Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3601results about "Distillation purification/separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

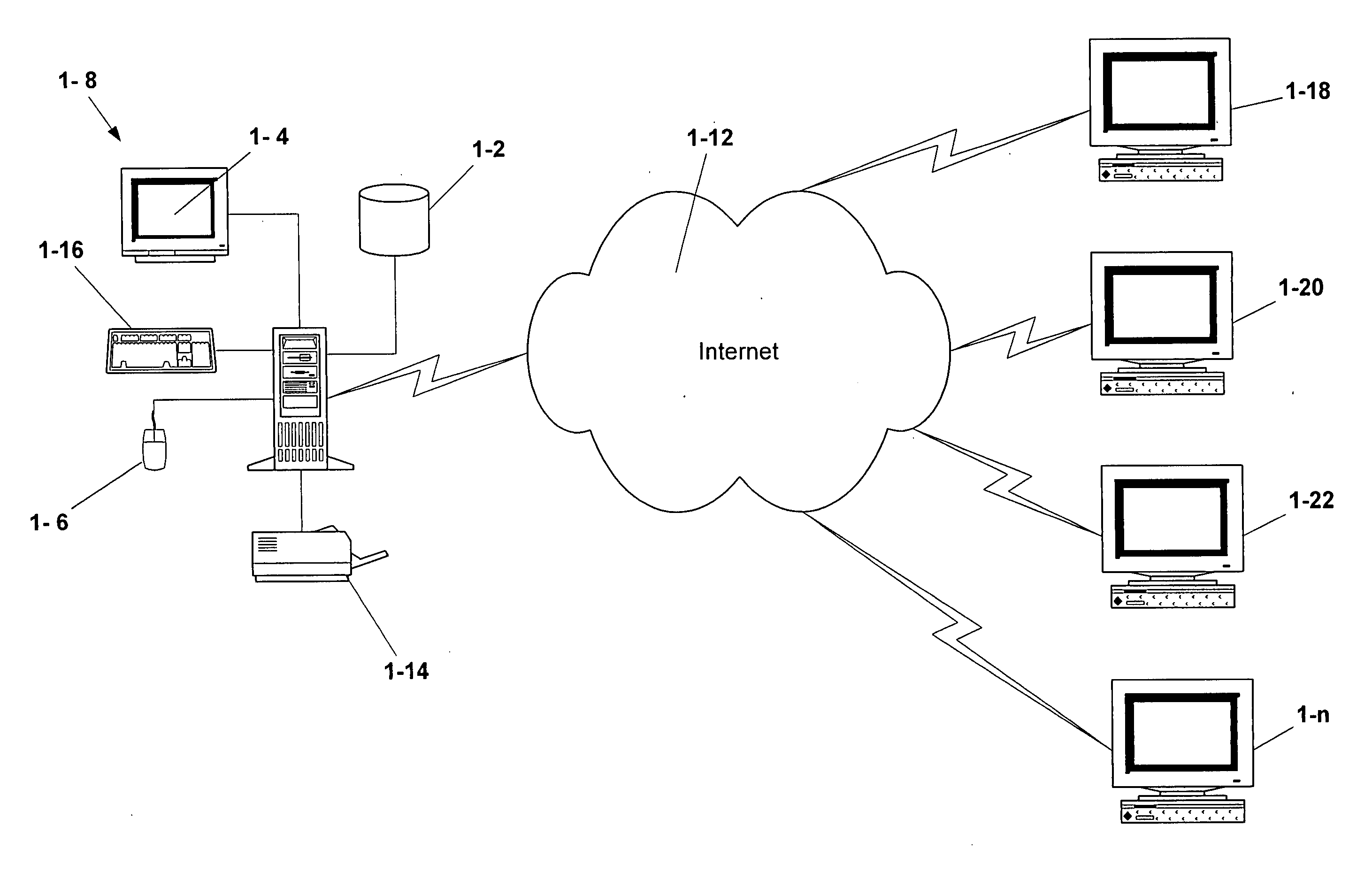

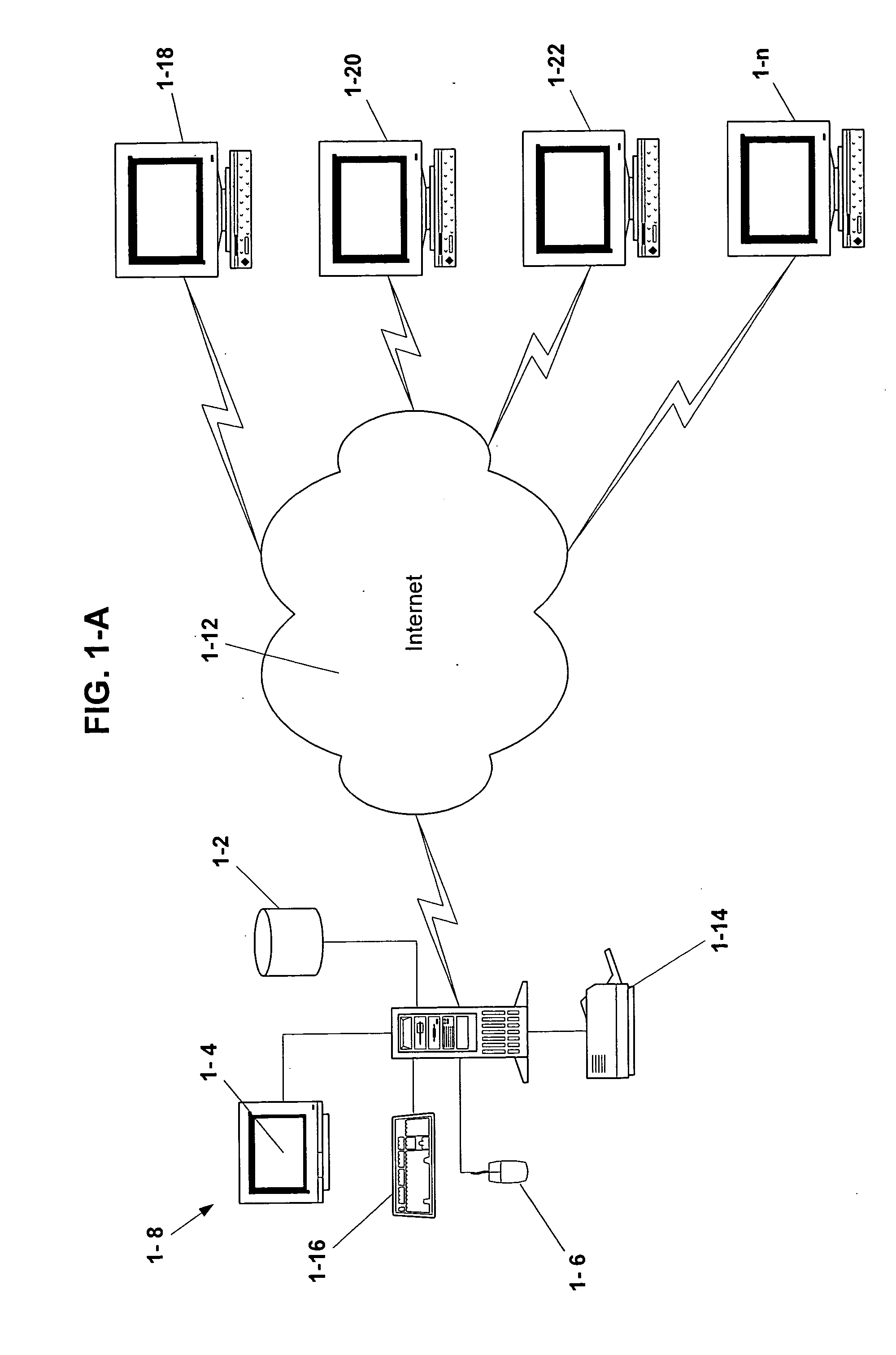

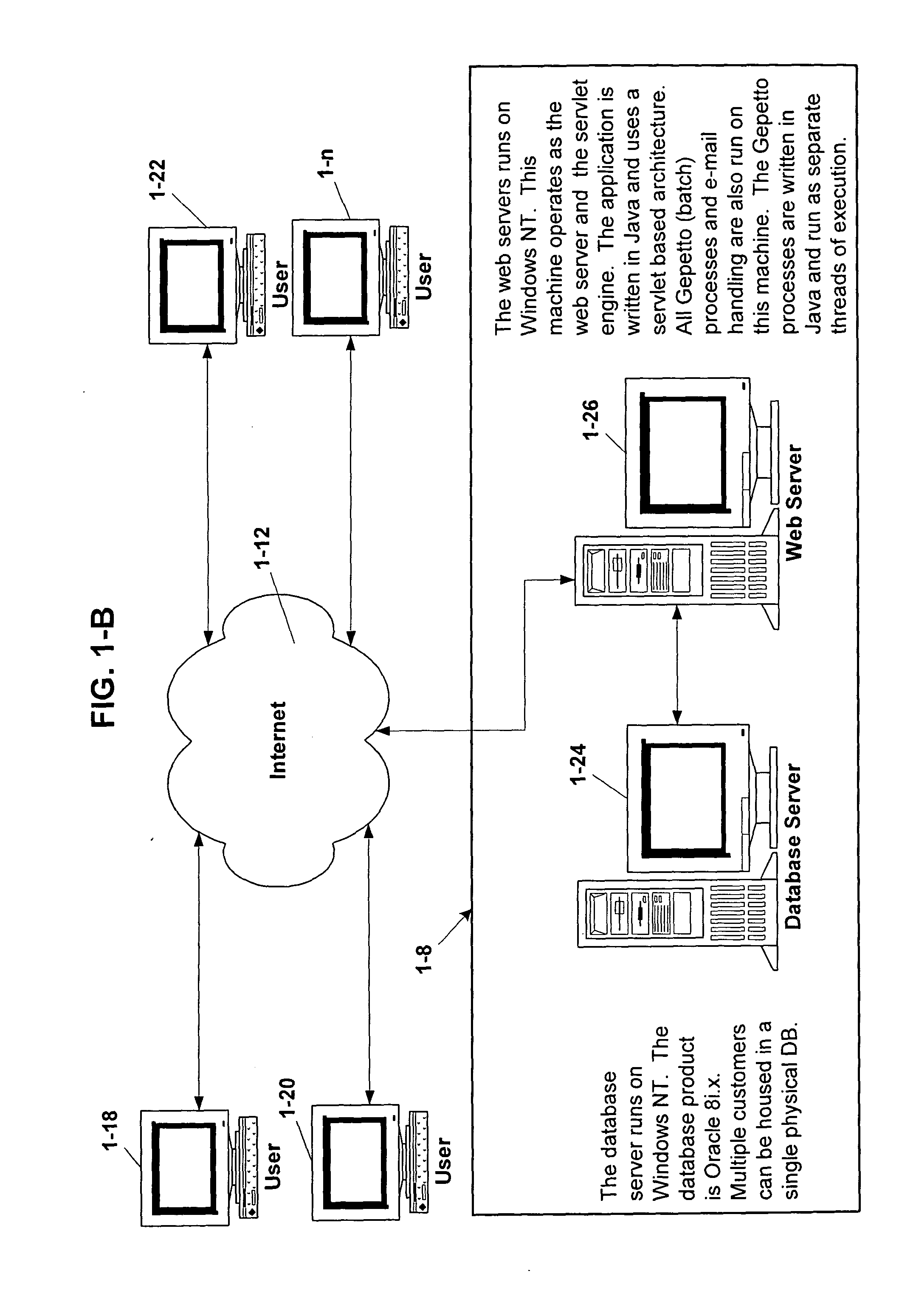

System for creating and maintaining a database of information utilizing user opinions

InactiveUS20040205065A1Easily and uniquely searchedInformed decision makingMetadata text retrievalOrganic compound preparationInternet basedHuman language

A system for automatically creating and maintaining a database of information utilizing user opinions about subjects, particularly exceptional experiences. Described is an Internet system assisting / motivating a population of users interested in information about certain categories of subjects to automatically maintain the database content and to improve the usefulness and quality of the database information without any substantial management by the website owner-manager. The user opinions are primarily in the form of both comments and ratings about which natural-language terms best describe a particular subject, enabling user searches of the subject database to be by way of preferred such descriptive natural-language terms, which terms are further preferred to be evaluative and approving. Also, a system for automatically creating and maintaining a database of information utilizing user knowledge about sales related subjects. Described is an Internet-based system for assisting / motivating a population of users interested in information about certain categories of sales related subjects to automatically maintain the database content and to improve the usefulness and quality of the database information without any substantial management by the website owner-manager. The user opinions are primarily in the form of both comments and ratings of which sales related subjects best provide assistance in completing a sale.

Owner:QUICK COMMENTS

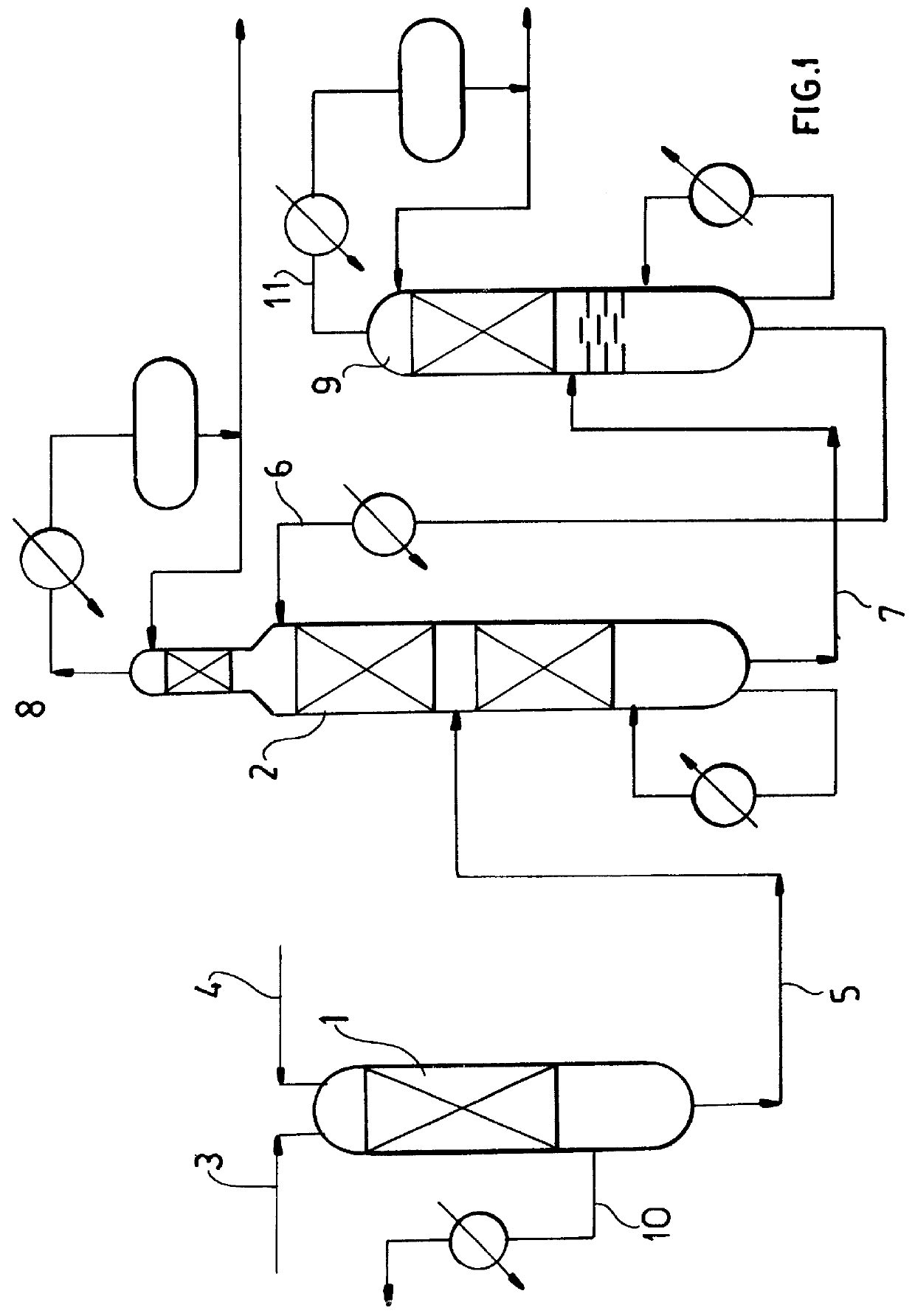

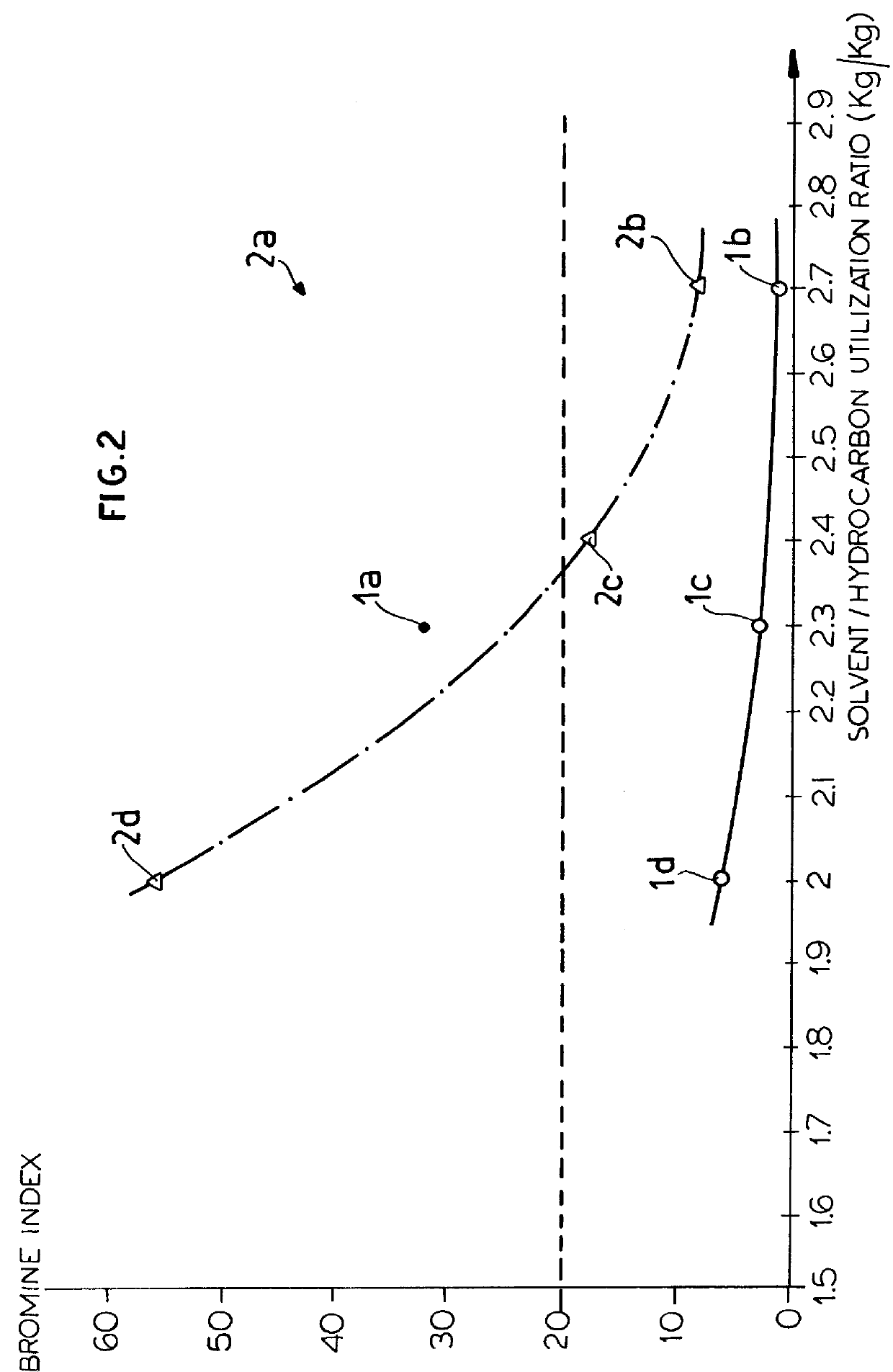

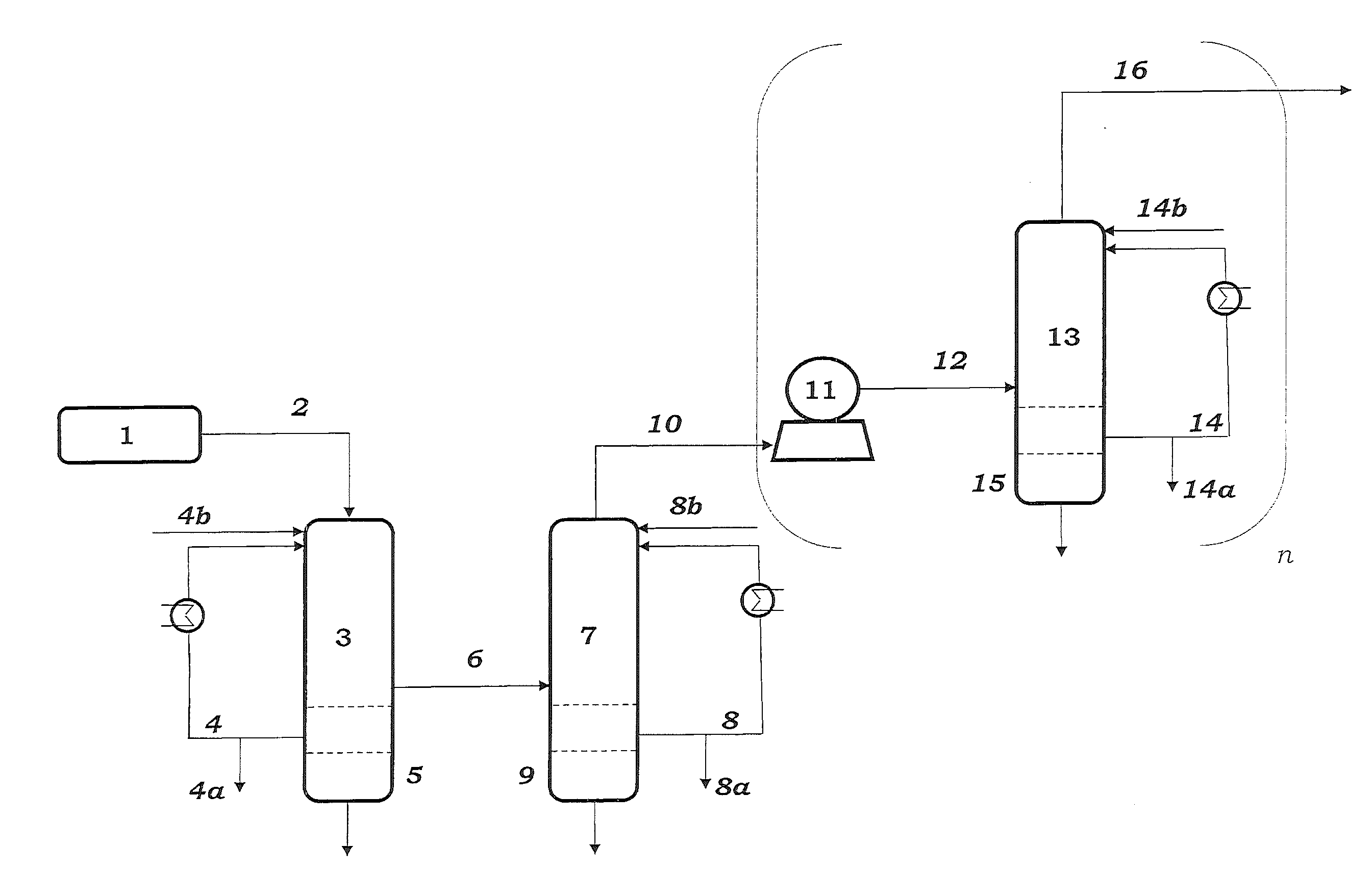

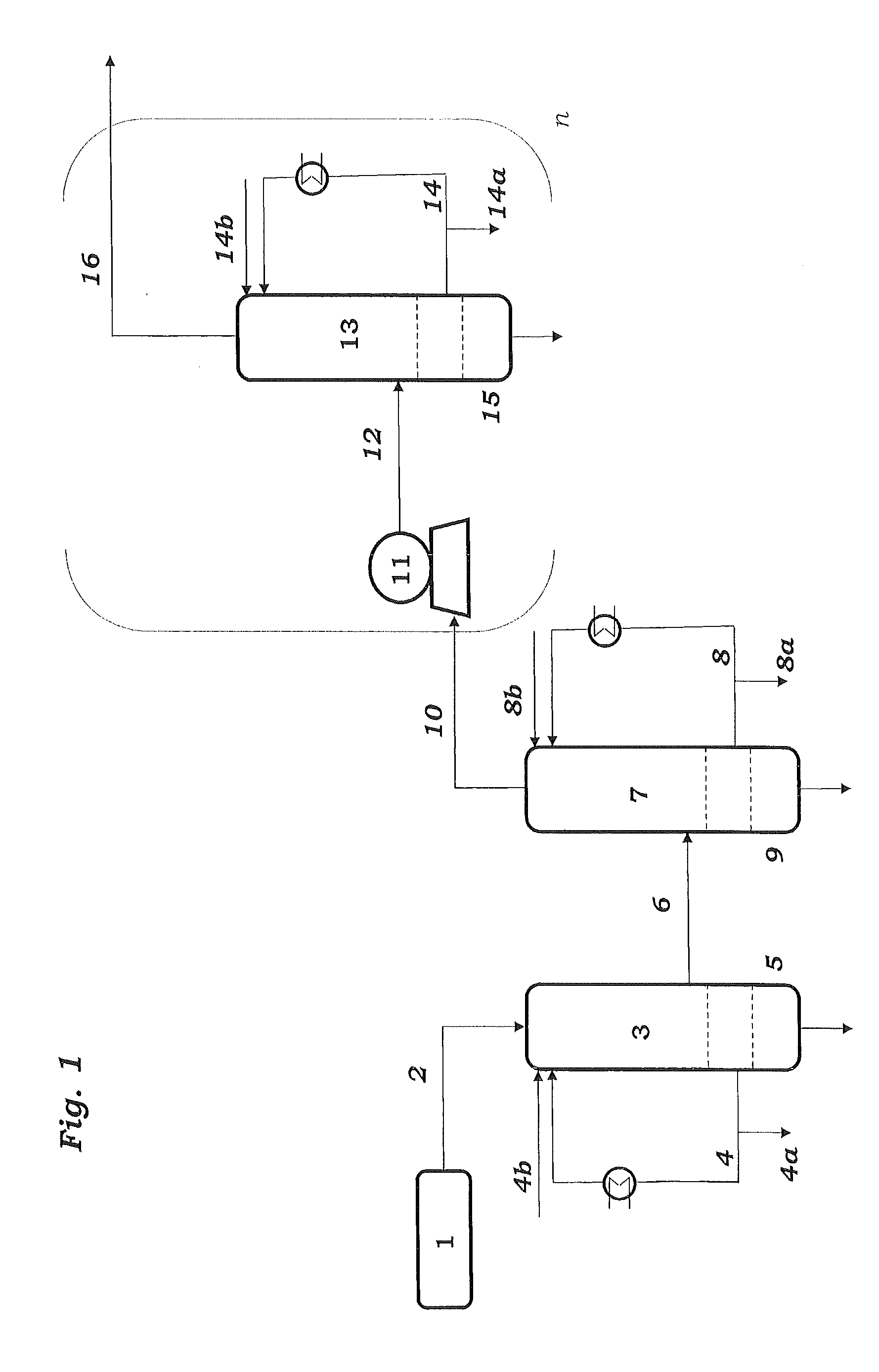

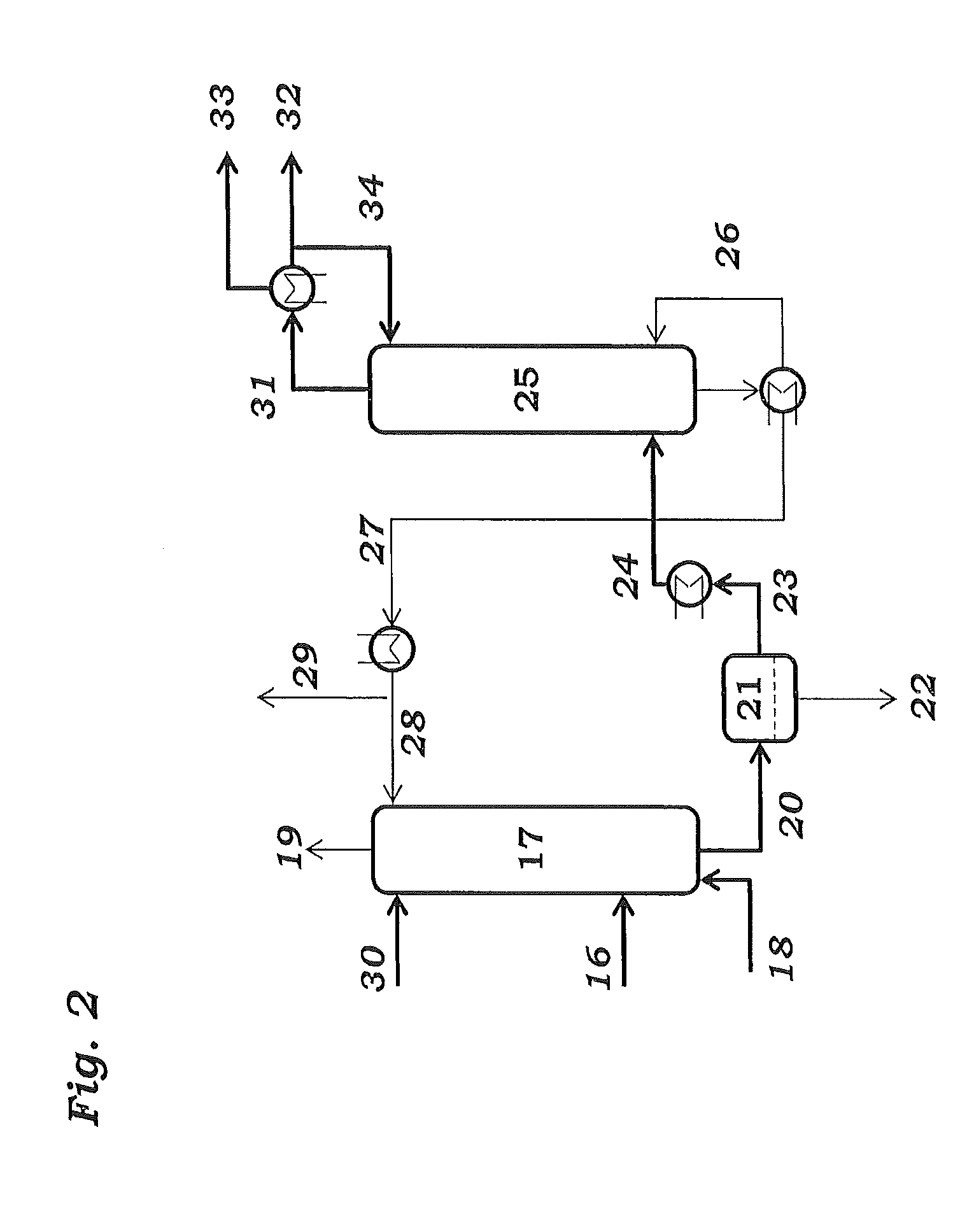

Process for generating pure benzene from reformed gasoline

InactiveUS6124514AReduce benzene contentAchieve separationThermal non-catalytic crackingCatalytic crackingBenzeneExtractive distillation

A process is disclosed for generating pure aromatic compounds from a reformed gasoline which contains aromatic compounds, olefins, diolefin, and triolefins, which comprises the steps of: (a) selectively hydrogenating the olefins, diolefins and triolefins in the reformed gasoline to obtain a mixture of hydrogenated, non-aromatic compounds and aromatic compounds; and (b) separating the aromatic compounds from the hydrogenated, non-aromatic compounds in the mixture formed during step (a) by either extractive distillation, liquid-liquid extraction or both to obtain the pure aromatic compounds.

