Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1661 results about "Octene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Octene is an alkene with the formula C 8H 16. Several isomers of octene are known, depending on the position and the geometry of the double bond in the carbon chain. The simplest isomer is 1-octene, an alpha-olefin used primarily as a co-monomer in production of polyethylene via the solution polymerization process. Several useful structural isomers of the octenes are obtained by dimerization of isobutene and 1-butene. These branched alkenes are used to alkylate phenols to give precursors to detergents.

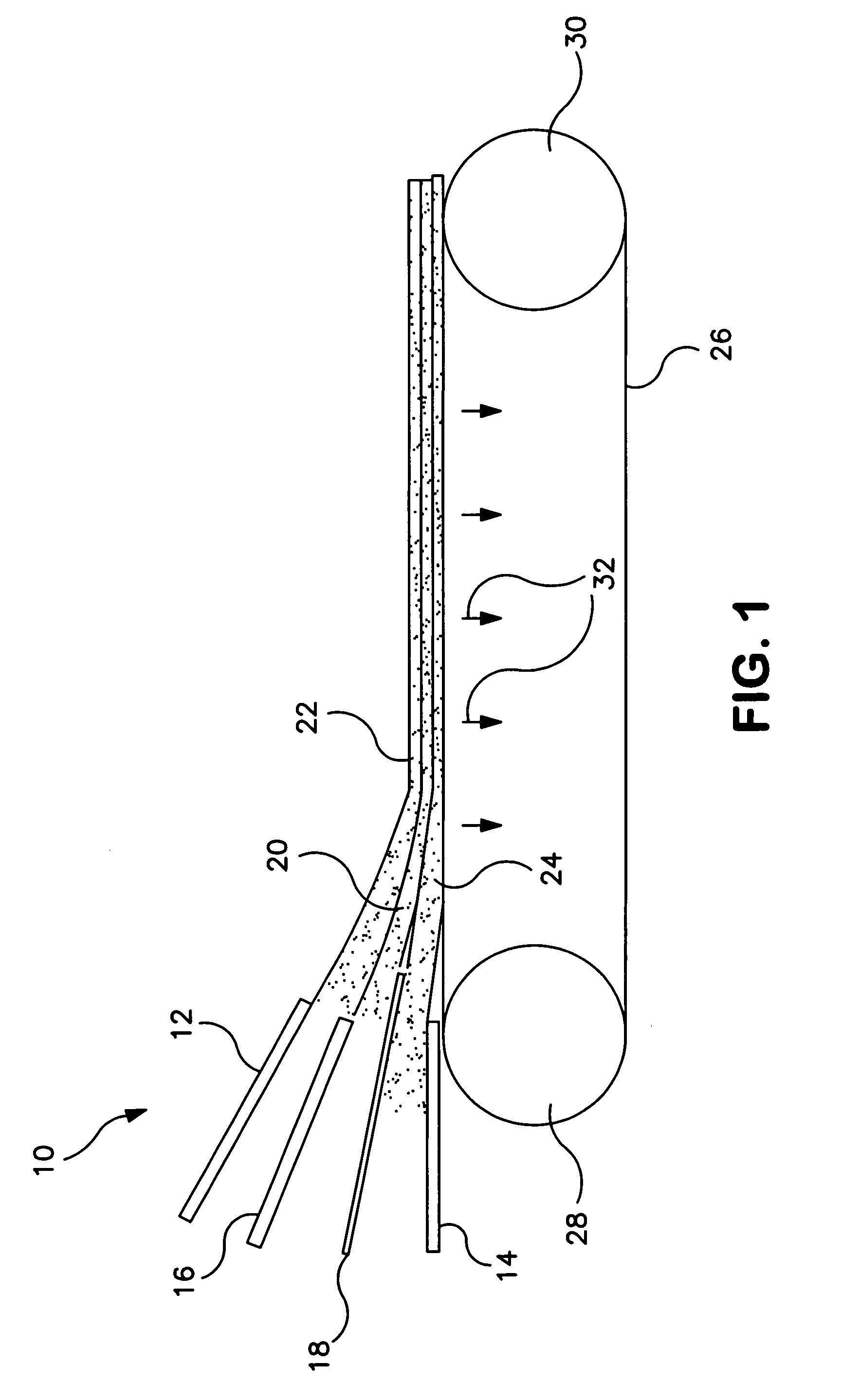

Embossed tissue products

InactiveUS20070137813A1Preserve strengthHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberPolymer science

