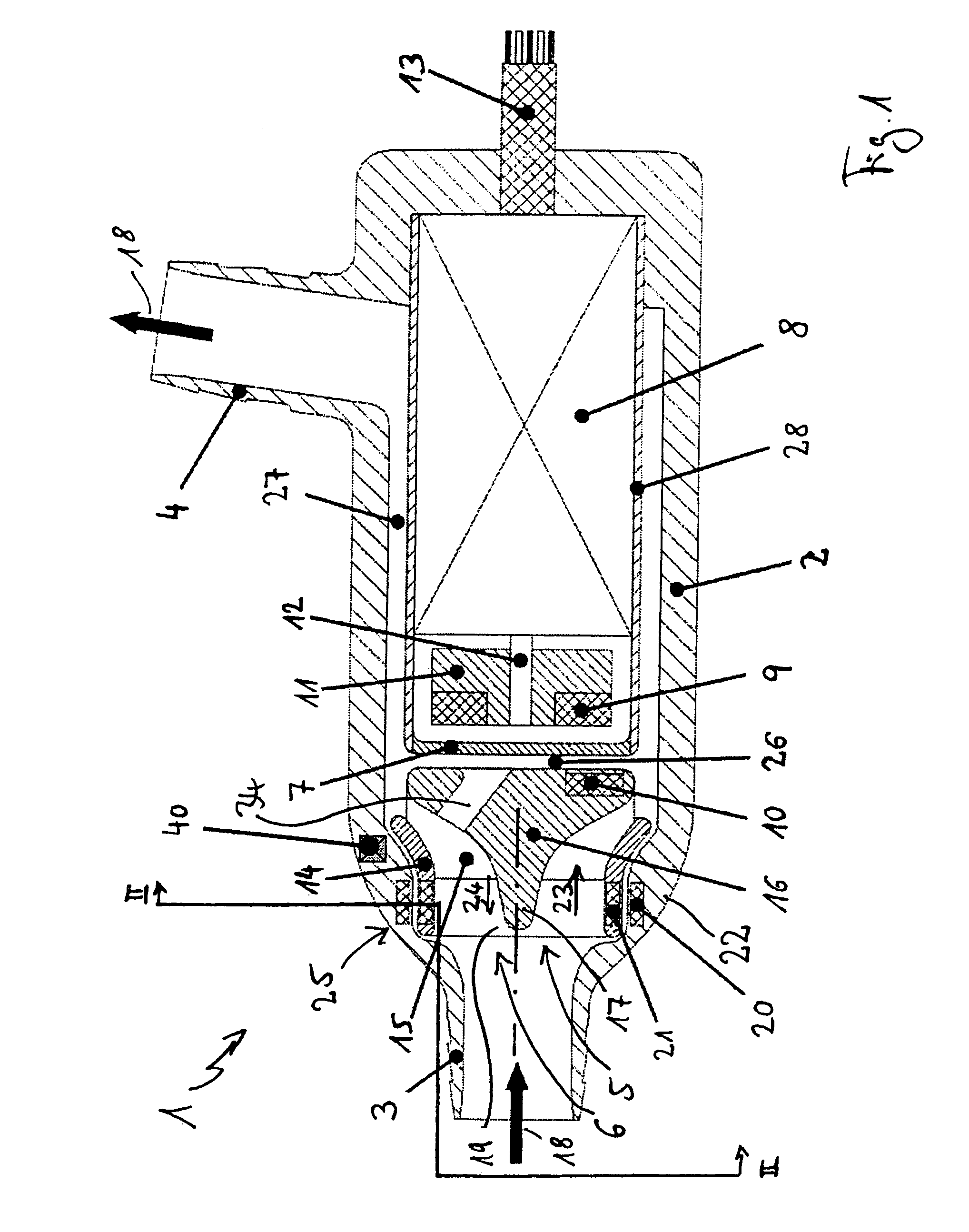

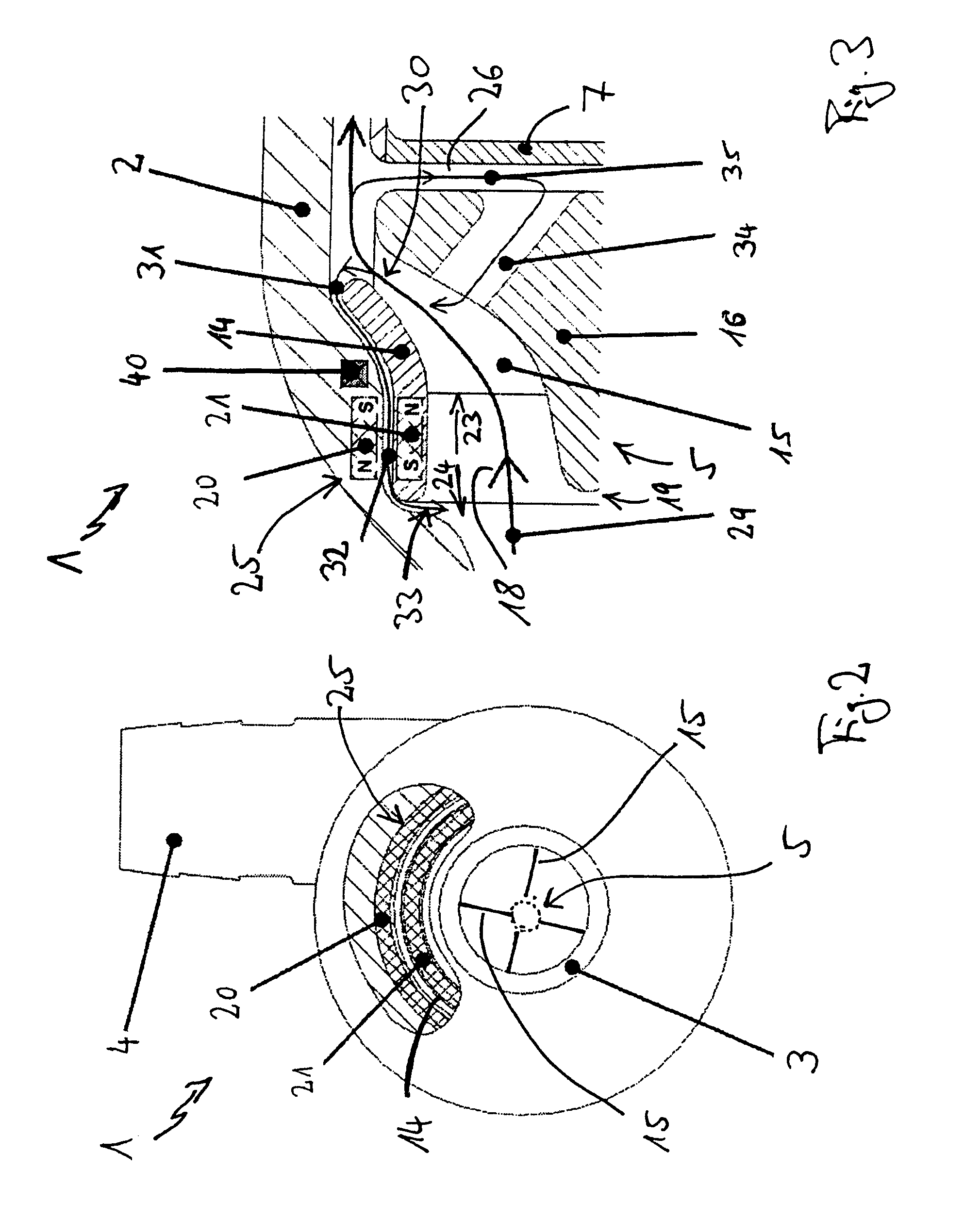

Axial force null position magnetic bearing and rotary blood pumps which use them

InactiveUS6227820B1Improve radial stiffnessSimple designPump componentsSurgeryAxial-flow pumpMagnetic tension force

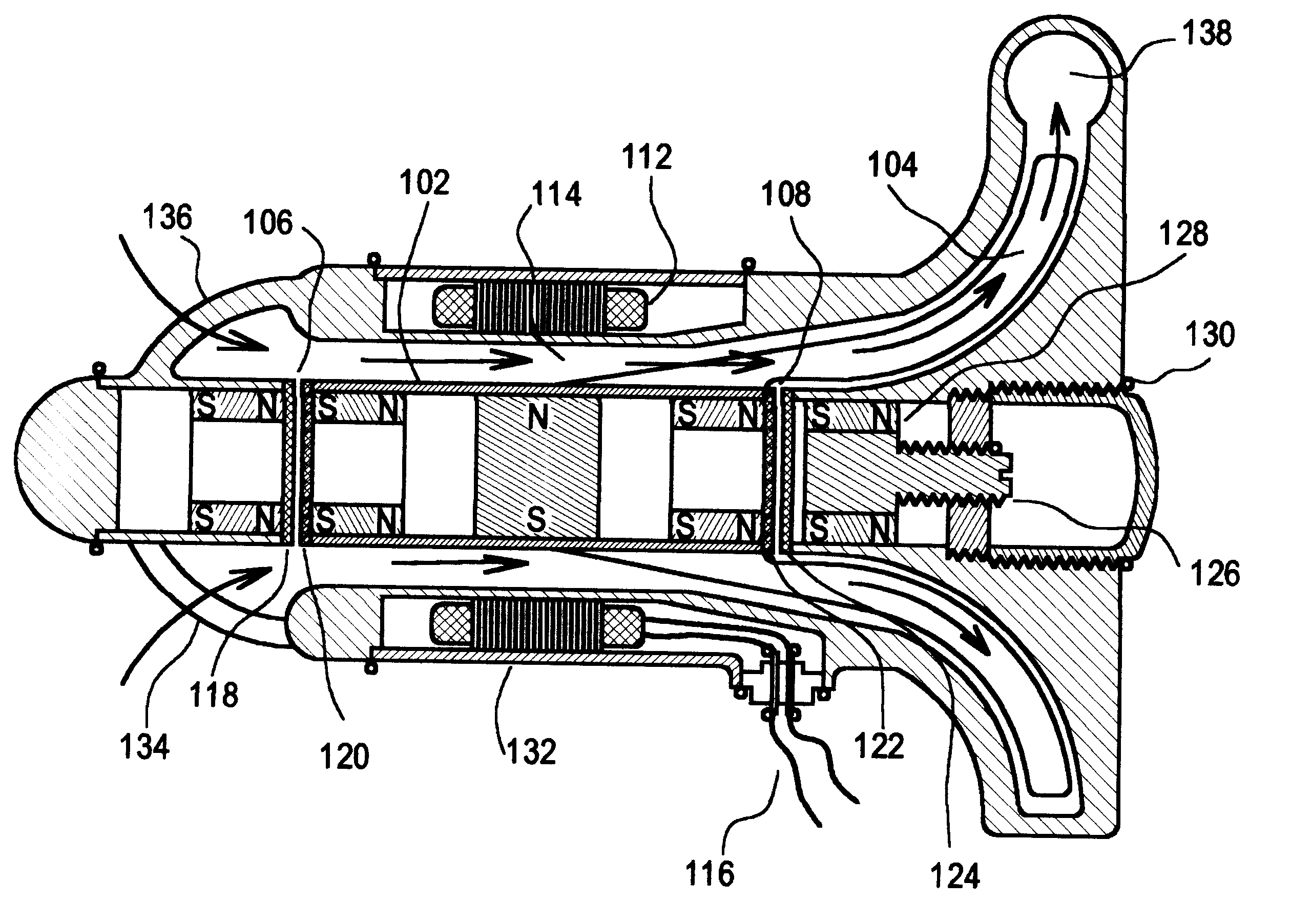

A generally cylindrical rotor very closely confined between two rigid thrust bearing surfaces is radially suspended by an array of attracting or repelling magnets or by a combination of permanent magnets and ring shaped members composed of ferromagnetic material. The geometry permits very small spacing between magnetic components to achieve high radial stiffness. High magnetic axial forces exerted between the rotor and stationary component on one end of the rotor are counter-balanced by equal and opposite forces at the other end of the rotor. Precise positioning of the rotor in the location where the opposing axial magnetic forces counterballance each other yields a net magnetic axial force on the rotor of near zero, hence the reference to this as the null position. Wear resistant mechanical thrust bearings confine the rotor axially to maintain this position during rotatioin. Precisely balance the magnetic axial forces in the proper geometry with relation to the mechanical thrust bearings. Blood pumps utilizing this type of bearing are disclosed, including both axial flow pump and centrifugal flow pump configurations with high flow washing of the junction of the rotating and stationary parts to prevent thrombus accumulation.

Owner:JARVIK ROBERT

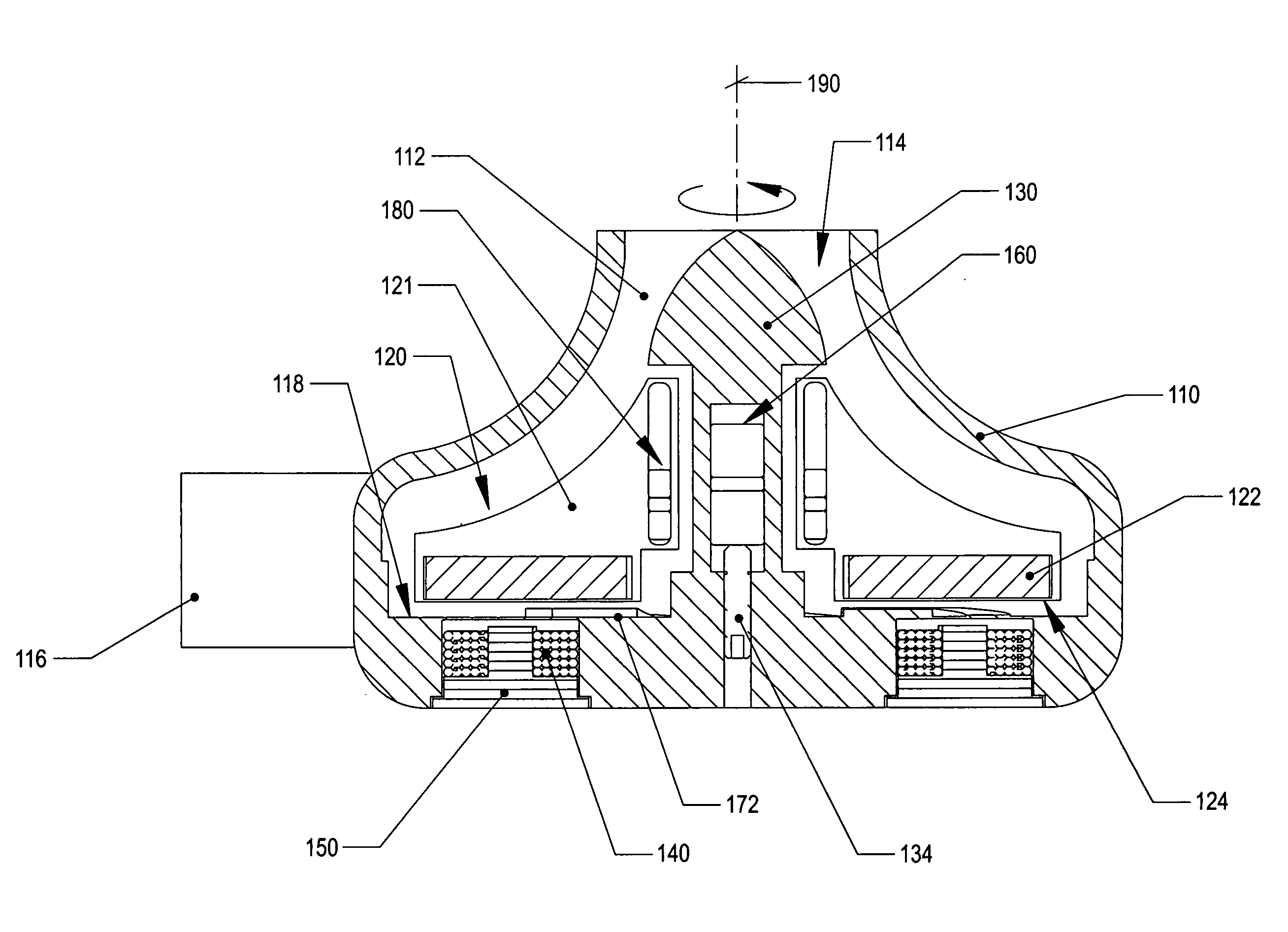

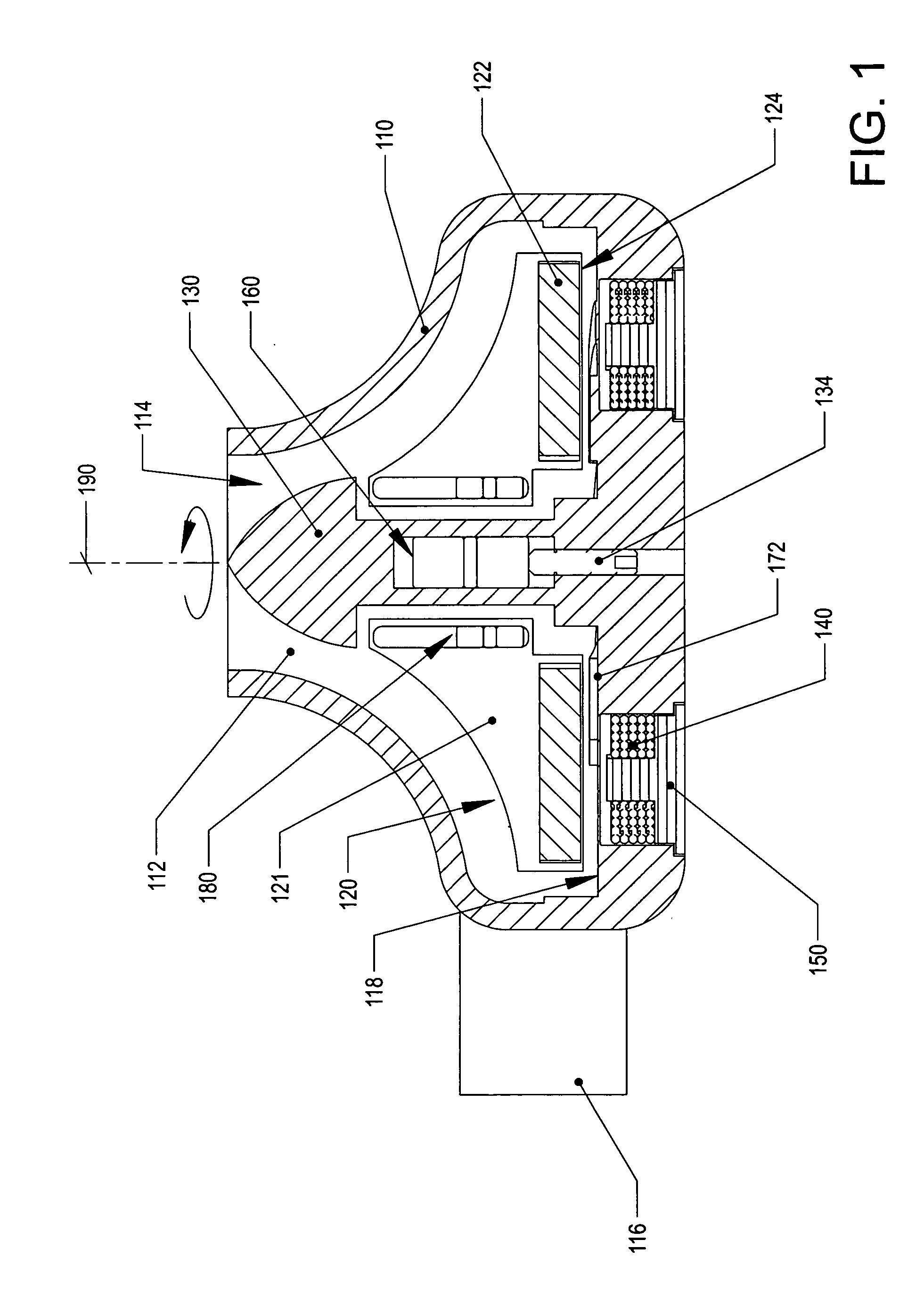

Hybrid magnetically suspended and rotated centrifugal pumping apparatus and method

InactiveUS6074180AAvoid displacementEfficient startSpecific fluid pumpsPump componentsMotor speedRotary pump

An apparatus and method for a centrifugal fluid pump for pumping sensitive biological fluids, which includes (i) an integral impeller and rotor which is entirely supported by an integral combination of permanent magnets and electromagnetic bearings and rotated by an integral motor, (ii) a pump housing and arcuate passages for fluid flow and containment, (iii) a brushless driving motor embedded and integral with the pump housing, (iv) a power supply, and (v) specific electronic sensing of impeller position, velocity or acceleration using a self-sensing method and physiological control algorithm for motor speed and pump performance based upon input from the electromagnetic bearing currents and motor back emf-all fitly joined together to provide efficient, durable and low maintenance pump operation. A specially designed impeller and pump housing provide the mechanism for transport and delivery of fluid through the pump to a pump output port with reduced fluid turbulence.

Owner:WORLD HEART +2

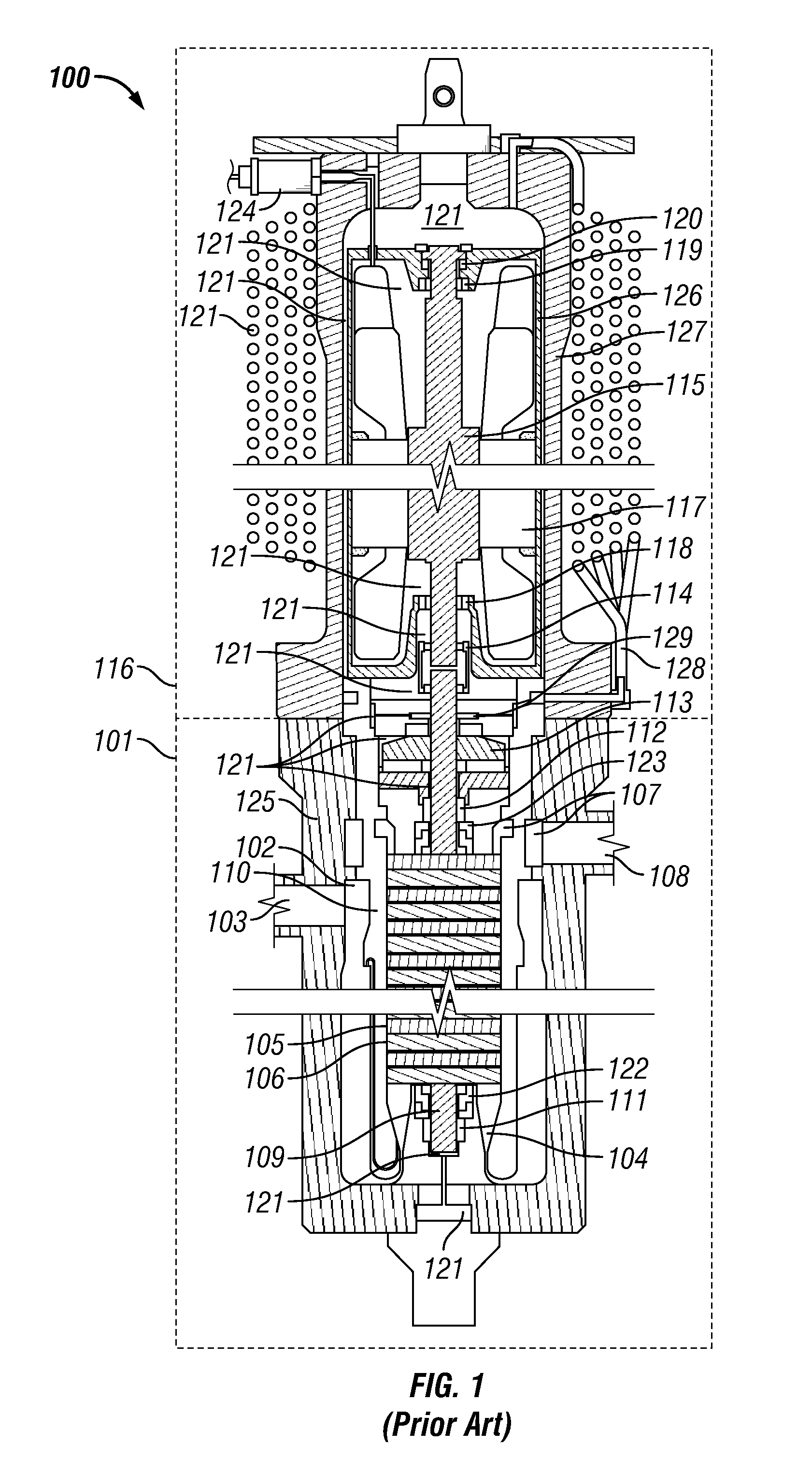

Streamlined unobstructed one-pass axial-flow pump

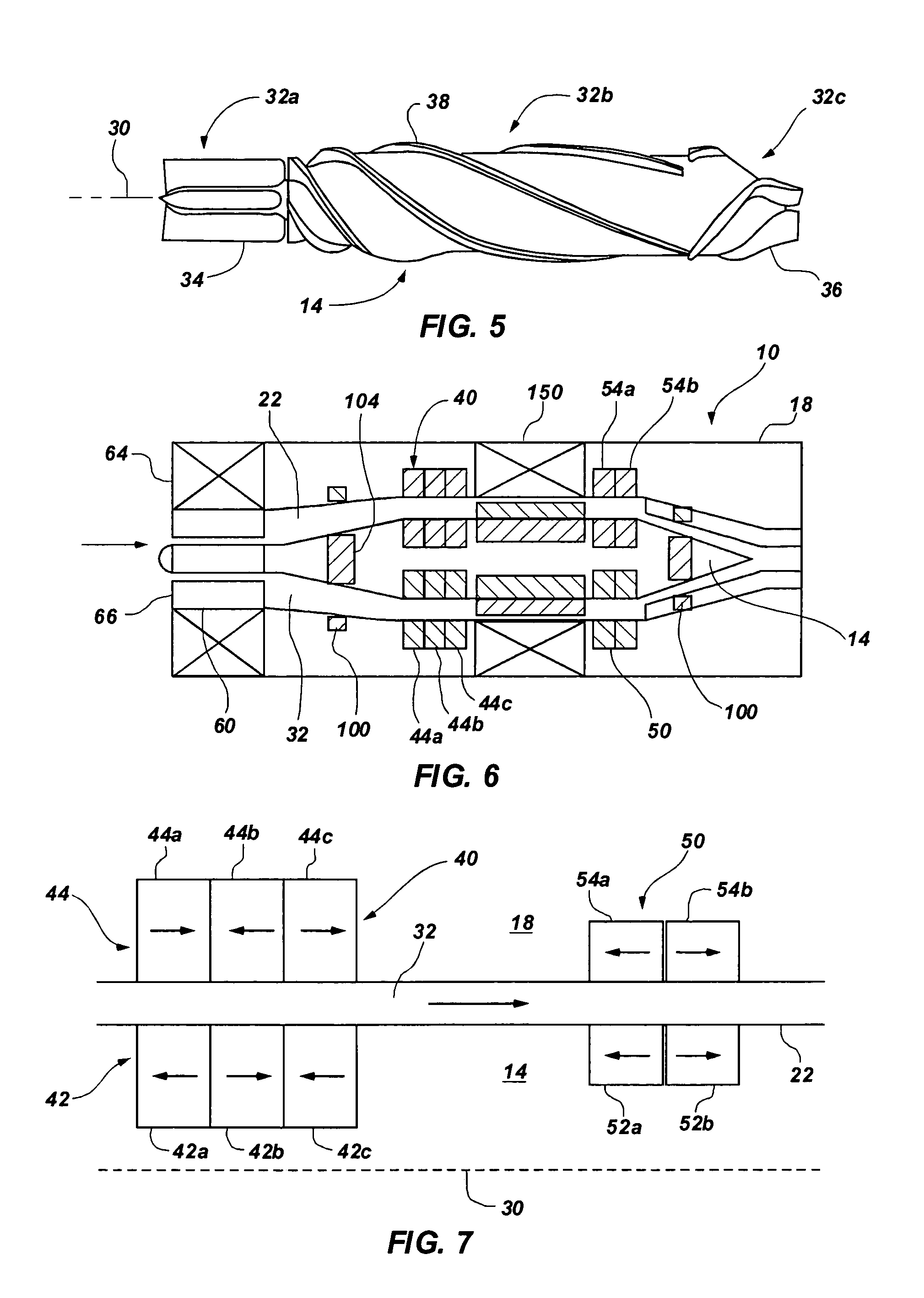

InactiveUS7229258B2Small sizeIncreased operating lifeBlood pumpsIntravenous devicesAxial-flow pumpOne pass

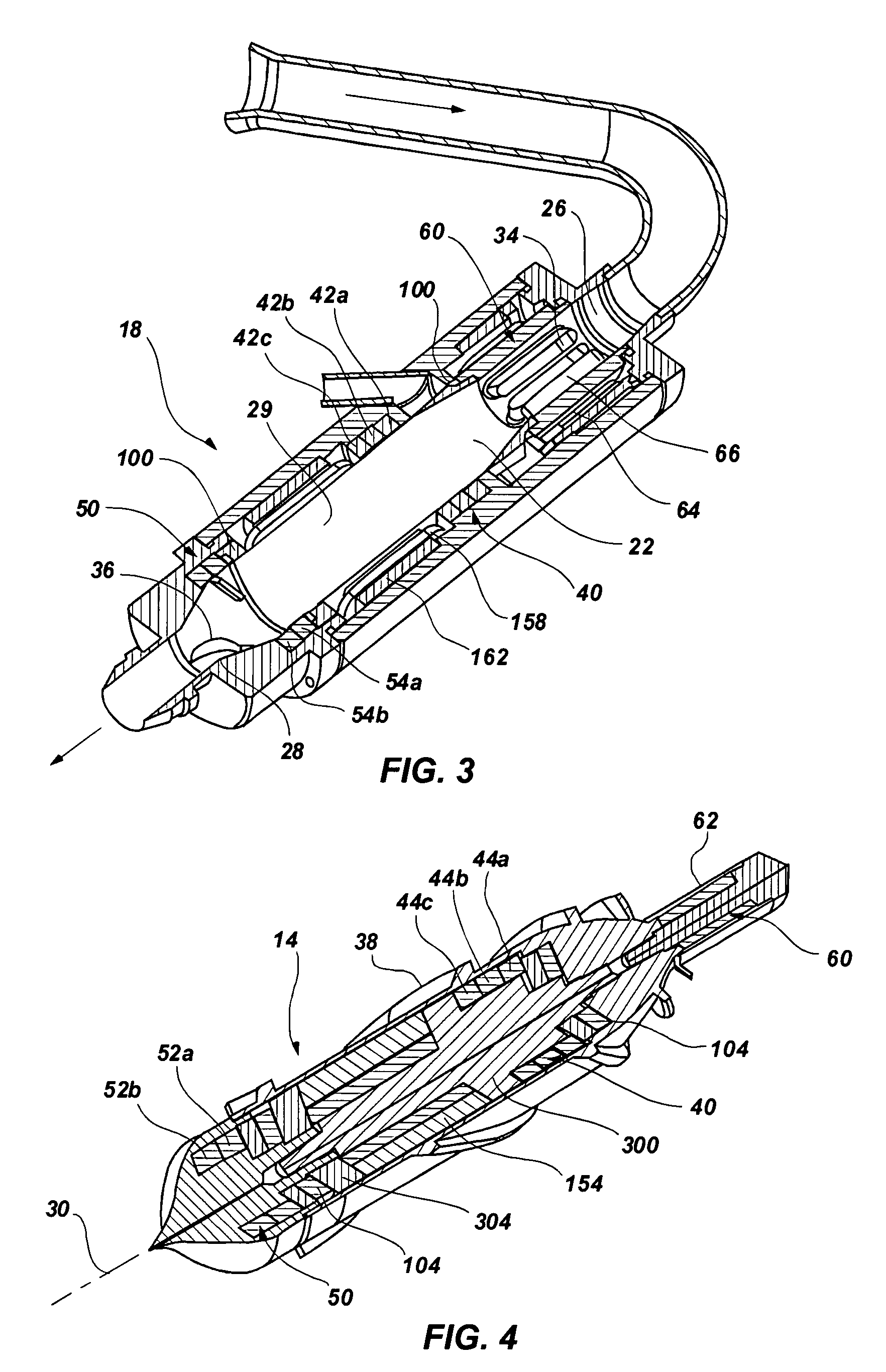

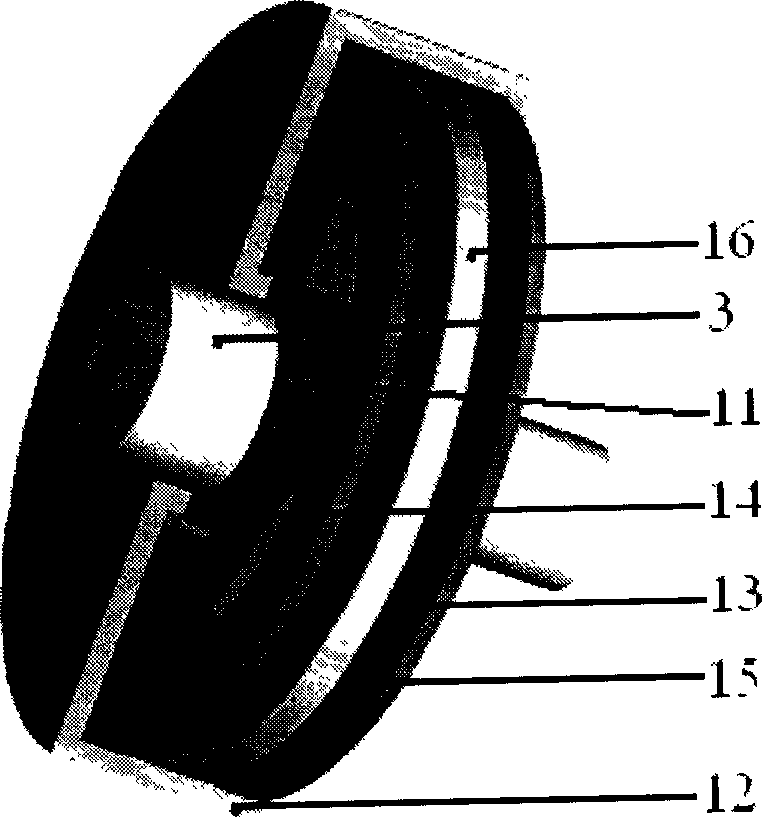

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings (passive permanent and active electromagnetic) having impeller magnets on the impeller and stator magnets or coils / poles on the stator. A motor includes impeller magnets on the impeller and coils / poles associated with the stator. A single, annular blood flow path extends axially through the cavity between the impeller and the stator, and between the impeller magnets on the impeller and the stator magnets or the coils / poles on the stator.