Owner:BASF AG

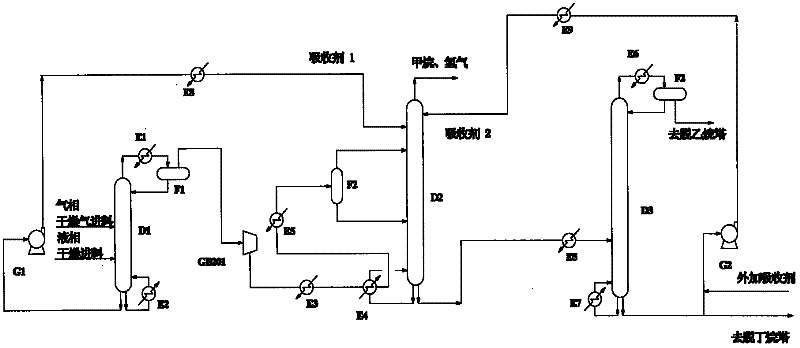

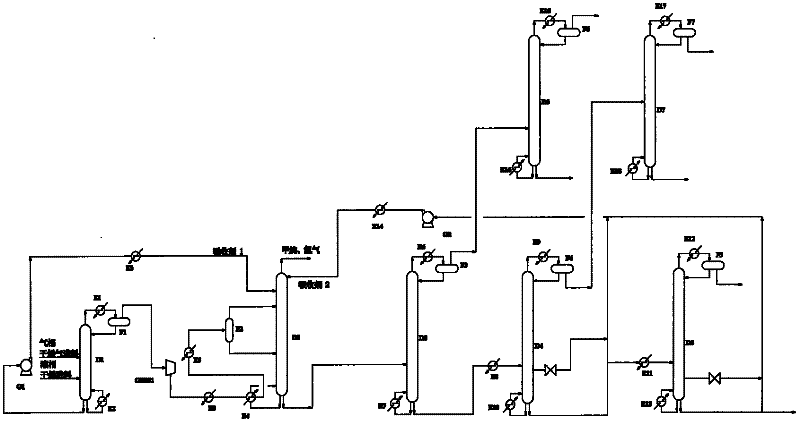

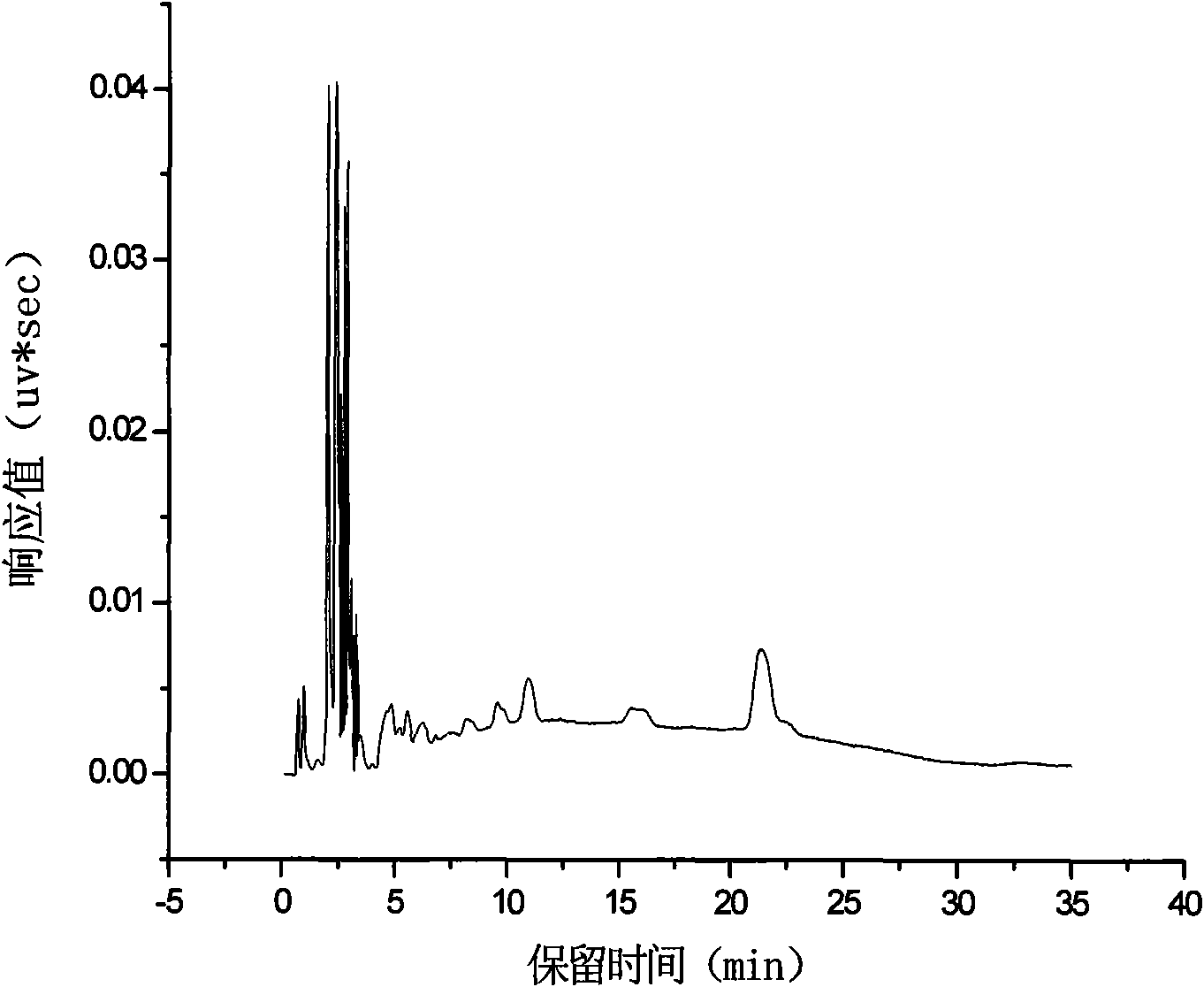

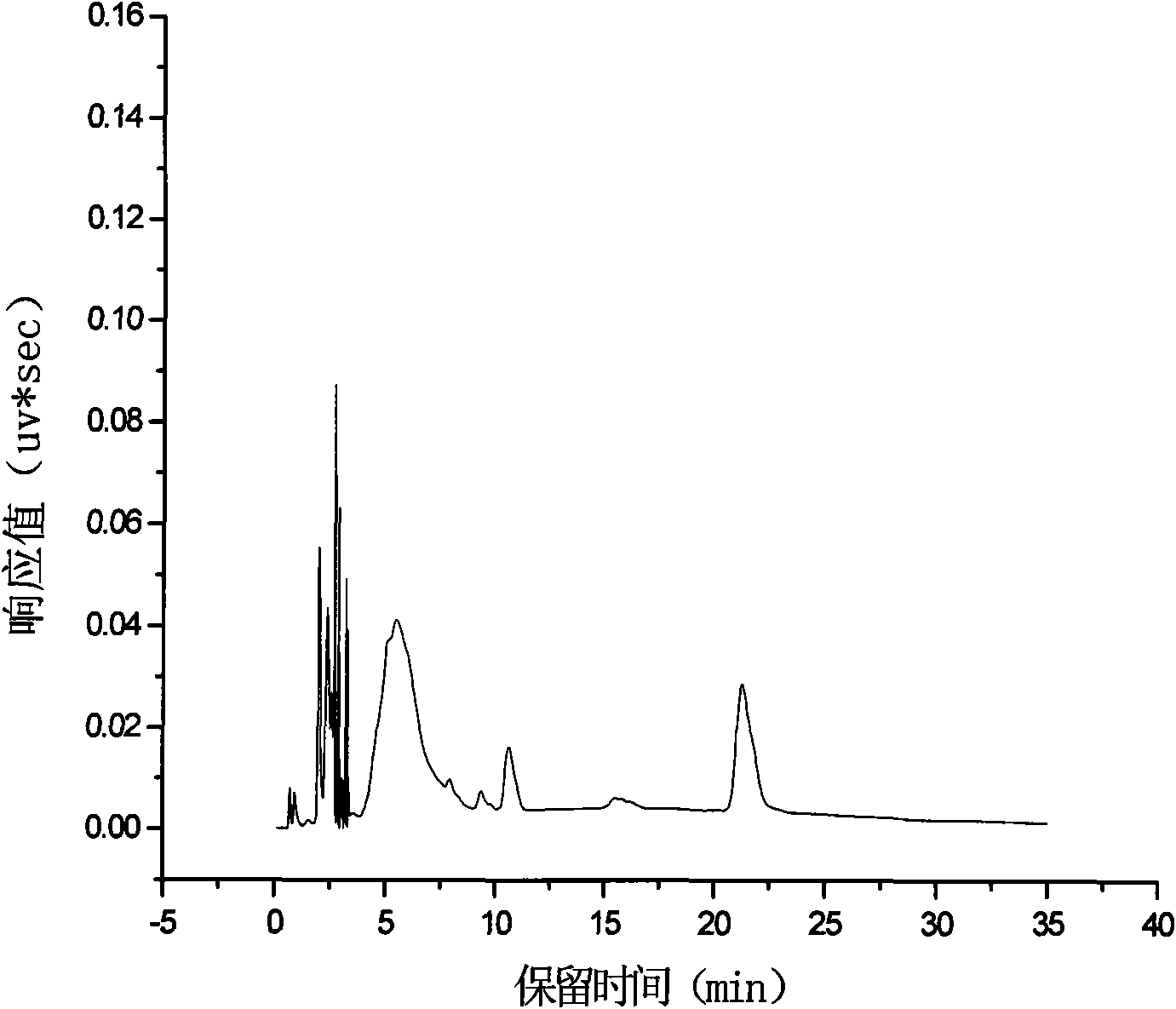

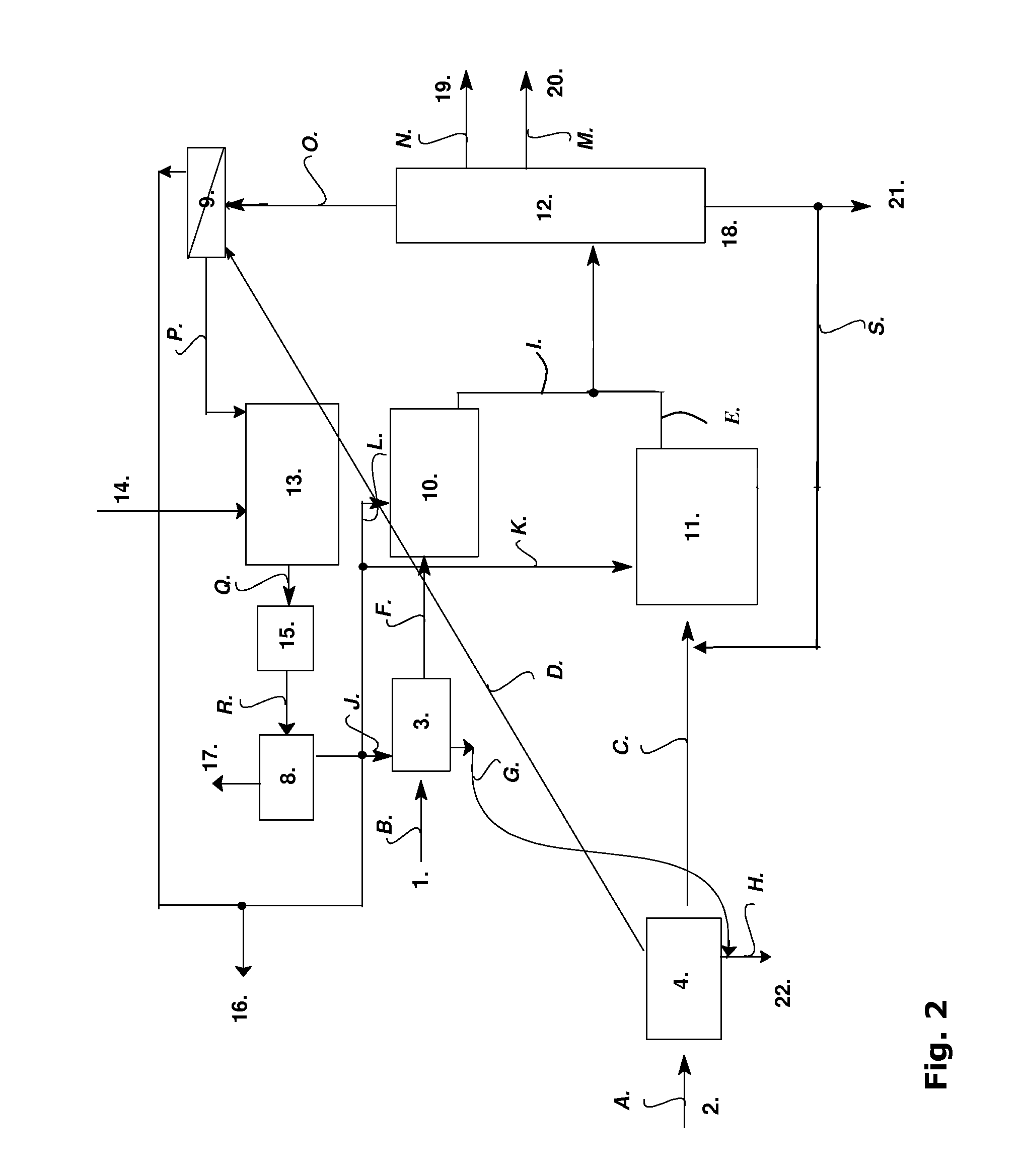

Process for Preparing Butadiene by Oxidative Dehydrogenation of N-Butenes with Monitoring of the Peroxide Content During Work-Up of the Product

InactiveUS20140200381A1Analysis using chemical indicatorsHydrocarbon by hydrogenationWater vaporDesorption

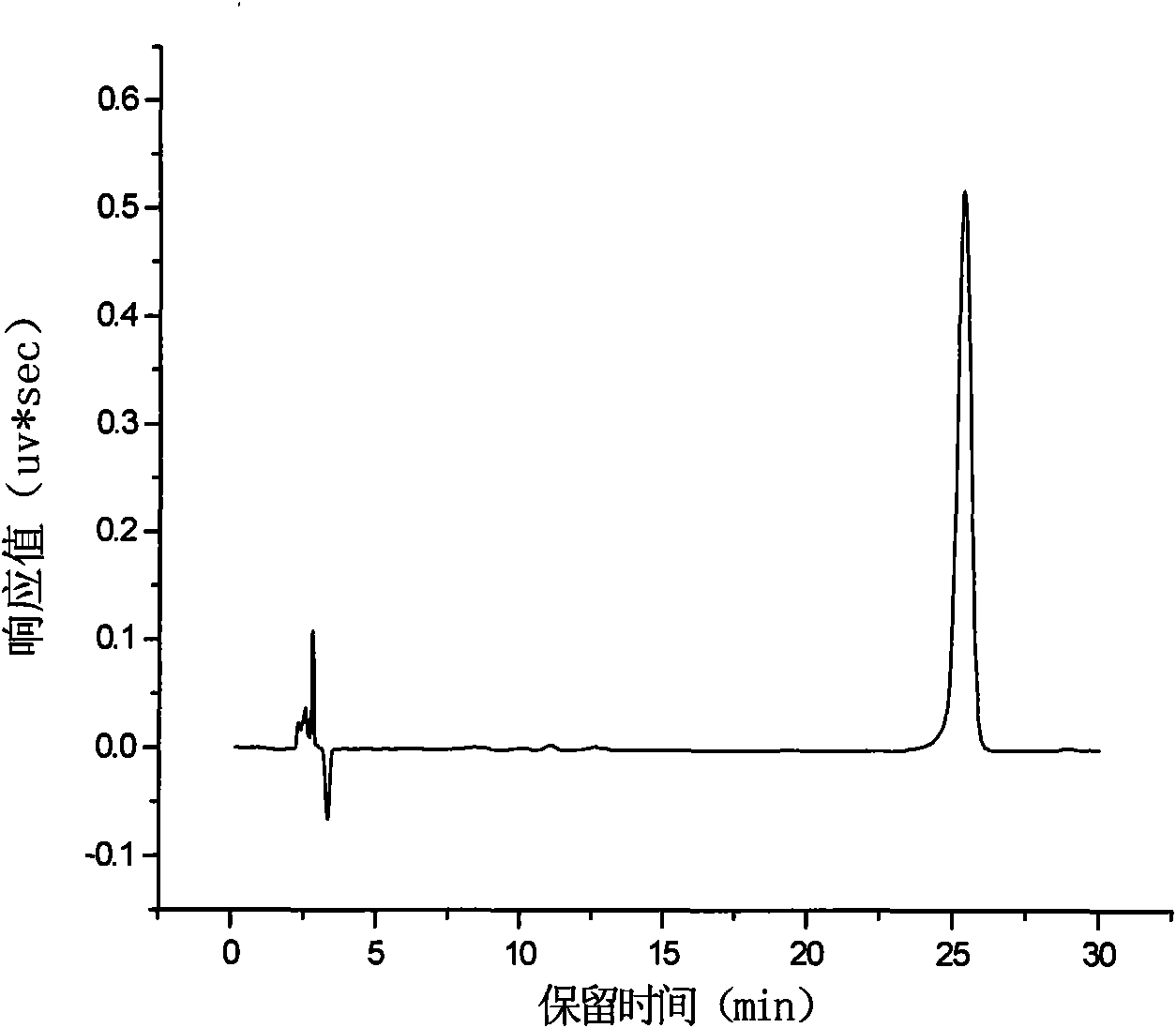

The invention relates to a process for preparing butadiene from n-butenes, which comprises the following steps:A) provision of a feed gas stream a comprising n-butenes;B) introduction of the feed gas stream a comprising n-butenes and an oxygen-comprising gas into at least one dehydrogenation zone and oxidative dehydrogenation of n-butenes to butadiene, giving a product gas stream b comprising butadiene, unreacted n-butenes, water vapor, oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases;C) cooling and compression of the product gas stream b in at least one cooling stage and at least one compression stage, with the product gas stream b being brought into contact with a circulated coolant to give at least one condensate stream c1 comprising water and a gas stream c2 comprising butadiene, n-butenes, water vapor, oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases;D) separation of incondensable and low-boiling gas constituents comprising oxygen, low-boiling hydrocarbons, possibly carbon oxides and possibly inert gases as gas stream d2 from the gas stream c2 by absorption of the C4-hydrocarbons comprising butadiene and n-butenes in a circulated absorption medium, giving an absorption medium stream loaded with C4-hydrocarbons and the gas stream d2, and subsequent desorption of the C4-hydrocarbons from the loaded absorption medium stream to give a C4 product gas stream d1;E) separation of the C4 product stream d1 by extractive distillation using a solvent which is selective for butadiene into a stream e1 comprising butadiene and the selective solvent and a stream e2 comprising n-butenes;F) distillation of the stream e1 comprising butadiene and the selective solvent to give a stream f1 consisting essentially of the selective solvent and a stream f2 comprising butadiene;where samples are taken from the circulated coolant in step C) and / or the circulated absorption medium in step D) and the peroxide content of the samples taken is determined by means of iodometry, differential scanning calorimetry (DSC) or microcalorimetry.