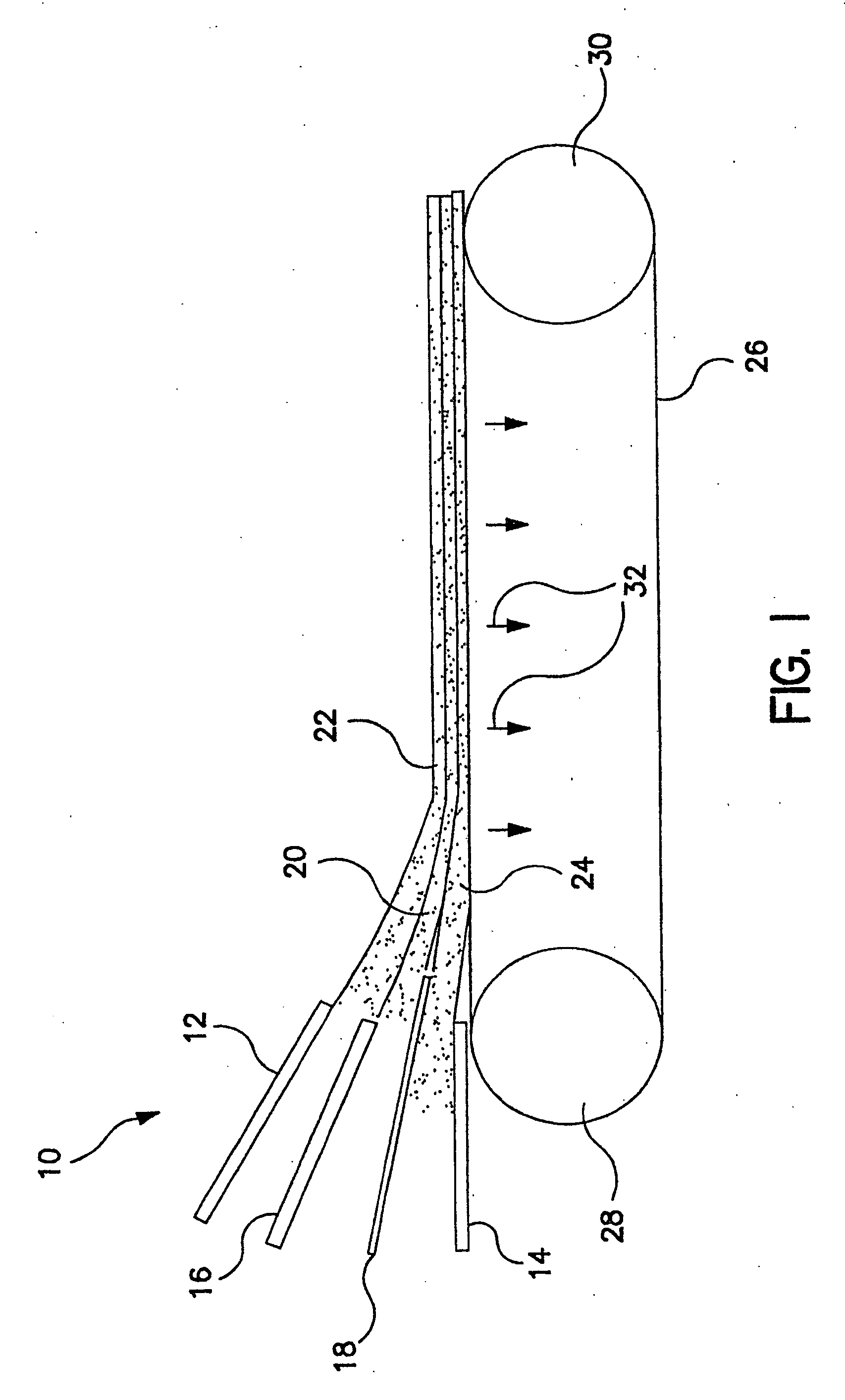

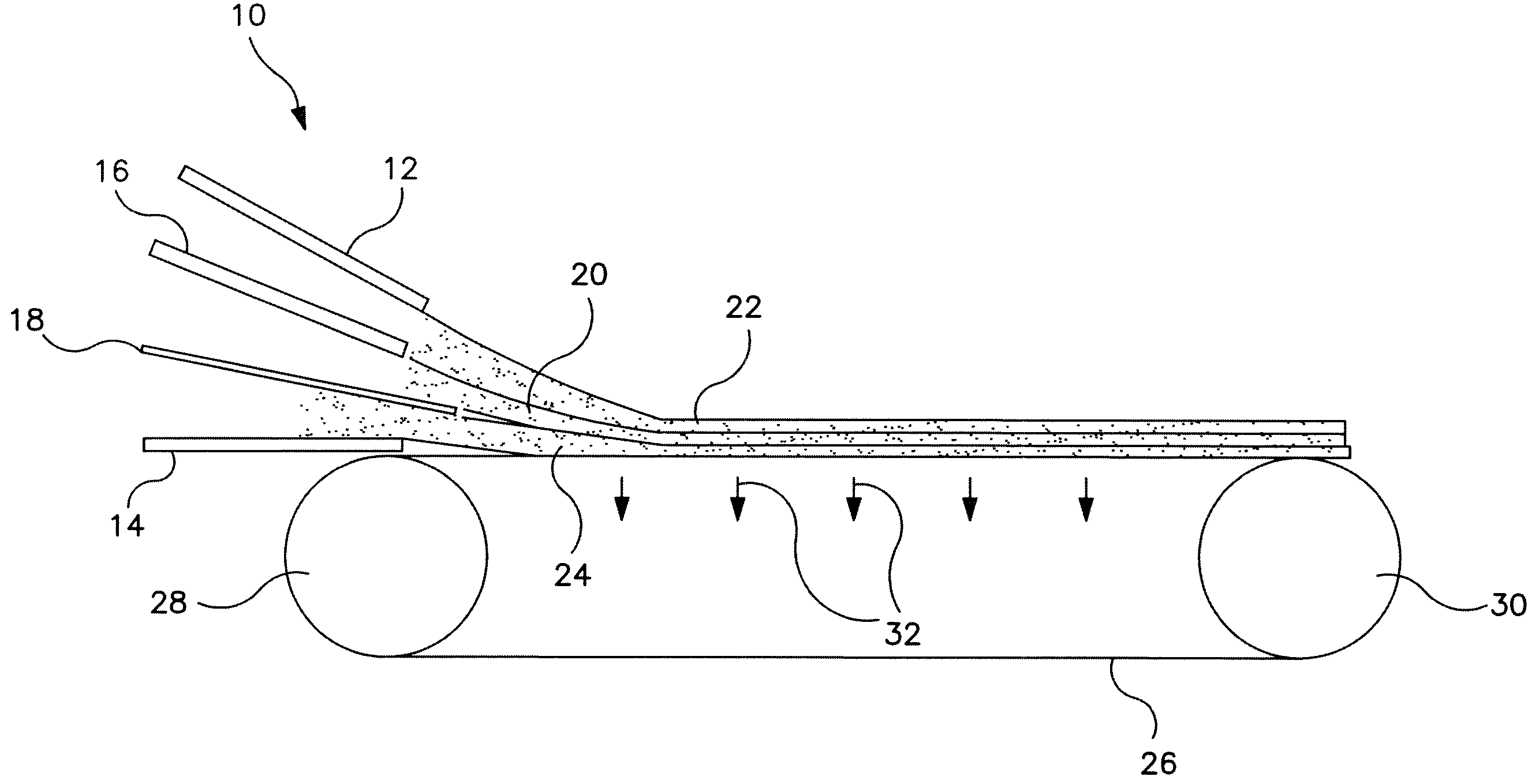

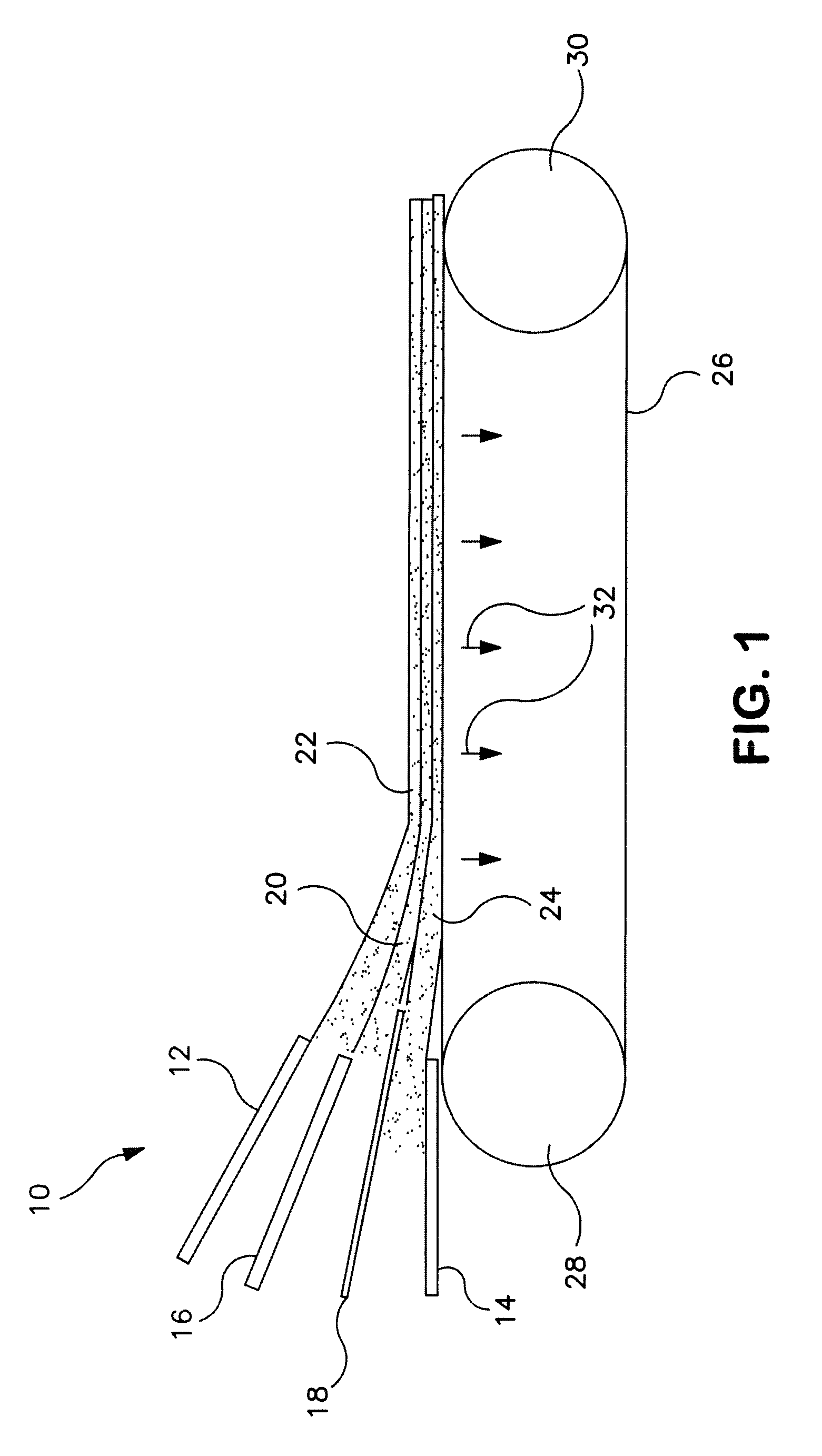

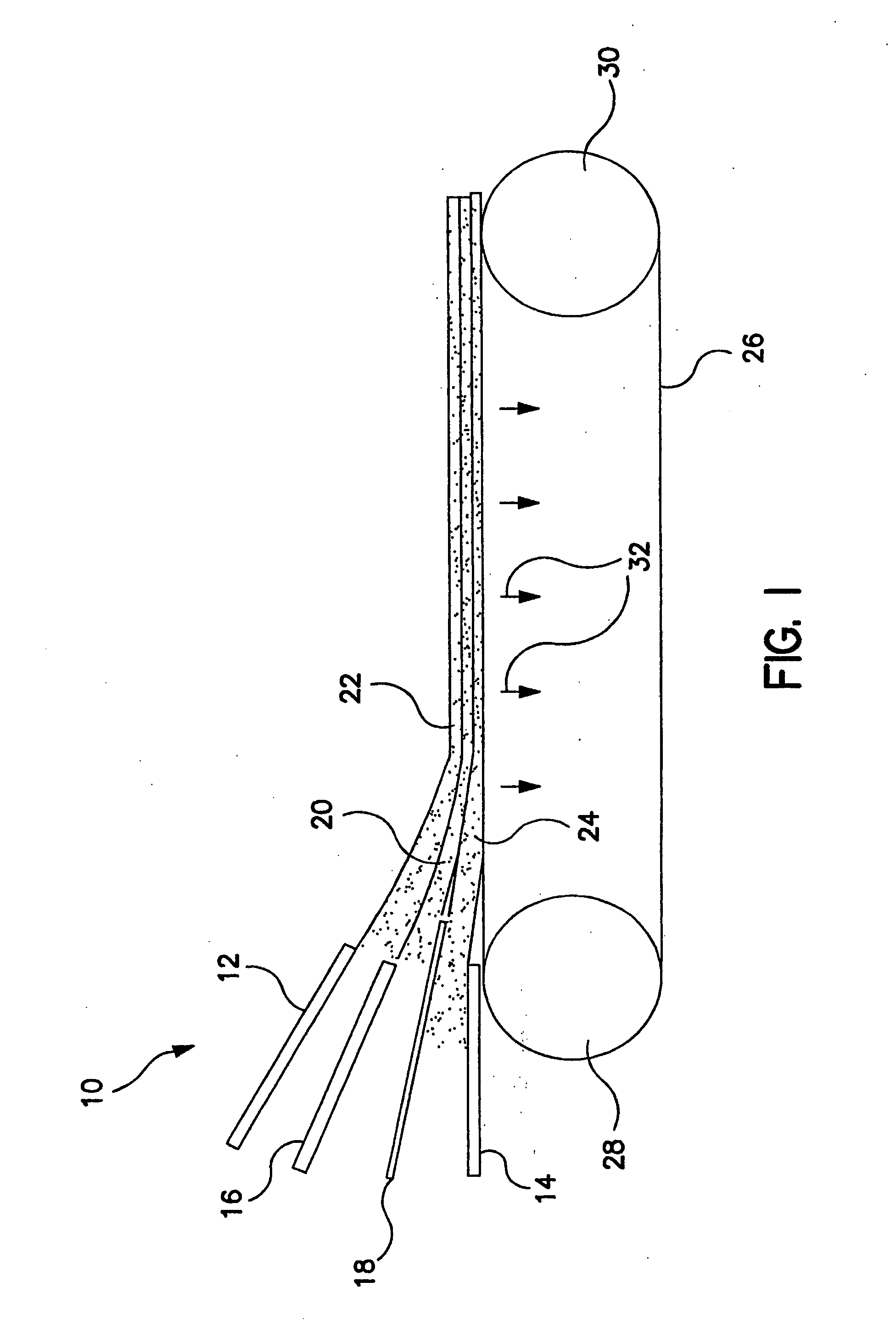

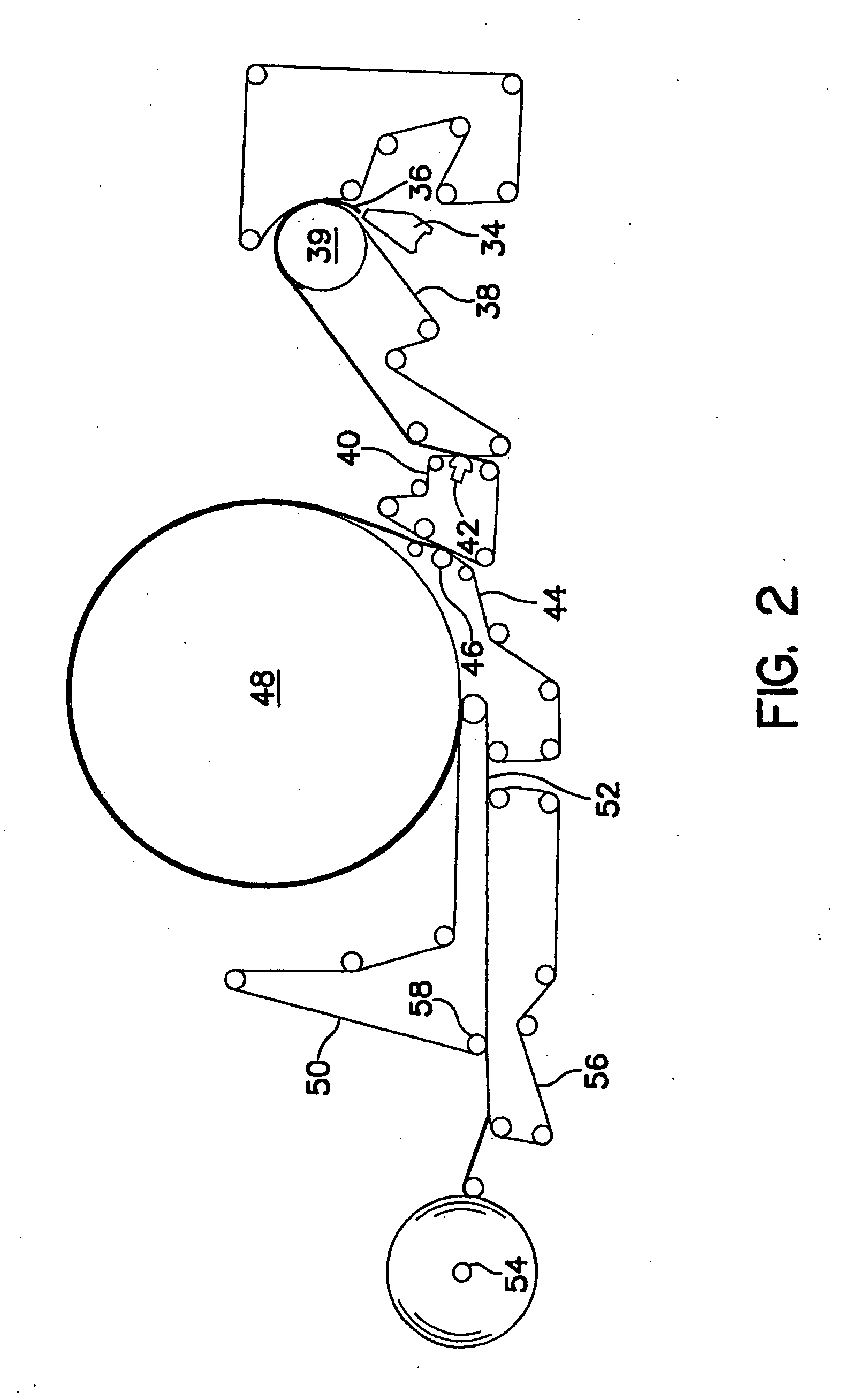

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. After the additive composition is applied to the web or otherwise incorporated into the tissue web, the tissue web is embossed. During embossing, the additive composition forms well defined embossments in the web that are water resistant. In one embodiment, the additive composition may also be used to bond multiple tissue webs together to form a multiple ply product during the embossing operation.

Owner:KIMBERLY-CLARK WORLDWIDE INC

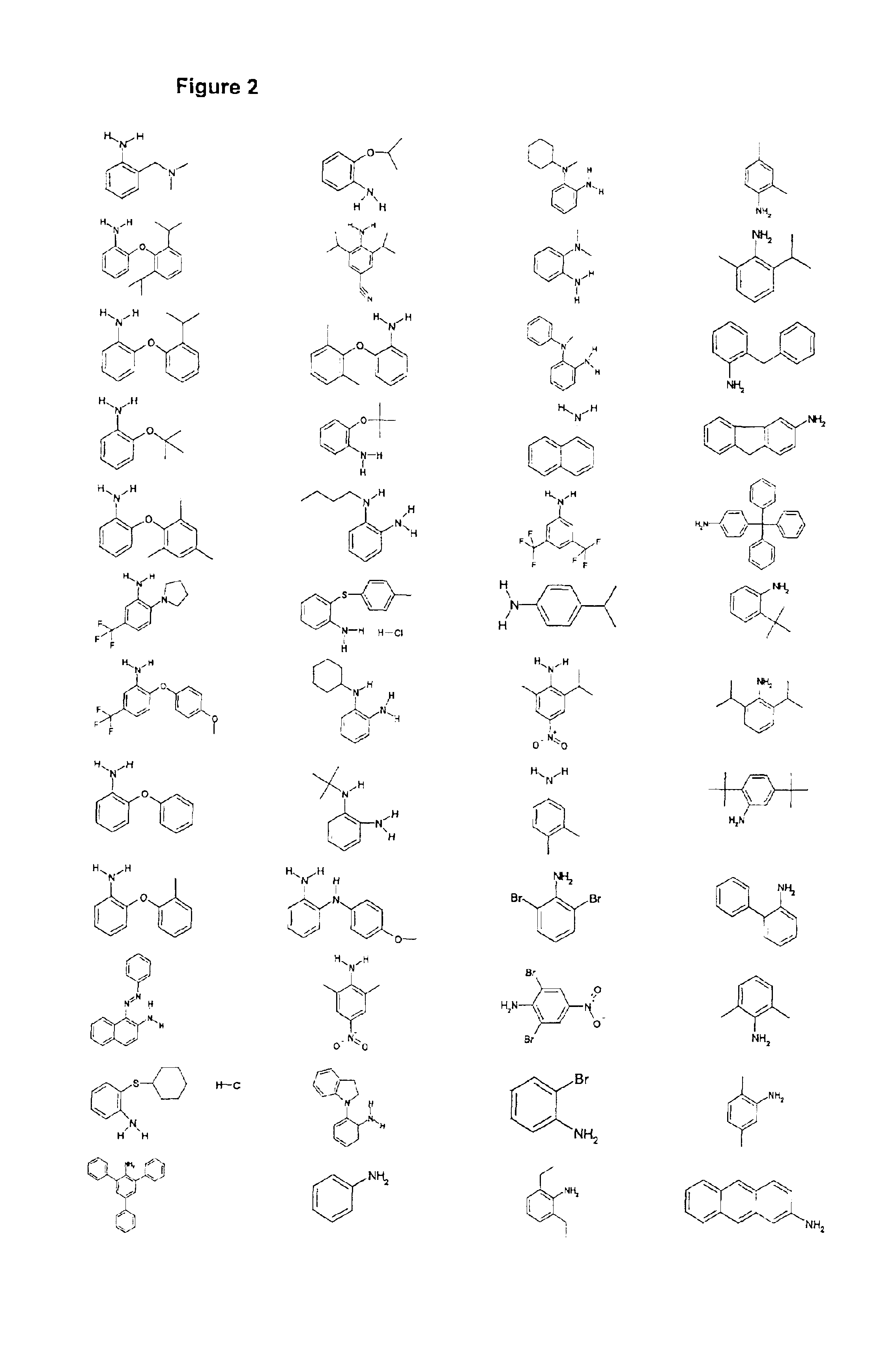

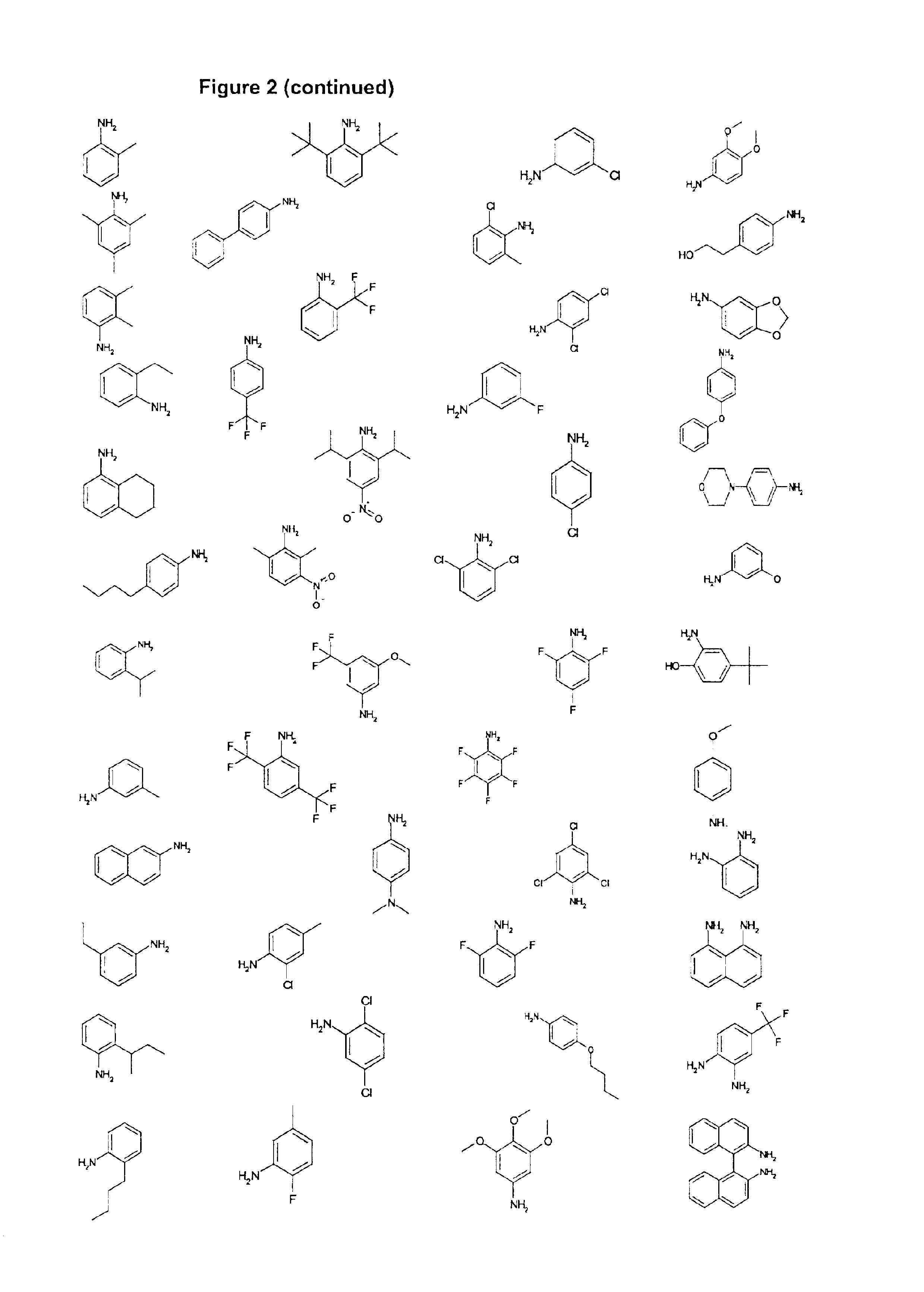

Substituted pyridyl amine complexes, and catalysts

InactiveUS6900321B2Improve catalytic performanceIncrease temperatureSilicon organic compoundsMacromolecular libraries1-OcteneHafnium