Owner:MEDFORTE RES FOUND +1

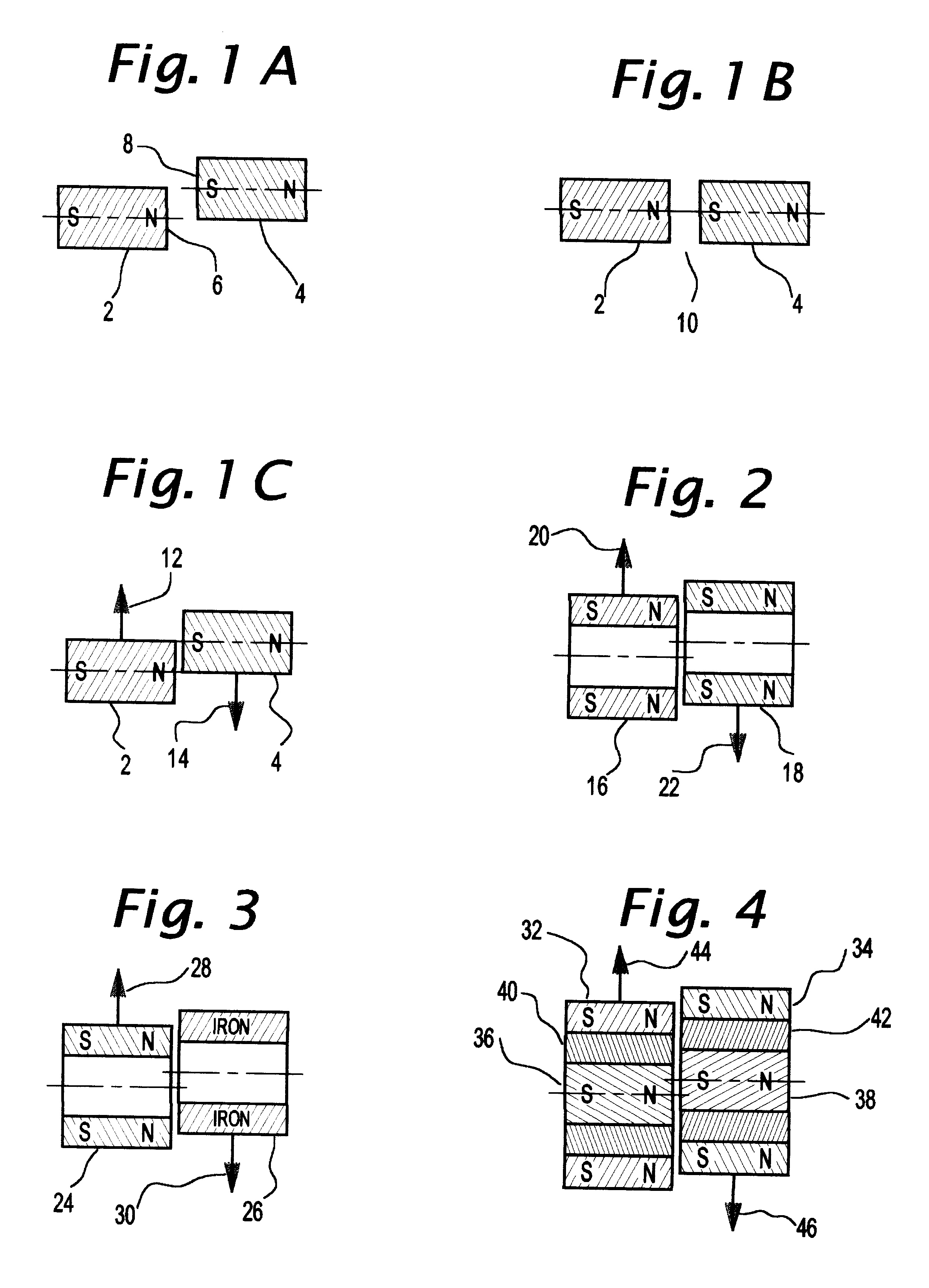

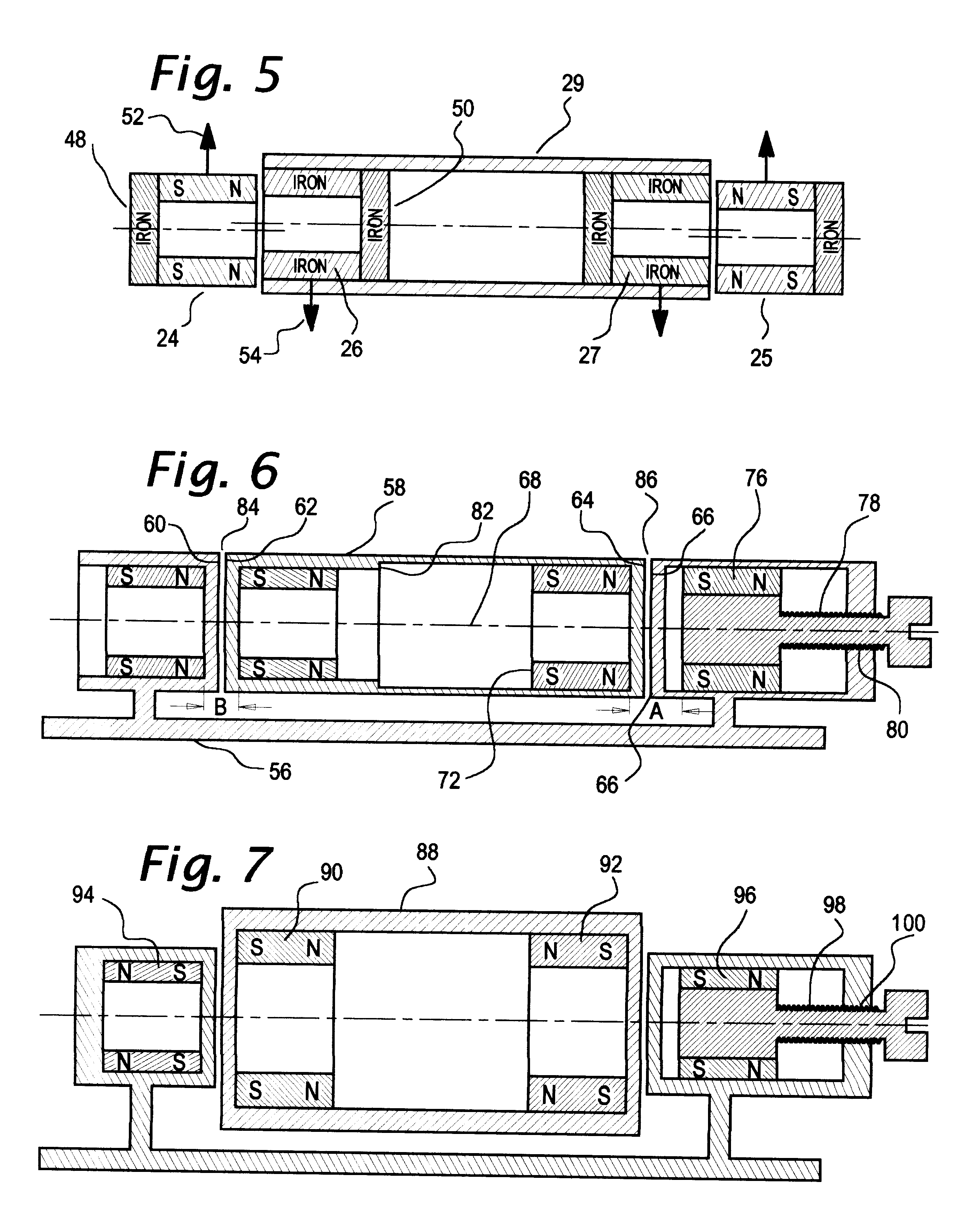

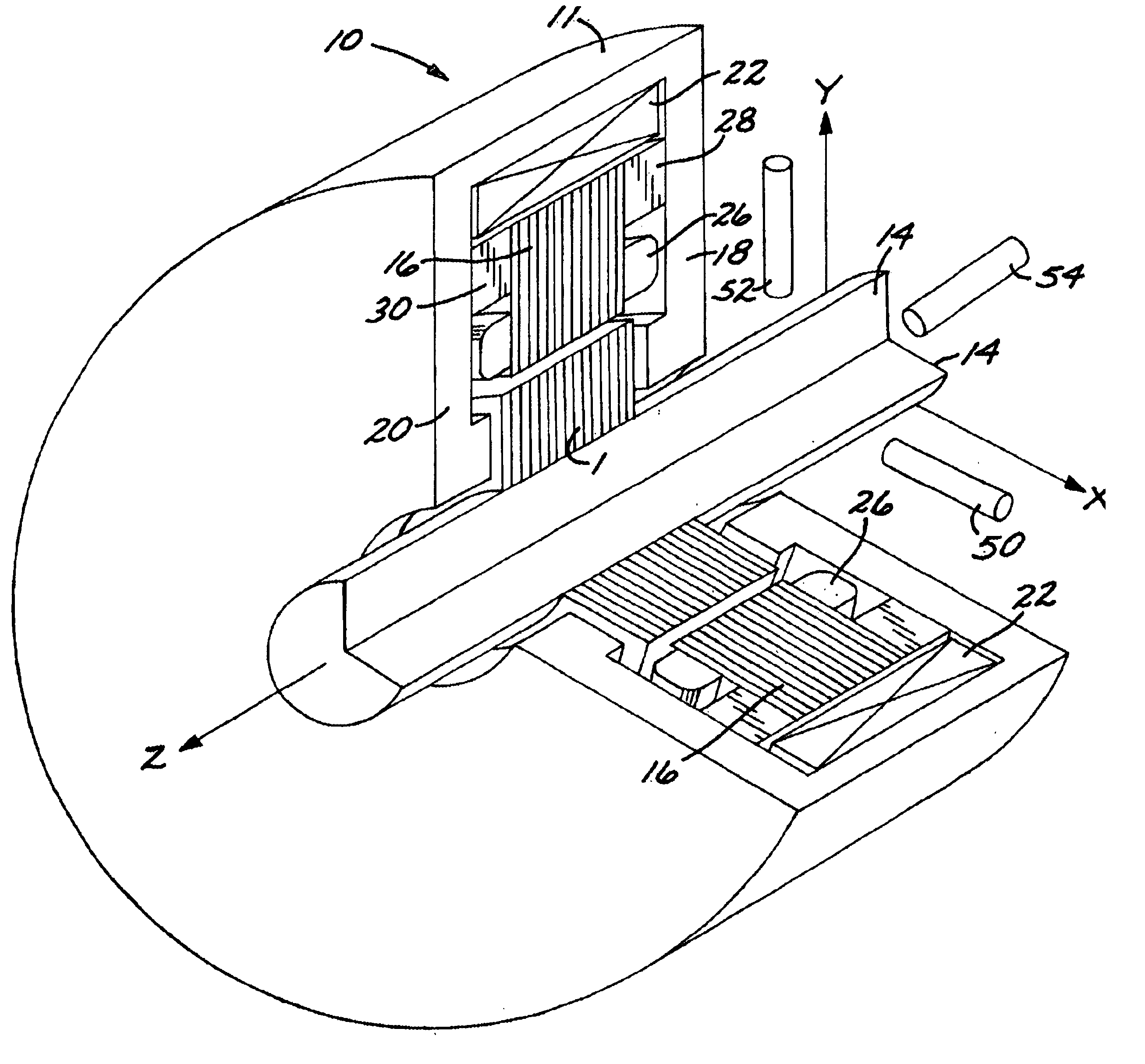

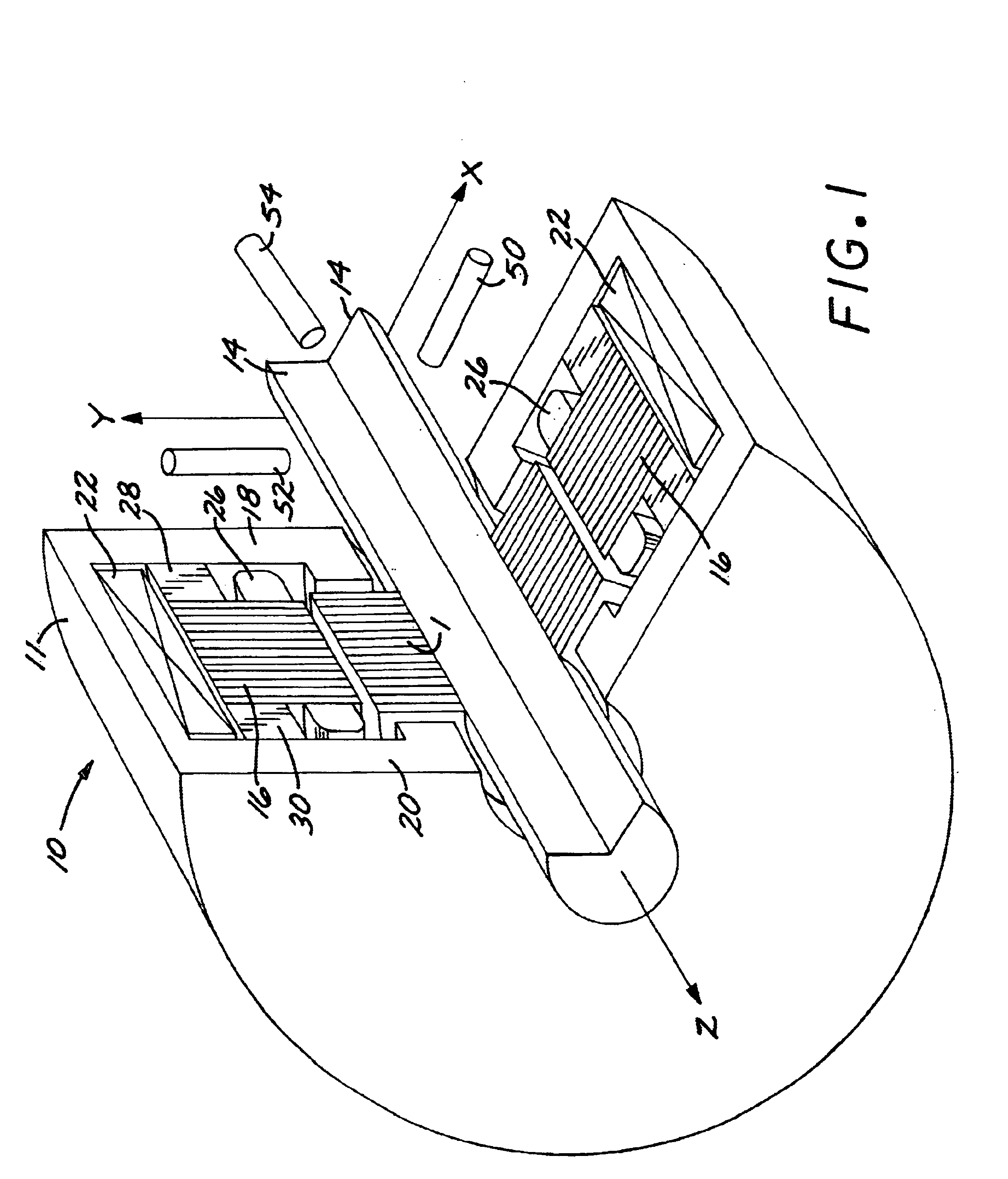

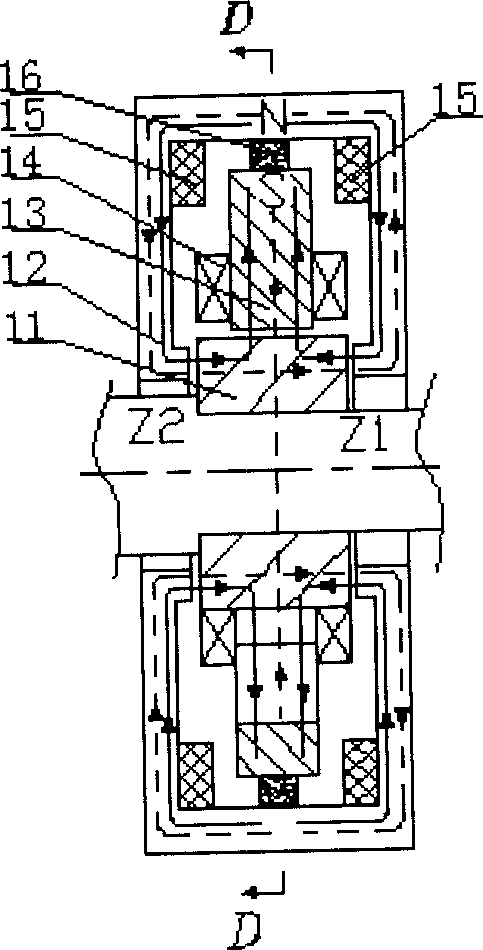

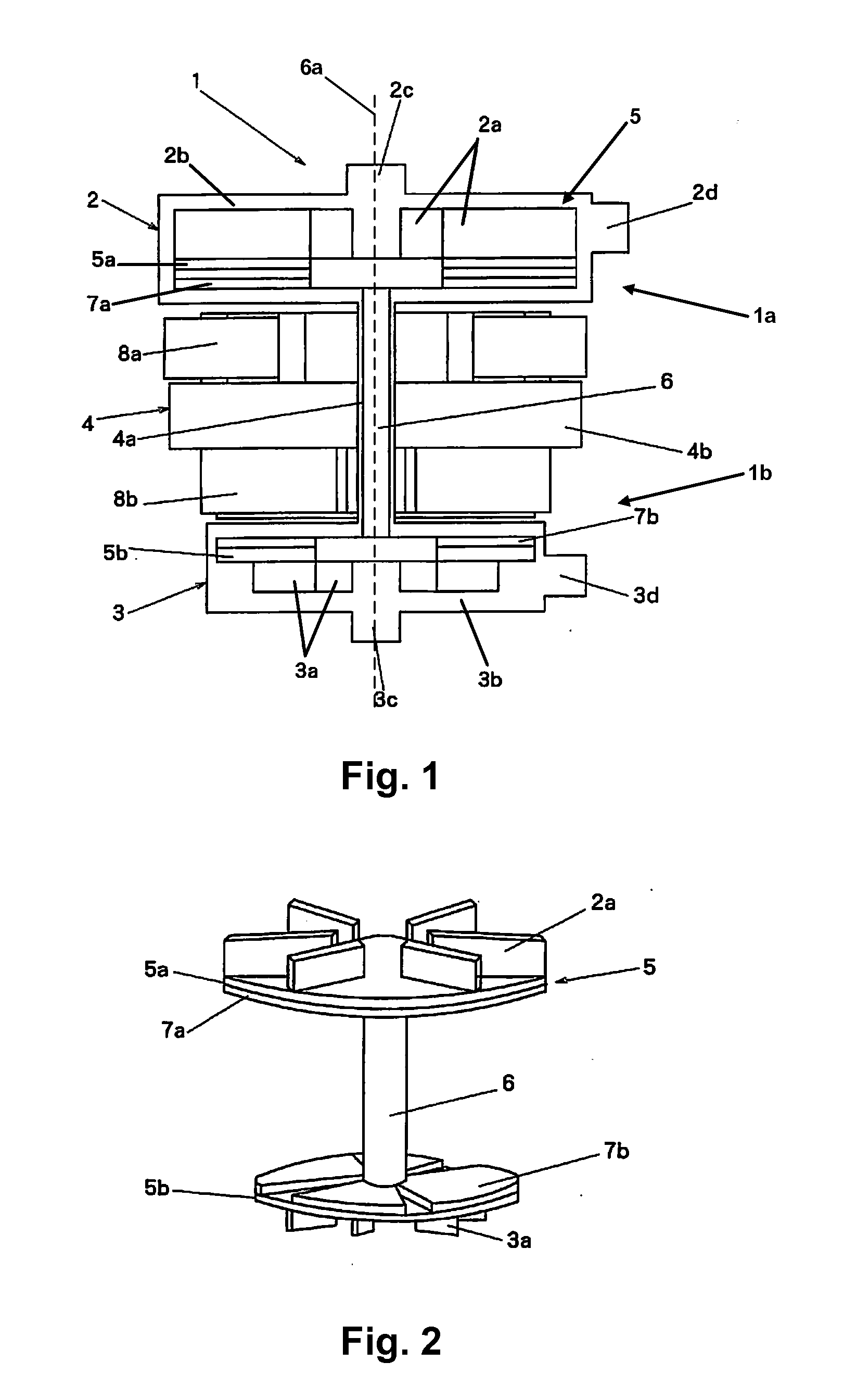

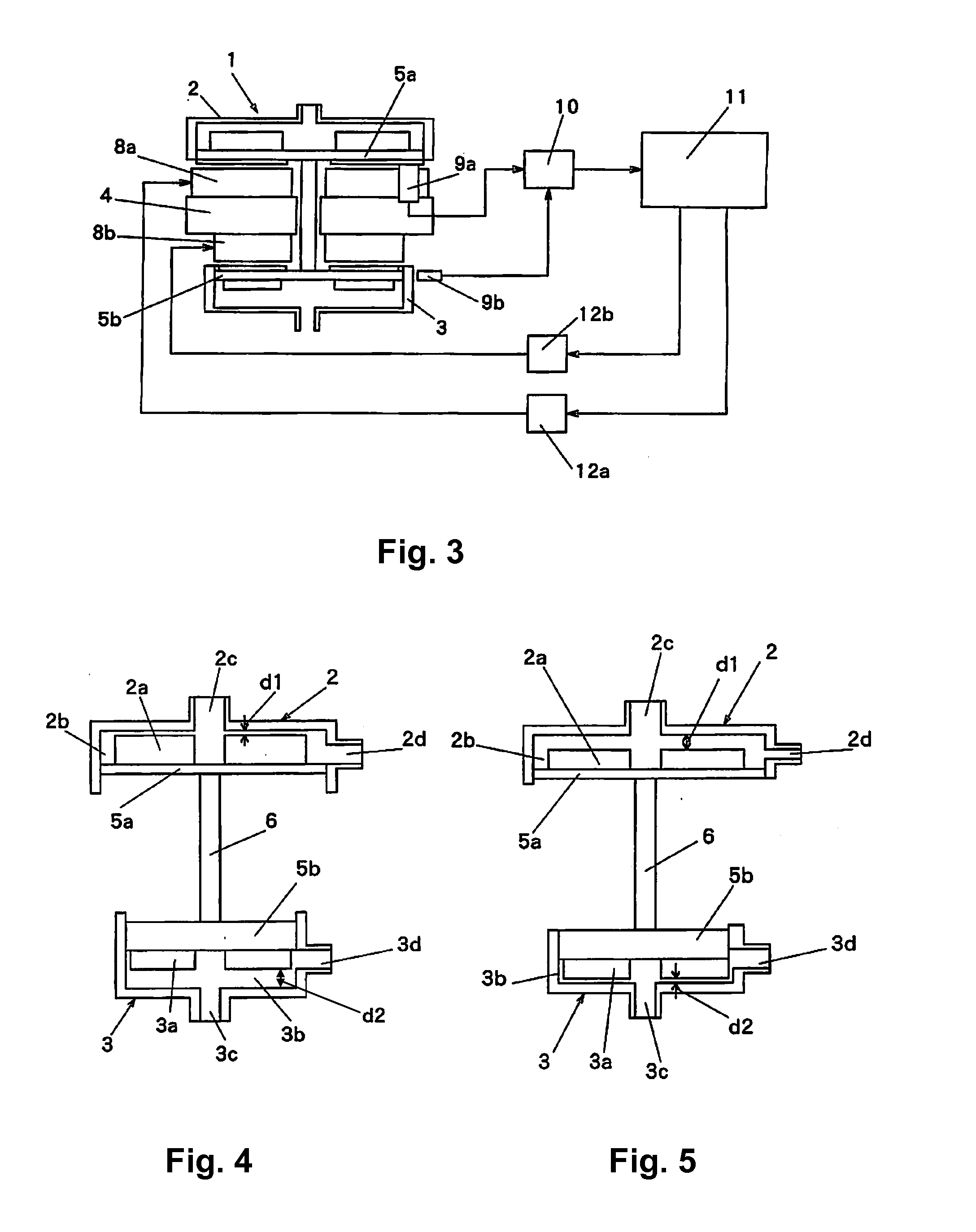

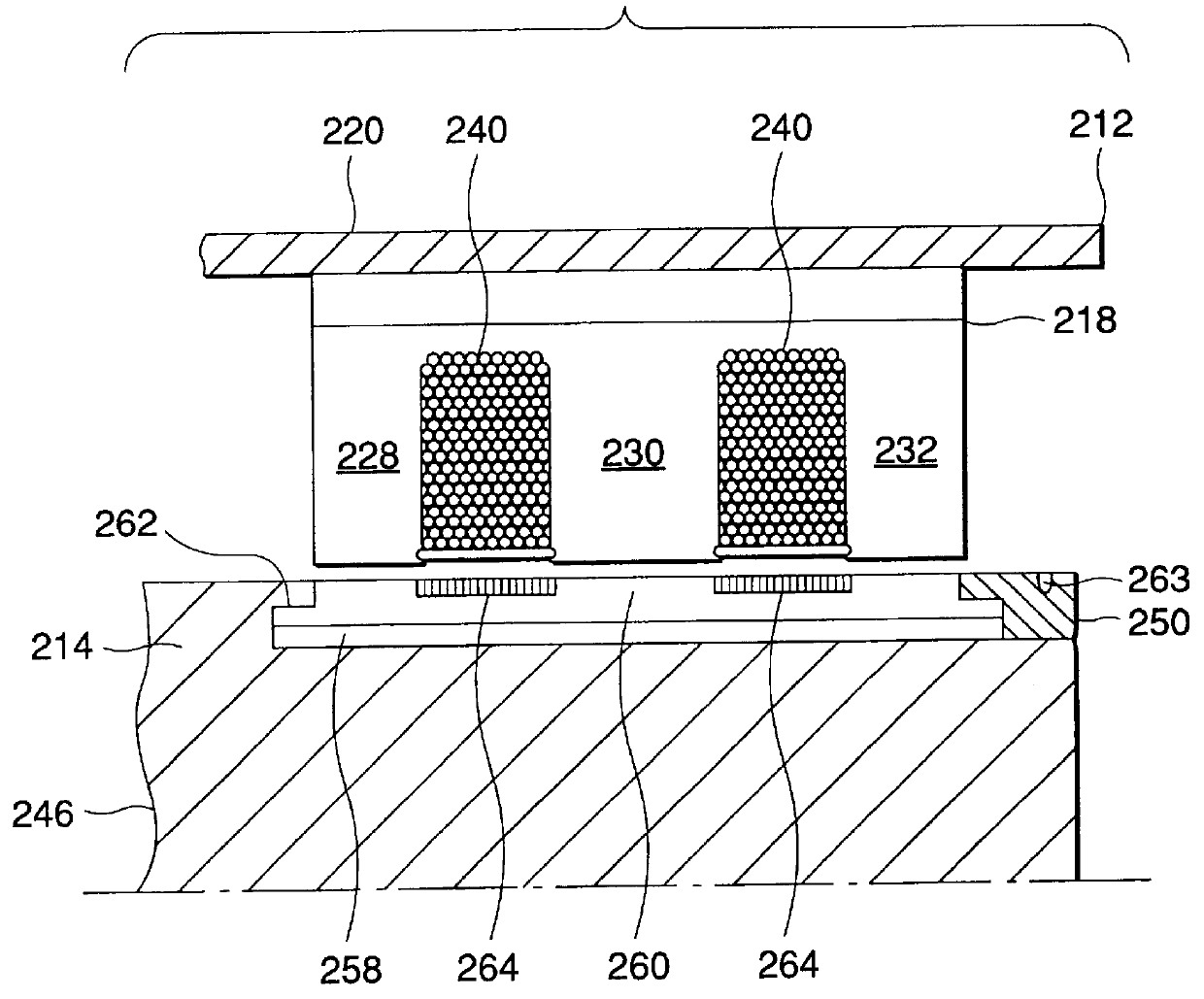

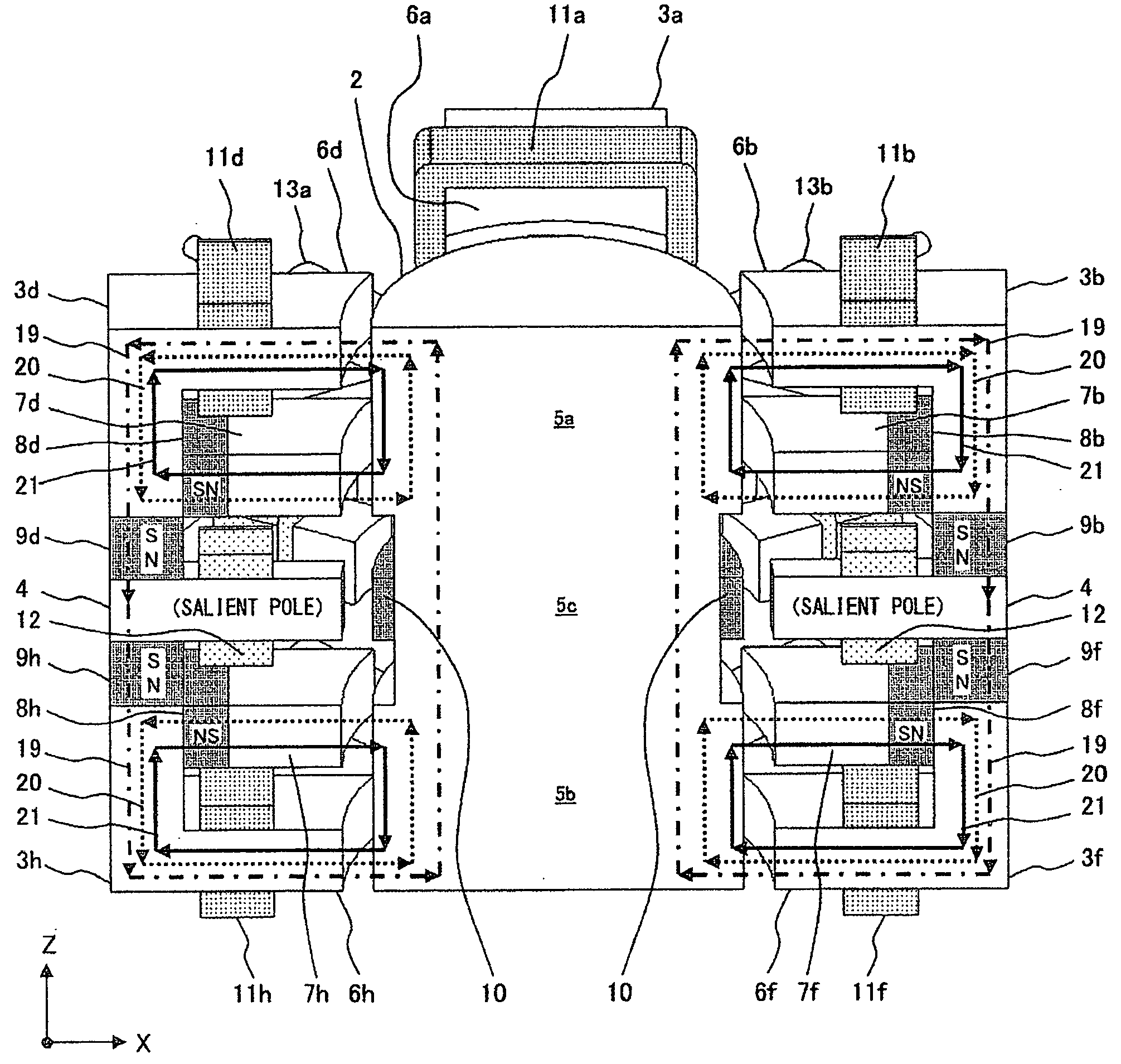

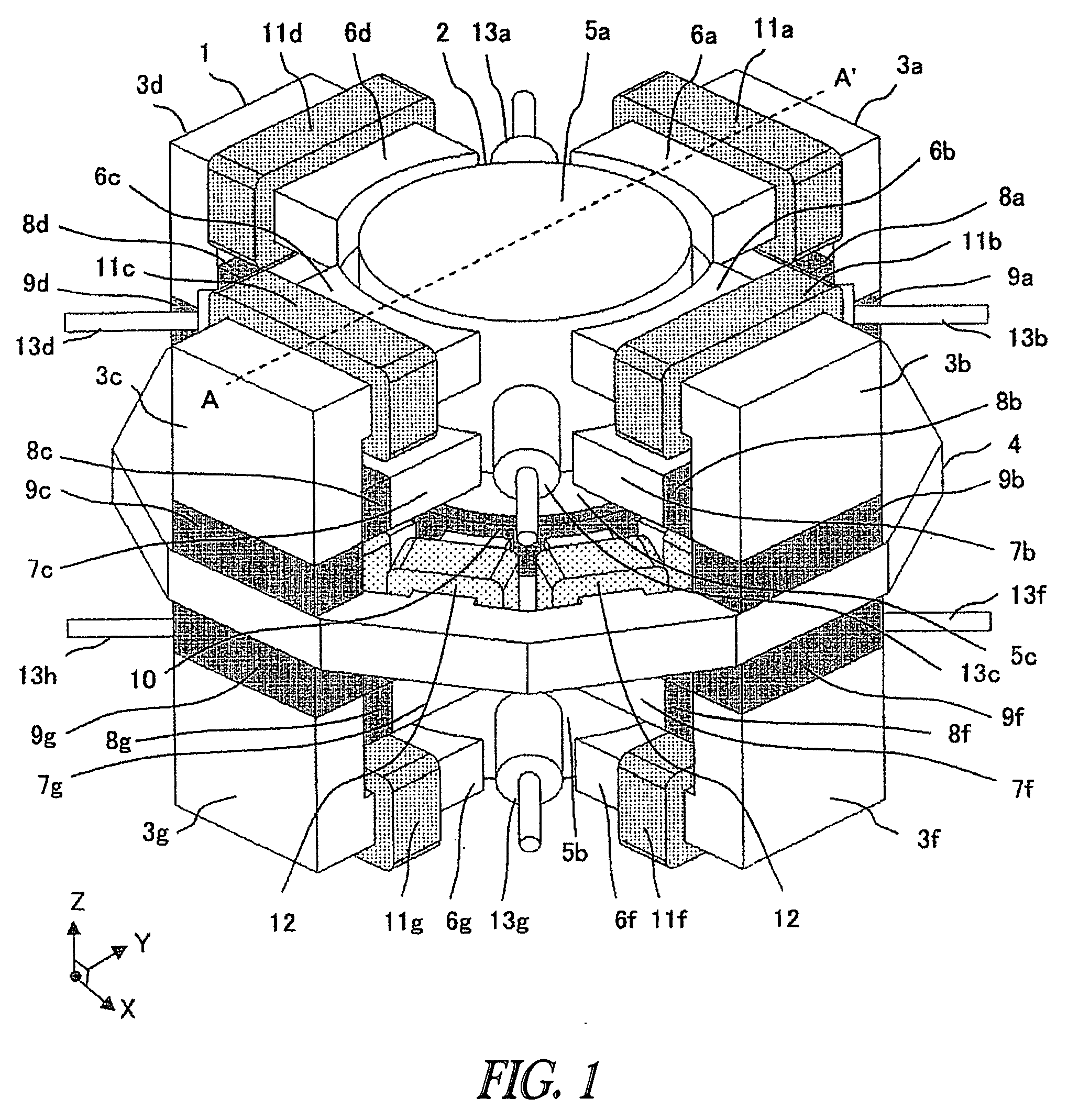

Method and apparatus for providing three axis magnetic bearing having permanent magnets mounted on radial pole stack

InactiveUS6727617B2Effective and inexpensive techniqueHighly linear magnetic biasMechanical energy handlingBearingsAxial displacementAudio power amplifier

An improved magnetic bearing that uses permanent magnets to provide the bias flux. The magnetic circuits generating the control flux and bias fluxes are substantially non-coincident but share the same path over some portions that include radial and axial airgaps allowing for a low reluctance and an efficient path for the electromagnetic flux. The flux paths of the permanent magnets are completely defined with minimized airgaps for achieving higher forces and efficiency and very low control currents that produce extremely large forces. A single coil and amplifier for the axial force control and two coils with one associated amplifier for each radial axis of control provides simplicity and cost effectiveness. A single thrust disk is provided that is reacted against for both radial and the axial displacement. The permanent magnets used in the present invention are first fabricated and axially magnetized as segments or as continuous rings prior to being mounted on the sides of the rotor pole, providing an effective and inexpensive technique of manufacturing magnetic bearings.