Owner:BASF AG

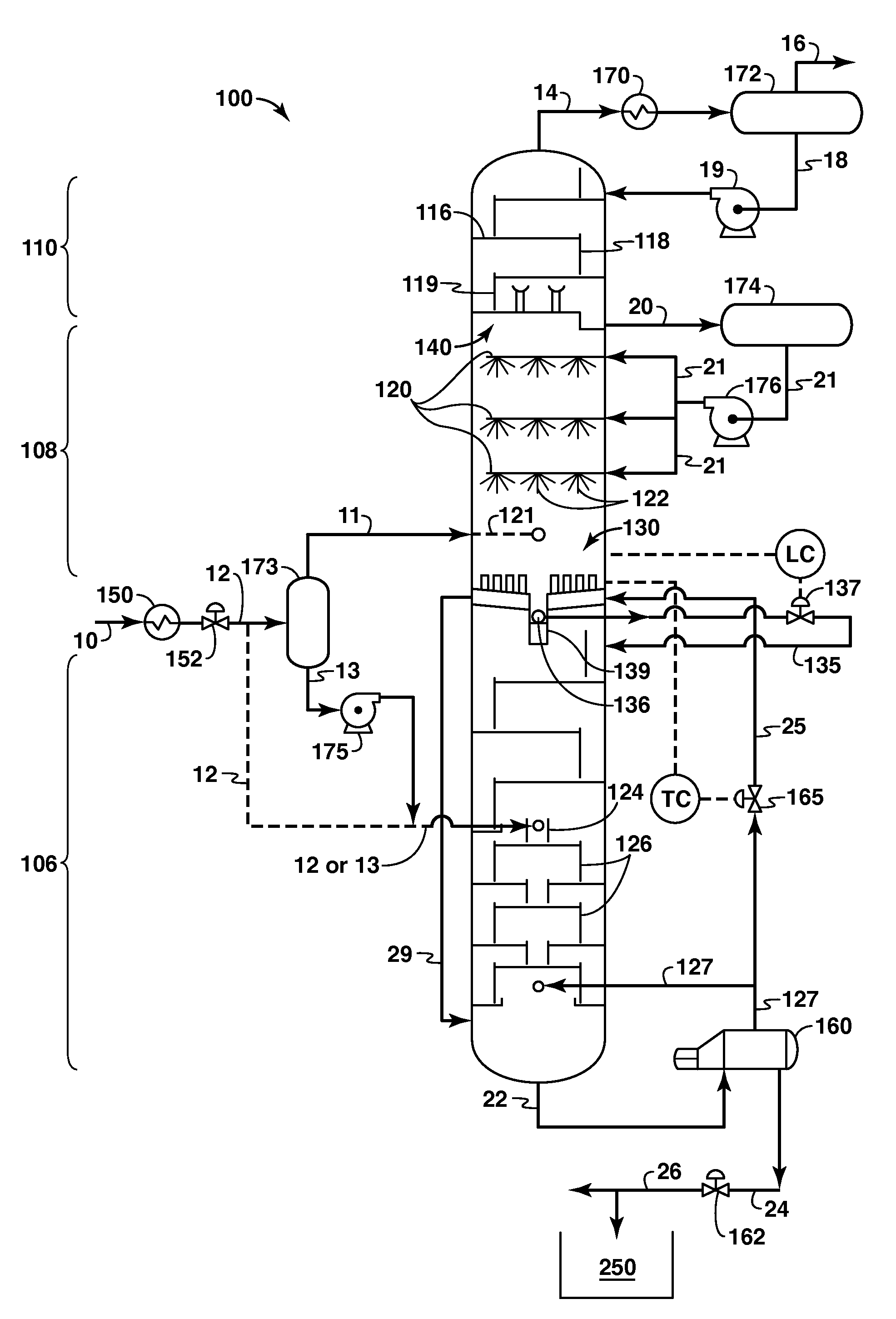

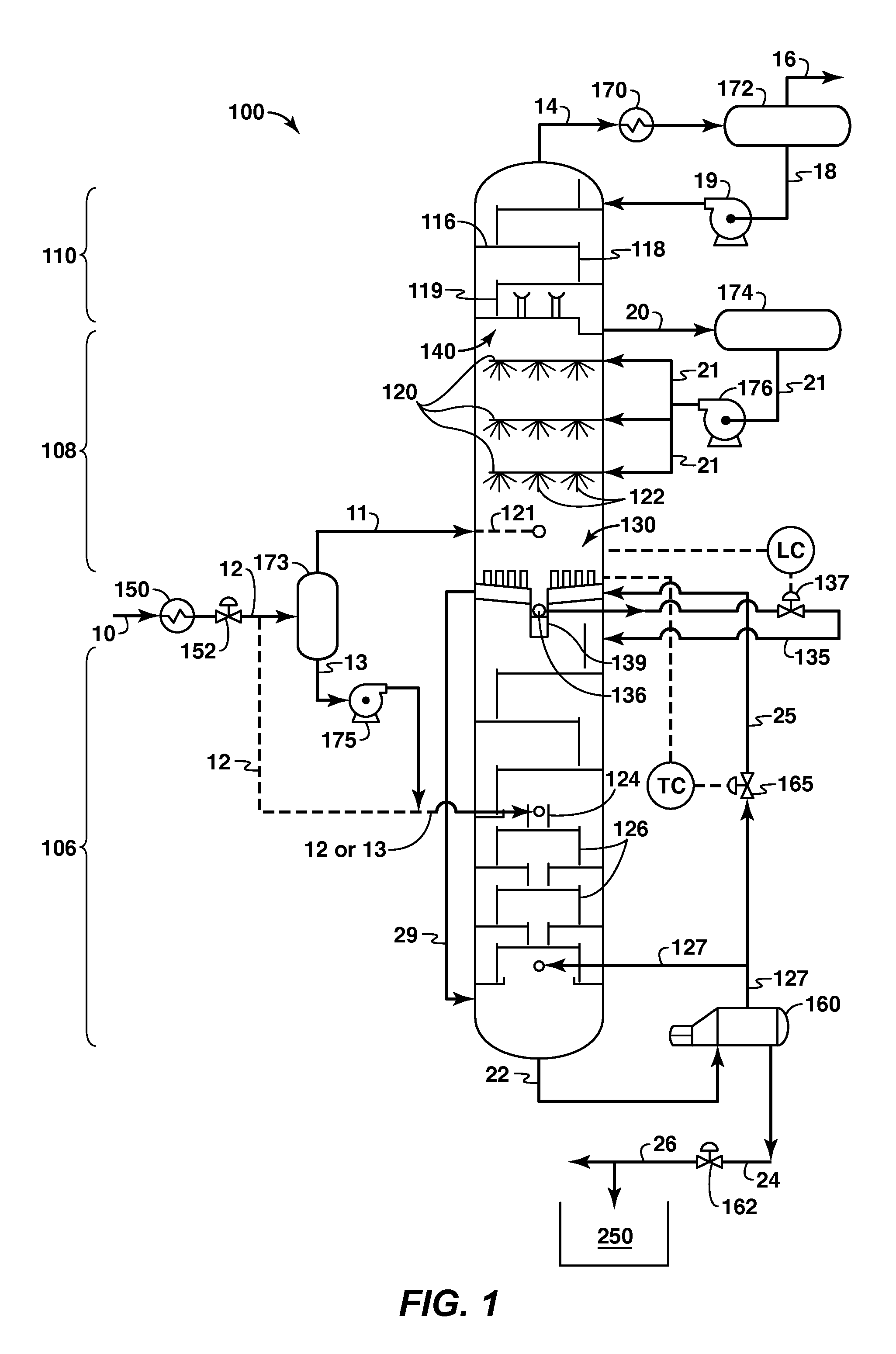

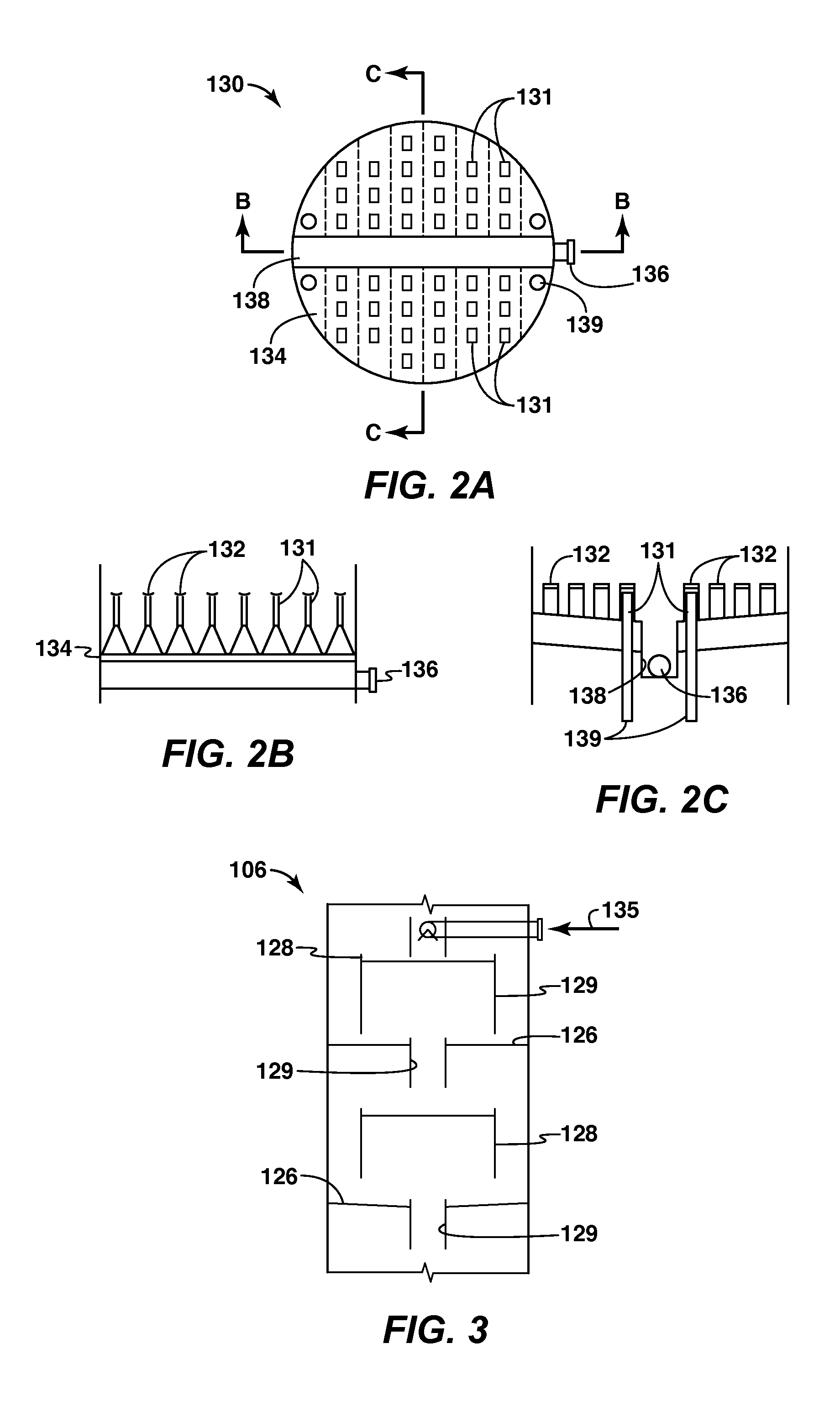

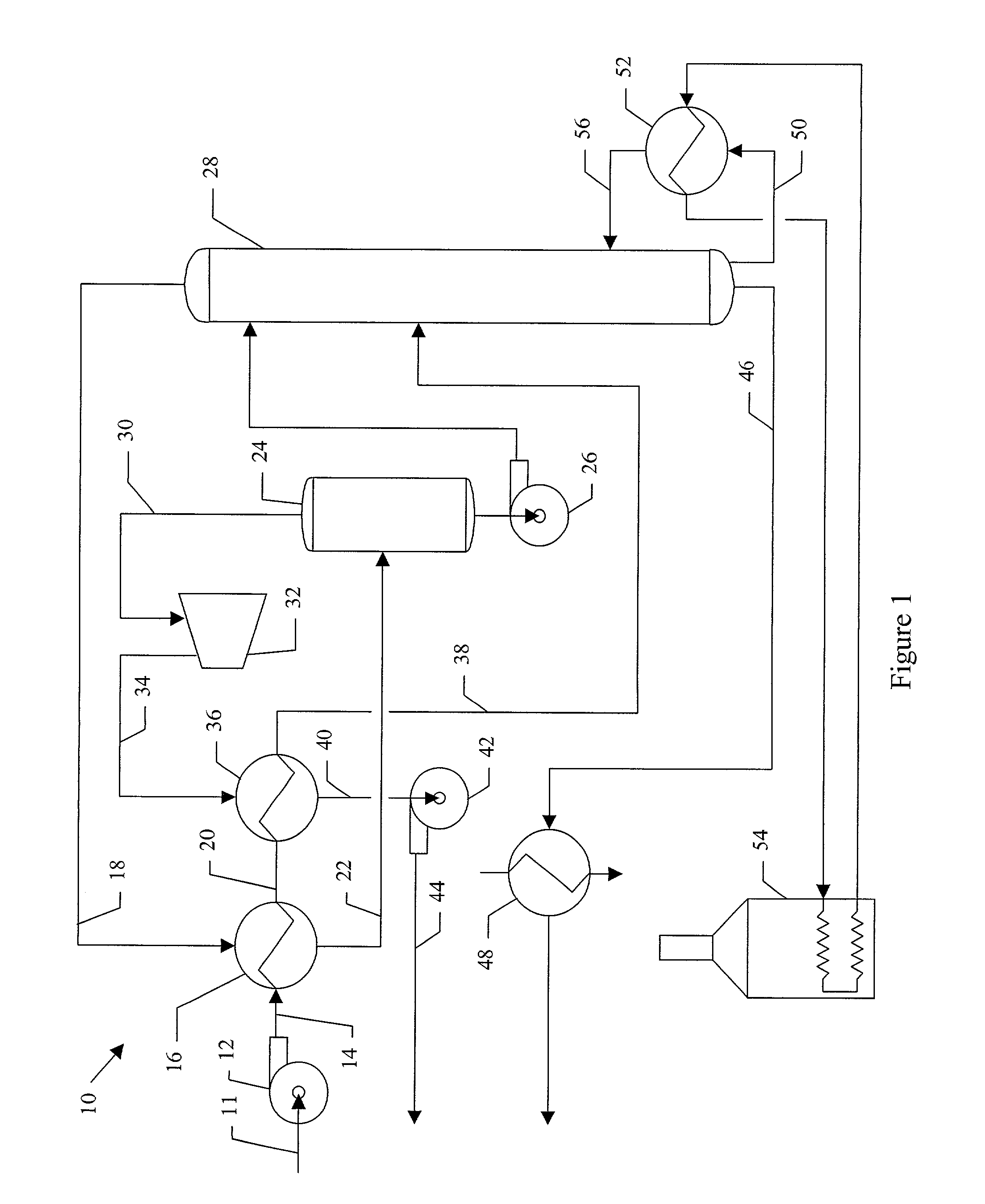

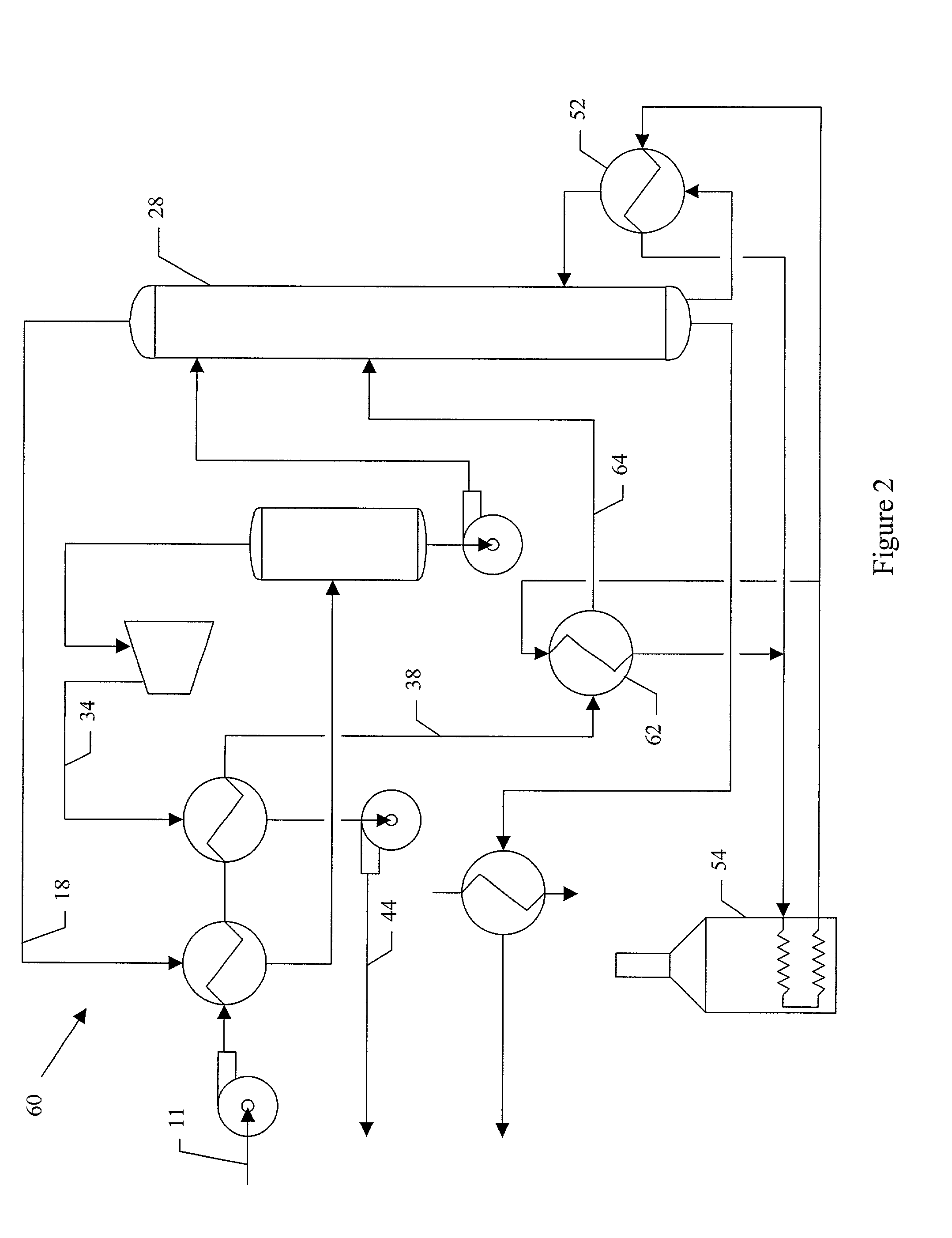

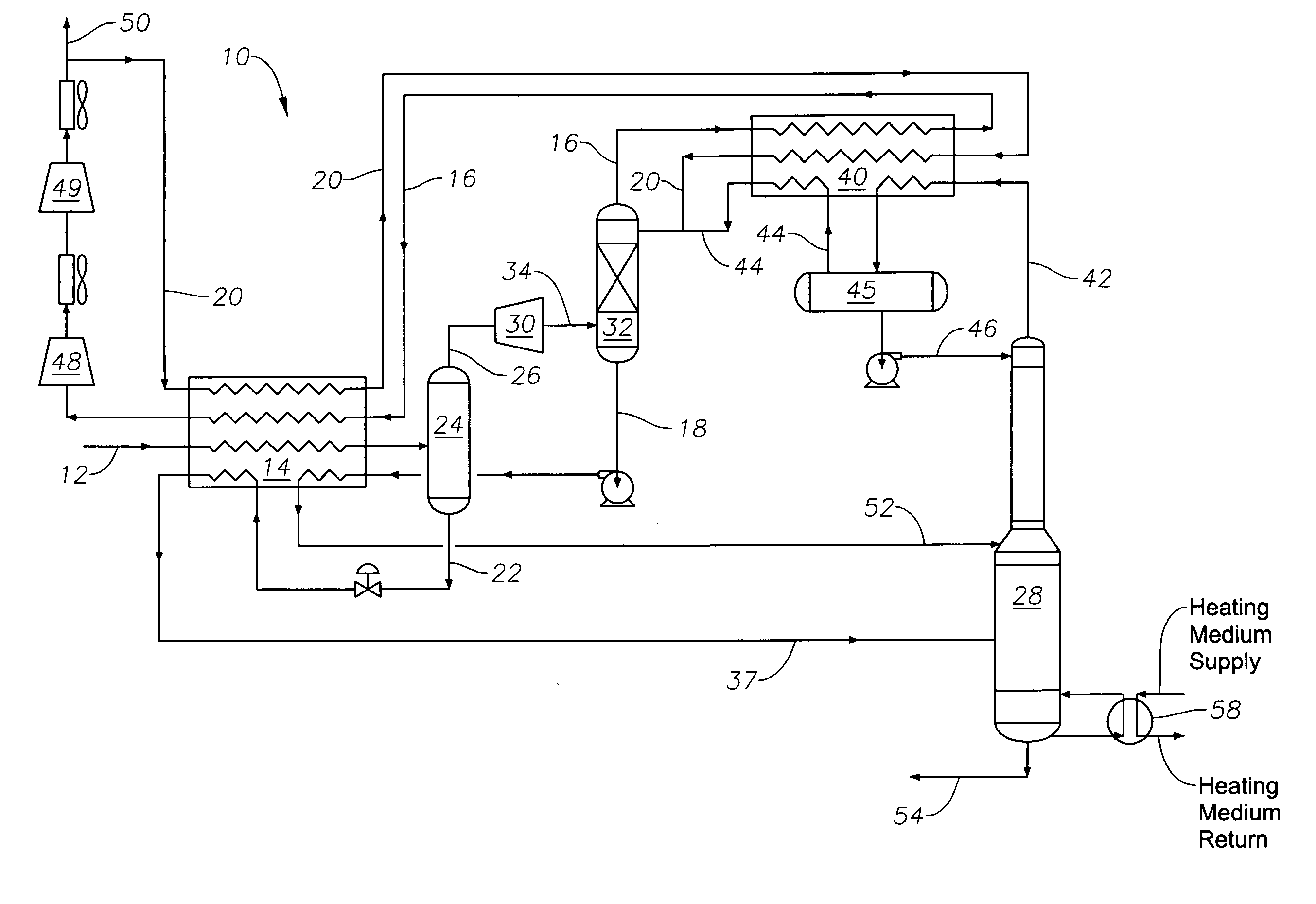

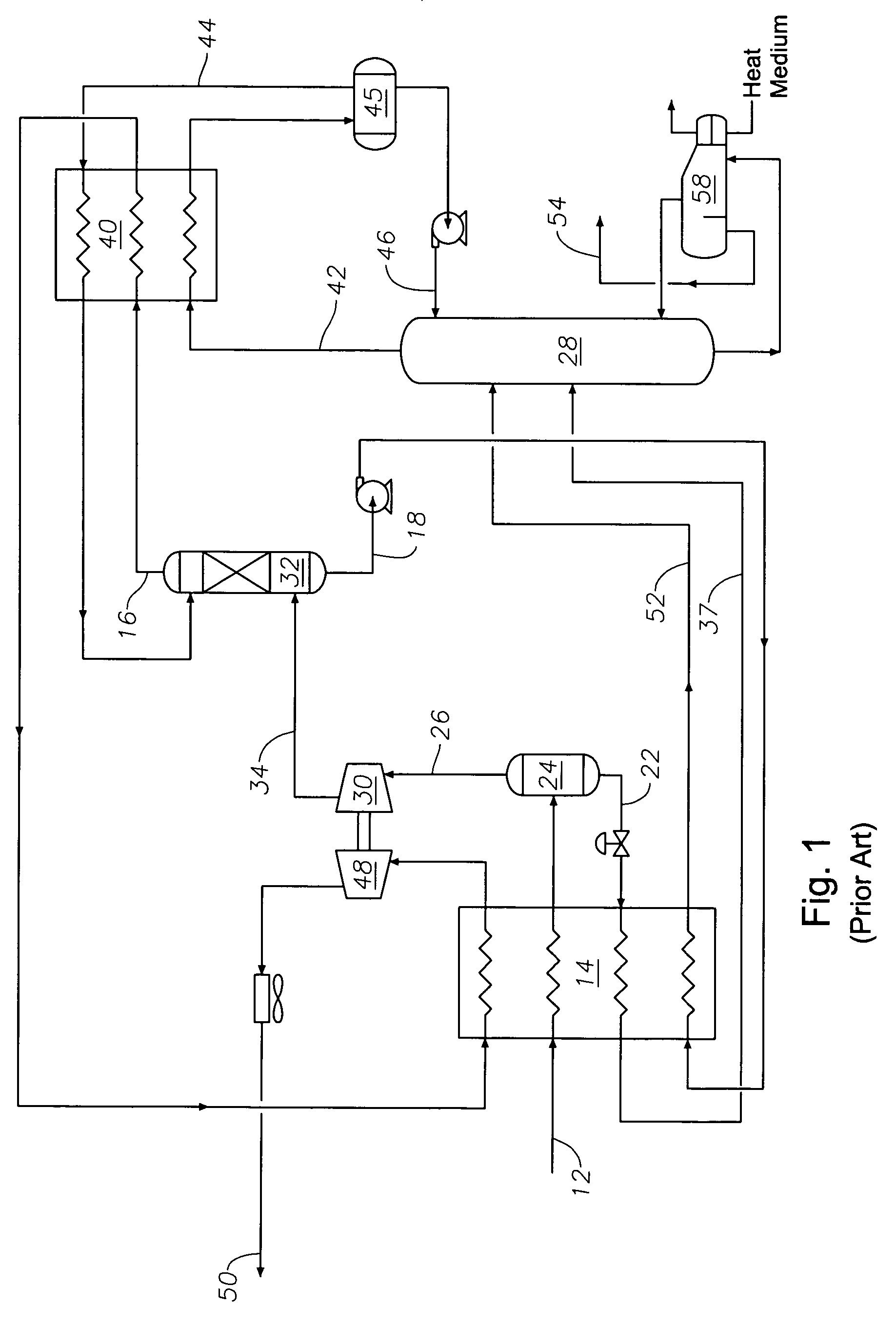

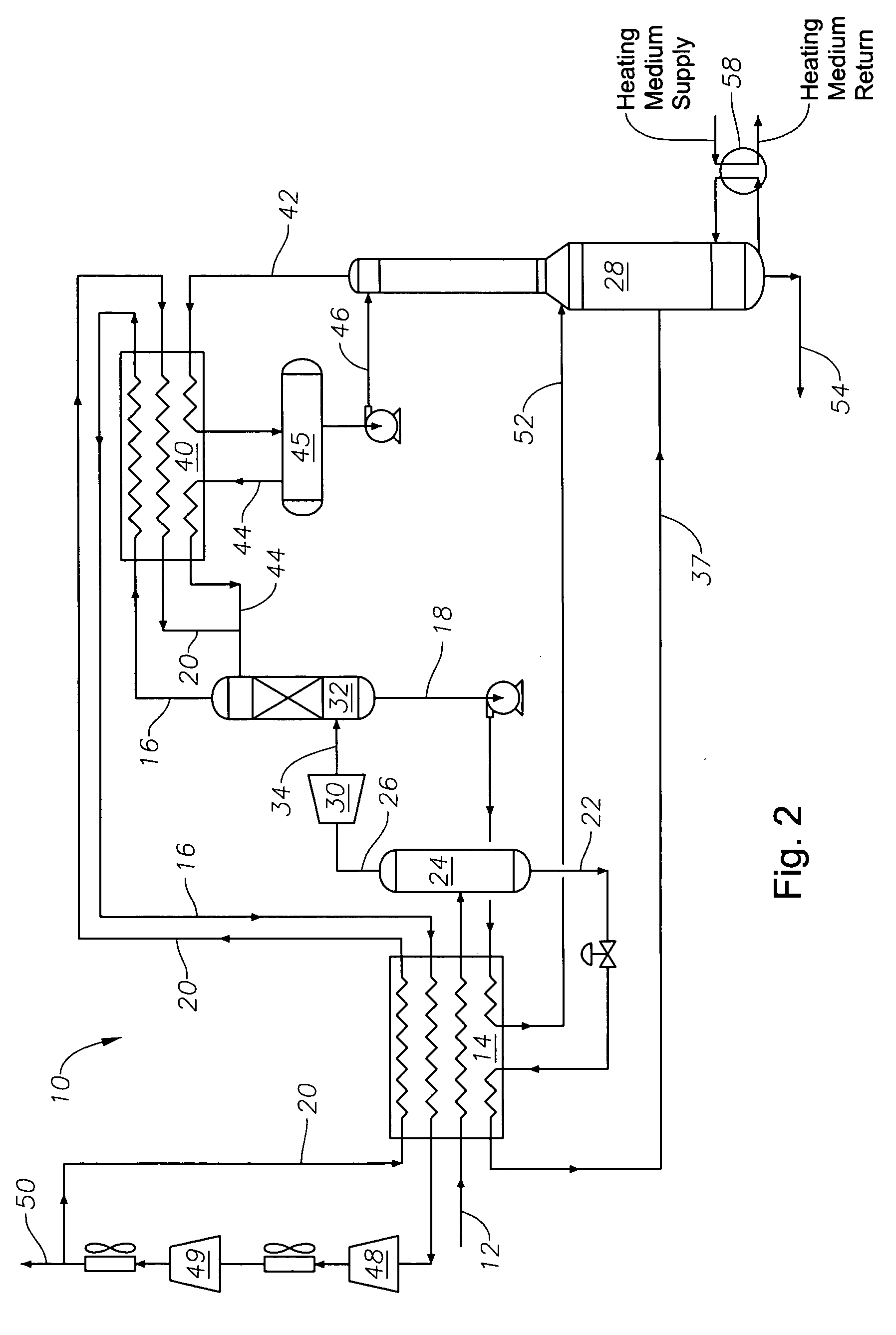

Systems and Methods for Removing Heavy Hydrocarbons and Acid Gases From a Hydrocarbon Gas Stream

A system for removing acid gases from a sour gas stream is provided. The system includes an acid gas removal system and a heavy hydrocarbon removal system. The acid gas removal system receives the sour gas stream and separates the sour gas stream into an overhead gas stream comprised primarily of methane, and a bottom acid gas stream comprised primarily of acid gases such as carbon dioxide. The heavy hydrocarbon removal system may be placed upstream or downstream of the acid gas removal system or both. The heavy hydrocarbon removal system receives a gas stream and separates the gas stream into a first fluid stream comprising heavy hydrocarbons and a second fluid stream comprising other components. The components of the second fluid stream will depend on the composition of the gas stream. Various types of heavy hydrocarbon removal systems may be utilized.

Owner:NORTHROP PAUL SCOTT +4

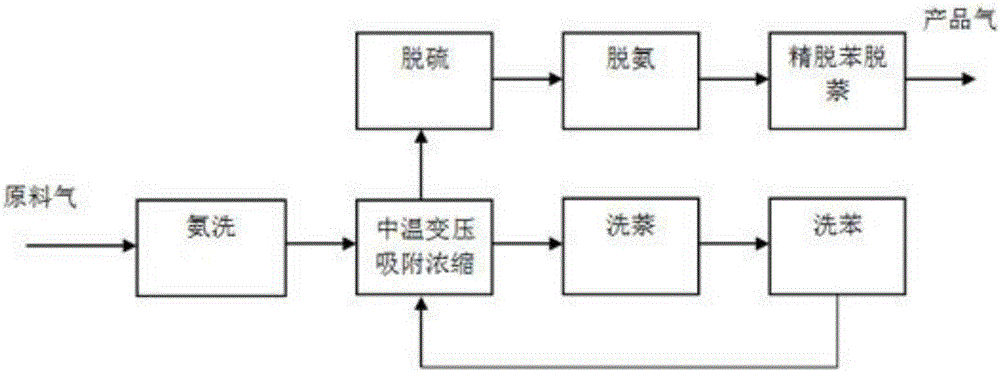

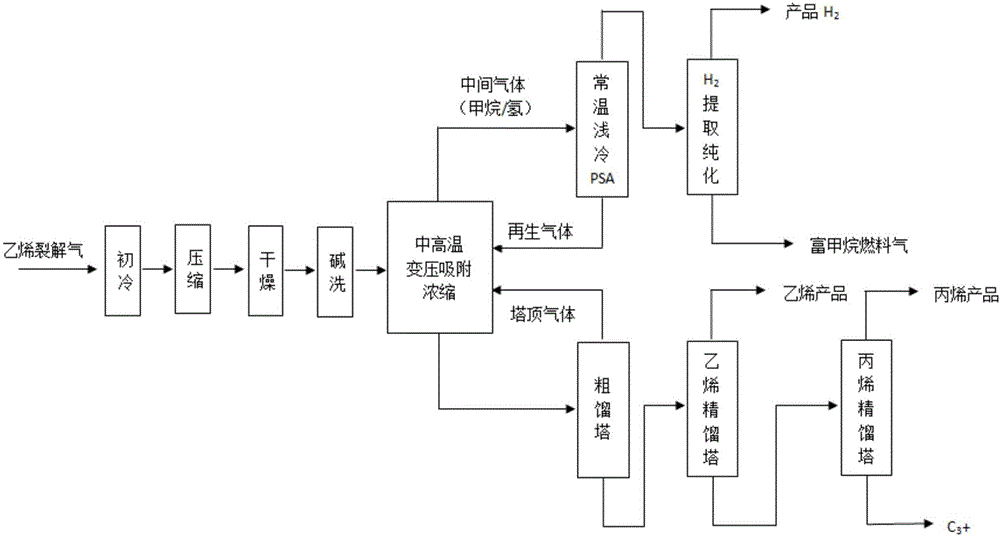

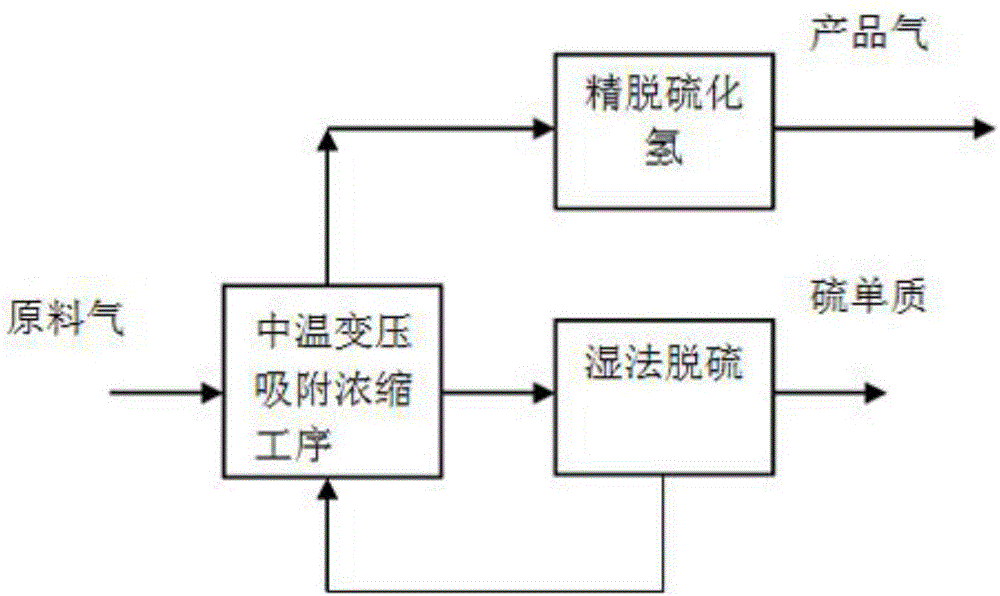

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

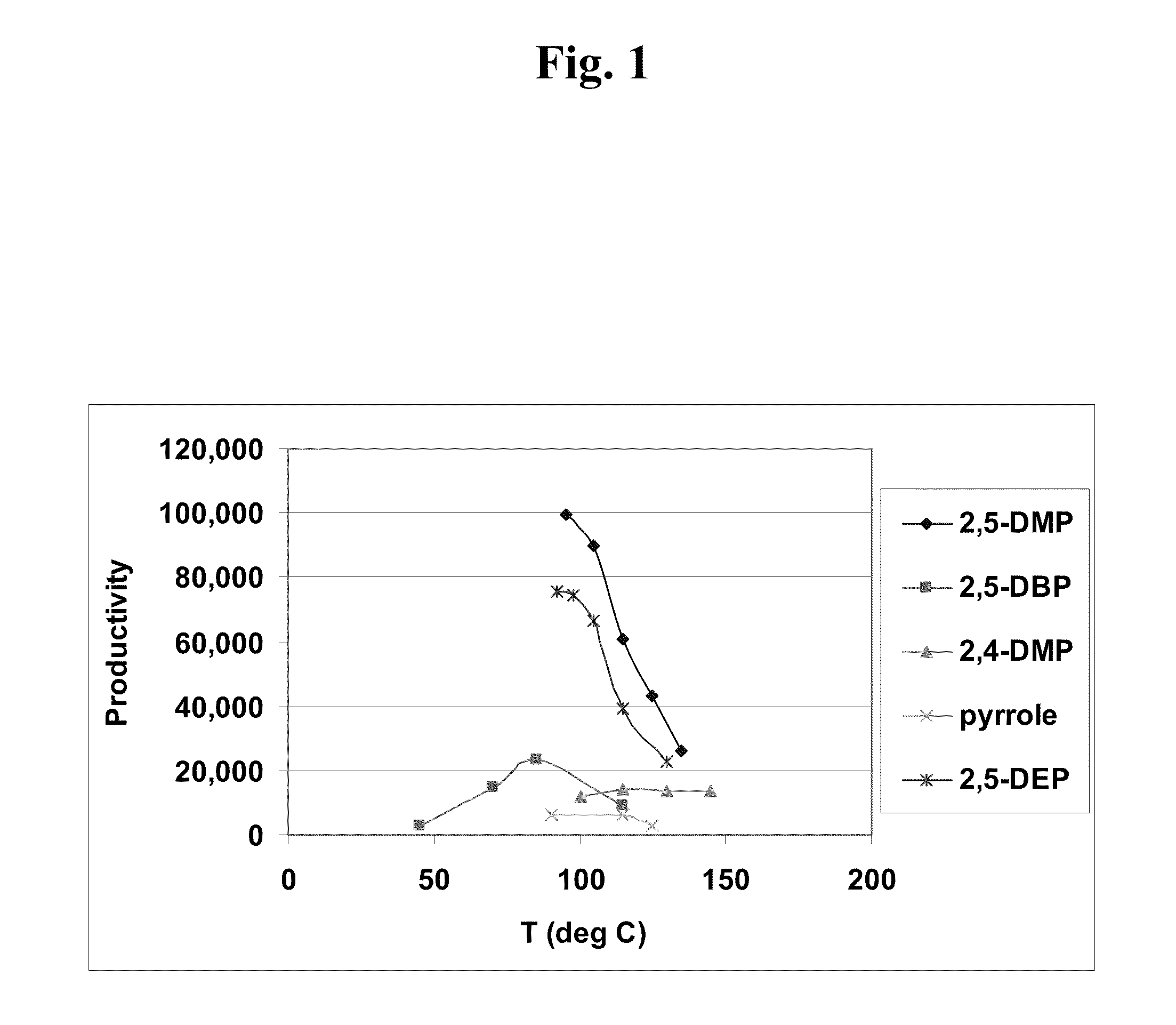

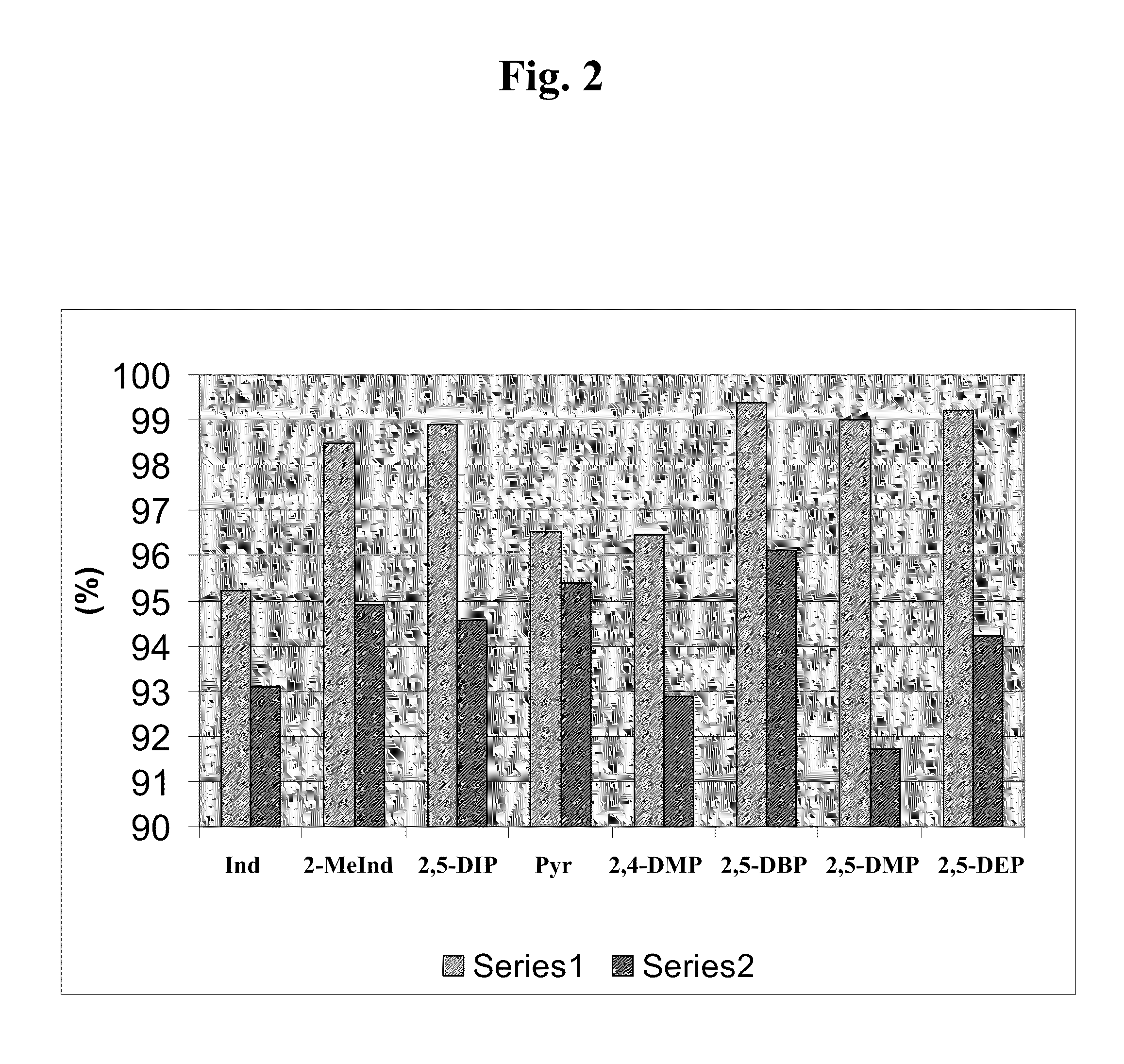

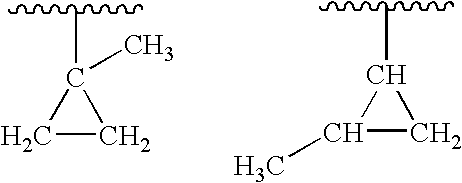

Oligomerization catalyst system and process for oligomerizing olefins

ActiveUS20100113852A1High catalytic activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsDistillation purification/separationAlkenePyrrole

Among other things, this disclosure provides an olefin oligomerization system and process, the system comprising: a) a transition metal compound; b) a pyrrole compound having independently-selected C1 to C18 organyl groups at the 2- and 5-positions, wherein at least one of the organyl group alpha-carbon atoms attached to the 2- and 5-positions of the pyrrole compound is a secondary carbon atoms; and c) a metal alkyl. For example, the 2,5-diethylpyrrole (2,5-DEP)-based catalyst systems can afford a productivity increases over unsubstituted pyrrole catalyst systems, non-2,5-disubstituted catalyst systems, and 2,5-dimethylpyrrole (2,5-DMP) catalyst systems.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Cascade reboiling of ethylbenzene/styrene columns

InactiveUS6171449B1Reduce use costEfficient and economical approachDistillation regulation/controlDistillation in boilers/stillsCascadeEngineering

Apparatus and process are disclosed for the distillation separation of styrene monomer from ethylbenzene utilizing a split feed to two distillation columns in conjunction with cascade reboiling utilizing thermal energy from the overhead of one column to supply heat to the second.

Owner:STONE & WEBSTER PROCESS TECH

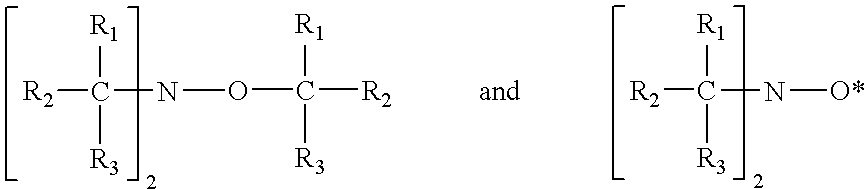

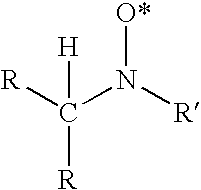

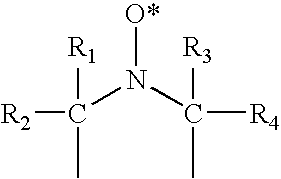

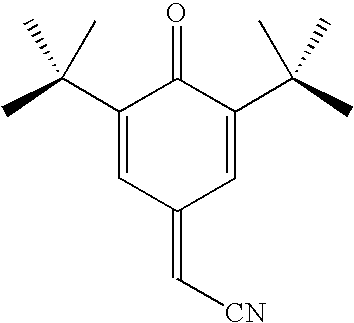

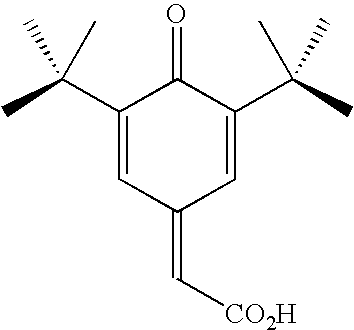

Blends of quinone alkide and nitroxyl compounds and polymerization inhibitors

InactiveUS7045647B2Improve performanceReduce the numberOrganic compounds purification/separation/stabilisationOrganic compound preparationQuinonePolymer science

Disclosed herein is a method for inhibiting the premature polymerization of ethylenically unsaturated monomers comprising adding to said monomers an effective amount of: A) at least one nitroxyl compound, and B) at least one quinone alkide compound having an electron-withdrawing group at the 7-position. Additionally, a composition is disclosed that comprises: A) at least one nitroxyl compound, and B) at least one quinone alkide compound having an electron-withdrawing group at the 7-position.

