Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205 results about "Stirling cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

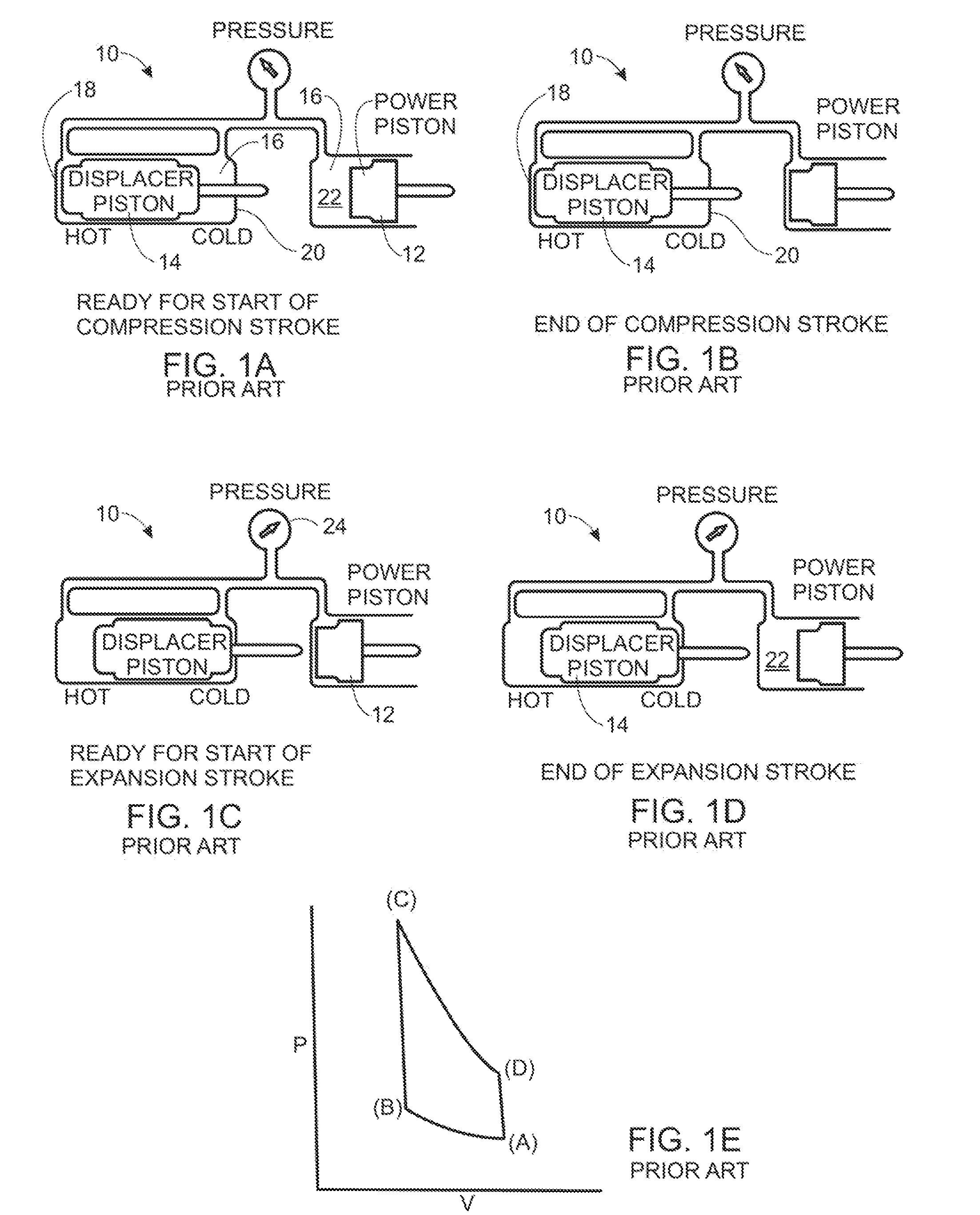

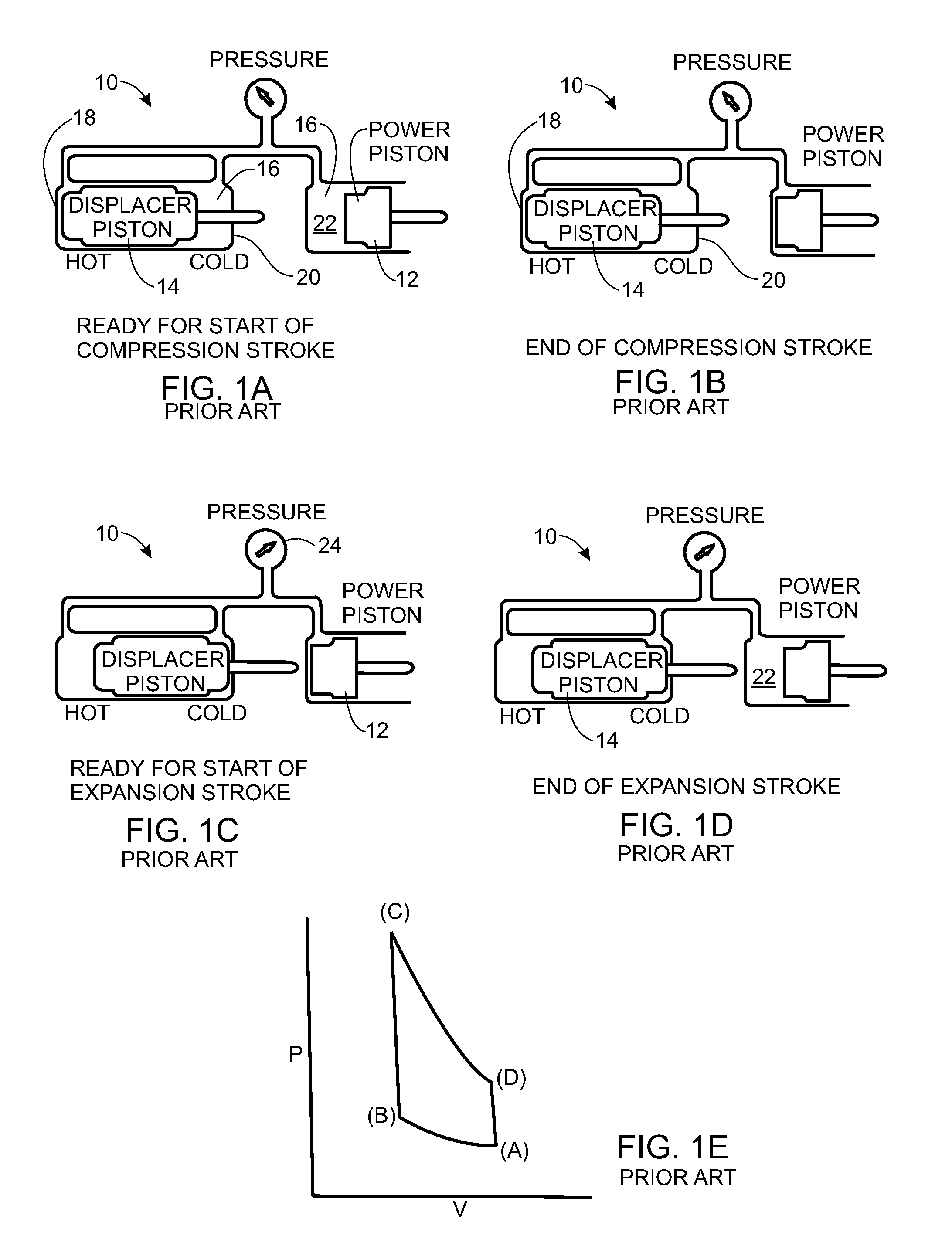

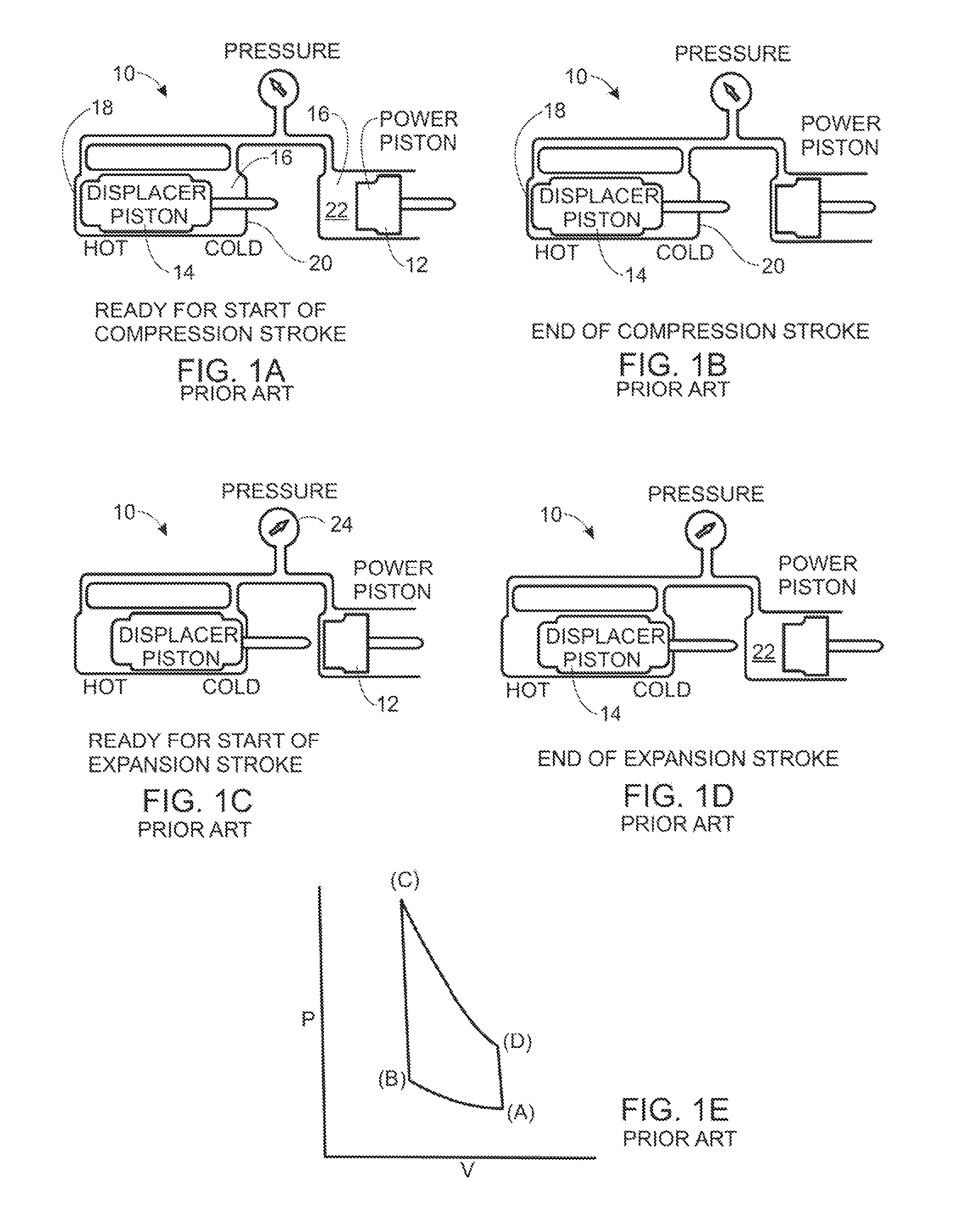

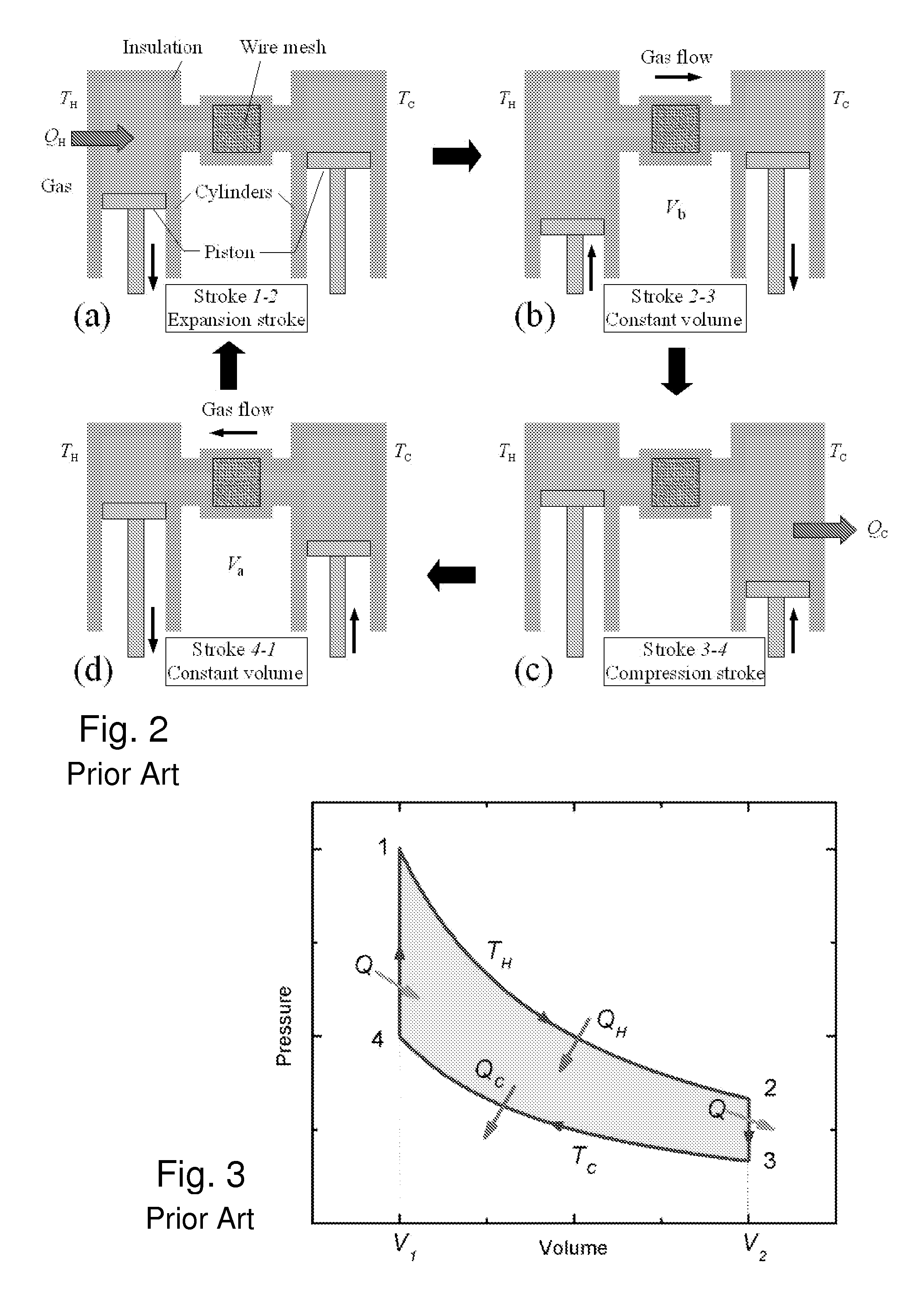

The Stirling cycle is a thermodynamic cycle that describes the general class of Stirling devices. This includes the original Stirling engine that was invented, developed and patented in 1816 by Robert Stirling with help from his brother, an engineer.