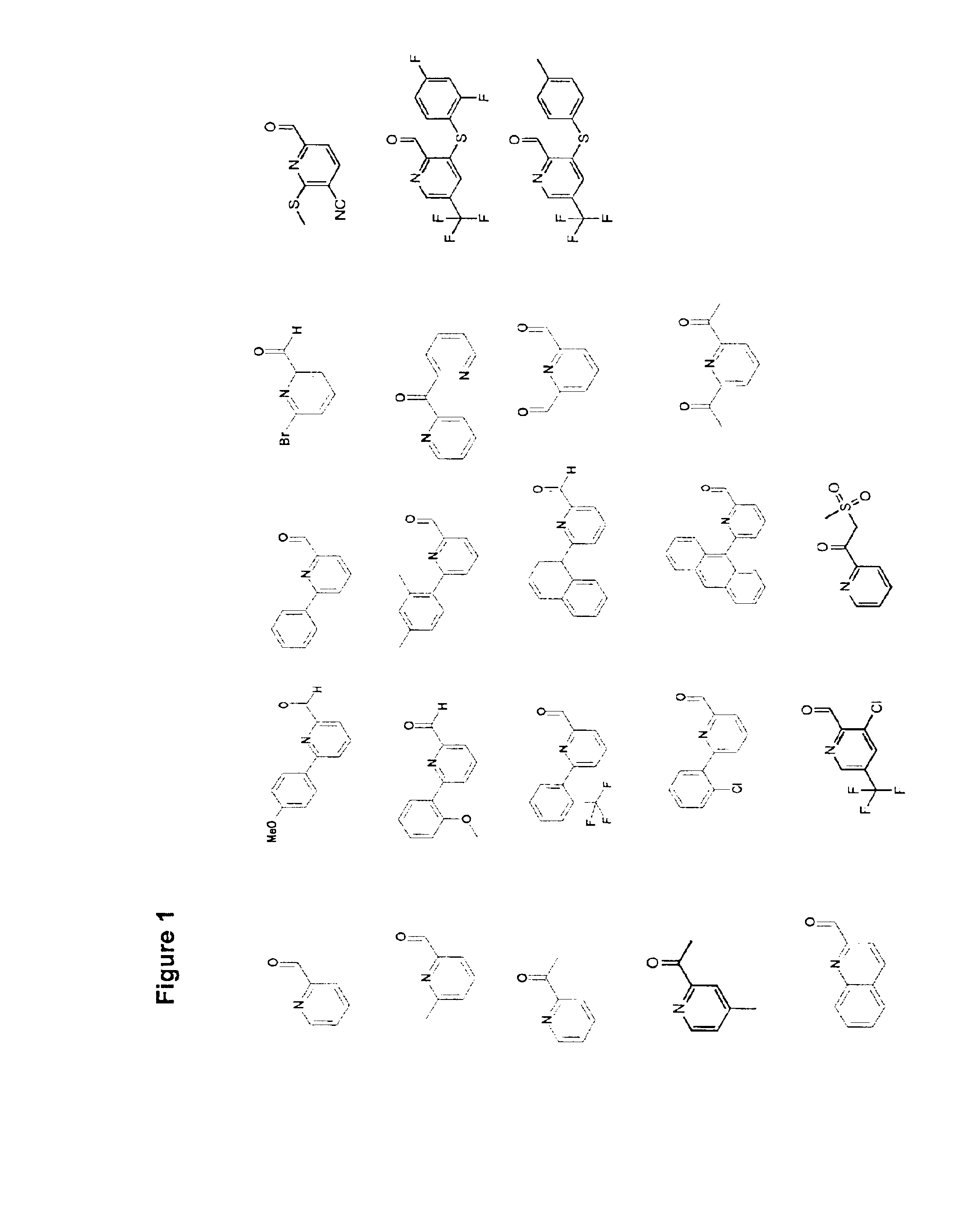

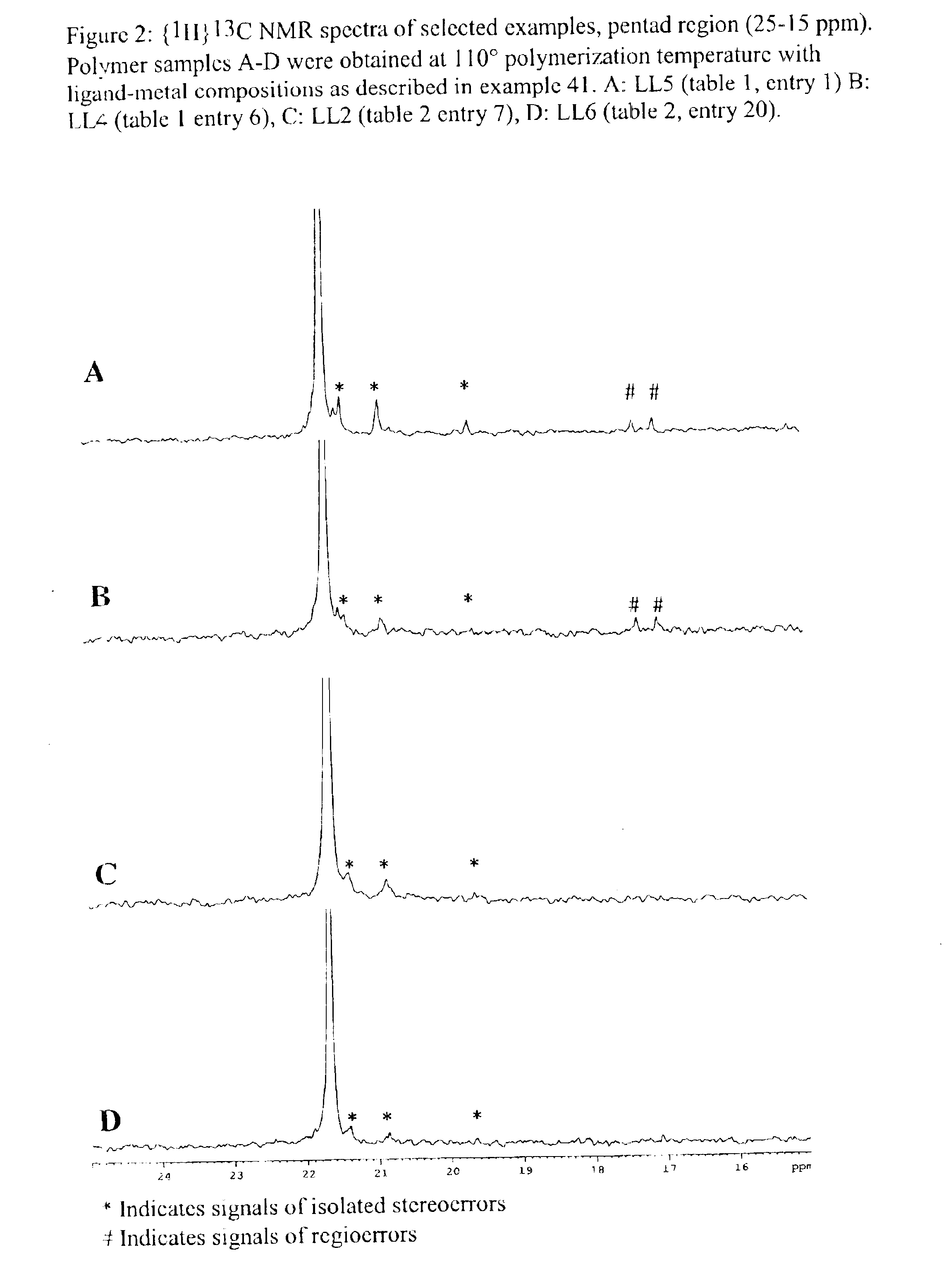

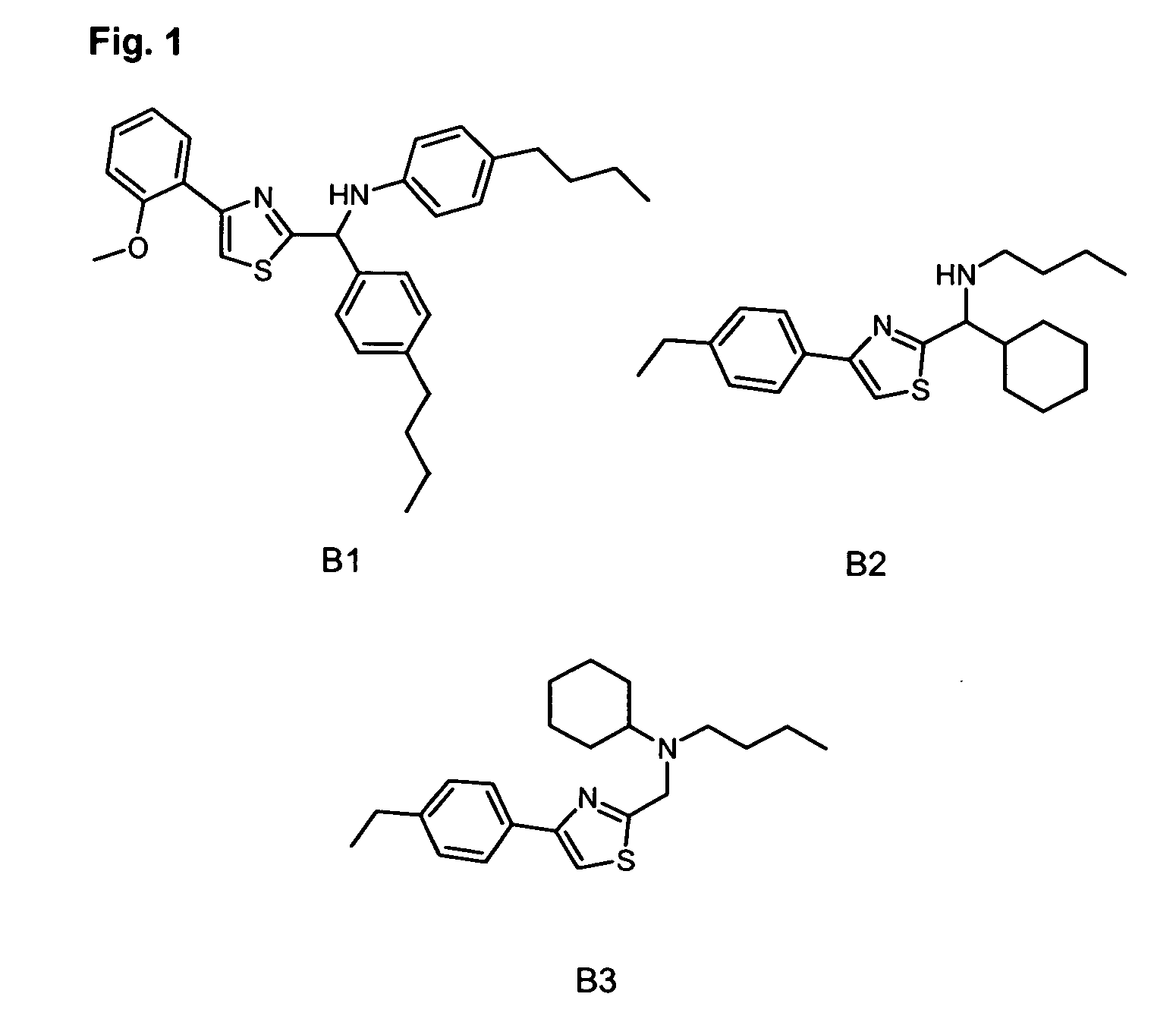

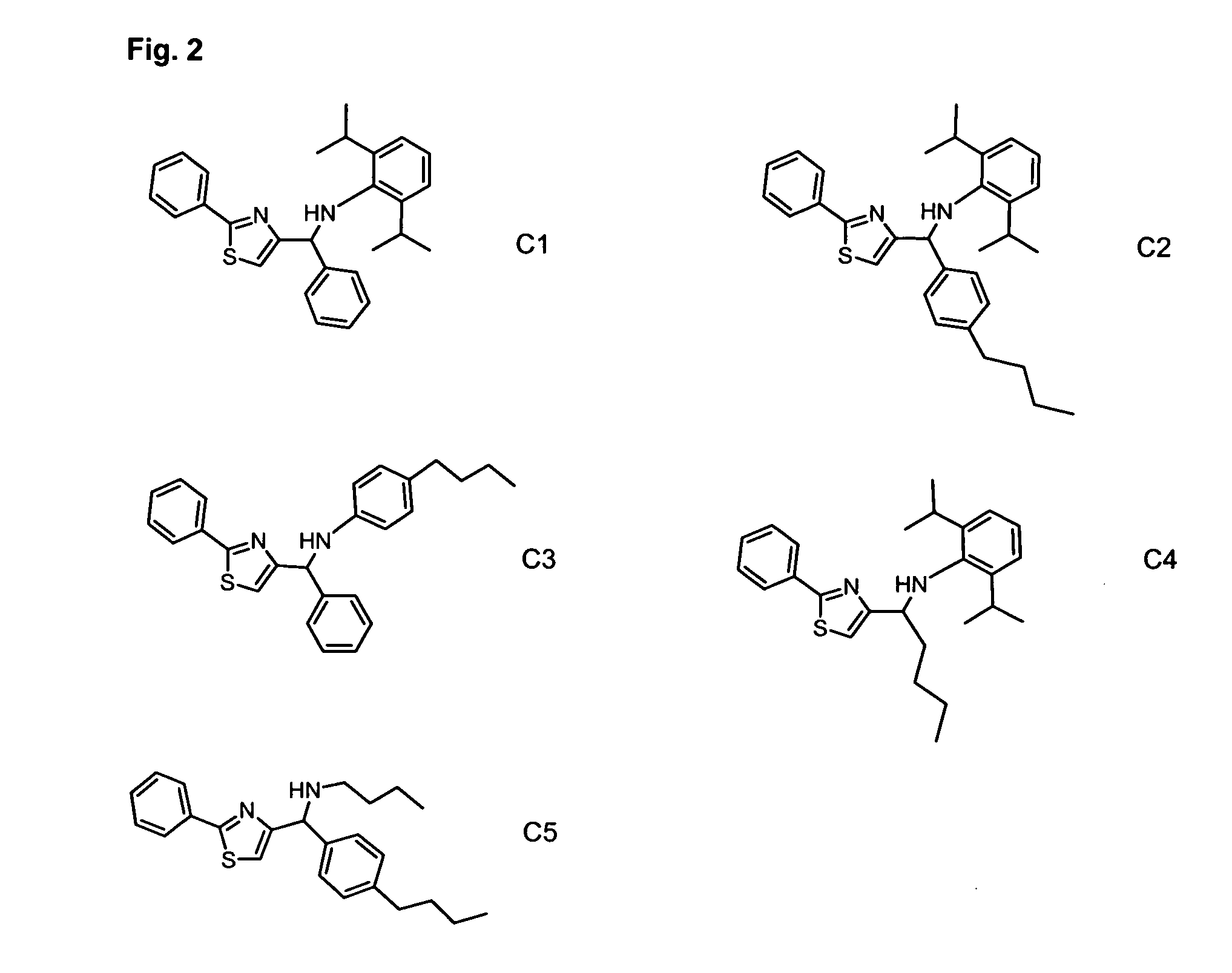

New ligands, compositions, metal-ligand complexes and arrays with pyridylamine ligands are disclosed that catalyze the polymerization of monomers into polymers. Certain of these catalysts with hafnium metal centers have high performance characteristics, including higher comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, isobutylene or styrene. Certain of the catalysts are particularly effective at polymerizing propylene to high molecular weight isotactic polypropylene in a solution process at a variety of polymerization conditions.

Owner:FREESLATE

Ionomer/rubber/polyolefin blend and uses thereof

A thermoplastic ionomer blend or alloy exhibiting advantageous properties upon molding or extrusion and / or thermoforming, consisting essentially of the following components:A. about 15 to 85 parts by weight of a thermoplastic copolymer containing about 91 to 80 weight percent of alpha-olefin units and about 9 to 20 weight percent of alpha, beta-ethylenically unsaturated carboxylic acid units said carboxylic acid units being about 20 to 90 percent neutralized with metal ions, preferably zinc,B. about 10 to 80 parts by weight of a rubber, preferably a thermoplastic elastomer selected from the group consisting of (a) crosslinked ethylene-propylene-diene copolymers and equivalent polyolefin copolymers such as ethylene-butene, hexene, or octene, (b) acrylonitrile-butadiene copolymers, (c) styrene-butadiene copolymers, and (d) styrene acrylonitrile graft-crosslinked butadiene rubbers, andC. about 5 to 40 parts by weight of a thermoplastic polymer selected from the group consisting of polyethylene and polypropylene copolymers and homopolymers, the total number of parts being 100,and molded or extruded and / or thermoformed products produced from the same.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

Tandem tetramerisation-polymerisation of olefins

InactiveUS20060128910A1Improve catalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OctenePolyolefin

The invention provides a process for polymerising olefins to branched polyolefins in the presence of a polymerisation catalyst and a cocatalyst, wherein the cocatalyst produces 1-octene in a selectivity greater than 30%.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