Owner:DEUT BANK AG NEW YORK BRANCH +1

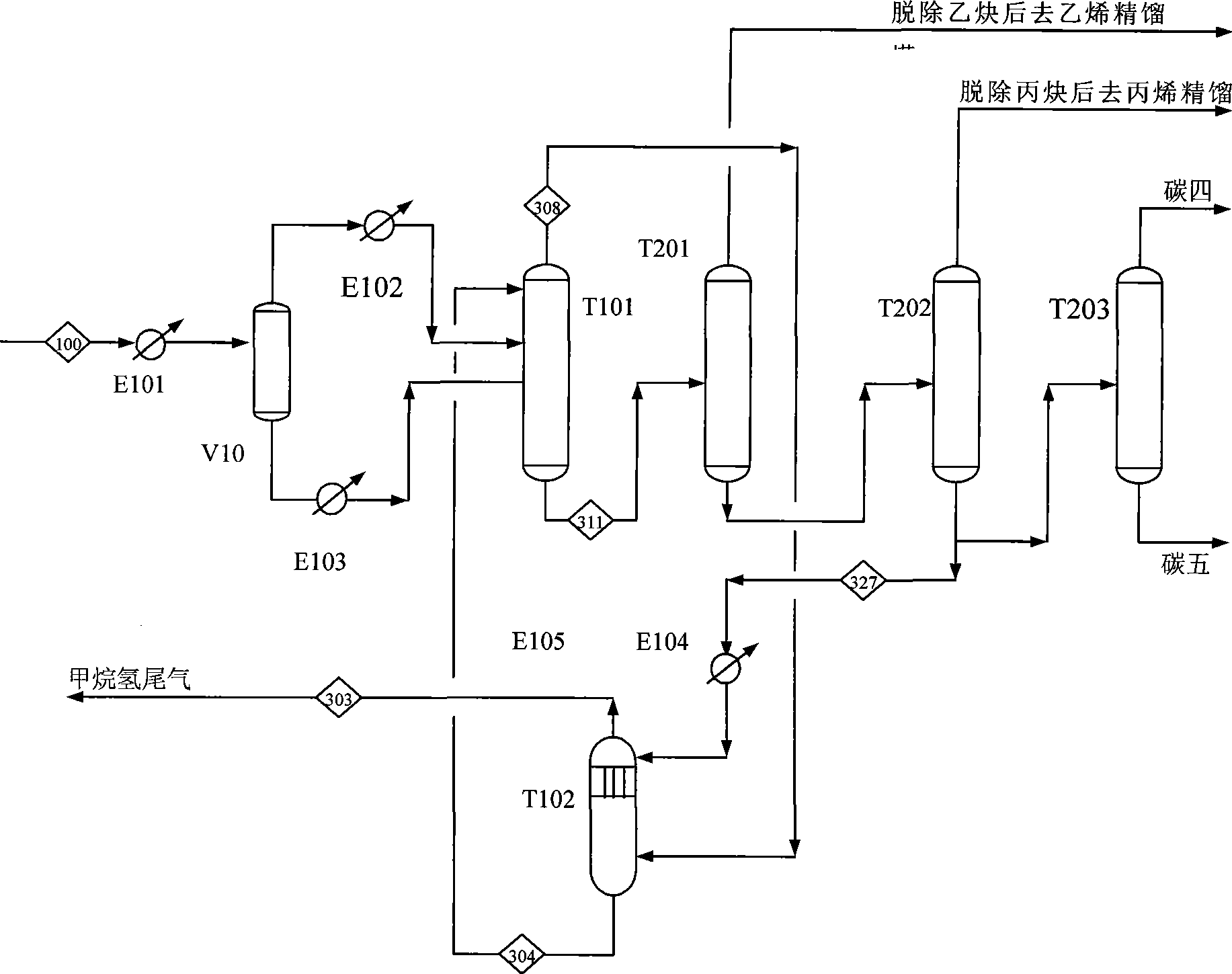

Separating method for converting methanol to prepare low carbon olefin gas

ActiveCN1847203AAvoid enteringReduce power consumptionDistillation purification/separationHydrocarbon from oxygen organic compoundsGas phaseTower

The present invention discloses separating method for converting methanol to prepare DMTO gas, and has improved process after four section compression in the front ethane eliminating process. The present invention has one increased hydrogenating oxygen conversion step between the five section compression and the reflux accumulator of ethane eliminating tower to eliminate acetylene and oxygen produced in the regeneration. Of the condensed and cooled material through the reflux accumulator of ethane eliminating tower, the liquid phase serves as the reflux liquid of the ethane eliminating tower, the gas phase is fed to the deep cooling methane eliminating system and the material after condensing and cooling enters the high pressure methane eliminating tower directly. The DMTO gas separating process can obtain ethylene recovering rate as high as 99.5 %.

Owner:CHINA PETROCHEMICAL CORP +1

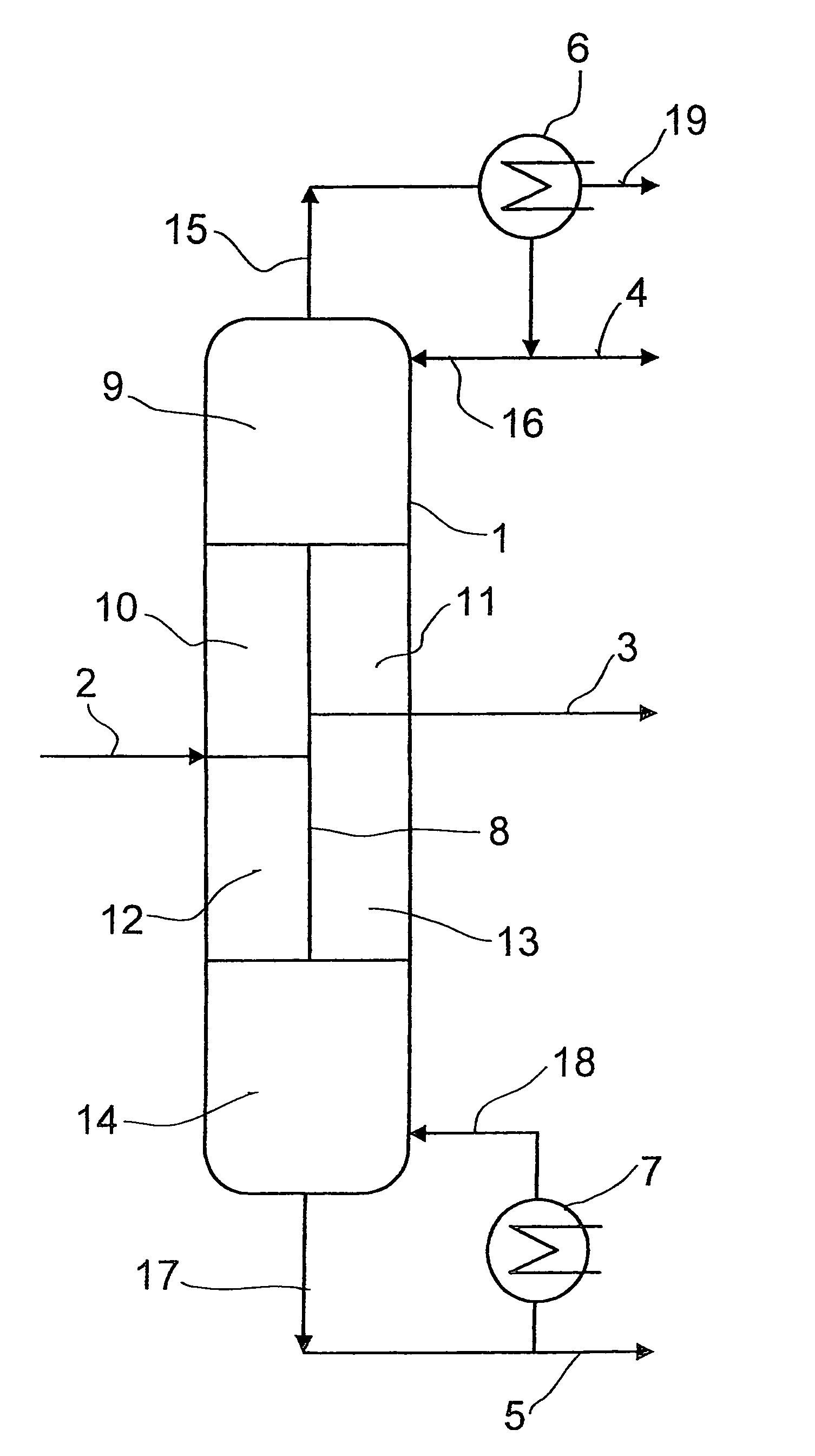

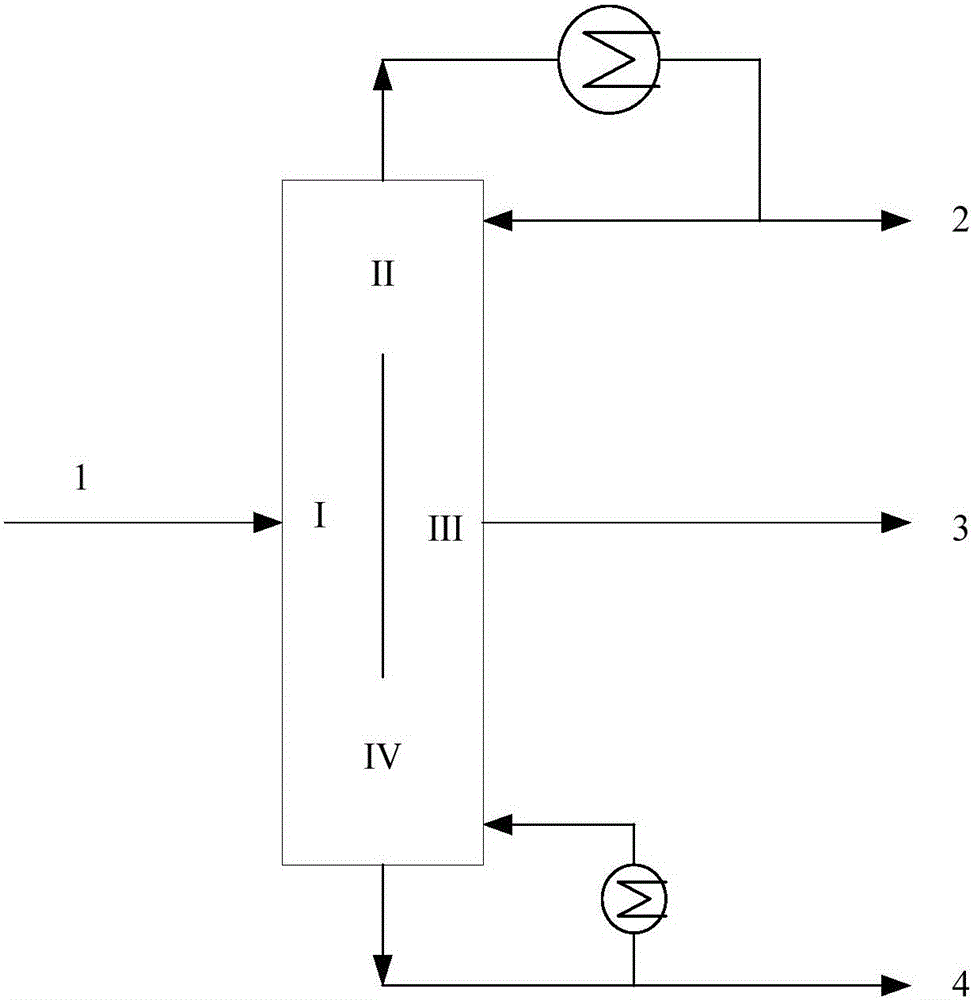

Apparatus and Methods for Separating Butene-1 from a Mixed C4 Feed

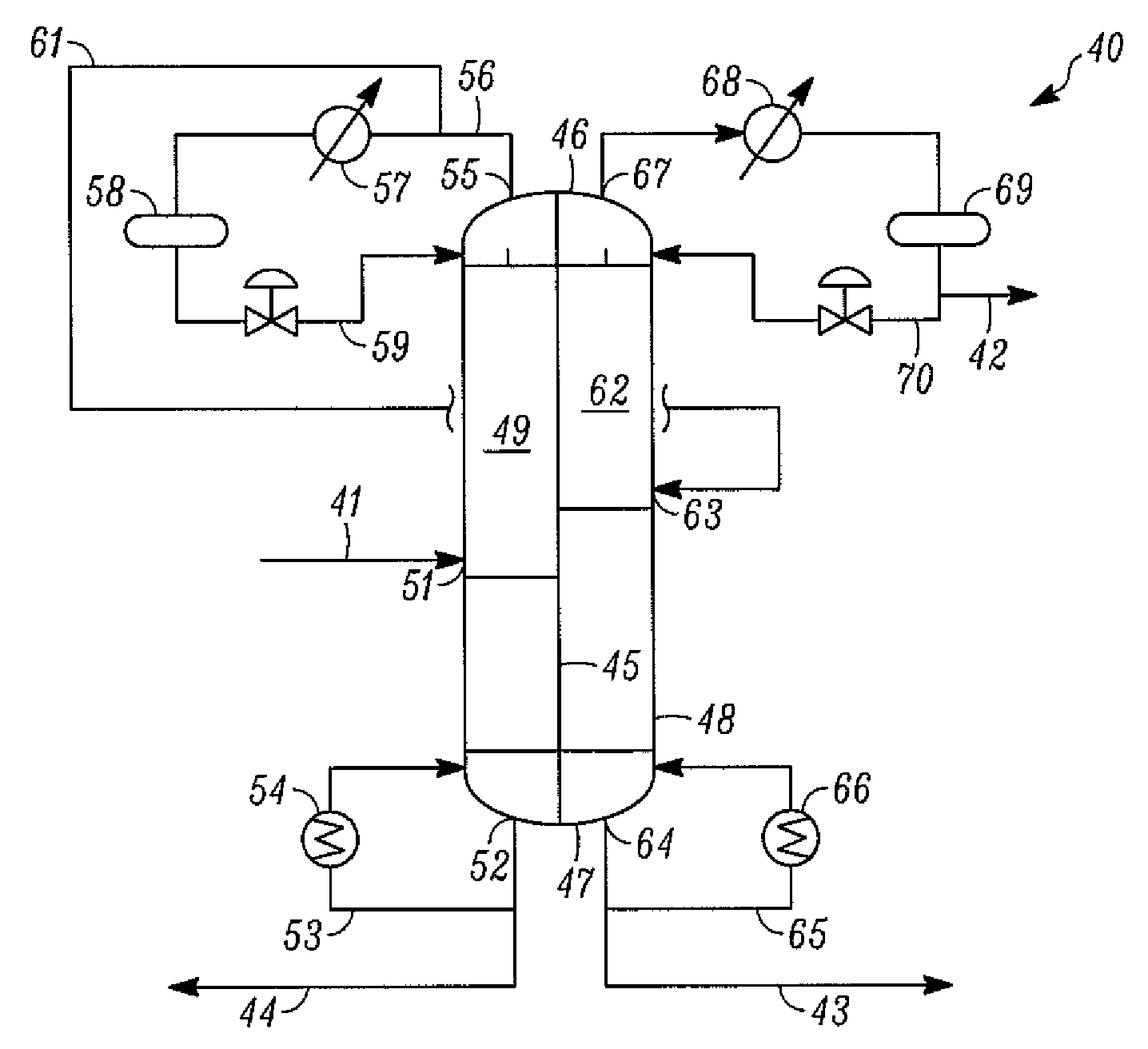

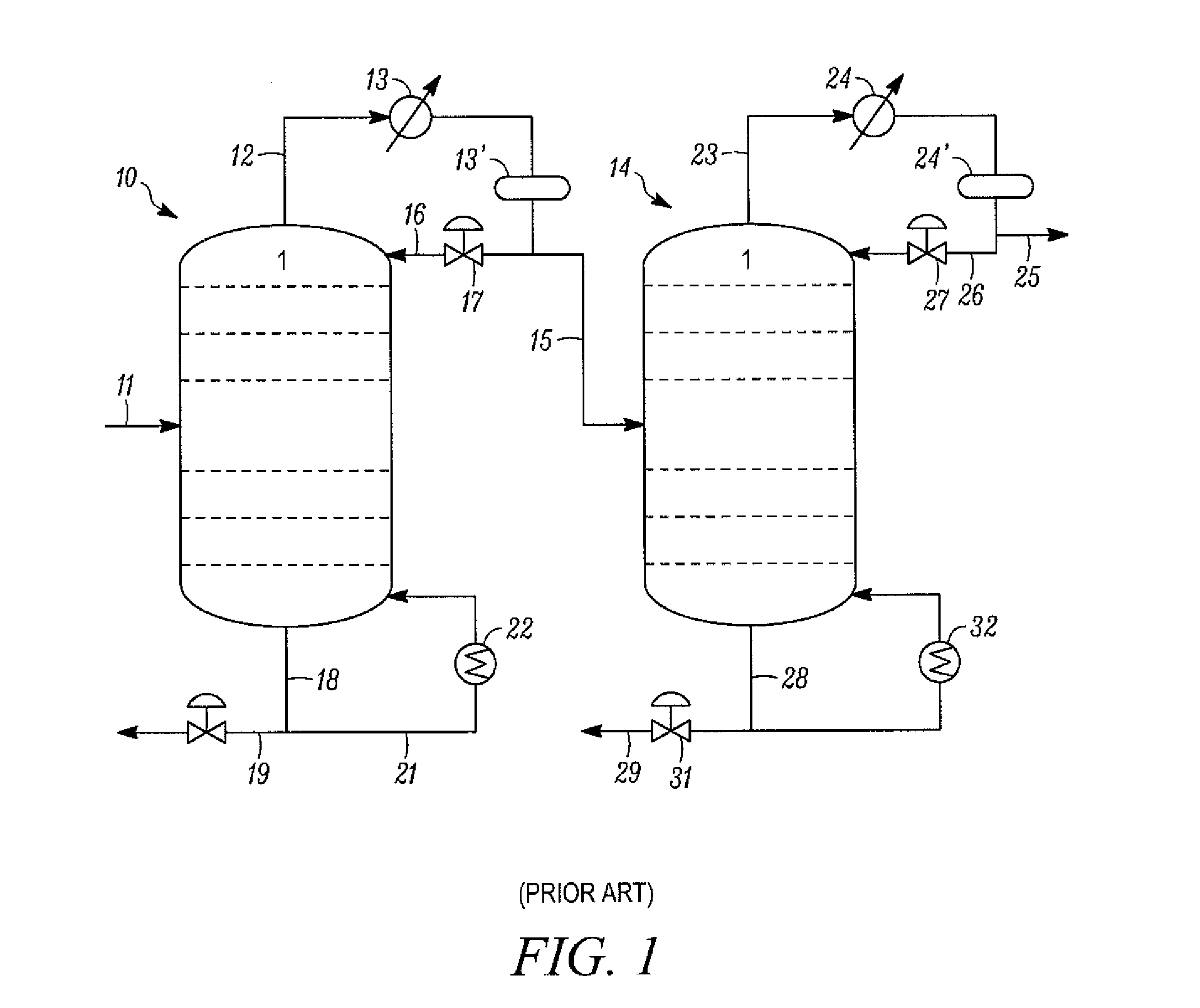

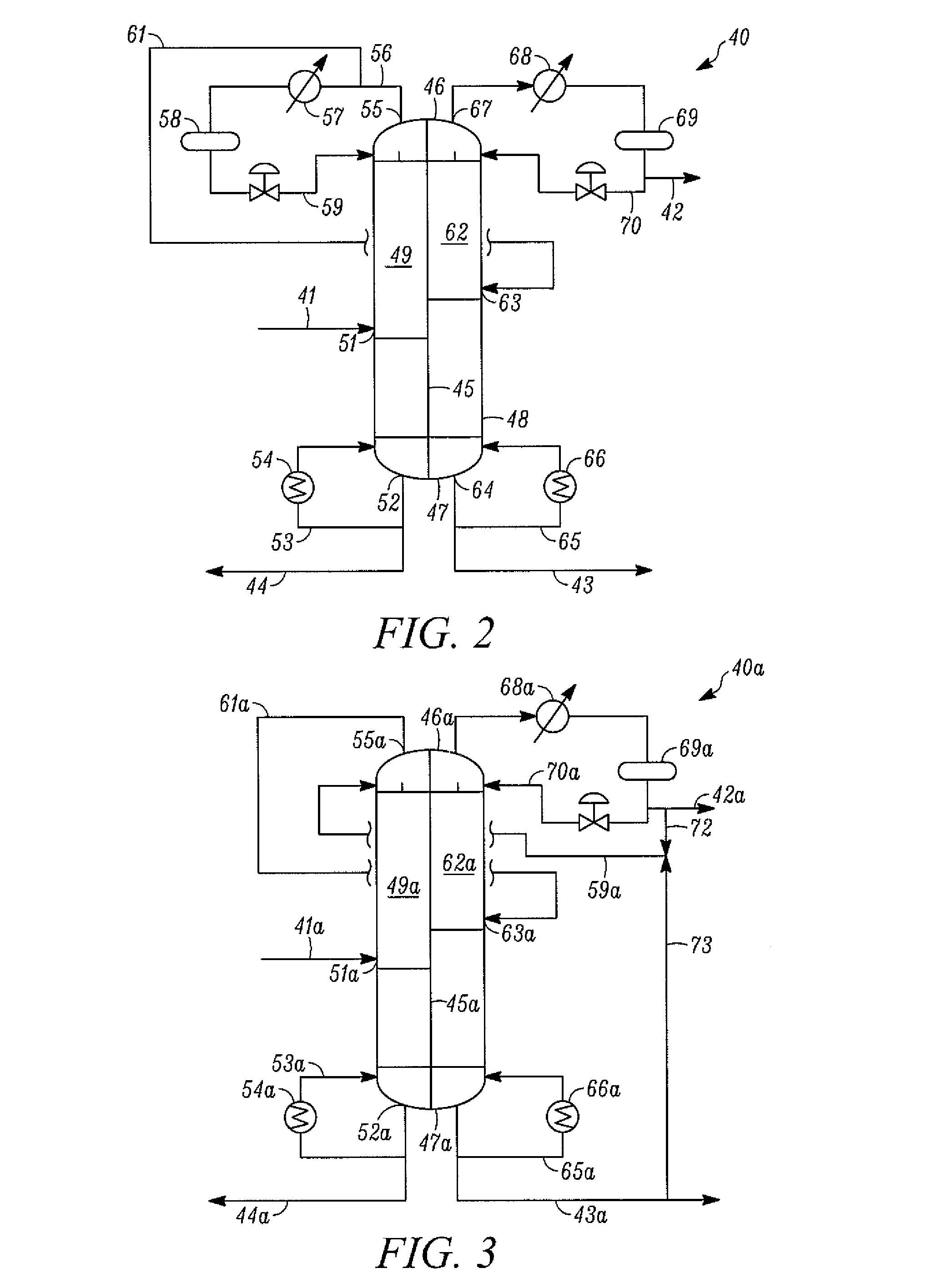

ActiveUS20080161618A1Reduce constructionLow costSolvent extractionDistillation in boilers/stillsButeneFractionating column

A process is disclosed for recovering 1-butene from a feed steam comprising n-butane, isobutane and butene isomers using a single, divided wall distillation column. The disclosed process includes introducing the feed steam into an inlet of a first side of a distillation column, wherein the distillation column comprises a top, a bottom and a center dividing wall extending between the bottom and the top of the column and dividing the column into the first side and a second side. The process includes taking off an isobutane stream from the top of the second side of column, taking off a 1-butene stream as a bottoms stream from the second side of the column, and taking off a combination 2-butene and n-butane stream as a bottom stream from the first side of column.

Owner:UOP LLC

System and method for recovery of C2+ hydrocarbons contained in liquefied natural gas

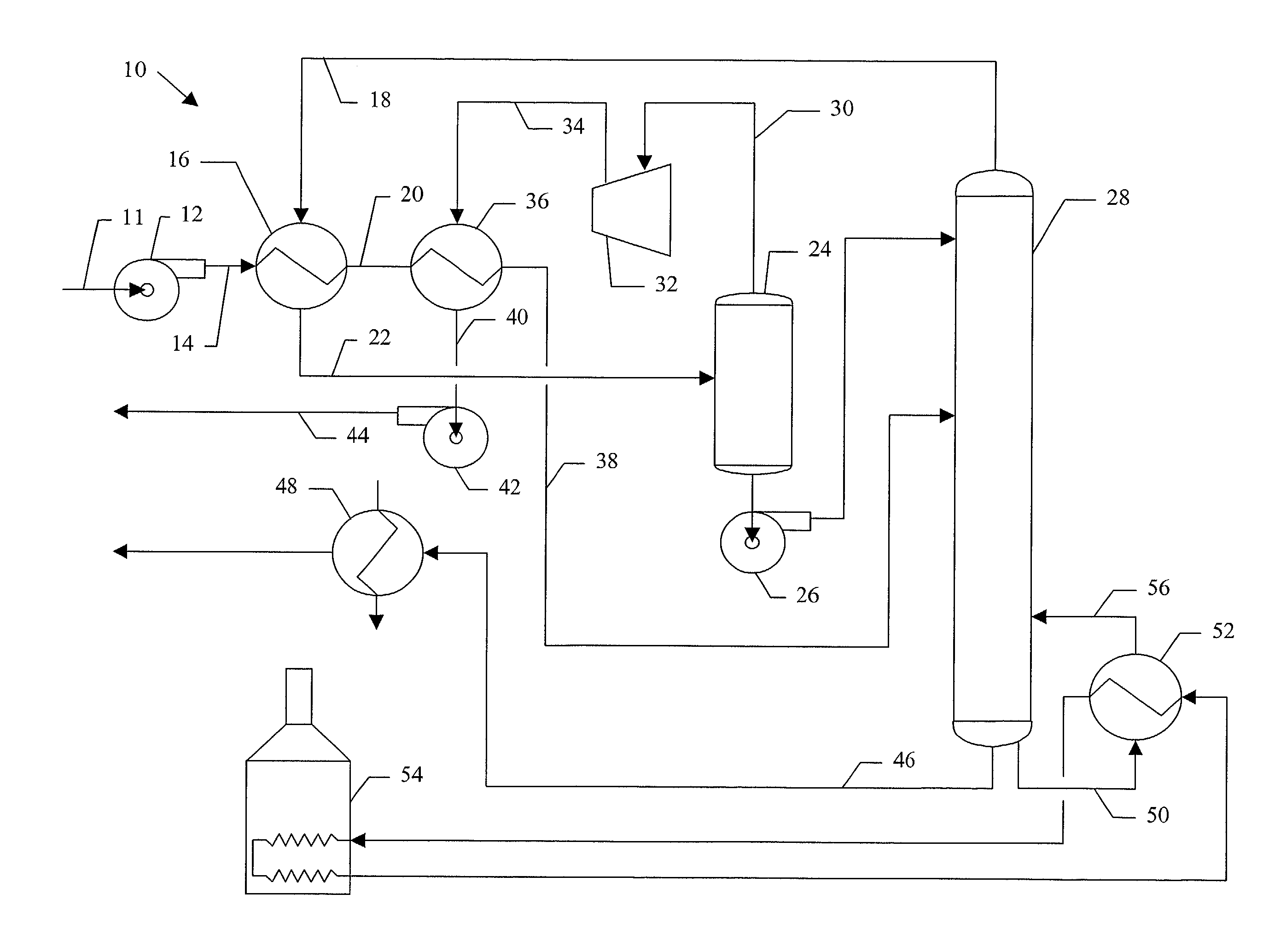

ActiveUS7069743B2Significant energy savingMinimizing heat inputSolidificationLiquefactionRefluxDistillation

A processing method and system for separating methane-rich and ethane-rich components from an LNG stream. The LNG stream is preheated against a distillation column overhead vapor stream and against an overhead vapor product prior to entering the column. The overhead vapor product is methane-rich. The LNG stream may further be preheated against the column bottoms and another heating medium. The method may also include compressing the methane-rich product, condensing it against the LNG stream, and pumping it. The system may also comprise third and fourth heat exchangers configured to preheat the LNG stream with the bottoms product and the heating medium. Further, the system may provide for compressing the overhead vapor product prior to the its exchanging heat with the LNG stream and a pump for pumping condensed overhead vapor product. Additionally, the system generates all of the required reflux by cross exchanging the column overhead with the incoming LNG stream.

Owner:PILOT ENERGY SOLUTIONS

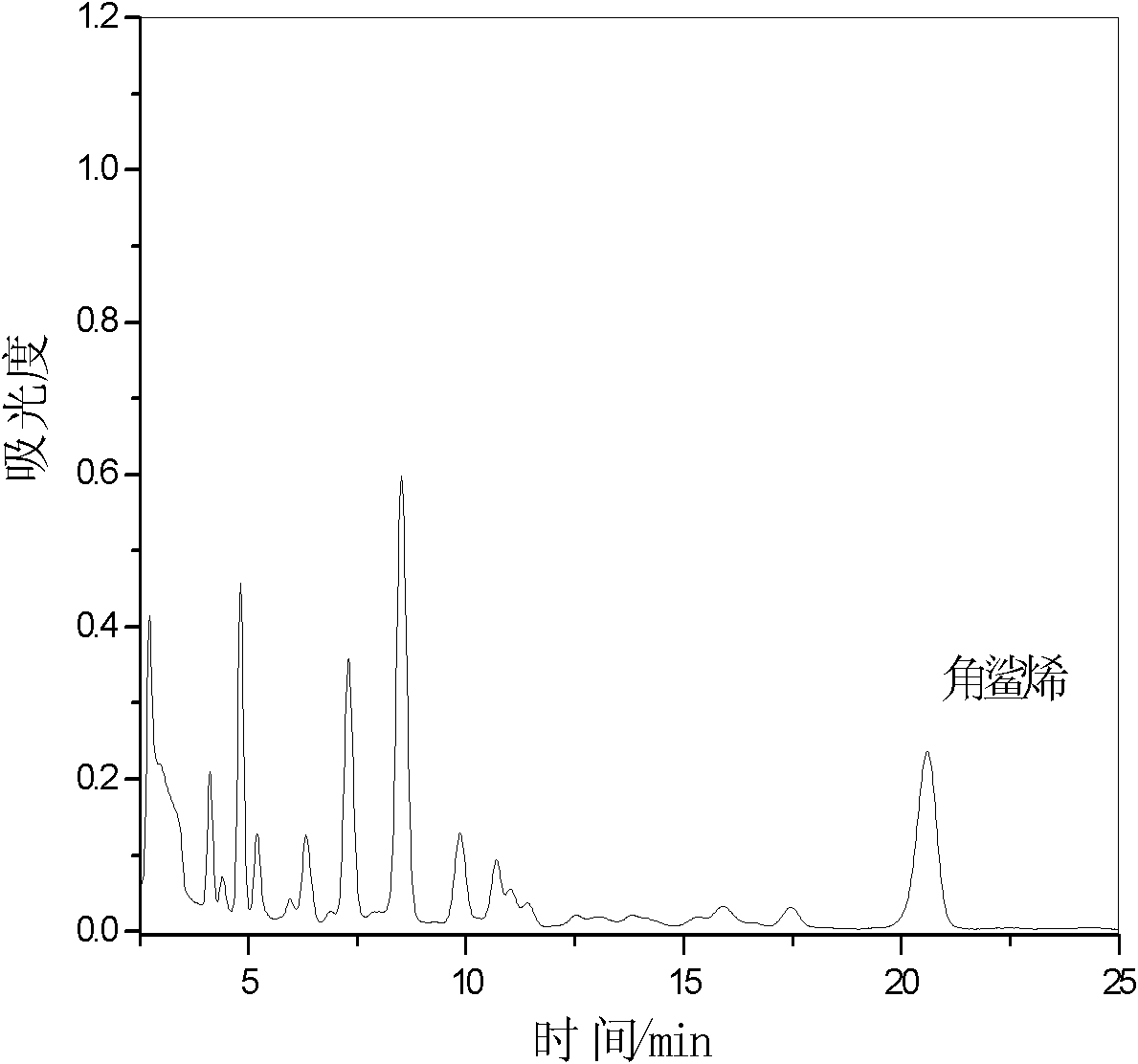

Method for extracting squalene from vegetable oil deodorized distillate

InactiveCN101830770AIdeal yieldIncrease contentDistillation purification/separationExtraction purification/separationHigh concentrationVegetable oil

The invention relates to a method for extracting squalene from vegetable oil deodorized distillate. A process method of combining molecular distillation with extraction and crystallization is used to extract high-concentration squalene and recover natural vitamin E and phytosterol with a certain purity from vegetable oil deodorized distillate. The method comprises the following steps of: carryingout a saponification reaction of the raw material; twice molecularly distilling unsaponifiable matter obtained by extraction; using the distillate obtained during the second distilling as a raw material for cold crystallization to obtain phytosterol; recovering squalene and mixed tocopherol from the filtrate; and extracting with multi-stage solvents to respectively enrich squalene and vitamin E in two phases. The process has simple flows, low-prices raw material and higher separation efficiency and recovery rate and comprehensively utilizes useful contents in the deodorized distillate.