Owner:CALNETIX TECH +1

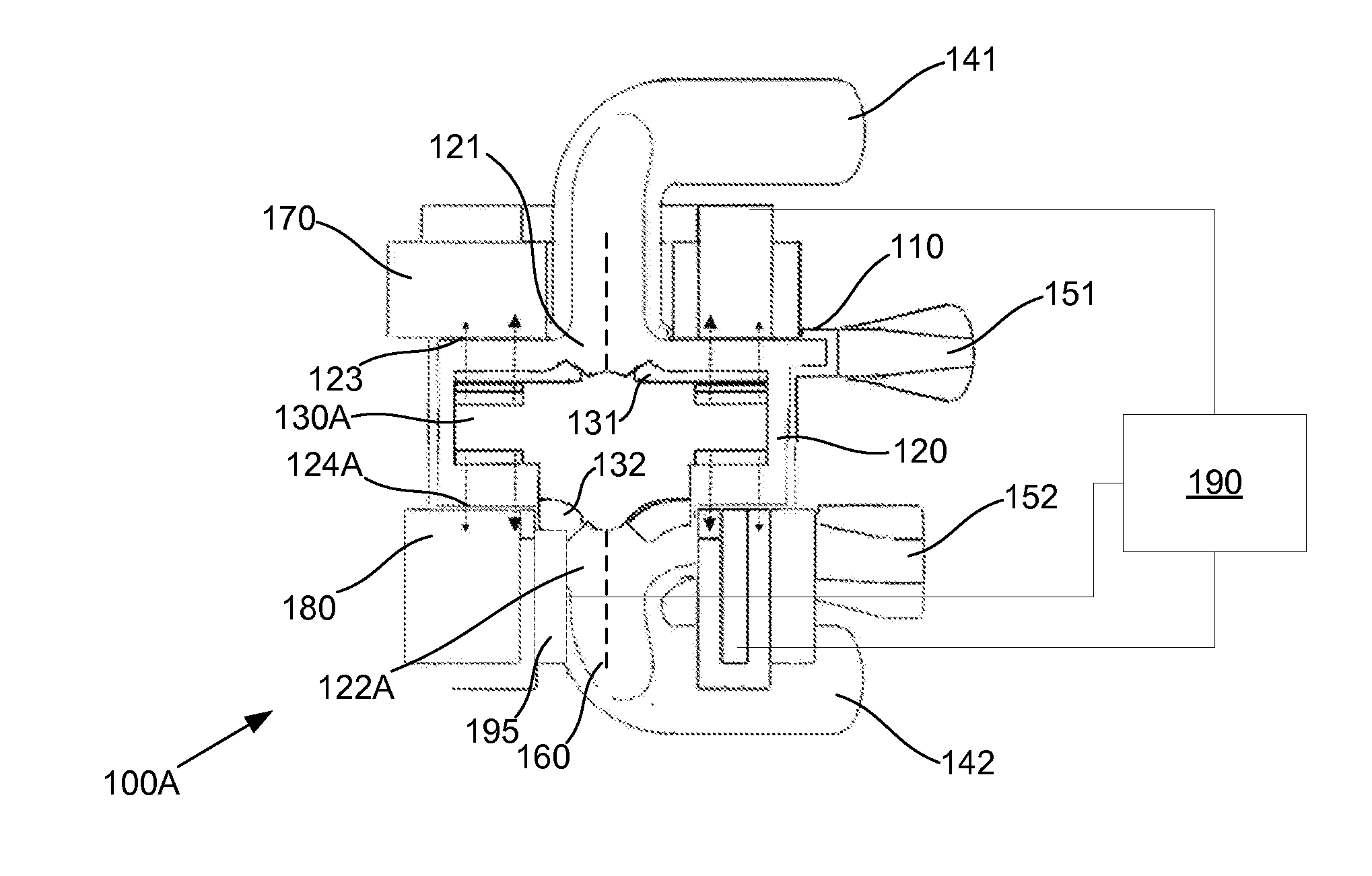

Integrated magnetic bearing

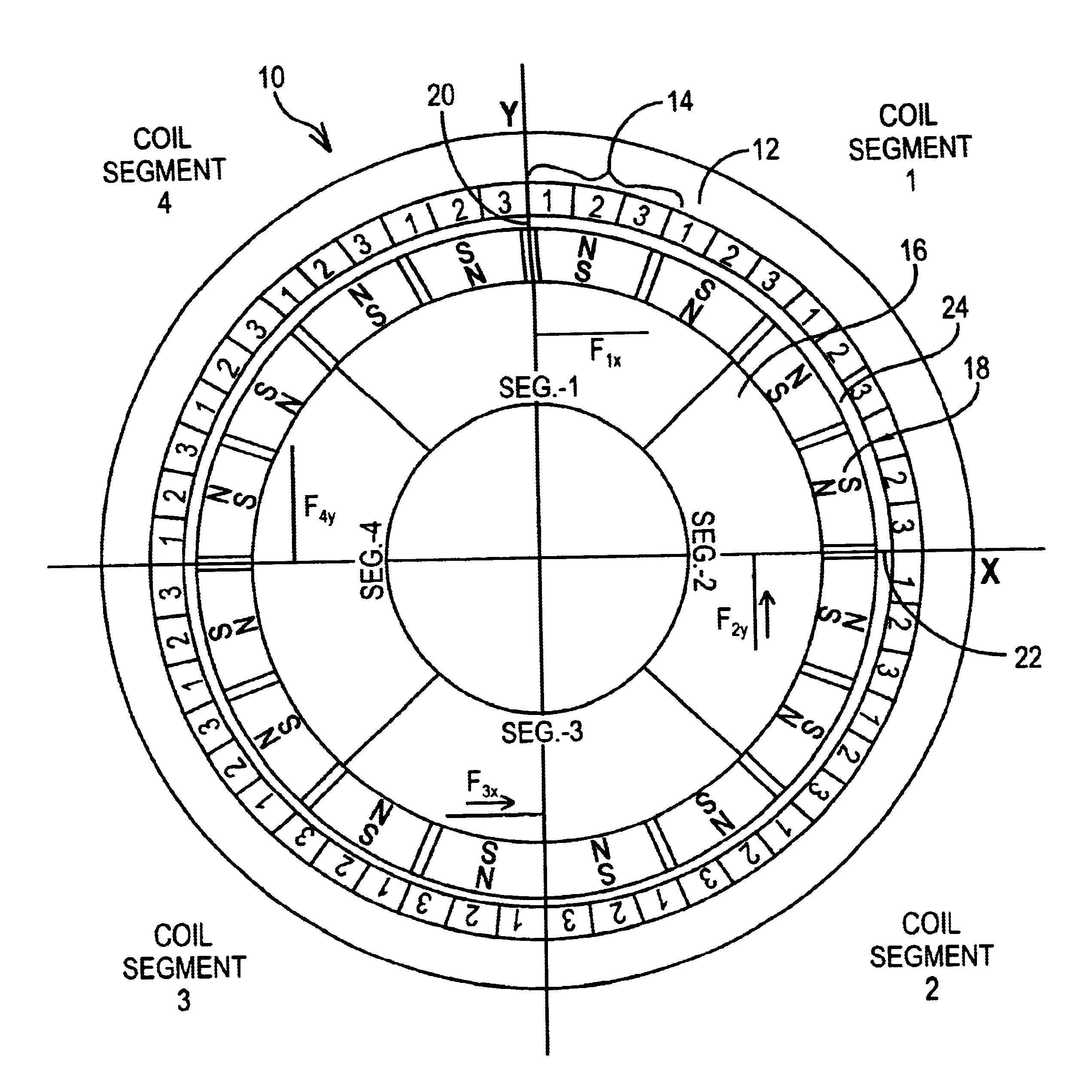

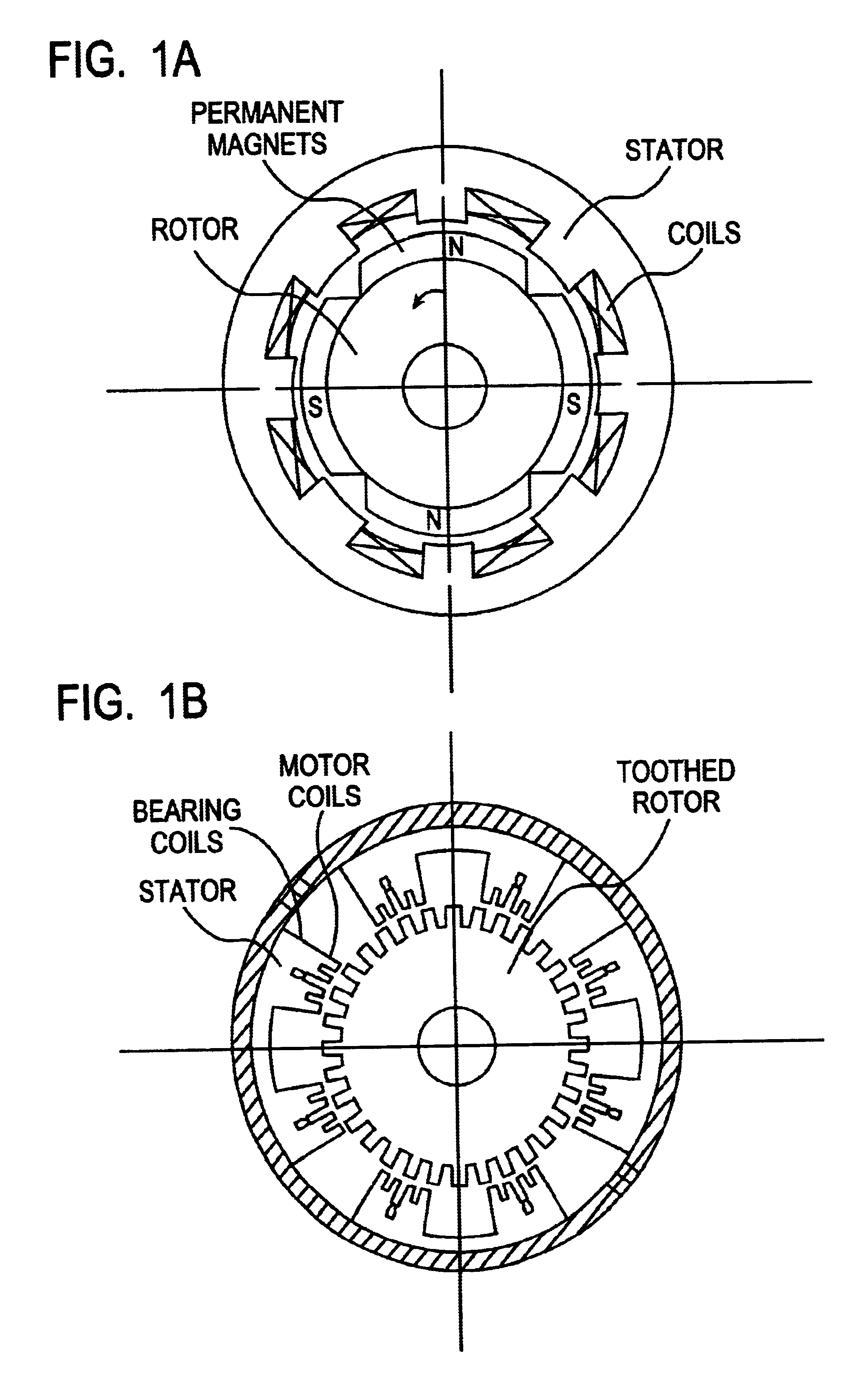

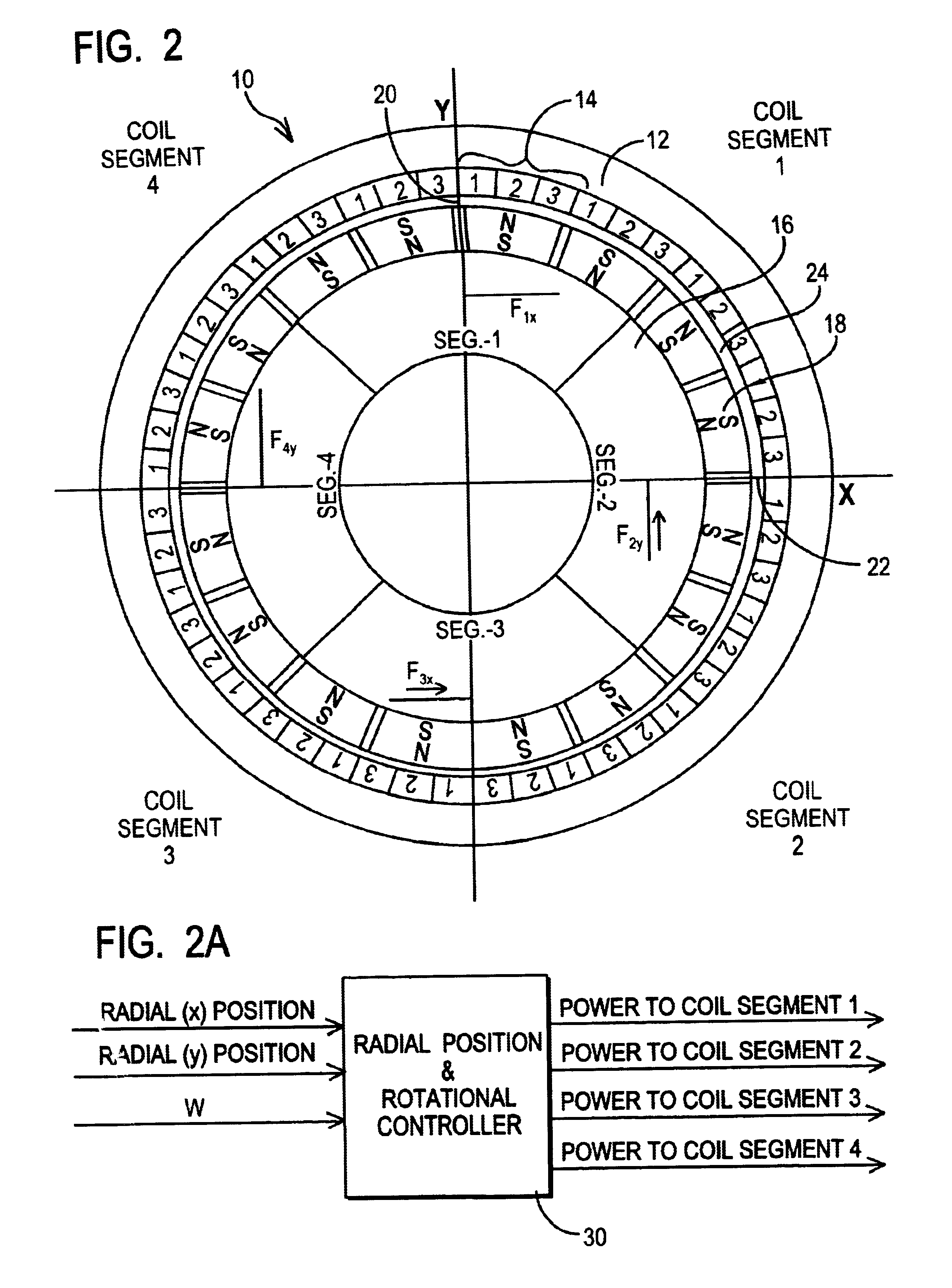

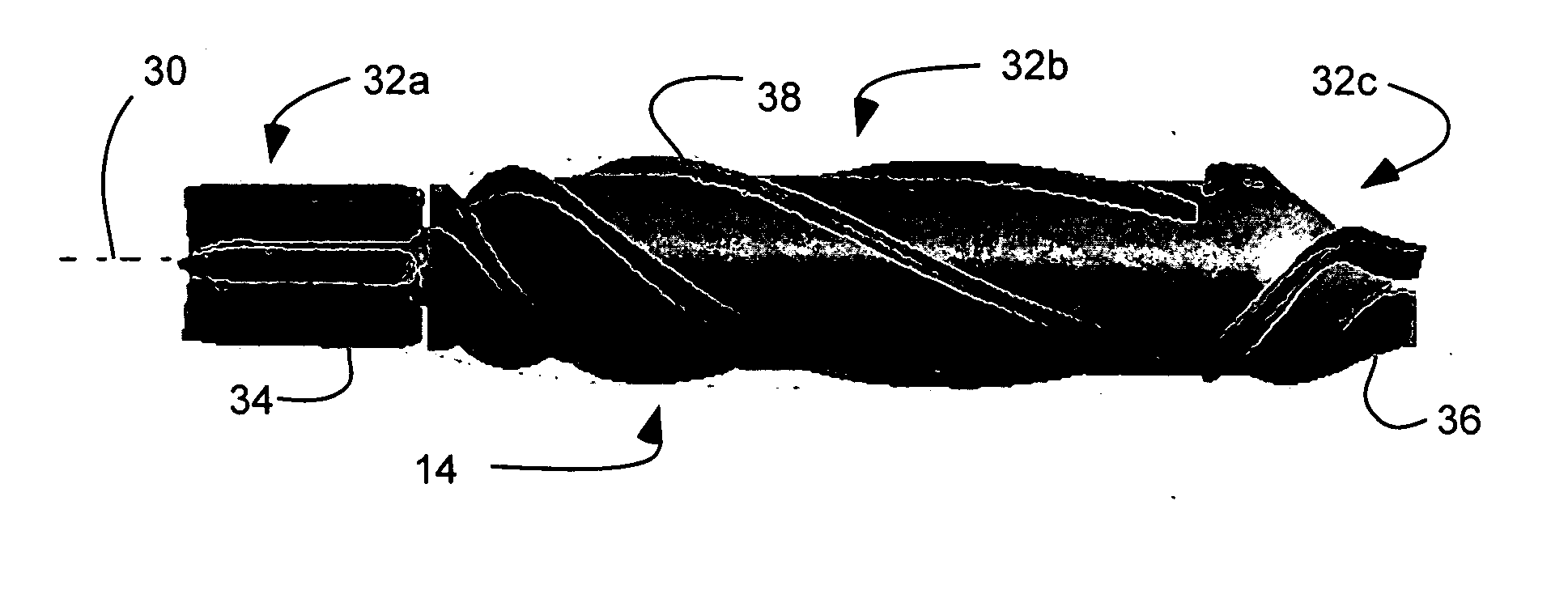

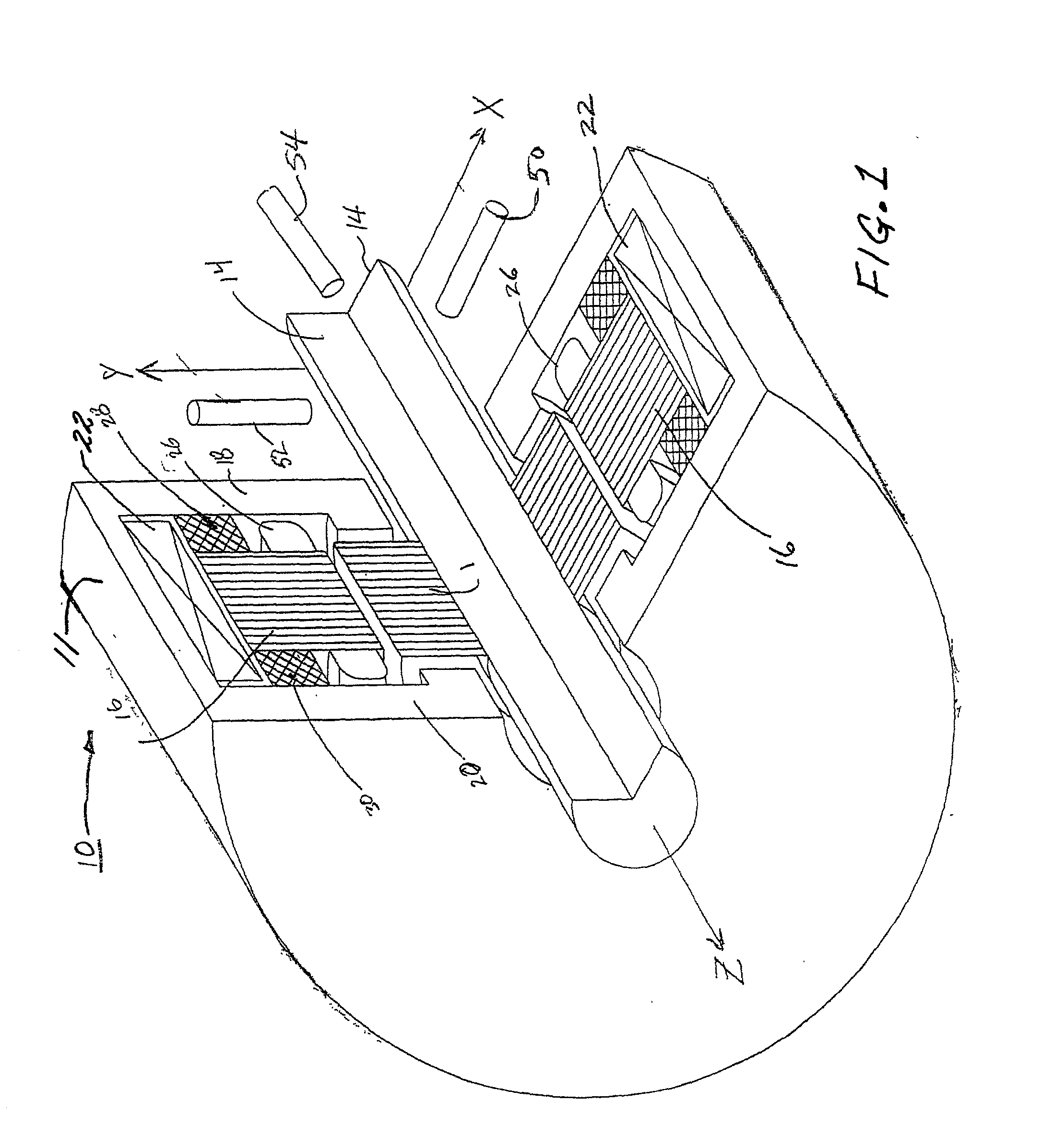

The present invention provides a rotational magnetic gimbal with an integral magnetic bearing. Brushless DC motor technology provides electromagnetic suspension, using a single electromagnetic actuator to perform both the radial bearing and rotary torque (motoring) functions. An integrated motor and magnetic bearing consistent with the invention comprises a rotor comprising a plurality of permanent magnets and a stator comprising a plurality of independently controlled coil segments magnetically coupled to the permanent magnets. Embodiments may further comprise first and second radial position sensors, the first radial position sensor disposed in or adjacent to a clearance gap between the rotor and the stator for sensing the position of the rotor with respect to the stator along a first axis, and a second radial position sensor disposed in or adjacent to the clearance gap between the rotor and the stator for sensing the position of the rotor with respect to the stator along a second axis. In method form, a method for providing integral electromagnetic motor and bearing functions comprises sensing a first radial position of a rotor, the rotor comprising a plurality of permanent magnets, with respect to a stator along a first axis, the stator comprising a plurality of independently controlled coil segments magnetically coupled to the permanent magnets; and sensing a second radial position of the rotor with respect to the stator along a second axis; and delivering current to at least one coil segment, the amount of current based on at least one sensed position.

Owner:AIREX CORP

Streamlined unobstructed one-pass axial-flow pump

InactiveUS20050135942A1Reduce coagulationSmall sizeBlood pumpsIntravenous devicesAxial-flow pumpImpeller

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings (passive permanent and active electromagnetic) having impeller magnets on the impeller and stator magnets or coils / poles on the stator. A motor includes impeller magnets on the impeller and coils / poles associated with the stator. A single, annular blood flow path extends axially through the cavity between the impeller and the stator, and between the impeller magnets on the impeller and the stator magnets or the coils / poles on the stator.

Owner:MEDFORTE RES FOUND +1

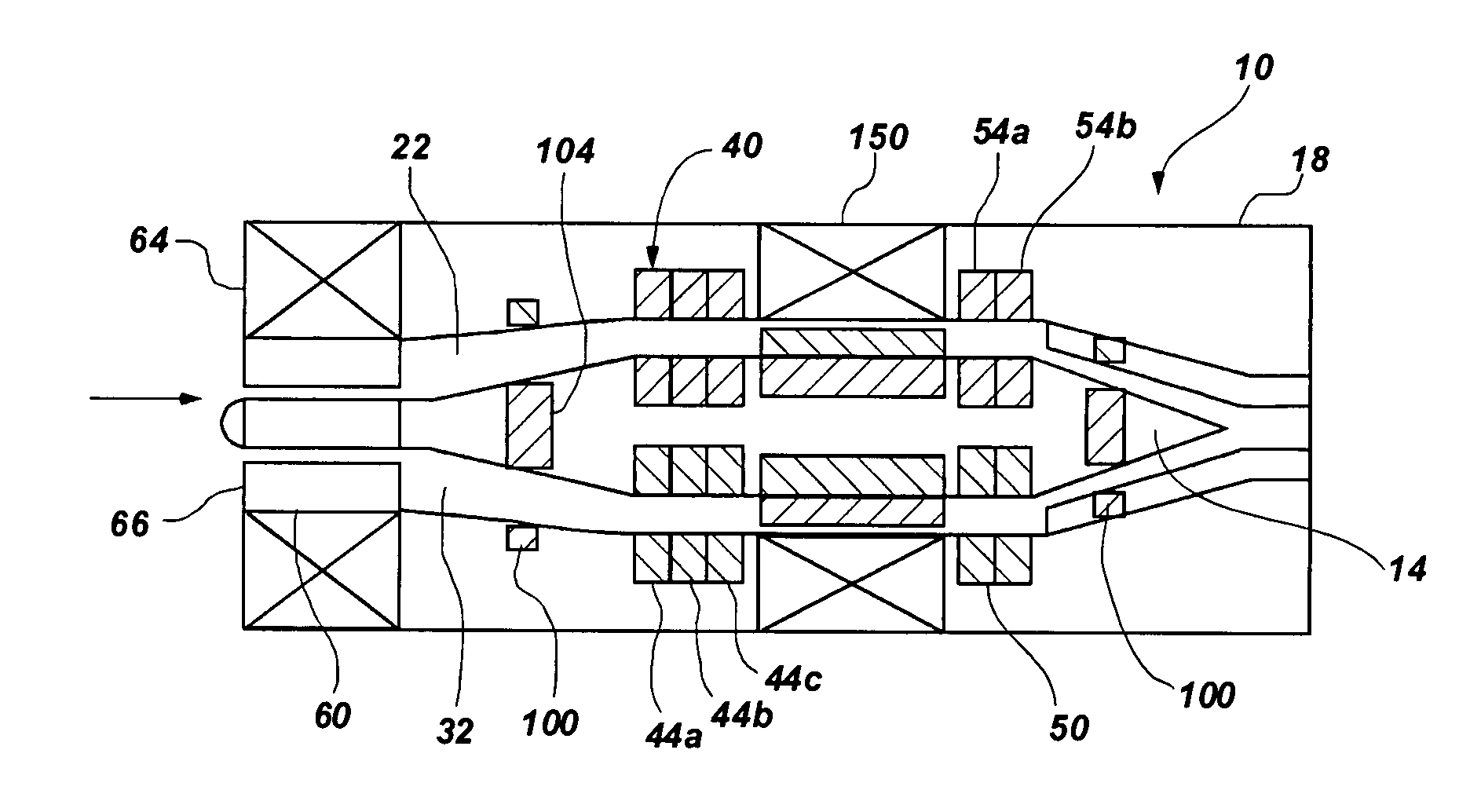

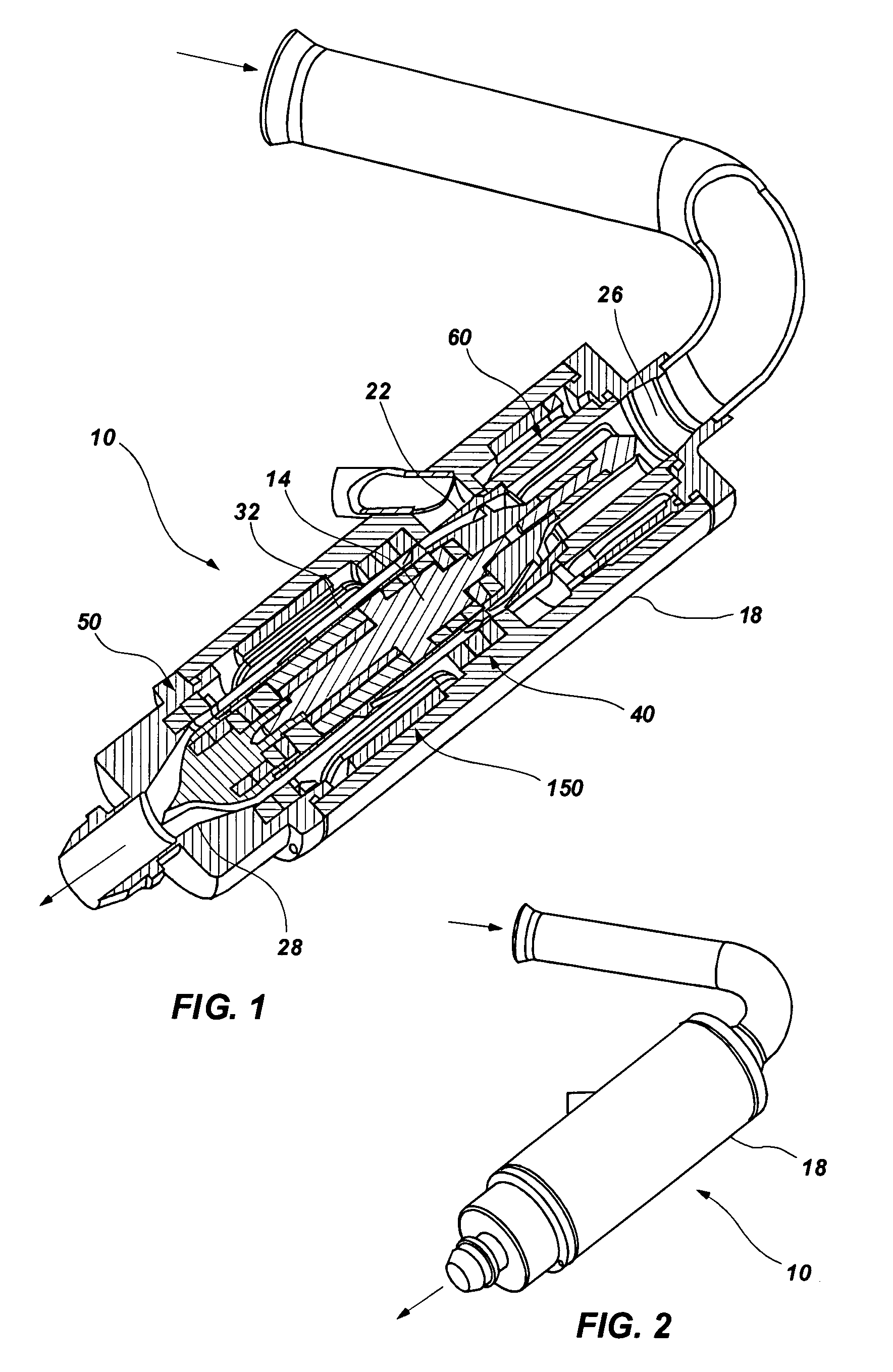

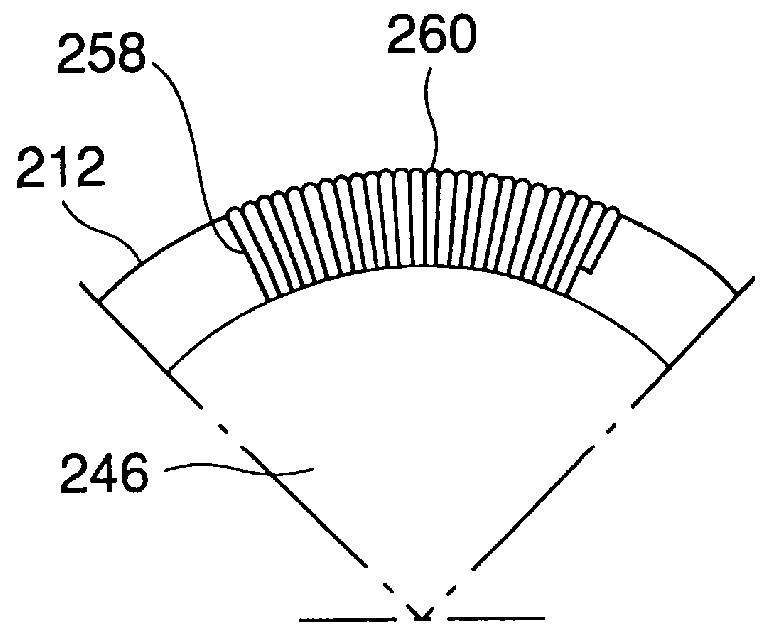

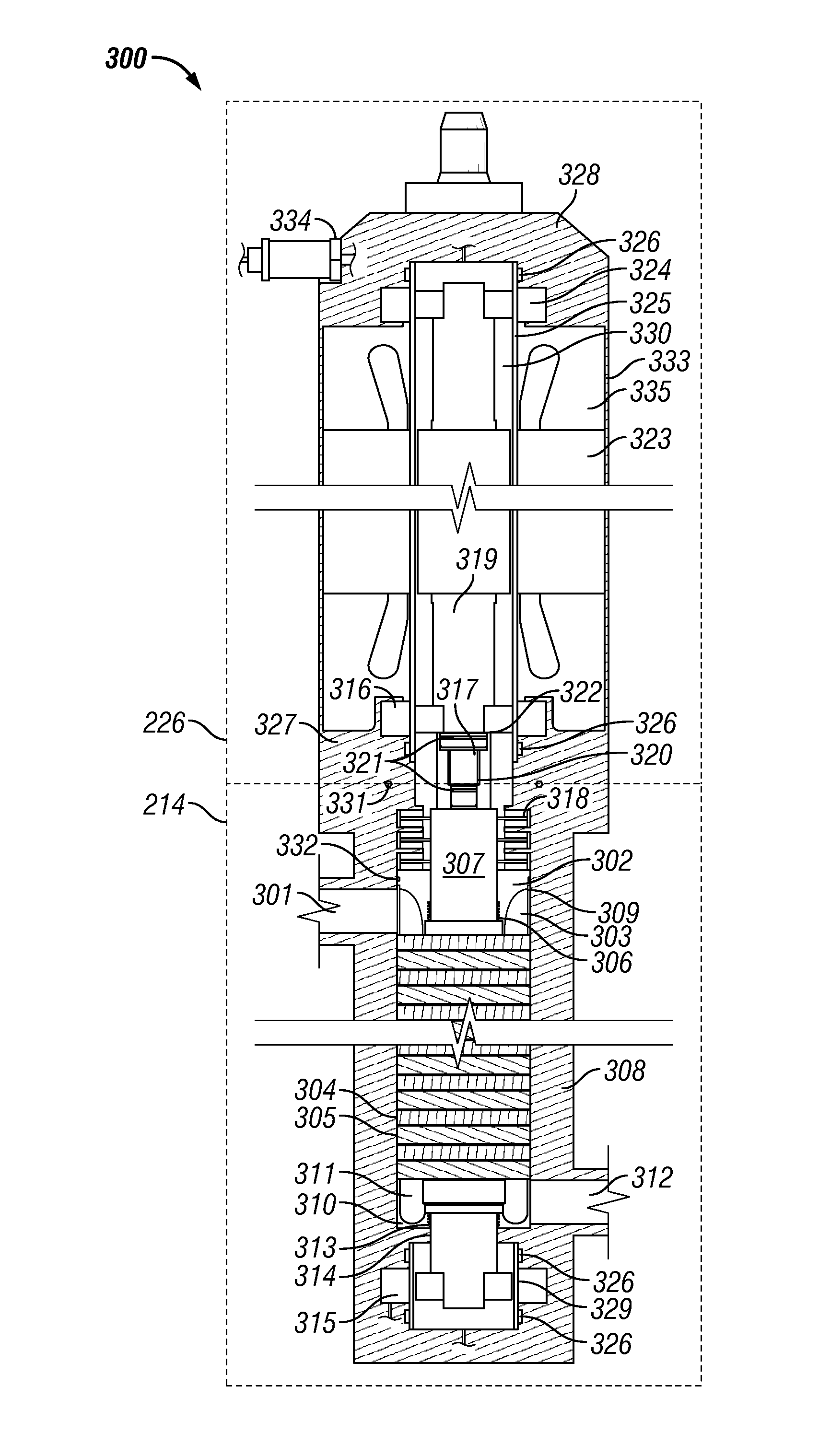

Axial-flow blood pump with magnetically suspended, radially and axially stabilized impeller

InactiveUS7070398B2Small sizeIncreased operating lifeBlood pumpsIntravenous devicesImpellerMagnetic bearing

A blood pump has an impeller rotatably disposed and magnetically suspended within a cavity of a stator by a plurality of magnetic bearings including an axial bearing to support the impeller axially in the cavity. The axial bearing includes adjacent impeller magnets and adjacent stator magnets with axially aligned polarities and reverse polarities with respect to adjacent magnets. A motor includes impeller magnets on the impeller and coils and poles associated with the stator. Radial permanent magnet and electromagnetic bearings are also included. The magnetic bearings and the motor have stator magnets or coils and poles disposed radially across the fluid passage from corresponding impeller magnets to define an annular gap positioned radially between the impeller and the stator, and positioned radially between all of the plurality of magnetic bearings, creating a straight through blood path without secondary flow paths.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND +1