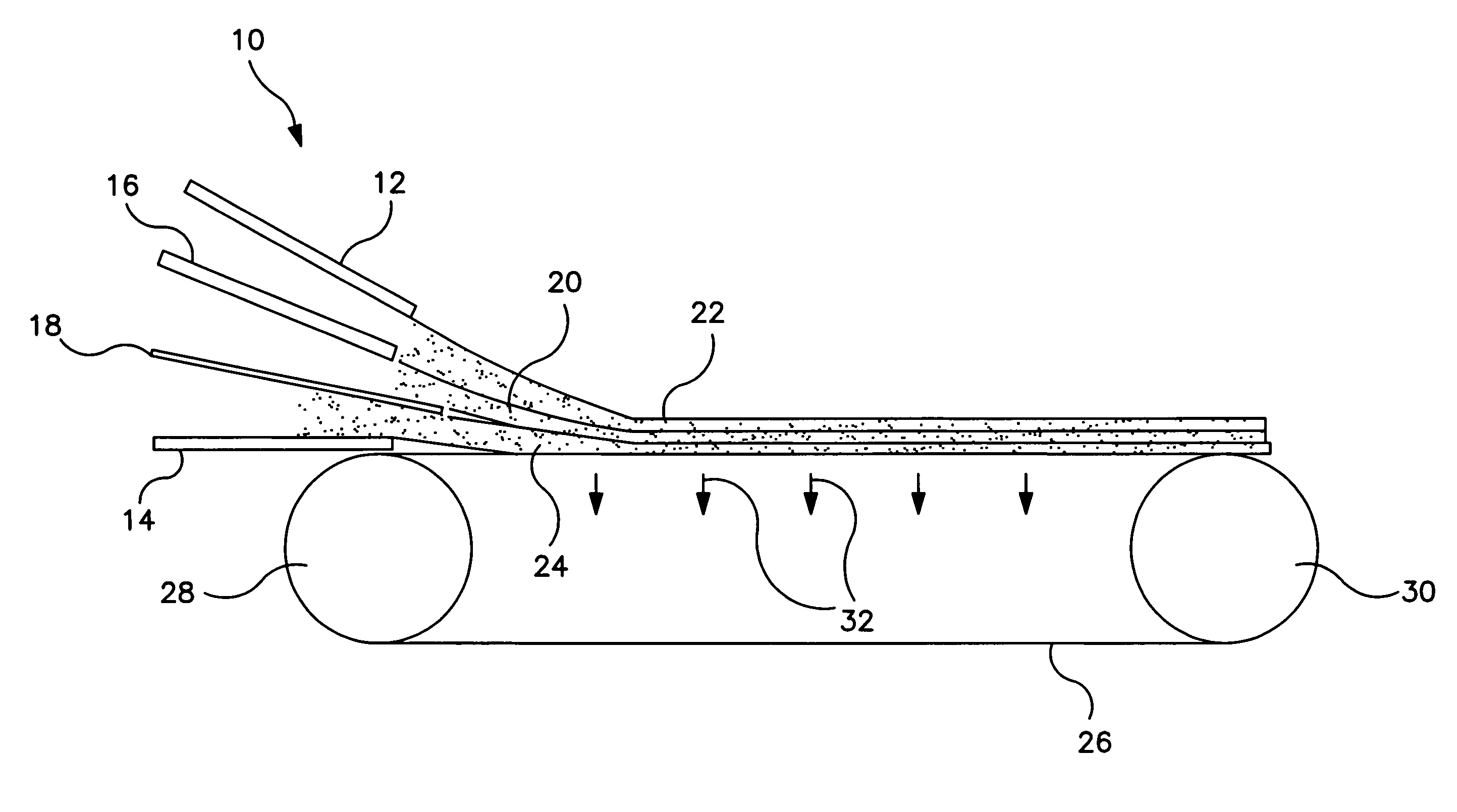

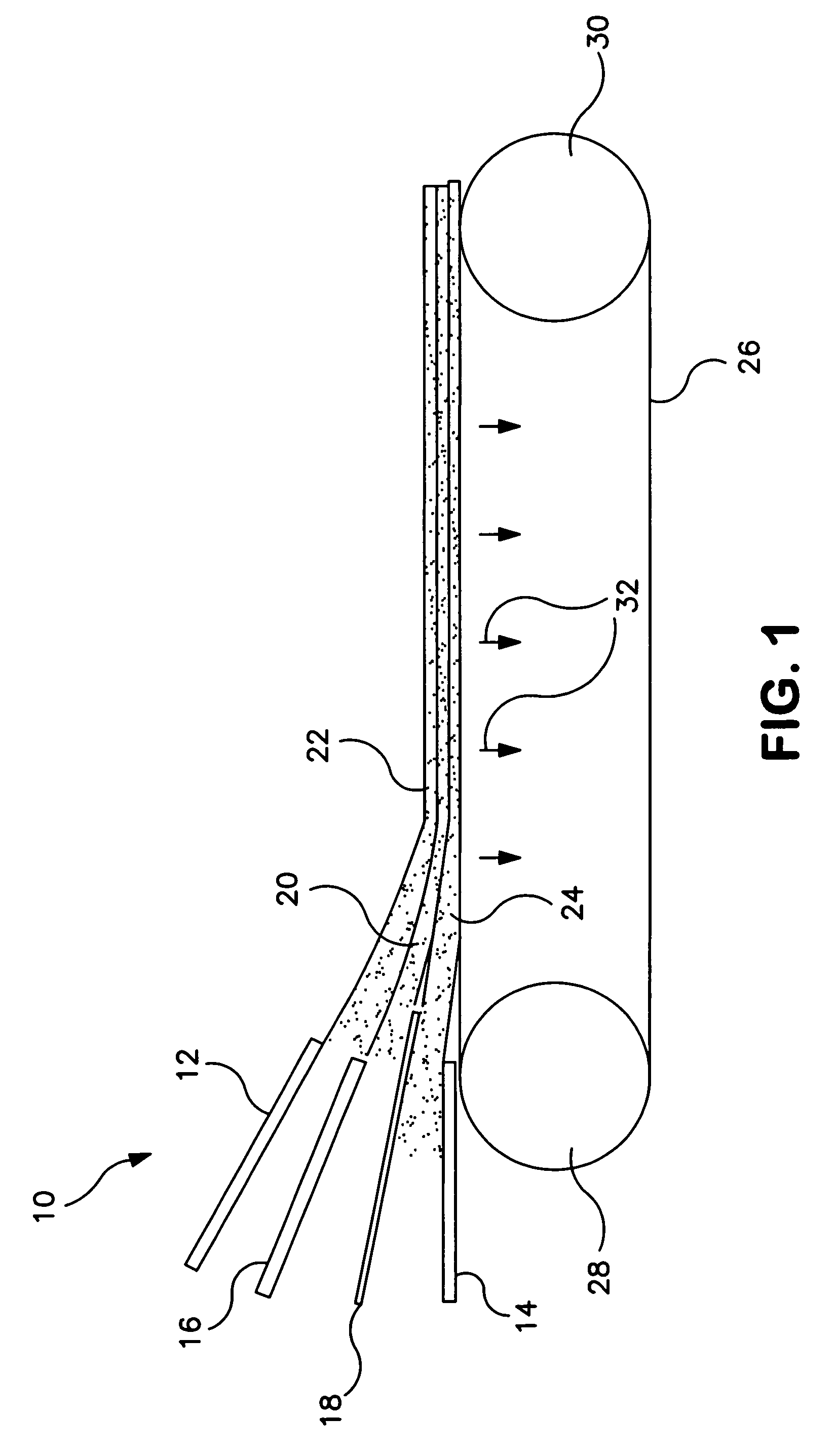

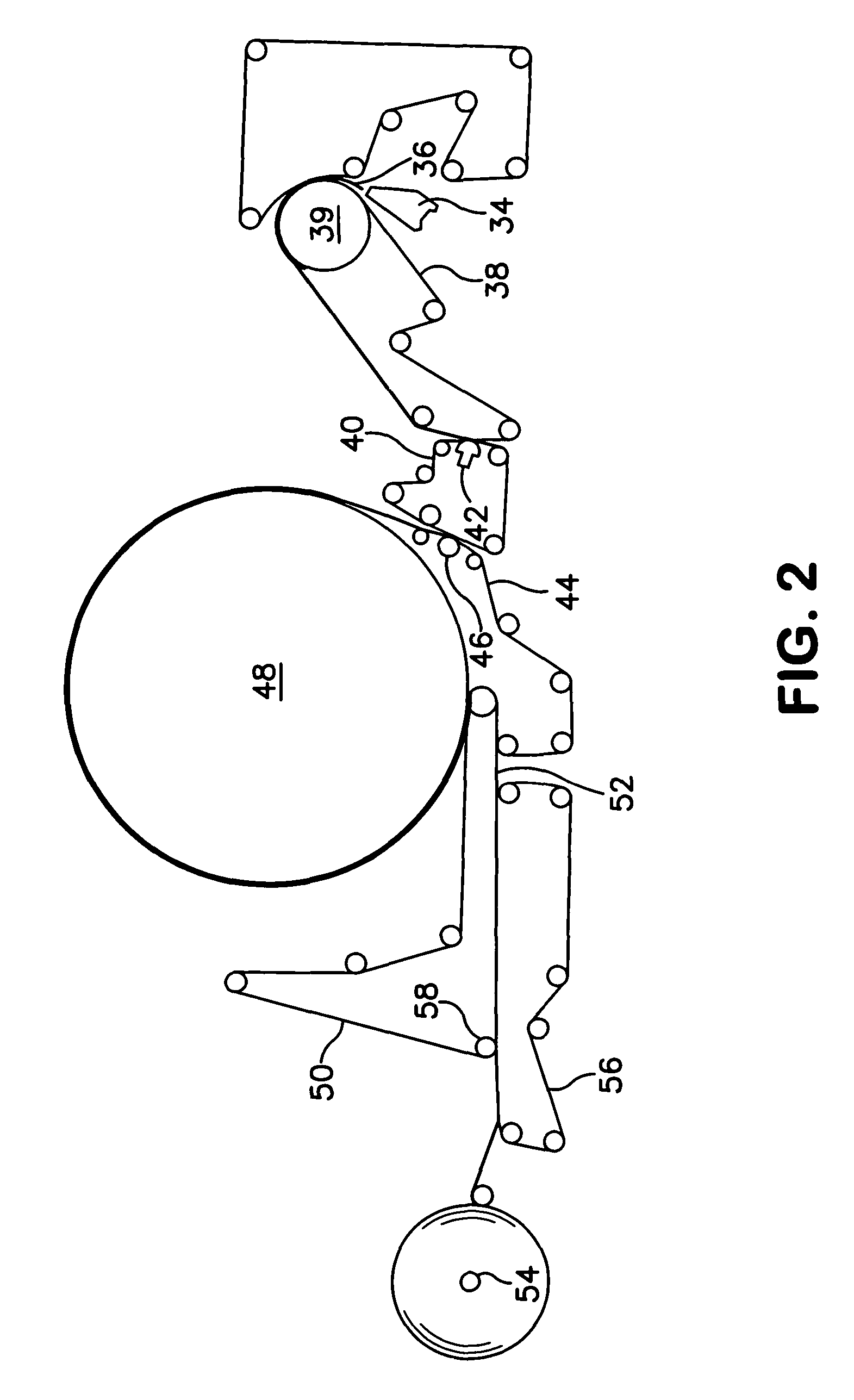

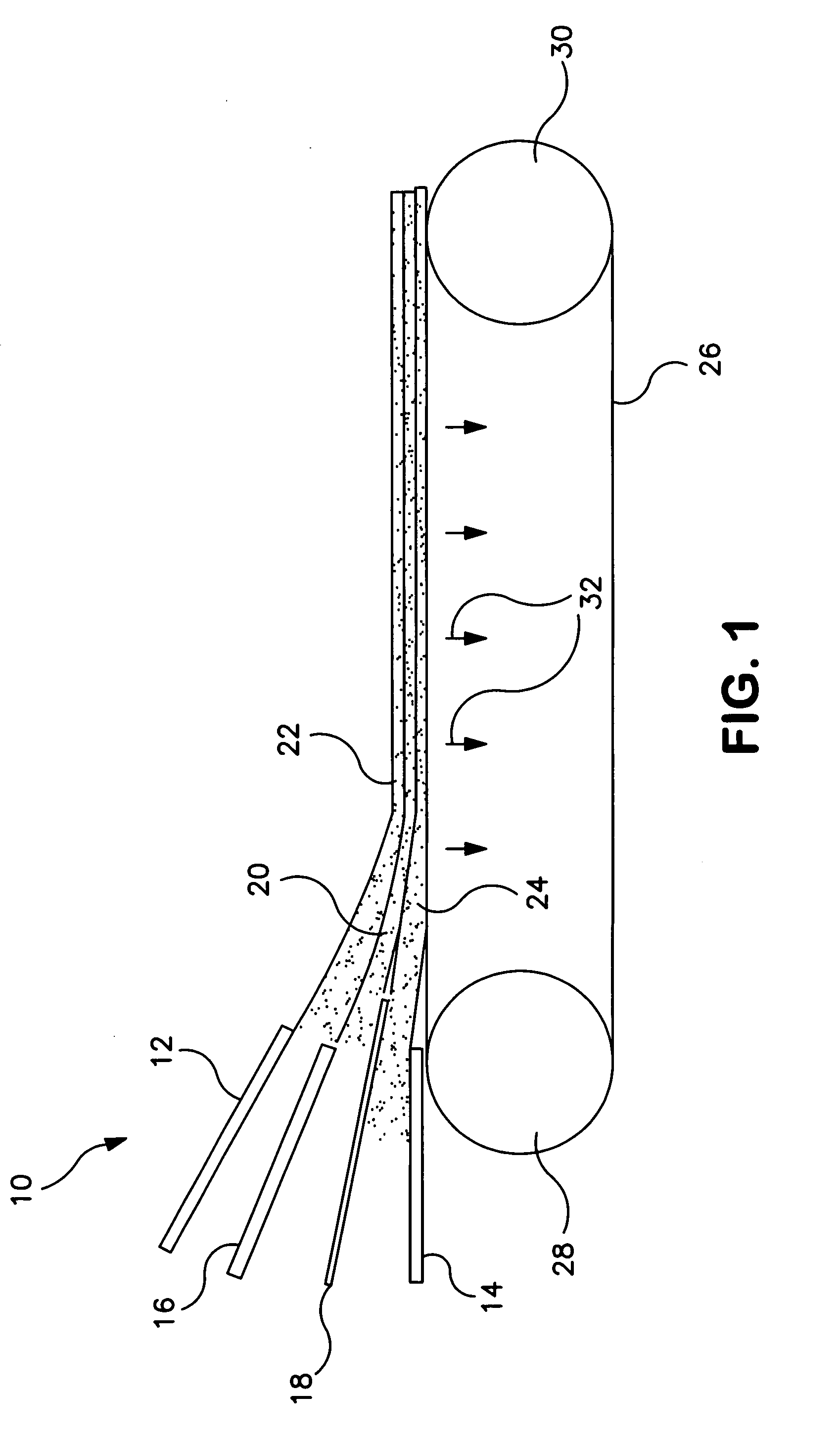

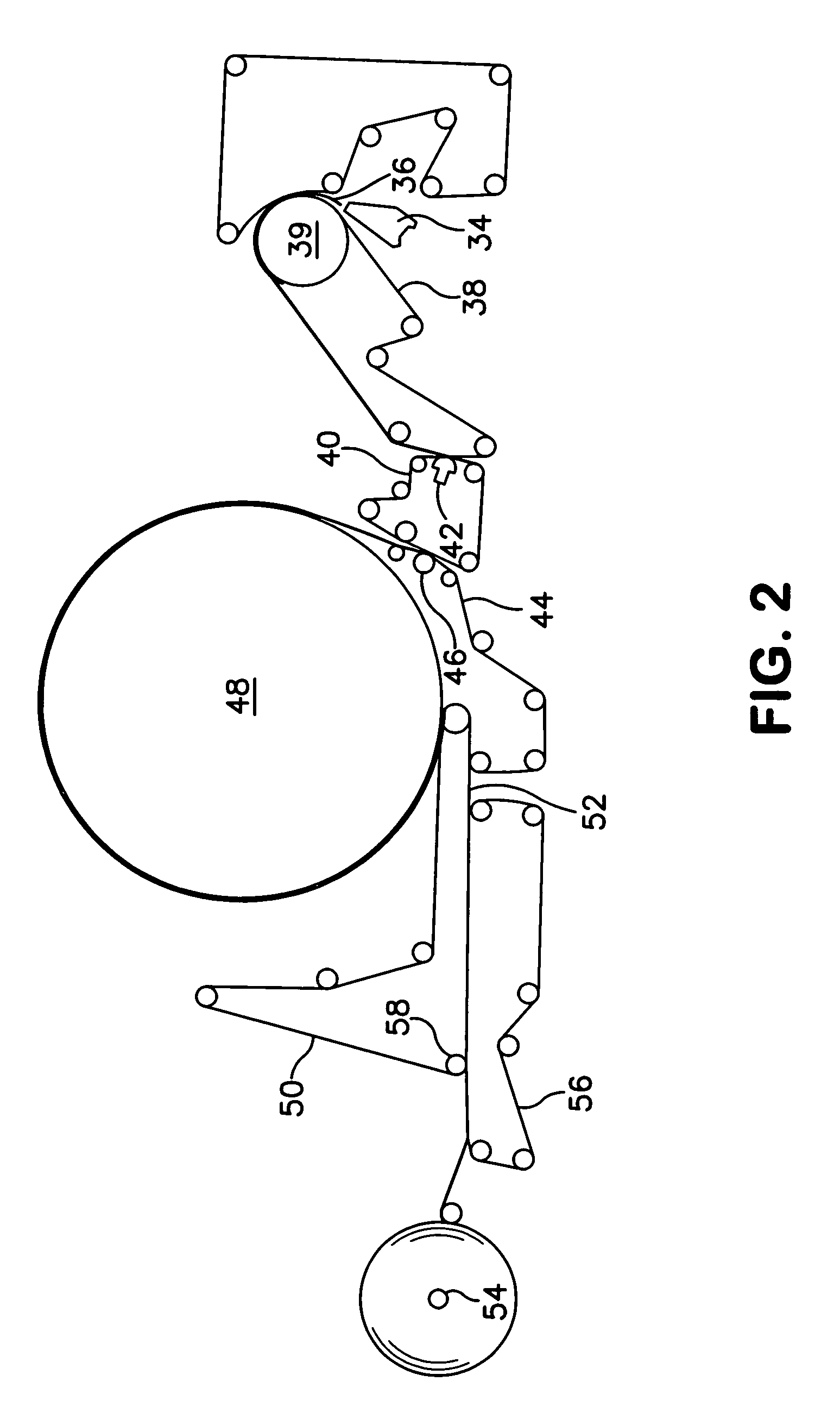

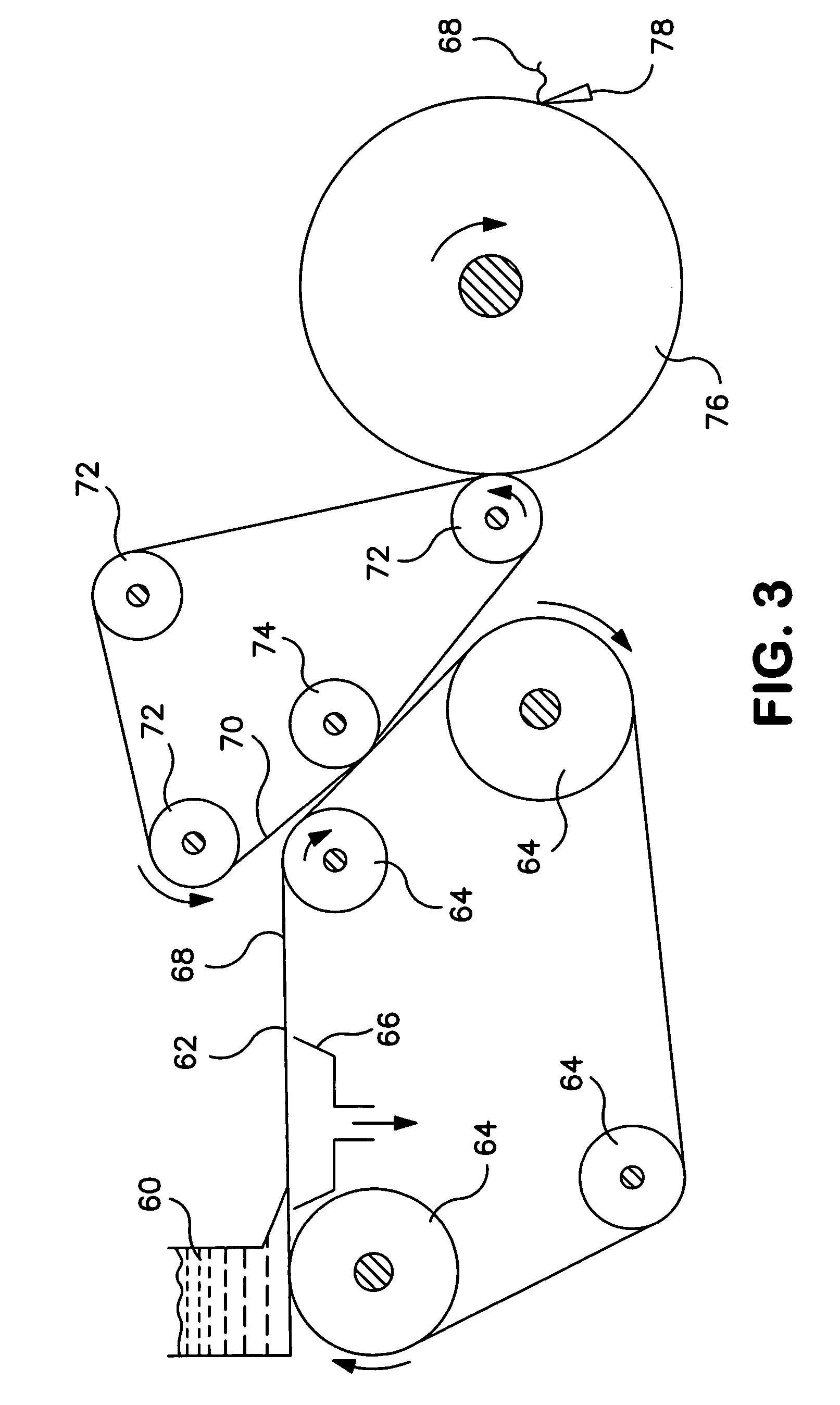

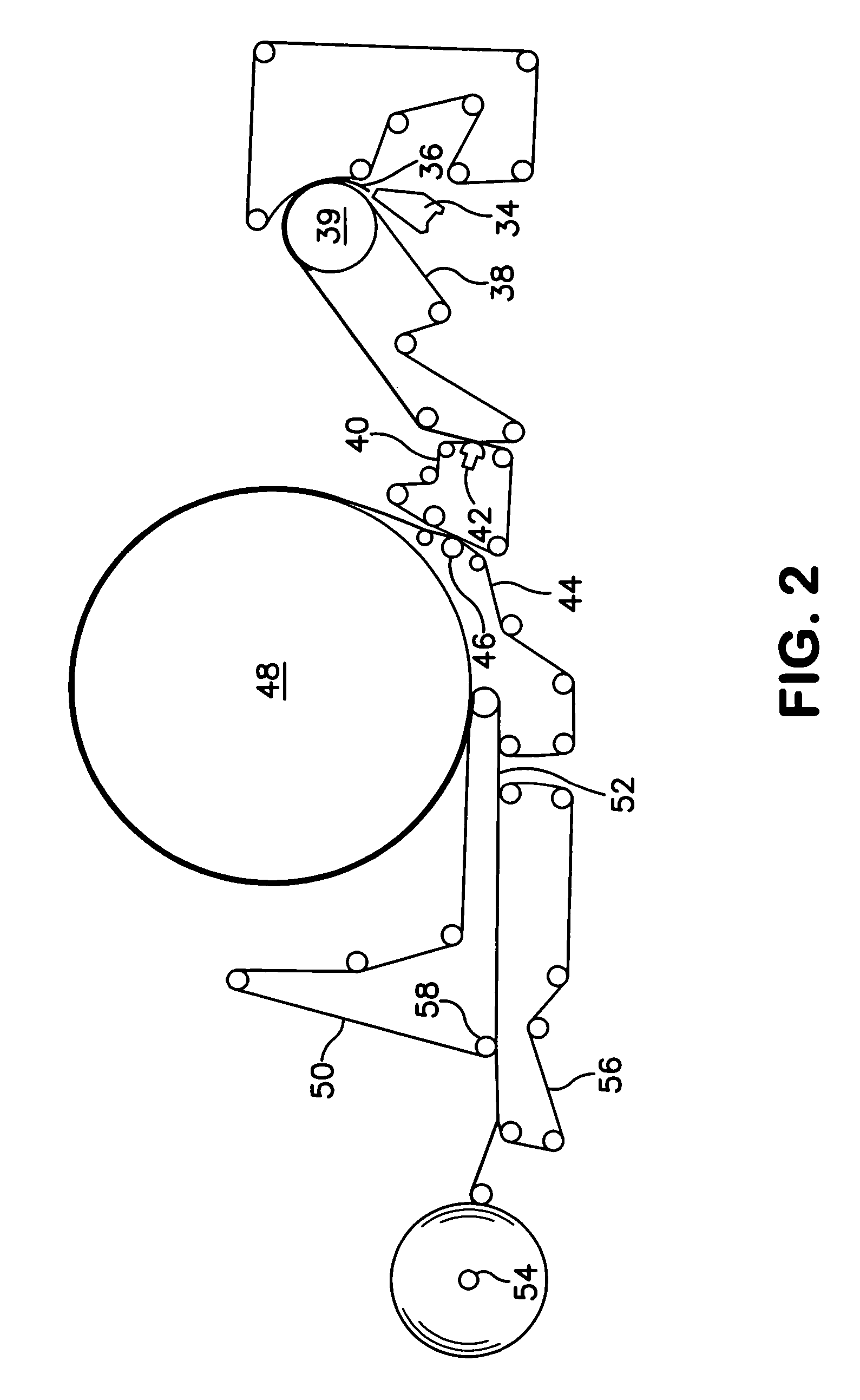

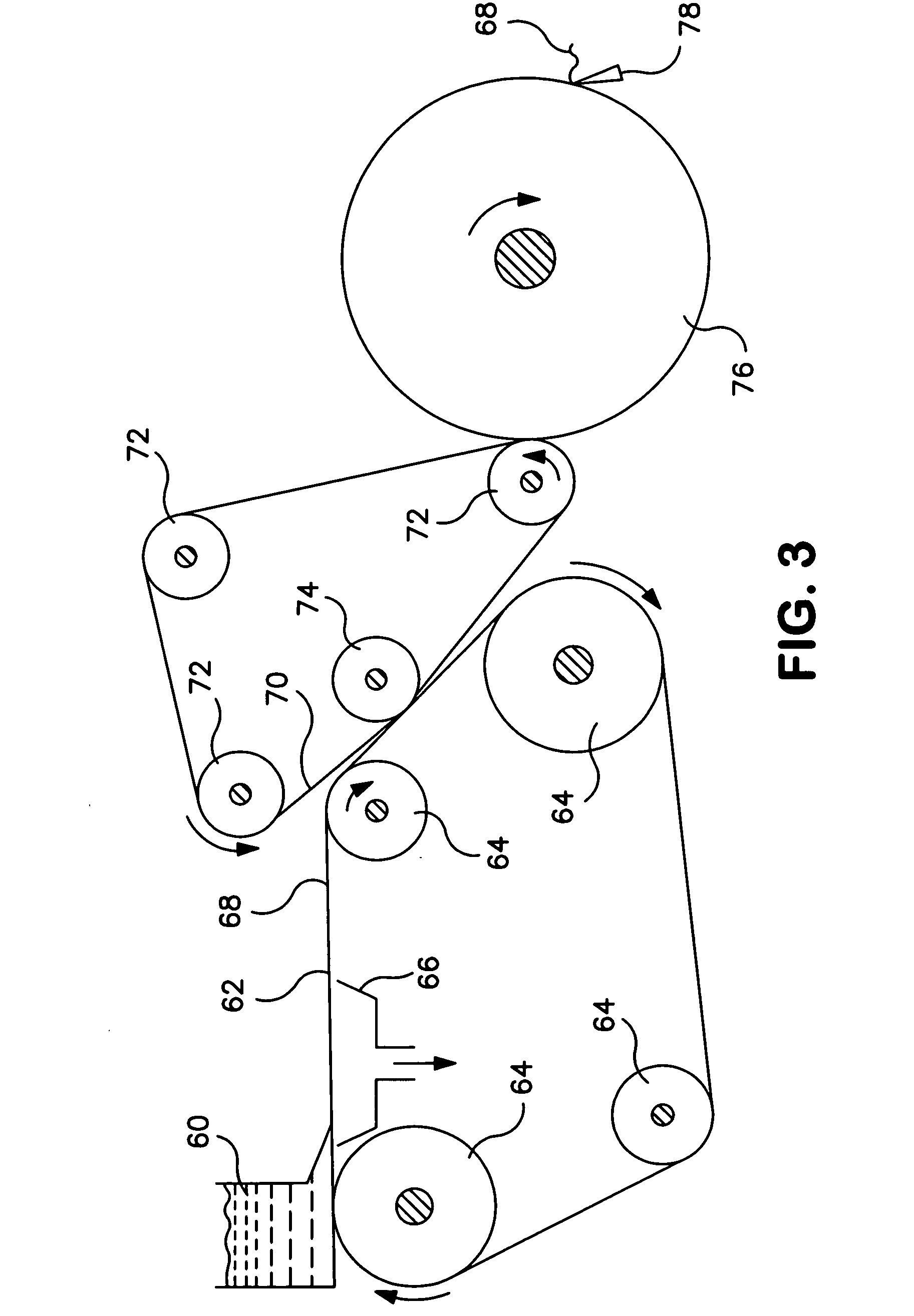

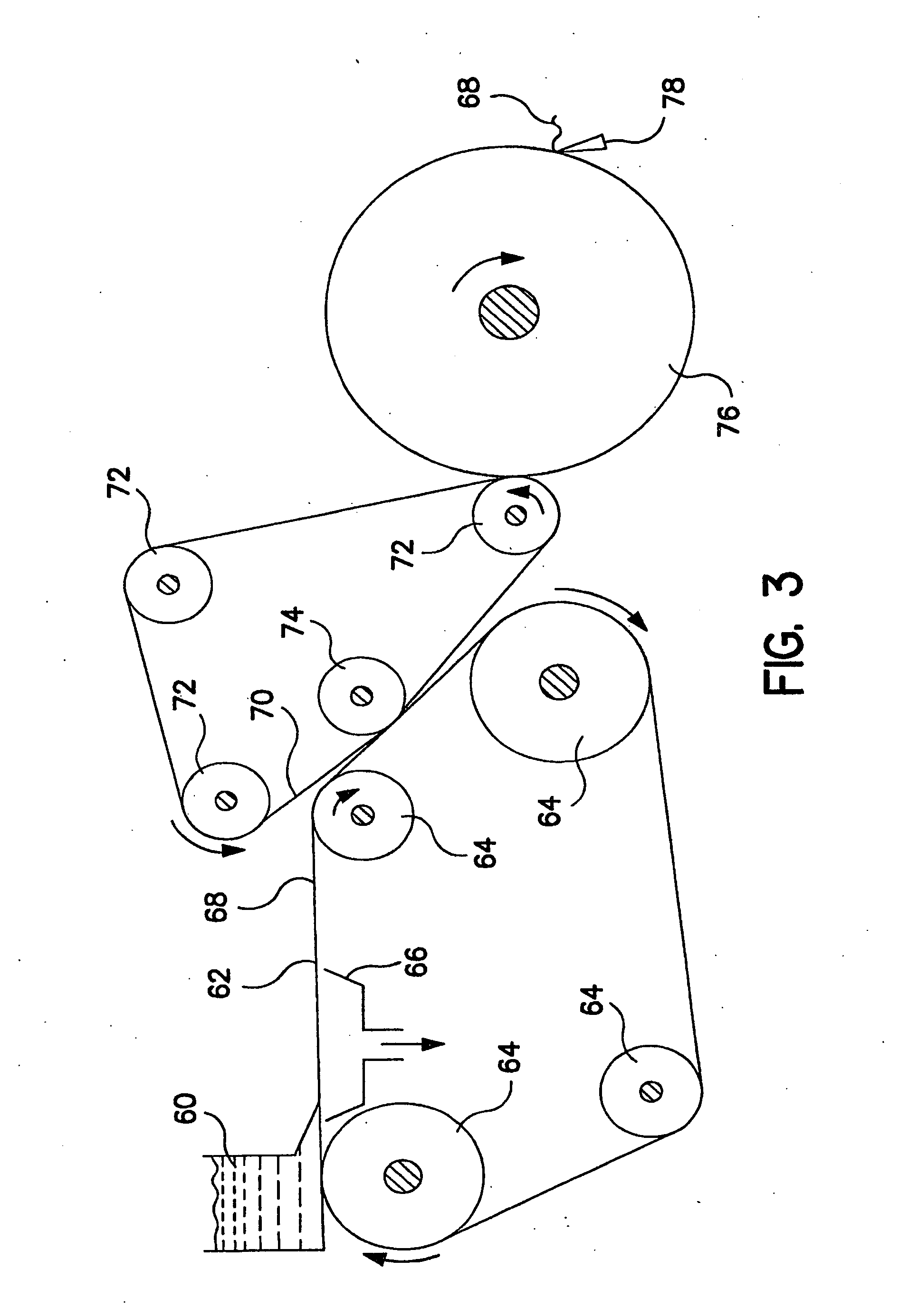

Creping process and products made therefrom

ActiveUS7883604B2Reduced strengthHigh strengthNatural cellulose pulp/paperMechanical working/deformationFiberPolymer science

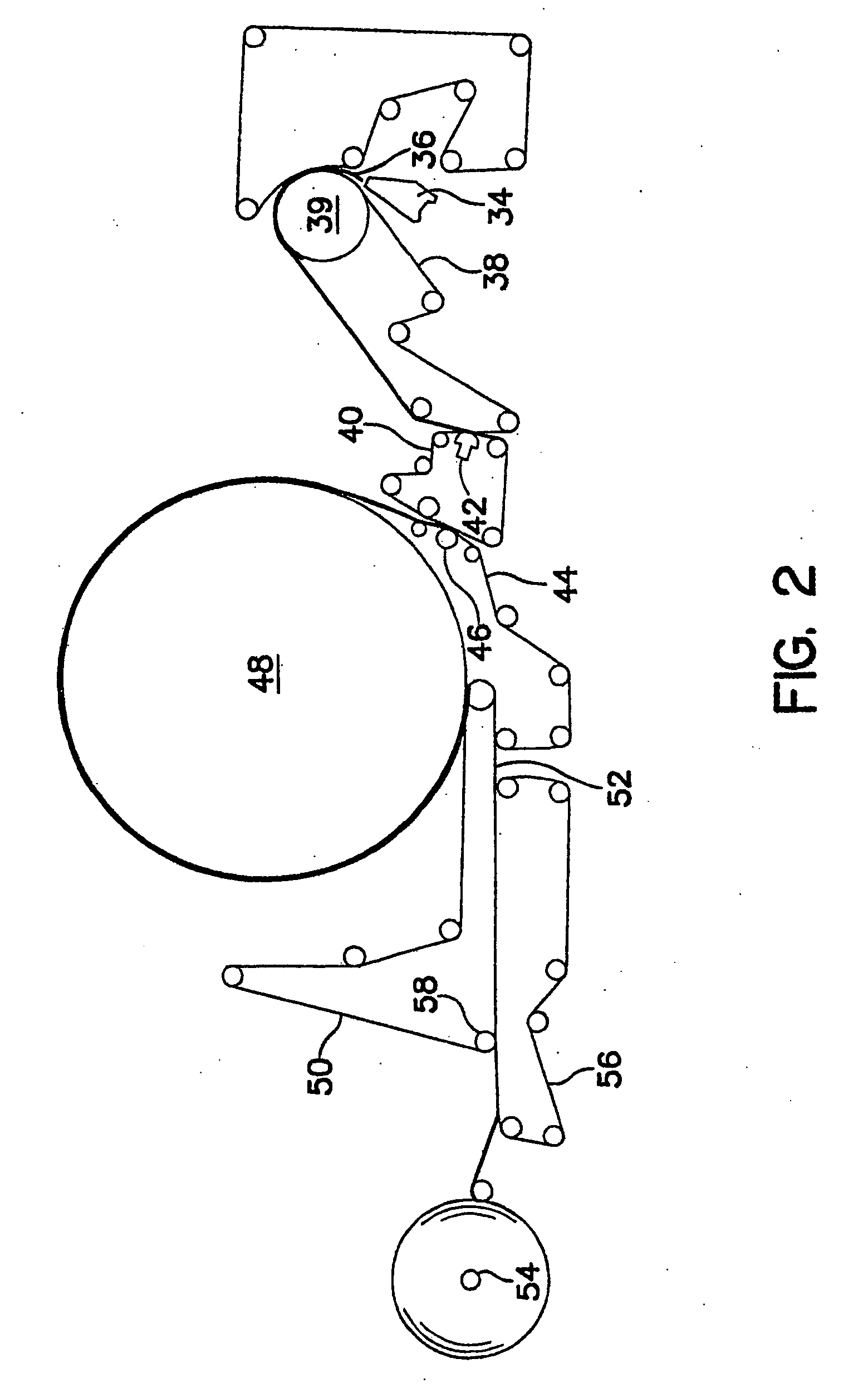

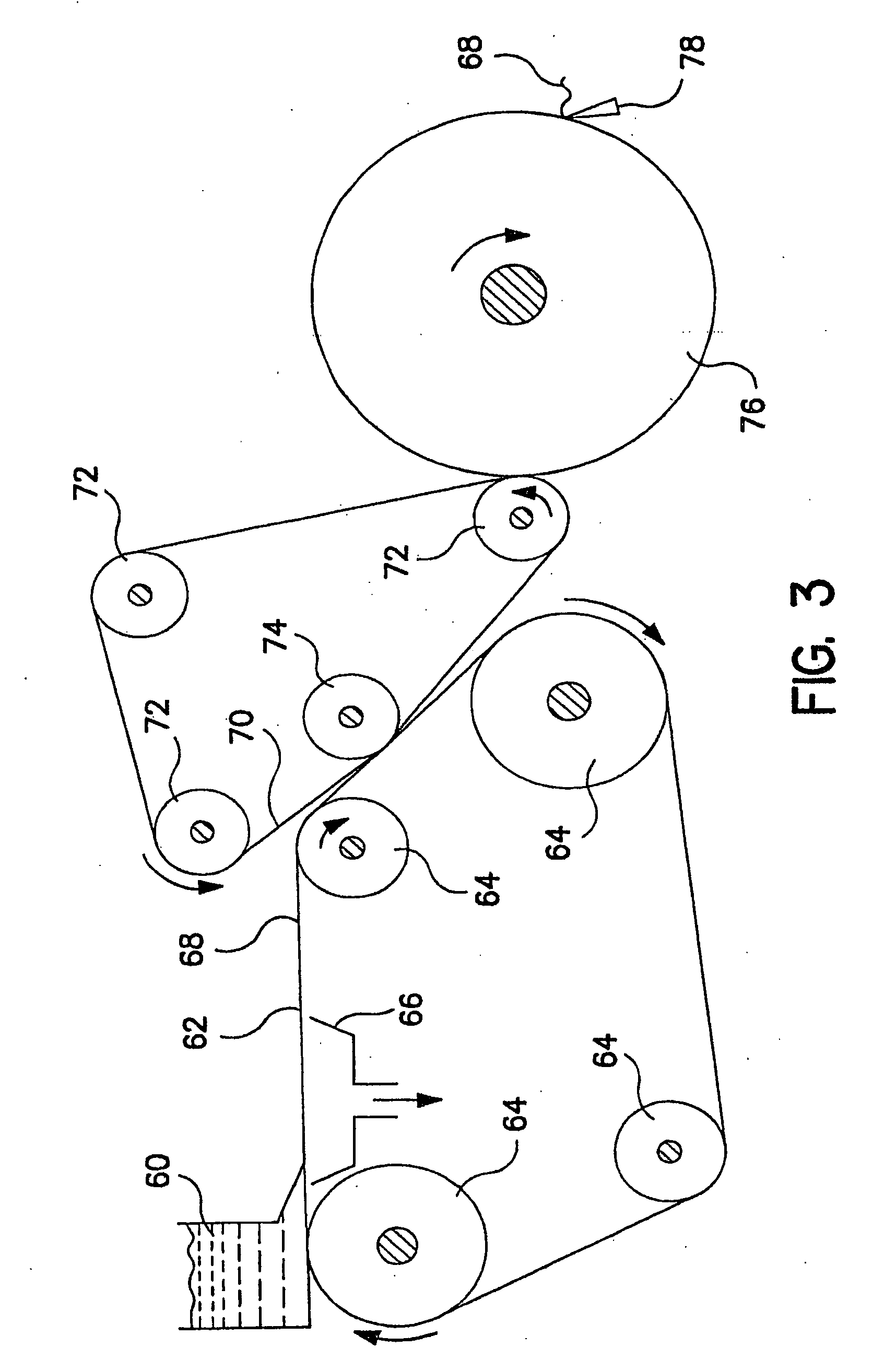

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an alpha-olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The alpha-olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Treated tissue products having increased strength

InactiveUS20070137808A1Reduced strengthHigh strengthBiocideNatural cellulose pulp/paperFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Creping process and products made therefrom

ActiveUS20070137810A1High strengthImprove propertiesNatural cellulose pulp/paperMechanical working/deformationFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an alpha-olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The alpha-olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

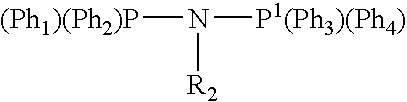

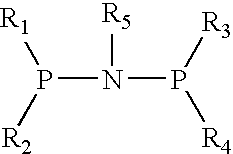

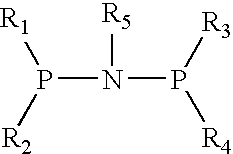

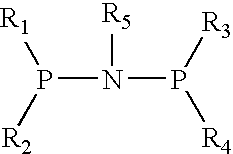

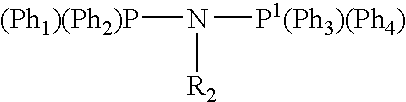

Tetramerization

ActiveUS7829749B2Organic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsAluminoxaneOligomer

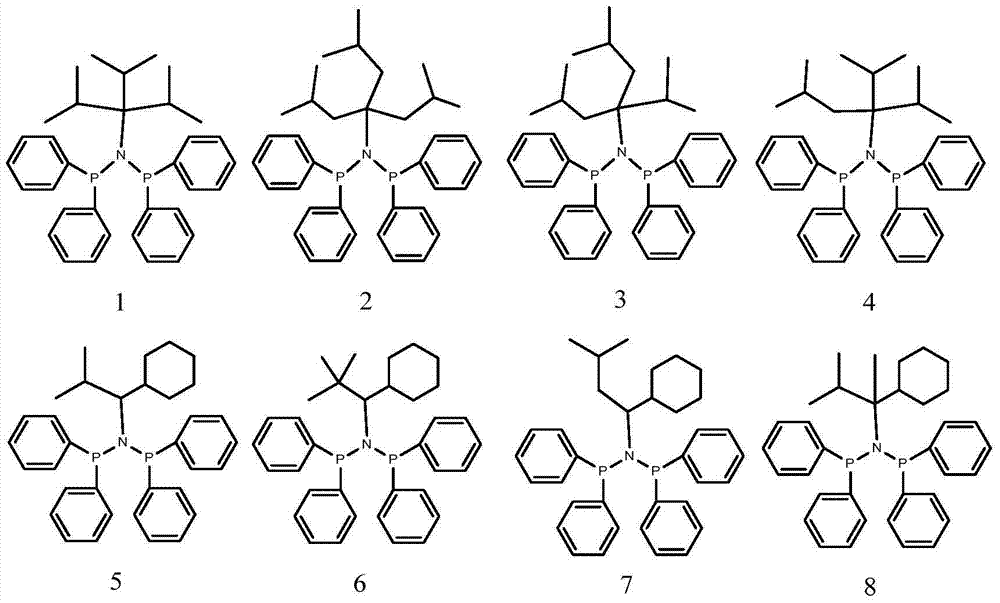

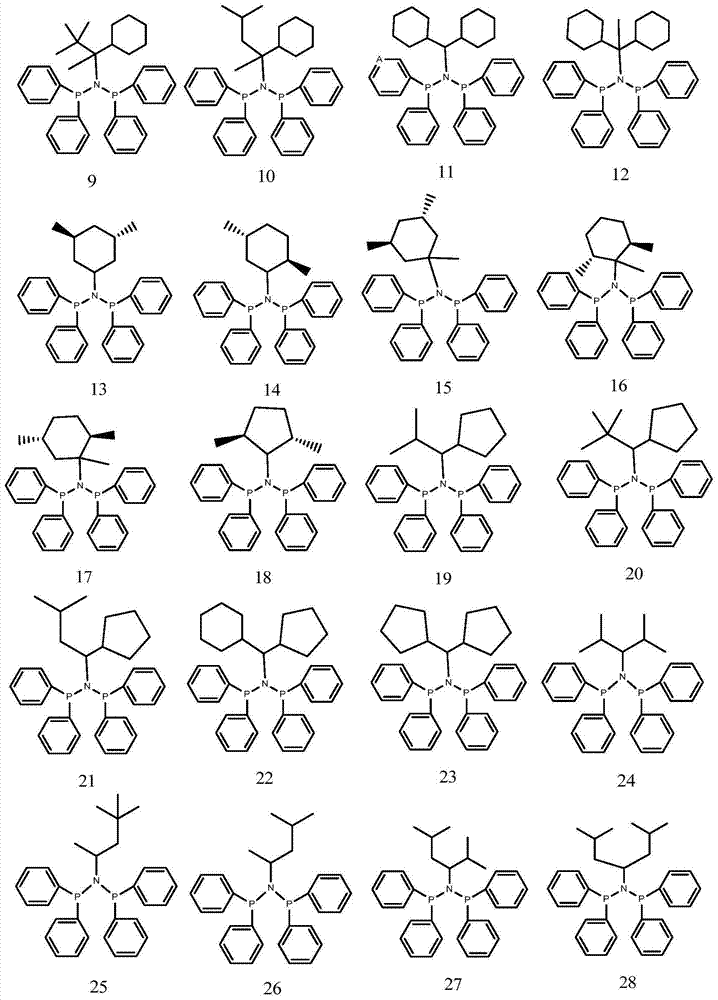

A new P-N-P ligand is useful in ethylene oligomerizations. In combination with i) a source of chromium and ii) an activator such as methylalumoxane; the ligand of this invention may be used to prepare an oligomer product that contains a mixture of hexenes and octenes. The hexenes and octenes produced with this ligand contain very low levels of internal olefins when produced under preferred reaction conditions.

Owner:NOVA CHEM (INT) SA

High viscosity polyalphaolefins based on 1-hexene, 1-dodecene and 1-tetradecene

ActiveUS7547811B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon addition1-OcteneOctene

This invention relates to the use of olefin mixtures containing 1-hexene / 1-decene / 1-dodecene and, additionally, 1-octene or 1-decene to produce high viscosity polyalphaolefins (PAOs) having a viscosity of from about 40 cSt to about 100 cSt at 100° C. (ASTM D-445) and a number average molecular weight of between about 1200 to about 4000, particularly useful as lubricant base stocks.

Owner:EXXONMOBIL CHEM PAT INC

Heat management in ethylene oligomerization

InactiveUS20120142989A1Hydrocarbons from unsaturated hydrocarbon additionCatalystsHeat managementOctene

The oligomerization of ethylene using a chromium catalyst having a heteroatomic ligand may be used to provide oligomerization products that are selective towards hexene and / or octene. However, such processes also typically produce some polymer as an undesirable by product. The present invention is directed towards improvements in the selective oligomerization of ethylene.

Owner:NOVA CHEM (INT) SA

Bridged bi-aromatic ligands, catalysts, processes for polymerizing and polymers therefrom

InactiveUS6841502B2Improve catalytic performanceOrganic compound preparationGroup 4/14 organic compounds without C-metal linkages1-OcteneAlkene

New ligands and compositions with bridged bis-aromatic ligands are disclosed that catalyze the polymerization of monomers into polymers. These catalysts with metal centers have high performance characteristics, including higher comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, propylene or styrene. The catalysts also polymerize propylene into isotactic polypropylene.

Owner:DOW GLOBAL TECH LLC

Methods for oligomerizing olefins

ActiveUS20060247399A1Organic-compounds/hydrides/coordination-complexes catalystsCatalystsChromium Compounds1-Octene

The present invention provides a method of producing oligomers of olefins, comprising reacting olefins with a catalyst under oligomerization conditions. The catalyst can be the product of the combination of a chromium compound and a heteroaryl-amine compound. In particular embodiments, the catalyst compound can be used to trimerize or tetramerize ethylene to 1-hexene, 1-octene, or mixtures of 1-hexene and 1-octene.

Owner:EXXONMOBIL CHEM PAT INC

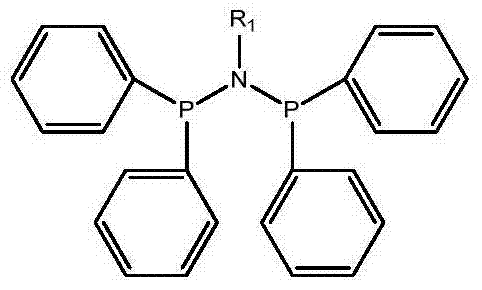

Amino phosphine

ActiveUS7994363B2Organic-compounds/hydrides/coordination-complexes catalystsCatalystsAluminoxaneOctene

A new P-N-P ligand in which each phosphorus atom is bonded to two ortho-fluorine substituted phenyl groups is useful in ethylene oligomerizations. In combination with i) a source of chromium and ii) an activator such as methalumoxane; the ligand of this invention may be used to prepare an oligomer product that contains a mixture of hexenes and octenes. The hexenes and octenes produced with this ligand contain very low levels of internal olefins when produced under preferred reaction conditions.

Owner:NOVA CHEM (INT) SA

Embossed tissue products

InactiveUS7842163B2Preserve strengthHigh strengthNatural cellulose pulp/paperMechanical working/deformationFiberCarboxylic acid

Owner:KIMBERLY-CLARK WORLDWIDE INC

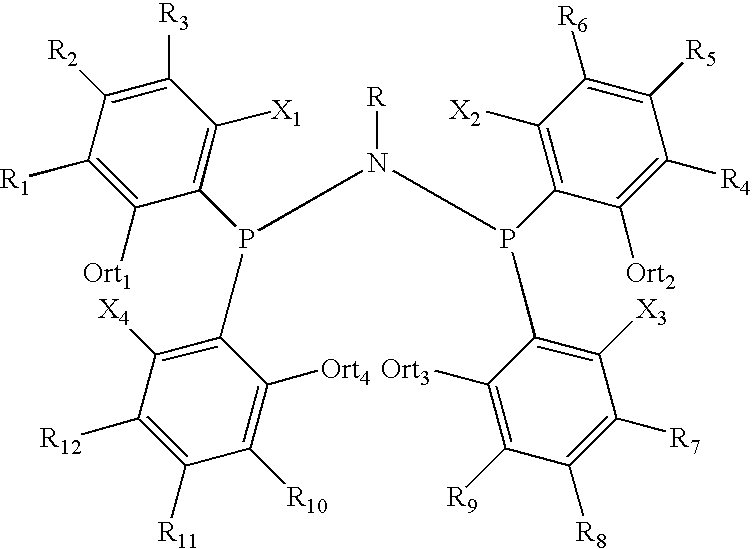

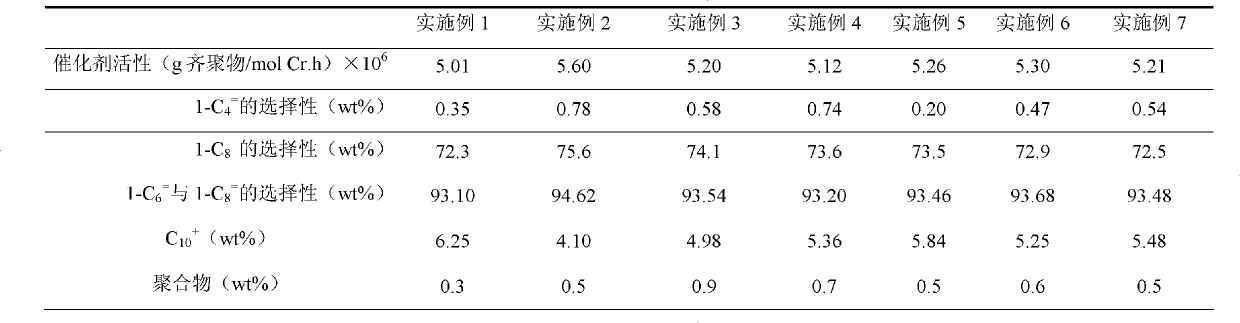

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS20070232481A1High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionChromium Compounds1-Octene

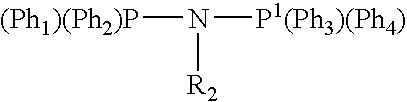

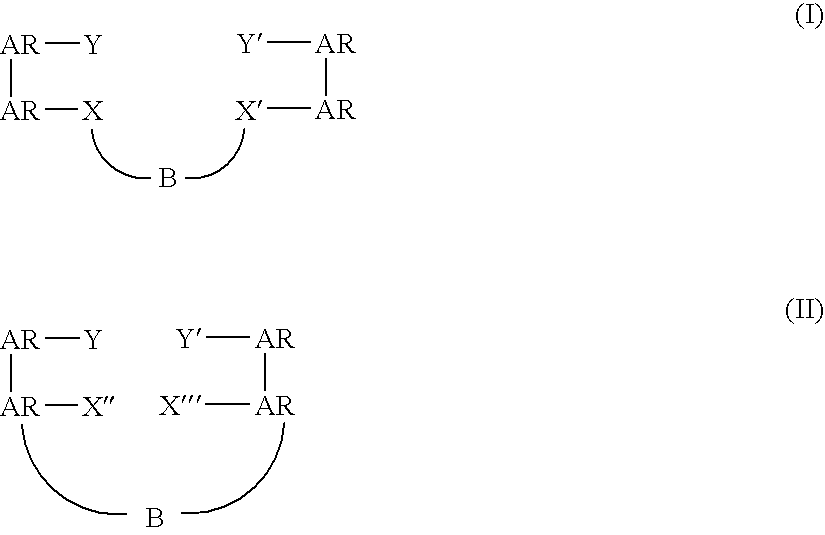

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and / or Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as: in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; general formula of the accelerator is X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkyl or aryl; the molar ratio of a, b, c and d is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·mol−1 Cr ·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

Amino phosphine

ActiveUS20080242811A1Sure easyOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsOligomerOctene

A new P—N—P ligand in which each phosphorus atom is bonded to two ortho-fluorine substituted phenyl groups is useful in ethylene oligomerizations. In combination with i) a source of chromium and ii) an activator such as methalumoxane; the ligand of this invention may be used to prepare an oligomer product that contains a mixture of hexenes and octenes. The hexenes and octenes produced with this ligand contain very low levels of internal olefins when produced under preferred reaction conditions.

Owner:NOVA CHEM (INT) SA

Polyolefin Based Hot Melt Containing a Solid Plasticizer

A hot melt adhesive that is composed of a metallocene catalyzed polyethylene polymer, a hydrogenated styrenic block copolymer, a tackifying resin, and a solid plasticizer. The preferred polyethylene polymer is an ethylene-octene copolymer, and the preferred styrenic block copolymer is a styrene-ethylene-butylene-styrene having less than 30% styrene content. The preferred solid plasticizer is either glycerol tribenzoate or 1,4-cyclohexane dimethanol dibenzoate.

Owner:BOSTIK INC

Ethylene oligomerization catalyst composition and application thereof

InactiveCN103285926AHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsArylAluminoxane

The invention relates to an ethylene oligomerization catalyst composition and an application thereof. The composition comprises the following components: a component a contains chromium acetylacetonate, tetrahydrofuran chromium chloride and / or chromium 2-ethylhexanoate; in the formula of a component b, R1, R2, R3 and R4 are phenyl, benzyl or naphthyl; and R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; a component c contains methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; a component d has a formula X1R6X2, wherein X1 and X2 are F, Cl, Br, I or alkoxy, and R6 is alkyl or aryl; in the formula of a component e, R is a linking group and selected from alkyl and derivatives thereof as well as aryl and derivatives thereof; and the molar ratio is 1: (0.5-10): (50-3000): (0.5-10): (0.5-10). The catalyst has the catalytic activity being more than 5.0*10<6>g mol<-1>Cr.h<-1>, and the mass of 1-hexene and 1-octylene is more than 93%.

Owner:PETROCHINA CO LTD

Trimerization

ActiveUS8252955B2Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionOligomerAluminoxane

A new P—N—P ligand is useful in ethylene oligomerizations. In combination with i) a source of chromium and ii) an activator such as methylalumoxane; the ligand of this invention may be used to prepare an oligomer product that contains a mixture of hexenes and octenes. The hexenes and octenes produced with this ligand contain very low levels of internal olefins when produced under preferred reaction conditions.

Owner:NOVA CHEM (INT) SA

Method for preparing low-contraction high-fluidity high-toughness polypropylene

InactiveCN101148528AInjection shrinkage reducedMeet the needs of industrial developmentElastomerPolyolefin

The present invention is one kind of low shrinkage high flowability and high toughness polypropylene composition and its preparation process and use. The polypropylene composition consists of high flowability polypropylene 35-65 weight portions, thermoplastic polyolefin elastomer 10-40 weight portions, toughening agent 6-20 weight portions, inorganic stuffing 10-25 weight portions, antioxidant 0.2-1.0 weight portion, weather resisting agent 0.2-1.0 weight portion and machining assistant 0.1-1.0 weight portion. The toughening agent is one or composition of ethylene-octene copolymer, ethylene propylene diene copolymer, styrene-butadiene-styrene block copolymer and hydrogenated styrene-butadiene-styrene block copolymer. The polypropylene composition is prepared through the following steps: 1. mixing all the materials and 0-50 wt% of inorganic stuffing for 3-8 min to obtain mixture; and 2. smelting and mixing the rest inorganic stuffing and mixture at 180-235 deg.c, and pelletizing.