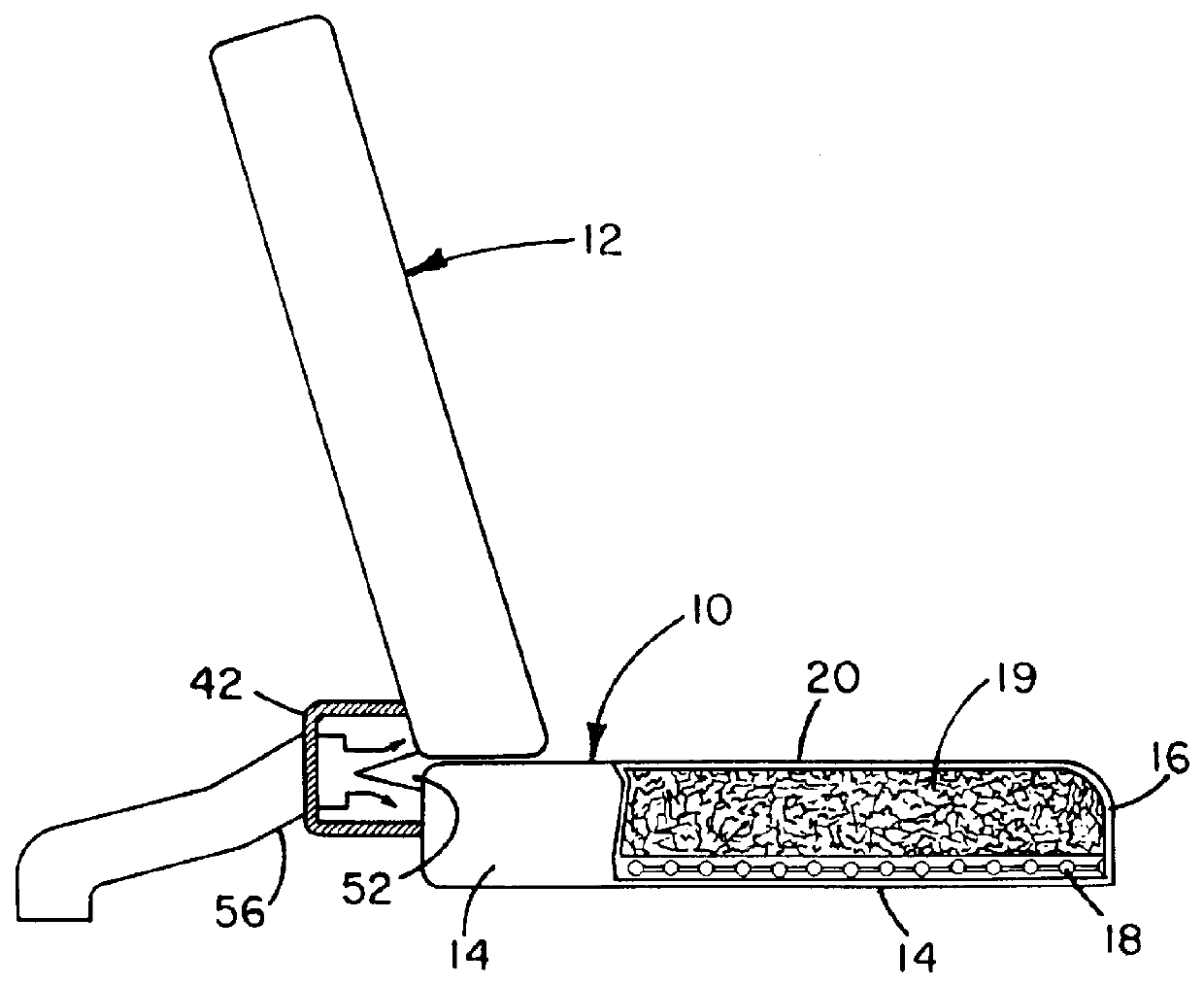

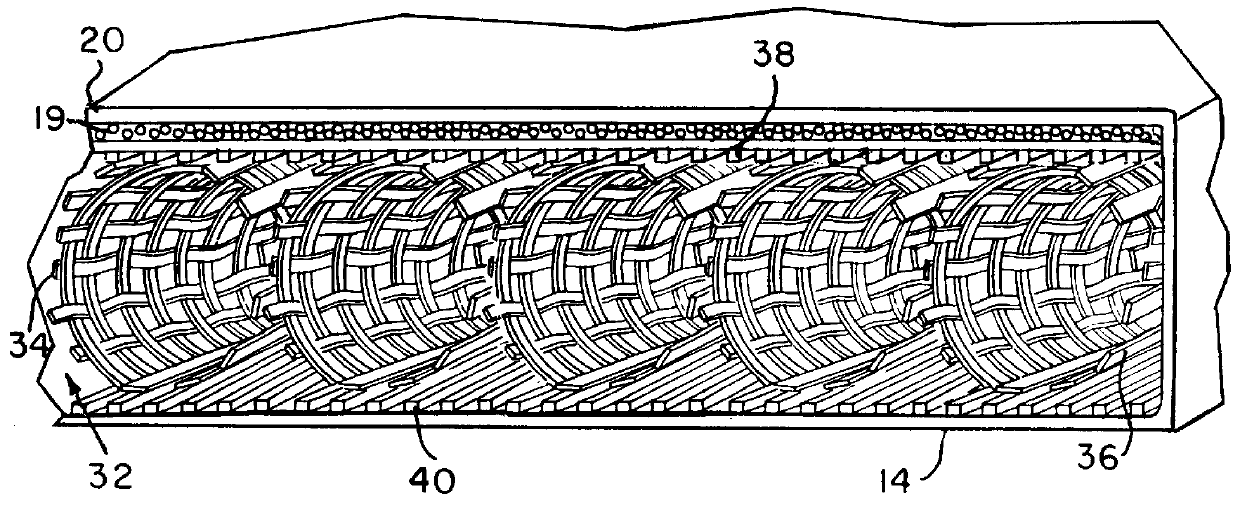

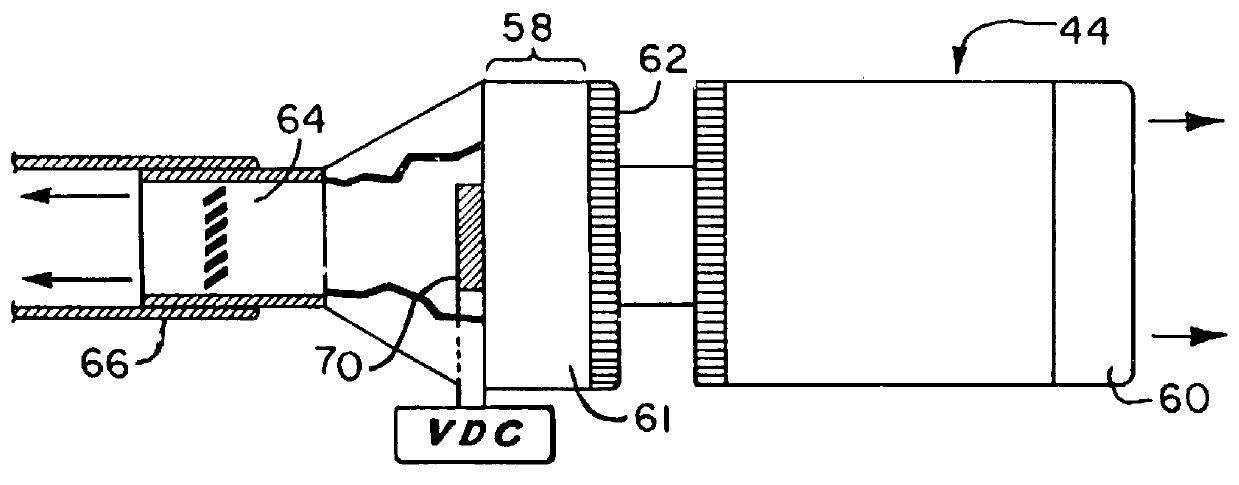

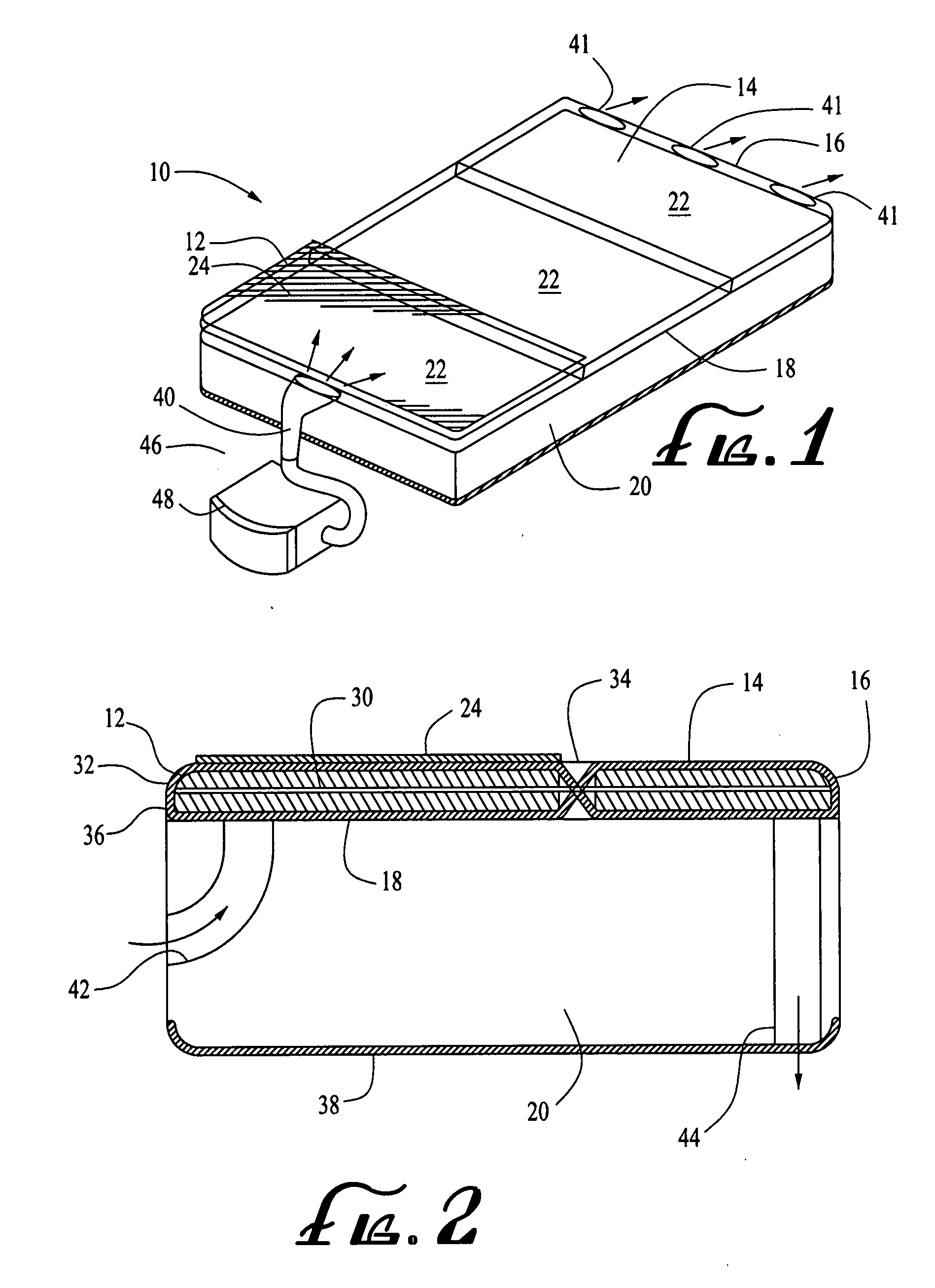

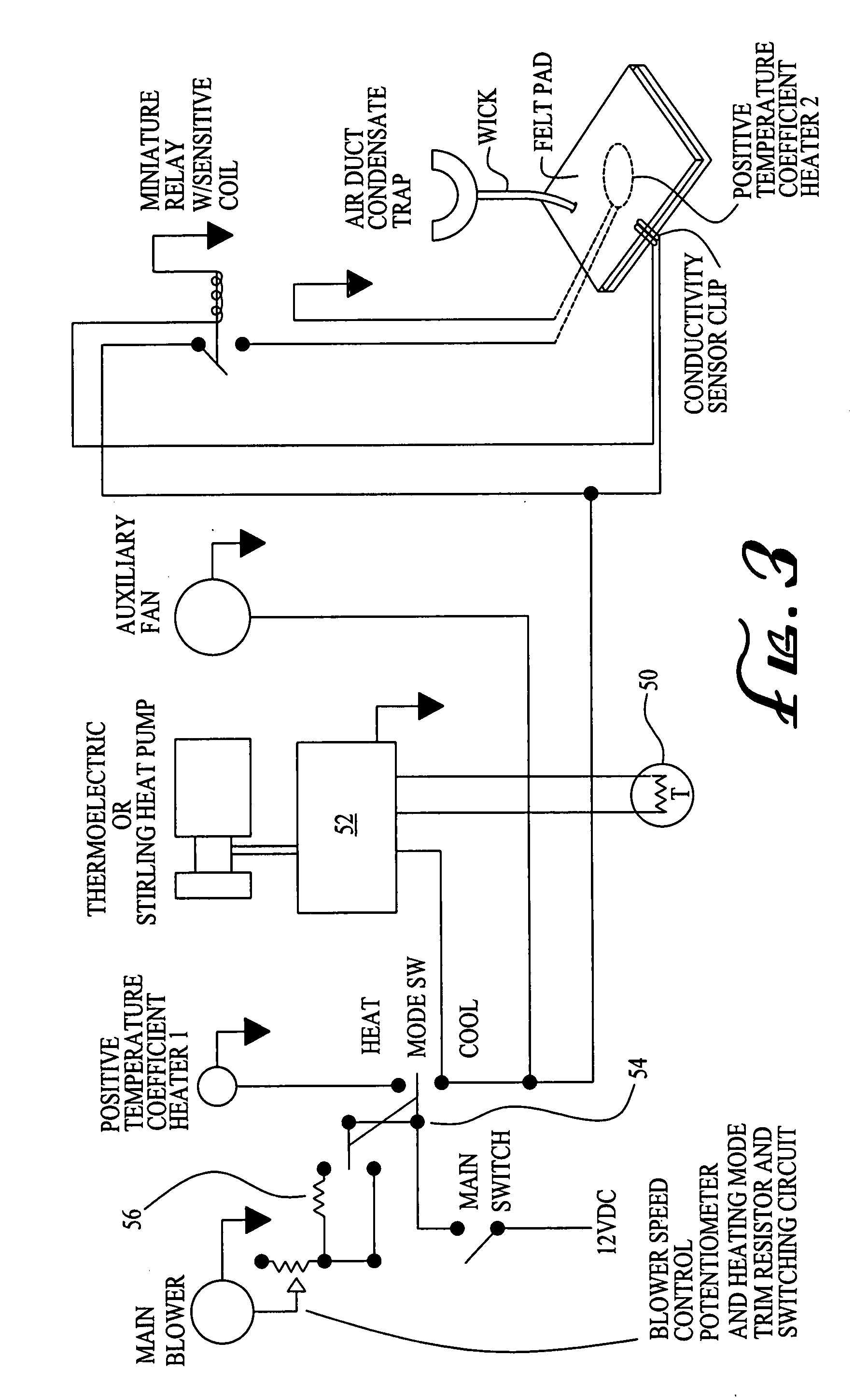

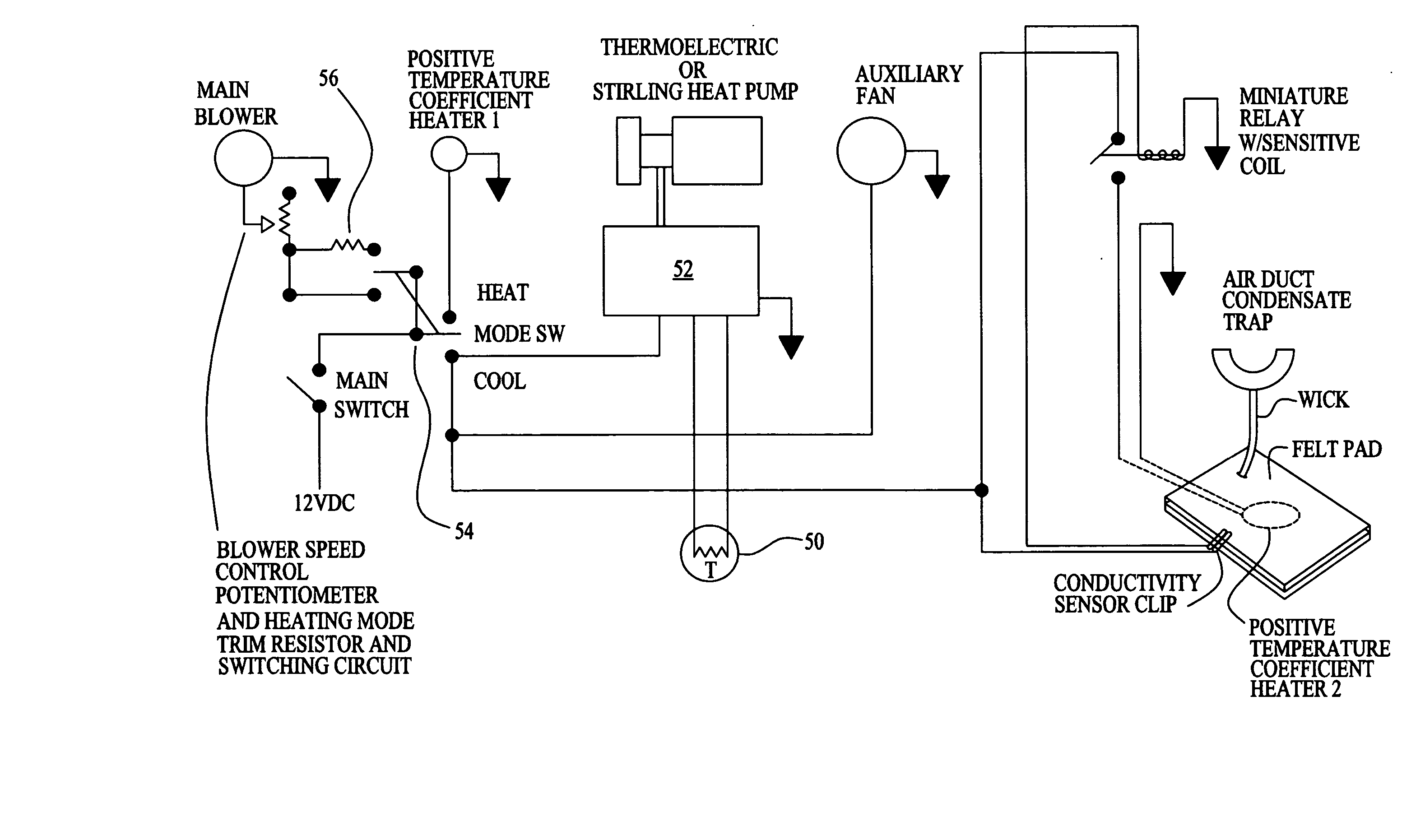

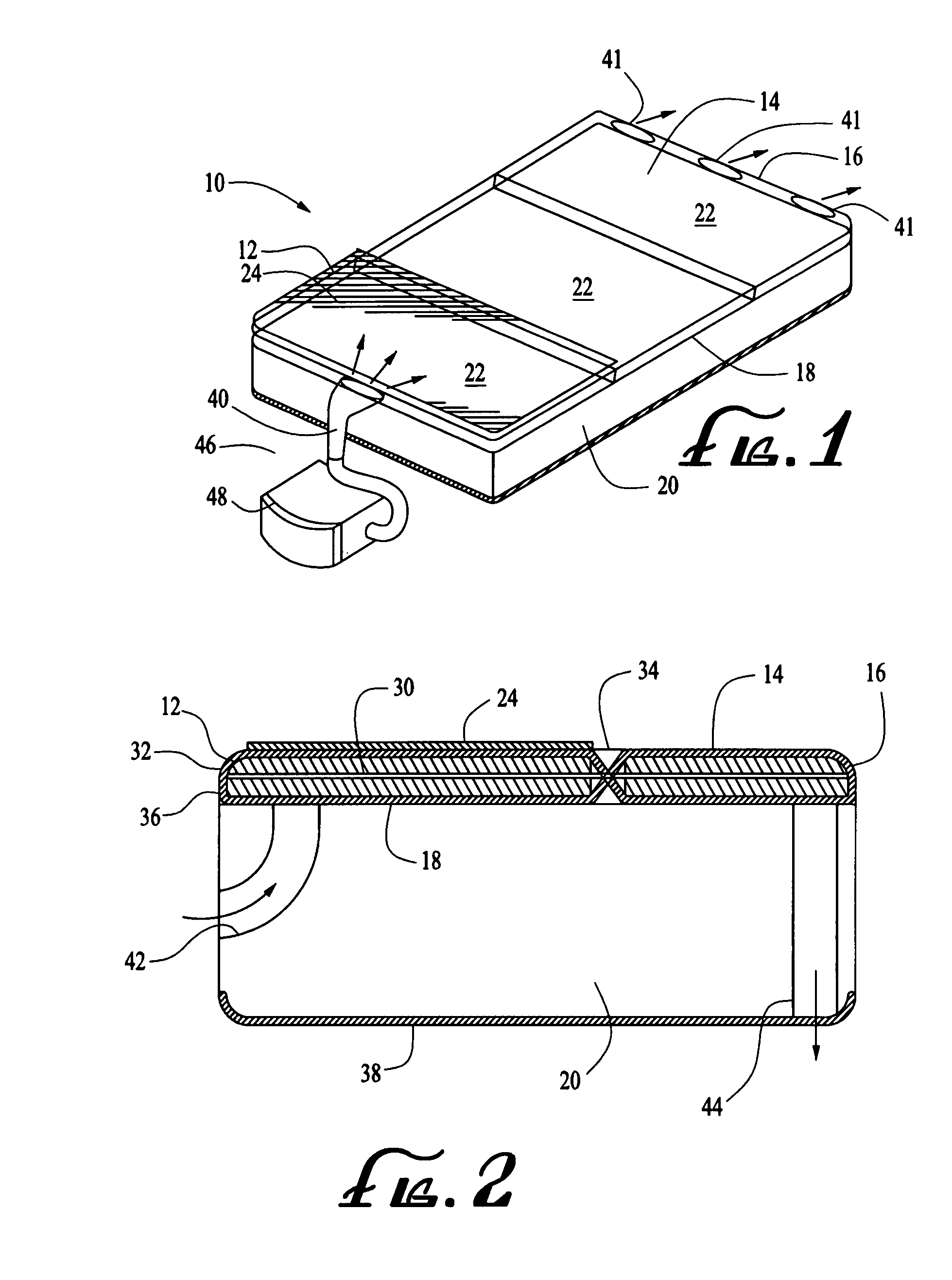

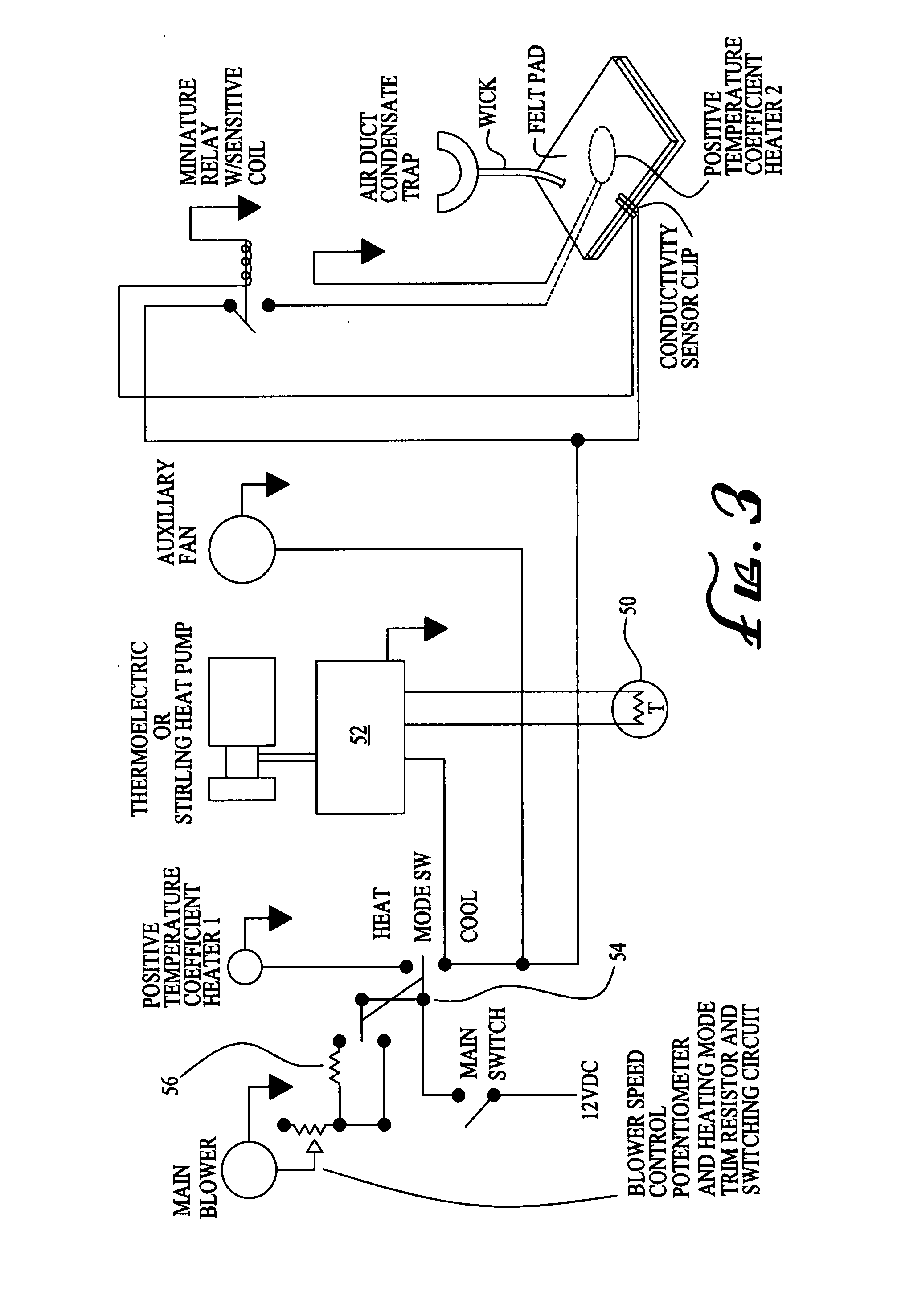

Selectively cooled or heated cushion and apparatus therefor

InactiveUS6085369AMore comfortableRigid enoughStuffed mattressesSpring mattressesMedium densityEngineering

A cushion (10, 12) has a plenum (16) which includes a plurality of flexible plastic woven tubes (34) held within a pair of similarly woven sheathes (38,40). The plenum has its sides and bottom covered by an air impermeable (14) layer with the top covered by an air permeable layer (20). A low to medium density foam pad (19) is located between the plenum (16) and the top layer (20). Conditioned air is provided to the cushions (10,12) from a Stirling cycle heat pump (44).

Owner:FEHER STEVE

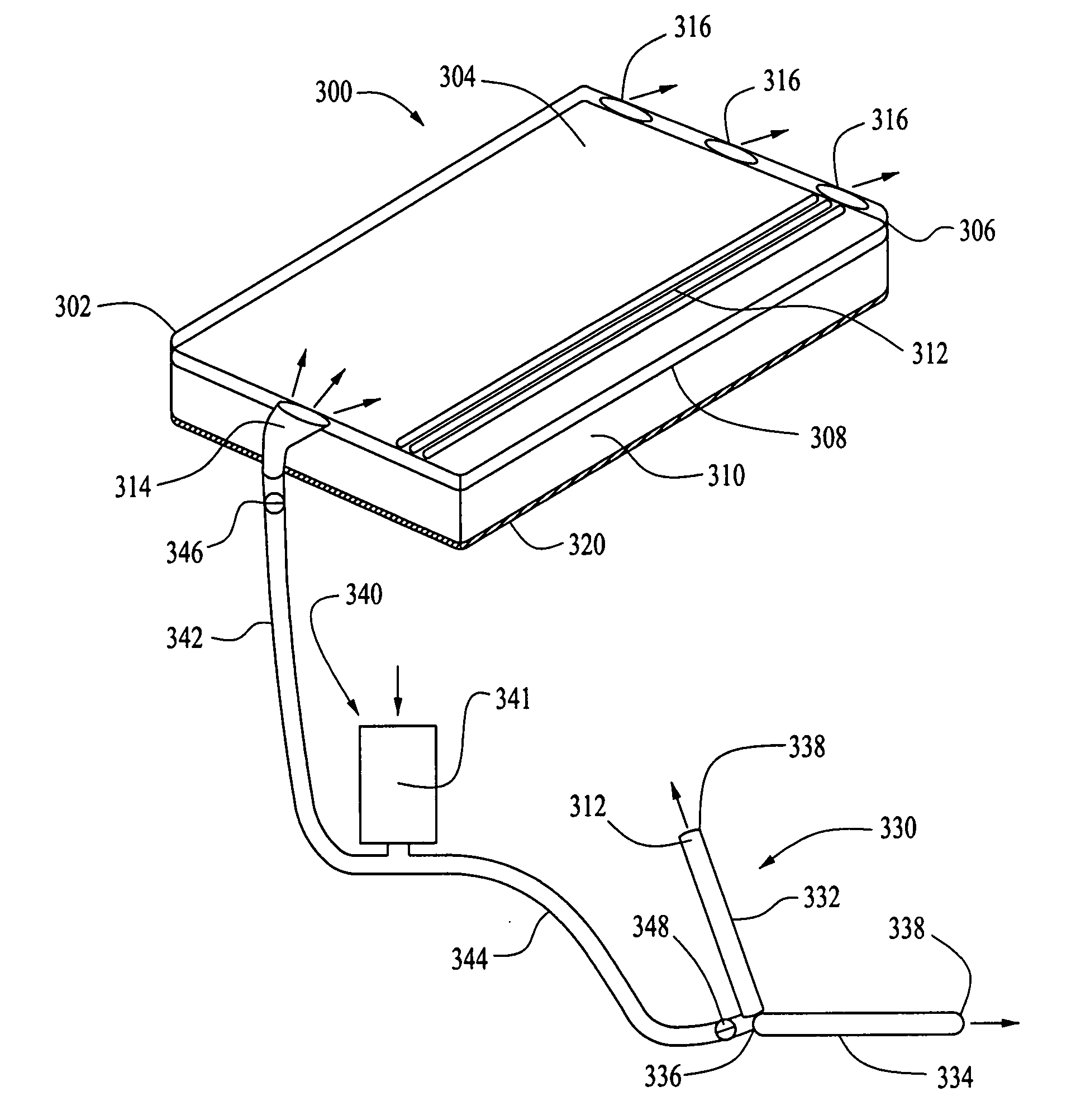

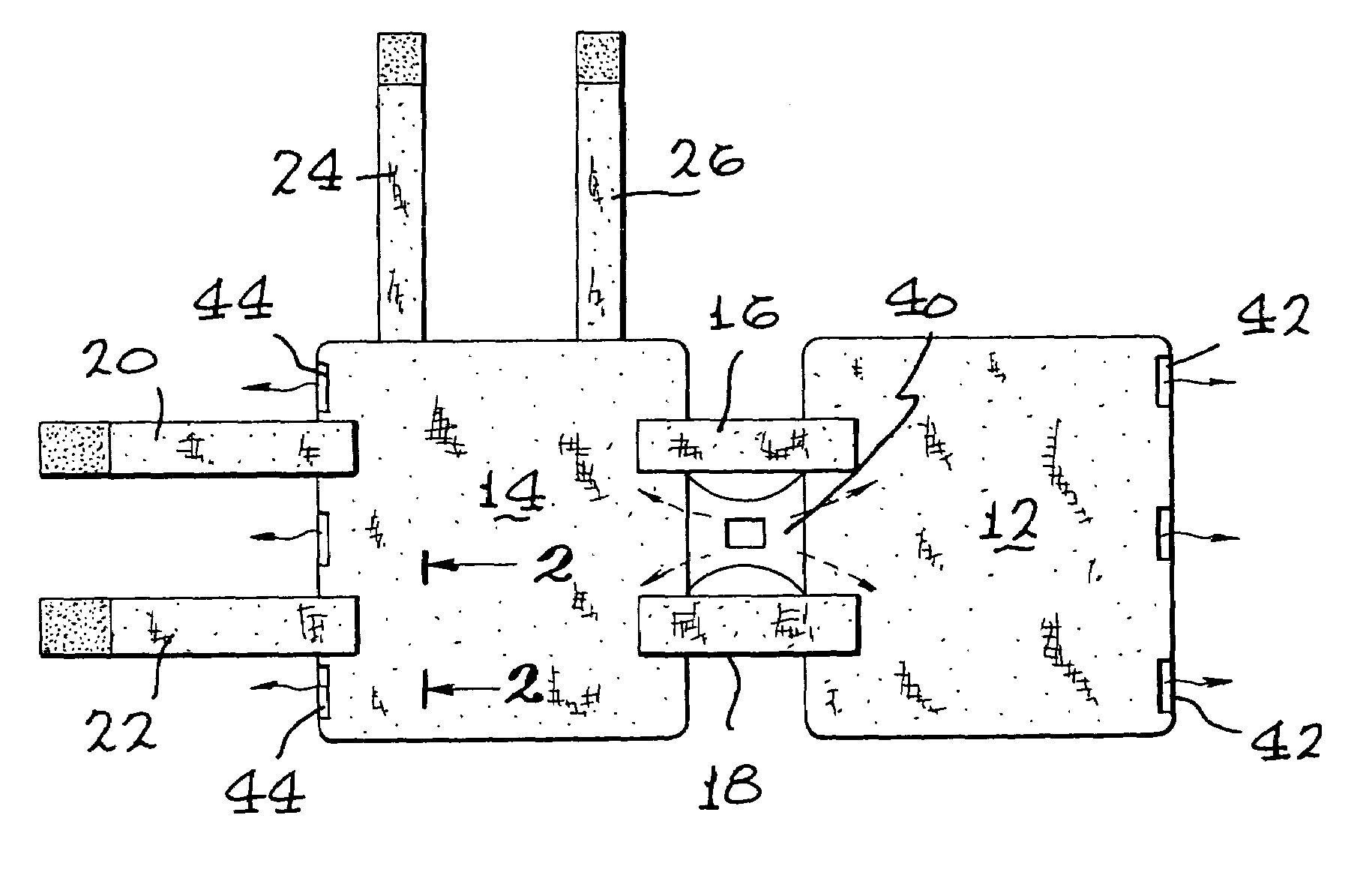

Multiple convective cushion seating and sleeping systems and methods

A multiple convective cushion seating and sleeping system for providing temperature modified air to multiple surfaces, such as a seating surface and a sleeping surface, with the same air cooling or heating source. The invention includes the use of tubular spacer material including tubular spacer fabric. A power unit including a heat pump and blower is in fluid communication with a first convective cushion by a first duct and with a second convective cushion by a second duct to provide the temperature modified air to both convective cushions for controllably heating or cooling multiple users. A thermoelectric heat pump, a Stirling cycle heat pump or other type of heat pump can be used. The invention includes the use or one or more valves to control the air flow to one or more of the convective cushions and provides for manual operation, electronic control and operation by a remote telecommunications unit. The invention can be utilized in vehicles, such as tractor trailers and recreational vehicles, and in buildings such as apartments, dorm rooms and houses.

Owner:FEHER STEVE

Convective seating and sleeping systems

InactiveUS20070251016A1Limit undesired unravelingEliminate requirementsStuffed mattressesSpring mattressesMagnetic bearingControl data

A convective seating and sleeping system with a plenum for use as a mattress, cushion or as part of seat or other structure to deliver air flow to a user or users. The convective cushion includes a modular plenum made of removable pockets and a thermocouple to provide control data to selectively control the temperature and / or quantity of the air delivered to the cushion. The cushion includes the use of tubular spacer material. The cushion has deep styling lateral and longitudinal pleats and air flow structures around the pleats to provide a controlled air flow to the cushion. The invention includes an improved Stirling cycle heat pump with magnetic bearing structures and relative humidity controls and an improved thermoelectric heat pump that selectively controls the relative humidity of the air delivered to the cushion. The cushion can be activated and operated by remote operation from a telecommunications device.

Owner:FEHER STEVE

Temperature conditioning apparatus for the trunk of a human body

InactiveUS7124593B2Domestic cooling apparatusMachines using electric/magnetic effectsHuman bodyHot weather

A temperature conditioning apparatus for the human body includes a vest or other clothing unitary with a thermoelectric or Stirling cycle heat pump worn by the user. The unit is powered by a battery source worn on the user's belt or other part of his or her body, or by an externally-mounted electrical energy source, for example, in a vehicle. The vest has front and rear panels with an air flow layer and permeable inside layer that accept and release conditioned air to the user. The vest may be used with body armor or other protective layers, that is, the vest may be worn underneath body armor or body armor may be built into the vest, or the vest may be used without body armor to cool the user in an exceptionally hot environment such as a non-air conditioned space in hot weather.