Owner:TIANJIN UNIV

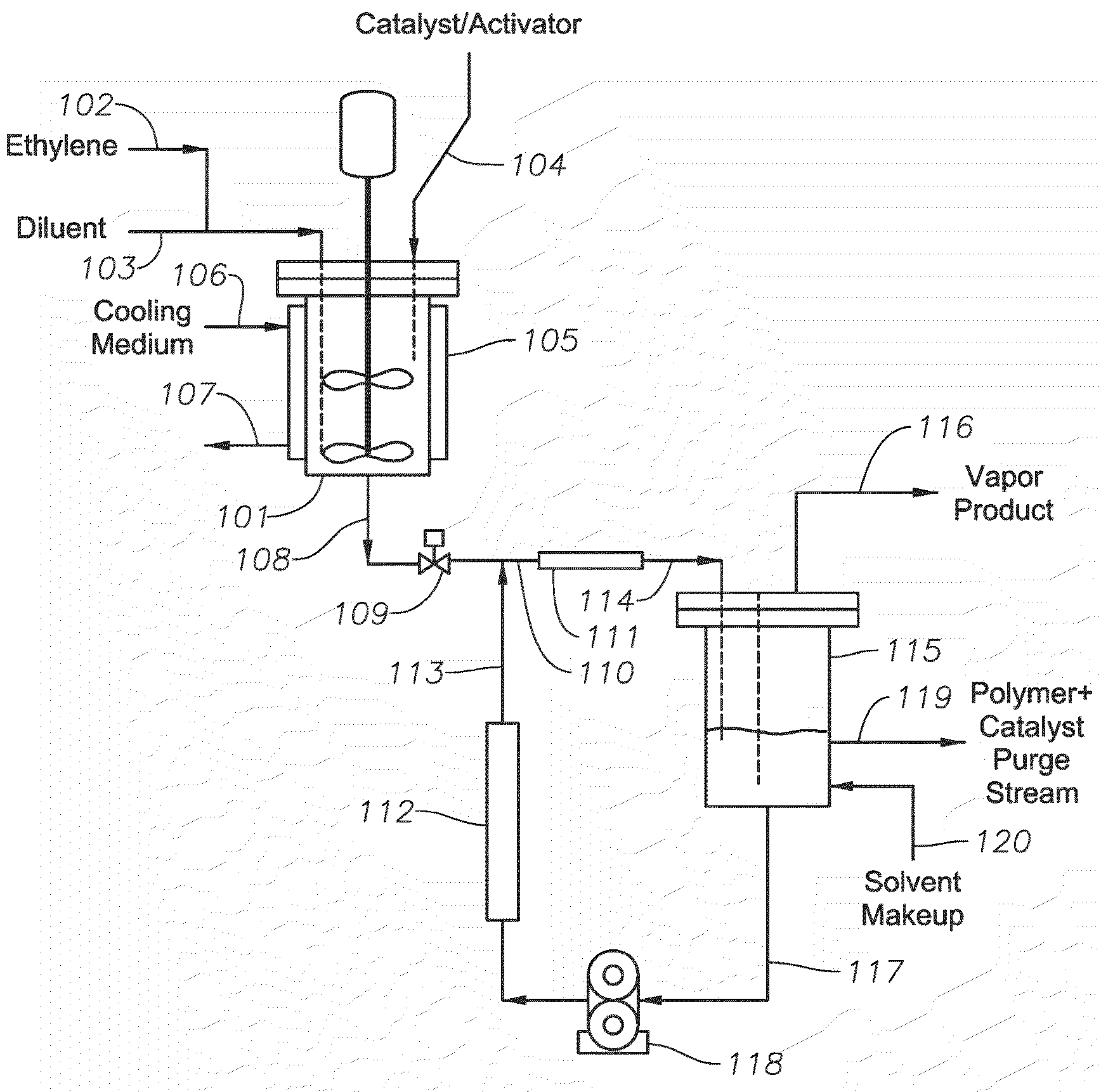

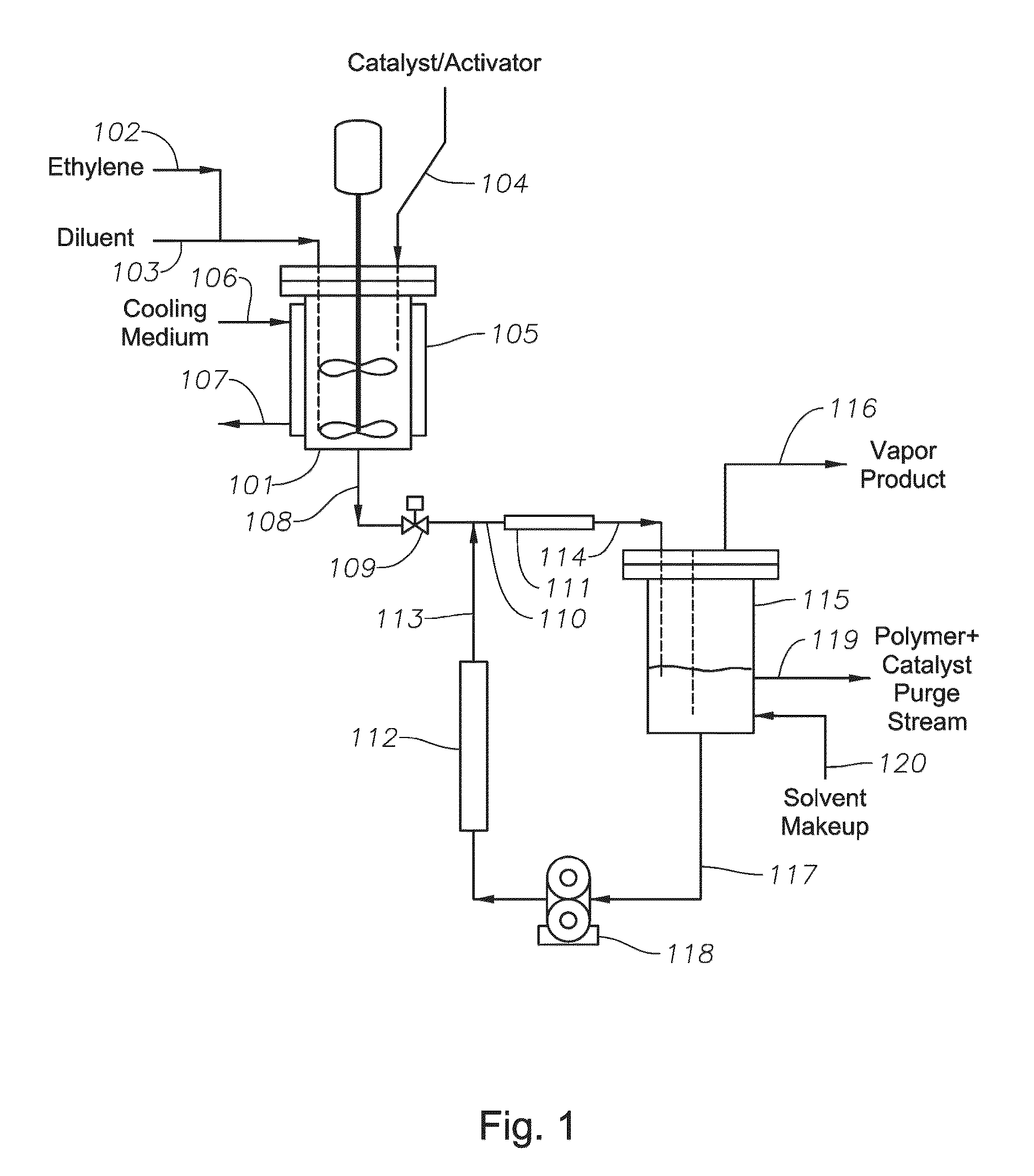

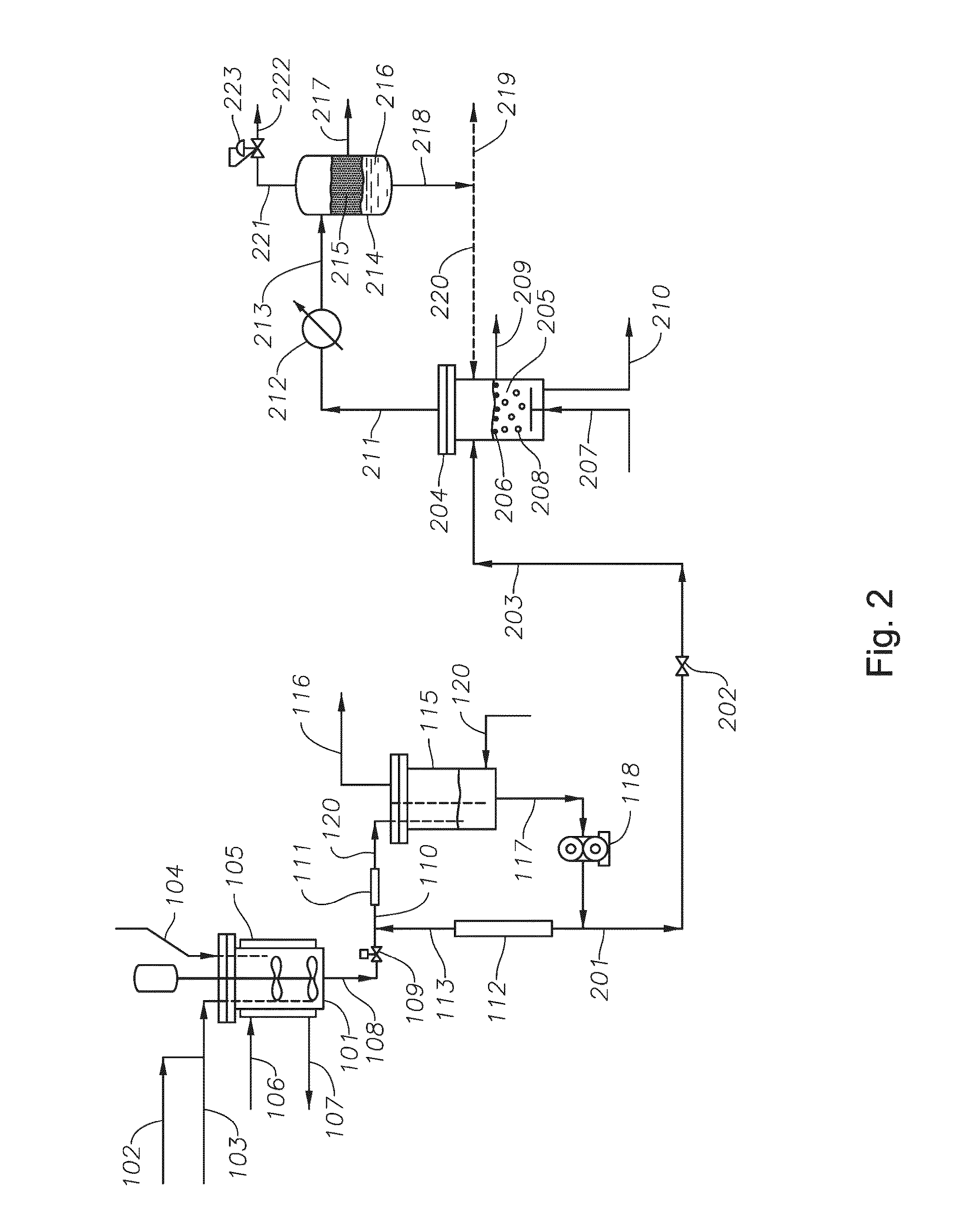

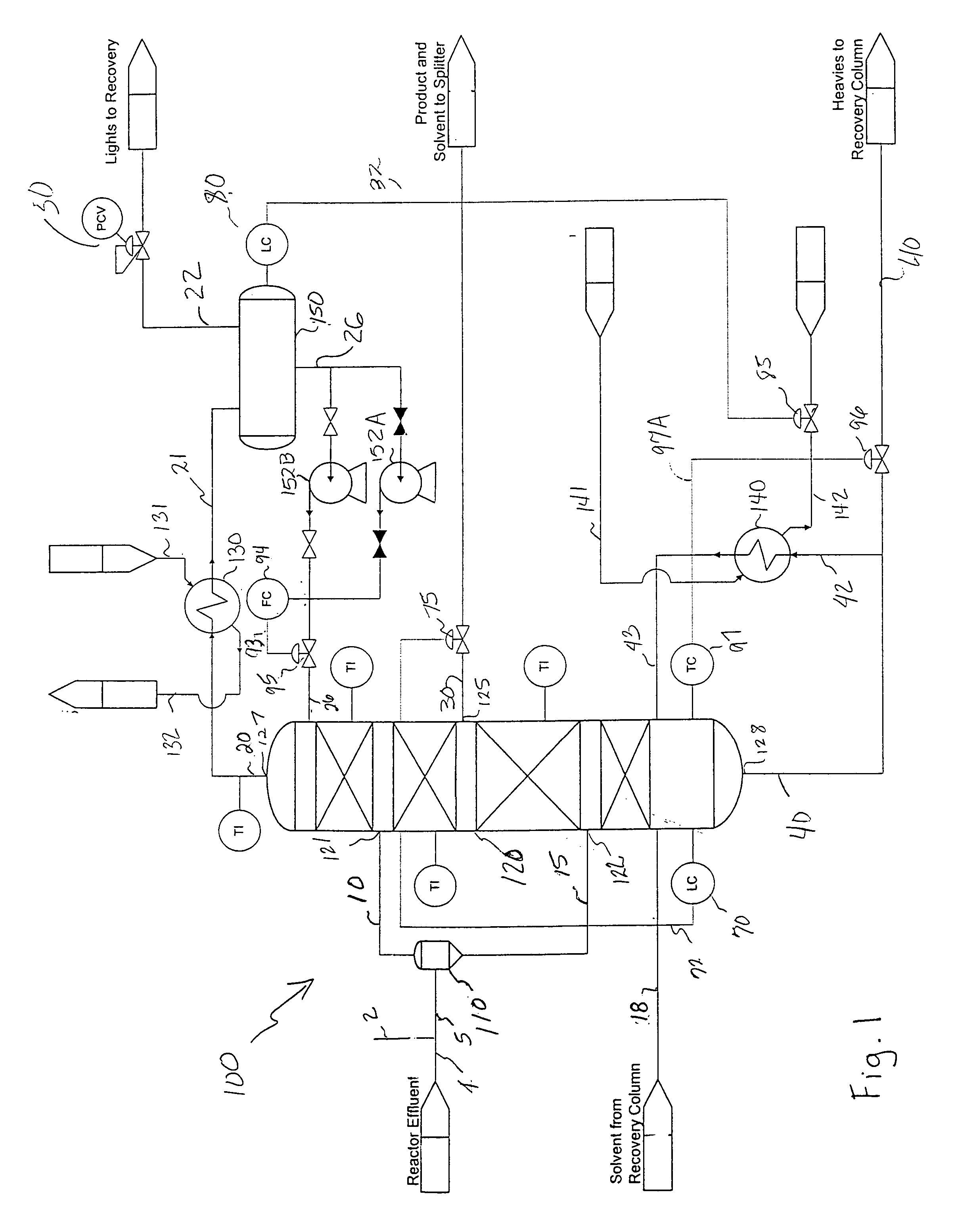

System and method for selective trimerization

ActiveUS8658750B2Distillation purification/separationMolecular sieve catalystsReactor systemDownstream processing

Disclosed herein is a method for separating from the reactor effluent of an olefin oligomerization procedure those catalyst materials and polymeric by-products which can cause difficulties in the downstream processing of such effluent. Polymer by-products and catalyst in the effluent are separated from reaction products by flash vaporization utilizing an in-situ hot solvent which is contacted with the effluent and serves as the heating medium to promote this flash vaporization step. Subsequent processing of a liquid portion of the effluent which is left after flash vaporization involves recovery of catalyst and polymeric by-products therefrom in a steam stripping vessel. Also disclosed is a multiple reactor system which can be used for continuous trimerization of ethylene to 1-hexene while at the same time washing polymeric by-products from one of the reactors in the series using a wash oil solvent.

Owner:EXXONMOBIL CHEM PAT INC

Composition and method for inhibition of formation of gas hydrates

InactiveUS6596911B2Using liquid separation agentDistillation purification/separationSolventOnium compound

A method and a composition used therein are disclosed for inhibiting formation of hydrocarbon hydrates. The composition comprises an onium compound, an amine salt and, optionally, a solvent. The method and composition are particularly useful for oil and gas production

Owner:BAKER HUGHES INC

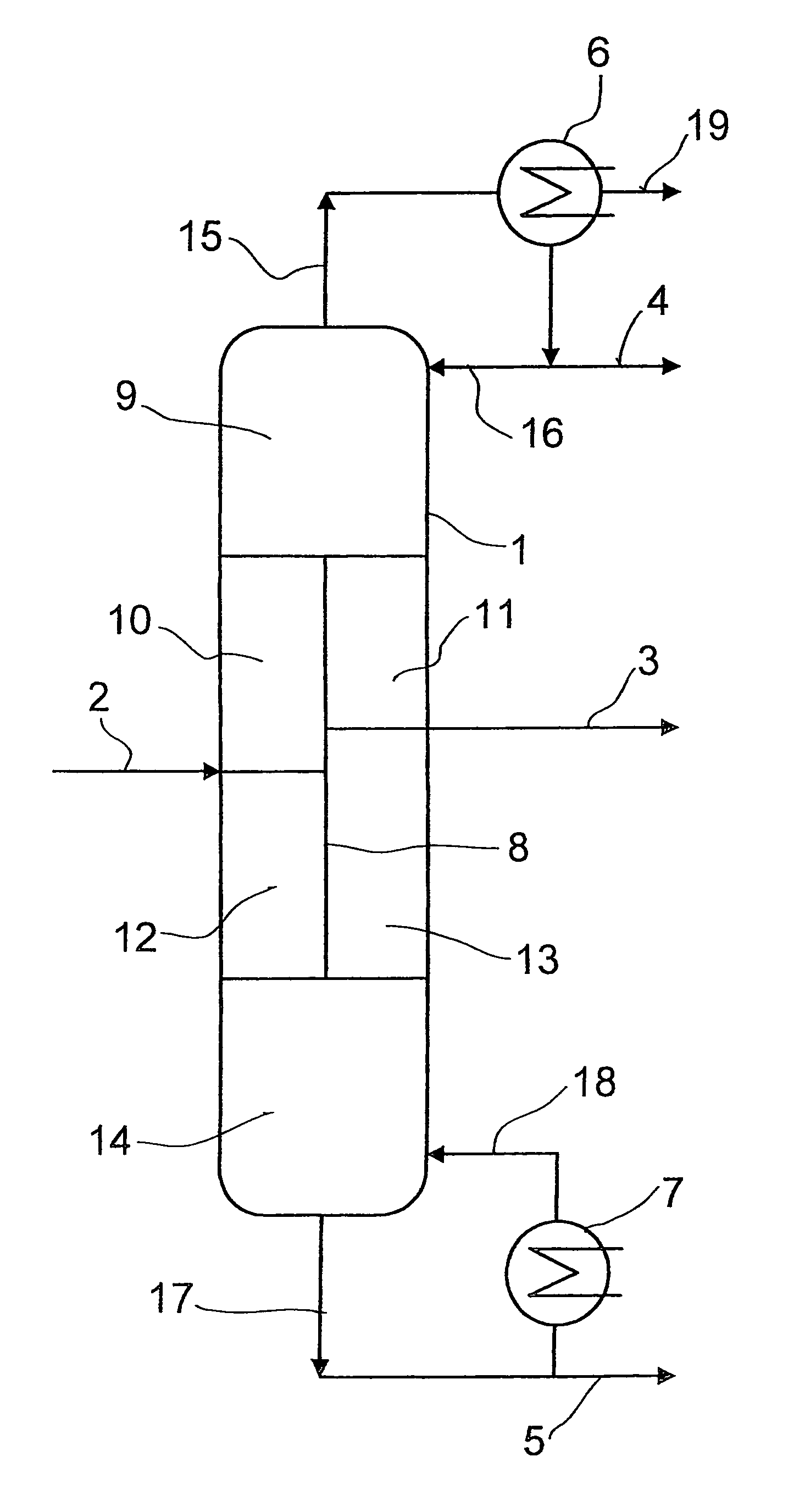

Method and device for obtaining 1,3 pure butadiene from 1,3 raw butadiene by distillation

InactiveUS7132038B2Meet specificationsThermal non-catalytic crackingDistillation regulation/controlDistillationChemistry

A process for obtaining pure 1,3-butadiene from crude 1,3-butadiene by distillation is carried out in a dividing wall column in which a dividing wall is located in the longitudinal direction of the column to form an upper common column region, a lower common column region, a feed section and an offtake section.

Owner:BASF AG

Polymer inhibition of vinyl aromatic monomers using a quinone methide/alkyl hydroxylamine combination

ActiveUS7651635B1Other chemical processesDistillation purification/separationHydroxylamineQuinone methide

The invention provides a composition of matter and a method of its use in preventing unwanted polymerization reactions. The composition comprises an inhibitor and a retarder. The inhibitor is highly effective. The retarder is reliable under extreme and emergency situations. The inhibitor can be an alkylhydroxylamine. The retarder can be a 7-cyano-quinone methide. The combination of the inhibitor and retarder has been found to be far more effective than expected.

Owner:ECOLAB USA INC

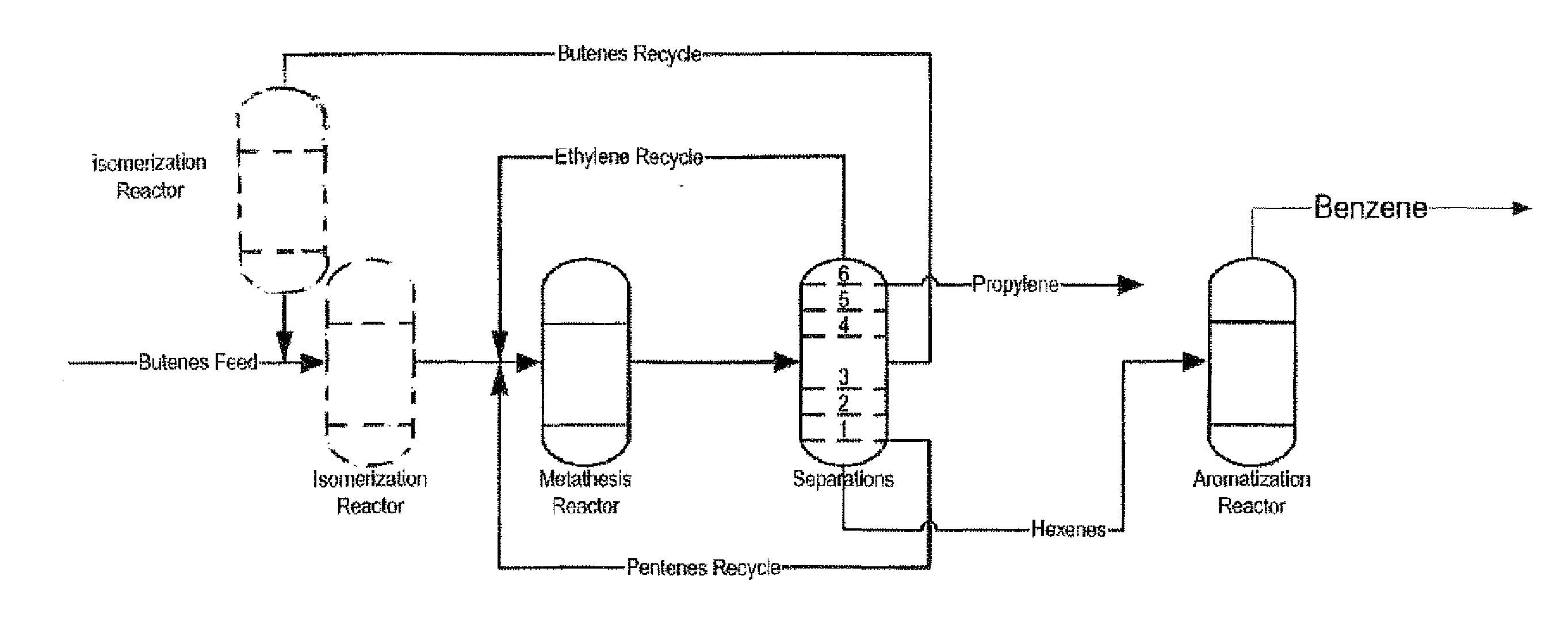

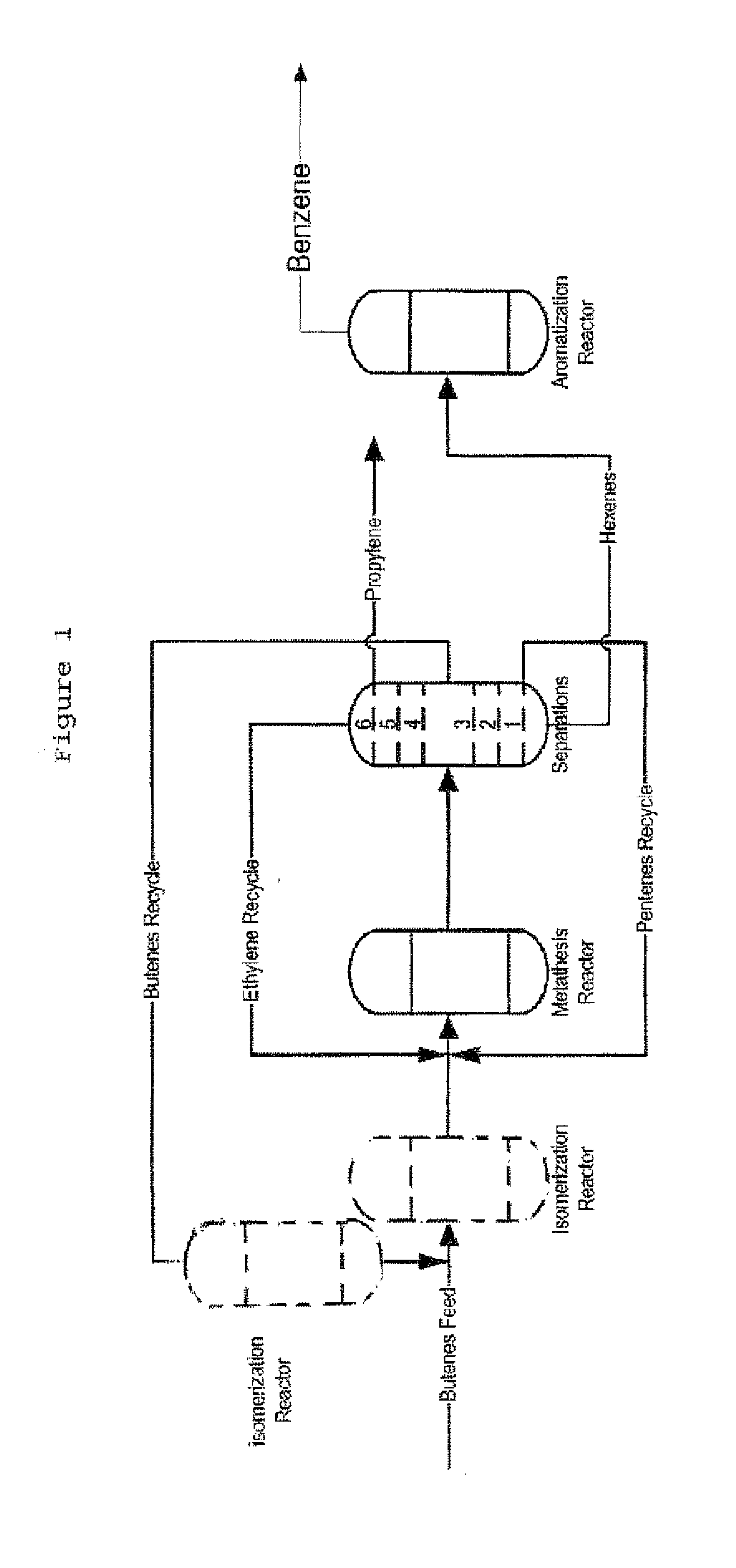

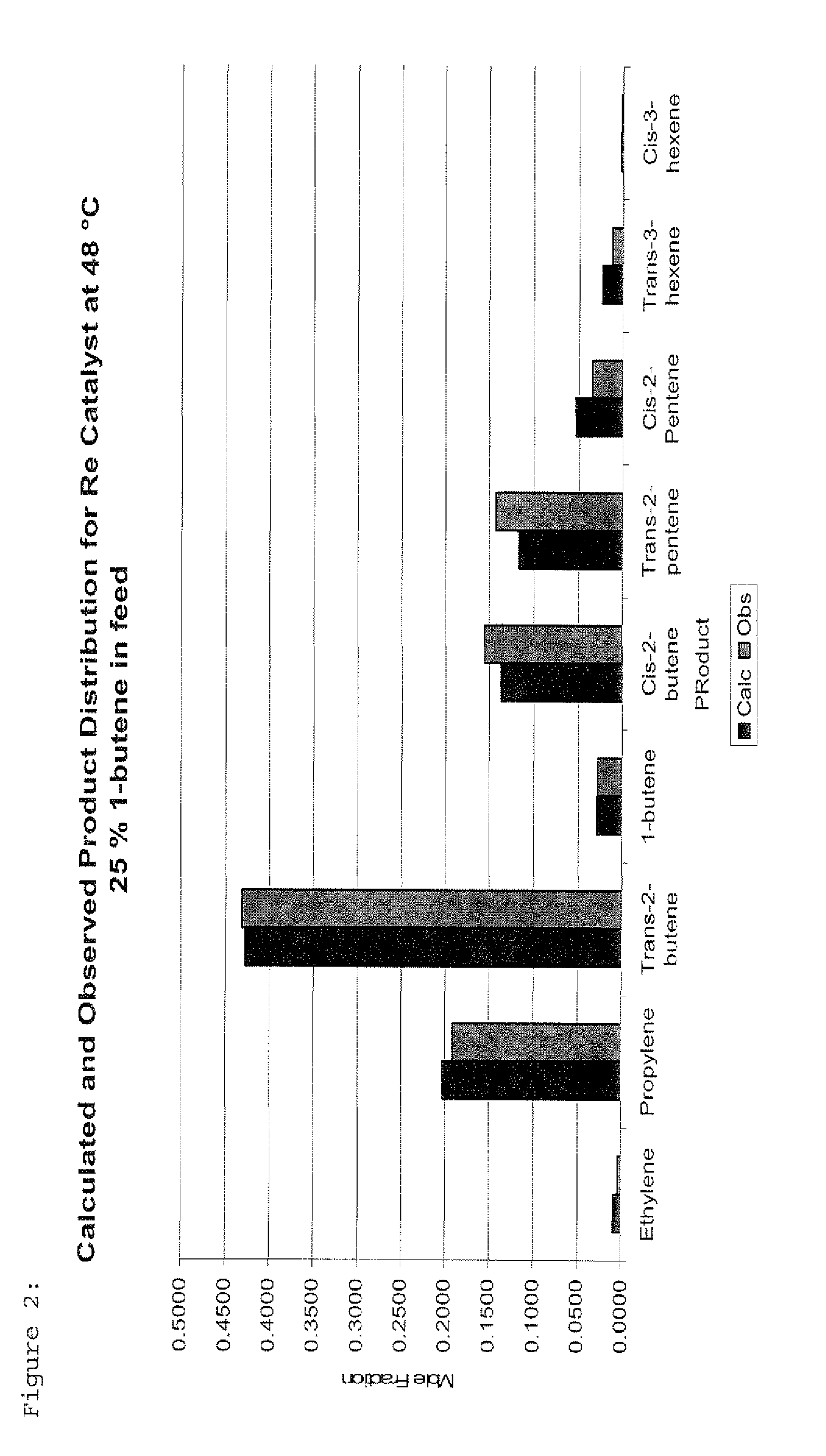

Process for Producing Propylene and Aromatics from Butenes by Metathesis and Aromatization

InactiveUS20110263917A1Molecular sieve catalystDistillation purification/separationIsomerizationOctene

The invention is for a process for producing propylene and hexene (along with ethylene, pentenes, product butenes, heptenes and octenes) by metathesis from butenes (iso-, 1- and cis and trans 2-) and pentenes and then aromatizing the hexenes (along with higher olefins, such as heptenes and octenes) to benzene (along with toluene, xylenes, ethylbenzene and styrene). Since the desired products of the metathesis reaction are propylene and hexene, the feed to the metathesis reaction has a molar ratio for 1-butene:2-butene which favors production of propylene and 3-hexene with the concentration of hexenes and higher olefins in the metathesis product being up to 30 mole %. An isomerization reactor may be used to obtain the desired molar ratio of 1-butene:2-butene for the feed composition into the metathesis reactor. After the metathesis reaction, of hexene and higher olefins are separated for aromatization to benzene and other aromatics.