Owner:SHANGHAI KINGFA SCI & TECH +1

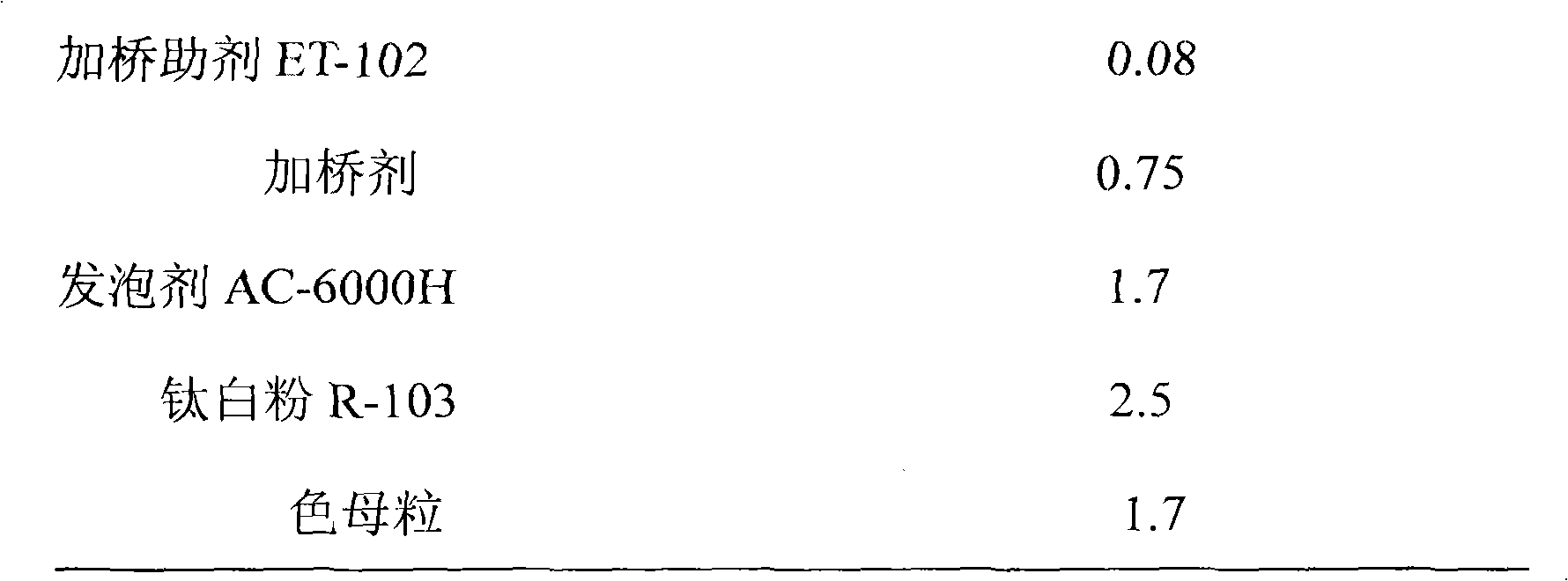

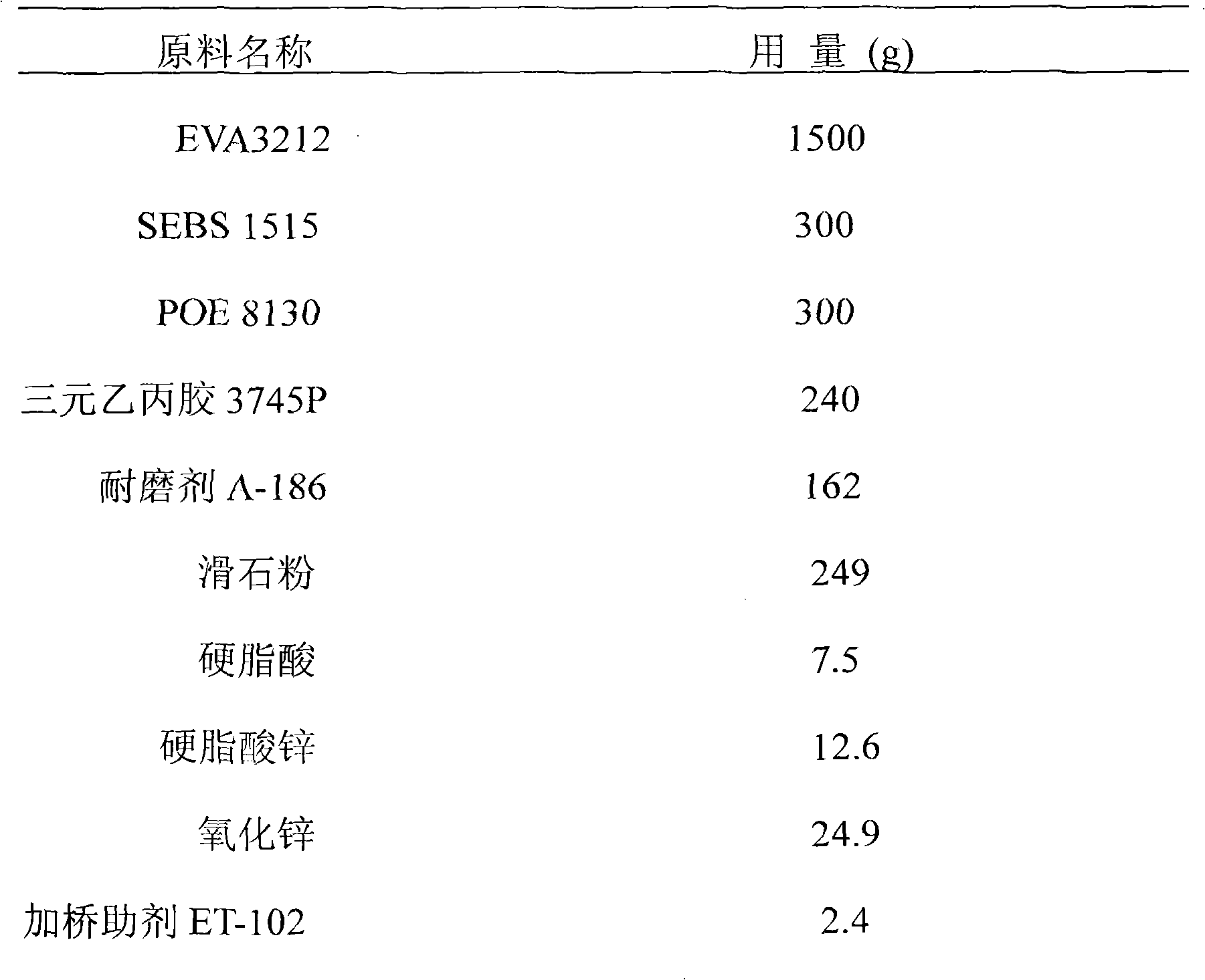

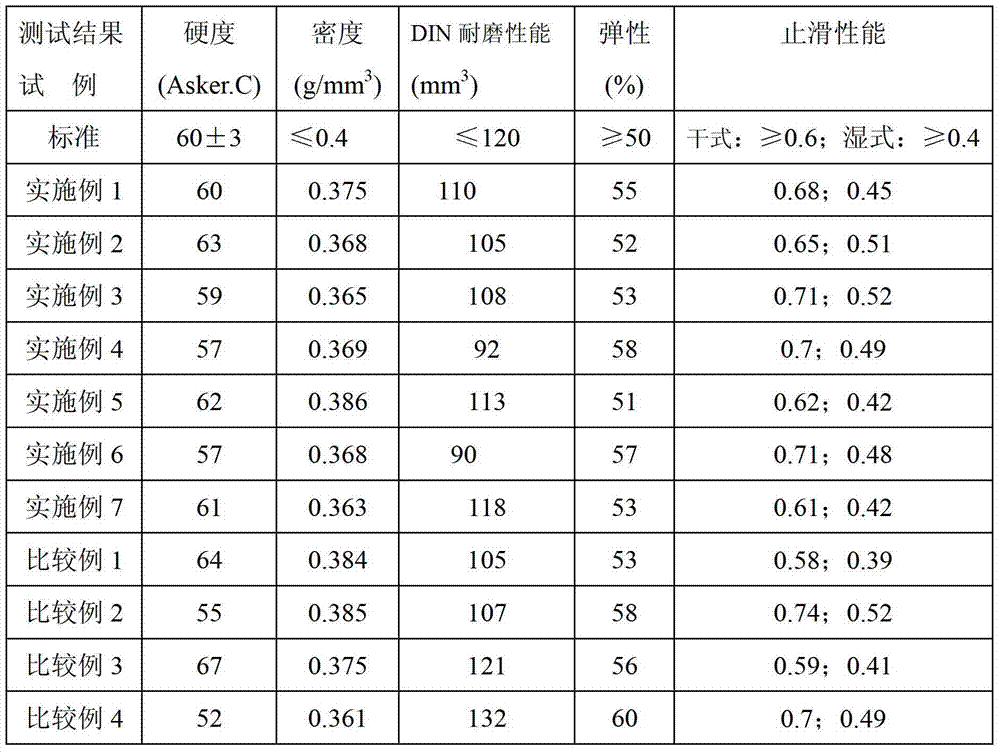

Formula of soles of PU-simulated foaming sneakers through injection and manufacturing method

The invention relates to a formula of soles of PU-simulated foaming sneakers through injection, which comprises the following raw materials in percentage by mass: 40 percent of 21 percent ethylene-vinyl acetate copolymer (EVA 7360), 16.7 percent of styrene butadiene copolymer SBBSJT-83, 12.5 percent of ethylene octylene copolymer POE8130, 8.3 percent of ethylene-propylene-diene copolymer 3745P, 65.9 percent of wear-resisting agent A-18, 8.3 percent of talcpowder, 0.25 percent of stearic acid, 0.42 percent of zinc stearate, 0.9 percent of zinc oxide, 0.08 percent of bridging auxiliary agent ET-102, 0.75 percent of bridging agent DCP, 1.7 percent of high-temperature foaming agent AC-6000H, 2.5 percent of titanium white powder R-103 and 1.7 percent of master batch. The preparation method comprises the steps of banburying, mixing, granulation, injection molding, physical property tests and the like. Thus, in the research and development and application, the PU-simulated foaming soles not only have the physical and chemical properties of no crease marks, high elasticity, low compression and wear resistance of PU soles, and but also have the advantages of low production cost, light specific gravity, good limited-slip properties, no hydrolysis and long service life.

Owner:泰亚投资集团有限公司

Tissue products containing a polymer dispersion

ActiveUS20070137809A1High strengthImprove propertiesNatural cellulose pulp/paperMechanical working/deformationFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Radiation cross-linked low-smoke halogen-free red phosphorus-free flame retardant material and its application

ActiveCN102766293AImprove flame retardant performanceAvoid it happening againInsulated cablesCable/conductor manufactureCross-linkAluminium hydroxide

The invention discloses a radiation cross-linked low-smoke halogen-free red phosphorus-free flame retardant material, which comprises the following components of: by weight, 10-80 parts of ethene-vinyl acetate copolymer, 5-30 parts of ethylene-octene copolymer and / or ethene-butene copolymer and / or terpolymer EP rubber, 0-100 parts of polyethylene, 1-20 parts of a polymer compatilizer, 0.5-10 parts of organosilicon polymer, 1-10 parts of a composite anti-oxidant, 0-200 parts of aluminium hydroxide and / or magnesium hydroxide and / or modified aluminium hydroxide and / or modified magnesium hydroxide, 0.1-100 parts of high molecular weight ammonium polyphosphate and / or 0.1-50 parts of a phosphate ester fire retardant and / or 0.1-50 parts of MCA. The material provided by the invention reaches American UL224VW-1 standard when applied in thermal shrinkable tubes, reaches American UL1581VW-1 standard when applied in electric wires and cables, contains no halogen or red phosphorus, and is environmentally friendly.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

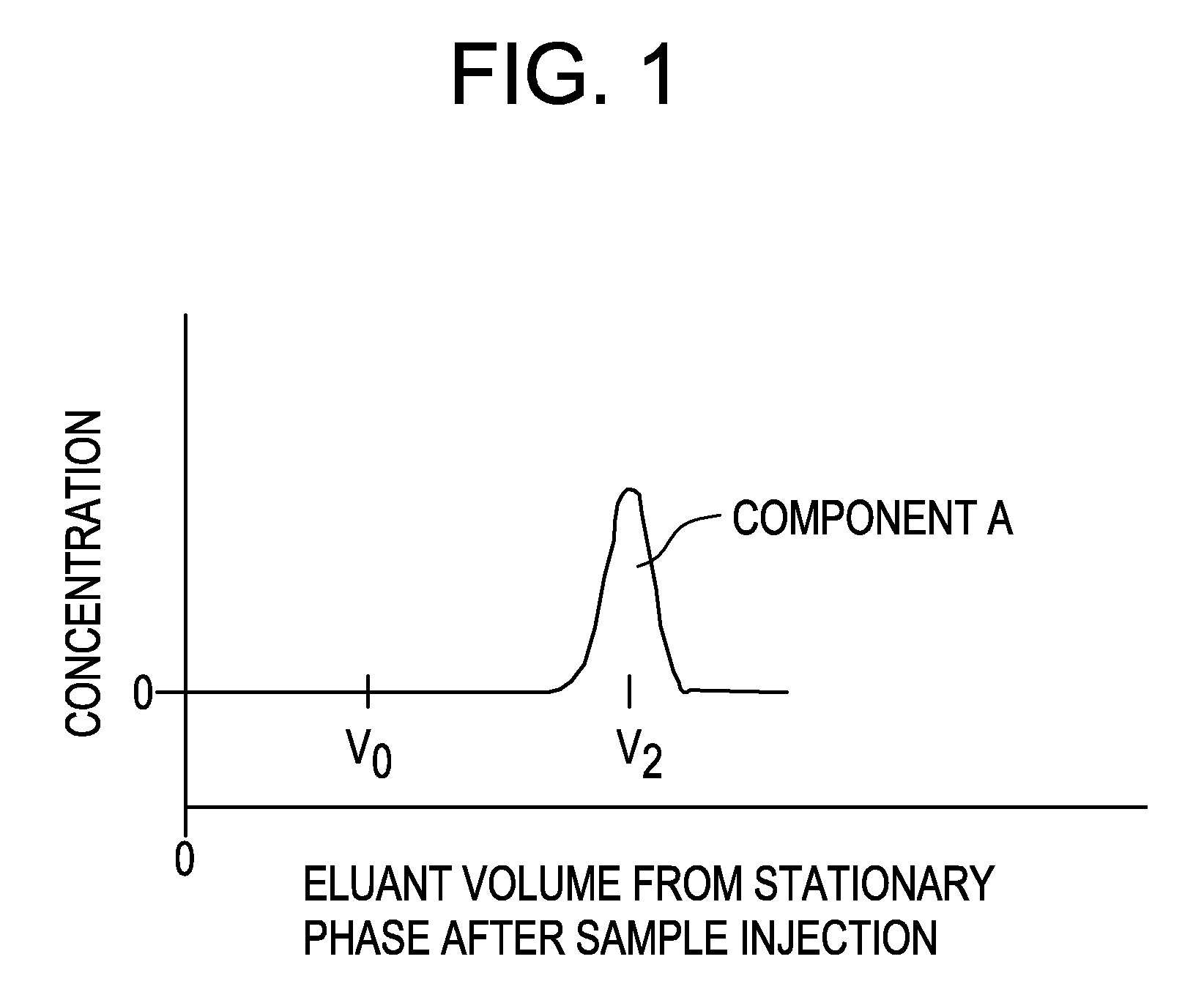

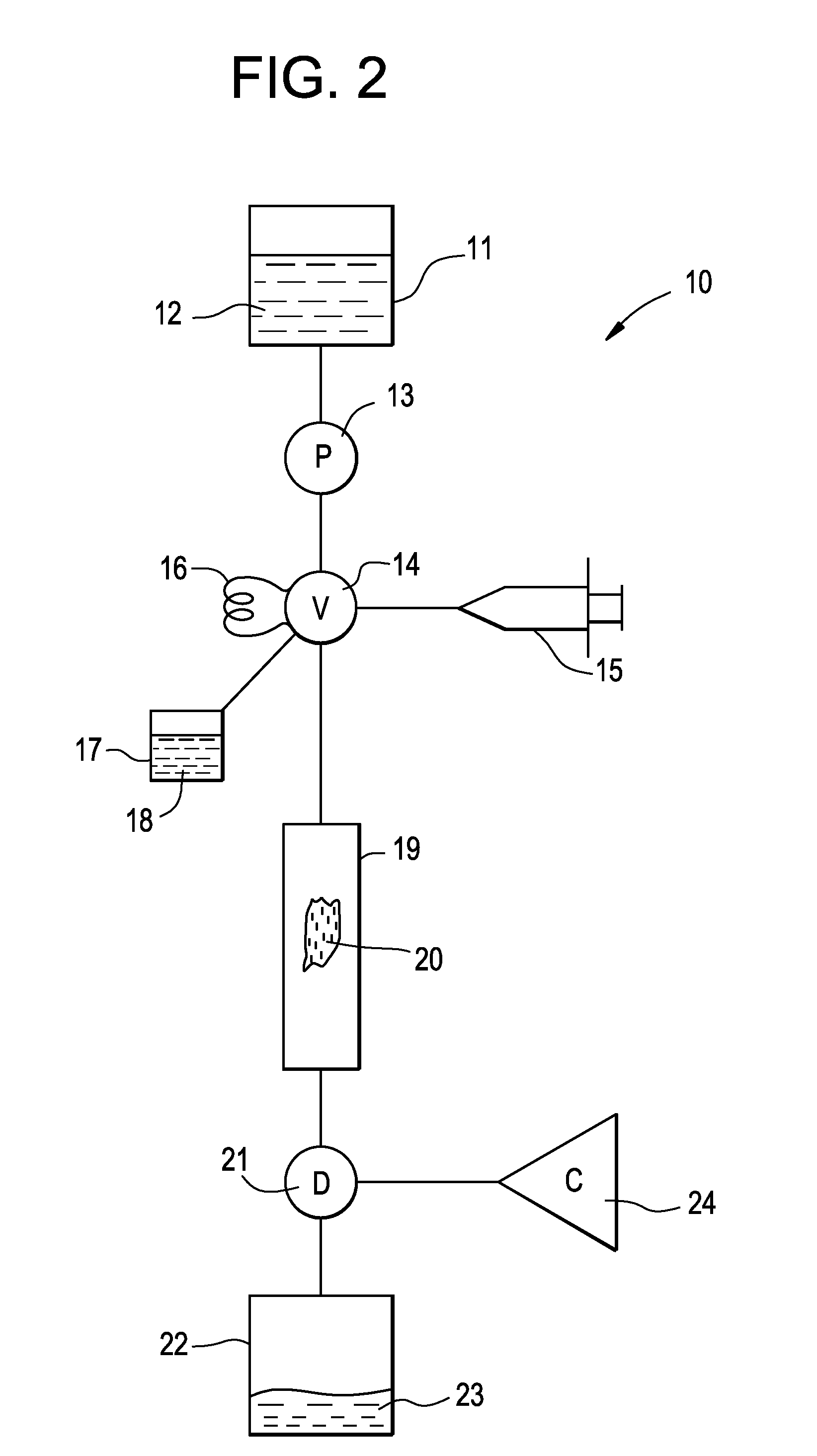

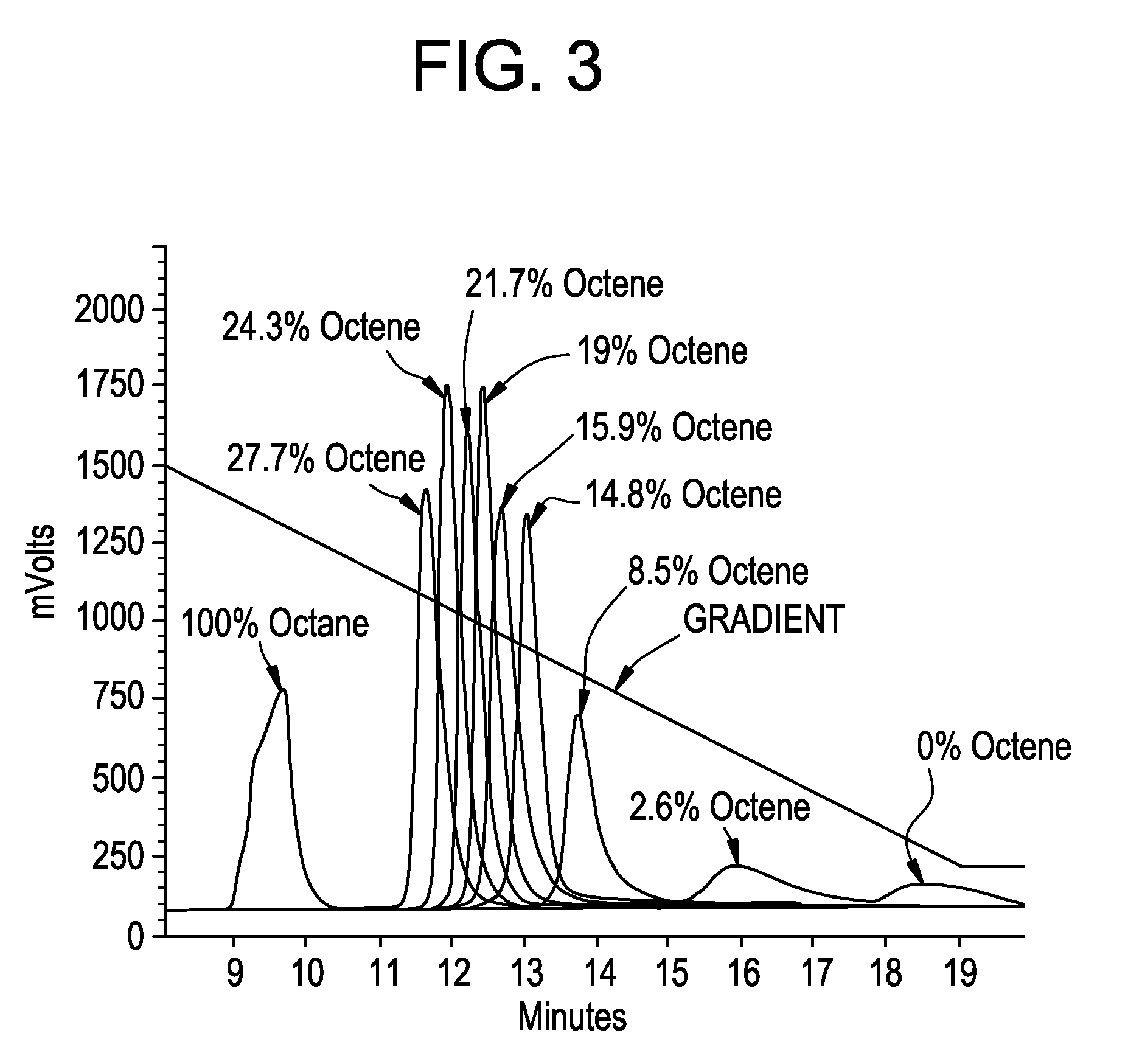

Chromotography of polyolefin polymers

ActiveUS8076147B2Separation efficiency can be improvedIon-exchange process apparatusComponent separationStationary phasePolymer science

A method and apparatus for chromatography of a polyolefin polymer by flowing a solution of the polyolefin polymer through liquid flowing through a graphitic carbon liquid chromatography stationary phase. The method can be used to determine the monomer to comonomer ratio of a polyolefin copolymer such as a copolymer of ethylene and 1-octene or a copolymer of propylene and ethylene.