Owner:FEHER STEVE

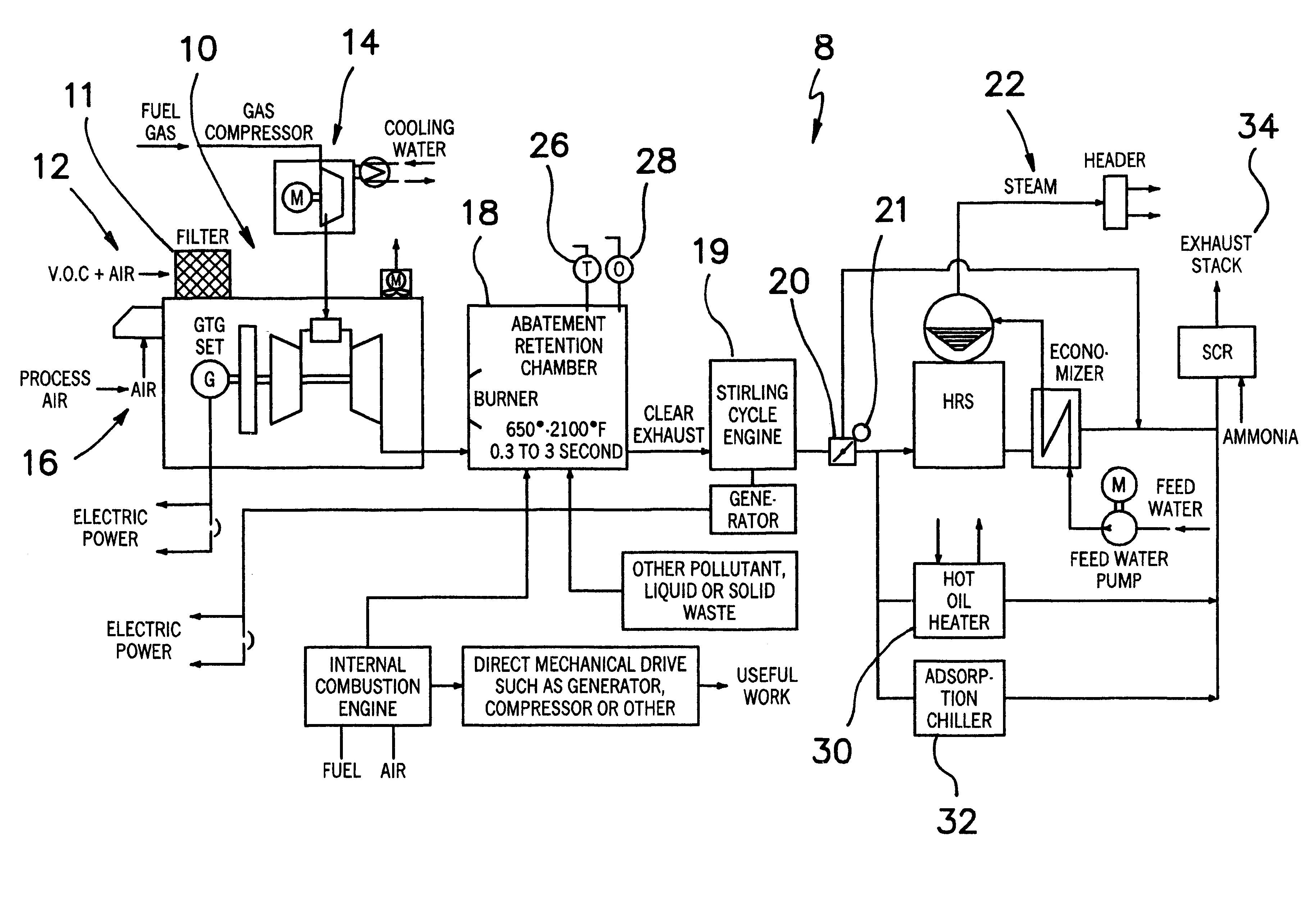

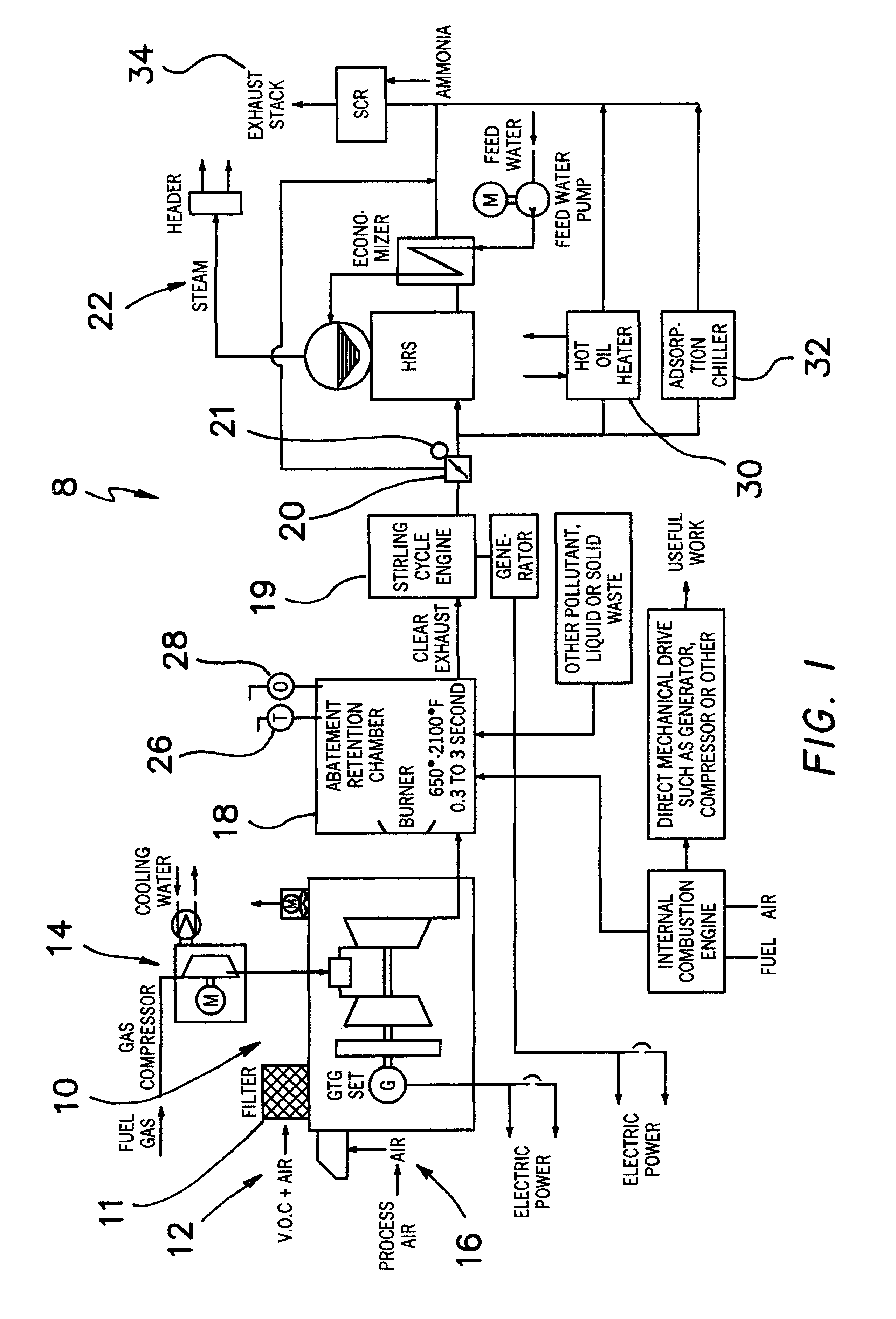

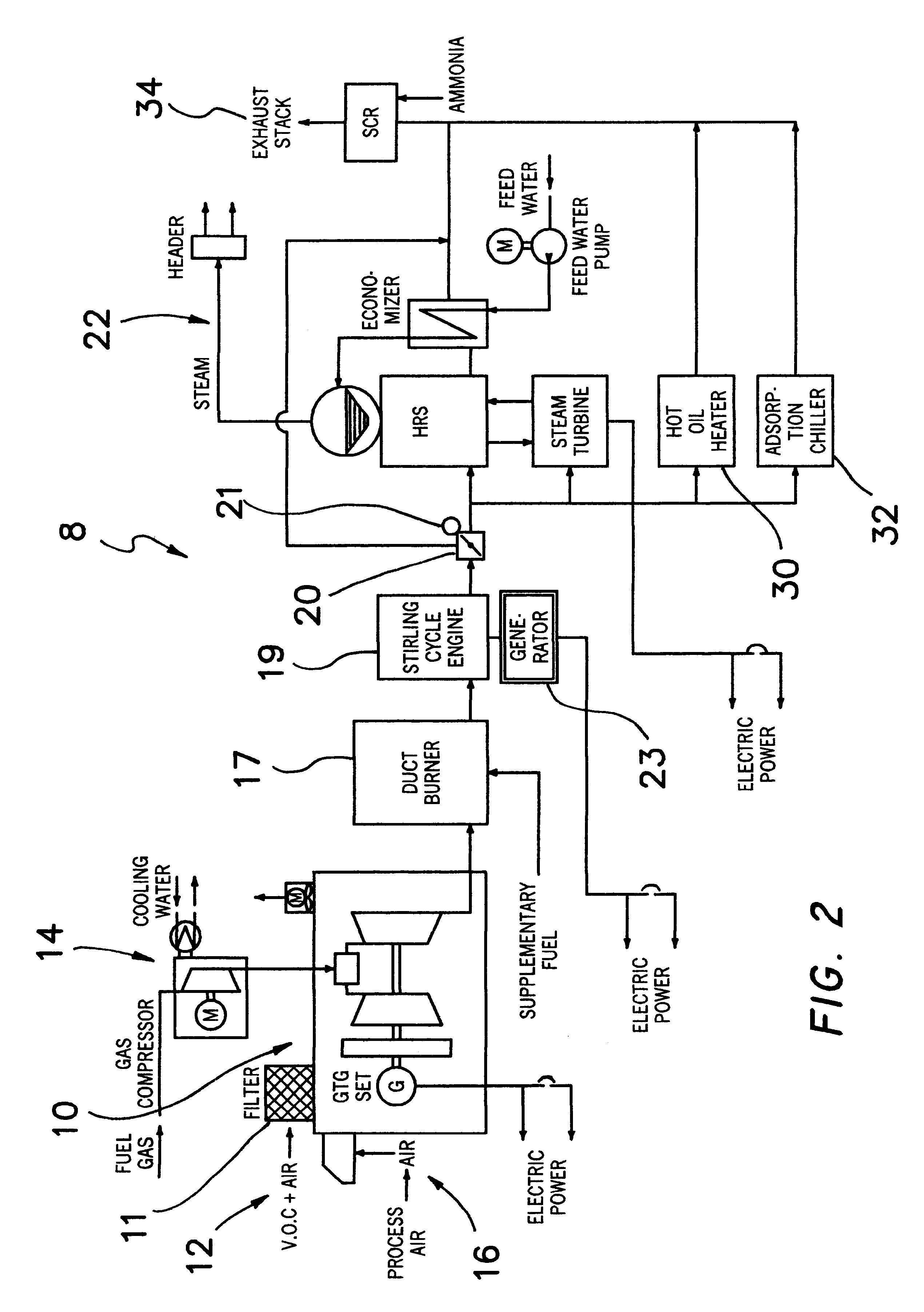

Advanced combined cycle co-generation abatement system

InactiveUS6655137B1Internal combustion piston enginesExhaust apparatusCombustionExternal combustion engine

The present invention is an advanced co-generation system for abating solid wastes, hydrocarbons and other volatile organic compounds (VOC's) produced by various processes utilizing a Stirling cycle engine, turbines or other internal combustion engines doing useful work. The turbine exhaust is directed into an abatement chamber which may include a catalyst that is designed to operate at high temperature and includes supplementary fuel and air inputs which are controlled by a computer that receives sensor inputs to achieve the requisite heat ranges necessary to convert exhaust and VOC's to non-toxic substances. The exhaust generated by the abatement chamber is directed to a Stirling cycle engine for additional heat generation and recovery. The exhaust generated from this process can also be used to perform direct or indirect heating.

Owner:SARDARI AMIR A

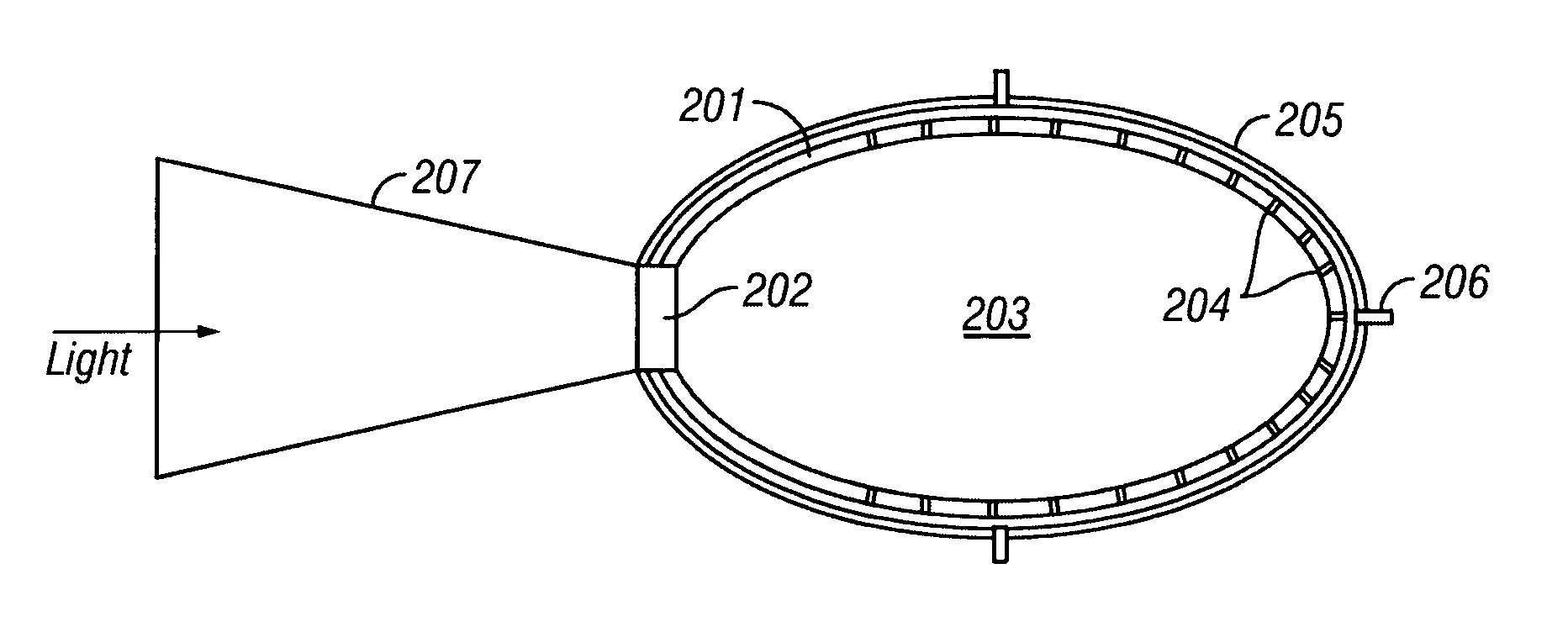

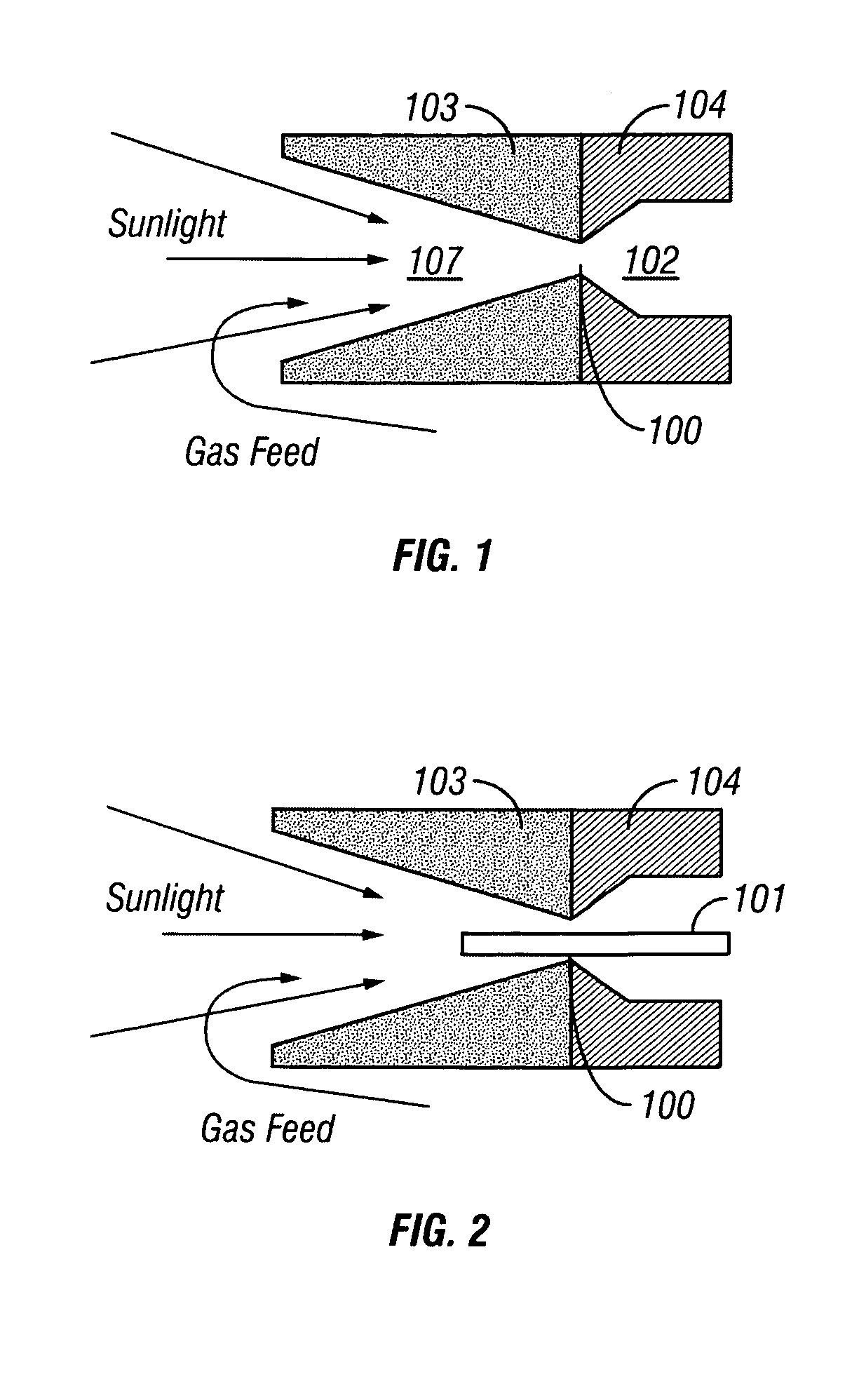

Reactor for solar processing of slightly-absorbing or transparent gases

InactiveUS7140181B1High strengthPrevent re-associating back-reactionsAuxillary drivesSolar heating energyEngineeringElectric power

Solar-powered reactor for processing of slightly absorbing and transparent gases. An obvious path to providing storable, renewable energy is through solar dissociation of gas molecules. These dissociation products are the precursors of modern liquid and gaseous fuels such as hydrogen and methanol / ethanol. An apparatus and method using a solar concentrator (such as a focusing trough or dish) directed at the receiving end of a reactor are disclosed. A range of designs of reactors for the dissociation of gases, both those that absorb slightly in the visible spectrum and those that are transparent in the visible and only absorb in the infrared, is described. For slightly-absorbing gases, a funnel-shaped reactor that preheats the gas and concentrates sunlight is the indicated embodiment. A system for dissociating CO2 using the invention is described. For transparent gases, a holraum embodiment is more appropriate for coupling solar energy into the gas. In both cases, heat from the hot stream of dissociated gas may also be used to produce electricity with a standard steam or Stirling cycle generator.

Owner:SUNDROP FUELS

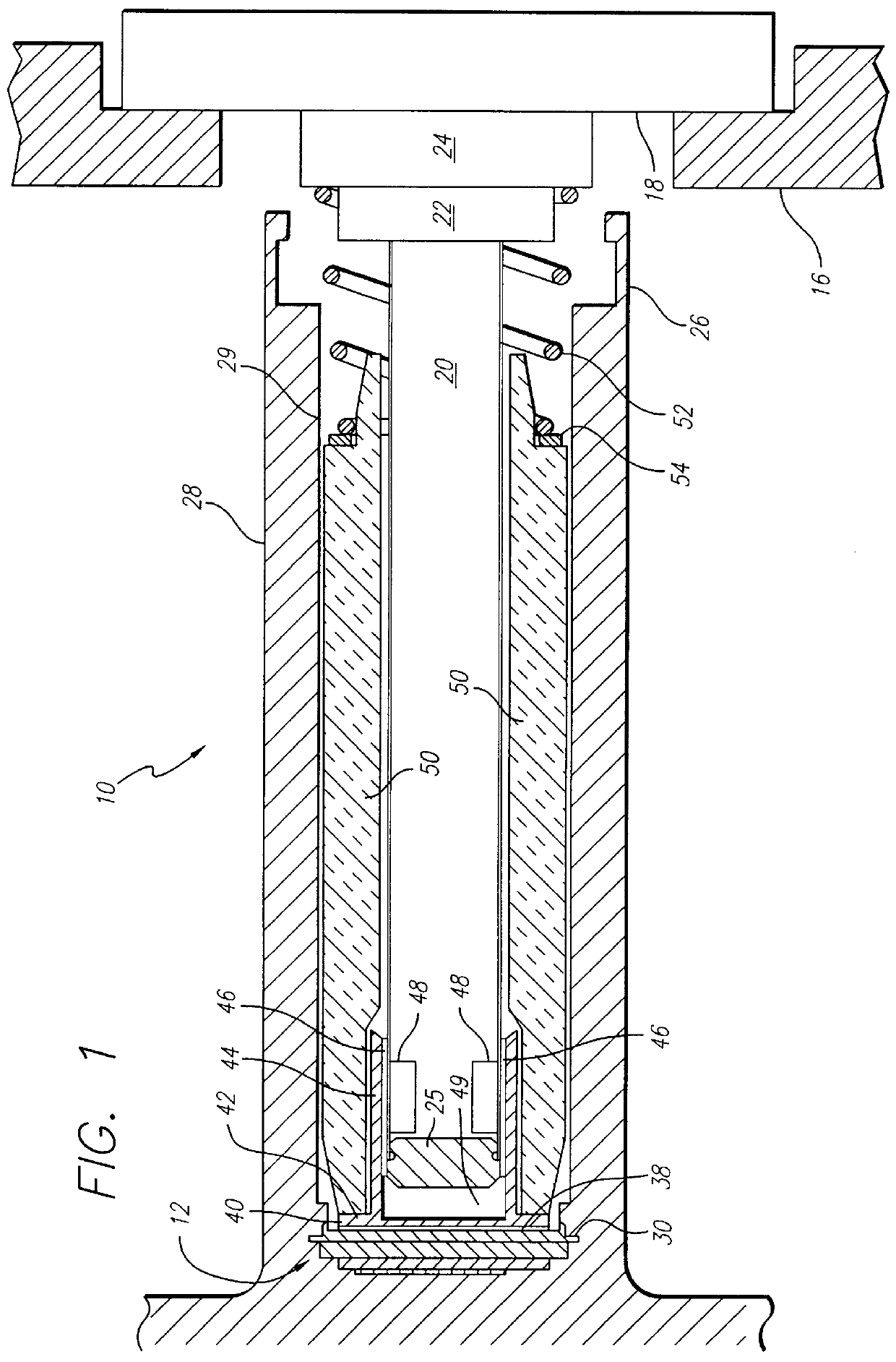

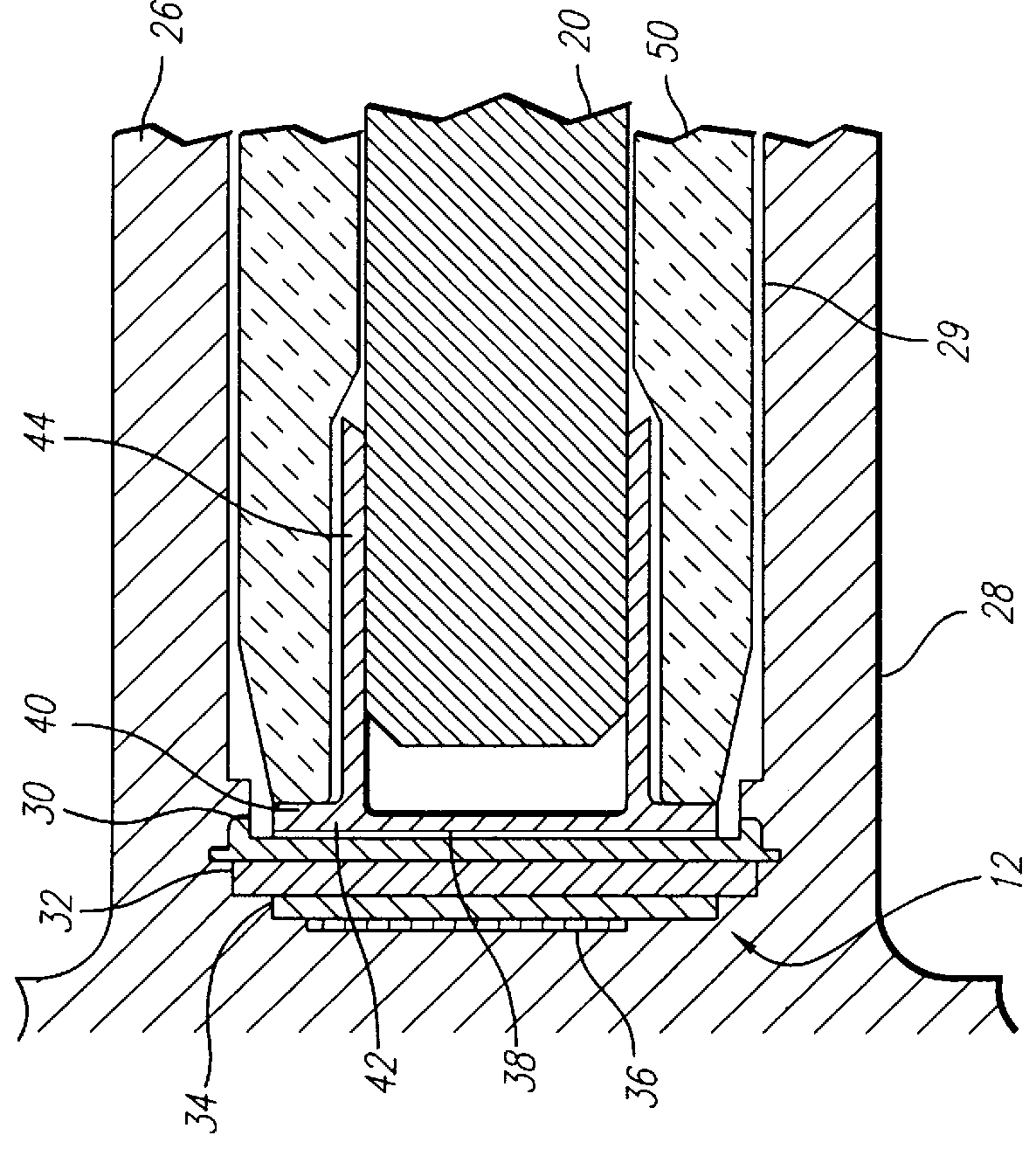

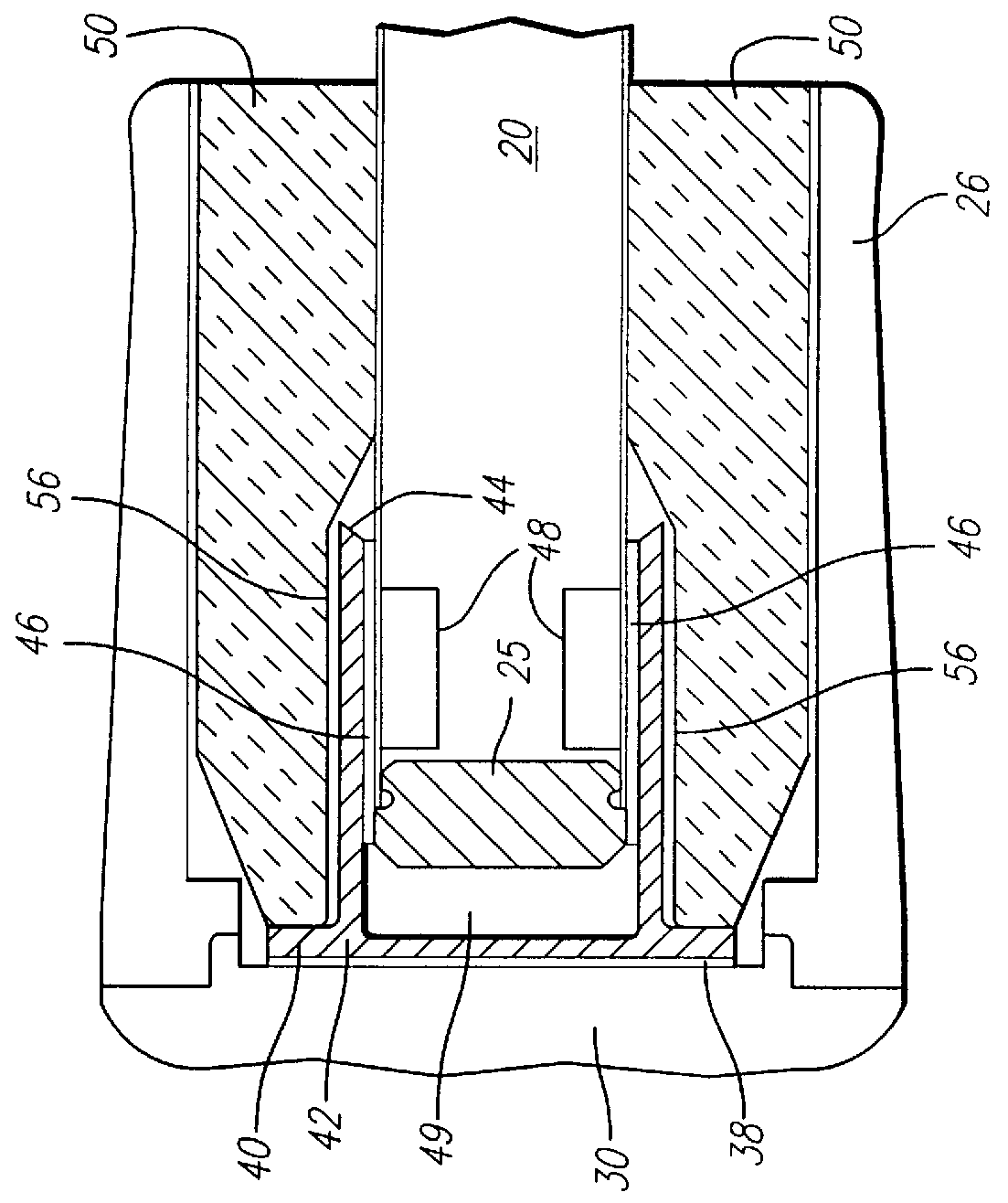

Cryogenic cooler with mechanically-flexible thermal interface

A cryogenic cooler and a dewar assembly including a cooled surface; a cooling surface for removing thermal energy from said cooled surface; and an adapter disposed between said cooling surface and the cooled surface for conducting thermal energy therebetween. A first fluid is disposed between the cooled surface and the adapter for conducting thermal energy from the cooled surface to the adapter. A second fluid is disposed between the cooling surface and the adapter for conducting thermal energy from the adapter to the cooling surface whereby the cooling surface remains free to move axially relative to the adapter at a temperature of the cooling surface at which the first fluid is susceptible to freezing. This allows for movement of the cold finger relative to the dewar and adapter, due to differential thermal coefficients of expansion or support structure motion, without adversely affecting the communication of thermal energy from the load. In the illustrative embodiment, the cooler is a Stirling cycle cooler, the first fluid is thermal grease and the second fluid is nitrogen. The cooling surface is a cylindrical cold finger of the Stirling cycle cooler and the cooled surface is an inner wall of a dewar assembly. The dewar is in thermal contact with a load. The adapter is disposed between the inner wall of the dewar and the cold finger. The adapter has an end cap and a cylindrical housing extending therefrom. The housing extends at least partially along a longitudinal axis of the cold finger. An insulator is disposed about the cold finger and the adapter housing. A spring is disposed between a proximal end of the insulator and a base of the cold finger to maintain a distal end of the insulator in contact with the adapter and the adapter in contact with the dewar.