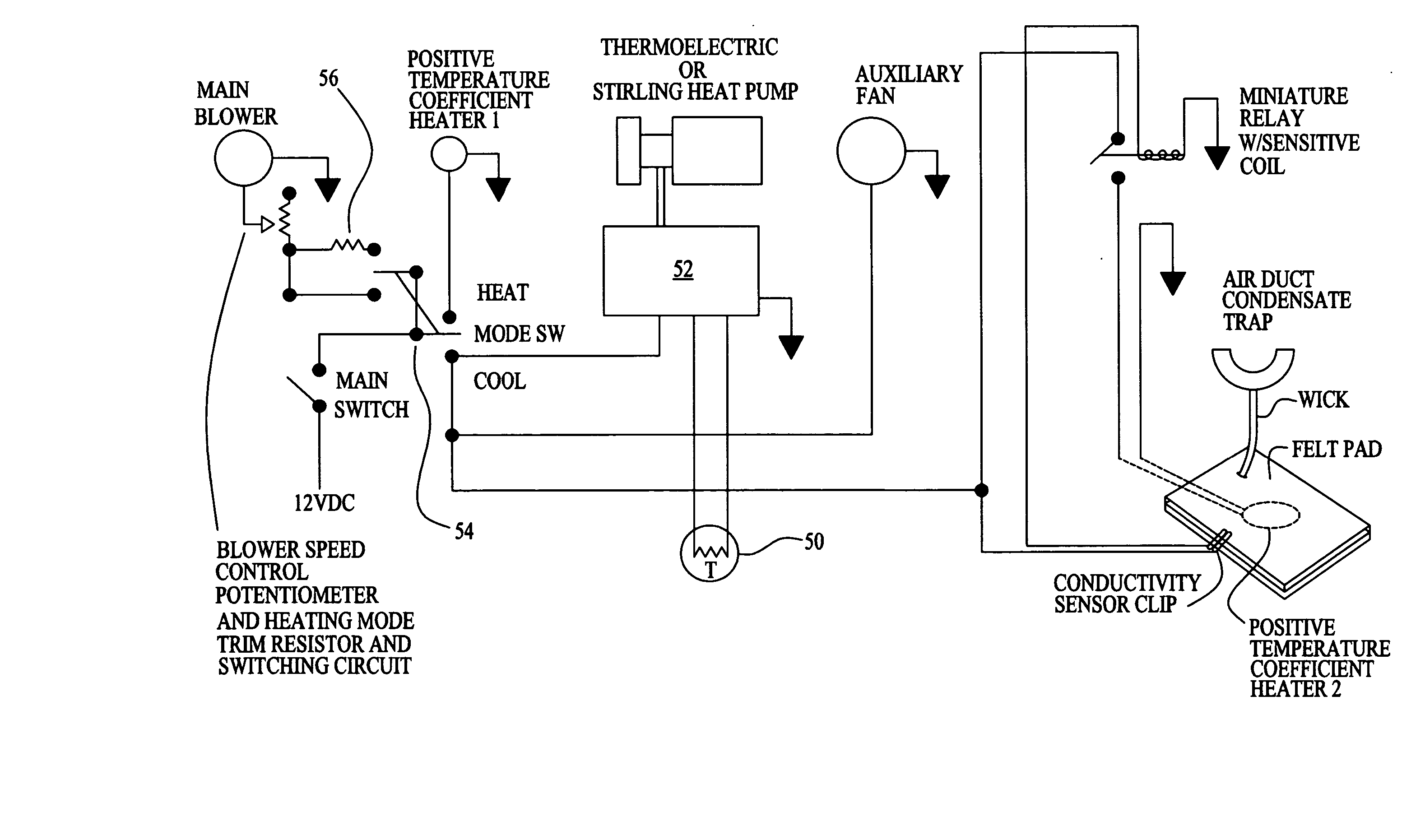

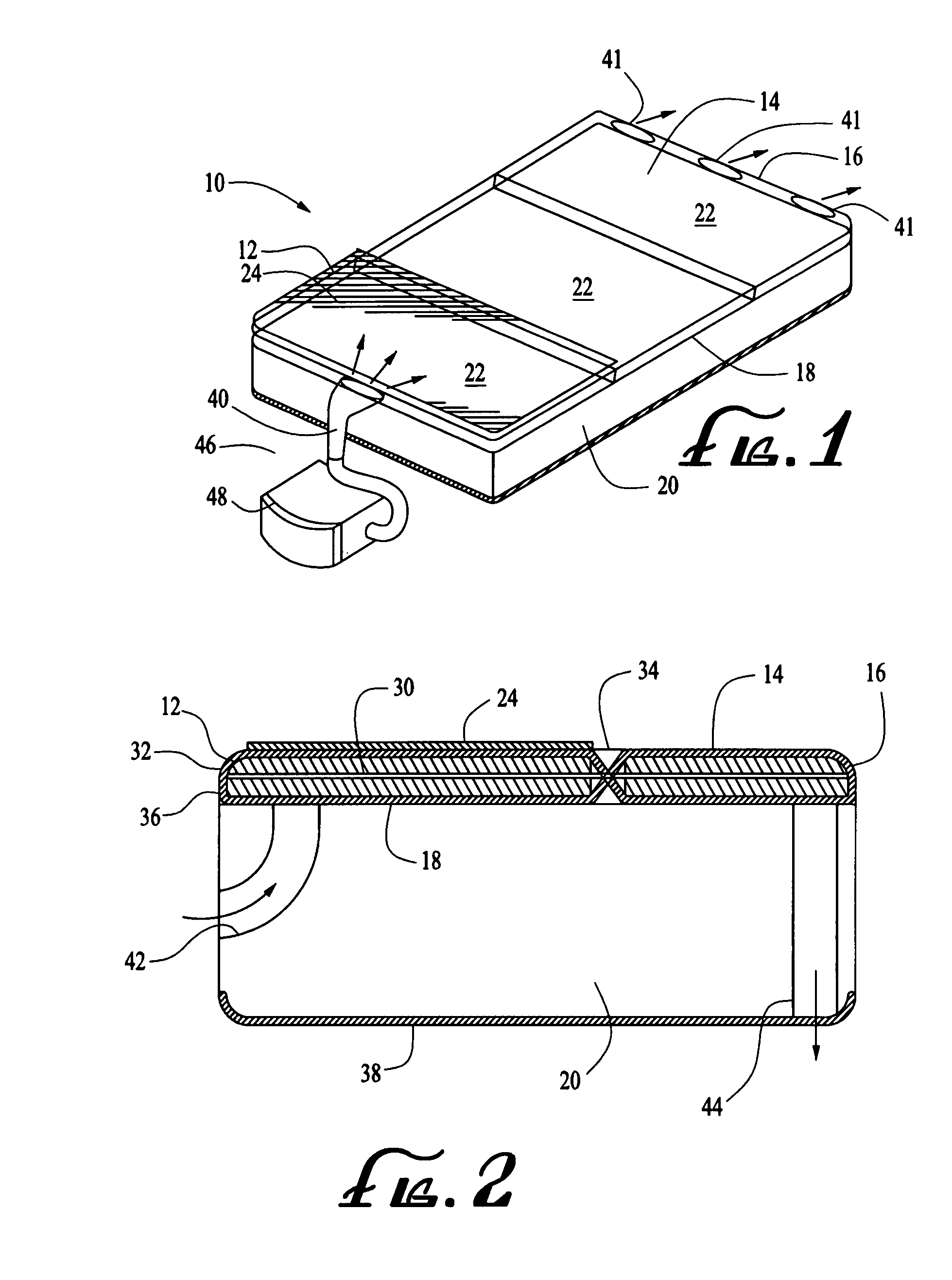

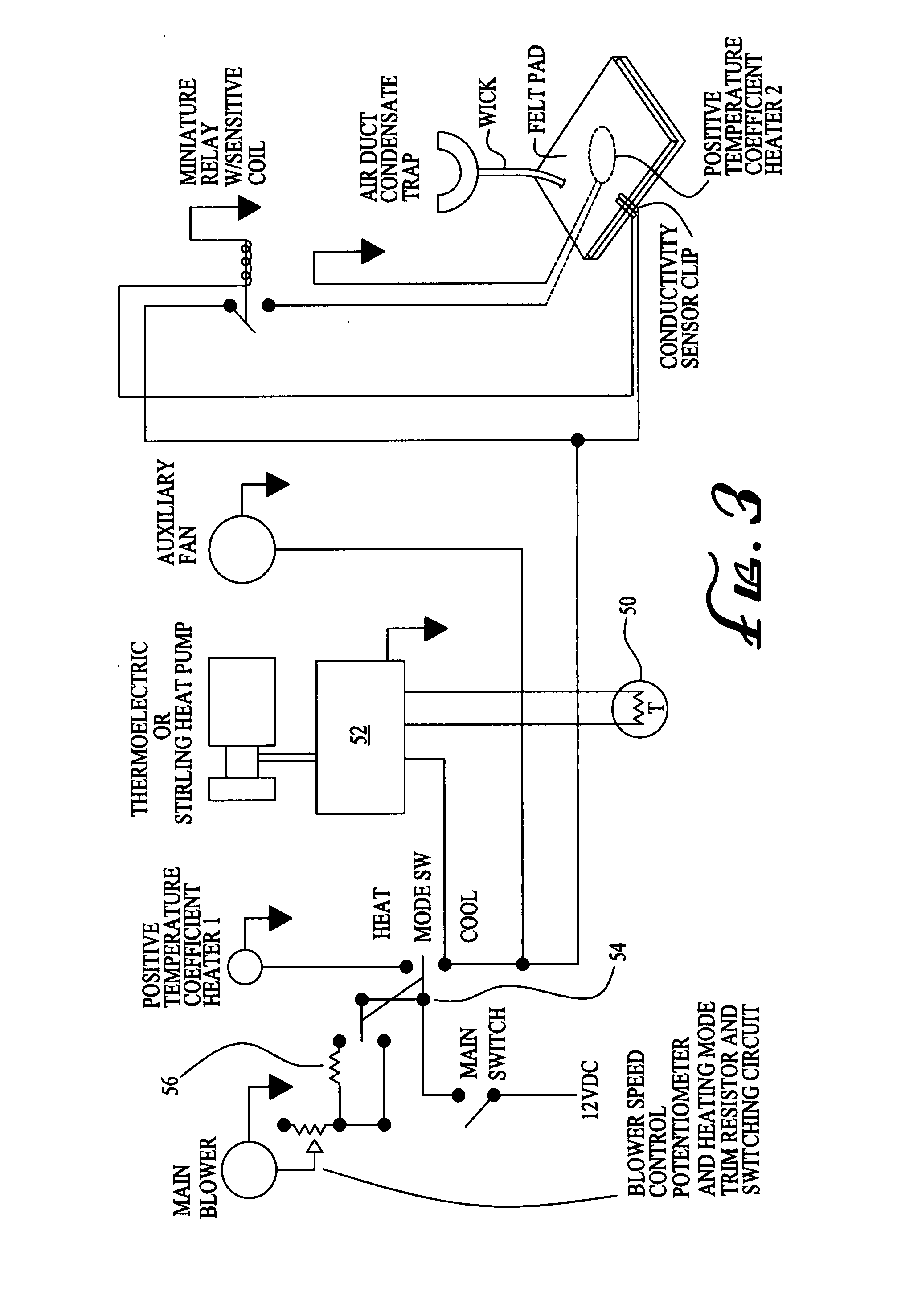

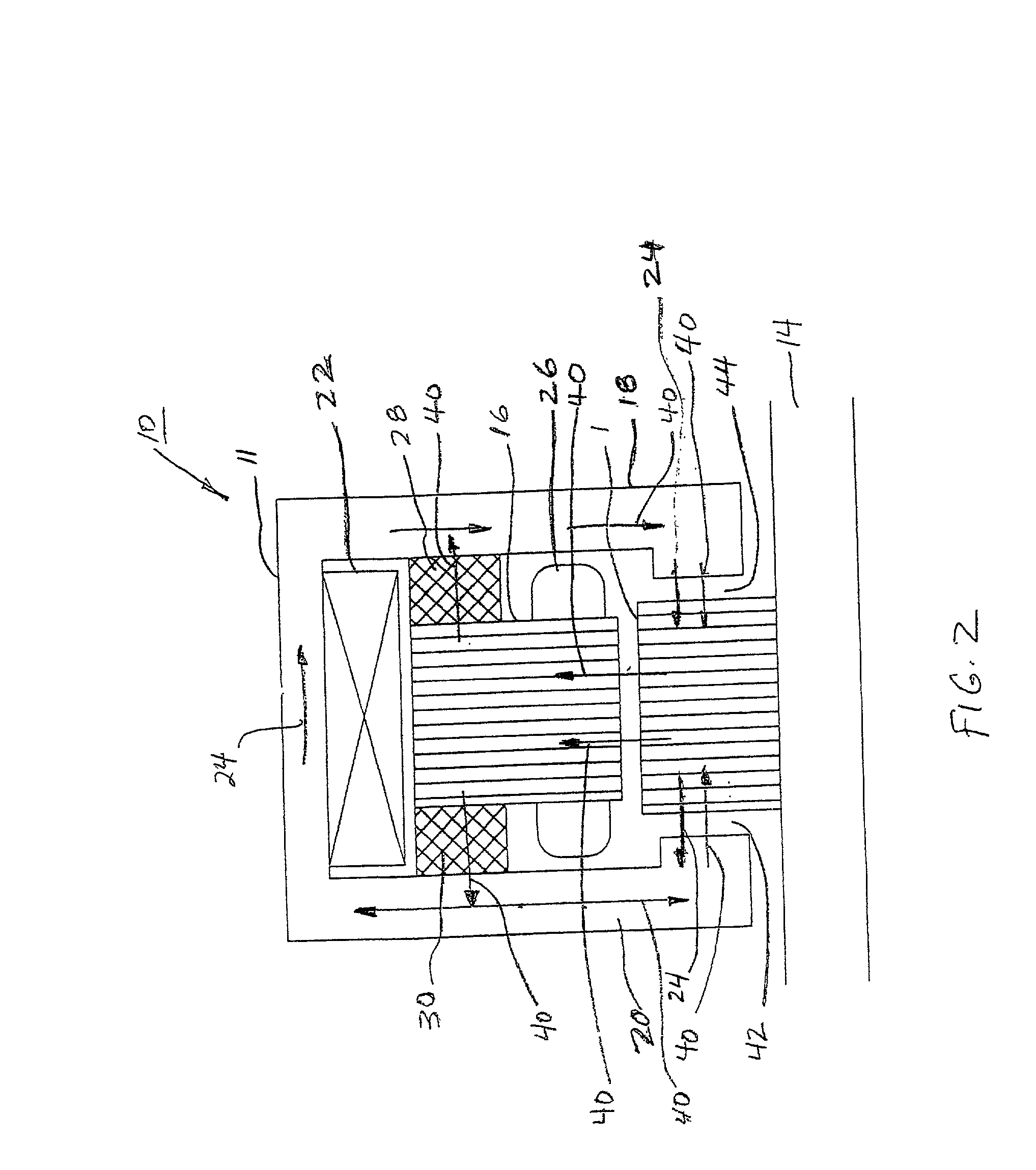

Convective seating and sleeping systems

InactiveUS20070251016A1Limit undesired unravelingEliminate requirementsStuffed mattressesSpring mattressesMagnetic bearingControl data

A convective seating and sleeping system with a plenum for use as a mattress, cushion or as part of seat or other structure to deliver air flow to a user or users. The convective cushion includes a modular plenum made of removable pockets and a thermocouple to provide control data to selectively control the temperature and / or quantity of the air delivered to the cushion. The cushion includes the use of tubular spacer material. The cushion has deep styling lateral and longitudinal pleats and air flow structures around the pleats to provide a controlled air flow to the cushion. The invention includes an improved Stirling cycle heat pump with magnetic bearing structures and relative humidity controls and an improved thermoelectric heat pump that selectively controls the relative humidity of the air delivered to the cushion. The cushion can be activated and operated by remote operation from a telecommunications device.

Owner:FEHER STEVE

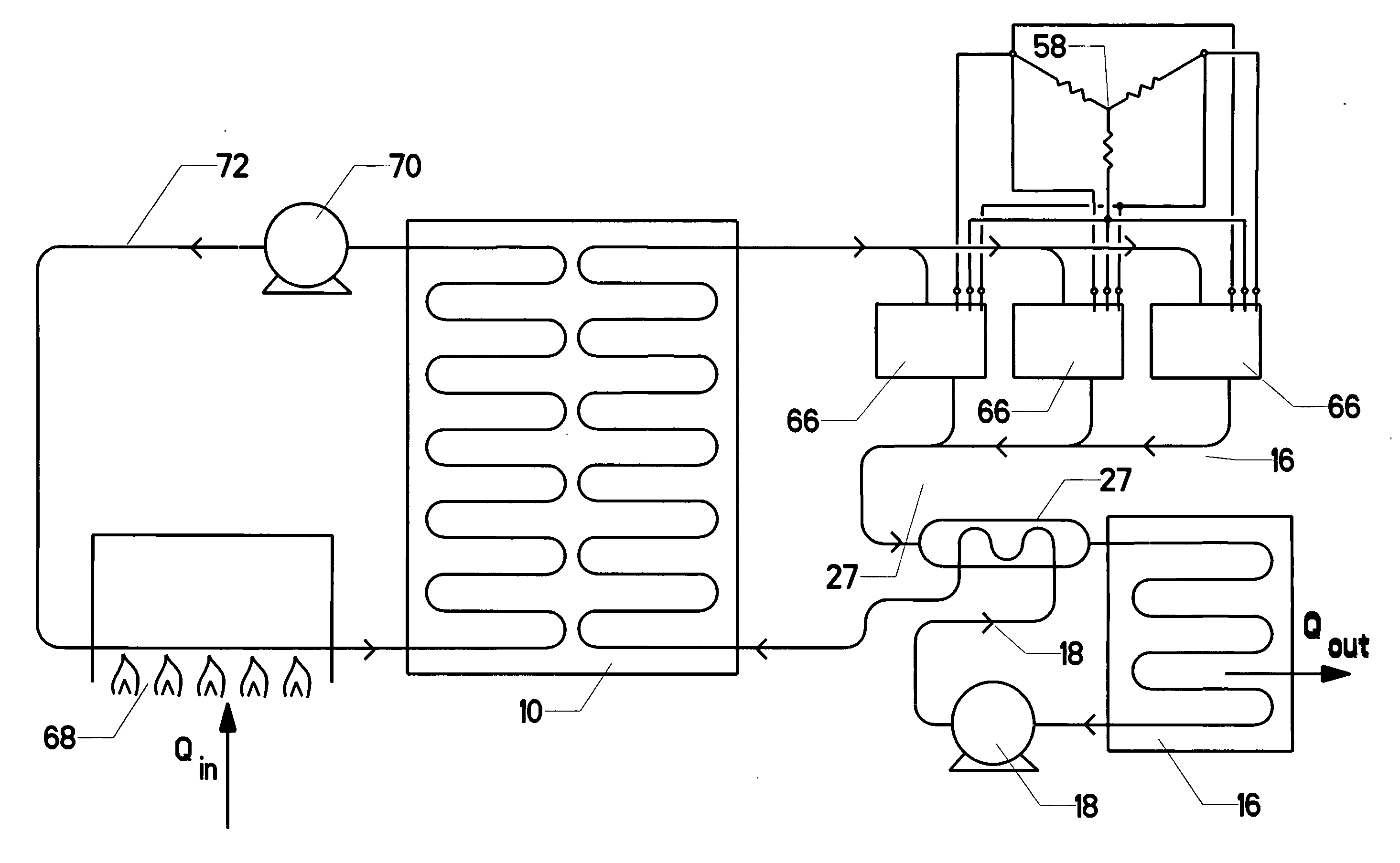

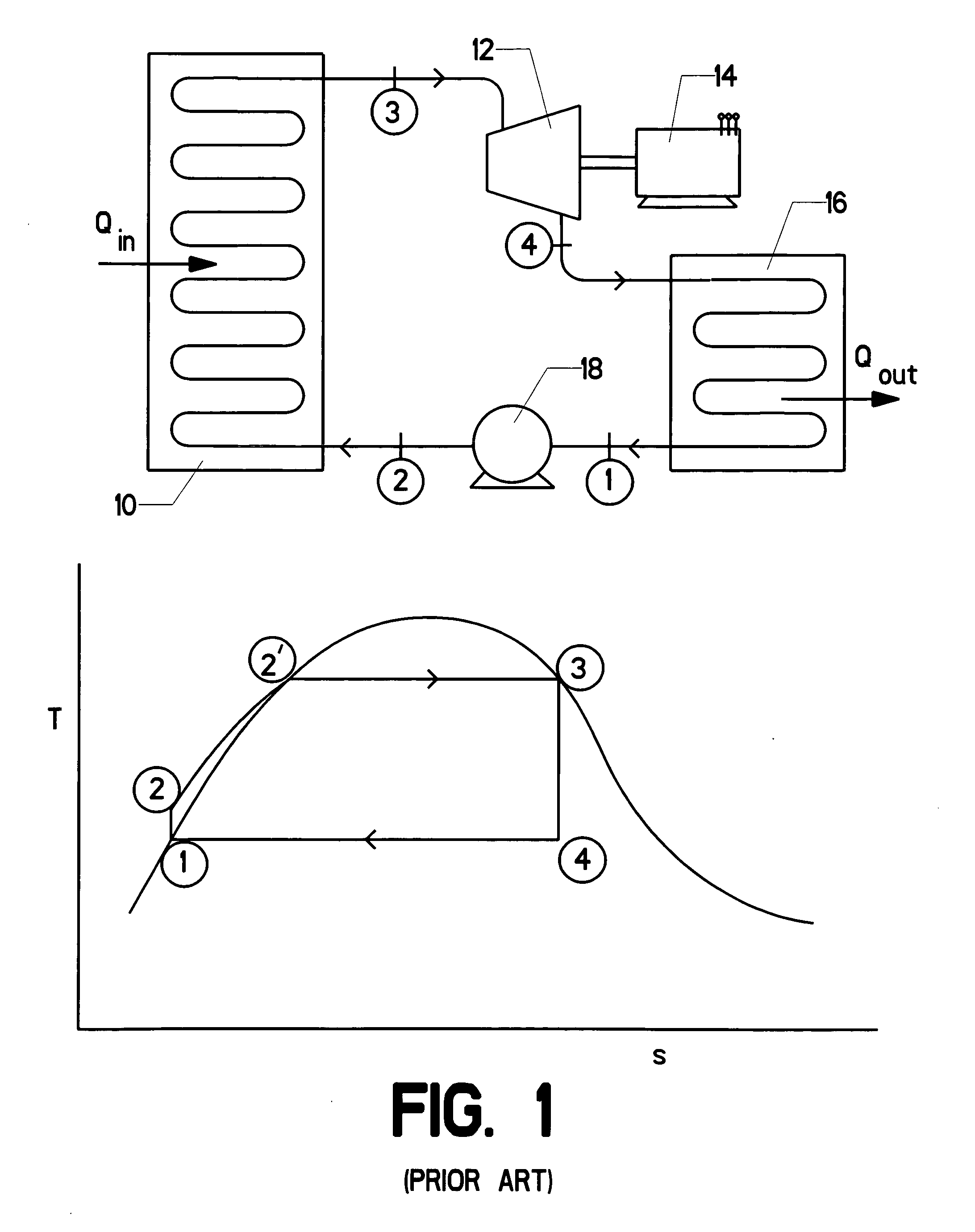

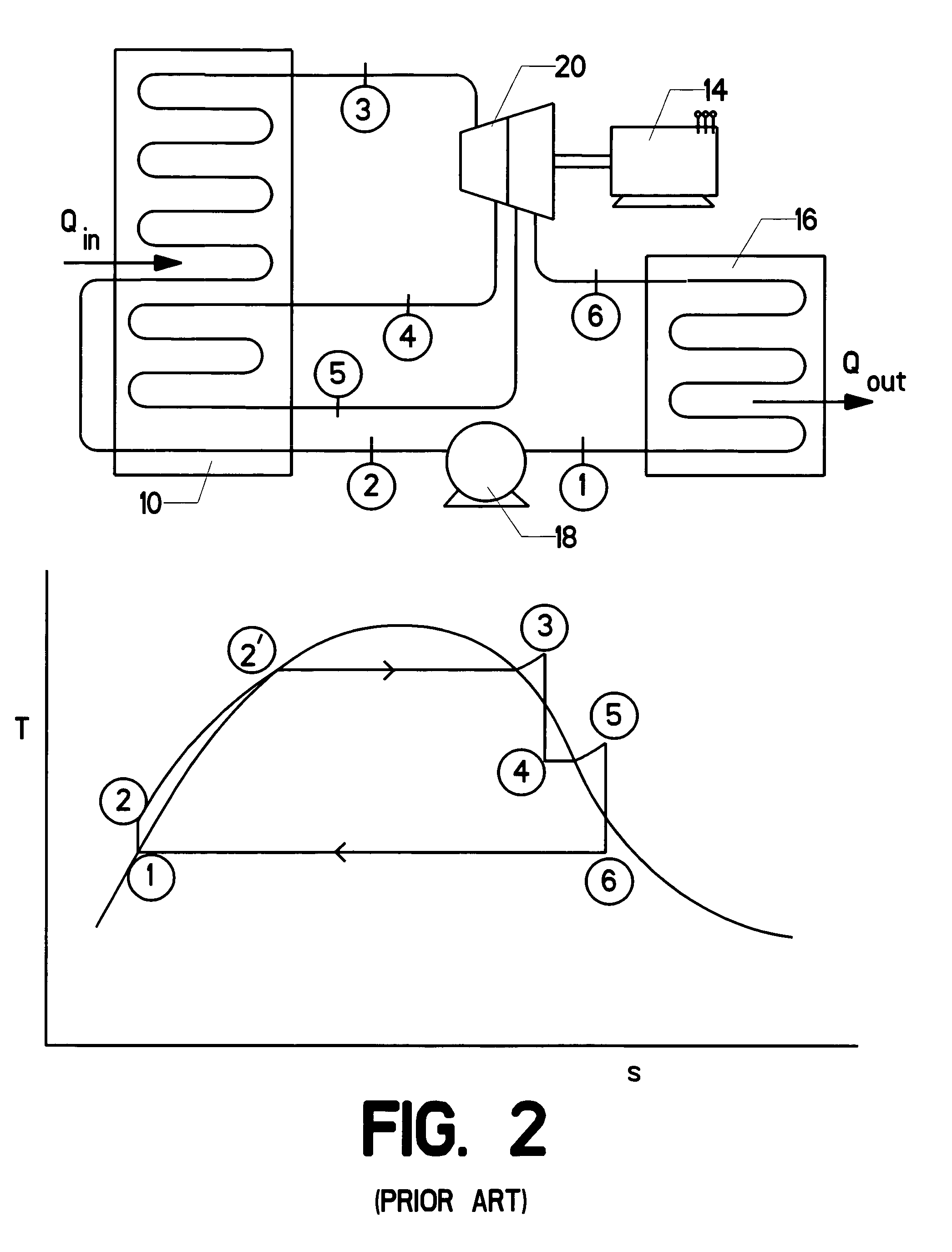

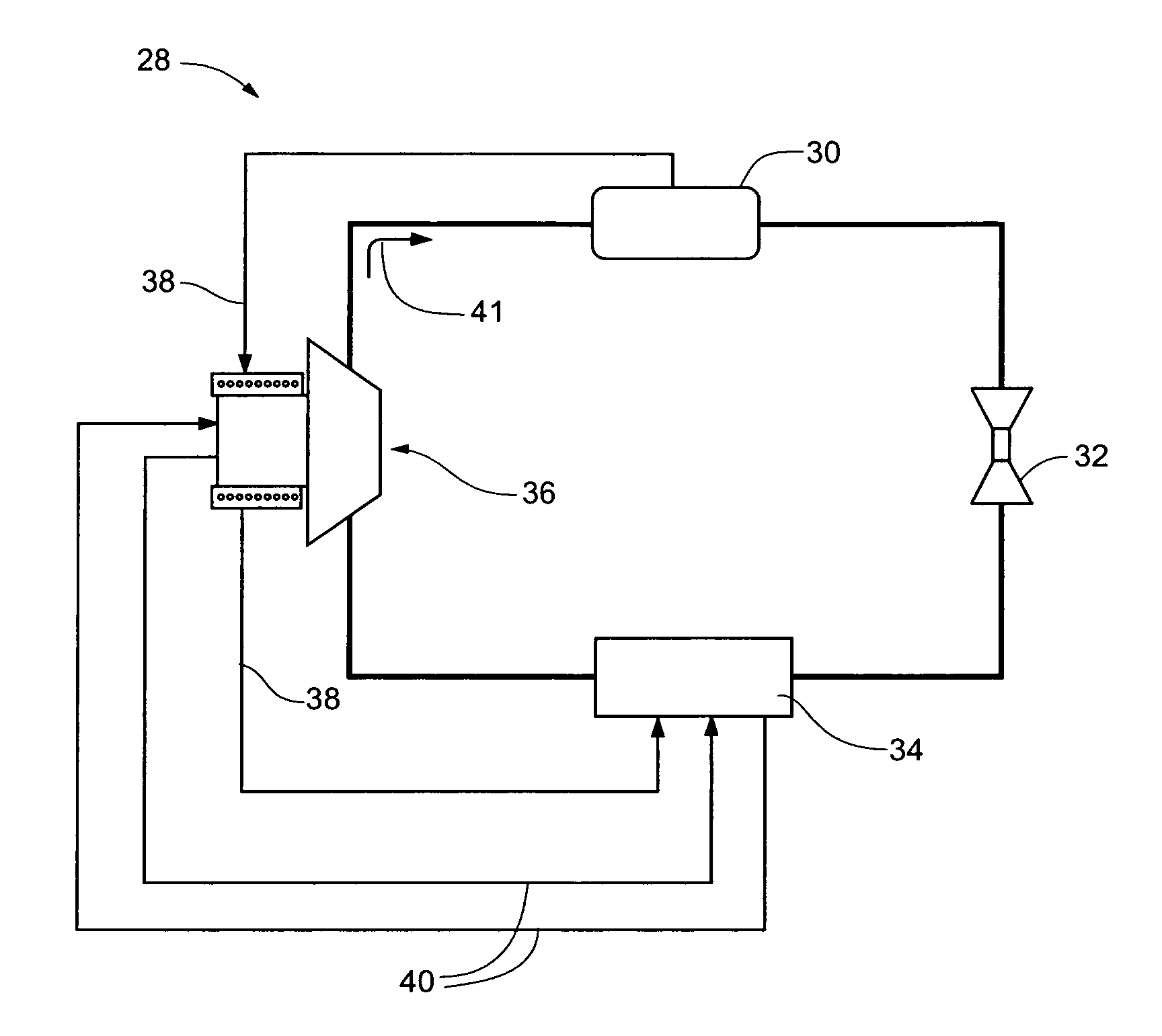

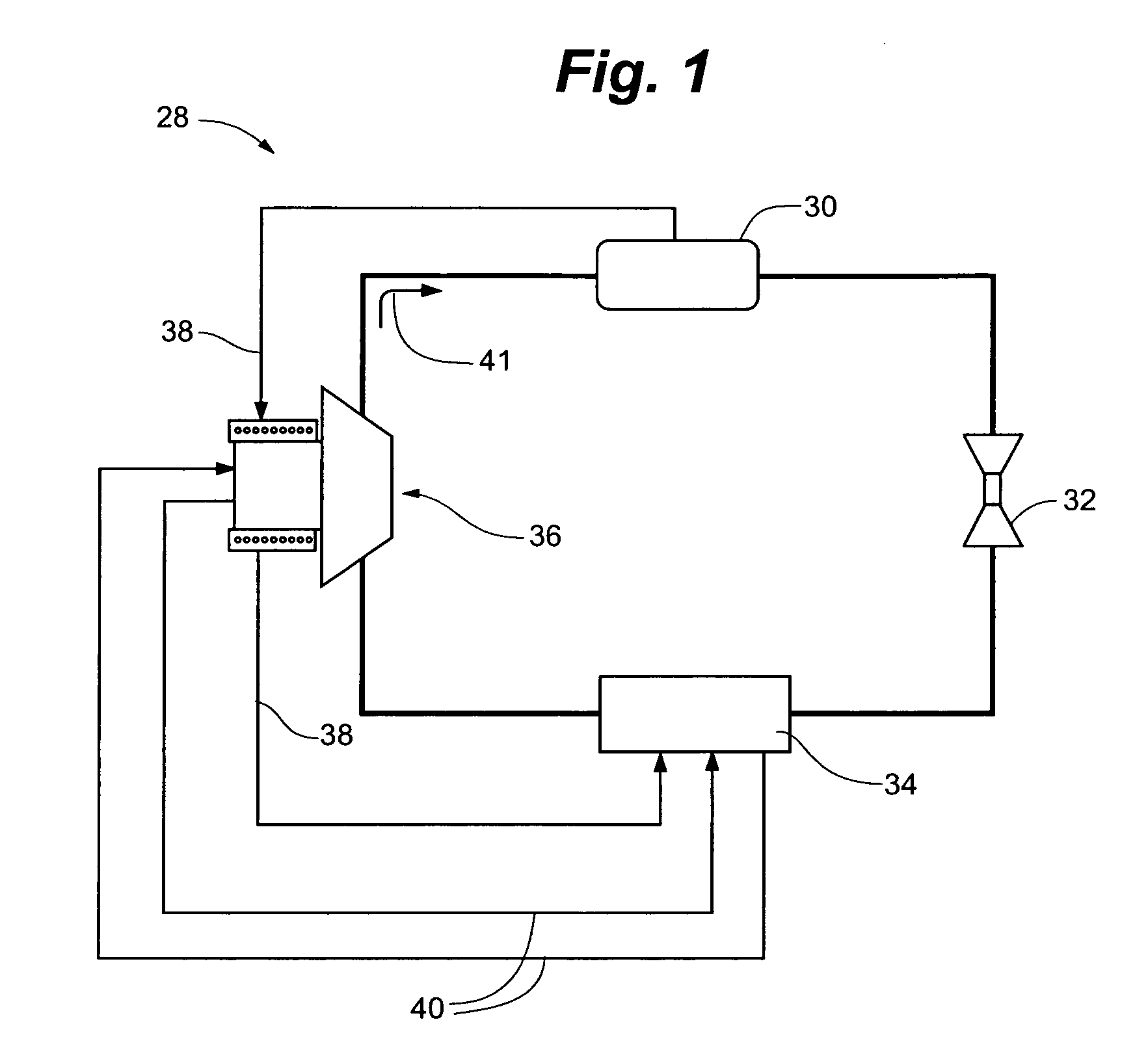

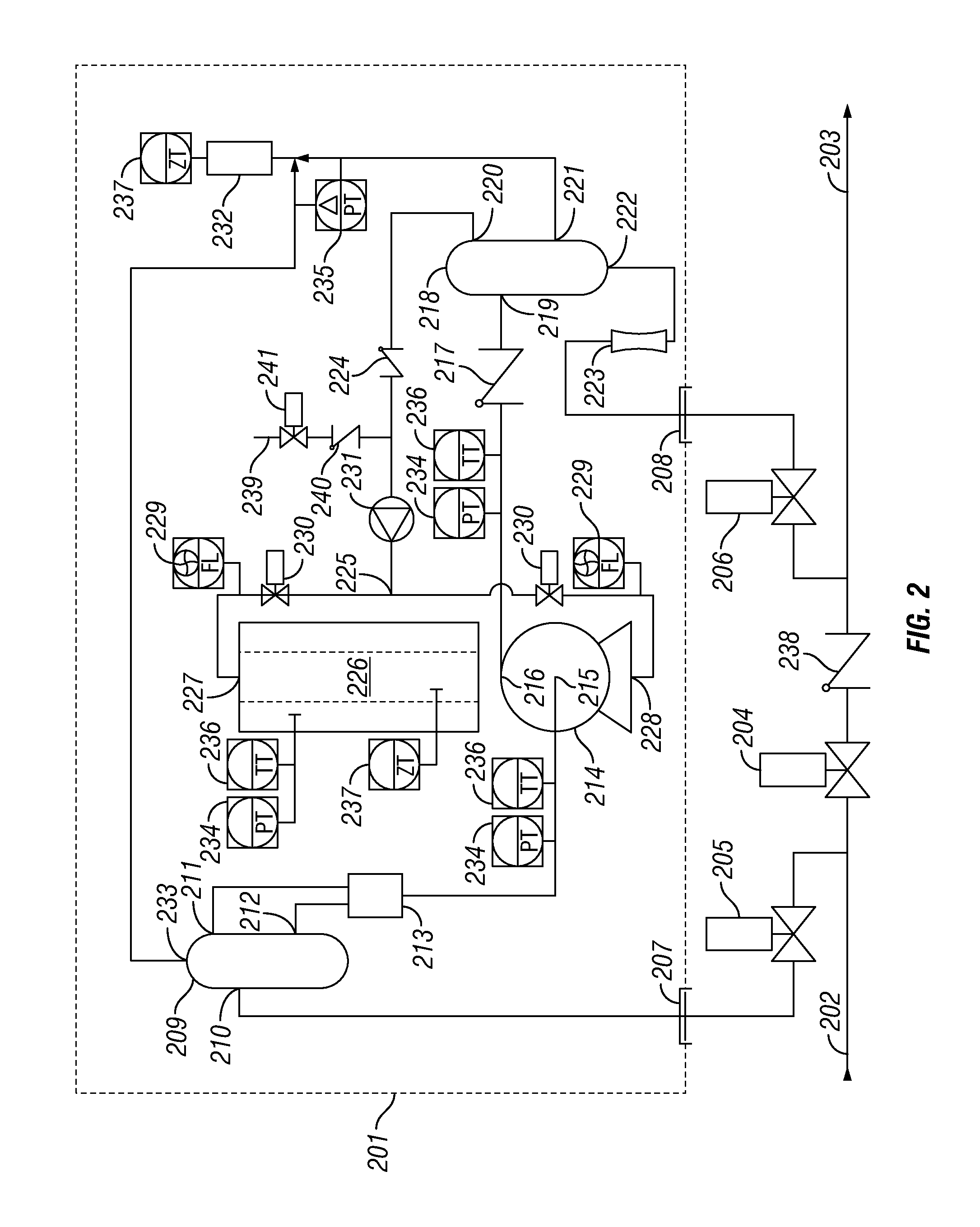

Rankine cycle heat recovery methods and devices

InactiveUS20090277400A1Minimize frictional lossIncrease speedLiquid coolingCoolant flow controlRecovery methodMagnetic bearing

An integrated expansion turbine / electrical generator assembly (collectively referred to as a “turbo-generator”) suitable for use in waste heat recovery and similar applications. The turbo-generator uses a common shaft mounting a one or more stage expansion turbine and a homopolar electrical generator. Magnetic levitating axial and thrust bearings are used to hold the common shaft in its proper position with a fixed housing. The magnetic bearings minimize frictional losses, allowing the common shaft to spin at a very high rotational velocity. Sensor rings continually monitor the common shaft's position. This information is used by control electronics to regulate the magnetic bearings in order to hold the rotating shaft's position. Electrical energy is extracted from the rotating shaft in the form of a direct current. Preferably integrated power-switching electronics are used to generate single or three-phase AC power, which can be phase-matched to an existing power grid or other application.