Owner:SAUDI BASIC IND CORP SA

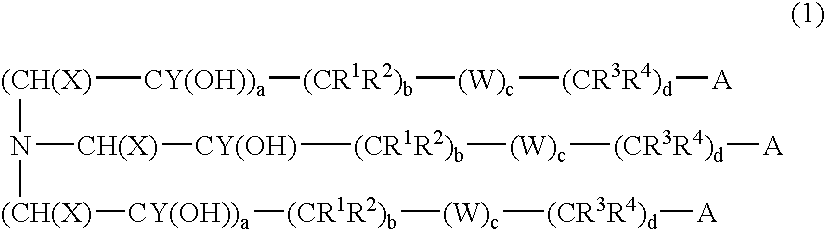

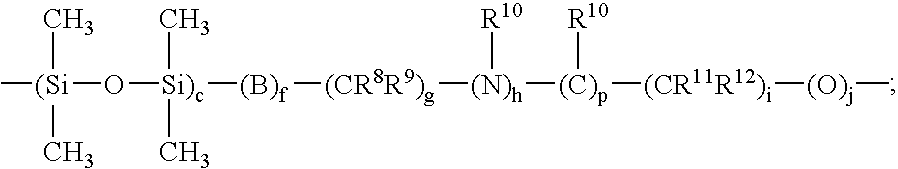

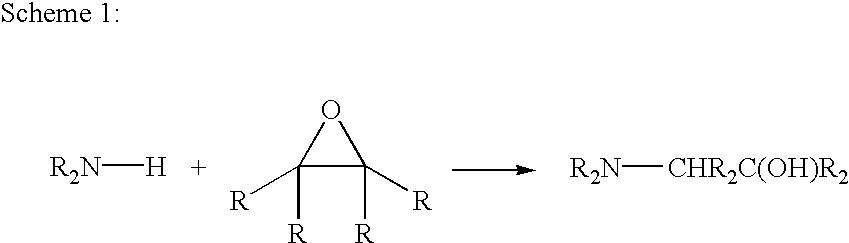

Amine compounds and curable compositions derived therefrom

InactiveUS7132557B2Readily exposed to waterExtended shelf lifeSilicon organic compoundsSynthetic resin layered productsCarbon–nitrogen bondOrganic chemistry

Disclosed are compounds produced by a process comprising the step of reacting an amine reactant with an epoxide reactant to form a hydrolytically stable carbon-nitrogen bond therebetween, wherein at least one of the amine or epoxide reactants comprises a terminal alkoxysiyl group. Also disclosed are curable compositions comprising the compounds of the present invention and the cured products derived therefrom.

Owner:VIRGINIA TECH INTPROP INC

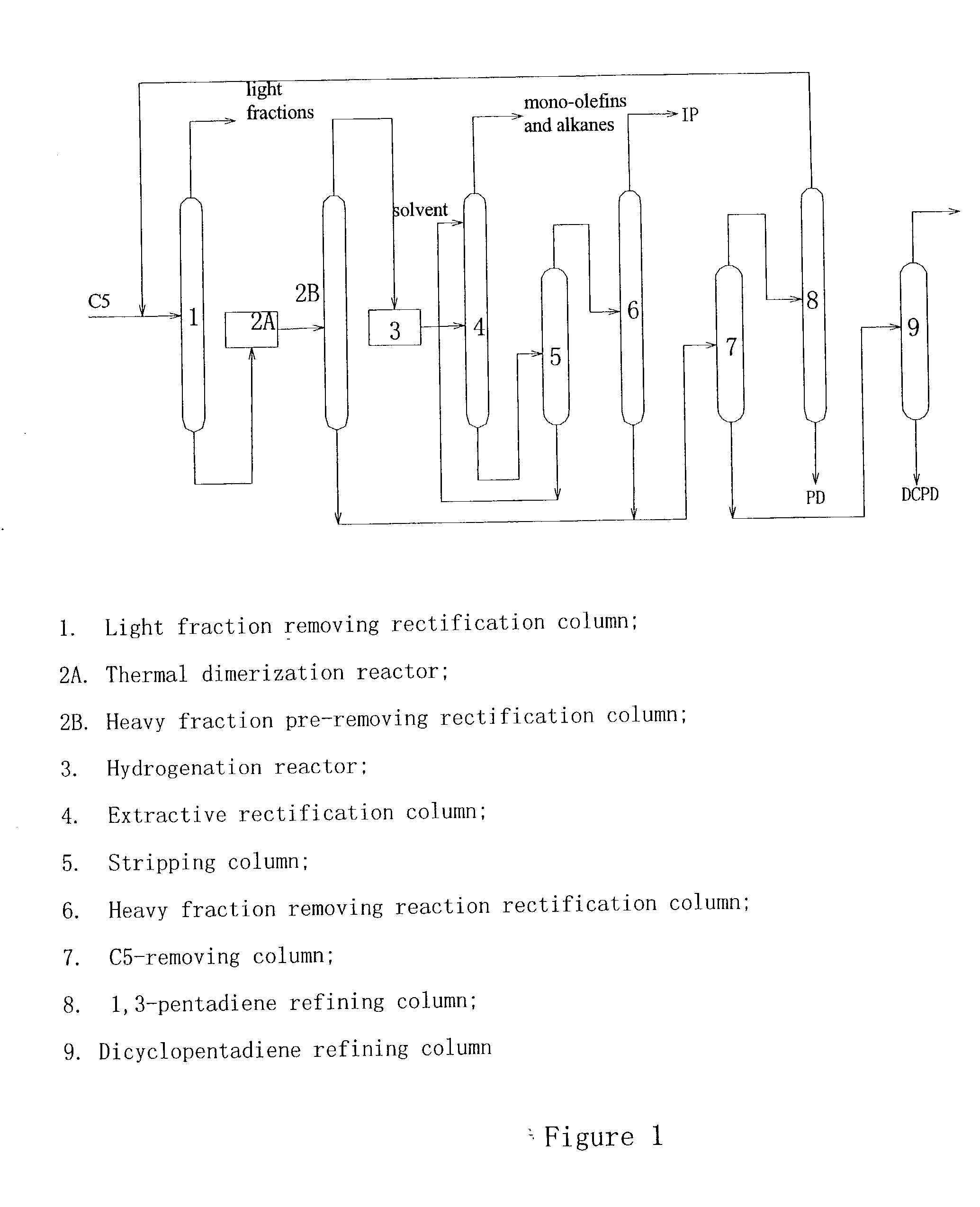

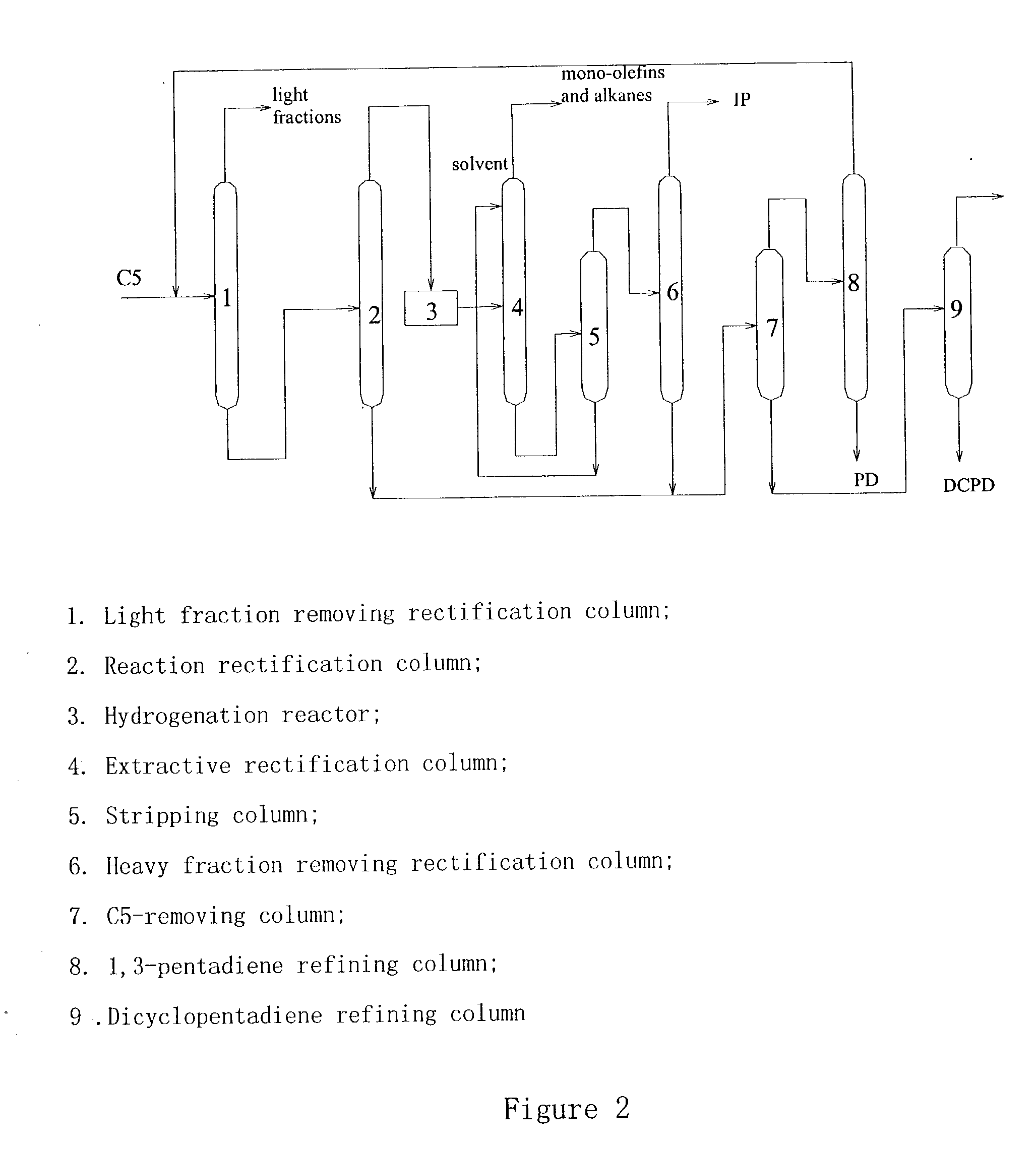

Process for separating C5 cuts obtained from a petroleum cracking process

ActiveUS20030100809A1Improve catalytic performanceHigh activityLiquid hydrocarbon mixtures productionDistillation purification/separationAlkyneSolvent

The present invention relates to a process for separating the isoprene, 1,3-pentadiene and dicyclopentadiene from a C5 cuts, comprising dimerization of the cyclopentadiene and selective catalytic hydrogenation. The second extractive rectification step can be omitted, because the alkynes are removed through selective catalytic hydrogenation prior to the extractive rectification. As a result, the solvent-recovering units can be simplified, and thus the process as a whole can be optimized. Correspondingly, the investment and energy consumption, the operation cost, and finally the production cost can be substantially reduced.

Owner:CHINA PETROCHEMICAL CORP +1

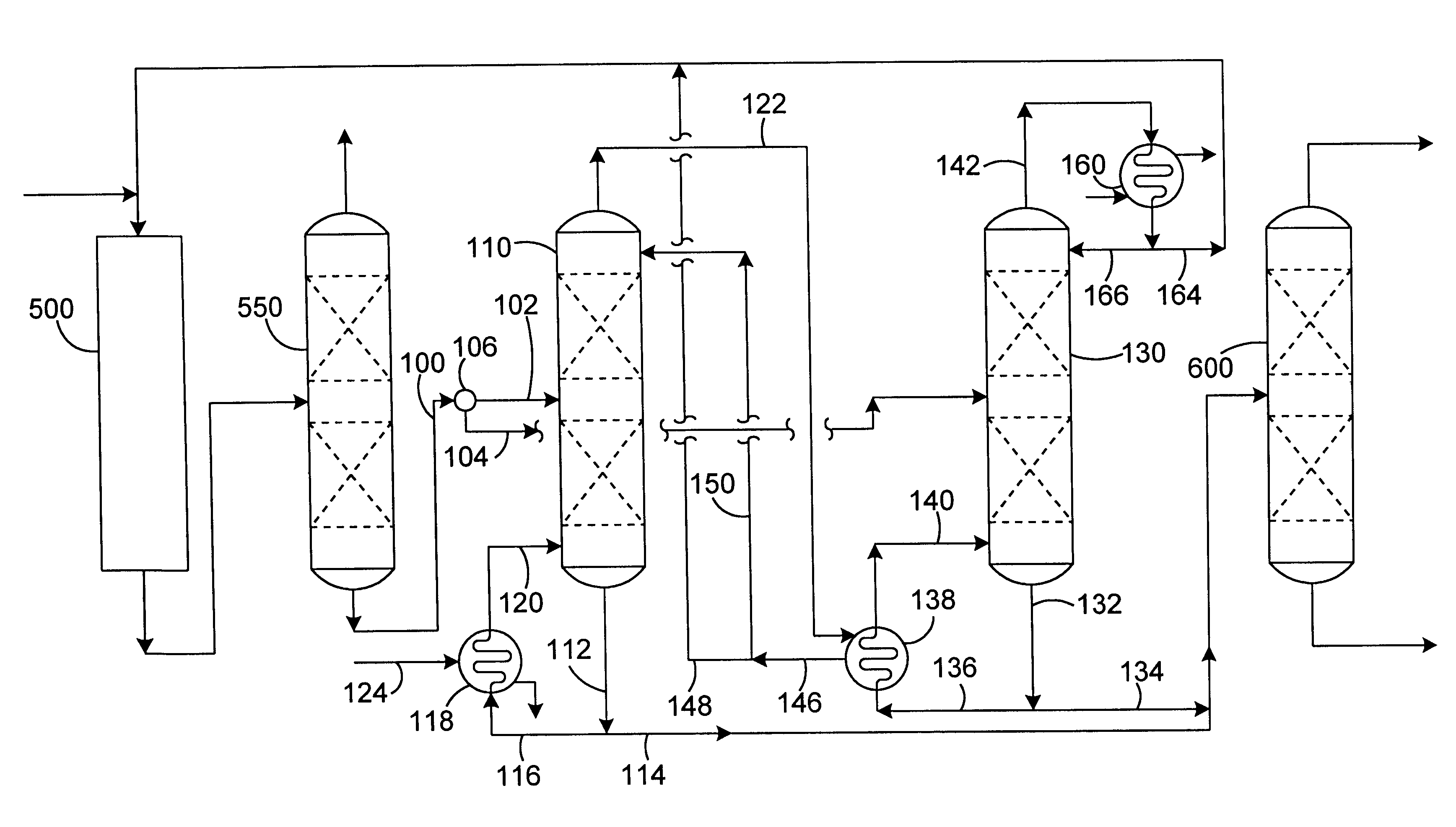

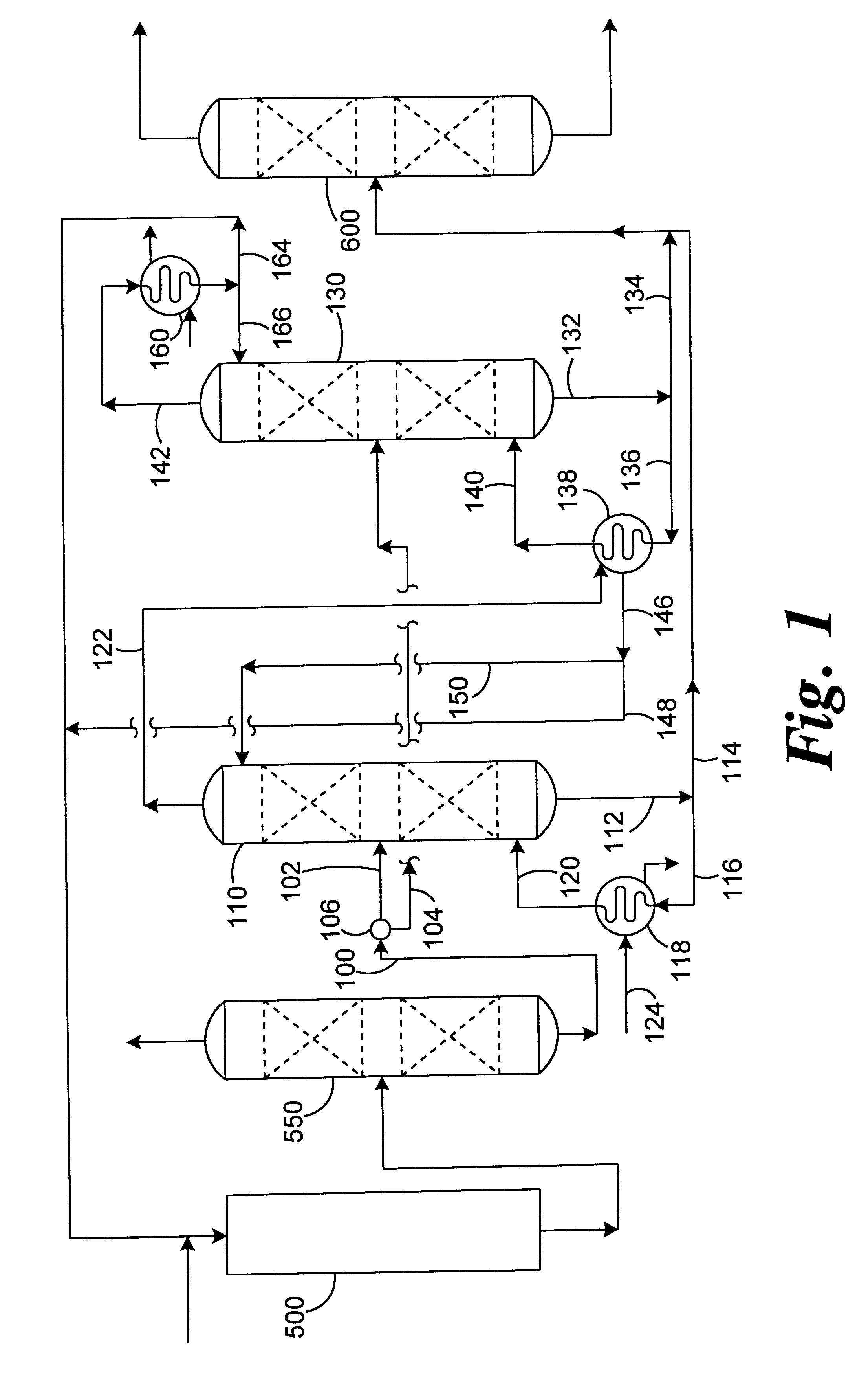

Lean reflux-high hydrocarbon recovery process

A two-tower scheme process for the recovery of propane and heavier components from a hydrocarbon gas stream is provided. Feed gas is cooled, partially condensed, and then separated to give a first liquid stream and a first vapor stream. First liquid stream is sent to a distillation tower that recovers at the bottoms a major portion of propane and heavier components and produces an overhead gas stream. First vapor stream is expanded and sent as bottom feed to the absorber. Absorber produces an absorber overhead stream containing essentially all the ethane and lighter components and an absorber bottoms stream. Absorber bottoms stream is heated and sent to the distillation tower as middle feed. Absorber overhead stream is warmed and optionally compressed. A part of the compressed stream is substantially condensed and sent to absorber as top feed. The process and apparatus can be used to recover ethane and heavier hydrocarbons.

Owner:LUMMUS TECH INC

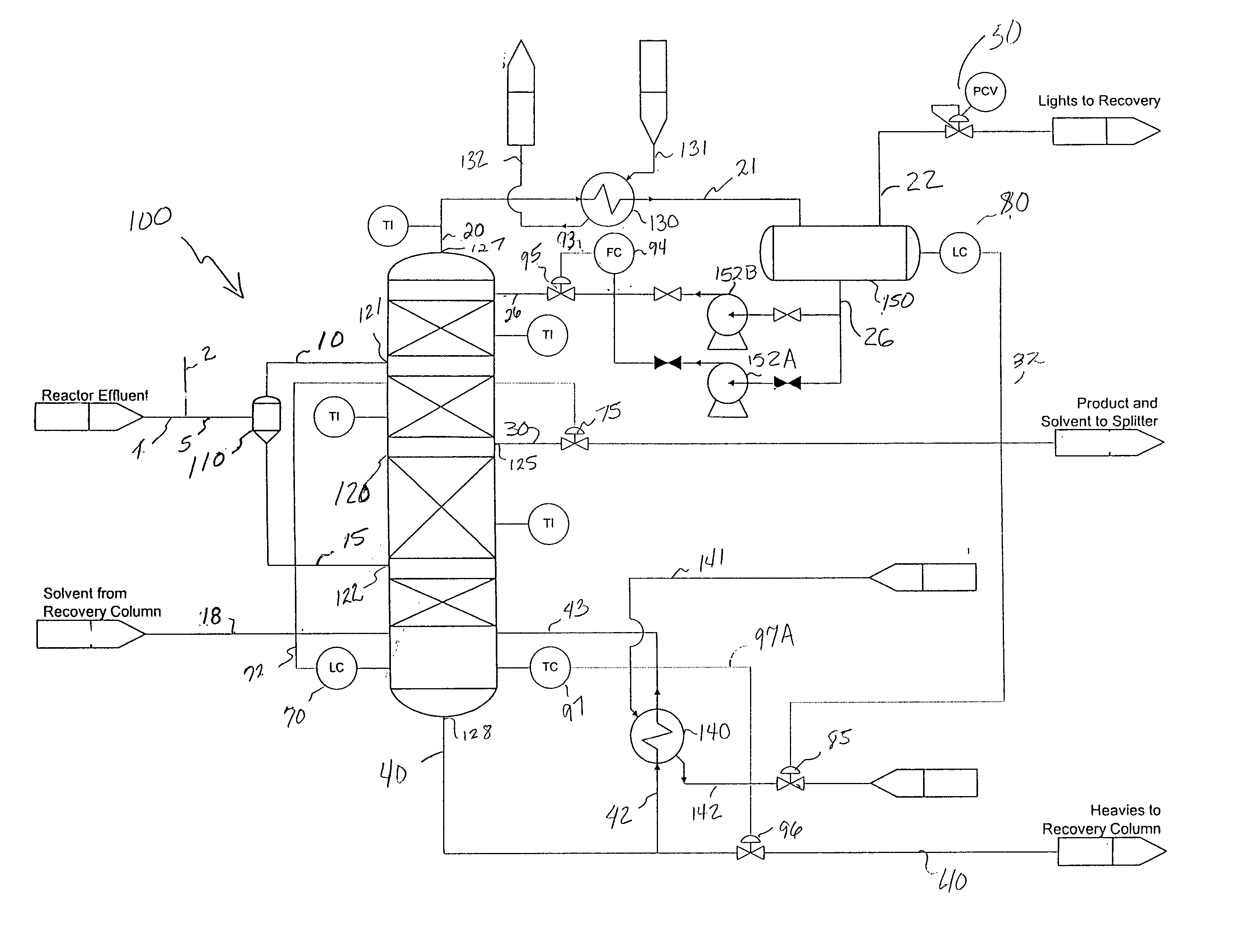

Method and system for separating an oligomerization reactor effluent

A method of separating an oligomerization reactor effluent, comprising: flashing the oligomerization reactor effluent into a liquid portion and a vapor portion, distilling the liquid and the vapor portions of the oligomerization reactor effluent and recovering an oligomerization product stream. A system for separating an oligomerization reactor effluent comprising liquid and vapor portions: a vapor / liquid separator to flash the oligomerization reactor effluent into a vapor portion and a liquid portion, and a distillation column in fluid communication with the vapor / liquid separator, wherein the distillation column has a side draw for withdrawing an oligomerization product stream and receives as separate feeds the vapor portion and the liquid portion from the vapor / liquid separator.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