Owner:RAYTHEON CO

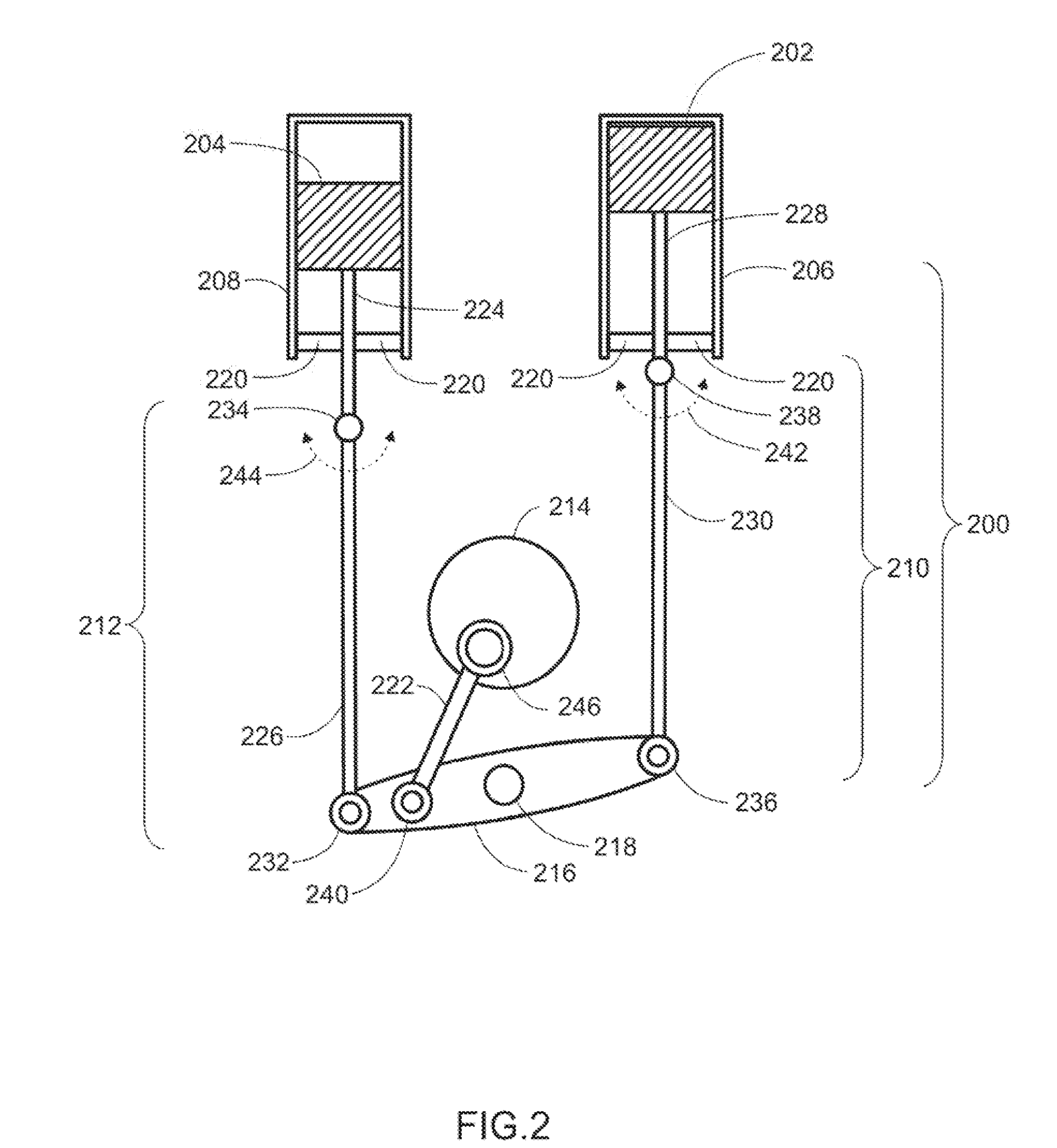

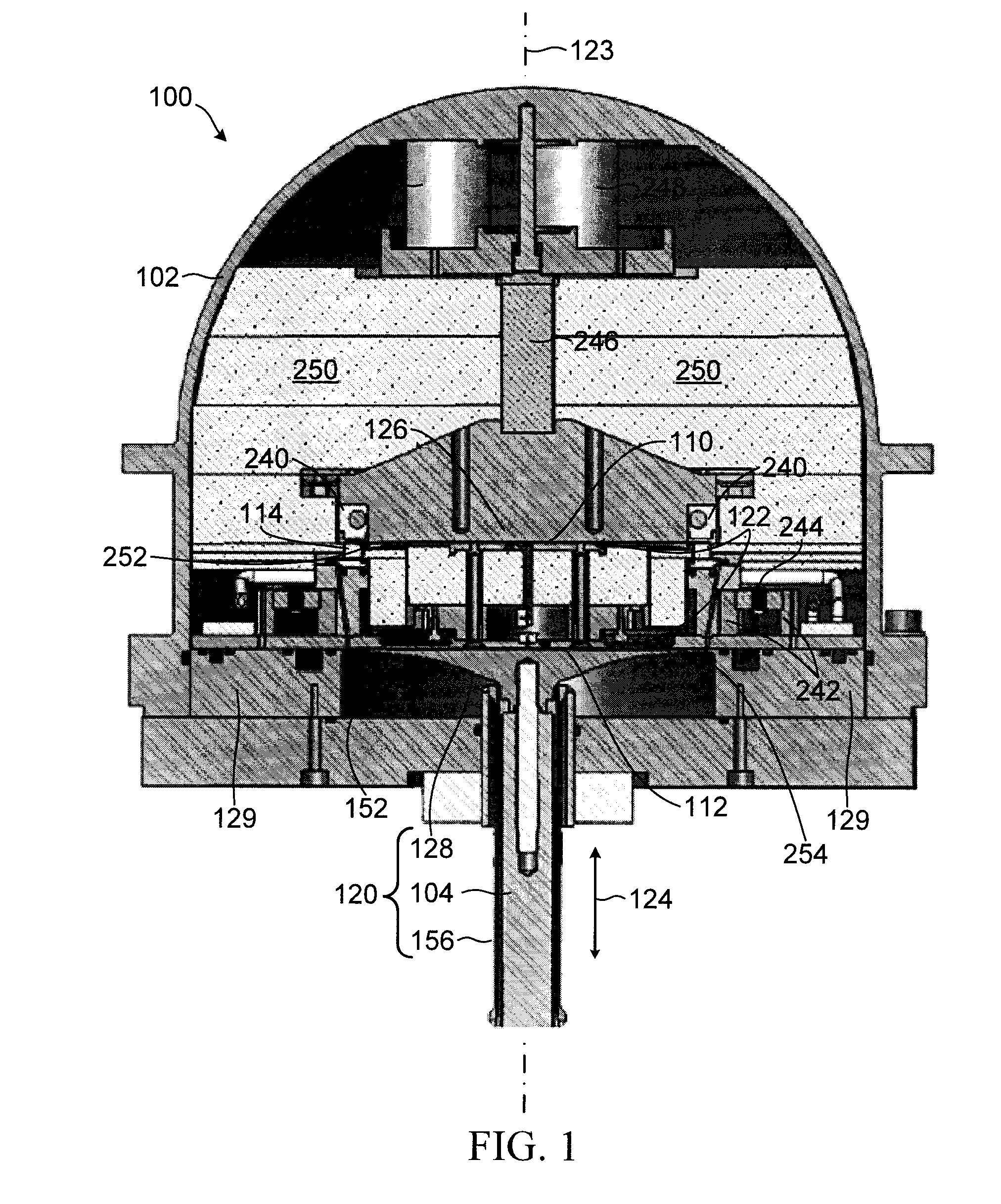

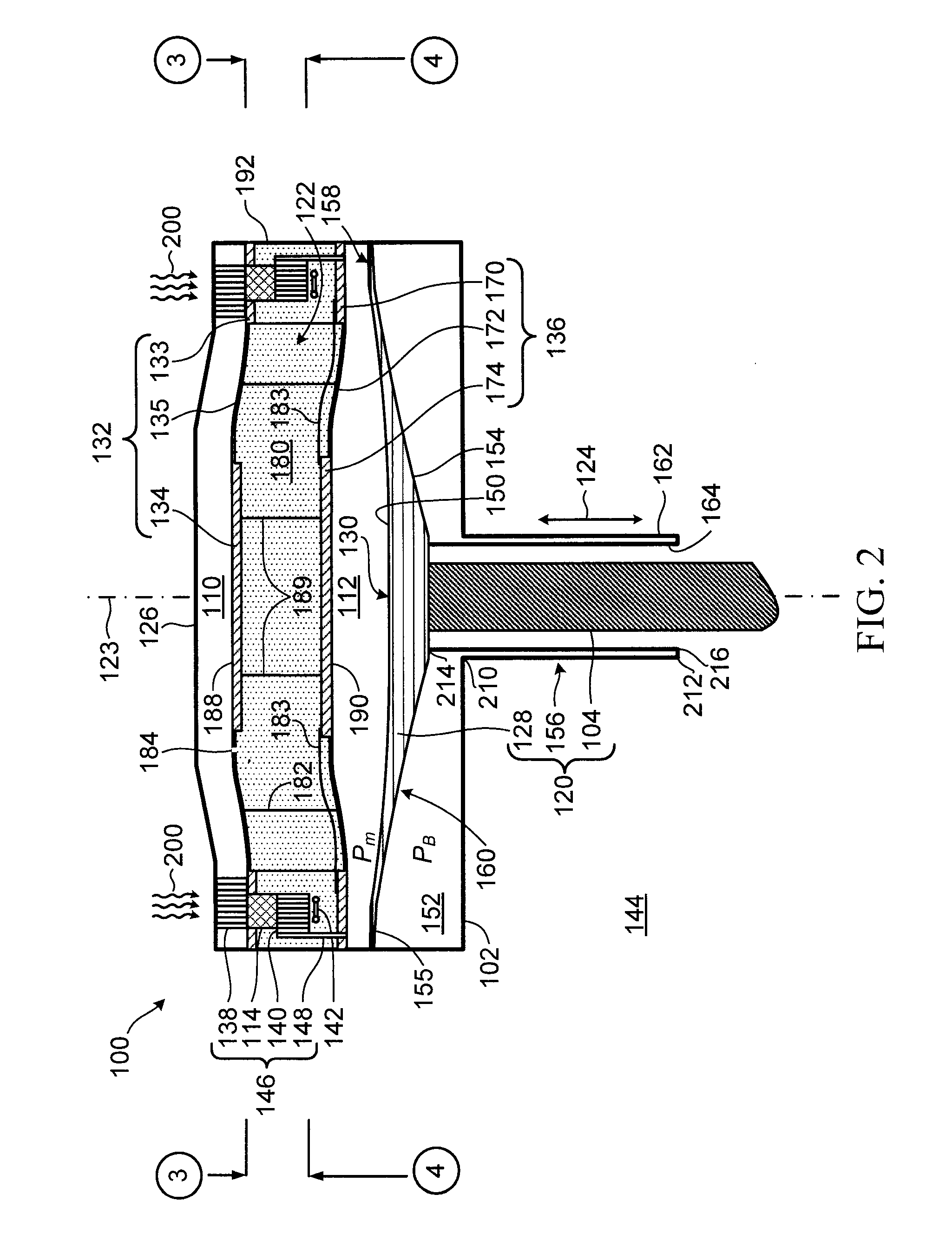

Stirling Cycle Machine

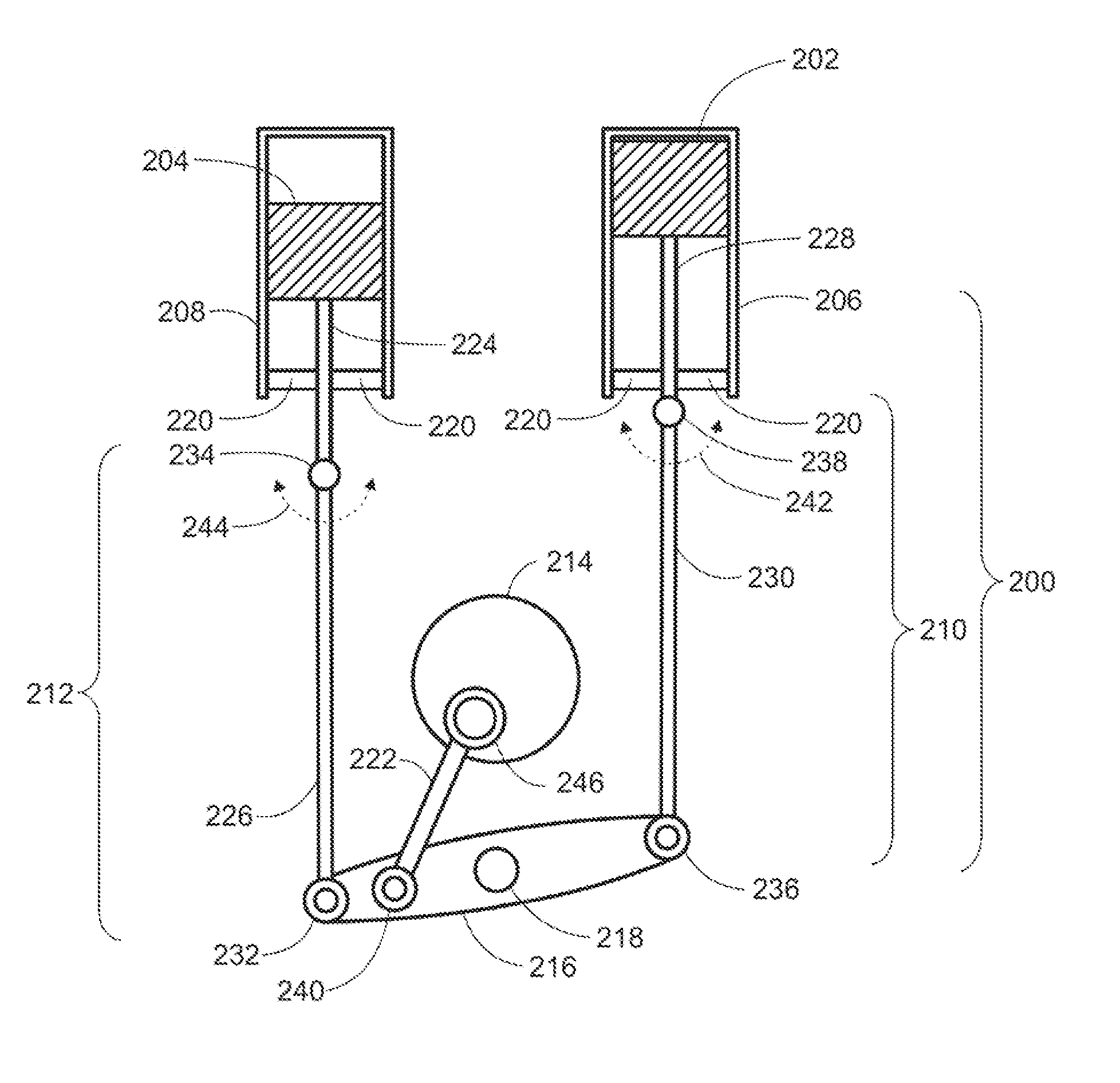

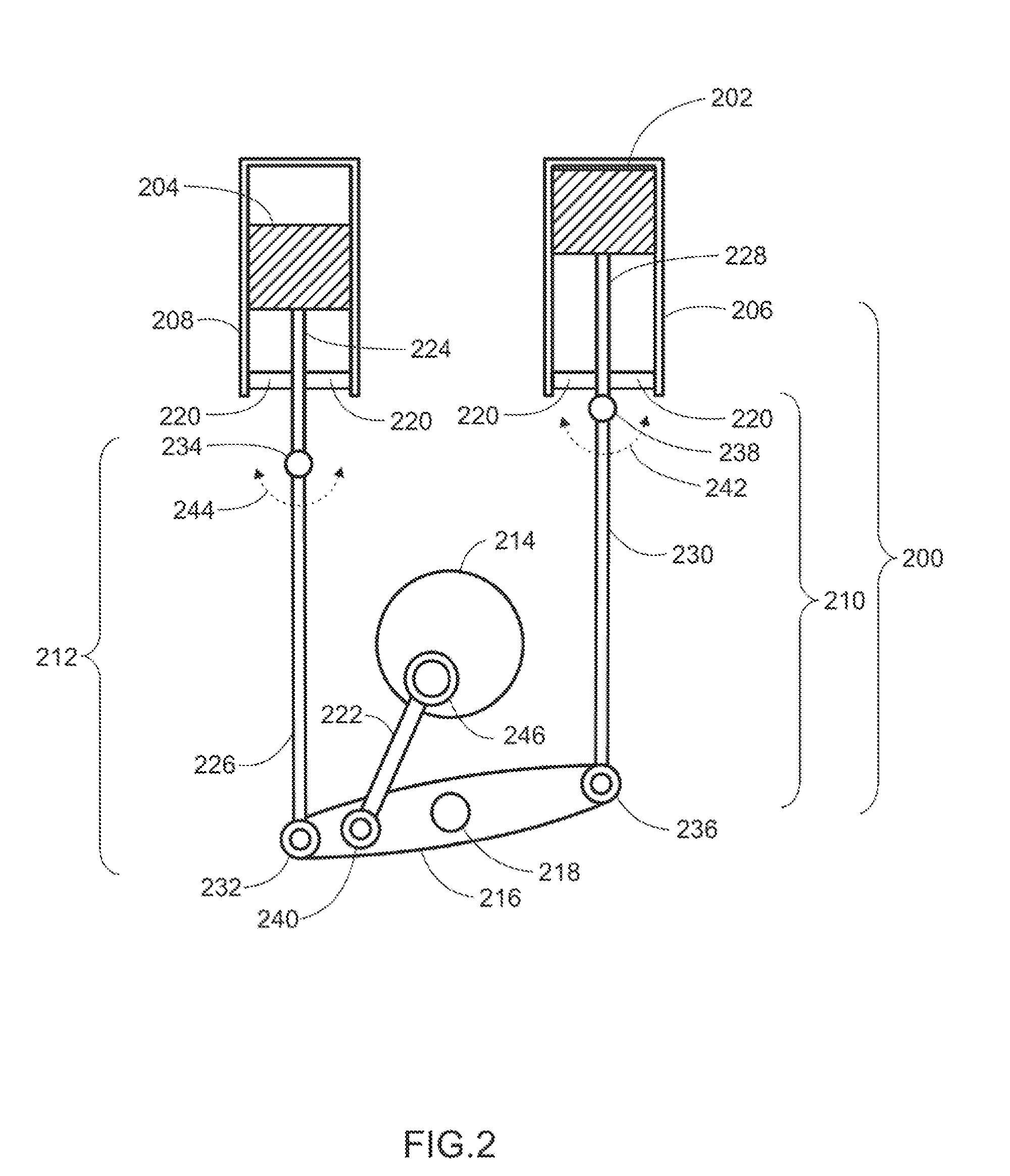

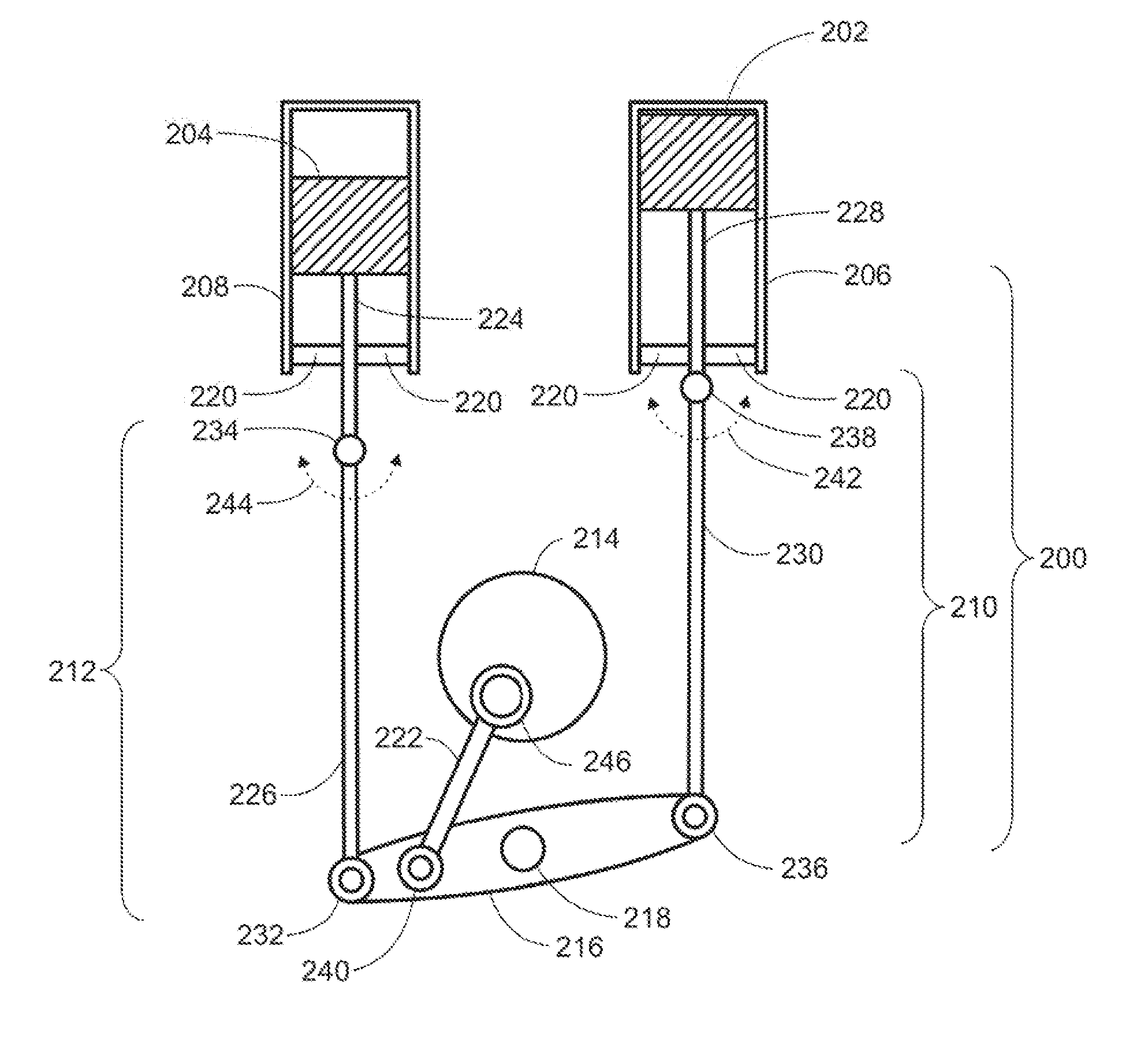

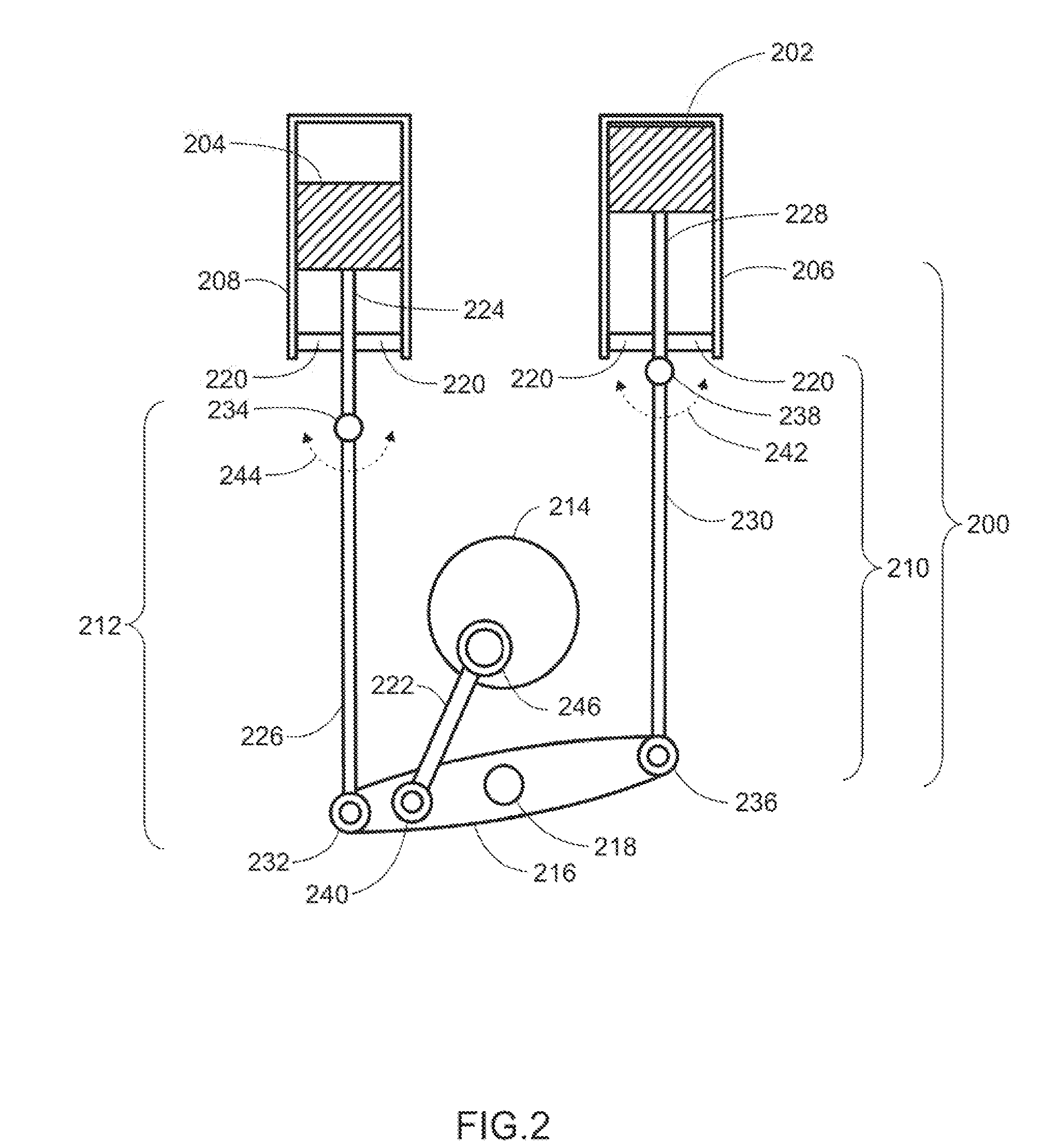

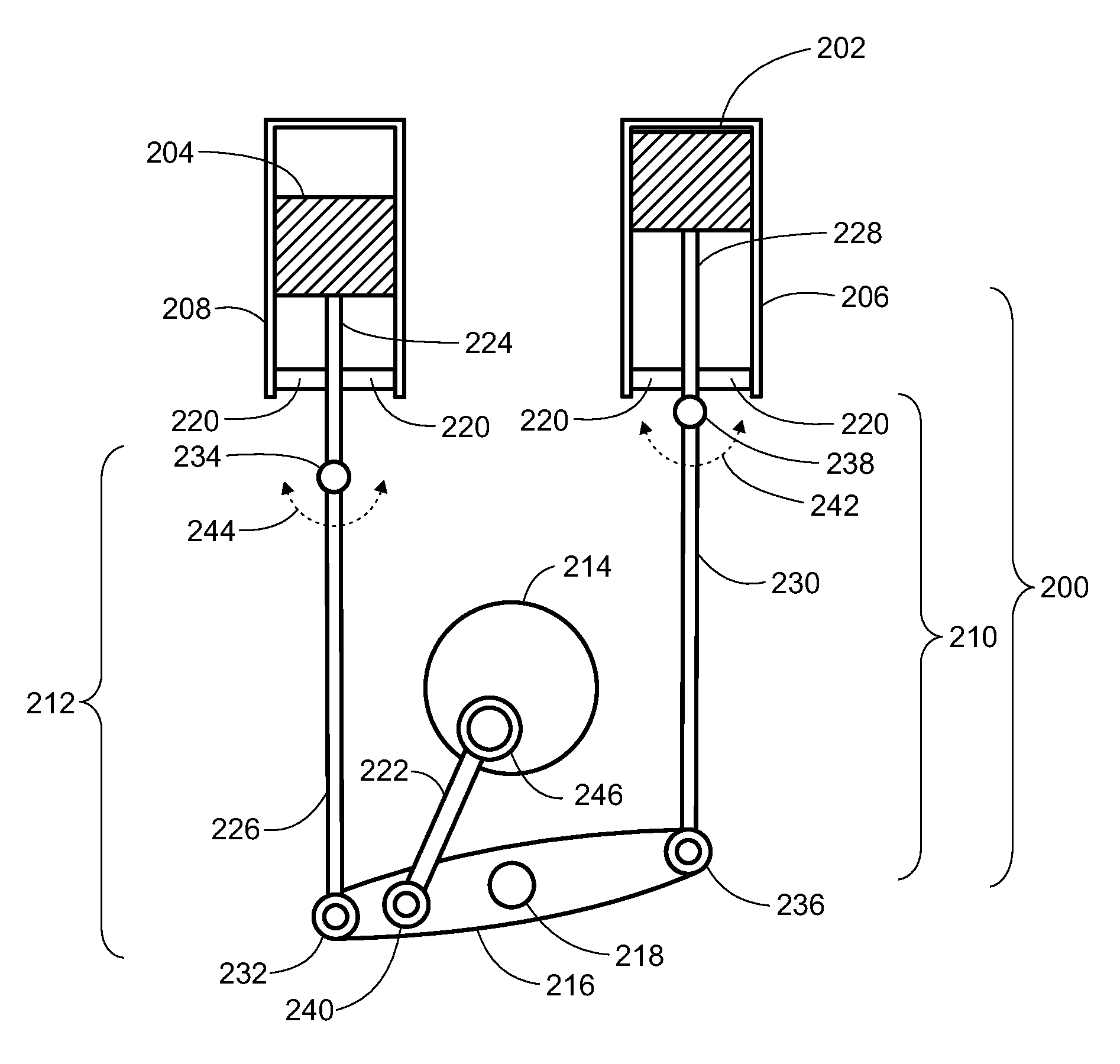

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The proximal end is connected to the piston and the distal end is connected to the rocking beam by an end pivot. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. A crankshaft coupled to the rocking beam by way of a connecting rod is also included. The rotary motion of the rocking beam is transferred to the crankshaft. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. A seal is included for sealing the workspace from the crankcase.

Owner:NEW POWER CONCEPTS

Stirling cycle machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

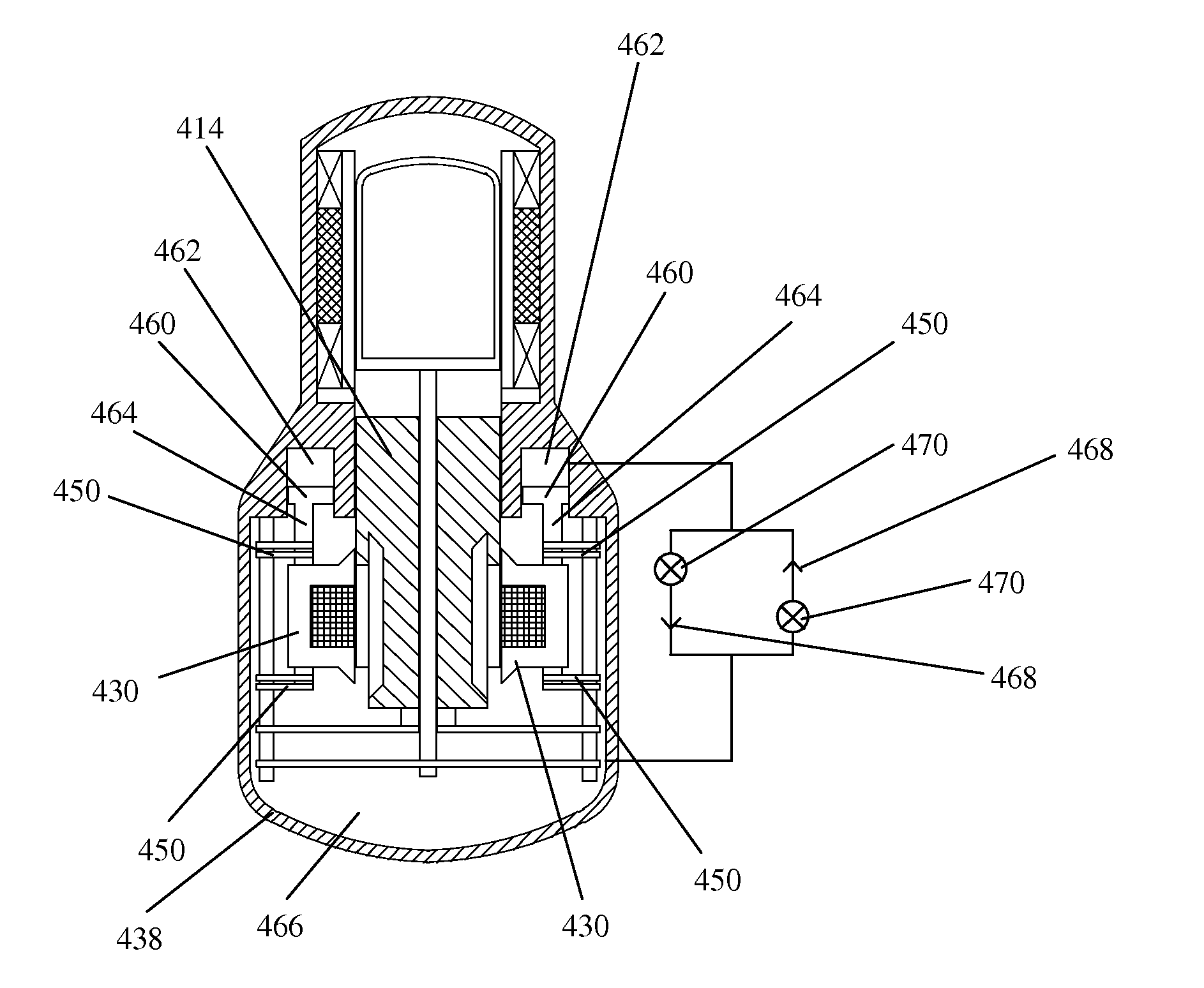

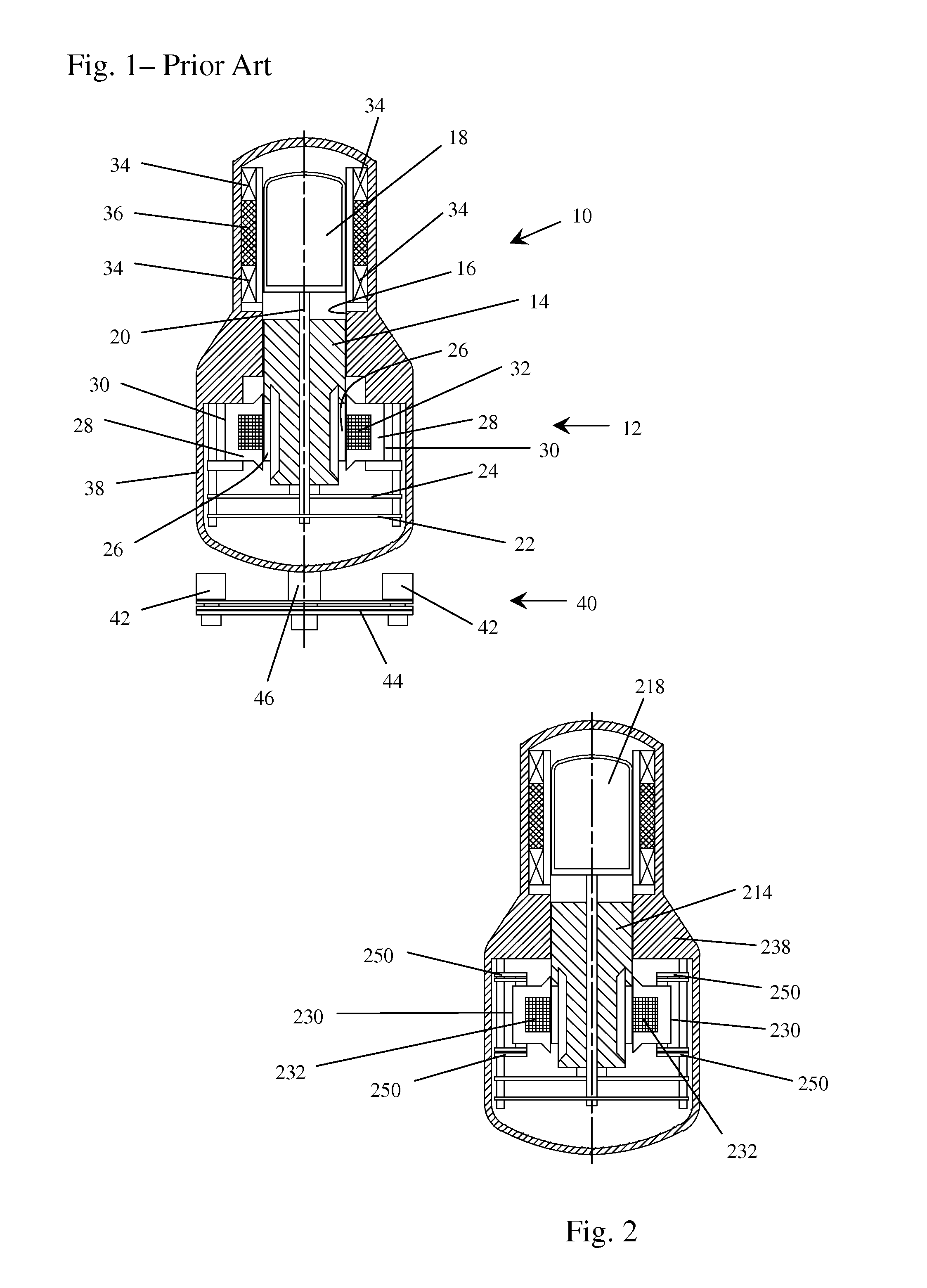

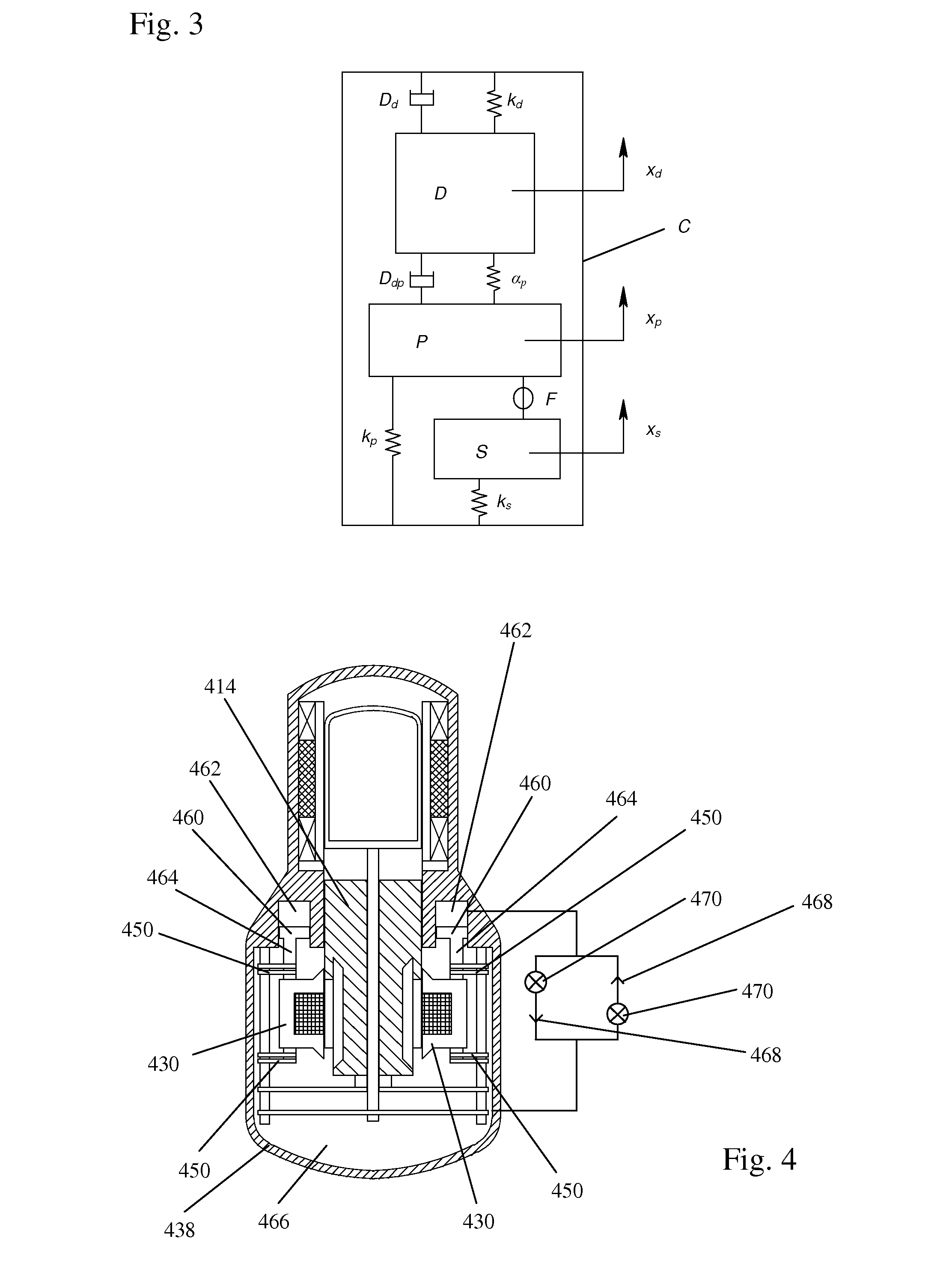

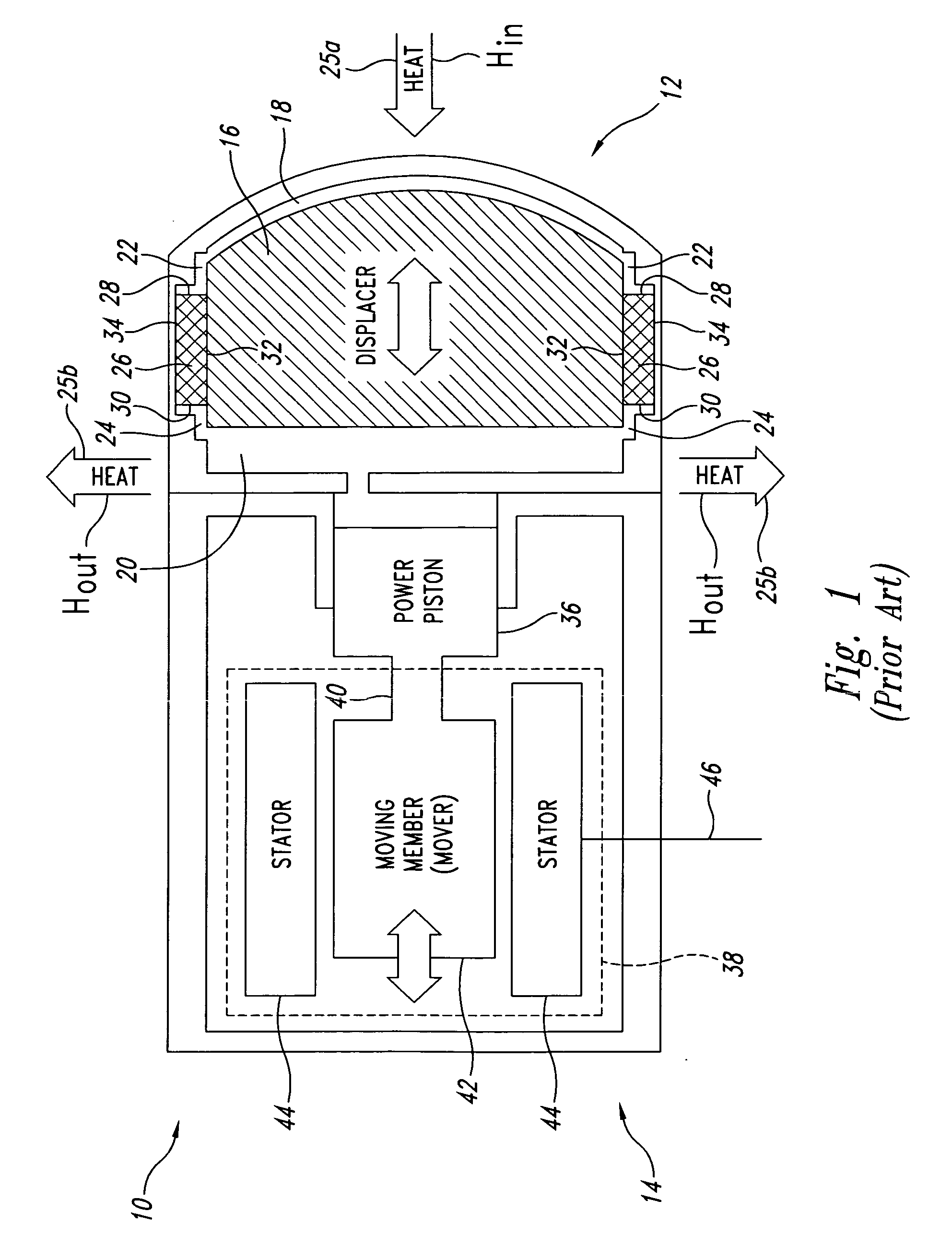

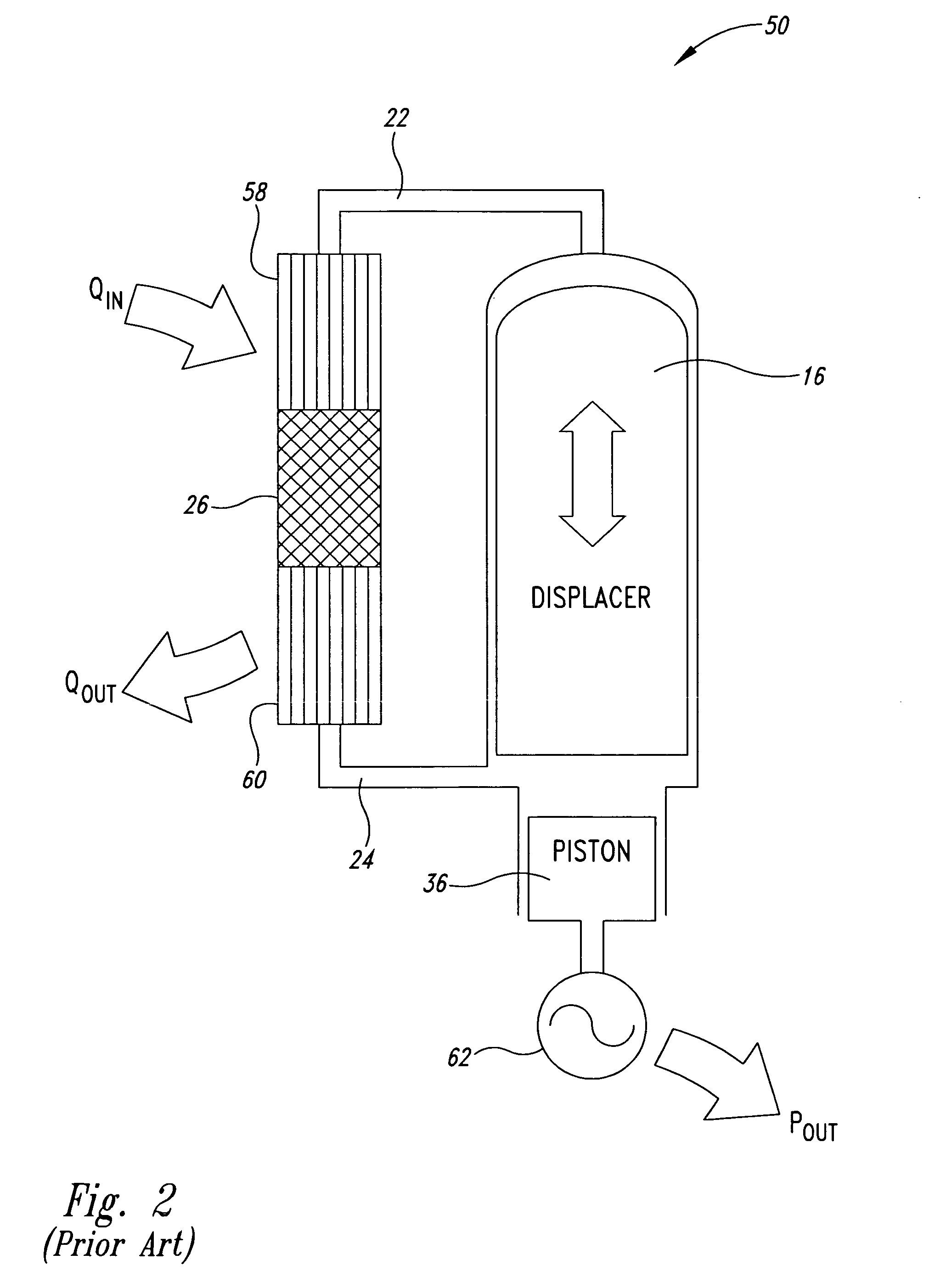

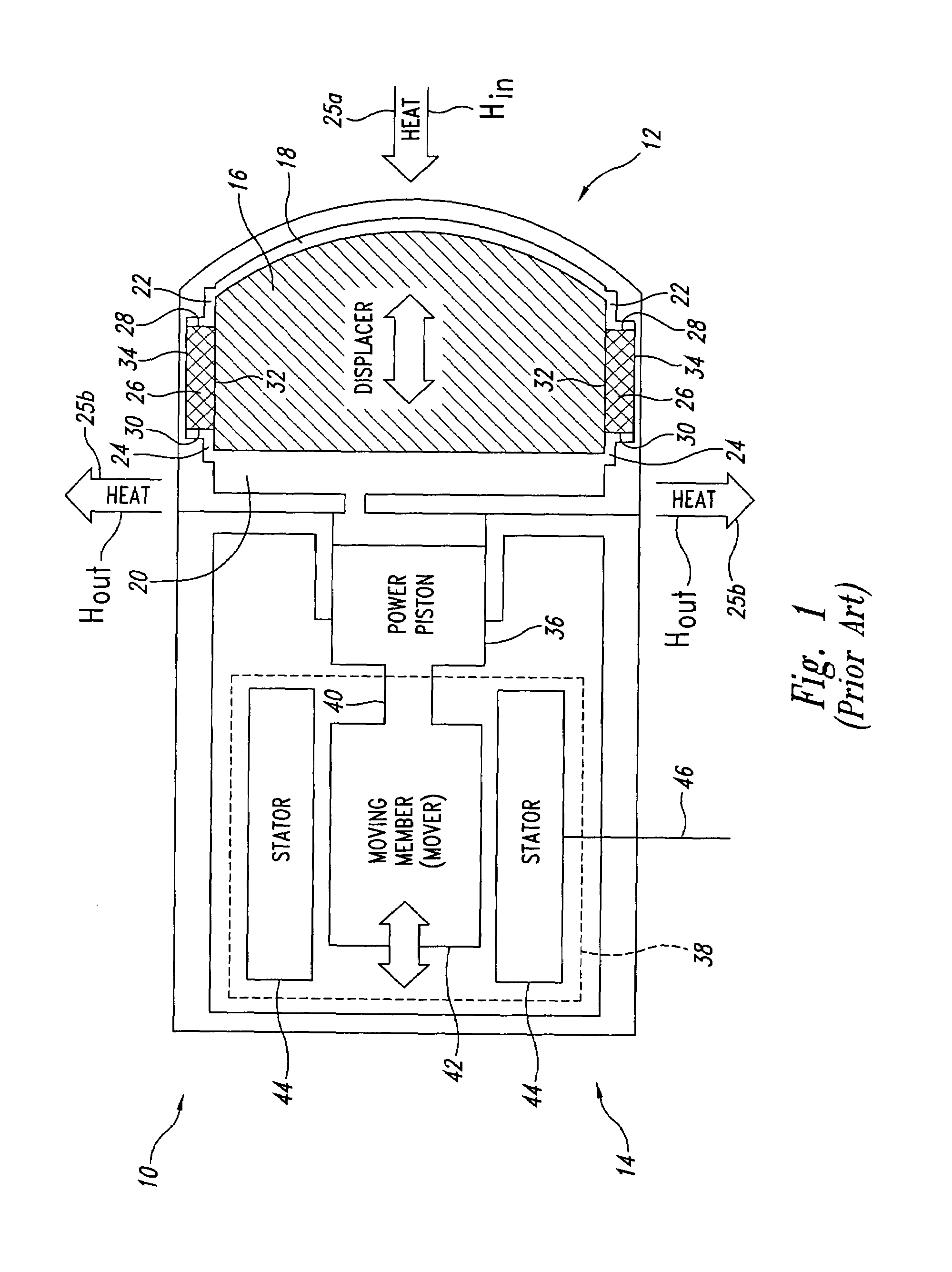

Resonant stator balancing of free piston machine coupled to linear motor or alternator

ActiveUS20090039655A1Vibration is reduced and minimized and eliminatedEliminate needSafety/regulatory devicesMechanical energy handlingEngineeringOperating frequency

A beta-type free-piston Stirling cycle engine or cooler is drivingly coupled to a linear alternator or linear motor and has an improved balancing system to minimize vibration without the need for a separate vibration balancing unit. The stator of the linear motor or alternator is mounted to the interior of the casing through an interposed spring to provide an oscillating system permitting the stator to reciprocate and flex the spring during operation of the Stirling machine and coupled transducer. The natural frequency of oscillation, ωs, of the stator is maintained essentially equal to ωpωp1-αpkpand the natural frequency of oscillation of the piston, ∩p, is maintained essentially equal to the operating frequency, ωo of the coupled Stirling machine and alternator or motor. For applications in which variations of the average temperature and / or the average pressure of the working gas cause more than insubstantial variations of the piston resonant frequency ωp, various alternative means for compensating for those changes in order to maintain vibration balancing are also disclosed.