Owner:DANFOSS AS

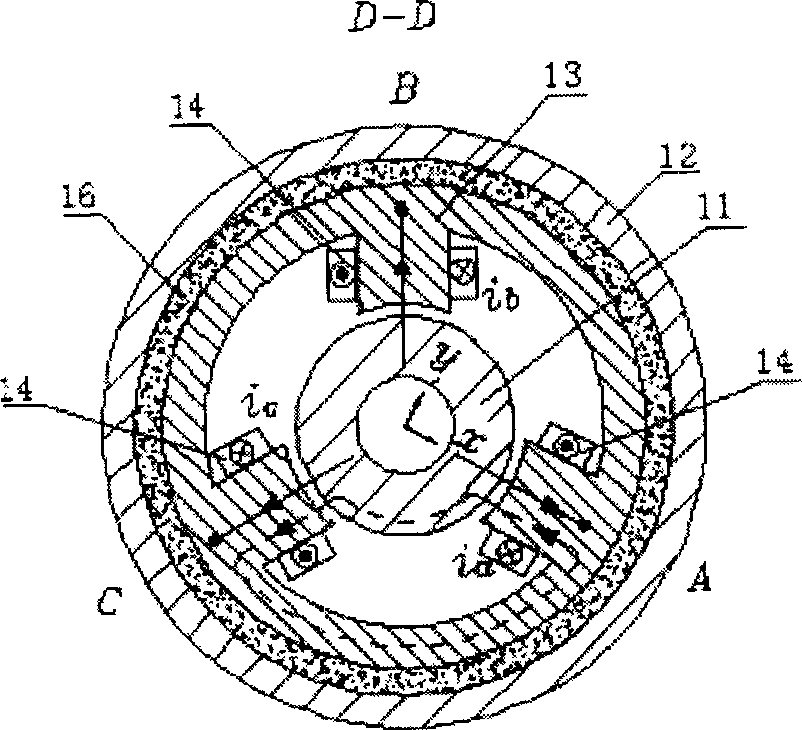

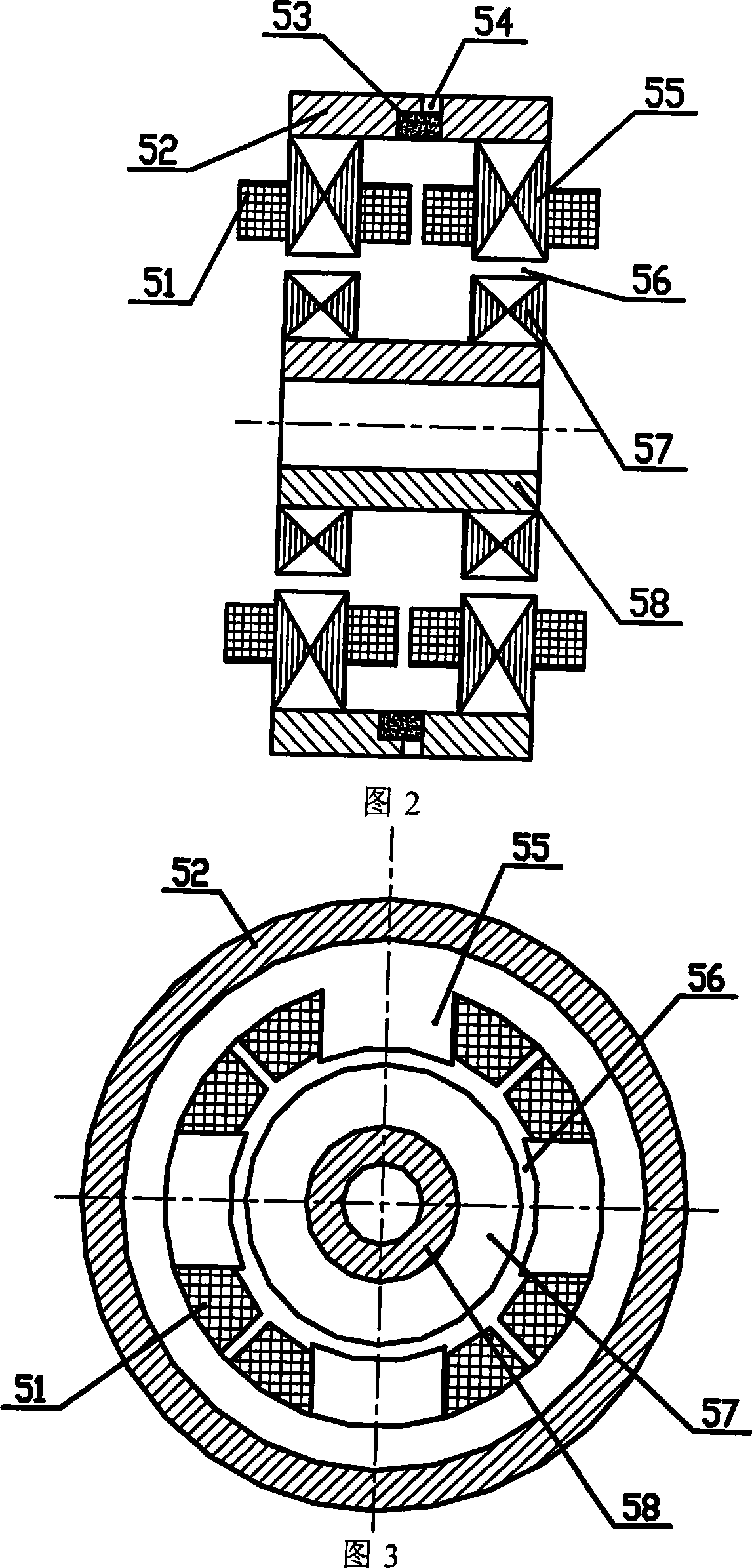

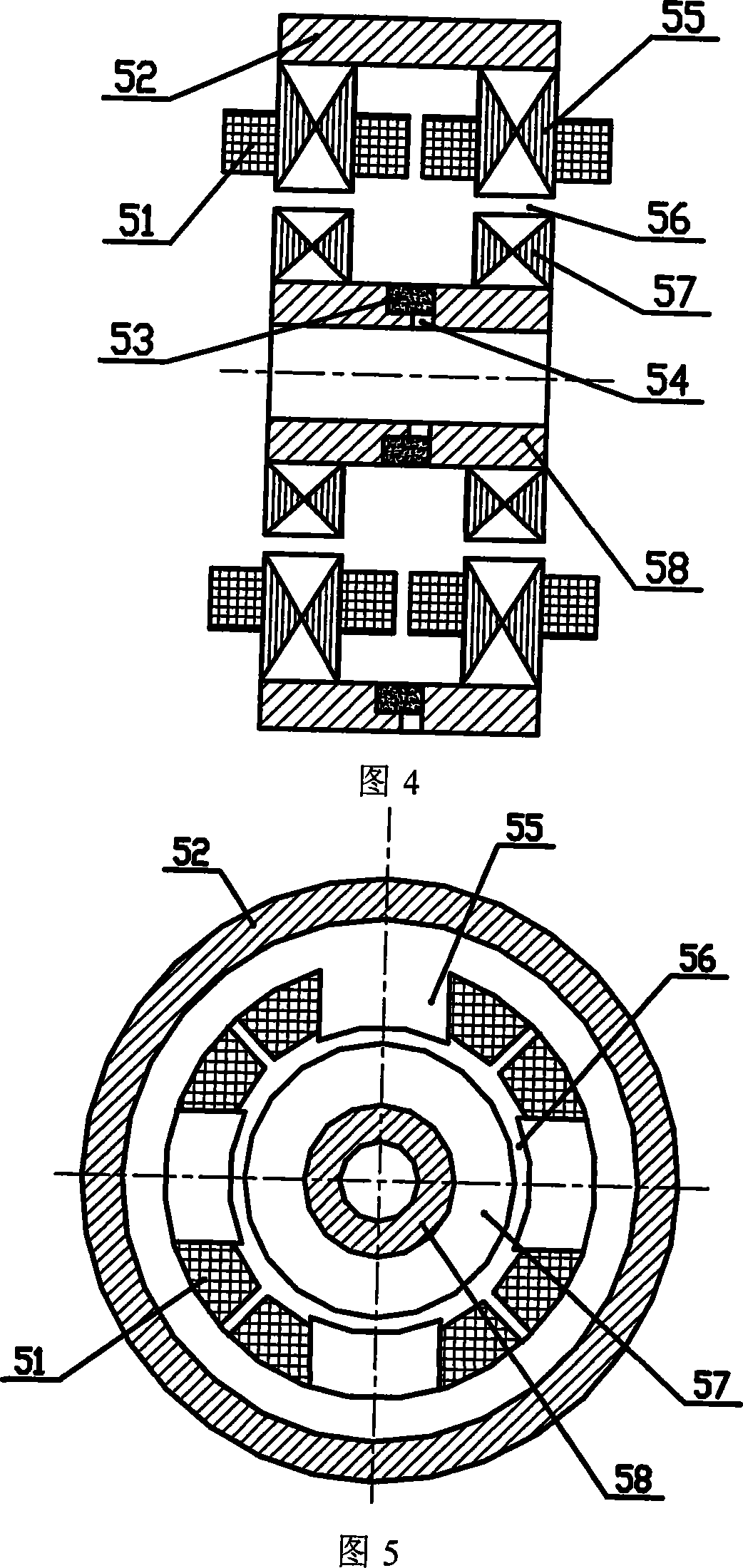

AC-DC radial-axial mixed magnetic bearing having three degrees of freedom and method for controlling the same

InactiveCN1737388ALarge suspension forceShorten the lengthBearingsMagnetic holding devicesMagnetic bearingThree degrees of freedom

This invention relates to a three freedom degree AC-DC radial-axial mixing magnetic bearing, which is fit for the electrical main shaft and rotary main shaft needs suspending support. The permanent magnet will provide radial-axial static bias magnetic flux to generate static bearing ability; the radial controlling coil and the axial controlling coil will provide magnetic flux to generate dynamic suspending force, making the rotor suspending on the balance place in radial-axial three freedom degree. The power enlarging circuit comprises axial liner power amplifier and radial CRPWM current tracking inverter, and the displacement sensor will test the shift of the rotor and then feedback to DSP controller; the DSP will operate PID compute and process, provide controlling signal to power enlarging circuit; the controlling signal will generate controlling current in magnetic bearing coil, and the controlling current will generate magnetic force in operation magnet, by which it can realize the stable suspending and real-time monitoring of the rotor in radial and axial.

Owner:JIANGSU UNIV

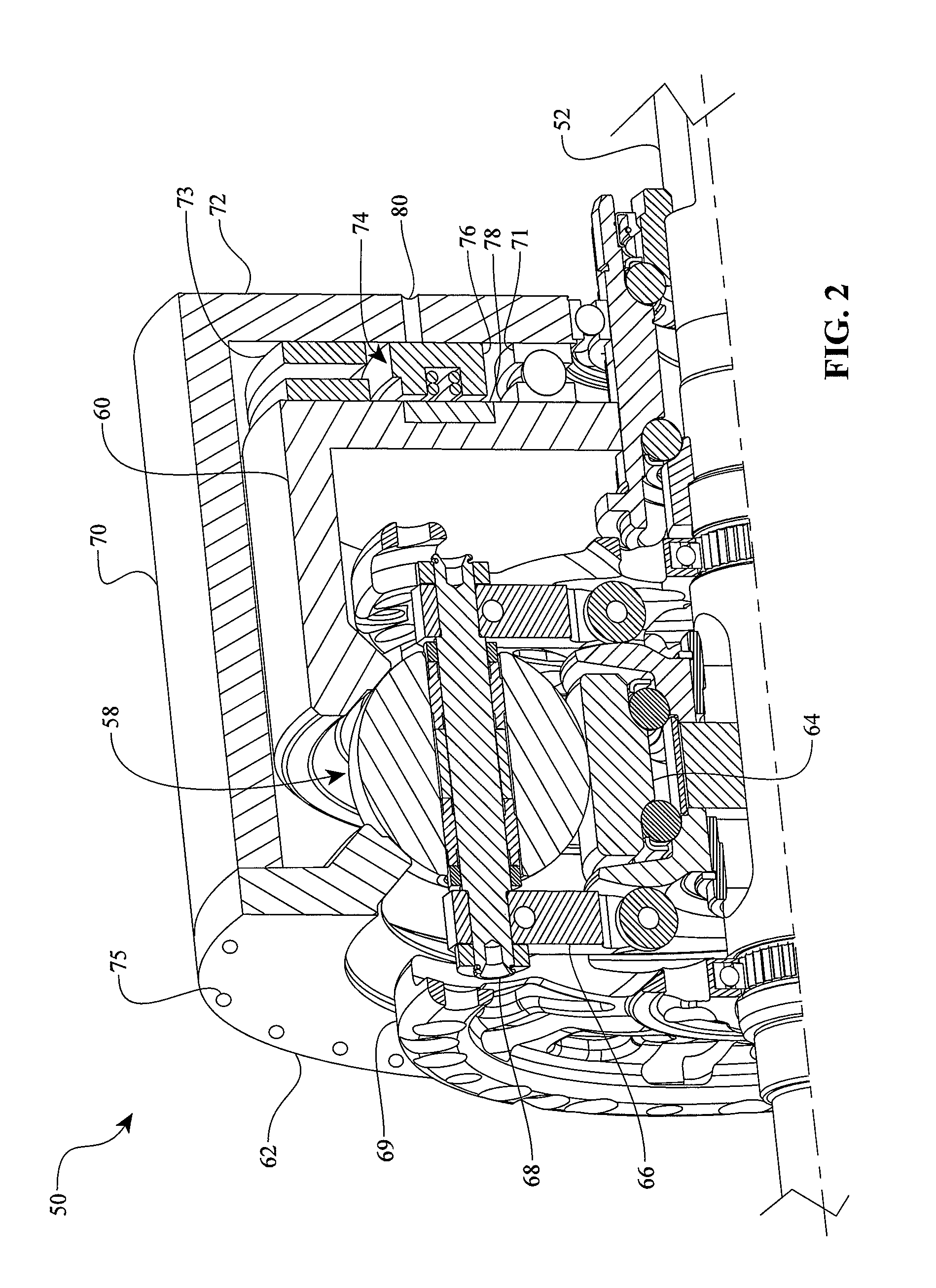

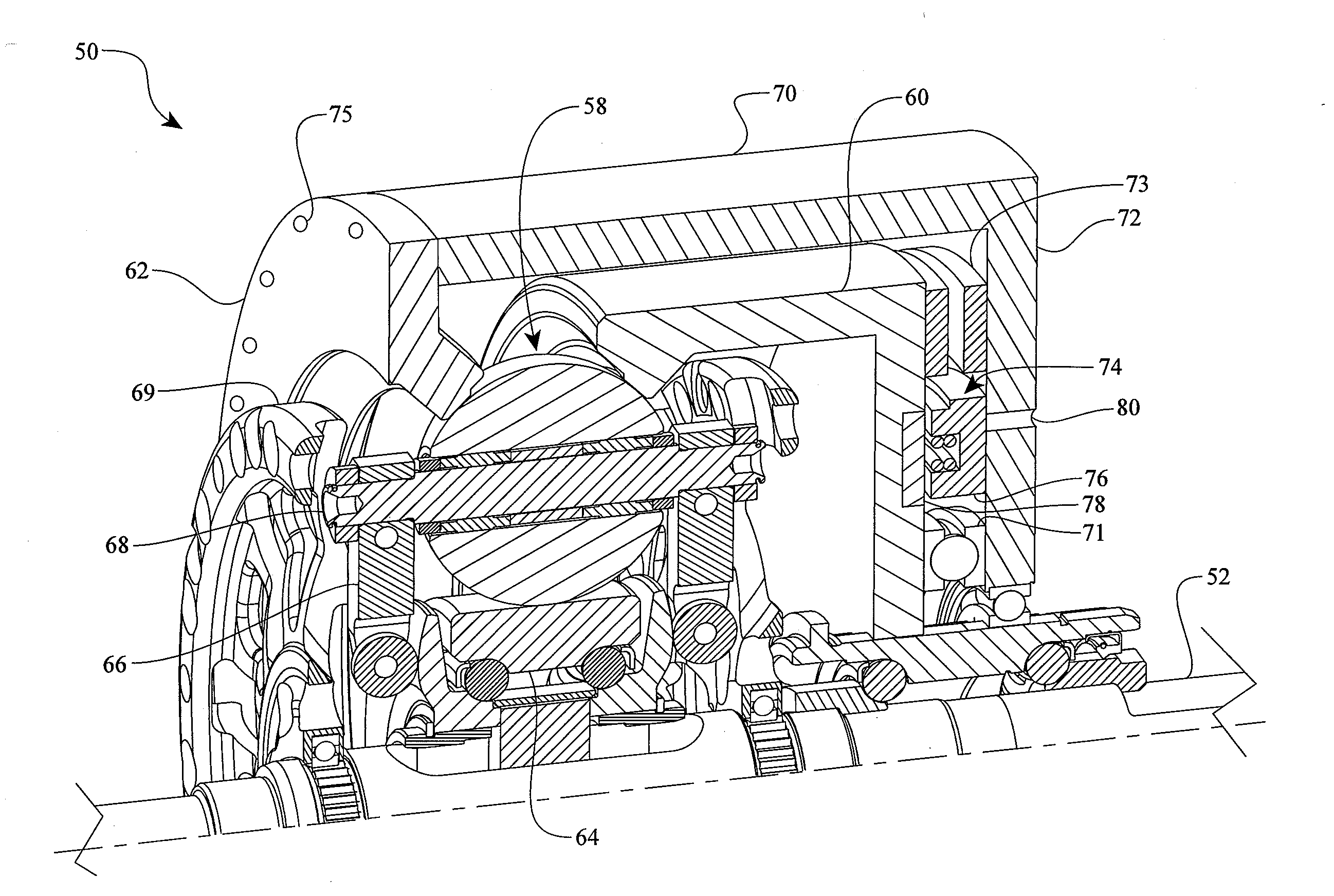

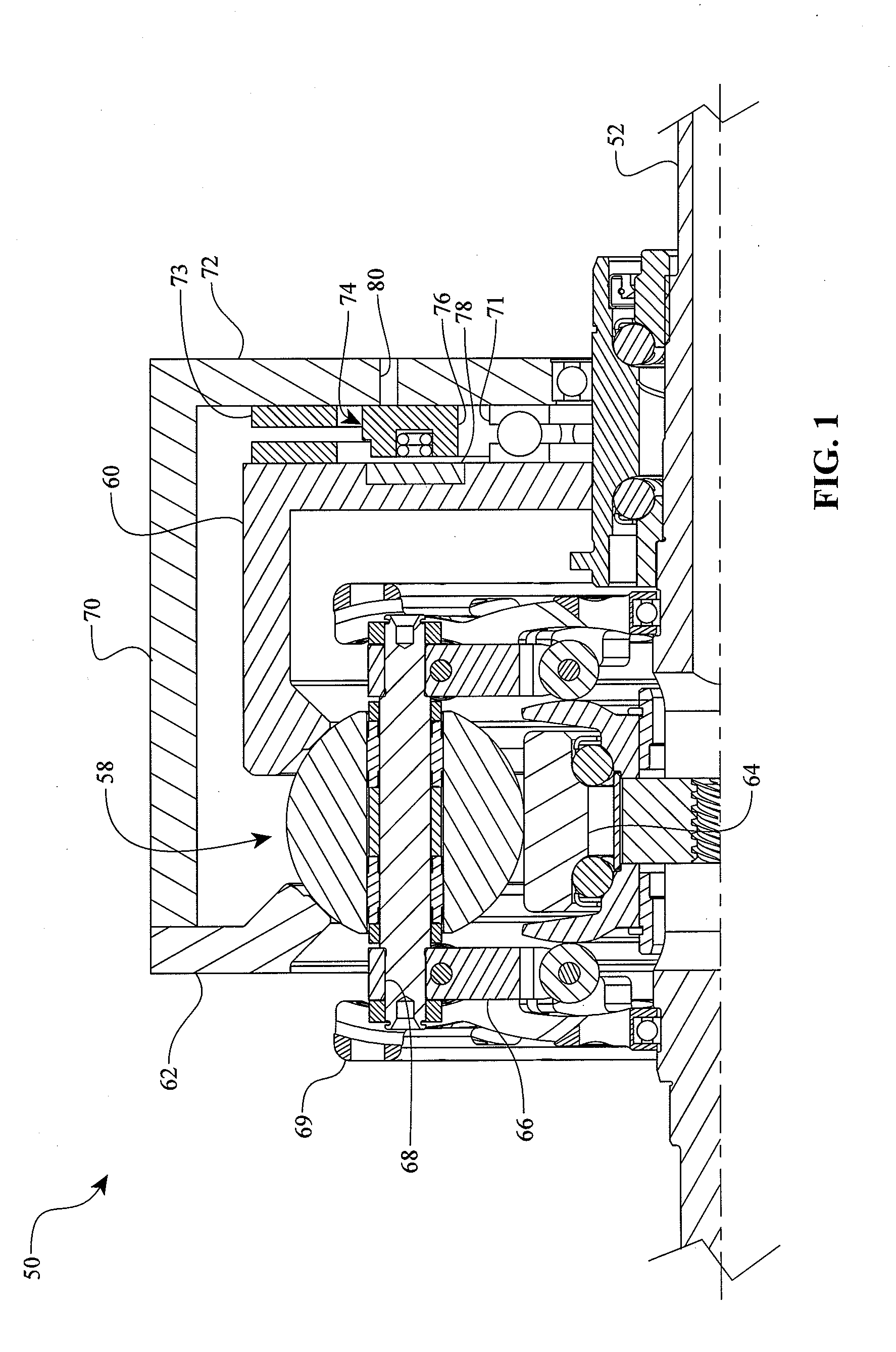

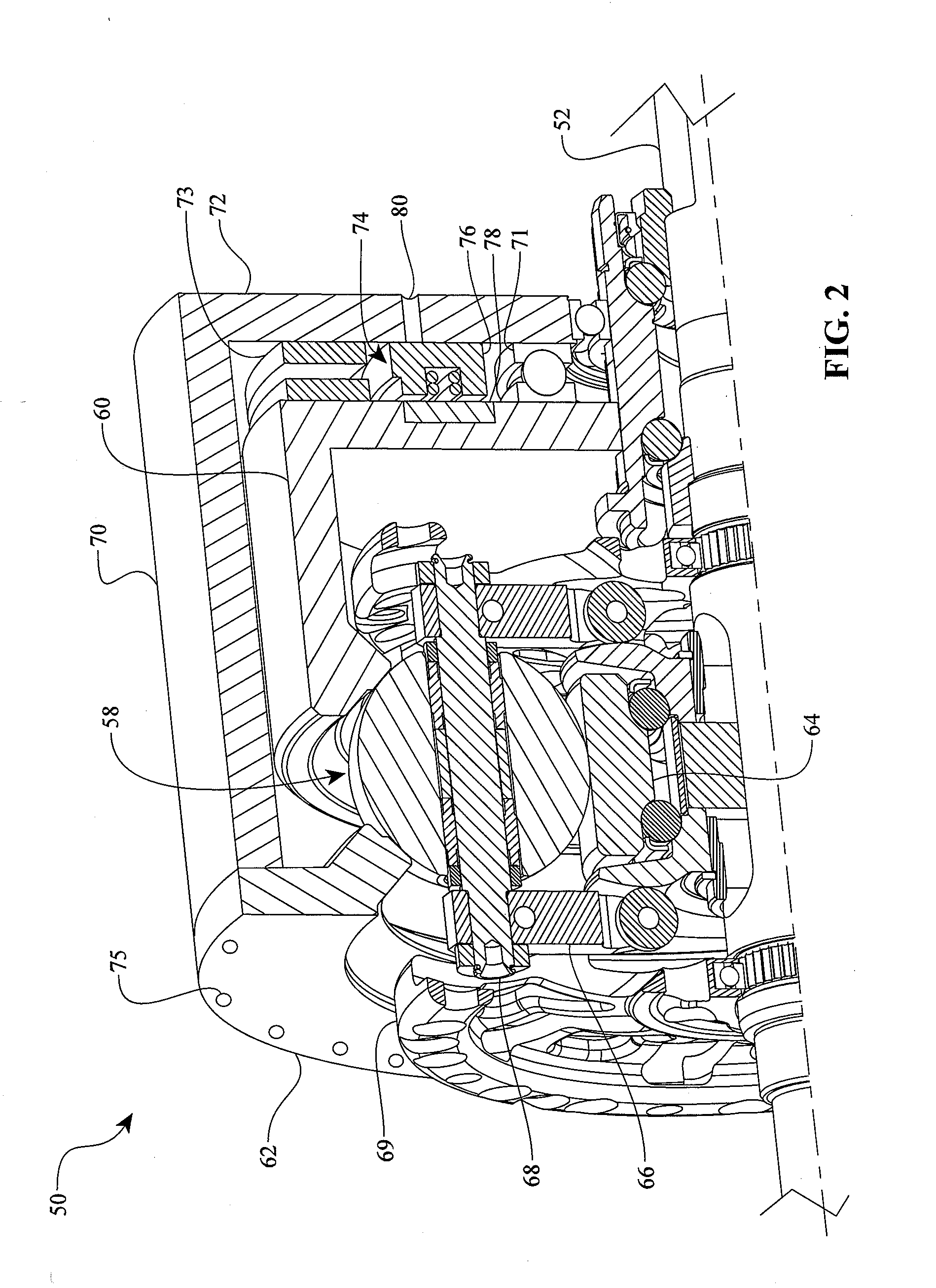

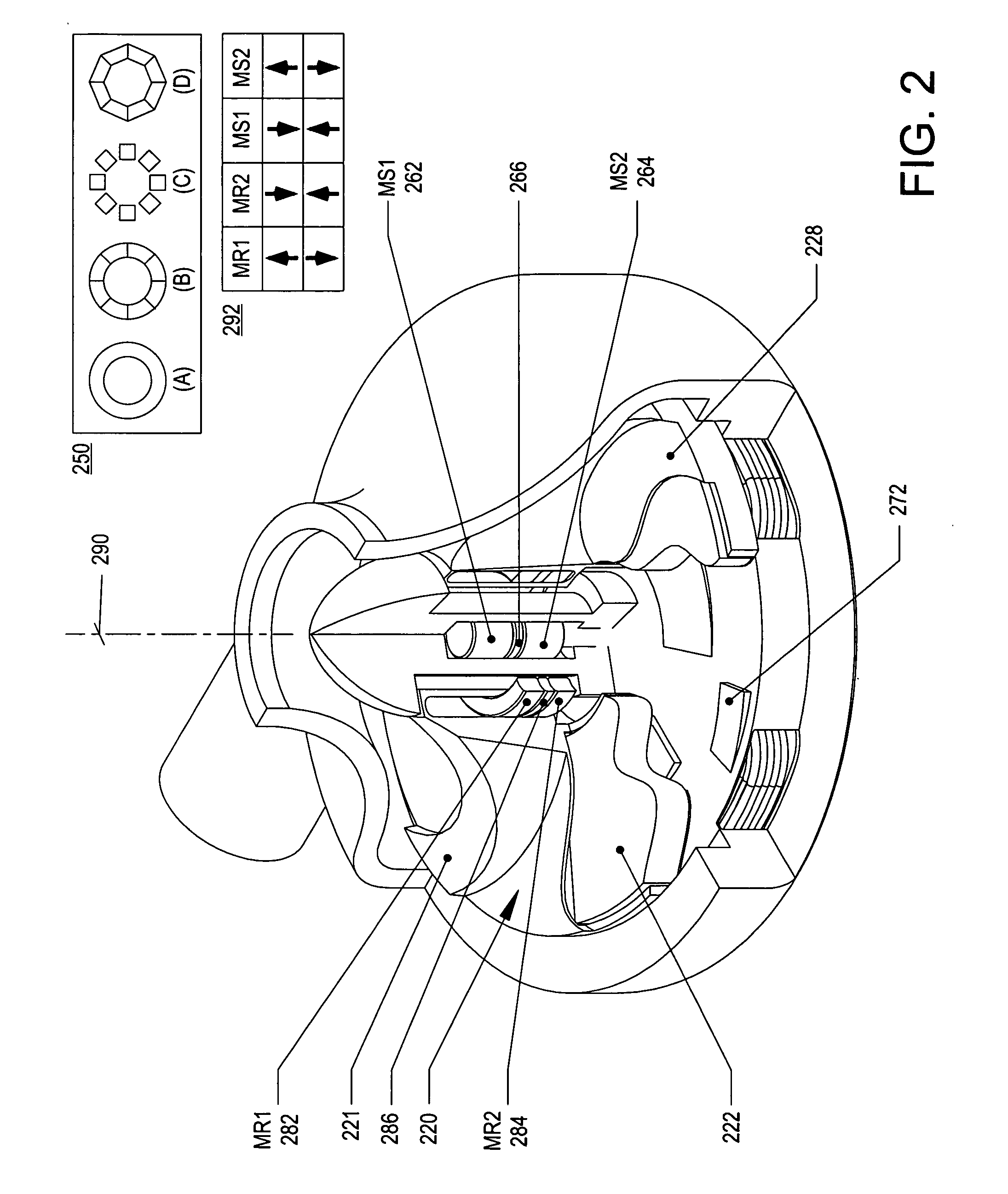

Assemblies and methods for clamping force generation

Mechanisms and methods for clamping force generation are disclosed. In one embodiment, a clamping force generator system includes a permanent magnet bearing coupled to a traction ring and to a torque coupling. The traction ring can be provided with an electromagnetic bearing rotor and the torque coupling can be provided with an electromagnetic bearing stator. In some embodiments, a mechanical load cam, a permanent magnet bearing, and an electromagnetic bearing cooperate to generate a clamping force between the traction rings, the power rollers, and the idler. In other embodiments, a series of permanent magnet bearings and a mechanical bearing configured to produce a clamping force. In one embodiment an electromagnetic bearing is coupled to a control system and produces a specified clamping force that is associated with a torque transmitted in the transmission during operation. In some embodiments, a mechanical load cam produces a clamping force proportional to torque, while a permanent magnet bearing provides a minimum clamping force.

