Method for extracting squalene from vegetable oil deodorized distillate

A technology for deodorizing distillate and vegetable oil, applied in the field of recovering vitamin E and phytosterol, can solve the problems of high price, waste of solvent and high production cost, and achieve the effects of reducing separation cost, reducing load and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Extraction of squalene from soybean oil deodorization distillate (SODD) and recovery of vitamin E, phytosterols

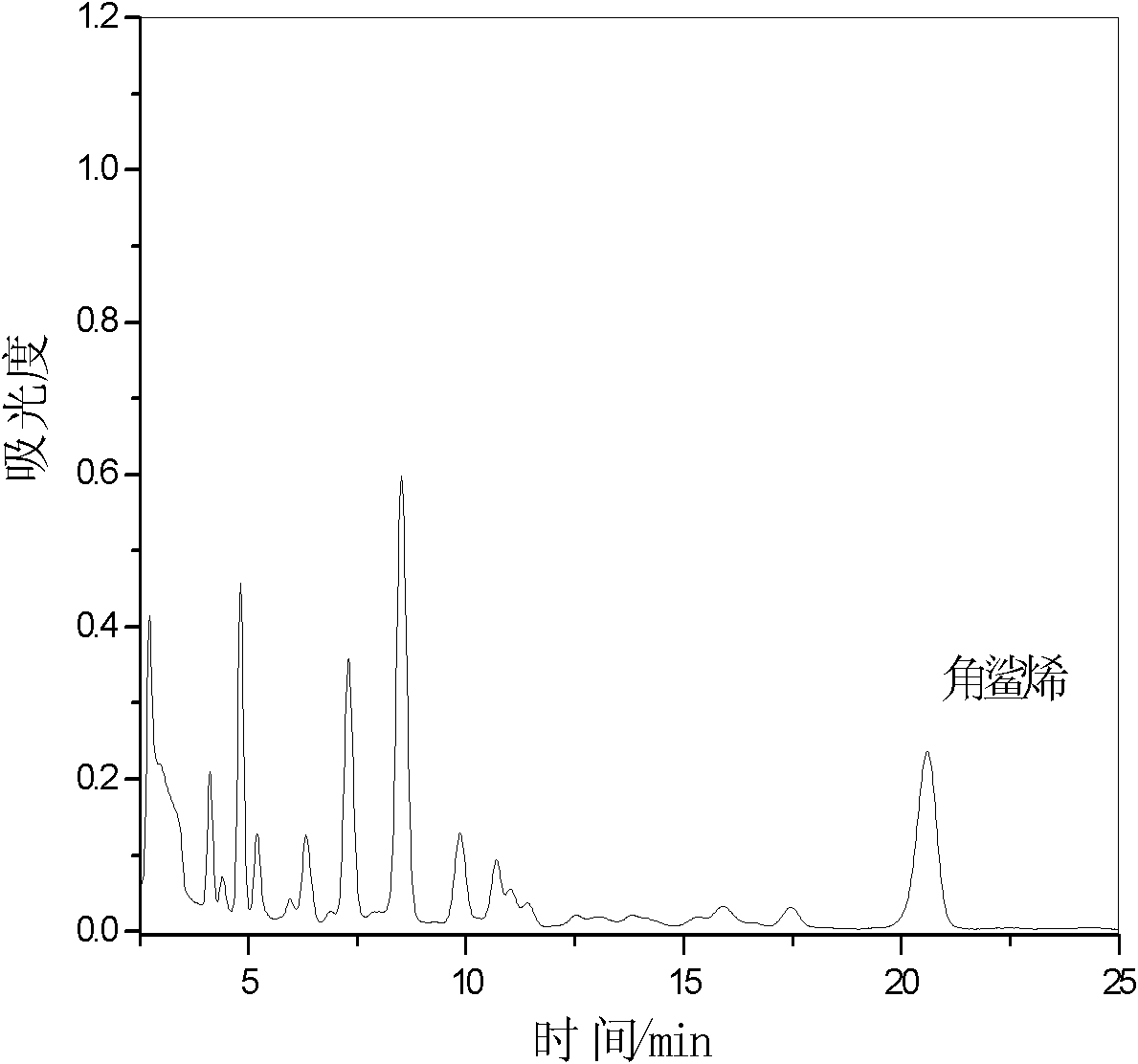

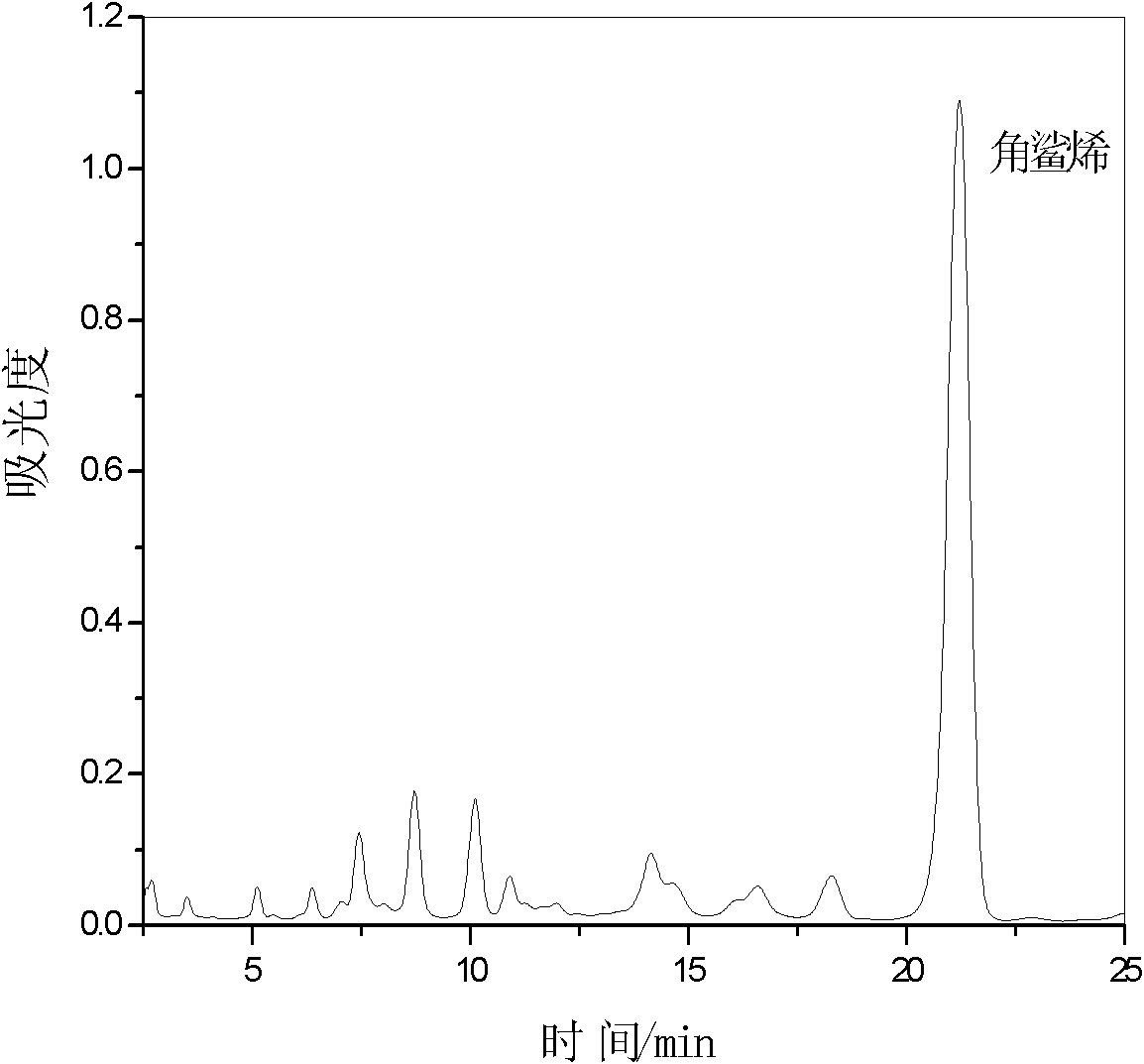

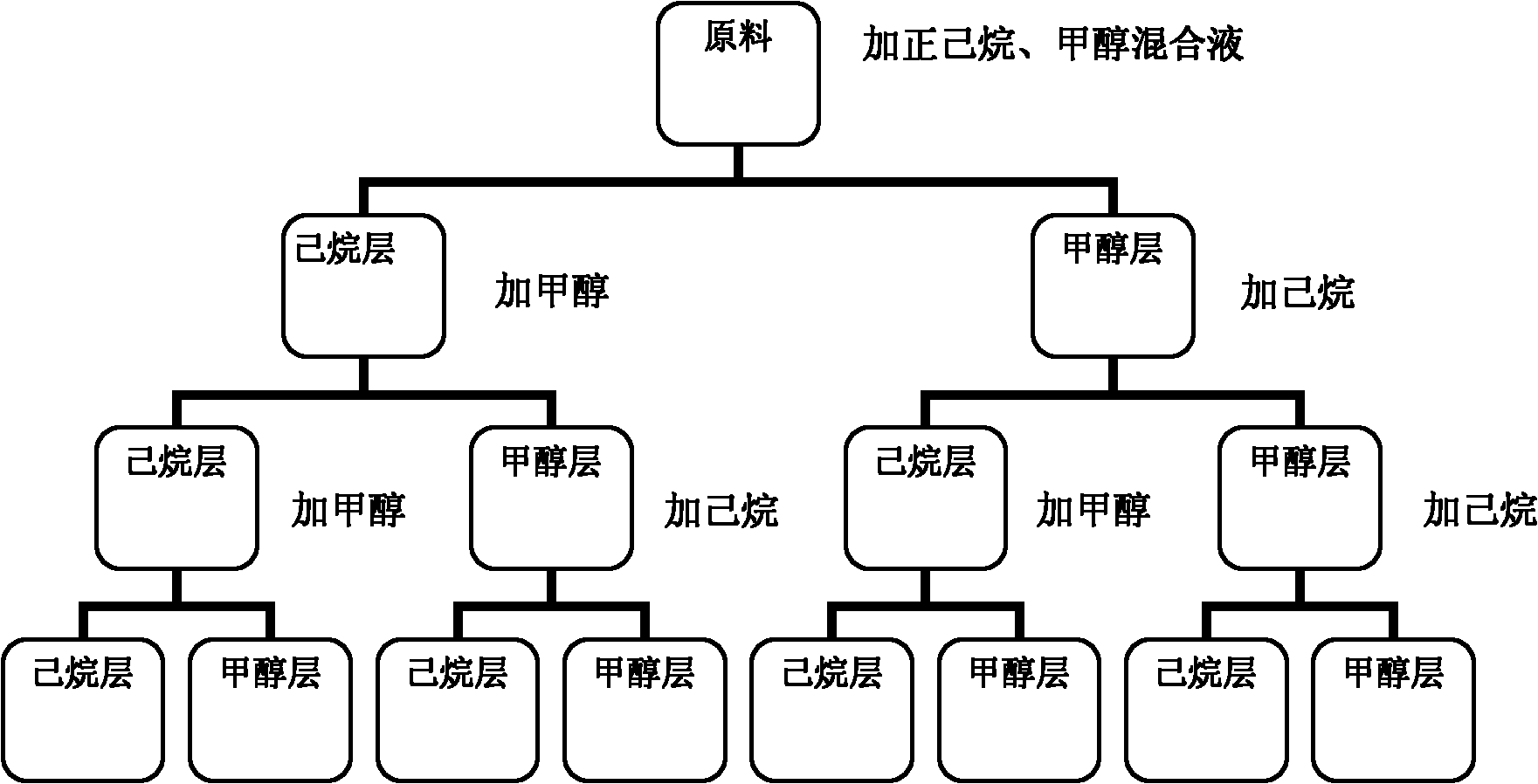

[0025] 1) Preparation of unsaponifiable matter: get 300gSODD (see attached figure 1 , the squalene retention time is 21min), the squalene content is 1.91%, vitamin E 4.82%), the KOH-ethanol solution of 1200ml 0.5mol / L is in the flask, reacts 1h under the situation of 90 ℃ of stirring refluxes, After stopping the reaction, add 500ml of distilled water at the top of the reflux tube, and rotate the shaking flask. After cooling, use 300ml of normal hexane to extract five times, combine the extraction phases, and then use 10% aqueous ethanol (V 乙醇 :V 水 =1:9) wash the extract phase, remove alkali and soap, then put the washed extract phase in the refrigerator, the soap is precipitated and removed, and the solvent is evaporated with a rotary evaporator at 100°C to obtain about 60g of unsaponifiable matter, liquid According to the phase determination, the content...

Embodiment 2

[0030] Basic technology is as embodiment 1, and concrete operation parameter is as follows:

[0031]1) Preparation of unsaponifiable matter: get 300gSODD (squalene content is 1.91%, vitamin E is 4.82%), in the KOH-ethanol solution of 600ml1.5mol / L and in the flask, react under the situation of stirring and reflux at 60 ℃ 4h, after stopping the reaction, add 500ml of distilled water at the top of the reflux tube, and rotate and shake the three-necked flask. After cooling, use 300ml of n-hexane to extract five times, combine the extraction phases, and then use 10% aqueous ethanol (V 乙醇 :V 水 =1:9) wash the extract phase, remove alkali and soap, then put the washed extract phase in the refrigerator, the soap is precipitated and removed, and the solvent is evaporated with a rotary evaporator at 100°C to obtain about 60g of unsaponifiable matter, liquid According to the phase determination, the content of squalene is 10.2%, and the fatty acid can be recovered after acidification of...

Embodiment 3

[0036] Basic technology is as embodiment 1, and concrete operation parameter is as follows:

[0037] 1) Preparation of unsaponifiable matter: get 300g rapeseed oil deodorization distillate (squalene content is 2.05%, vitamin E is 4.84%), the KOH-ethanol solution of 900ml 1.5mol / L is in the flask, at 75 ℃ React for 2.5 hours with stirring and reflux. After stopping the reaction, add 500ml of distilled water to the top of the reflux tube, and rotate and shake the three-necked flask. Aqueous solution (V 乙醇 :V 水 =1:9) wash the extract phase, remove alkali and soap, then put the washed extract phase in the refrigerator, the soap is precipitated and removed, and the solvent is evaporated with a rotary evaporator at 100°C to obtain about 55g of unsaponifiable matter, liquid The content of squalene is 13.8% according to phase determination, and fatty acid can be recovered after acidification of the obtained saponification.

[0038] 2) Two-stage molecular distillation to obtain squa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com