Owner:GLOBAL COOLING

Stirling cycle machine

An external combustion engine is disclosed. The external combustion engine containing a working fluid and including a burner element for heating the working fluid of the engine, at least one heater head defining a working space containing the working fluid, at least one piston cylinder containing a piston for compressing the working fluid, a cooler for cooling the working fluid, a crankcase. The crankcase includes a crankshaft for producing an engine output, a rocking beam rotating about a rocker pivot for driving the crankshaft, a piston rod connected to the piston, a rocking beam driven by the piston rod, and a connecting rod connected at a first end to the rocking beam and at a second end to a crankshaft to convert rotary motion of the rocking beam to rotary motion of the crankshaft. The external combustion engine also includes an airlock space separating the crankcase and the working space for maintaining a pressure differential between the crankcase housing and the working space housing and an airlock pressure regulator connected between the crankcase and one of the airlock space and working space.

Owner:DEKA PROD LLP

Stirling cycle machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

Micro-scalable thermal control device

InactiveUS6385973B1Wide rangeIncrease surface areaCompression machinesRefrigeration componentsThermal energySteady state temperature

A microscalable thermal control module consists of a Stirling cycle cooler that can be manipulated to operate at a selected temperature within the heating and cooling range of the module. The microscalable thermal control module is particularly suited for controlling the temperature of devices that must be maintained at precise temperatures. It is particularly suited for controlling the temperature of devices that need to be alternately heated or cooled. The module contains upper and lower opposing diaphragms, with a regenerator region containing a plurality of regenerators interposed between the diaphragms. Gaps exist on each side of each diaphragm to permit it to oscillate freely. The gap on the interior side one diaphragm is in fluid connection with the gap on the interior side of the other diaphragm through regenerators. As the diaphragms oscillate working gas is forced through the regenerators. The surface area of each regenerator is sufficiently large to effectively transfer thermal energy to and from the working gas as it is passed through them. The phase and amplitude of the oscillations can be manipulated electronically to control the steady state temperature of the active thermal control surface, and to switch the operation of the module from cooling to heating, or vice versa. The ability of the microscalable thermal control module to heat and cool may be enhanced by operating a plurality of modules in series, in parallel, or in connection through a shared bottom layer.

Owner:NAT AERONAUTICS & SPACE ADMININSTRATION UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC

Electricity generating system driven by traveling wave thermoacoustic engine

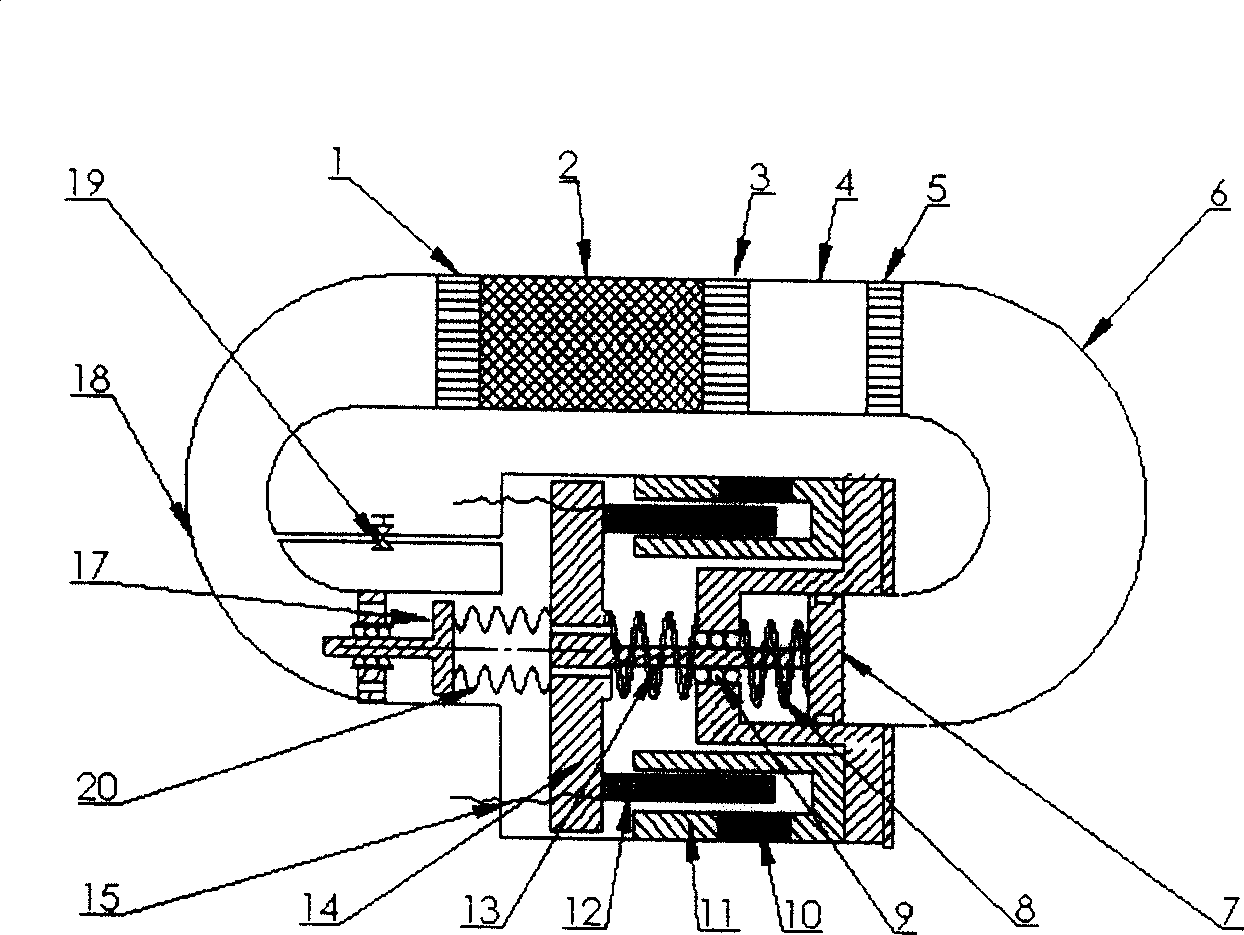

InactiveCN1766314ASmall sizeIncreased sound powerMachines/enginesMechanical power devicesElectricityThermoacoustics

The invention discloses a fluctuation thermoacoustic generation system, which comprises the following loop parts in sequence: cold junction heat exchanger, heat regenerator, heater, heat buffer pipe, hot junction heat exchanger, ring-shaped connection pipe and line generator in the pipe, wherein the generator contains a cylinder with one end of casing on the pipe and the other end with line sliding bearing; a double-loop magnetic-inductive soft iron with ring orifice is set in the cavity between cylinder and casing; the permanent magnet is inserted in the outer ring magnetic wall of soft iron; the coil rack is fixed on cylinder inner wall with part of coil in the ring orifice; the elastic or quality component is set in the hot junction pipe; the quality component does shift sliding along the elastic element; the elastic or quality phase modulation component is set in the greenhouse pipe; the quality component does shift sliding along the elastic phase modulation element. The invention can adjust the phase difference of pressure fluctuation and bulk flow fluctuation, which feedbacks the acoustic power to accomplish high effective Stirling cycle as well as inhibits the loop ring current to improve property of entire machine.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

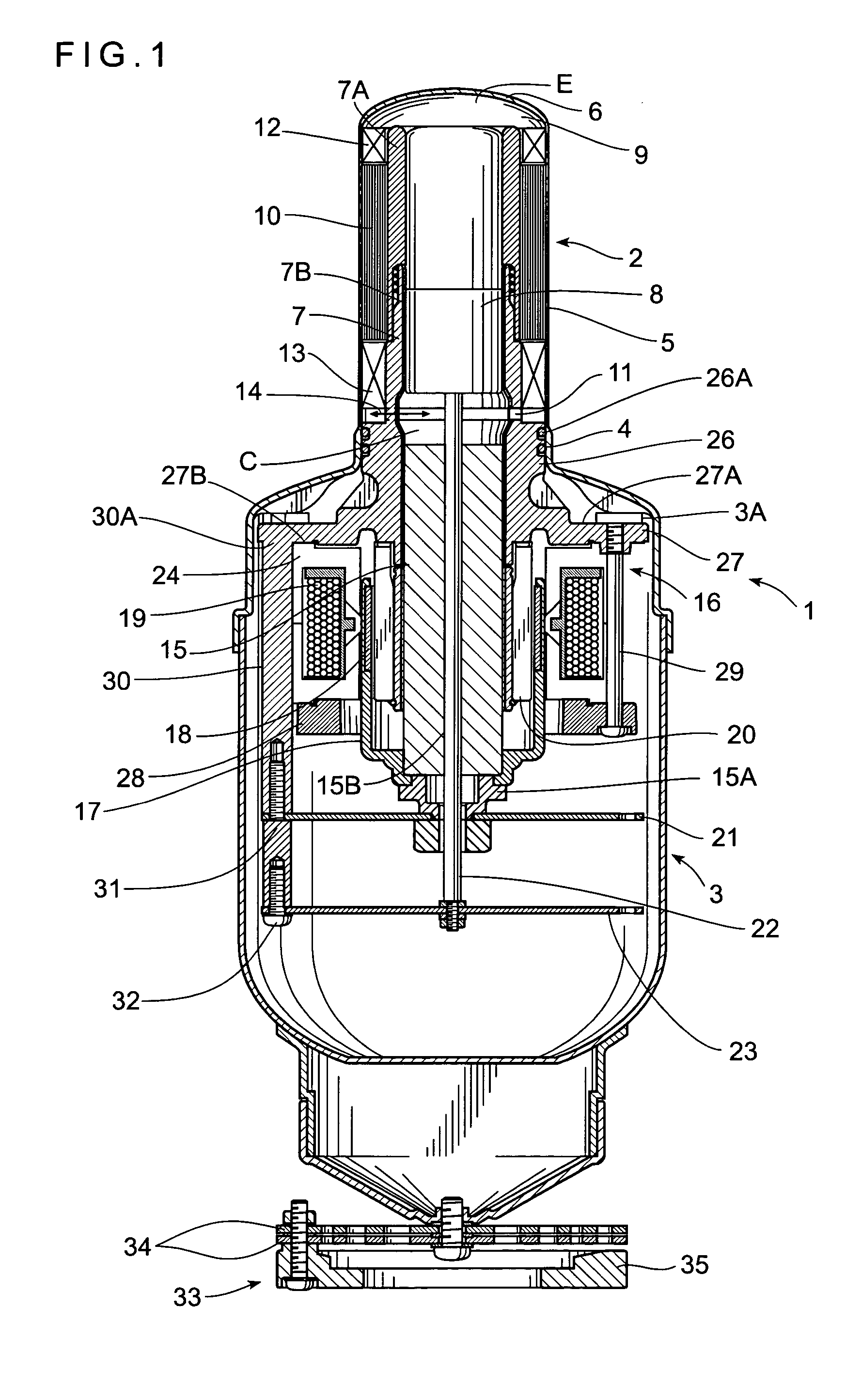

Stirling cycle engine

A stirling cycle engine whose cylinder, including a mount, can be easily fabricated and securely attached. The stirling cycle engine of the invention comprises a casing having a cylindrical portion 2; a metallic cylinder 7 coaxially inserted into the cylindrical portion 2 of the casing 1; a piston 15 inserted into the cylinder 7; a drive mechanism 16 for reciprocally driving the piston 15; and a mount 28 which is attached to an outer periphery of the cylinder 7 for fixing the cylinder 7 to the casing 1 and retaining the drive mechanism 16. The mount 28 is made of a material of low heat conductance, constructed separately from the cylinder 7. The mount 28 is attached to the outer periphery of the cylinder 7. Thus, the easier working thereof is resulted, so that the working time is shortened, to thereby improve productivity, and reduce working costs. Further, The heat from the drive mechanism 16 is less likely to transfer to the cylinder 7 via the mount 28.

Owner:TWINBIRD CORP

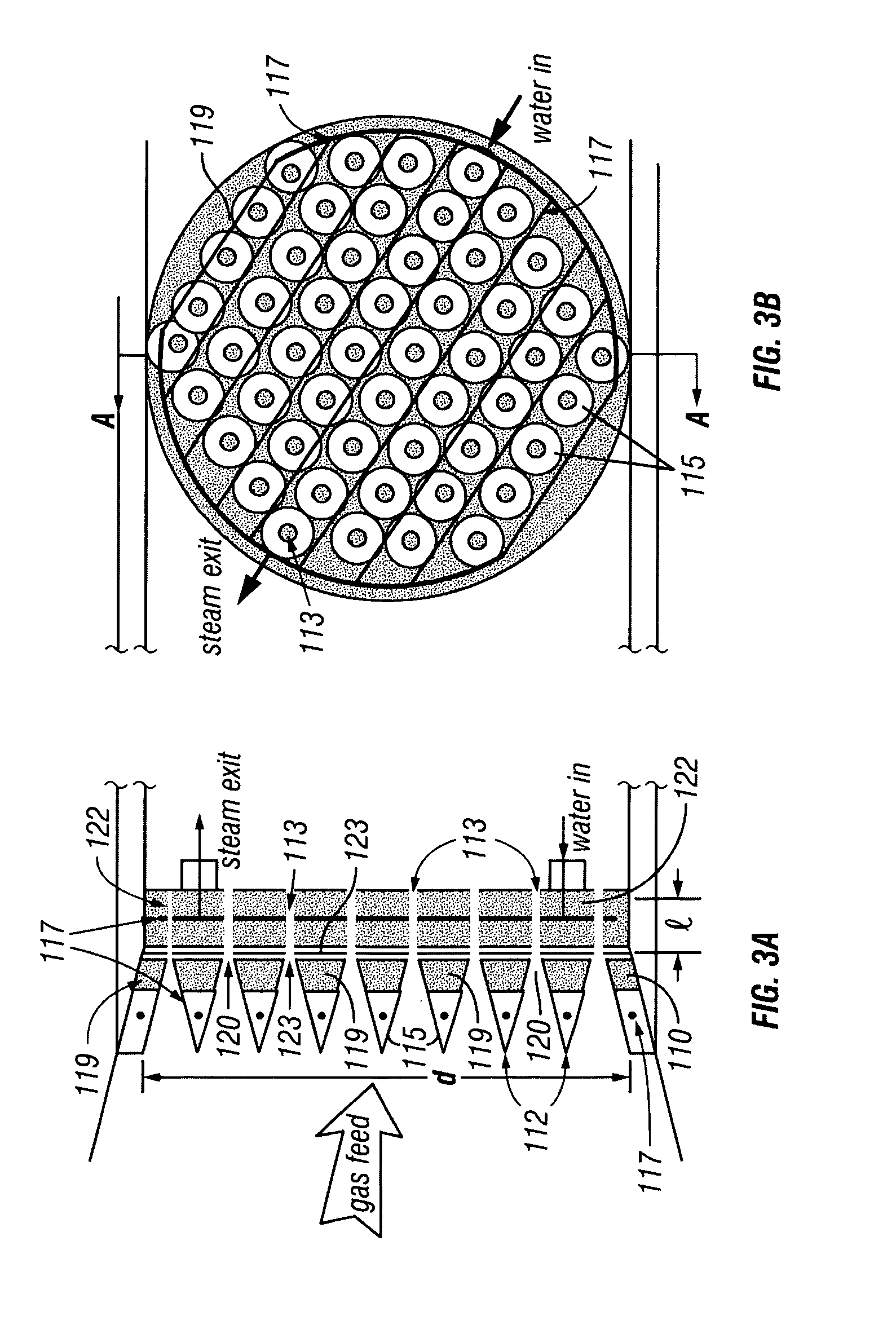

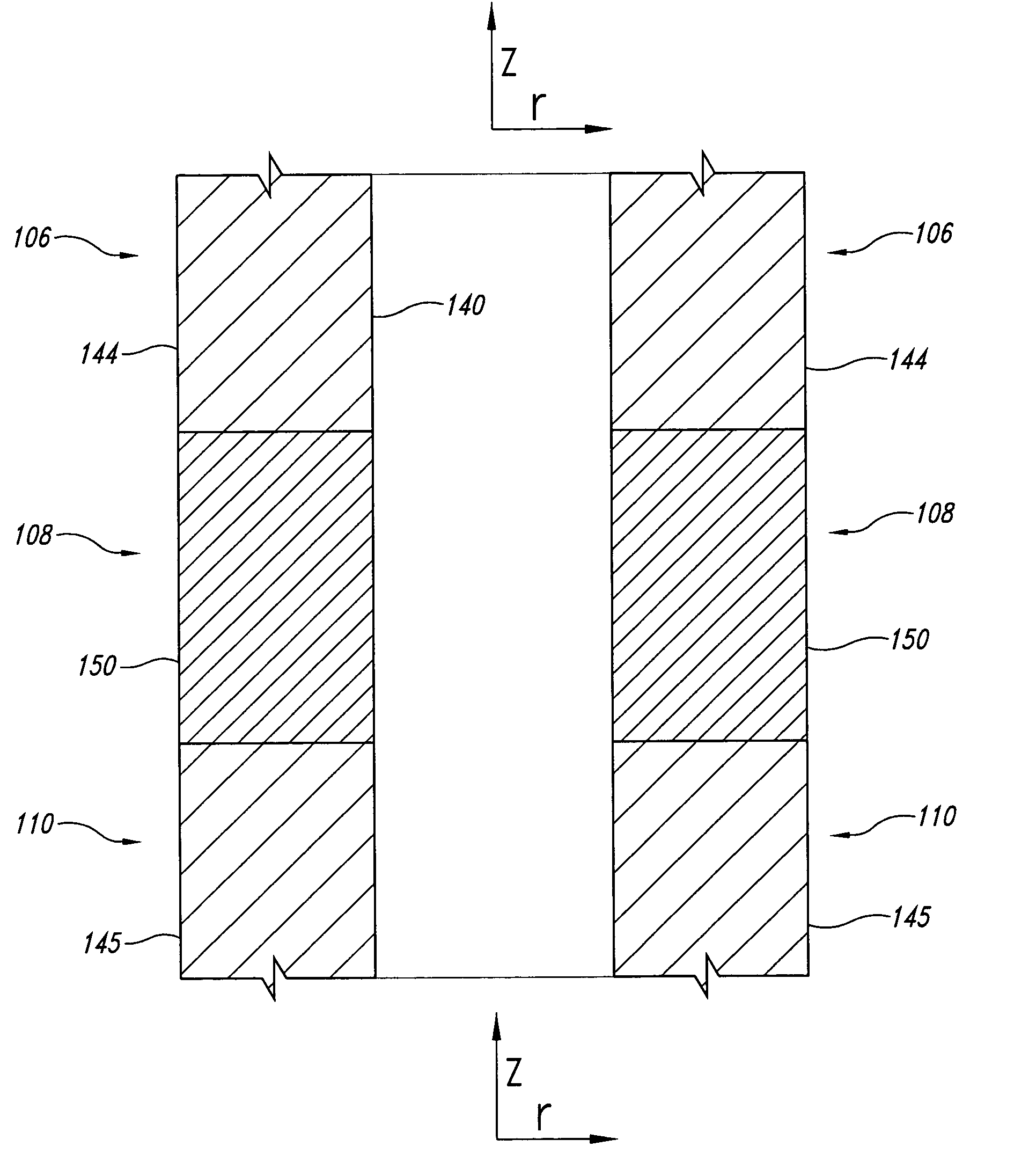

Channelized stratified regenerator with integrated heat exchangers system and method

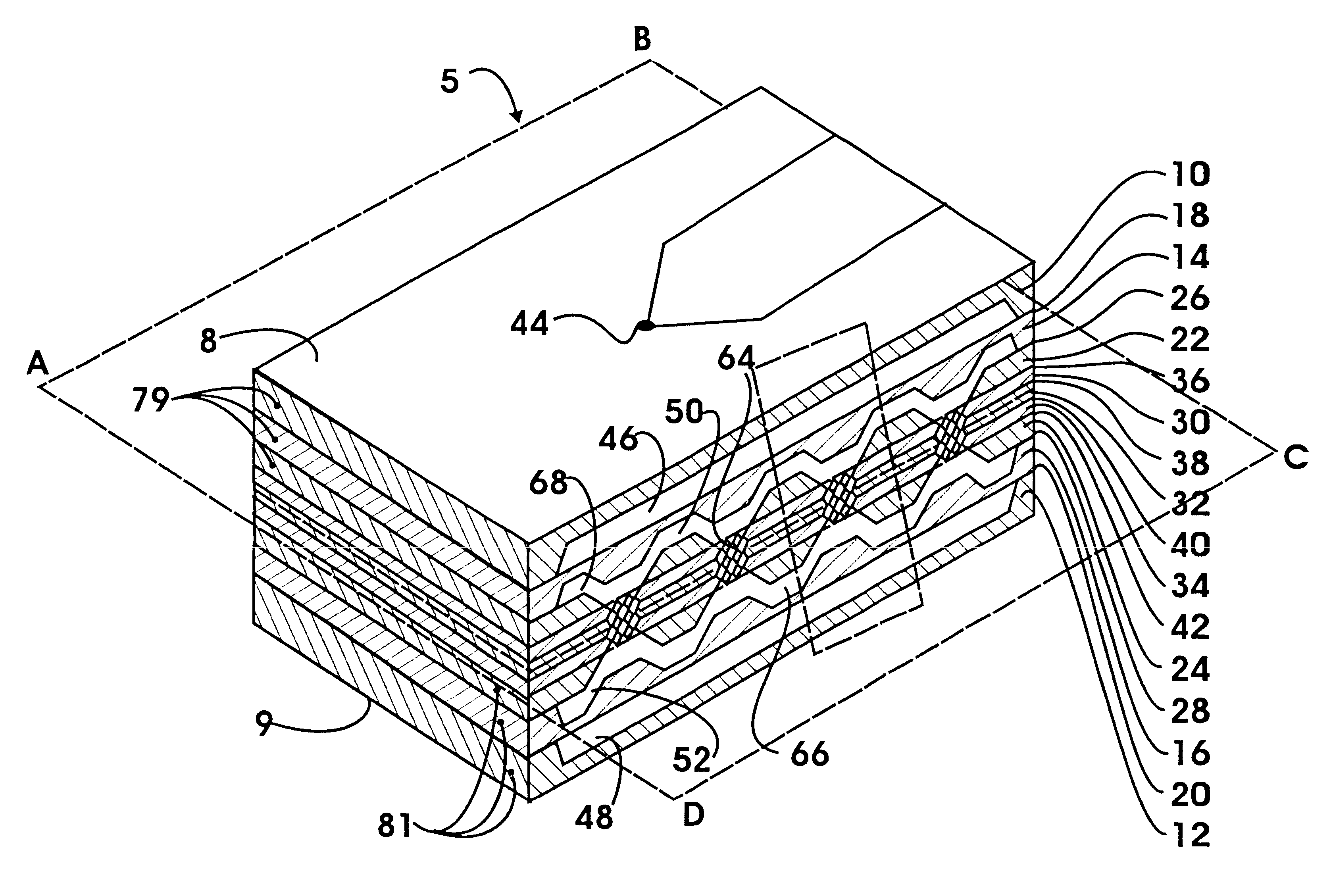

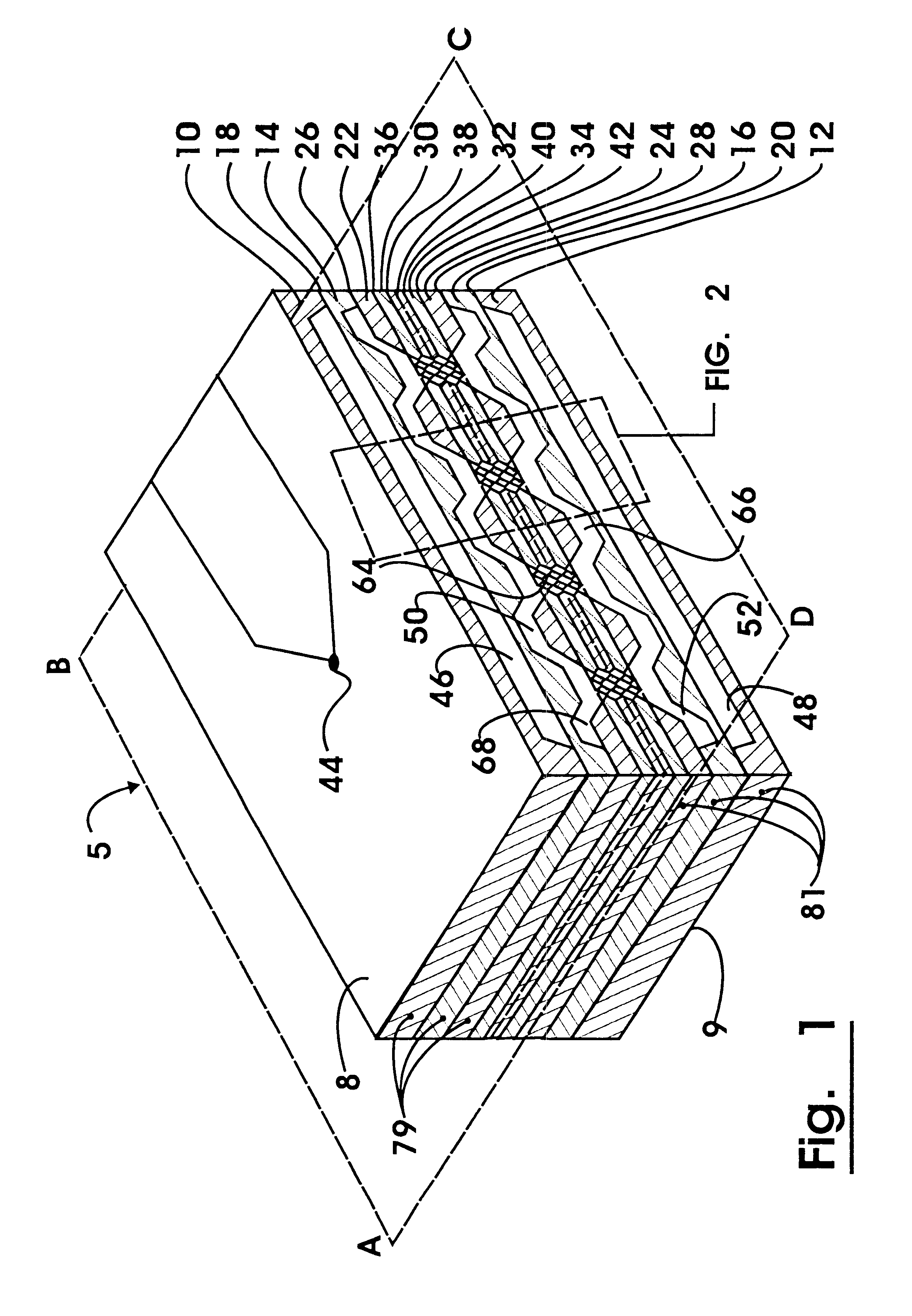

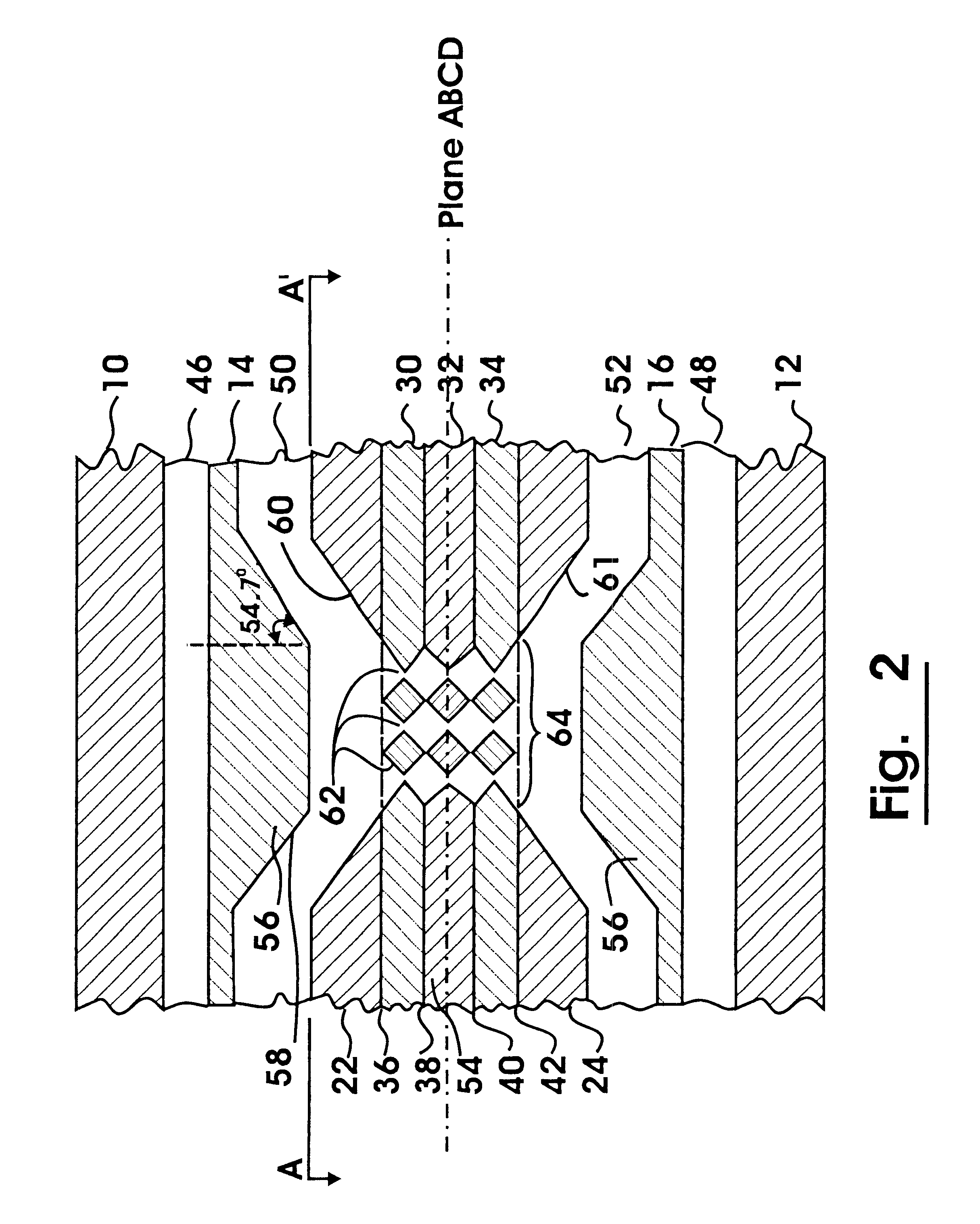

InactiveUS20060179835A1Avoid short travelRegenerative heat exchangersClosed-cycle gas positive displacement engine plantWorking fluidStructural geometry

A channelized stratified regenerator with integrated heat exchangers are disclosed using micromachining to precisely construct structural geometries, such as fins and axial stratification of material to be used in a Stirling cycle based system. In operation, a working fluid passes through the regenerator when traveling between two heat exchangers. In some implementations, the regenerator and the heat exchangers are formed as a single construction. In other implementations, the regenerator and heat exchangers are formed separately, but are constructed to integrate efficiently with one another.