Owner:FALLBROOK INTPROP COMPANY

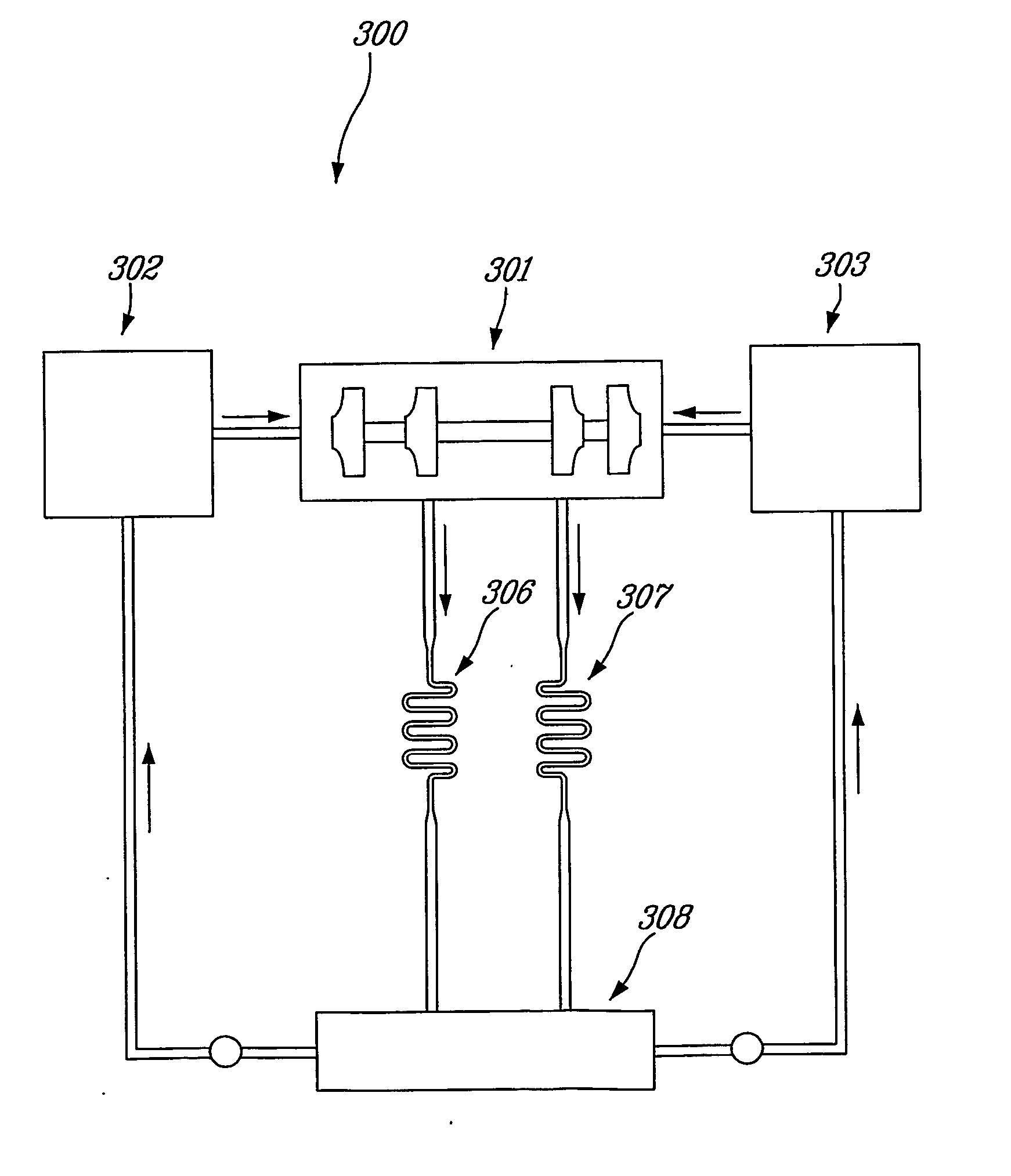

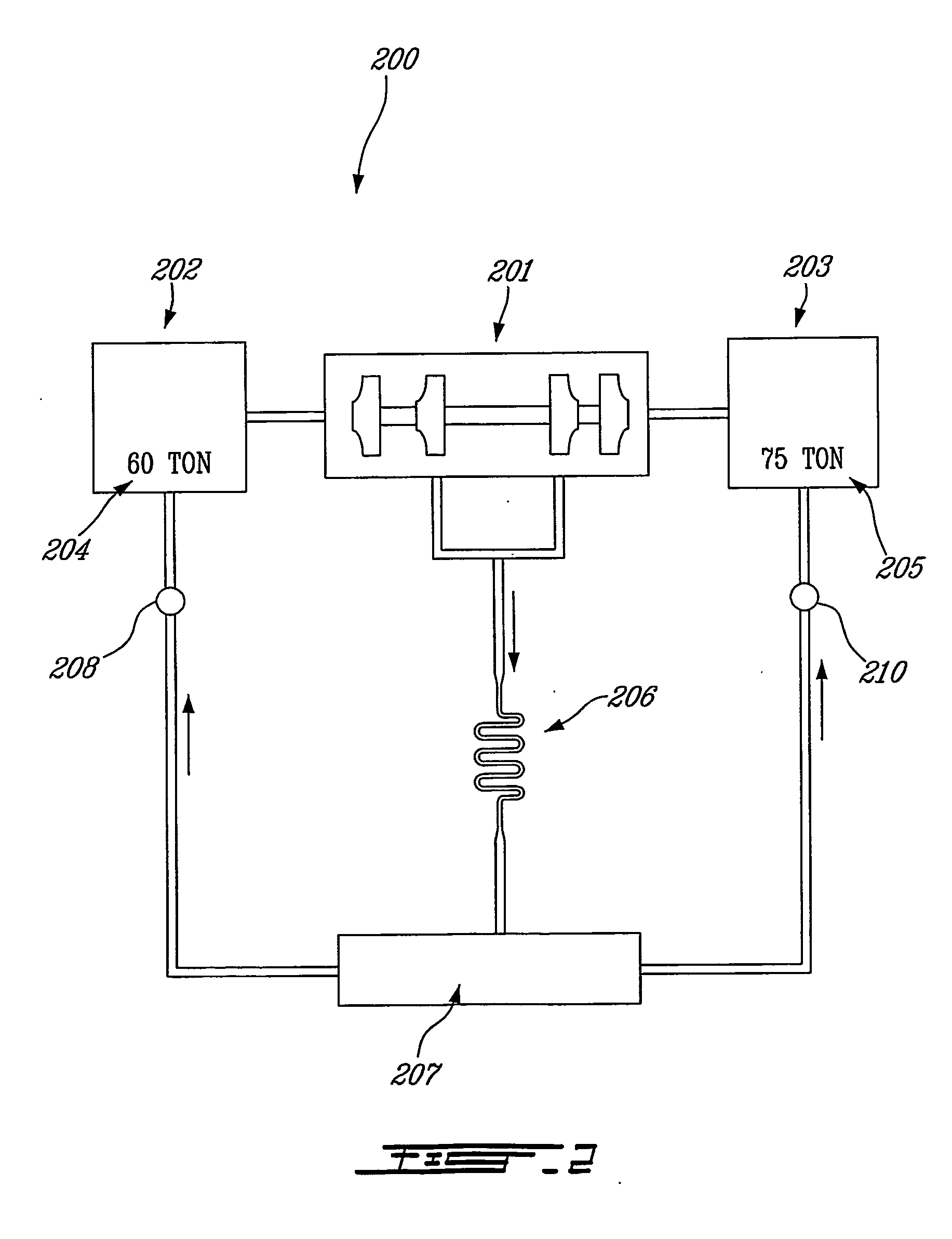

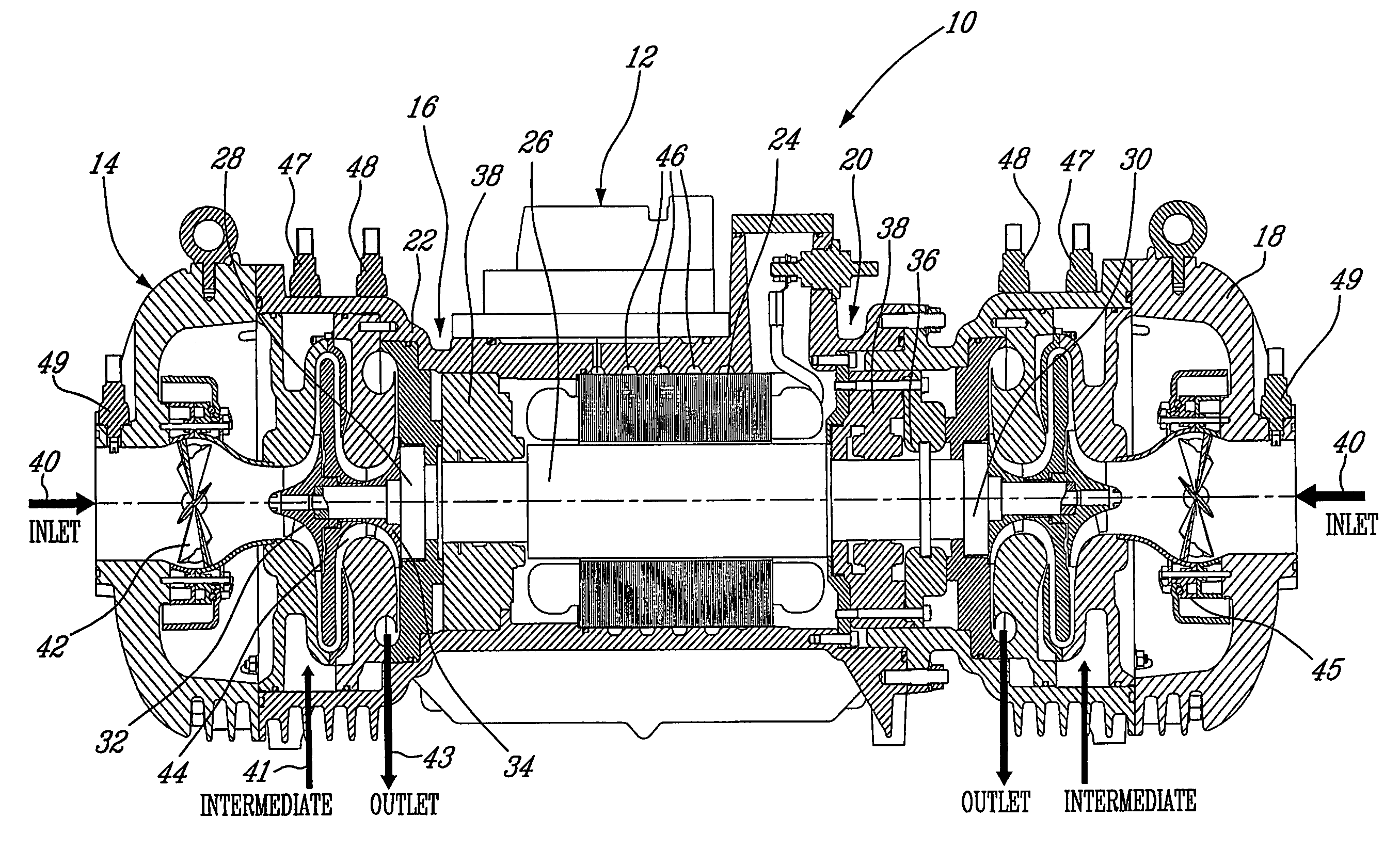

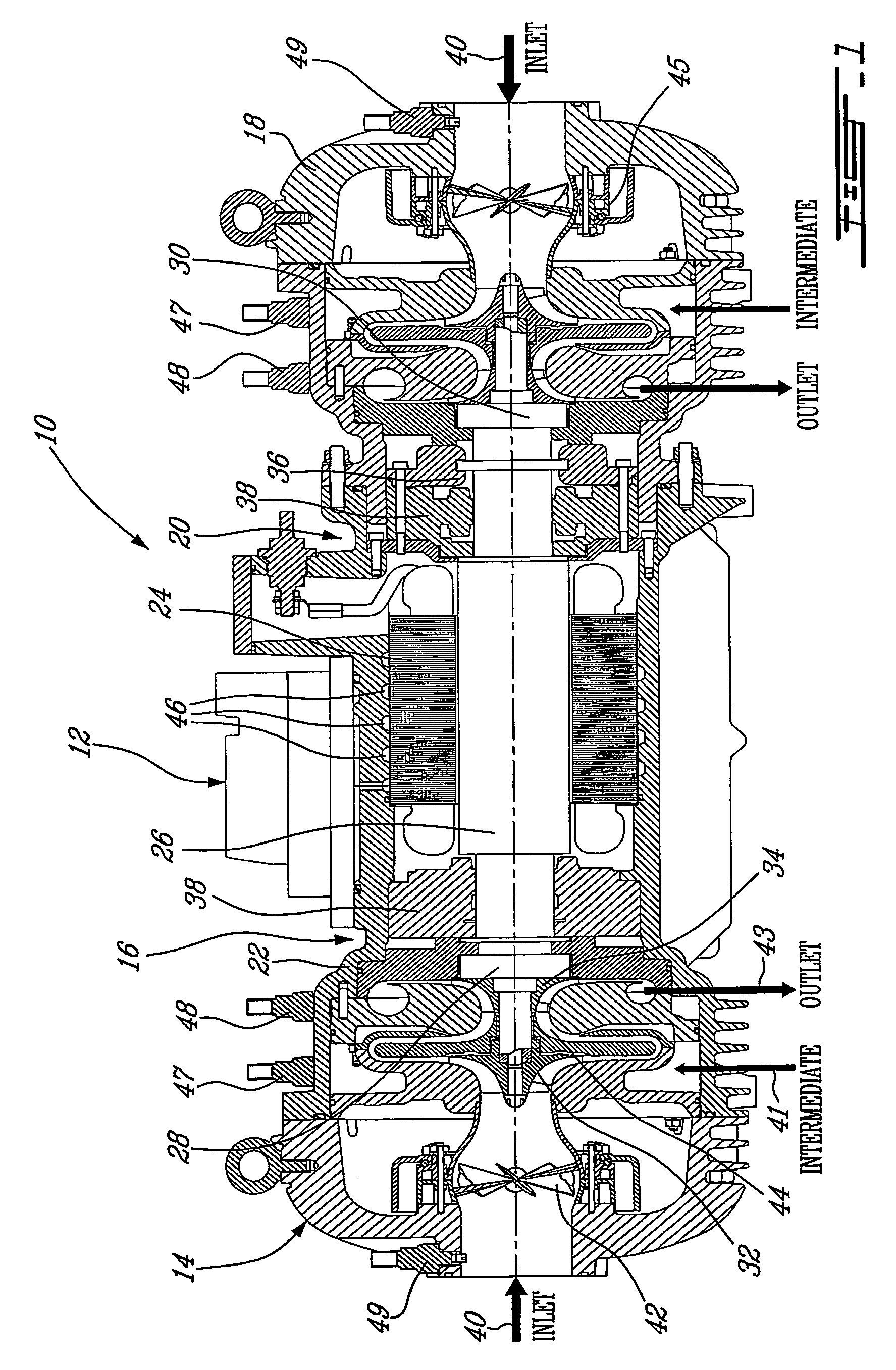

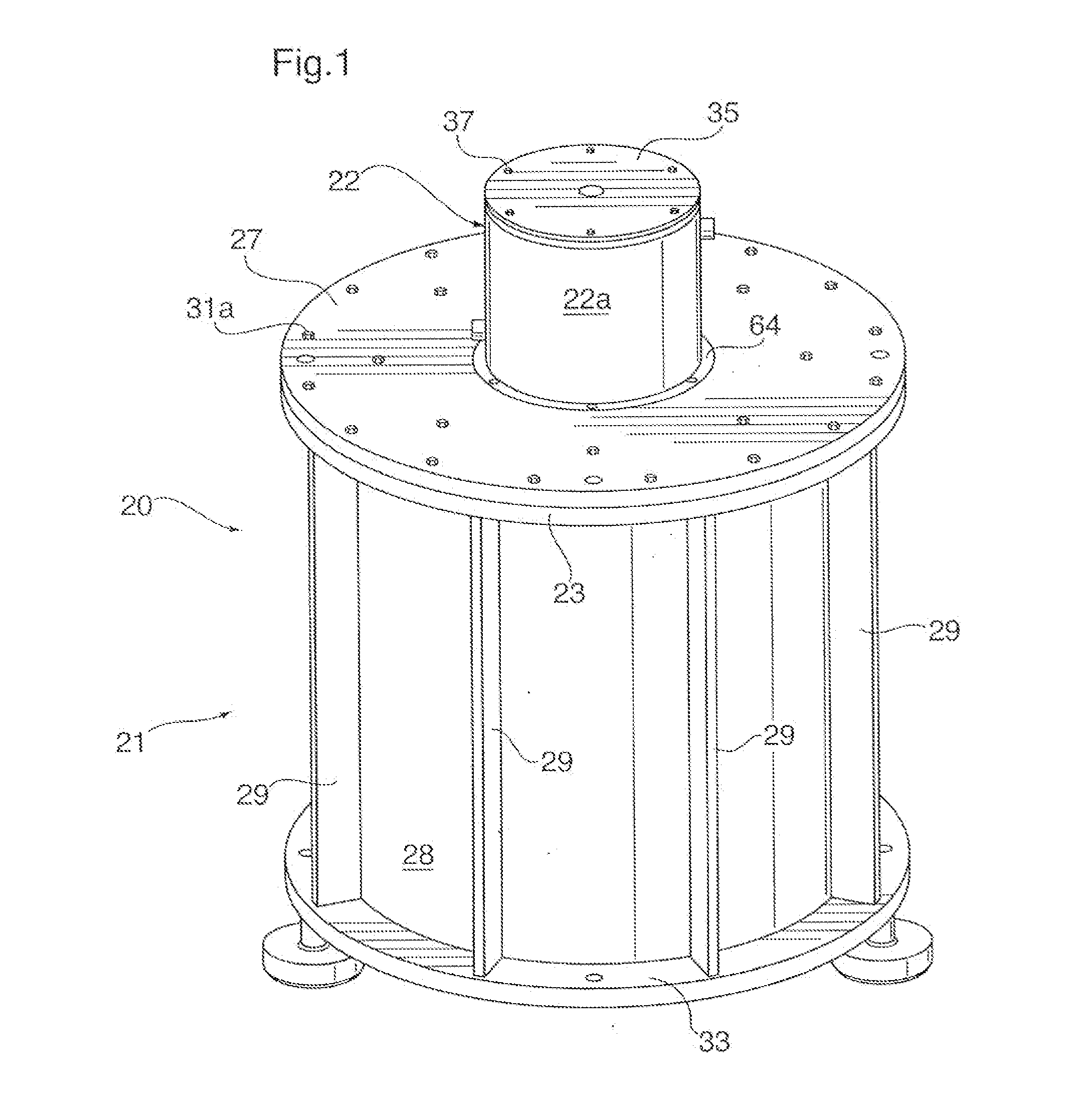

Centrifugal compressor

ActiveUS20050223737A1Improved centrifugal compressorCompressorPump componentsMagnetic bearingControl system

A compact and efficient compressor is provided, based on using magnetic bearing technology, which can operate at high speed and comprises a reliable control system. The compressor of the present invention makes use of two separate compressors mounted on a single common motor, thus sharing a single drive. The balancing of the thrust at high RPM is improved by using a pair of electromagnetic bearings.

Owner:DANFOSS AS

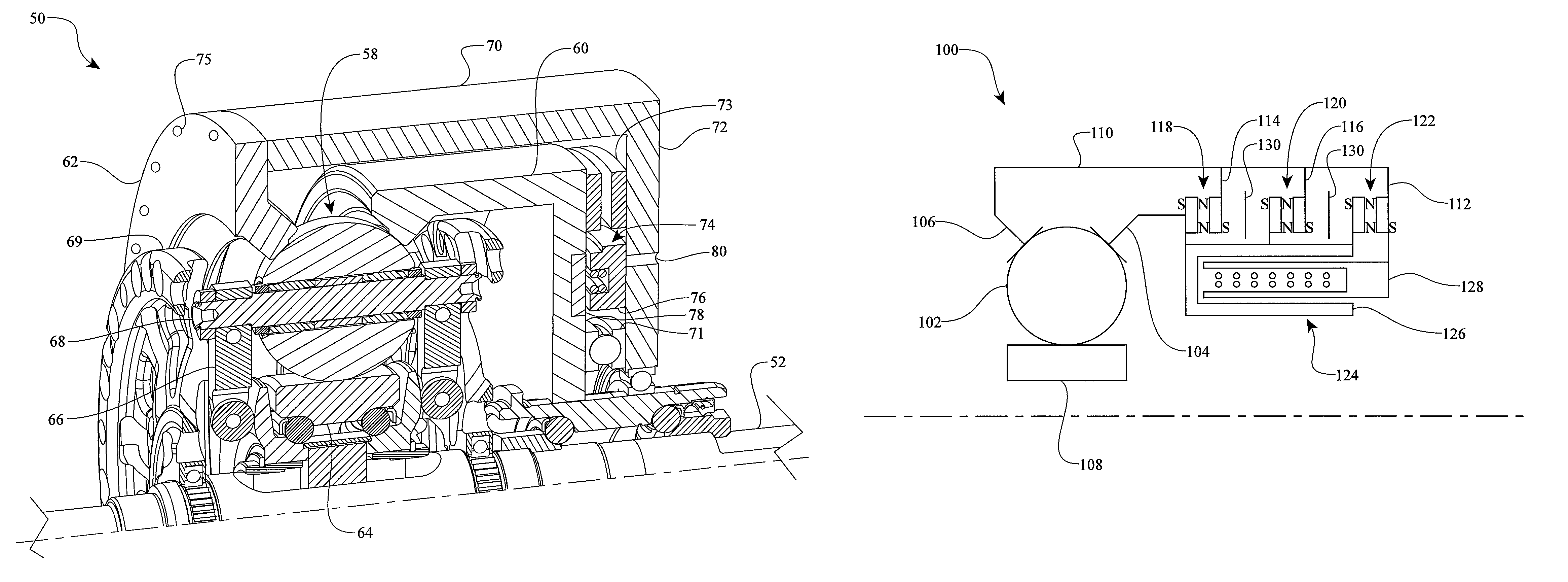

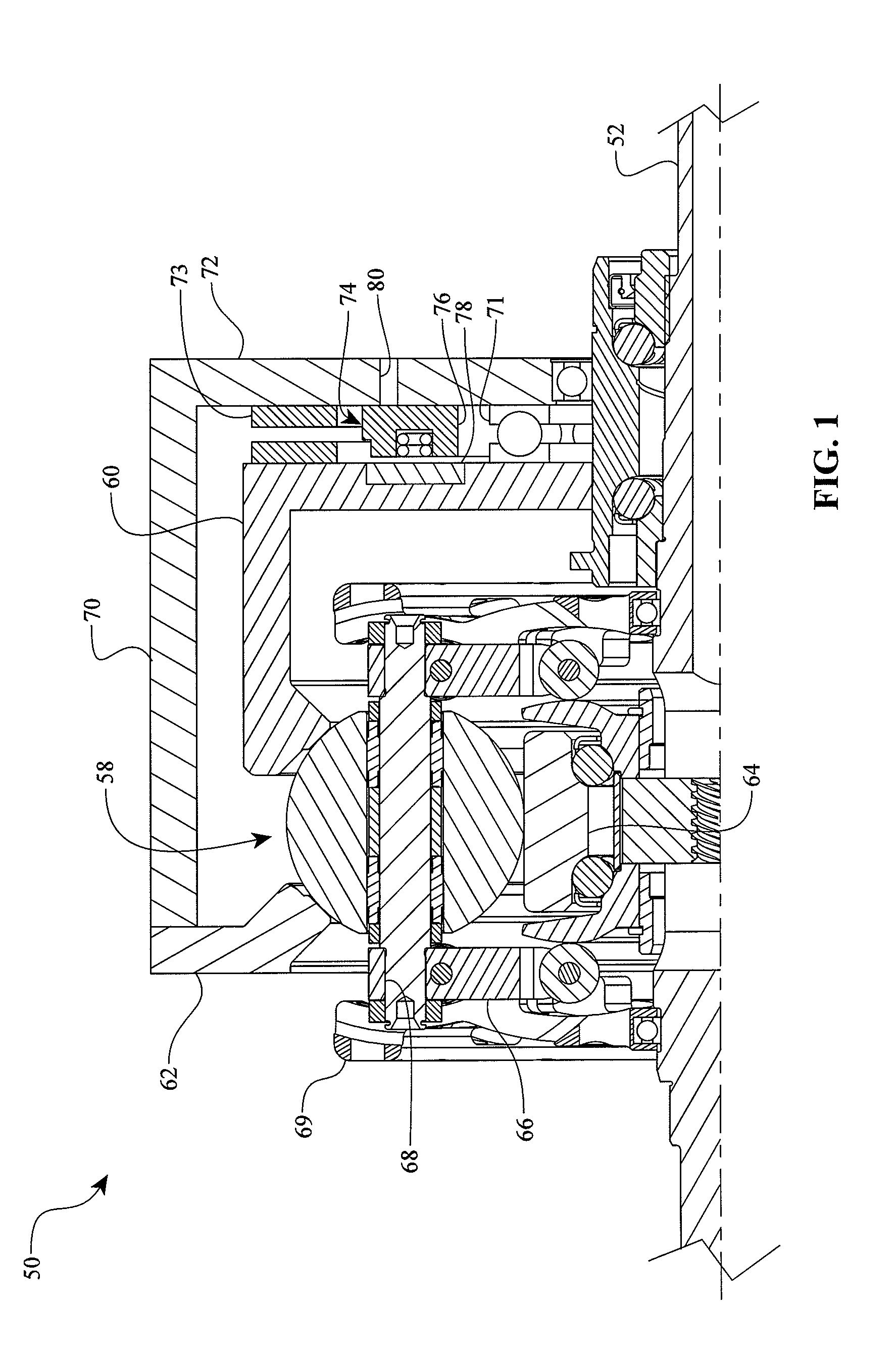

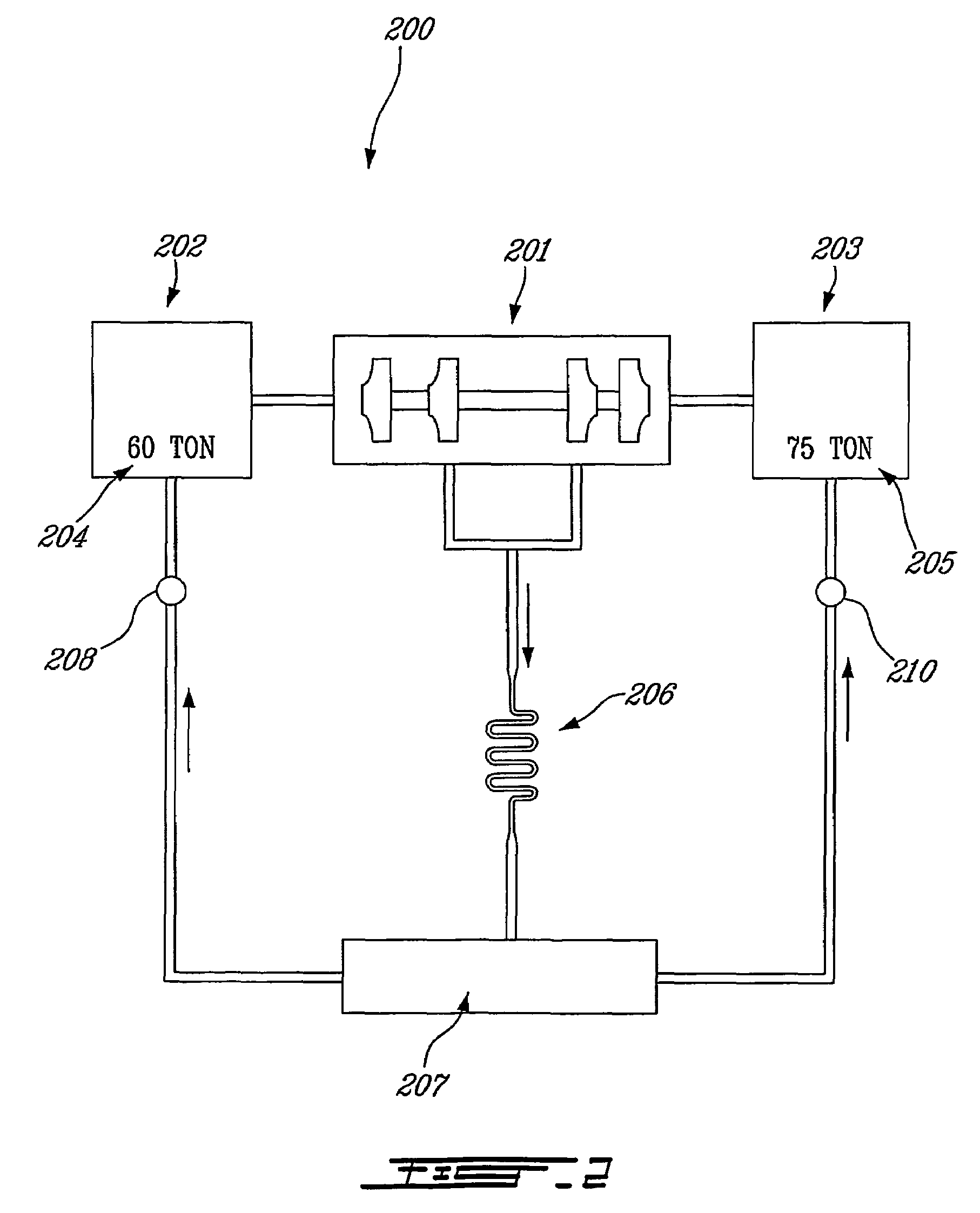

High capacity chiller compressor

ActiveUS20080115527A1Improve efficiencyIncrease power outputWind motor controlEfficient regulation technologiesMagnetic bearingEngineering

A high efficiency, low maintenance single stage or multi-stage centrifugal compressor assembly for large cooling installations. The assembly is highly efficient by virtue of a variable frequency drive (VFD) that drives a permanent magnet motor and matches compressor speed with compressor load, a direct drive impeller that eliminates gearing losses, and magnetic bearings that reduce frictional losses. The back-emf produced by the motor provides an intermediate power source for the magnetic bearings in the event of a loss of electrical power. A cooling system provides direct cooling of the rotor with gas refrigerant, and cooling of the stator with liquid refrigerant. Modular construction allows the compressor to be retrofit with upgrades. An inlet guide vane system operates without need for oil lubrication. The use of light metal castings and elimination of gearing reduces the weight to one-third or less of comparably powered conventional units.

Owner:DAIKIN IND LTD

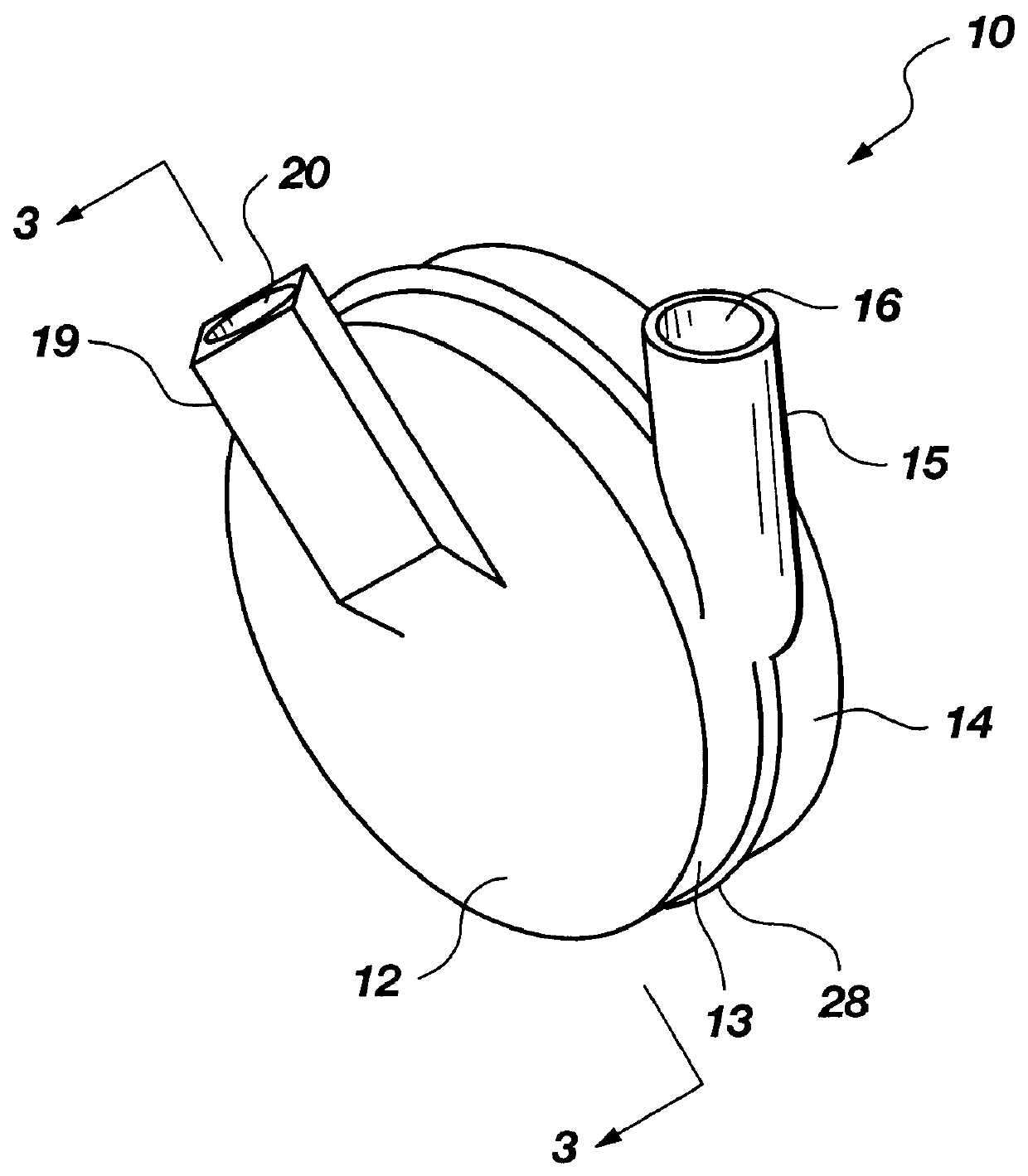

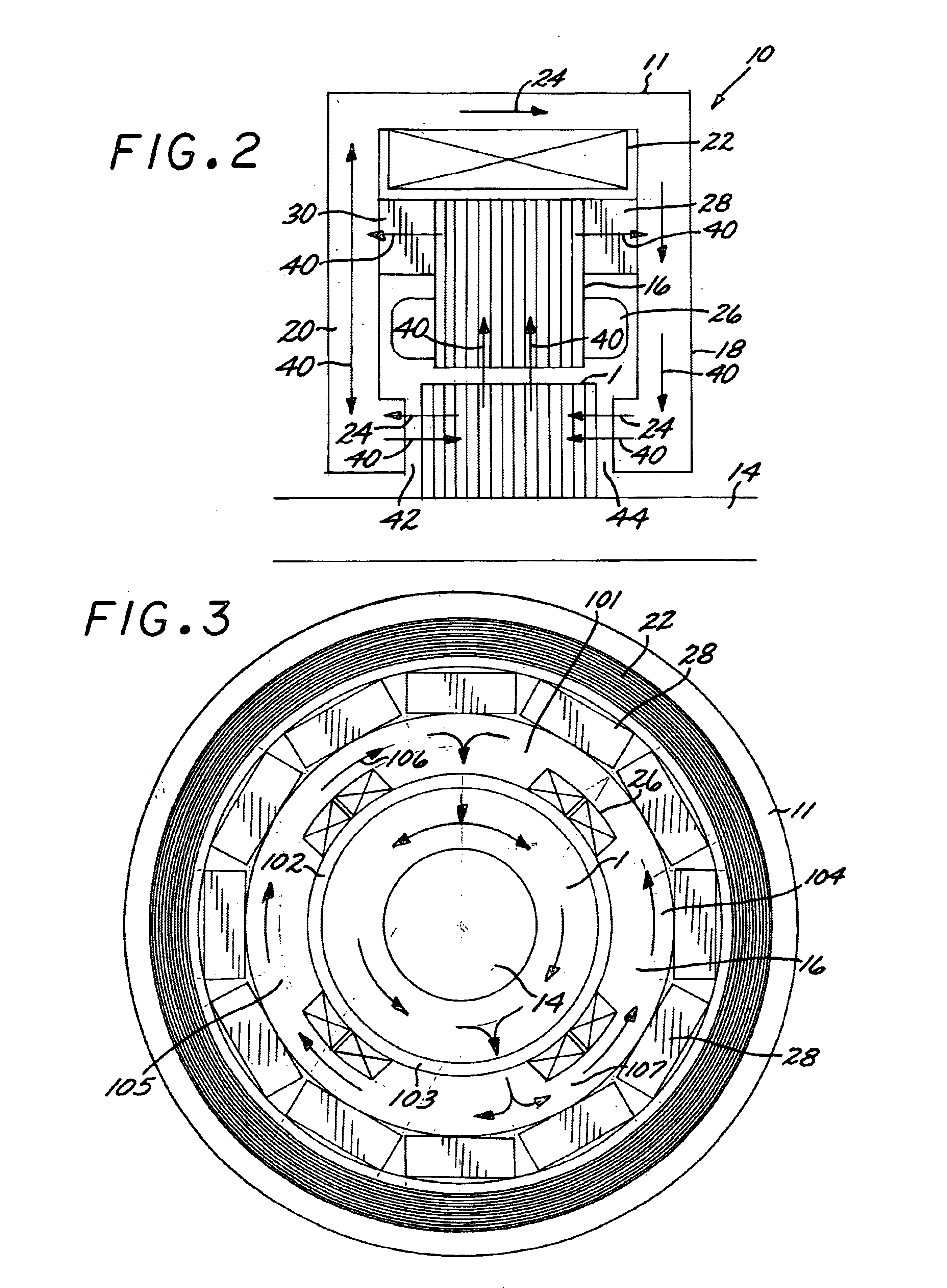

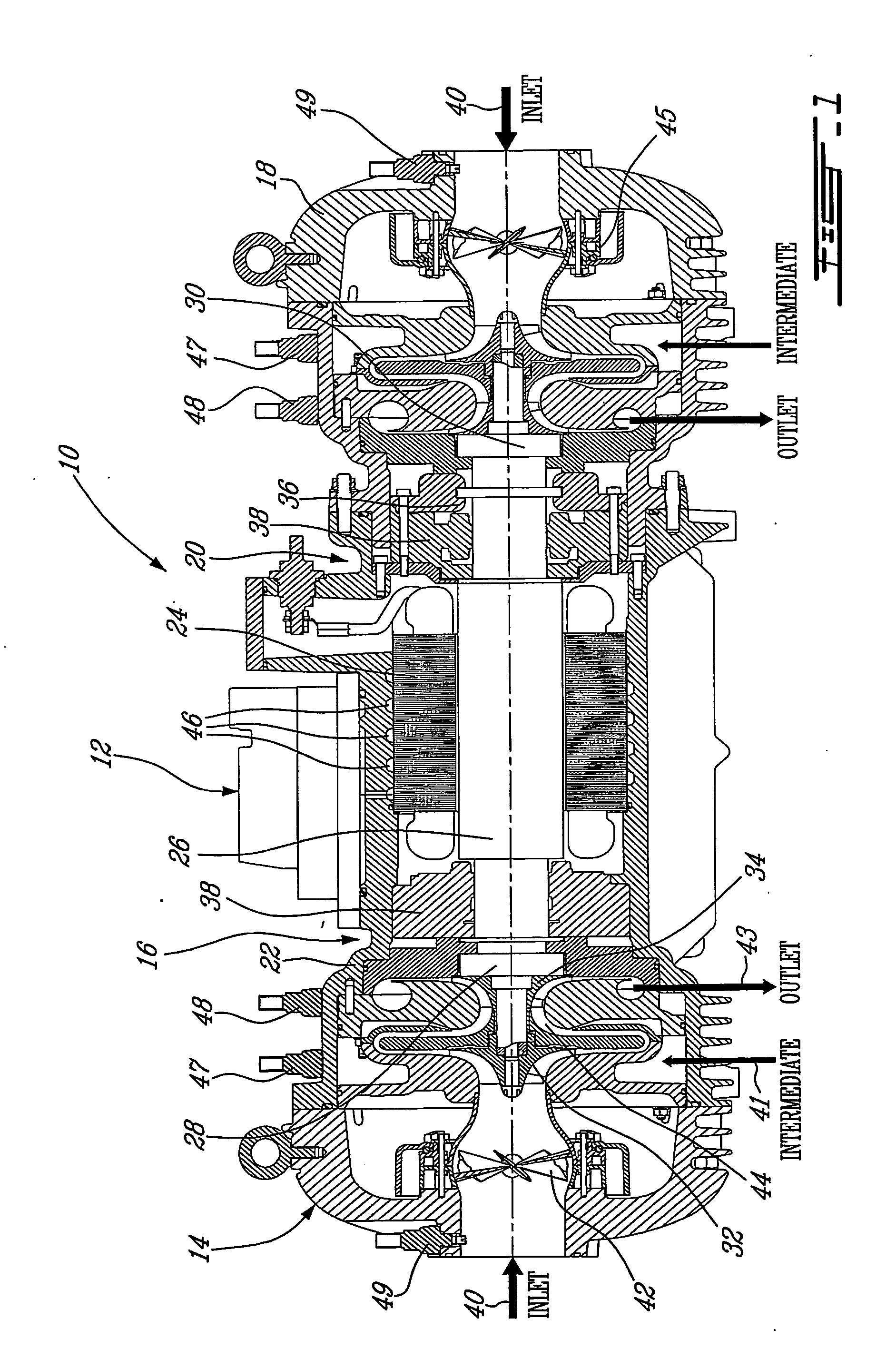

Heart pump controller

A heart pump including first and second cavities, each cavity including a respective inlet and outlet, a connecting tube extending between the first and second cavities, an impeller including: a first set of vanes mounted on a first rotor in the first cavity portion; a second set of vanes mounted on a second rotor in the second cavity portion; and, a shaft connecting the first and second rotors, the shaft extending through the connecting tube, a drive for rotating the impeller and a magnetic bearing including at least one bearing coil for controlling an axial position of the impeller, at least one of the drive and magnetic bearing being mounted outwardly of the connecting tube, at least partially between the first and second cavity portions.

Owner:BIVACOR

Magnetic bearing

There is disclosed a magnetic bearing which is an improvement over conventional radial magnetic bearings, and has a very small bearing loss. At least three U-shaped laminates 10 of electromagnetic steel sheets are circumferentially arranged around a rotation shaft 1, and are fixedly mounted on a housing 100. Exciting coils 31 and 32 are wound on each electromagnetic steel sheet laminate 10, and permanent magnets 20 and 21 are provided in the laminate 10. Rotor cores 2, each comprising a laminate of I-shaped electromagnetic steel sheets stacked together in the circumferential direction, are mounted on the rotation shaft 1 in such a manner that each rotor core 2 is opposed to magnetic pole surfaces of the electromagnetic steel sheet laminates 10. In accordance with a signal from position sensors 5 which detect the radial position of the rotation shaft 1, control current is caused to flow through the exciting coils 31 and 32 to thereby control the position of the rotation shaft 1. Thus, merely by causing the control current to flow through the exciting coils 31 and 32 when this is required, the control of the rotation shaft 1 can be achieved, and with this method, the energy consumption can be much reduced.

Owner:NSK LTD

Assemblies and methods for clamping force generation

Mechanisms and methods for clamping force generation are disclosed. In one embodiment, a clamping force generator system includes a permanent magnet bearing coupled to a traction ring and to a torque coupling. The traction ring can be provided with an electromagnetic bearing rotor and the torque coupling can be provided with an electromagnetic bearing stator. In some embodiments, a mechanical load cam, a permanent magnet bearing, and an electromagnetic bearing cooperate to generate a clamping force between the traction rings, the power rollers, and the idler. In other embodiments, a series of permanent magnet bearings and a mechanical bearing configured to produce a clamping force. In one embodiment an electromagnetic bearing is coupled to a control system and produces a specified clamping force that is associated with a torque transmitted in the transmission during operation. In some embodiments, a mechanical load cam produces a clamping force proportional to torque, while a permanent magnet bearing provides a minimum clamping force.