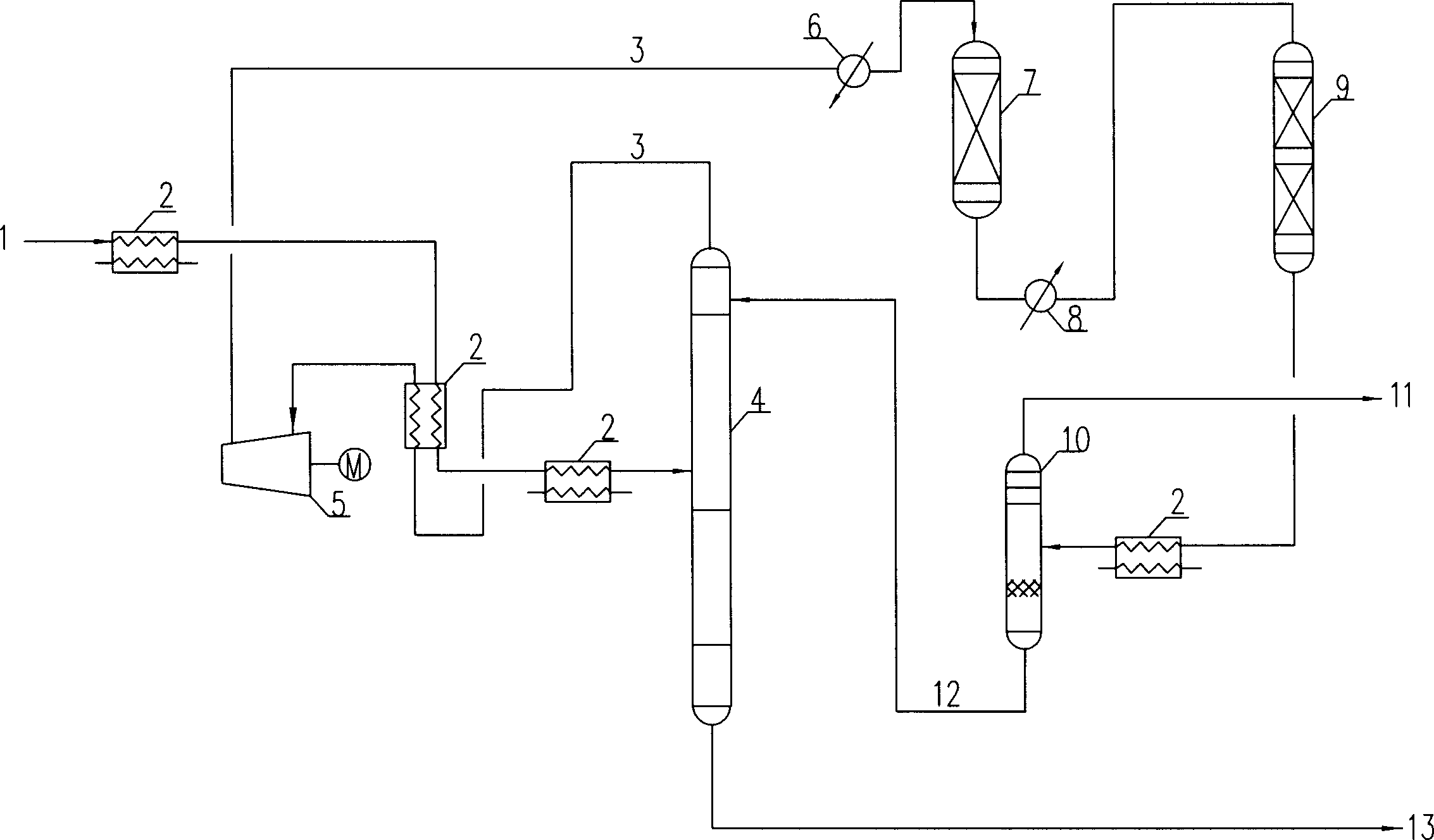

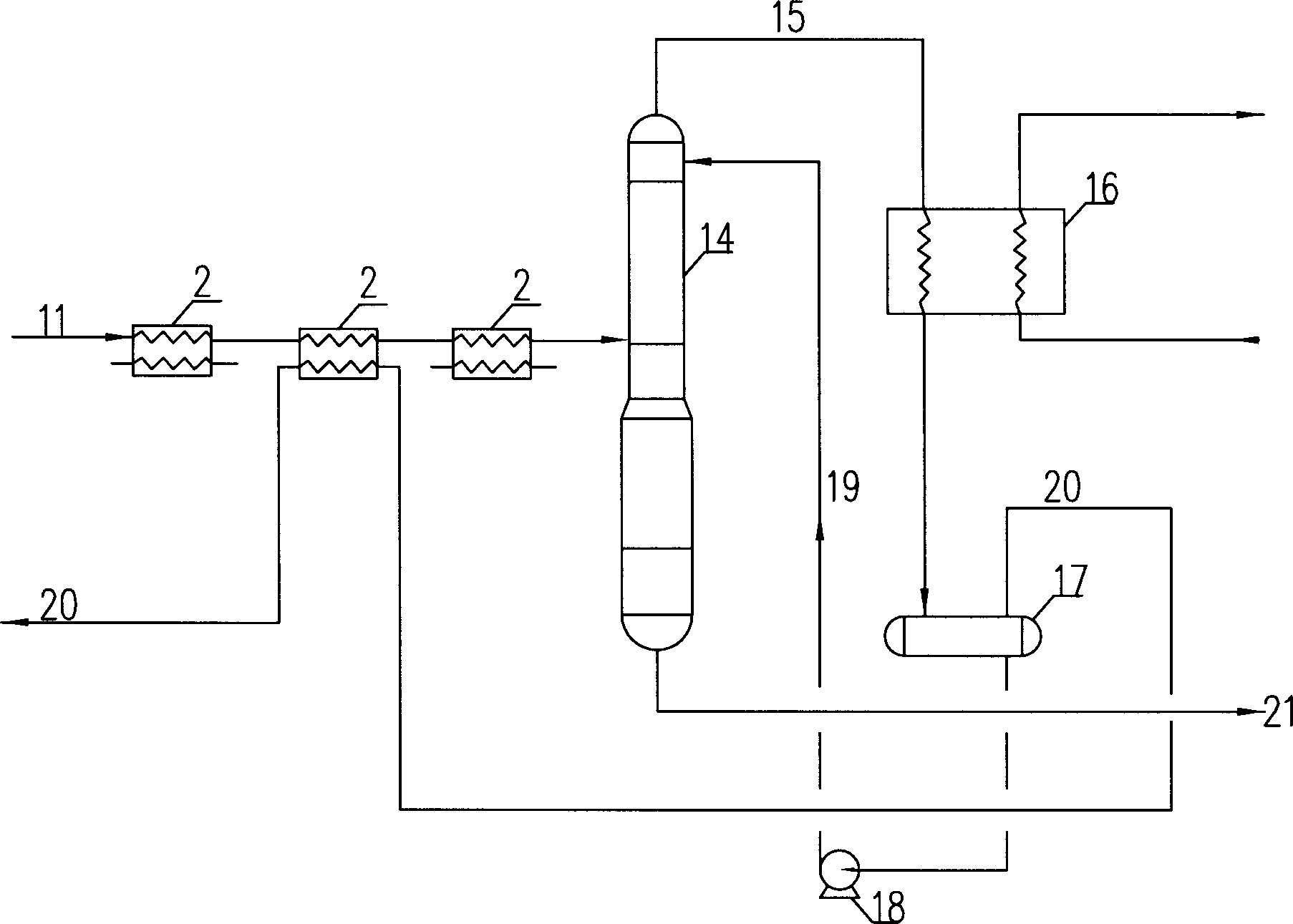

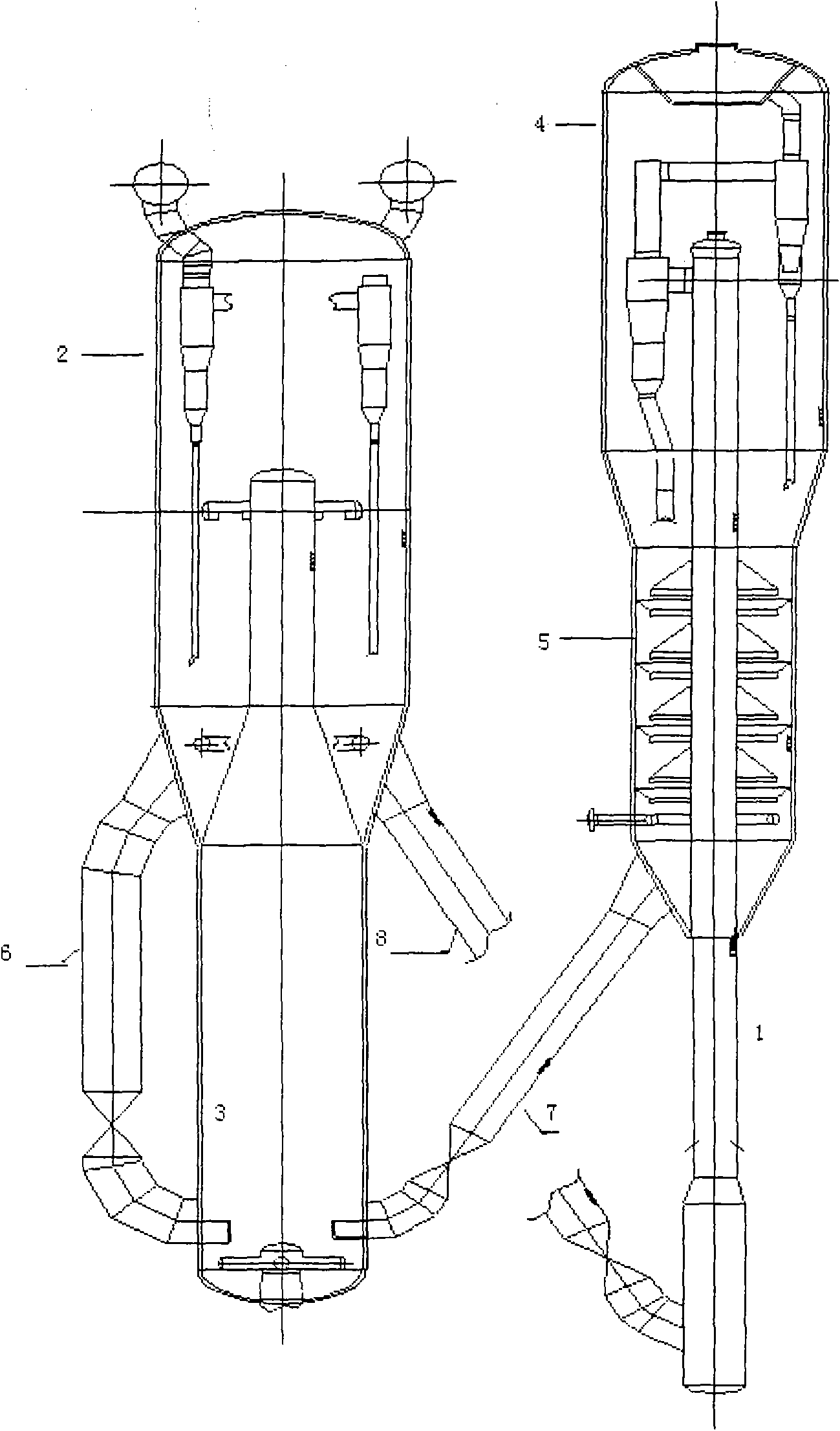

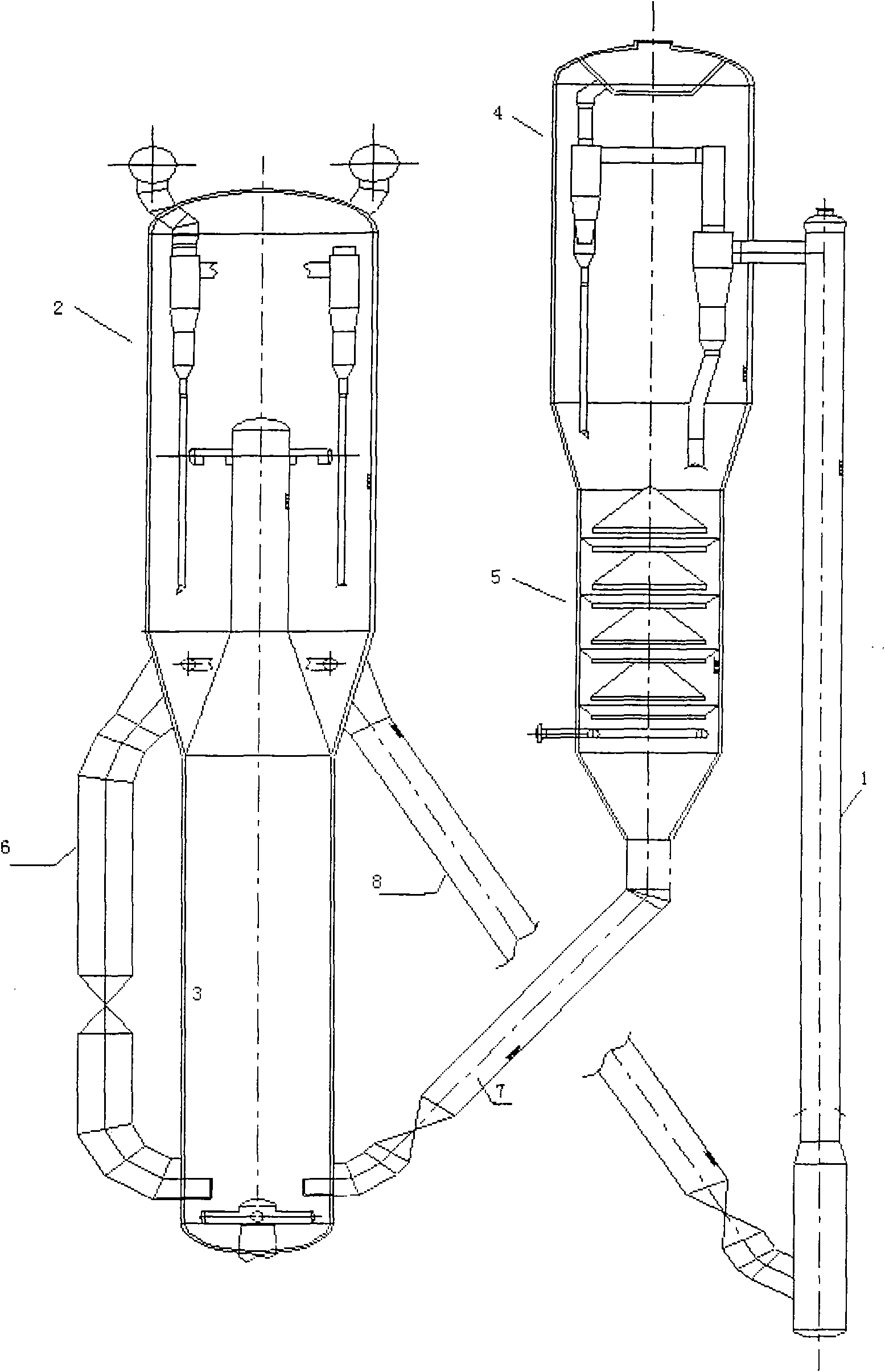

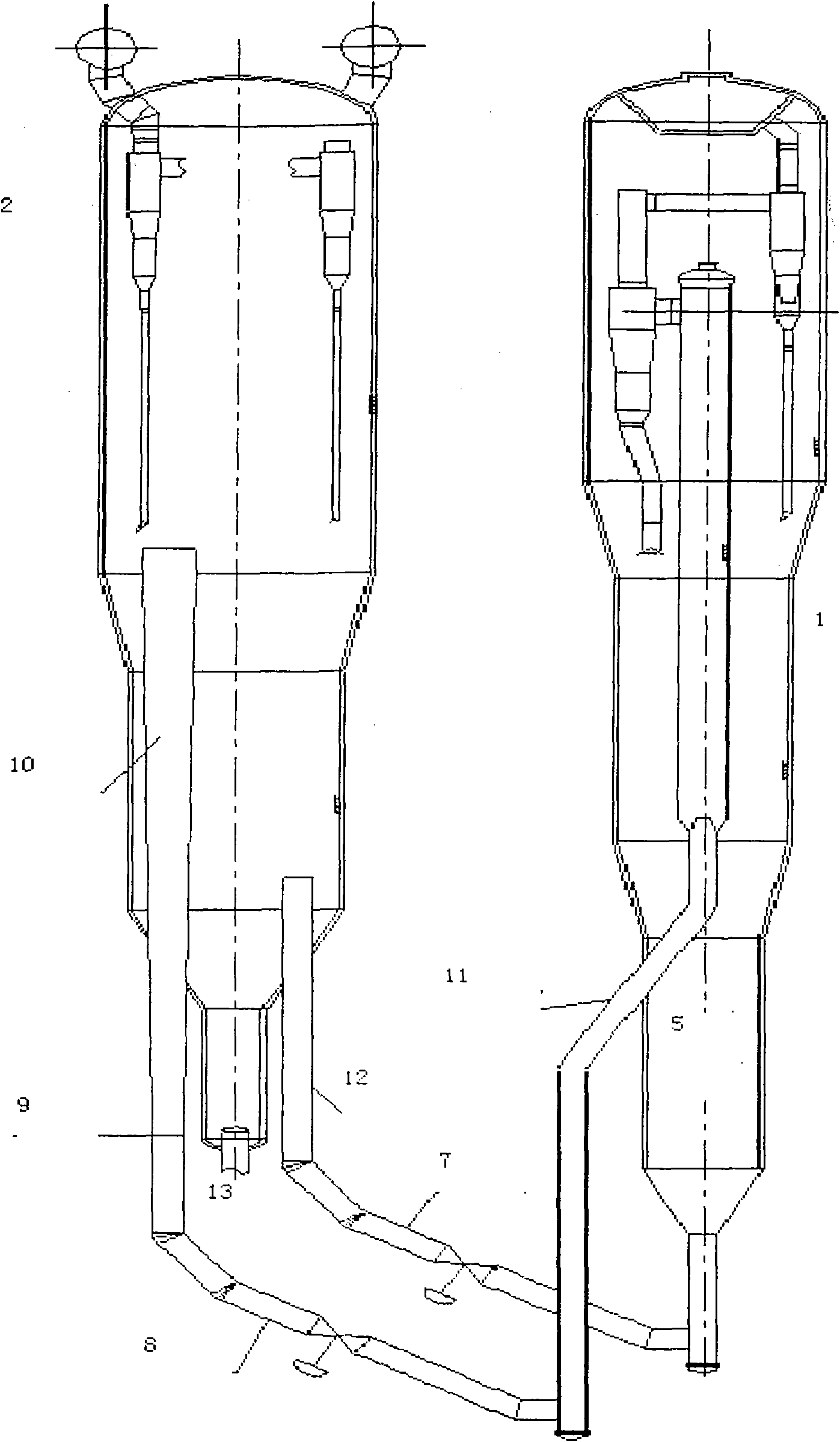

Technology device and method for preparing propylene by dehydrogenating propane or propane-enriched low carbon hydrocarbon

ActiveCN102040445AReduce energy consumptionLow unit priceHydrogen separationDistillation purification/separationGas phaseAlkali metal oxide

The invention provides a technology device and method for preparing propylene by dehydrogenating propane or propane-enriching low carbon hydrocarbon. The device comprises a reacting / regenerating part and a product fractionating part. A reacting / regenerating system is divided into a parallel type arrangement scheme and a coaxial type arrangement scheme by a fluidized bed reacting / regenerating technology, wherein a raising pipe of the parallel type reacting / regenerating system is an internal or external raising pipe, and a raising pipe of the coaxial type reacting / regenerating system is an external raising pipe. The method comprises the steps: leading raw materials and reaction products to enter into a raising pipe reactor after heat exchange; performing a dehydrogenating conversion reaction under the conditions that the reaction temperature is 500-700 DEG C, the pressure is 0.1-0.4MPa, and the ratio of a microspherical catalyst to oil is 5-60, wherein the microspherical catalyst consists of chromium, rare earth oxides, alkali metal oxides and a gamma-Al2O3 carrier, preferably, the temperature is 550-670 DEG C, the pressure is 0.1-0.15MPa, and the ratio of the microspherical catalyst to oil is 6-14; leading the reaction products and the raw materials to enter into a gas-oil separator to separate a gas phase, a liquid phase from a water phase after heat exchange and cooling; leading the separated gas to enter into a gas compressor to be compressed and be transported to an absorbing / stabilizing part; pumping the liquid to an absorbing tower; transporting the liquefied gas from a return tank at the top of a stabilizing tower to a propylene / propane separating tower by a charging pump of a propylene tower; discharging the fine propylene separated from the top of the tower out of the device as a product; discharging the separated byproduct hydrogen out of the device; and returning products at bottom of the tower to the reacting / regenerating part to be recycled.

Owner:卓润生 +1

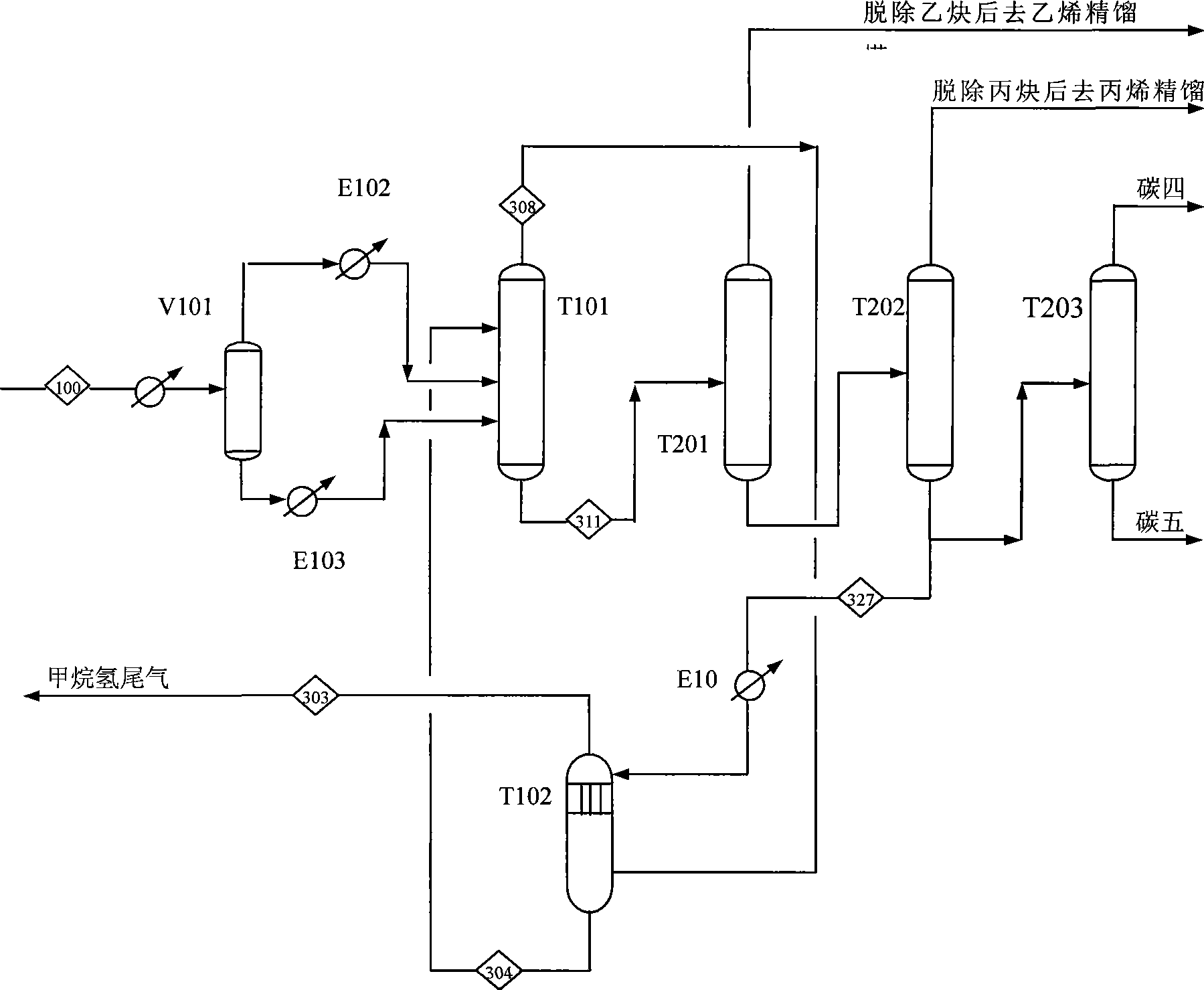

Method for separating lower hydrocarbon containing light gas by combining distillation and solvent absorption

ActiveCN101445419AHigh recovery rateLess investmentDistillation purification/separationAbsorption purification/separationHydrocarbon mixturesDistillation

The invention relates to a method for separating lower hydrocarbon containing light gas by combining distillation and solvent absorption, comprising the steps as follows: (1) pre-disposed gas at the outlet of a reactor is cooled to the temperature ranging from 10 DEG C to -37 DEG C and sent to a pre-cutting tower; (2) the gas at the outlet of the pre-cutting tower is sent to an absorption tower and C1 and C2 in the gas are separated by taking C3 or C4 or C5 or C6 or hydrocarbon mixtures as absorbent; (3) outcomes generated at the bottom of the absorption tower are sent to the pre-cutting tower; with C2 distillate further absorbed and methane and lighter components removed in the pre-cutting tower, the outcome is sent to a deethanizer so that the C2 and C3 are clearly cut. Compared with the prior art, the method has the advantages of little investment, low energy dissipation, high material recovery rate, simple operation, small maintenance quantity, reliable running, requiring no ethane refrigerant compressor, and the like.

Owner:WISON ENG

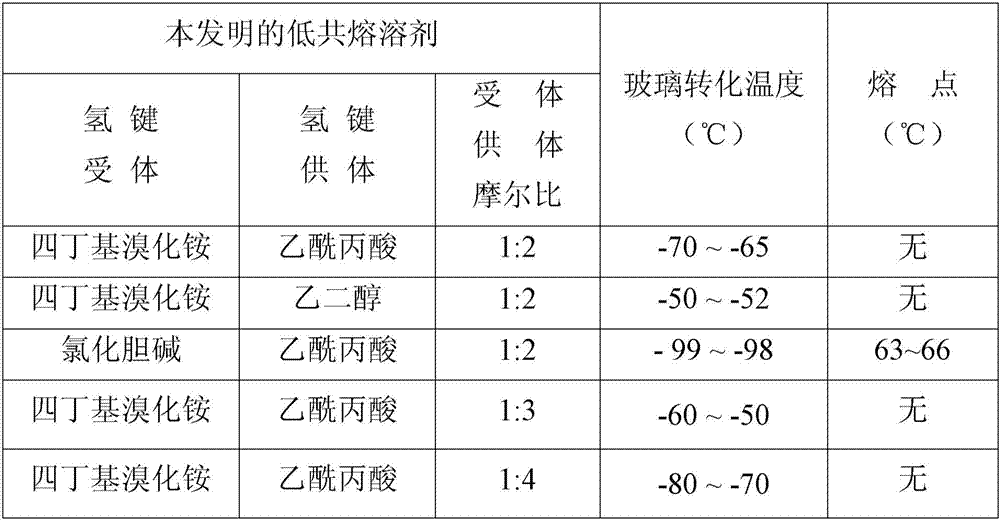

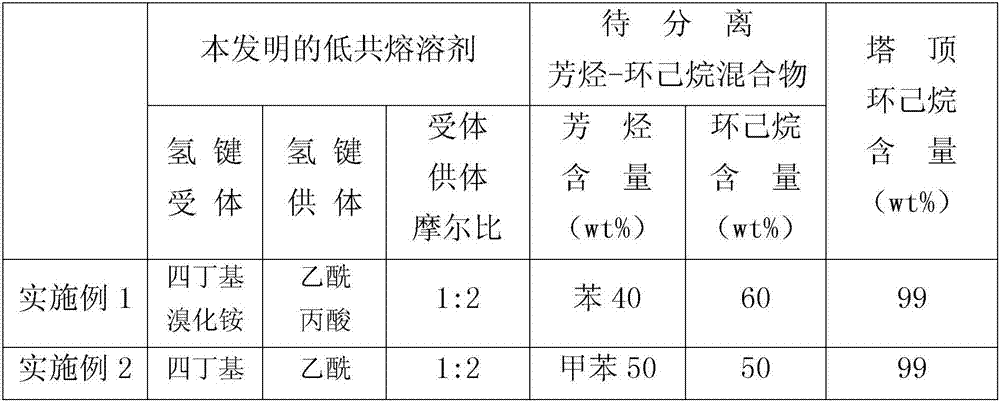

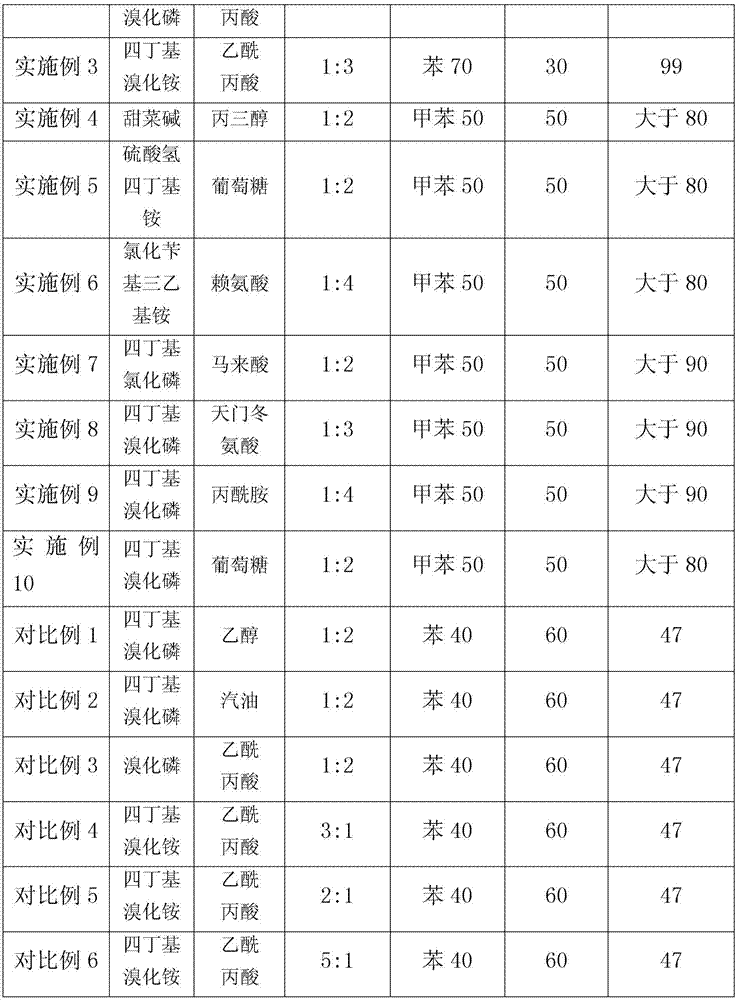

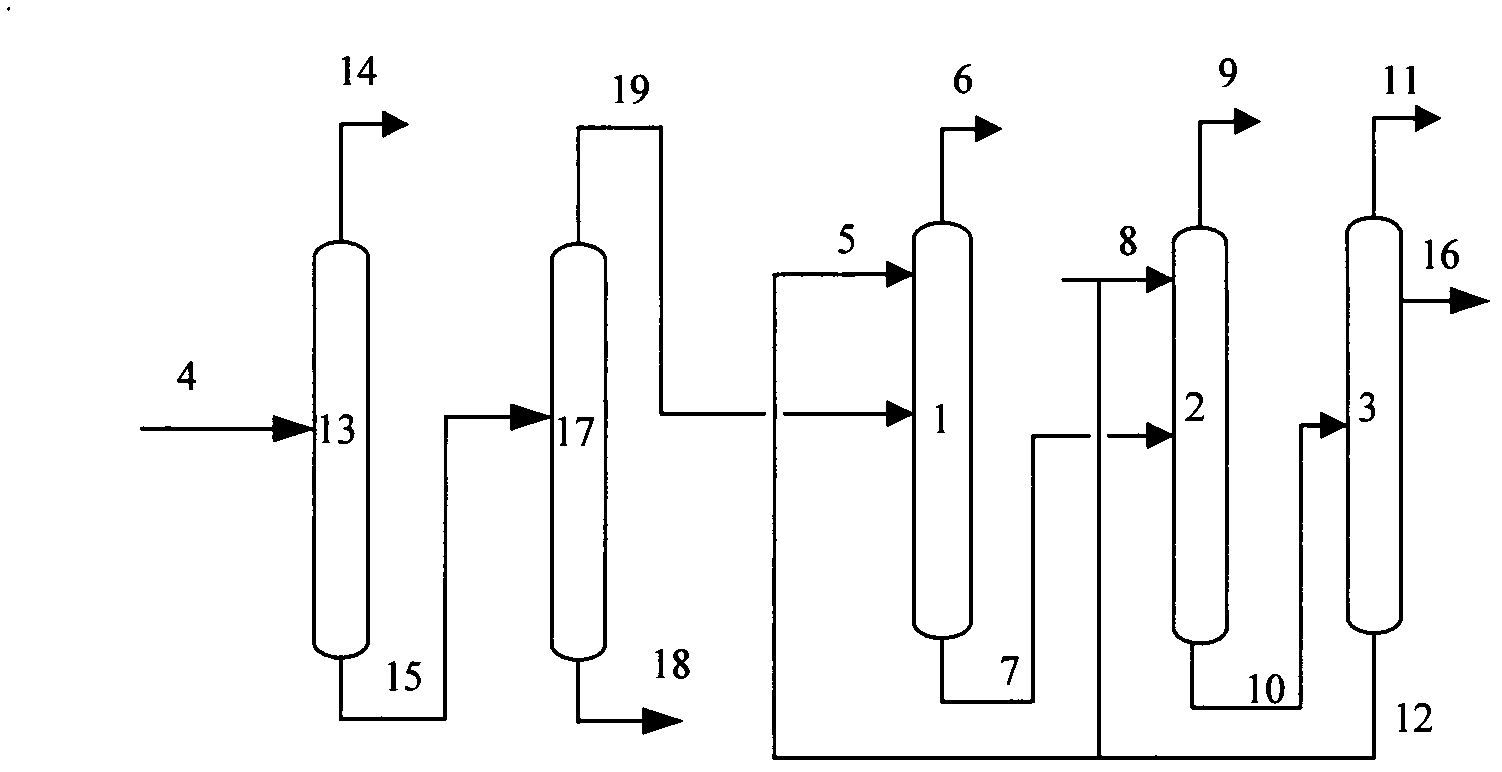

Low eutectic solvent for aromatic hydrocarbon separation and application thereof to extractive distillation

ActiveCN107311833AOvercome dosageOvercoming a large amountDistillation purification/separationExtractive distillationExtractive distillationReactive distillation

The invention discloses a low eutectic solvent for aromatic hydrocarbon separation. The low eutectic solvent is obtained by mixing hydrogen bond receptors and hydrogen bond donors according to a certain ratio (the molar ratio of 1: 1 to 1:10), and stirring till being in a uniform transparent state at 70-100 DEG C. The low eutectic solvent is low in toxicity, environment-friendly and high in efficiency, and can be applied to the process of separating aromatic hydrocarbons from non-aromatic hydrocarbons in coal tar and petroleum oil.

Owner:烟台中科恩吉科创新产业园管理有限公司

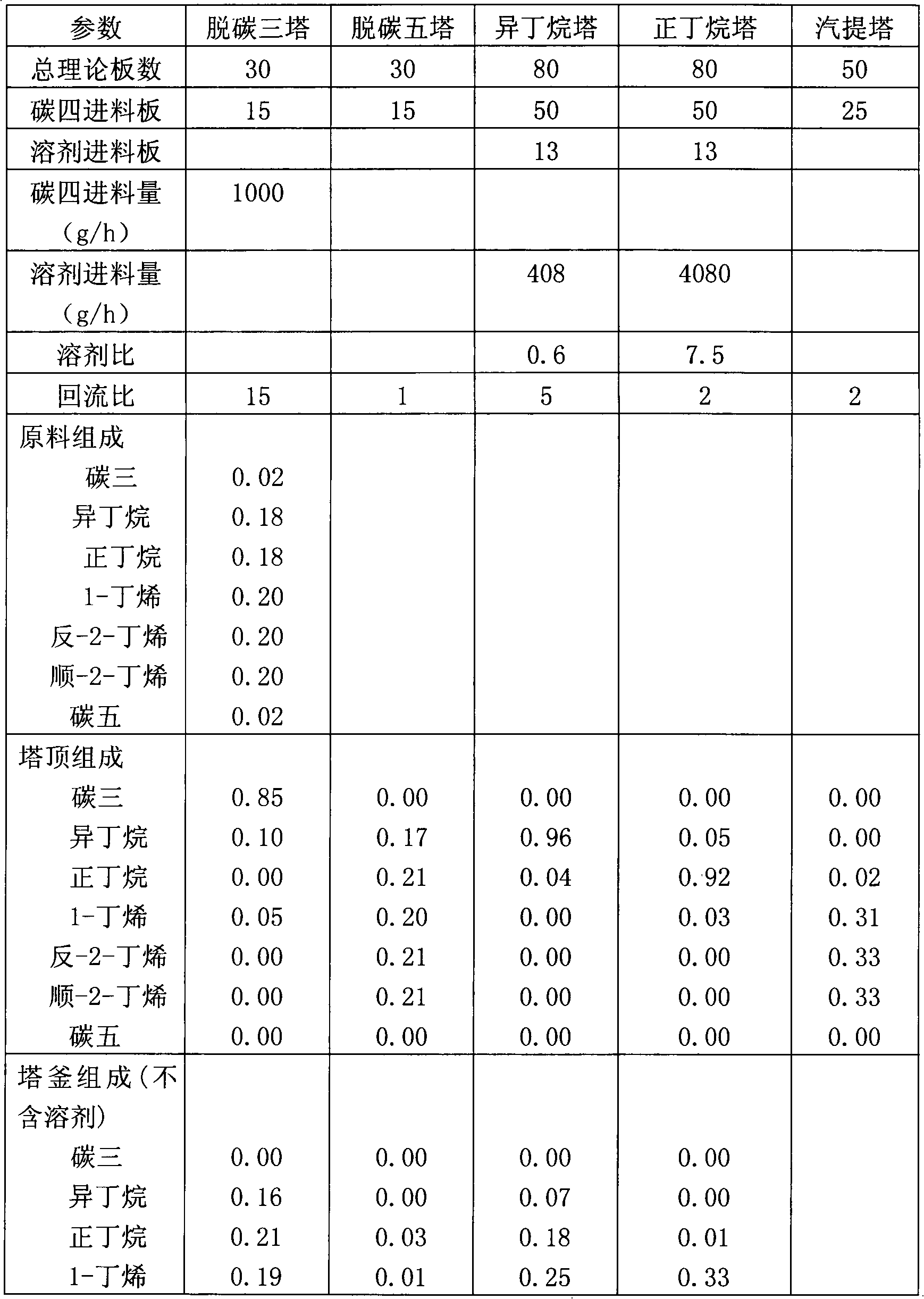

Iso-butane, n-butane and butylene separation and purification method

InactiveCN102603454ALess investmentReduce energy consumptionDistillation purification/separationButenePurification methods

The invention provides an iso-butane, n-butane and butylene separation and purification method. C4 raw materials are successively put into a C3 decarburization tower, a C5 decarburization tower, an iso-butane tower, an n-butane tower and a stripping tower to obtain high-purity iso-butane, n-butane and butylene. Solvents are cyclically utilized. The iso-butane, n-butane and butylene separation and purification method has the technical advantages that not only can equipment investment be reduced, but also the advantages of extractive distillation are used and the energy consumption is reduced.