Owner:QNERGY

Resonant stator balancing of free piston machine coupled to linear motor or alternator

ActiveUS8011183B2Vibration is reduced and minimized and eliminatedEliminate needMechanical energy handlingSafety/regulatory devicesReciprocating motionTransducer

Owner:GLOBAL COOLING

Stirling cycle machine

A Stirling cycle machine. The machine includes at least one rocking drive mechanism which includes: a rocking beam having a rocker pivot, at least one cylinder and at least one piston. The piston is housed within a respective cylinder and is capable of substantially linearly reciprocating within the respective cylinder. Also, the drive mechanism includes at least one coupling assembly having a proximal end and a distal end. The linear motion of the piston is converted to rotary motion of the rocking beam. Also, a crankcase housing the rocking beam and housing a first portion of the coupling assembly is included. The machine also includes a working space housing the at least one cylinder, the at least one piston and a second portion of the coupling assembly. An airlock is included between the workspace and the crankcase and a seal is included for sealing the workspace from the airlock and crankcase. A burner and burner control system is also included for heating the machine and controlling ignition and combustion in the burner.

Owner:NEW POWER CONCEPTS

Method and apparatus for a waste heat recycling thermal power plant

This invention, a waste heat recycling thermal power plant (1000), extracts heat from the environment, and concentrates this heat to produce a cfc super-ambient temperature heat source (1330) having an elevated temperature sufficient to supply a useable heat flow to an incorporated heat engine (e.g., Rankine cycle, Stirling cycle, Seebeck cycle, etc.) flow circuit (1400). Further, waste heat recycling thermal power plant (1000) produces an sfc sub-ambient temperature heat sink (1250), thus increasing the applied temperature differential, thereby permitting the thermal efficiency of ihefc pressure expansion device (1460) to be increased as well. Lastly, waste heat recycling thermal power plant (1000) captures for reuse, much of the waste heat that its own operation liberates, thus lowering its net energy utilization per unit of mechanical power produced (a.k.a., heat rate, Btu / kwhr). In the main embodiment of its use, waste heat recycling thermal power plant (1000) would be used as the driver for a mod driven mechanical device (1520), specifically an electrical generator. Deriving its source heat by intercepting the heat that would be rejected to the environment by an electrical power generating station's cooling device, and routing this heat to waste heat recycling thermal power plant (1000). Then converting this heat to mechanical power, and subsequently to electrical power. This would result in an improvement of the electrical power generating station's net electrical power generating capacity and fuel efficiency, while simultaneously reducing the quantity of thermal (and potentially chemical) pollution released to the environment.

Owner:KIRBY TIMOTHY MICHAEL +1

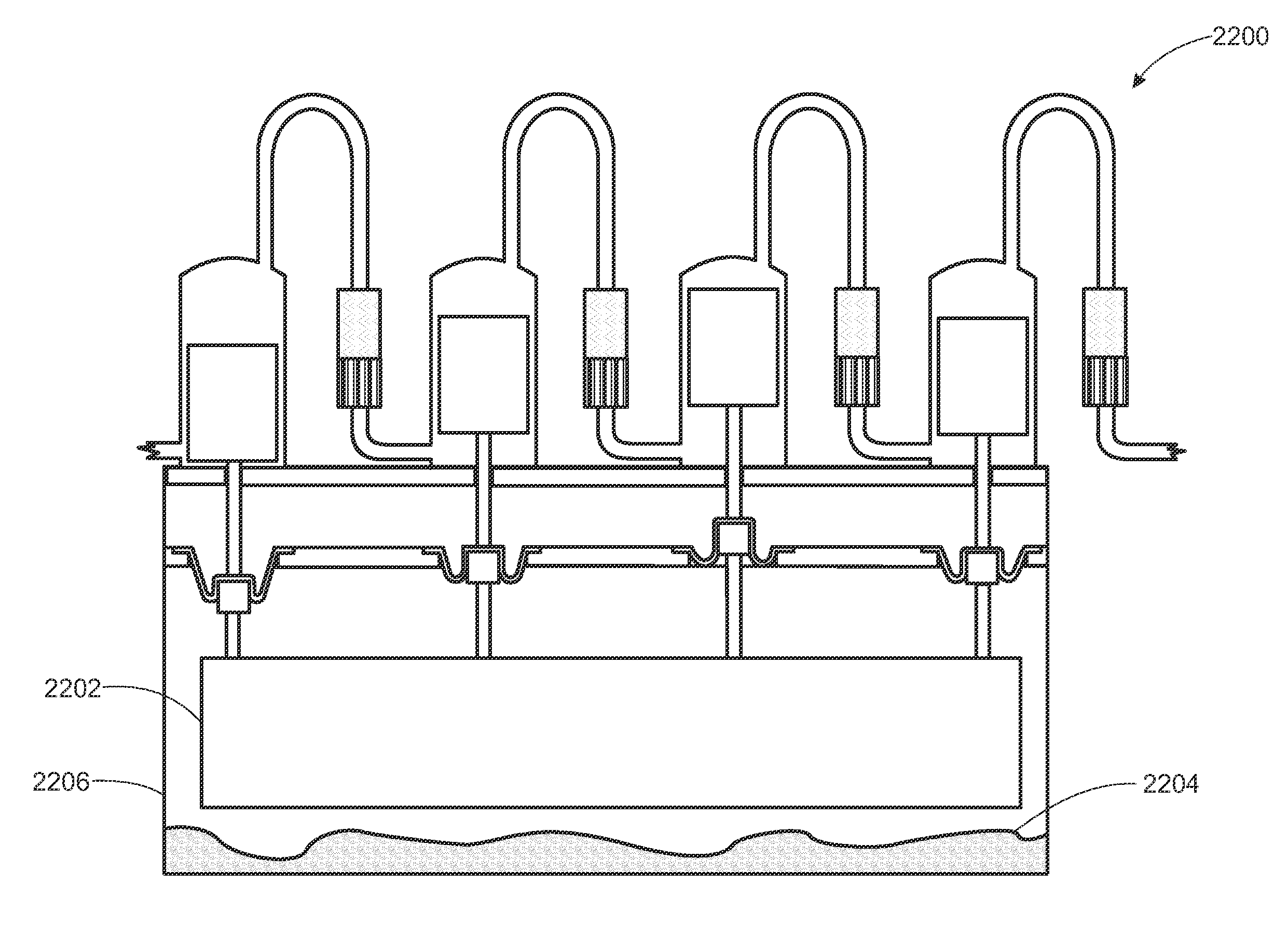

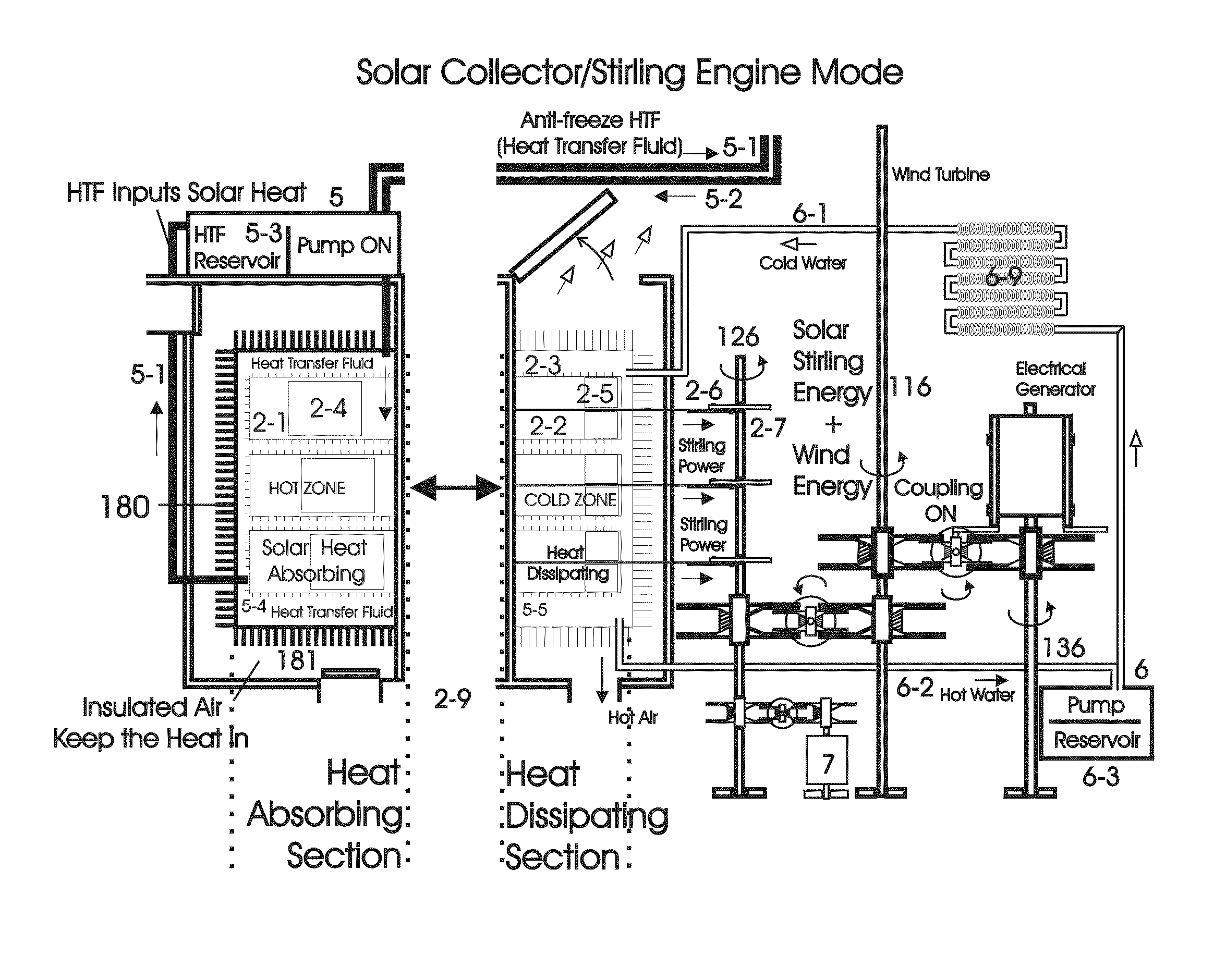

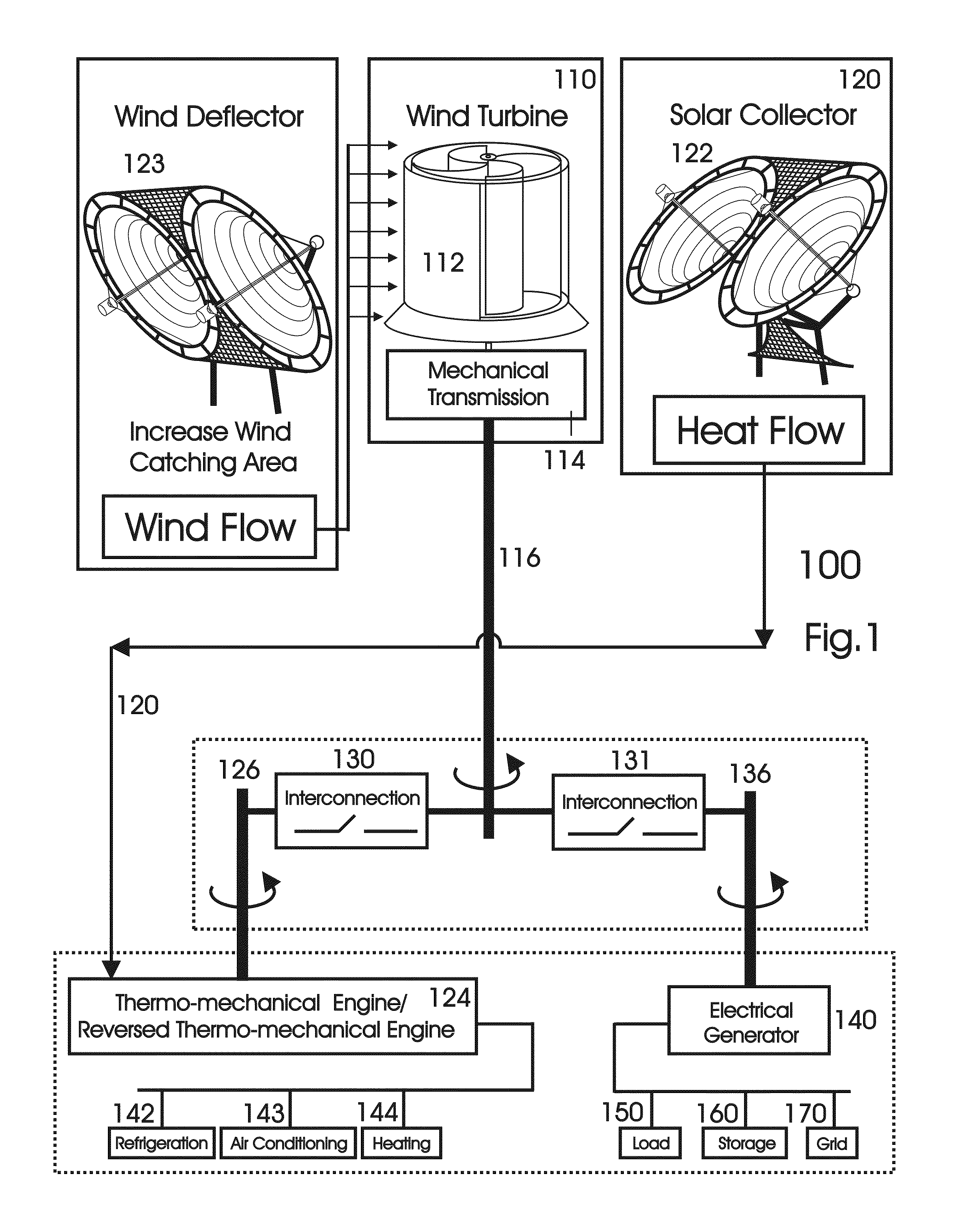

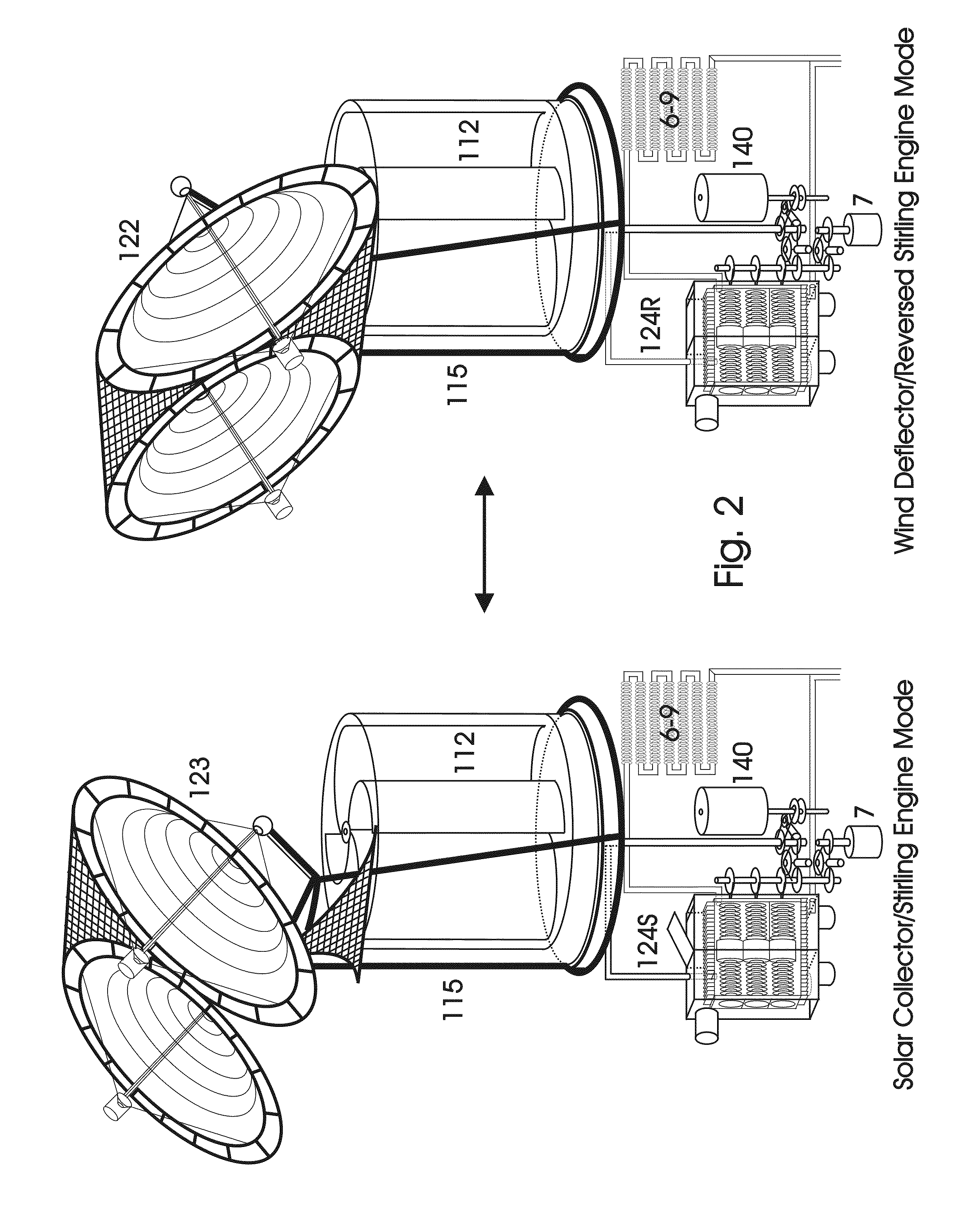

Solar collector/wind deflector conversion of a solar and wind converter

InactiveUS20110232630A1Increase wind areaIncrease energy generatedSolar heating energySolar heat devicesTurbineSolar energy harvesting

An integrated solar and wind hybrid energy generating system is capable of converting a solar collector to a wind deflector to increase wind catching area for the wind turbine during the nighttime and on overcast days and exchangeable between modes of Stirling cycle and reversed Stirling cycle for electricity generation and environmental control. During the sunny days, the system concurrently derives energy from both wind and solar energy sources.

Owner:TSAO JASON

Heat exchanger element and heat exchanger member for a stirling cycle refrigerator and method of manufacturing such a heat exchanger member

InactiveUS7225859B2Increase contact areaImprove thermal conductivityCompression machinesRefrigeration componentsEngineeringRefrigerated temperature

A heat exchanger element for a Stirling cycle refrigerator is produced by integrally forming an annular corrugate fin that is produced by forming a sheet material, corrugated so as to have a large number of grooves, into a cylindrical shape with the grooves parallel to an axis of the cylindrical shape and an inner ring-shaped member that is placed in contact with the inner periphery of the annular corrugate fin. A heat rejector or heat absorber for a Stirling cycle refrigerator is produced by inserting this heat exchanger element into the hollow portion of a tubular body.

Owner:SHARP KK

Electricity generation in a turbomachine

ActiveUS7685828B2Improve efficiencySolution to short lifeEfficient propulsion technologiesGas turbine plantsWorking fluidEngineering

A turbomachine comprising at least one Stirling cycle thermal engine which is mounted at the end of a radial arm of the exhaust casing and comprises a working chamber located outside the primary and secondary flows, a displacing piston associated with a moving element of an energy generation system, and two exchangers, heating and cooling, formed in parts of the radial arm respectively intercepting the primary flow and the secondary flow, these two exchangers communicating with each other and with the working chamber for the circulation of a working fluid.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

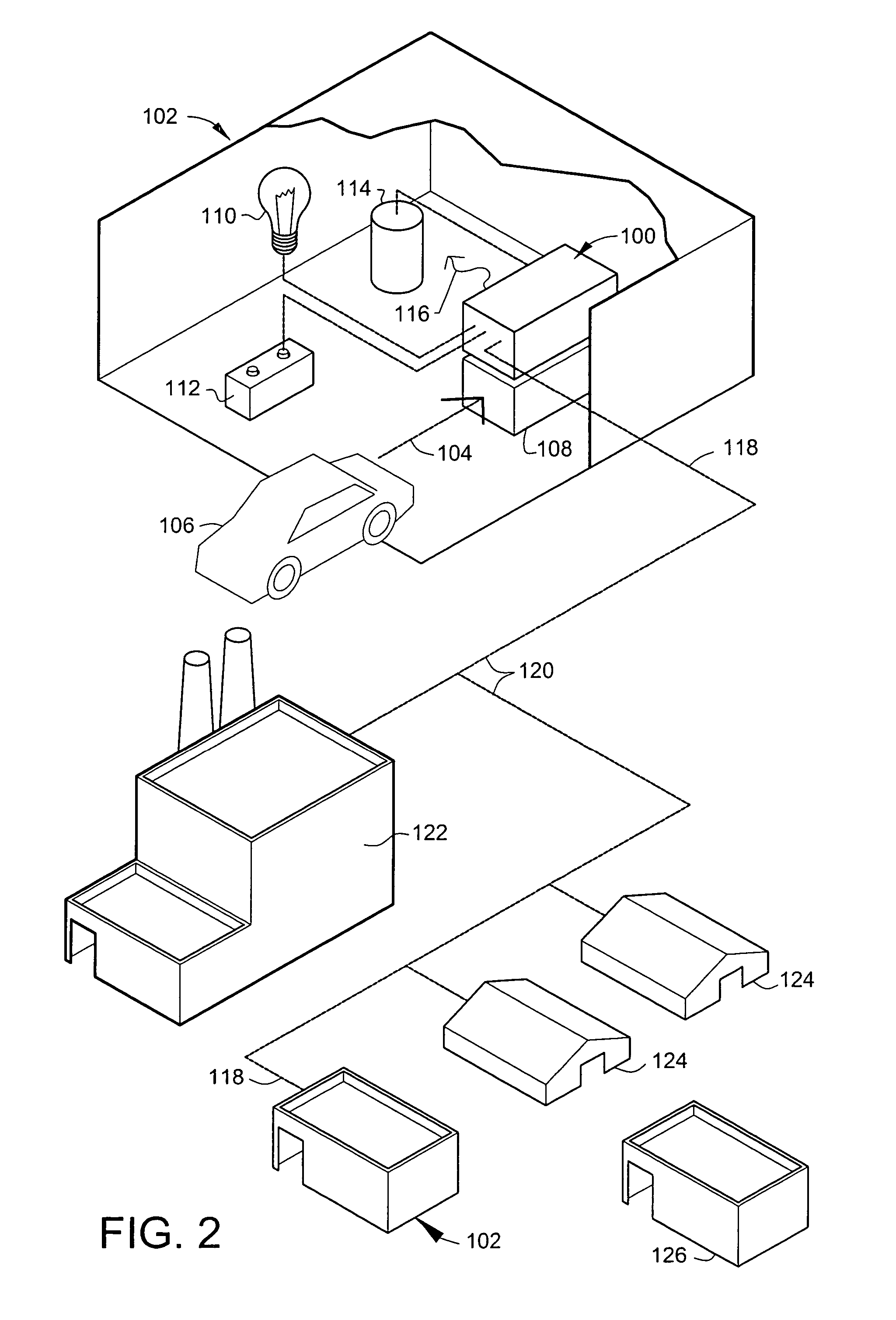

Waste oil electrical generation system

An improved electrical generation system utilizing environmentally hazardous waste oils as a combustible fuel. More particularly, a system to generate electrical power using a Stirling-cycle engine driving an electrical generator. The Stirling-cycle engine is powered by the heat energy produced by a waste-oil-fired furnace. The system is of a co-generation type, producing electricity and a combination of space heating and hot water.

Owner:BASSETT TERRY EDGAR

Stirling cycle engine

InactiveUS20050268604A1Simple structureExcellent abrasion resistanceStirling type enginesEngine componentsCarbon fibersReciprocating motion

A Stirling cycle engine of a simplified structure, having enhanced reliability by improving abrasion resistance and lubricity of components thereof. When a piston reciprocates in a cylinder along the axial direction thereof by a driving mechanism, a displacer reciprocates in the cylinder along the axial direction thereof accompanying the reciprocation of the piston. The piston and the displacer slide in contact with the inner peripheral surface of the cylinder, but the piston and the displacer are each integrally made from an engineering plastic such as PPS having fine strength, dimensional stability, abrasion resistance and formability, while PPS is made CFRP. Moreover, solid lubricity agent is added to PPS. Accordingly, abrasion resistance, lubricity, strength and precision of the piston and displacer are enhanced, while the piston and the displacer can be simply produced by a well-known plastic molding.