Owner:FALLBROOK INTPROP COMPANY

Method and apparatus for providing three axis magnetic bearing having permanent magnets mounted on radial pole stack

InactiveUS20030155829A1Effective and inexpensive techniqueHighly linear magnetic biasMechanical energy handlingBearingsAxial displacementMagnetic bearing

An improved magnetic bearing that uses permanent magnets to provide the bias flux. The magnetic circuits generating the control flux and bias fluxes are substantially non-coincident but share the same path over some portions that include radial and axial airgaps allowing for a low reluctance and an efficient path for the electromagnetic flux. The flux paths of the permanent magnets are completely defined with minimized airgaps for achieving higher forces and efficiency and very low control currents that produce extremely large forces. A single coil and amplifier for the axial force control and two coils with one associated amplifier for each radial axis of control provides simplicity and cost effectiveness. A single thrust disk is provided that is reacted against for both radial and the axial displacement. The permanent magnets used in the present invention are first fabricated and axially magnetized as segments or as continuous rings prior to being mounted on the sides of the rotor pole, providing an effective and inexpensive technique of manufacturing magnetic bearings.

Owner:CALNETIX TECH +1

Pump with magnetic bearings

A pump unit includes a motor, a pump, a shaft spanning the motor and the pump, and at least a first magnetic bearing supporting the shaft. A hydrocarbon production system includes an underwater well and a pump unit exposed to an underwater environment. The pump unit is operable to pump a production fluid from the well and includes a motor, a pump, a shaft spanning the motor and the pump, and at least a first magnetic bearing supporting the shaft.

Owner:FMC TECH INC

Magnetic levitation motor and pump

A magnetic levitation motor including a stator having magnetic bearing units and a motor unit, and a rotor provided to the stator. And the occurrence of an eddy current at a magnetic bearing is suppressed and the rotation loss of the rotor can be reduced, and also to provide a pump using such the magnetic levitation motor.

Owner:IWAKI

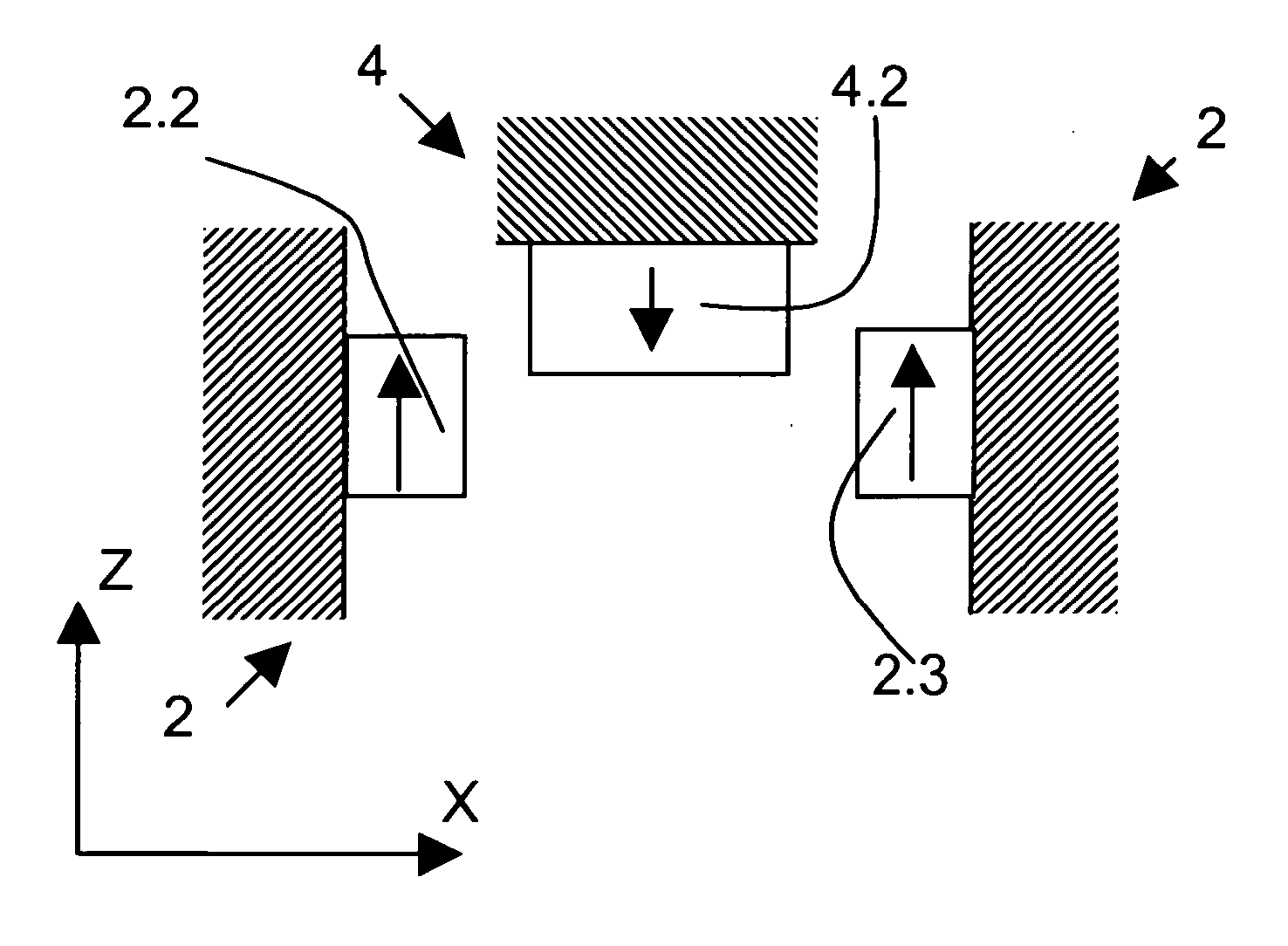

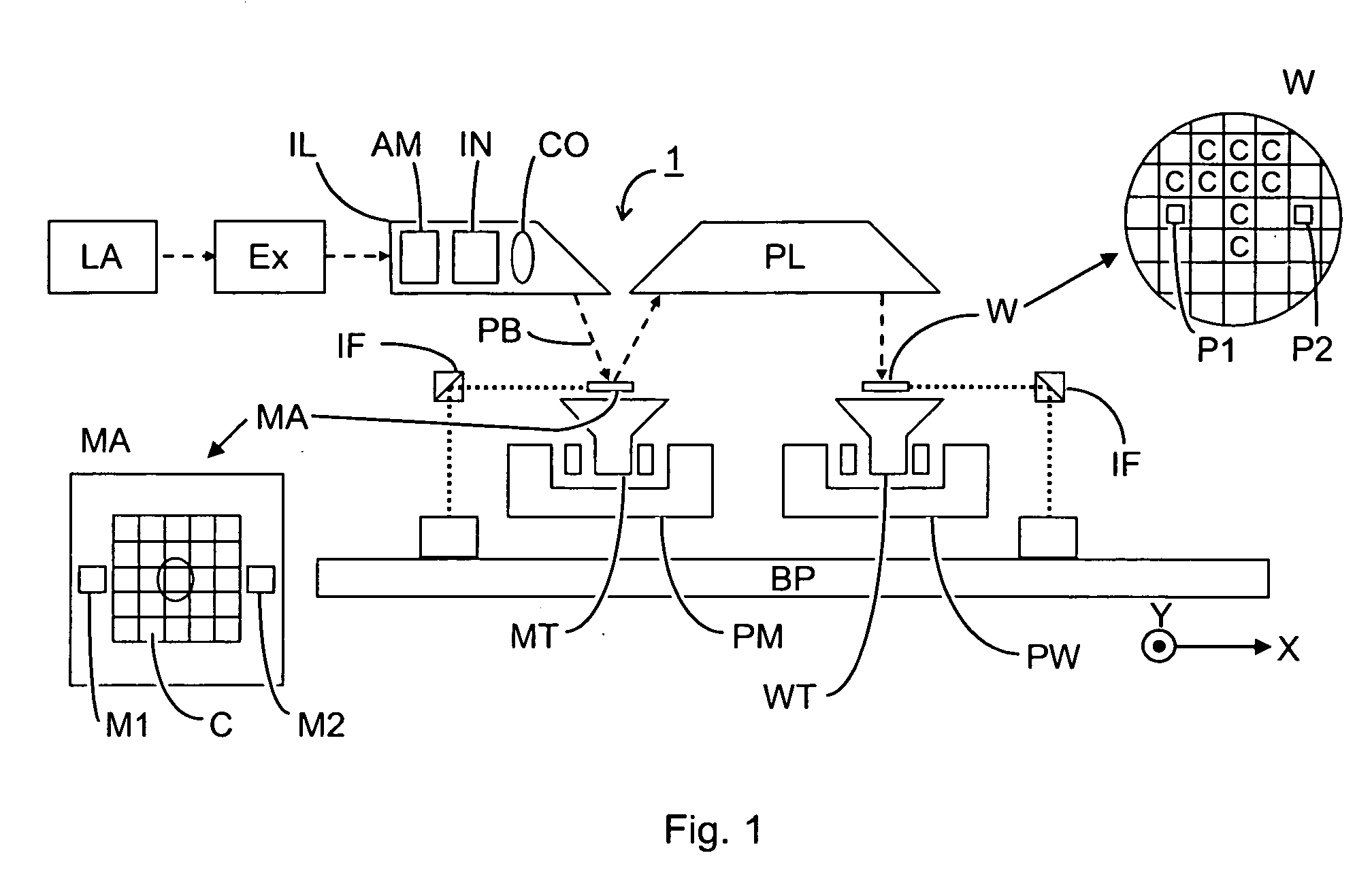

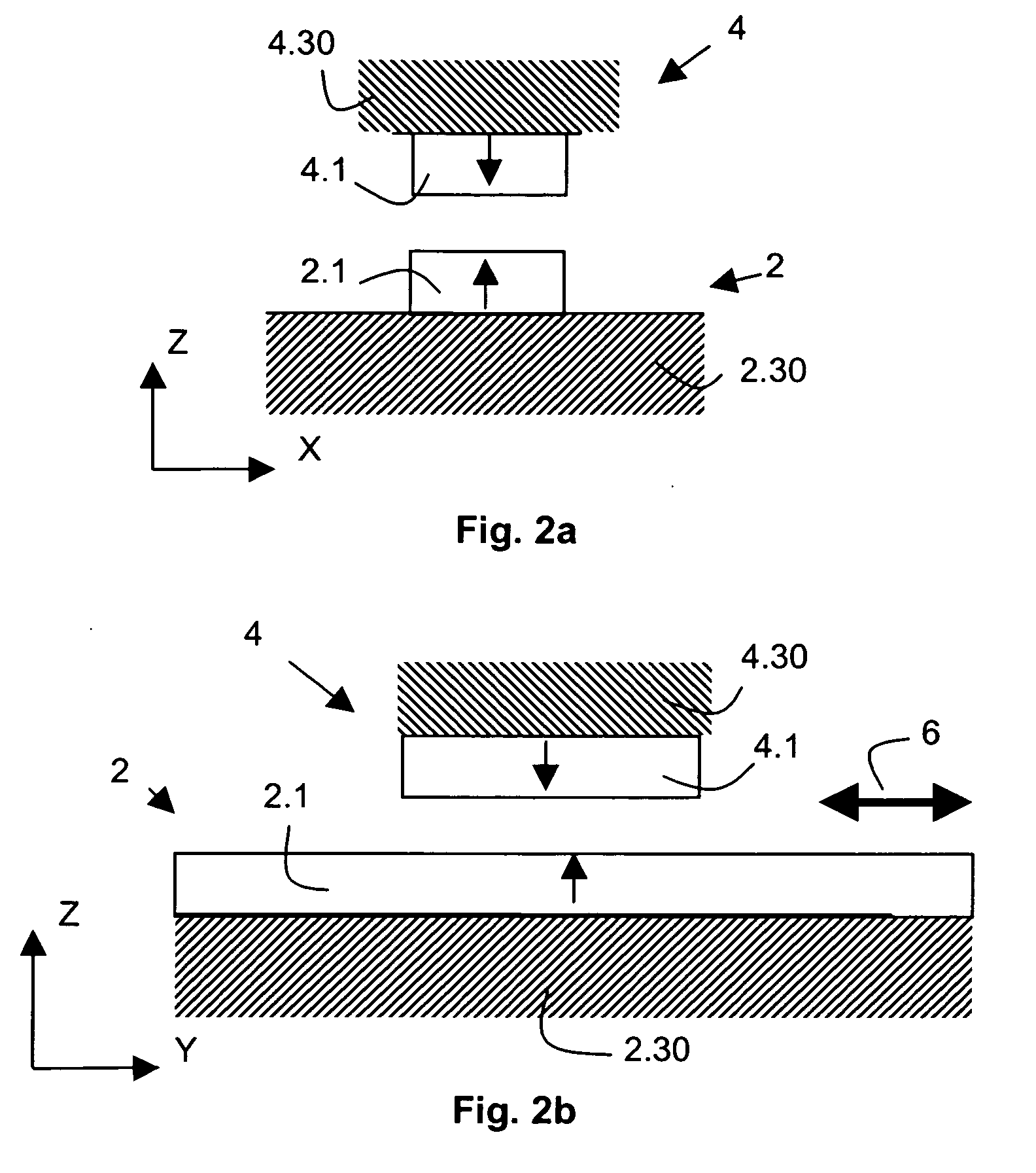

Lithographic apparatus, device manufacturing method and device manufactured thereby

InactiveUS20050002008A1Low stiffnessMinimal effortBearing assemblyInvestigating moving sheetsMagnetic bearingEngineering

A lithographic projection apparatus includes a passive magnetic bearing configured to provide support between a first and second part of the lithographic apparatus and allow both parts to be displaced relative to each other in a direction perpendicular to the support direction. The passive magnetic bearing includes first and second magnetic assemblies. Each magnetic assembly includes at least one permanent magnet.

Owner:ASML NETHERLANDS BV

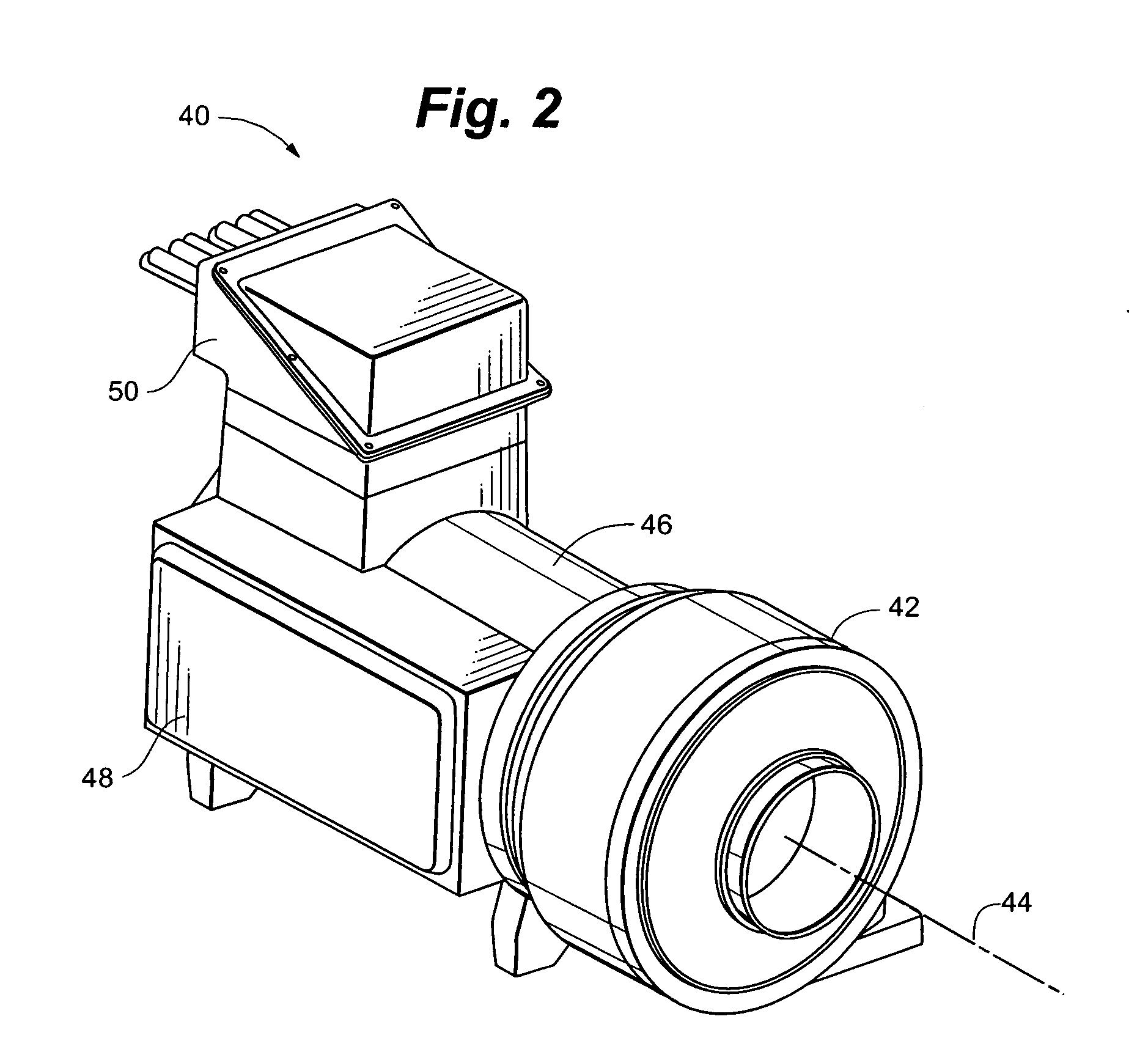

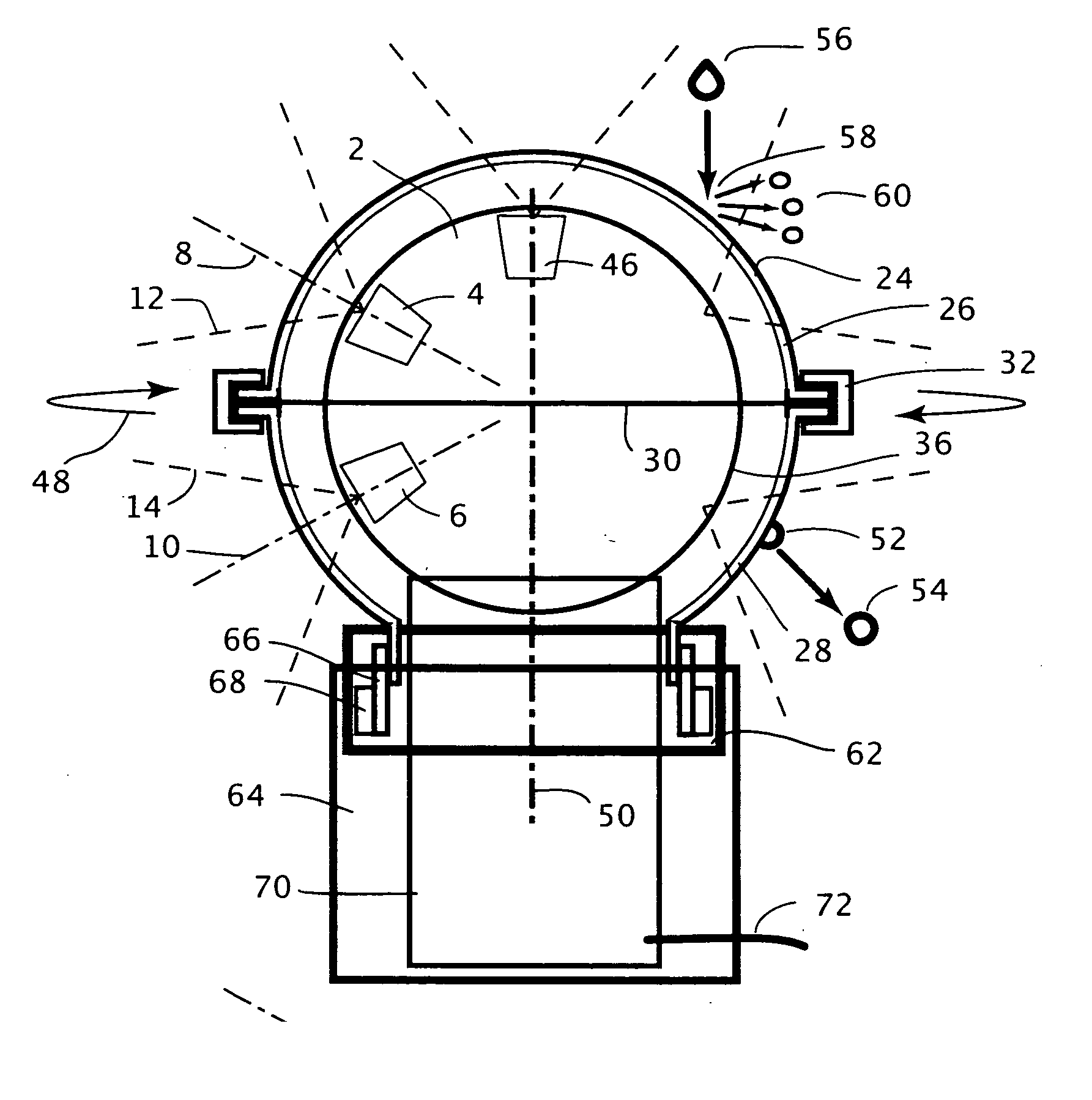

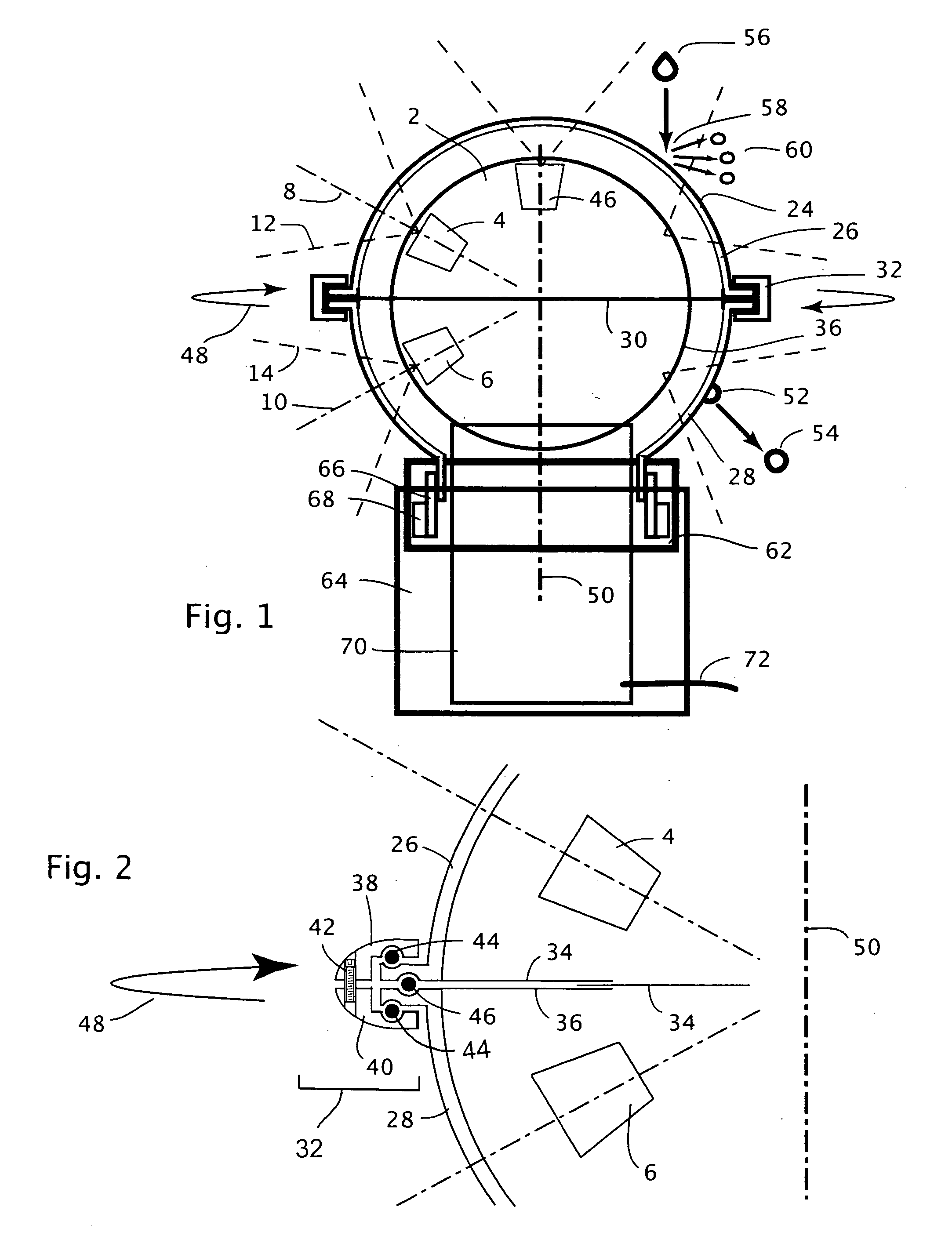

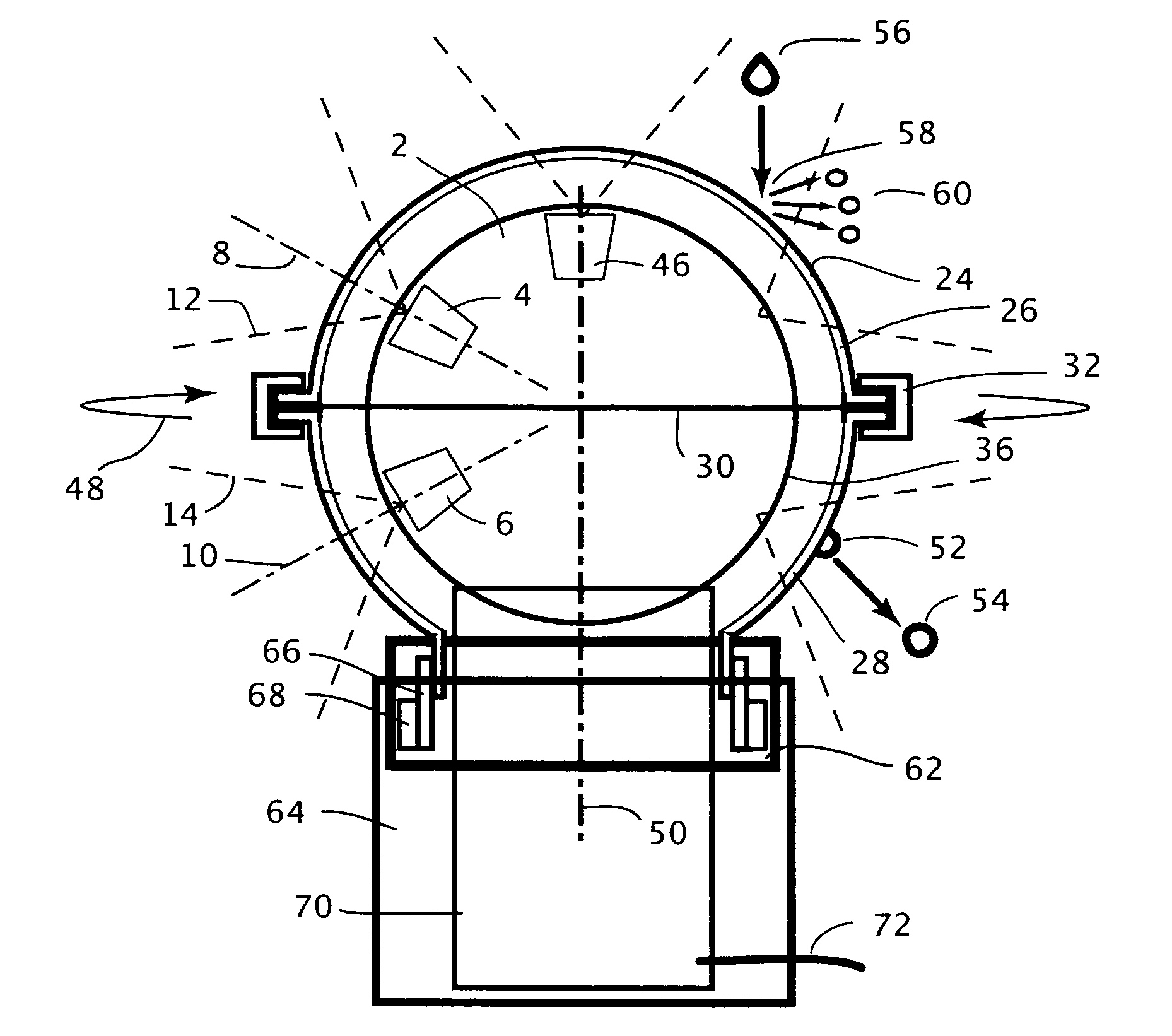

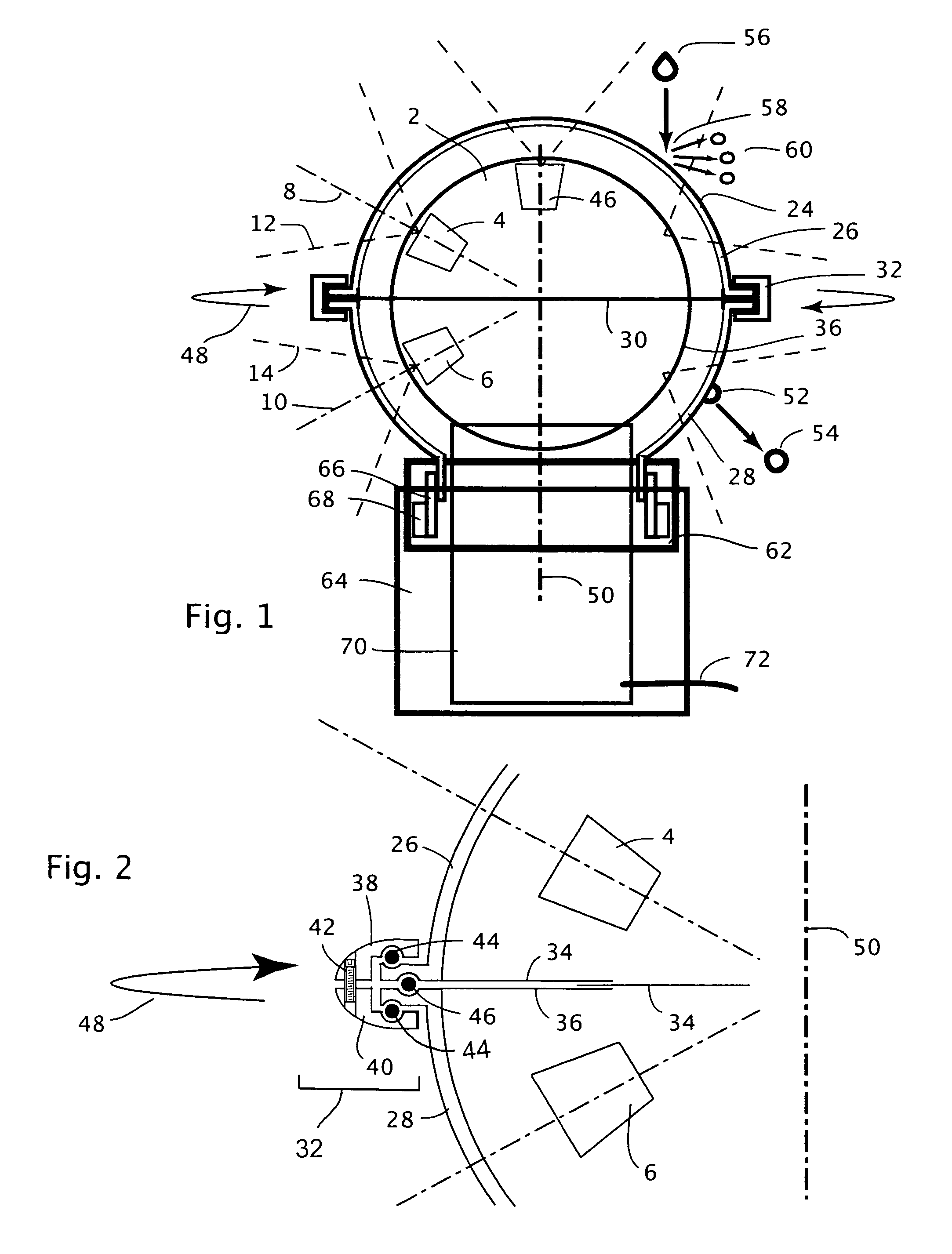

Spinning camera enclosure for environmental protection

ActiveUS20070217782A1Clear imagingLower performance requirementsTelevision system detailsColor television detailsMagnetic bearingWide field

An environmental protection system features a clear spinning curved volumetric enclosure to shed and throw off environmental contaminants such as rain, fog and dust that would affect a sensor image. The described design is especially suitable for cameras with extremely wide fields of view, such as panoramic or immersive cameras. Alternate forms of volumetric enclosures are described for different lens arrangements in compound camera systems. In all of these embodiments it is possible to keep the cover and the mechanism spinning it invisible to the cameras. An additional modification of the shape of the volumetric enclosure is described that prevents any accumulation of liquid drops within the fields of view of the sensors within the spinning volumetric enclosure. Alternate forms of construction with air and magnetic bearings are described for smoother and quieter operation of the spinning enclosure.

Owner:IMMERSIVE LICENSING

Centrifugal compressor

ActiveUS7240515B2Improved centrifugal compressorCompressorPump componentsMagnetic bearingControl system

A compact and efficient compressor is provided, based on using magnetic bearing technology, which can operate at high speed and comprises a reliable control system. The compressor of the present invention makes use of two separate compressors mounted on a single common motor, thus sharing a single drive. The balancing of the thrust at high RPM is improved by using a pair of electromagnetic bearings.

Owner:DANFOSS AS

Pump

ActiveUS8512012B2Easy to handleEasy to monitorPump componentsFlexible member pumpsImpellerMagnetic bearing

A pump and a method for operating a pump is proposed for mounting an impeller, which is inexpensive, free from contact and wear and thus extremely permanent. For this the invention uses a combination of permanent magnetic bearings and flow-mechanical bearings. The mounting is thus based on purely passive elements without using actively controlled and / or regulated elements.