Owner:YANTAI UNIV

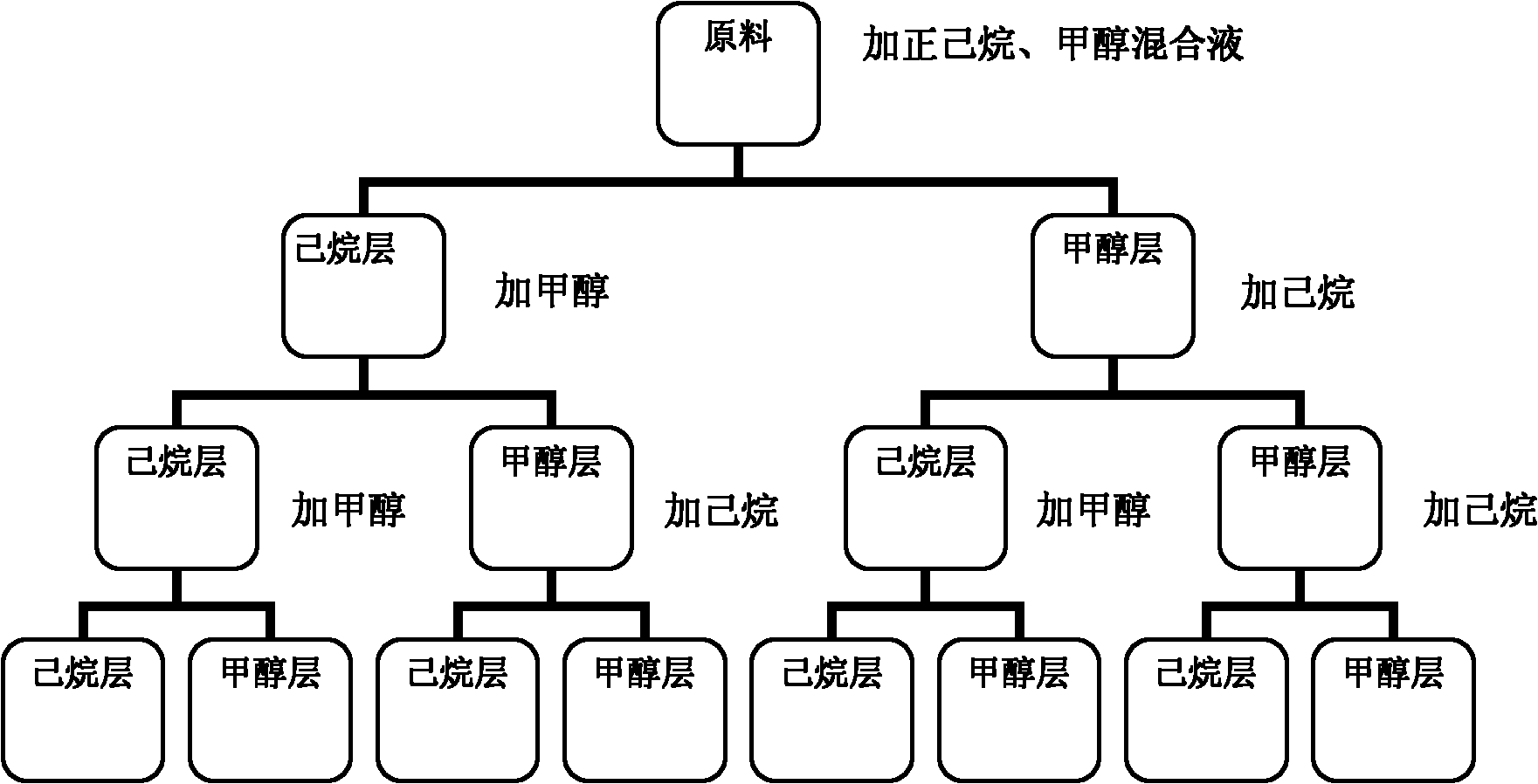

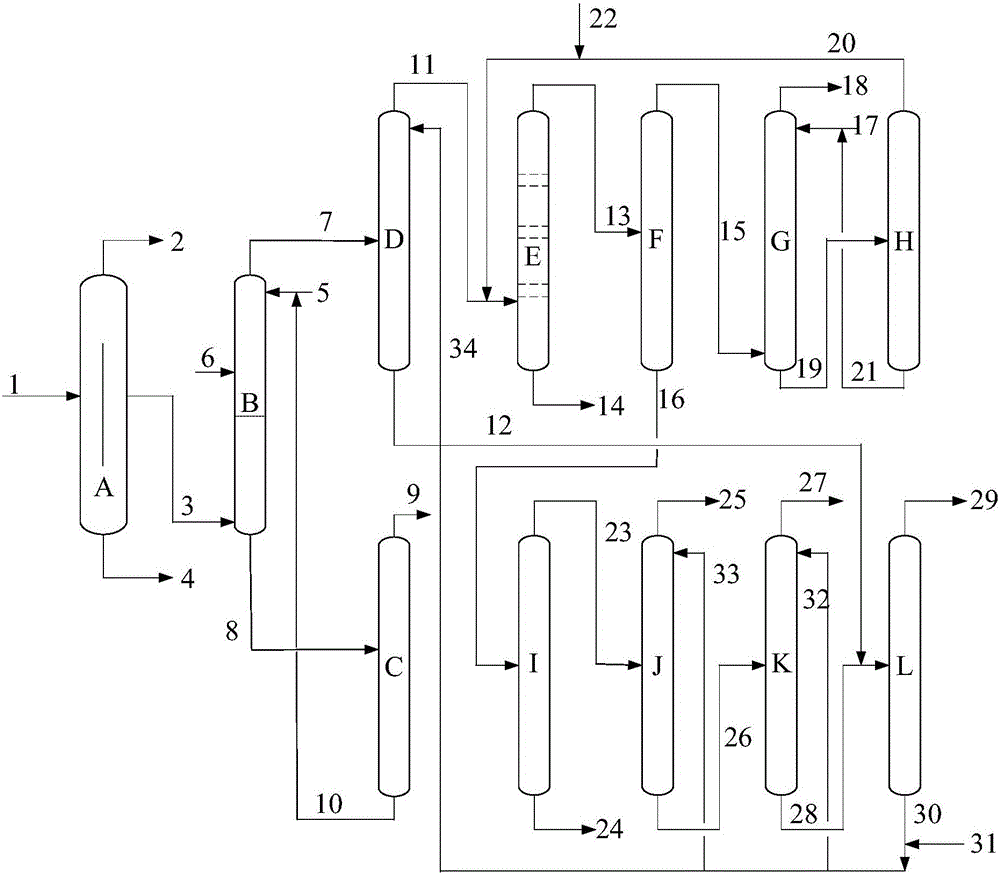

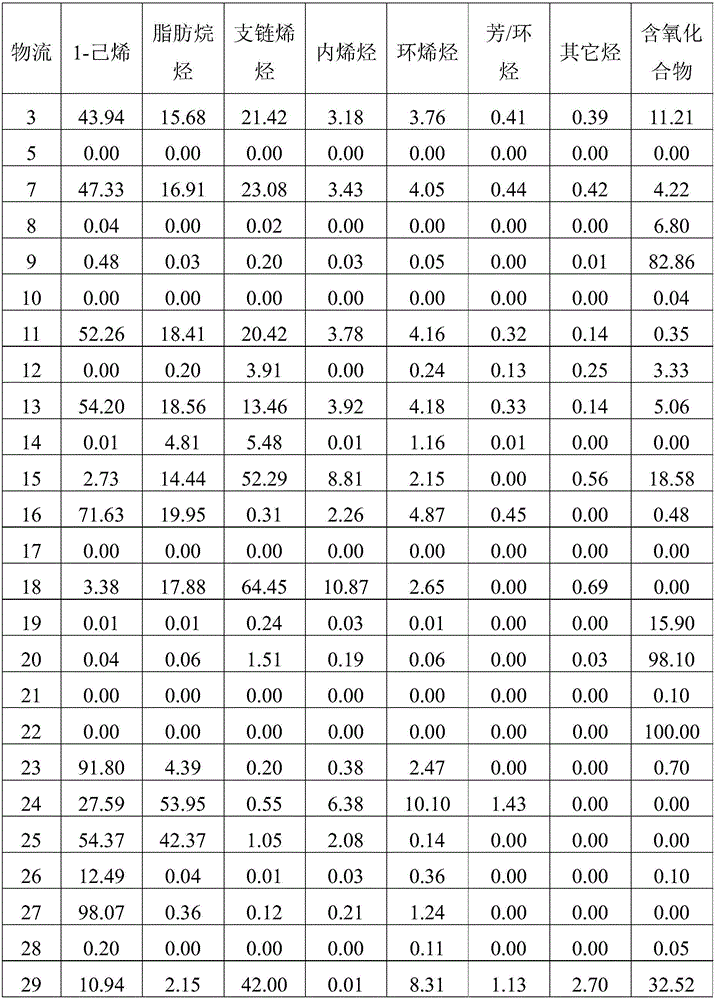

Method for separating oxygenated chemicals and 1-hexene from Fischer-Tropsch synthesis oil product

ActiveCN105777467AIncrease productionExpand product rangeOrganic compound preparationDistillation purification/separationAlkaneAlcohol

The invention relates to a method for separating oxygenated chemicals and 1-hexene from a Fischer-Tropsch synthesis oil product.The method comprises the steps that C6 fraction material flow is obtained through distillation in a predistillation tower by taking the Fischer-Tropsch synthesis oil product as a raw material, and two streams of extraction agents are fed to remove oxygenated chemicals in an extraction tower to obtain material flow rich in the oxygenated chemicals and crude C6 hydrocarbon material flow; the oxygenated chemicals contained in the crude C6 hydrocarbon material flow are further removed through a third extraction agent, tertiary olefins are converted into corresponding ethers through methyl alcohol under the action of an etherification catalyst to be removed, further purification is performed through rectification, and then C6 isoparaffin components and cycloolefin components are removed sequentially through a fourth extraction agent and a fifth extraction agent respectively to obtain 1-hexene product material flow.Compared with the prior art, the method has the advantages of being simple in technological process, low in cost and the like, and not only is 1-hexene separated and purified from the Fischer-Tropsch synthesis oil, but also the oxygenated chemicals can be separated.

Owner:YANKUANG ENERGY R&D CO LTD

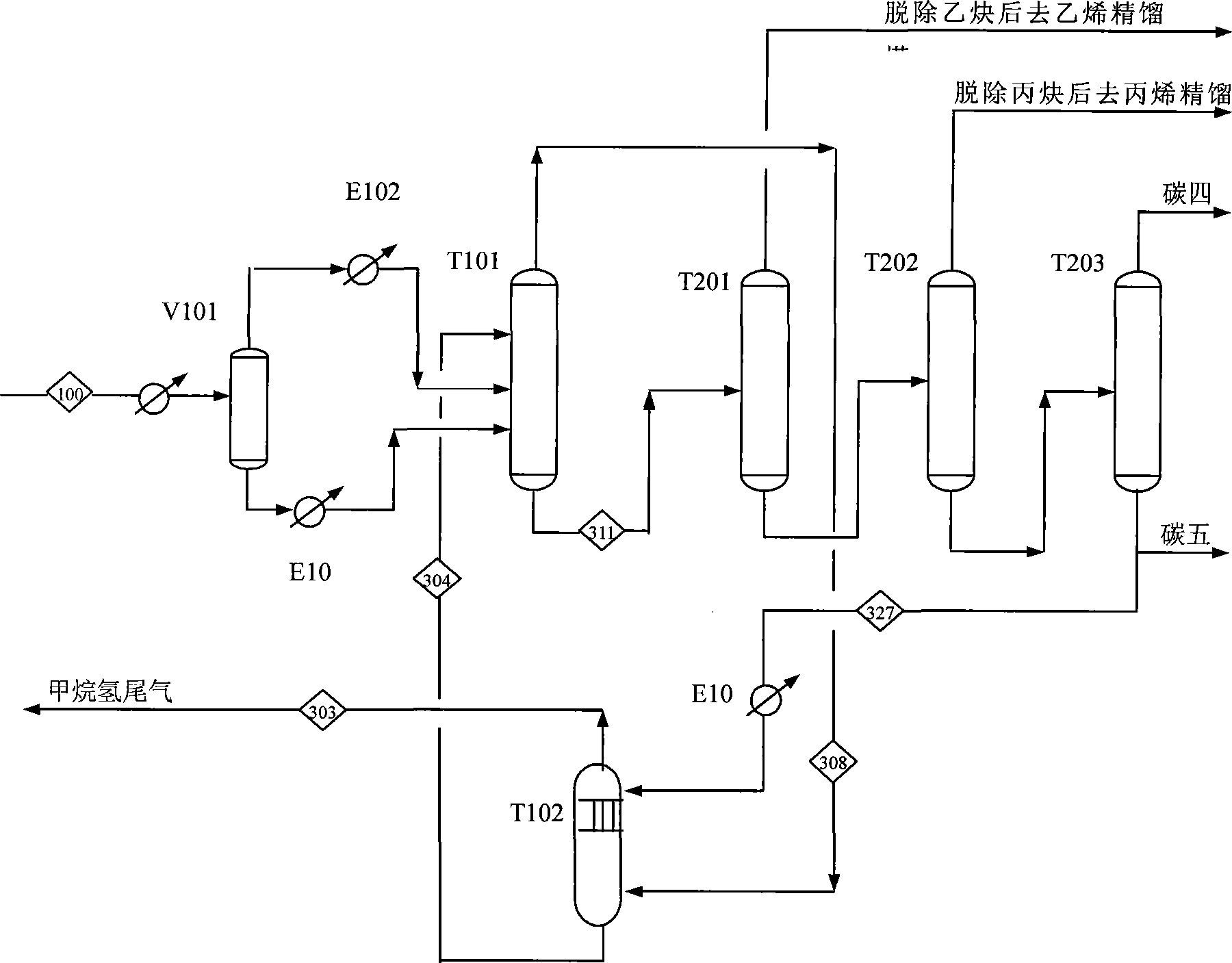

Process flow for separating low-carbon hydrocarbons and separating gas during production of olefins (M-OS/MTO) from methanol

ActiveCN102503757ALess investmentReduce energy consumptionDistillation purification/separationEthylene productionOlefiant gasAbsorption effect

The invention provides a non-cryogenic oil absorption separation method for a mixture of low-carbon hydrocarbons, which is used for separating the mixture of the hydrocarbons from gas during production of olefins from methanol. Methane / hydrogen can be separated from heavy components, namely C2 and above by absorbing fractions of the C2 and above by adopting two or more strands of absorbing agents. According to the method disclosed by the invention, an absorbing agent separating tower is increased before a demethanization tower, one strand of material flow, which is separated from the tower is taken as a main absorbing agent of the demethanization tower for absorbing the C2 and C3, the strand of the absorbing agent is the mixture of the fractions, which is from the former system and needs to be separated, and circulation is not required. The second strand of the absorbing agent of the demethanization tower is from a system including a depropanization tower and a debutanization tower, and the absorption effect is further enhanced. Compared with the prior art, the method can greatly reduce the using quantity of the circulating absorbing agents; moreover, the multiple strands of the absorbing agents are adopted, equipment investment and energy consumption are significantly reduced, the recovery rate of ethylene and propylene is further improved; and furthermore, the flow is simple, the operation cost is low, and the operation is safe and reliable.

Owner:SINOPEC SHANGHAI ENG +1

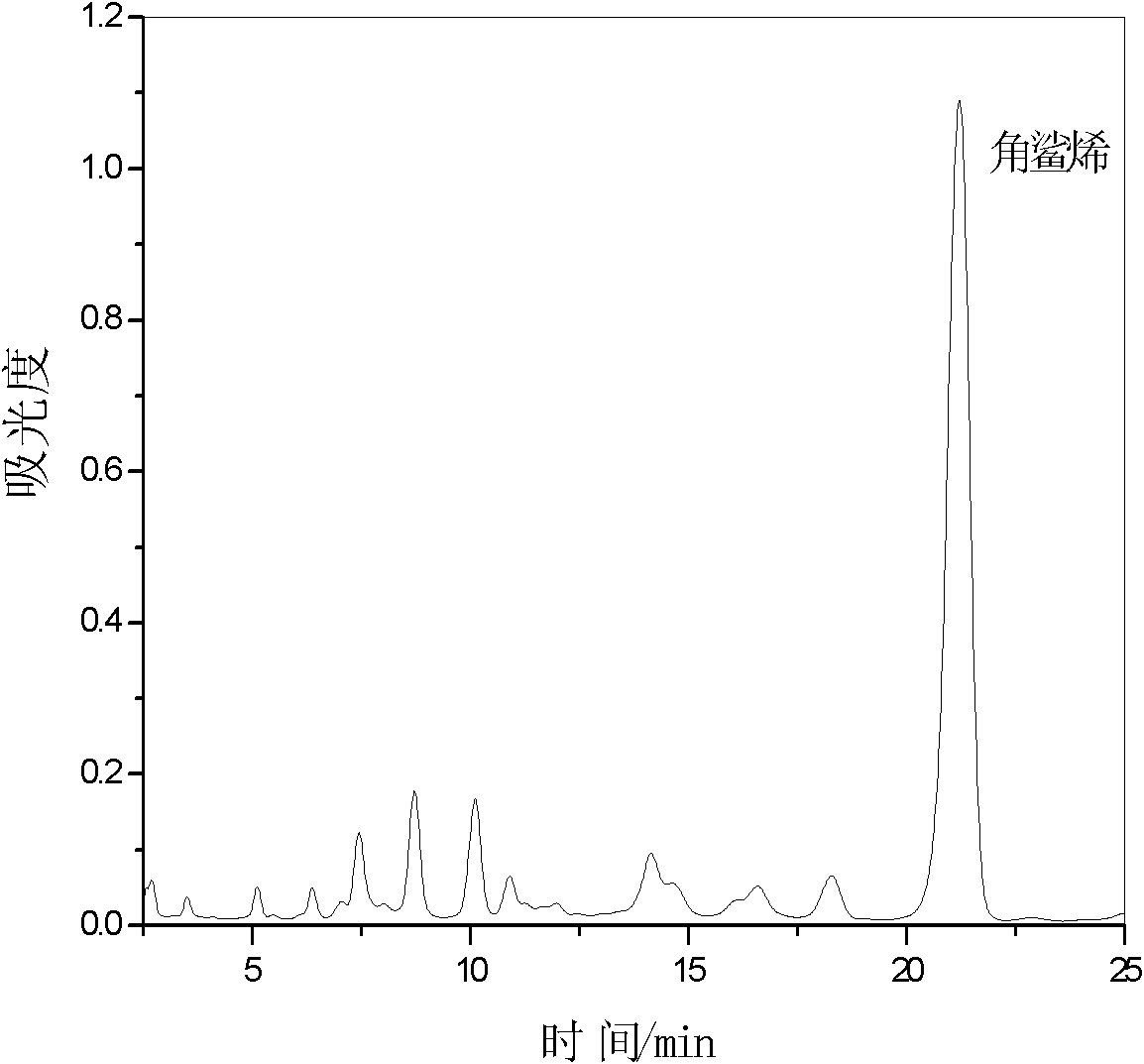

Method for extracting high-purity squalene by taking olive oil as raw material

ActiveCN101597204AIncrease productionImprove qualityDistillation purification/separationAdsorption purification/separationDistillationEvaporation

The invention relates to a method for extracting high-purity squalene by taking olive oil as a raw material. A technological route formed by adopting a secondary molecular distillation and silica gel column chromatography is as follows: an olive oil unsaponifiable substance is taken, squalene is separated and purified by using two stages of molecular distillation, primary molecular distillation is carried out under the conditions of the evaporation surface temperature of 100 to 200 DEG C, the systemic pressure of 0.001 to 0.01mbar and the scraping film rotor speed of 150 to 300rpm, and secondary molecular distillation is carried out to the obtained distillate; the secondary molecular distillation is carried out under the conditions of the evaporation surface temperature of 150 to 300 DEG C, the systemic pressure of 0.001 to 0.01mbar and the scraping film rotor speed of 200 to 350rpm, and the obtained distillate is a squalene crude product; ethyl acetate-normal hexane with different concentrations is used as a mobile phase to carry out gradient elution, the obtained eluent is collected according to time and a solvent is evaporated, the same fractions are merged through chromatographic detection, and the high-purity squalene can be obtained, wherein the content of the raw material olive oil of the squalene is enhanced from 3.6% to about 98%; and especially, by considering the requirement of industrialized production to select an extraction condition especially, the large-scale production of the squalene taking the olive oil as the raw material can be realized.

Owner:JIANGSU ZODIAC MARINE BIOTECH

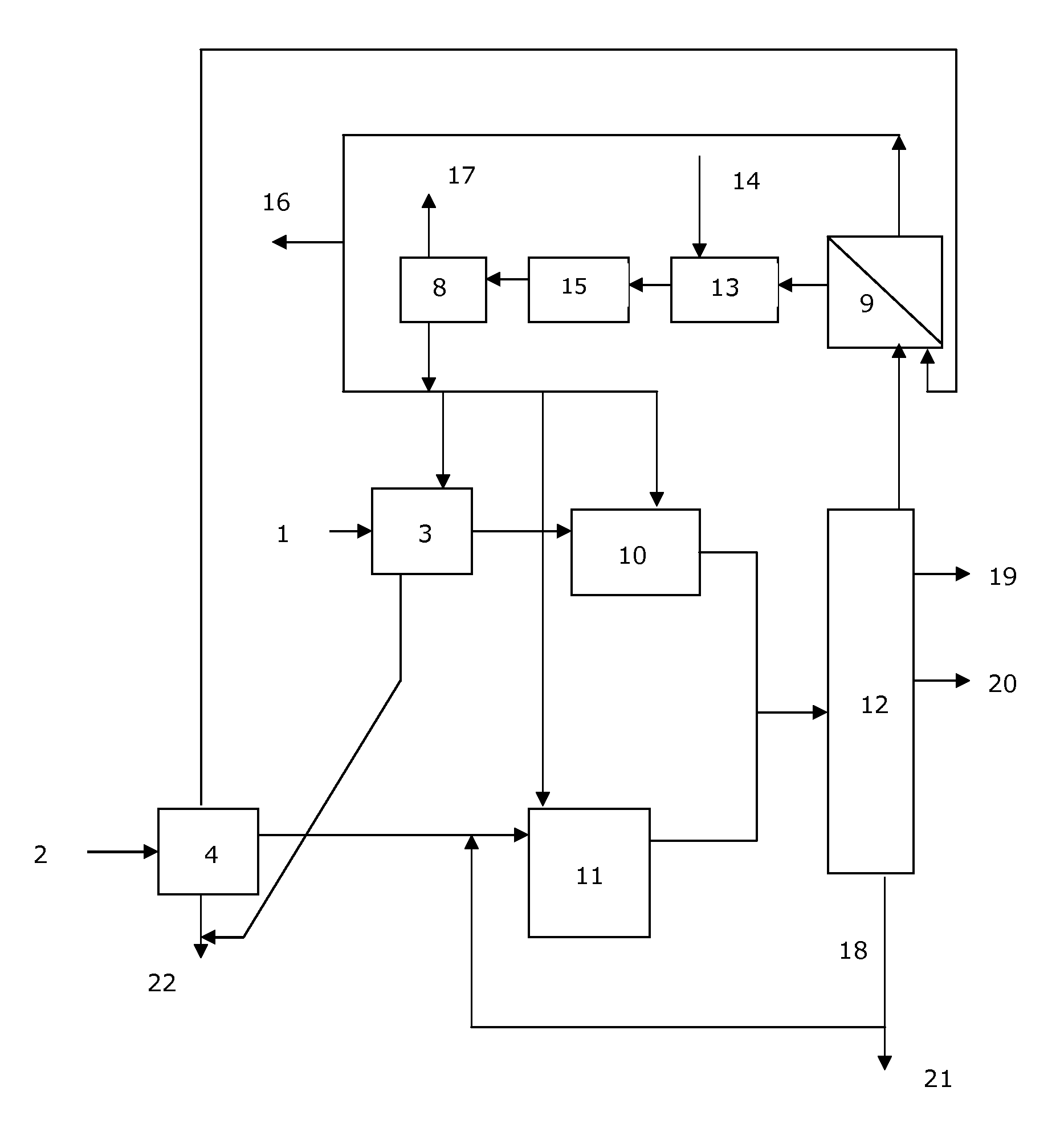

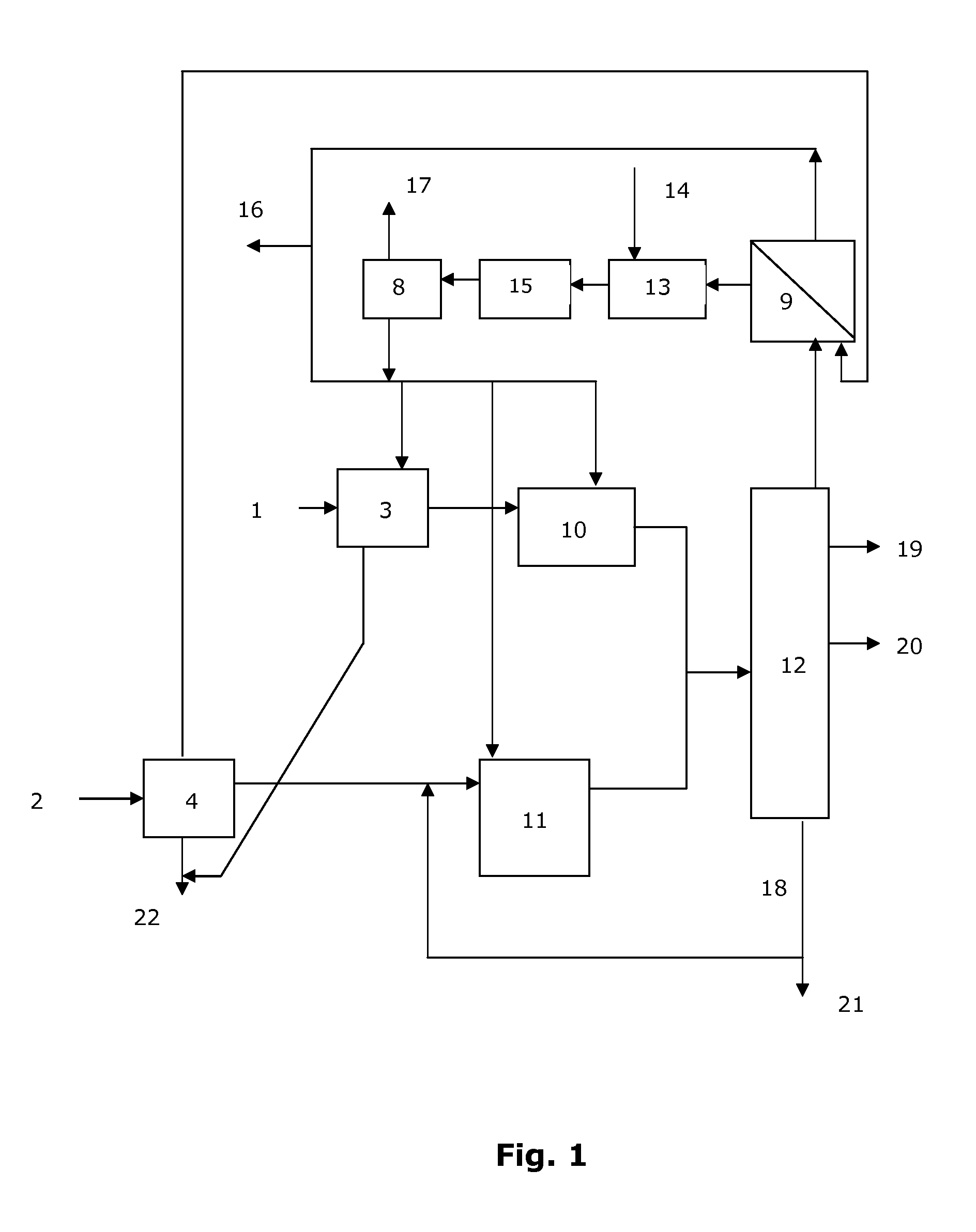

Integrated Process for Producing Diesel Fuel from Biological Material and Products, Uses and Equipment Relating to Said Process

InactiveUS20100317903A1Quality improvementMaximize utilizationRefining to change hydrocarbon structural skeletonCombustible gas catalytic treatmentCelluloseHydrocotyle bowlesioides

The present invention relates to an integrated process for producing diesel fuel or fuel additive from biological material by producing paraffins by a Fischer-Tropsch reaction on one hand and by a catalytic hydrodeoxygenation of bio oils and fats on the other hand. The two hydrocarbon streams are combined and distilled together. The invention also relates to the use of lignocellulosic material, such as by-products of the wood-processing industry for producing diesel fuel and to a method for narrowing the chain length distribution of Fischer-Tropsch derived diesel fuel. The invention provides a high-quality middle distillate fraction from various biological sources and most preferably from by-products of the wood-processing industry. The invention also relates to equipment for producing fuel form biological material, which comprises a hydrodeoxygenation reactor (3) for hydrocarbons, a cracking / isomerization reactor (11) for FT paraffins and a separation unit (12) for the combined hydrocarbons. Hydrogen is separated from light fractions in a separation unit (9) and reformed in the process. The equipment is advantageously integrated with a pulp and paper mill, which provides biological material and receives waste and energy.

Owner:UPM-KYMMENE OYJ

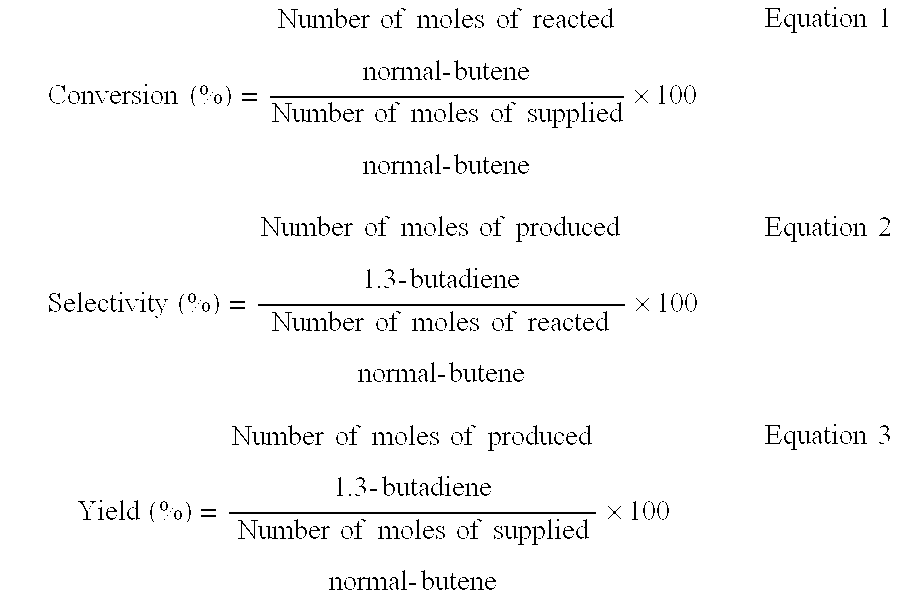

Method for preparing 1,3-butadiene as high yield

ActiveUS20130281748A1Excellent catalytic performanceHigh dehydrogenation activityDistillation purification/separationCatalystsButenePolymer science

Disclosed is a method for producing 1,3-butadiene through oxidative dehydrogenation of normal-butene using a parallel reactor in which catalysts are charged into fixed bed reactors and are not physically mixed. More specifically, disclosed is a method for efficiently producing 1,3-butadiene through oxidative dehydrogenation of normal-butene using the parallel reactor containing multi-component bismuth molybdate-based catalysts exhibiting different activities to oxidative dehydrogenation for normal-butene isomers (1-butene, trans-2-butene and cis-2-butene), and butene separated from a C4 mixture containing normal-butene and normal-butane, as a reactant.

Owner:LG CHEM LTD

Popular searches

Digital data processing details Hydroxy compound preparation Special data processing applications Text database browsing/visualisation Fractional distillation Catalytic naphtha reforming Hydrocarbon oil cracking process Treatment with hydrotreatment processes Naphtha treatment Refining by selective hydrogenation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com