Owner:TWINBIRD CORP

Channelized stratified regenerator system and method

InactiveUS7089735B1Avoid short travelClosed-cycle gas positive displacement engine plantPlate heat exchangerWorking fluid

A channelized stratified regenerator with integrated heat exchangers are disclosed using micromachining to precisely construct structural geometries, such as fins and axial stratification of material to be used in a Stirling cycle based system. In operation, a working fluid passes through the regenerator when traveling between two heat exchangers. In some implementations, the regenerator and the heat exchangers are formed as a single construction. In other implementations, the regenerator and heat exchangers are formed separately, but are constructed to integrate efficiently with one another.

Owner:QNERGY

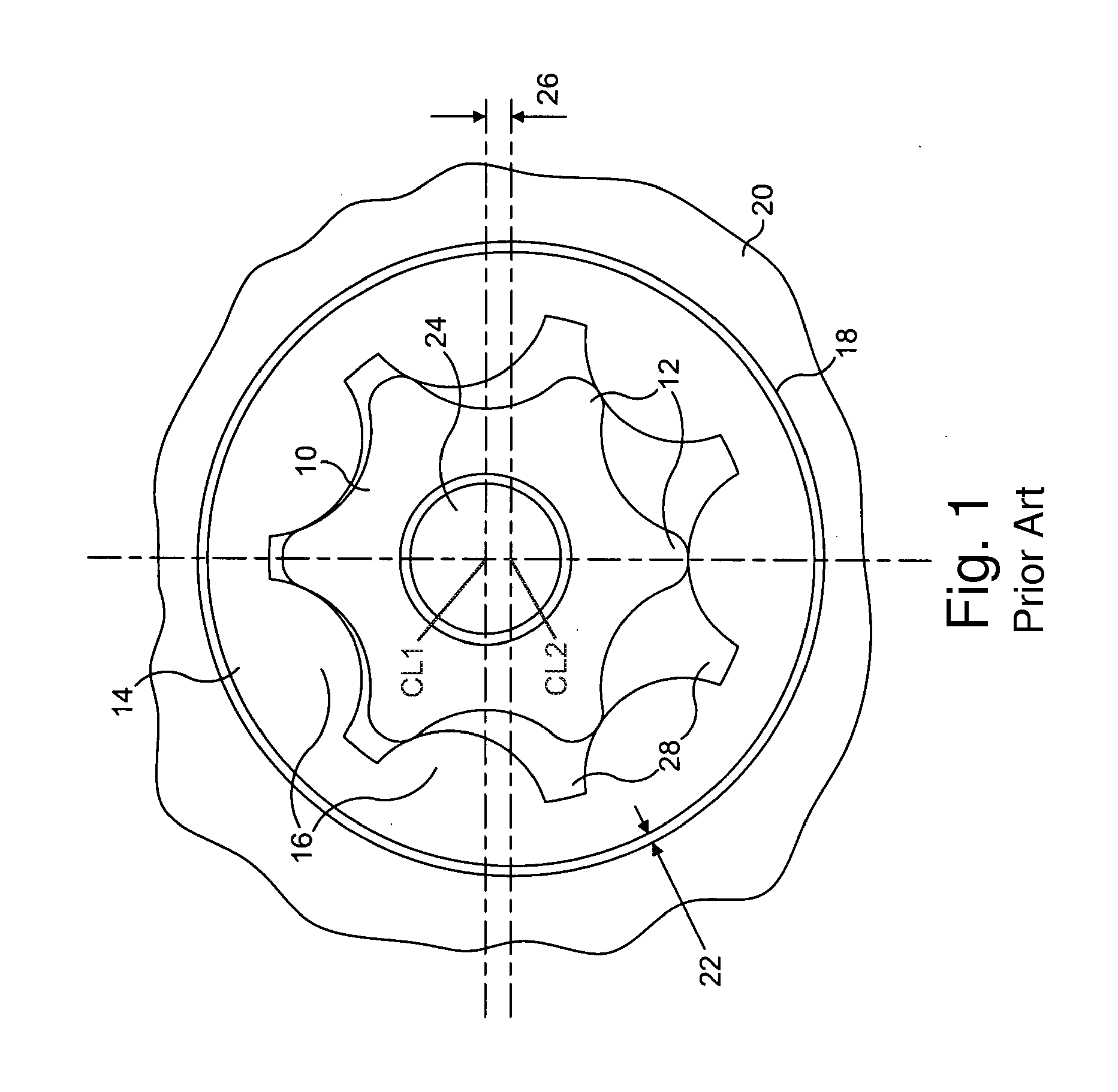

Gerotor rotary stirling cycle engine

ActiveUS20140271308A1Low thermal conductivityEngine sealsInternal combustion piston enginesEngineeringGerotor

Stirling cycle engines with hot and cold gerotor sets separated by an insulation barrier. The barrier has regenerative gas passages to allow gasses to flow therethrough thus connecting displacing chambers of the hot and cold gerotor sets. Each gerotor set has a rotor within a stator and displacing chambers created in an offset space therebetween. The stators may rotate about the rotors, or vice-versa. Either the rotor of the cold gerotor set has an axis of rotation offset with respect to the rotor of the hot gerotor set or the stator of the cold gerotor set has an axis of rotation offset with respect to the stator of the hot gerotor set, and the non-offset rotors or stators rotate about a common axis and are rotationally connected and create an angular phase offset between connected hot and cold chambers. The gerotor apparatuses may be utilized for a Stirling cycle engine for generating electricity, for example.

Owner:FRLIN ETHAN W

Porous restrictor for gas bearing

InactiveCN1561429AReduce the likelihood of cloggingAvoid enteringLinear bearingsGas cushion bearingsBand shapeEngineering

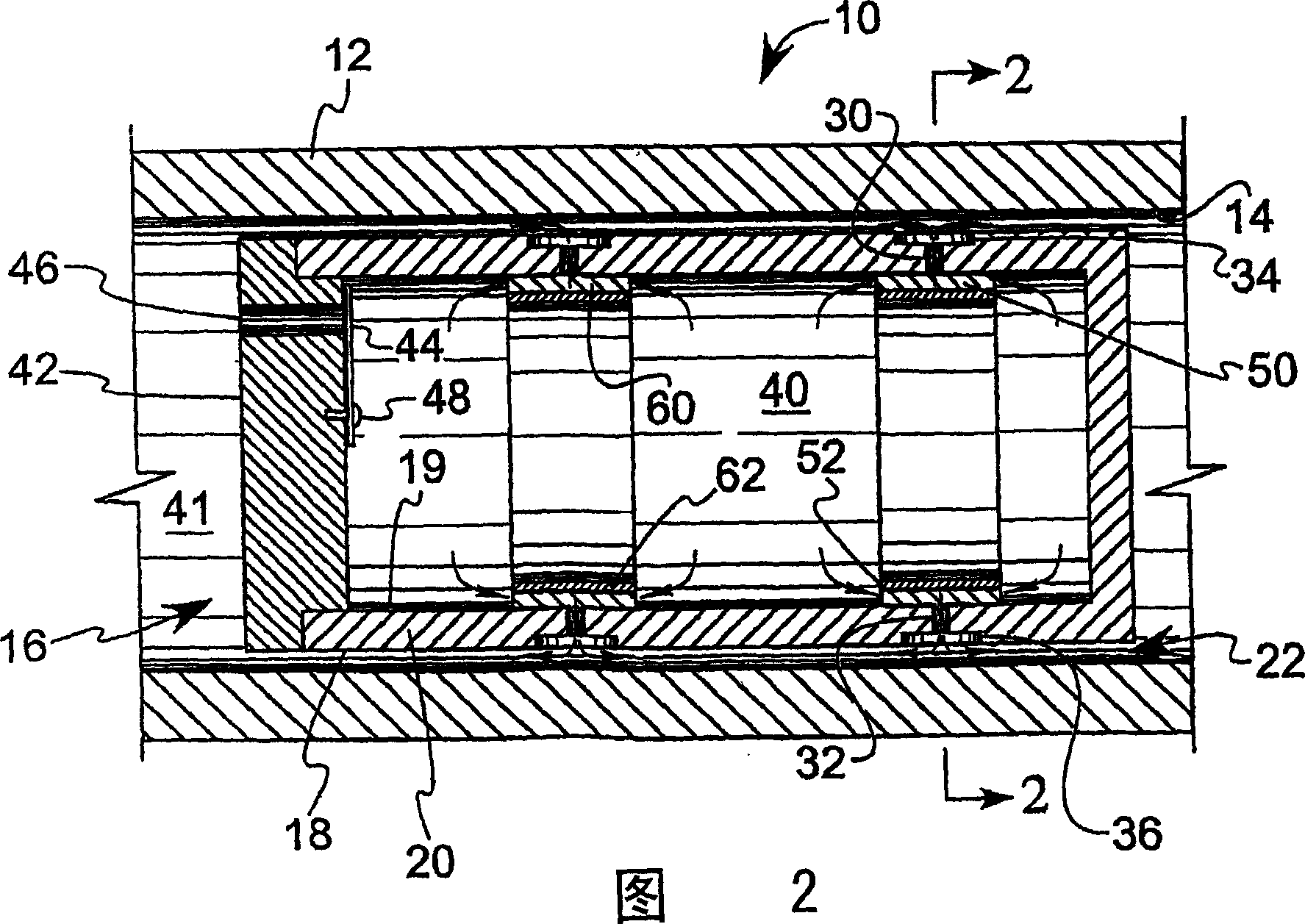

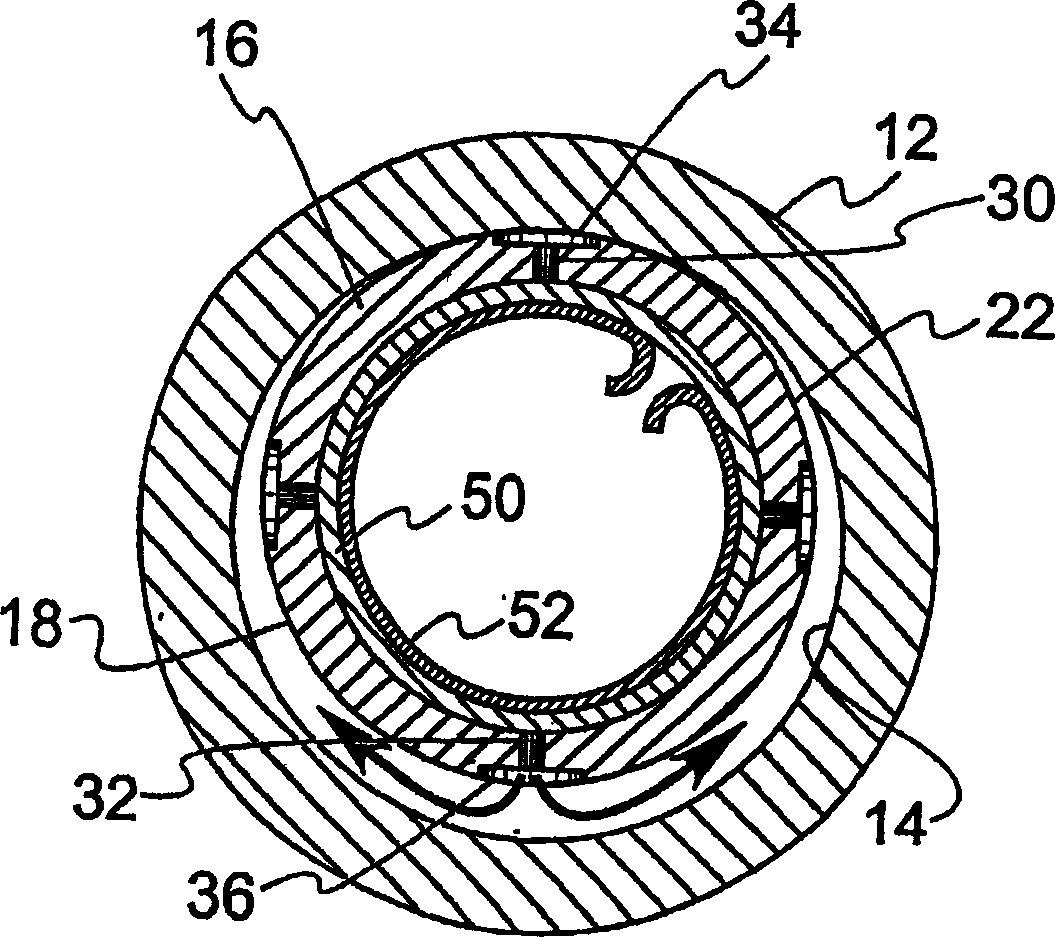

A gas restrictor particularly useful for application in gas bearings as used, for example, in free-piston Stirling cycle machinery. Porous strip material (52) together with a backing plate (60) and orifice (32) is used to provide the restriction to the flow of gas into an annular gap (22) between a piston (16) and a cylinder (12).

Owner:GLOBAL COOLING

System and method for monitoring and control

The invention provides for the monitoring and control of a system, such as a linear electro-mechanical transducer, e.g. a linear electric motor, particularly when driven in a reciprocating manner. A dynamic model of the linear motor and its load is used to calculate from the input drive to the motor a predicted response of the motor. The predicted response is compared to a measured response and the model parameters are varied by global optimisation until the two match as closely as desired. The drive may be the voltage input to the electrical motor and the response may be the electrical current in the motor coils. The parameters and variables of the model, after optimisation, can be taken as good estimates of the actual operating parameters and variables of the linear motor. This gives a measurement of such quantities as the stoke and offset of the linear motor. The invention is particularly applicable to the use of linear motors to drive compressors, for instance in Stirling cycle coolers. The system can be applied to balanced pairs of compressors and to compressor systems which use an active balancer to cancel vibration in the system. In this case a balancer model is created and used in an analogous way to the motor model.

Owner:OXFORD UNIV INNOVATION LTD

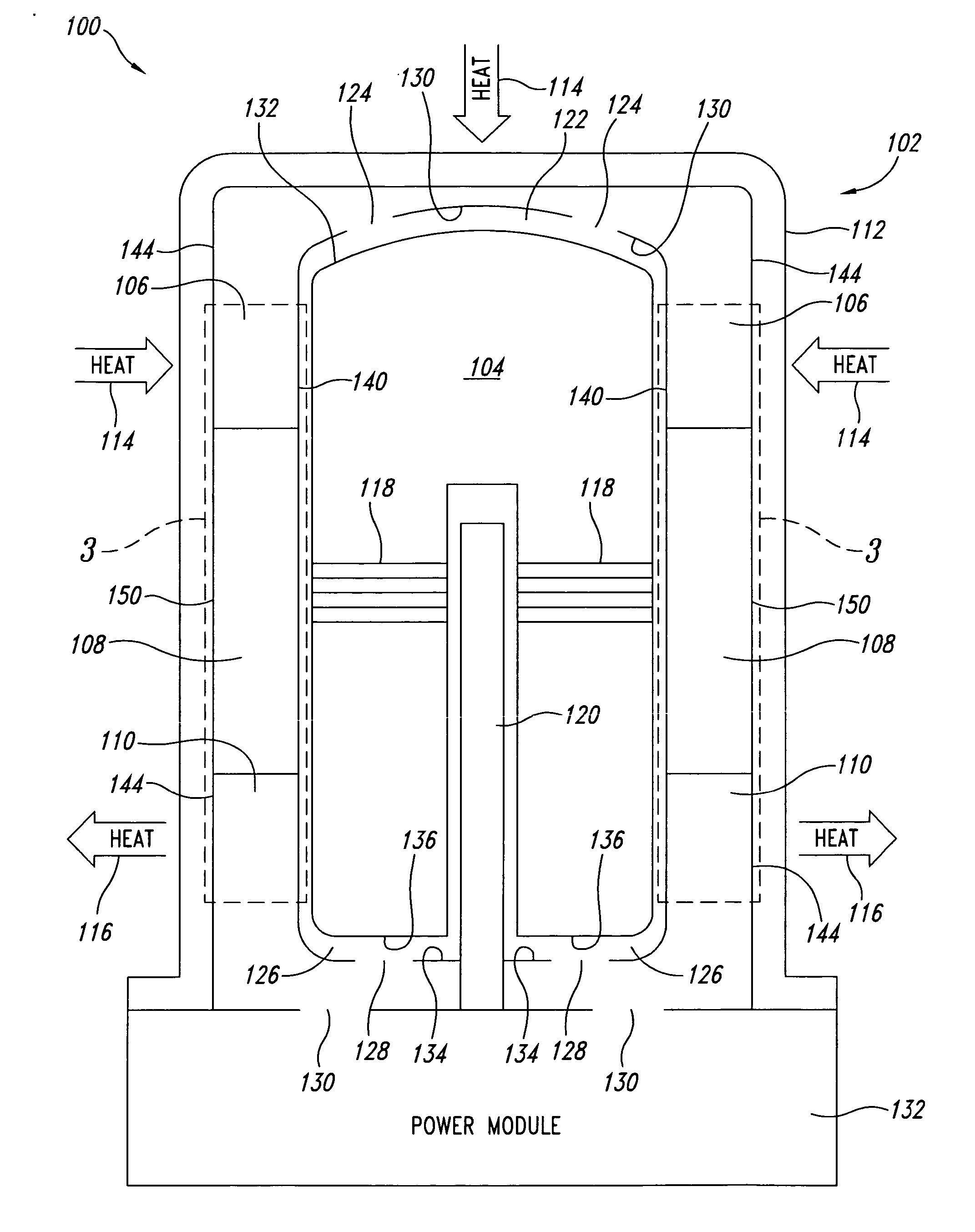

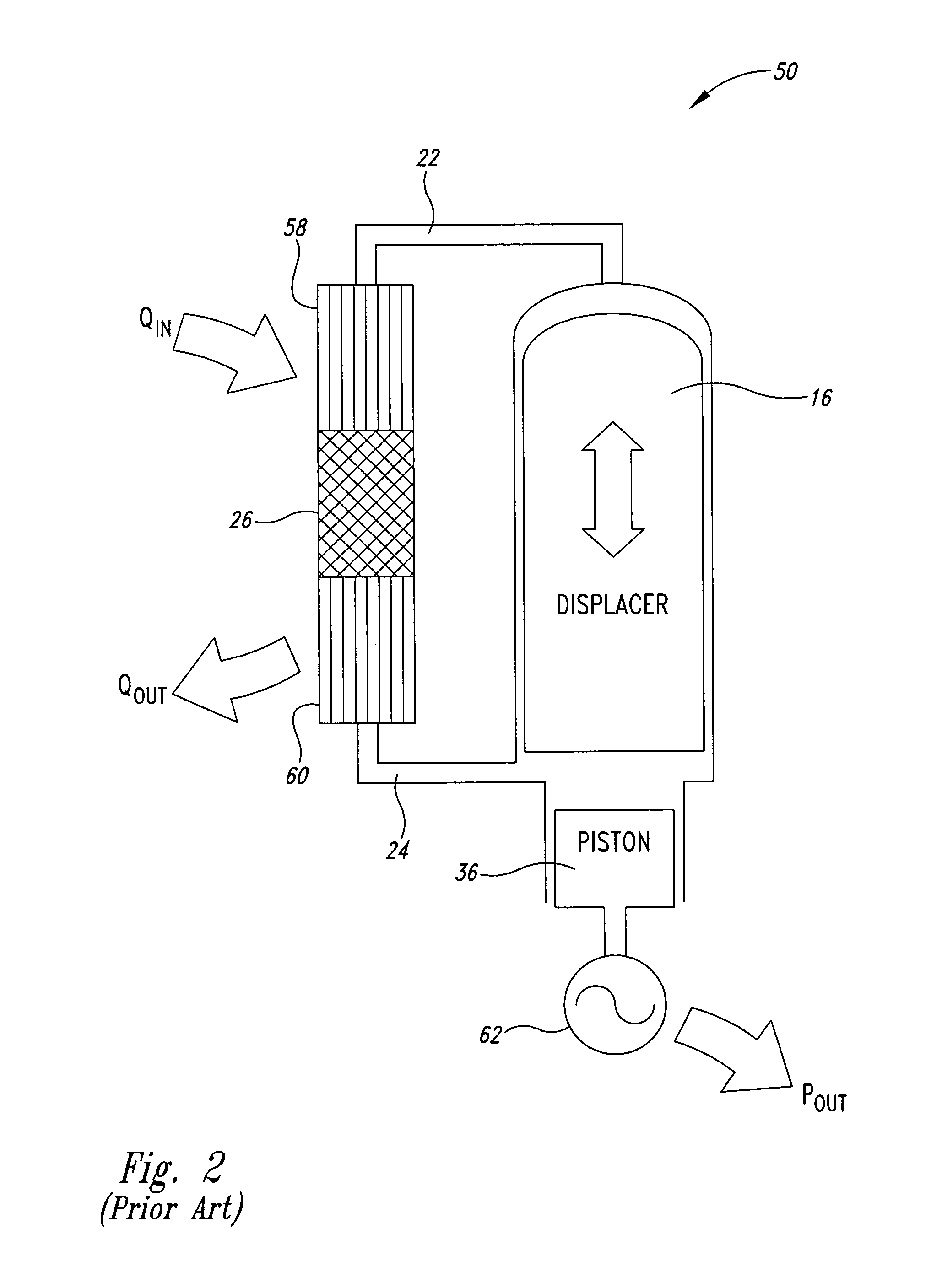

Stirling cycle transducer for converting between thermal energy and mechanical energy

ActiveUS20120159943A1Reduce mechanical stressStirling type enginesClosed-cycle gas positive displacement engine plantThermal energyReciprocating motion

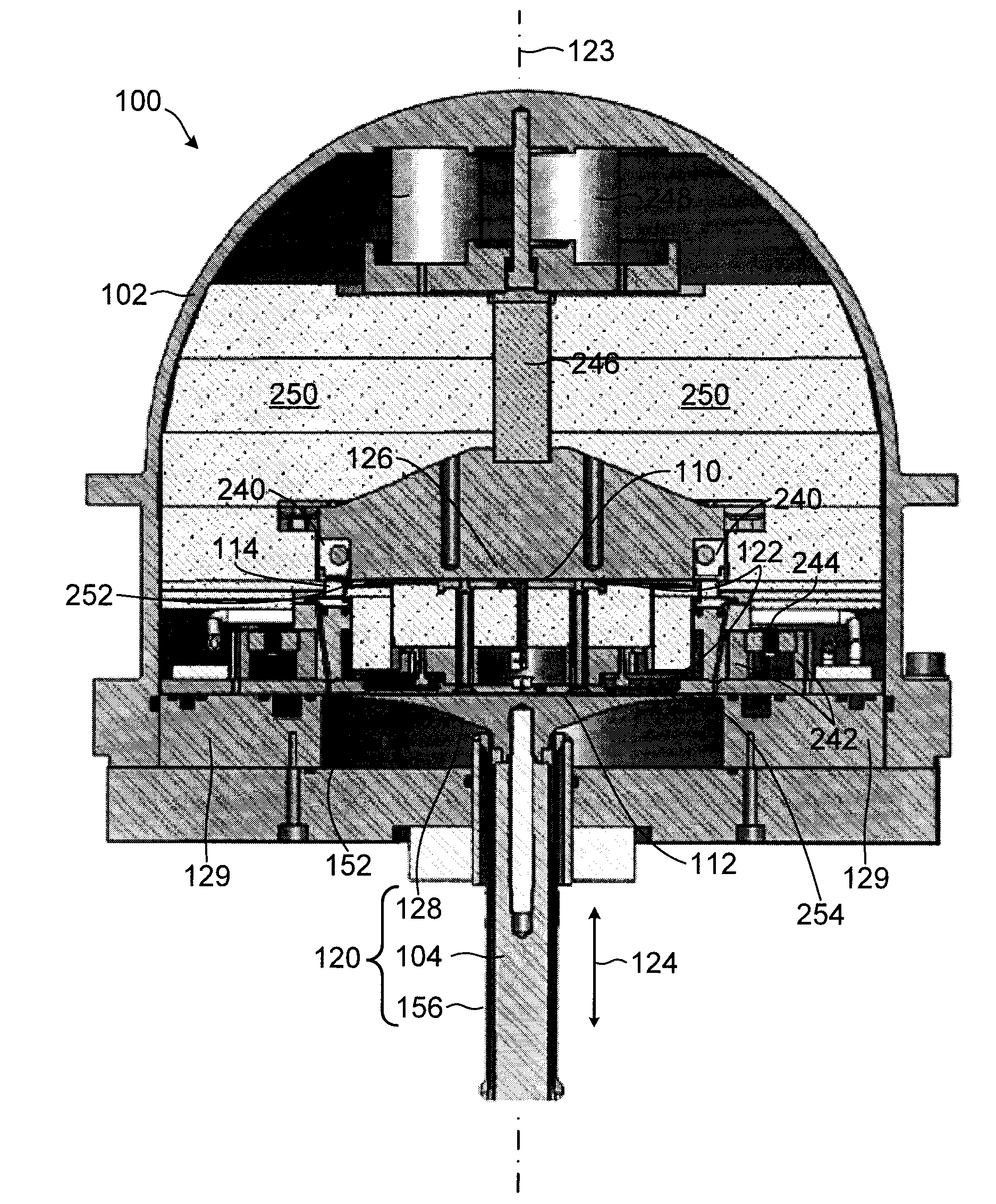

The apparatus includes a housing, a compression chamber disposed in the housing and having at least a first interface operable to vary a volume of the compression chamber, an expansion chamber disposed in the housing and having a second interface operable to vary a volume of at least the expansion chamber, and a thermal regenerator in fluid communication with each of the compression chamber and the expansion chamber. The thermal regenerator is operable to alternatively receive thermal energy from gas flowing in a first direction through the regenerator and to deliver the thermal energy to gas flowing in a direction opposite to the first direction through the regenerator. The compression chamber, the expansion chamber, and the regenerator together define a working volume for containing a pressurized working gas. Each of the first and second interfaces are configured for reciprocating motion in a direction aligned with a transducer axis, the reciprocating motion being operable to cause a periodic exchange of working gas between the expansion and the compression chambers. In one aspect, at least one of the first and second interfaces includes a resilient diaphragm, and a cylindrical tube spring coupled between the diaphragm and the housing, the tube spring being configured to elastically deform in a direction generally aligned with the transducer axis in response to forces imparted on the tube spring by the diaphragm to cause the at least one of the first and second interfaces to have a desired natural frequency. In another aspect the apparatus includes a first heat exchanger in communication with the expansion chamber, a second heat exchanger in communication with the compression chamber, the thermal regenerator is disposed between the first and second heat exchangers, and each of the first and second heat exchangers are peripherally disposed within the housing with respect to the transducer axis and configured to receive working gas flowing to or from the respective chambers and to redirect the working gas flow through the regenerator.

Owner:ETALIM

Temperature conditioning apparatus for the trunk of a human body

InactiveUS20050066401A1Domestic cooling apparatusMachines using electric/magnetic effectsHuman bodyHot weather

A temperature conditioning apparatus for the human body includes a vest or other clothing unitary with a thermoelectric or Stirling cycle heat pump worn by the user. The unit is powered by a battery source worn on the user's belt or other part of his or her body, or by an externally-mounted electrical energy source, for example, in a vehicle. The vest has front and rear panels with an air flow layer and permeable inside layer that accept and release conditioned air to the user. The vest may be used with body armor or other protective layers, that is, the vest may be worn underneath body armor or body armor may be built into the vest, or the vest may be used without body armor to cool the user in an exceptionally hot environment such as a non-air conditioned space in hot weather.

Owner:FEHER STEVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com