Owner:CIRCULITE

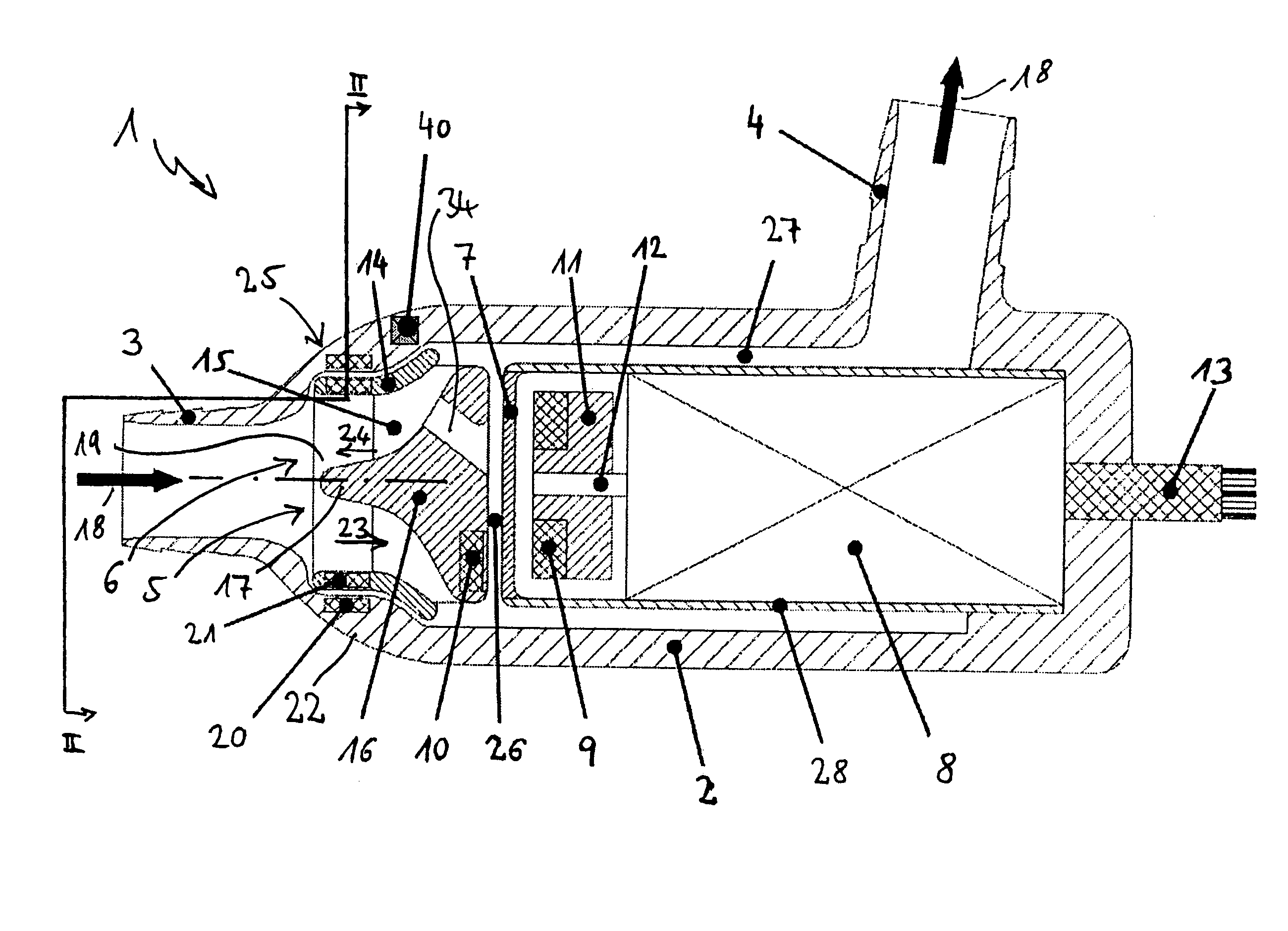

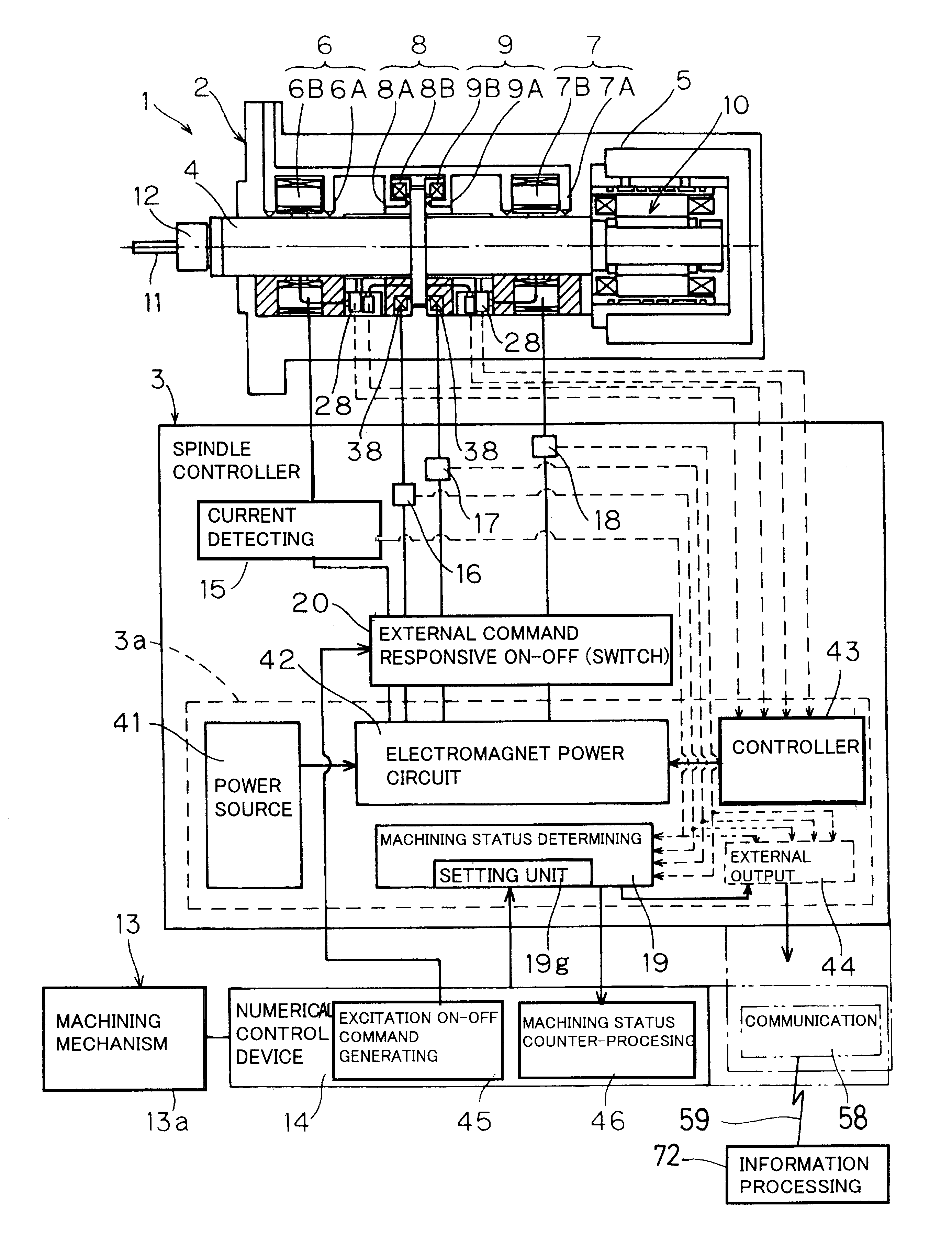

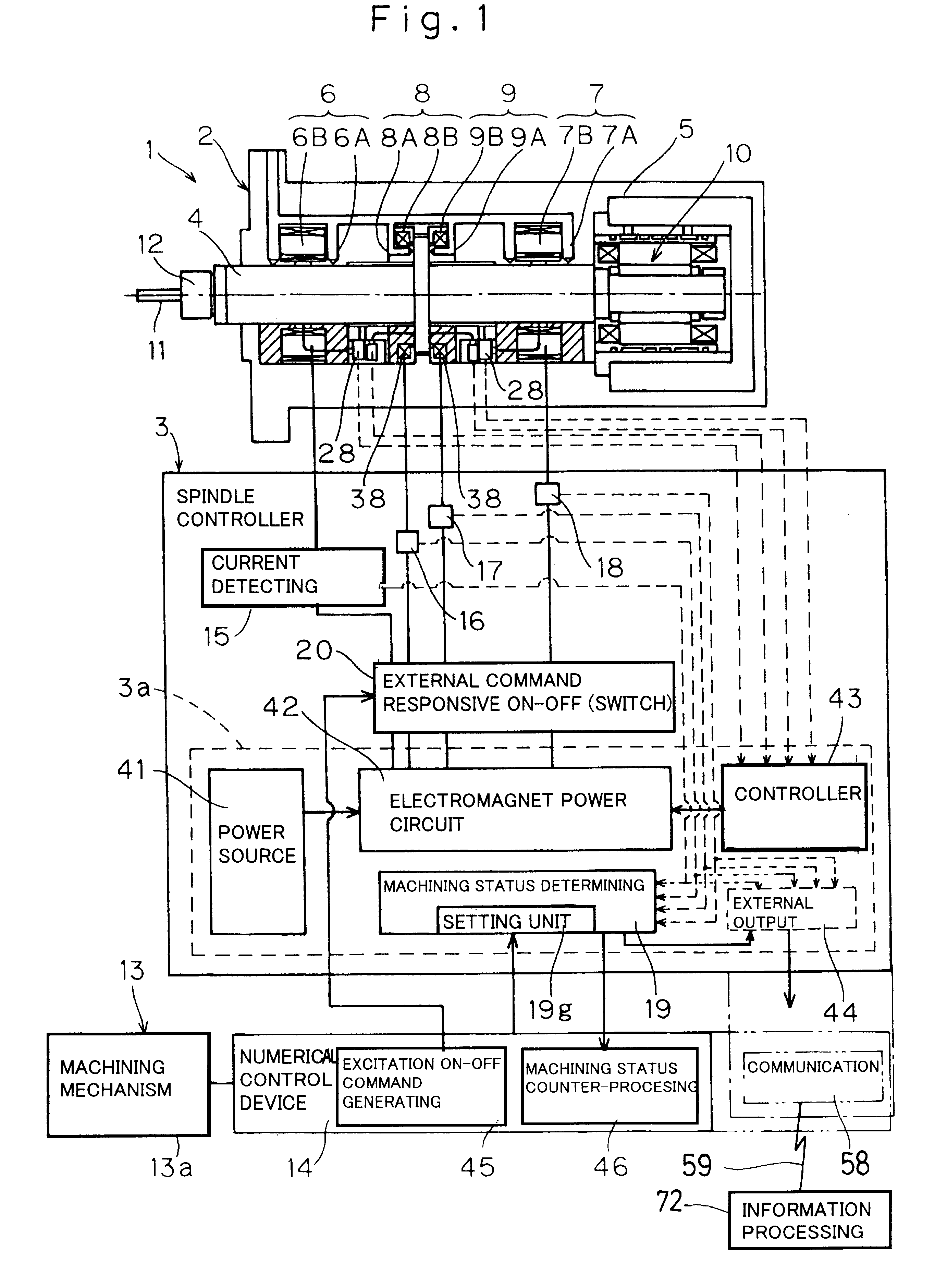

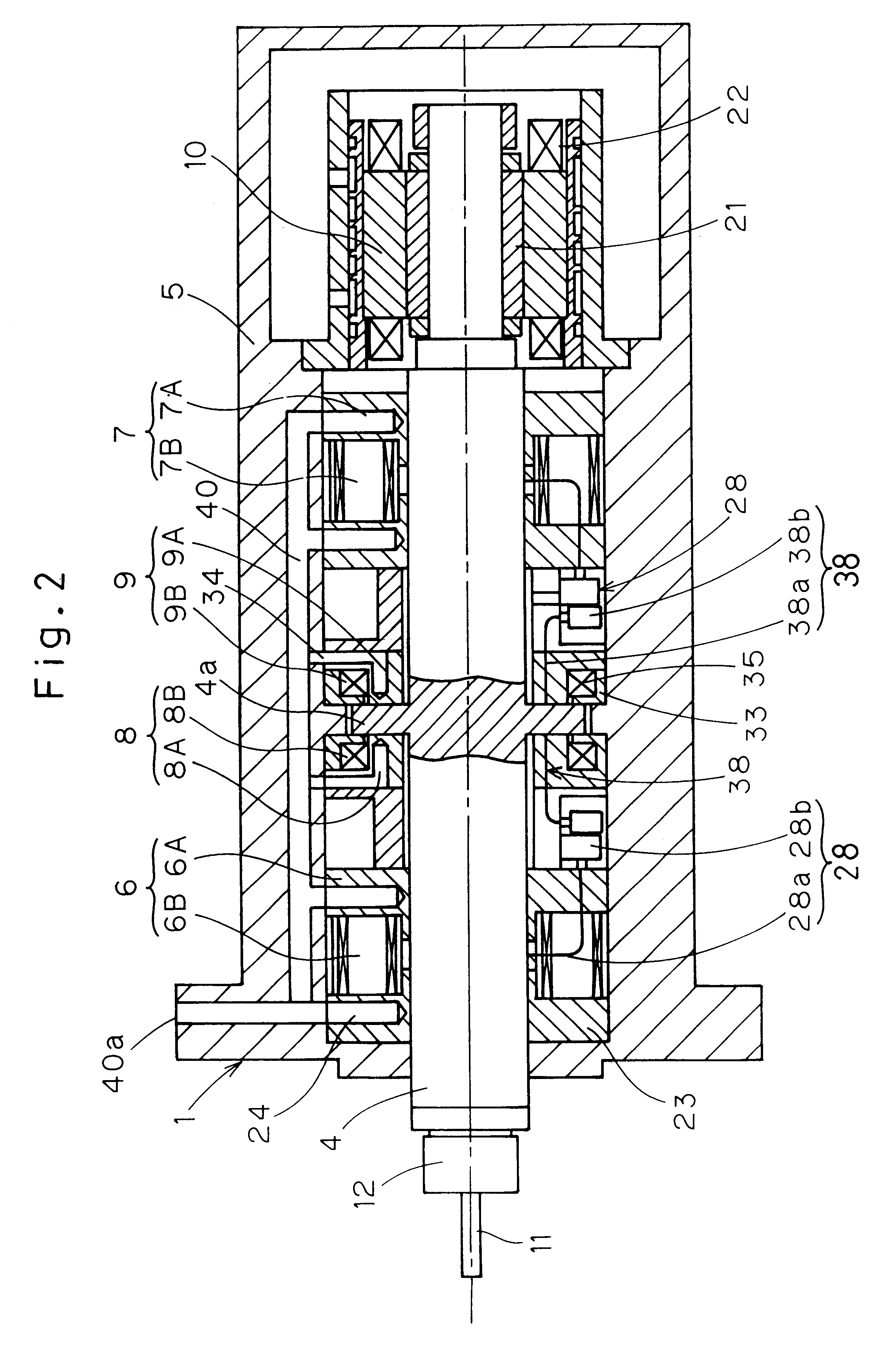

Spindle device and machine tool utilizing the same

A spindle device equipped with a combined externally pressurized gas-magnetic bearing assembly, and a machining apparatus utilizing the spindle device. The spindle device is capable of accomplishing a high speed rotation with high rotational precision and includes a main shaft (4) rotatably supported by the combined bearing assembly (6 to 9), an electric current detecting device (15 to 18) disposed in a spindle controller (3) for detecting a current supplied to electromagnets of the combined bearing assembly (6 to 9). Also provided is a machining status determining device (19) for determining the machining status in reference to the current detected by the current detecting device (15 to 18). The machining status may be an indication of the extent to which a machining tool is impaired.

Owner:NTN CORP

Rotary blood pump

ActiveUS20050095151A1Avoid damageLong pump operationPump componentsBlood pumpsMagnetic bearingRotary pump

Owner:TC1 LLC

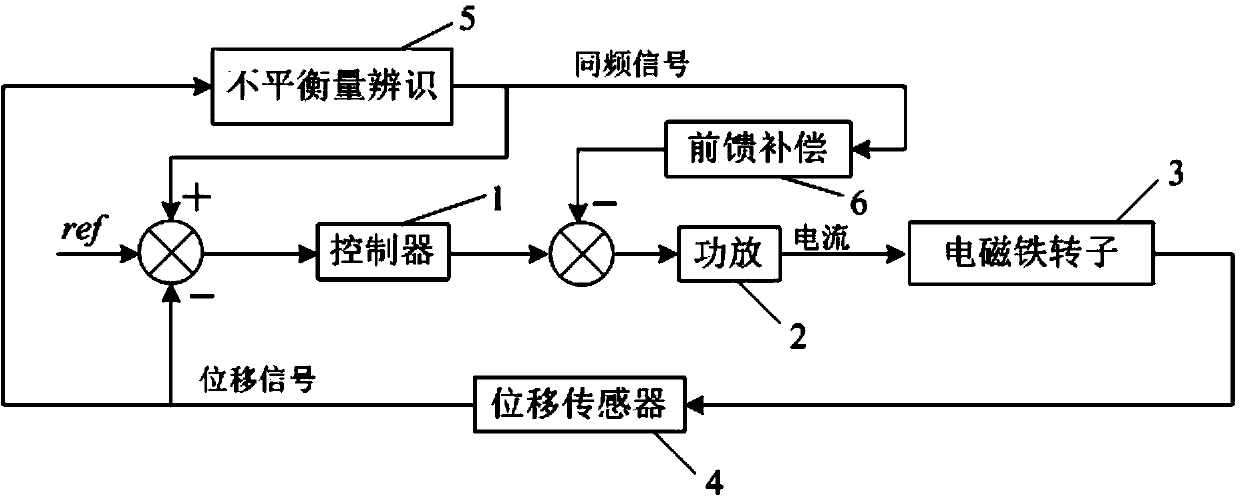

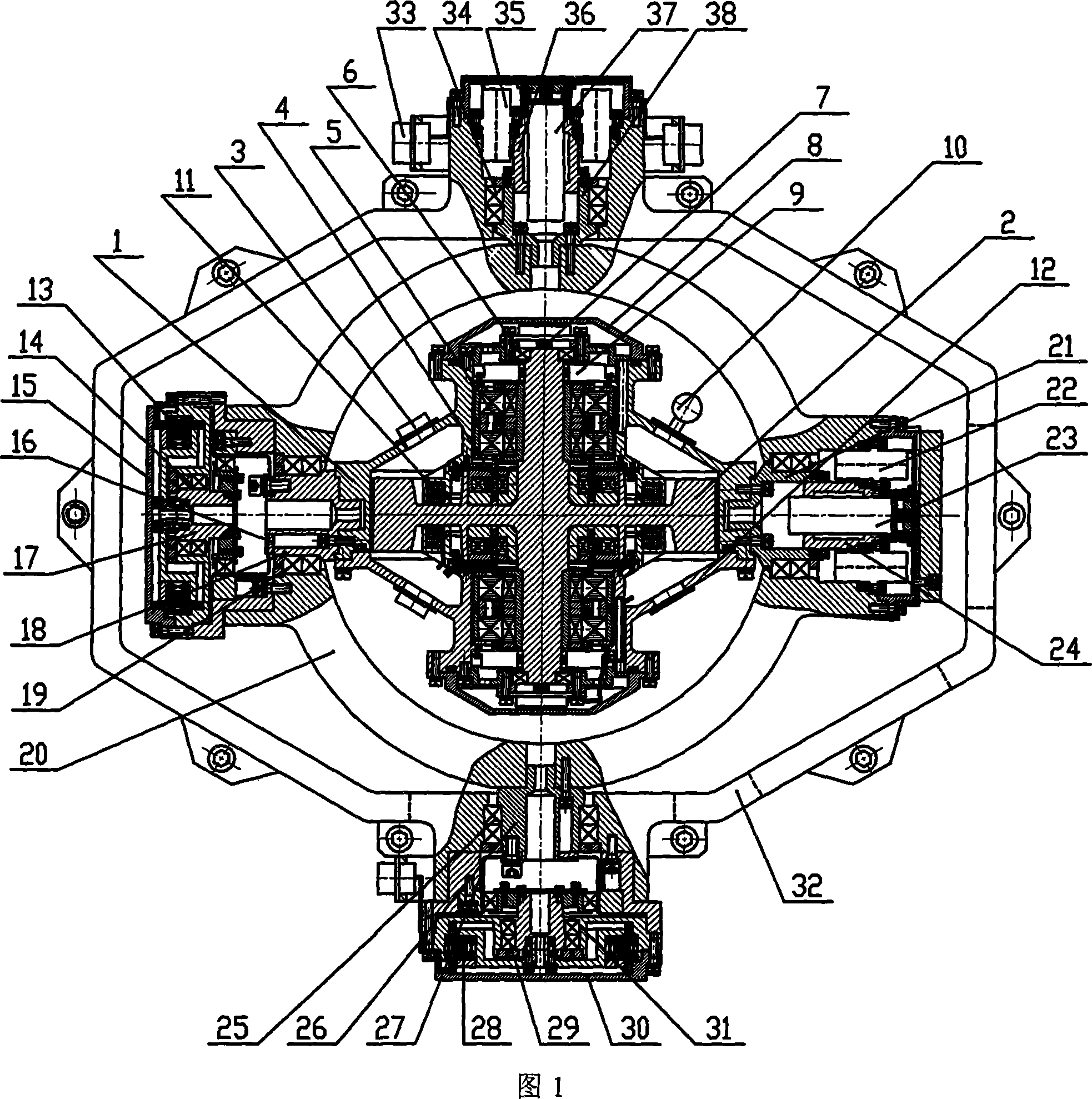

Unbalance identification and vibration suppression control system for magnetic suspension rotating machinery

ActiveCN103425051AHigh compensation accuracyOvercoming Compensation Attenuation ProblemsMechanical oscillations controlAdaptive controlMagnetic bearingStabilization control

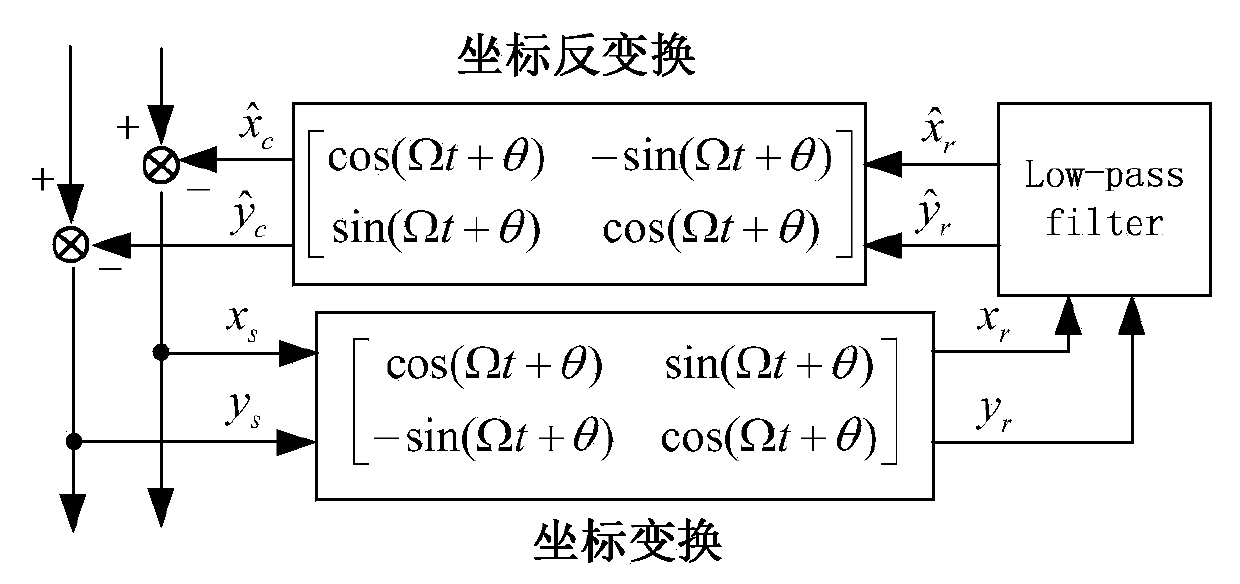

An unbalance identification and vibration suppression control system for a magnetic suspension rotating machinery comprises an unbalance identification module, an unbalanced force compensation module, a magnetic bearing power amplifier, an electromagnet rotor and a displacement sensor. Based on stable control of a magnetic suspension rotor, the unbalance of a magnetic bearing is identified in an online manner by a novel wave trap based on coordinate transformation, on one hand, the identification amount is used for compensating common-frequency current stiffness force, on the other hand, proper common-frequency current stiffness force is generated according to the identification amount to compensate common-frequency displacement stiffness force, and the influence of the low-pass characteristic of the power amplifier on compensation precision of the common-frequency displacement stiffness force is eliminated by leading a simplified inverse model of the magnetic bearing power amplifier into a feed-forward channel. When the magnetic suspension rotor rotates at a high speed, common-frequency bearing force is greatly reduced, and unbalanced vibration of the magnetic suspension rotor is remarkably suppressed. The unbalance identification and vibration suppression control system is simple, convenient, easy and particularly suitable for an actual high-speed magnetic suspension rotor system.

Owner:BEIHANG UNIV

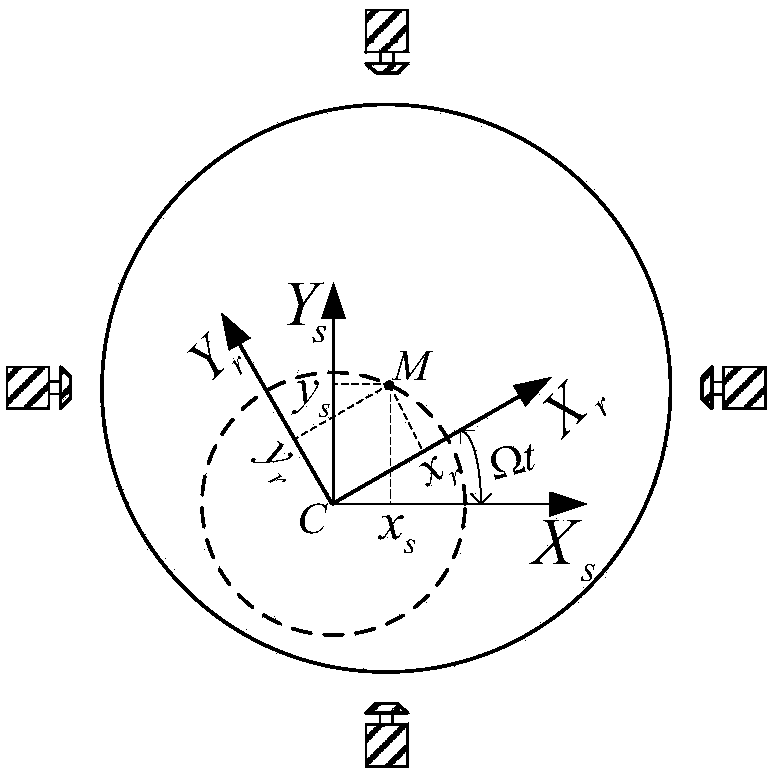

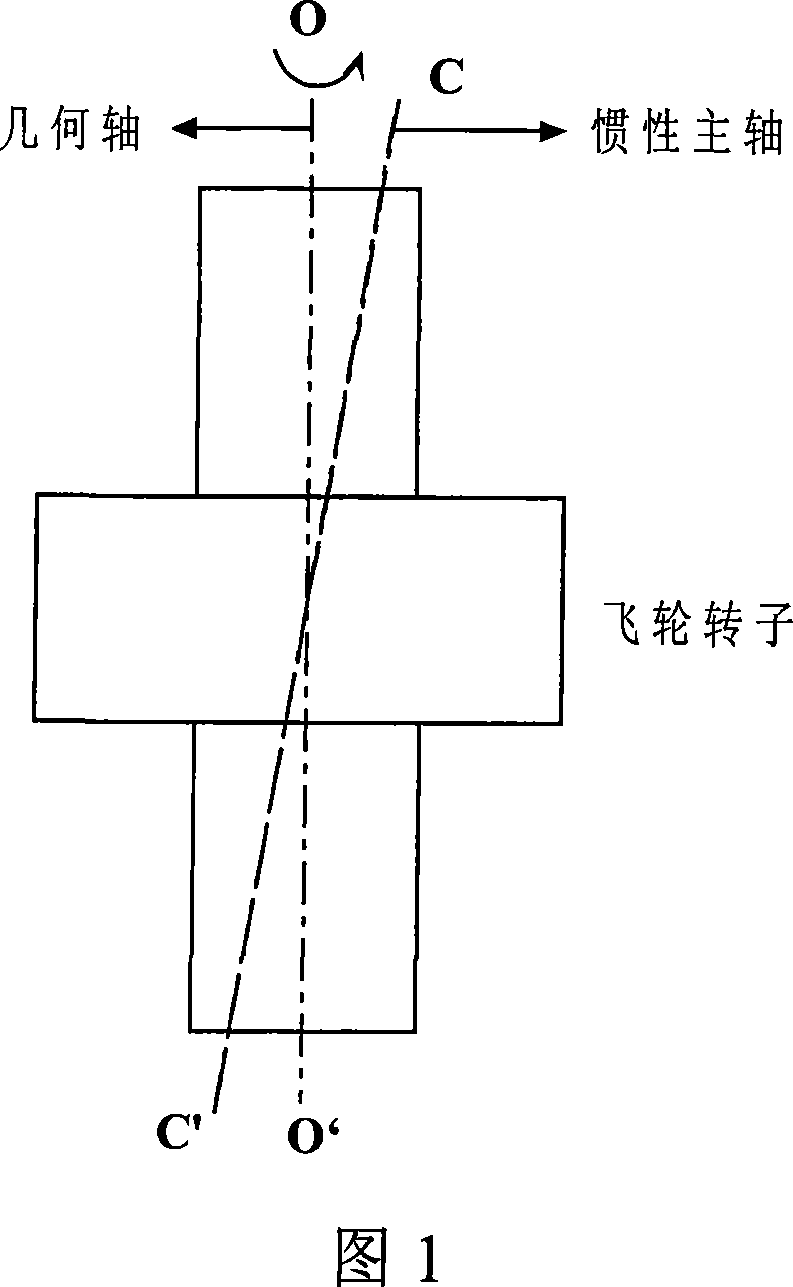

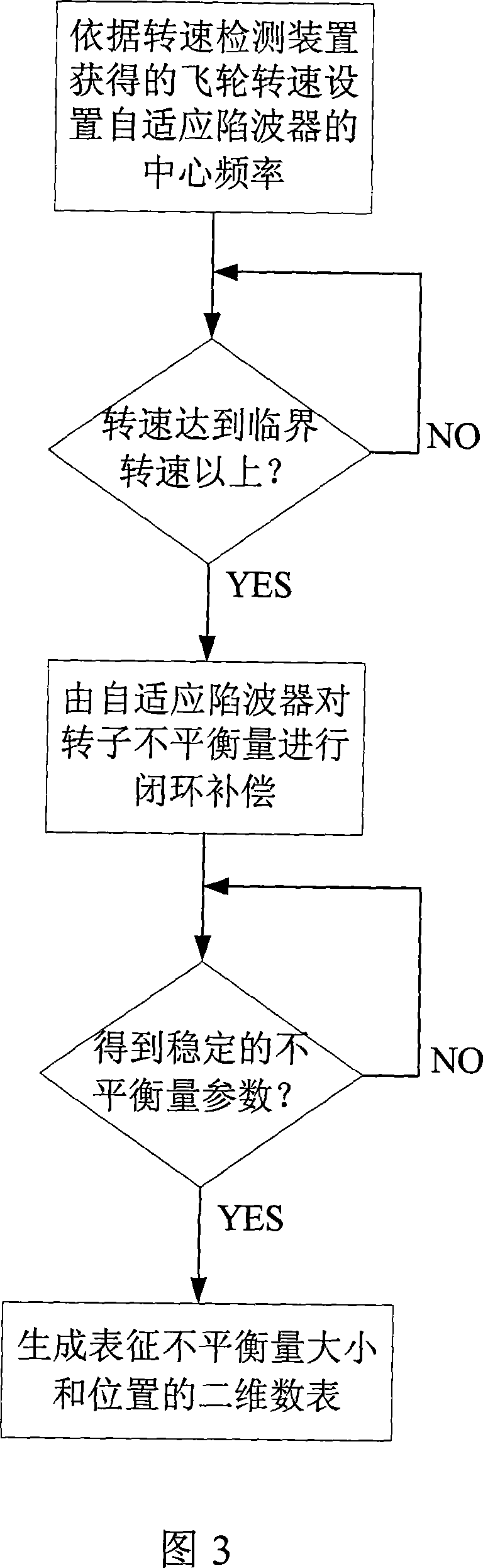

Split-ring high precision unbalance vibration control system of magnetic suspension reaction flywheel

InactiveCN101046692AFix stability issuesRealization of high-precision unbalanced vibration controlIgnition automatic controlAttitude controlVibration controlMagnetic bearing

Owner:BEIHANG UNIV

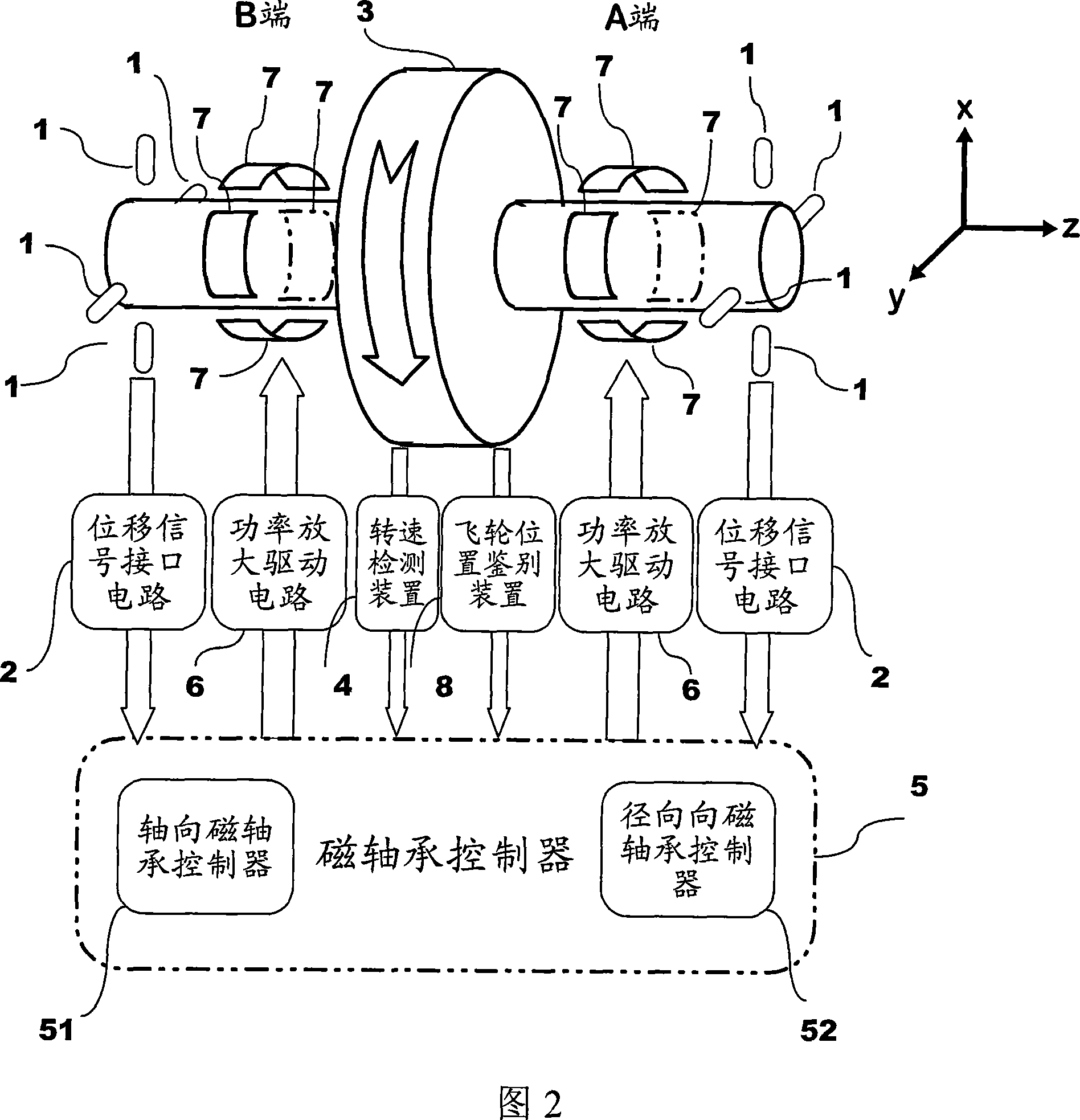

Double-frame magnetic suspension control moment gyro

InactiveCN101219714AReduce volumeReduce weightSpacecraft guiding apparatusAxial displacementMagnetic bearing

The invention relates to a magnetic suspension controlled moment gyro with double frames, essentially consisting of a flywheel, an inner frame system and an outer frame system. The flywheel is arranged in the middle of the magnetic suspension controlled moment gyro with the double frames and essentially comprises a rotary shaft, a radial mixed magnetic bearing, an axial magnetic bearing, a radial displacement sensor, an axial displacement sensor, a high-speed motor and a gyro room; the inner frame system and the outer frame system essentially comprise the frames, a mechanical bearing, a moment motor, a reducer, an angle position sensor, a conductive slip ring a control system; the inner frame system is connected with a shaft hole on one end of the gyro room through the reducer and at the same time the conductive slip ring and the angle position sensor are connected with the shaft hole on the other end of the gyro room; the outer frame system is connected with a shaft hole on one end of the inner frame through the reducer and at the same time the conductive slip ring and the angle position sensor are connected with the shaft hole on the other end of the inner frame. The invention reduces noise, size and weight of the system through the mixed magnetic bearing, and eliminates bearing friction, and thus prolongs life span and promotes control accuracy of the controlled moment gyro.

Owner:BEIHANG UNIV

Spinning camera enclosure for environmental protection

ActiveUS7627235B2Lower performance requirementsTelevision system detailsColor television detailsMagnetic bearingWide field

An environmental protection system features a clear spinning curved volumetric enclosure to shed and throw off environmental contaminants such as rain, fog and dust that would affect a sensor image. The described design is especially suitable for cameras with extremely wide fields of view, such as panoramic or immersive cameras. Alternate forms of volumetric enclosures are described for different lens arrangements in compound camera systems. In all of these embodiments it is possible to keep the cover and the mechanism spinning it invisible to the cameras. An additional modification of the shape of the volumetric enclosure is described that prevents any accumulation of liquid drops within the fields of view of the sensors within the spinning volumetric enclosure. Alternate forms of construction with air and magnetic bearings are described for smoother and quieter operation of the spinning enclosure.

Owner:IMMERSIVE LICENSING

Flywheel energy system

An energy storage system comprises a housing and a flywheel having a drive shaft portion attached to a cylindrical ferromagnetic rotor portion. The drive shaft portion defines a substantially vertical axis about which the rotor portion is mounted for rotation. A magnetic bearing assembly comprised of an annular permanent magnet having no electromagnetic components is mounted on the housing in stationary centered relation about the vertical axis above the rotor portion so as to attract the rotor portion axially upwardly towards a lower face of permanent magnet, thereby supporting a significantly high portion of the weight of the flywheel. At least one low friction mechanical bearing assembly is mounted within the housing about the drive shaft portion to provide radial positioning of the rotor portion and to limit at least upward axial movement of the rotor portion in relation to the lower face. The annular permanent magnet overlies a portion of the end face of the rotor with the balance providing a return path for magnetic flux.

Owner:BC NEW ENERGY (TIANJIN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com