Owner:THE DOW CHEM CO

Radiation cross-linked low-smoke halogen-free phosphor-free nanometer flame retardant thermal shrinkage material and method for preparing the same

ActiveCN1803907AImprove flame retardant performanceAvoid secondary disastersFireproof paintsCross-linkPhosphate

The disclosed radiation crosslinking low-fume non-halogen / phosphate nano flame-retardant heat-shrinkable material contains the ethene / vinyl-acetate copolymer, ethene / octene copolymer, polymer solvent, organosilicon polymer, composite antioxidant, nano Mg(OH)2 flame retardant, ultrafine Al(OH)3 Mg(OH)2 with activating-treated surface, lubricant, and lubricant; and can be manufactured by sitrring, extruding, drawing, air cooling, cutting grain, radiating, stretching and cooling form. The product has super flame-retardant effect and affects little to environment or human after abandonment. The preparation method is low cost and fit to industrial production.

Owner:广州凯恒科塑有限公司

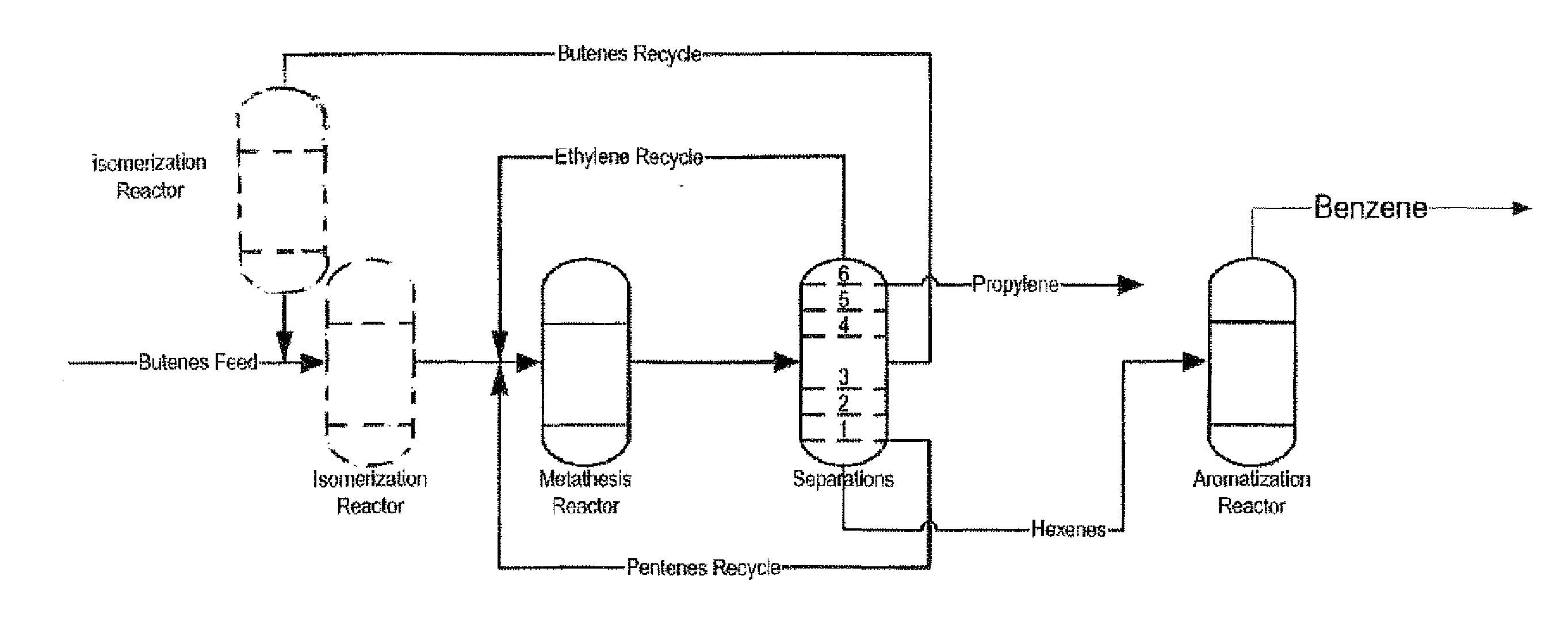

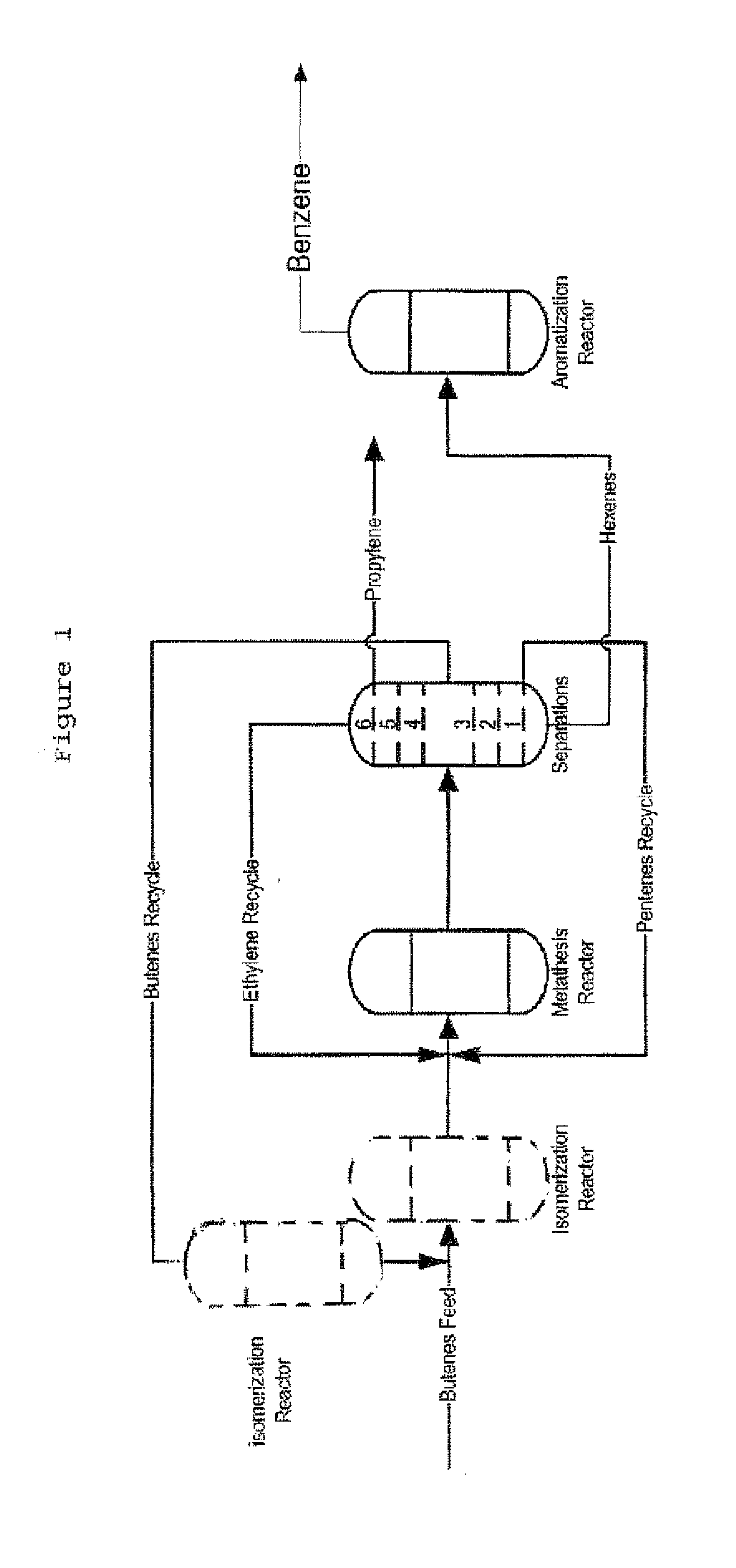

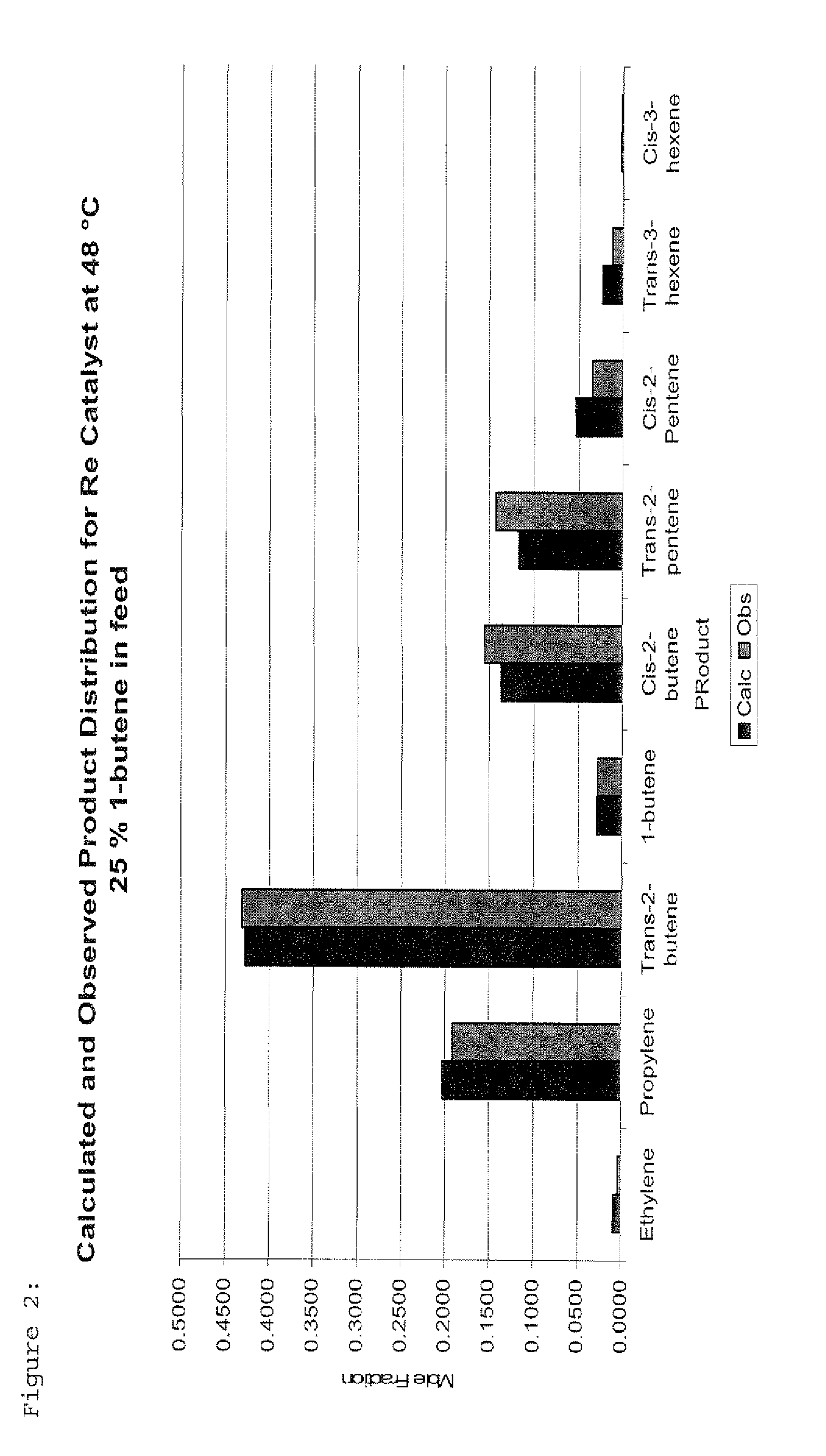

Process for Producing Propylene and Aromatics from Butenes by Metathesis and Aromatization

InactiveUS20110263917A1Molecular sieve catalystDistillation purification/separationIsomerizationOctene

The invention is for a process for producing propylene and hexene (along with ethylene, pentenes, product butenes, heptenes and octenes) by metathesis from butenes (iso-, 1- and cis and trans 2-) and pentenes and then aromatizing the hexenes (along with higher olefins, such as heptenes and octenes) to benzene (along with toluene, xylenes, ethylbenzene and styrene). Since the desired products of the metathesis reaction are propylene and hexene, the feed to the metathesis reaction has a molar ratio for 1-butene:2-butene which favors production of propylene and 3-hexene with the concentration of hexenes and higher olefins in the metathesis product being up to 30 mole %. An isomerization reactor may be used to obtain the desired molar ratio of 1-butene:2-butene for the feed composition into the metathesis reactor. After the metathesis reaction, of hexene and higher olefins are separated for aromatization to benzene and other aromatics.

Owner:SAUDI BASIC IND CORP SA

High-selectivity catalyst system used in trimerization and tetramerization of ethylene and use method thereof

ActiveCN104511311AIncreased co-selectivityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChromium Compounds1-Octene

The invention provides a high-selectivity catalyst system used in trimerization and tetramerization of ethylene and a use method thereof. The catalyst system includes three components: (1) a chromium compound, (2) a ligand, of which a general structure formula is (Ph2)P-N(R1)-P(Ph2), wherein R1 is a synthetic phenyl group, alkyl group or cycloalkyl group; and (3) an activating agent or a co-catalyst. According to the catalyst system, a conventional PNP chromium-series catalyst is improved so that a co-selectivity of 1-hexane and 1-octylene is increased, wax-like products are reduced and a high activity is maintained.

Owner:EAST CHINA UNIV OF SCI & TECH

Ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material and preparation method thereof

ActiveCN104893088AImprove mechanical propertiesImprove flame retardant performancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention provides an ultraviolet light crosslinking low-smoke zero-halogen flame-retardant cable material. The cable material comprises polyolefin, a compatilizer, an inorganic flame retardant, an organic phosphorus-nitrogen-containing flame retardant, a flame-retardant synergist, a photoinitiator, an assistant crosslinker, a surfactant, an antioxidant and a lubricant, wherein polyolefin contains low-density polyethylene, an ethylene-octylene copolymer and an ethylene-vinyl acetate copolymer in the weight proportion being (10-25):(20-35):(55-65); the compatilizer is polyethylene for grafting of maleic anhydride; the inorganic flame retardant is selected from magnesium hydroxide and aluminum hydroxide; the organic phosphorus-nitrogen-containing flame retardant contains polyphosphoric acid, pentaerythritol and melamine in the weight proportion being (10-20): (4-8): (15-30); the flame-retardant synergist contains zinc borate and / or polydimethylsiloxane. The cable material has good thermal resistance and anti-aging performance, can be used at the temperature of 125 DEG C for a long time and is excellent in comprehensive mechanical performance and better in flame retardance.

Owner:上海至正新材料有限公司

Polypropylene-based resin composition and injection molded article thereof

InactiveUS6011102AReduced impact strengthInferior appearanceFilm/foil adhesivesMixingPolymer scienceOctene

A polypropylene-based resin composition comprising: (1) 55 to 75% by weight of a polypropylene-based resin (A) selected from the following (i) and (ii); (i) a crystalline propylene-ethylene block copolymer composed of a propylene homopolymer portion as a first segment and a propylene-ethylene random copolymer as a second segment, and (ii) a mixture of the crystalline propylene-ethylene block copolymer (i) and a crystalline propylene homopolymer; (2) 10 to 15% by weight of an ethylene-octene copolymer rubber (B) having a melt flow rate (measured according to JIS-K-6758, 190 DEG C.) of 0.5 to 10 g / min., an octene content of 20 to 25% by weight and a density of 0.860 to 0.875; and (3) 15 to 30% by weight of talc (C) having an average particle diameter of not more than 3 mu m, the total amount of (A), (B) and (C) being 100% by weight, wherein said polypropylene-based resin composition satisfies the following expression:0.25< / =(A)' / [(A)'+(B')]< / =0.40in which (A)' represents an amount by weight of the second segment of the crystalline propylene-ethylene block copolymer (i) in the polypropylene-based resin composition and (B') represents an amount by weight of the ethylene-octene copolymer rubber (B) in the polypropylene-based resin composition, and further has a specific flexural modulus, Izod impact strength, elongation, melt flow rate and density.

Owner:TOYOTA JIDOSHA KK +1

Soles of ejection foamed rubber-plastic sports shoes and manufacturing method of soles

The invention relates to a pair of soles and particularly relates to a pair of soles of ejection foamed rubber-plastic sports shoes and a manufacturing method of the soles. The pair of soles of the ejection foamed rubber-plastic sports shoes consists of the following raw materials: an ethylene-vinyl acetate copolymer, an ethylene-octene copolymer, a hydrogenated styrene-butadiene-styrene block copolymer, an ethylene propylene diene monomer, polysiloxane resin, talcum powder, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide, azobisformamide and masterbatch. The manufacturing method comprises the steps of: mixing the dicumyl peroxide and an azo foaming agent for later use, mixing other raw materials and then pouring into an internal mixer for first-stage internal mixing, then adding a mixture of the dicumyl peroxide and the azo foaming agent for second-stage internal mixing to obtain an internally mixed mixture, thinning the mixture on a roller machine, conveying the material which is evenly mixed by the roller machine into a granulator for granulation, proportioning aggregates after granulation according to set ratios, injecting the aggregates into a shoe mould by using an injection molding machine for molding, and sizing the molded soles into foamed profile products by using an incubator.

Owner:泉州泰亚鞋业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com